Patents

Literature

88 results about "Cascade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemical engineering, a cascade is a plant consisting of several similar stages with each processing the output from the previous stage. Cascades are most commonly used in isotope separation, distillation, flotation and other separation or purification processes.

Robust process identification and auto-tuning control

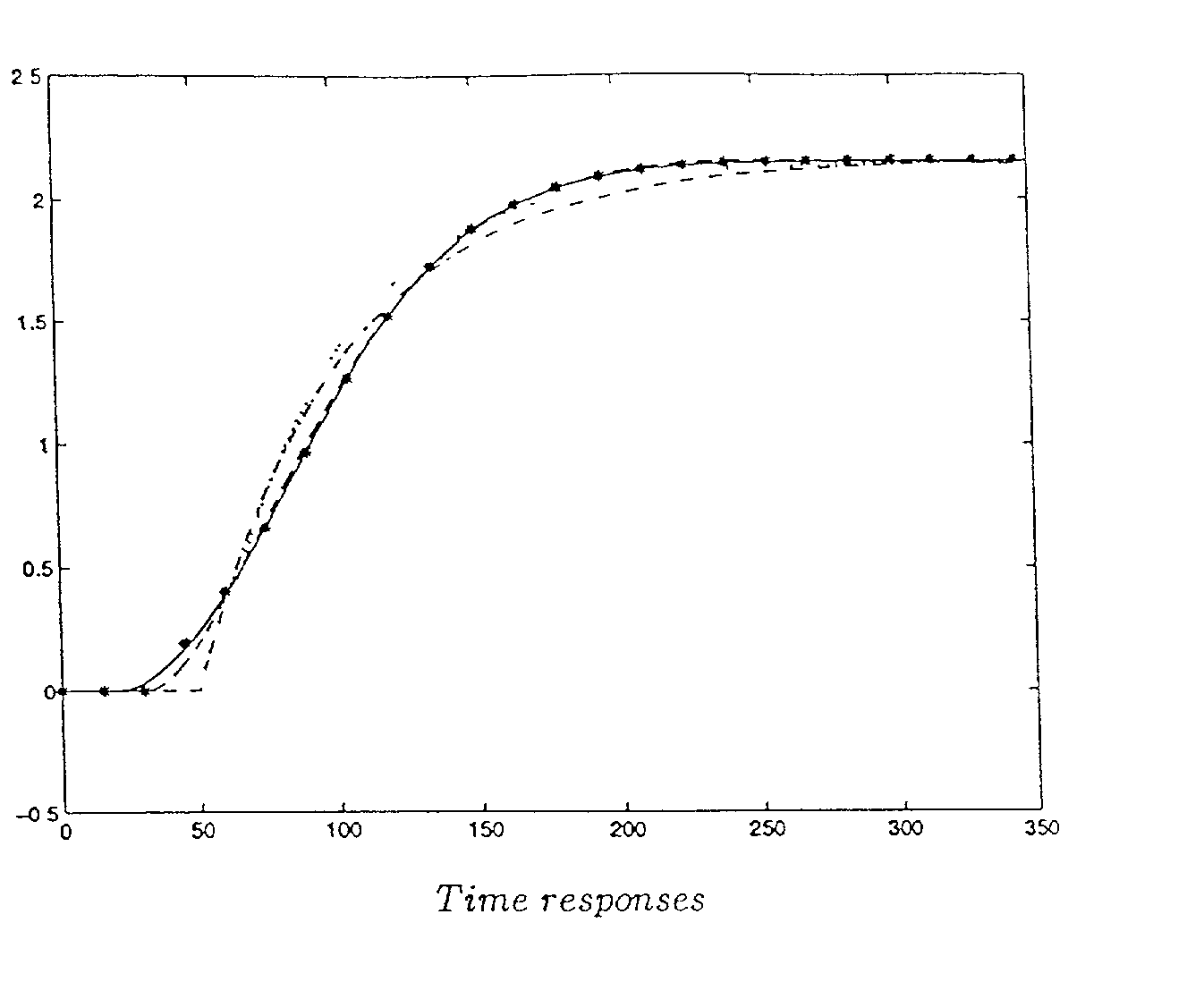

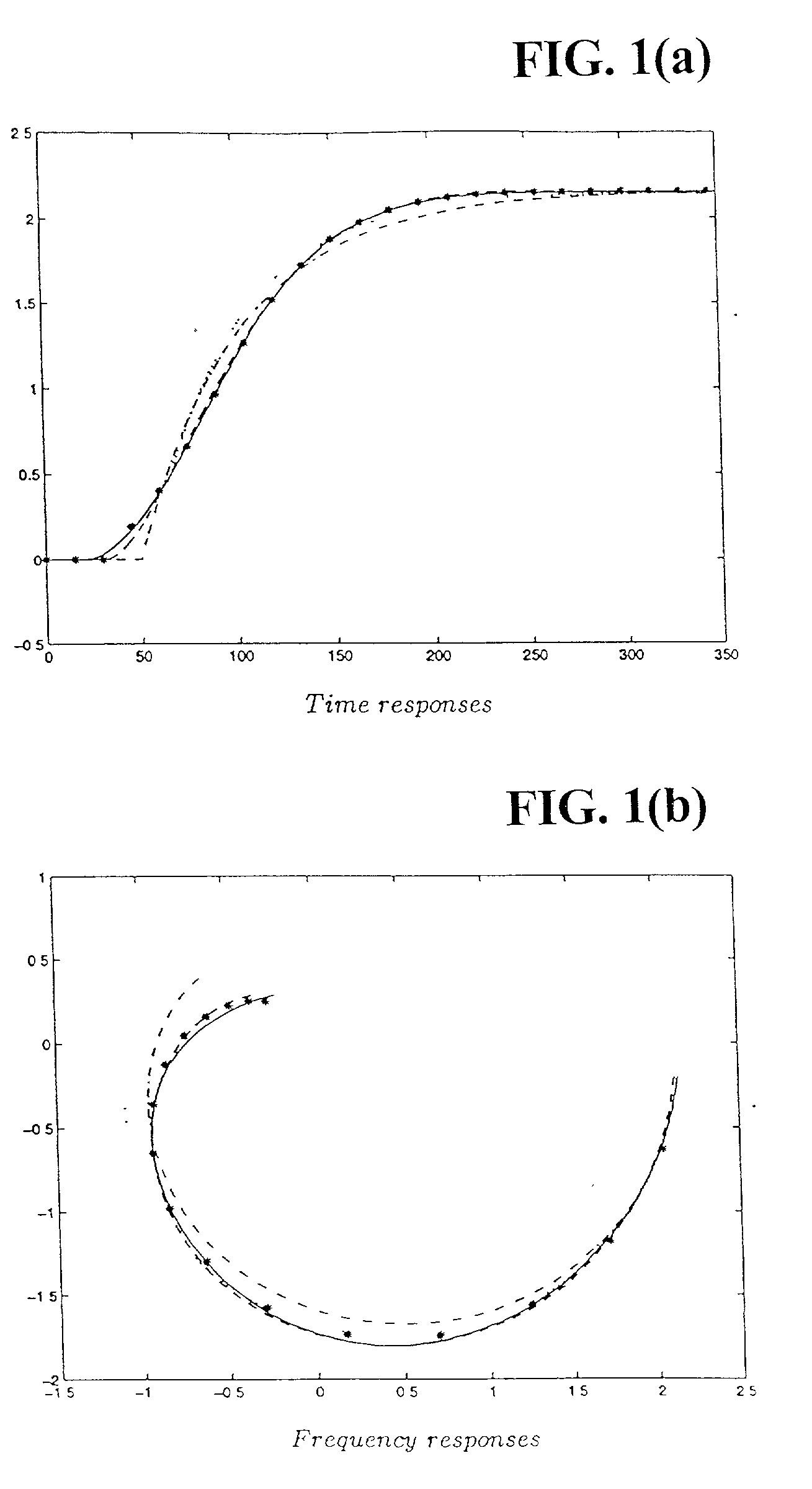

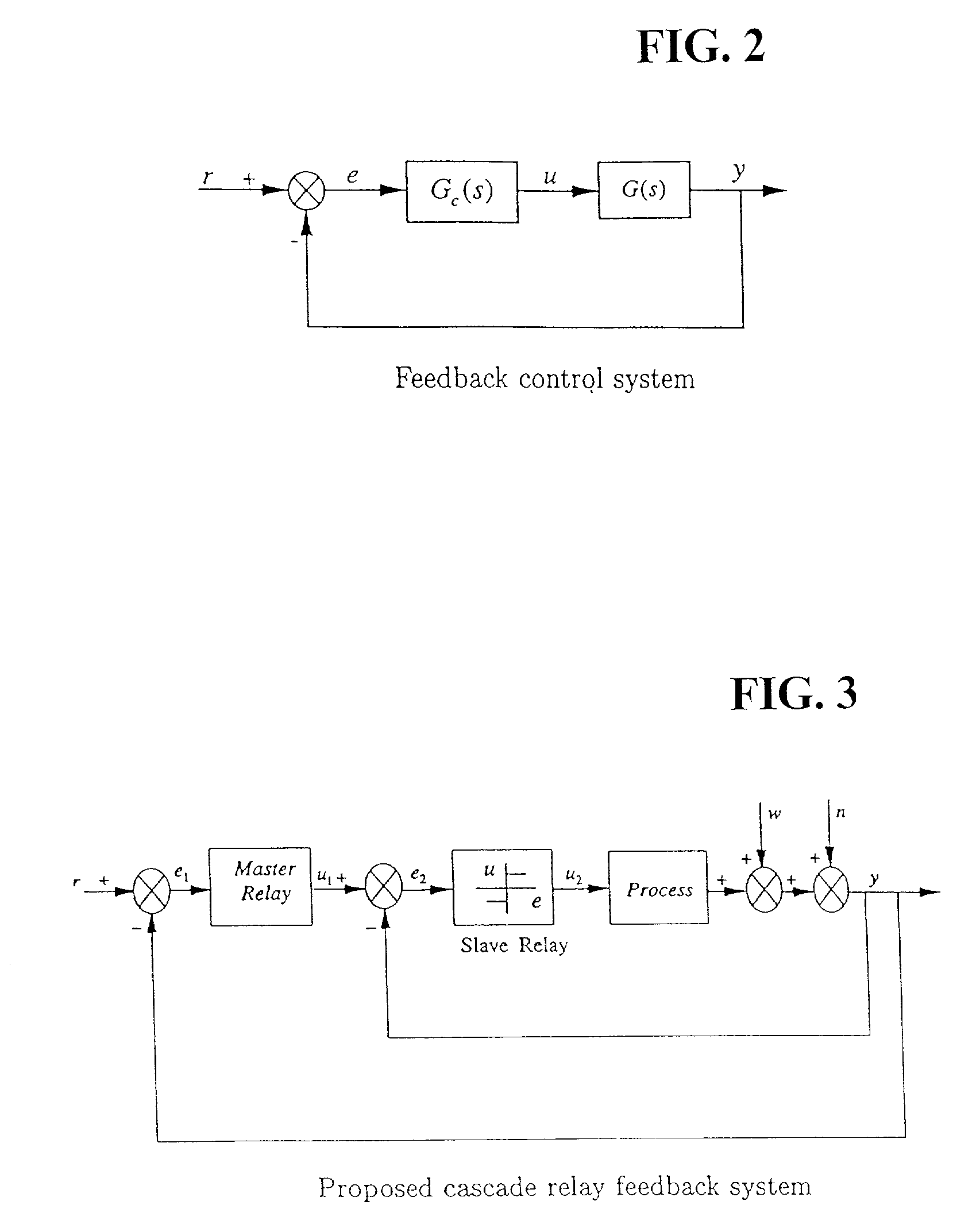

InactiveUS20020111758A1Accurate estimateImprove performanceAmplifier modifications to reduce noise influenceVoltage-current phase angleGuidelineTime delays

A simple yet effective and robust identification method is presented using process step responses for process identification that can provide a continuous transfer function with time-delay without iteration. A cascade relay provides accurate and reliable more points on the process frequency response. The internal model principle is employed to design single-loop controller of PID or high-order types with best achievable control performance for controller tuning, e.g. both single and multivariable cases are covered. The process identification and control design portions can be easily integrated into a control system auto-tuning package. Further, a general control scheme for disturbance rejection is given which can significantly improve disturbance rejection performance over conventional feedback systems with time delays. Practical issues such as noises, real-time implementation and tuning guidelines are also provided. The present invention provide general, systematic, effective, and applicable methods for process identification and control for a wide range of industries such as process and chemical plants, food processing, waste water treatment and environmental systems, oil refinery, servo and mechatronic systems, where a system model is needed for analysis, prediction, filtering, optimization and management, and / or where control or better control is required for their systems.

Owner:NAT UNIV OF SINGAPORE

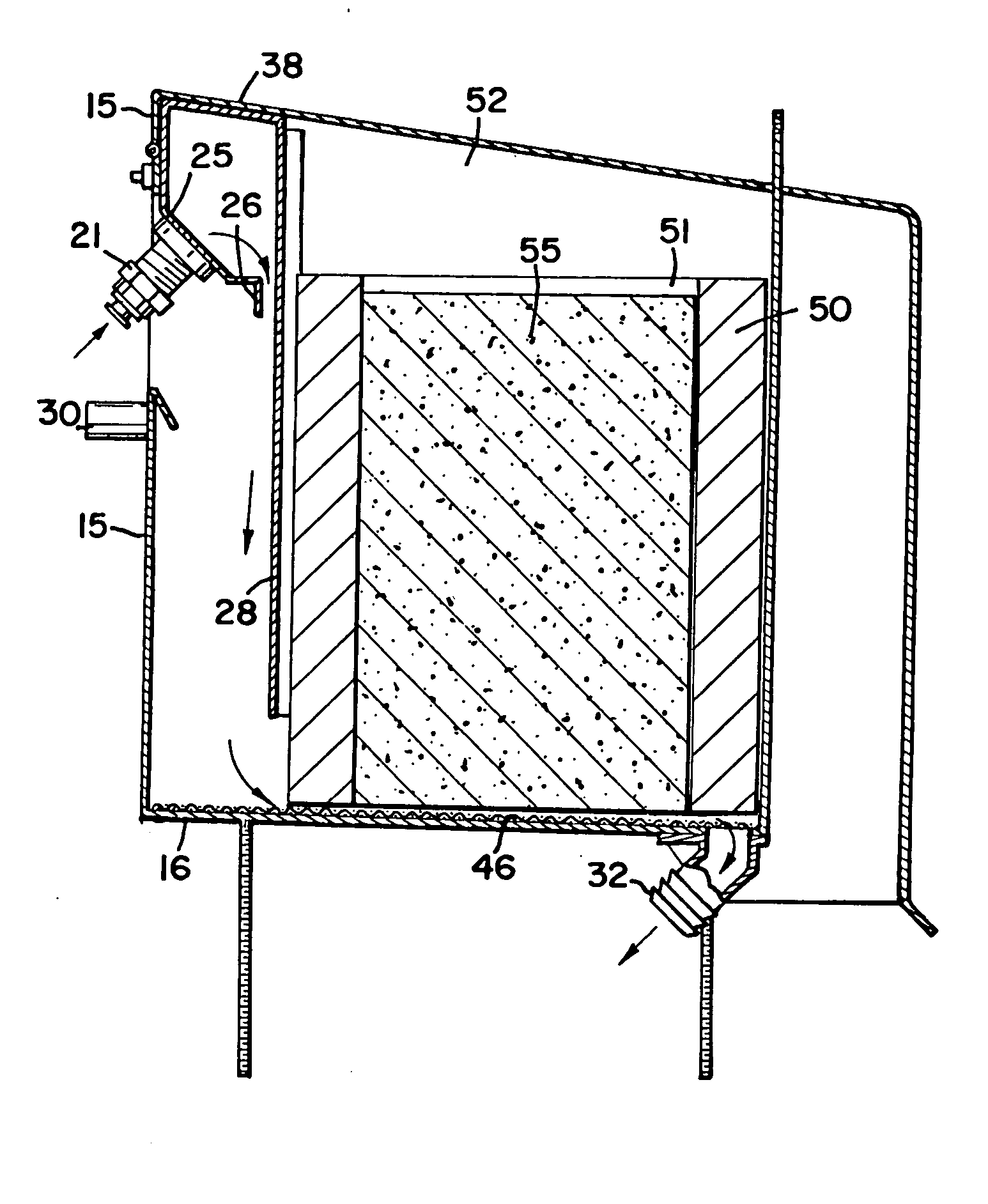

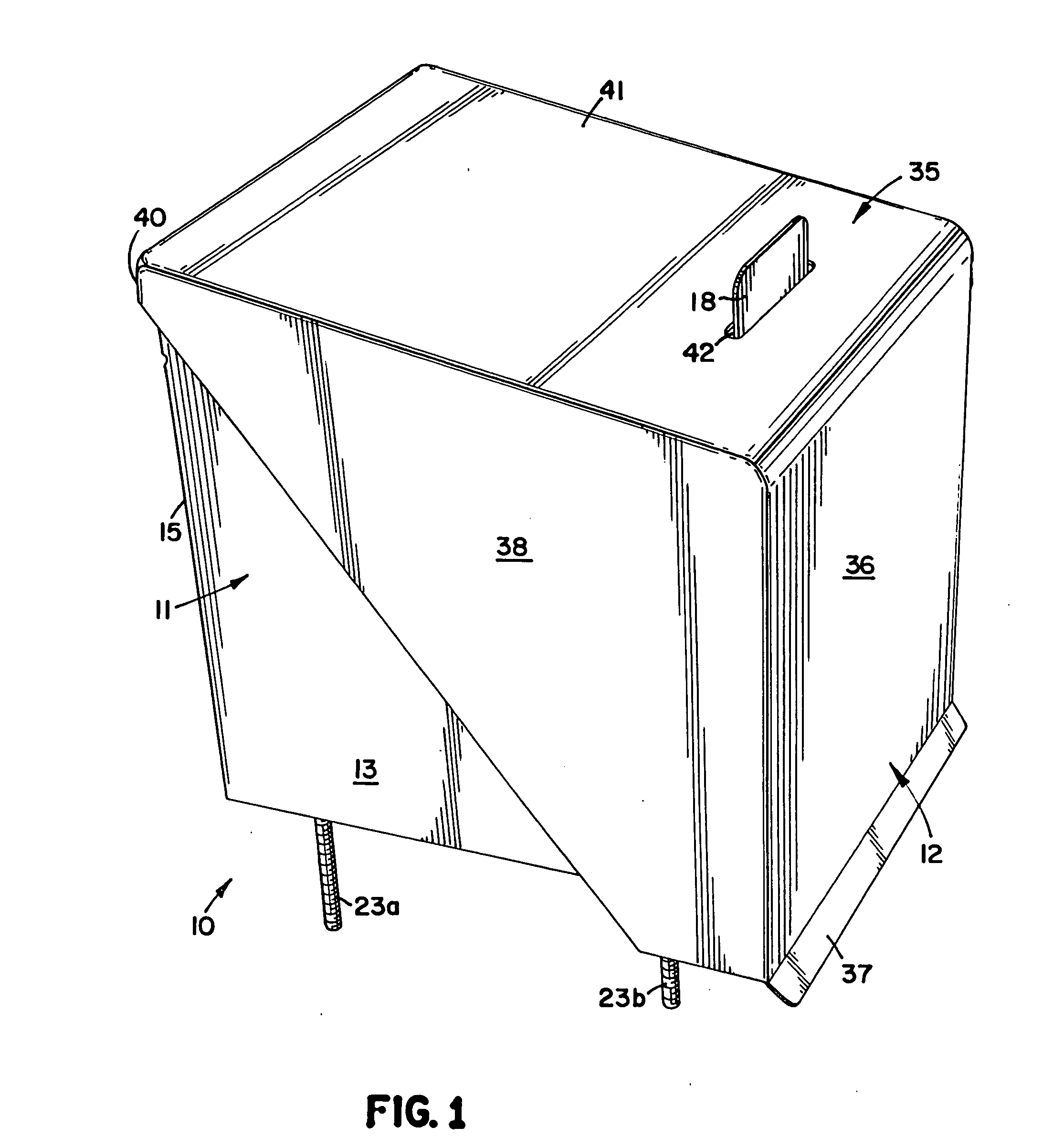

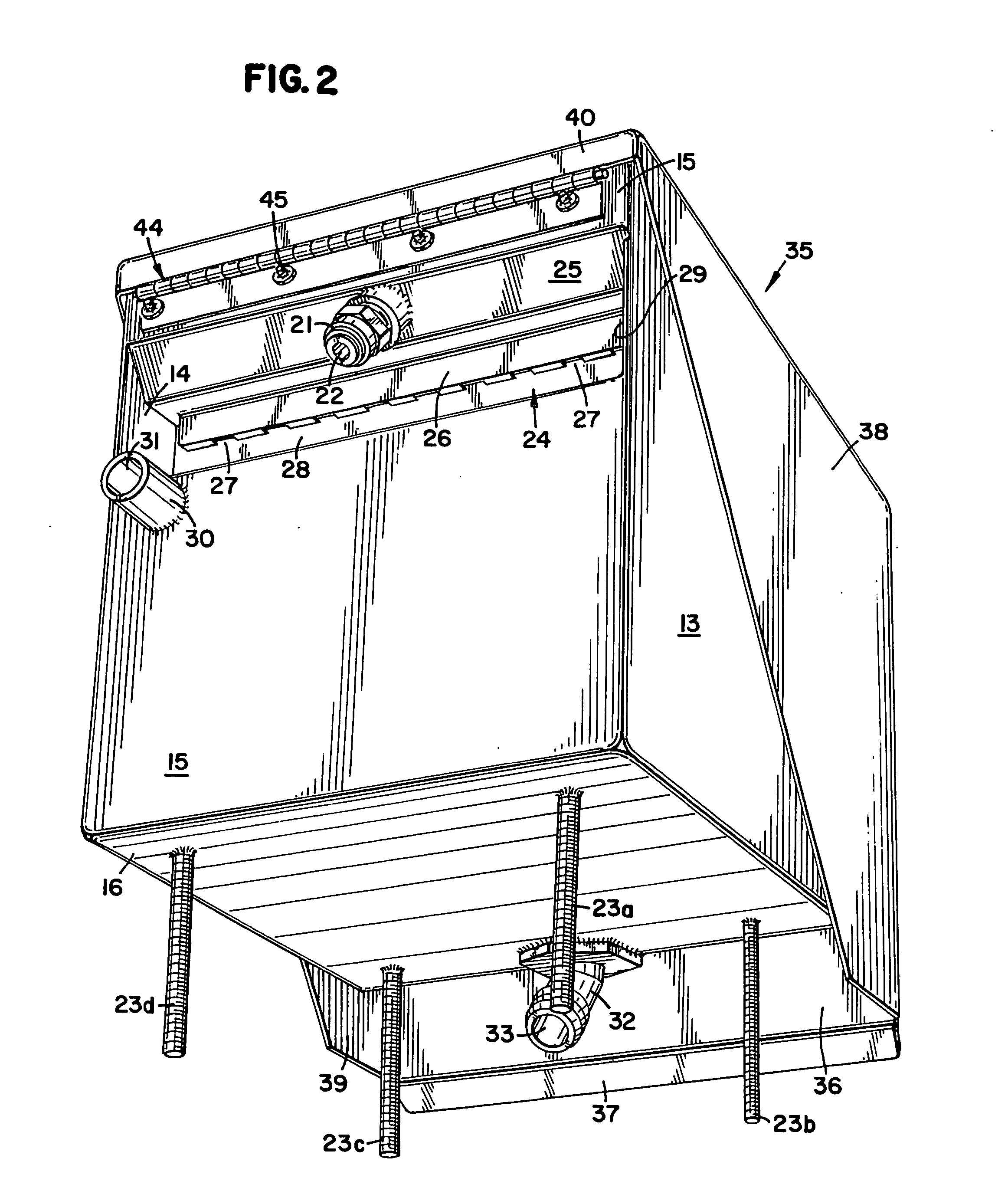

Solid rinse additive dispenser

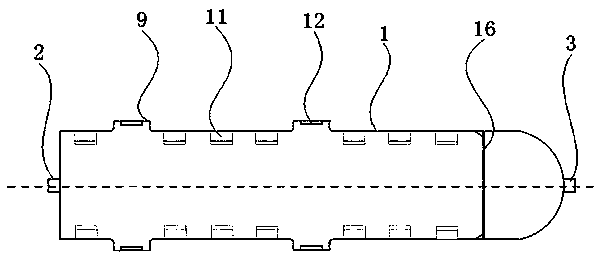

A product dispenser (10) for dispensing a use solution from a solid product includes a chamber (11) having a front (12), a back (15), and a bottom (16). The chamber (11) defines a cavity (20) configured and arranged to receive a solid product and a diluent. An inlet (21) proximate the back (15) of the chamber (11) is configured and arranged to receive the diluent, and an outlet portion (26) is in fluid communication with the inlet (21). The outlet portion (26) spans a length of the back (15) and includes a plurality of apertures (27) along the length of the back (15). The plurality of apertures (27) allows diluent to fan out along the back (15), flow down the back (15), and cascade evenly with relatively even pressure from proximate the back (15) toward proximate the front (12) of the chamber (11). A use solution outlet (32) proximate the bottom (16) and the front (12) of the chamber (11) allows diluent and a use solution to exit the chamber (11).

