Patents

Literature

11872 results about "Pneumatic pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

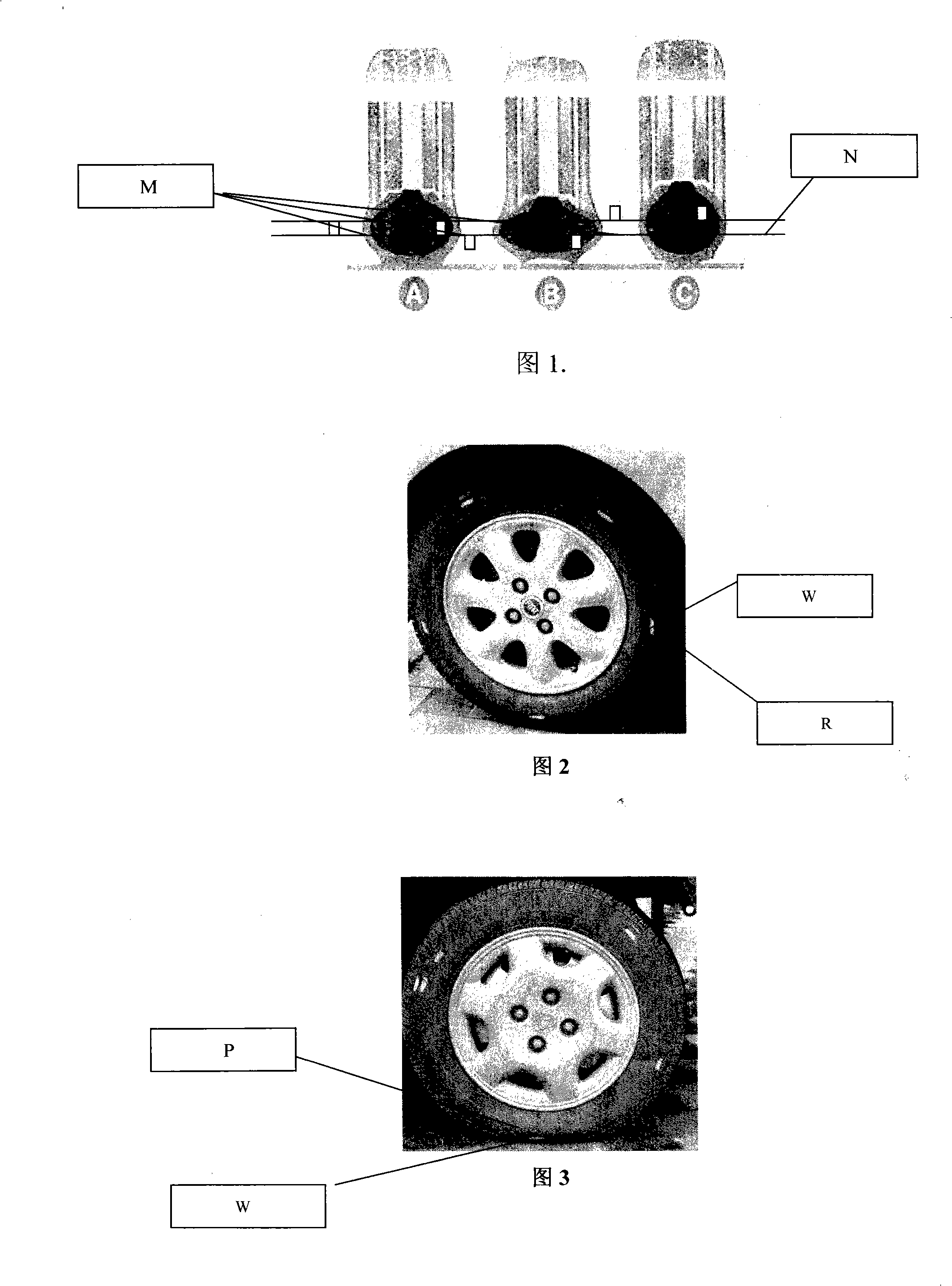

New method of automotive tire pressure detection and safe identification

InactiveCN101337492AImprove safety performanceWith reflective effectTyre measurementsVisibilityLacquer

