Patents

Literature

31 results about "Gallium trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gallium trichloride is the chemical compound with the formula GaCl₃. Solid gallium trichloride exists as a dimer with the formula Ga₂Cl₆. It is colourless and soluble in virtually all solvents, even alkanes, which is truly unusual for a metal halide. It is the main precursor to most derivatives of gallium and a reagent in organic synthesis.

High Flow GaCl3 Delivery

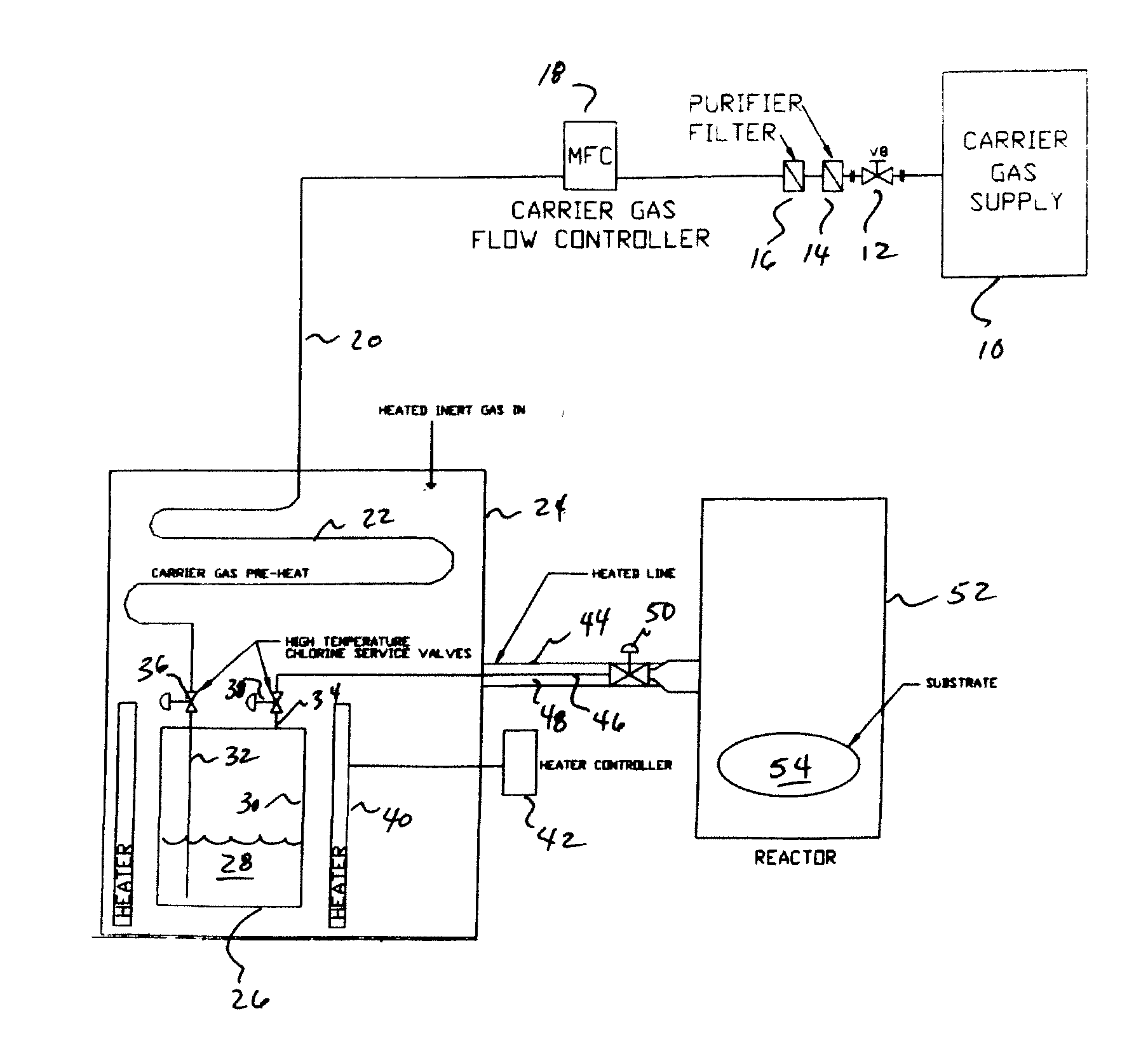

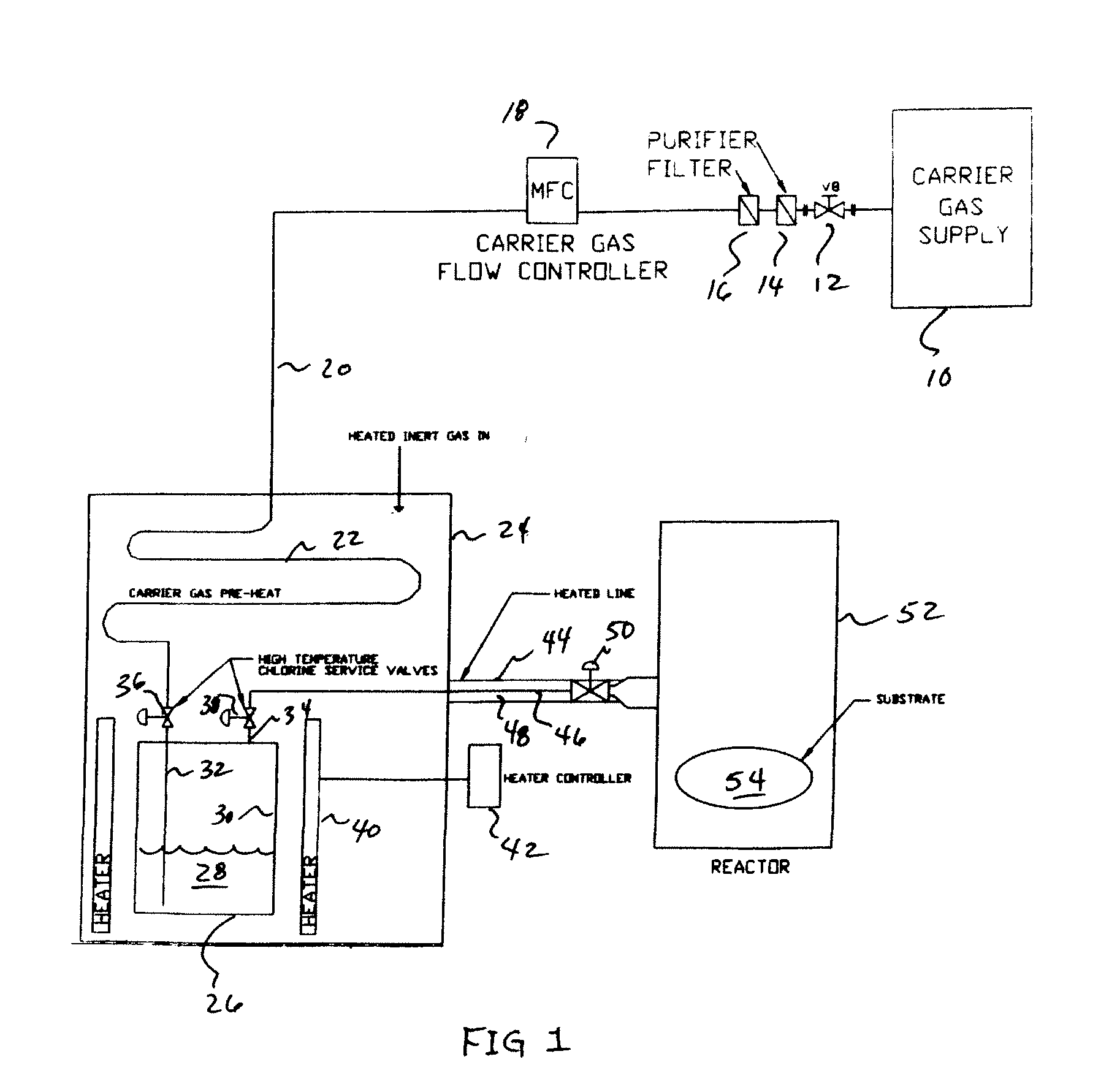

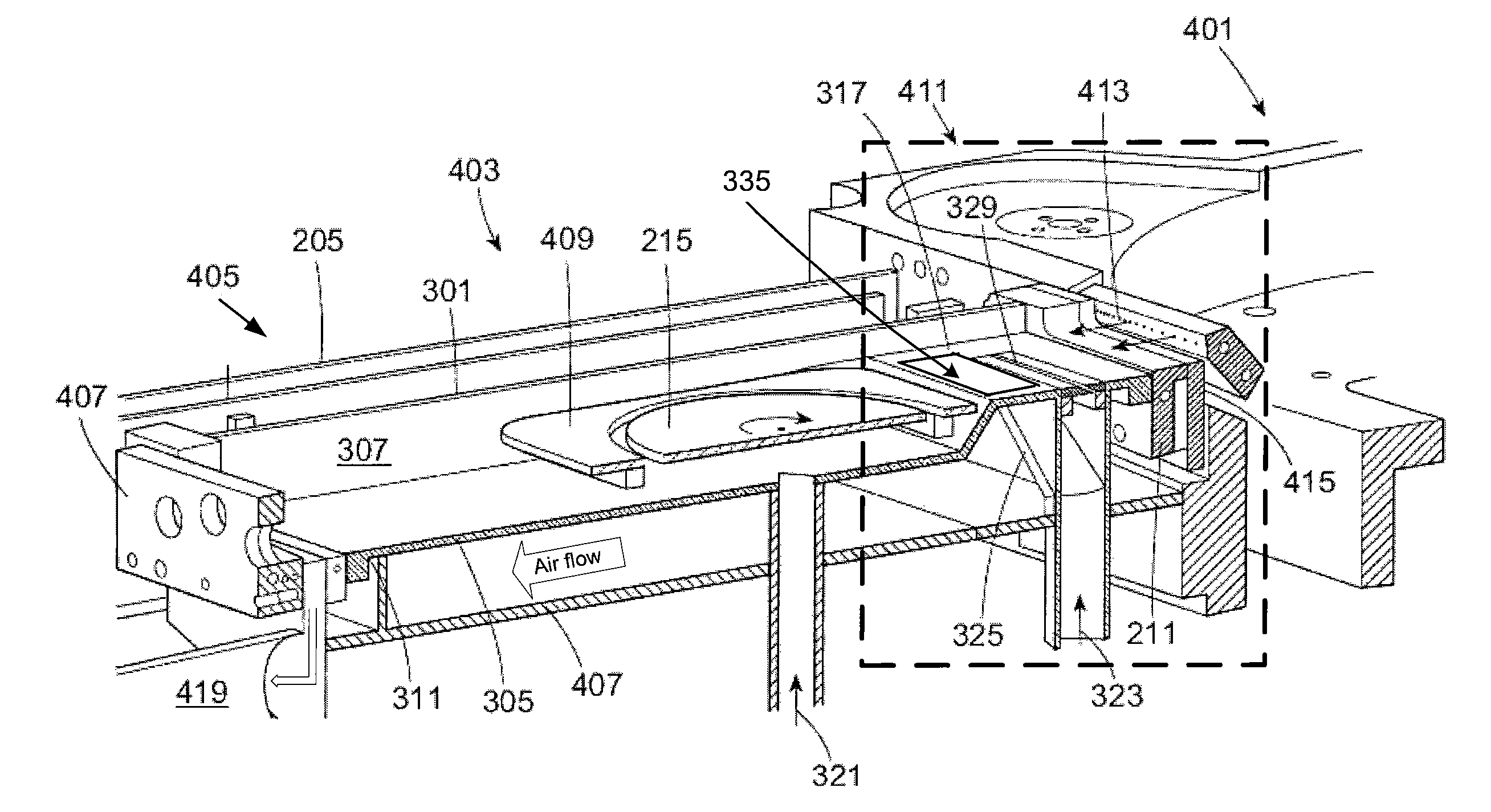

InactiveUS20080018004A1Avoid insufficient heatingCarburetting airPolycrystalline material growthGas phaseReaction zone