Owner:ECOLAB USA INC

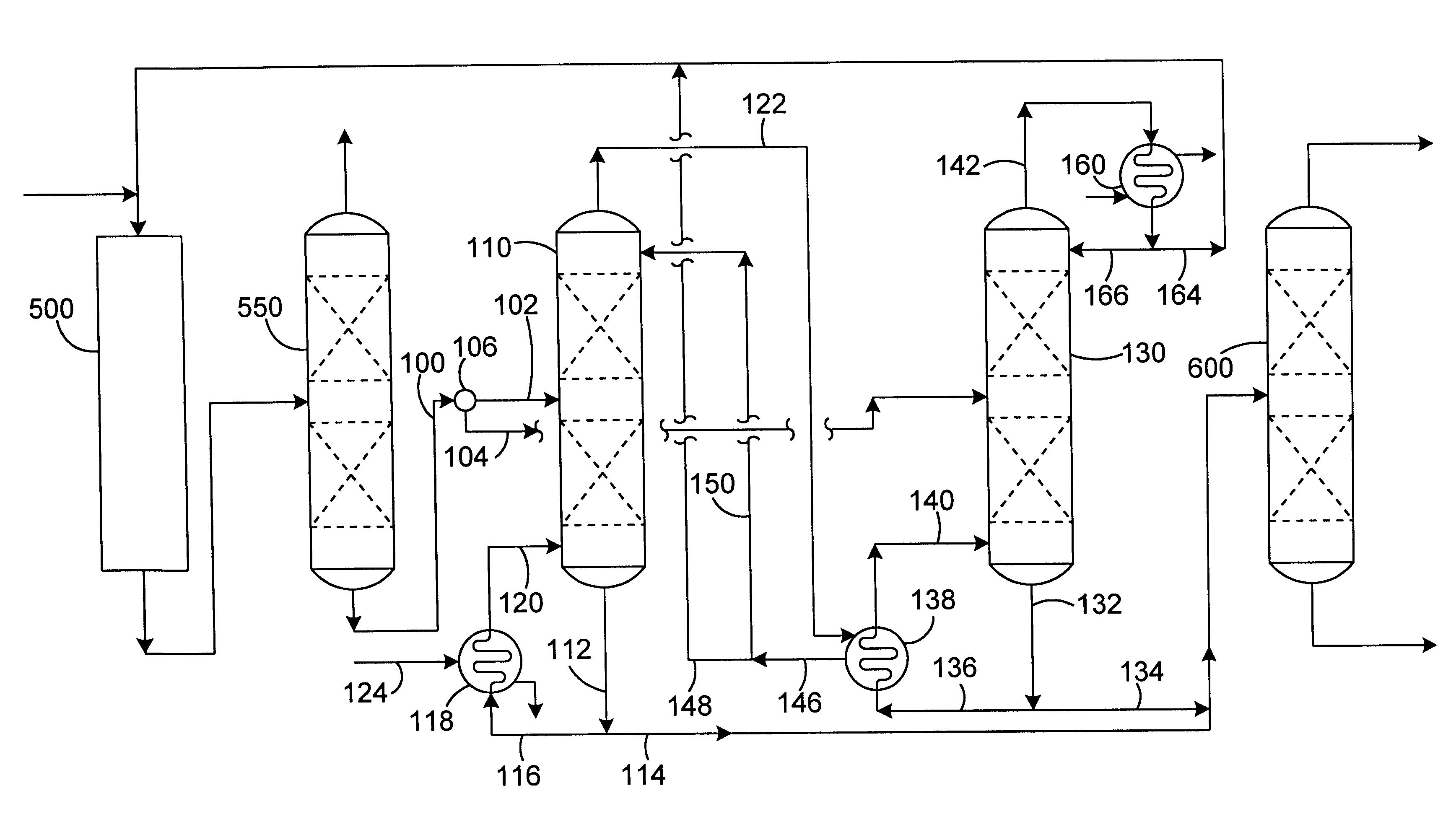

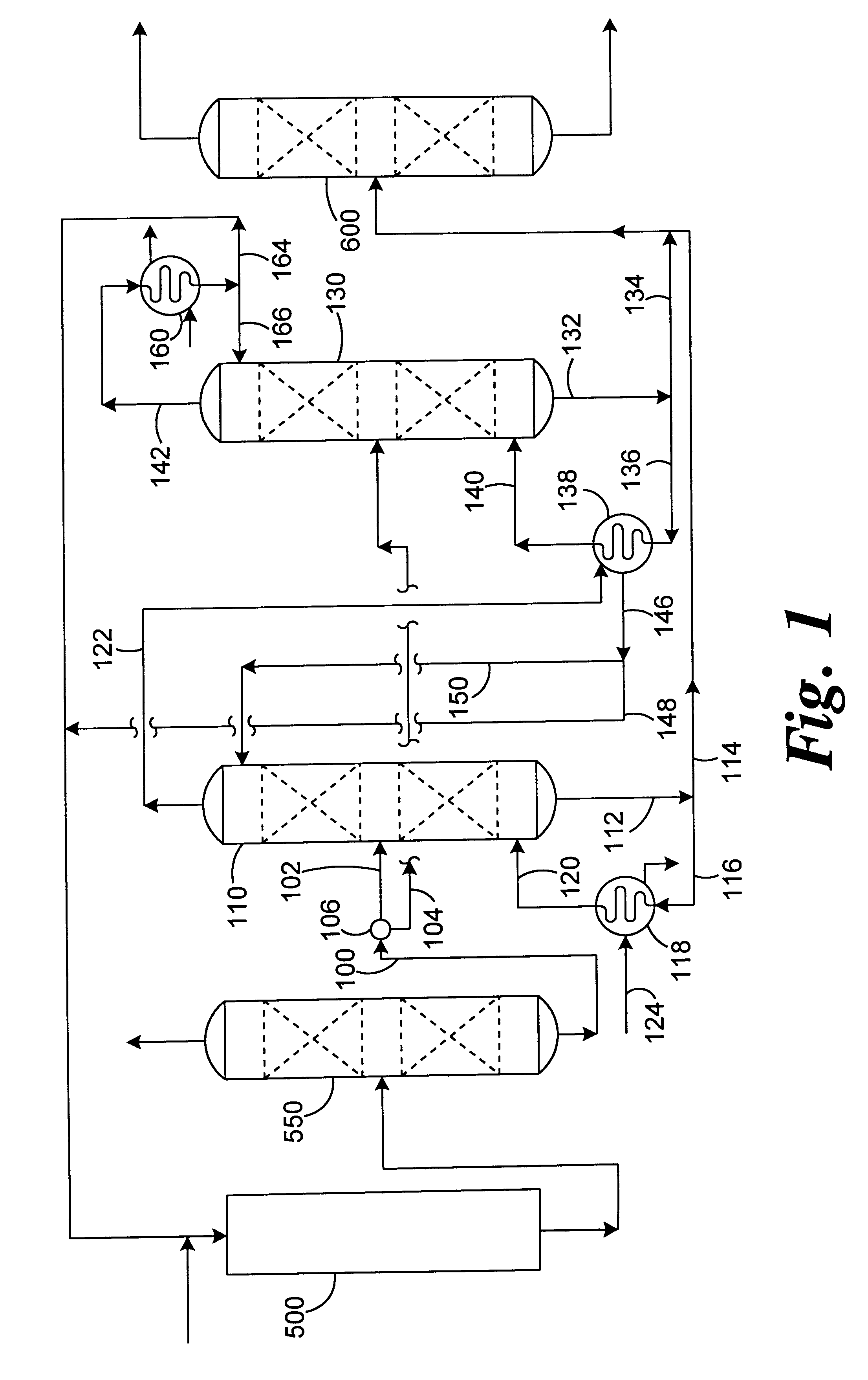

Cascade reboiling of ethylbenzene/styrene columns

InactiveUS6171449B1Reduce use costEfficient and economical approachDistillation regulation/controlDistillation in boilers/stillsCascadeEngineering

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

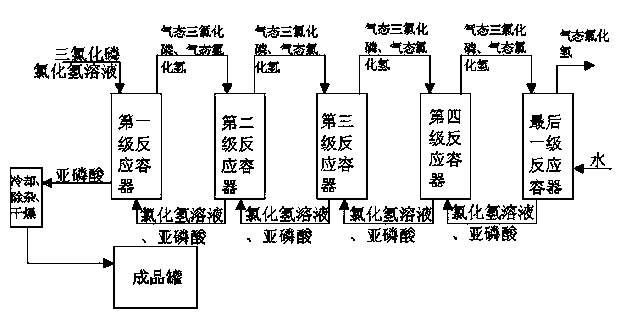

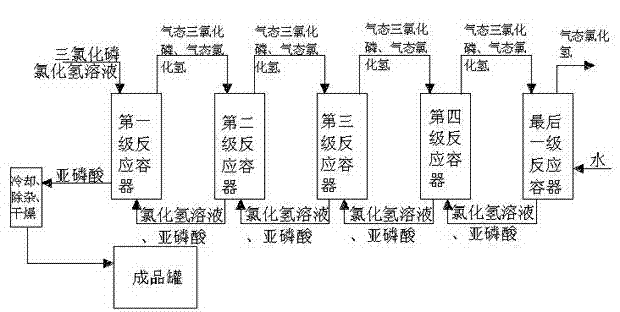

Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

The invention relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride, and in particular relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride under a mild reaction condition. According to the process, phosphorus trichloride and a hydrogen chloride solution are subjected to hydrolysis reaction in sequence in at least four stages of cascade reaction vessels under the condition that the temperature is 65-85 DEG C and the pressure is not more than 0.1Mpa to generate a phosphorous acid solution and gaseous hydrogen chloride. In the process, the phosphorus trichloride reacts with the water in a hydrochloric acid solution, the phosphorus trichloride is subjected to an exothermic reaction, the temperature of the process can reduce the hydrolysis rate to ensure that the reaction is performed mildly, and at least four stages of cascade bubbling reactions are adopted by the process, so that the utilization ratio of raw materials is improved, the phosphorus trichloride in the reaction vessel of the previous stage can enter the reaction vessel of the next stage, the content of the phosphorus trichloride in the reaction vessel of the previous stage is reduced in other ways, the intensity of the reaction is reduced again, the production safety is improved, and the service life of equipment is prolonged.

Owner:HENAN QINGSHUIYUAN TECH

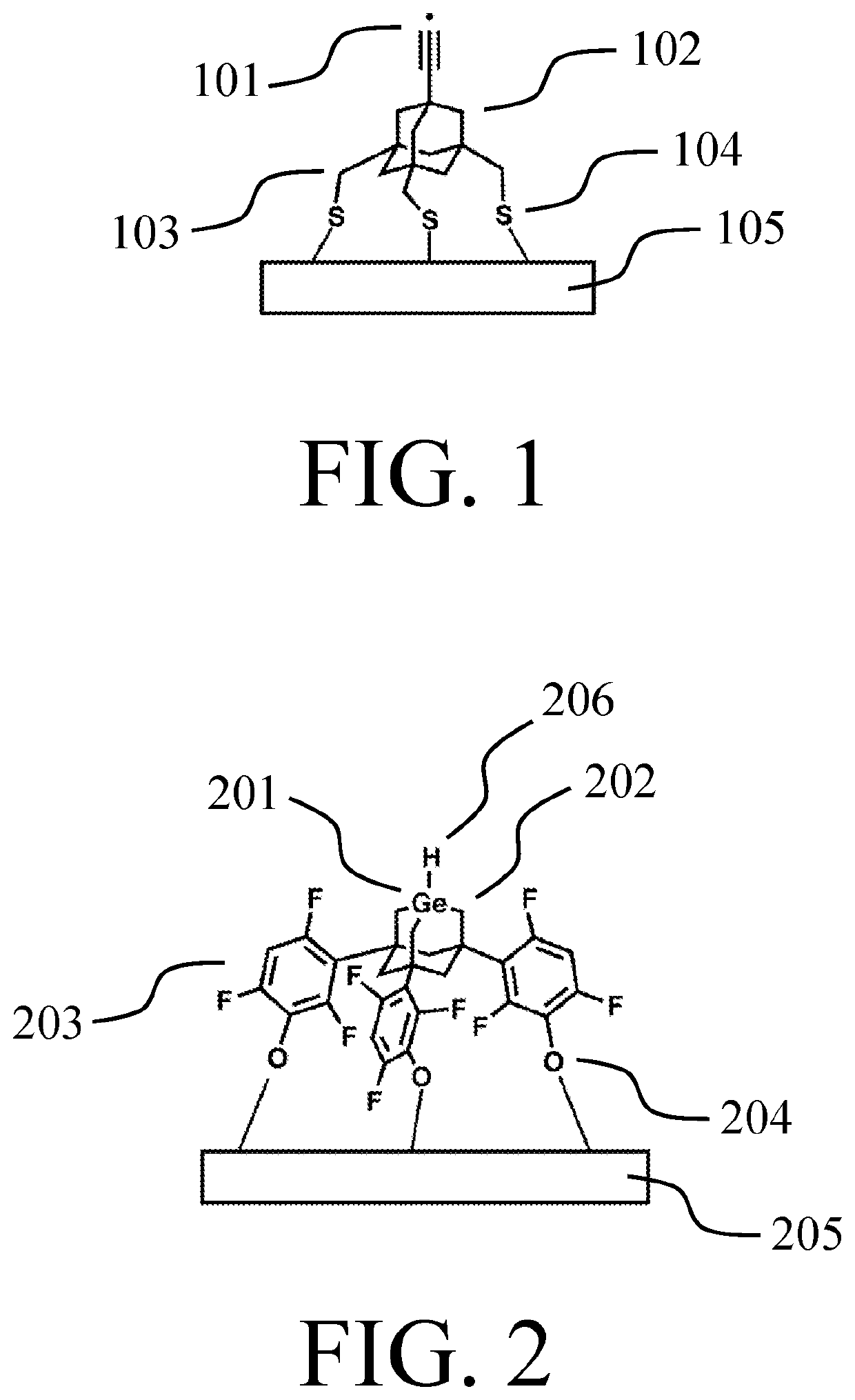

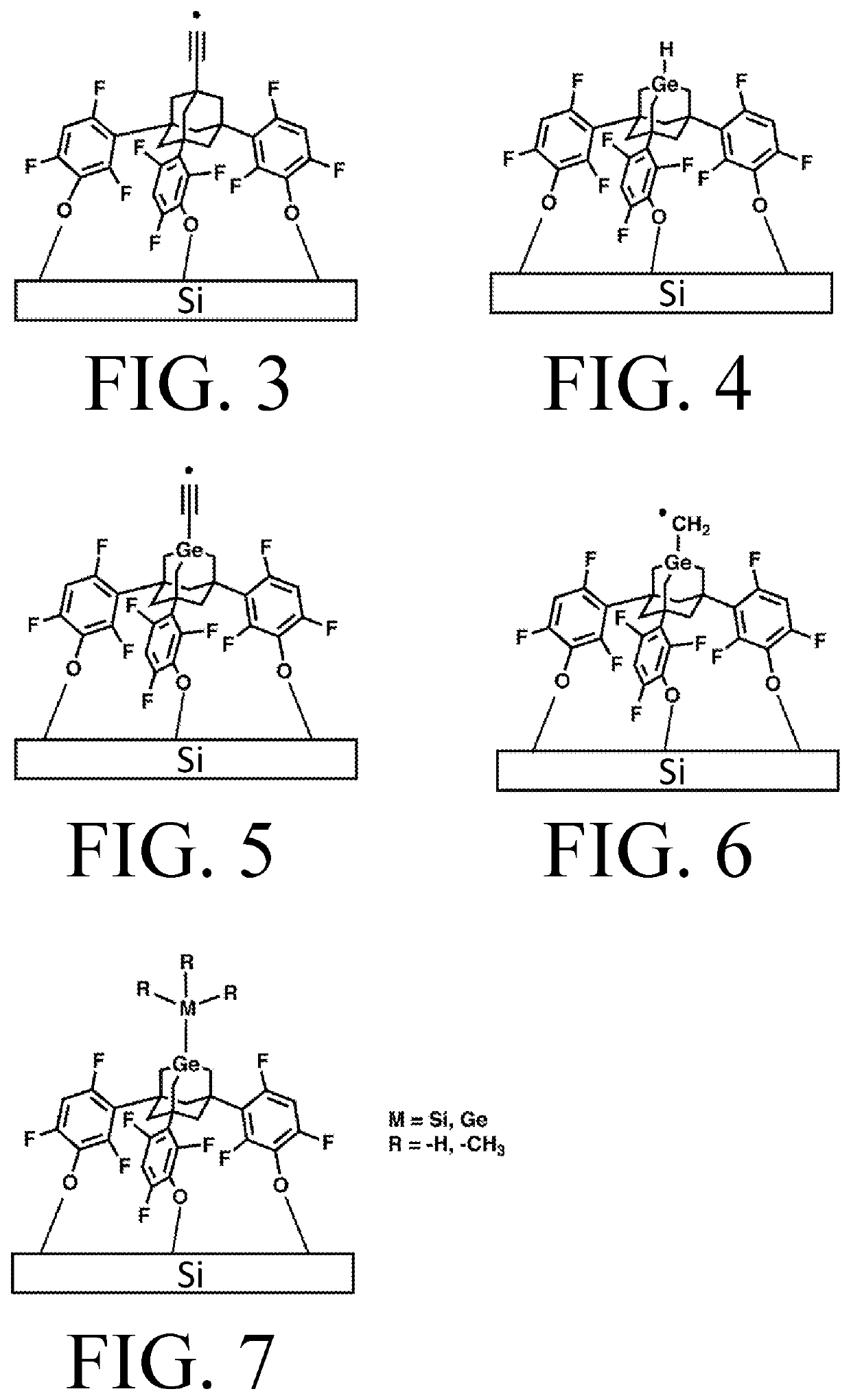

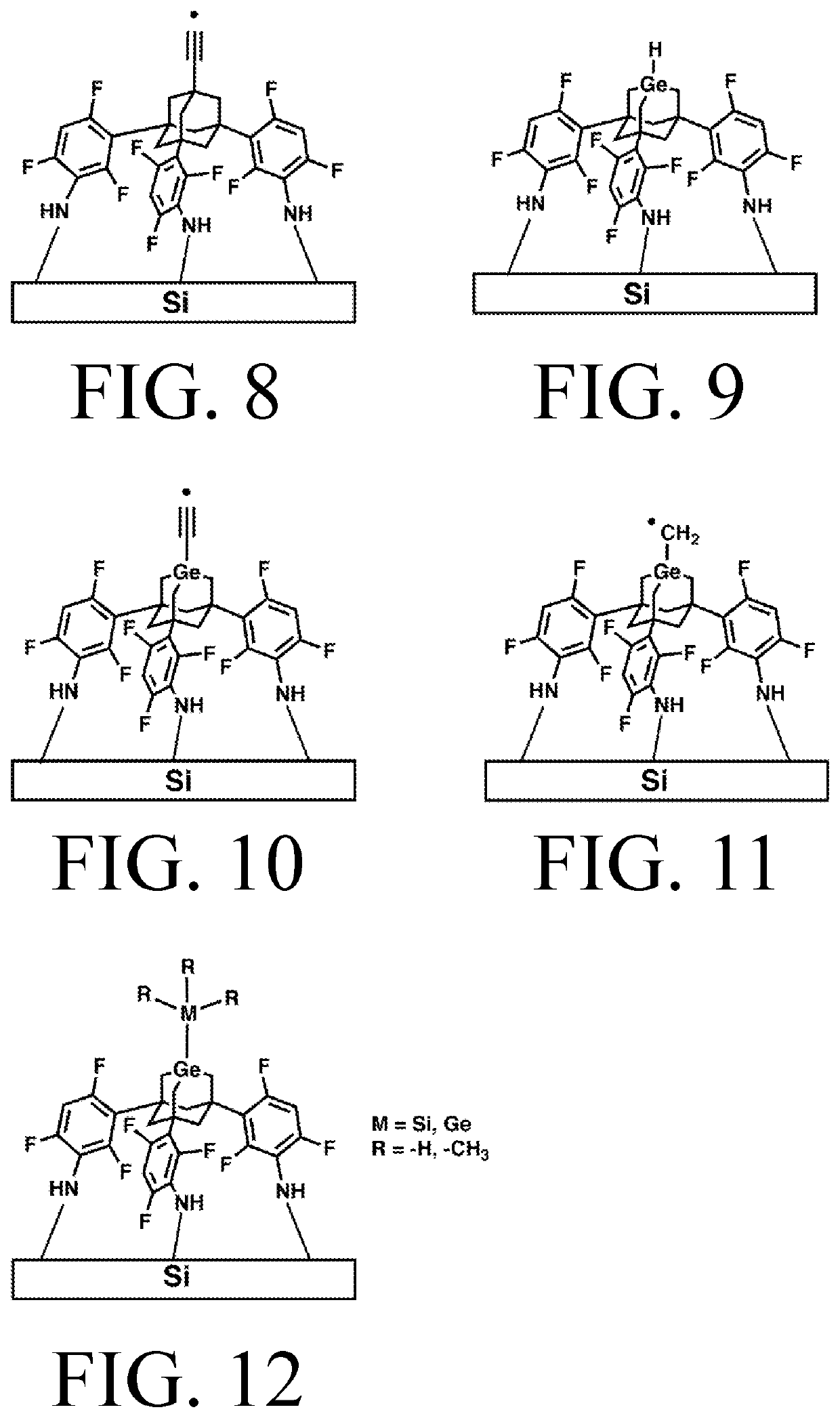

Systems and methods for mechanosynthesis

Improved methods, systems and devices for mechanosynthesis, including those that involve the bulk chemical preparation of tips, multiple tips on a presentation surface, and multiple tips used sequentially in a thermodynamic cascade. These improvements can simplify starting requirements, improve versatility, and reduce equipment and process complexity.

