Patents

Literature

1165results about How to "Prevent flying out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

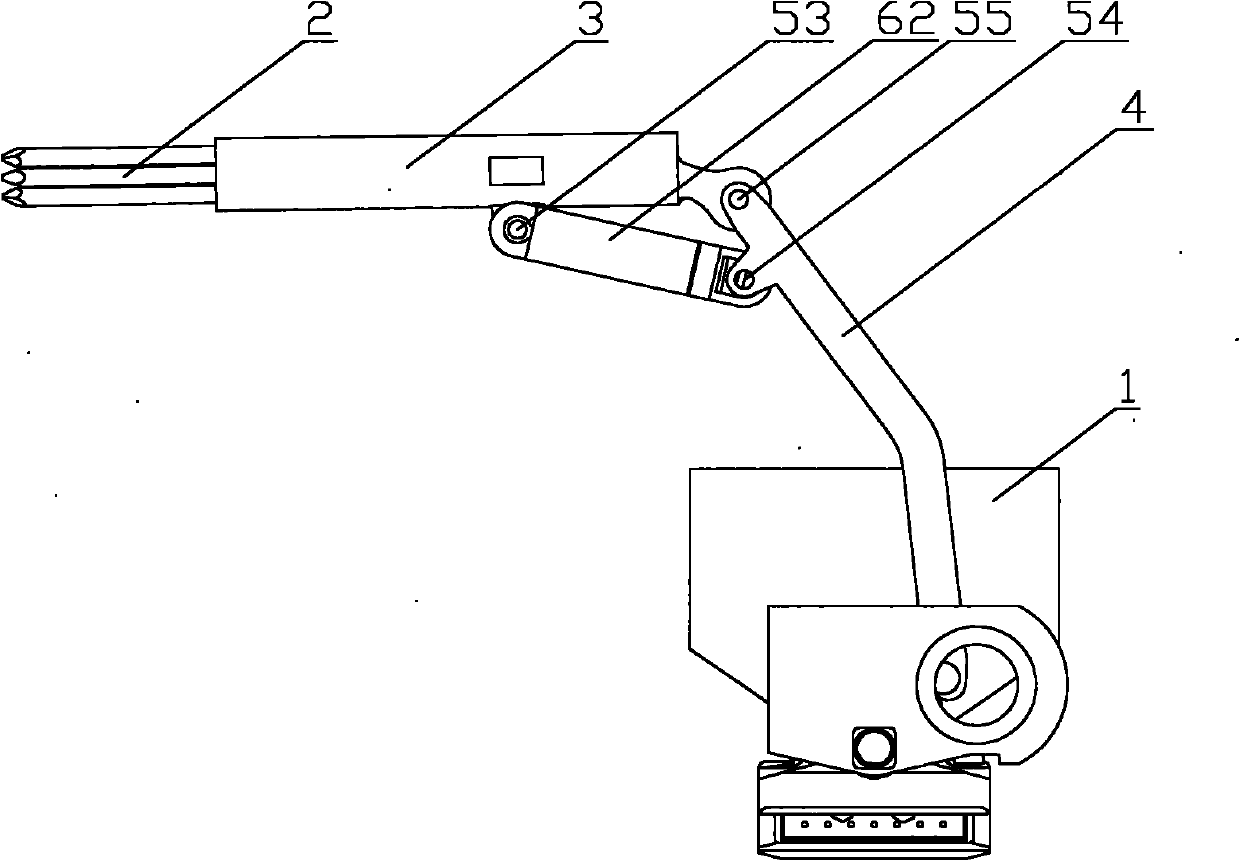

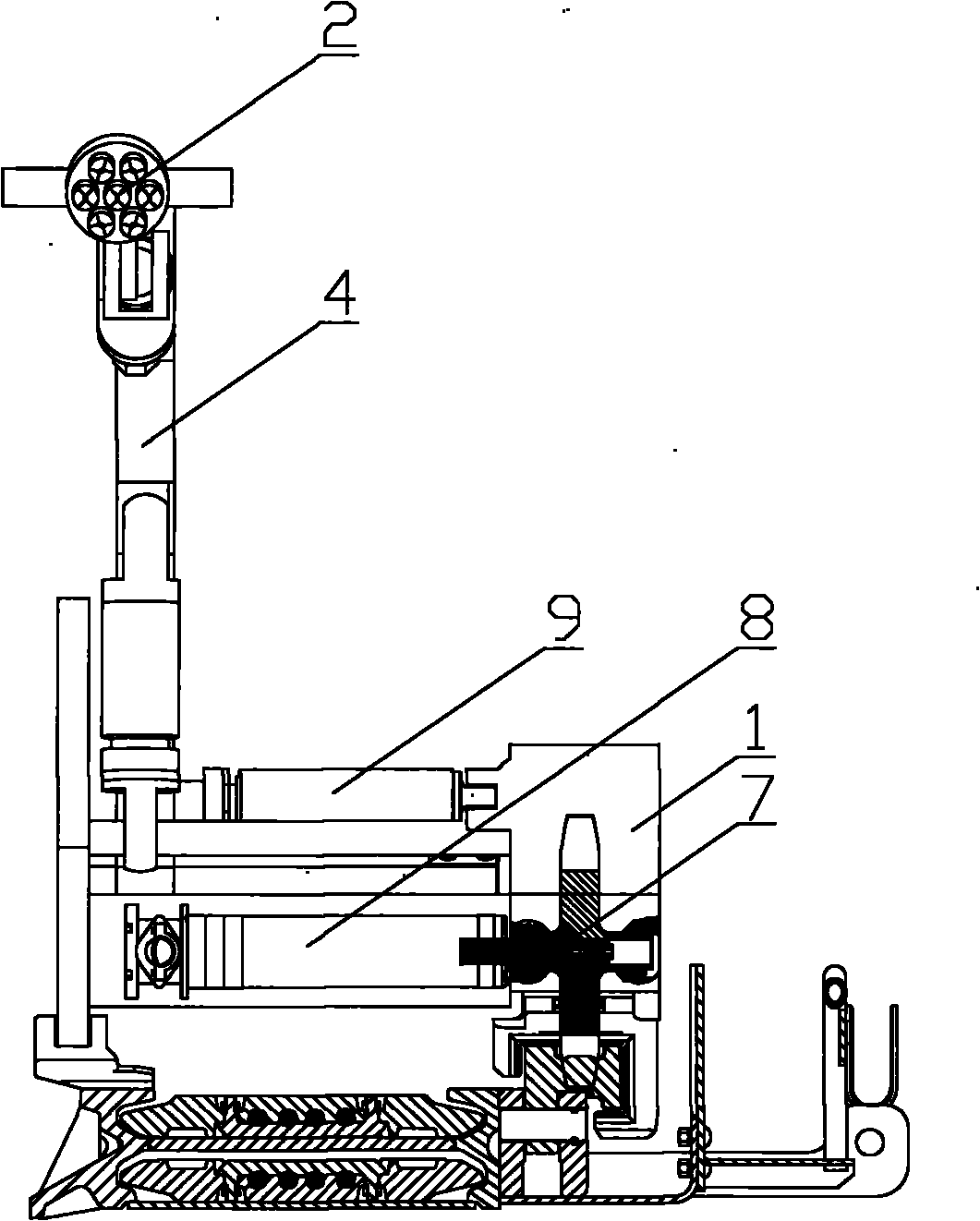

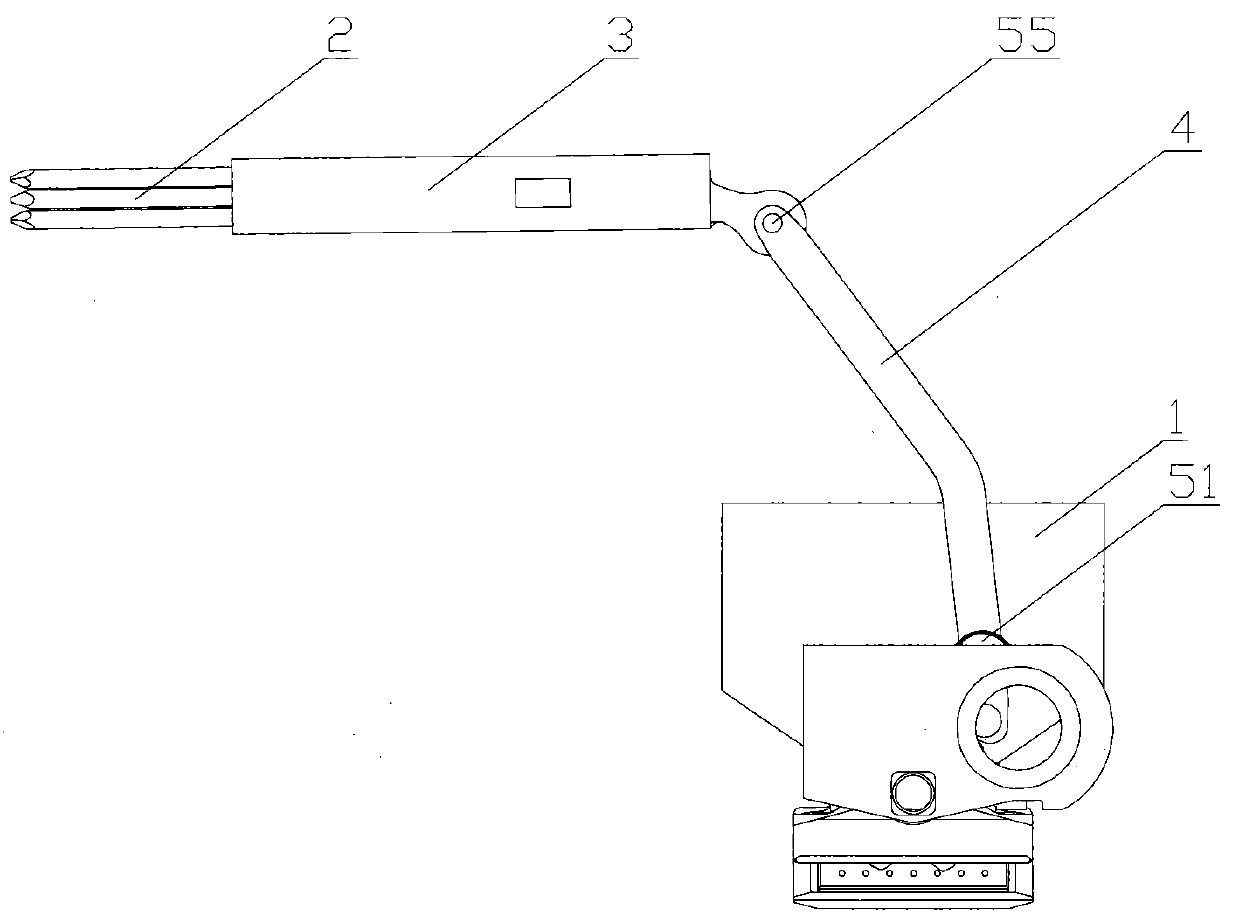

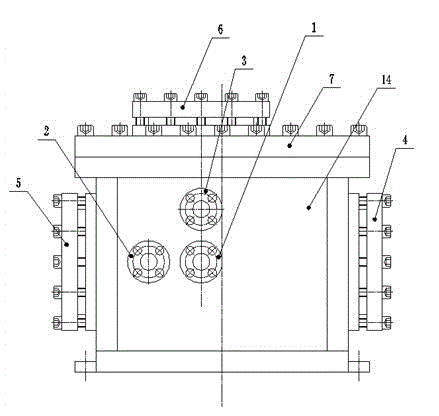

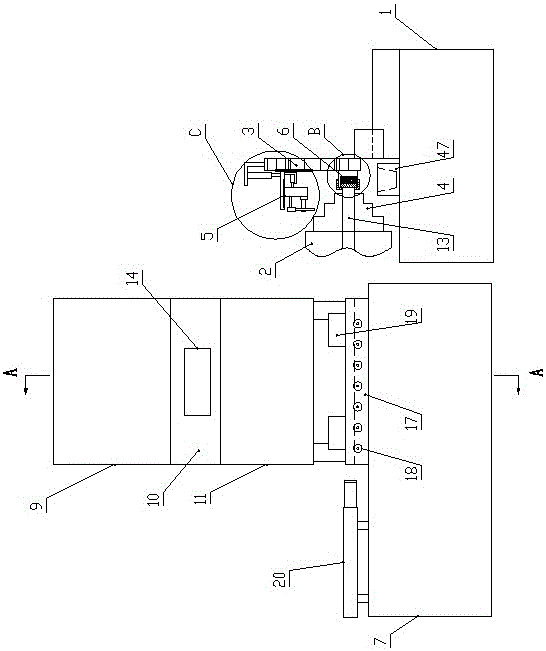

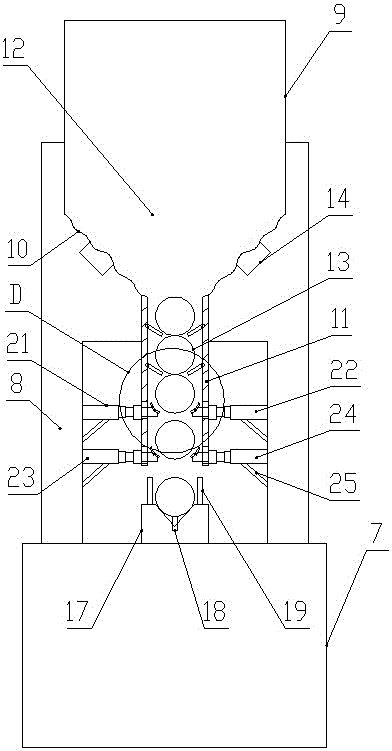

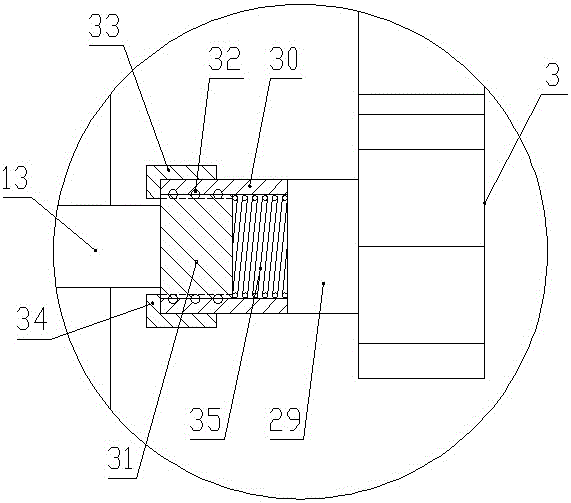

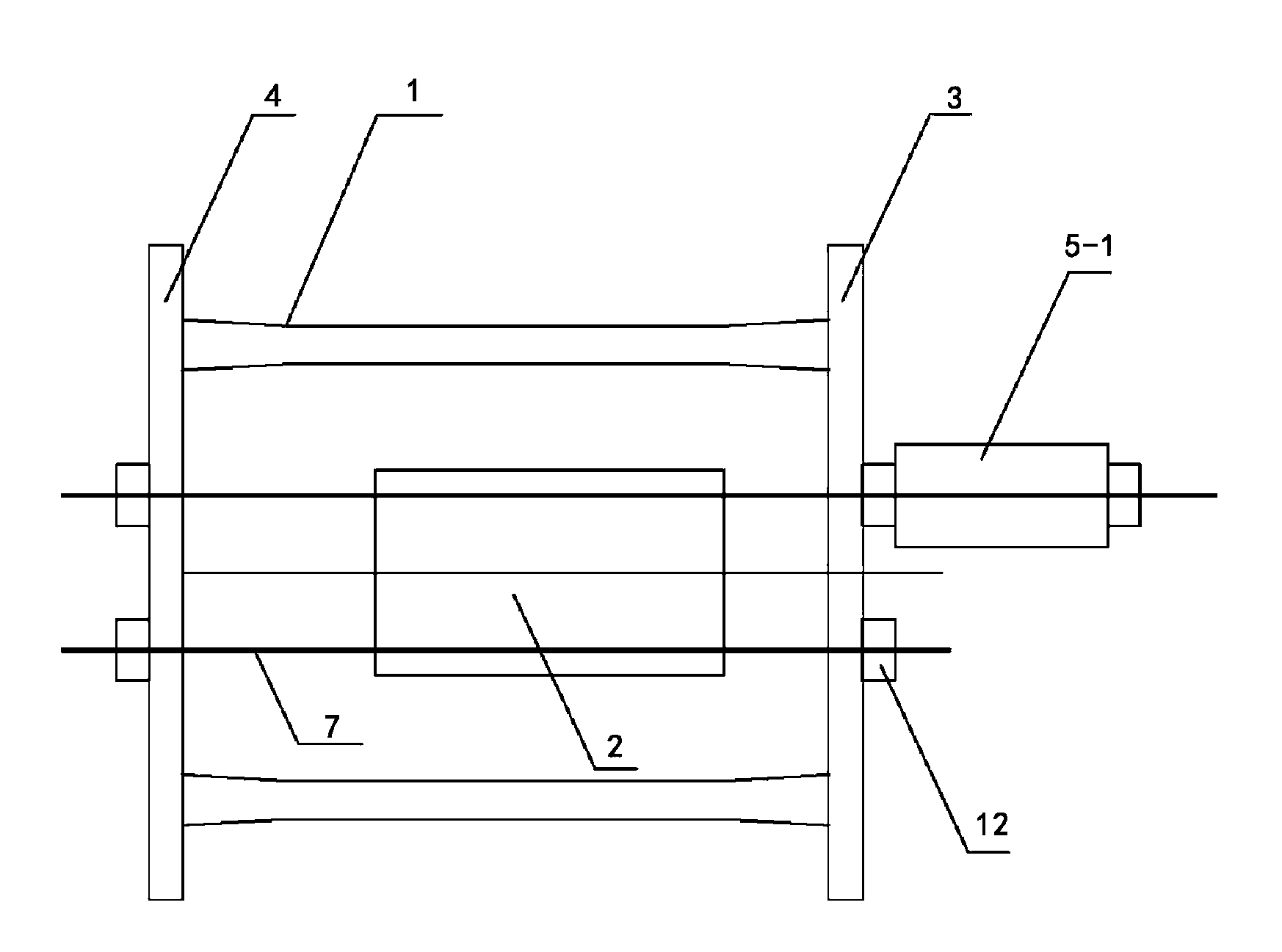

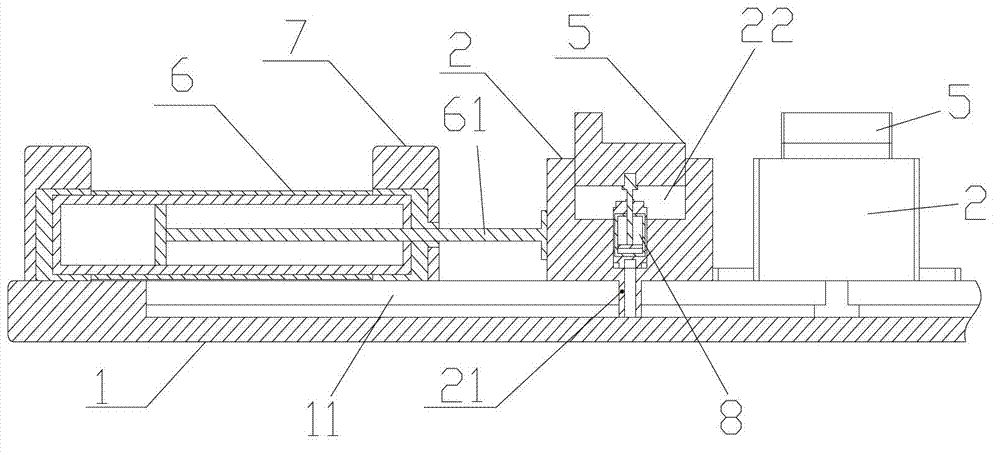

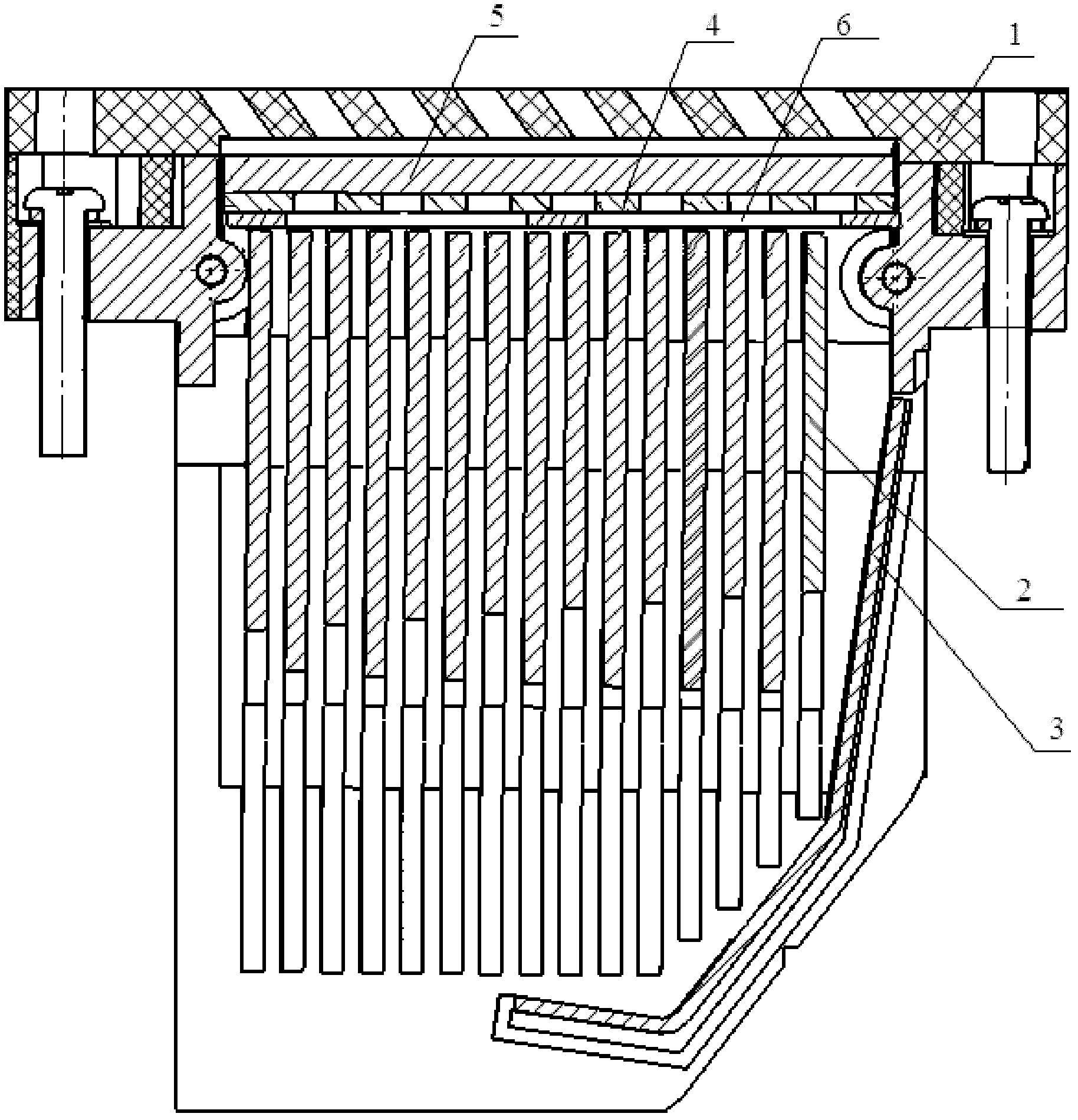

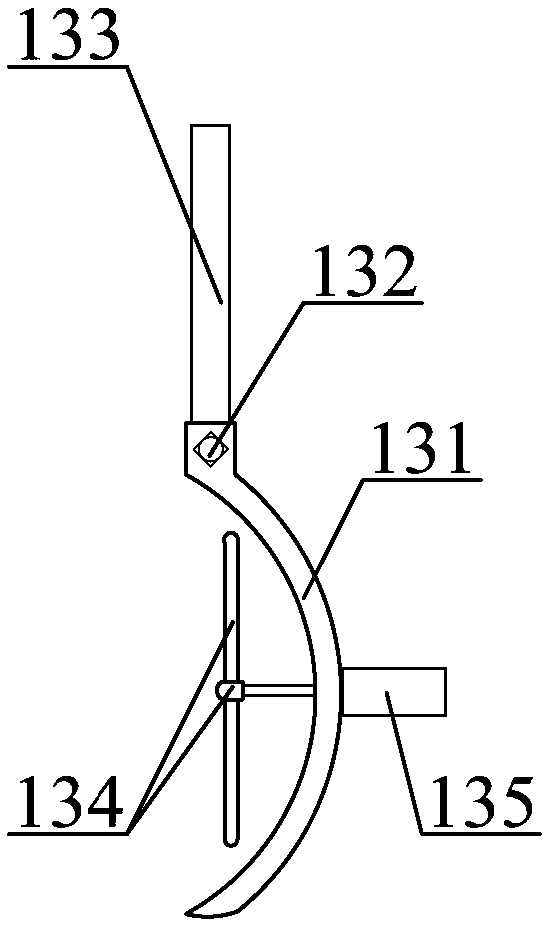

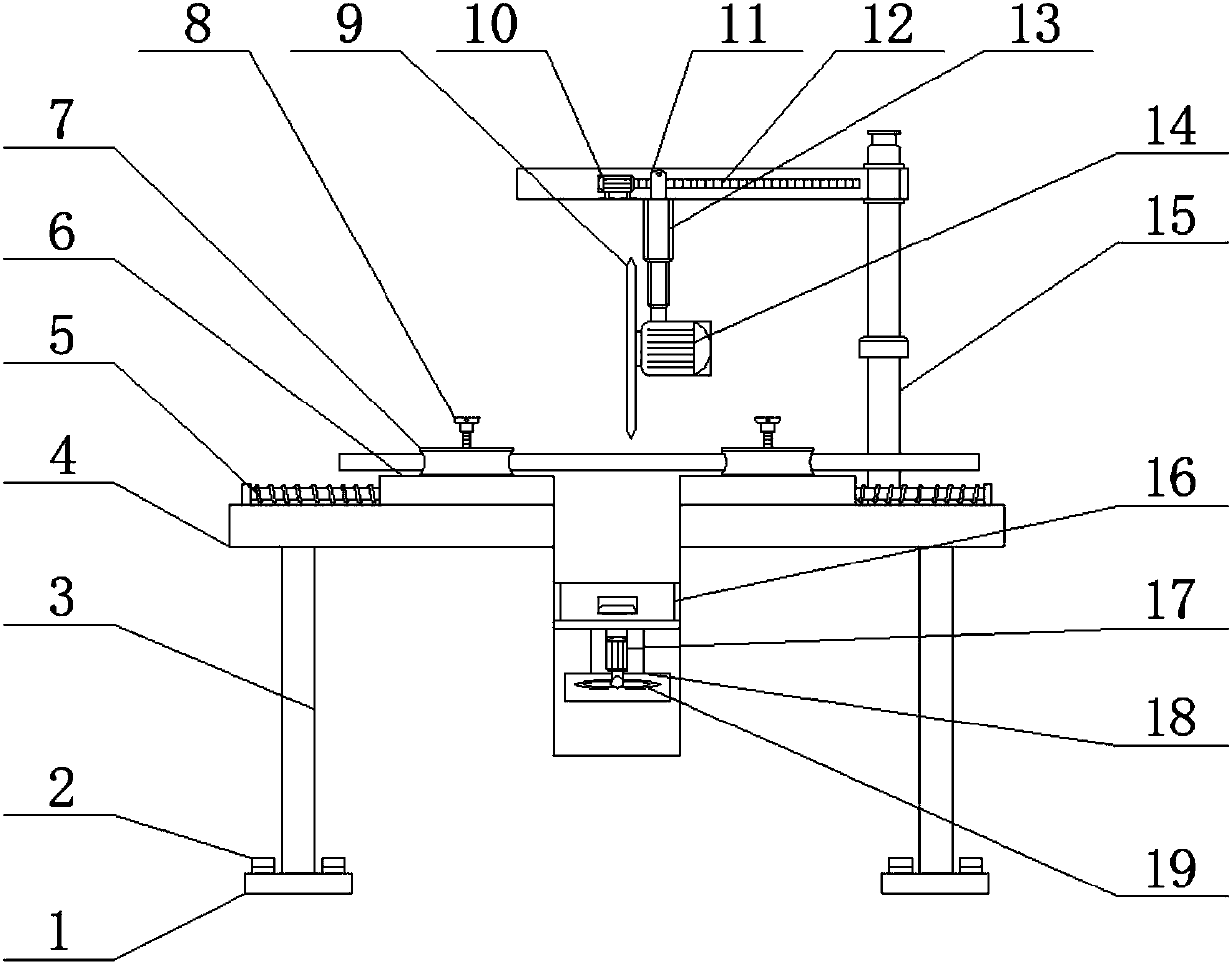

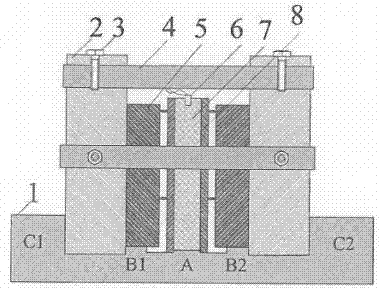

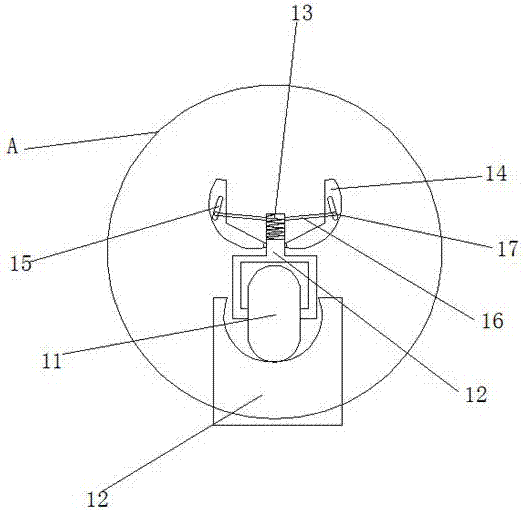

Coal mining device and crushing mechanism thereof

InactiveCN101906969AImprove crushing efficiencyPrevent flying outDriving meansEngineeringCentrifugal force

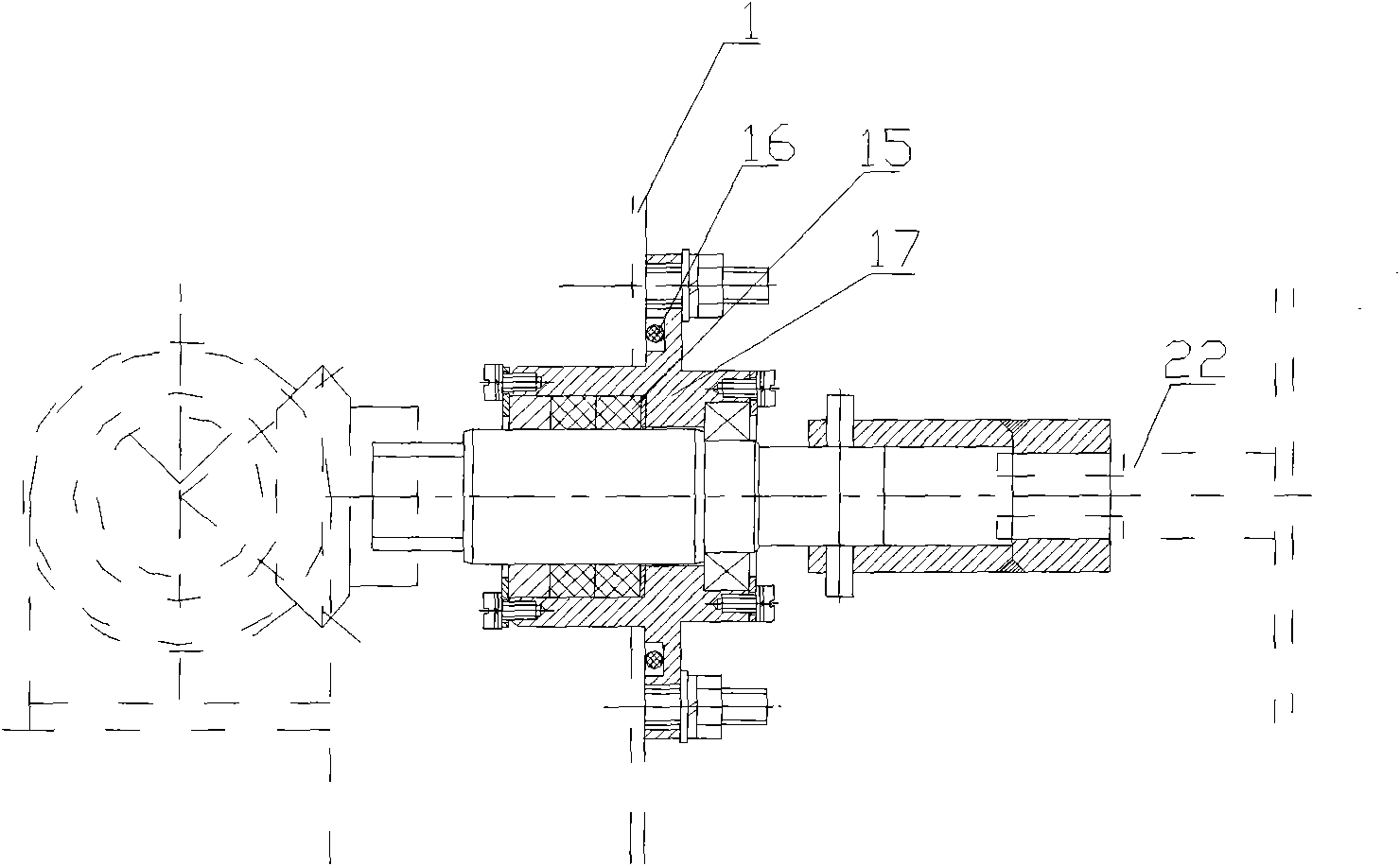

The invention discloses a crushing mechanism for a coal mining device, comprising a main body part (1), a power component installed on the main body part (1) and a work component (2) driven by the power component, wherein the power component is used for driving the work component (2) to do the reciprocating straight line motion. In the work process of the crushing mechanism, the straight line motion does not generate a centrifugal force, thereby preventing the crushed coals from flying out in crushing process and guaranteeing the personal safety of the staffs in the tunnel; meanwhile, the coal crushed by the straight line motion is not cut into powders so as to prevent coal dusts from flying in the tunnel and to improve the air quality in the tunnel; in addition, the single motion stroke of the straight line motion is large so as to improve the crushing efficiency of the crushing mechanism. The invention further discloses a coal mining device including the crushing mechanism.

