Patents

Literature

54results about How to "Extend protection life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preventing corrosion and marine creature fouling on ship propeller

InactiveCN102336256ASolve corrosiveSolve the defacementVessel cleaningMolten spray coatingOxide ceramicThermal spraying

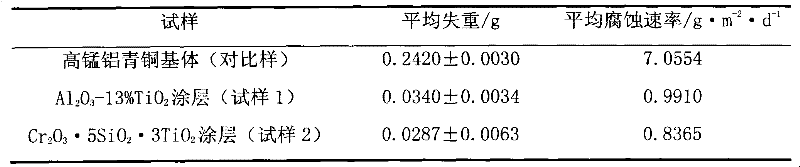

The invention relates to a method for preventing corrosion and marine creature fouling on a ship propeller. Cathode protection, a ceramic insulating coating and a metallic antifouling coating are organically combined in the method. The method comprises the following steps of: removing scales on the surface of the copper alloy propeller, obtaining a uniform and rough surface, and spraying a metallic adhesive coating by adopting a thermal spraying method; preparing a metallic oxide ceramic insulating coating on the surface of the adhesive coating by adopting the thermal spraying method, wherein the ceramic insulating coating comprises single-component oxides such as Al2O3, Cr2O3 and the like and multi-component composite powder of TiO2 or SiO2 with low melting point; preparing the metallic antifouling coating on the ceramic insulating coating, wherein the metallic antifouling coating is made of pure copper or copper alloy with antifouling function; and meanwhile, performing cathode protection on the propeller. The ceramic and the metallic coating adopted in the method have higher bonding force and longer protection life, the current requirement of the ship cathode protection is reduced, the corrosion and marine creature fouling problems of the ship propeller can be simultaneously solved, and the ceramic and the metallic coating have obvious corrosion resistance and antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Metal rust-proofing wax and method for manufacturing same

InactiveCN101104774AExtended service lifeHydrophobicWax coatingsAnti-corrosive paintsWaxPreservative

Disclosed is an antirust wax for metal and the preparation method. The wax comprises 8-28kg of wax product, 4-10kg of synthetic resin, 6-10kg of metal corrosion inhibitor, 4-9kg of surfactant, 1-2kg of antiseptic and water. The preparation method comprises the steps: 1. slowly heating the mixture in a stainless steel vessel containing wax product, synthetic and metal corrosion inhibitor added in proportion into an oil phase material; 2. adding surfactant into water and heating the mixture until the mixture turns into aqueous phase material; 3. adding oil phase material into the aqueous phase material by high-speed stirring; 4.adding antiseptic into the container. Wax product and synthetic resin are used as film forming materials in this invention, which provides the antirust wax with hydrophobicity as well as good compactness and toughness so as to lengthen the service life. The wax has the advantages of no harm, no smell, and no pollution to the environment. The surfactant provides the product with antistatic properties and better antirust performance.

Owner:金京

Acrylic polyurethane silicofluoride coating as well as preparation method and application method thereof

ActiveCN104017480AImprove adhesionGood flexibilityAntifouling/underwater paintsPretreated surfacesPolymer scienceAcrylic resin

Owner:湖南惠电科技有限公司

Process for preparing antioxidant and wear-resistant layer on surface of copper

InactiveCN101638788AImprove the protective effectExtend protection lifeMolten spray coatingThermal sprayingWear resistant

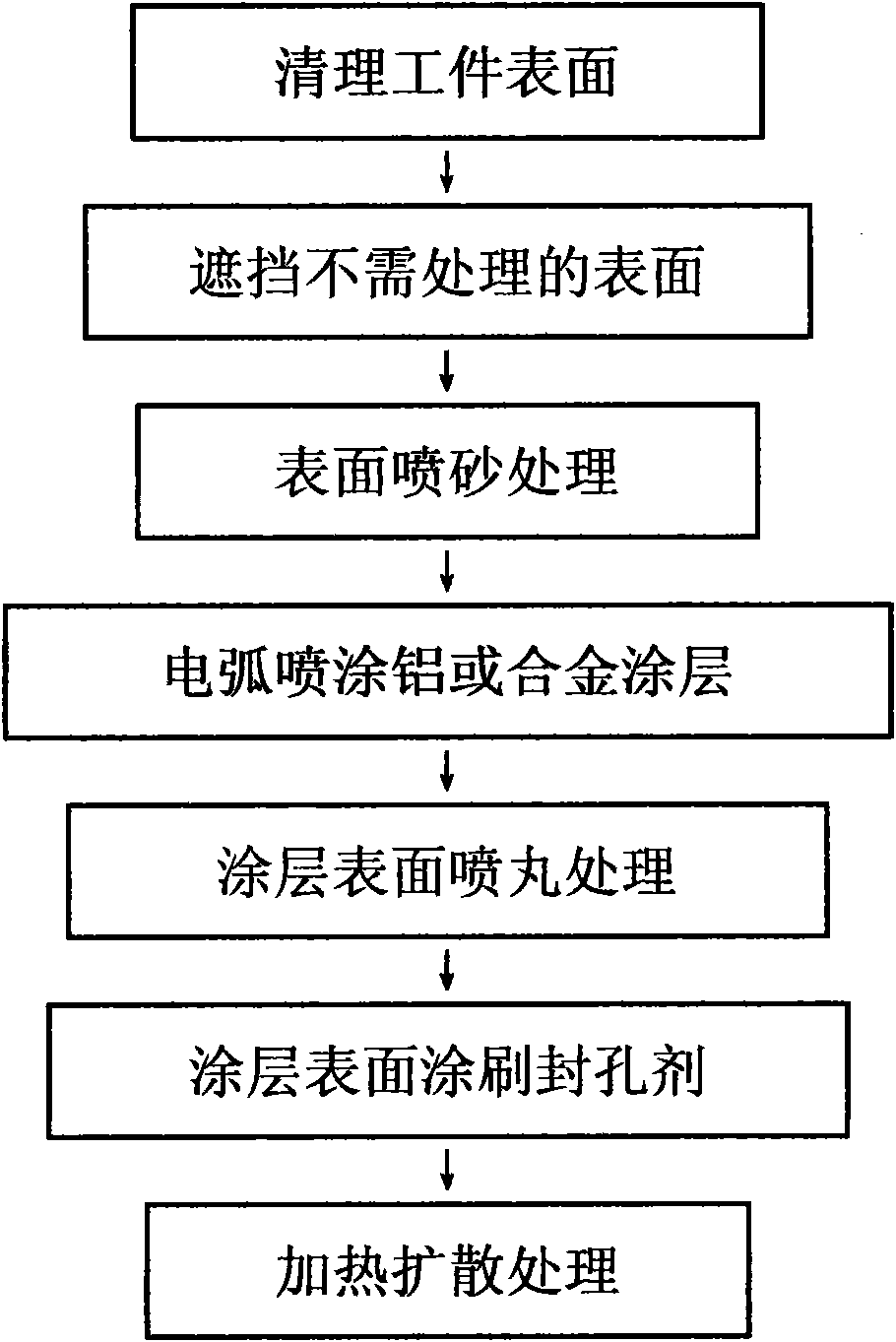

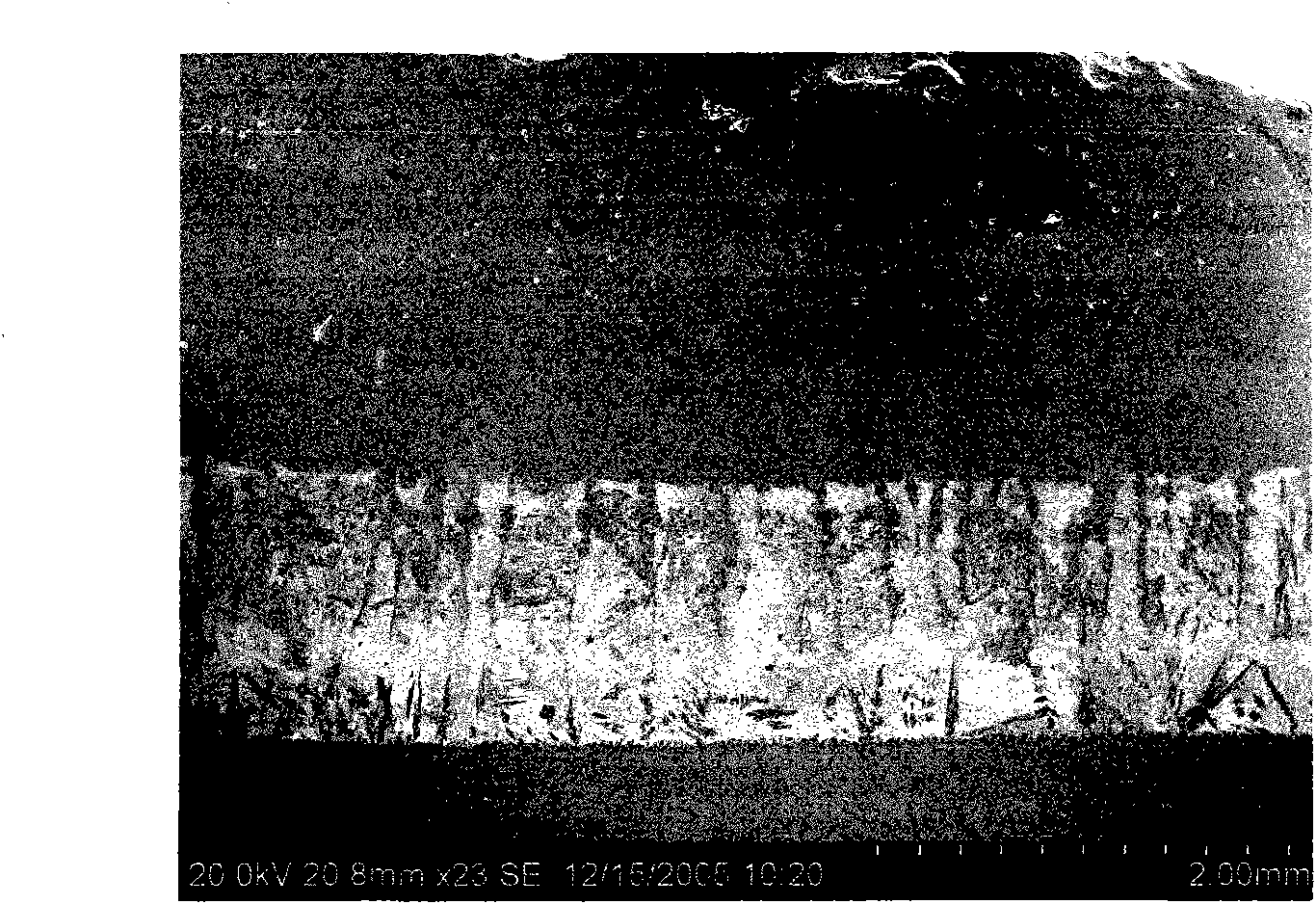

The invention provides a process method for preparing an aluminide penetrating layer on the surface of pure copper or a copper alloy by combining the thermal spraying technology and the thermal treatment technology, which comprises the following steps: firstly, spraying a layer of pure aluminium coating on the surface of a copper product through arc; secondly, performing shot blasting and sealingagent coating treatment on the surface of the coating; and finally, performing thermal treatment at a temperature of between 800 and 900 DEG C, maintaining the temperature for 2 to 4 hours, and obtaining an aluminide layer over 3mm on the surface of the pure copper. The aluminide layer prepared by the method has good combination with a copper substrate, good antioxidant performance and good wear resistance. The method can prepare the aluminide penetrating layer, and also can prepare aluminium-molybdenum, aluminium-silicone, aluminium-chromium binary or multi-metallic diffusion layers.

Owner:SHENYANG POLYTECHNIC UNIV

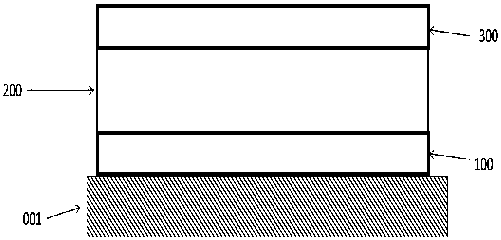

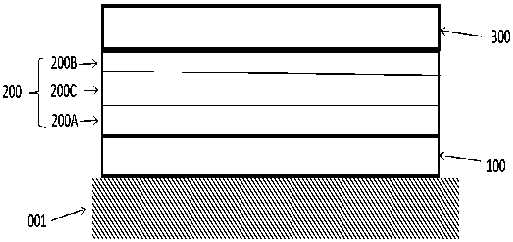

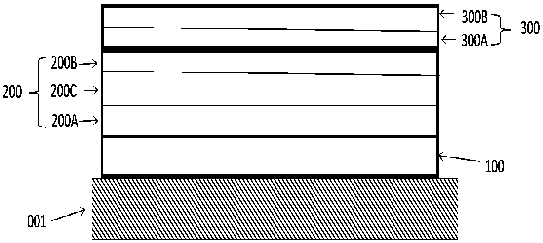

Article with intermediate layer and protective layer, and its fabrication

InactiveUS6838190B2Improve antioxidant capacityTrend downPropellersRotary propellersPlatinumRuthenium