Owner:CBN NANO TECH INC

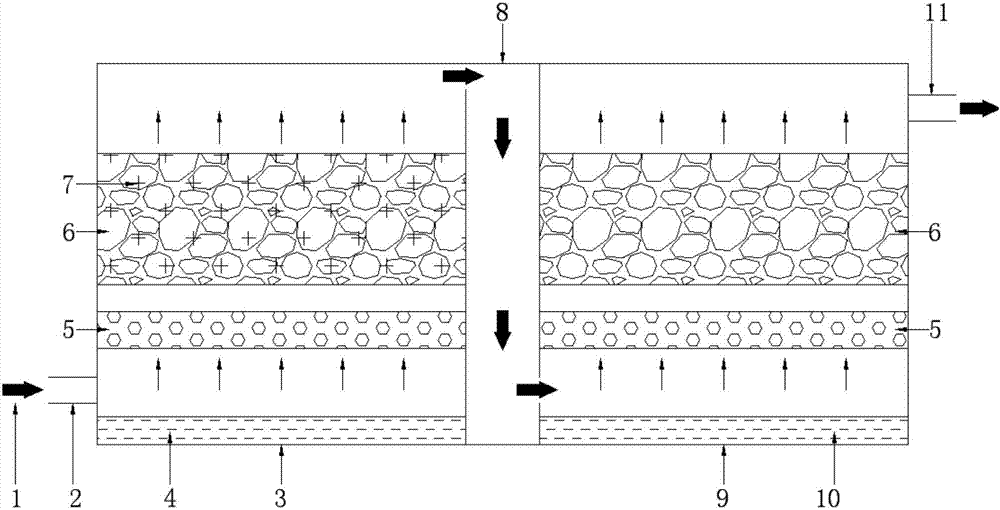

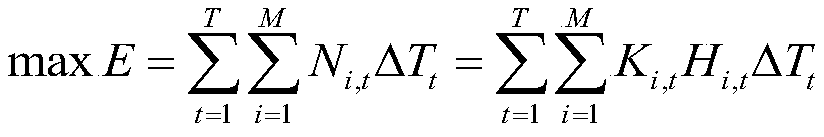

High-efficiency biological deodorizing technology and system

InactiveCN106975343AGet goodImprove stabilityGas treatmentDispersed particle separationSlagEnvironmental engineering

The invention relates to a high-efficiency biological deodorizing technology and system. A primary treatment unit in a biological reactor with an integral two-stage cascade structure is used for treating to-be-treated gas to remove most of pollutants; then a secondary treatment unit in the biological reactor with the integral two-stage cascade structure is used for treating pollutant gas from the primary treatment unit to remove residual pollutant, and the treated gas is exhausted out of the biological reactor; fillers in the primary treatment unit are volcanic rock, fishshell and sulfur and iron ore slag, and fillers in the secondary treatment unit are volcanic rock and fishshell. The high-efficiency biological deodorizing technology and system have the beneficial effects that the land occupation area of the biological deodorizing equipment and the total water usage amount of the biological deodorizing system are effectively reduced, the service life of the fillers is prolonged, the pressure loss of the system is reduced, the stability of the biological deodorizing system is enhanced, and the treatment efficiency of the biological deodorizing system on various pollutants is improved.

Owner:SHANGHAI YEMA ENVIRONMENTAL PROTECTION EQUIP ENG

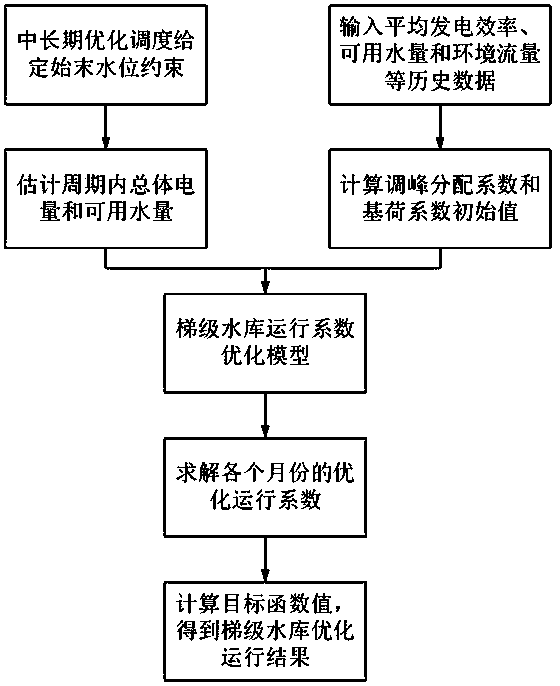

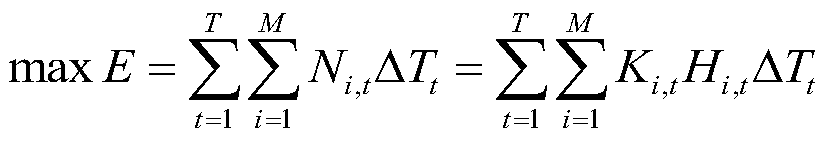

Cascade reservoir optimal operation method based on cascade reservoir operation coefficients

ActiveCN110942212AIncrease storage capacityImprove resource utilization efficiencyForecastingSystems intergating technologiesThermodynamicsNew energy

The invention relates to the technical field of cascade reservoir operation, in particular to a cascade reservoir optimal operation method based on cascade reservoir operation coefficients, which is characterized by comprising the following steps of: 1, calculating the cascade reservoir operation coefficients; 2, establishing a cascade reservoir operation coefficient optimization model; and 3, carrying out comprehensive solution. The method has the beneficial effects that two indexes of the reservoir peak distribution coefficient and the base load coefficient are provided, and how to distribute the residual electric quantity of the system among the cascade hydropower stations in the research period and how to distribute the total power generation capacity of the hydropower stations in timesequence are determined. The minimum of the maximum output power shortage rate in a month is taken as an optimization target; conditions such as cascade reservoir output constraint, reservoir capacity constraint, flow constraint and hydraulic relation constraint are considered, an optimization model of cascade reservoir operation coefficients is established, a cascade hydropower space-time optimization distribution result is obtained through solving, and the method has important guiding significance for long-term planning and construction of a new energy base.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID QINGHAI ELECTRIC POWER COMPANY +2

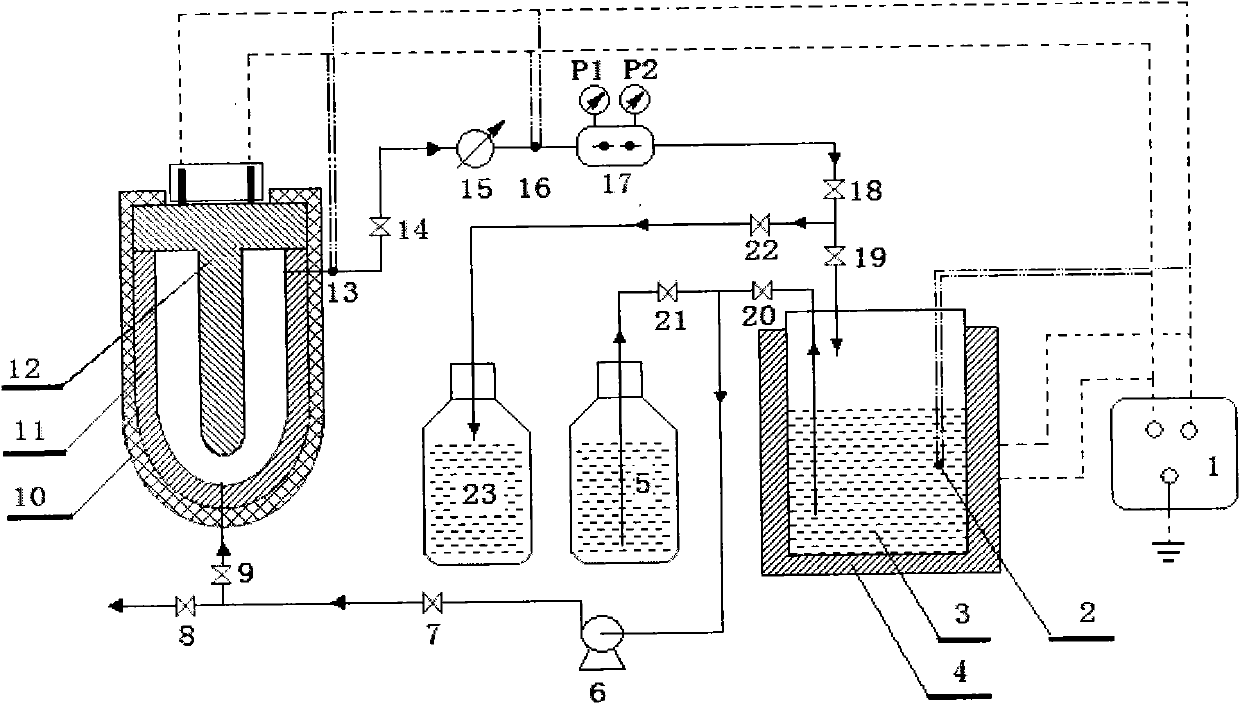

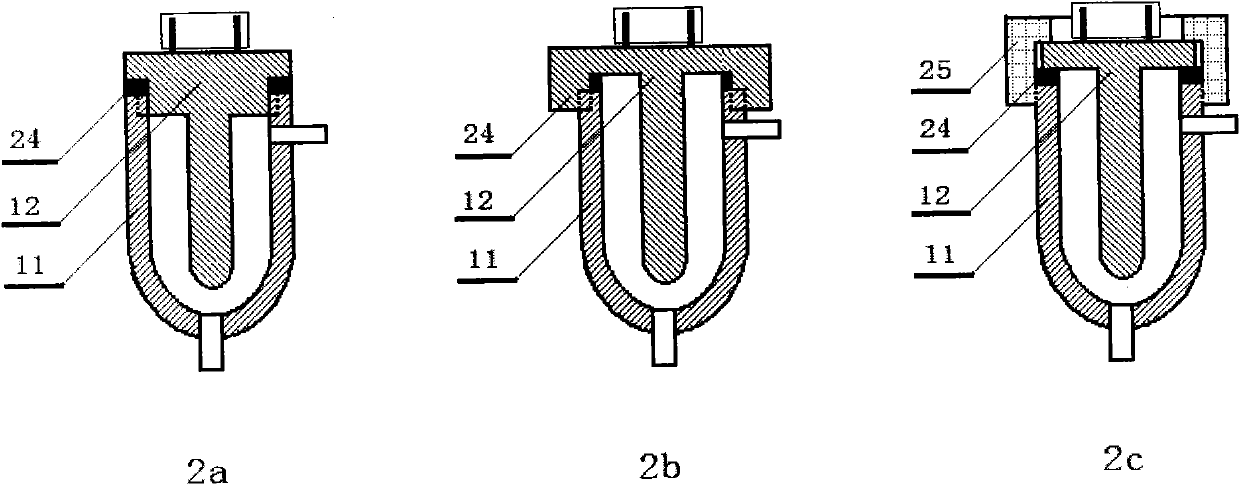

Evaluation method of oil-soluble scale inhibitor and tester

The invention provides an evaluation method of an oil-soluble scale inhibitor, comprising the steps of: firstly pre-heating a test raw material and keeping the temperature at a constant value; leading the test raw material to pass through an annular space between an electric heating bar and a scale test tube at a relatively low flow speed, heating up and scaling; adjusting and stabilizing the temperature of the scale test tube by means of temperature cascade control of the electric heating bar and the scale test tube outlet; adjusting and maintaining the pressure of a scale generating part by a constant pressure valve; finally performing cycle test for the flow of returning to the original pot after being cooled, wherein the scale deposition amounts at beginning and end of blank test and agent added test are used as the evaluation standard. The method has the characteristics of easy implementation, small process parameter fluctuation, strong practicability to test raw materials, good simulation of real use working conditions of oil-soluble scale inhibitor, accurate evaluation result, and safe and reliable test procedure. Simultaneously, the flow of the tester is simplified, the volume of the tester is reduced, the constant process parameters are ensured during the evaluation procedure, and the adaptability of the tester to different raw materials is widened.

Owner:洛阳康润石油化工科技开发有限公司

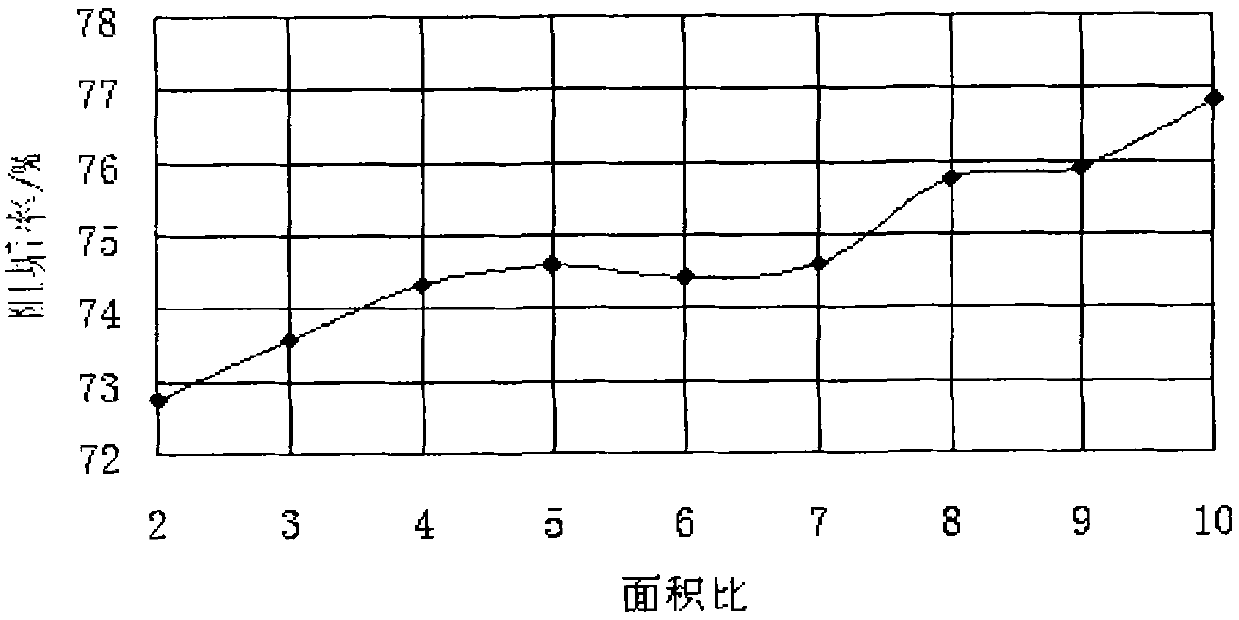

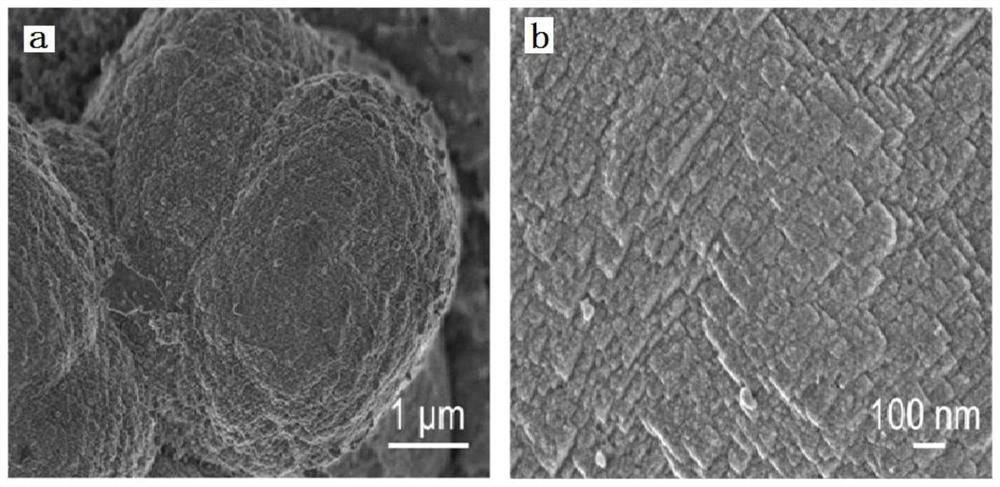

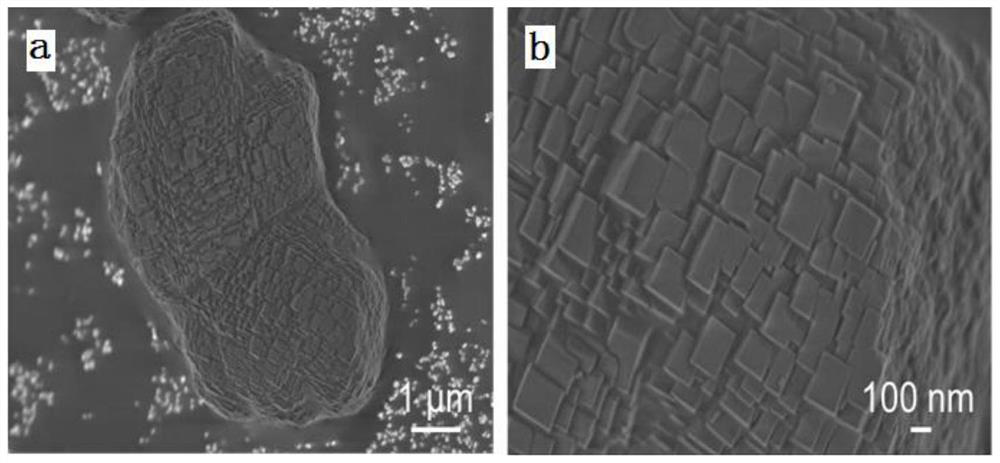

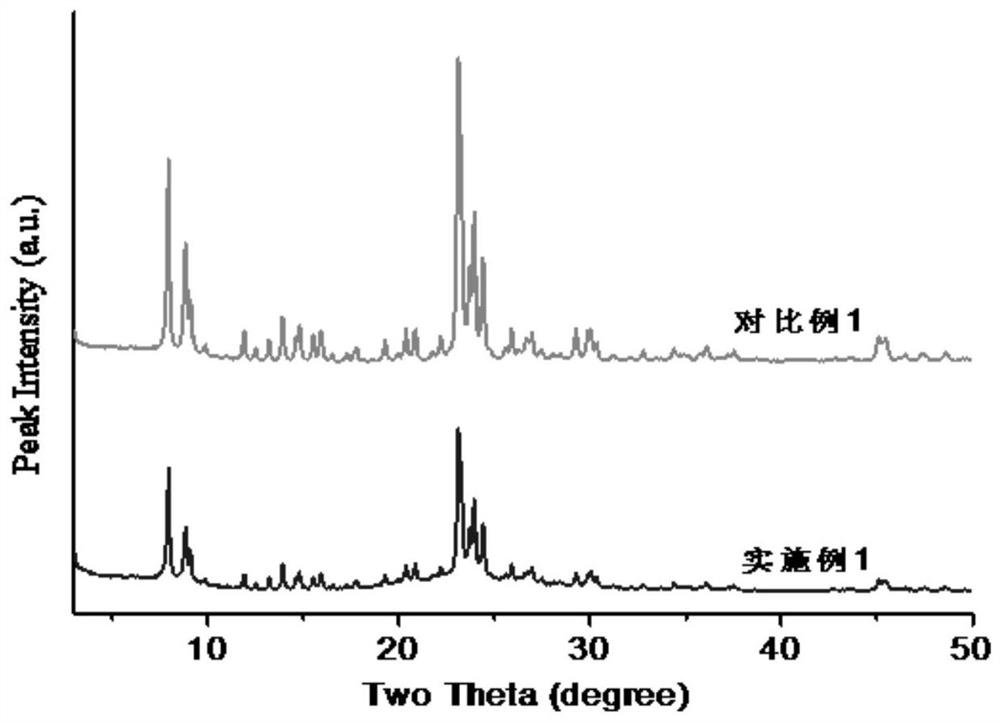

Preparation method of cascade pore molecular sieve

ActiveCN113149026AWide applicabilityImprove adsorption capacityFaujasite aluminosilicate zeoliteBulk chemical productionChemical treatmentMolecular sieve

The invention relates to a preparation method of a cascade pore molecular sieve, which comprises the following steps: (1) dispersing a silicon source, an aluminum source and / or a phosphorus source and a template agent in water, uniformly conducting stirring and mixing, placing the obtained mixture in a crystallization kettle, and conducting heating for 0.5-30 days in a drying oven at the heating temperature of 5-300 DEG C; (2) taking out a sample obtained in the step (1) from the oven, conducting filtering and separating, fully conducting washing with deionized water, and conducting drying; (3) roasting the dried sample obtained in the step (2), and removing the template agent in the molecular sieve while satisfying that the crystallinity of the obtained initial molecular sieve is 50-90% and the total crystallization sample is 100%; and (4) carrying out hydrothermal treatment or chemical treatment on the template agent removed sample obtained in the step (3) to finally obtain the cascade pore molecular sieve. According to the method, the compact and stable structure on the surface layer of the molecular sieve is dissolved while the pore channel structure of the molecular sieve is regulated and controlled, and the mass transfer diffusivity of the molecular sieve can be improved to a greater extent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process for producing high-quality melamine from urea

InactiveCN102015663ADelayed expansionSpeed up heat exchangeProcess control/regulationOrganic chemistryFluid phasePhysical chemistry