Owner:SANY HEAVY EQUIP

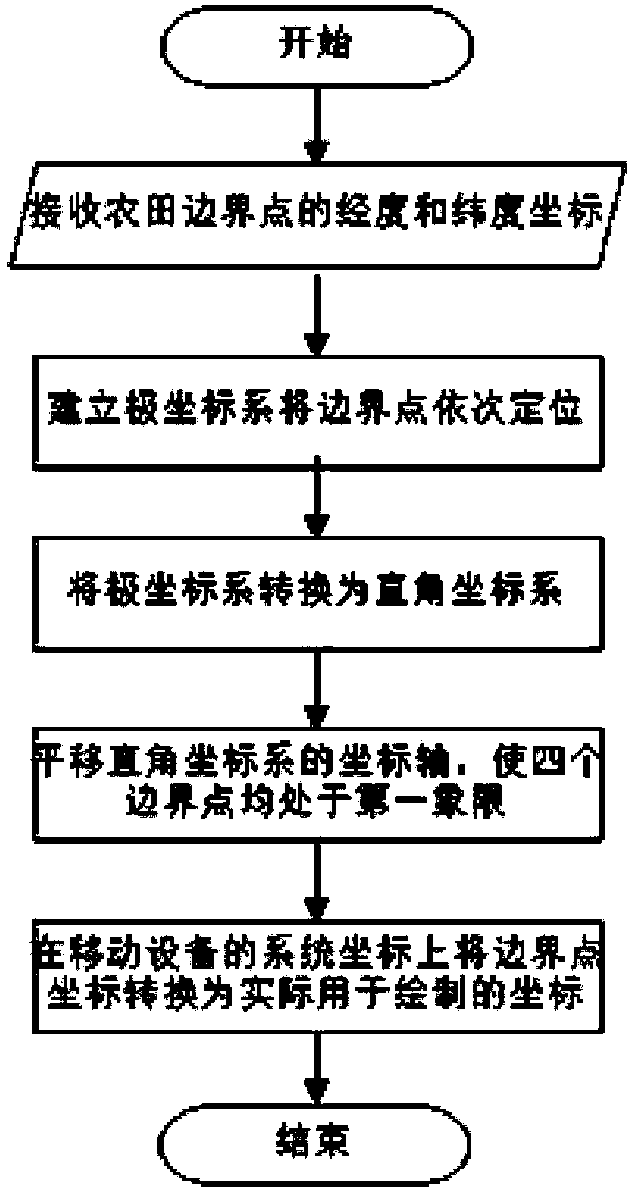

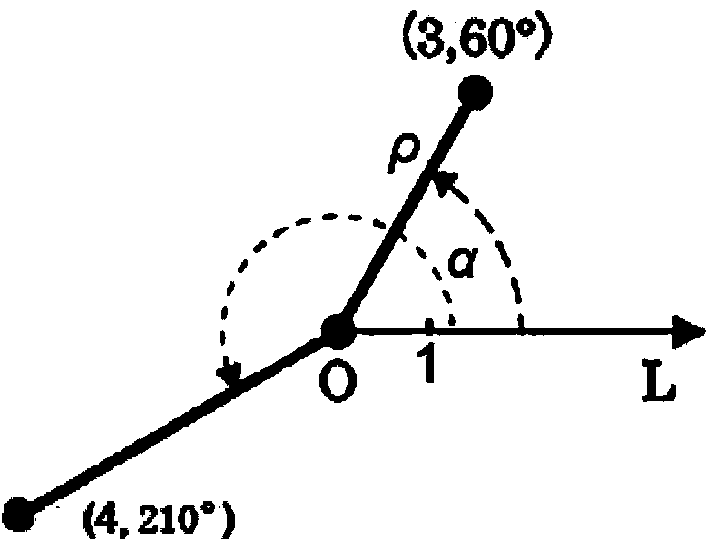

Farmland operation area boundary point and unmanned helicopter position point drawing method

ActiveCN103728637AImprove Boundary AccuracyImprove real-time performanceSatellite radio beaconingAir safetyRectangular coordinates

The invention discloses a farmland operation area boundary point and unmanned helicopter position point drawing method. The method includes the steps of determining an appropriate coordinate transformation system according to longitude and latitude information uploaded to a mobile device through a GPS module and a handheld GPS device which are carried by an unmanned helicopter, correctly expressing a farmland operation area boundary point, represented by the longitude transmitted by the handheld GPS device and the latitude transmitted by the handheld GPS device, as a coordinate point in a two-dimensional rectangular coordinate system with scales, drawing a farmland operation area boundary on a screen display program of the mobile device, converting the point represented by the longitude transmitted by the handheld GPS device of the unmanned helicopter and the latitude transmitted by the handheld GPS device of the unmanned helicopter into the coordinate point in the two-dimensional rectangular coordinate system where a farmland operation area is located, and drawing the real-time flight path of the unmanned helicopter. The farmland operation area boundary drawn through the method is extremely high in accuracy, good in instantaneity and high in reliability; the operation difficulty of an unmanned helicopter controller is greatly lowered, the air safety coefficient of the unmanned helicopter is increased, and the mechanical work efficiency is improved.

Owner:CENT SOUTH UNIV

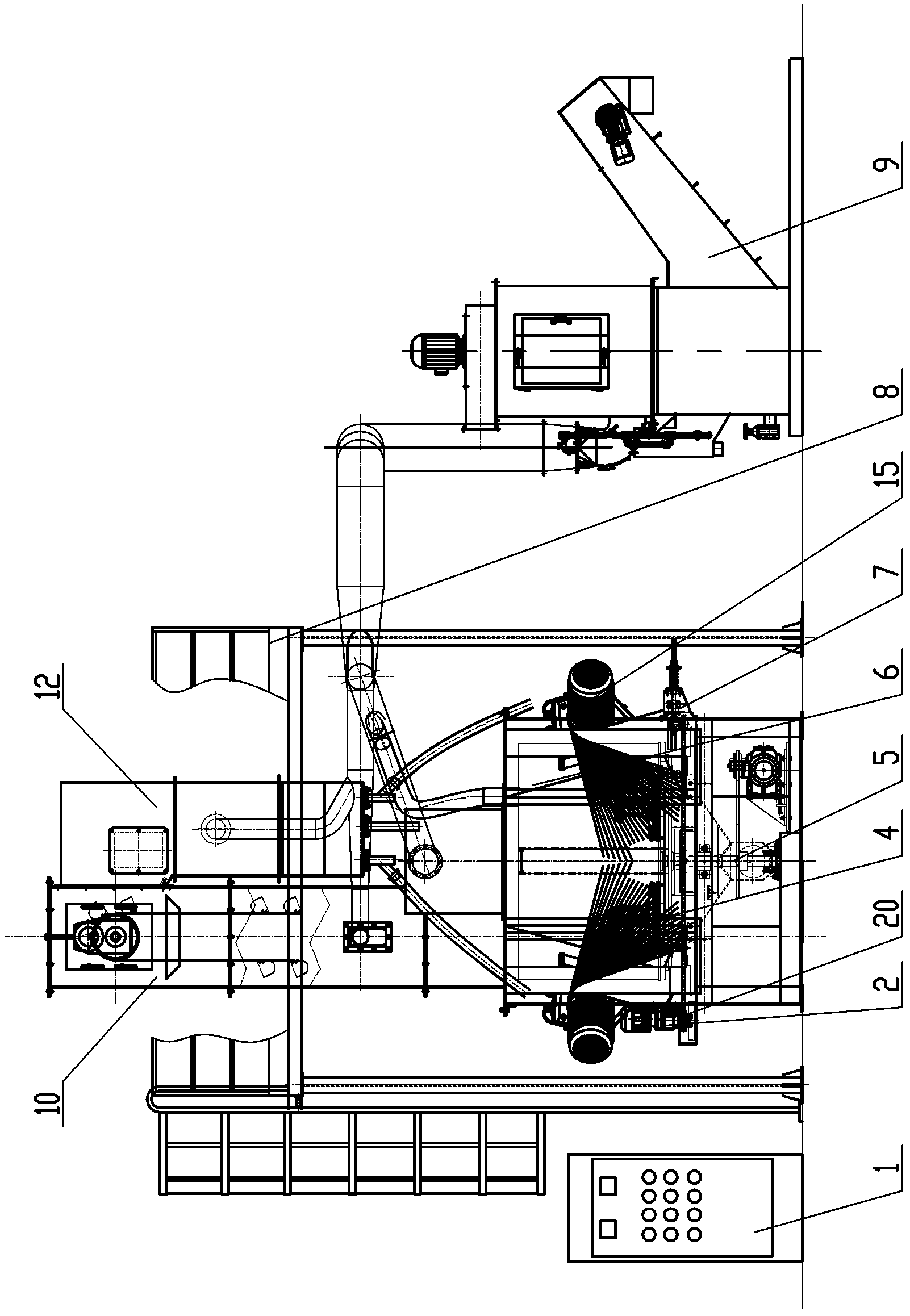

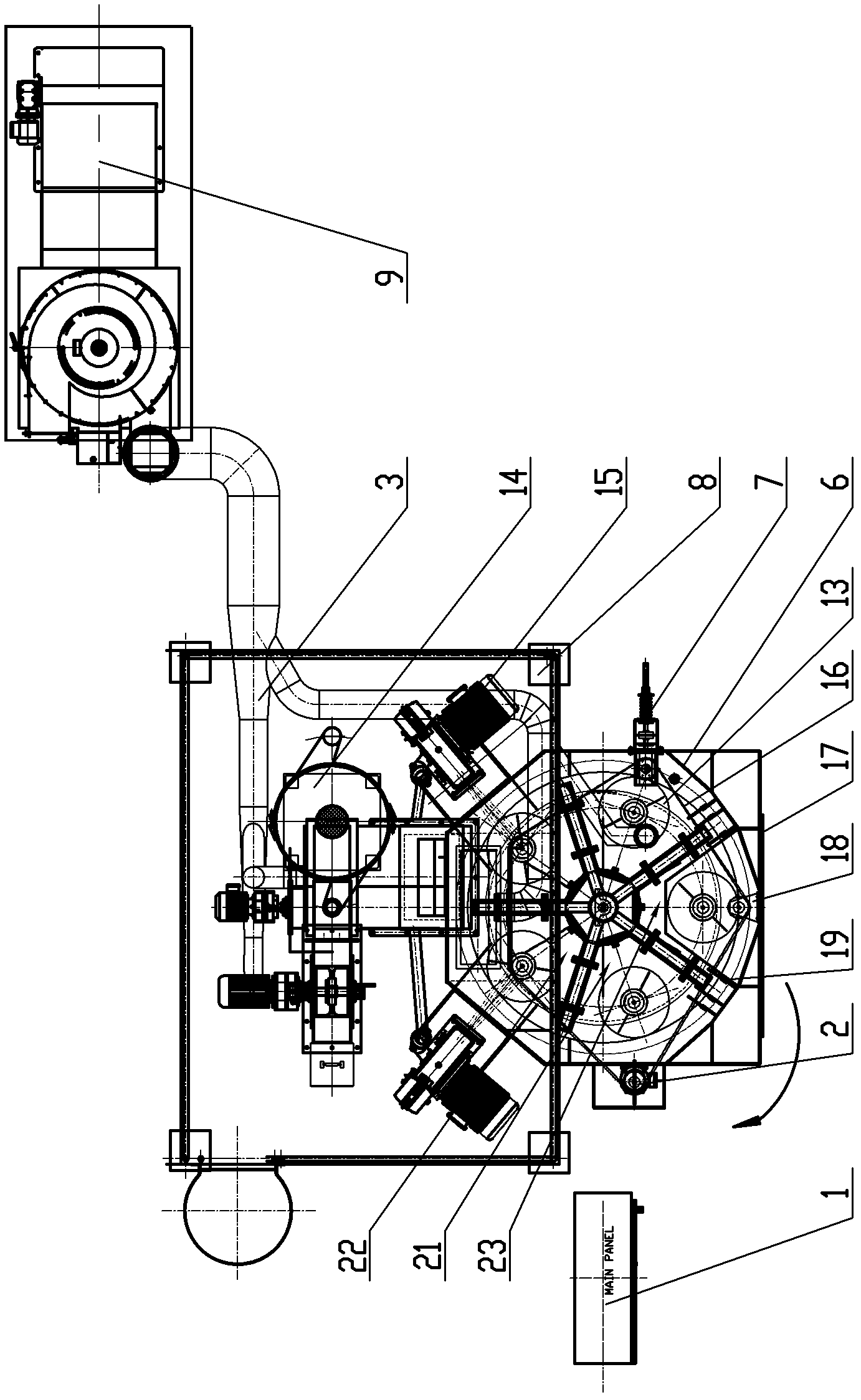

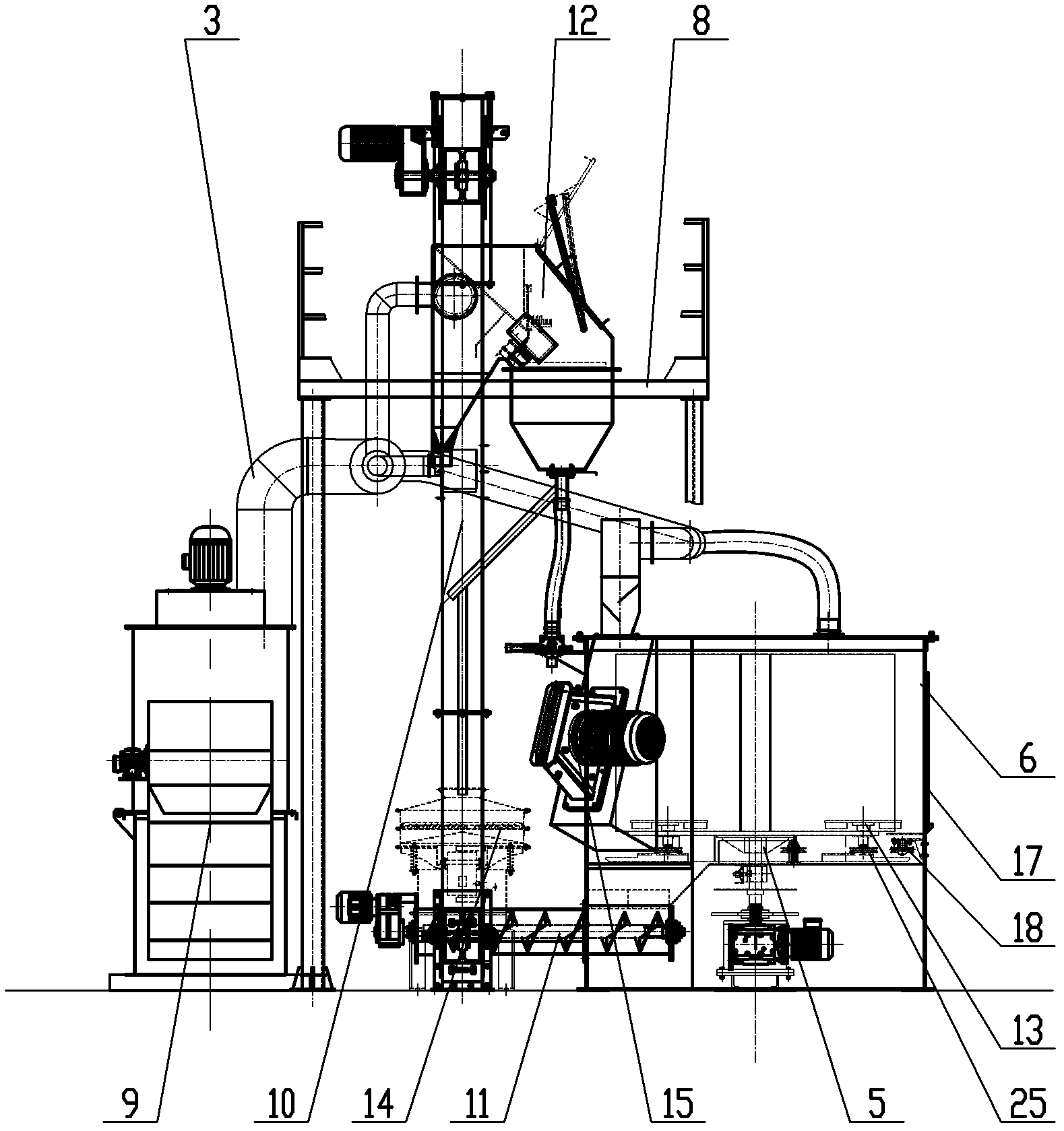

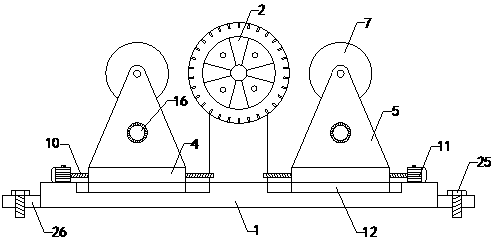

Reinforced shot blast machine for multi-position turntable

InactiveCN102248493APrevent flying outPrevent splashAbrasive blasting machinesEngineeringLoading unloading

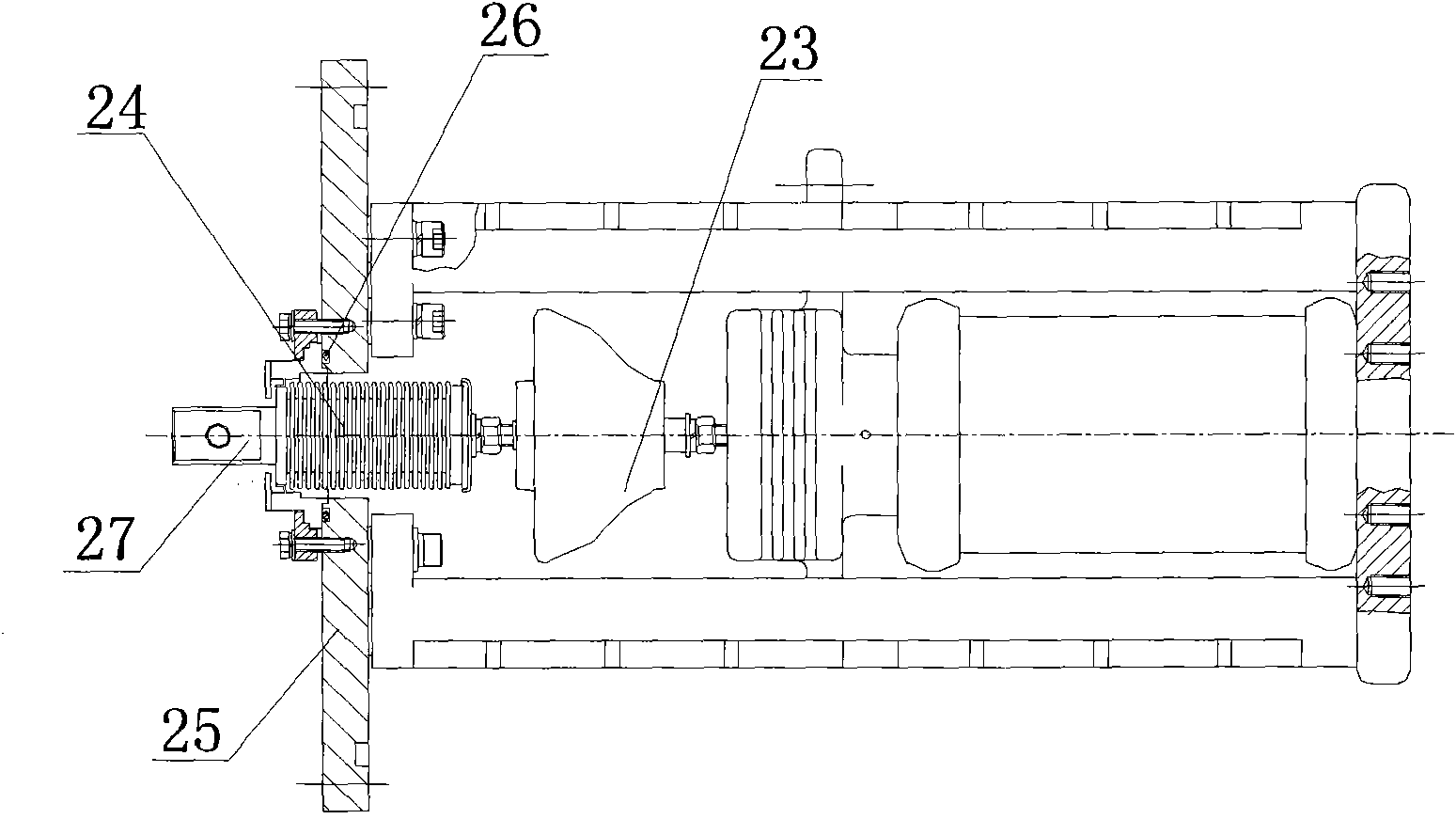

The invention relates to a reinforced shot blast machine for a multi-position turntable. A main rotary worktable is mounted in a shot blast cleaning room, a shot blast machine is arranged out of the shot blast cleaning room, a steel shot selector is fixed above the shot blast cleaning room, a helical conveying device is fixed below the shot blast cleaning room, a hopper-type lifter is arranged behind the shot blast cleaning room, a feeding port and a discharging port of the hopper-type lifter are respectively connected with the helical conveying device and the steel shot selector, a discharging port of a steel shot separator is connected with the shot blast machine; the main rotary worktable is fixed with a partition wall assembly for partitioning the table-board of the main rotary worktable into five stations which are respectively two shot blast stations, two isolation stations and a loading-unloading station, and each station is rotatably equipped with a planetary worktable. The main rotary worktable is partitioned into the shot blast stations, the isolation stations and the loading-unloading station, the isolation stations are arranged between the loading-unloading station andthe shot blast stations with the effect of sealing; therefore, the shot can be prevented from flying out from the shot blast station, and the security is good.

