Patents

Literature

83 results about "Liquid gallium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

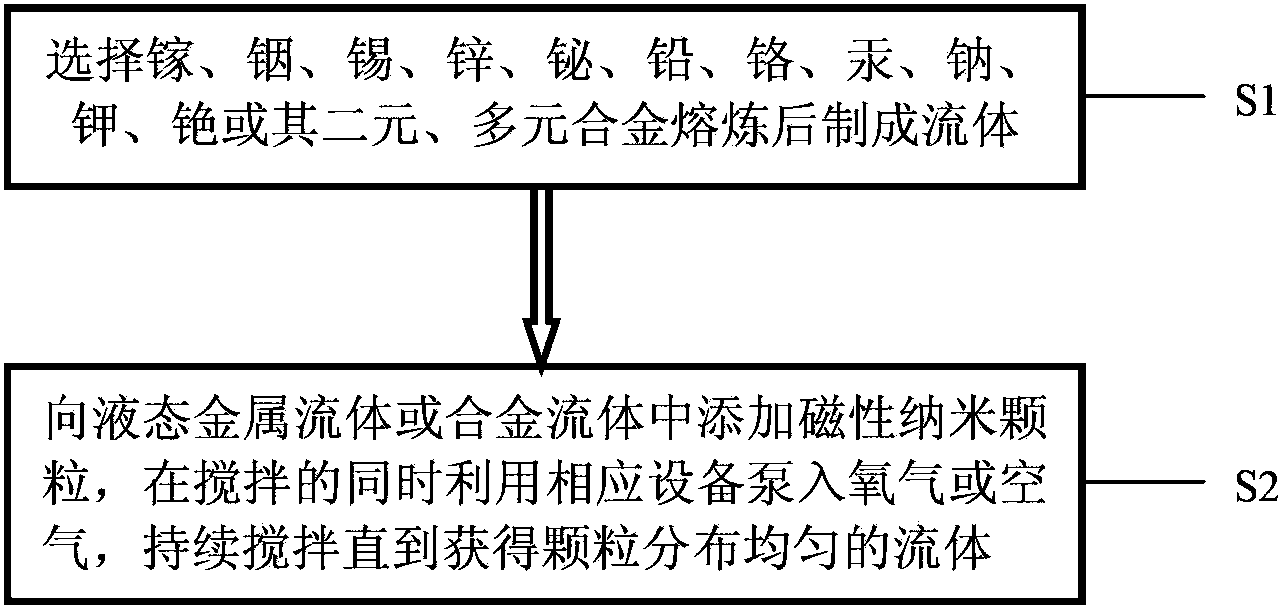

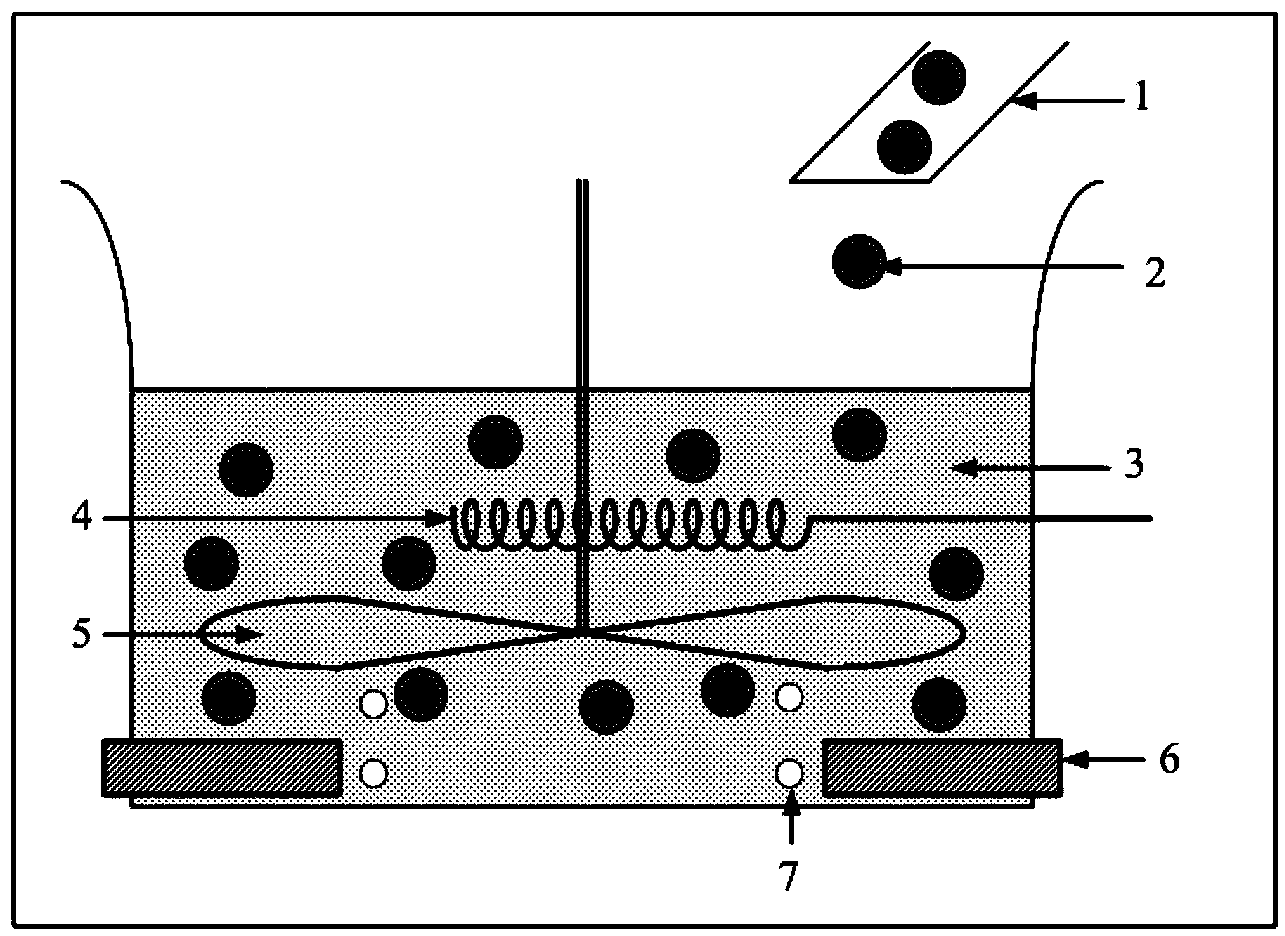

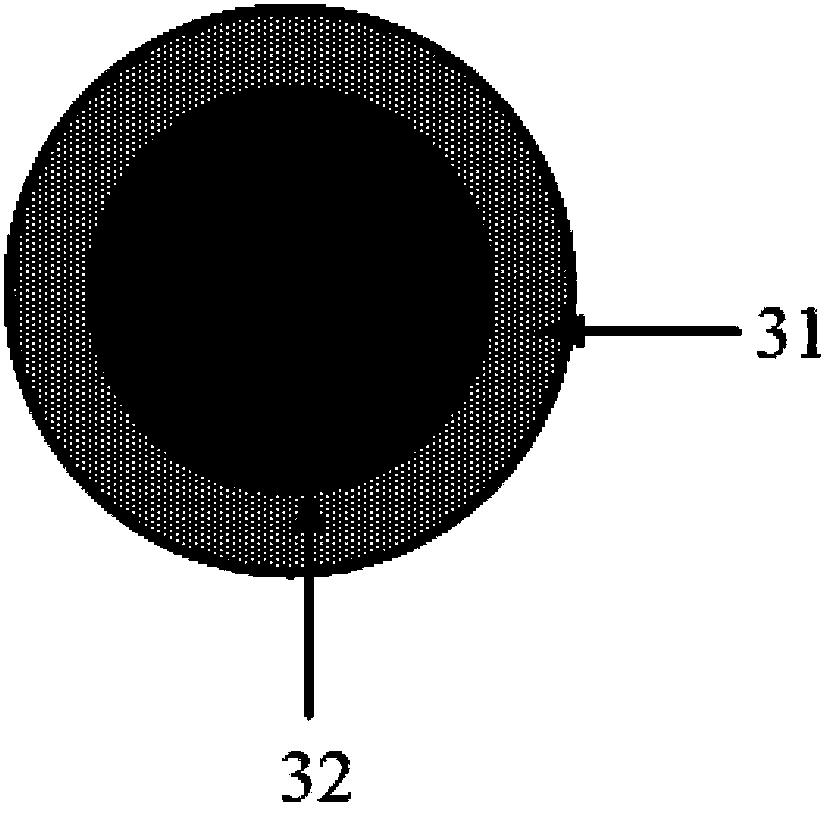

Magnetic nanometer-sized metal fluid and preparation method thereof

ActiveCN104124031AHigh thermal conductivityImprove liquidityMaterial nanotechnologyMagnetic liquidsIndiumPotassium

The invention discloses magnetic nanometer-sized metal fluid. The magnetic nanometer-sized metal fluid comprises liquid gallium, liquid indium, liquid tin, liquid zinc, liquid bismuth, liquid lead, liquid chromium, liquid mercury, liquid sodium, liquid potassium, liquid cesium or a dual-component alloy or a multi-component alloy of the metal materials and magnetic nanometer-sized particles added to the metal materials. The volume ratio of the magnetic nanometer-sized particles to the liquid metal materials / the alloy is smaller than or equal to 0.5:1. Oxygen is actively introduced through a specific oxygen supply mechanism to adjust and control the adhesiveness of the fluid and the particles, and taking the liquid gallium, the liquid indium, the liquid tin, the liquid zinc, the liquid bismuth, the liquid lead, the liquid chromium, the liquid mercury, the liquid sodium, the liquid potassium, the liquid cesium or the dual-component alloy or the multi-component alloy of the metal materials as basic liquid, the magnetic nanometer-sized metal fluid which is high in heat conductivity and electric conductivity, good in fluidity and not prone to volatilization or leakage can be obtained fast and efficiently.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

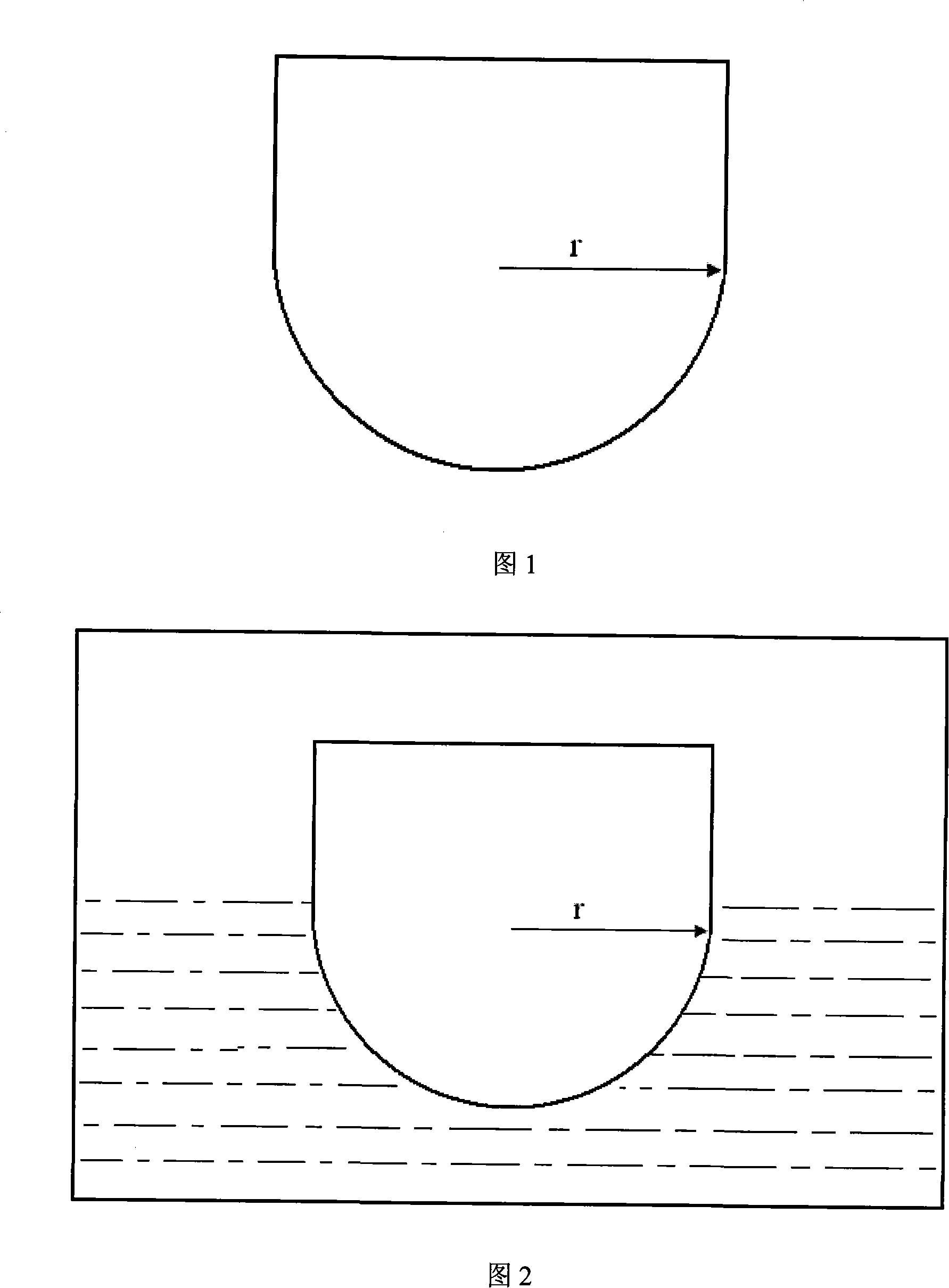

Preparation method of high-purity gallium

The present invention provides high purity gallium preparing process, which includes the following steps: 1. heating cleaned and dried semispherical reaction container in a water bath, coating high purity liquid gallium of 5-10 g serving as seed crystal to the inner surface of the reaction container, adding molten coarse gallium product into the reaction container, solidifying 60-90 % of gallium in the controlled rate of 0.5-1.5 cu cm / min, and pouring out liquid gallium; and 2. repeating the step 1 with the obtained solid gallium as material for 3-5 times to obtain high purity gallium.

Owner:SOUTHEAST UNIV

Liquid gallium alloy and preparation method thereof

The invention discloses a liquid gallium alloy and a preparation method of the alloy. The liquid gallium alloy comprises the following components in percentage by weight: 60-75% of gallium, 10-25% of indium, 1-11% of tin, and 1-8% of zinc. The preparation method of the liquid gallium alloy comprises the following steps: firstly weighing gallium, indium, tin and zinc according to the mass percent of each component, heating gallium to 29 DEG C to melt, and stopping heating; pouring the liquid gallium into a stainless steel container, and pouring indium, tin and zinc into the stainless steel container too; at normal temperature, using a stainless steel made spoon to mix and stir the metals uniformly until the four raw materials are totally dissolved to be liquid, and finishing the preparation of the liquid gallium alloy. The liquid gallium alloy can be taken as a working medium for power generation of a liquid-metal magnetic fluid generator.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

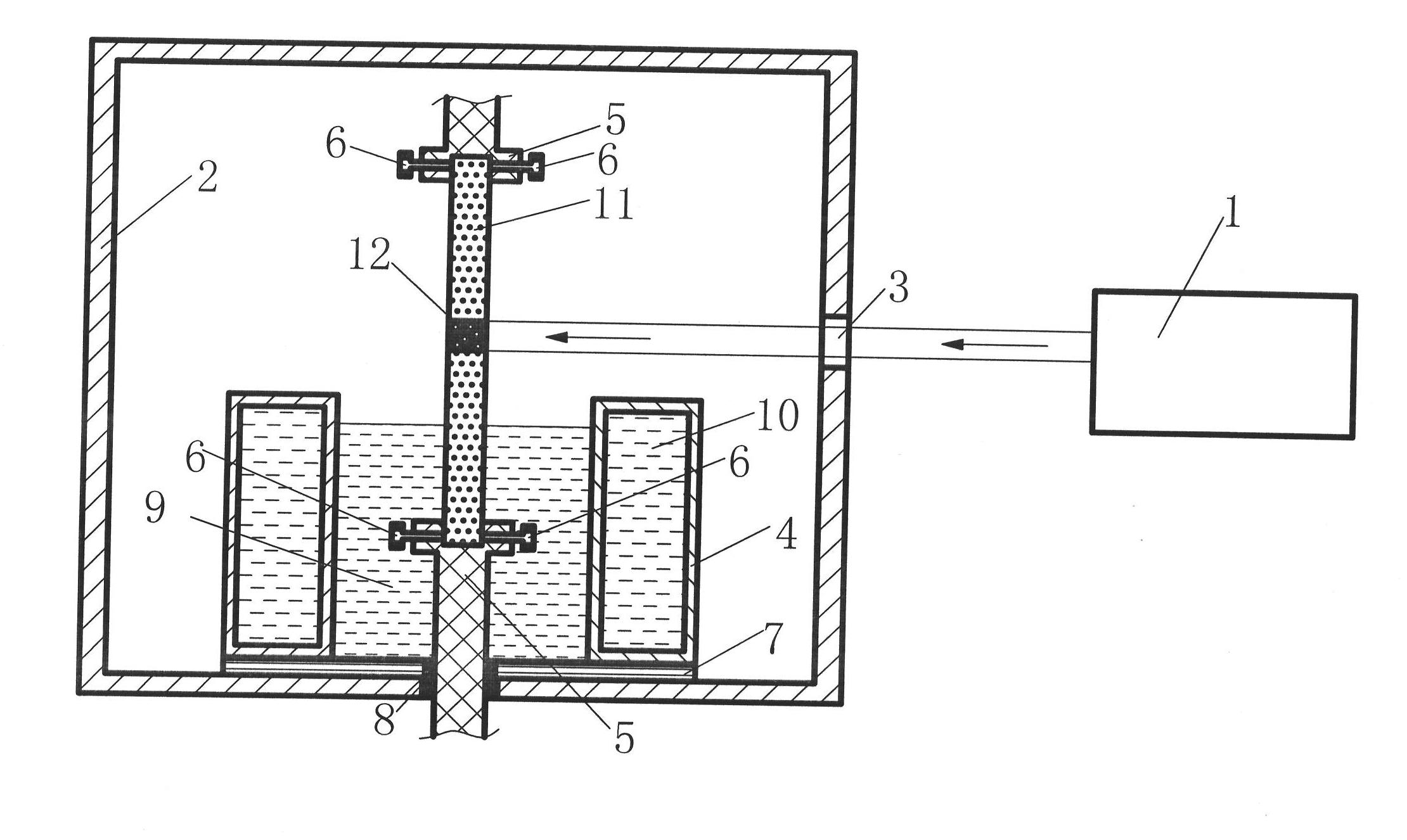

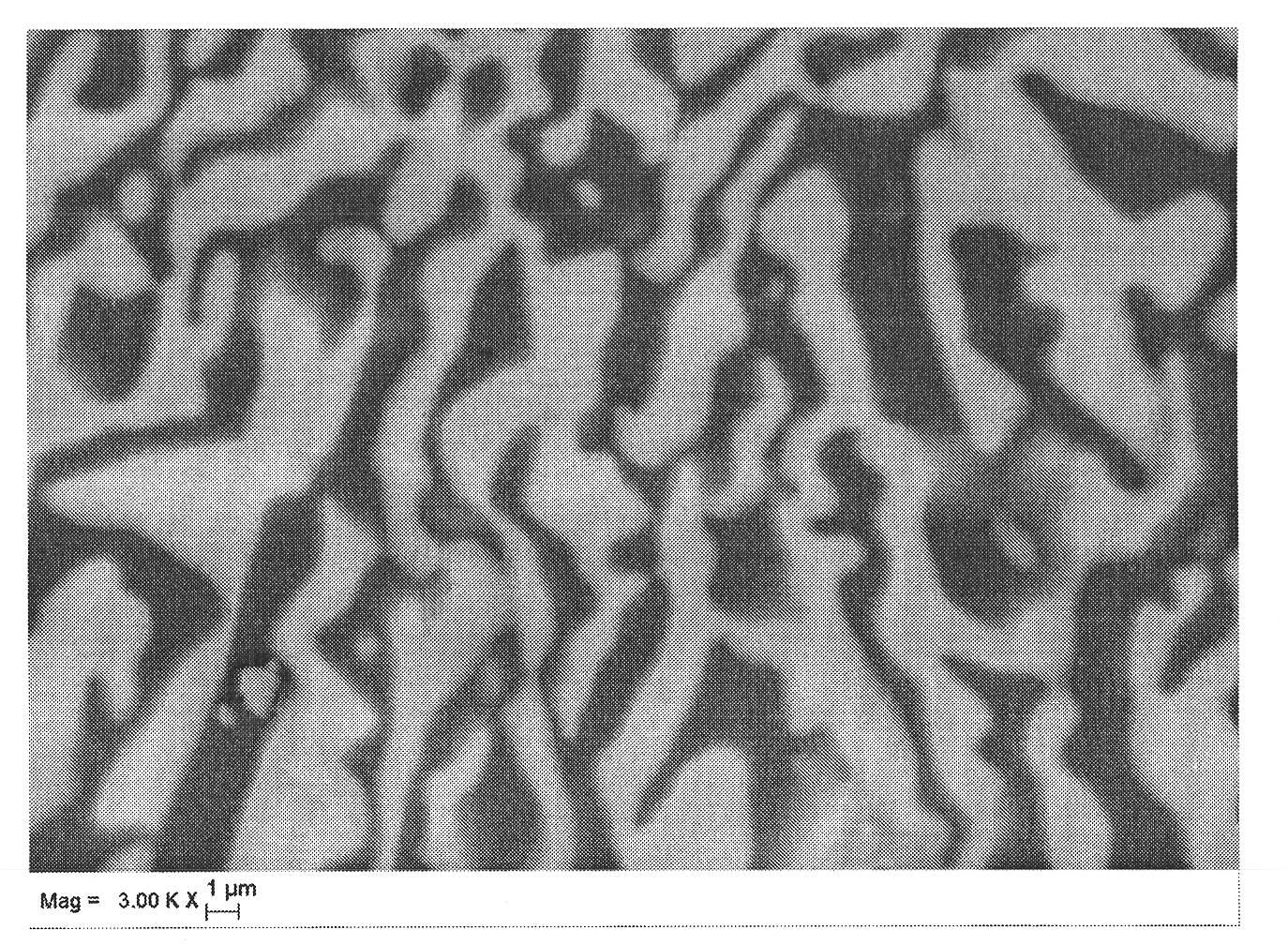

10<5> K/cm temperature gradient directional solidification device and directional solidification method

ActiveCN102051668AUniform tissueGood orientationPolycrystalline material growthFrom frozen solutionsIndiumZone melting

The invention relates to a 10<5> K / cm temperature gradient directional solidification device and a directional solidification method. The 100000 K / cm temperature gradient directional solidification device is characterized in that laser light generated by a laser horizontally passes through a plate lens to enter a vacuum chamber, intersects vertically the axis of a drawing system, and is used for heating a preform; and liquid gallium-indium-tin alloy serves as cooling medium. The distance between the lower surface of a melting zone and the liquid level of the liquid gallium-indium-tin alloy is 1mm to 5 mm. When directional solidification is performed to the preform, the power of the laser is increased to 200 w to 1400 w. After the preform is zone-melted, a drawing mechanism is started to enable the preform to move at the speed of 1 to 300 microns per second and to be cooled, so that directional solidification of the preform is accomplished. In the invention, laser floating zone melting is combined with liquid metal cooling, so that the obtained oxide eutectic in-situ composite is uniform in structure, fine and compact, has good directing property, and is remarkably improved in mechanical property and other functions, the sizes and the shapes of produced function materials can satisfy the application of various photoelectric components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

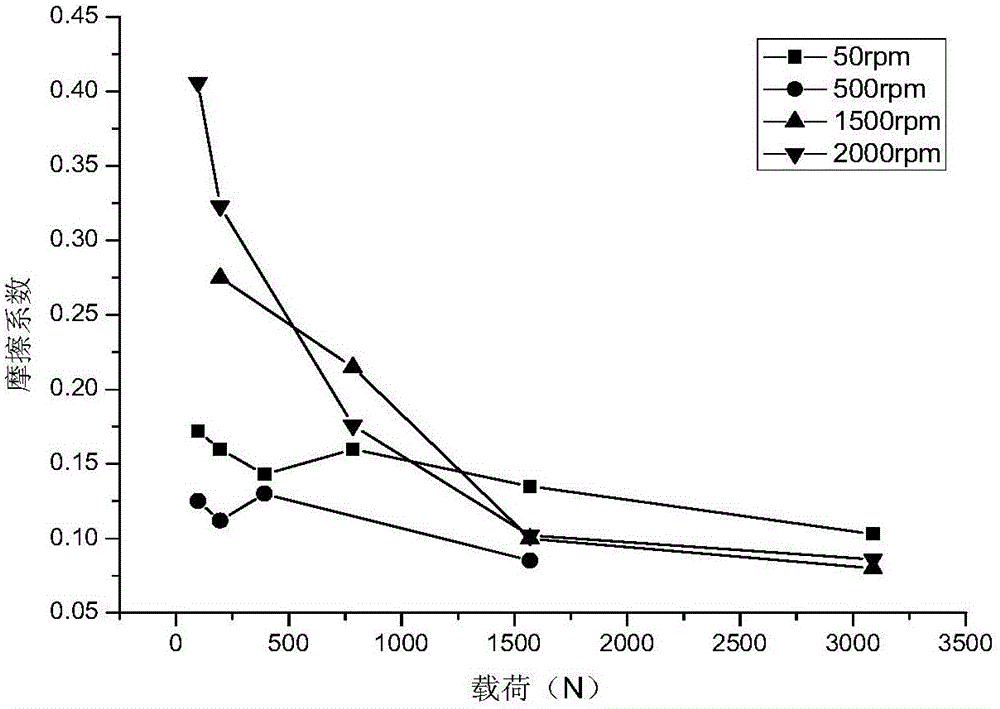

Lubricant as well as preparation method and application thereof

The invention provides a lubricant as well as a preparation method and application thereof. The lubricant disclosed by the invention adopts pure-liquid gallium or gallium-base liquid metal, wherein the gallium-base liquid metal comprises the components in percentage by weight: 72%-78% of gallium and 22%-28% of indium, or 60%-70% of gallium, 20%-30% of indium and 8%-16% of tin, or 60%-69% of gallium, 20%-29% of indium, 8%-15% of tin and 0.1%-3% of zinc. The lubricant disclosed by the invention has an excellent lubricating property under the serious working conditions of heavy load, high temperature and the like. According to the lubricant conforming to the Chinese standard GB / T 12583-1998, through the determination of an extreme pressure performance determination method, the sintering load of the lubricant disclosed by the invention is far higher than that of a conventional extreme-pressure lubricant in the market.