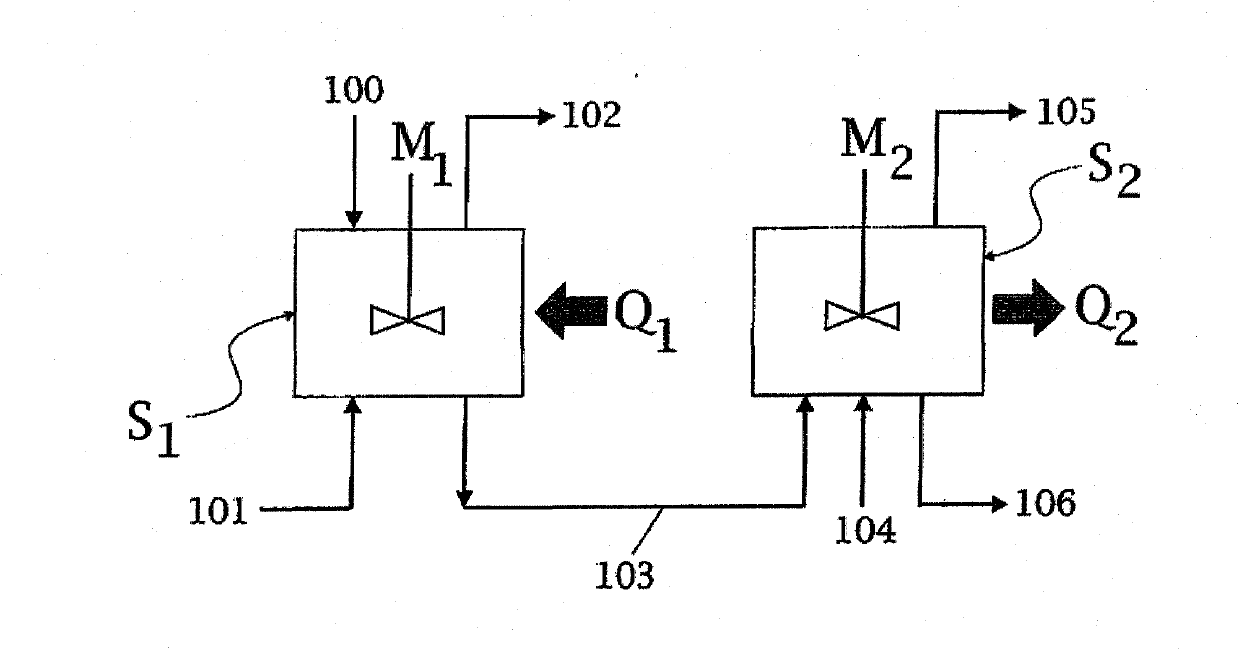

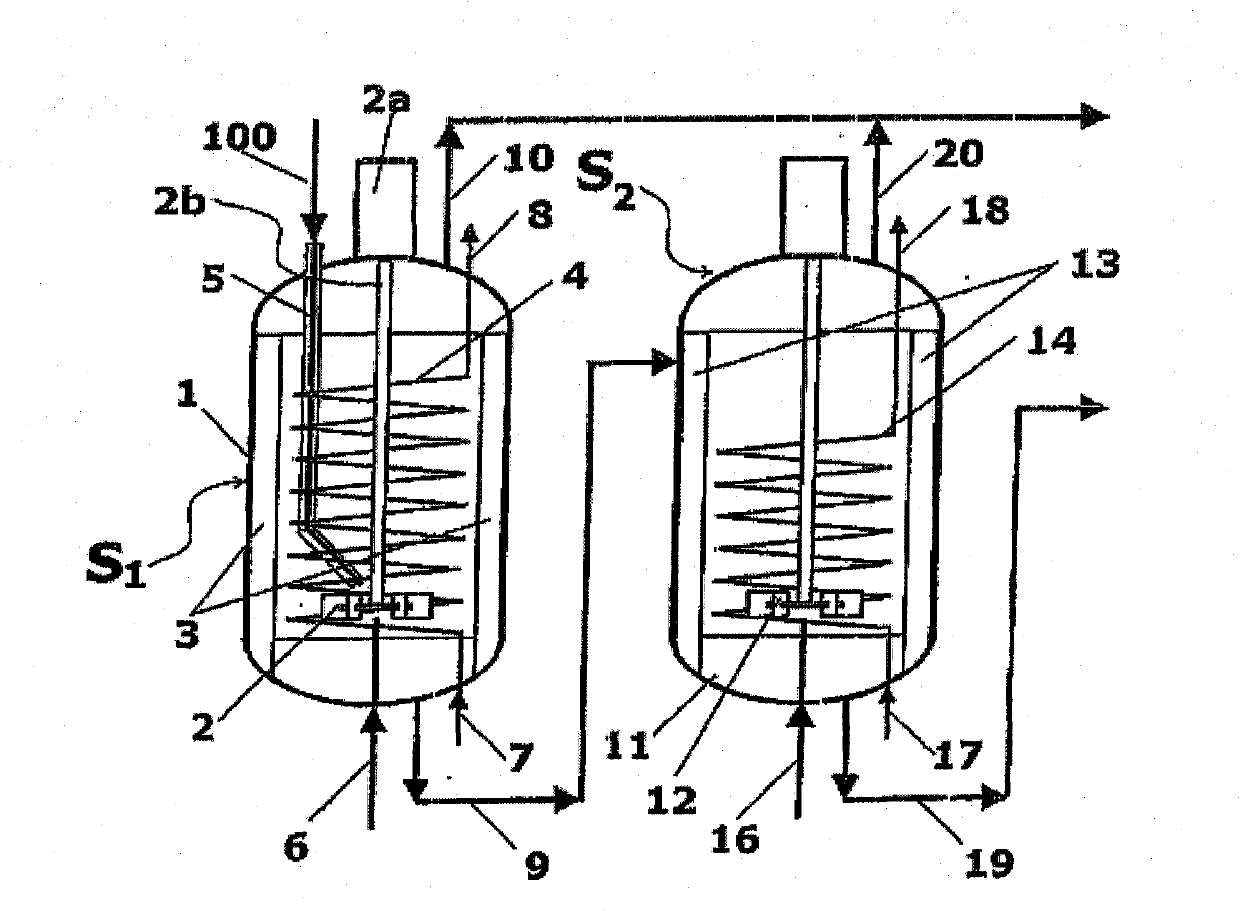

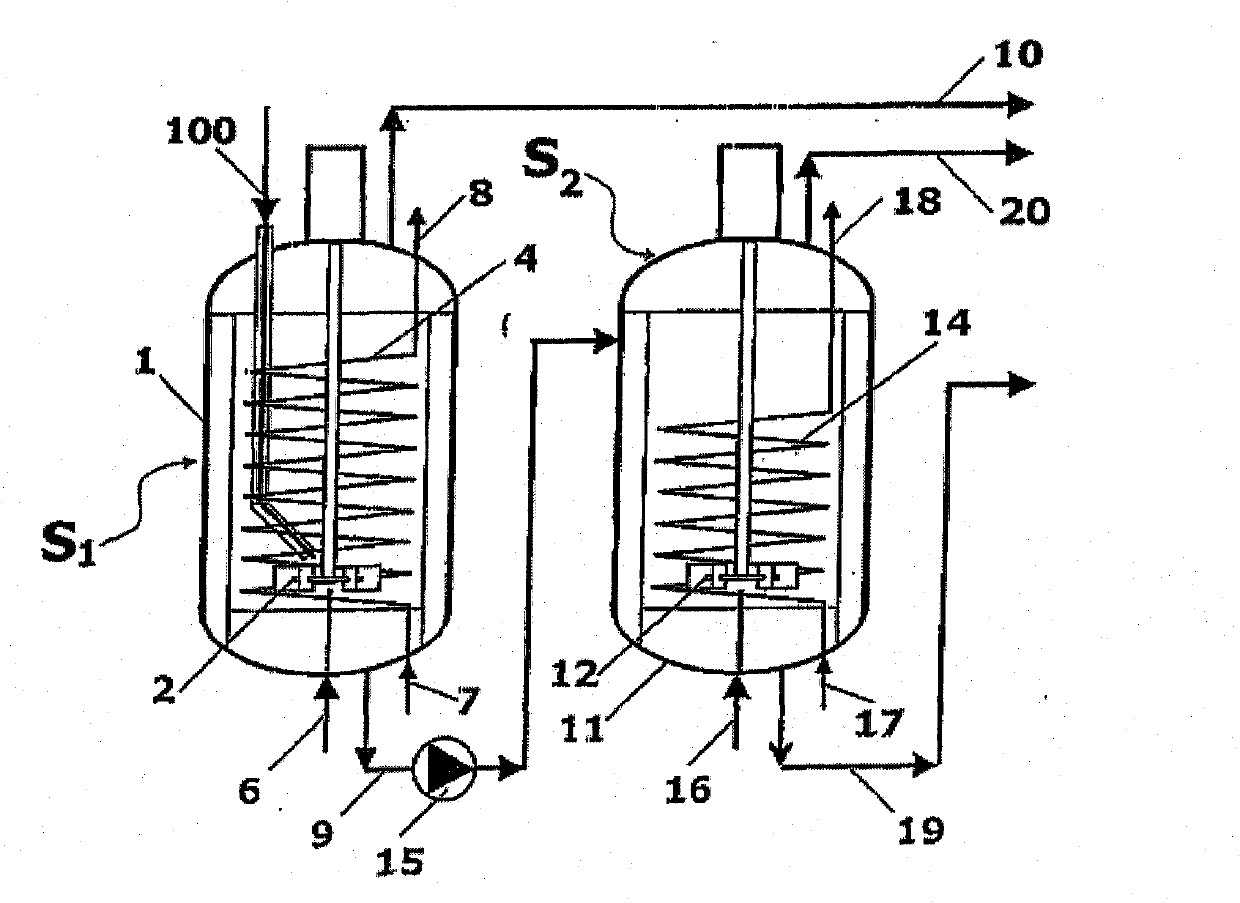

A process for high-pressure, liquid phase conversion of urea into melamine is disclosed, where molten urea is fed to a first reaction zone (S1 ) where the melamine melt is under mechanical agitation, and a heat input (Q1 ) is provided to maintain the endothermic reaction, and the liquid is then passed to a second reaction zone (S2) kept at a lower temperature and where further agitation is provided. Embodiments of plants adapted to carry out the process are also disclosed, including multiple stirred reactors in cascade and a single reactor with multiple internal compartments defining said first and second reaction zones.

Owner:UREA CASALE SA

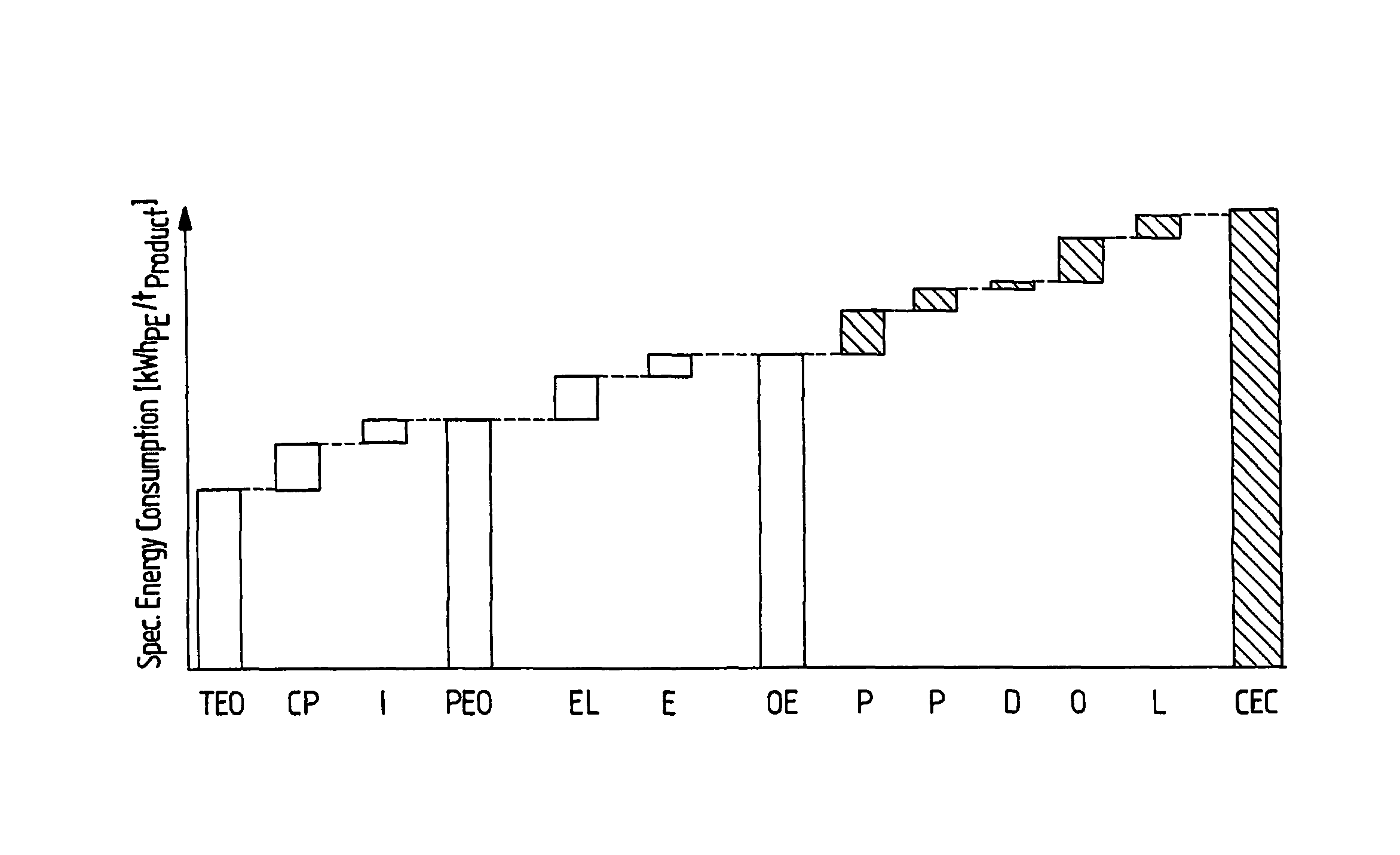

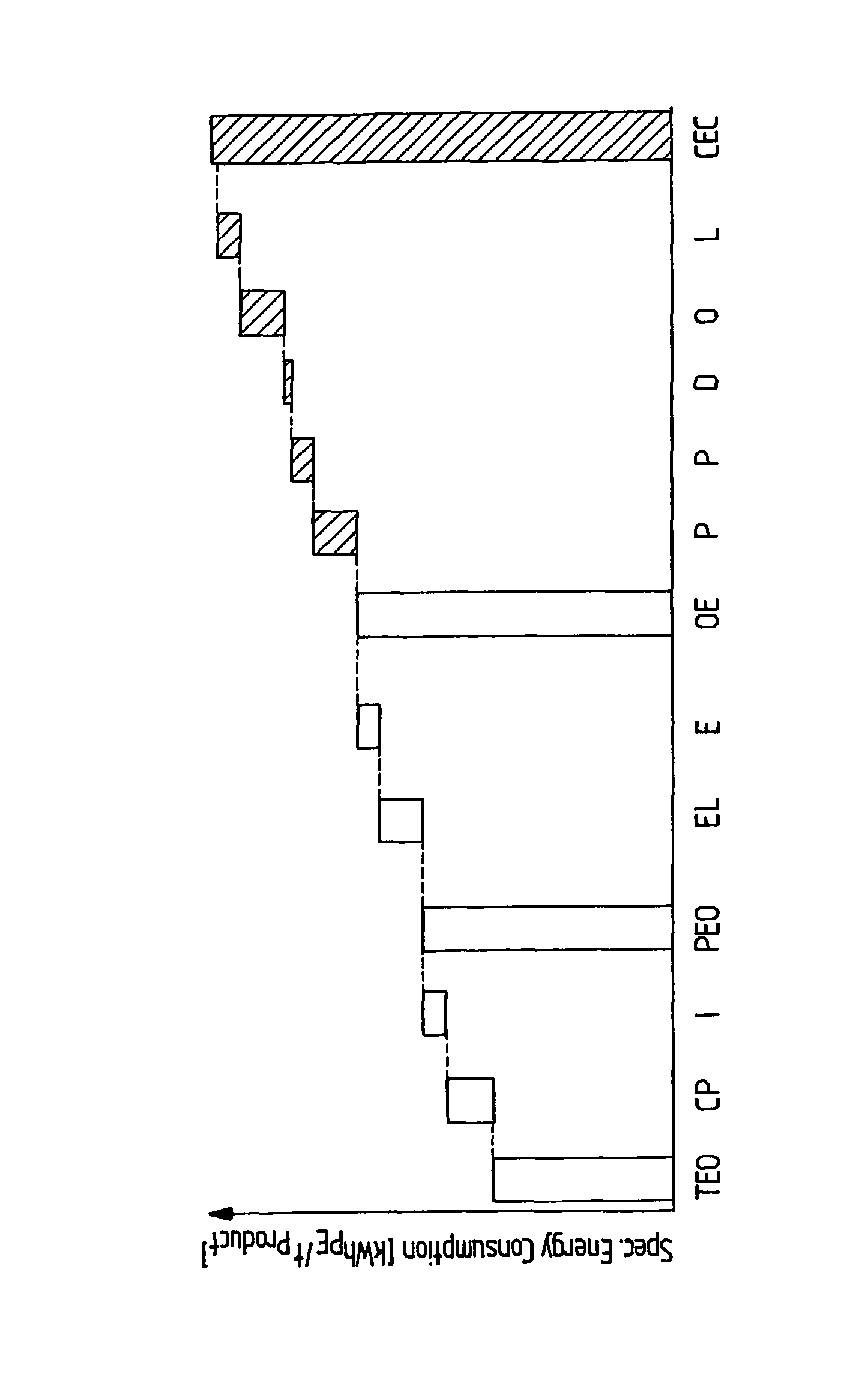

Method and system for monitoring and analyzing energy consumption in operated chemical plants

ActiveUS8554381B2Ensures sustainabilityShort time intervalMechanical power/torque controlSampled-variable control systemsAgricultural engineeringCascade

A computer-implemented method for monitoring and analyzing energy consumption of a chemical plant in operation. Plant type specific theoretical energy consumption optimum value based on a corresponding modeled plant are determined, parameters contributing to increased energy consumption are identified and grouped. Energy consumption of a plant is periodically graphed starting from the theoretical energy consumption optimum value and getting up as an energy cascade to a current energy consumption, by adding the provided, partly retrieved single energy consumption rates of the respective parameters in groups such that the resulting energy cascade allows to monitor at least a part of the individual parameters and to automatically compare the current energy consumption of the at least one plant with an energy consumption of another plant and / or with a previous energy consumption of the at least one plant with respect to the individual parameters. Furthermore, an appropriate system is provided.

Owner:COVESTRO DEUTSCHLAND AG

Method of preparing pentaerythritol

InactiveUS20100152500A1Reduce energy consumptionIncreased cost-effectivenessOrganic compound preparationOxygen compounds purification/separationCost effectivenessPentaerythritol

A method of preparing monopentaerythritol, dipentaerthritol, and sodium formate through high temperature condensation and cascade recrystallization is disclosed. The method lowers the energy consumption dramatically and improves the cost-effectiveness by carrying out the reaction in a non-low-temperature zone, and thereby avoiding the requirement for refrigeration. The method alleviates the difficulty of separation and improves the product quality by means of cascade separation process, and thereby avoiding the low purity from a single separation. In addition, the mother liquor obtained after each separation step is recycled to the previous step as the recycling liquor, which avoids discharging waste, increases the product yield and lowers raw materials consumption.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

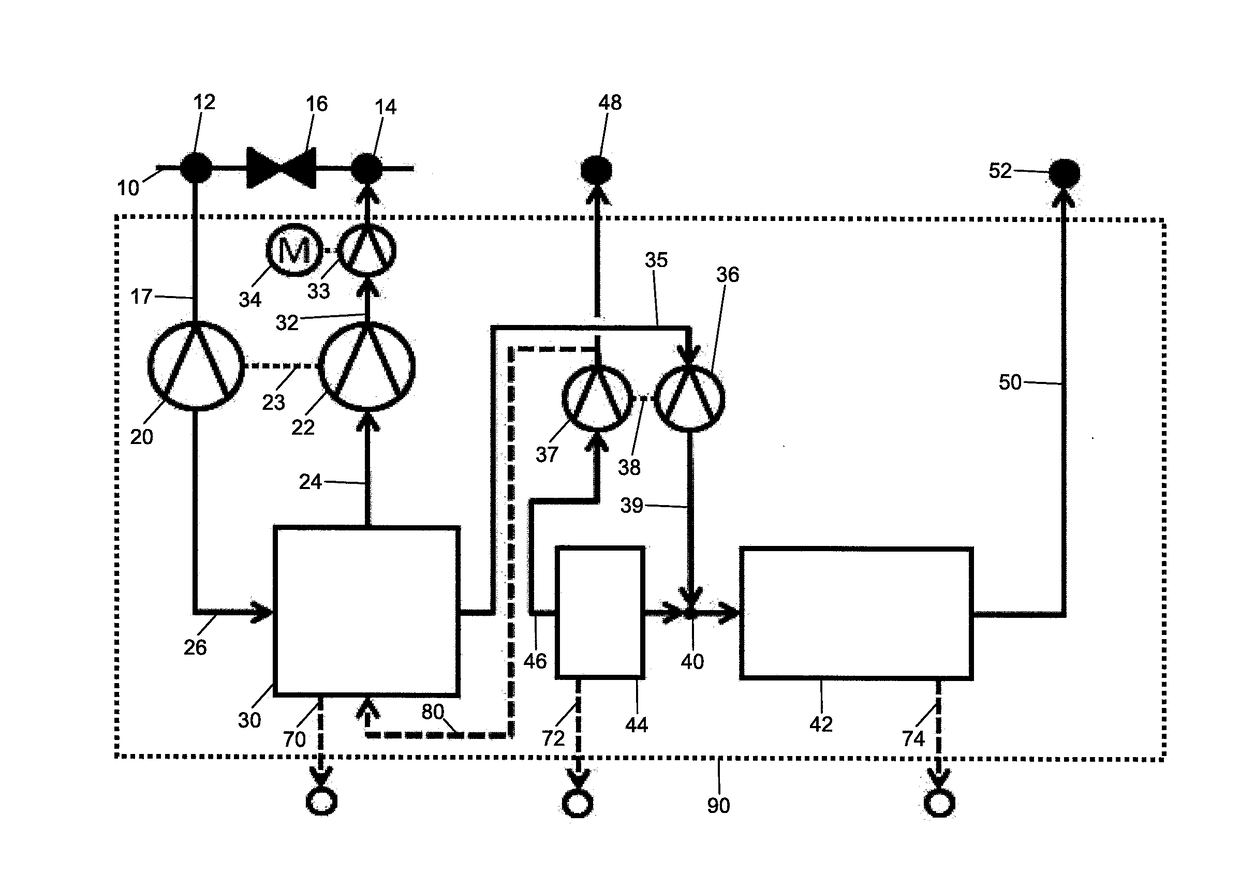

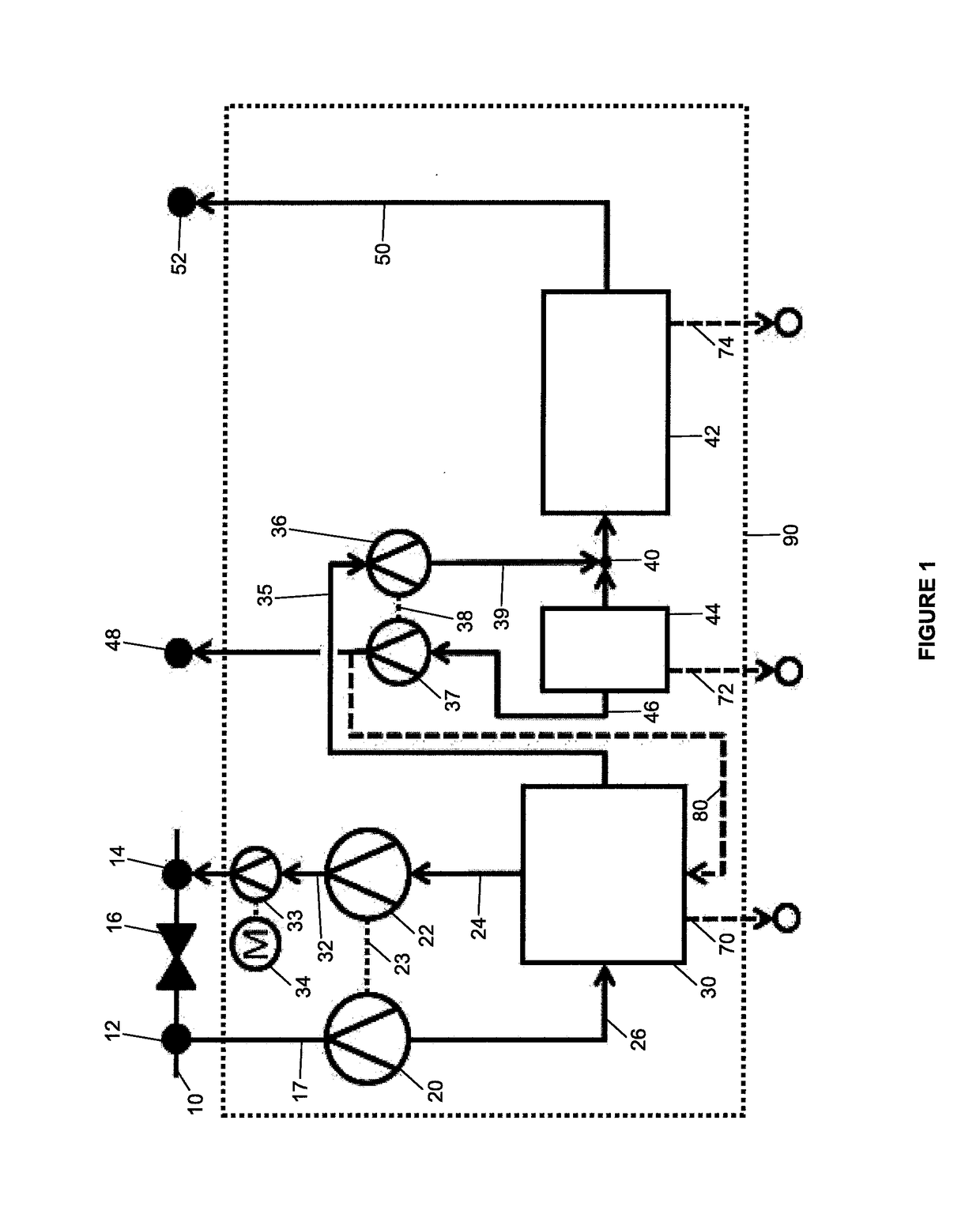

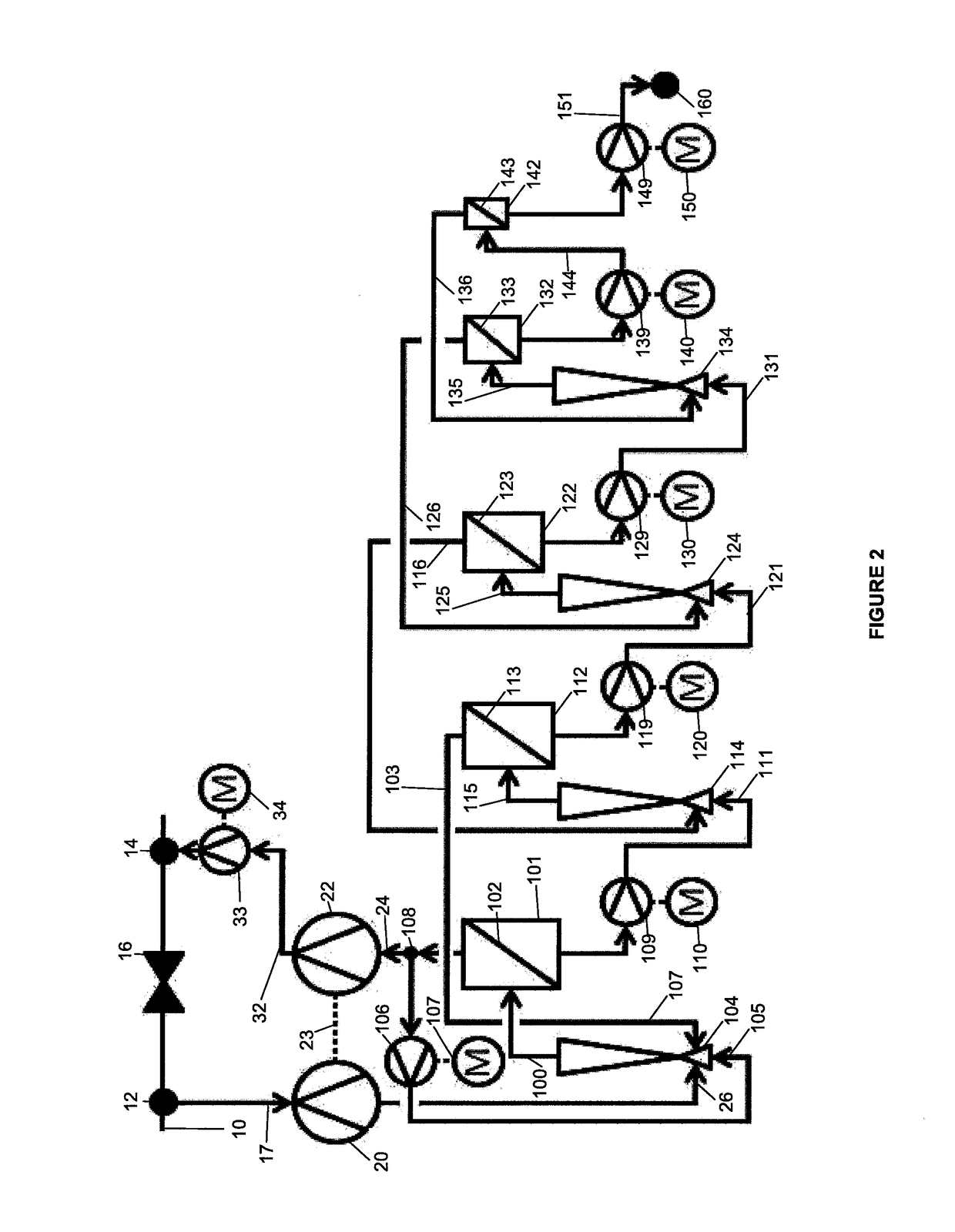

Device for the removal and separation of helium isotopes from natural gas

InactiveUS20170114294A1Efficiently separates HeliumMinimizing pressure differenceSemi-permeable membranesGas treatmentCompressed natural gasIsotopes of helium

This disclosure presents a new device for the removal and separation of isotopes of Helium in Compressed Natural Gas, based on a system with two cascades operating together to increase, in the first cascade, the concentration of Helium in the cascade head, and at the tail of the same cascade, Helium-depleted Compressed Natural Gas is discharged, while the second cascade, fed from the head of the first cascade, allows separation of the isotopes of Helium-3 and Helium-4, discharging Helium-3 through the head of the second cascade, while Helium-4 is discharged through the tail of the second cascade, with a configuration that is efficient from the energy consumption standpoint, while using a small number of rotating parts.

