Patents

Literature

209results about How to "Spraying speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

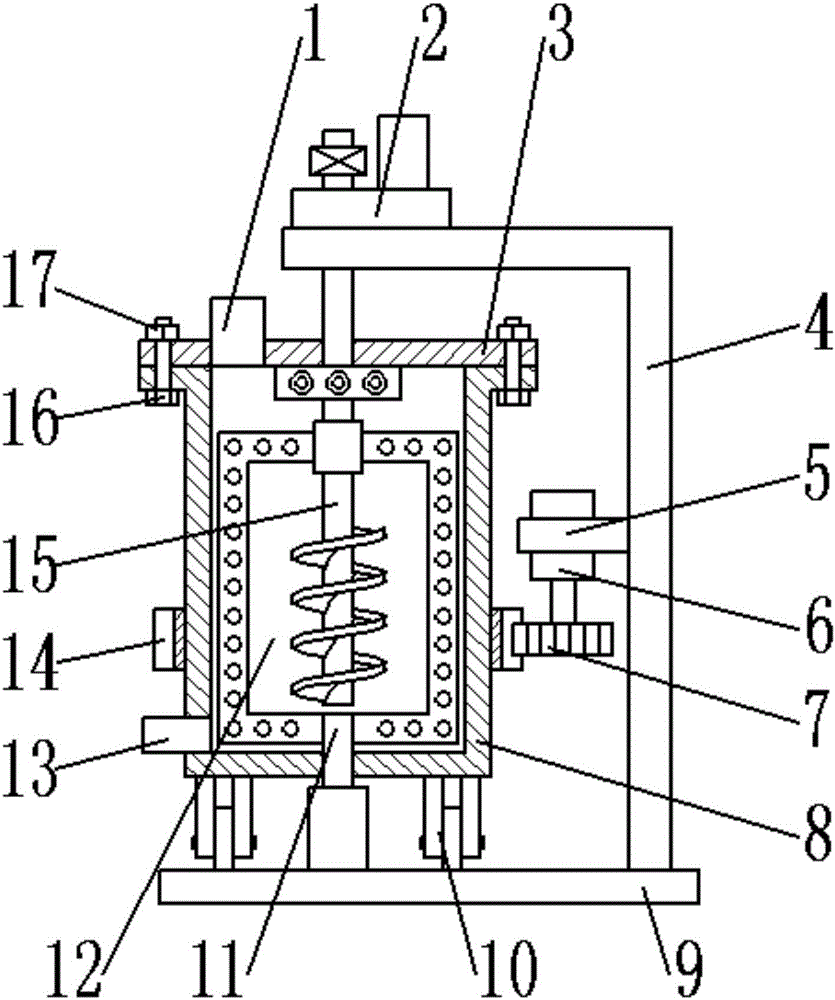

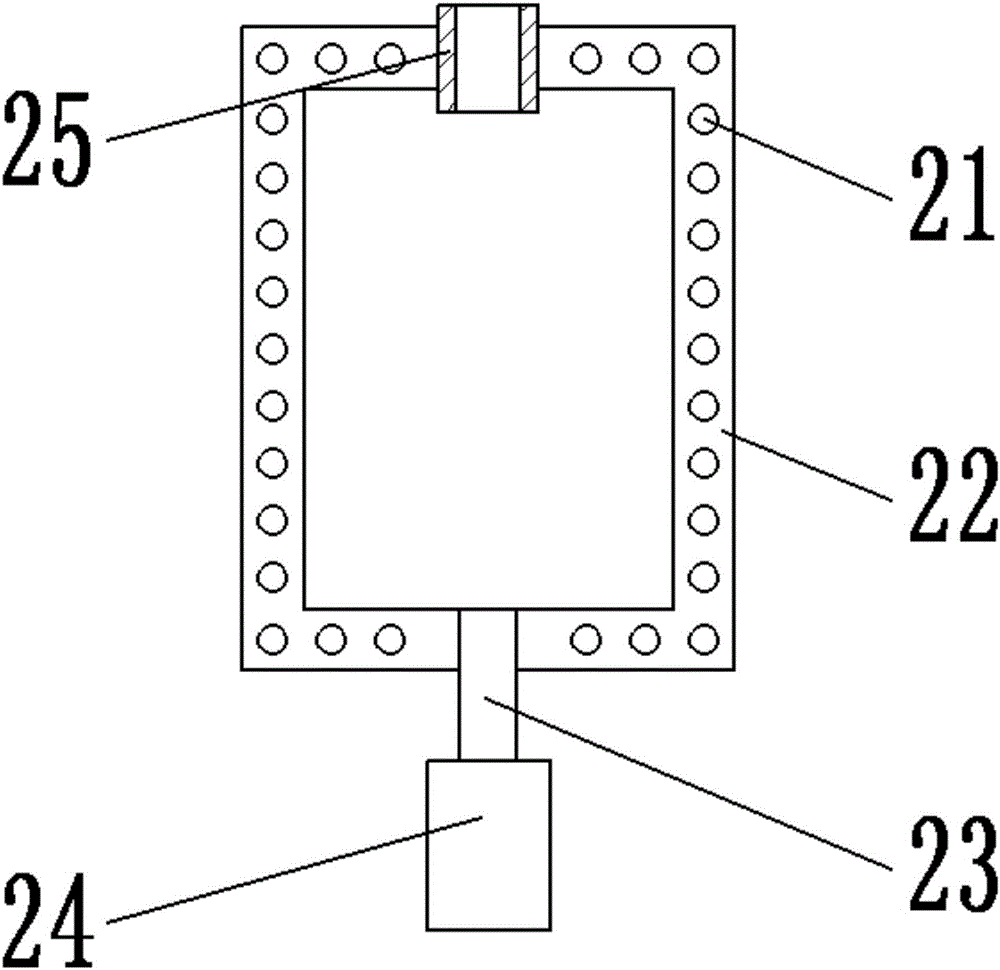

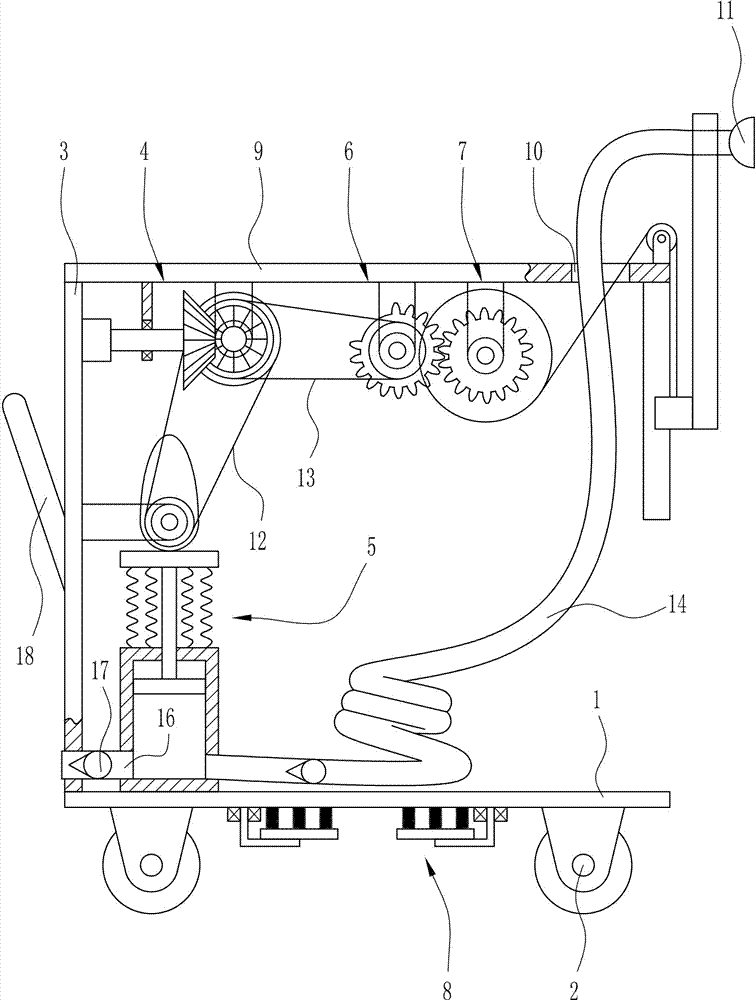

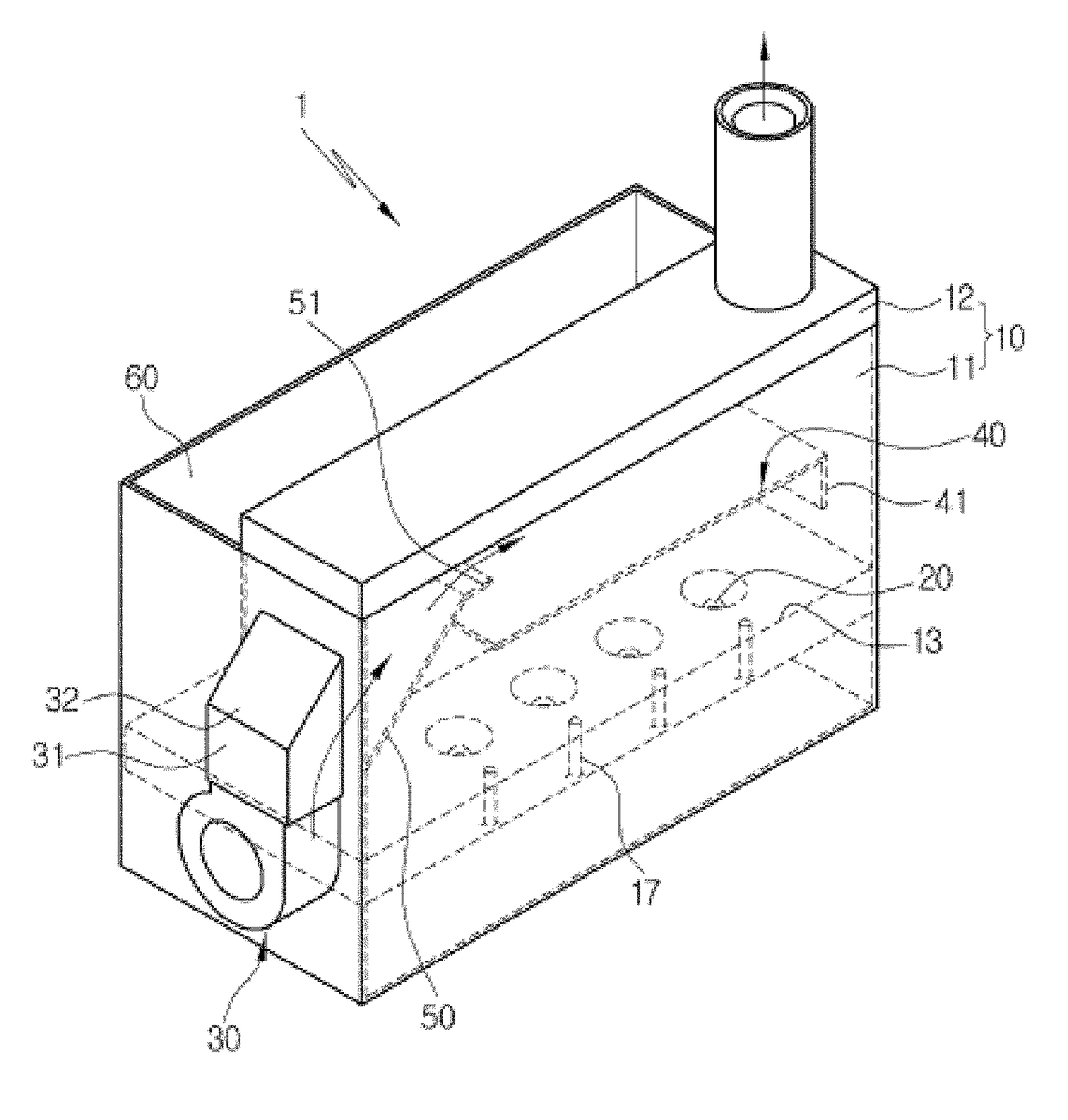

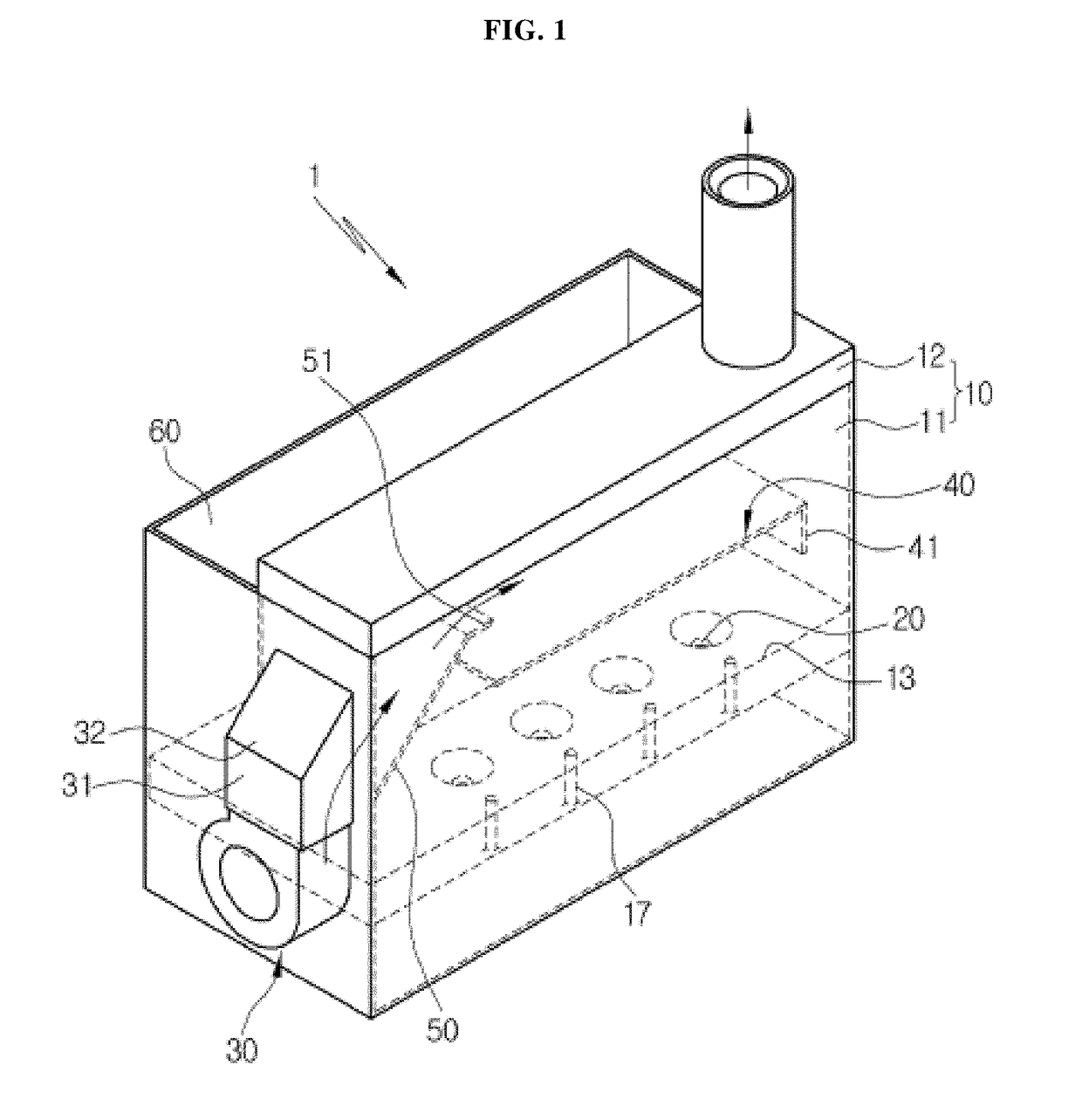

Efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering

InactiveCN106582389AEnsure mixing uniformityMixing uniformity does not existRotating receptacle mixersRotary stirring mixersElectric machineryRaw material

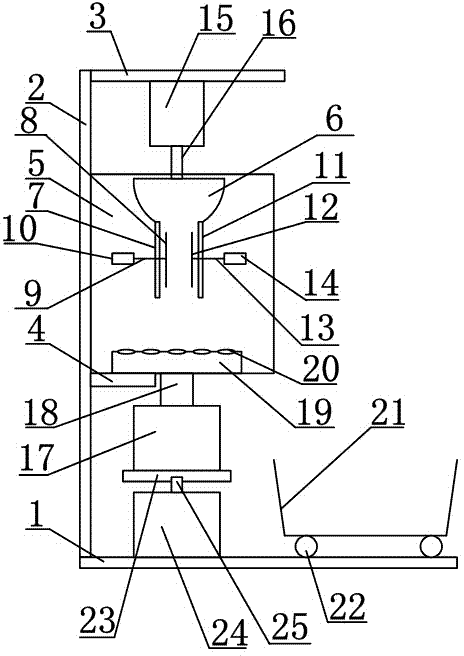

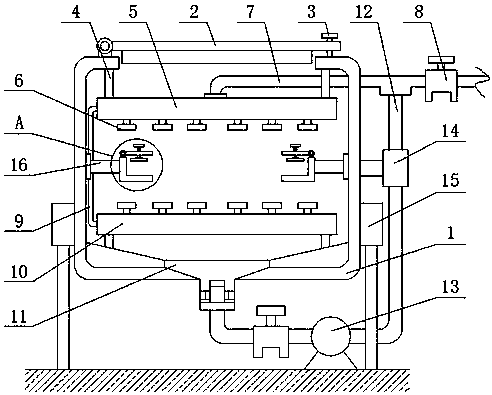

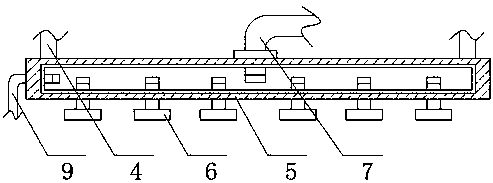

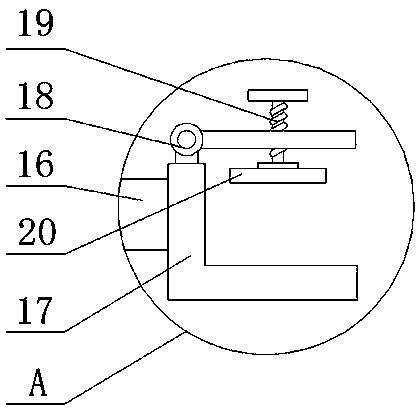

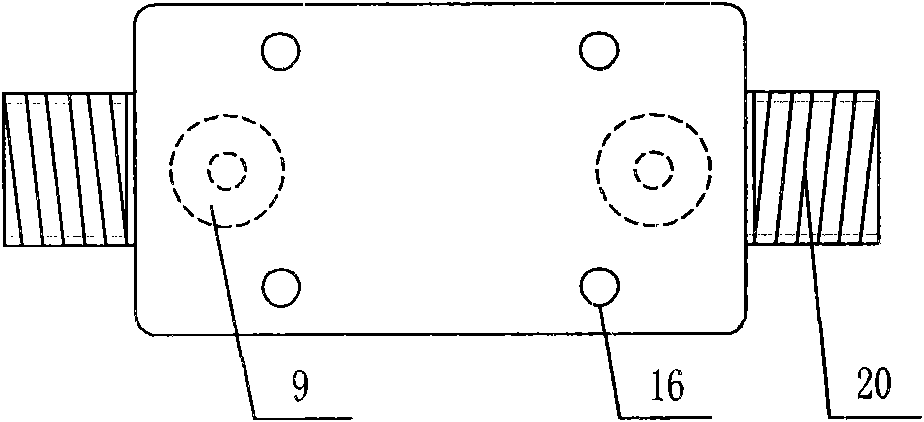

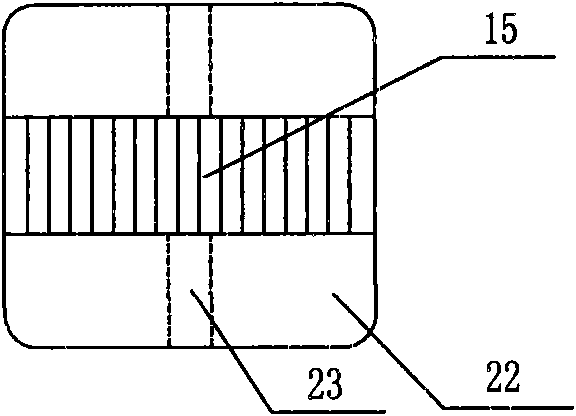

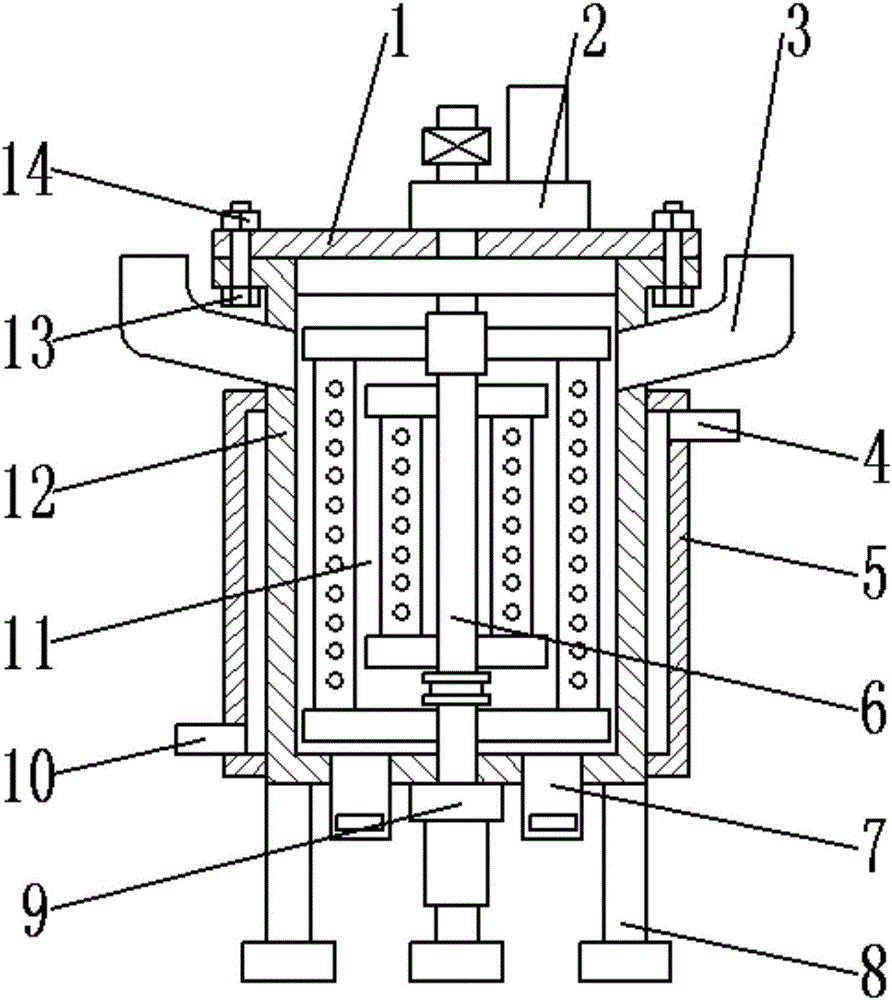

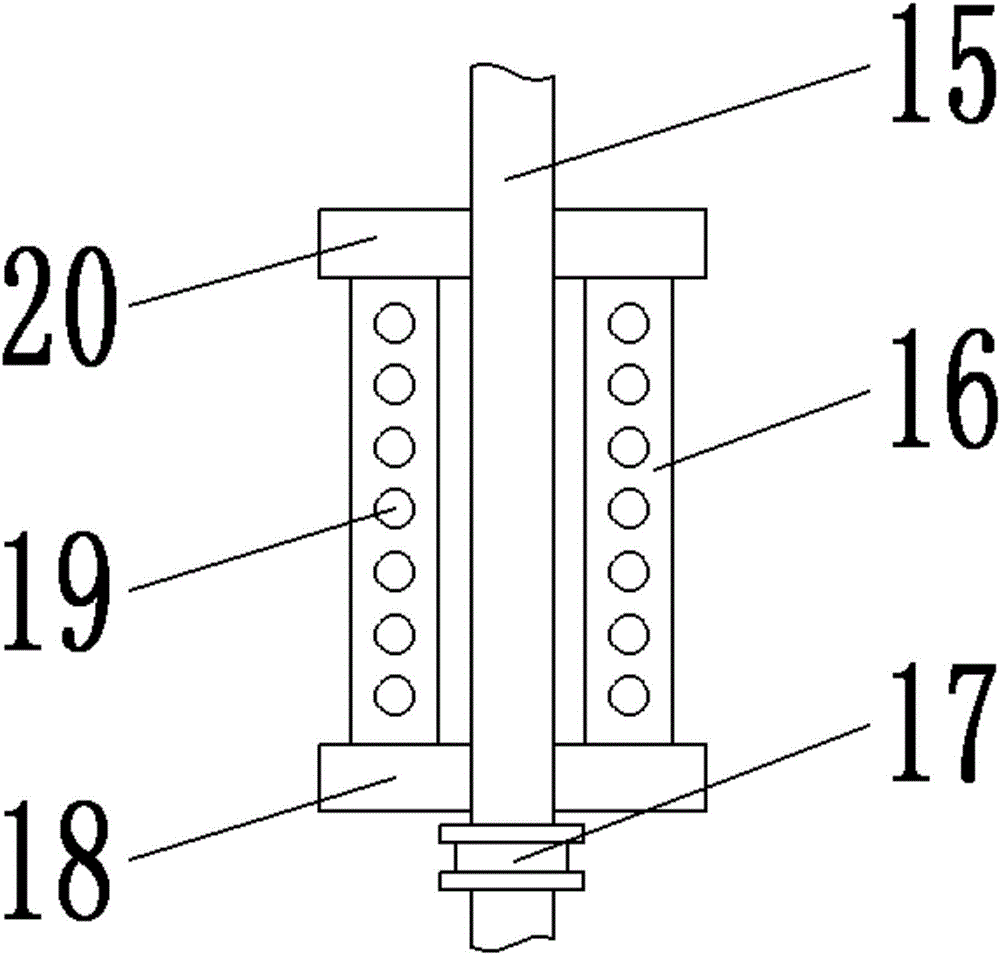

The invention provides efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering. The efficient stirring and mixing equipment comprises a tank body; a stirring cavity is formed in the tank body, an upper cover is installed on an opening formed in the top of the tank body, and four sets of rollers are installed on the lower surface of the tank body; the rollers are installed in a sliding groove formed in a base plate, a support is installed at the end of the base plate, and the vertical portion of the support is fixedly connected with a second motor through a fixing plate; a liquid feeding device is installed on the upper surface of the horizontal portion of the support, the liquid feeding device is composed of a transmission box, a first motor, a liquid feeding pipe, a connecting pillar and a spraying disc, and a first stirring device and a second stirring device are installed in the stirring cavity. According to the efficient stirring and mixing equipment of the solid-liquid raw materials for chemical engineering, through the liquid feeding device, the spraying area and speed of liquid materials are enlarged, so that the liquid materials make sufficient contact with solid materials; through the first stirring device, circulating stirring and mixing of the materials are achieved, so that the spraying speed of the liquid materials is improved; and through arrangement of the second stirring device, the materials are further stirred and mixed.

