Patents

Literature

926results about How to "Speed up melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High melt strength polypropylene

InactiveUS7365136B2Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer sciencePtru catalyst

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

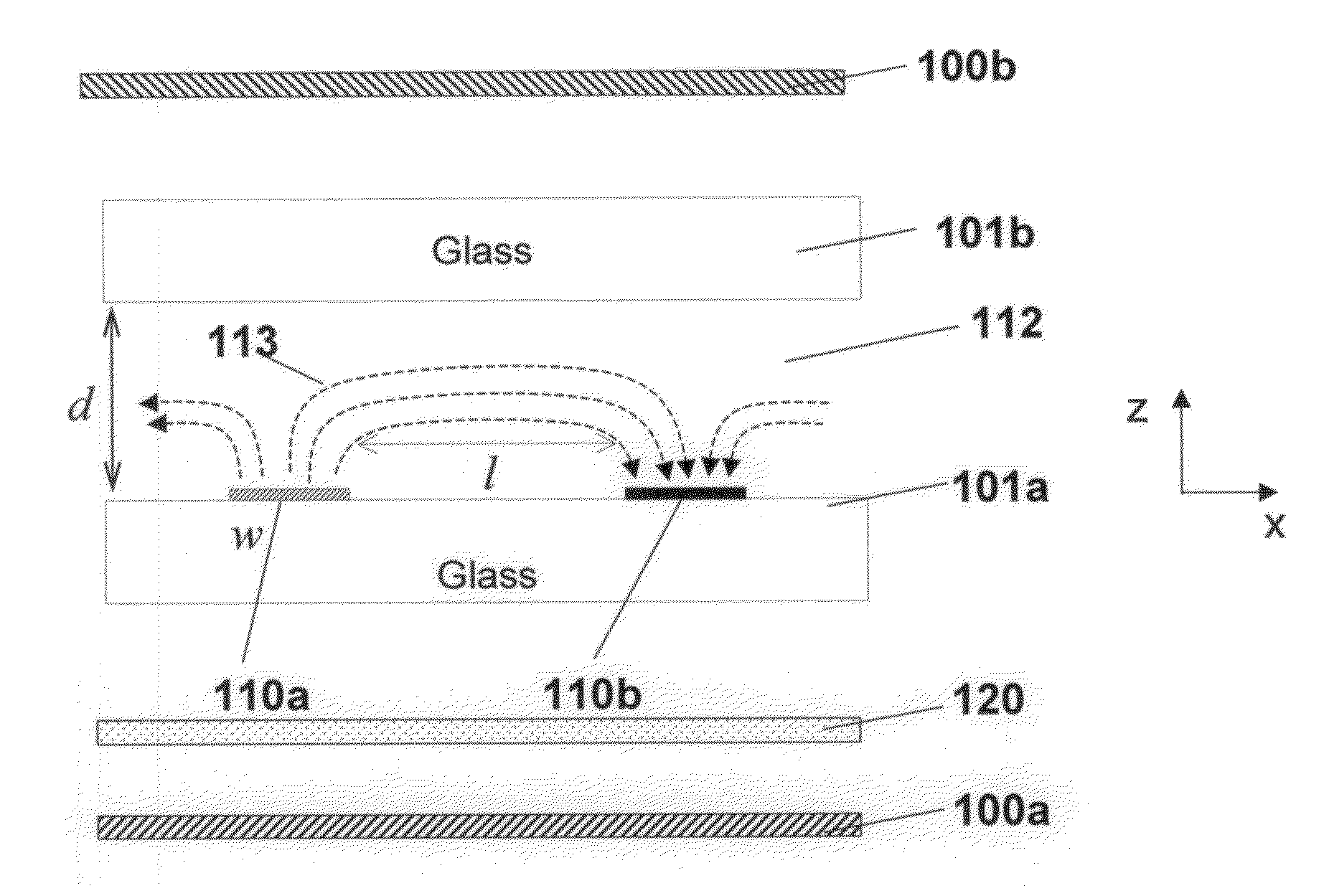

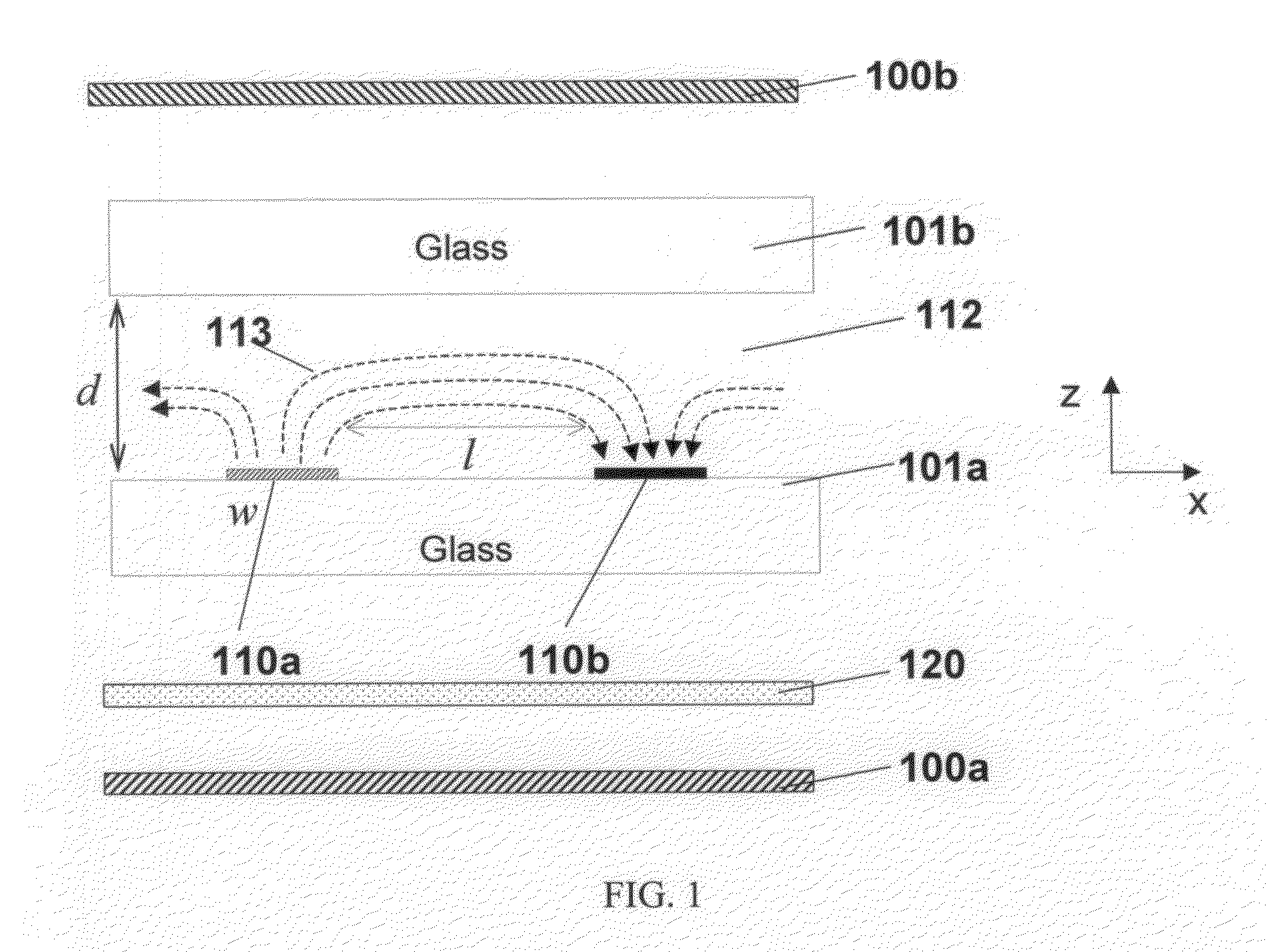

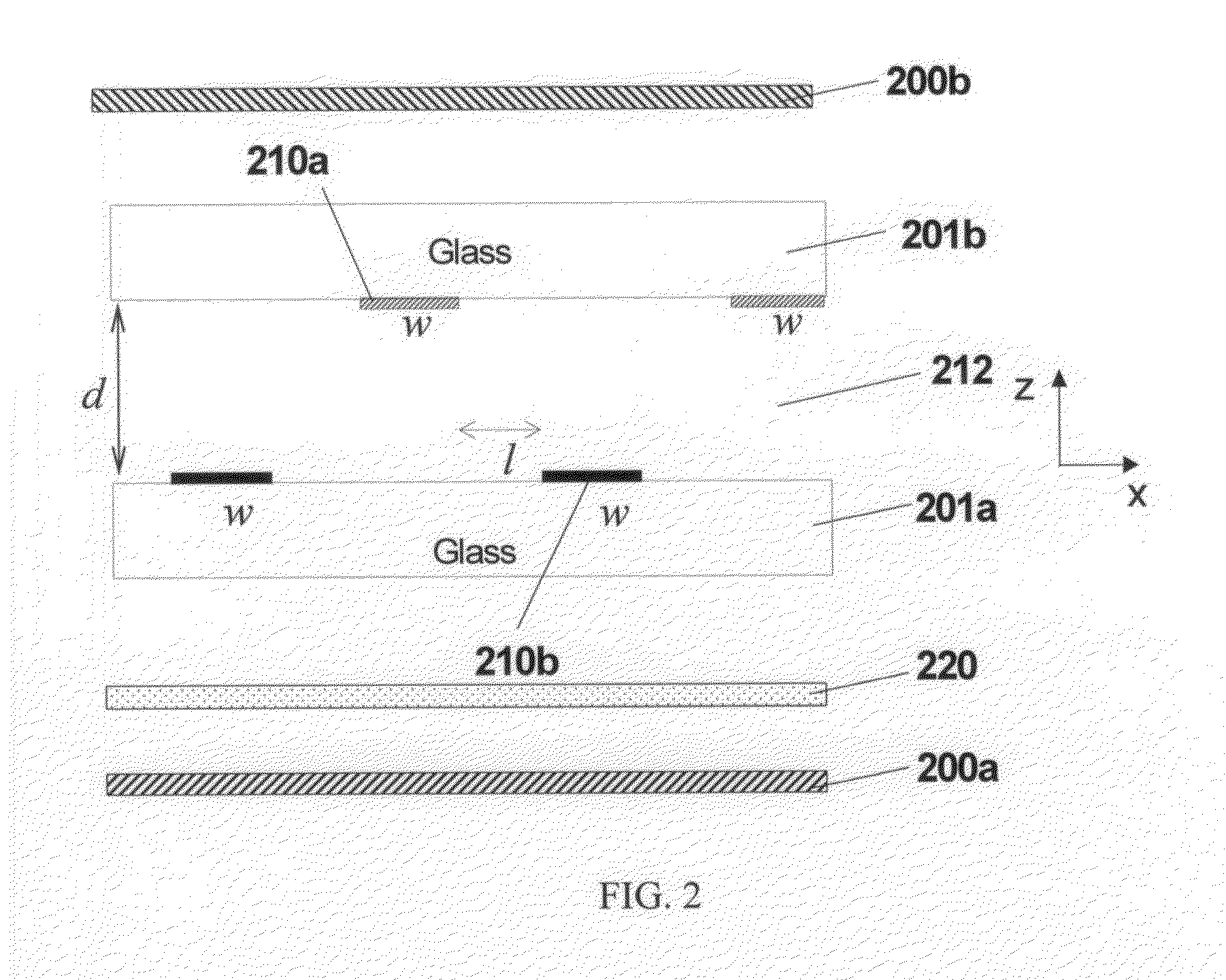

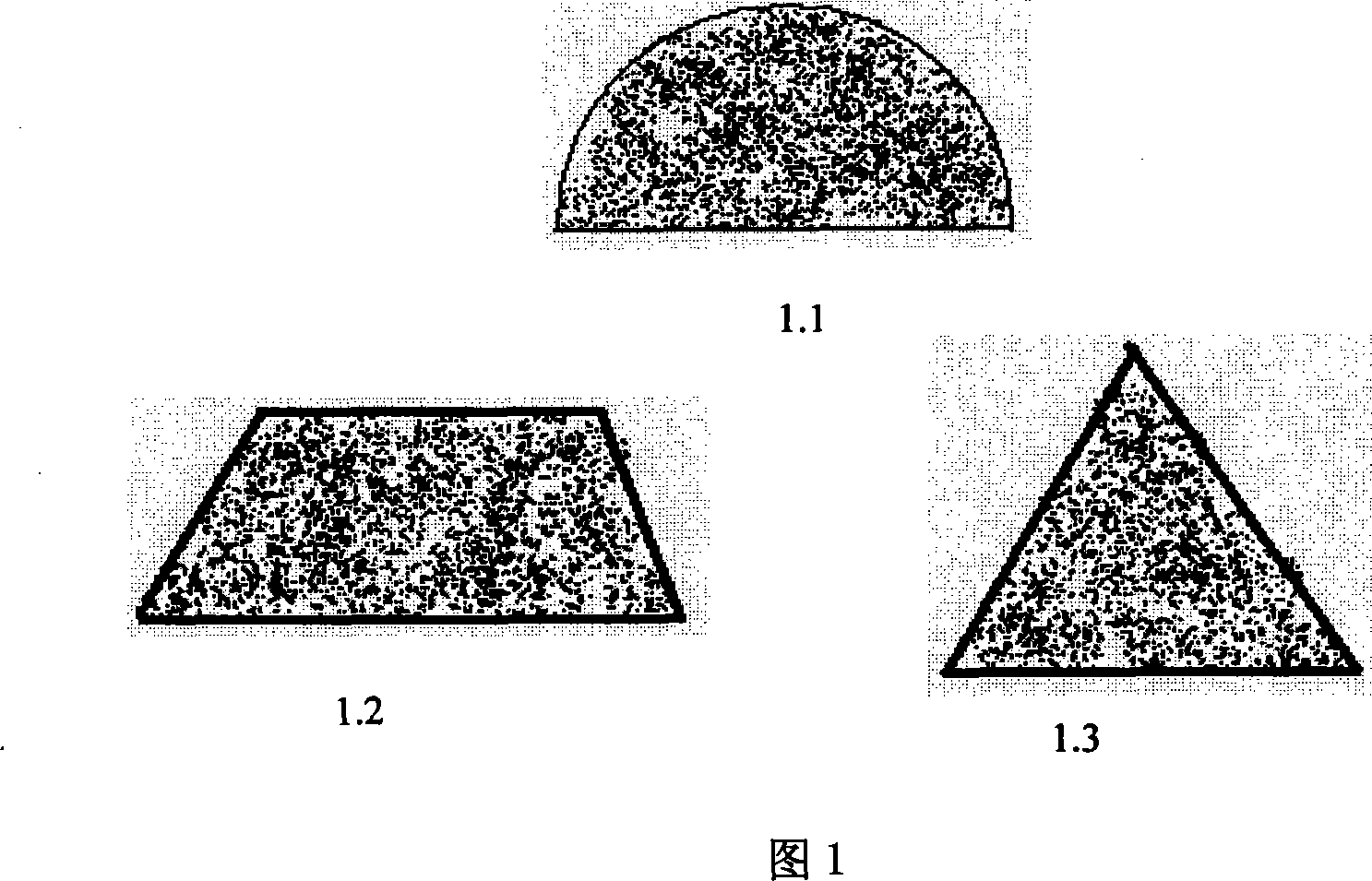

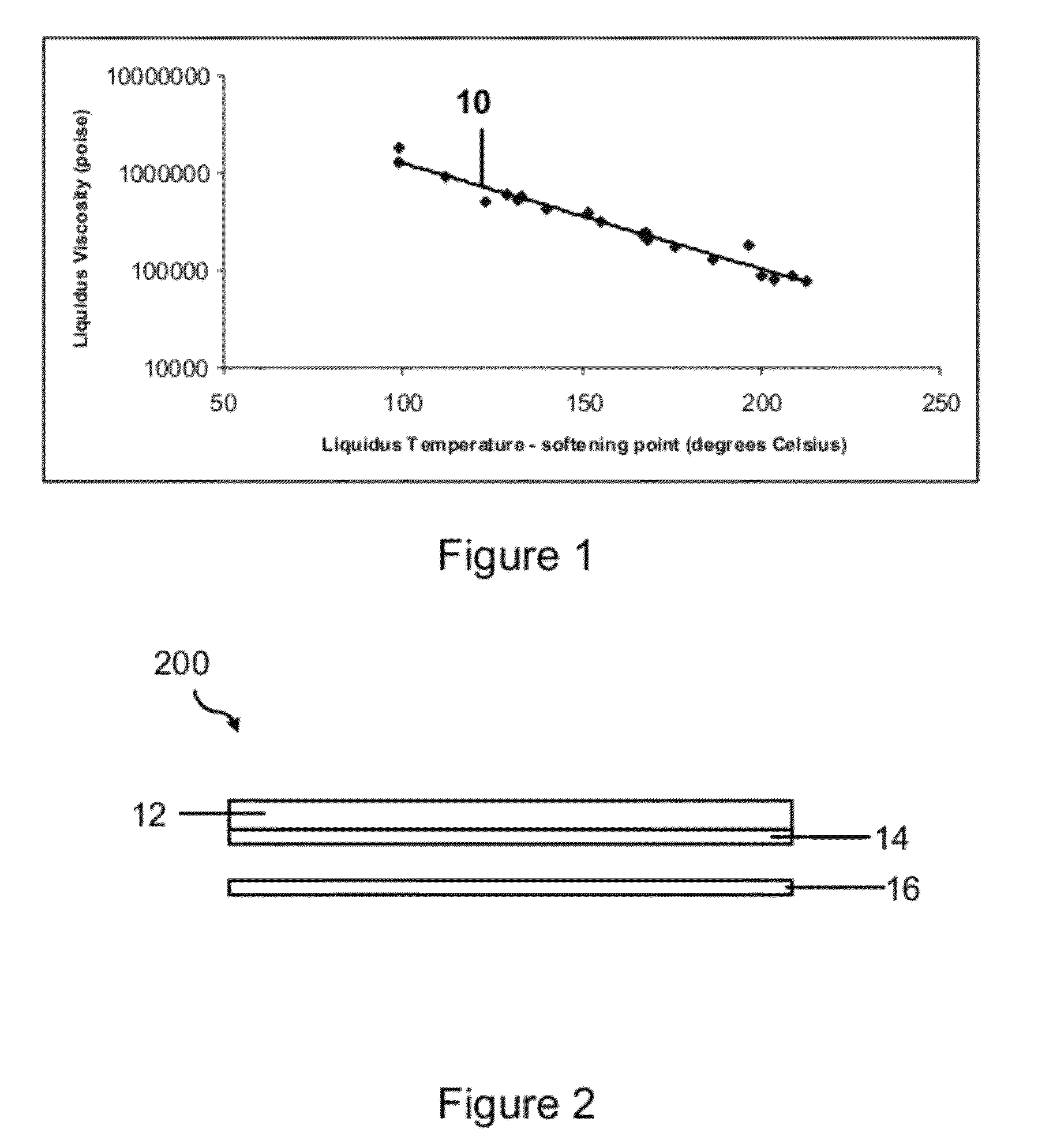

Liquid Crystals Composition and Liquid Crystal Display with Patterned Electrodes

InactiveUS20110075074A1High light efficiencyProcess stabilityLiquid crystal compositionsThin material handlingCrystallographyDisplay device

A blue phase liquid crystal composition and a LC display using the composition. The liquid crystal composition includes a first class including a highly polar compound and a second class including a highly conjugated liquid crystal compound. The blue phase liquid crystal display device includes first and second substrates each with polarizer on the exterior surface and the blue phase liquid crystal composition sandwiched therebetween with and patterned electrodes on one of the substrates or both substrates. The patterned electrodes can be T-shaped, chevron or v-shaped, thin comb like shape and can also be flat or trapezoidal. The device outputs different light transmissions from the electrically controllable induced birefringence of the blue phase LC material for a low driving voltage, high transmittance blue phase liquid crystal display device.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

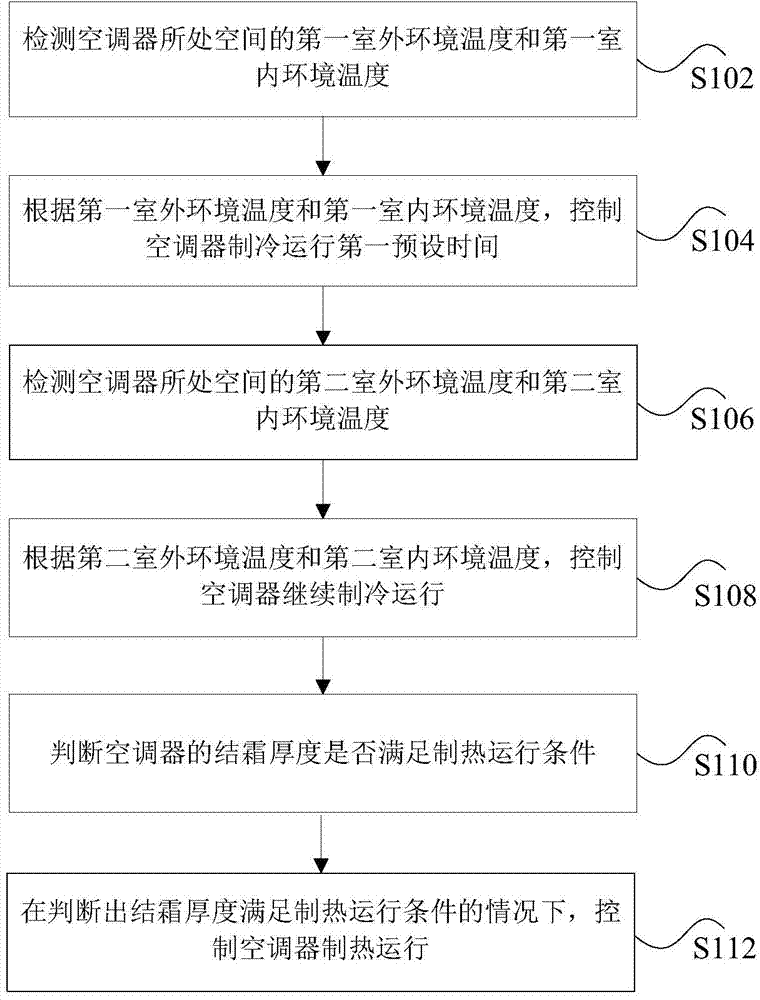

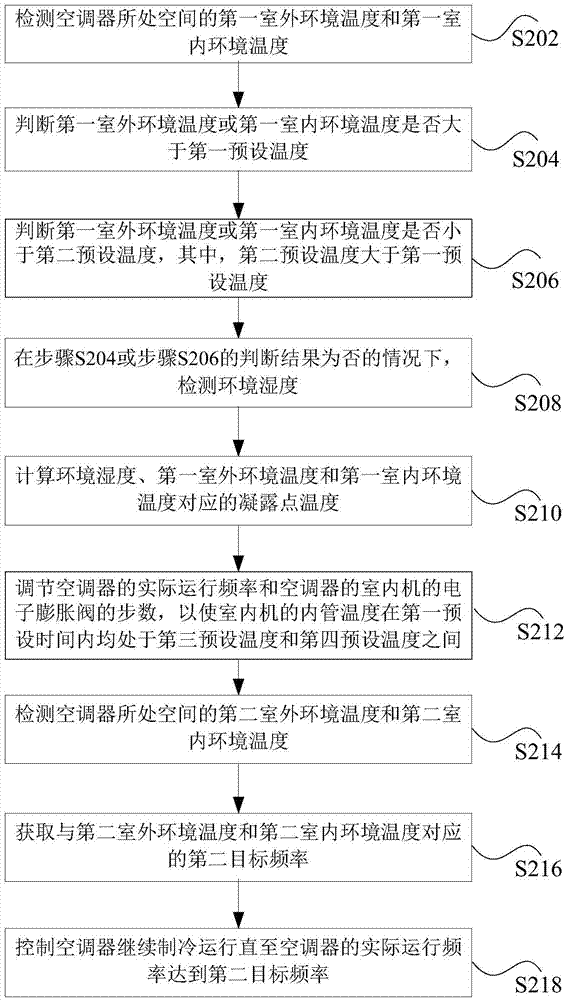

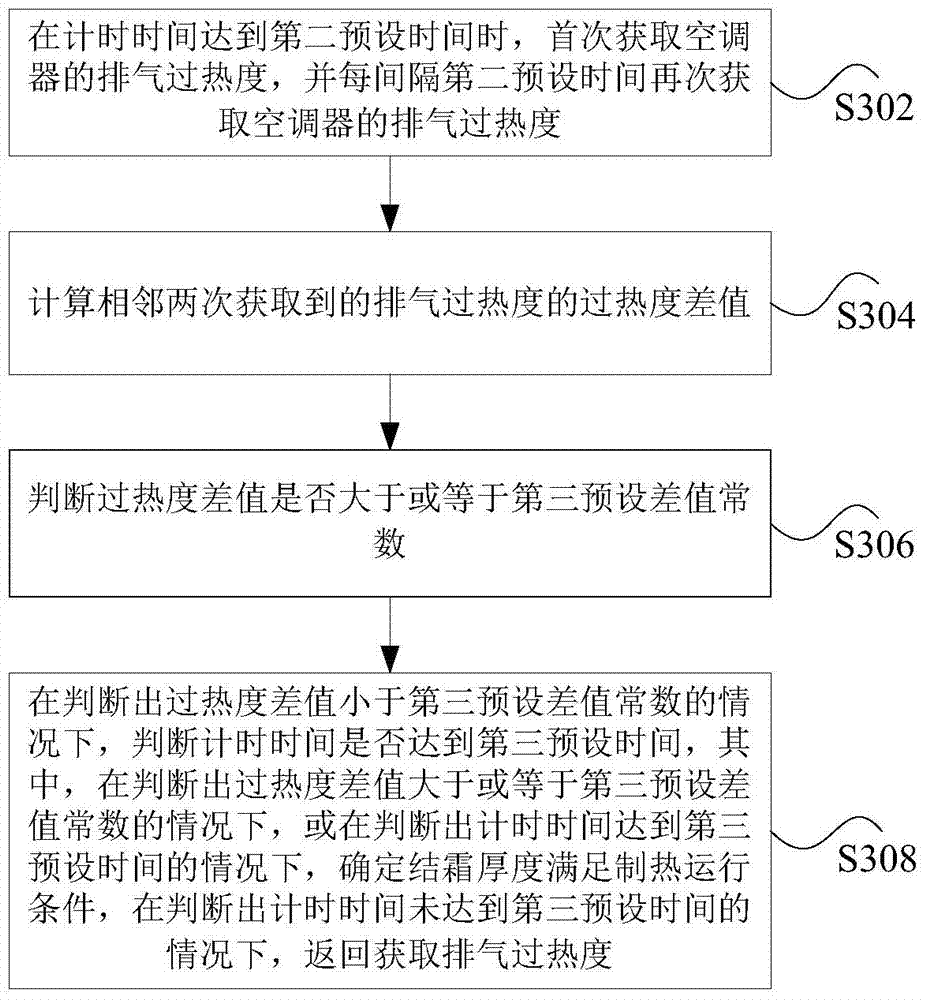

Air conditioner and control method and device thereof

ActiveCN104764171ARealize take awayReduced activityMechanical apparatusSpace heating and ventilation safety systemsFrostEngineering