Owner:INVAP SE

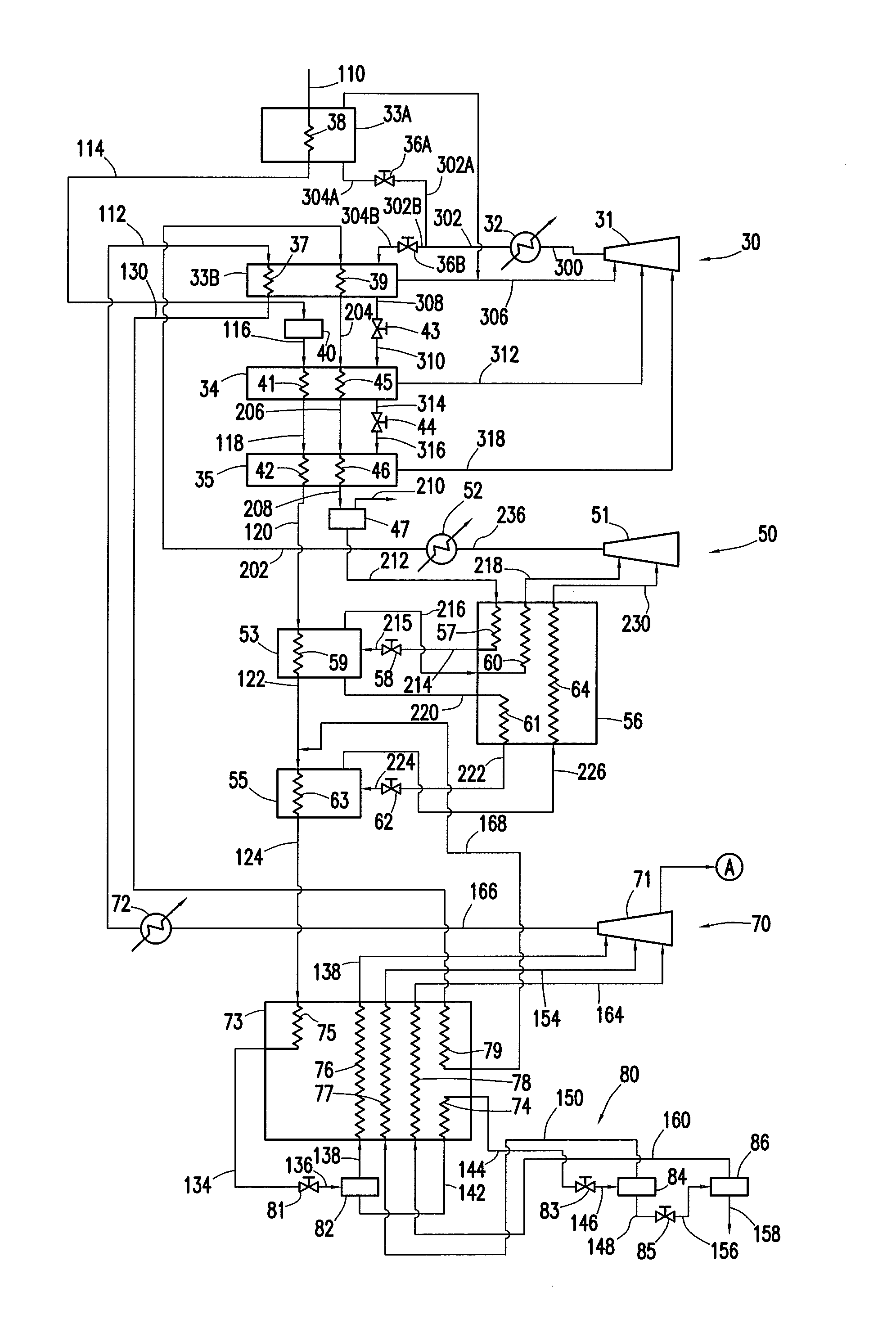

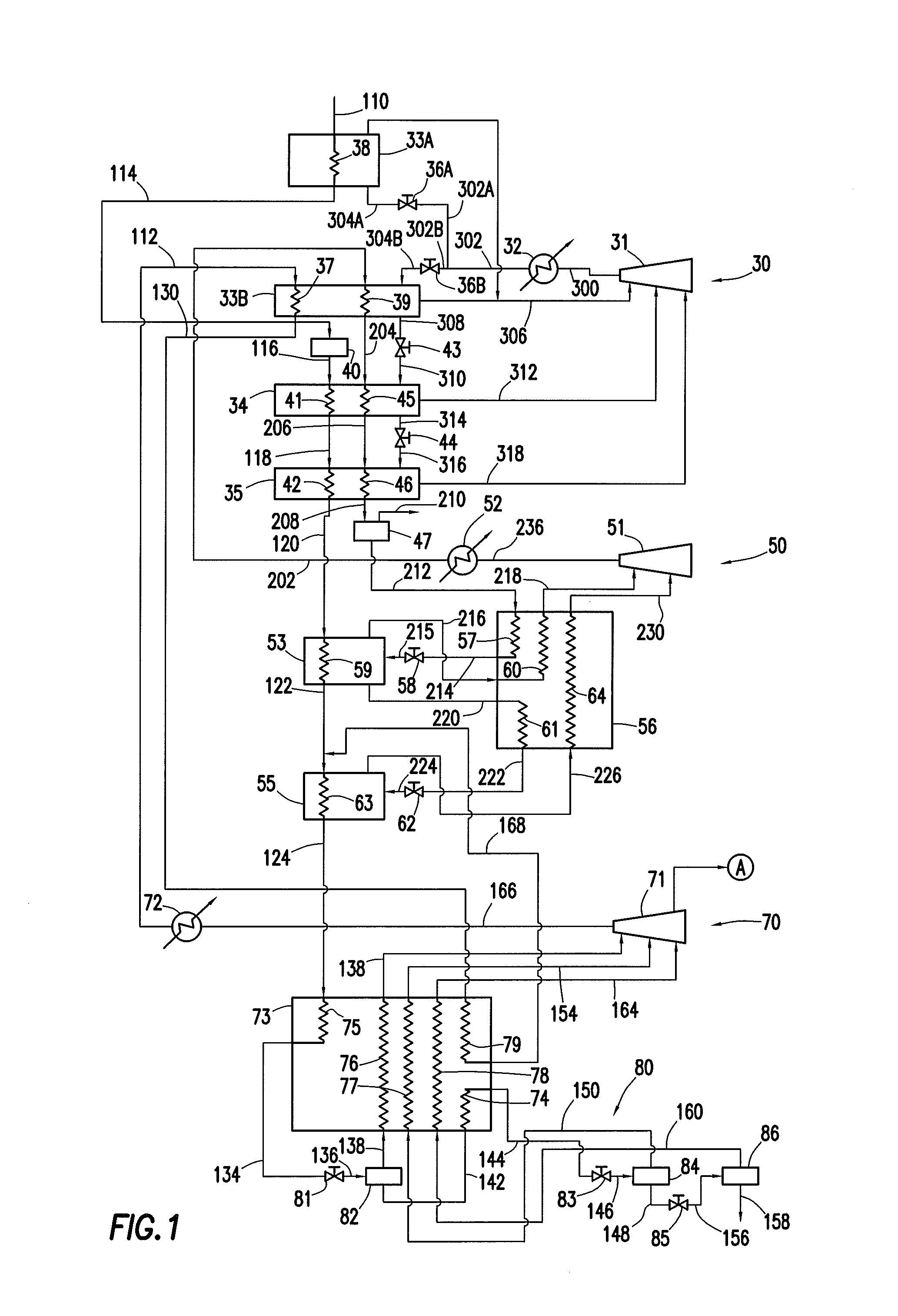

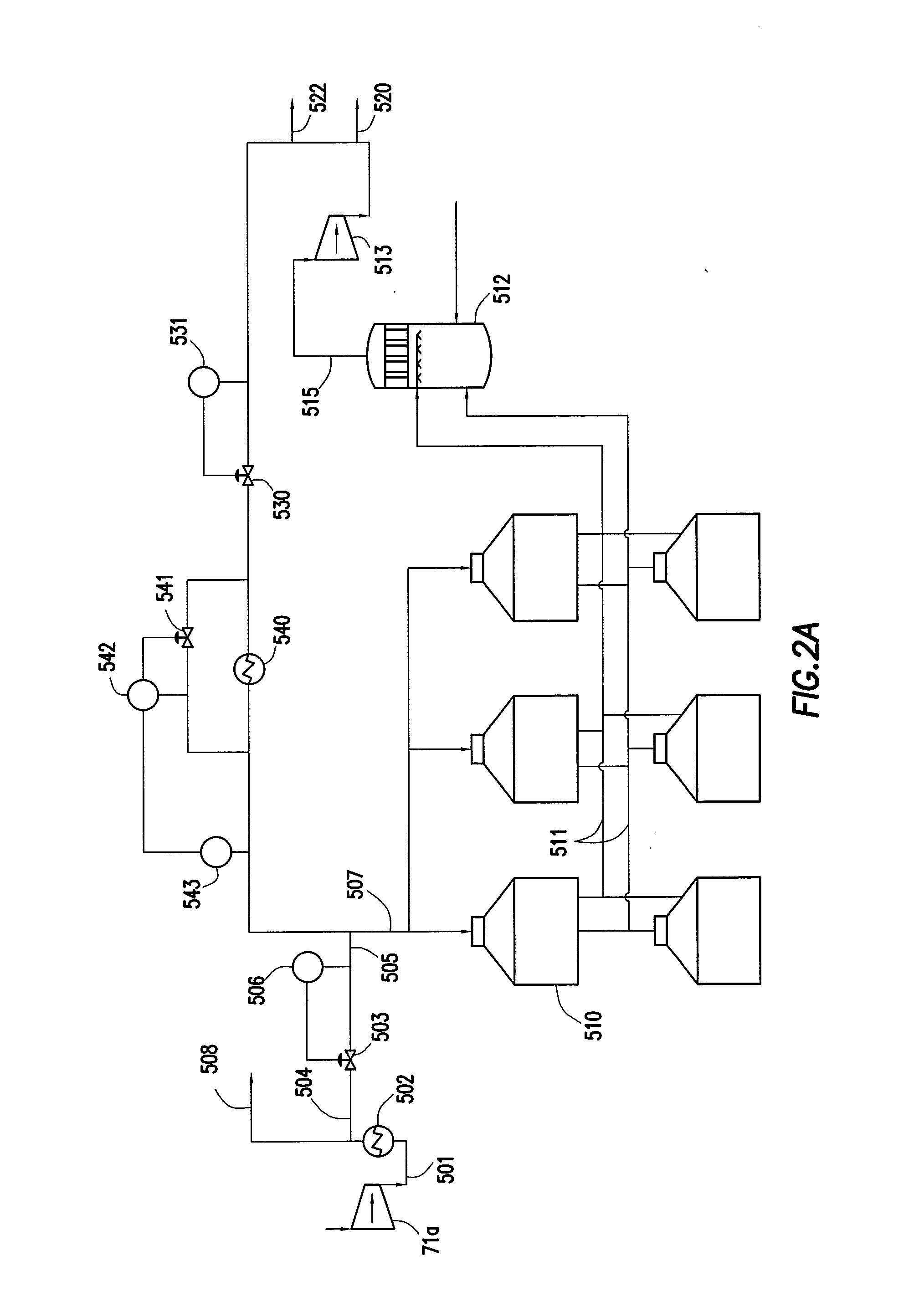

Integrated cascade process for vaporization and recovery of residual LNG in a floating tank application

Methods and systems for vaporizing and recovering LNG are provided. One method includes: a) heating at least a portion of the LNG to provide a boil-off gas stream and a liquid quench stream; b) routing the boil-off gas stream and the liquid quench stream to a quench system, wherein the quench system cools the boil-off gas stream to provide a quenched stream; and c) compressing the quenched stream to provide a compressed quenched stream.

Owner:CONOCOPHILLIPS CO

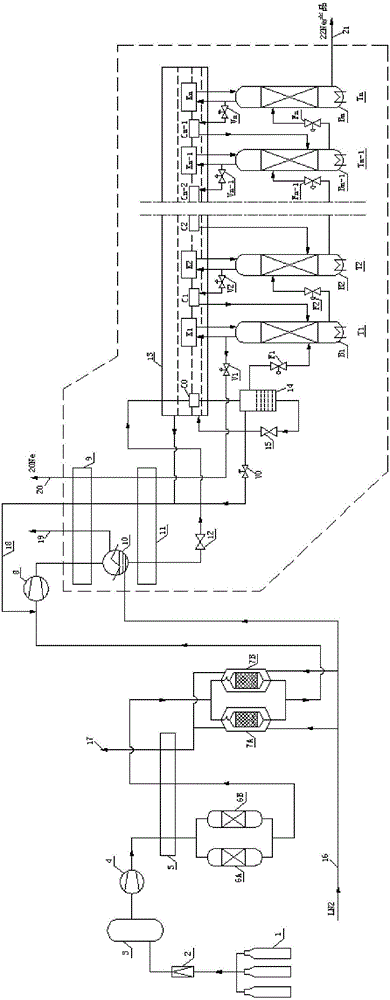

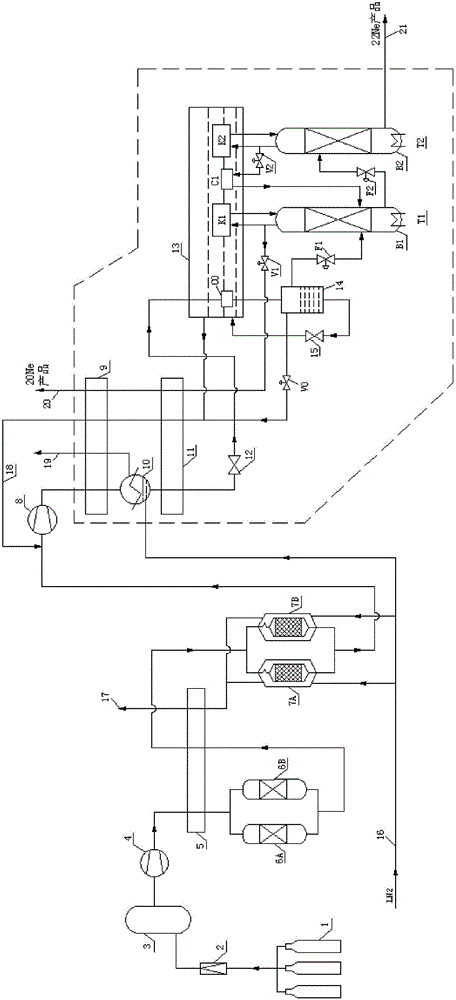

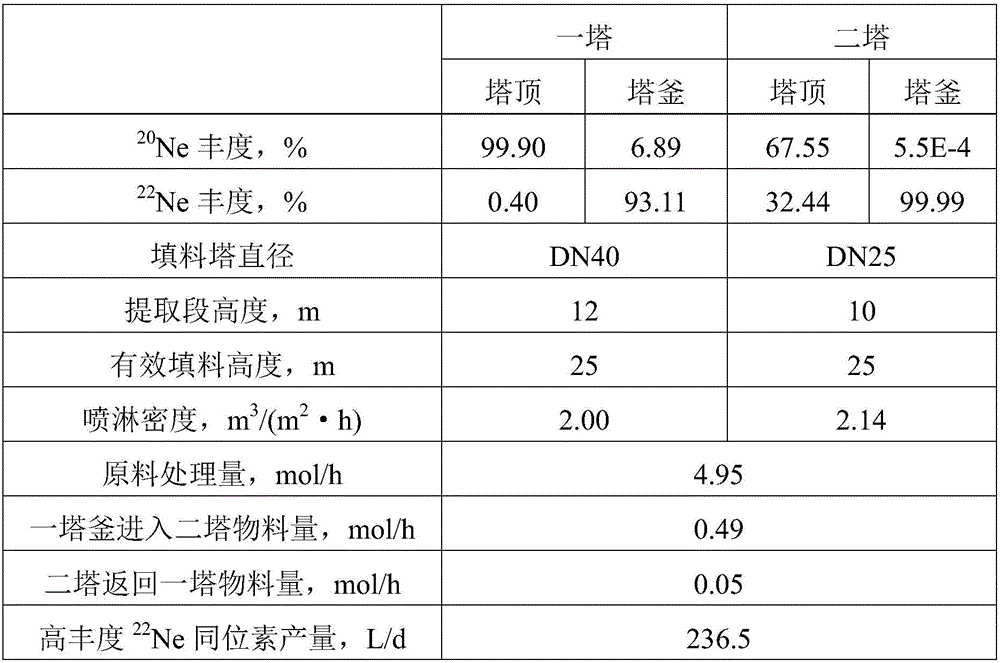

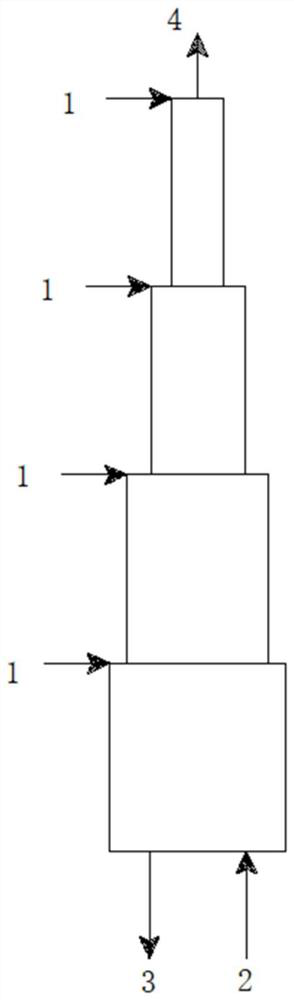

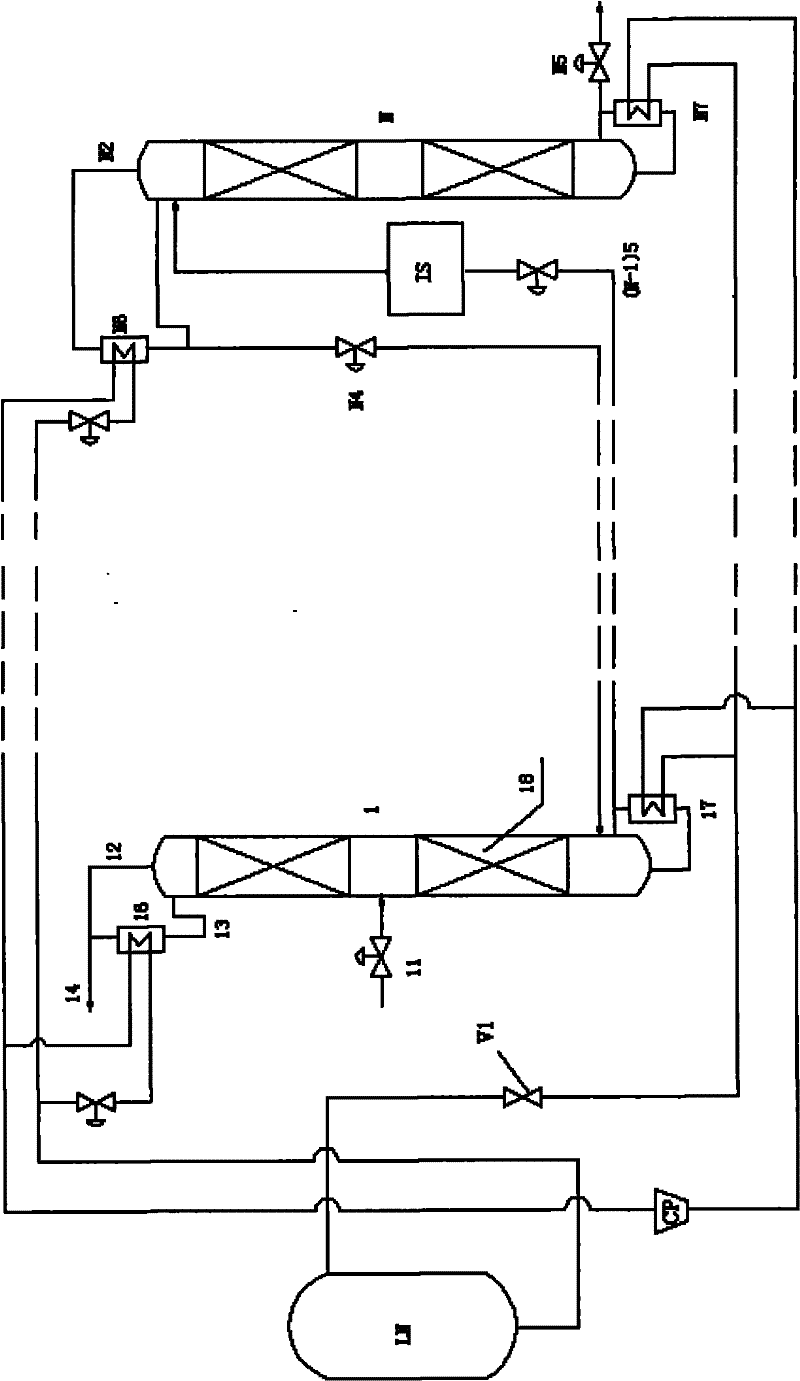

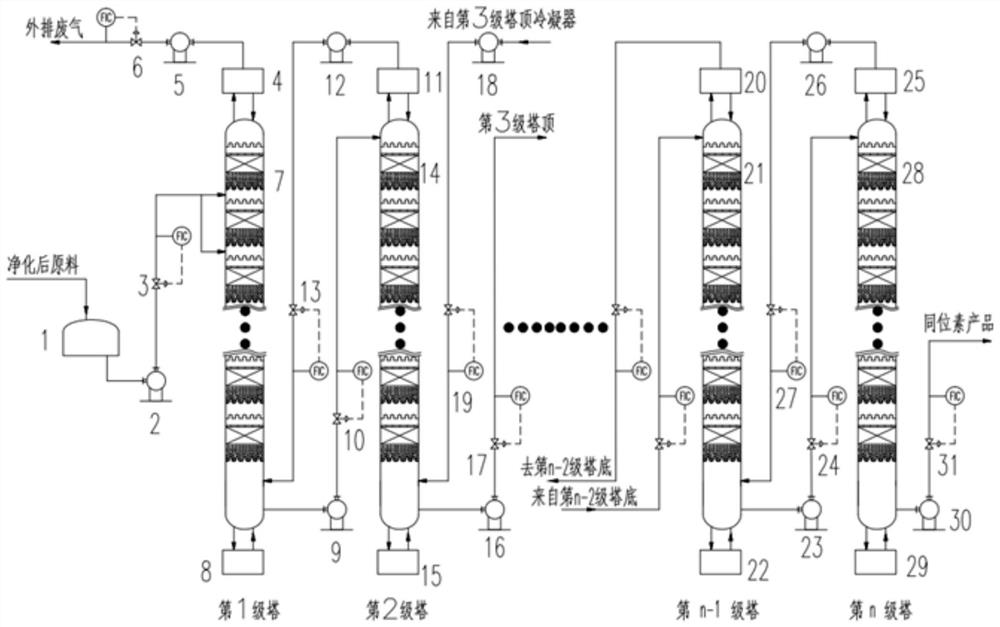

Rectifying process and device of stable isotopes produced by neon gas

ActiveCN106731837AOvercoming the difficulty of zooming inReduce material transfer volumeIsotope separationNeonProcess engineering

