Patents

Literature

10230results about How to "Reduce error rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic Network Connection System and Method

ActiveUS20120196644A1Reduce error rateReduce noiseAssess restrictionRadio transmissionNetwork connectionChoice making

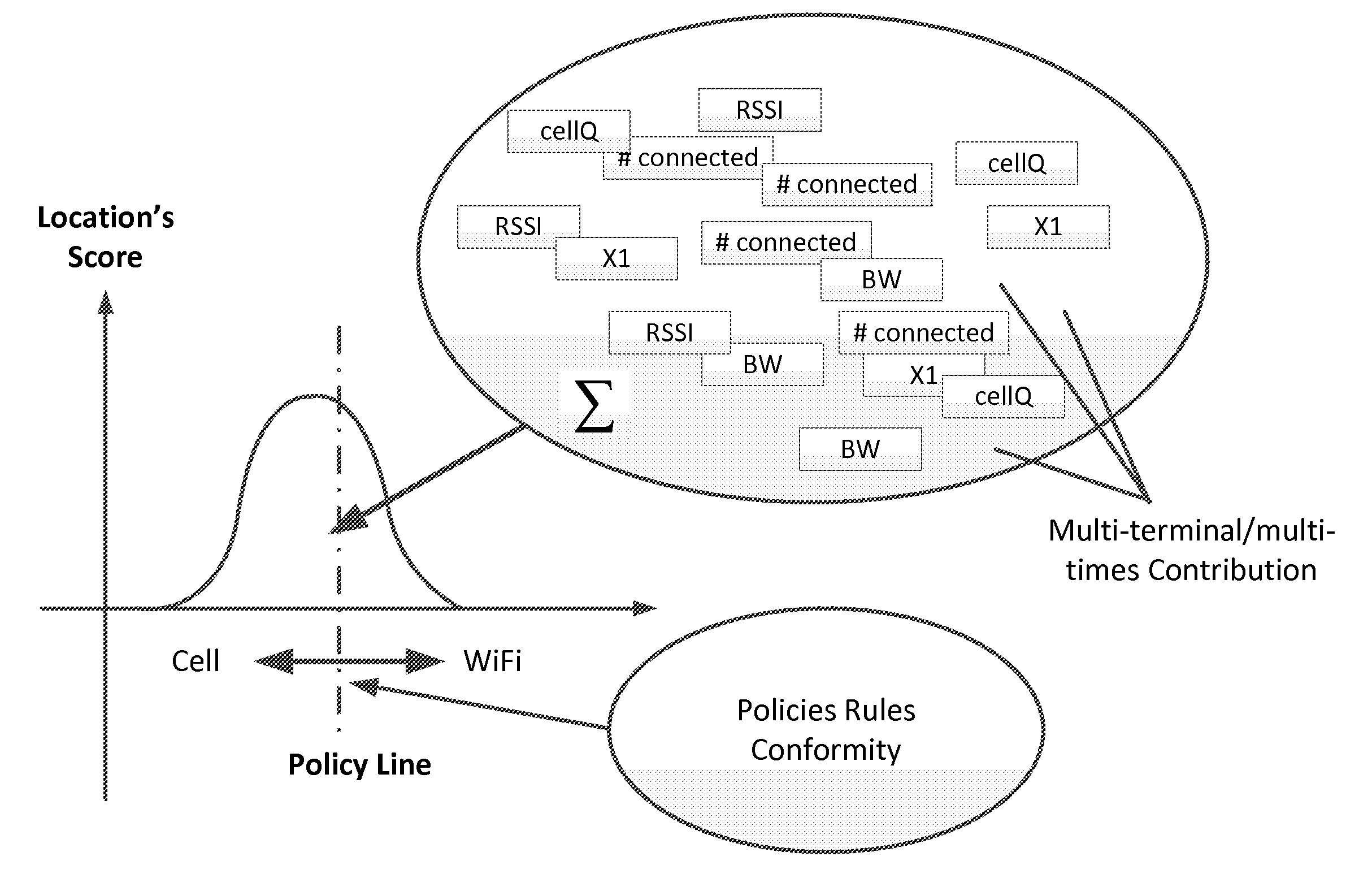

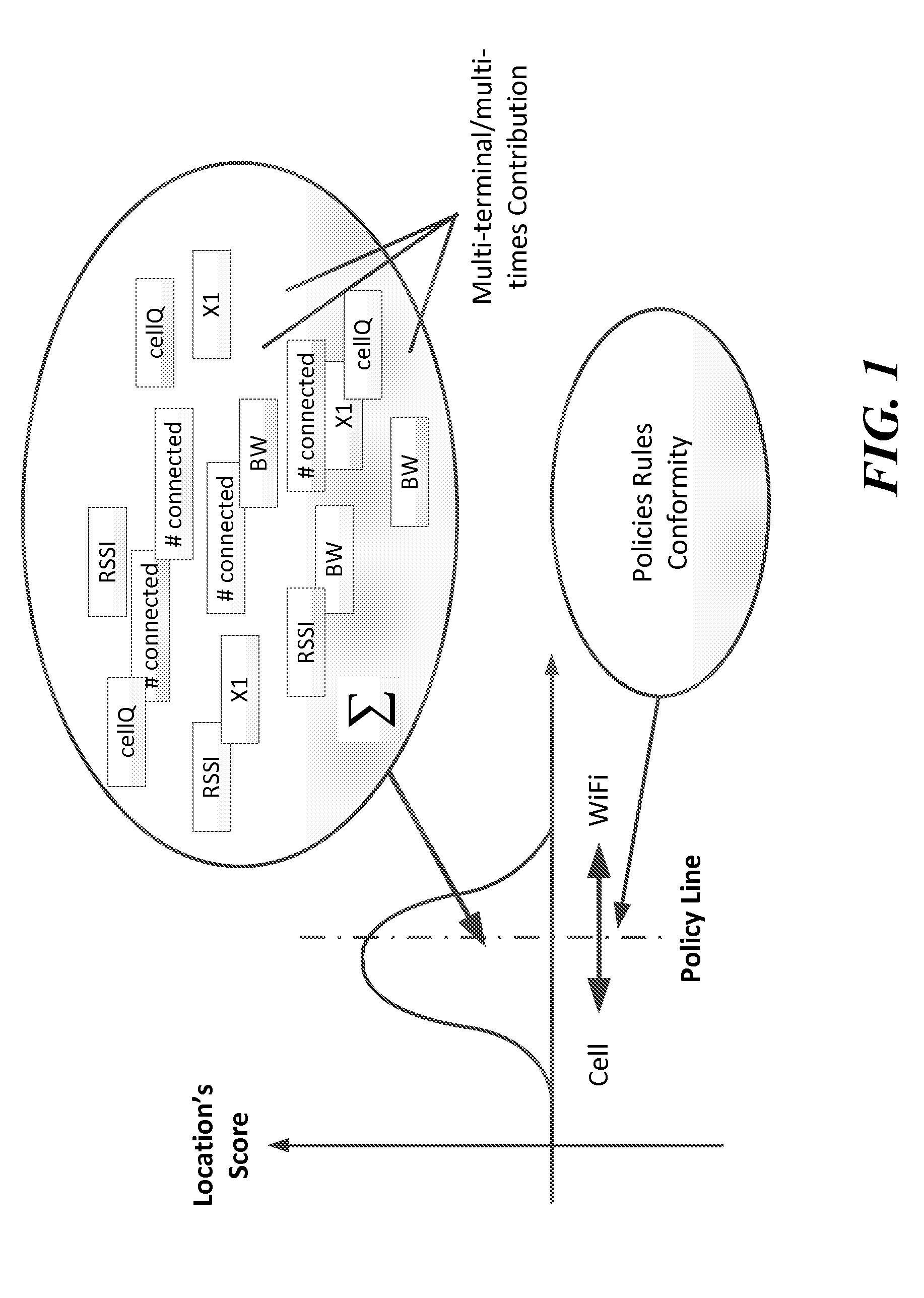

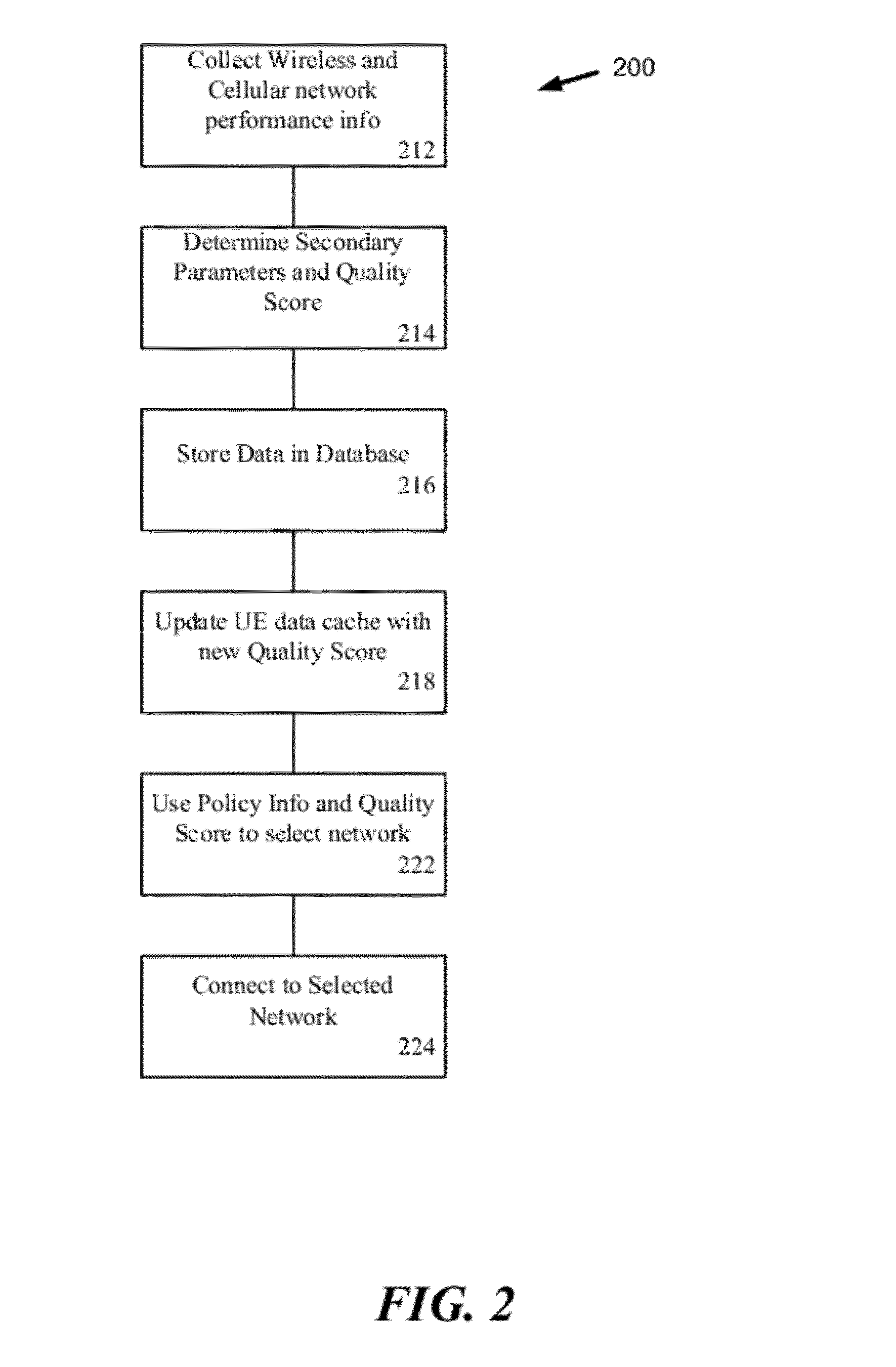

A method and system for selecting a network to establish a connection to from a set of available network includes a network database providing historical information about each of the networks and sends the database information to end user terminals. The end user terminals monitor real-time performance information about each of the available networks and can send this information to the network database. The end user terminals also include network connection policy information which can be used to make the selection decision. The end user terminal determines a network quality score for each available network as a function of the historical information from the network database, the real-time performance information about each available network and the network connection policy information. The end user terminal can select the available network as a function of the network quality score, for example, selecting the available network with the highest network quality score.

Owner:WEFI

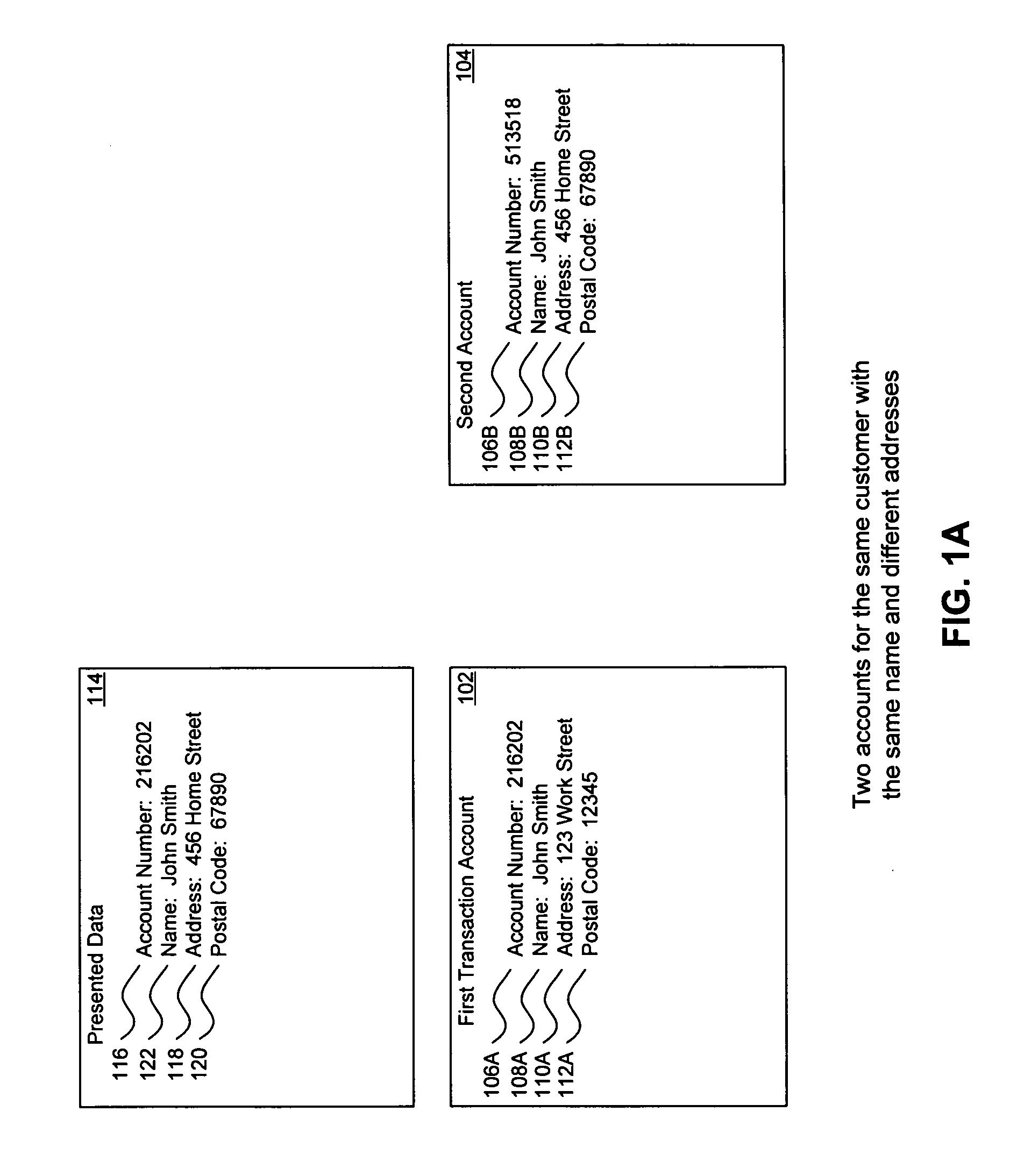

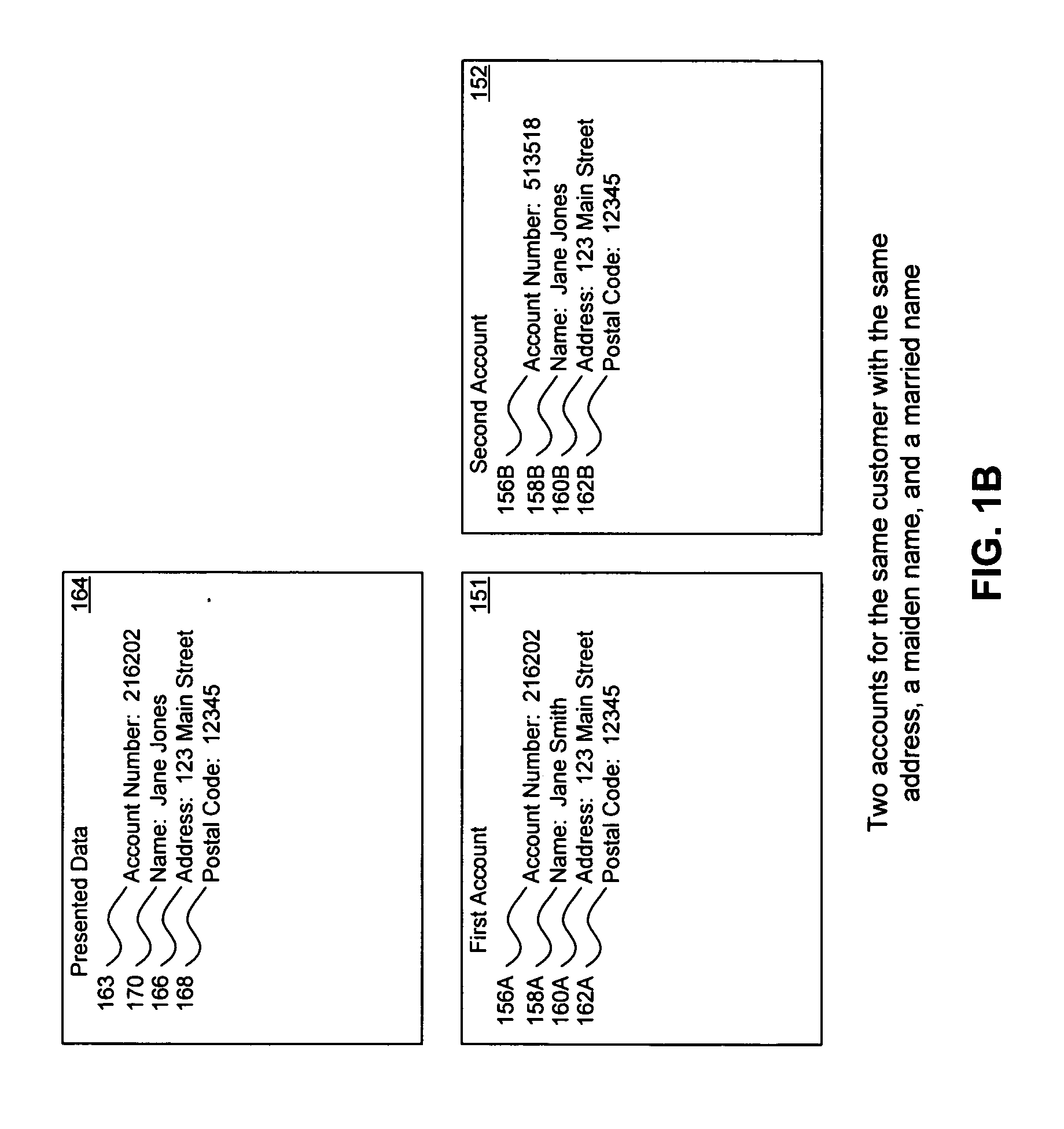

Method, system, and computer program product for customer-level data verification

ActiveUS20070284433A1Improve accuracyReduce error rateComplete banking machinesFinanceData validationSource Data Verification

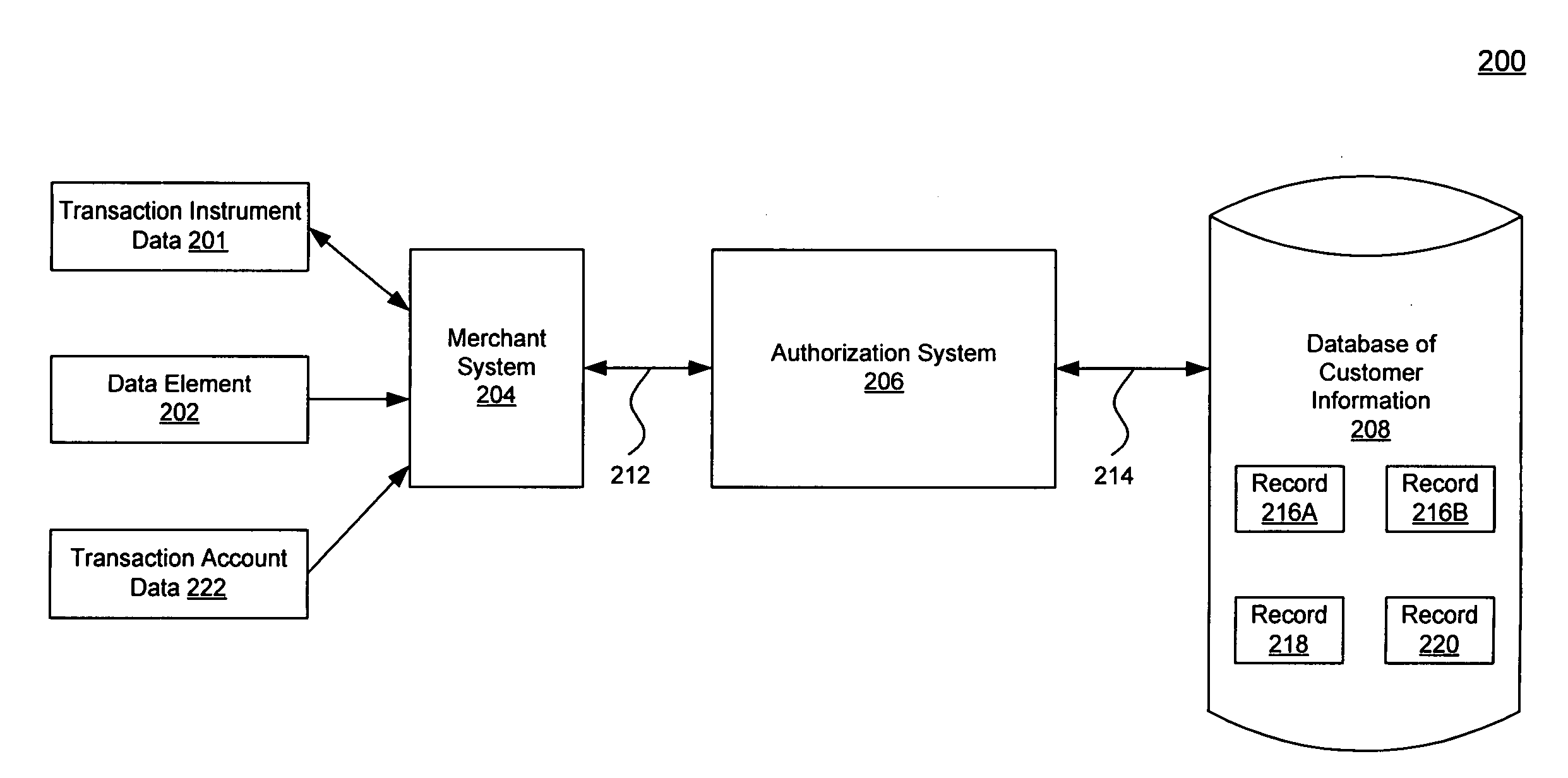

A system, method, and computer program to reduce incorrectly declined transactions and improve risk calculation accuracy by reducing error probability during fraud detection. The tool first receives at least one data element as well as transaction account data and / or financial transaction instrument data. Then a customer is determined from a first record associated with the transaction account data and / or financial transaction instrument data. A record search is performed to identify at least one additional record associated with the customer. Finally, the data element is compared to the information contained in the additional record to create a comparison result that verifies a customer address. The comparison result may be used as an input to transaction risk calculations. The comparison result may also be provided to a merchant system and / or merchant for use in a decision-making process, for example, to verify customer identity.

Owner:LIBERTY PEAK VENTURES LLC

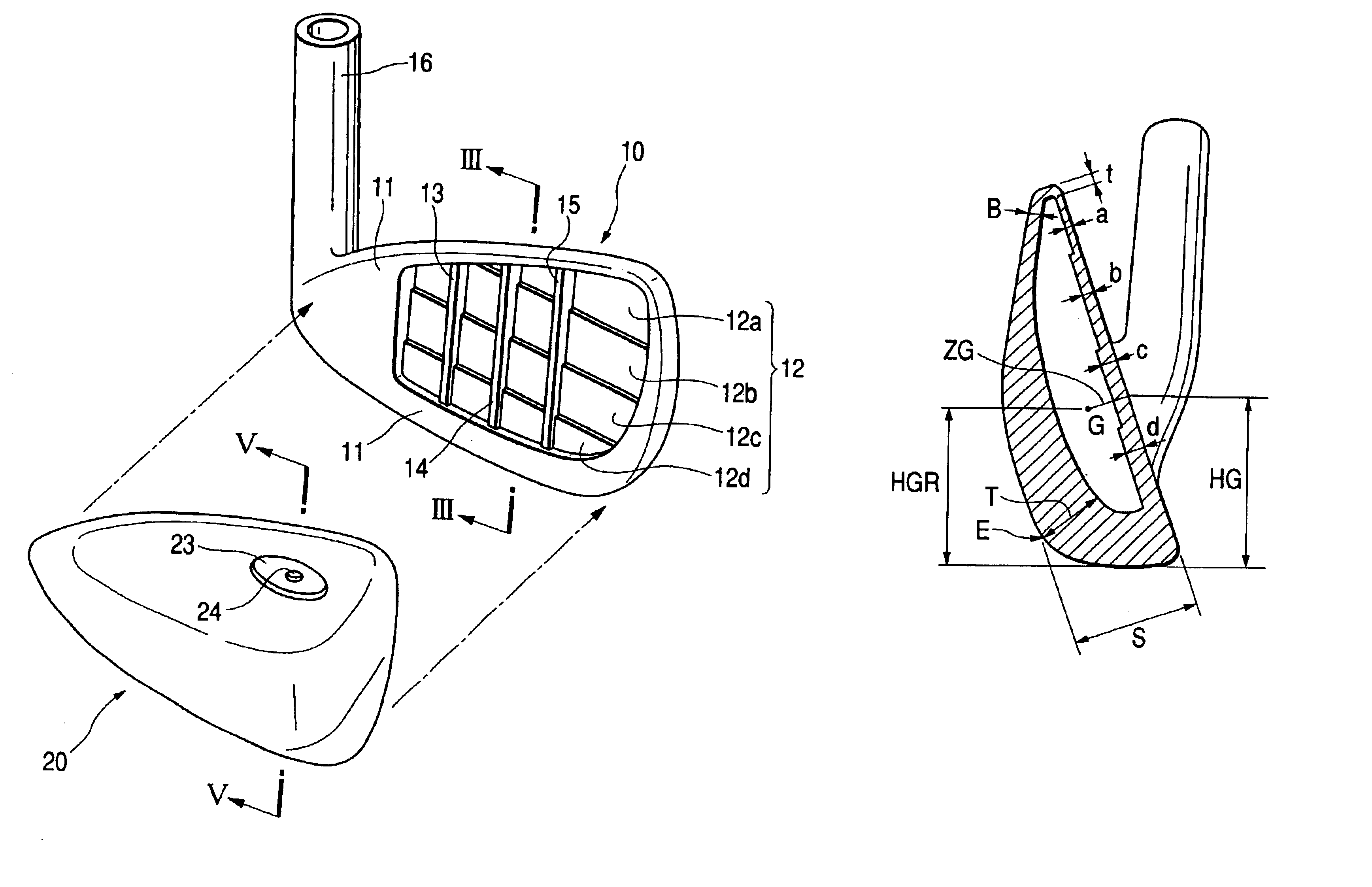

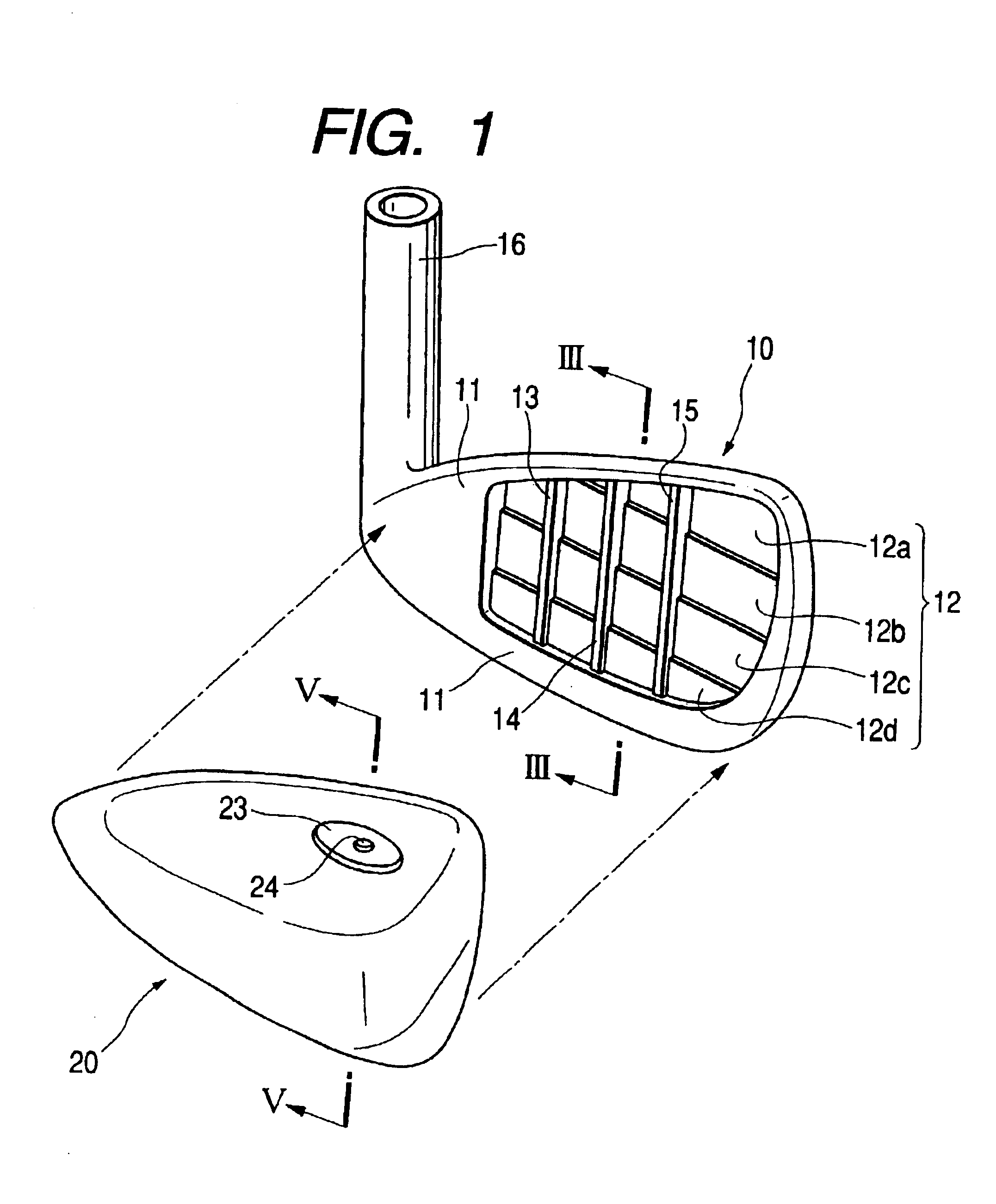

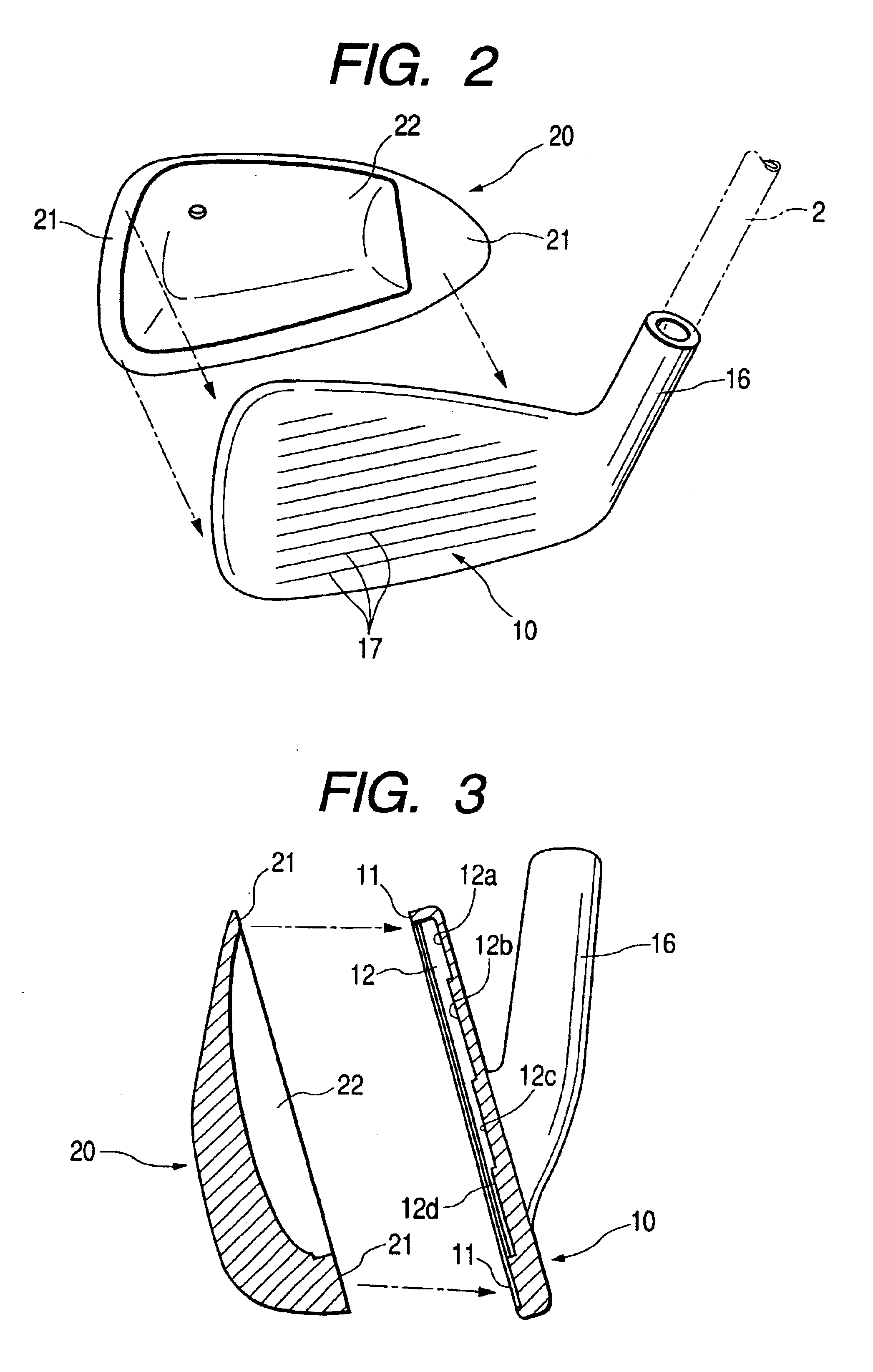

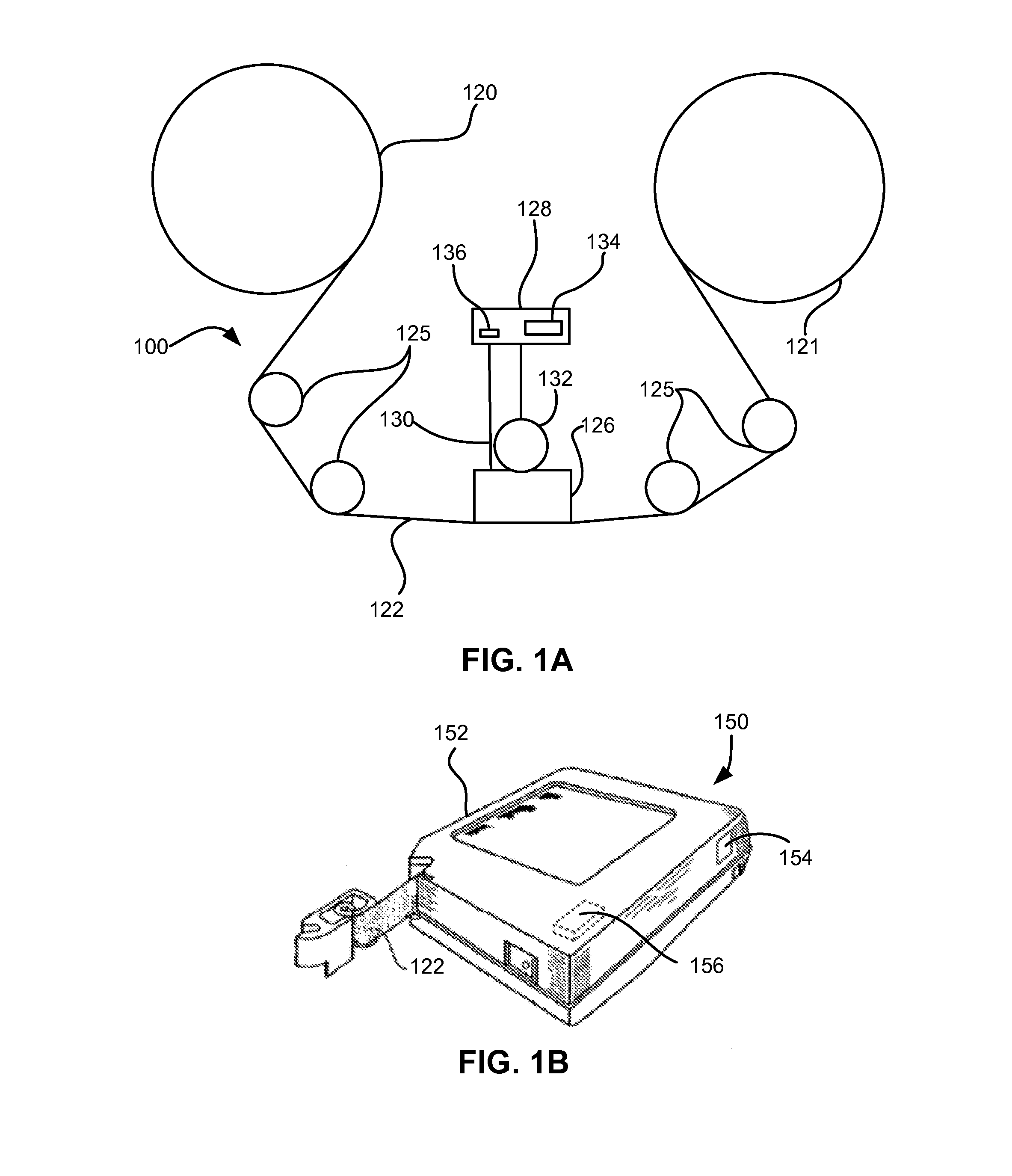

Golf club set

InactiveUS6780123B2Efficient use ofIncrease the number ofGolf clubsRacket sportsGravity centerEngineering