The invention discloses an air conditioner and a control method and device thereof. The control method comprises the steps of detecting the environment temperature of the space where the air conditioner is located; controlling the air conditioner to perform refrigeration running for a preset time according to the environment temperature to enable the air conditioner to form frost, judging whether the thickness of the formed frost meets the heating running condition or not; controlling the air conditioner to perform heating running when it is determined that the thickness of the formed frost meets the heating running condition. According to the environment temperature, the air conditioner is controlled to form frost, so that frost is formed to generate low temperature so as to lower the activity and survival ability of bacteria of an indoor unit, then the air conditioner is controlled to perform heating running to generate high temperature rapidly to kill the bacteria or lower the activity of the bacteria again, meanwhile, flowing water formed after a frost layer is molten by heating can bring away dust and bacteria, automatic cleaning and dust removal can be achieved, a running mechanism of the air conditioner does not need to be added, and the problems that due to an existing dust removal mode that a moving mechanism is added, the cost of the air conditioner is increased, and stability is low are solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

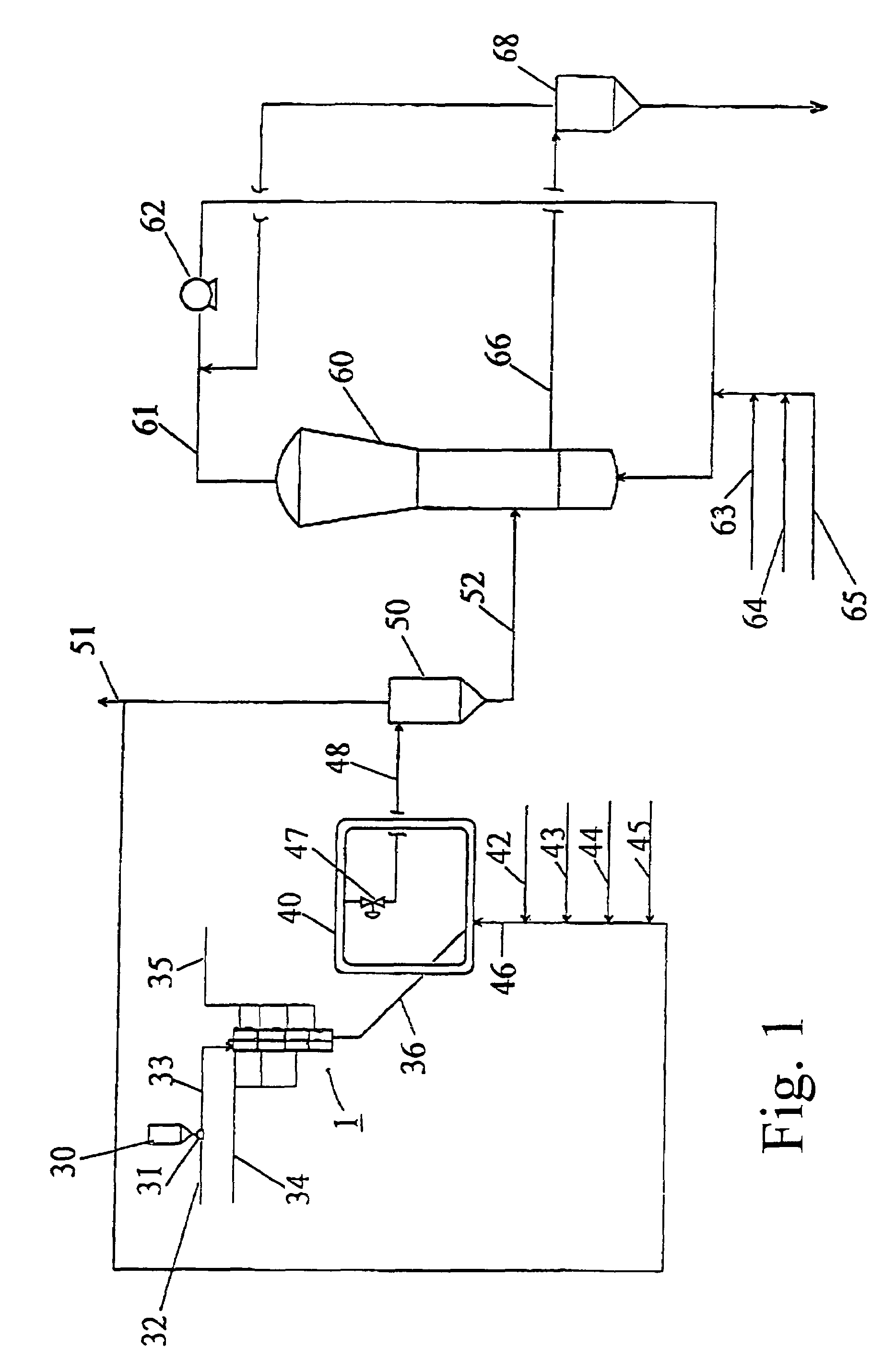

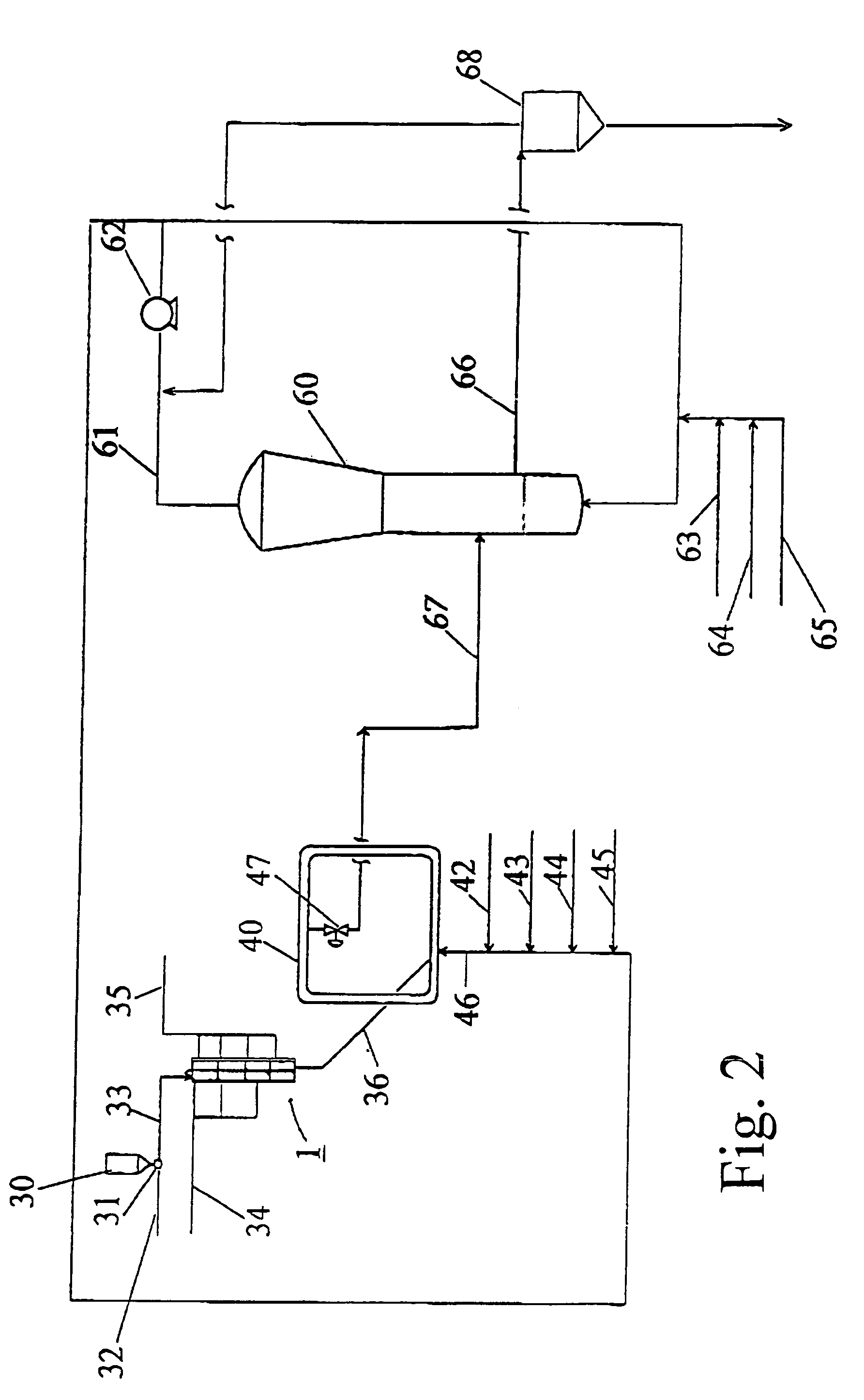

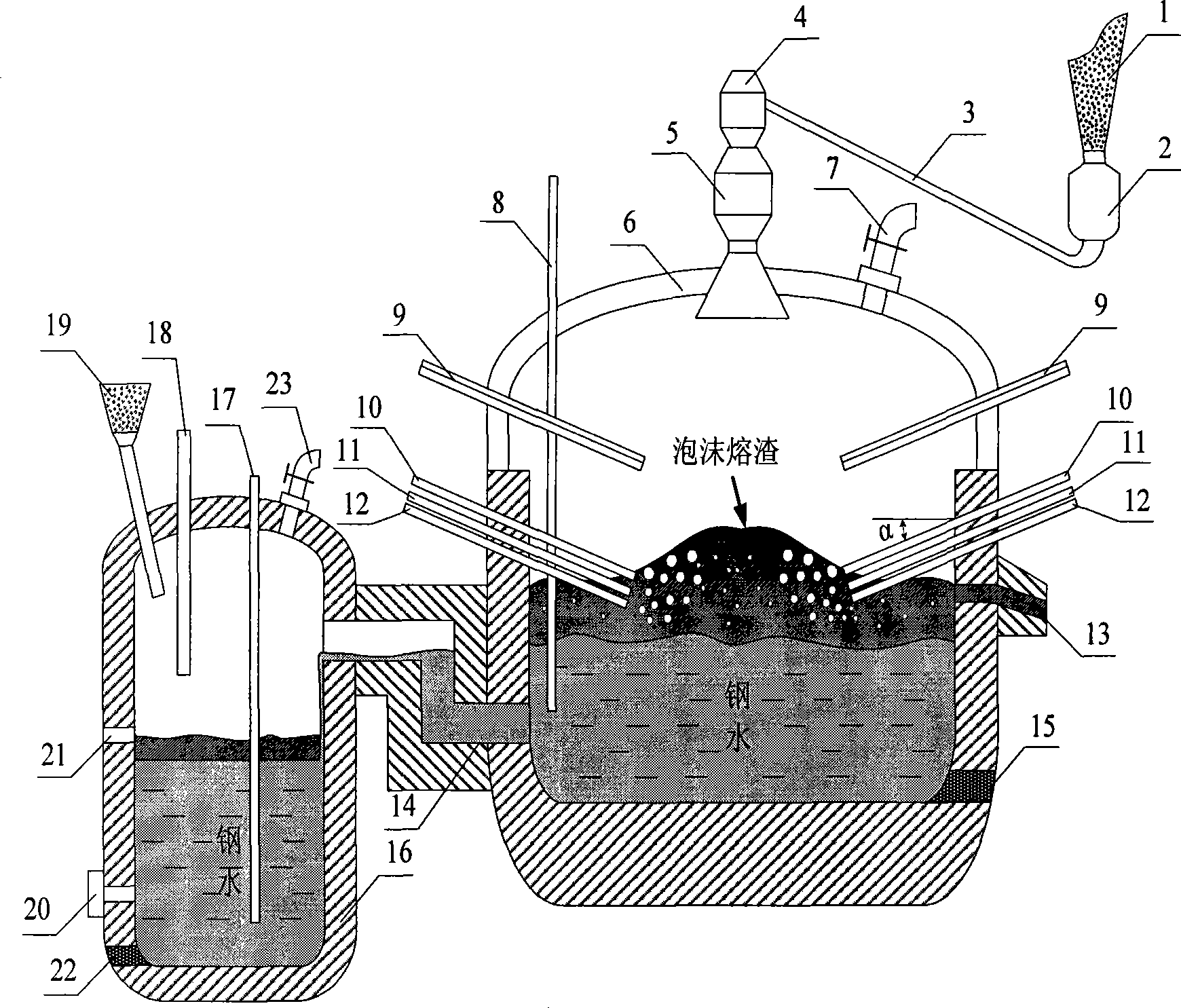

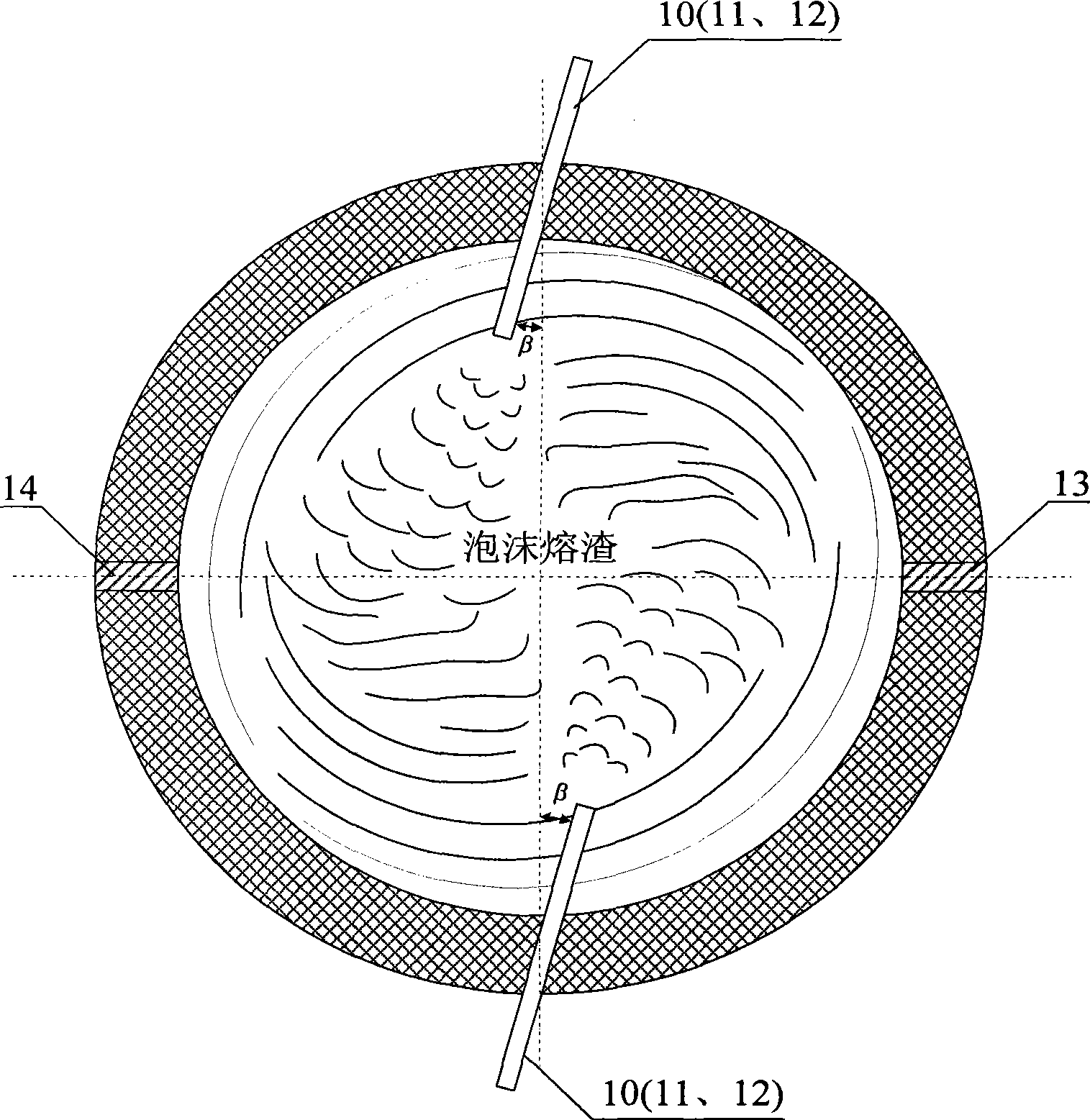

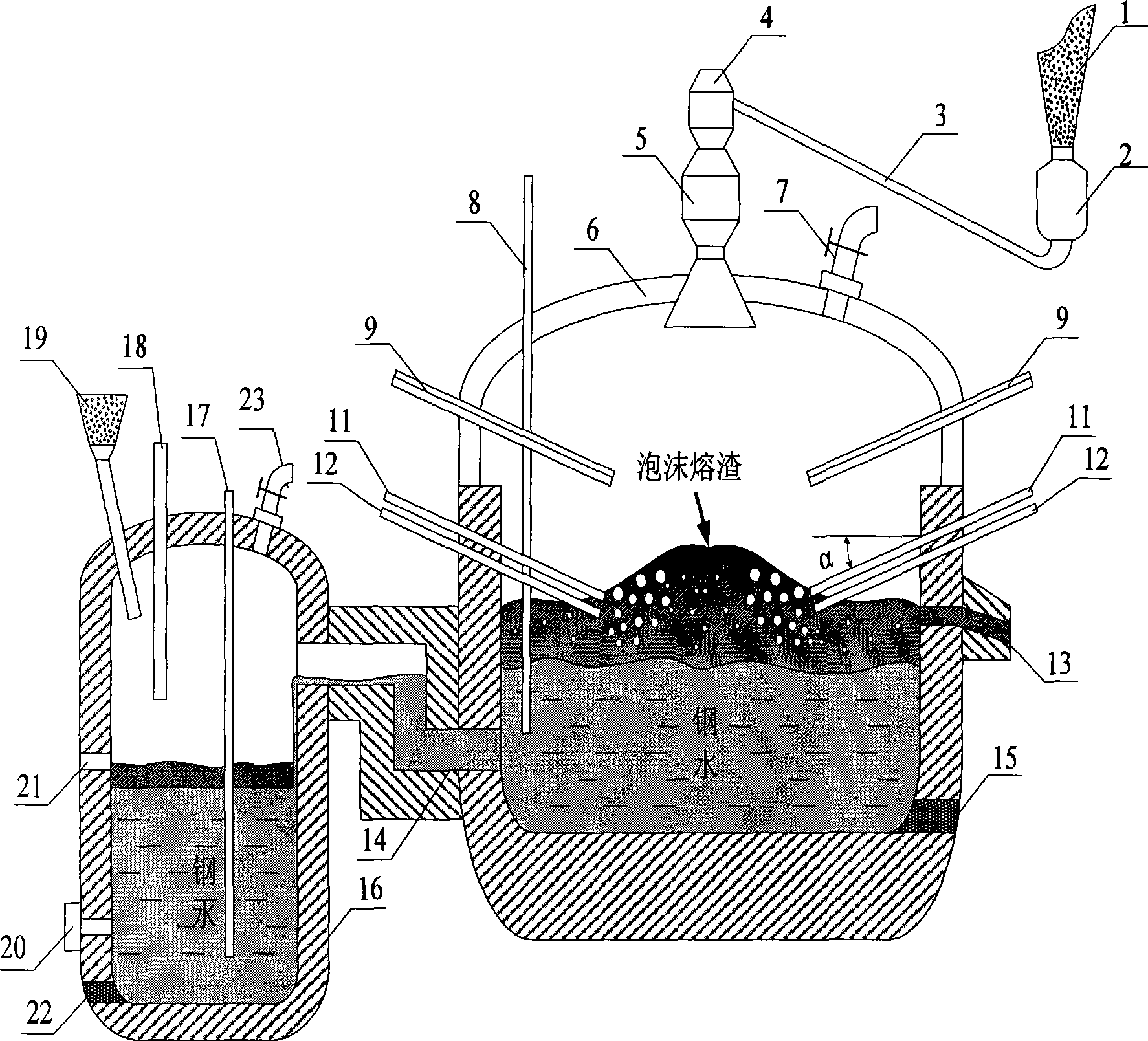

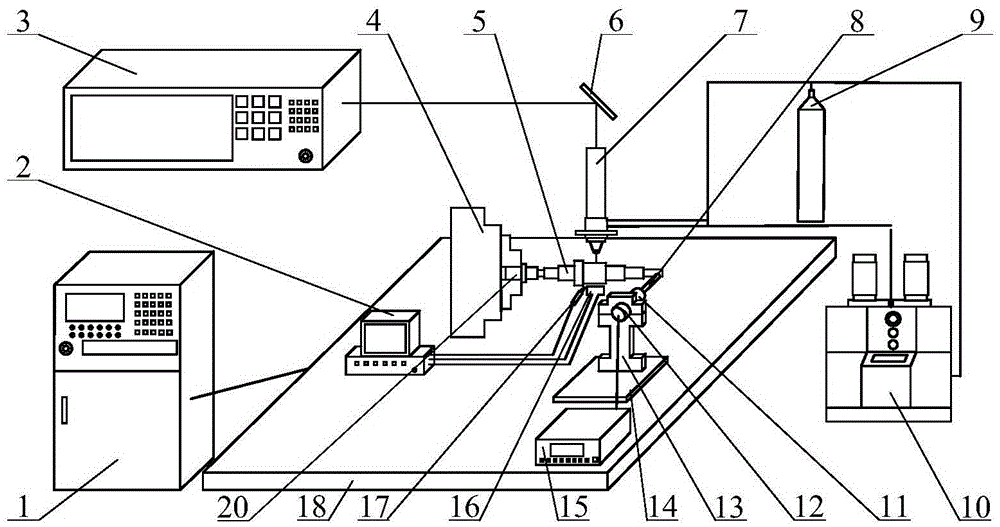

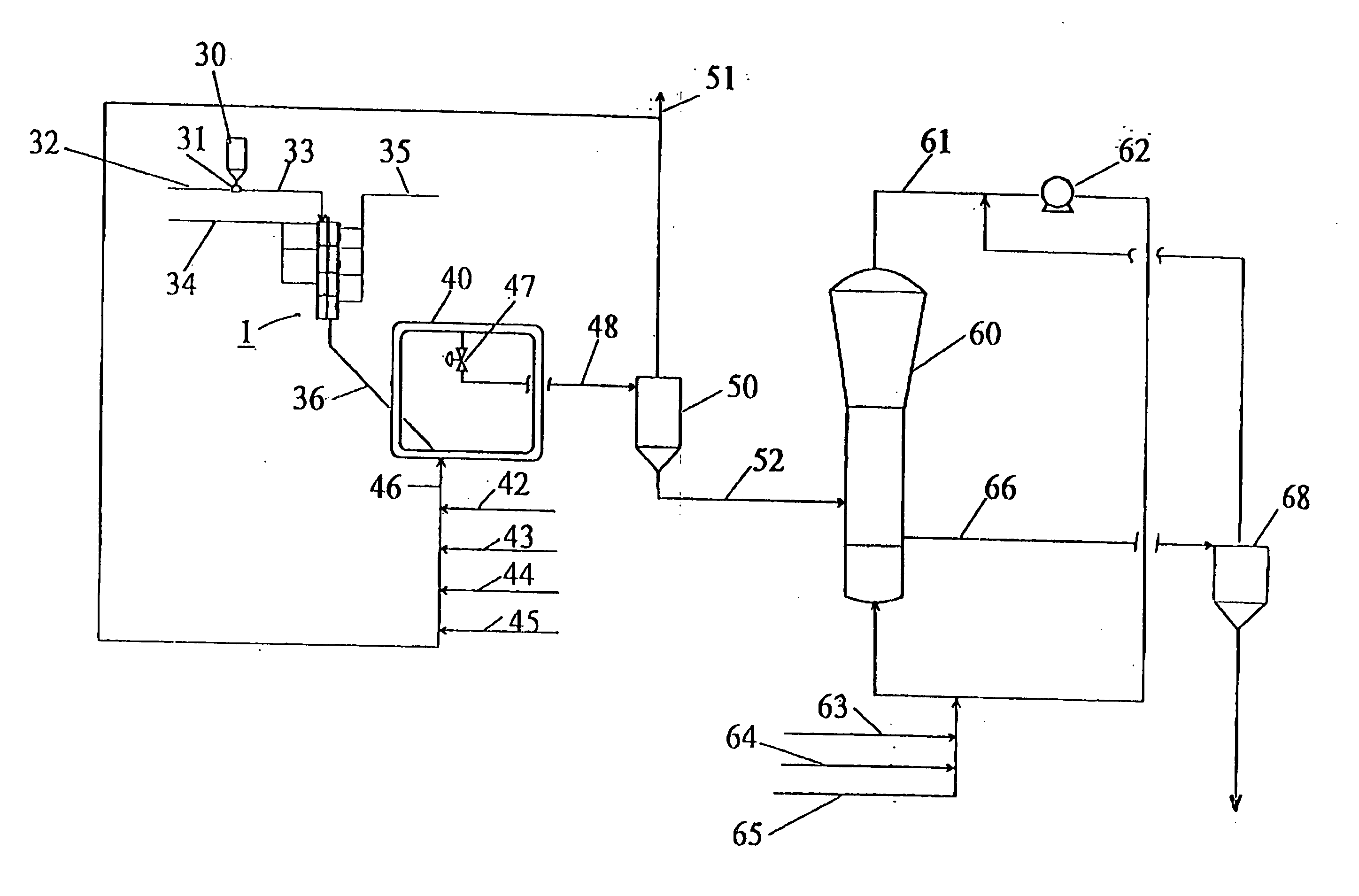

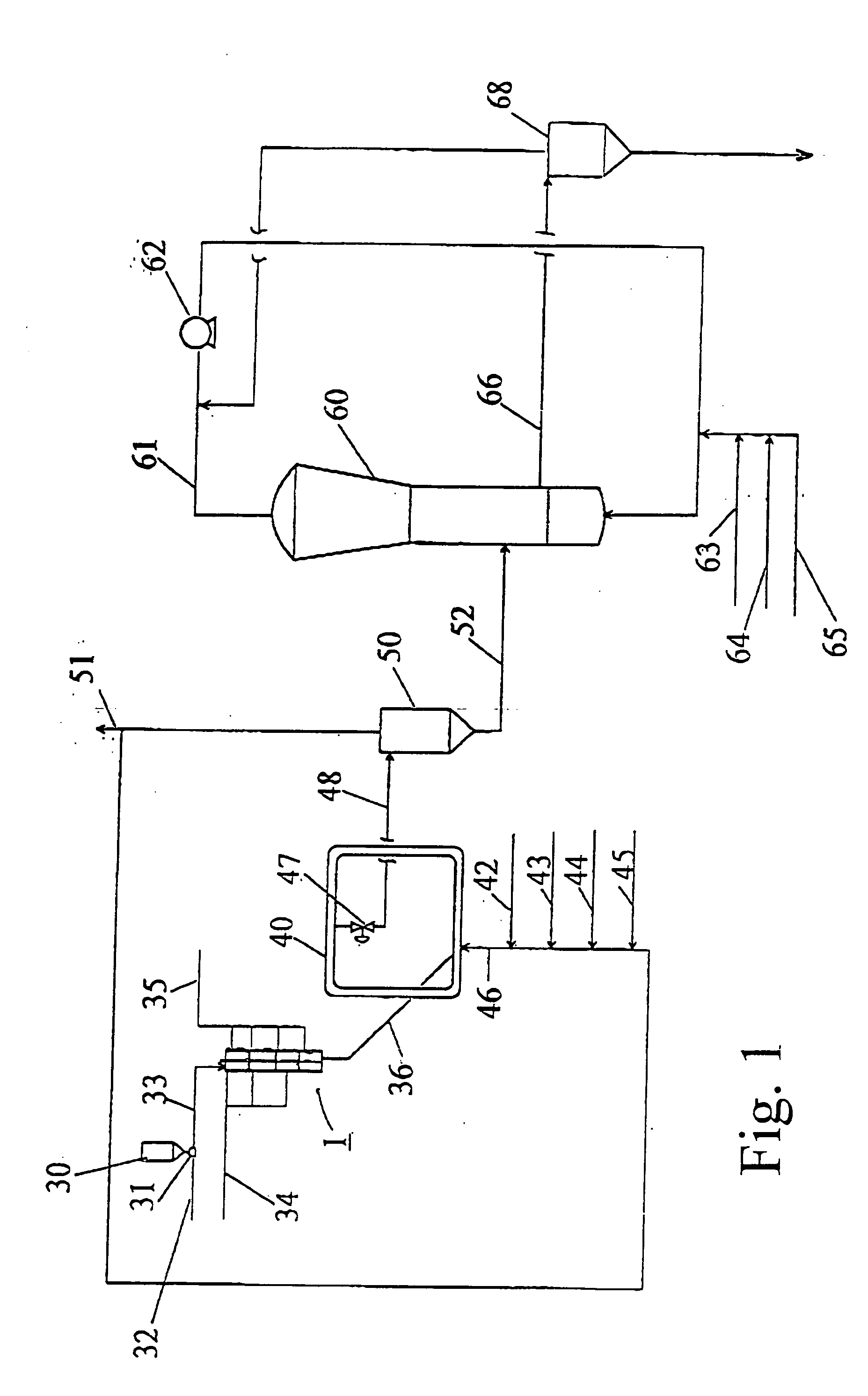

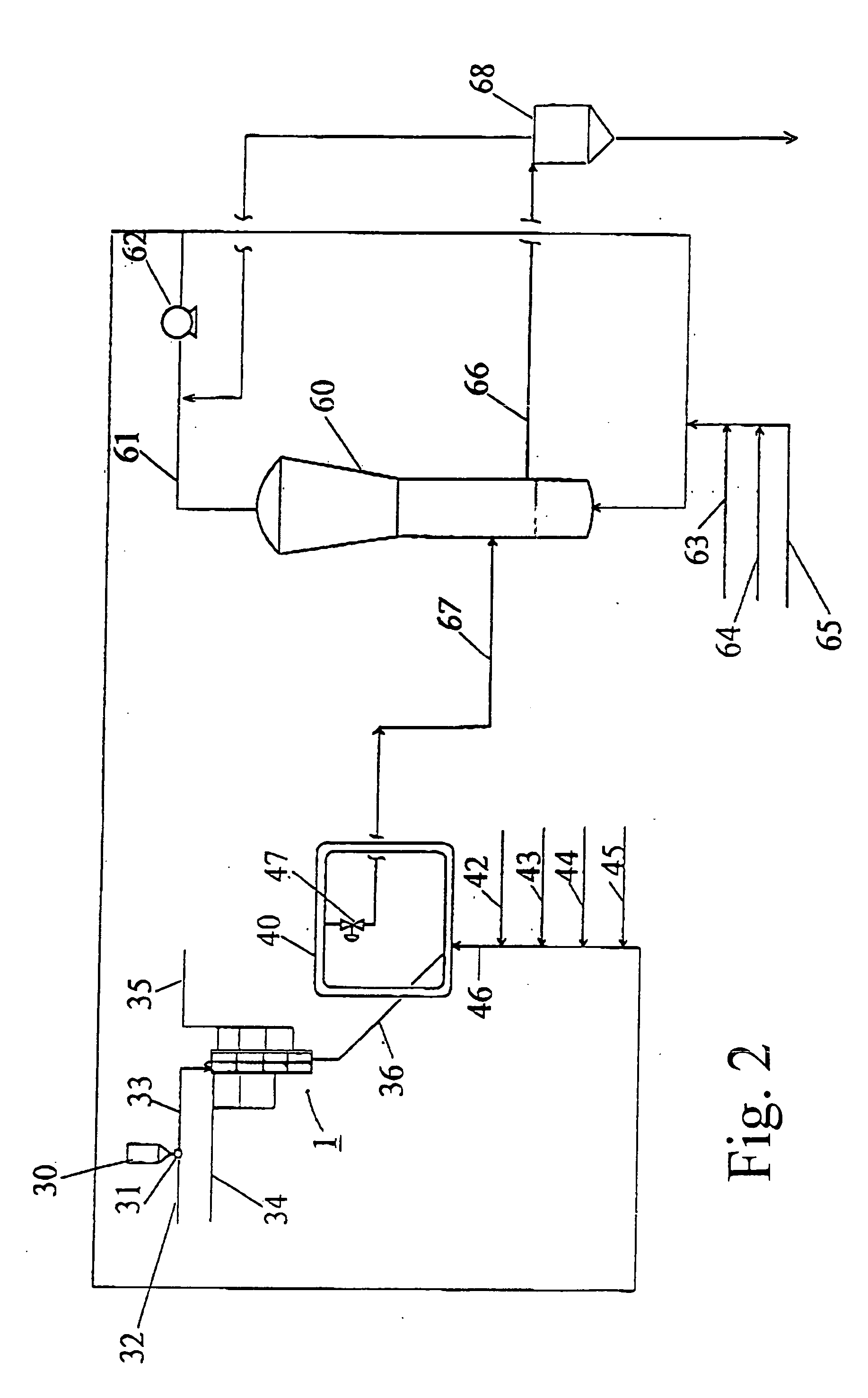

Process and device for continuous steelmaking from ferriferous material

ActiveCN101445848AReduce carbon contentIncrease temperatureFurnace typesProcess efficiency improvementSteelmakingMelting tank

The invention relates to a process for continuous steelmaking from a ferriferous material. A molten pool is formed in a steel-smelting furnace at first, and carbonic material and oxygen are insufflated to form foaming slag; the ferriferous material and a fluxing agent are added into the smelting furnace to be molten and reduced, oxygen is insufflated into the molten steel so as to reduce the carbon content in the molten steel, the temperature of the molten steel is risen, and the molten steel is stirred with the generated CO gas; high temperature oxygen or oxygen-enriched air is insufflated and burns with CO gas generated in the smelting furnace; and the molten steel continuously flows into an oxygen blowing furnace through a siphon nozzle, and a small quantity of the fluxing agent is added into the oxygen blowing furnace so that slag formation, desulfurization and dephosphorization are performed, the C content and the temperature in the molten steel are further adjusted through blowing oxygen by an insertion oxygen lance, therefore, the obtained molten steel is directly supplied for an LF refining furnace or an RH refining furnace. The invention has the advantages that the productivity equipment including a suspended pre-reduction furnace, the smelting furnace and the oxygen blowing furnace, the investment for devices and capital construction is saved, the land is saved, the physical distribution is simplified, and the continuous production and the automatic control are facilitated.

