Patents

Literature

505 results about "Arc spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sputtering of thermally resistive materials including metal chalcogenides

ActiveUS20080099326A1Reduce heat loadLow thermal conductivityVacuum evaporation coatingSputtering coatingPhase-change memoryMetal chalcogenides

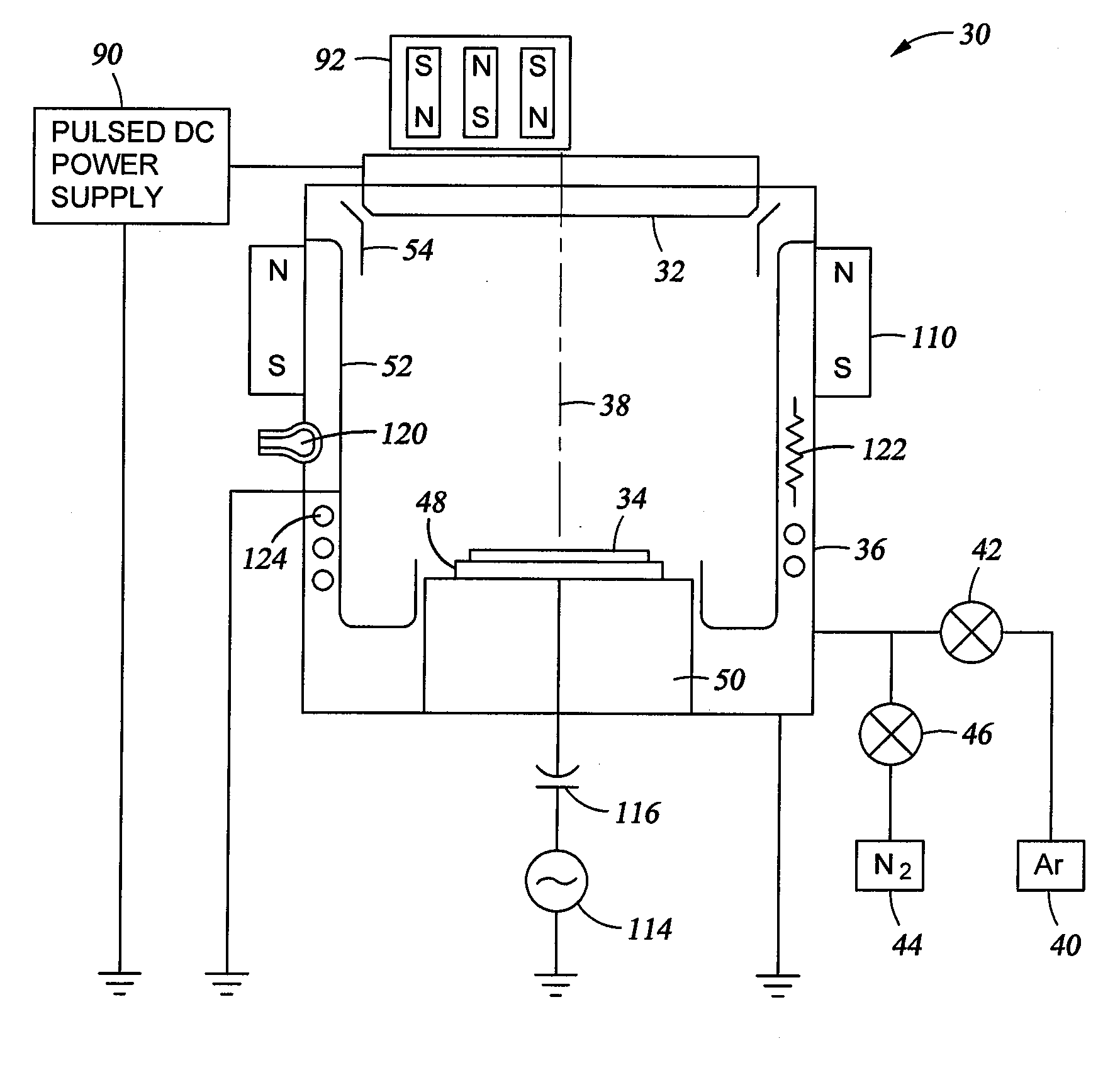

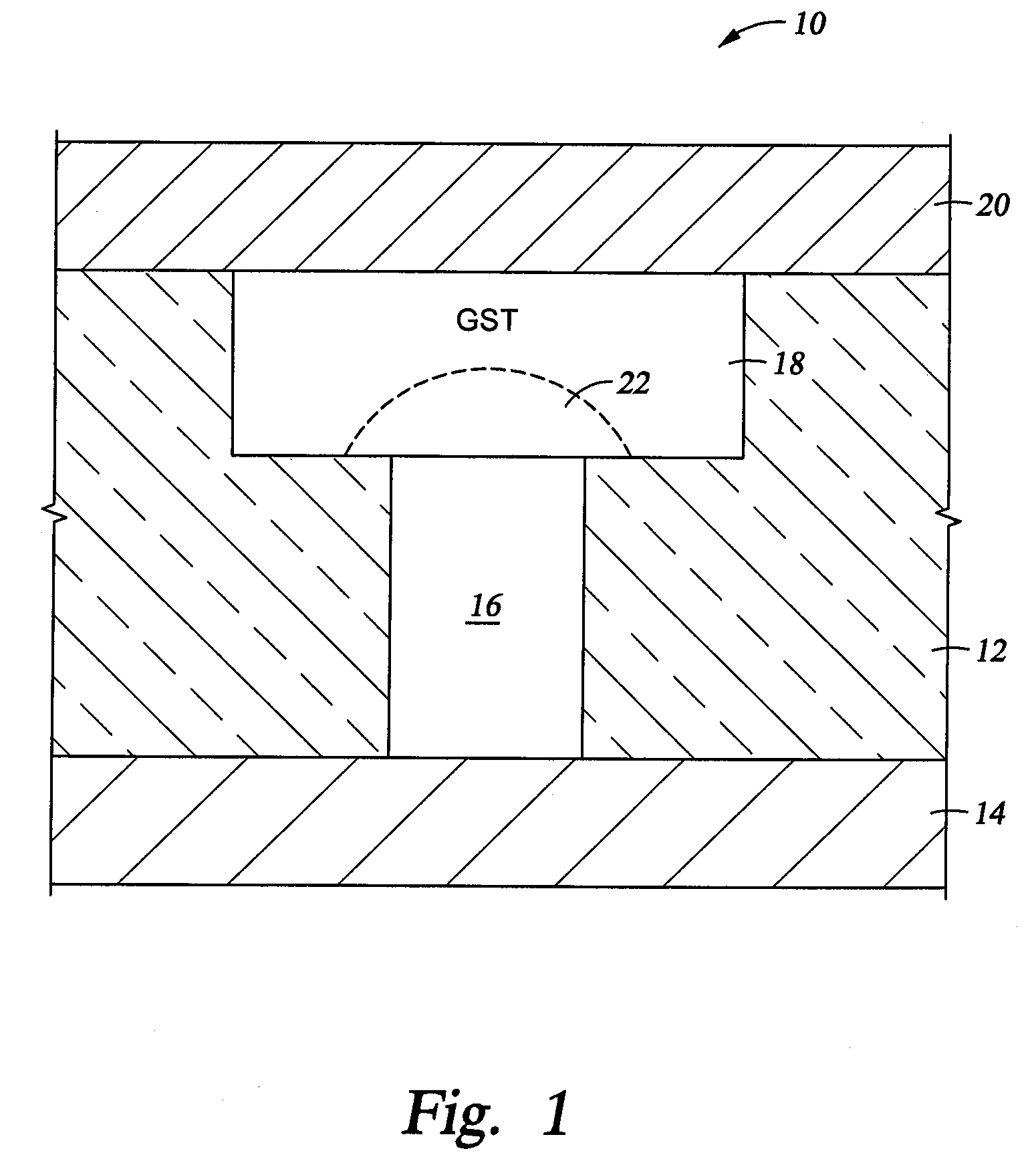

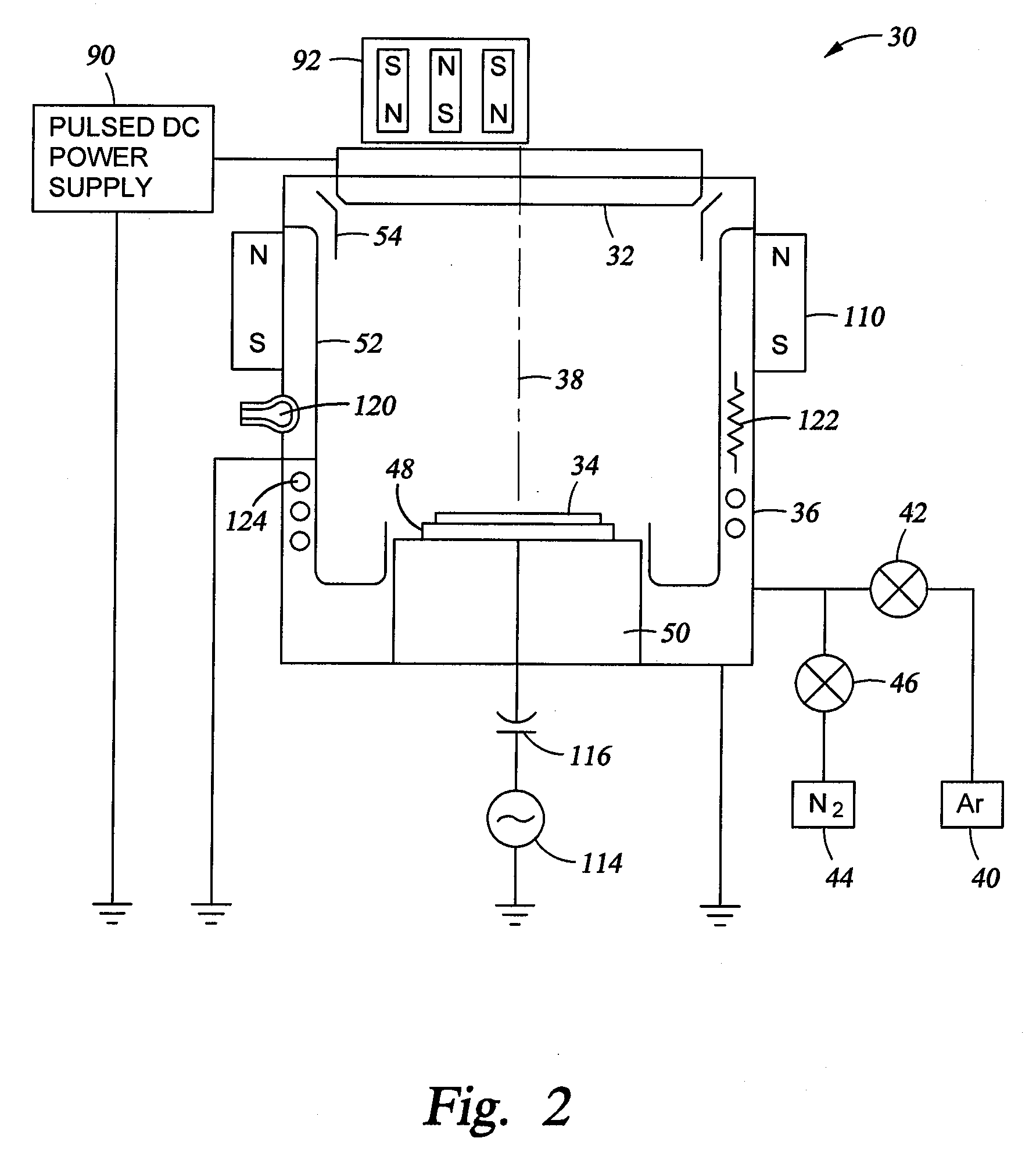

A plasma sputtering method for metal chalcogenides, such as germanium antimony telluride (GST), useful in forming phase-change memories. The substrate is held at a selected temperature at which the material deposits in either an amorphous or crystalline form. GST has a low-temperature amorphous range and a high-temperature crystalline range separated by a transition band of 105-120° C. Bipolar pulsed sputtering with less than 50% positive pulses of less than 10:s pulse width cleans the target while maintain the sputtering plasma. The temperature of chamber shields is maintained at a temperature favoring crystalline deposition or they may be coated with arc-spray aluminum or with crystallographically aligned copper or aluminum.

