Patents

Literature

4439 results about "Vapor phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

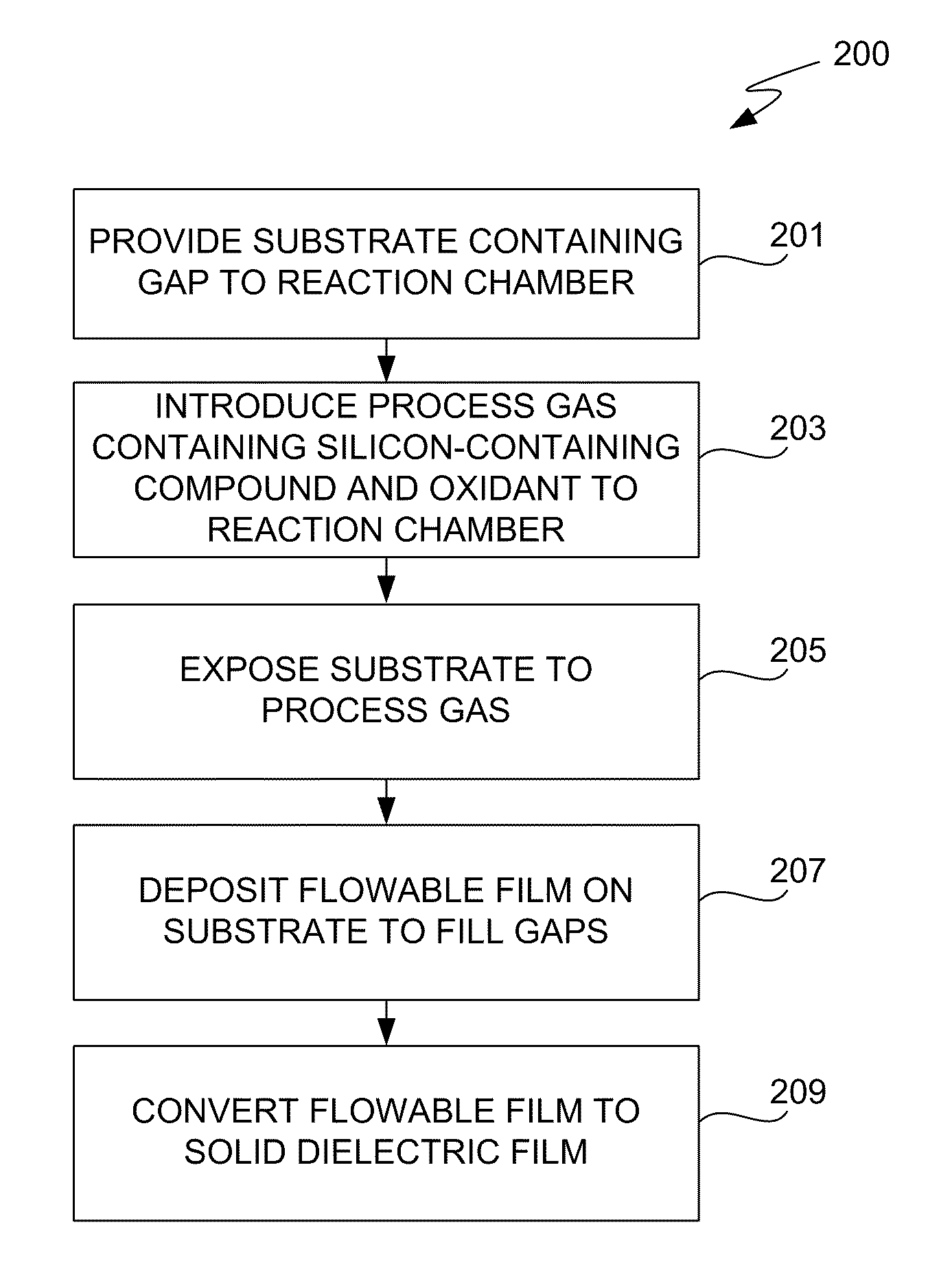

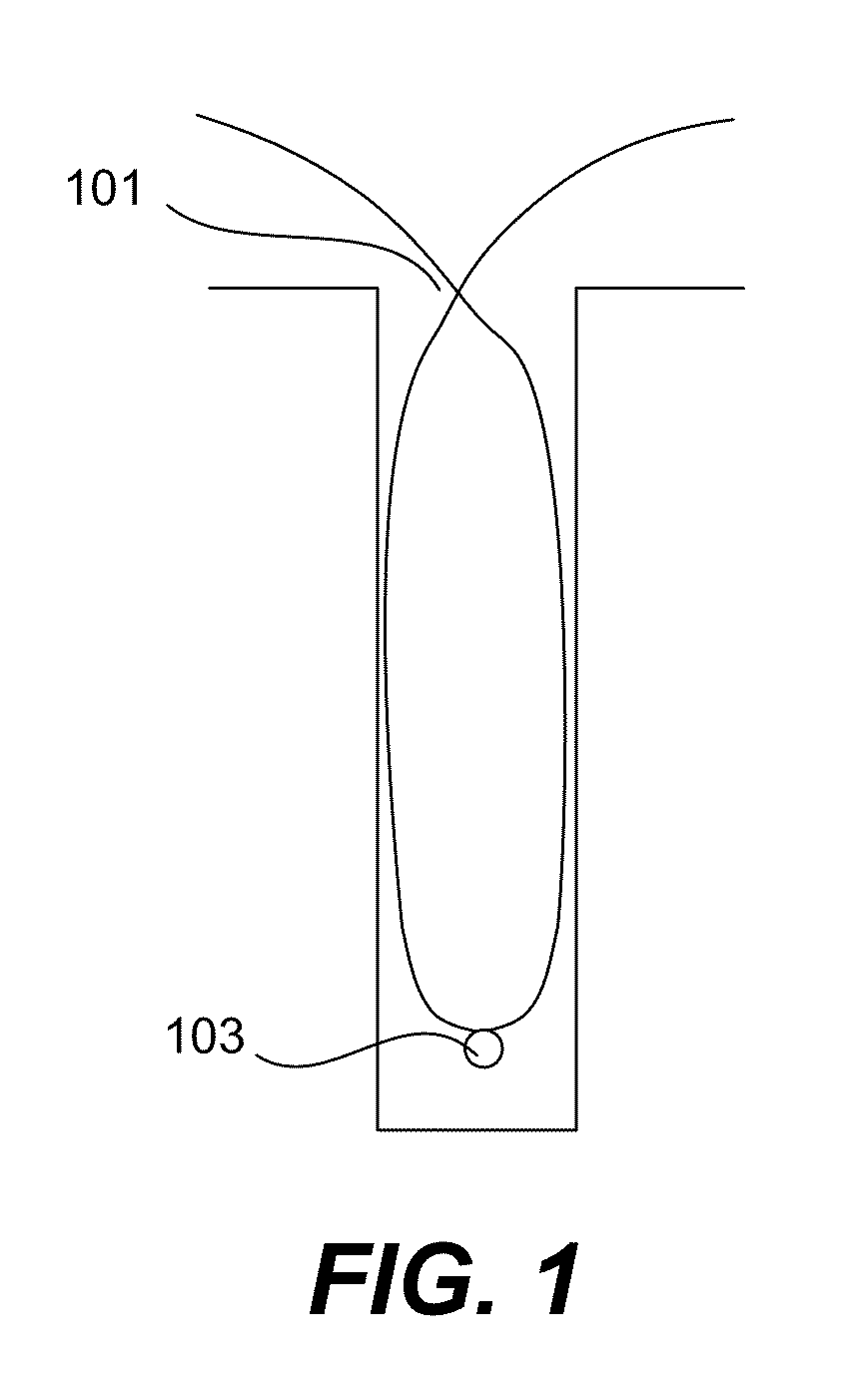

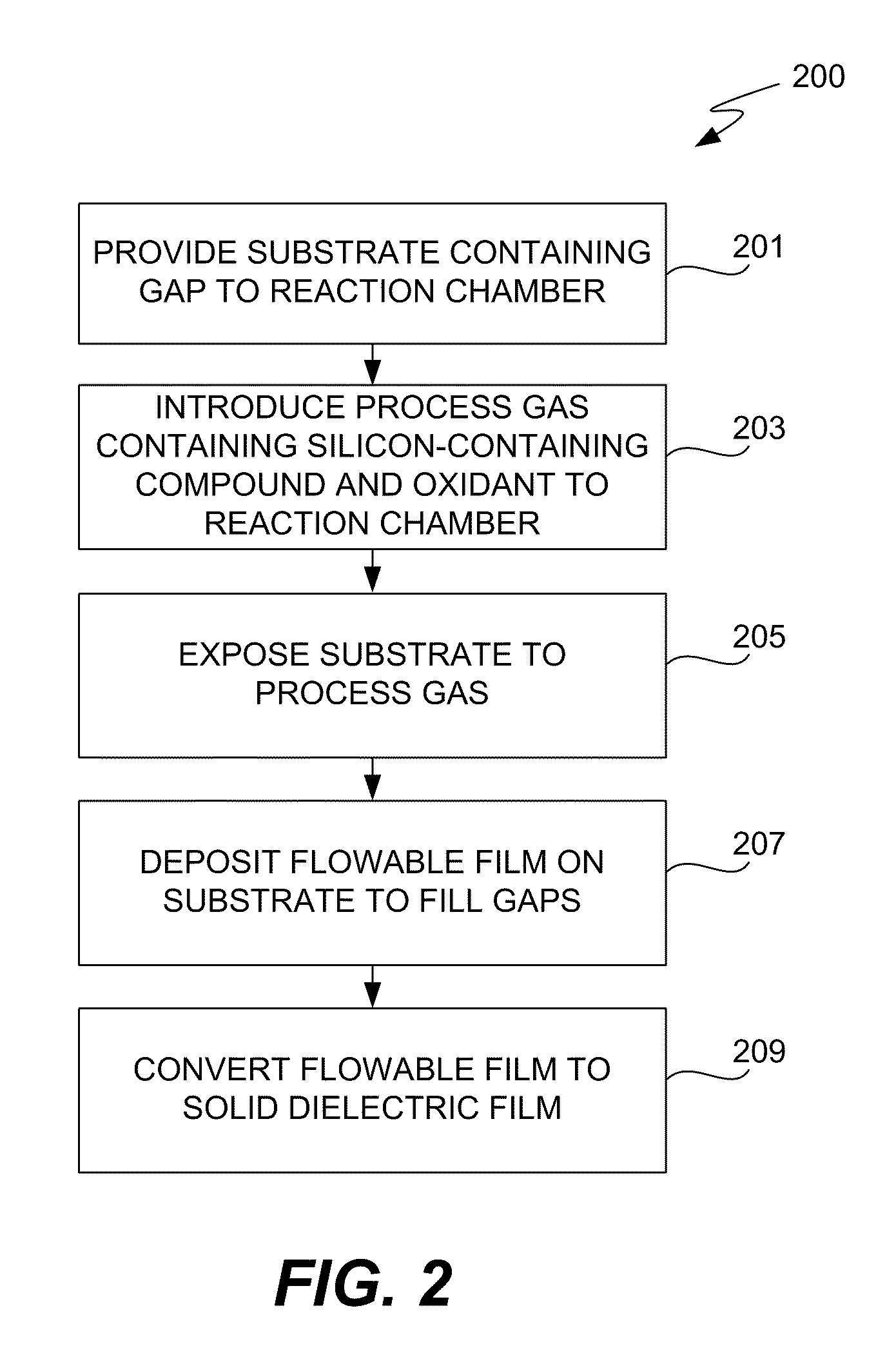

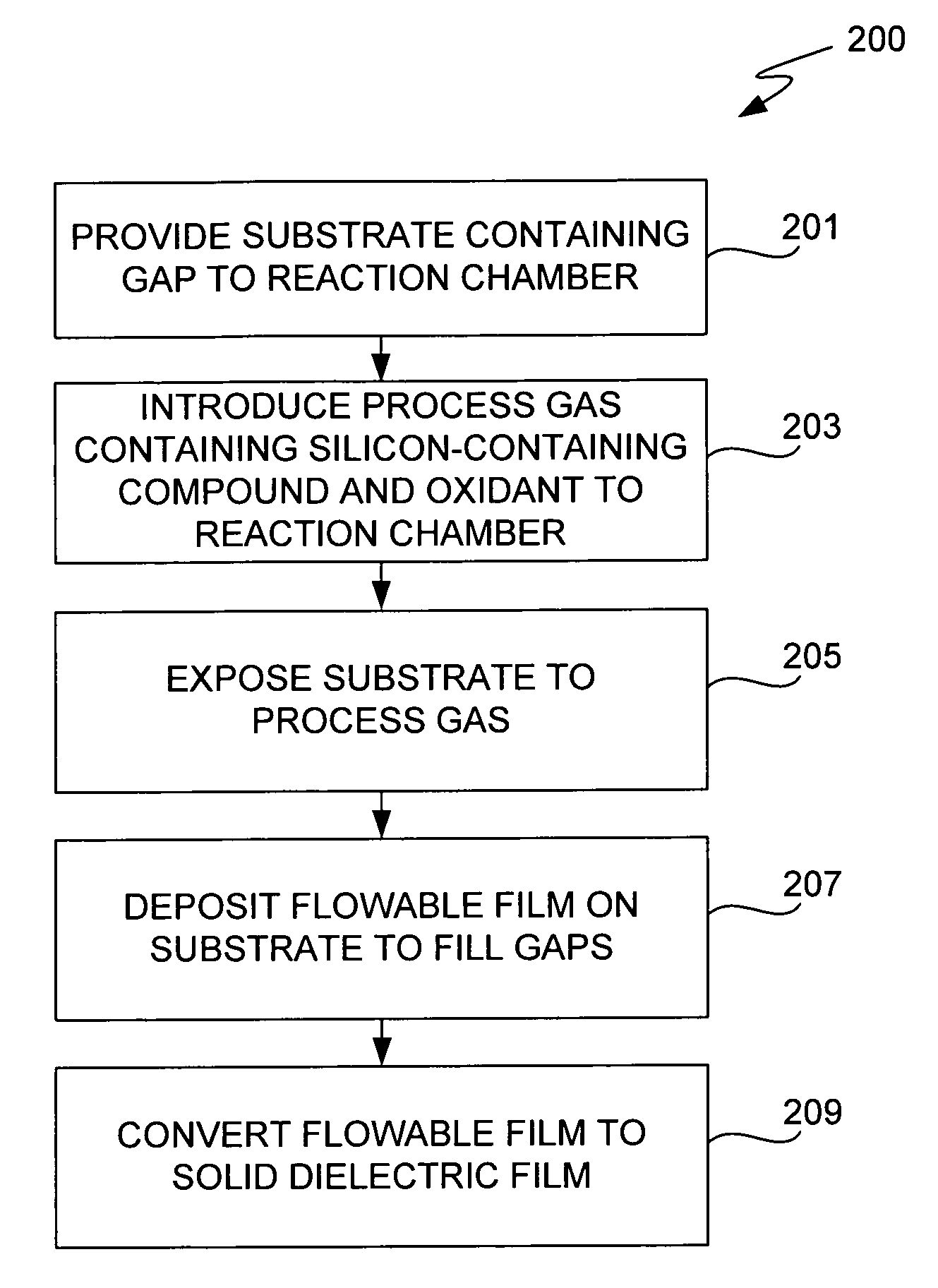

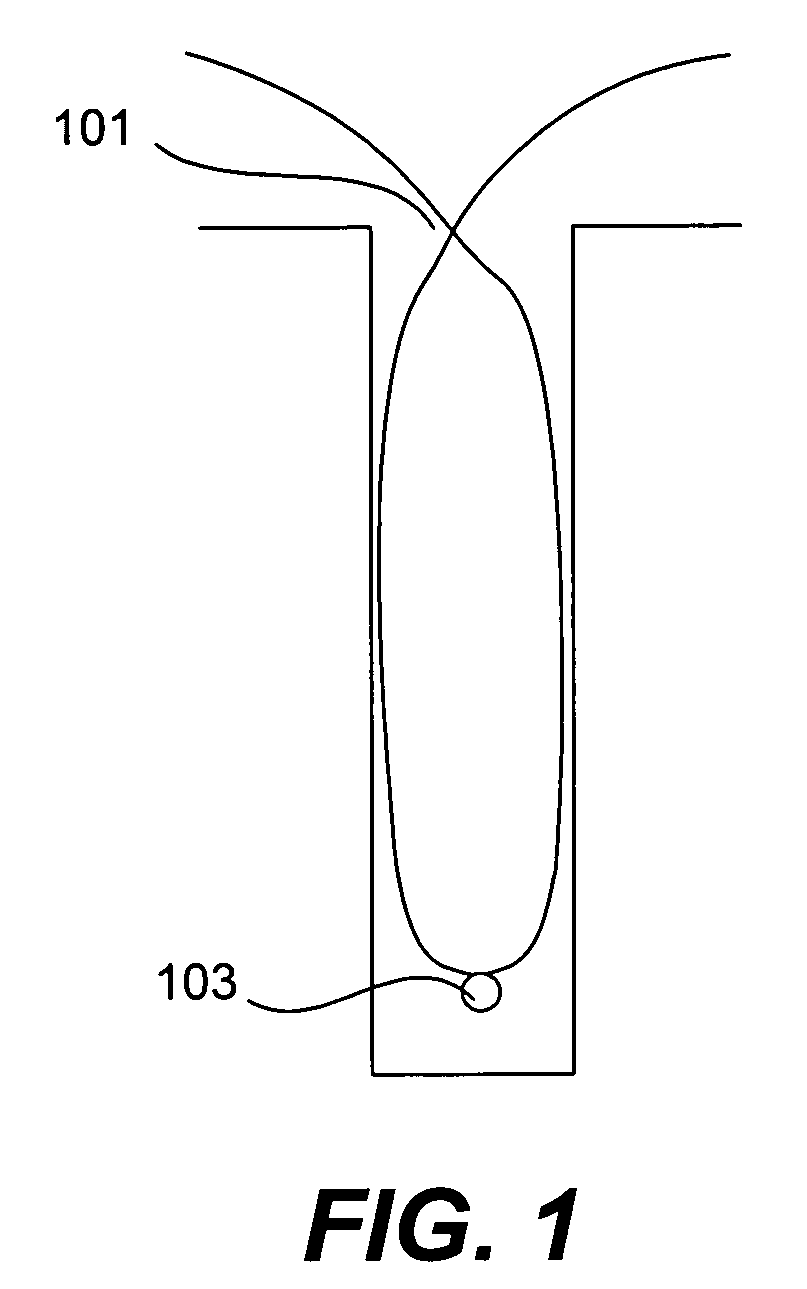

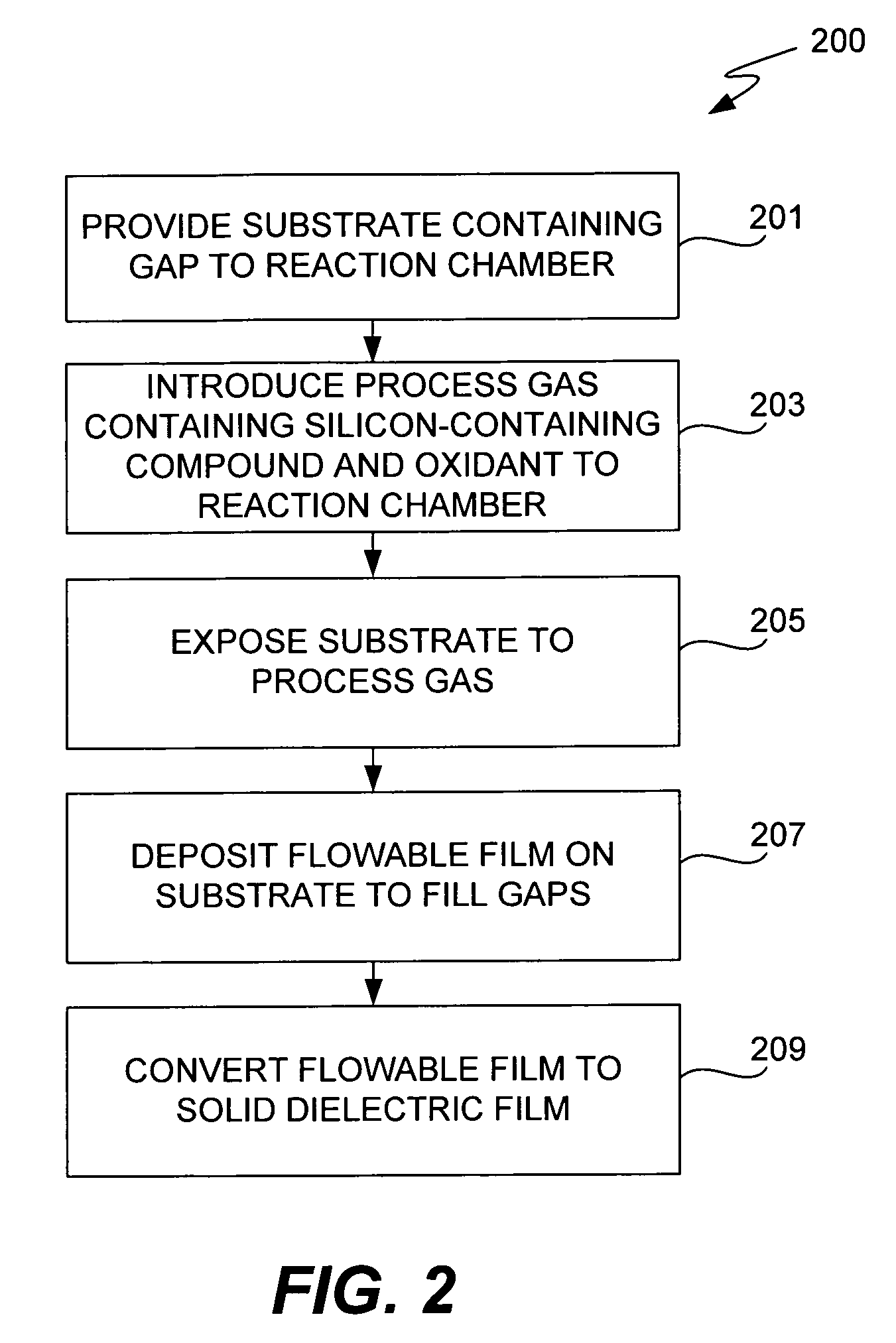

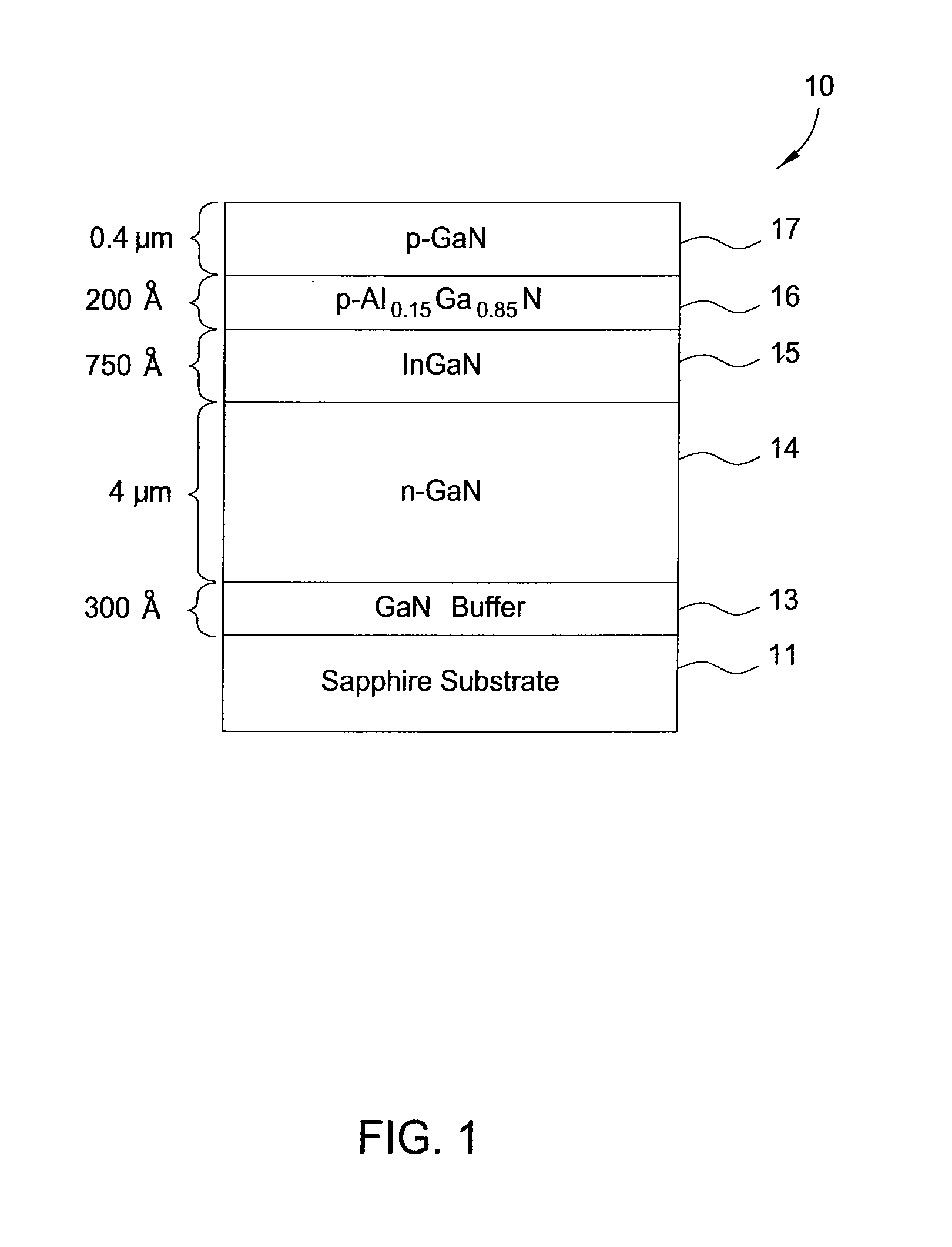

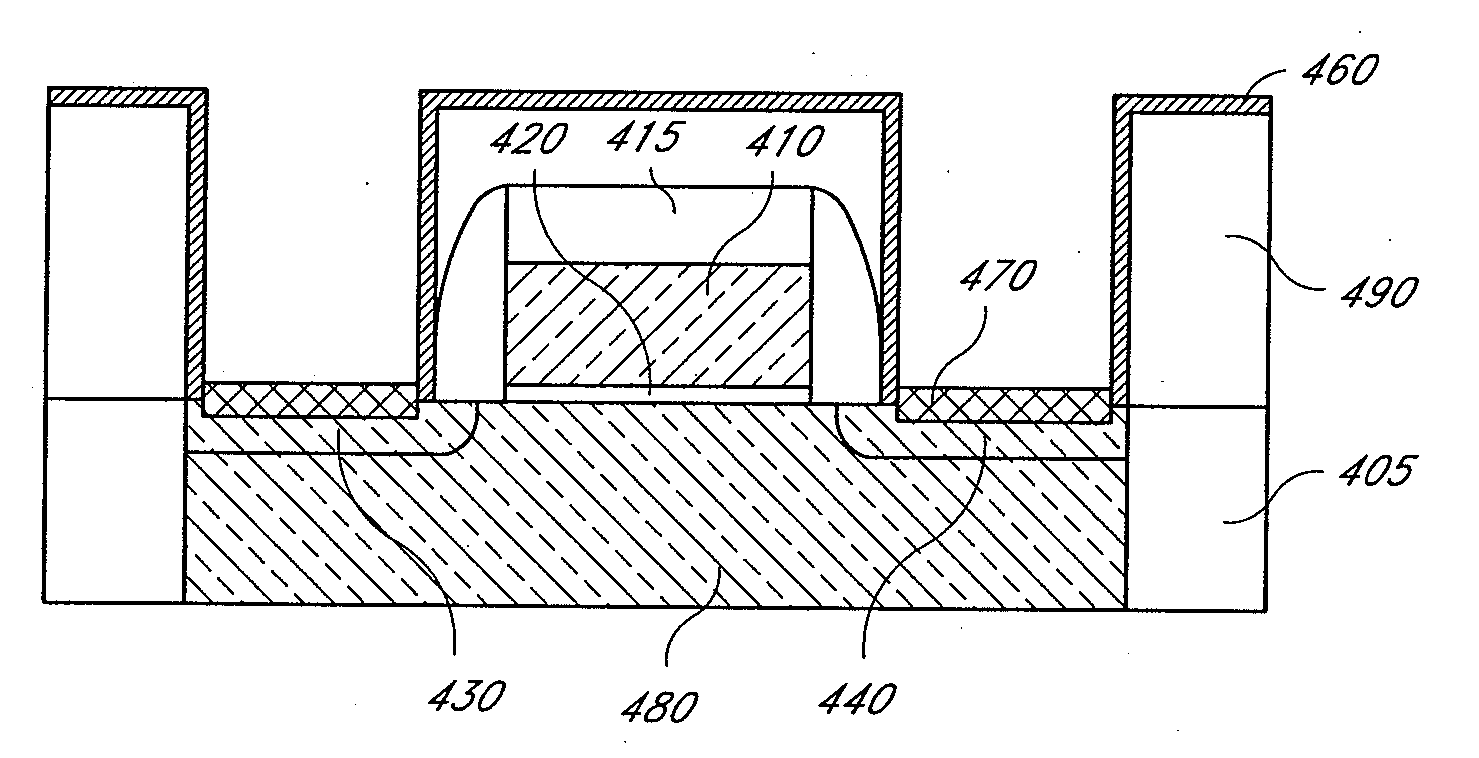

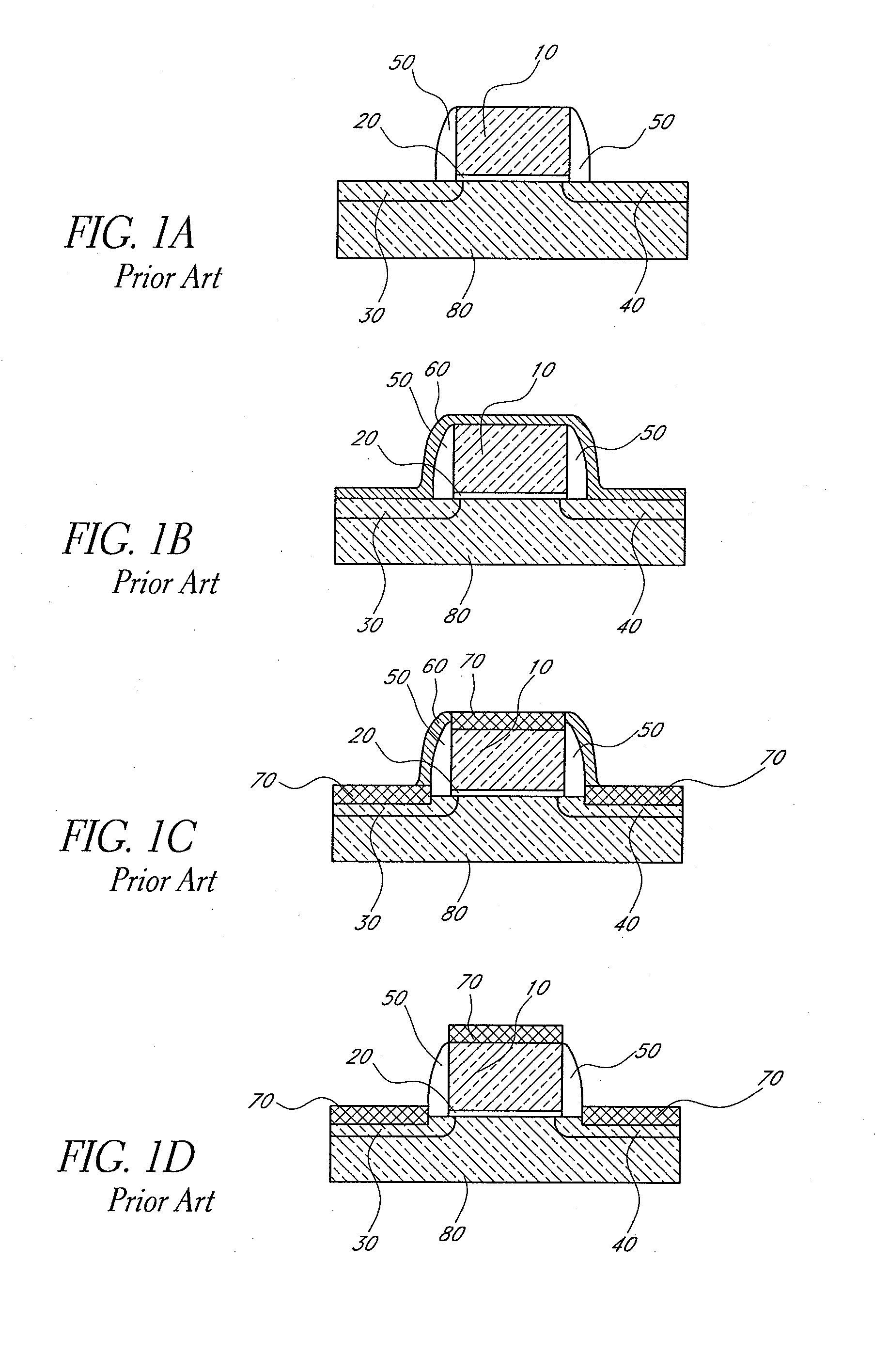

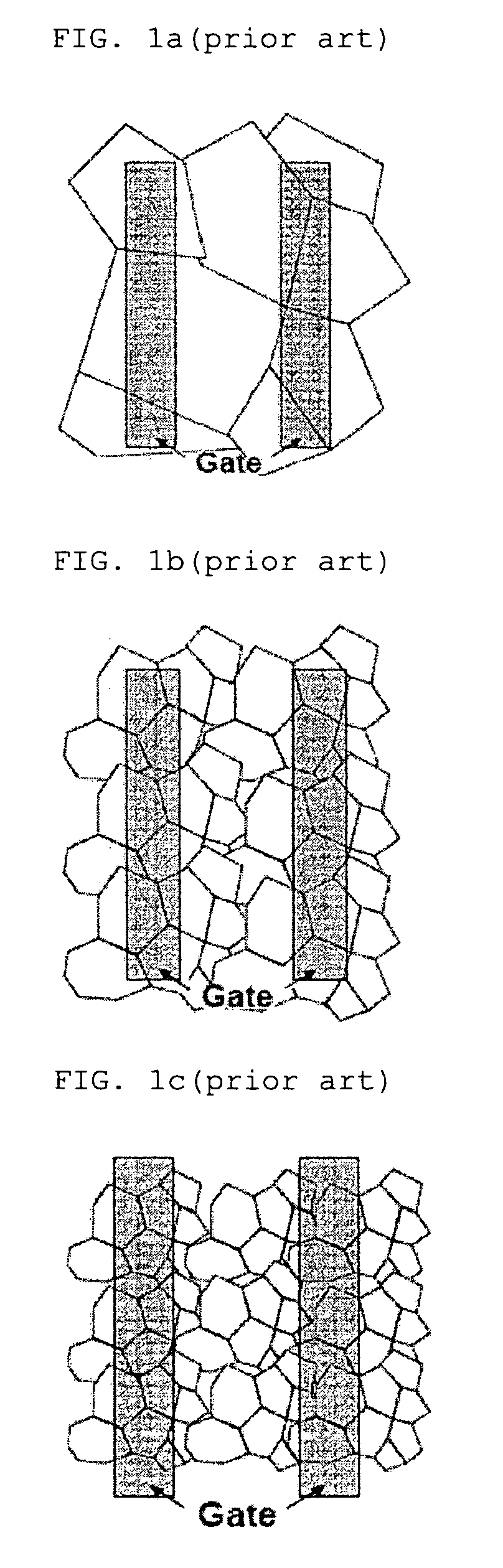

CVD flowable gap fill

The present invention meets these needs by providing improved methods of filling gaps. In certain embodiments, the methods involve placing a substrate into a reaction chamber and introducing a vapor phase silicon-containing compound and oxidant into the chamber. Reactor conditions are controlled so that the silicon-containing compound and the oxidant are made to react and condense onto the substrate. The chemical reaction causes the formation of a flowable film, in some instances containing Si—OH, Si—H and Si—O bonds. The flowable film fills gaps on the substrates. The flowable film is then converted into a silicon oxide film, for example by plasma or thermal annealing. The methods of this invention may be used to fill high aspect ratio gaps, including gaps having aspect ratios ranging from 3:1 to 10:1.