Owner:无锡国达机械设备有限公司

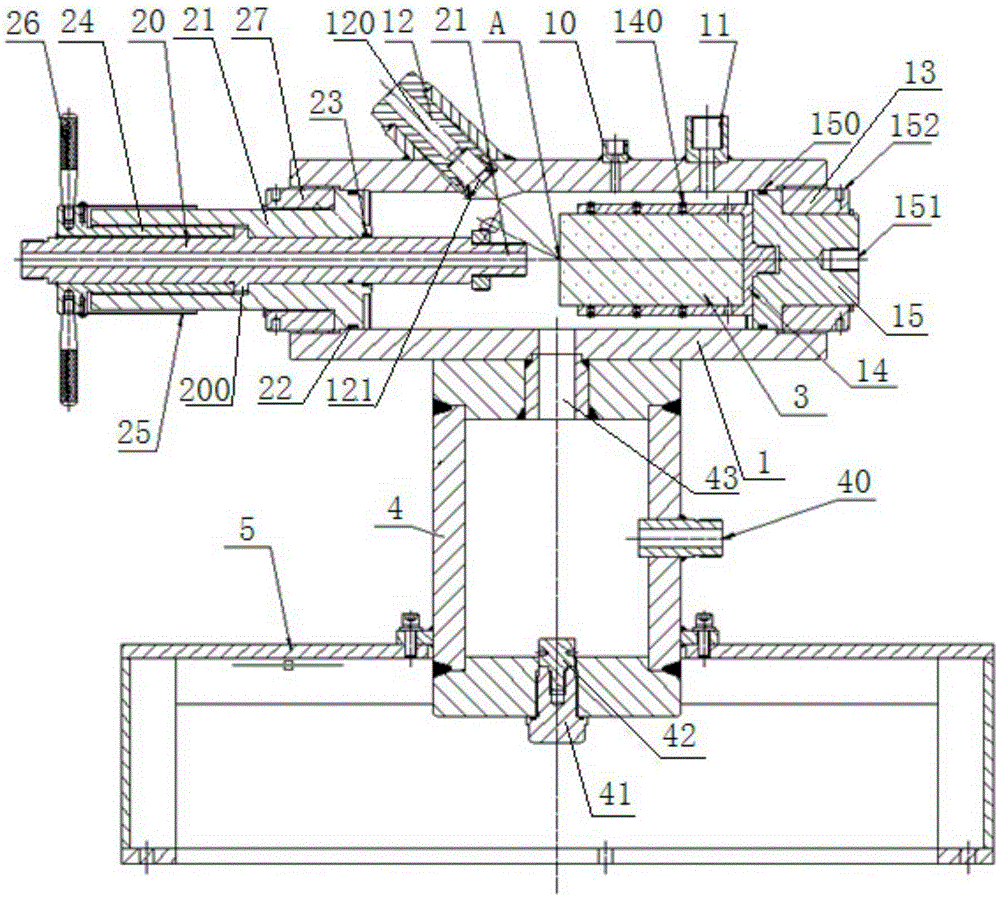

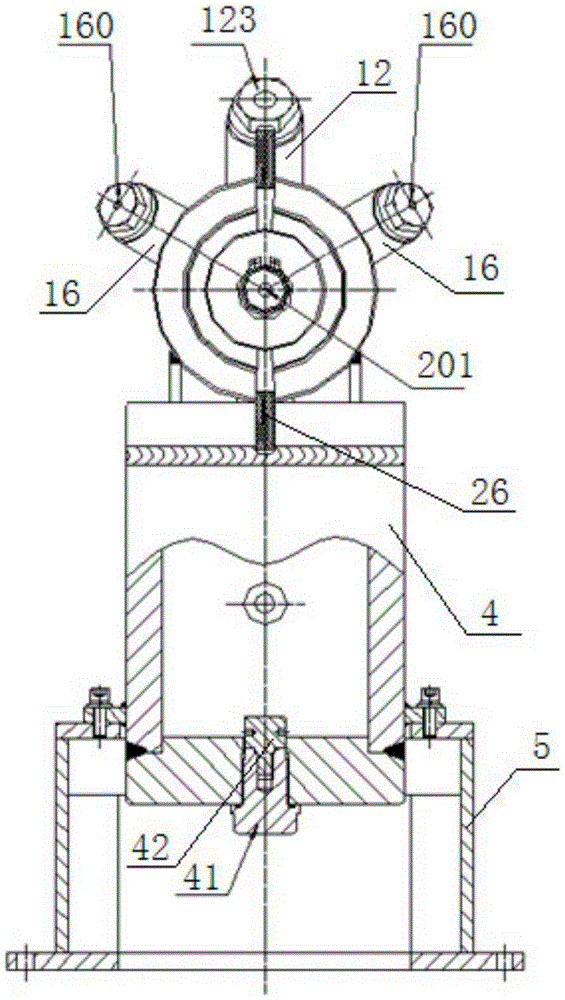

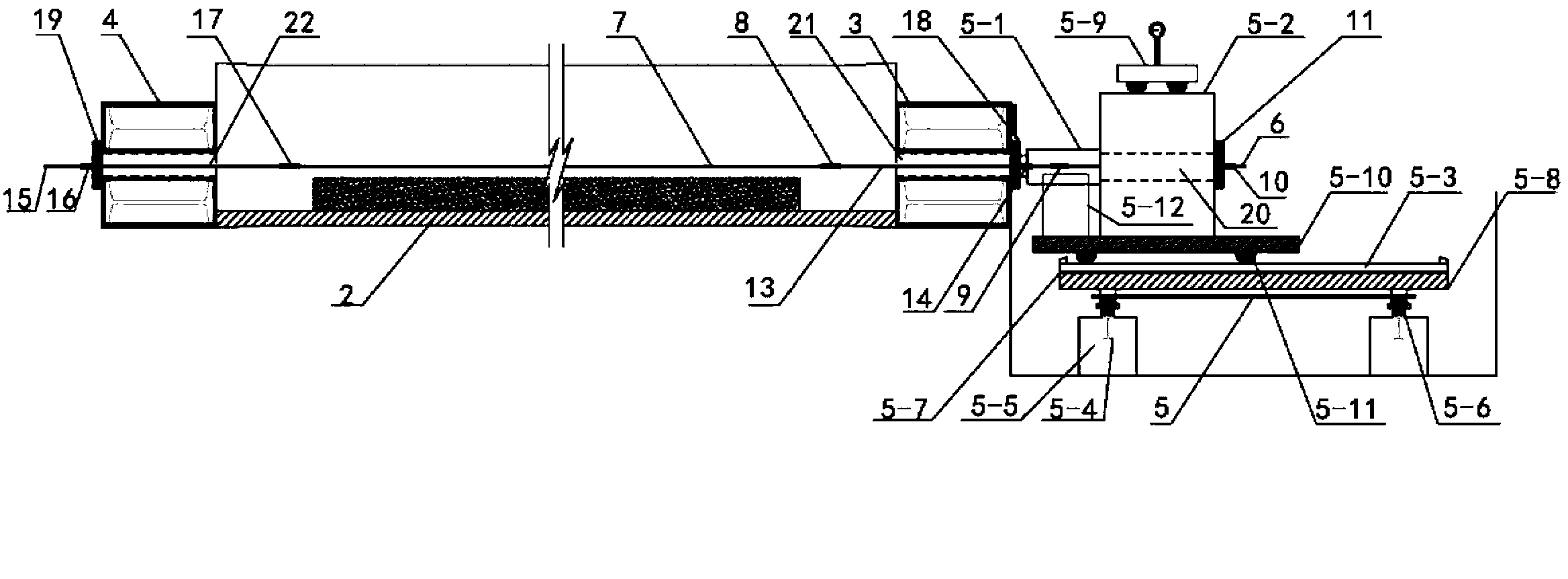

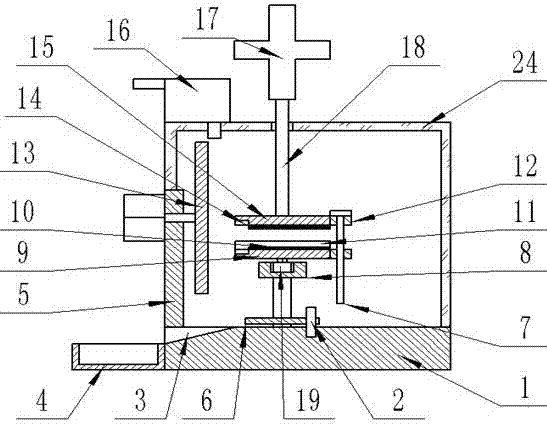

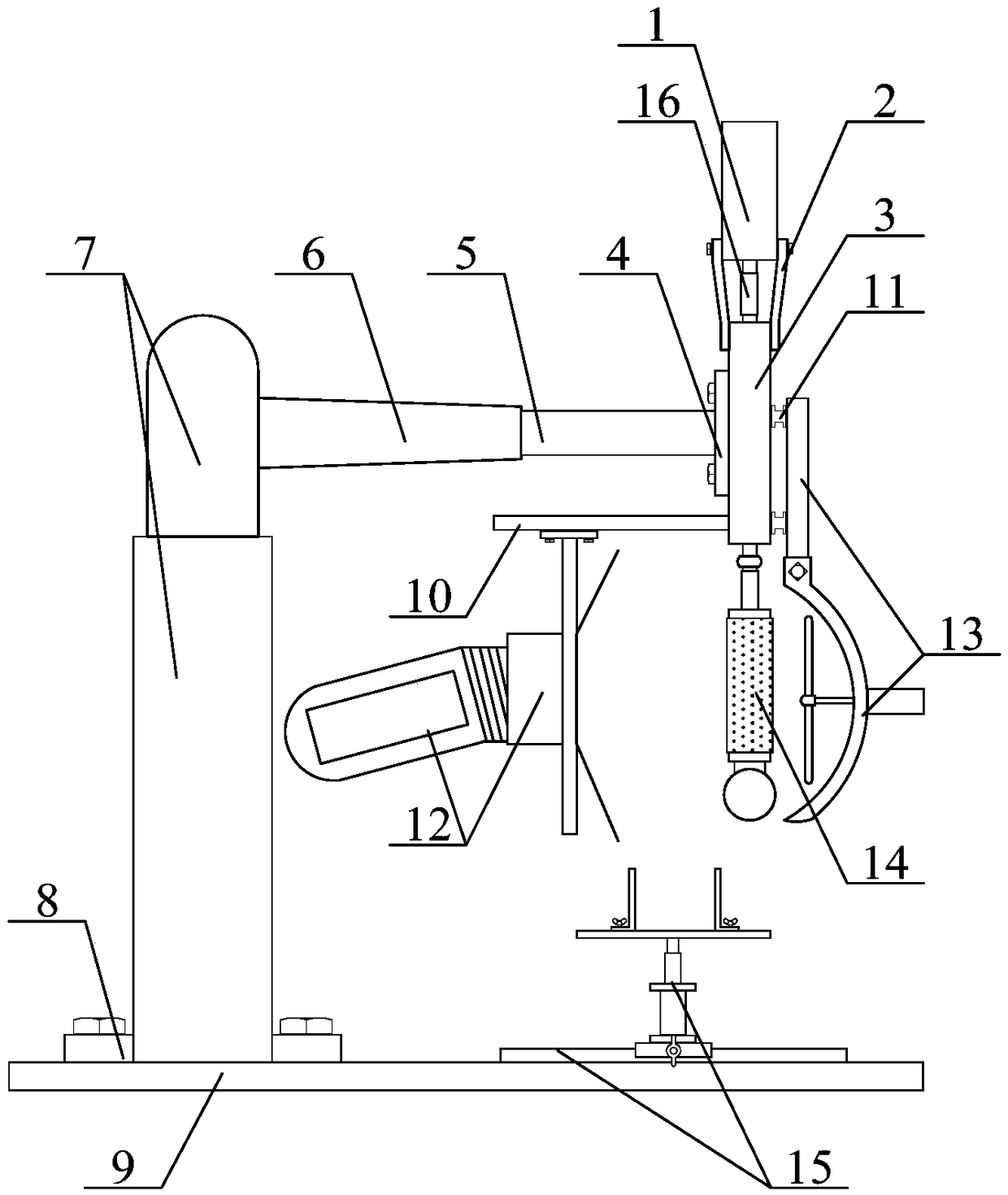

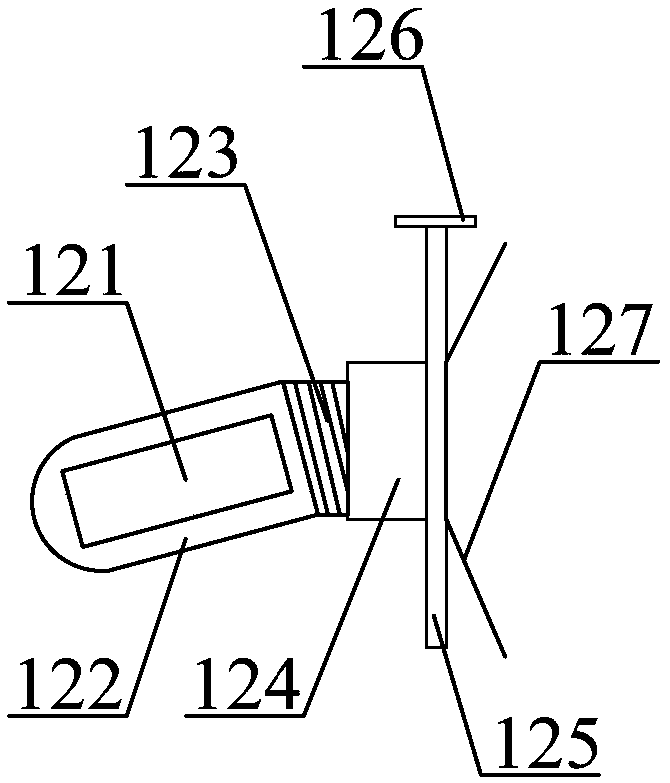

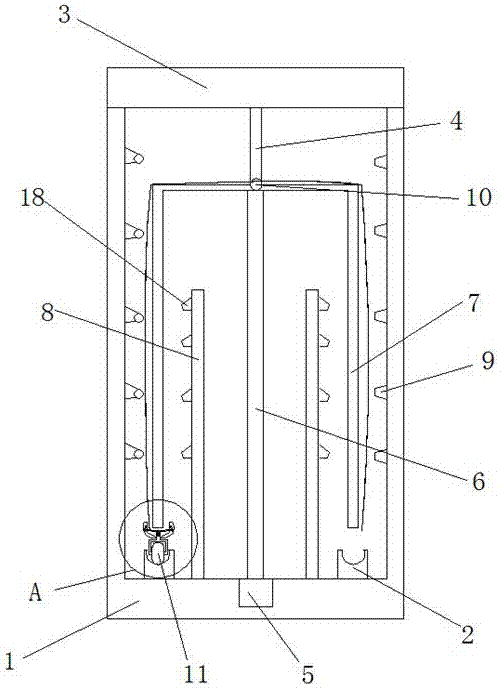

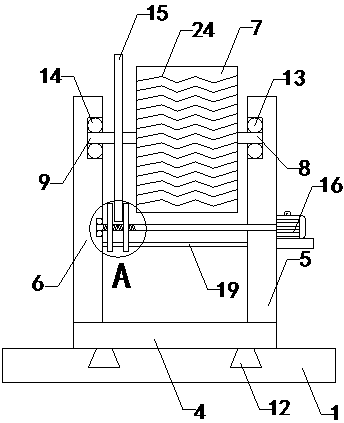

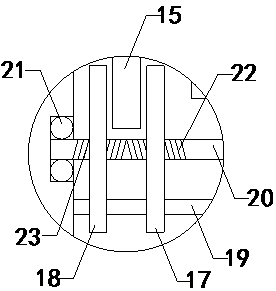

Downhole confining pressure abrasive material jet flow simulation experimental device and method

ActiveCN105234826ASimple structureRecord motion trackBlast gunsAbrasive machine appurtenancesEngineeringHigh pressure

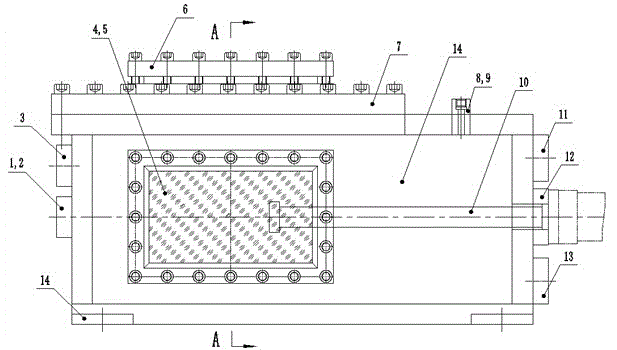

The invention relates to a downhole confining pressure abrasive material jet flow simulation experimental device and method. The downhole confining pressure abrasive material jet flow simulation experimental device comprises a confining pressure barrel. A nozzle installation adjustment component is arranged at the left end of the confining pressure barrel. A test-piece clamping component is arranged at the right end of the confining pressure barrel. A pressure meter used for measuring the pressure in the confining pressure barrel and a safety valve used for decompression are arranged on the wall of the confining pressure barrel. A visual nozzle and lighting nozzles are arranged at the top of the confining pressure barrel, and the center hole of the visual nozzle and the center holes of the lighting nozzles are communicated with the confining pressure barrel. A sapphire high-pressure resistant lens is installed at the bottom end of the center hole of the visual nozzle in a sealed mode. A high-speed camera directly facing the sapphire high-pressure resistant lens is arranged in the visual nozzle. Optical fiber light sources are installed in the center holes of the lighting nozzles in a sealed mode. A material storage tank is communicated with the bottom of the confining pressure barrel. A closed cavity is formed by the confining pressure barrel and the material storage tank. The material storage tank is installed on a base. The invention further provides a downhole confining pressure abrasive material jet flow simulation experimental method. According to the scheme, the problems that an existing experimental device is low in pressure bearing capacity and inconvenient to operate and the experimental process is not observed clearly are solved.

Owner:CHONGQING UNIV

Box-sharing gas-insulated metal enclosed switching device

InactiveCN102044849AReduce volumeReduce areaBus-bar/wiring layoutsSwitchgear arrangementsTransformerPotential transformer

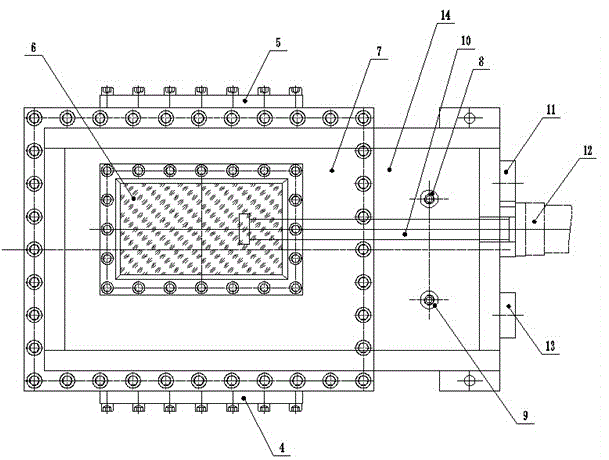

The invention discloses a box-sharing gas-insulated metal enclosed switching device. An upper sealed air box and a lower sealed air box are arranged in a cabinet body; a three-position isolating switch, a main bus casing and a main bus are arranged in the upper air box; an output shaft of a three-position spring operating mechanism extends into the upper air box and is connected with the three-position isolating switch through a rotary sealed connector; the three-position isolating switch is connected with a vacuum circuit breaker in the lower air box through a bus connector; the vacuum circuit breaker is connected with a spring mechanism through a metal corrugated pipe sealing mechanism; the vacuum circuit breaker is connected with an inner conical insulator which is sealed and fixed on the wall of the lower air box through a lead; and the inner conical insulator is inserted into a voltage transformer, a cable joint, a zero sequence transformer and a lightning arrester respectively. The switching device has the characteristics of good sealing effect, long service life, small size and wide application range and is safe and reliable.

Owner:昇辉智能科技股份有限公司

Submerging jet flow testing box and testing method

ActiveCN102721525AEffectively withstandGuaranteed reliabilityMachine part testingHydrodynamic testingParticle imagingJet flow

The invention discloses a submerging jet flow testing box and a testing method. The testing box includes a box body, jet flow water inlets, a vision window, a pressure gauge interface, a relief port, a clamp holder, a feeding device interface, a liquid stream valve port, a drainage port and the like. During the laboratory experiment process, a submerging fluid field environment is improved, and the approximate engineering practical submerging jet flow is simulated; other testing instrument is combined, the submerging jet flow fluid field structure is observed; the potential core of jet under the submerging condition is observed combined with a three dimensional laser particle imaging velocimeter (3DPIV) system; the variation of different jet nozzle jet flow fluid field structures is analyzed, and the internal structures of the jet nozzles are optimized; the accelerating mechanism and distribution condition of grinding material particles during the submerging grinding material jet flow testing are analyzed; and meanwhile, the observation experiment for cutting and flushing material under the submerging condition can be performed. The submerging jet flow testing box and the testing method have the advantages that the structure is simple, the operation is convenient, nozzles can be replaced easily, a plurality of testing functions are provided, and compared with other jet flow testing devices, the submerging jet flow testing box not only can test the jet flow fluid field structure under the submerging condition, but also can be reutilized repeatedly, thereby saving the experimental expense at the same time.

Owner:CHONGQING UNIV

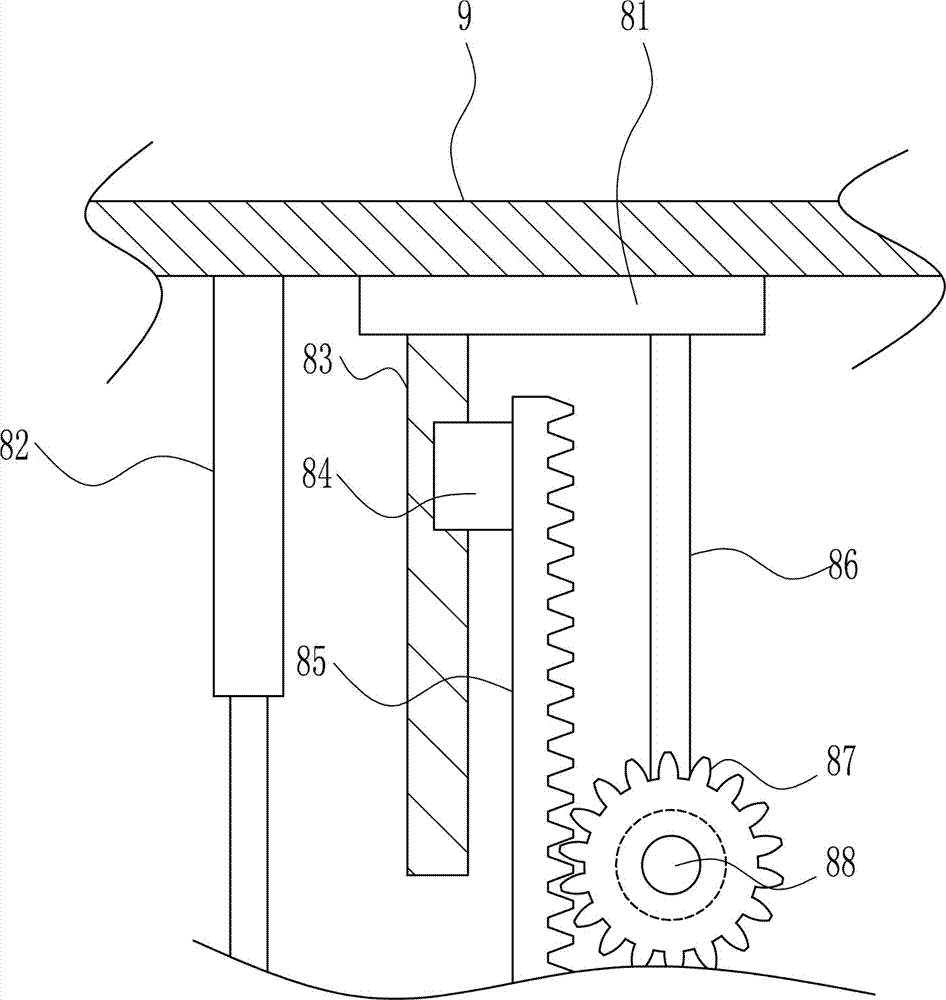

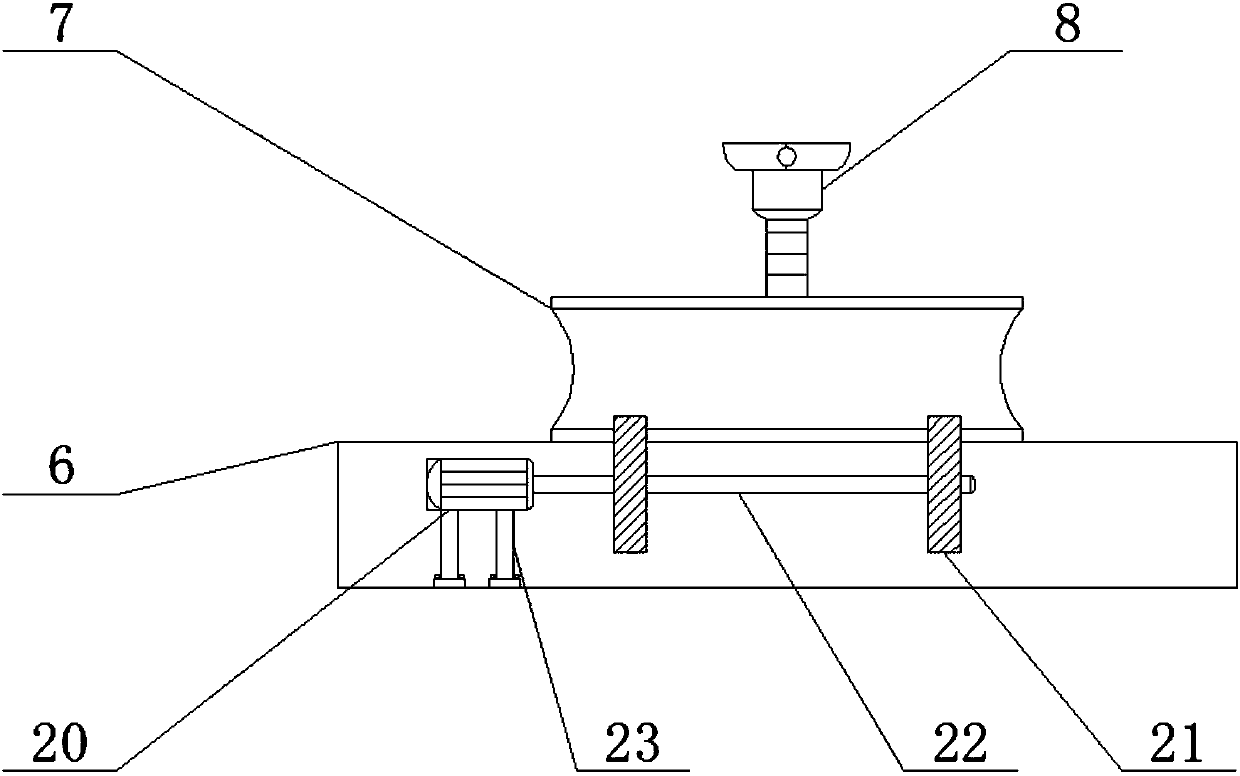

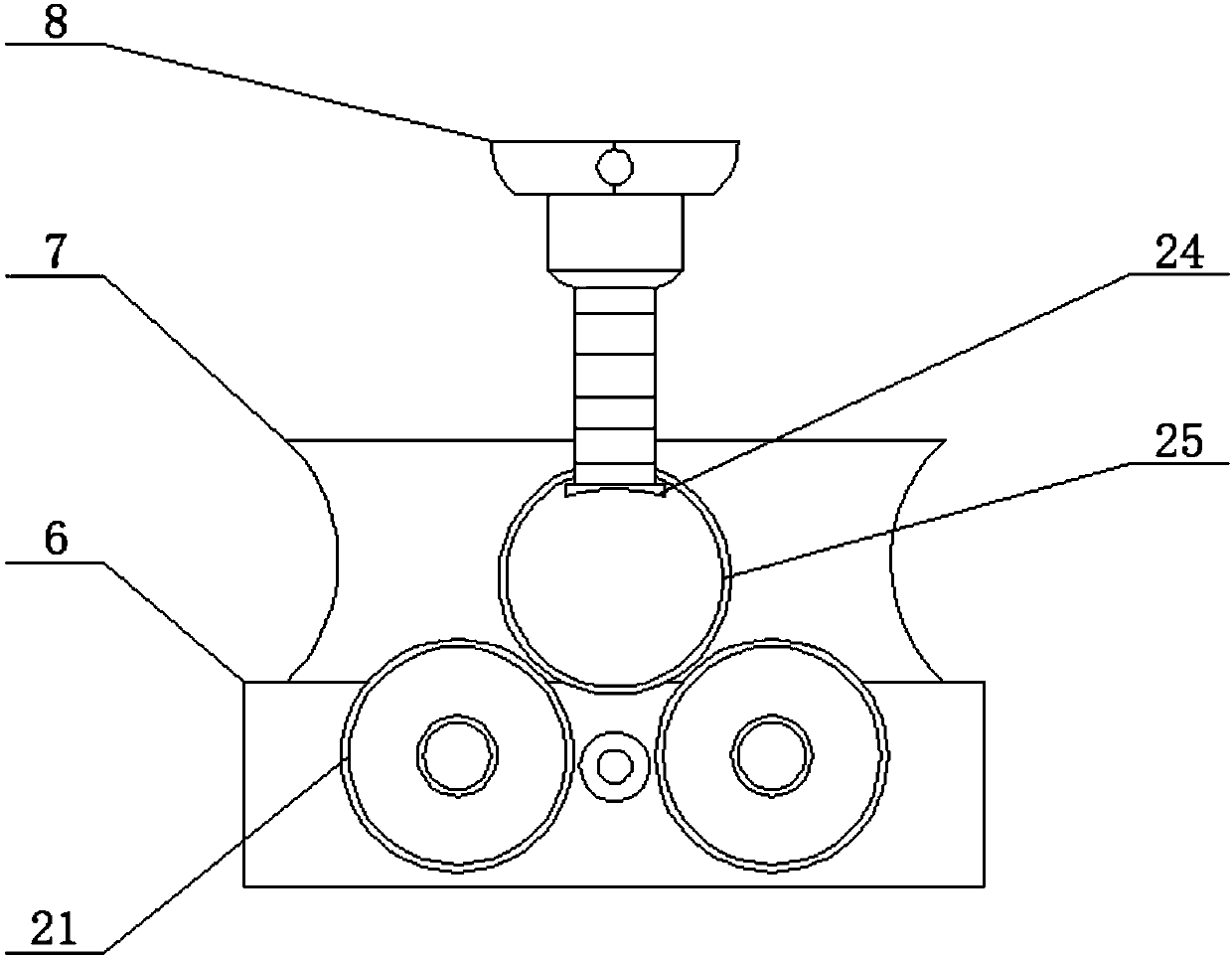

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

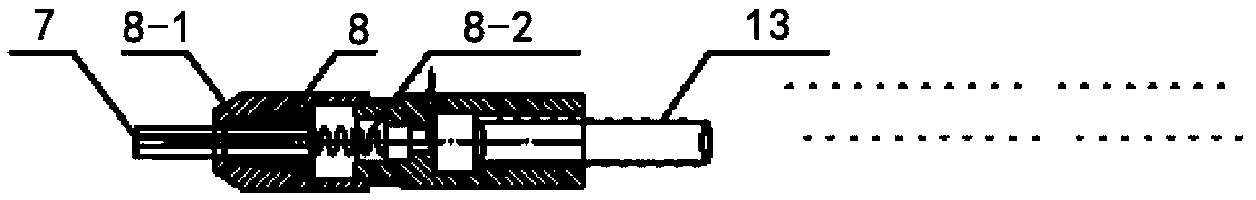

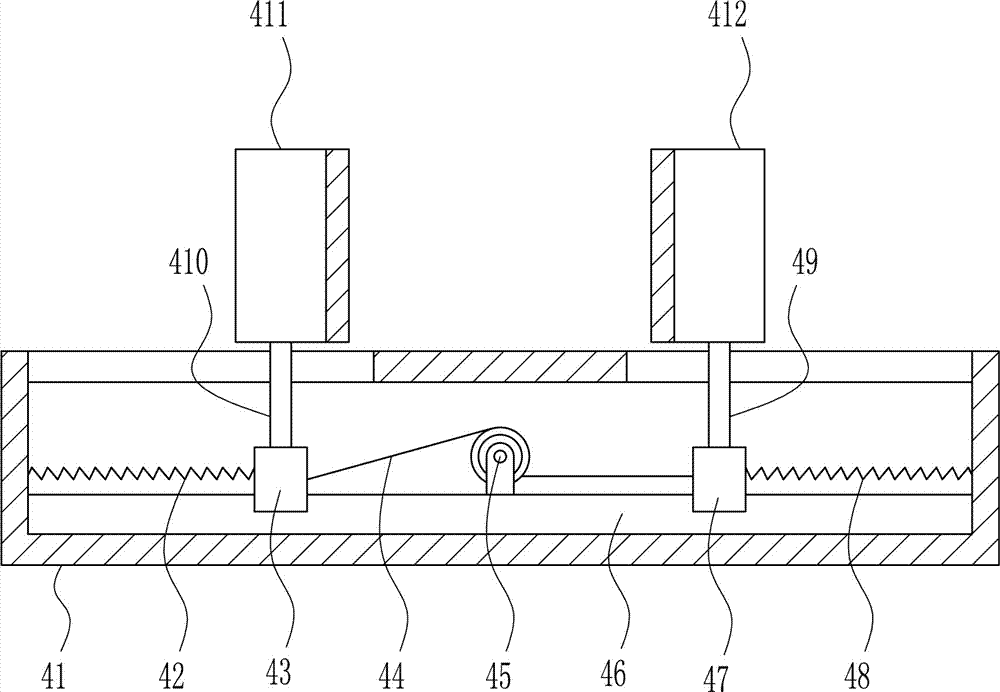

Pre-tensioning method plate-beam track movable type steel transverse beam integer tensioning device and tensioning technology

ActiveCN103255718AImprove construction progressShorten the timeCeramic shaping apparatusBridge erection/assemblyBridge typeMovable type

The invention relates to a pre-tensioning method plate-beam track movable type steel transverse beam integer tensioning device and a tensioning technology. The pre-tensioning method plate-beam rail movable type steel transverse beam integer tensioning device comprises a tensioning end fixing steel transverse beam, an anchoring end fixing steel transverse beam, steel strands, beam restraining table bases arranged between the tensioning end fix fixing steel transverse beam and the anchoring end fixing steel transverse beam, a force transmission column arranged on one side of each beam restraining table base, a track movable type platform arranged on one side of the tensioning end fix fixing steel transverse beam and up-and down adjusting steel plates, wherein the up-and-down steel plates are connected on the tensioning end fixing steel transverse beam, the anchoring end fixing steel transverse beam and a lifting jack moving transverse beam in a buckling mode, and each steel strand is provided with two dual-connecting elements, a single connecting element and three sections of precision rolling twisted steel bars. The pre-tensioning method plate-beam track movable type steel transverse beam integer tensioning device is further provided with a pre-tensioning plate lifting device. The pre-tensioning method plate-beam track movable type steel transverse beam integer tensioning device can conduct construction on multiple beams simultaneously, saves materials, is safe, reliable, capable of being used in multiple times, suitable for construction of all bridge types, simple in operation, continuous in construction and suitable for construction of all beam-plate types, and improves effects. The pre-tensioning plate lifting device is capable of rotating at 360 degrees, storage of movable beams is convenient, occupation of a crane is reduced, and efficiency is improved.

