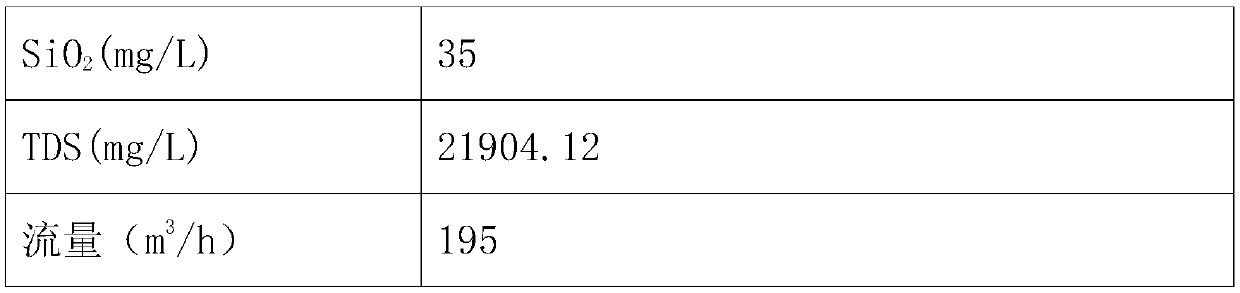

Patents

Literature

1846results about How to "Reduce fouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-volatile phosphorus hydrocarbon gelling agent

ActiveUS20070173413A1Reduce volatilityEliminate badOther chemical processesGroup 5/15 element organic compoundsCompound (substance)Fracturing fluid

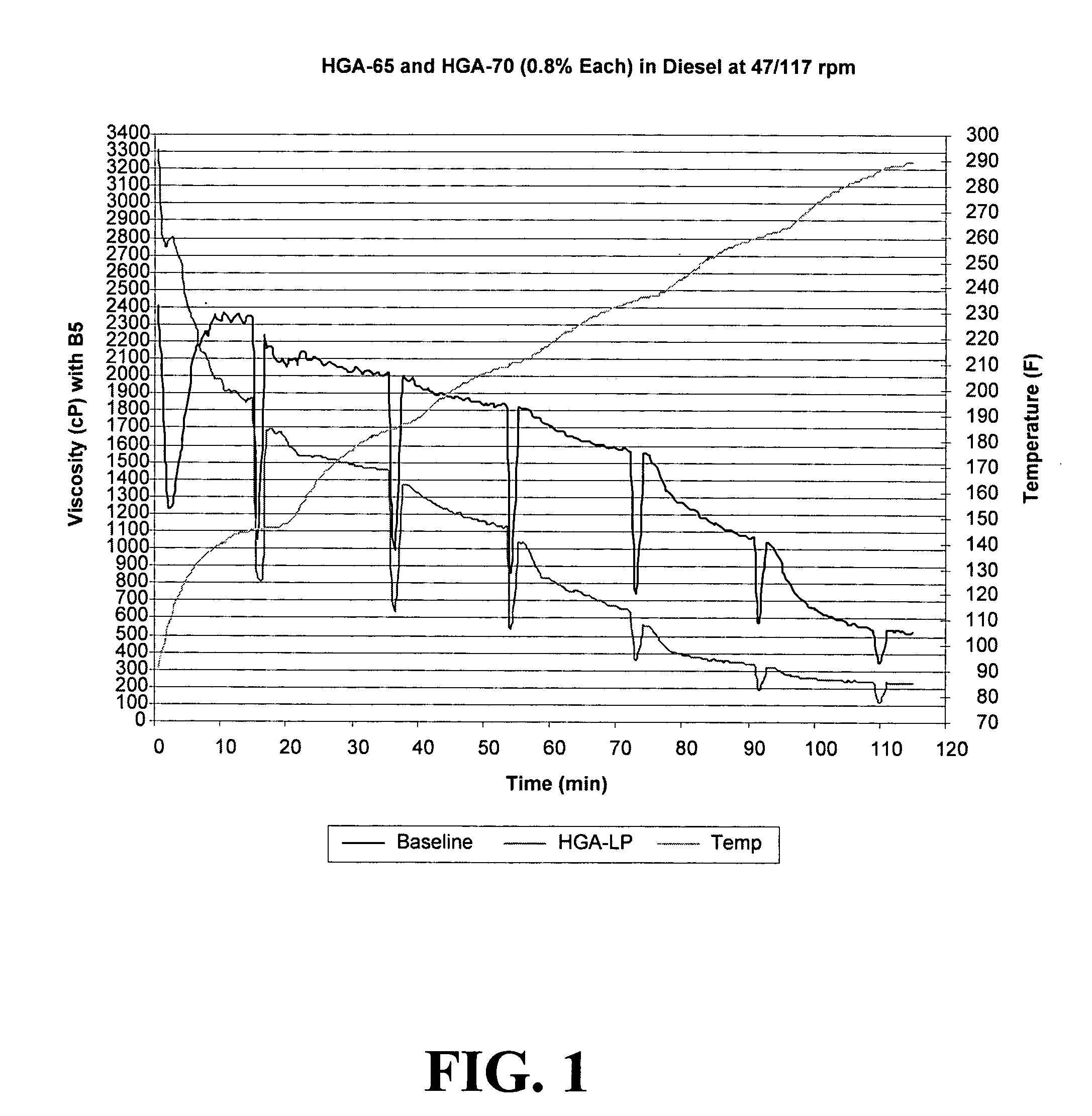

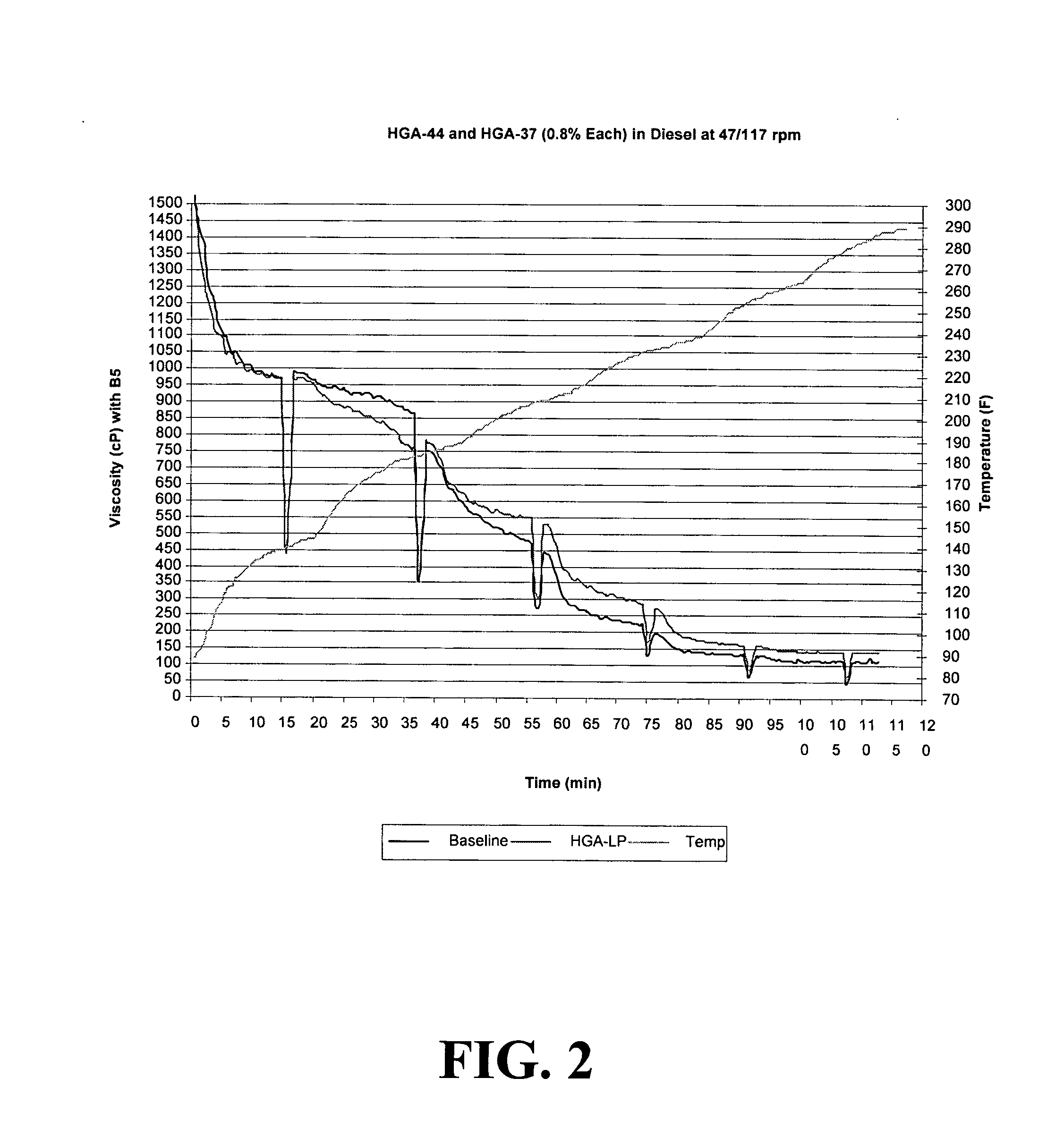

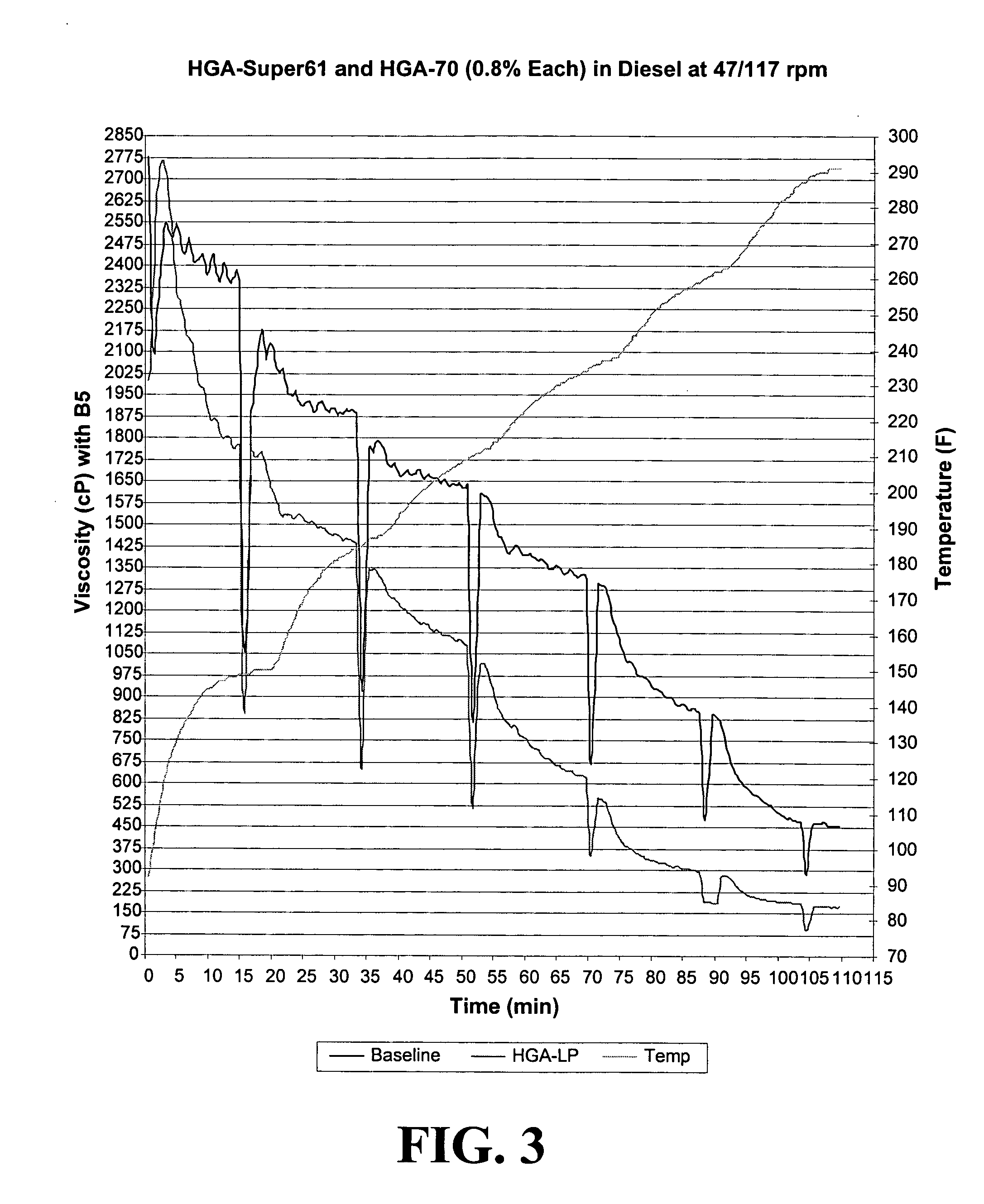

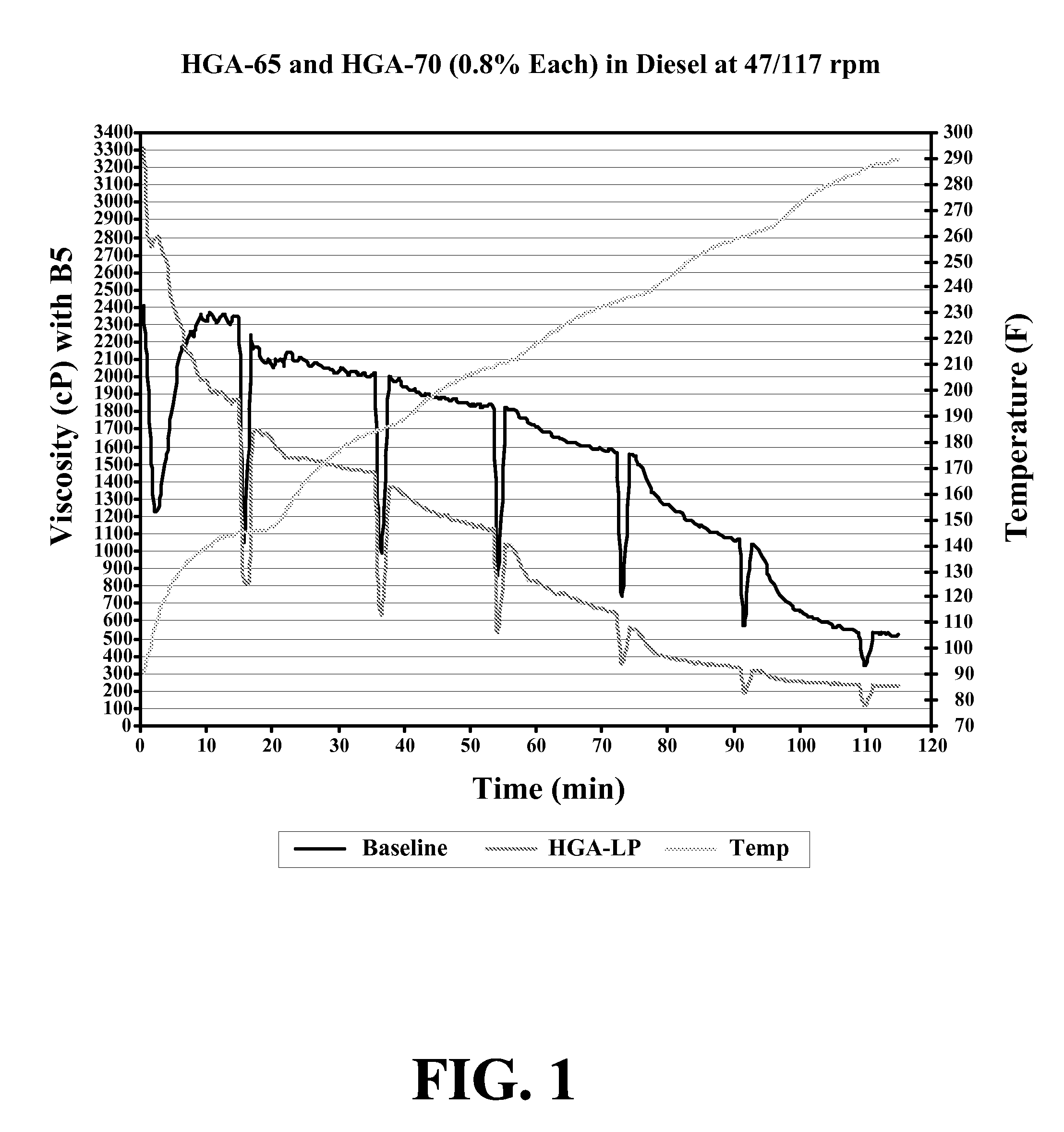

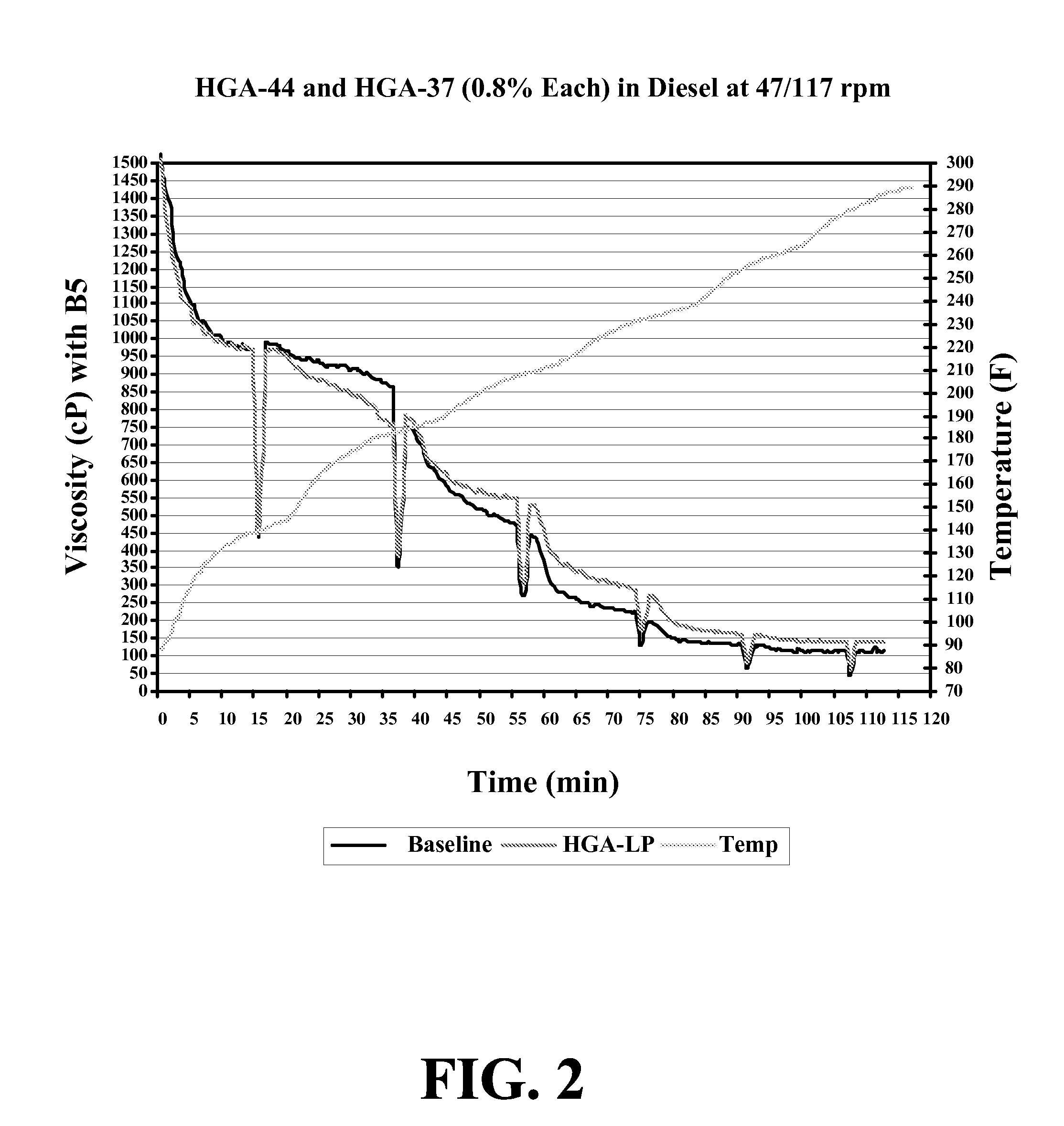

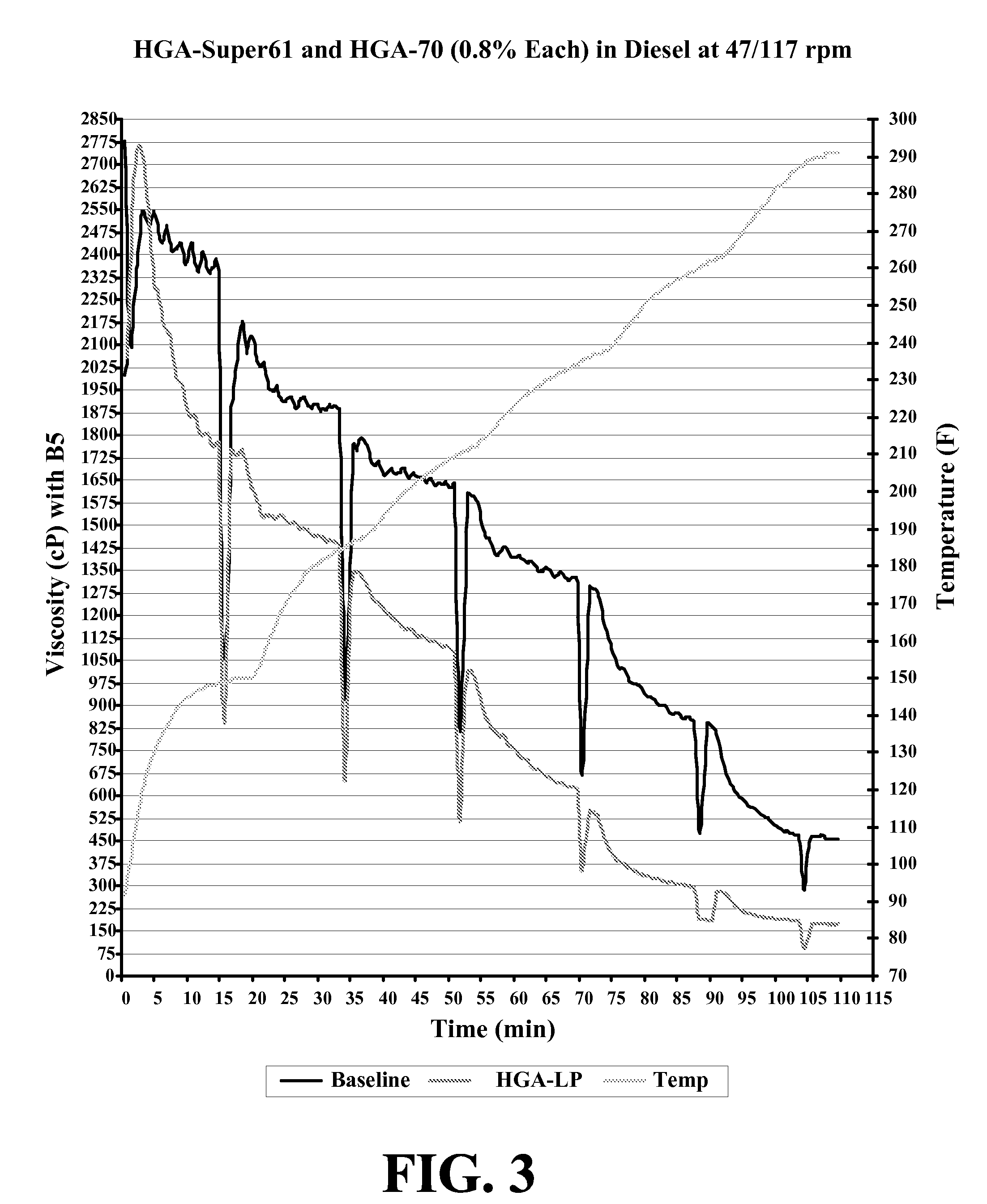

New fluids are disclosed for use in servicing subterranean formations containing oil and gas. In particular, an improved chemical gelling additive for hydrocarbon based fracturing fluids is disclosed having reduce, negligible or no volatile phosphorus at temperatures below about 250° C.