Owner:APPLIED MATERIALS INC

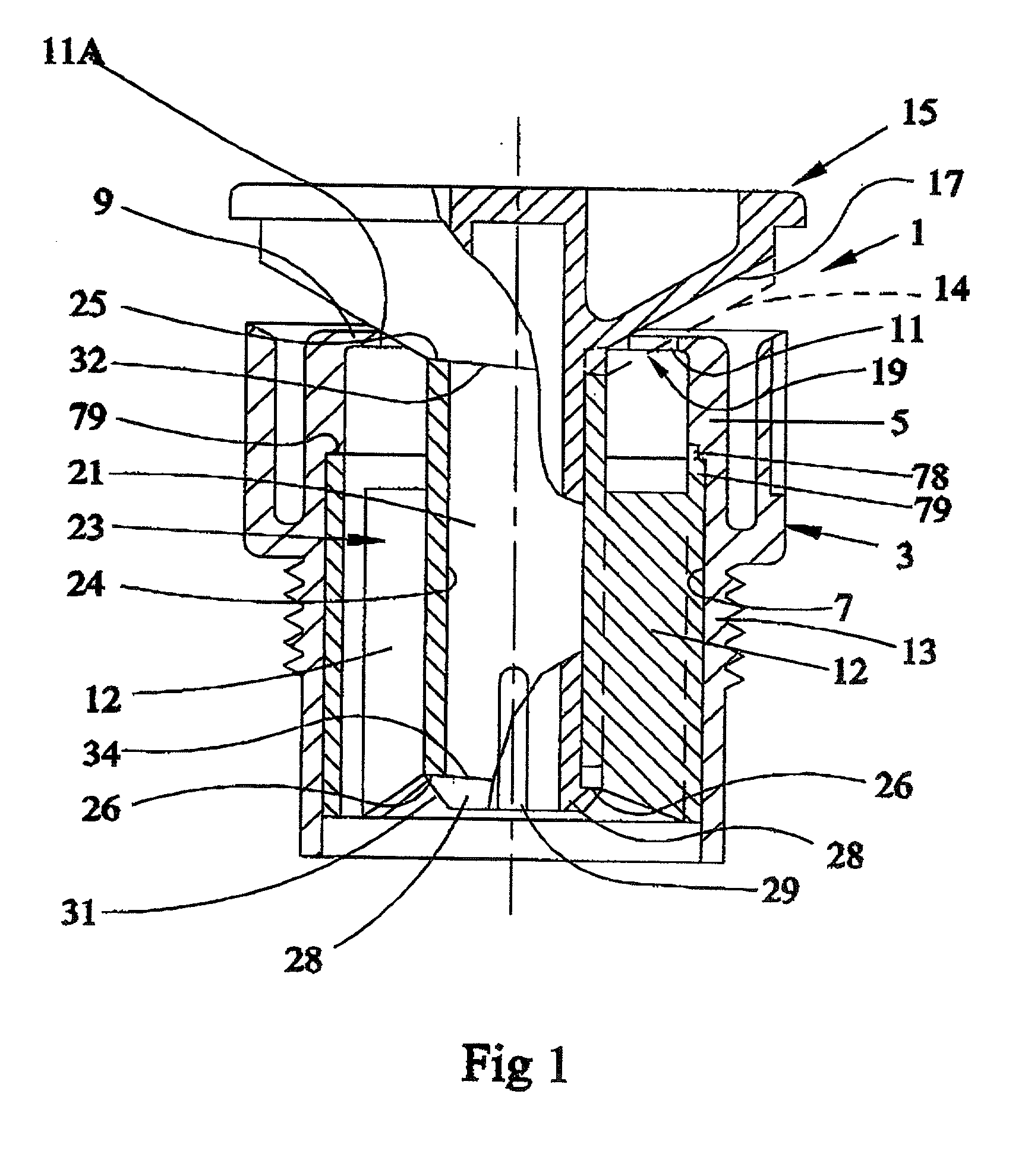

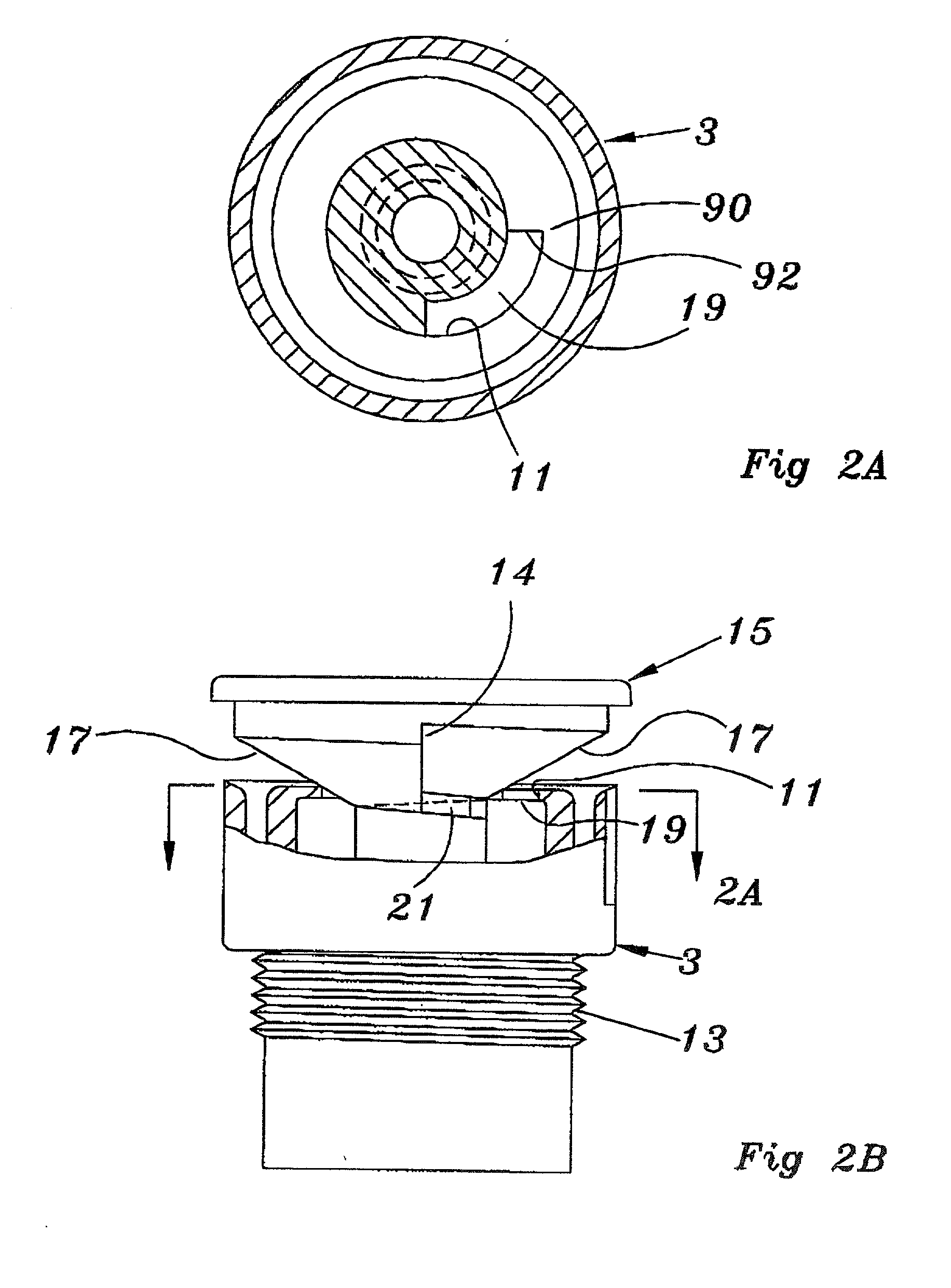

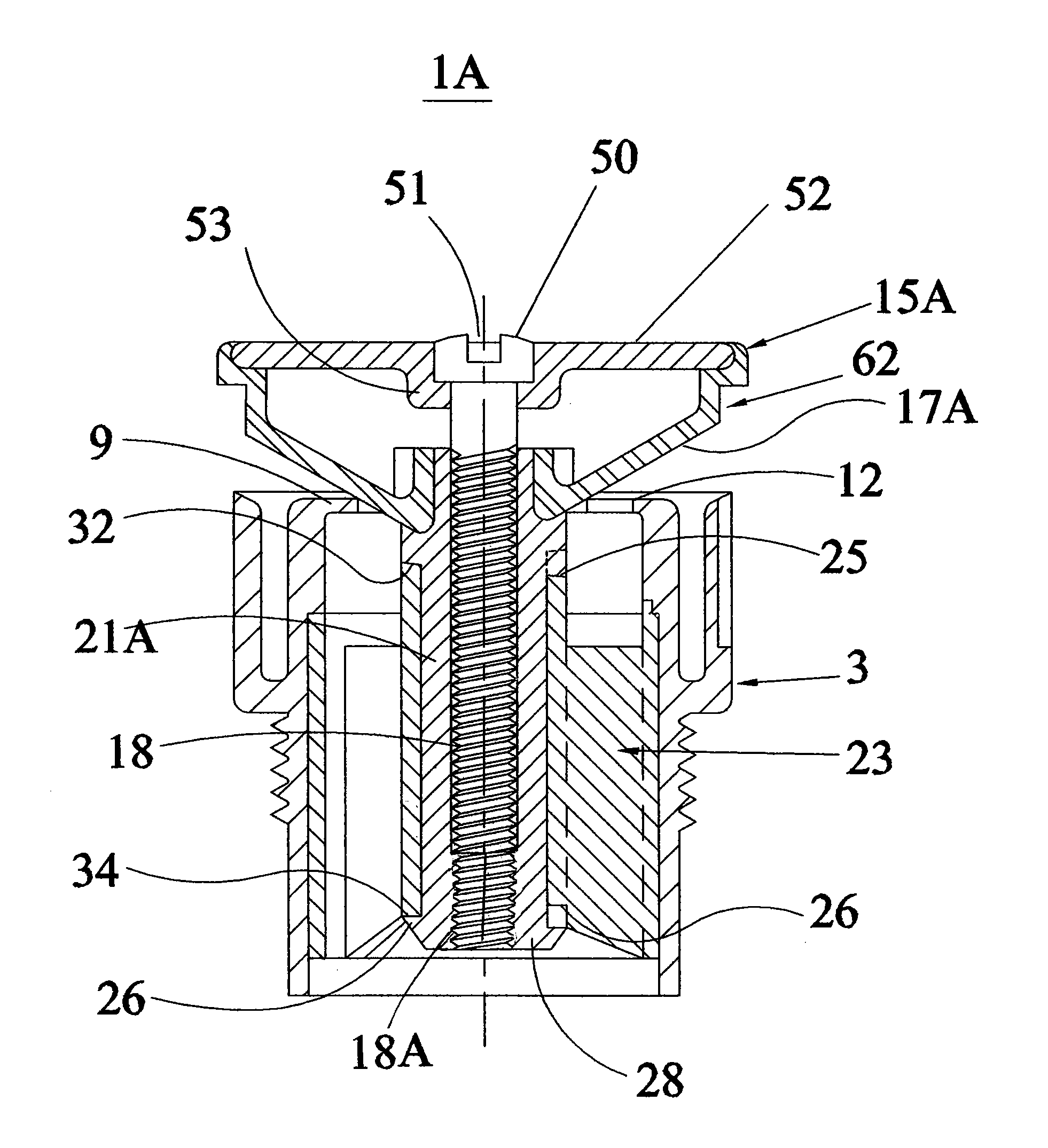

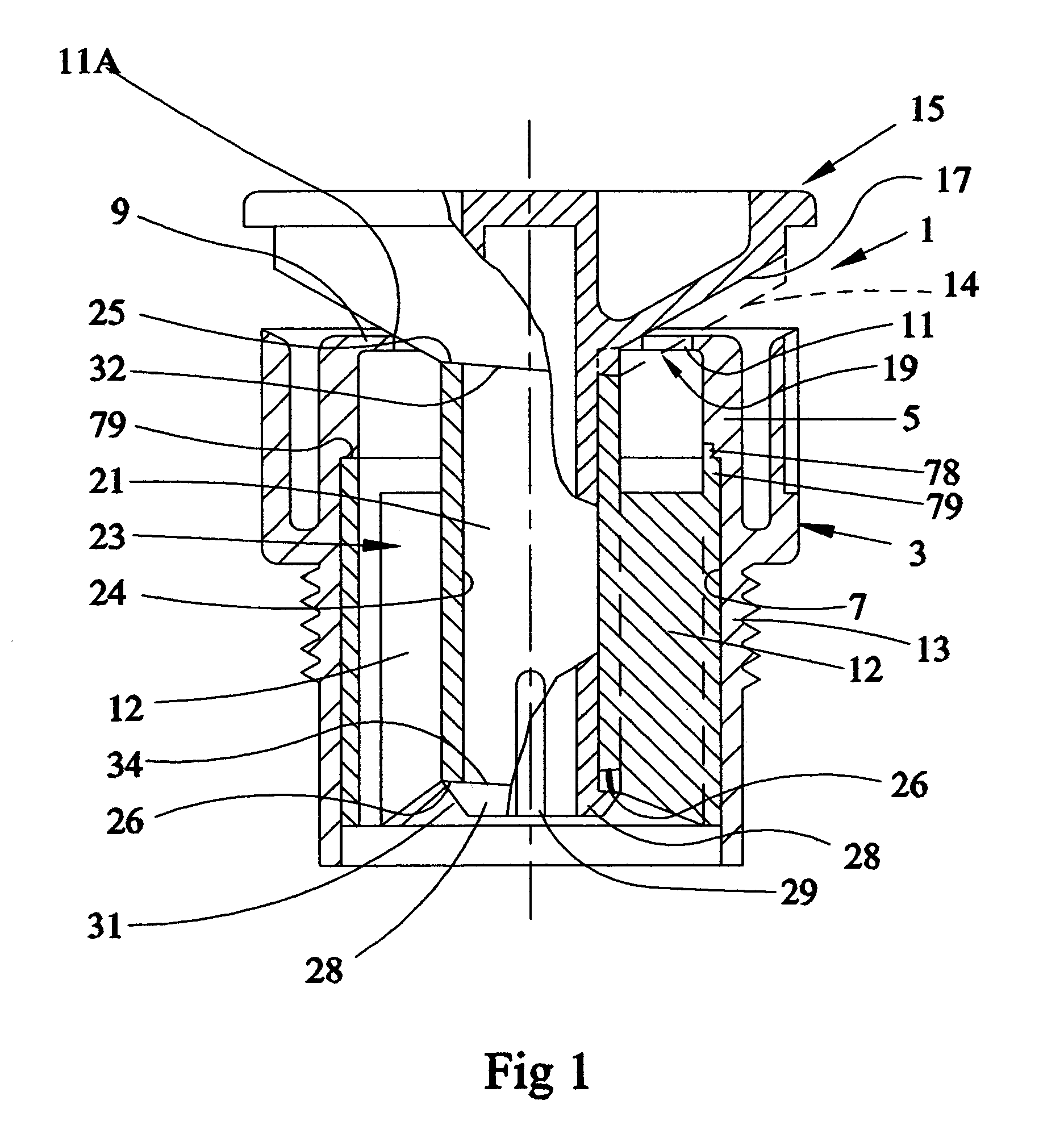

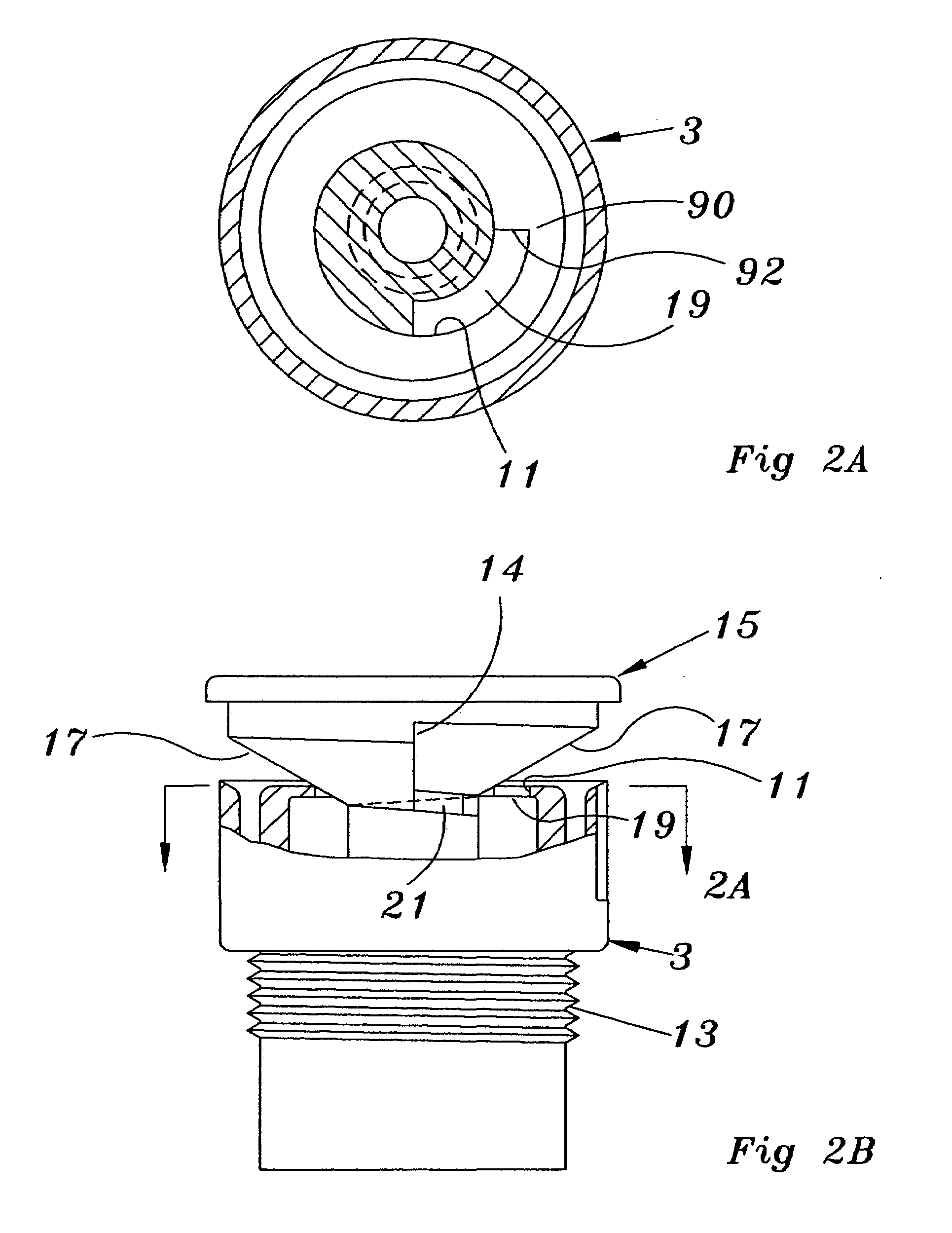

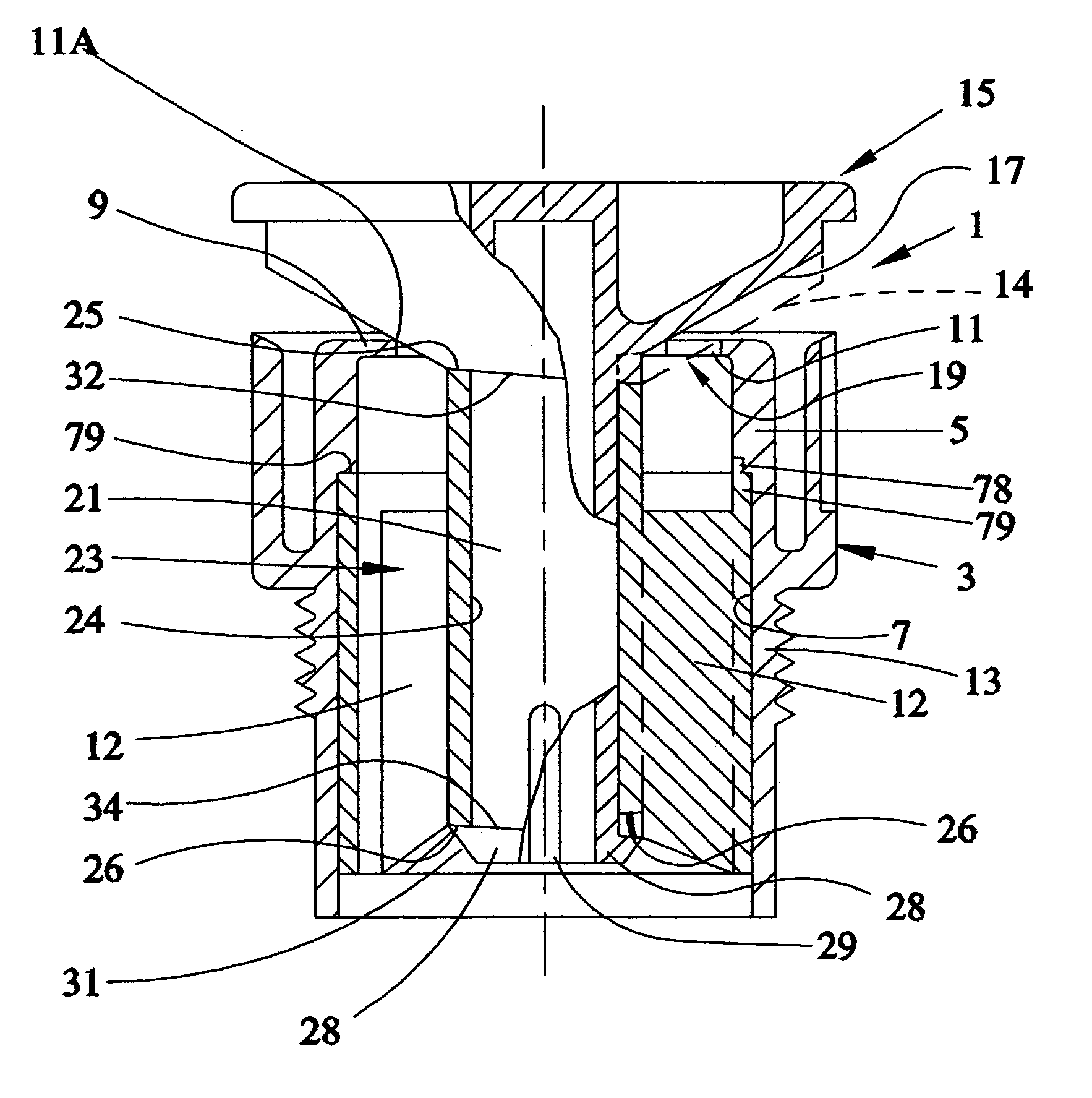

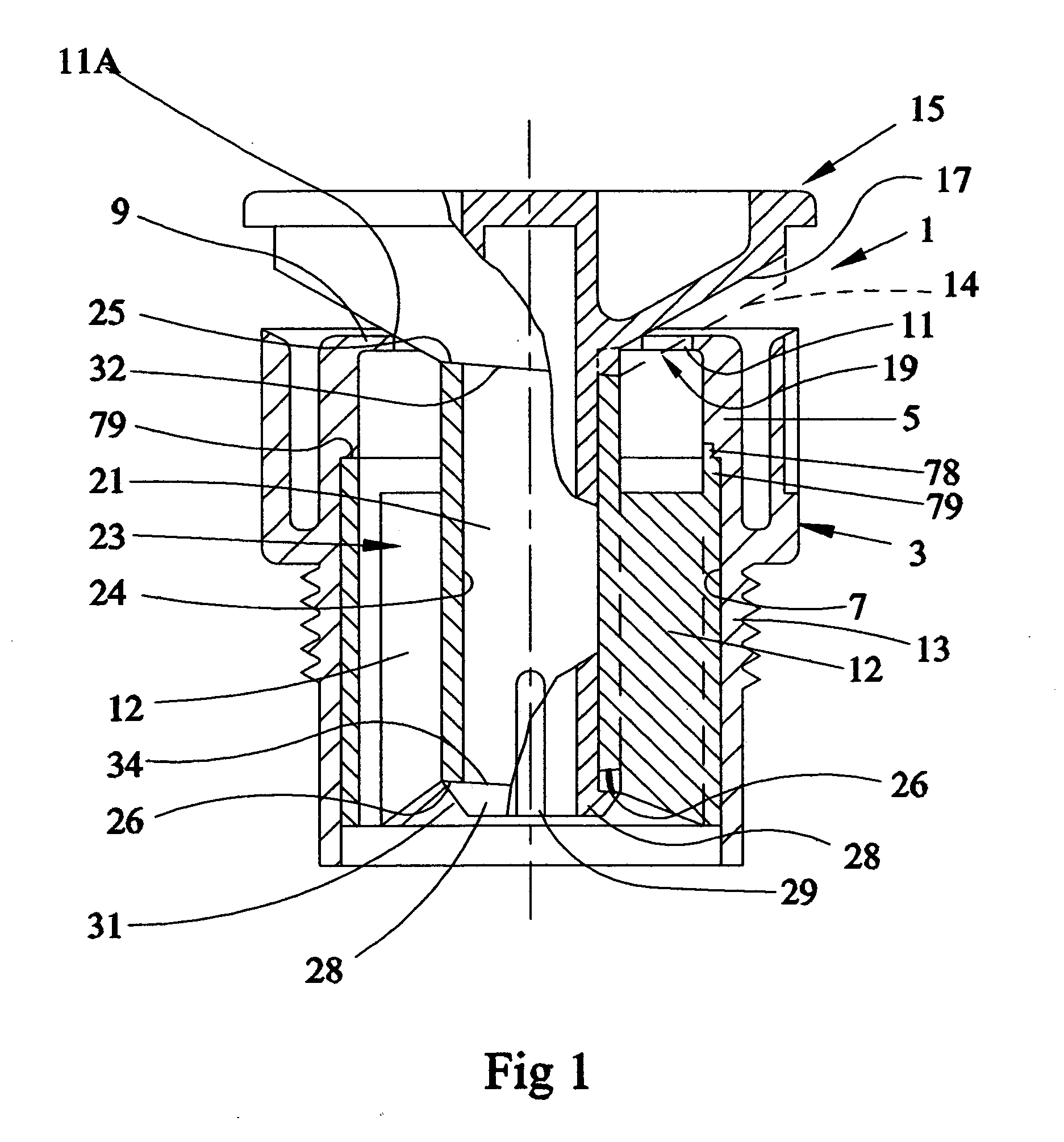

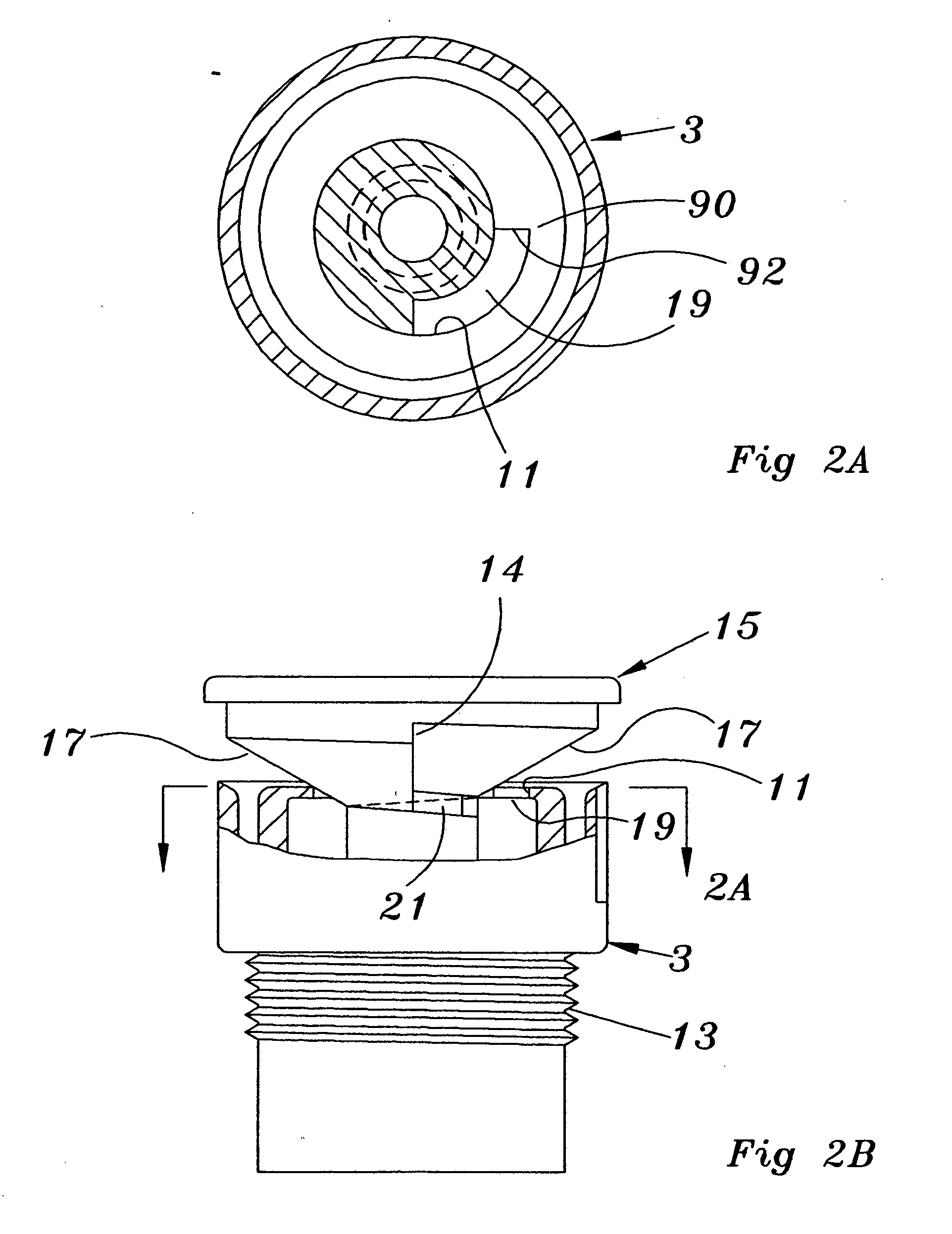

Spray nozzle with adjustable arc spray elevation angle and flow

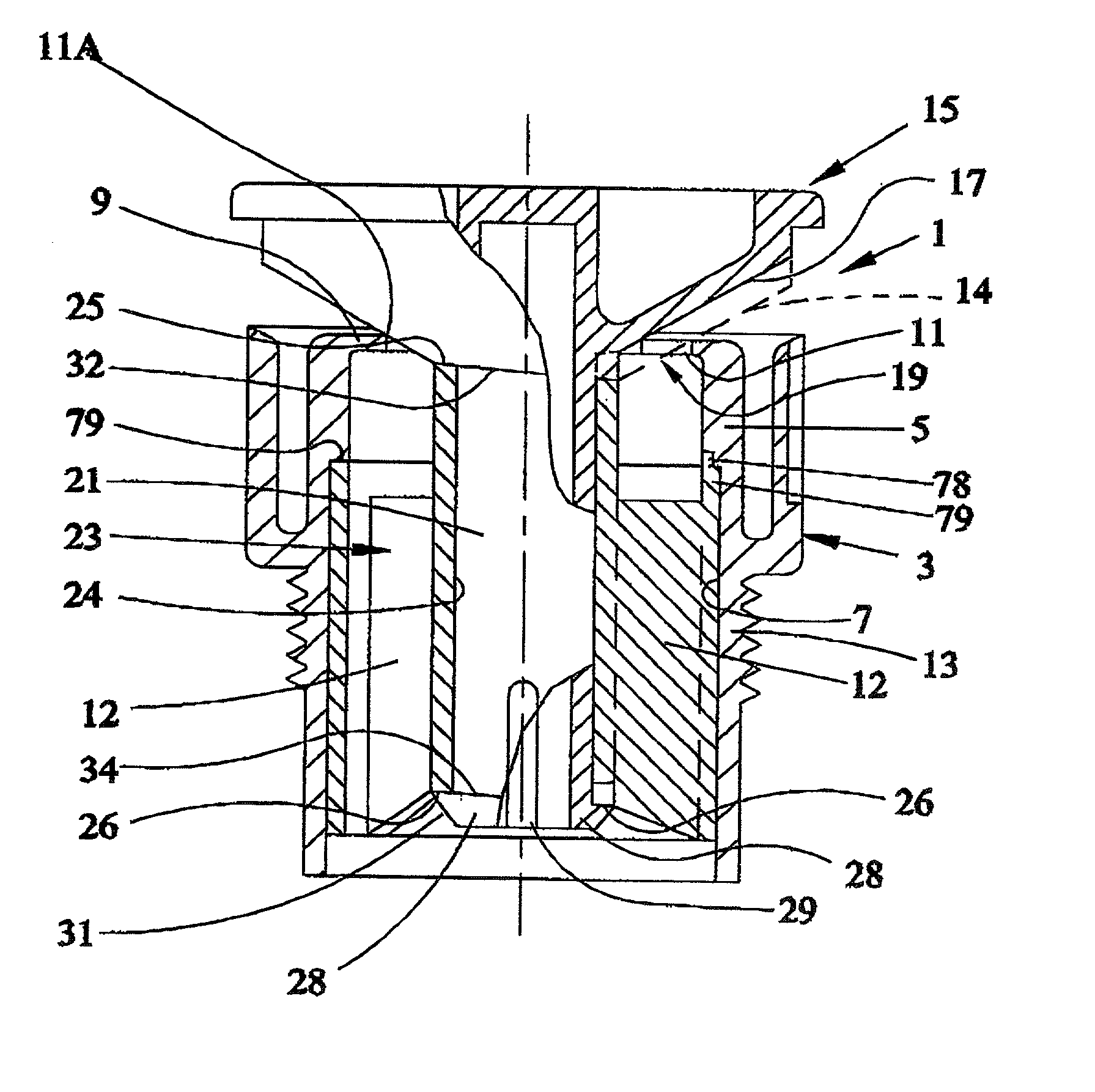

An adjustable spray nozzle with adjustable arc of coverage as well as spray elevation angle and flow rate. A very simple adjustable arc of coverage spray nozzle configuration is also disclosed which may be easily assembled for a particular precipitation rate and / or range of coverage at a selected nominal pressure. Also disclosed is a simple fixed arc of coverage spray nozzle with selectable ranges for a particular precipitation rate.

Owner:KAH CARL L JR +1

Spray nozzle with adjustable ARC spray elevation angle and flow

An adjustable spray nozzle with adjustable arc of coverage as well as spray elevation angle and flow rate. A very simple adjustable arc of coverage spray nozzle configuration is also disclosed which may be easily assembled for a particular precipitation rate and / or range of coverage at a selected nominal pressure. Also disclosed is a simple fixed arc of coverage spray nozzle with selectable ranges for a particular precipitation rate.

Owner:KAH JR CARL L +1

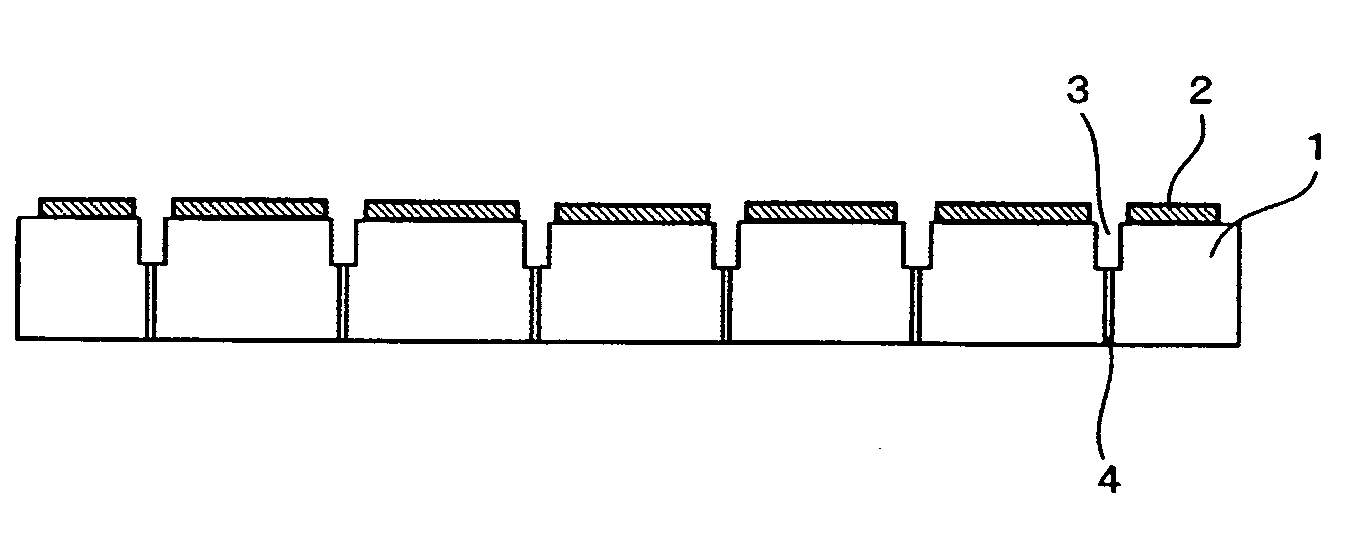

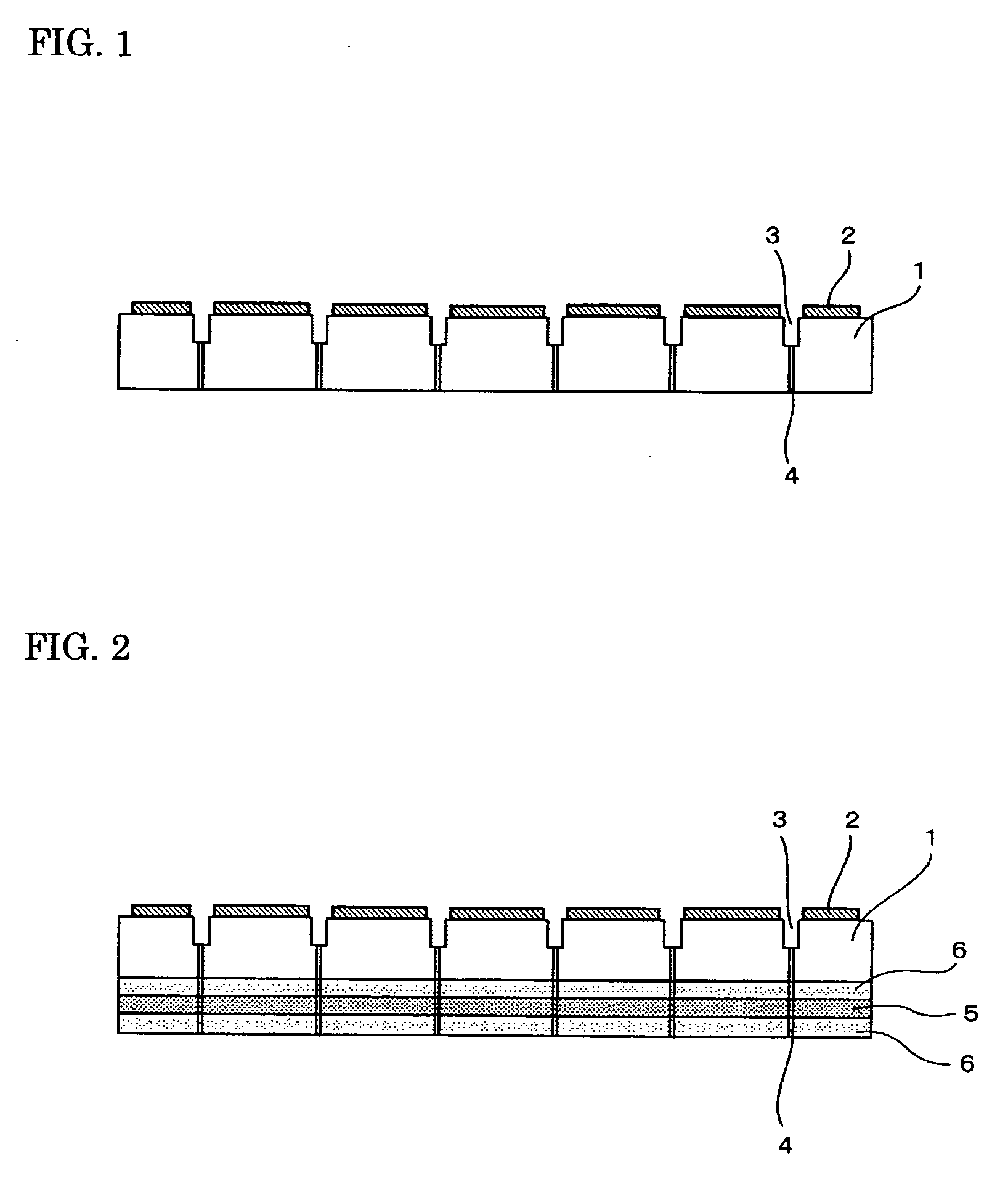

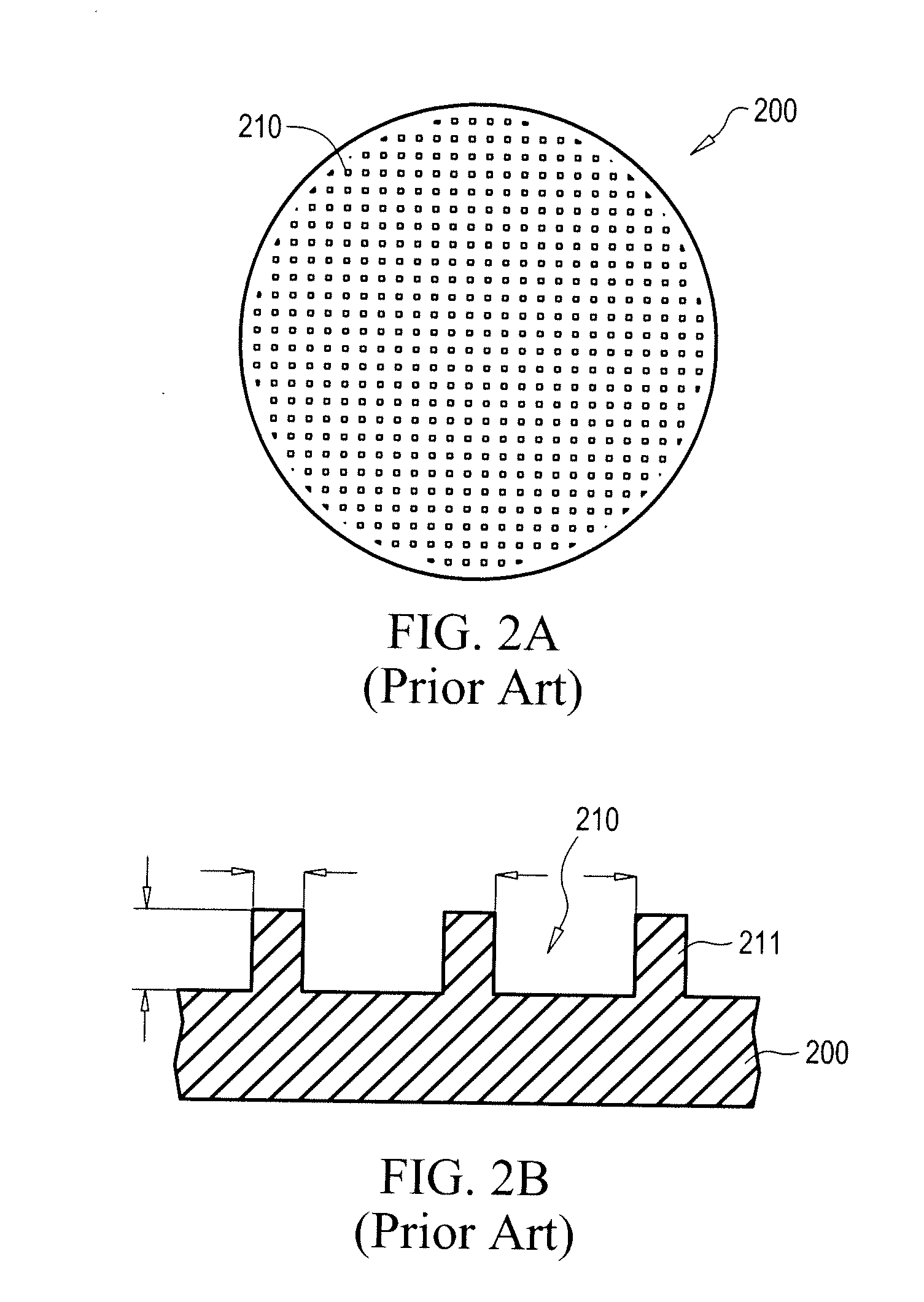

Sputtering target producing few particles, backing plate or sputtering apparatus and sputtering method producing few particles

InactiveUS6858116B2Avoid separationAvoid flyingCellsLiquid surface applicatorsOptoelectronicsPlasma sprayed

A sputtering target producing few particles, a backing plate or a sputtering apparatus, and a sputtering method producing few particles. An arc-spraying coating film and a plasma-spraying coating film over the former are formed on the sputtering target, a backing plate, or another surface in the sputtering apparatus, where an unwanted film might be formed. Thus a deposit is prevent from separating / flying from the target, backing plate, or another surface where an unwanted film might be formed in the sputtering apparatus.