Owner:CCCC THIRD HIGHWAY ENG +1

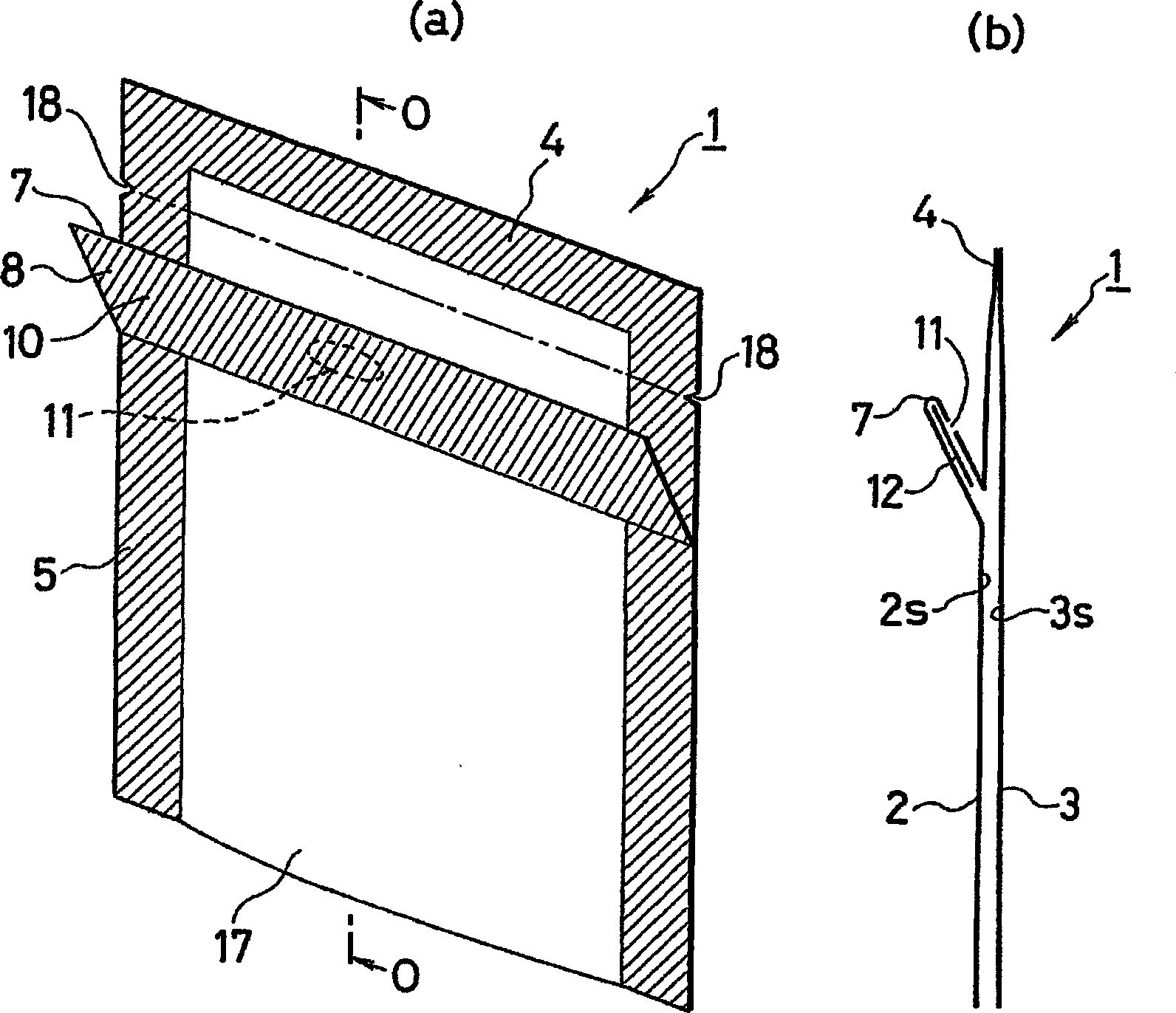

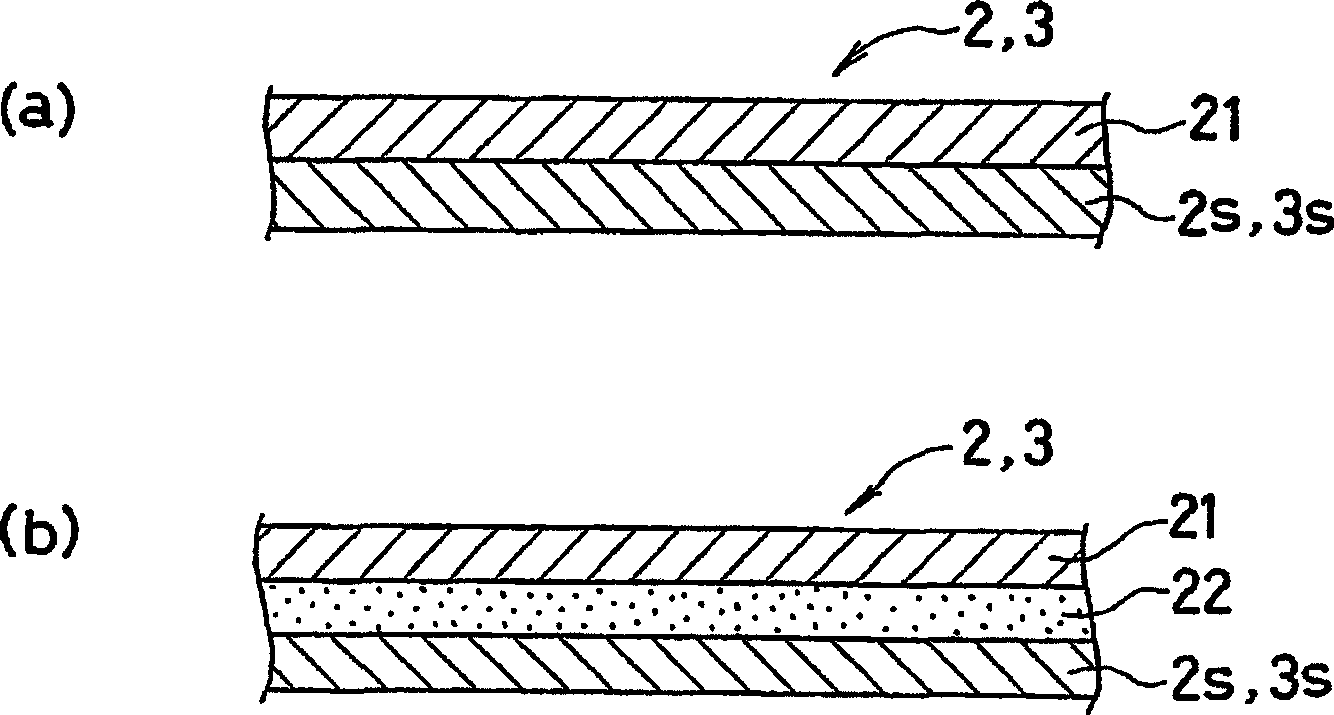

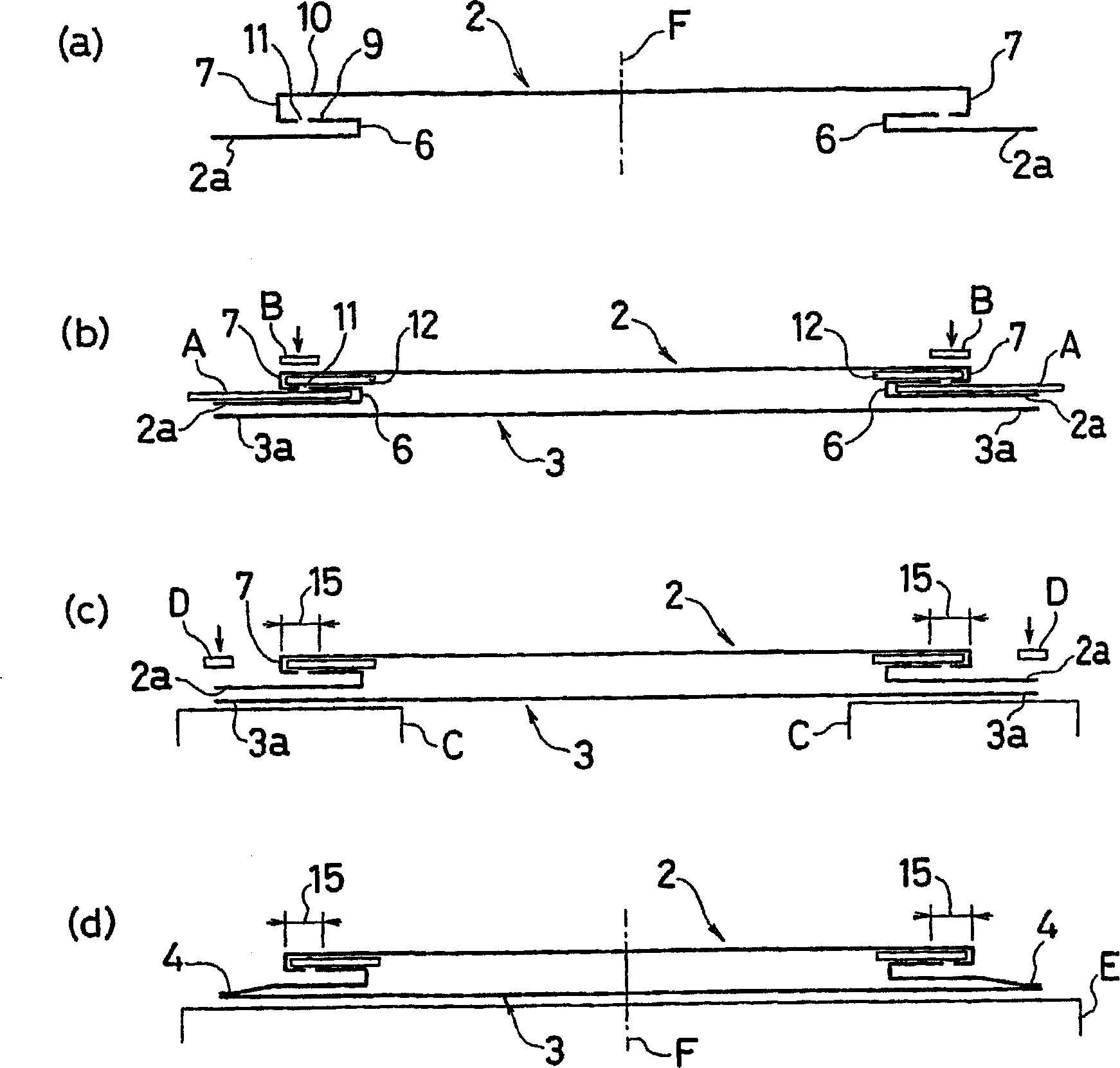

Packaging bag with steam releasing function and packaging body using the packaging bag

A packaging bag with steam releasing function capable of releasing pressure inside a packaging body even when heating cooking is performed by a microwave oven and preventing the inside of the bag from being contaminated and the packaging body using the packaging bag. The packaging bag (1) comprises two sheets of front and rear body films (2) and (3) having sealant layers (2s) and (3s) which are opposed to each other with the sealant layers facing inward, side seal parts (5), and a bottom seal part (4). The front body film (2) is bent near the bottom seal part (4) throughout the entire width of the bag and parallel with the bottom seal part to form a folded part (8). A steam releasing port (11) is formed in the folded part (8), and an easy peeling tape (12) covering the steam releasing port (11) is disposed on the inside of the folded part (8) throughout the width of the bag and parallel with the folded part (8), and then heat-sealed.

Owner:TOPPAN PRINTING CO LTD

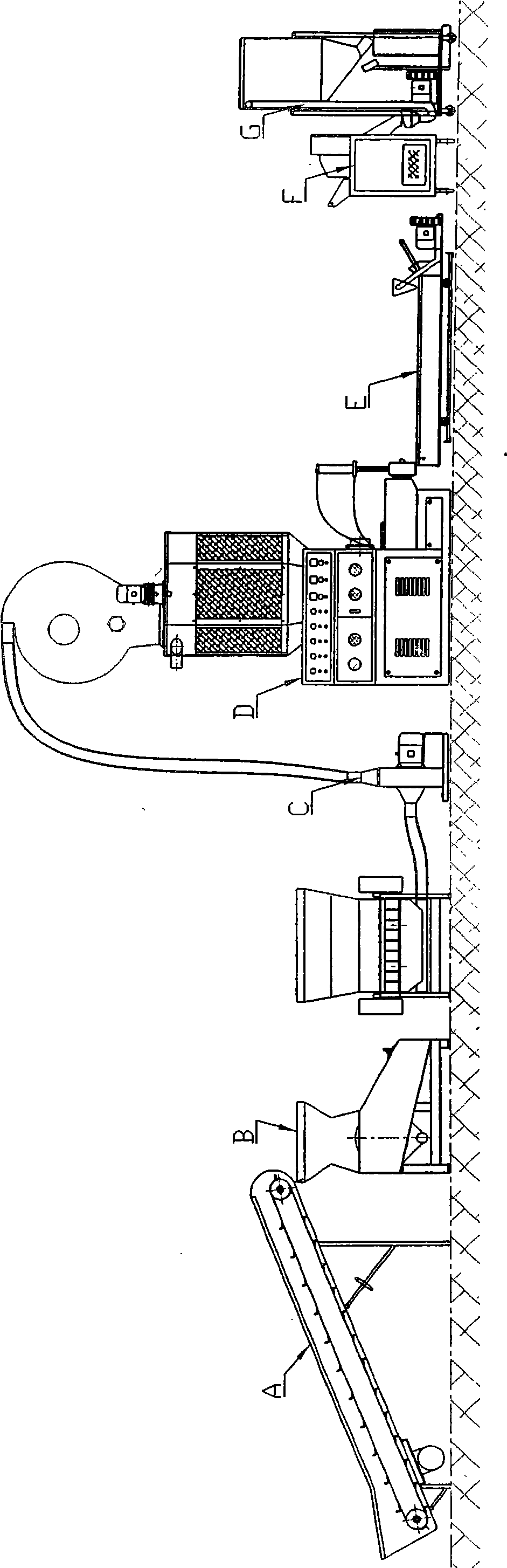

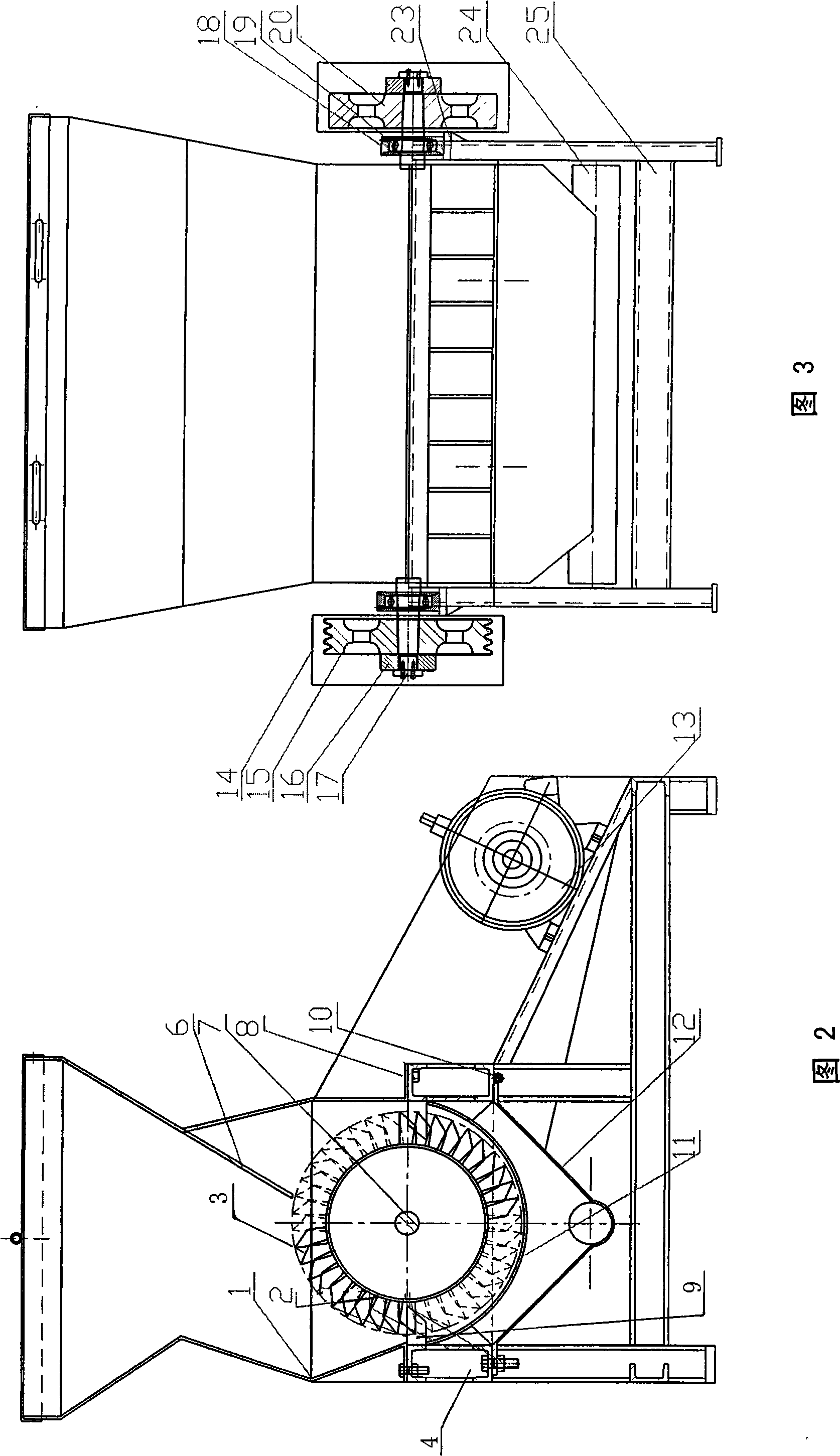

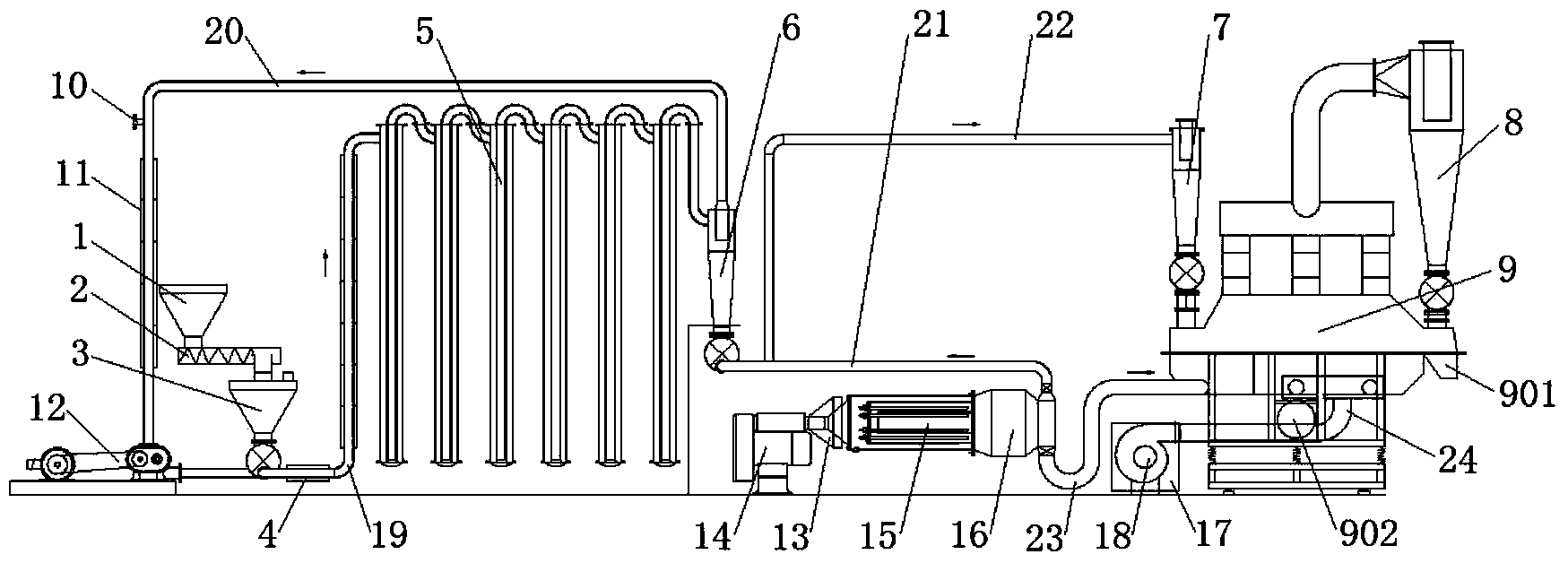

Environment friendly recycling prilling unit for plastic foam

InactiveCN101486234AEasy accessEasy access to crushing processGrain treatmentsMaterial supplyEnergy loss

The invention relates to a foamed plastic environment-friendly recovery granulating machine set. A pulverizer comprises a feeding main body, a pulverizing roller which is arranged in the feeding main body, a screen mesh plate which is arranged below the pulverizing roller and a wind gathering discharge hopper which is connected with the feeding main body. A conveyer pipeline comprises a radial material loading pipeline consisting of a material loading blower and a pipeline, a tangential feeder which is connected with the radial material loading pipeline and a regular polygon feeding tank which is connected with the tangential feeder. A host machine comprises a primary compression extruding part and a secondary compression extruding part which is connected with the primary compression extruding part. The foamed plastic environment-friendly recovery granulating machine set adopts a closed circular material supply system, improves the environment-friendly regeneration utilization rate, reduces the recovery cost, saves the energy loss, and reduces the recovery secondary pollution.

Owner:余姚市绿岛橡塑机械设备有限公司

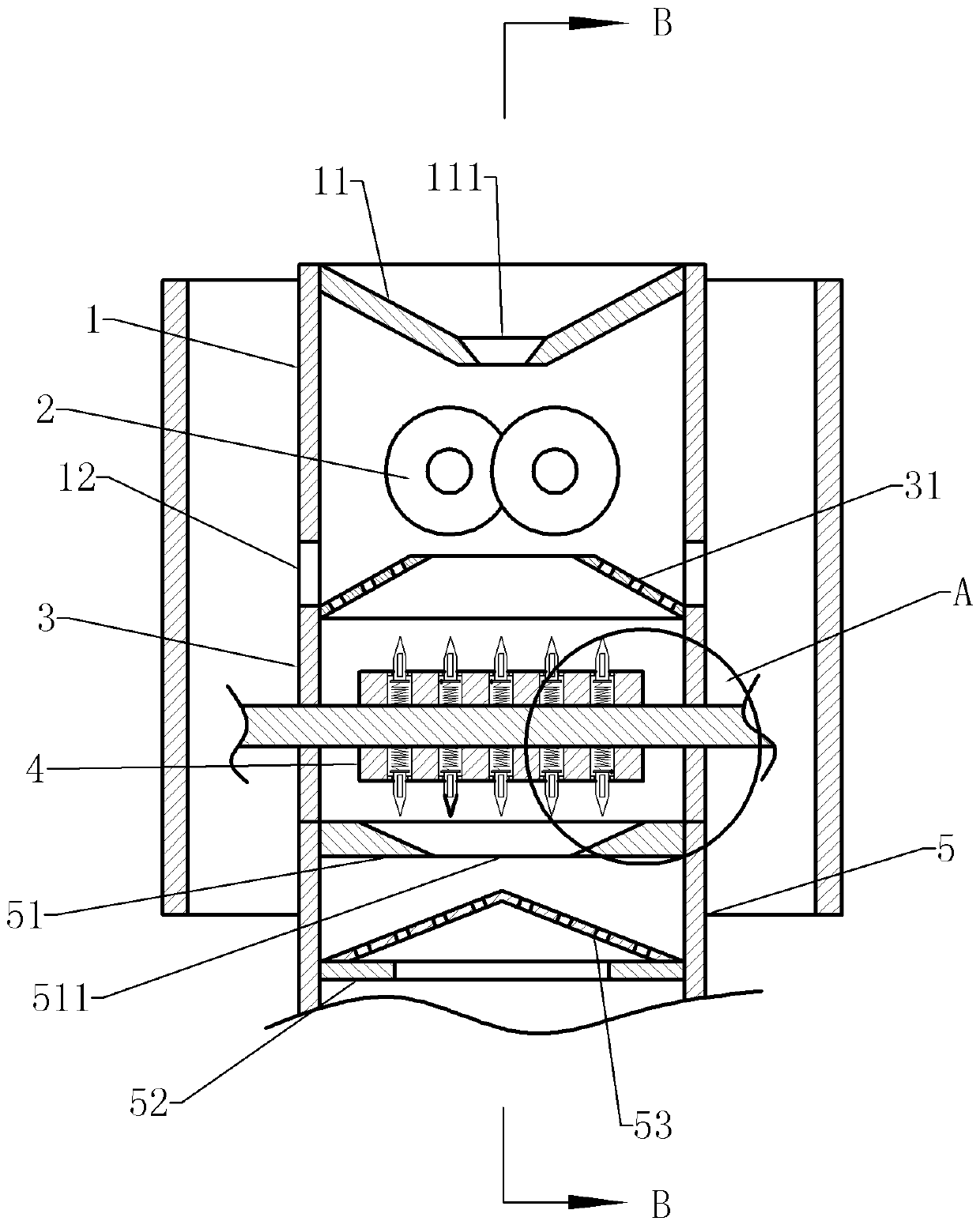

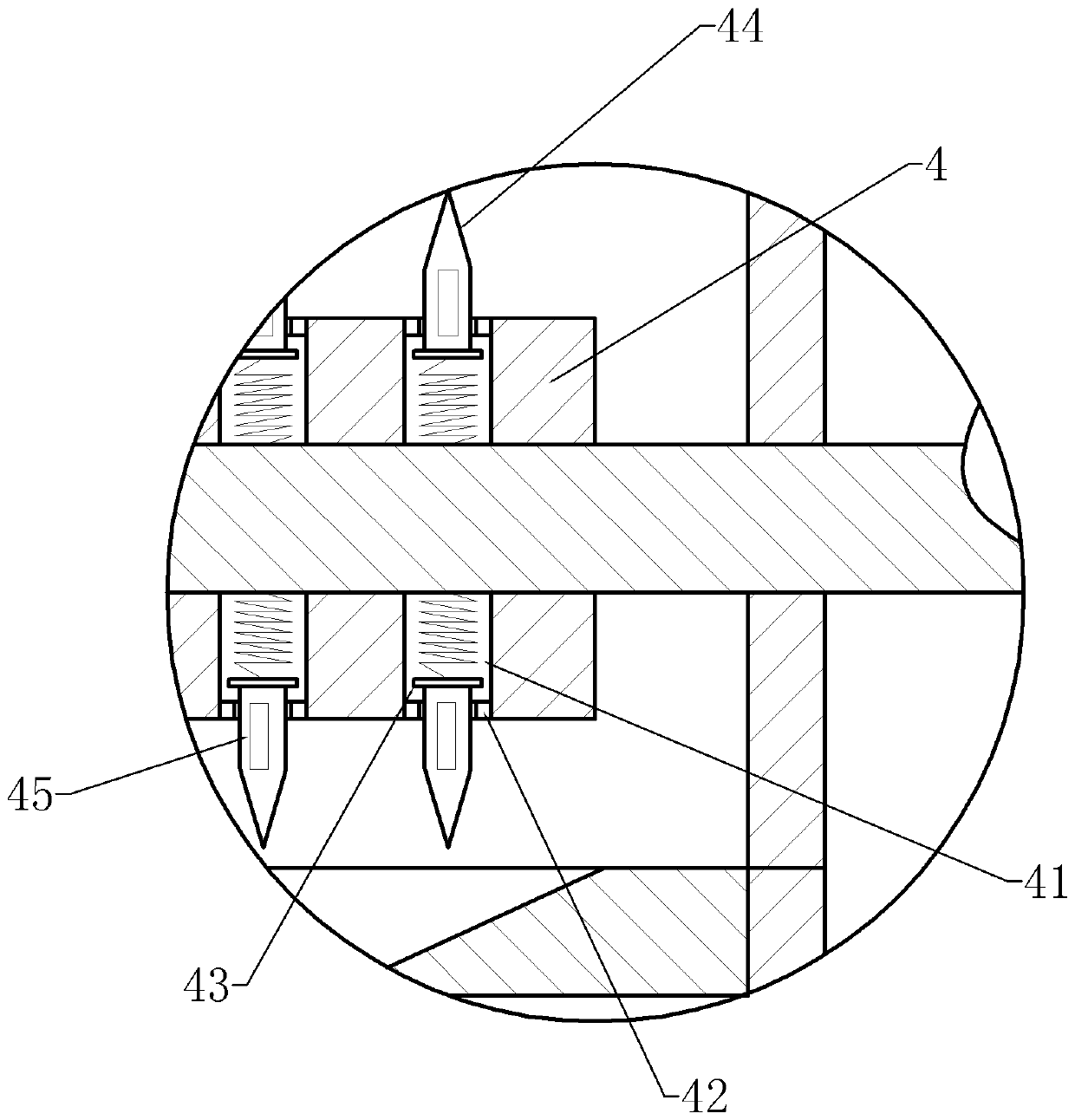

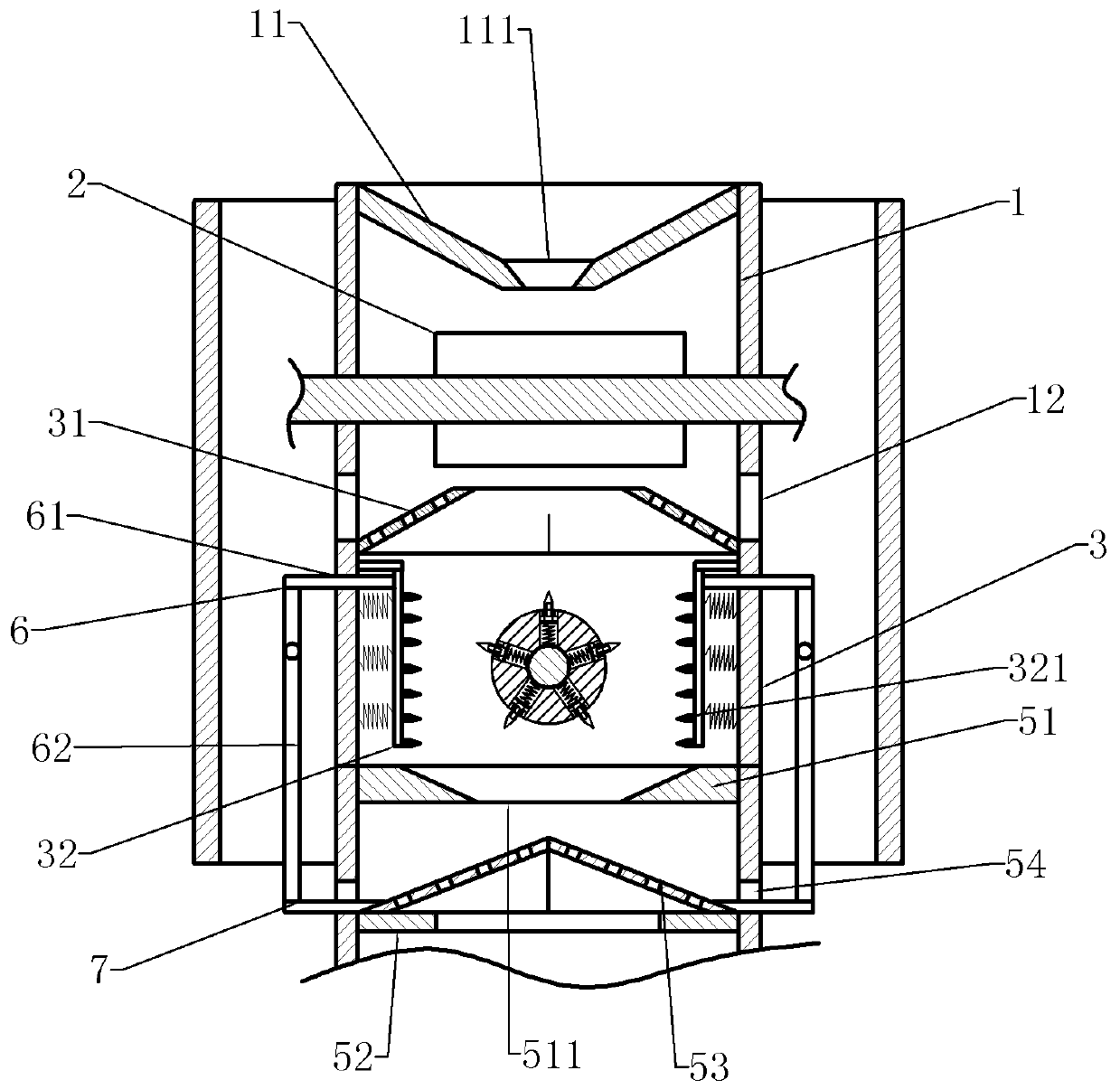

Uniform crushing device for rubber

The invention belongs to the technical field of crushing machinery, and discloses a uniform crushing device for rubber. The uniform crushing device for rubber comprises a machine body, wherein a firstcrushing bucket, a second crushing bucket and a receiving bucket are arranged in the machine body, a first rotary shaft and a second rotary shaft are rotationally connected in the first crushing bucket, and a crushing roll knife is arranged on each of the first rotary shaft and the second rotary shaft; a third rotary shaft is rotationally connected in the second crushing bucket, and vertical to the first rotary shaft; a sleeve is arranged on the third rotary shaft, a plurality of through holes are formed in the sidewall of the sleeve, and a first shearing knife and a spring are arranged in each through hole; two material-stopping plates are further arranged in the second crushing bucket, a compression spring is arranged between each of the two material-stopping plates and the second crushing bucket, and a second shearing knife is arranged on each material-stopping plate; and a strip-shaped magnet is arranged in each of the first shearing knife and the second shearing knife. The uniform crushing device for rubber solves the problems that the crushed rubber particles are non-uniform in particle size, and the rubber particles with large particle sizes need to be crushed again, so that the crushing time is long, in the prior art.