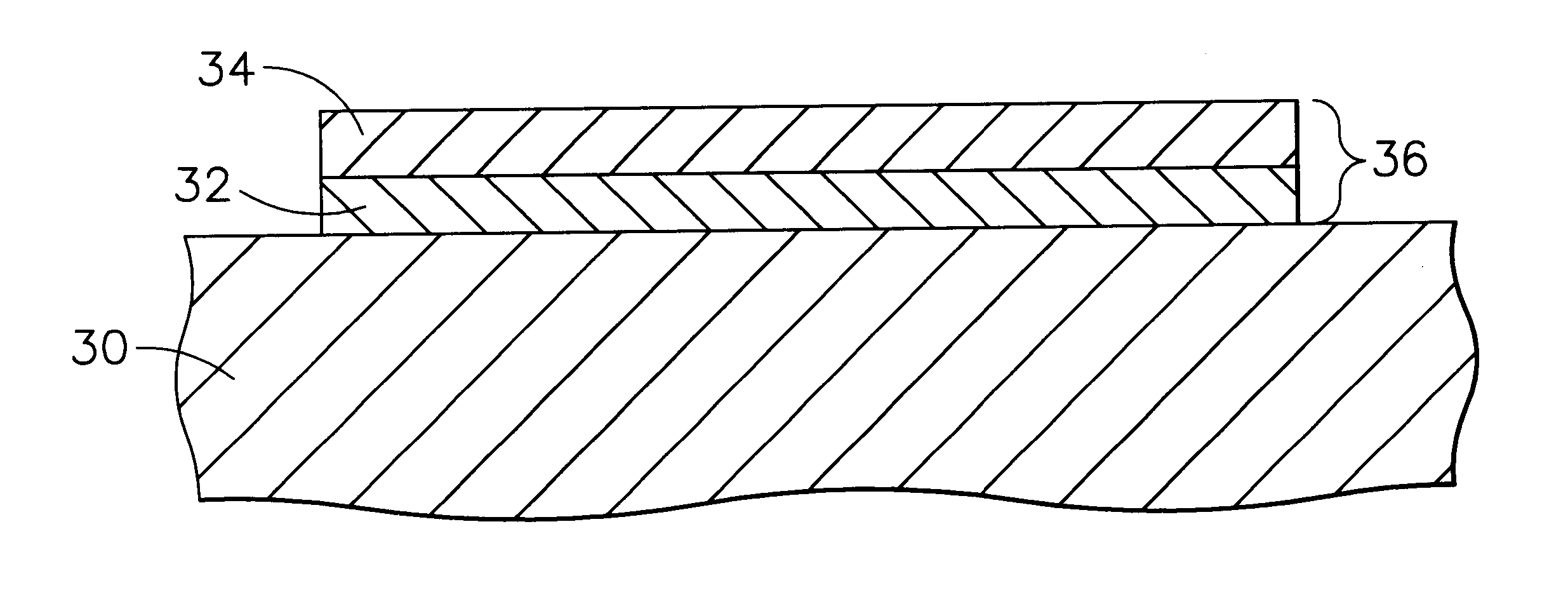

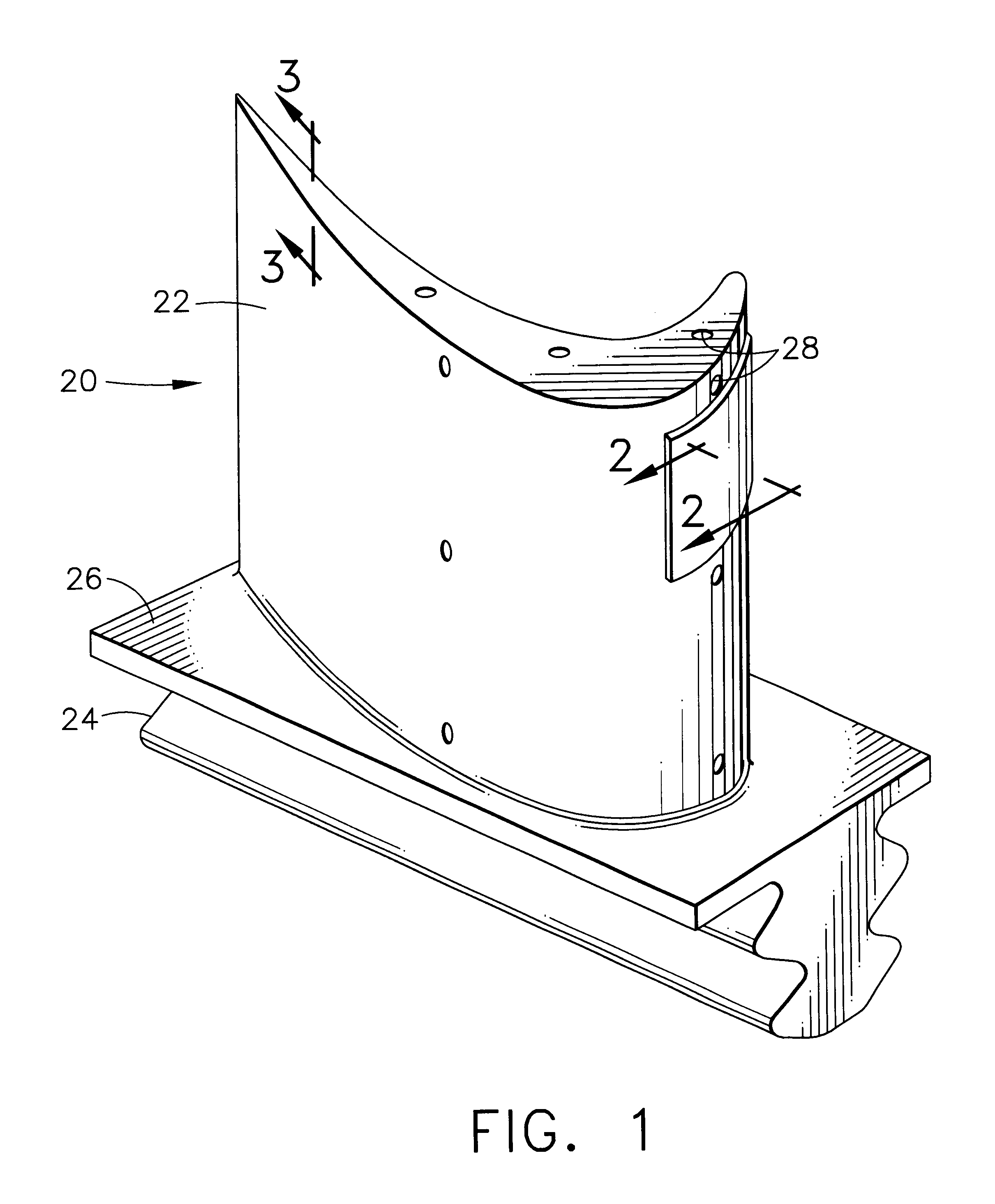

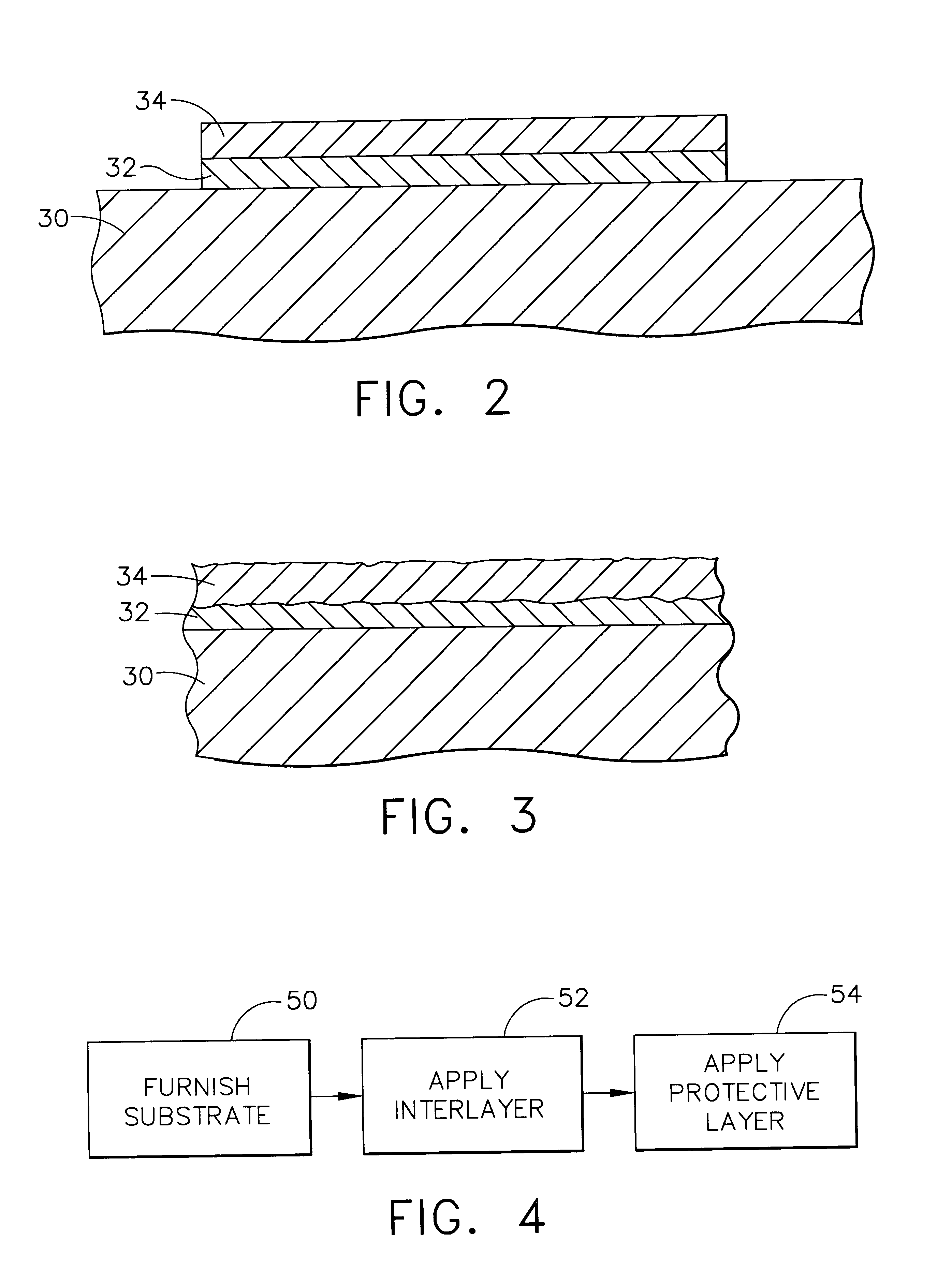

A protected article includes a nickel-base superalloy substrate, an interlayer overlying the substrate, and a protective layer overlying the interlayer. The protective layer has a composition comprising at least one of rhodium, platinum, palladium, and ruthenium. In one composition, palladium is present in an amount of from about 1 to about 41 atomic percent; platinum is present in an amount of about (40+atomic percent palladium) atomic percent for palladium ranging from about 1 atomic percent to about 14 atomic percent and up to about 54 atomic percent for palladium ranging from about 15 atomic percent up to about 41 atomic percent; rhodium is present in an amount of at least about 24 atomic percent; zirconium, hafnium, titanium, and mixtures thereof are present in an amount of from zero up to about 5 atomic percent; and ruthenium is present in an amount of from zero up to about 5 atomic percent, balance impurities. The interlayer has a coefficient of thermal expansion intermediate between that of the substrate and that of the protective layer. The protected article is fabricated by furnishing the substrate, applying the interlayer over the substrate, and applying the protective layer over the interlayer. The application of the protective layer may be, for example, by welding or attachment of a solid piece.

Owner:GENERAL ELECTRIC CO

Bicomponent silicofluoride acrylic polyurethane coating as well as preparation and application methods thereof

ActiveCN104017479AImprove adhesionGood flexibilityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

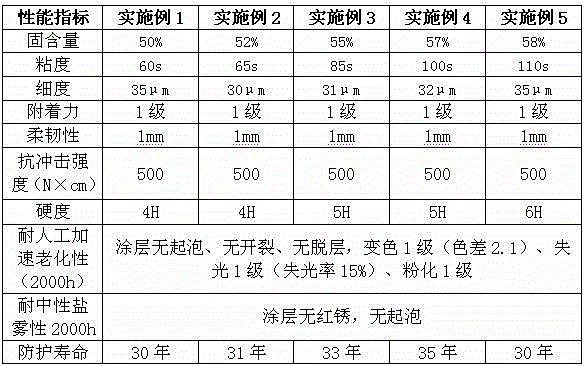

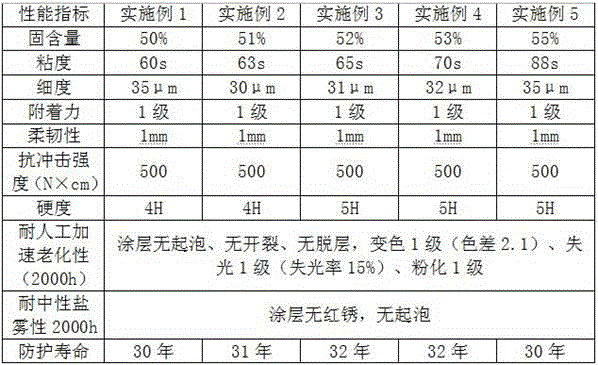

The invention relates to the technical field of protection coatings and in particular relates to a bicomponent silicofluoride acrylic polyurethane coating. The coating comprises a first component and a second component, wherein the mass ratio of the first component to the second component is (3 : 1) to (5 : 1); the first component comprises the following raw materials by weight parts: 50-70 parts of hydroxy acrylic resin, 15-24 parts of a solvent, 0.1-3 parts of fluorine-containing micropowder, 10-25 parts of a pigment, 1-3 parts of high-hardness oxide and 2-5 parts of aids; the second component comprises the following raw materials in parts by weight: 50-80 parts of a closed isocyanate curing agent and 20-50 parts of a solvent. According to the coating, the capability of protecting a steel structure can be improved; the coating has the characteristics of good ageing resistance, scratch resistance, corrosion prevention, color change prevention, pollution prevention and the like, and can achieve a very good long-acting protection effect on the steel structure by combination with other base paint and intermediate paint with excellent performance; and the protection life can be 30 years.

Owner:广东惠电科技发展有限公司

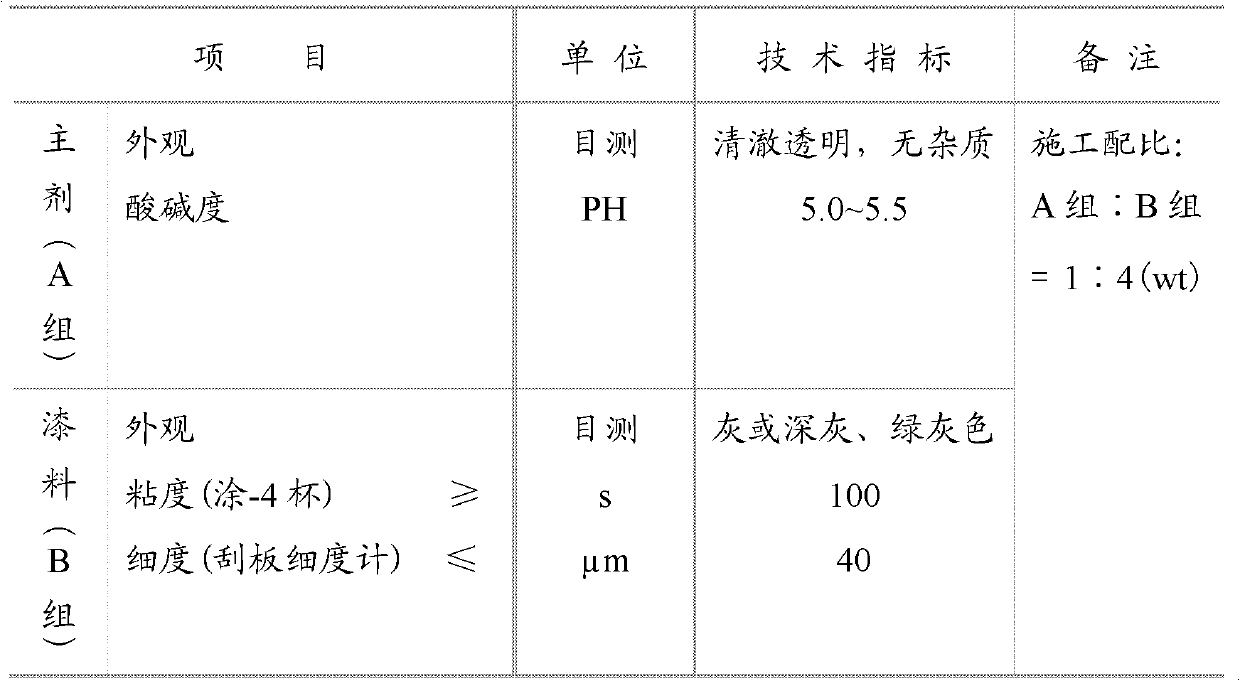

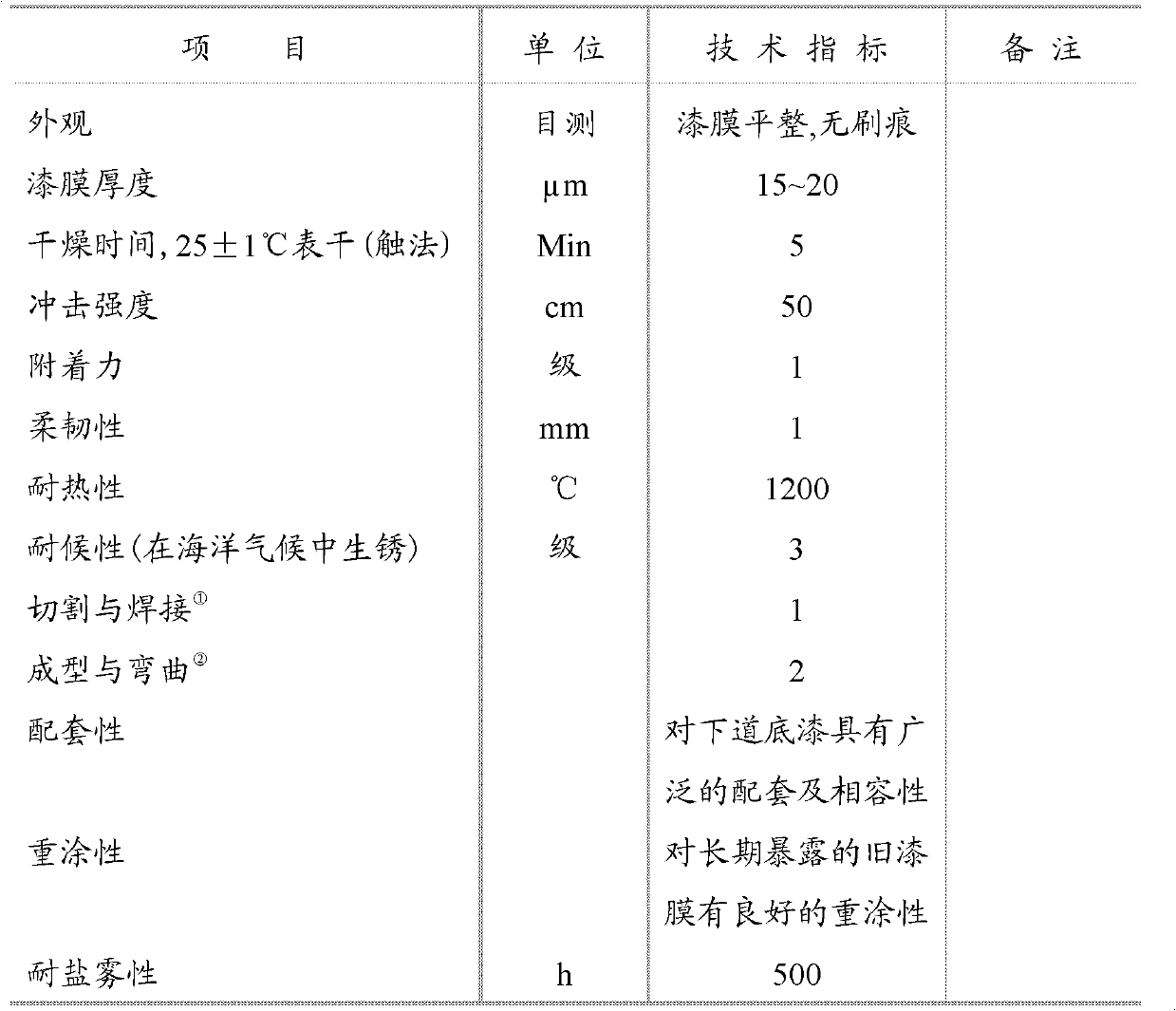

Delayed-combustion-retarding high-temperature-resisting workshop primer and preparation method thereof

ActiveCN102558922AGuaranteed Membrane PerformanceSmall burning areaCoatingsCombustionHeat resistance

The invention discloses a delayed-combustion-retarding high-temperature-resisting workshop primer. The key technology is that high-temperature film-forming materials are used. Two high-temperature film-forming materials are compounded in the formula, the melting points of the high-temperature film-forming materials are respectively in a range of 480-490 DEG C and a range of 680-700 DEG C, accordingly a primary film material can be followed to form a secondary continuous film and a ternary continuous film before the high-temperature heat weightlessness is not yet invalid completely, and coatings are ensured to be not crack. Simultaneously, the heat resistance of the coatings reaches to more than 800 DEG C, the area of the burning loss is very small, and smoke is hardly produced in the cutting or welding operation process.