Owner:郑州吉音动漫科技有限公司

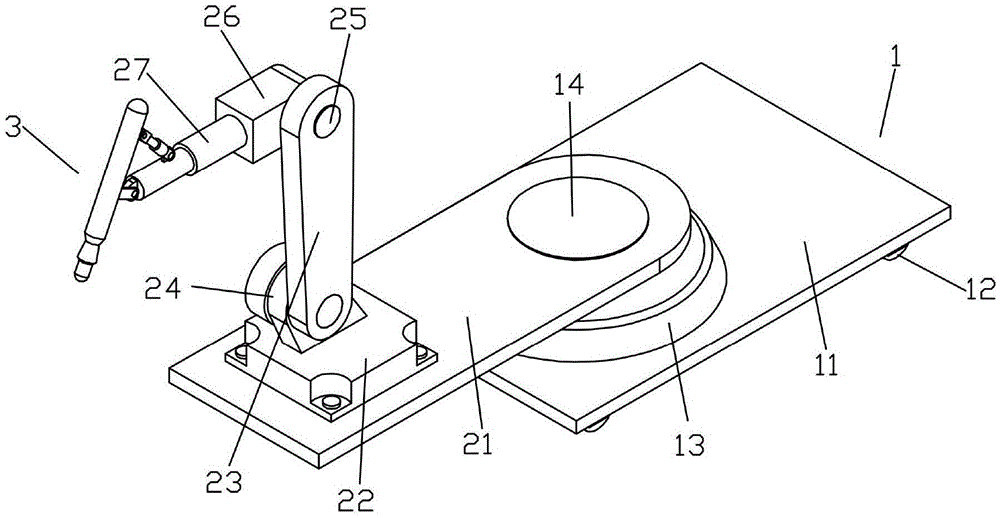

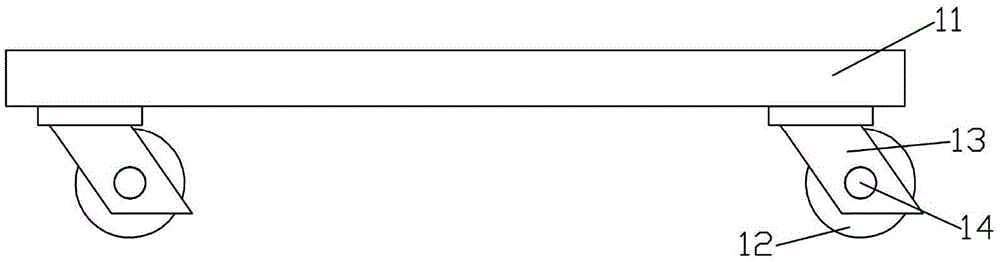

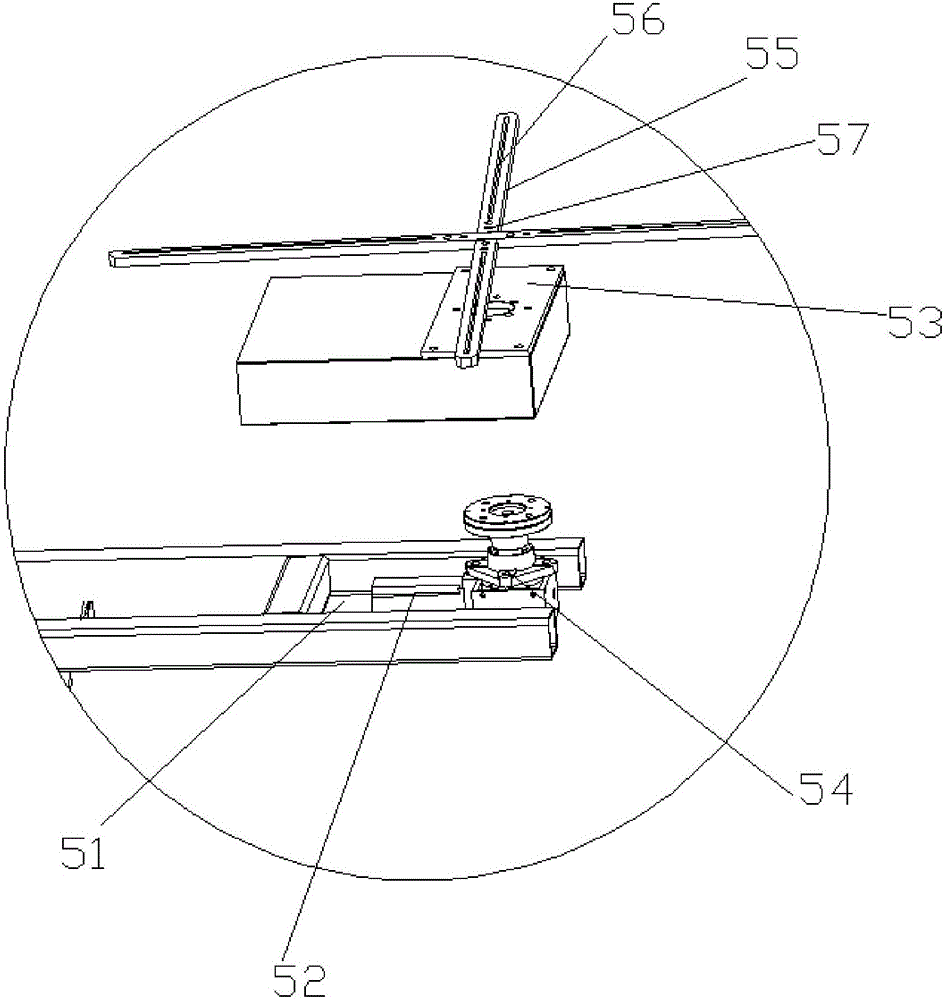

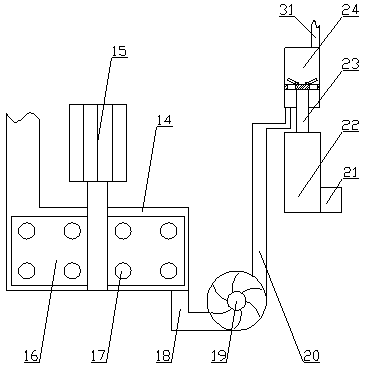

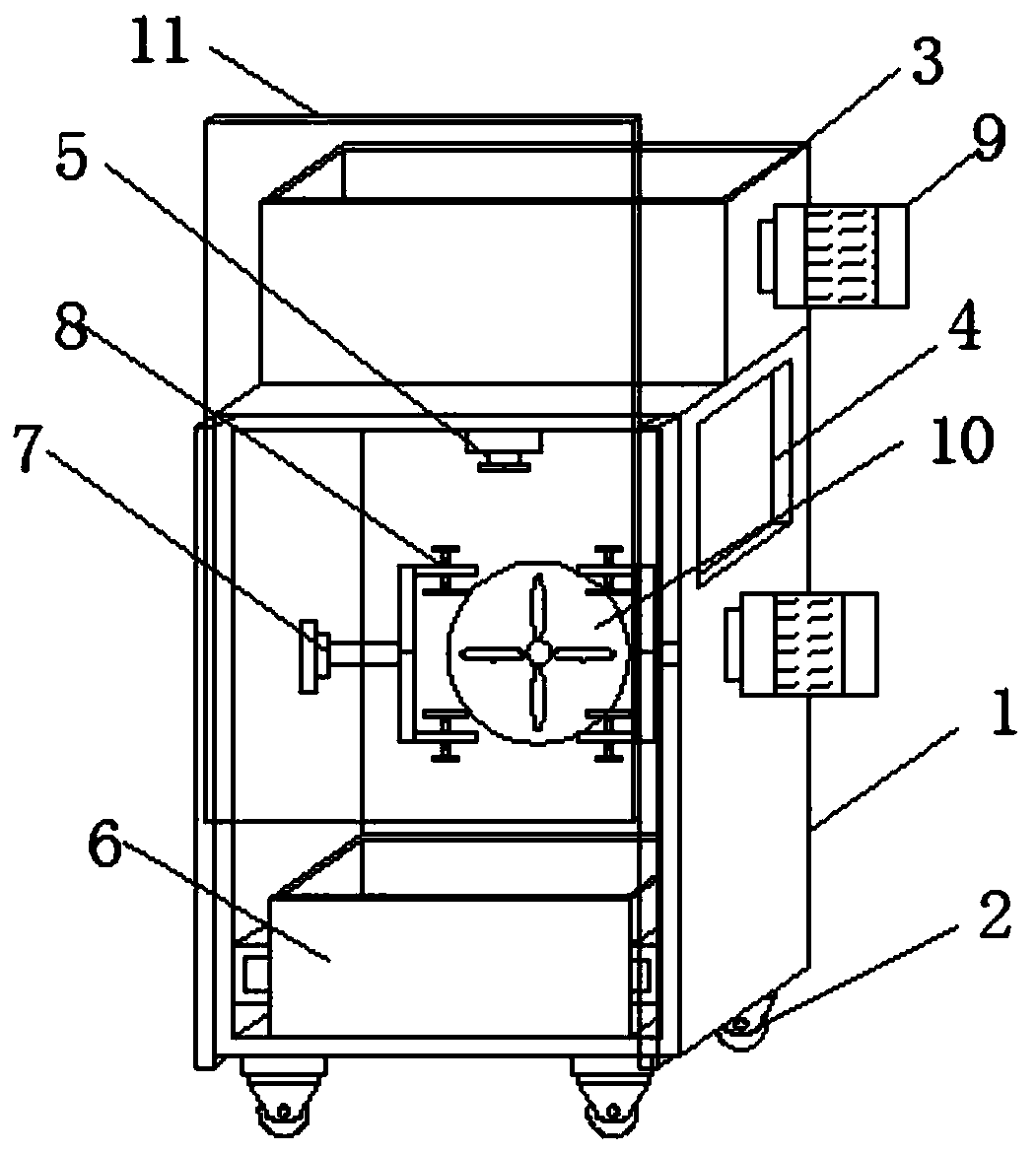

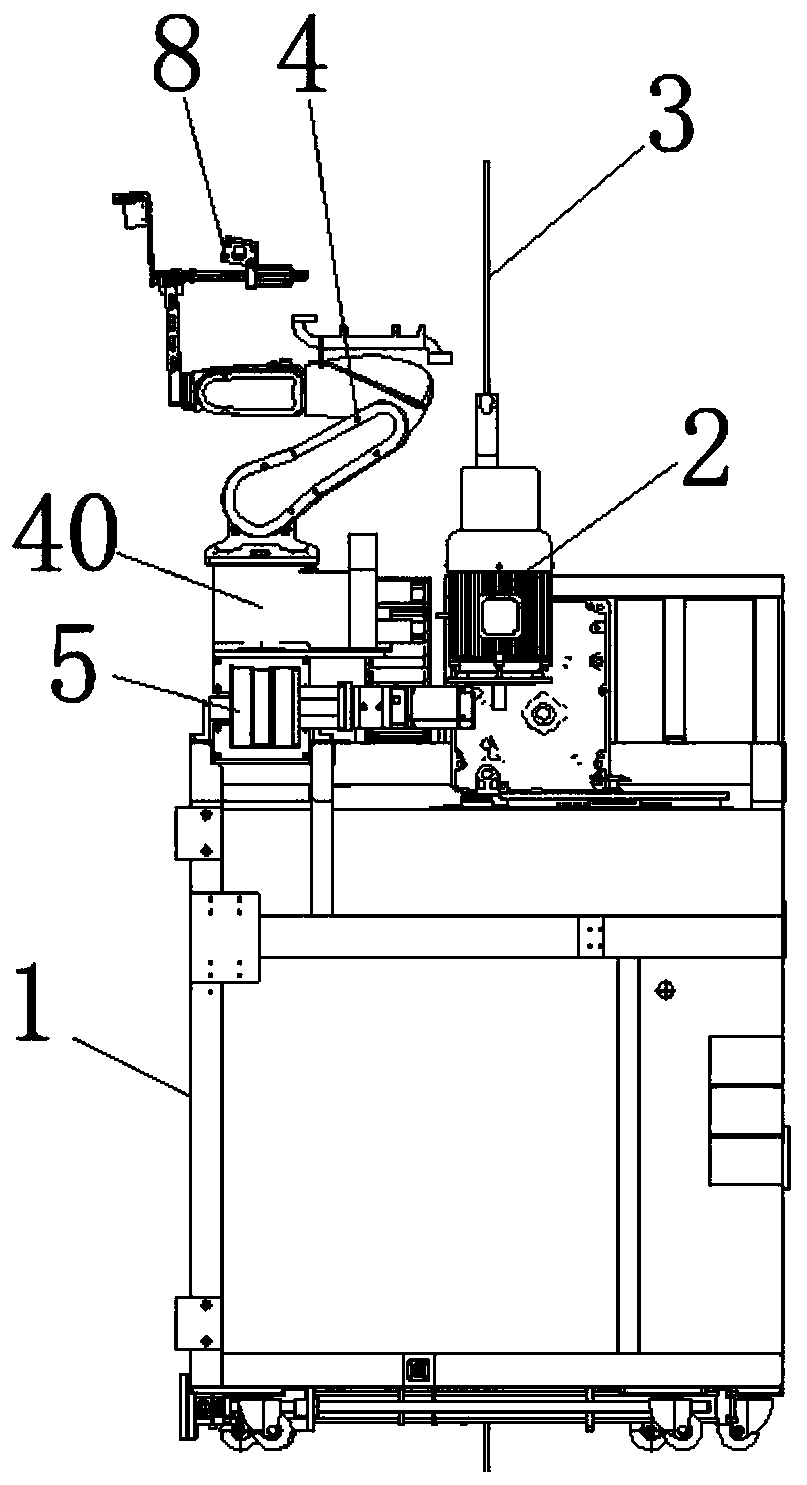

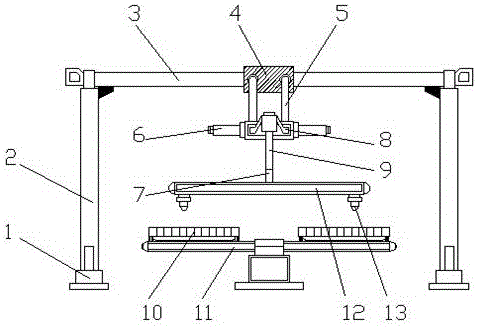

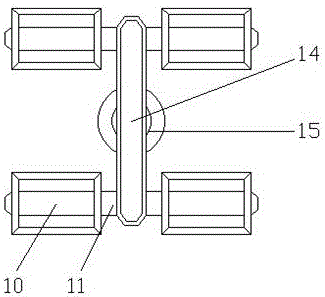

Movable paint spraying machine

InactiveCN105521899AImprove final performanceAvoid manual interventionSpraying apparatusControl systemMechanical engineering

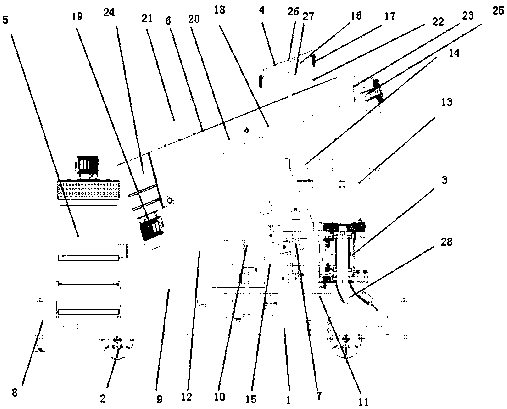

The invention discloses a movable paint spraying machine. The movable paint spraying machine comprises a movable frame, a swinging and rotating unit, a spray gun, a travelling driver, a swinging and rotating driver and a control system. The swinging and rotating unit is connected to the movable frame rotationally. The spray gun is hinged to the swinging and rotating unit. The travelling driver is used for driving the movable frame to move. The swinging and rotating driver is used for controlling the swinging and rotating unit to swing and rotate. The control system is connected with the travelling driver and the swinging and rotating driver electrically to control movement of the movable frame and the swinging and rotating unit. The movable paint spraying machine has the advantages that the movable paint spraying machine has multi-angle multi-direction moving and swinging functions and can spray paint automatically, so that manual work is avoided, and personal injuries are reduced; the spraying speed is high, and paint is smooth and fine in hand feel; the paint is sprayed out in the form of mist, so that the paint can be well sprayed to corners and gaps, and final effect of paint films is good.