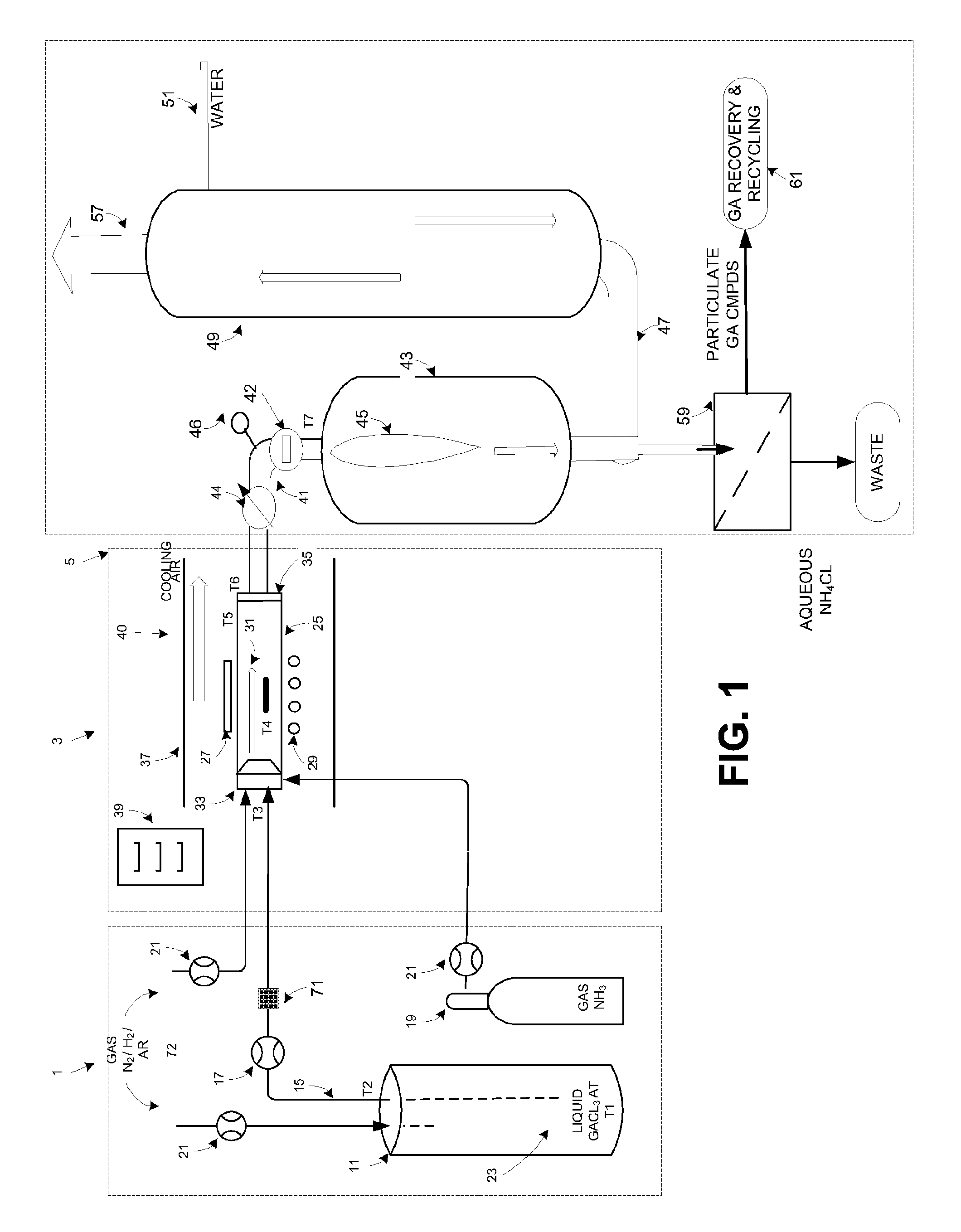

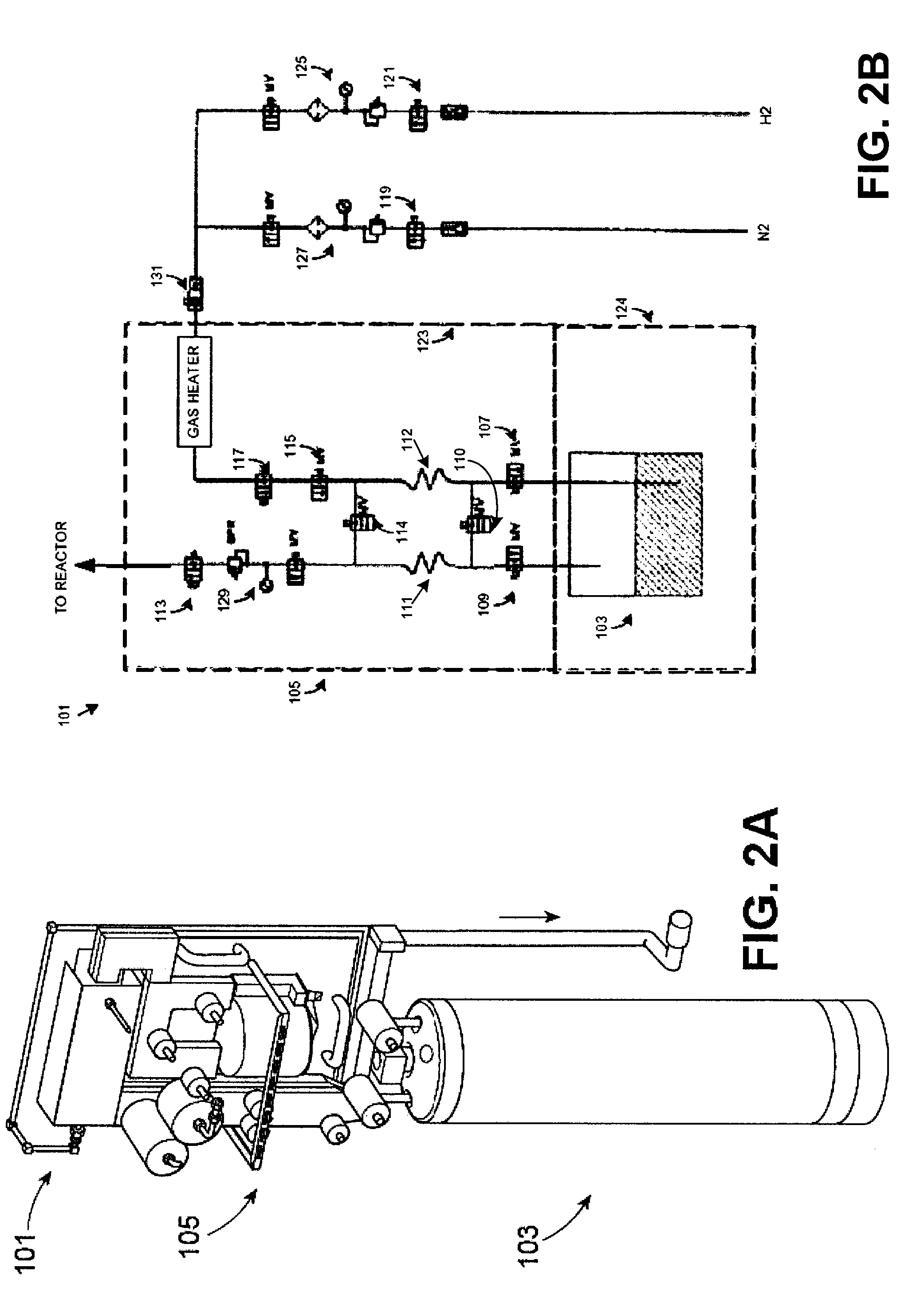

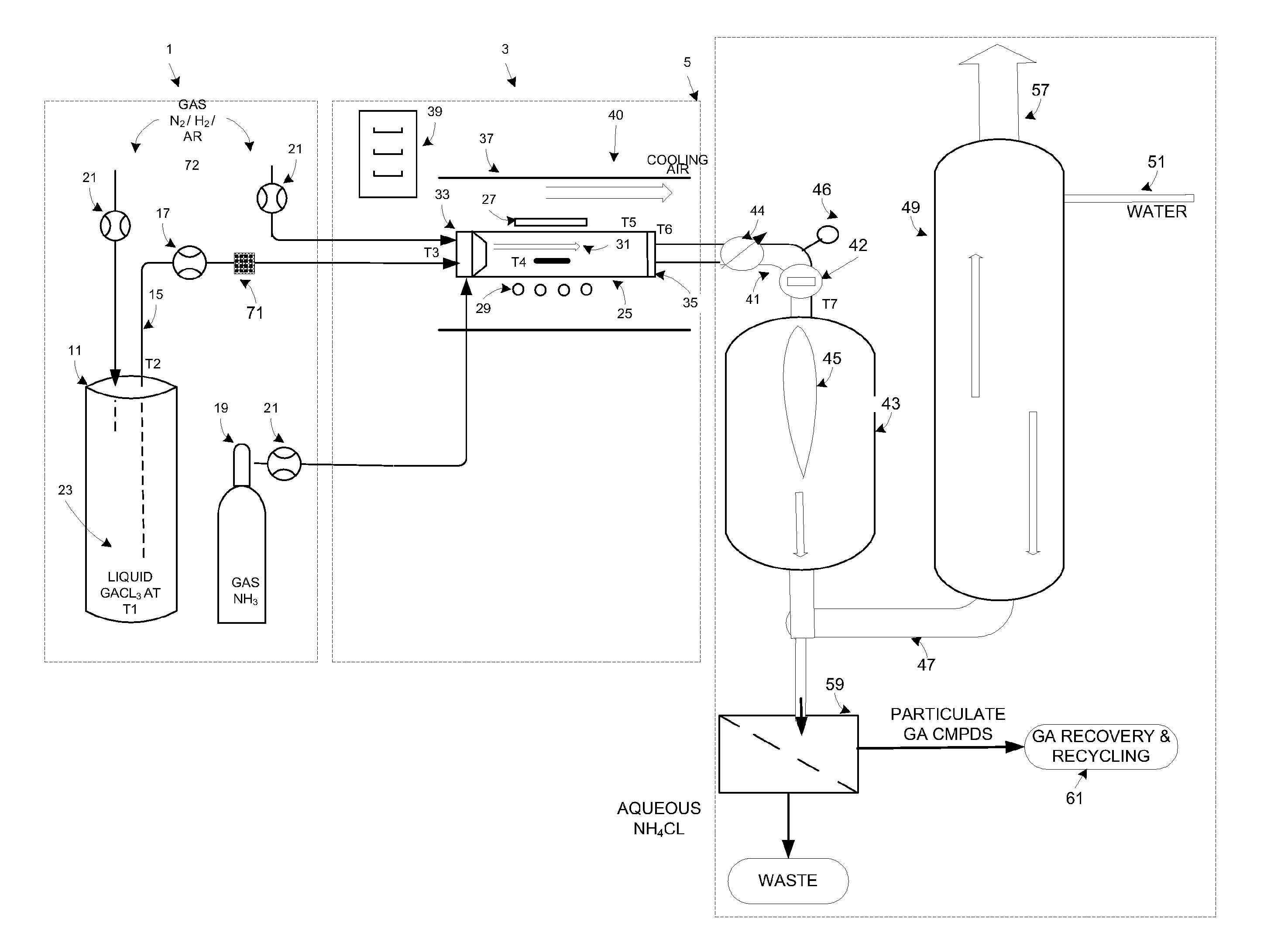

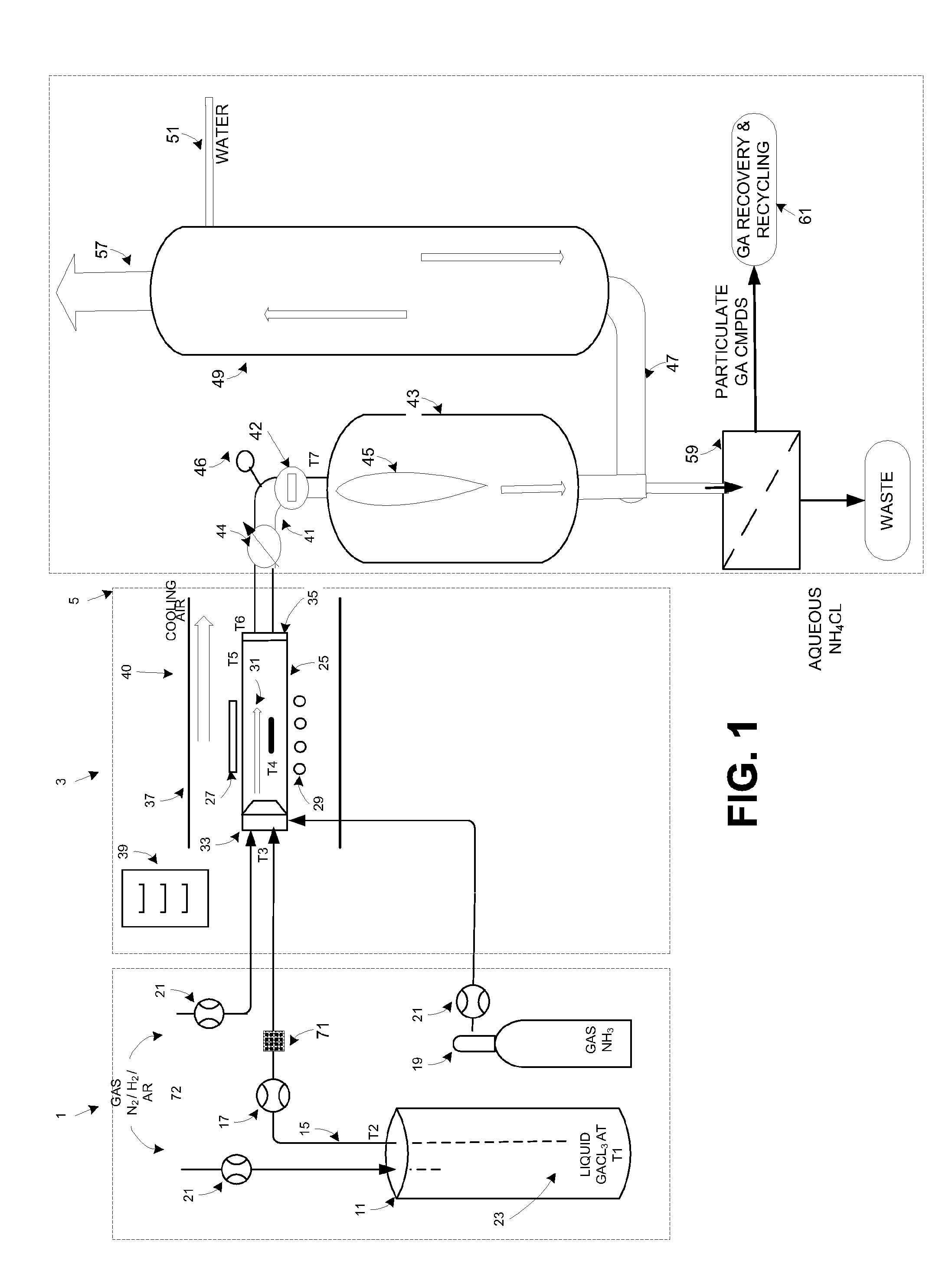

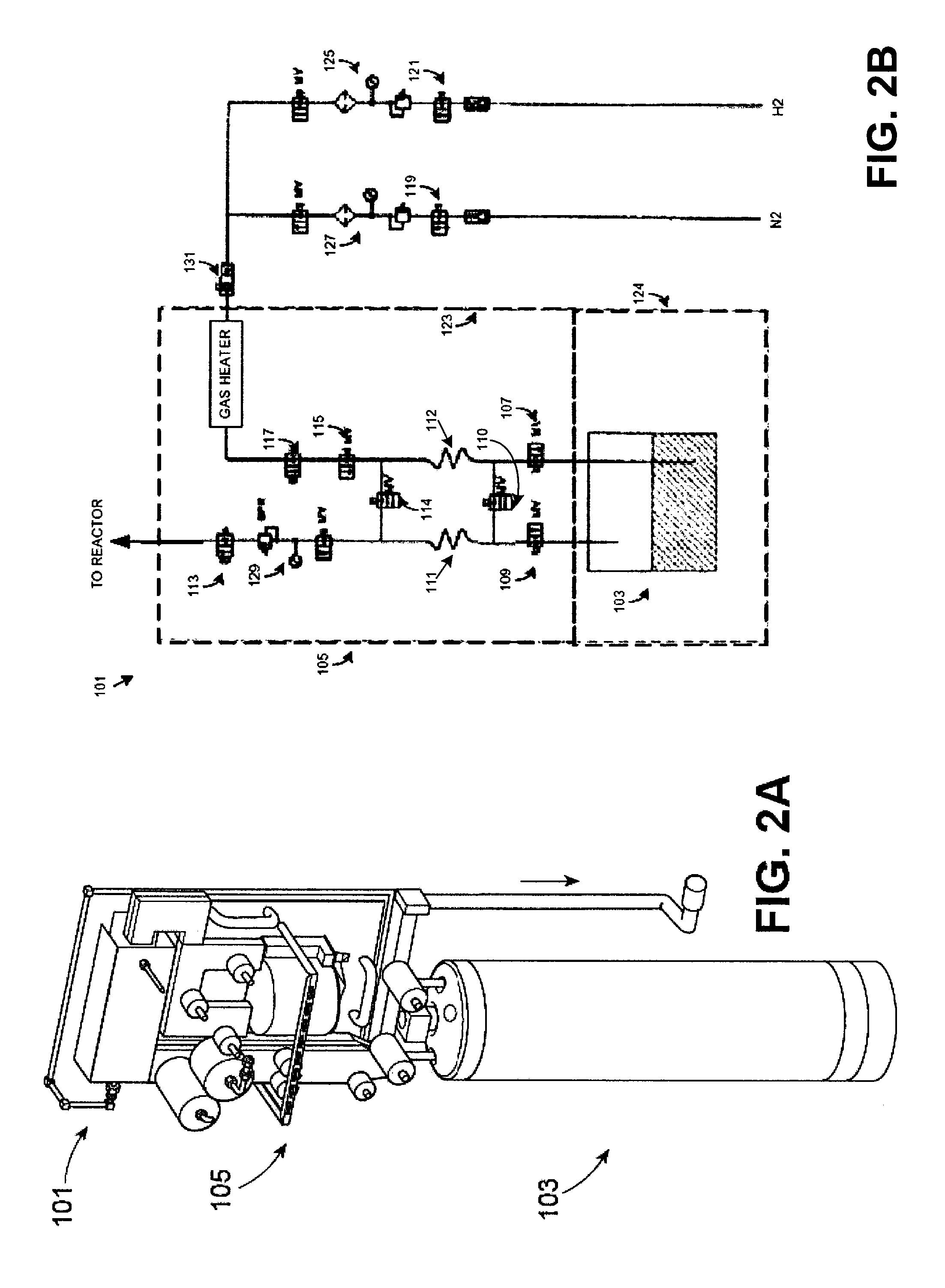

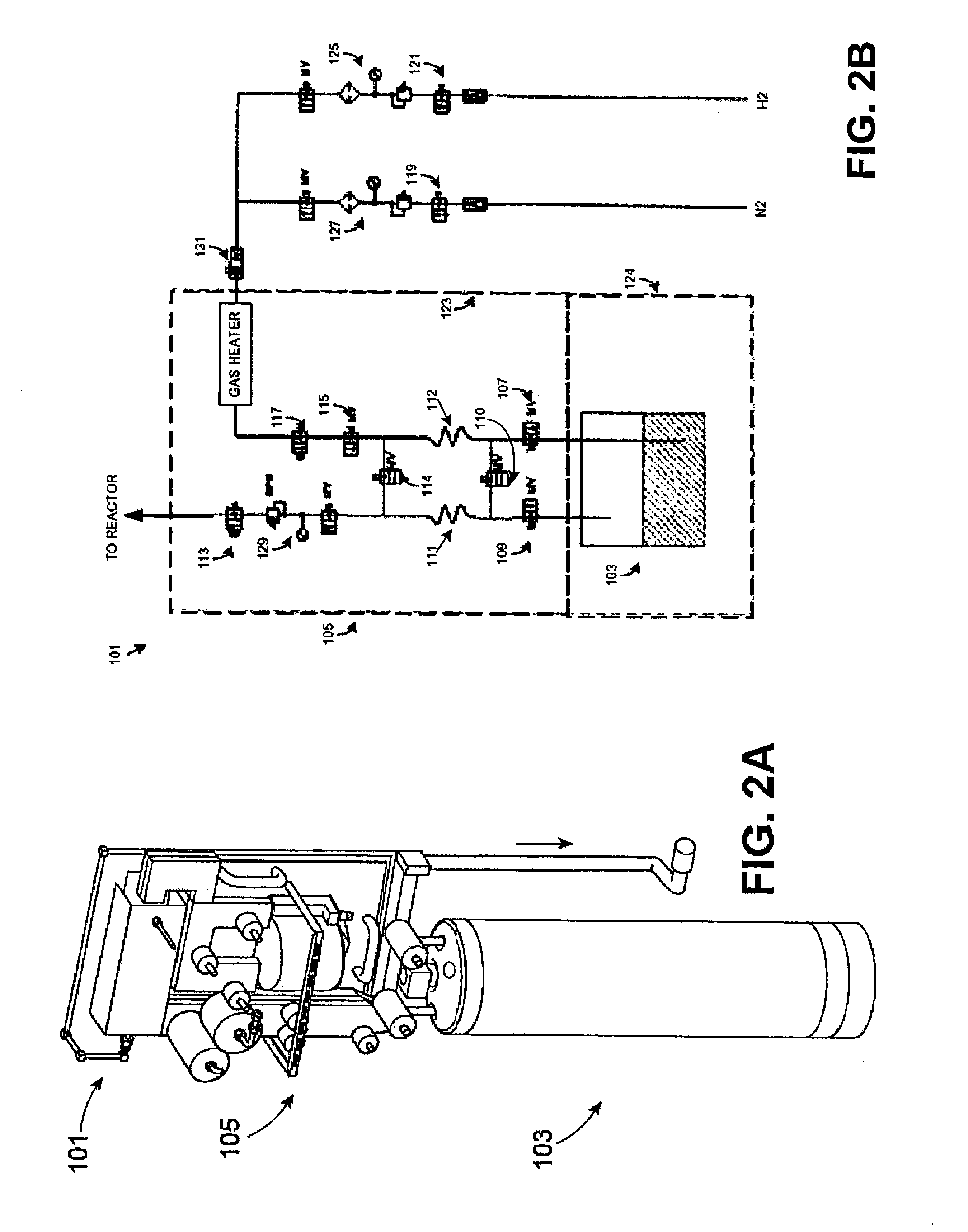

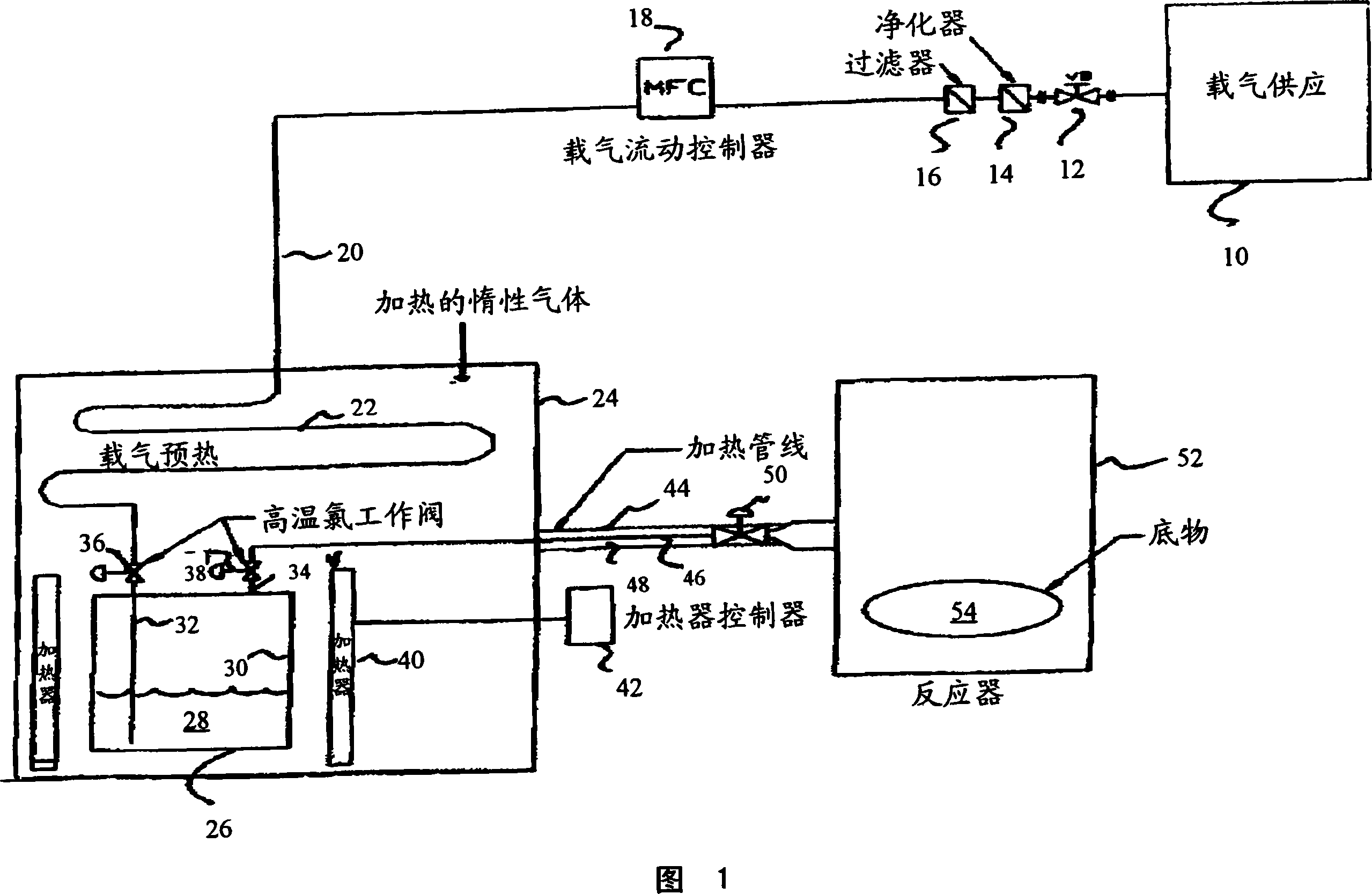

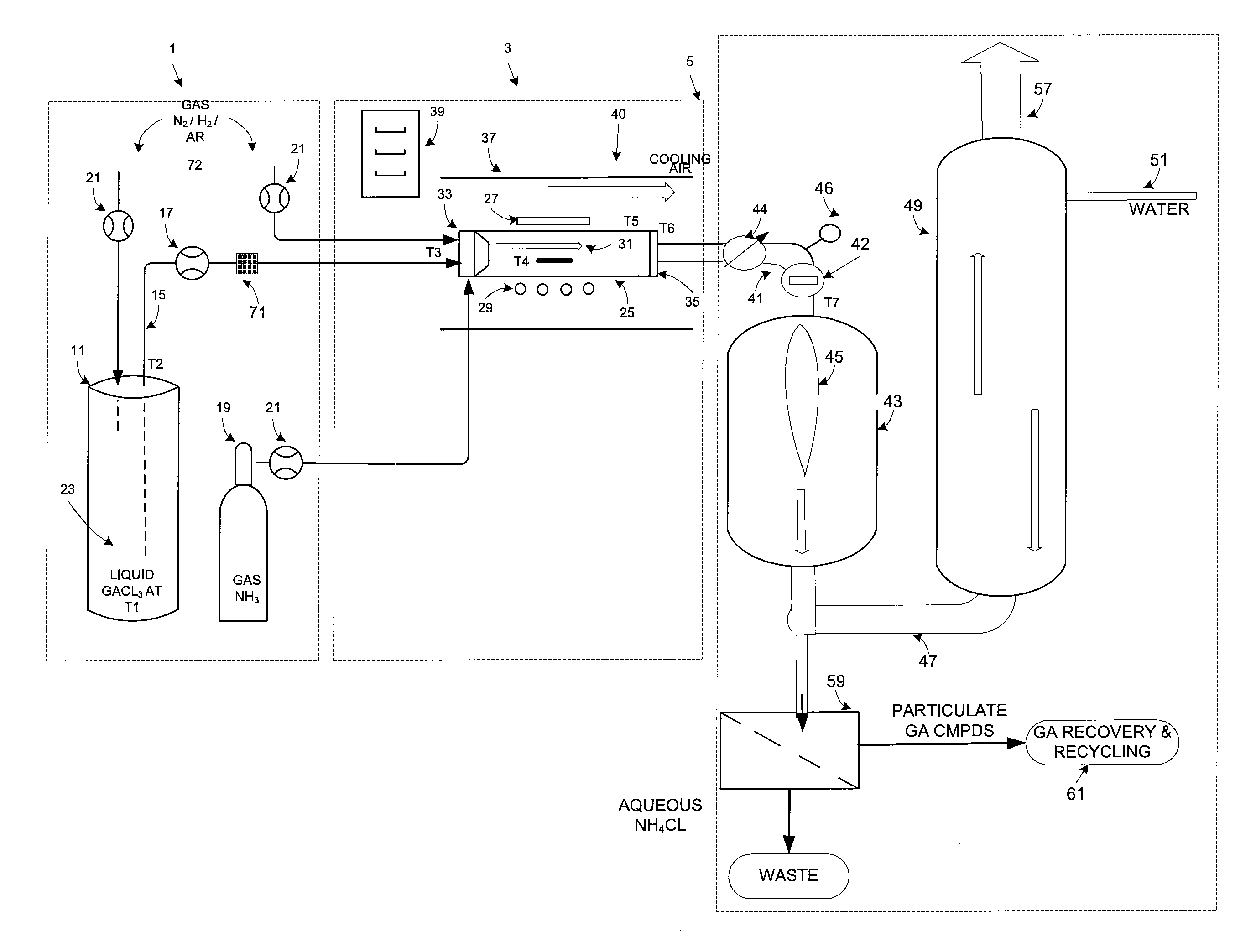

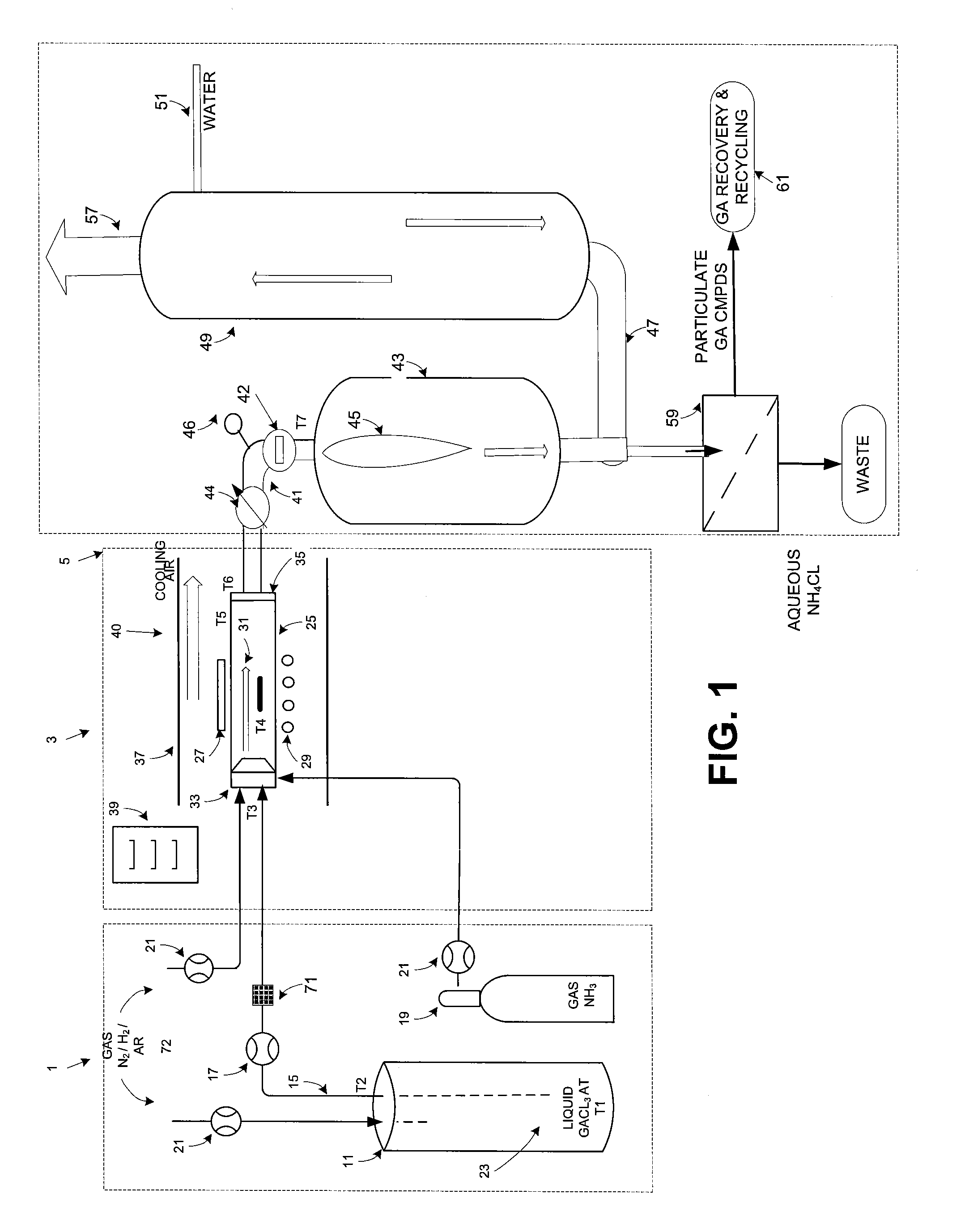

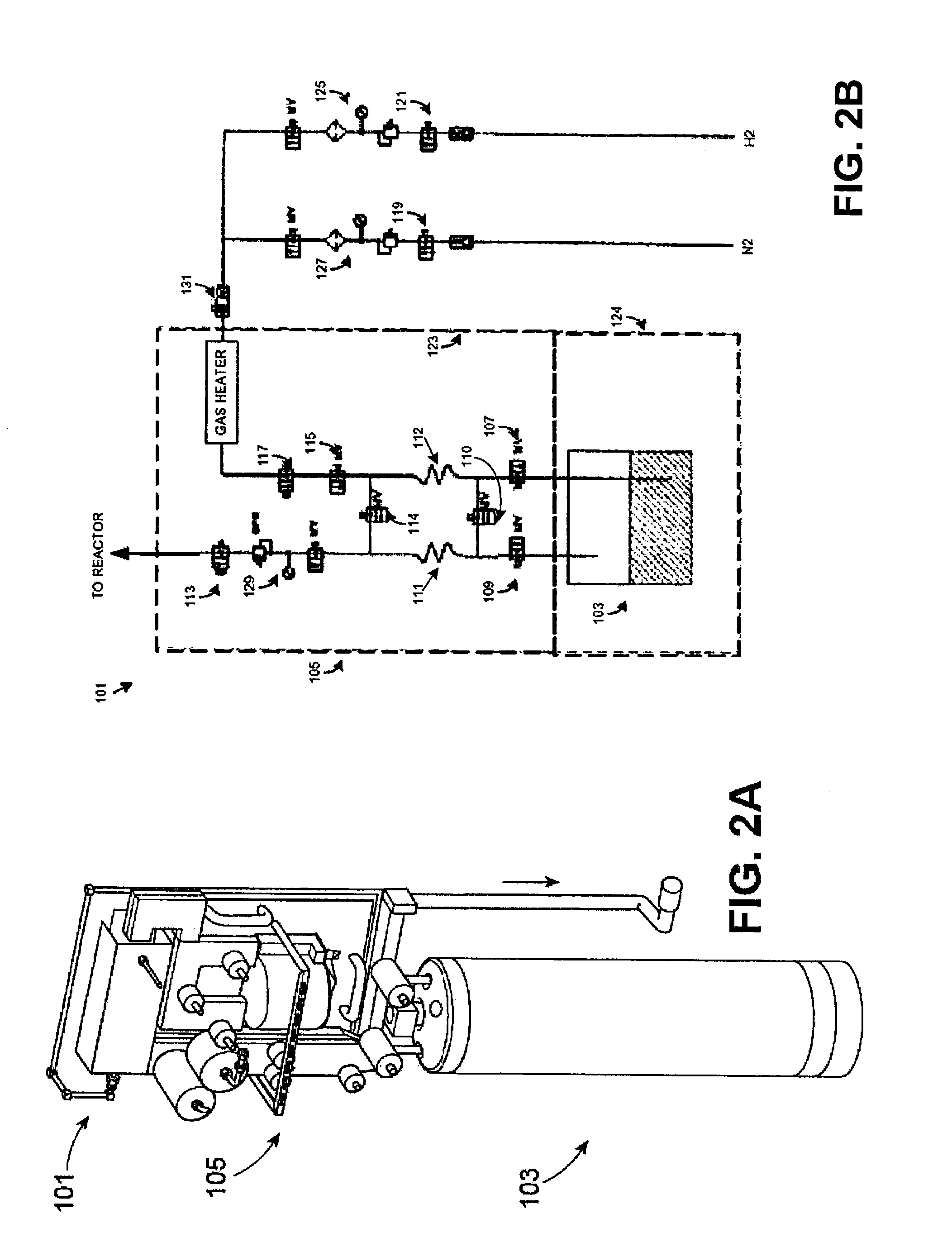

The present invention is an apparatus for deliverying high purity gallium trichloride in the vapor phase to a gallium nitride reactor, comprising; a source of carrier gas at an elevated pressure; a purifier to remove moisture from the carrier gas; a heater capable of heating the carrier gas to at least 80° C.; a container having a supply of gallium trichloride, a valve