Owner:NOVELLUS SYSTEMS

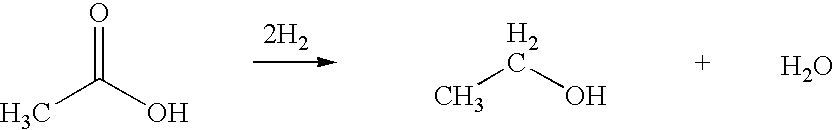

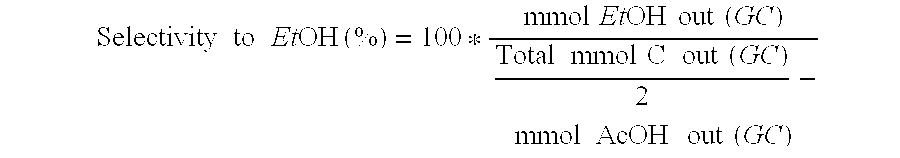

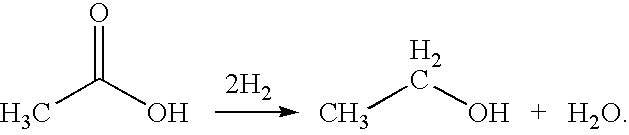

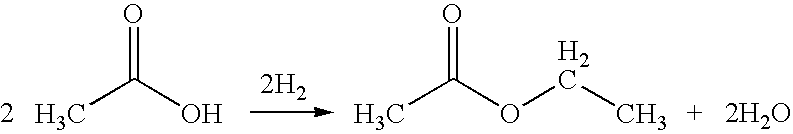

Ethanol production from acetic acid utilizing a cobalt catalyst

InactiveUS7608744B1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionAcetic acidPlatinum

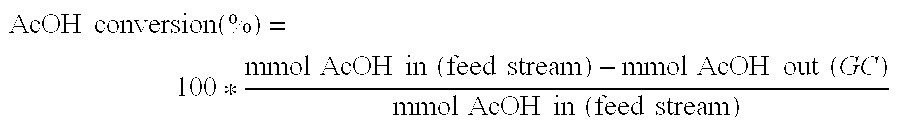

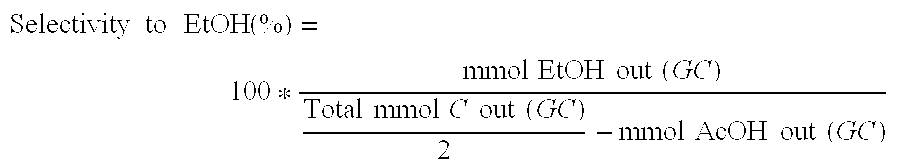

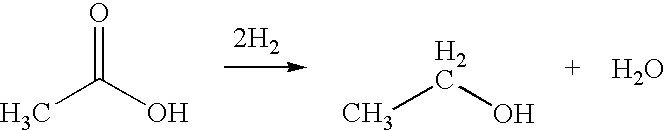

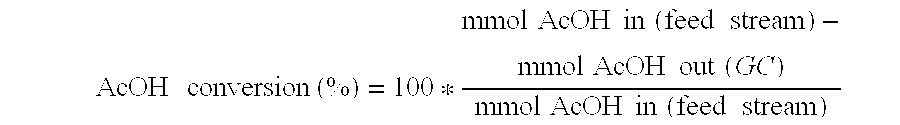

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either cobalt and palladium supported on graphite or cobalt and platinum supported on silica selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS7863489B2High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicateAcetic acid

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

CVD flowable gap fill

The present invention meets these needs by providing improved methods of filling gaps. In certain embodiments, the methods involve placing a substrate into a reaction chamber and introducing a vapor phase silicon-containing compound and oxidant into the chamber. Reactor conditions are controlled so that the silicon-containing compound and the oxidant are made to react and condense onto the substrate. The chemical reaction causes the formation of a flowable film, in some instances containing Si—OH, Si—H and Si—O bonds. The flowable film fills gaps on the substrates. The flowable film is then converted into a silicon oxide film, for example by plasma or thermal annealing. The methods of this invention may be used to fill high aspect ratio gaps, including gaps having aspect ratios ranging from 3:1 to 10:1.

Owner:NOVELLUS SYSTEMS

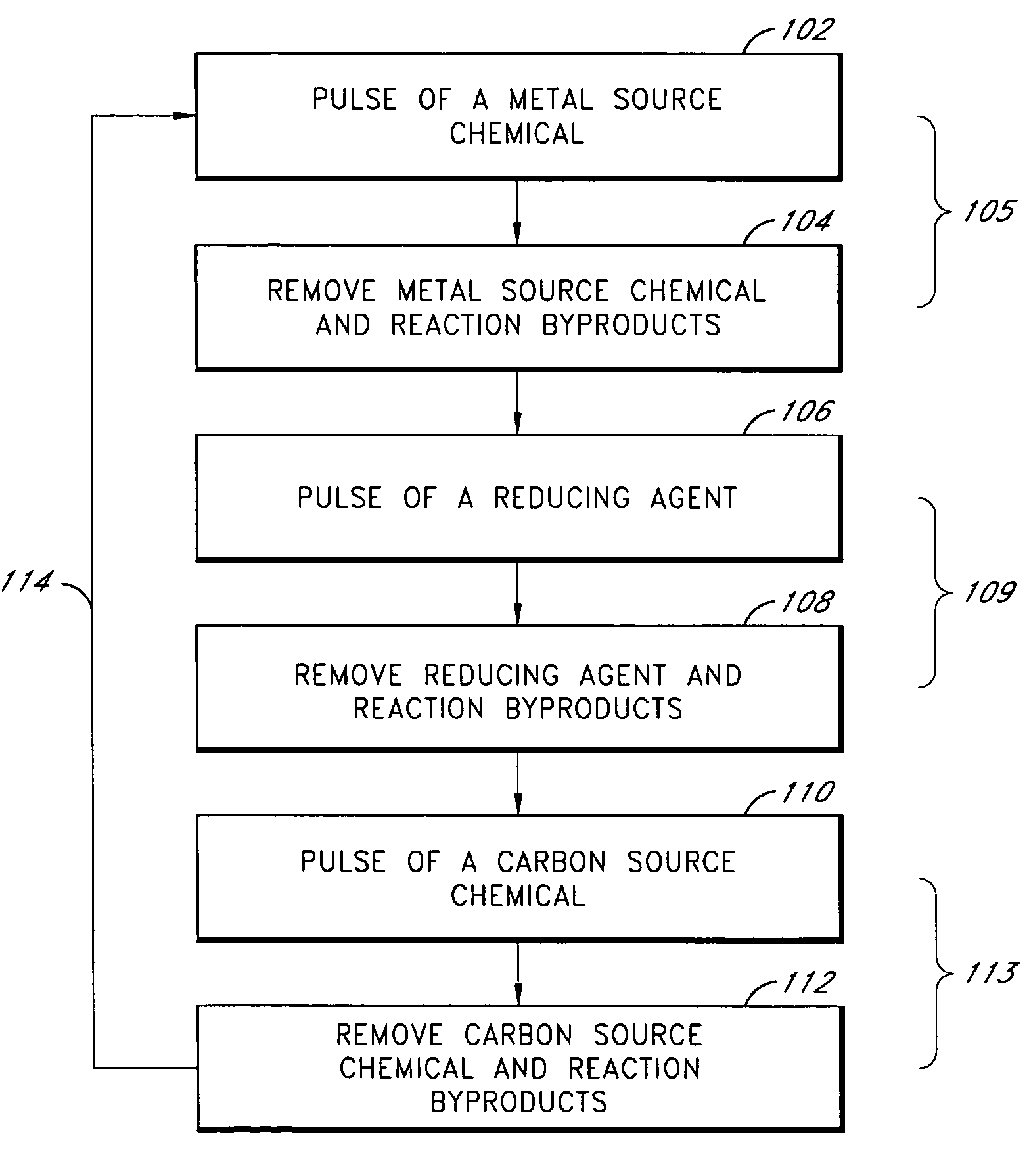

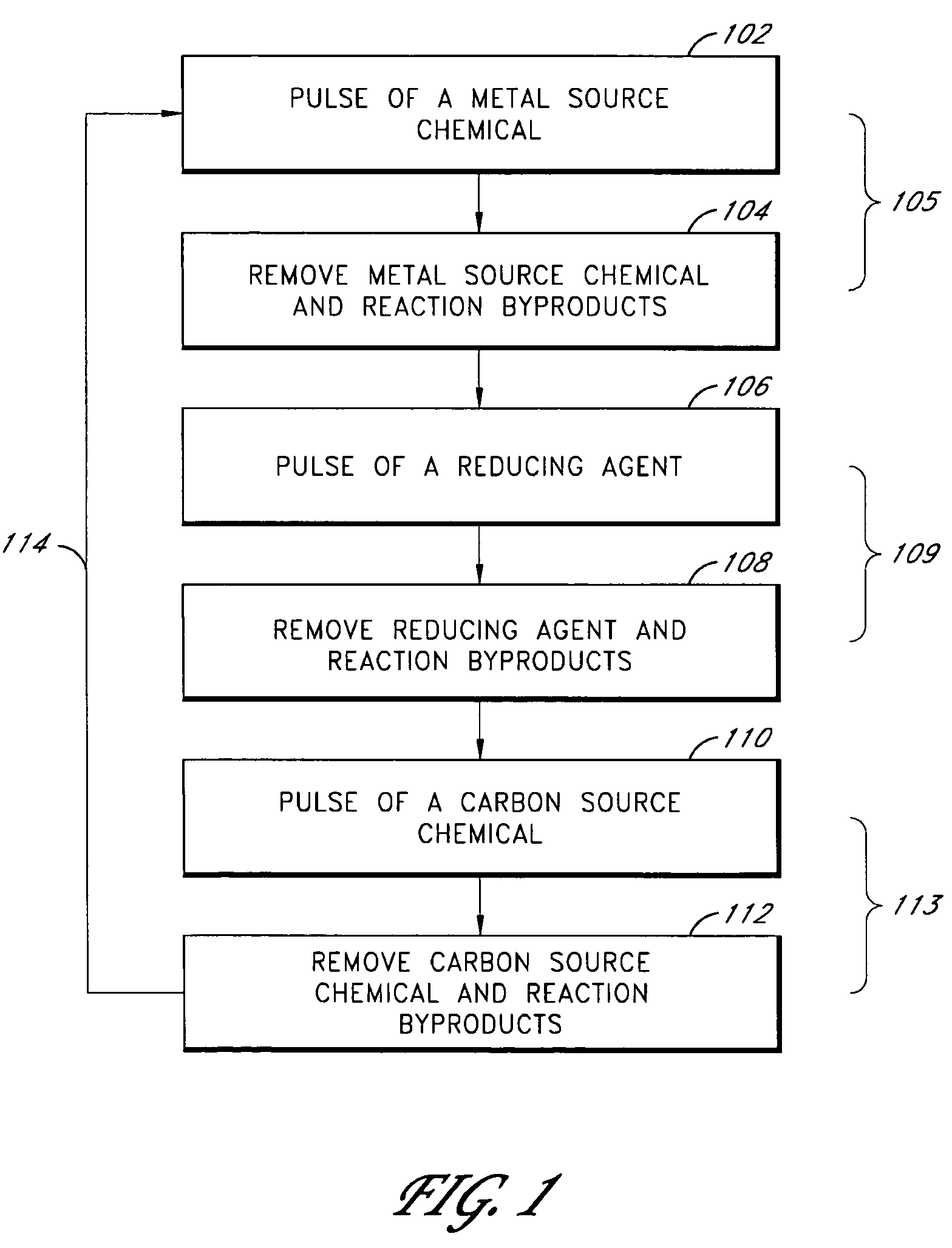

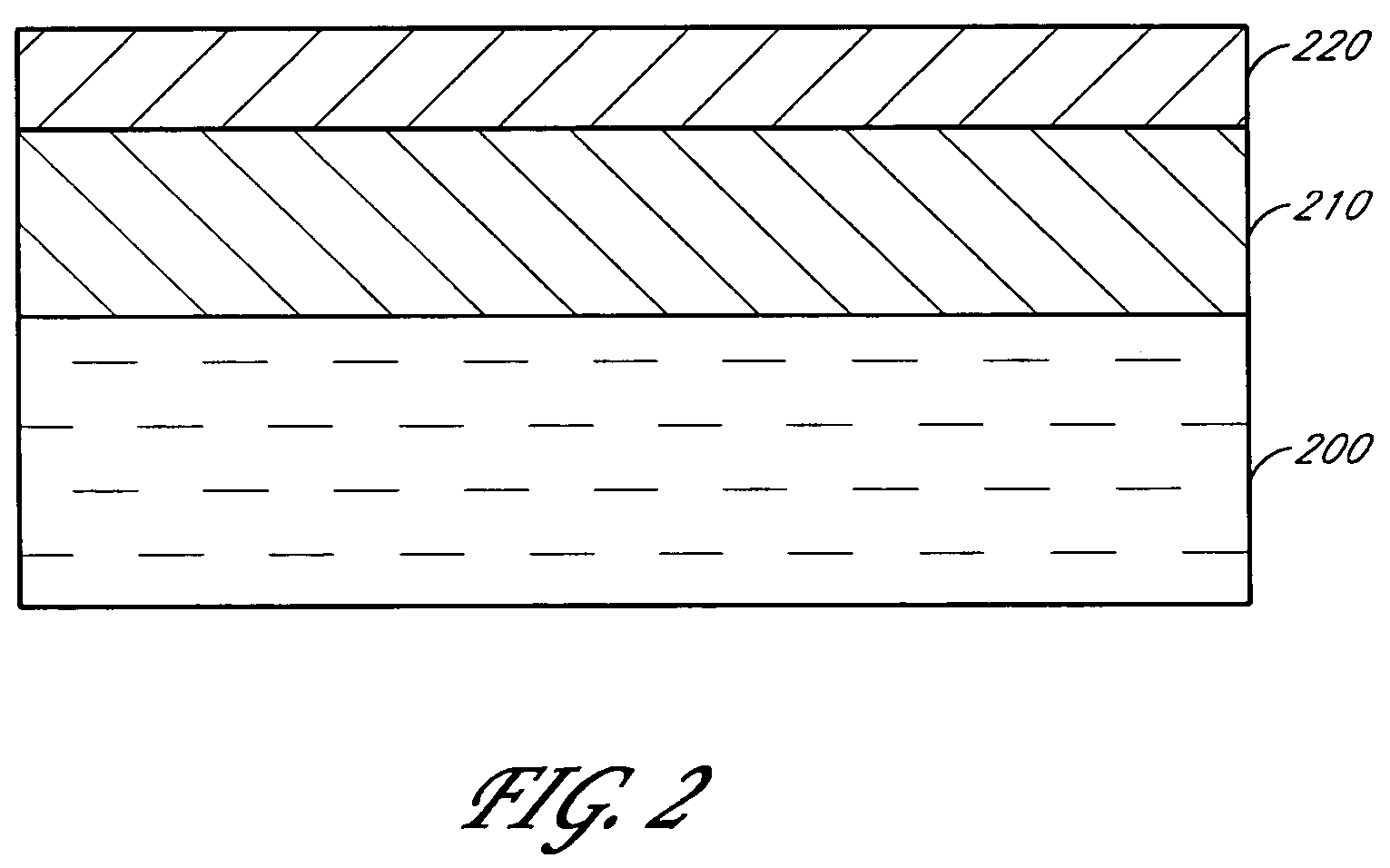

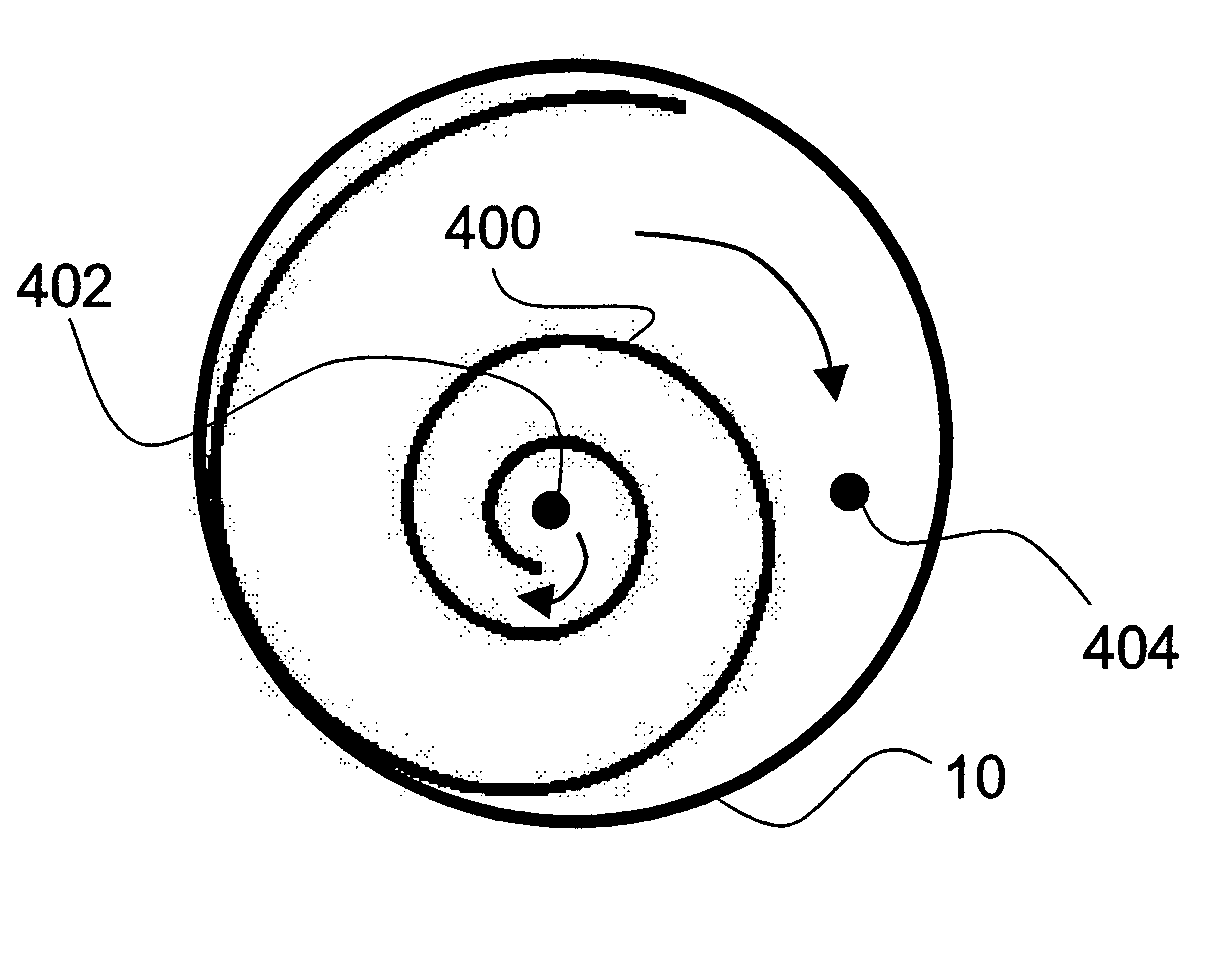

Vapor deposition of metal carbide films

Methods of forming metal carbide thin films are provided. According to preferred embodiments, metal carbide thin films are formed in an atomic layer deposition (ALD) process by alternately and sequentially contacting a substrate in a reaction space with spatially and temporally separated vapor phase pulses of a metal source chemical, a reducing agent and a carbon source chemical. The reducing agent is preferably selected from the group consisting of excited species of hydrogen and silicon-containing compounds.

