Multifunctional heavy anti-corrosion coating as well as preparation method and application thereof

A heavy-duty and multi-functional technology, applied in anti-corrosion coatings, coatings, anti-fouling/underwater coatings, etc., can solve problems that need to be further improved, to reduce marine biofouling, improve compatibility, and extend protection life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A multi-functional heavy-duty anti-corrosion coating, the multi-functional heavy-duty anti-corrosion coating is composed of two components A and B, in parts by weight: wherein component A is calculated by weight percentage: 60% of water-based epoxy emulsion, MgCr 2 o 4 -TiO 2 Ceramic powder 6.8%, Disperbykl03 0.8%, silicone defoamer 0.8%, polyether modified polydimethylsiloxane 0.5%, DP-10 adhesion promoter 0.3%, bentonite 0.8% and deionized water 30% .

[0035] Component B is calculated by weight percentage: 40% of seashell powder composite zinc-aluminum flake powder, 35% of polyurethane curing agent, and 25% of n-butanol.

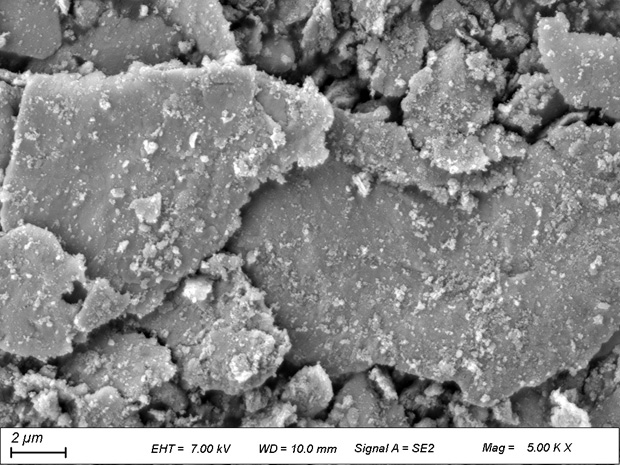

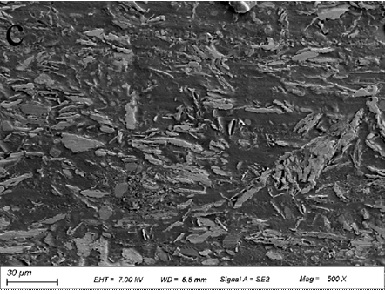

[0036] Such as figure 1 As shown, the interior of the seashell powder composite zinc-aluminum flake powder is zinc-aluminum flakes, and the surface is coated with seashell powder; the thickness of the seashell powder composite zinc-aluminum flake powder is 0.1-0.3 μm, and the sheet diameter is 15-35 μm.

[0037] MgCr 2 o 4 -TiO 2 The particl...

Embodiment 2

[0047] A multi-functional heavy-duty anti-corrosion coating, the multi-functional heavy-duty anti-corrosion coating is composed of A and B two components, in parts by weight: wherein component A is calculated in weight percentage: 70% of water-based epoxy emulsion, MgCr 2 o 4 -TiO 2 Ceramic powder 6.8%, Disperbykl03 0.9%, silicone defoamer 1.2%, polyether modified polydimethylsiloxane 0.8%, DP-10 adhesion promoter 0.4%, bentonite 1.1%, deionized water 18.8% .

[0048] Component B is calculated by weight percentage: 55% of sea shell powder composite zinc-aluminum flakes, 40% of polyurethane curing agent, and 5% of n-butanol.

[0049] The MgCr 2 o 4 -TiO 2 The particle size of the ceramic powder is 0.8 μm.

[0050] A method for preparing a multifunctional heavy-duty anti-corrosion coating, comprising the following steps:

[0051] Step 1, preparation of seashell powder composite zinc-aluminum flake powder: spherical aluminum-zinc powder, seashell powder, and compound grind...

Embodiment 3

[0057] A multi-functional heavy-duty anti-corrosion coating, the multi-functional heavy-duty anti-corrosion coating is composed of two components A and B, in parts by weight: wherein component A is calculated by weight percentage: 65% of water-based epoxy emulsion, MgCr 2 o 4 -TiO 2 Ceramic powder 6.7%, Disperbykl03 0.7%, silicone defoamer 1.1%, polyether modified polydimethylsiloxane 0.7%, DP-10 adhesion promoter 0.4%, bentonite 0.9%, deionized water 24.5% .

[0058] Component B is calculated by weight percentage: 48% of sea shell powder composite zinc-aluminum flakes, 38% of polyurethane curing agent, and 14% of n-butanol.

[0059] A method for preparing a multifunctional heavy-duty anti-corrosion coating, comprising the following steps:

[0060] Step 1, preparation of seashell powder composite zinc-aluminum flake powder: spherical aluminum-zinc powder, seashell powder, and compound grinding aid are proportioned according to weight percentage 88:10:2, ball milled in a bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com