Owner:BRIDGESTONE SPORTS

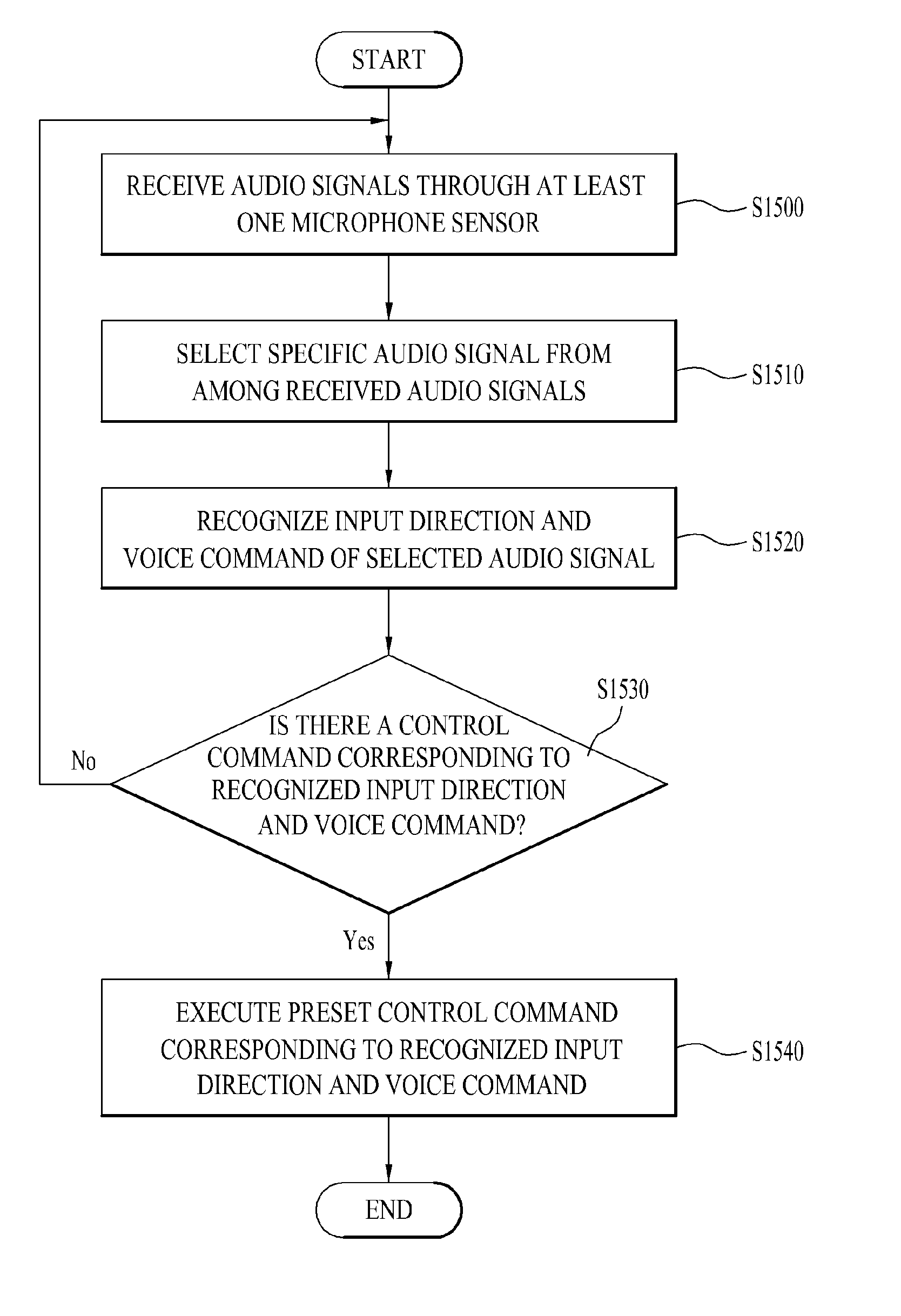

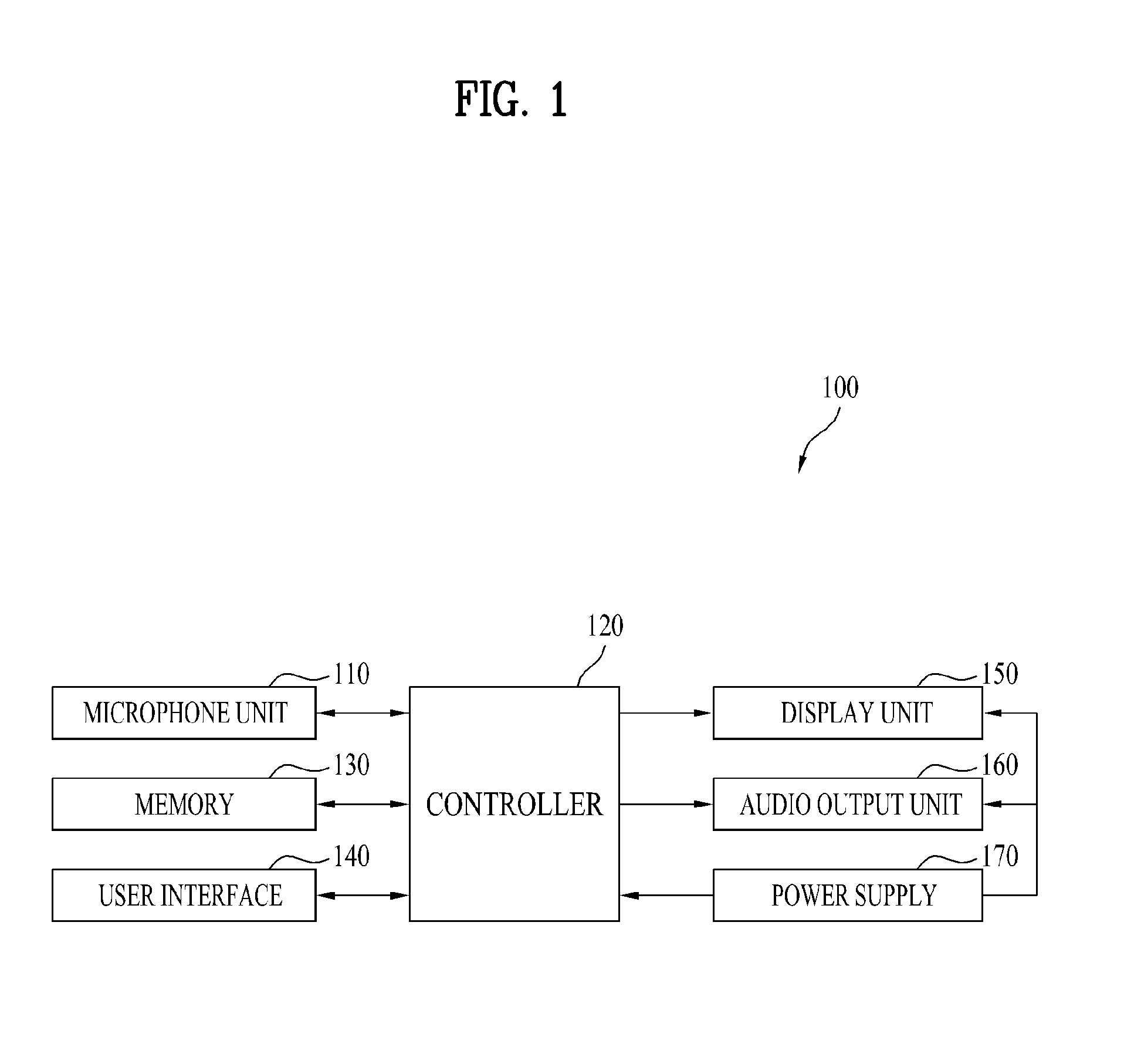

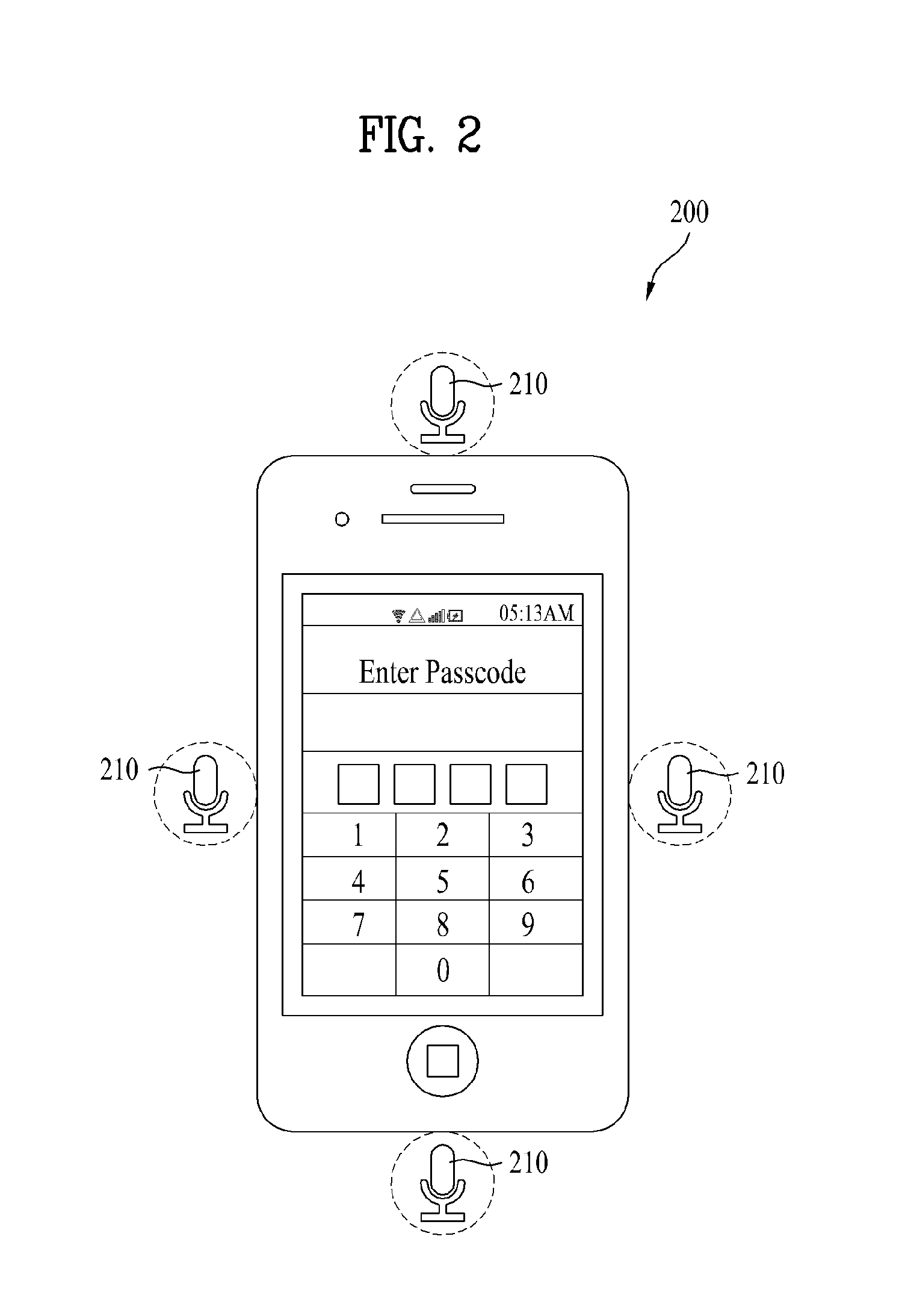

Mobile device having at least one microphone sensor and method for controlling the same

A mobile device having at least one microphone sensor and a method for controlling the same are disclosed. The method includes receiving at least two audio signals through the at least one microphone sensor within a predetermined time period, recognizing input directions and voice command from the at least two audio signals sequentially, determining whether the recognized input directions and voice command match to preset input directions and preset voice command mapped to the preset directions, sequentially for the at least two received audio signals, and executing a preset control command, if the recognized input directions and voice command match to the preset input directions and voice command.

Owner:LG ELECTRONICS INC

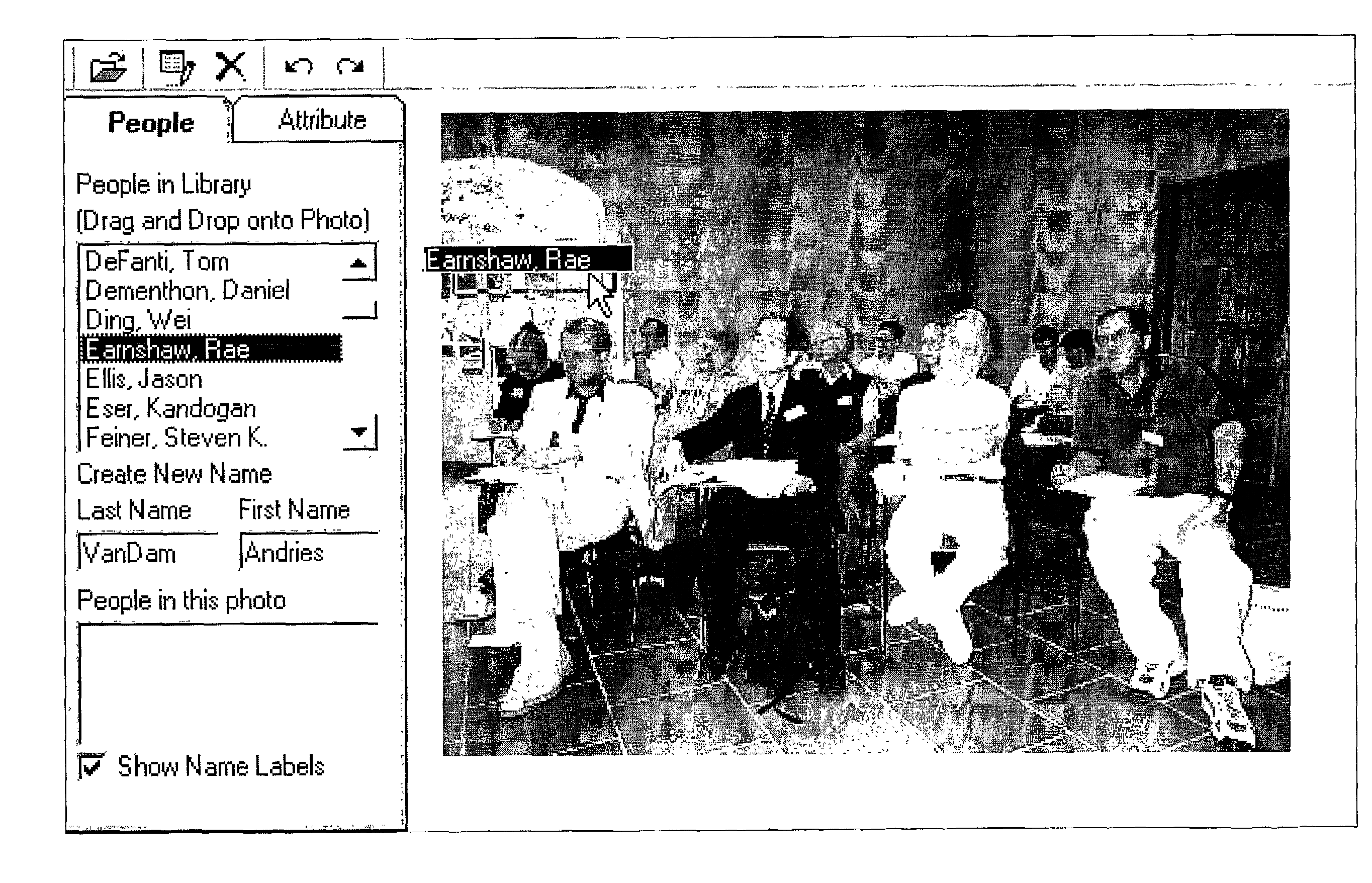

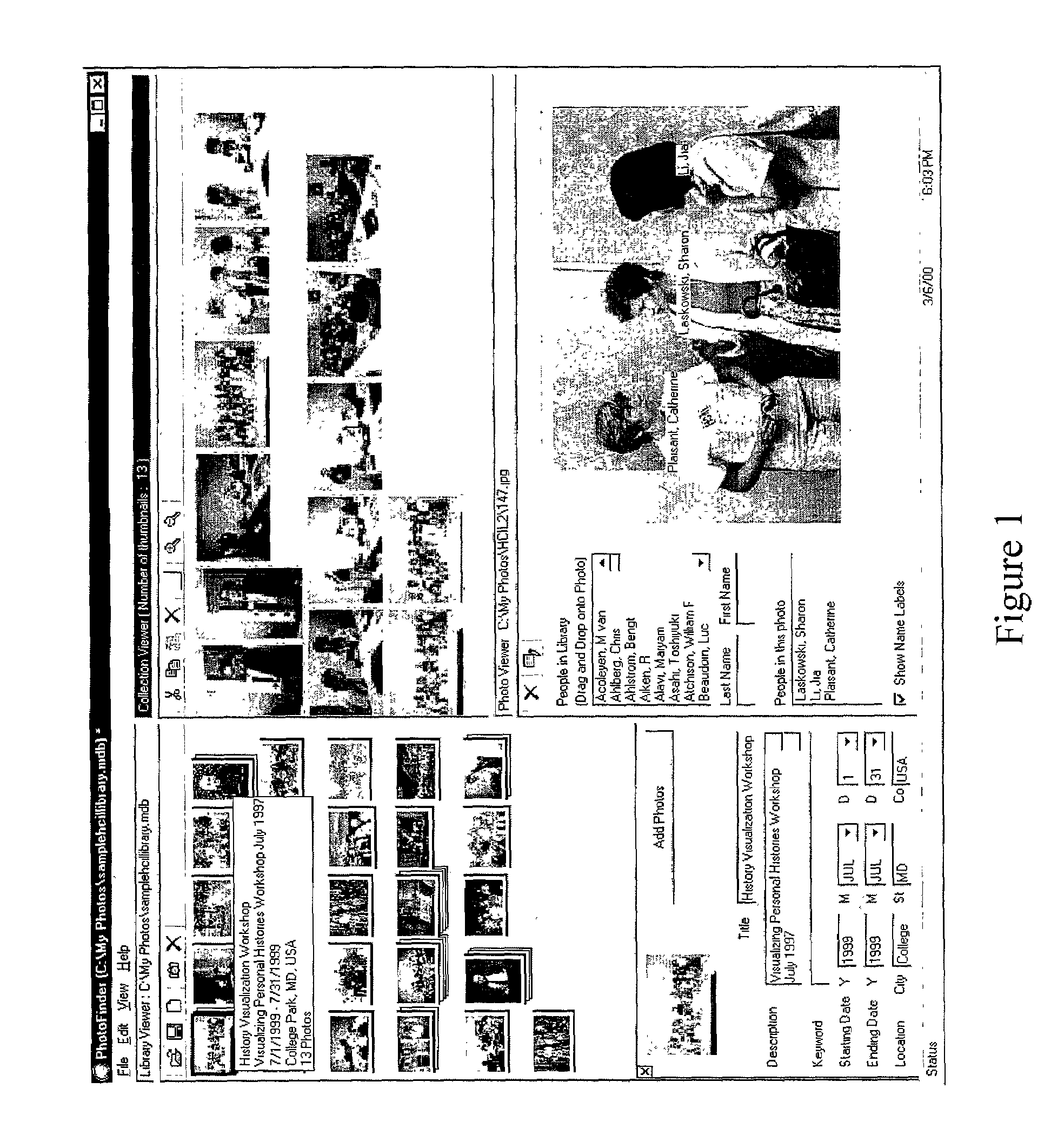

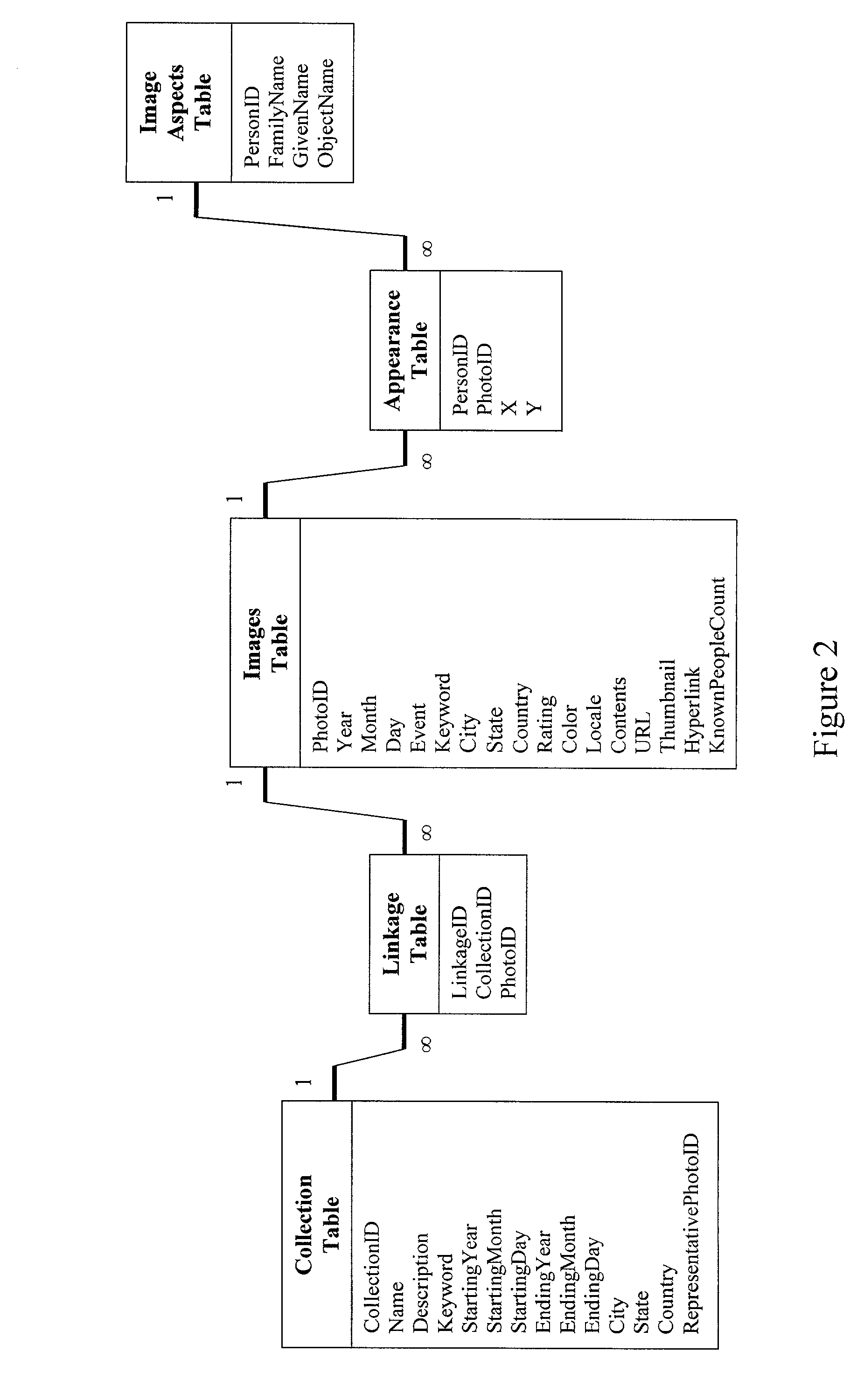

Methods for the electronic annotation, retrieval, and use of electronic images

InactiveUS7010751B2Flexible and easy to learnReduce error rateData processing applicationsDigital data processing detailsDrag and dropComputer graphics (images)

The present invention provides software for electronically annotating electronic images, such as drawings, photographs, video, etc., through the drag-and-drop of annotations from a pre-defined, but extendable, list. The annotations are placed at a user-selected X, Y location on the image, and stored in a searchable database. Thus, they can be searched in order to retrieve, organize, group, or display desired electronic images or collections of such images. The annotations may be text, images, sounds, etc. The invention provides a flexible, easy to learn, rapid, low error rate and satisfying interface for accomplishing such tasks.