Owner:ASM IP HLDG BV

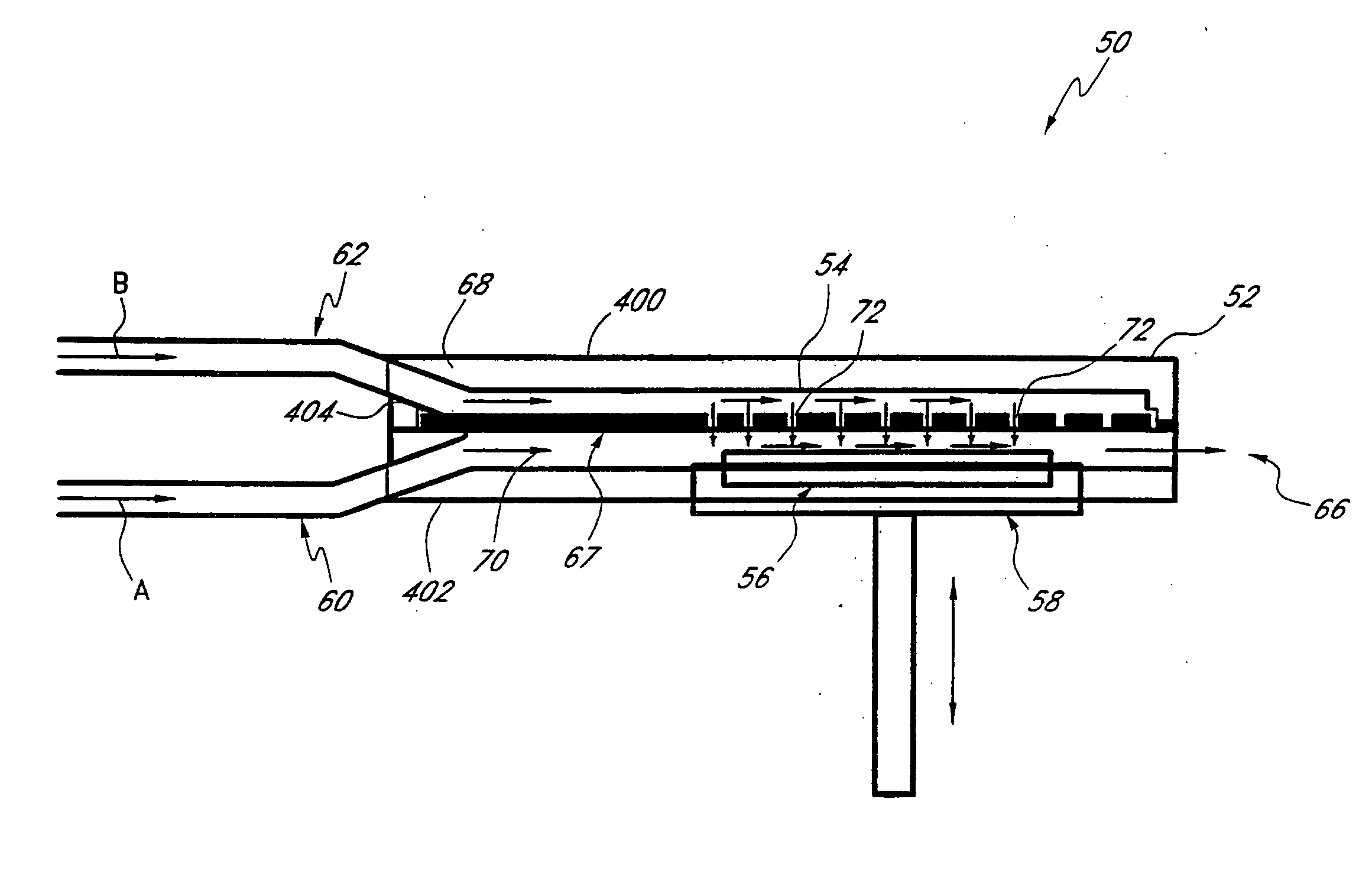

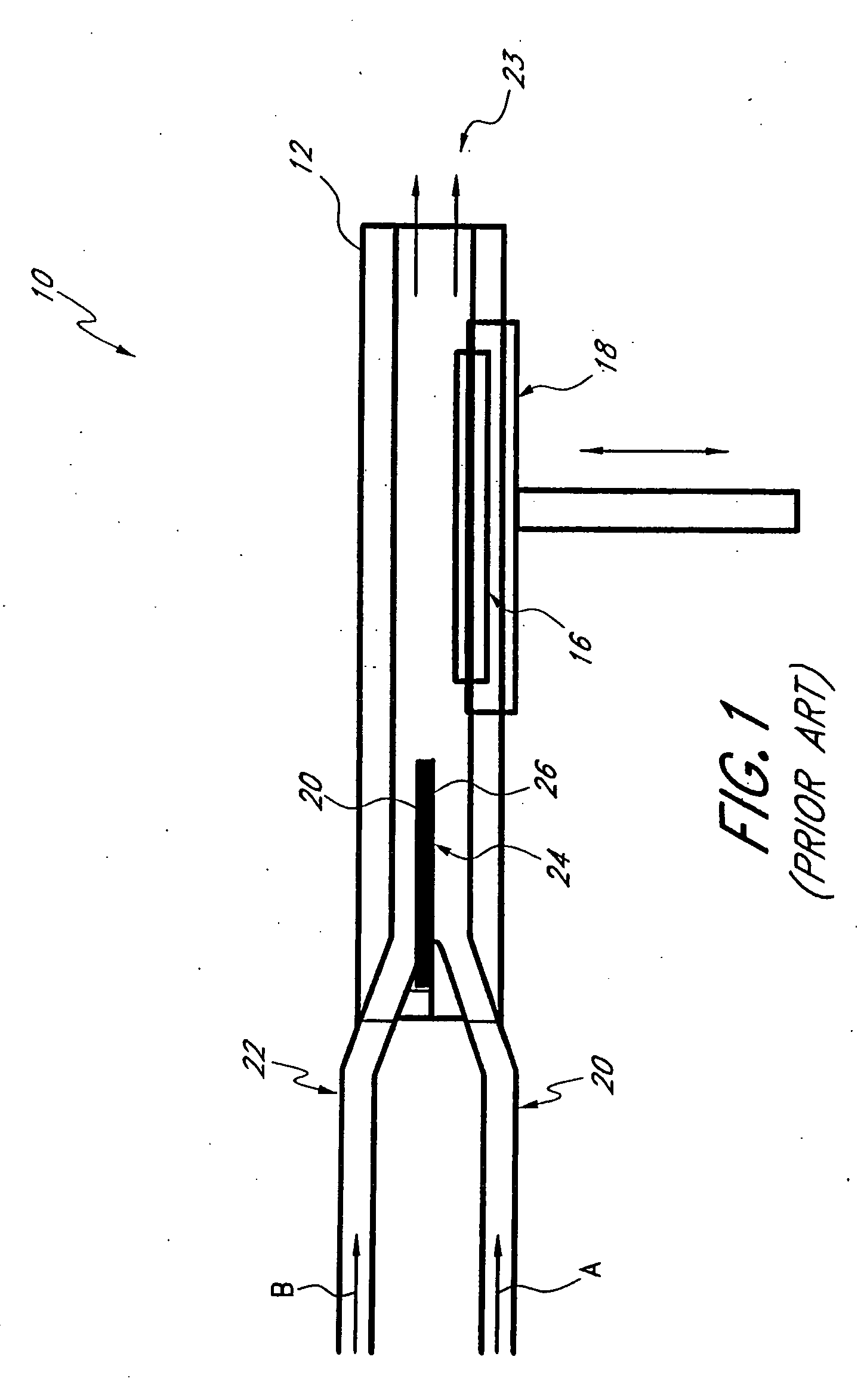

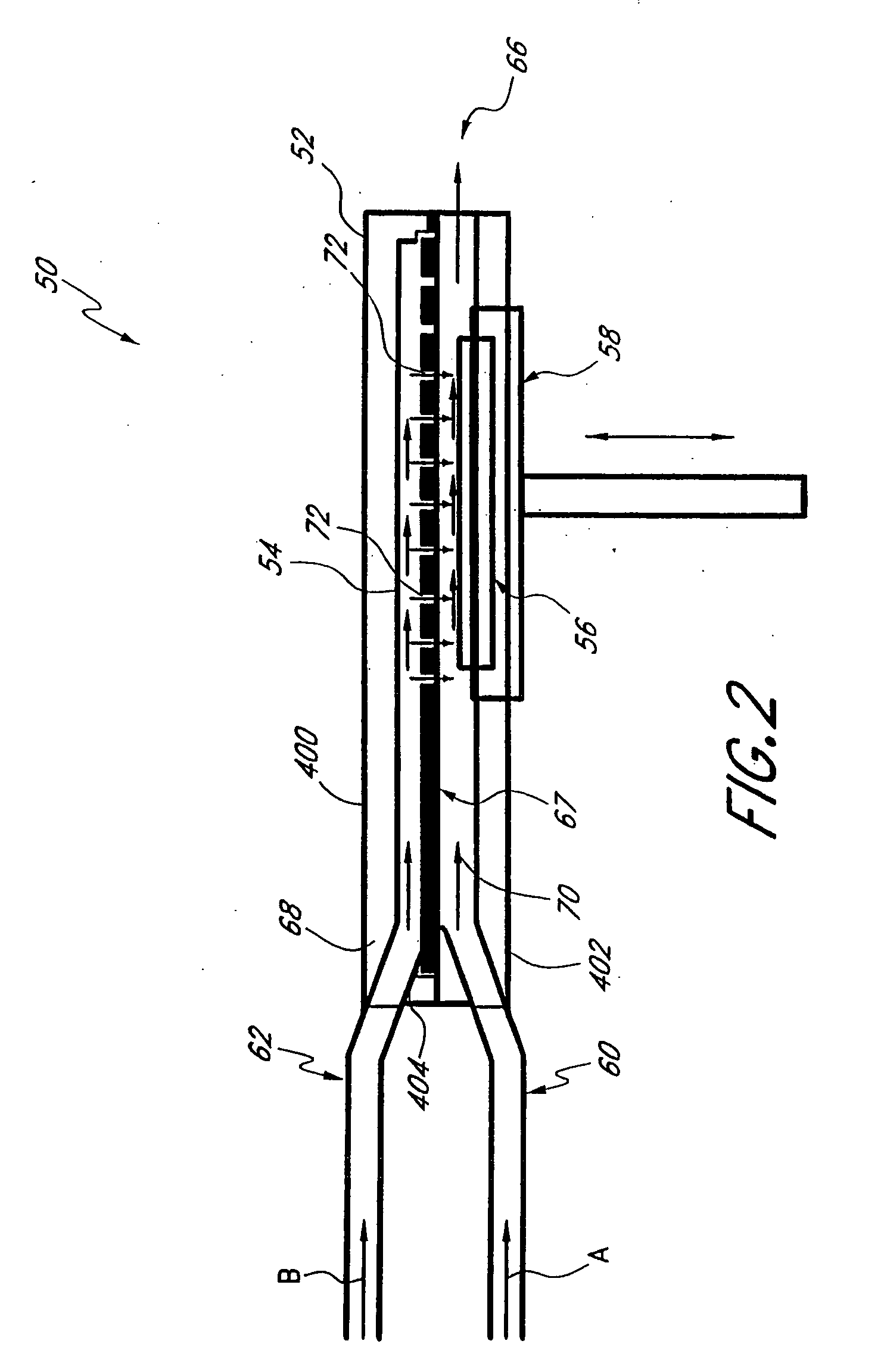

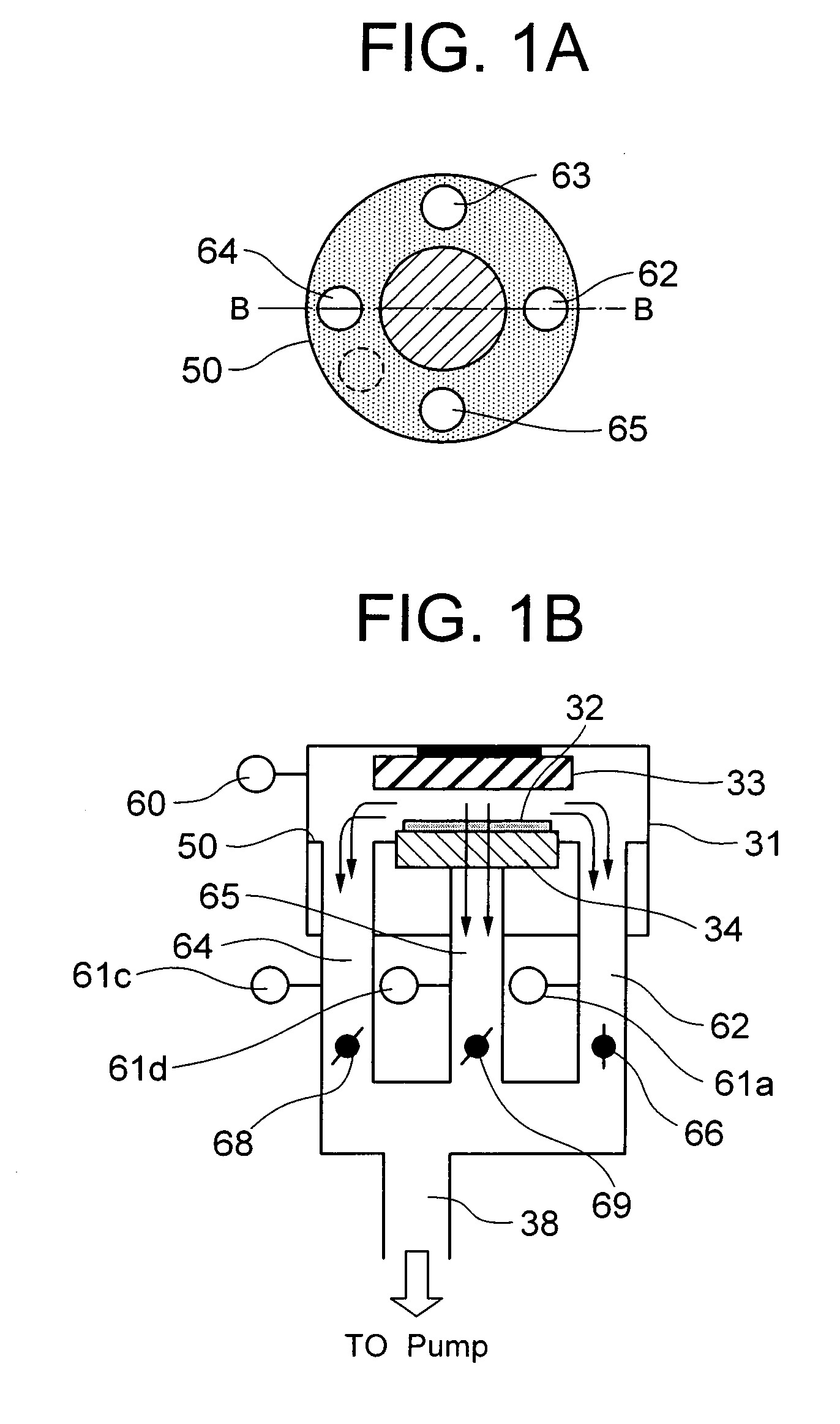

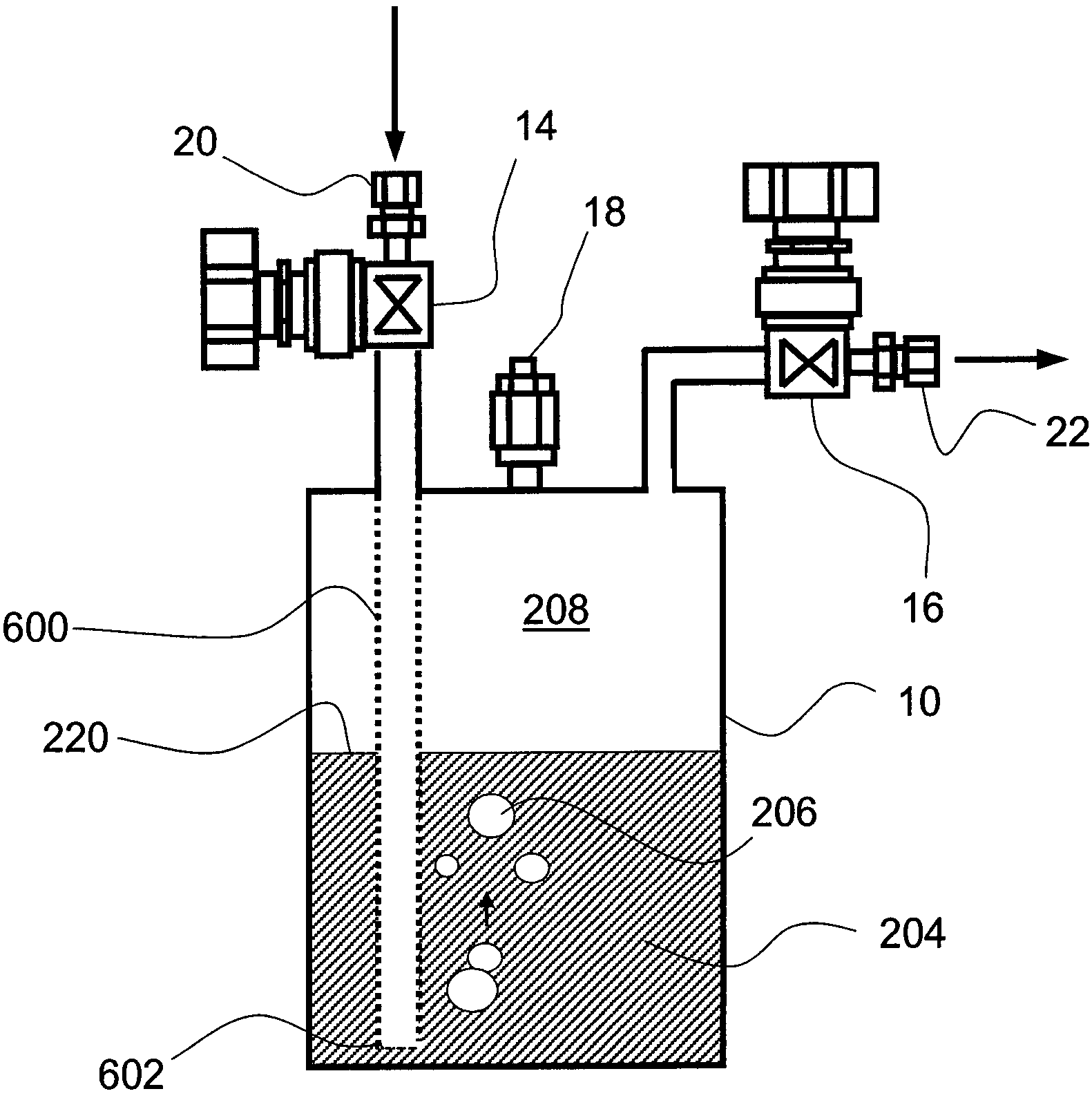

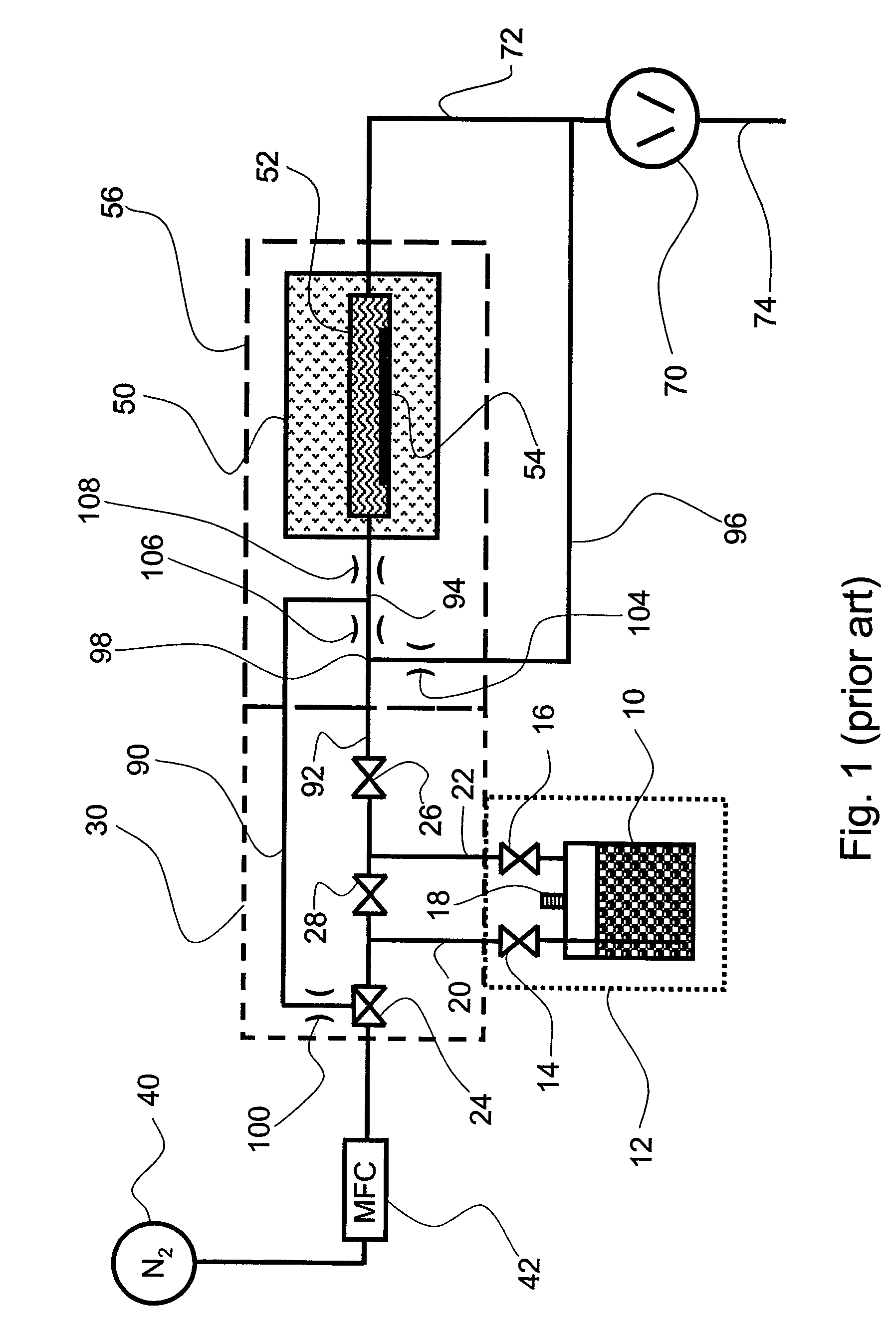

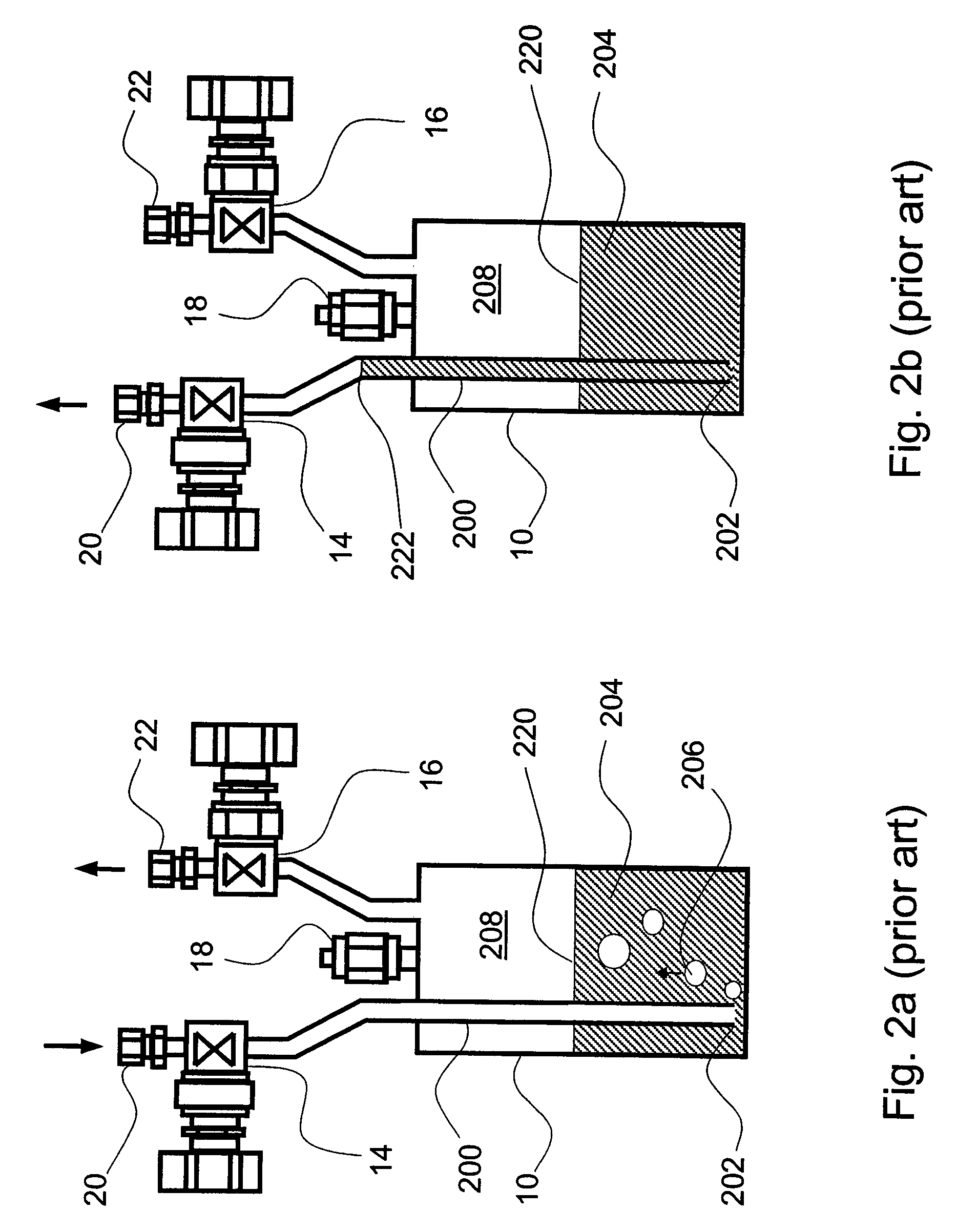

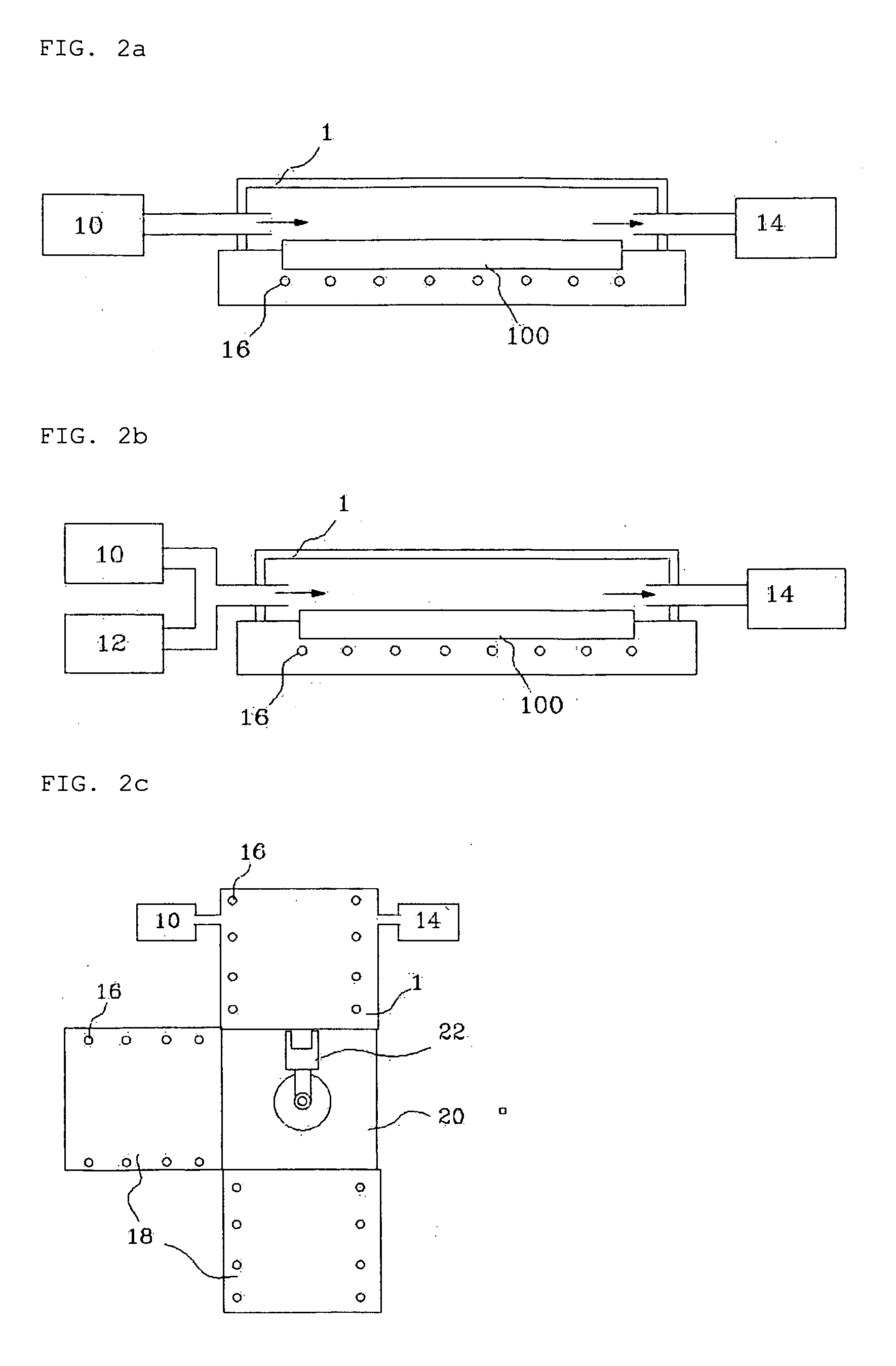

Safe liquid source containers

ActiveUS20050066893A1Excessive pressure increaseEncouraging capillary migrationCarburetting airMixing methodsPorous membraneEngineering

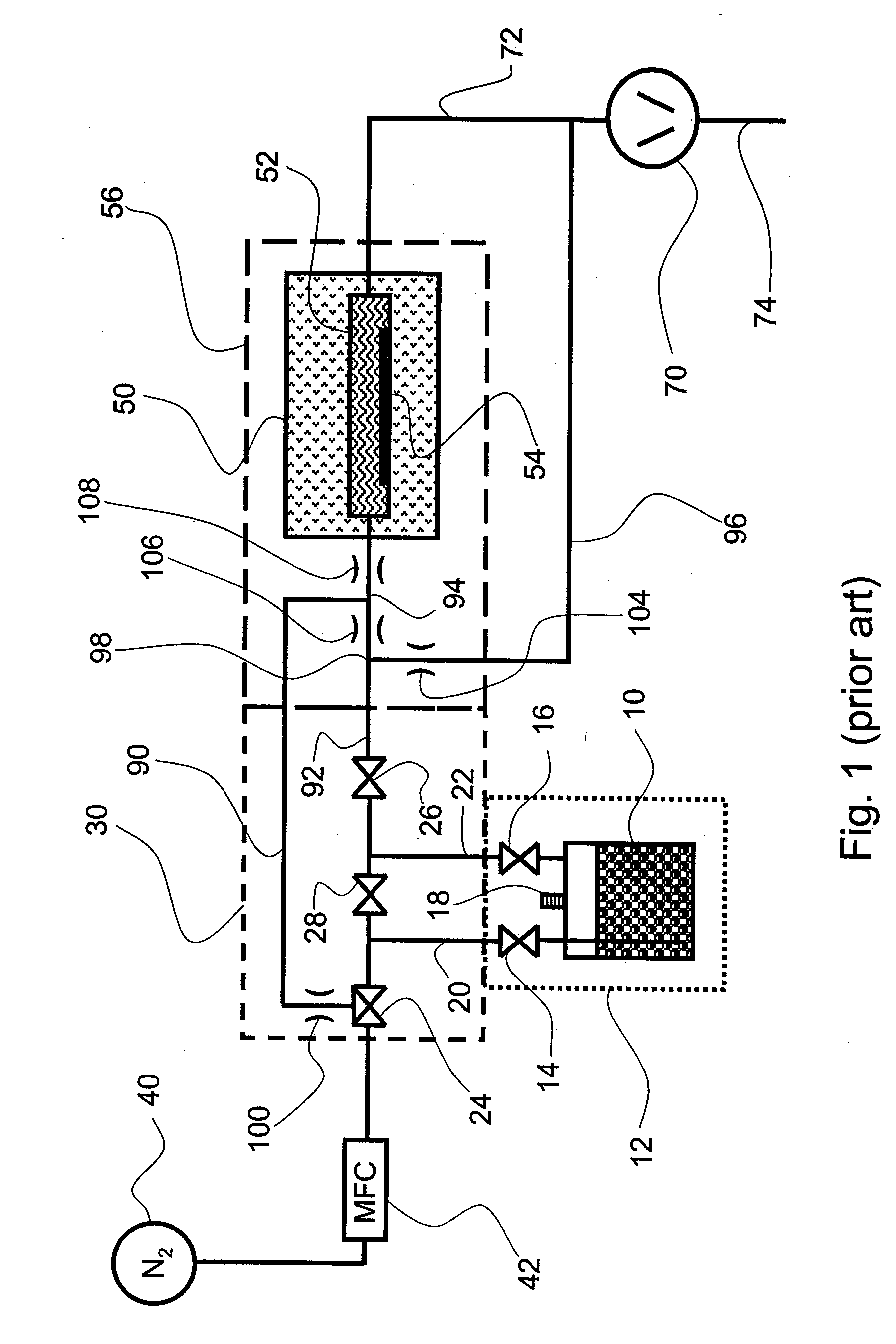

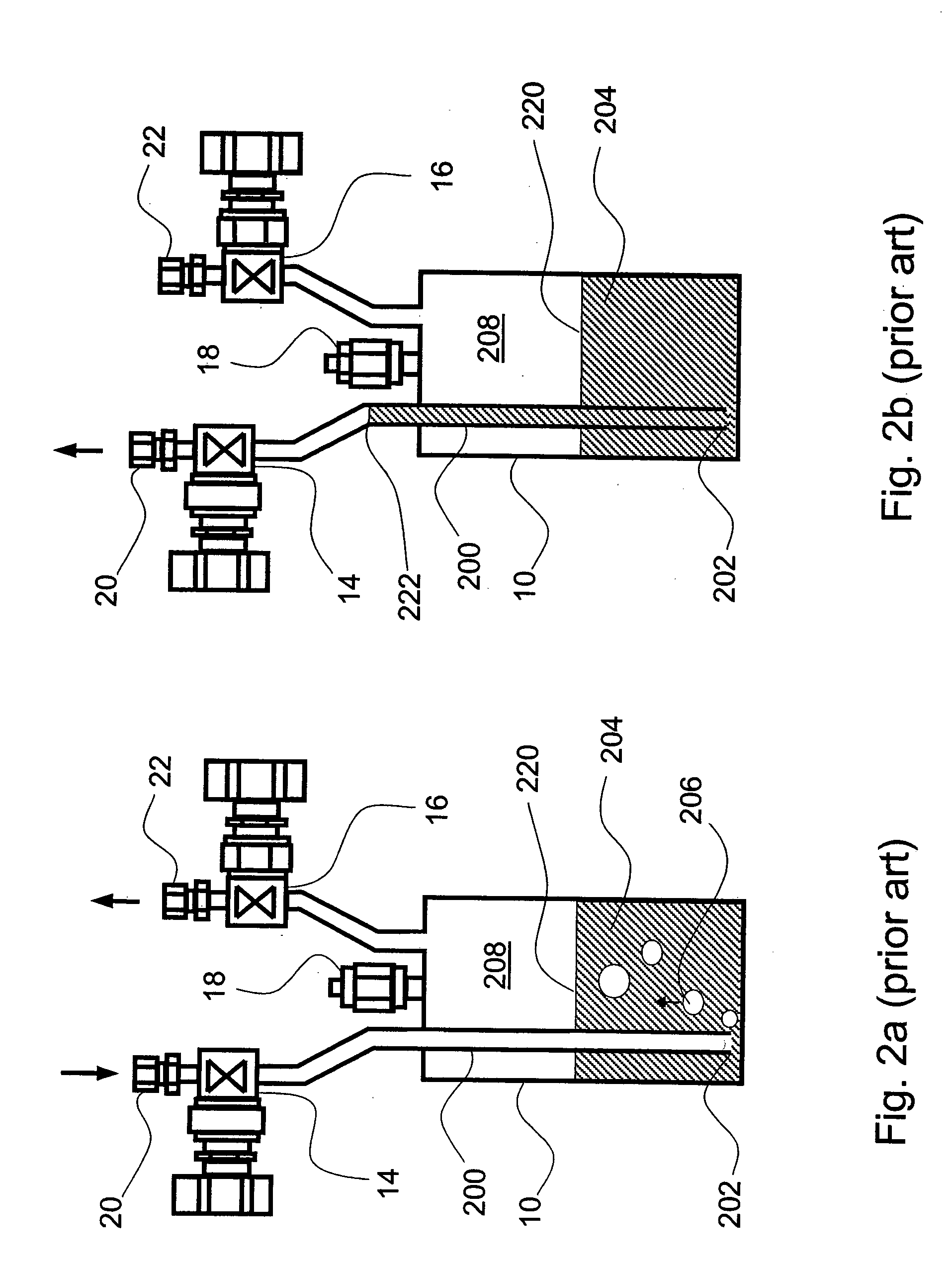

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

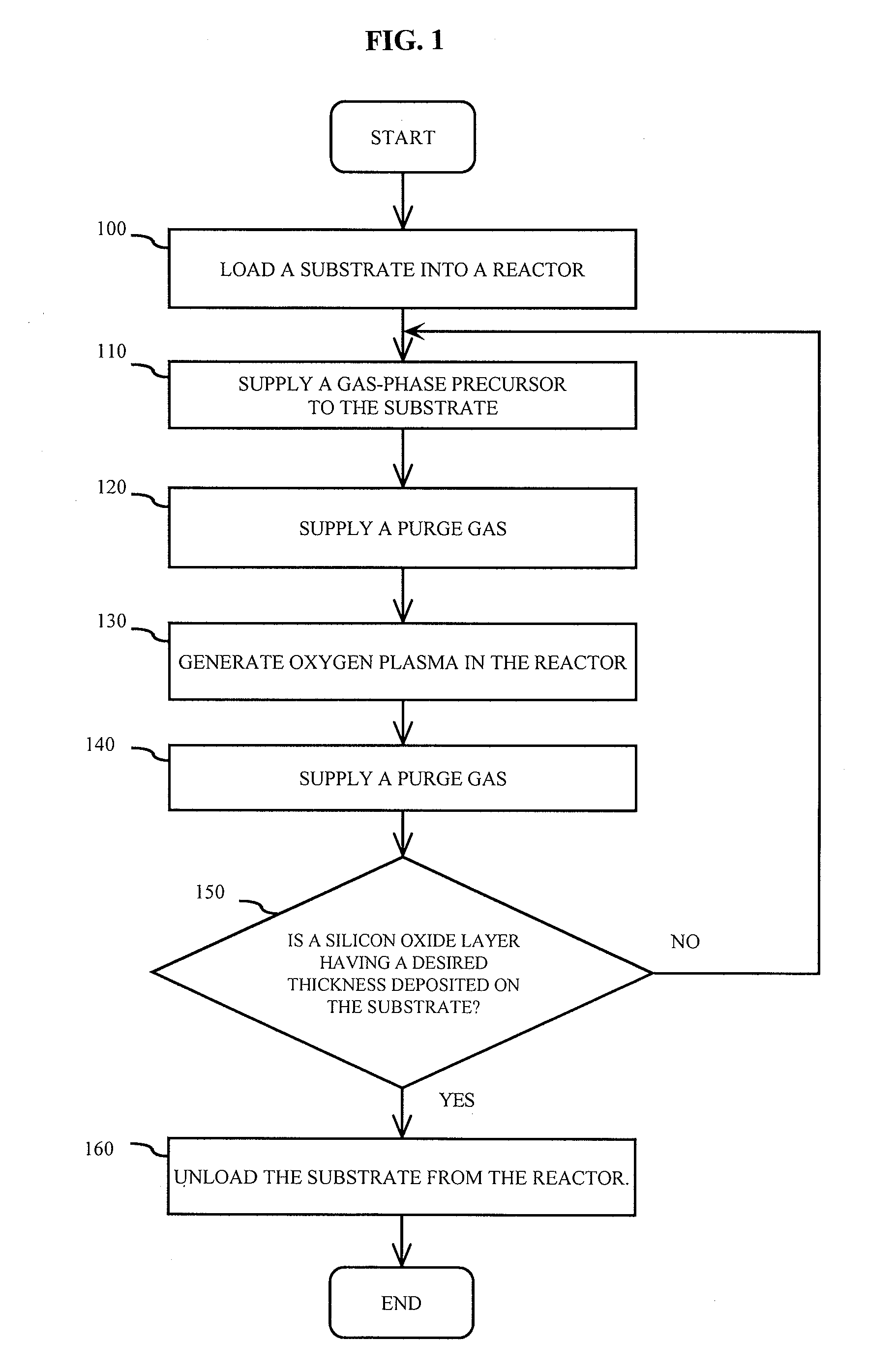

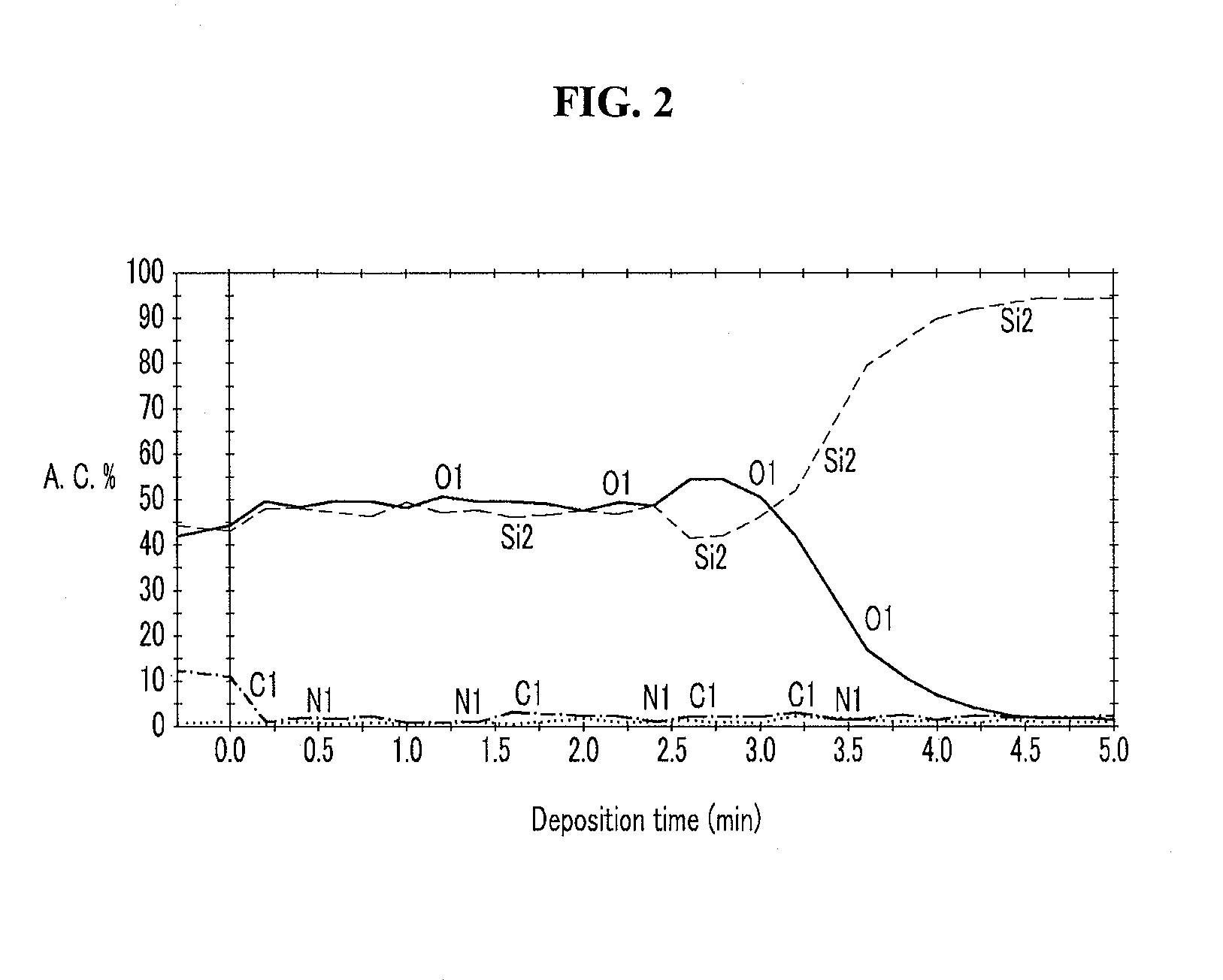

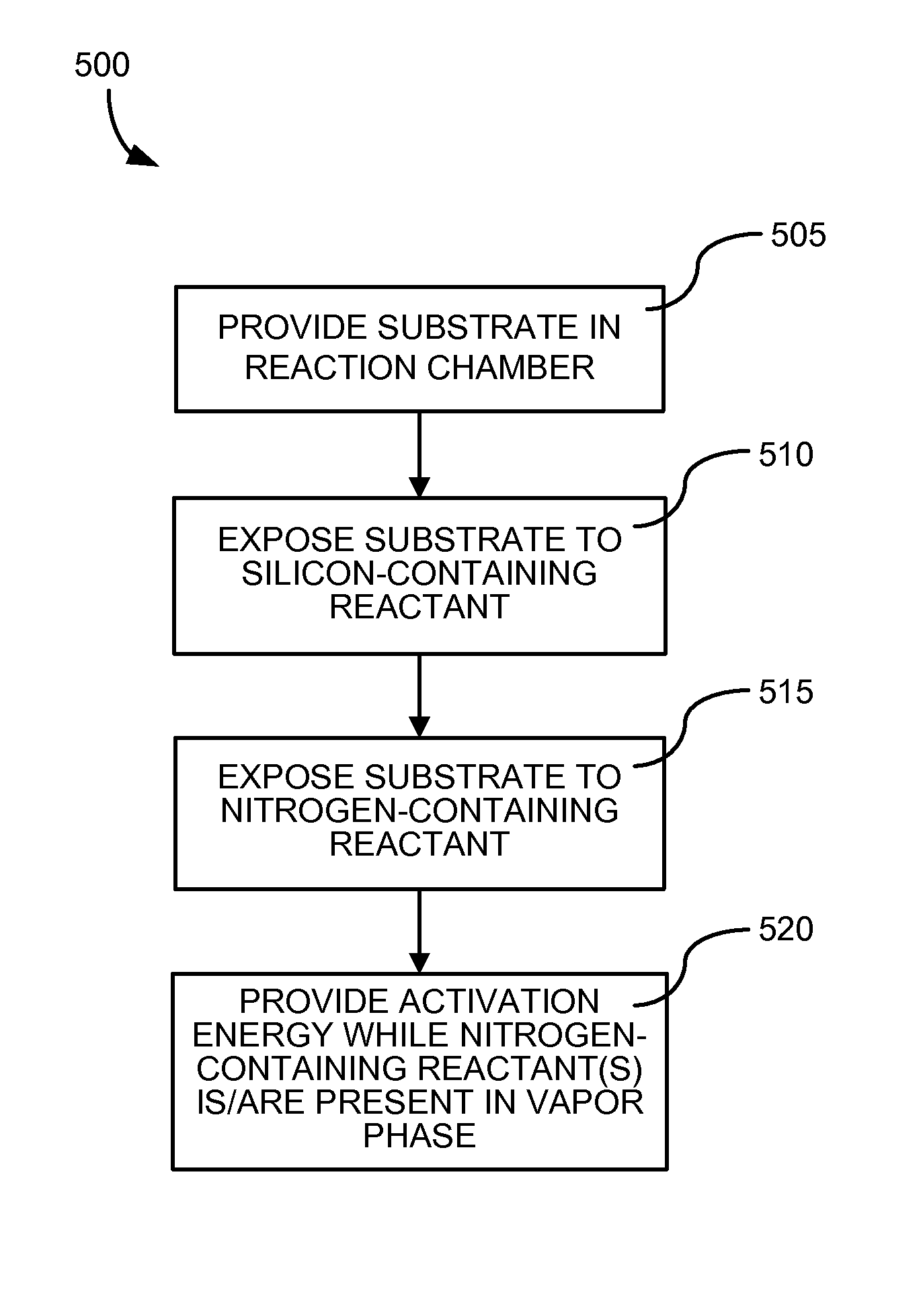

Method of depositing silicon oxide films

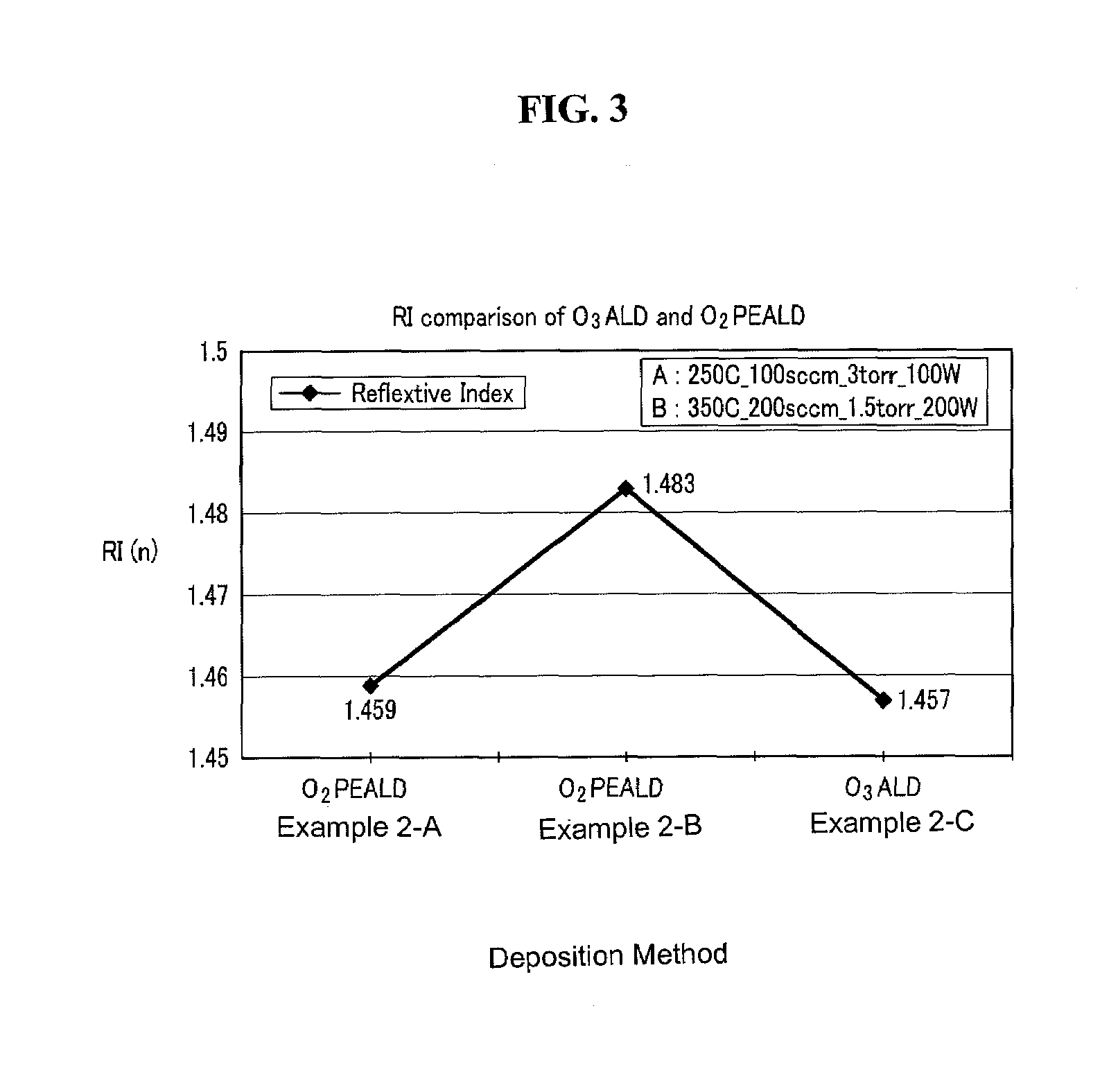

InactiveUS20090041952A1Semiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingOxygen plasmaGas phase

Methods of depositing a silicon oxide film are disclosed. One embodiment is a plasma enhanced atomic layer deposition (PEALD) process that includes supplying a vapor phase silicon precursor, such as a diaminosilane compound, to a substrate, and supplying oxygen plasma to the substrate. Another embodiment is a pulsed hybrid method between atomic layer deposition (ALD) and chemical vapor deposition (CVD). In the other embodiment, a vapor phase silicon precursor, such as a diaminosilane compound, is supplied to a substrate while ozone gas is continuously or discontinuously supplied to the substrate.