Owner:THE LUBRIZOL CORP

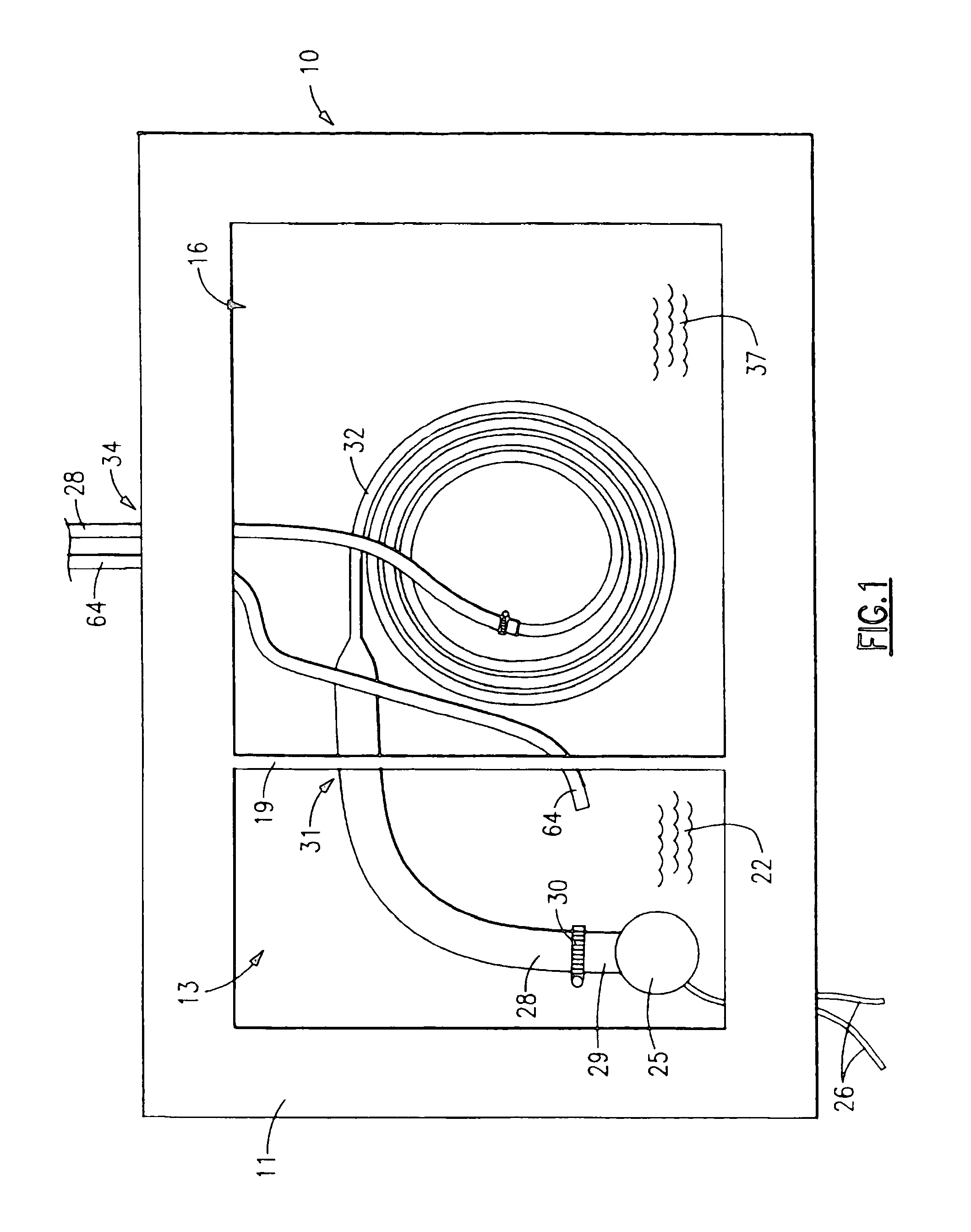

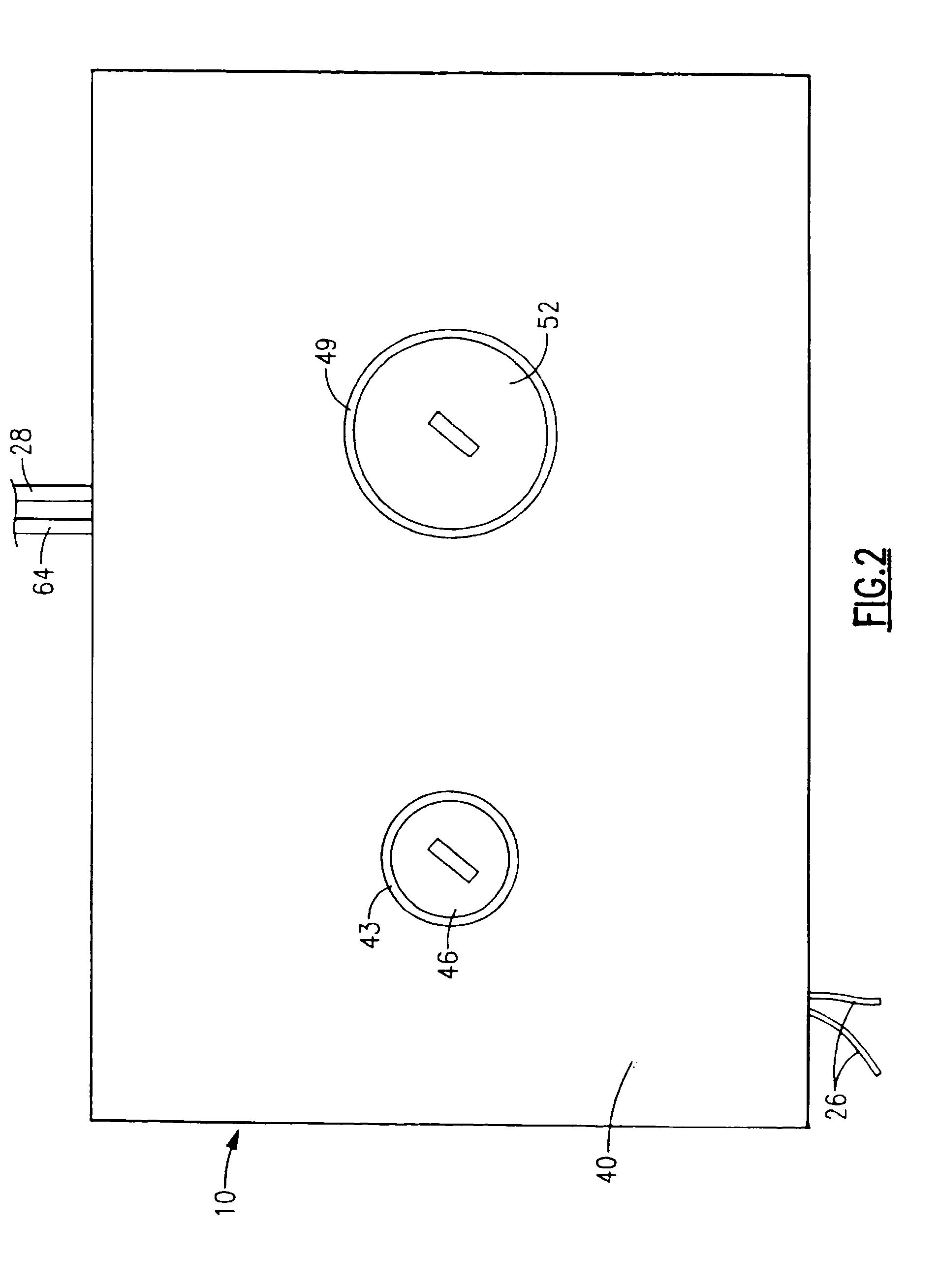

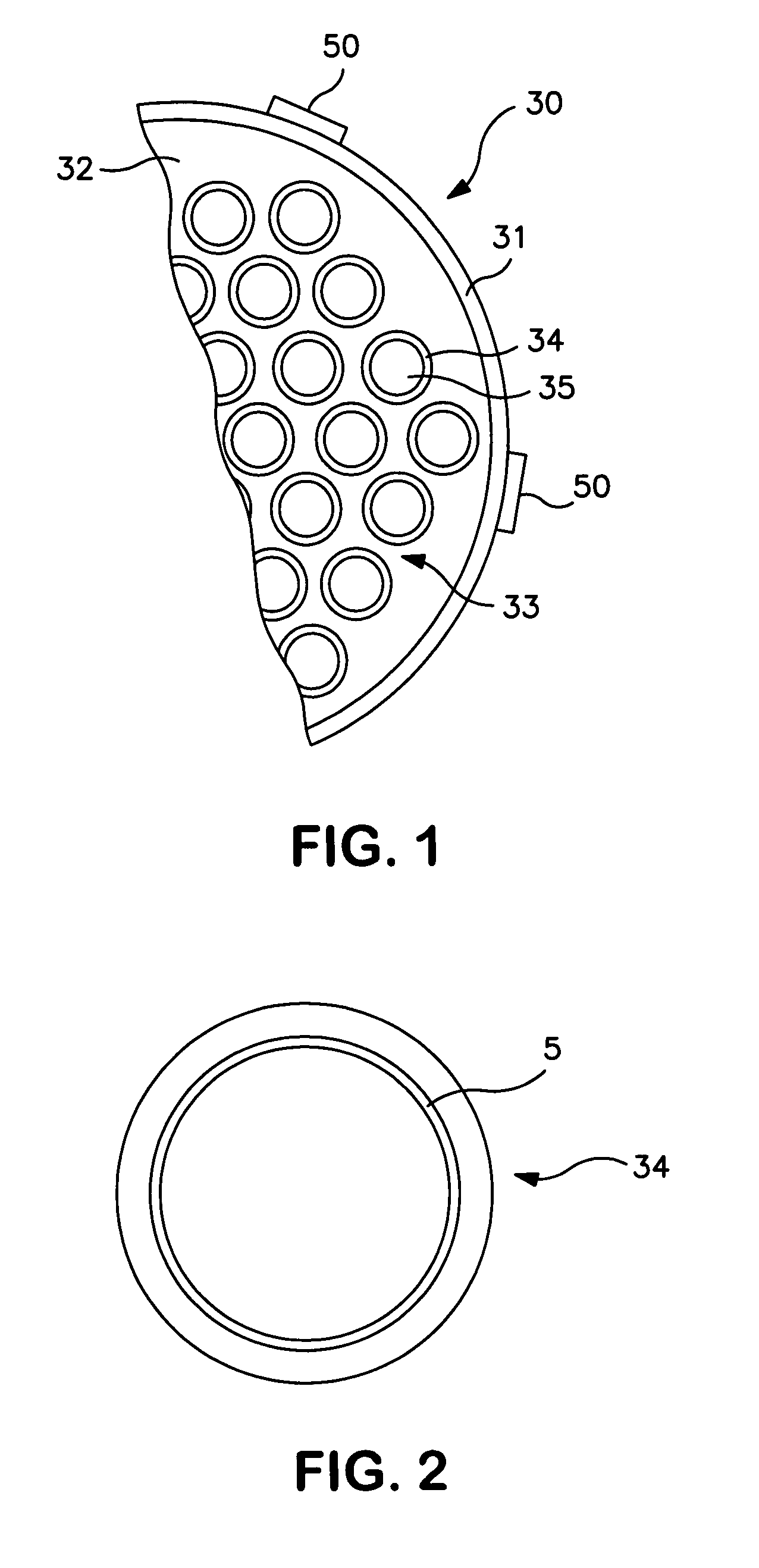

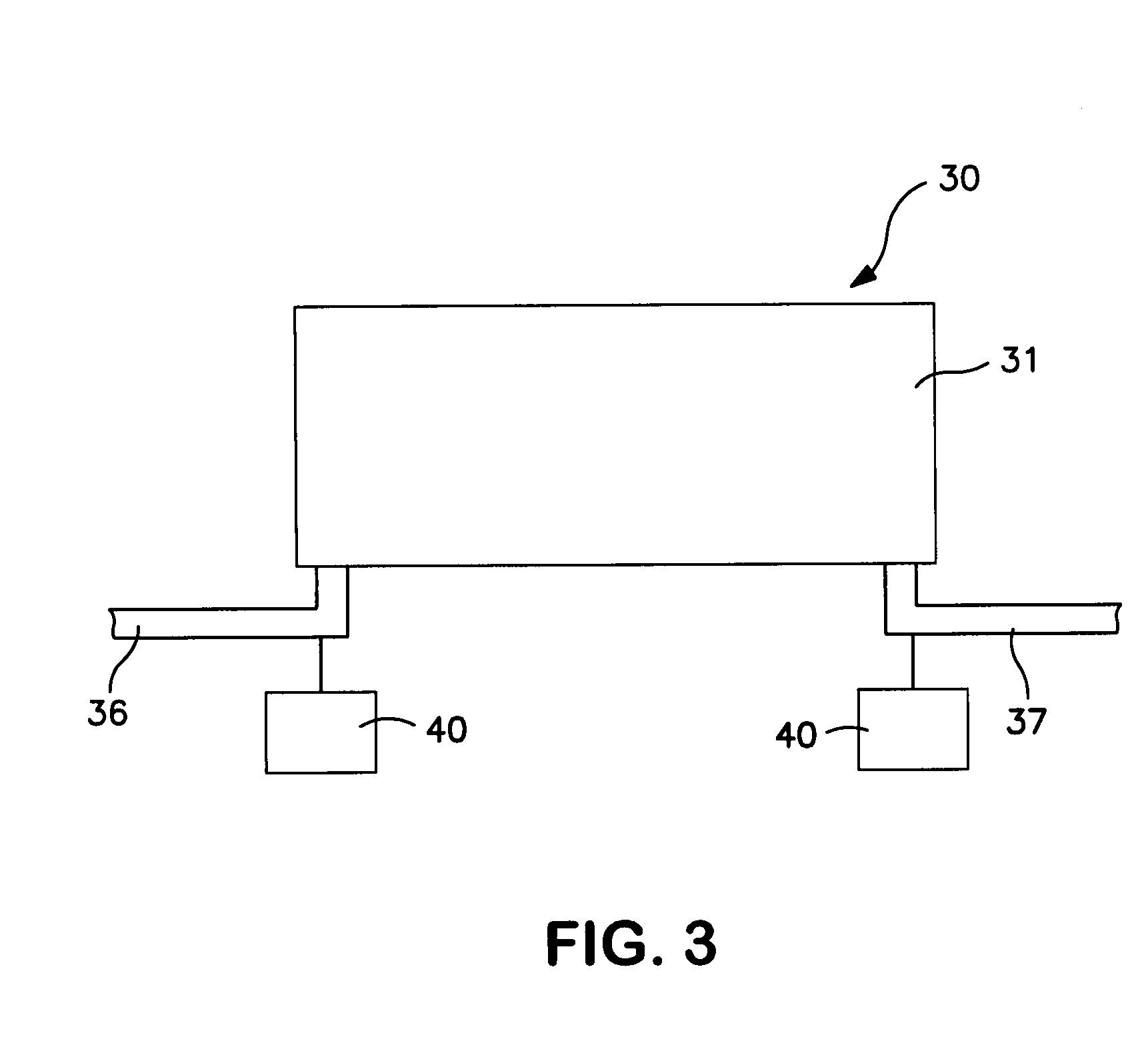

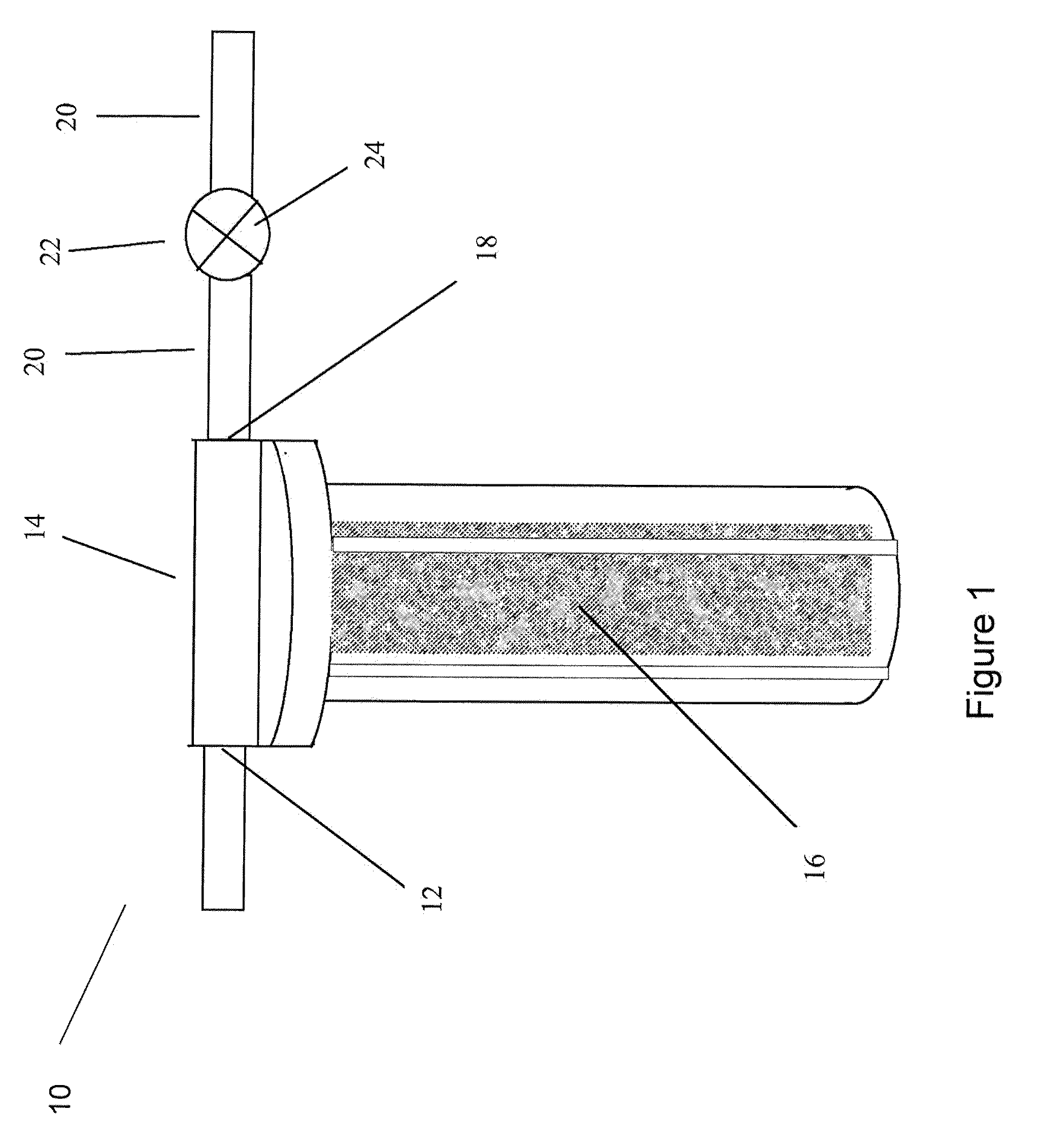

Body heating/cooling apparatus

InactiveUS6942015B1Reduce impactImprove protectionChemical protectionHeat protectionBiomedical engineeringFront panel

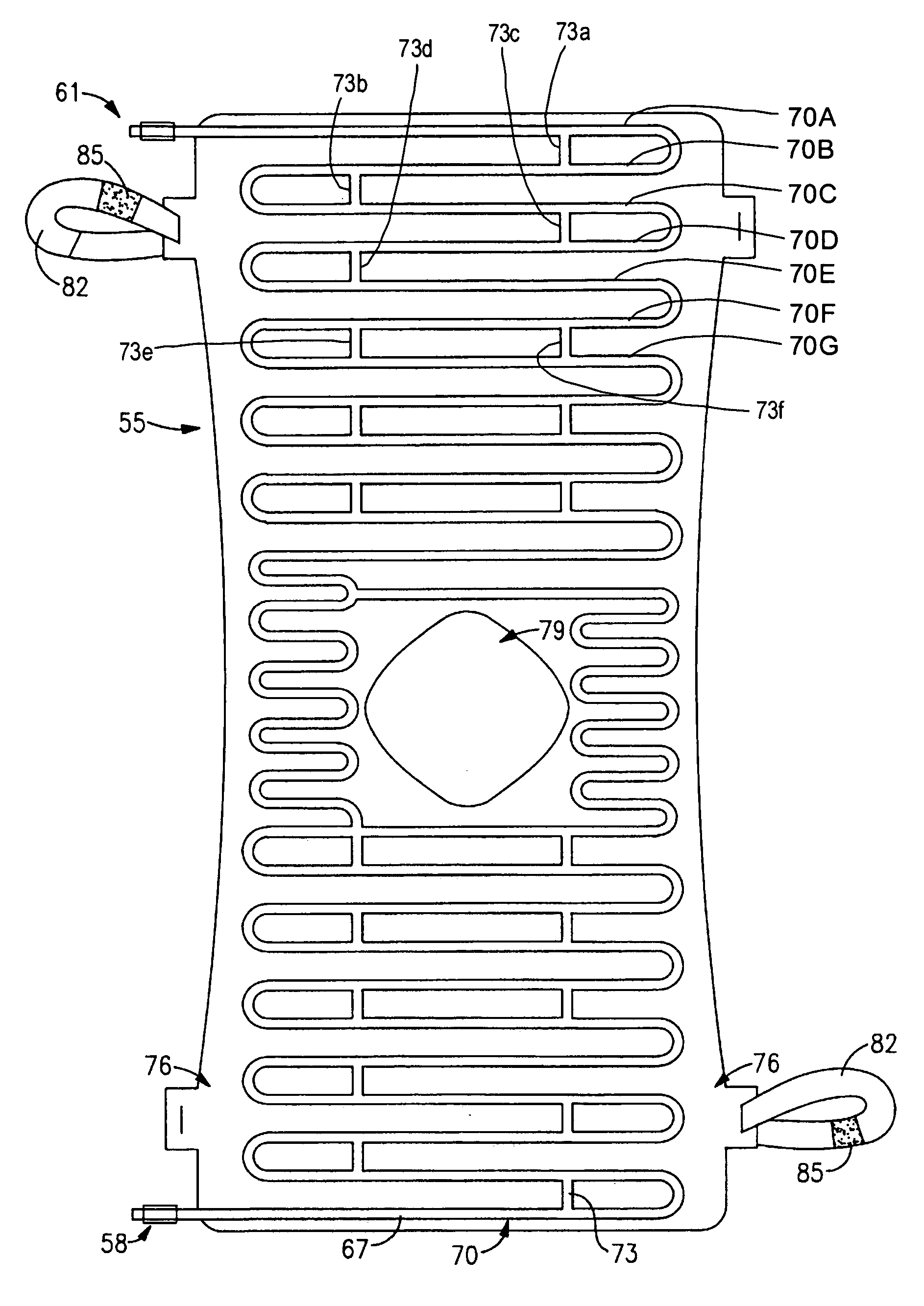

A body heating / cooling apparatus includes a vest having a front panel and a back panel defining a cavity therebetween. A flexible, continuous channel is disposed in serpentine fashion throughout the cavity and has adjacent portions. An inlet and an outlet are provided for infusing a fluid into the channel and for withdrawing the fluid from the channel. The adjacent portions of the channel are placed in fluid communication by passageways extending between corresponding adjacent portions at locations intermediate the ends of the adjacent portions. The passageways are configured with respect to the corresponding adjacent portions such that substantially all of a fluid flowing through the corresponding adjacent portions normally bypasses the passageways. The passageways are configured with respect to the corresponding adjacent portions such that if one of the corresponding adjacent portions suffers a constriction, fluid will enter a connected one of the passageways to flow from one corresponding adjacent portion to another so as to bypass the constriction.