Owner:TSINGHUA UNIV

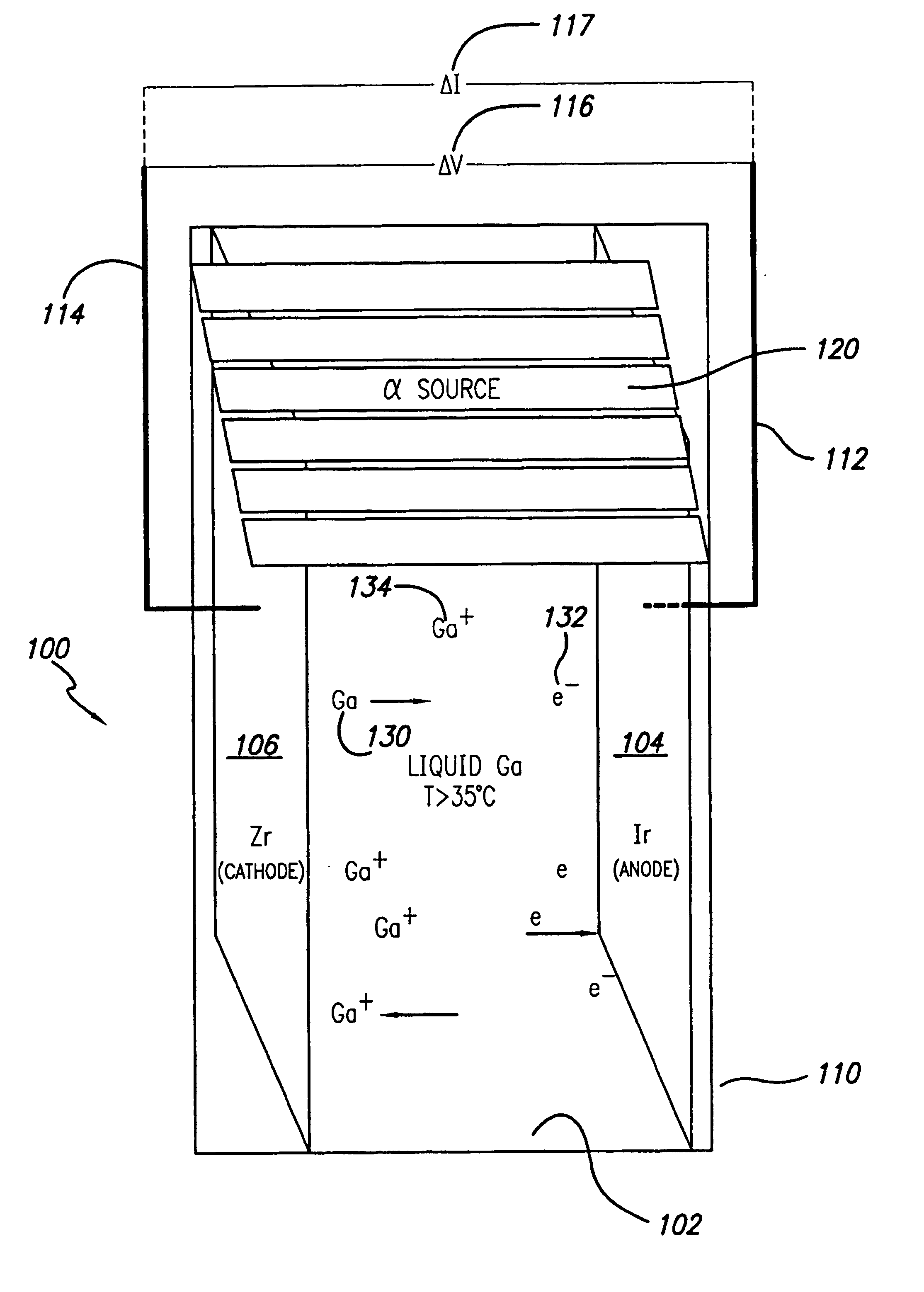

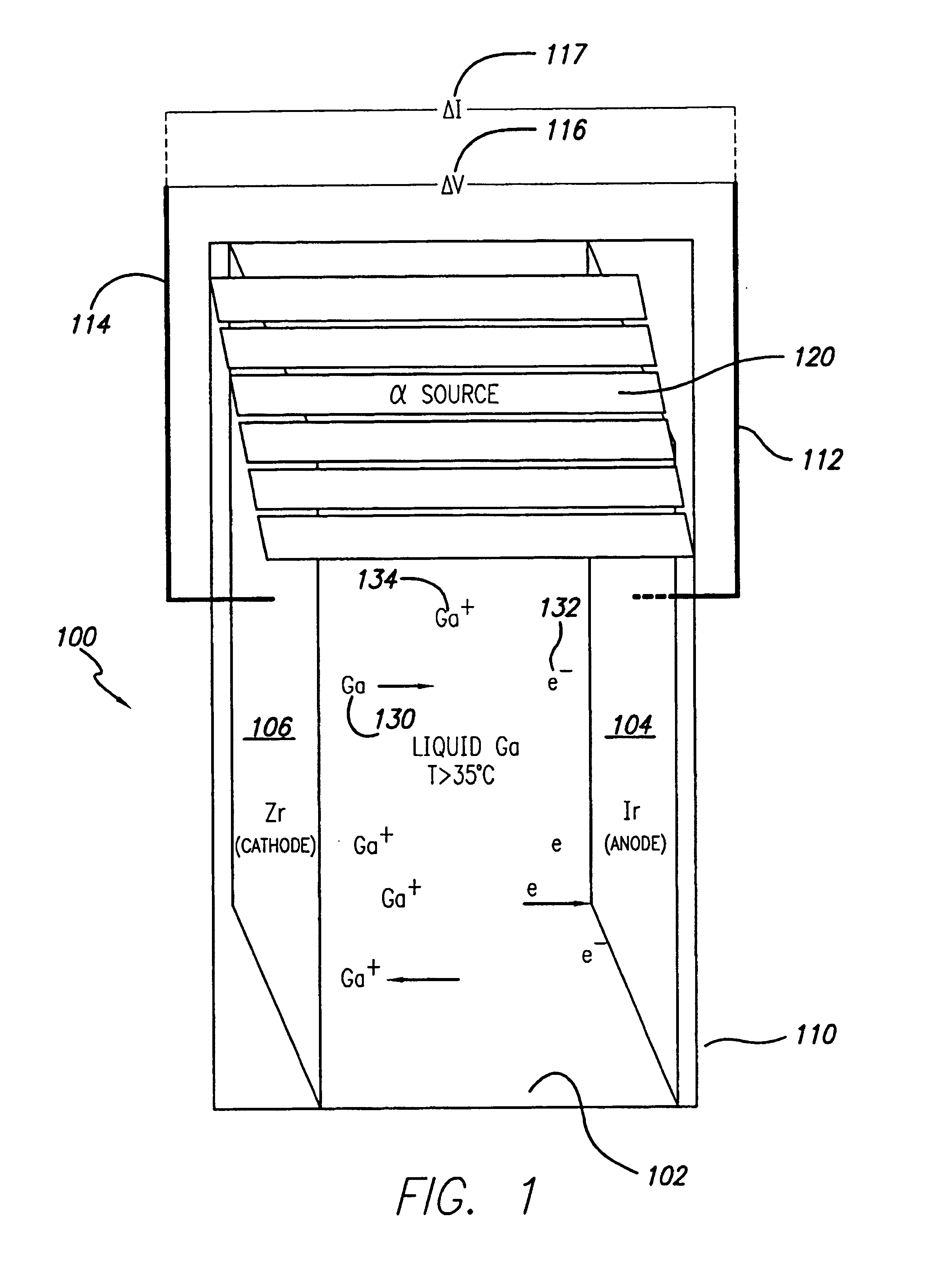

Extremely-efficient, miniaturized, long-lived alpha-voltaic power source using liquid gallium

A power source converts alpha-particle energy to electricity for use in electrical systems. Liquid gallium or other liquid medium is subjected to alpha-particle emissions. Electrons are freed by collision from neutral gallium atoms to provide gallium ions. The electrons migrate to a cathode while the gallium ions migrate to an anode. A current and / or voltage difference then arises between the cathode and anode because of the work function difference of the cathode and anode. Gallium atoms are regenerated by the receiving of electrons from the anode enabling the generation of additional electrons from additional alpha-particle collisions.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE

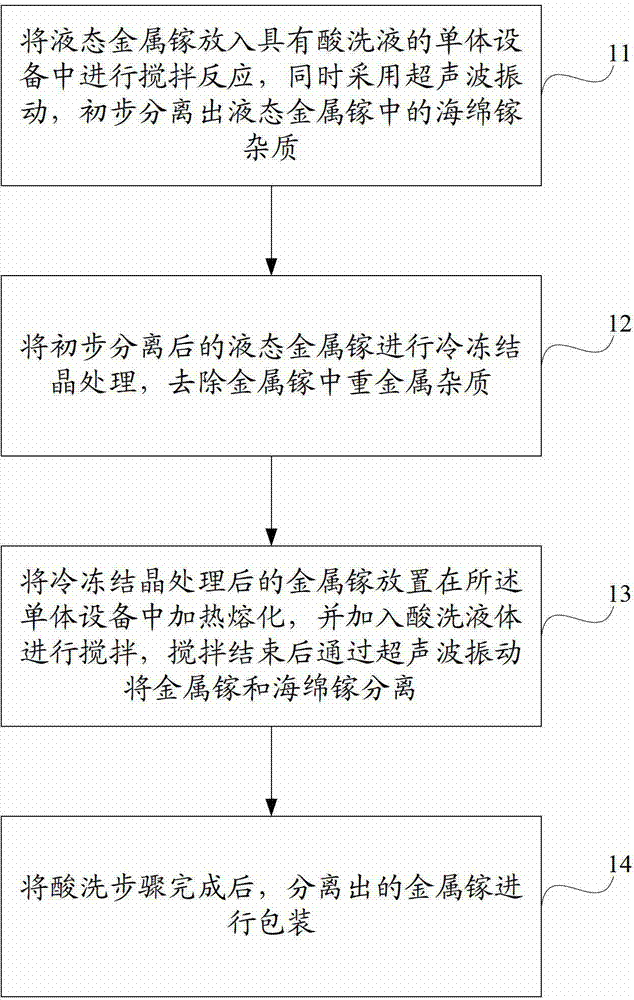

Purification method for gallium

ActiveCN103031450AQuality assuranceTo achieve the purpose of purificationProcess efficiency improvementAutomatic controlPurification methods

Owner:BEIJING JIYA SEMICON MATERIAL

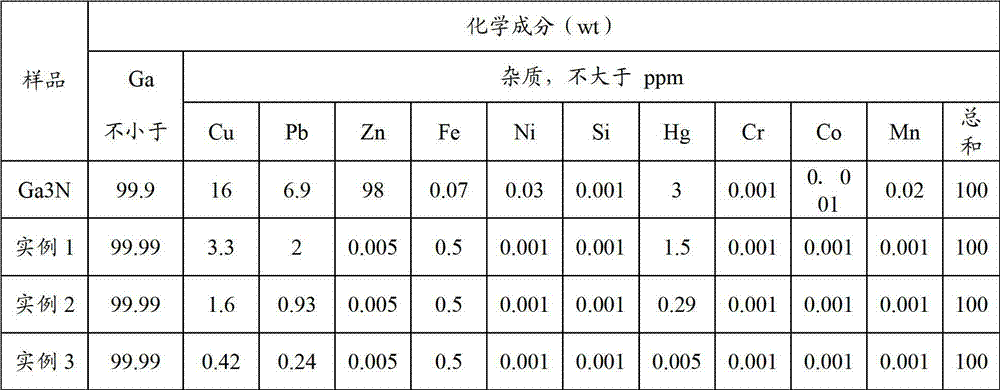

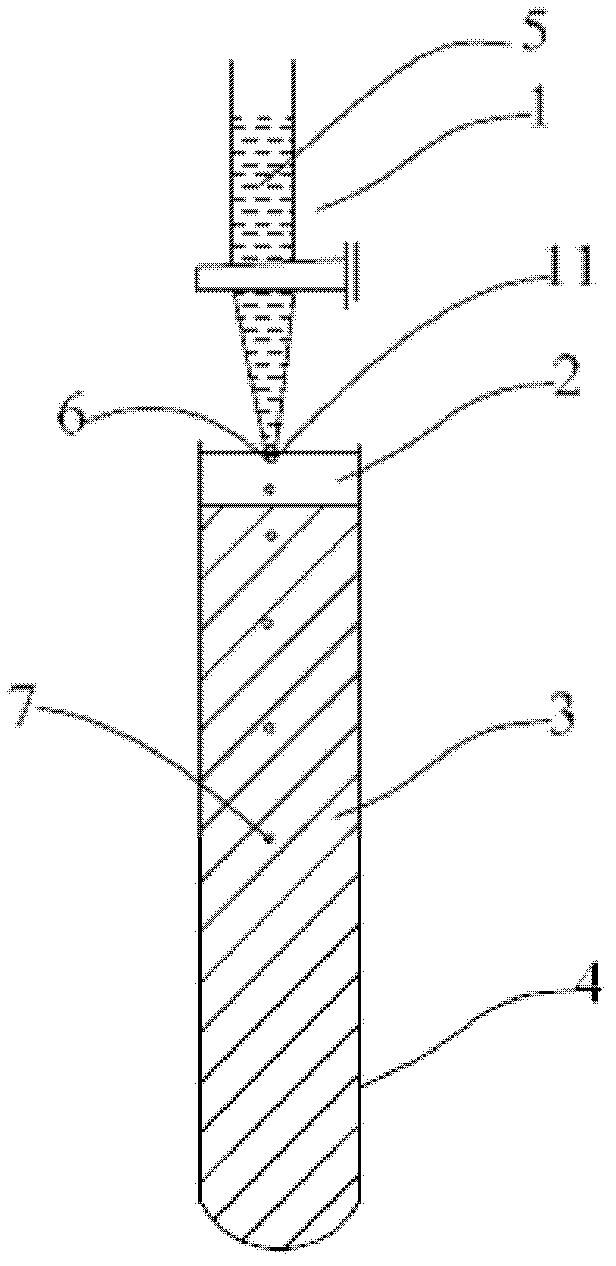

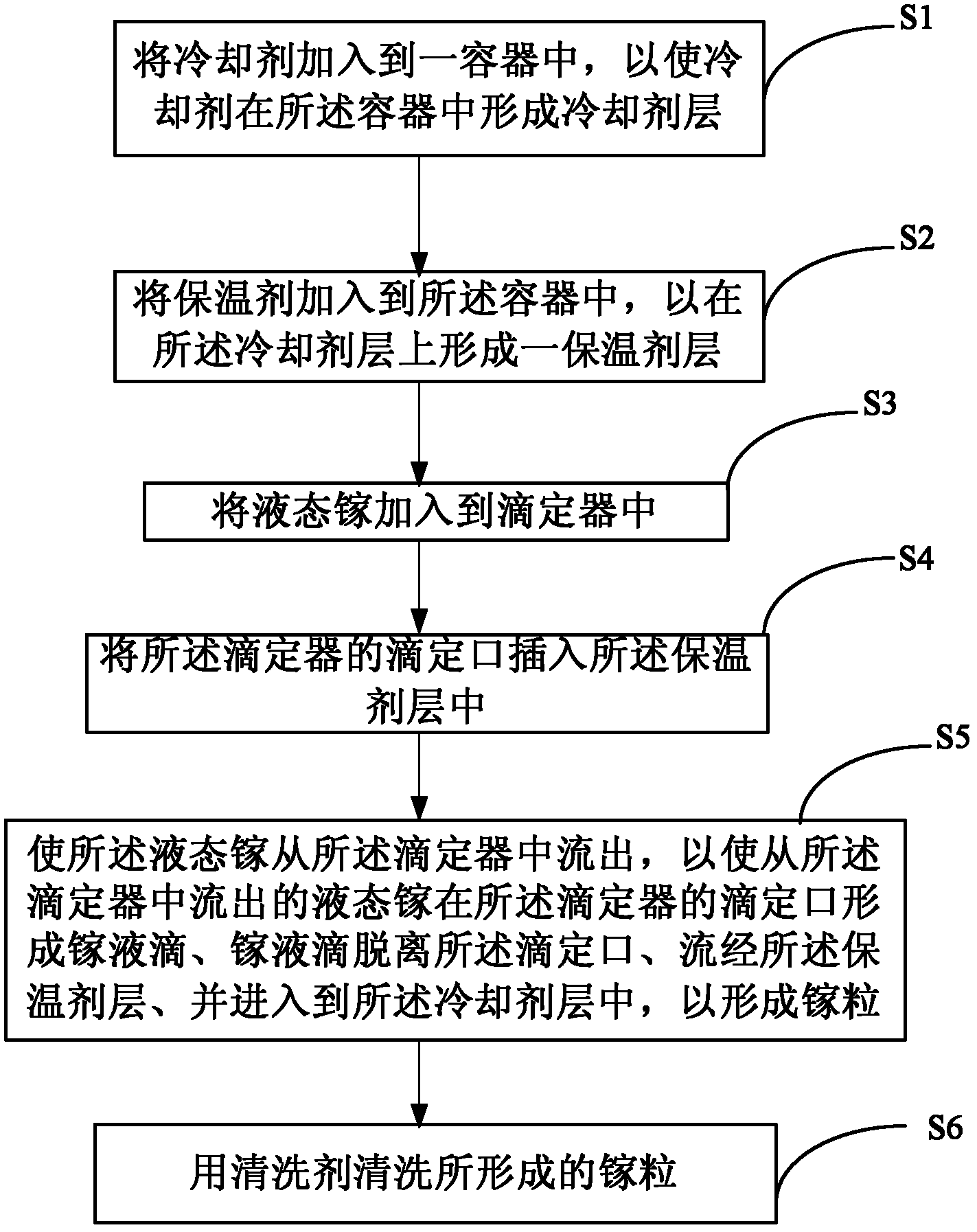

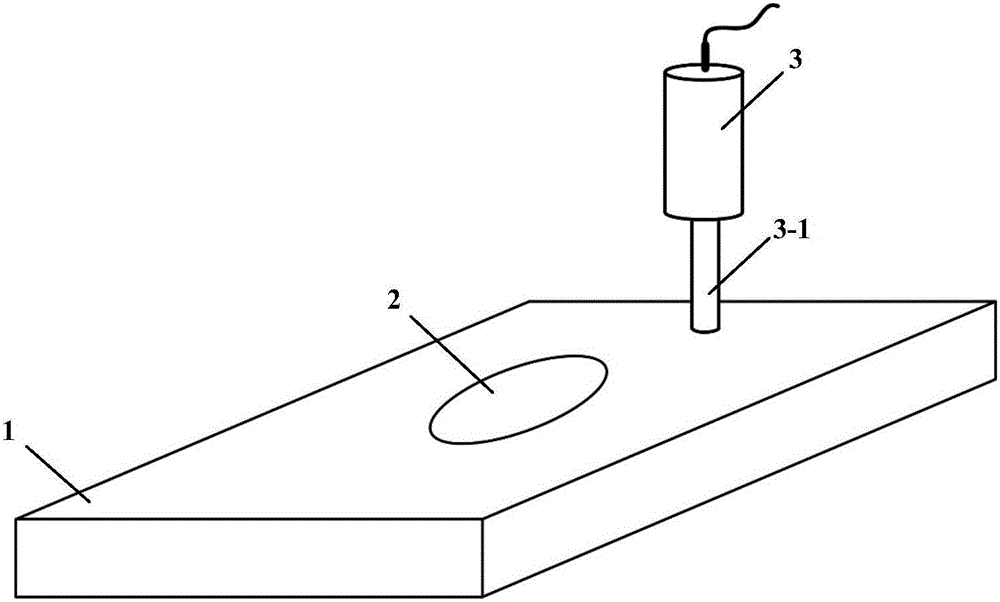

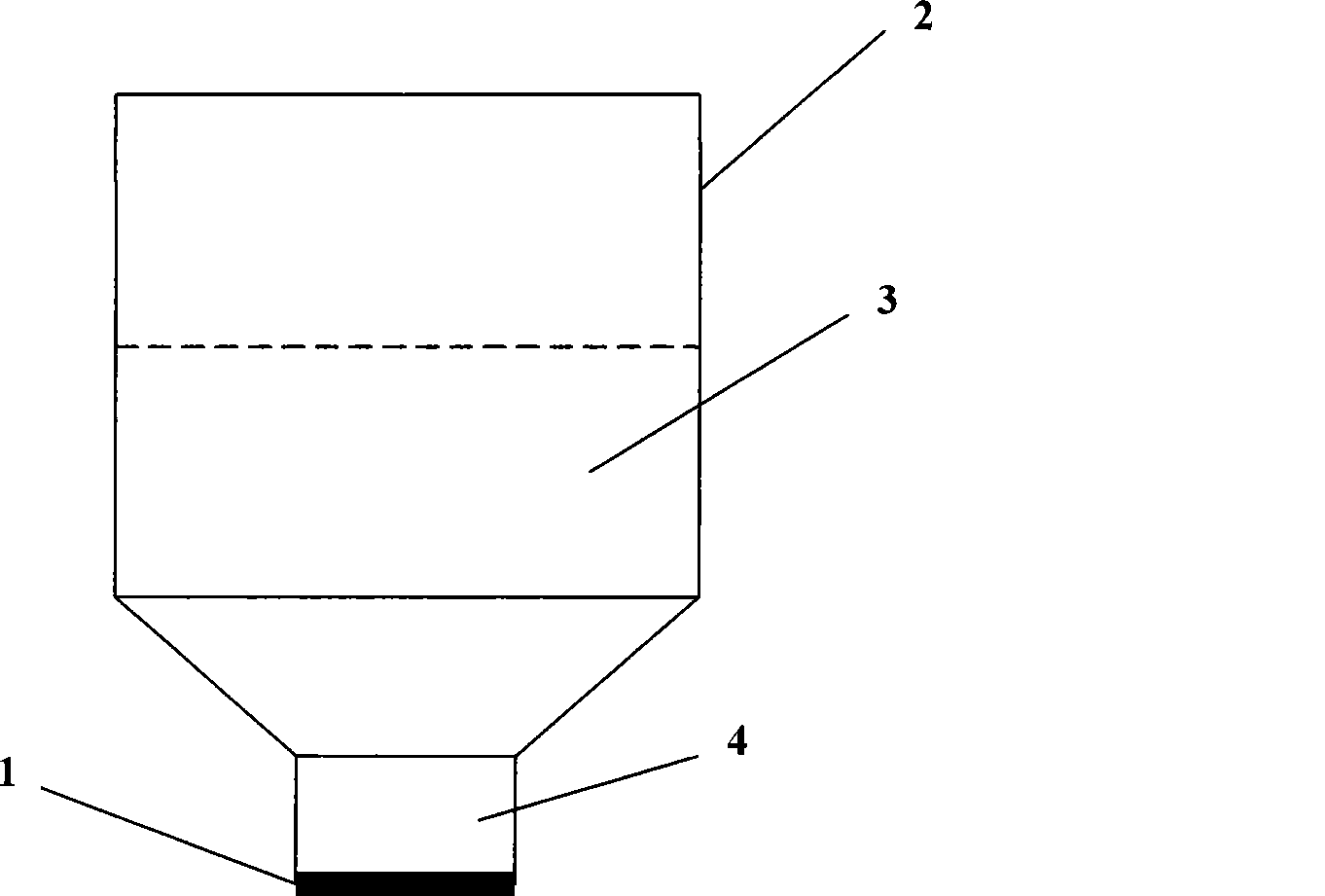

Preparation method of gallium particles

The invention provides a preparation method of gallium particles. The preparation method includes the steps: adding coolants to a container, so that forming a coolant layer in the container by the coolants; adding insulation agents to the container, so that forming an insulation agent layer on the coolant layer; adding liquid state gallium to a titrator; inserting a titration opening of the titrator into the insulation agent layer, enabling the liquid state gallium to flow out from the titrator, so that forming gallium drops on the titration opening by the liquid state gallium flowing out the titrator, the gallium drops break array the titration opening and flow the insulation agent layer and then enter into the coolant layer, then forming the gallium particles. According to the preparation method of the gallium particle, due to fact that operation is done, combination of the insulation agent and the coolant is adopted, the preparation method is capable of simplifying technologies, easy to operate, and quality of products is easy to observe, and particle diameters of the gallium particles are controllable, and uniformity is good.