Owner:CHONGQING WEIXING RUBBER

Portable dustproof jade polishing device

InactiveCN107097118AEasy to openEasy to slideEdge grinding machinesGrinding work supportsGlass coverMillstone

The invention provides a portable dustproof jade polishing device and belongs to the field of jewel processing. The portable dustproof jade polishing device comprises a base. A supporting plate is vertically and fixedly connected on the left side of the upper end face of the base. A rotary table is horizontally arranged at the center of the upper end face of the base. A sliding way body in a horizontal position is fixedly connected on the upper side of the rotary table through a supporting rod. A millstone is used for polishing jade; a glass cover is used for preventing fly-out of dust in the polishing process and is convenient for an operator to observe the internal situation; a first clamping plate and a second clamping plate jointly clamp the jade and enables the edge, needing to be polished, of the jade to abut against the end face of the millstone; when a corner to be polished is linear, a movable rod is slid forth and back along a strip-shaped penetrating opening, the first clamping plate and the second clamping plate slide forth and back jointly by means of a sliding wheel on the lower side, and accordingly the side edge of the jade is polished; and when the corner to be polished is curve, the first clamping plate and the second clamping plate are rotated circumferentially by means of the rotary table connected at the bottom of the sliding way body to polish.

Owner:龚俏枚

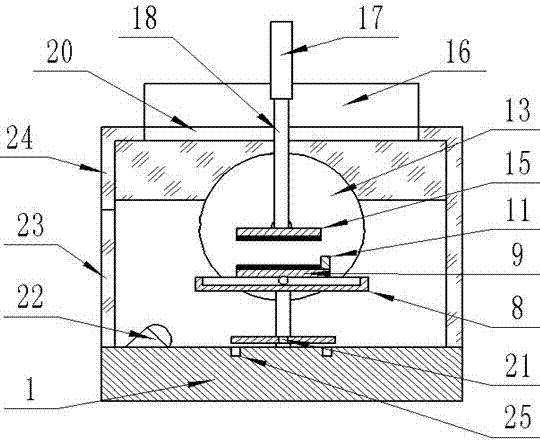

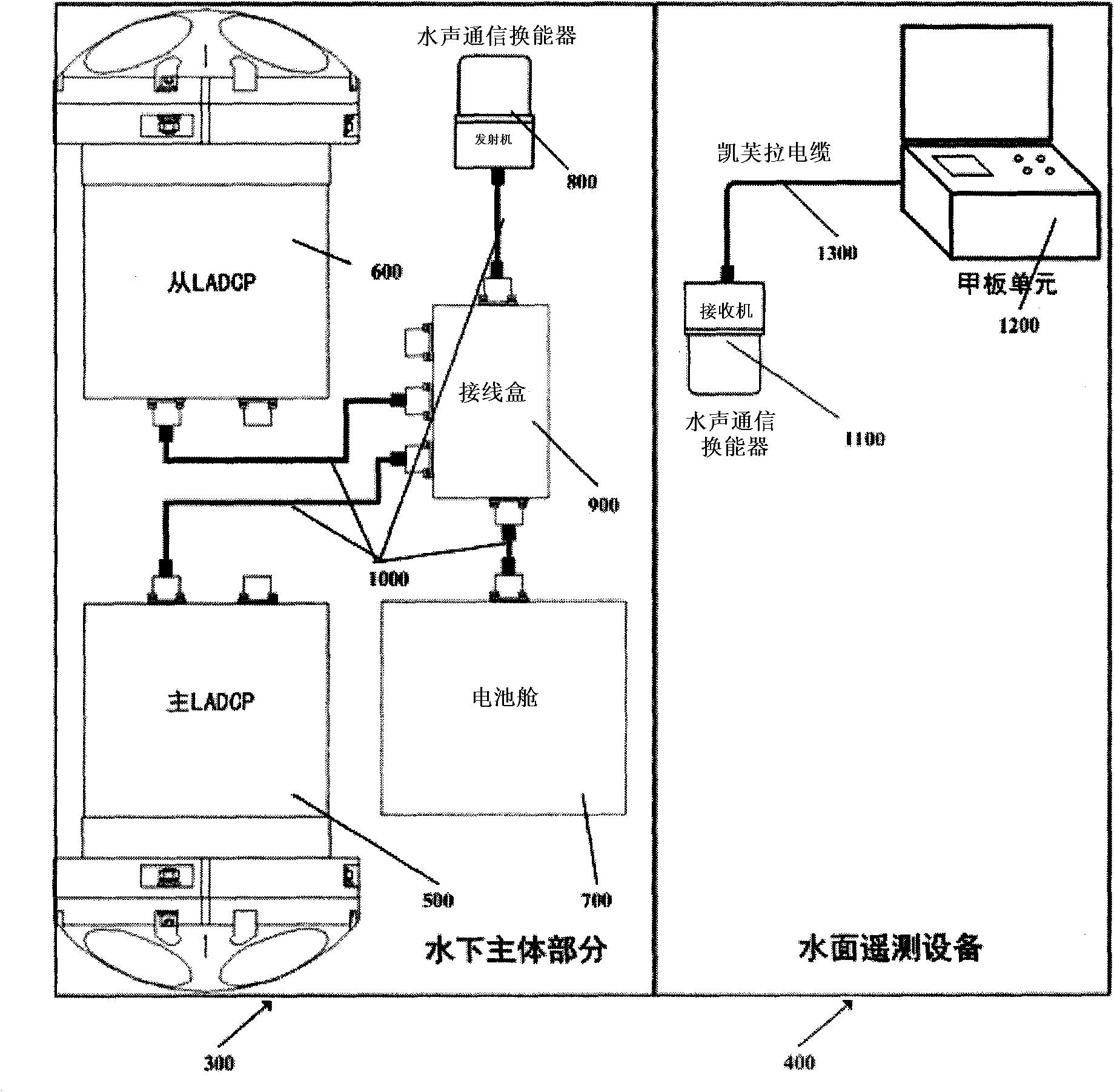

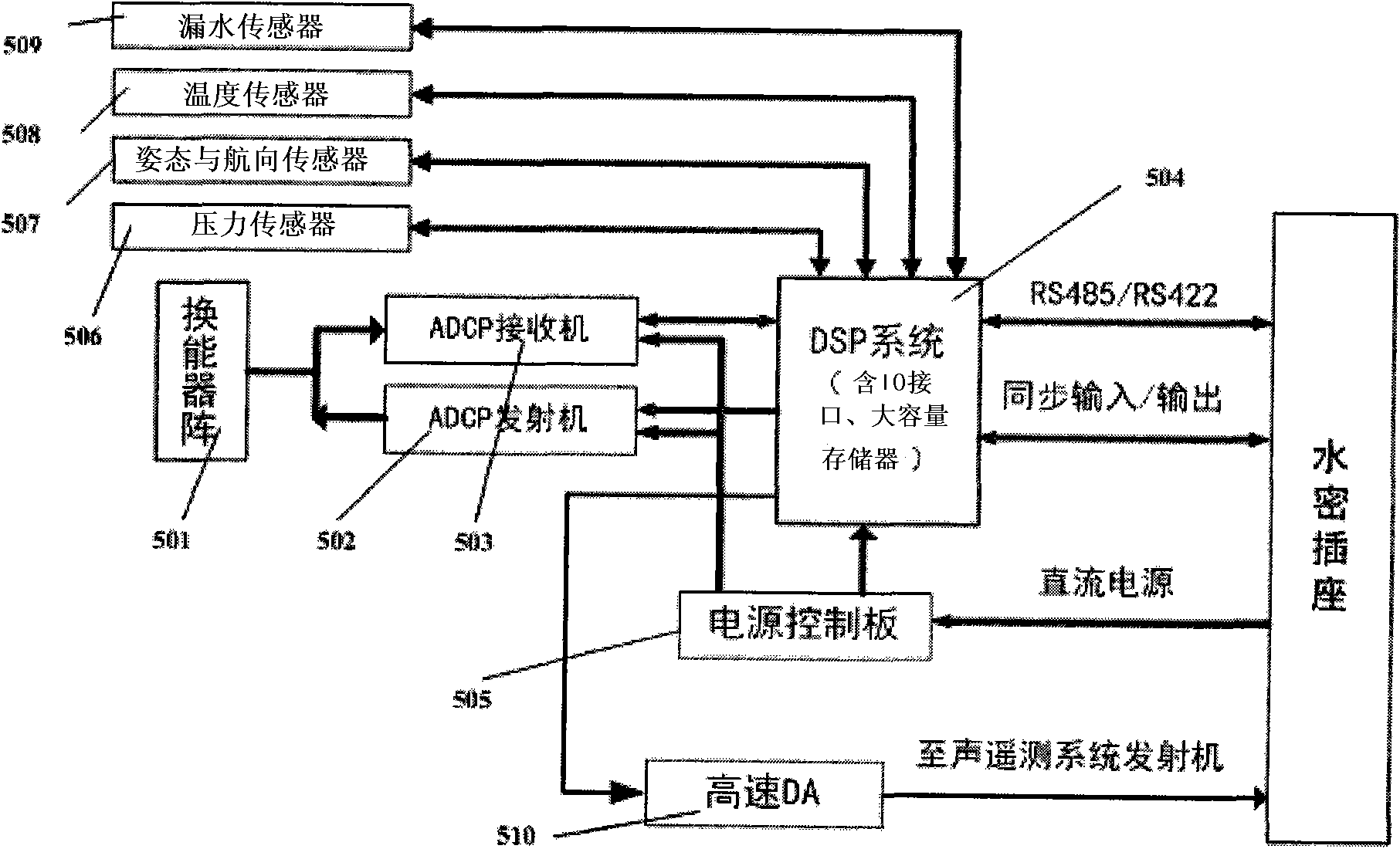

Lowered acoustic Doppler current profiler with acoustic telemonitoring function

InactiveCN101644716ALower requirementThe main LADCP measurement flow will not be affectedFluid speed measurementAcoustic wave reradiationCode division multiple accessFiltration

The invention relates to a lowered acoustic Doppler current profiler (LADCP) with an acoustic telemonitoring function, wherein, an underwater acoustic communication technology is adopted to transmit the data of depth and height from the bottom of an LADCP suspension system in real time to a water surface control unit by code and decode with code division multiple access for monitoring the positionin water of the suspension system in real time. The lowered acoustic Doppler current profiler comprises an underwater main body part and a water surface telemonitoring part; a master LADCP is internally provided with a communication encoding module, wherein, the master LADCP circularly measures a current profile at fixed time and obtains the height to the bottom according a bottom tracking resultand a depth value by a pressure sensor at the same time; the communication encoding module carries out CDMA code modulation on the height value and the depth value and then outputs the values by a high-speed DA every 1-10s or so, preferably 5s, and emits out the values through a watertight cable and an underwater acoustic communication transmitter; and the underwater acoustic communication transmitter at a water surface telemonitoring part carries out amplification, automatic gain control and filtration on the received signal and then sends the signal to a deck unit through a Kevlar cable.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

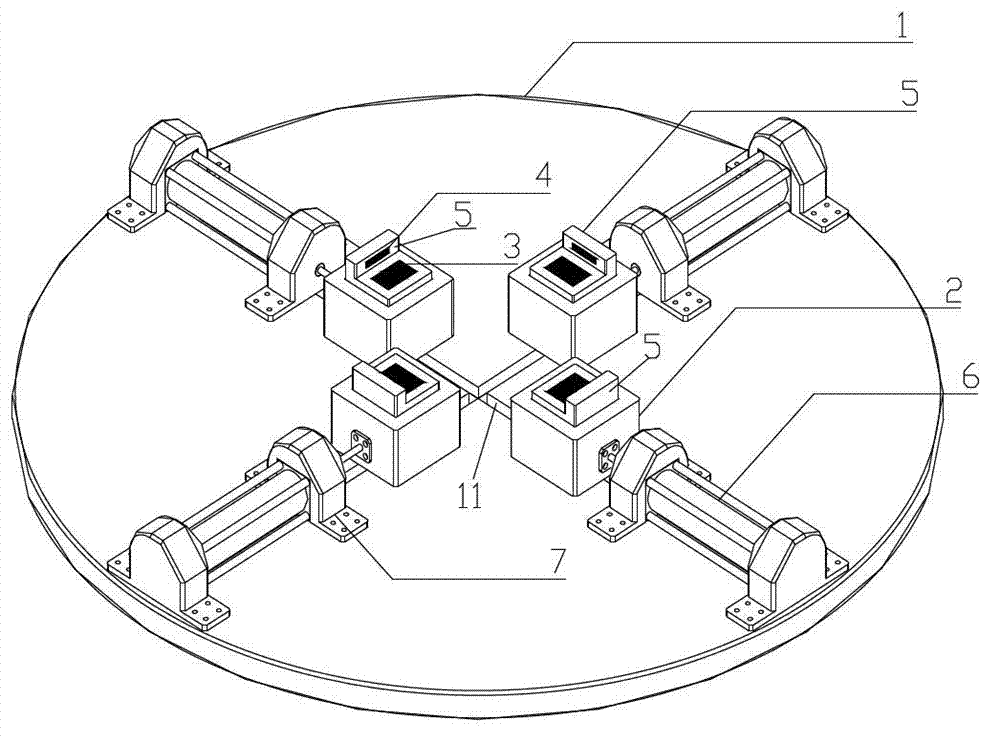

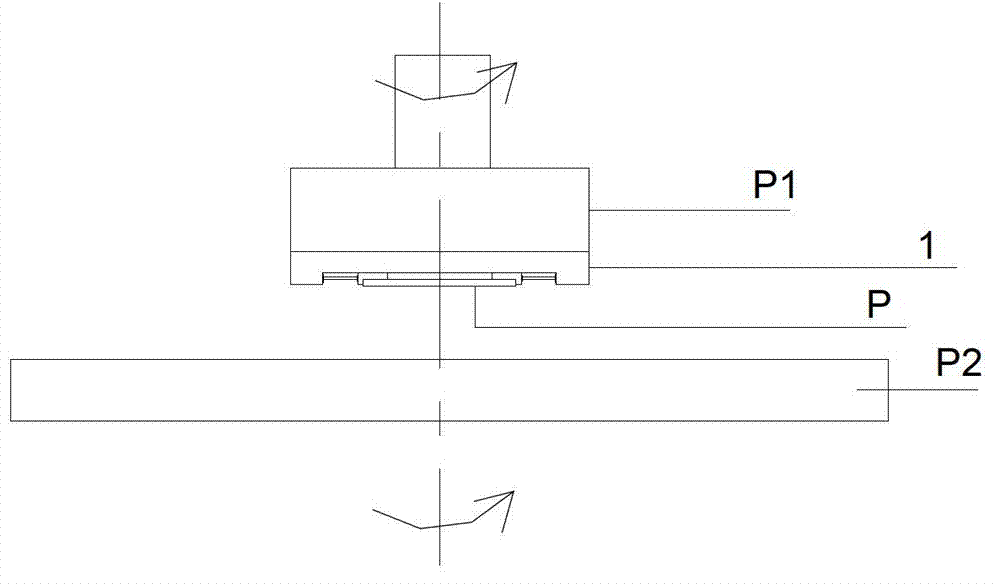

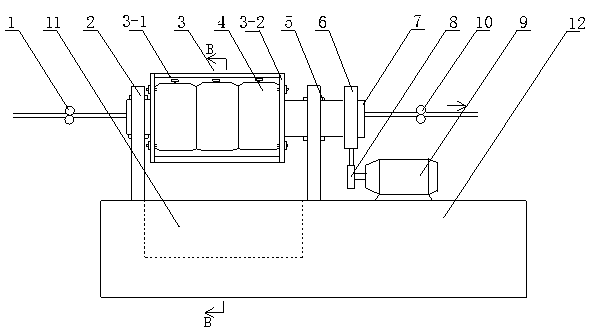

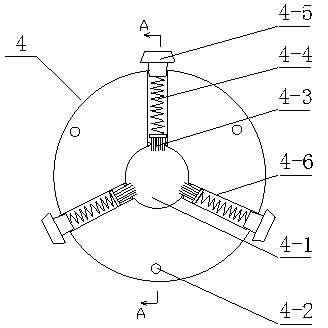

Online adjustable fixture for polishing machine tool

The invention discloses an online adjustable fixture for a polishing machine tool, and relates to a work fixture. The online adjustable fixture is provided with a base plate and at least three sets of clamping and regulation mechanisms which have the same structure. The clamping and regulation mechanisms are centrifugally and uniformly arranged on the surface of the base plate by taking the central axis of the base plate as a reference. Each clamping and regulation mechanism is provided with a horizontal sliding block, a horizontal cylinder, a perpendicular sliding block, a perpendicular cylinder, a perpendicular pressure sensor and a horizontal pressure sensor, wherein the response speed of the horizontal pressure sensor is adjustable; the horizontal sliding block is matched with the base plate in a centrifugal sliding way; a piston rod of the horizontal cylinder is connected with the horizontal sliding block; the perpendicular sliding block is arranged on the horizontal sliding block, and is matched with the horizontal sliding block in a perpendicular sliding way; the perpendicular cylinder is arranged on the horizontal sliding block; a piston rod of the perpendicular cylinder is connected with the perpendicular sliding block; the perpendicular pressure sensor is arranged on the horizontal surface of a clamping part of the perpendicular sliding block; and the horizontal pressure sensor is arranged on the perpendicular surface of the clamping part of the perpendicular sliding block. The horizontal position of the machined surface of a workpiece can be regulated on line (in real time), so that the machined surface of the workpiece can be uniformly stressed to be matched with the polishing machine tool.

Owner:XIAMEN UNIV

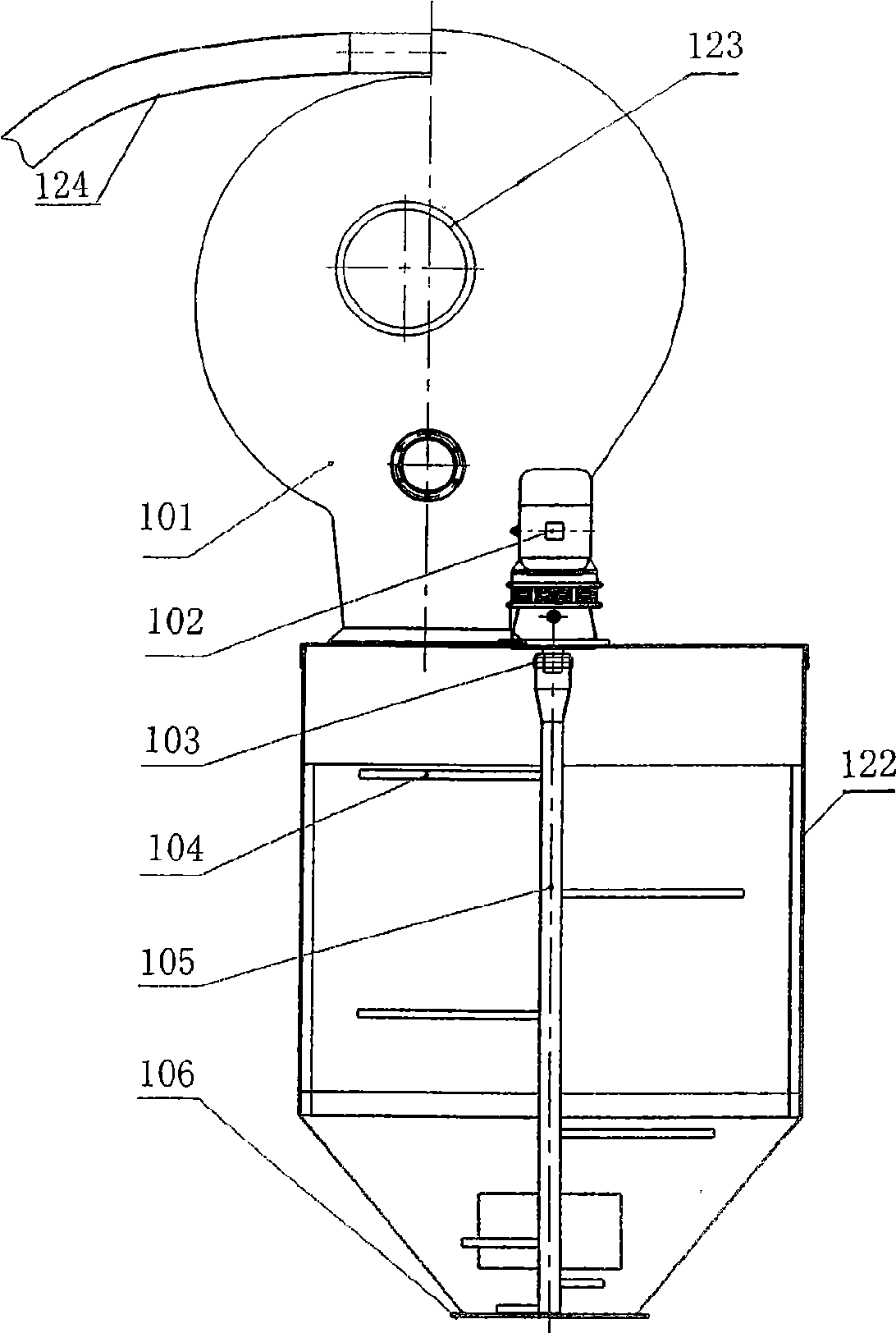

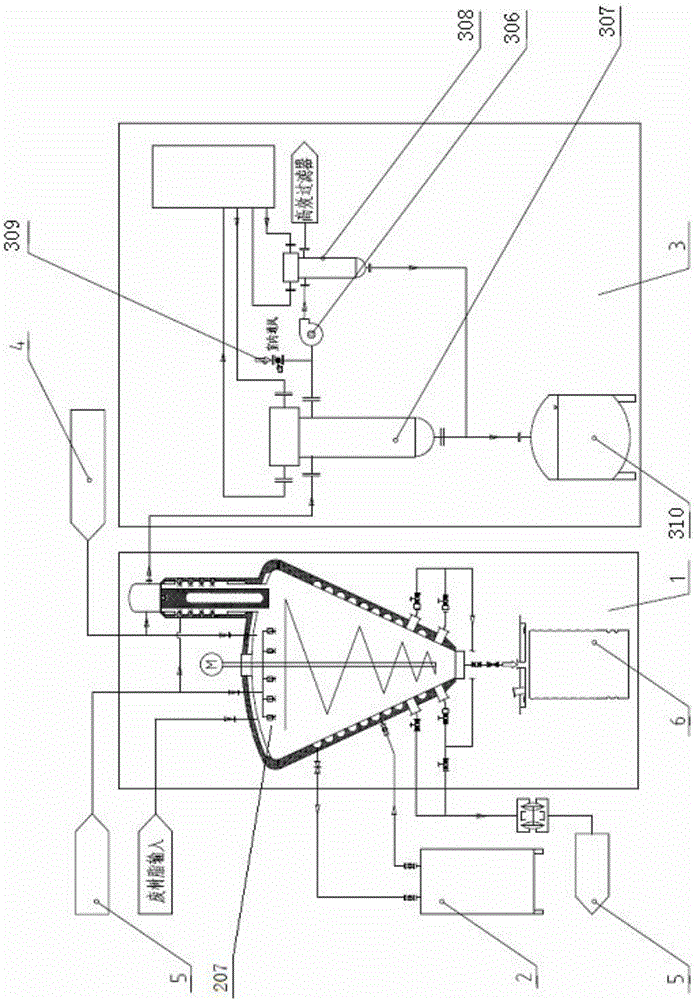

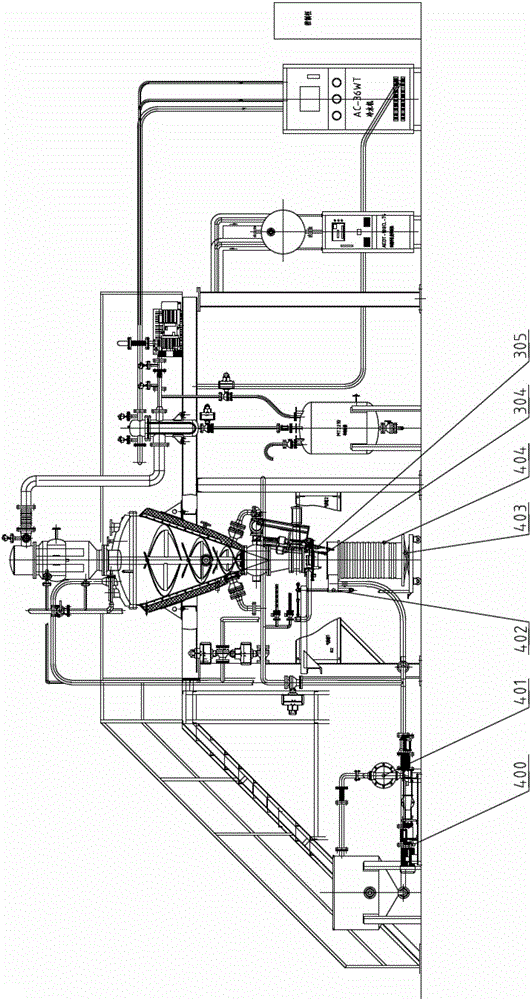

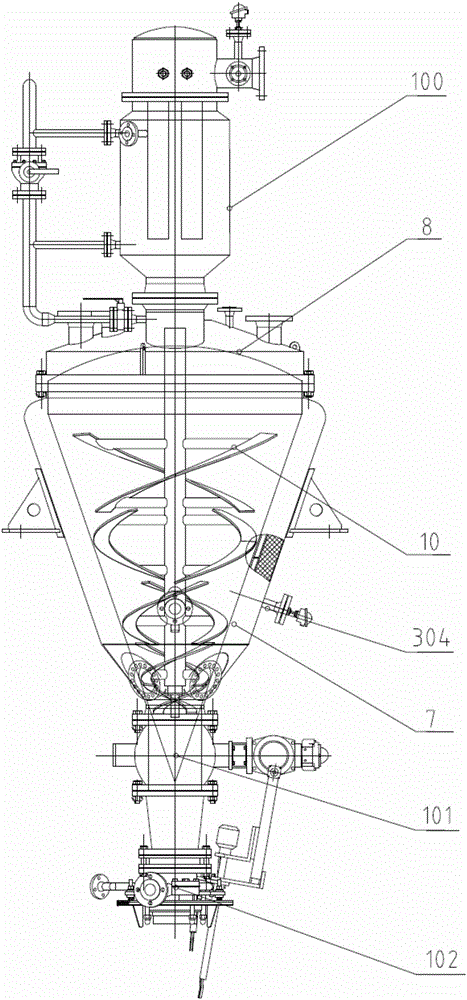

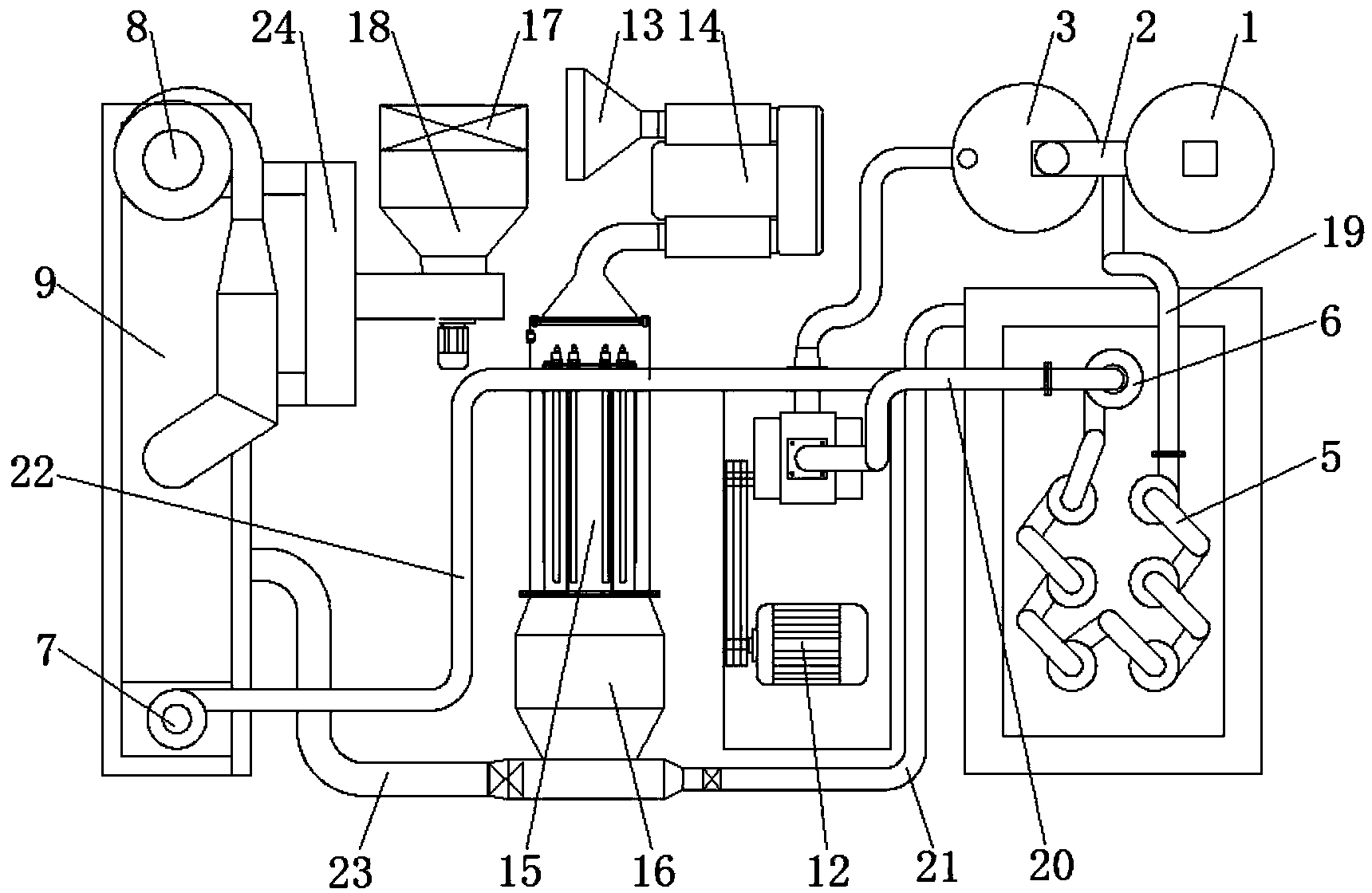

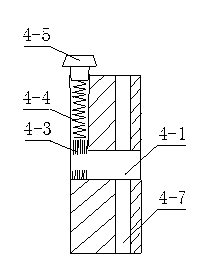

Conic nuclear power plant waste resin drying device

ActiveCN106558352AEvenly heatedReasonable structureDrying solid materials without heatDrying chambers/containersNitrogenEngineering

The invention discloses a conic nuclear power plant waste resin drying device. The conic nuclear power plant waste resin drying device comprises conic dryer body equipment used for waste resin vacuum drying, a hot oil unit used for heating and cooling a conic dryer, an air exhausting and condensation system used for maintaining the vacuum degree in a dryer body and condensing steam, a nitrogen purging system used for protecting the system and washing a washable filter, a washing and dewatering system used for dewatering waste resin and washing system pipelines, and a resin barreling system used for simulating a nuclear island SRTF station. The provided conic nuclear power plant waste resin drying device is safe, reliable, easy to operate and control, reasonable in structure configuration, high in drying efficiency and large in resin volume reduction ratio.