Owner:MARYLAND COLLEGE PARK UNIV OF +1

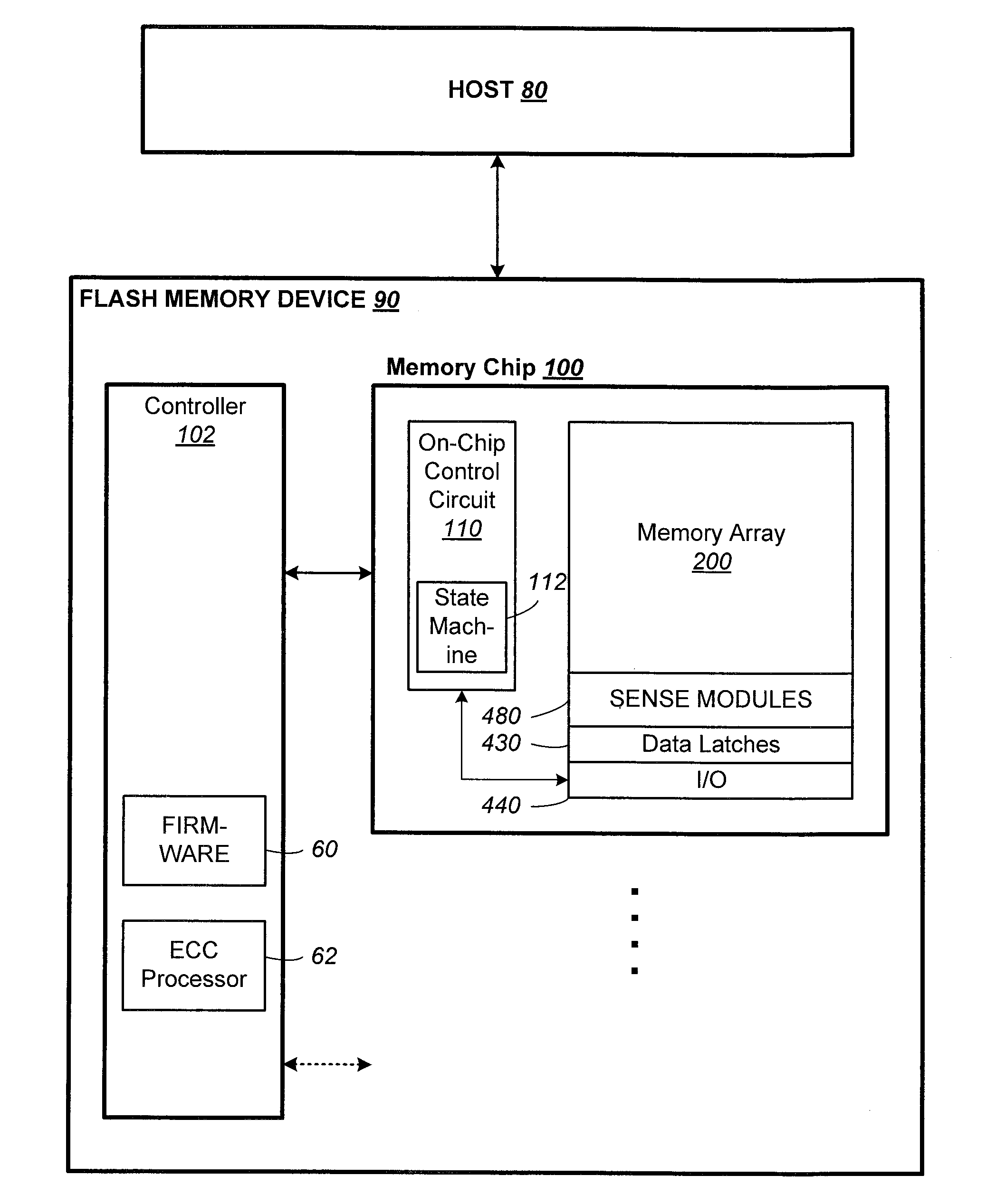

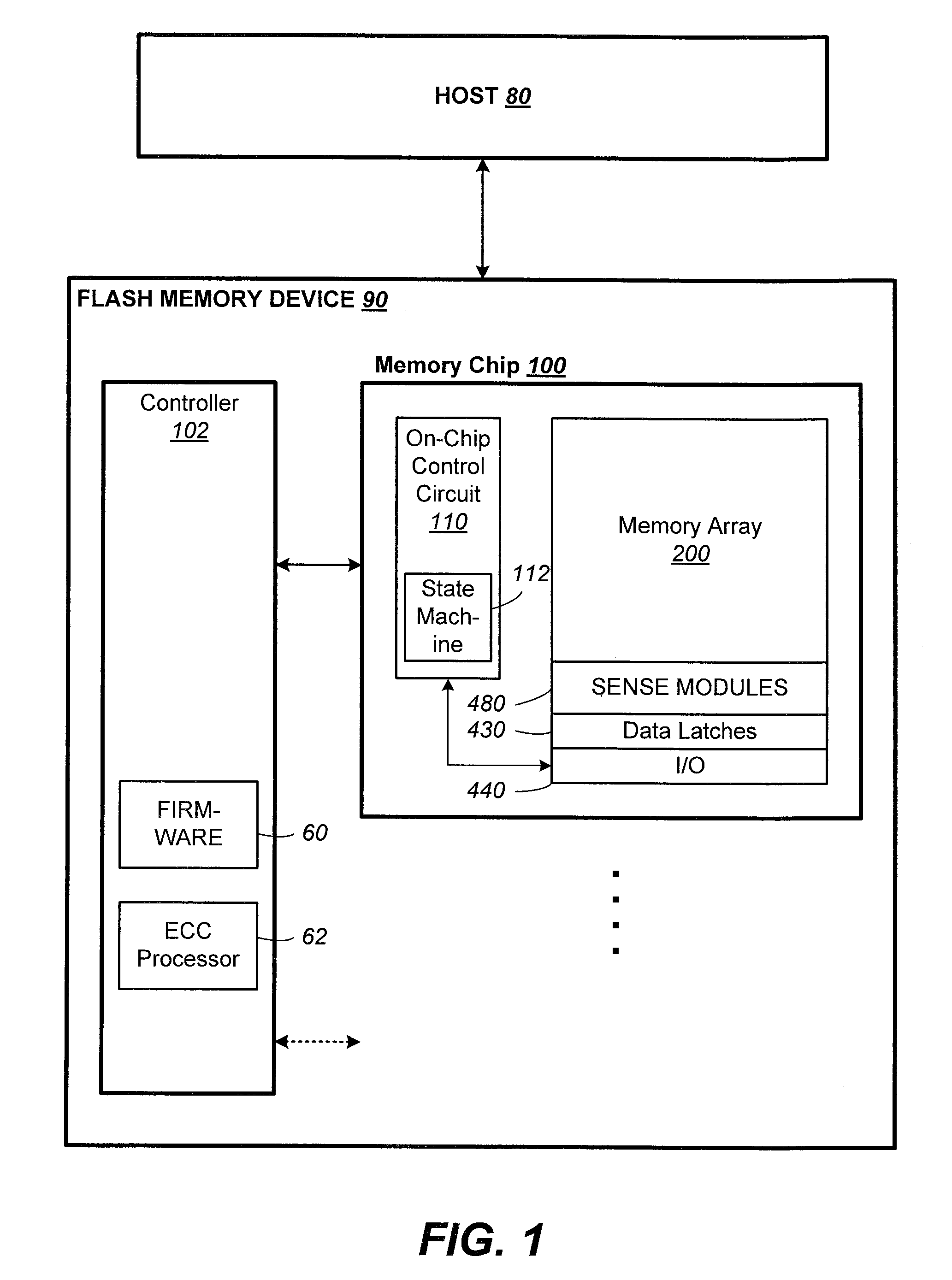

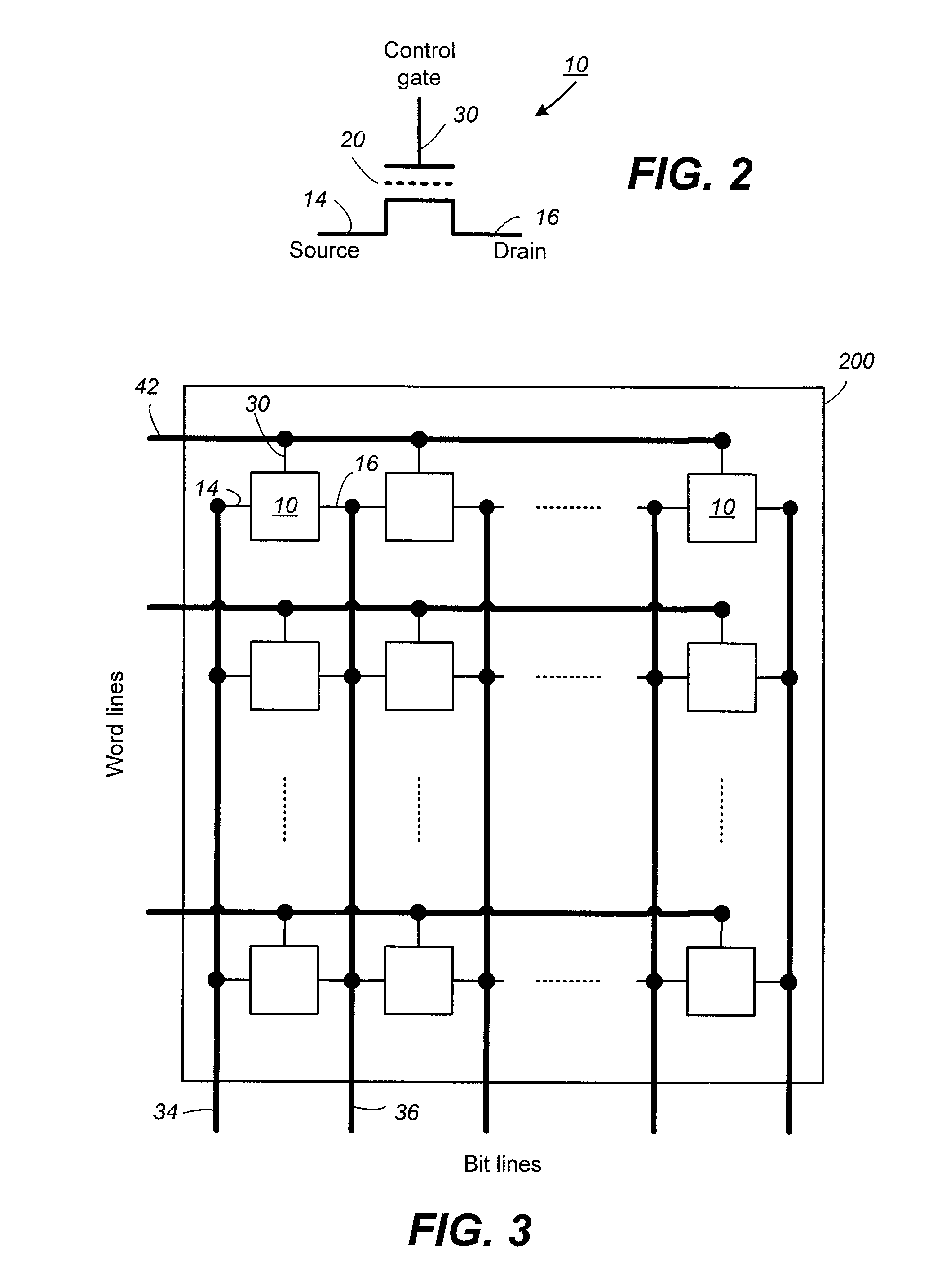

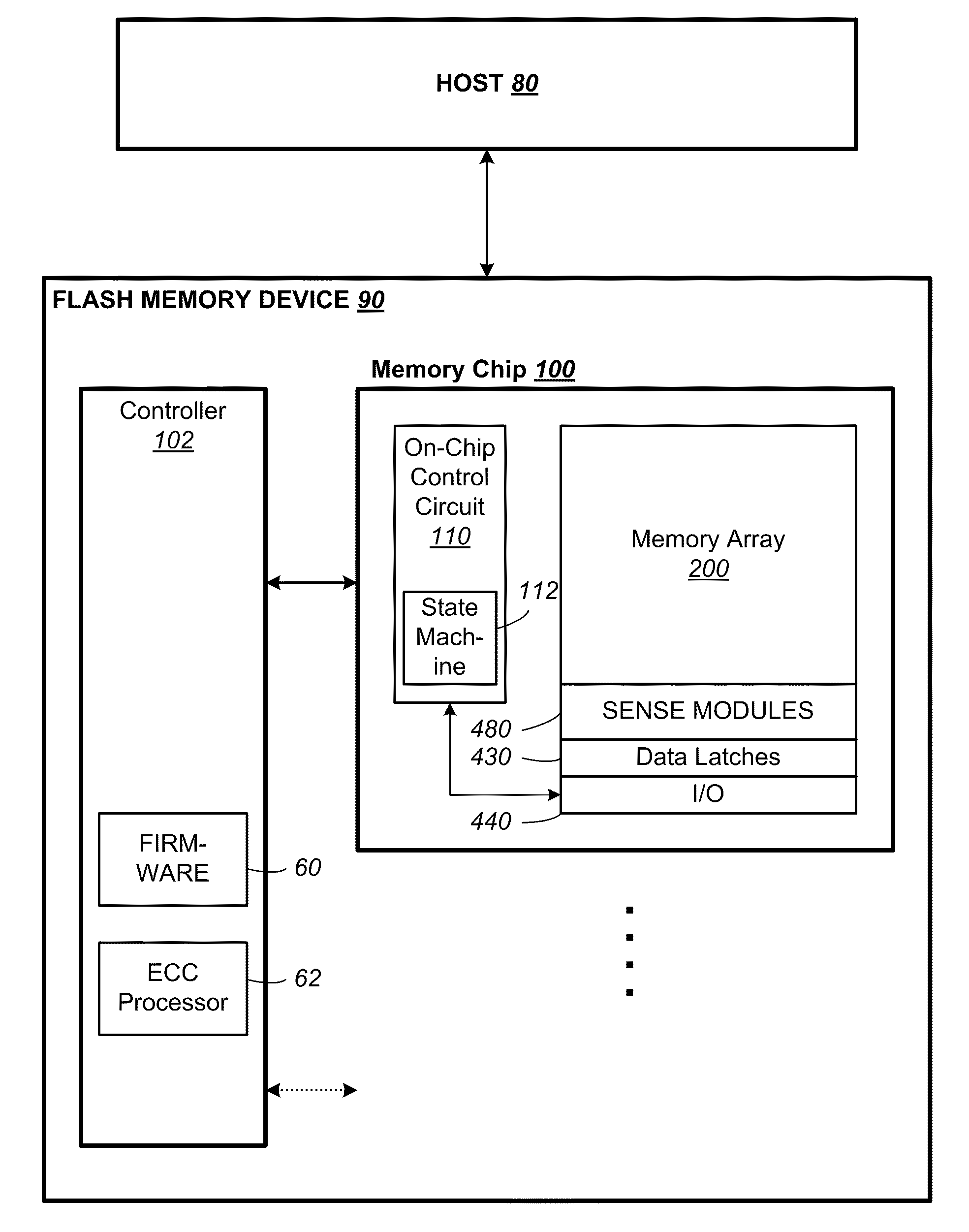

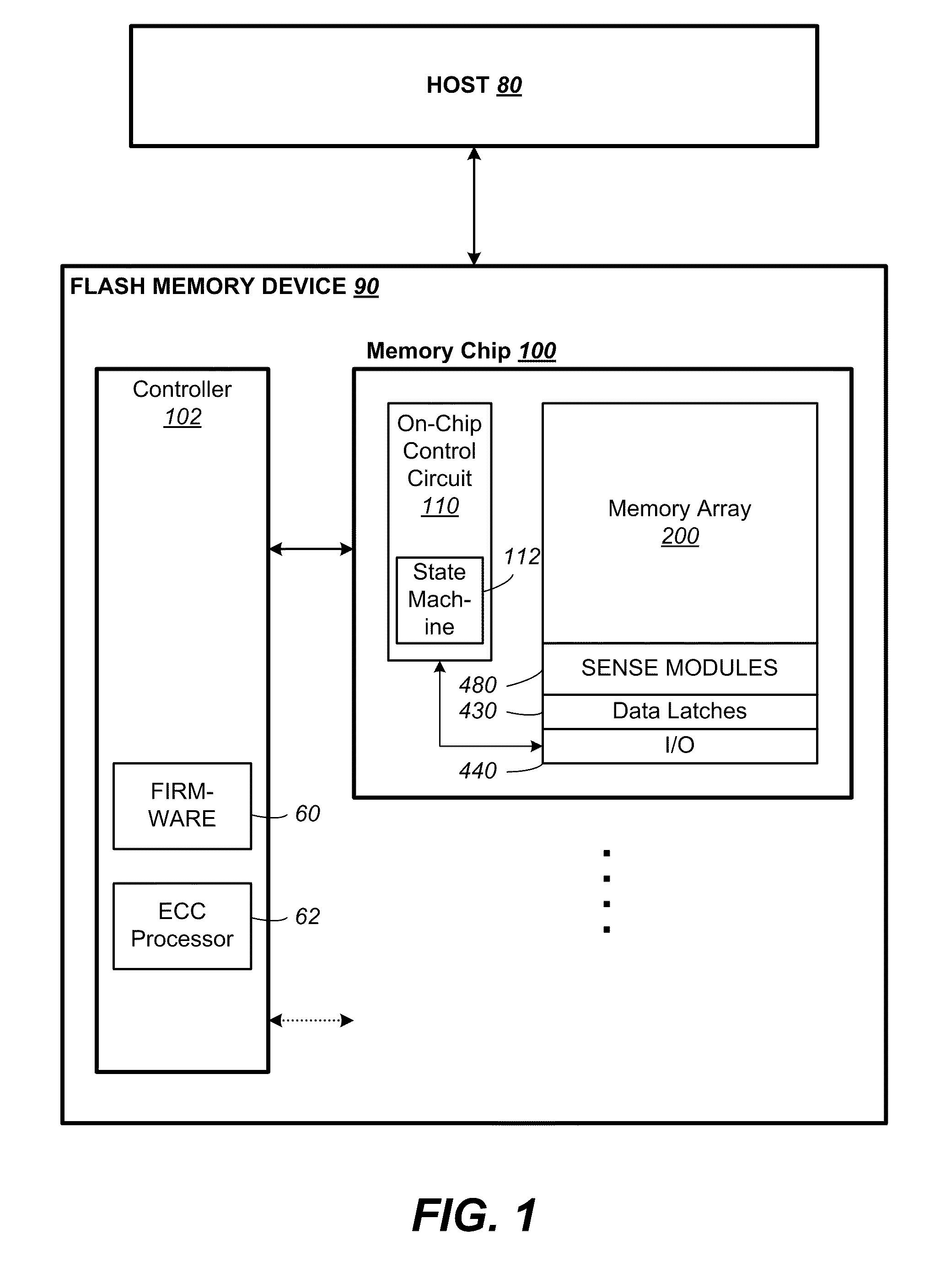

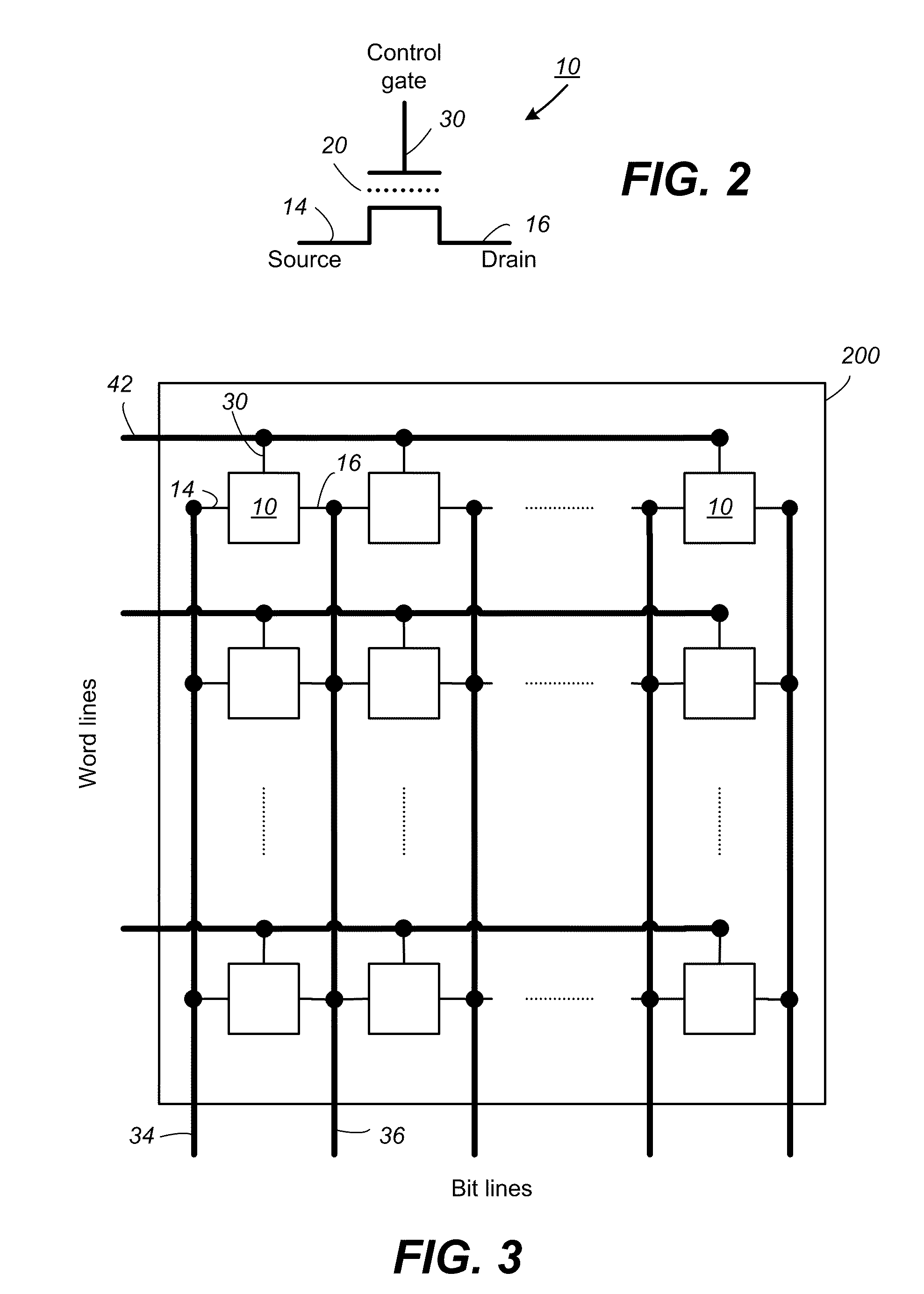

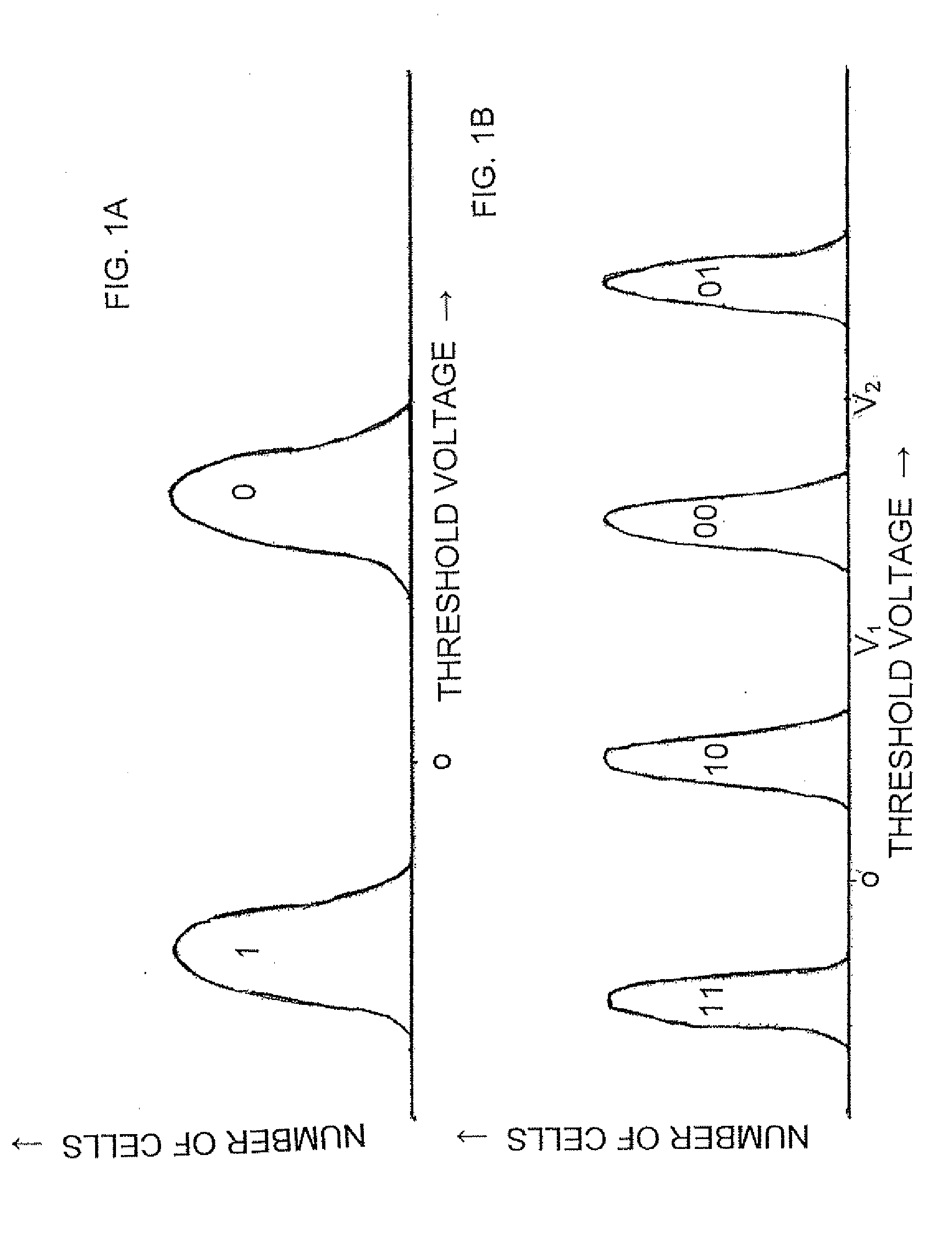

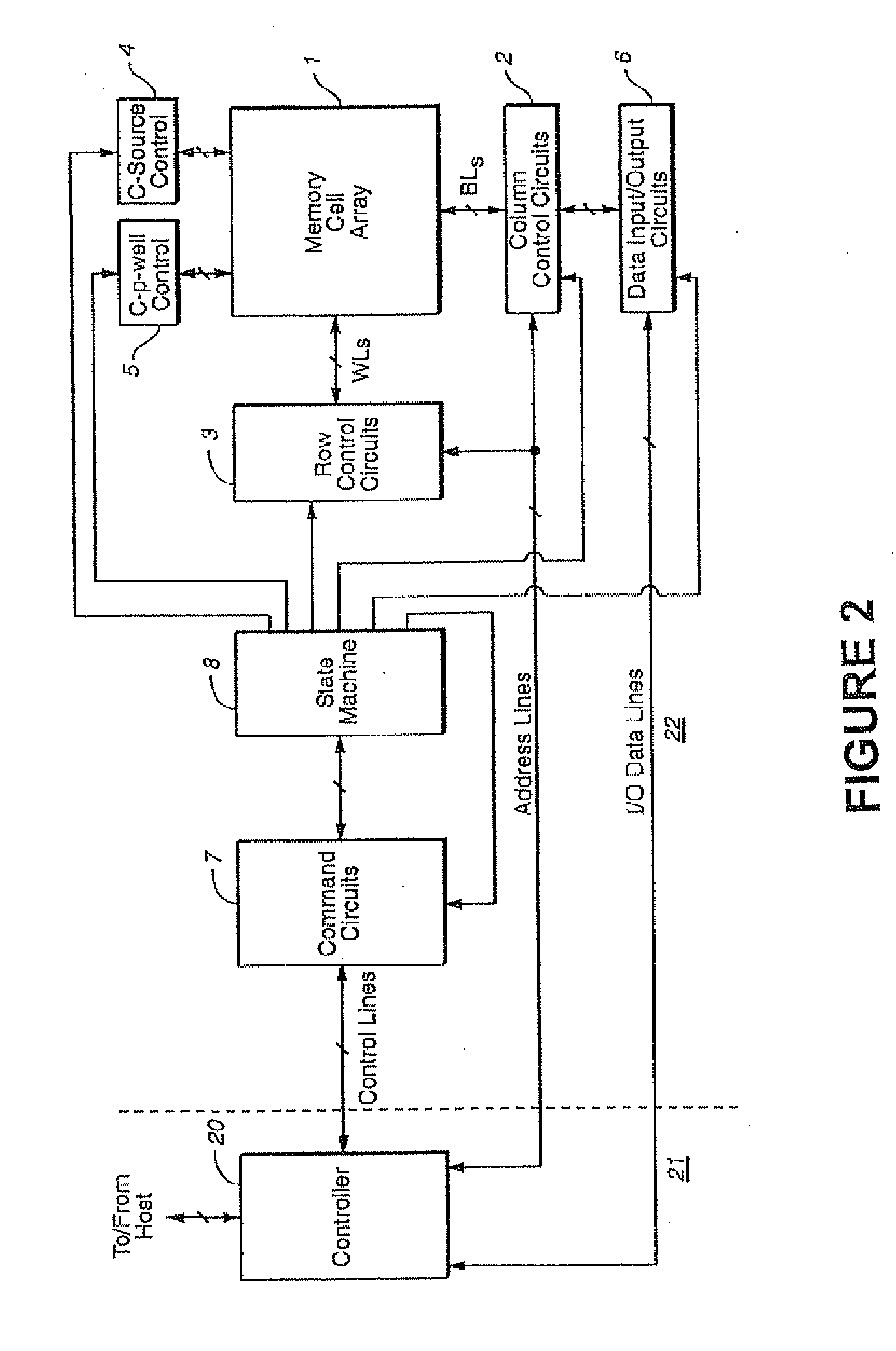

Non-Volatile Memory And Method With Post-Write Read And Adaptive Re-Write To Manage Errors

ActiveUS20110099460A1Small marginImprove performanceMemory loss protectionRead-only memoriesHigh densityLow density

Data errors in non-volatile memory inevitably increase with usage and with higher density of bits stored per cell. The memory is configured to have a first portion operating with less error but of lower density storage, and a second portion operating with a higher density but less robust storage. Input data is written and staged in the first portion before being copied to the second portion. An error management provides checking the quality of the copied data for excessive error bits. The copying and checking are repeated on a different location in the second portion until either a predetermined quality is satisfied or the number or repeats exceeds a predetermined limit. The error management is not started when a memory is new with little or no errors, but started after the memory has aged to a predetermined amount as determined by the number of erase / program cycling its has experienced.

Owner:SANDISK TECH LLC

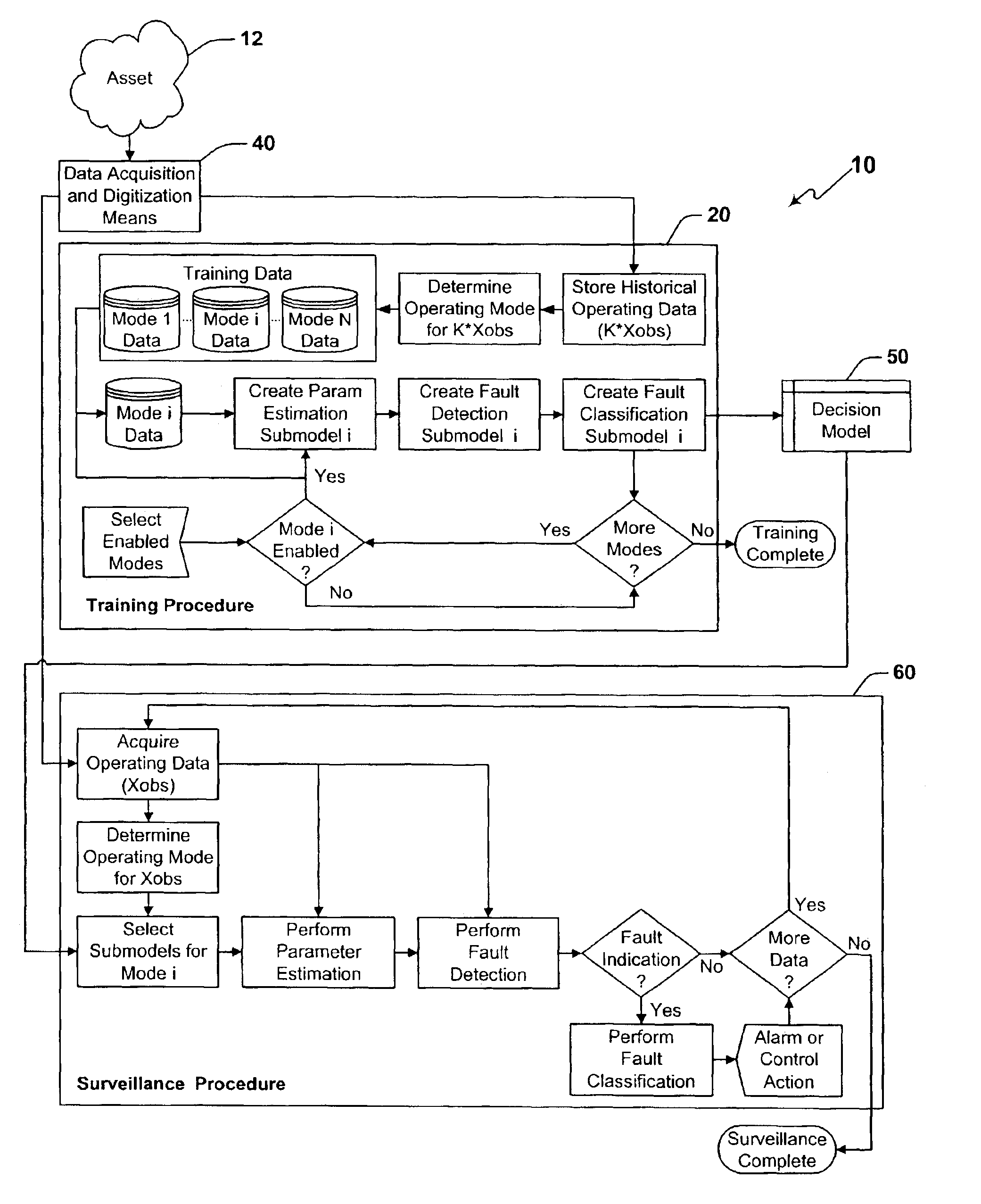

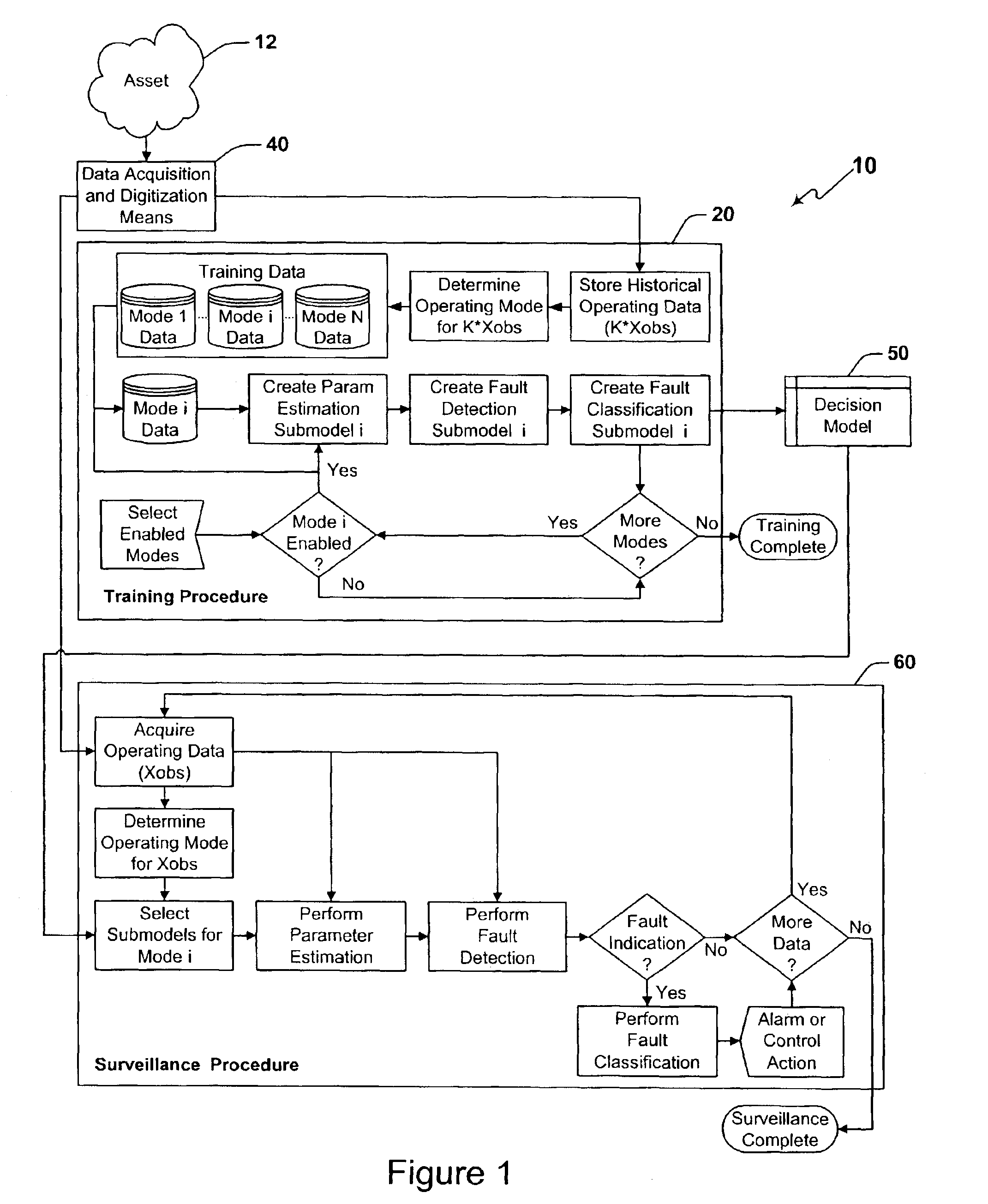

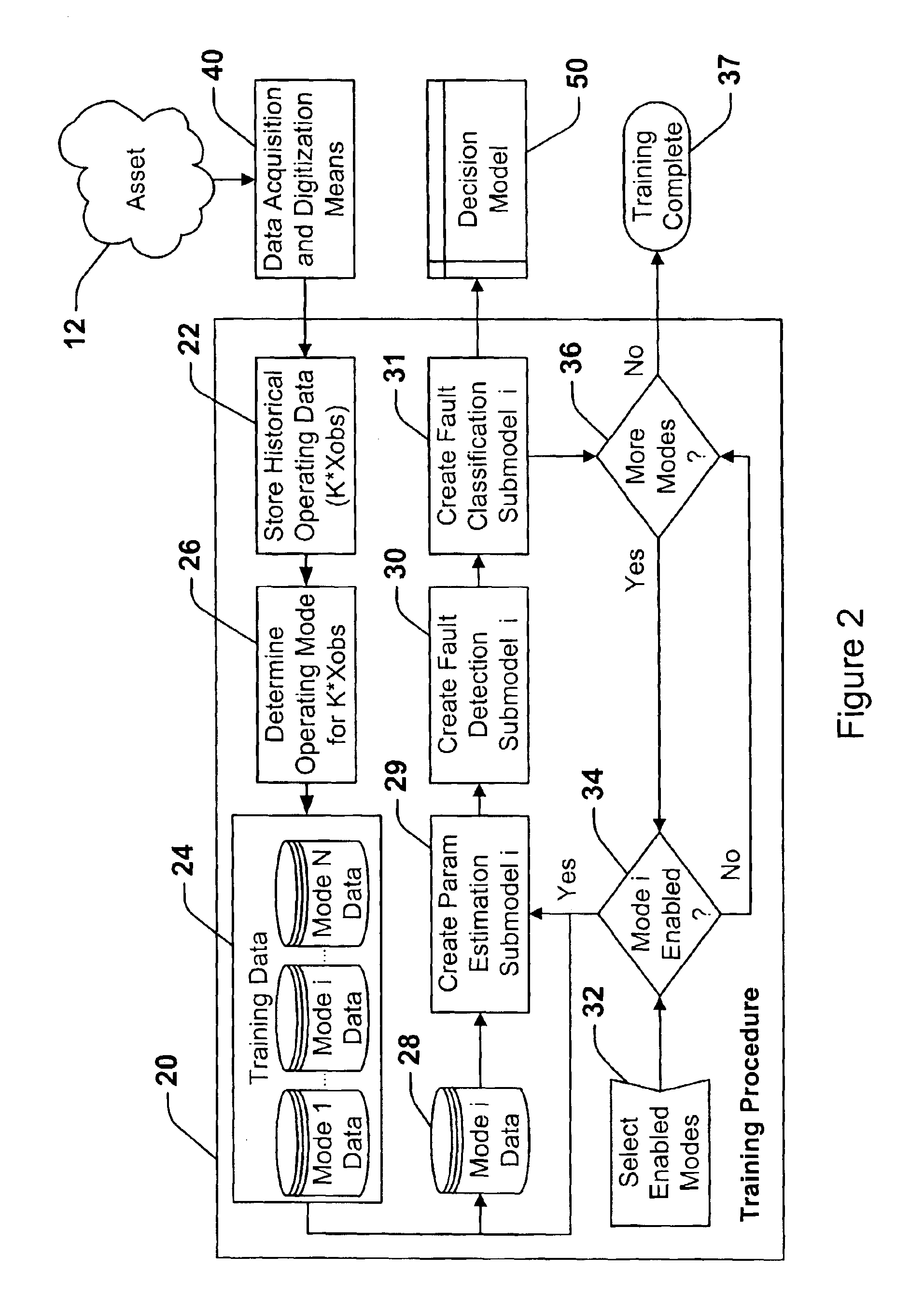

Surveillance system and method having an operating mode partitioned fault classification model

InactiveUS6917839B2Improve surveillance capabilitiesPerformance trade-offCosmonautic vehiclesDigital data processing detailsMonitoring systemOperation mode

A system and method which partitions a parameter estimation model, a fault detection model, and a fault classification model for a process surveillance scheme into two or more coordinated submodels together providing improved diagnostic decision making for at least one determined operating mode of an asset.

Owner:INTELLECTUAL ASSETAB

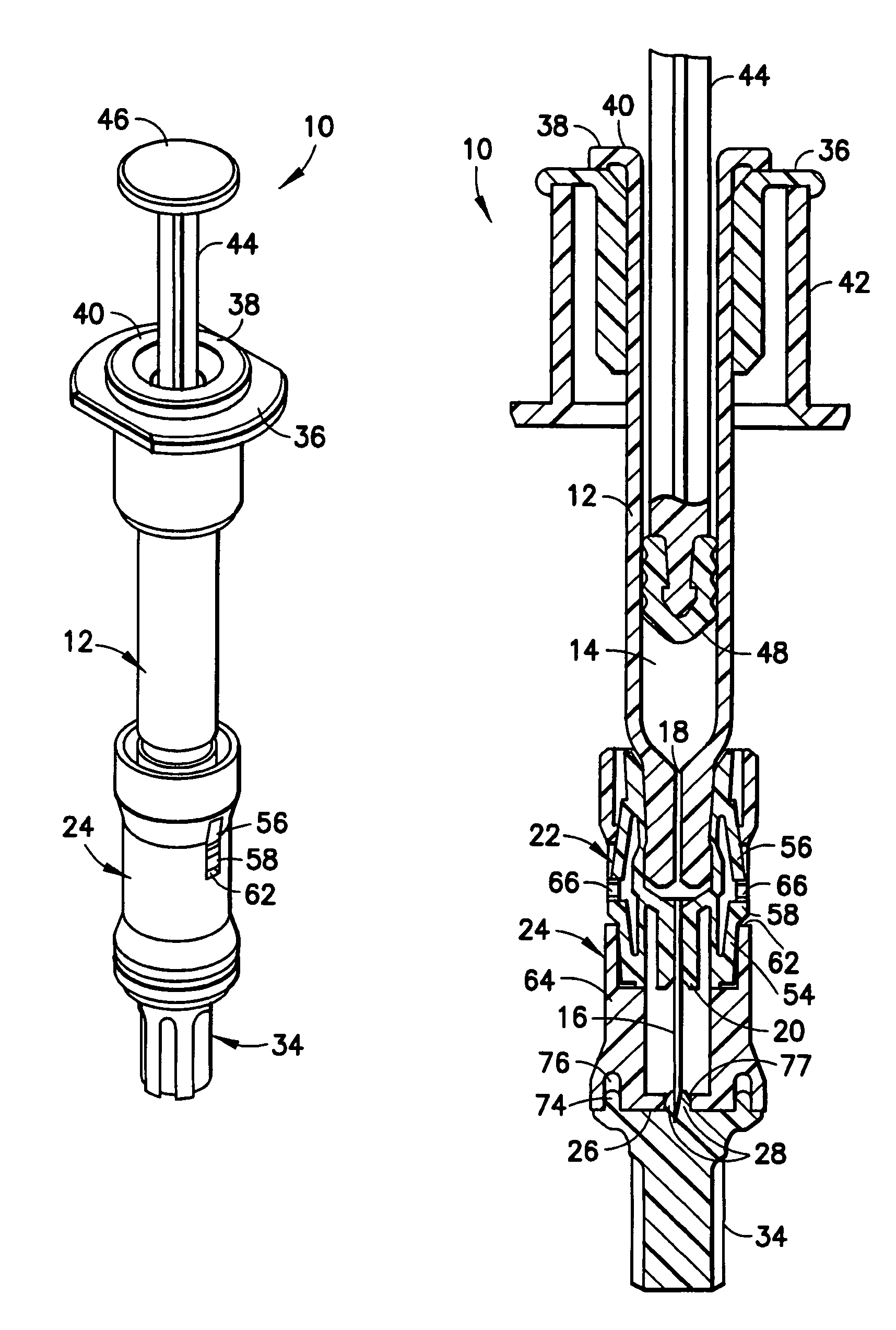

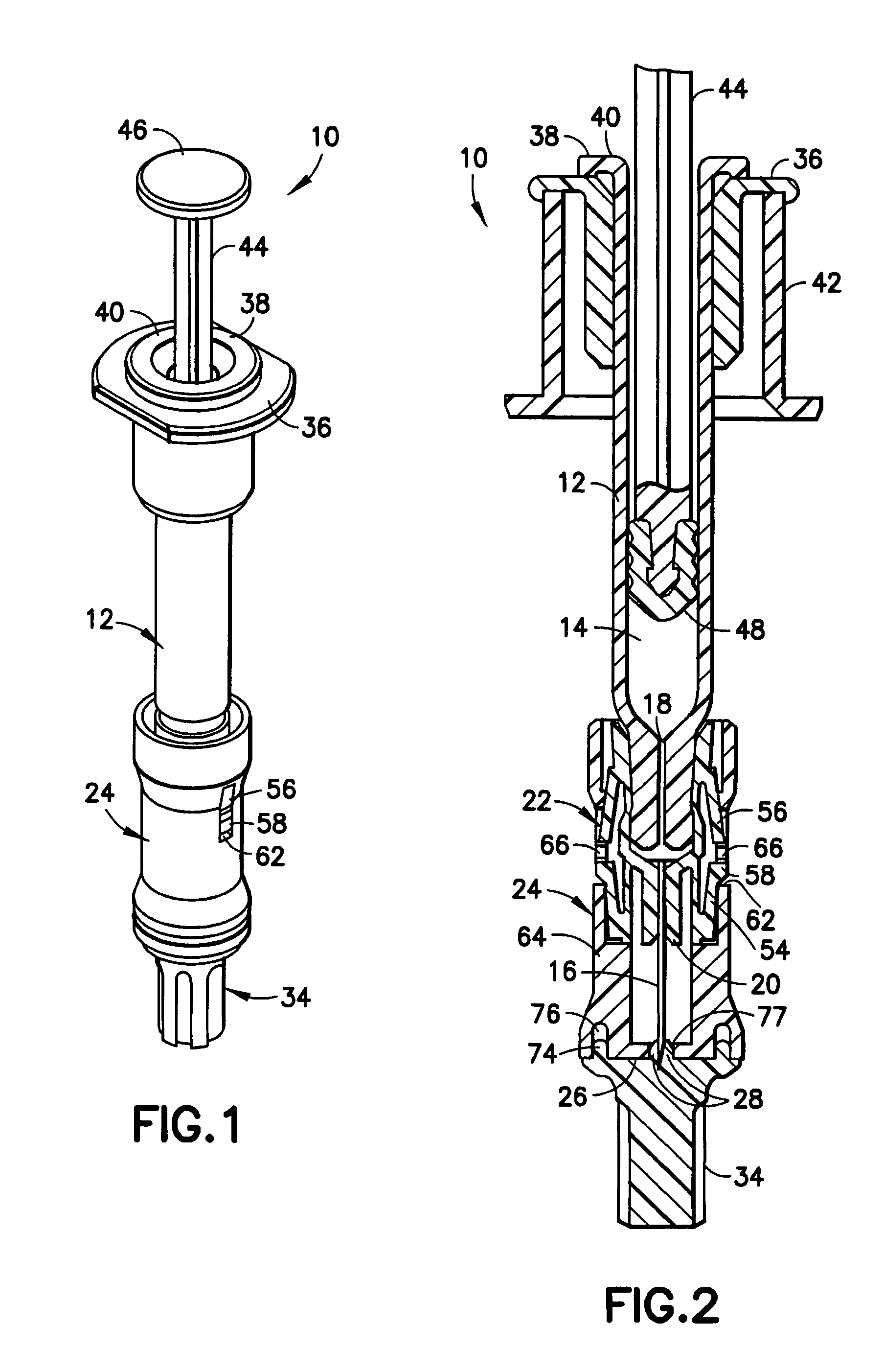

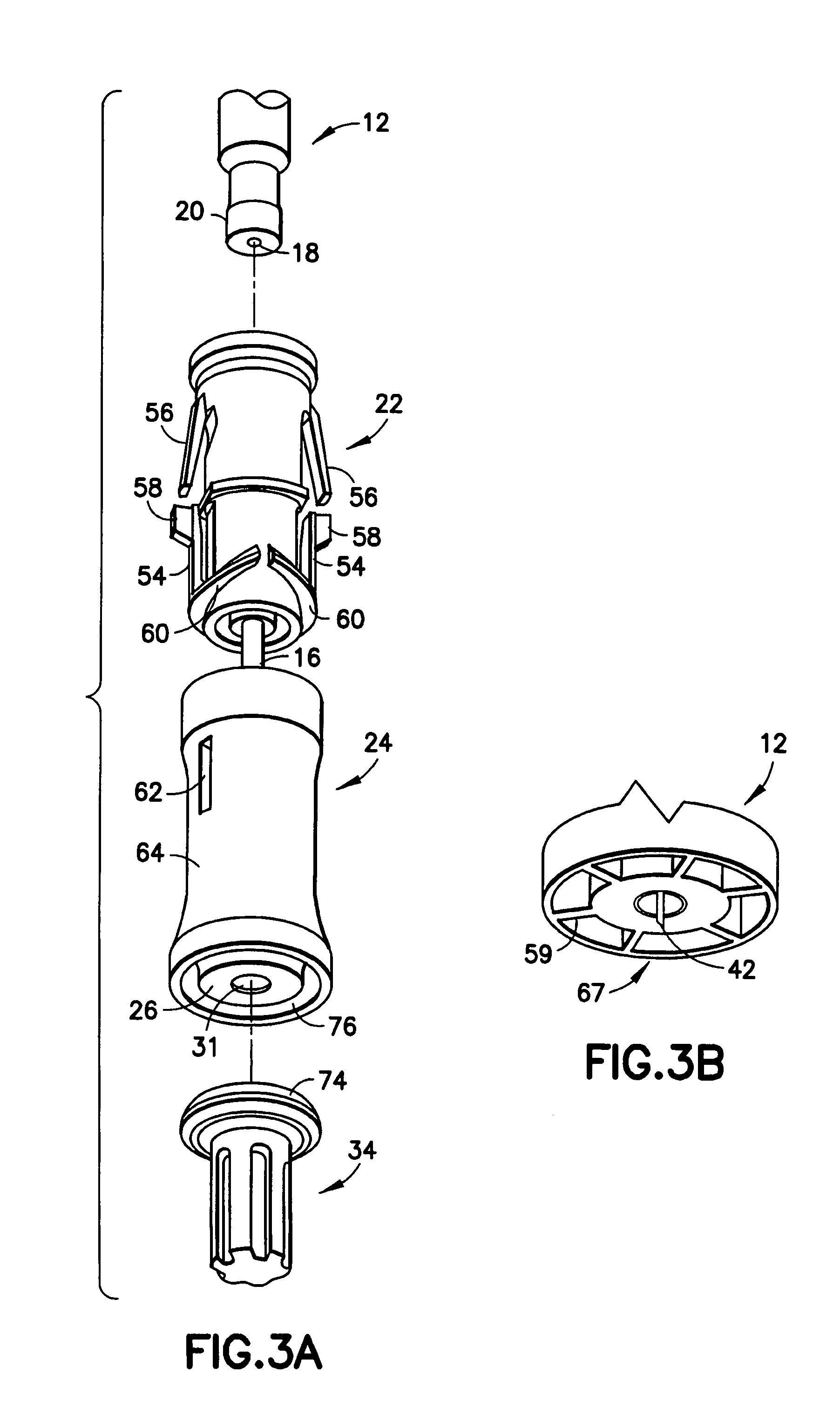

Prefillable intradermal delivery device

An intradermal delivery device for use in intradermally injecting substances into the skin of an animal includes a needle cannula supported by a hub portion that is attachable to a prefillable container. A limiter portion surrounds the needle cannula and extends away from the hub portion toward a forward tip of the needle cannula. The limiter portion includes a skin engaging surface extending in a plane generally perpendicular to an axis of the needle cannula. The skin engaging surface is received against skin of an animal to administer an intradermal injection. The forward tip extends beyond the skin engaging surface a distance that enables penetration of the needle cannula into the dermis layer of the skin of the animal enabling injection of the substance into the dermis layer of the animal. The device includes enclosure means that is moveable for concealing the needle cannula after the injection has been administered.