Owner:威科赛乐微电子股份有限公司

Graphene silicon solar cell and manufacturing method

InactiveCN105449016AAvoid destructionPreserve integrityFinal product manufacturePhotovoltaic energy generationAnti-reflective coatingIndium

The invention provides a graphene silicon solar cell and a manufacturing method thereof. The structure of the solar cell comprises a copper adhesive tape bottom layer, a liquid gallium indium alloy electrode layer, an N type silicon wafer layer, a silicon dioxide layer, a PMMA layer (polymethyl methacrylate) protected graphene transparent electrode layer and a silver conductive adhesive electrode layer arranged successively from bottom to top. The technical solution of the invention can obtain high efficiency graphene silicon solar cell and is advantaged by that firstly, damage to the grapheme in the protection layer removing process of the prior transferring method is avoided by adjusting the thickness of the grapheme transfer protection layer PMMA and using the method not removing the protection layer PMMA to transfer the grapheme; secondly, the property of the grapheme is protected well in the transferring process by reserving the PMMA layer, simultaneously P type doping is carried out to the grapheme, the work function of the grapheme is increased, therefore the open-circuit voltage of the graphene silicon solar cell is effectively improved, finally, the reserved PMMA layer has the advantage of an antireflection film, the solar cell of this type remarkably improves the quantum efficiency and energy conversion efficiency of the graphene silicon solar cell under illumination of the same energy.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

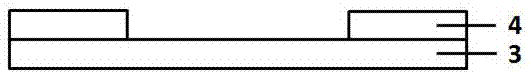

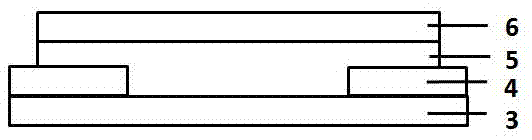

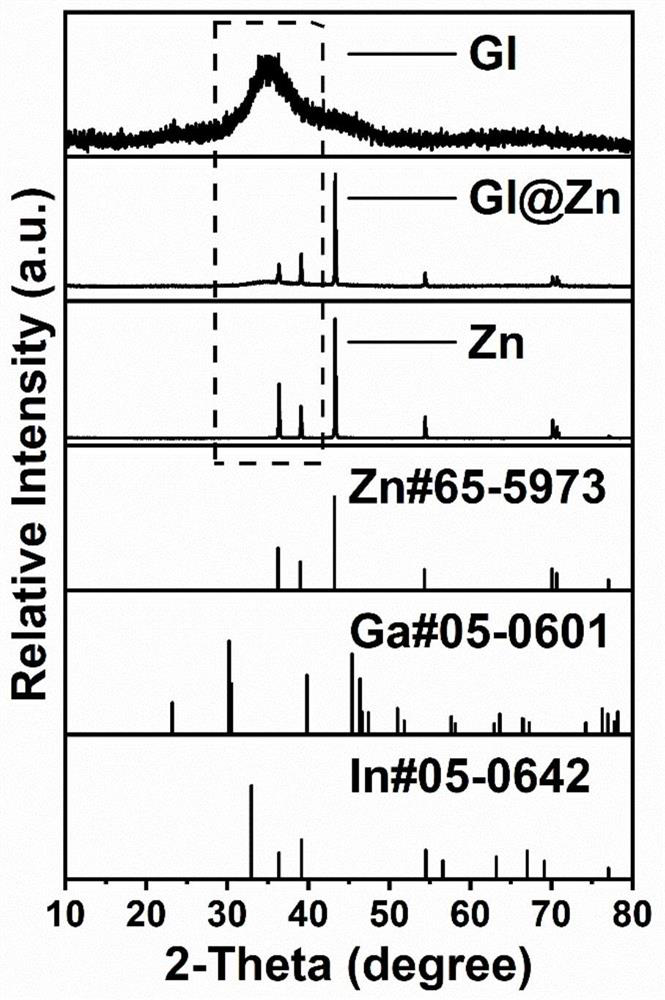

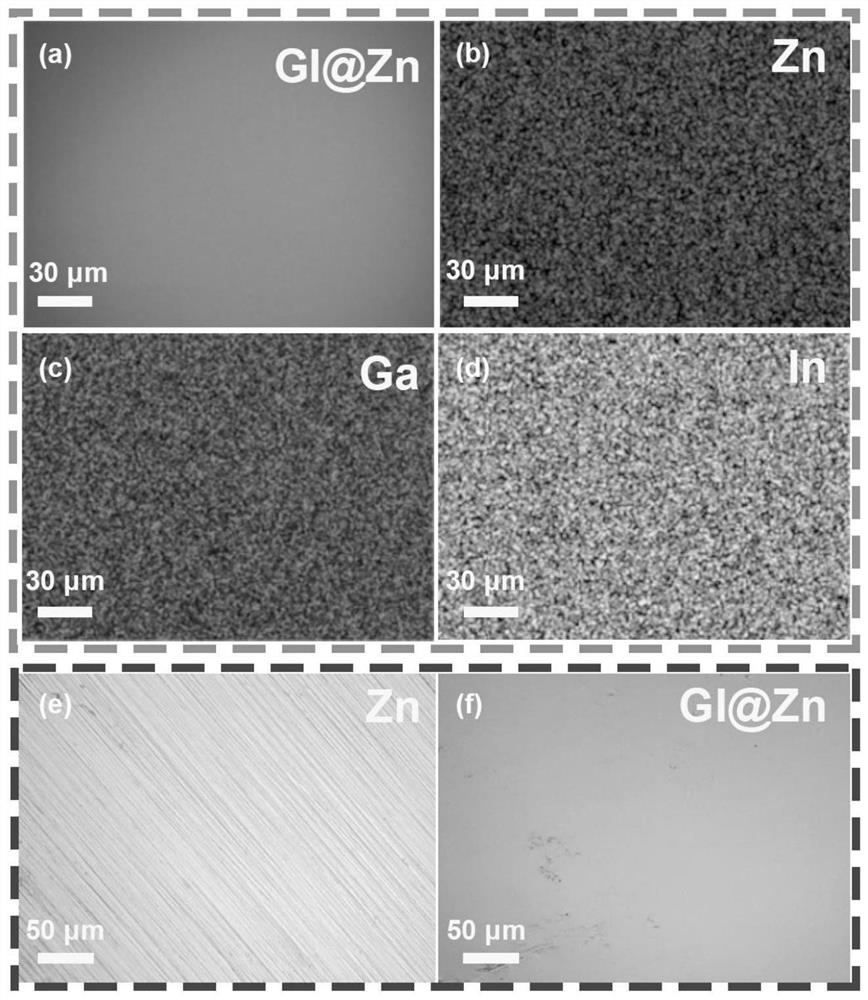

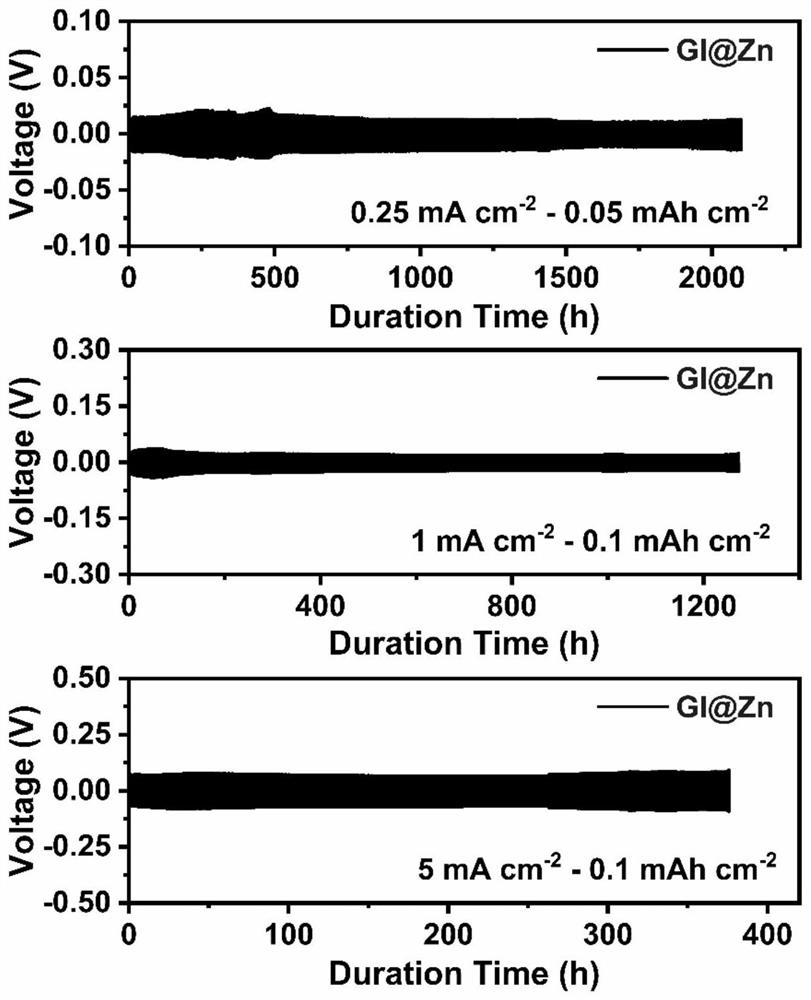

Zinc ion battery liquid metal composite negative electrode and preparation method and application thereof

ActiveCN111916744AImprove corrosion resistanceAvoid corrosionFinal product manufactureCell electrodesElectrolytic agentIndium

The invention discloses a zinc ion battery liquid metal composite negative electrode and a preparation method and application thereof. The composite negative electrode comprises a zinc metal matrix and a liquid alloy layer, and the liquid alloy layer is arranged on the surface of the zinc metal matrix. The characteristic of low solubility of zinc metal in the liquid gallium-based alloy is utilized, the zinc metal can be used as an electrochemically inert liquid coating material, the liquid alloy layer is formed by coating the surface of the zinc metal matrix with the liquid gallium-based alloy, and zinc ion flow, close to the surface of the negative electrode, of electrolyte can be well homogenized. Meanwhile, zinc is in a saturated state in the liquid gallium-based alloy, so zinc in the circulation process finally uniformly nucleates and grows on the surface of the zinc metal matrix, and dendrites are prevented from being formed on the surface of the composite negative electrode. Meanwhile, by compounding with gallium and indium with high hydrogen evolution overpotential, the corrosion resistance of the composite zinc negative electrode can be improved, the problem of side reactions such as negative electrode corrosion hydrogen production in the zinc ion battery is relieved, the cycle life of the zinc ion battery is prolonged, and the use stability and safety of the battery are improved.

Owner:CENT SOUTH UNIV

Magnetic liquid metal printing ink and preparation method thereof

The invention relates to the technical field of electronic materials, in particular to magnetic liquid metal printing ink and a preparation method thereof. The magnetic liquid metal printing ink is formed by evenly mixing liquid metal and magnetic liquid, gallium alloy serves as the liquid metal, the liquid gallium alloy can increase magnetism of the printing ink, meanwhile good conductivity of the liquid metal is maintained, the melting point of the liquid metal is increased, the magnetic liquid is mainly composed of soft magnetic nano magnetic particles, and water, organic solvent, oil or a mixture of the water, the organic solvent and the oil are added to serve as a base solution, so that the printing and forming effect is improved, and an ink material is not prone to magnetization. The magnetic liquid metal printing ink is simple in preparation method, good in formability, low in cost and has wide application prospect.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

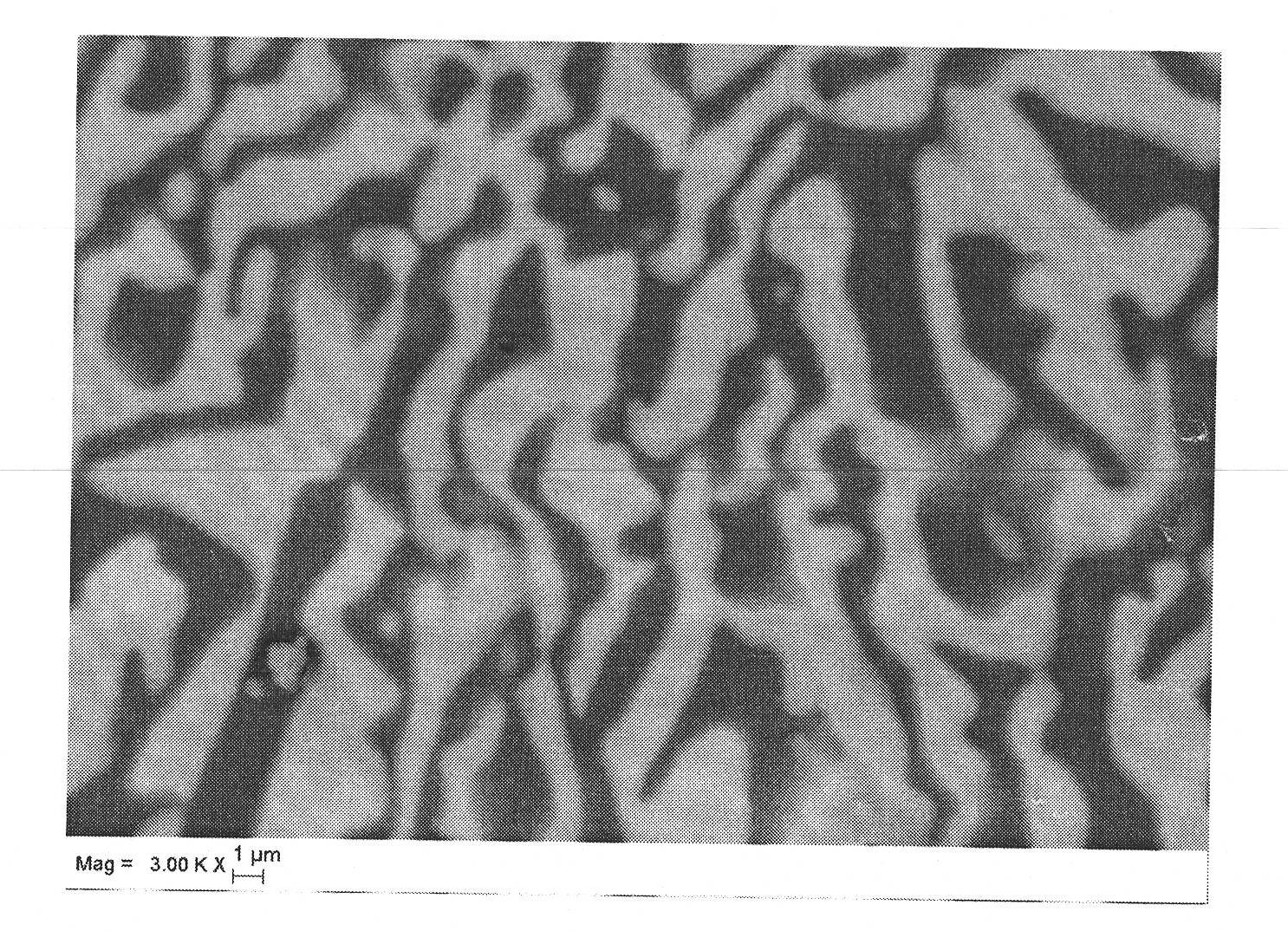

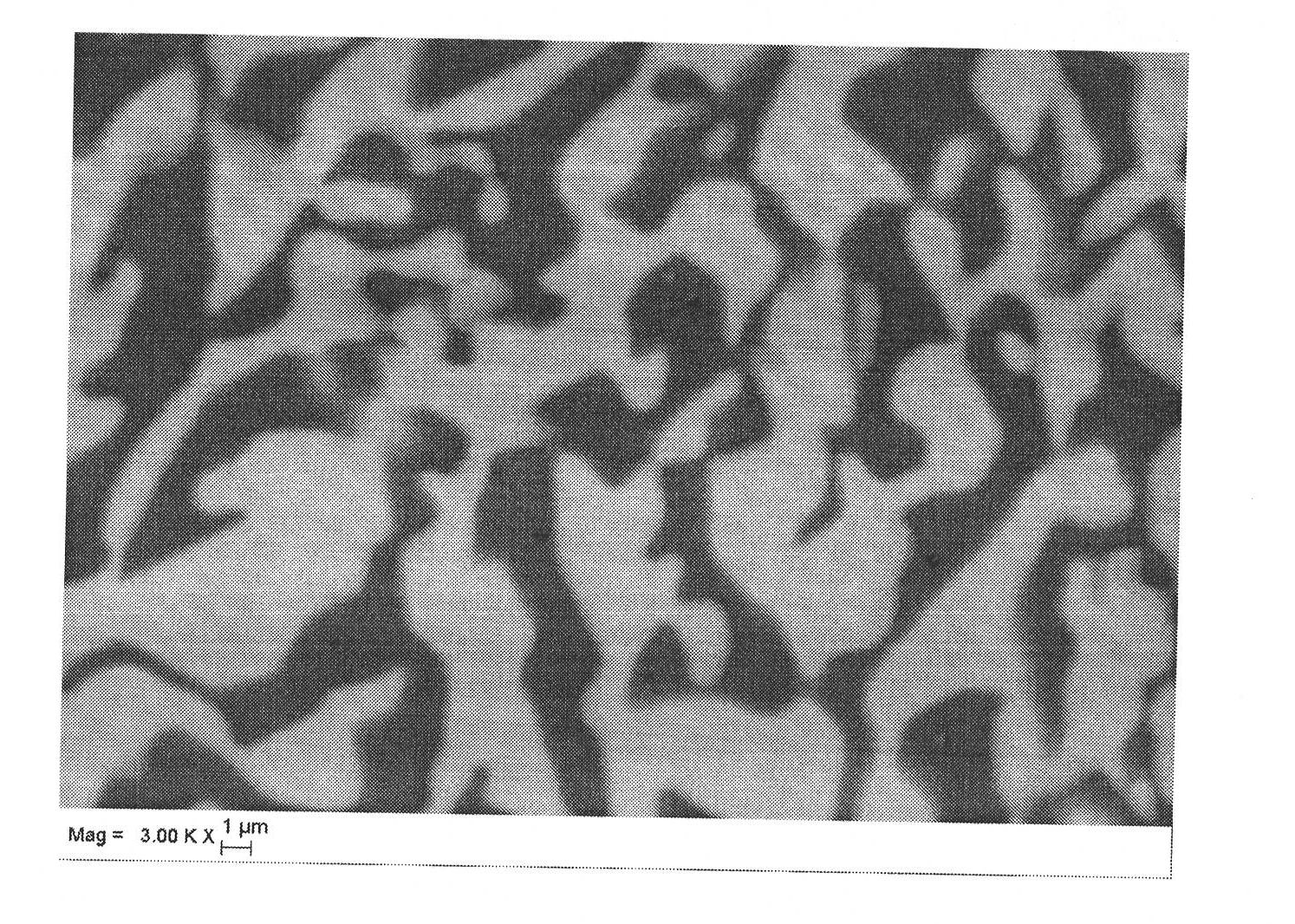

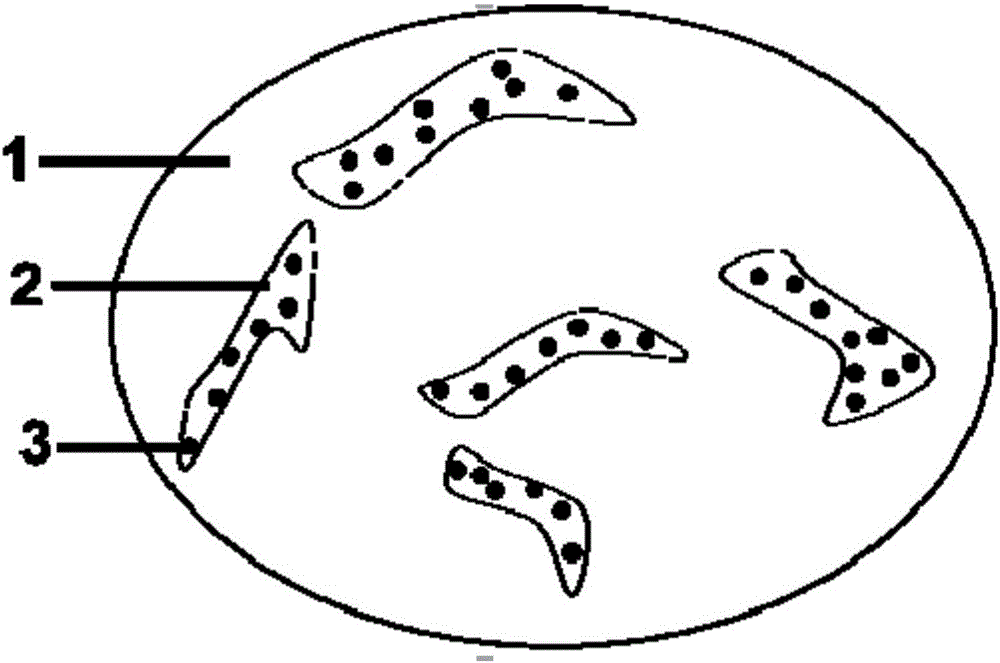

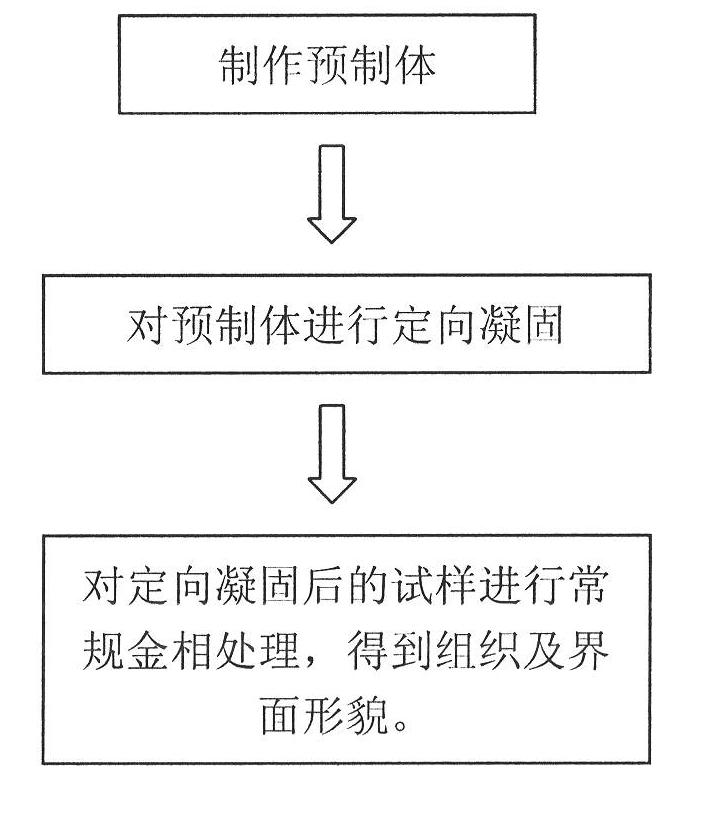

Method for obtaining texture topography of alumina-based binary eutectic melt growth ceramic

ActiveCN102020457AIncrease superheatIncreasing the temperature gradient of the solid phaseIndiumRare earth

The invention provides a method for obtaining the texture topography of alumina-based binary eutectic melt growth ceramic. The method comprises the following steps of: with a laser beam as a heating source and liquid gallium-indium-tin alloy as a cooling medium, respectively carrying out directional solidification on prefabticated members consisting of alumina and rare earth oxide; taking the vertical section and the cross section of each prefabticated member and performing conventional metallographical treatment; and carrying out surface metal spraying to finally obtain the texture topographies and the interface topographies of the alumina-based binary eutectic melt growth ceramic at different growth rates. In directional solidification, draw rate is 1mu m / s-10000 um m / s, and laser poweris 200W-1500W. By using the method, the obtained directional texture is quite different from a texture in a melting area and has no obvious texture transition area, and interface topography is preserved very well.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

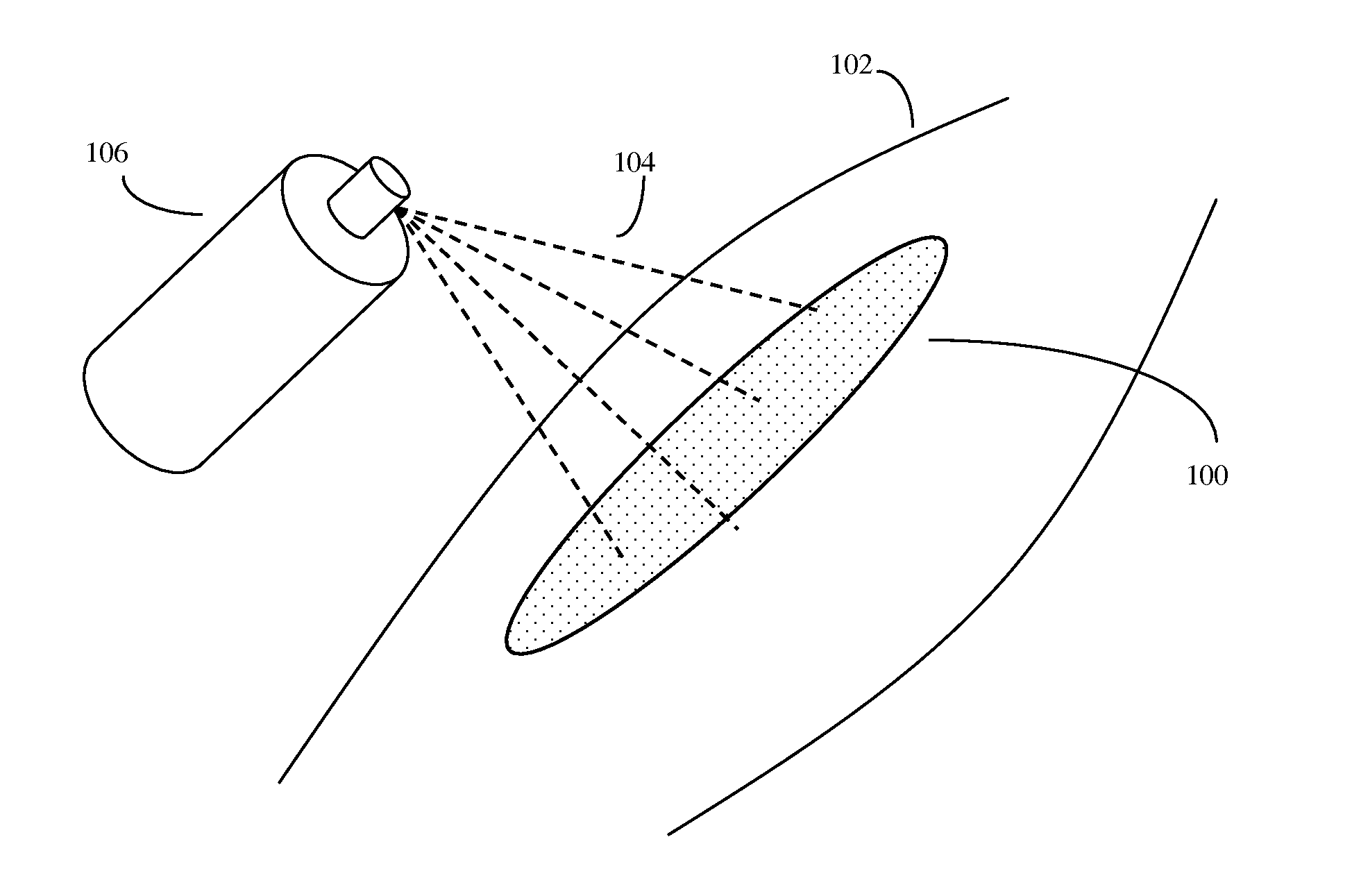

Method of wound treatment using liquid gallium nitrate

InactiveUS20110104246A1Promotion of the early stages of hemostasisBiocideHeavy metal active ingredientsAdditive ingredientTopical treatment

A pharmaceutical composition and method for topical wound treatment by topical treatment with gallium salts, preferably gallium nitrate. In a preferred embodiment, the gallium nitrate is in an aqueous form without coagulation inhibitors such as citrate. The aqueous gallium salt formulation may be administered by a variety of methods including spraying, topical lotions, topical foams, and / or bandages containing or packaged with breakable ampoules of aqueous gallium salt formulations, and liquid bandage formulations. The aqueous gallium salt formulation may additionally contain other active and inactive ingredients, such as viscosity modifying agents, foaming agents, antiseptics, antibiotics, enzymes, fibrinogen, fibrin, polymers and growth factors.