Owner:GUANGZHOU GEMBOND CHEM

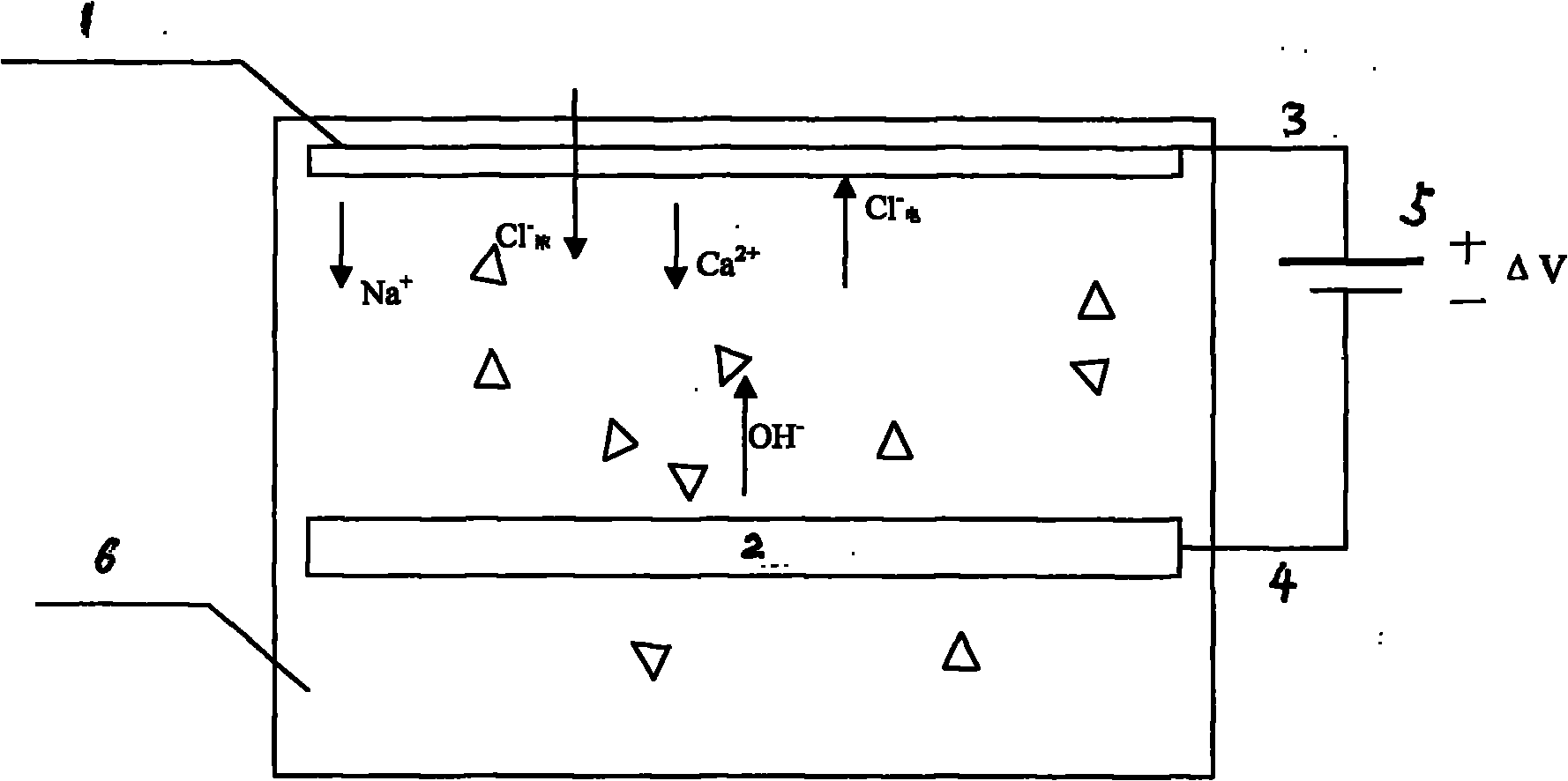

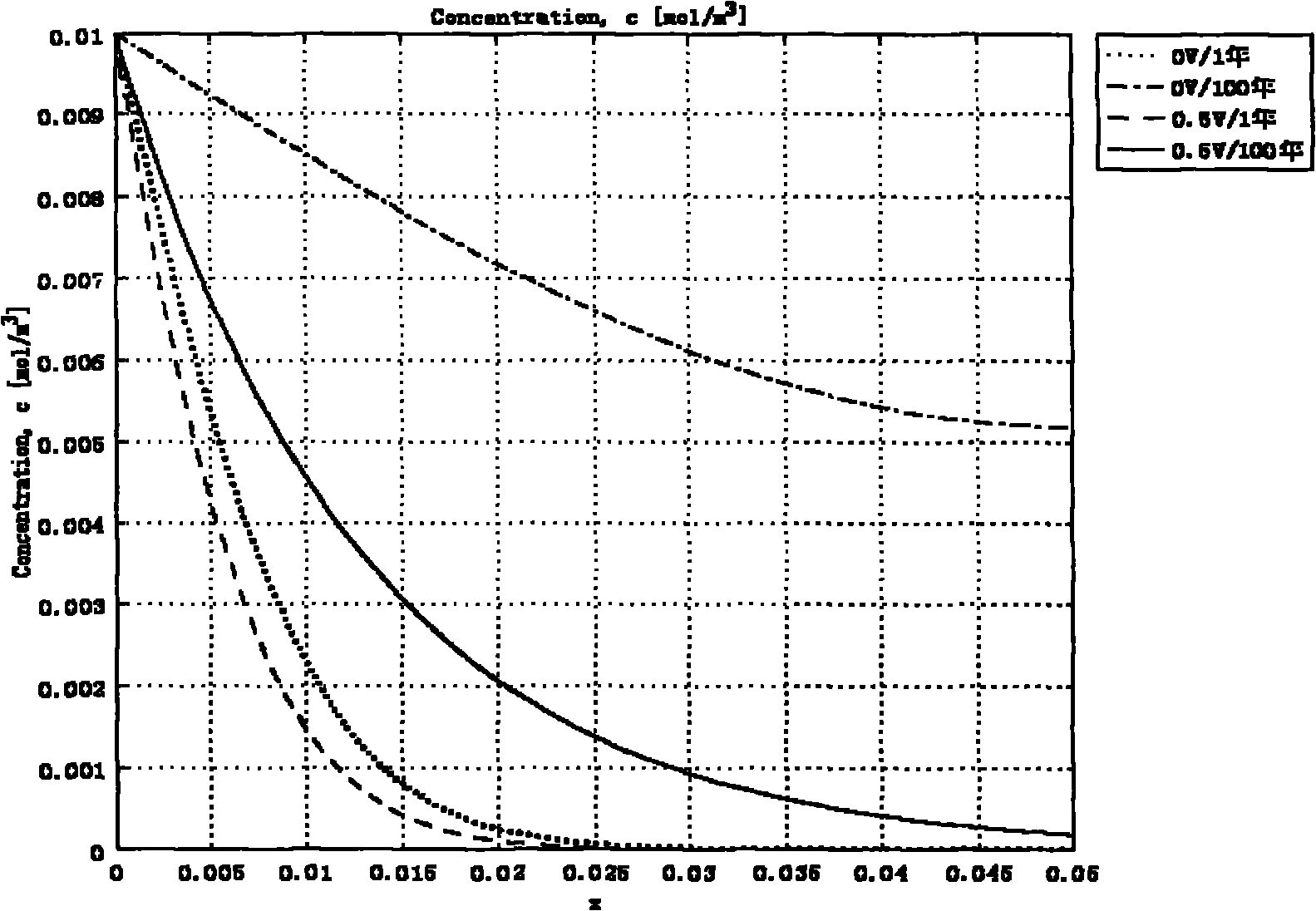

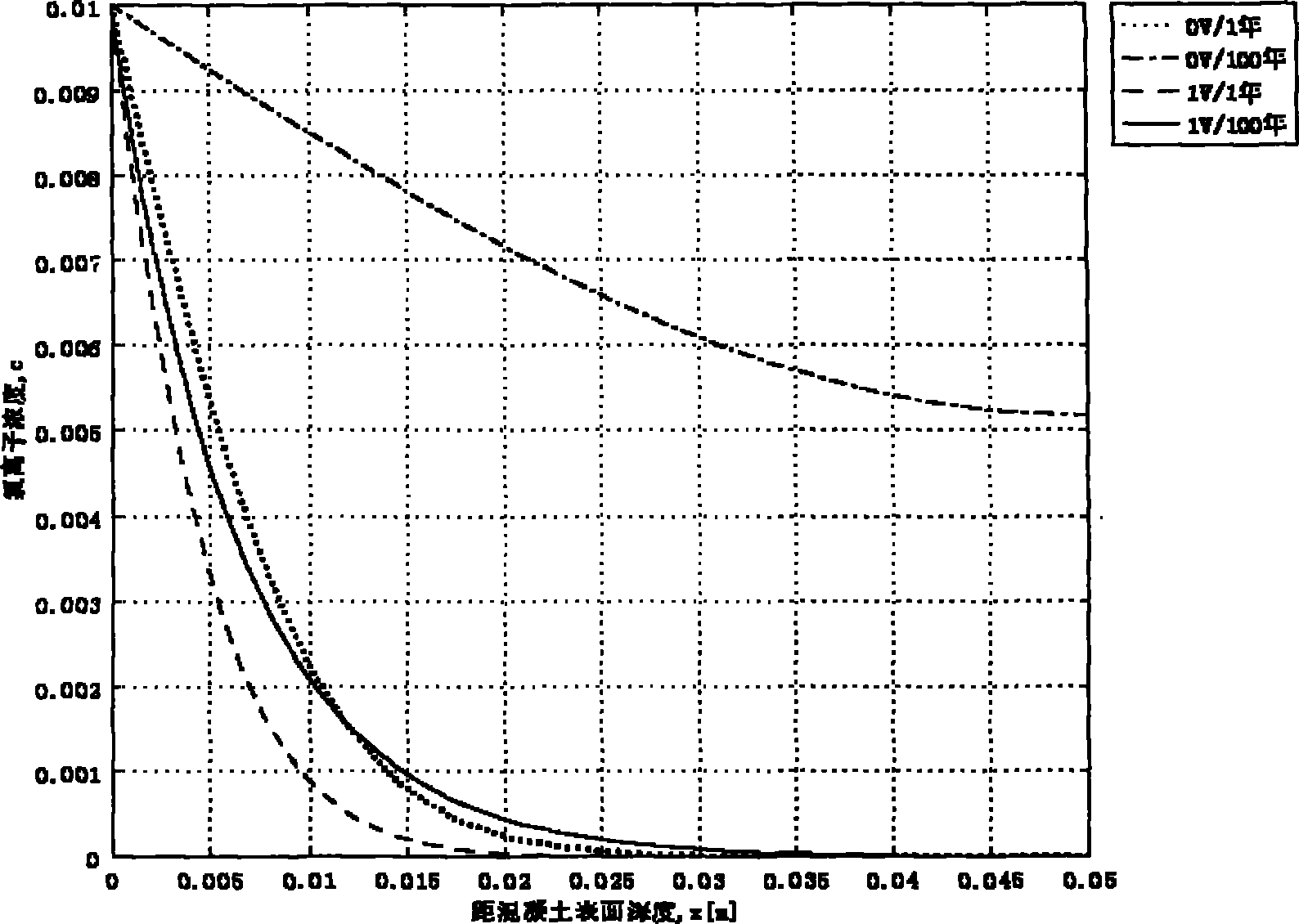

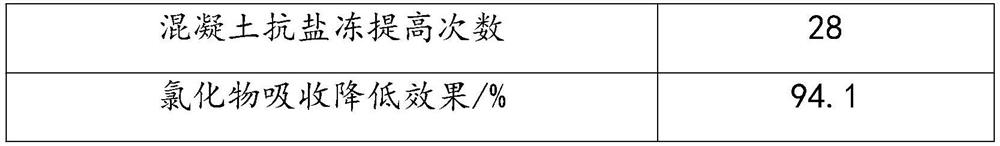

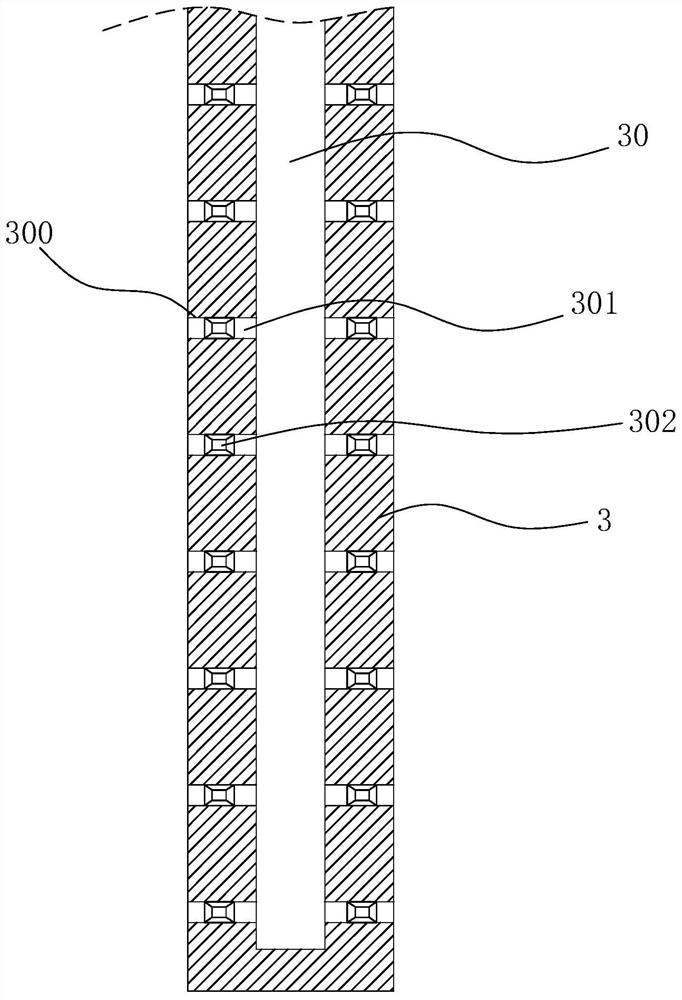

Electric field salt rejection protective system protected by reinforced concrete structure in chloride environment

InactiveCN101839024APrevent intrusionLong-lasting protection against corrosionBuilding insulationsRebar corrosionEngineering

The invention discloses an electric field salt rejection protective system protected by a reinforced concrete structure in chloride environment, which is provided with an anode arranged on the surface layer of the concrete structure and an anode cable connected on the anode; the reinforcement in the concrete is used as a cathode and is provided with a cathode cable connected on the reinforcement and simultaneously provided with a direct-current power supply. The invention is characterized in that the output voltage of the direct-current power supply between the anode and the cathode is 0.5-1V; and the current density in the reinforcement is 0.3-0.7mA / m<2>. The new corrosion guard introduced by the invention provides a new electric field salt rejection system aiming at the essence that chloride in external environment invades concrete to cause reinforcement corrosion; aiming at the new reinforced concrete structure in chlorine environment, the adoption of the system can effectively prevent chloridions from penetrating into the environment, thus achieving the purpose of protecting durable non-corrosion on the internal reinforcement. The electric field salt rejection system has simple constitution, good salt rejection effect and long protective service life, and is convenient for implementation and maintenance management.