Owner:LAIWU IRON & STEEL GRP

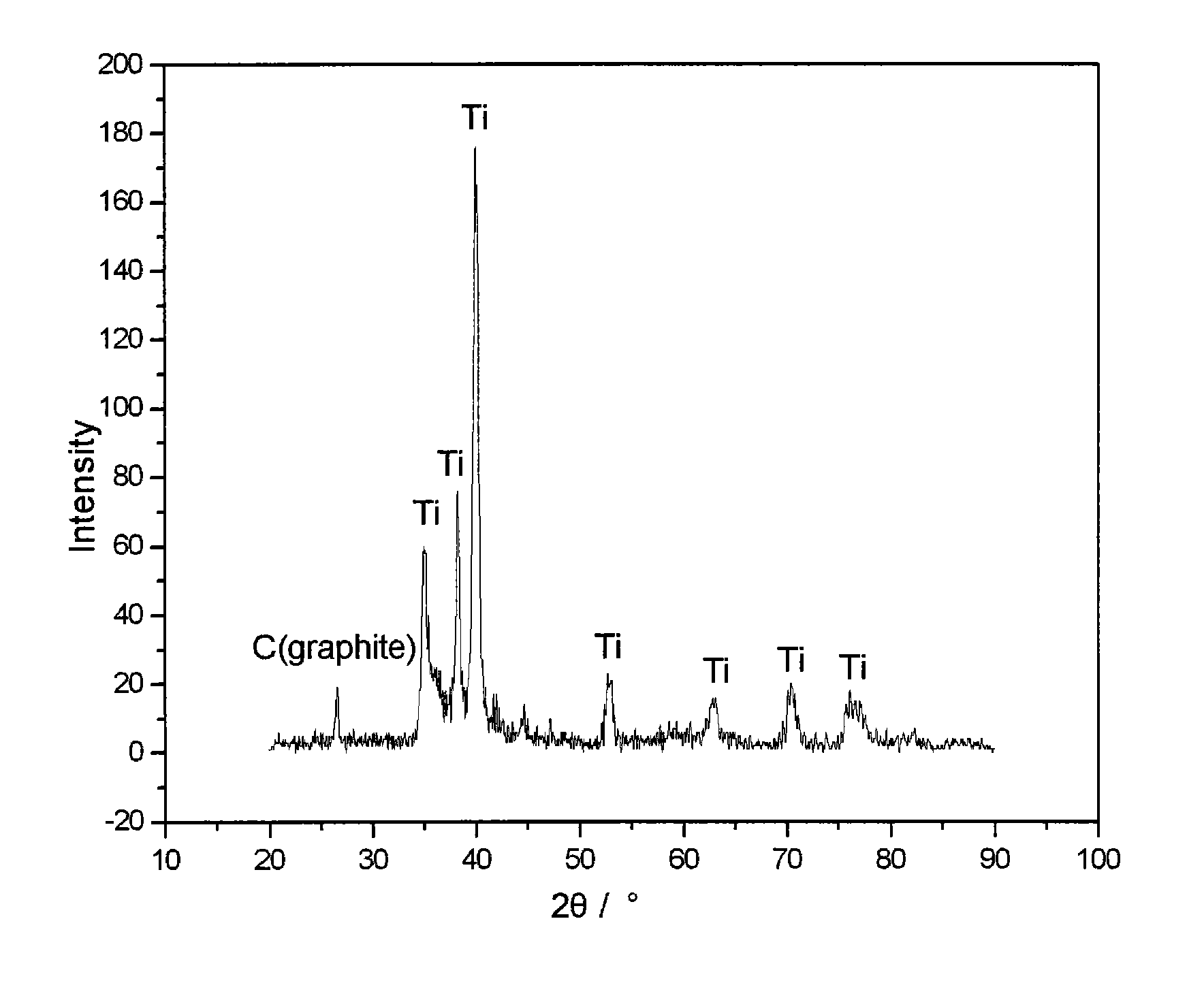

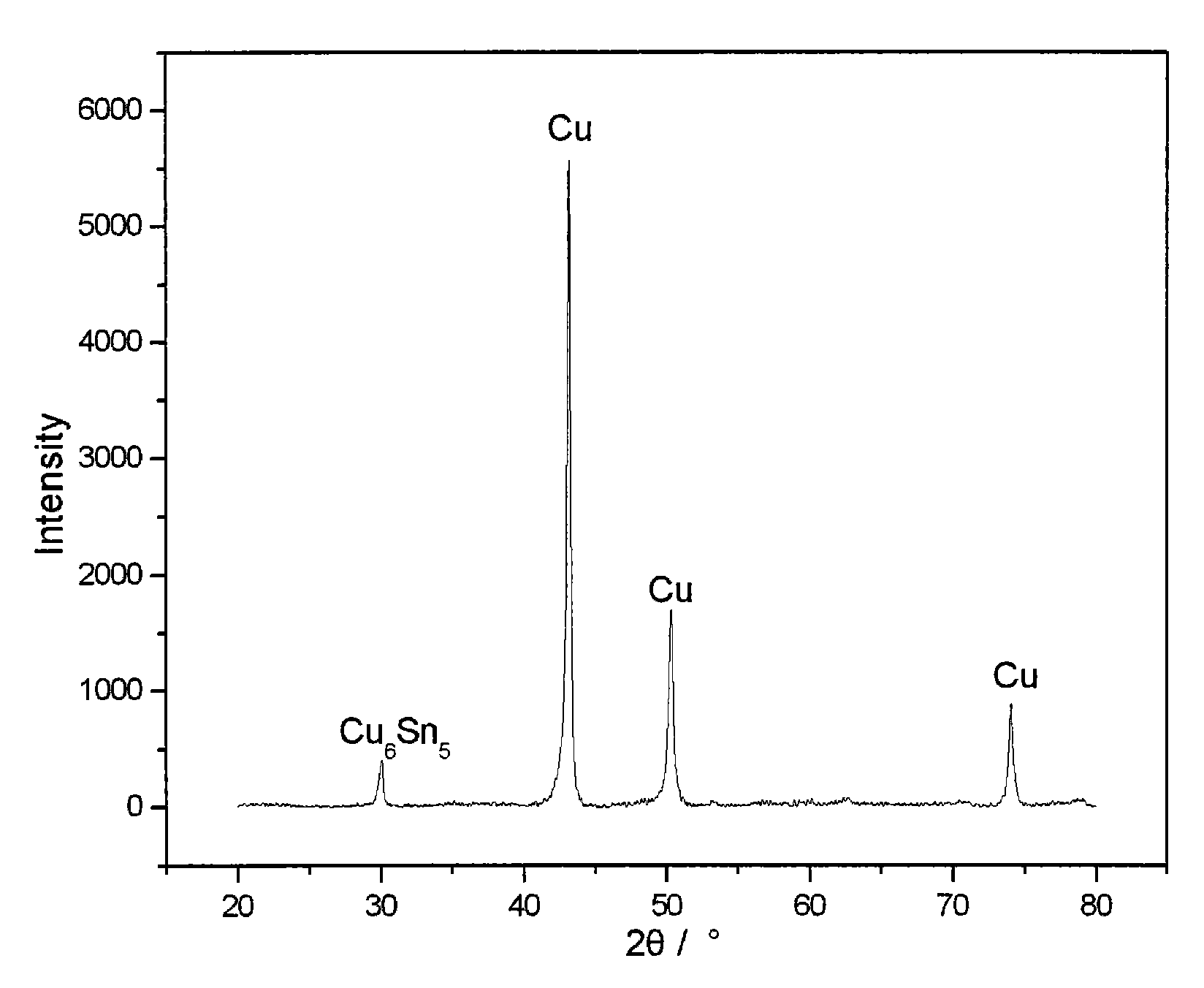

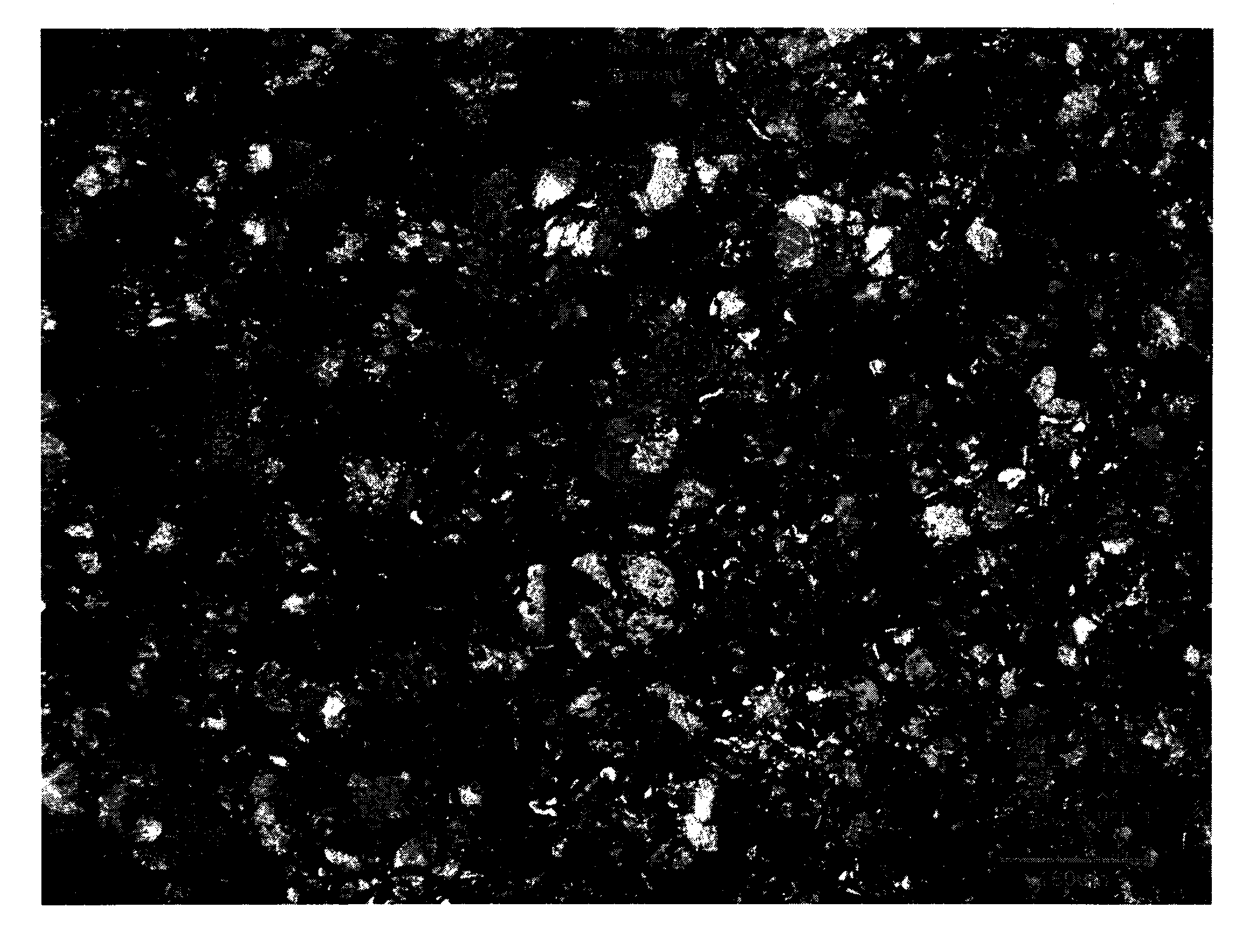

Metal-based powder metallurgy brake lining material and preparation methods thereof

InactiveCN101602105AExcellent material performanceSimple material compositionFriction liningPowder metallurgyCeramic particle

The invention discloses a metal-based powder metallurgy brake lining material and preparation methods thereof. The invention aims to solve the problems that the strength of a material is reduced along with the adding of ceramic particles when the powder metallurgy brake lining material is produced by the prior art and the like. The material comprises the following components in percentage by weight: 10 to 80 percent of Cu-Sn mechanical alloy powder, 1.25 to 15 percent of Ti-C mechanical activated powder, 2 to 65 percent of Fe powder, 0 to 10 percent of Ni powder, 0 to 12 percent of Cr powder, 2 to 8 percent of Al2O3 powder, and 7.75 to 23 percent of graphite, wherein the Cu-Sn mechanical alloy powder is prepared from Sn powder and Cu powder which contains 6 to 10 percent of Sn powder by mechanical alloying beforehand; and the Ti-C mechanical activated powder is prepared from Ti powder and C powder according to the ratio of 2:1-8:1 through mechanical activation beforehand, and forms TiC during the sintering. The invention also provides two preparation methods which combine the mechanical activation and the mechanical alloying with the prior powder metallurgy or discharge plasma sintering method.

Owner:JILIN UNIV

Tungsten titanium target material with high purity and high tungsten-rich phase, and preparation method thereof

ActiveCN101748365AUniform densityHigh strengthVacuum evaporation coatingSputtering coatingHigh densityRefractory

The invention relates to a refractory alloy tungsten titanium target material and a preparation method thereof, in particular to a tungsten titanium target material with high purity and high content of tungsten-rich phase, and a hot-pressing preparation method thereof, which belongs to the technical field of refractory alloy target materials. The method prepares high-density tungsten alloy targetmaterial by taking high-purity W powder and Ti powder, as well as high-purity Mo, Cr, Ta, Nb and other additive metal powder as raw materials and adopting a high-temperature high-pressure hot-pressing molding process, wherein the relative density of the target material reaches 95 to 99 percent, and the content of tungsten-rich phase reaches 80 to 93 percent. Relative to the prior art, the method adds part of high-purity Nb, Mo, Cr, Ta and other metal powder while mixing materials so as to stabilize the tungsten-rich phase in alloy, increase the content of the tungsten-rich phase in the alloy and improve the using quality of the target material.