The invention relates to a rectifying process and device of stable isotopes produced by neon gas. The rectifying device comprises a raw material purifying system and a cryogenic rectification cascade system, wherein the raw material purifying system comprises a first compressor, a water removing and drying component and a denitrifying and deoxidizing component which are sequentially connected in the raw material neon gas inlet direction; the cryogenic rectification cascade system comprises a condensing component and a cryogenic rectification cascade component which are sequentially connected; the cryogenic rectification cascade component is formed by cascading n stages of rectification towers, wherein n is an integer that is not less than 1; a cascade condenser is arranged between the two adjacent stages of rectification towers, materials from a tower kettle of the previous stage of rectification tower are conveyed into a feeding point of the later stage of rectification tower, part of the materials at the tower top of the previous stage of rectification tower is conveyed into the cascade condenser and is condensed into a liquid phase to be returned into the previous stage of rectification tower, and the other part of the materials is condensed and returned. Compared with the prior art, the rectifying process and device provided by the invention overcome the defect of difficult amplification of a thermal diffusion method, are suitable for large-scale production needs of kilograms, dozens of kilograms and even hundreds of kilograms and can realize long-term and stable operation.

Owner:SHANGHAI RES INST OF CHEM IND

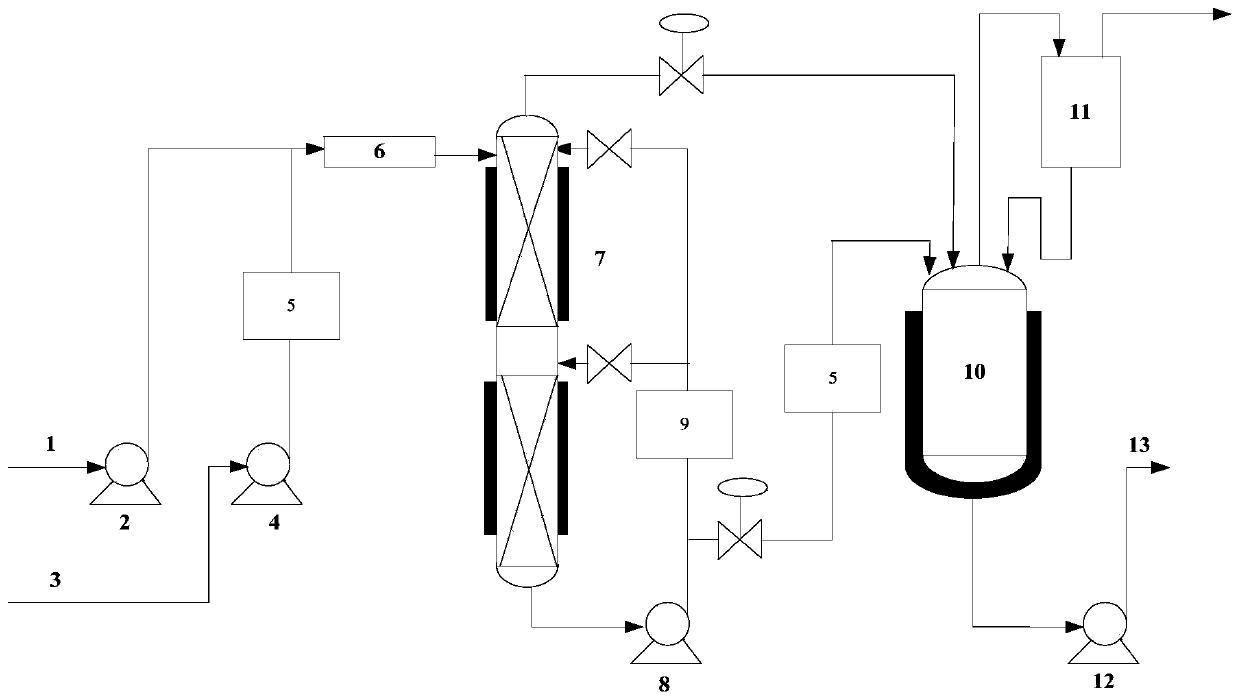

Safe production technique for manufacturing high-purity phosphine on large scale

InactiveCN104058375AAvoid pollutionAvoid corrosionChemical industryHydrogen phosphidesEthylic acidEngineering

The invention discloses a safe production technique for manufacturing high-purity phosphine on large scale. Aluminum phosphide and deionized water or zinc phosphide and acetic acid used as raw materials are subjected to sealed solid feeding, negative-pressure three-stage cascade reactor reaction, low-temperature low-pressure trapping purification, tail gas oxidation trivalent phosphorus removal, and absorption of phosphorus pentoxide by alkali liquor and activated charcoal under closed reaction conditions. The technique can simultaneously satisfy the four requirements of capability of large-scale industrial manufacturing from laboratories to industrialization, control on the virulent phosphine in air in the production workshop and surrounding environment to be lower than allowable concentration, no intricate corrosion problem in equipment, and high product purity, and provides a safe and reliable production technique for industrial production.

Owner:李达刚 +3

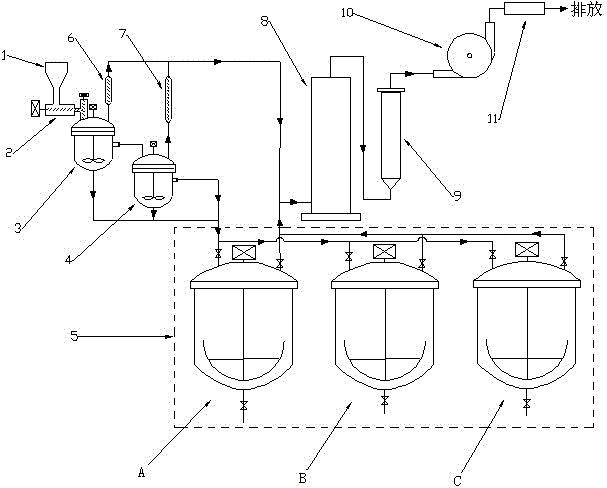

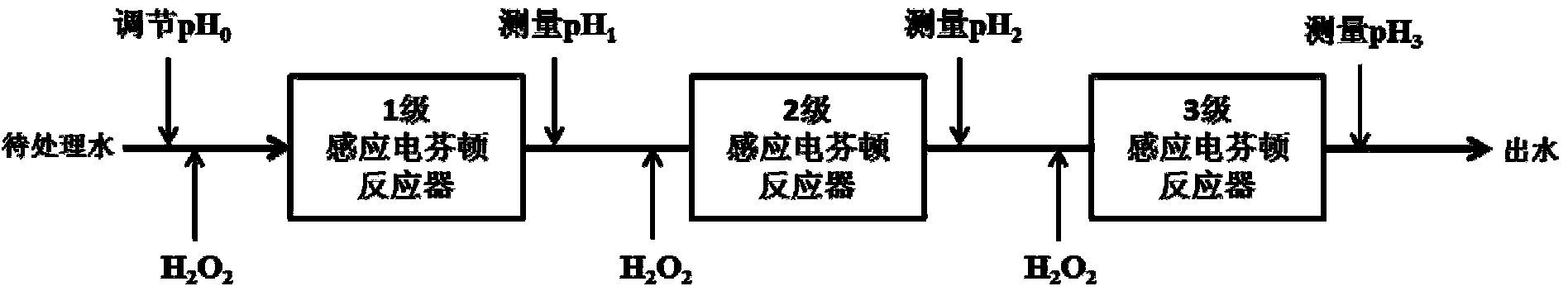

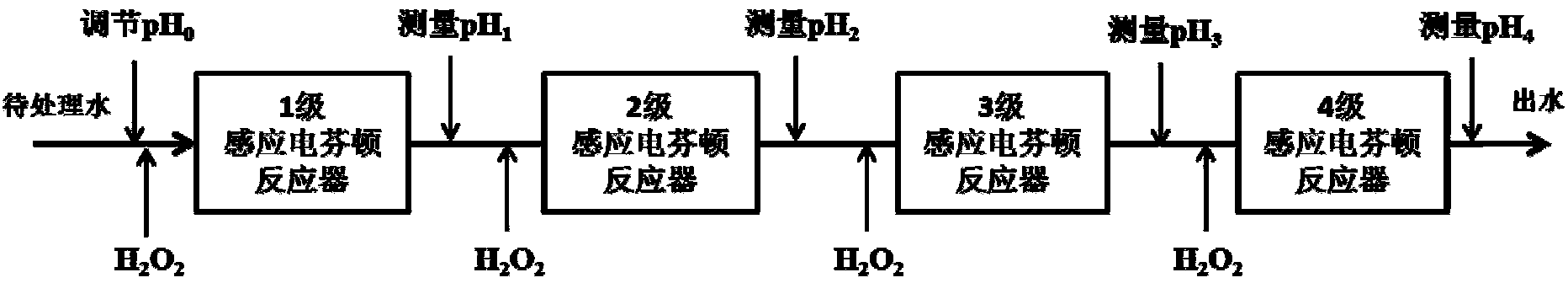

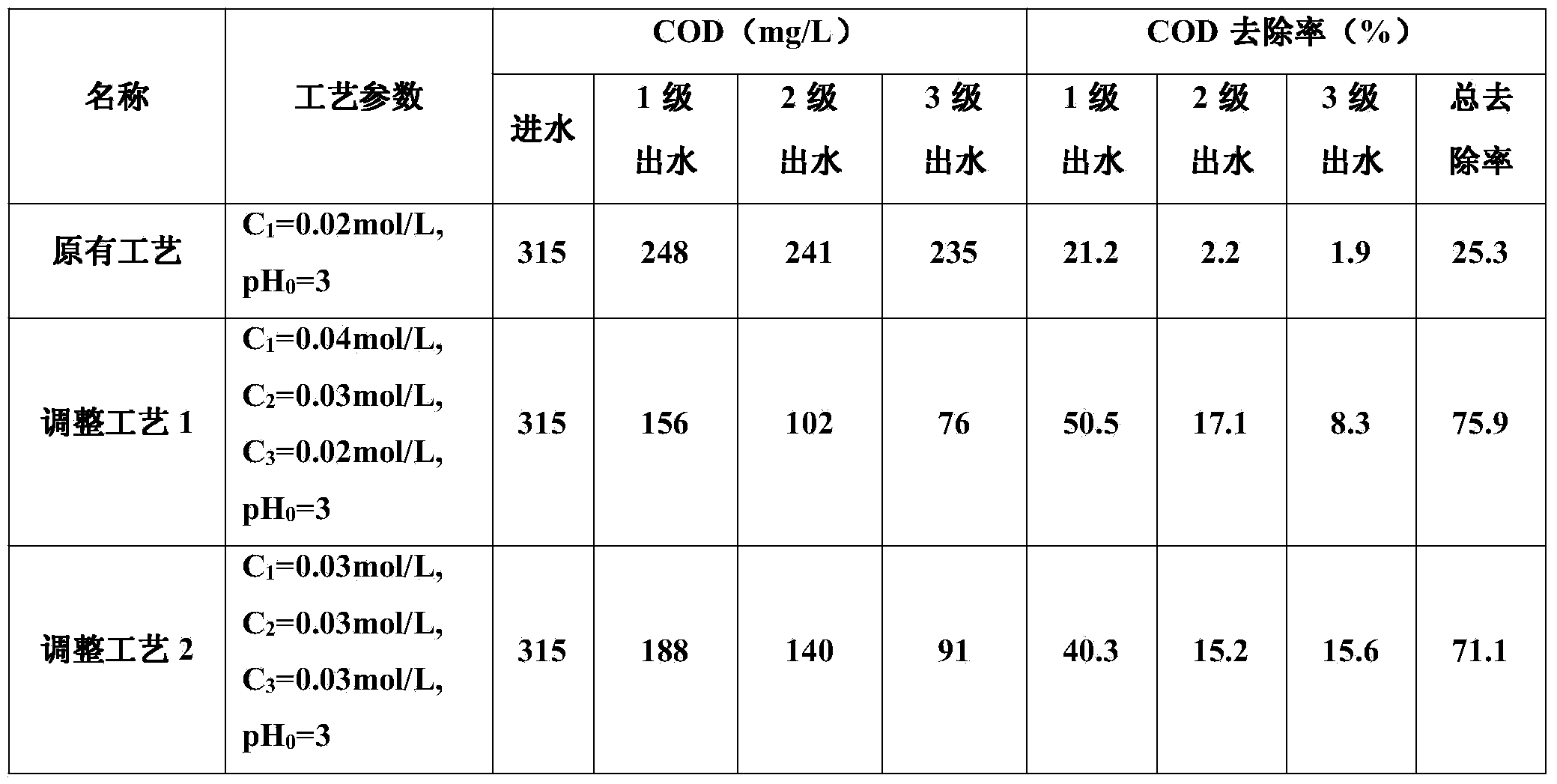

Method for regulating multistage-cascade induction electro-Fenton by graded addition of H2O2 on basis of pH indication

ActiveCN103979648AProlonged catalytic oxidation processImprove oxidation treatment efficiencyWater/sewage treatment using germicide/oligodynamic-processElectrochemistryTreated water

The invention discloses a method for regulating multistage-cascade induction electro-Fenton by graded addition of H2O2 on the basis of pH indication, belonging to the field of electrochemical water treatment. The invention is characterized in that the method can determine whether to regulate the concentration value of H2O2 entering multiple stages of induction multistage reactors according to the pH value change and determine the concentration of H2O2 of each stage to be regulated. The method mainly comprises the following steps: regulating influent water entering the first-stage induction electro-Fenton reactor, H2O2 concentration and pH value while controlling the total hydraulic retention time Tn of all stages of induction electro-Fenton reactors at 0.1-12 hours, introducing treated water into all stages of cascade induction electro-Fenton reactors, and switching on the external power supply; and when the stable operation time of the system is greater than or equal to Tn, comparing the pH values of all stages, and performing corresponding treatment. The method effectively solves the problems that the high-to-low turning point of the induction electro-Fenton treatment efficiency can not be easily determined and the H2O2 addition time can not be easily determined in the organic wastewater treatment in the electro-Fenton oxidation technique.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

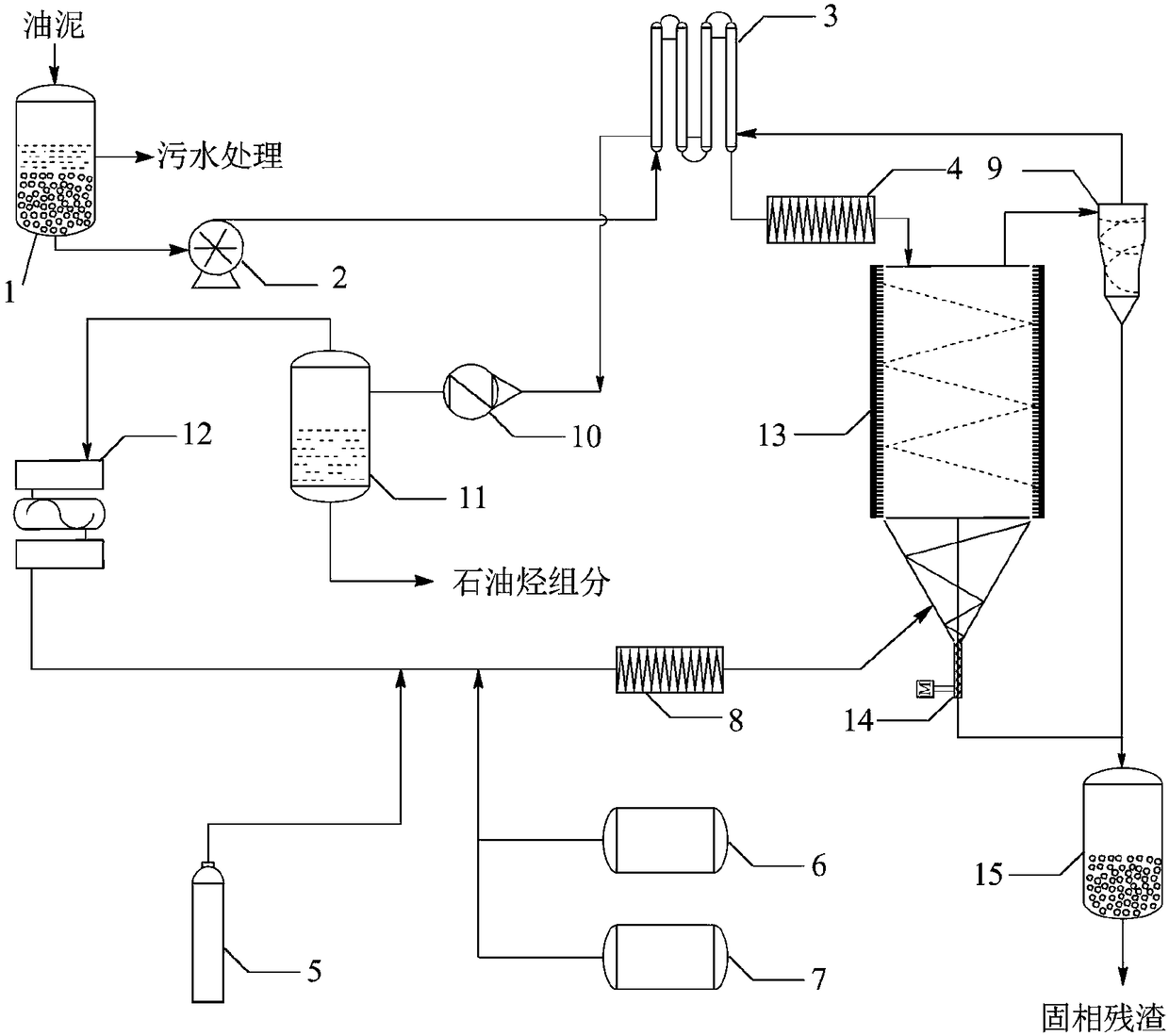

Supercritical fluid cascade extraction and oxidative degradation coupling combined process for treating oily sludge

ActiveCN108423952AEfficient resource utilizationEasy to separateSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationTreatment effectOil sludge

The invention discloses a supercritical treatment combination process for treating oily sludge, in particular to resourceization and harmlessization treatment of the oily sludge in the coupling oxidative degradation process and a supercritical state. The supercritical treatment combination process comprises the following operation steps: firstly, mixing the oily sludge with an oxidant under the conditions of supercritical temperature and pressure, and cracking heavy oil fractions in the oily sludge into light oil by a supercritical oxidation method; secondly, adding an extracting agent into the oily sludge, and realizing cascade separation operation of petroleum hydrocarbon components from small to large by regulating the overall polarity of the extracting agent. The combined technology disclosed by the invention has the advantages that the treatment effect on the oily sludge is good, the petroleum hydrocarbon components in the oily sludge can be lightened while harmlessization treatment of the oily sludge is realized; the petroleum hydrocarbon components are extracted according to the polarity sequence and resourceization utilization of the oily sludge is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