Owner:NANJING HYDRAULIC RES INST

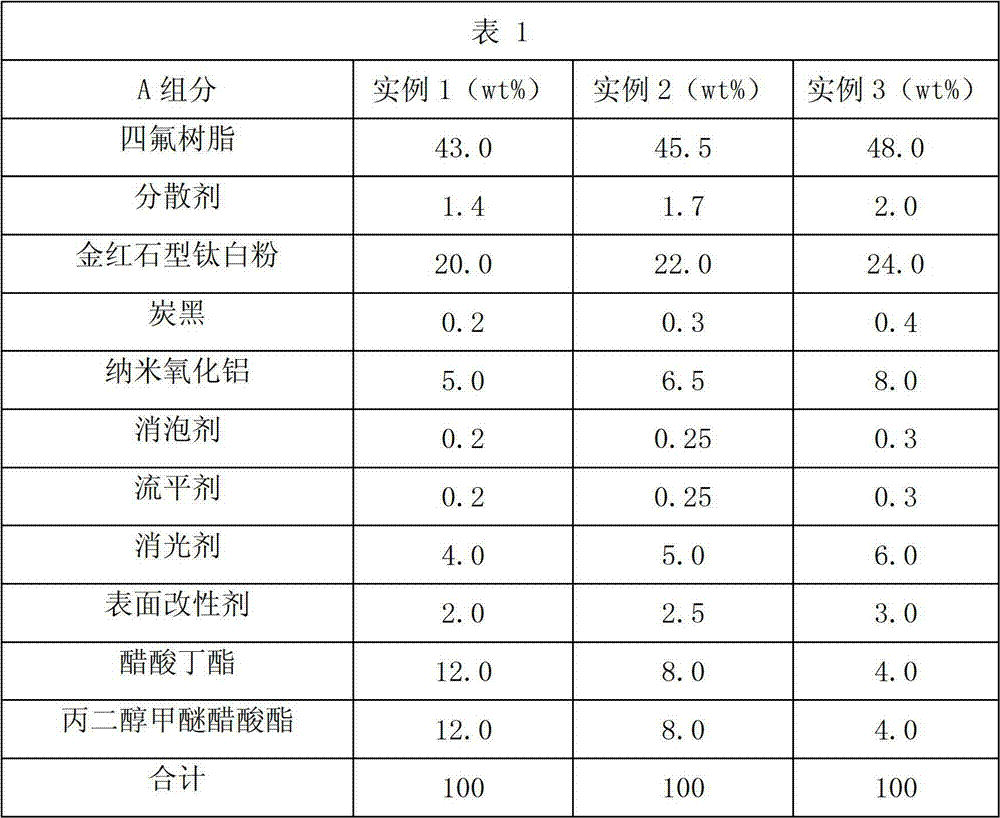

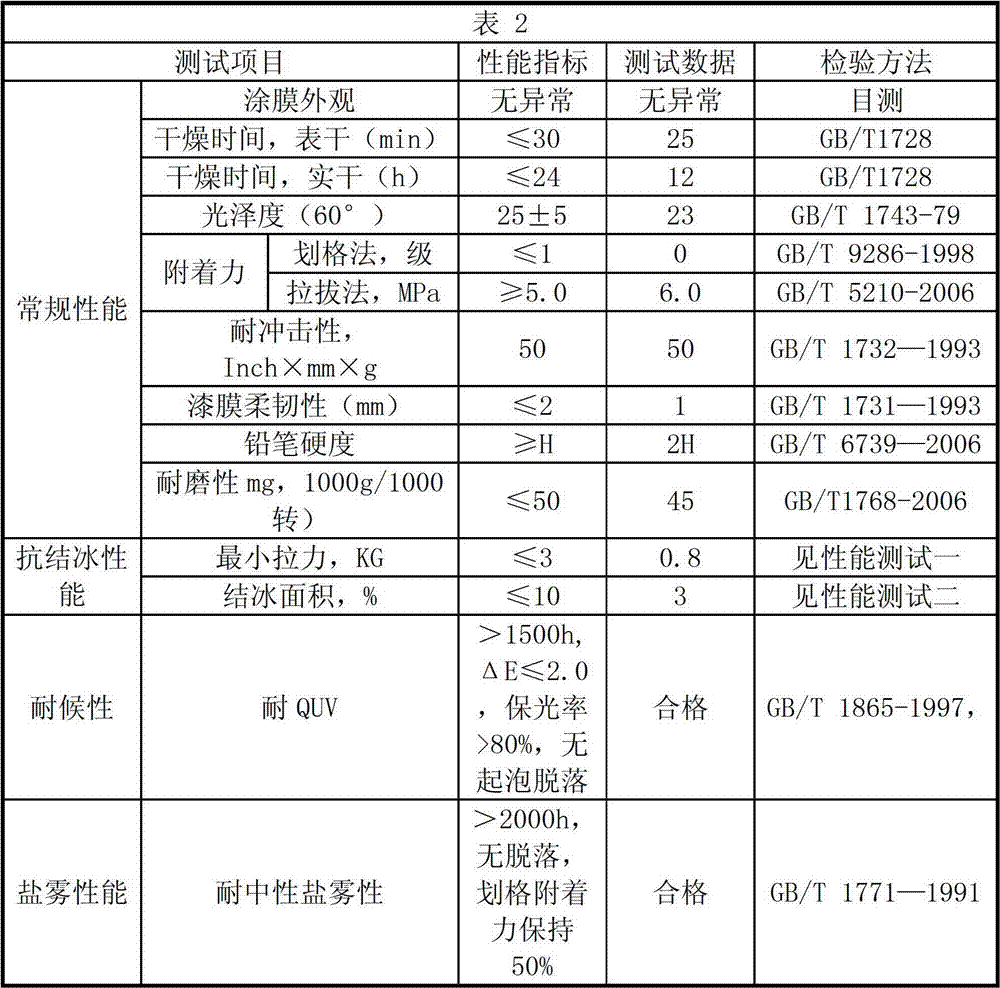

Anti-icing coating for wind turbine blade, and preparation method of anti-icing coating

The invention relates to an anti-icing coating for a wind turbine blade, and a preparation method of the anti-icing coating for the wind turbine blade. The anti-icing coating for the wind turbine blade consists of a component A and a component B, wherein the mass ratio of the component A to the component B is 1.5:1. The component A comprises the following components: tetrafluoro-resin, a dispersant, rutile type titanium dioxide, carbon black, nano alumina, a defoamer, a leveling agent, a flatting agent, a surface modifier, butyl acetate, propylene glycol methyl ether acetate, and the component B is hexamethylene diisocyanate (HDI) trimer. The preparation method of the anti-icing coating for the wind turbine blade comprises the following steps: preparing the component A, preparing the component B, and mixing the component A and the component B in the mass ratio of 1.5:1 to prepare the coating, and the anti-icing coating for the wind turbine blade has the advantages of excellent weatherability, wear resistance and flexibility property and also has outstanding anti-icing performance.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN +2

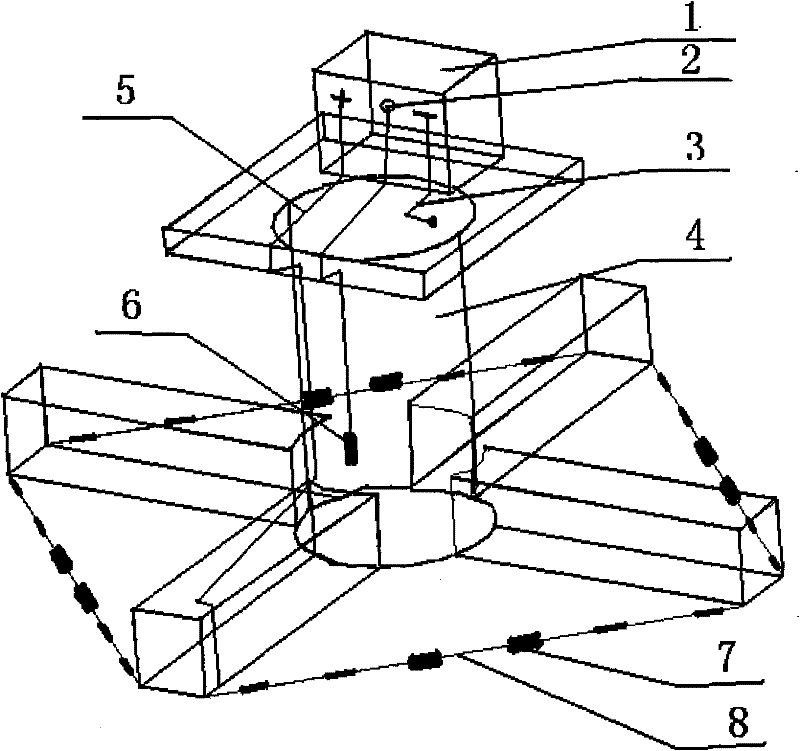

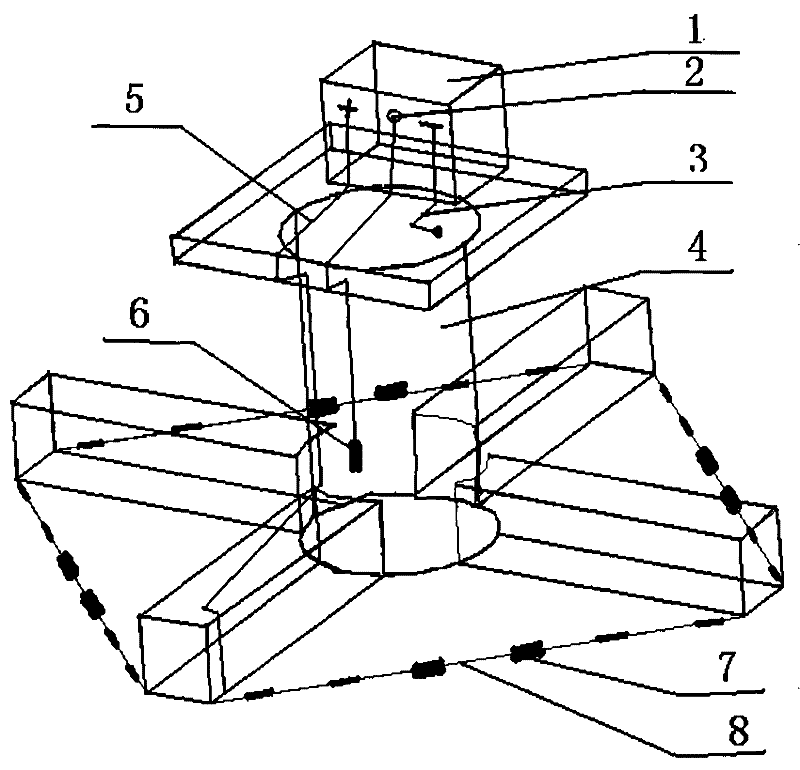

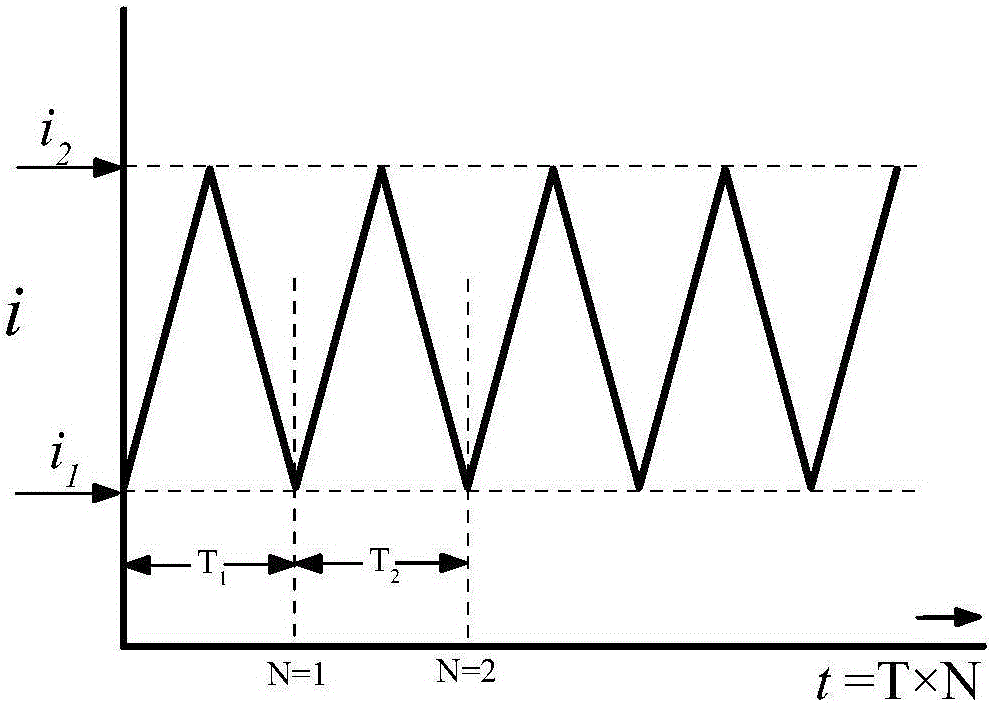

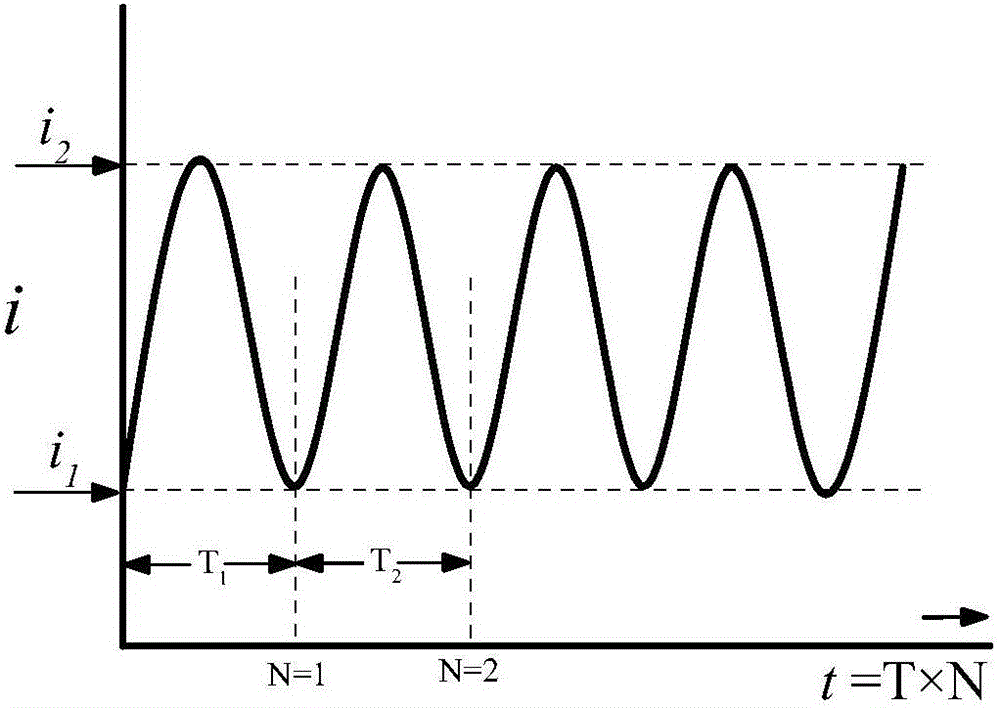

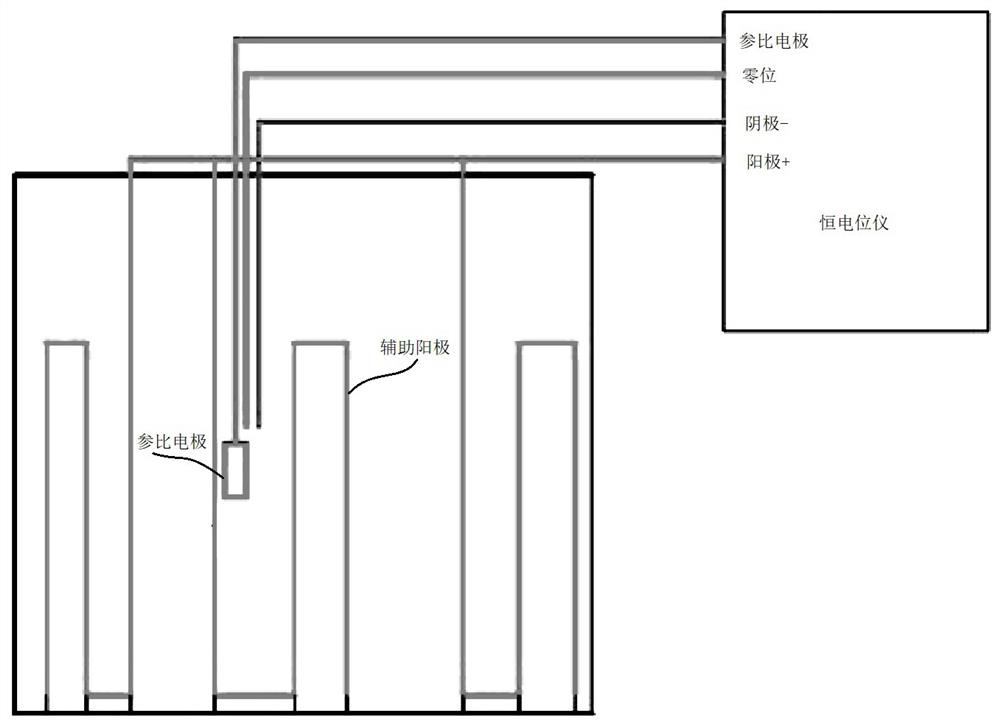

Impressed current cathodic protection method for tension leg platform

A cathodic protection method with applied current for a tension leg platform, which is provided with a DC power supply, an auxiliary anode string, a reference electrode and a connecting cable, the negative pole of the DC power supply is connected to the upper part of the platform through a cathode cable, and the positive pole is connected to the auxiliary anode string through an anode cable Connection, the DC power supply is provided with a reference electrode terminal, the DC power supply is connected to the reference electrode through the electrode terminal, and the reference electrode is installed and fixed on the tension leg platform and immersed in seawater. The invention can effectively protect the tension leg platform and prevent seawater from corroding the tension leg platform, and is especially suitable for a large tension leg platform; moreover, it is easy to install, has a long protection life and strong reliability.