controlled inlet for the carrier gas having a dip tube with an outlet below the level of the gallium trichloride, a valve controlled outlet for removing the carrier gas and entrained gallium trichloride; a heater capable of heating sufficient to melt the gallium trichloride; a delivery line connected to the valve controlled outlet for carrying the entrained gallium trichloride to a reaction zone for gallium nitride. A process is also described for the apparatus.

Owner:VERSUM MATERIALS US LLC

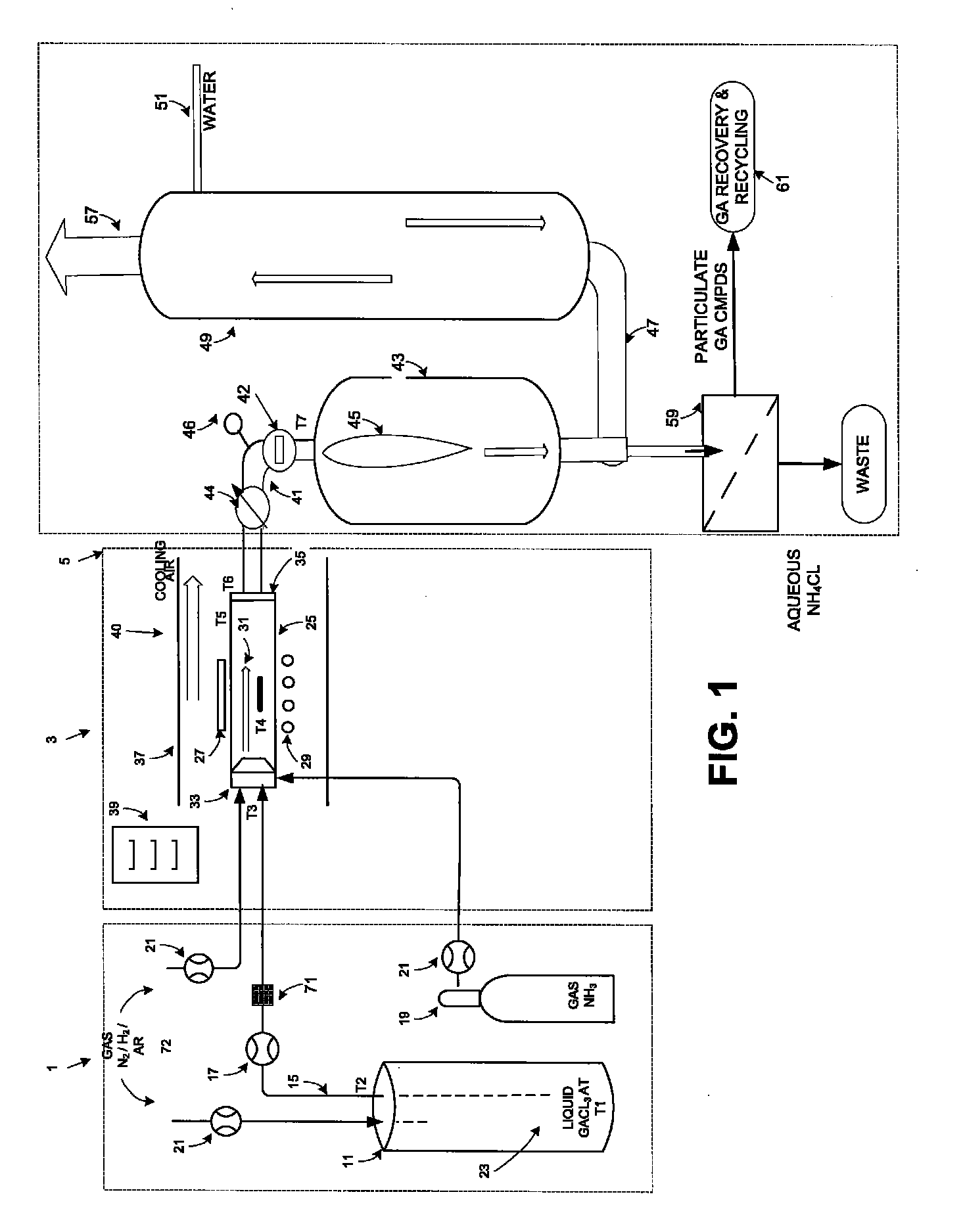

High volume delivery system for gallium trichloride

InactiveUS20090223441A1High manufacturing processEasy to prepare in large batchesPolycrystalline material growthSemiconductor/solid-state device manufacturingHigh volume manufacturingSemiconductor materials

