Device and method for preparing high-purity gallium

A high-purity, seed crystal technology, applied in the preparation equipment and field of high-purity gallium, can solve the problems of inconvenient separation of residual liquid gallium, reduce production cost, unfavorable operation process, etc., achieve good application prospects, increase crystallization and melting speed , Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

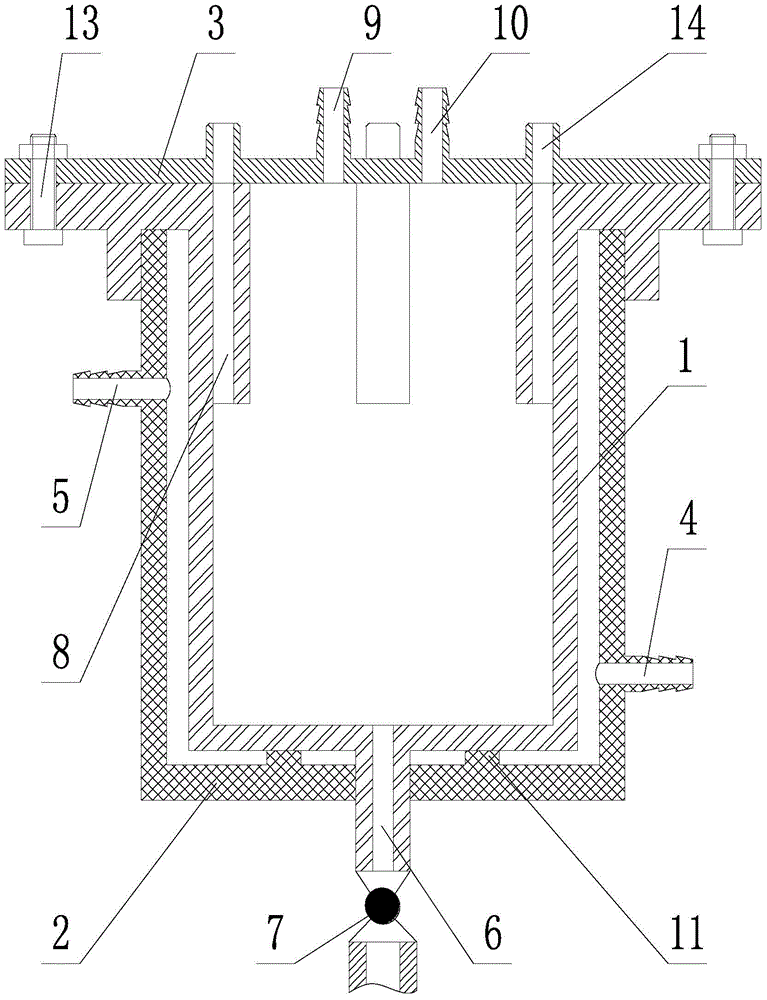

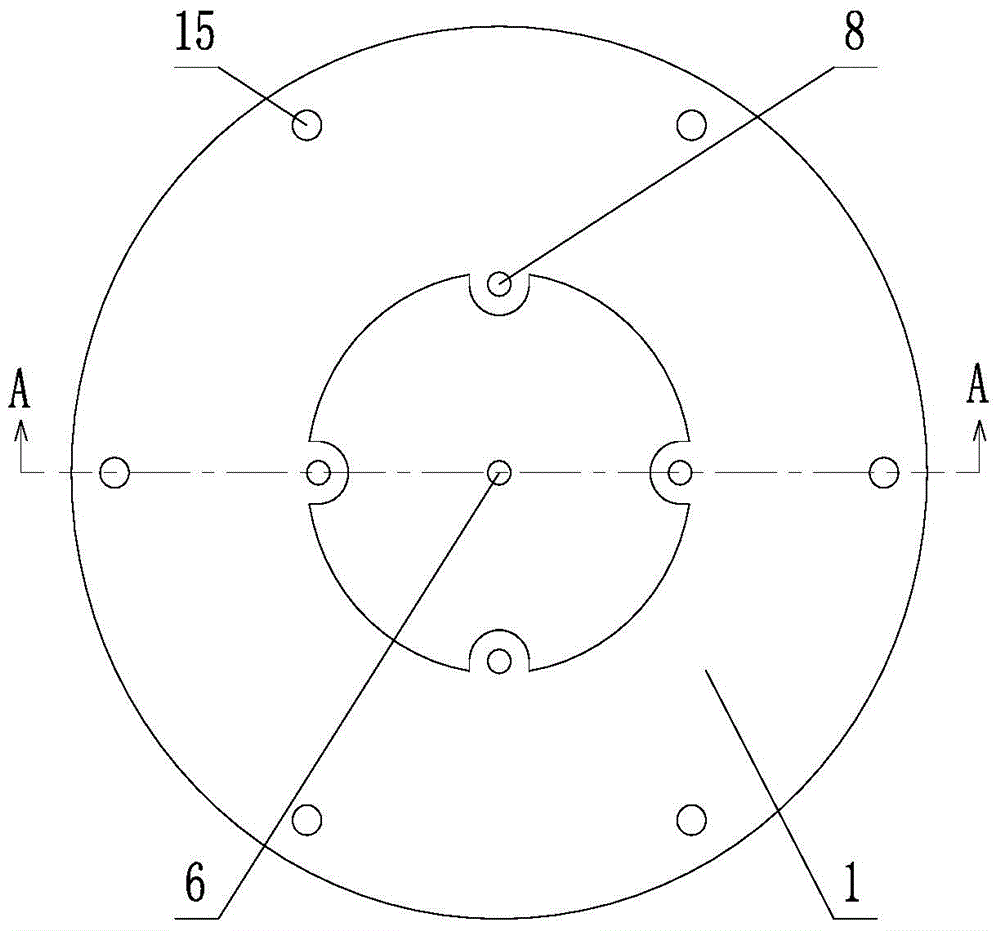

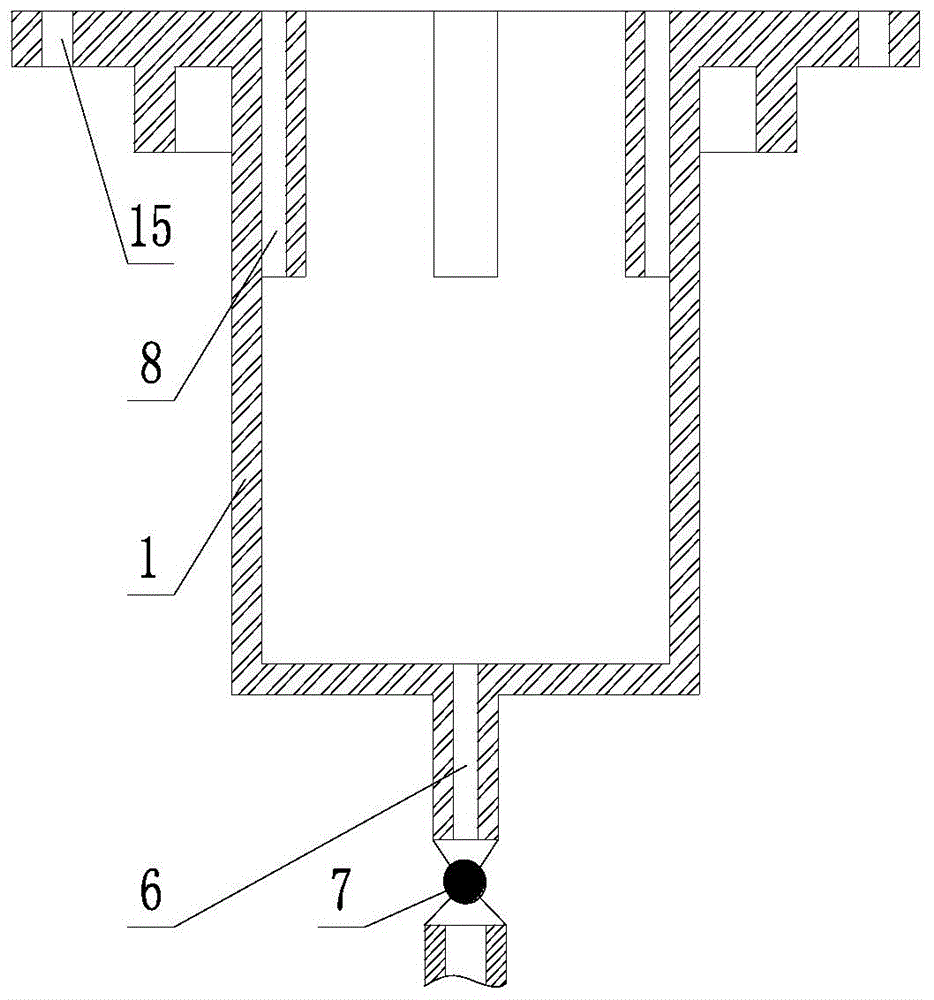

[0048] A device for preparing high-purity gallium, comprising an inner tank 1, an outer tank 2 and a cover 3, both of which are columnar or platform-shaped, and can be cylinders, prisms, circular frustums or prisms; the bottom of the inner tank 1 is provided with drainage The tube 6 and the drainage tube 6 are provided with a switch 7, and the inner wall of the liner 1 is provided with tubular seed crystal addition holes 8, the seed crystal addition holes 8 are evenly distributed on the inner wall of the liner, and the upper edge of the liner 1 is evenly distributed with bands. Threaded inner tank through