Owner:JENKINS COMFORT SYST

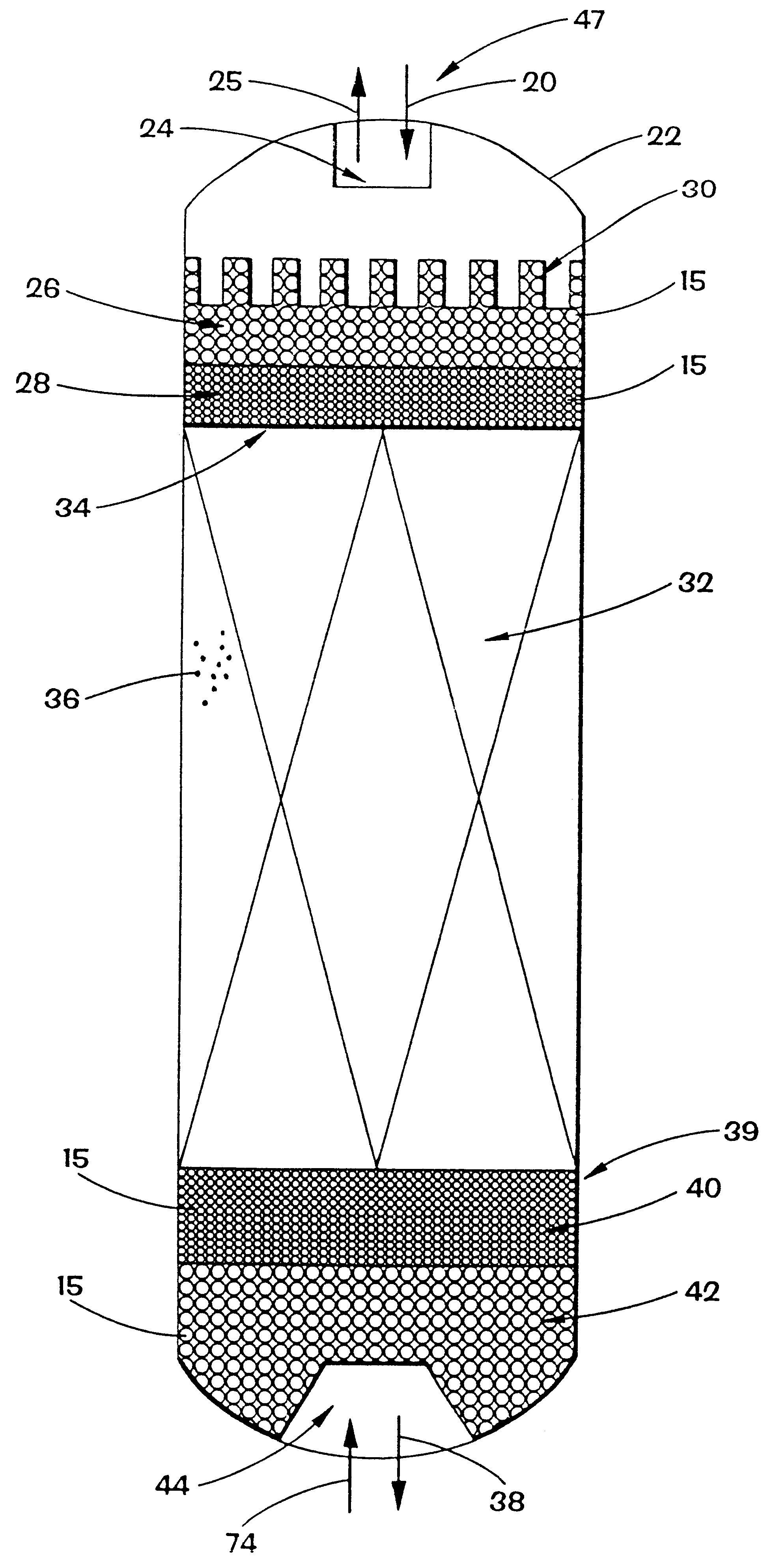

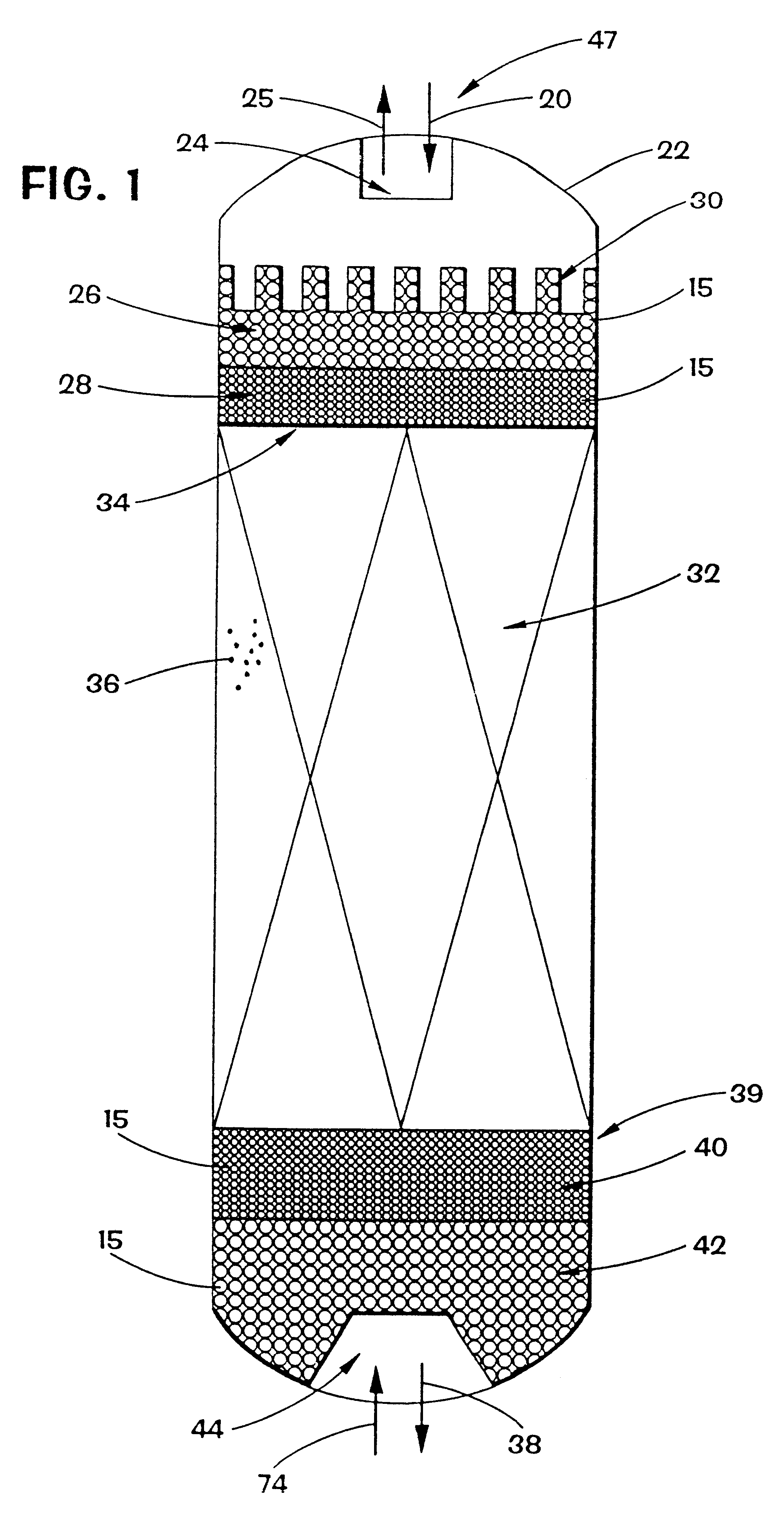

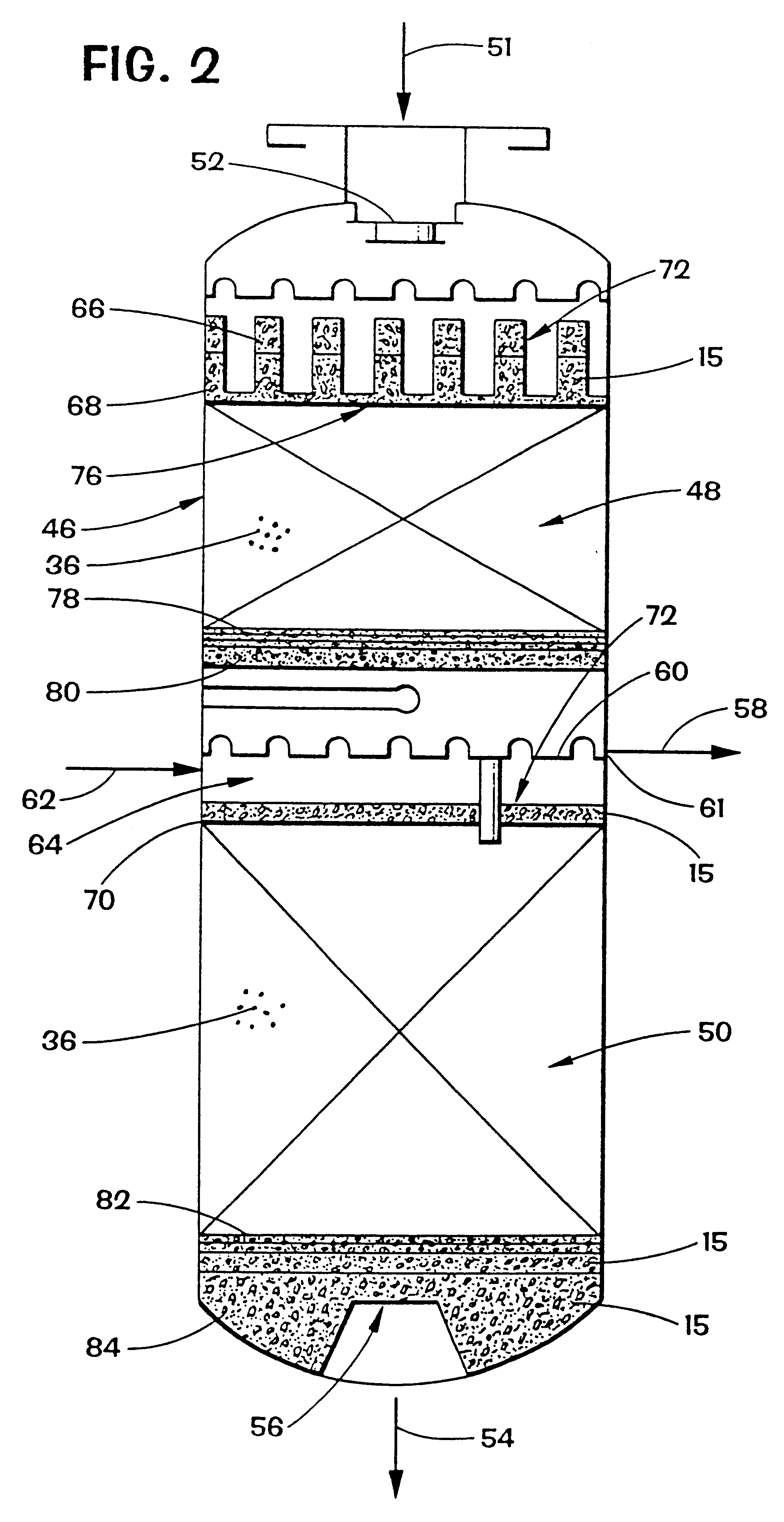

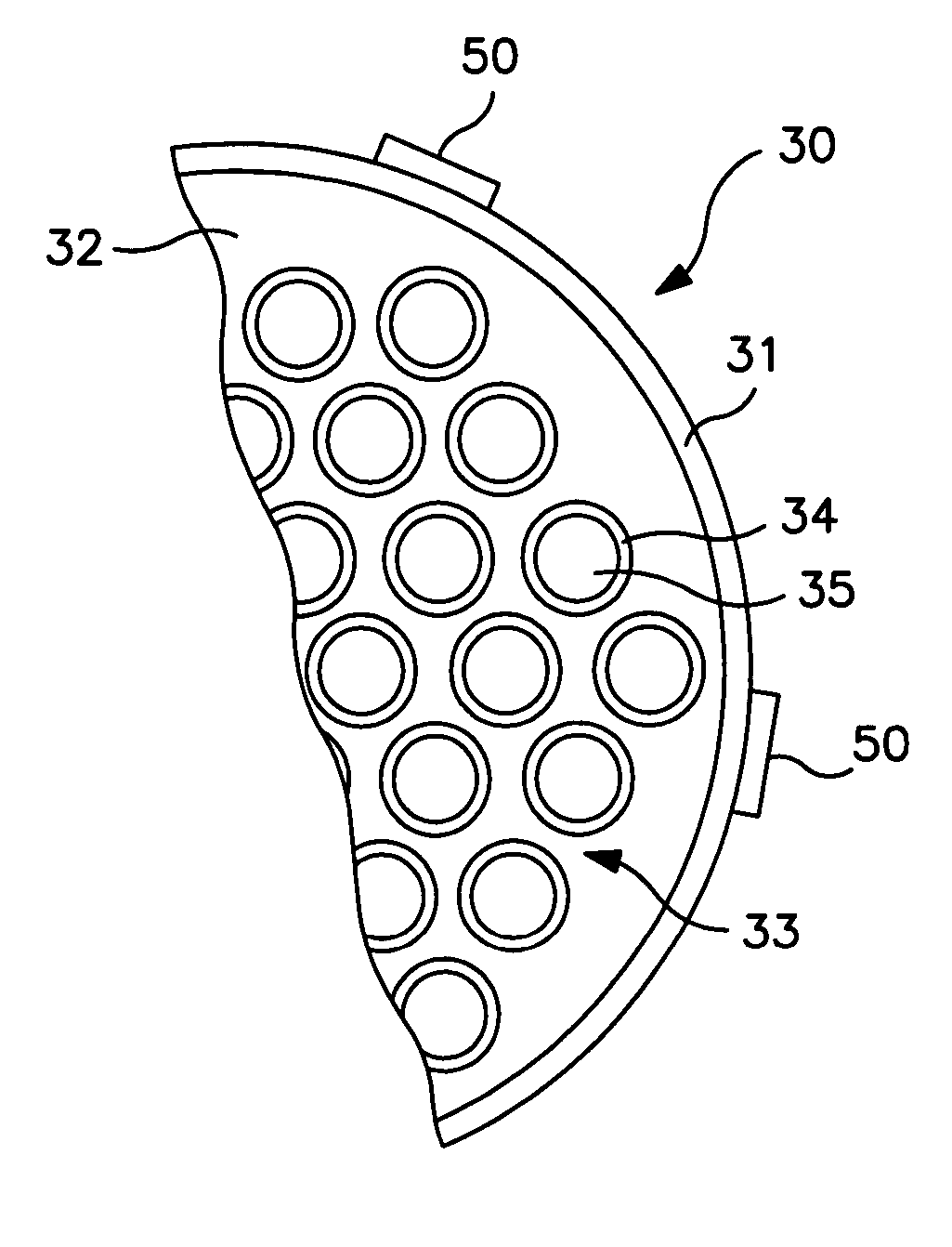

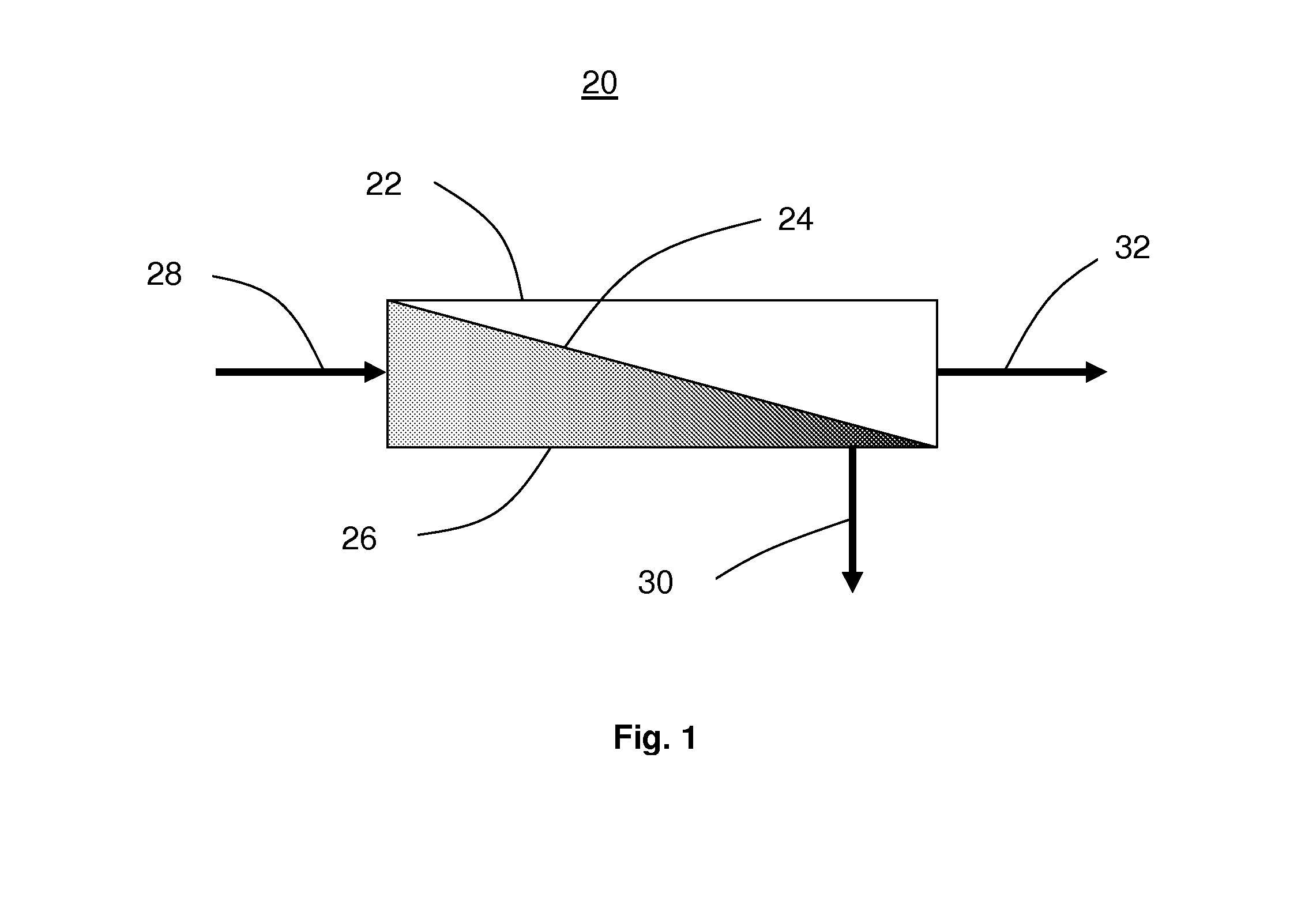

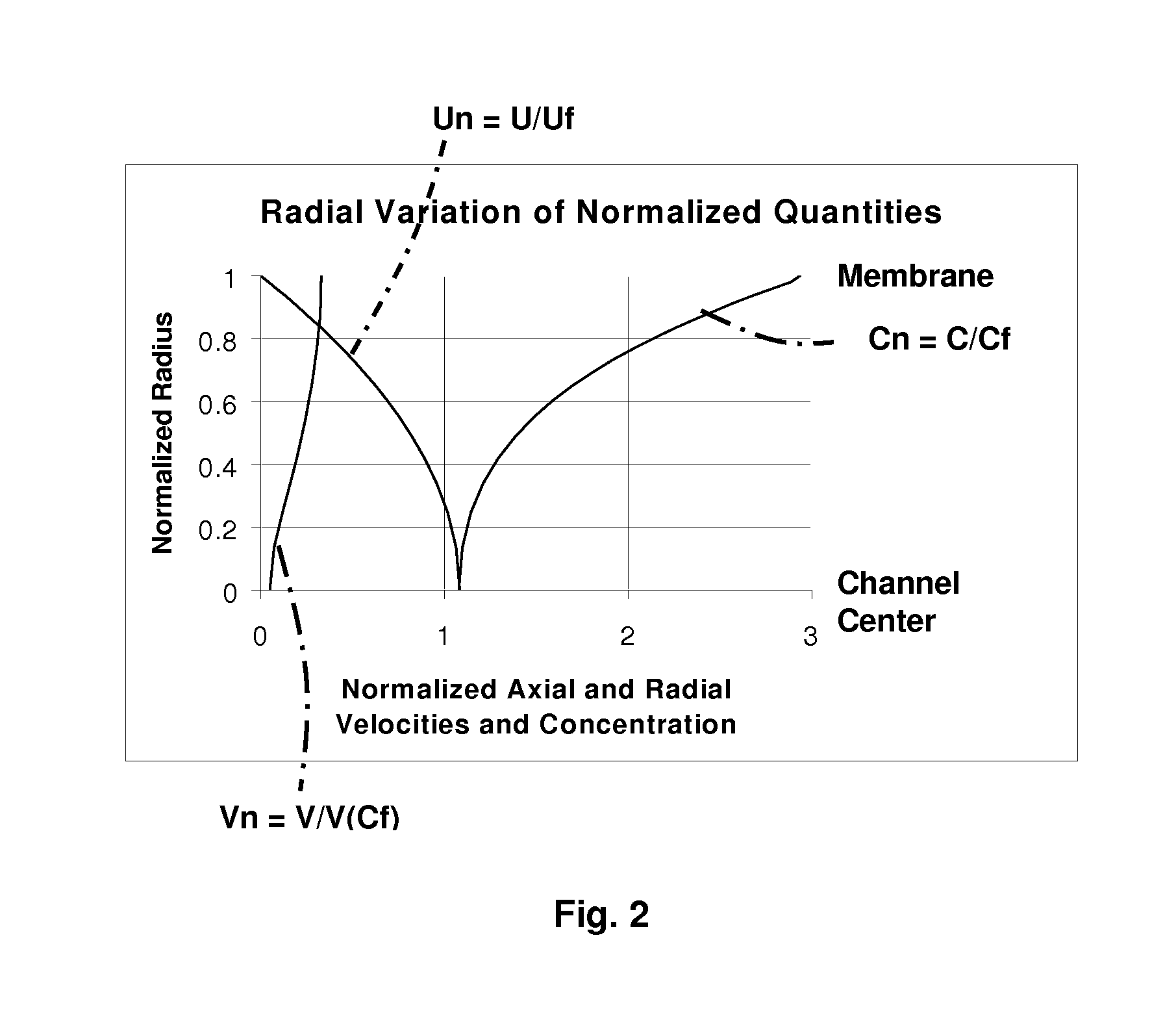

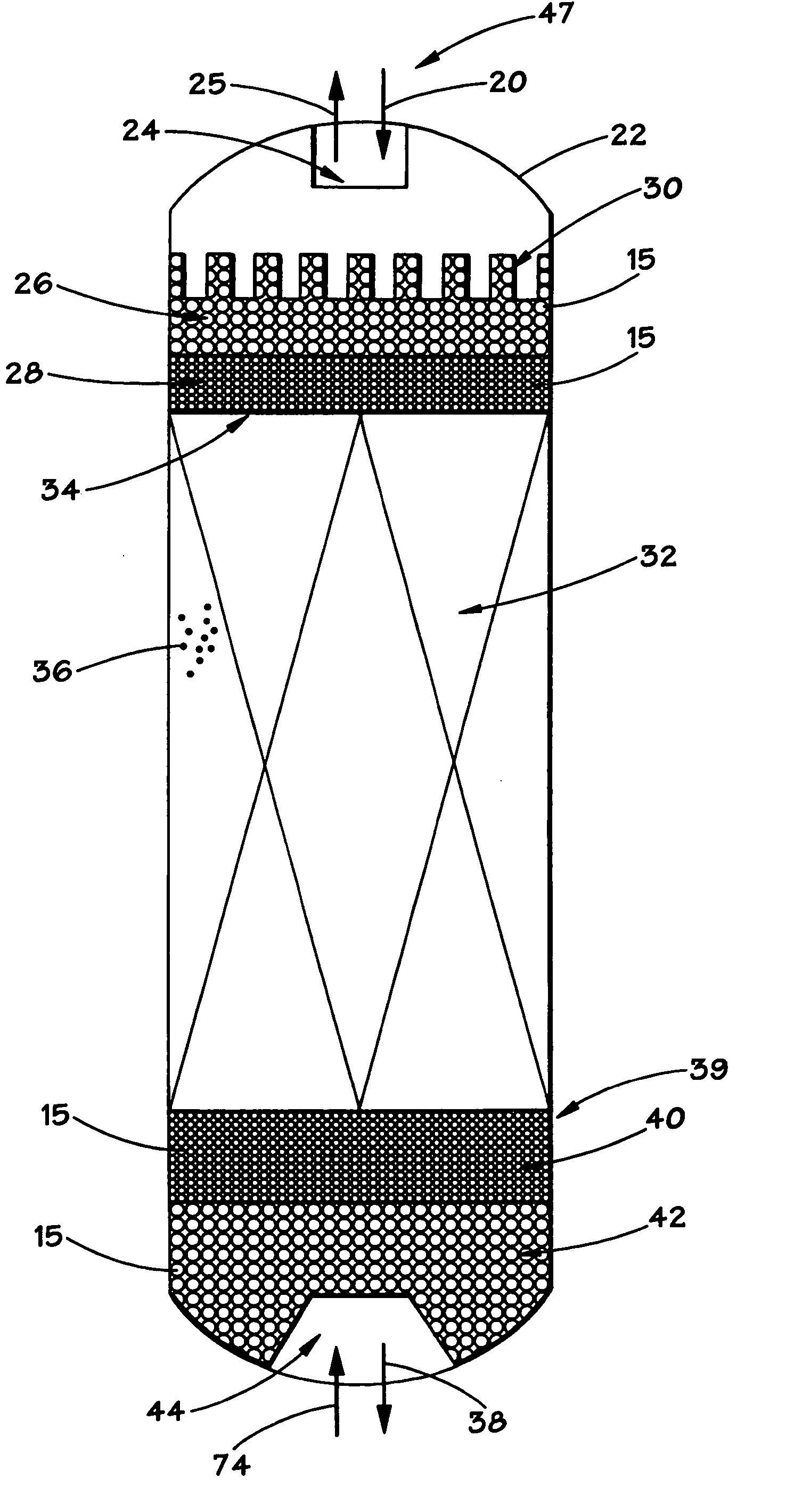

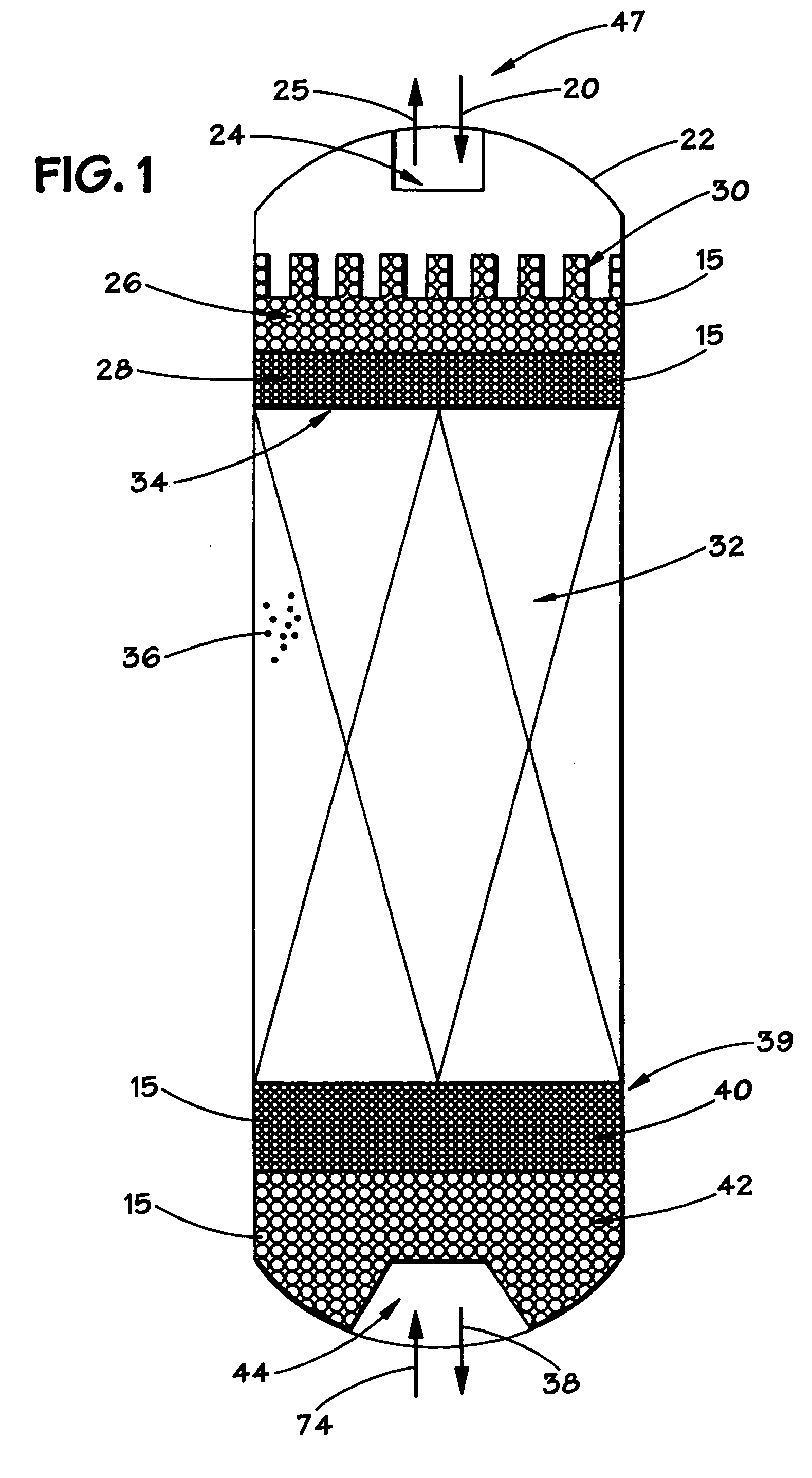

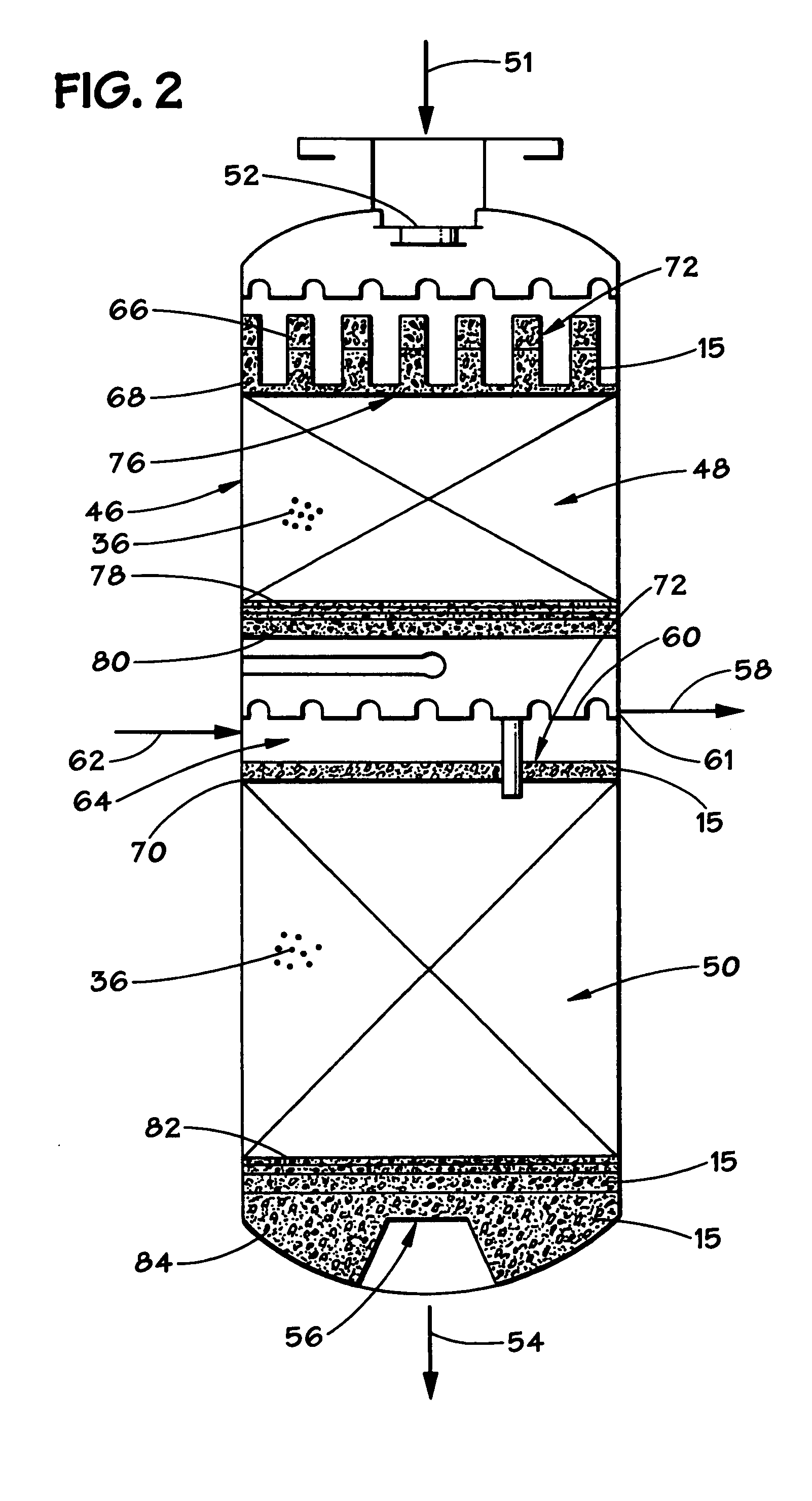

Filtration and flow distribution method for chemical reactors

InactiveUS6258900B1Reduce turbulenceHigh trafficCatalytic naphtha reformingMembrane filtersChemical reactorFiltration

Owner:CRYSTAPHASE PRODS

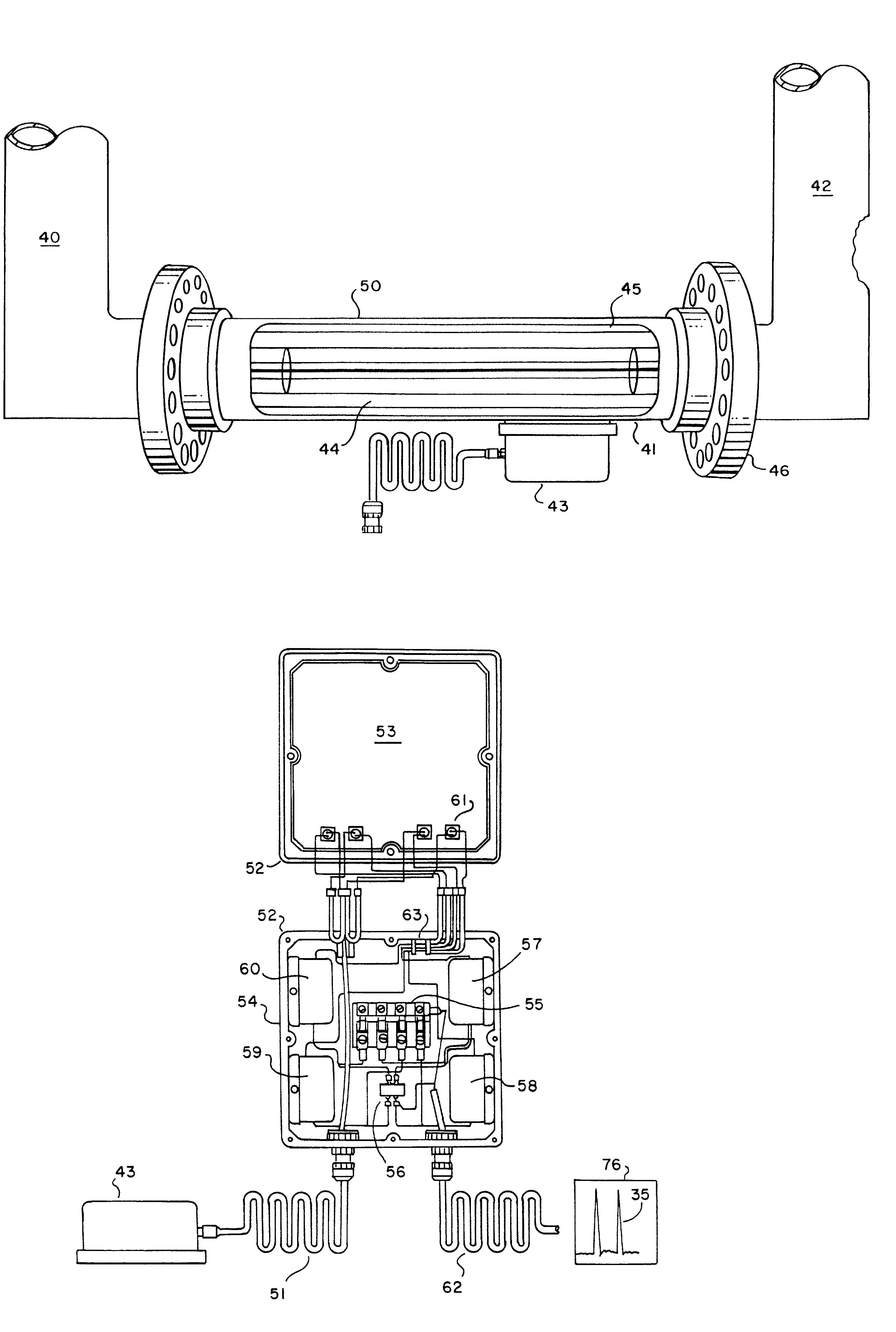

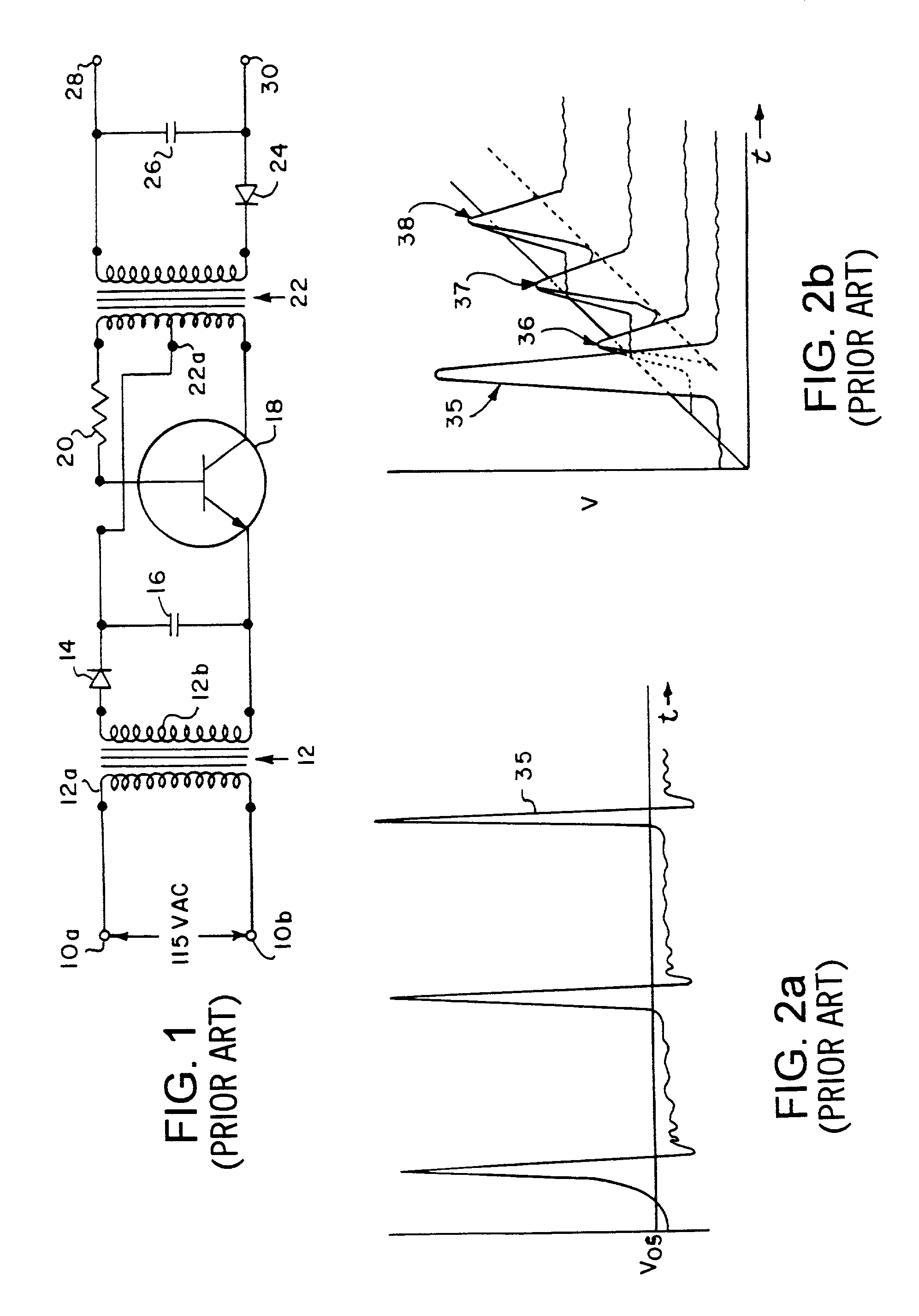

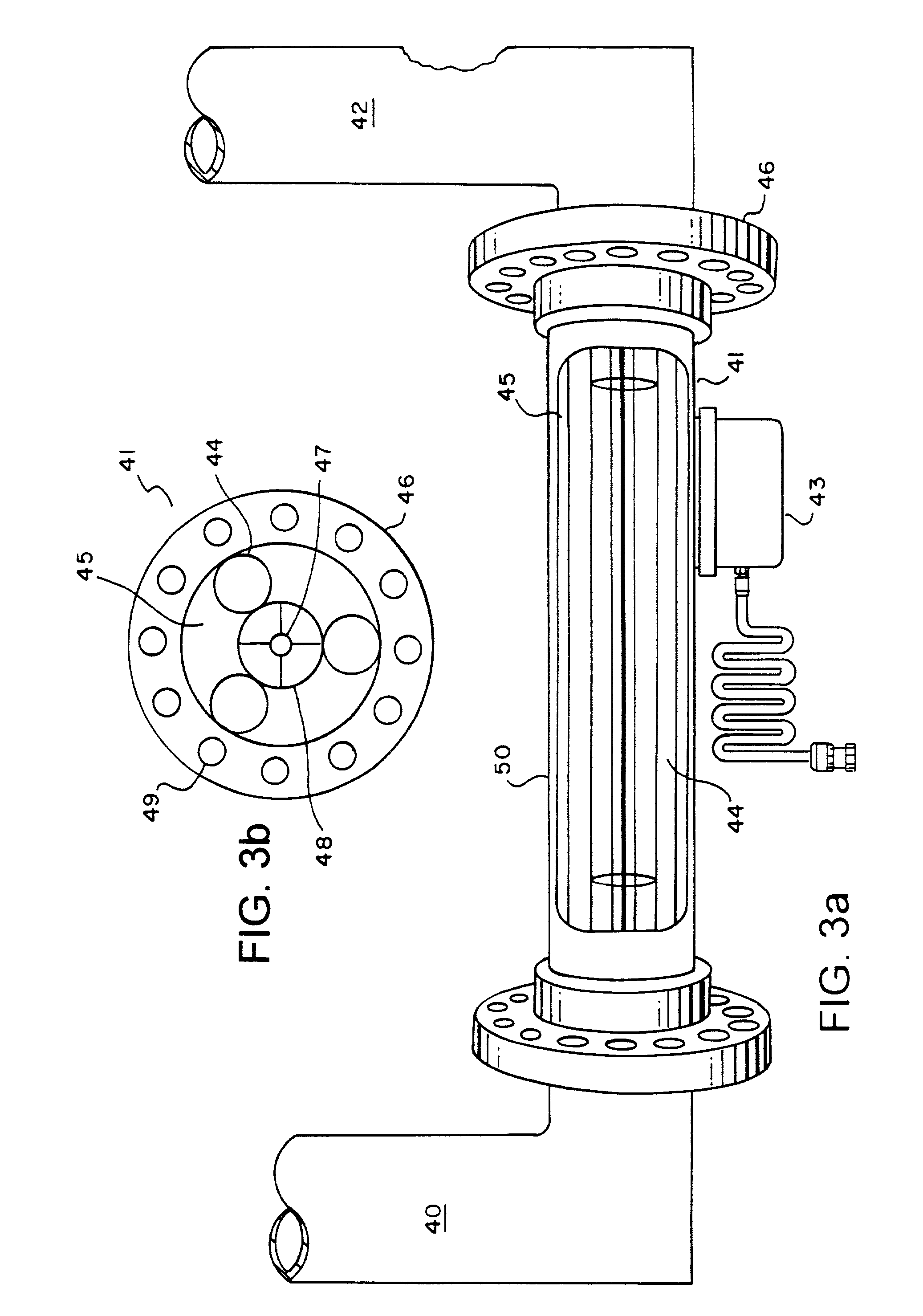

Reduction of fouling in heat exchangers

InactiveUS20080073063A1Reduce amountCost savingCorrosion preventionVibration cleaningCorrosionPetroleum

A method for reducing the formation of deposits on the inner walls of a tubular heat exchanger through which a petroleum-based liquid is flowing comprises applying one of fluid pressure pulsations to the liquid flowing through the tubes of the exchanger and vibration to the heat exchanger to effect a reduction of the viscous boundary layer adjacent the inner walls of the tubular heat exchange surfaces. Reduction of the viscous boundary layer at the tube walls not only reduces the incidence of fouling with its consequential beneficial effect on equipment life but it also has the desirable effect of promoting heat transfer from the tube wall to the liquid in the tubes. Fouling and corrosion are further reduced by the use of a coating on the inner wall surfaces of the exchanger tubes.