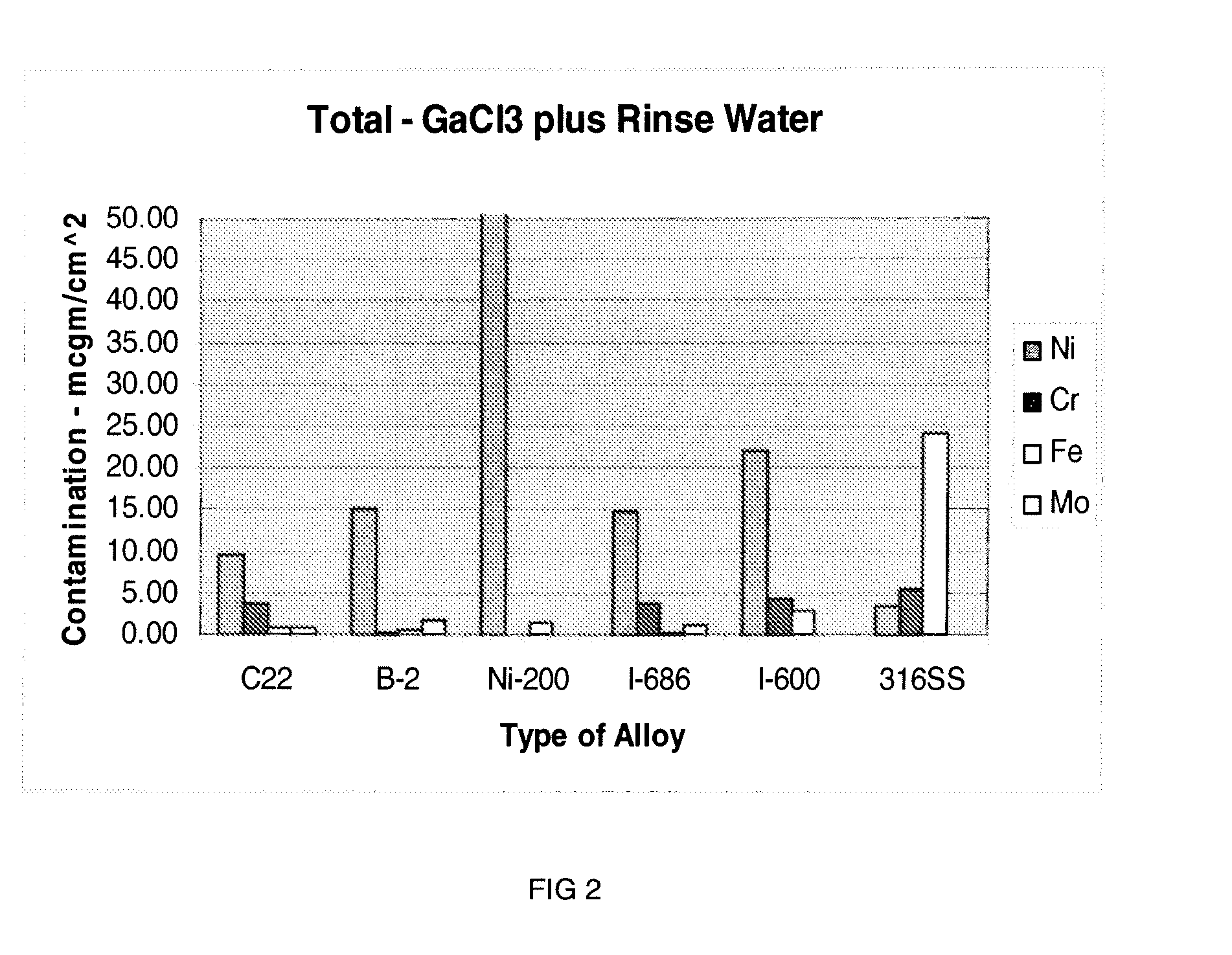

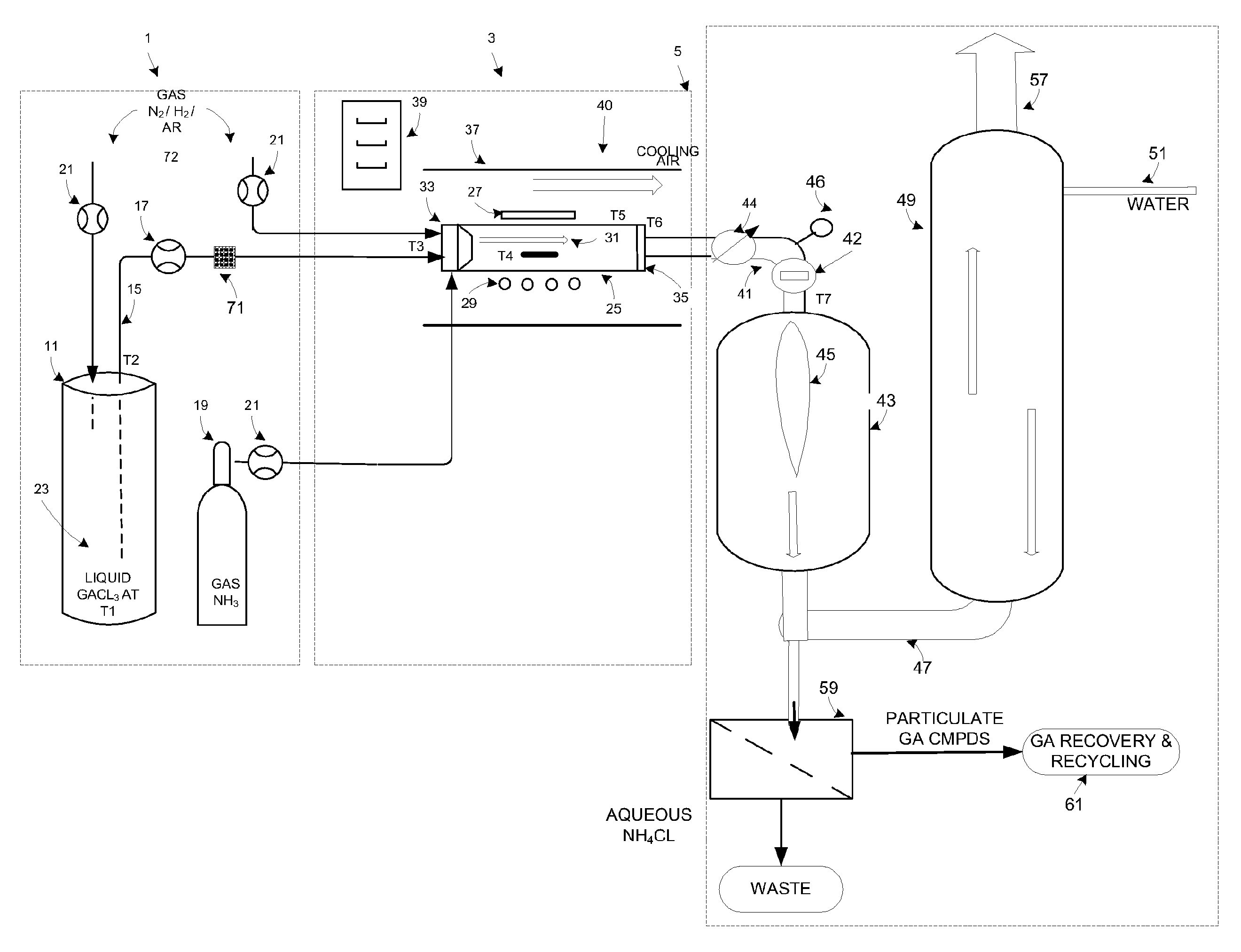

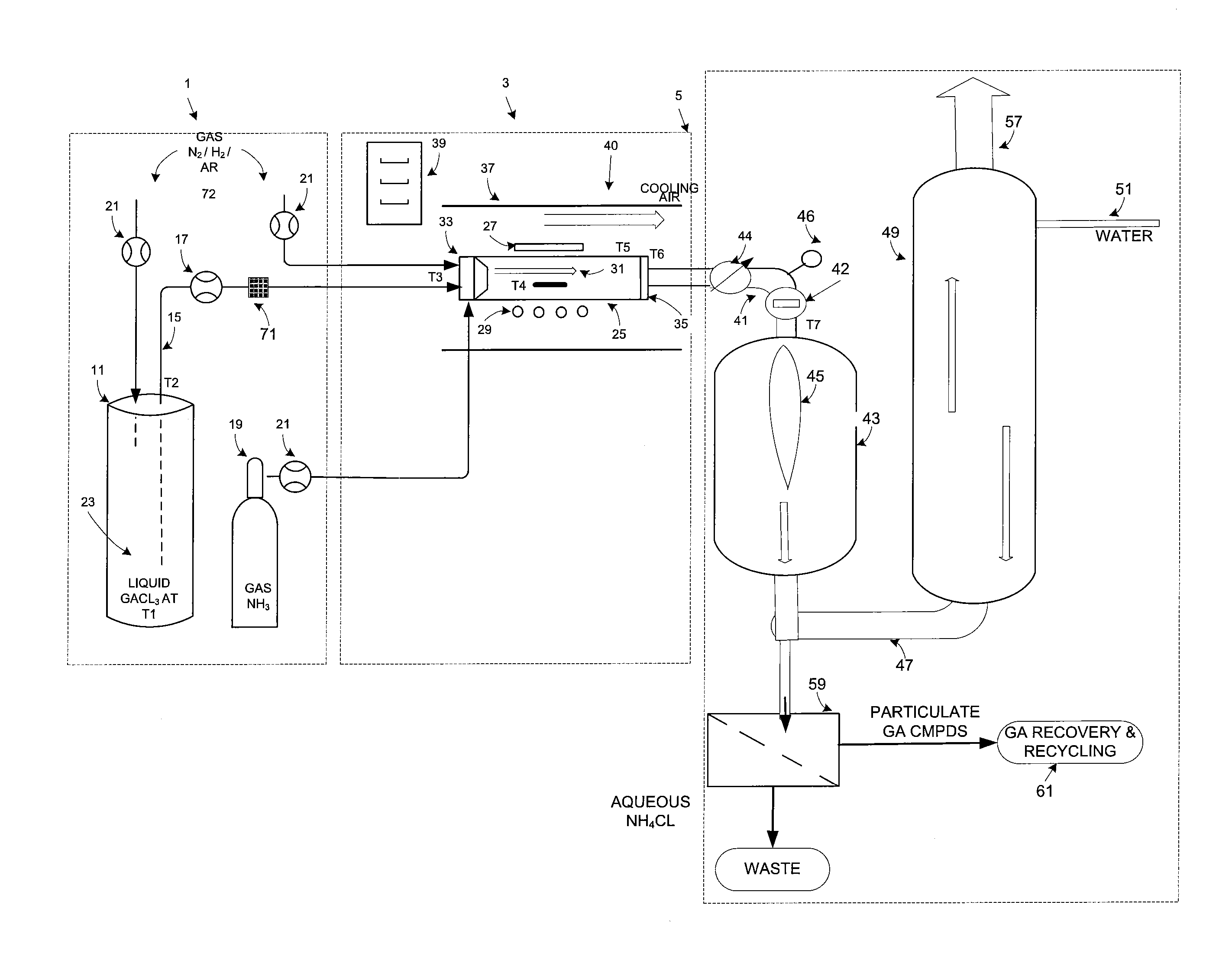

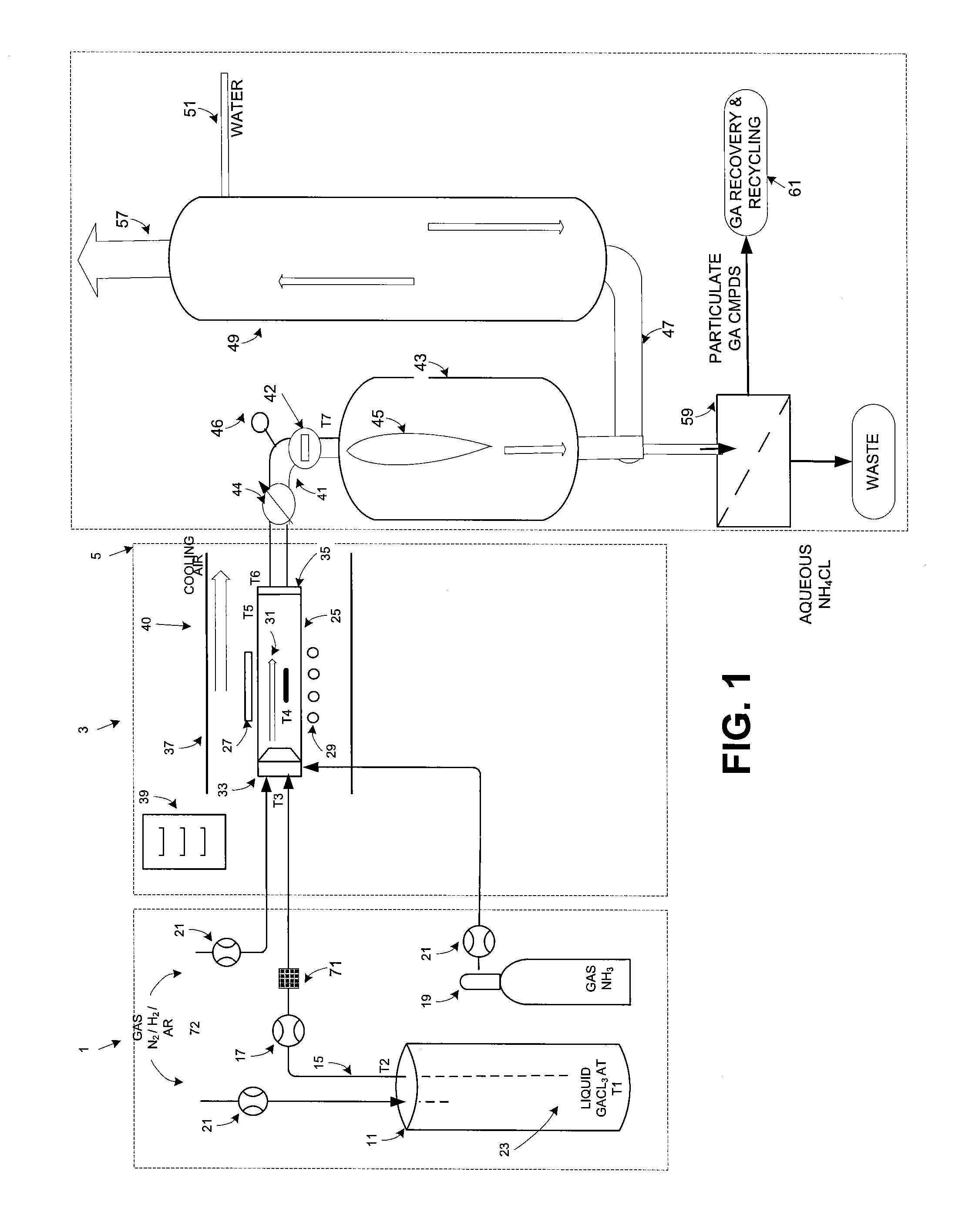

The present invention is related to the field of semiconductor processing equipment and methods and provides, in particular, methods and equipment for the sustained, high-volume production of Group III-V compound semiconductor material suitable for fabrication of optic and electronic components, for use as substrates for epitaxial deposition, for wafers and so forth. In preferred embodiments, these methods and equipment are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the precursor is provided at a mass flow of at least 50 g Group III element / hour for a time of at least 48 hours to facilitate high volume manufacture of the semiconductor material. Advantageously, the mass flow of the gaseous Group III precursor is controlled to deliver the desired amount.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Gallium trichloride injection scheme

InactiveUS20090178611A1Low reaction temperatureLong operating timeLighting and heating apparatusSolid-state devicesHigh volume manufacturingSemiconductor materials

The present invention is related to the field of semiconductor processing equipment and methods and provides, in particular, methods and equipment for the sustained, high-volume production of Group III-V compound semiconductor material suitable for fabrication of optic and electronic components, for use as substrates for epitaxial deposition, for wafers and so forth. In preferred embodiments, these methods are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the method includes reacting an amount of a gaseous Group III precursor as one reactant with an amount of a gaseous Group V component as another reactant in a reaction chamber under conditions sufficient to provide sustained high volume manufacture of the semiconductor material on one or more substrates, with the gaseous Group III precursor continuously provided at a mass flow of 50 g Group III element / hour for at least 48 hours. A system for conducting the method is also provided.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

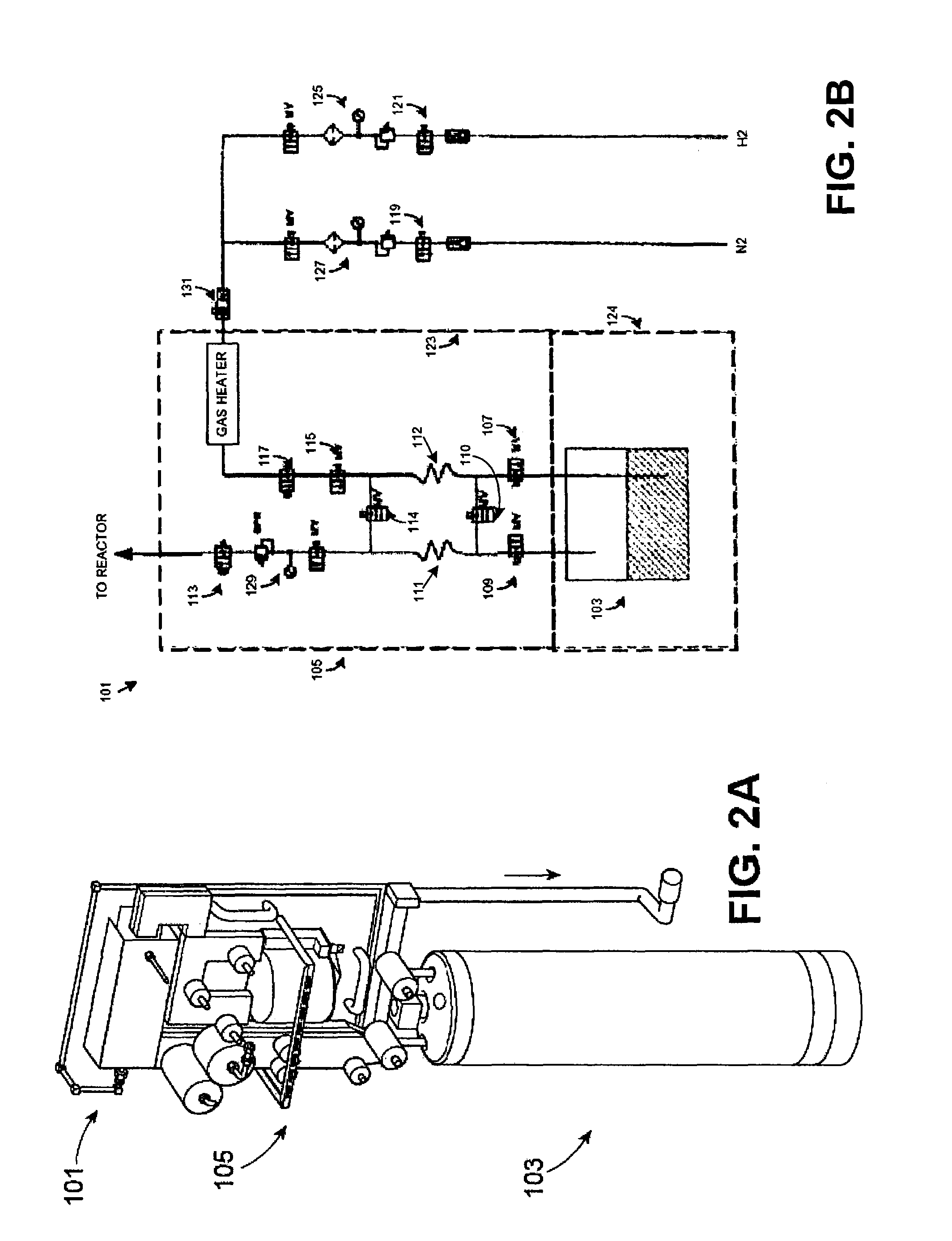

Gallium trichloride injection scheme

ActiveUS20120048182A1Efficiently formedLow reaction temperatureLighting and heating apparatusSolid-state devicesSemiconductor materialsReaction temperature

The invention relates to a method and system for epitaxial deposition of a Group III-V semiconductor material that includes gallium. The method includes reacting an amount of a gaseous Group III precursor having one or more gaseous gallium precursors as one reactant with an amount of a gaseous Group V component as another reactant in a reaction chamber; and supplying sufficient energy to the gaseous gallium precursor(s) prior to their reacting so that substantially all such precursors are in their monomer forms. The system includes sources of the reactants, a reaction chamber wherein the reactants combine to deposit Group III-V semiconductor material, and one or more heating structures for heating the gaseous Group III precursors prior to reacting to a temperature to decompose substantially all dimers, trimers or other molecular variations of such precursors into their component monomers.