Owner:CHINA NAT OFFSHORE OIL CORP +2

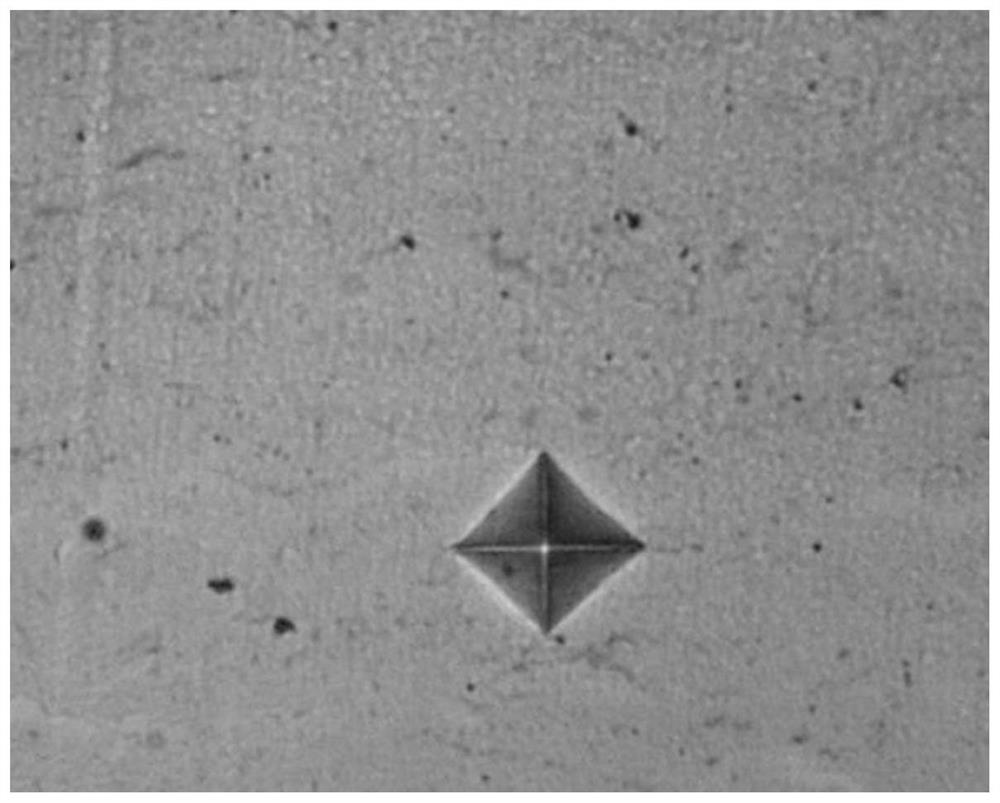

Nickel alloy composition modulated multilayer alloy (CMMA) coating and preparation method thereof

The invention provides a nickel alloy composition modulated multilayer alloy (CMMA) coating and a preparation method thereof. The nickel alloy CMMA coating is of a multilayer structure, and the number of layers of the nickel alloy CMMA coating is 50-1000. The coating structure comprises a nanoparticle phase and amorphous embedded nanocrystalline composite structure phase. The preparation method of the nickel alloy CMMA coating comprises the step that during electrodeposition, the nickel alloy CMMA coating with the compositions and structure changing periodically is obtained by changing the current density periodically to control the liquid-phase mass transfer process of an electrolyte in the cathode. According to the nickel alloy CMMA coating, performance design and microstructure adjustment and control can be achieved, the bonding force of the nickel alloy CMMA coating and a base material is good, the corrosion resistance and the abrasion resistance are excellent, and the nickel alloy CMMA coating can be widely applied to surface protection treatment of offshore engineering machines, water engineering metal structures and mechanical parts.

Owner:HOHAI UNIV

Nano material modified fluorocarbon resin stone waterproof coating

The invention discloses a nano material modified fluorocarbon stone stone waterproof coating. The coating includes the following raw material components: resin raw material consisting of vinylidene fluoride resin and acrylic resin, multi-layer graphene oxide, a silane coupling agent, dibutyltin dichloride and solvent oil. The hardness, wear resistance and permeability resistance of the nano material modified fluorocarbon stone stone waterproof coating can be greatly improved by two-dimensional nanomaterial technology on the premise of guaranteeing of the transmittance and glossiness of the stone waterproof coating, and the protection life and the protection effect of the stone waterproof coating are greatly improved.

Owner:云浮华云创新设计有限公司

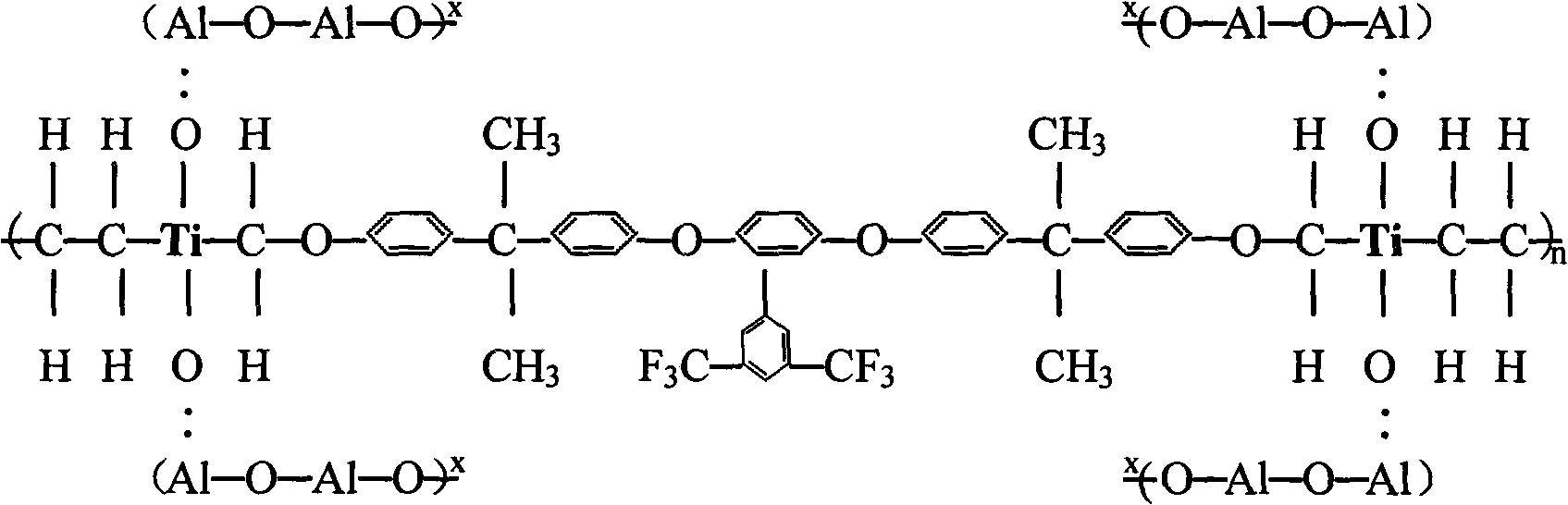

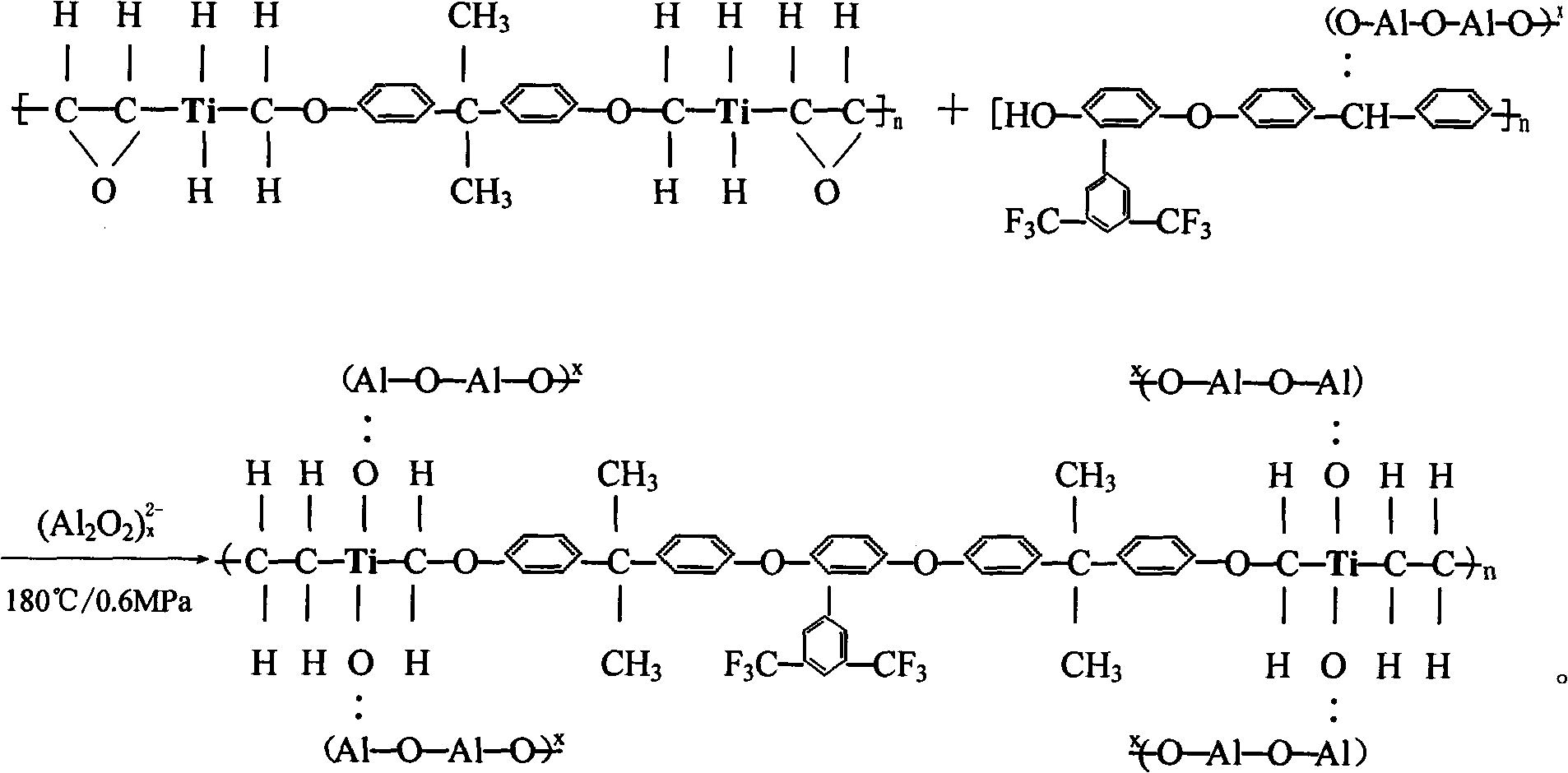

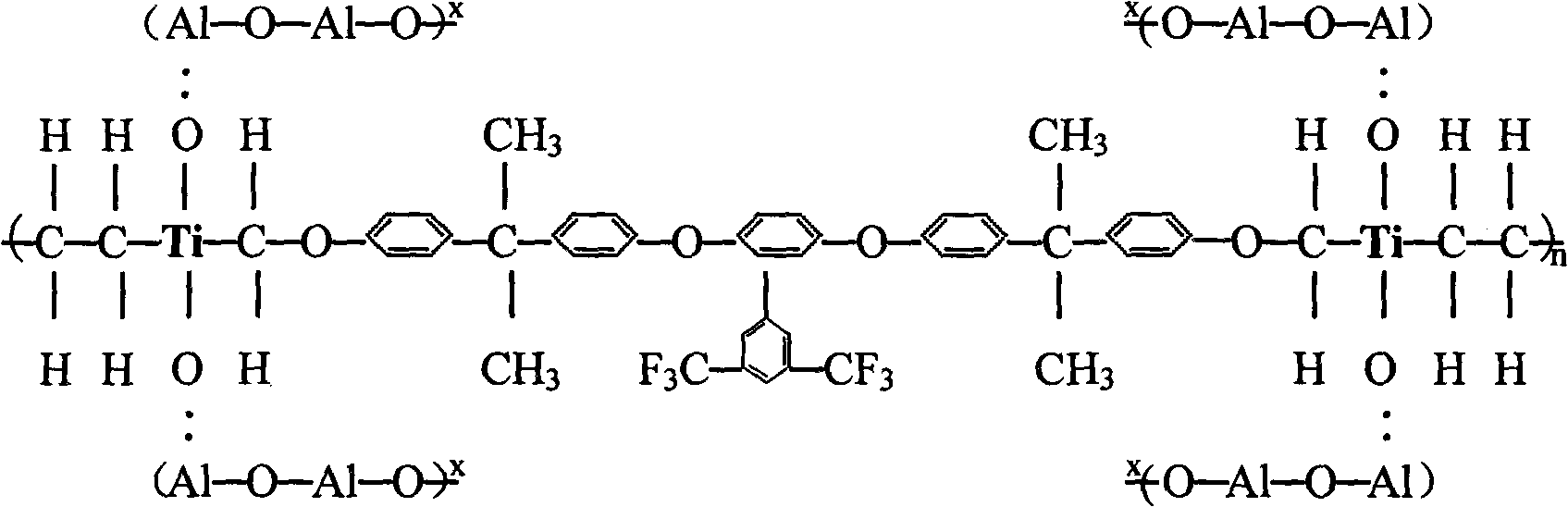

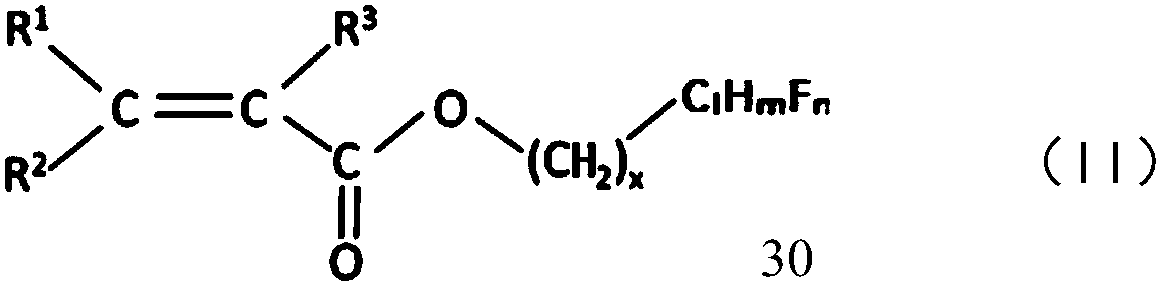

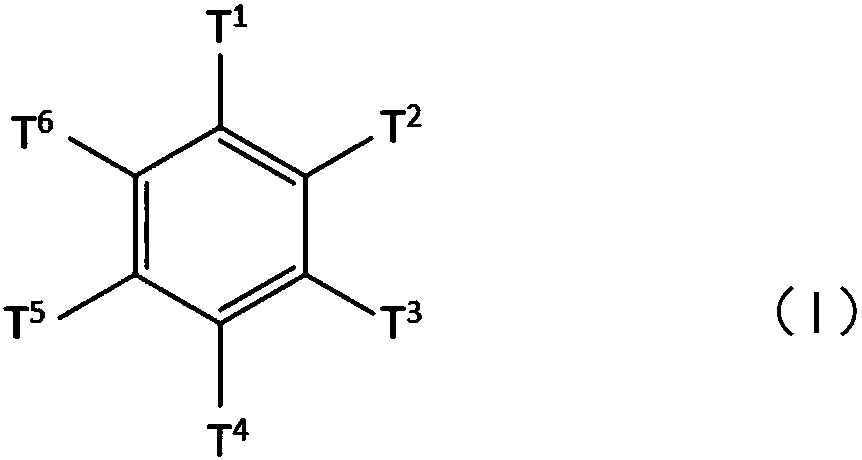

Titanium and nano fluorine-containing poly (aryl ether ketone) copolymer, coating made thereof and manufacturing method thereof

InactiveCN101671438AImprove performanceReduce mining costsDrilling rodsAnti-corrosive paintsKetonePetroleum

The invention makes further technical innovation in the prior invention and obtains a titanium and nano fluorine-containing poly (aryl ether ketone) macromolecular alloy copolymer by copolymerizationof a nano organic titanium polymer and a nano alumina-modified fluorine-containing poly (aryl ether ketone) polymer. The novel material has a series of excellent physicochemical characteristics and isextremely suitable to meet the special protection requirements of exploitation equipment of underground deep crude oil and natural gas such as high hardness, corrosion resistance, high temperature resistance, high-pressure hot vapor penetrability resistance, dirt picking up and scale deposition prevention, aging resistance, durability and other properties. A nano organic titanium macromolecular alloy coating manufactured by using the novel chemical material of the invention as a substrate film forming material resin is used in anticorrosion coatings of oil-gas field well exploitation drillingtools and well pipes and has the advantages of prolonging the protection life of a nano ceramic film coating and an organic titanium special anticorrosion coating by several times, greatly reducing oil and natural gas exploitation cost and equipment maintenance cost and obviously improving comparable relative production efficiency compared with the product of the prior invention.