Owner:ROGOSNITZKY MOSHE

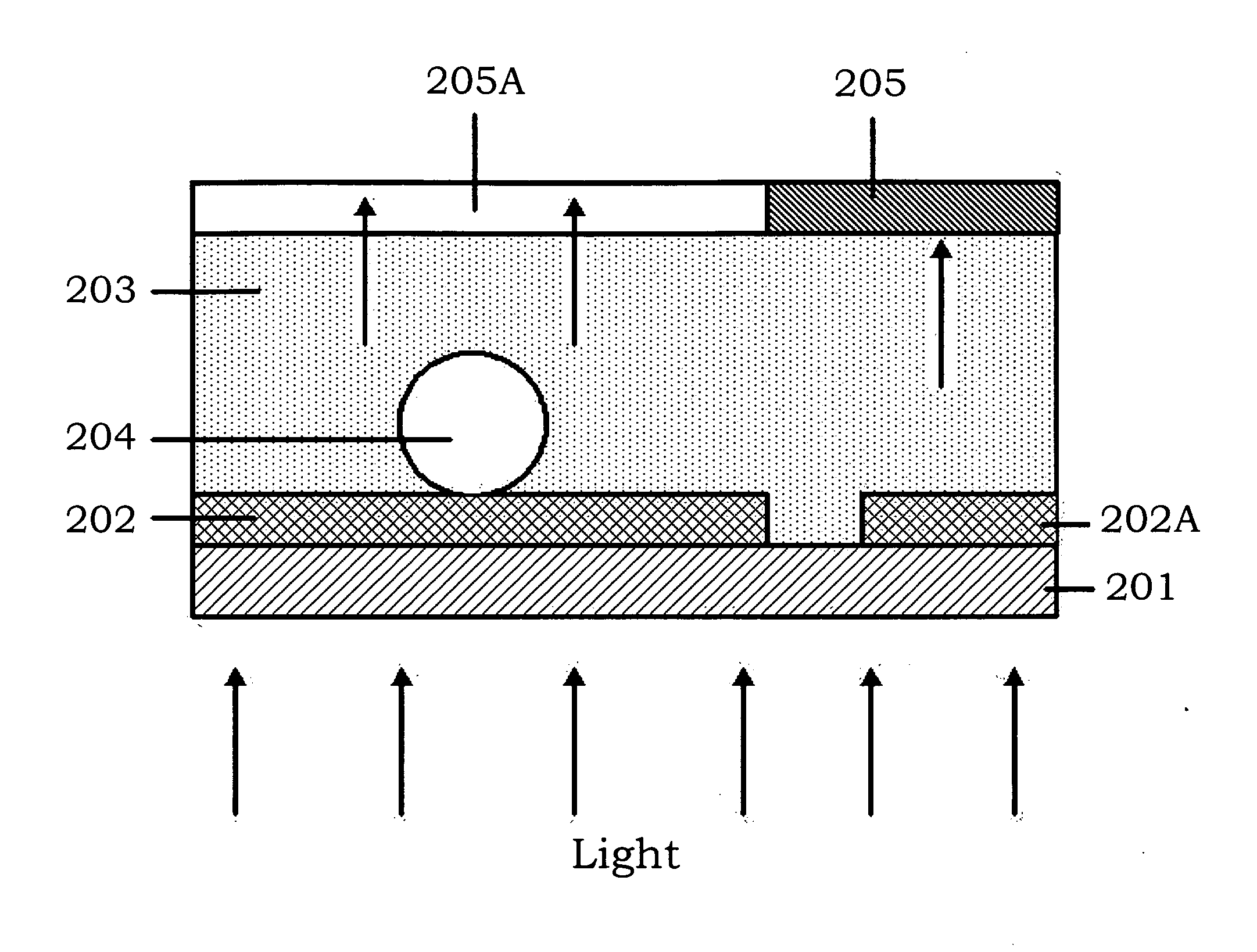

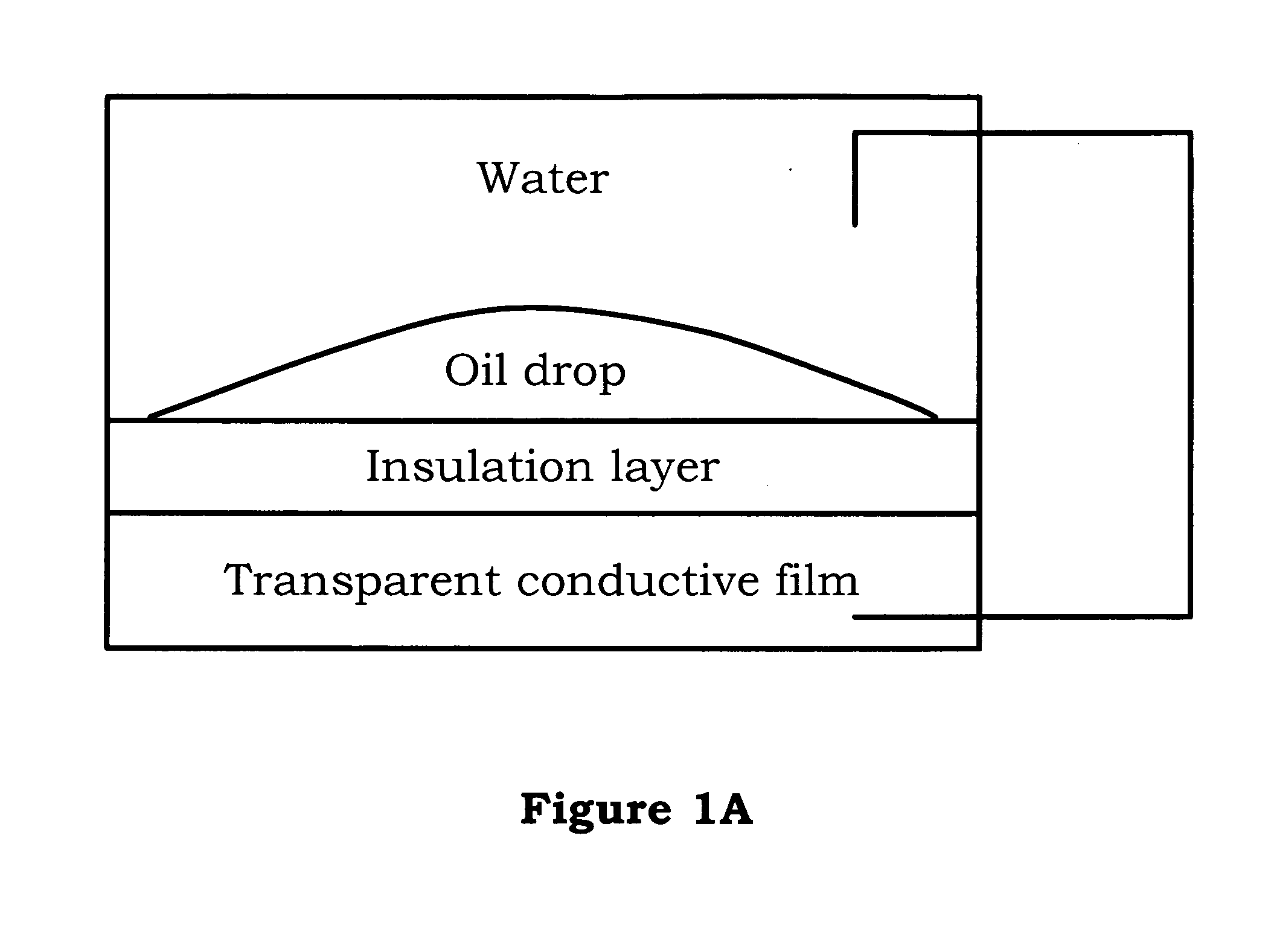

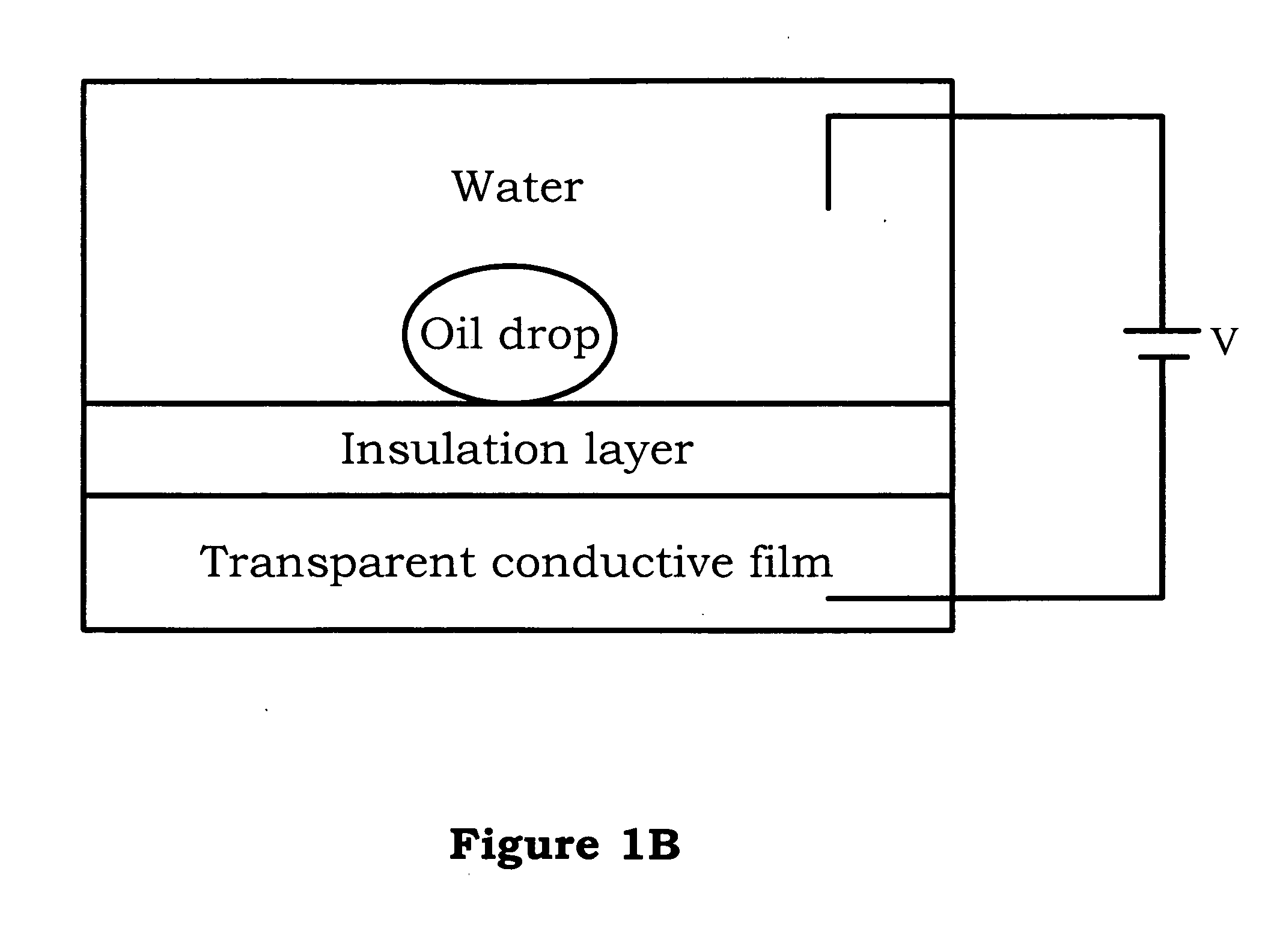

Electrical control light valve apparatus having liquid metal

ActiveUS20110194165A1Increase contrastFast switching speedOptical elementsElectrical controlLiquid metal

The present invention discloses an electrical control light valve apparatus having liquid gallium. The invention comprises the transparent glass as a substrate, ITO transparent conductive film as the electrodes, the liquid gallium as the valve located on the ITO transparent conductive film, and the partial-transparent glass is located on the top of the electrical control light valve apparatus.