Owner:有研资源环境技术研究院(北京)有限公司

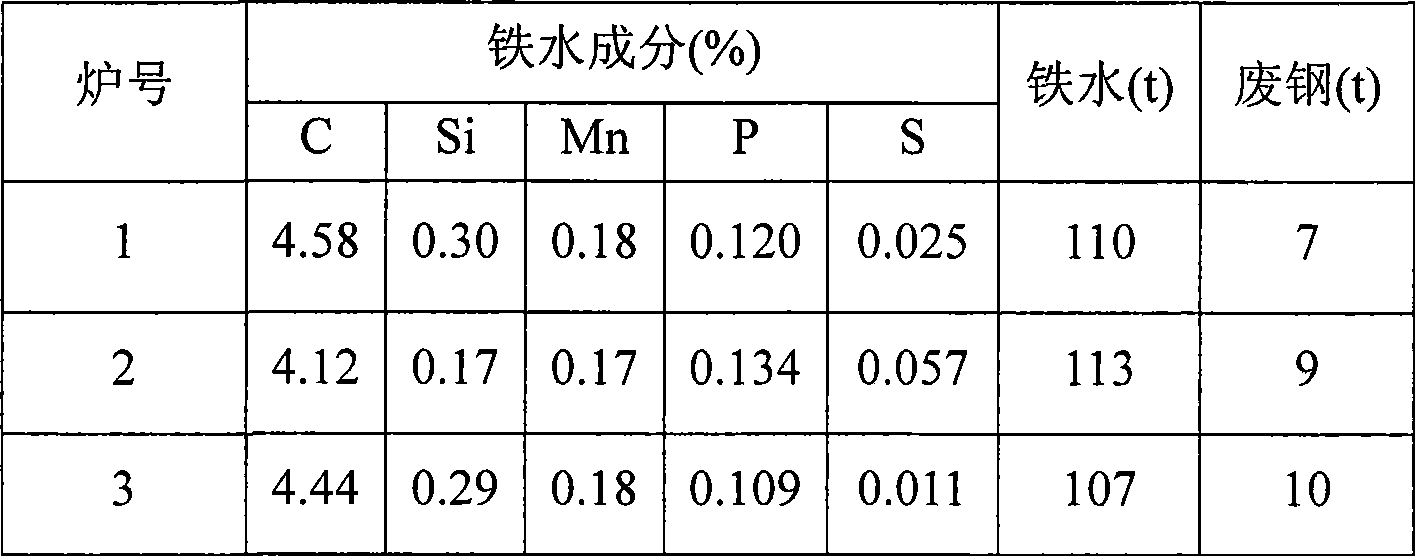

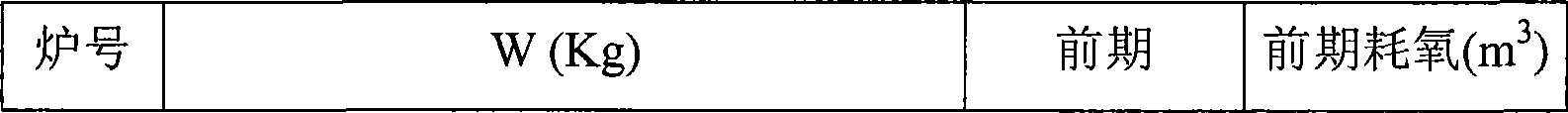

Steelmaking and slagging method

The invention provides a steelmaking and slagging method. The method comprises the following steps of: adding semisteel from which vanadium is extracted into a steel refining furnace; blowing oxygen into the steel refining furnace and blowing; in two minutes after the blowing is started, adding 9 to 11kg of lime, 9 to 11kg of high-magnesium lime, 3 to 8kg of fluxing agent, and 11 to 14kg of acid composite slag into the steel refining furnace based on one ton of semisteel from which vanadium is extracted; and in 9 minutes after the first slag is formed and blowing is started, adding 9 to 11kg of lime and 9 to 11kg of high-magnesium lime into the steel refining furnace based on one ton of semisteel from which vanadium is extracted, and continuously blowing to obtain molten steel and final slag. The fluxing agent is refined steel slag. Slagging is performed by the method, the slag can be formed quickly, the consumption of an iron and steel material is reduced, smelting time is shortened and steelmaking cost is saved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

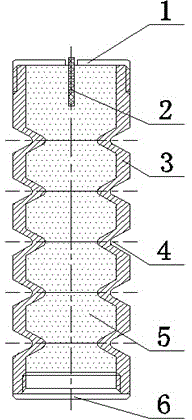

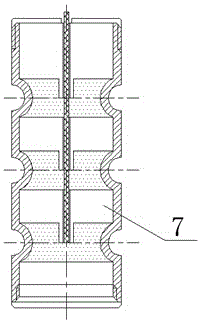

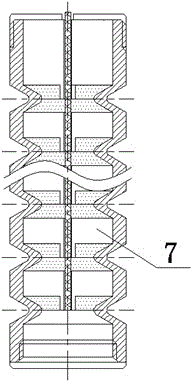

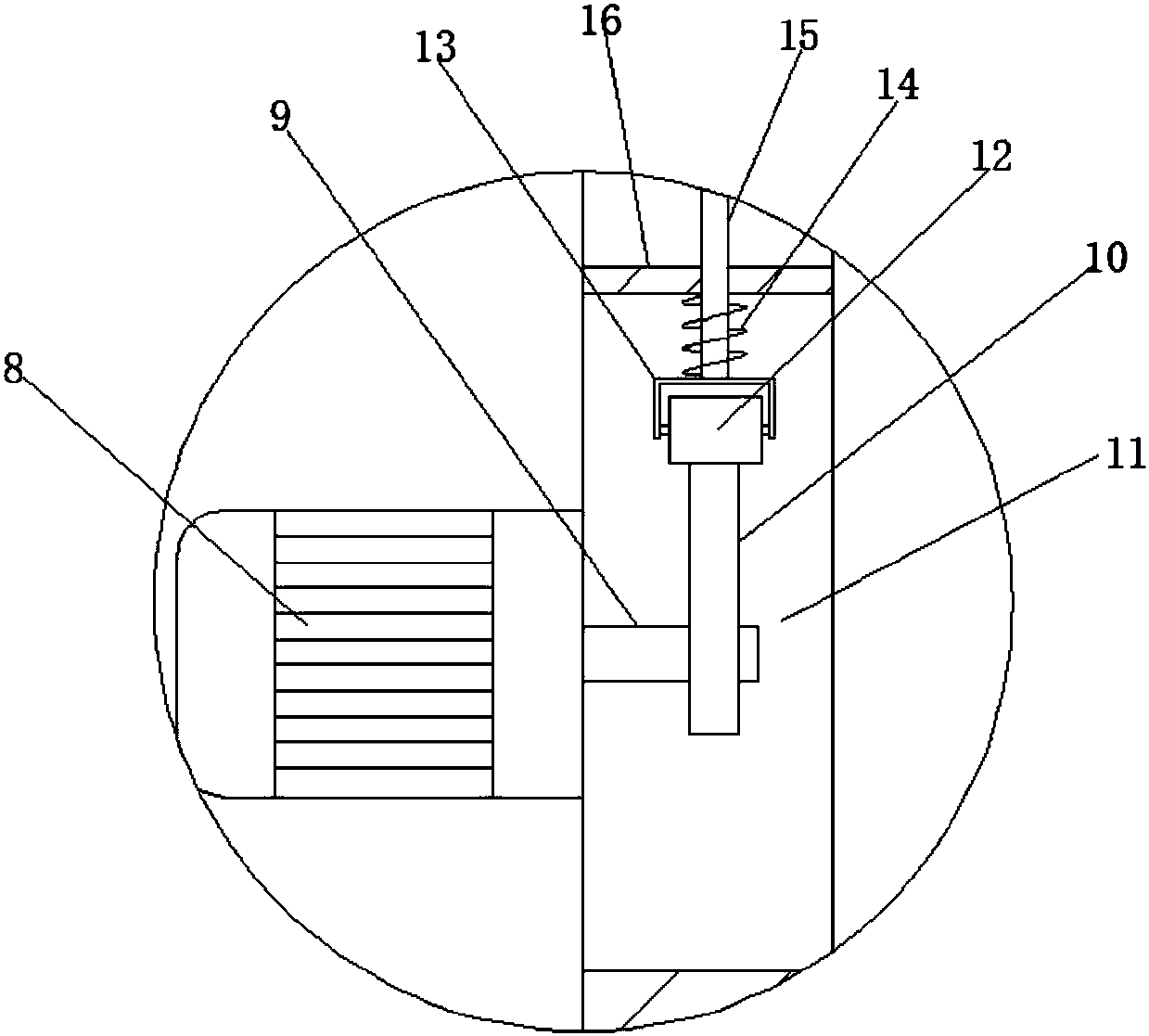

Case circular discontinuous energy concentrating jet flow cracker

InactiveCN103983153AHas energy-gathering effectSpeed up meltingFluid removalBlastingExplosive AgentsEngineering

The invention belongs to the technical field of engineering blasting and ammunition engineering. A circular discontinuous energy concentrating jet flow cracker comprises a round tube-shaped case, an end cover and a detonating unit; explosives are mounted inside the cavity the round tube-shaped case; the detonating unit is leaded out of the case through a hole formed in the end cover; the outer round surface of the round tube-shaped case is provided with circular grooves which are parallel to one another, and the circular grooves are in a conical or semicircular shape and form circular protrusions in the corresponding shape on the inner wall surface of the cavity of the round tube-shaped case; the width of the circular grooves is 1 / 2-1 / 5 as much as the outer diameter of the case, the length of the generatrix of the conical cross sections or the diameter of the semicircular cross sections of the circular grooves is 1-7 times larger than the thickness of the wall of the case, the apex angle of the conical cross sections is 40-120 degrees, and the distance between the central axises of every two neighboring circular grooves is 1.5-40 times as large as the width of the circular grooves. The circular discontinuous energy concentrating jet flow cracker impacts a target at a high speed through the high-temperature, high-pressure and energy-concentrated discontinuous jet flows which are generated by the case, is simple in structure, convenient to machine and use, small in amounts of explosives used in a single blasting, low in vibration, low in production cost and capable of ensuring the safety and meeting various usage requirements.

Owner:UNIV OF SCI & TECH OF CHINA

Gradient wear-resistant coating and method for preparing same

ActiveCN105543839AImprove wear resistanceHigh temperature resistantSuperimposed coating processWear resistantUltrasonic oscillation

Provided are a gradient wear-resistant coating and a method for preparing the same. Co50+0.15% CeO2 powder, Co50+0.25% CeO2+6% Ni / Wc powder and Co50+0.4% CeO2+12% Ni / WC powder are used for preparing the gradient wear-resistant coating with the structure of a bottom layer, a transition layer and a wear-resistant layer on the surface of a workpiece in a coaxial powder supply manner and a laser cladding manner, and the wear resisting performance of the work surface of a part is improved. An ultrasonic vibration device and a contour tracing electromagnetic induction heating device are adopted in the cladding process. Ultrasonic oscillation of a certain degree is applied to the area close to a cladded area of the workpiece, the grain size of a cladding layer can be remarkably refined, residual stress can be remarkably eliminated, and therefore generated cracks are reduced, and a cladding layer structure with good performance is obtained. The contour tracing electromagnetic induction heating device can be utilized for effectively reducing thermal stress brought by the temperature gradient of the cladding layer and relieving the cracking tendency. According to the technological parameters of the ultrasonic vibration device, the work frequency ranges from 10 kHz to 20 kHz, the maximum output power is 1,000 W, and the pneumatic pressure ranges from 0.3 MPa to 0.6 MPa. According to the technological parameters of the contour tracing electromagnetic induction heating device, the voltage is 380 V, the frequency is 60 Hz, and the heating temperature ranges from 150 DEG C to 1,000 DEG C.

Owner:CHANGCHUN UNIV OF SCI & TECH

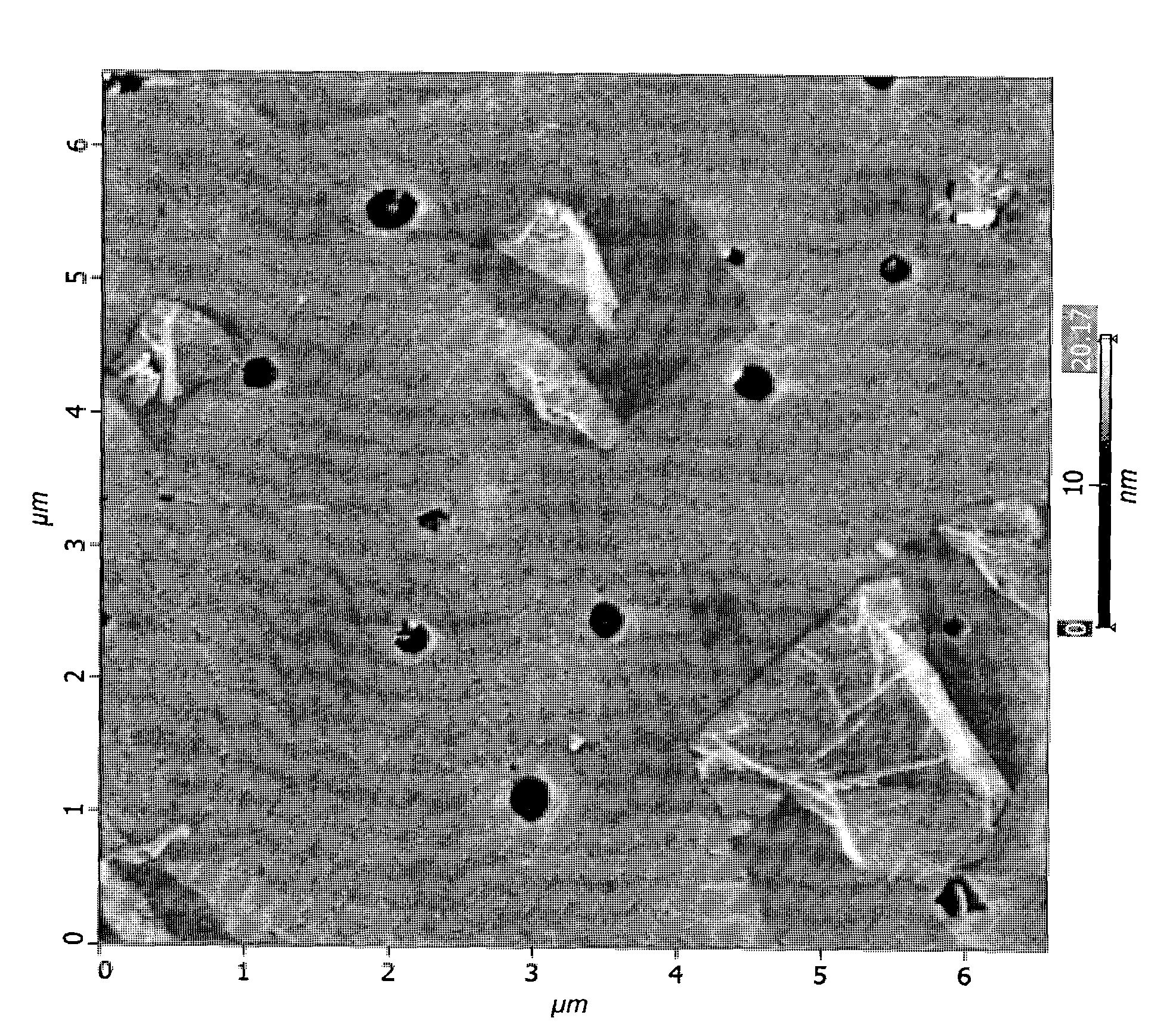

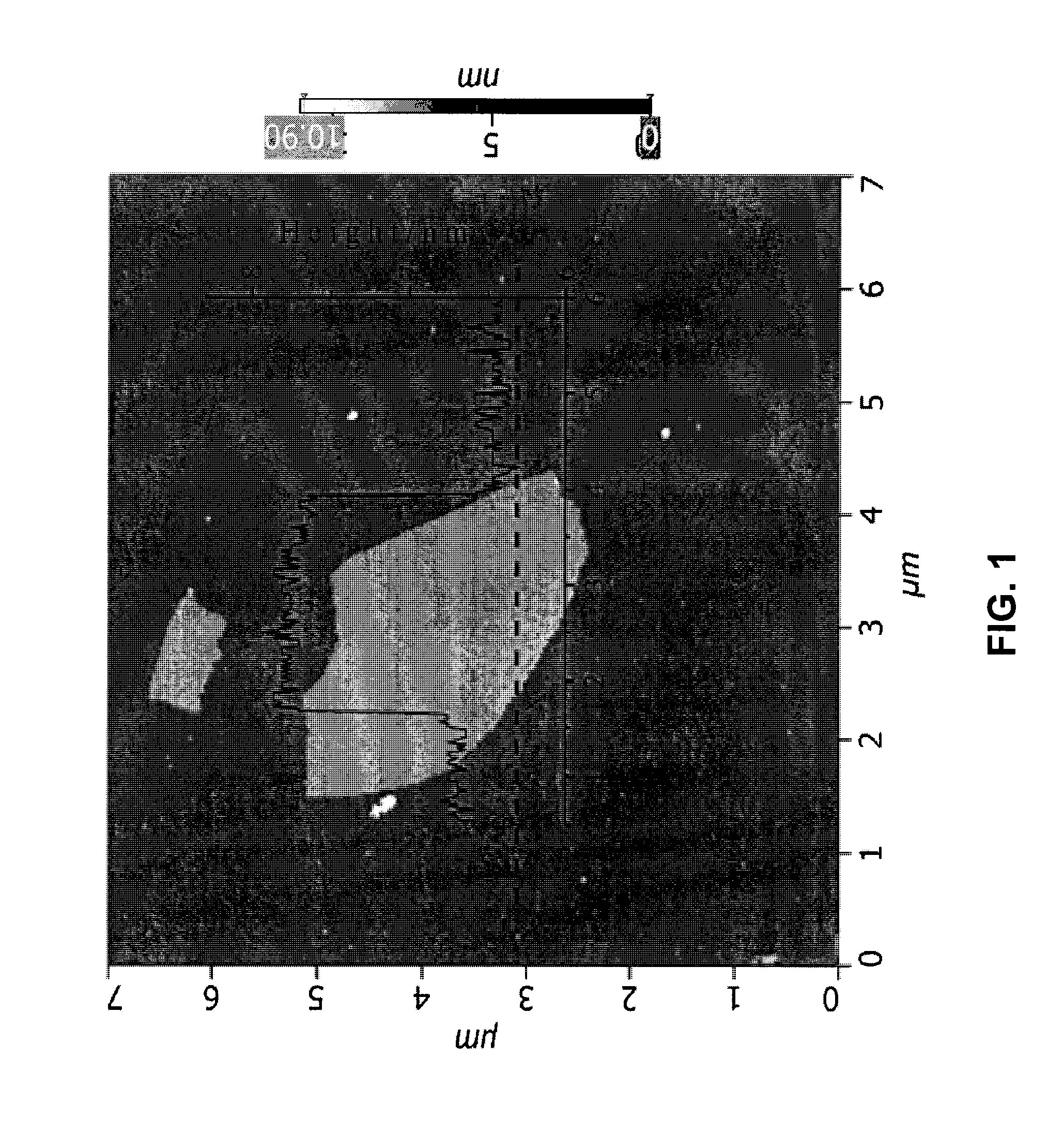

Method for making polymer composites containing graphene sheets

ActiveUS20120068122A1Optimal macroscopic performance propertyImproved performance characteristicsMaterial nanotechnologyNon-metal conductorsPolymer scienceGraphene flake

In one embodiment, a method for producing a graphene-containing composition is provided, the method comprising: (i) mixing a graphene oxide with a medium to form a mixture; and (ii) heating the mixture to a temperature above about 40° C., whereby a graphene-containing composition is formed from the mixture. Composites of polymers with disperse functionalized graphene sheets and the applications thereof are also described.

Owner:COLLEGE OF WILLIAM & MARY

High melt strength polypropylene

InactiveUS20050159564A1Improve melt strengthHigh viscosityChemical/physical/physico-chemical stationary reactorsPolymer scienceHydrogen

The present invention concerns a high melt strength propylene polymer or copolymer suitable for manufacturing foams and thermoformed product exhibiting a melt strength of at least 3 g and comprising a high molar mass portion and a low or medium molar mass portion. The polymers are produced by subjecting propylene and optionally other olefins to polymerization in a plurality of polymerization reactors connected in series, employing different amounts of hydrogen as a molar mass modifier in at least two of the reactors, and carrying out the polymerization reaction in the presence of a catalyst system capable of catalyzing the formation of a high molar mass polymerization product having a MFR2 of less than 0.1 g / 10 min and a low or medium molar mass polymerization product having a MFR2 of more than 0.5 g / 10 min.

Owner:BOREALIS TECH OY

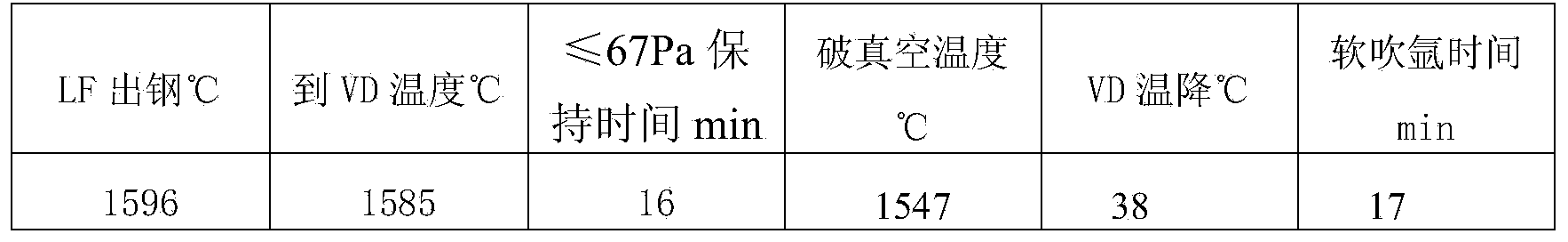

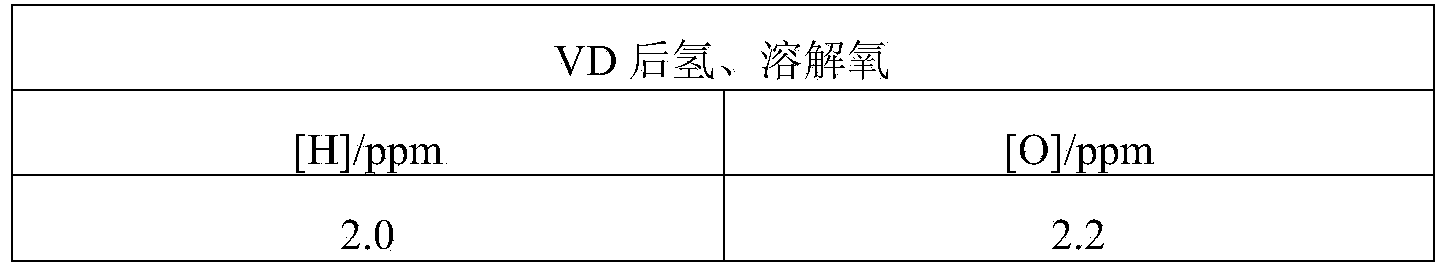

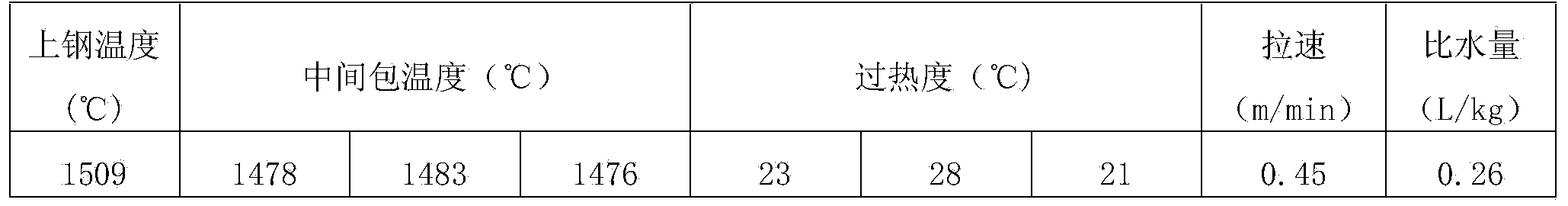

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

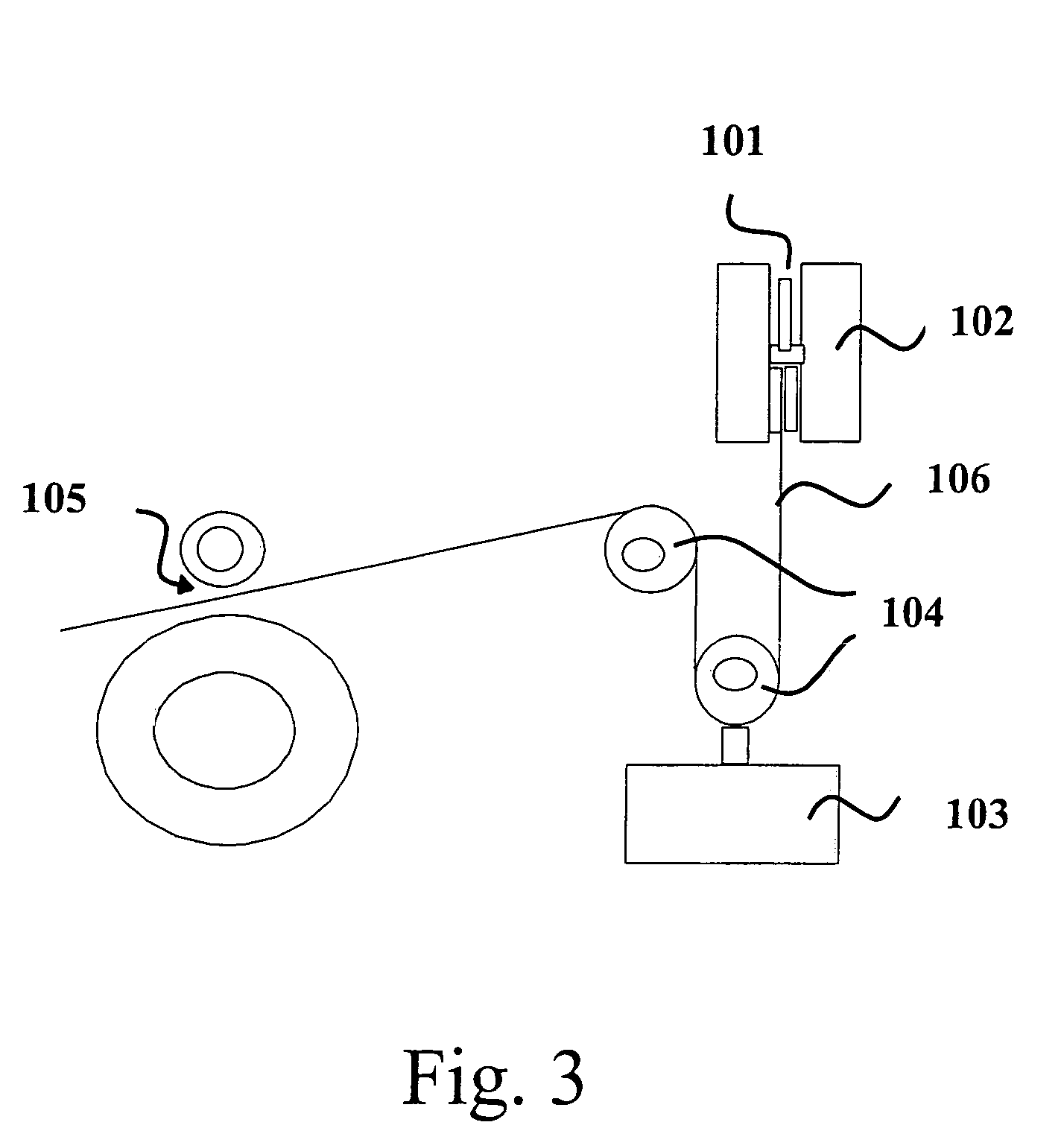

Method for producing oxygen-free copper rod from secondary copper

ActiveCN103114208ALow costReduce physical workloadProcess efficiency improvementMetal rolling arrangementsNatural gasMetal impurities

The invention discloses a method for producing an oxygen-free copper rod from secondary copper, which comprises the following steps of: (A) feeding the secondary copper into a furnace, and heating for melting; (B) refining to remove metal impurities; (C) reducing with natural gas to obtain pure copper; (D) adding rare earth and a complex deoxidizer and then outputting copper; and (E) casting, and performing continuous casting and rolling to obtain an oxygen-free copper rod. Compared with a traditional up-draw process, the method disclosed by the invention can adopt the easily available secondary copper as a raw material for production and can process a great quantity of secondary copper once, and overcomes the shortcomings of high production cost and low production efficiency of the up-draw process adopting secondary copper as raw material; natural gas reduction replaces poling, thereby being more environment-friendly and ensuring lower cost; and moreover, the labor capacity is small, and the defect of bad working condition in poling is overcome.