Owner:ASM KOREA LTD

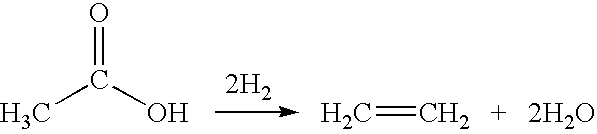

Process for catalytically producing ethylene directly from acetic acid in a single reaction zone

InactiveUS20100030001A1High selectivityHigh yieldHydrocarbonsBulk chemical productionAcetic acidHydrogen

A process for the selective production of ethylene by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethylene in a single reaction zone is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either a copper supported on iron oxide, copper-aluminum catalyst, cobalt supported on H-ZSM-5, ruthenium-cobalt supported on silica or cobalt supported on carbon selectively produces ethylene in a vapor phase at a temperature in the range of about 250° C. to 350° C.

Owner:CELANESE INT CORP

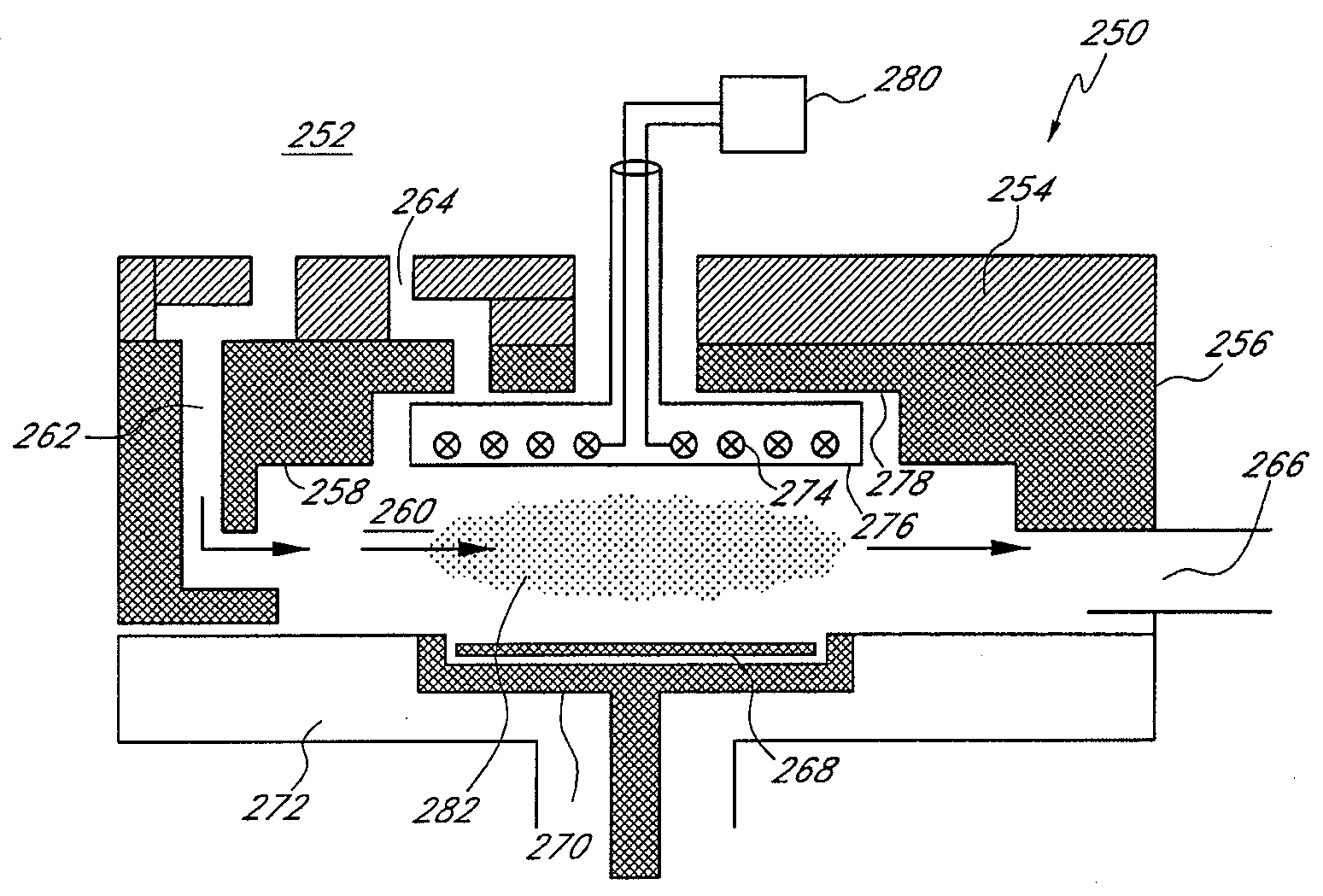

Atomic layer deposition reactor

Various reactors for growing thin films on a substrate by subjecting the substrate to alternately repeated surface reactions of vapor-phase reactants are disclosed. In one embodiment, the reactor comprises a reaction chamber. A showerhead plate divides the reaction chamber into upper and lower parts. A first precursor is directed towards the lower half of the reaction chamber and a second precursor is directed towards the upper half of the reaction chamber. The substrate is disposed within the lower half of the reaction chamber. The showerhead plate includes plurality passages such that the upper half is in communication with the lower half of the reaction chamber. In another arrangement, the upper half of the reaction chamber defines a plasma cavity in which in-situ radicals are formed. In yet another arrangement, the reaction chamber includes a shutter plate, which is configured to selectively open and close the passages in the showerhead plate. In other arrangements, the showerhead plate is arranged to modify the local flow patterns of the gases flowing through the reaction chamber.

Owner:KILPELA OLLI +6

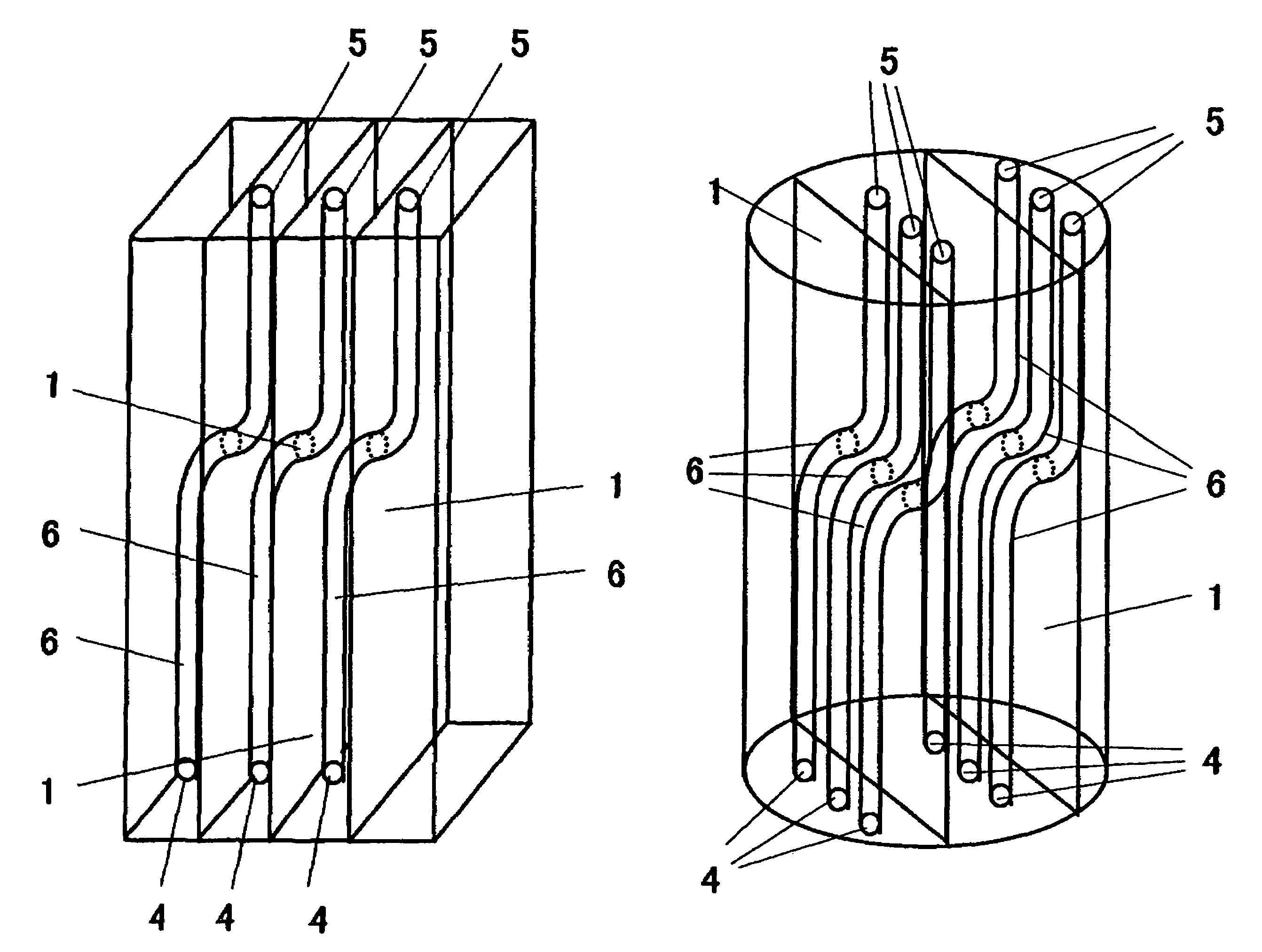

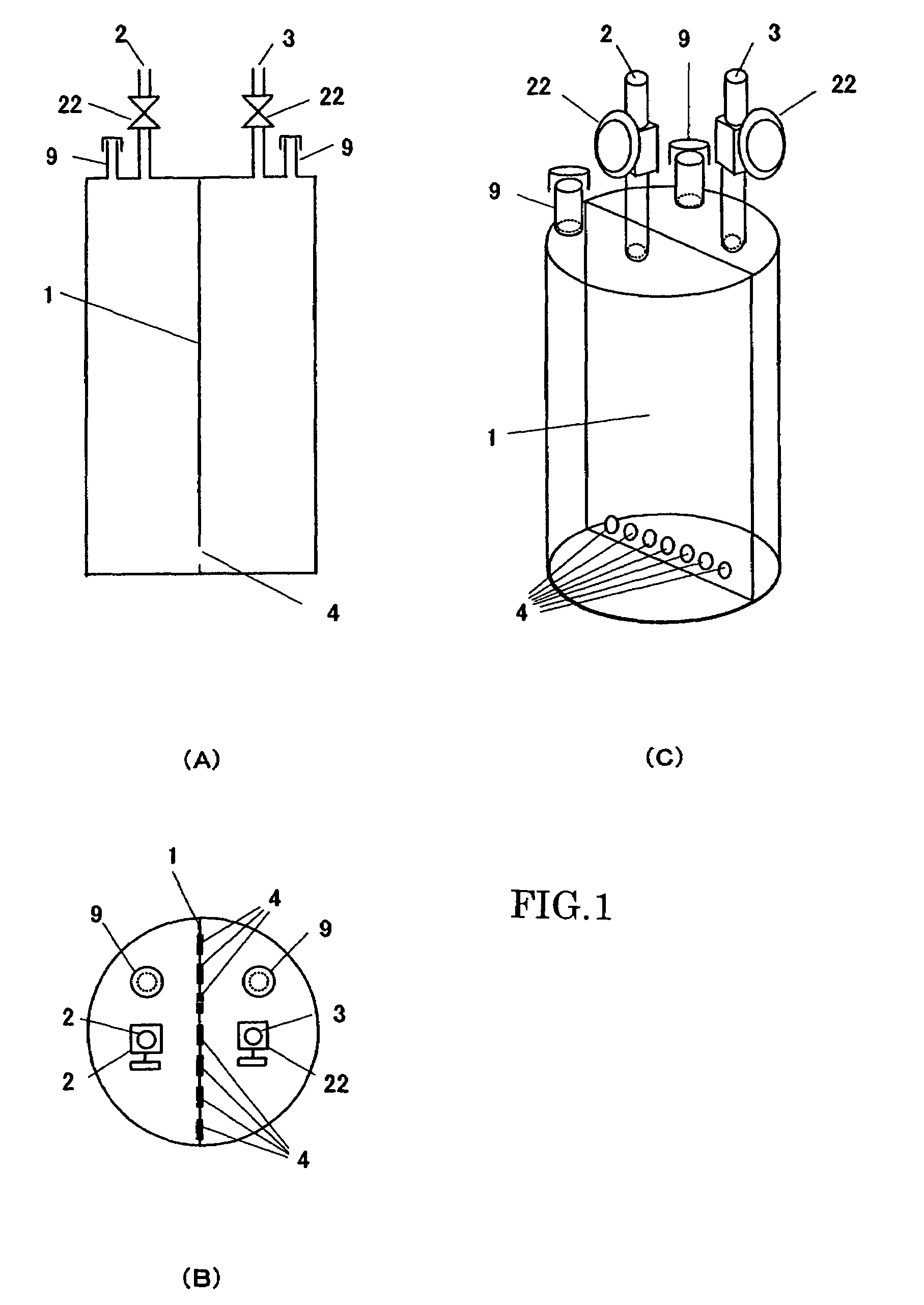

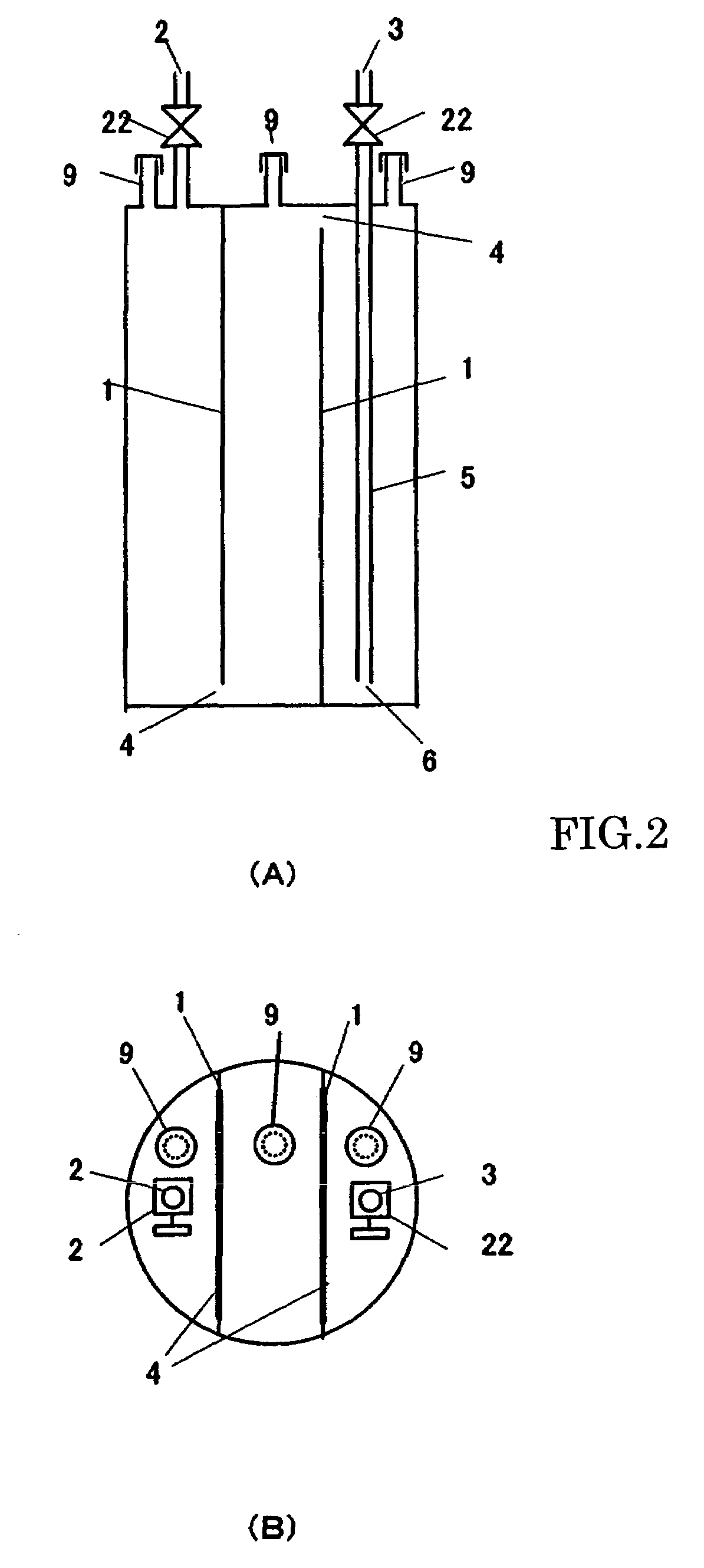

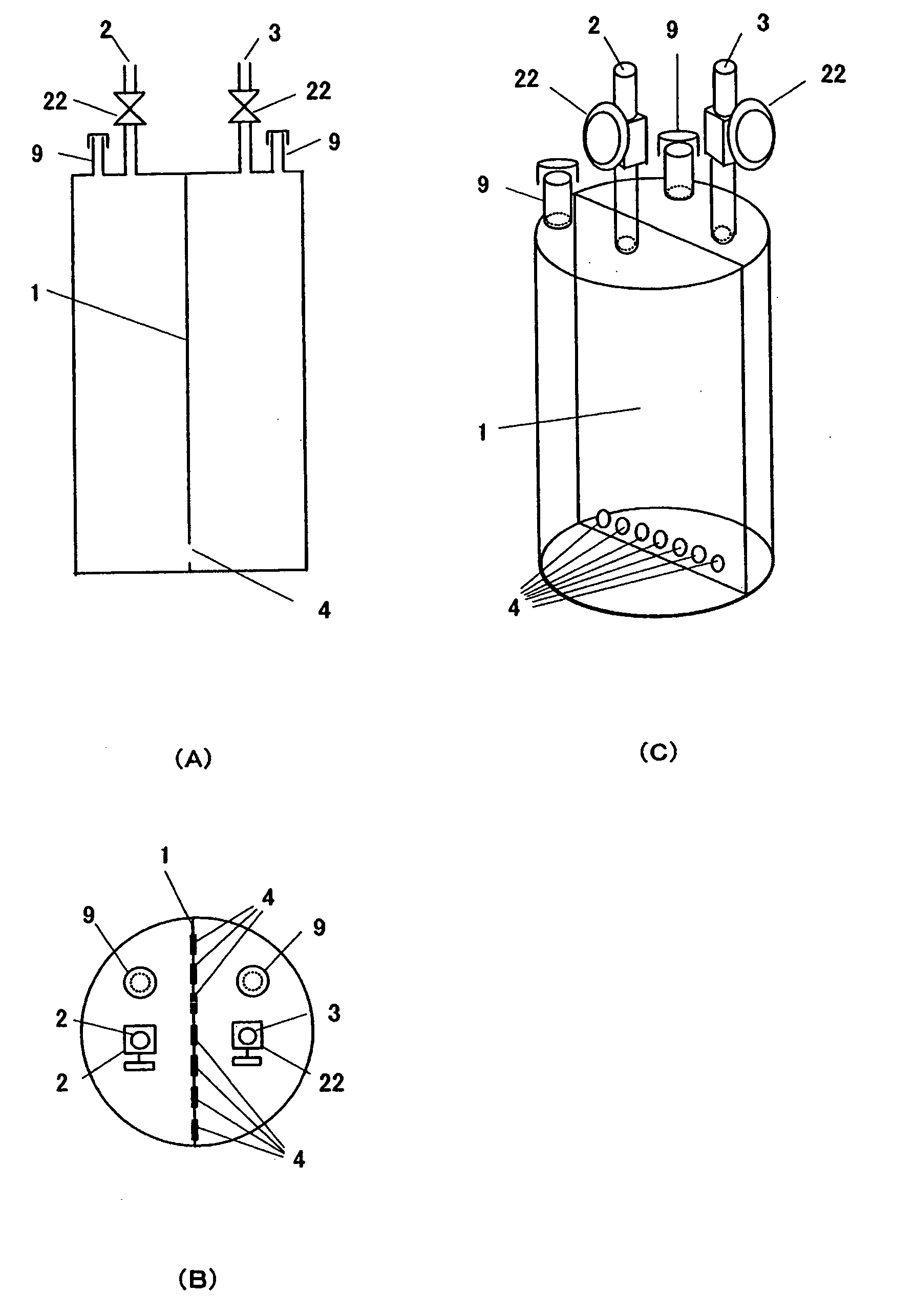

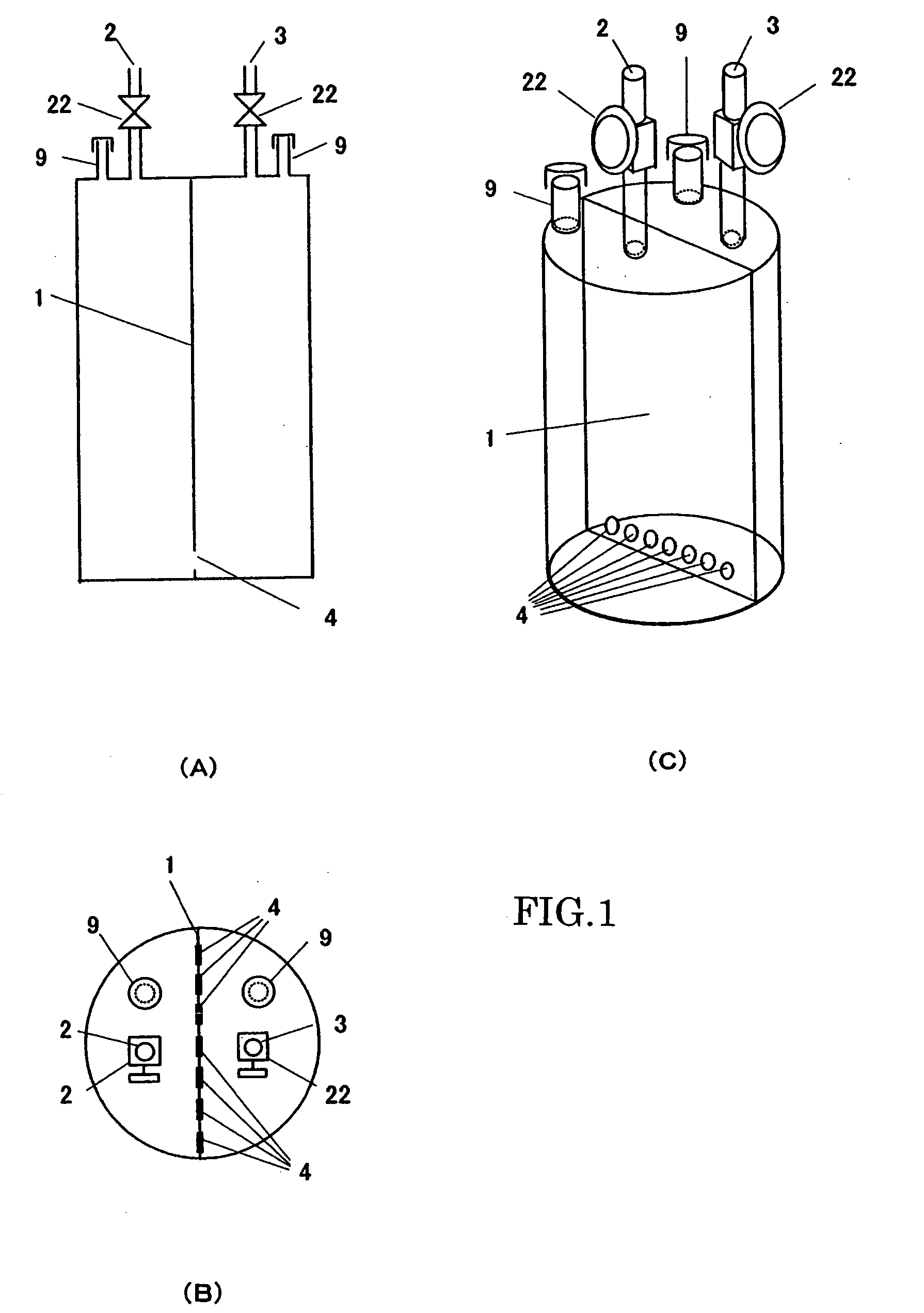

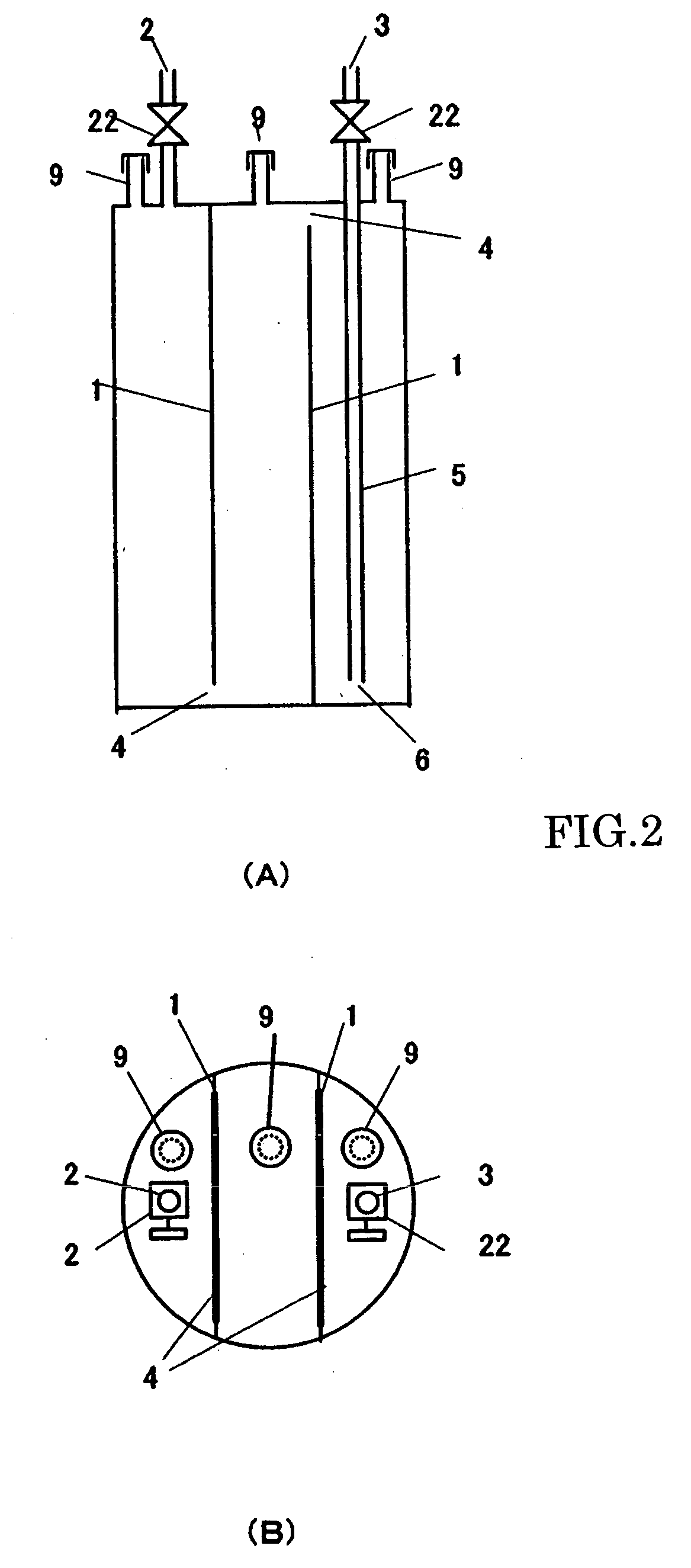

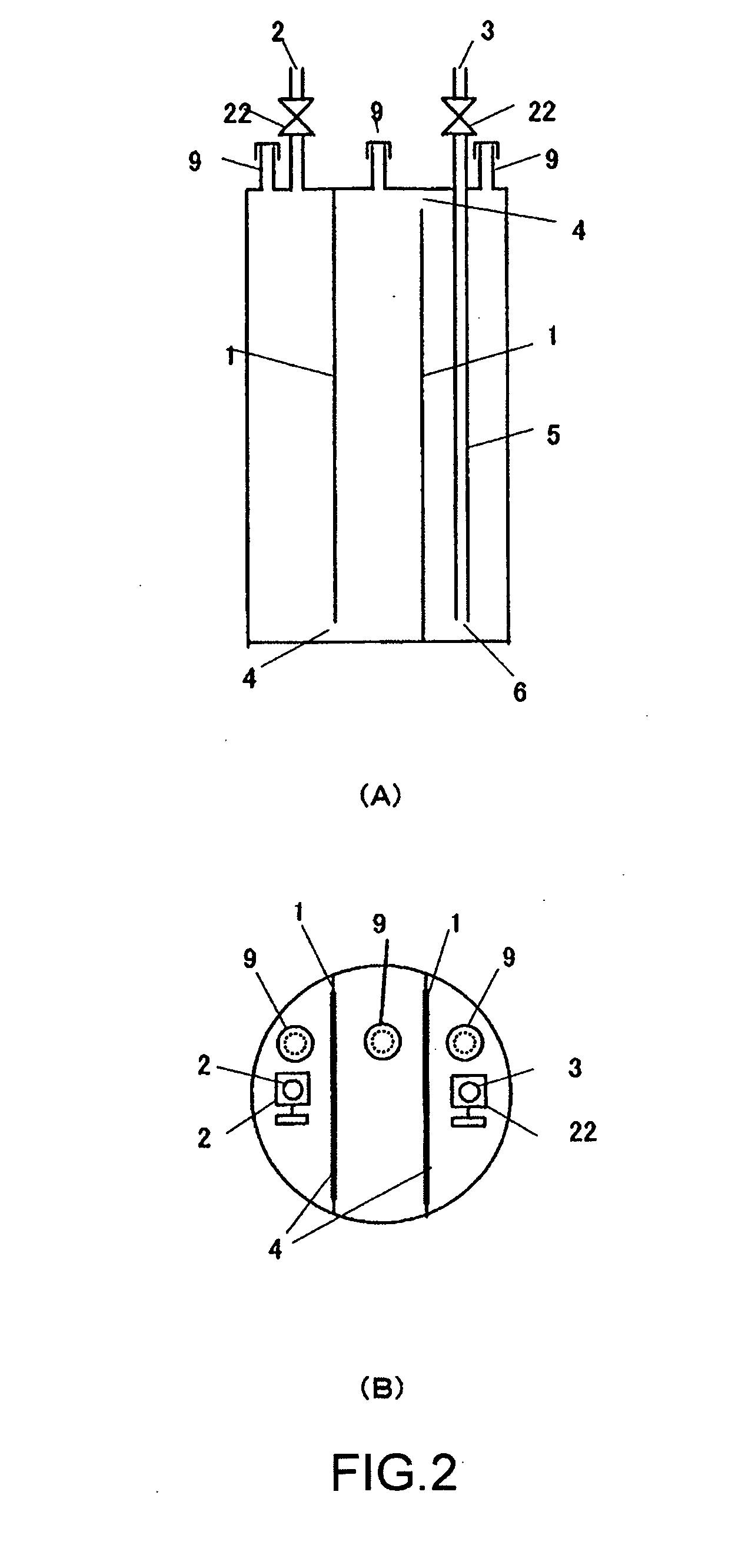

Solid organometallic compound-filled container and filling method thereof

InactiveUS7547363B2Increasing outer sizeExtended maintenance periodEnvelopes/bags making machineryLayered productsGas phaseEngineering

A solid organometallic compound novel filled container stably supplies an apparatus for vapor phase epitaxial growth such as an MOCVD apparatus with a solid organometallic compound over a long term. The solid organometallic compound-filled container has a carrier gas inlet and a carrier gas outlet. The interior of the filled container is separated into a plurality of vertical compartments. A carrier gas introduced via the carrier gas inlet flows through each of the vertical compartments and is then discharged via the carrier gas outlet.