Owner:NAT TAIWAN UNIV +1

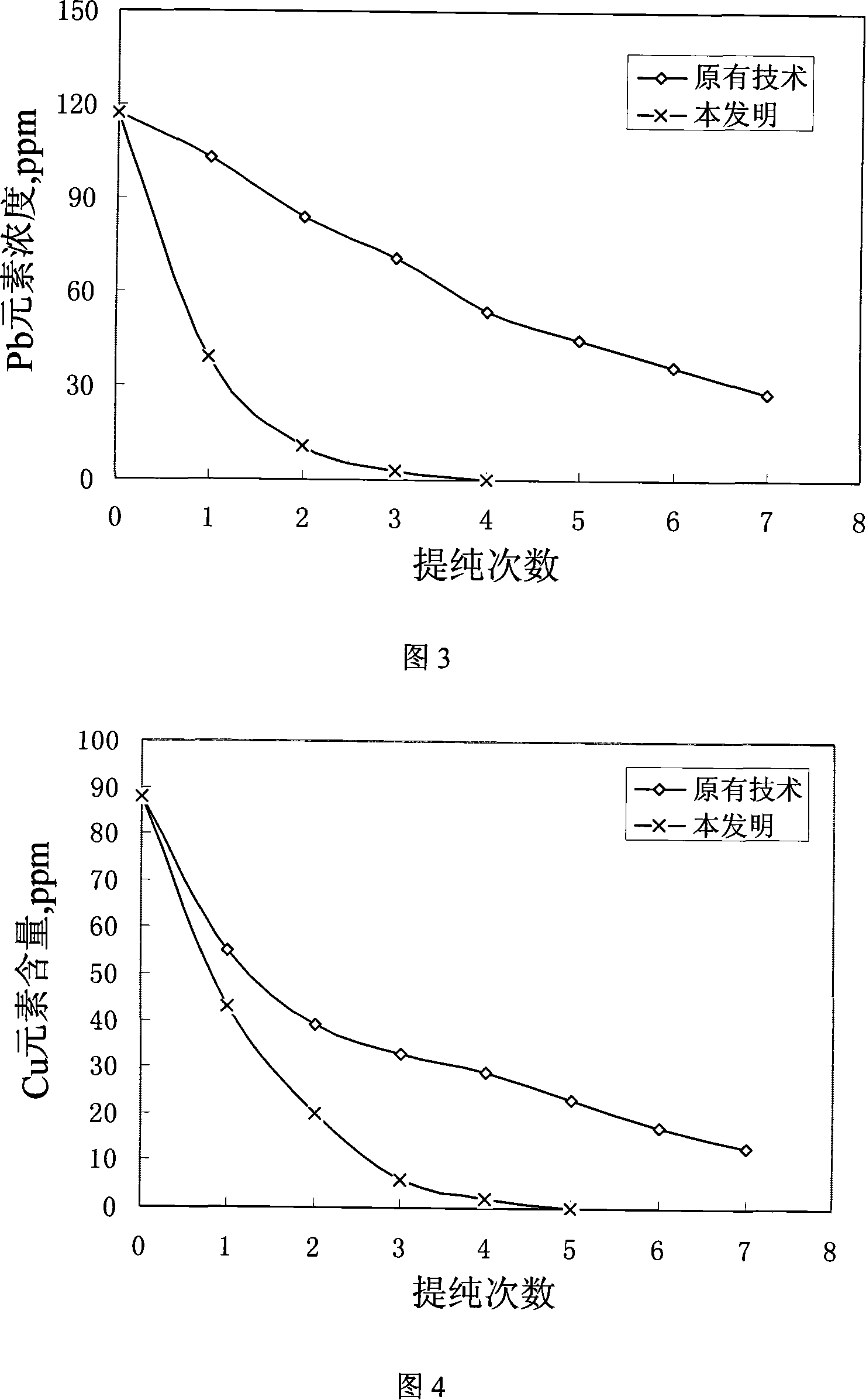

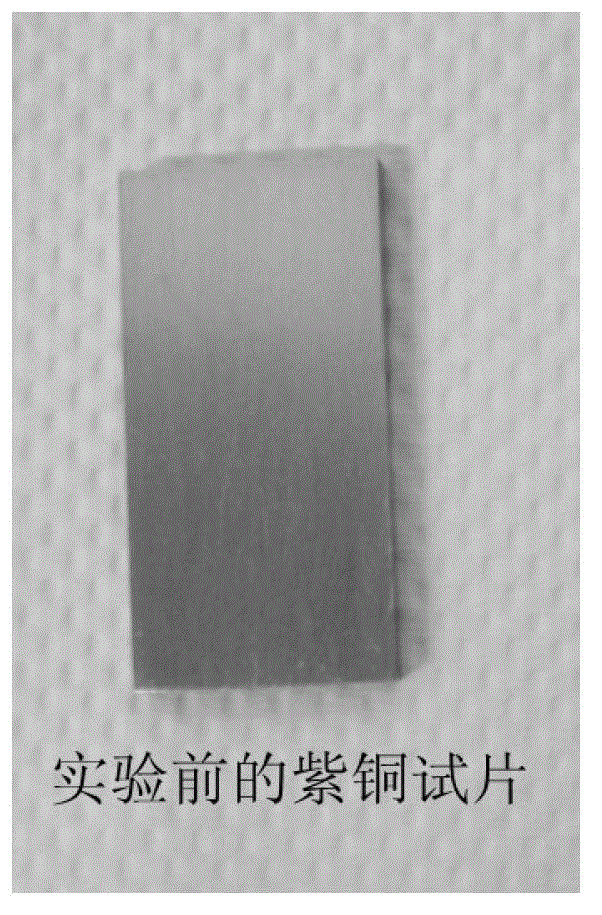

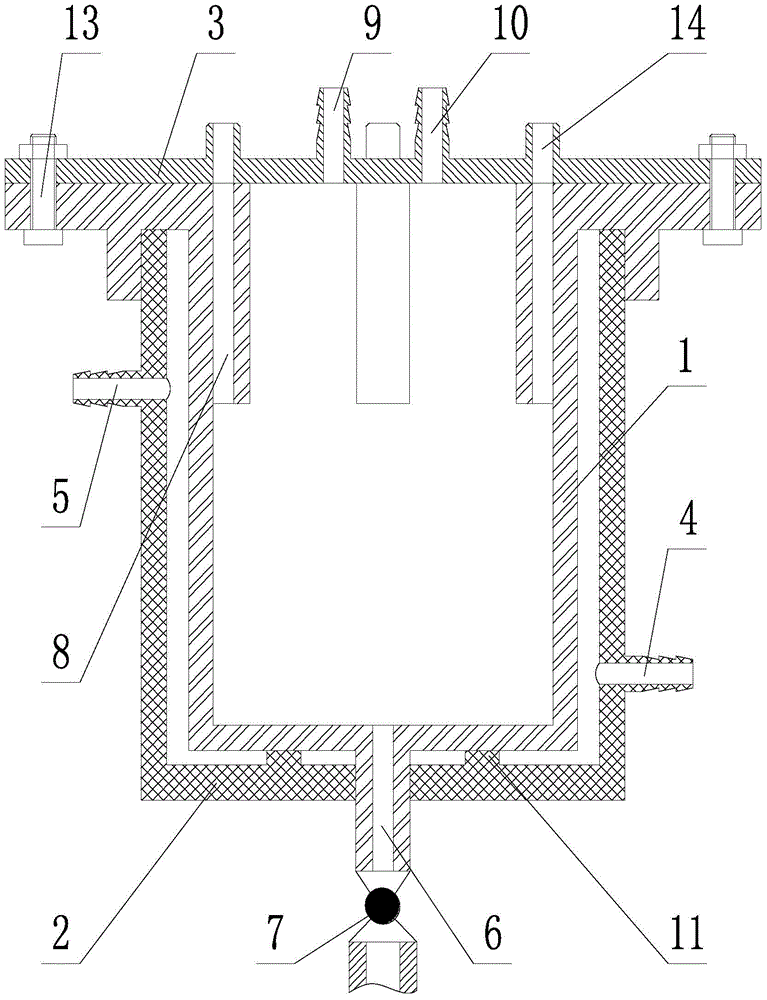

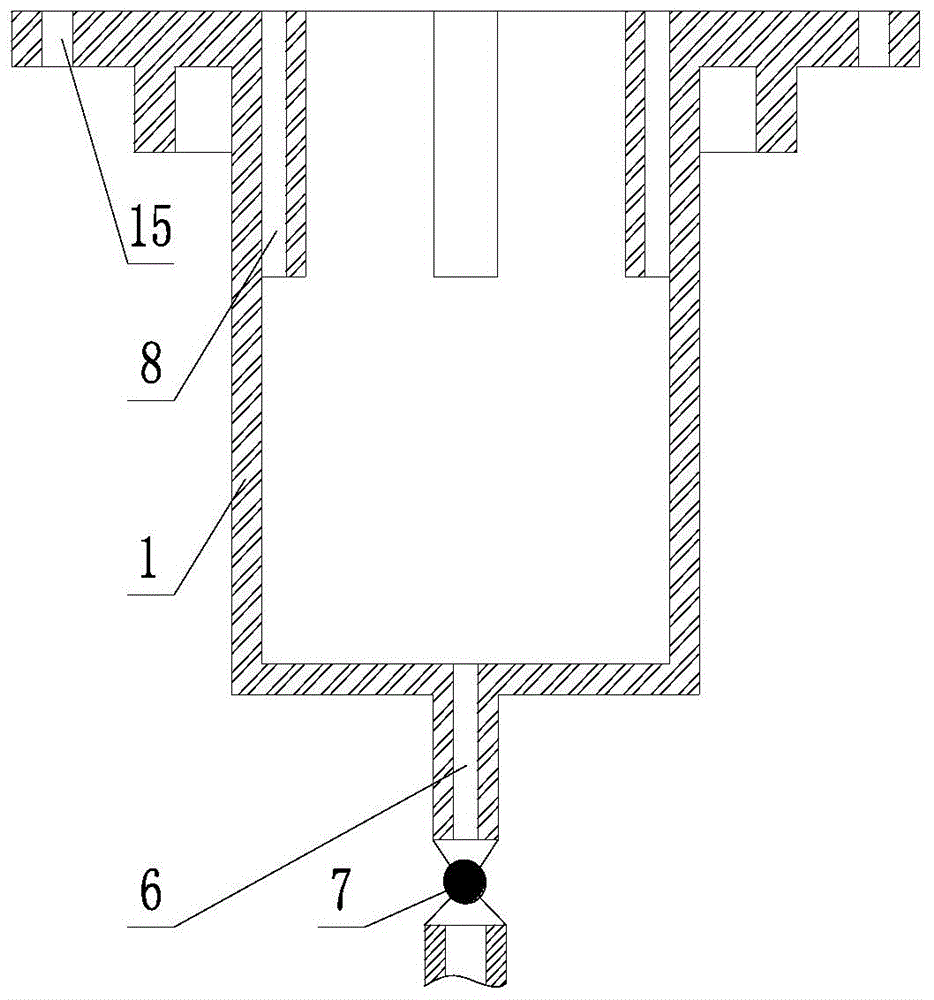

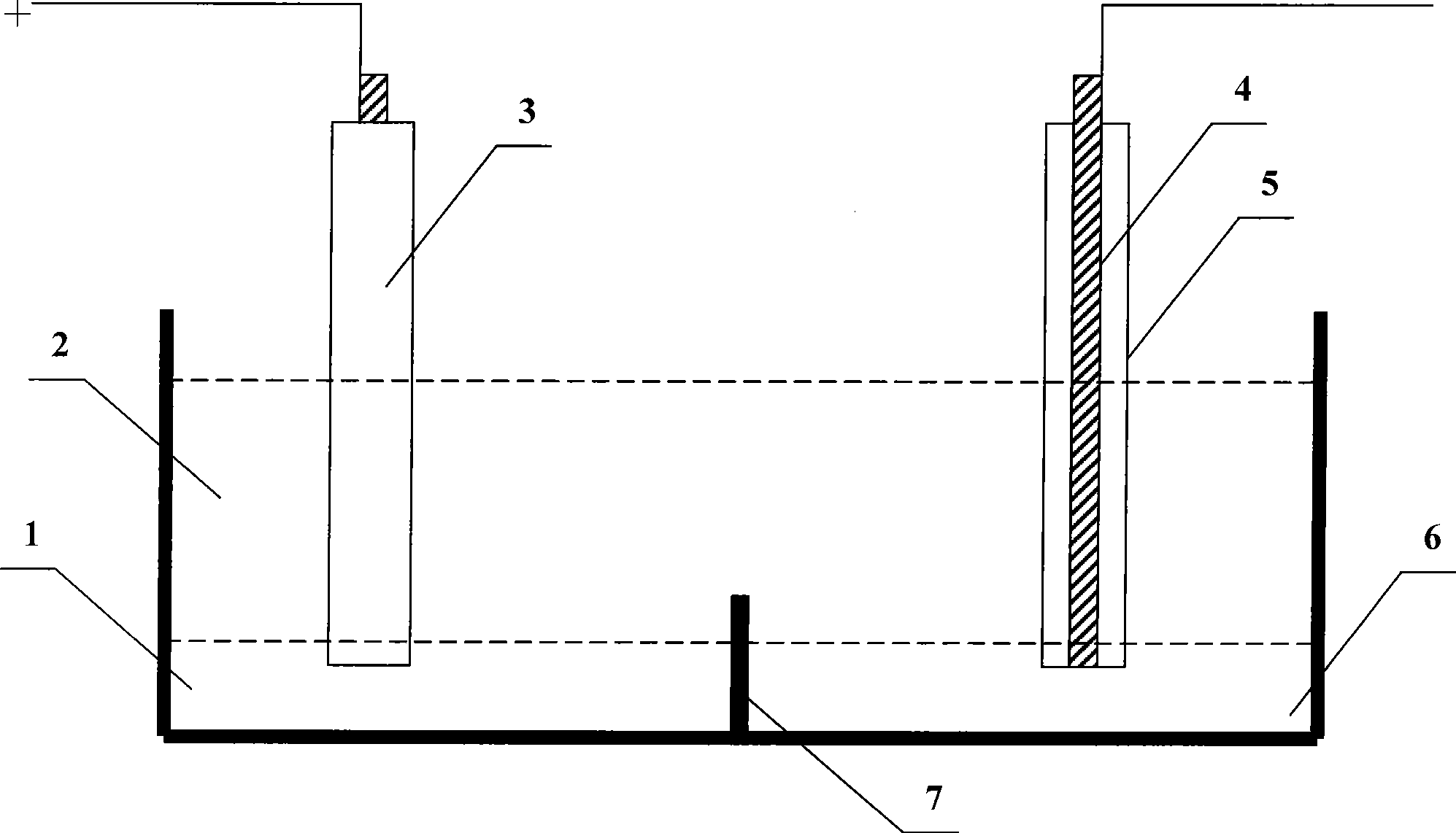

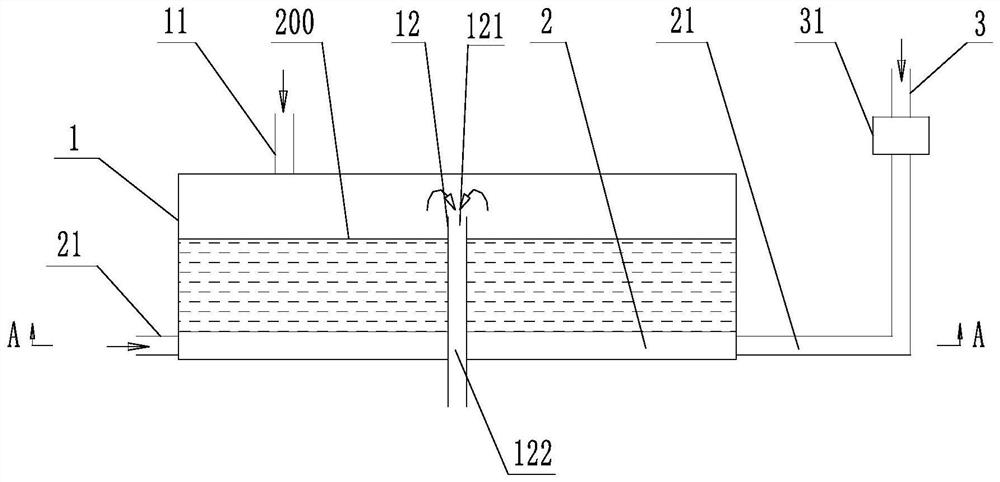

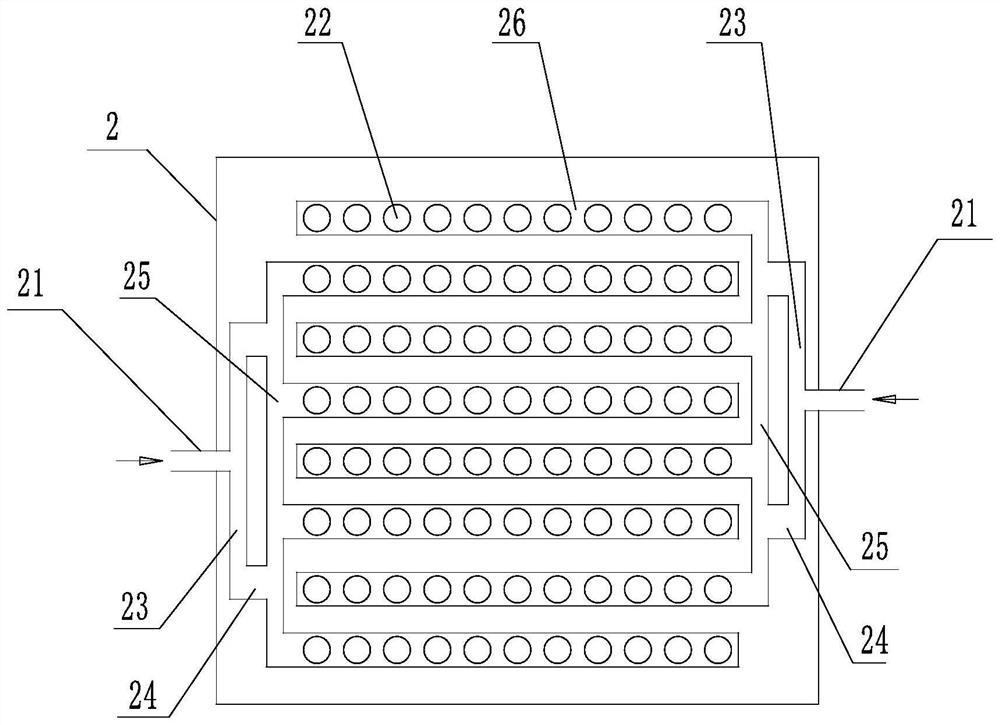

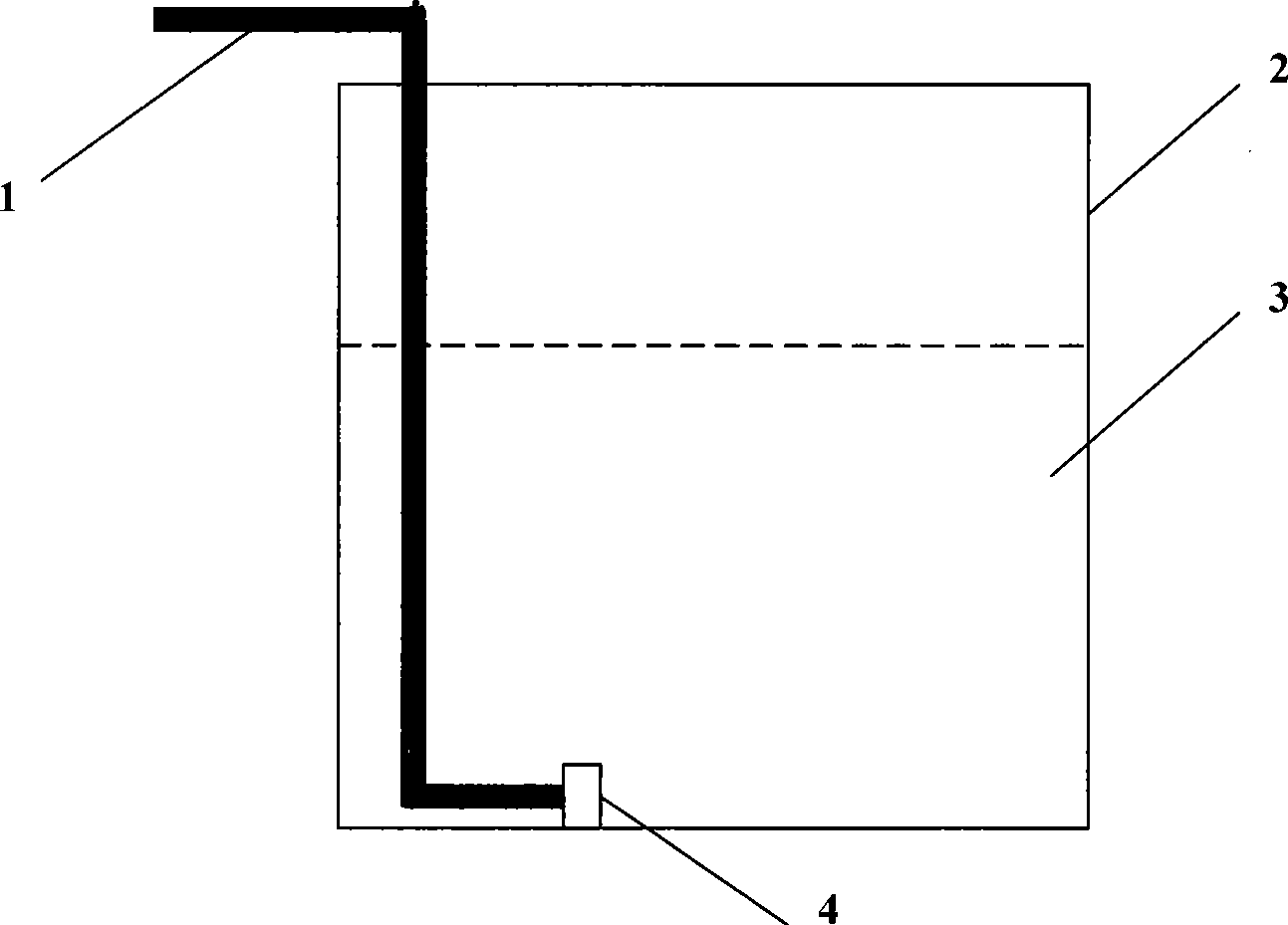

Device and method for preparing high-purity gallium

The invention provides a device and a method for preparing high-purity gallium, aims at the problems of the existing high-purity gallium preparation technology and belongs to the fields of the preparation equipment and the preparation technology of the high-purity gallium. The device comprises an inner container, an outer container and a cover; the inner container is located inside the outer container; a cavity for cold water and hot water to circulate alternately is arranged between the inner container and the outer container; the drainage tube of the inner container extends out of the outer container via the drainage tube passing hole of the outer container; the inner container is hermetically connected with the outer container; the cover is fixed on the top of the device. The method comprises the following steps: putting coarse gallium into the inner container, introducing cooling water into the cavity between the inner container and the outer container to crystallize the gallium, when the solidification rate of the gallium is within the range of 90-97%, discharging the left liquid gallium and then introducing hot water to melt the gallium, next, introducing the cooling water, and repeating crystallization for 6-8 times to improve the purity, thereby obtaining the high-purity gallium of 6N or 7N. The application method of the device is simple and convenient to operate; the obtained gallium is high in purity and high in yield, and has favorable application prospect.

Owner:NORTHEASTERN UNIV

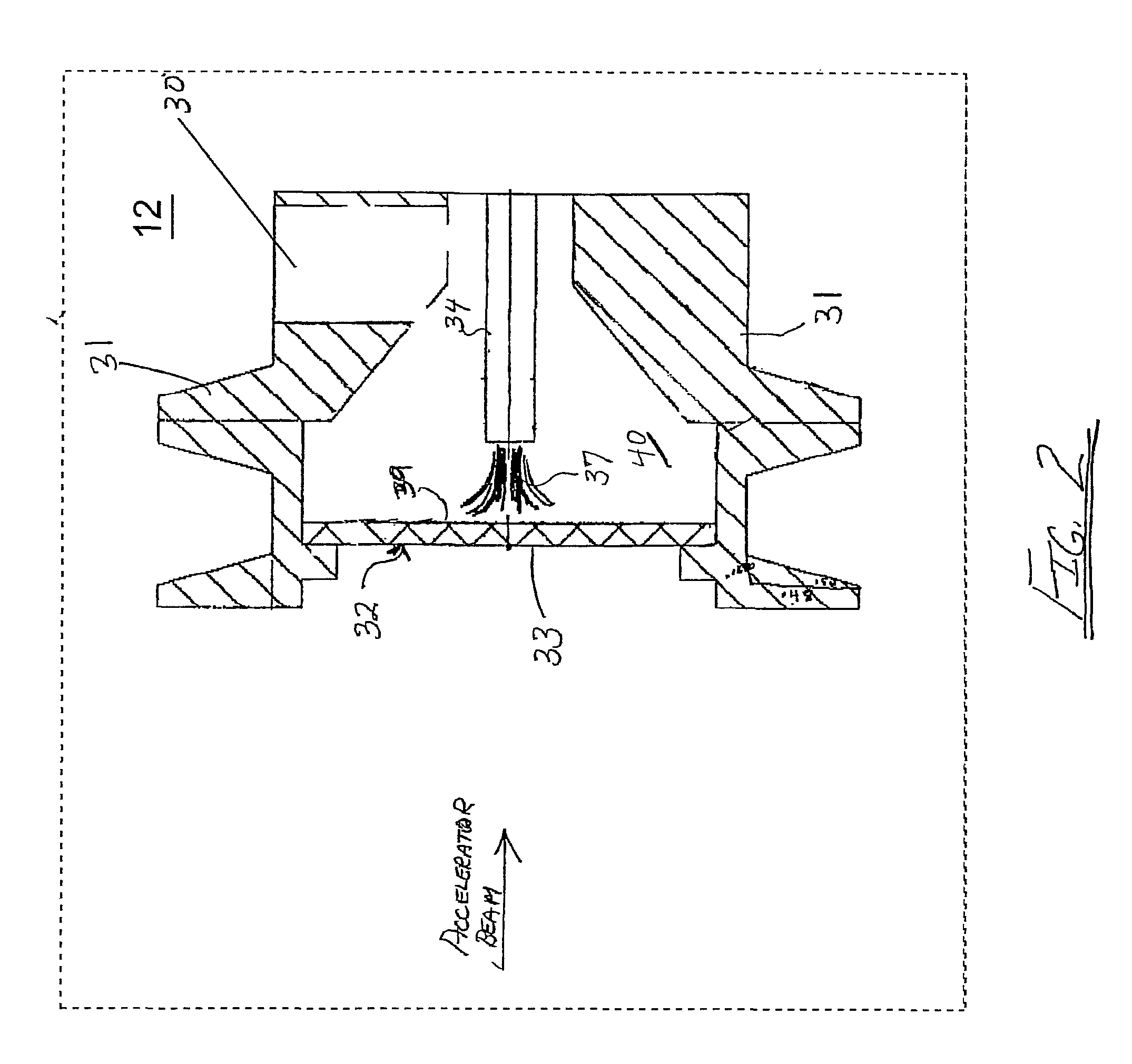

Liquid gallium cooled high power neutron source target

InactiveUS7978805B1Improve heat transfer performanceSmall flow rateConversion outside reactor/acceleratorsNuclear targetsControl flowProton

A neutron source includes a low atomic number element target that is bombarded by incident energetic particles to provide a neutron flux. The source receives a controlled flow of liquid gallium that cools the target. The energetic particles may be for example protons or deuterons and the target is housed in a moderator / reflector assembly. Advantageously, the liquid gallium provides improved heat transfer, smaller flow rates and reduced stress on the target in comparison to prior art liquid coolants.

Owner:MASSACHUSETTS INST OF TECH

Movable hydrogen source preparation method

The invention provides a movable hydrogen source preparation method, and relates to a metal material preparation method. The movable hydrogen source preparation method aims at solving the problems that a traditional hydrogen preparation technology is complicated, high in cost and low in production efficiency and potential safety hazard exists in transportation. The movable hydrogen source preparation method comprises the following steps: step one, fixing a metal aluminum sheet, and scrubbing the upper surface of the aluminum sheet by using an organic solvent; step two, preparing metallic gallium for later use: taking a right amount of metallic gallium and putting the metallic gallium in a beaker, heating the beaker till the metallic gallium is molten into liquid; step three, dumping liquid gallium in the step two onto the upper surface of the aluminum sheet, and heating the zone with the liquid gallium from the lower part of the aluminum sheet; step four, eliminating an oxidation film; step five, enabling a supersonic vibration device to closely contact with the aluminum sheet; step six, obtaining an aluminum-gallium alloy, to be specific, turning on the supersonic vibration device, so that the liquid gallium and the aluminum sheet mechanically vibrate together with the end of a supersonic tool head, and the liquid gallium enters the aluminum sheet, thereby obtaining the aluminum-gallium alloy with the uniform microstructure; and step seven, obtaining hydrogen. The movable hydrogen source preparation method is used for preparing hydrogen.

Owner:HARBIN INST OF TECH

Electrode lead for electrolyzing metal gallium

InactiveCN101413135ASolving Corrosion ProblemsEliminate pollutionPhotography auxillary processesProcess efficiency improvementPlatinumElectrolysis

The invention discloses an electrode lead wire used in the process of gallium metal electrolysis, which is made of solid gallium metal, wherein a lead wire of the solid gallium metal is provided with a cooling device which is a cooling fluid circulating cooling device. The design uses the solid gallium metal as the lead wire of a liquid gallium electrode to solve the problem that the liquid gallium erodes various metal material lead wires; and with the solid gallium metal lead wire, the pollution caused by nickel to refined gallium is thoroughly eliminated. While greatly improving the electrolysis refining effect, the electrode lead wire greatly reduces the production cost and reduces the consumption of noble metals such as platinum.

Owner:NANJING JINMEI GALLIUM

A device and method for preparing high-purity gallium

Owner:NORTHEASTERN UNIV LIAONING

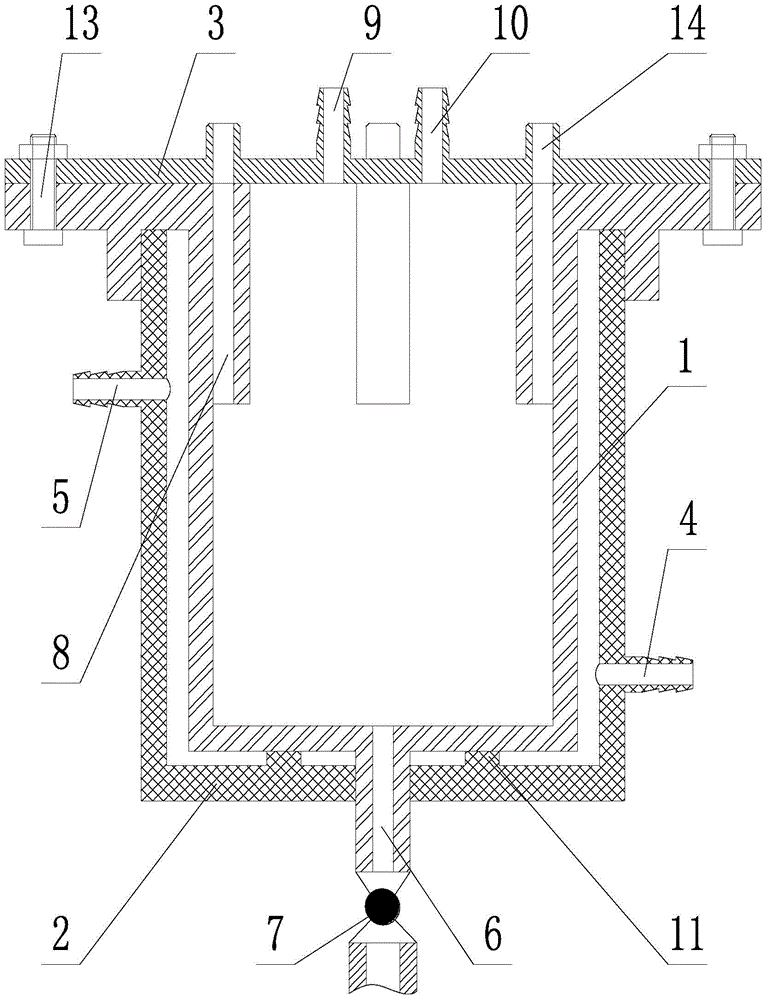

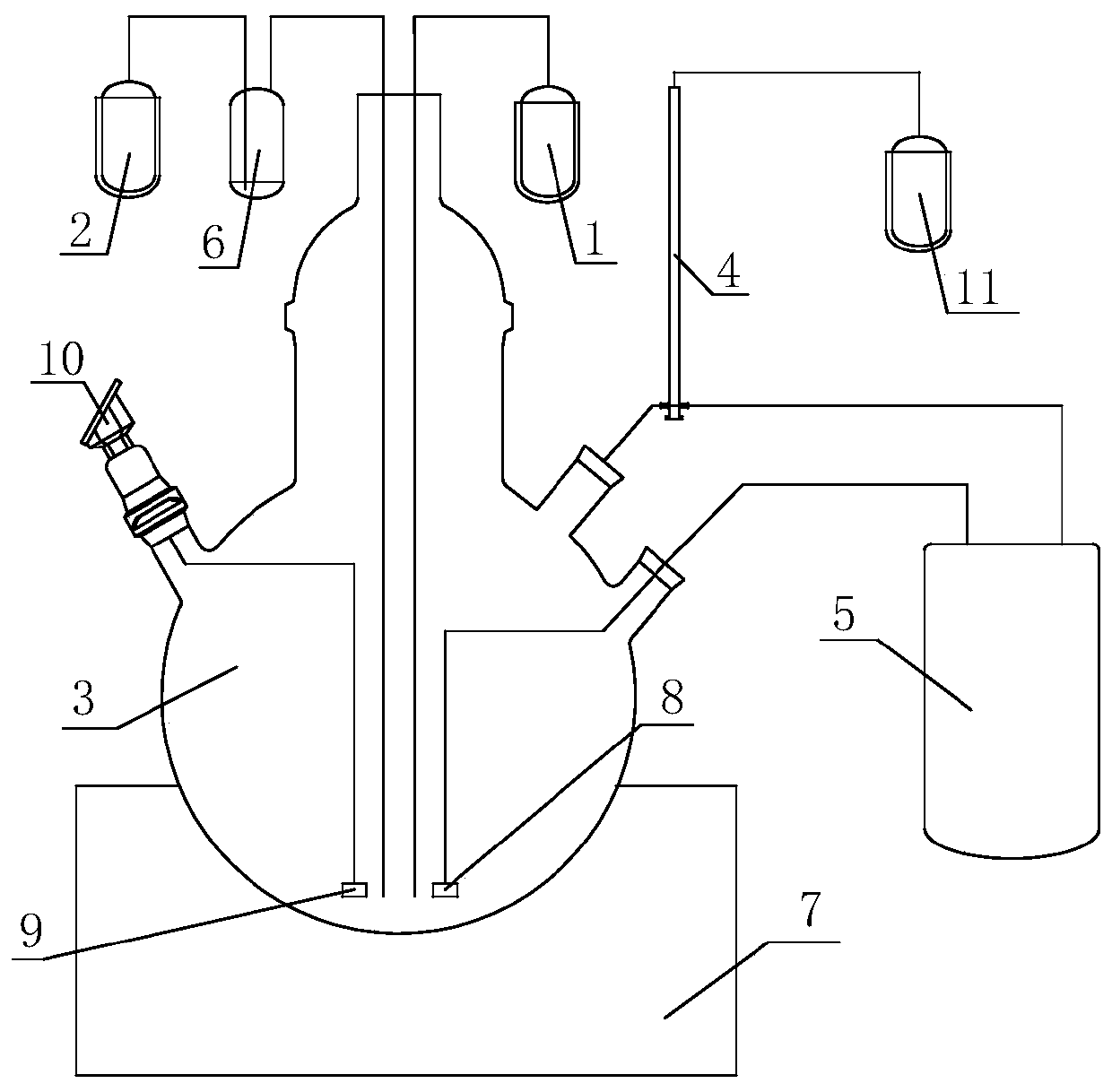

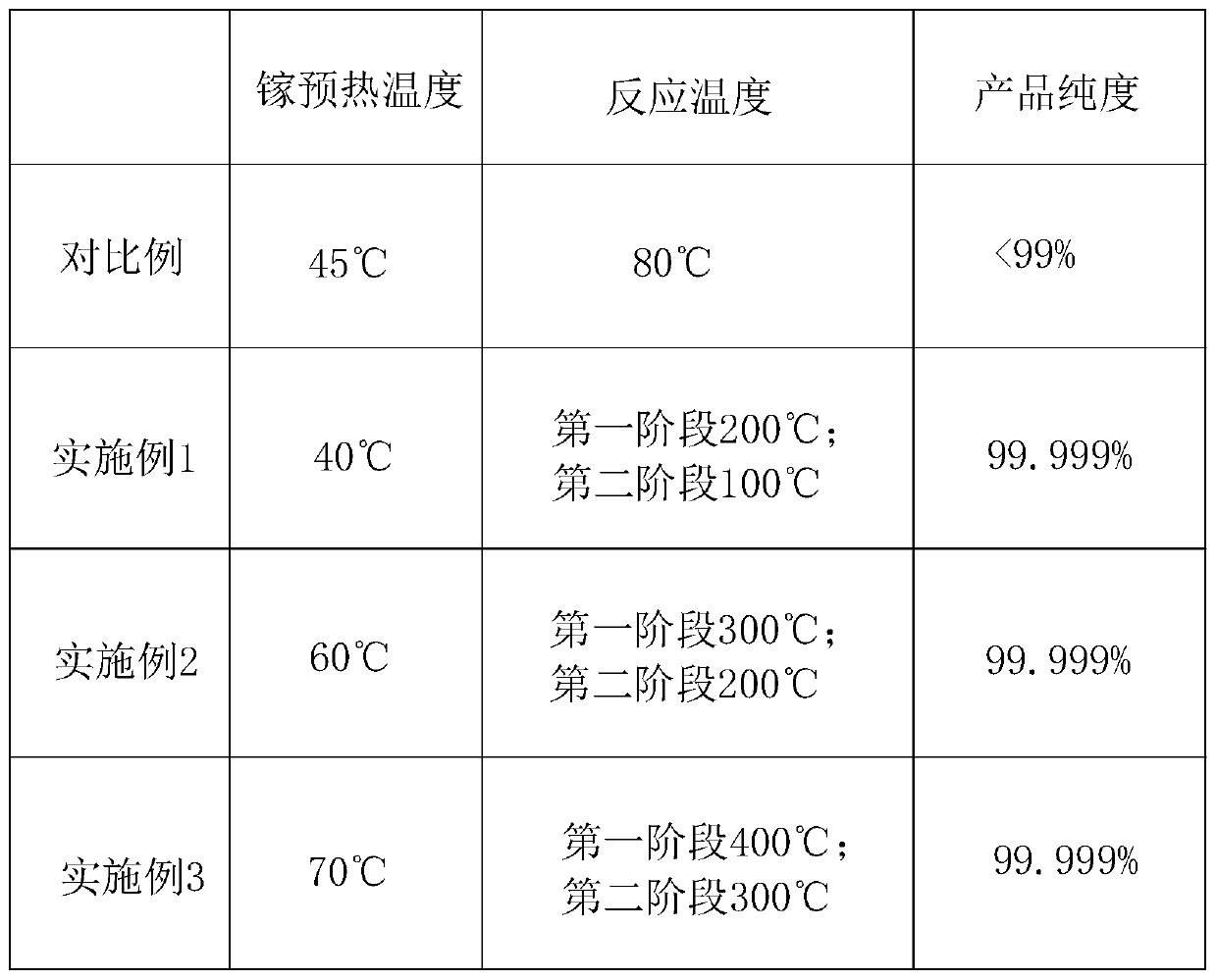

Method and equipment for preparing gallium trichloride

ActiveCN111072058ASolve technical problemsGallium/indium/thallium compoundsPressure vessel componentsReaction temperatureWater chlorination

The invention discloses a method for preparing gallium trichloride. The method comprises the following steps: adding liquid metal gallium into a reaction kettle, and introducing chlorine into the liquid metal gallium; controlling the temperature of the reaction kettle to be 200-400 DEG C, and obtaining a main product gallium monochloride and a byproduct gallium trichloride after a first preset time period; controlling the temperature of the reaction kettle to be 100-300 DEG C, and obtaining liquid gallium trichloride and gaseous gallium trichloride after a second preset time period; evaporating the obtained gaseous gallium trichloride into a fractionating tube, and performing cooling to enable the gaseous gallium trichloride to become liquid gallium trichloride to flow into a storage device. According to the method for preparing gallium trichloride provided by the invention, by setting reactions of two stages and setting different reaction temperatures of the two stages, the technicalproblem that a large amount of gallium monochloride and chlorine impurities are generated when chlorine is directly introduced into liquid metal gallium for reaction in the prior art can be effectively solved.