Owner:绵阳铜鑫铜业有限公司

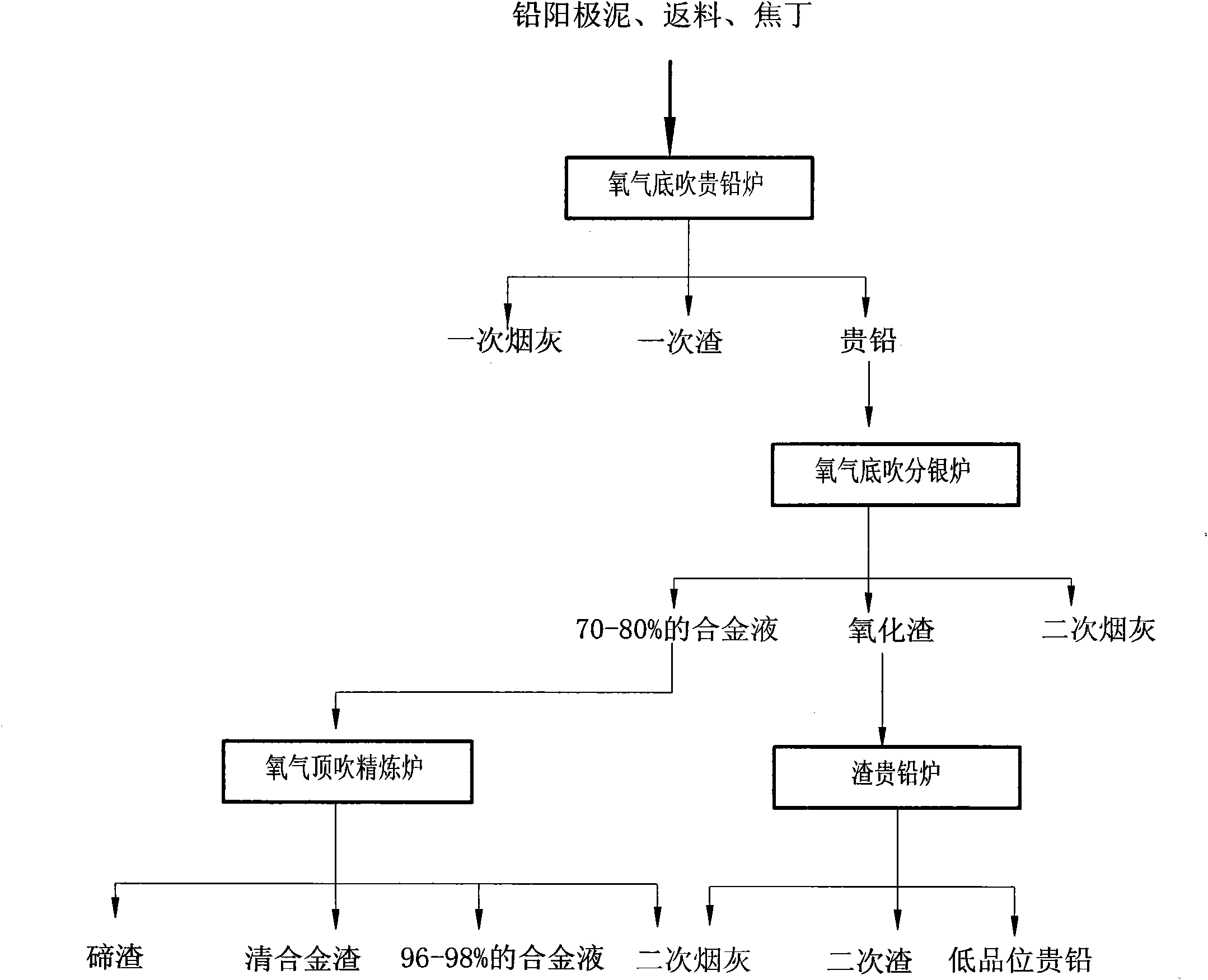

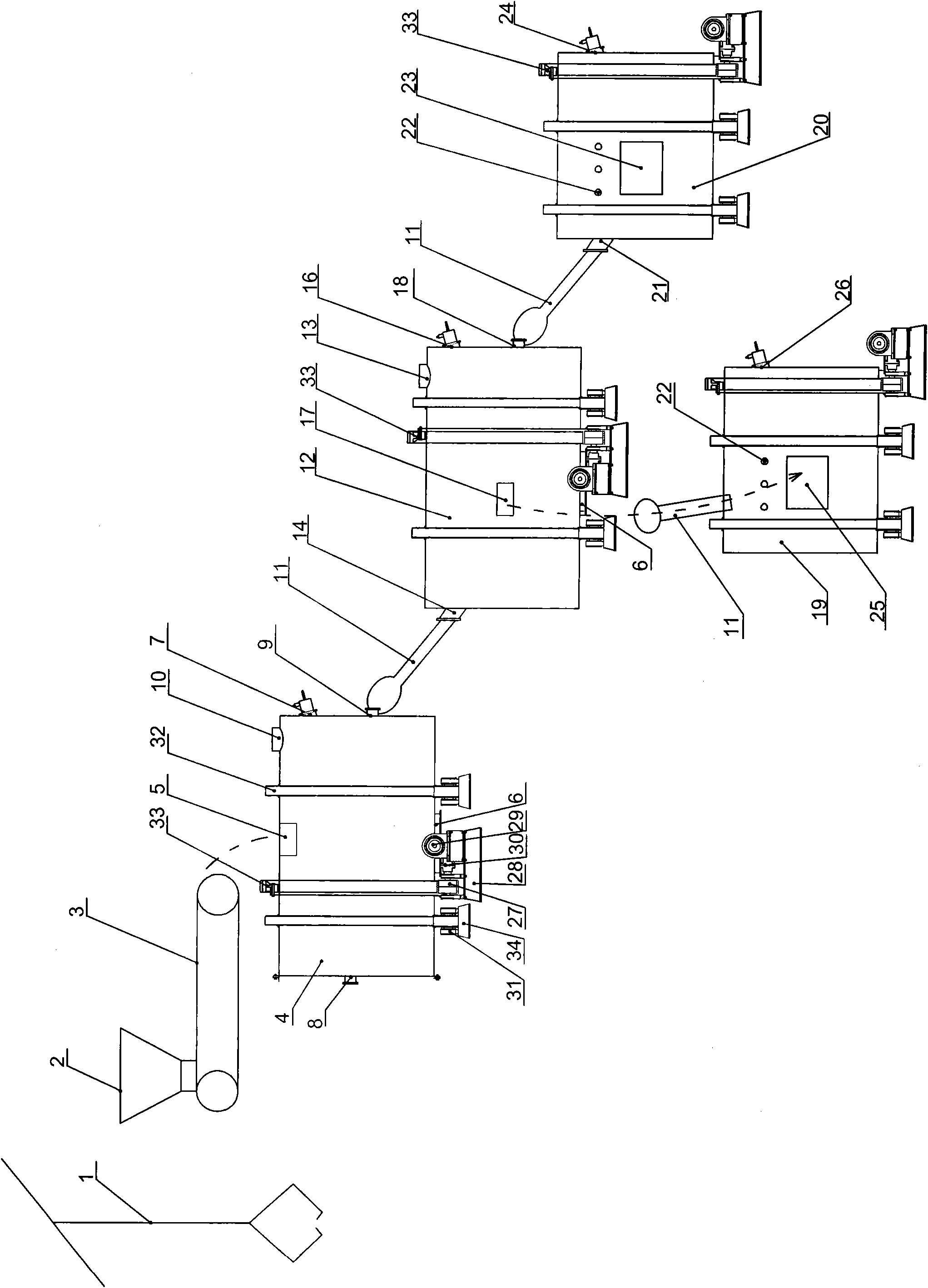

Method and device for continuously treating lead anode slime

ActiveCN101892388AEnables continuous processingShort processing cycleProcess efficiency improvementMelting tankSmelting process

The invention relates to a method and device for continuously treating lead anode slime by bath smelting. The method comprises the following steps: proportionally adding lead anode slime, recycled materials and nut coke as charging materials into an oxygen bottom blowing bullion lead furnace for smelting to generate bullion lead of which the bullion grade is 25-50%, primary slag and primary soot; adding the bullion lead into an oxygen bottom blowing silver-smelting furnace to react to generate oxidizing slag, secondary soot and alloy liquid of which the bullion grade reaches 70-80%; introducing the alloy liquid into an oxygen top blowing refining furnace to react to generate tellurium slag, clear alloy slag, secondary soot and alloy liquid of which the bullion grade reaches 96-98%; and discharging the oxidizing slag, then enabling the oxidizing slag to enter a slag bullion lead furnace, and adding the nut coke to react to generate low-grade bullion lead, secondary slag and secondary soot, wherein the low-grade bullion lead is returned for proportioning. The invention realizes the continuous treatment of the anode slime, strengthens the smelting process, improves the direct recovery rate of the bullion, lowers the production cost, reduces the environmental pollution, and shortens the treatment period of the anode slime.