Owner:TOSOH FINECHEM CORP

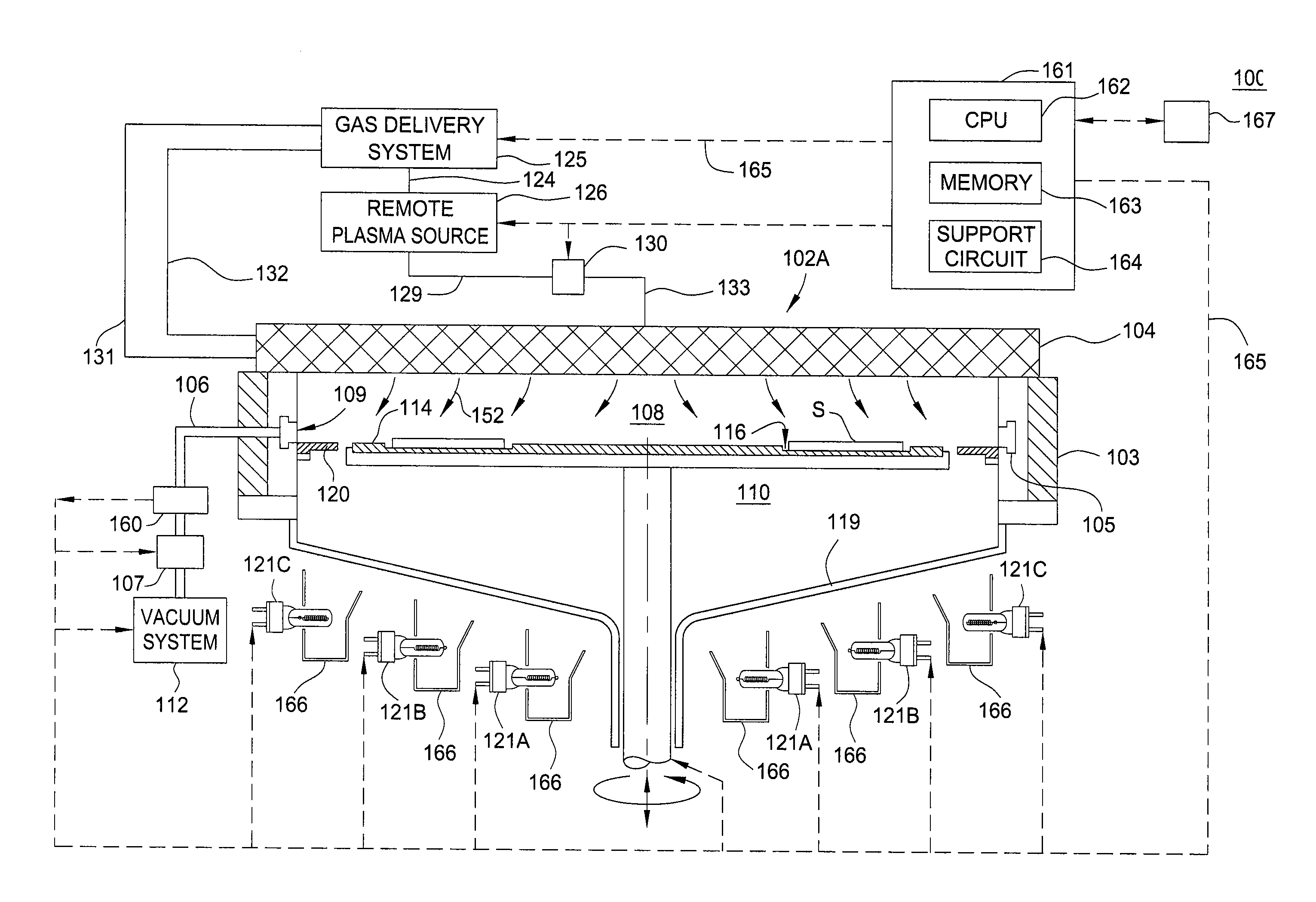

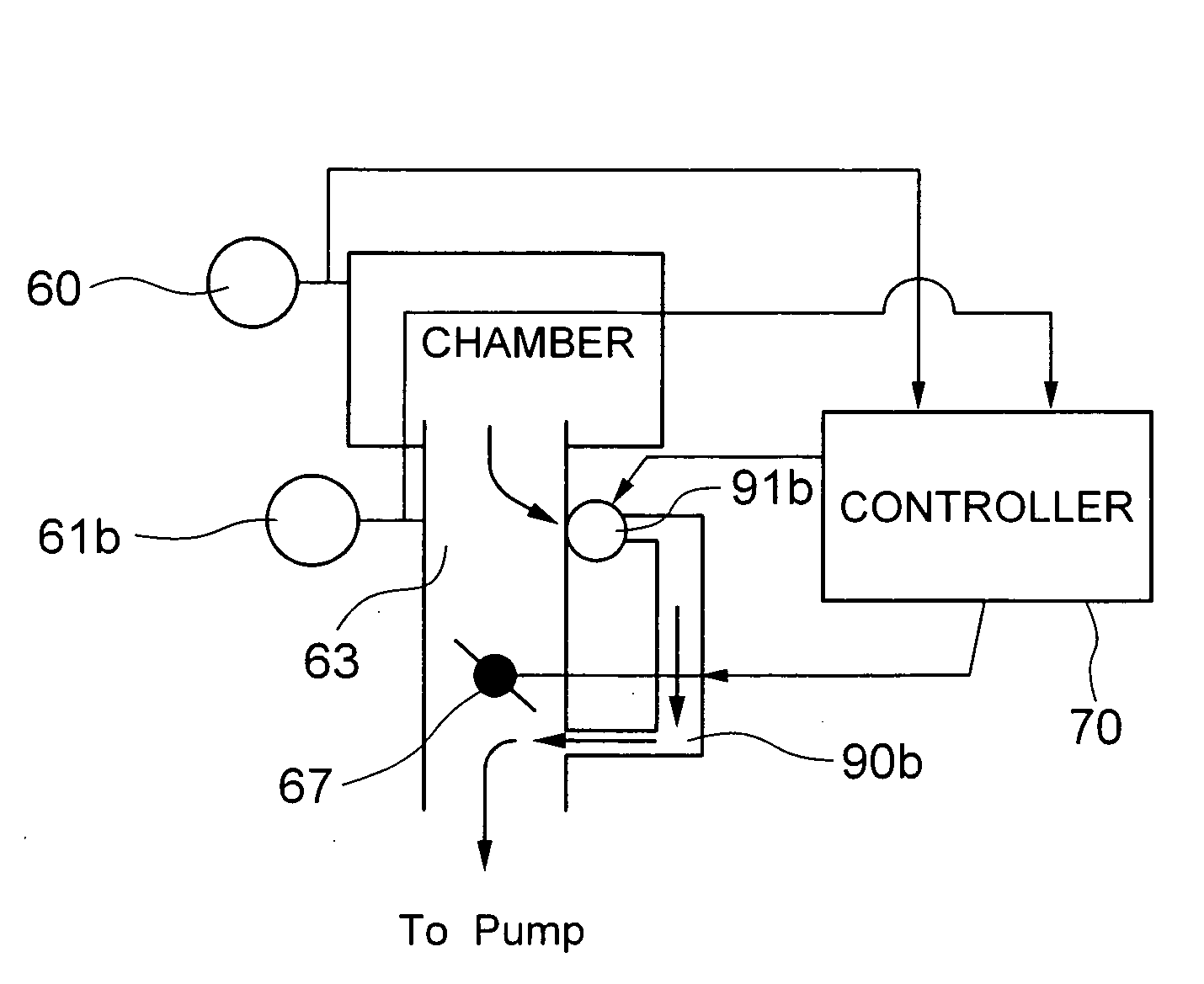

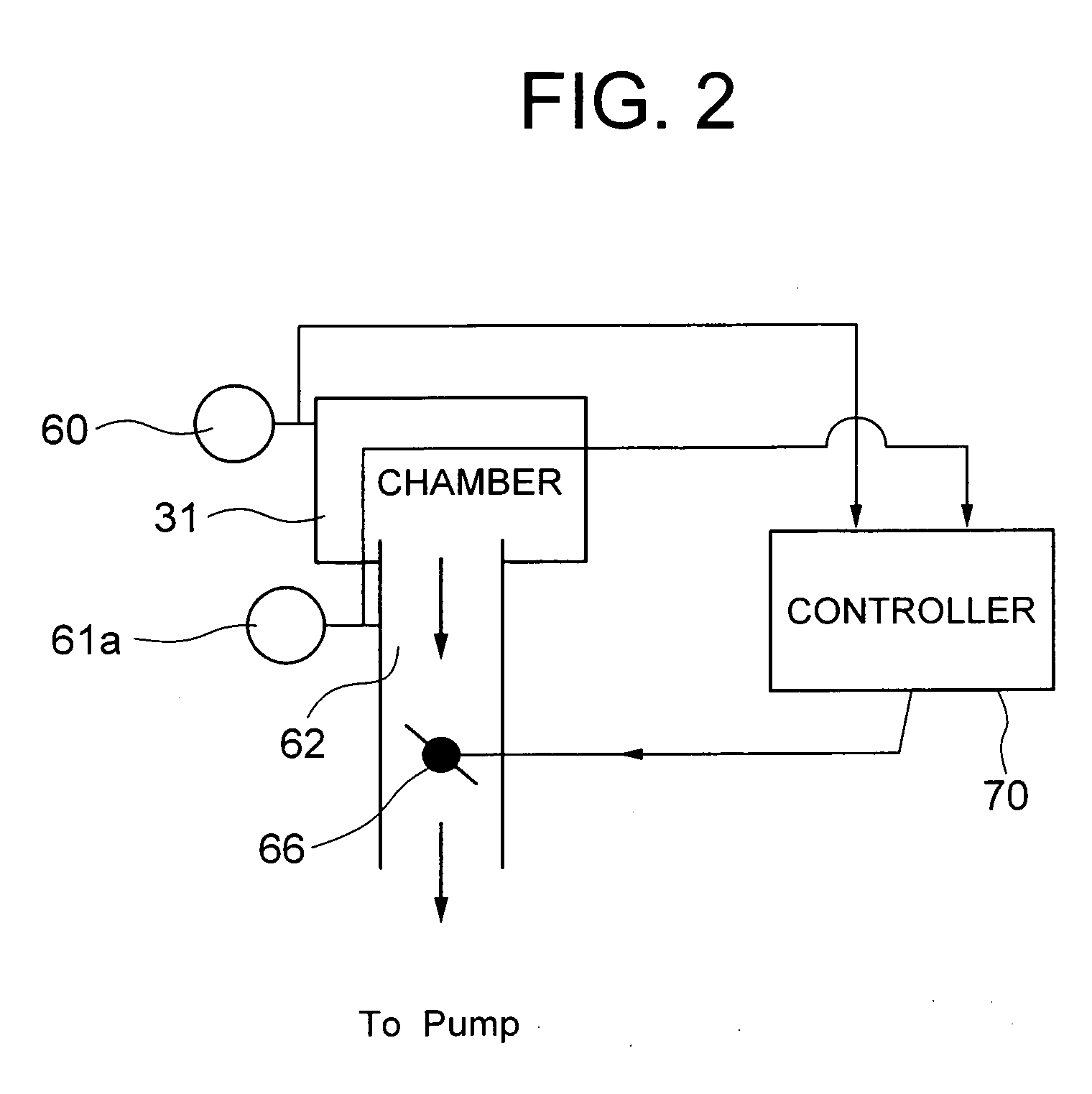

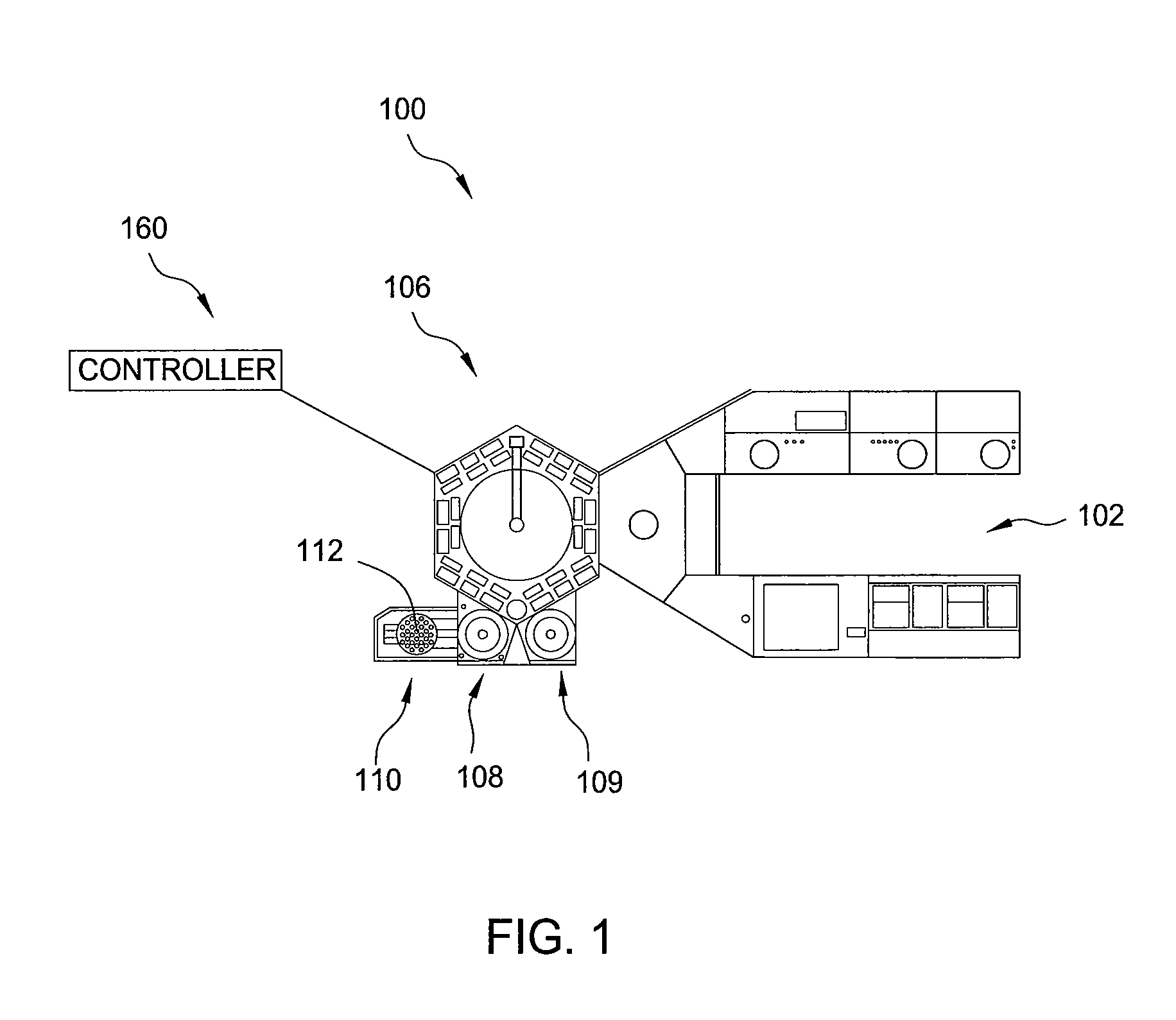

Closed loop mocvd deposition control

InactiveUS20110308453A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingGas phaseControl system

A method and apparatus are provided for monitoring and controlling substrate processing parameters for a cluster tool that utilizes chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition. In one embodiment, a metal organic chemical vapor deposition (MOCVD) process is used to deposit a Group III-nitride film on a plurality of substrates within a processing chamber. A closed-loop control system performs in-situ monitoring of the Group III-nitride film growth rate and adjusts film growth parameters as required to maintain a target growth rate. In another embodiment, a closed-loop control system performs in-situ monitoring of film growth parameters for multiple processing chambers for one or more film deposition systems.

Owner:APPLIED MATERIALS INC

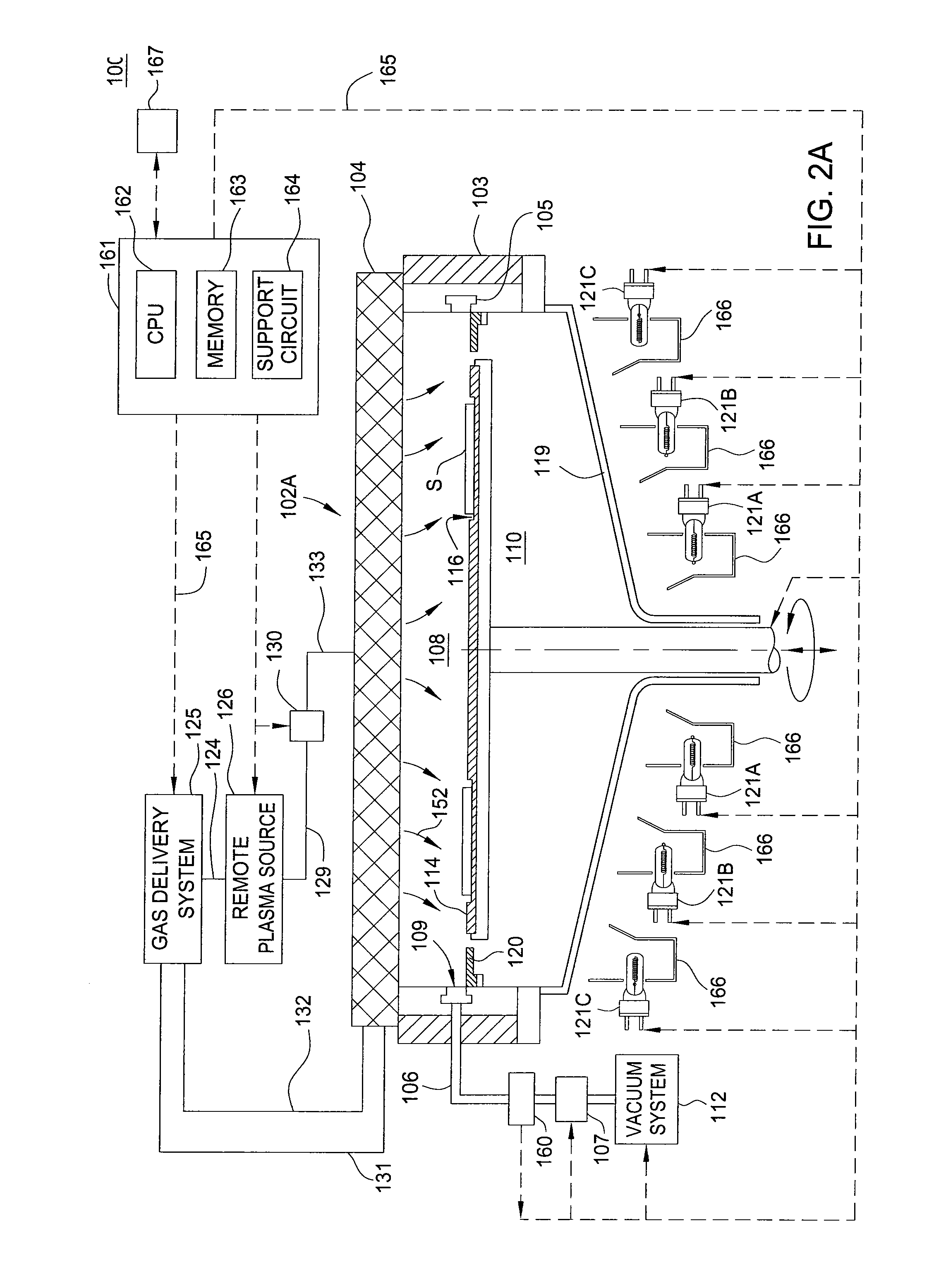

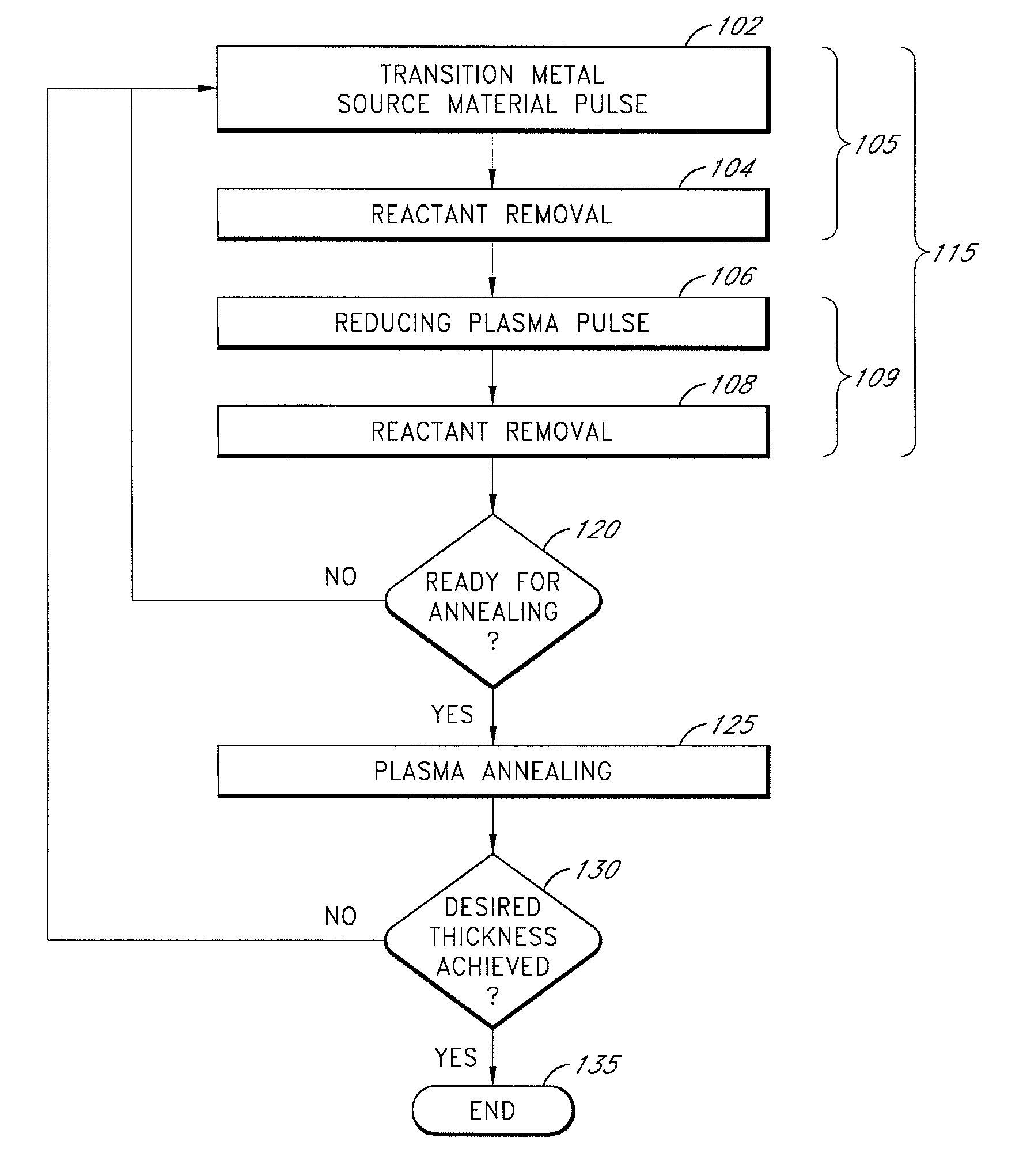

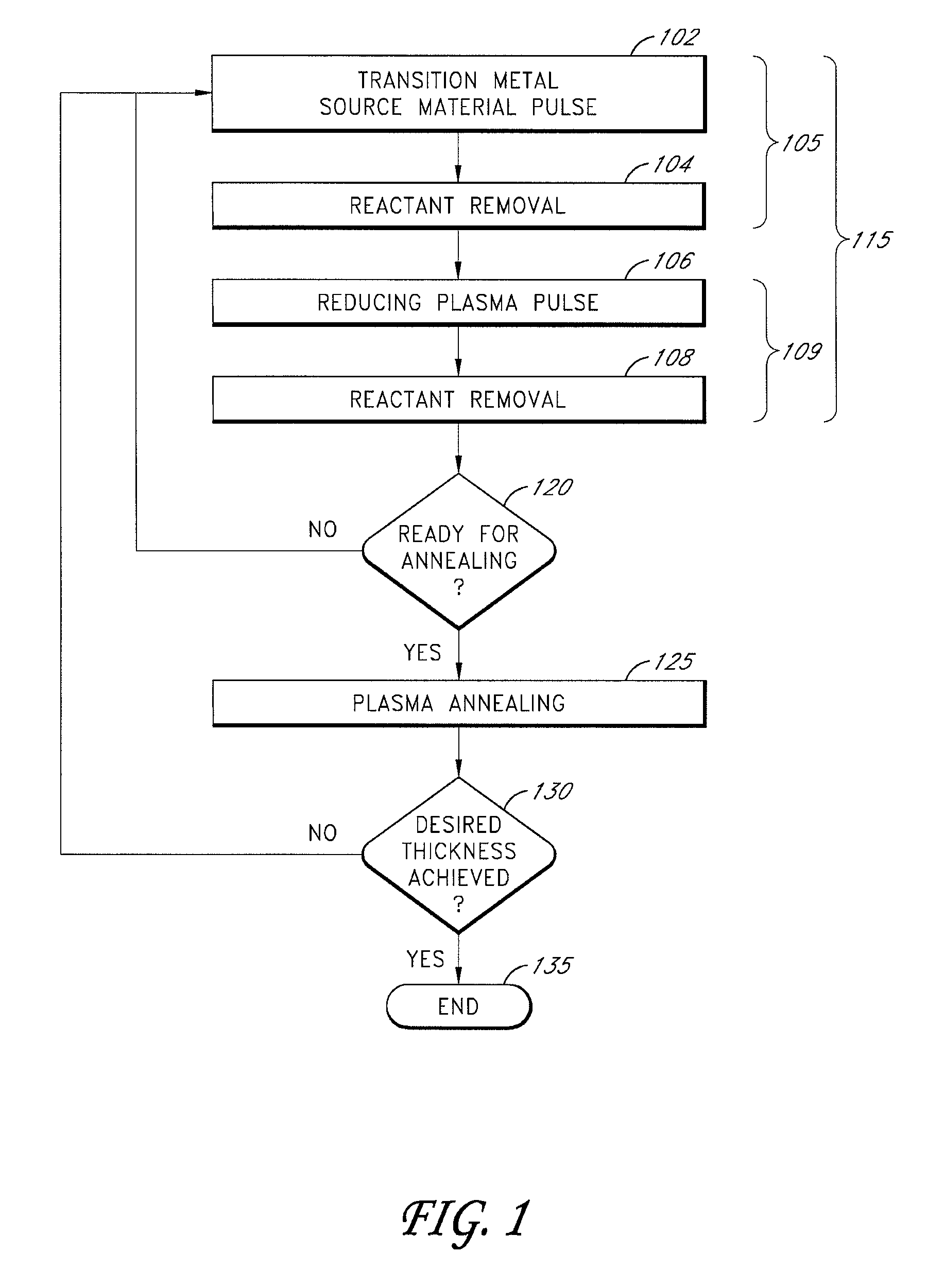

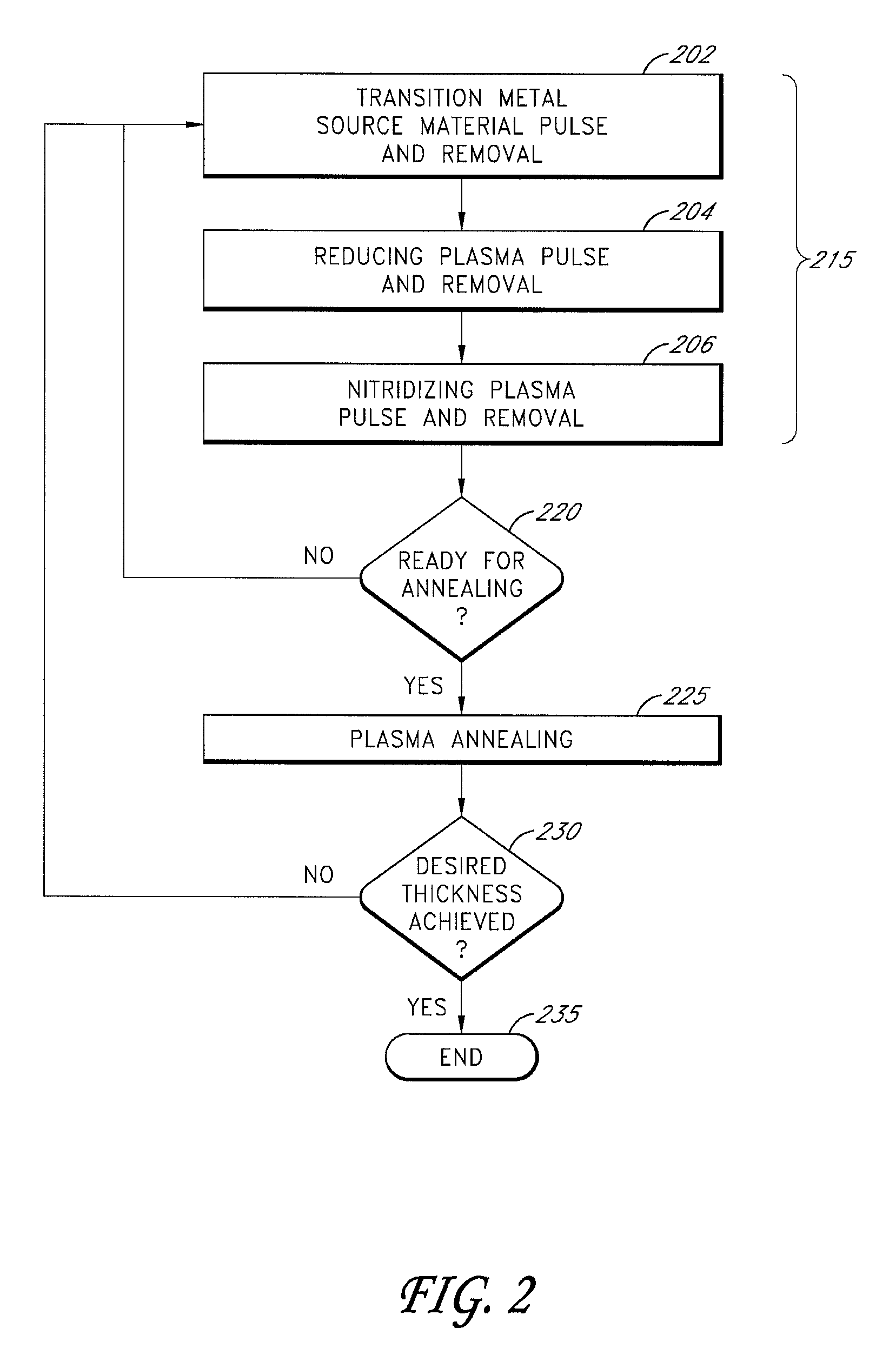

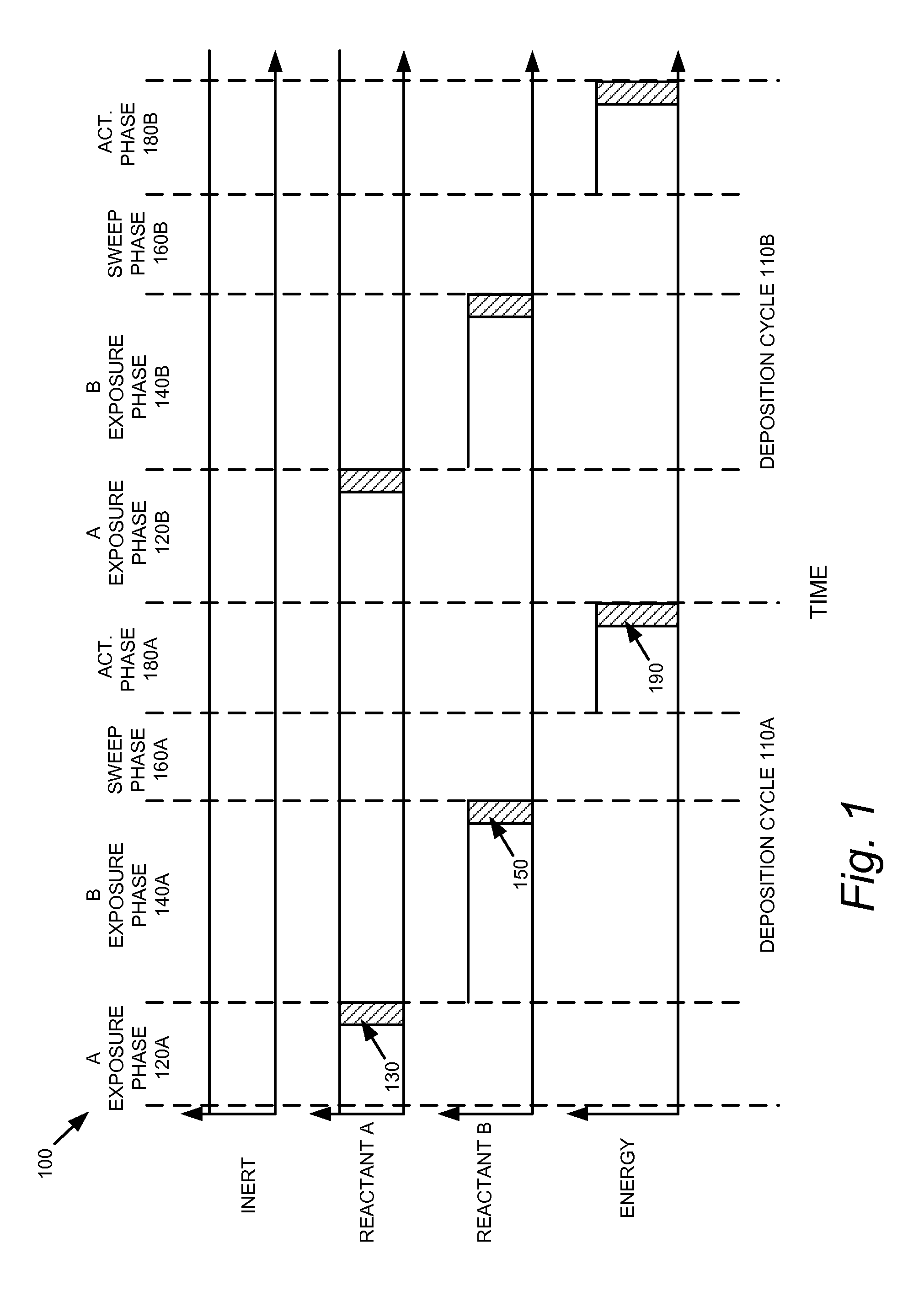

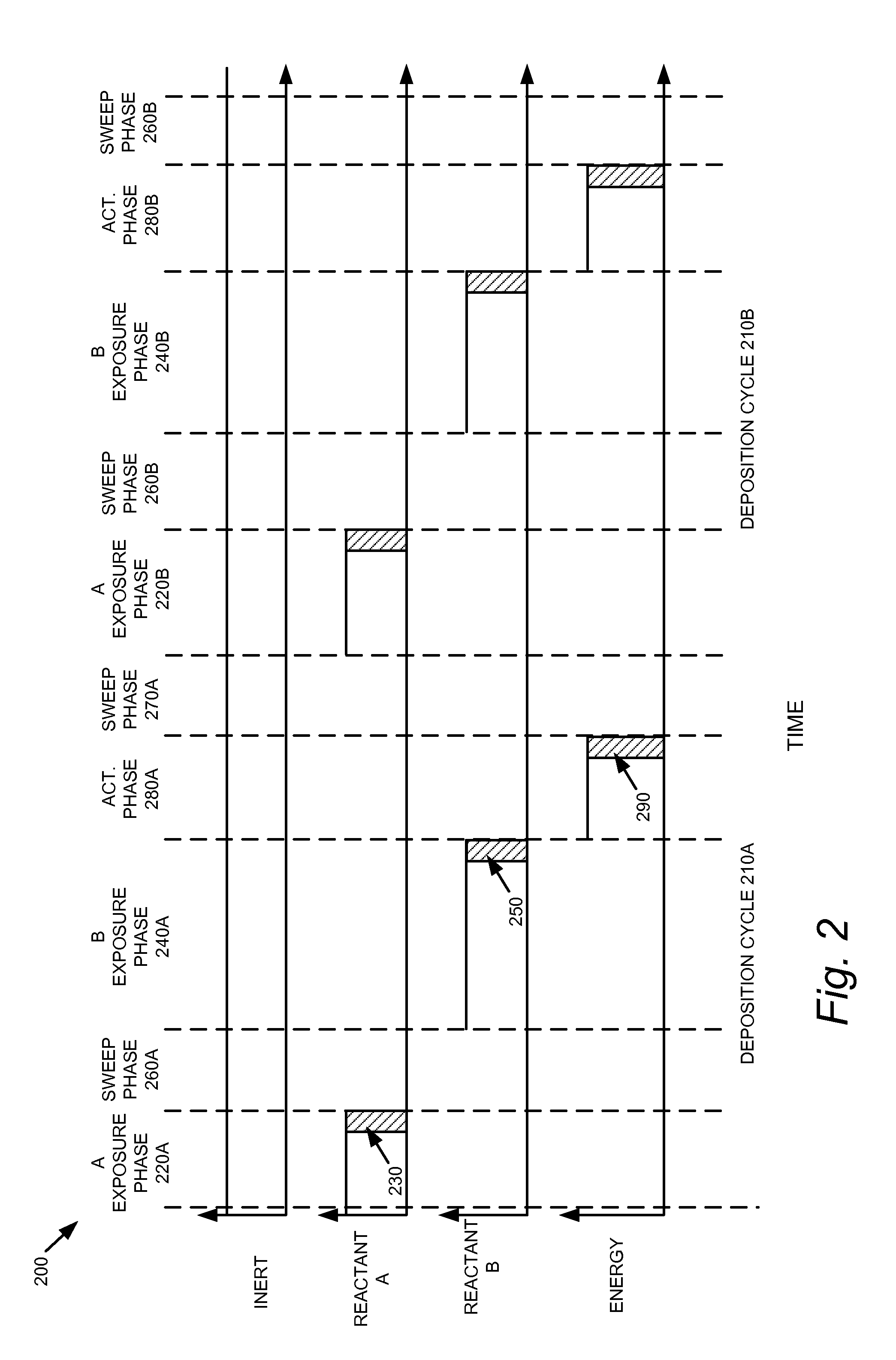

Periodic plasma annealing in an ALD-type process

ActiveUS7713874B2Increase probabilityReduce susceptibility to oxidationPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseVapor phase

Methods for performing periodic plasma annealing during atomic layer deposition are provided along with structures produced by such methods. The methods include contacting a substrate with a vapor-phase pulse of a metal source chemical and one or more plasma-excited reducing species for a period of time. Periodically, the substrate is contacted with a vapor phase pulse of one or more plasma-excited reducing species for a longer period of time. The steps are repeated until a metal thin film of a desired thickness is formed over the substrate.

Owner:ASM IP HLDG BV

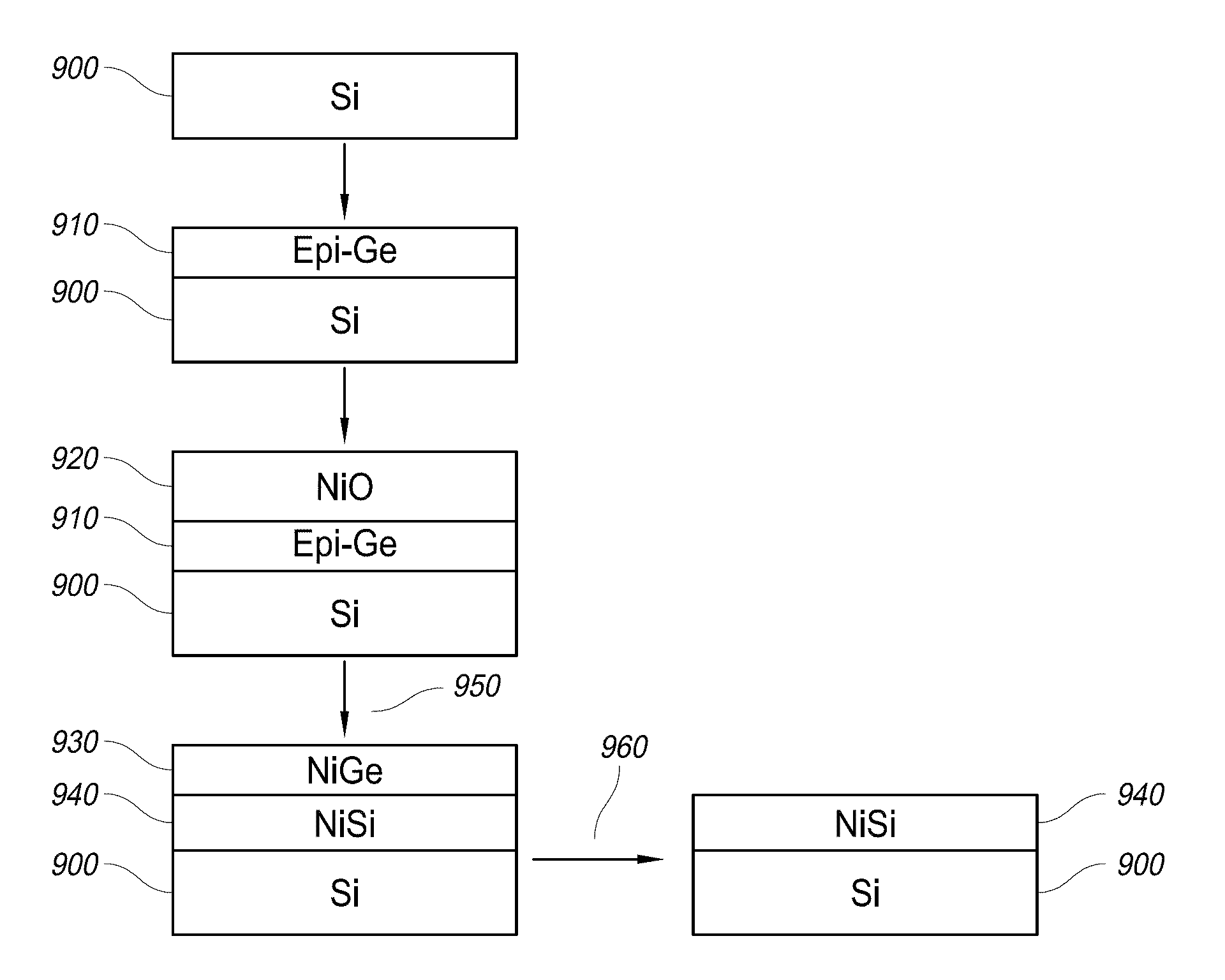

Methods for depositing nickel films and for making nickel silicide and nickel germanide

ActiveUS20130115768A1Semiconductor/solid-state device manufacturingSemiconductor devicesGas phaseMetal silicide

In one aspect, methods of silicidation and germanidation are provided. In some embodiments, methods for forming metal silicide can include forming a non-oxide interface, such as germanium or solid antimony, over exposed silicon regions of a substrate. Metal oxide is formed over the interface layer. Annealing and reducing causes metal from the metal oxide to react with the underlying silicon and form metal silicide. Additionally, metal germanide can be formed by reduction of metal oxide over germanium, whether or not any underlying silicon is also silicided. In other embodiments, nickel is deposited directly and an interface layer is not used. In another aspect, methods of depositing nickel thin films by vapor phase deposition processes are provided. In some embodiments, nickel thin films are deposited by ALD. Nickel thin films can be used directly in silicidation and germanidation processes.