Owner:BECTON DICKINSON & CO

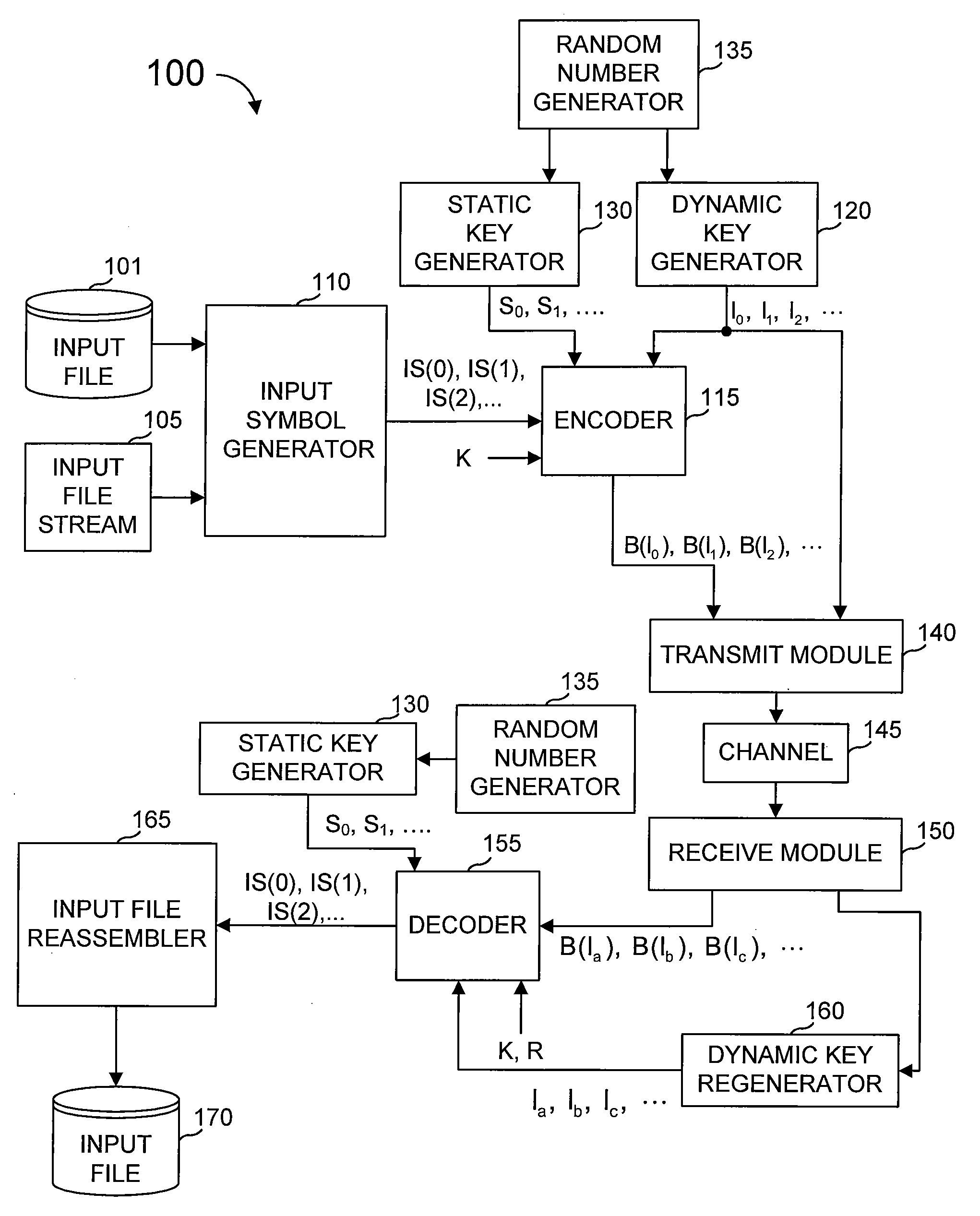

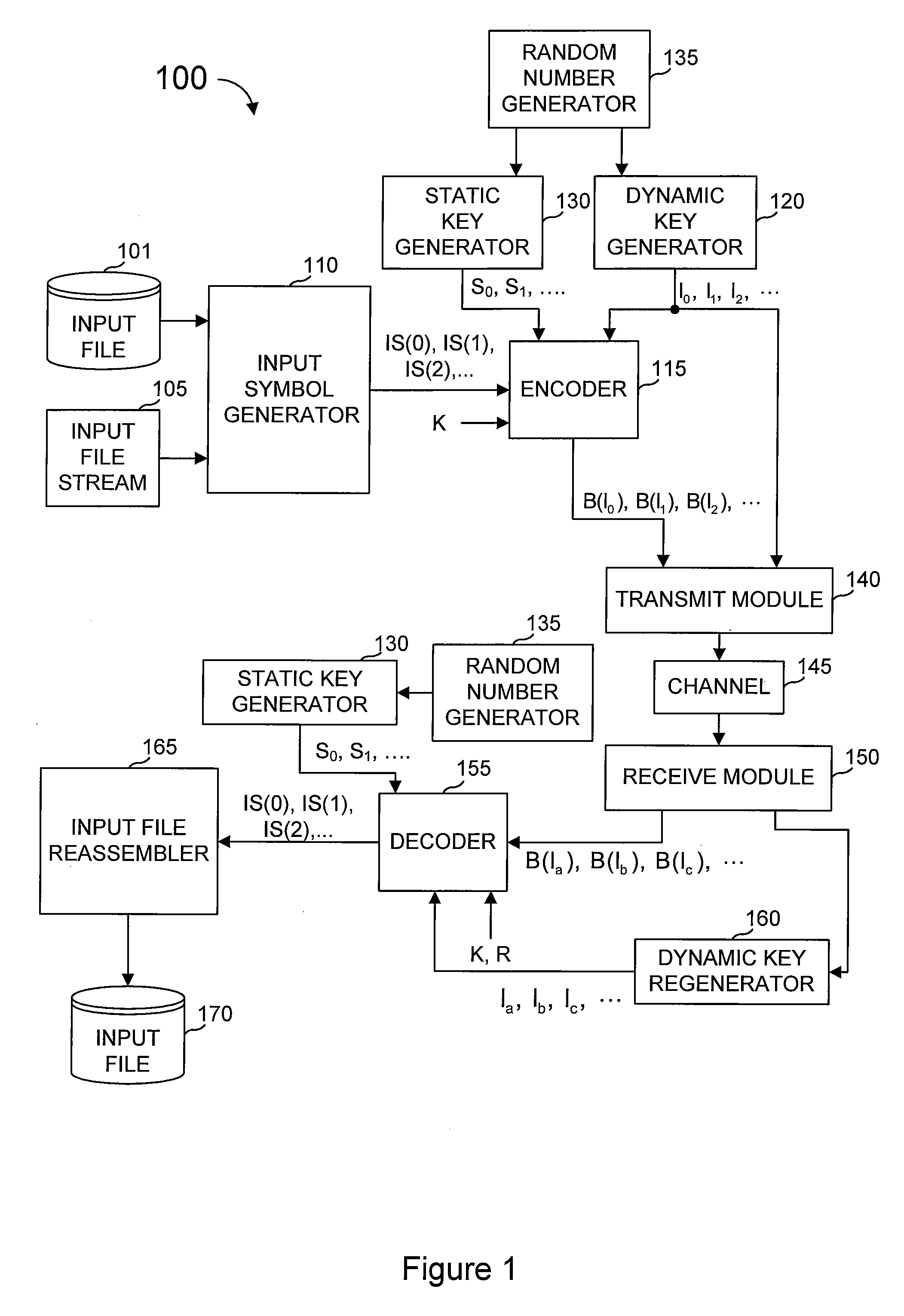

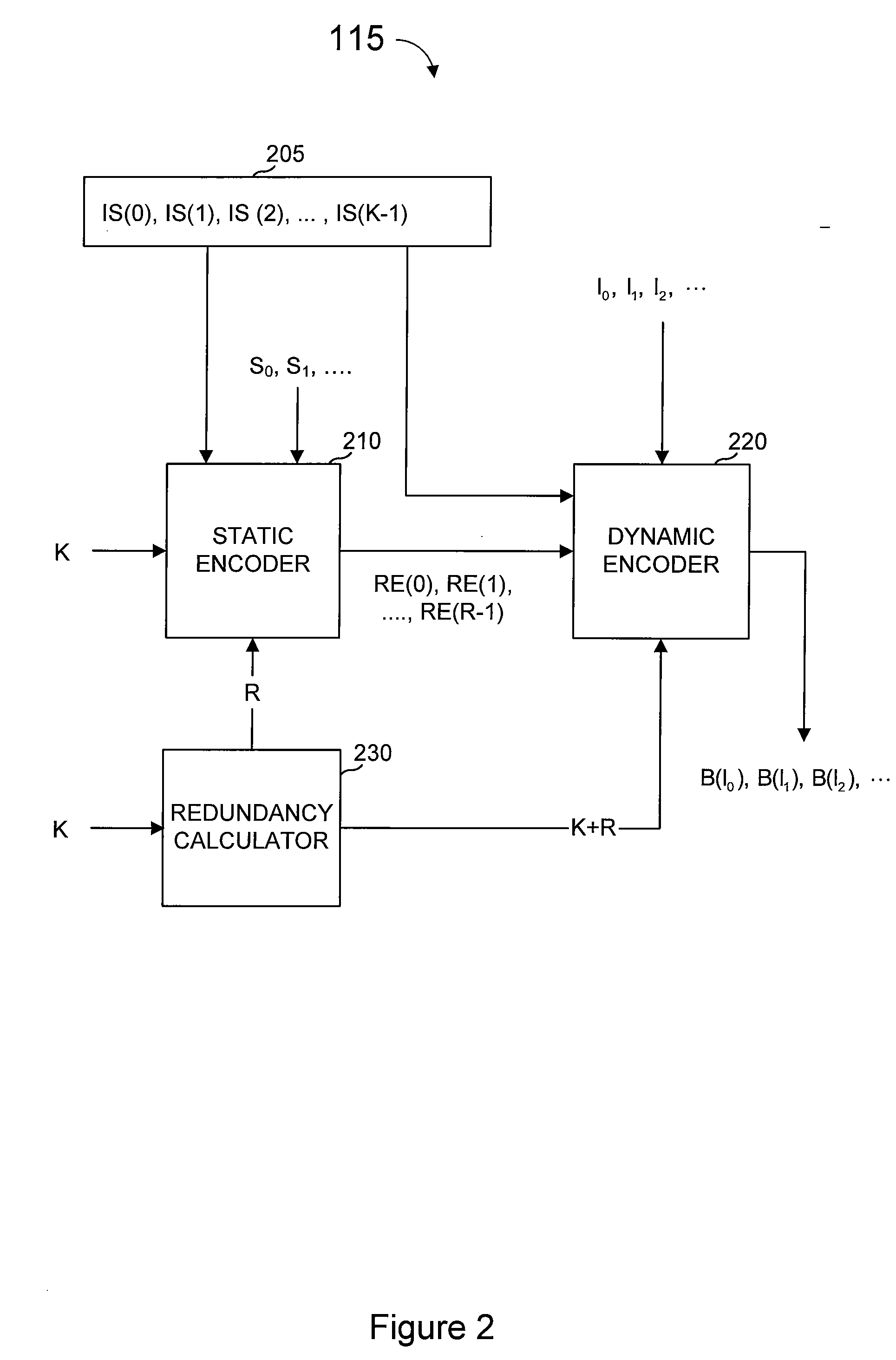

Multiple-field based code generator and decoder for communications systems

InactiveUS20070195894A1Reduces computational expenseReduce probability of errorError preventionCode conversionOrder setAlgorithm

Owner:QUALCOMM INC

Non-Volatile Memory And Method With Accelerated Post-Write Read To Manage Errors

ActiveUS20110096601A1Small errorHigh error rateRead-only memoriesDigital storageData errorPosted write

Data errors in non-volatile memory inevitably increase with usage and with higher density of bits stored per cell. The memory is configured to have a first portion operating with less error but of lower density storage, and a second portion operating with a higher density but less robust storage. An error management provides reading and checking the copy after copying to the second portion. If the copy has excessive error bits, it is repeated in a different location either in the second or first portion. The reading and checking of the copy is accelerated by reading only a sample of it. The sample is selected from a subset of the copy having its own ECC and estimated to represent a worst error rate among the copy it is sampling. One embodiment has the sample taken from one bit of each multi-bit memory cell of a group.

Owner:SANDISK TECH LLC

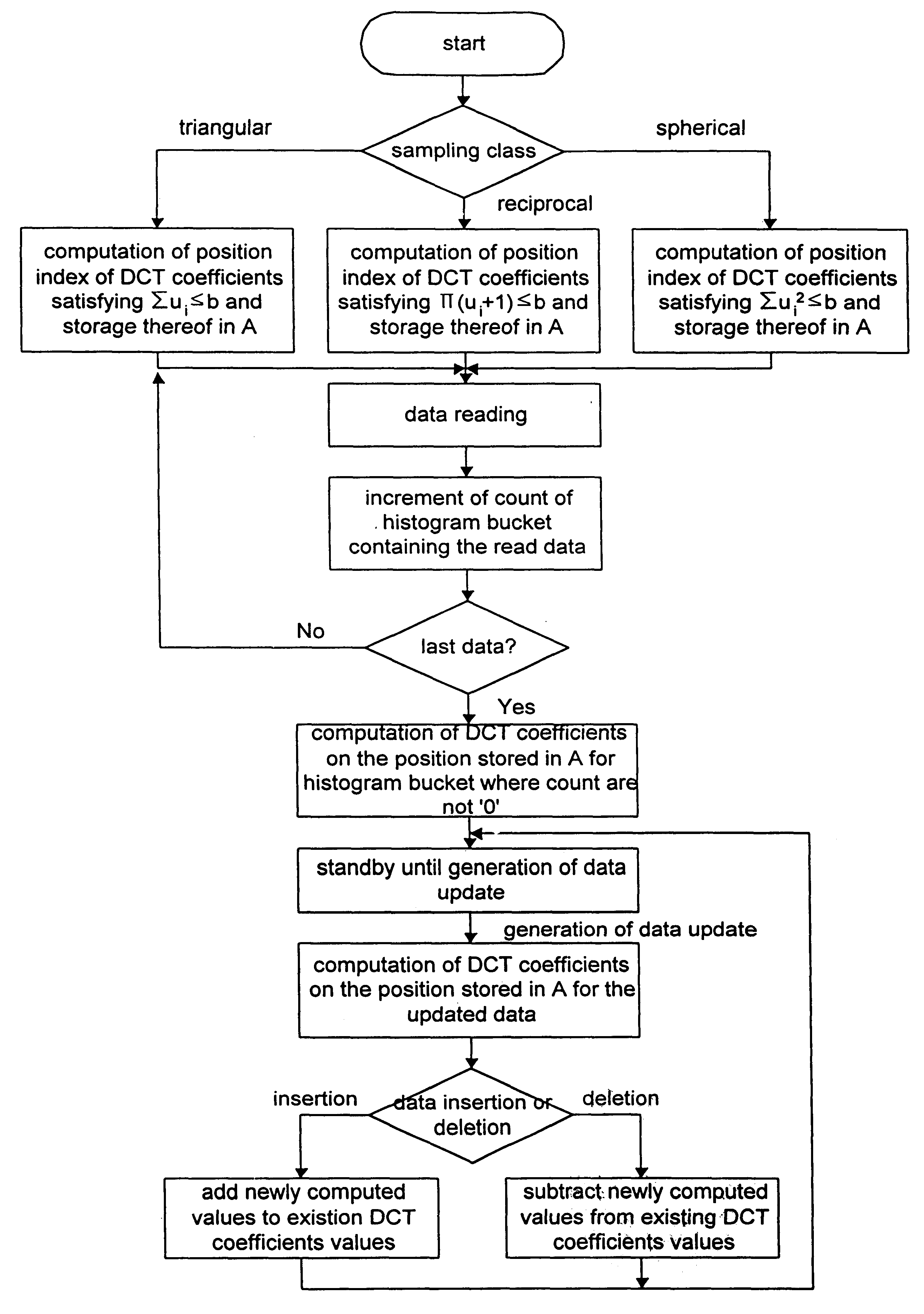

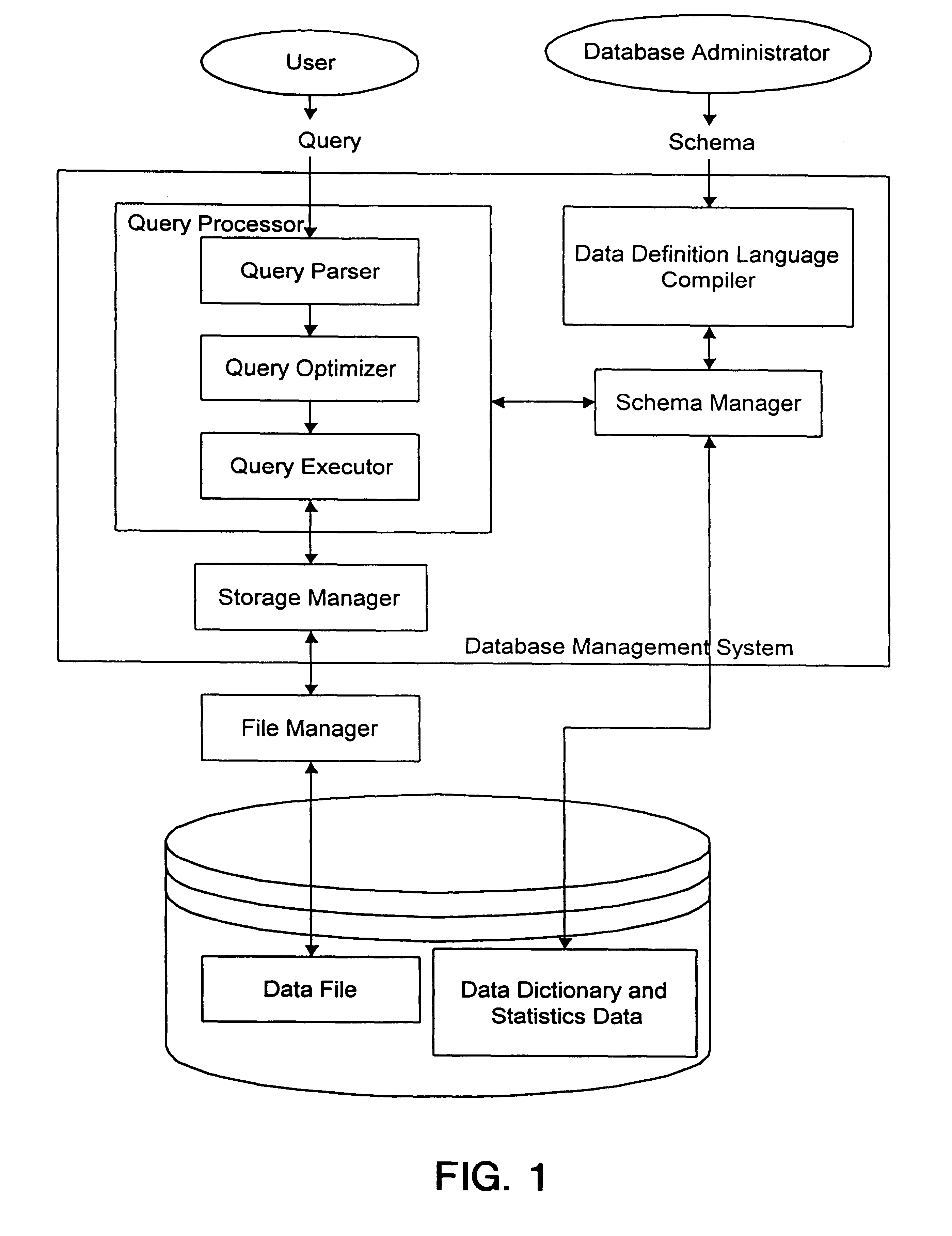

Multi-dimensional selectivity estimation method using compressed histogram information

InactiveUS6311181B1Reduce error rateReduce storage overheadData processing applicationsDigital data processing detailsExecution planHigh probability

Disclosed is a multi-dimensional selectivity estimation method using compressed histogram information which the database query optimizer in a database management system uses to find the most efficient execution plan among all possible plans. The method includes the several steps to generate a large number of small-sized multi-dimensional histogram buckets, sampling DCT coefficients which have high values with high probability, compressing information from the multi-dimensional histogram buckets using a multi-dimensional discrete cosine transform(DCT) and storing compressed information, and estimating the query selectivity by using compressed and stored histogram information as the statistics.

Owner:KOREA ADVANCED INST OF SCI & TECH

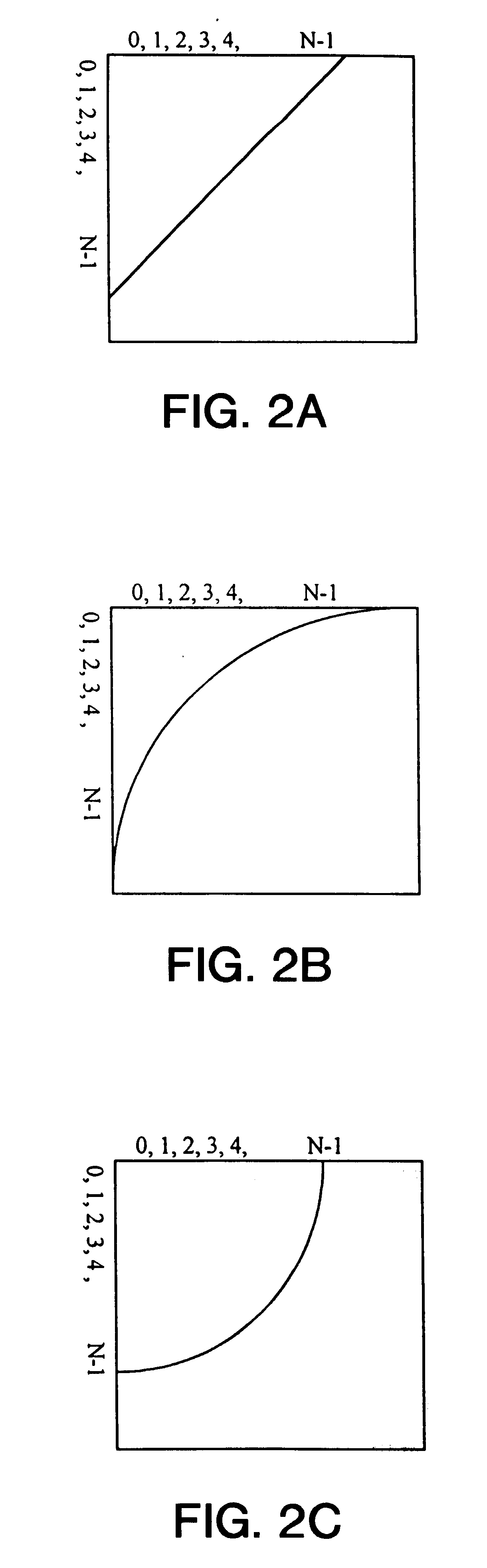

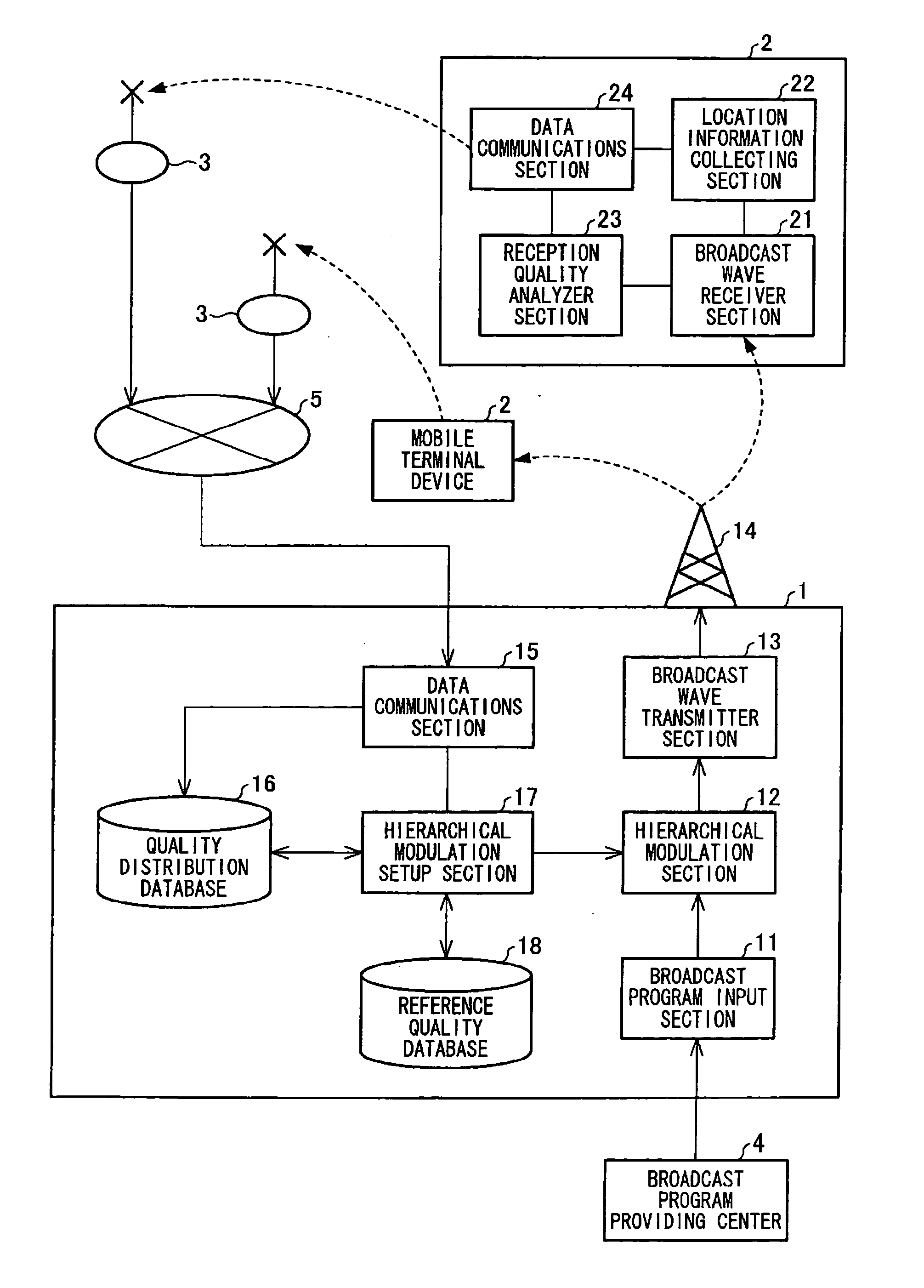

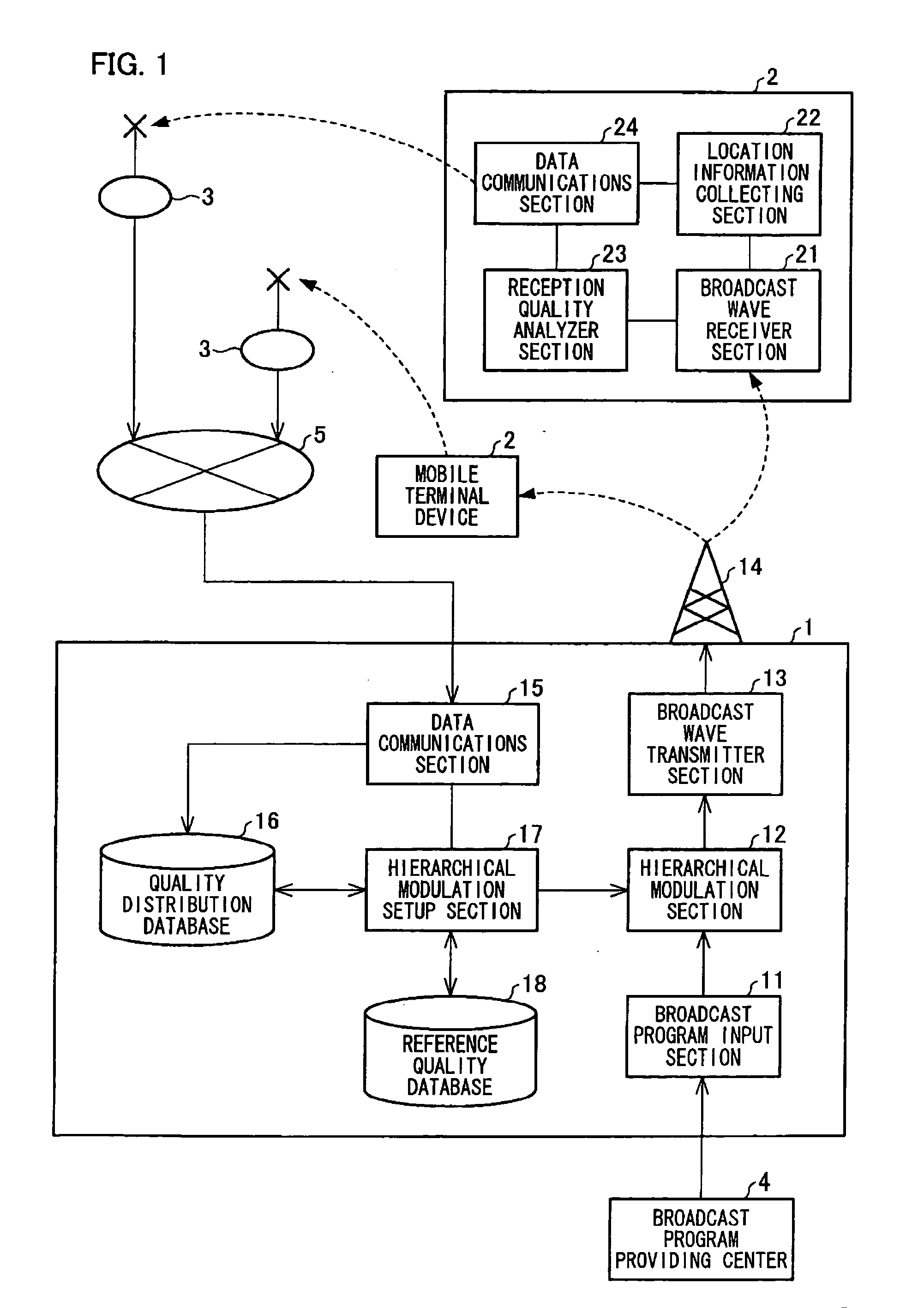

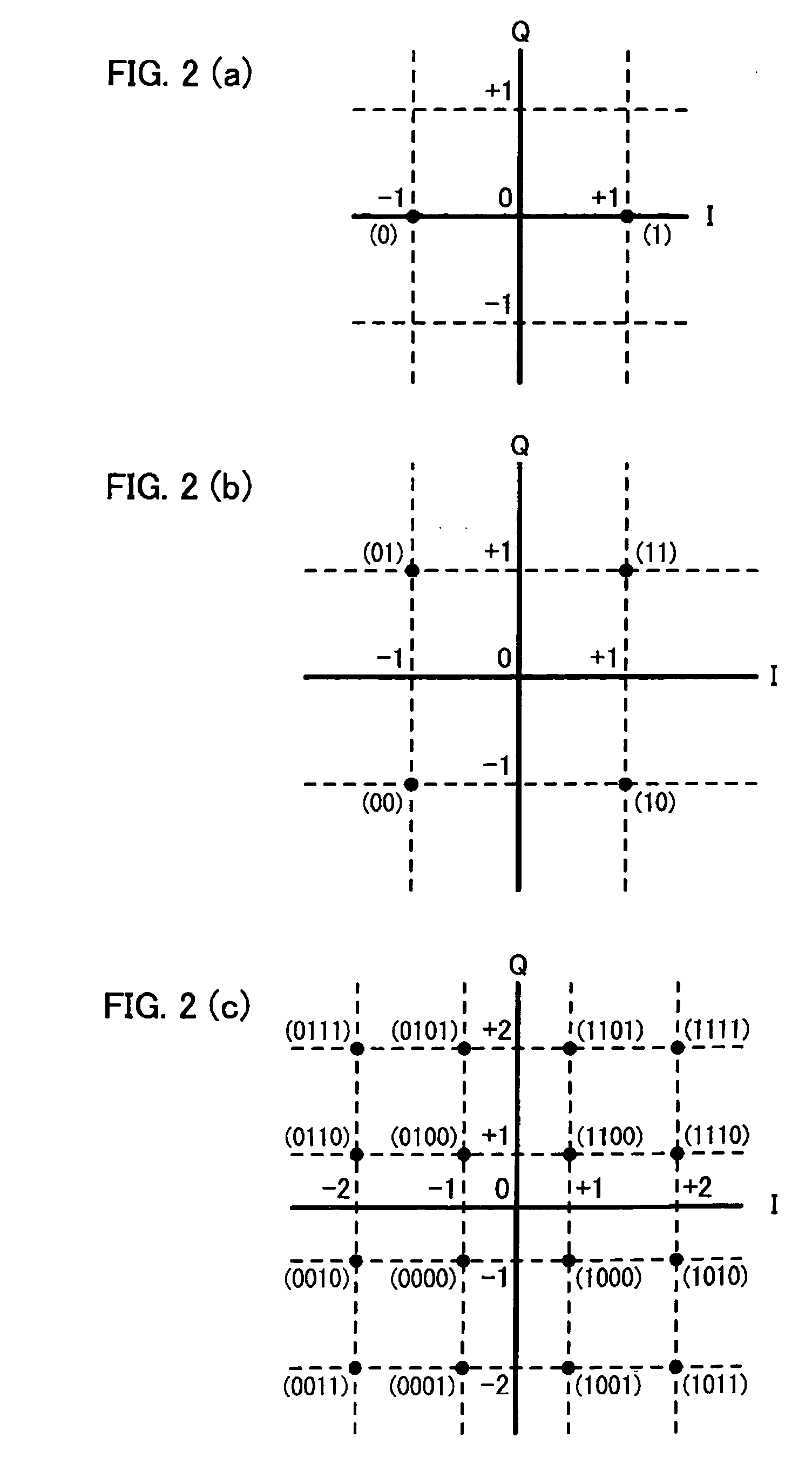

Broadcasting base station device, mobile terminal device, hierarchical modulation setup method, broadcast system, and hierarchical modulation setup computer program

InactiveUS20070054624A1High error rateReduce error rateBroadcast with distributionModulated-carrier systemsTerminal equipmentConstellation

A broadcasting base station device transmits broadcast signals modulated by a hierarchical modulation scheme to a mobile terminal device. A hierarchical modulation setup section compares the reception quality of the broadcast signals at the location of the mobile terminal device to predetermined reference quality. Based on the result of the comparison, the hierarchical modulation setup section specifies a hierarchical modulation scheme. For example, the constellation in each quadrant is reduced or enlarged. Accordingly, the broadcasting base station device can transmit optimal broadcast signals that match with actual reception quality to each mobile terminal device.