Owner:JX NIPPON MINING& METALS CORP

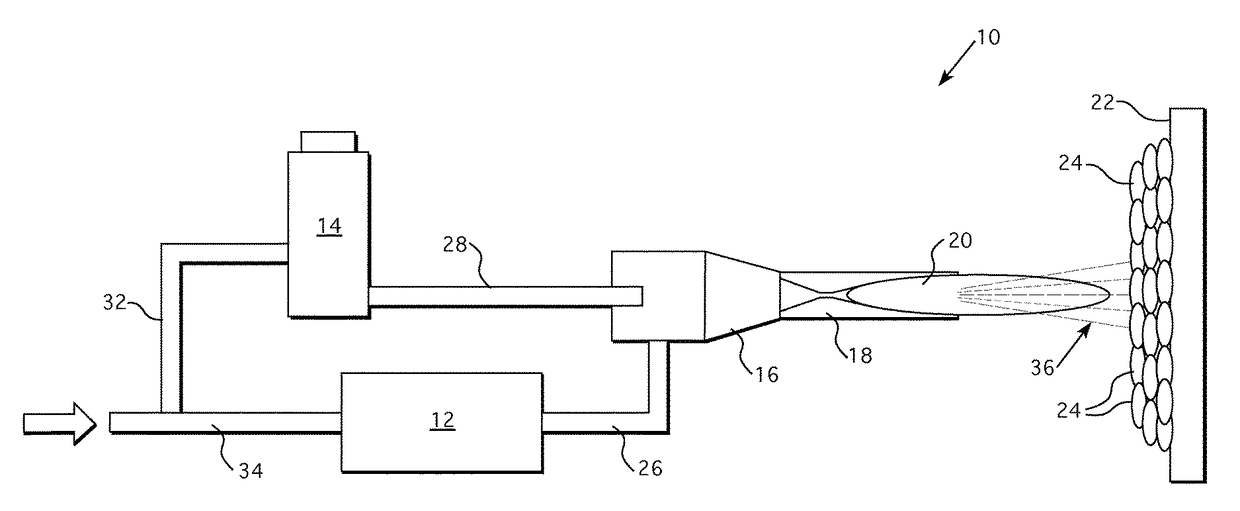

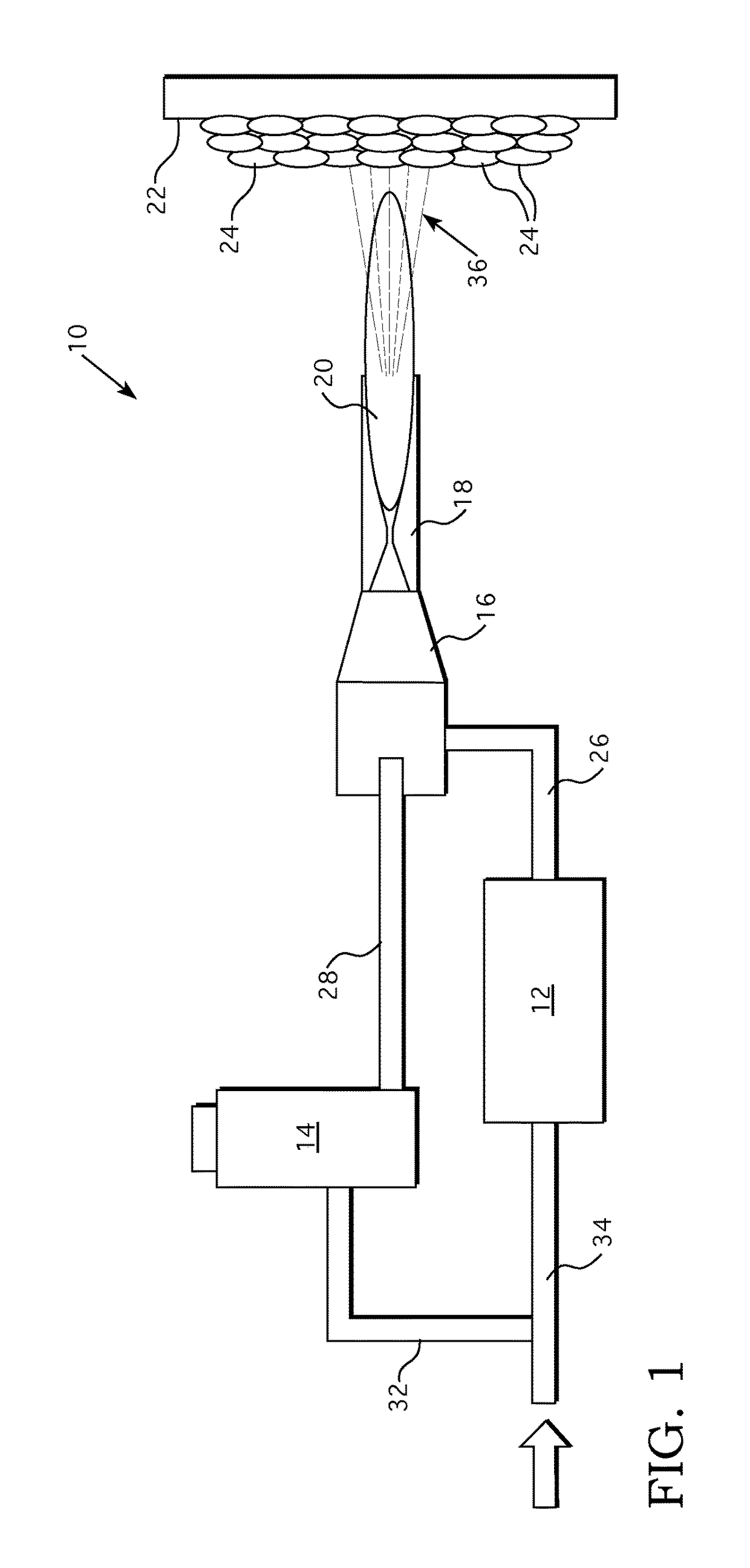

Spray methods for coating nuclear fuel rods to add corrosion resistant barrier

InactiveUS20180025794A1Increase entropyPrevent and to mitigate diffusionMolten spray coatingOptical rangefindersHigh entropy alloysZirconium alloy

A method is described herein for coating the substrate of a component for use in a water cooled nuclear reactor to provide a barrier against corrosion. The method includes providing a zirconium alloy substrate; and coating the substrate with particles selected from the group consisting of metal oxides, metal nitrides, FeCrAl, FeCrAlY, and high entropy alloys. Depending on the metal alloy chosen for the coating material, a cold spray or a plasma arc spray process may be employed for depositing various particles onto the substrate. An interlayer of a different material, such as a Mo, Nb, Ta, or W transition metal or a high entropy alloy, may be positioned in between the Zr-alloy substrate and corrosion barrier layer.

Owner:WESTINGHOUSE ELECTRIC CORP +1

Catalyst members having electric arc sprayed substrates and methods of making the same

Electric arc spraying a metal onto a substrate produces an anchor layer on the substrate that serves as a surprisingly superior intermediate layer for a catalytic material deposited thereon. Spalling of catalytic material is resisted even when subjected to the harsh conditions imposed by small engines or in a close-coupled position for a larger engine.

Owner:ENGELHARD CORP

Method and process of steel structure arc spraying composite corrosion proof coating system

ActiveCN101451243AUndamagedDecorativeLiquid surface applicatorsMolten spray coatingCoating systemArc spray

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Spray nozzle with adjustable ARC spray elevation angle and flow

Owner:KAH JR CARL L +1

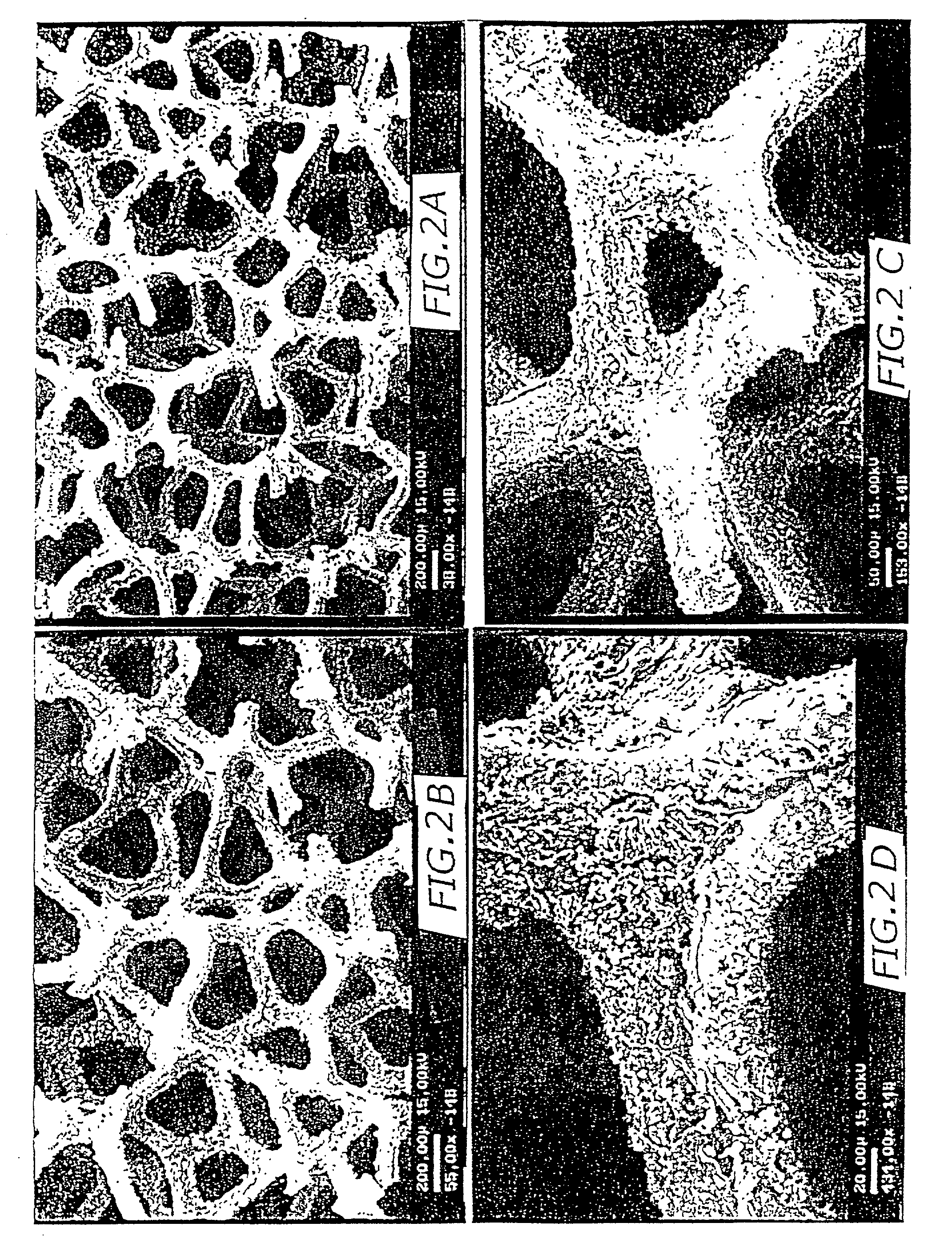

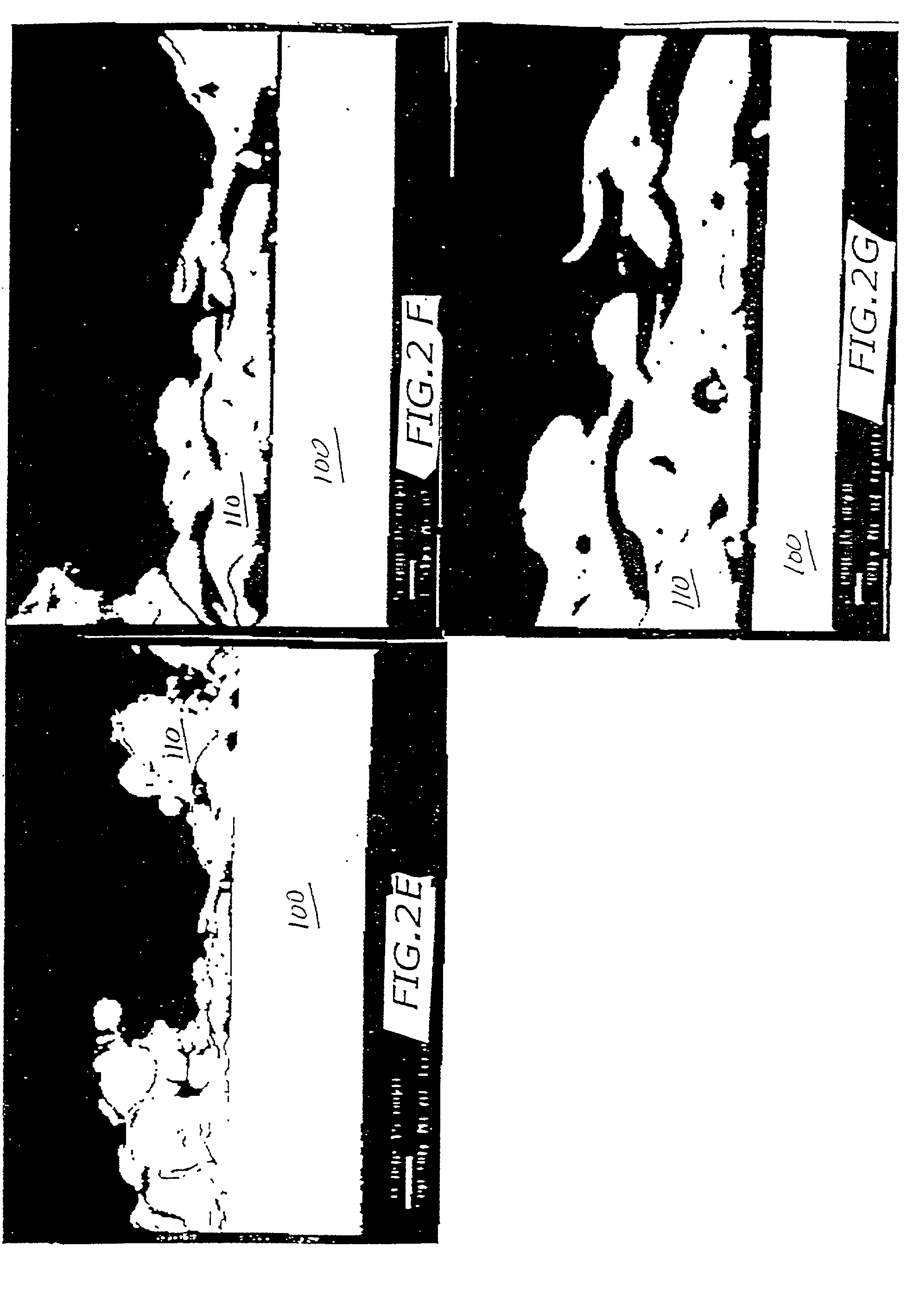

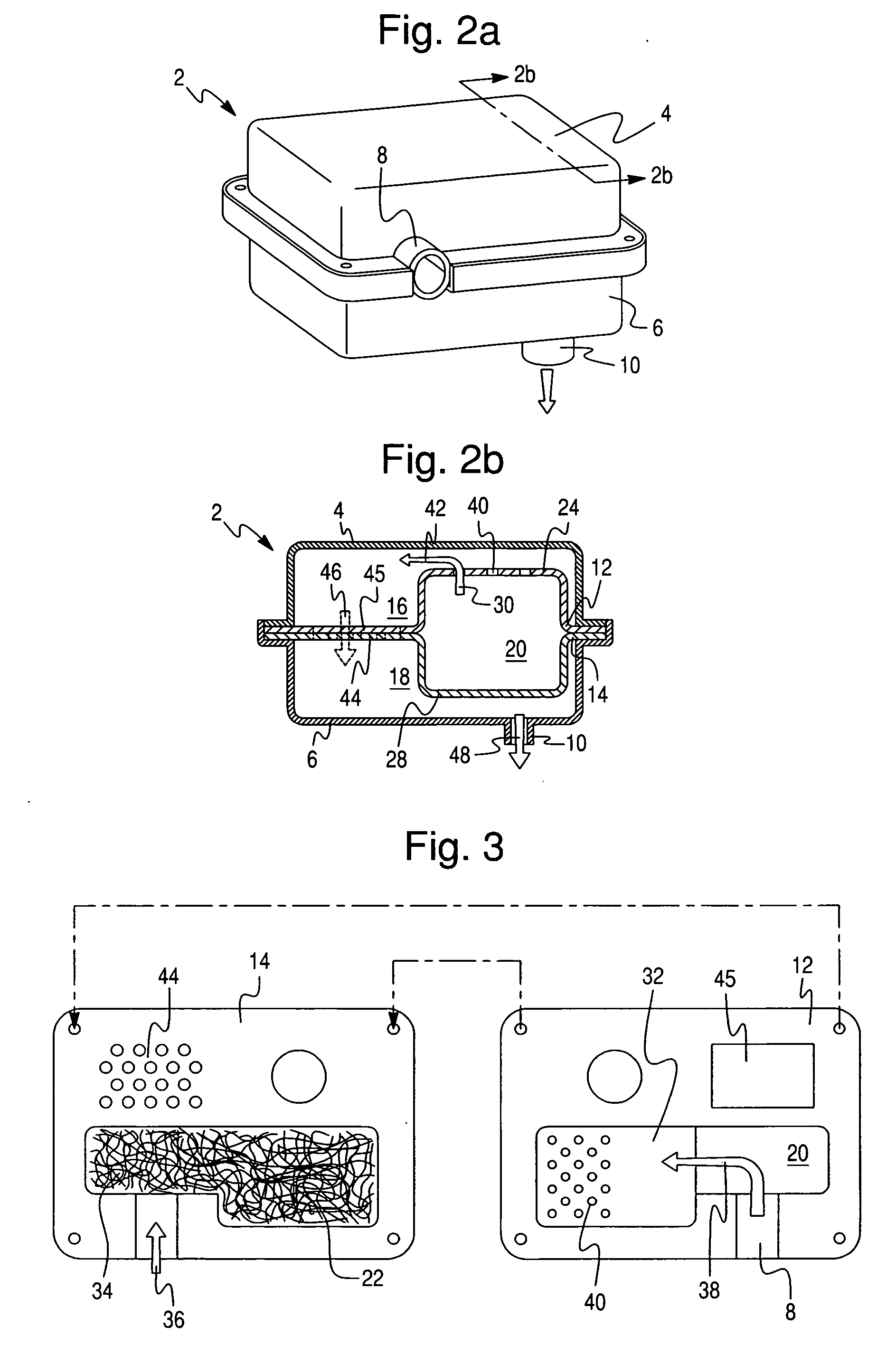

Inlet metallic foam support coupled to precious metal catalyst for application on 4 stroke platforms

InactiveUS20070144828A1Reduce noiseImprove adhesionNitrogen compoundsCombustion enginesNitrogen oxideMetal foam

The present invention is directed to an improved dual phase muffler for the abatement of reduction of sound and emission pollutants such as hydrocarbons, carbon monoxide, and nitrogen oxides. More specifically, the muffler comprises a muffler casing, an inner chamber formed in the muffler, and a catalytically coated supported material contained within the inner chamber. The present invention is also directed to a catalytically coated metallic foam catalyst support, which optionally can be pre-coat with a metallic thermal arc sprayed layer.

Owner:BASF CATALYSTS LLC

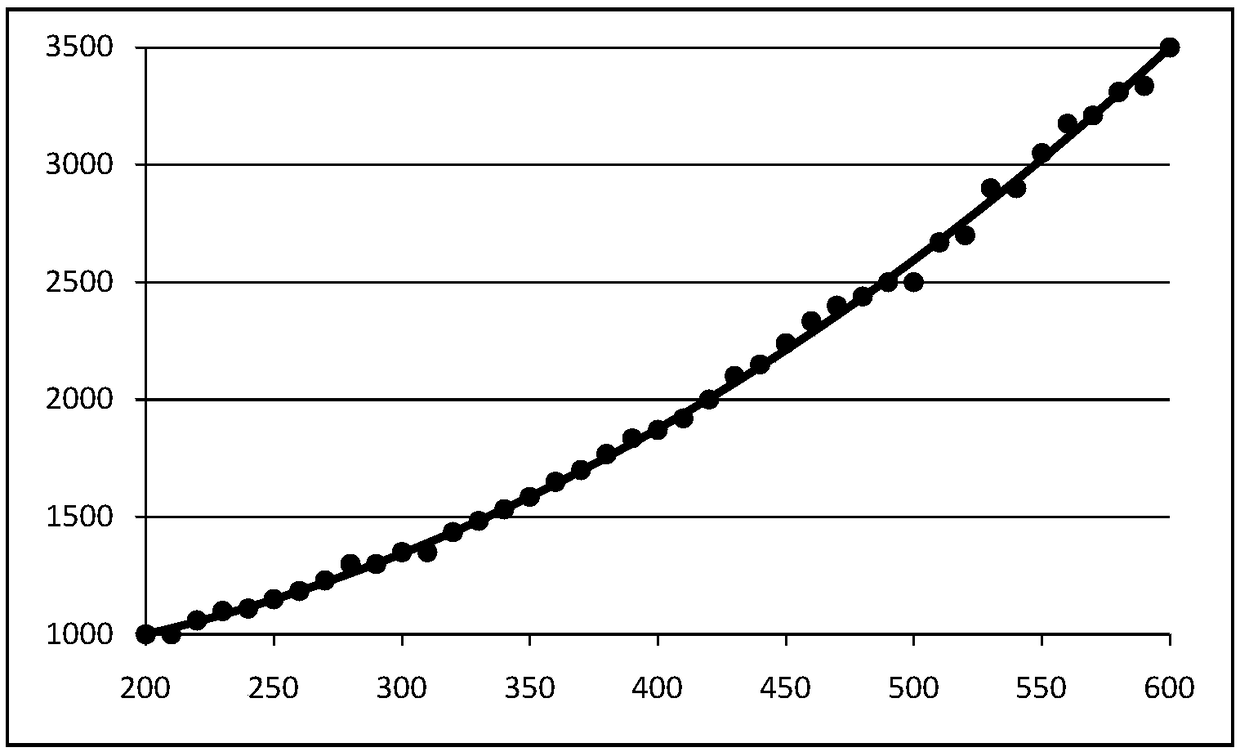

Nano micrometer modefied wear resistant erosion resistant thermal coated tubular wire

The present invention relates to surface processing material technology, and especially a kind of nanometer modified wear resistant and erosion resistant arc sprayed wire material. The wire material has coating of Fe or Ni, and powdered core comprising high carbon ferrochrome 45-60 wt%, Ni 10-20 wt%, ferrosilicon 4-10 wt%, ferroboron 5-10 wt%, Cr3C2, TiB2 or TiC 10-15 wt%, micron level TiB2 5-15 wt%, nanometer level Al2O3 5-15 wt%, and optional wollastonite 1-3 wt%, ZrO2 2-5 wt% and TiO2 5-15 wt%. The material is used mainly for coating the surface of blower blade, pipe wall in power station boiler, etc. and the coated layer can increase the surface life of the said parts.