Owner:AEROSUN CORP +1

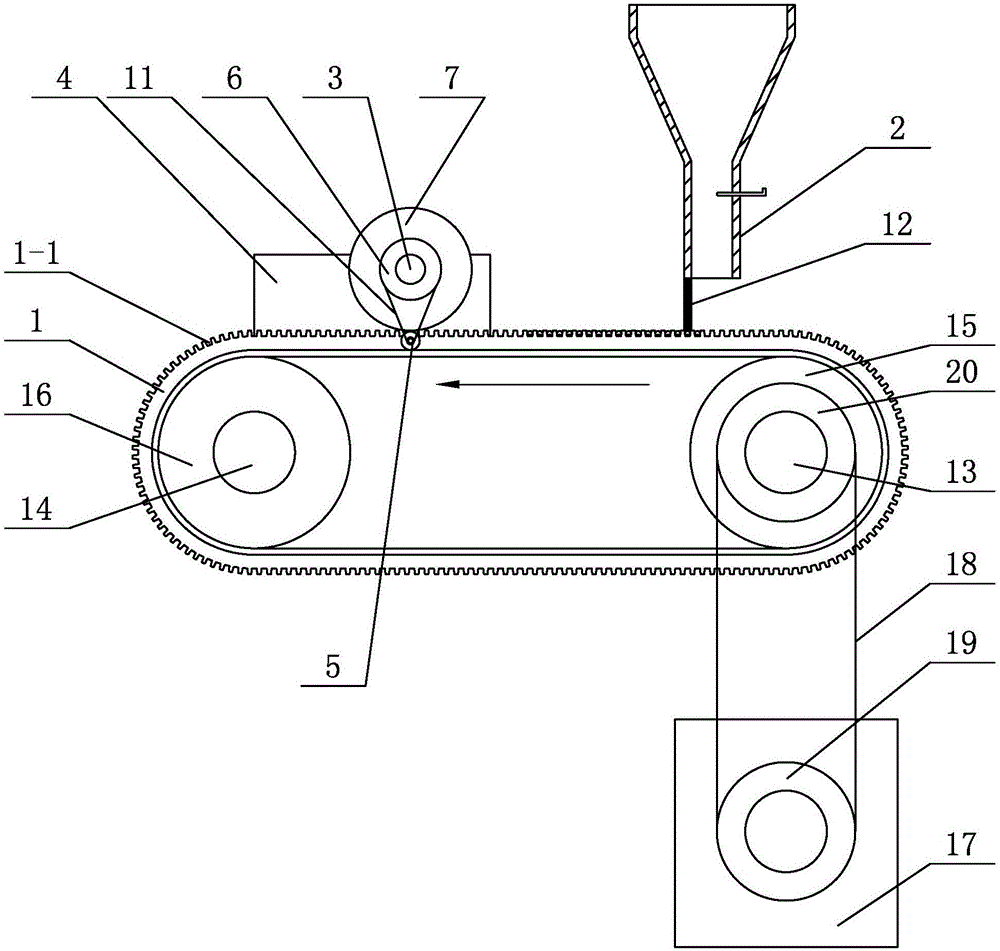

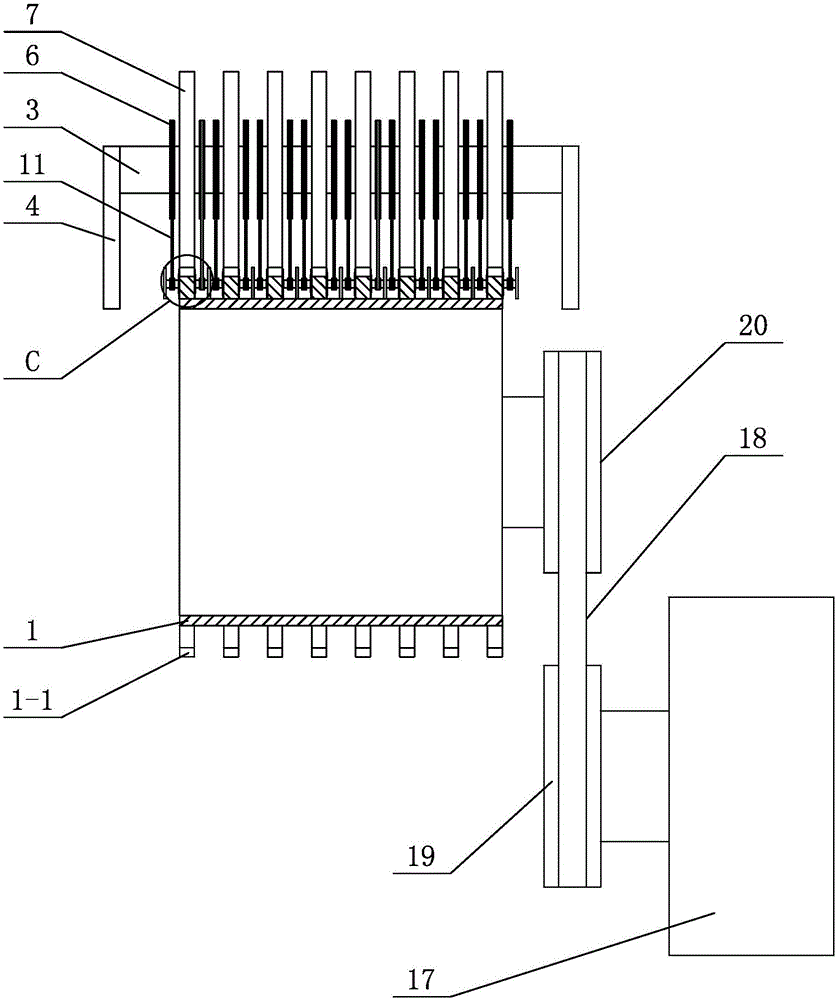

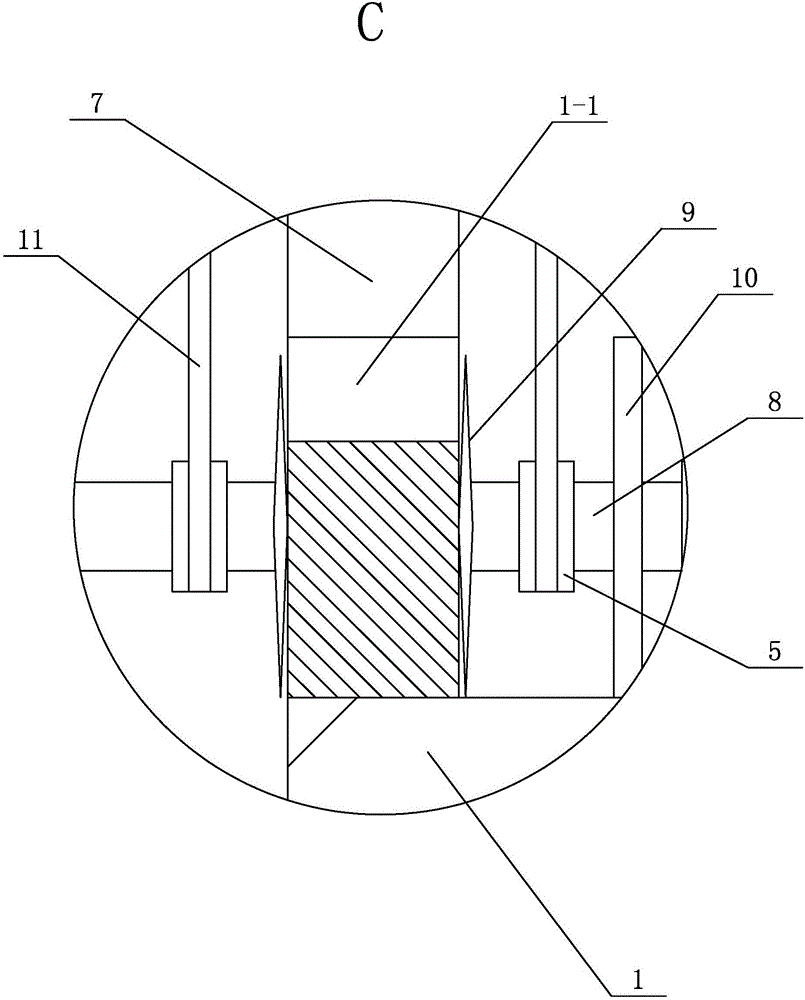

Rice germ cutting device

InactiveCN106625828AReduce breakage rateKeep the tasteMetal working apparatusEconomic benefitsEngineering

The invention provides a rice germ cutting device, relates to a cutting device, and aims at solving the problem that two ends of rice cannot synchronously impact edge parts of blades when an existing rice germ separating device runs, thus the rice is easily broken off and crushed, and as a result, the rice breaking rate increases, and the economic benefit is reduced. The rice germ cutting device comprises a rack, a main driving mechanism, a conveyor belt, a hopper, a press roll shaft, two side plates, at least one small belt wheel, at least one big belt wheel, at least one press roll, at least two saw-blade shafts, at least two saw blades, at least two separating plates and at least one transmission belt. The rice germ cutting device belongs to the field of agricultural mechanisms.

Owner:HARBIN QUANQING TECH SERVICE CO LTD

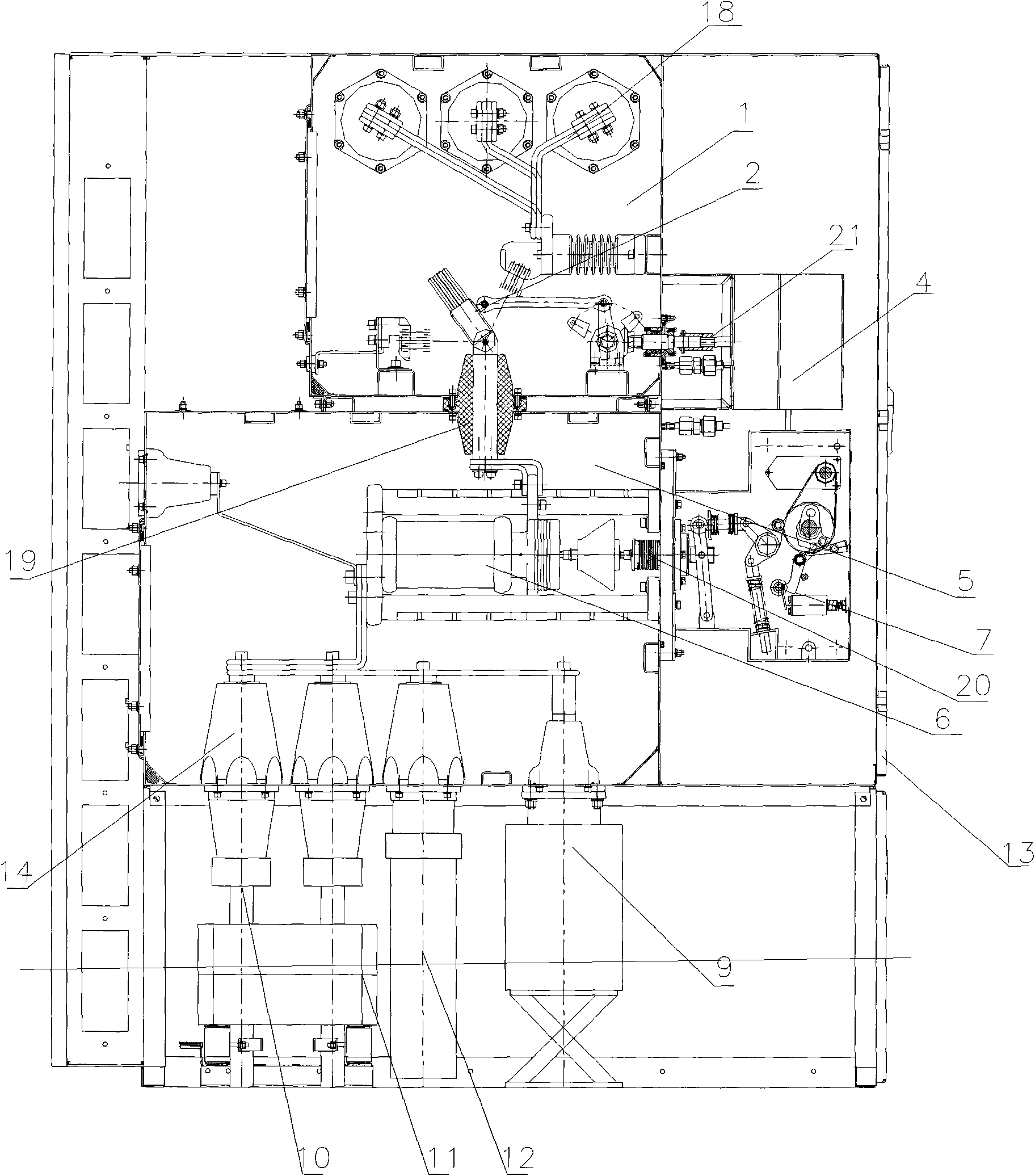

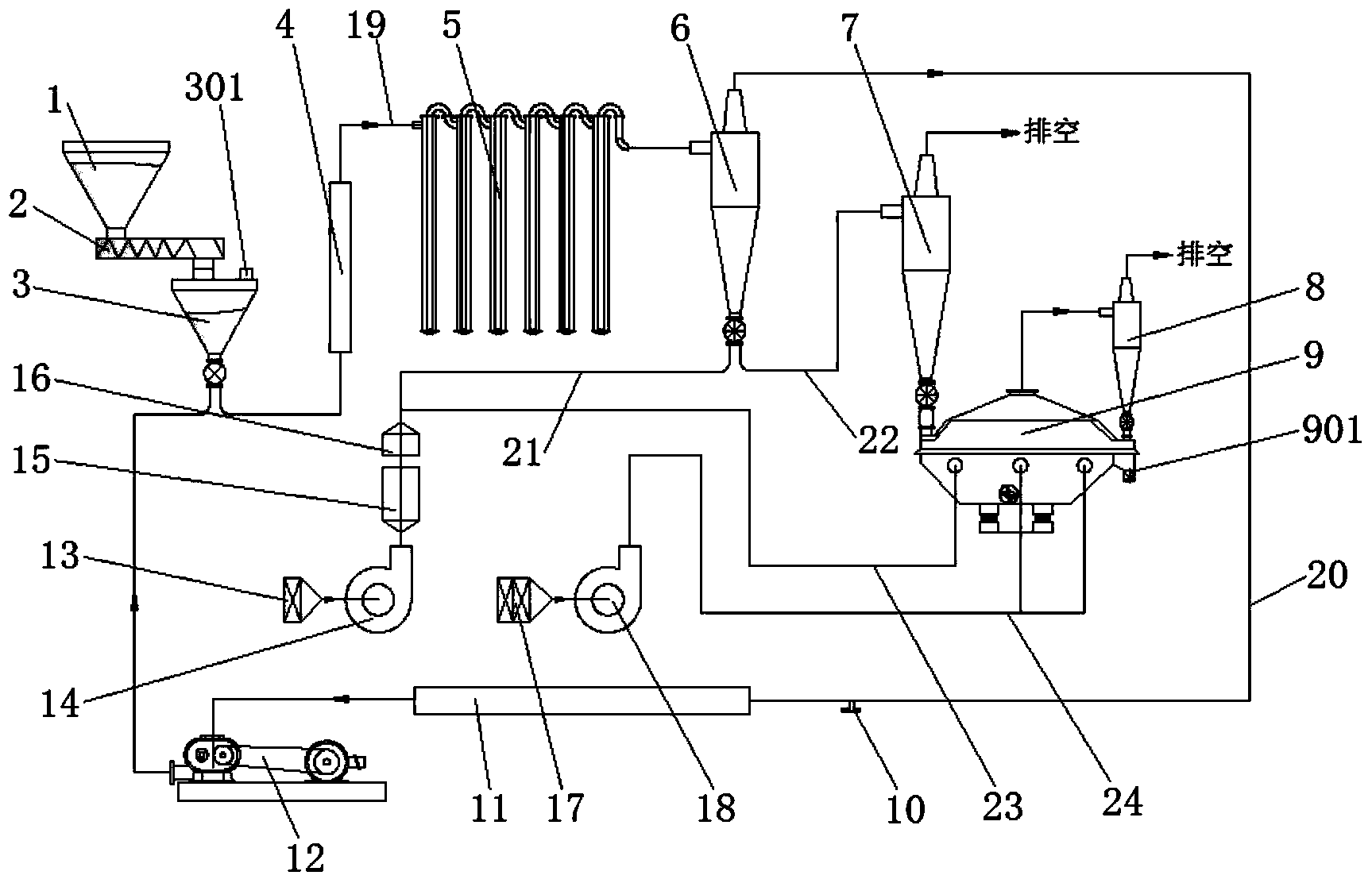

Technology and system of powder body superheated steam sterilization

The invention discloses a technology and a system of powder body superheated steam sterilization, and belongs to the field of material sterilization and drying. The technology comprises the following steps: (1) adding a powder body material steam into a superheated steam stream; (2) controlling the superheated steam stream to form a cyclone stream, so that the material is dispersed in the cyclone stream, and utilizing the steam heat for sterilization for 3-10 seconds, and controlling the sterilization temperature within the range of 120-250 DEG C; (3) causing the steam stream to form cyclone stream, and utilizing the centrifugal force to separate the material and the steam stream; (4) utilizing the dried hot wind to dry the material, and utilizing dried cold air to cool the dried material; (5) performing steam and temperature compensation on the steam stream in the step (3), and participating in the superheated steam stream feeding technology in the step (1). The invention further discloses a system of powder body superheated steam sterilization. According to the invention, the technology is convenient in operation and simple in device structure, realizes automatic and continuous sterilization production, is low in consumption for sterilization, and is greatly increased in production efficiency.

Owner:FANQUN DRYING EQUIP FACTORY WUJIN CITY

Copper rod polishing machine

InactiveCN103009226AImprove cylindricityDoes not affect polishing effectPolishing machinesGrinding/polishing safety devicesWire rodEngineering

The invention relates to a copper rod polishing machine, which comprises a machine body, a rotary cage and a speed reduction motor, wherein the machine body is provided with a support. The copper rod polishing machine is characterized in that the two ends of the rotary cage are respectively provided with a hollow rotating shaft; the upper end of the support is connected with the hollow rotating shaft through a bearing; the hollow rotating shaft at one end of the rotary cage is provided with a belt wheel; the belt wheel is connected with an output belt wheel of the speed reduction motor through a belt; the rotary cage is provided with a polishing disk or a plurality of polishing disks; and the center of the polishing disk is provided with a wire passing hole. The copper rod polishing machine has the beneficial effects that as the rotary cage and a polishing disk structure are adopted, a rotatable polished wire passing hole is formed in the rotary cage; when wire rods or copper rods pass through the wire passing hole, the materials such as copper rods are polished in all directions; and compared with static polishing of a polishing head in the prior art, the materials such as copper rods can reach good cylindrical degree, so that the polishing efficiency and quality can be greatly improved.

Owner:常熟中佳新材料有限公司

A bridge anti-collision guardrail and a construction method thereof

InactiveCN109056523AIncrease impact forcePlay a protective effectBridge structural detailsBridge erection/assemblyCushioningArchitectural engineering

The invention discloses a bridge anti-collision guardrail and a construction method thereof, Collision barriers include columns, An upper rail and a low rail are respectively sleeved with a buff cylinder and a swirling ring on that upright column, the two ends of the upright column are fix on the upper rail through a limiting seat, the lower rail is provided with a fixing ring on the upright column, the fixing ring is in contact with the limiting seat located below, an L-shaped mounting plate is provided on the upper rail, an L-shaped mounting plate is provided with an anti-collision plate, and a cushioning guardrail plate is provided on the anti-collision plate; The construction method comprises the following steps: (a) route marking; (b) Post positioning; (c) Installation of lower railings; (d) installation of an upper railing; (e) Installation of cushion shields; (f) Installation of bumper plates; (g) Installation of remaining uprights. The anti-collision guardrail of the inventionhas the advantages of high stability, convenient installation, cushioning and anti-collision, high safety, easy operation, orderly and reasonable construction, fast and convenient construction, time and labor saving, low construction intensity and convenient maintenance in the later period. The invention has the advantages of high stability, convenient installation, cushioning and anti-collision,high safety, easy operation, orderly and reasonable construction method, fast and convenient construction, and low construction intensity.