Owner:佛山市顺德区赛富龙化工材料科技有限公司 +1

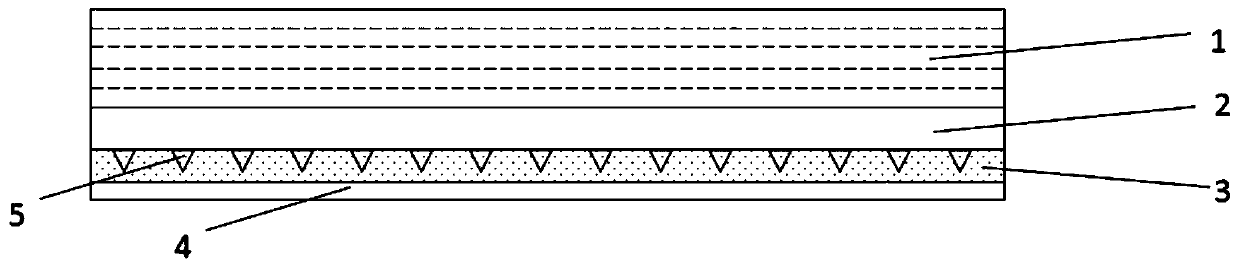

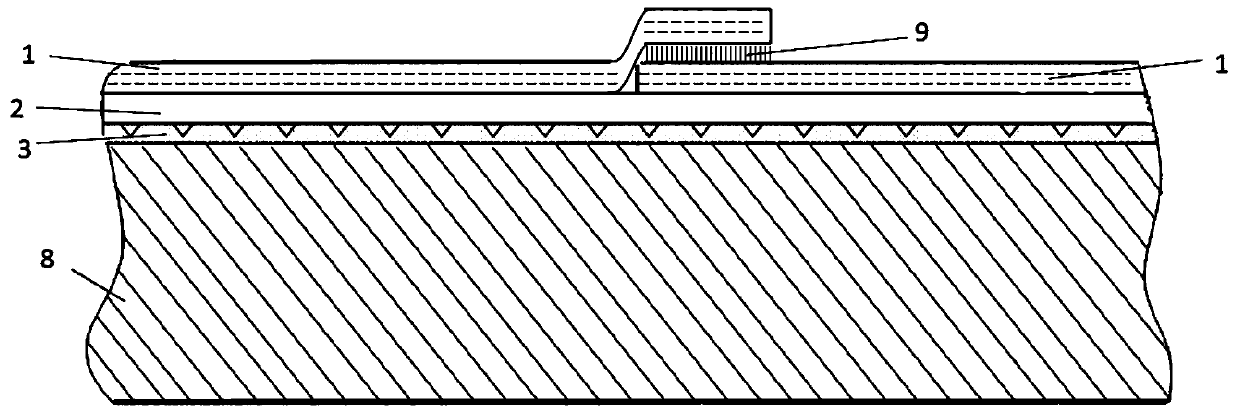

Leading edge protecting layer technology for fan blades

ActiveCN107903422AExtend protection lifeEasy maintenanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolyureaEngineering

The invention discloses a leading edge protecting layer technology for blades of a wind driven generator. The leading edge protecting layer is used for protecting leading edges of the blades of the wind driven generator from being eroded by rainwater. Protecting layers of the leading edge protecting layer technology mainly comprise three layers, namely an adhesive layer, a protective film layer and an oil paint layer which are upward arranged from a conventional coating on the surface of each blade; the lower surface of the adhesive layer is attached to the conventional coating on the surfaceof each fan blade so as to realize the effects of bonding the protective film layer with the blade; the film protecting layer is made of colorless transparent high-elasticity plastic which can be butnot limited to thermoplastic elastomer polyurethane (TPU). The oil paint layer is an epoxy resin or polyurethane / polyurea elastomer coating. According to the leading edge protecting layer technology disclosed by the invention, the rain erosion resistance of the fan blades is greatly improved, and the times of high-altitude maintenance at later stage are reduced.

Owner:萍乡高恒材料科技有限公司

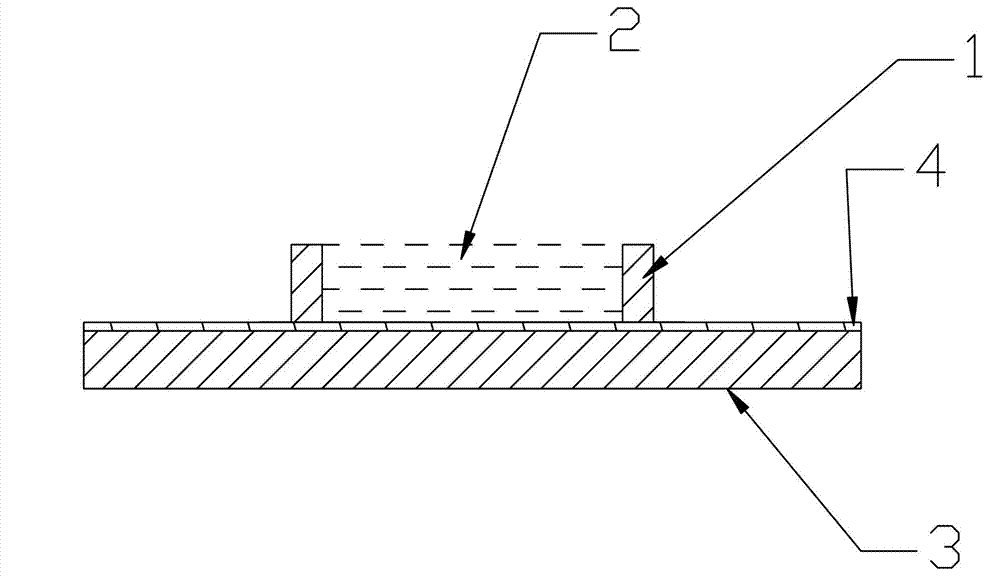

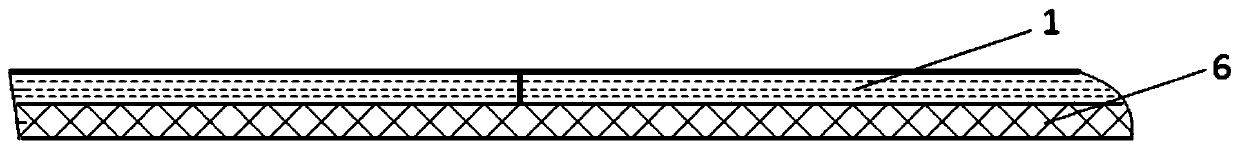

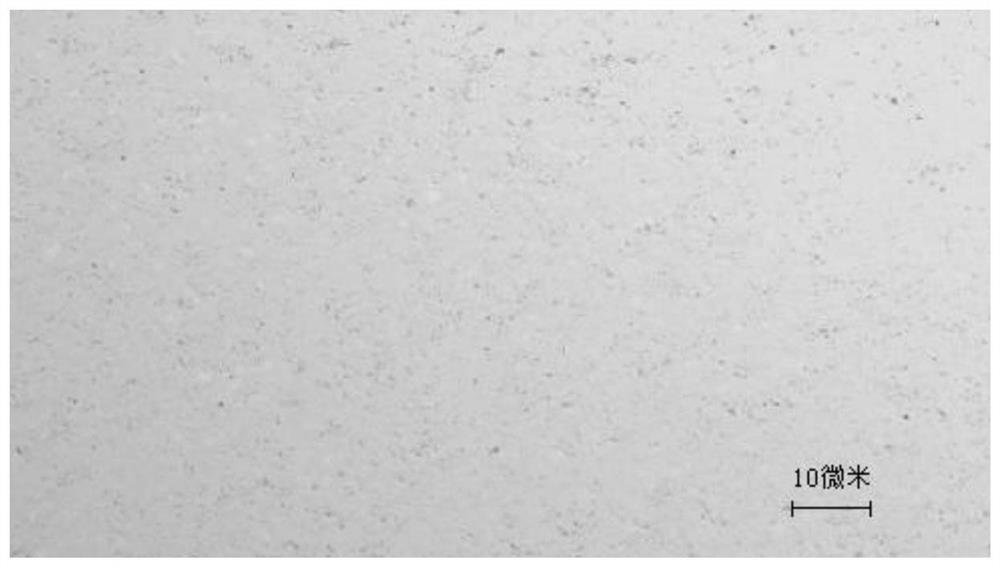

Paint prefabricated film, protection structure and preparation method of protection structure

PendingCN111173675AUniform thicknessReduce internal defectsLamination ancillary operationsSynthetic resin layered productsFilm baseEngineering

The invention provides a paint prefabricated film, a protection structure and a preparation method of the protection structure. The surface, deviated from a back glue layer, of a substrate base material layer is a smooth plane, the smooth plane has the relatively low surface tension, and a paint coating formed on the surface of the smooth plane can be more uniform in thickness and fewer in insidedefects, so that the quality is higher; a plurality of bulge parts are arranged on the surface, facing the back glue layer, of the substrate base material layer, so that the binding force of the substrate base material layer and the paint coating is smaller than that of the substrate base material layer and the back glue layer, separation of the paint coating from a paint prefabricated film base body can be realized by the aid of the external force, and the paint coating is used for protecting the outer surface of a wind turbine blade base body. The paint prefabricated film is applied to preparation of the wind turbine blade protection structure, and the large-area damage to the paint coating due to sand erosion and rain erosion of the area having the low thickness of the paint coating dueto the non-uniform thickness of the paint coating can be avoided, so that the protection effect of the protection structure can be improved.

Owner:SINOMATECH WIND POWER BLADE

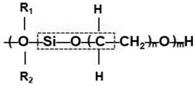

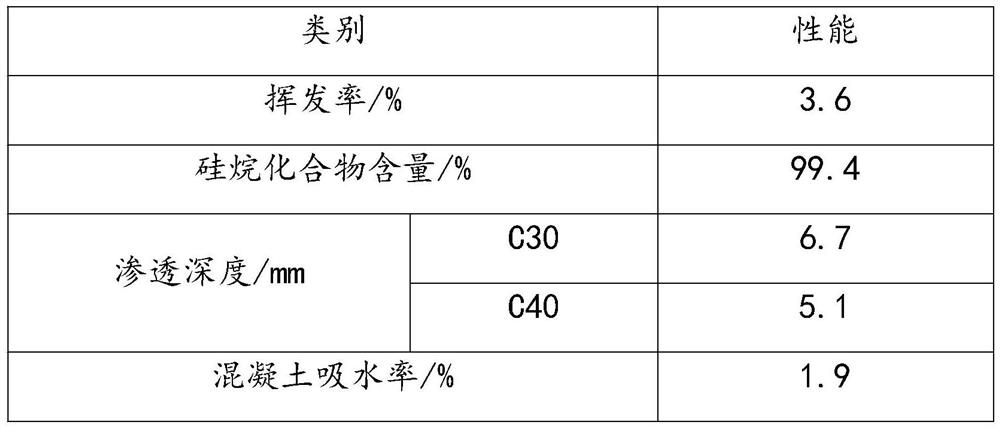

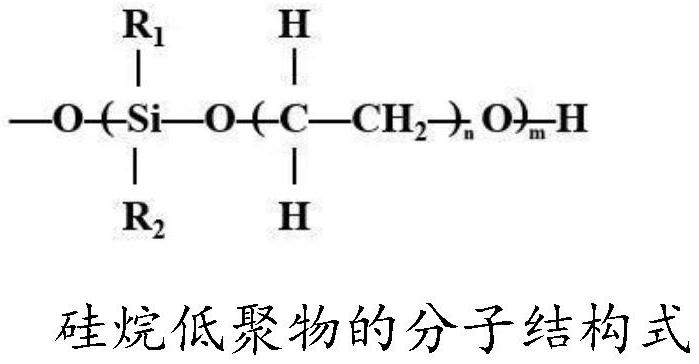

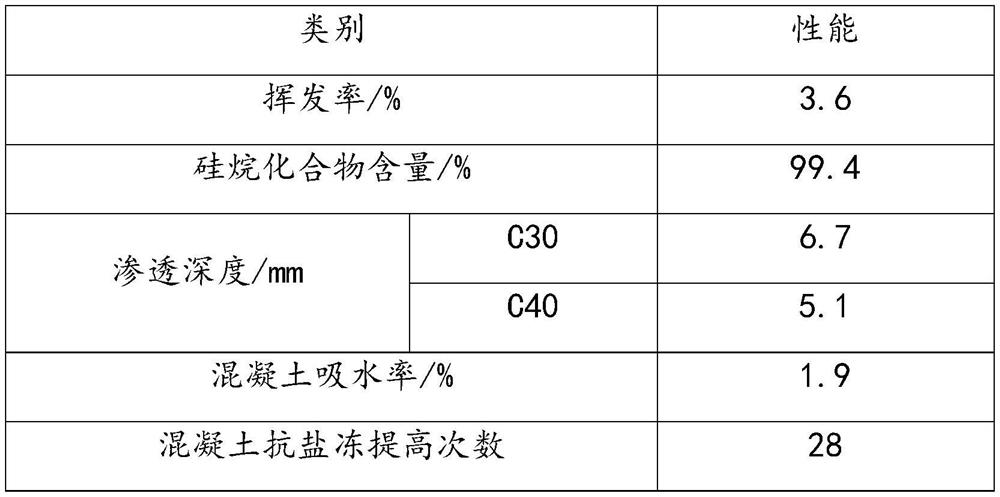

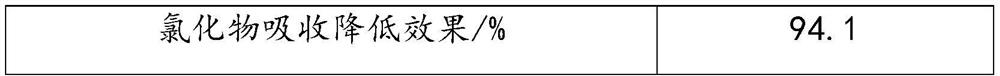

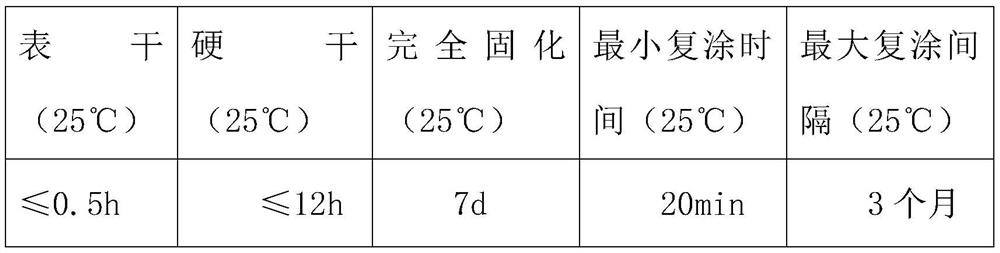

Silane waterproof material for concrete protection and preparation method thereof

ActiveCN113402912AImprove permeabilityImprove the protective effectCoatingsPolymer scienceChain scission

The invention relates to a silane waterproof material for concrete protection. The material comprises the following specific components: chain alkyl silane, a silane oligomer, an amino silane coupling agent, a defoaming agent, an antioxidant and a preservative. When the silane oligomer is in contact with the concrete, an S< i-O-C > bond of the concrete is easily subjected to hydrolysis chain scission due to the alkaline environment and internal moisture of the concrete, and a silane compound with a low polymerization degree is formed, so a traditional volatile non-environment-friendly solvent is replaced, the ultra-low surface energy, high interface wettability and migration anti-corrosion characteristics of the silane oligomer are realized, and the problems that a traditional silane waterproof material is not environmentally friendly, high in volatilization rate, poor in permeability, insufficient in durability and the like are solved.