Owner:JIAMA MACHINERY COATING SCI & TECH SUZHOU CO LTD

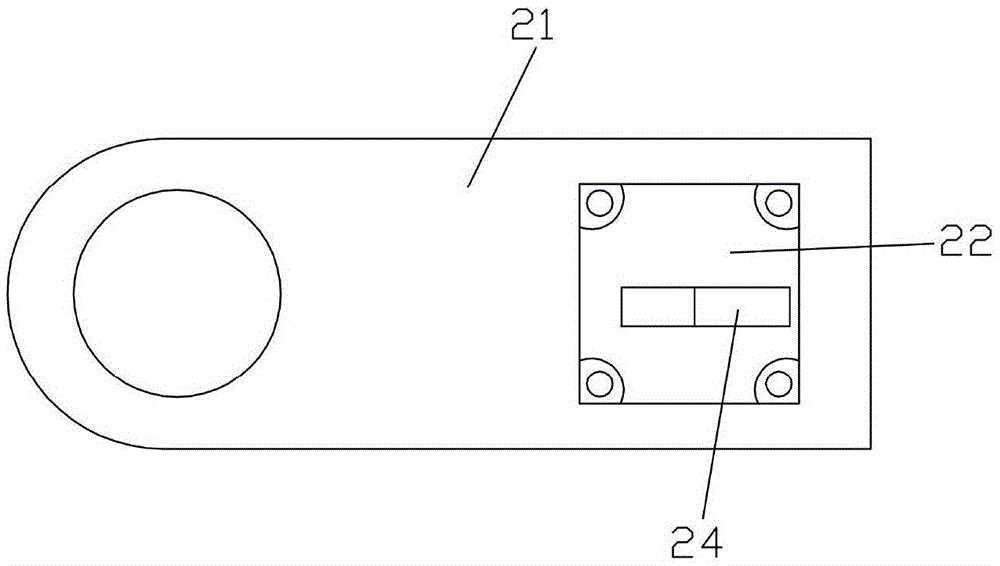

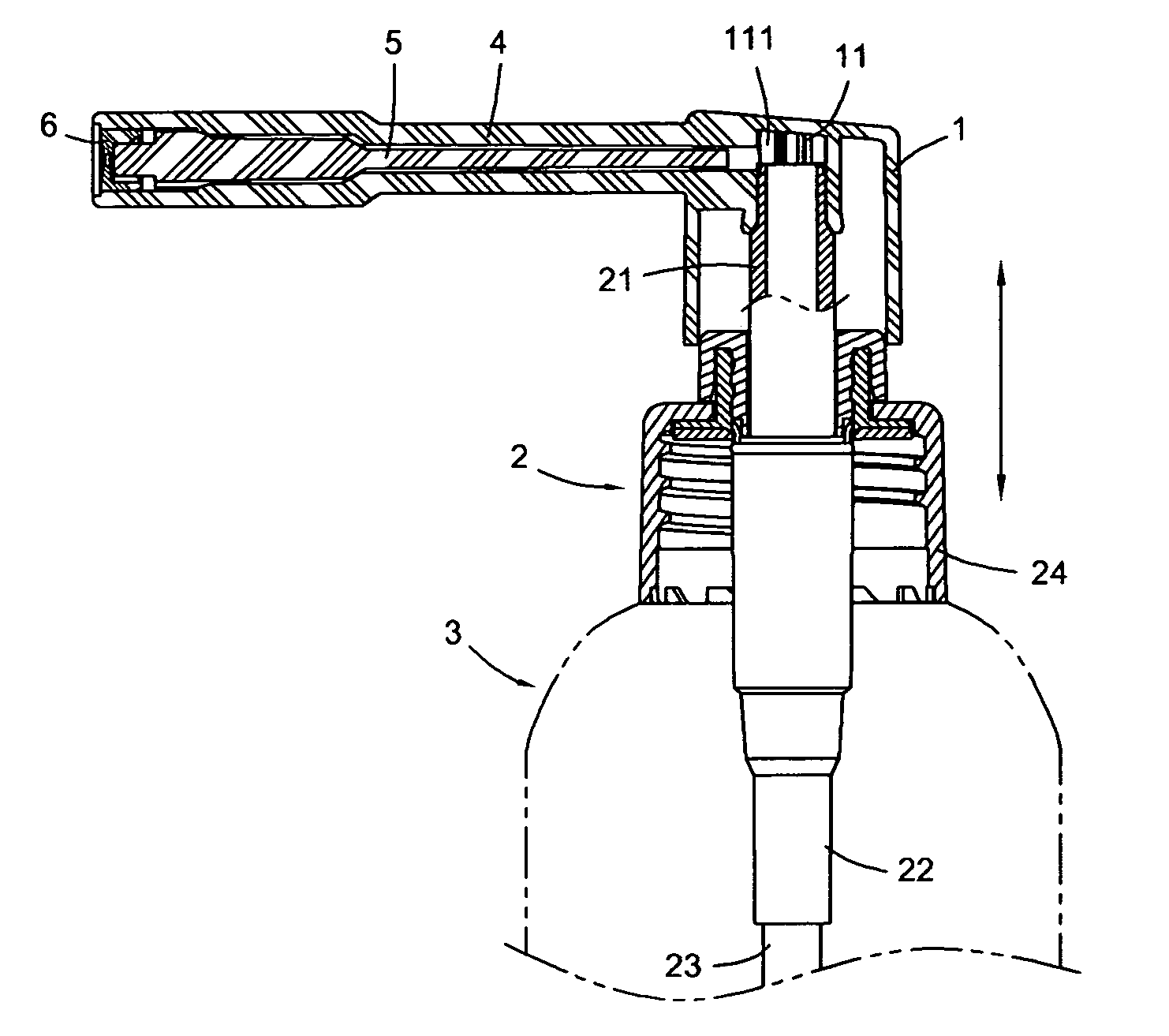

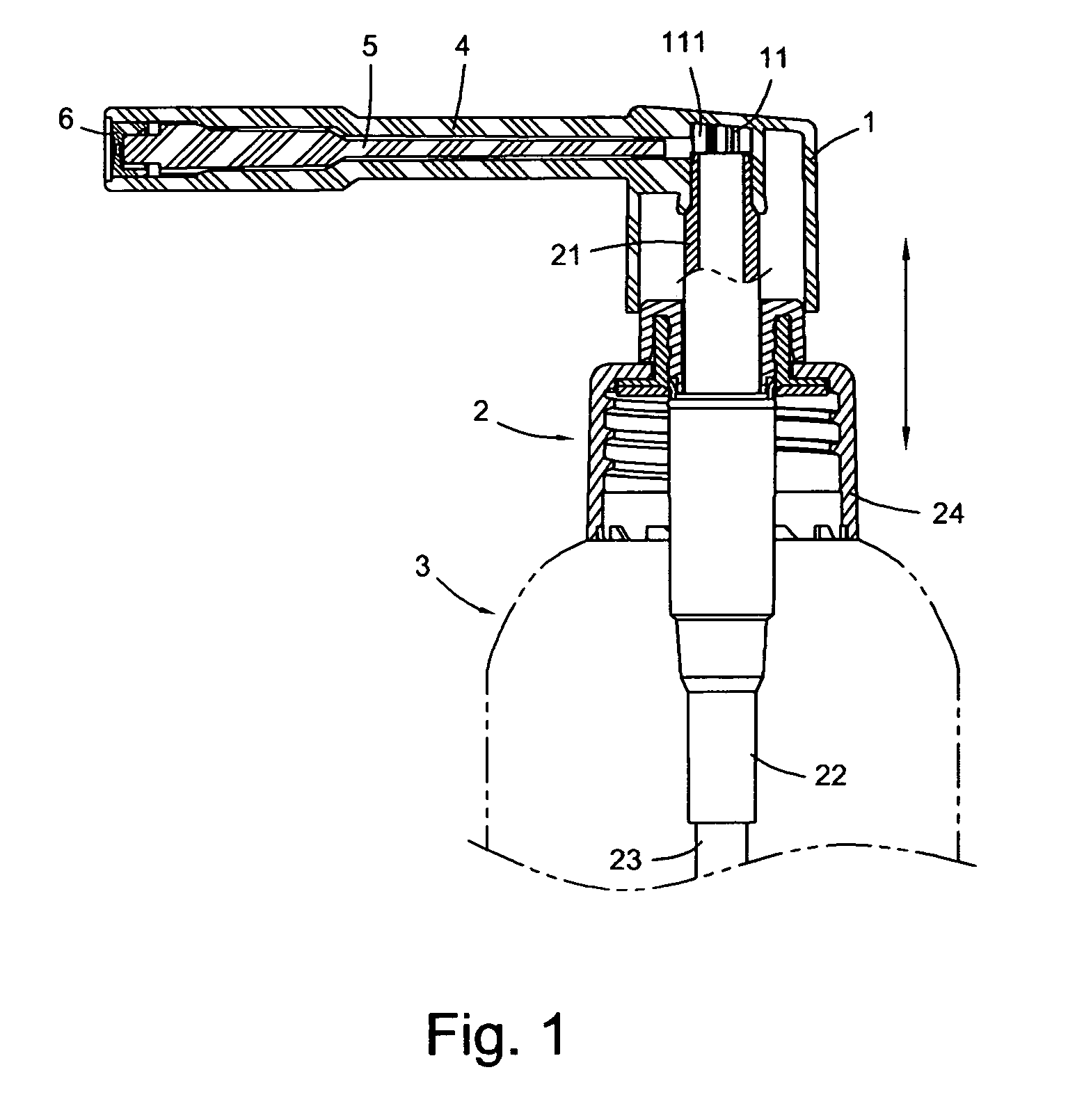

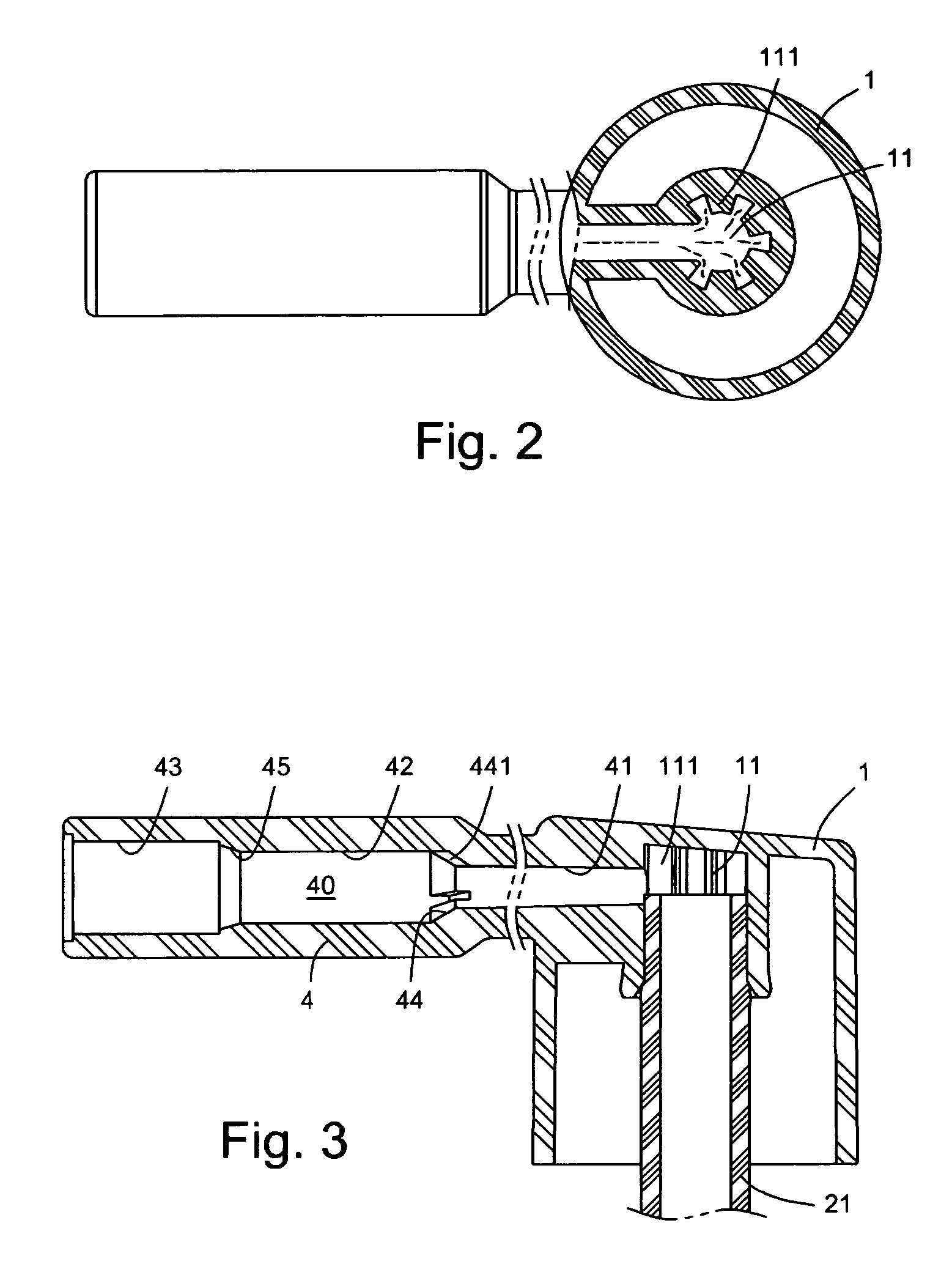

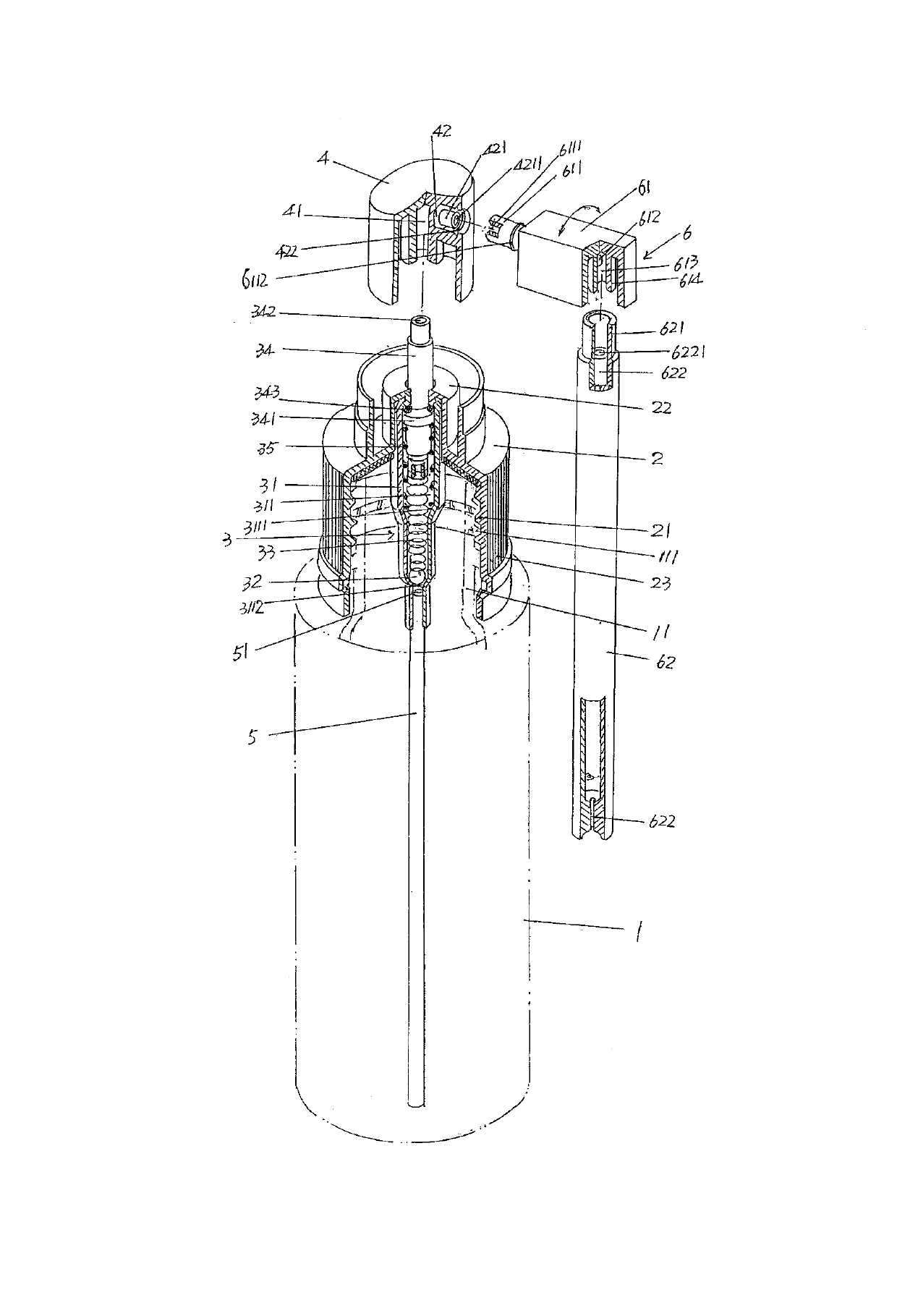

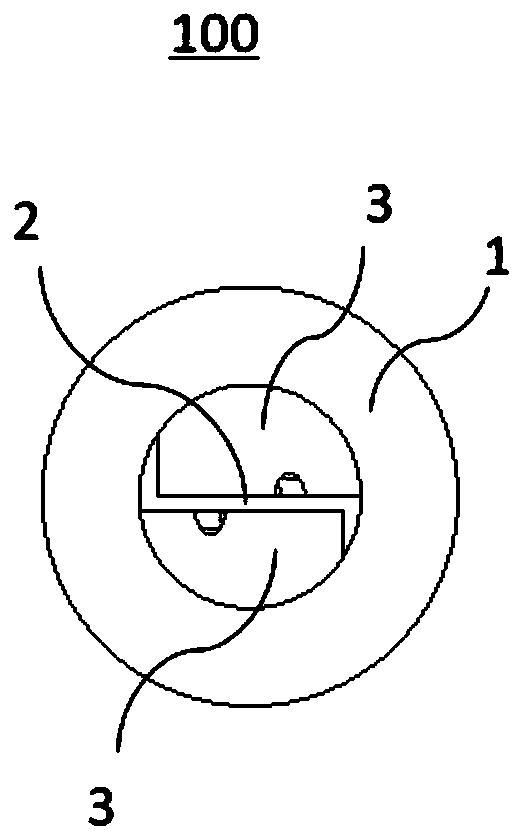

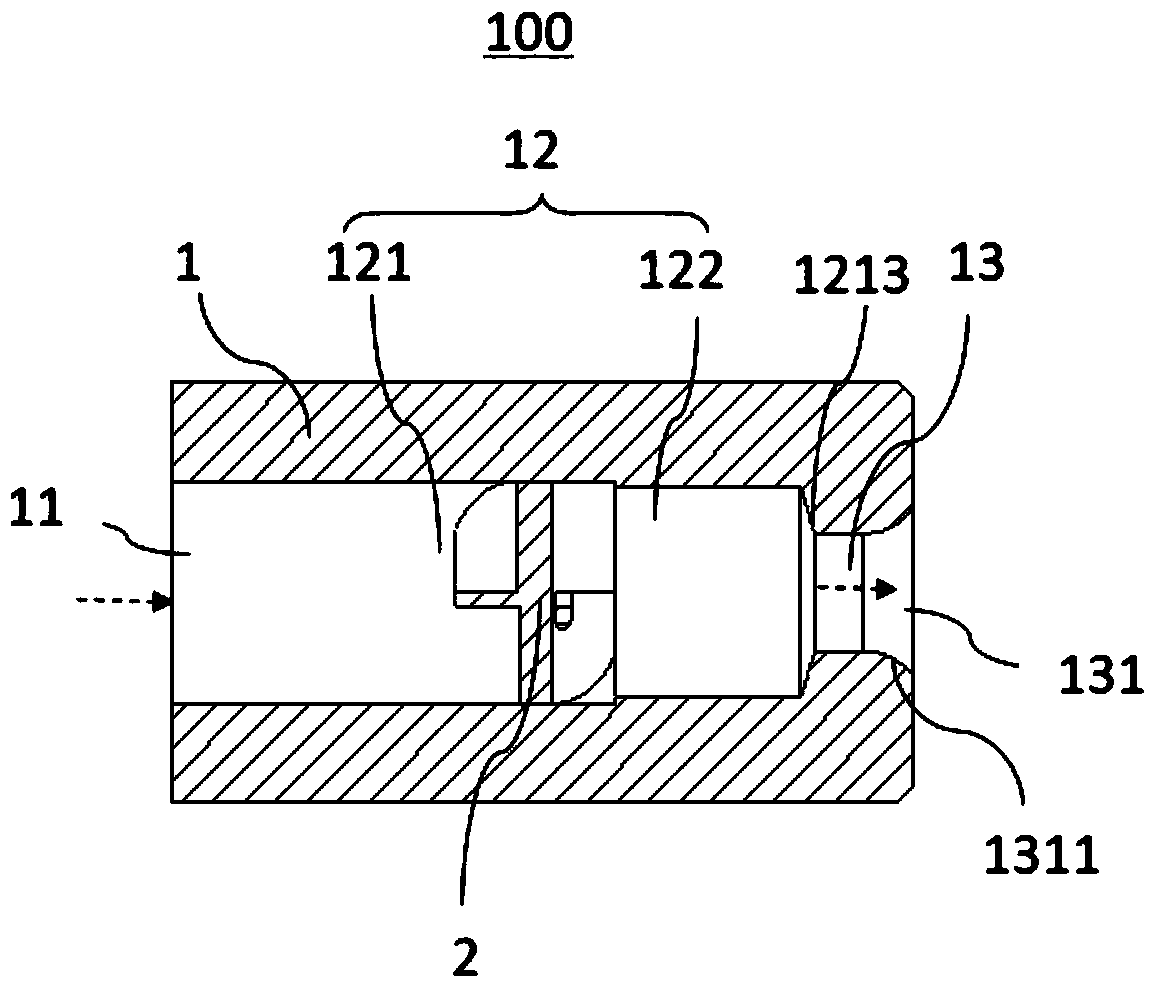

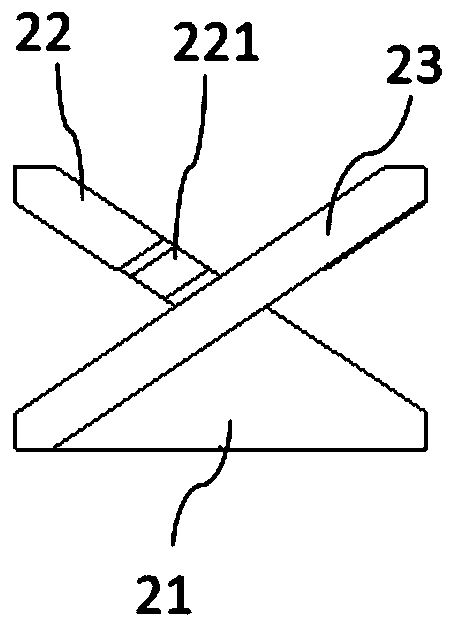

Pump-dispensing atomizer

InactiveUS20070051831A1Spraying speed is fastIncrease speedMedical devicesSpray nozzlesSpray nozzleEngineering

A pump-dispensing atomizer includes a dispensing pump with a closure to engage with a container. The dispensing pump includes a pressing button with a booster chamber formed inside, a nozzle with one end extending from the pressing button and a probe formed with at least one section. An interior of the nozzle is formed with a guide chamber, and one end of the guide chamber is connected to the booster chamber. The guide chamber has at least one expanding sub-chamber. After the probe is disposed in the guide chamber, a boosting channel is formed between the expanding sub-chamber and the stepped section. Moreover, the pressure accumulator is mounted on the other end of the nozzle, which is formed with a spraying opening communicated to outer environment. As such, the pressure of liquid flowing in the nozzle will be increased effectively so that liquid is sprayed out with a higher pressure to increase the spraying speed of the liquid.

Owner:KUO ROY

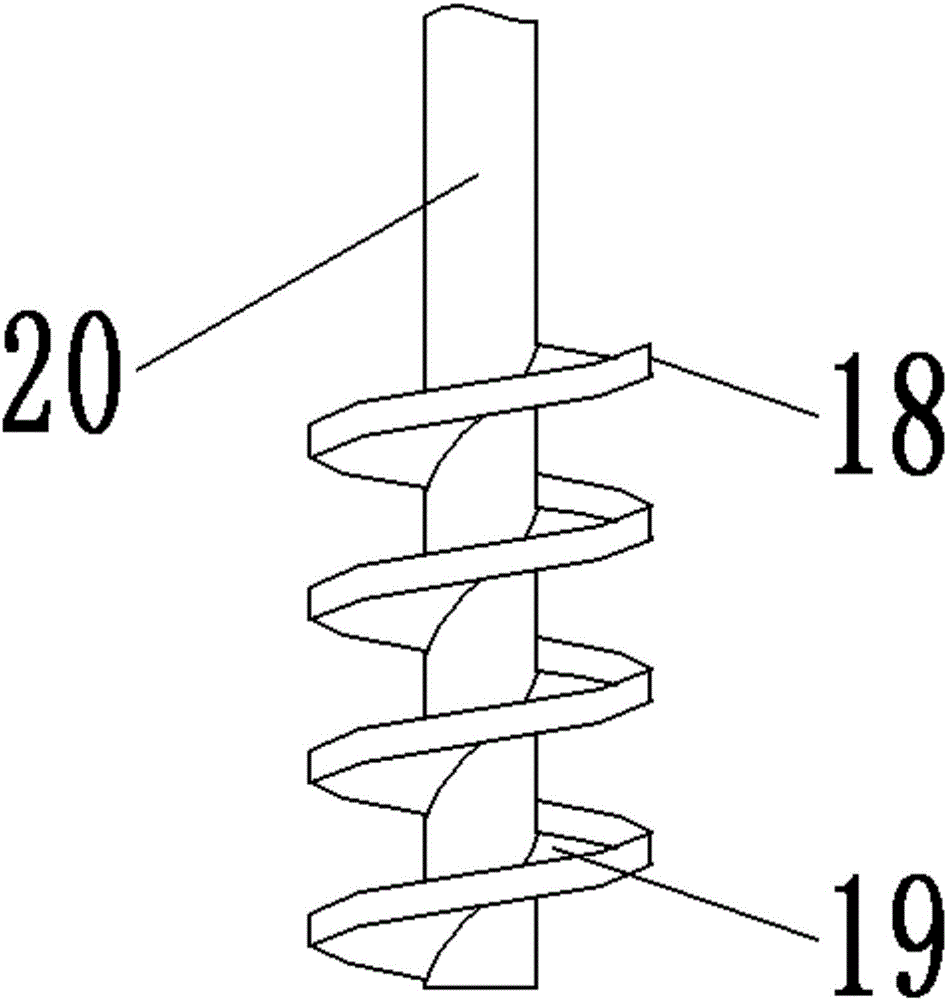

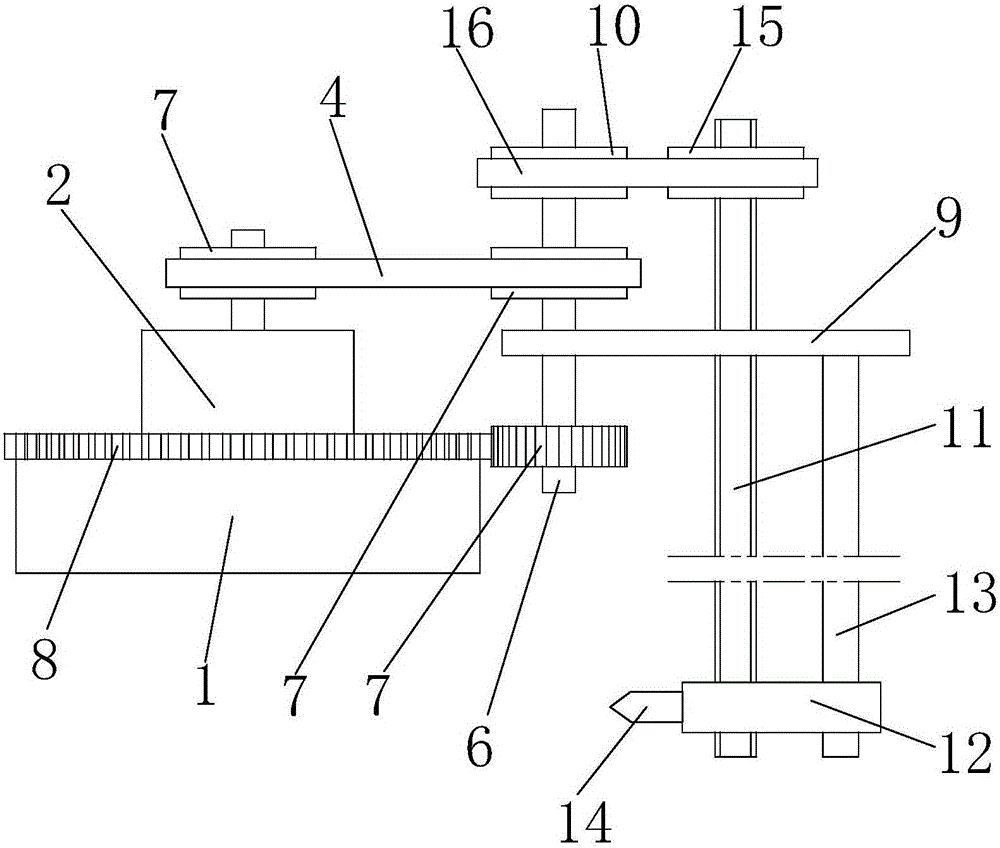

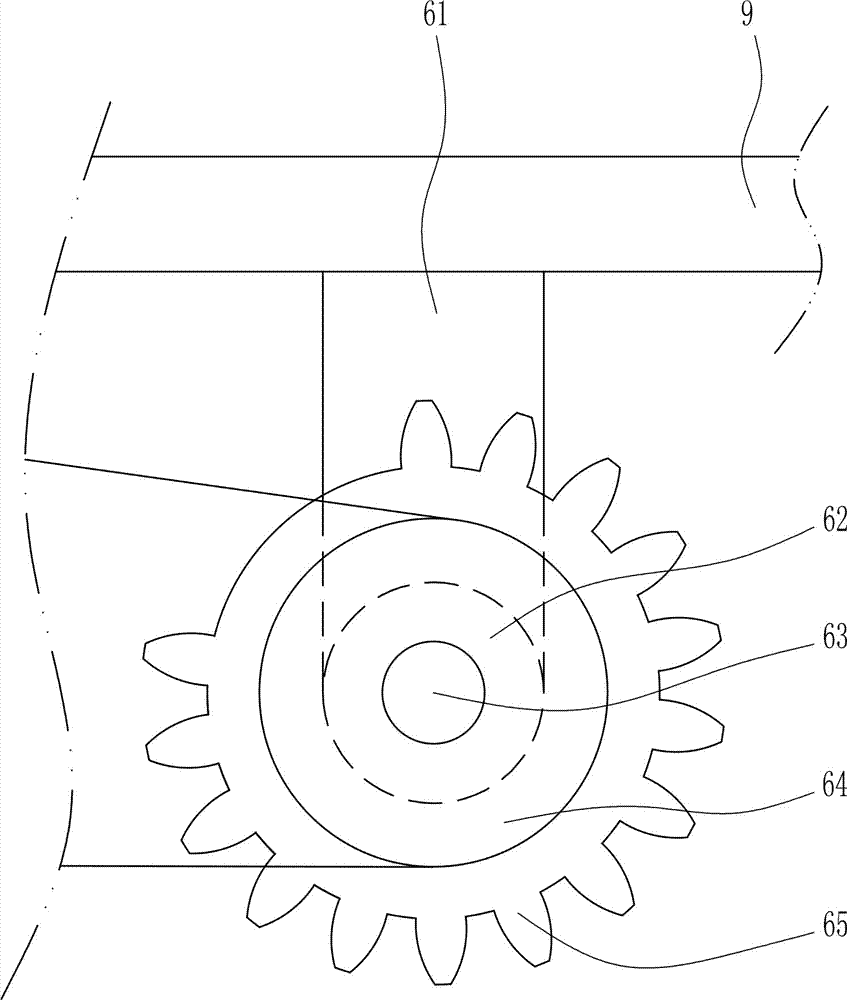

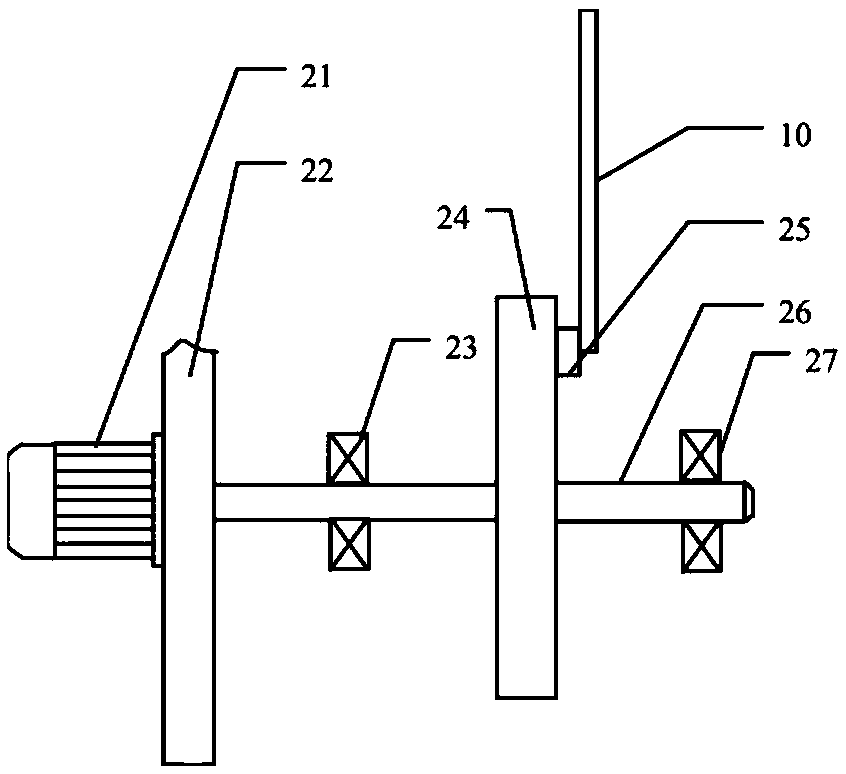

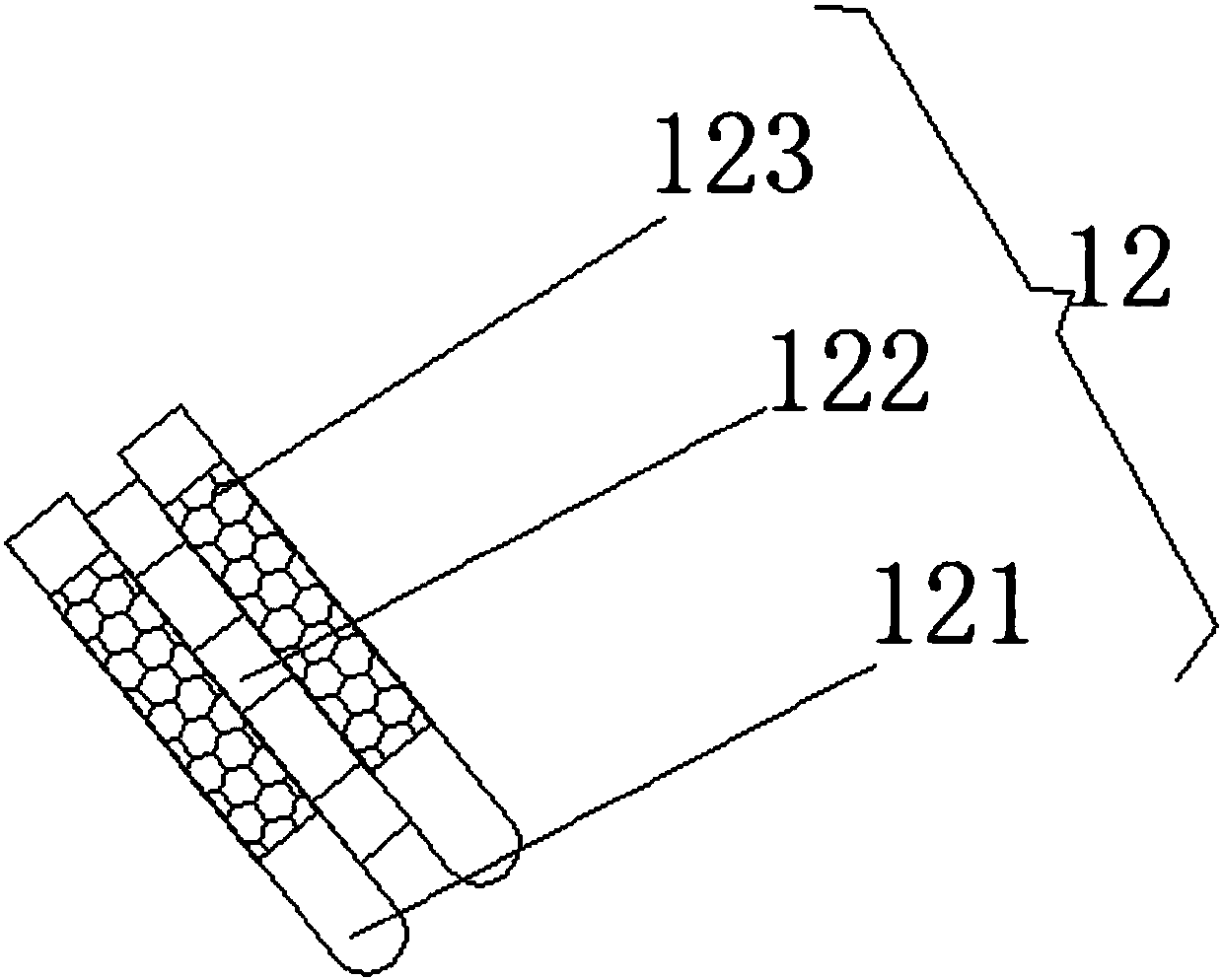

Spiral type spraying device used for cylindrical copper part

The invention relates to a spiral type spraying device used for a cylindrical copper part. The spiral type spraying device comprises a base. A motor is installed on the base and connected with a first belt. A first belt wheel is sleeved with the first belt in a connected manner. A second belt wheel is sleeved with the first belt in a connected manner. The second belt wheel is connected with a circular shaft. The lower portion of the circular shaft is connected with a gear which is meshed with an outer gear ring. A bearing plate is installed in the middle portion of the circular shaft. A ball screw is installed on the bearing plate. An installation base is installed on the ball screw in a threaded manner. A guide rod used for installing the installation base in a sliding manner is welded to the lower end of the bearing plate. A spray gun is installed on the installation base. The upper portion of the ball screw is connected with a third belt wheel. The third belt wheel is sleeved with a second belt in a connected manner. A fourth belt wheel installed on the upper portion of the circular shaft is sleeved with the left portion of the second belt in a connected manner. According to the spiral type spraying device, by controlling the spray gun to synchronously move around and slide downwards, the effect of conducting spiral type spraying protection on the arc face of the copper part is achieved. Therefore, the spiral type spraying device is high in spraying speed, high in quality and easy to control.