Owner:BEIJING UNIV OF TECH

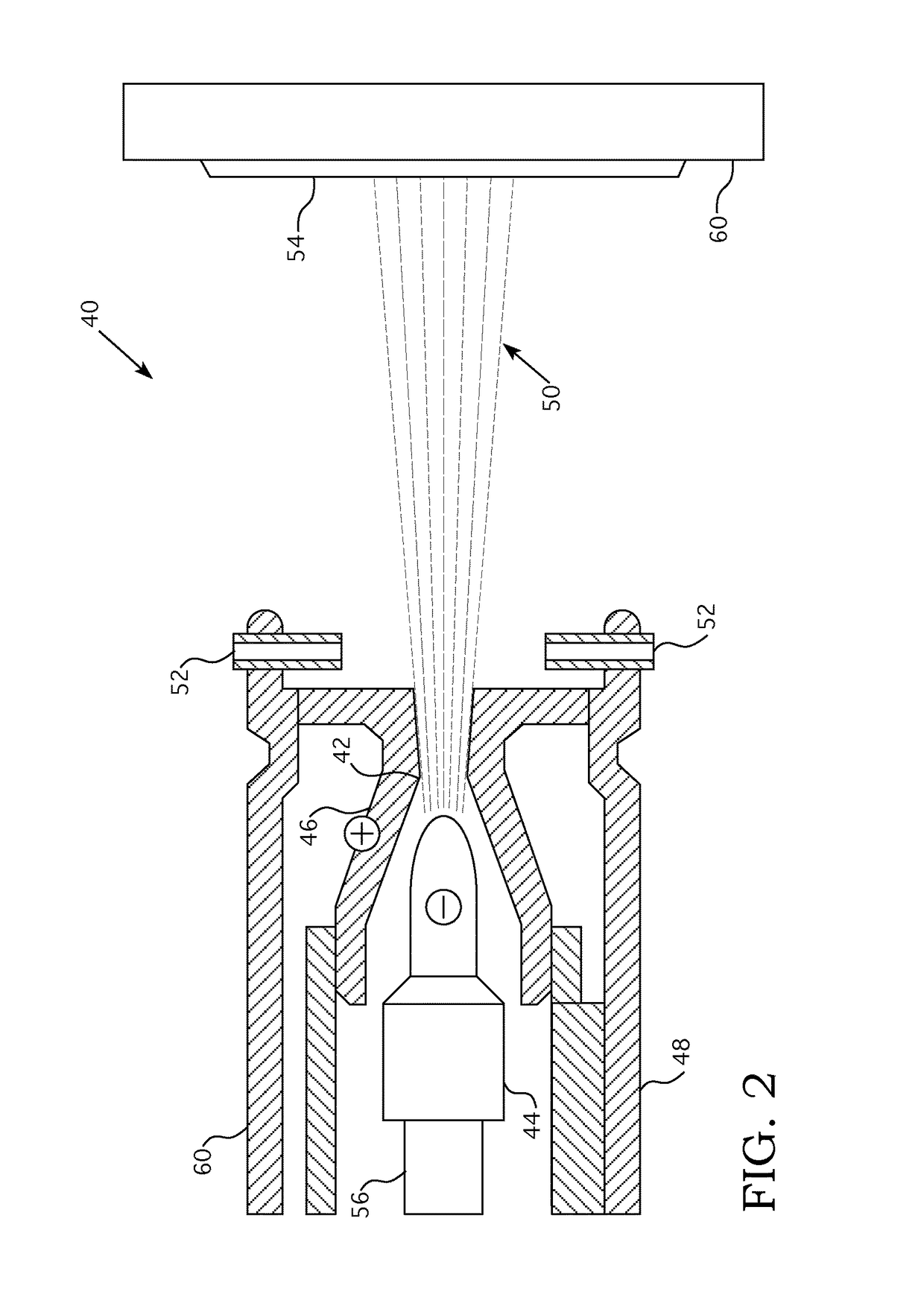

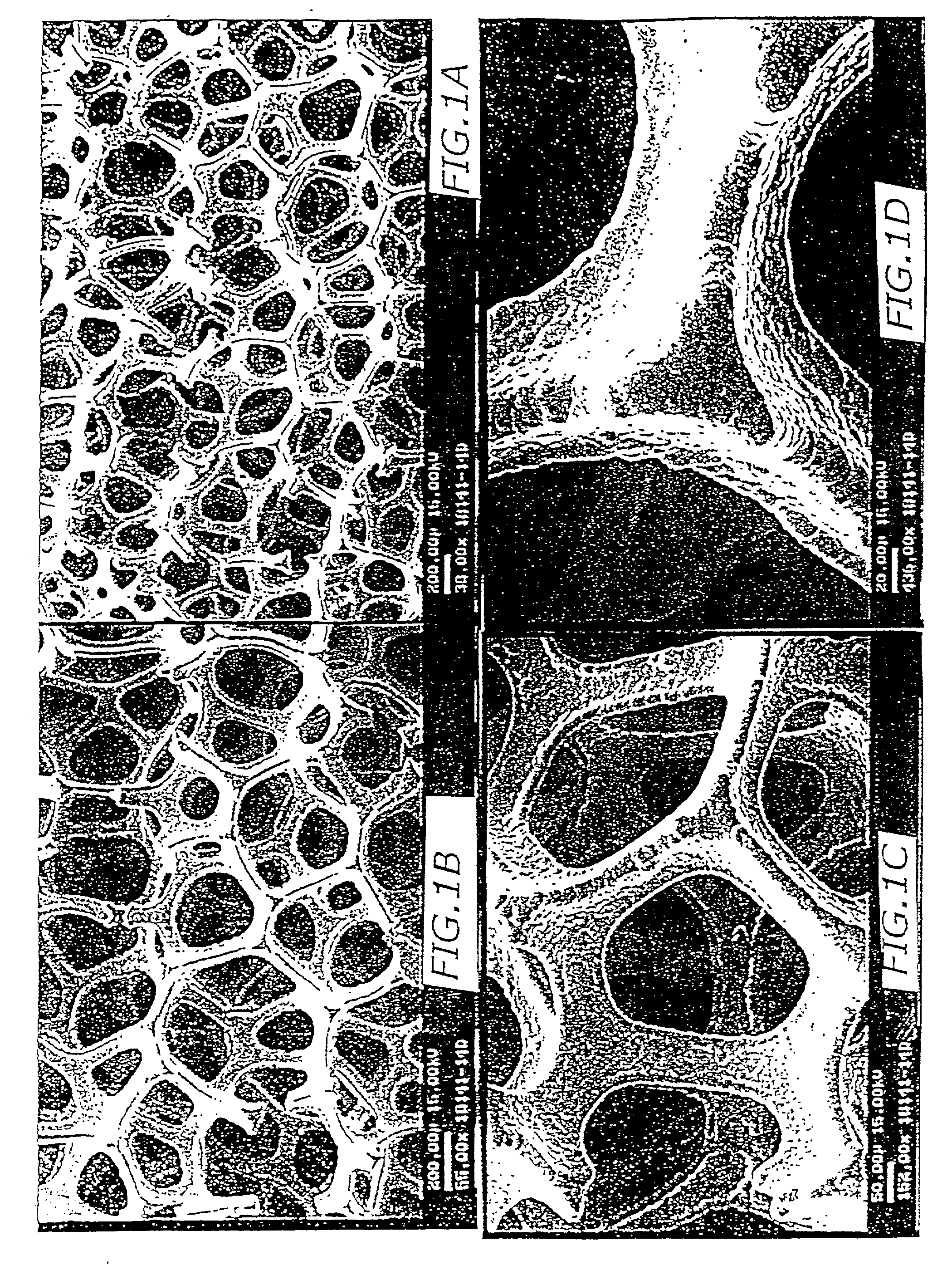

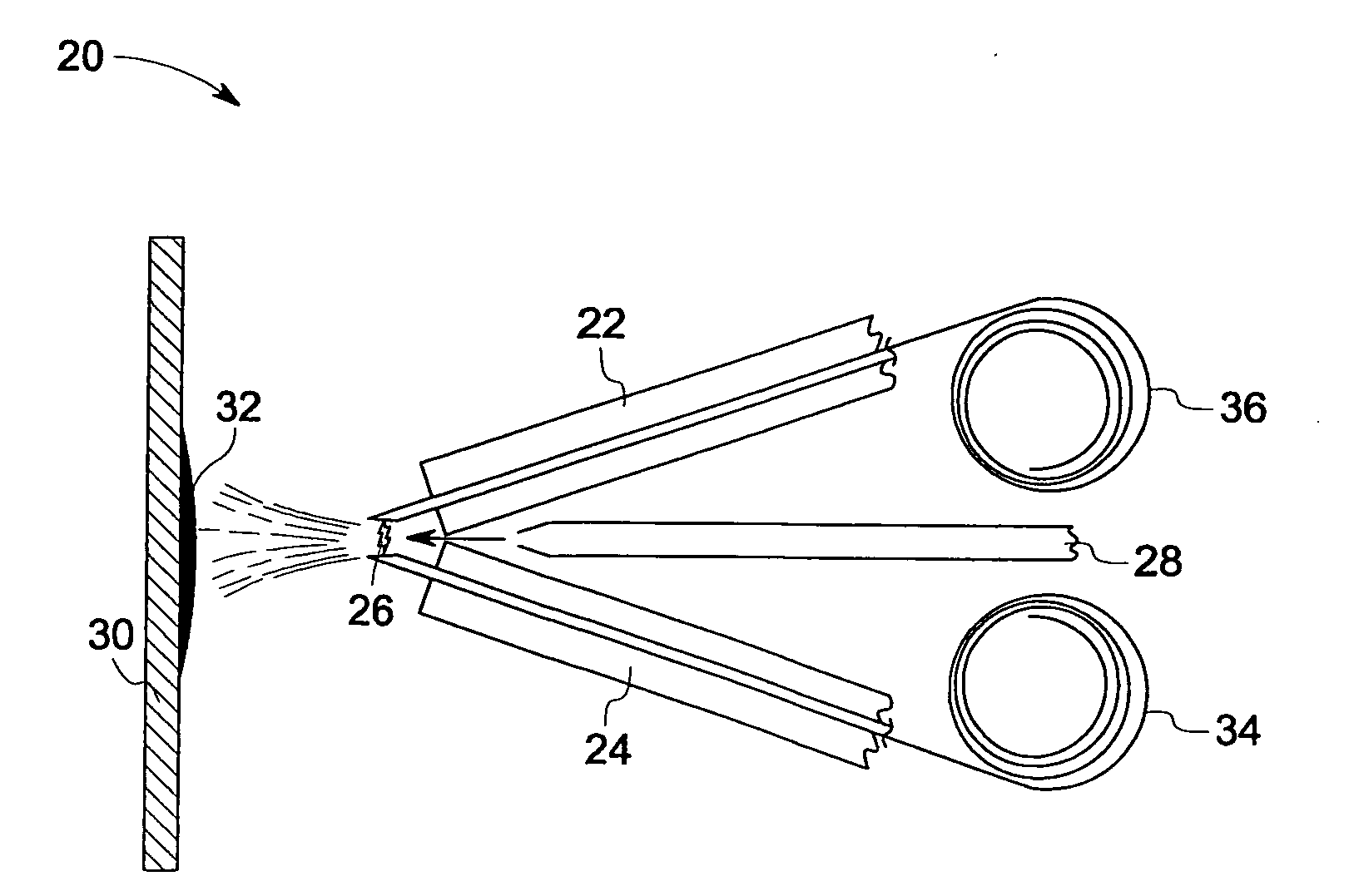

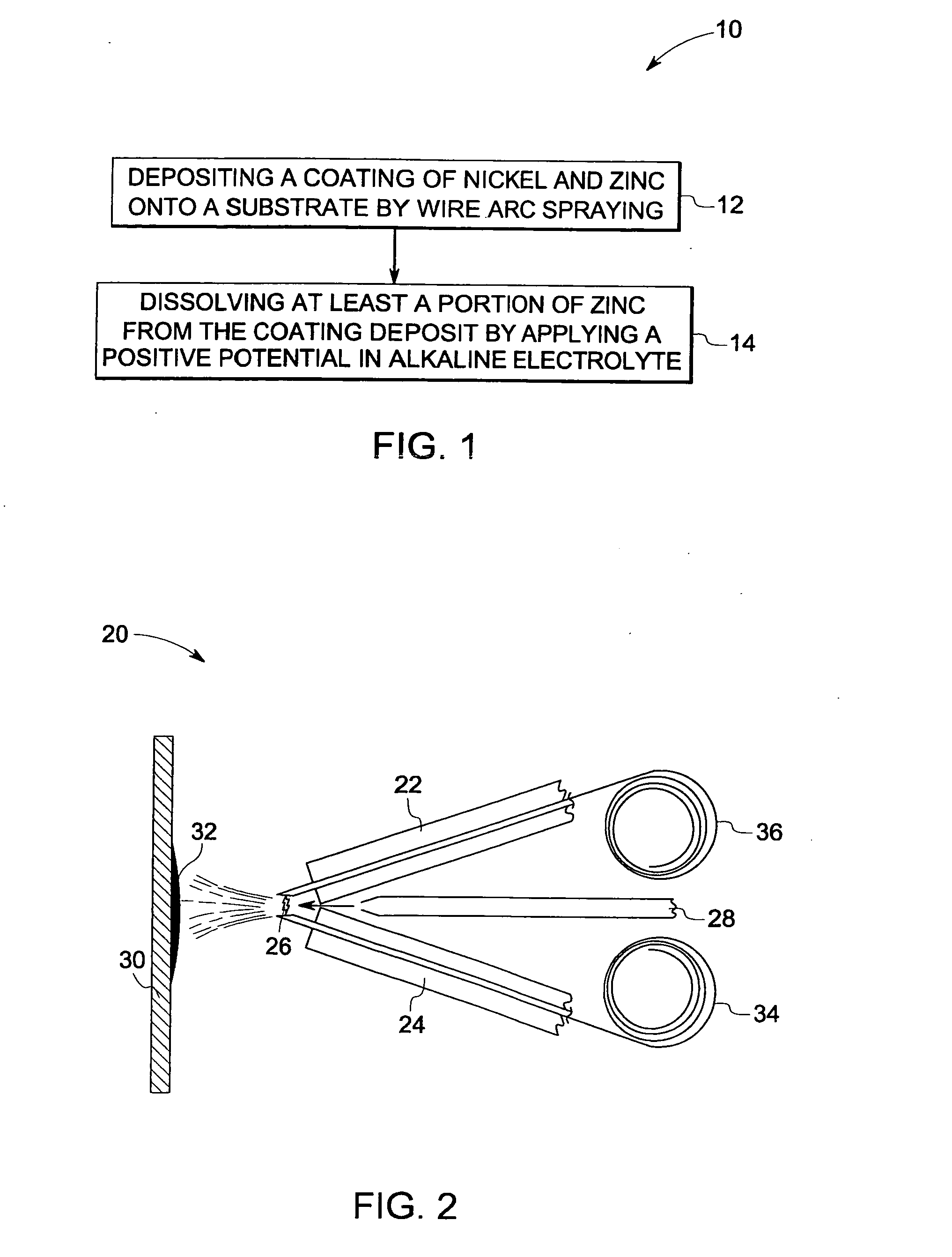

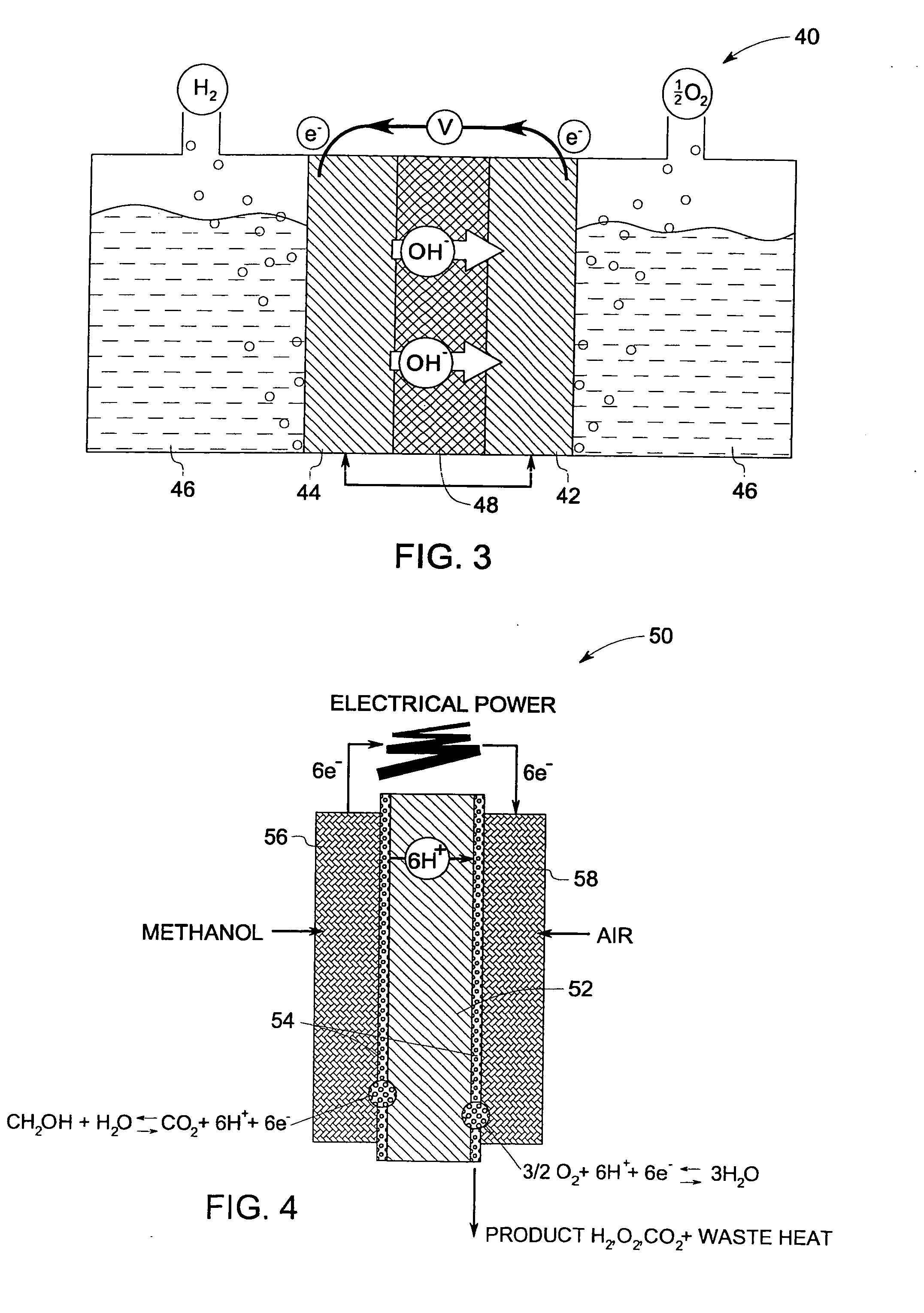

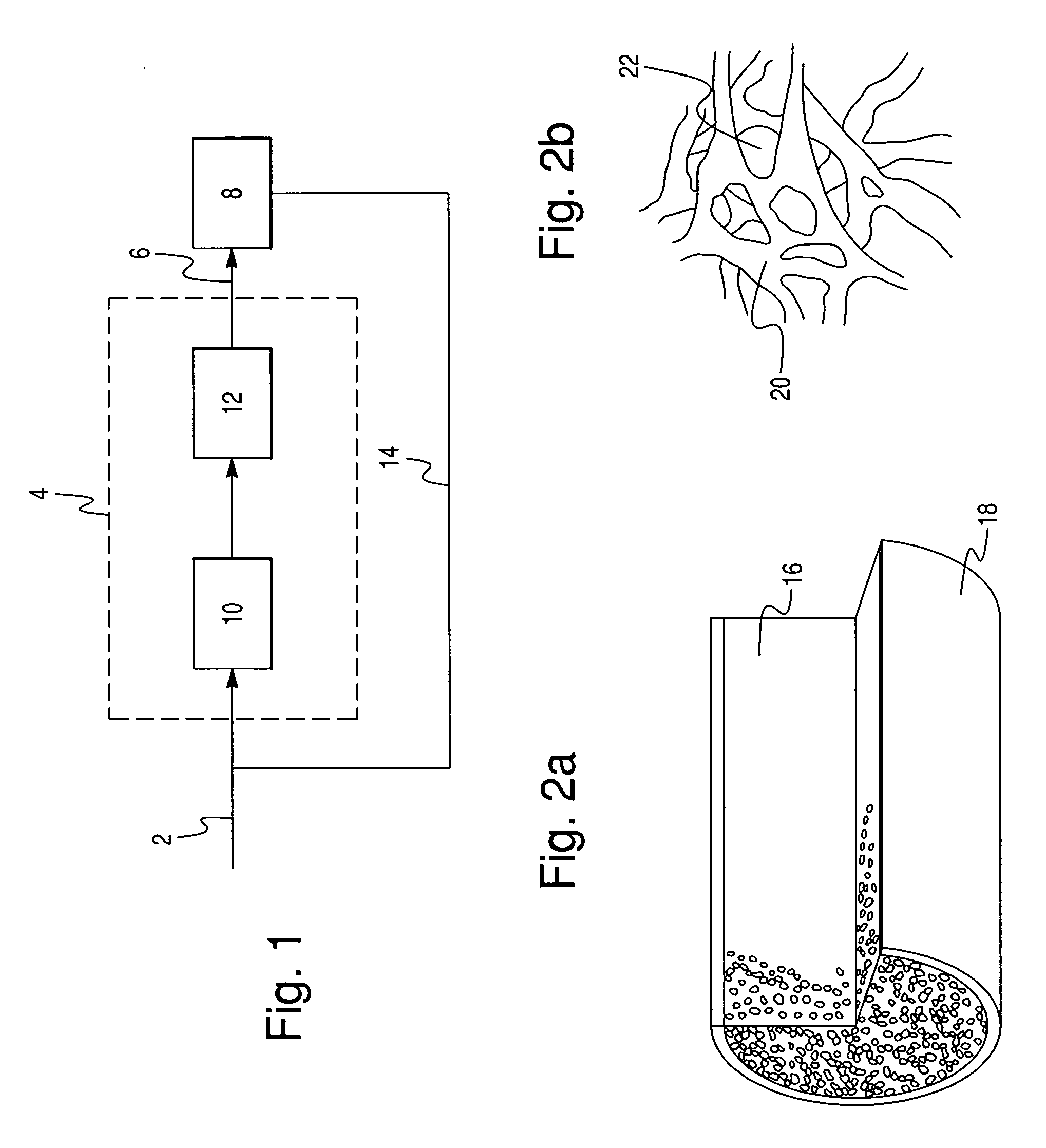

Method of forming a porous nickel coating, and related articles and compositions

InactiveUS20070278108A1Improve performanceEfficient productionPolycrystalline material growthFrom normal temperature solutionsSacrificial metalArc spray

A method of forming a porous nickel coating is provided. The method includes the steps of: depositing a coating onto a substrate by melting and atomizing two consumable electrode wires of a selected composition in a wire-arc spray device, so as to form a molten, atomized material, and directing the material to the substrate to form a coating deposit; the selected composition including nickel and a sacrificial metal; and then dissolving at least a portion of the sacrificial metal from the coating deposit by applying a positive potential in an alkaline electrolyte, so as to obtain a porous nickel coating. An electrolytic cell that includes a porous nickel coating is also described.

