A bridge anti-collision guardrail and a construction method thereof

A technology for anti-collision guardrails and bridges, used in bridges, bridge parts, bridge construction, etc., can solve the problems of turning out of the bridge, difficult maintenance, and high cost, improving structural stability, consuming impact energy, and reducing installation errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

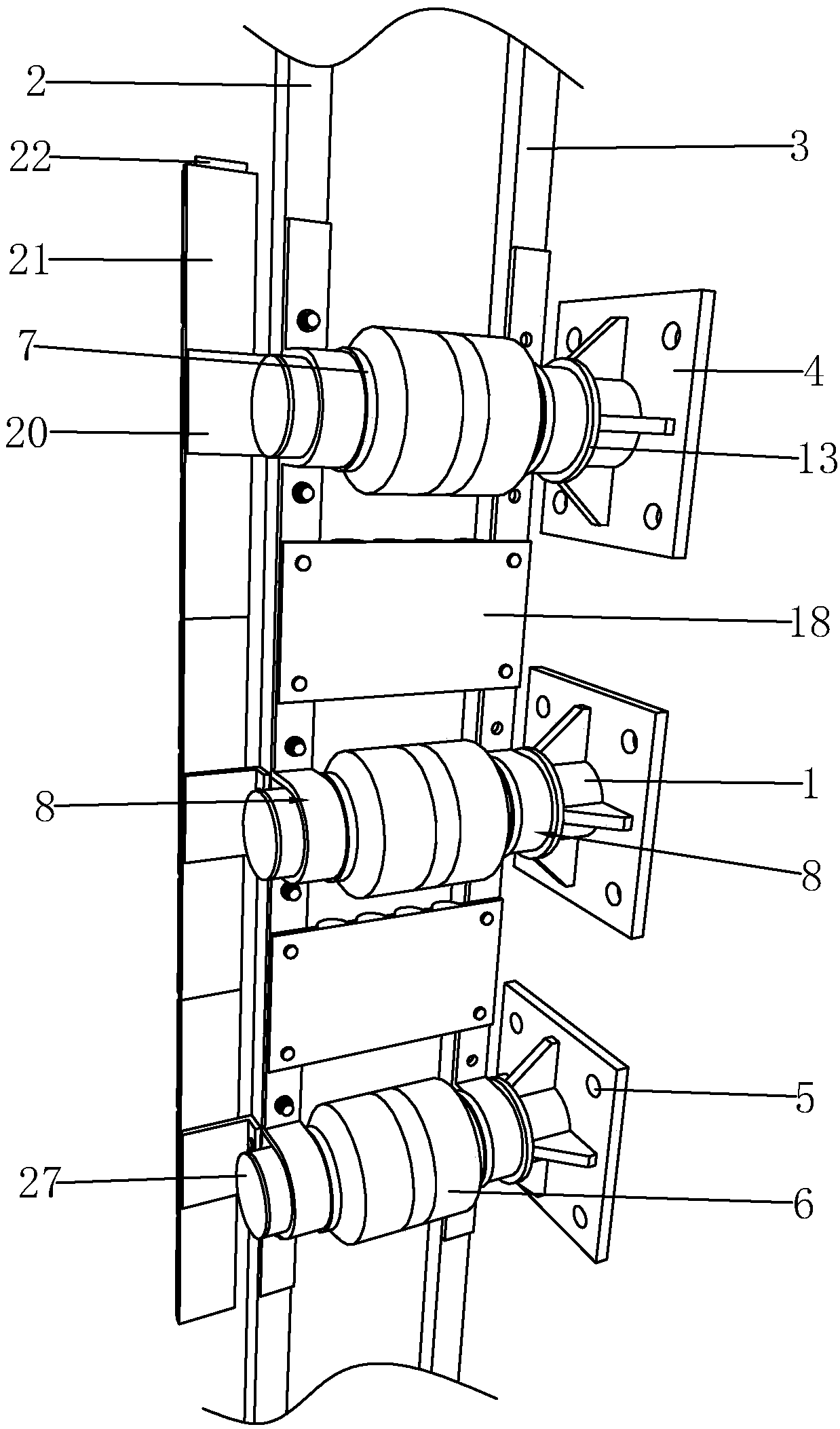

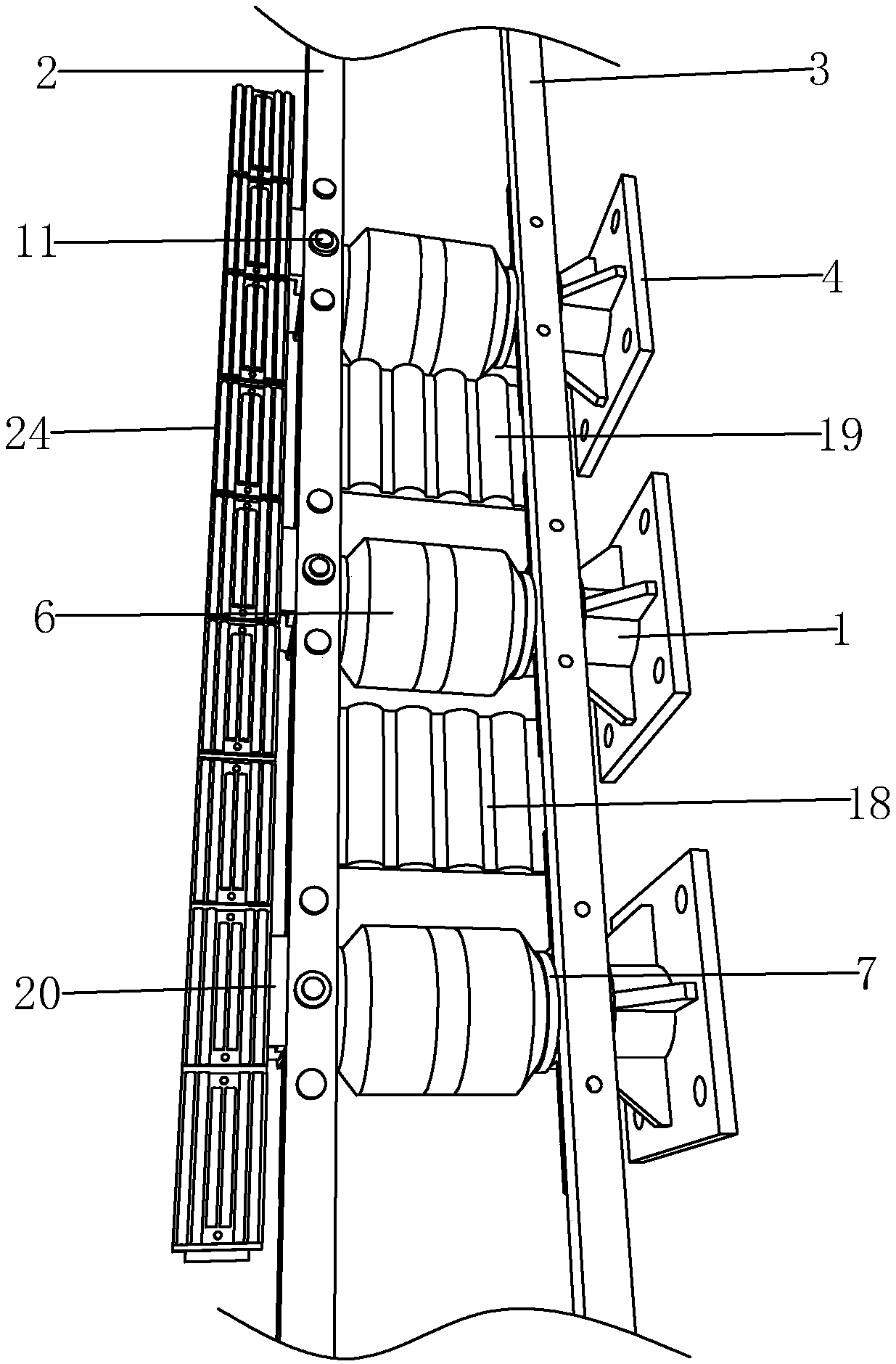

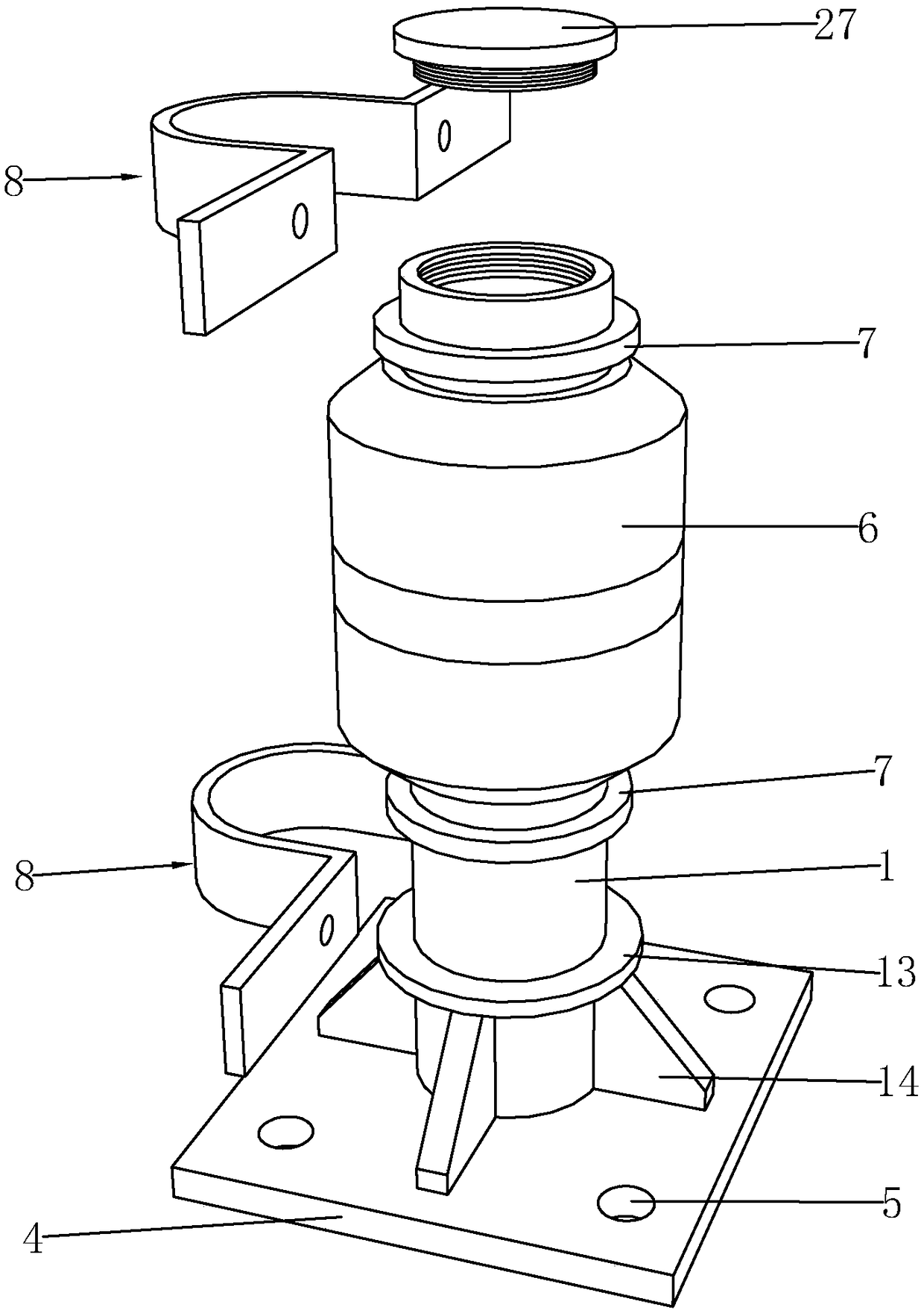

[0035] like Figure 1 to Figure 6 Shown, be a kind of bridge anti-collision guardrail of the present invention, comprise column 1, upper railing 2 and lower railing 3, column 1 is located between upper railing 2 and lower railing 3, the bottom of column 1 is provided with support plate 4, supports An anchor hole 5 is provided on the plate 4, and ground nails are driven into the anchor hole 5 to realize the fixing of the column 1 on the bridge surface, which is easy to disassemble and convenient for maintenance. The column 1 is respectively sleeved with a buffer cylinder 6 and a convolving ring 7. The buffer cylinder 6 is located between the limit seats 8, and the convolute ring 7 is located between the buffer cylinder 6 and the limit seat 8. The convoluted circles 7 arranged up and down are convenient for the buffer cylinder. 6 Rotate smoothly when being hit, both ends of the column 1 are fixed on the upper railing 2 and the lower railing 3 through the limit seat 8, the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com