Owner:WUWEI HONGXI SPORTS GOODS CO LTD

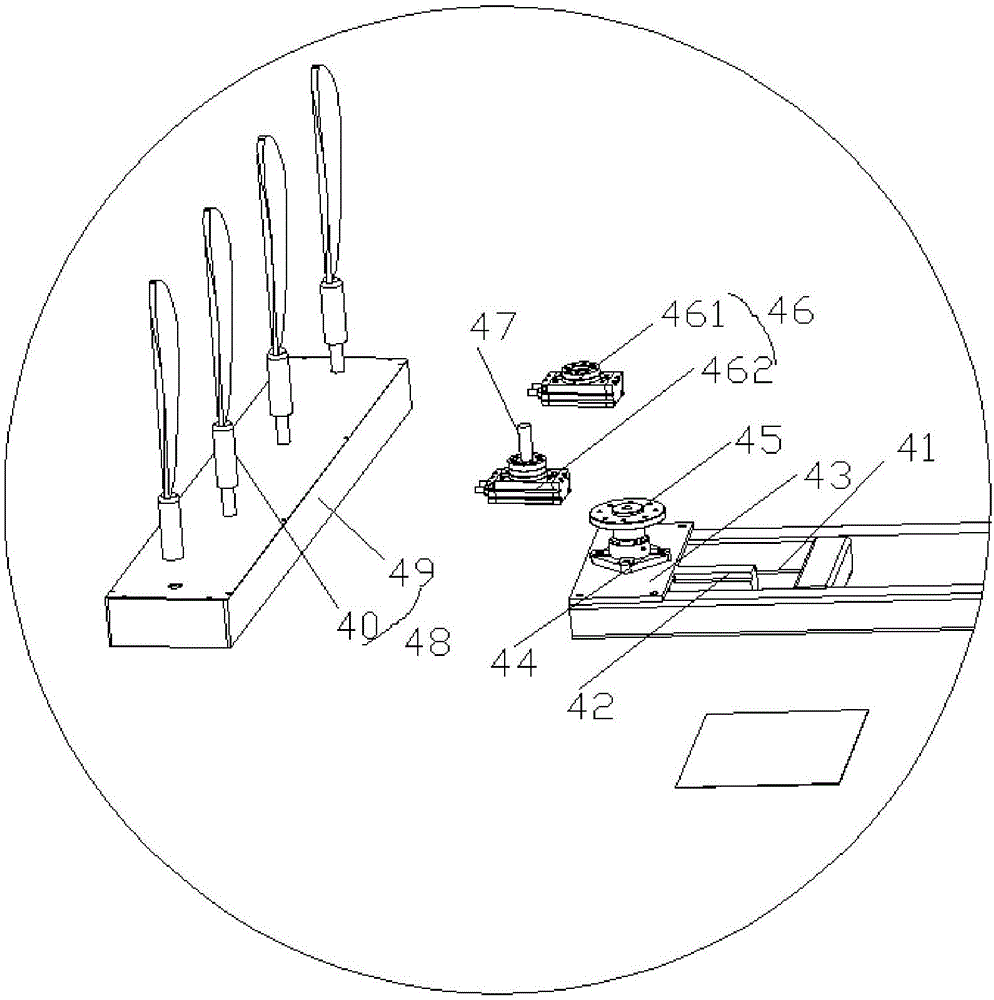

Inner-face painting robot

InactiveCN101337352AReduce labor intensityReduce volumeProgramme-controlled manipulatorControl engineeringOperating environment

An internal surface spraying robot is used for the spraying operation of the internal surface of a box body, and comprises a base, a control box connected to the base and used for controlling the spraying operation, and a spraying part connected to the control box. The spraying part comprises a fixed tube connected to the base, a multilevel telescopic arm connected to the fixed tube and capable of extending longitudinally along the fixed tube, and a spray gun bracket connected to the farthest-extending end of the telescopic arm. An automatic spray gun is arranged on the spray bracket. The spraying robot of the invention improves operating environment, reduces labor intensity, improve spraying quality of paint on the internal surface, and reduces paint consumption.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

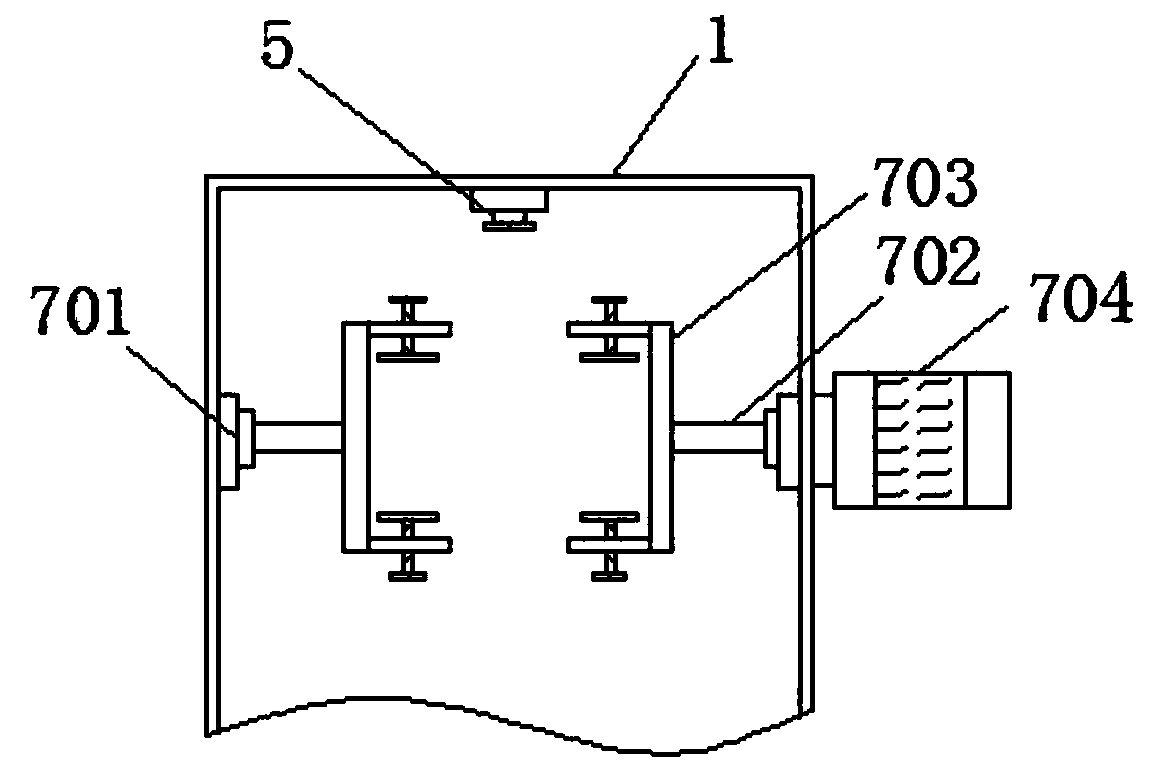

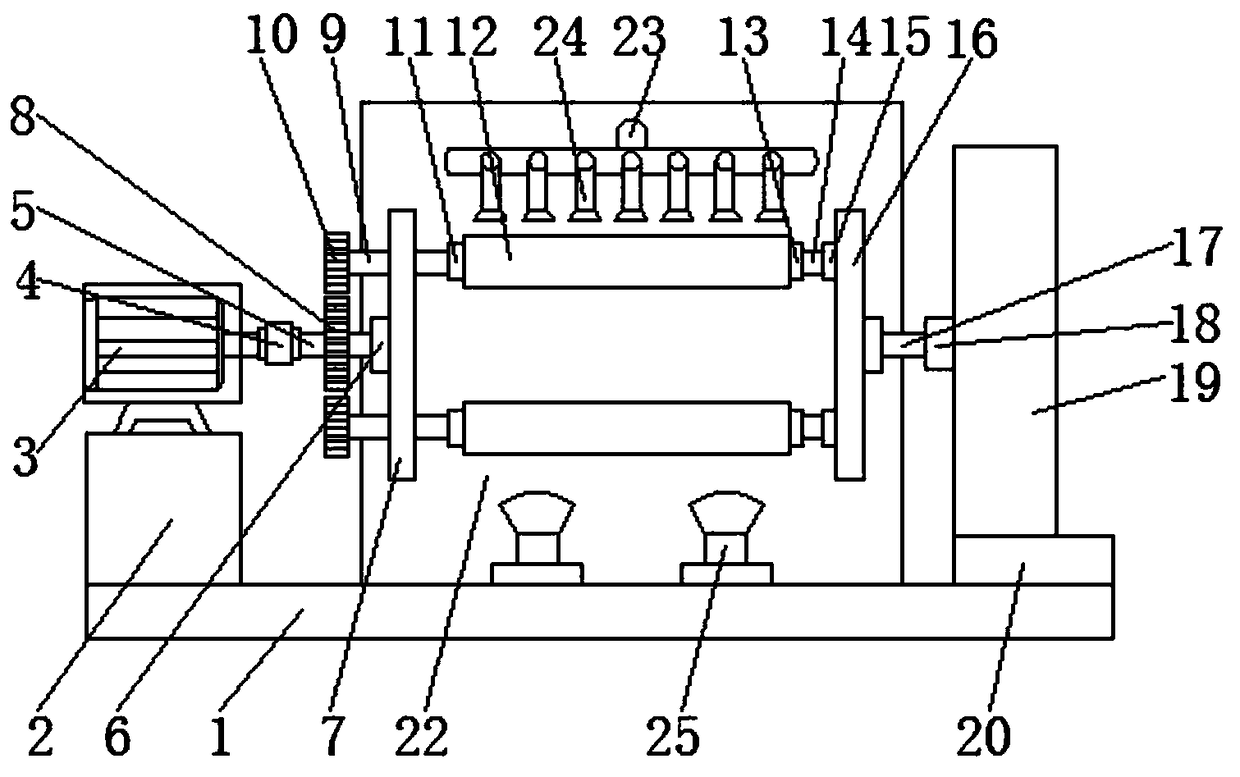

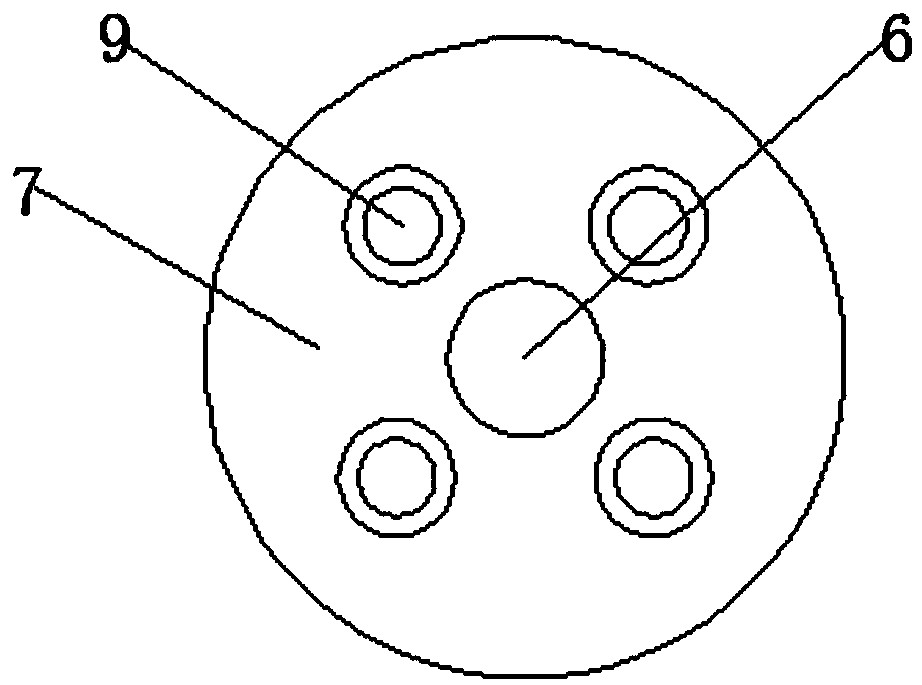

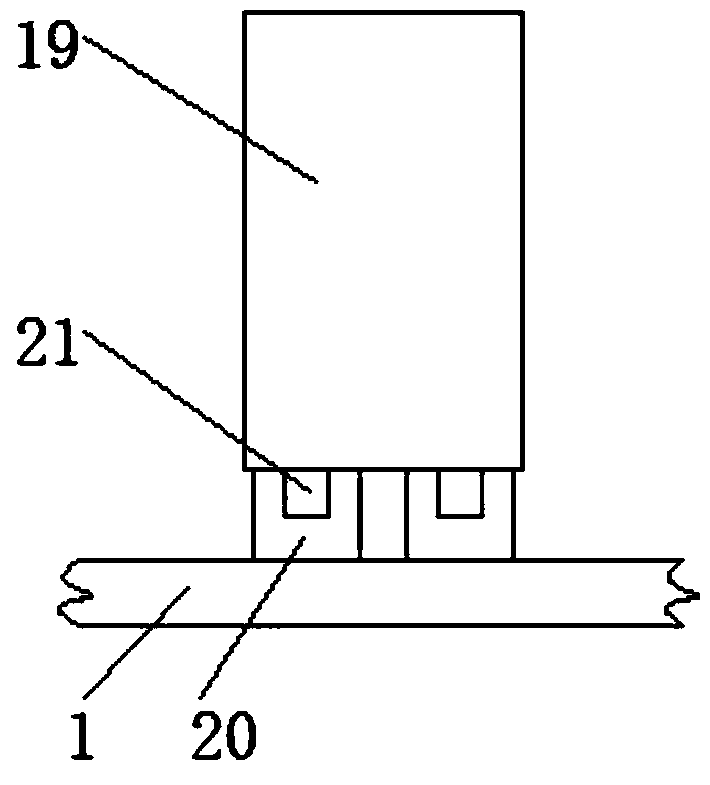

Electric bicycle frame painting device

ActiveCN104511385ASpray evenlyEasy to spray onLiquid surface applicatorsCoatingsVehicle frameDrive shaft

The invention discloses an electric bicycle frame painting device. The electric bicycle frame painting device comprises a bottom plate. The bottom plate is provided with a side plate, the top of the side plate is provided with a top plate, the inside surface of the side plate is provided with a baffle plate and a painting chamber arranged on the baffle plate, a rotating plate is arranged in the painting chamber, a stepper motor is arranged below the top plate and connected to a drive shaft, the drive shaft penetrates through the painting chamber to be connected to the rotating plate, the bottom plate is provided with a painting unit connected to a spraying channel, the inner bottom of the painting chamber is provided with a spraying plate, a spraying cavity is arranged in the spraying plate and connected to the spraying channel, the top of the spraying plate is provided with a plurality of spraying holes arranged at equal intervals, the spraying holes are communicated with the spraying cavity in the spraying plate, and the spraying plate is arranged below the rotating plate. The electric bicycle frame painting device can spray paint to a frame easily, quickly, efficiently and evenly.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

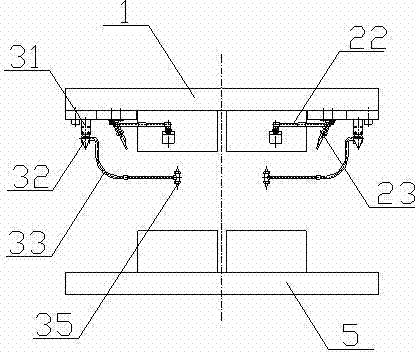

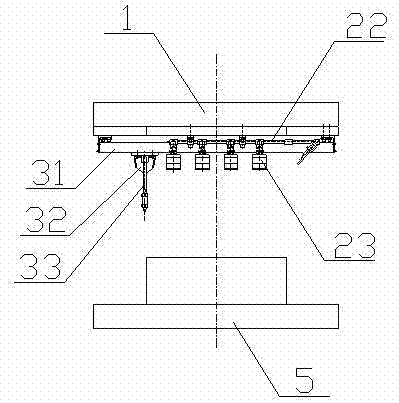

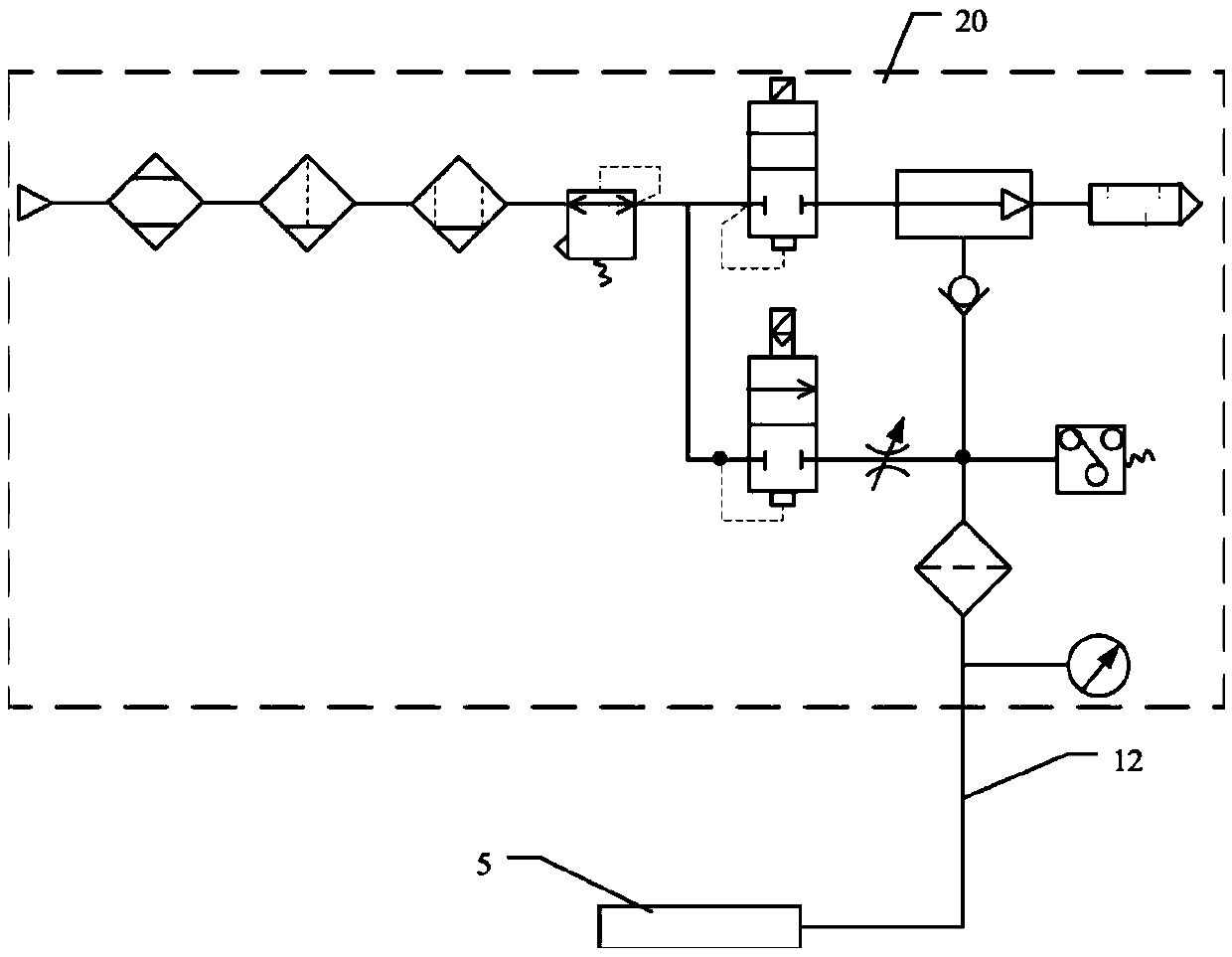

Automatic ink-jet blowing system for hot die forging press

InactiveCN103111574AQuality improvementExtended service lifeForging/hammering/pressing machinesMechanical engineering

The invention discloses an automatic ink-jet blowing system for a hot die forging press. The automatic ink-jet blowing system comprises an ink-jet system and a blowing system, which are arranged on an upper die seat of the hot die forging press, wherein the ink-jet system is used for jetting ink to cavities of dies on upper and lower die seats of the hot die forging press; and the blowing system is used for blowing air to the cavity of the die on the lower die seat of the hot die forging press. The automatic ink-jet blowing system is simple in structure, reduces the labor intensity of workers, can shorten production takt and improve the production efficiency; and particularly, the system is good in blowing cleaning effect, uniform and disperse in spraying, high in spraying speed and stable and reliable in operation.

Owner:CHONGQING UNIV +2

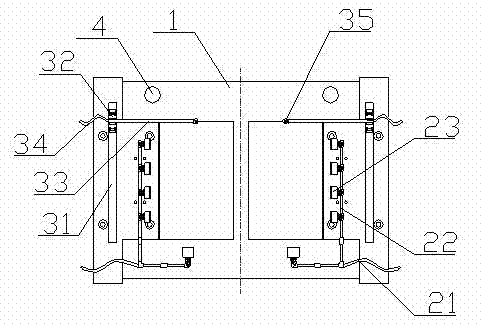

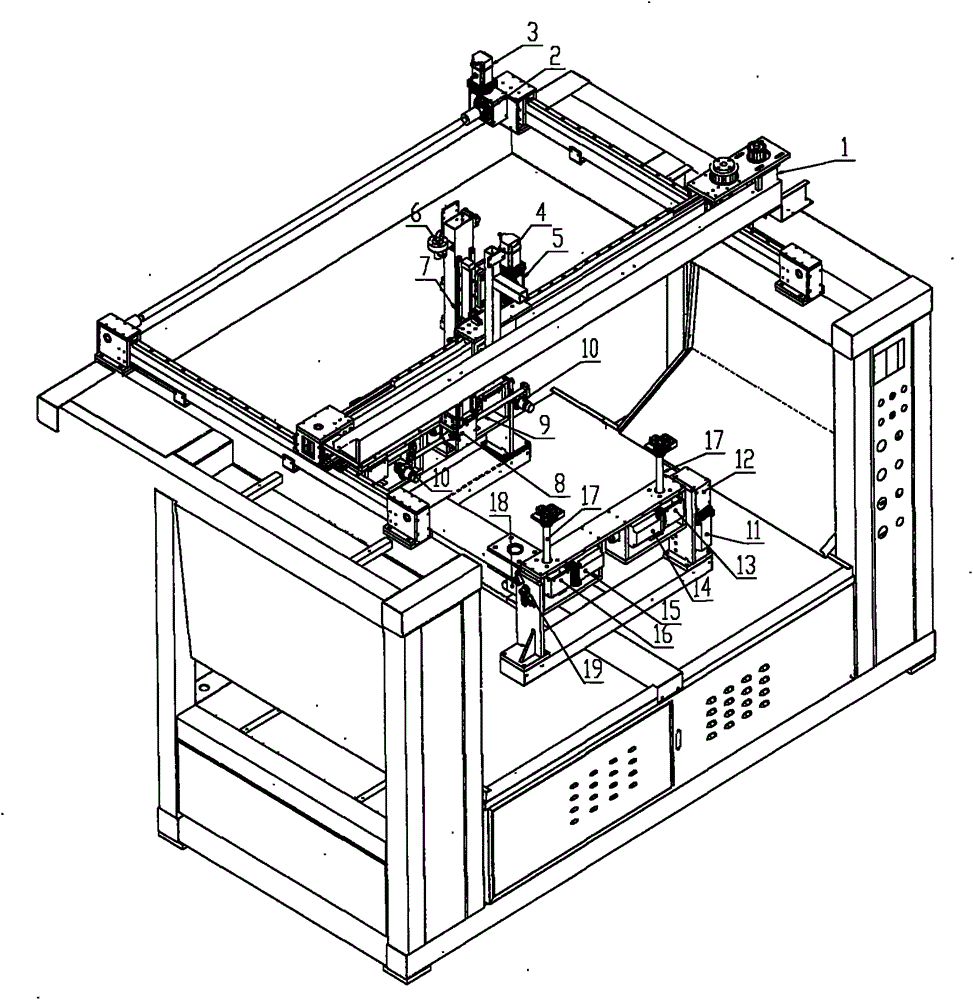

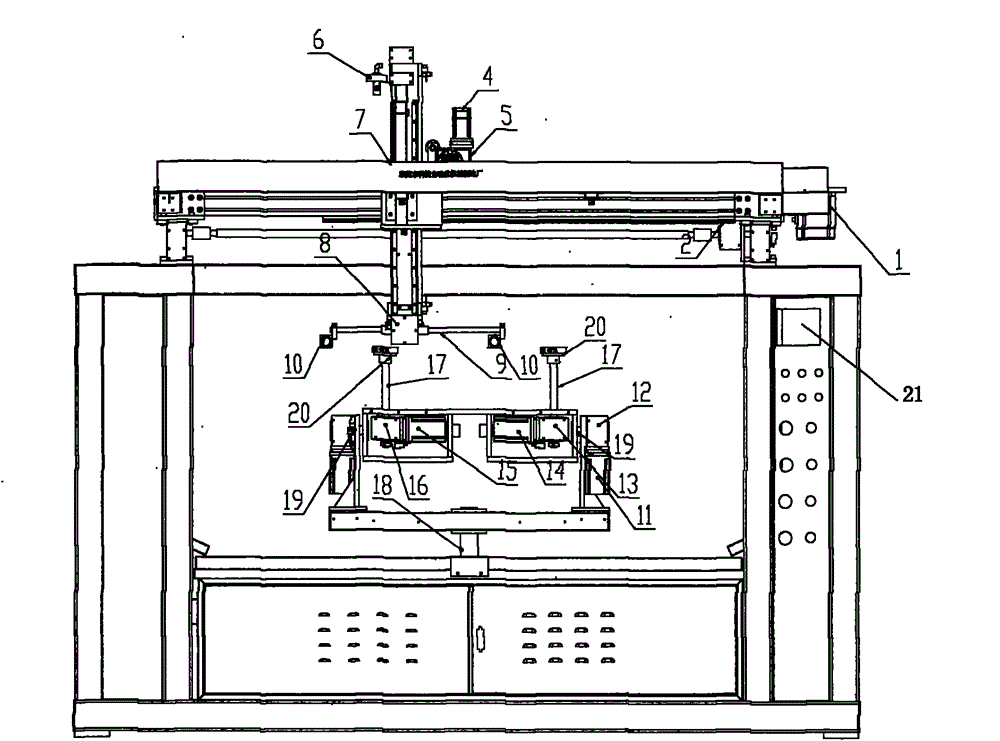

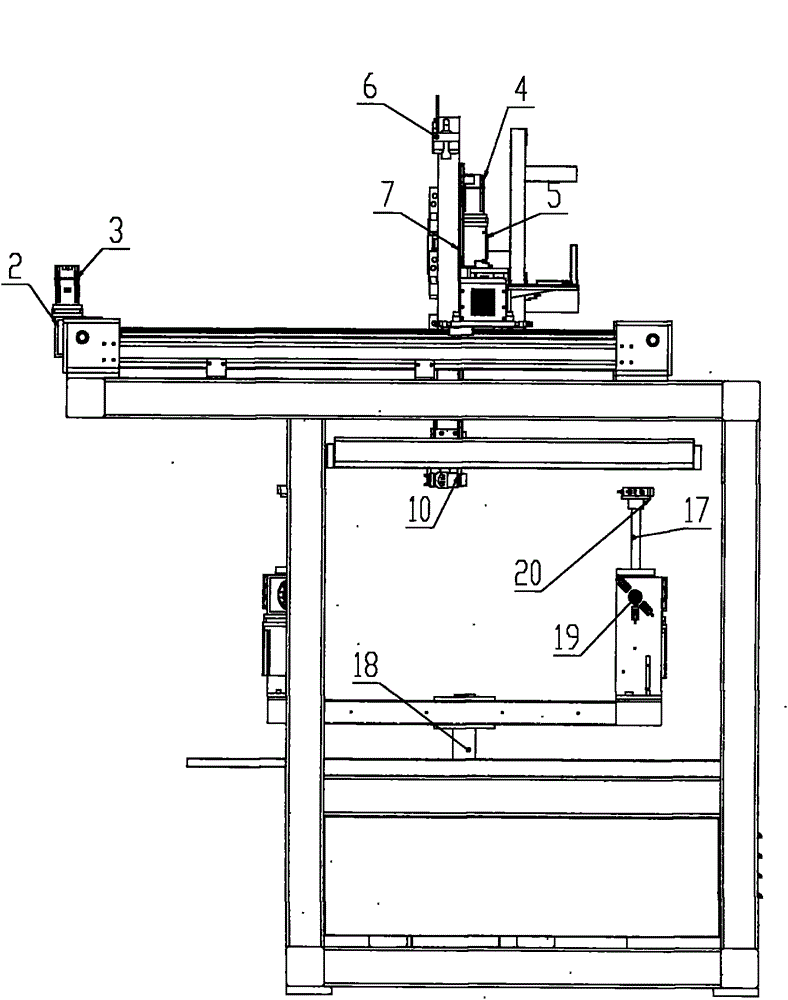

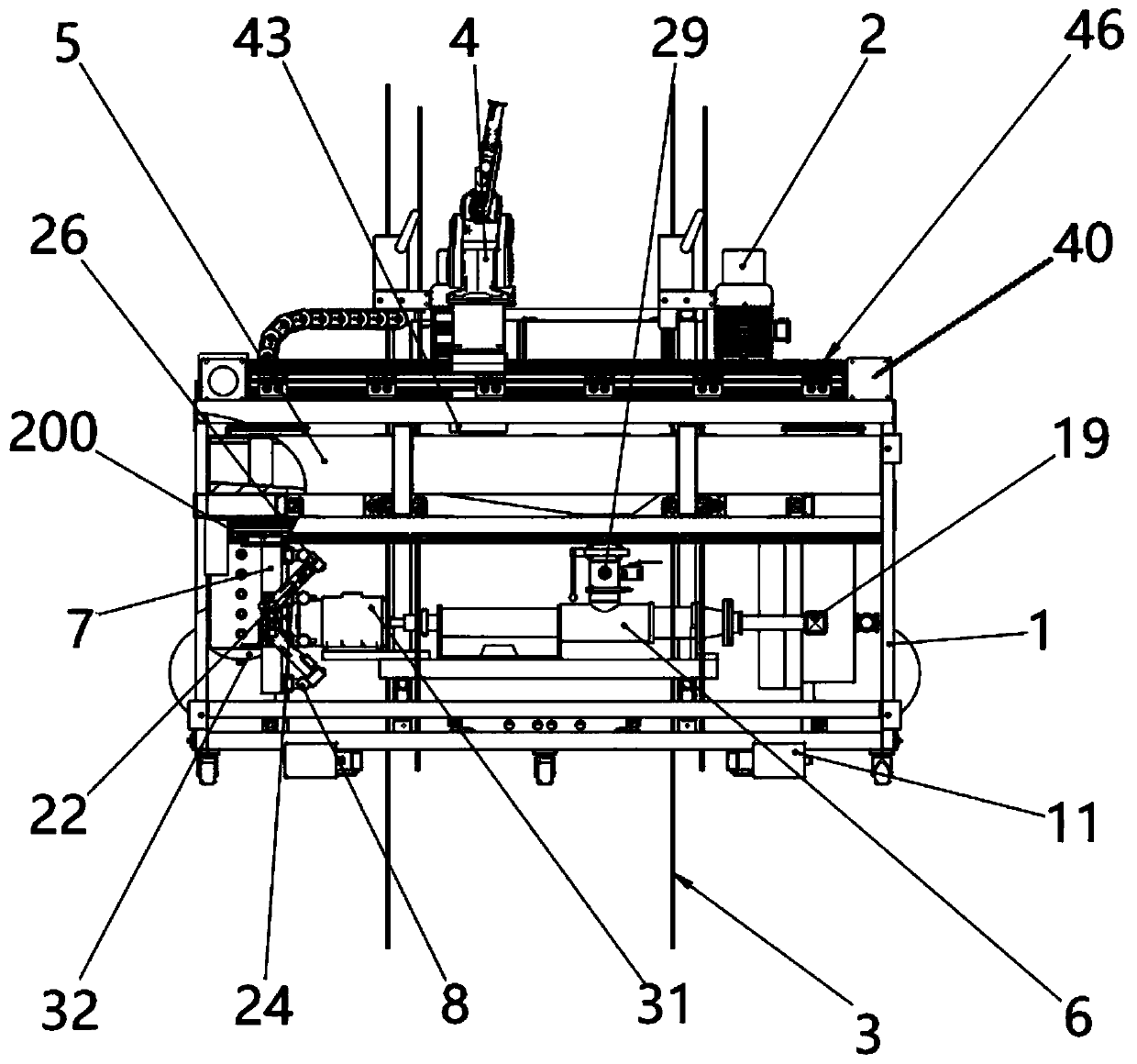

Box body coating machine

The invention discloses a box body coating machine which comprises a machine seat, and a machine frame which is arranged on the machine seat. A working platform and a workpiece fixing fixture are arranged on the machine seat. A first motor which is used for enabling a workpiece to rotate by 90 degrees, a speed reducer which is matched with the motor, a second motor which is used for enabling the workpiece to rotate by 90 degrees again, a second speed reducer which is matched with the second motor, a workpiece rotary shaft, a workpiece material-exchanging shaft, a vertical shaft which is used for controlling the action of the fixing fixture, and a driving motor are arranged along the periphery of the working platform. The box body coating machine further comprises an X shaft, an X-shaft motor, a speed reducer, a Y shaft, a Y-shaft motor, a speed reducer, a Z shaft, a Z-shaft motor, a speed reducer, a R rotary shaft, a R-shaft motor, a speed reducer and a spray gun, wherein the X shaft is arranged on the machine frame, the X-shaft motor and the speed reducer are used in a matching mode, the Y-shaft motor and the speed reducer are used in a matching mode, the Z shaft, the Z-shaft motor and the speed reducer are arranged on the X shaft, and the R shaft, the R-shaft motor and the speed reducer are arranged on the Z shaft. Coating to six faces of a box body can be completed one time, horizontal rotary shafts and vertical rotary shafts of the equipment enable coating faces of the box body and the spray gun to form a perfect angle, and the fact that no coating dead angle exists during box body coating is guaranteed.