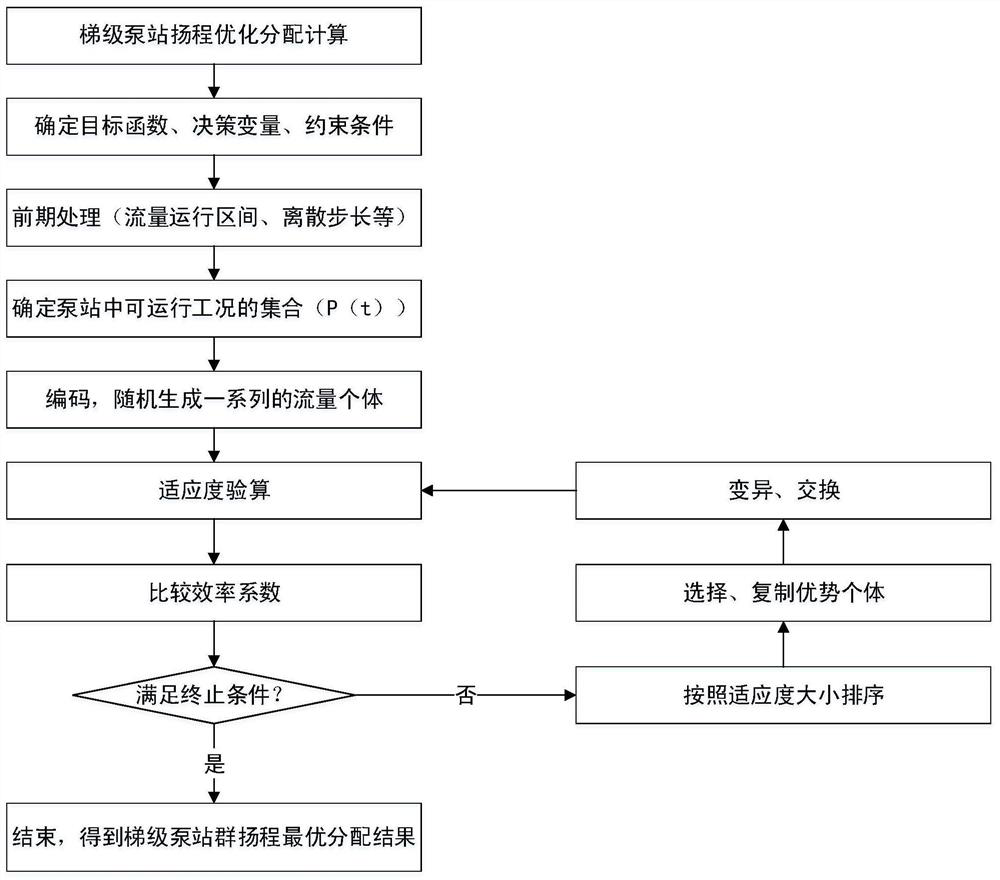

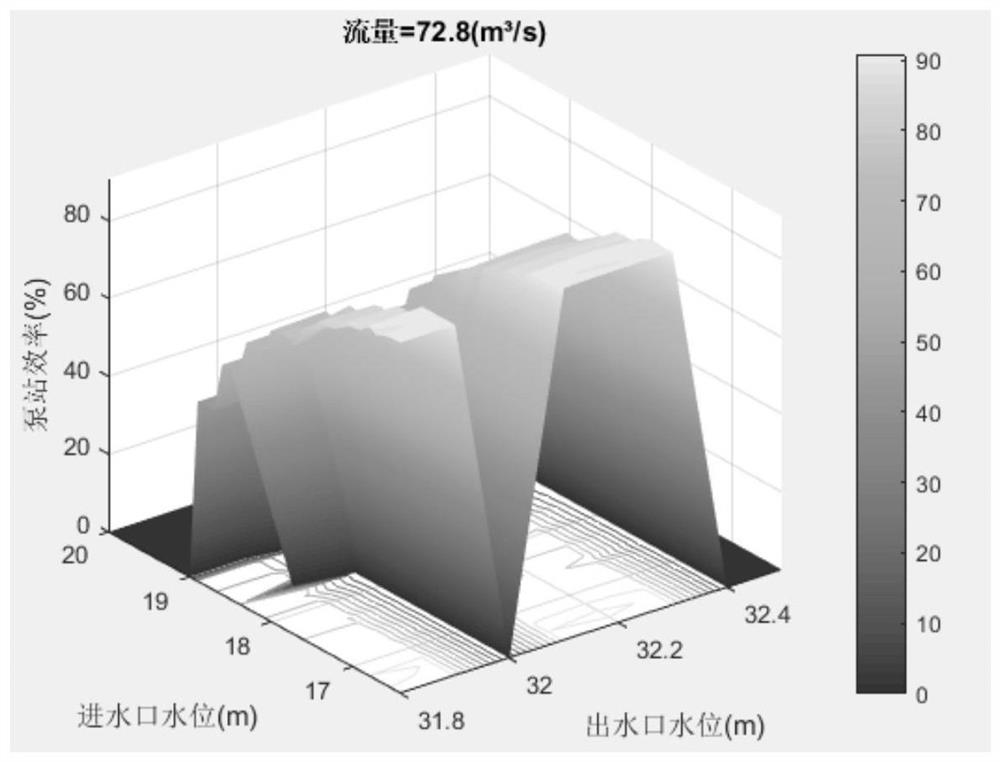

GA algorithm-based cascade pump station group lift optimal distribution method

InactiveCN111767677AImprove survival rateAvoid the danger of "curse of dimensionality"Data processing applicationsDesign optimisation/simulationAlgorithmDistribution method

The invention discloses a GA algorithm-based cascade pump station group lift optimal distribution method, which comprises the following steps of S1, determining a target function, a decision variableand a constraint condition; s2, carrying out earlier-stage treatment on the pump stations in the cascade pump station group; and S3, solving the target function by adopting a GA algorithm to obtain anoptimal distribution result of the lift of the cascade pump station group. The method has the advantages that the pump station group system is optimally dispatched under all working conditions, and compared with an existing mode, the practicability is higher.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

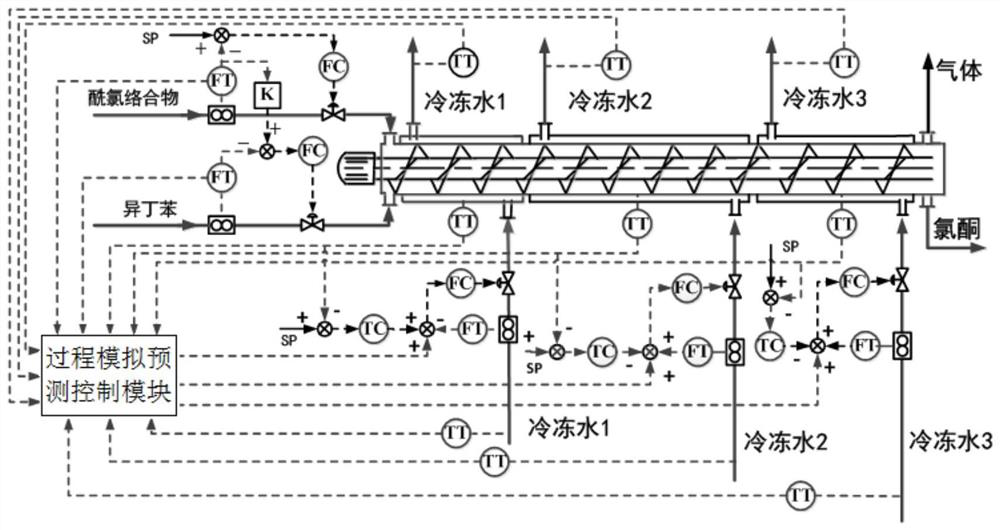

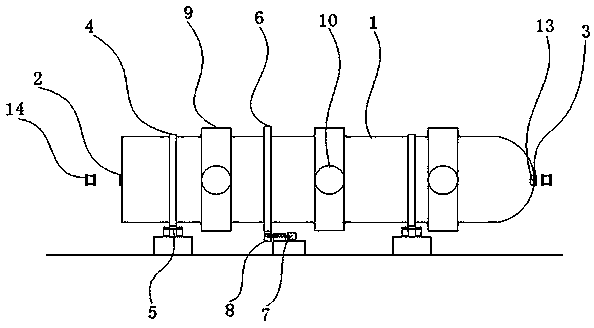

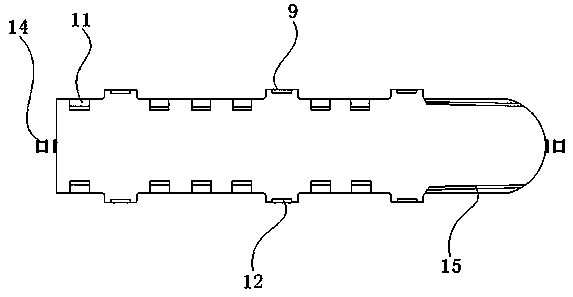

A kind of precise temperature control device and method suitable for Ibuprofen Friedel-Crafts reaction

ActiveCN112882513BEasy to controlOvercoming the lag effectAuxillary controllers with auxillary heating devicesTemperature controlControl system

Owner:QINGDAO UNIV OF SCI & TECH

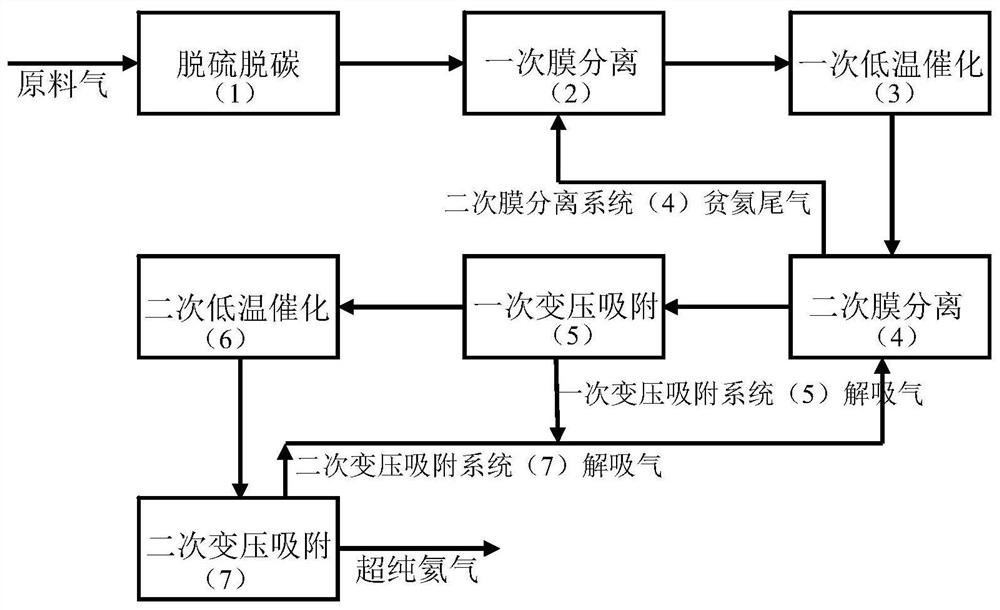

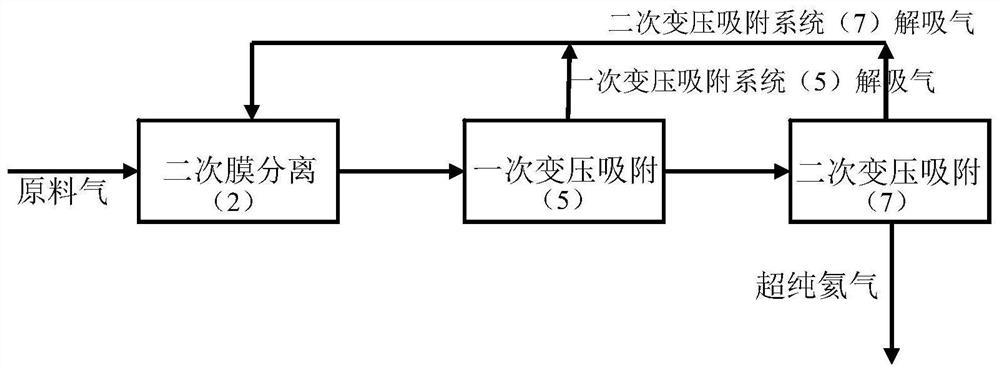

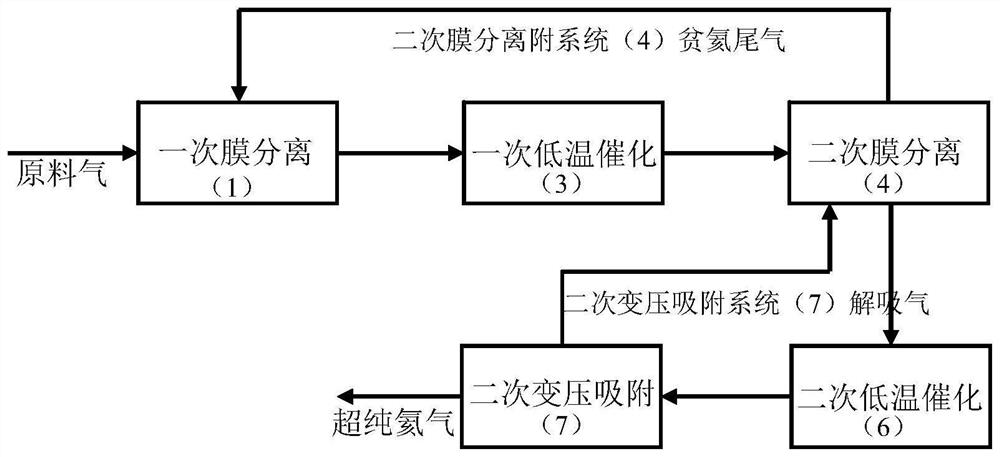

Method and production device for extracting ultra-pure helium from helium-containing natural gas at normal temperature in gradient manner

The invention discloses a method and a production device for extracting ultra-pure helium from helium-containing natural gas at normal temperature in a gradient manner, and belongs to the technical field of petrochemical engineering. Membrane separation, pressure swing adsorption, low-temperature catalysis and desulfurization and decarburization technologies are integrated according to the treatment capacity in a cascade mode, when helium in helium-containing natural gas / geothermal water dissolved gas is purified, the desulfurization and decarburization technologies, the membrane separation technologies, the pressure swing adsorption technologies and the low-temperature catalysis technologies are placed at proper separation positions according to the optimal separation interval of the separation technologies, and a multi-technology cascade integration process is formed. Helium contained in helium-containing natural gas / geothermal water dissolved gas is purified step by step through the process, and finally helium with the volume fraction not lower than 99.9999% is obtained. According to the process, through cascade combination and mutual cooperation of multiple technologies, the development bottleneck of a single separation technology is successfully broken, the helium yield is greatly improved, the investment and energy consumption in the process of extracting helium from helium-containing natural gas / geothermal water dissolved gas are reduced, the service life of a separation system is prolonged, and available helium resources are broadened.

Owner:李保军

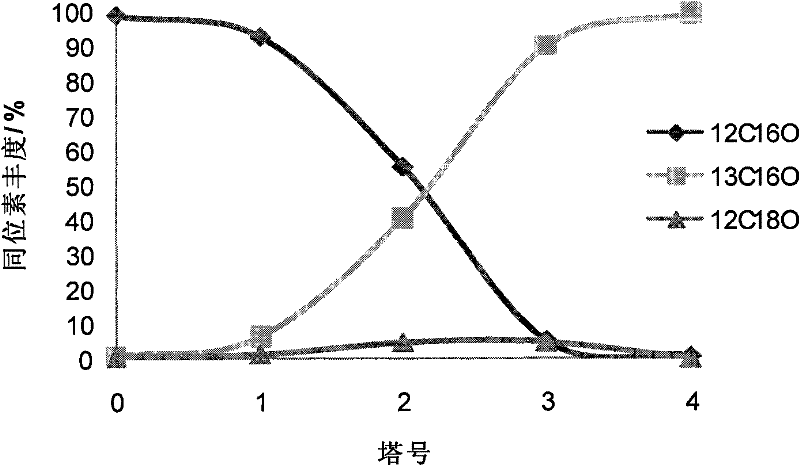

Production method of high-abundance boron-11 isotope

The invention relates to a production method of high-abundance boron-11 isotope. The method comprises the following steps: continuously feeding boron trifluoride from the bottom of a gas-liquid exchange device, and continuously feeding a complexing agent capable of carrying out complexing reaction with a boron trifluoride raw material from the top and the middle of the gas-liquid exchange device, and enabling the boron trifluoride and the complexing agent to be in countercurrent contact in the gas-liquid exchange device; and continuously extracting the boron-11-rich product from a top outlet and / or a middle outlet of the gas-liquid exchange device. Compared with the prior art, the method has the advantages that the unique single-tower process is adopted, the previous serial and cascade complex processes are simplified, the production stability is greatly improved, the enrichment efficiency of the boron-11 is improved, the energy consumption is reduced, and the abundance of the boron-11 isotope produced by the method can reach 99.9% or above.

Owner:SHANGHAI RES INST OF CHEM IND +1

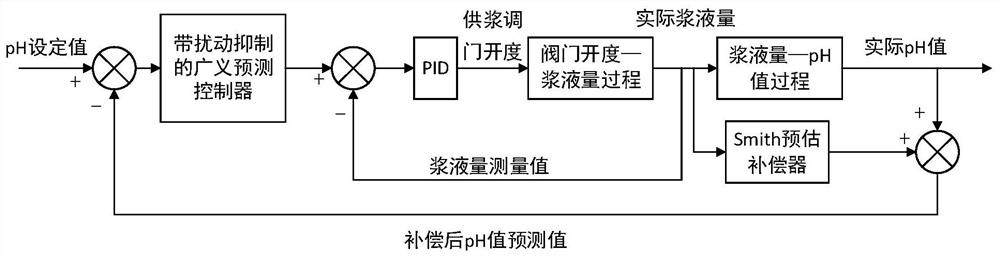

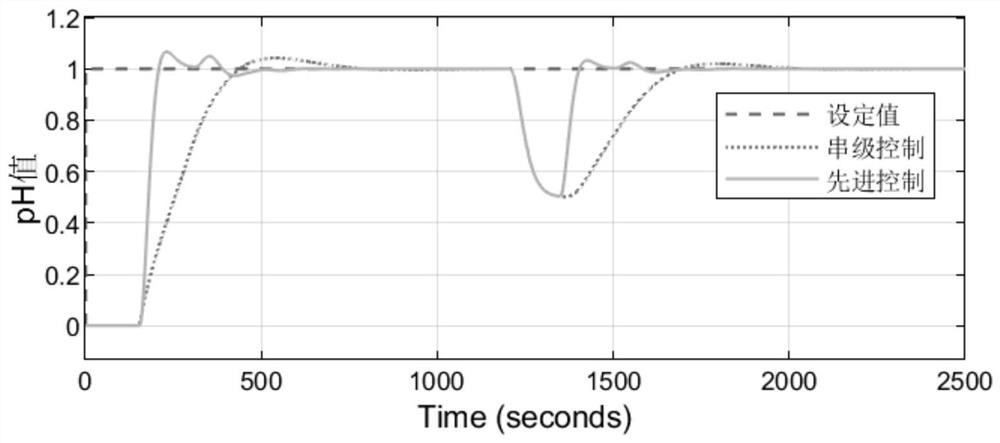

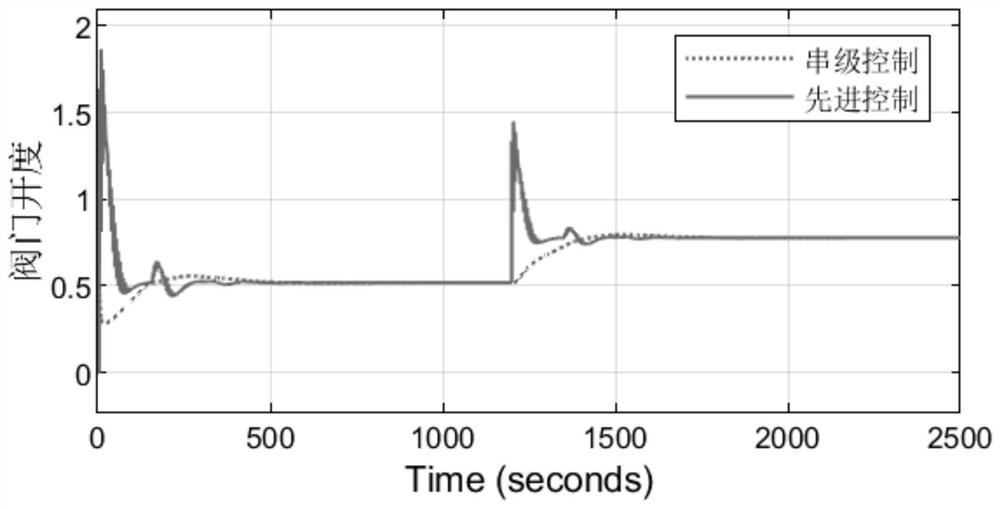

Desulfurization system pH value control system and method based on predictive control

PendingCN114035430AImprove control qualityImprove control effectAdaptive controlControl systemPh control

The invention discloses a desulfurization system pH value control system and method based on predictive control in the technical field of wet flue gas desulfurization, and the method comprises the steps of obtaining a PH set value, and processing the PH set value based on a generalized predictive control model with disturbance control; performing rolling optimization based on a processing result; and performing feedback correction on the PH set value based on an optimization result. The generalized predictive control model with disturbance suppression is adopted to replace a PID regulator of a traditional cascade control main regulation loop, compared with a traditional cascade control strategy, the control effect is better, and for the set tracking performance, the regulation time and overshoot of the advanced pH control strategy are obviously better than those of the traditional cascade control strategy; in the aspect of anti-disturbance performance, the advanced control callback time is shorter, the anti-disturbance capability is higher, the control quality of the wet desulphurization pH value can be obviously improved based on the generalized predictive control with disturbance suppression, and the method plays an important role in stable and economical operation of wet desulphurization.

Owner:湖北华电襄阳发电有限公司 +1

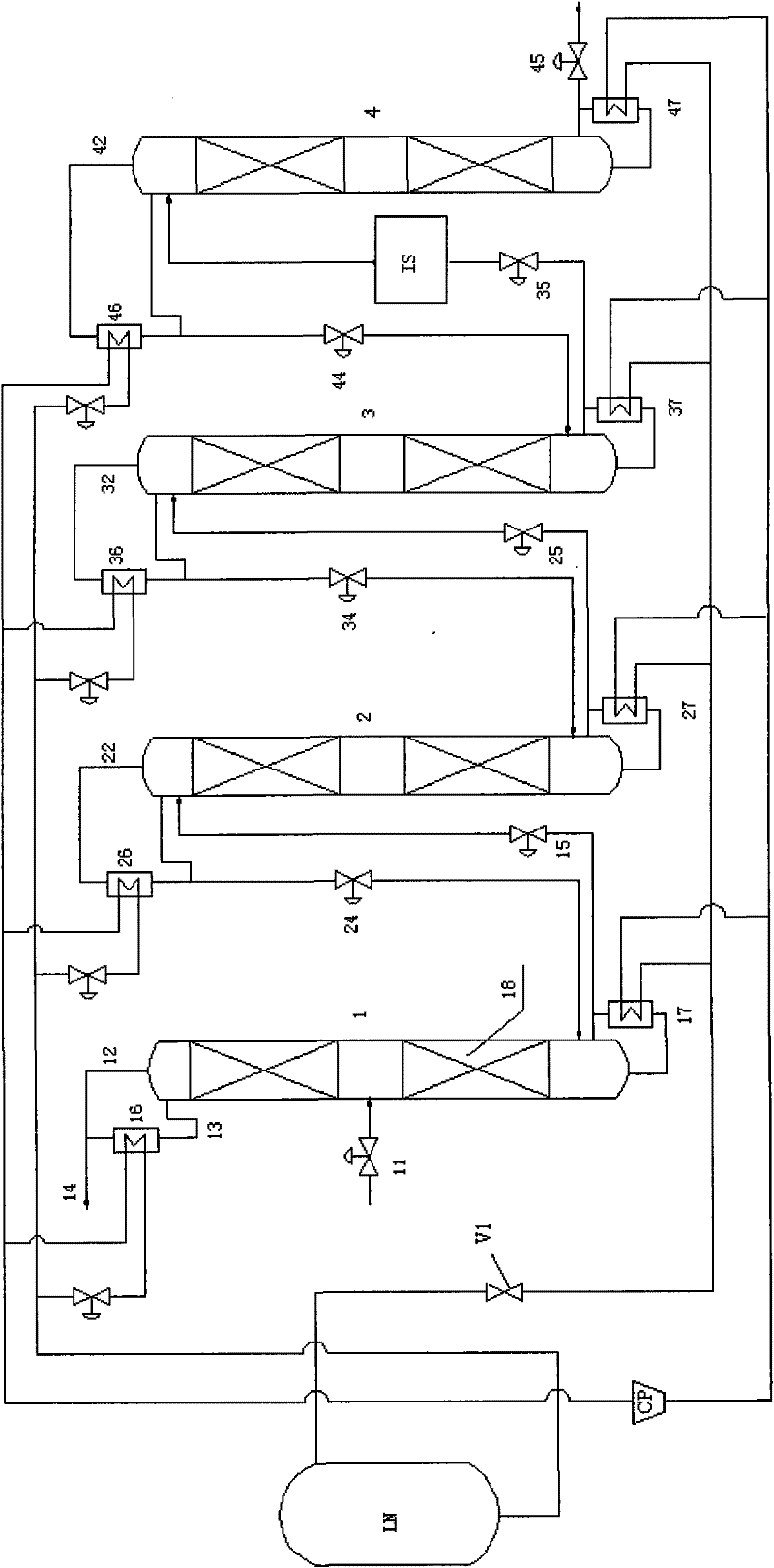

Process and device for rectifying and separating stable isotope 13C at low temperature by adopting CO