Owner:ZHEJIANG COLLEGE OF CONSTR

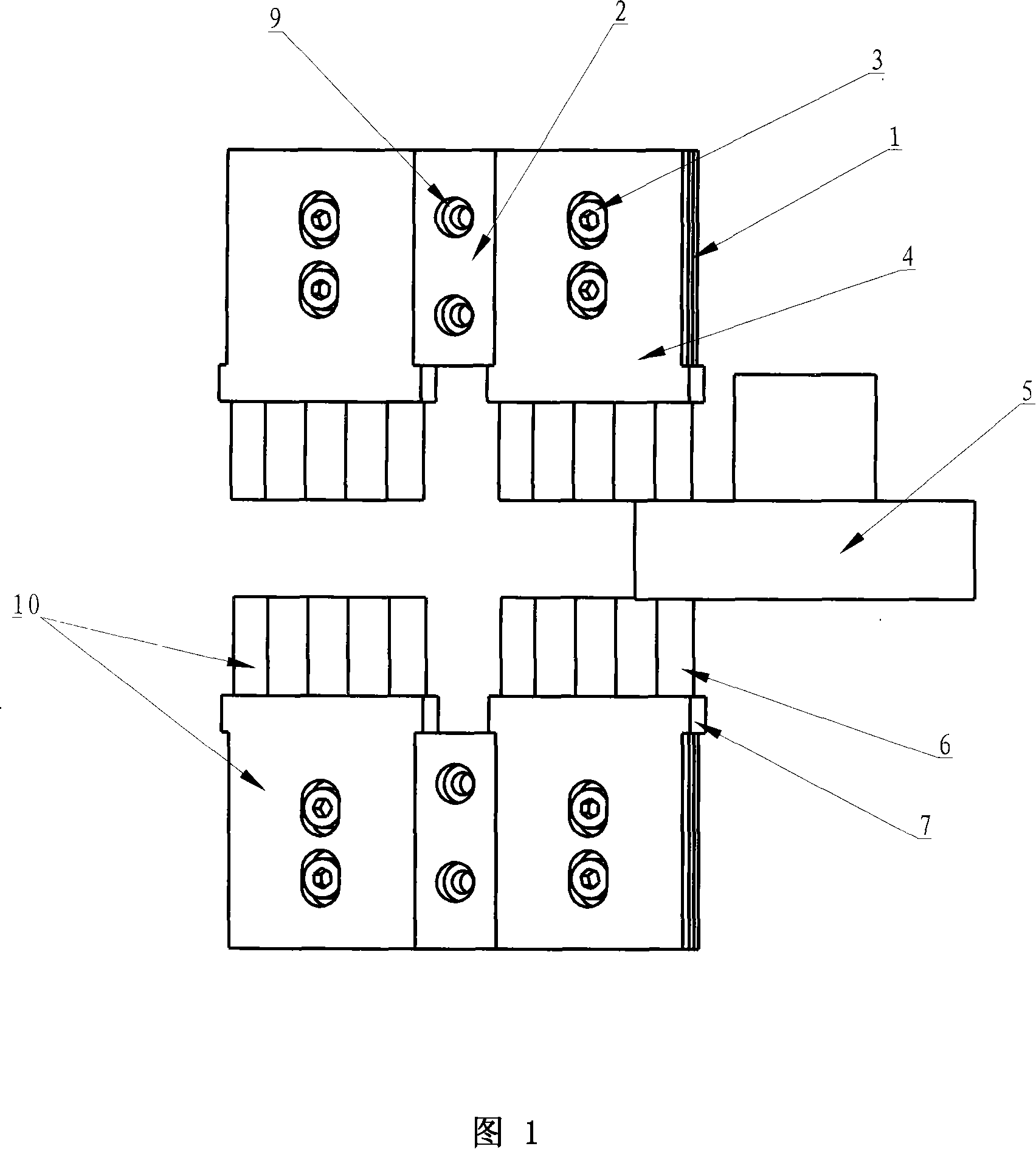

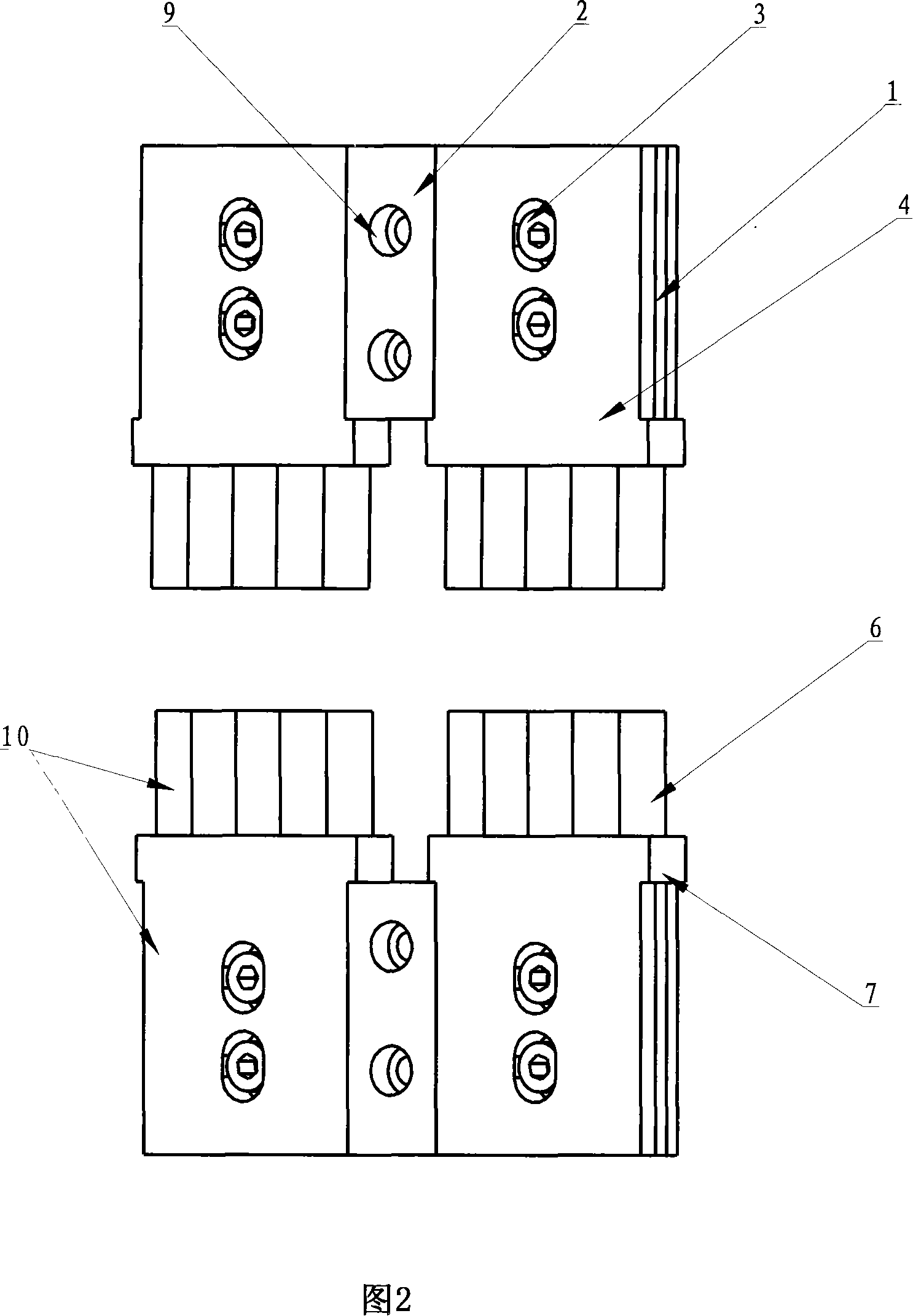

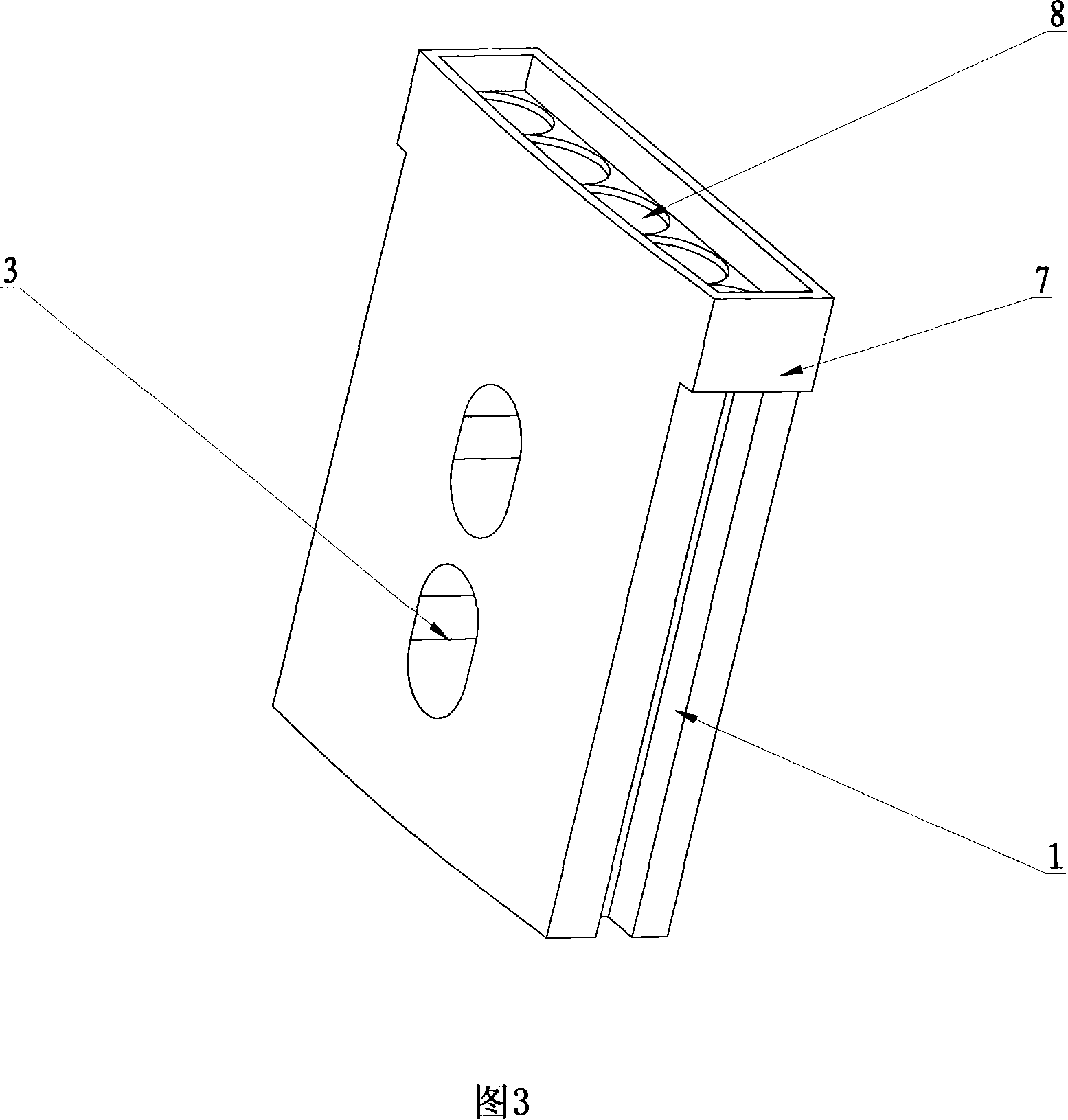

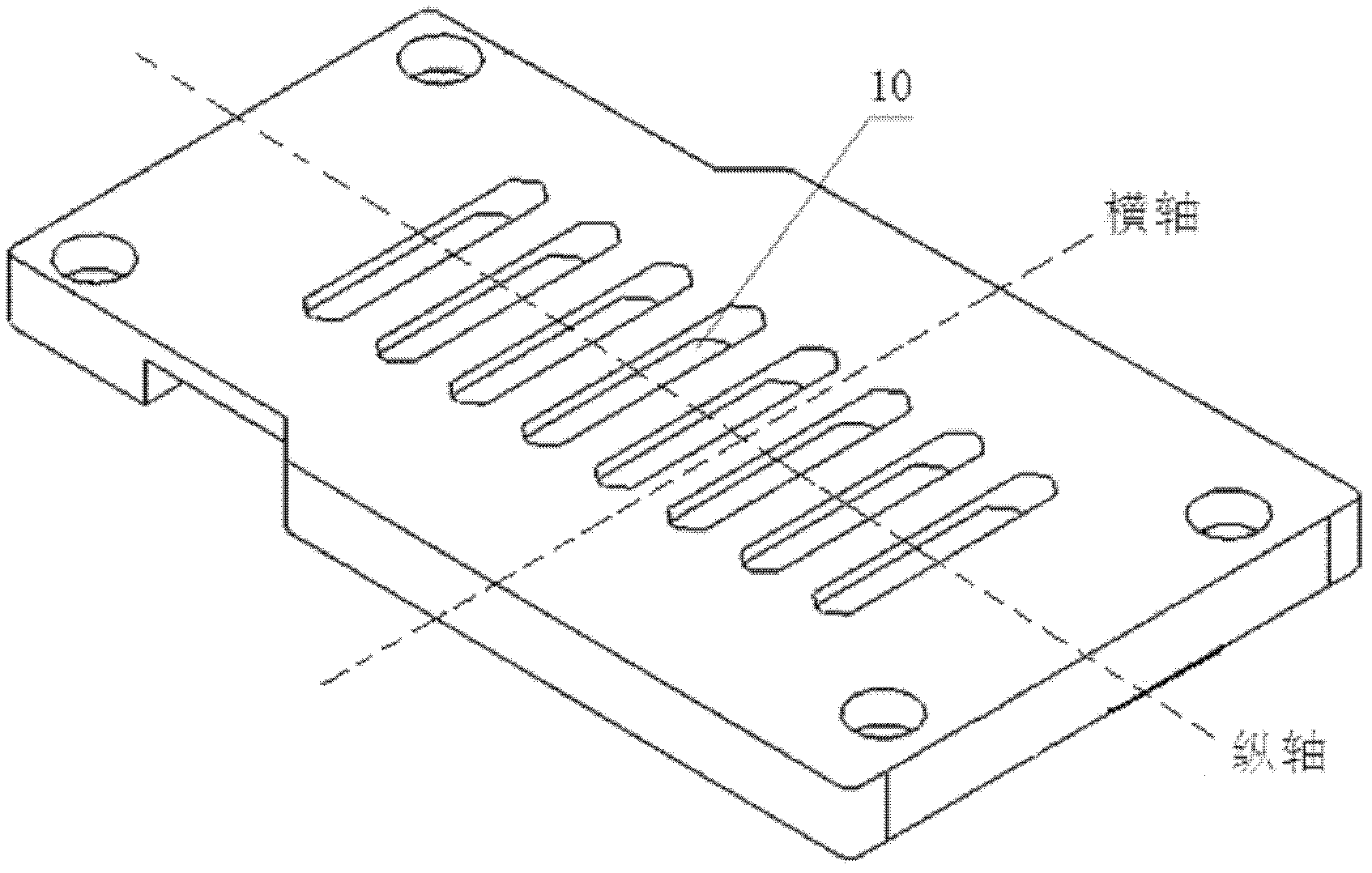

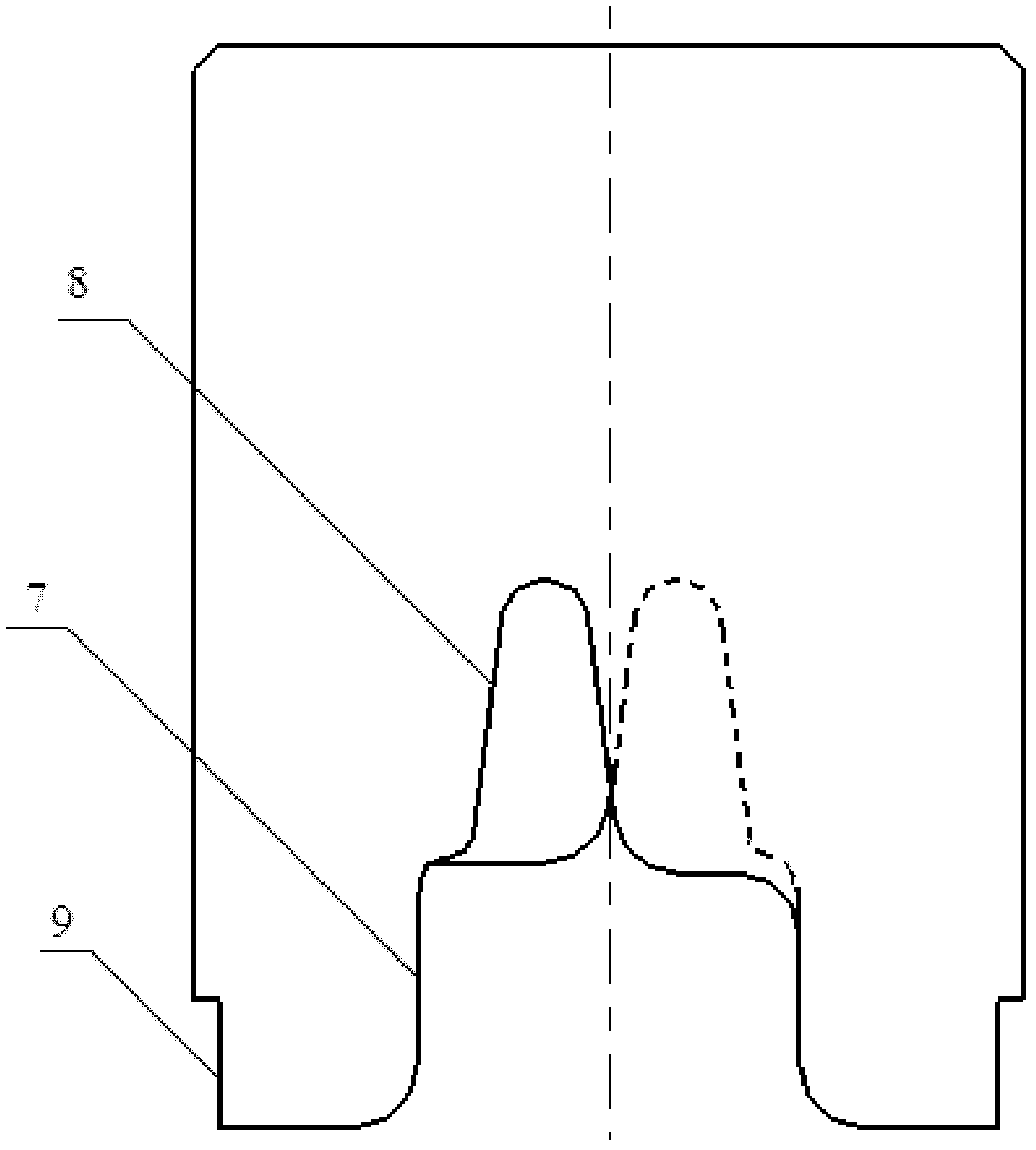

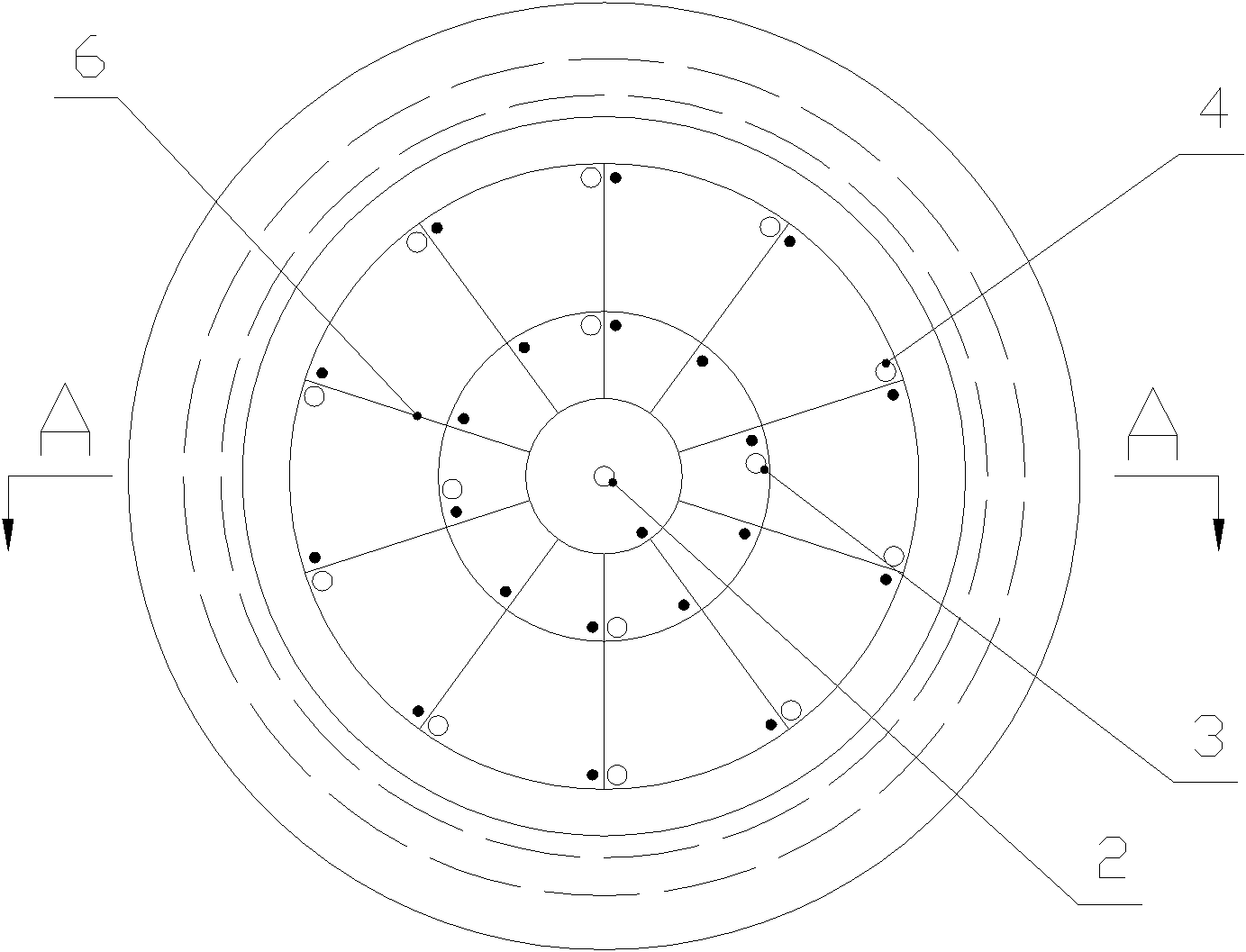

Re-griding-cutting cube boron-nitride grinding-block device, its base and grinding-block preparing method

InactiveCN101069961APrevent flying outCompactGrinding machine componentsBonded abrasive wheelsAirplaneGrindstone

An automatic grinder device and the preparation method of grindstones relates to the mechanical field. It specially relates to a heavy grinding cubic boron nitride grindstone device of the heavy grinding double-sided high precision automatic grinder of various brake discs in automobile and aircraft aviation industry and the preparation method of its seat and grindstone. The device is composed of a seat, a grinder device and five cylinder CBN grindstones embedded on the alloy seat. The method contains preparation technology of the alloy seat, the sintering technology, fastening and binding method of five CBN grindstones. It mainly resolves the technologies of CBN grindstones device and the preparation method of its seat and grindstones. With its characterizes of multi-point cutting capability and small cutting resistibility, the invention has advantages of convenient clamping, strong rigidity, convenient tool setting and grinding at initial stage and high efficiency.

Owner:上海达特精密机械配件有限公司

Zero arc extinguishing device

ActiveCN102446642AEasy to stretchImprove cooling effectElectric switchesCircuit-breaking switch detailsEngineeringIonization

The invention discloses a zero arc extinguishing device. The arc extinguishing device comprises an arc separation cover, an arc striking sheet, two arc separation walls, grid sheets and one or more than one group of arc extinguishing sheets, wherein each group of arc extinguishing sheets comprises an insulating frame, an arc extinguishing plate and a de-ionization net. The top parts of two arc extinguishing walls are connected through the arc separation cover; two or more than two pairs of longitudinal slots are machined on the inner walls of the two arc separation walls; the two or more than two grid sheets are sequentially inserted into the slots forwards and backwards; and the arc striking sheet is inserted into the slots at the end parts of the arc separation walls. The one or more than one group of arc extinguishing sheets is installed between the top parts of the grid sheets and the arc separation cover. In order to increase a cooling area of the grid sheets on electric arcs, the tops of the grid sheets abut against the insulating frame, the bottoms of the grid sheets are arranged stepwise along an inclining surface of the arc striking sheet without contacting the arc striking sheet, and the length of the grid sheets can reach the range from 1 / 2 to 2 / 3 height of an arc extinguishing chamber. Compared with the traditional arc extinguishing chamber, the arc extinguishing device can realize the effects of small size, high breaking and zero arc.

Owner:CHANGSHU GUORUI TECH CO LTD

Multifunctional robot polishing equipment

ActiveCN108655911ATimely collectionAdd collection functionGrinding carriagesGrinding machinesCouplingEngineering

The invention provides multifunctional robot polishing equipment. The multifunctional robot polishing equipment comprises a polishing motor, a fixed plate, a fixed sleeve, a connecting plate, a robotpower arm, a robot extension arm, an ER50-3200 six-axle robot, a fixed clamping base, a base, a support plate, an I-shaped frame, a waste chip and dust collecting environmental-protection barrel structure, an adjustable dust and waste chip blowing machine structure, a quick polishing replacement rod structure, a height-adjustable clamping plate structure and a sleeve coupling. Through arrangementof a collecting barrel, a metal hose, a dust guide pipe, a joint base, a support lining base and a dust guide hopper, dust and waste chips generated by polishing are timely collected, the collecting function is added, the pollution is prevented, and the environment is protected; through arrangement of a transparent piece, the collecting condition of the dust and the waste chips in the collecting barrel can be timely determined to achieve replacement or cleaning; and through arrangement of fan blades and a blowing motor, the waste chips and the dust generated by polishing are timely blown out to guarantee the polishing efficiency.

Owner:柳州中科机器人自动化股份有限公司

Buffing attachment with high stability for leather shoe factories

The invention relates a buffing attachment, in particular to a buffing attachment with high stability for leather shoe factories. The invention aims at solving the technical problem of providing a buffing attachment with high operation stability, sufficient polishing and high work efficiency for leather shoe factories. In order to solve the technical problems above, the invention provides the buffing attachment with high stability for leather shoe factories. The buffing attachment realizes the effects of high operation stability, sufficient polishing and high work efficiency, and an elevator mechanism of the buffing attachment can drive a buffing mechanism to move up and down to provide convenience for adjusting the height of the buffing mechanism.

Owner:李水旺

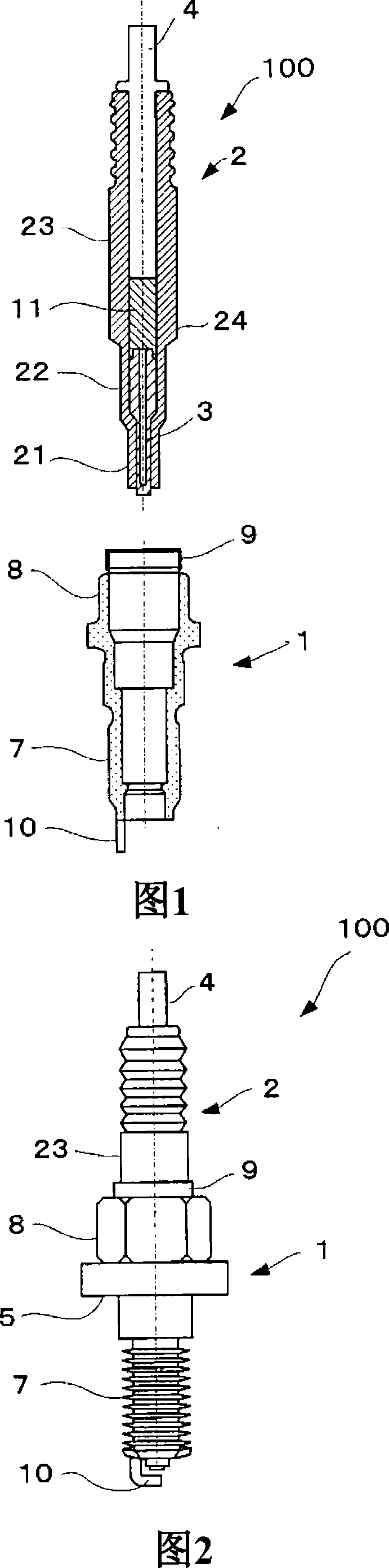

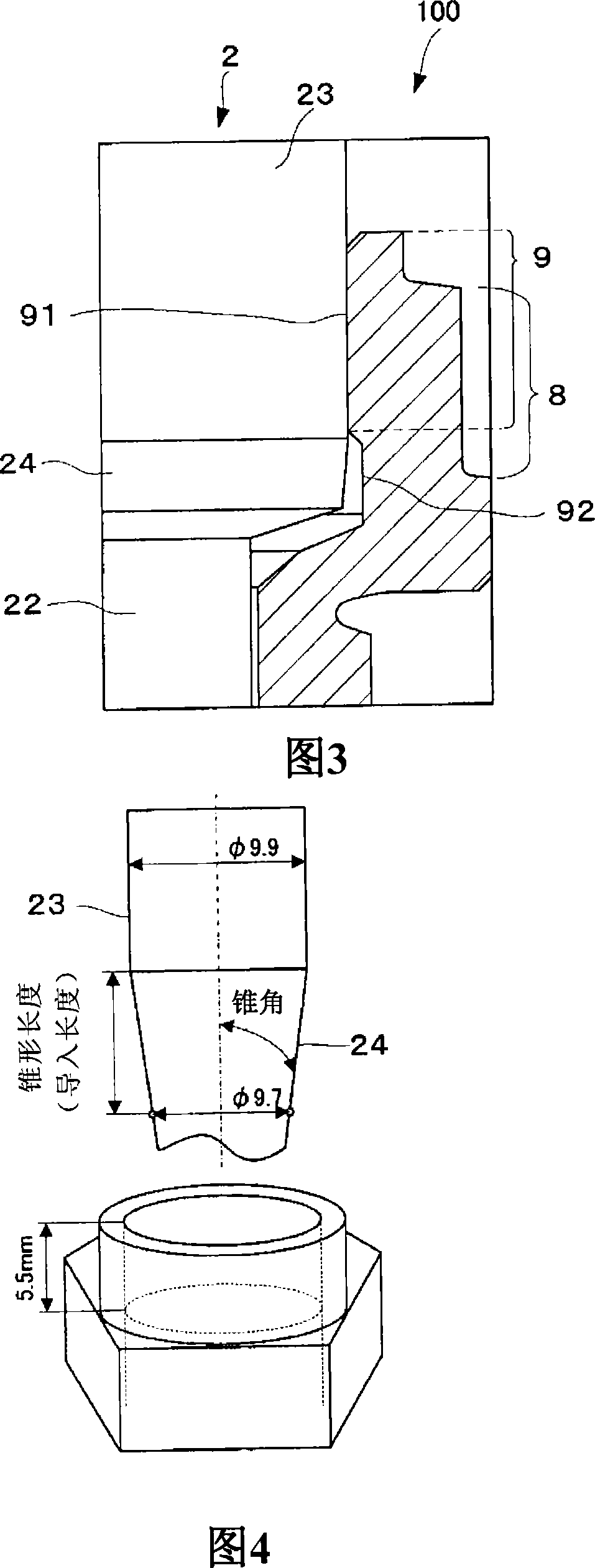

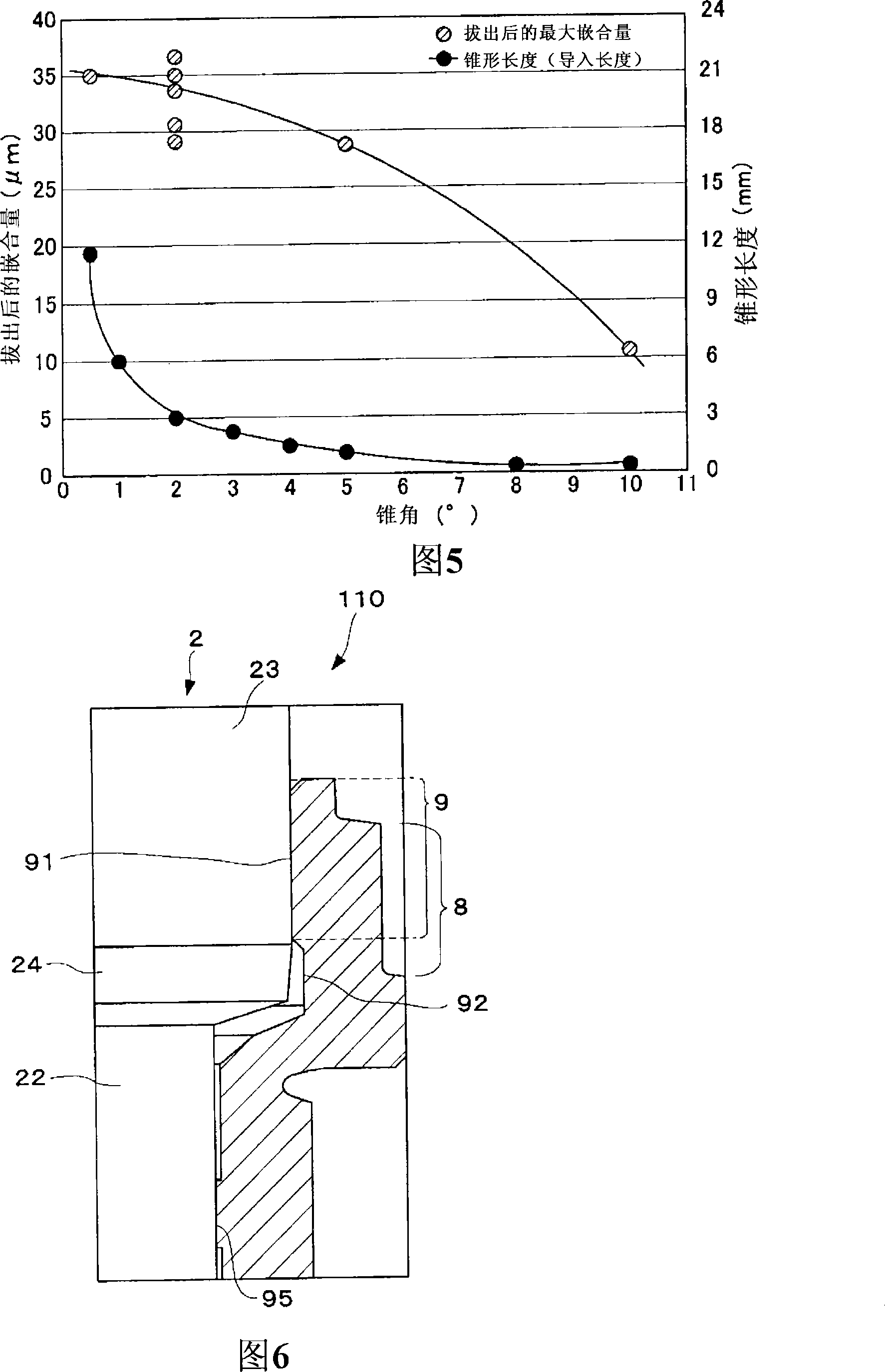

Spark plug

InactiveCN101248564AImprove reliabilityHigh vibration frequencySparking plugsMachines/enginesEngineeringMetal

Disclosed is a spark plug (100) comprising a center electrode (3) extending in the axial direction, a cylindrical insulator (2) holding the center electrode (3), and a cylindrical main metal fixture (1) having an earth electrode (10) at its tip part and having a tool engagement part (8) for fitting to an engine. The main metal fixture (1) comprises a metal fixture side fitting part (9) at a portion thereof on the rear end side more than the tool engagement part (8), and the insulator (2) is radially held by the metal fixture side fitting part (9) in a shrink-fit state.

Owner:NGK SPARK PLUG CO LTD

Safe and dustproof pipe cutting machine

InactiveCN107717122APrevent flying outPrevent splashPositioning apparatusMaintainance and safety accessoriesArchitectural engineeringProcessing cost

The invention discloses a safe and dust-proof pipe cutting machine, which includes a workbench, rollers and a pipe gripper. The connection between the rod and the fixed foot is provided with a fixed bolt, the left end of the workbench is provided with a screw rod, and the right side of the screw rod is provided with a moving slider; the existing pipe cutting machine is provided with a clamping slider , Rotate the fixed clamp, move the slider and rollers, use the clamp slider to cover the pipe, and fix the pipe with the rotating fixed clamp to avoid the pipe head flying out when cutting the pipe head, and use the moving slider to easily and conveniently adjust the measurement of the pipe length, use the rotation of the roller to make the workpiece roll together, no large amount of debris will be generated during cutting, the incision is smooth and flat, no need for secondary polishing, reducing processing costs, and avoiding debris splashing into the eyes, ensuring the safety of operators Personal safety, eliminating potential safety hazards.