Owner:黄争志 +1

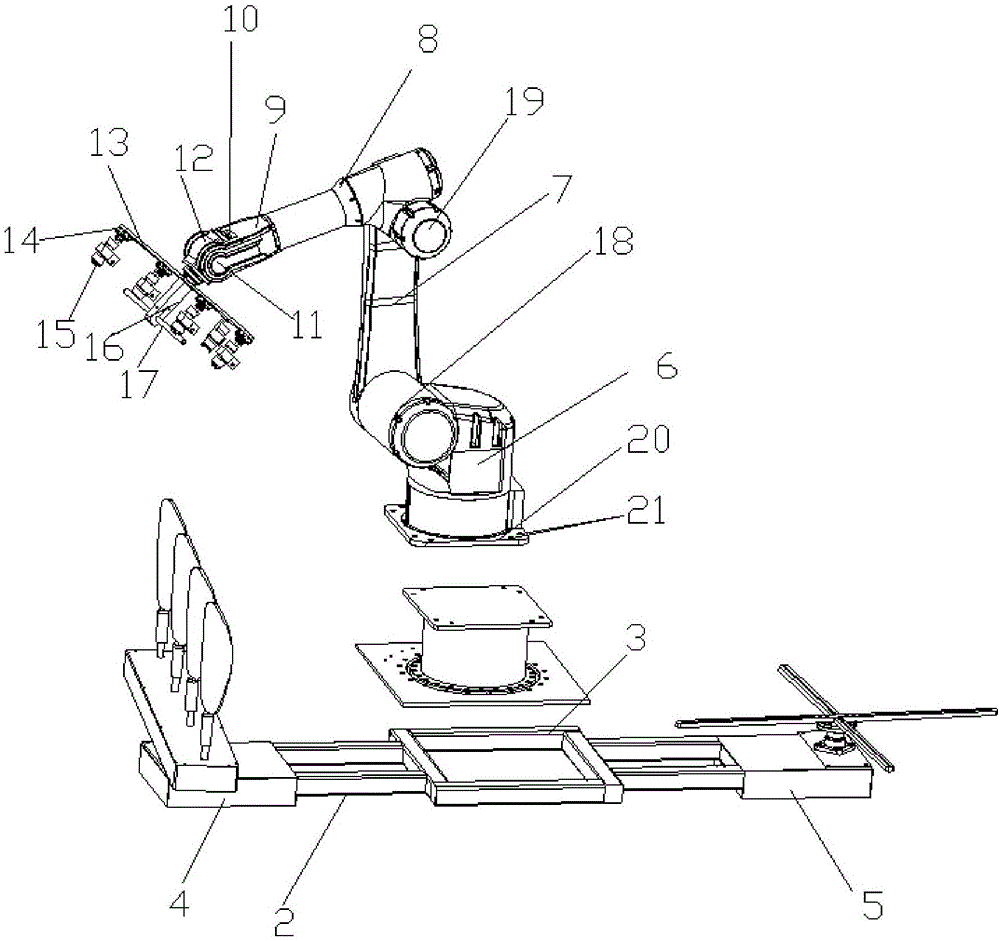

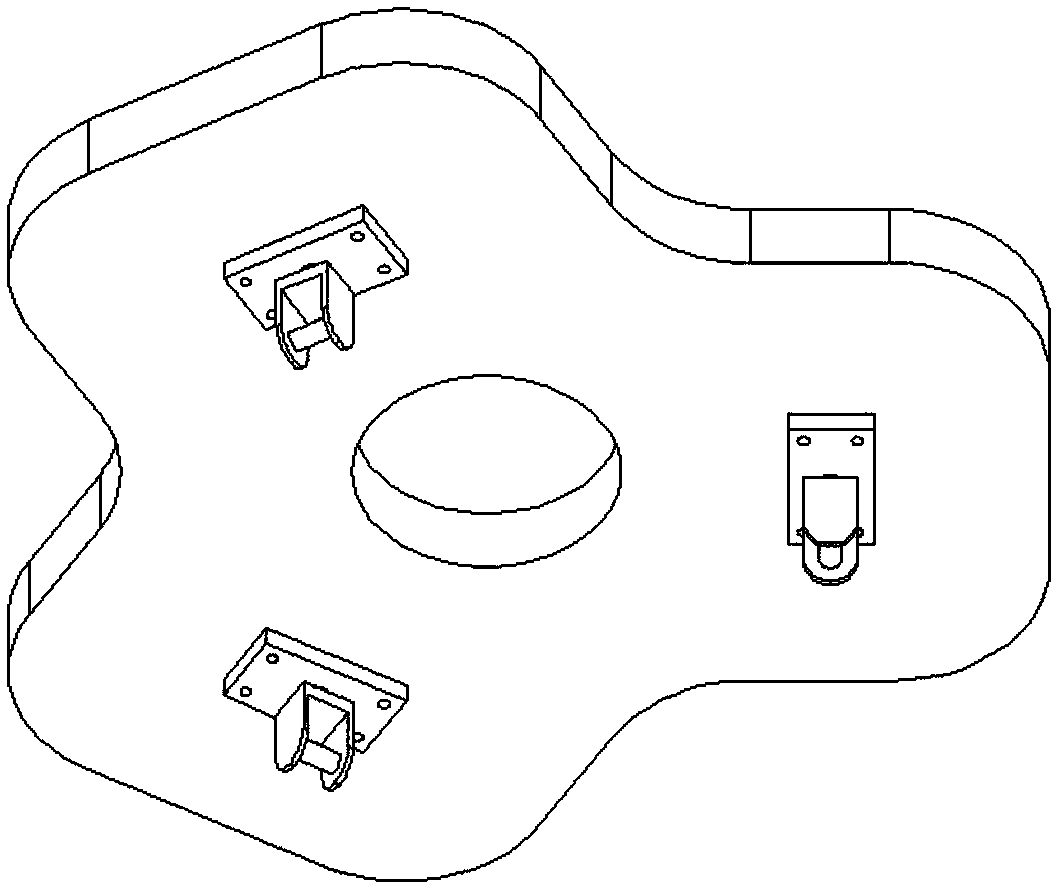

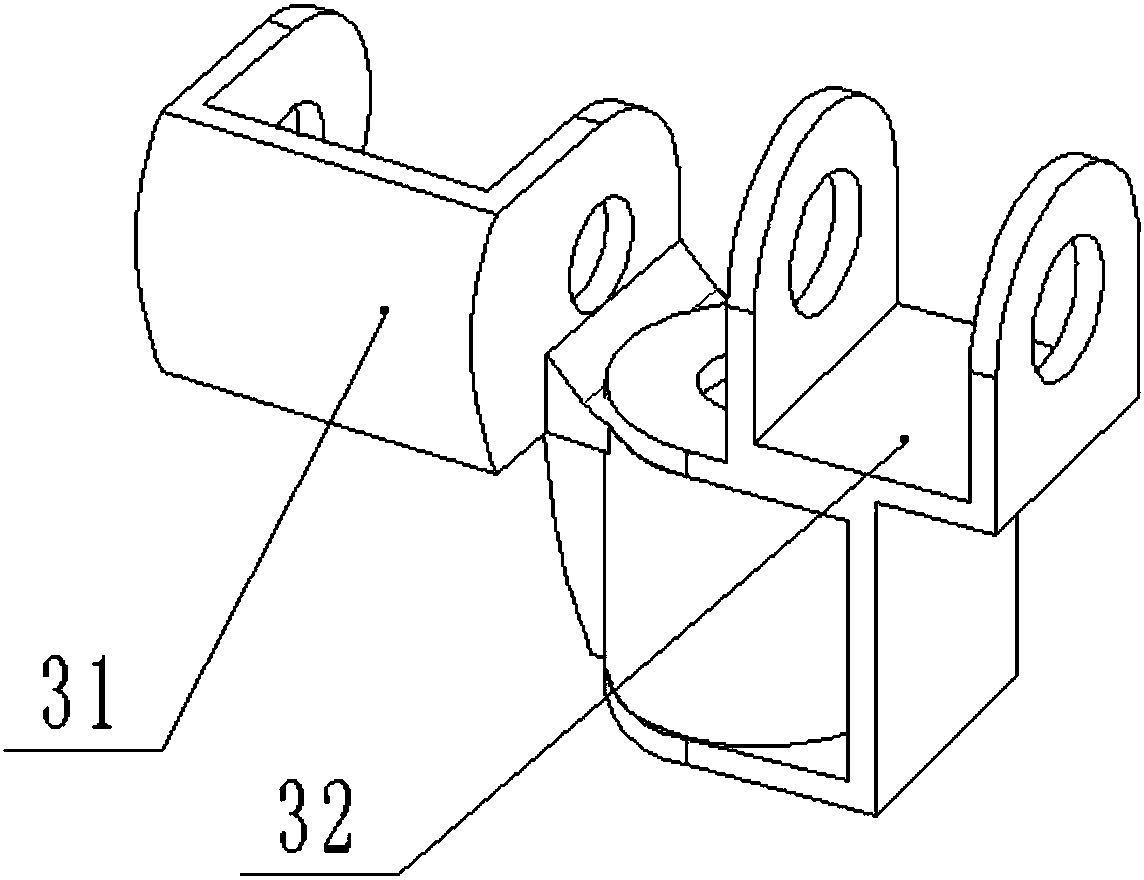

Spray manipulator device

The invention discloses a spray manipulator device. The spray manipulator device comprises a horizontal support table and a manipulator device, wherein a central frame is arranged in the middle of the horizontal support table, a product fixing and turning device for fixing upright products is arranged at one end of the horizontal support table, a horizontally placed product fixing and turning device for fixing horizontally placed products is arranged at the other end of the horizontal support table, a tail end manipulator arm is arranged at one end of the manipulator arm, a U-shaped notch is arranged in one end of the tail end manipulator arm, drive assemblies are arranged on two side arms of the U-shaped notch and control a drive rod to rotate, a spray motor is mounted on the drive rod, and an angle-rotatable spray head support is mounted on an output shaft of the spray motor. The spray manipulator device is simple in structure, facilitates manipulator spraying, requires no manual turning and side change and can realize turning spraying.

Owner:DONGGUAN LEBAOT ROBOT

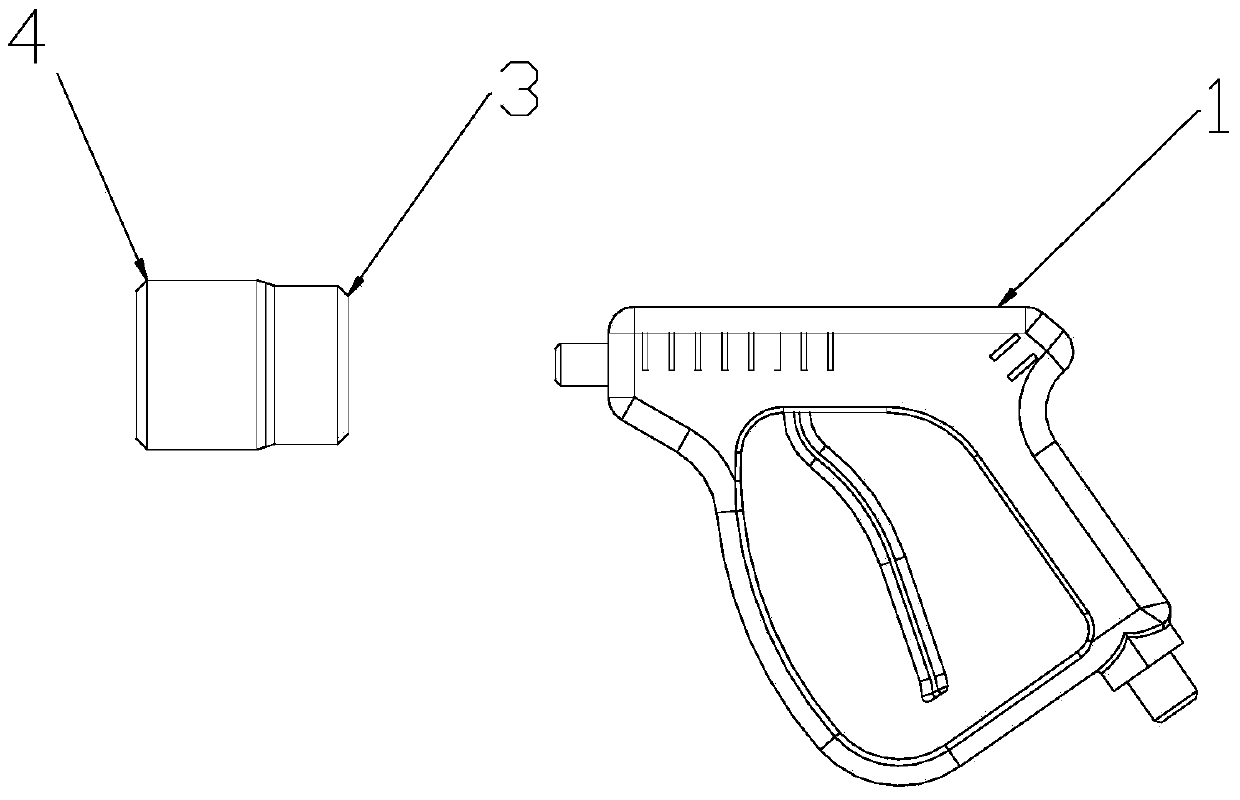

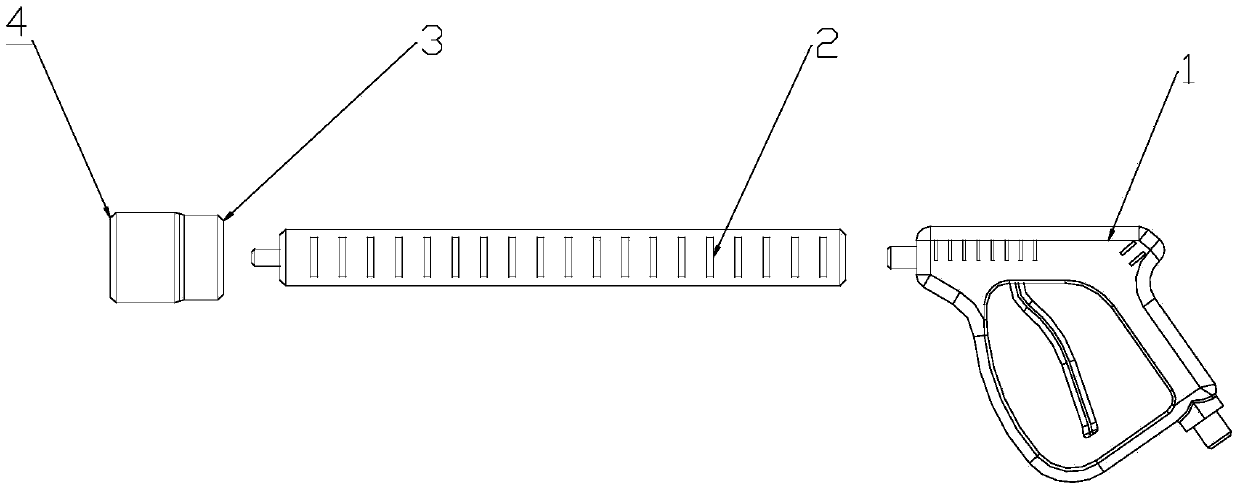

High-pressure airless spray gun without blind spraying corner

InactiveCN103464324AStable forceEliminate the problem of harsh working environmentSingle-unit apparatusDiaphragm pumpSpray coating

The invention discloses a high-pressure airless spray gun without a blind spraying corner. The high-pressure airless spray gun comprises a gun grip and a high-pressure spray nozzle. A pressure-regulating valve is mounted on the high-pressure spray nozzle, an access end of the high-pressure spray nozzle is a connector matched with an exit end of the gun grip, and the exit end of the gun grip is connected with the access end of the high-pressure spray nozzle. The high-pressure airless spray gun further comprises a diaphragm pump driven by a motor. During a spraying operation, the high-pressure airless spray gun sprays coatings directly on the surface of a workpiece to be sprayed and processed by means of taking static pressure generated from the diaphragm pump as driving force to spray the coatings. Due to the fact that compressed air is not taken as the driving force to spray the coatings, rebounding and splashing of the coatings during the spraying process are basically avoided, and coating fog particles sprayed out can smoothly enter corner cracks and edges of the workpiece with less spraying pollution and no dead corner. The high-pressure airless spray gun has the advantage that a sprayed coating is compact, uniform, glossy, high in flatness and the like.

Owner:SHANDONG URBAN MINING ENVIRONMENTAL PROTECTION GRP

Pesticide sprayer having good mixing effect and quantitative spraying function

InactiveCN107821368AImprove the mixing effectGood mixing effect and good quantitative spraying functionInsect catchers and killersEngineeringMixing effect

The invention relates to a pesticide sprayer with good mixing effect and quantitative spraying function, which comprises a casing, a fixed block and four wheels. The casing is provided with a feed tank, a water tank, a water pump, a mixing mechanism and a quantitative mechanism. The fixed block There is a rotating mechanism on it. The mixing mechanism includes a stirring unit and at least two feeding units. The quantitative mechanism includes a conveying unit, an extrusion unit and a recovery unit. The pesticide sprayer with good mixing effect and quantitative spraying function, through the mixing mechanism, Not only can a single pesticide be sprayed, but also a variety of pesticides can be uniformly mixed and sprayed, which enhances the control effect on crop diseases. Not only that, through the quantitative structure, the pesticide sprayer can accurately control the spraying of the pesticide solution per unit area Quantitative spraying of pesticides can save the amount of pesticides and protect the environment on the premise of ensuring the control effect of crop diseases.

Owner:南京市雨花台区创新创业法治宣传与法律服务中心

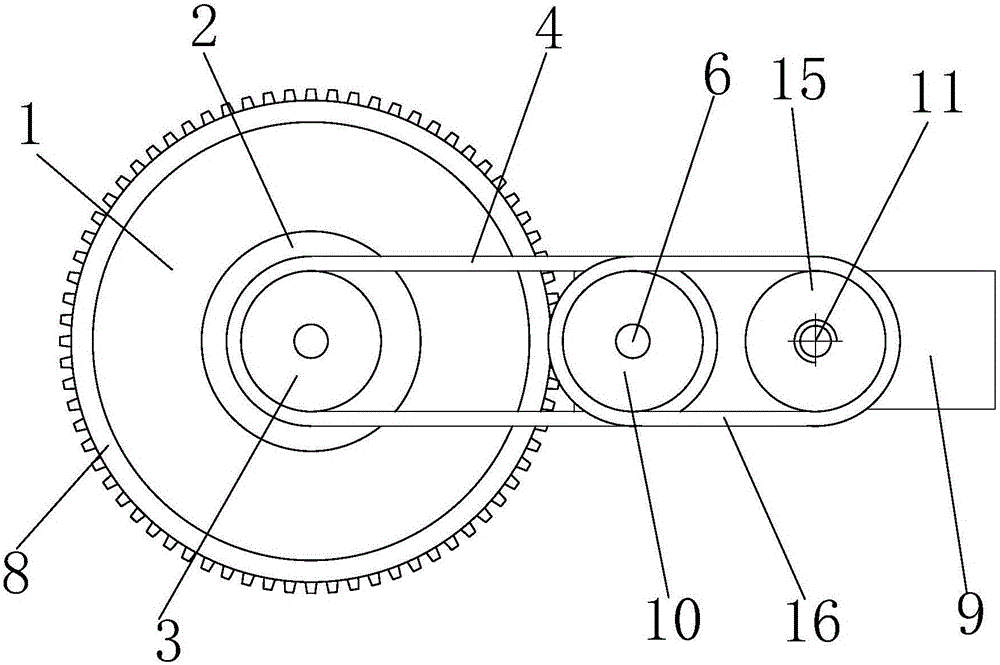

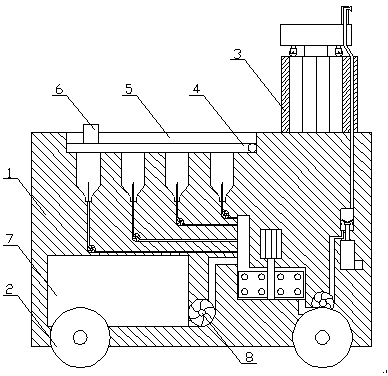

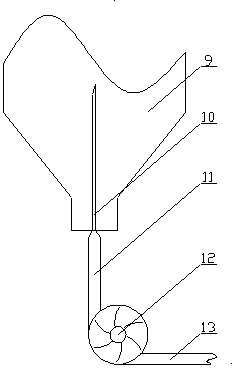

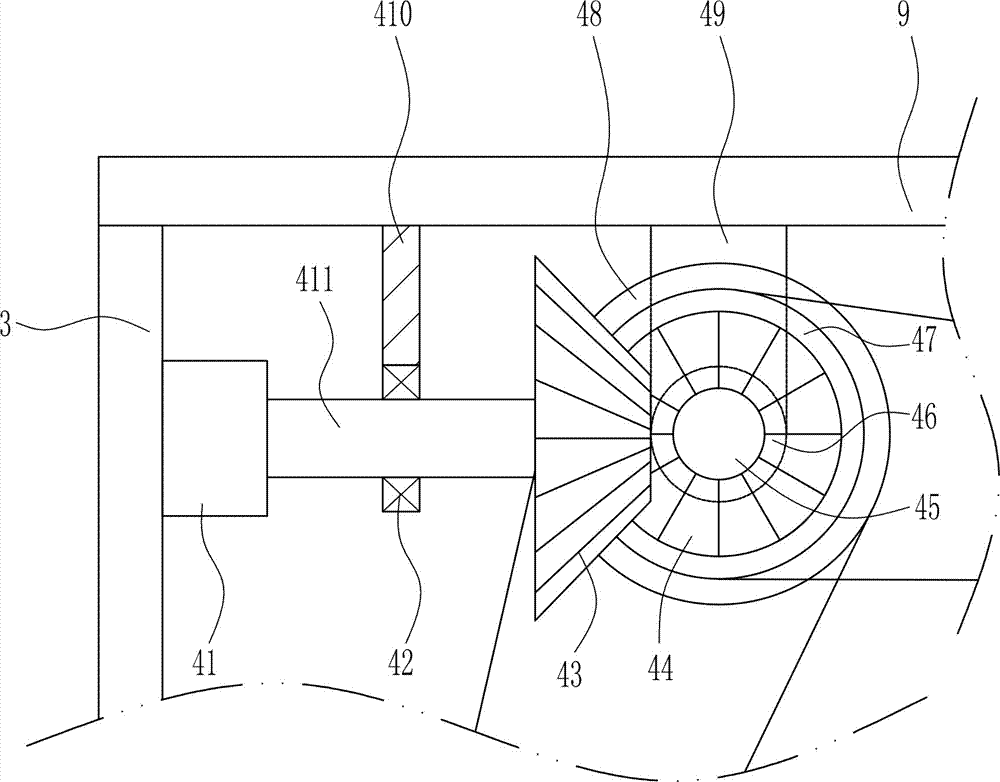

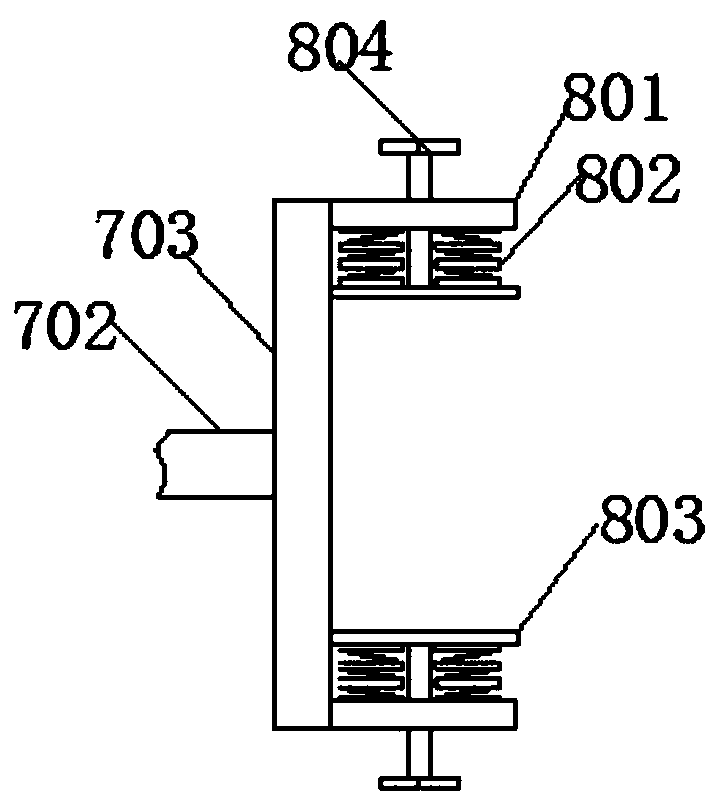

Convenient spraying machine for irrigation and water conservancy

The invention relates to a spraying machine, in particular to a convenient spraying machine for irrigation and water conservancy. The technical purpose of providing the convenient spraying machine which is high in spraying speed and long in spraying distance for irrigation and water conservancy is achieved. In order to achieve the technical purpose, the convenient spraying machine for irrigation and water conservancy comprises a base plate, universal wheels, a side plate, a driving mechanism, a water delivery mechanism, a linkage mechanism, a lifting mechanism, a fixing mechanism, a top plate, a spray head, a first flat belt, a second flat belt, a water delivery pipe, a first check valve, a water pump pipe and a second check valve; the universal wheels are fixedly connected to the bottom of the base plate, the fixing mechanism is fixedly connected to the bottom of the base plate and located between the universal wheels, and the side plate is fixedly connected to the base plate in the vertical direction. Accordingly, farmland can be fully sprayed, and the rapid farmland spraying effect is achieved.

Owner:连云港市连发机械有限公司

Hub spraying equipment

InactiveCN110743732AImprove spraying efficiencySpray evenlyPretreated surfacesCoatingsSpray nozzleStorage tank

The invention provides hub spraying equipment and relates to the technical field of hub spraying. The hub spraying equipment comprises a case, wherein universal wheels are fixed at the top end of thecase; a storage tank is fixed at the top end of the case; a vent is formed in one side of the case; a spray nozzle is fixed in the case, penetrates the top end of the case and is fixedly connected with the storage tank; an aggregate box is installed at the bottom end of the case; a clamping mechanism is installed in the case, and the interior of the clamping mechanism comprises a first rotating shaft; the first rotating shaft is fixedly connected with the case. According to the hub spraying equipment, a hub can be clamped by clamping plates on two sides in the case, the clamping plates are driven to rotate by a first motor, the hub in the clamping plates can rotate, the rotating hub is sprayed by the spray nozzle, and thus, spraying is more uniform, the spraying speed is higher, and spraying efficiency of the hub is improved.