Owner:EXXON RES & ENG CO

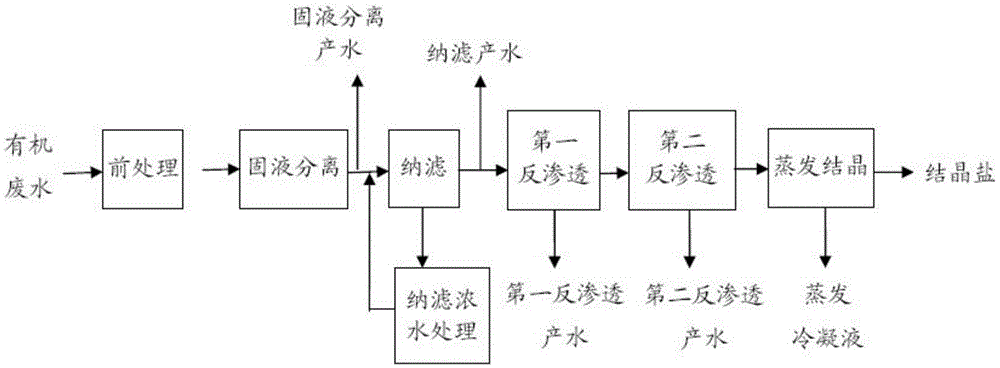

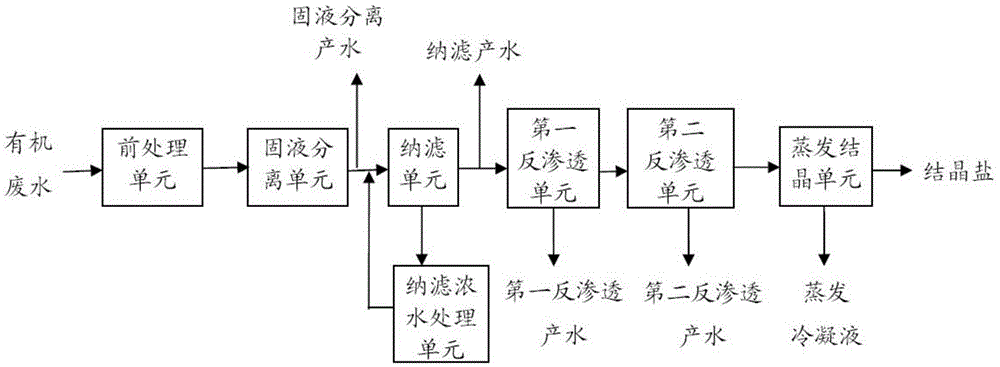

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

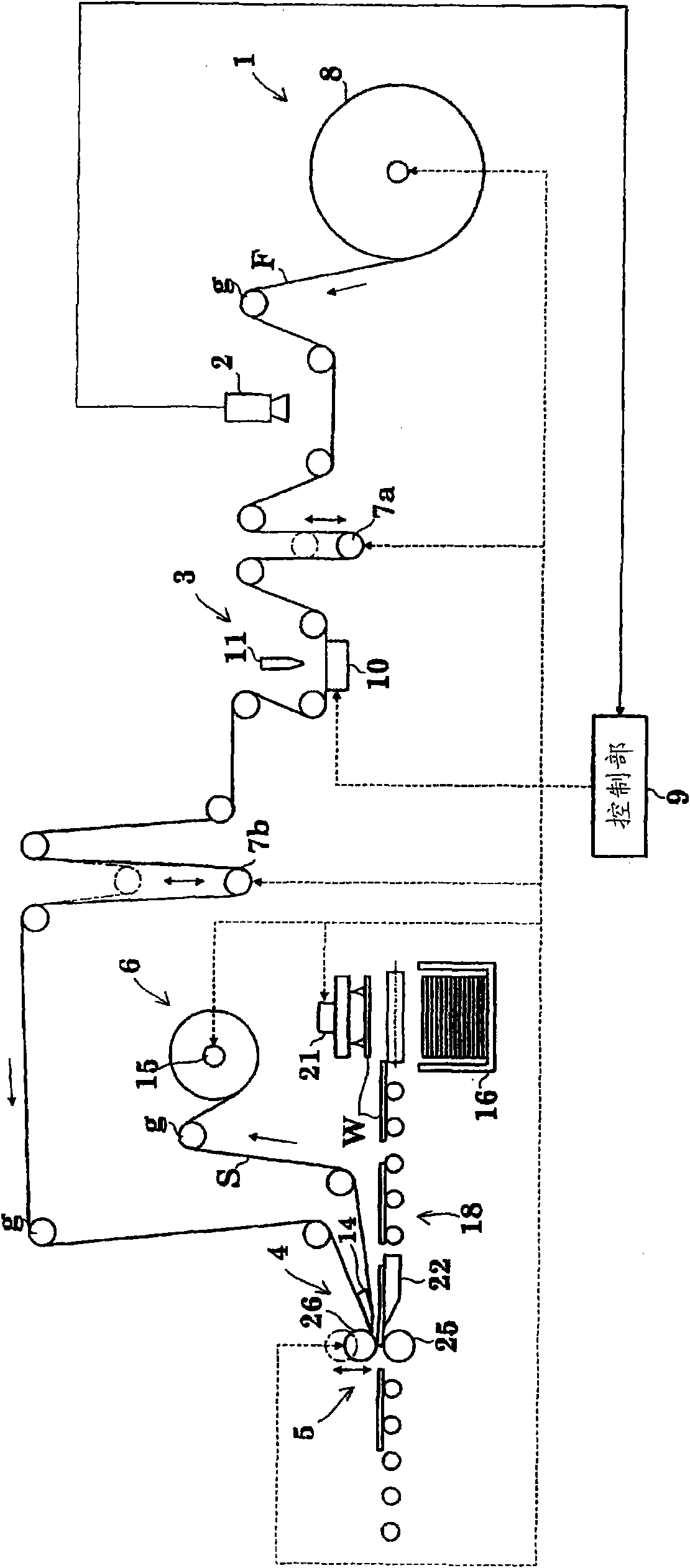

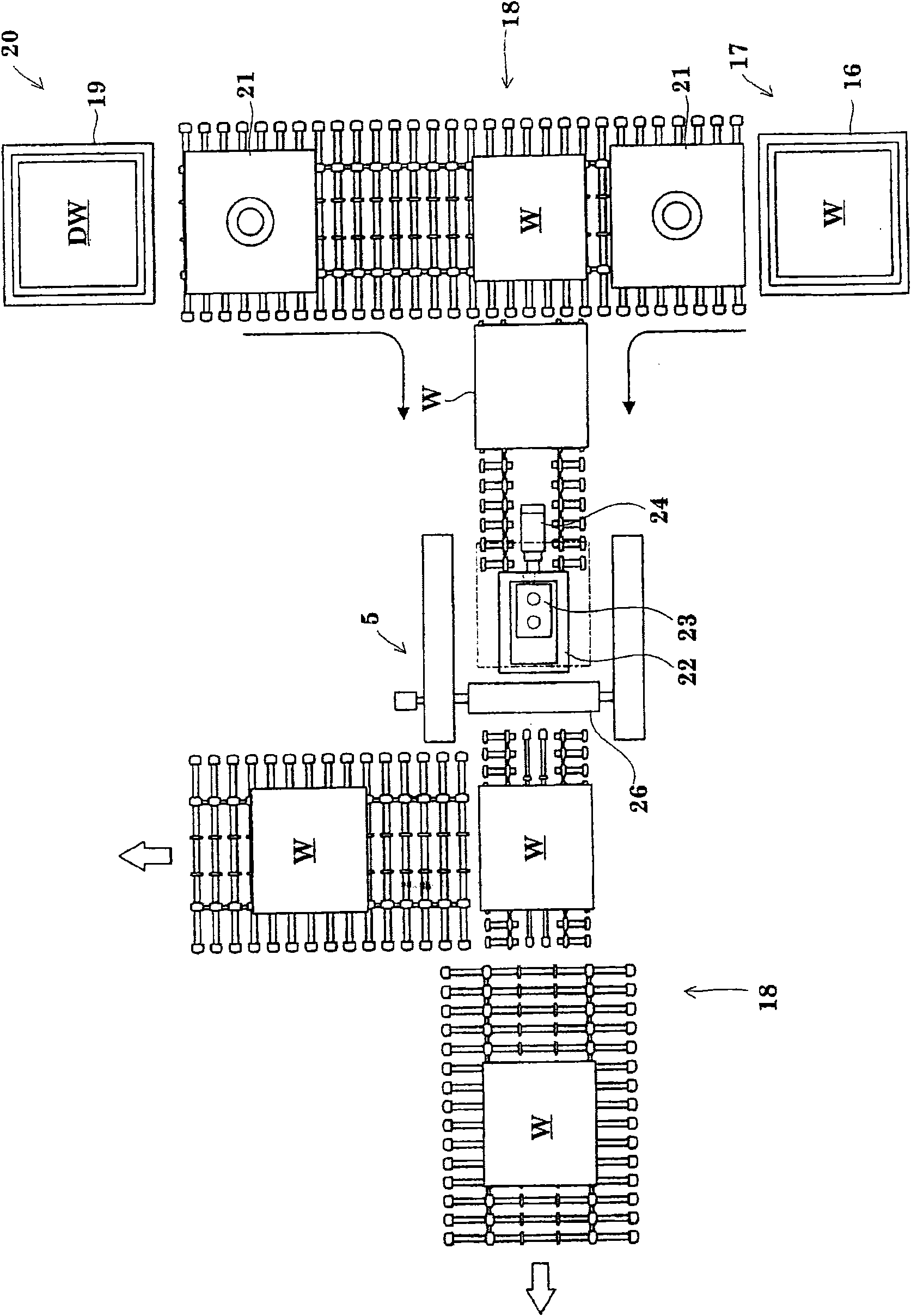

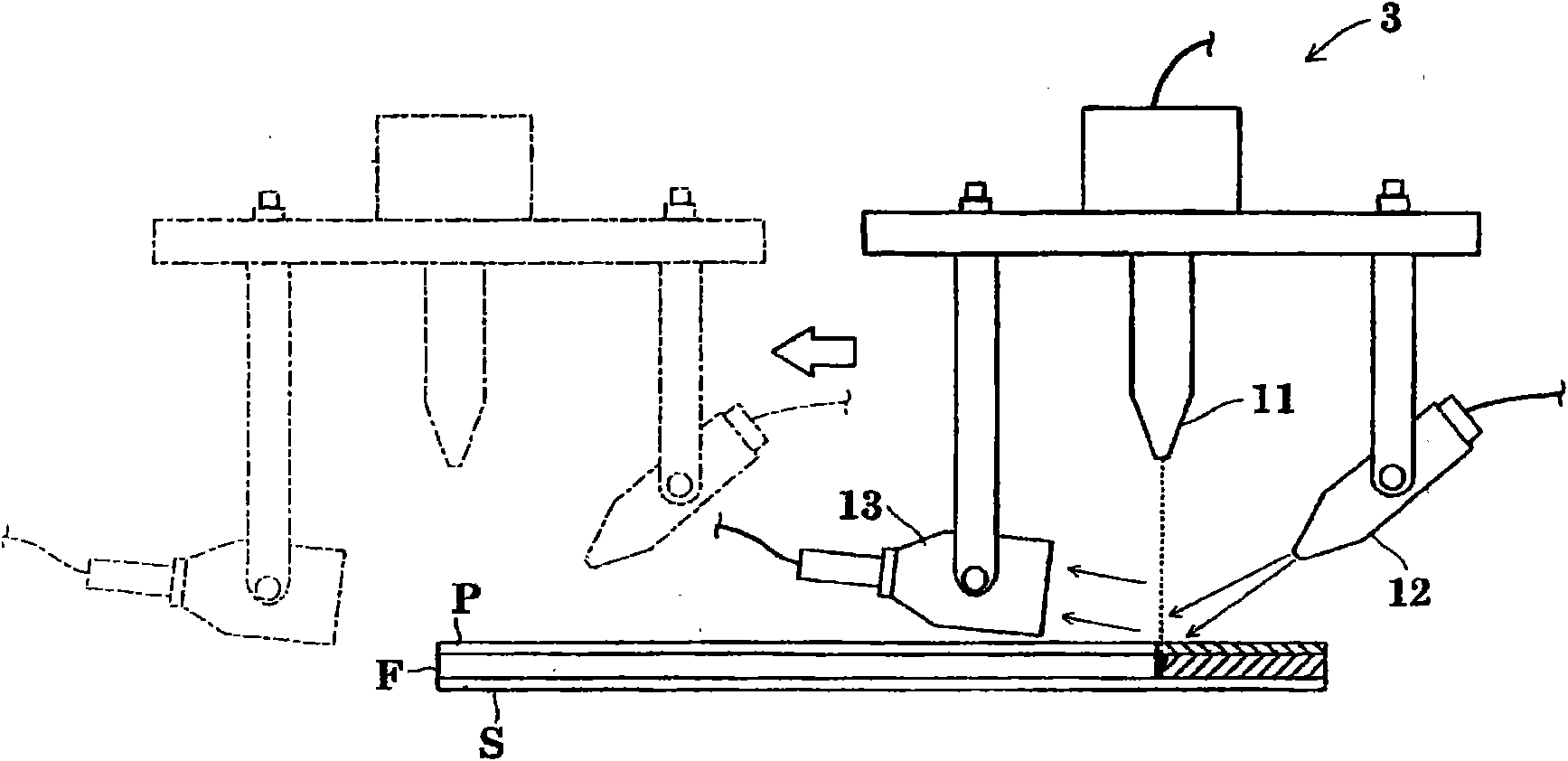

Optical member adhering method, and apparatus using the method

ActiveCN101528445AReduce foulingImprove qualityMaterial analysis by optical meansOptical articlesSynchronismLiquid crystal

A band-shaped polarization film (F), which has a protection film extended on one face and a separator extended on the other face, is let off and fed from a film feeding unit (1), and is subjected to a visual inspection. The protection film and the polarization film (F) are then half-cut by a laser device (11) while leaving the separator. After this, the films are transferred and guided to a peeling mechanism (4) so that the polarization film (F) is fed, while the separator being peeled by a knife edge, into an adhering mechanism (5). In synchronism with this feeding action of the polarization film (F), a liquid crystal panel (W) fed from a panel transfer device (18) is transferred and guided to the adhering mechanism (5), and the polarization film (F) is adhered to the liquid crystal panel (W).

Owner:NITTO DENKO CORP

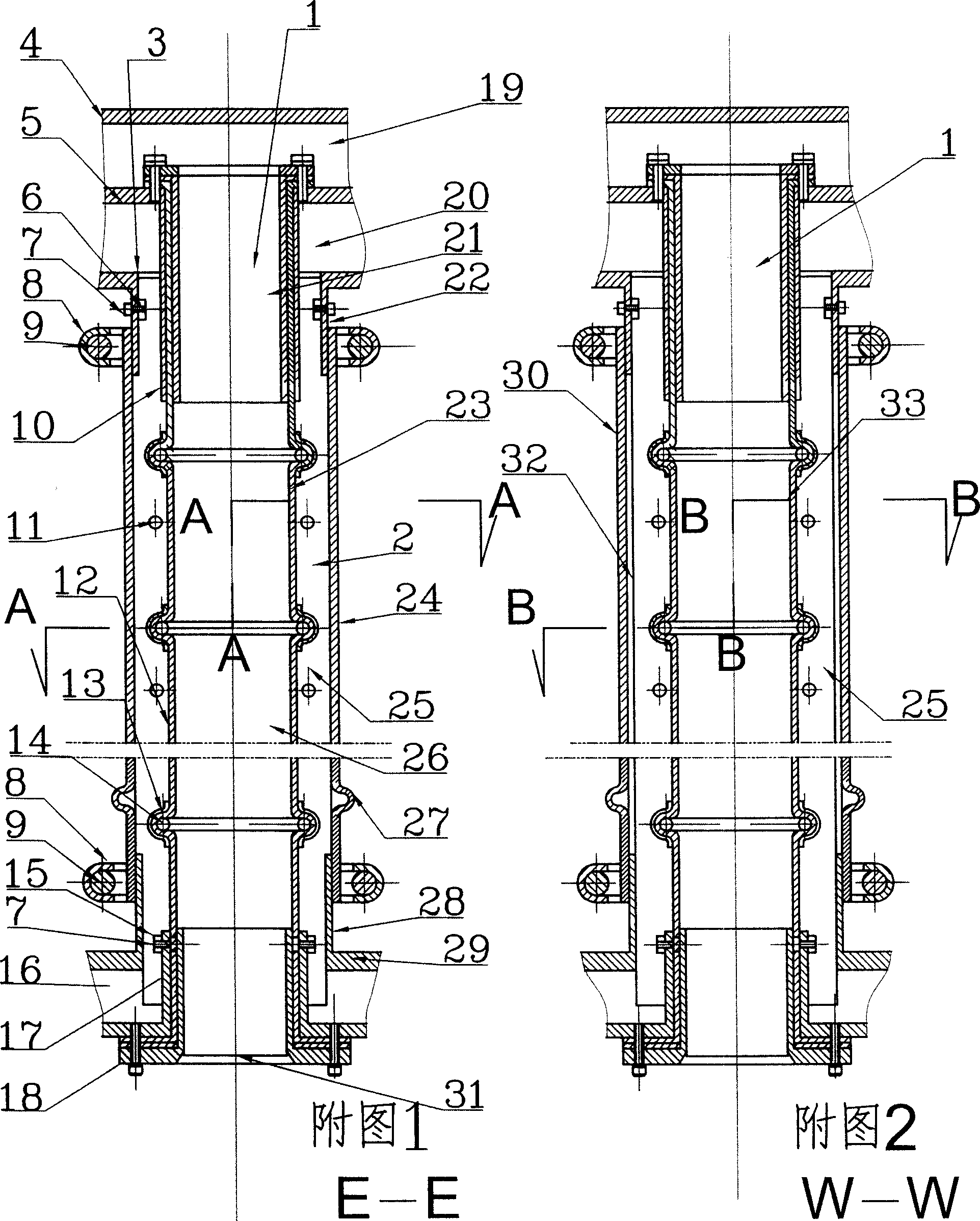

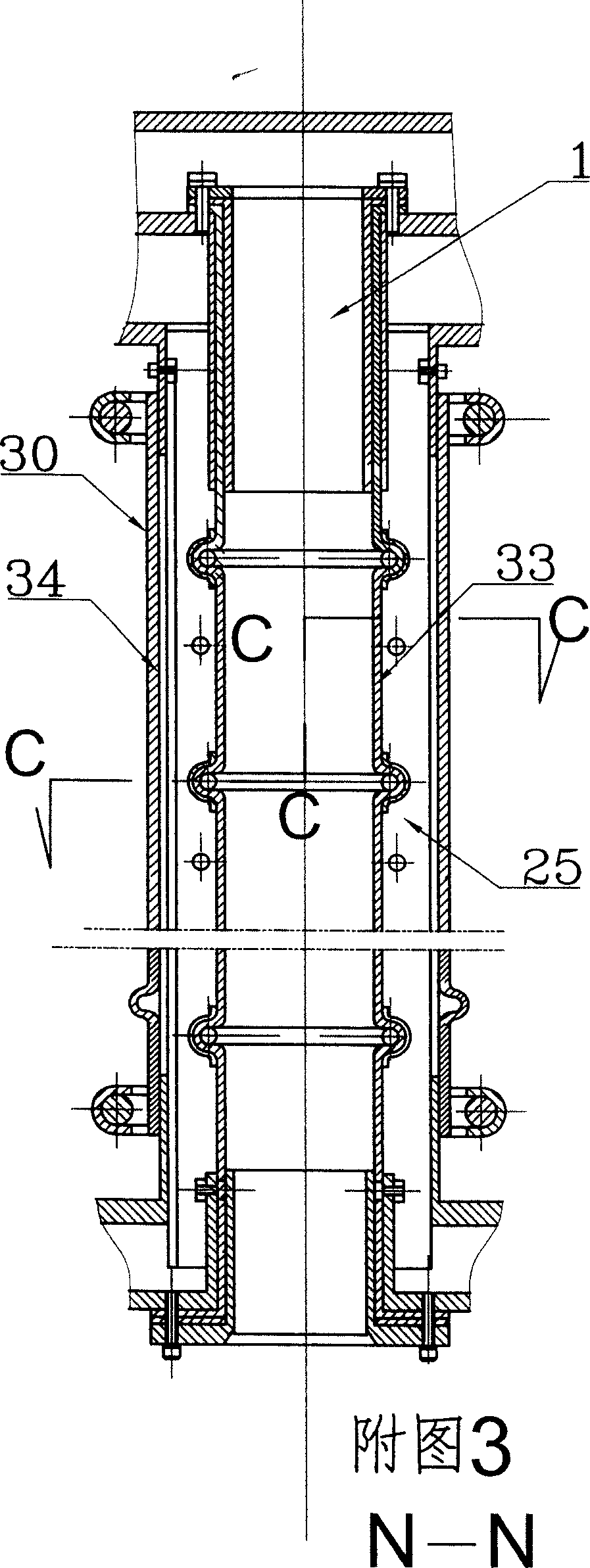

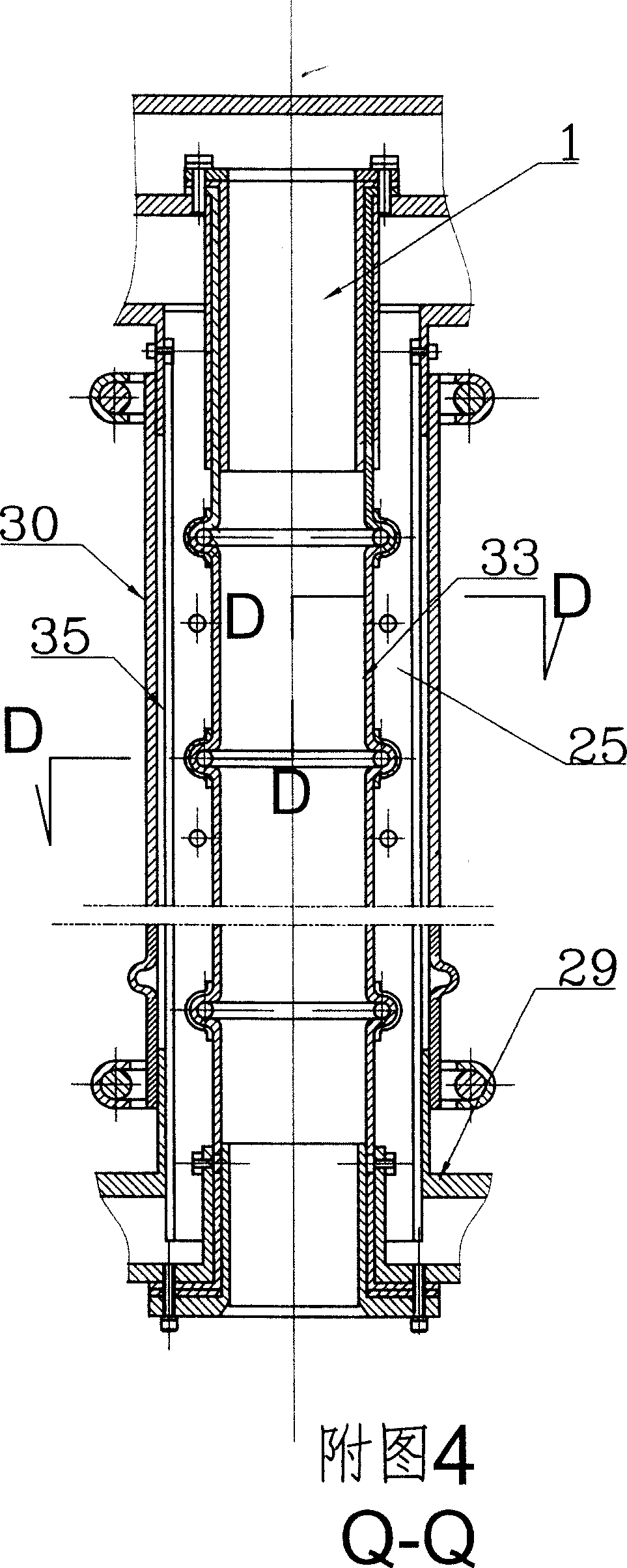

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

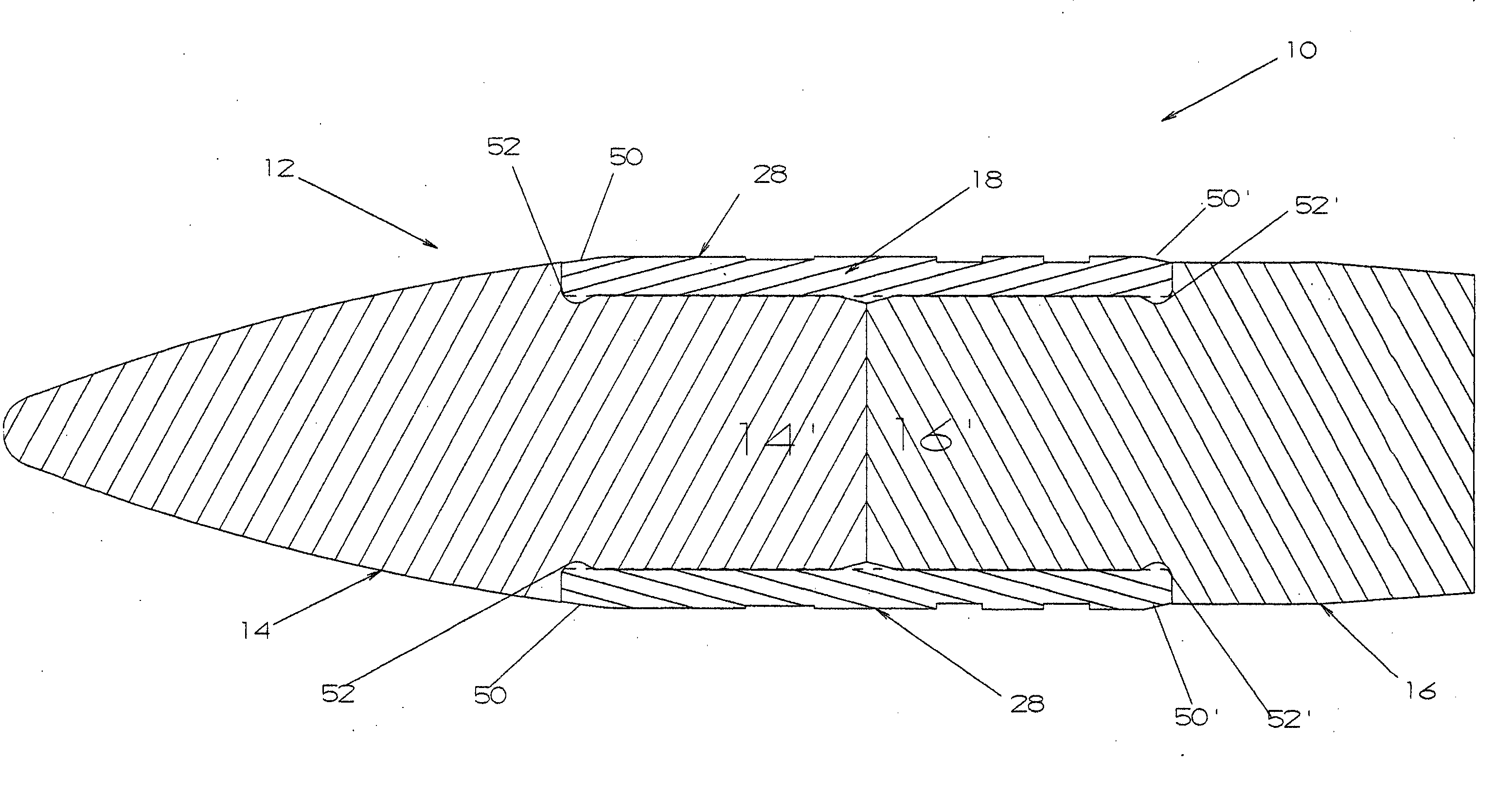

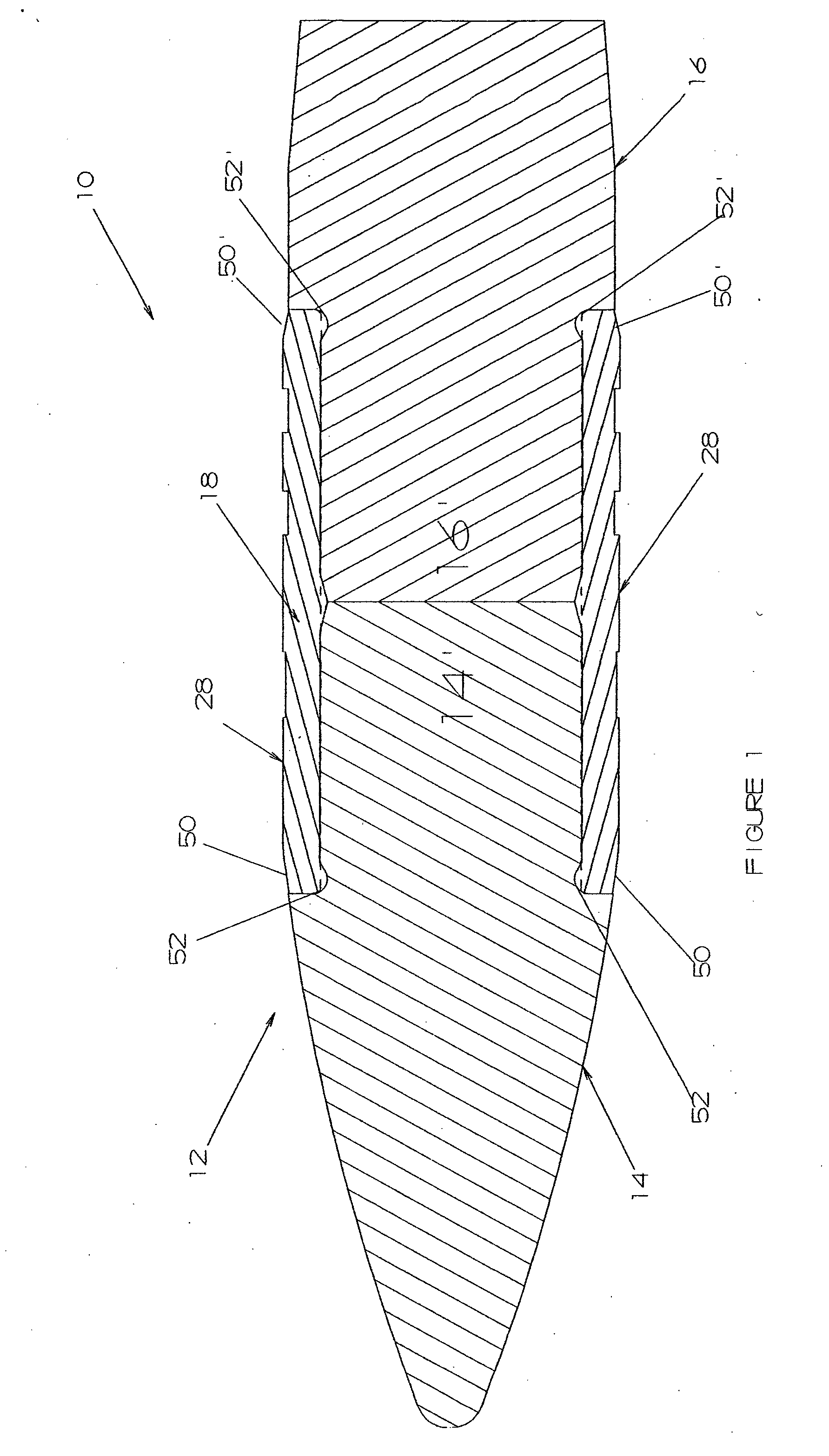

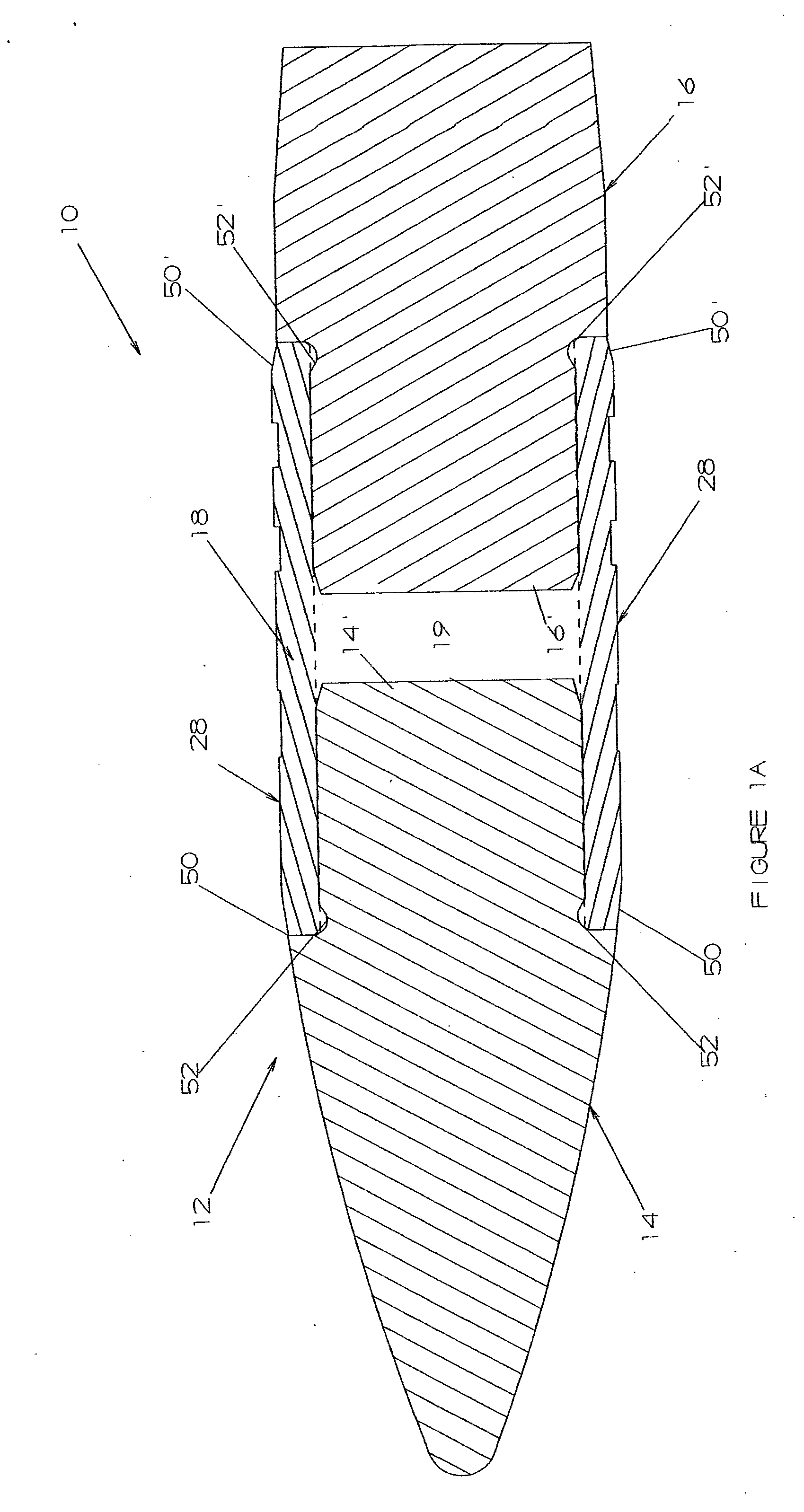

Firearms projectile

Owner:LIBERTY OPCO LLC

Non-volatile phosphorus hydrocarbon gelling agent

ActiveUS8084401B2Eliminate badReduce foulingOther chemical processesGroup 5/15 element organic compoundsFracturing fluidOil and natural gas

New fluids are disclosed for use in servicing subterranean formations containing oil and gas. In particular, an improved chemical gelling additive for hydrocarbon based fracturing fluids is disclosed having reduce, negligible or no volatile phosphorus at temperatures below about 250° C.