Owner:CNBM ZHONGYAN TECH +1

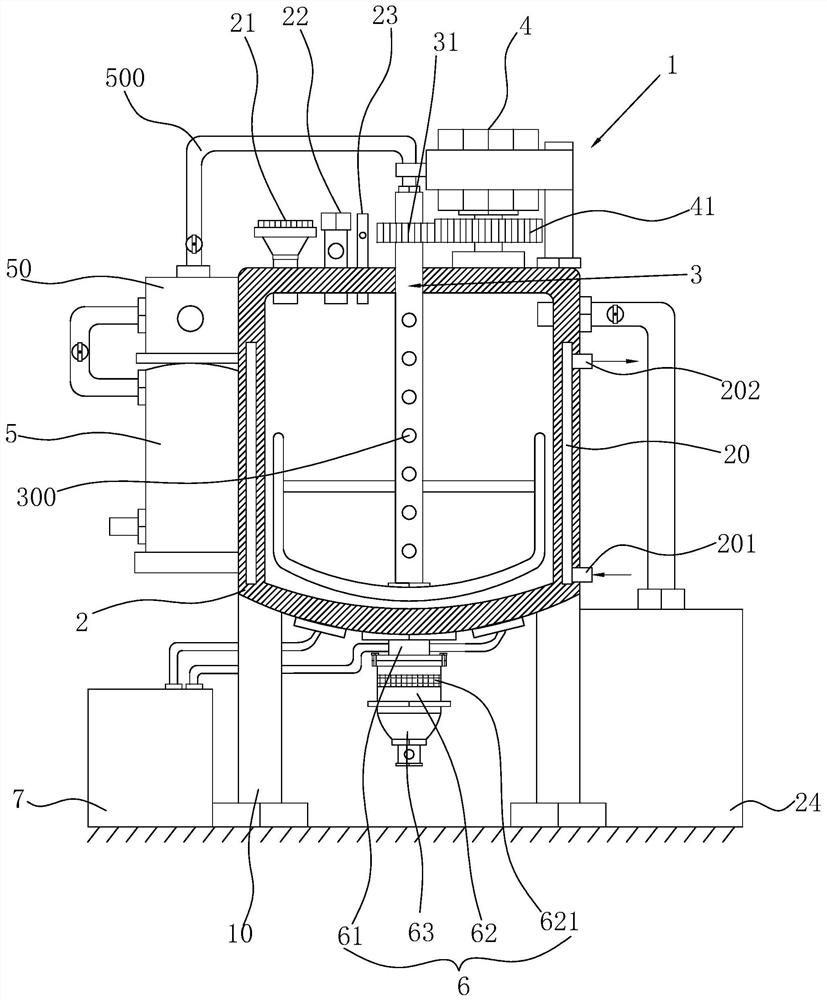

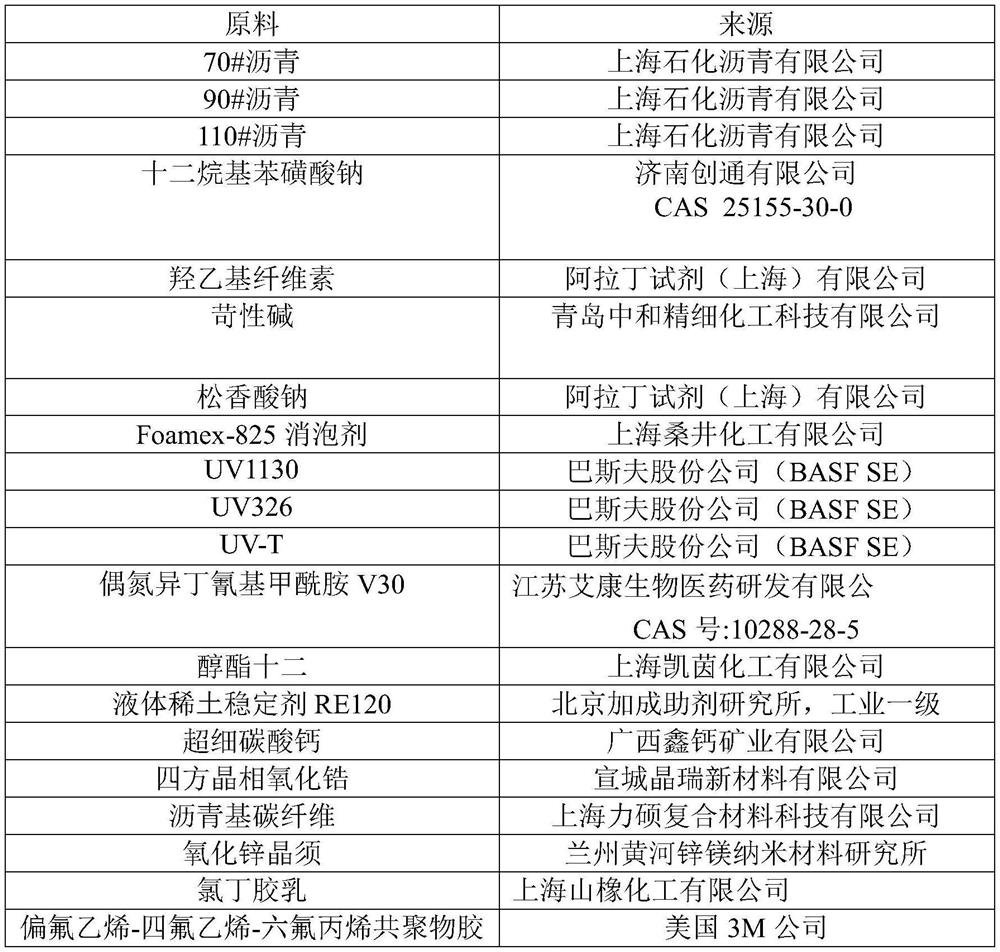

Outdoor floor water-based asphalt bottom paint and processing technology thereof

ActiveCN112574672AHigh impact strengthHigh mechanical strengthMixing methodsTransportation and packagingEnvironmental engineeringAsphalt

The invention relates to the technical field of asphalt coating production, and in particular, relates to outdoor floor water-based asphalt bottom paint and a processing technology thereof. The outdoor floor water-based asphalt bottom paint is prepared from the following raw materials in parts by weight: modified asphalt, a filler, a film-forming resin emulsion, an emulsifier, a liquid-phase rareearth stabilizer, a film-forming stabilizer, a defoaming agent, an initiator, a UV agent and deionized water. The water-based asphalt bottom paint provided by the invention has good corrosion resistance, low temperature resistance and aging resistance, and can improve the impact strength of outdoor floors. The processing technology comprises the steps: weighing the modified asphalt, adding the modified asphalt into a proportioning device, weighing the film-forming resin emulsion and deionized water, sequentially adding the weighed filler, the weighed liquid-phase rare earth stabilizer, the weighed UV agent, the weighed emulsifier, the weighed film-forming stabilizer, the weighed defoaming agent and the weighed initiator into the proportioning device, stirring, vacuumizing, naturally cooling to room temperature, and finally screening and filling. The process has the advantage that the high-quality asphalt bottom paint can be obtained through quantitative production.

Owner:安徽欣苗新材料科技有限公司

Treatment process for improving adhesion of steel surface coating

ActiveCN110184574AReduce reflectivityCause changeAnodisationElectrolytic inorganic material coatingMetallurgySurface coating

The invention discloses a treatment process for improving adhesion of a steel surface coating. The treatment process specifically comprises the following treatment steps of 1, cleaning treatment of the steel surface; 2, plating treatment of the steel surface; and 3, pulse electrodeposition treatment of the steel surface. According to the treatment process, the surface characteristics of the steelare obviously improved and the roughness of the surface of the steel is increased by carrying out a special treatment method on the surface of the steel, so that the adhesion of the surface of the steel is improved, the bonding firmness of the coating and the steel is enhanced, the protection life of the coating is prolonged, and the treatment process has a wide application prospect.

Owner:西安致远航空科技有限公司

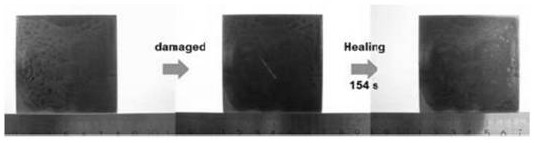

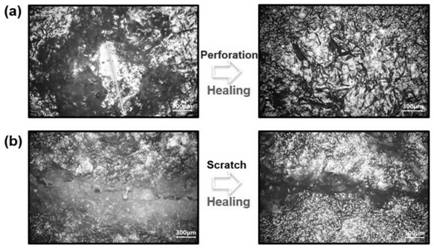

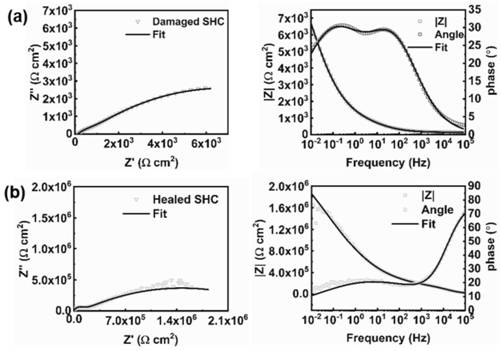

Metal-based self-repairing coating as well as preparation method and application thereof

The invention provides a metal-based self-repairing coating as well as a preparation method and application thereof, and belongs to the field of electrodeposition micro-nano composite coatings and self-repairing. The metal-based self-repairing coating is composed of a metal coating and a nano container doped in the metal coating, the nano container takes a mesoporous material as a carrier, corrosion inhibitor molecules are supported inside the nano container, and a pH response material is modified on the surface of the nano container. The method comprises the following steps that firstly, a corrosion inhibitor is supported in the nano container, then surface hole sealing treatment is performed on the nano container containing the corrosion inhibitor by adopting a solution with the pH response, then the nano container is further modified through a cationic surface modification solution to enable the surface to have the certain positive charge, finally, a metal electrodeposition solutionis prepared, the nano container which contains the corrosion inhibitor and is provided with the pH response is added into the electrodeposition solution, co-deposition is realized under the action ofcurrent, and the metal coating with a self-repairing function is prepared. According to the metal-based self-repairing coating as well as the preparation method and application thereof, the protective life of the metal coating can be effectively prolonged, and a new idea is provided for preparing the novel metal composite coating.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

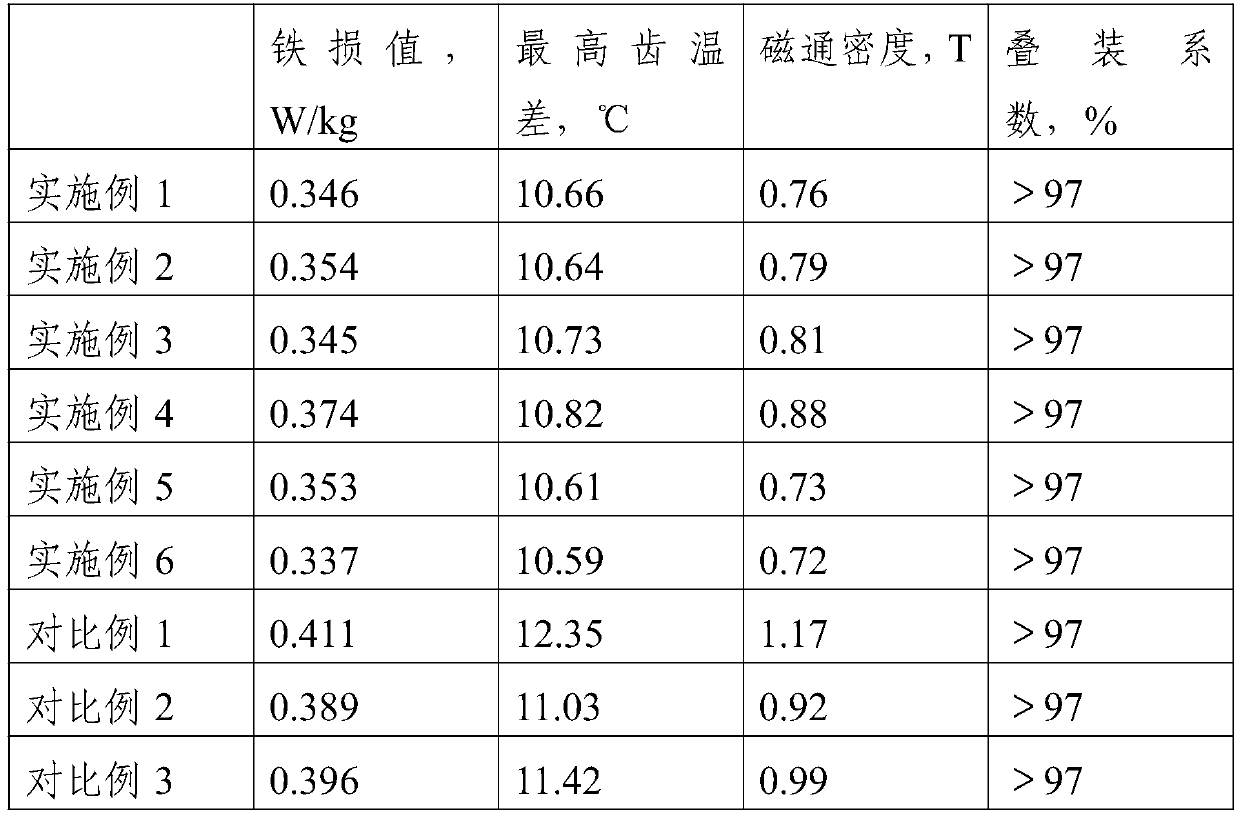

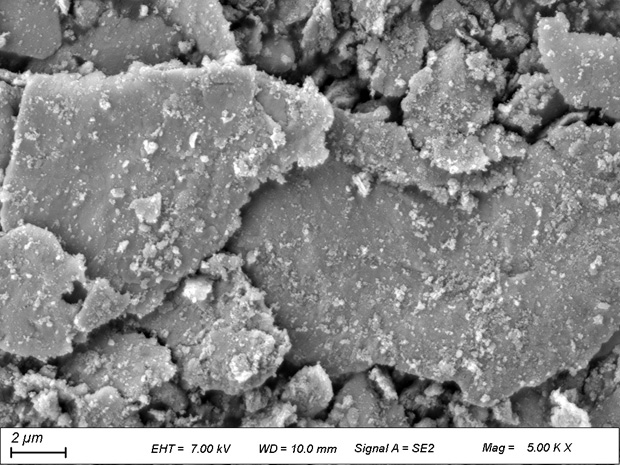

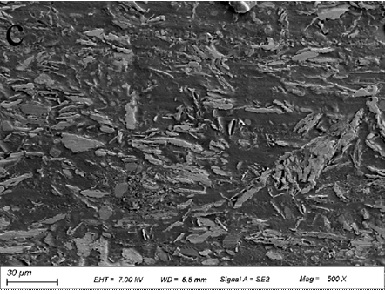

Low-iron-loss automobile engine stator iron core and preparation process thereof

InactiveCN111064288AImprove mechanical propertiesAccelerated corrosionMolten spray coatingAntifouling/underwater paintsAlloyVarnish

The invention provides a low-iron-loss automobile engine stator iron core and a preparation process thereof. The stator iron core is of a multi-layer structure and comprises a silicon steel sheet body, a loss reduction outer layer and a protective paint layer which are sequentially designed from inside to outside. The silicon steel sheet body is a rare earth boron silicon steel sheet, and the thickness of the silicon steel sheet body is 0.28-0.30 mm. The loss reduction outer layer is made of a composite alloy material, and the thickness of the loss reduction outer layer is 0.02-0.04 mm. The protective paint layer is compound impregnating varnish, and the thickness of the layer ranges from 0.04 mm to 0.08 mm. According to the invention, the silicon steel sheet body material and surface treatment and protection of the stator core are comprehensively improved and proportioned, so that the mechanical property and the corrosion resistance of the stator iron core are effectively improved, excellent low iron loss rate is achieved, the hysteresis loss and the eddy current loss are reduced by 22% and 19.3% respectively, the comprehensive quality of the stator iron core is higher, economic benefits are effectively improved, and meanwhile the service life is obviously prolonged.

Owner:安徽嘀通网络科技有限公司

Multifunctional heavy anti-corrosion coating as well as preparation method and application thereof

ActiveCN114106679AHas a negative moisture-sensitive characteristicResists scour and abrasionAntifouling/underwater paintsPaints with biocidesFirming agentN-Butyl Alcohol

The invention discloses a multifunctional heavy anti-corrosion coating which consists of a component A and a component B. The component A is prepared from the following components in percentage by weight: 60 to 70 percent of waterborne epoxy emulsion, 5.5 to 8.3 percent of MgCr2O4-TiO2 ceramic powder, 0.6 to 1.0 percent of polymer nonionic dispersant, 0.9 to 1.2 percent of organic silicon defoaming agent, 0.5 to 0.8 percent of polyether modified polydimethylsiloxane, 0.3 to 0.4 percent of DP-10 adhesion promoter, 0.8 to 1.1 percent of bentonite and 15 to 30 percent of deionized water; and the component B comprises the following components in percentage by weight: 40-55% of seashell powder composite zinc-aluminum flake powder, 35-40% of a polyurethane curing agent and 5-25% of n-butyl alcohol. The invention further discloses a preparation method and application of the multifunctional heavy anti-corrosion coating. Good mechanical properties of the coating are guaranteed, and seawater erosion and abrasion are effectively resisted.