Owner:SOITEC SA

Preparation method of gallium oxide hydroxide nano-crystals

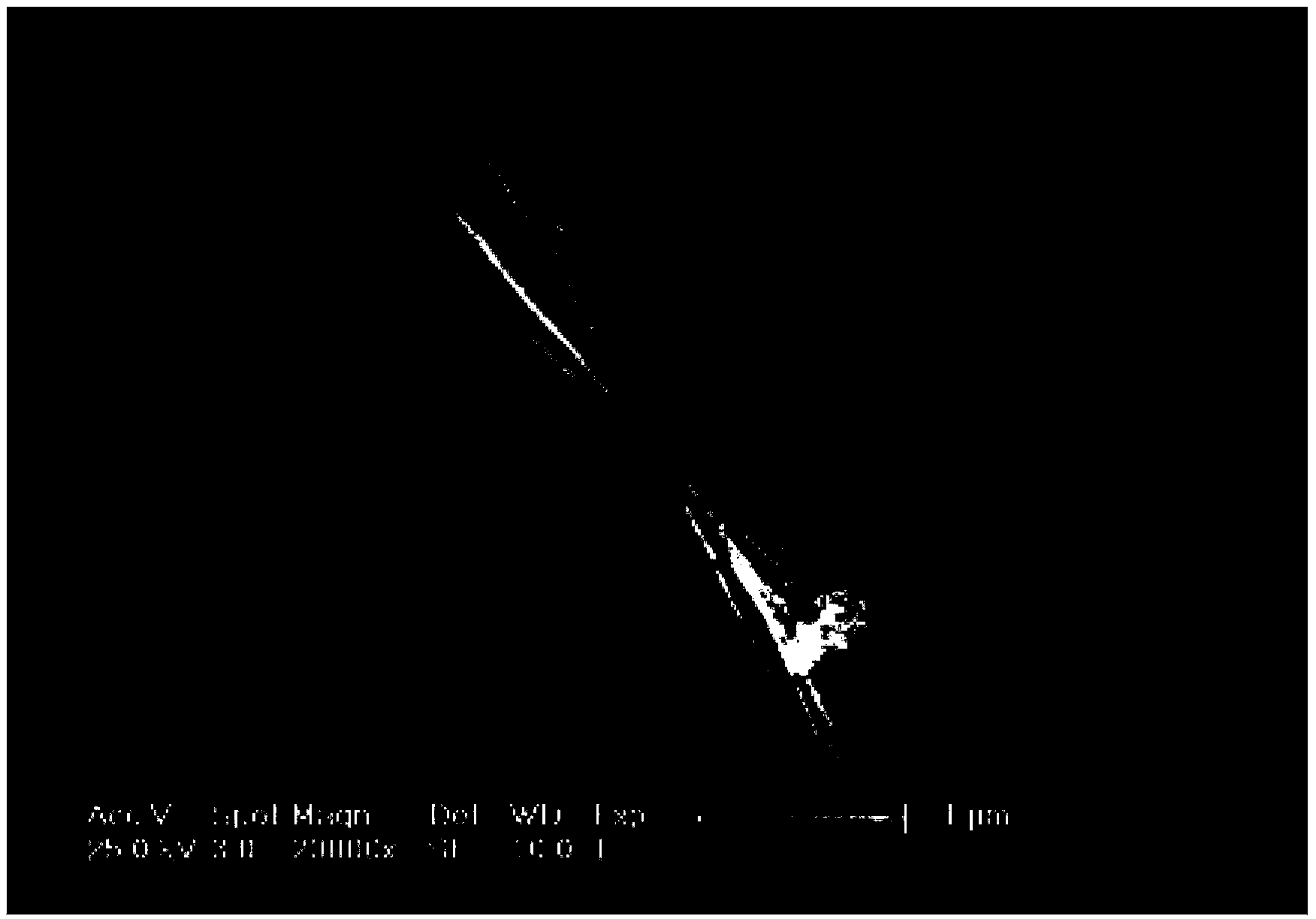

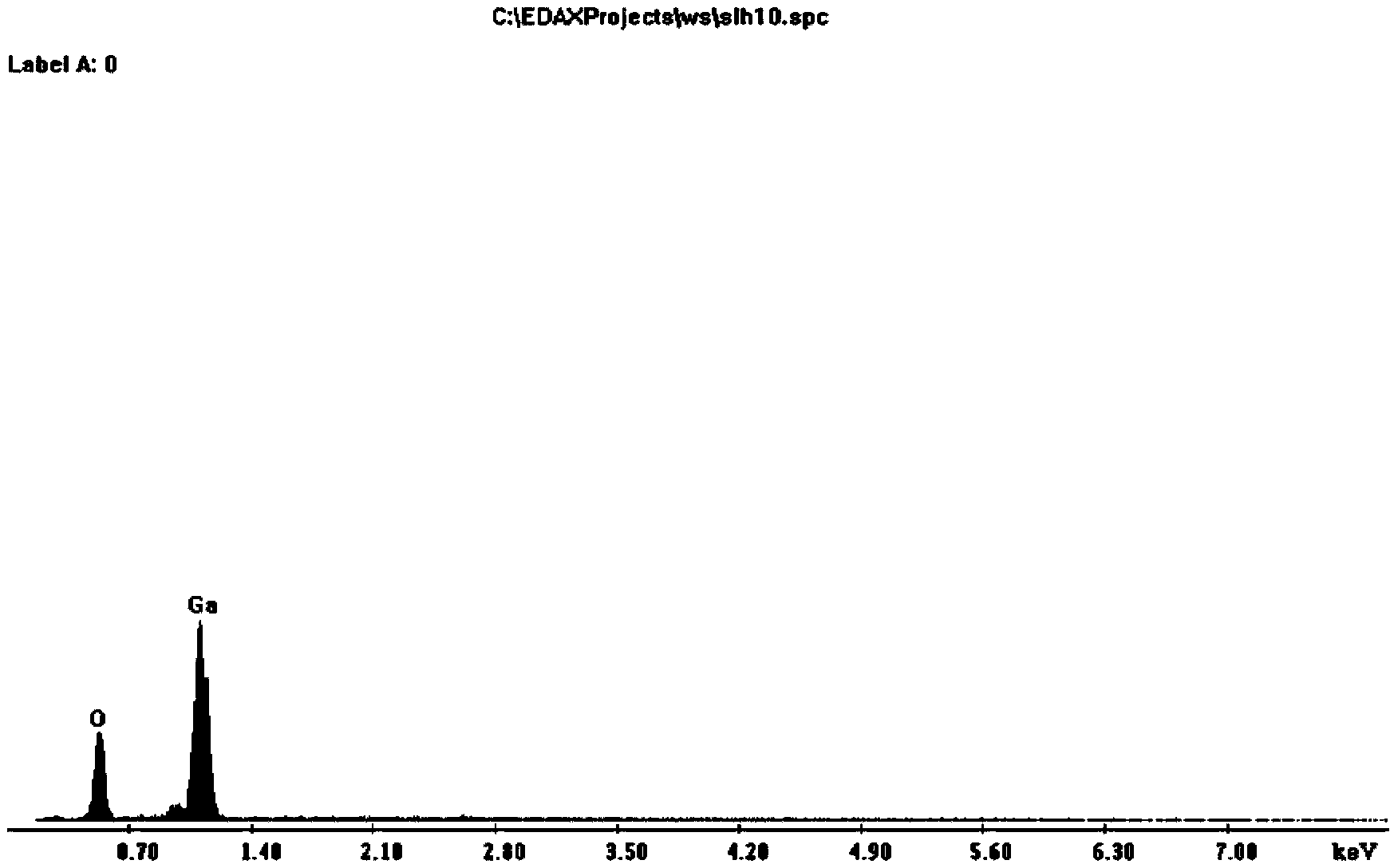

InactiveCN102976393AOvercome the disadvantage of easy water absorption and deliquescenceResponse speed blockMaterial nanotechnologyGallium/indium/thallium compoundsMoistureMethanol

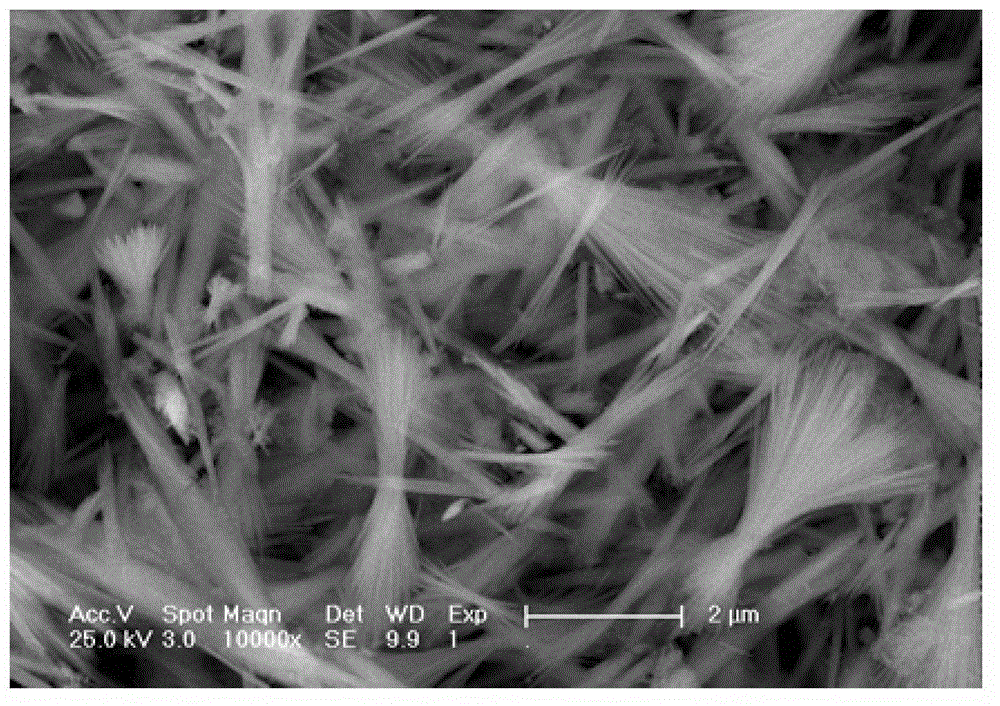

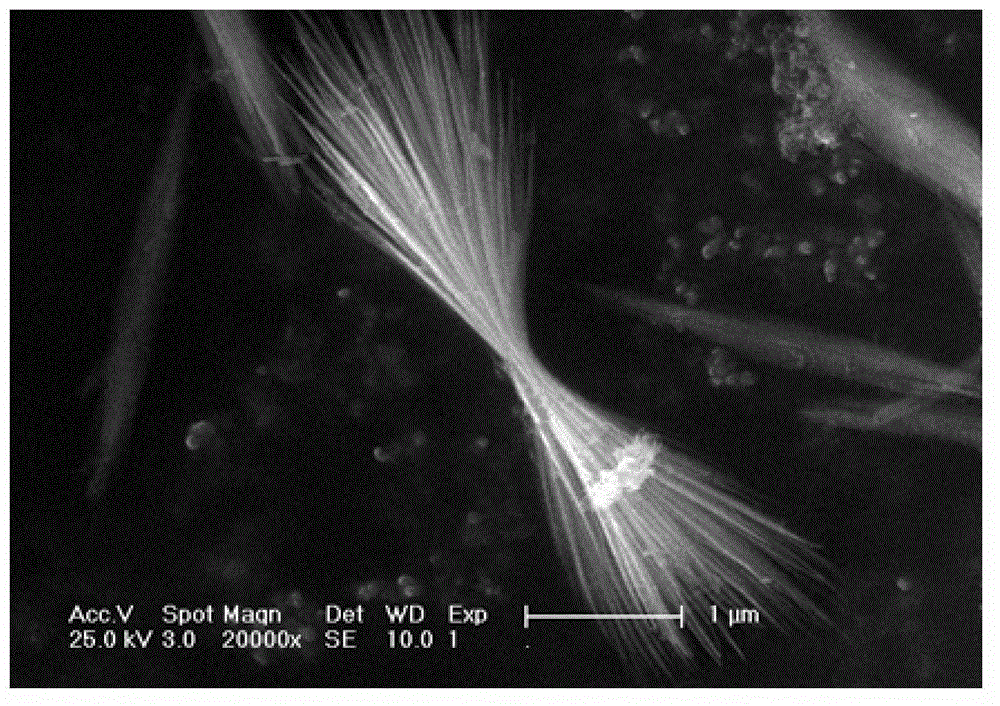

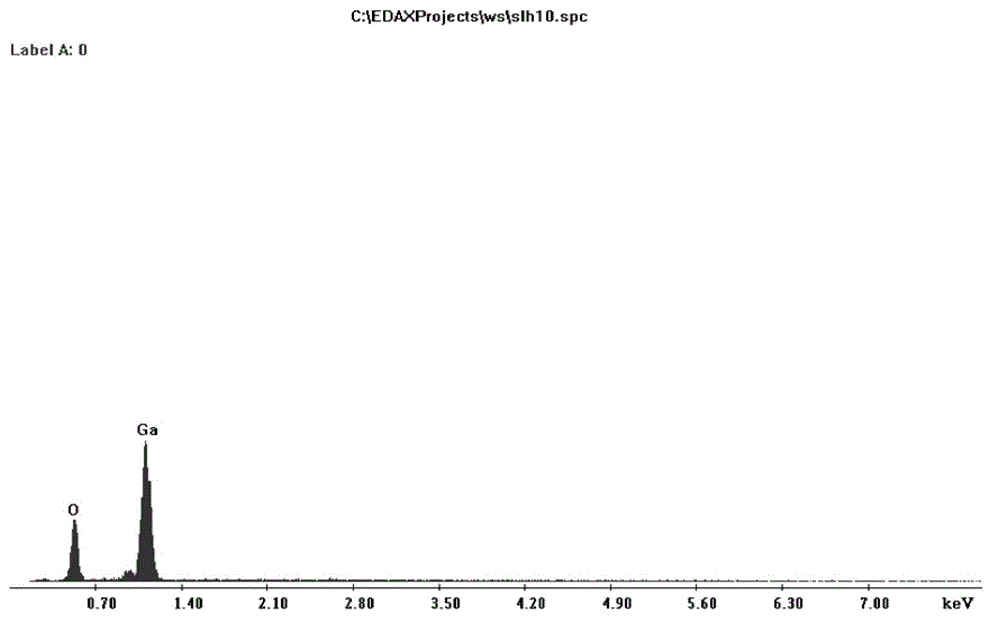

The invention provides a preparation method of gallium oxide hydroxide nano-crystals and belongs to the technical field of preparation of gallium oxide hydroxide nano-materials. According to the reaction kettle sealed heating alcoholysis method and the liquid-liquid interface reaction principle, through gradually dropwise adding methanol into a gallium oxide benzene solution disposed in an ultrasonic appliance and then enabling the mixed solution to be subjected to sealed low-temperature heating reaction, the prepared sample is white powders. The crystals in nano brush shape and which in smooth in surface, complete in shape and uniform in size are prepared under a preferable condition. According to the invention, the synthesis of gallium oxide hydroxide nano-crystals is carried out by using the alcoholysis reaction method for the first time, the disadvantage that the gallium oxide is very liable to absorb water and be decomposed by moisture is overcome, the operations are finished without adjusting pH (potential of hydrogen) and without using a vacuum condition, the reaction speed of the gallium oxide is significantly inhibited, so that the shape of the generated gallium oxide hydroxide is more easy to control. In addition, the product prepared by the method provided by the invention is high in yield and high in purity; and the preparation method is simple, excellent in repeatability and low in cost.

Owner:JILIN UNIV

High flow gaci3 delivery

InactiveCN101135416APolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseEngineering

The present invention is an apparatus for deliverying high purity gallium trichloride in the vapor phase to a gallium nitride reactor, comprising; a source of carrier gas at an elevated pressure; a purifier to remove moisture from the carrier gas; a heater capable of heating the carrier gas to at least 80 DEG C.; a container having a supply of gallium trichloride, a valve controlled inlet for the carrier gas having a dip tube with an outlet below the level of the gallium trichloride, a valve controlled outlet for removing the carrier gas and entrained gallium trichloride; a heater capable of heating sufficient to melt the gallium trichloride; a delivery line connected to the valve controlled outlet for carrying the entrained gallium trichloride to a reaction zone for gallium nitride. A process is also described for the apparatus.

Owner:AIR PROD & CHEM INC

Gallium trichloride injection scheme

ActiveUS20130104802A1Efficiently formedLow reaction temperatureAfter-treatment apparatusPolycrystalline material growthSemiconductor materialsGallium trichloride

A system for epitaxial deposition of a Group III-V semiconductor material that includes gallium. The system includes sources of the reactants, one of which is a gaseous Group III precursor having one or more gaseous gallium precursors and another of which is a gaseous Group V component, a reaction chamber wherein the reactants combine to deposit Group III-V semiconductor material, and one or more heating structures for heating the gaseous Group III precursors prior to reacting to a temperature to decompose substantially all dimers, trimers or other molecular variations of such precursors into their monomer forms.

Owner:SOITEC SA

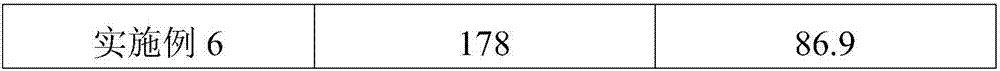

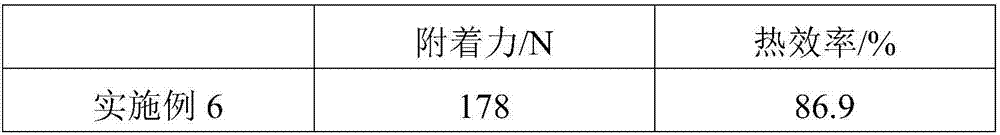

Saturated solution used to prepare electrothermal film

The invention discloses a saturated solution used to prepare an electrothermal film. The saturated solution comprises a soluble tin-based chloride, titanium tetrachloride, nickel tetrachloride, a zinc dopant, gallium trichloride, a catalyst, isopropanol and absolute ethyl alcohol. According to the invention, the saturated solution used to prepare the electrothermal film has the advantages of simple preparation technology and easy quantitative doping. The electrothermal film prepared by the solution has the advantages of stable work, long service life, good substrate adhesion and high thermal efficiency.

Owner:江苏一森电采暖科技有限公司

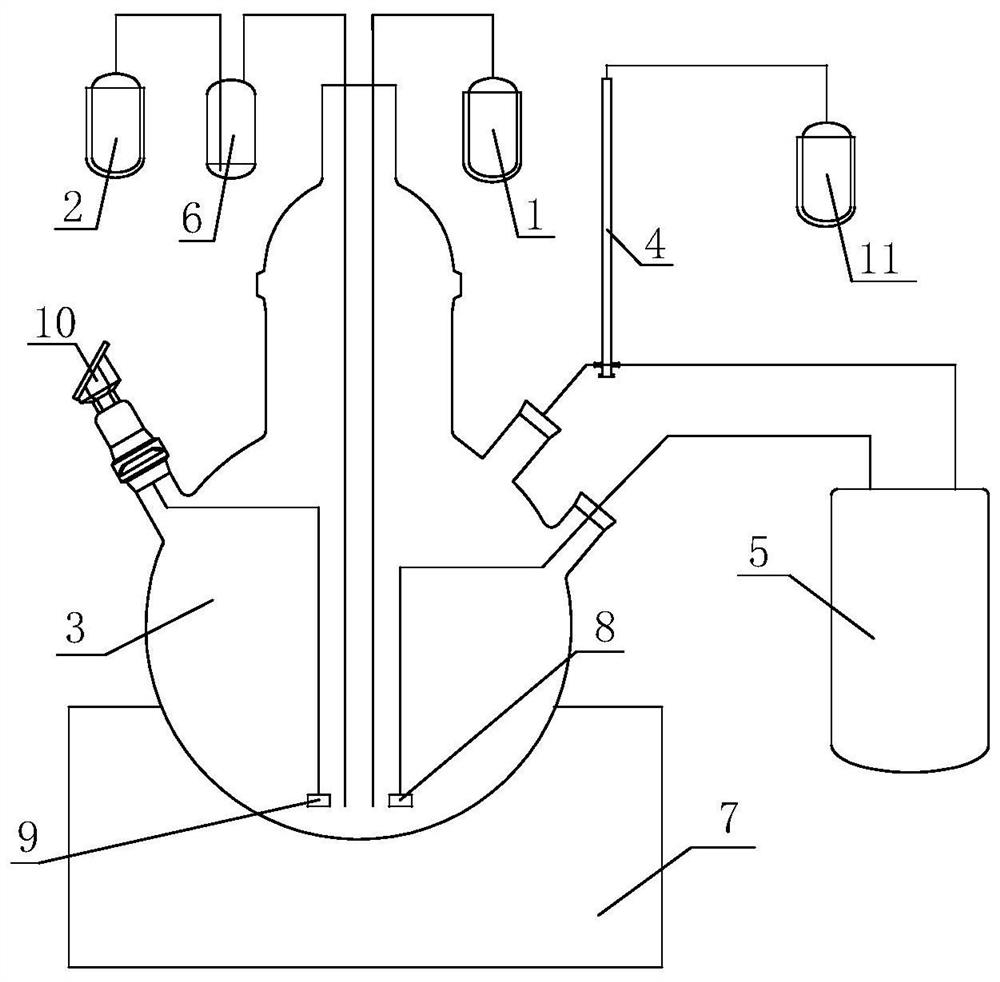

Preparation method of trimethyl gallium

The invention discloses a preparation method of trimethyl gallium. The preparation method comprises the following steps of: adding a curafume gas into a mixture of metal magnesium and organic ether under the protection of an inert gas at the temperature of 30-100 DEG C and under the normal pressure to generate a methyl-magnesium-bromide solution; continuously stirring at the temperature of 50-100 DEG C for 2-3 hours, and lowering the temperature below 40 DEG C; adding an organic ether solution of absolute gallium trichloride or absolute gallium trichloride into the methyl-magnesium-bromide solution at the temperature of 30-100 DEG C and under the normal pressure, reacting, and continually stirring a reactant for 3-5 hours after reacting; heating a reaction kettle under the normal pressure to 130-190 DEG C, distilling a crude trimethyl gallium product out, and controlling the receiving temperature at 56-62 DEG C; and rectifying the crude product once again under the normal pressure to obtain pure trimethyl gallium, wherein the product collecting temperature is 56 DEG C. The method has the advantages of difficulty in introducing impurities, low cost, high reaction efficiency, high safety, easiness of recovering solvents from produced waste and environment friendliness.