Owner:陕西威斯特高新技术投资有限公司

Medical spraying type medicine bottle

InactiveCN103340746AReduce resistanceFast resetPharmaceutical containersMedical packagingLiquid wasteEngineering

The invention discloses a medical spraying type medicine bottle and belongs to the technical field of spraying dosing containers. The medical spraying type medicine bottle comprises a bottle body, a bottle cap, a liquid pumping mechanism, a hand pressing gland, a sucker and a liquid outlet mechanism. The liquid pumping mechanism comprises a piston pipe sleeve, a ball valve, a first spring, a piston pipe and a second spring, the upper end of the piston pipe sleeve is fixed with the central position of the bottle cap, the middle of the piston pipe sleeve forms a first narrow indentation step, the lower portion of the piston pipe sleeve forms a second narrow indentation step, the ball valve is arranged in a piston pipe sleeve cavity of the piston pipe sleeve, the middle of the piston pipe forms a piston, the first spring is arranged on the lower portion of the piston pipe sleeve cavity, the second spring is sleeved at the lower end of the piston pipe, and the central position of the hand pressing gland forms a piston pipe matching hole. The liquid outlet mechanism comprises a spraying pipe base and a spraying pipe, a liquid through hole is formed in the spraying pipe base, a flow diversion pipe joint is arranged on one side of the spraying pipe base, a flange is formed on the flow diversion pipe joint, the flow diversion pipe joint forms a flow diversion pipe cavity, and the sucker is in matched connection with the lower end of the piston pipe sleeve. The liquid pumping effect is improved, the liquid spraying speed is improved, medicine liquid waste is avoided, and the structure is simple.

Owner:苏州汇涵医用科技发展有限公司

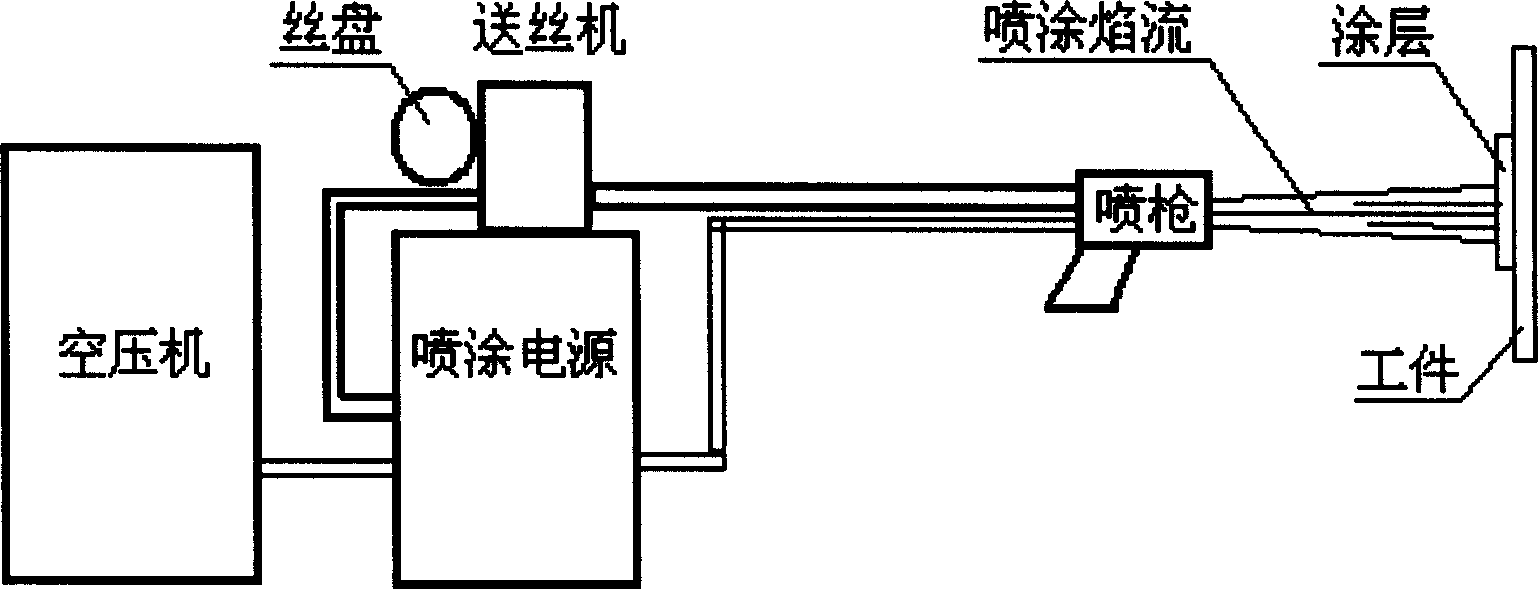

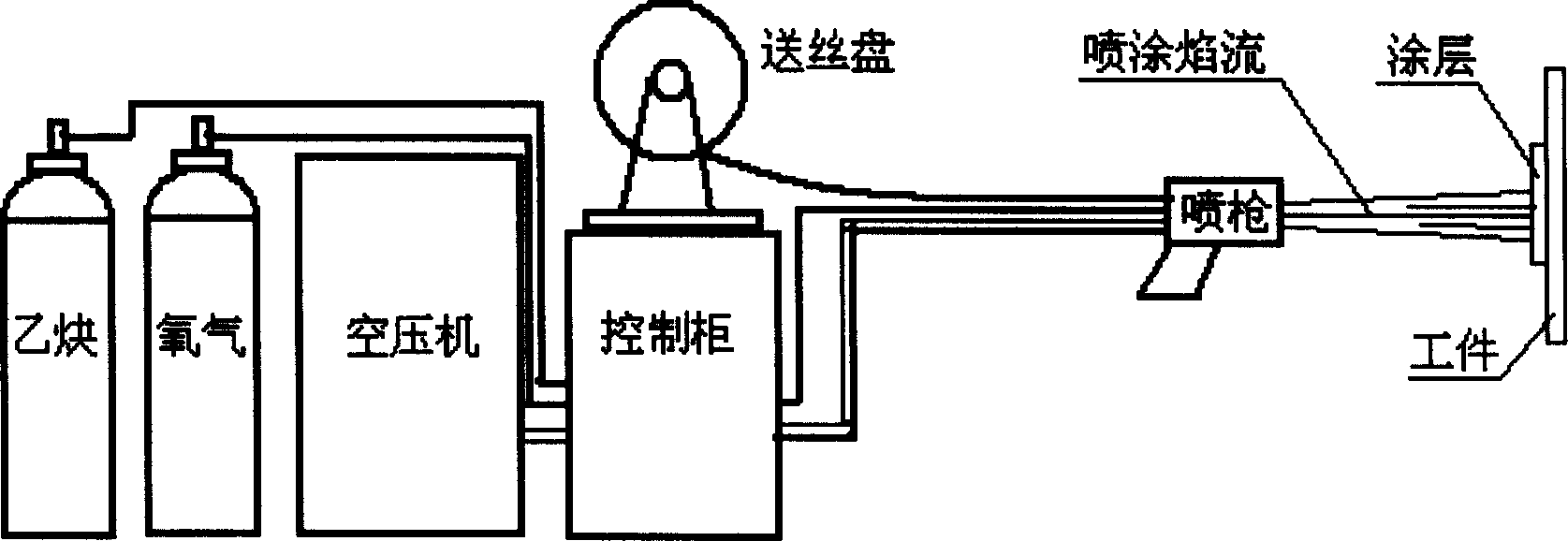

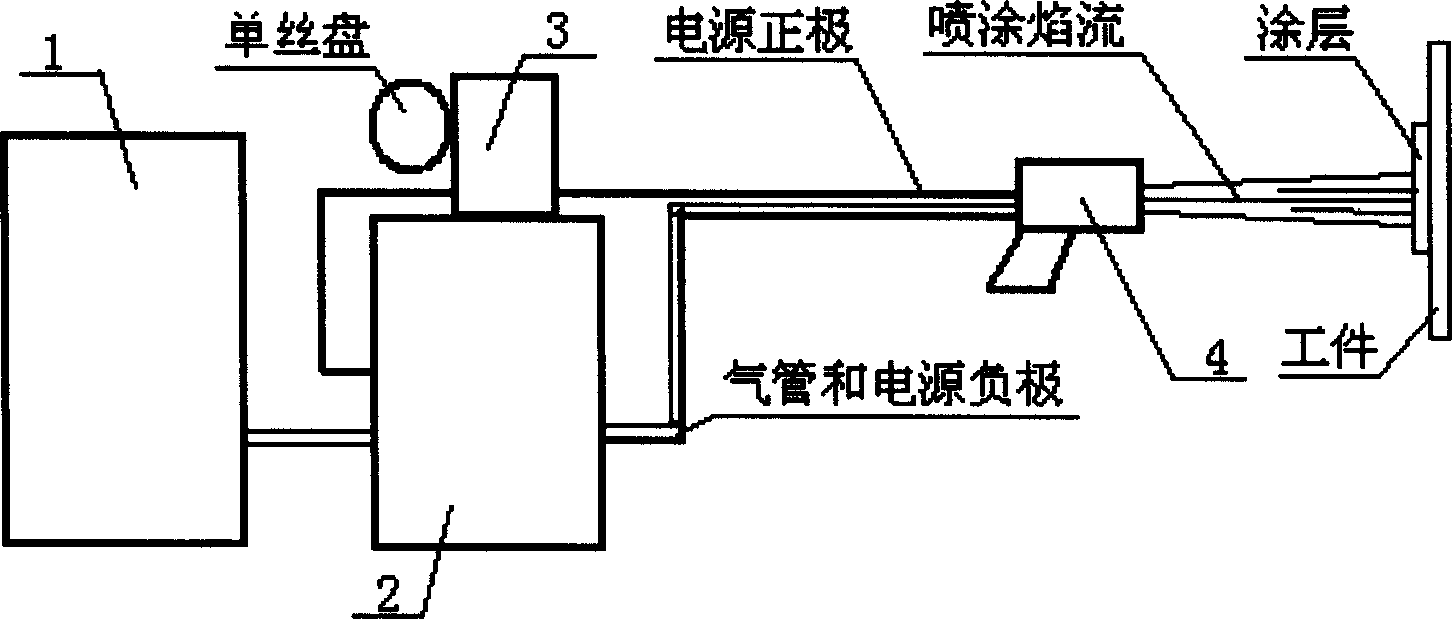

Unifilar tungsten arc spray equipment

InactiveCN1593781AImprove spraying efficiencyRealize comprehensive utilizationLiquid spraying apparatusElectrically conductiveTungsten

The invention relates to a kind of arc spray device. The existing spraying devices have disadvantage of poor spraying quality. An air- compressed tube is fixed at the inner of the device's body, and it connects to negative pole of the electric source and the metal gun spout. Above center shaft of the gun body is a metal tube .At the place where the metal tube is near to the gun spout is a conducting spout .The invention is used for surface modifying of new workpiece .It can prolong the service life of the machine save material and energy , and therefore cut down the cost .

Owner:HARBIN INST OF TECH

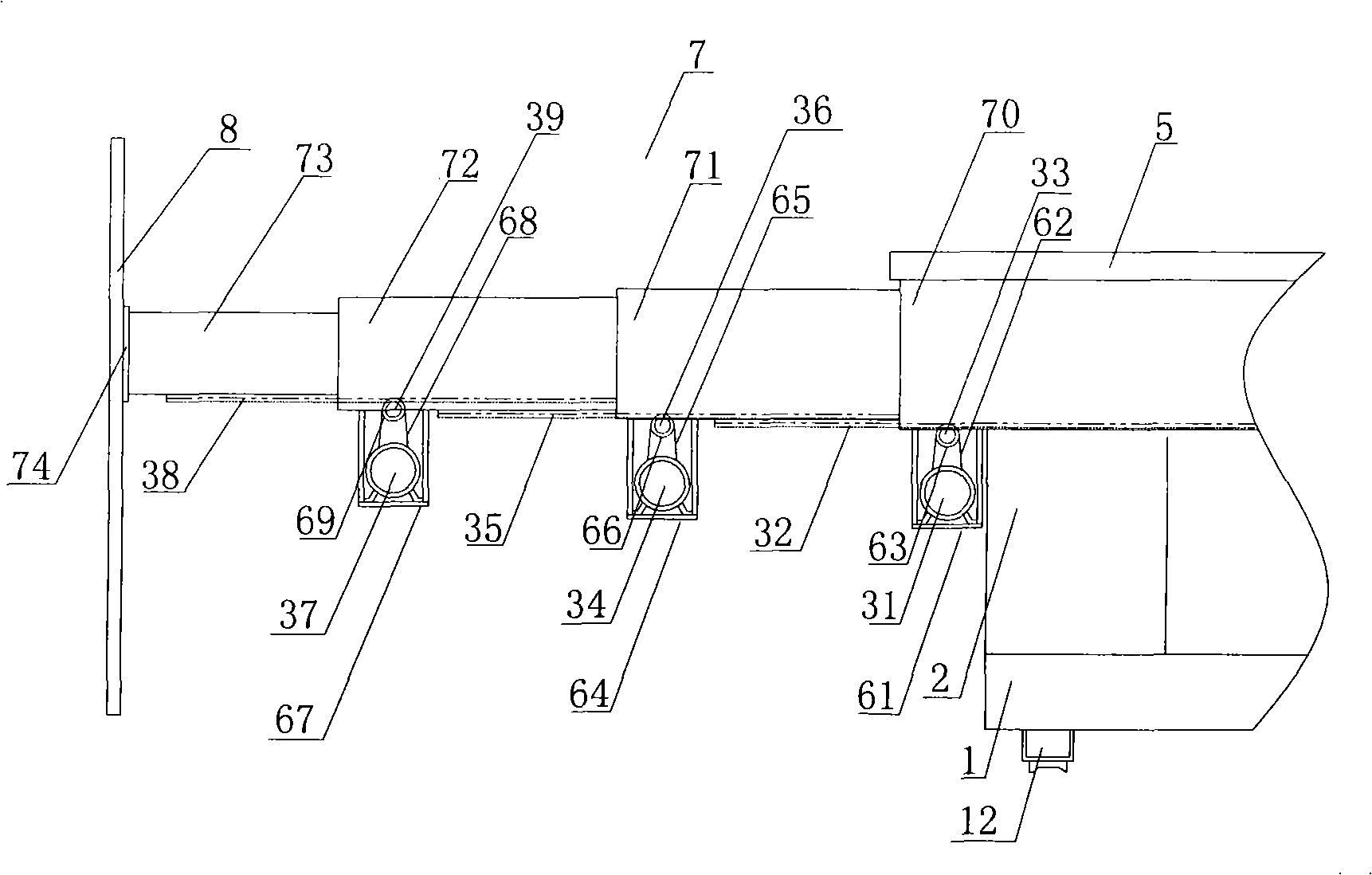

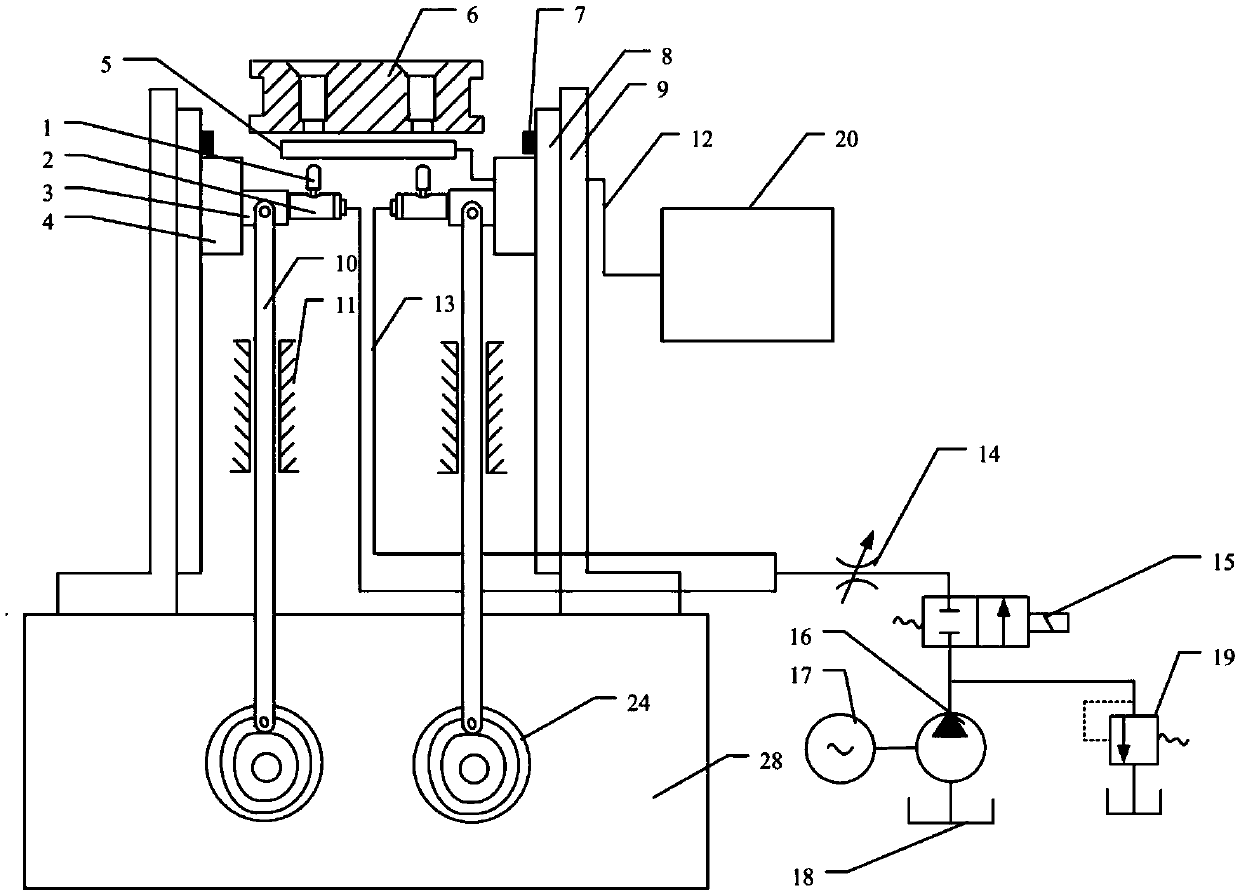

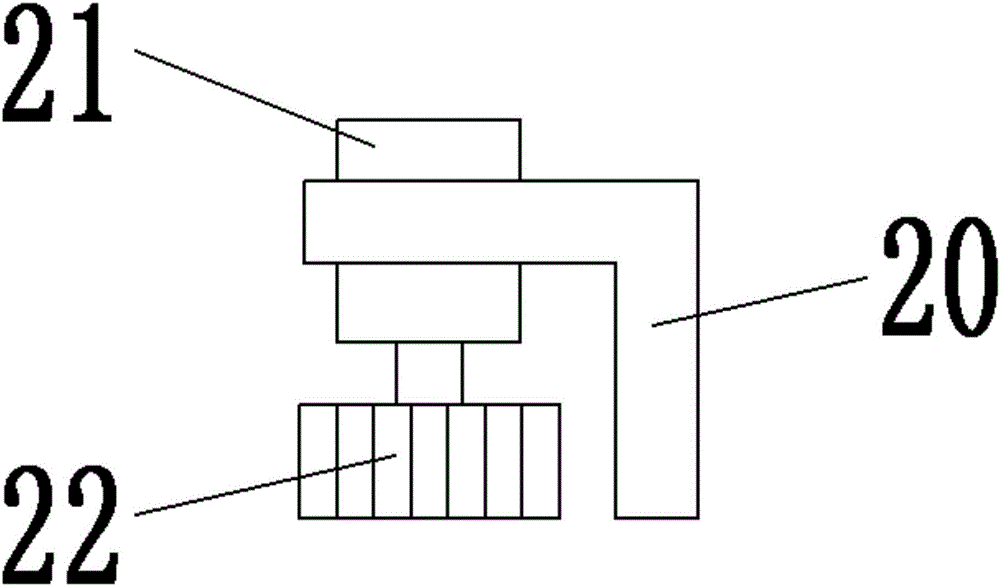

Hard capsule sealing liquid spraying device and method

ActiveCN105498991ASpray evenlySolve the shortcomings of unsatisfactory sealing effectSpray nozzlesCapsule deliveryHard CapsuleSpray nozzle

The invention discloses a hard capsule sealing liquid spraying device and a method thereof. The sealing liquid spraying device comprises a module with a cavity containing capsules, a sealing liquid jetting mechanism and a sealing liquid recovery mechanism; the cavity containing the capsules of the module is located above a nozzle of the sealing liquid jetting mechanism, the nozzle and the cavity containing the capsules are coaxially arranged, and meanwhile the nozzle is connected with a lifting mechanism; the sealing liquid recovery mechanism comprises a negative pressure recovery tank, a sealing liquid recovery pipeline and a vacuum circuit system; the vacuum circuit system is communicated with the negative pressure recovery tank through a sealing liquid recovery pipeline, and the negative pressure recovery tank can make a space close to the lower portion of the module form a negative pressure space under the action of the vacuum circuit system; the nozzle does lifting motion relative to the cavity containing the capsules under the power drive of the lifting mechanism, and the nozzle can pass through the negative pressure recovery tank. Therefore, by means of the hard capsule sealing liquid spraying device and the method thereof, even spraying of sealing liquid in a hard capsule annular space can be effectively guaranteed, the sealing effect of the hard capsule annular space is improved, and therefore the quality of a product is effectively improved.

Owner:JIANGSU LEFAN CAPSULE

Building outer wall spraying device with positioning function

InactiveCN111364736AImprove spraying effectSufficient working hoursBuilding constructionsColor recognitionDistance detection

The invention discloses a building outer wall spraying device with a positioning function. The building outer wall spraying device comprises a frame body. A spraying robot, a multi-channel spraying assembly, a material storage bin, a pump and a controller are installed on the frame body. A climbing elevator is further installed on the frame body. A spray gun is installed at the output end of the spraying robot. The spray gun is connected with the outlet end of the pump through a pipeline. The multi-channel spraying assembly comprises a material distributor and multiple spray guns. The feedingend of the material distributor is connected with the outlet end of the pump through a pipeline. The material distributor comprises multiple discharging ends, and the multiple spray guns are connectedto the multiple discharging ends in a one-to-one correspondence manner. The inlet end of the pump is connected with the material storage bin. The controller is electrically connected with the spraying robot, the spraying guns, the pump and the climbing elevator. The climbing elevator is connected with an encoder, and the encoder is connected with the controller. A color recognition system and a distance detection system are arranged at the position of the spray gun at the output end of the spraying robot. The color recognition system and the distance detection system are connected with the controller. The building outer wall spraying device is reasonable in structural design, convenient to use and capable of preferably improving the spraying efficiency and spraying effect.

Owner:涂强(上海)智能科技有限公司

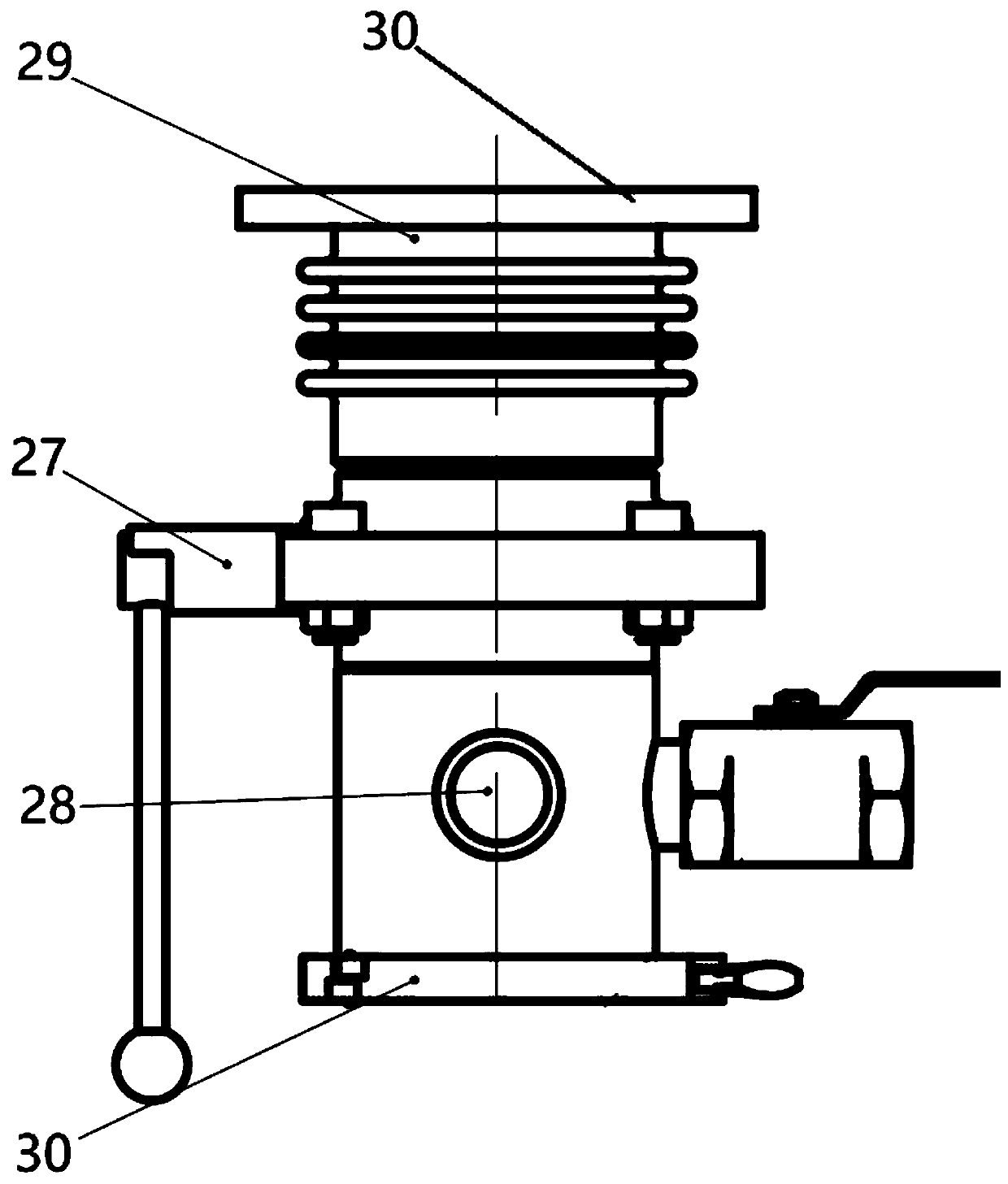

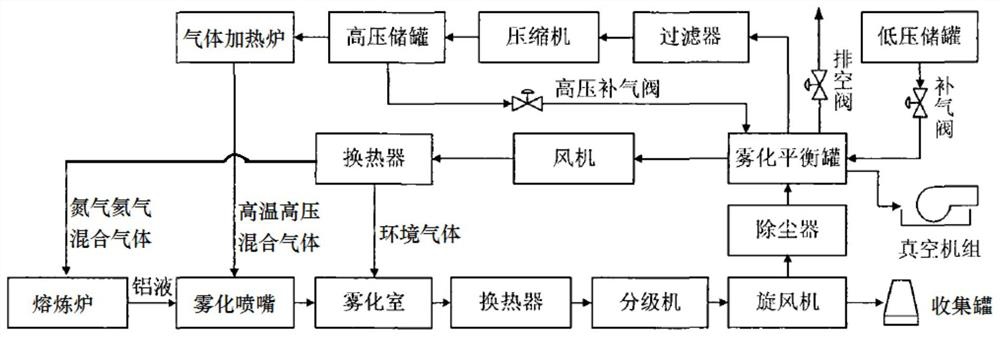

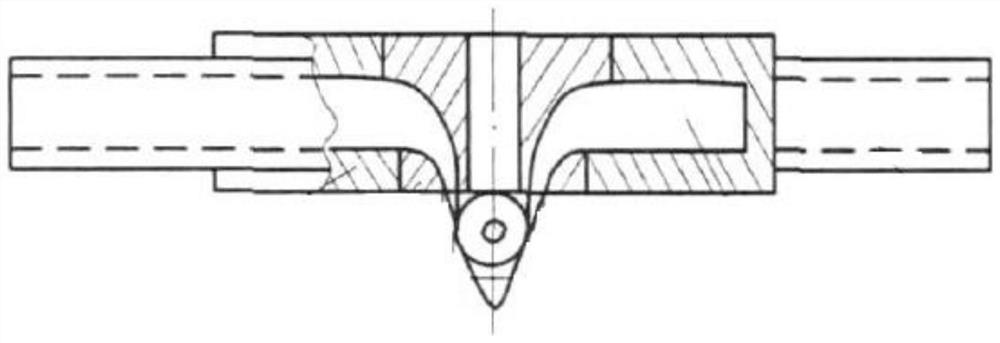

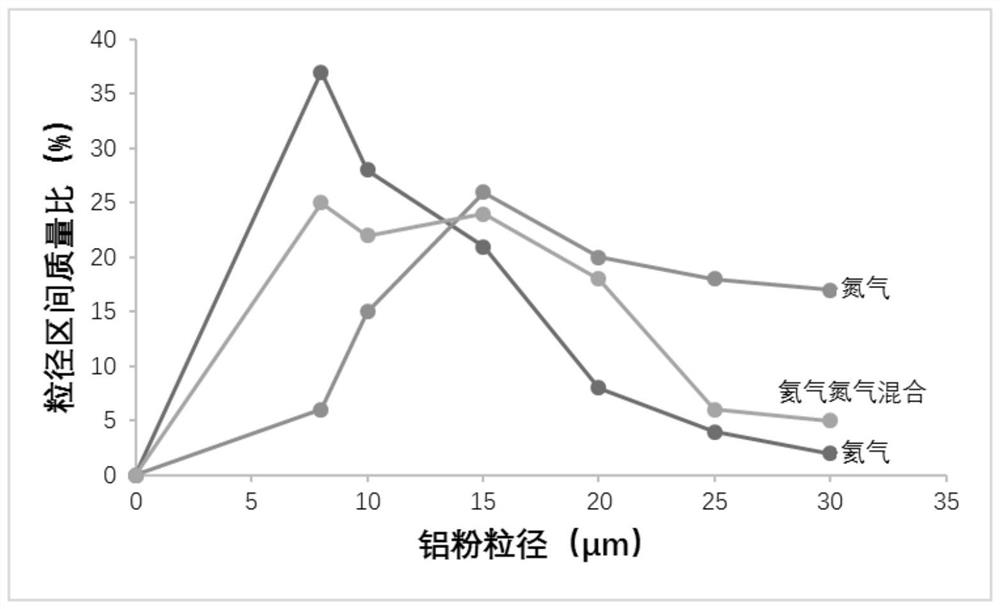

Method for preparing superfine spherical aluminum powder by high-pressure atomization

The invention provides a method for preparing a superfine spherical aluminum powder by high-pressure atomization. Firstly, under the protection of the mixed gas of nitrogen and helium, aluminum ingotsare heated and melted in a melting furnace to become aluminum liquid and warm is kept; then the obtained aluminum liquid is transported through an aluminum liquid catheter to an atomization chamber where the above mixed gas is used as the ambient gas, and meanwhile, the mixed gas is sprayed out through a tightly coupled gas atomization nozzle to atomize the aluminum liquid to form mist-like aluminum liquid droplets; then the liquid aluminum droplets are cooled and rapidly solidified under the cooling and protection of the ambient gas to form atomized aluminum powder; and then the mixed gas isused as a transmission medium, and the atomized aluminum powder is sent to a grading system for graded screening treatment to obtain the superfine spherical aluminum powders of different particle sizes. The method for preparing the superfine spherical aluminum powder by high-pressure atomization provided by the invention uses the mixed gas of nitrogen and helium as the atomization medium, and hasthe advantages of high atomization efficiency, high fine powder yield, uniform particle size distribution, good aluminum powder sphericity and uniform size.