Owner:THE LUBRIZOL CORP

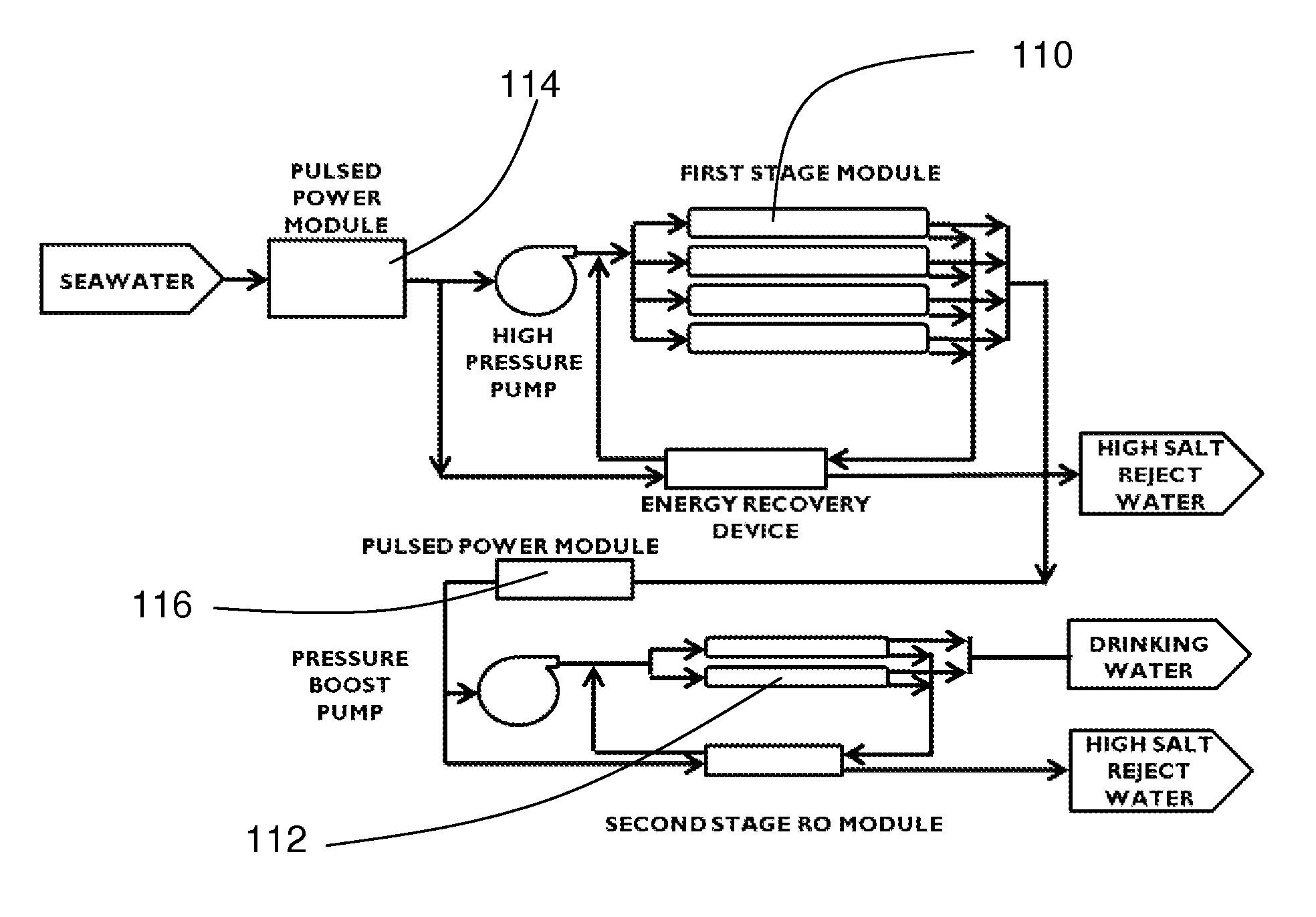

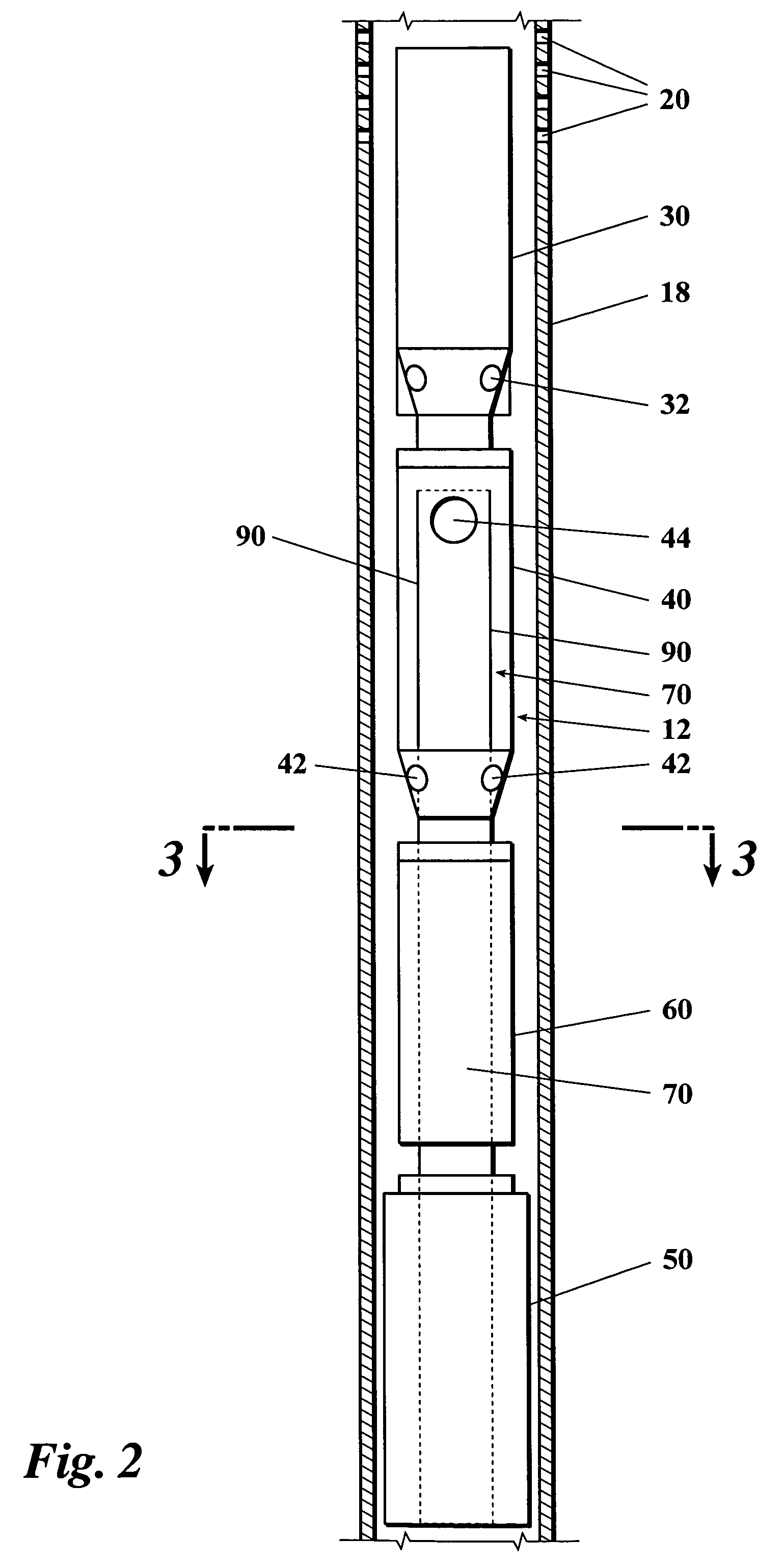

Systems and methods for filtration

InactiveUS20120298578A1Reduce foulingImprove water qualityMaterial nanotechnologyGeneral water supply conservationMicroorganismFiltration membrane

Filtration systems (40) utilize a pre-treatment method to cause scale formation to occur on particles (94) in the fluid stream (96) rather than on the filter surface and may also destroy microorganisms in the fluid stream. More specifically, but not limited to, a filtration device can be a filtration membrane, such as spiral wound filtration membrane (60), that utilizes an open feed spacer (80), such for example an embossed or printed pattern on the membrane, to create a thin feed spacer channel which replaces a conventional feed spacer mesh material. System (40) further utilizes a treatment device (54) to enable a pulsed power, magnetic, electro-magnetic, electro-static, or hydrodynamic fluid treatment scheme to condition particles in the fluid stream (96) such that scale forming elements precipitate (94) on to the particles in the fluid stream rather than on the filtration surfaces.

Owner:AQUA MEMBRANES +1

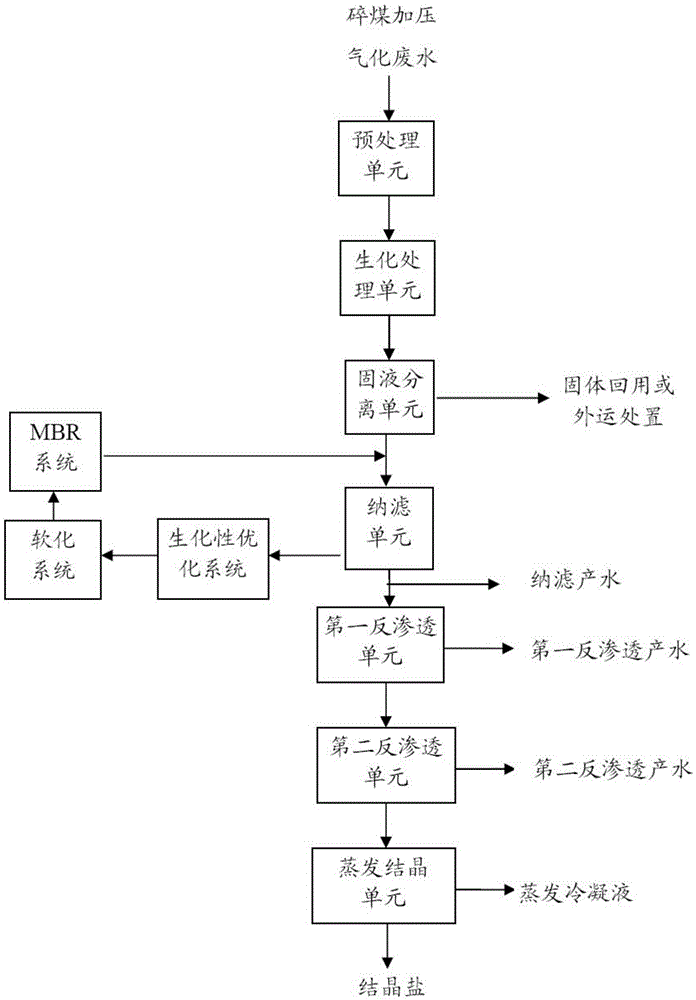

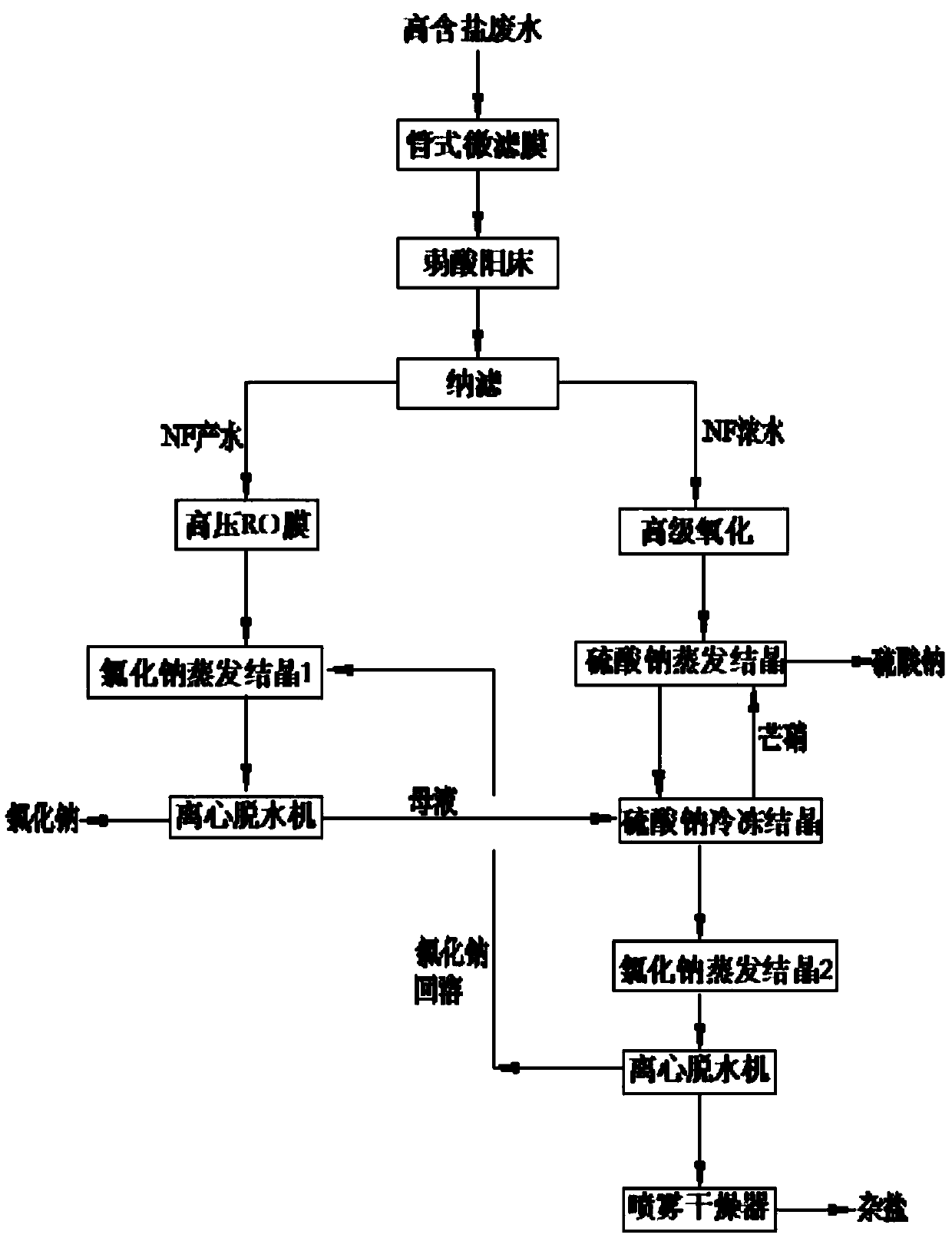

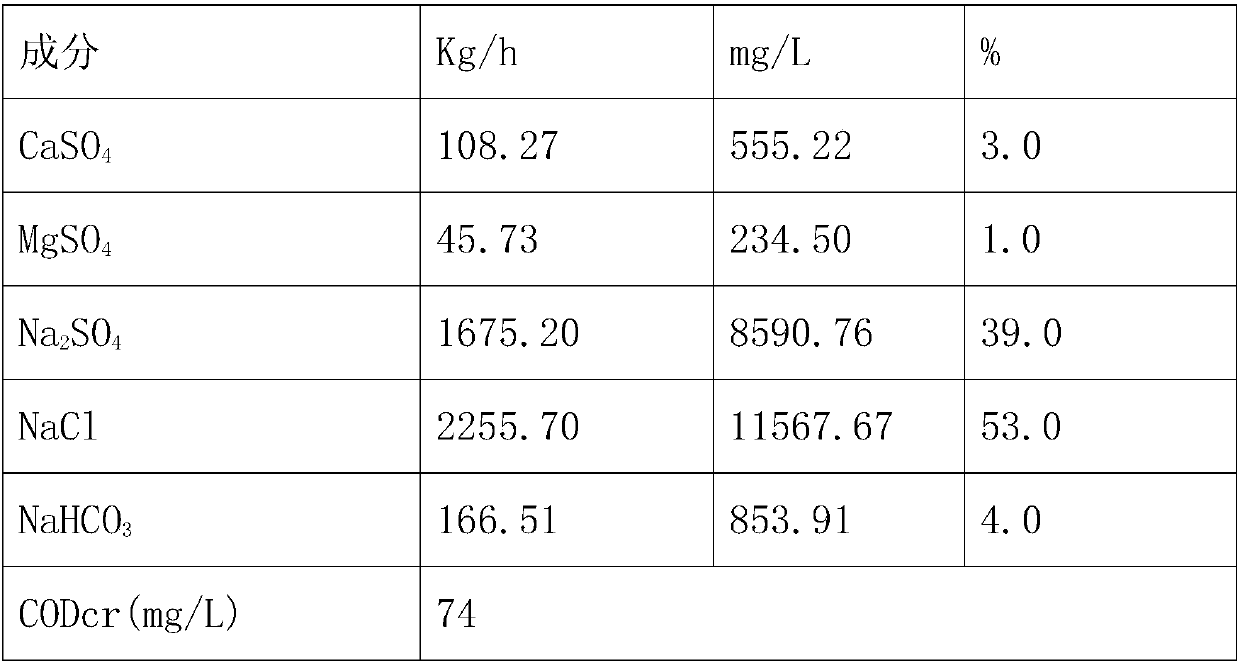

Resource technology and system for separating salt from high-salinity wastewater

InactiveCN107619144ASolve the problem of pipe blockageReduce energy consumptionMultistage water/sewage treatmentAlkali metal chloridesMirabiliteProduced water

The invention discloses a zero-drainage technology for recycling crystallizing salt from high-salinity wastewater and a treatment system thereof. The treatment system comprises a tubular microfiltration system, a weak acid resin hardness removal system, a nanofiltration membrane salt separating system, a nanofiltration concentrated water oxidizing system, a nanofiltration concentrated water sodiumsulfate evaporating and crystallizing system, a sodium sulfate freezing and crystallizing system and the like. The zero-drainage technology has the advantages that the pretreated wastewater is subject to nanofiltration primary salt separating, the salt component in the produced water is mainly sodium chloride, the sodium chloride with purity no lower than 98.5% is obtained by membrane concentration, evaporating and crystallizing, and the sodium sulfate with purity 99.1% or more is produced by MVR (mechanical vapor recompression) crystallizing after concentrated water oxidizing; a mother liquid after evaporating and crystallizing of sodium sulfate and a mother liquid after nanofiltration evaporating and crystallizing are mixed and frozen, so as to obtain mirabilite, and the mirabilite is converted into anhydrous sodium sulfate after sodium sulfate evaporating and crystallizing; at the premises of ensuring quality, the whole recycling rate of salt reaches 90% or above; finally, a smallamount of mother liquid is sprayed, dried and cured, and the zero-drainage effect of wastewater is realized.

Owner:侯新春 +1

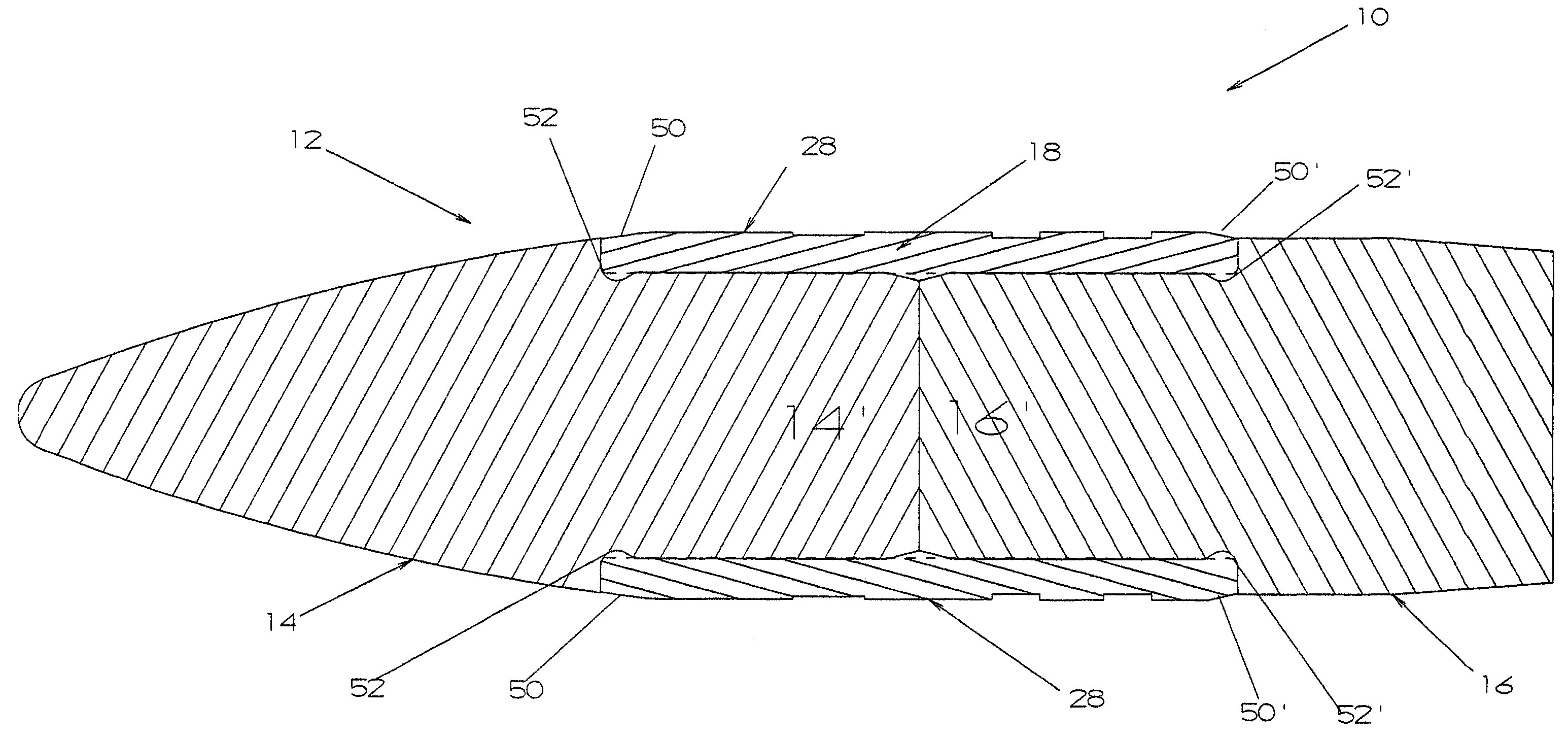

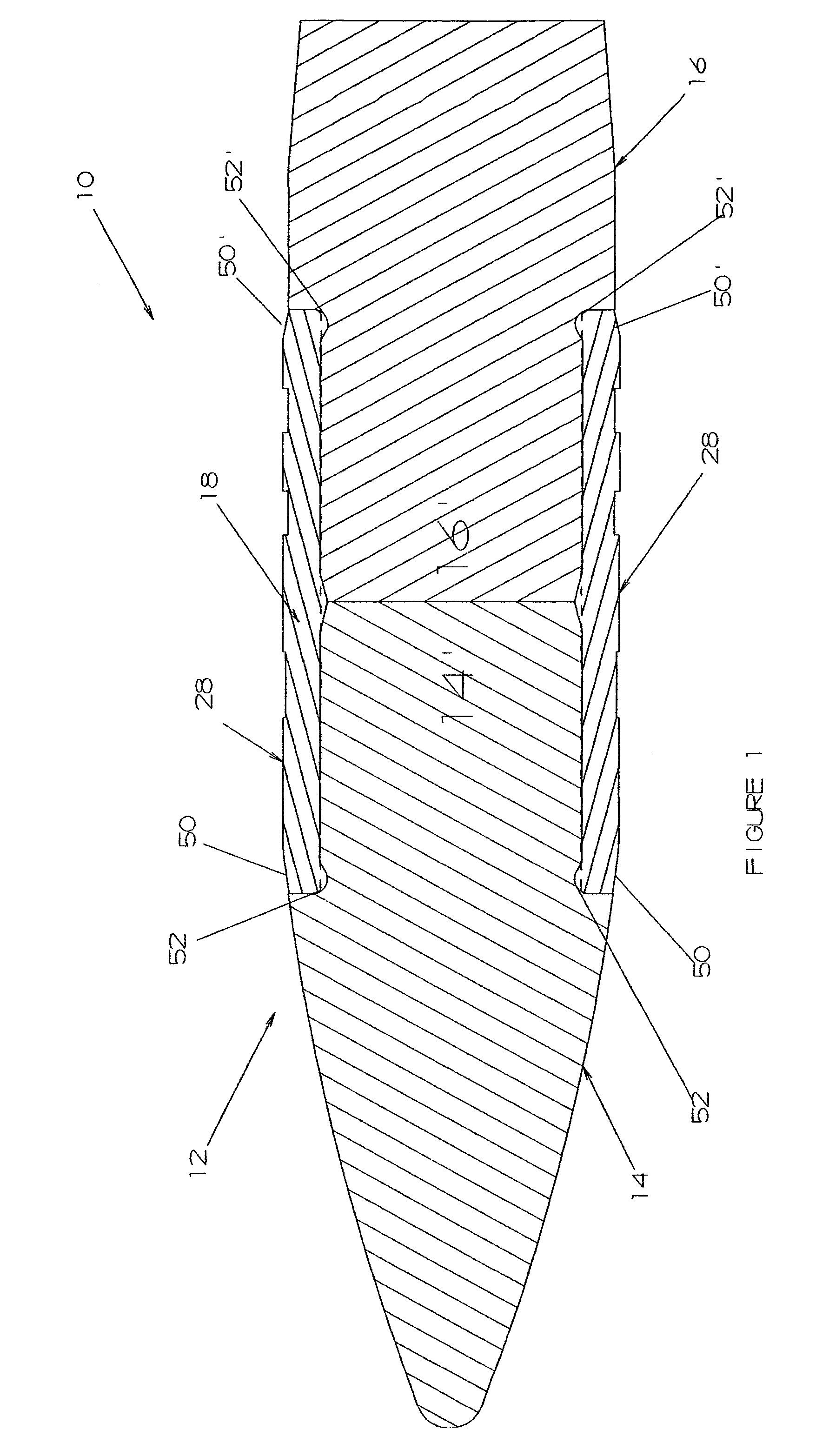

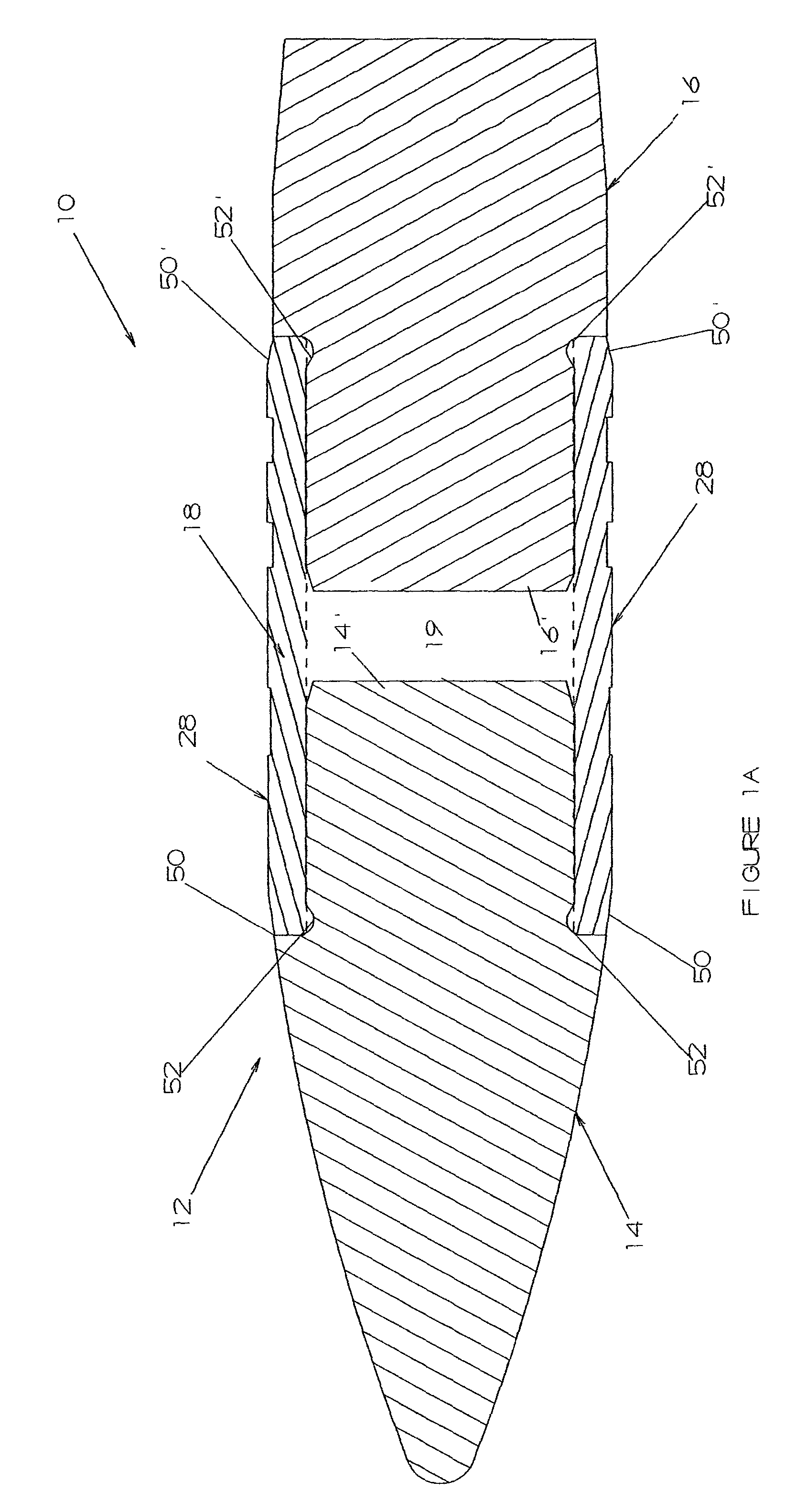

Firearms projectile

ActiveUS20070089629A1Short timeModest expenseAmmunition projectilesTraining ammunitionNoseProjectile

A projectile structured to be discharged from a firearm comprising a body including a nose portion and a tail portion separable from one another when the projectile strikes a target. The body further includes an interface disposed intermediate opposite ends of the body of the projectile and structured to removably interconnect the nose and tail portions. Separation of the nose and tail portions such as when striking a soft tissue or like material target is caused by the tumbling of the projectile and the cooperative structuring of the interface to facilitate separation of the nose and tail portions. Further, the interface is disposed, dimensioned and structured to define the primary area of contact of the projectile body with the rifling or interior surface of the barrel of the firearm. At least one additional embodiment of the projectile comprises one of the nose or tail portions, preferably the tail portion structured to contain a supplemental payload which is carried to the target upon discharge of the firearm.