Owner:SHANGHAI RES INST OF CHEM IND

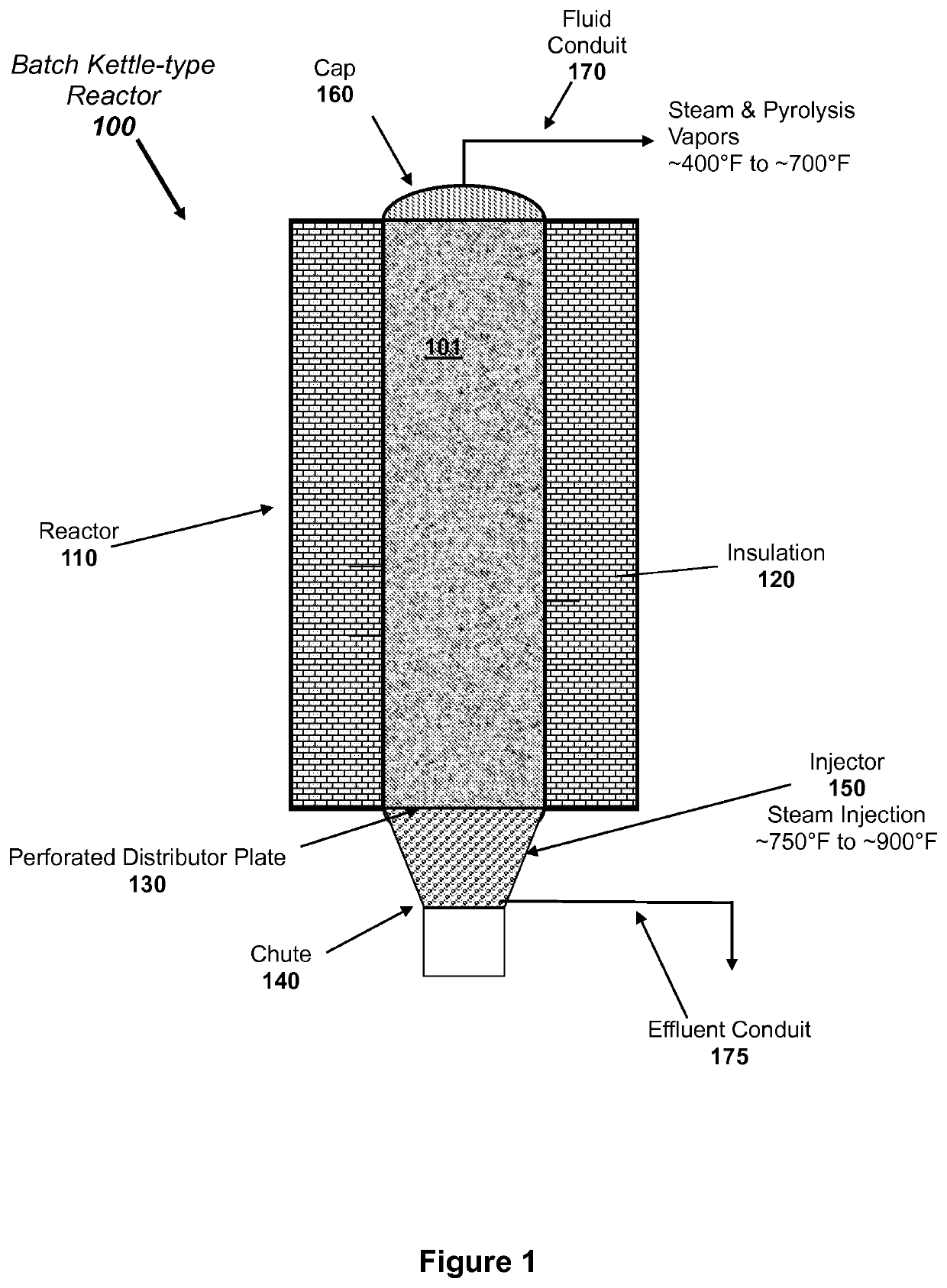

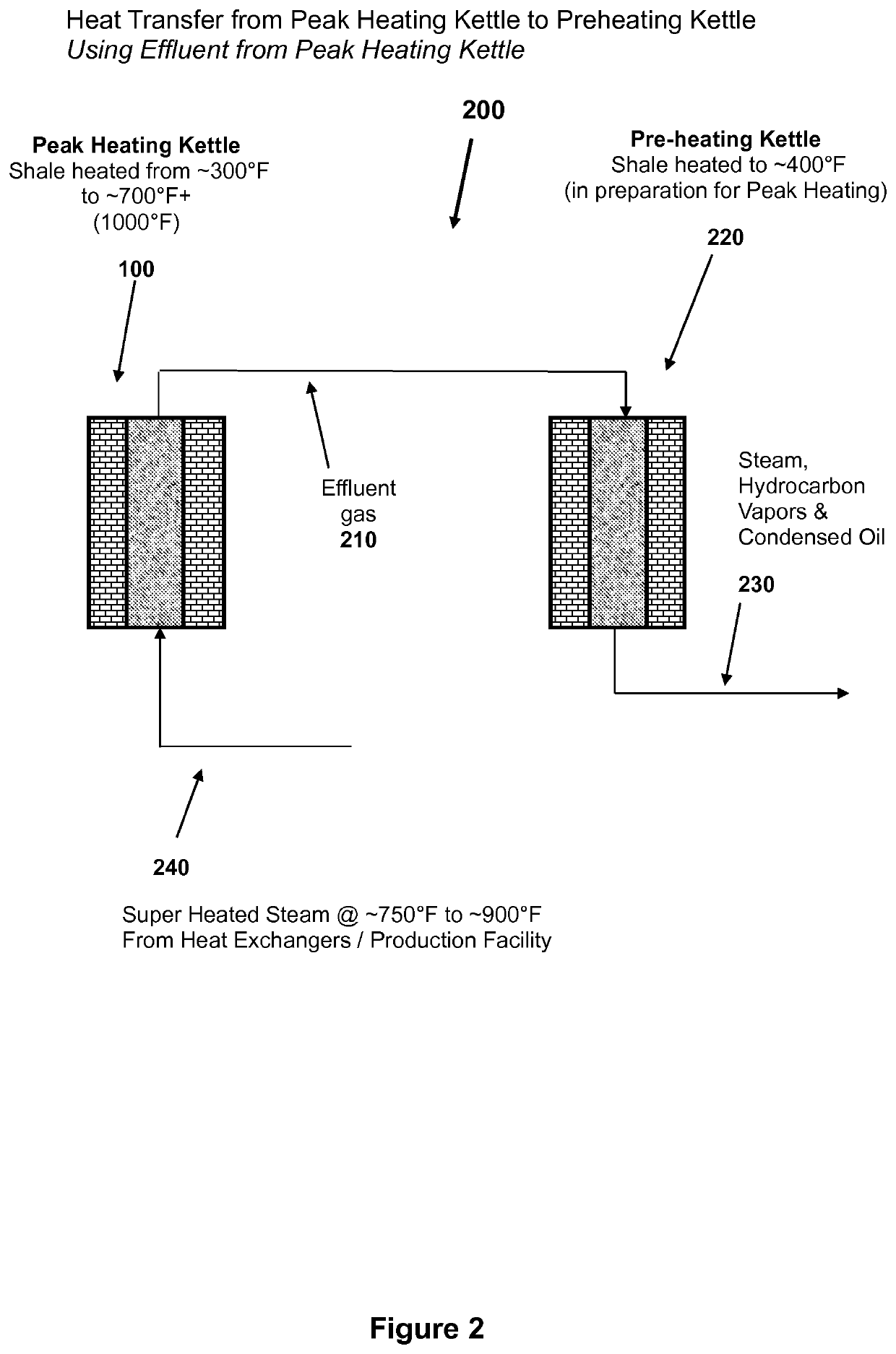

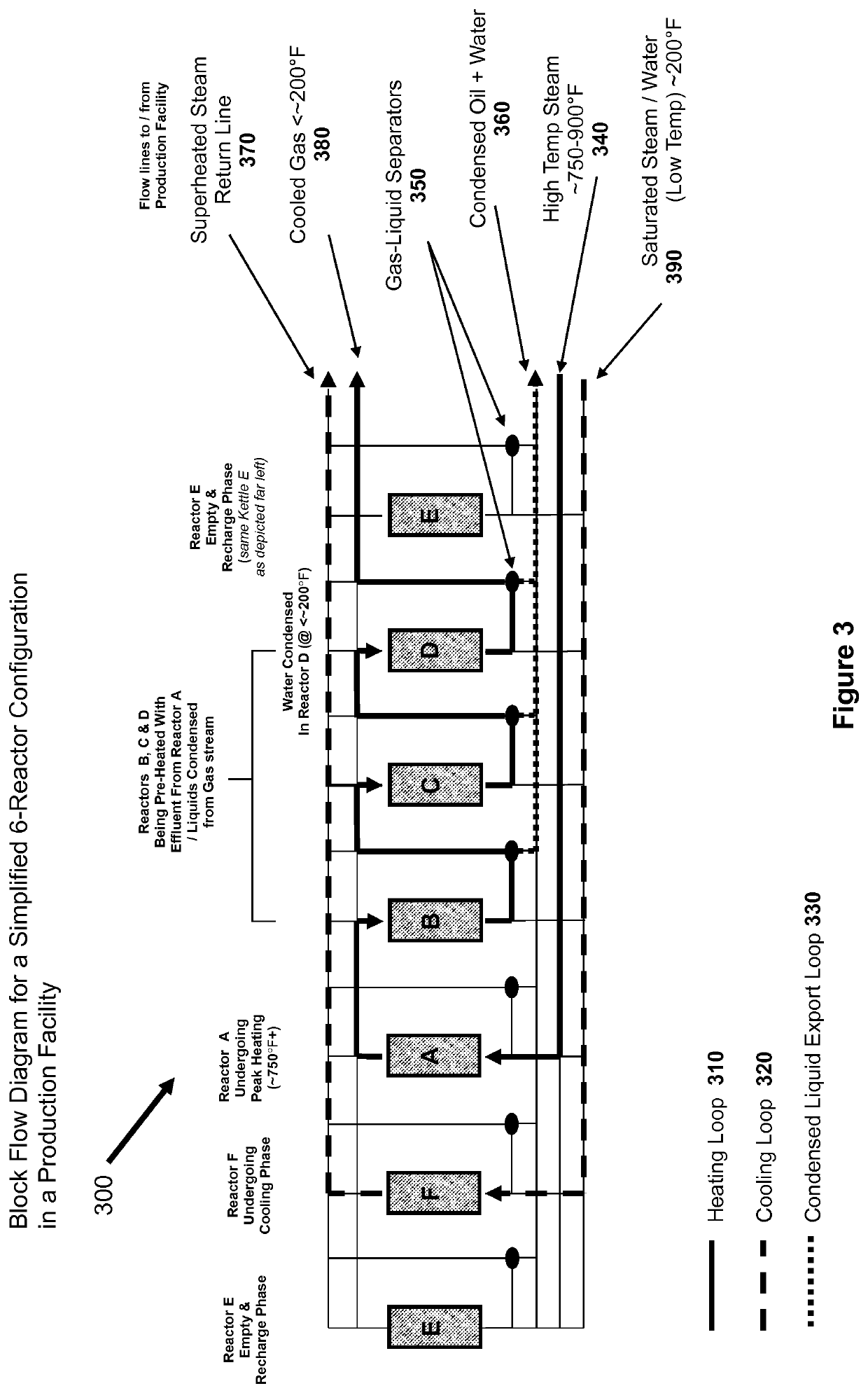

Batch oil shale pyrolysis

ActiveUS11312911B2Maximum efficiencyUniform rateLiquid hydrocarbon mixture productionKerogenThermodynamics

Owner:KERACIK CHARLES STERLING

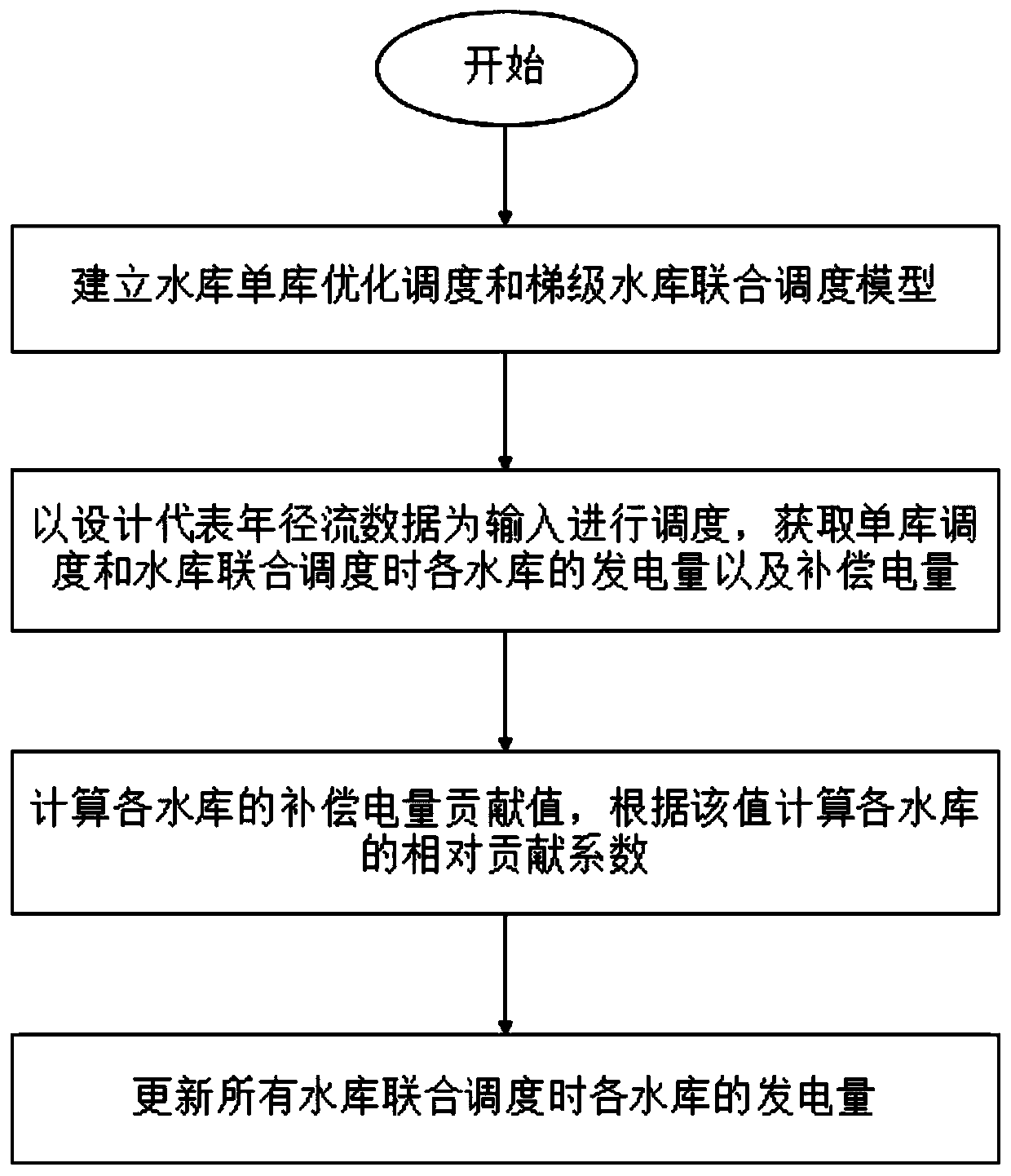

Cascade reservoir power generation scheduling compensation electric quantity distribution method

PendingCN111080152AHigh feasibilityEffective Guided Assignment QuestionsResourcesInformation technology support systemControl engineeringCascade

The invention discloses a cascade reservoir power generation scheduling compensation electric quantity distribution method. The invention belongs to the technical field of reservoir scheduling, the method comprises the following steps: respectively inputting runoff data of a design representative year into a reservoir single-reservoir optimization scheduling model and a cascade reservoir joint scheduling model, calculating the generating capacity of each reservoir during single-reservoir scheduling and joint scheduling of all reservoirs and the total generating capacity when a certain reservoir is runoff and the rest reservoirs are subjected to joint scheduling, and calculating compensation electric quantity and a relative contribution coefficient; calculating a relative contribution coefficient of each reservoir according to the compensation electric quantity contribution value of each reservoir; and according to the compensation electric quantity, the relative contribution coefficient and the power generation quantity of each reservoir during single-reservoir scheduling, updating the power generation quantity of each reservoir during joint scheduling of all reservoirs. Accordingto the method, the problem of distribution of cascade compensation electric quantity can be effectively guided, and the feasibility of joint scheduling is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Autogenous grinding type roller replacement reactor and re-dissolution-resisting multi-energy cascade purge technology

ActiveCN111434786AControllable purificationQuick purificationPhotography auxillary processesProcess efficiency improvementElectrolysisCascade

The invention discloses an autogenous grinding type roller replacement reactor. The autogenous grinding type roller replacement reactor comprises a replacement reactor body, a liquid inlet, a liquid outlet, supporting rings, supporting wheels, a gear ring, a driving device, a driving gear ring, strengthened autogenous grinding grooves, feeding holes, shoveling plates, and powder shoveling plates.The re-dissolution-resisting multi-energy cascade purge technology is characterized in that the technology adopts a first replacement reactor, a second replacement reactor, a first clear liquid cushion tank, a filtering machine, a clear liquid storage tank, a lixivium storage tank, a second clear liquid cushion tank and connecting methods thereof. The connecting methods comprise single-stage series connection, multistage series connection, single-stage parallel connection, multistage parallel connection and circulation connection methods. The invention aims to solve the problems and difficulties that when a lixivium which is large in flow and low in zinc concentration is processed by conventional purge equipment and technology, particularly, when a zinc-ammonia complex solution obtained through an ammonia process electrolysis technology is processed, the quantity of involved processing equipment is large, the technological process is long, the area occupation is large, consumption of zinc powder is large, energy consumption is high, and the efficiency is low, and aims to provide the autogenous grinding type roller replacement reactor and re-dissolution-resisting multi-energy cascade purge technology which can achieve mass production.

Owner:彭勃

Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

Owner:HENAN QINGSHUIYUAN TECH

Cascade-pressurization hydrolysis reaction process and system for benzyl alcohol

PendingCN110776398AReduce corrosionShort reaction timeOrganic compound preparationHydroxy compound preparationDistillationCascade

The invention relates to a cascade-pressurization hydrolysis reaction process and system for benzyl alcohol. The process comprises the following steps: subjecting benzyl chloride and a soda ash solution to a rapid reaction in a tower reactor under a low-pressure condition; then further reducing the content of benzyl chloride in the above reactants in a hydrolysis kettle under a normal-pressure condition; and subjecting the obtained crude hydrolysis product of benzyl alcohol to cooling and continuous oil-water separation, and subjecting an oil phase to reduced-pressure crude distillation and rectification to obtain a product. The method has the production characteristics of mild reaction conditions, short reaction time, low dibenzyl ether yield and low requirements on equipment material, can lower project construction cost and production cost, and overcomes the defects of conventional multi-kettle tandem atmospheric pressure hydrolysis production processes and high-temperature high-pressure continuous hydrolysis reaction processes for benzyl alcohol.

Owner:LUXI CHEM GRP

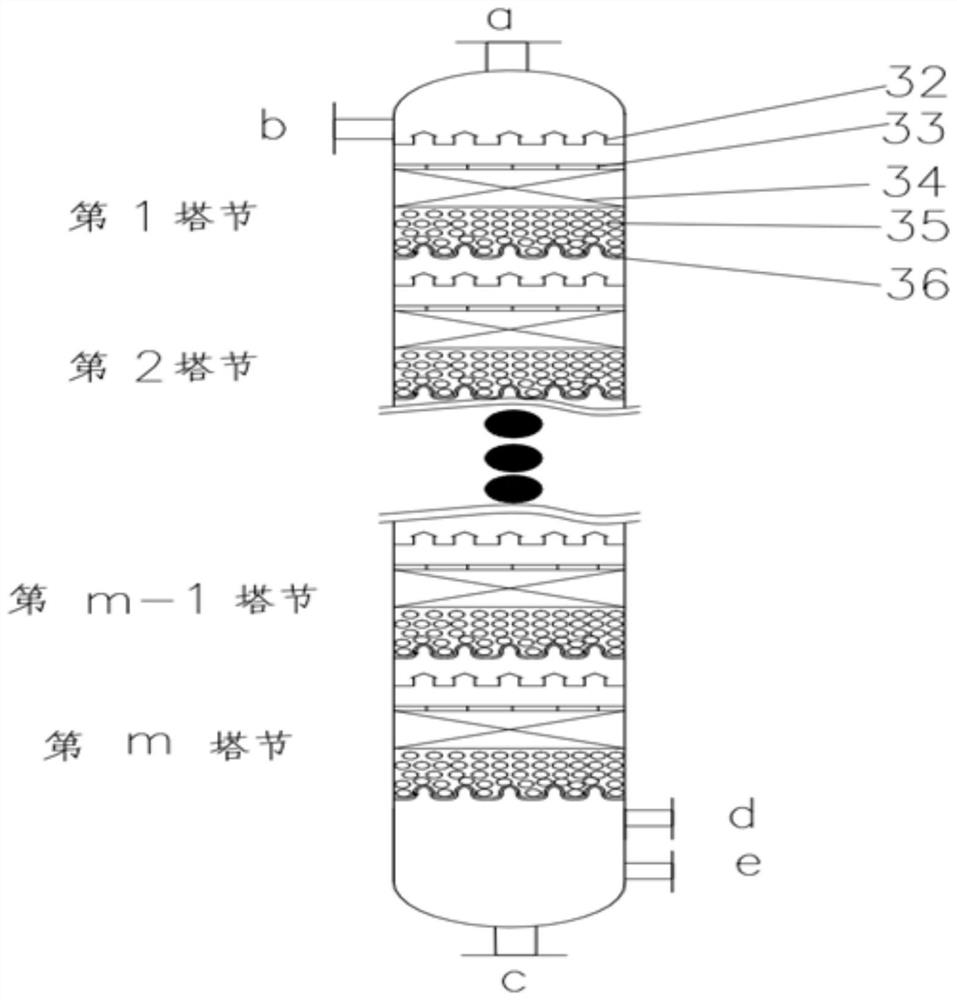

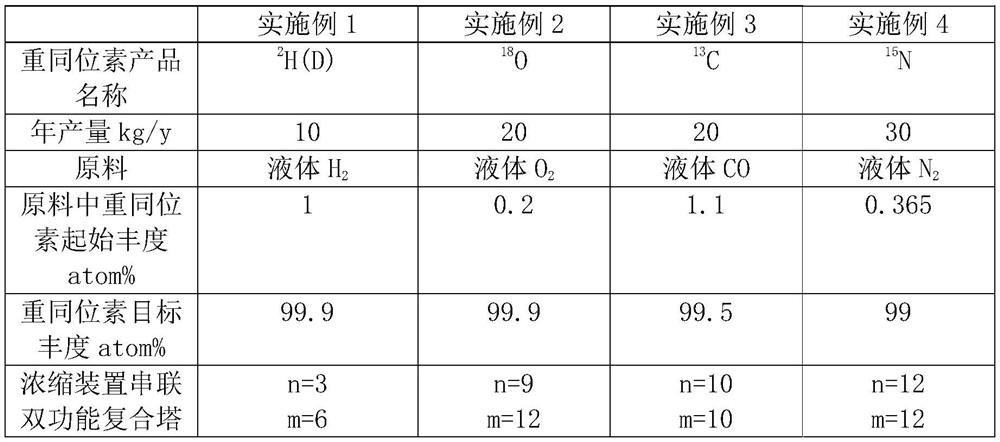

Stable isotope low-temperature separation and concentration device and technology

PendingCN112156653AOvercome the disadvantages of single rectification functionReduce the number of cascade towersIsotope separationThermodynamicsReboiler

The invention relates to a stable isotope low-temperature separation and concentration device and technology. The technology comprises the following steps that purified high-purity feed gas enters a low-temperature separation and concentration device formed by the series connection of n difunctional composite separation towers from a buffer tank through pump metering, and each tower top provides an initial liquid phase of the tower corresponding to a condenser; and each tower bottom provides an initial vapor phase of the tower corresponding to a reboiler, vapor and liquid are in countercurrentcontact in each tower, two processes of isotope exchange reforming and vapor-liquid rectification are continuously and alternately carried out, a heavy isotope product is continuously produced at thelast nth-stage tower bottom through pump metering, and waste gas subjected to heavy isotope separation is continuously produced at the first-stage tower top condenser through pump metering. The device is a cascade system formed by connecting n bifunctional composite separation towers which are horizontally arranged in series, and each bifunctional composite separation tower is composed of m towersections; and the device and the technology effectively overcome the defects of single function and the like of the separation tower in the traditional low-temperature rectification process, reduce the number of cascaded towers, simplify the process and save the energy consumption.

Owner:湖北楚儒同位素科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com