Method for controlling expansion and shrinkage of lamination of multiple layers of boards

A control method and multi-layer board technology, applied in the field of control, can solve problems such as large influence and short circuit of circuit boards, and achieve the effects of improving production efficiency, reducing scrap rate, and narrowing the scope of influence

Inactive Publication Date: 2014-08-13

奥士康精密电路(惠州)有限公司

View PDF10 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to reduce production costs, improve plate utilization and improve production efficiency, the large layout production can be changed to meet the requirements of the factory. Layer copper thickness, core board thickness, production film and production environment have a great influence on the expansion and contraction, which leads to the short circuit of the circuit board caused by the deviation of the drilled hole during the drilling process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

[0030] A specific embodiment of the present invention, a method for controlling expansion and contraction of multi-layer boards, comprising the following steps:

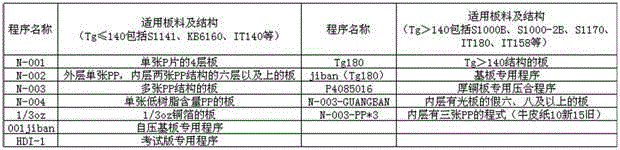

[0031] S01. Plate incoming inspection, and dimensional stability test, select the material number according to the test results.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

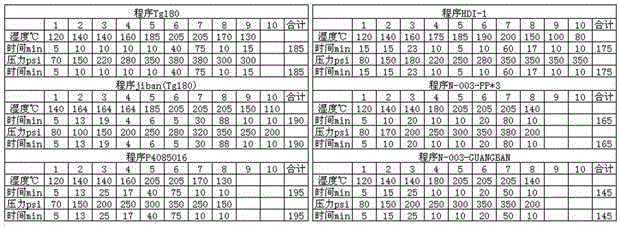

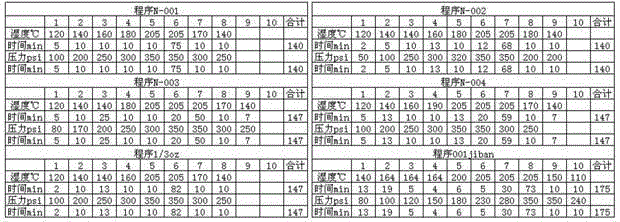

The invention relates to a method for controlling expansion and shrinkage of lamination of multiple layers of boards. The method comprises the steps that board incoming quality inspection is conducted, a dimensional stability test is conducted, and a part number is selected according to a test result; according to relevant parameters, an expansion and shrinkage library is established; inner films are produced, and measurement and statistics are conducted on the produced films; punching is conducted on multiple layers of boards which are not laminated; according to the thickness of each board, rivets with appropriate height are selected for riveting; the pattern is adjusted, the lamination conditions are set; lamination is conducted; holes are drilled through an X-RAY target drilling machine. Compared with the prior art, the method for controlling expansion and shrinkage of lamination of the multiple layers of boards has the advantages that the demand for large-composition production is met, production cost is effectively reduced, the utilization ratio of the boards is increased, the production efficiency is improved, and the rejection rate is reduced. Factors influencing control over expansion and shrinkage are controlled, the range of the influence caused by expansion and shrinkage is effectively narrowed, the error rate of drilling is effectively reduced, defective products and scrapped products caused by overall displacement of the multiple layers of boards are reduced, the drilling first-workpiece percent of pass is increased, and halt determination time is shortened.

Description

technical field [0001] The invention relates to a control method, in particular to a method for controlling expansion and contraction of multi-layer plates. Background technique [0002] Printed circuit board, also known as printed circuit board, printed circuit board, referred to as printed board, referred to as PCB or PWB in English, uses an insulating board as the base material, cuts to a certain size, has at least one conductive pattern attached to it, and is clothed with Holes (such as component holes, fastening holes, metallized holes, etc.) are used to replace the chassis of electronic components installed in the past, and to realize the interconnection between electronic components. [0003] In order to reduce production costs, improve plate utilization and improve production efficiency, the large layout production can be changed to meet the requirements of the factory. Layer copper thickness, core board thickness, production film and production environment have a g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H05K3/00H05K3/46

Inventor 贺波梁波

Owner 奥士康精密电路(惠州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com