Owner:ANHUI BOTAI ELECTRONIC MATERIALS CO LTD

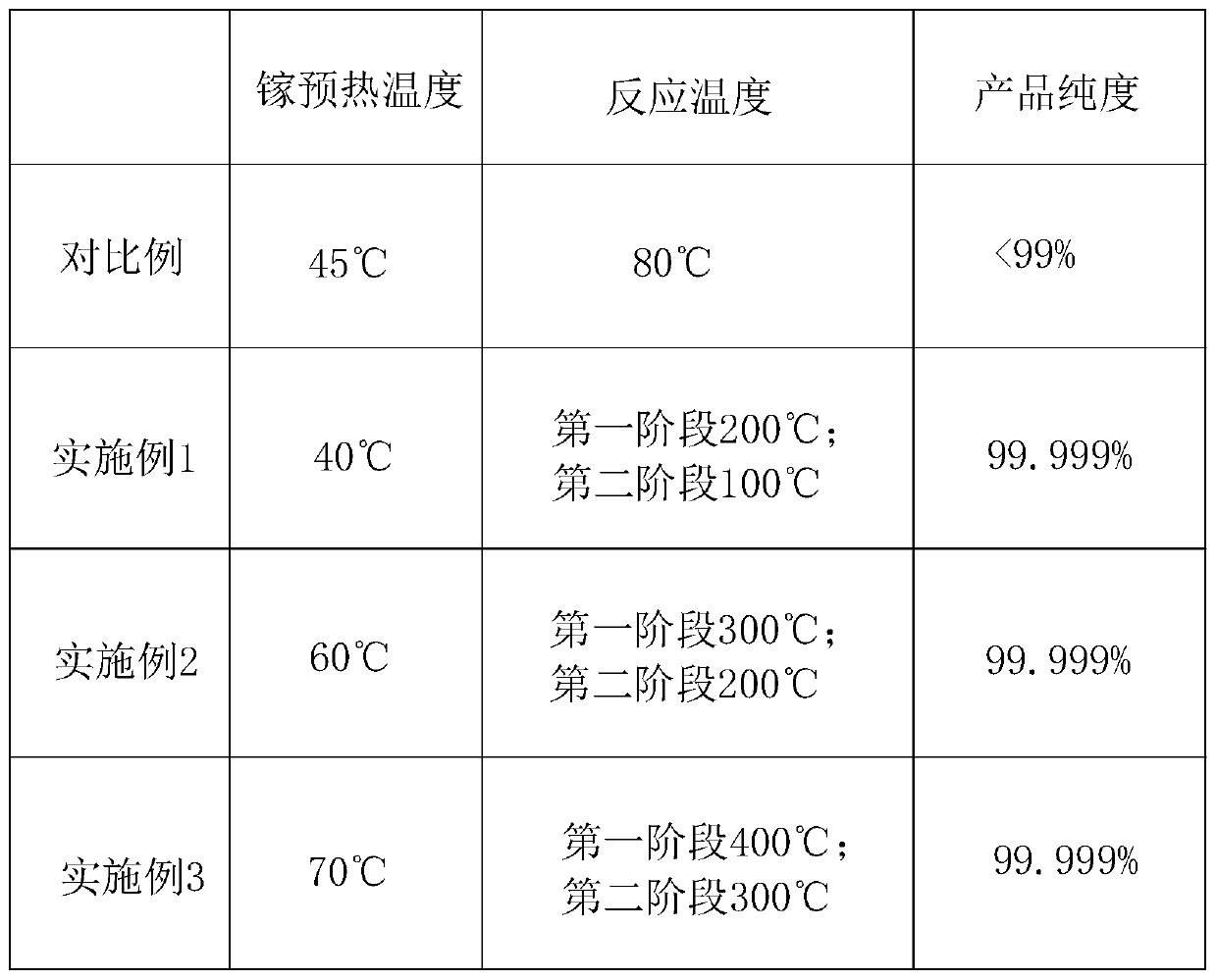

Method and equipment for preparing gallium trichloride

ActiveCN111072058ASolve technical problemsGallium/indium/thallium compoundsPressure vessel componentsReaction temperatureWater chlorination

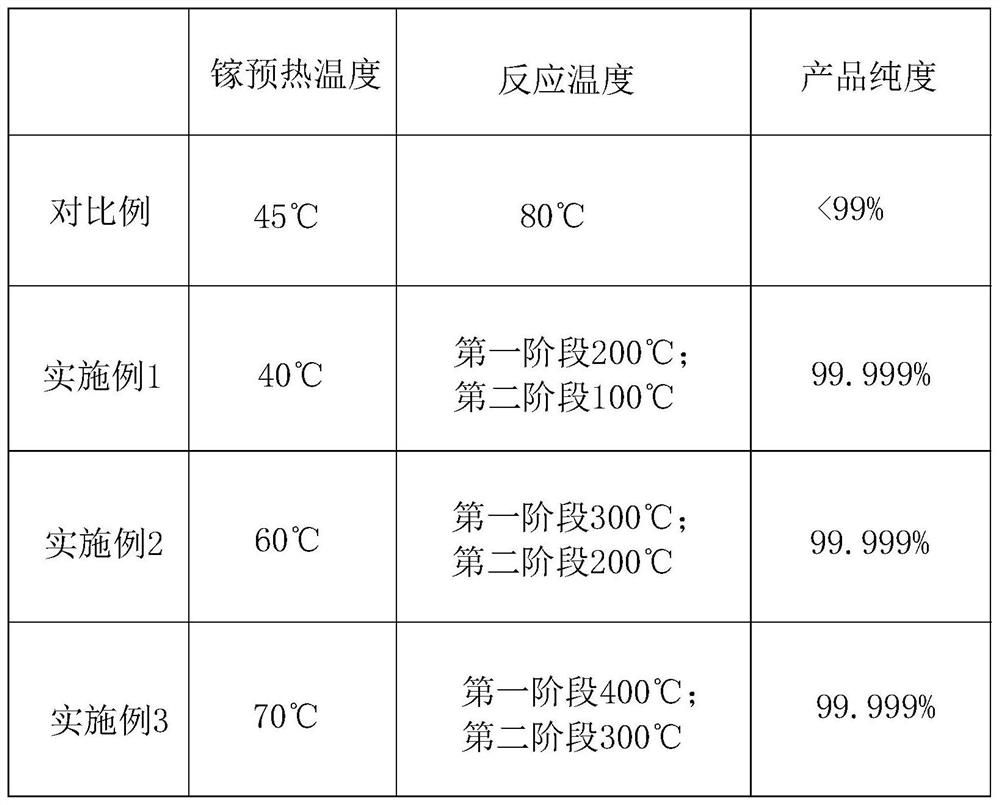

The invention discloses a method for preparing gallium trichloride. The method comprises the following steps: adding liquid metal gallium into a reaction kettle, and introducing chlorine into the liquid metal gallium; controlling the temperature of the reaction kettle to be 200-400 DEG C, and obtaining a main product gallium monochloride and a byproduct gallium trichloride after a first preset time period; controlling the temperature of the reaction kettle to be 100-300 DEG C, and obtaining liquid gallium trichloride and gaseous gallium trichloride after a second preset time period; evaporating the obtained gaseous gallium trichloride into a fractionating tube, and performing cooling to enable the gaseous gallium trichloride to become liquid gallium trichloride to flow into a storage device. According to the method for preparing gallium trichloride provided by the invention, by setting reactions of two stages and setting different reaction temperatures of the two stages, the technicalproblem that a large amount of gallium monochloride and chlorine impurities are generated when chlorine is directly introduced into liquid metal gallium for reaction in the prior art can be effectively solved.

Owner:昆明先导新材料科技有限责任公司

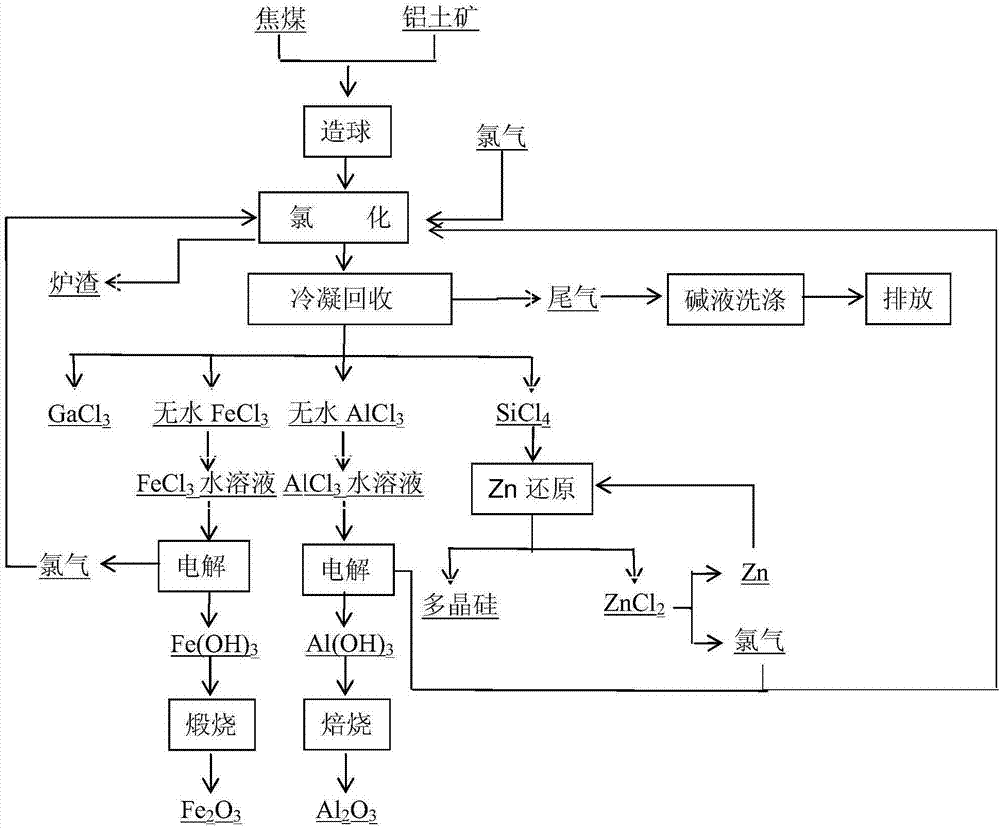

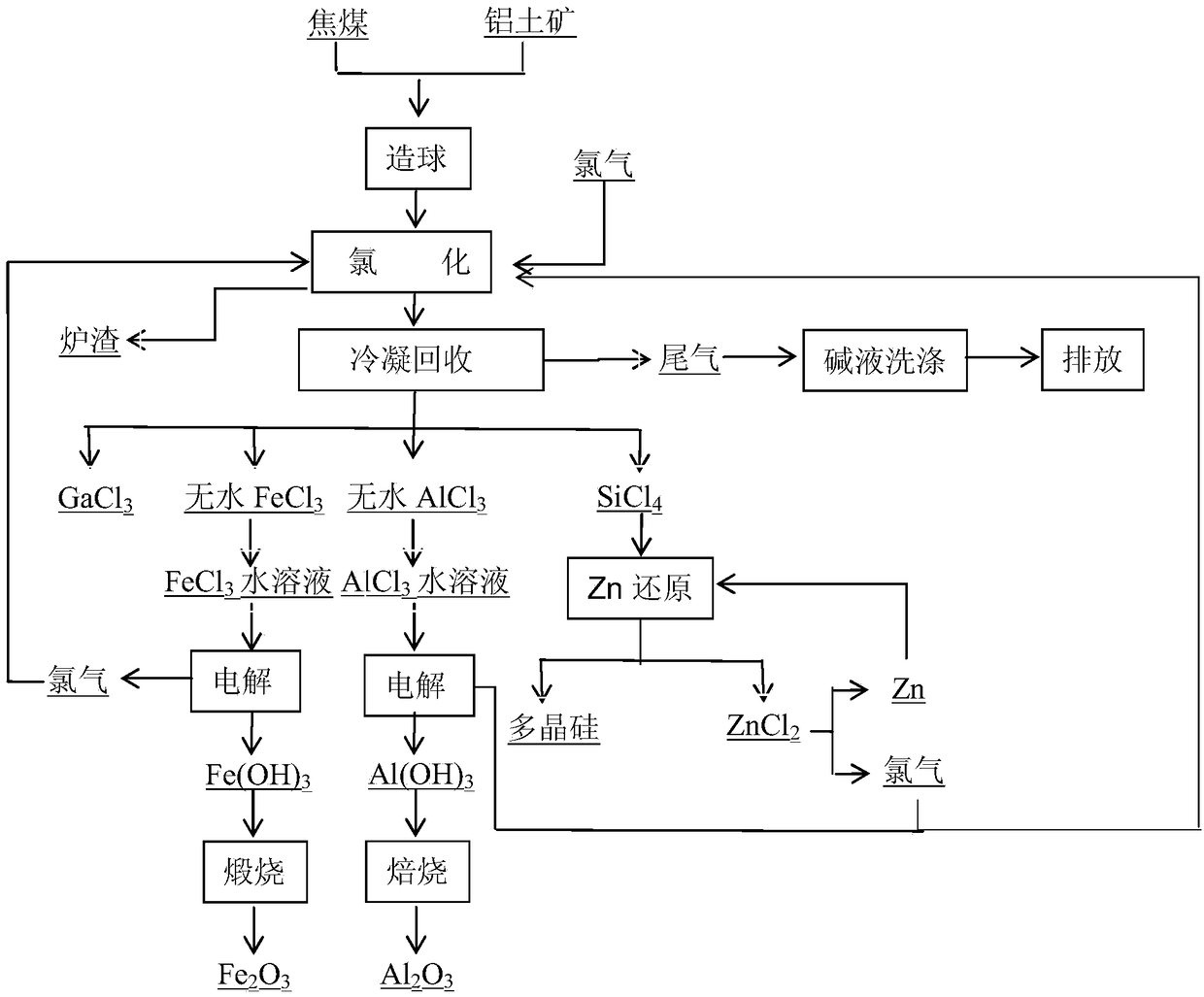

Method for preparing and comprehensively utilizing aluminum oxide by pelletizing, chloridizing and electrolyzing bauxite

ActiveCN107235499AReduce processing linksLow costAfter-treatment apparatusZinc halidesFerric hydroxideElectrolysis

The invention relates to a method for preparing and comprehensively utilizing aluminum oxide by pelletizing, chloridizing and electrolyzing bauxite. The method comprises the following steps: mixing bauxite, a carbon source and kaolin at a ratio; adding a binder and water, pelletizing and airing; chloridizing, separating and purifying, thereby obtaining anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium trichloride; converting anhydrous aluminum chloride and anhydrous ferric chloride into a corresponding chloride solution; controlling voltage and current density to electrolyze, thereby obtaining aluminum hydroxide, ferric hydroxide, hydrogen and chlorine; returning the chlorine to a chloridizing section; roasting aluminum hydroxide, thereby obtaining metallurgical / chemical aluminum oxide; roasting ferric hydroxide, thereby obtaining iron oxide red or other iron-containing products; purifying silicon tetrachloride; refining titanium tetrachloride, thereby obtaining a titanium sponge raw material; and enriching scandium chloride to serve as a scandium raw material. The method provided by the invention is low in cost, the raw materials are low-cost and are easily obtained, the complete chlorination is realized through pelletizing and chloridizing, the operation process is simple, the degree of automation is high, the product purity is high, and the raw materials, such as, chlorine and zinc, can be reused.

Owner:NORTHEASTERN UNIV

Preparation method for powder metallurgy antifriction bearing

InactiveCN107377961AHigh strengthHigh hardnessTransportation and packagingMetal-working apparatusBorideAlloy

The invention discloses a preparation method for a powder metallurgy antifriction bearing. The preparation method comprises the step that 60-65 parts of titanium powder, 15-20 parts of magnesium powder, 10-15 parts of molybdenum disulfide, 10-20 parts of silicon carbide, 3-11 parts of gallium trichloride, 10-15 parts of magnesite powder, 2-8 parts of nanometer silicon nitride, 1-6 parts of hafnium boride, 6-8 parts of phenolic resin, 6-7 parts of cadmium selenide and 12-16 parts of auxiliaries are weighed by weight, wherein the auxiliaries are made of flax seed oil, pentaerythritol triacrylate and polydimethylsiloxane by weight of 3: 5: 6. The powder metallurgy antifriction bearing obtained through the preparation method has higher strength, hardness, abrasion resistance and corrosion resistance than like products on the market, and the service life of alloy parts is prolonged; and raw materials are easy to obtain, the processing cost is low, the preparation technology is simple, parameters are easy to control, the production process is safe and environment-friendly, and the powder metallurgy antifriction bearing is suitable for large-scale industrialized production.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

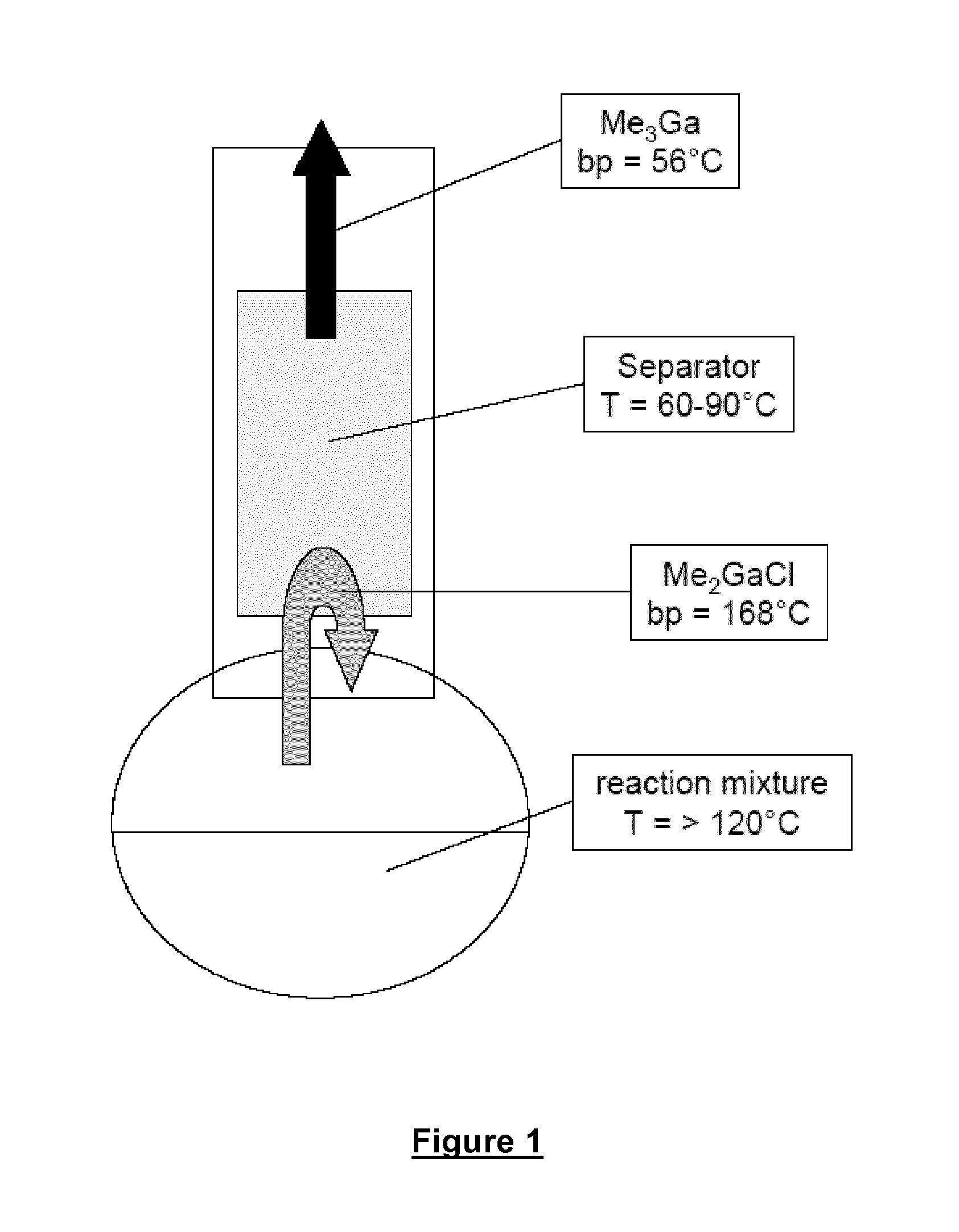

Process for preparing trialkylgallium compounds

ActiveUS20140256974A1Carry-out inexpensivelyReduce the temperatureGroup 3/13 element organic compoundsChemical recyclingAluminum alkylCombinatorial chemistry

The invention relates to a process for preparing trialkylgallium compounds of the general formula R3Ga. The process is based on the reaction of gallium trichloride (GaCh), optionally in a mixture with partially alkylated products, with an alkylaluminium compound of the type RaAlClb (where R═C1-C5-alkyl, a=1, 2 or 3, b=0, 1 or 2 and a+b=3) in the presence of at least two alkali metal halides (e.g. NaCl and KCl) as auxiliary base. Preference is given to using alkylaluminium sesquichloride (R3Al2Cl3) or trialkylaluminium (R3Al). The reaction mixture is heated to a temperature in the range from 120° C. to 250° C. and the trialkylgallium compound formed is separated off via a separator which is operated at a temperature which is more than 30° C. below the boiling point of the most volatile partially alkylated product. Complete alkylation is achieved here and partially alkylated products are recirculated to the reaction mixture. In a further step, the reaction mixture can be heated to a maximum of 350° C. and the remaining fully alkylated and partially alkylated products can be separated off. The process provides a high yield of trialkylgallium compound and displays high gallium utilization; the products are used, e.g., as precursors for MOCVD processes.