Owner:昆明先导新材料科技有限责任公司

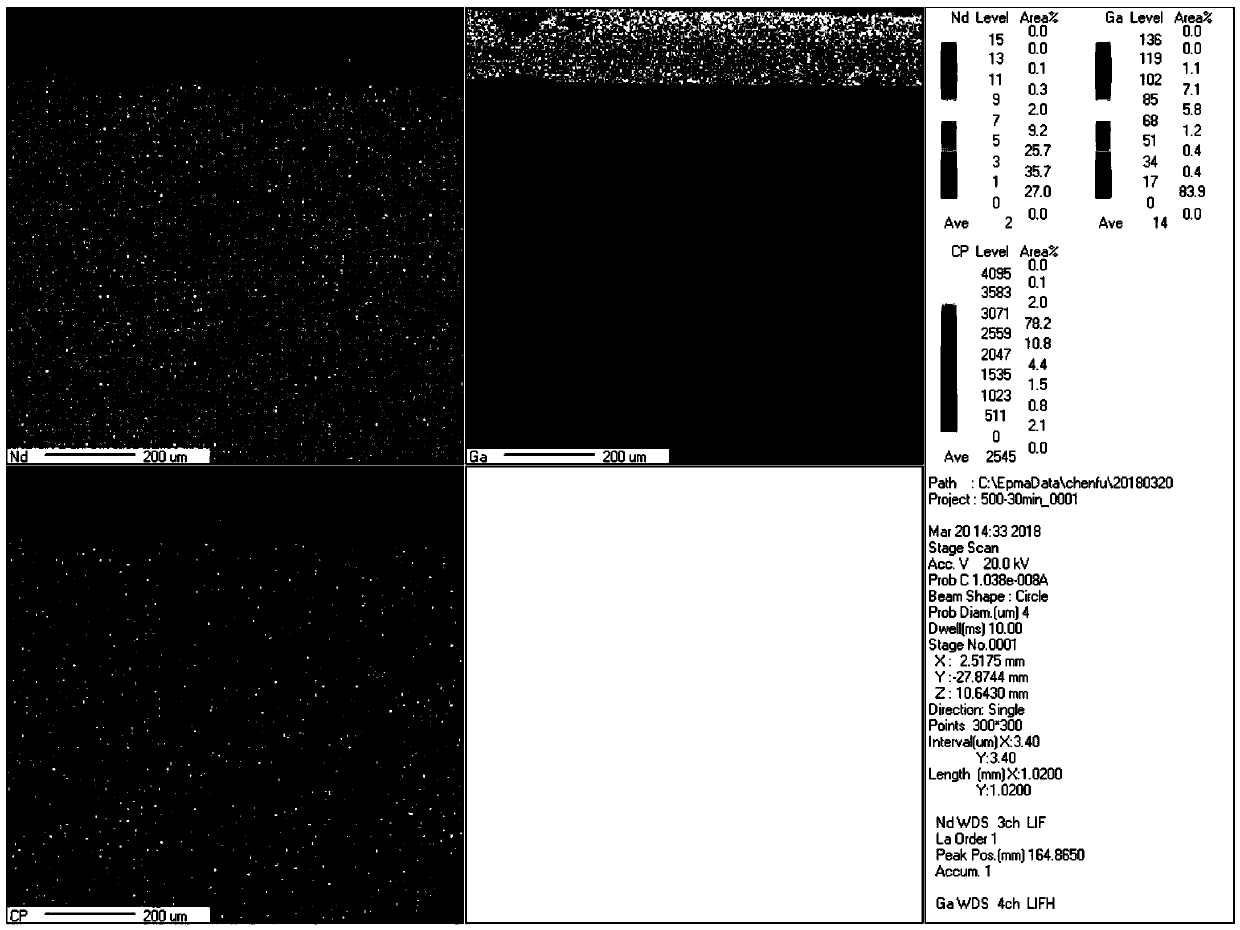

Method for improving corrosion resistance and coercive force of sintered neodymium-iron-boron magnet

InactiveCN108682550AImprove corrosion resistanceImprove coercive forceSolid state diffusion coatingPermanent magnet manufactureCrucibleGallium alloy

The invention provides a method for improving corrosion resistance and coercive force of a sintered neodymium-iron-boron magnet, and belongs to the technical field of magnetic materials. The performance of the magnet is improved by adopting a method that the sintered neodymium-iron-boron magnet is soaked in a liquid gallium solution at a certain temperature. The method particularly comprises the steps that firstly a pretreated sintered neodymium-iron-boron magnet and moderate solid gallium are taken to be placed in a crucible, then the crucible is placed in a vacuum thermal treatment furnace to be heated, wherein the temperature is 400-600 DEG C, the time is 0.5-1 hour, then after the thermal treatment is completed, the crucible is taken out and heated in the air until the temperature is 30 DEG C, then the magnet is taken out from the melted gallium. The corrosion resistance and coercive force of the treated magnet are improved.

Owner:BEIJING UNIV OF TECH

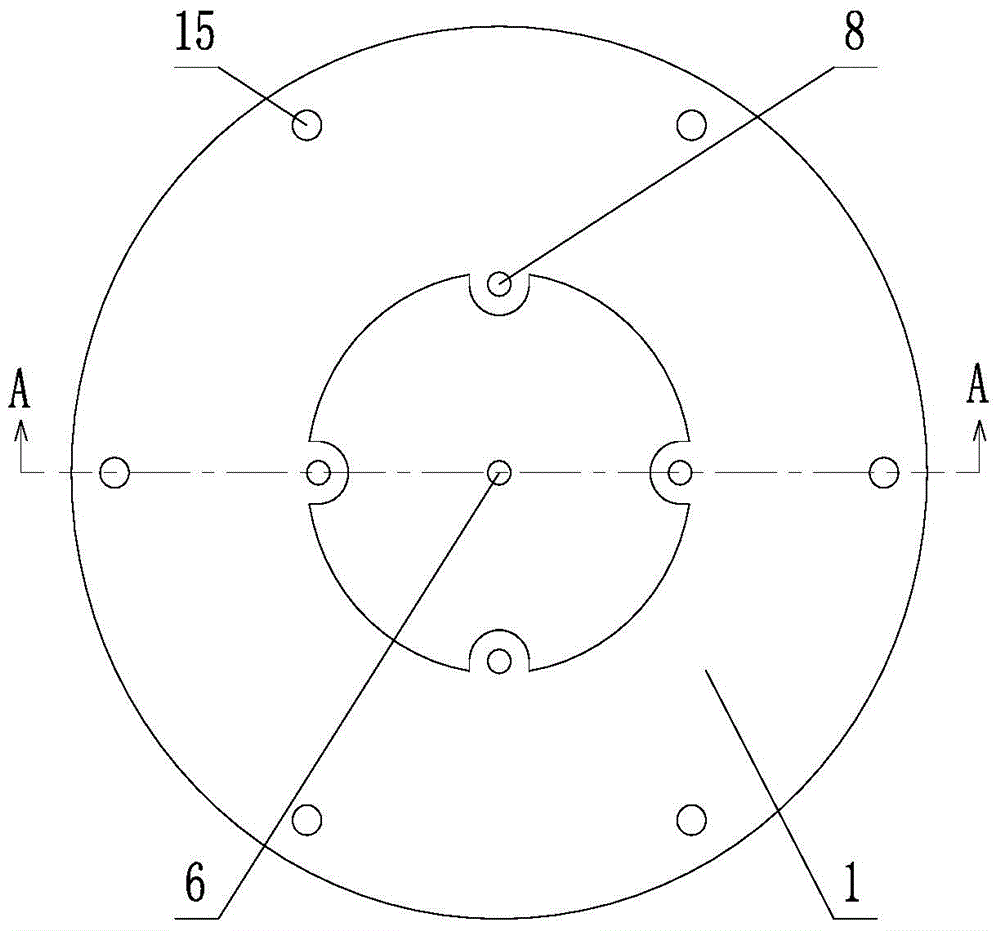

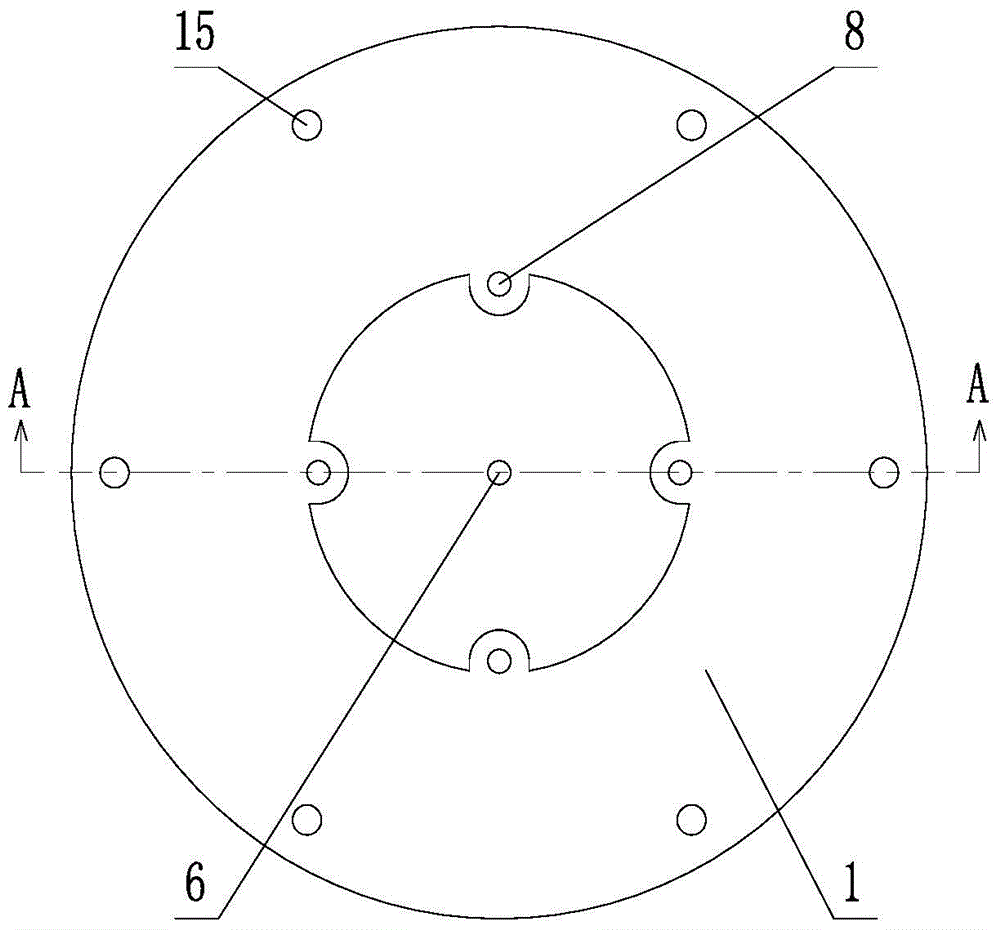

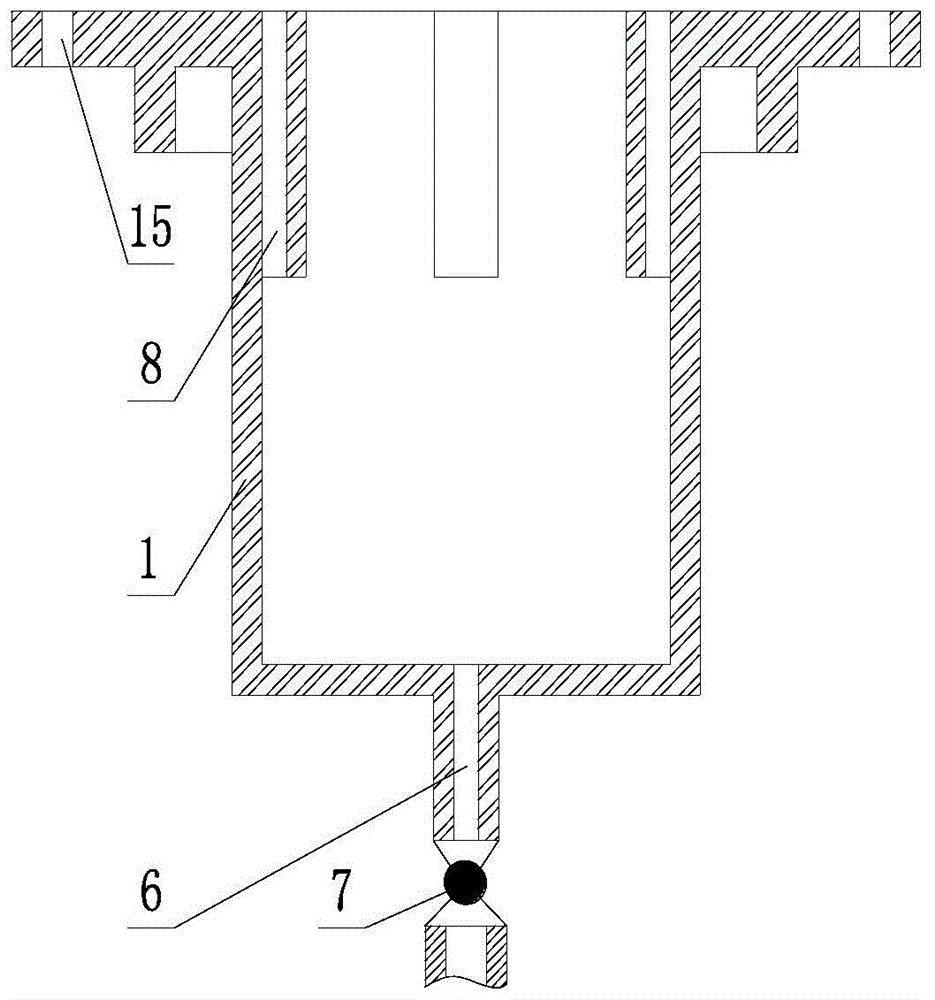

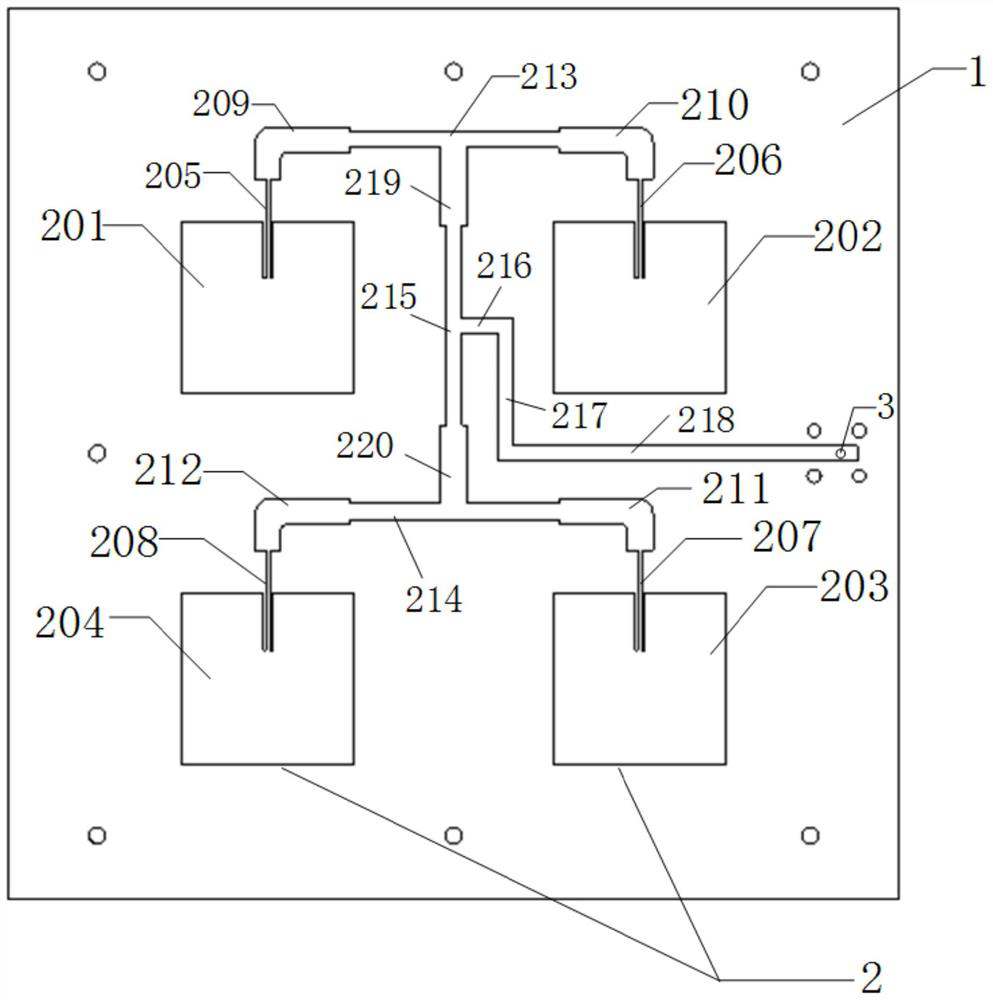

Hydride vapor phase epitaxy gallium boat structure

ActiveCN112126976AExtended pathImprove conversion ratePolycrystalline material growthFrom chemically reactive gasesVapour phase epitaxyEngineering

The invention relates to the technical field of semiconductors, and discloses a hydride vapor phase epitaxy gallium boat structure which comprises a boat body, and further comprises a gallium source inlet formed in the top of the boat body. A liquid gallium source is contained in the boat body. A reactant outlet pipeline arranged in the boat body, the top end of thereactant outlet pipeline is higher than the liquid level of theliquid gallium source, the bottom end of the reactant outlet pipeline penetrates out of the bottom wall of the boat body; a gas distribution disc is also arranged on thebottom wall in the boat body, a hydrogen chloride inlet is formed in the side face of the gas distribution disc, at least one hydrogen chloride outlet is formed in the top end of a pipeline of the gas distribution disc, and each hydrogen chloride outlet is located below the liquid level of the liquid gallium source. The gallium boat structure has the advantages that the hydrogen chloride conversion rate is high, the contact area of hydrogen chloride and a liquid gallium source is large, and the hydrogen chloride path is effectively prolonged.

Owner:紫石能源有限公司

Chemical extraction method and apparatus for metal gallium

ActiveCN101413067AImprove extraction efficiencySimple structureProcess efficiency improvementLiquid stateEngineering

The invention discloses a chemical extraction device for metallic gallium. The device comprises an extraction container, wherein the bottom of the extraction container is provided with a hole; compressed gas is blown into the extraction container through the hole; and the hole is provided with a one-way valve plate for preventing liquid in the extraction container from flowing out. A chemical extraction device for metallic gallium comprises a step of leading gas into the bottom of the extraction container so as to roll and stir the liquid in the extraction container. The invention greatly improves extraction efficiency and obtains extremely good extraction effects. Experimental data shows that the content of zinc and copper in liquid gallium can be reduced from 500-300 ppm to less than 1 ppm after the liquid gallium is extracted three times by use of the device, so the invention is remarkable in purification effects. The device has the advantages of simple structure, low cost, convenient maintenance and easy popularization, thereby laying a low-cost industrialized mass-production foundation for further extracting high-purity metallic gallium.