Owner:SHARP KK

Magnetic tape

InactiveUS20120196156A1Good electromagnetic characteristicGood characteristic frictionMagnetic materials for record carriersRecord information storageMagnetic tapeNon magnetic

An aspect of the present invention relates to a magnetic tape comprising, on one surface of a nonmagnetic support, a nonmagnetic layer containing a nonmagnetic powder and a binder, and thereon, a magnetic layer containing a ferromagnetic powder and a binder, whereinthe magnetic layer contains a nonmagnetic filler the average particle diameter φ of which satisfies relation (I) below with a thickness t of the magnetic layer:1.0≦φ / t≦2.0 (I);the thickness t of the magnetic layer ranges from 30 to 200 nm;the nonmagnetic layer has a thickness ranging from 30 to 200 nm;a composite elastic modulus as measured on a surface of the magnetic layer ranges from 6.0 to 8.0 GPa; anda centerline average surface roughness Ra of the surface of the magnetic layer, as measured by an optical three-dimensional profilometer, ranges from 0.2 to 1.5 nm.

Owner:FUJIFILM CORP

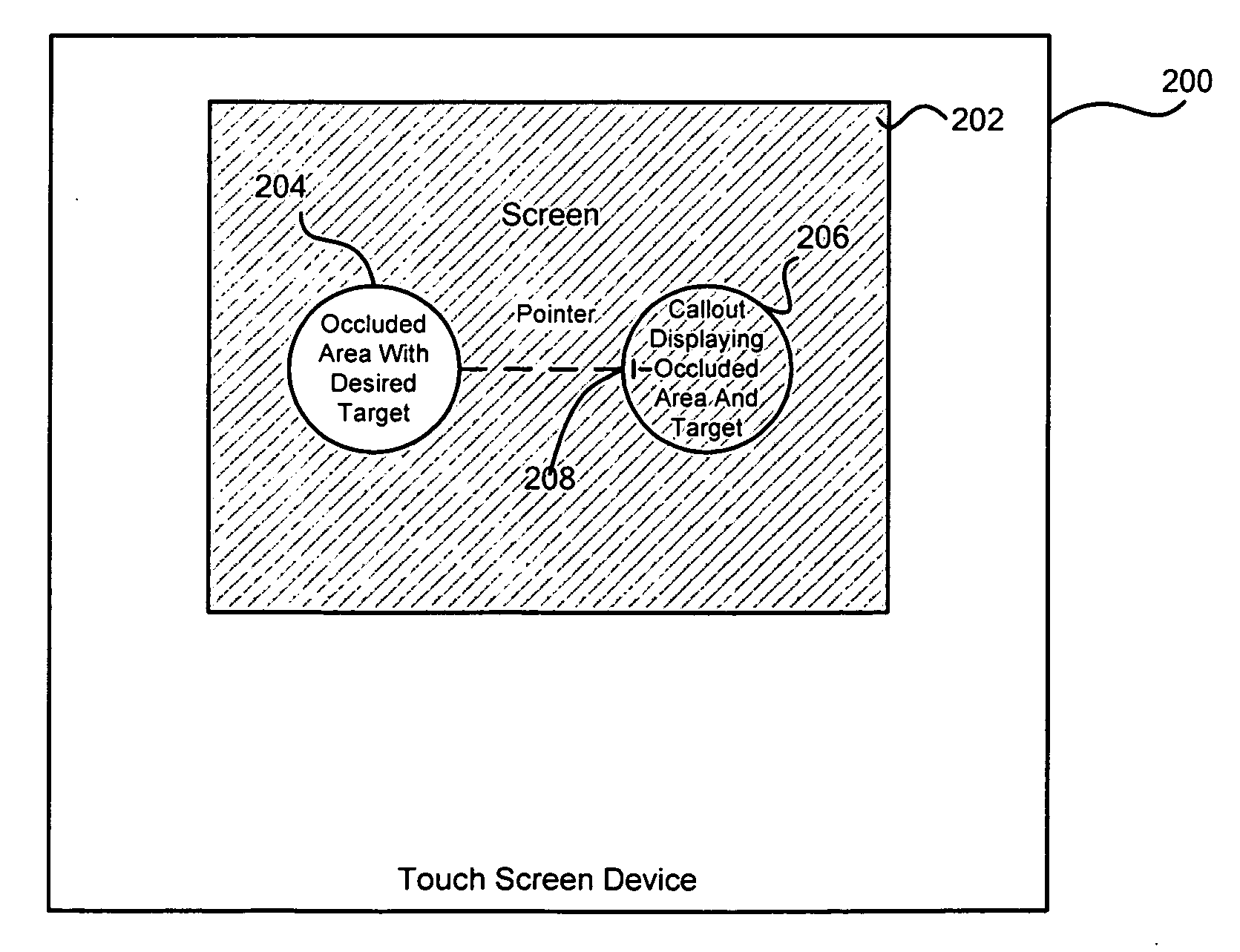

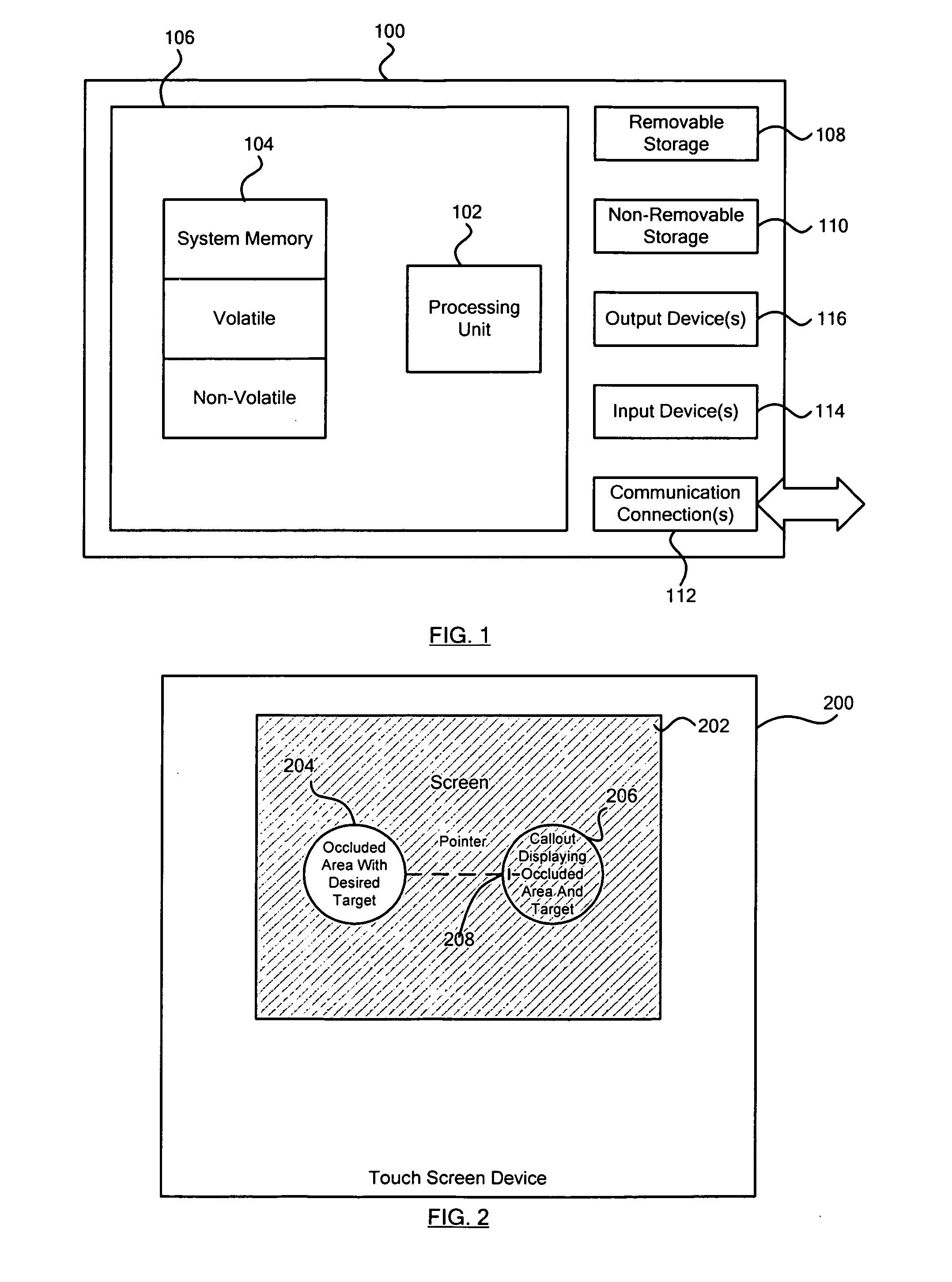

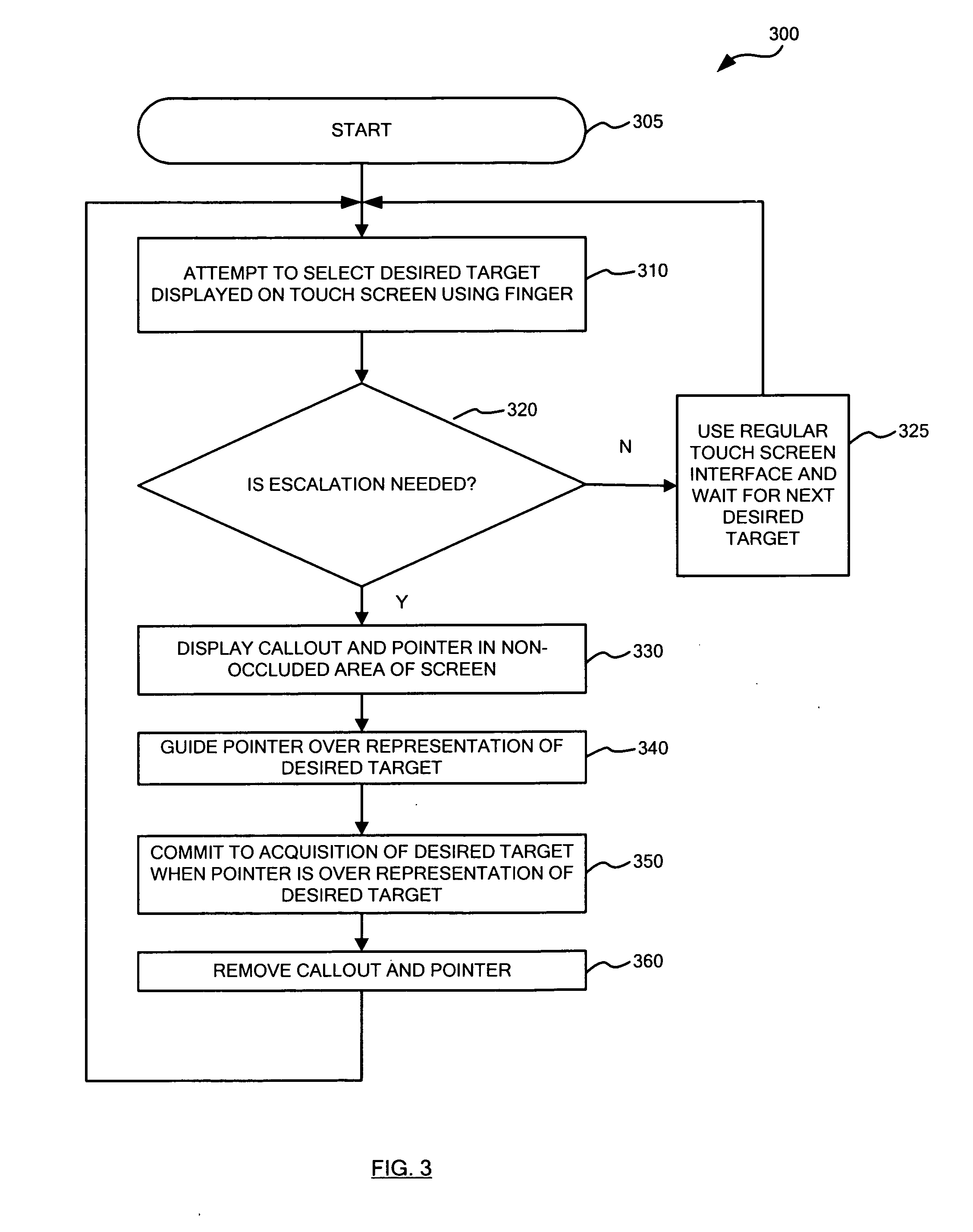

Operating touch screen interfaces

ActiveUS20080136785A1Avoid occlusionImprove performanceCathode-ray tube indicatorsDigital output to display deviceTouchscreen

Owner:MICROSOFT TECH LICENSING LLC

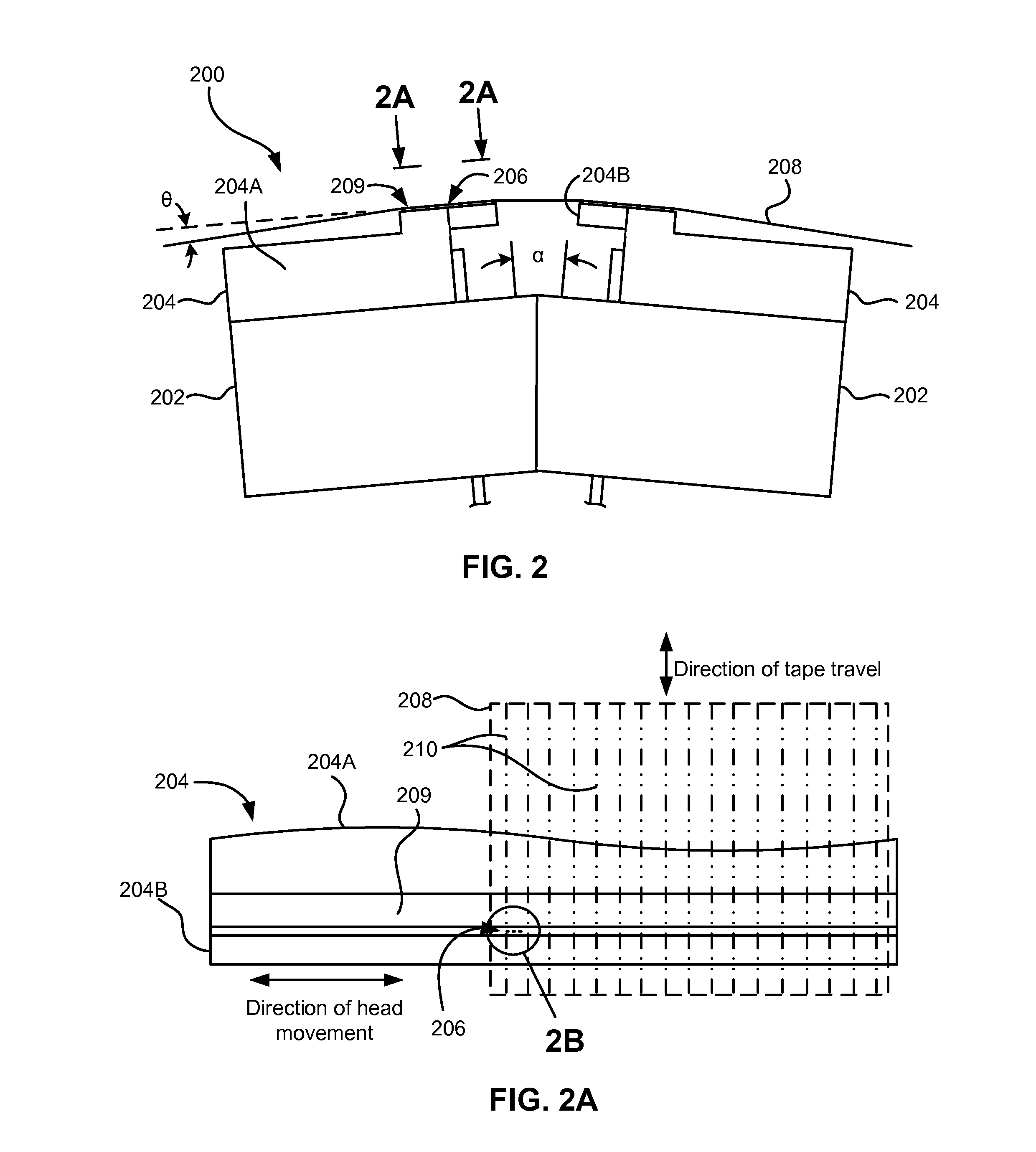

Measurement and correction of magnetic writer offset error

ActiveUS20160260449A1Reduced readback error rateImprove read performanceAlignment for track following on tapesRecord information storageComputer scienceComputer program

A method, according to one embodiment, includes writing a plurality of shingled tracks using an array of writers, determining first and second positions of an array of readers relative to the shingled tracks, the first and second positions being above and / or beyond track edges of the shingled tracks, repositioning the array of readers to various locations between the first and second positions and reading data from the shingled tracks, determining a read offset point where read performance is about the highest during the reading performed when repositioning the array of readers between the first and second positions, and computing, using the read offset point, data describing a lateral writing position to use during writing such that shingled tracks are written in a location specified by a format. Other systems, methods, and computer program products are described in additional embodiments.

Owner:IBM CORP

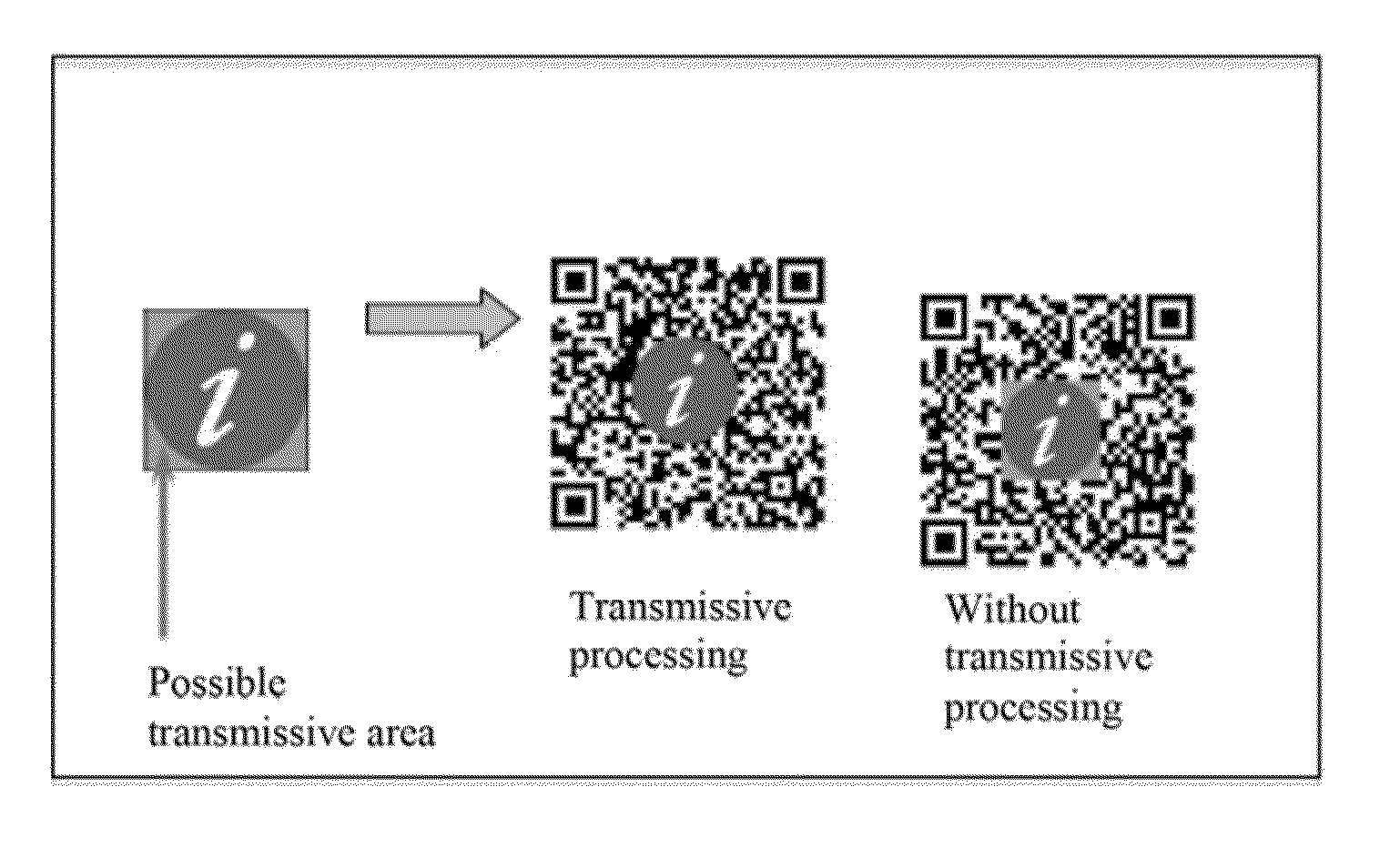

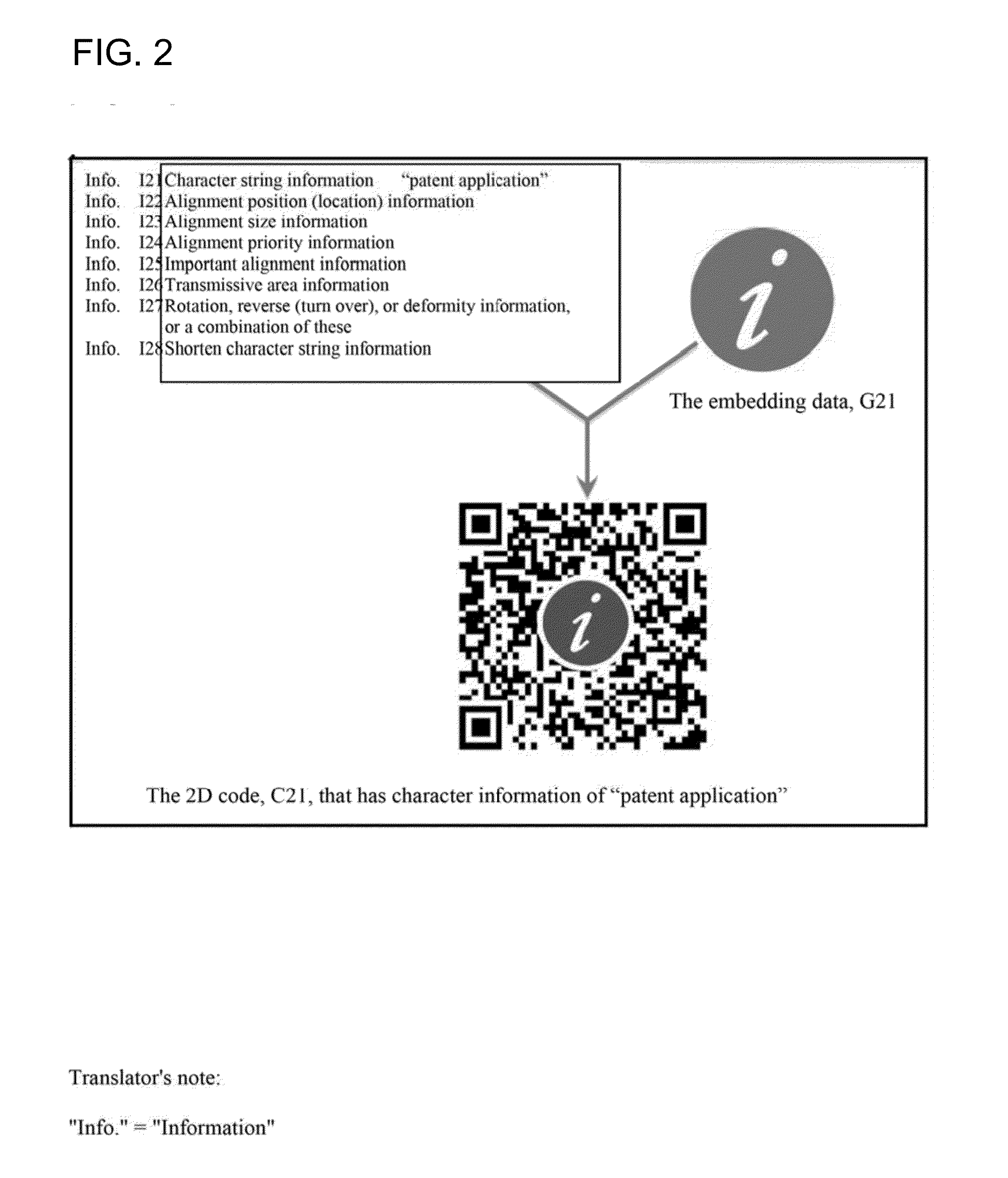

Device and its use for creation, output and management of 2d barcodes with embedded images

InactiveUS20130026241A1Low costHigh resolutionCharacter and pattern recognitionRecord carriers used with machinesDigital advertisingBarcode

Provided is a Device, a System, applications and an associated Ecosystem for the consistent and reliable production, creation, generation, management and utilization of two-dimensional (‘2D’) barcodes (‘Codes’) featuring embedded Images, designating the alignment position and alignment size of the embedding Images in 2D Codes and enabling the corresponding outputted Code files by the Device System to be downloaded and or showcased digitally within all forms of digital advertising, media, television, mobile telephony and the world wide web as well as integrated with the production processes for consumer products and packaged goods, printed products, merchandise and other items featuring such 2D Codes creating a public telecommunications platform and or private intranet services featuring a searchable database, directory and or registry of the 2D Codes with embedded Images that have been created by, produced by and outputted by the Device or System.

Owner:4GQR

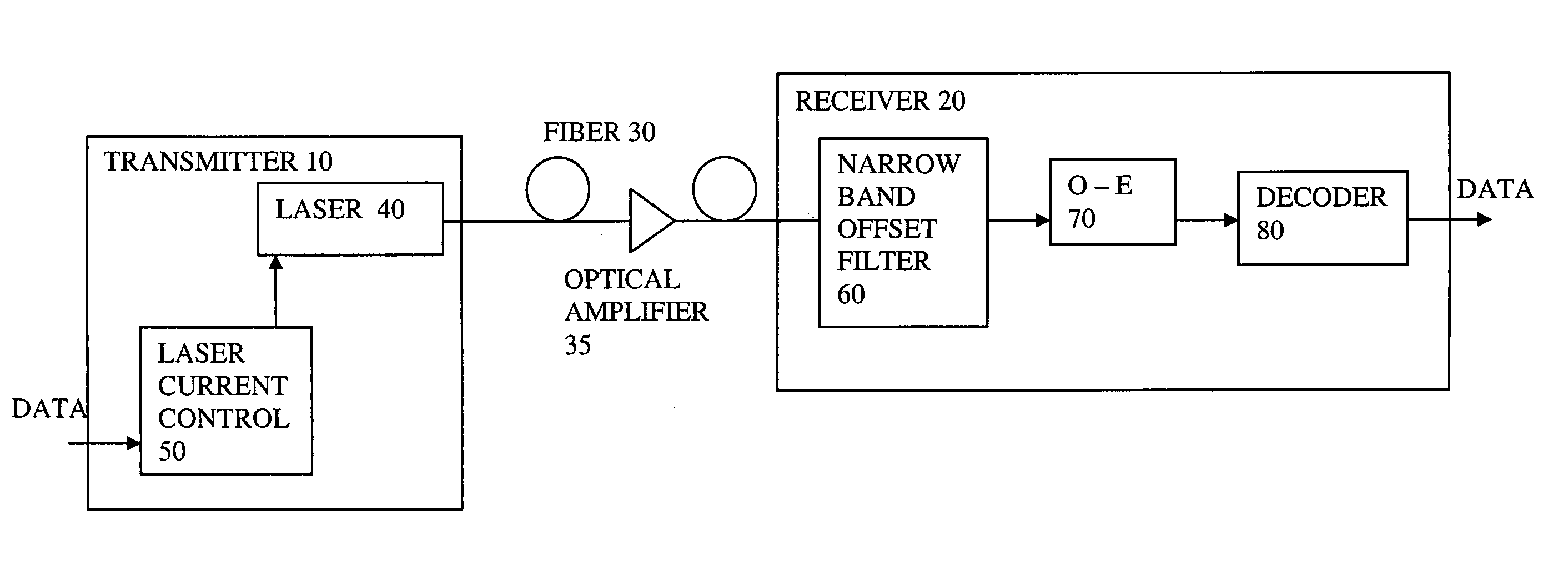

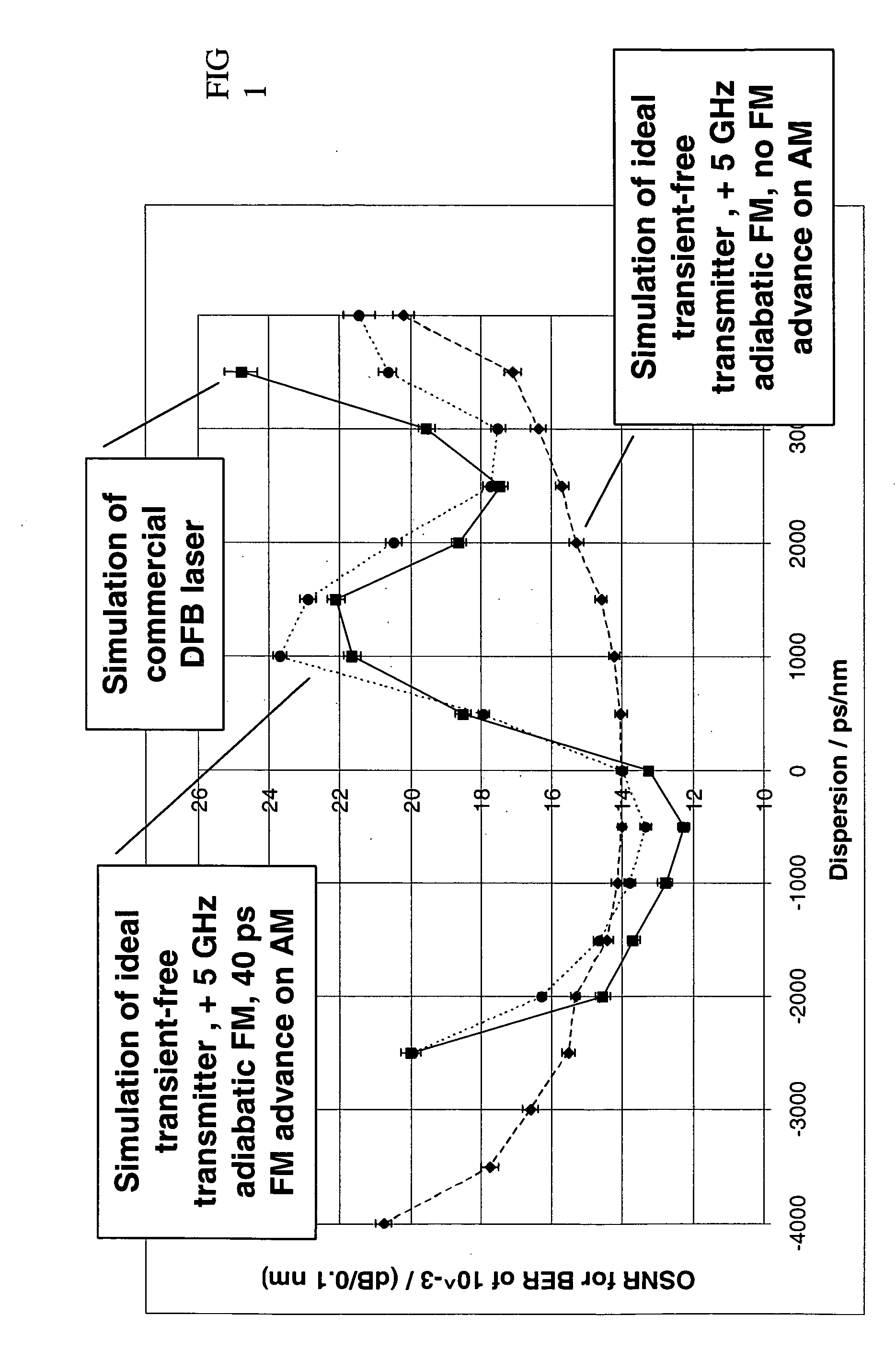

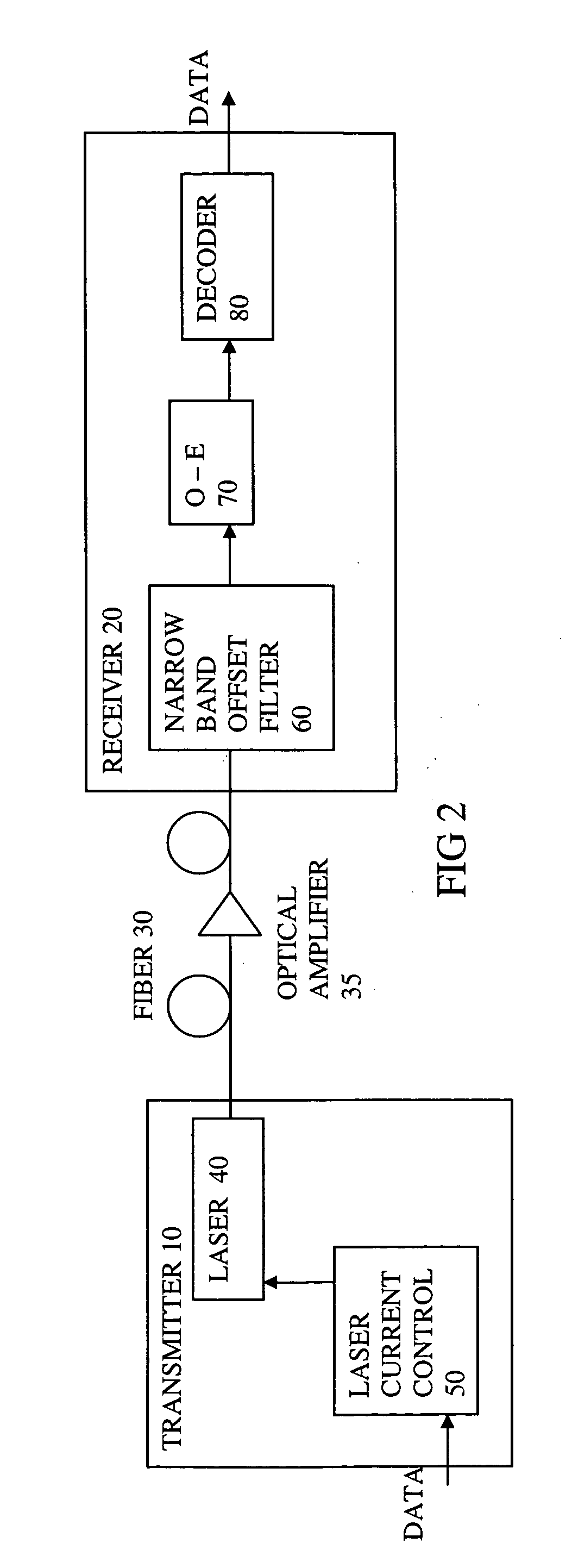

Filter to improve dispersion tolerance for optical transmission

InactiveUS20050271394A1Reduce phase differenceInexpensive optical filteringElectromagnetic transmittersFrequency spectrumPhase difference

An optical transmission system has a directly modulated laser for modulating data directly on an optical signal, and a narrow band optical filter having a band center frequency offset from a central optical frequency of the optical signal, to reduce the phase difference between FM and AM of the modulated optical signal, the filter having a bandwidth sufficiently narrow to substantially remove frequencies outside a spectrum of adiabatic frequency chirp resulting from the modulation, combined with Fourier broadening caused by the data modulation. This is a cost effective way of improving the dispersion tolerance to give greatly improved system reach and to make it practical to use directly modulated lasers with existing NDSF. The narrow band filter can be located at the transmitter or the receiver, and can have a center frequency locked to a feature in the frequency spectrum of the laser.