Owner:GENERAL ELECTRIC CO

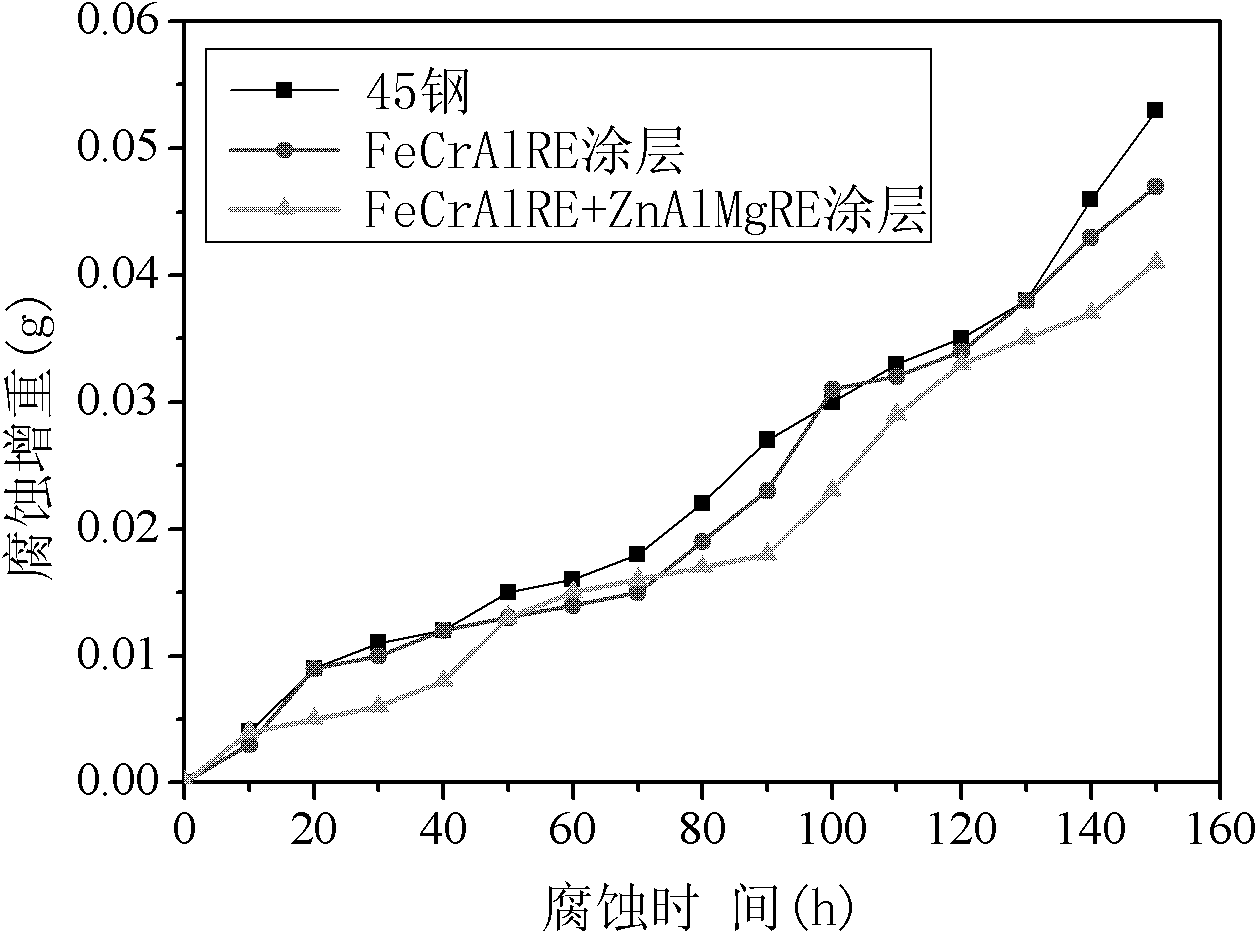

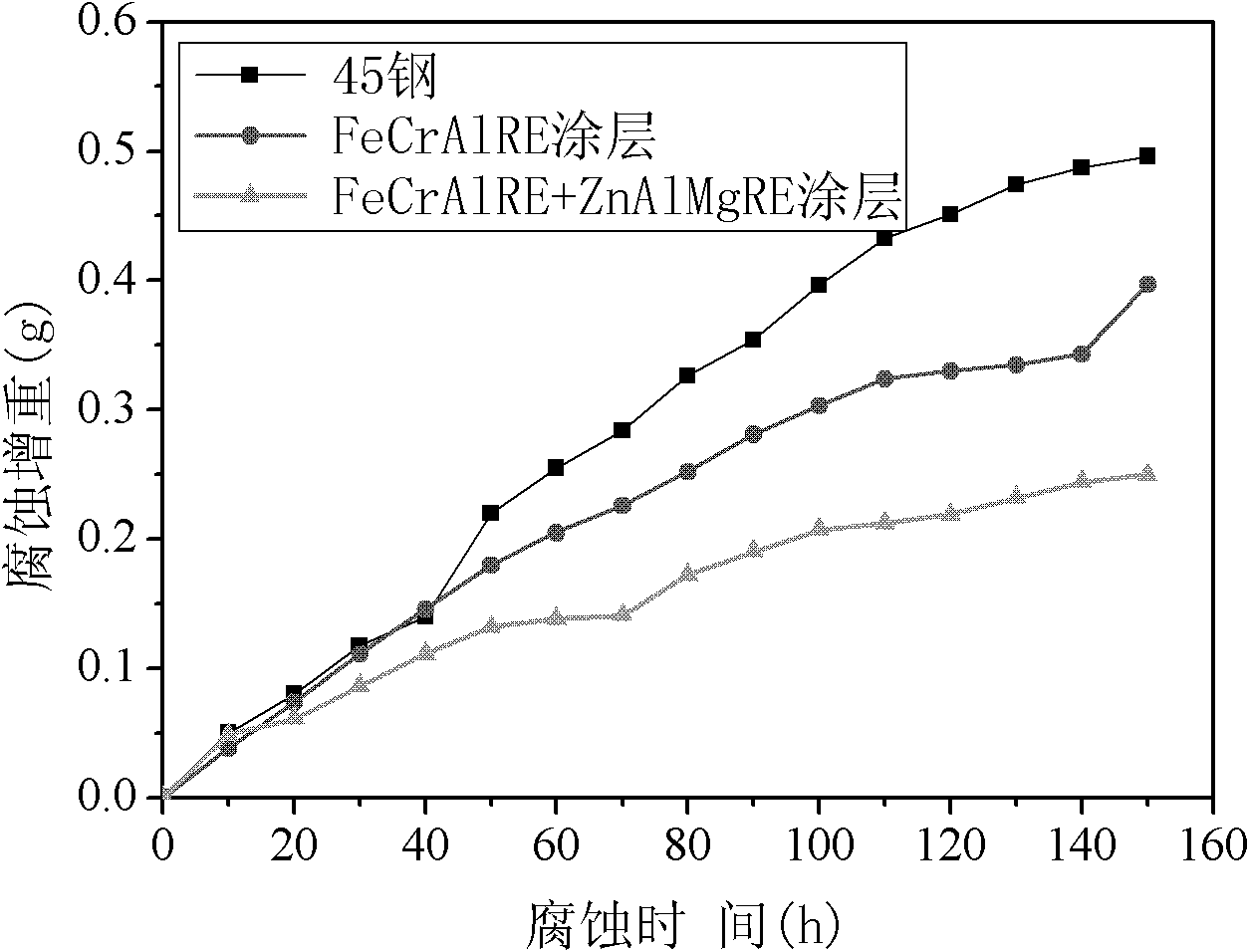

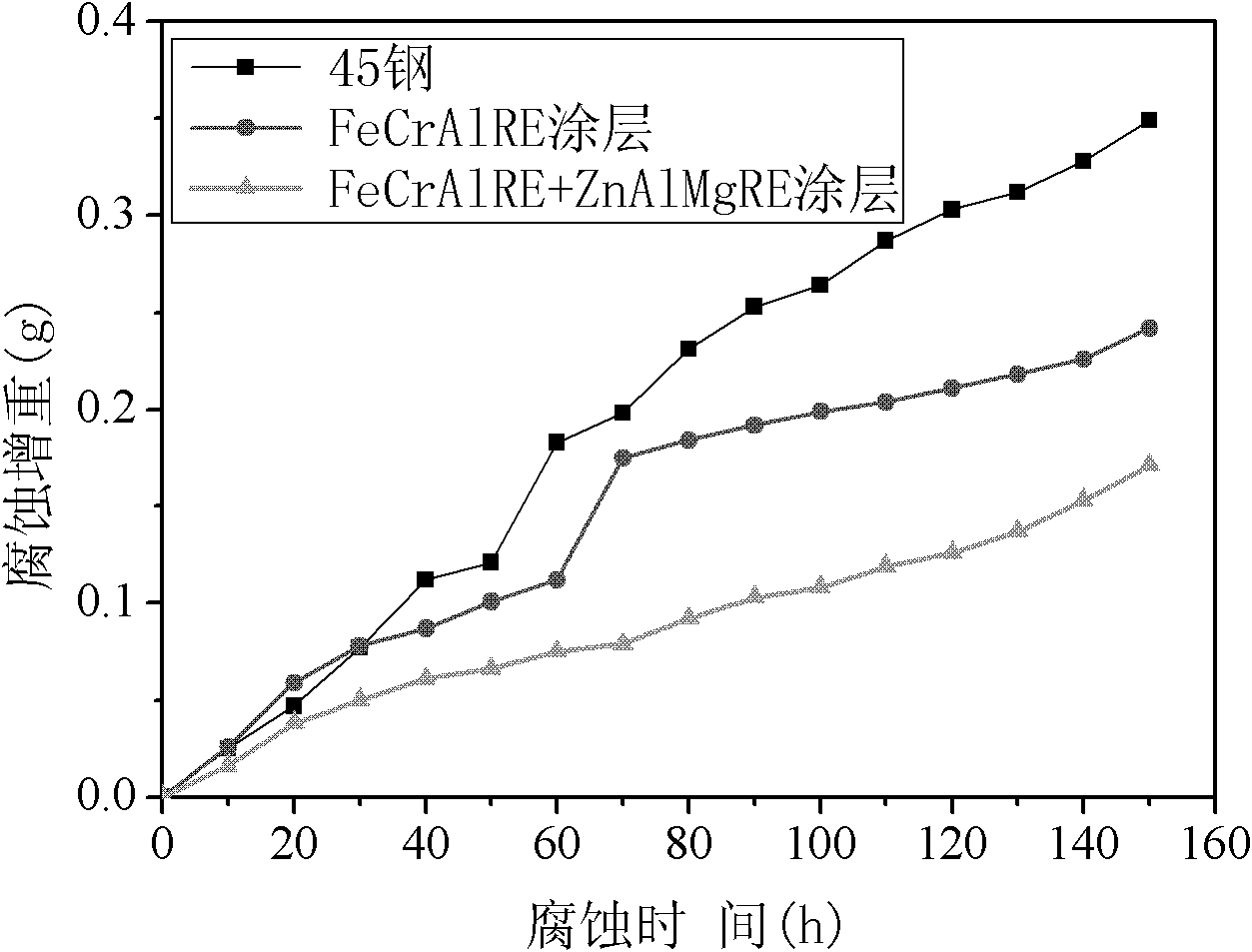

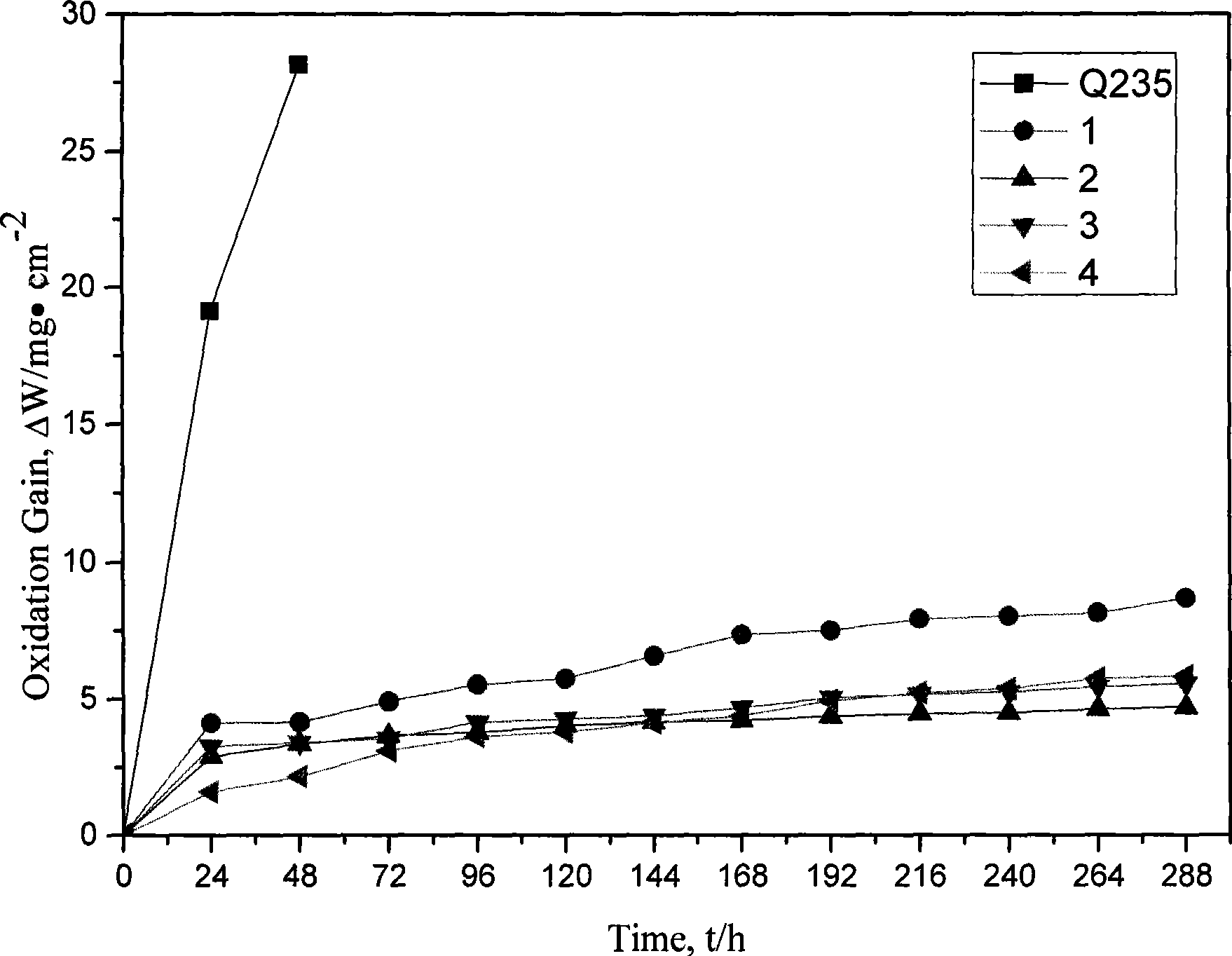

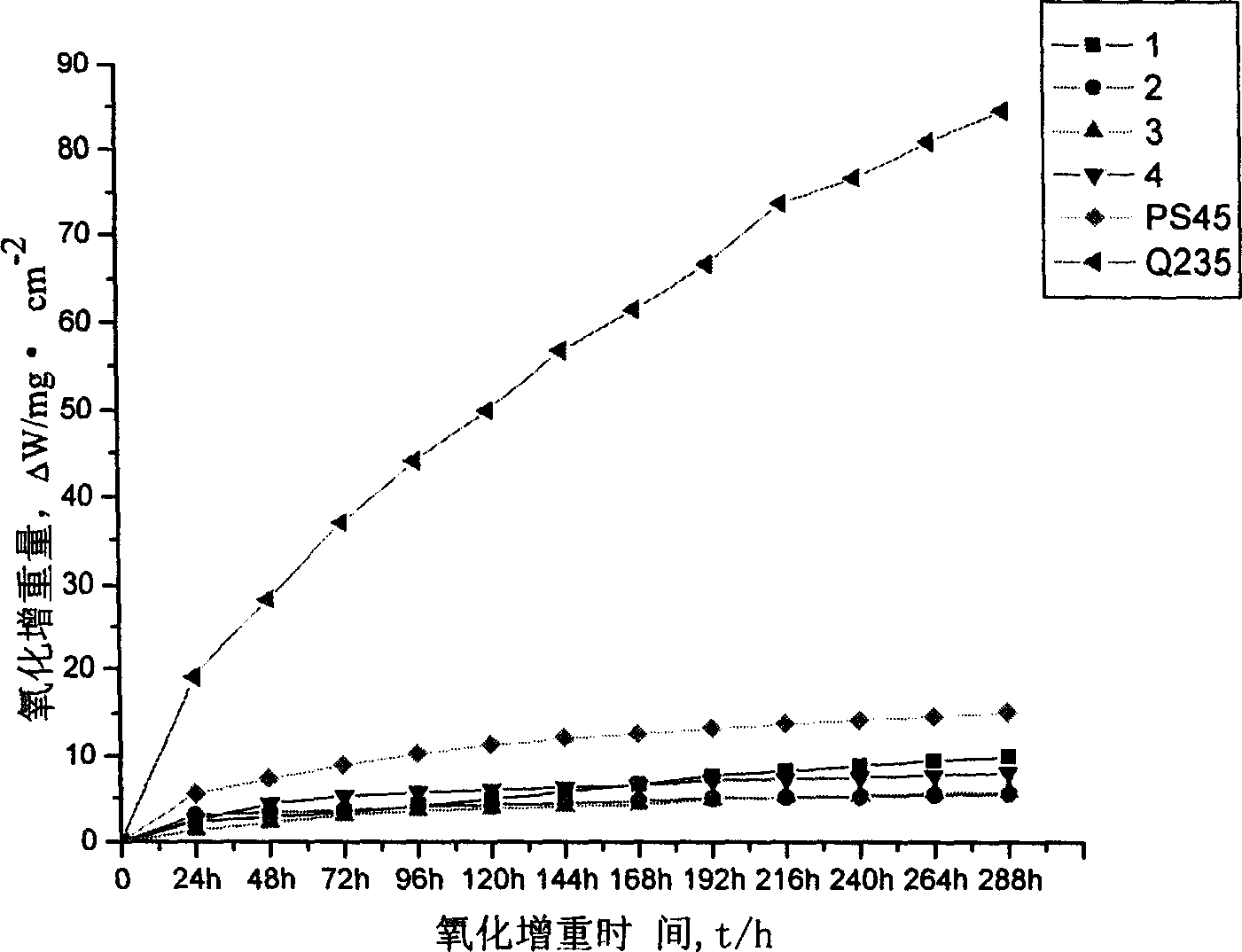

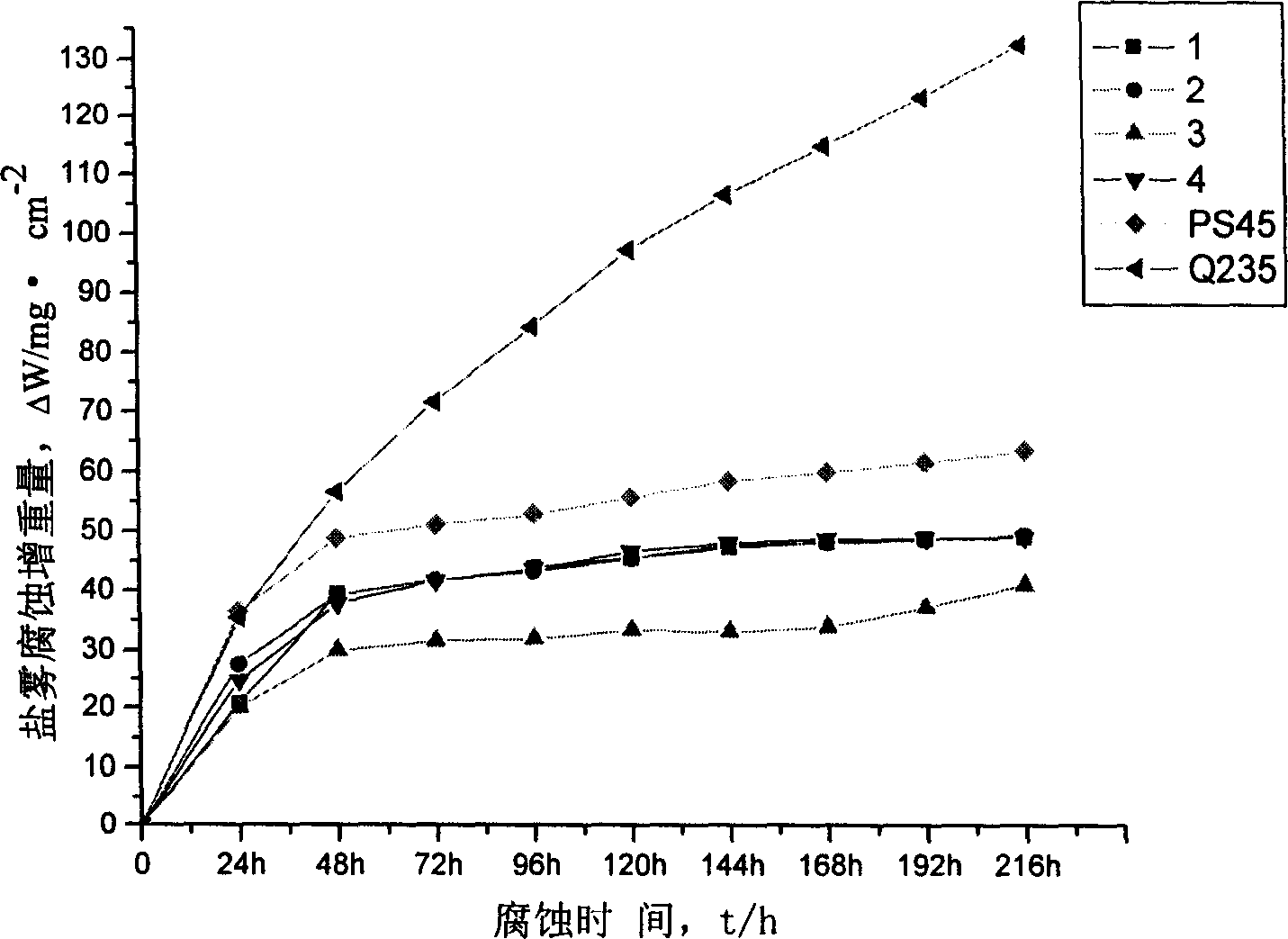

Marine-corrosion/hot-corrosion-resistant composite coating and preparation method thereof

ActiveCN102206797AGood high temperature corrosion resistanceGood self-sealingMolten spray coatingHigh humidityAlloy coating

The invention discloses a marine-corrosion / hot-corrosion-resistant composite coating and a preparation method thereof, belonging to the technical field of metal surface protection. A novel FeCrAlRe hot-corrosion-resistant powder core wire material is prepared by coating mixed powder, containing Cr powder, Al powder and the like, on a carbon steel band. A ZnAlMgRe powder core wire material is prepared by coating mixed powder, containing Al, Mg, Zn and Re, on a Zn-base alloy band. The preparation method of the composite coating comprises the following steps: spraying the FeCrAlRe powder core wire material by using a high-speed arc spraying device to form an alloy coating on a pretreated steel base surface, and spraying a ZnAlMgRe coating to form a double-layer composite structure protective coating. The prepared coating can resist hot corrosion, and has excellent corrosion resistance in a marine high-humidity high-salt-mist environment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Metallized substrate

InactiveUS20060063024A1Little warpingDense and smooth surfaceMolten spray coatingExtrusion containersMetallurgyMachined surface

The present invention provides a metallized substrate that has little warping and a fine, smooth surface. In the metallized substrate of the present invention, a conductive film is formed by spraying on the surface of a ceramic substrate or a composite substrate of a ceramic and a metal. The surface roughness of the conductive film formed by the spraying is preferably Ra≦1.0 μm. The surface of the conductive film may be a machined surface. The spraying is preferably arc spraying, plasma spraying, or flame spraying.

Owner:SUMITOMO ELECTRIC IND LTD

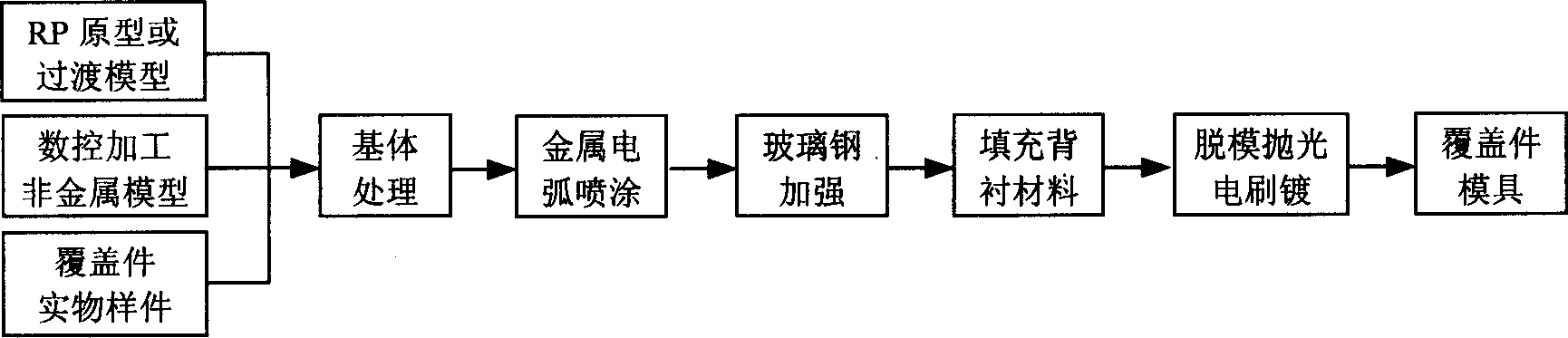

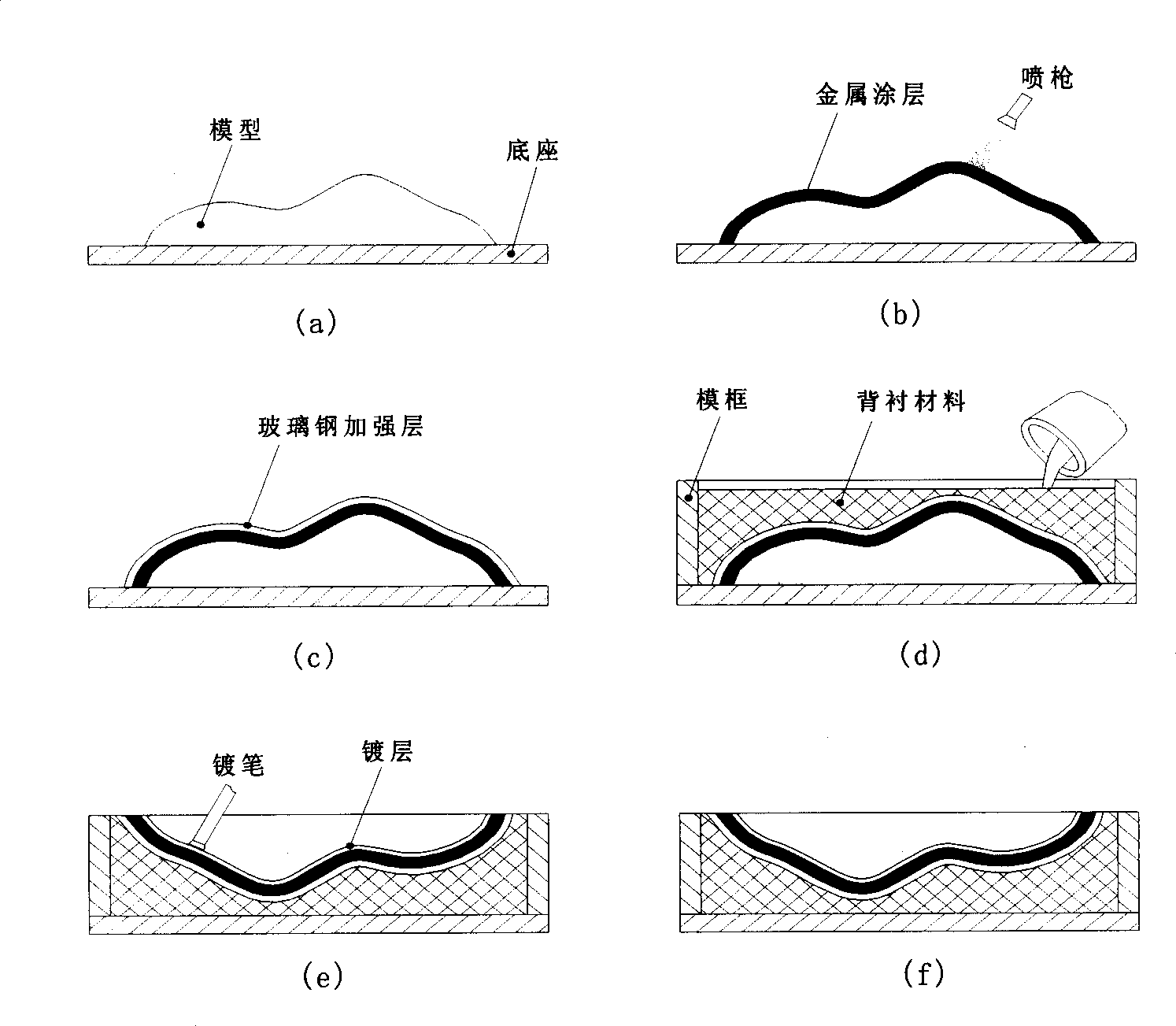

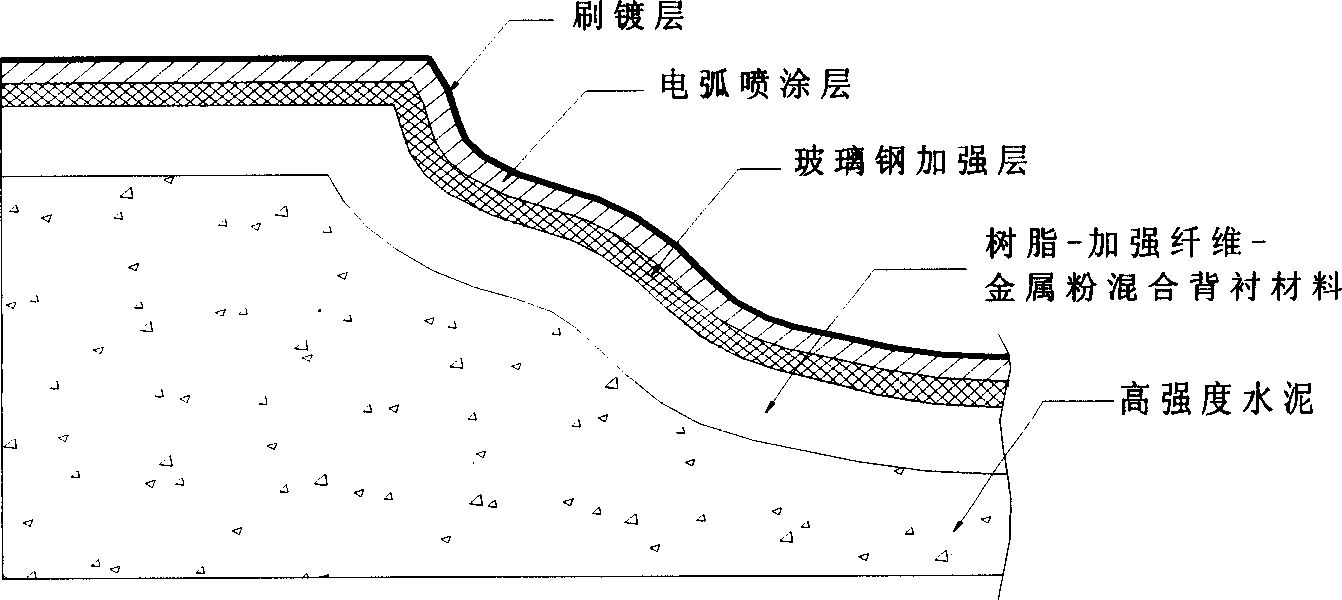

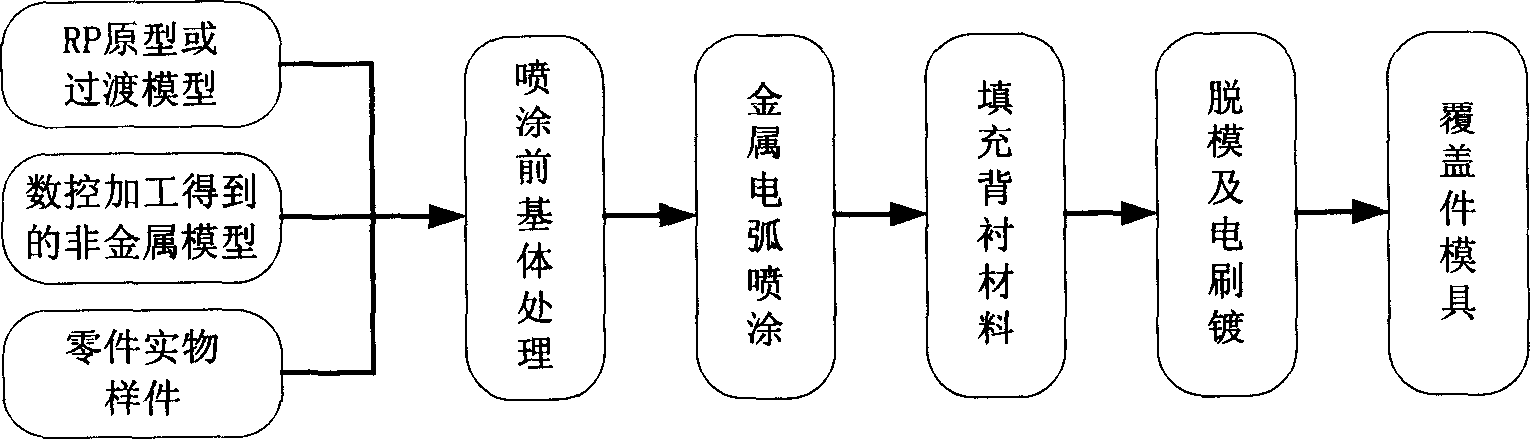

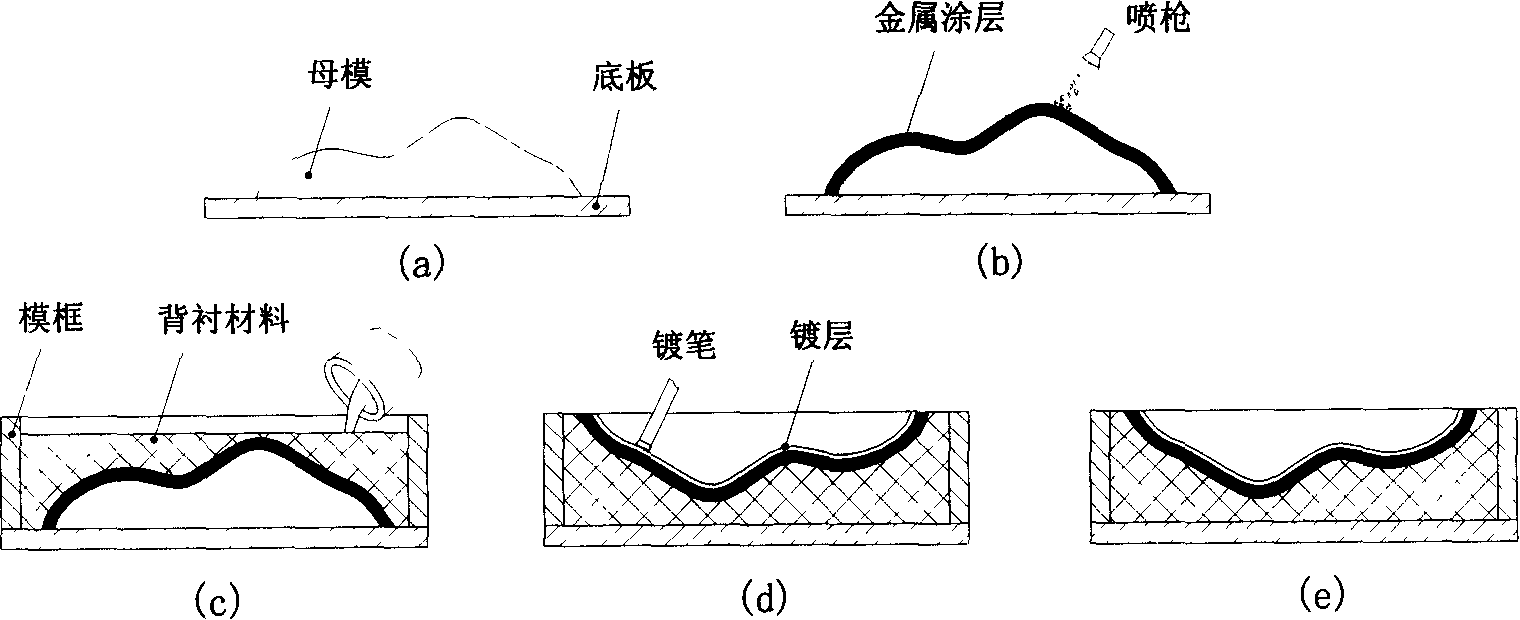

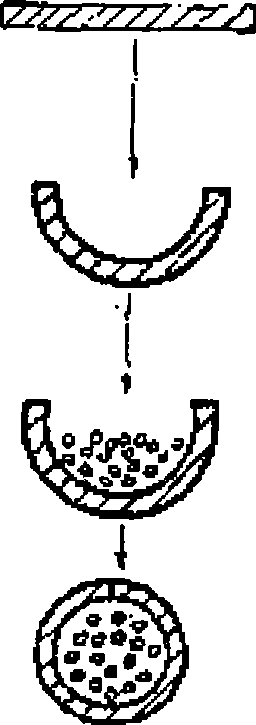

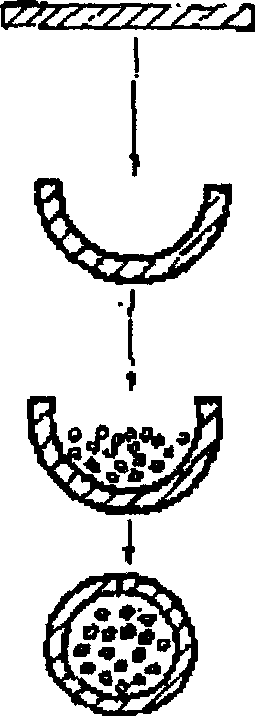

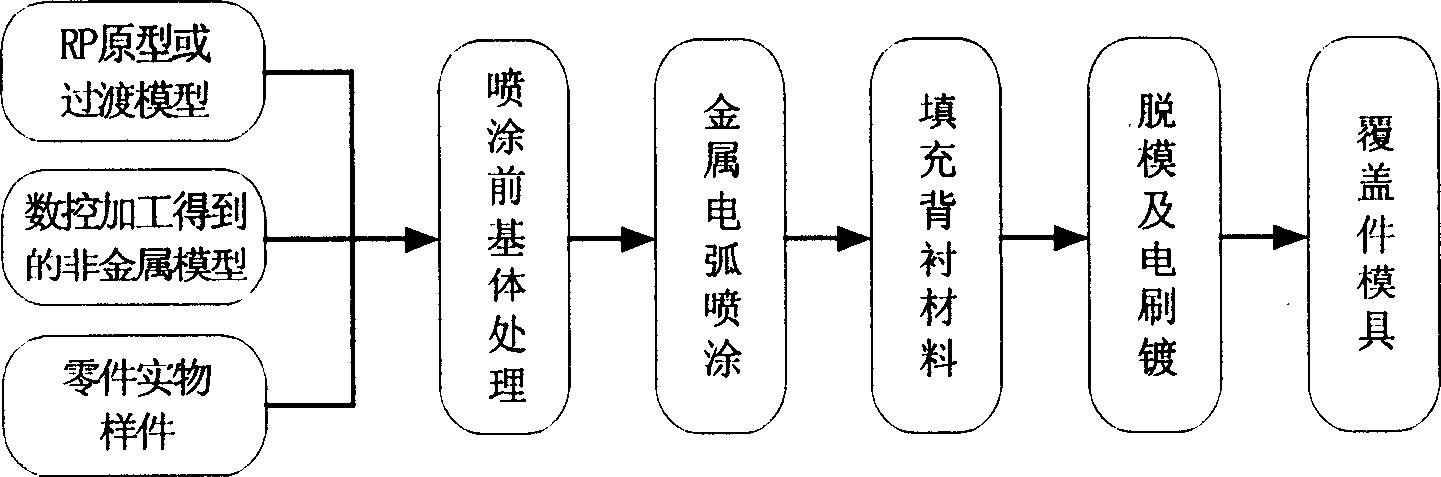

Method of rapid manufacture of stamping die for arc spraying covering-piece for automobile

The invention discloses a fast manufacturing method for punching die of metal arc painting car covers. The invention mainly uses metal arc paint technology, combines with glass steel forming, epoxy forming, electrical brush plating. The method includes: paint mother die preparation, basic process, metal arc paint, back materials filling, electrical brush plaiting. The final die is grad layer structure, each layer has different mechanism performance, easy to display material speciality. The invention simplifies the craft and reduces the cost.