Owner:WUHAN UNIV OF SCI & TECH

Spraying equipment for surface anticorrosion of water-pump pump case

InactiveCN109365192ALow costAvoid wastingLiquid spraying apparatusSpray boothsEngineeringMechanical engineering

The invention belongs to the technical field of pump case processing equipment, and particularly relates to spraying equipment for surface anticorrosion of a water-pump pump case. The spraying equipment for the surface anticorrosion of the water-pump pump case comprises a spraying box, a movable cover is fixedly arranged on one side of the top of the spraying box, the top of the movable cover is in threaded connection with the other side of the top of the spraying box through a fixing bolt, and the top of an inner cavity of the spraying box is fixedly connected with connecting rods. The bottoms of the connecting rods are fixedly connected with a first material conveying pipe, spray heads are fixedly arranged at the bottom of the first material conveying pipe, a material inlet pipe is fixedly connected to the middle of the top end of the first conveying pipe in sleeve mode, and a valve is fixedly arranged outside the material inlet pipe. The spraying equipment for the surface anticorrosion of the water-pump pump case is provided with a collecting funnel, a circulating pipe and a transportation pump, and can be used to collect and recycle residual anti-corrosion paint in the processof spraying anti-corrosion paint to the surface of a pump case, therefore problem of anti-corrosion paint waste is avoided, costs for spraying anti-corrosion paint to the pump case is reduced and a concept of energy conservation and environmental protection comes true.

Owner:阜宁丰隆机电制造有限公司

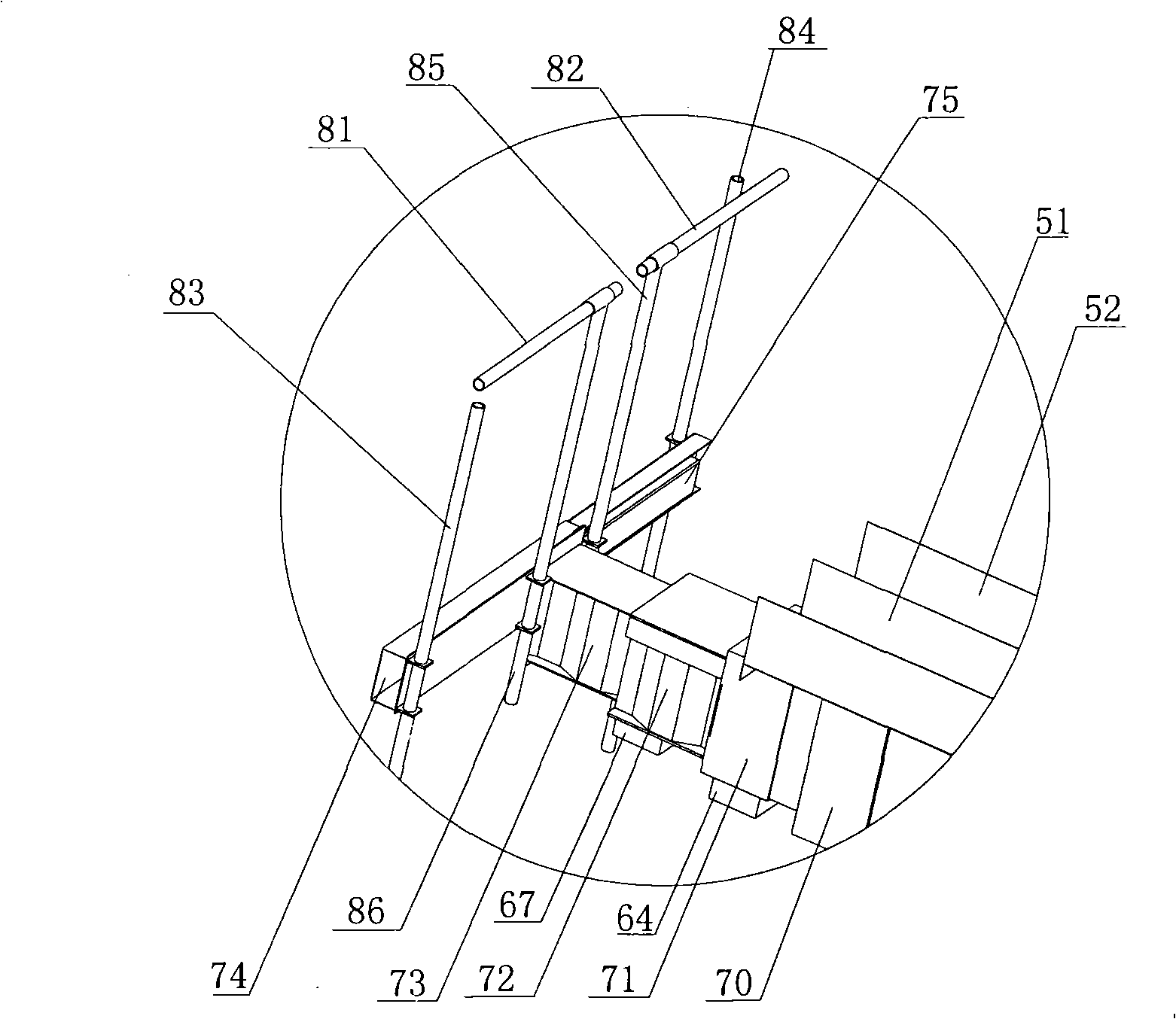

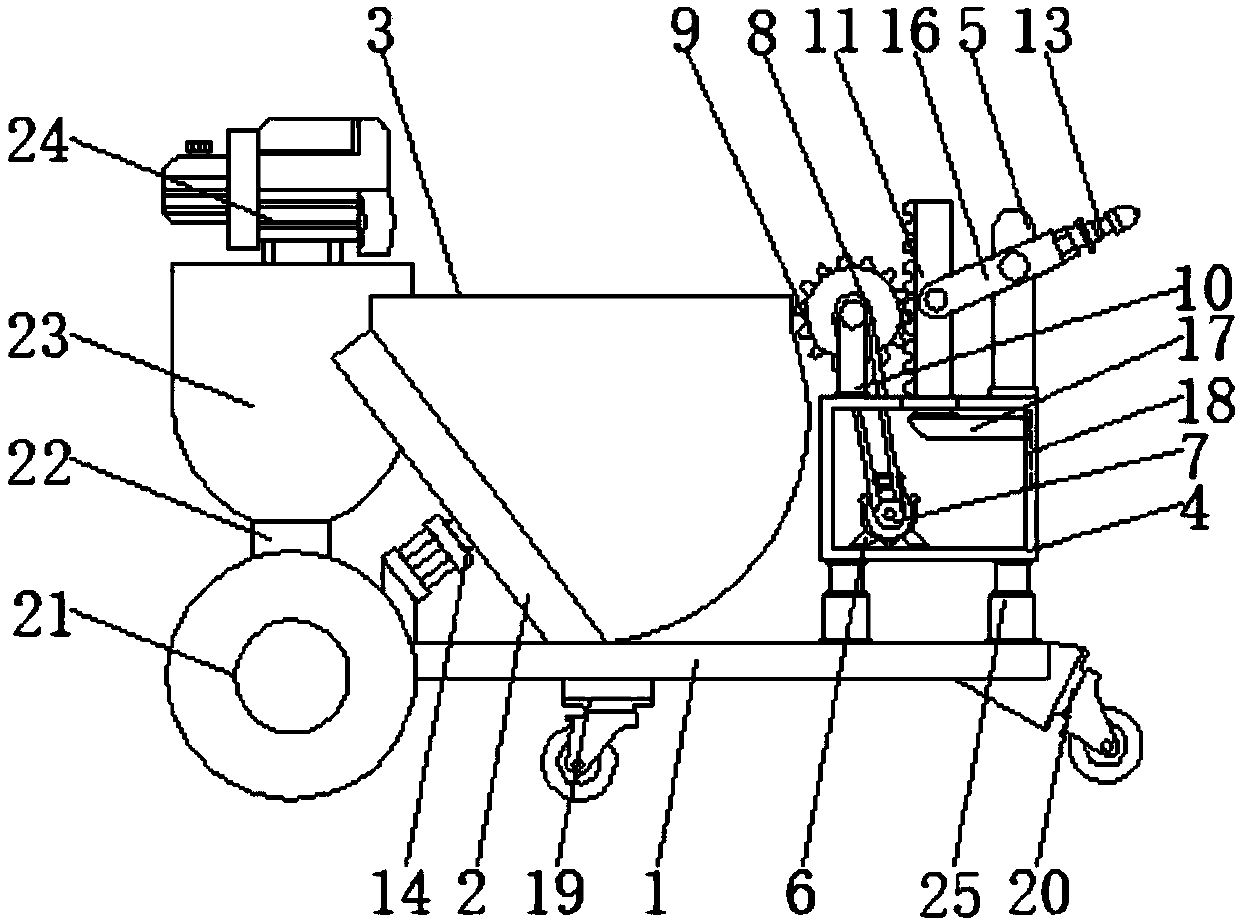

Novel rotor type concrete injection unit

PendingCN109356617AConvenient feedingFeeding opening increasedUnderground chambersTunnel liningEngineeringSmall unit

The invention discloses a novel rotor type concrete injection unit, and belongs to the field of anchoring and shotcreting support such as mine well lanes, railway (highway) tunnels and subways. The novel rotor type concrete injection unit comprises a chassis machine frame, walking wheels installed on the lower part of the chassis machine frame, a concrete injection machine body, an automatic setting accelerator adding mechanism, a dust removing device, a feeding device and a hydraulic tensioning device. Connecting bolts are installed at the left and right ends of the chassis machine frame, andthe chassis machine frame is provided with the dust removing device, a lower support rod, the feeding device, the automatic setting accelerator adding mechanism, an upper support rod, an injection machine body support frame, the hydraulic tensioning device and the concrete injection machine body from left to right in sequence. The novel rotor type concrete injection unit has the beneficial effects that the dust removal efficiency is high, tiny fine dust with the particle diameter larger than 5 microns can collected, and the dust removal efficiency can reach more than 99%; the novel rotor typeconcrete injection unit is flexible to use, can be arranged directly indoors and placed in small units near equipment; and the structure is relatively simple, the operation is relatively stable, theinitial investment is less, and the maintenance is convenient.

Owner:徐州大屯工贸实业有限公司

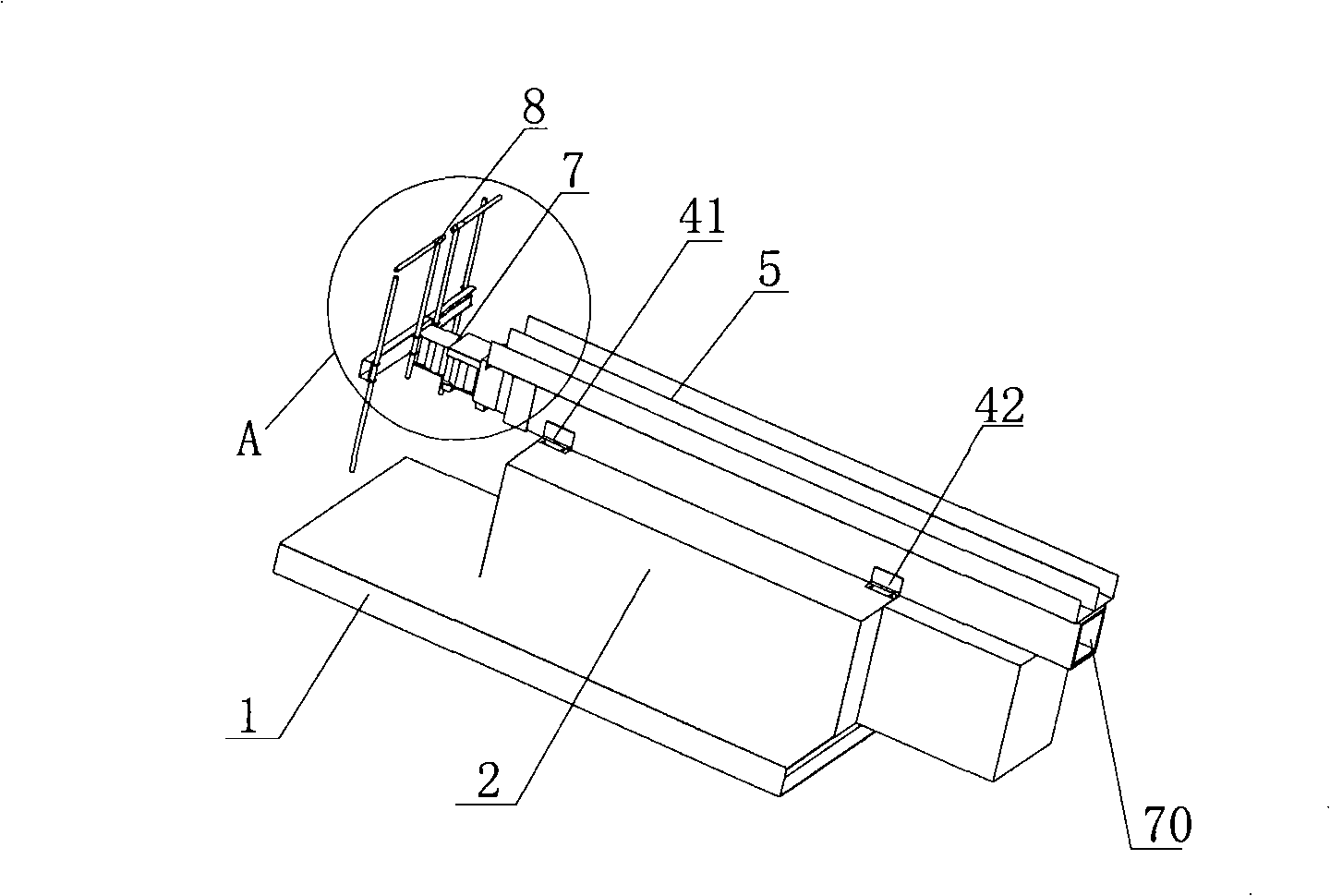

Small wall surface spraying equipment convenient to adjust

InactiveCN107859293AEasy to adjustSolve the inconvenience of adjustmentBuilding constructionsEngineeringTelescopic cylinder

The invention discloses small wall surface spraying equipment convenient to adjust and relates to the technical field of wall surface spraying equipment. The small wall surface spraying equipment comprises a bottom plate; the top of the bottom plate is fixedly connected with an inclined plate; one side of the inclined plate is fixedly connected with a stirring box; one side of the bottom plate isfixedly connected with telescopic air cylinders; the tops of the telescopic air cylinders are fixedly connected with a protection box; one side of the top of the protection box is fixedly connected with a supporting column; one side of the bottom of the inner wall of a fixed box is fixedly connected with a first motor; an output shaft of the first motor is fixedly connected with a first belt wheel; and the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. According to the small wall surface spraying equipment convenient to adjust, the problem that as for an existing spraying head machine, generally people hold a spray head by hand to align the spray head with the wall surface for working, and adjusting is inconvenient is solved, the workamount of people is reduced, the workload of people is relieved, and the work efficiency of people is improved.

Owner:李建

Spraying device for surface of PVC profile

InactiveCN109013113AEasy to removeSpray evenlySpraying apparatusPretreated surfacesElectric machineryAir blower

The invention discloses a spraying device for the surface of a PVC profile. The spraying device comprises a base, a servo motor is fixedly mounted on the top of a motor fixing block, two sliders are movably connected inside a sliding rail, the bottom of the slide rail is fixedly connected to the top of the base, the top of the base is fixedly provided with a baffle, the interior of a coating tubeis fixedly provided with spray guns, and the top of the base is fixedly provided with a hot air blower. The servo motor is arranged, and under the driving action of the servo motor, by using self rotation and revolution of the PVC profile, in cooperation with simultaneous cooperation of the multiple spray guns, the spraying speed of the spraying device for the surface of the PVC profile is high; the sliders and the slide rail are arranged, so that the PVC profile is conveniently detached after spraying is completed; and the hot air blower is arranged, drying of the coating on the surface of aPVC profile body is accelerated, coverage on the surface of the PVC profile is not easily damaged, and the better use prospect is achieved.