Owner:浙江红鑫铜业有限公司

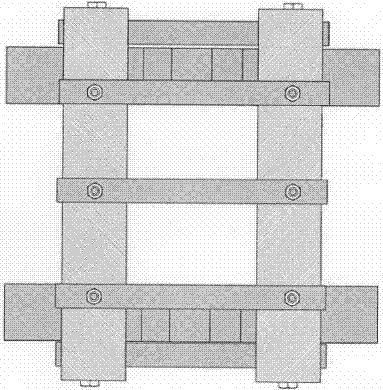

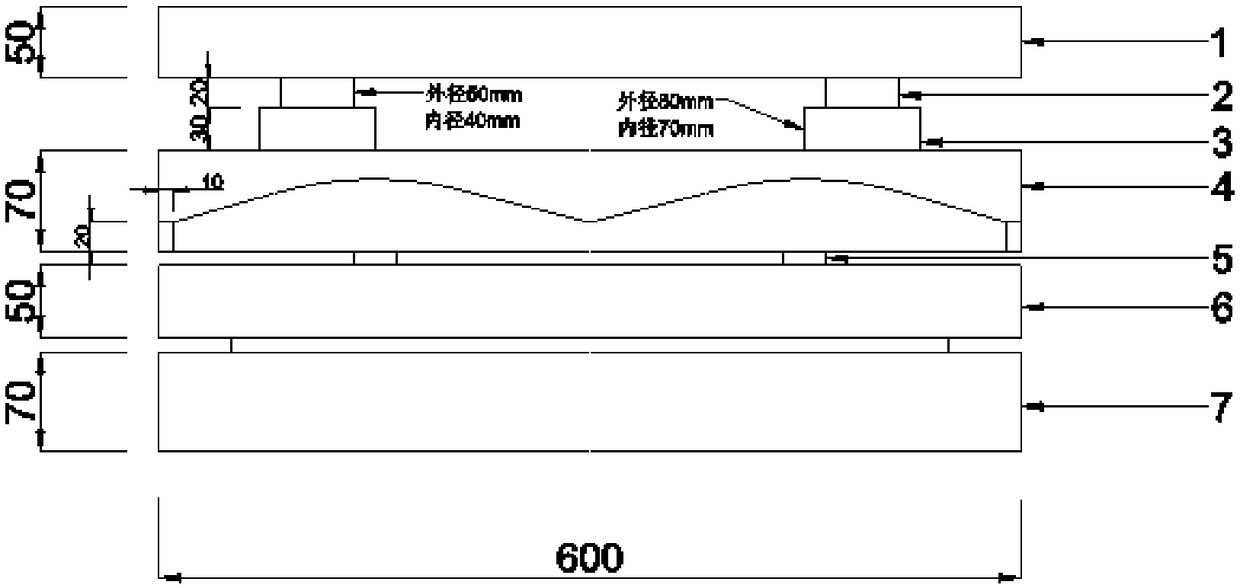

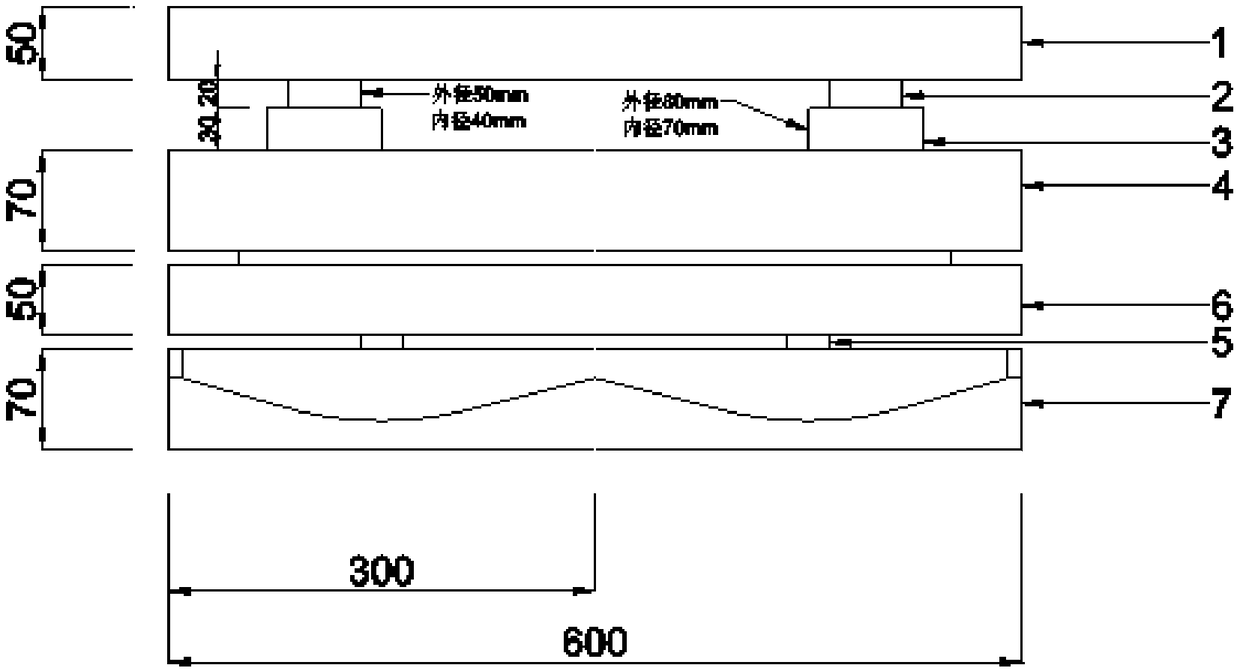

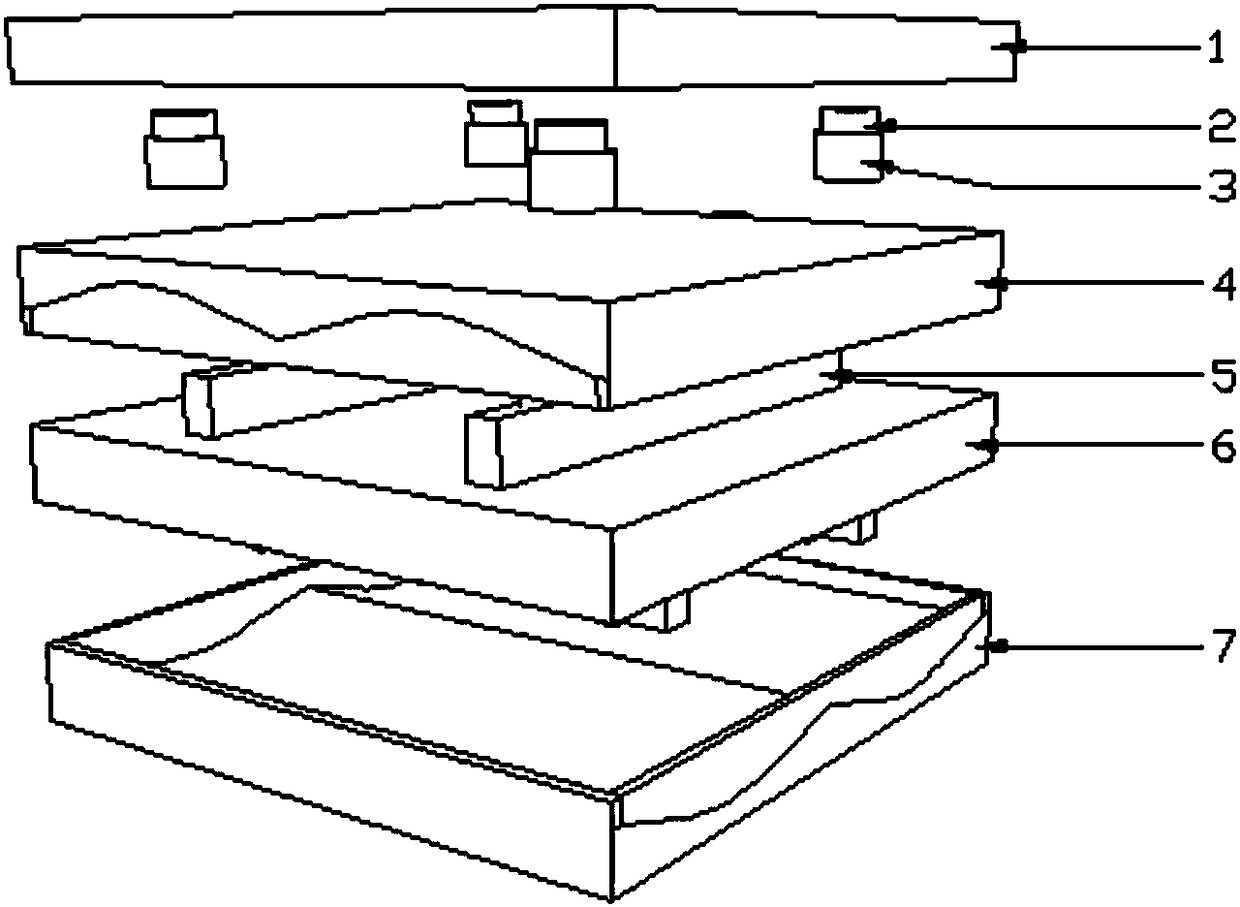

Self-locking protective mounting device with doubly-vertical explosive welding effects

InactiveCN104259654AEasy to installPrevent flying outNon-electric welding apparatusArchitectural engineeringSelf locking

The invention discloses a self-locking protective mounting device with doubly-vertical explosive welding effects. The self-locking protective mounting device aims to implement a novel method for realizing the doubly-vertical explosive welding effects. Reasonable gaps among components such as base plates, compound plates, explosive and protective plates are guaranteed by the aid of a fixed mounting plate during doubly-vertical explosive welding, the left large protective plate and the right large protective plate are inlaid in the base, and masts are connected with screws, so that self-locking protective effects can be realized for the doubly-vertical welded compound plates which laterally fly off. The self-locking protective mounting device has the advantages that the self-locking protective mounting device is provided with the mounting base, so that vertical structures for realizing the doubly-vertical explosive welding effects can be guaranteed, and the problem of difficulty in controlling various technological mounting parameters of explosive welding by the aid of vertical structures can be effectively solved; owing to the self-locking protective structures, the doubly-vertical compound plates can be assuredly effectively protected, the quality of the doubly-vertical compound plates can be assuredly controlled, the self-locking protective structures are favorable for assembling replacement components for the different compound plates with different sizes, the applicability of the protective mounting device can be improved, and the production cost can be reduced.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Method for blasting big boulder in artificially dug pile

The invention discloses a method for blasting a big boulder in an artificially dug pile, which can prevent broken stones from flying around and comprises the following steps: a, drilling a plurality of blast holes in the big boulder; b, placing detonators and explosive in the blast holes; c, connecting the detonators in parallel, connecting the detonators with a head lead, leading the head lead out of an artificially dug pile well, and connecting the head lead with a detonating primer; d, arranging a broken stone separating layer in the artificially dug pile well; e, pressing the detonating primer down to detonate and clear blasted stones; and f, repeating steps from step a to step e until the big boulder in the artificially dug pile is completely dismantled. Because the broken stone separating layer is arranged in the artificially dug pile well, in a blasting process, the broken stone separating layer can obstruct the blasted stones and prevent the potential safety hazard caused when the broken stones fly out of the artificially dug pile well. The method is suitable for popularization and application on occasion when big boulders need to be dismantled in artificially dug piles of various construction works.

Owner:CHINA 19TH METALLURGICAL CORP

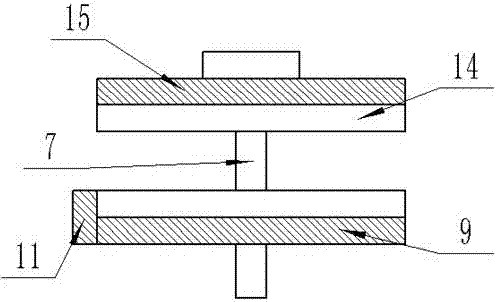

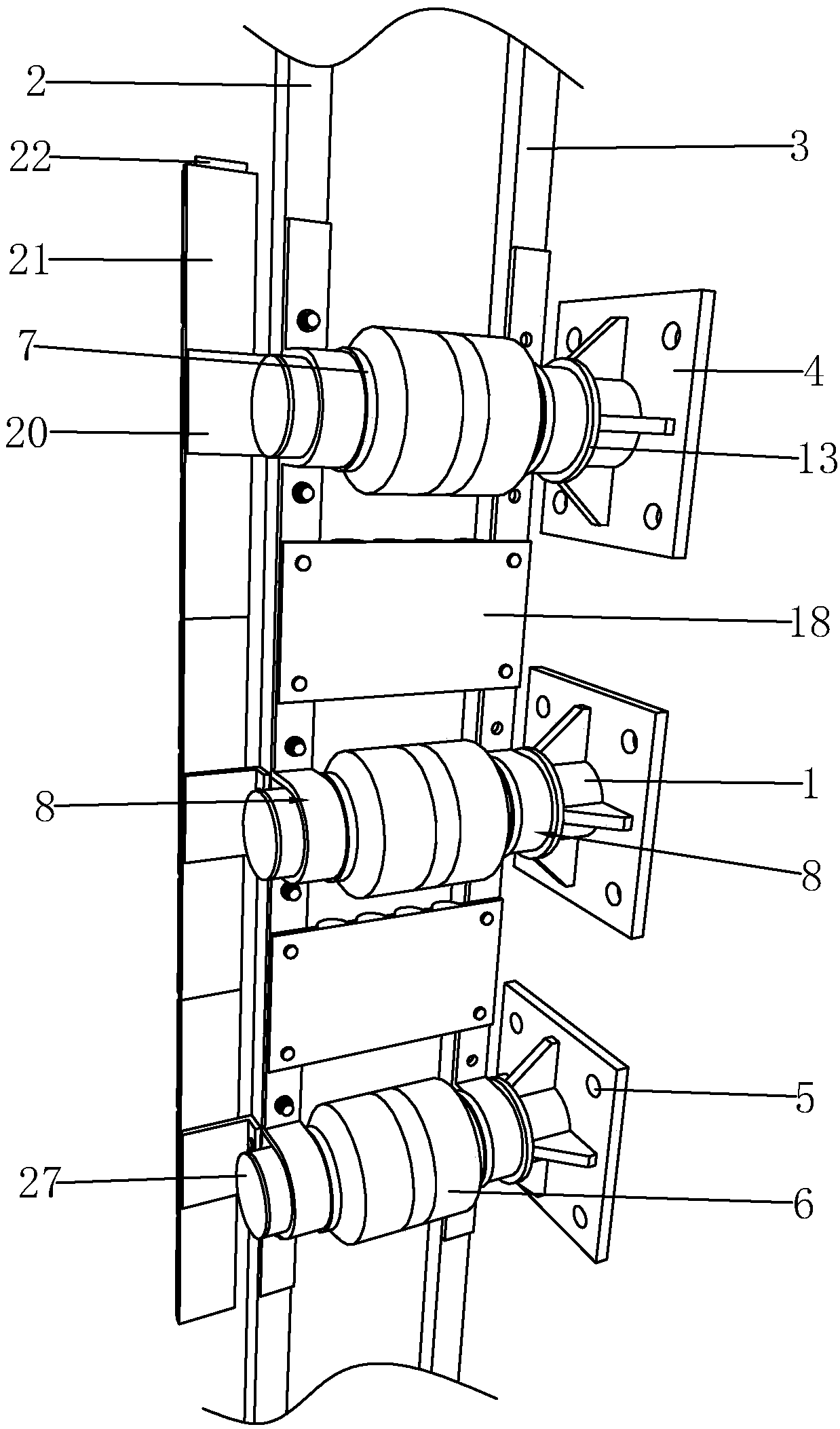

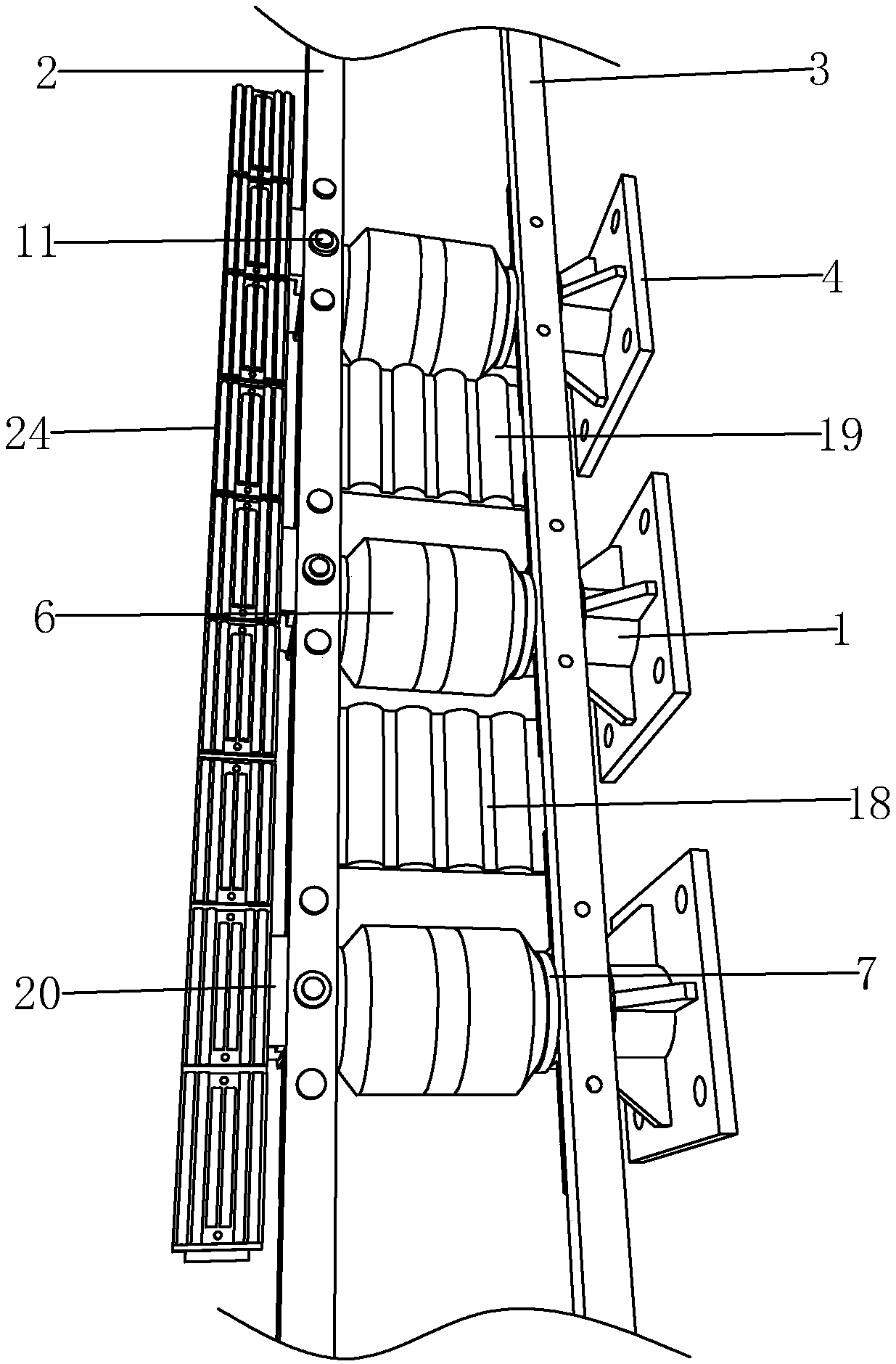

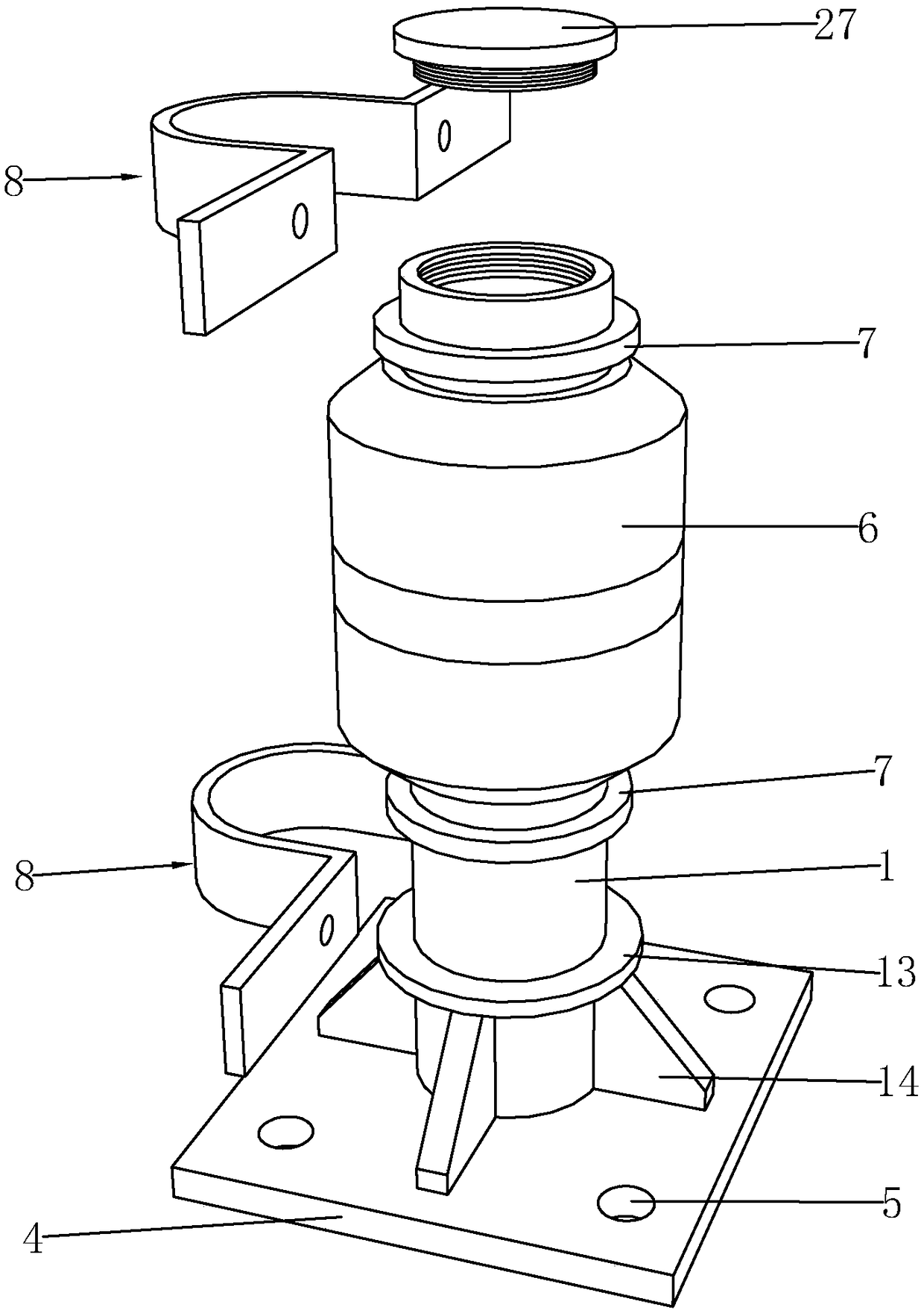

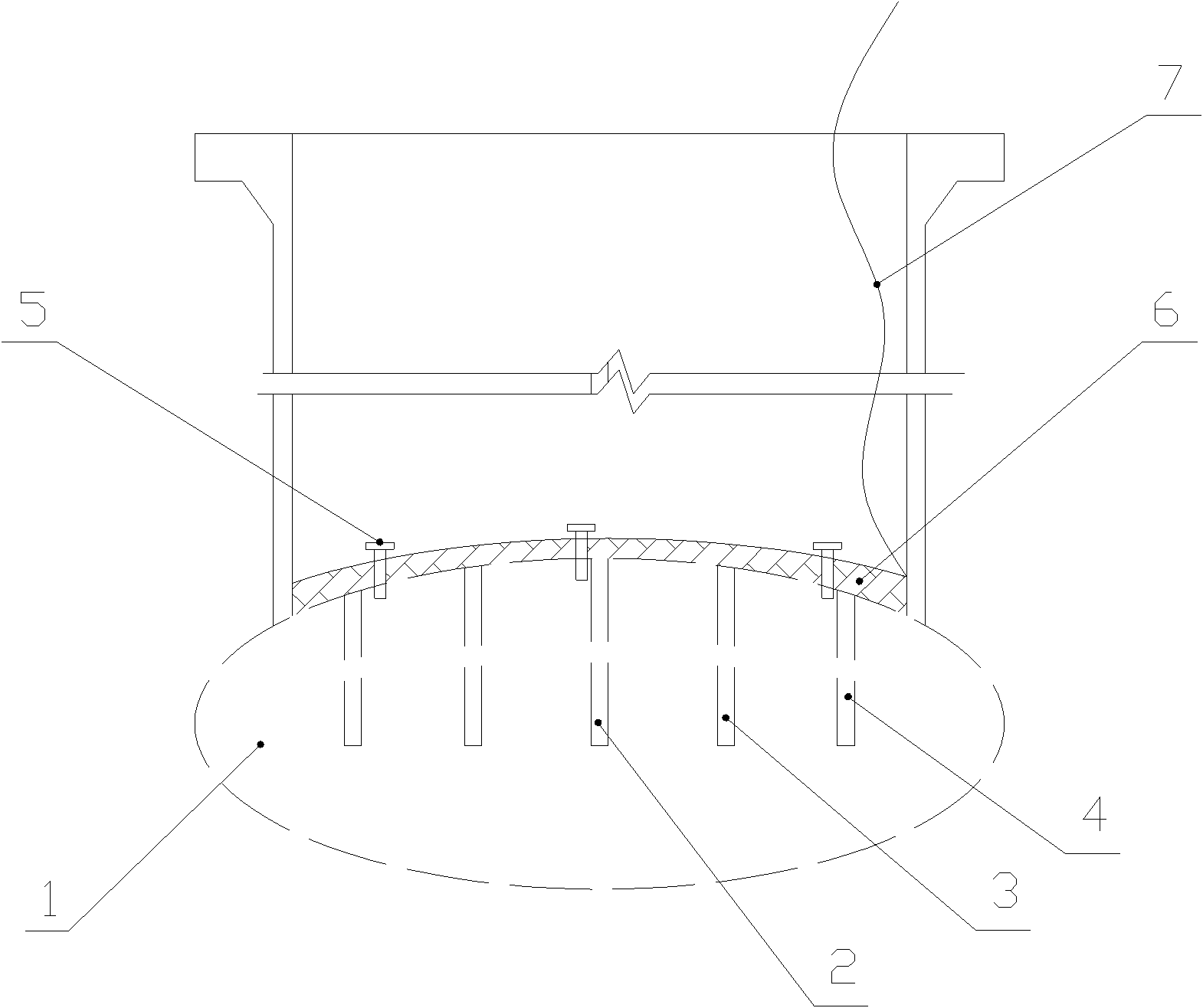

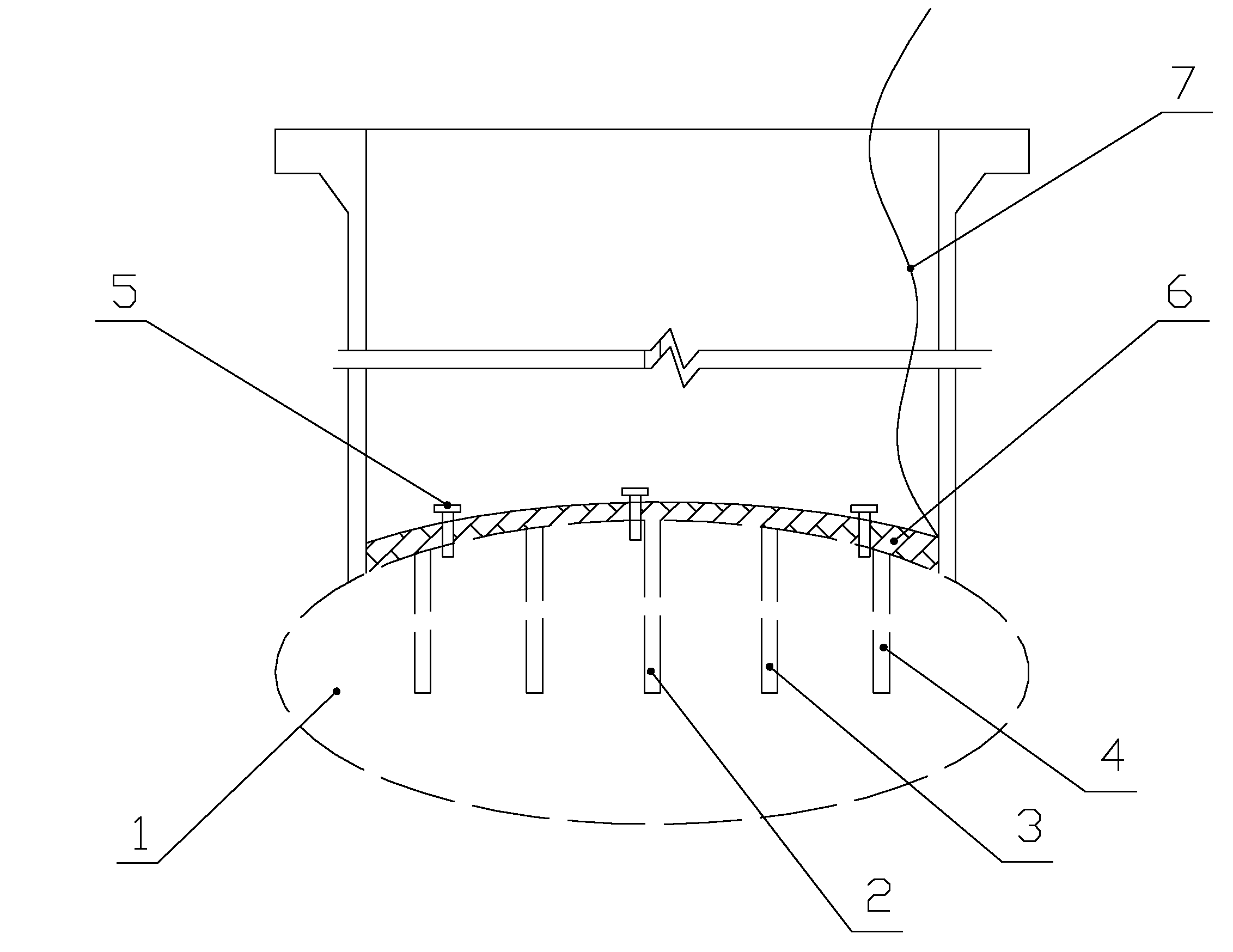

Three-dimensional friction pendulum isolation bearing

PendingCN108266611AGood stabilityOvercoming resonance problemsNon-rotating vibration suppressionStands/trestlesEngineeringPendulum

The invention discloses a three-dimensional friction pendulum isolation bearing which comprises a bottom double-slideway plate, an upper-side double-slideway plate, a bearing plate, a middle slider, aplurality of spring sleeves and springs, wherein the upper-side double-slideway plate is arranged above the bottom double-slideway plate; the bearing plate is arranged above the upper-side double-slideway plate; the middle slider is arranged between the bottom double-slideway plate and the upper-side double-slideway plate; a sliding block is arranged on each of the upper surface and the lower surface of the middle slider; the spring sleeves are connected between the upper-side double-slideway plate and the bearing plate; the springs are separately arranged in the corresponding spring sleeves;and the springs are connected with the bearing plate and the upper-side double-slideway plate. The three-dimensional friction pendulum isolation bearing realizes the decoupling of horizontal earthquake and vertical earthquake, and vertical isolation is performed by the springs with good isolation reduction effects. The bearing has necessary isolation capacity, the structure gravity is used as restoring force to enable the bearing to be reset. Position limitation protection is considered, three-way isolation parameters can be amended according to different cultural relics, and the three-dimensional friction pendulum isolation bearing has high practicability. Compared with a traditional friction pendulum, the sliding effect of rolling balls is better, and the isolation effect in the horizontal direction is excellent.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Filter bag cleaning device

Owner:JIANGSU XINKEDA FILTER BAG

New energy vehicle tire wear-resisting performance detection device

InactiveCN108956163APrevent flying outAvoid damageVehicle tyre testingInvestigating abrasion/wear resistanceBall bearingNew energy

The present invention relates to the technical field of tire detection accessory devices, especially to a new energy vehicle tire wear-resisting performance detection device. The device can simulate acondition in an actual usage process of tires, the obtained tire wear-resisting performance has more representativeness, the practicability is improved, the hidden dangers are reduced, and the safetyis improved. The new energy vehicle tire wear-resisting performance detection device comprises a detection substrate, the detection substrate is provided with a tire installation disc, the rear end of the tire installation disc is provided with a variable speed motor, the new energy vehicle tire wear-resisting performance detection device further comprises two sets of brake devices which are respectively installed at left and right sides of the top end of the detection substrate and are bilaterally symmetrically arranged, each brake device comprises one installation plate, one front support plate, one rear support plate, one friction disk, one front rotation shaft, one rear rotation shaft, one lead screw, one first motor, one brake gear, two sets of forked tail sliding blocks, one front ball bearing and one rear ball bearing, the top end of the detection substrate is provided with two forked tail grooves, and each brake gear comprises one brake disk, one second motor, one front clamping plate, one rear clamping plate, one limited rod, one transmission shaft and one lower ball bearing.

Owner:山西云度知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com