Owner:JIYUAN YUGUANG NONFERROUS METALLURGY DESIGN & RES INST CO LTD

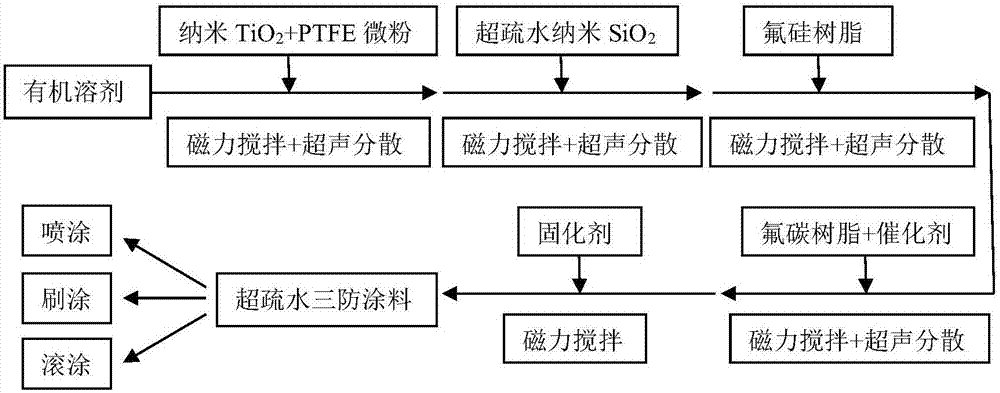

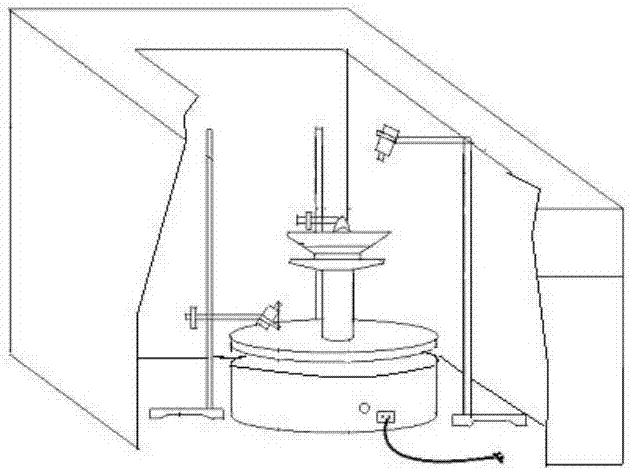

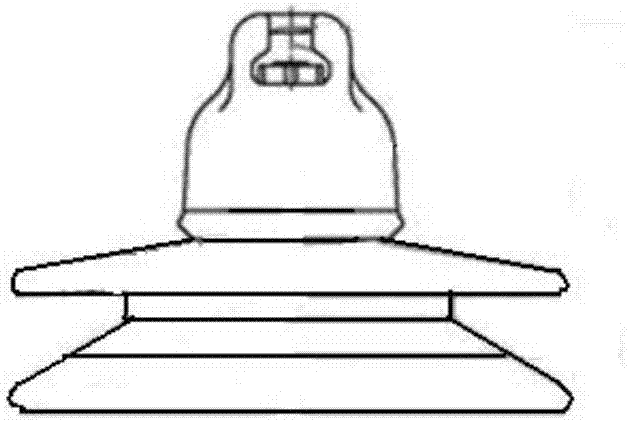

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

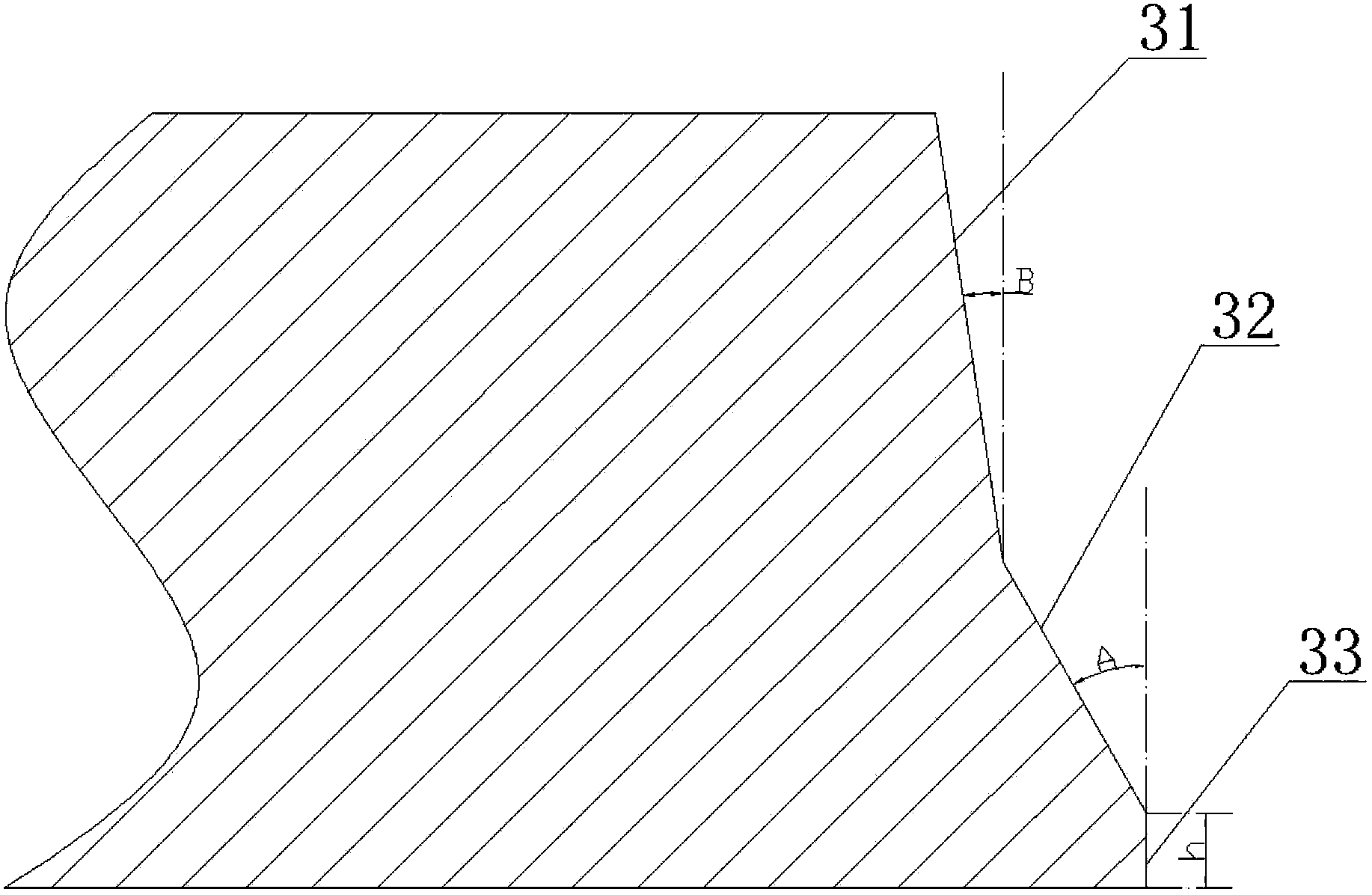

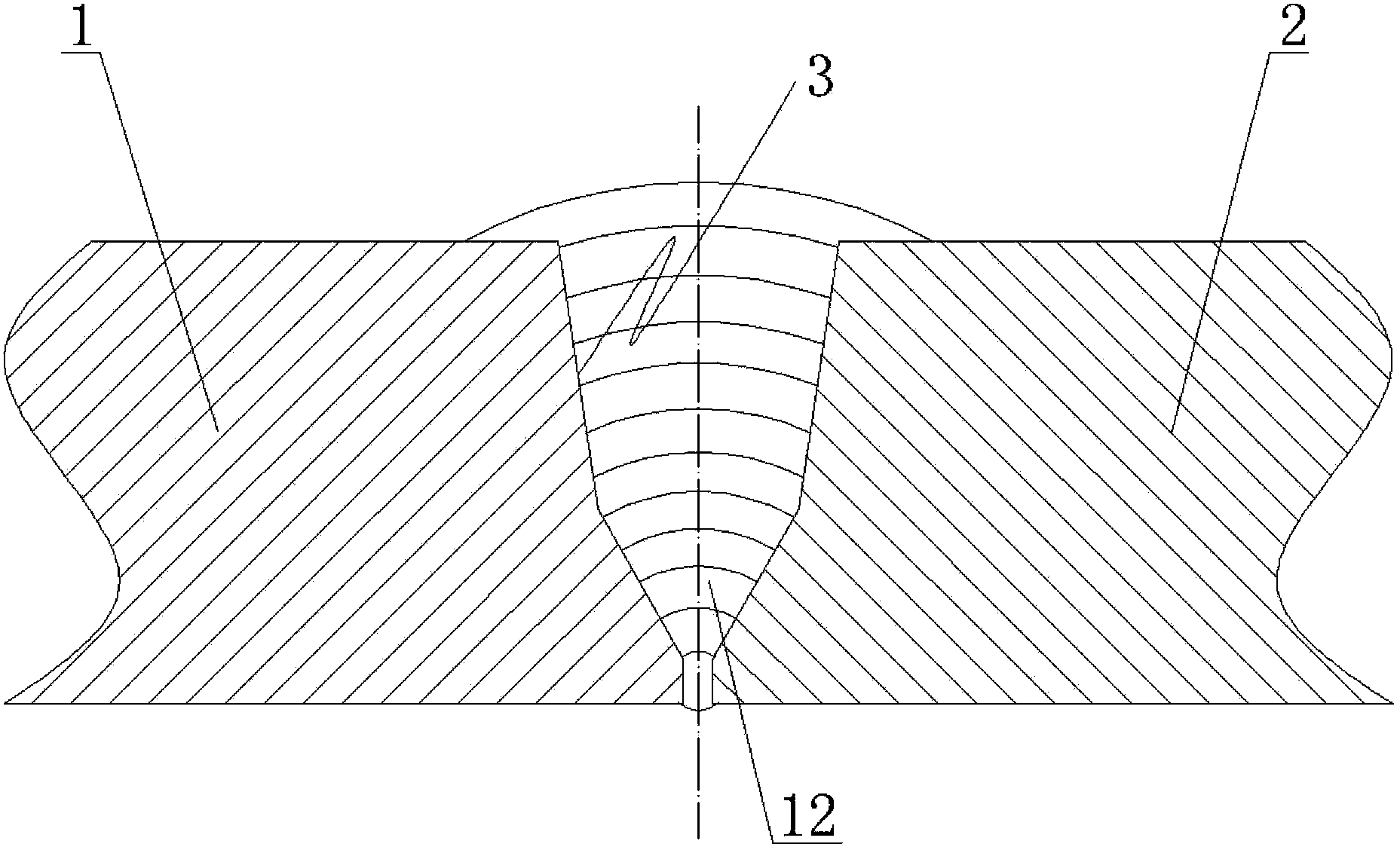

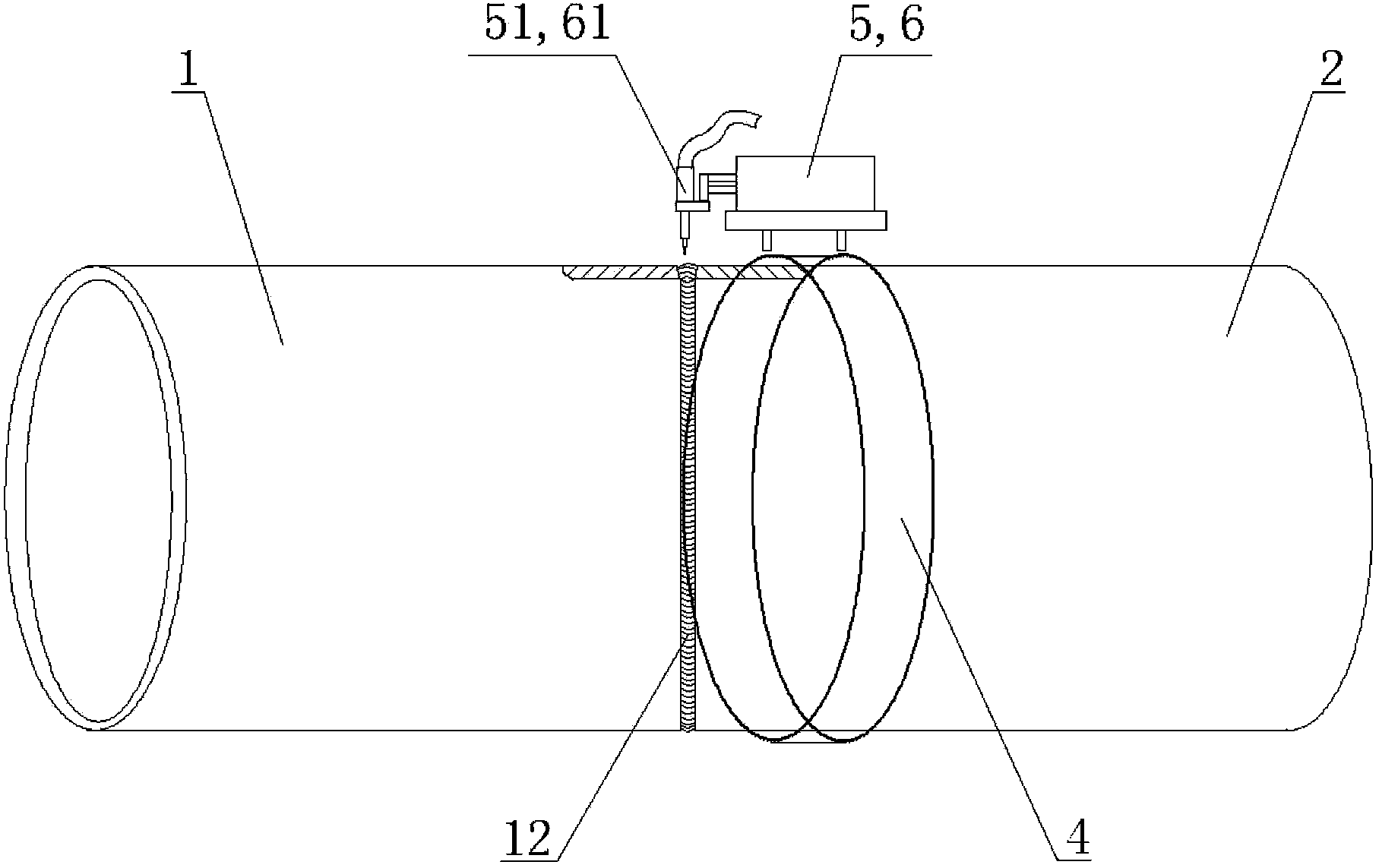

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

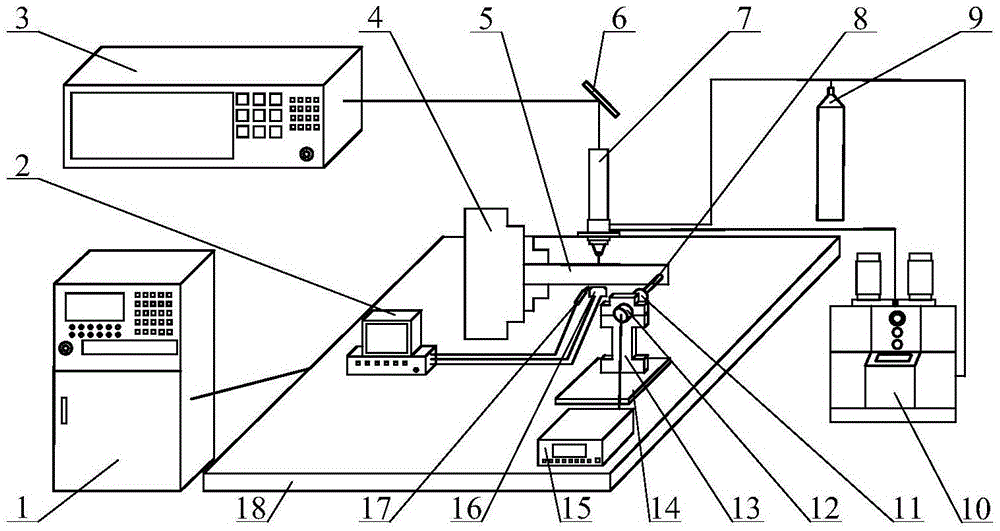

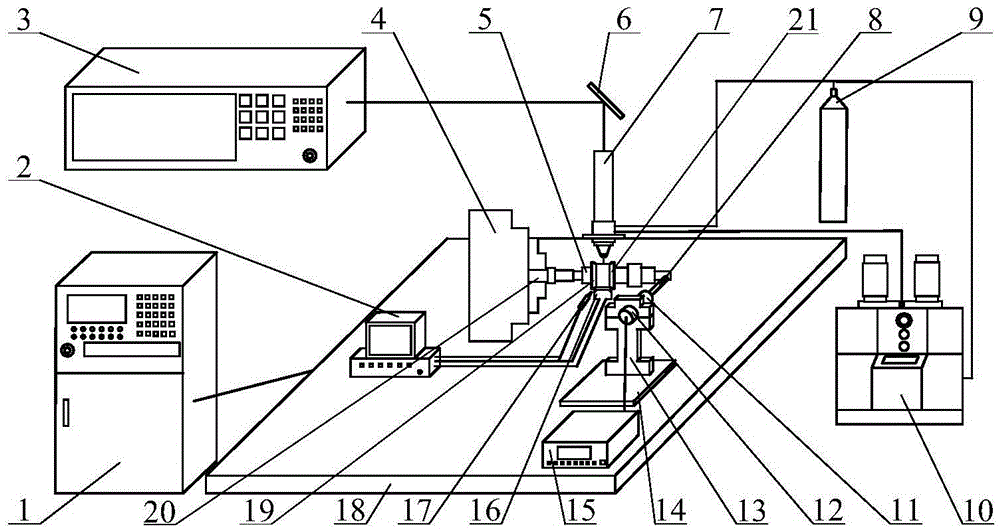

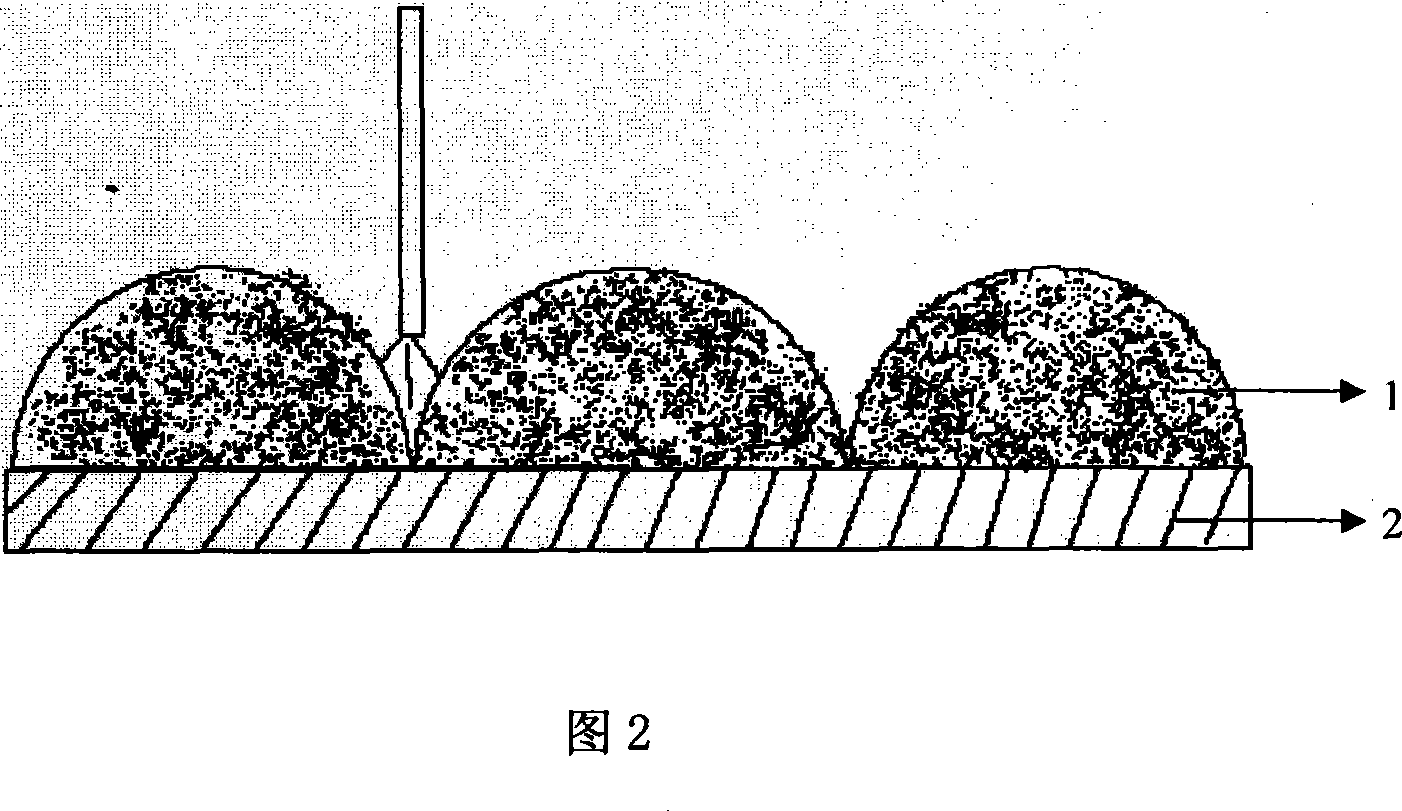

Alloy powder block used for built-up welding

InactiveCN101053931ASpeed up meltingSolve the problem that it is difficult to melt and easy to be blown away by the plasma flow force of the arcArc welding apparatusHigh frequency current welding apparatusPlasma jetAdhesive

The present invention discloses the alloy pulverescent used for builtup weld. The present invention is characterized in that the alloy pulverescent is produced by metal, iron alloy powder, adhesive and plasticizer, wherein the weight ratio of component is that metal and iron alloy powder : adhesive : plasticizer = 100 : 5~15 : 0~8; the alloy pulverescent is discretionary geometrical body, wherein the size, length and surface shape of the alloy pulverescent can be discretionarily determined according to the requirement of the surface which is to be builtup welded, and the splicing margina thickness of the alloy pulverescent is 0~0.1mm when the alloy pulverescent is arranged on the surface which is to be builtup welded. In the present invention, by designing the cross section geometry of the alloy pulverescent, the electric arc can more easily pass through the alloy pulverescent which is difficult to be melted so as to melt the base metal, and the melting of the base metal accelerates the melting of the alloy pulverescent, thereby the problem of that the alloy pulverescent is difficult to be melted and is easy to be blown about by the plasma jet of the electric arc can be solved, and the production efficiency is greatly improved.

Owner:SHANDONG UNIV

Puffed lentinus edodes free from sulfur peculiar smell, and production technology of puffed lentinus edodes

InactiveCN103504284AShorten the timeImprove yieldFood preservationFood shapingNutritionNutritional composition

The invention relates to puffed lentinus edodes free from a sulfur peculiar smell, and a production technology of the puffed lentinus edodes, and discloses the puffed lentinus edodes and a production method thereof. The sulfur peculiar smell is removed from the lentinus edodes; the technology is simple; the obtained lentinus edodes is low in contractility; the time required by rewatering soaking is short; and a nutrition preservation rate is high. The puffed lentinus edodes is prepared by a pretreatment, predrying, peanut oil leaching and varying temperature differential pressure puffing and drying method. In a leaching process, the time is short, a finished product rate is high, and nutritional ingredients of the lentinus edodes are preserved to the greatest extent; in a puffing process, moisture in a tissue of the lentinus edodes is instantly vaporized and dissipated, so that a raw material expands intracellularly or intercellularly to form a uniform honeycomb structure, and the puffed lentinus edodes has good crisp property, can be rapidly molten in a mouth after eaten, and is good in taste and easy to digest; and in addition, the uniform and porous texture allows the puffed lentinus edodes to absorb water easily, and the puffed lentinus edodes has good rewatering property.

Owner:食品行业生产力促进中心

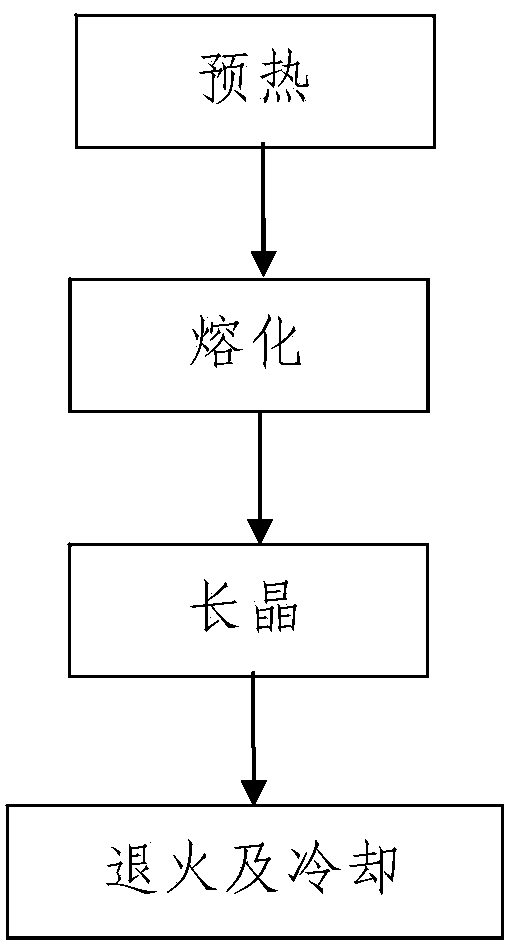

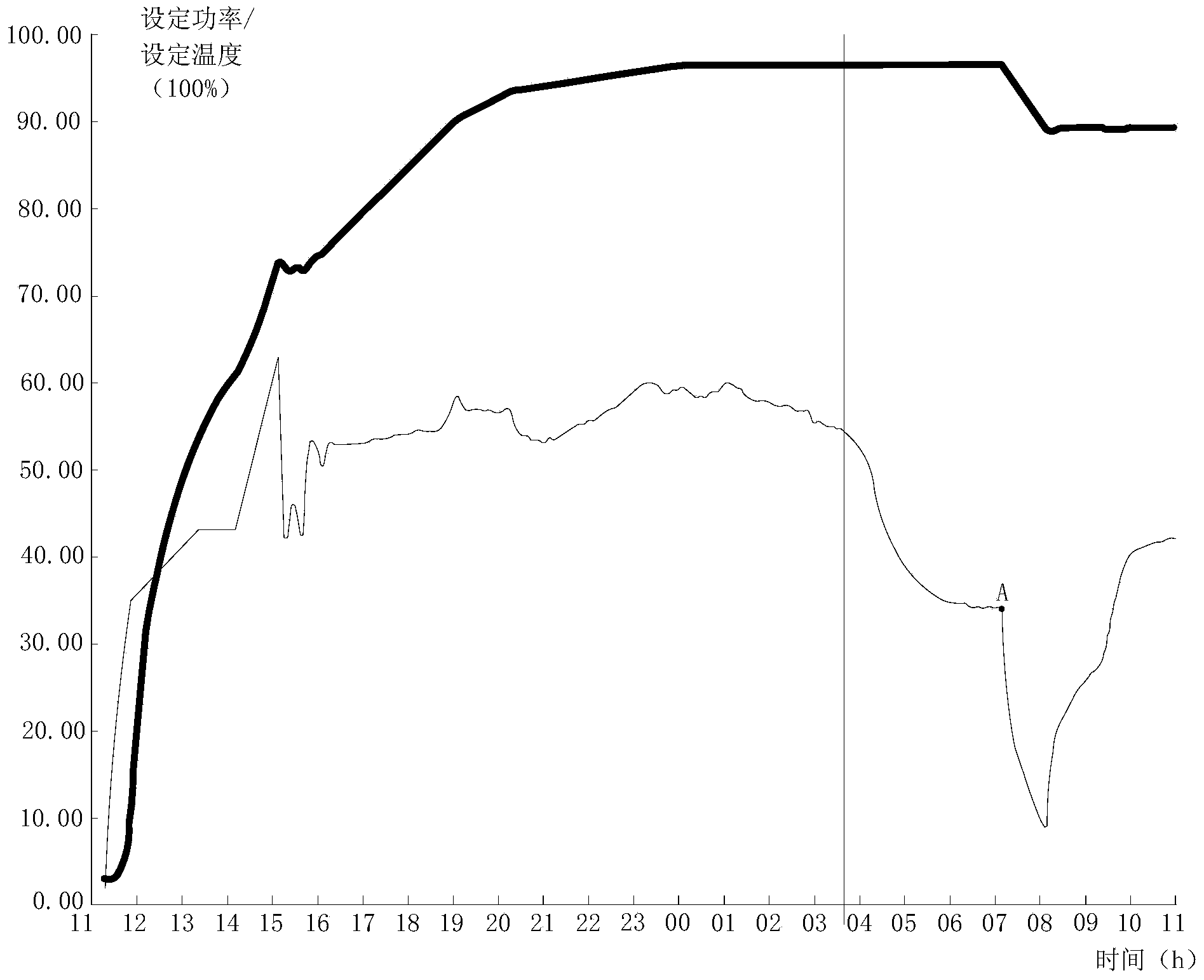

Polycrystalline silicon ingot casting process

InactiveCN103741214AReasonable designSimple processing stepsPolycrystalline material growthSingle crystal growth detailsPolycrystalline siliconMetallurgy

The invention discloses a polycrystalline silicon ingot casting process. The process comprises the following steps: 1, preheating; 2, melting; 3, growing crystal: the temperature is controlled to T6 and is preserved for 1h, and T6=1420 DEG C; the hoisting height of a heat insulation cage is 90mm; the temperature is controlled to T6 and is preserved for 2h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T6 and is preserved for 3h, and the hoisting height of the heat insulation cage is 110mm; the temperature is gradually lowered from T6 to T7, the temperature lowering time is 7-9h, and the hoisting height of the heat insulation cage is 210mm; T7=1405 DEG C; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is gradually lowered from T7 to T8, and the hoisting height of the heat insulation cage is not changed; T8=1395 DEG C; 4, annealing and cooling. The polycrystalline silicon ingot casting process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect and can reasonably control the ingot casting crystal growth process.

Owner:XIAN HUAJING ELECTRONICS TECH

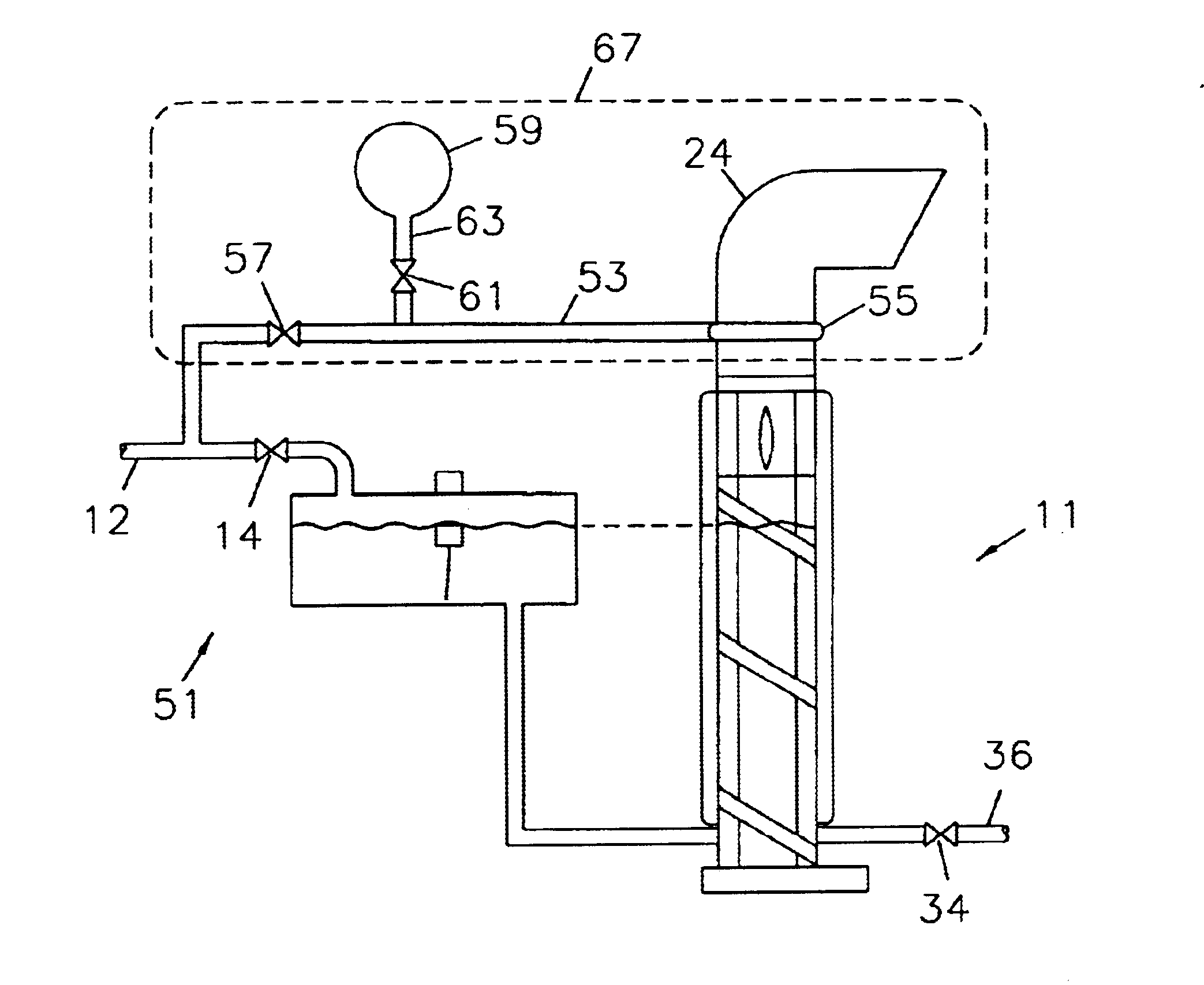

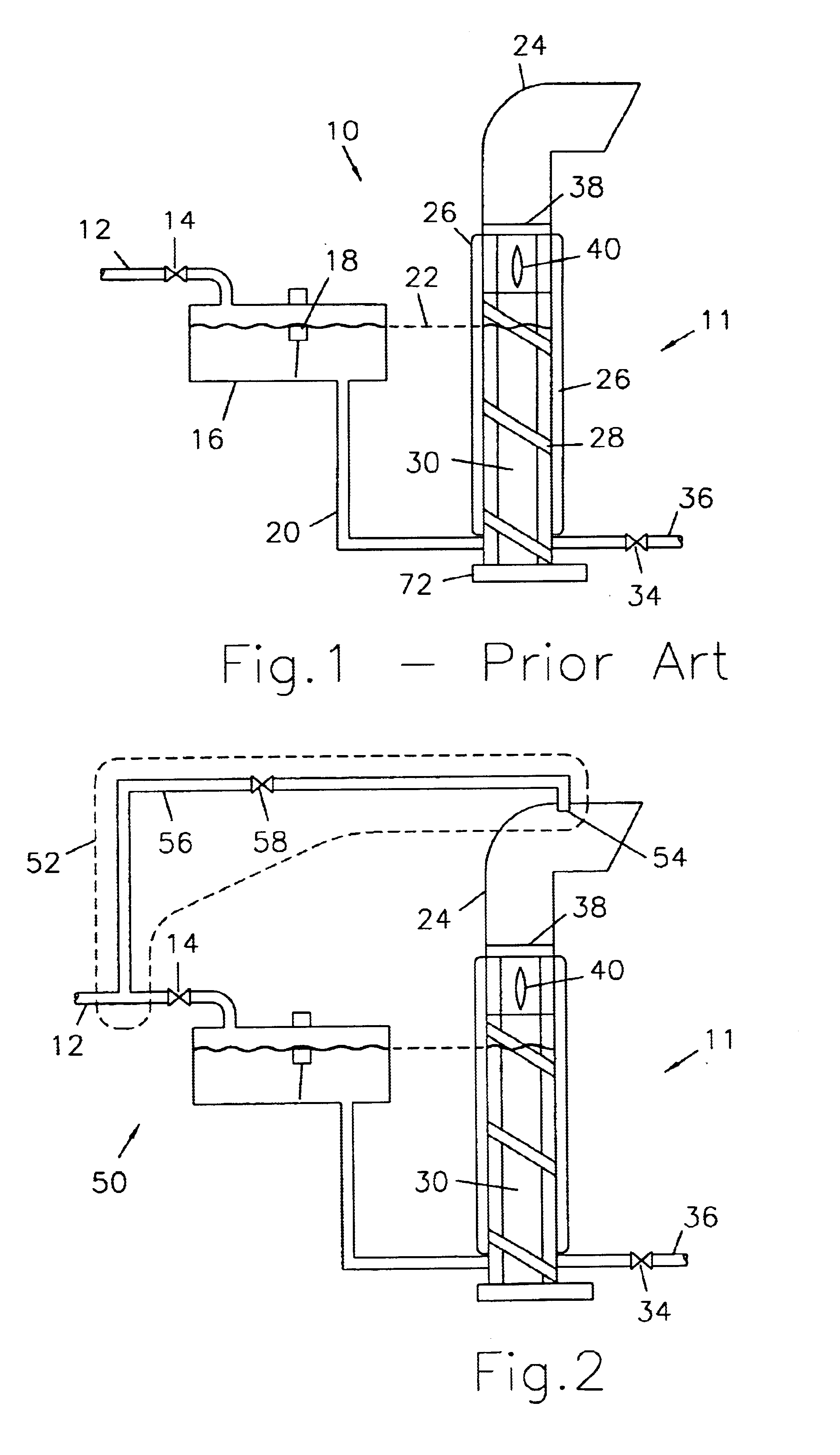

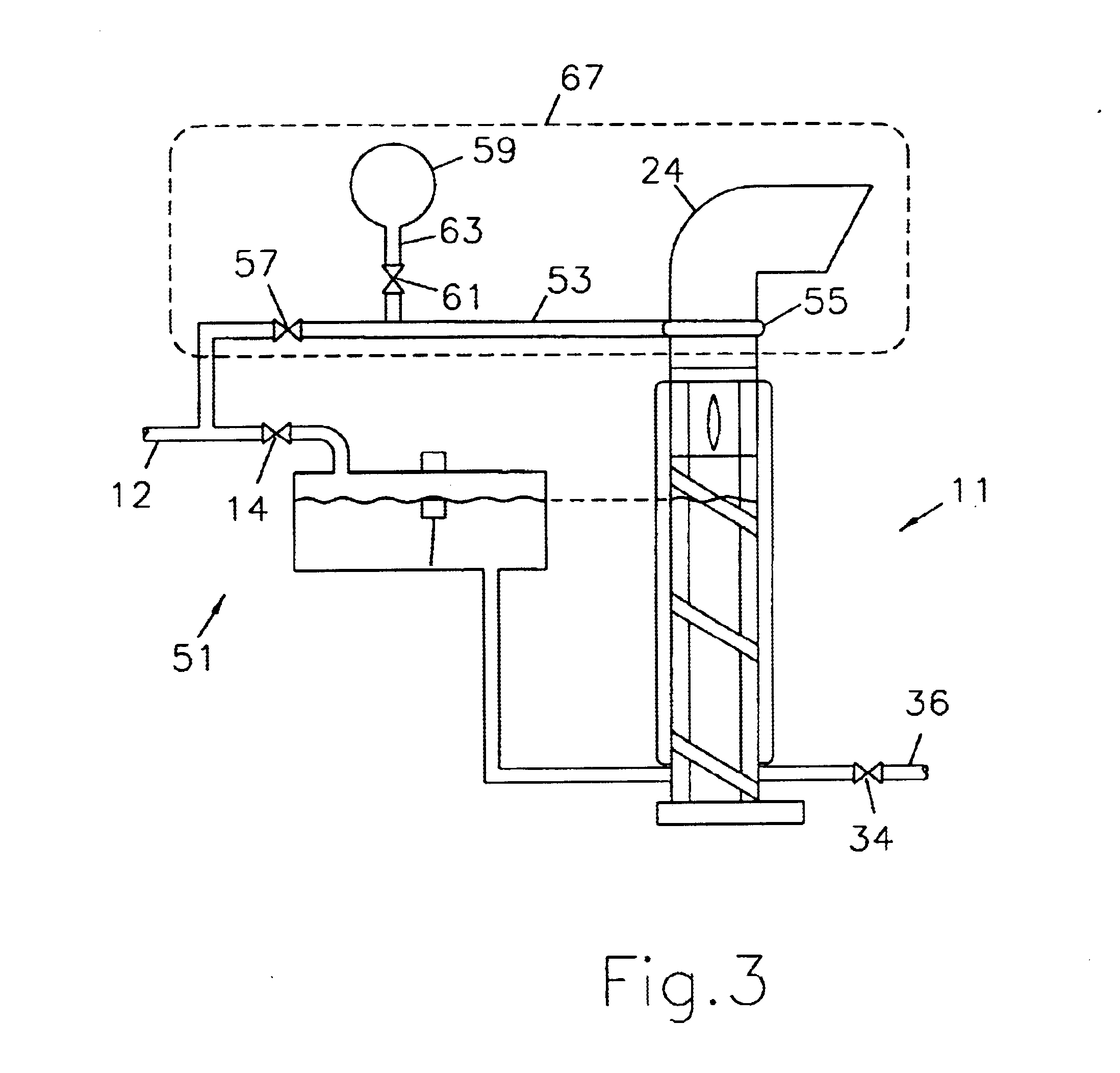

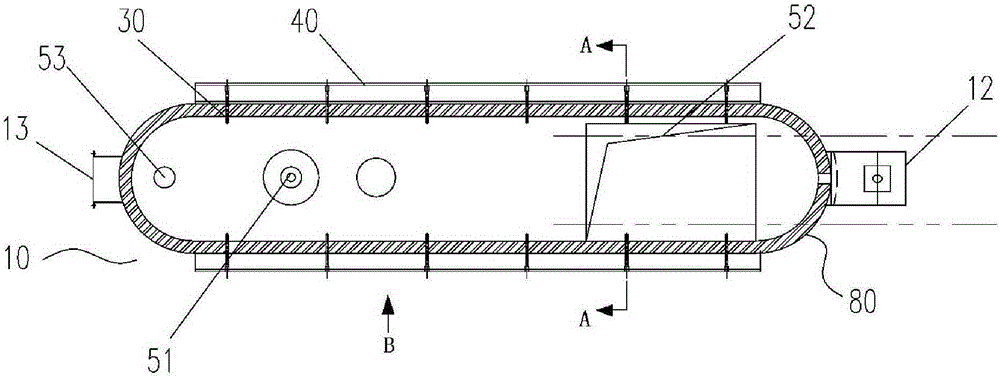

Flushing system for screw-type crushed ice extrusion machine

ActiveUS6857284B1Speed up meltingEasy to mergeLighting and heating apparatusIce productionEngineeringMechanical engineering

An improved apparatus and method for flushing an auger-type crushed ice making machine prevents build up of scale and other contaminants. The system feeds a flushing liquid to the top of the extrusion head such that it flows down through the device, thereby cleaning the auger and sleeve. The flushing liquid may be water or a solution having chemicals that help to remove built up scale or other contaminants.