Owner:LIBERTY OPCO LLC

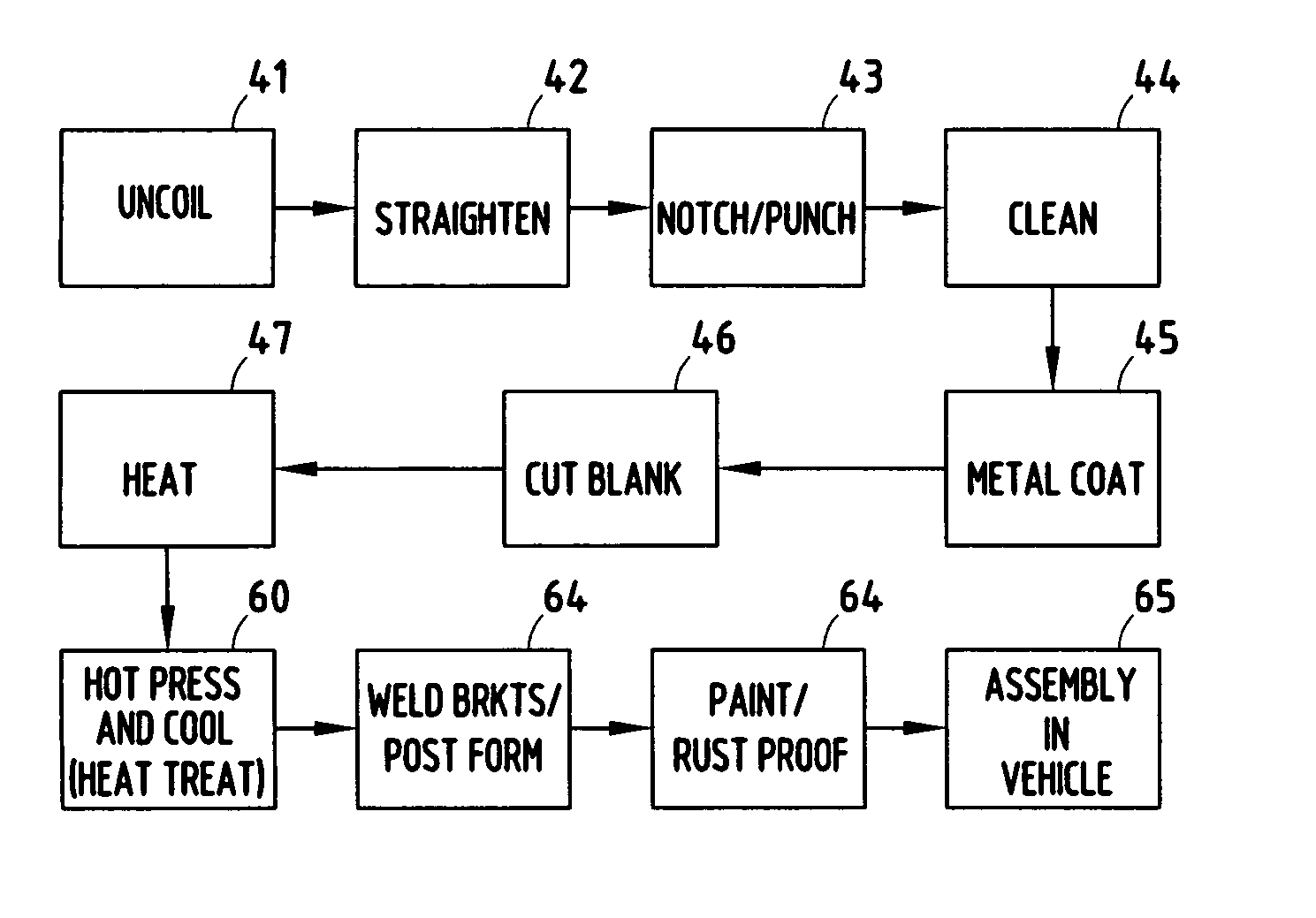

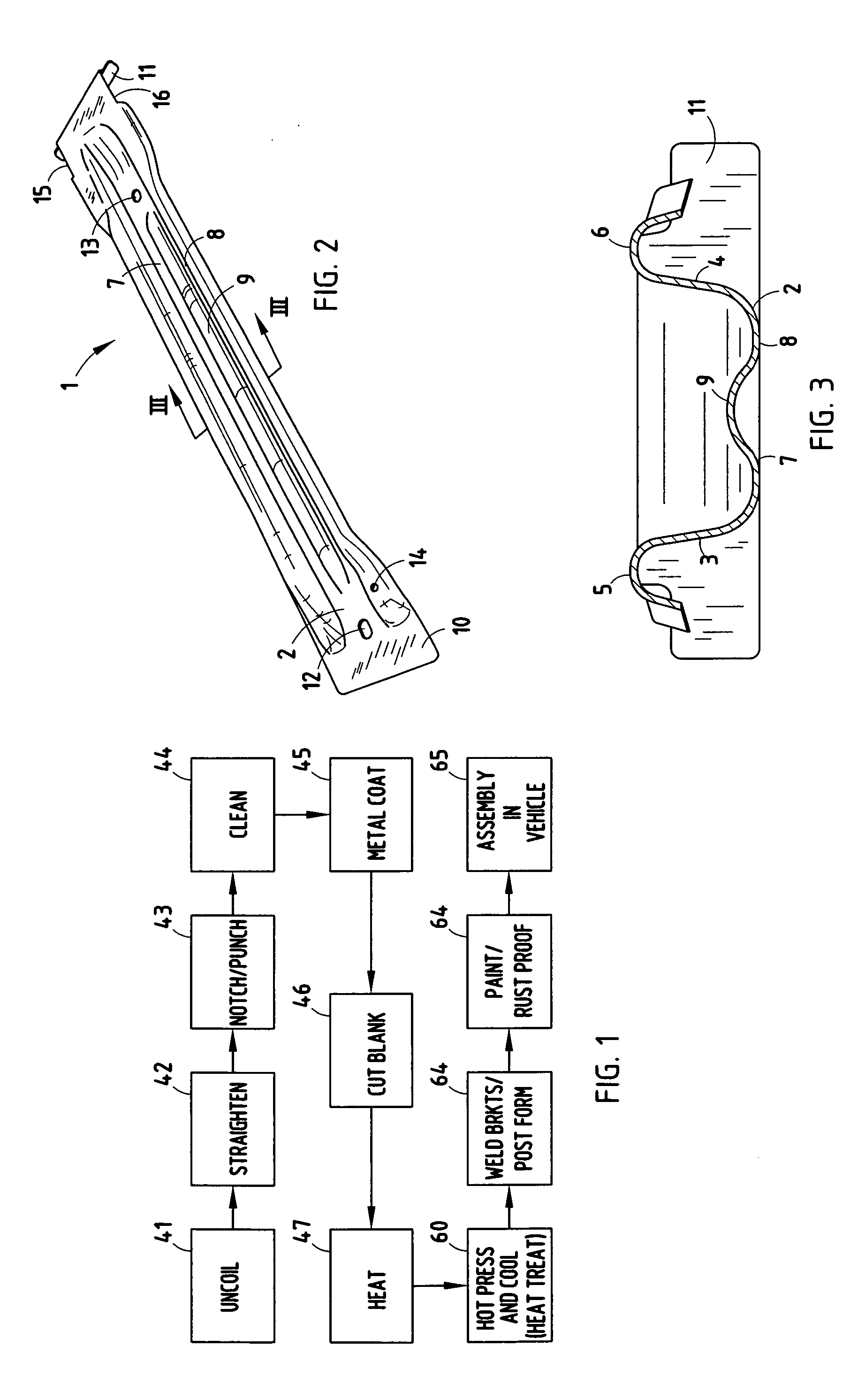

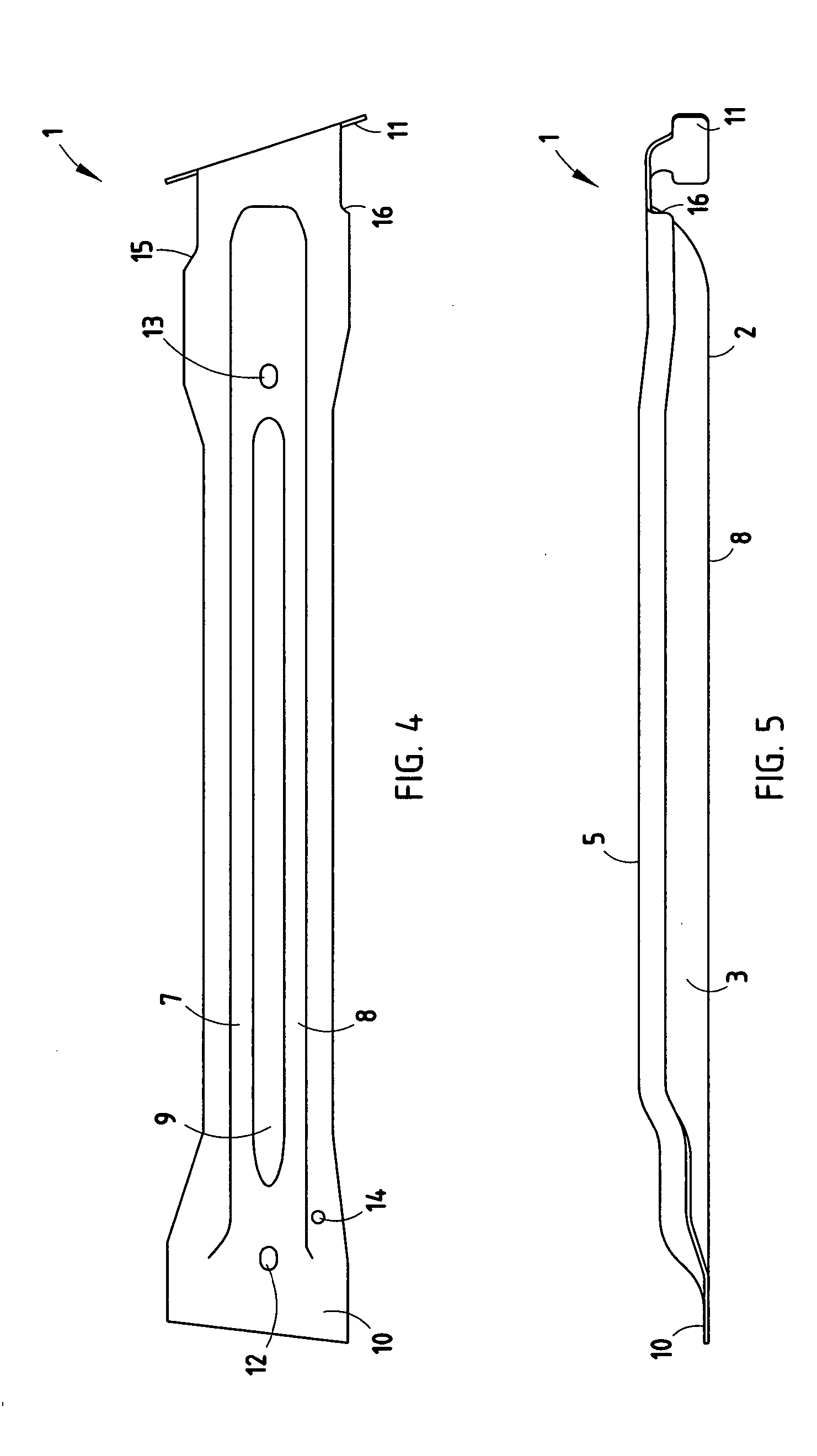

Method for making structural automotive components and the like

InactiveUS20060130940A1Reduce scaleReduced decarburizationVacuum evaporation coatingSurface reaction electrolytic coatingHigh intensityPhase change

A method for making structural automotive components and the like provides a strip of high strength steel having a selected thickness. A predetermined thickness of a metal coating, such as nickel, is applied to the opposite faces of the steel strip. The coated steel strip is cut to form a blank. The blank is heated in a generally open atmosphere to a temperature in the range of 800° C. to 1000° C. within less than ten minutes, thereby diffusing at least a portion of the metal coating a predetermined distance into the faces of the steel strip portion of the blank to alleviate scale formation, and simultaneously raise the temperature of the blank for hot forming the same. The heated blank is hot formed in a pressing tool, and cooled therein to heat treat the formed component through microstructure phase change, without substantial scale formation, such that the component need not be descaled prior to post-form processing and / or assembly in a vehicle.

Owner:BENTELER AUTOMOTIVE CORP

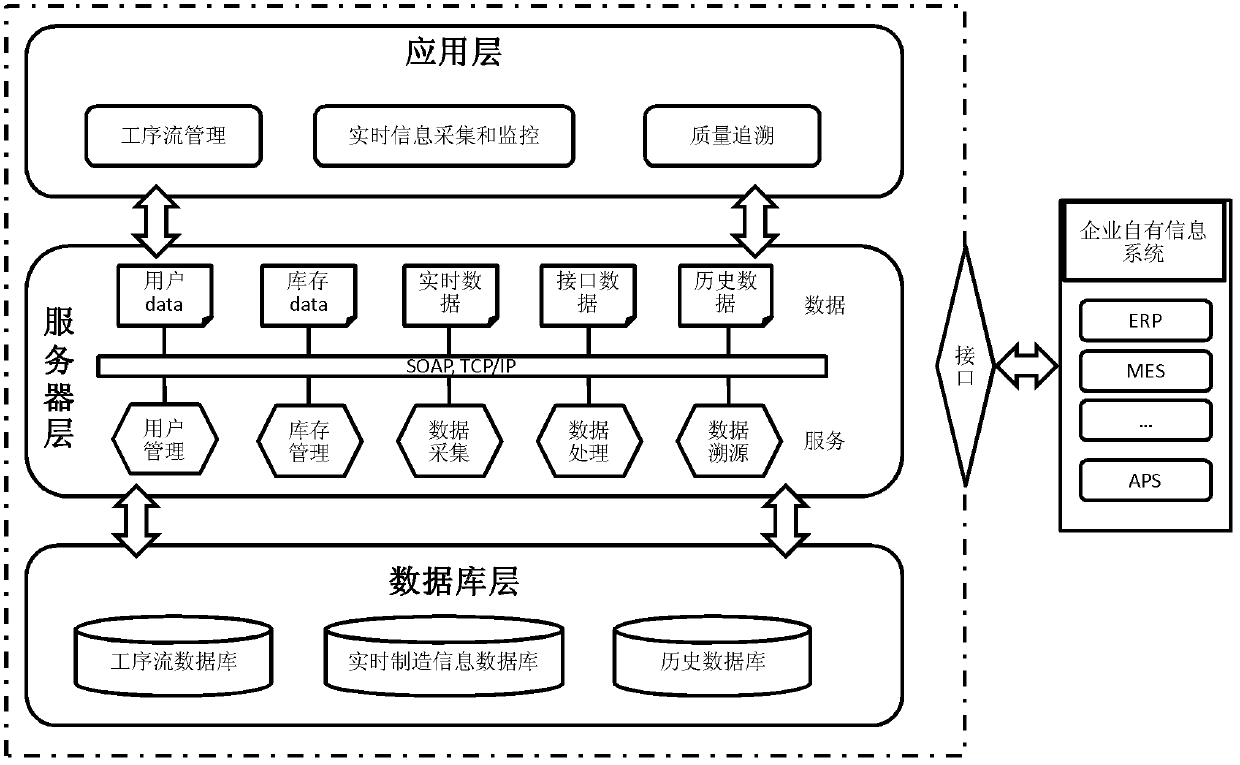

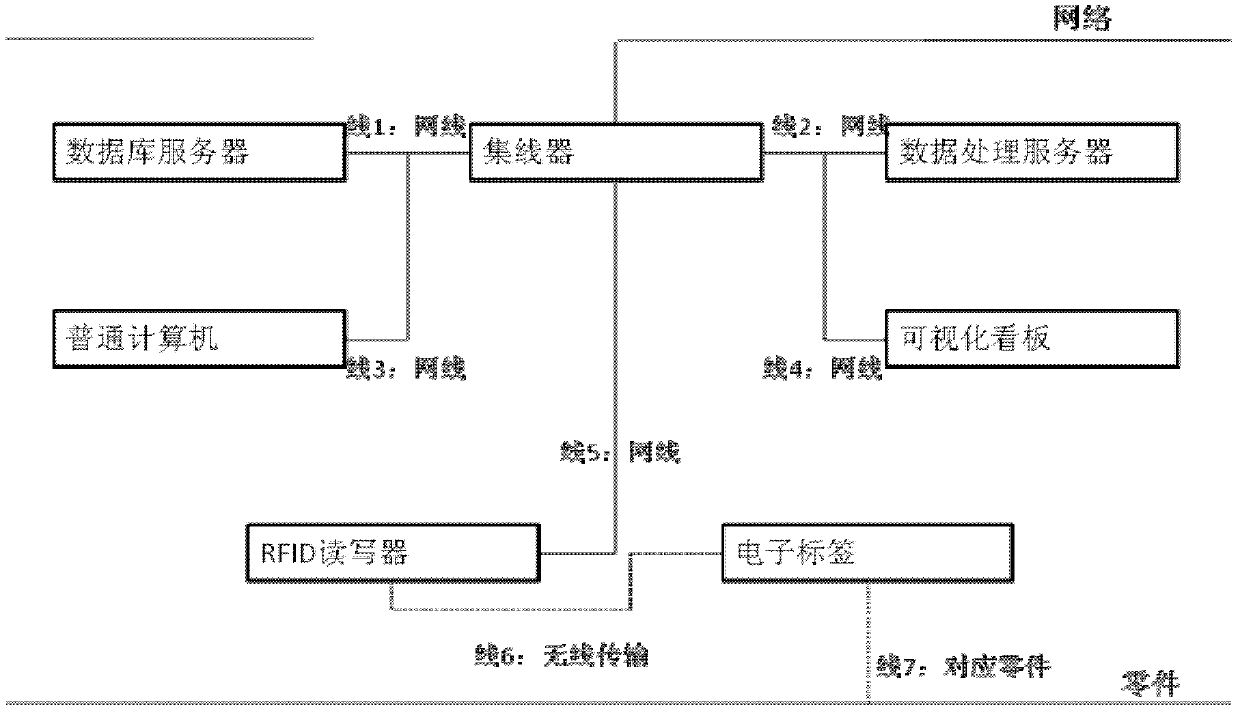

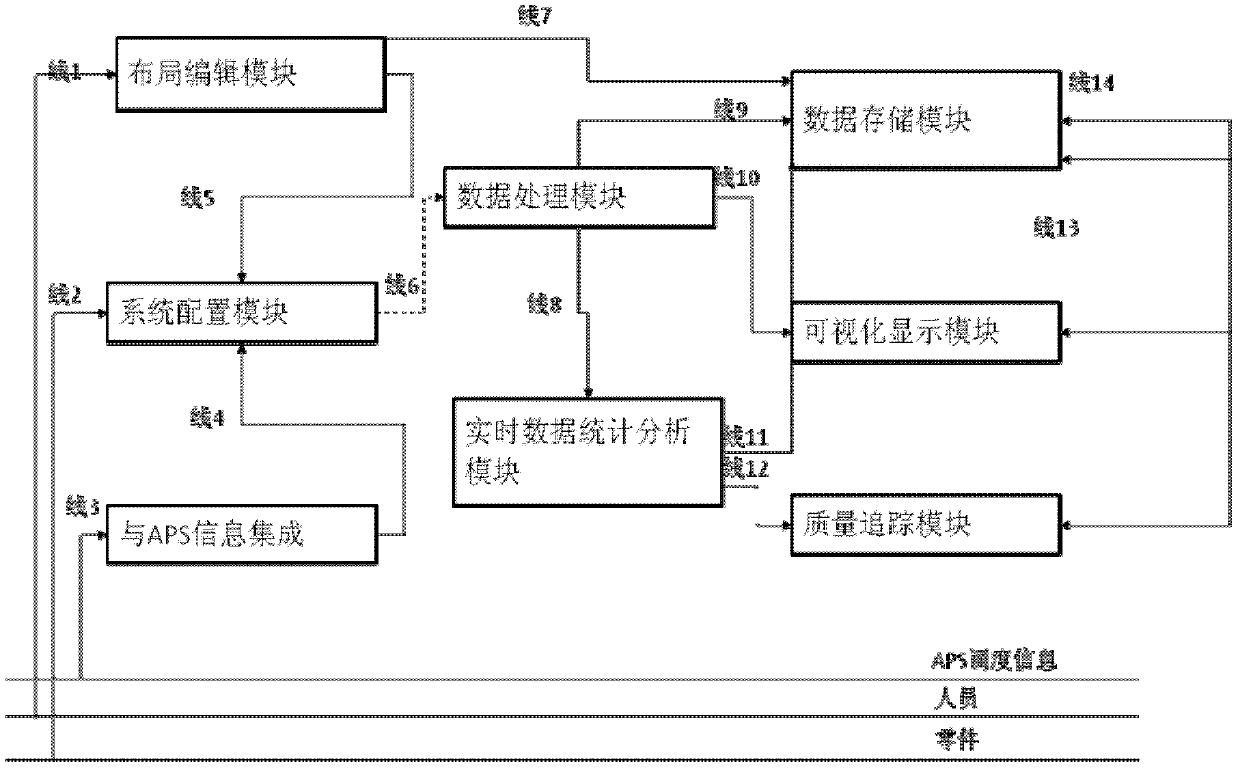

System and method for real-time tracking and quality tracing of procedure logistics in discrete manufacturing

InactiveCN102646221AHigh degree of transparencyAddressing Information DisconnectsCo-operative working arrangementsResourcesReader writerHuman power

The invention discloses a system and a method for real-time tracking and quality tracing of procedure logistics in discrete manufacturing. The system comprises a concentrator, and a computer, a database server, a data processing server, a visual board, a RFID (Radio Frequency Identification) tag and an RFID reader-writer which are connected with the concentrator by network cables. The invention is beneficial to improving the transparency of a manufacturing workshop; the problem of information disconnection of bottom-level real-time information and top-level management information of the workshop is solved and the problem of unsmooth information caused by difficult acquisition of information of the bottom-level workshop is reduced. The invention is beneficial to improving the production efficiency of the manufacturing workshop, improving the utilization rate of equipment and labor and increasing the economic benefit of enterprises, and is also beneficial to improving the management level of the procedure logistics of the enterprises, reducing material loss and reducing the cost consumption due to transport errors and the like.

Owner:XI AN JIAOTONG UNIV

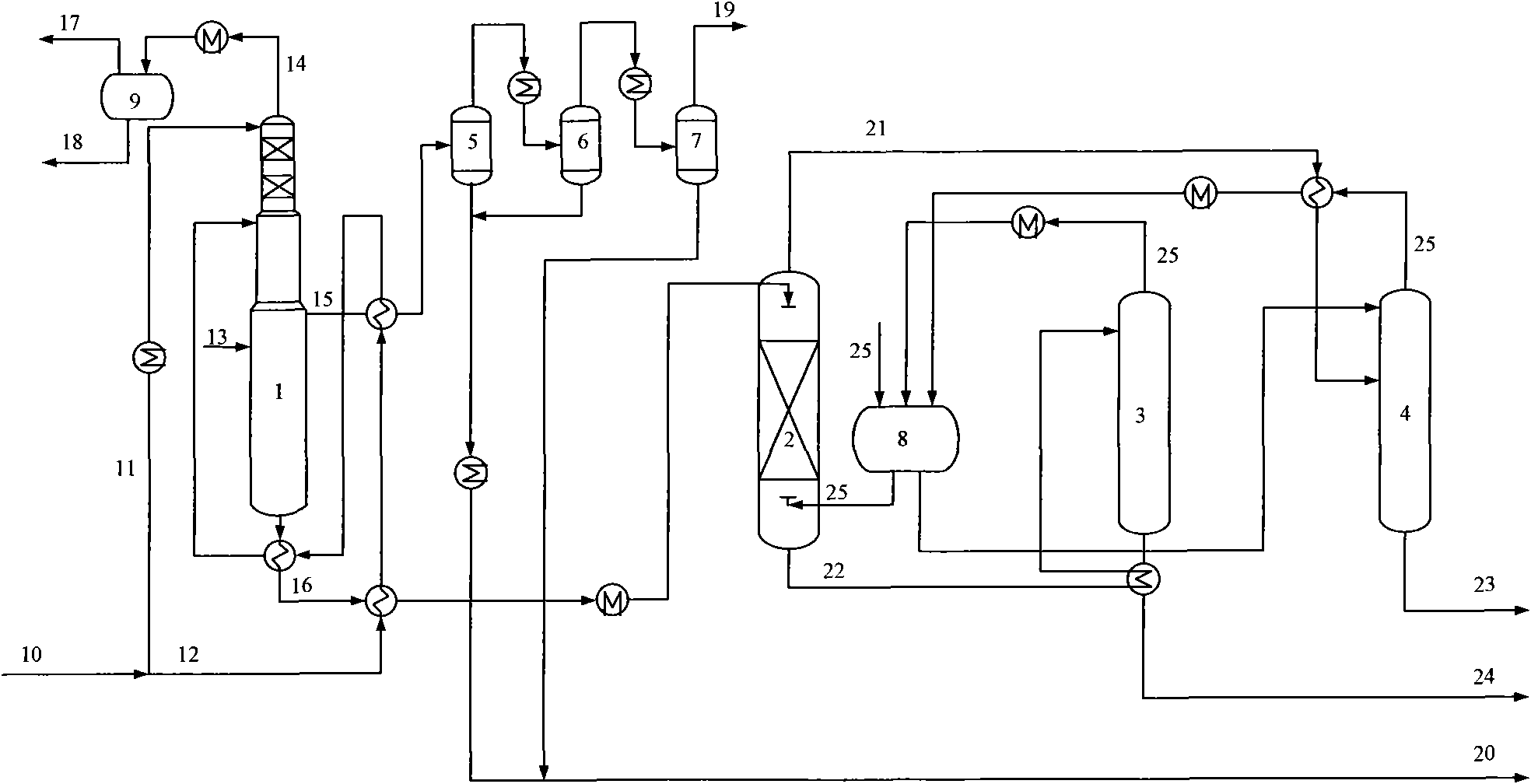

Method for treating coal gasification wastewater containing phenol and ammonia

InactiveCN101597124AEffective removal of fixed ammonia contentMeet the requirements of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by degassingCoal gasification wastewaterHigh concentration

The invention relates to a method for treating coal gasification wastewater containing phenol and ammonia. The method comprises the following steps: single tower alkali injection and pressurization steam stripping removal of acidic gas and ammonia, three-level dephlegmation of lateral line tapped gas, extraction of phenol by diisopropyl ether and solvent recovery. The cold and hot coal gasification wastewater, according to a certain proportion, respectively enters a pressurization single tower from the upper part and middle upper part of a wastewater steam stripping tower, and acid gas is discharged from the tower top; the lateral line withdrawal mixed gas goes through three-level dephlegmation to obtain high-concentration ammonia, alkali is injected at the position below the lateral line to transform fixed ammonia into free ammonia which is to be removed; counter-current extraction is carried out on removed ammonia, residue of acid gas and diisopropyl ether to dephenolize; extraction solvent is recovered by a solvent recovery tower and a solvent steam stripping tower to obtain the byproduct, namely crude phenol. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, and the purified coal gasification wastewater meets the requirement of follow-up biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH +2