hole 15; the side wall of the outer tank 2 is provided with a water inlet and 4 water outlets 5, and the bottom of the outer tank 2 is provided with a drainage tube piercing hole 12, and the inner side of the bottom of the outer tank 2 is evenly distributed for supporting the inner tank. The support column 11 of the liner 1; the cover 3 is provided with a protective gas inlet ...

Embodiment 2

[0061] The structure of the device for preparing high-purity gallium is the same as in Example 1, the difference is that:

[0062] 1. The wall thickness of the polytetrafluoroethylene liner is 1.3mm;

[0063] 2. The ratio of the volume of the cavity between the inner and outer tanks to the volume of the inner tank is 0.5:1.

[0064] Method is with embodiment 1, and difference is:

[0065] (1) The protective gas in the device is high-purity argon;

[0066] (2) the purity of grafted seed crystals is 6N;

[0067] (3) When the solidification rate of gallium in the device reaches 95%, open the switch on the residual gallium drainage tube to make the remaining liquid gallium flow out;

[0068] (4) Steps 4 and 5 were repeated until the gallium in the device was recrystallized 8 times, and 6N high-purity gallium was prepared in the device.

[0069] The yield of 6N high-purity gallium prepared by the method is 67%.

Embodiment 3

[0071] The structure of the device for preparing high-purity gallium is the same as in Example 1, the difference is that:

[0072] 1. The inner liner 1 and the outer liner 2 are sealed and connected by thread at the upper edge of the two, and at the drainage tube 6 and the drainage tube exit hole 12;

[0073] 2. The cover 3 is fixed on the top of the device by snapping on the upper edge of the liner 1;

[0074] 3. The ratio of the volume of the cavity between the inner and outer tanks to the volume of the inner tank is 0.6:1.

[0075] Method is with embodiment 1, and difference is:

[0076] (1) The temperature of the cooling water is 20°C;

[0077] (2) the purity of grafted seed crystals is 6N;

[0078] (3) When the solidification rate of gallium in the device reaches 95%, open the switch on the residual gallium drainage tube to make the remaining liquid gallium flow out;

[0079] (4) Steps 4 and 5 were repeated until the gallium in the device was recrystallized seven time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com