Owner:UMICORE AG & CO KG

Preparation method of gallium chloride

PendingCN113087008ALow costAvoid security issuesGallium/indium/thallium compoundsHydrogen chlorideGallium trichloride

The invention discloses a preparation method of gallium chloride, wherein the preparation method comprises the steps: adding anhydrous ammonium chloride and gallium which are used as reaction raw materials into a reaction kettle, wherein the molar ratio of anhydrous ammonium chloride to gallium is more than 3:1; raising the temperature of the reaction kettle to 320-500 DEG C, decomposing ammonium chloride into ammonia gas and hydrogen chloride, and reacting the hydrogen chloride with metal gallium to generate gaseous gallium chloride; cooling the reaction kettle, recrystallizing ammonium chloride obtained by reaction of ammonia gas and residual hydrogen chloride to generate solid ammonium chloride, separating out the solid ammonium chloride, and keeping gallium chloride in a gaseous state; replacing gas in the reaction kettle with protective gas and storing the gas in a sealed container; and cooling the gaseous gallium chloride in the sealed container to obtain a gallium chloride solid product. Anhydrous ammonium chloride and gallium are used as raw materials, gaseous gallium chloride is generated from hydrogen chloride and gallium obtained by ammonium chloride decomposition through heating, and the gaseous gallium chloride is packaged and stored after being cooled, crystallized and separated, so that the cost of synthesizing gallium trichloride is remarkably reduced, and the potential safety hazard problem existing in gas synthesis is avoided.

Owner:SHENHUA ZHUNNENG RESOURCE COMPREHENSIVE DEV COMPANY

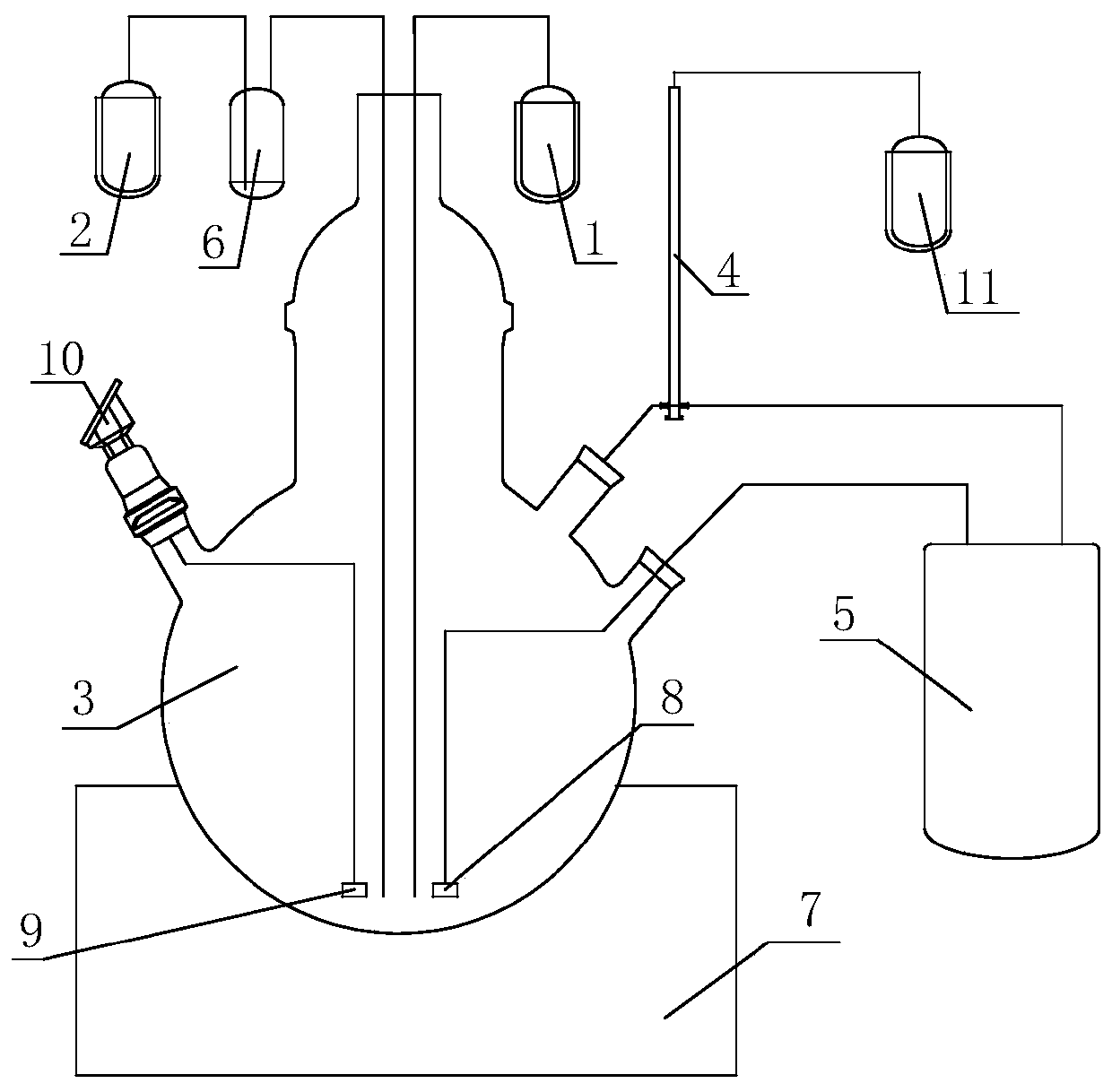

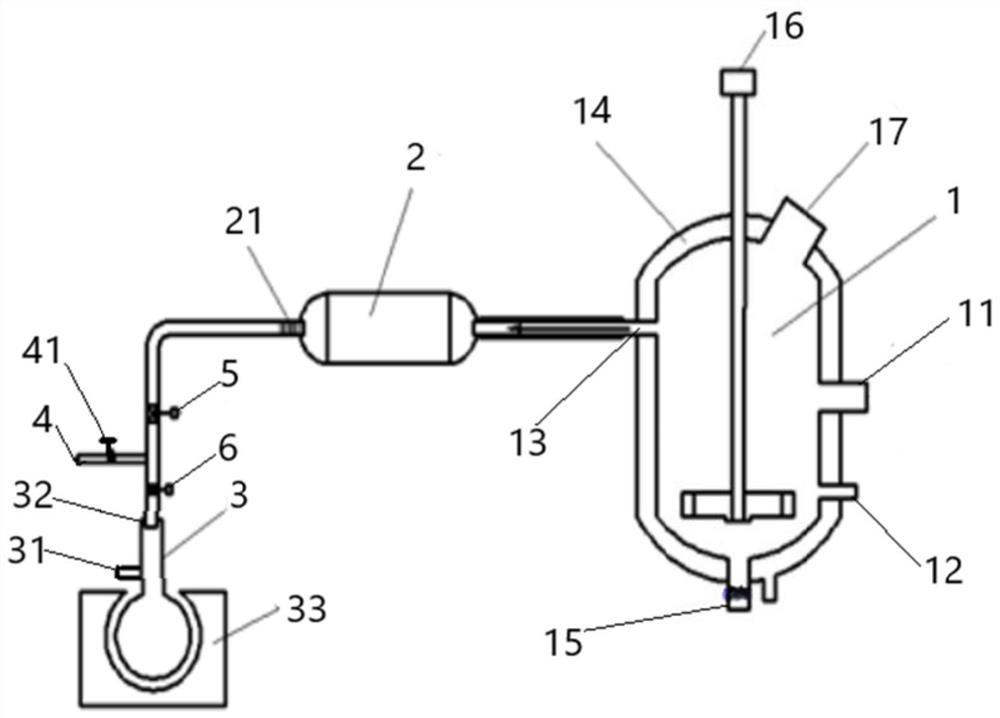

Device and method for preparing gallium chloride

PendingCN113070014ALow costChemical/physical/physico-chemical stationary reactorsHydrogen chlorideGallium trichloride

The invention discloses a device and a method for preparing gallium chloride. The device comprises a reaction kettle, a surge flask and a sealed container. The reaction kettle is provided with a feed port, a first shielding gas inlet and a discharge port. The surge flask is provided with openings in both ends, the opening in one end is connected to the discharge port of the reaction kettle through a pipeline, and the opening in the other end is connected to the sealed container through a pipeline. The sealed container is provided with a second shielding gas inlet and a communication port connected with the opening in the other end of the surge flask. Anhydrous ammonium chloride and gallium are used as raw materials, gaseous gallium chloride is generated from hydrogen chloride and gallium obtained by ammonium chloride decomposition through heating, and the gaseous gallium chloride is packaged and stored after being cooled, crystallized and separated, so that the cost of synthesizing gallium trichloride is remarkably reduced, and the potential safety hazard problem existing in gas synthesis is avoided.

Owner:SHENHUA ZHUNNENG RESOURCE COMPREHENSIVE DEV COMPANY

Process for removing trace chlorine gas in gallium trichloride

ActiveCN105905937AChlorine impurity levels are reducedHigh yieldGallium/indium/thallium compoundsPhysical chemistryWater chlorination

The invention relates to a process for purifying gallium trichloride; in the process, an end point of a reaction is determined by excess chlorine gas, and then the excess chlorine gas is consumed by adding metal gallium back to remove chlorine impurities; the process comprises the process steps: adding 500 g-3000 g of the metal gallium into a reaction kettle, at the reaction temperature of 180 DEG C, introducing chlorine gas, and carrying out a reaction; and when gallium trichloride is reacted to the end point, namely, a reaction solution is pale yellow green, stopping introduction of the chlorine gas, opening nitrogen gas purging, adding 1.0 g-2.0 g of metal gallium to the reaction kettle, and continuing to maintain 180 DEG C until the reaction solution turns from yellow green to colorless. In the process, the end point of the reaction is determined by excess chlorine gas, and then the excess chlorine gas is consumed by adding the metal gallium back to remove the chlorine impurities, so that the content of the chlorine gas impurities in the gallium trichloride is decreased to 1 ppm or less, and the product yield is high.

Owner:DALIAN KELIDE OPTOELECTRONICS MATERIALS CO LTD

A kind of preparation method and equipment of gallium trichloride

ActiveCN111072058BSolve technical problemsGallium/indium/thallium compoundsPressure vessel componentsLiquid stateReaction temperature

The invention discloses a preparation method of gallium trichloride, which comprises the following steps: firstly adding liquid metal gallium into a reactor, and then feeding chlorine gas into the liquid metal gallium; controlling the temperature of the reactor at 200-400 °C, after the first preset time period, the main product-gallium monochloride and the by-product-gallium trichloride are obtained; by adjusting the temperature of the reactor at 100-300 °C, the liquid state is obtained after the second preset time period Gallium trichloride and gaseous gallium trichloride; the obtained gaseous gallium trichloride is evaporated into the fractionating tube, and then the gaseous gallium trichloride becomes liquid gallium trichloride and flows into the storage device through cooling. A preparation method of gallium trichloride provided by the present invention can effectively solve the prior art problem of directly feeding chlorine gas into liquid metal gallium by setting two-stage reactions and setting different reaction temperatures in the two stages Carrying out the reaction creates technical problems with large quantities of gallium monochloride and chlorine gas impurities.

Owner:昆明先导新材料科技有限责任公司

Saturated solution for preparing electrothermal film and preparation method thereof

Owner:上海中孚油品集团有限公司

Preparation method of gallium oxide hydroxide nano-crystals

InactiveCN102976393BOvercome the disadvantage of easy water absorption and deliquescenceResponse speed blockMaterial nanotechnologyGallium/indium/thallium compoundsMoistureMethanol

The invention provides a preparation method of gallium oxide hydroxide nano-crystals and belongs to the technical field of preparation of gallium oxide hydroxide nano-materials. According to the reaction kettle sealed heating alcoholysis method and the liquid-liquid interface reaction principle, through gradually dropwise adding methanol into a gallium oxide benzene solution disposed in an ultrasonic appliance and then enabling the mixed solution to be subjected to sealed low-temperature heating reaction, the prepared sample is white powders. The crystals in nano brush shape and which in smooth in surface, complete in shape and uniform in size are prepared under a preferable condition. According to the invention, the synthesis of gallium oxide hydroxide nano-crystals is carried out by using the alcoholysis reaction method for the first time, the disadvantage that the gallium oxide is very liable to absorb water and be decomposed by moisture is overcome, the operations are finished without adjusting pH (potential of hydrogen) and without using a vacuum condition, the reaction speed of the gallium oxide is significantly inhibited, so that the shape of the generated gallium oxide hydroxide is more easy to control. In addition, the product prepared by the method provided by the invention is high in yield and high in purity; and the preparation method is simple, excellent in repeatability and low in cost.

Owner:JILIN UNIV

Electrolyte salt of lithium/thionyl chloride battery and preparation method thereof

InactiveCN106299466AThe synthesis method is simpleRaw materials are easy to getSecondary cellsLithium chloridePhysical chemistry

The invention discloses an electrolyte salt of a lithium / thionyl chloride battery and a preparation method thereof, and the electrolyte salt is characterized in that the electrolyte salt is synthetic lithium tetrachlorogallate (LiGaCl4), and the molar concentration range of the lithium tetrachlorogallate in the electrolyte is 0.5 mol / L to 1.5 mol / L. The lithium tetrachlorogallate is synthesized by fusing anhydrous lithium chloride (LiCl) and anhydrous gallium trichloride (GaCl3) in a dry reaction vessel. The anhydrous lithium chloride and the anhydrous gallium trichloride require drying treatment.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Preparation method of gallium trichloride granules

The invention relates to the technical field of gallium trichloride synthesis and discloses a preparation method of gallium trichloride granules. The preparation method includes the steps of: 1) moving gallium trichloride in a glove box, controlling the contents of water and oxygen in the glove box to be lower than 5 ppm, and increasing the temperature to melt the gallium trichloride; 2) adding the molten gallium trichloride dropwisely in liquid nitrogen in the glove box; 3) solidifying the molten gallium trichloride to obtain spherical or spherical-like gallium trichloride granules. The preparation method is simple in process steps, employs low-cost and easy-to-obtain raw materials, is free of introduction of impurities and can prepare regular spherical granules. These regular spherical granules have strong flowability, are not adhered on wall of a container, are very easy to move and apply, and are very easy to control in addition amount.

Owner:清远先导材料有限公司

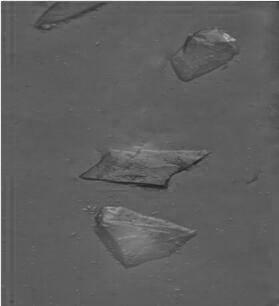

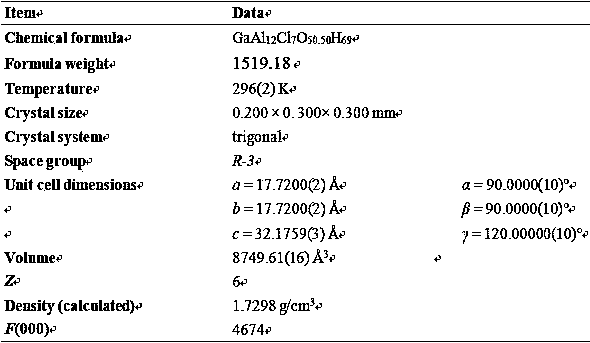

Method for preparing Keggin polycation chloride crystal

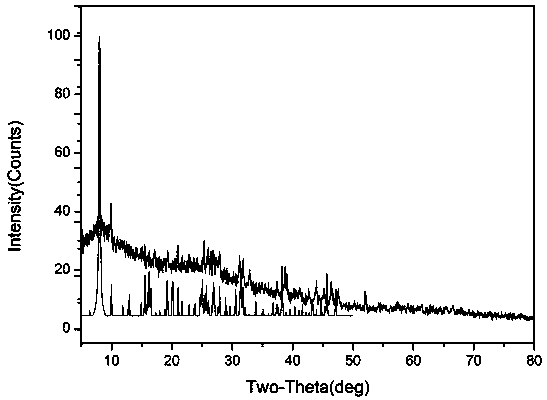

ActiveCN109778303AEasy to makeAvoid separation and purification stepsPolycrystalline material growthFrom normal temperature solutionsX-raySpontaneous hydrolysis

The invention provides a novel method for preparing Keggin-GaAl12 chloride single crystal and polycrystalline powder, and belongs to the technical field of inorganic high polymer synthesis. The inorganic polymer cluster MeAl12 ([MeO4Al12(OH)24(H2O)12]7+, Me=Al and Ga) with thirteen metal cores is a typical Keggin type polycation, and occupies an important position in modern material chemistry. However, Keggin- MeAl12 (Me = Al and Ga) chloride crystals are not obtained. In the method, a spontaneous hydrolysis product polyaluminum chloride PAC solid is dissolved in a methanol solvent, a galliumchloride solid is dissolved in the solution, and slow crystallization is performed at room temperature to precipitate the Keggin-GaAl12 chloride crystal. The obtained single crystal particles are confirmed to have a Keggin type structure by X-ray single crystal diffraction analysis.

Owner:INNER MONGOLIA UNIVERSITY

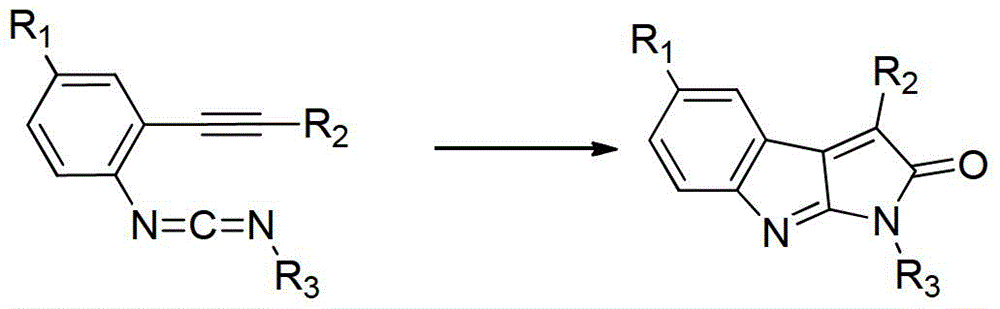

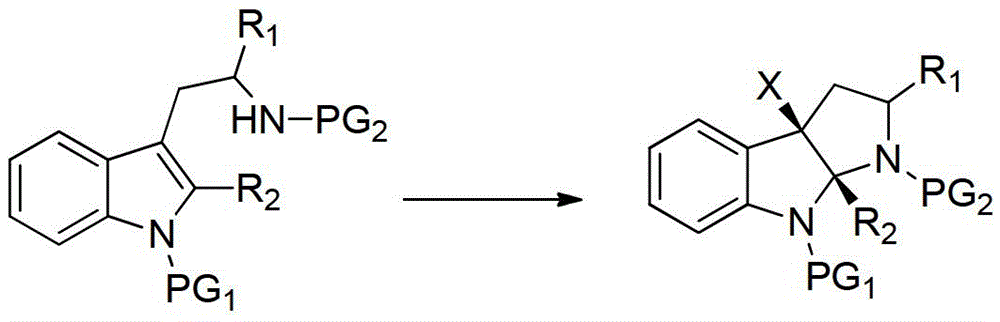

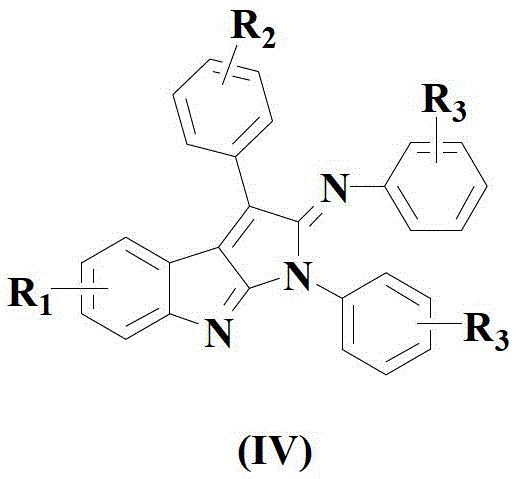

Catalytic synthetic method of pyrrolindole compounds

The invention relates to a catalytic synthetic method of pyrrolindole compounds represented by formula (IV) shown in the description. The method comprises the following steps: sequentially adding a compound represented by formula (I), a compound represented by formula (II), a compound represented by formula (III), a composite catalyst, gallium trichloride, an organic ligand and an organic base to an organic solvent at room temperature in nitrogen atmosphere, heating above materials to 70-85DEG C, fully stirring and reacting the materials for 4-6h, and post-processing the obtained material to obtain the compounds represented by formula (IV). The formula (I), the formula (II) and the formula (III) are shown in the description; and in the formula (I), the formula (II) and the formula (III), R1 is selected from H or a C1-C6 alkyl group, R2 is selected from H, a C1-C6 alkyl group, a C1-C6 alkyloxy group or halogen, R3 is selected from H or halogens, and X is halogen. The method adopts comprehensive selection and coordination of an appropriate reaction substrate, the catalyst, the organic ligand, the organic base and the organic solvent and use of gallium trichloride, so the target product is obtained at a high yield, and the target product has good application prospect and wide market promotion values in the field of synthesis of medicine intermediates.