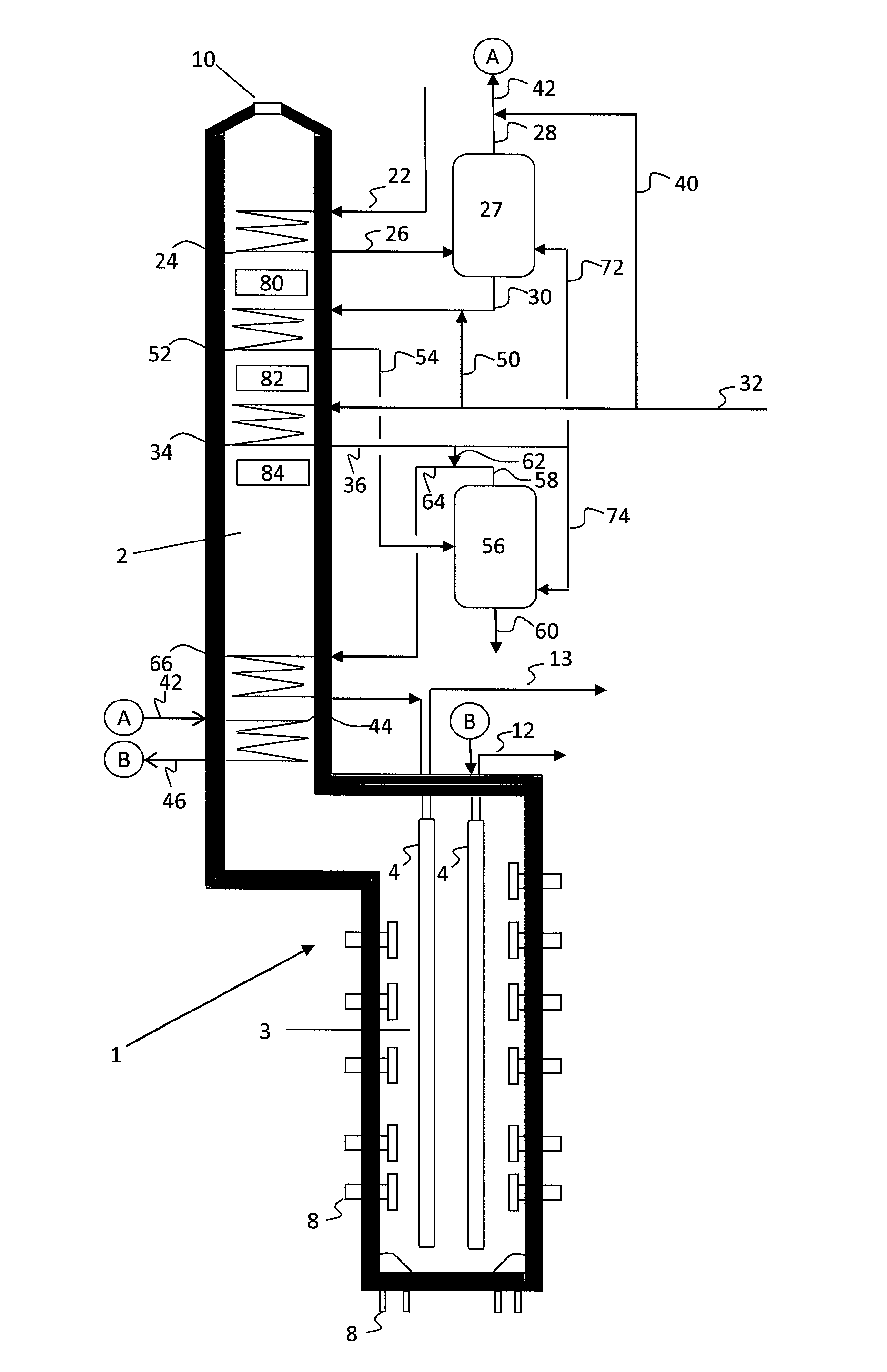

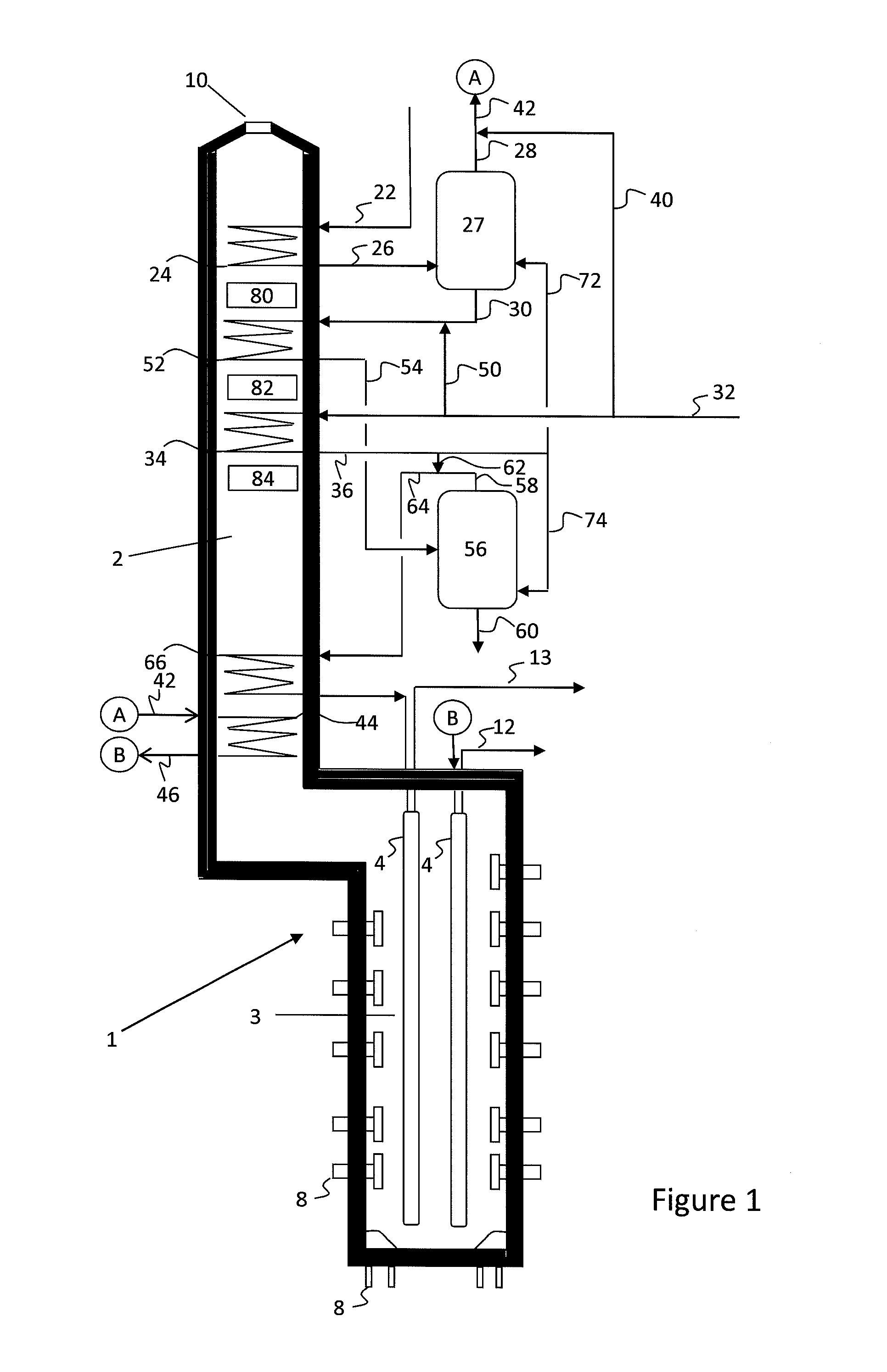

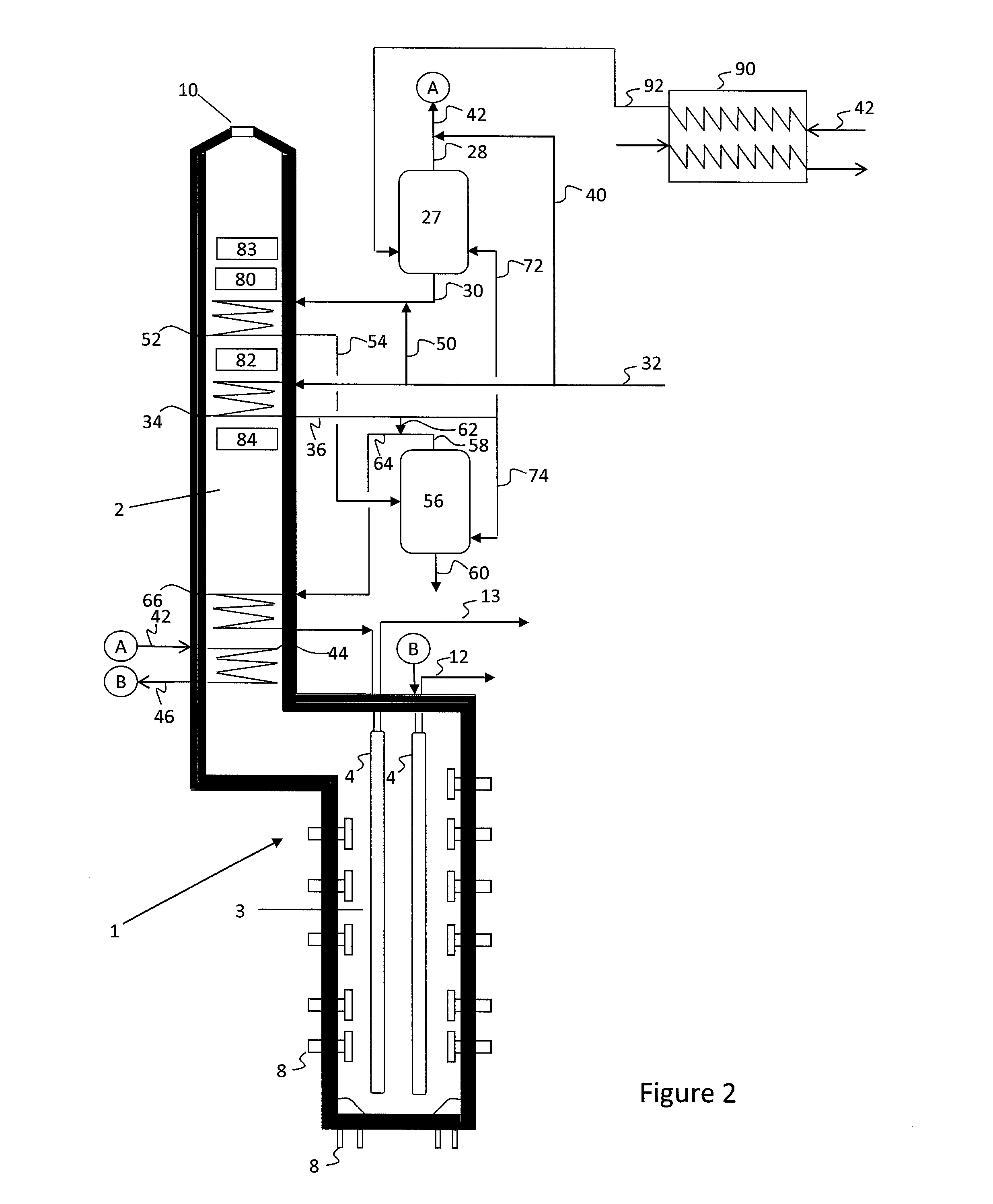

Thermal cracking of crudes and heavy feeds to produce olefins in pyrolysis reactor

ActiveUS20160097002A1Alleviate cokingReduce foulingThermal non-catalytic crackingTreatment with plural serial stages onlyHydrocarbon mixturesReactor system

Systems and processes for efficiently cracking of hydrocarbon mixtures, such as mixtures including compounds having a normal boiling temperature of greater than 450° C., 500° C., or even greater than 550° C., such as whole crudes for example, are disclosed.

Owner:LUMMUS TECH LLC

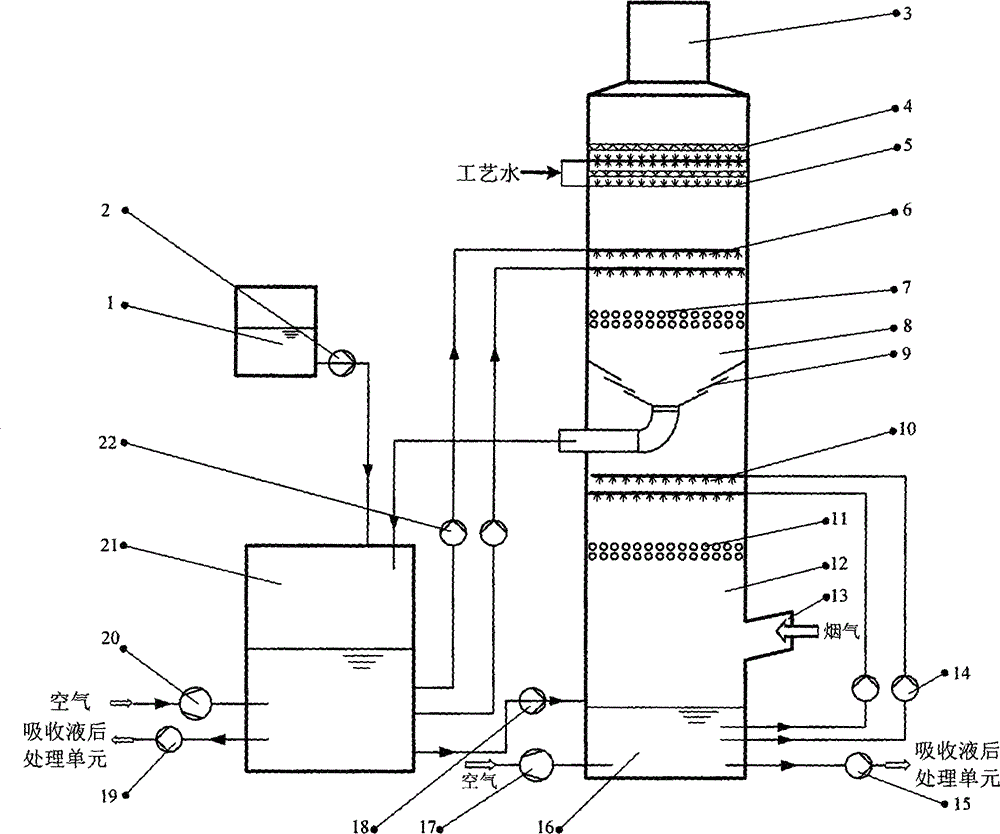

Multifunction carbon rod filter cartridge and manufacturing method thereof

InactiveCN102580405AHigh specific surface areaHigh activityWater/sewage treatment using germicide/oligodynamic-processFiltration separationResidual chlorineActivated carbon

The invention relates to a carbon rod filter cartridge, in particular to a multifunction carbon rod filter cartridge and a manufacturing method thereof. The multifunction carbon rod filter cartridge is capable of effectively removing residual chlorine and heavy metal in tap water and has good effects of killing and restraining bacteria. The multifunction carbon rod filter cartridge comprises, by mass percentage, 50%-98% of activated carbon, 1%-30% of modified cellular material powder and 1%-20% of adhesive. The preparation method includes mixing the activated carbon, the modified cellular material powder and the adhesive, drying, pouring dried mixing materials into a charging port of a screw extruder, heating the screw extruder, extruding the hollow column-shaped formed carbon rod filter cartridge, and cutting the carbon rod filter cartridge according to required lengths.

Owner:XIAMEN RUNNER IND CORP

Filtration, flow distribution and catalytic method for process streams

ActiveUS20040192862A1Increased operating lifeExtended run timeDispersed particle filtrationMembrane filtersProcess equipmentCatalytic method

A method for removing contaminants from an process stream that includes the use of reticulated material to filter the process stream. The reticulated material also facilitate process stream flow distribution in process units. The reticulated material can be packed with a void space between a substantial number of the reticulated material that can be varied to enhance filtration and flow distribution. The method of filtering also provides a method of removing contaminants leaving process equipment. The methods can be used on a variety of process streams and process equipment. The reticulated material can include ceramics, metallic materials, and chemical vapor deposition elements. The reticulated material can be of various shapes and sizes, and can also be catalytically active.

Owner:CRYSTAPHASE PRODS

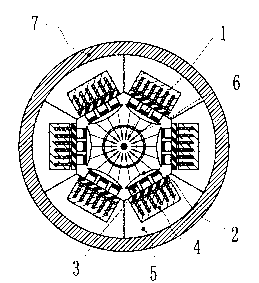

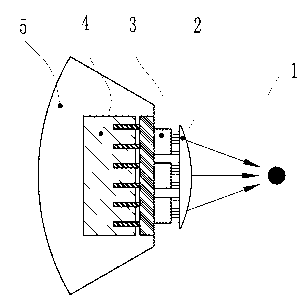

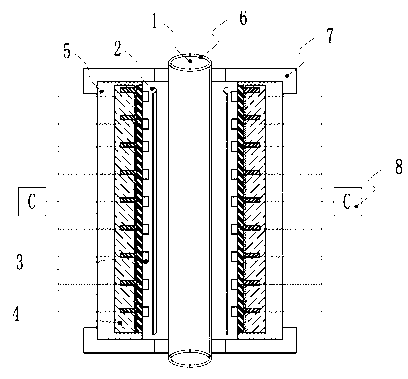

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

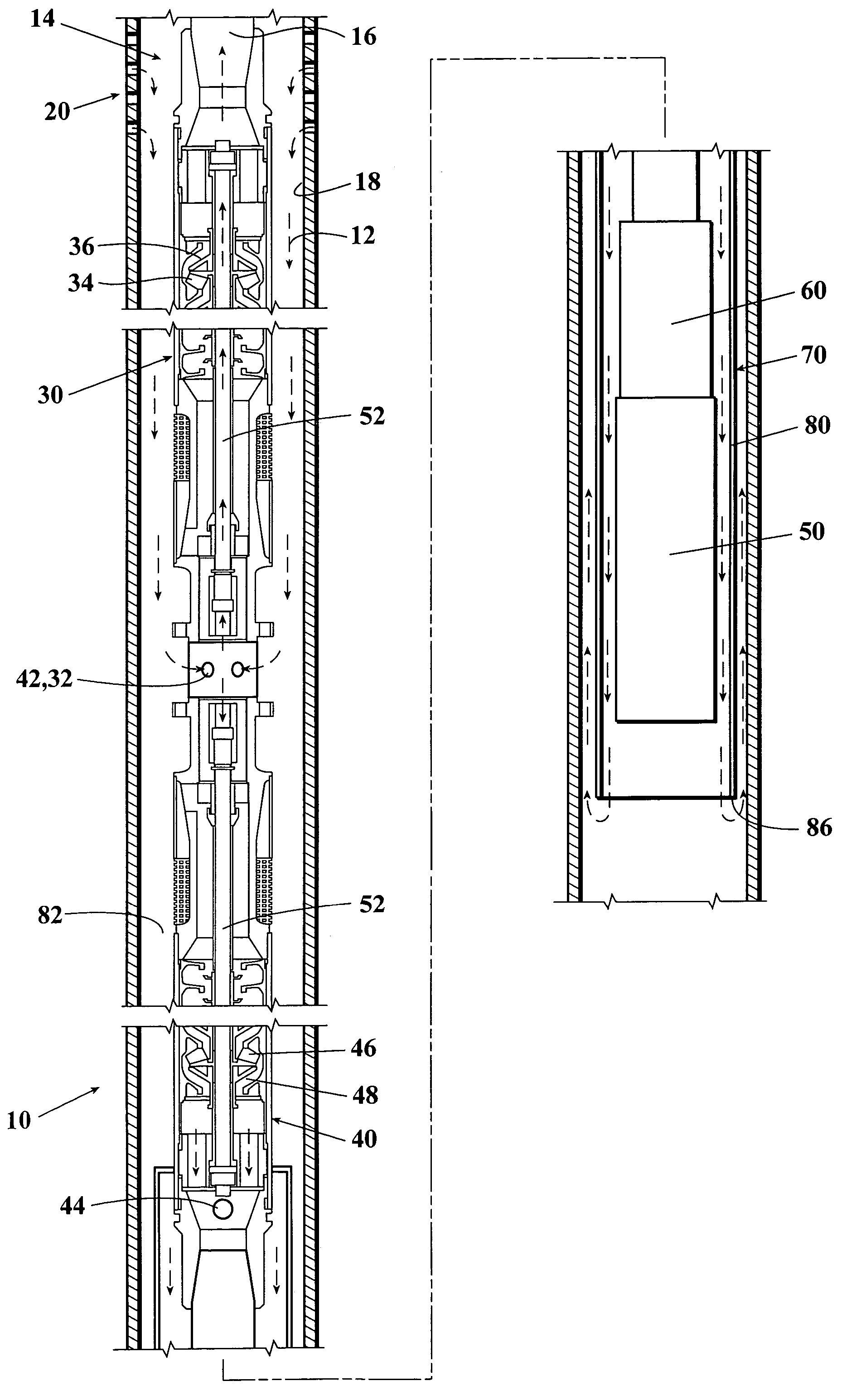

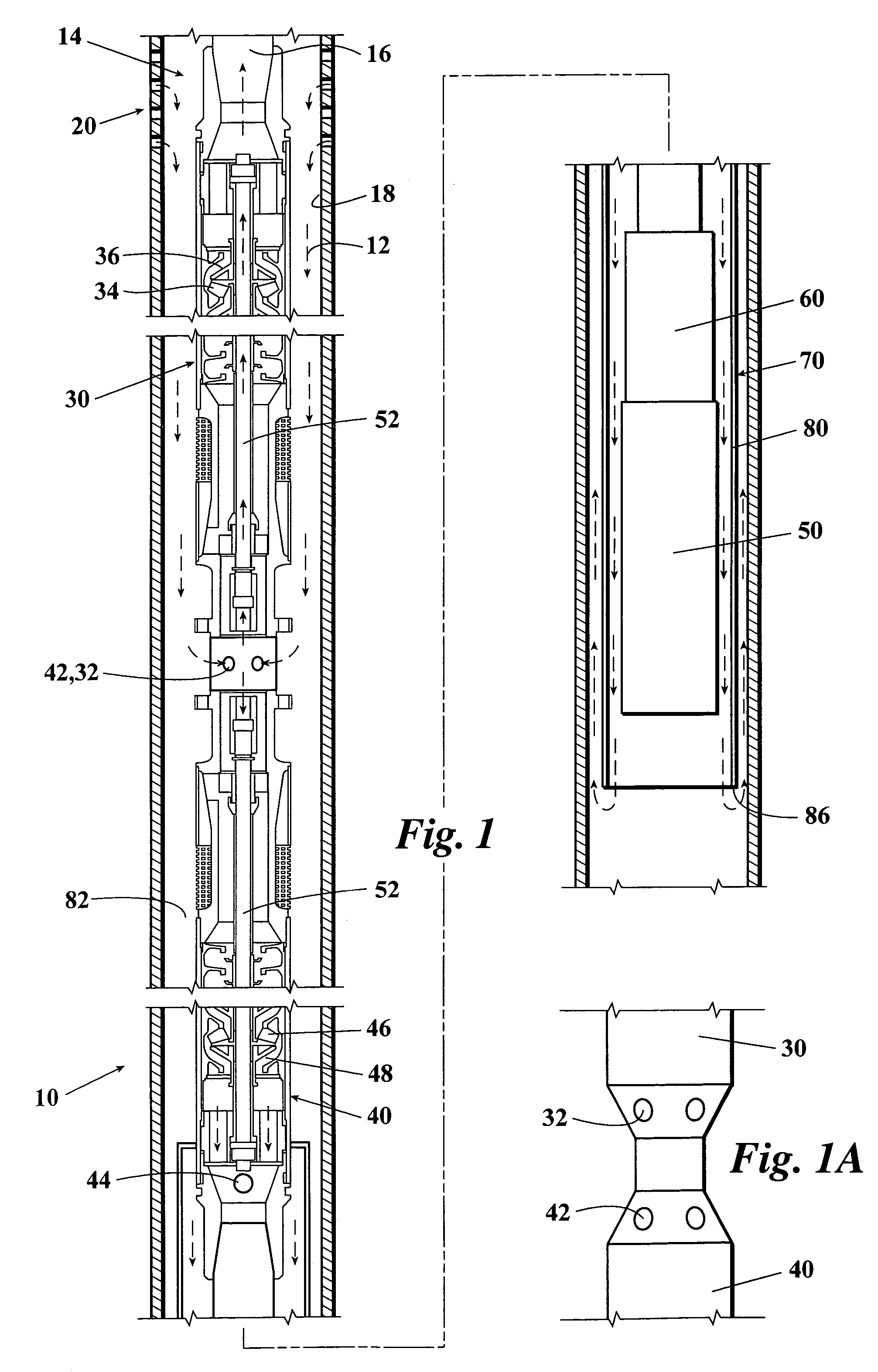

Motor cooler for submersible pump

ActiveUS7188669B2Reduce problem sizeLower potentialInsulationFluid removalElectric machineryEngineering

A motor cooler for an electrical submersible pump (ESP). The ESP is typically deployed within casing and defines an annular space between the ESP and the casing. The ESP includes a pump having an intake, a motor cooler pump having an output port, a seal section below the motor cooler pump, and a motor located below a well inlet. Fluid is directed downwardly from the motor cooler pump output port to cool the motor. In one example, a shroud directs fluid received from the motor cooler pump output port downwardly past the motor and back up an outside of the shroud. In another example, longitudinal ribs direct flow in an annular space between the ESP and the casing. Fluid from the motor cooler pump output port is directed downwardly between adjacent ribs over a surface of the motor and then back up between another pair of ribs.

Owner:BAKER HUGHES INC

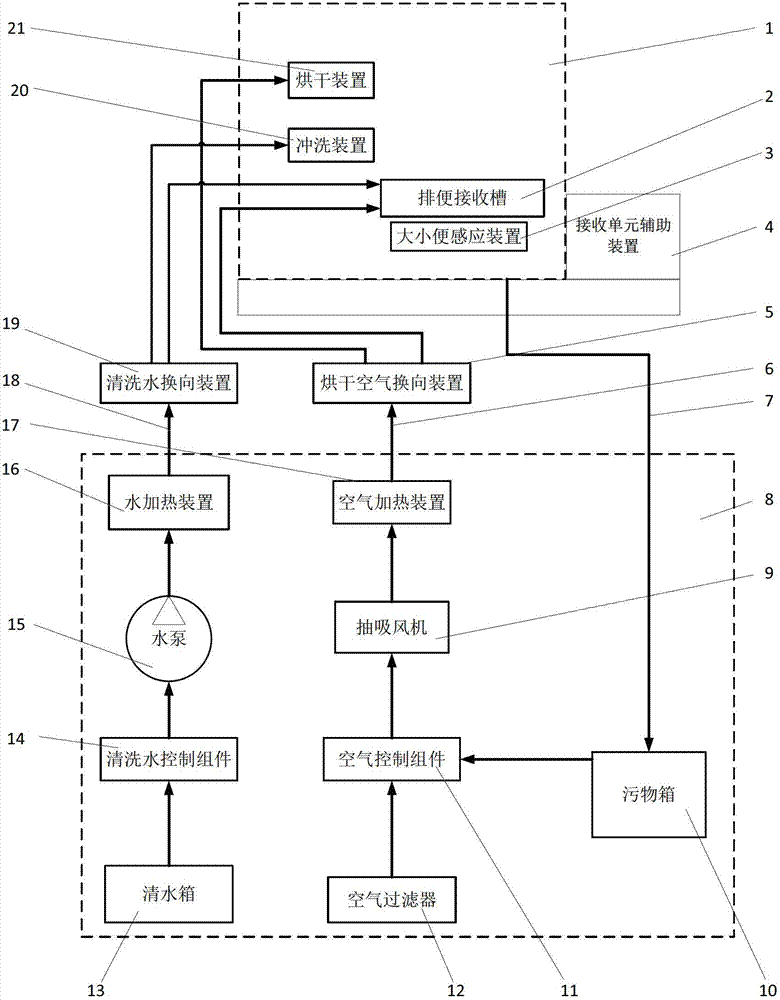

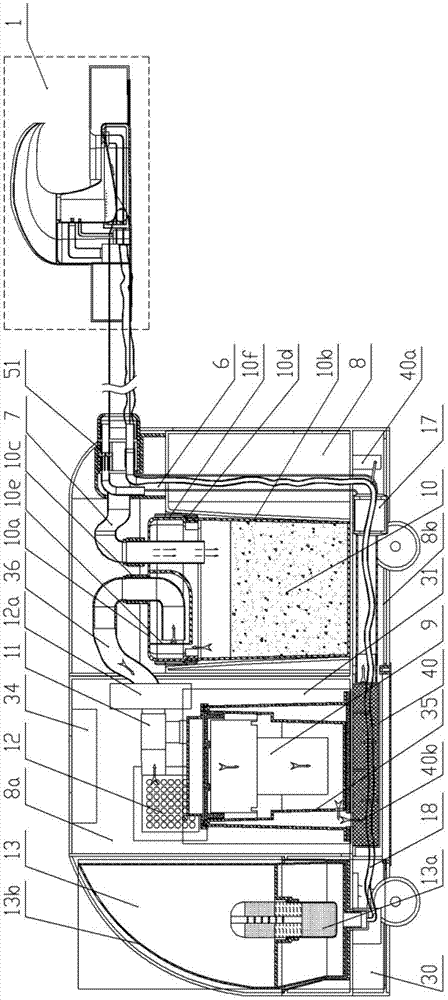

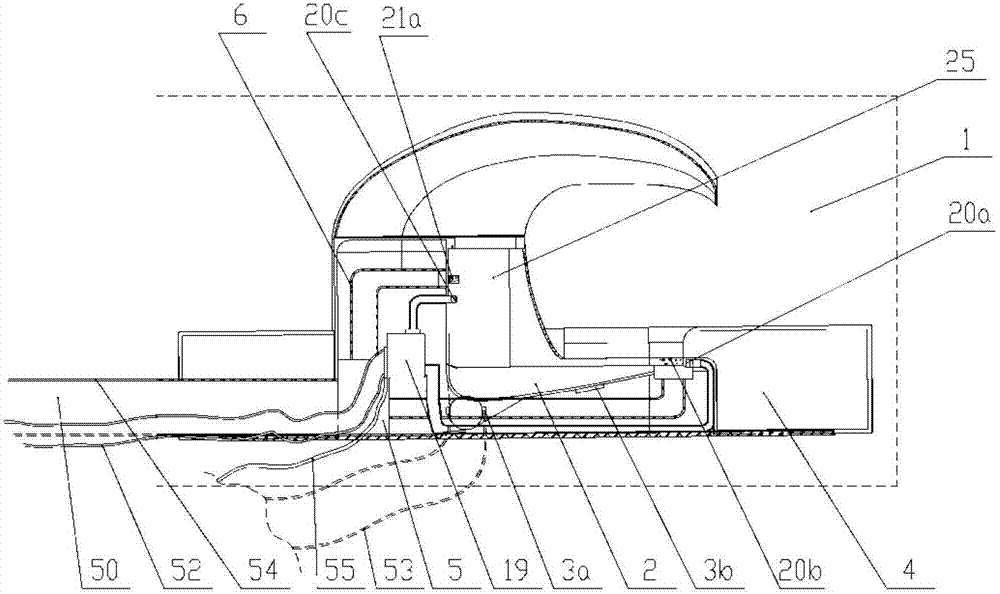

Intelligent nursing toilet system

ActiveCN102920565AGood dirt absorption effectGuaranteed cleaning comfortMedical transportElectrical and Electronics engineeringToilet

The invention particularly discloses an intelligent nursing toilet system. The system comprises a defecation receiving assembly, a toilet host assembly and a connecting pipeline assembly, wherein the connecting pipeline assembly comprises a washing pipeline, a blow-off pipeline, a vacuum pipeline and an electrical pipeline; the defecation receiving assembly comprises a drying unit, a flushing unit, a defecation receiving unit and a detection unit, the drying unit and the flushing unit are arranged over the defecation receiving assembly, and the detection unit is arranged in the defecation receiving assembly; the defecation host assembly comprises a dirt box, a washing water unit, a vacuum control unit and a control unit; the detection unit, the washing water unit and the vacuum control unit are connected with the control unit respectively through the electrical pipeline; the defecation receiving assembly is connected with the dirt box through the blow-off pipeline on one hand and connected with the vacuum control unit and the washing water unit respectively on the other hand; and the flushing unit is connected with the washing unit through the washing pipeline, the drying unit is connected with the vacuum control unit through the vacuum pipeline, and the dirt box is connected with the vacuum control unit.

Owner:CRRC SHANDONG CO LTD

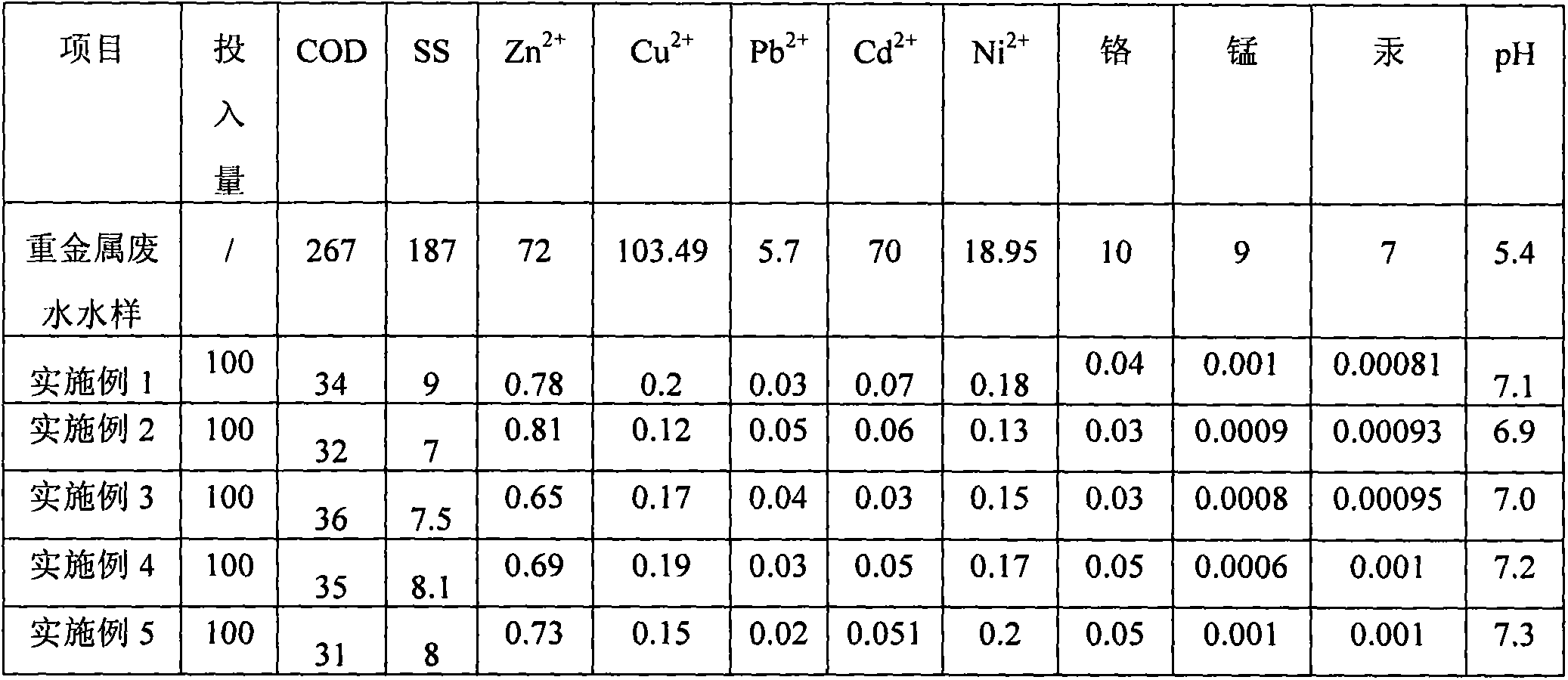

Heavy metal sewage treating agent and preparation method thereof

InactiveCN103641226AReduces corrosion and scalingReduce manufacturing costScale removal and water softeningWater/sewage treatmentSodium polyacrylateChemistry

The invention belongs to the technical field of sewage treating agents and particularly relates to a heavy metal sewage treating agent and a preparation method thereof. The heavy metal sewage treating agent is prepared from the following raw materials in parts by weight: 0.5-2 parts of amino trimethylene phosphonic acid, 1-5 parts of ethylene glycol tetraacetic acid, 10-20 parts of sodium polyacrylate, 5-15 parts of diethylene triaminepentaacetic acid pentasodium salt, 10-20 parts of polyaspartic acid, 20-30 parts of starch xanthate, 3-6 parts of graphene nanolayer / MnO2 compounds, 15-20 parts of crosslinked rectorite, 10-30 parts of polyaluminum chloride, 5-10 parts of chitosan-graphene composite and the balance of deionized water. The heavy metal sewage treating agent provided by the invention is high in purity, nontoxic, free of influence to operating staff and capable of ensuring no secondary pollution and other problems after water is treated.

