Stable isotope low-temperature separation and concentration device and technology

A stable isotope, concentration device technology, applied in the separation of different isotopic elements, separation methods, dispersed particle separation, etc., can solve the problems of single distillation function, small number of cascades, separation and concentration efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

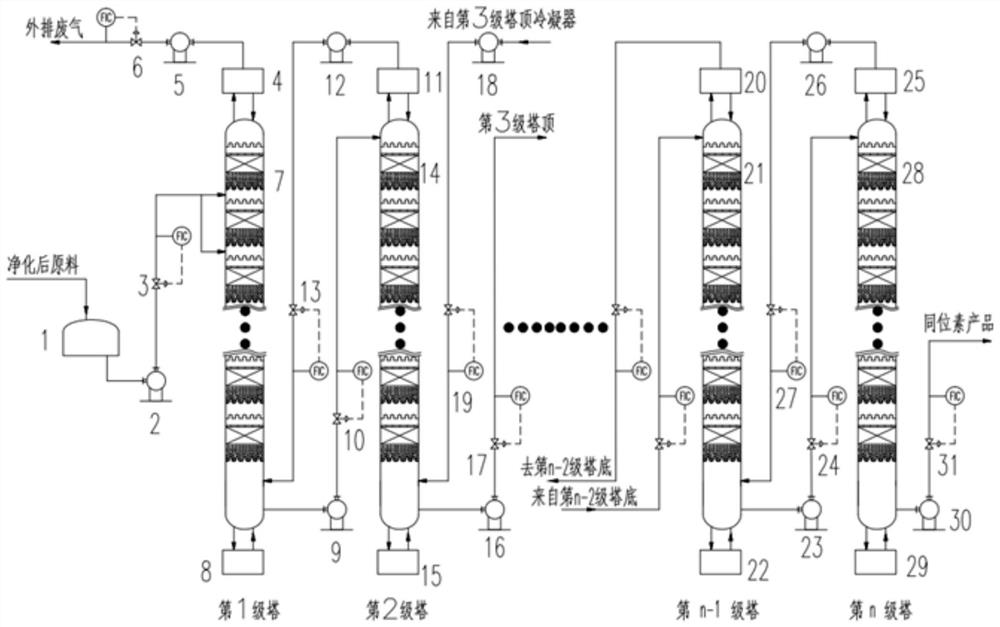

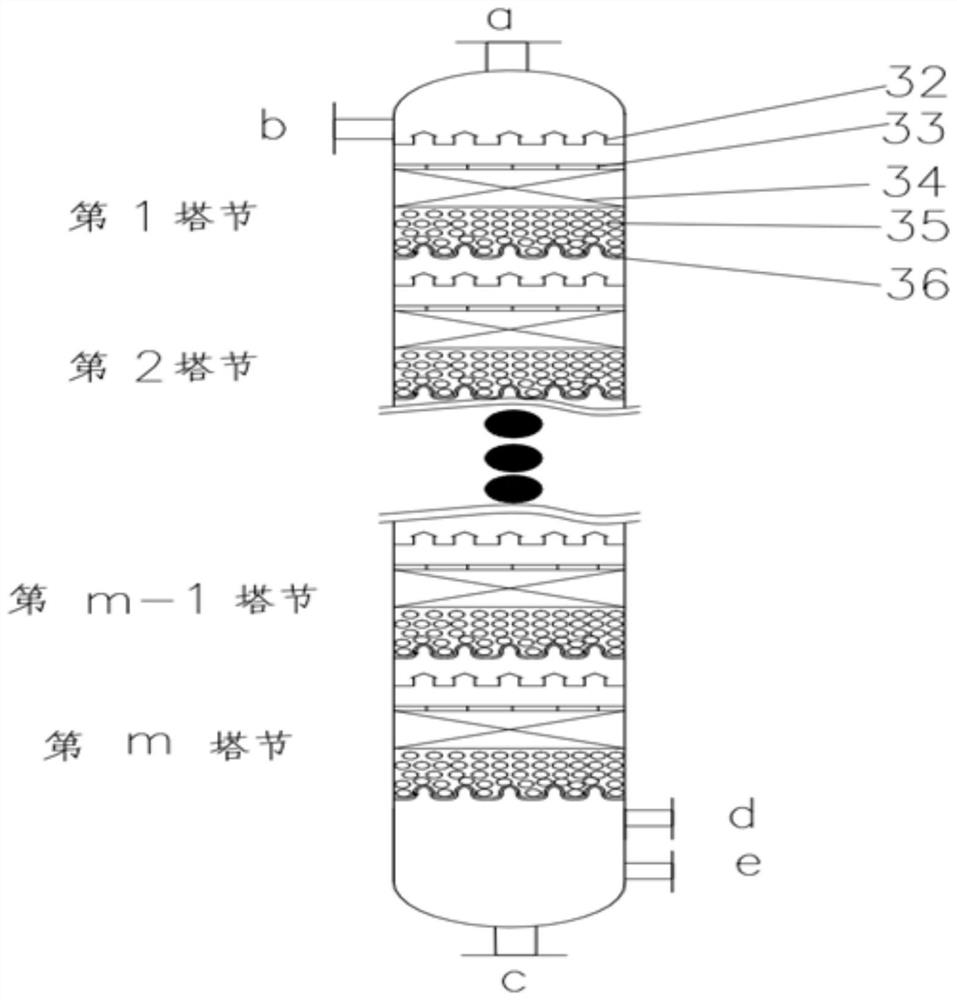

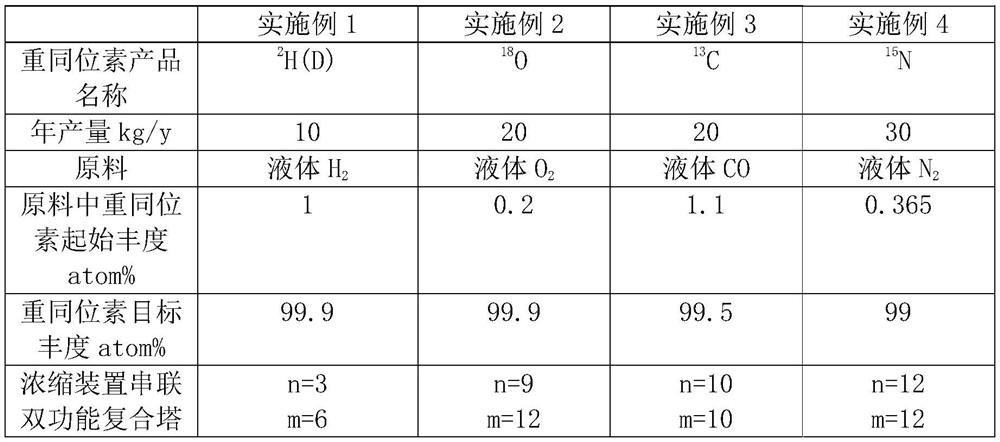

[0036] The invention provides a stable isotope low-temperature separation and concentration process, which comprises the following steps: the purified high-purity raw material gas is metered from a buffer tank through a pump into a low-temperature separation and concentration device composed of n dual-function composite separation towers connected in series , the corresponding condenser at the top of each column provides the initial liquid phase of the column, and the corresponding reboiler at the bottom of each column provides the initial vapor phase of the column, and the vapor-liquid contacts in countercurrent in each column, and isotope exchange reforming and There are two processes of vapor-liquid rectification. The heavy isotope product is continuously extracted by pump metering at the bottom of the last nth stage, and the waste gas after separation of heavy isotope is continuously extracted by pump metering in the top condenser of the first stage. This stable isotope low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tower diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com