Owner:ASM INTERNATIONAL

Atomic layer deposition system including a plurality of exhaust tubes

InactiveUS20080176412A1Uniform film qualityHigh aspect ratioLiquid surface applicatorsSemiconductor/solid-state device manufacturingControl valvesVapor phase

An atomic layer deposition system includes a reaction chamber, a plurality of exhaust tubes communicated to the reaction chamber, a plurality of first vacuum gauges for monitoring the degree of vacuum of the respective exhaust tubes, a second vacuum gauge for monitoring the degree of vacuum of the reaction chamber, and control valves for adjusting the exhaust volume of the exhaust tubes independently of one another. The control valves are controlled based on the pressures measured by the first and second control valves for achieving a uniform flow of the vapor phase reactant.

Owner:PS4 LUXCO SARL

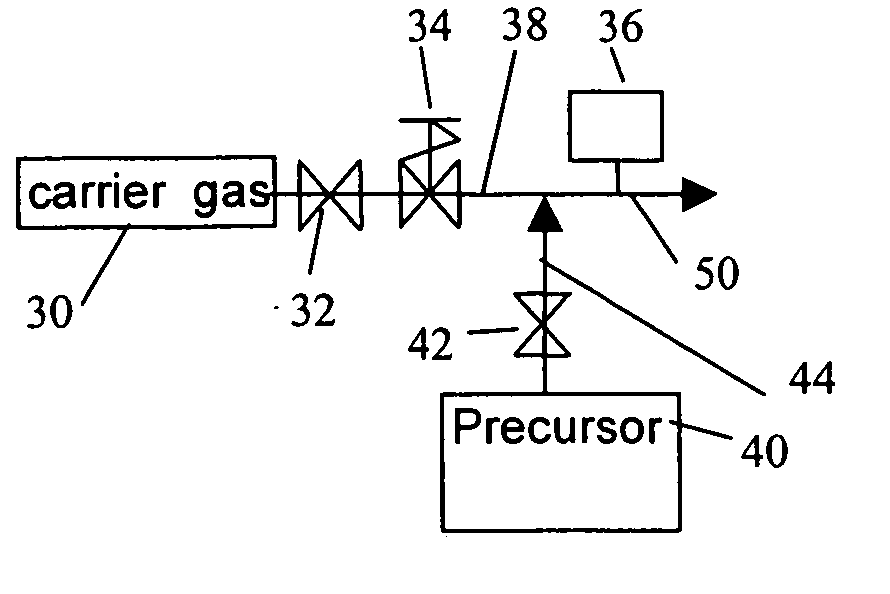

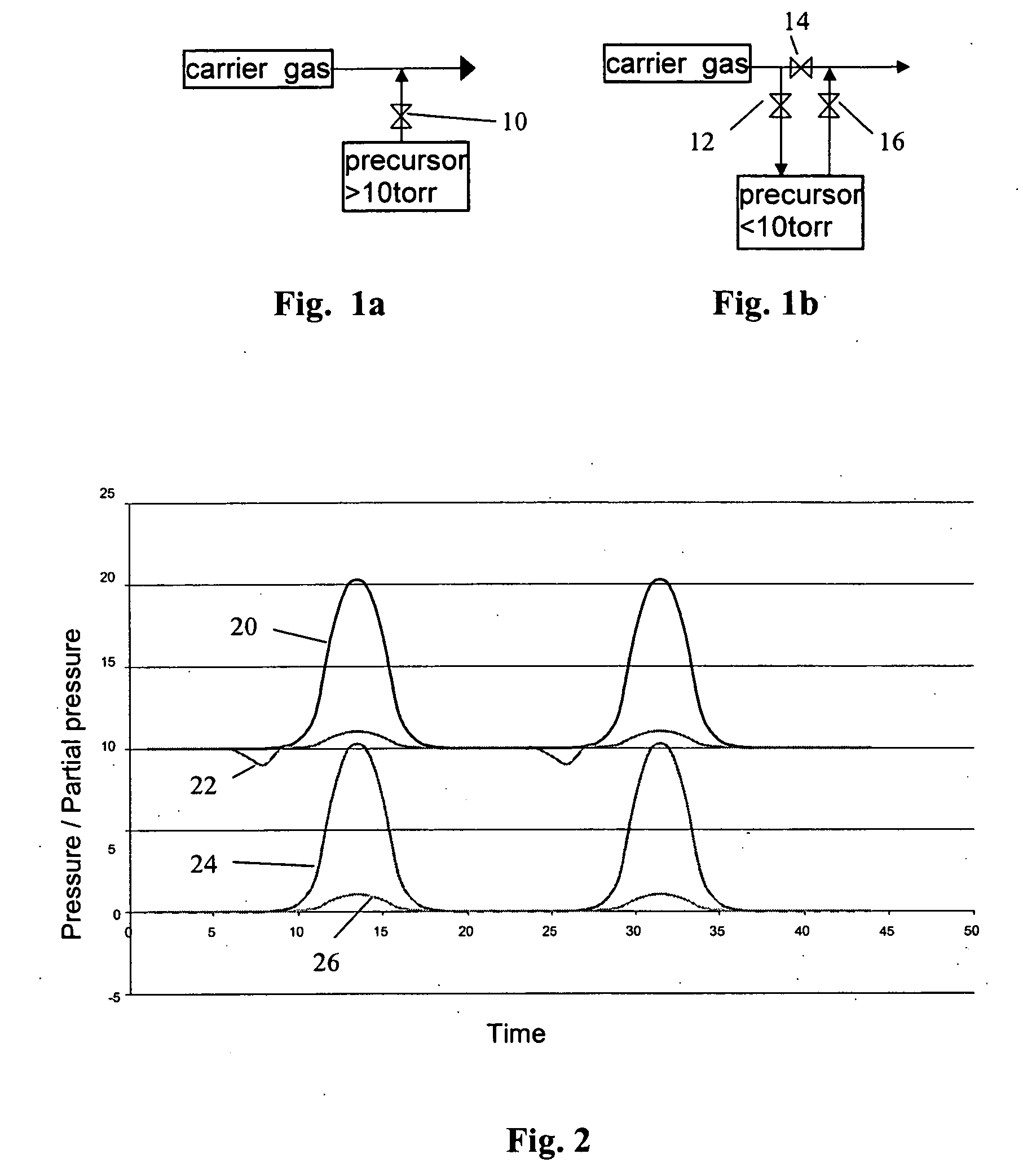

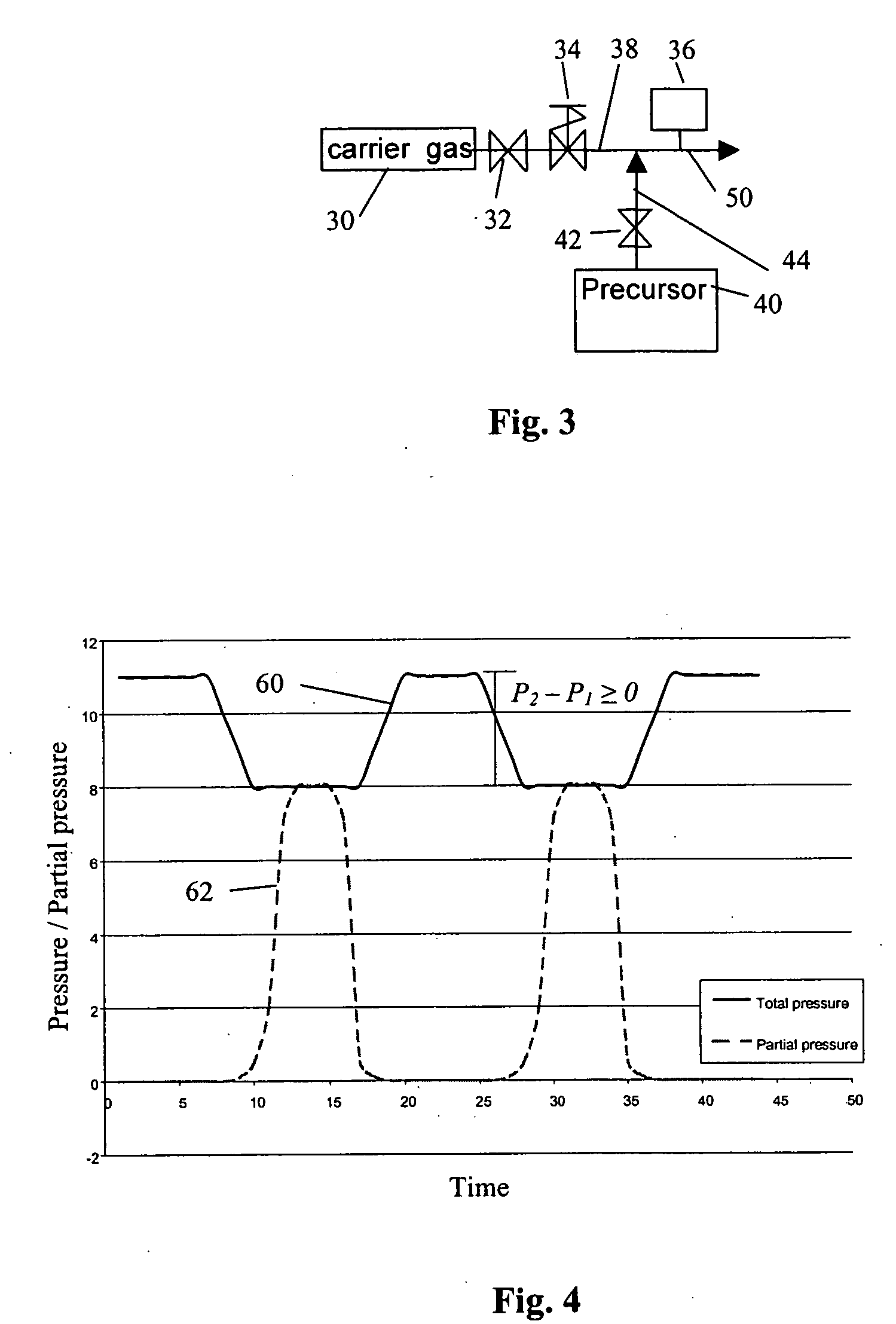

Method of pulsing vapor precursors in an ALD reactor

ActiveUS20060147626A1Faster film growthImproved pulse separationPolycrystalline material growthFrom chemically reactive gasesSource materialGas phase

A method of growing a thin film on a substrate by pulsing vapor-phase precursors material into a reaction chamber according to the ALD method. The method comprises vaporizing at least one precursor from a source material container maintained at a vaporising temperature, repeatedly feeding pulses of the vaporized precursor via a feed line into the reaction chamber at a first pressure, and subsequently purging the reaction chamber with pulses of inactive gas fed via the feed line at a second pressure. The second pressure is maintained at the same as or a higher level than the first pressure for separating successive pulses of said vaporized precursor from each other.

Owner:ASM IP HLDG BV

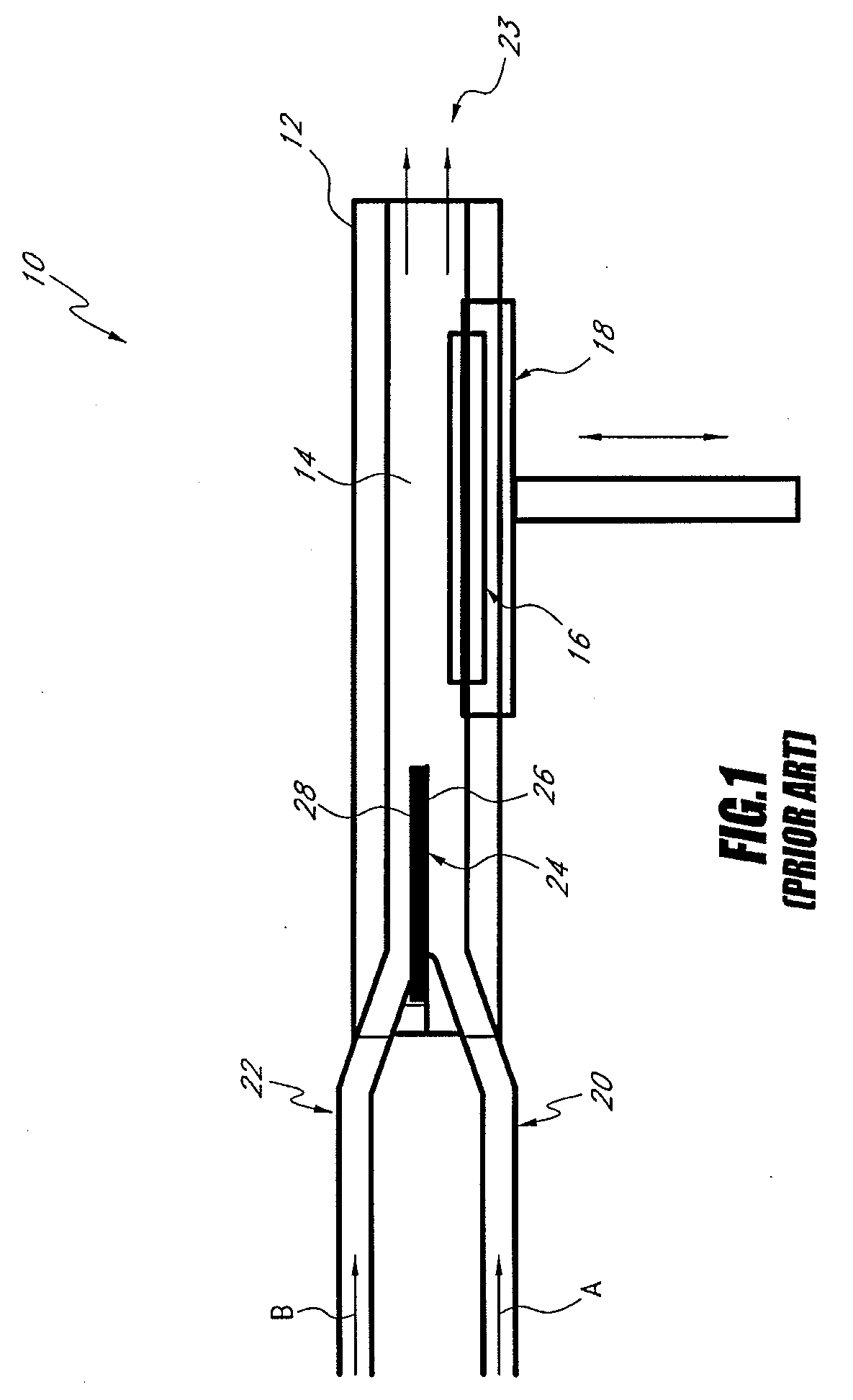

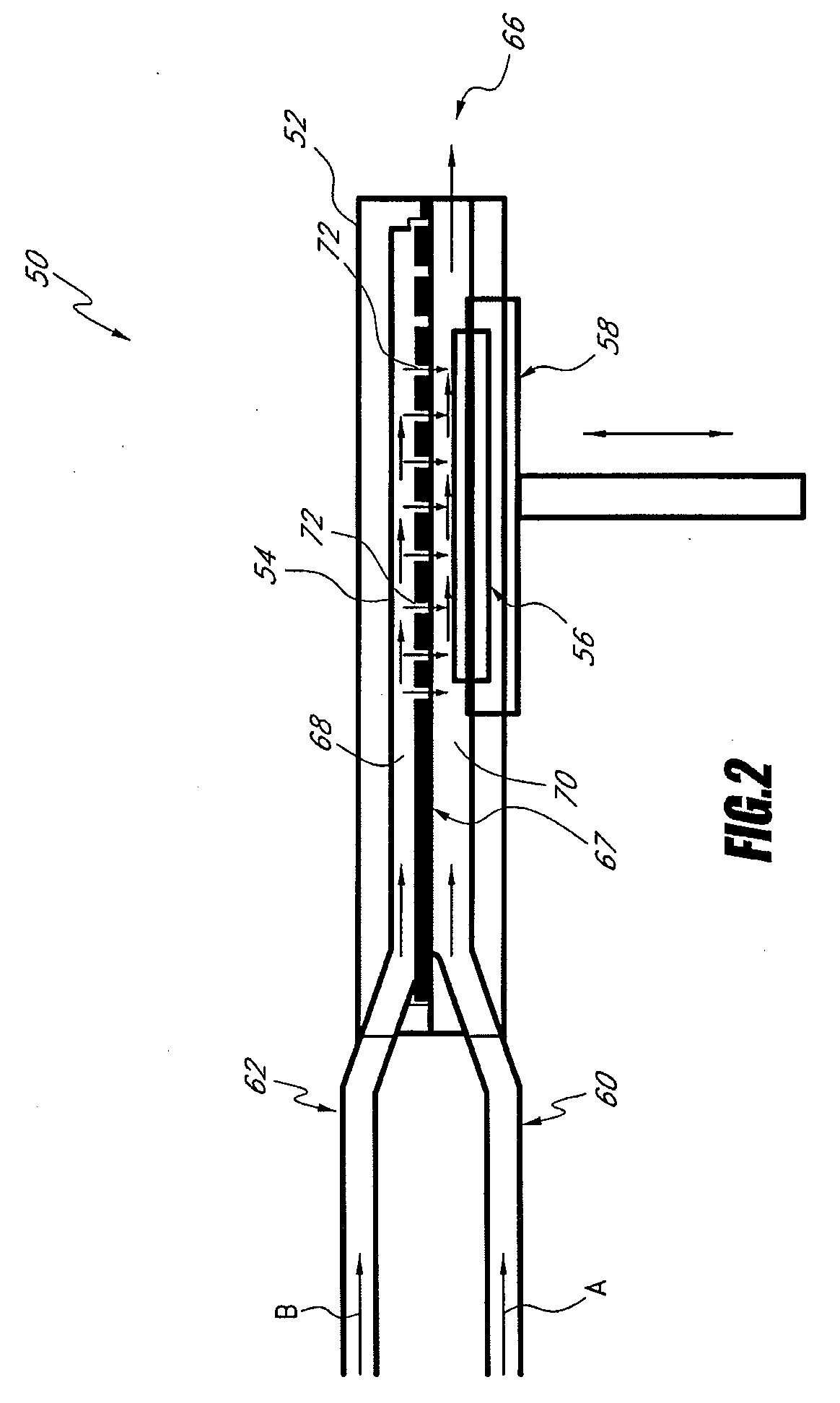

Solid organometallic compound-filled container and filling method thereof

InactiveUS20050008799A1Increasing outer sizeStable supplyEnvelopes/bags making machineryPipe laying and repairEngineeringVapor phase

A novel filled container is provided, which can stably supply an apparatus for vapor phase epitaxial growth such as an MOCVD apparatus with a solid organometallic compound over a long term. The solid organometallic compound-filled container has a carrier gas inlet and a carrier gas outlet. The interior of the filled container is separated into a plurality of vertical compartments. A carrier gas introduced via the carrier gas inlet flows through each of the vertical compartments and is then discharged via the carrier gas outlet.

Owner:TOSOH FINECHEM CORP

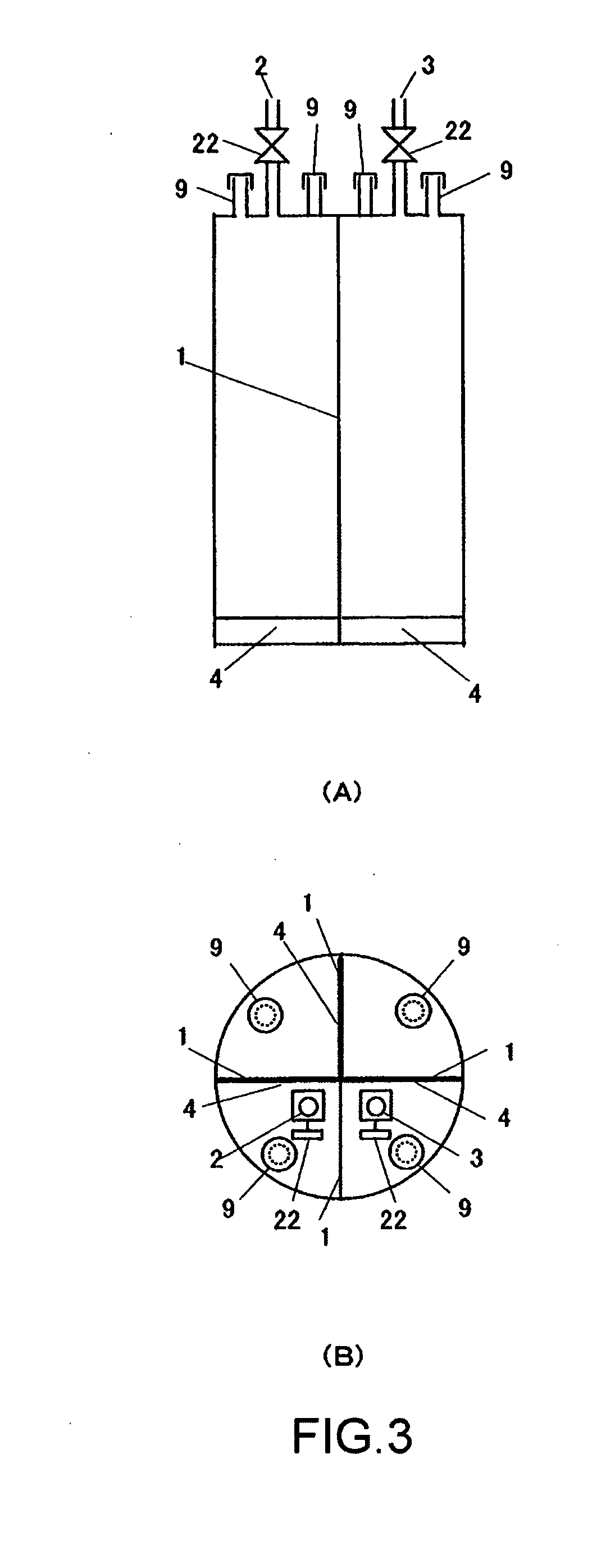

Method for packing solid organometallic compound and packed container

InactiveUS20070175397A1Ensure supply stabilityStable supplyChemical vapor deposition coatingThin material handlingCompound (substance)Vapor phase

A method for packing a solid organometallic compound into a container for packing the compound is provided, wherein the solid organometallic compound can be stably supplied to a vapor phase epitaxial growth apparatus such as an MOCVD apparatus at a constant concentration for a long period of time. In the method for packing a solid organometallic compound into a container for packing, the compound is composed of grains having a grain size of 8 mm or less and the grains of the compound essentially comprise grains having a grain size of 2.5 to 6 mm.

Owner:TOSOH FINECHEM CORP

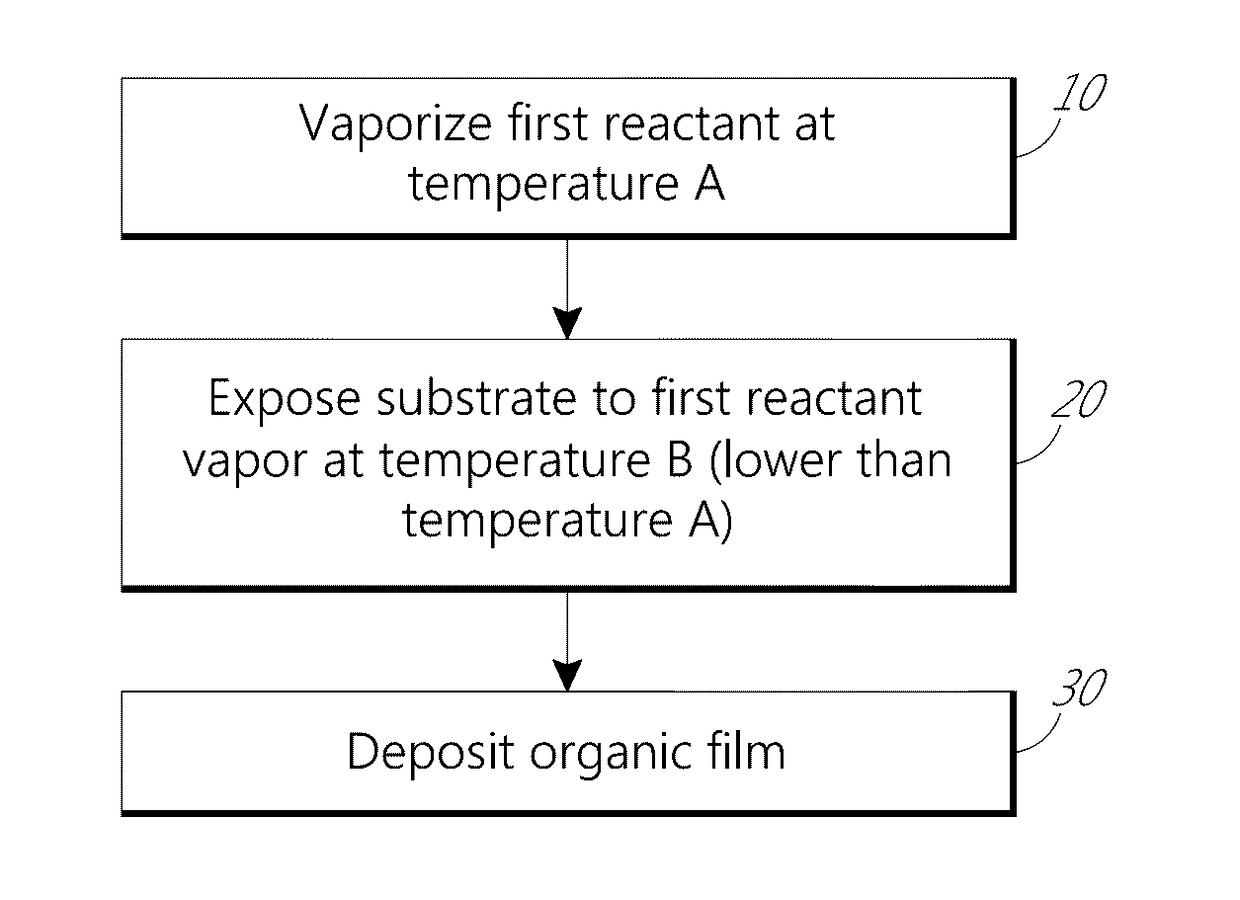

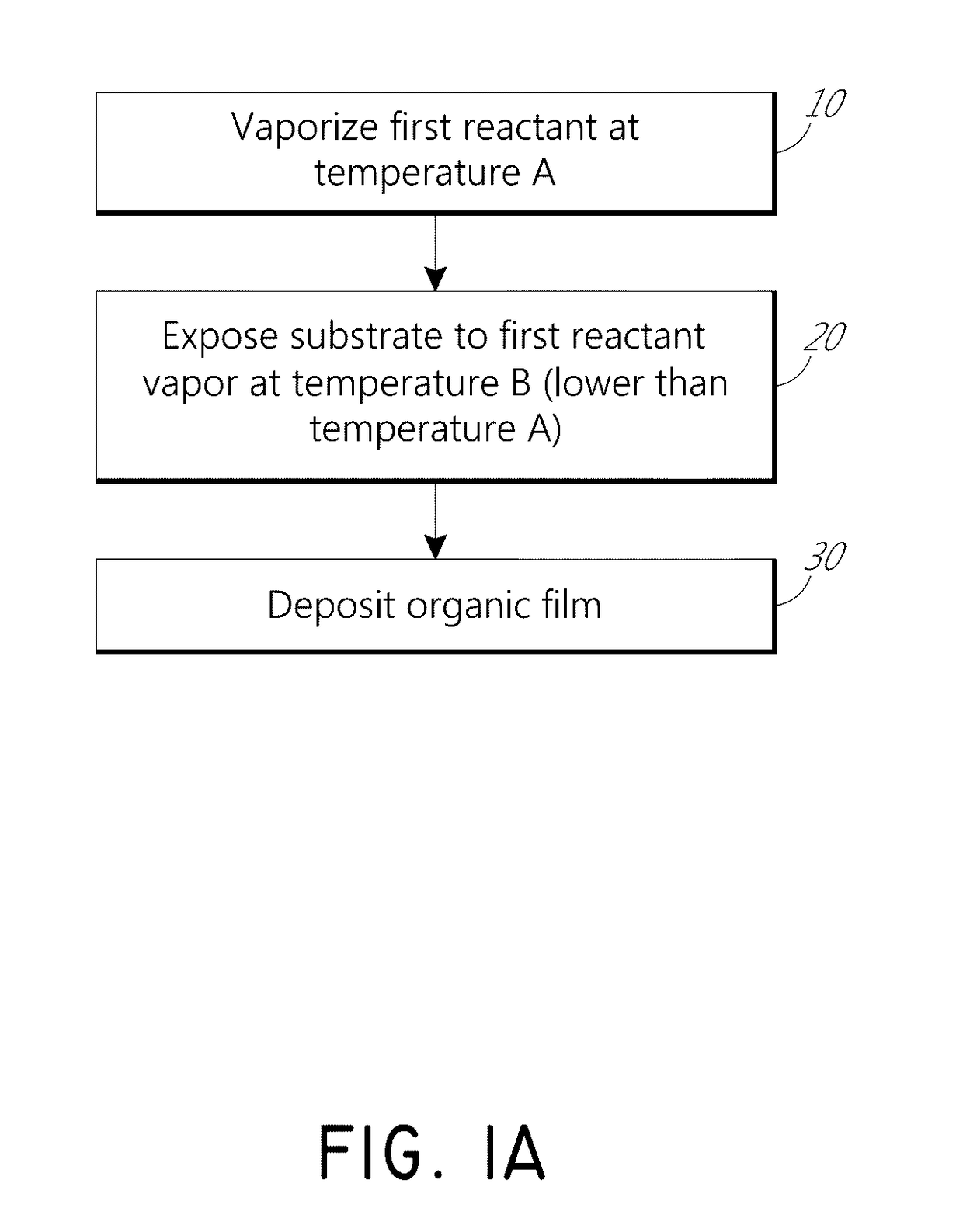

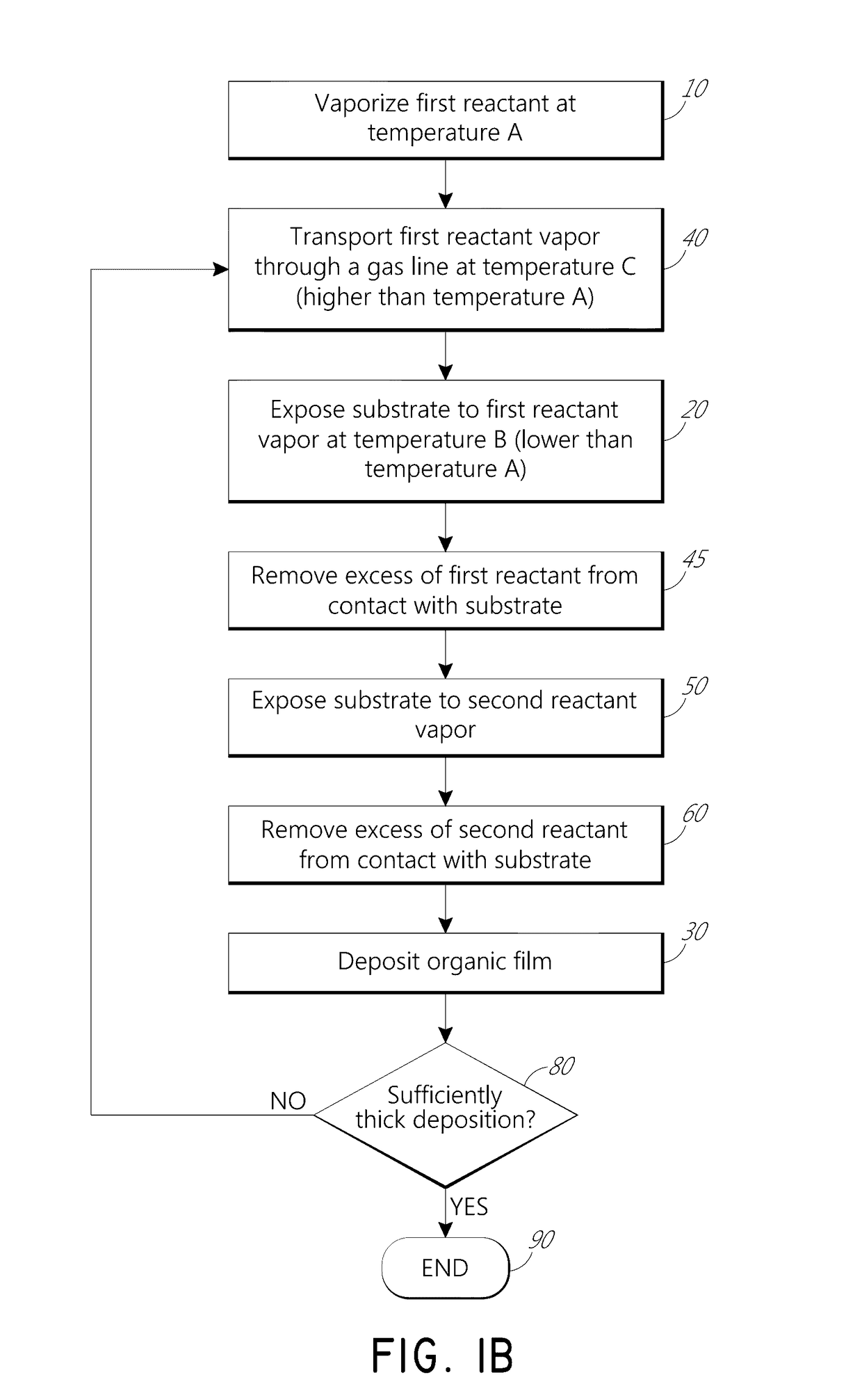

Vapor phase deposition of organic films

ActiveUS20170100742A1Reduce aspect ratioLiquid surface applicatorsChemical vapor deposition coatingOrganic filmGas phase

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve.