Owner:NANJING INST OF TECH

Silane waterproof material for concrete protection and preparation method thereof

The invention relates to a silane waterproof material for concrete protection. The specific components of the material are as follows: chain alkyl silane, silane oligomer, amino silane coupling agent, defoamer, antioxidant, antiseptic; wherein, silane is low When the polymer comes into contact with concrete, the alkaline environment of the concrete itself and the internal moisture will easily lead to the hydrolysis of its Si-O-C bond and chain scission, forming a silane compound with a low degree of polymerization, so as to replace the traditional volatile, non-environmental protection Non-toxic solvents, realize its ultra-low surface energy, high interface wettability and migration anti-corrosion properties, solve the problems of traditional silane waterproof materials such as non-environmental protection, high volatility, poor permeability, and insufficient durability.

Owner:CNBM ZHONGYAN TECH +1

Formula of coating under wet and rusty conditions

InactiveCN113667376ALow level of rust removalGood maintenance cycleAnti-corrosive paintsEpoxy resin coatingsGraphiteGraphene

The invention relates to the technical field of steel structure treatment, in particular to a formula of a coating under wet and rusty conditions, which comprises the following basic components: SBS modified resin, graphene, resin, a solvent, a diluent, pigment, auxiliaries, an anti-rust rust remover and the like, and the mass ratio of the components are 0.01-0.06% of graphene; 40%-80% of resin; 10%-30% of the solvent; 1%-6% of the diluent; 6%-40% of the pigment; 0.1%-3% of an auxiliary agent; and 1%-15% of the antirust rust remover. The requirement for the rust removal grade of the metal surface is low; the coating operation can be carried out under saturated humidity and lower temperature, the coating is more suitable for site construction requirements and skylight point internal operation requirements, the coating is more grounded, the whole coating is safe, rapid, good in quality, excellent in price and environmentally friendly, the anti-corrosion effect is improved, the protection service life is prolonged, meanwhile, the environmental protection problem is solved, no harm is caused to personnel, the protection effect is good, and the maintenance period is long.

Owner:深圳瑞腾船舶与海洋工程防腐科技有限公司

Marine steel structure long-term protection multi-layer epoxy heavy-duty anti-corrosion coating and preparation method

ActiveCN103990588BImprove bindingImprove compactnessPretreated surfacesEpoxy resin coatingsEpoxySolvent free

The invention discloses a long-acting protection multi-layer epoxy heavy-corrosion-prevention coating for a sea steel structure and a manufacturing method of the long-acting protection multi-layer epoxy heavy-corrosion-prevention coating and belongs to the field of sea heavy corrosion prevention. The epoxy heavy-corrosion-prevention coating comprises three layers of structures which are a poly-carboxy epoxy resin coating body, a solvent-free epoxy coating body and acrylic epoxy finish coat or polyurethane epoxy finish cost or organic silicone epoxy finish coat or fluorocarbon finish coat. The multi-layer epoxy heavy-corrosion-prevention coating meets the low metal surface treatment requirement and can be constructed on a humid metal surface with rust, due to three-dimensional crosslinking curing and chemical bonding with a base material, the obtained coating interface bonding force is good, the crosslinking degree is high, the compactness is good, the weather resistance is excellent, the service life in a sea environment can reach more than 30 years, and the coating is simple in technology, easy to popularize and capable of being used for long-acting protection of seal steel and iron facilities.

Owner:HOHAI UNIV

Sunlight-driven self-repairing coating, coating layer, and preparation method of coating layer

ActiveCN113861800AExcellent sunlight-driven self-healing effectExtend protection lifePolyurea/polyurethane coatingsPolyamide coatingsCoating systemPolymer chemistry

The invention provides a sunlight-driven self-repairing coating, a coating and a preparation method thereof. The self-repairing coating is prepared from 2-50 parts of organic resin, 0.1-5.1 parts of a photo-thermal material and 2-25 parts of a thermoplastic phase-change material. The specific organic resin, the photo-thermal material and the thermoplastic phase-change material are reasonably matched to obtain the self-repairing coating, and a substrate is further coated with the coatig to prepare the self-repairing organic coating layer, the self-repairing coating layer has an excellent sunlight-driven self-repairing effect, defects of the organic coating layer can be repaired for multiple times under sunlight, the protection life of the organic coating layer is prolonged, a novel selection scheme is provided for a self-repairing coating system, and the application range is wide.

Owner:SUN YAT SEN UNIV

Method for forming protective layers on surface of object and product with protective layers formed on surface

InactiveCN109675775AExtend protection lifeImprove bindingPhysical treatmentPretreated surfacesProtection layerMaterials science

The invention provides a method for forming protective layers on the surface of an object. The method comprises the steps that at least part of the surface of the object is exposed in first plasma, sothat the first protective layer is formed on the at least part of the surface of the object; and the at least part of the surface, where the first protective layer is formed, of the object is exposedin second plasma, so that the second protective layer is formed. The invention further provides a product with protective layers formed on the surface. The protective layers include the first protective layer and the second protective layer. The first protective layer is formed on the at least part of the surface of the product by exposing the at least part of the surface of the product in firstplasma. The second protective layer is formed on the outer surface of the first protective layer by exposing the at least part of the surface, where the first protective layer is formed, of the product in second plasma.

Owner:上海稷以科技有限公司

Method for preparing tungsten carbide coating on surface of roller for lithium battery production

PendingCN113699478AReduce decarbonizationLower flame temperatureMolten spray coatingRollsAdhesive beltCombustion chamber

The invention relates to a method for preparing a tungsten carbide coating on the surface of a roller for lithium battery production. The method comprises the following steps of (1) carrying out visual inspection and magnifying glass inspection on the surface of the roller for lithium battery production; (2) after the surface of the roller is subjected to oil removal, impurity removal and purification, conducting rough grinding and texturing treatment on the surface of the roller through a rough polishing machine; (3) carrying out protection treatment on the non-spraying surfaces at the two ends of the roller subjected to rough grinding and texturing by adopting a high-temperature-resistant adhesive tape and a tool; and (4) using liquid-phase propane as a main combustion gas, using compressed air as a combustion-supporting gas, using nitrogen as a carrier gas powder feeding gas, inputting all the gases into a combustion chamber through a porous ceramic sheet, initially igniting by a spark plug for high-pressure combustion, generating high-velocity flames with the flame flow speed being more than 7 times of the sound velocity, spraying tungsten carbide powder on the surface of the roller to be sprayed by adopting a powder flame spraying technology, and rapidly cooling and solidifying to form the tungsten carbide coating; and (5) carrying out fine polishing treatment on the surface of the roller sprayed with the tungsten carbide coating by adopting a fine polishing machine.

Owner:宁德市福能新能源科技有限公司

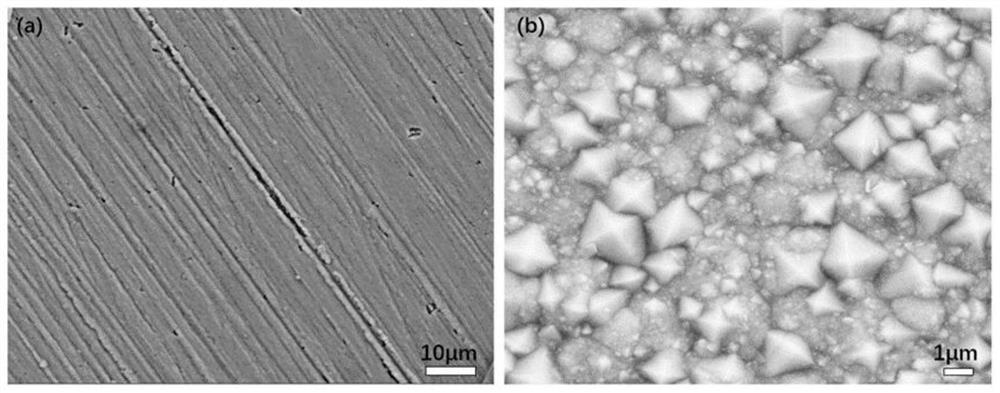

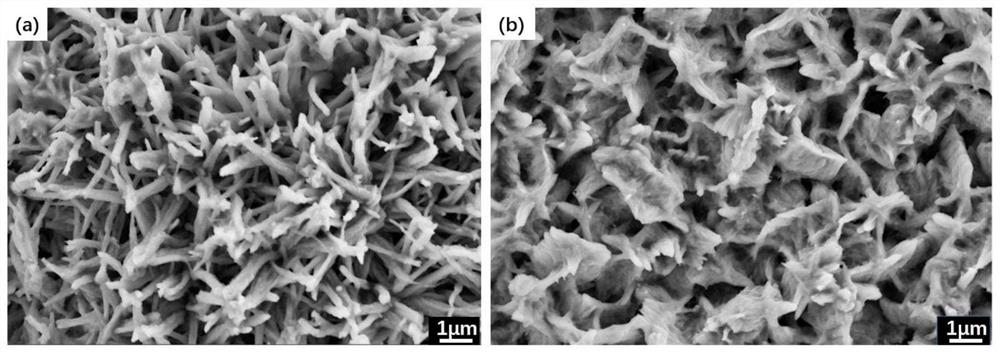

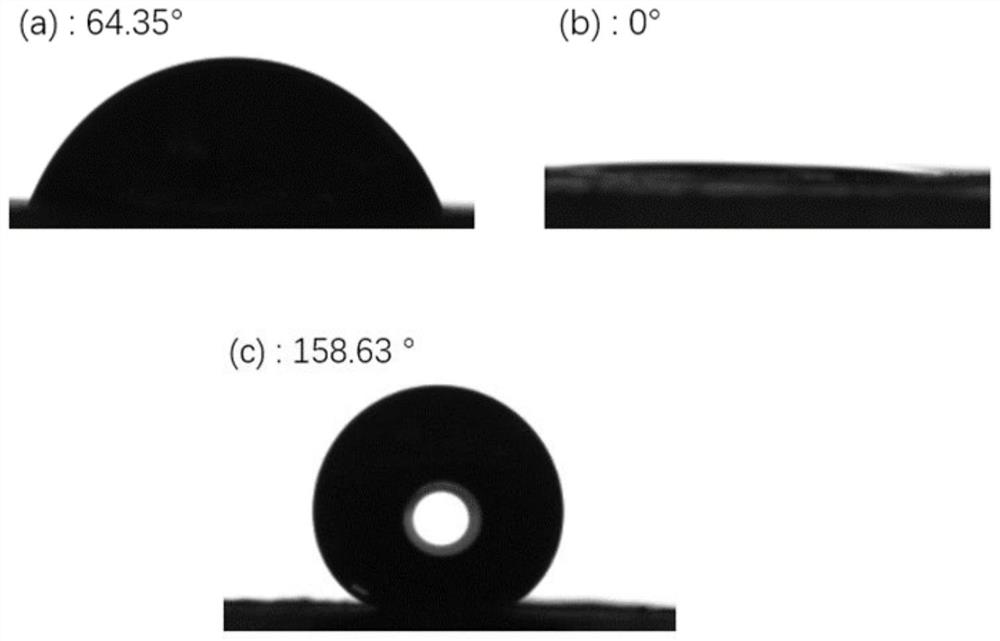

A kind of ni-co/cu superhydrophobic coating and preparation method thereof

The invention provides a Ni-Co / Cu super-hydrophobic coating and a preparation method thereof, belonging to the field of electrodeposited composite coatings. The coating comprises a metal substrate, a Ni-Co coating coated on the surface of the metal substrate, a copper coating coated on the surface of the Ni-Co coating, and after the copper coating is oxidized into a dendritic structure, a low surface energy substance is modified on the surface. The preparation method is as follows: first prepare a nickel-cobalt coating on the surface of the metal substrate; then carry out surface treatment on the nickel-cobalt coating, then coat a layer of copper coating on the surface, put the composite coating into the prepared oxidizing solution, and soak for a certain period of time. After taking it out, blow it dry with cold air; finally carry out low surface energy modification to obtain Ni‑Co / Cu composite coating. The invention can effectively improve the protective effect of the Ni-Co coating. When the corrosive medium such as water reaches the surface of the coating, due to the existence of the surface hydrophobic layer, it is difficult for the corrosive medium to enter the interior of the coating, thereby improving the anti-corrosion effect of the coating and prolonging the protection of the coating. It provides a new idea for the preparation of new metal composite coatings.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

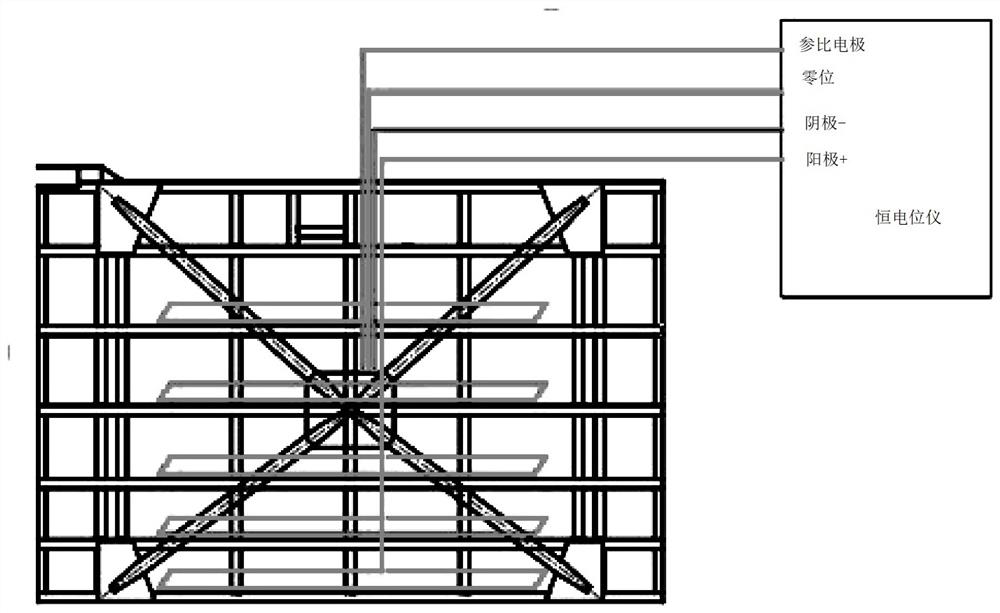

Anti-corrosion treatment process for ship lock inverted-V-shaped door metal structure

InactiveCN113814145AReduce the impactSolve pollutionPretreated surfacesCoatingsMechanical engineeringElectrical current

The invention provides an anti-corrosion treatment process for a ship lock inverted-V-shaped door metal structure. The anti-corrosion treatment process comprises the following steps that S1, surface pretreatment is conducted on the inverted-V-shaped door metal structure, and attachments, rust and other impurities are removed; S2, coating corrosion prevention is conducted, specifically, a moisture-curing coating is sprayed on the inverted-V-shaped door metal structure, and the spraying thickness is 0.4-1mm; and S3, a direct-current power source and an auxiliary anode are additionally arranged, the auxiliary anode is connected with the positive electrode of the direct-current power source to serve as an anode, the ship lock inverted-V-shaped door metal structure is connected with the negative electrode of the direct-current power source to serve as a cathode, protective current is provided by the direct-current power source, and an impressed current cathodic protection system is formed. Through the operation, anti-corrosion treatment of the ship lock inverted-V-shaped door metal structure is completed. According to the anti-corrosion treatment process, the comprehensive anti-corrosion technology combining the coating and impressed current cathodic protection is adopted, effective corrosion prevention of the large ship lock inverted-V-shaped door metal structure can be achieved, and the service life of the inverted-V-shaped door metal structure is prolonged.

Owner:THREE GORNAVIGATION AUTHORITY

A Treatment Process for Improving Coating Adhesion on Steel Surface

ActiveCN110184574BImprove surface propertiesIncrease roughnessAnodisationElectrolytic inorganic material coatingGalvanic depositionSurface coating

The invention discloses a treatment process for improving adhesion of a steel surface coating. The treatment process specifically comprises the following treatment steps of 1, cleaning treatment of the steel surface; 2, plating treatment of the steel surface; and 3, pulse electrodeposition treatment of the steel surface. According to the treatment process, the surface characteristics of the steelare obviously improved and the roughness of the surface of the steel is increased by carrying out a special treatment method on the surface of the steel, so that the adhesion of the surface of the steel is improved, the bonding firmness of the coating and the steel is enhanced, the protection life of the coating is prolonged, and the treatment process has a wide application prospect.

Owner:西安致远航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com