Owner:XI AN JIAOTONG UNIV

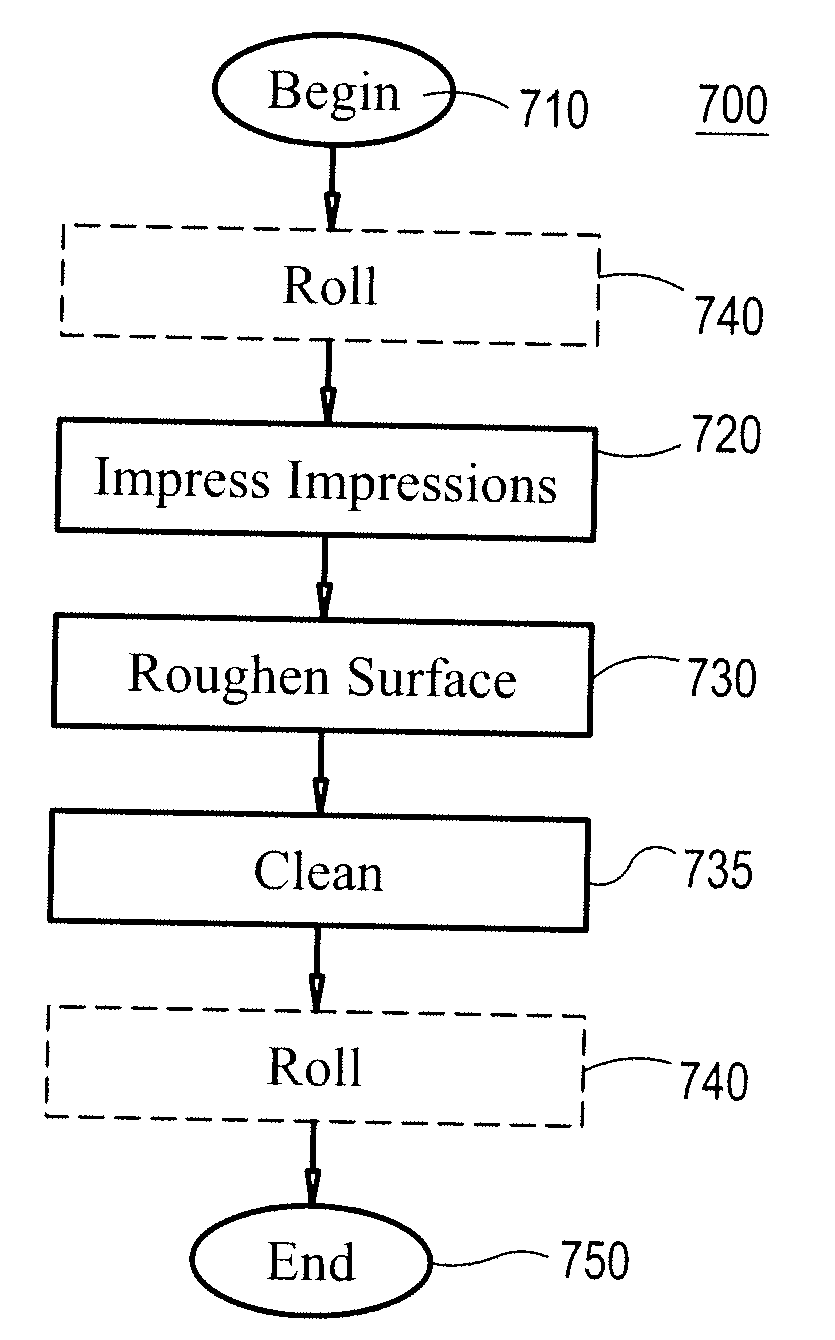

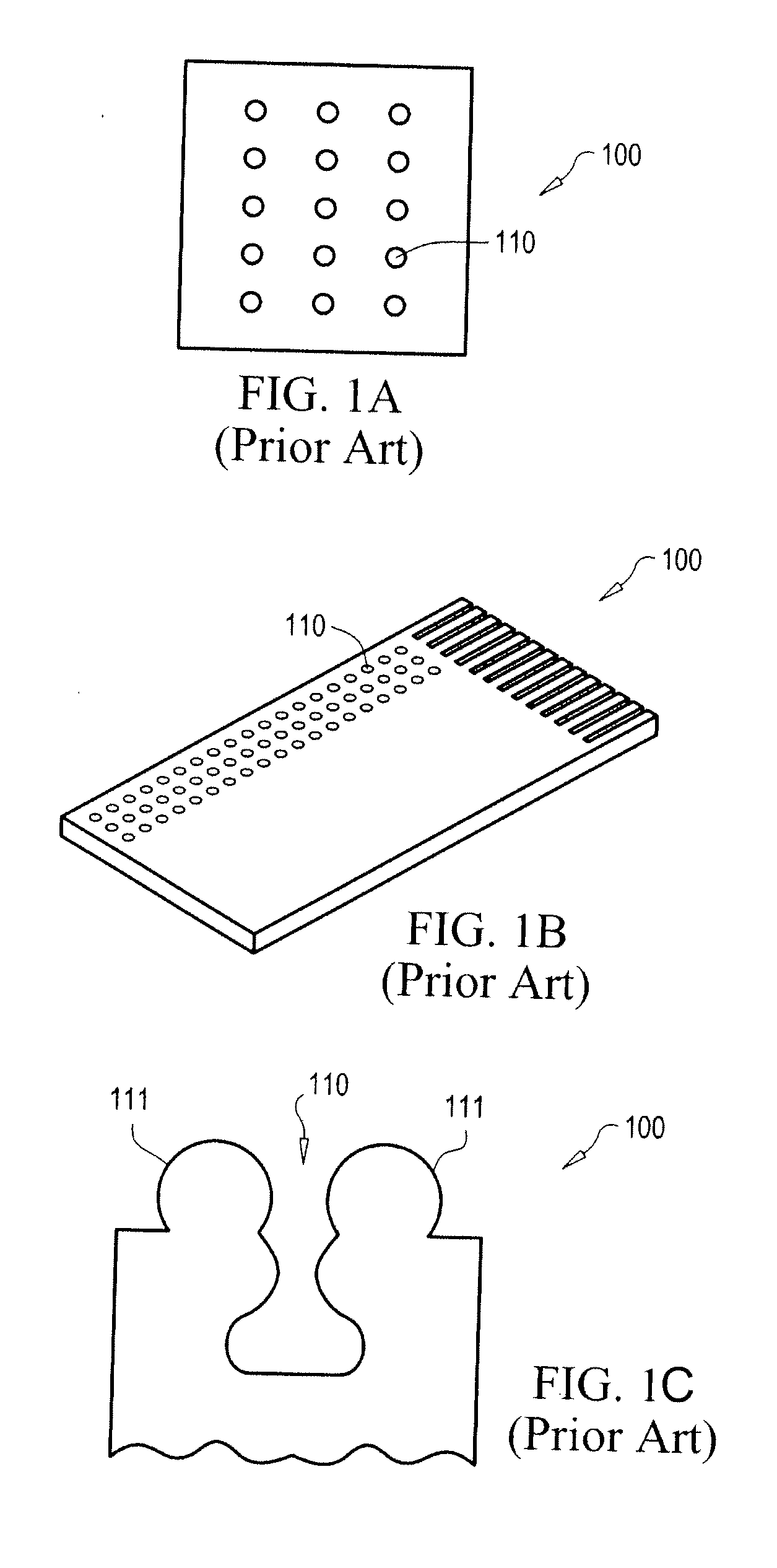

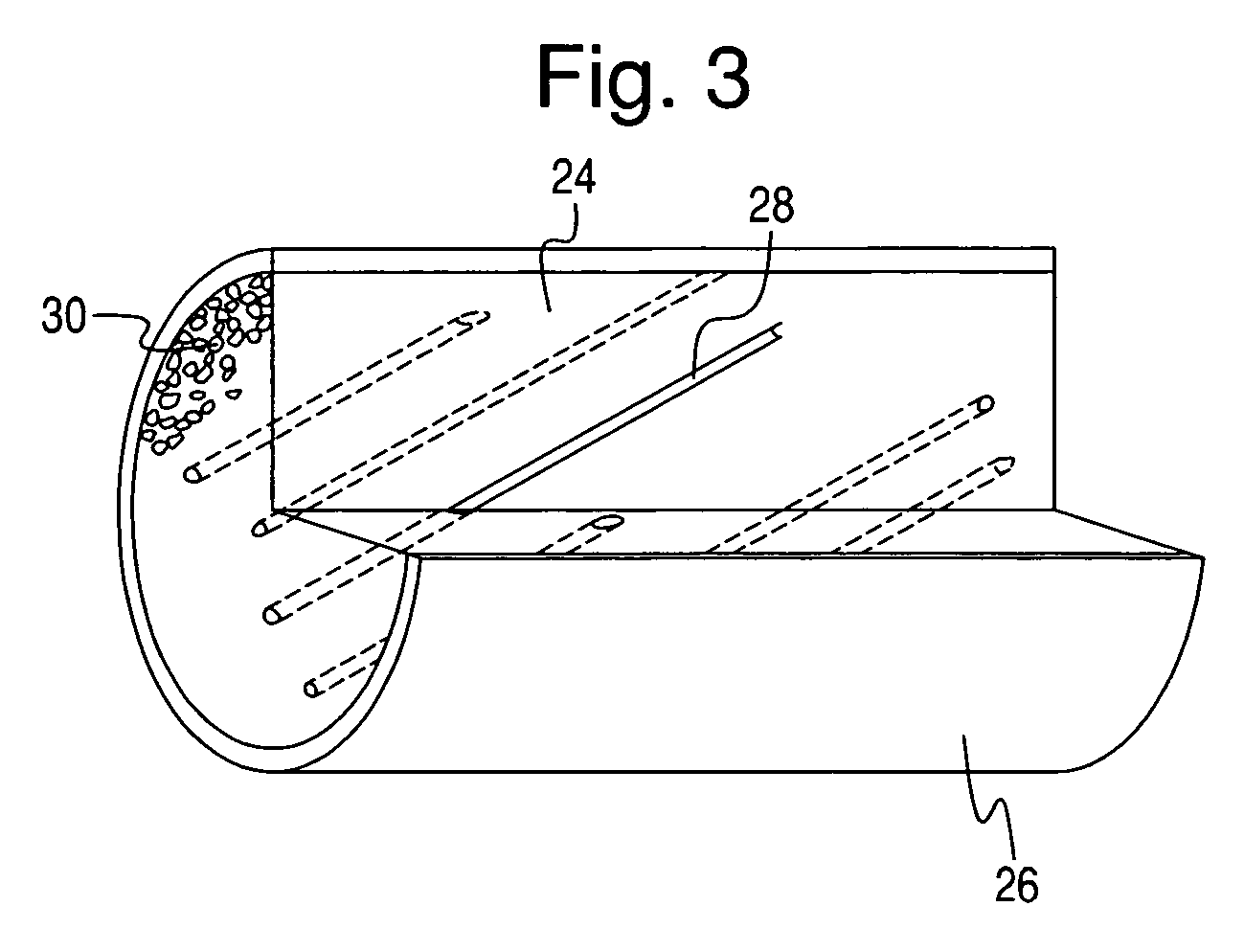

Method of manufacturing liner for semiconductor processing chamber, liner and chamber including the liner

A method for manufacturing a liner for a process chamber, a liner and a process chamber including the liner. A surface of a liner material is impressed with impressions by pressing, punching, dimpling, embossing, drilling, knurling or otherwise mechanically altering the surface without removing material. The impressions include depressions, protuberances, or a combination of depressions and protuberances that are separate or merge together. The impressions may be formed as one group or as two consecutive groups and may have different shapes and arrangement patterns. The surface may be roughened before or after forming the impressions. The roughening may be obtained from particulate blasting, plasma spray, and arc spray. The sheet of material may be aluminum, steel, an alloy or a composite material that is capable of being impressed by pressing or punching. The liner may be disposable or may be cleaned after a certain number of usage cycles.

Owner:B&H ENG

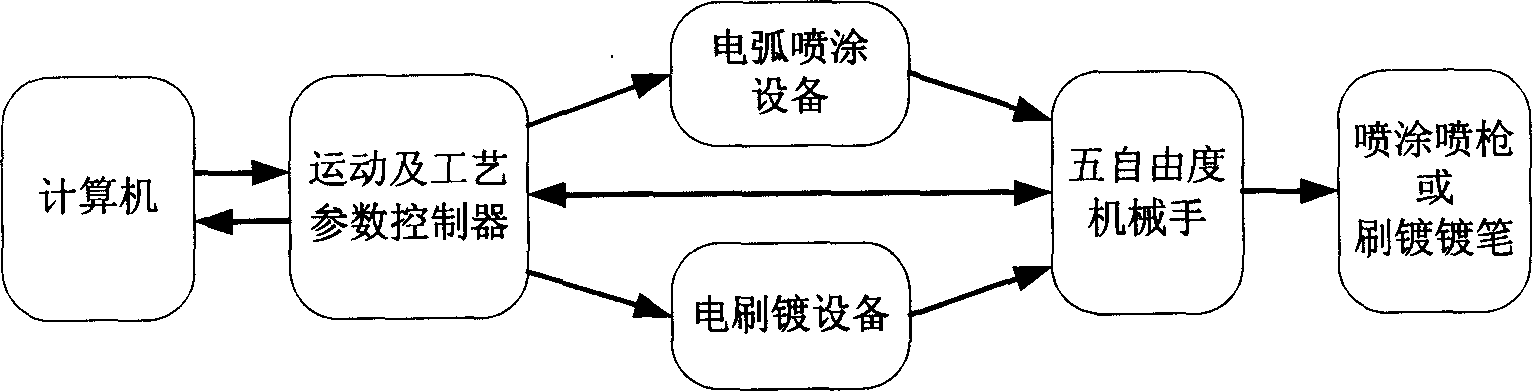

Special robot of die for rapid manufacture of covering piece for automobile by metal arc-spraying

InactiveCN1488473AAutomatic optimization of process parametersRealize complementary advantagesProgramme-controlled manipulatorSpatial positioningPunching

The invention discloses a metal arc painting fast mould-producing robot which can produce the punching die of car cover elements fast and economically. The robot integrates the electric paint and electric brush plating, and it is made up of movement and craft parameter controller, electric arc paint device, electric brush plating device and mechanical body. The robot is five variances rectangular coordination structure, the allocation mechanism uses gantry structure and has three movement variances, which is used to adjust the space position of ejection gun or plating pole, wrist has two rotation variances for adjusting the space posture of election gun or plating pole. The wrist part is designed with two parallelogram structure, realizes the decoupling of rotation variances and movement variances, makes the adjustment of posture not affect the space position of the working place. The robot uses CAD model as input, and is driven by CAD data, neední»t to program manually.

Owner:SUZHOU BC TECH

High-melting metal arc spraying rapid die-manufacturing method

InactiveCN101434026ALow costShort preparation cycleMolten spray coatingFoundry mouldsAfter treatmentHigh intensity

The invention belongs to the field of the advanced manufacturing technology in the manufacturing industry, relates to a quick die manufacturing method, in particular to a quick die manufacturing method through arc spraying of high-melting metals. The method adopts a non-roasting ceramic master die as a composite mold base, arranges fused drop on the surface of the master die through arc spraying of the high-melting metals, adds a die frame on the rear of a shell after spraying of a certain thickness, fills resin and high-strength cement back lining, and performs after-treatment such as edge cutting and polishing on the surface of the shell after demoulding. The invention provides the quick and low-cost die manufacturing integrated technology.

Owner:XI AN JIAOTONG UNIV +1

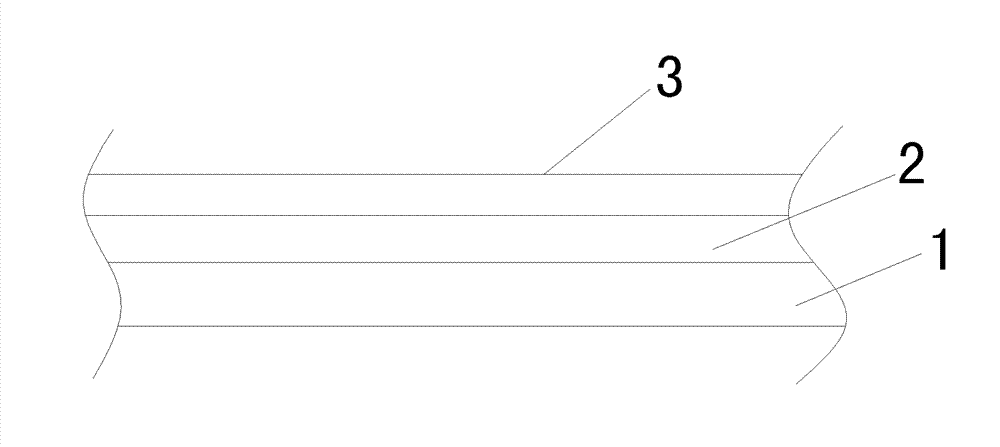

Metal anticorrosion coating and electric arc spraying process thereof

ActiveCN102774114AImprove adhesionEnhance the effective anti-corrosion lifeMolten spray coatingAnti-corrosive paintsSurface layerLacquer

The invention provides a metal anticorrosion coating and an electric arc spraying process thereof. The metal anticorrosion coating comprises a priming zinc-aluminum alloy layer with a thickness of 100 mu m, a middle pure aluminum metal layer with a thickness of 80 to 100 mu m and a seal coat surface layer with a thickness of 70 to 90 mu m, wherein seal coat is a fluoro-carbon top coat. The priming zinc-aluminum alloy layer and the middle pure aluminum metal layer are sprayed by using secondary atomization electric arc spraying for metals, and the seal coat surface layer is coated through spraying. An adhesive force between the metal anticorrosion coating provided by the invention and the surface of a steel structure substrate is up to more than 15 to 16 MPa, and the metal anticorrosion coating can be used in the field of heavy duty anticorrosion of large-scale steel structures.

Owner:SHANGHAI JIANYE TECH ENG

Powder core wire material for high chrome molybdenum alloy arc spraying

InactiveCN101497978AGood resistance to high temperature oxidationGood high temperature corrosion-abrasion resistanceMolten spray coatingThermal sprayingMetallic aluminum

The invention relates to a high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire which belongs to electric arc spraying powder cored wires which resist high-temperature oxidation and corrosion and used for the surface protection of metal materials. The high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire belongs to the field of hot spraying in material processing engineering and is mainly used for the high-temperature corrosion, erosion and abrasion resistance of four tubes of a general coal-powder boiler of a coal-fired power station boiler, the corrosion prevention and the abrasion resistance of a converter smoke hood and a flue in a steel works and the repair of various axles, crankshafts, plunger pistons, paper-making drying cylinders, and the like. The high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire is characterized by comprising the powder core components according to percentages by weight of 22-29 percent of crome metal, 5-9 percent of metallic molybdenum, 2.5-10 percent of metallic nickel, 4.0-6.5 percent of metallic aluminum, 0.5-1 percent of carbon, 1.0-3.0 percent of rare-earth, and metallic iron. A preparation method of the high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire adopts the prior processes of firstly rolling a low-carbon cold-rolled strip into a U shape, adding powder core powders which account for 30-40 percent of the gross weight of spraying wires into the U-shaped groove, closing the U-shaped groove and wrapping the powder cores in the U-shaped groove, drawing gradually and lightening through a wire-drawing die to lead the diameter to reach 3.0mm.

Owner:北京赛亿表面工程技术有限公司

Aluminum oxide ceramic coating and preparation method thereof

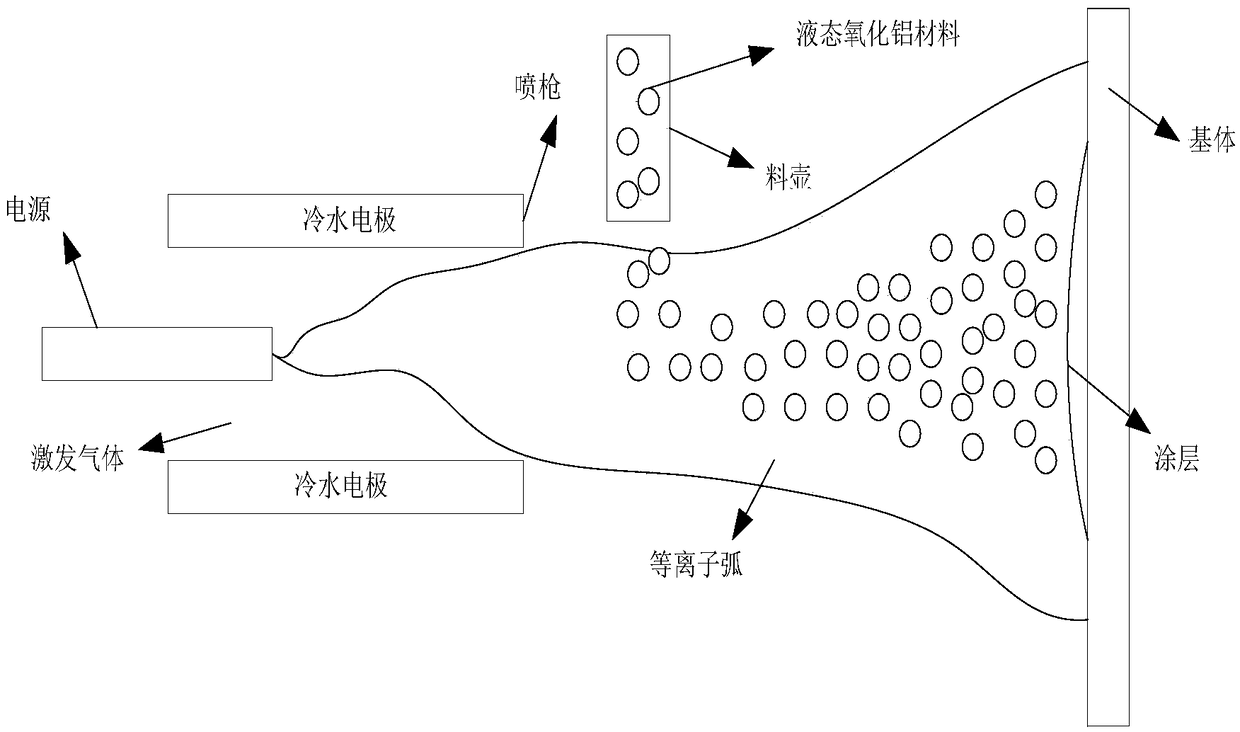

PendingCN109440051AImprove bindingThe binding effect is not enough to meet the strength goodMolten spray coatingMolten stateCeramic coating

The invention belongs to the technical field of plasma arc spraying, and particularly relates to a high-hardness, high-wear-resistance and high-toughness aluminum oxide ceramic coating and a preparation method thereof. The method comprises the following steps that (1.1) a matrix is selected; (1.2) sand blasting or sanding pretreatment is carried out on the matrix; (1.3) aluminum oxide raw materialpowder is prepared; (1.4) the aluminum oxide nano-sintered powder is heated to a molten state; and (1.5) an aluminum oxide nano-liquid material is sprayed. The core step of the method is the molten step which before the aluminum oxide nano-liquid material is sprayed, a traditional aluminum oxide spraying technology is characterized in that aluminum oxide nano particles are directly placed into aspray gun for heating and spraying, and the combination effect cannot sufficiently meet a strength requirement and an adhesion degree requirement; and the sintered powder is melted into the molten state before feeding by the spray gun through the method, so that the defect is avoided, and the comprehensive parameters of the strength, hardness, toughness and the like of the ceramic coating are obviously better than the effect of a common spraying technology.

Owner:陈涛

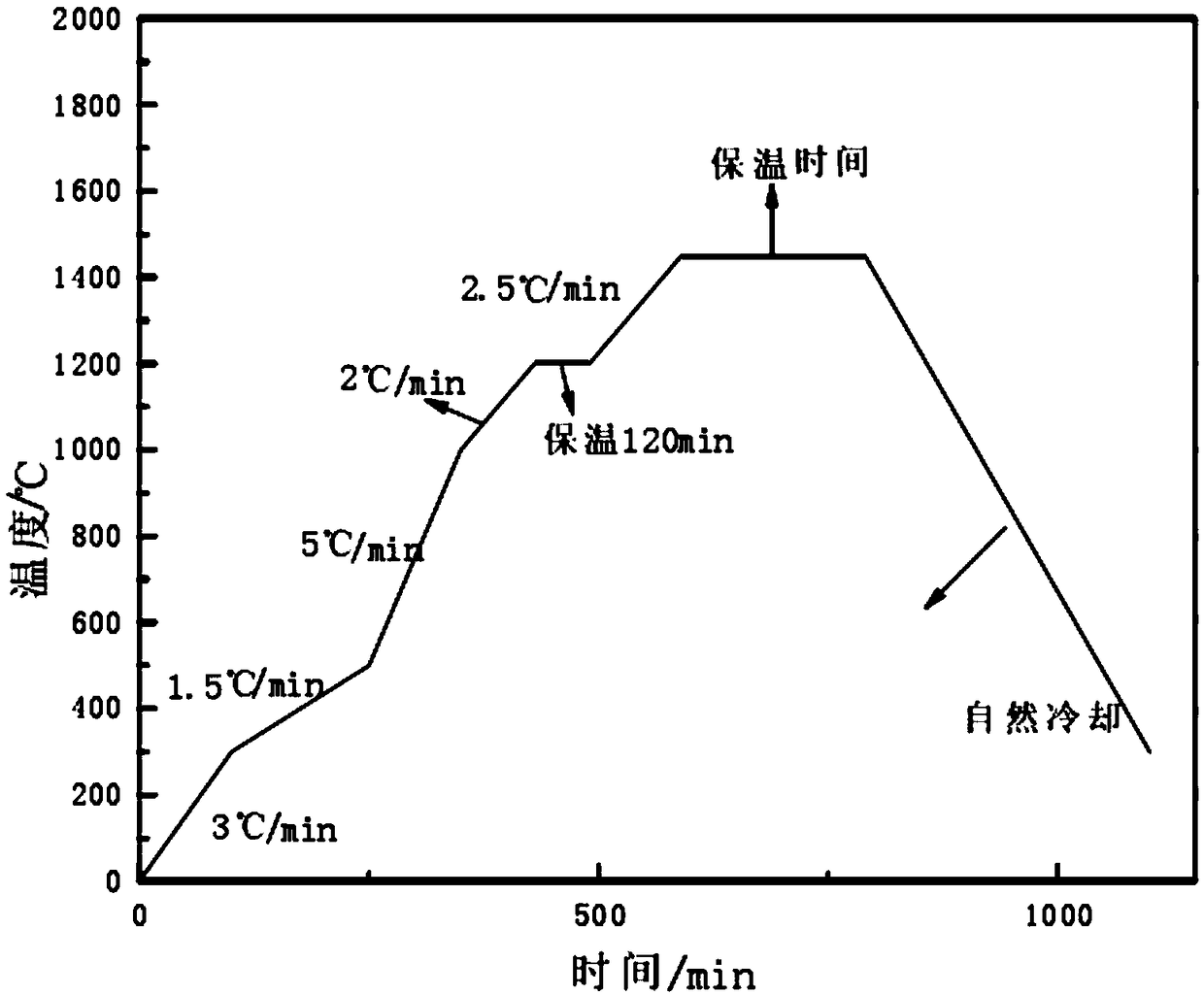

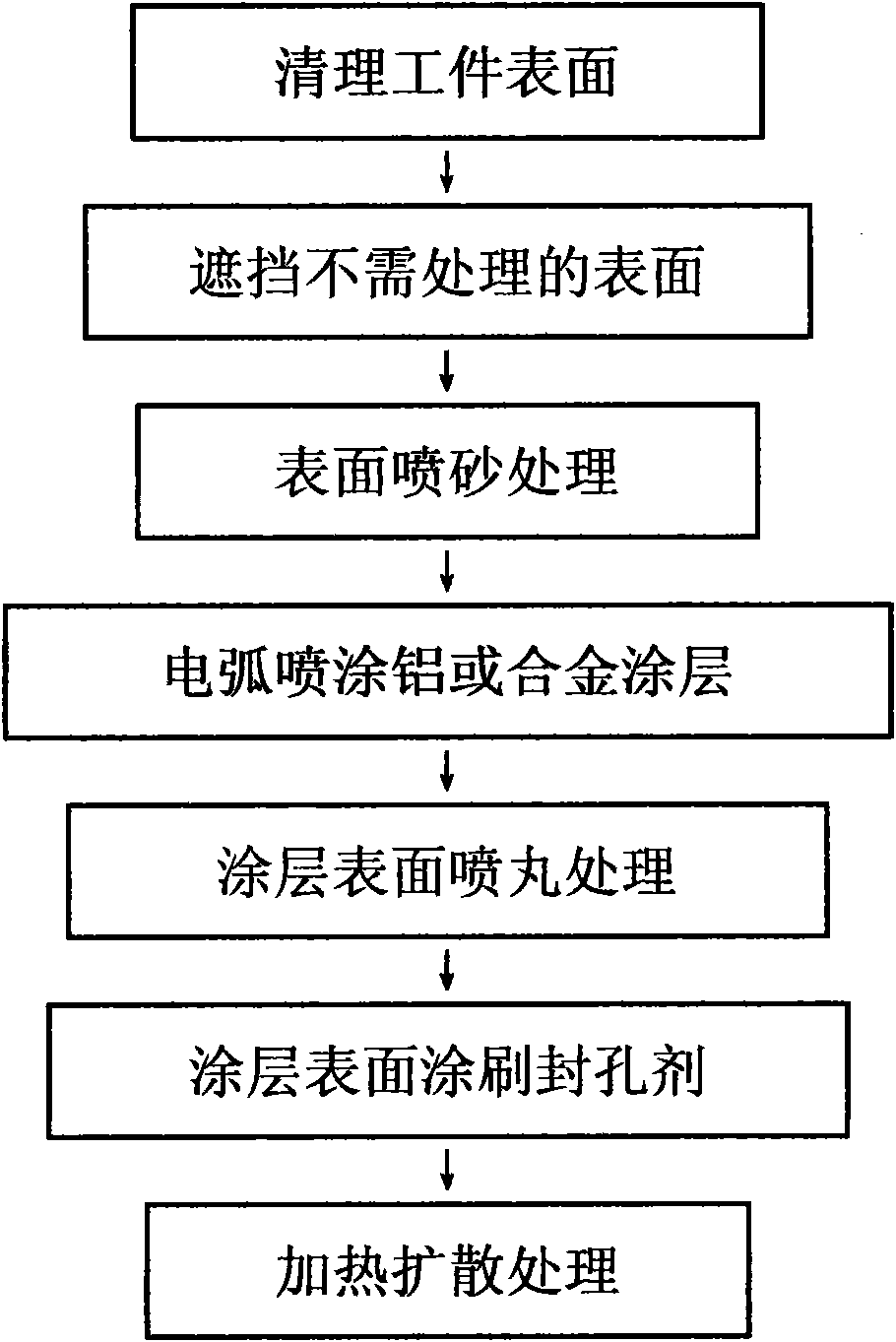

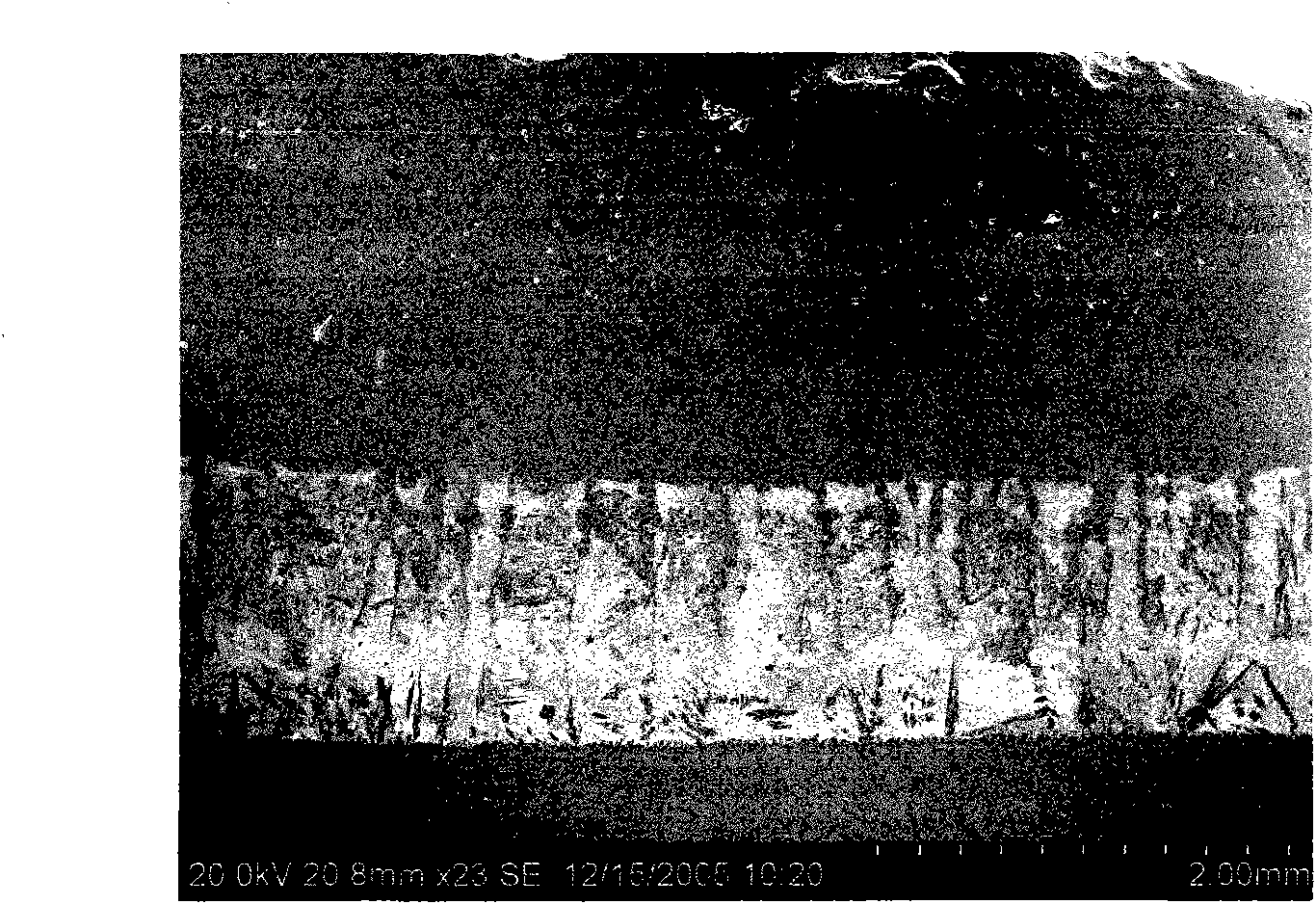

Process for preparing antioxidant and wear-resistant layer on surface of copper

InactiveCN101638788AImprove the protective effectExtend protection lifeMolten spray coatingThermal sprayingWear resistant

The invention provides a process method for preparing an aluminide penetrating layer on the surface of pure copper or a copper alloy by combining the thermal spraying technology and the thermal treatment technology, which comprises the following steps: firstly, spraying a layer of pure aluminium coating on the surface of a copper product through arc; secondly, performing shot blasting and sealingagent coating treatment on the surface of the coating; and finally, performing thermal treatment at a temperature of between 800 and 900 DEG C, maintaining the temperature for 2 to 4 hours, and obtaining an aluminide layer over 3mm on the surface of the pure copper. The aluminide layer prepared by the method has good combination with a copper substrate, good antioxidant performance and good wear resistance. The method can prepare the aluminide penetrating layer, and also can prepare aluminium-molybdenum, aluminium-silicone, aluminium-chromium binary or multi-metallic diffusion layers.