Owner:ASM IP HLDG BV

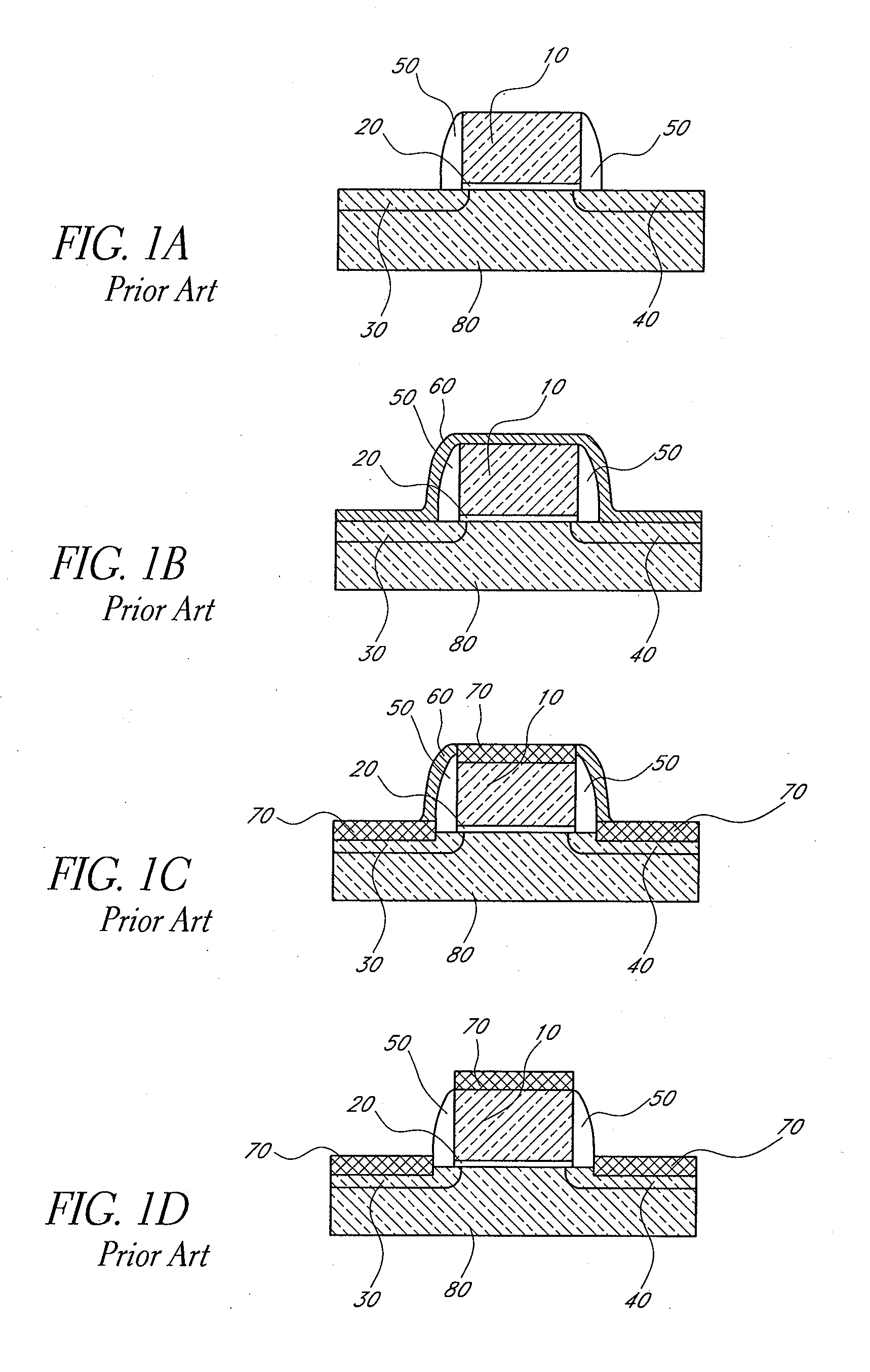

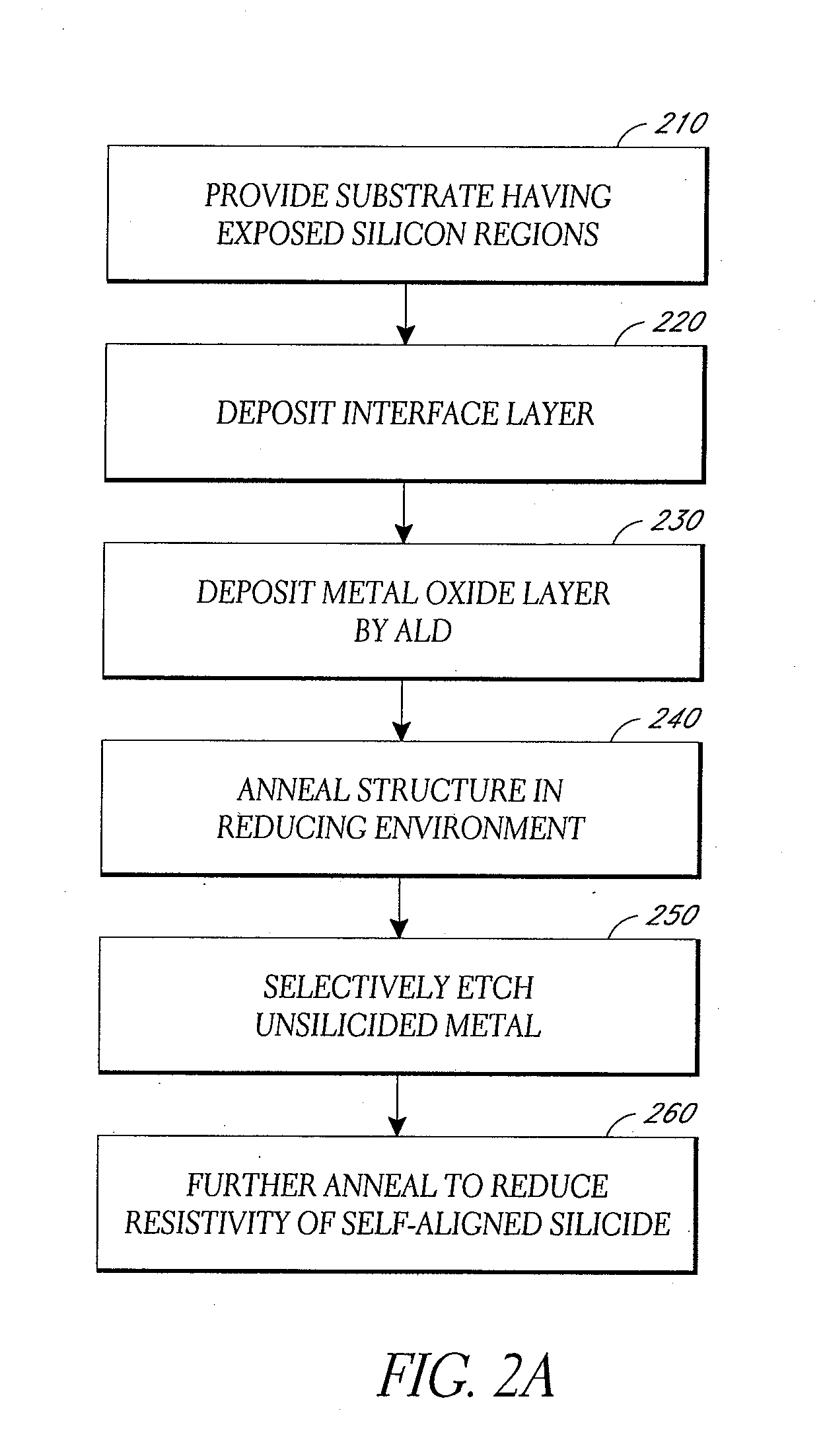

Metal silicide, metal germanide, methods for making the same

ActiveUS20120270393A1Prevent oxidationSelective silicidationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal silicideGermanide

In one aspect, methods of silicidation and germanidation are provided. In some embodiments, methods for forming metal silicide can include forming a non-oxide interface, such as germanium or solid antimony, over exposed silicon regions of a substrate. Metal oxide is formed over the interface layer. Annealing and reducing causes metal from the metal oxide to react with the underlying silicon and form metal silicide. Additionally, metal germanide can be formed by reduction of metal oxide over germanium, whether or not any underlying silicon is also silicided. In other embodiments, nickel is deposited directly and an interface layer is not used. In another aspect, methods of depositing nickel thin films by vapor phase deposition processes are provided. In some embodiments, nickel thin films are deposited by ALD.

Owner:ASM INTERNATIONAL

Safe liquid source containers

ActiveUS7156380B2Encouraging capillary migrationFine surfaceCarburetting airMixing methodsPorous membraneProduct gas

Containers for providing vapor phase reactant from liquid sources include bubbler designs and designs in which carrier gas flows over the liquid surface. Among the bubbler arrangements, a bypass conductance is provided to release excess pressure from the gas volume inside the container, or an enlarged bubbler tube is provided with a volume sufficient to accommodate all possible liquid backflow without having the liquid exit the container. Among the overflow designs, flow dividers provide a tortuous path for the gas to increase the time exposure of carrier gas packets to the evaporating liquid surface. The flow dividers can be microporous to encourage capillary action, thereby increasing the evaporating surface. The tortuous gas flow path can be separated from the liquid phase by a breathable semi-porous membrane that permits vapor phase reactant to pass through but prohibits liquid from passing in the other direction.

Owner:ASM INTERNATIONAL

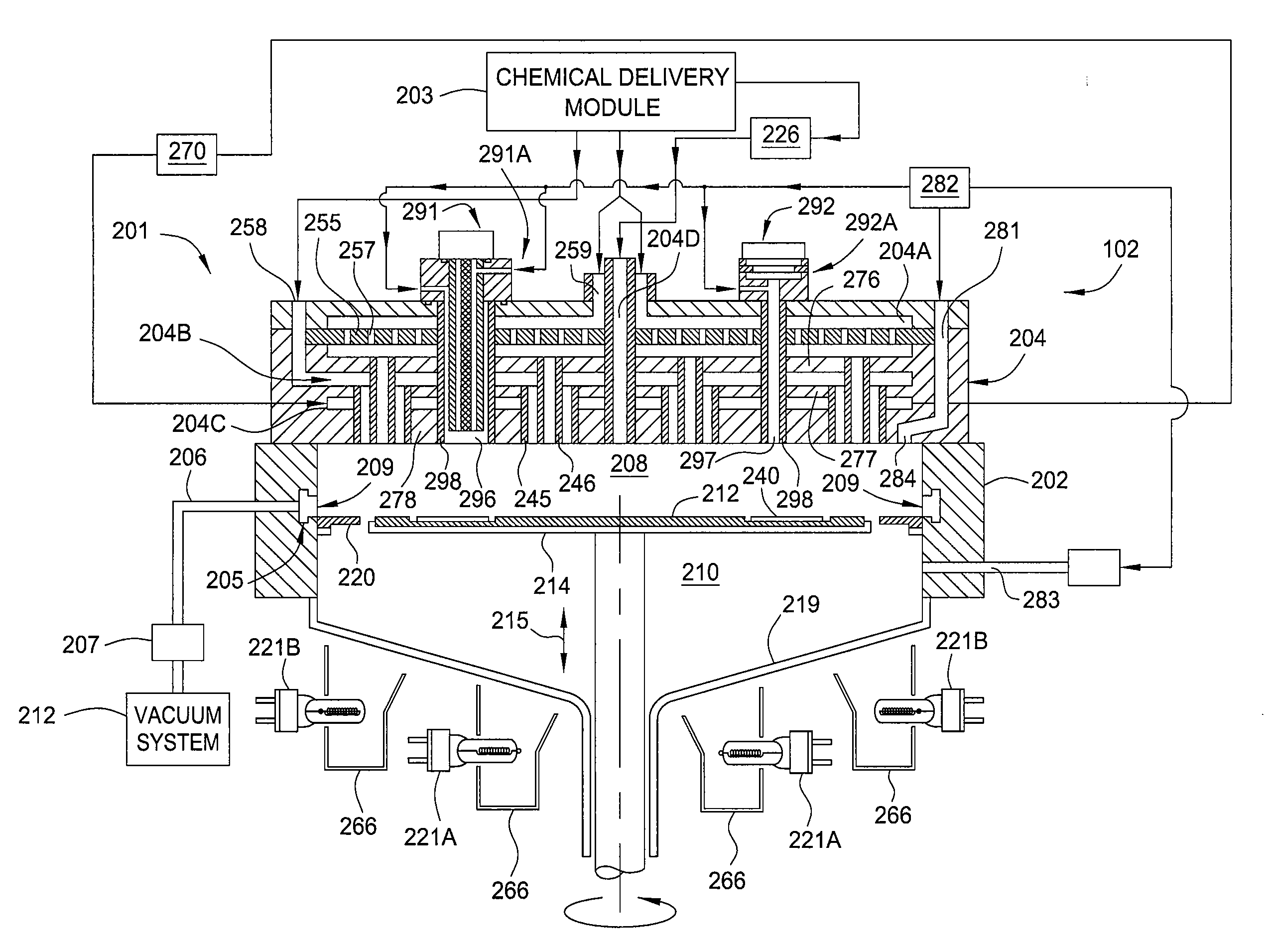

Showerhead assembly with metrology port purge

InactiveUS20110253044A1Avoid depositionLiquid surface applicatorsSpray nozzlesOptical measurementsChemical vapor deposition

A method and apparatus that may be utilized for chemical vapor deposition and / or hydride vapor phase epitaxial (HVPE) deposition are provided. In one embodiment, the apparatus is a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, the showerhead includes metrology ports with purge gas assemblies configured and positioned to deliver a purge gas to prevent deposition thereon. In one embodiment, the metrology port is configured to receive a temperature measurement device, and the purge gas assembly is a concentric tube configuration configured to prevent deposition on components of the temperature measurement device. In one embodiment, the metrology port has a sensor window and is configured to receive an optical measurement device, and the purge gas assembly and sensor window are configured to prevent deposition on the sensor window.

Owner:APPLIED MATERIALS INC

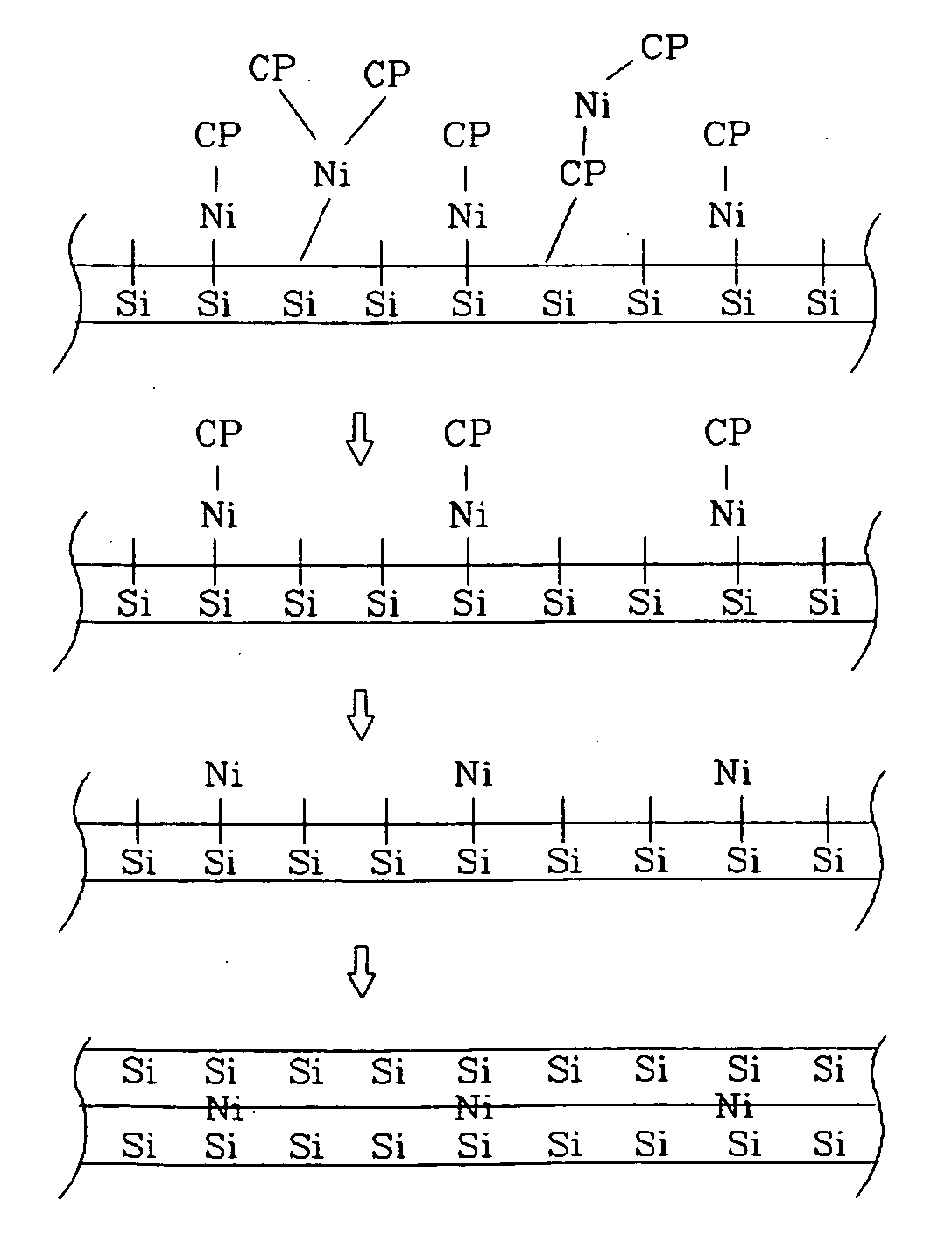

Apparatus and method for forming polycrystalline silicon thin film

ActiveUS20070054499A1Increase the rate of crystallizationDecrease in crystallization temperatureAfter-treatment apparatusSemiconductor/solid-state device manufacturingGas phaseAmorphous silicon

Apparatus and method for forming a polycrystalline silicon thin film by converting an amorphous silicon thin film into the polycrystalline silicon thin film using a metal are provided. The method includes: a metal nucleus adsorbing step of introducing a vapor phase metal compound into a process space where the glass substrate having the amorphous silicon formed thereon is disposed, to adsorb a metal nucleus contained in the metal compound into the amorphous silicon layer; a metal nucleus distribution region-forming step of forming a community region including a plurality of silicon particles every metal nucleus in a plane boundary region occupied by the metal compound by a self-limited mechanism due to the adsorption of the metal nucleus; and an excess gas removing step of purging and removing an excess gas which is not adsorbed in the metal nucleus distribution region-forming step.

Owner:WONIK IPS CO LTD

Sequential UV induced chemical vapor deposition

Ion-induced, UV-induced, and electron-induced sequential chemical vapor deposition (CVD) processes are disclosed where an ion flux, a flux of ultra-violet radiation, or an electron flux, respectively, is used to induce the chemical reaction in the process. The process for depositing a thin film on a substrate includes introducing a flow of a first reactant gas in vapor phase into a process chamber where the gas forms an adsorbed saturated layer on the substrate and exposing the substrate to a flux of ions, a flux of ultra-violet radiation, or a flux of electrons for inducing a chemical reaction of the adsorbed layer of the first reactant gas to form the thin film. A second reactant gas can be used to form a compound thin film. The ion-induced, UV-induced, and electron-induced sequential CVD process of the present invention can be repeated to form a thin film of the desired thickness.

Owner:NOVELLUS SYSTEMS

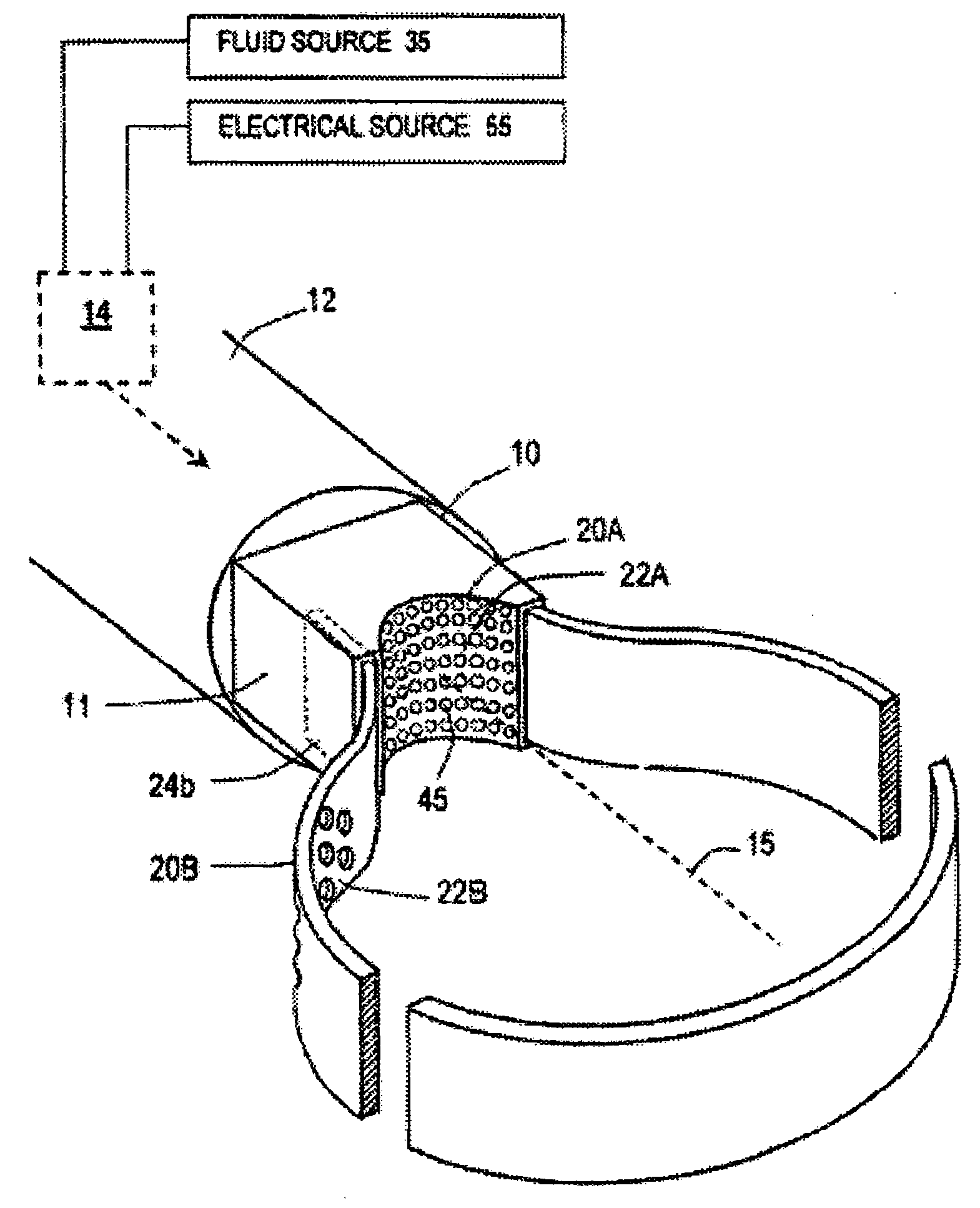

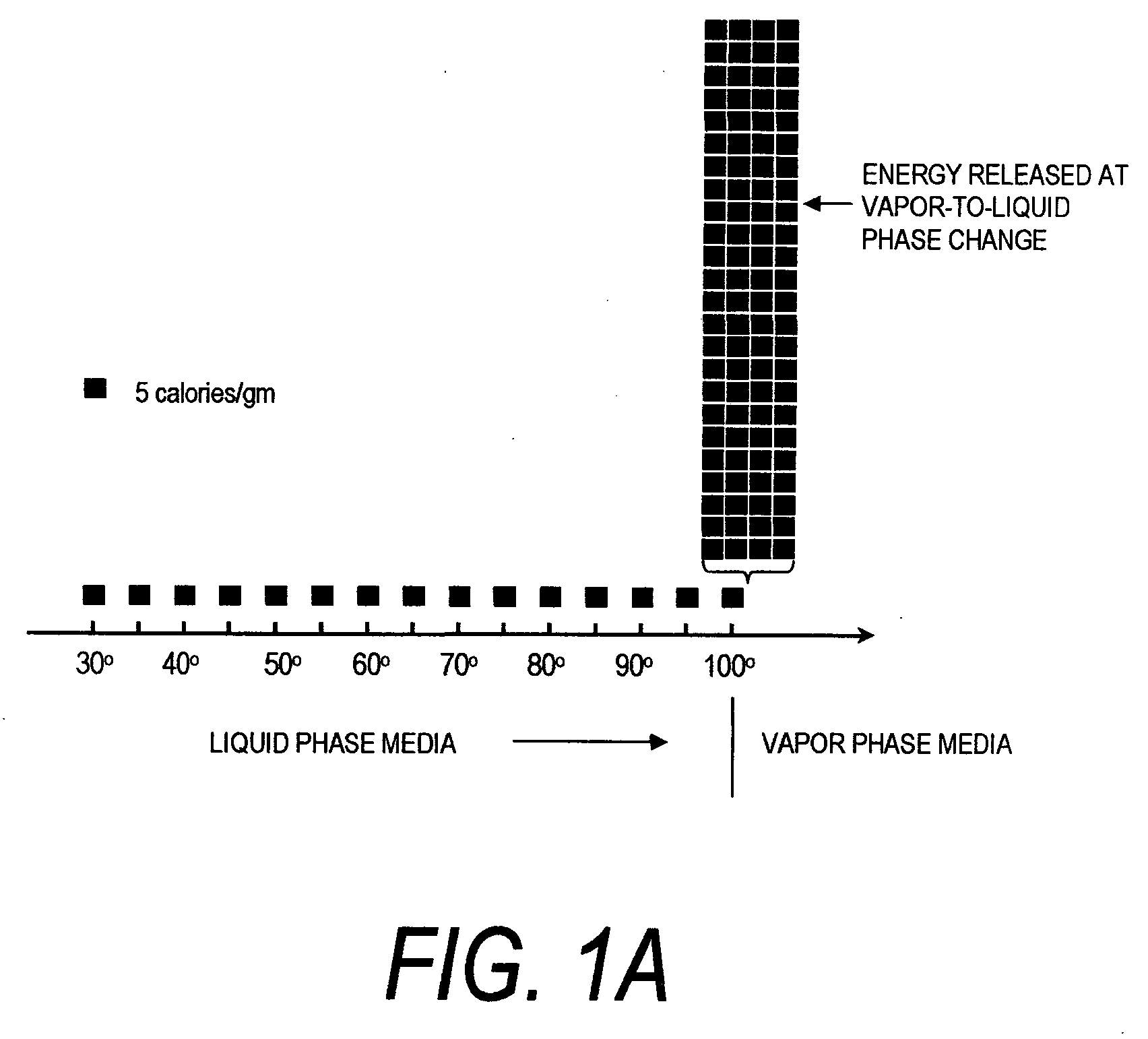

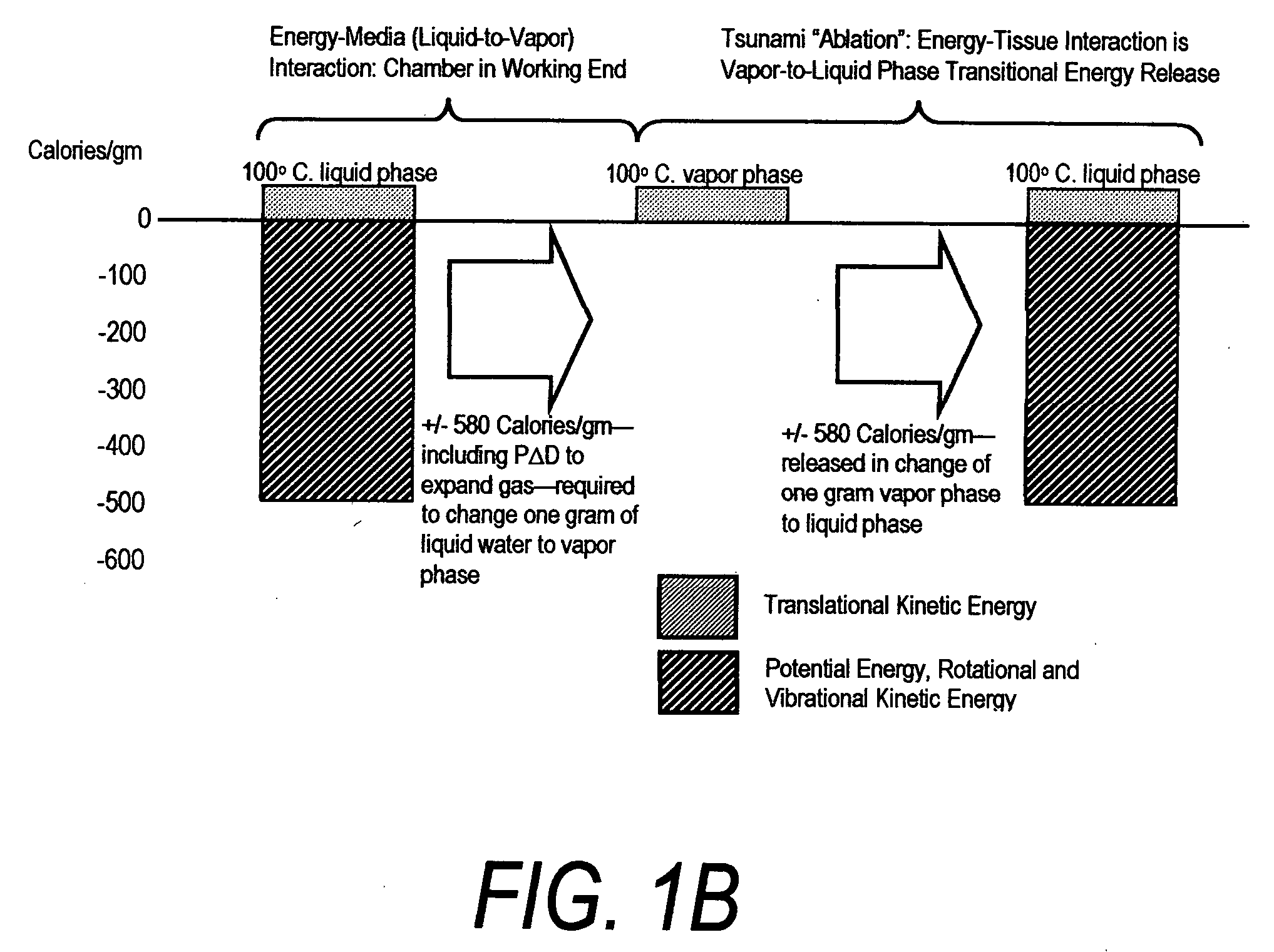

Medical instrument and method of use

ActiveUS20060224154A1Prevents desiccationPrevents escharSurgical instruments for heatingTherapeutic coolingThermal energyGas phase

An instrument for thermally-mediated therapies in targeted tissue volumes or for volumetric removal of tissue. In one embodiment, the instrument has an interior chamber that includes a diffuser structure for diffusing a biocompatible conductive fluid that is introduced under high pressure. The interior chamber further includes surfaces of opposing polarity electrodes for vaporizing the small cross-section diffused fluid flows created within a diffuser structure. In one embodiment, the diffuser structure includes a negative temperature coefficient of resistance material between the opposing polarity surfaces. The NTCR structure can self-adjust the lengths of current paths between the opposing polarities to insure complete vaporization of the volume of flow of conductive fluid. The non-ionized vapor phase media is ejected from a working surface of the instrument and a controlled vapor-to-liquid phase change in an interface with tissue applies thermal energy substantially equal to the heat of vaporization to ablate tissue. In another embodiment, the instrument provides voltage means for converting the non-ionized vapor phase media into an ionized media or plasma for applying energy to body structure.

Owner:TSUNAMI MEDTECH

Atomic layer deposition reactor

InactiveUS20080241387A1Electric discharge tubesChemical vapor deposition coatingSurface reactionEngineering

Various reactors for growing thin films on a substrate by subjecting the substrate to alternately repeated surface reactions of vapor-phase reactants are disclosed. The reactor according to the present invention includes a reaction chamber, a substrate holder, a showerhead plate, a first reactant source, a remote radical generator, a second reactant source, and an exhaust outlet. The showerhead plate is configured to define a reaction space between the showerhead plate and the substrate holder. The showerhead plate includes a plurality of passages leading into the reaction space. The substrate is disposed within the reaction space. A first non-radical reactant is supplied through the showerhead plate to the reaction space. The remote radical generator produces the radicals of a second reactant supplied from the second reactant source. The radicals are supplied directly to the reaction space without passing through the showerhead plate.