Owner:NORTEL NETWORKS LTD

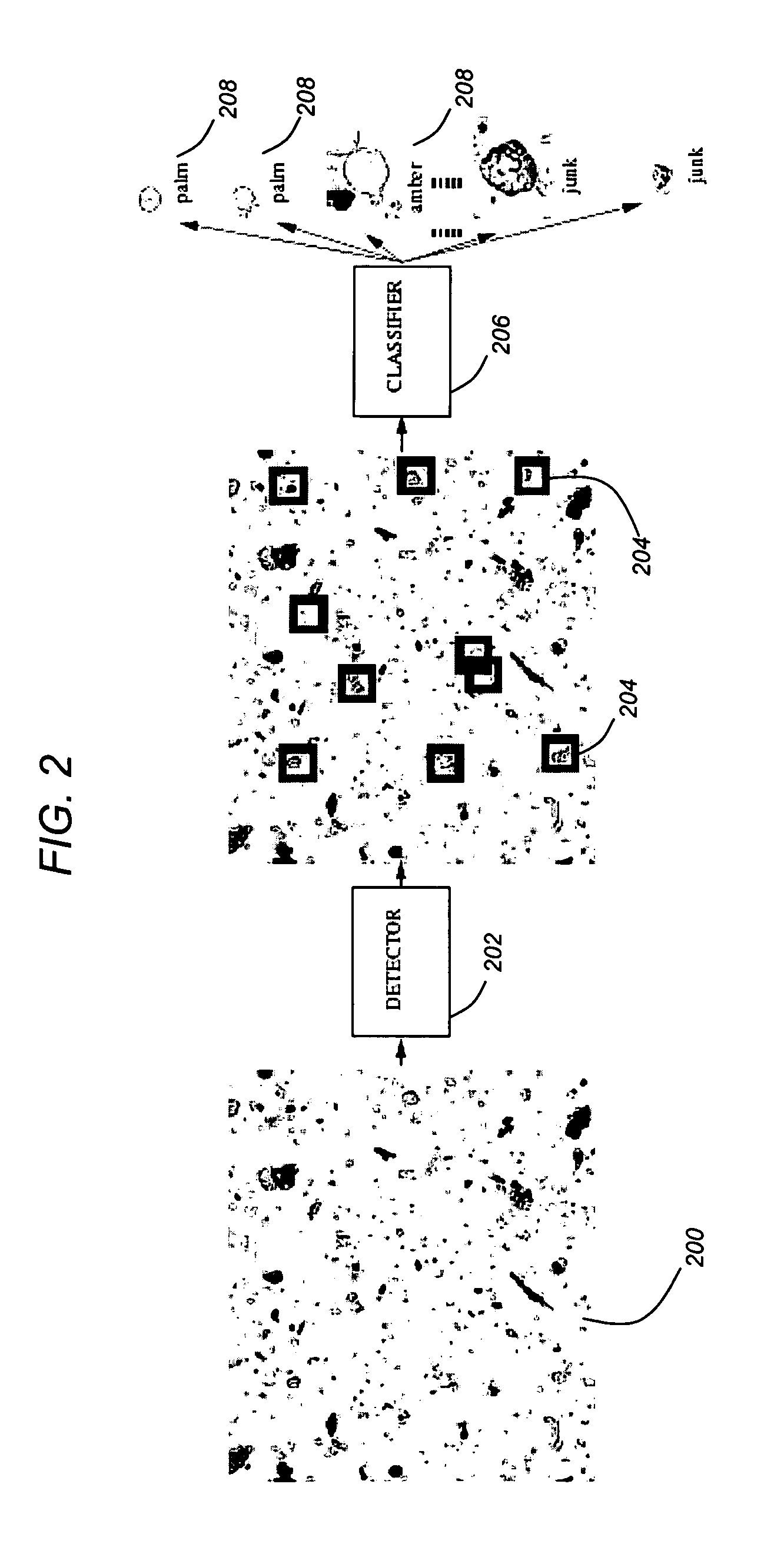

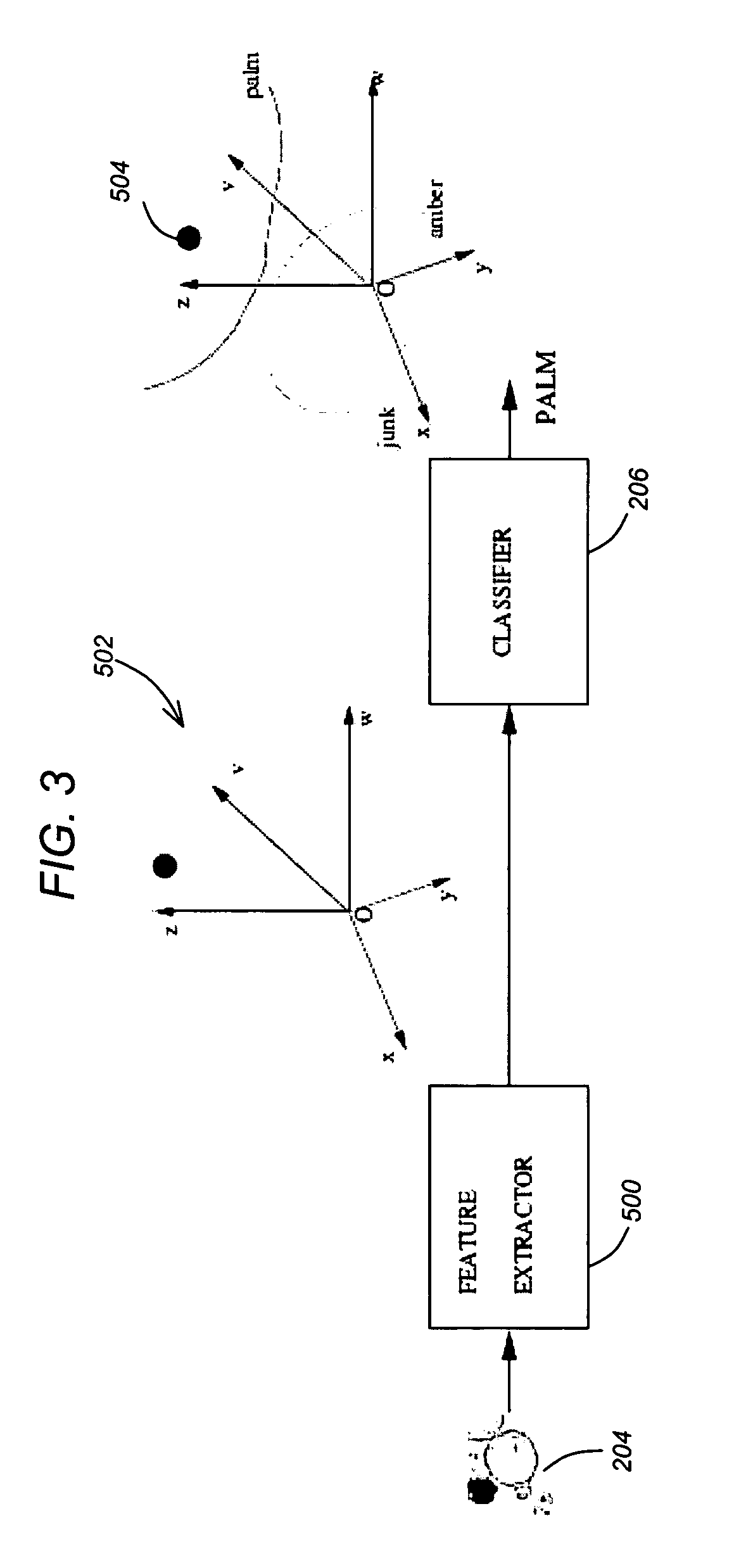

Automatic visual recognition of biological particles

InactiveUS20050251347A1Reduce error rateError rateBiological testingSpecial data processing applicationsUrine productionImage based

A method and system provide the ability to automatically recognize biological particles. An image of biological particles (e.g., airborne pollen or urine) is obtained. One or more parts of the image are detected as containing one or more particles of interest. Feature vector(s) are extracted from each detected part of the image. Non-linearities are applied to each feature vector. Each part of the image is then classified into a category of biological particle based on the one or more feature vectors for each part of the image.

Owner:PERONA PIETRO +2

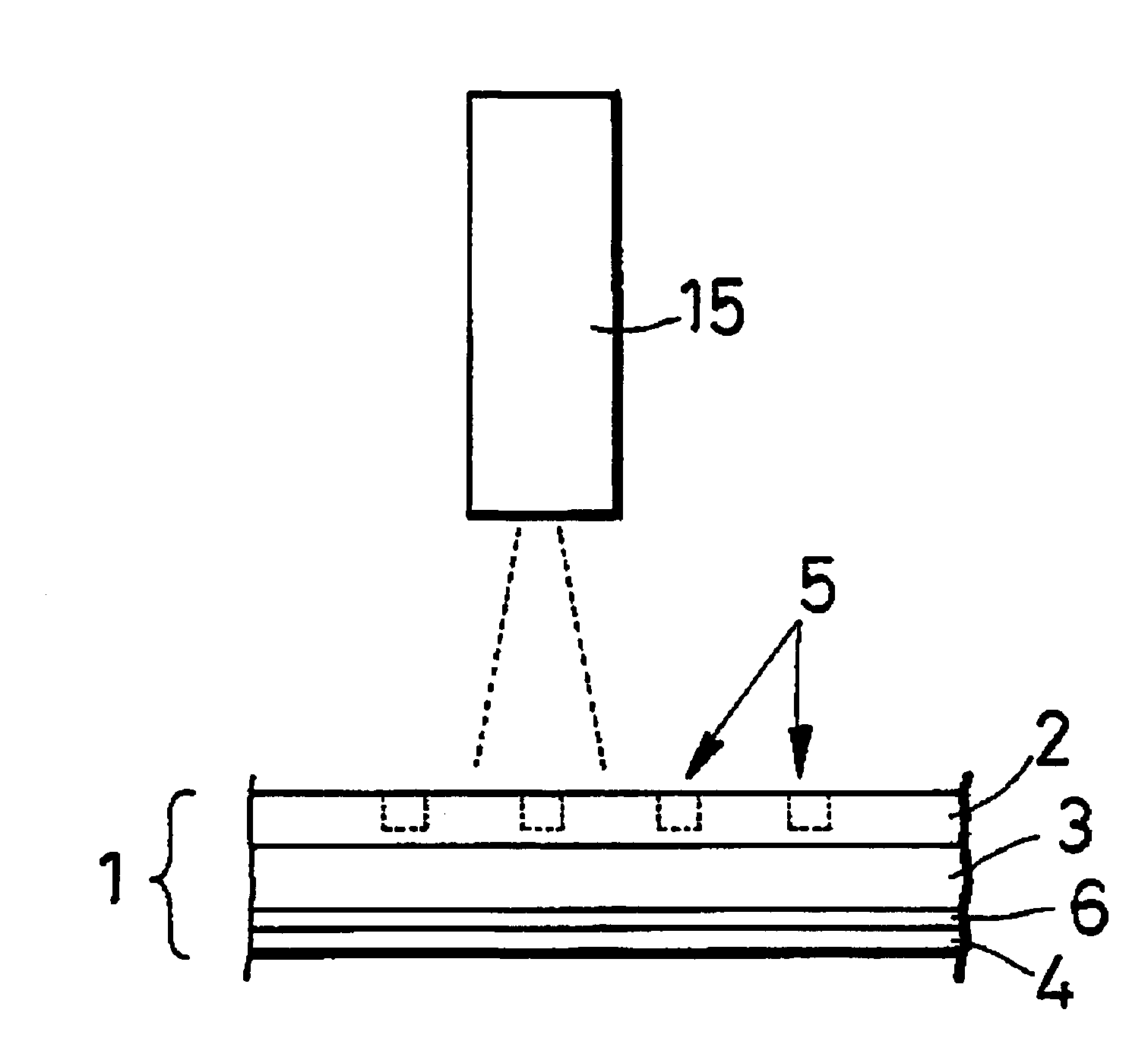

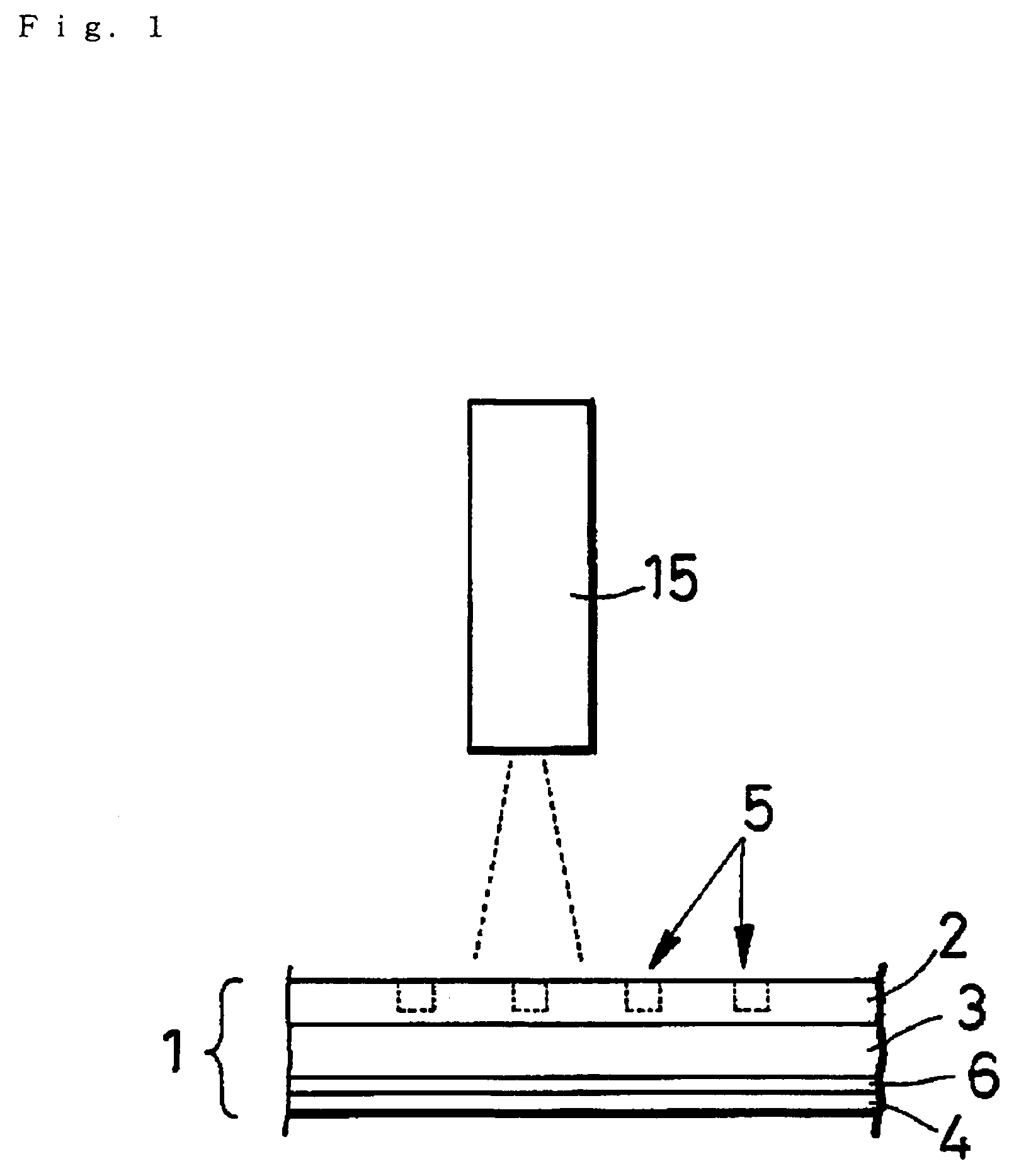

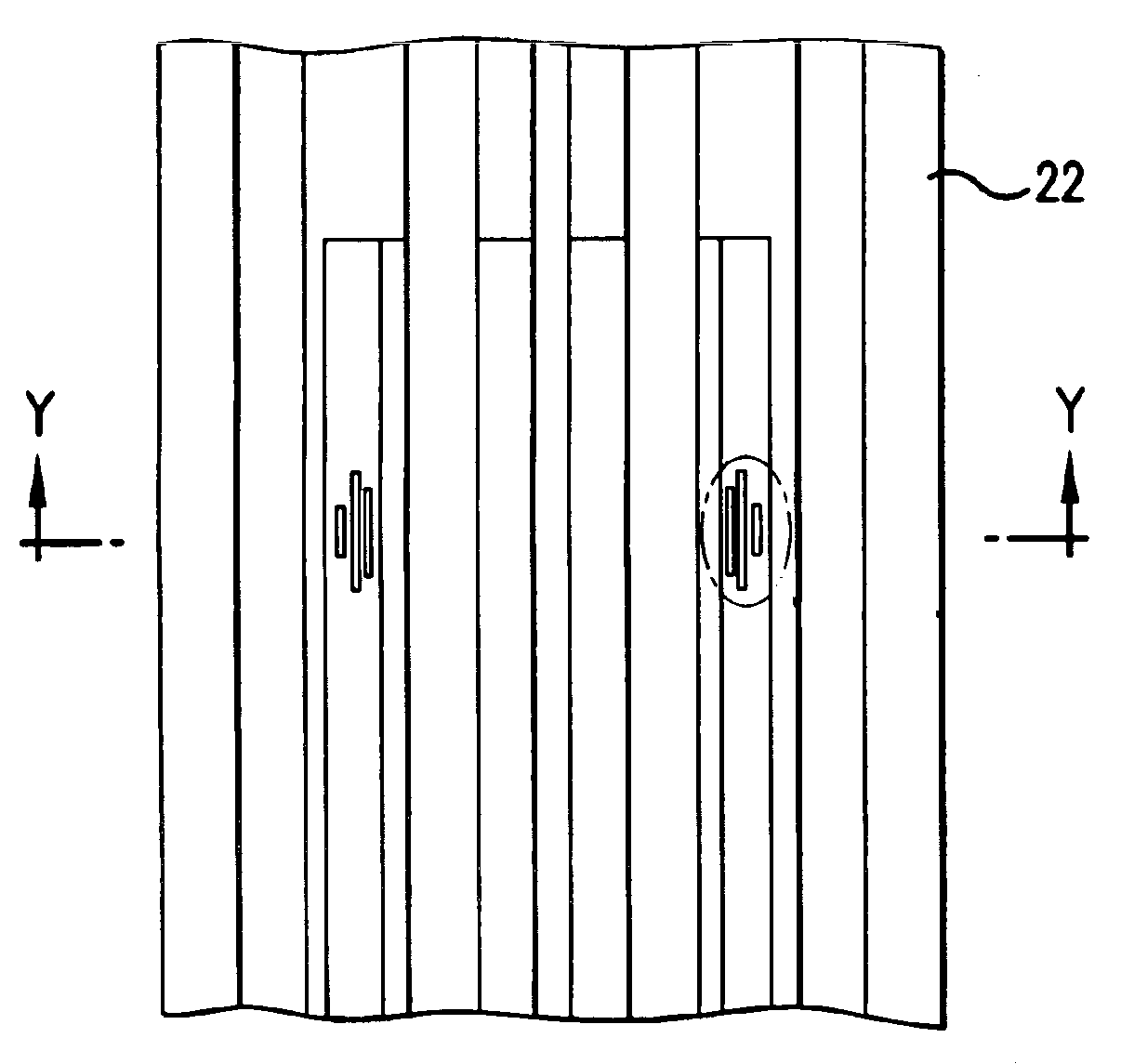

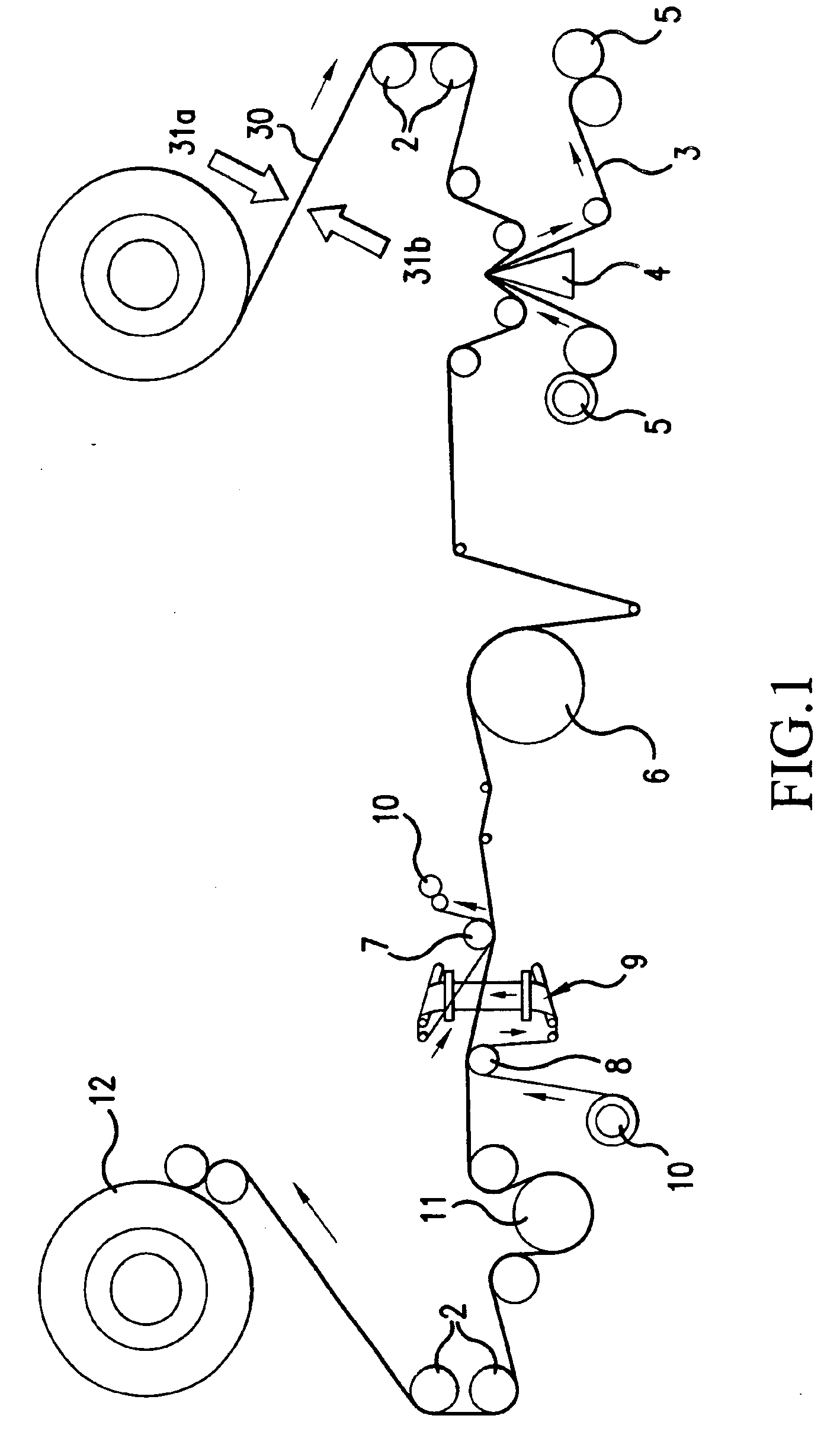

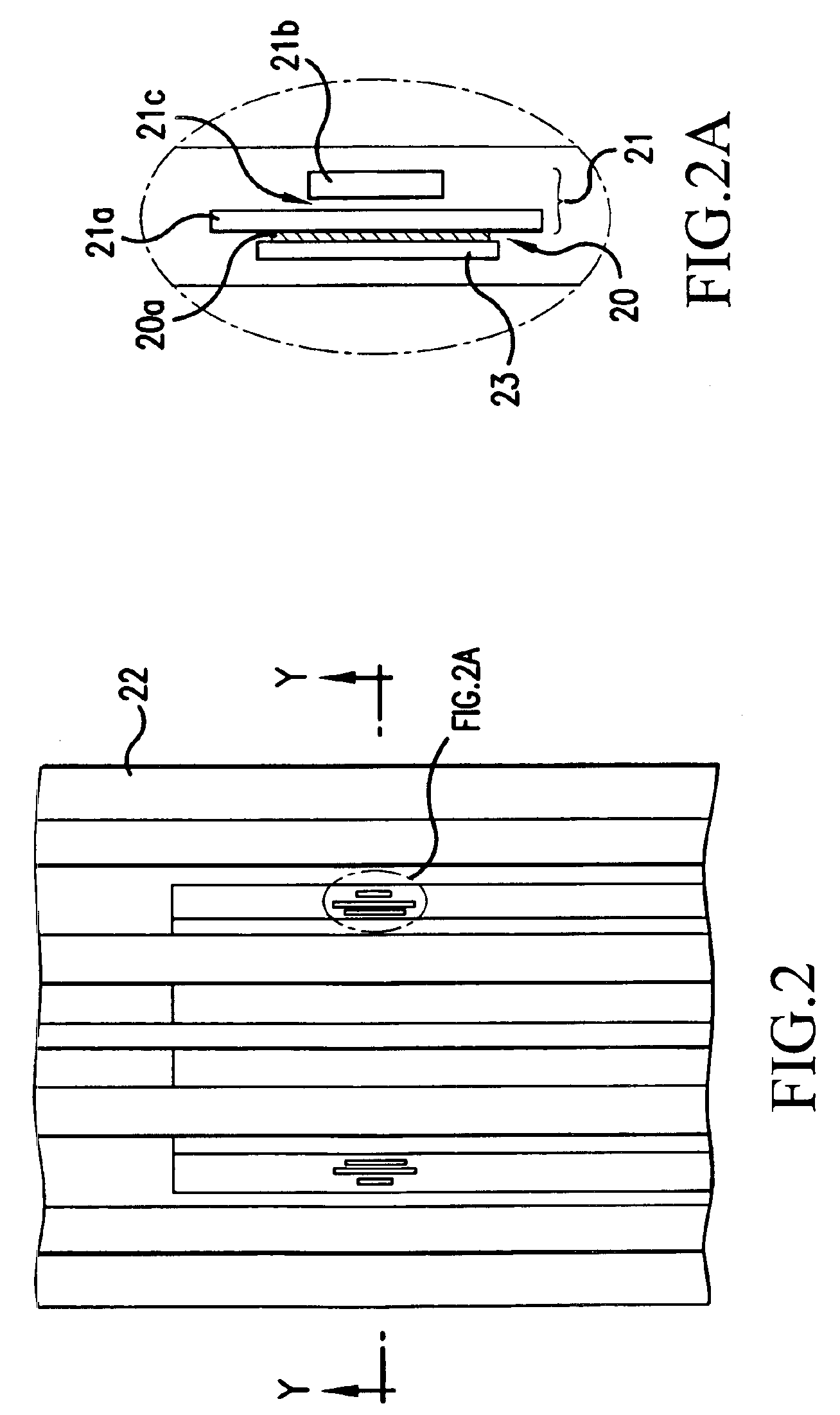

Magnetic tape, its cleaning method, and optical servotrack forming/cleaning apparatus

InactiveUS7803471B1Improve signal-to-noise ratioDecreasing rate of fluctuationMagnetic materials for record carriersReconditioning/cleaning record carriersReflectivityMaximum rate

A magnetic tape which comprises a nonmagnetic support, a magnetic layer which is formed on one surface of the nonmagnetic support, and a backcoat layer which comprises a binder and nonmagnetic powder containing carbon black as a component and which is formed on the other surface of the nonmagnetic support, having pits for optical servo formed thereon, characterized in that the average of the reflectance on the flat portion of the backcoat layer is 8.5% or higher, and that the maximum rate of fluctuation of the reflectance on the flat portion, depending on a position of the magnetic tape:[Maximum of absolute value of (Reflectance−Average reflectance)]×100 / (Average reflectance)is 10% or lower. This magnetic tape is high in the initial S / N of the servo signal, and also high in the S / N of the servo signal found after the magnetic tape is run twice.

Owner:FUJIFILM CORP

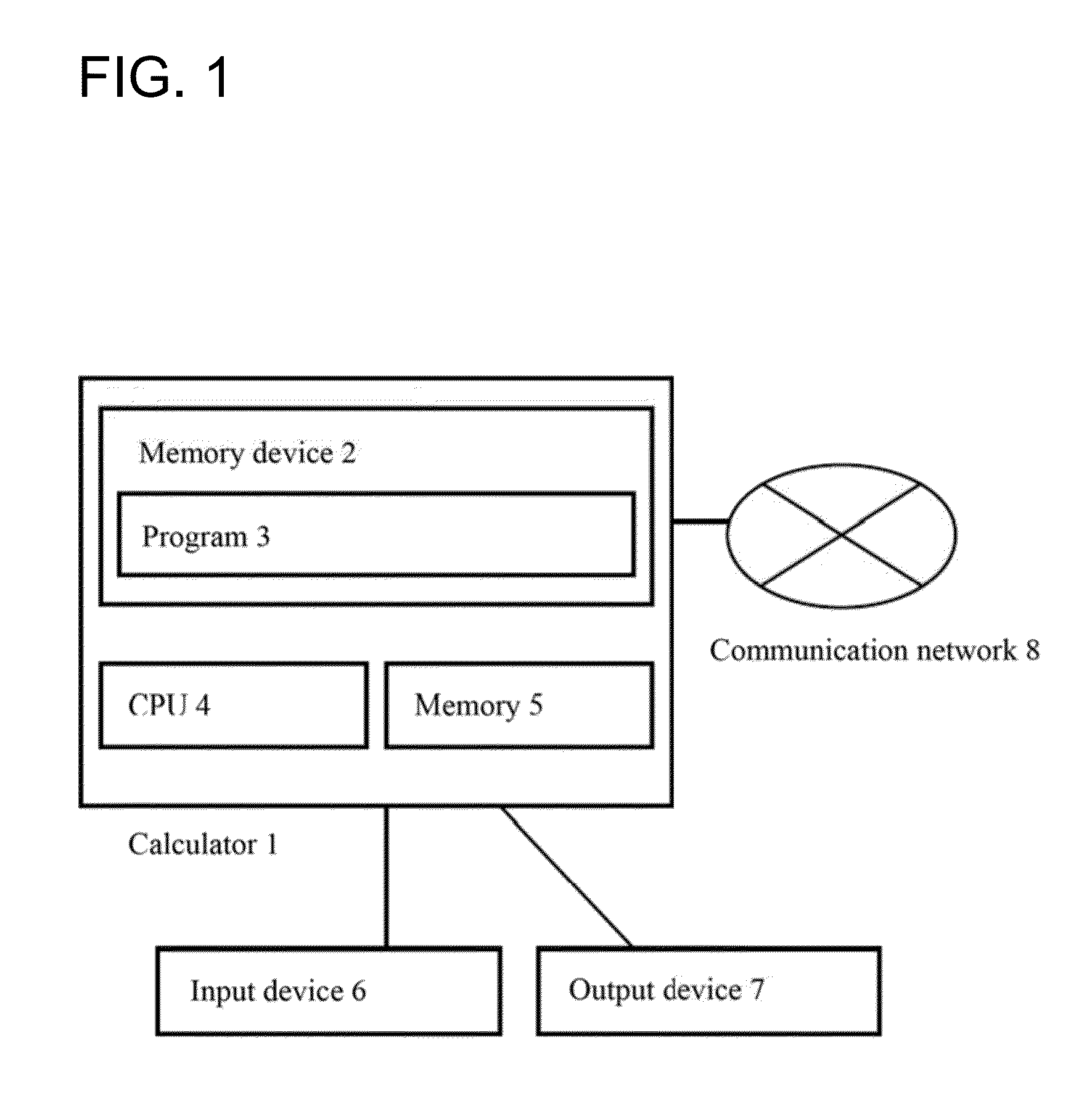

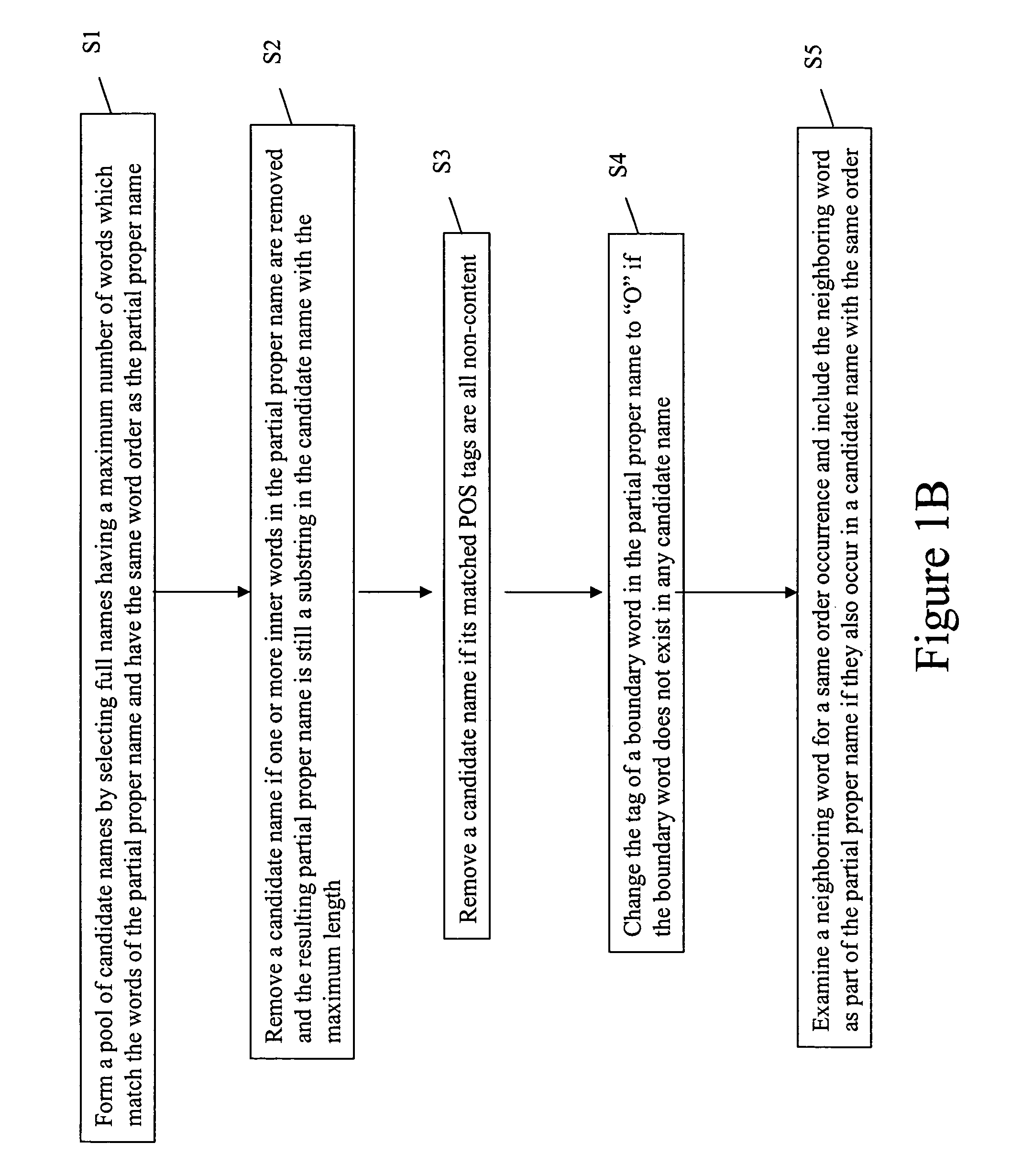

Unified treatment of data-sparseness and data-overfitting in maximum entropy modeling

ActiveUS20070100624A1Reduce error rateNatural language data processingSpeech recognitionFeature selectionComputer science

A method of statistical modeling is provided which includes constructing a statistical model and incorporating Gaussian priors during feature selection and during parameter optimization for the construction of the statistical model.

Owner:ROBERT BOSCH CORP

Magnetic recording medium comprising a magnetic layer having specific thickness, surface roughness and friction coefficient

InactiveUS6921592B2Reduce space lossReduce error rateMagnetic materials for record carriersBase layers for recording layersSurface roughnessNon magnetic

A magnetic recording medium comprising a non-magnetic support, at least one primer layer formed on one surface of the non-magnetic support, a magnetic layer formed on the primer layer, and a backcoat layer formed on the other surface of the non-magnetic support, wherein the magnetic layer has a thickness of 0.30 μm or less and a centerline average surface roughness Ra of 3.2 nm or less, and (P1−P0) is 30 nm or less and (P1-P20) is 5 nm or less in which P0 is an averaged height of projections of the magnetic layer, and P1, P2, - - - and P20 are heights of the highest, the second highest, - - - and the 20th highest projections of the magnetic layer, respectively.