Owner:BROOKS CHRYSTAL L +1

Floride-free low-boron and alkaline-free glass fiber prescription and preparation method

The invention relates to a glass fiber production prescription, in particular to an environment-friendly alkaline-free glass fiber prescription emitting less toxic gas. The prescription is characterized in that the components include SiO2, Al2O3, B2O3, CaO, MgO, K2O and Na2O2. Compared with the E glass fiber widely applied presently, the glass fiber prepared with the prescription of the invention is improved as follows: the raw material containing floride which is most harmful is completely abandoned and the raw material containing volatile boron is largely reduced, but the glass fiber of the invention still remains similar electric performance and mechanical performance. The invention is characterized in that an alkaline-free glass fiber using blast furnace slag as one of the main raw materials, realizing reduction of operation difficulty and great reduction of exhaust emission is preferential and can be produced directly in large scale in a tank furnace including an electric boosting structure. The use of an industrial raw material easy for melting and clearing, namely, the blast furnace slag, ensures the glass fiber to have similar operating performance as the E glass fiber and to adapt to large-scale production under the existing E glass fiber tank furnace production technology.

Owner:TAISHAN FIBERGLASS INC

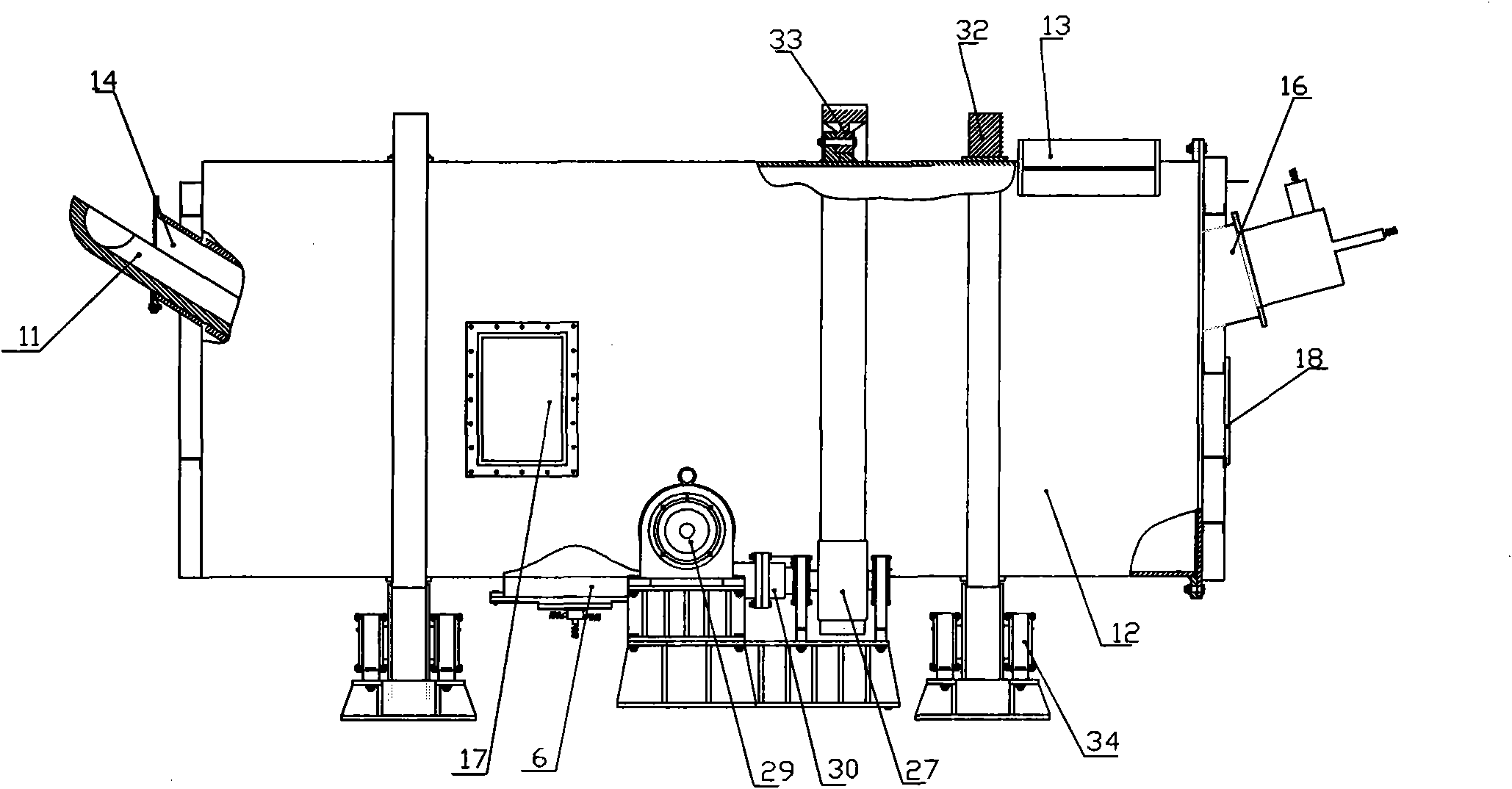

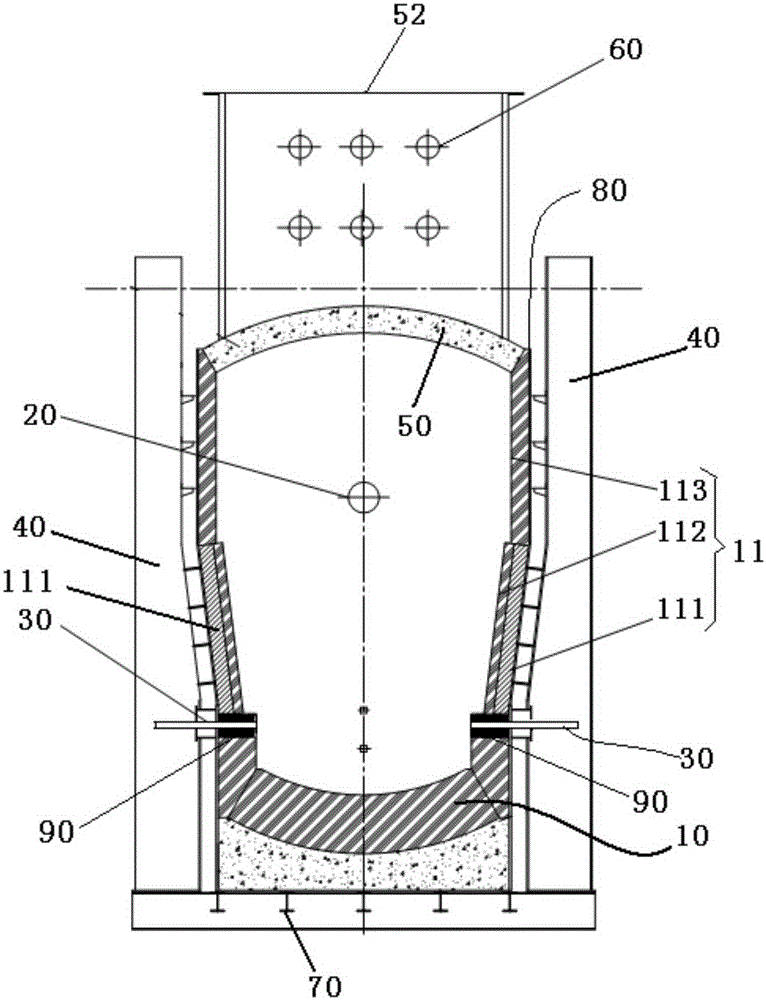

Improved type side-blowing molten pool smelting furnace

ActiveCN105698529ADry fastSpeed up decompositionIncreasing energy efficiencyCrucible furnacesSlagStraight segment

The invention provides an improved type side-blowing molten pool smelting furnace. The improved type side-blowing molten pool smelting furnace comprises a long round furnace body, a furnace cylinder, a furnace top, a furnace body frame structure and a plurality of multi-channel spray guns. The multi-channel spray guns are arranged on the two sides of the long round furnace body correspondingly. The long round furnace body is formed by a furnace body protective plate in an enclosed mode. A water sleeve is installed on the lower portion of the inner side of the furnace body protective plate. A first firebrick layer is further inlayed in the inner side of the water sleeve. A second firebrick layer is arranged on the water sleeve and the first firebrick layer and installed on the inner side of the furnace body protective plate. The furnace cylinder is arranged at the bottom of the long round furnace body. The long round furnace body is provided with a metal discharge outlet and a slag outlet. The furnace body frame structure comprises steel vertical pillars, cross beams and pulling rods. The multi-channel spray guns are arranged on the two sides of the middle straight segment of the long round furnace body, and the output ends of the multiple multi-channel spray guns extend into the long round furnace body. By means of the improved type side-blowing molten pool smelting furnace, the problem that in the prior art, the temperature in a molten pool smelting furnace is difficult to control can be solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Smelting process for efficient slagging and desulfurization of LF aluminum killed steel

ActiveCN112322837AShort processing cycleRealize reducing pre-desulfurizationManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a smelting process for efficient slagging and desulfurization of LF aluminum killed steel. The smelting process for efficient slagging and desulfurization of the LF aluminum killed steel comprises the following steps that S1, converter steelmaking is carried out, and the end point temperature of a converter is controlled within 1610-1660 DEG C; the adding amount of scrap steel is less than or equal to 70 tons; and a strong bottom blowing mode is adopted in the later converter blowing stage to enhance molten pool stirring. According to the smelting process for efficientslagging and desulfurization of LF aluminum killed steel, converter tapping, argon blowing station and LF refining tasks are adjusted through process design to form a three-in-one refining process ofconverter tapping, argon blowing station and LF refining, LF slagging work is advanced, a rapid slagging process system is formulated, 80% or above of slagging slag materials are added in the tappingprocess through design optimization, and slag melting is promoted by fully utilizing tapping steel flow impact kinetic energy, molten steel sensible heat and ladle bottom argon blowing stirring kinetic conditions; an argon station adopts a top-bottom strong stirring proper deoxidation process, slag is rapidly formed to promote steel slag reaction, top slag reduction pre-desulfurization is realized, and LF slagging desulfurization burden is reduced; and an LF target is heated once to basically complete slagging and desulfurization tasks.

Owner:MAANSHAN IRON & STEEL CO LTD

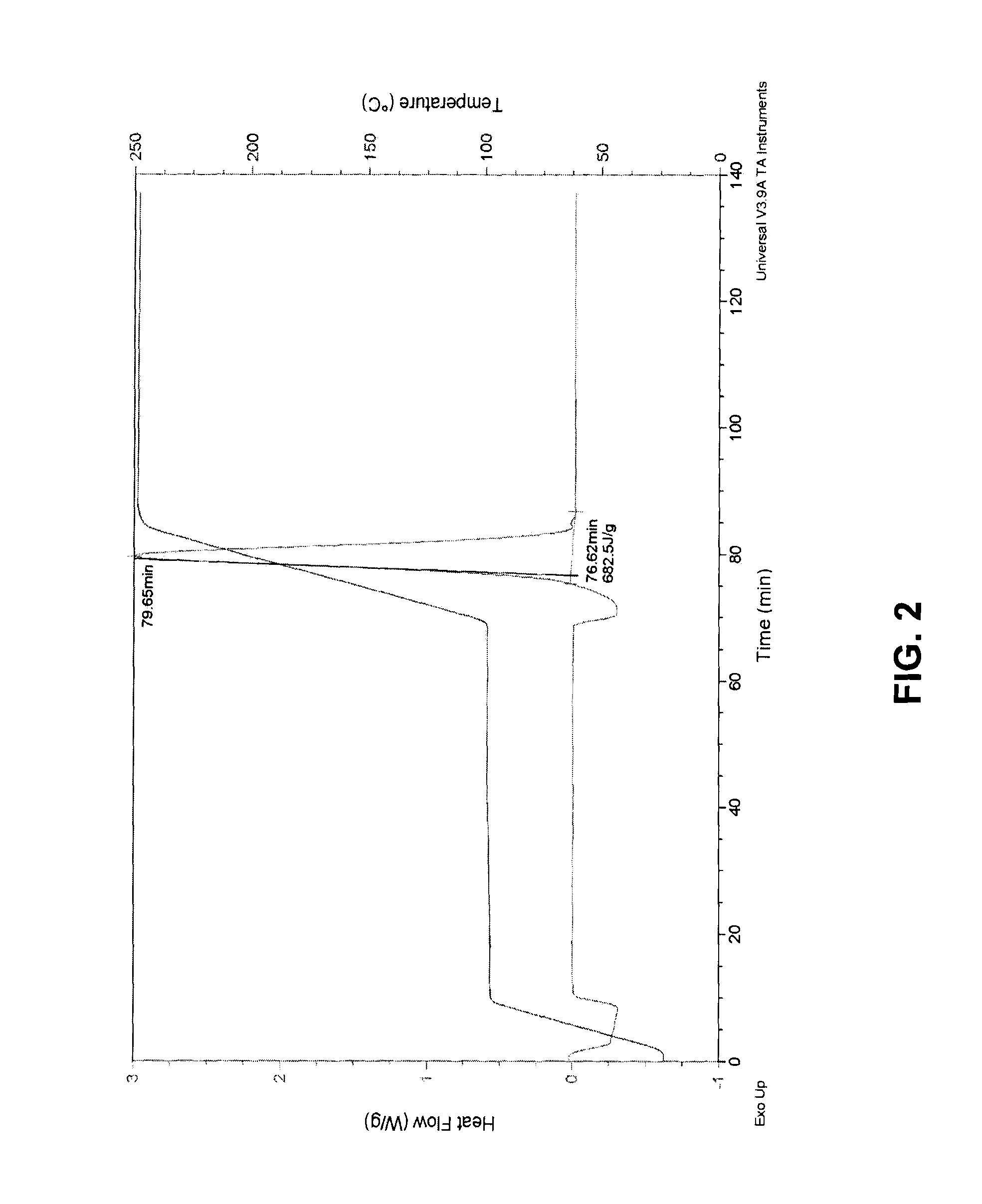

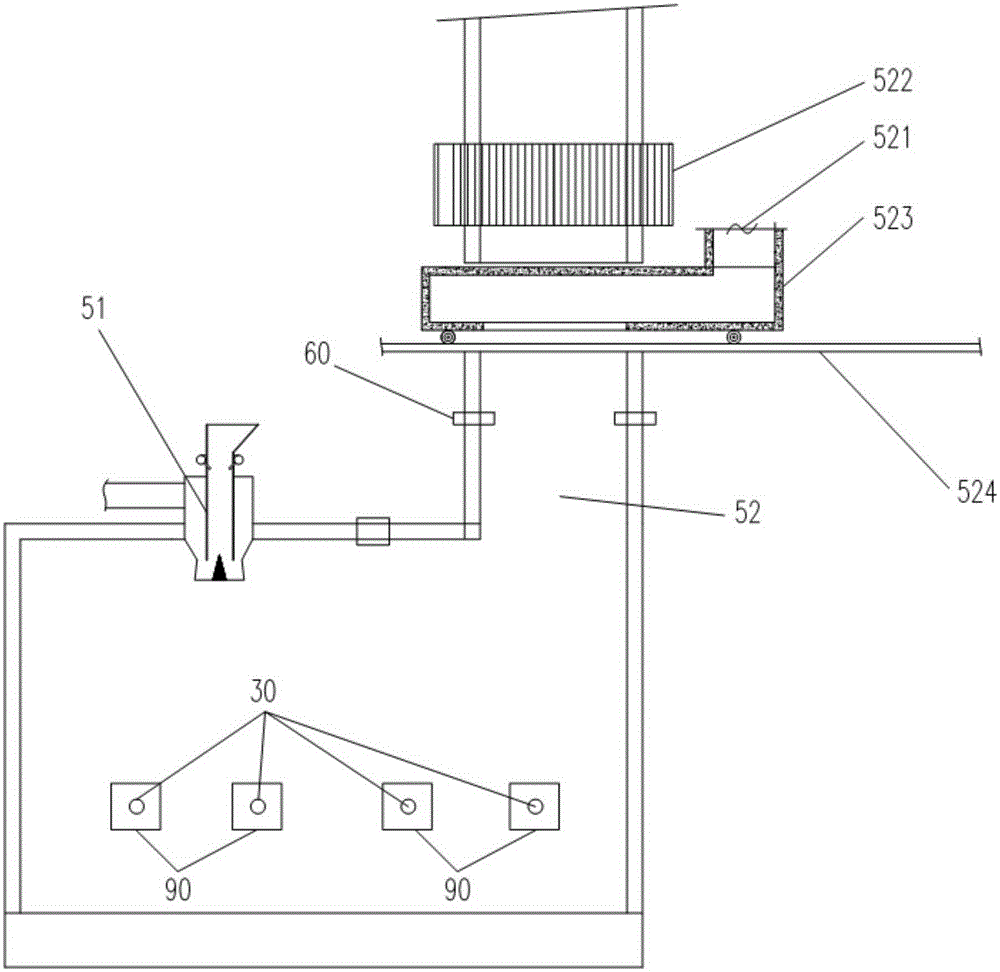

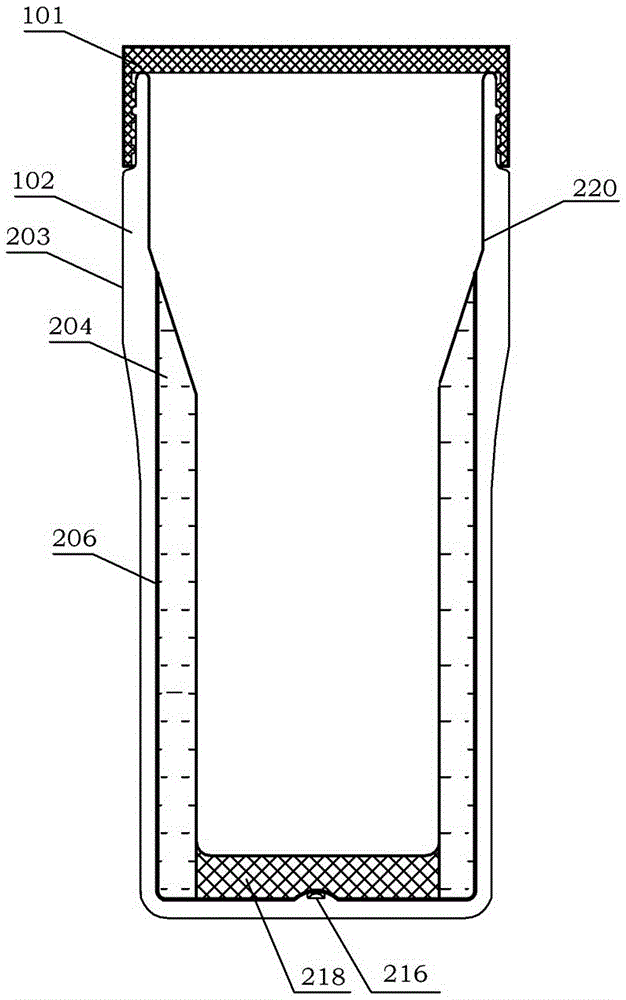

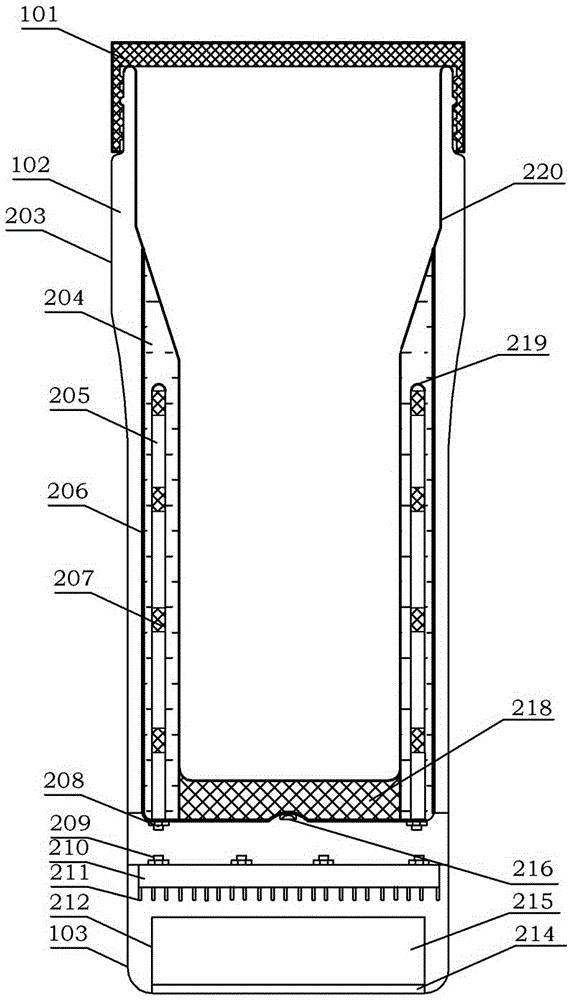

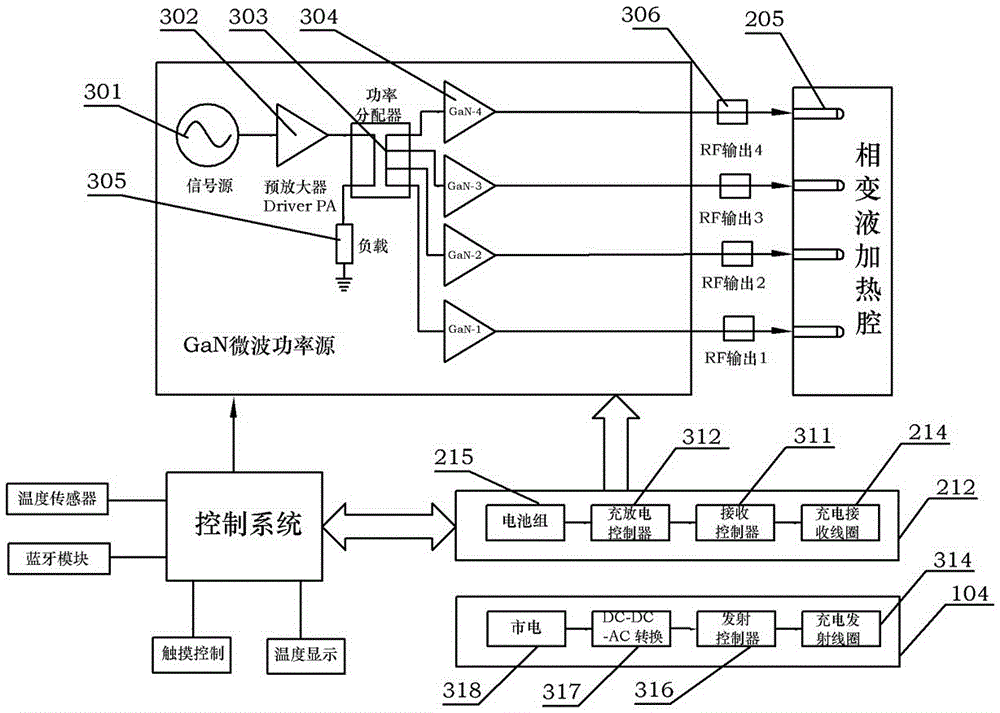

Solid-liquid compound-phase variable-speed cooling constant-temperature cup and microwave heating constant-temperature cup

ActiveCN106361101AEasy to useLarge latent heat of phase changeDwelling equipmentWarming devicesSolid-stateInternal cavity

The invention relates to a daily used vacuum cup, in particular to a compound-phase variable-speed cooling constant-temperature cup. The solid-liquid compound-phase variable-speed cooling constant-temperature cup comprises a cup lid and a cup body, wherein the cup lid is in sealed connection with the cup body, the cup body comprises an inner cup wall, a middle cup wall and an outer cup wall, the internal cavity of the inner cup wall forms a beverage containing cavity, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid, the airtight cavity between the bottom of the inner cup wall and the bottom of the middle cup wall is designed into a phase change alloy rapid-cooling interlayer, and the phase change alloy rapid-cooling interlayer is provided with built-in low-melting-point phase change alloy. In a solid-liquid compound-phase variable-speed cooling microwave heating constant-temperature cup, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid to form a phase change liquid heating cavity, one or more distributed rod-like microwave antennae are arranged in the phase change liquid heating cavity, and a solid-state microwave power source, a power supply part and a control system are arranged in a cup base.