Owner:ASM INTERNATIONAL

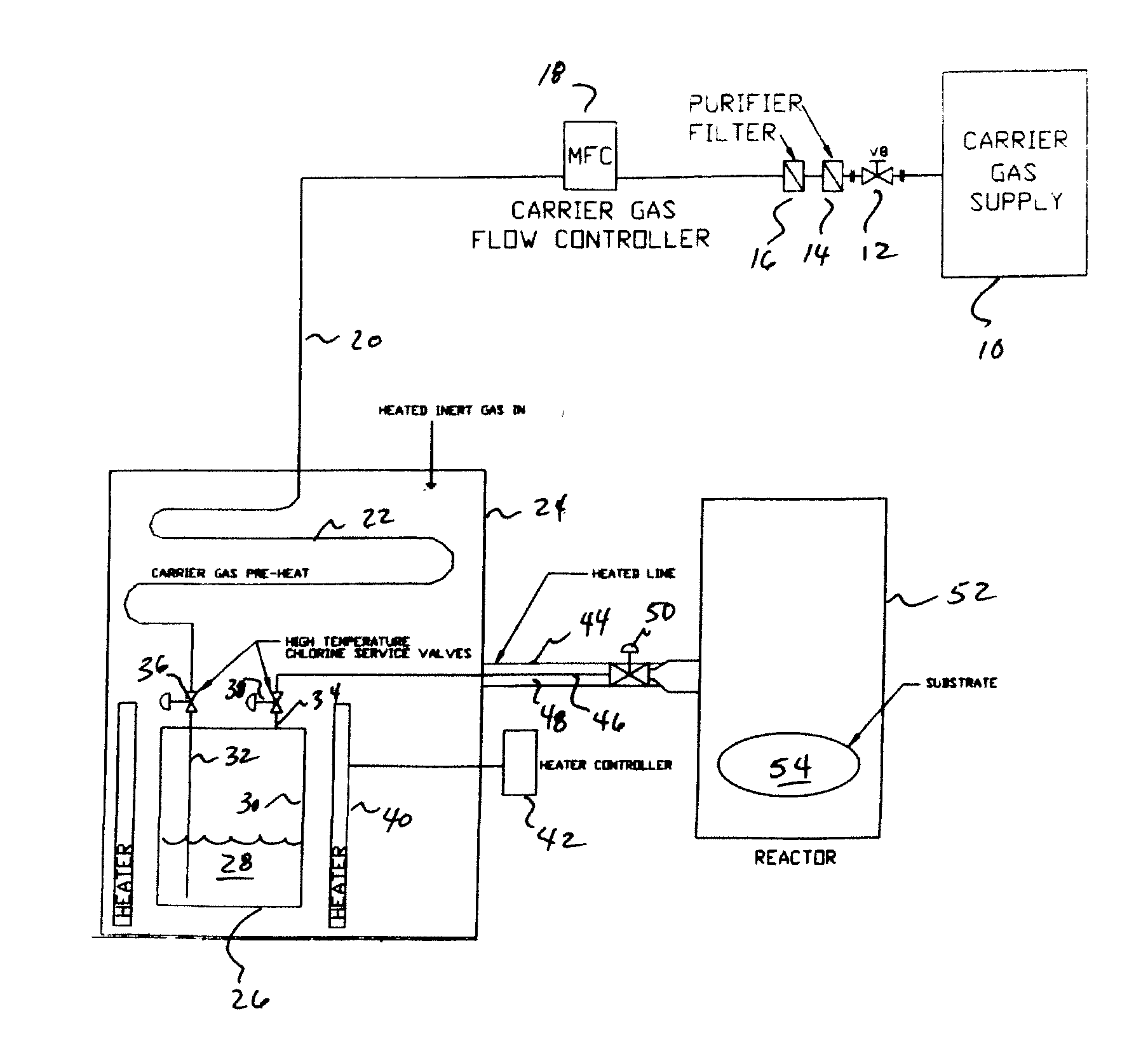

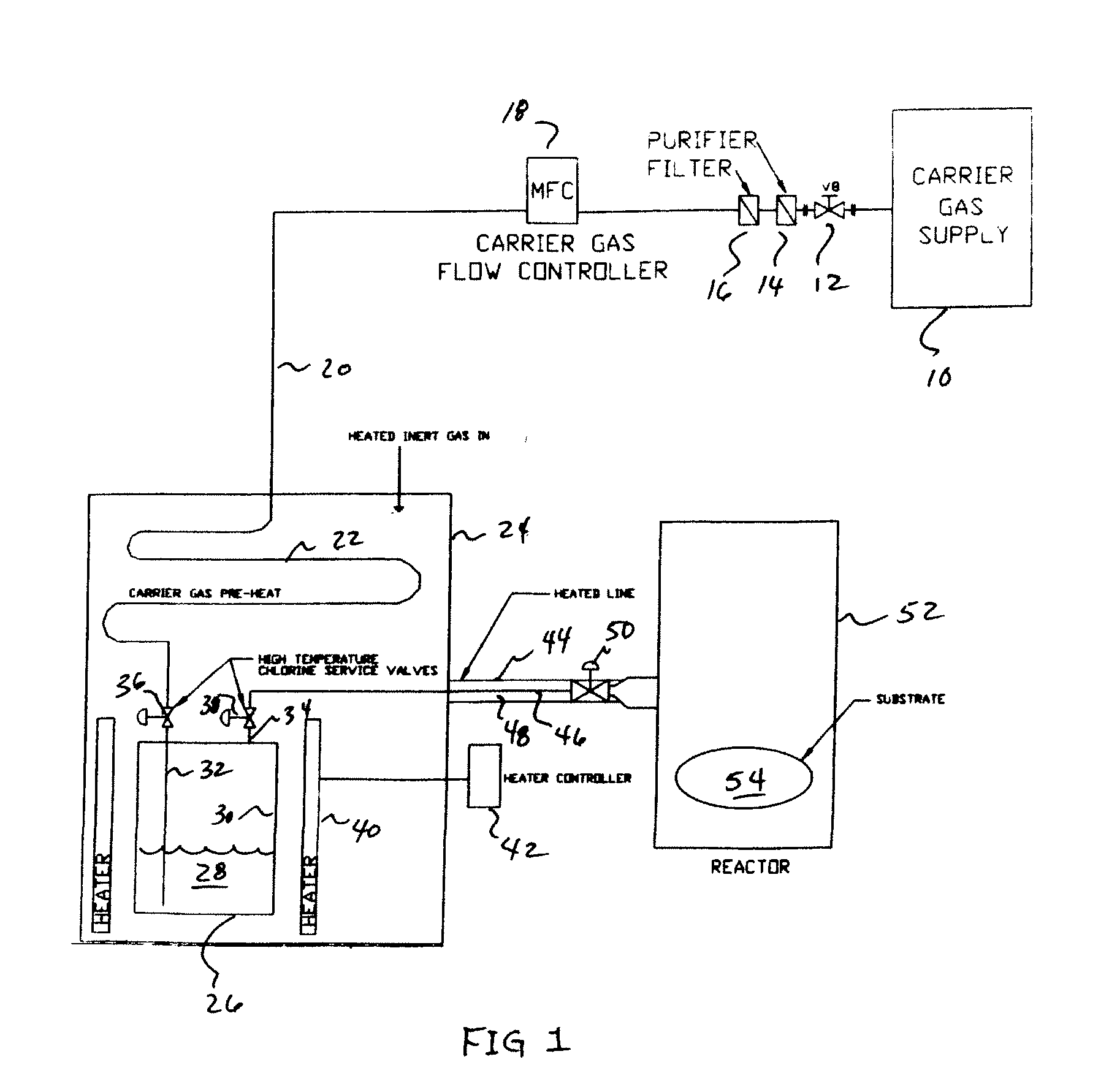

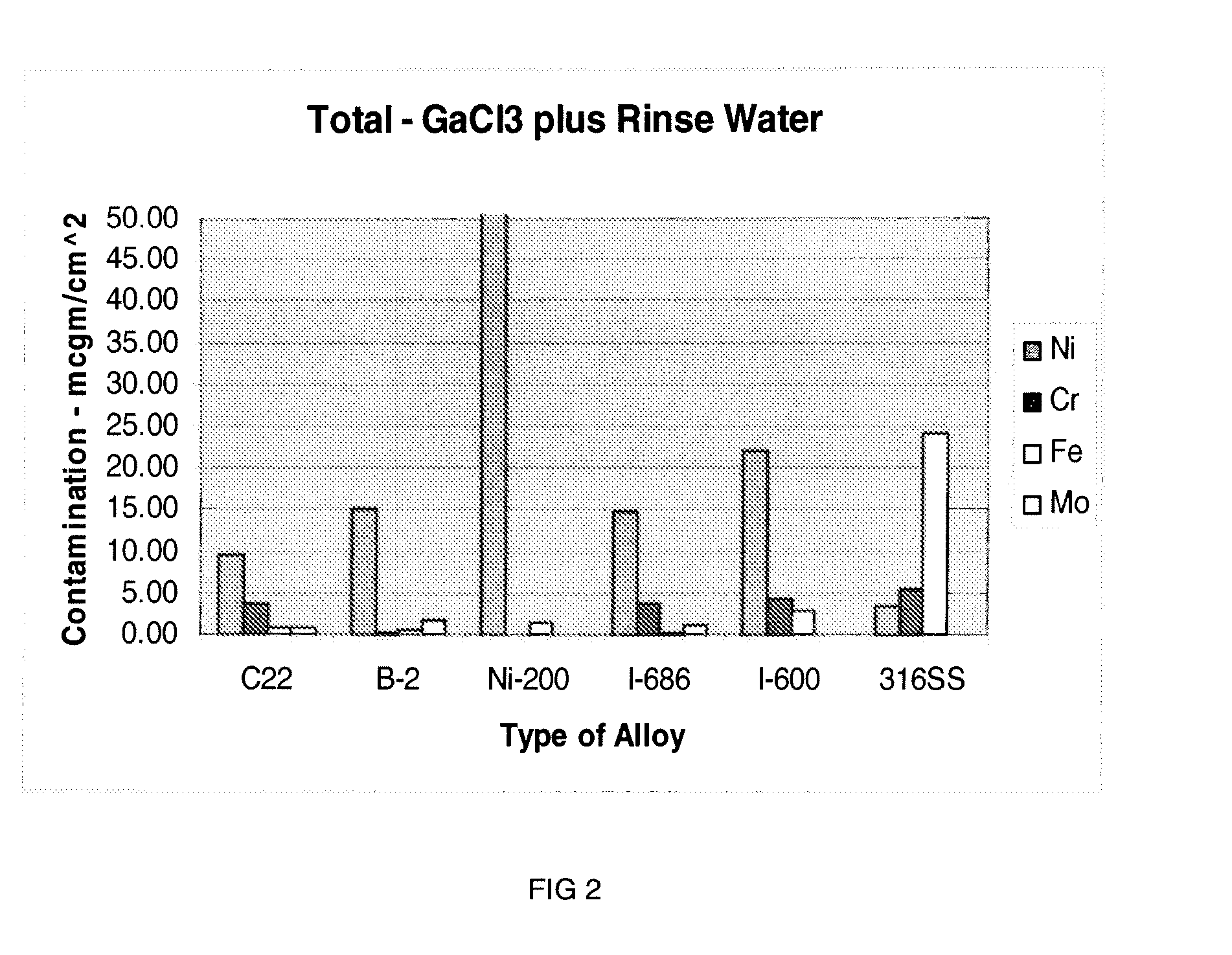

High Flow GaCl3 Delivery

InactiveUS20080018004A1Avoid insufficient heatingCarburetting airPolycrystalline material growthGas phaseReaction zone

The present invention is an apparatus for deliverying high purity gallium trichloride in the vapor phase to a gallium nitride reactor, comprising; a source of carrier gas at an elevated pressure; a purifier to remove moisture from the carrier gas; a heater capable of heating the carrier gas to at least 80° C.; a container having a supply of gallium trichloride, a valve controlled inlet for the carrier gas having a dip tube with an outlet below the level of the gallium trichloride, a valve controlled outlet for removing the carrier gas and entrained gallium trichloride; a heater capable of heating sufficient to melt the gallium trichloride; a delivery line connected to the valve controlled outlet for carrying the entrained gallium trichloride to a reaction zone for gallium nitride. A process is also described for the apparatus.

Owner:VERSUM MATERIALS US LLC

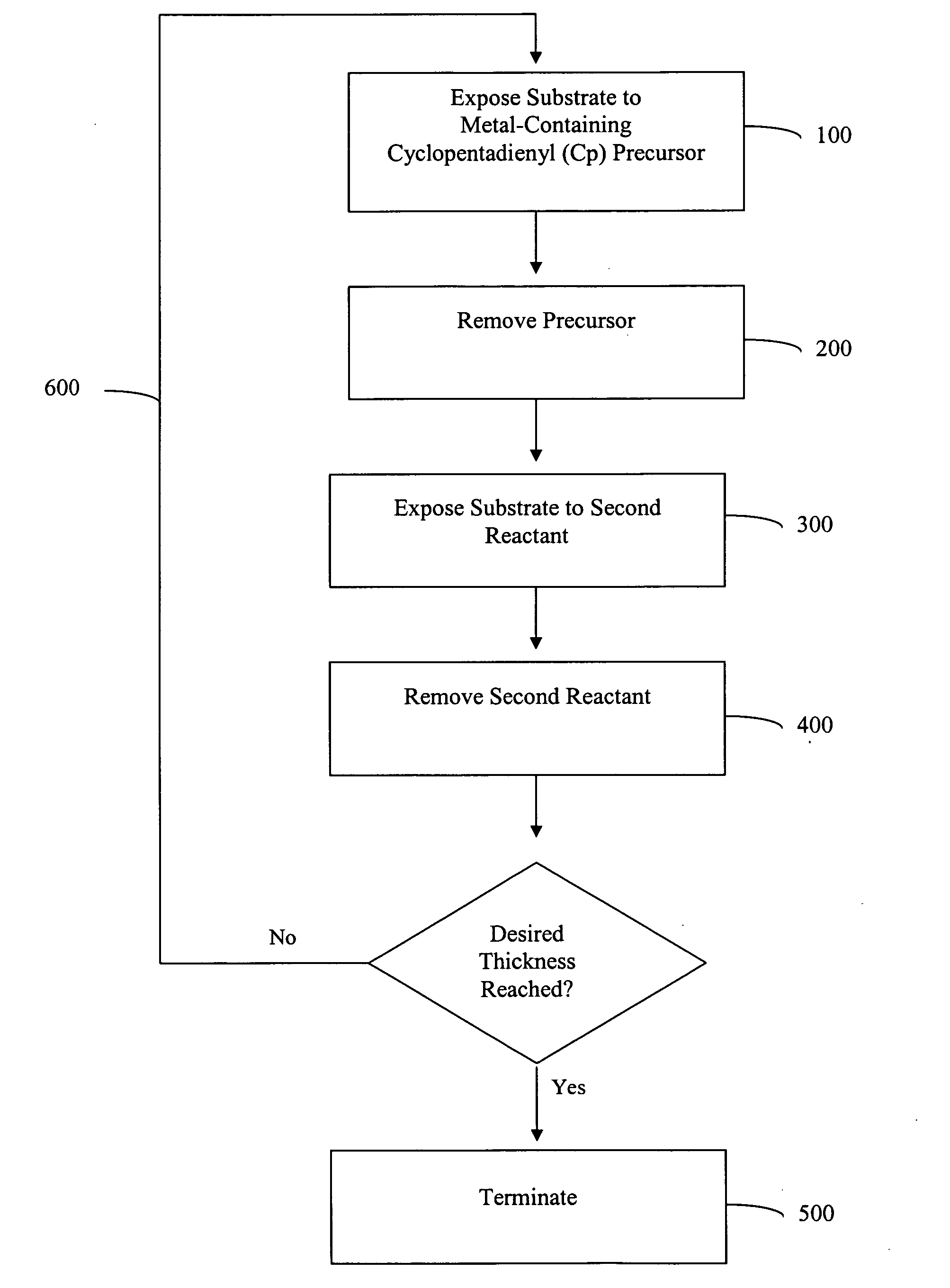

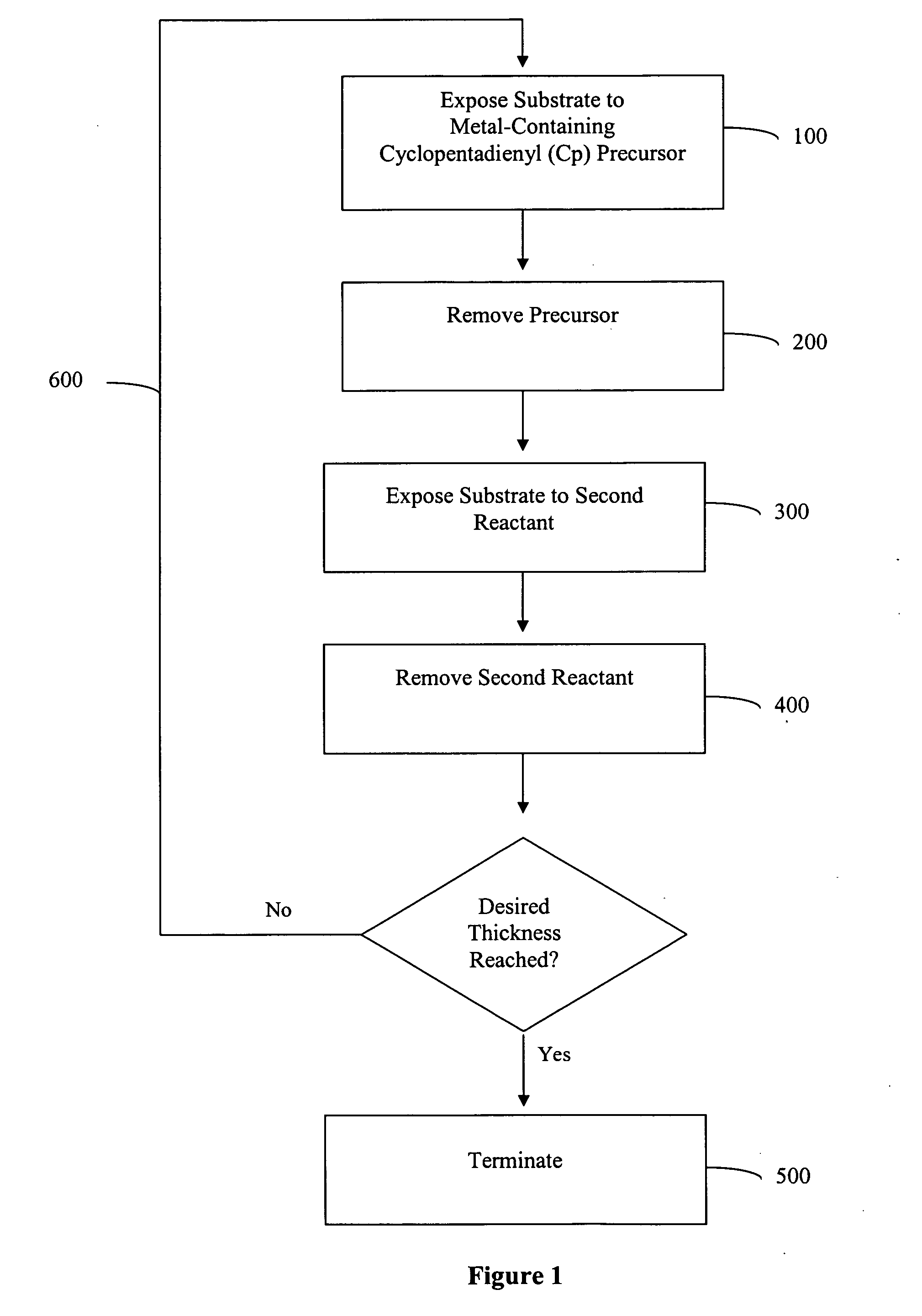

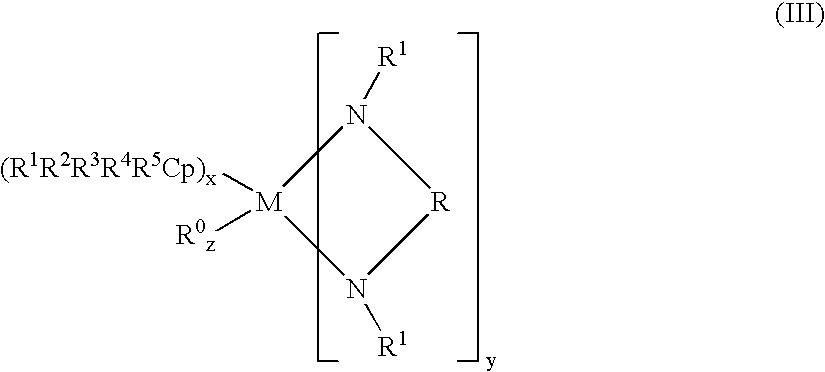

ALD of metal-containing films using cyclopentadienyl compounds

Atomic layer deposition (ALD) type processes for producing metal containing thin films comprise feeding into a reaction space vapor phase pulses of metal containing cyclopentadienyl precursors as a metal source material. In preferred embodiments the metal containing cyclopentadienyl reactant comprises a metal atom that is not directly bonded to an oxygen or halide atom. In other embodiments the metal atom is bonded to a cyclopentadienyl compound and separately bonded to at least one ligand via a nitrogen atom. In still other embodiments the metal containing cyclopentadienyl compound comprises a nitrogen-bridged ligand.

Owner:ASM IP HLDG BV

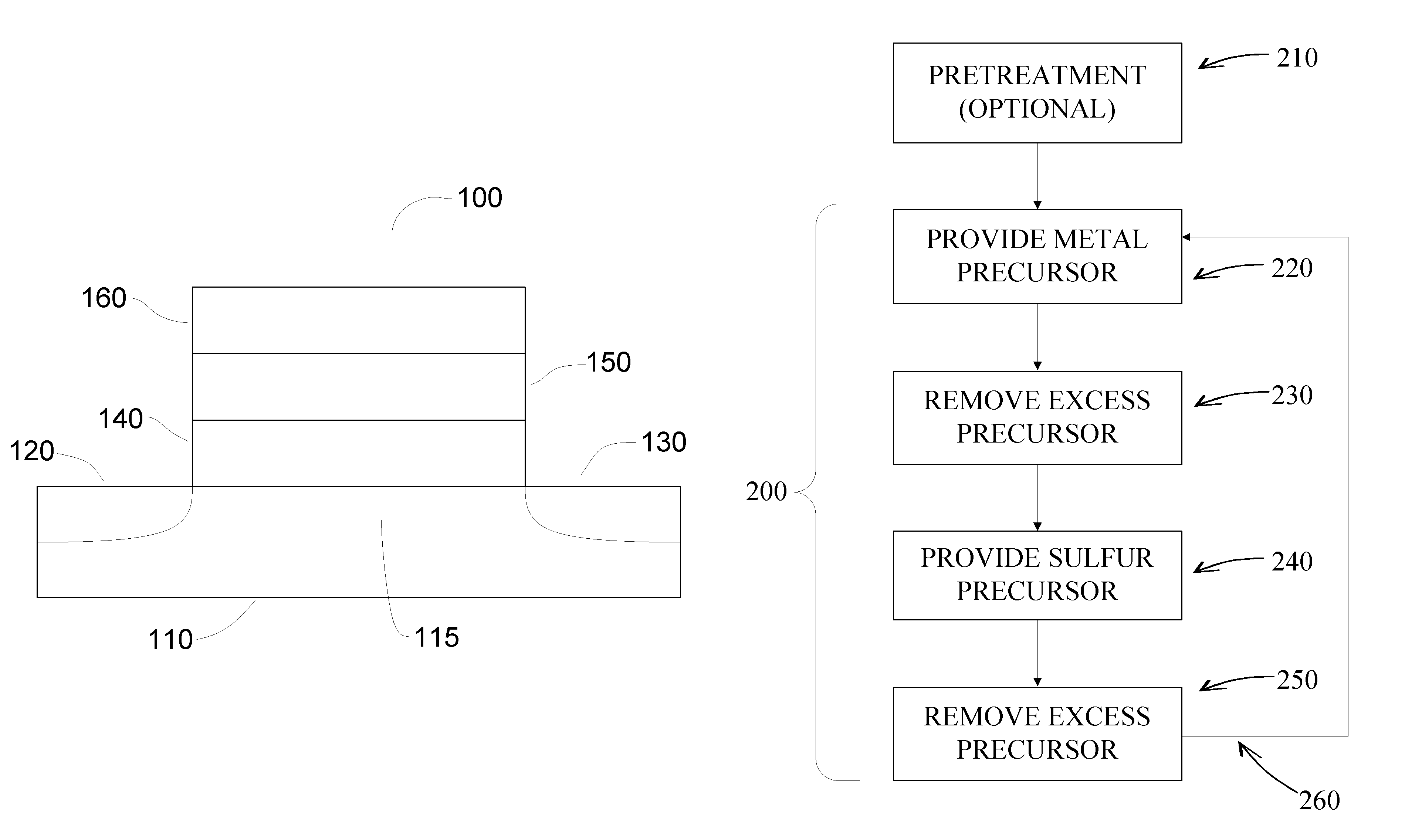

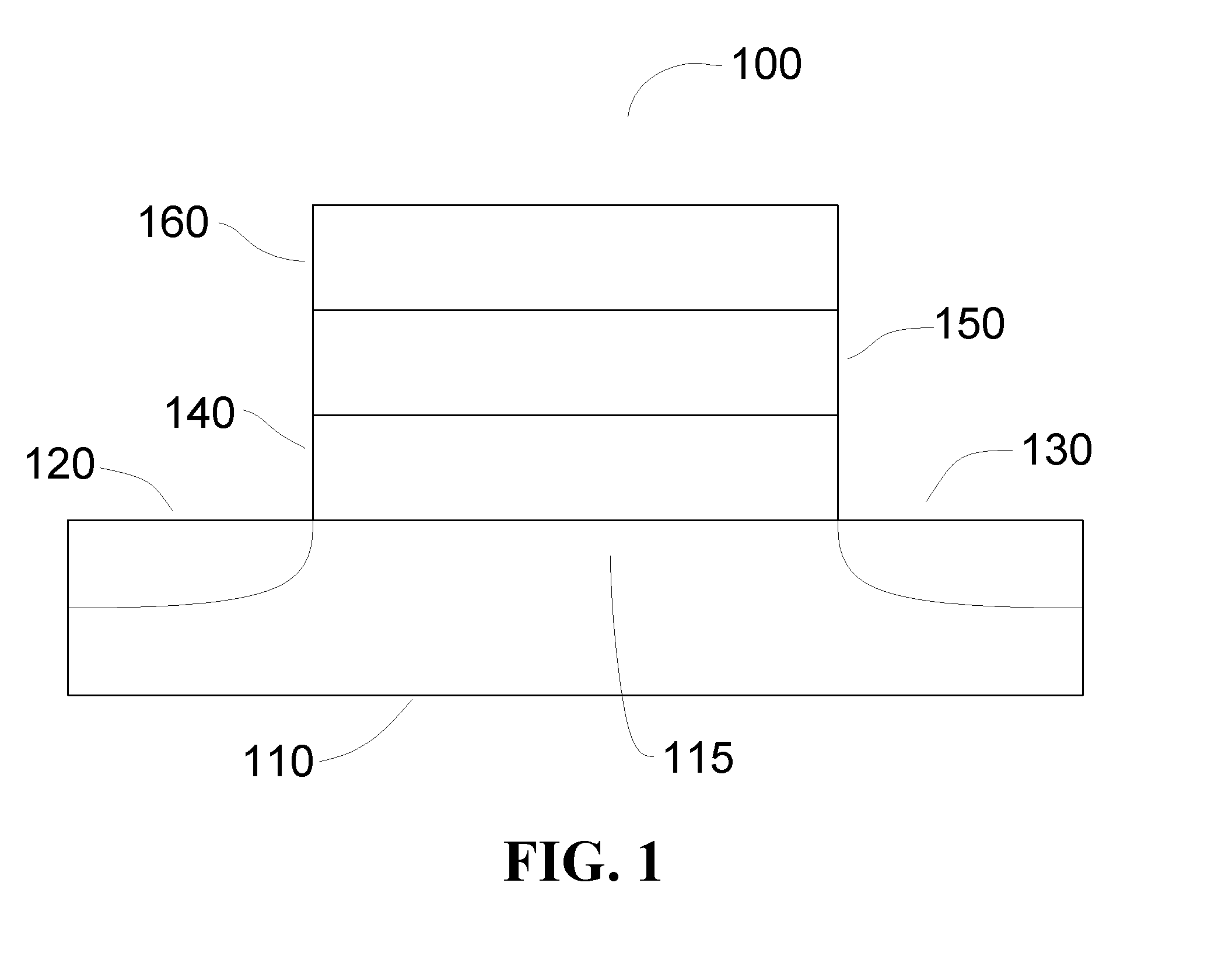

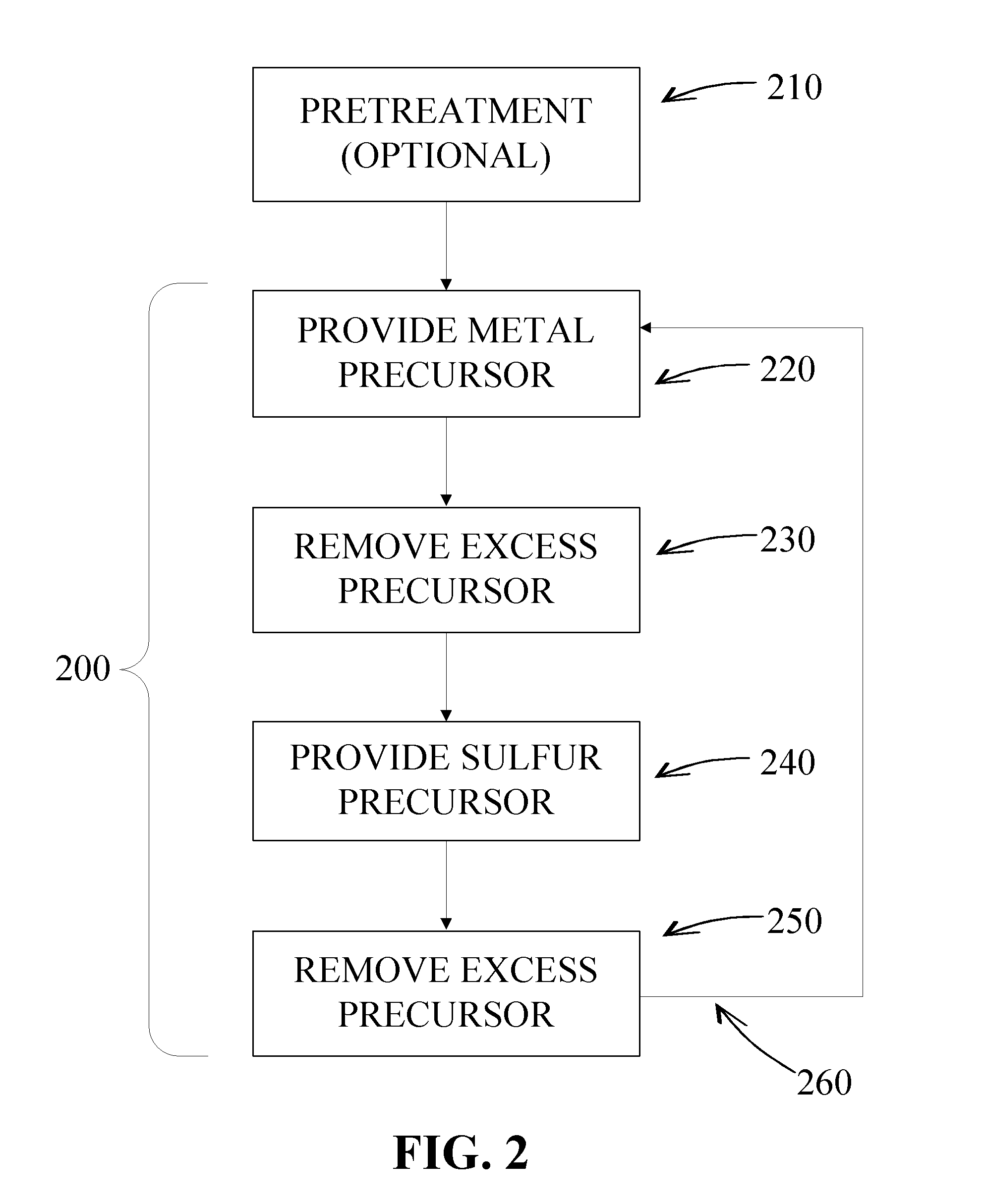

Sulfur-containing thin films

ActiveUS9245742B2Semiconductor/solid-state device manufacturingSemiconductor devicesThree dimensional architectureOptoelectronics

In some aspects, methods of forming a metal sulfide thin film are provided. According to some methods, a metal sulfide thin film is deposited on a substrate in a reaction space in a cyclical process where at least one cycle includes alternately and sequentially contacting the substrate with a first vapor-phase metal reactant and a second vapor-phase sulfur reactant. In some aspects, methods of forming a three-dimensional architecture on a substrate surface are provided. In some embodiments, the method includes forming a metal sulfide thin film on the substrate surface and forming a capping layer over the metal sulfide thin film. The substrate surface may comprise a high-mobility channel.

Owner:ASM IP HLDG BV

Methods for UV-assisted conformal film deposition

InactiveUS8647993B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBiological activationElectromagnetic radiation

Owner:NOVELLUS SYSTEMS

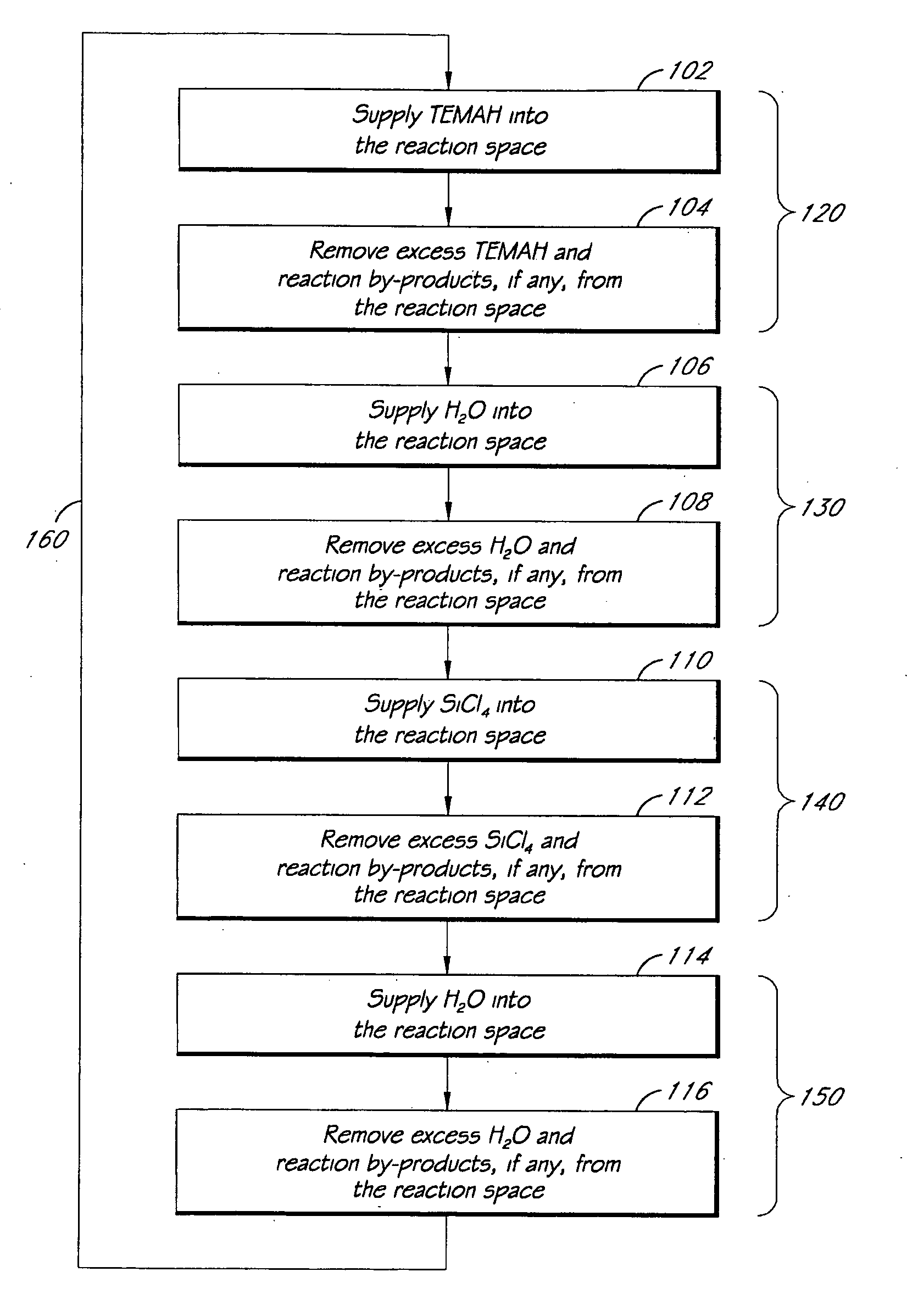

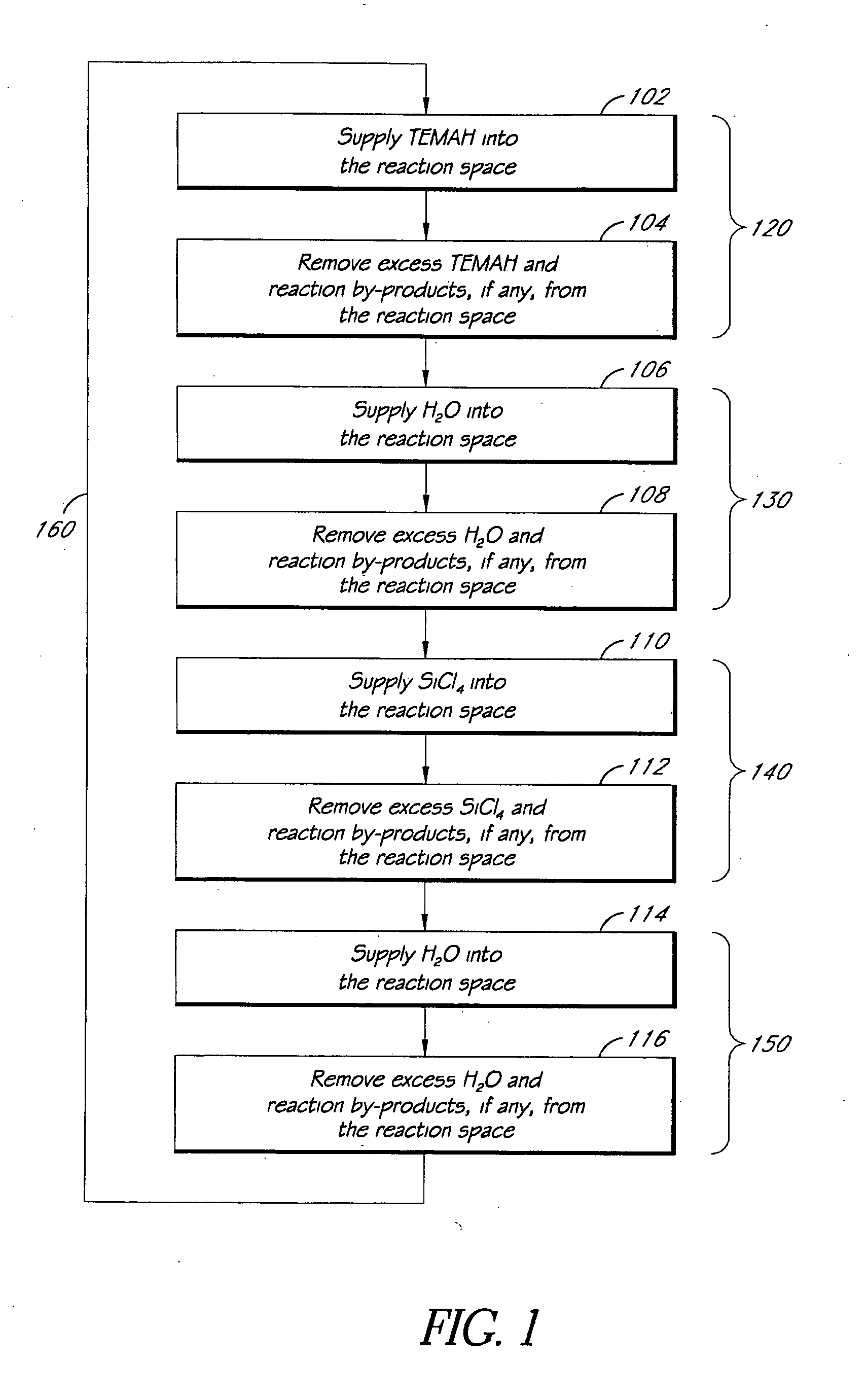

ALD of metal silicate films

ActiveUS20080020593A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHafnium

Methods for forming metal silicate films are provided. The methods comprise contacting a substrate with alternating and sequential vapor phase pulses of a metal source chemical, a silicon source chemical and an oxidizing agent. In preferred embodiments, an alkyl amide metal compound and a silicon halide compound are used. Methods according to preferred embodiments can be used to form hafnium silicate and zirconium silicate films with substantially uniform film coverages on substrate surfaces comprising high aspect ratio features (e.g., vias and / or trenches).

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com