Owner:FUJIFILM CORP

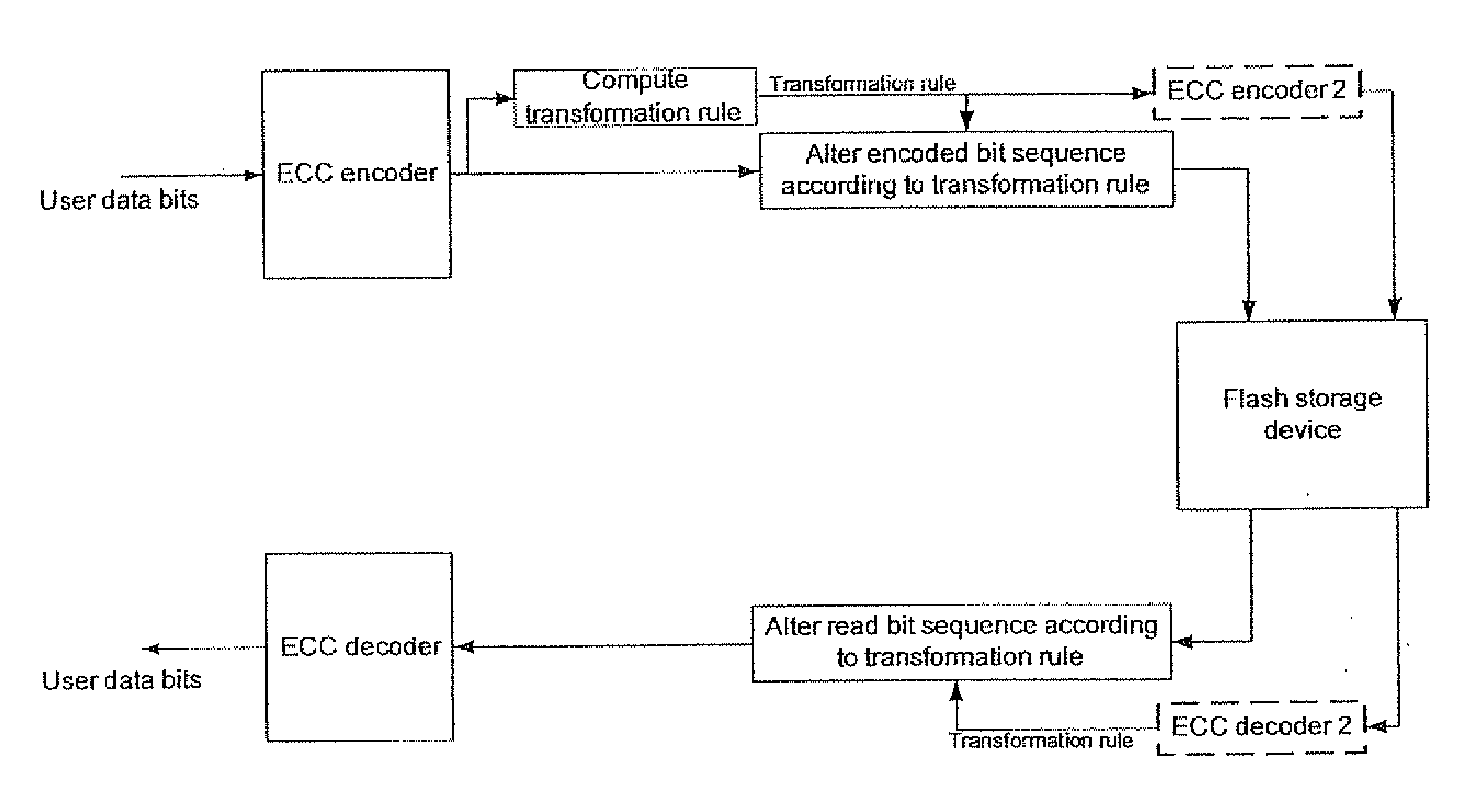

Avoiding errors in a flash memory by using substitution transformations

InactiveUS20080158948A1Reduce impactImprove reliabilityMemory loss protectionRead-only memoriesMemory cellAlgorithm

Owner:RAMOT AT TEL AVIV UNIV LTD

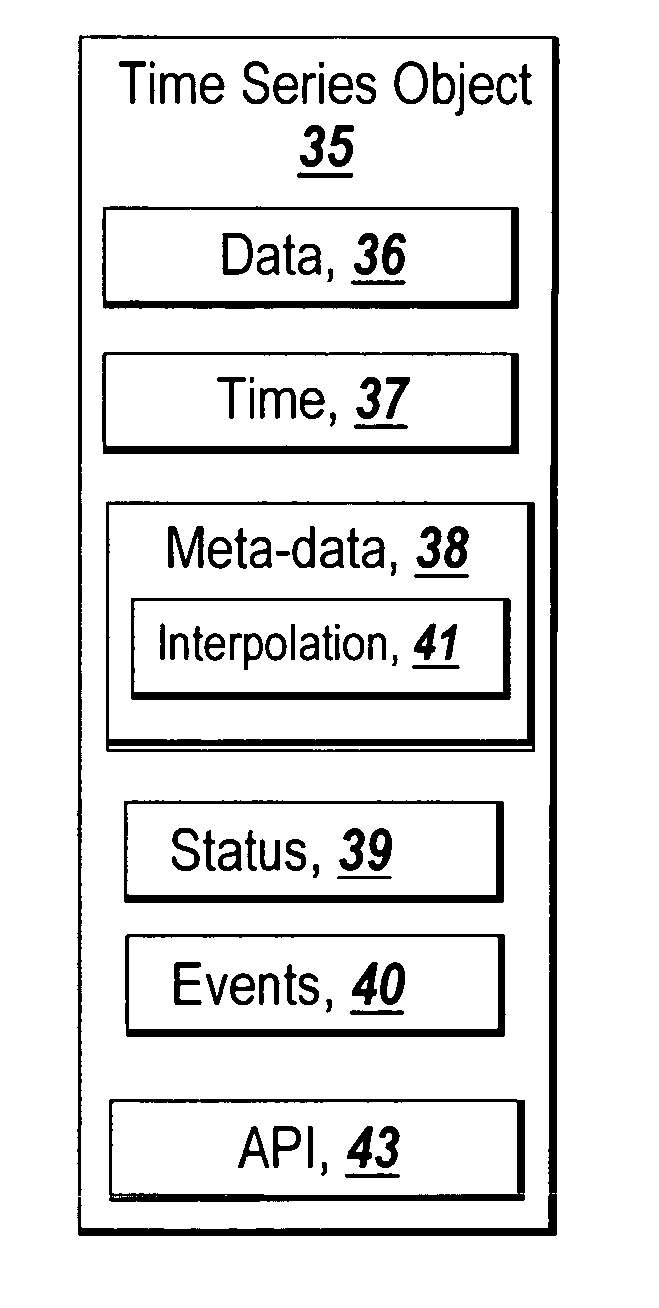

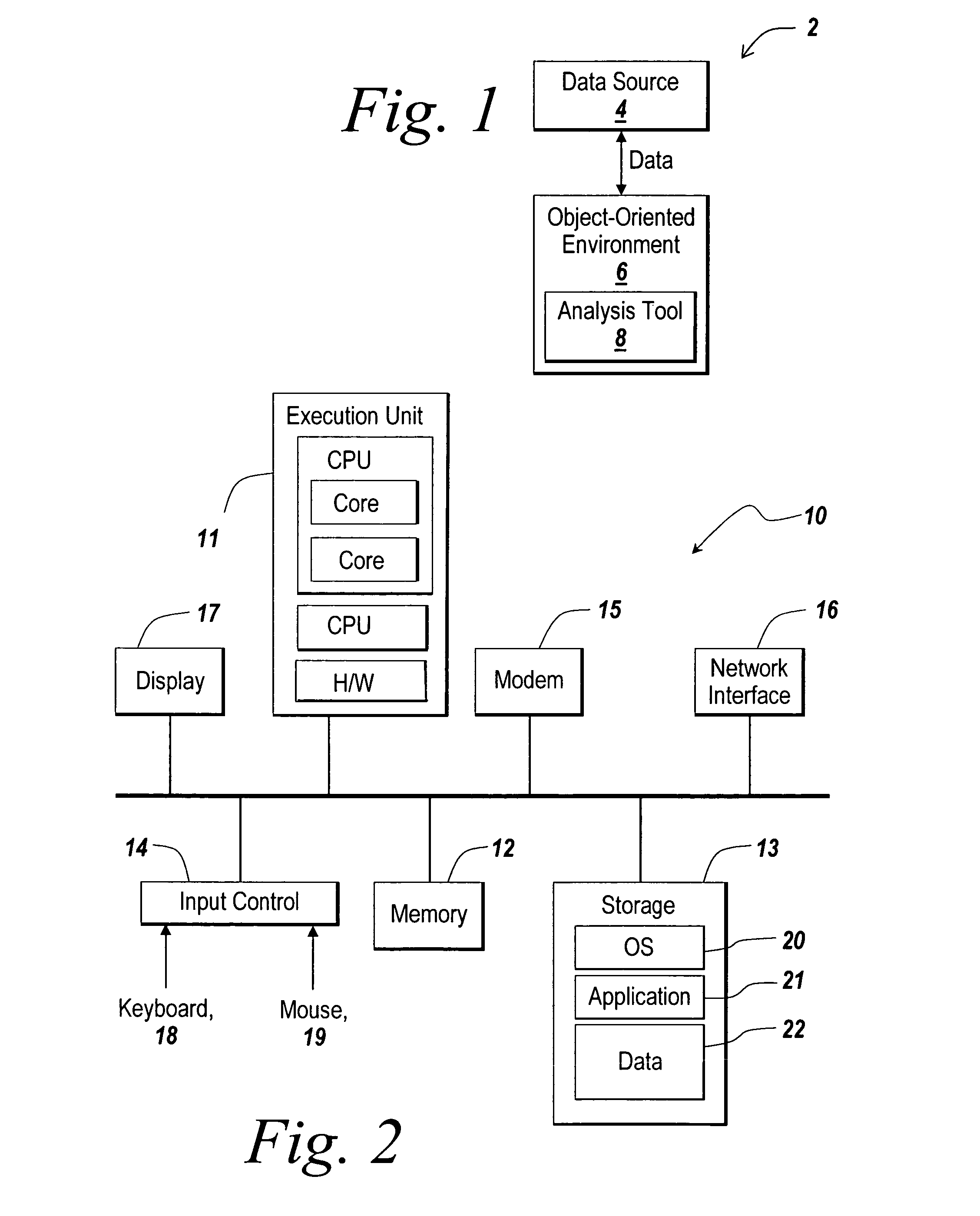

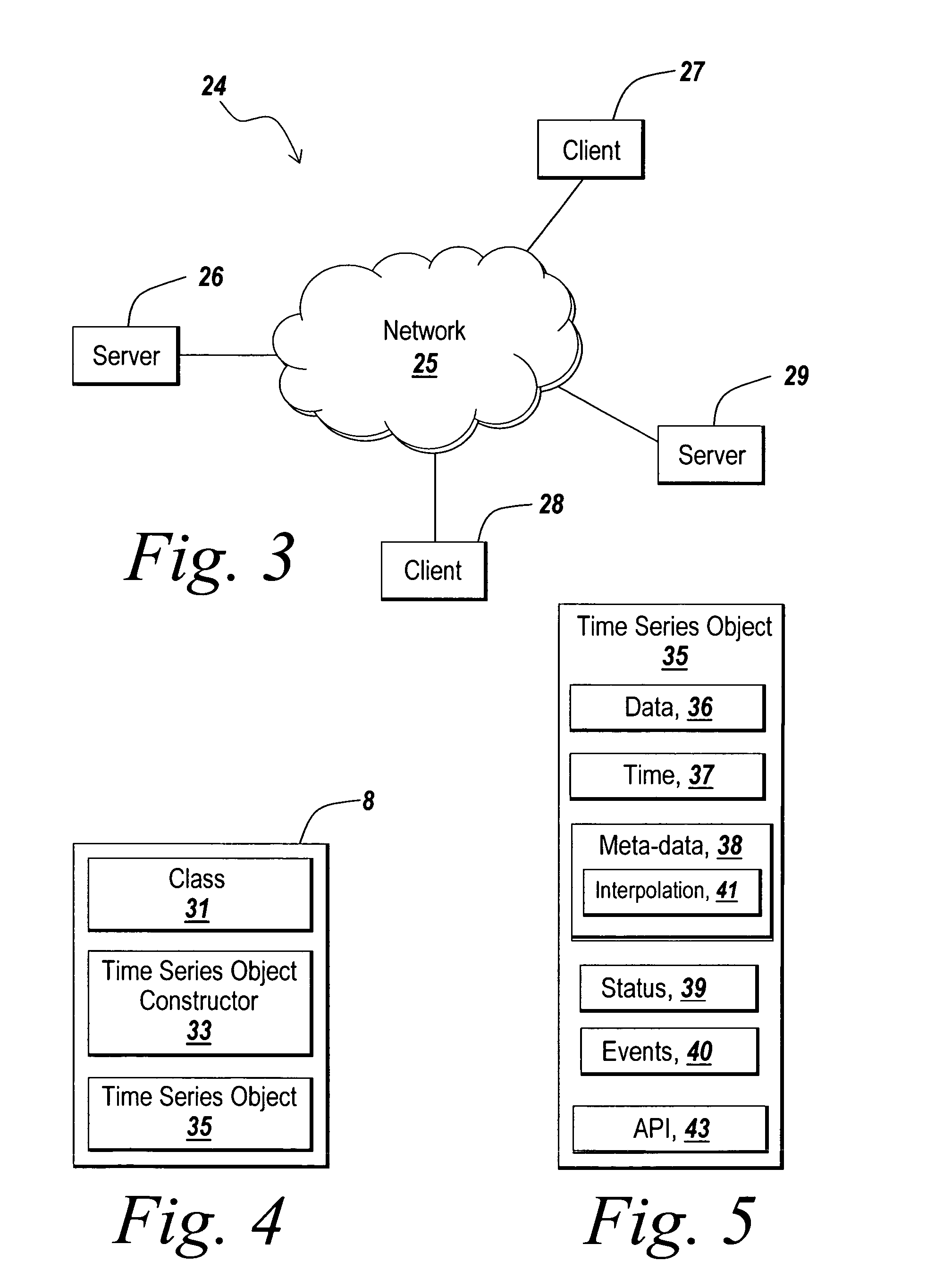

Analysis of a sequence of data in object-oriented environments

ActiveUS8046749B1Simplifies syntaxEasy and efficientSpecific program execution arrangementsMemory systemsCommand-line interfaceTheoretical computer science

A tool for analyzing a sequence of data in an object-oriented environment is disclosed. In an embodiment, the sequence of data may include time-indexed sequence of data (“time series data”). The tool may enable a user to generate a time series object for encapsulating the time series data in the object-oriented environment. The user may construct the time series object from data or mathematical expressions using a command line interface. The time series object may include a sequence of objects implementing APIs that supply an interface for analyzing the times series data in the time series object. The user may analyze the time series data encapsulated in the time series object using the APIs of the time series object.

Owner:THE MATHWORKS INC

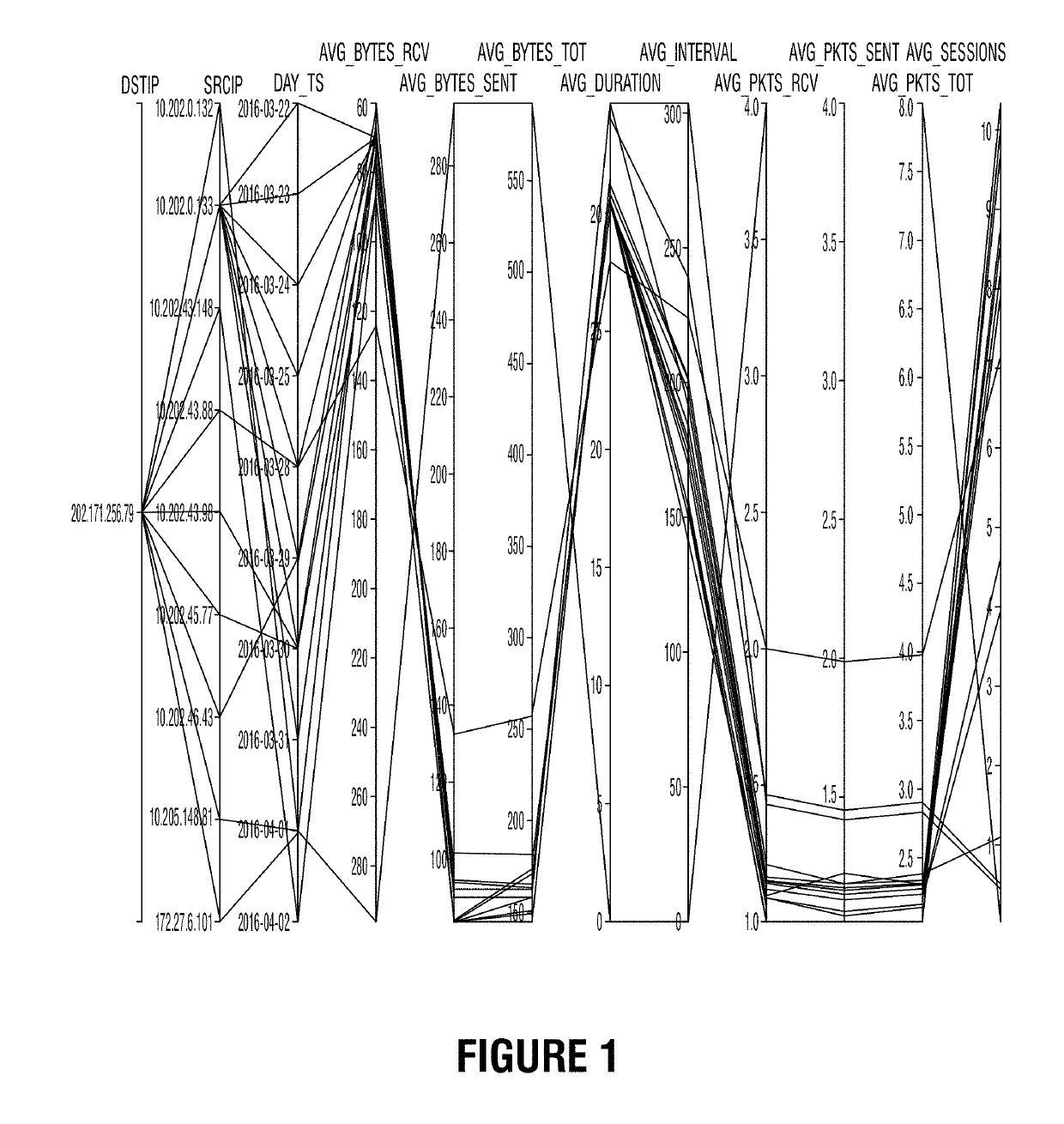

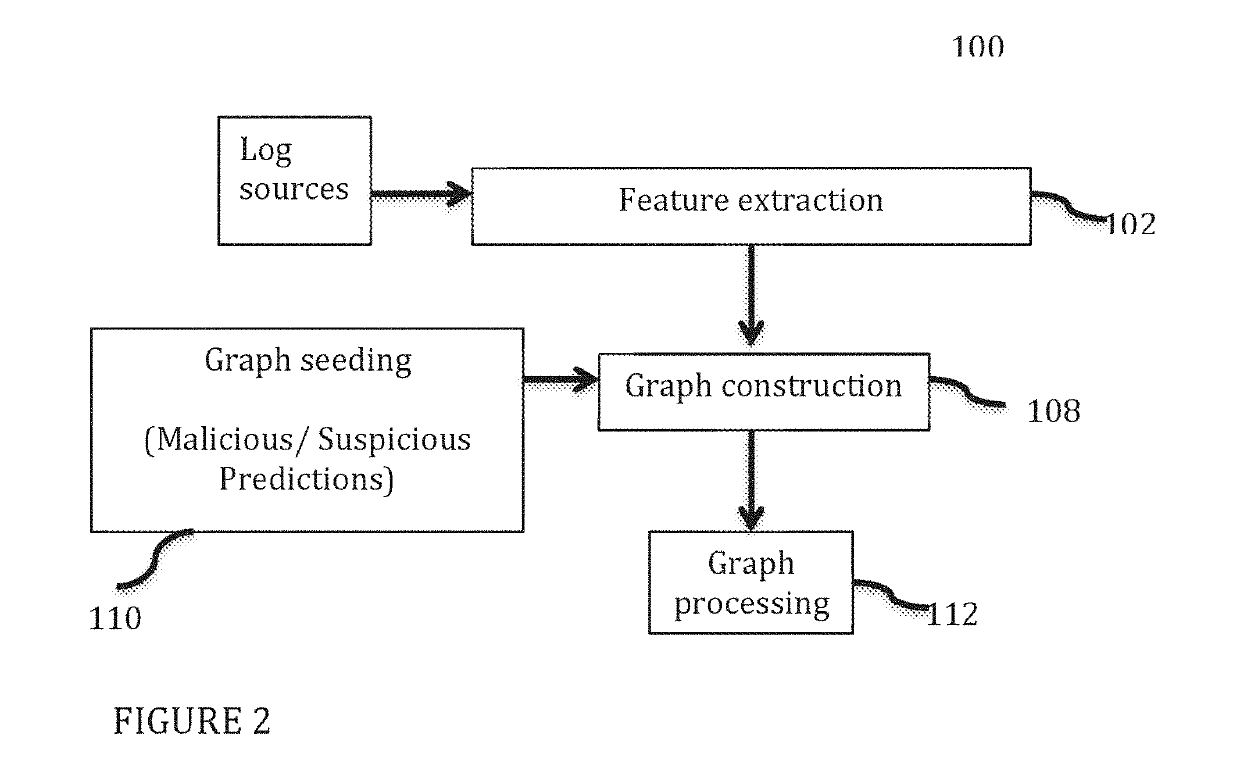

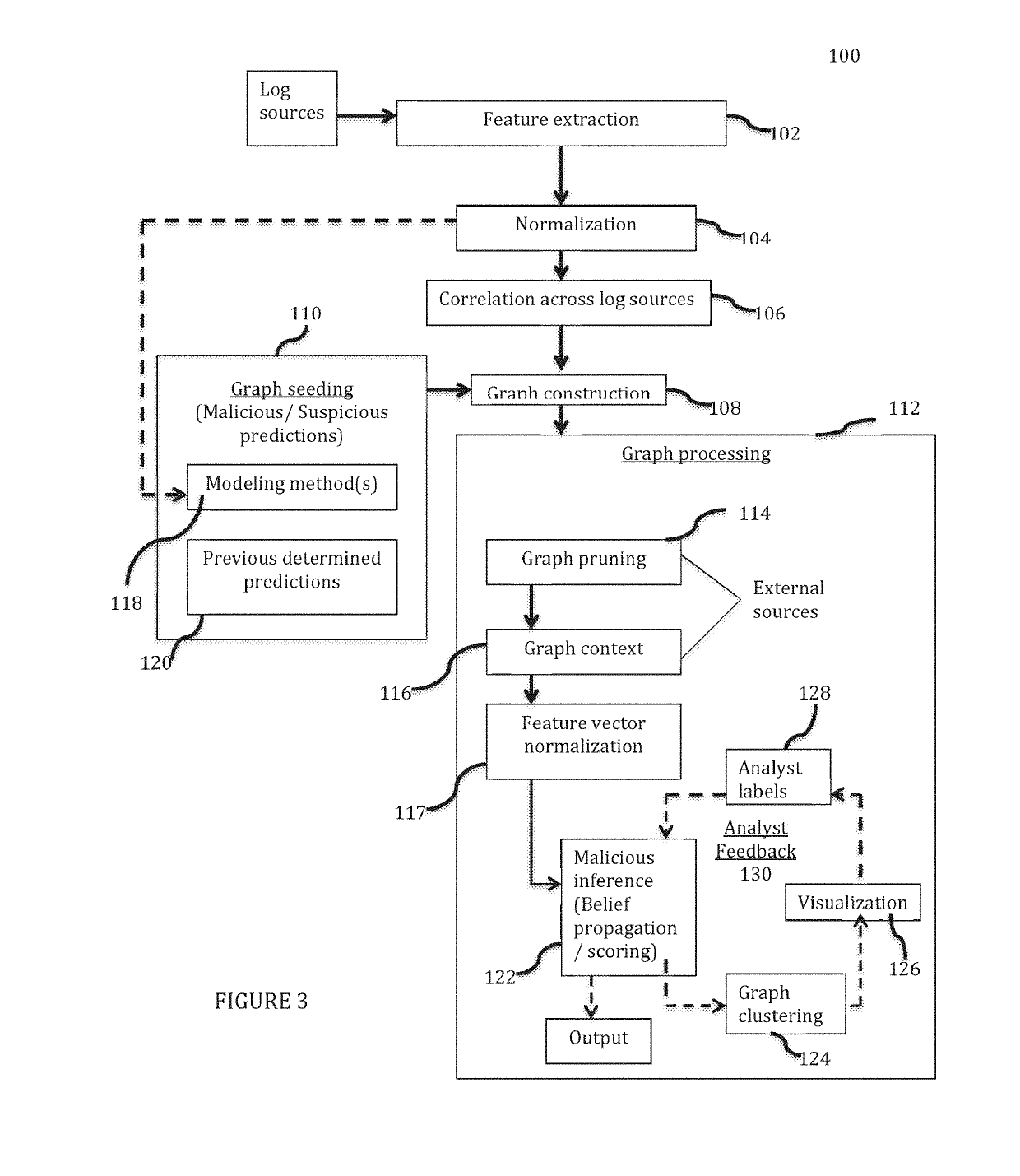

Method and system for employing graph analysis for detecting malicious activity in time evolving networks

ActiveUS20190132344A1Demonstrate scalabilityDemonstrate effectivenessComputer security arrangementsProbabilistic networksGraph inferenceClassification methods

Disclosed is a method and system for detecting malicious entities and malicious behavior in a time evolving network via a graph framework by modeling activity in a network graph representing associations between entities. The system utilizes classification methods to give score predictions indicative of a degree of suspected maliciousness, and presents a unified graph inference method for surfacing previously undetected malicious entities that utilizes both the structure and behavioral features to detect malicious entities.

Owner:CORELIGHT INC

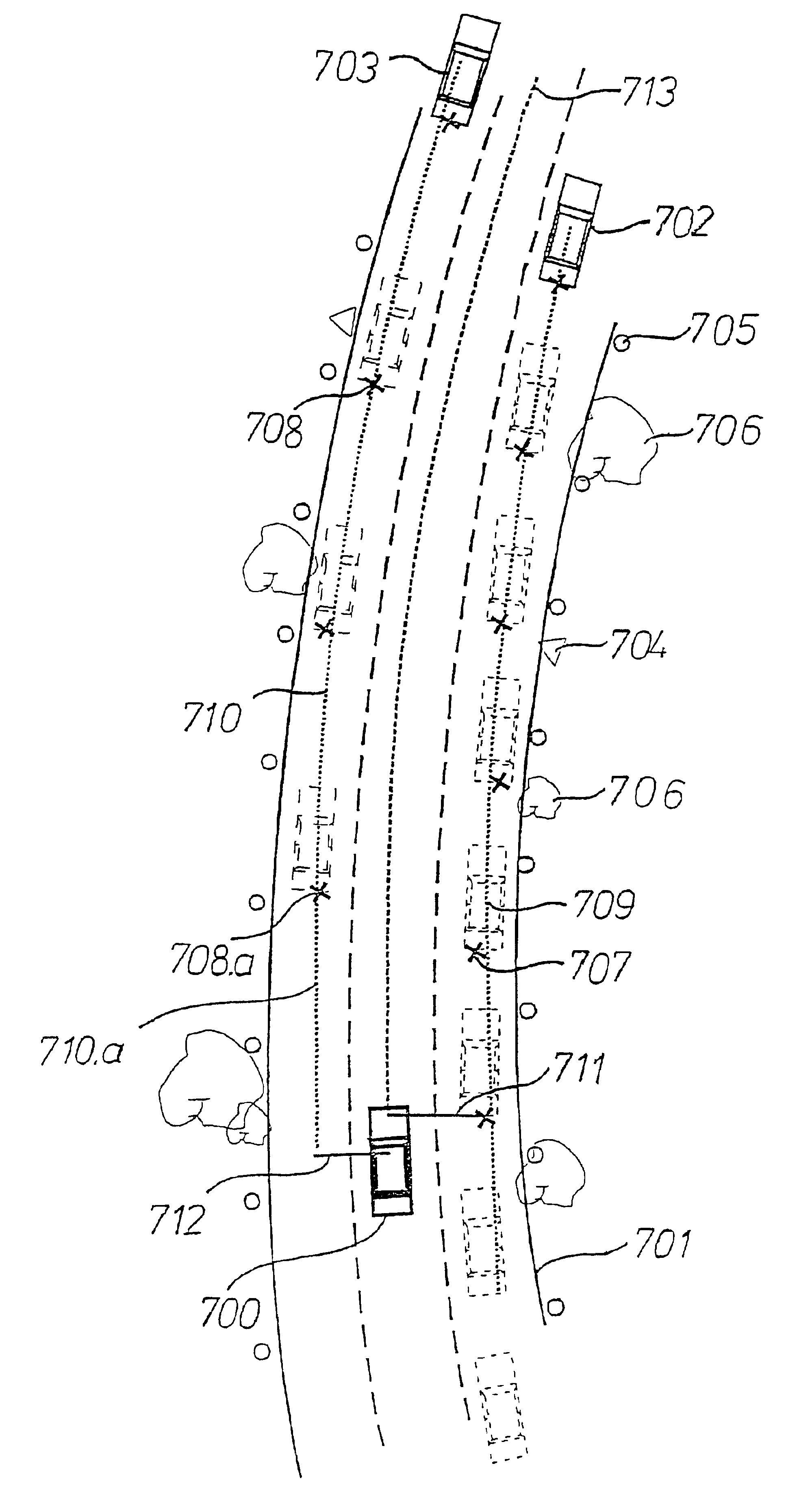

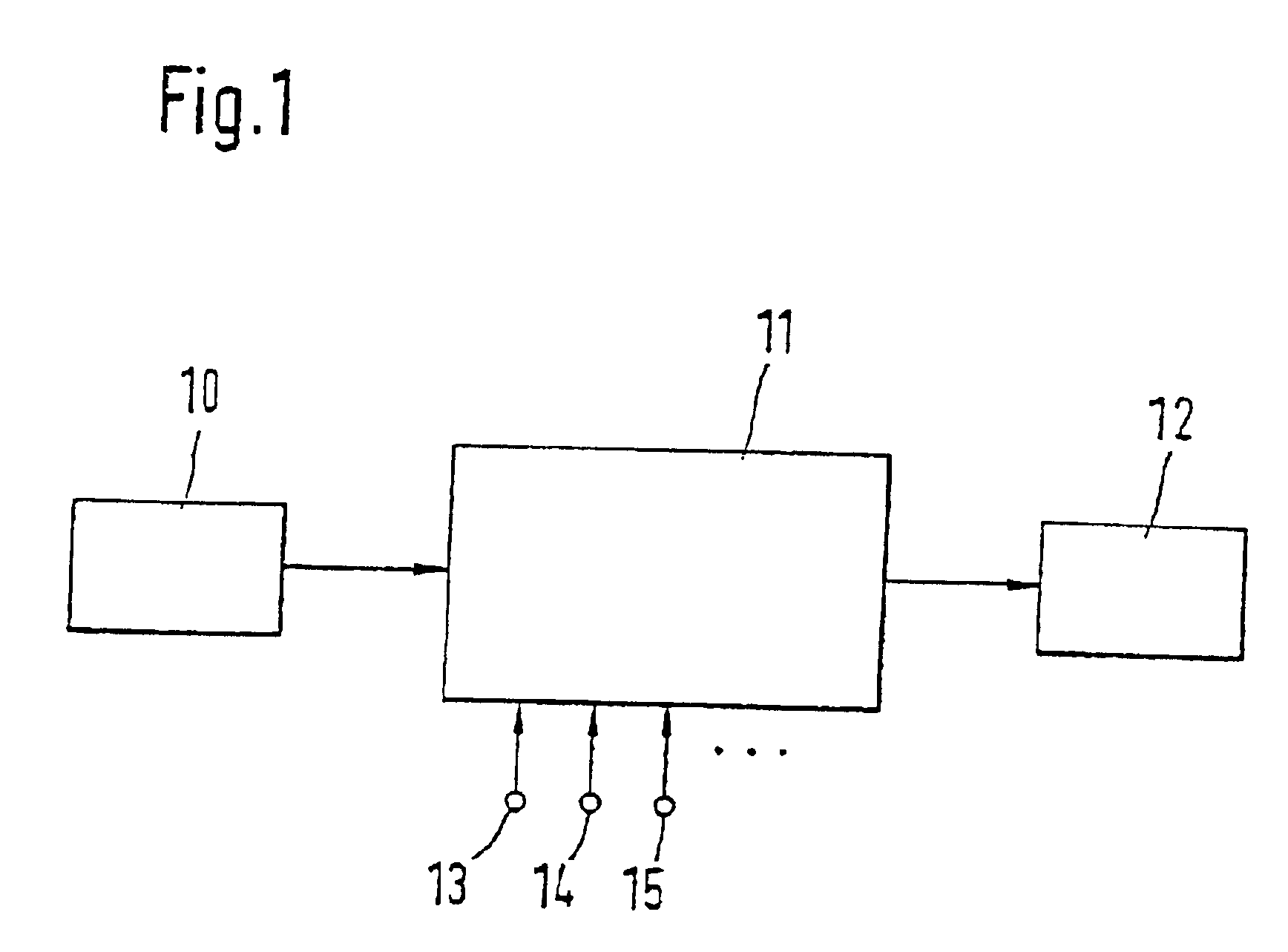

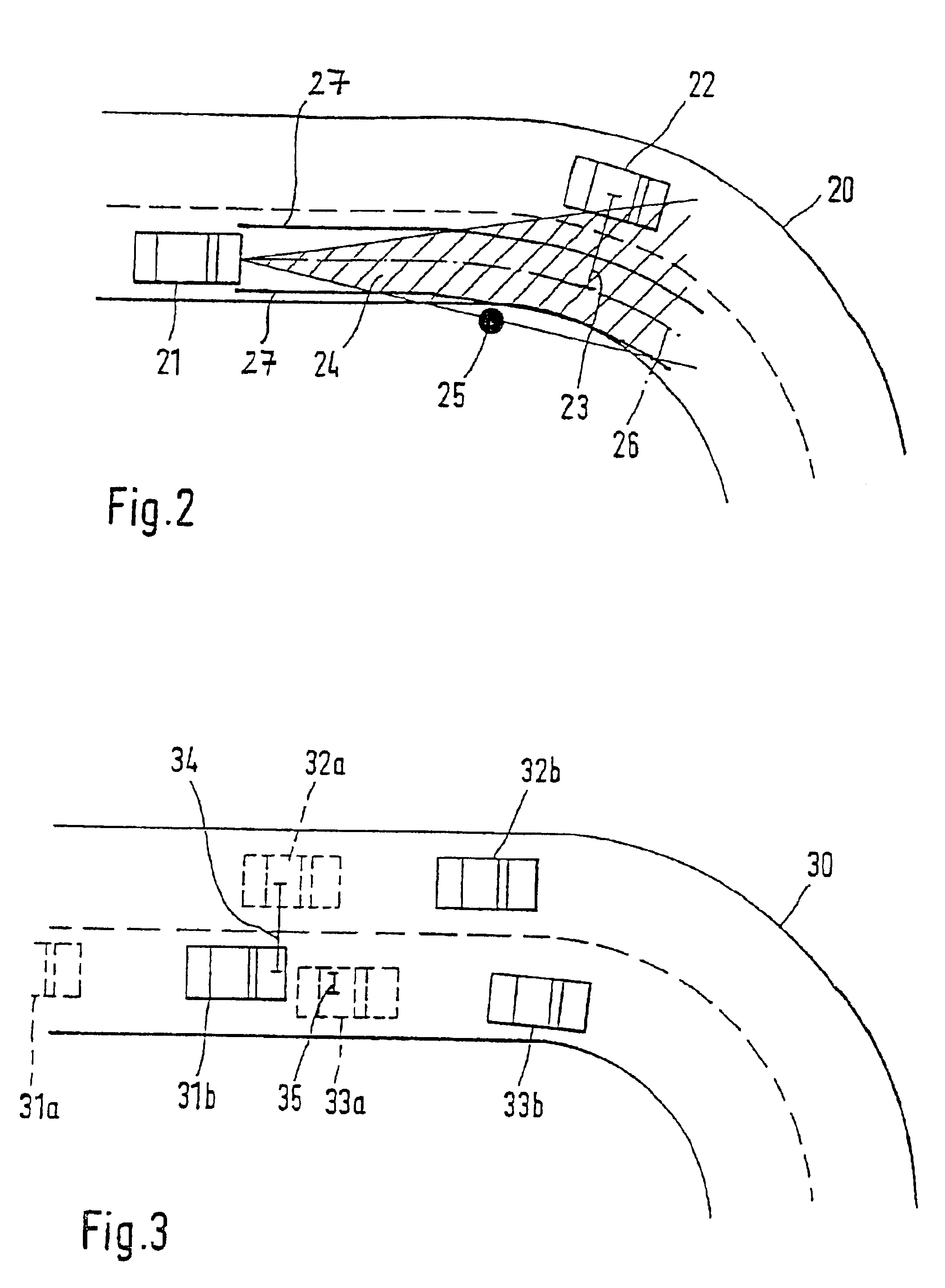

Method and device for determining a future travel-path area of a vehicle

InactiveUS6853906B1Reliably determinedReduce error rateInstruments for road network navigationVehicle fittingsDistance sensorsEngineering

Owner:ROBERT BOSCH GMBH

Apparatus and method for trellis encoding data for transmission in digital data transmission systems

InactiveUS6937617B2Sufficient redundancyIncorrect determinationPulse modulation television signal transmissionError preventionDigital dataPhase difference