Owner:SHENYANG POLYTECHNIC UNIV

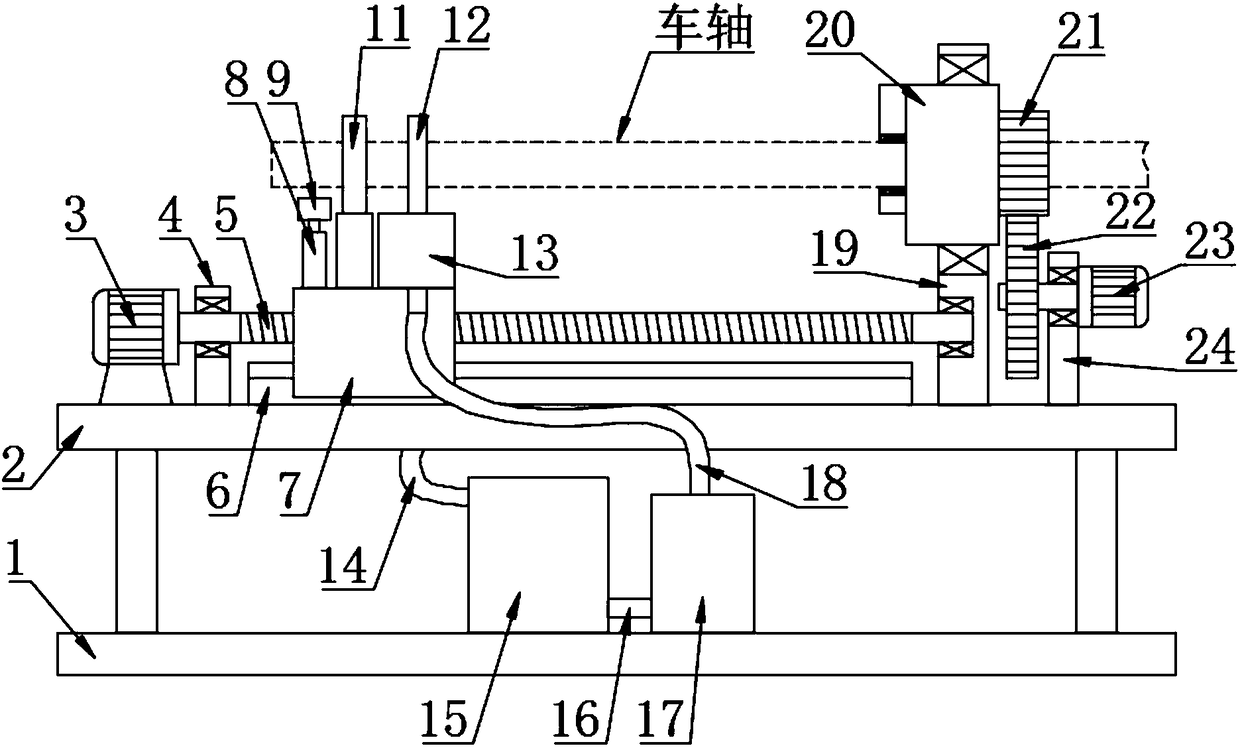

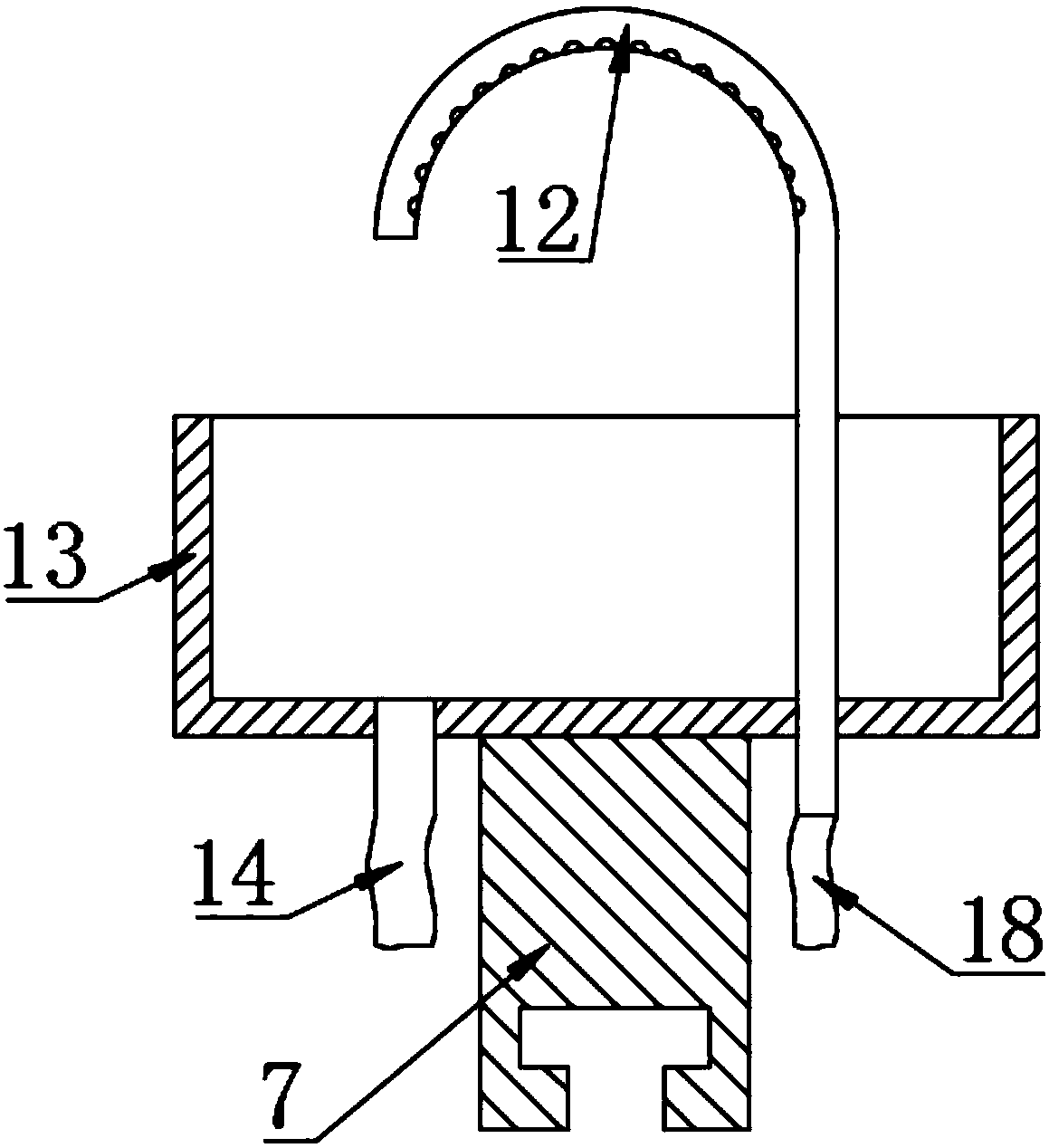

Painting device for automobile axle with drying and polishing functions

InactiveCN108296051AImprove performanceImprove aestheticsPolishing machinesPretreated surfacesMechanical engineeringArc spray

The invention discloses a painting device for an automobile axle with drying and polishing functions. The painting device for the automobile axle with the drying and polishing functions comprises a base, a support plate is fixedly arranged on the top of the base through a support, a fixed seat is fixedly arranged on the right side of the top of the support plate, and a three-claw chuck is rotatably connected to the top of the fixed seat. A sliding rail is fixedly arranged on the top of the support plate, a sliding seat is slidably connected above the sliding rail, a material receiving box is fixedly arranged on the right side of the top of the sliding seat, and a spray pipe is fixedly connected to the bottom wall of the material receiving box. A paint bucket and a paint spraying pump are fixedly arranged at the top of the base, and the bottom end of the spray pipe passes through the bottom wall of the material receiving box and is connected with a discharging opening of the paint spraying pump through a discharging hose. A material returning hose is further connected to the bottom of the material receiving box, and the material returning hose passes through the side wall of the paint bucket to be connected into the paint bucket. According to the automobile axle with the drying and polishing functions, the paint spraying pump is connected to the arc spray pipe for painting, andthe painting effect is good; and the material receiving box is arranged to receive surplus paint, paint flows back into the paint bucket again for recycling through the material returning hose, and resources are saved.

Owner:周佳裕

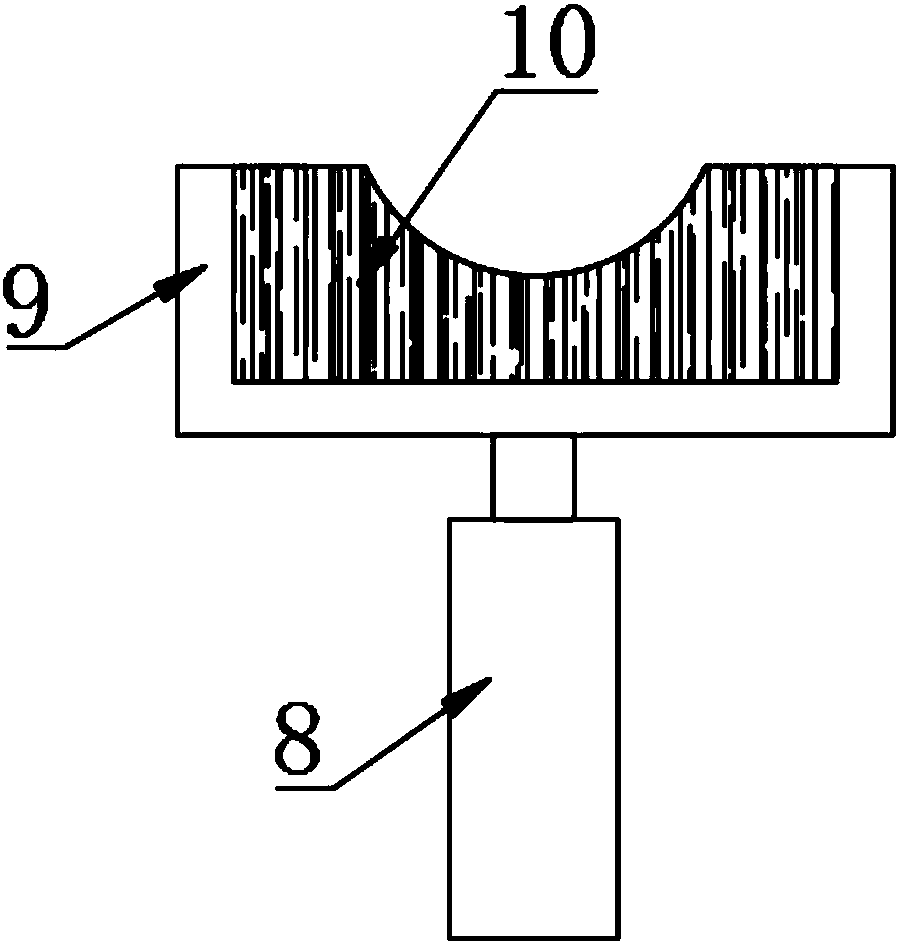

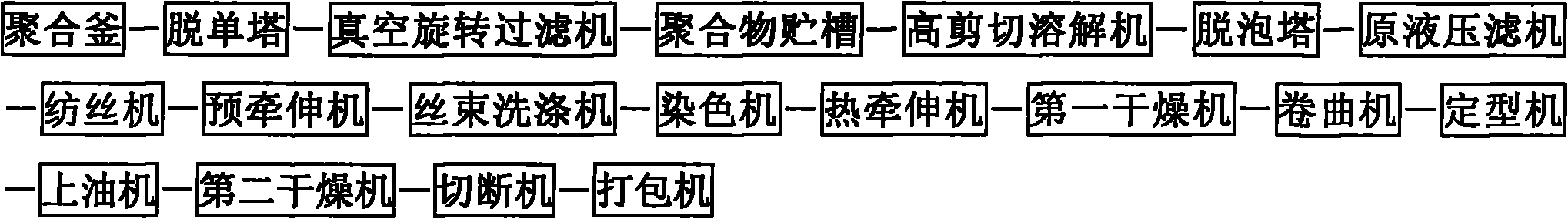

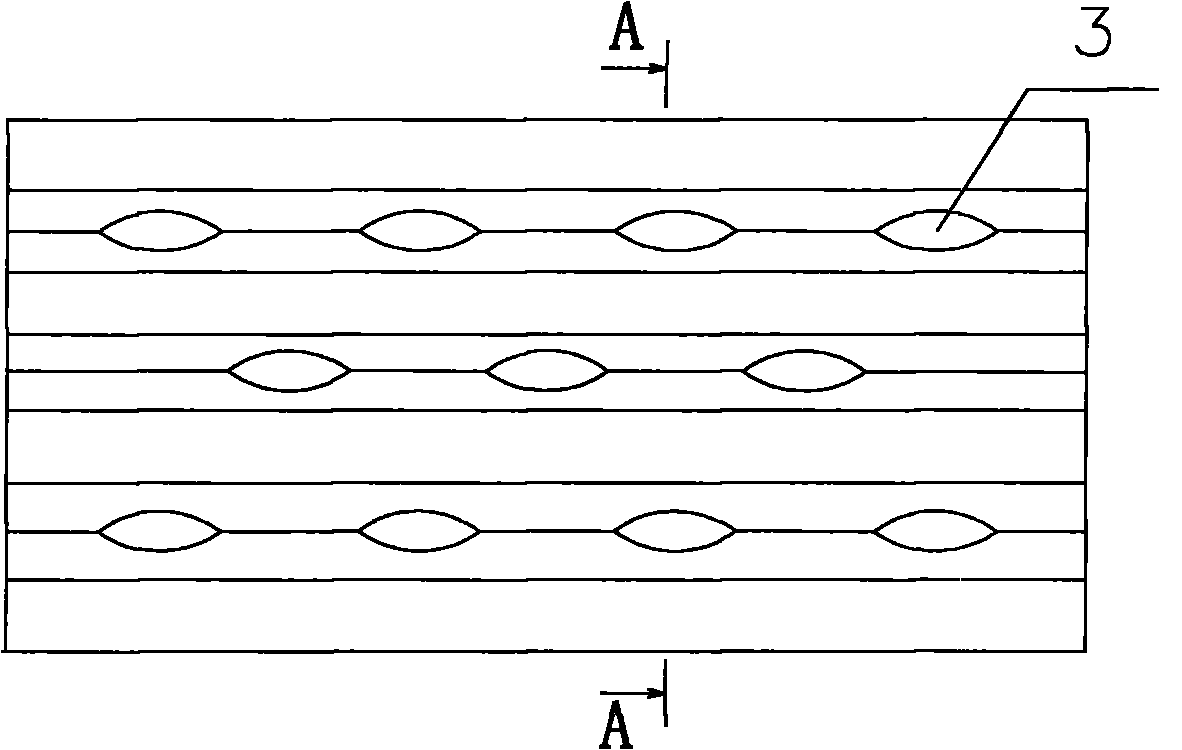

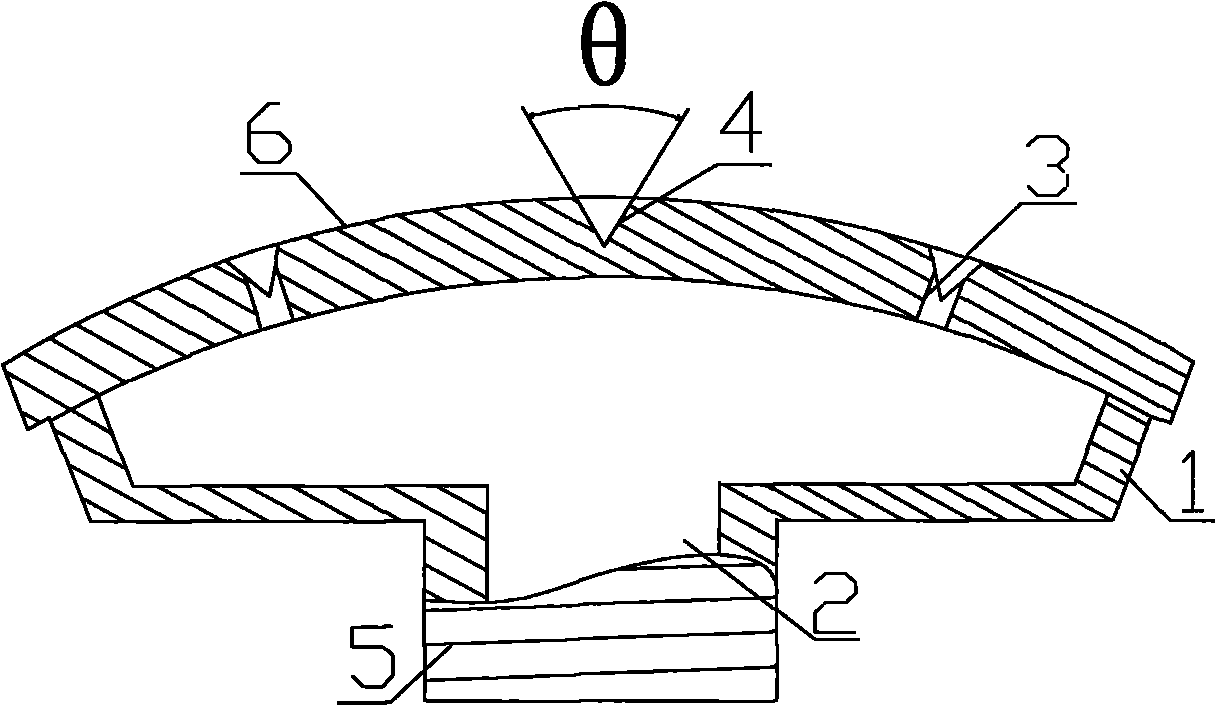

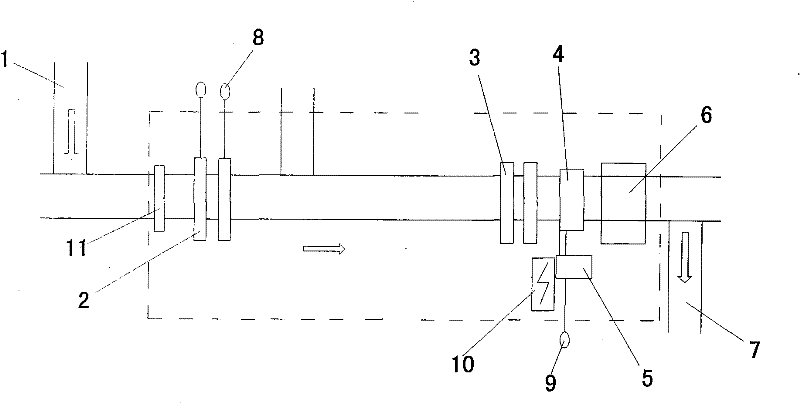

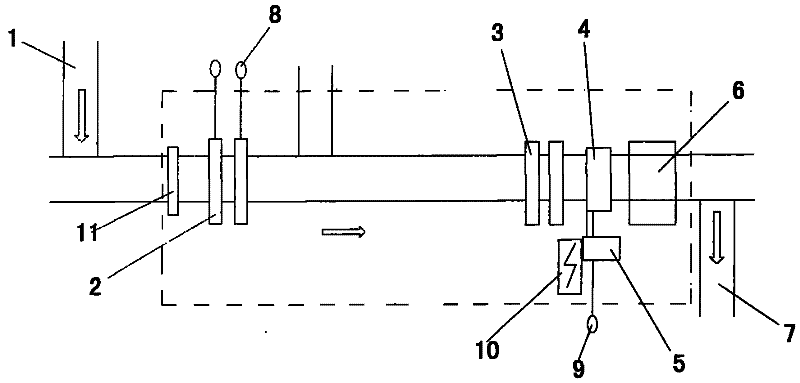

Production process of colored flat acrylic fiber and production line thereof

InactiveCN101922059AIncrease extrusion speedSolve the problem of uneven spinning and dyeingArtificial thread manufacturing machinesWet spinning methodsProduction lineSodium sulfocyanate

The invention relates to a production process of colored flat acrylic fiber and a production line thereof, which are a production process and a production line thereof for producing the colored flat acrylic fiber in a plurality of color systems with vivid colors, little chromatic aberration and great flatness by adopting a cationic dye, in particular to a spinning production line for producing the colored flat acrylic fiber by adopting a ternary aqueous suspension polymerization and sodium sulfocyanate wet method. In the invention, a long-strip arc dye liquor spray head is used for dying, and the long-strip arc dye liquor spray head is an arc spray head which comprises a spray head seat, a spray head cover and a dye liquor inlet pipe and has a hollow T-shaped cross section, wherein the spray head is a long-strip semi-cylindrical surface, and a plurality of penetrative spraying holes are arranged on the spray head cover in a staggered way. The invention overcomes the defects of stripy and uneven dyeing, great chromatic aberration, large volume of colored wastewater, long product processing period, and the like commonly existing in a production process and a production line thereof for producing white flat acrylic fiber by adopting a traditional dyeing mode of steaming loose fibers at a high temperature.

Owner:DONGHUA UNIV

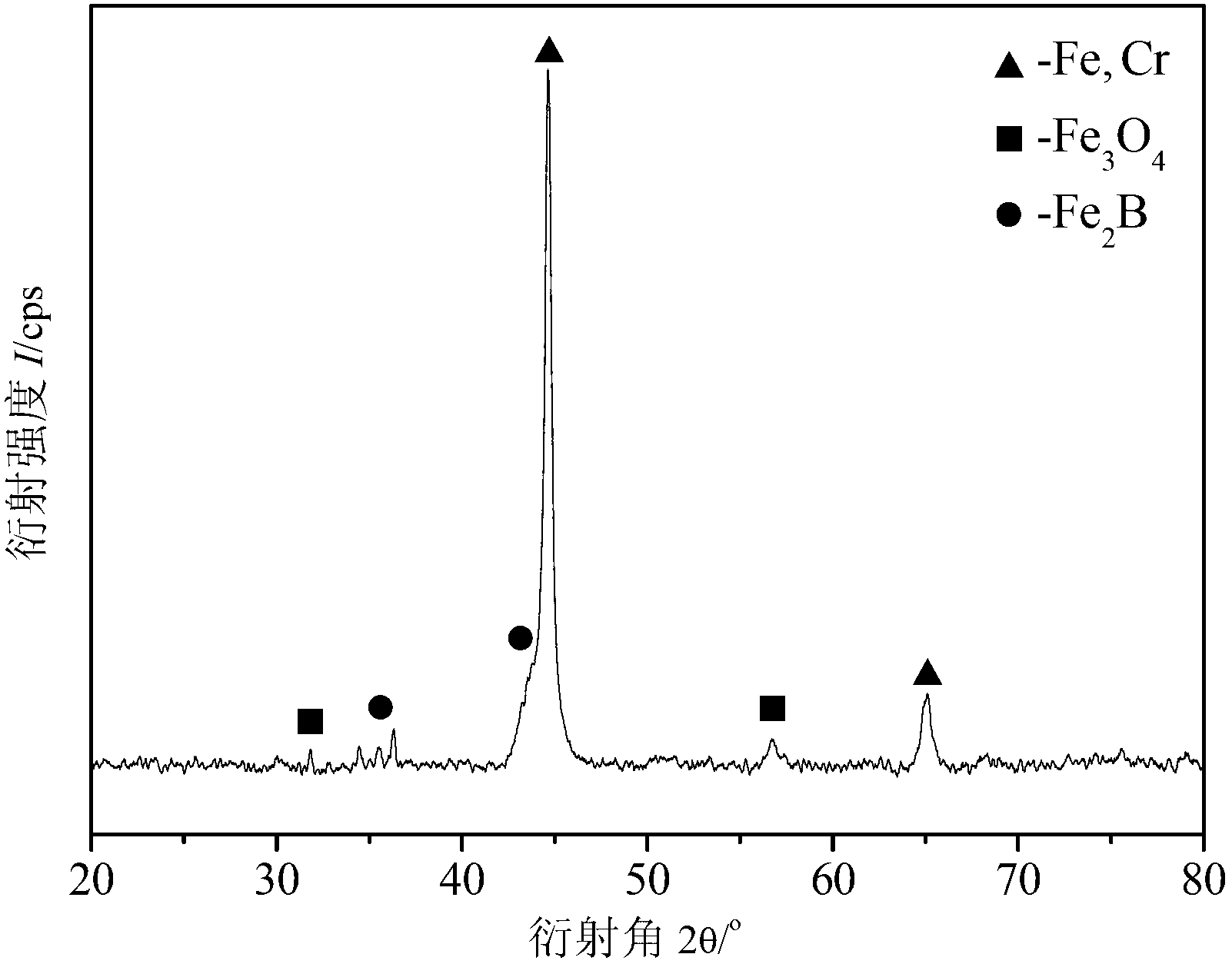

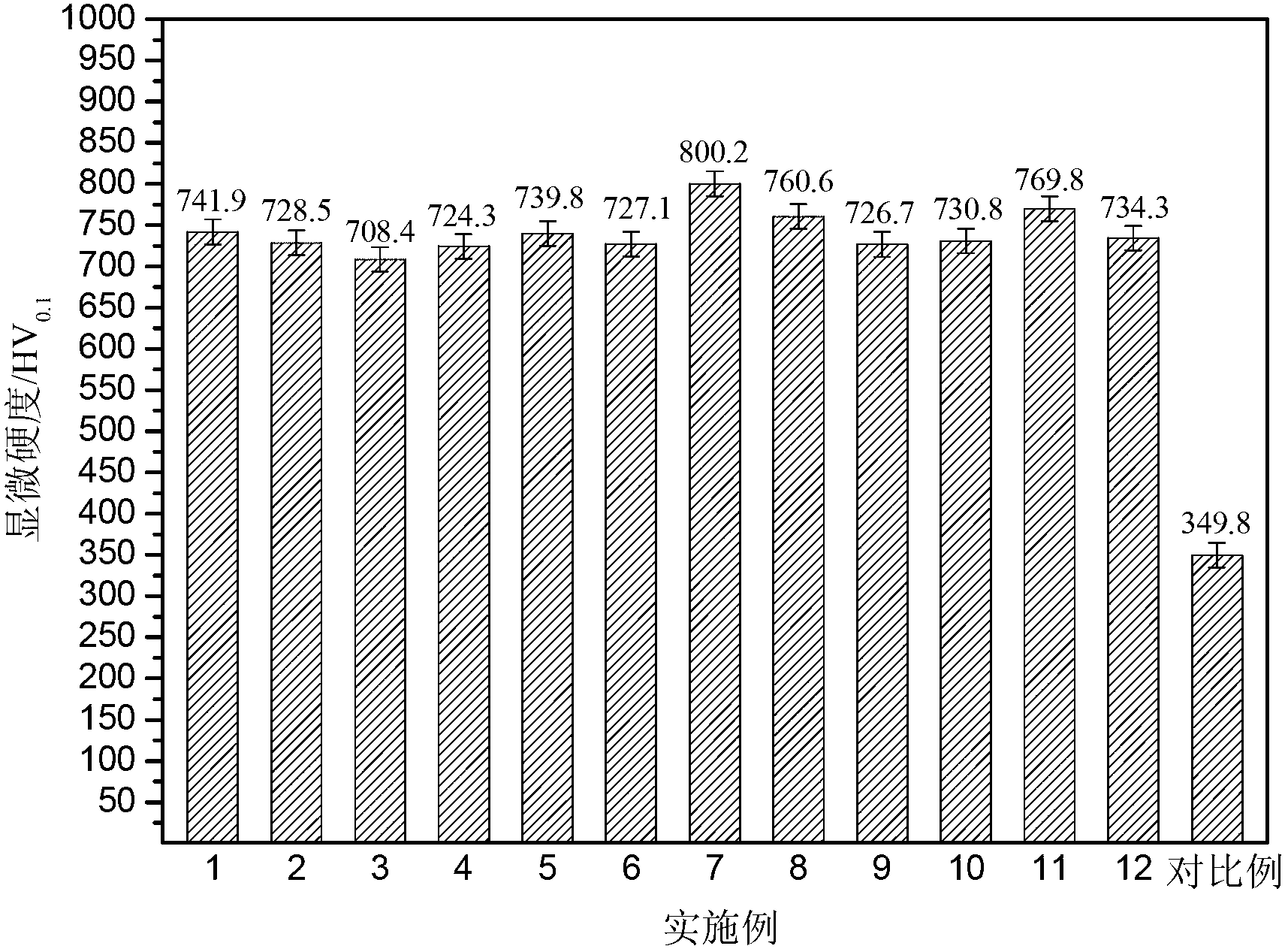

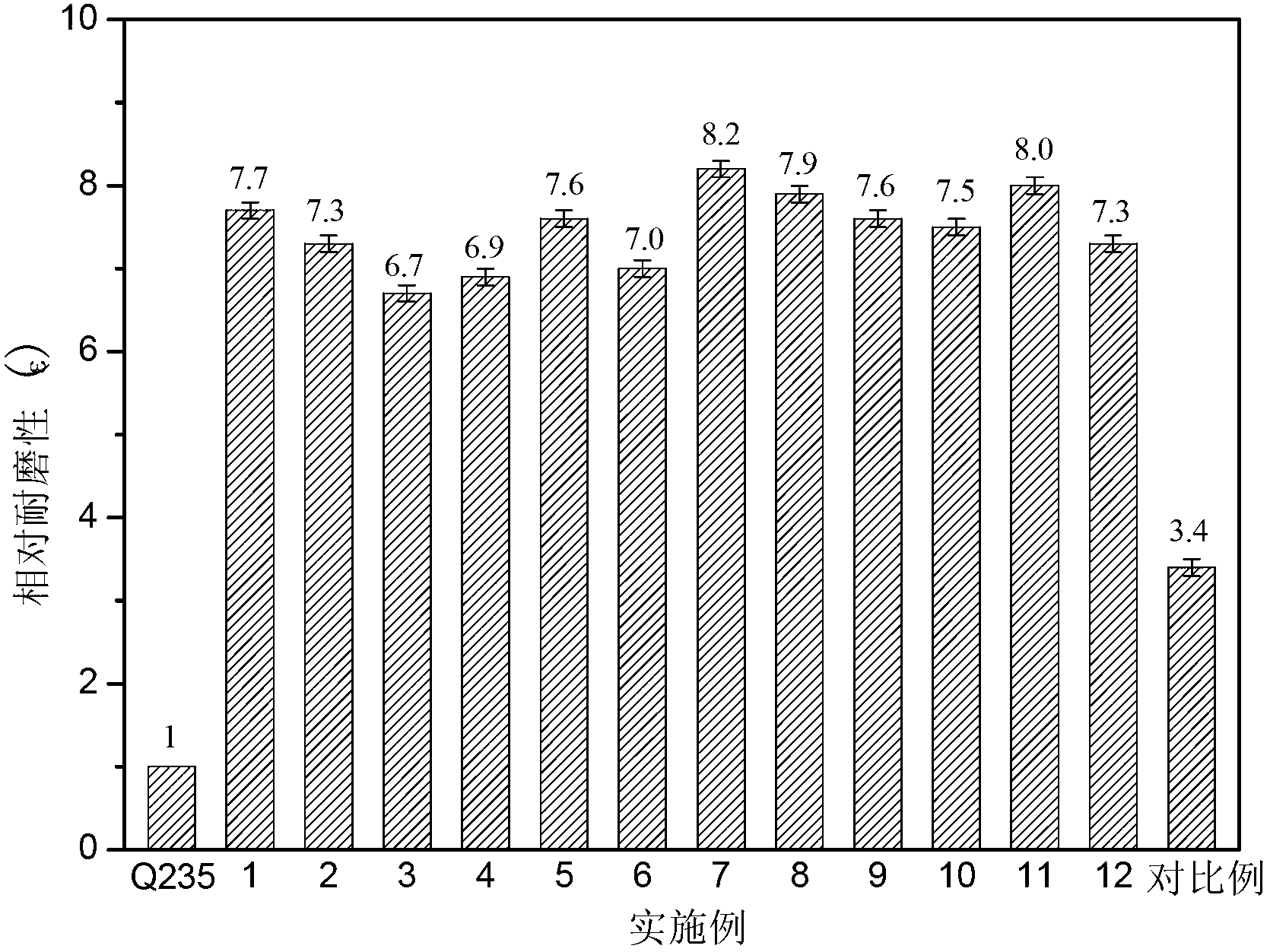

Cored wire for preparing FeCrB coating through electric arc spraying and coating preparation method

InactiveCN102703849AEfficient formationImprove operational reliabilityMolten spray coatingThermal sprayingFilling rate

The invention relates to a cored wire for preparing a FeCrB coating through electric arc spraying and a coating preparation method, belonging to the field of thermal spraying in material processing engineering. Strips for manufacturing skins of wires are stainless steel belts; filling rate of the cored wire is 32-34%; fillers of a core of the cored wire is as follows: chromium metal powder, metallic iron powder and boron carbide powder, wherein the boron carbide powder contains 88 wt% of boron and 12 wt% of carbon; the prepared cored wire contains 18-28 wt% of Cr and 4-10 wt% of B. when the coating is prepared, a surface is processed at first, and then spraying is performed. The coating is featured with strong high-temperature resistance, oxidation resistance and corrosion resistance, high hardness and combination strength, and good mechanical property.