Owner:陈鹏

Health characteristic Caramel Flavored Confection, Chews, Hard Candy, and Caramel Flavored Milk

The present invention provides for caramel flavored confections, chews, hard candies or caramel flavored milk that has an improved, healthier fat structure, unique antioxidant taste profile, fiber component, and a 0% or greater supplement component that can add additional dietary benefits. Cholesterol reduction and cardiovascular health and removal of cholesterol from the bloodstream can be accomplished within certain compositions of this invention. Specific ratios of ingredients create a taste, texture, to mouthfeel, and rich flavor similar to a high milk fat or butter fat based caramel without the negative health ramifications of high milk fat based type caramels. Additionally, the method for preparing a caramel flavored confection, chews, and milk with these improved health characteristics, taste profile, and dietary benefits are covered.

Owner:ERVIN GARY

Converter smelting process using dephosphorization agent

InactiveCN101476013ALow investment costShorten the smelting cycleManufacturing convertersSteelmakingSmelting process

The invention pertaining to the field of convertor steelmaking technology provides a technique of converter smelting by using a dephosphorization agent. In a same convertor, dephosphorization is performed by using a CaO-base ephosphorization agent containing a few CaCl2 under favorable thermodynamics and combined-blowing dynamics conditions such as low temperature at the prior period, high content of iron oxide and the like, the prior period, desilication and dephosphorization slags of 50-70% are poured away in the molten iron preprocessing process, in the later period, decarburization process is performed and decarburization slag is formed and is then utilized as dephosphorization slag of the lower converter. According to the smelting technology, CaCl2 is added to the CaO-base ephosphorization agent to accelerate the burn-off rate of CaO by using the eutectic point character of CaCl2 and CaO binary system, the utilization ratio of lime is also improved, the utilizing of decarburization slag not only fully utilizes the physics heat brought by the decarburization slag, but also provides high content iron oxide for the dephosphorization of the prior period and accelerates the dephosphorization reaction.The invention has advantages of low cost of investment, shortened smelting period, carbon content of 0.4% at the end point of smelting, phosphorus content capable of being reduced to 0.006% and dephosphorization ratio up to 95.5%.

Owner:CHINA IRON & STEEL RES INST GRP +1

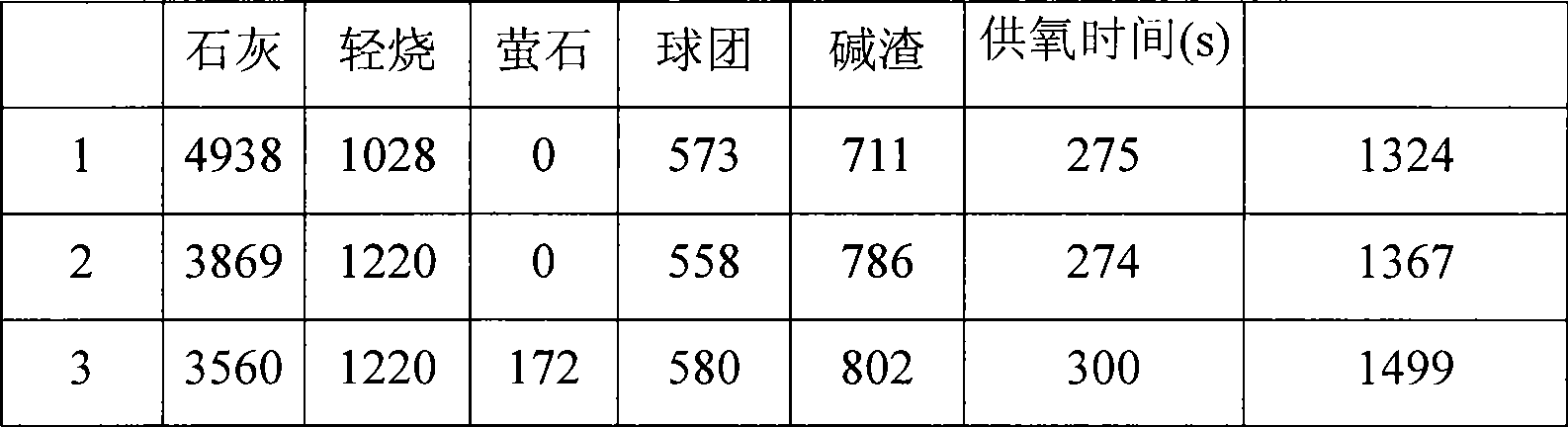

Intermediate thermal expansion coefficient glass

ActiveUS8445394B2Speed up meltingHigh ratePV power plantsPhotovoltaic energy generationSilicate glassEffect light

Aluminoborosilicate glasses which may be useful in photovoltaic, photochromic, electrochromic, or Organic Light Emitting Diode (OLED) lighting applications are described.

Owner:CORSAM TECH

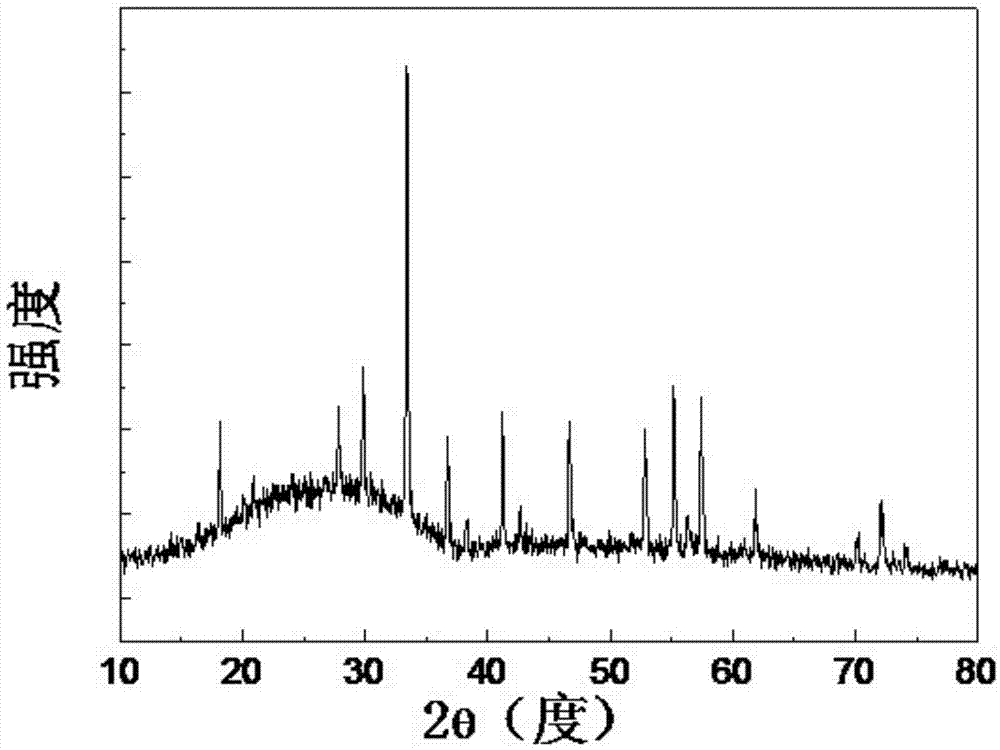

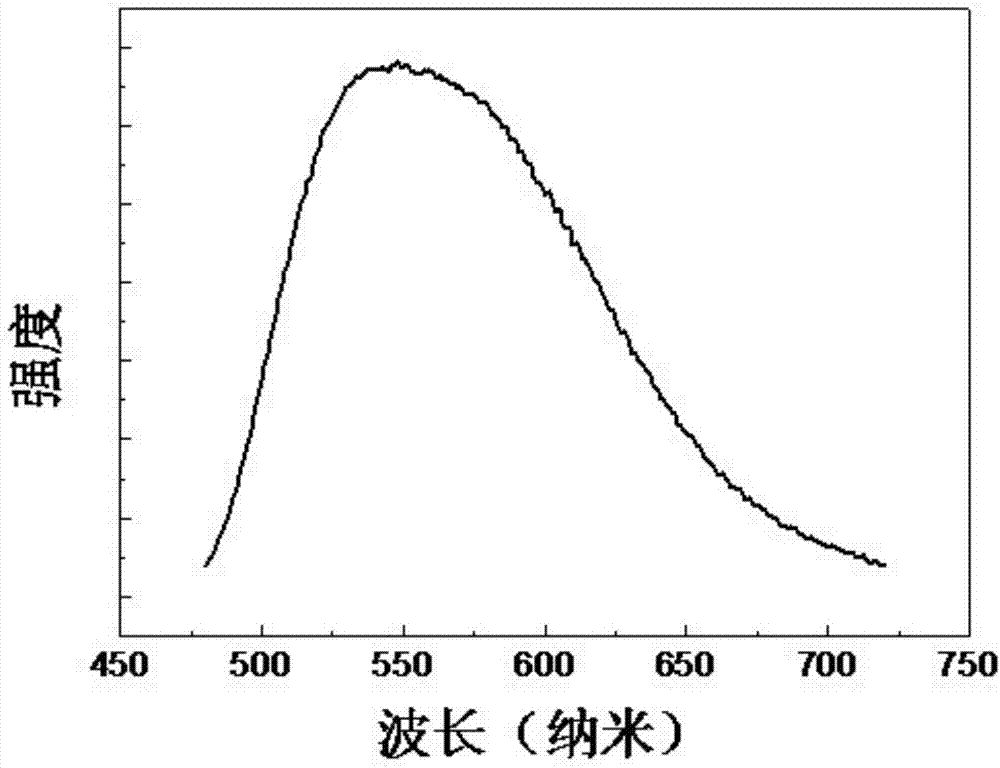

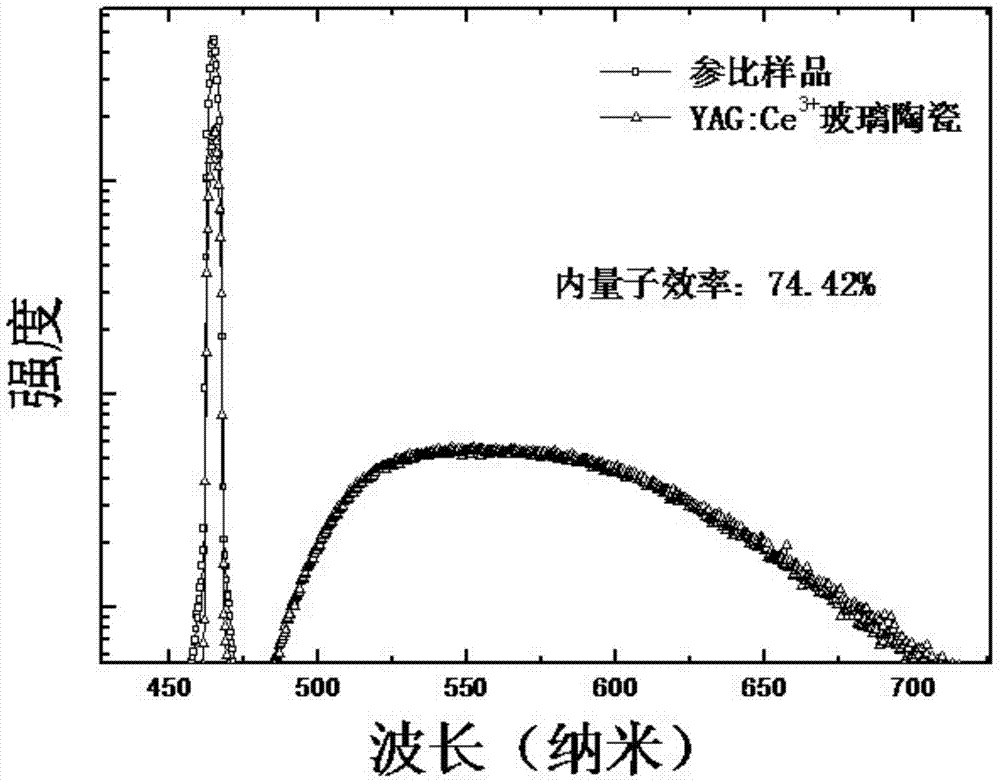

Glass ceramic for blue light-excited white-light LED (Light-Emitting Diode), and preparation method thereof

The invention discloses a glass ceramic for a blue light-excited white-light LED (Light-Emitting Diode), and a preparation method thereof. The glass ceramic is structurally characterized in that R3M5O12:Ce, R' micrometer crystallized phase is inlaid in an oxide glass substrate, wherein R is one of Y, Gd, Lu, Sc and La; M is one of Al, Ga and In; R' is one of Eu, Sm, Pr and Mn; the content of the micrometer crystallized phase accounts for 10-50wt% of the glass ceramic. The glass ceramic is prepared by adopting a melt quenching method or combining the melt quenching method with follow-up thermal treatment. The glass ceramic can be used as a fluorescent material for manufacturing a novel blue light-excited white-light LED device.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

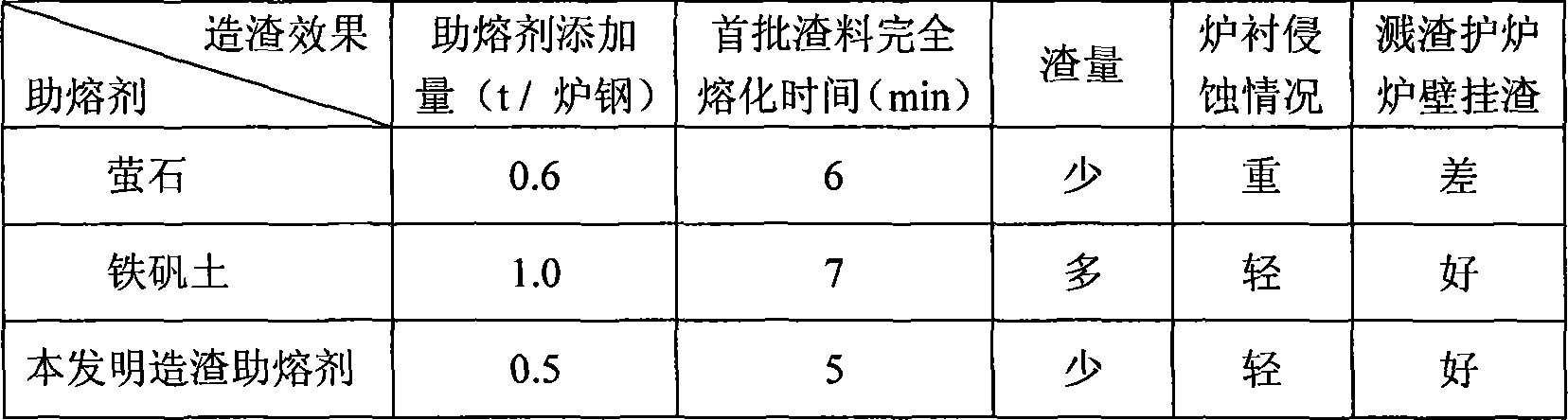

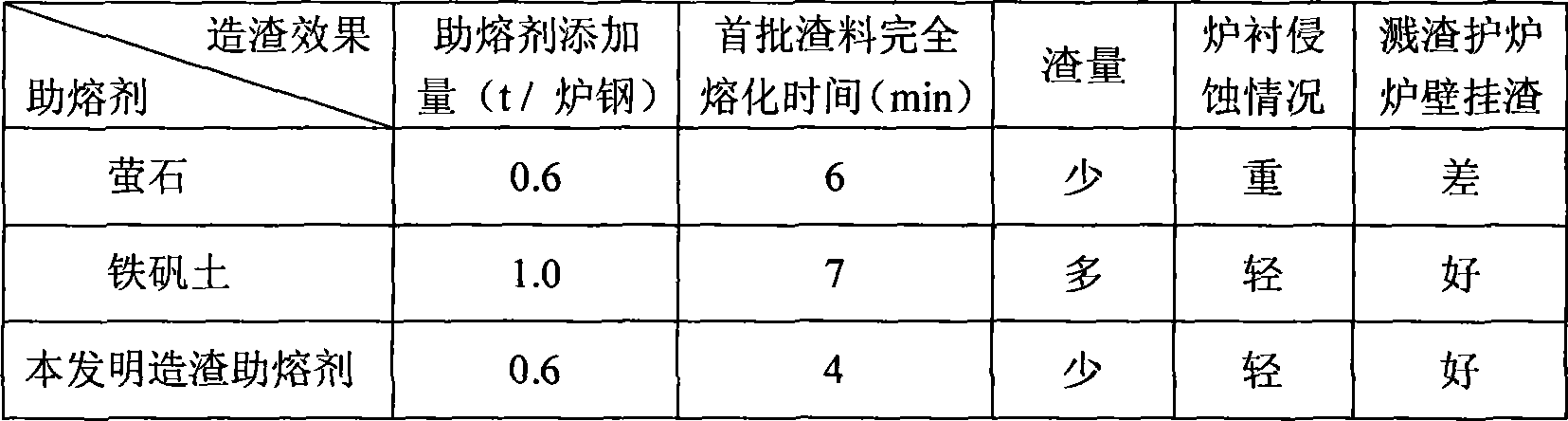

Alkaline oxygen converter steelmaking slagging fluxing agent and its preparing method and slagging method

InactiveCN101033496ASpeed up meltingReduce consumptionManufacturing convertersOxygen converterMetallurgy

The invention relates to the slagging flux of oxygen converter steelmaking and its preparation methods as well as slagging method. The slagging flux contains by percentage of quality as follow: 5~10% of B2O3, 45~50% of CaO, 20~25% of MgO, 15~20% of Al2O3, 10~15% of Fe2O3. The slagging flux is added for slagging in accordance with the ratio of 2~10kg / ton steel, and the slagging flux is added into the furnace with slagging materials in batches, i.e. it adds the first batch of slagging materials (usually the slagging materials is expected to be half of the total) and prescriptive half of the slagging flux, that is, 1~5kg / t steel, when the gun starts oxygen blowing oxygen. It adds the second batch of slagging materials and the remaining part of the slagging flux at the time of the interim blowing.

Owner:JIANGSU UNIV

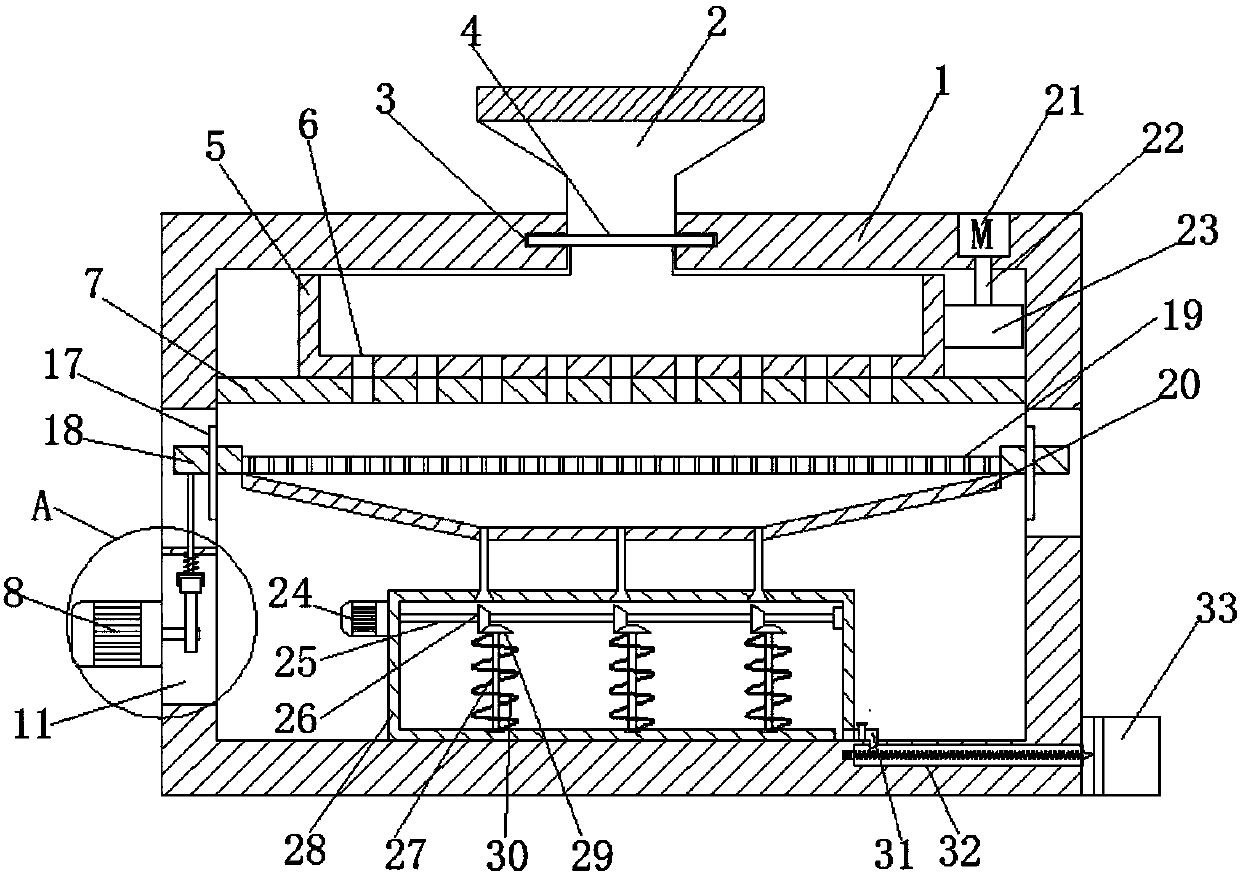

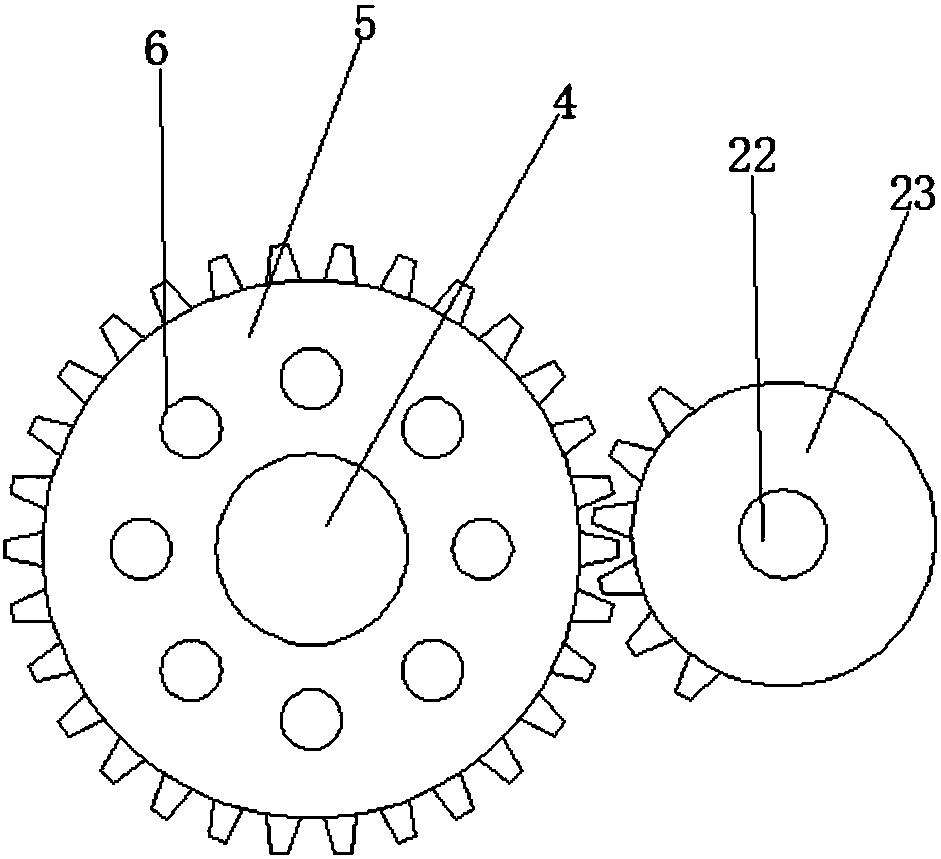

Plastic product production equipment

The invention discloses a production equipment for plastic products, which comprises a casing, the casing is a hollow structure, and the upper side wall of the casing is provided with a feed port, and the side wall of the feed port is provided with an annular Rotary groove, and a rotating ring is connected to the circular rotating groove, a rotating block is arranged on the side wall of the rotating ring, and the rotating block is a hollow structure, and a horizontal partition is arranged in the housing, and the partition Set against the side wall of the rotating block, the rotating block and the partition are surrounded by a plurality of through holes, the outer side wall of the rotating block is provided with a ring rack, and the side wall of the housing is There is a second drive motor on it. In the present invention, the plastic product processing equipment can control the amount of plastic used in a production process, and at the same time, the plastic particles are completely melted during the production process, and the melted plastic is stirred to make the particles uniform, so that the quality of the processed plastic products is relatively high. high.

Owner:安徽省榛瑞塑胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com