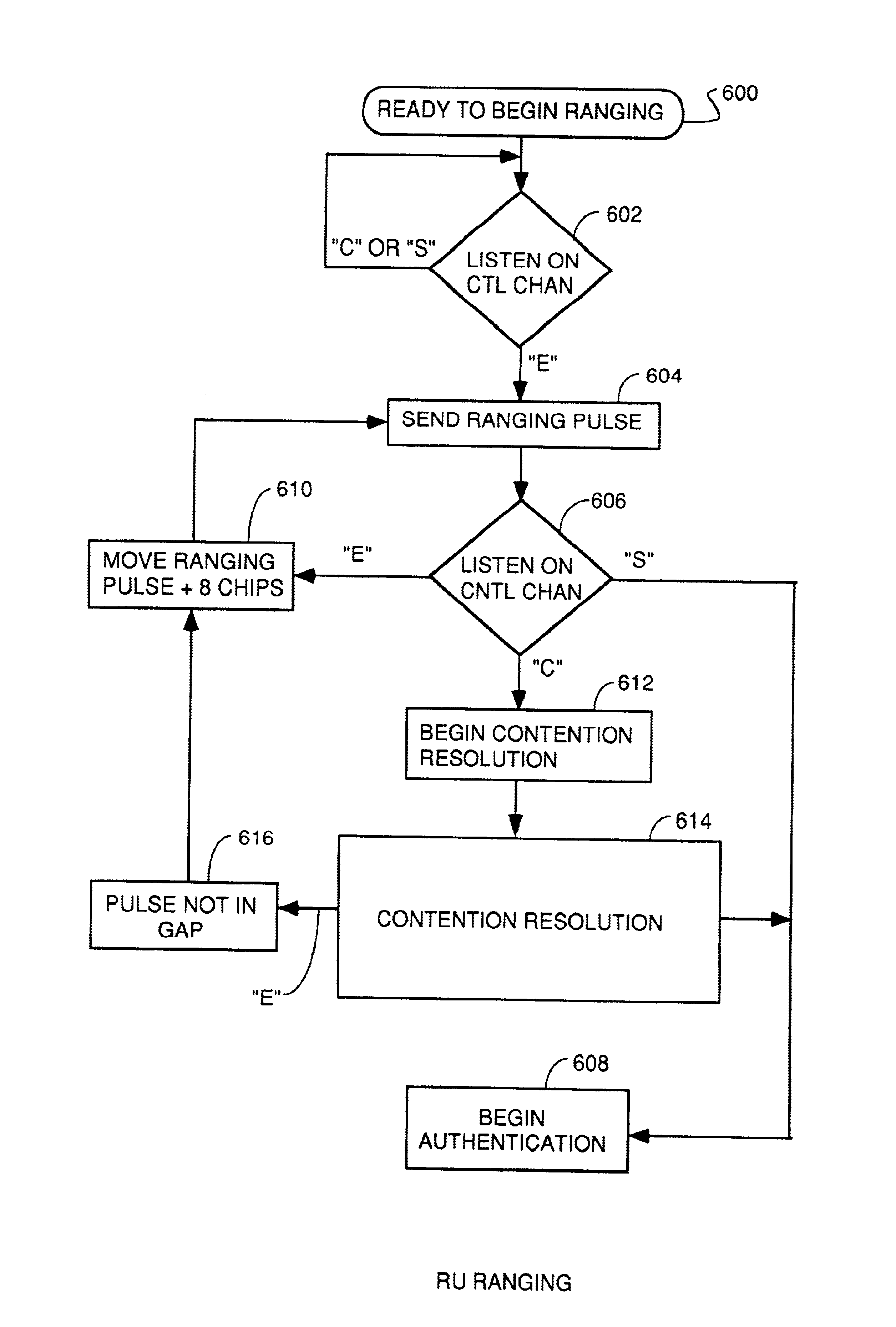

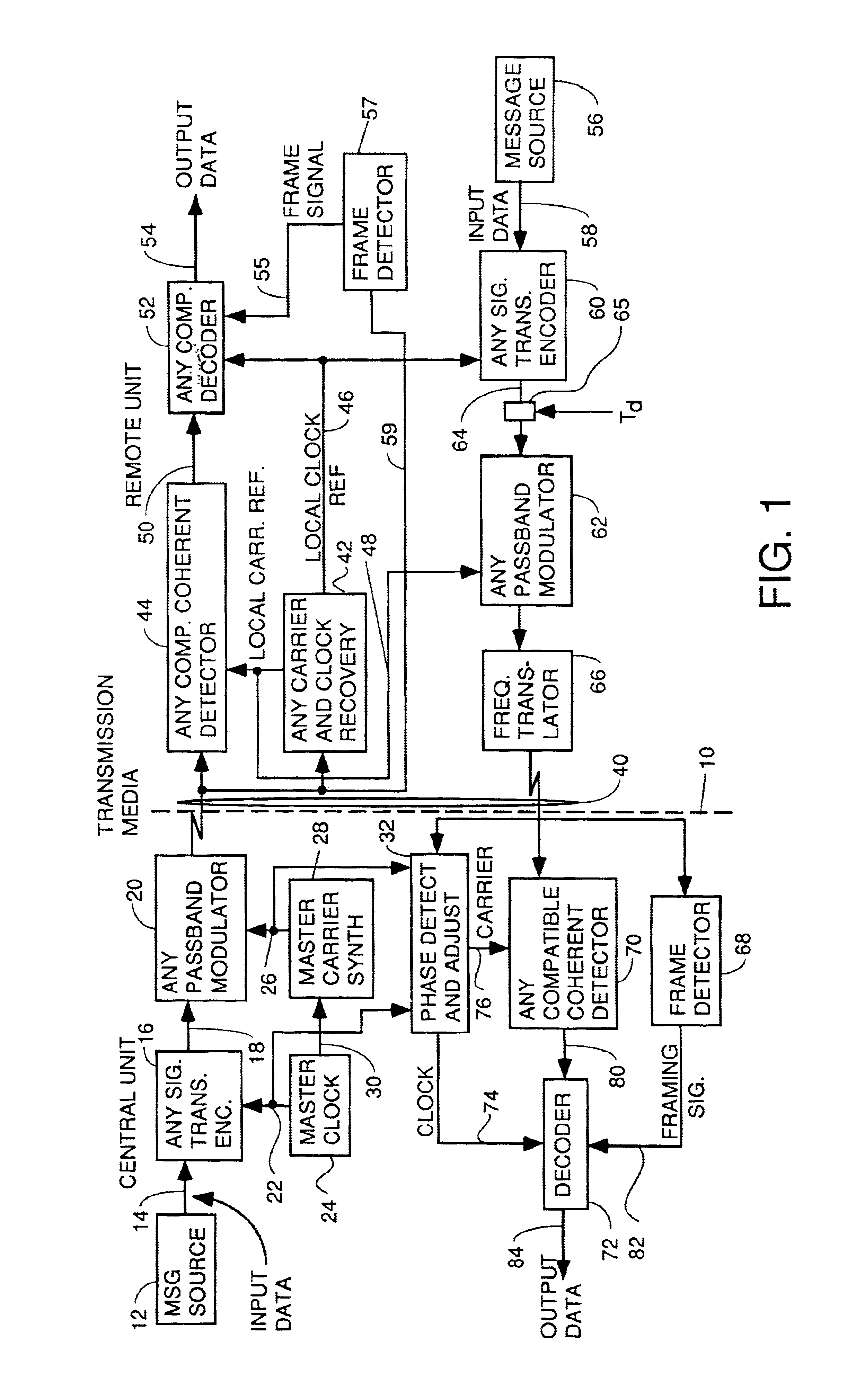

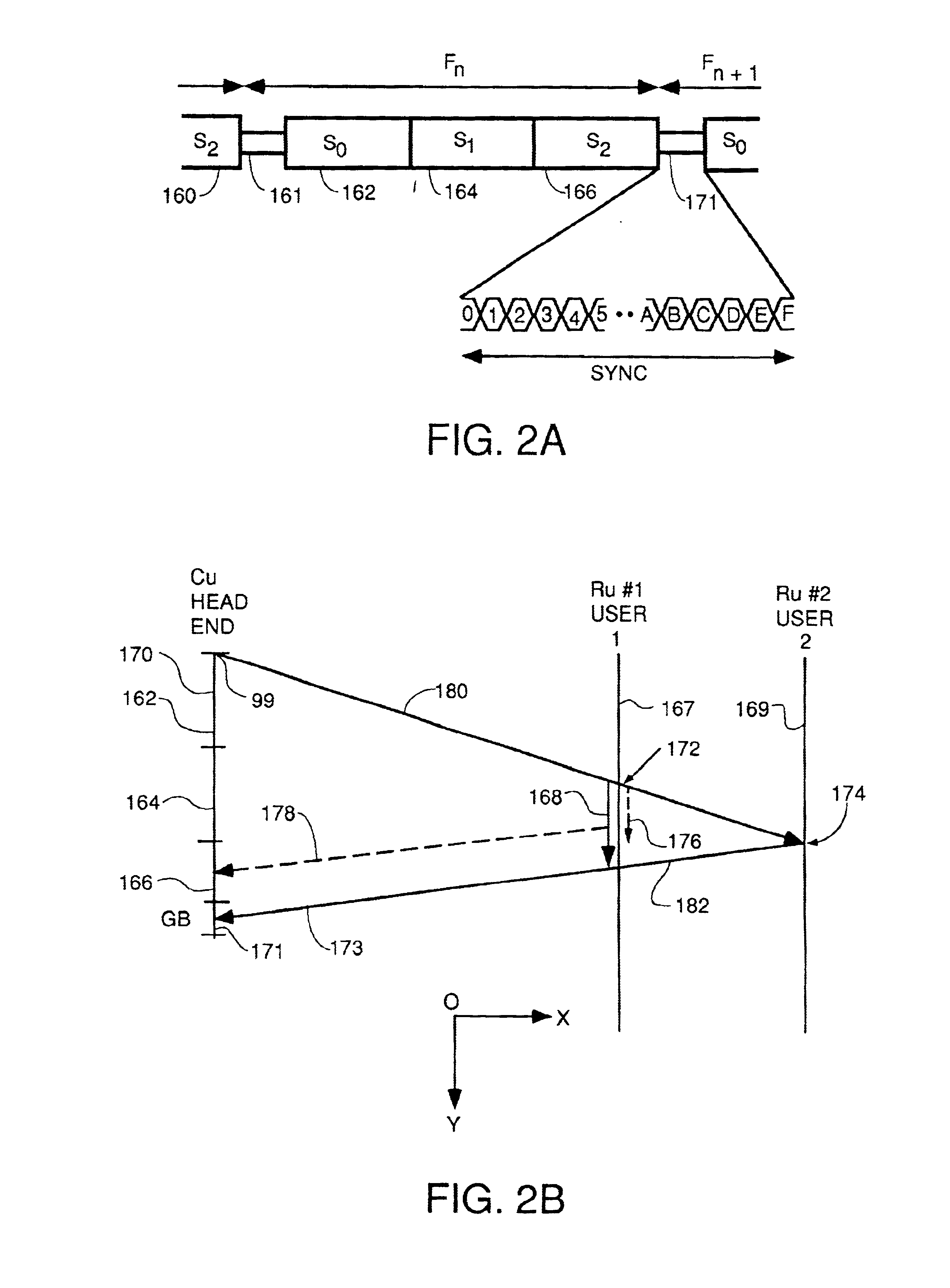

A system for bidirectional communication of digital data between a central unit and a remote unit wherein the need for tracking loops in the central unit has been eliminated. The central unit transmitter generates a master carrier and a master clock signal which are used to transmit downstream data to the remote units. The remote units recover the master carrier and master clock and synchronize local oscillators in each remote unit to these master carrier and master clock signals to generate reference carrier and clock signals for use by the remote unit receiver. These reference carrier and clock signals are also used by the remote unit transmitters to transmit upstream data to the central unit. The central unit receiver detects the phase difference between the reference carrier and clock signals from the remote units periodically and adjusts the phase of the master carrier and master clock signals for use by the central unit receiver to receive the upstream data.

Owner:GOOGLE TECH HLDG LLC

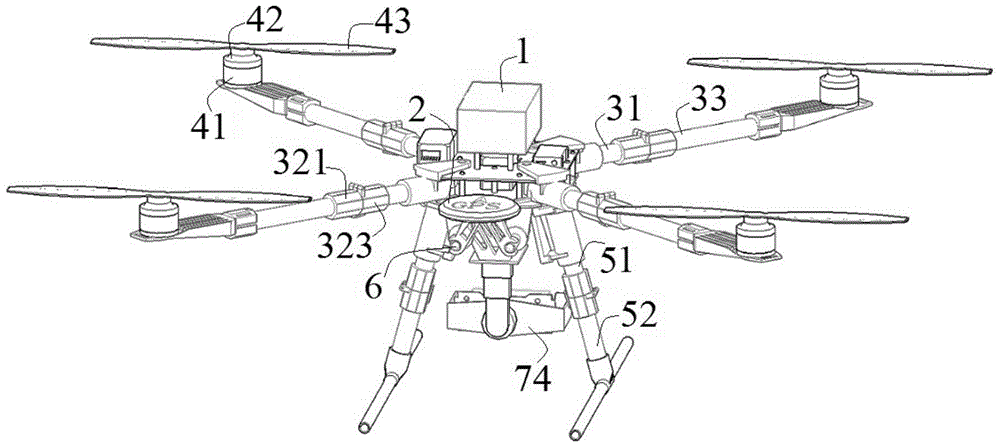

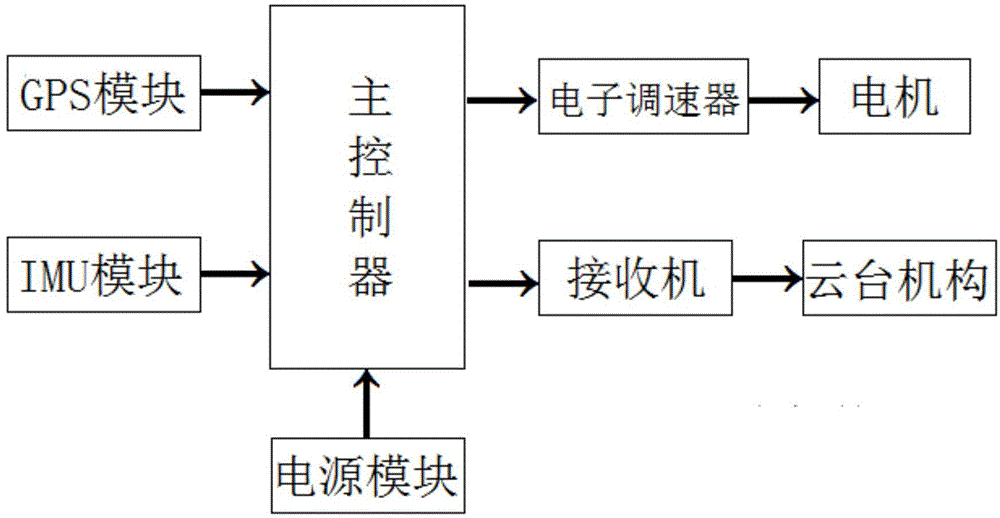

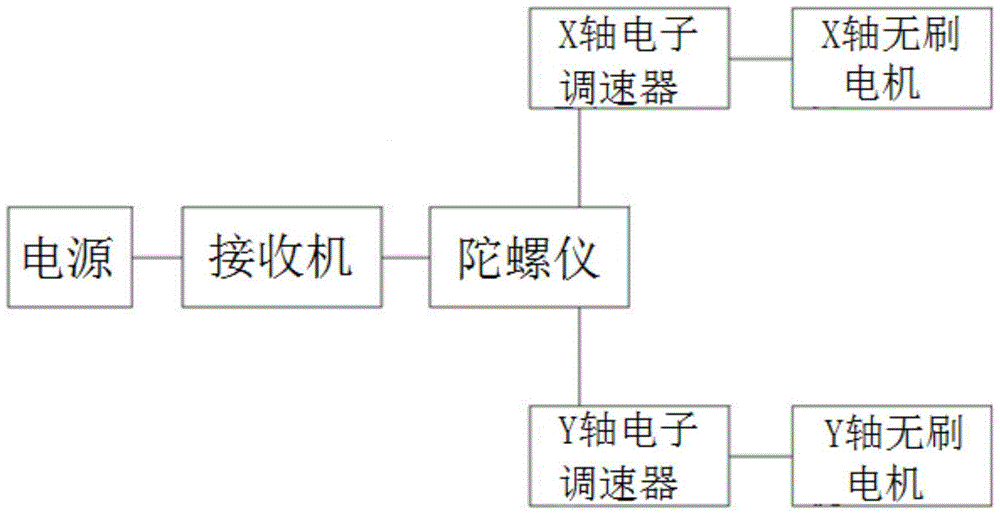

Multi-rotor unmanned aerial vehicle for fast surveying and surveying method of multi-rotor unmanned aerial vehicle

InactiveCN104386249APrecise positioningAccurate flight attitudeAircraft componentsRotocraftAviationCamera lens

The invention discloses a multi-rotor unmanned aerial vehicle for fast surveying and a surveying method of the multi-rotor unmanned aerial vehicle, and belongs to the technical field of aviation surveying. The multi-rotor unmanned aerial vehicle comprises a rack, flight lifting mechanisms, a cloud deck mechanism and a control mechanism, wherein four plane arms extend out from the rack along a plane body, the lower part of the plane body is provided with foot stools, the plane arms and the foot stools are of foldable structures; and the flight lifting mechanisms are arranged at tail ends of the four plane arms, the cloud deck mechanism is mounted at the bottom of the unmanned aerial vehicle body through a mounting rod; the cloud deck mechanism is provided with a camera and is used for regulating an optical axis of the camera to be always perpendicular to the ground; and the control mechanism is used for controlling the unmanned aerial vehicle to fly to the appointed height and regulating the overturn of the cloud deck mechanism. The surveying method disclosed by the invention can be used for determining the relation between the shooting height and the imaging proportion by analyzing camera lens parameters, and then setting the flight line of the unmanned aerial vehicle. Through the adoption of the unmanned aerial vehicle, the surveying result can be fast obtained, and the surveying precision and efficiency are high.

Owner:安徽靓马信息科技股份有限公司

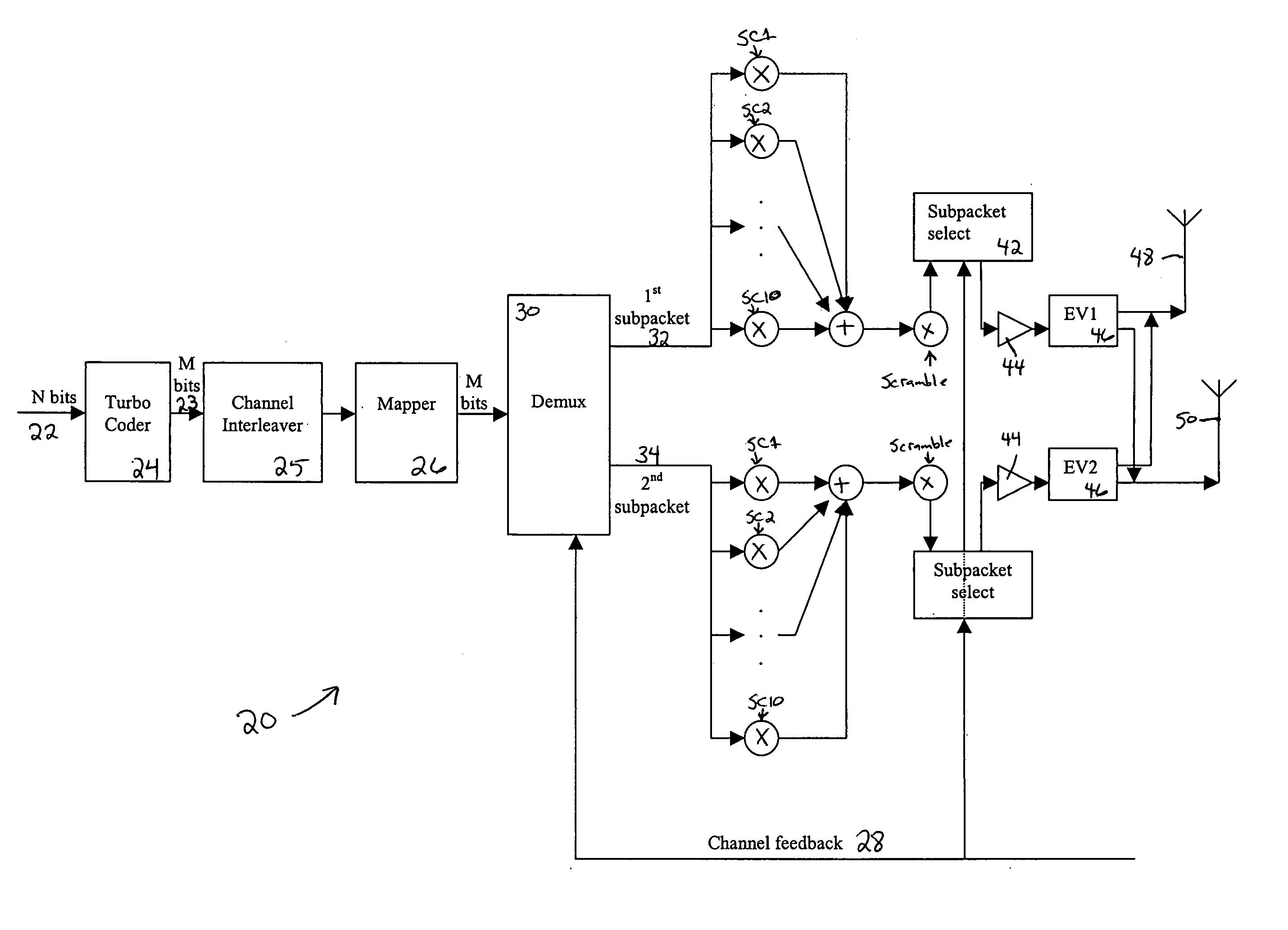

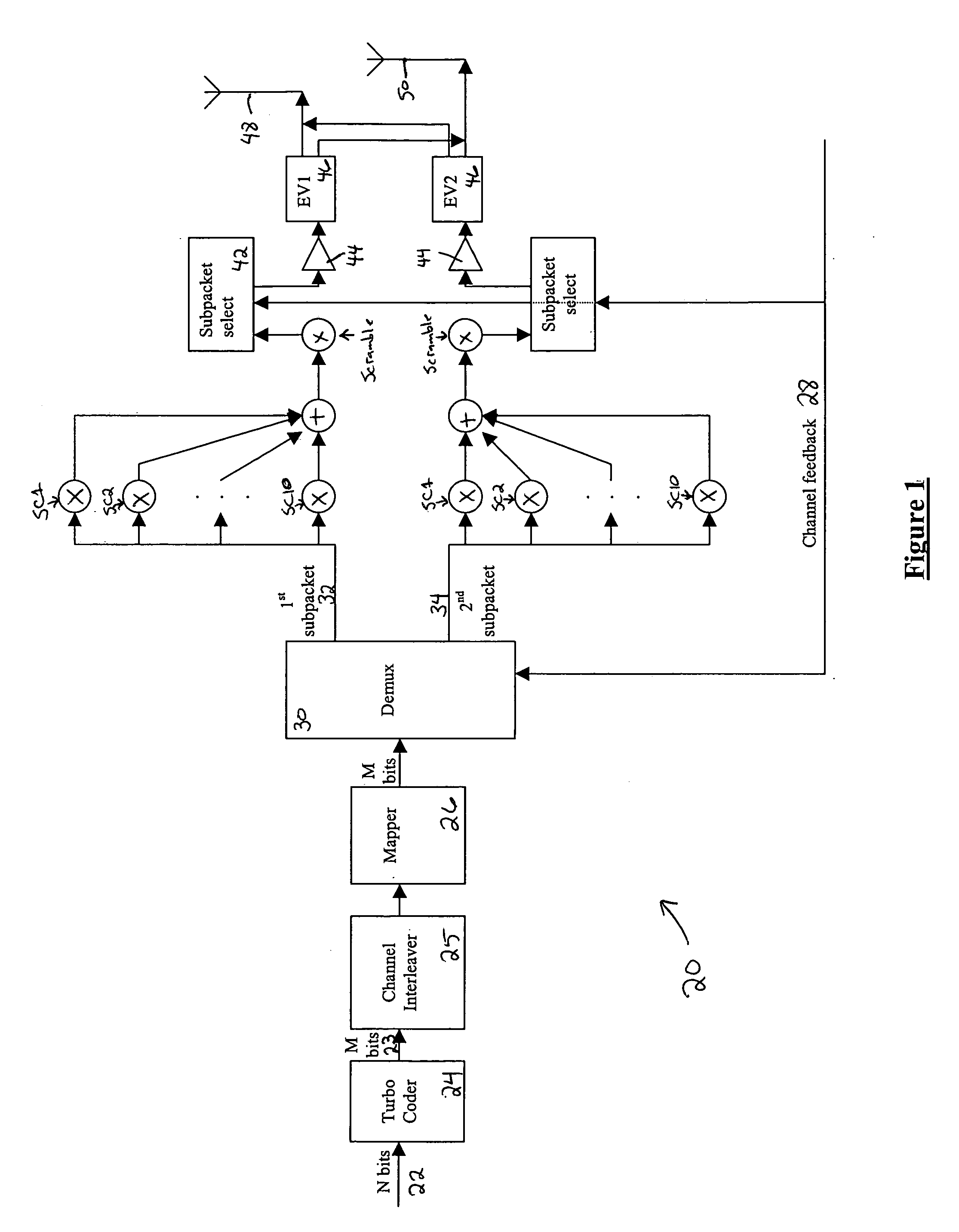

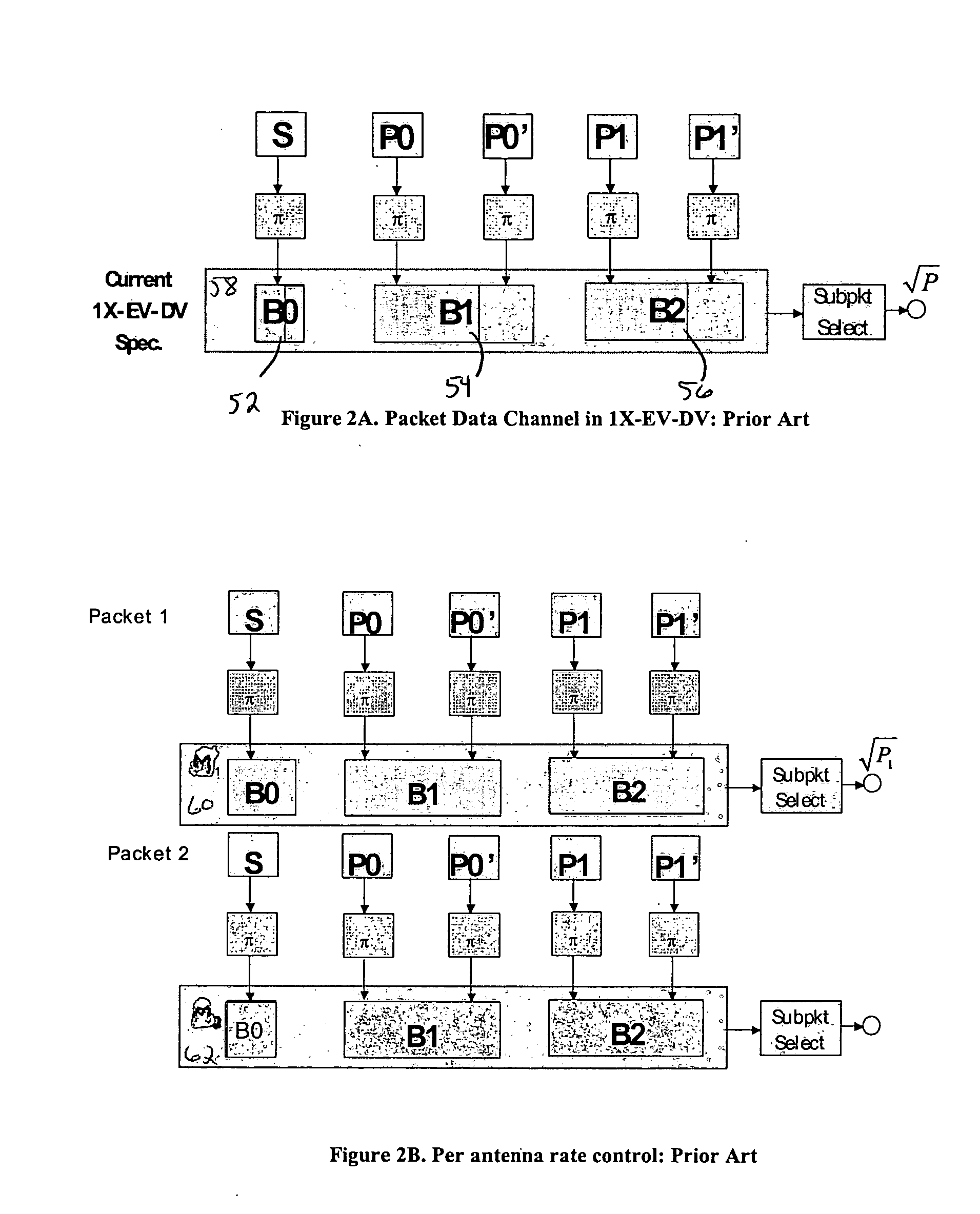

Flexible rate split method for MIMO transmission

InactiveUS20050111376A1Wide diversityReduce error rateSpatial transmit diversityFrequency-division multiplex detailsMimo transmissionSelection system

A method for transmitting a packet of N input bits includes encoding all of the N bits as a single entity, such as with an interleaver of length N within a turbo coder, outputting M encoded bits, channel interleaving the M bits, splitting the M encoded bits into a parallel first and second portion, and transmitting them over separate channels to achieve spatial diversity. The size of the first and second portion is determined based on a closed feedback loop that provides some knowledge of the channel, preferably a measure of channel capacity. The feedback loop may also provide channel knowledge to a subpacket selector associated with each transmit antenna, which determines an appropriate rate for that channel and selects subpackets to fill a transmission packet for that channel. The subpacket selectors choose a subpacket of systematic bits and fill the remaining transmission packet size with subpackets of parity bits. Eigenvectors may be employed to transmit each transmission packet over more than one channel with a power disparity between the channels. A transmitter according to the present invention is also described.

Owner:NOKIA CORP

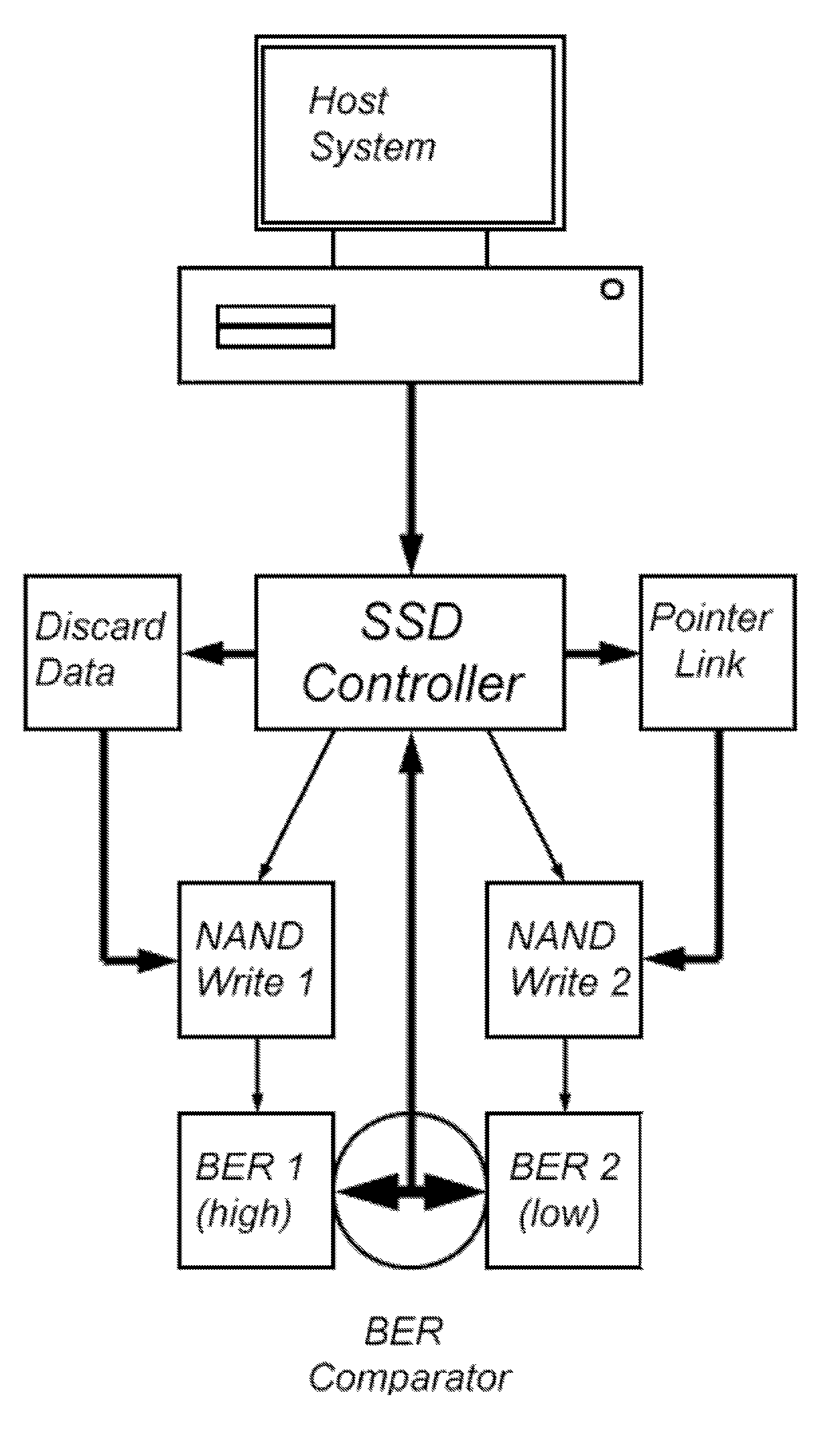

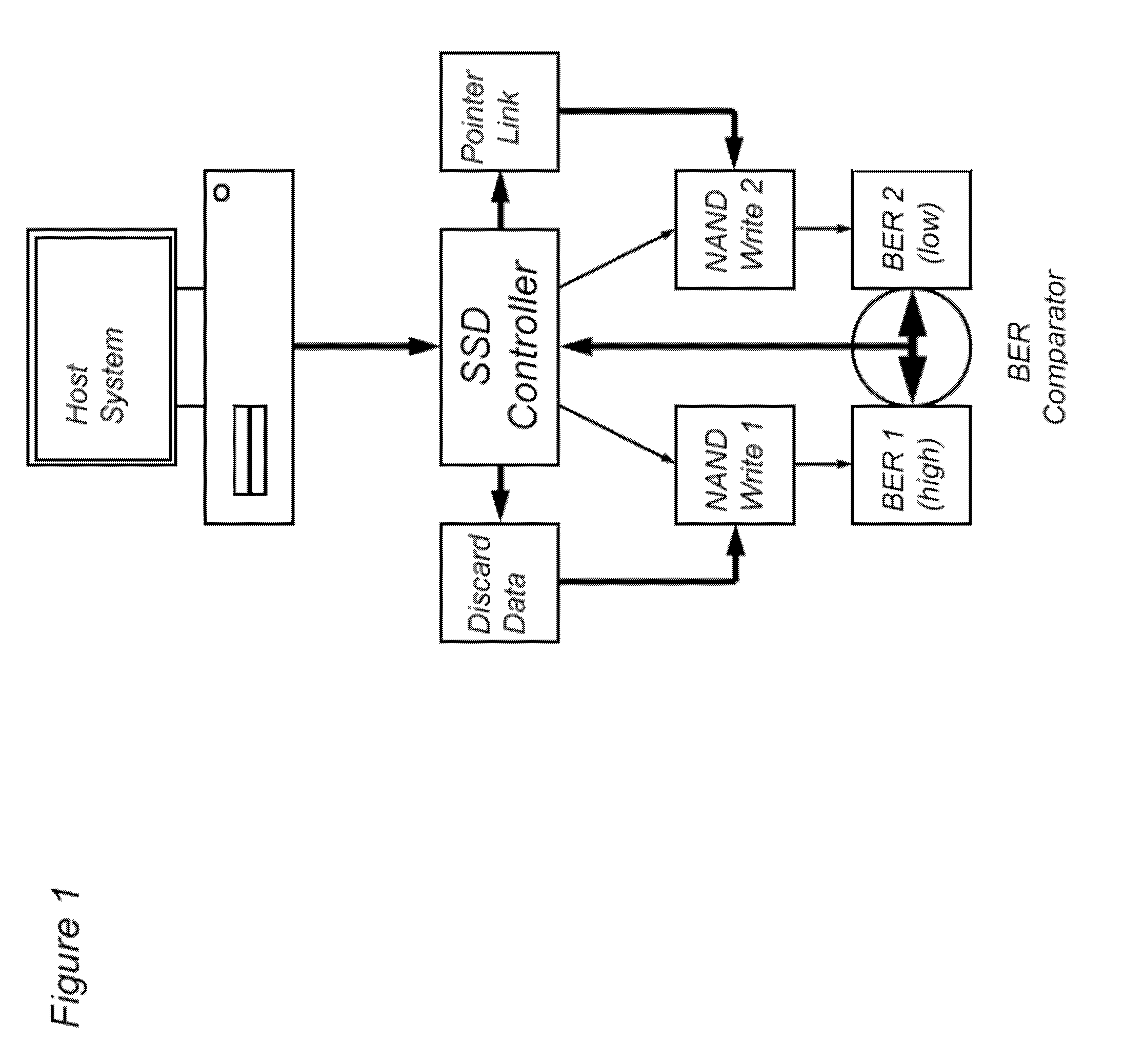

Solid-state memory-based storage method and device with low error rate

InactiveUS20130024735A1Low initial error rateReduce error rateError correction/detection using block codesRedundant data error correctionData setNon-volatile memory

Non-volatile solid-state memory-based storage devices and methods of operating the storage devices to have low initial error rates. The storage devices and methods use bit error rate comparison of duplicate writes to one or more non-volatile memory devices. The data set with a lower bit error rate as determined during verification is maintained, whereas data sets with higher bit error rates are discarded. A threshold of bit error rates can be used to trigger the duplication of data for bit error comparison.

Owner:OCZ STORAGE SOLUTIONS

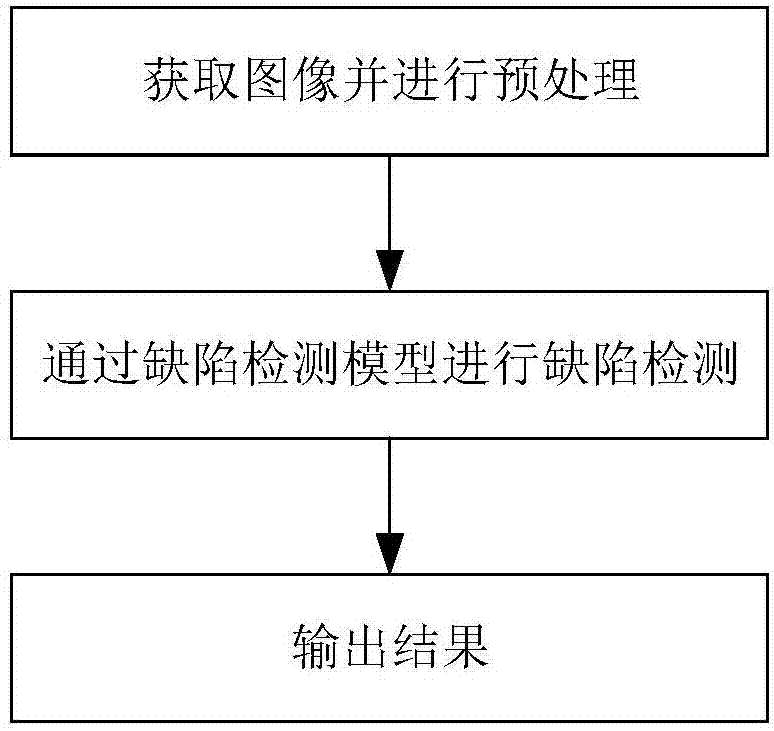

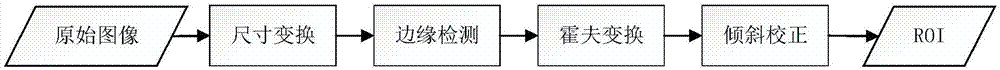

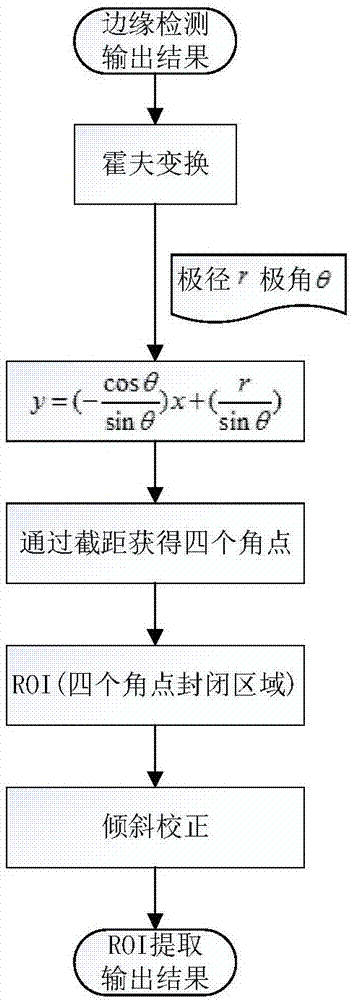

Mobile phone casing defect detecting method based on depth learning

ActiveCN106875381AImprove detection accuracyReliable test resultsImage analysisGeometric image transformationFeature extractionMobile phone

The invention relates to a mobile phone casing defect detecting method based on depth learning. The method comprises the steps that (1) the image of a mobile phone casing to be detected is acquired and pre-processed; and (2) the pre-processed image is input into a pre-trained defect detection model for defect detecting to acquire the position of a defect on the mobile phone casing, and the confidence of the position as the defect is provided. The defect detection model is a depth network based on depth learning, and comprises a feature extraction network and a classifier and regression device network, wherein the feature extraction network and the classifier and regression device network are in successive cascade. The feature extraction network carries out feature extraction on the pre-processed image to acquire a feature image. The classifier and regression device network classifies and regresses the feature image to acquire the defect position and the confidence of the mobile phone casing. Compared with the prior art, the method provided by the invention has the advantages of high detection precision and accurate and reliable detection result.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com