Owner:李乃温

Gallium trichloride injection scheme

ActiveUS9481943B2Efficiently formedLow reaction temperatureAfter-treatment apparatusPolycrystalline material growthSemiconductor materialsMolecular variation

Owner:SOITEC SA

A process for removing trace amounts of chlorine in gallium trichloride

ActiveCN105905937BChlorine impurity levels are reducedHigh yieldGallium/indium/thallium compoundsReaction temperatureNitrogen gas

Owner:DALIAN KELIDE OPTOELECTRONICS MATERIALS CO LTD

Method for preparing anhydrous gallium trichloride through chlorination method

InactiveCN105565368AIncrease profitSolve difficult to collectGallium/indium/thallium compoundsReaction temperatureLiquid metal

The invention discloses a method for preparing anhydrous gallium trichloride through a chlorination method. The method comprises the following steps of adding liquid metal gallium into a reactor; then directly pumping chlorine gas into the liquid metal gallium; controlling the reaction temperature to be 80 DEG C to 200 DEG C; collecting liquid gallium trichloride produced through reaction in a packaging bottle. According to the method disclosed by the invention, the chlorine gas is directly pumped into the liquid metal gallium, so that the reaction efficiency is high, the utilization rate of the chlorine gas is high, waste gas produced through the reaction is less, and industrial production is easy.

Owner:NANJING JINMEI GALLIUM

Saturated solution for the preparation of electrothermal film

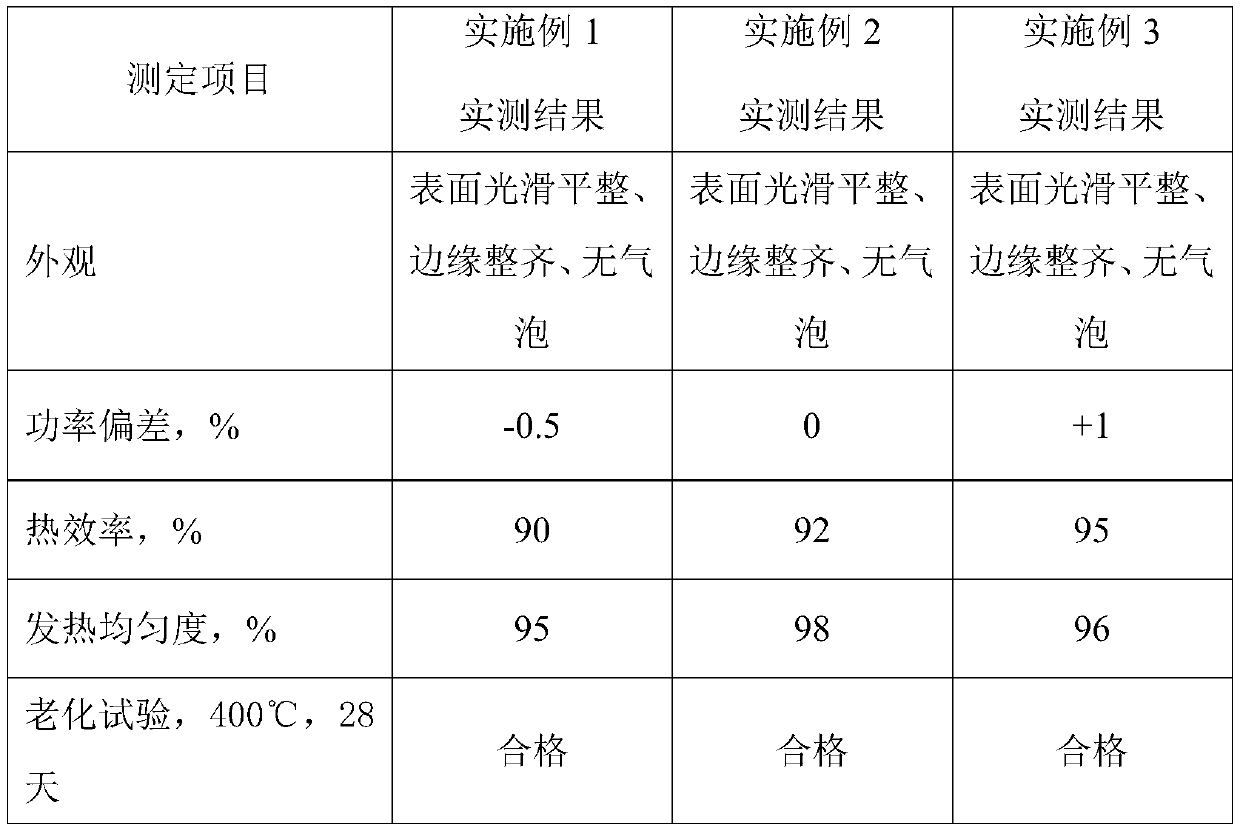

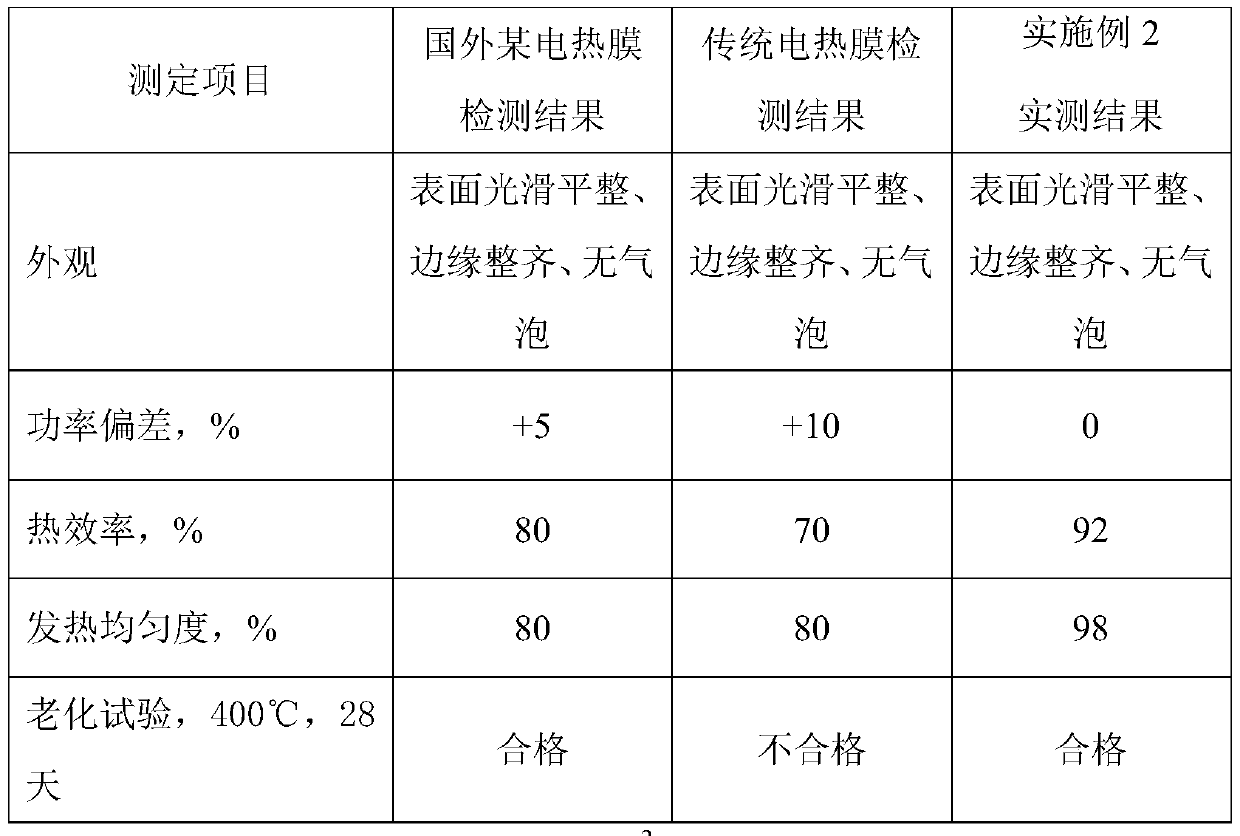

ActiveCN106998596BGood adhesionImprove thermal efficiencyHeating element materialsDopantTetrachloride

The invention discloses a saturated solution used to prepare an electrothermal film. The saturated solution comprises a soluble tin-based chloride, titanium tetrachloride, nickel tetrachloride, a zinc dopant, gallium trichloride, a catalyst, isopropanol and absolute ethyl alcohol. According to the invention, the saturated solution used to prepare the electrothermal film has the advantages of simple preparation technology and easy quantitative doping. The electrothermal film prepared by the solution has the advantages of stable work, long service life, good substrate adhesion and high thermal efficiency.

Owner:江苏一森电采暖科技有限公司

A method for preparing alumina and its comprehensive utilization by chlorination and electrolysis of bauxite pellets

ActiveCN107235499BReduce processing linksLow costAfter-treatment apparatusZinc halidesFerric hydroxideElectrolysis

A method for preparing alumina by chlorination electrolysis and comprehensive utilization of bauxite pellets. The steps are as follows: batch bauxite, carbon source and kaolin according to the proportion, add binder and water, pelletize and air-dry, chlorine, Separate and purify to obtain anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium chloride; convert anhydrous aluminum chloride and anhydrous ferric chloride into corresponding Chloride solution is electrolyzed by controlling the voltage and current density to obtain aluminum hydroxide, ferric hydroxide, hydrogen and chlorine. The chlorine is returned to the chlorination section; aluminum hydroxide is roasted to obtain metallurgical grade / chemical alumina; ferric hydroxide is calcined to obtain iron. red or other iron-containing products; purify silicon tetrachloride; refine titanium tetrachloride to make sponge titanium raw materials; enrich scandium chloride to make scandium extraction raw materials. The method of the invention is low in cost, the raw materials are cheap and easy to obtain, the chlorination reaction is completed through pelletizing chlorination, the operation process is simple, the degree of automation is high, the product purity is high, and raw materials such as chlorine and zinc can be recycled.

Owner:NORTHEASTERN UNIV LIAONING

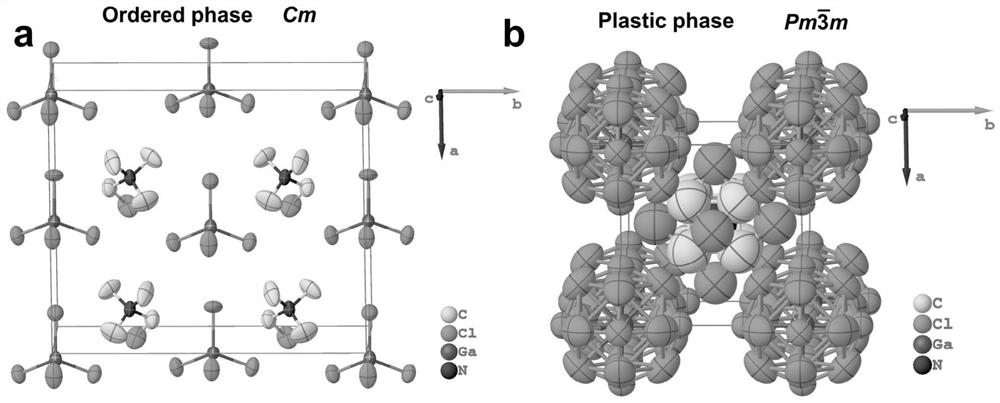

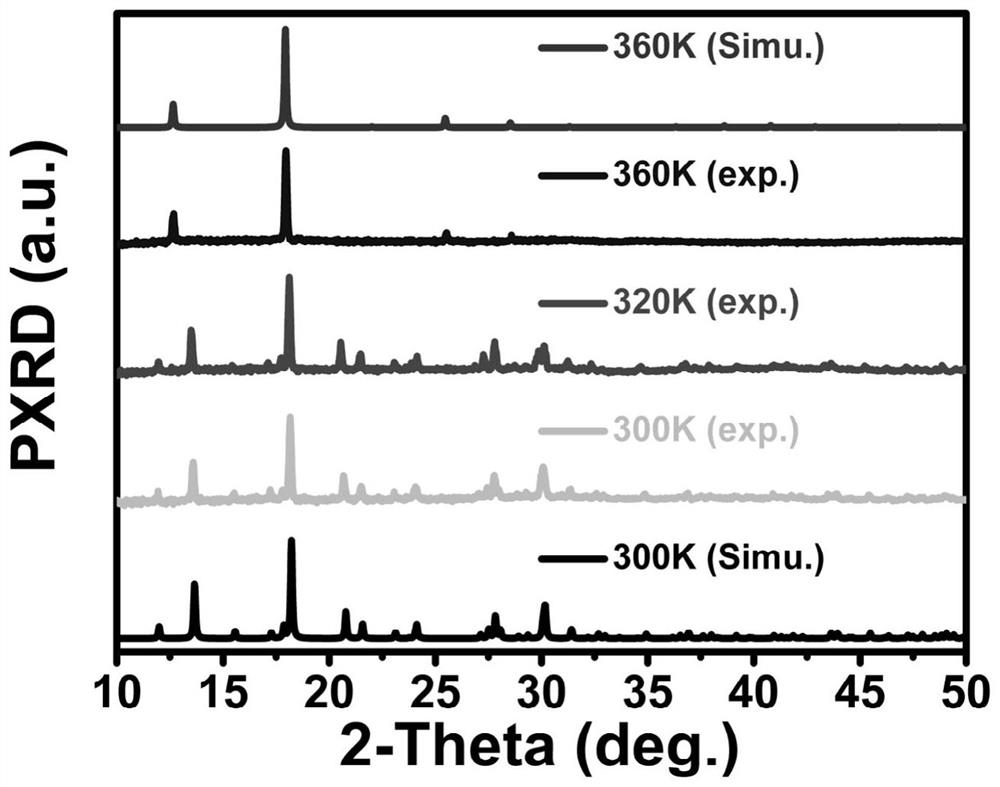

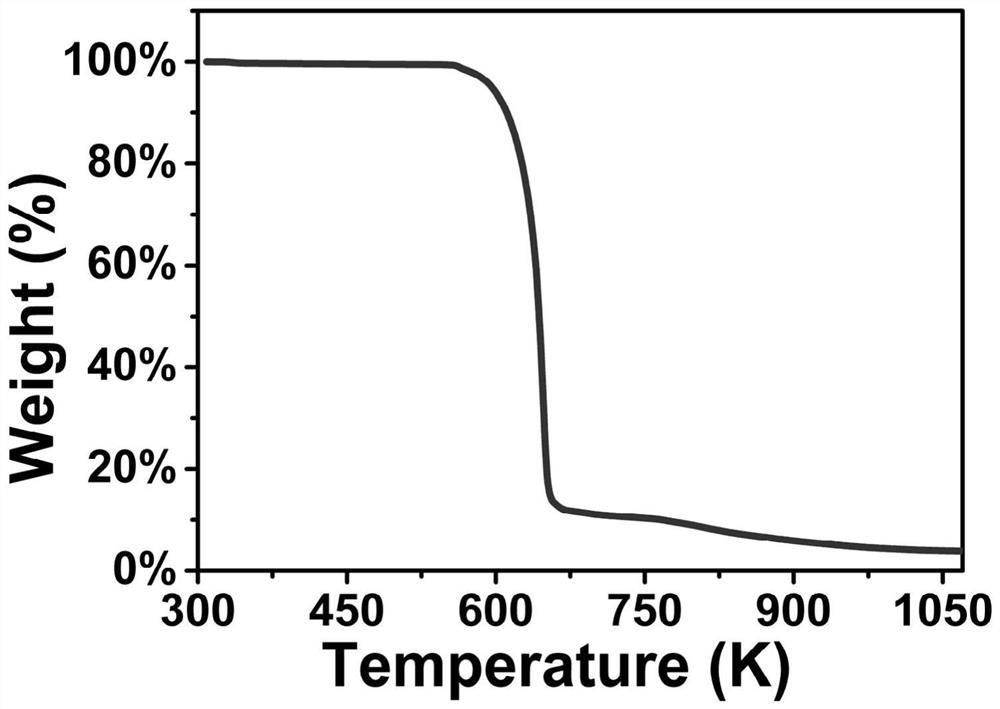

Trimethylchloroethylamine-containing multipolar axis plastic ferroelectric and piezoelectric material as well as preparation and application thereof

PendingCN113089101AEasy to prepareHigh purityPolycrystalline material growthFrom normal temperature solutionsTabletingGallium trichloride

The invention discloses a trimethylchloroethylamine-containing multipolar axis plastic ferroelectric and piezoelectric material as well as preparation and application thereof, which relates to ferroelectric and piezoelectric materials. The chemical formula of the trimethylchloroethylamine-containingmultipolar axis plastic ferroelectric and piezoelectric material is [(CH3)3NCH2Cl]GaCl4. The preparation method comprises the following steps of mixing trimethylchloroethyl ammonium chloride with a solvent, then adding gallium trichloride, stirring, volatilizing and growing a clear solution obtained by filtering, and standing to obtain the trimethylchloroethylamine-containing multipolar axis plastic ferroelectric and piezoelectric material, namely [(CH3)3NCH2Cl]GaCl4. A polycrystalline tabletting sample of the obtained multipolar axis plastic ferroelectric and piezoelectric material at room temperature has excellent piezoelectric property. The trimethylchloroethylamine-containing multipolar axis plastic ferroelectric and piezoelectric material can be applied to preparation of ferroelectric storage materials, signal sensing materials, energy collection materials and the like.

Owner:XIAMEN UNIV

A kind of preparation method of trimethylgallium

The invention discloses a preparation method of trimethyl gallium. The preparation method comprises the following steps of: adding a curafume gas into a mixture of metal magnesium and organic ether under the protection of an inert gas at the temperature of 30-100 DEG C and under the normal pressure to generate a methyl-magnesium-bromide solution; continuously stirring at the temperature of 50-100 DEG C for 2-3 hours, and lowering the temperature below 40 DEG C; adding an organic ether solution of absolute gallium trichloride or absolute gallium trichloride into the methyl-magnesium-bromide solution at the temperature of 30-100 DEG C and under the normal pressure, reacting, and continually stirring a reactant for 3-5 hours after reacting; heating a reaction kettle under the normal pressure to 130-190 DEG C, distilling a crude trimethyl gallium product out, and controlling the receiving temperature at 56-62 DEG C; and rectifying the crude product once again under the normal pressure to obtain pure trimethyl gallium, wherein the product collecting temperature is 56 DEG C. The method has the advantages of difficulty in introducing impurities, low cost, high reaction efficiency, high safety, easiness of recovering solvents from produced waste and environment friendliness.

Owner:ANHUI BOTAI ELECTRONIC MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com