Owner:沈靖林

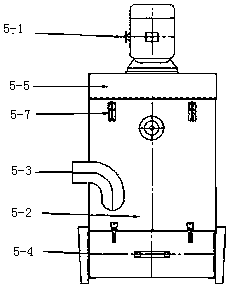

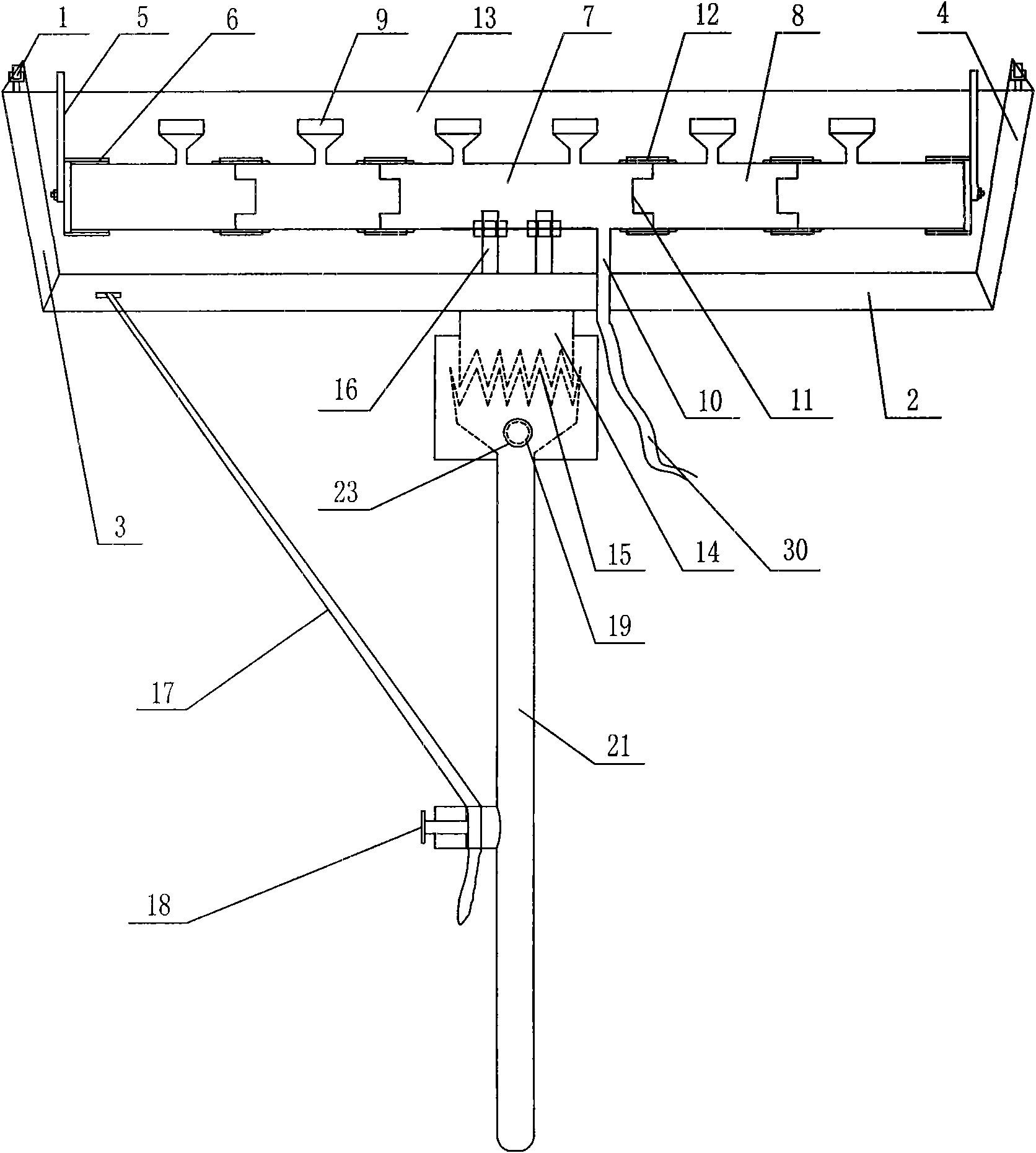

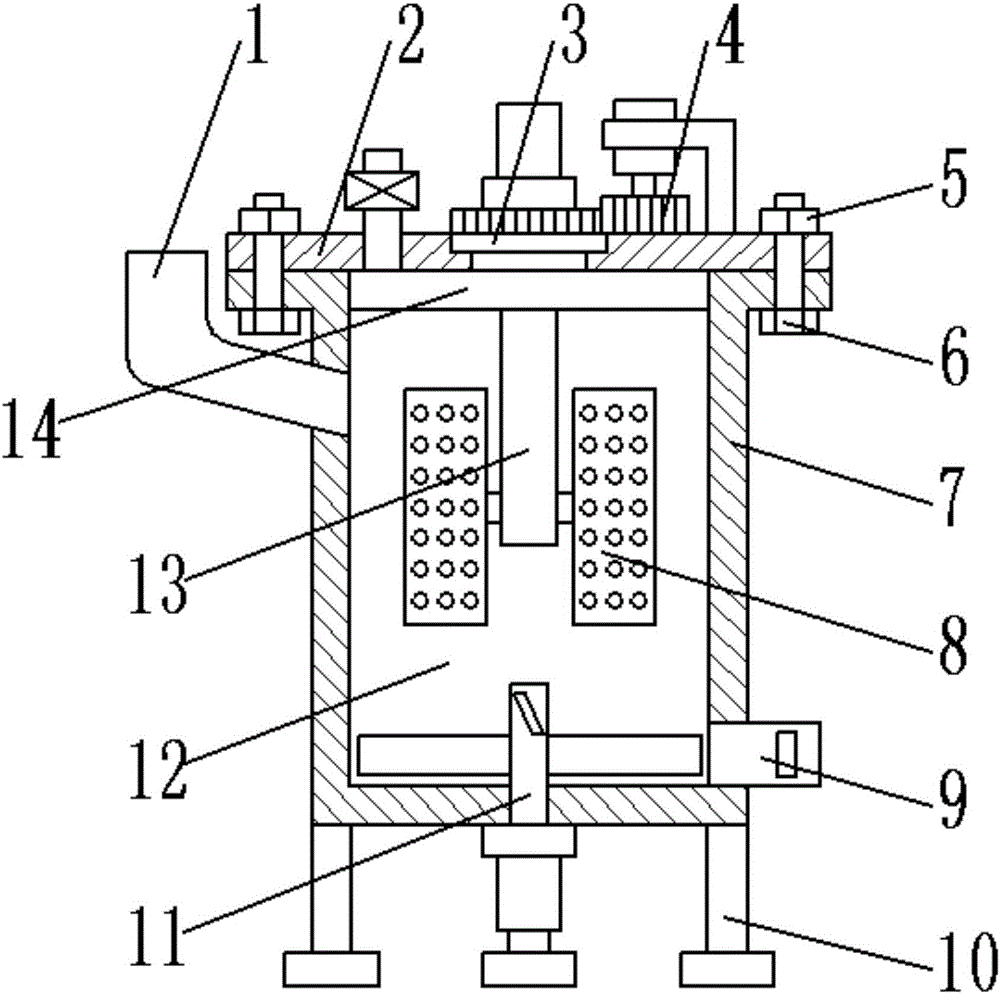

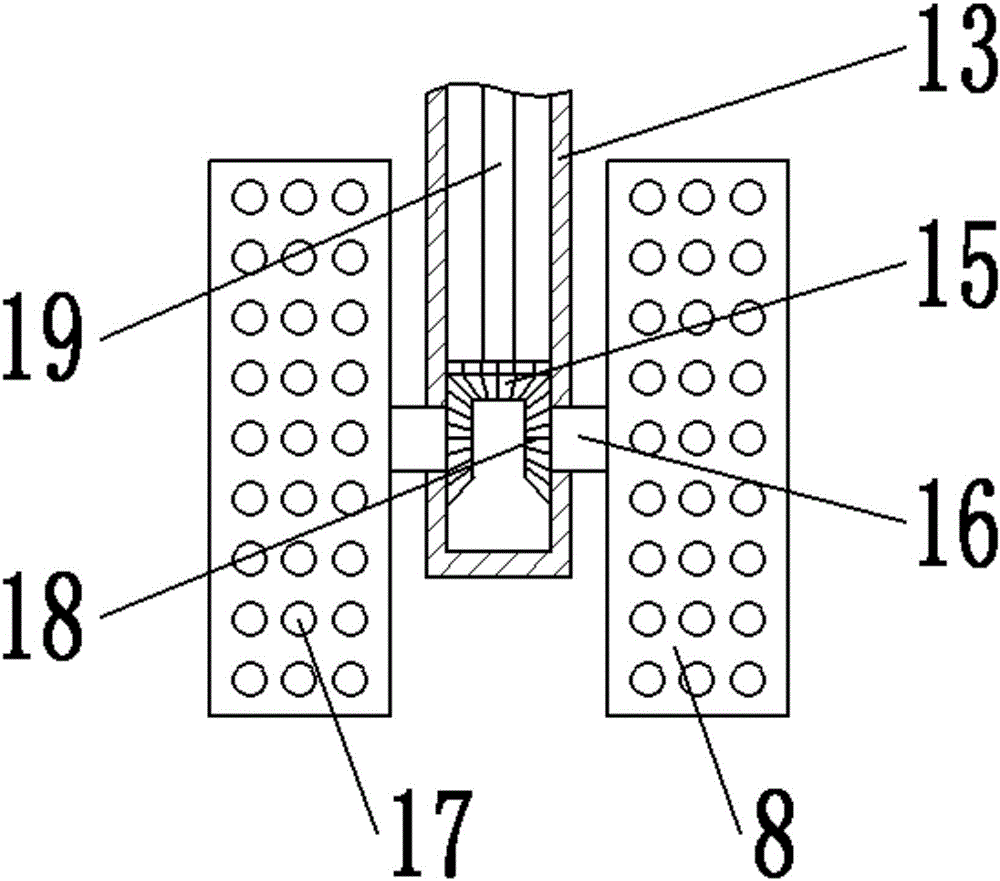

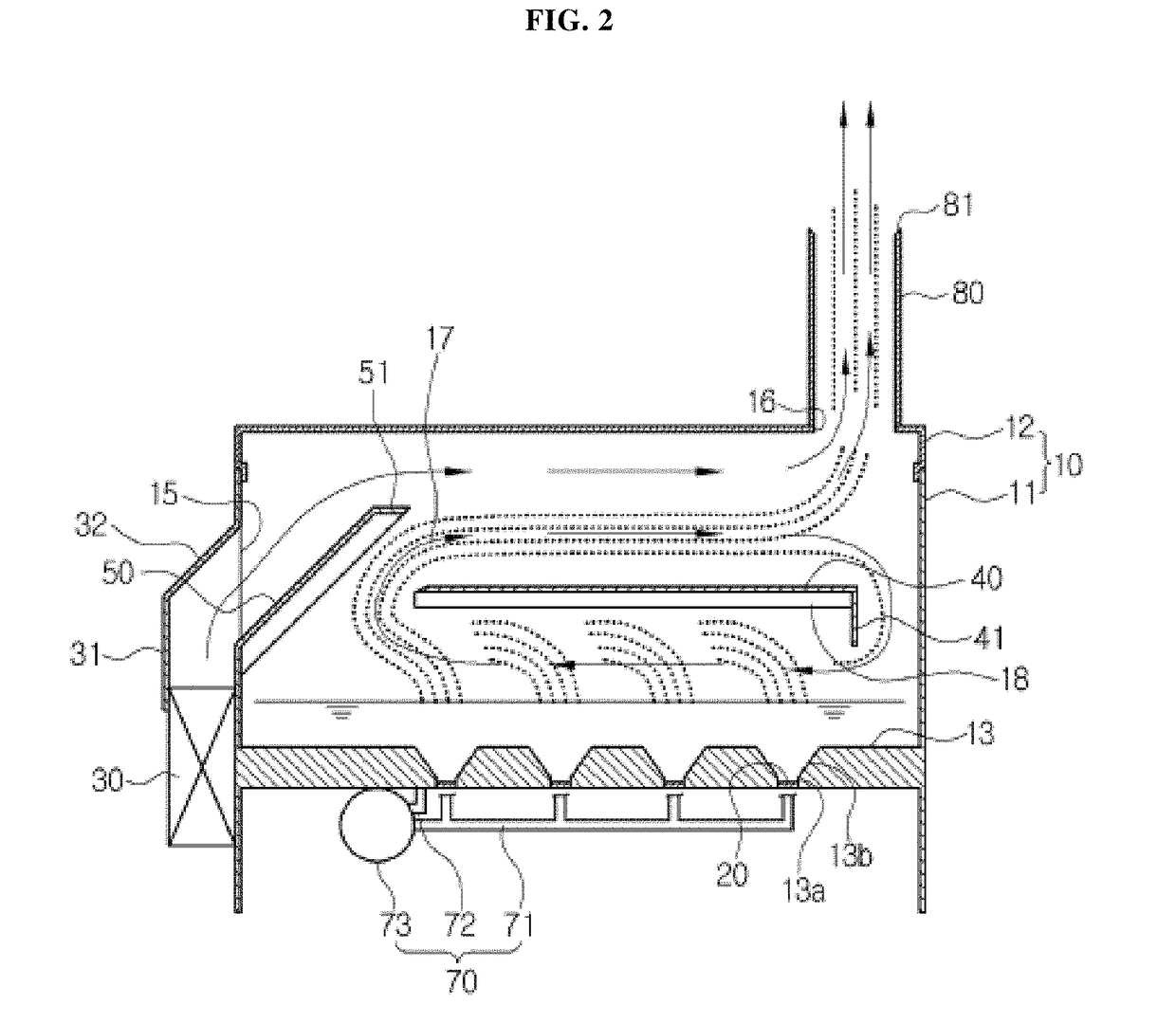

Chemical material stirring and mixing equipment with cleaning device

InactiveCN106693776AExpand the spraying areaSpraying speed is fastRotary stirring mixersTransportation and packagingEngineeringWater pipe

The invention provides chemical material stirring and mixing equipment with a cleaning device. The chemical material stirring and mixing equipment comprises a tank body; a mixing cavity is arranged in the tank body; an upper cover is arranged in an opening at the top part; the cleaning device is arranged on the upper cover; the cleaning device comprises a transmission case, a first motor, a water inlet pipe and a rotary spraying disc; a stirring device is arranged at the bottom part of the mixing cavity; the stirring device comprises a second motor, a stirring shaft, a horizontal stirring sheet, a vertical stirring sheet and a stirring plate; and the side wall of the rotary spraying disc is fixedly connected with a scraper plate. The spraying area and the spraying speed of clean water are increased and accelerated through the cleaning device, so that the used tank body can be conveniently efficiently cleaned; due to the arrangement of the stirring device, the material in the tank body is efficiently stirred and mixed through the horizontal stirring sheet, the vertical stirring sheet and the stirring plate; due to the arrangement of the scraper plate, the material adhered on the inner wall of the tank body is scraped, the material mixing accuracy is improved, the material can be completely discharged in the process of discharging the material, and the use ratio of the material is improved.

Owner:河南微服网络科技有限公司

Coating machine for wall coatings

InactiveCN101658831ASpraying speed is fastWide range of usesLiquid surface applicatorsSpraying apparatusEngineeringNozzle

The invention relates to a coating device for large-area wall advertisements, propagandas and under colors of posters, and discloses a coating machine for wall coatings, which comprises a main board;the inner lateral surface of the main board is fixed with a tubular main nozzle piece; the front of the main nozzle piece is provided with a nozzle; the rear of the main nozzle piece is provided witha feed pipe passing through the main board; two ends of the main nozzle piece are enclosed by end caps; and outer end faces of the end caps are provided with liquid baffle plates. The coating machineis provided with the liquid baffle plates to ensure neat edges of the coating, can be provided with a plurality of additional nozzle pieces to achieve wide spraying amplitude, and is provided with rollers to ensure labor-saving spraying and quick spraying. The coating machine is suitable for coating various coatings, and has wide application, simple structure, light weight because parts are made of light materials such as plastics and the like, and convenient operation and carrying.

Owner:郭照沛

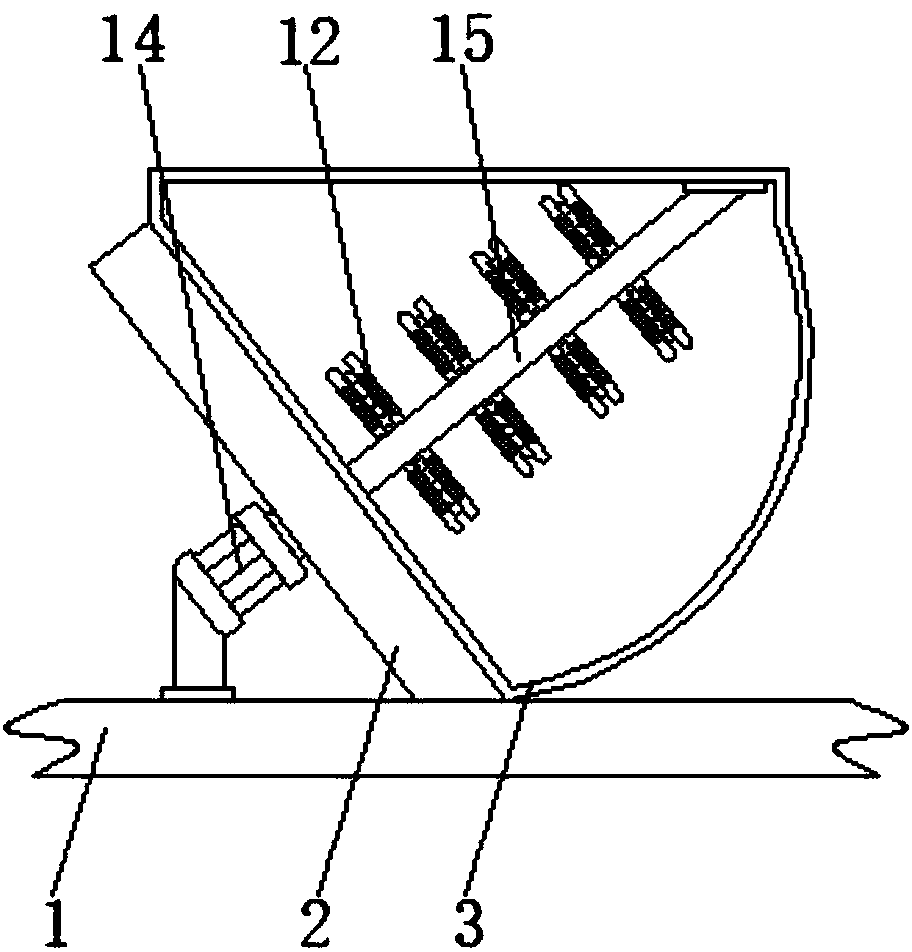

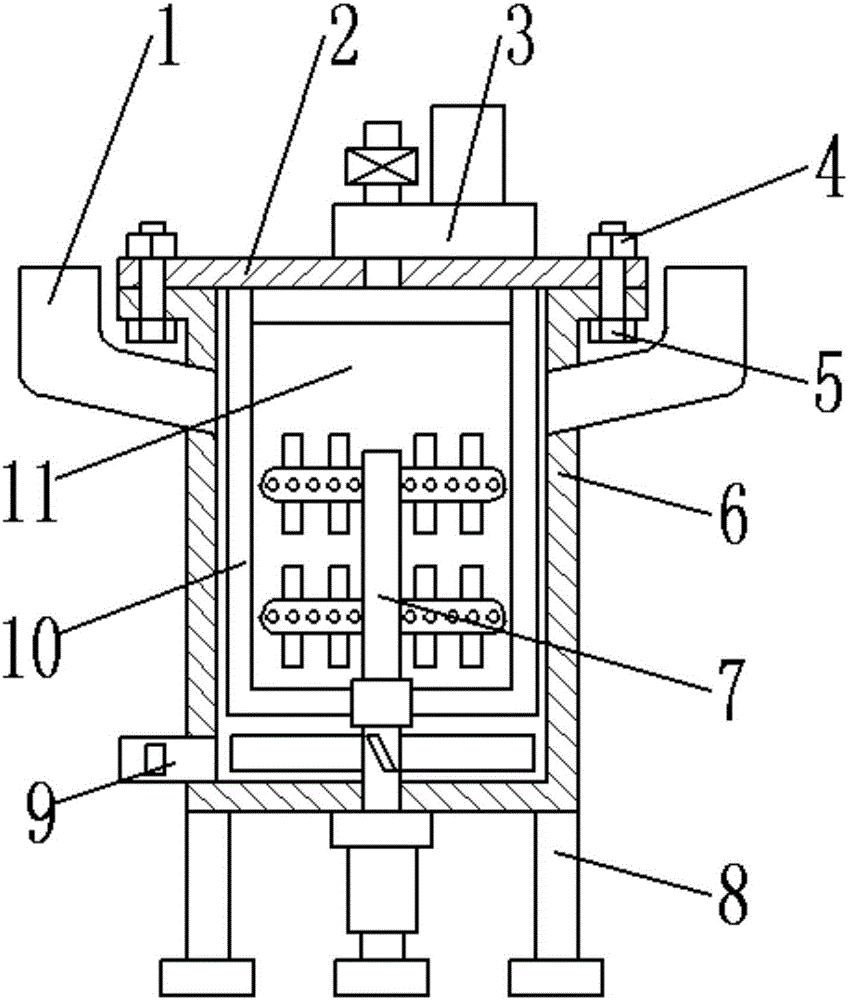

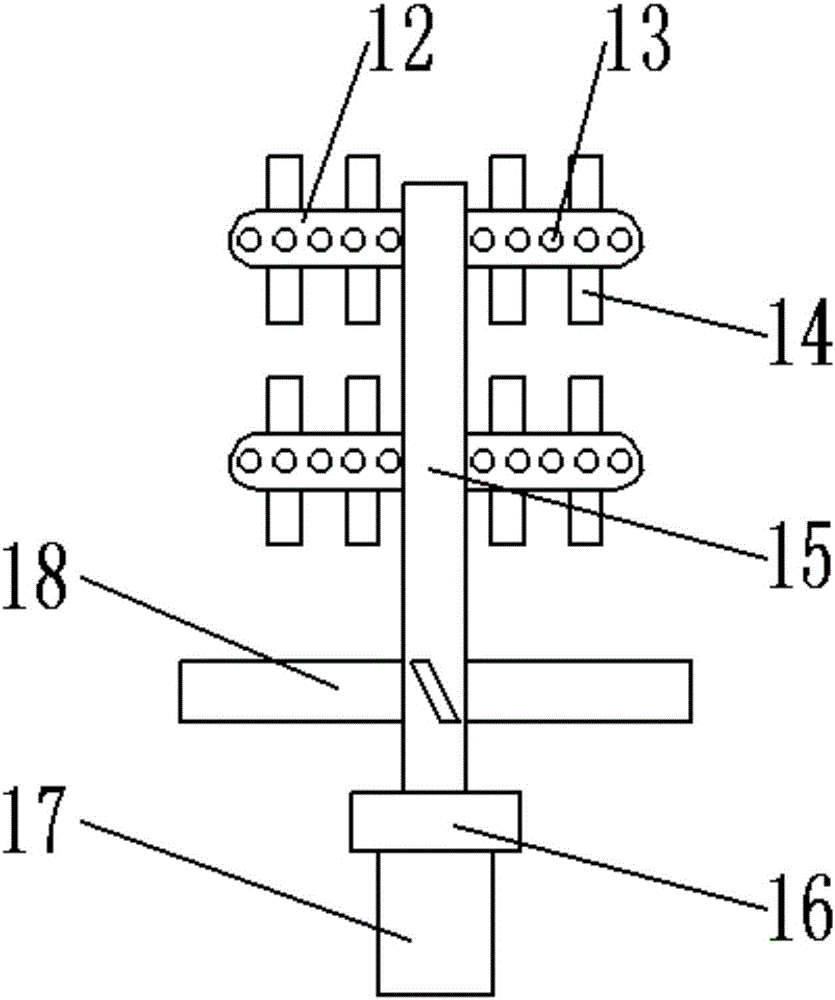

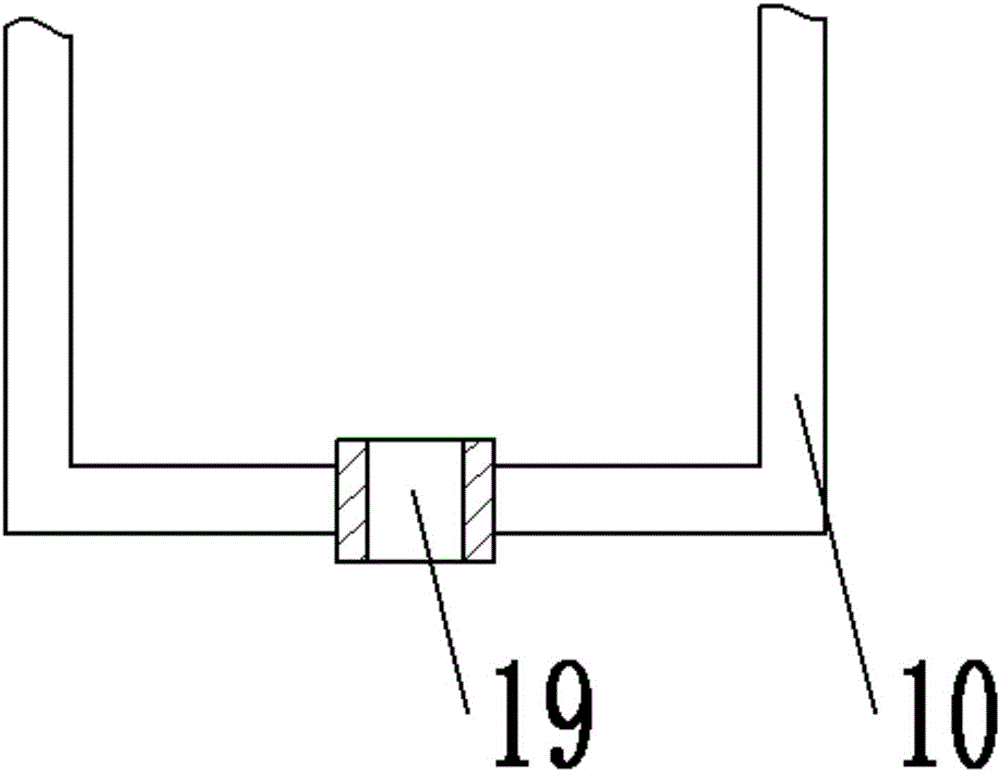

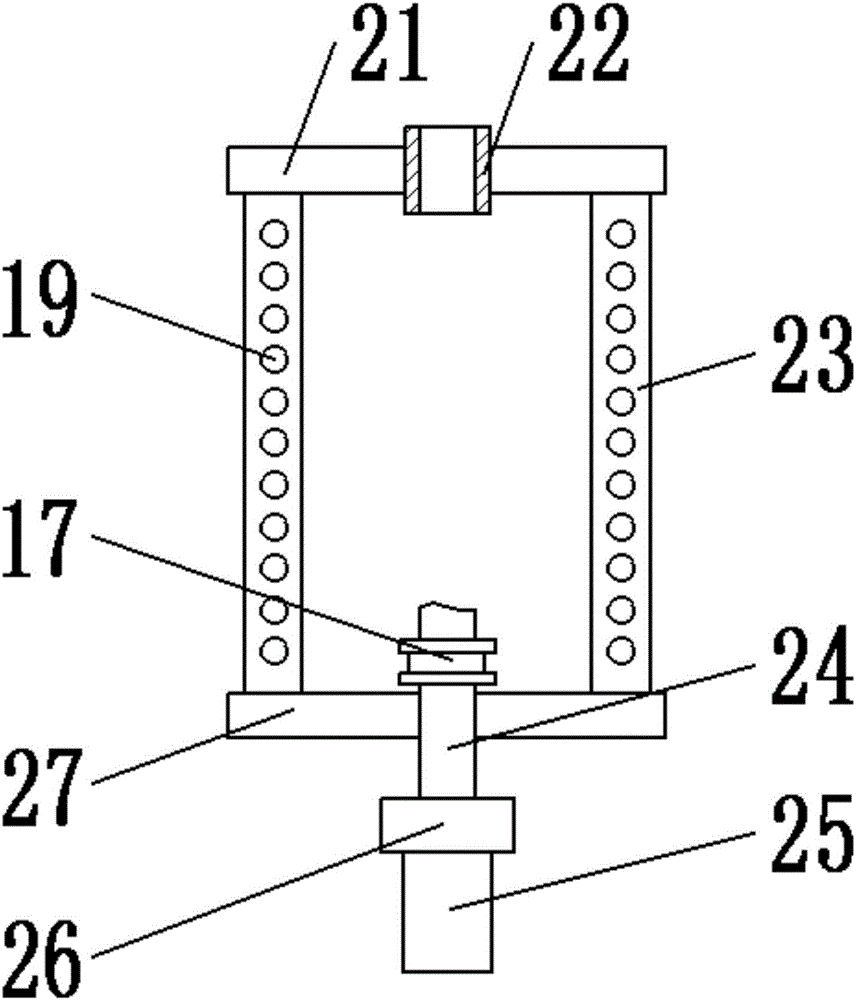

Vertical stirring and mixing equipment with bidirectional stirring devices

InactiveCN106512800AExpand the spraying areaSpraying speed is fastRotary stirring mixersTransportation and packagingEngineeringSolid material

The invention provides vertical stirring and mixing equipment with bidirectional stirring devices. The vertical stirring and mixing equipment comprises a tank and an upper cover. A stirring cavity is arranged inside the tank; a liquid inlet and driving device is arranged on the upper cover; the liquid inlet and driving device comprises a transmission box, a first motor, a liquid inlet pipe and a rotary spray disc; the forward stirring device and the reverse stirring device are arranged in the stirring cavity; the forward stirring device comprises a forward stirring shaft and forward stirring blades; the reverse stirring device comprises a second motor, a reverse stirring shaft and reverse stirring blades; feed hoppers are arranged on the side walls of the top of the tank; a jacket is arranged on the outer wall of the tank. The vertical stirring and mixing equipment has the advantages that the spray areas and the spray speed can be increased for liquid materials by the liquid inlet and driving device, accordingly, the liquid materials and solid materials can be conveniently in sufficient contact with one another, and the mixing quality can be improved; the materials in the tank can be bidirectionally stirred by the forward stirring device and the reverse stirring device, accordingly, the stirring and mixing quality can be improved, and stirring dead spaces in the tank can be avoided.

Owner:郑州吉音动漫科技有限公司

Multi-joint spraying robot

InactiveCN106111404AAvoid damageIncrease freedomSpraying apparatusProduction rateAgricultural engineering

The invention discloses a multi-joint spraying robot. The multi-joint spraying robot comprises a cross arm, a moving device, a sprayer connecting shaft and a rotary disc. Stand columns are arranged at the left end and right end of the cross arm. The cross arm is fixed to the inner side of the moving device. A third joint is installed on the outer side of a second joint. The third joint is connected with a lifting shaft through a fourth joint. The lower side of the sprayer connecting shaft is connected with sprayers. A connecting plate is arranged at the upper end of the rotary disc. Revolution tables are fixed to the upper end and lower end of the connecting plate, and rotation tables are installed on the outer sides of the revolution tables. The multi-joint spraying robot is provided with multiple joints, the degree of freedom is high, and the spraying robot is suitable for working at any trajectory and angle, high in flexibility, high in spraying precision and high in spraying speed. Through cooperation with the rotary tables, the production rate is greatly increased. By means of free programming, automation work can be completed, operation is easy and convenient, manual operation can be replaced, and harm to human health by paint is reduced.

Owner:WUXI XINGUANG COMP INSTALLATION

Chemical material stirring and mixing equipment with high stirring force

InactiveCN106693764AEfficient mixingReduce stirring resistanceRotary stirring mixersTransportation and packagingEngineeringSolid material

The invention provides chemical material stirring and mixing equipment with high stirring force. The chemical material stirring and mixing equipment comprises a tank body and an upper lid; the inside of the tank body is provided with a stirring cavity; the upper surface of the upper lid is provided with a driving device and a transmission device, and the lower surface of the upper lid is provided with a liquid entering device; the transmission device is arranged in a turntable mounting groove; the transmission device is composed of a first motor and a first straight gear; the transmission device is composed of a turntable, a second straight gear, a second gear and a sleeve; the liquid entering device is composed of a spraying dish and a liquid entering pipe; the bottom of the stirring cavity is provided with a stirring device; the stirring device is composed of a third motor, a stirring shaft and a stirring plate. According to the chemical material stirring and mixing equipment with the high stirring force, the driving device and the transmission device drive a stirring piece to conduct the rotation in the horizontal direction and the rotation in the vertical direction, which is beneficial to conducting efficient stirring on materials in the tank body; the spraying area and the spraying speed of liquid materials are increased through the liquid entering device, which brings convenience to sufficient contact with solid materials, and is beneficial to fast stirring and mixing among the materials.

Owner:郑州吉音动漫科技有限公司

Supraparticle atomizing device

ActiveUS20180147594A1Improve spraying effectSpraying speed is fastSpace heating and ventilation safety systemsLighting and heating apparatusMicroparticleEngineering

Owner:SEOUL NAT UNIV R&DB FOUND +1

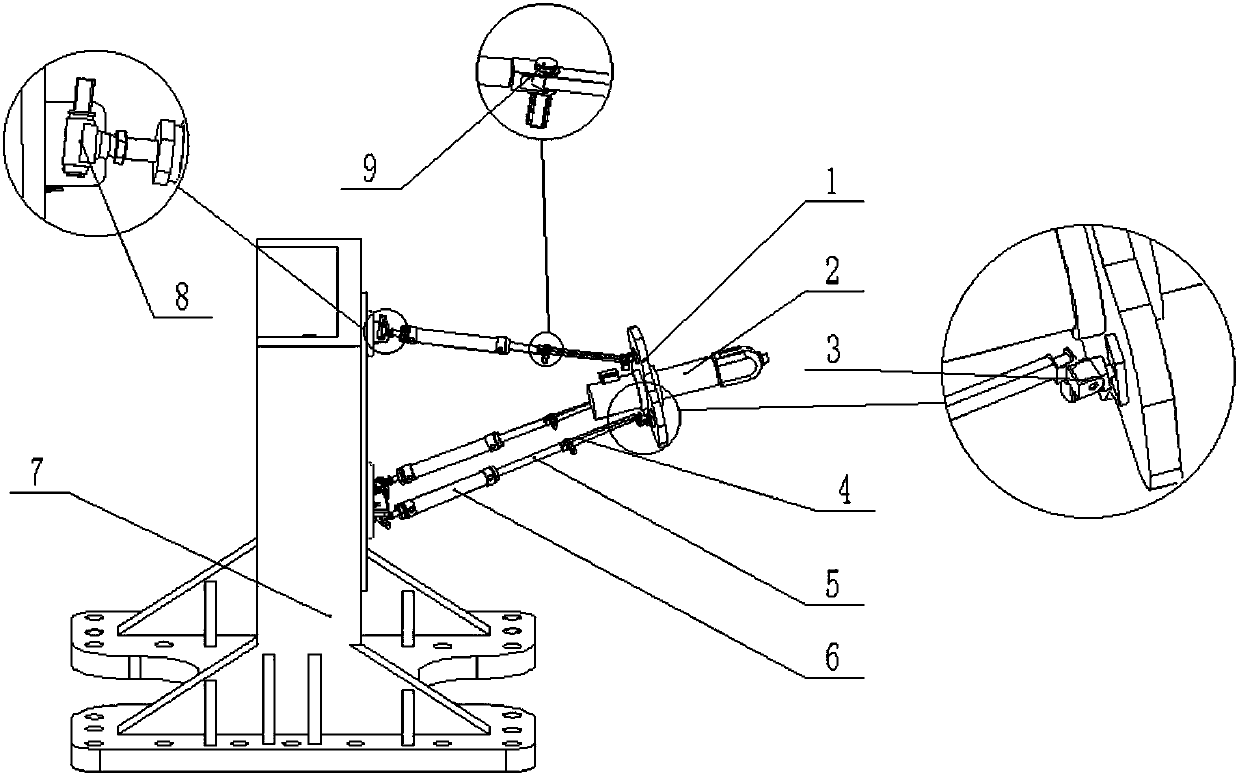

Six-degree-of-freedom self-reconfigurable parallel spray painting robot

ActiveCN107932476ASpraying speed is fastWith six degrees of freedomProgramme-controlled manipulatorSprayerEngineering

A six-degree-of-freedom self-reconfigurable parallel spray painting robot consists of a sprayer, a sprayer supporting platform, three sprayer hinges with completely the same structure, three completely identical long fulcrum bars, a brake, three cylinders with the same specifications, three structurally identical support hinges and a rack. The spray painting robot can realize four configurations,and appropriate configurations can be flexibly selected to accomplish different working contents. Compared with a traditional series spray painting robot, the parallel spray painting robot is light and simple in body, high in flexibility, good in stability and excellent in dynamic response, and can adapt to different spray painting works, from simple linear spray painting to complicated spatial curved spray painting, through flexible conversion of the configurations.

Owner:GUANGXI UNIV

Angular blowing spray nozzle used for condensing evaporator

The invention discloses an angular blowing spray nozzle used for a condensing evaporator. The angular blowing spray nozzle comprises a spray nozzle body and a spray nozzle core. A fluid inlet, a spraynozzle hole and a fluid outlet are formed in the spray nozzle body in the axial direction in sequence and communicate with one another coaxially. The spray nozzle core is arranged in the spray nozzlehole, and two rotary runners are formed between the spray nozzle core and the inner wall of the spray nozzle hole, so that fluid entering the two rotary runners is sprayed out of the fluid outlet inthe shape of conical thin film under the effects of high pressure and rotating. The angular blowing spray nozzle has the efficient atomizing effects of large spray speed, large atomizing angle and uniform spraying, and therefore, the evaporator is fast and efficiently cooled.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com