Owner:朝阳金美镓业有限公司

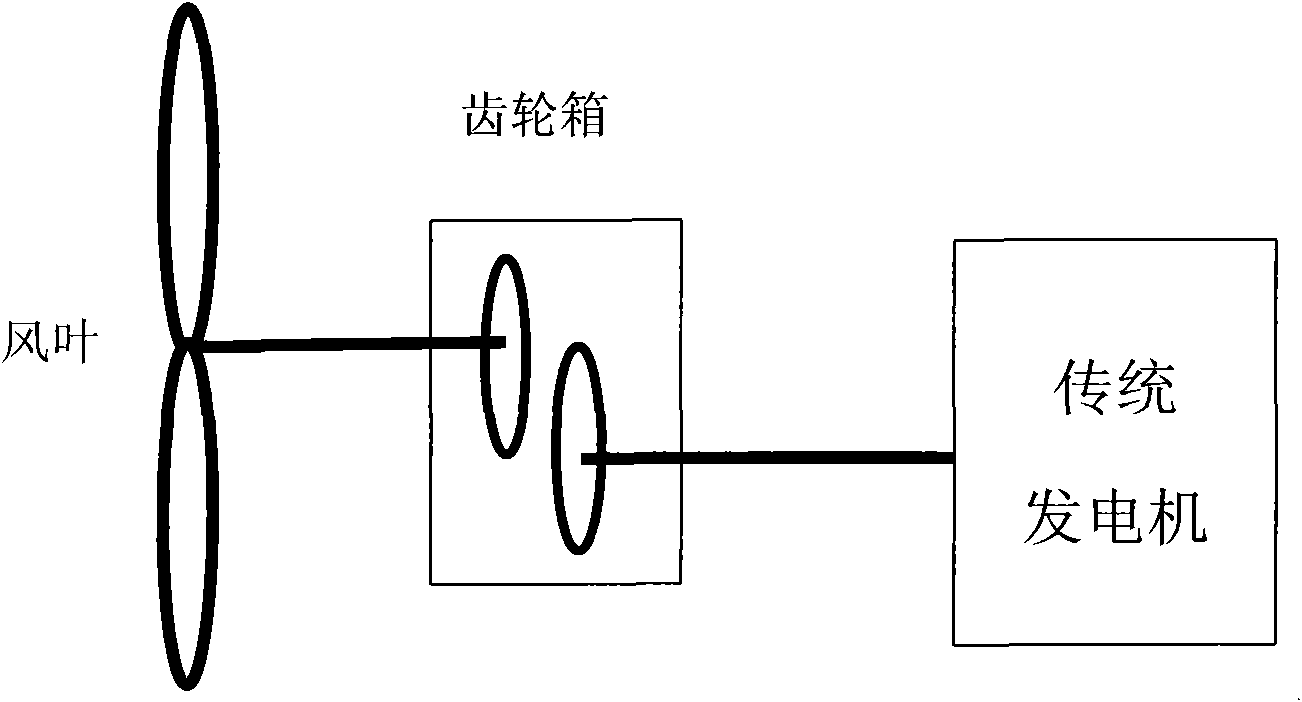

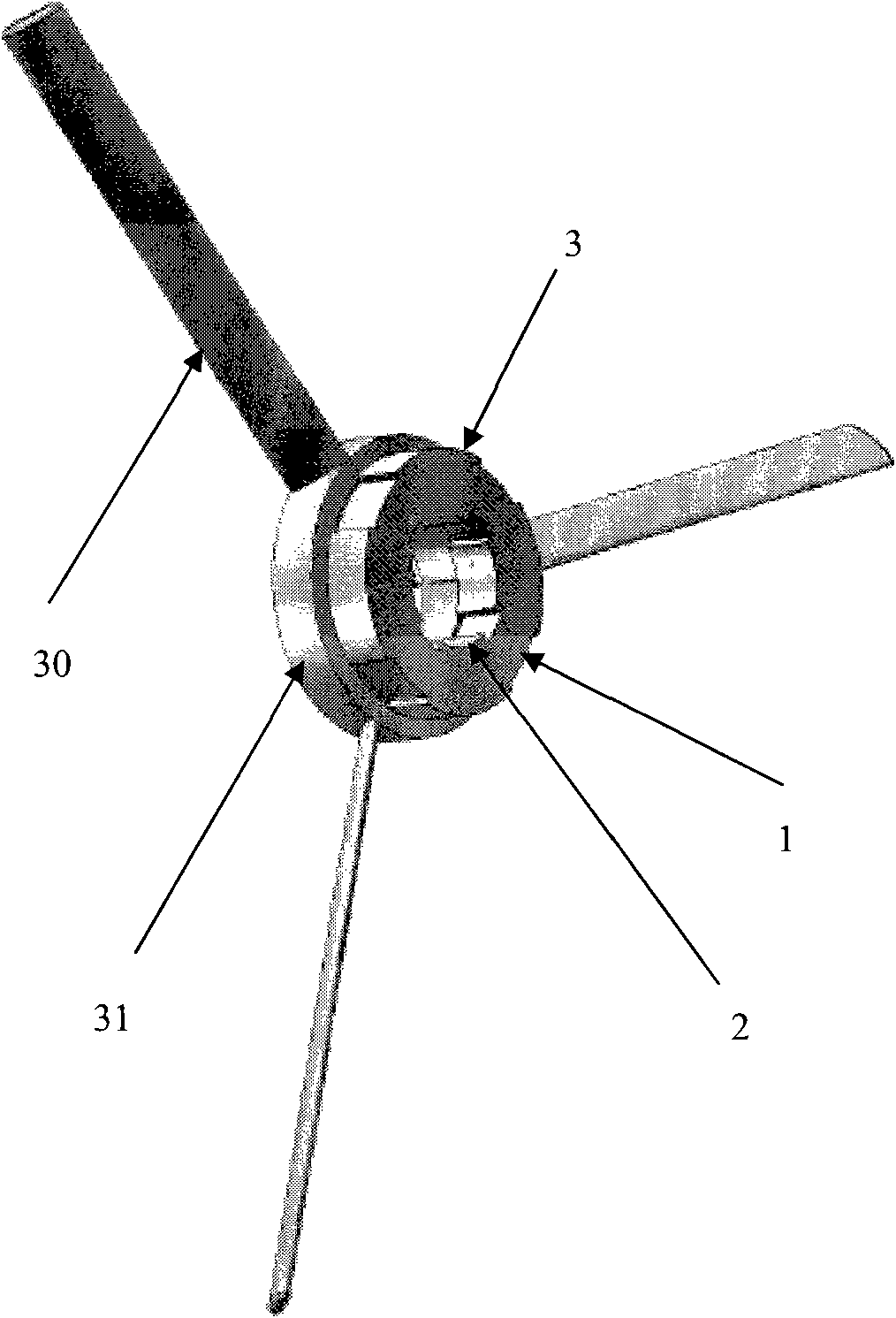

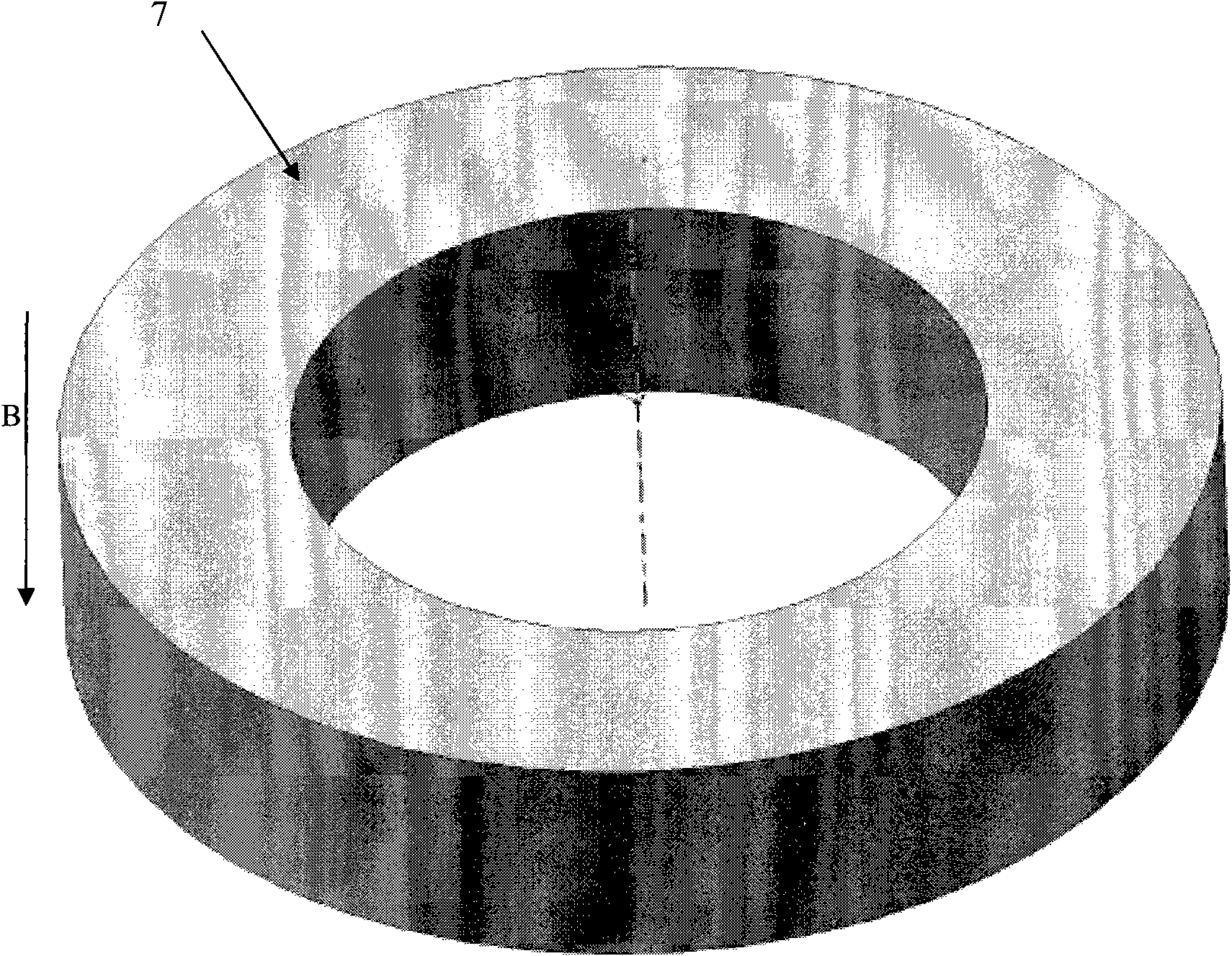

High-power magnetic fluid power generator system for wind power generation

InactiveCN102146883AReduce weightImprove power generation efficiencyWind motor combinationsMachines/enginesCore componentEngineering

The invention provides a magnetic fluid power generator system for wind power generation, which comprises a wind impeller and a magnetic fluid power generator, wherein the magnetic fluid power generator comprises a magnet capable of generating a magnetic field, magnetic conductive fluid, a fluid passage and a control system; and the magnetic conductive fluid of the magnetic fluid power generator can be liquid metal such as liquid gallium or alloy of gallium. The power generator system adopts a novel magnetic fluid power generator as a core component for converting the wind energy into the electric energy and simultaneously eliminates a heavy gear box structure, so that the weight of the power generator system is lightened, the power generation efficiency and the operating reliability of the entire magnetic fluid power generator system are greatly improved, and the power of the wind power generator is favor of being improved to dozens to hundreds of Class MW (Million watts). Therefore, the magnetic fluid power generator system has huge potential of application development.

Owner:李希南

Flexible antenna array based on microwave energy transmission

ActiveCN113036457AHigh gainImprove efficiencyRadiating elements structural formsDisturbance protectionPatch arrayDielectric substrate

The invention discloses a flexible antenna array based on microwave energy transmission. The flexible antenna array comprises a dielectric substrate, a patch array and an equivalent grounding plate layer. One surface of the dielectric substrate is fixedly connected with the patch array, and the other surface of the dielectric substrate is fixedly connected with the equivalent grounding plate layer. A liquid metal antenna which works at 2.45 GHZ and is used for microwave energy transmission is printed by applying a liquid metal printing technology and a flexible material. The liquid metal patch antenna gives full play to the advantages of repairability, flexibility, reconfigurability, fatigue resistance, corrosion resistance and the like of the liquid gallium indium metal and the flexible dielectric substrate, is applied to integrated small-sized electronic equipment, realizes receiving and transmitting of electromagnetic waves, is applied to long-distance energy wireless transmission, and overcomes the disadvantage of low unit energy collection and conversion efficiency of a traditional antenna.

Owner:CHONGQING UNIV

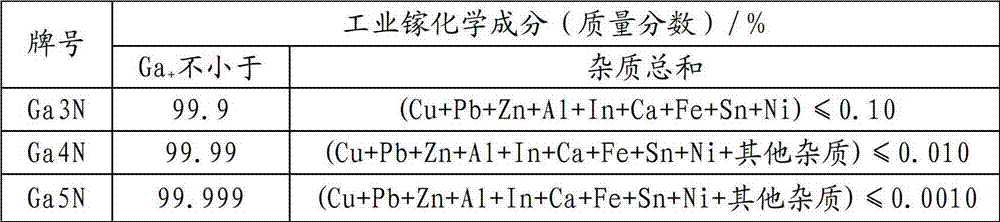

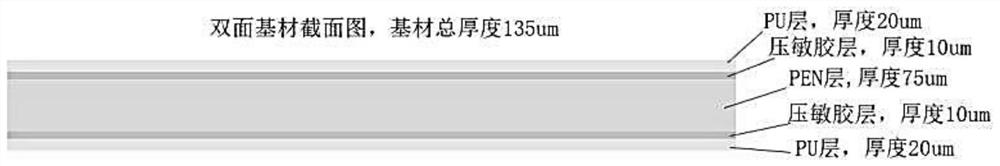

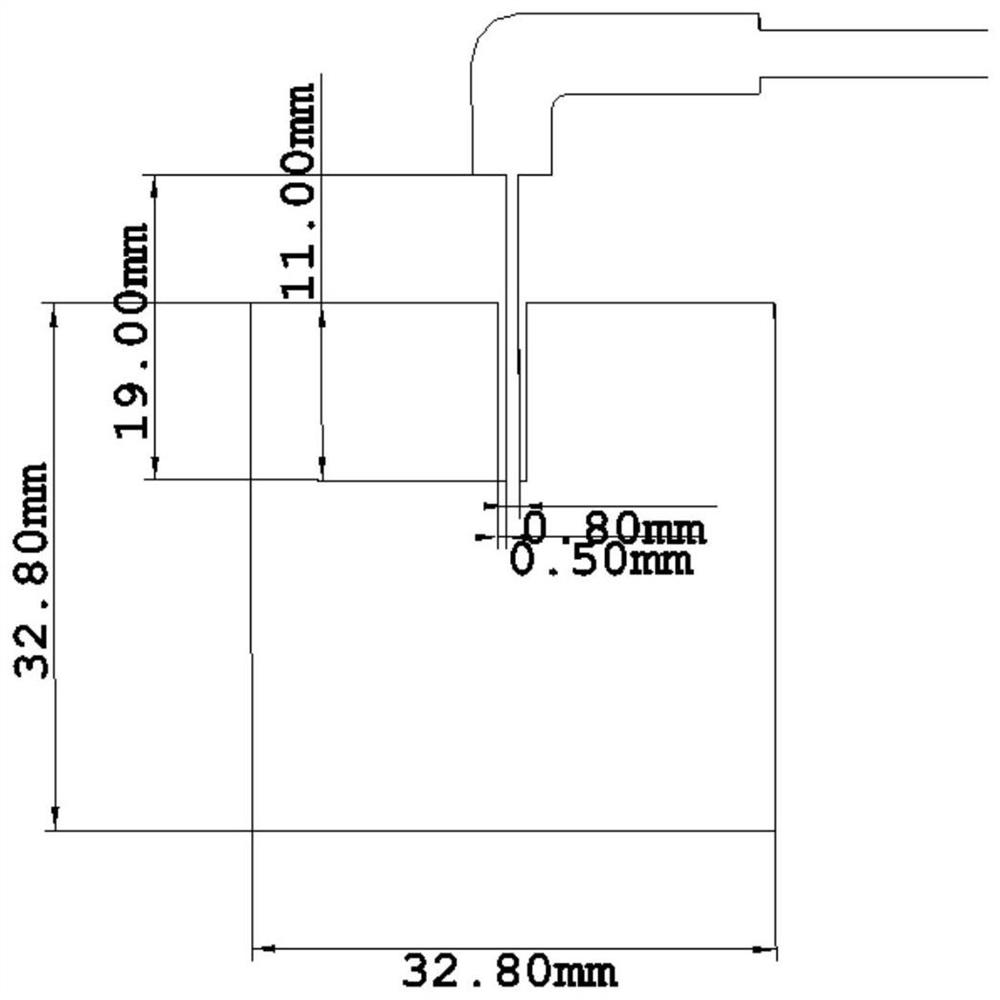

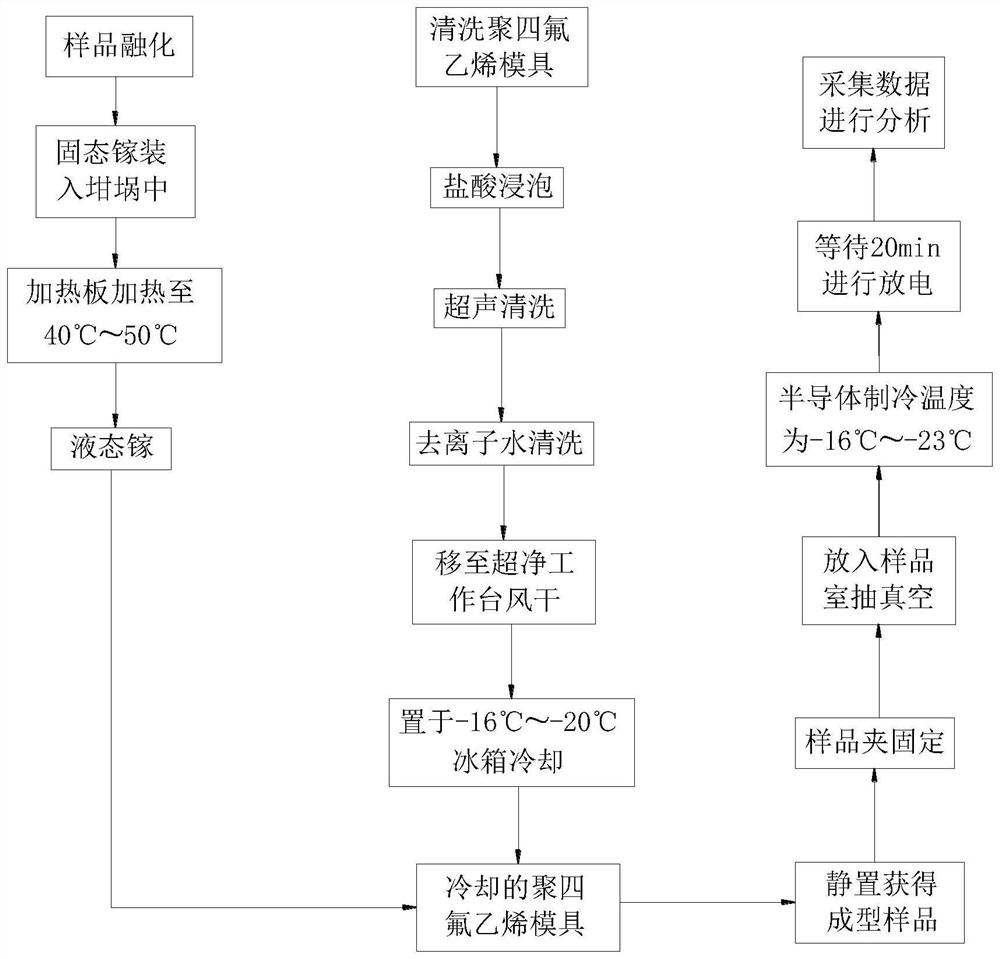

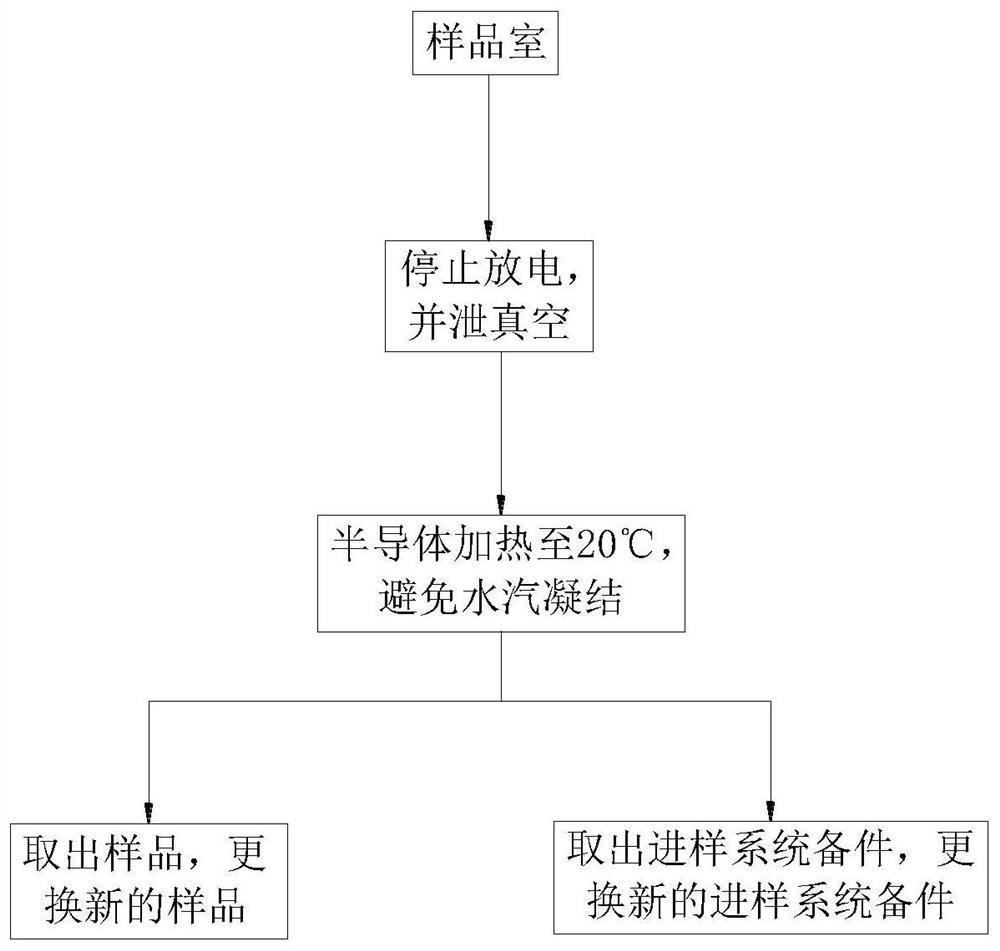

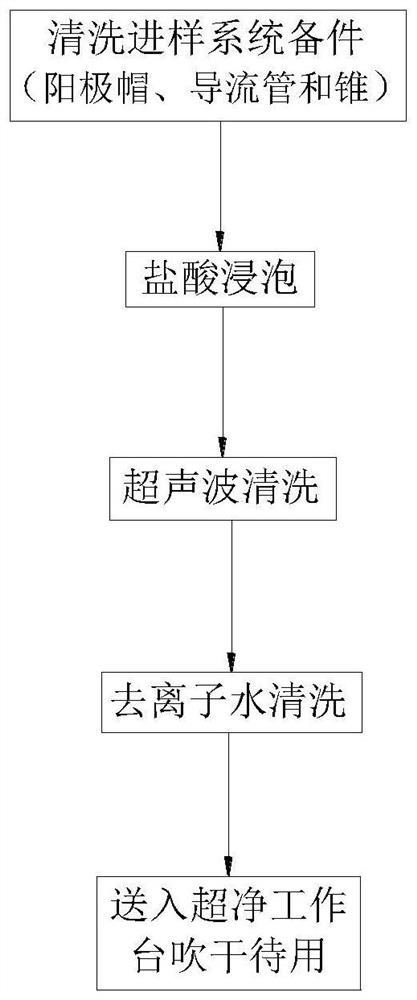

Glow discharge mass spectrometry high-purity gallium testing method

PendingCN113533493AGuaranteed cooling effectPreparing sample for investigationMaterial analysis by electric/magnetic meansIndiumMass spectrometry

One or more embodiments of the invention provide a glow discharge mass spectrometry high-purity gallium testing method, which comprises the following steps: heating solid gallium to obtain liquid gallium, cleaning a polytetrafluoroethylene mold, air-drying, putting the polytetrafluoroethylene mold on a cooling device, pouring the liquid gallium into the polytetrafluoroethylene mold placed on the cooling device, transferring the polytetrafluoroethylene mold into an ultra-clean bench within a set time, standing until a formed sample is obtained, fixing the formed sample, charging the sample into a GDMS sample chamber, vacuumizing, cooling the sample in a semiconductor refrigeration mode, discharging within the set time, and removing surface pollution through discharge sputtering; after the signal is stable, collecting and analyzing data are through the GDMS, and after the analysis is finished, recording and storing the data, so that the purpose that the plane to be measured can be obtained through a form conversion mode for low-melting-point metal such as gallium and indium for measurement is achieved.

Owner:宣城开盛新能源科技有限公司 +1

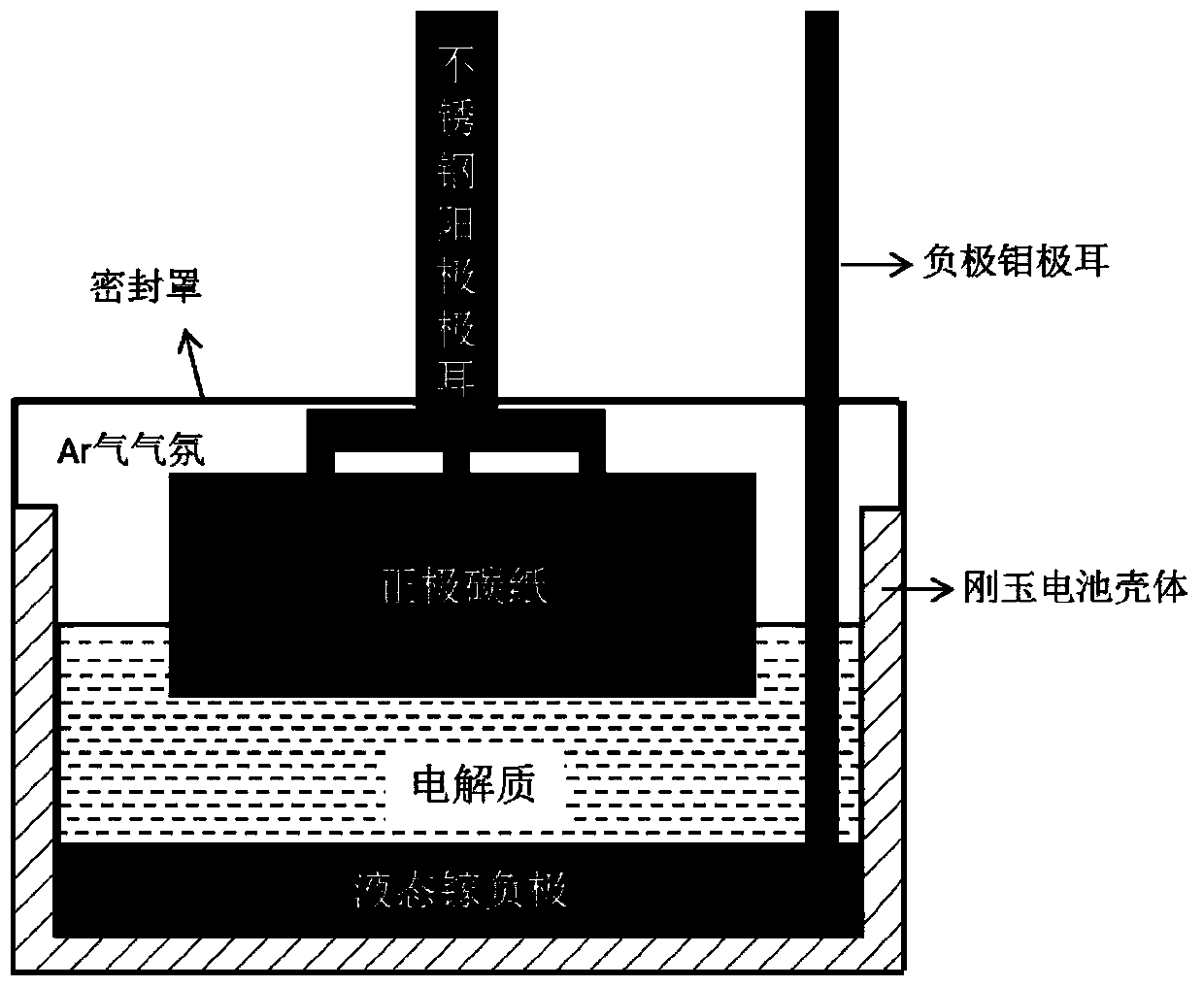

Aluminum ion battery using liquid metal gallium as negative electrode

InactiveCN110289444AImprove cycle lifeIncrease energy densityCell electrodesSecondary cellsAluminum IonHigh energy

The invention discloses an aluminum ion battery using liquid metal gallium as a negative electrode, which belongs to the field of electrochemical batteries. The battery is characterized by comprising a liquid gallium negative electrode with the purity of 99.9% to 99.999%, a positive electrode, an aluminum chloride and inorganic acid salt electrolyte and a separator selected according to specific situations. The liquid metal gallium is directly placed on the bottom layer of the battery as a negative electrode or placed in a crucible as a negative electrode. A solid conductive material is used as the lead of the liquid gallium negative electrode. During the charging process, aluminum ions are reduced to aluminum atoms on the surface of the liquid gallium negative electrode and dissolved and diffused into the liquid gallium body phase. During the discharging process, the aluminum atoms dissolved in the liquid gallium are diffused to the surface of the gallium and are oxidized to the aluminum ions to enter the electrolyte. The charging and discharging voltage range is 0.1 to 2.4 V, and the current density range is 0.01 to 10 Ag<-1>. The liquid gallium negative electrode adopted in the invention has the characteristics of corrosion resistance, inhibition of Al dendrites and recycling. The aluminum ion battery based on the negative electrode has the advantages of long cycle life, high energy density, safety and stability, and can be used for large-scale energy storage or automobile power batteries.