Owner:上海东振环保工程技术有限公司

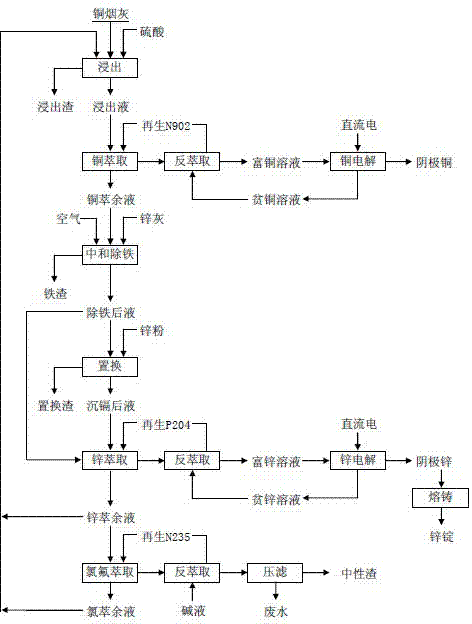

Technology for recovering production of electrolytic copper and zinc from smelting ash

ActiveCN102851693AWide adaptabilityFlexiblePhotography auxillary processesProcess efficiency improvementElectrolysisCopper oxide

The invention discloses a technology for recovering production of electrolytic copper and zinc from smelting ash. The technology comprises a step of smelting ash leaching, a step of copper extraction and purification through copper electrodeposition, a step of iron removal through neutralization, a step of cadmium removal, and a step of zinc extraction and purification through zinc electrodeposition. The method is characterized in that chemical components in the smelting ash are analyzed, and the smelting ash is leached by a sulfuric acid solution leaching agent; the leachate obtained after the above leaching reaction undergoes a separation operation of copper extraction and purification through the copper electrodeposition; the resultant copper extraction liquor is neutralized by high-zinc dust which is a neutralizer to remove iron; cadmium is displaced and deposited by zinc powder having a mass same with cadmium after the iron removal through the neutralization; and the zinc extraction is carried out through the zinc electrodeposition by casting zinc ingot products. The technology has a wide adaptability, adopts two steps to complete the exchange reaction of zinc oxide and copper oxide in the raw material with an acid, and adopts the high-zinc dust as the neutralizer, so the massive zinc loss caused by entrainment of routine neutralizers comprising calcium oxide and sodium hydroxide is avoided. A zinc extraction liquor obtained in the above step is purified by N235, so economy and effectiveness are realized.

Owner:江西自立环保科技有限公司

Methods of preparing and using electrostatically treated fluids

InactiveUS6974561B1Measurably betterIncrease crop yieldElectrolysis componentsLiquid separation by electricityWater basedVoltage spike

The present invention includes an improved electrostatic device for energizing fluids, in particular water based fluids, which will be used to provide a benefit to living organisms, machinery, processes and substances. The improved device of the invention will include an electrostatic voltage spike signal generator, two or more radio frequency signal generators, one or more antennas, optional one or more signal boosters and a fluid conduit. When fluid is treated with the improved device of the invention, the fluid will become energized and can be used to provide significant benefits in applications such as milk production, flower production, fruit production, crop production, vegetable production, shrimp production, egg production, meat production, gasoline combustion, waste fluid combustion, scale removal, water purification, fluid tracking, fluid sterilization and more.

Owner:COMPLETE WATER SYST L L C

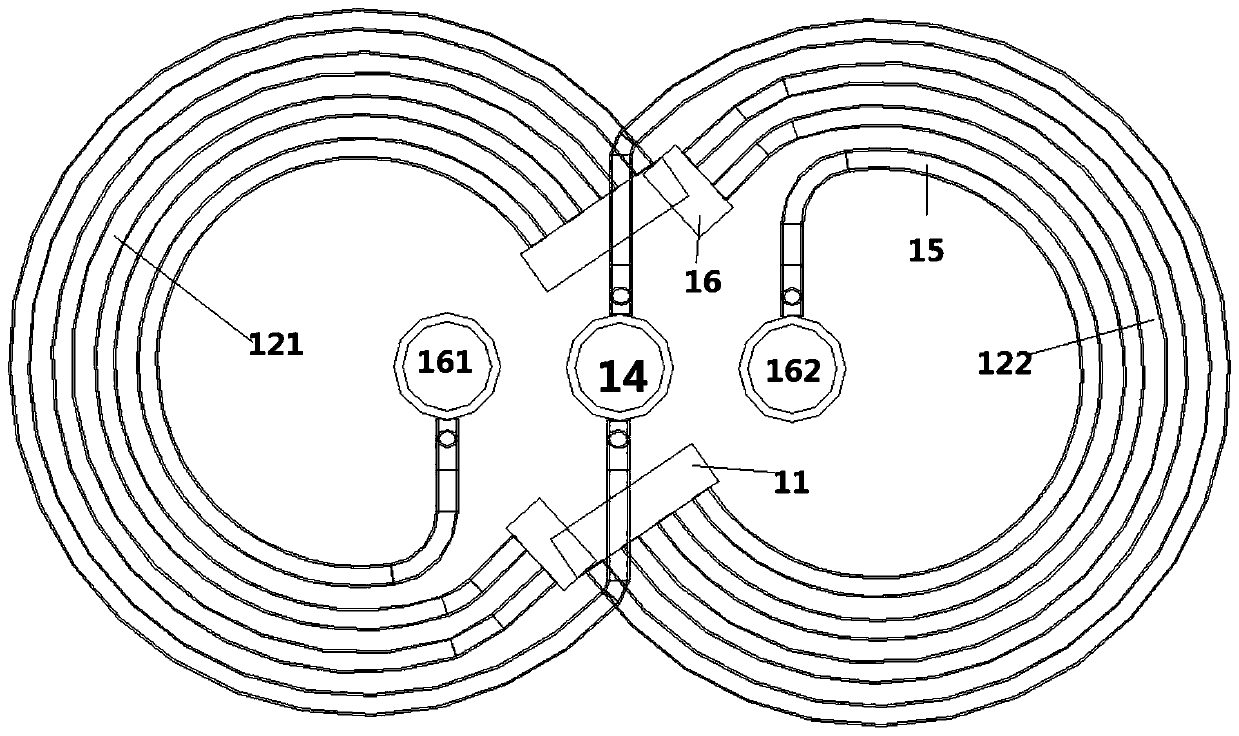

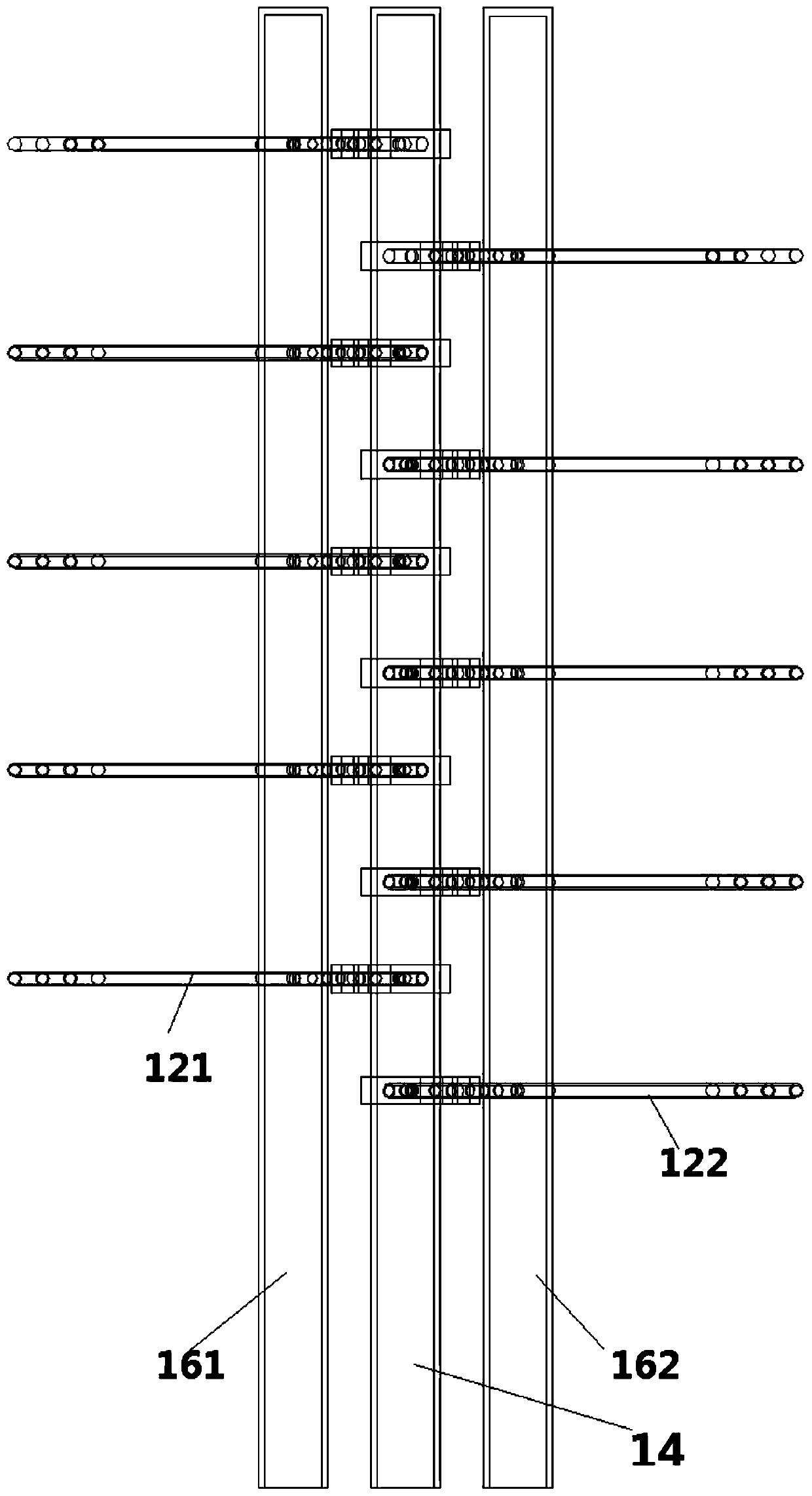

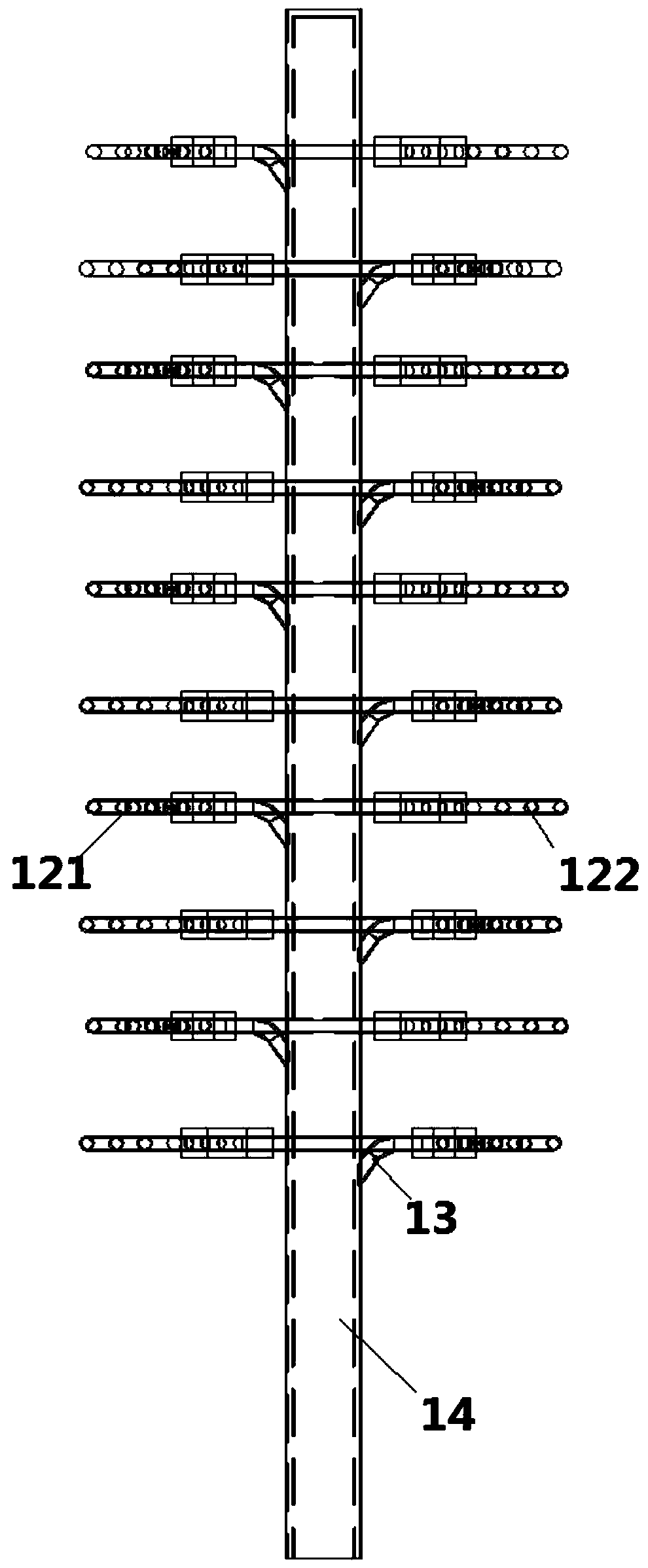

Three-riser pulsating tube bundle

ActiveCN110081739AIncreased vibration rangeImprove heat transfer performanceHeat storage plantsStationary tubular conduit assembliesEngineeringHeat transfer

The invention provides a three-riser pulsating tube bundle. The three-riser pulsating tube bundle comprises a middle riser, a left risers, a right riser and a plurality of coil tubes, wherein each coil tube comprises a plurality of arc-shaped heat exchange tubes, the ends of adjacent heat exchange tubes communicate, the plurality of heat exchange tubes form a series structure, the ends of the heatexchange tubes form free ends of the heat exchange tubes, the inlet of the middle riser is connected with a pulsating flow generating device for generating pulsating flow in the heat exchange tubes,the coil tubes comprise a left coil tube and a right coil tube, one side of the middle riser is connected with the inlet of the left coil tube, the other side is connected with the inlet of the rightcoil tube, the outlet of the left coil tube is connected with the left riser, and the outlet of the right coil tube is connected with the right riser. According to the pulsating tube bundle with the novel structure, more coil tubes are arranged in a limited space to increase the vibration range of the pulsating tube bundle, so that heat transfer and descaling are enhanced.

Owner:SHANDONG UNIV

Additive for strengthening wet flue gas desulfurization technology

InactiveCN102580514AImprove qualityAchieve reuseCalcium/strontium/barium sulfatesDispersed particle separationOrganic acidAdipic acid

The invention belongs to the technical field of a limestone / gypsum wet flue gas desulfurization technology, and particularly relates to an additive for strengthening a wet flue gas desulfurization technology, which comprises the following components in percentage by mass: 35-45% of mixed organic acid, 5-10% of organic acid salt, 6-9% of surfactant, 1-6% of heavy metal salt and 35-45% of dirt dispersion agent; and the mixed organic acid comprises adipic acid, wherein the percentage of mass of the adipic acid in the mixed organic acid is not less than 50%. The additive can be added and used for strengthening the wet flue gas desulfurization technology, improve the desulfurization efficiency of a system, reduce the energy consumption, strengthen oxidization, improve the limestone quality and restrain system scaling, and accordingly, the purposes of energy conservation, consumption reduction and waste recycling are realized.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

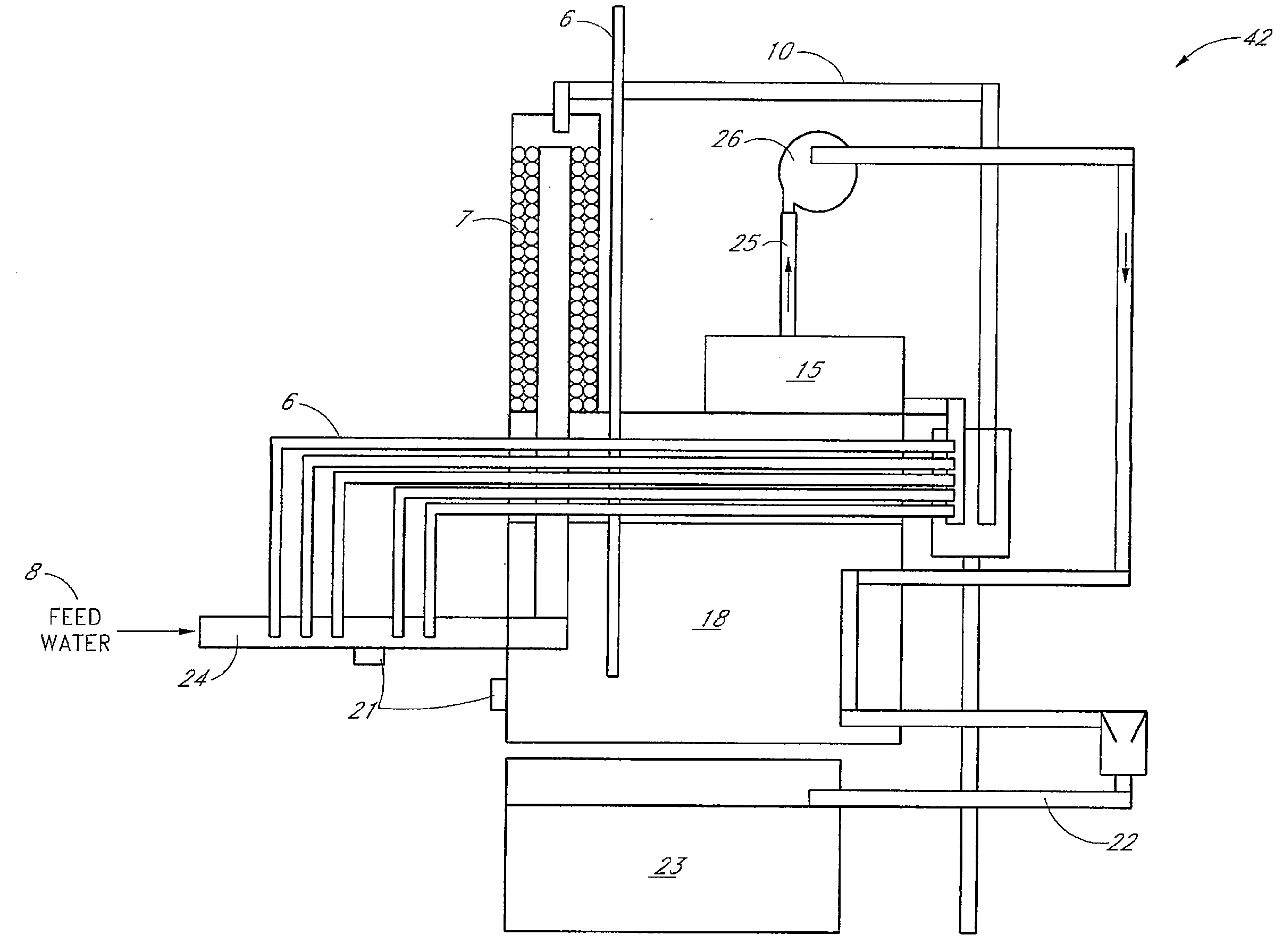

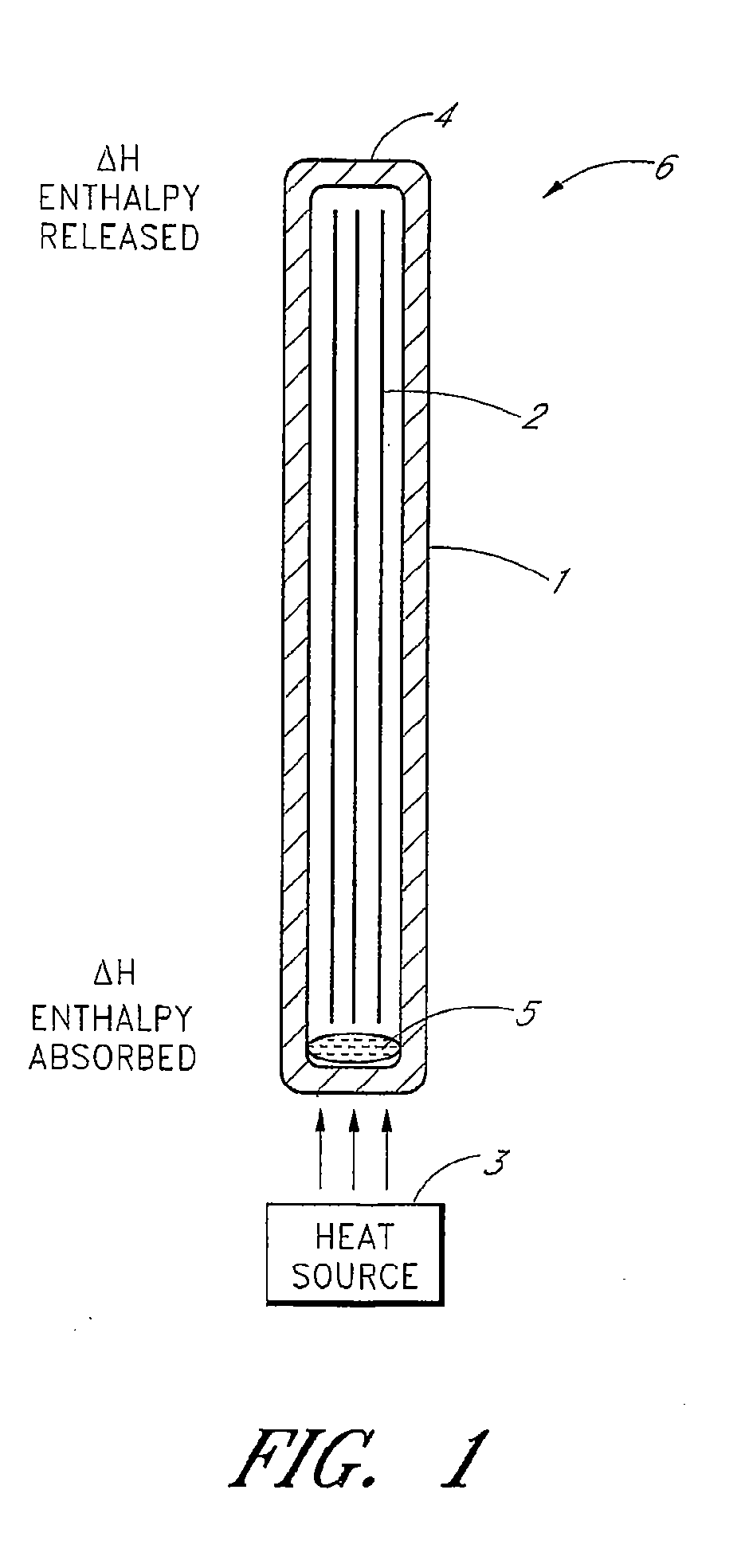

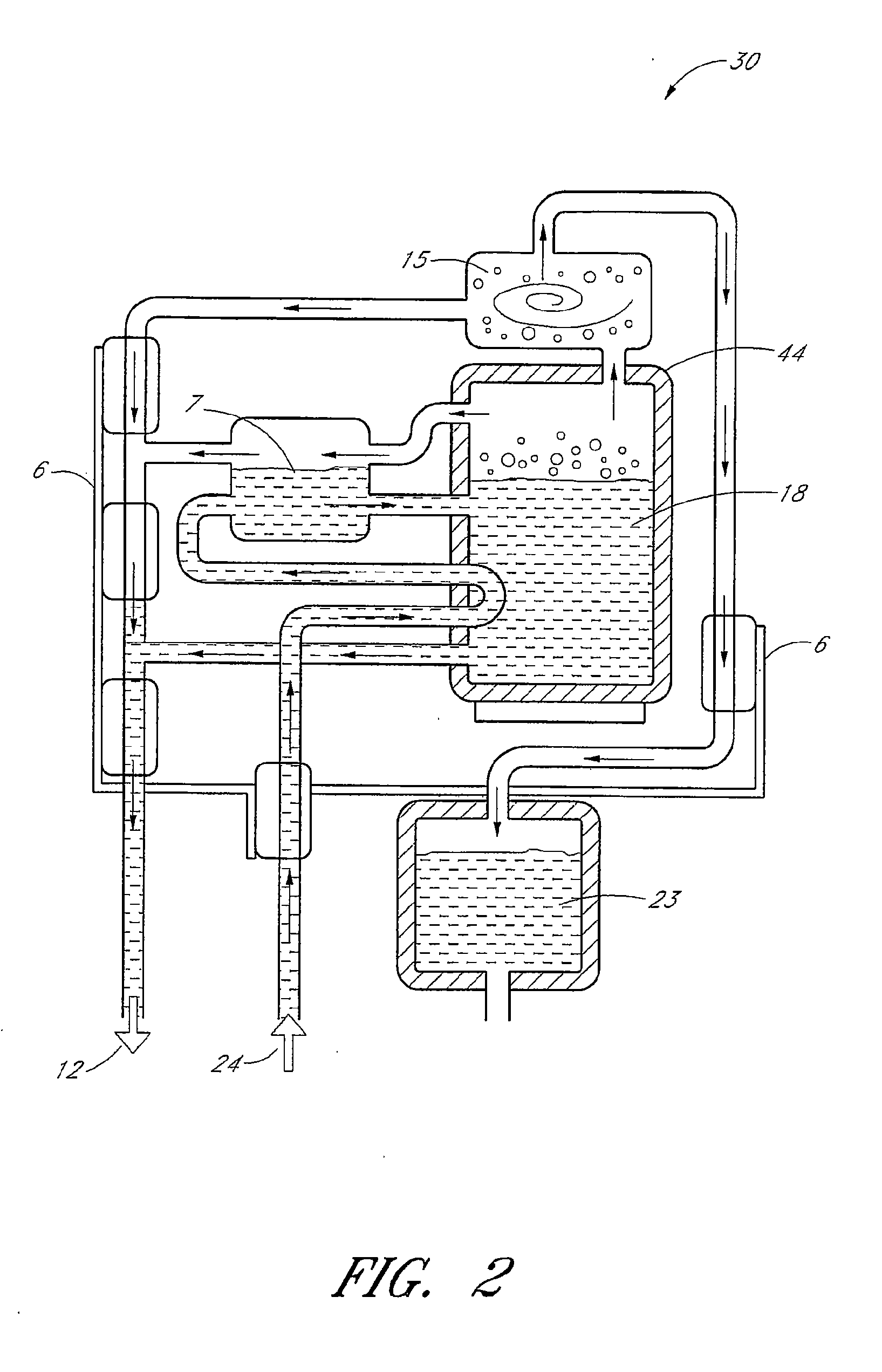

Energy-efficient distillation system

InactiveUS20090218210A1Reduce foulingLiquid degasification with auxillary substancesEvaporator accessoriesEngineeringDistillation

Methods and devices are provided for an energy-efficient distillation system (42). An energy-efficient distillation system (42) can include a fluid inlet (24), one or more heat-yielding purification elements (7, 15, 44) downstream of the fluid inlet (24), one or more heat pipes (6), and a fluid outlet (23) downstream of the heat-yielding purification element (7, 15, 44). The heat-yielding purification element (7, 15, 44) can be, for example, a degasser (7), a demister (15), or an evaporation chamber (44). A heat pipe (6) has a first end operably connected to the heat-generating purification element(s) (7, 15, 44), a second end operably connected to the fluid inlet (24), and a body therebetween. The heat pipe (6) is configured to transfer latent heat energy from the first end to the second end, thereby heating a fluid (8) within the fluid inlet (24). The distillation system (42) can also include one or more descaling elements (21) for reducing scale formation of the fluid (8).

Owner:SYLVAN SOURCE

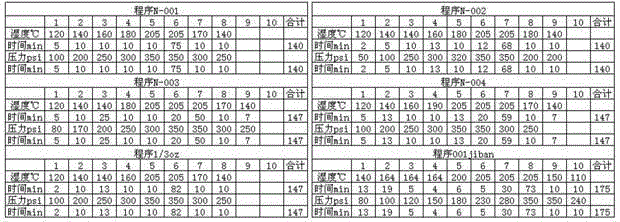

Method for controlling expansion and shrinkage of lamination of multiple layers of boards

InactiveCN103987194AIncrease profitMeet the needs of large typesetting productionMultilayer circuit manufacturePunchingX-ray

The invention relates to a method for controlling expansion and shrinkage of lamination of multiple layers of boards. The method comprises the steps that board incoming quality inspection is conducted, a dimensional stability test is conducted, and a part number is selected according to a test result; according to relevant parameters, an expansion and shrinkage library is established; inner films are produced, and measurement and statistics are conducted on the produced films; punching is conducted on multiple layers of boards which are not laminated; according to the thickness of each board, rivets with appropriate height are selected for riveting; the pattern is adjusted, the lamination conditions are set; lamination is conducted; holes are drilled through an X-RAY target drilling machine. Compared with the prior art, the method for controlling expansion and shrinkage of lamination of the multiple layers of boards has the advantages that the demand for large-composition production is met, production cost is effectively reduced, the utilization ratio of the boards is increased, the production efficiency is improved, and the rejection rate is reduced. Factors influencing control over expansion and shrinkage are controlled, the range of the influence caused by expansion and shrinkage is effectively narrowed, the error rate of drilling is effectively reduced, defective products and scrapped products caused by overall displacement of the multiple layers of boards are reduced, the drilling first-workpiece percent of pass is increased, and halt determination time is shortened.

Owner:奥士康精密电路(惠州)有限公司

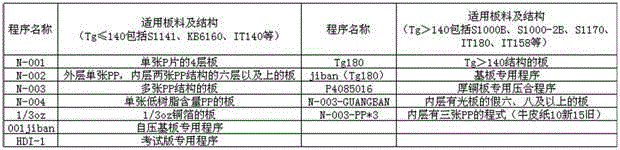

Flue gas dust removal desulphurization system of double-circulation Venturi rod tower

The invention belongs to the field of environment protection, and discloses a wet-method flue gas dust removal desulphurization system of a double-circulation Venturi rod tower. The system comprises an adsorption-liquid supplying unit, a flue-gas purification unit and an adsorption-liquid postprocessing unit. The flue-gas purification unit comprises an upper Venturi rod tower section, a lower Venturi rod tower section, a shutter-type separation cone separating the upper Venturi rod tower section and the lower Venturi rod tower section, an upper circulation liquid pool, a lower circulation liquid pool, upper circulation-liquid sprayers, lower circulation-liquid sprayers, and demisters. Flue gas in the upper tower section and flue gas in the lower tower section are in series connection. A circulation-liquid spraying system is operated independently. Dust removal and desulphurization are separately optimized and performed. The "homogenization" gas flow distribution, "gas in liquid" efficient mass transfer, highly-turbulent "self-cleaning", and other effects of Venturi rod layers are fully utilized by the system so as to perform efficient cooling, dust removal desulphurization of the flue gas. The system is advantages by high dust removal desulphurization efficiency, low operation liquid gas ratio, small resistance, less scale, small occupation area, low investment, low operation energy consumption, less discharge of high-salt water, and the like, and is suitable for dust removal and desulphurization for various kinds of flue gas, particularly suitable for processing of high-temperature high-dust high-sulfur flue gas such as regenerated flue gas of a petroleum catalytic cracking device.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Methods and apparatus for controlling water hardness

InactiveUS20100263689A1Reduce scale formationReduce foulingSpecific water treatment objectivesSolid sorbent liquid separationChemistryHardness

The present invention is related to methods, apparatuses, and compositions for controlling water hardness. The methods, apparatuses and compositions also reduce scale formation. The present invention includes substantially water insoluble resin materials. The resin materials may be loaded with a plurality of cations.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com