Owner:BEIJING UNIV OF TECH

Nickle-base corrosion-resisting electric-arc spraying powdered core-wire material

InactiveCN1775996AMolten spray coatingHeat inorganic powder coatingPetrochemicalMaterials processing

The invention relates to surface protection of components used in petrochemical equipment. The feature of nickel base arc spraying powder core wire material that is made up from 56-74% metal nickel, 21-40% metal chrome, 5-9% molybdenum, 2-6% boron, and 2-4% aluminum. The invention solves the surface protection problem existing in petrochemical equipment under the condition of high temperature erosion, high temperature corrosion. Moreover, it solves the problem of salt solution ion drop corrosion on device and pipeline.

Owner:BEIJING UNIV OF TECH

Metallic foam trap for poisons: aircraft ozone

InactiveUS20070154375A1Improve trapping efficiencyCombination devicesOrganic chemistryOil additiveAir purification

The present invention is directed to an improved apparatus and method of minimizing catalyst poisoning by inorganic deposits from lube oil additives and particulate matter, especially in aircraft. More specifically, the present invention is directed to an air purification system comprising an upstream metallic foam trap and downstream converter, wherein the trap physically blocks inorganic deposits and particulate matter from poisoning the downstream catalysts. The present invention is also directed to a metallic foam trap containing a coat comprising a first metallic thermal arc sprayed layer and optionally a second refractory metal oxide.

Owner:BASF CATALYSTS LLC

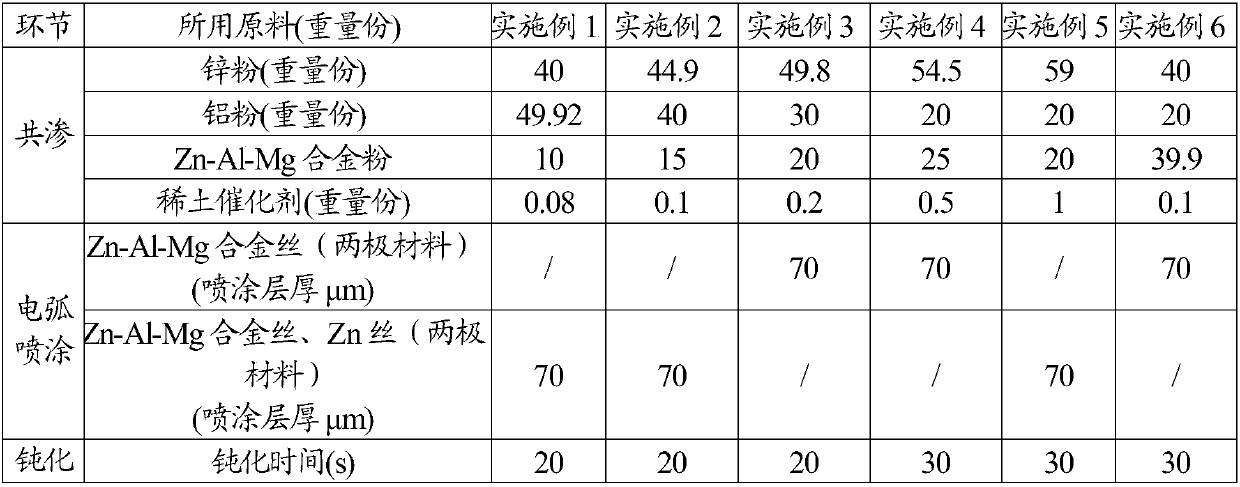

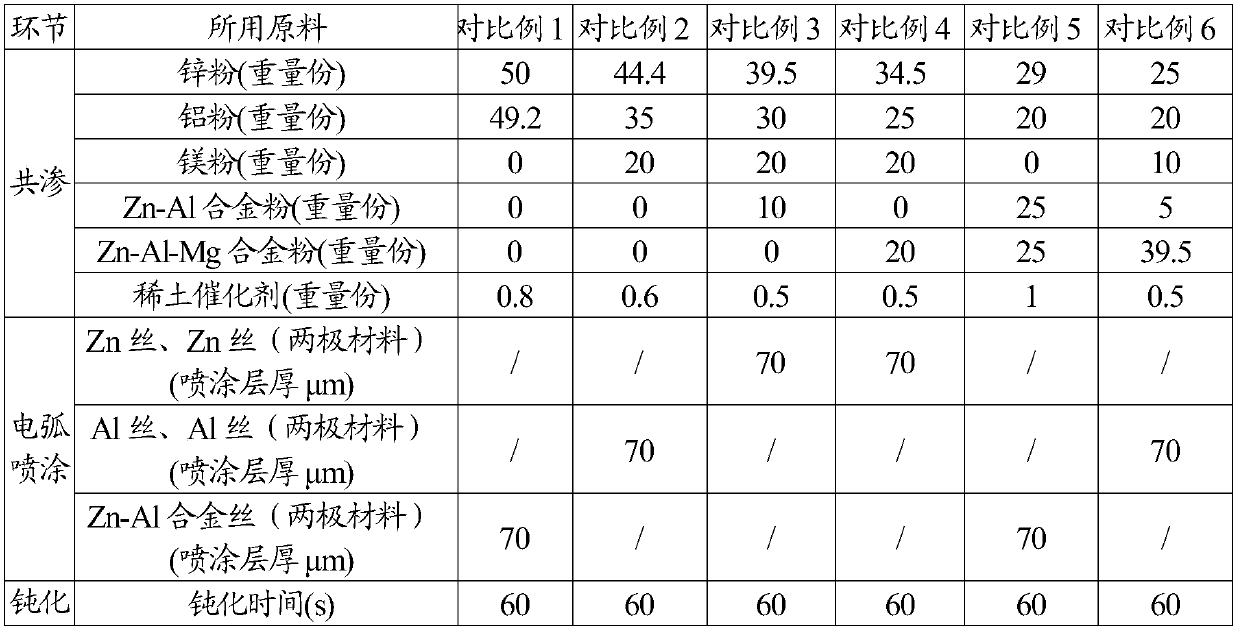

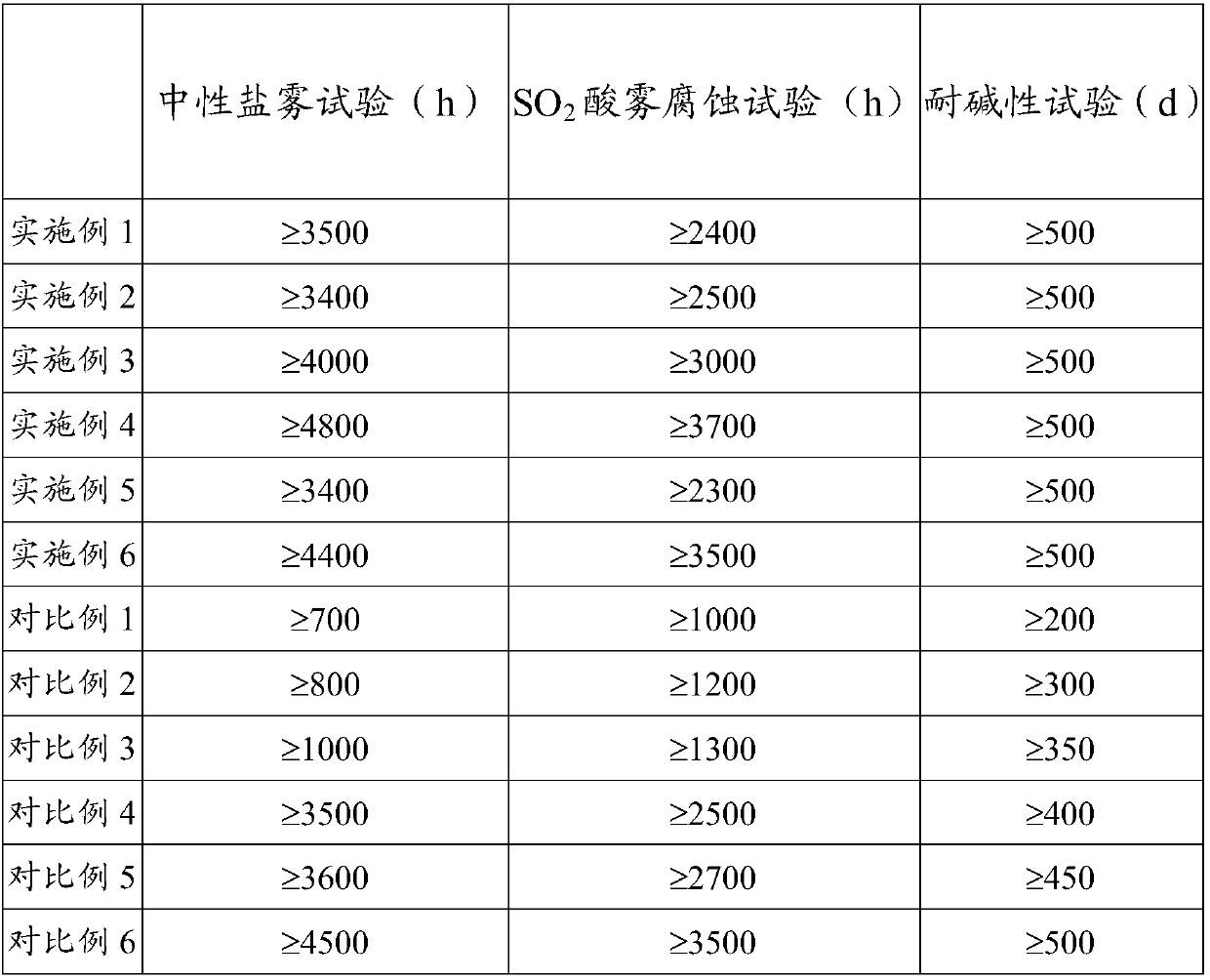

Surface passivation composite cementation layer treatment for concrete bridge affiliate steel structural component and co-cementation agent adopted therein

ActiveCN107557729AImprove machinabilitySolve technical problemsMolten spray coatingSolid state diffusion coatingRare earthAlloy

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

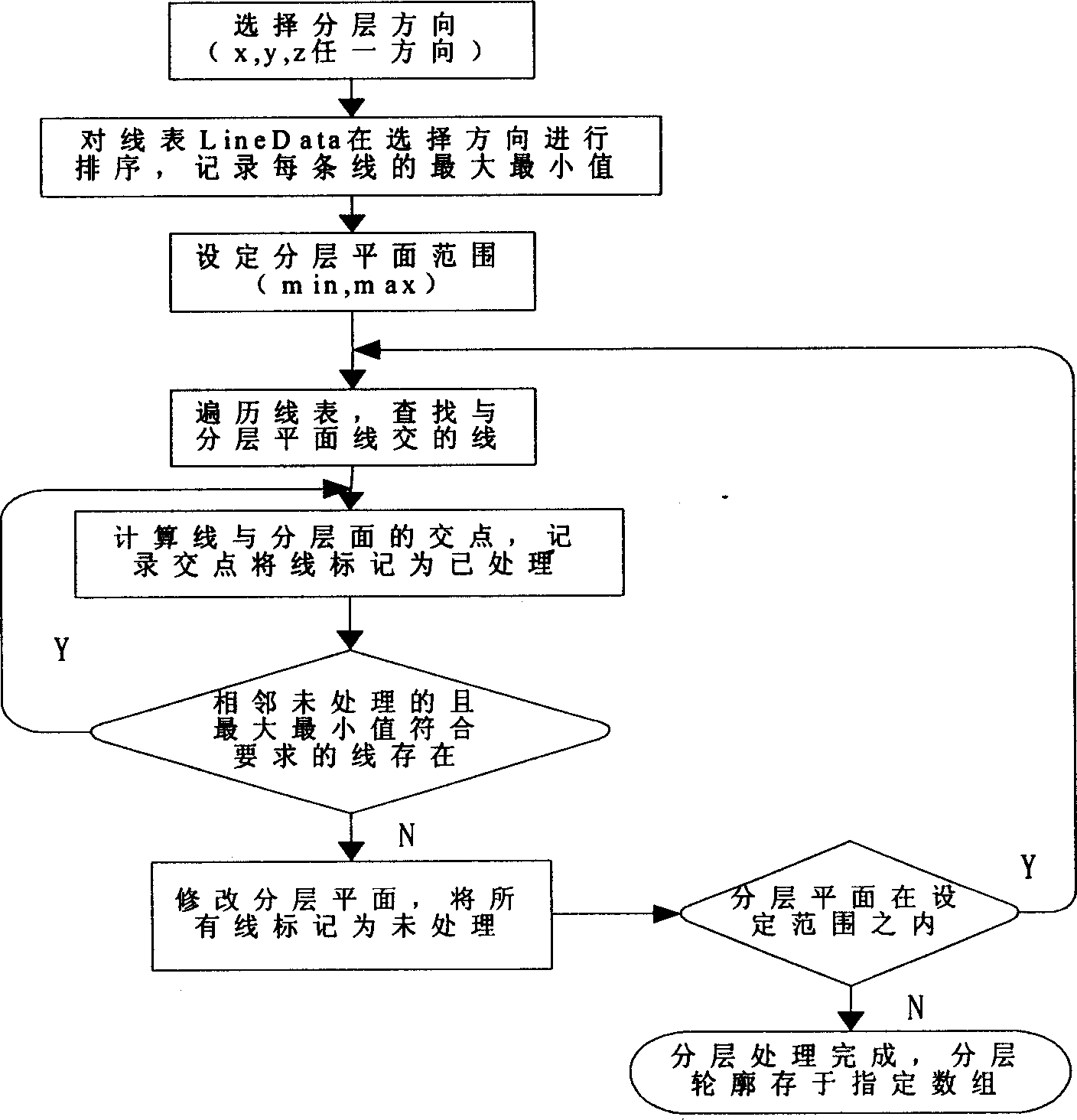

Special robot motion method with three-dimensional CAD data driving directly

InactiveCN1583373AEasy motion track controlReliable trajectory controlProgramme-controlled manipulatorShaping toolsSpatial positioningControl system

A method for using 3D CAD data to directly drive the dedicated robot used to metal arc spray on the punch die of the covering part for car includes such steps as generating the 3D CAD data of said punch die, hierarchica process of data model, slicing layer by layer, coordinate transform between the coordinate systems of computer and die-making equipment, and movement, control.

Owner:TONGJI UNIV

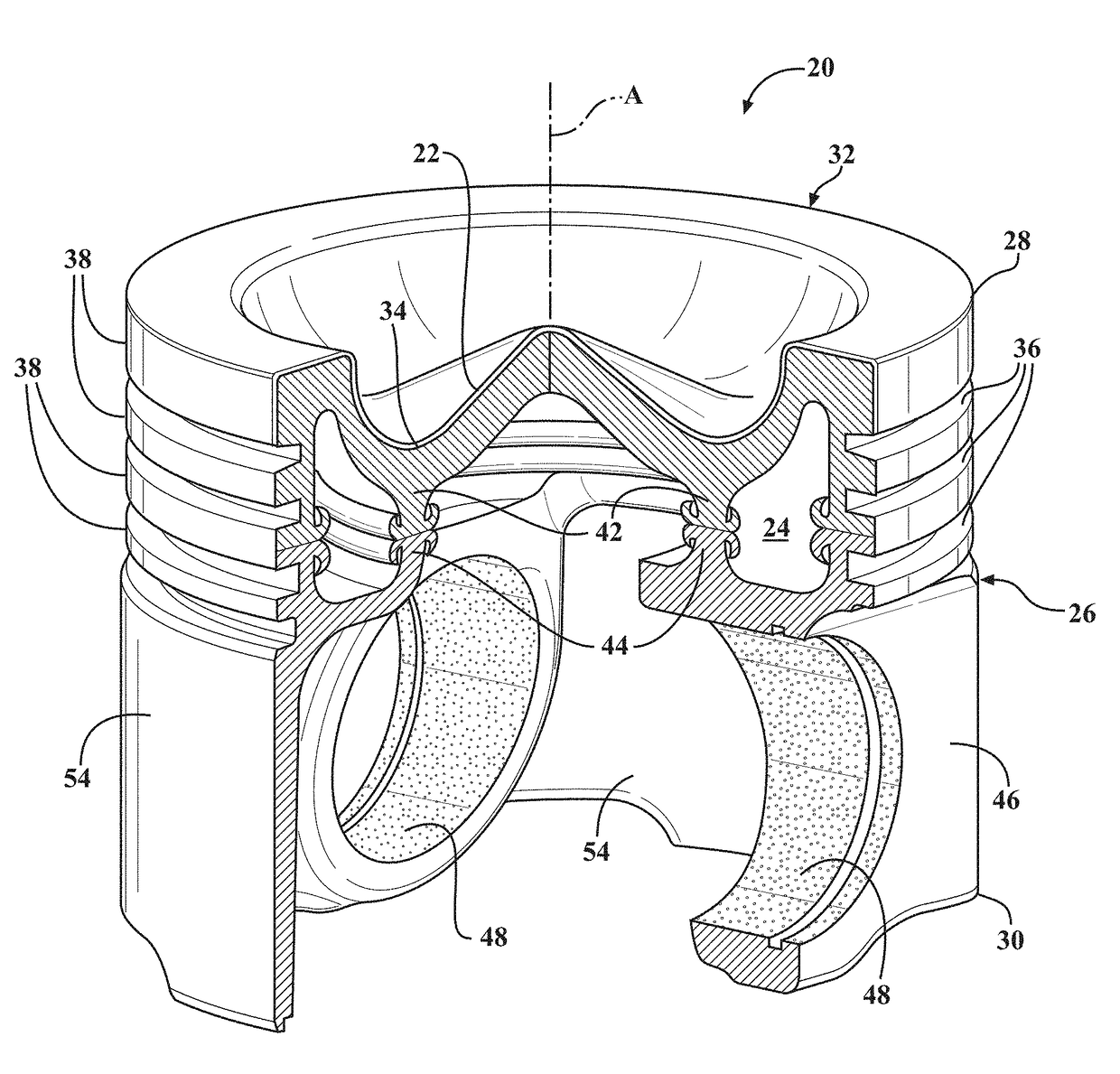

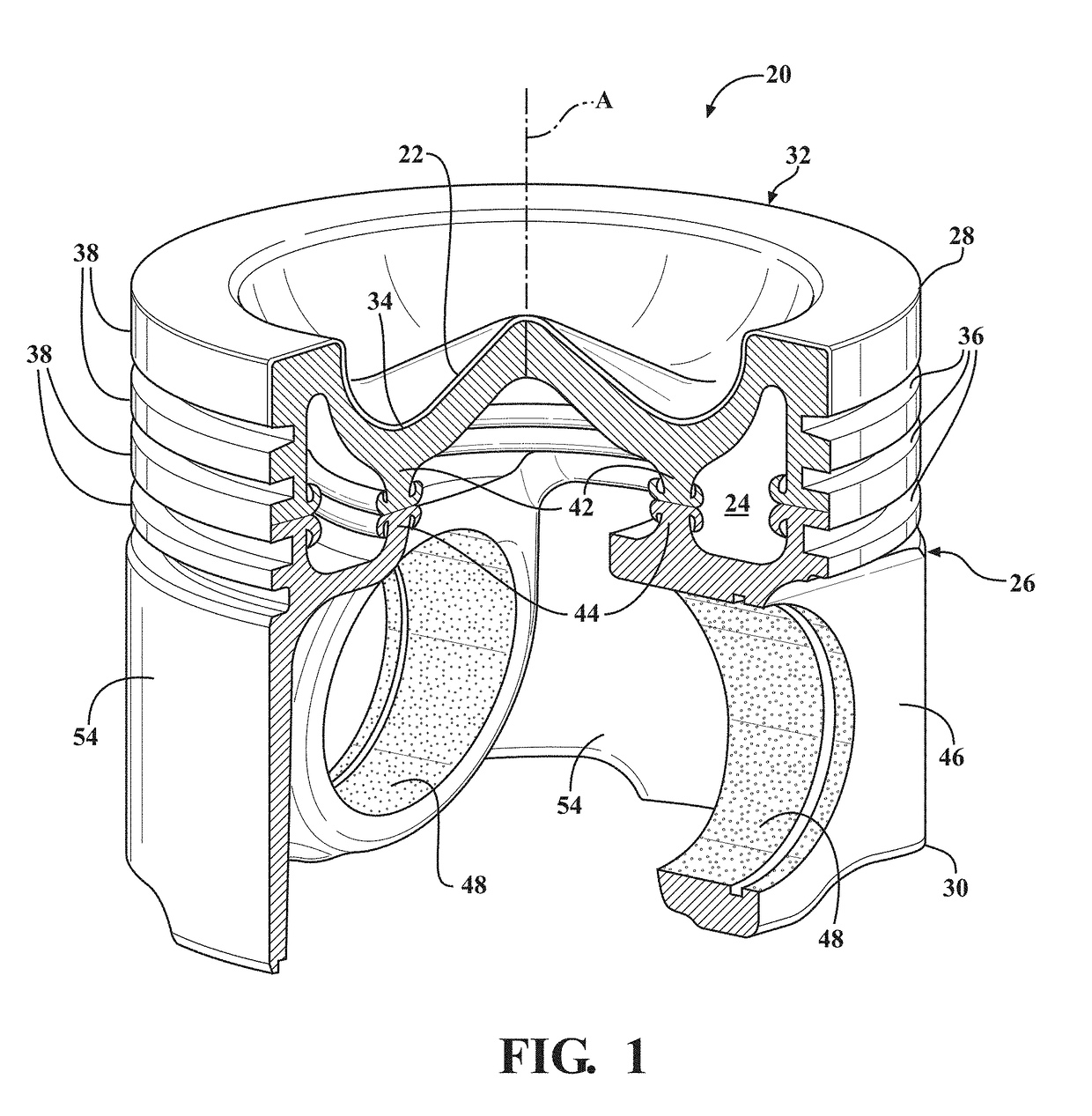

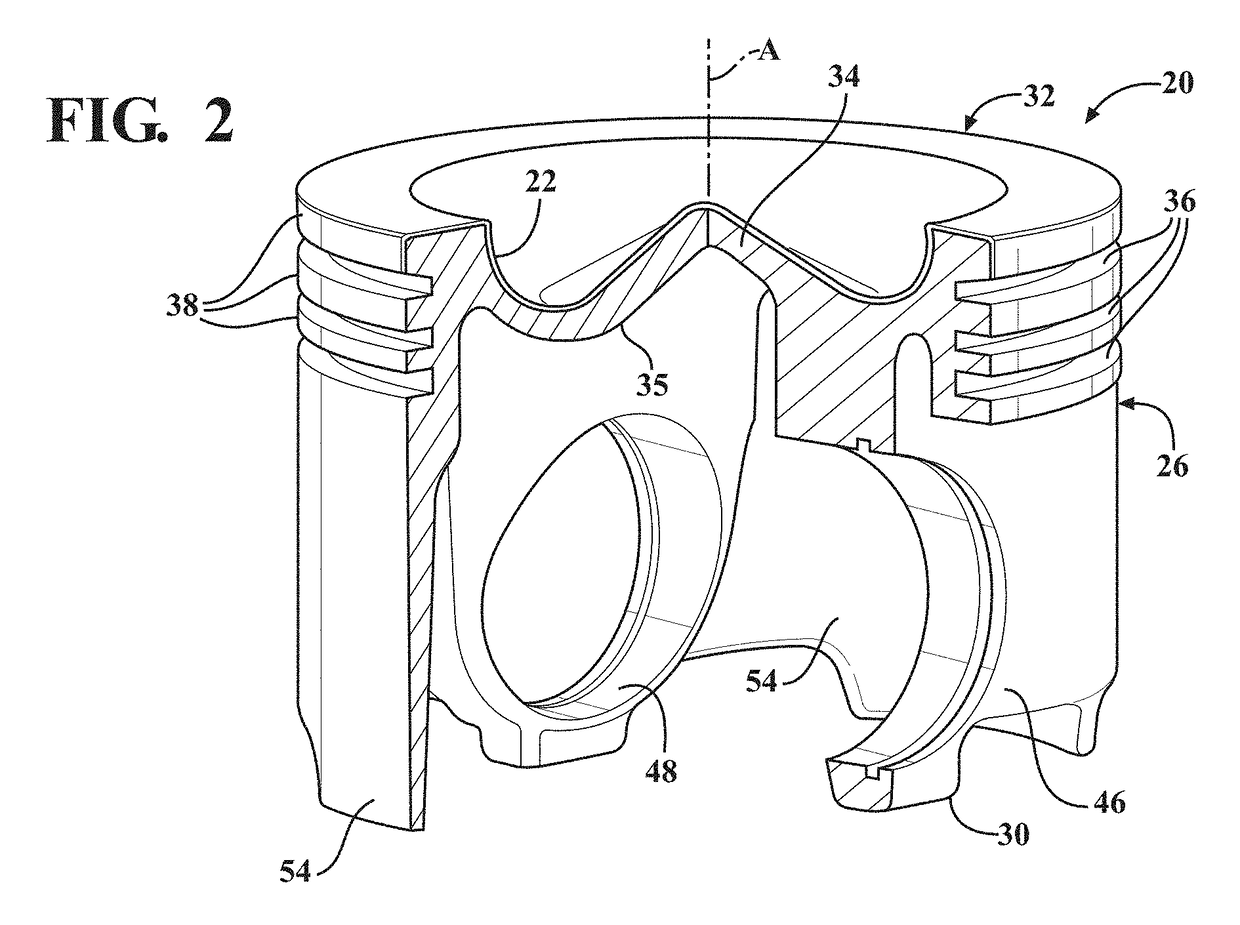

Steel piston crown and/or combustion engine components with dynamic thermal insulation coating and method of making and using such a coating

ActiveUS20180128166A1Improved thermal barrier coatingMolten spray coatingMachines/enginesThermal insulationInternal combustion engine

A piston for an internal combustion engine is provided. The piston includes a thermal barrier coating applied to a crown formed of steel. According to one embodiment, a bond layer of a metal is applied to a combustion surface of the crown, followed by a mixed layer of metal and ceramic with a gradient structure, and then optionally a top layer of metal. The thermal barrier coating can also include a ceramic layer between the mixed layer and top layer, or as the outermost layer. The ceramic includes at least one of ceria, ceria stabilized zirconia, yttria, yttria stabilized zirconia, calcia stabilized zirconia, magnesia stabilized zirconia, and zirconia stabilized by another oxide. The thermal barrier coating is applied by thermal spray, HVOF, or wire arc spraying. The thermal barrier coating preferably has a thickness less than 200 microns and a surface roughness Ra of not greater than 3 microns.

Owner:TENNECO

Automatic coating process of composite coating of large-size steel pipe

ActiveCN102211083AImprove performanceImprove bindingMolten spray coatingPretreated surfacesEpoxyWeather resistance

The invention provides an automatic coating process of a composite coating of a large-size steel pipe, comprising the following steps of: surface purification treatment, derusting by sandblast, arc aluminum spray, electrostatic epoxy resin powder spraying, and the like, wherein the thickness of an aluminum coating achieves 80-120 micrometers, and the thickness of an epoxy resin coating achieves 160-220 micrometers. According to the method disclosed by the invention, the composite coating combined by the aluminum coating and the epoxy resin coating is formed on the surface of the large-size steel pipe by combining the arc aluminum spray with the electrostatic epoxy resin powder spraying; the composite coating not only retains the excellent properties of a single coating, but also combines the characteristics of the sealing action of an arc spraying coating and the long-term protection of a cathode, has an anticorrosion coating having high binding power with the surface of the large-size steel pipe, which averagely reaches 12.0 MPa, service life more than 80 years and intermediate-frequency heating step saving, has the advantages of water resistance, impact resistance, weather resistance, environment friendliness, long-term protection, and the like, can achieve the purpose of long-term anticorrosion, also improves the structural appearance and is mainly used for the large-size steel pipe which has higher requirements for anticorrosion.

Owner:SHANGHAI JIANYE TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com