Owner:UNIV OF SCI & TECH BEIJING +1

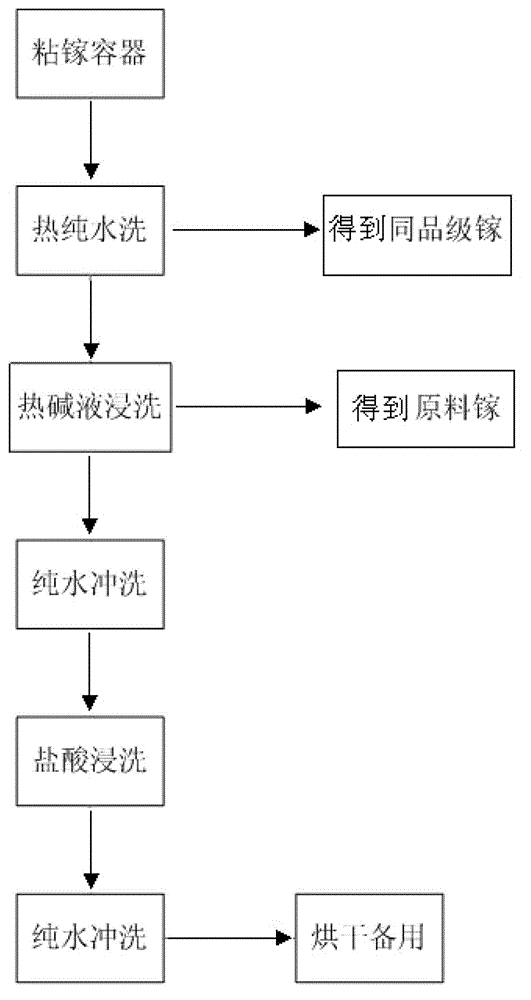

Method for cleaning high-purity gallium container

The invention discloses a method for cleaning a high-purity gallium container. The method is characterized by comprising the following steps of: (1) heating high-purity water to temperature of 60 to 80 DEG C, immersing the container for 15 to 25 minutes, and oscillating a table so that liquid gallium is formed, wherein a small amount of liquid gallium can be separated from the container; (2) heating by using electronically pure inorganic aqueous alkali with high alkalinity to temperature of 60 to 80 DEG C, immersing the container for 5 to 15 minutes, and oscillating for 10 to 15 minutes at the same time; (3) flushing the container without the gallium by using the high-purity water; (4) completely immersing the flushed container into the electronically pure inorganic aqueous alkali for 0.5 to 2 minutes; (5) flushing the container again by using the high-purity water; and (6) drying the container for later use. By the method, the high-purity gallium is recycled, so the production cost is saved; the method is simple and feasible; and the container can be completely cleaned, so that the container can be reused.

Owner:桐乡乐维新材料有限公司

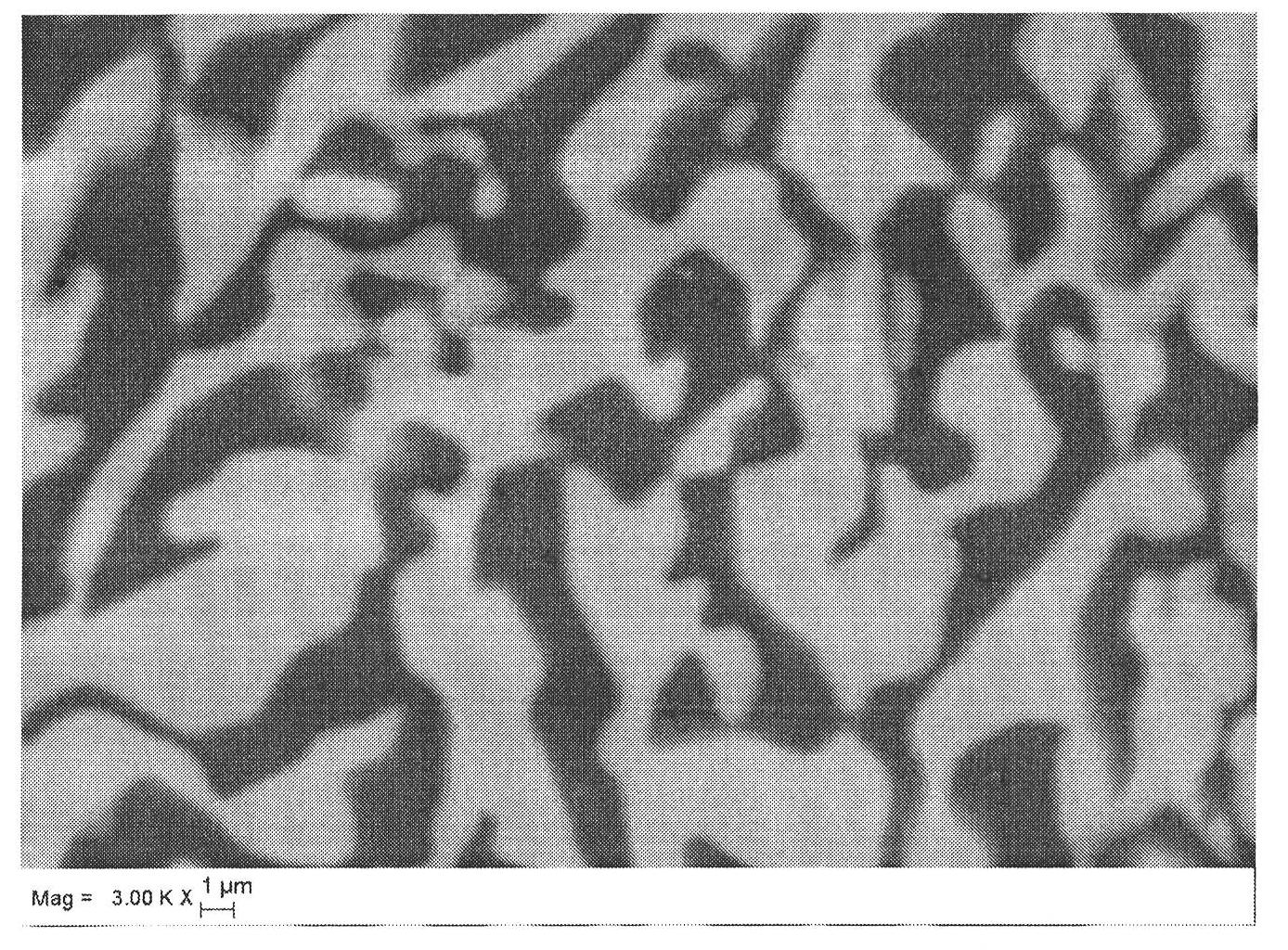

Preparation method of surface enhanced Raman scattering substrate

InactiveCN108275651ASimple methodEasy to prepare in large areaDecorative surface effectsChemical vapor deposition coatingAir atmosphereEvaporation

The invention discloses a preparation method of a surface enhanced Raman scattering substrate. The method comprises the following specific steps: depositing metal gallium with an equivalent thicknessof 100 nanometers on the surface of a cleaned silicon wafer by using an electron beam evaporation technology, wherein the substrate temperature is 50 DEG C, and the vacuum degree is 4x10<-4>PA; placing a sample into a muffle furnace after the deposition, and annealing in an air atmosphere at the annealing temperature 400 to 500 DEG C for 4 to 5 minutes, wherein after the reaction, a large number of solid nanoscale gallium oxide particles are grown on the surface of the silicon wafer; and then depositing a layer of silver, gold or copper film on the surface by heat evaporation or ion sputteringto obtain a rough metal surface which can be used as the surface enhanced Raman scattering substrate. According to the preparation method, the non-infiltration characteristic of liquid gallium on thesilicon wafer is used for preparing a template with a rough surface, and the surface roughness can be changed by changing the deposition parameters of gallium or annealing conditions, thus changing the surface enhanced Raman scattering effect of the substrate.

Owner:LINYI UNIVERSITY

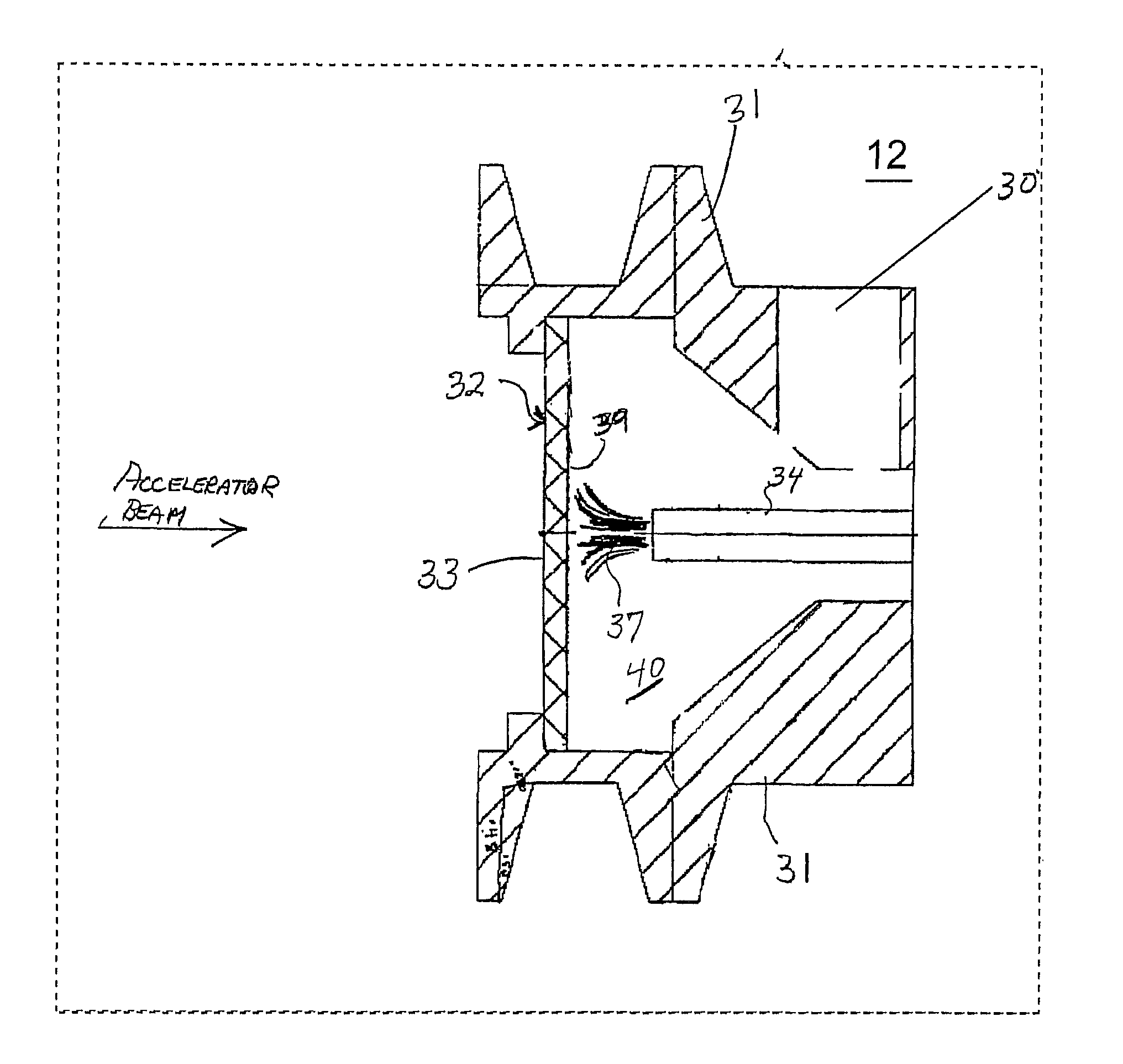

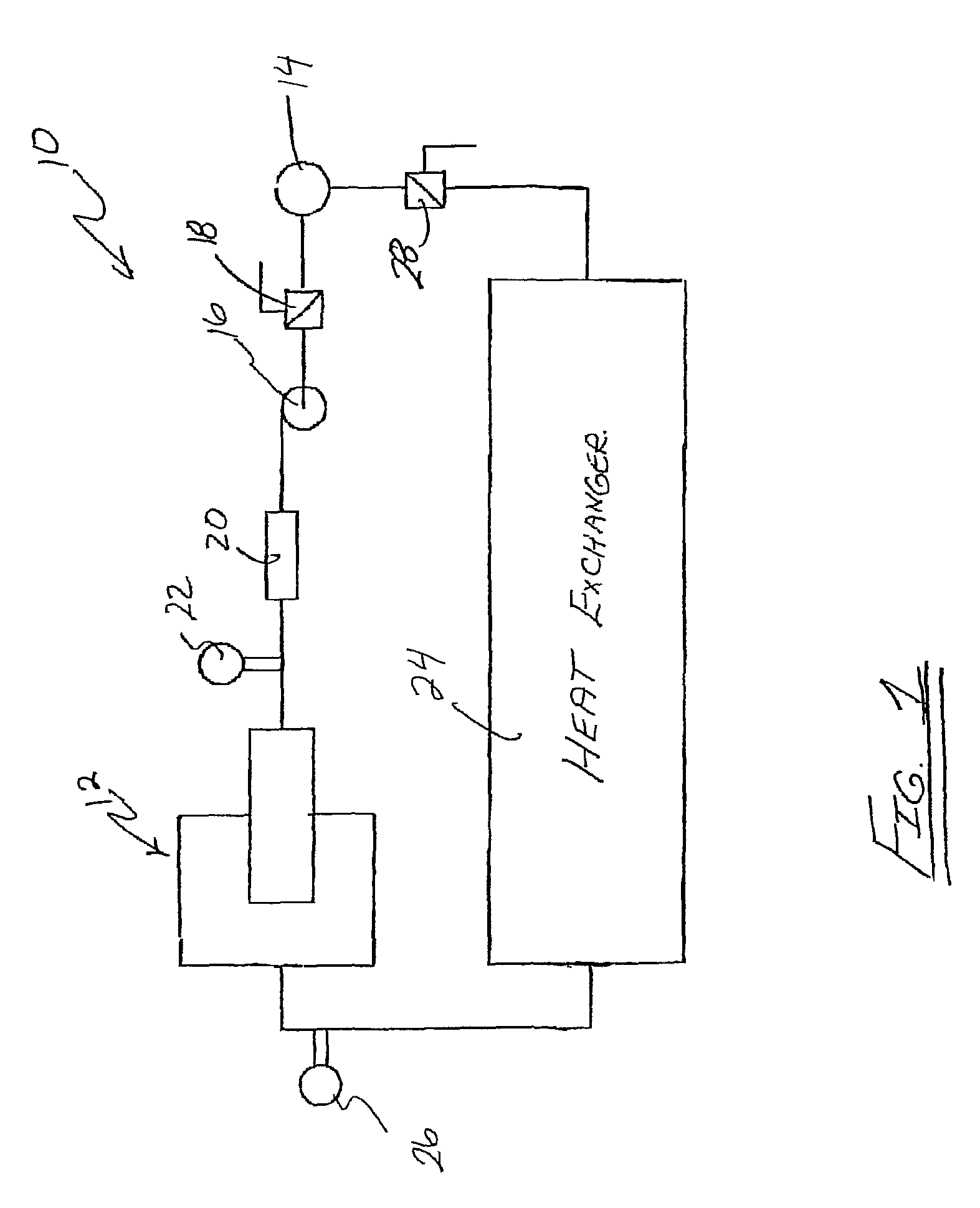

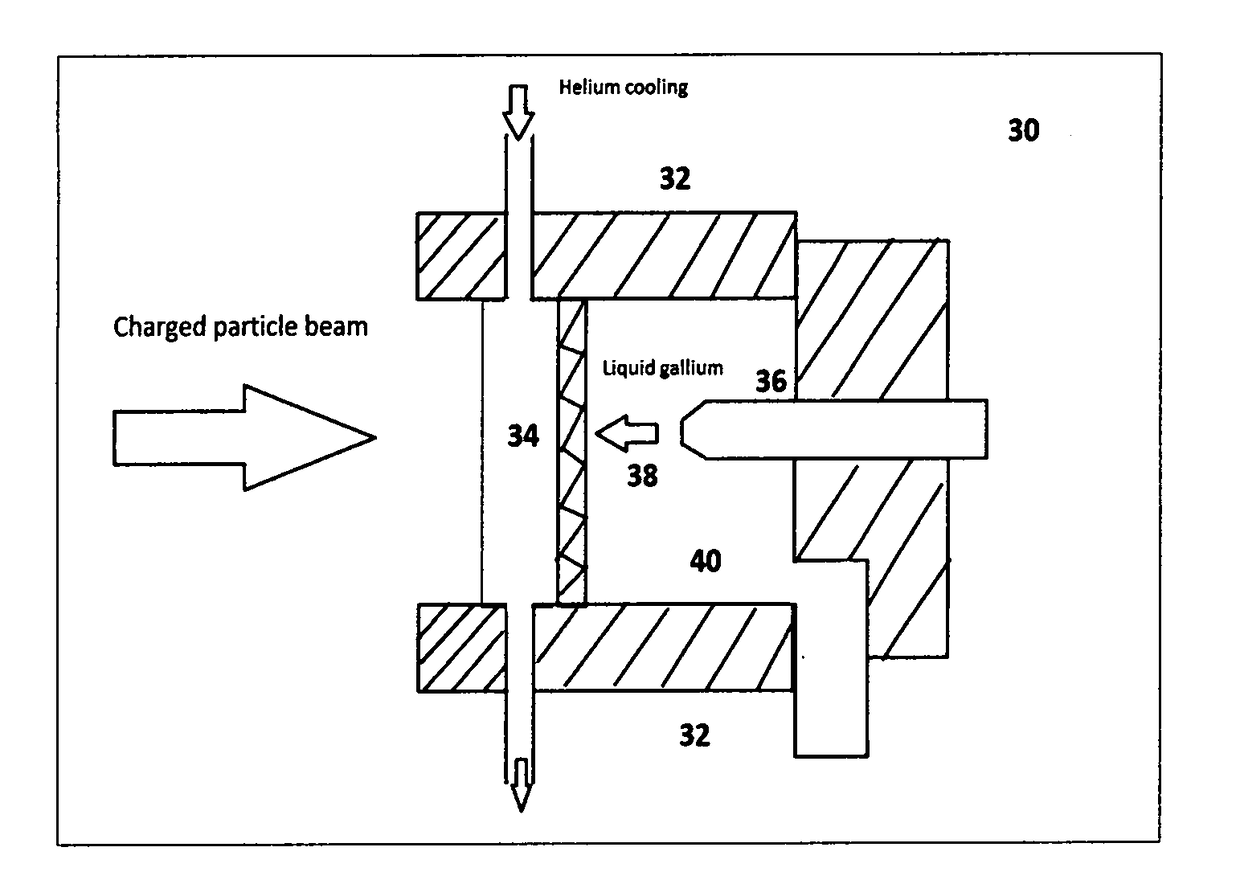

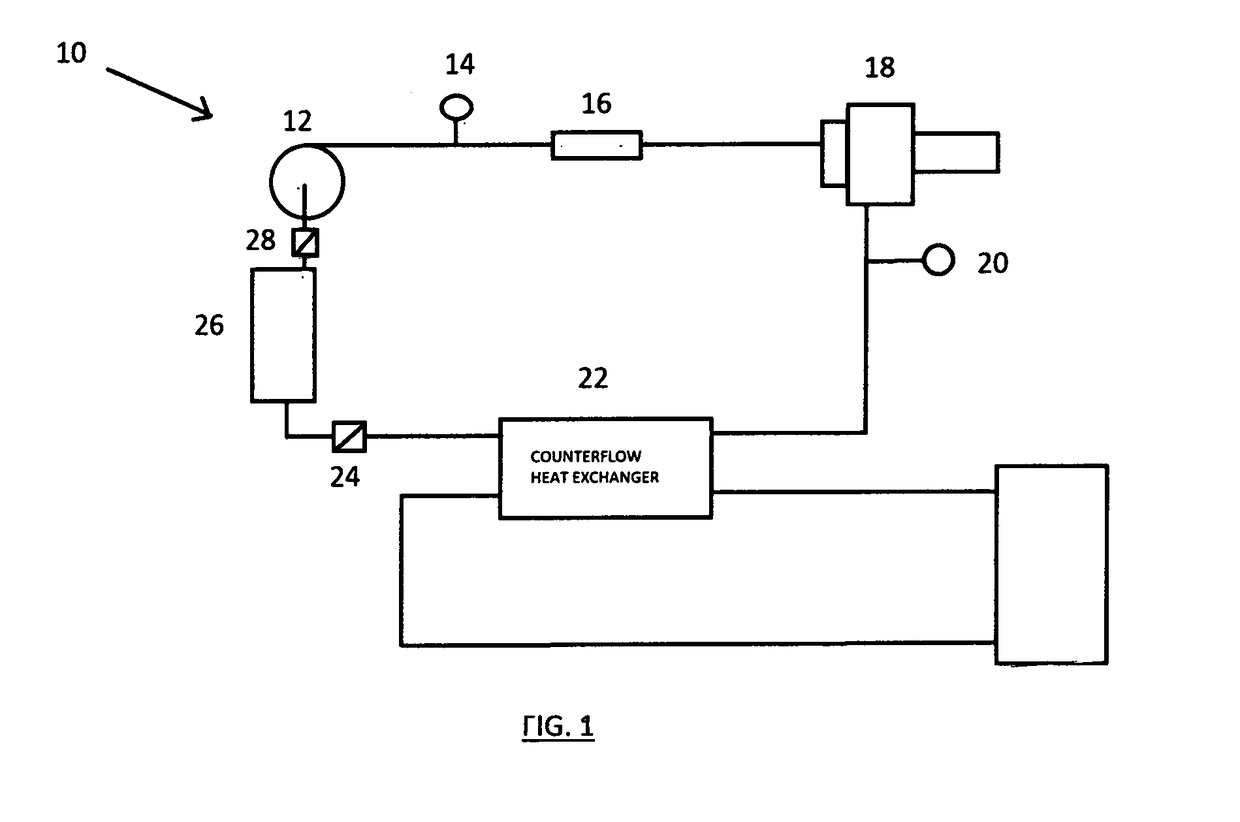

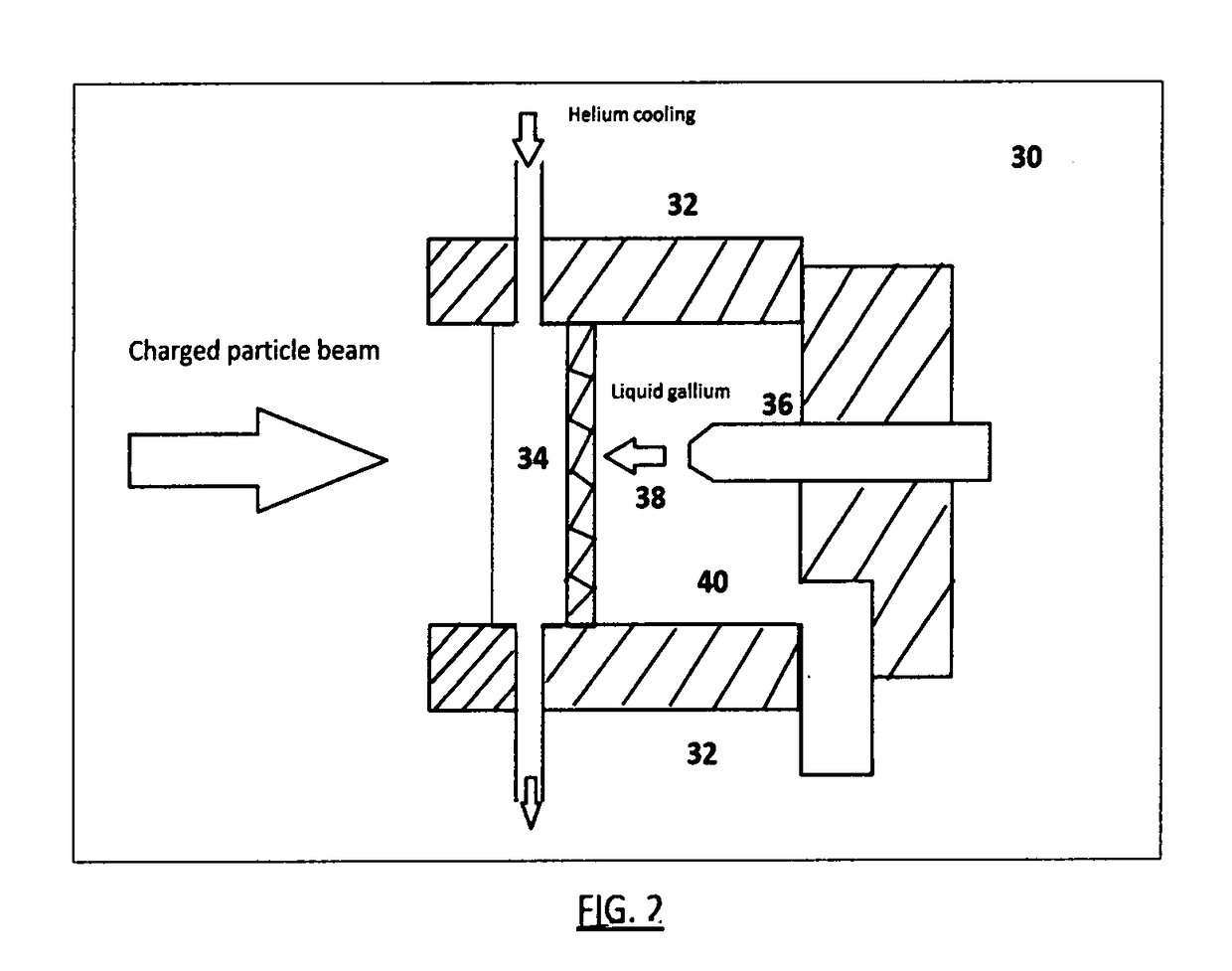

Liquid gallium cooled high current accelerator target

InactiveUS20170287580A1High currentConversion outside reactor/acceleratorsNuclear targetsWorking fluidHeat flux

Radioisotopes are produced by irradiating enriched stable isotopes in a particle accelerator target assembly with a beam of protons, deuterons, or other charged particles exhibiting sufficient incident energy and current to induce a nuclear reaction. The target assembly receives a recirculating flow of liquid gallium to remove heat flux that would damage the target assembly when operated with high intensity beam currents. The choice of liquid gallium and its eutectic alloys, all liquids at room temperature, over prior art working fluids for the coolant system is advantageous by providing significantly increased heat transfer to prevent target damage, minimizing enriched material losses, thereby decreasing production costs, and realizing greater radioisotope output.

Owner:YLIMAKI ROBERT JOHN

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com