The invention provides a method for correspondingly marking the most protuberant part of the deformed rubber corresponding to the outer side of an automobile tire with a white fluorescent paint line and coating a red fluorescent paint line in the position which is one second distance below from the white line as a safety mark according to the allowable normal inflation pressure standard range calibrated when the tires of sedans and miniature vehicles leave the factory (for example, the allowable normal inflation pressure standard ranges of a 1.5t FIAT sedan, a 0.6t CHANG'AN STAR miniature minibus and a 1.0t LINGYANG sedan are respectively 2.3 to 2.8 Kg / cm<2>, 2.2 to 2.5Kg / cm<2> and 2.2 to 2.6Kg / cm<2>). When the red fluorescent paint line disappears and the most protuberant part of the deformed rubber on the outer side of the tire is above the white fluorescent paint line, the tire pressure is indicated to be too low, and measures, such as inflation, tire repair, etc., should be carried out. When the most protuberant part is below the white fluorescent paint line and above the red fluorescent paint line, the tire pressure is indicated to be too high, and the measure of deflation should be carried out. The method has the advantages of visibility, rapidness, convenience, safety, practicality and low cost, and is easily accepted by drivers and tire manufacturers, completed at one time in the tire manufacturer and easily generalized and applied.

Owner:谢子晋

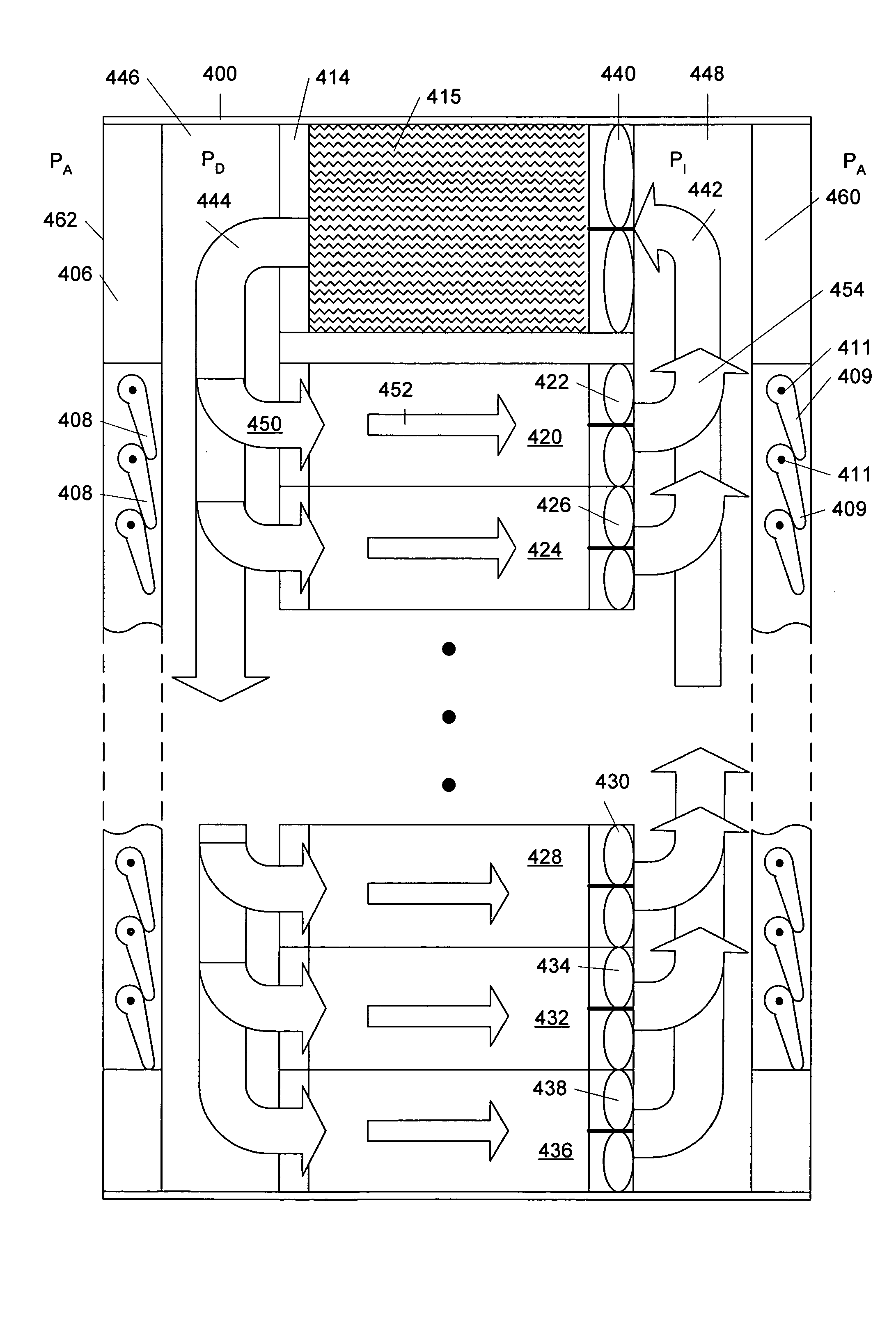

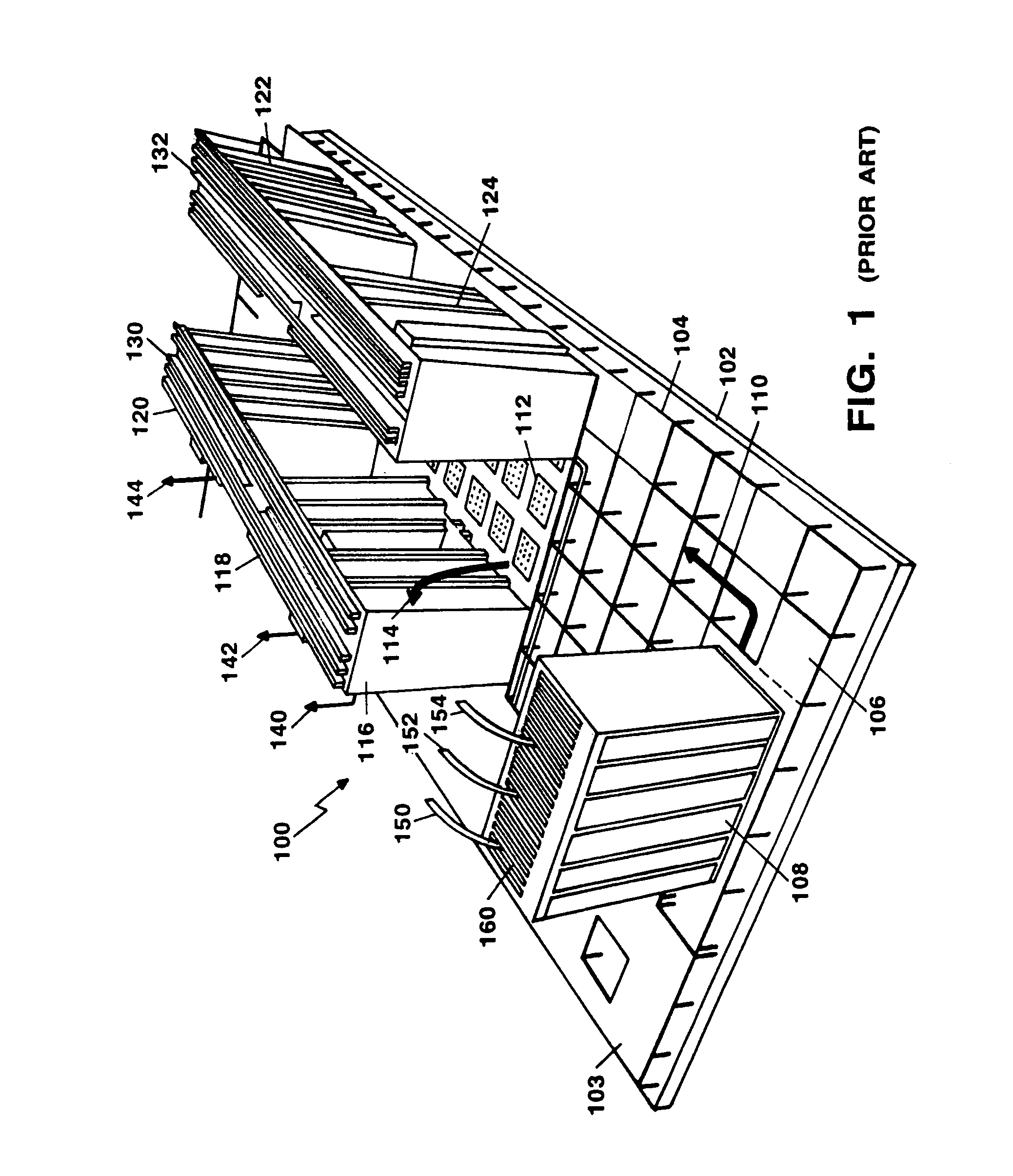

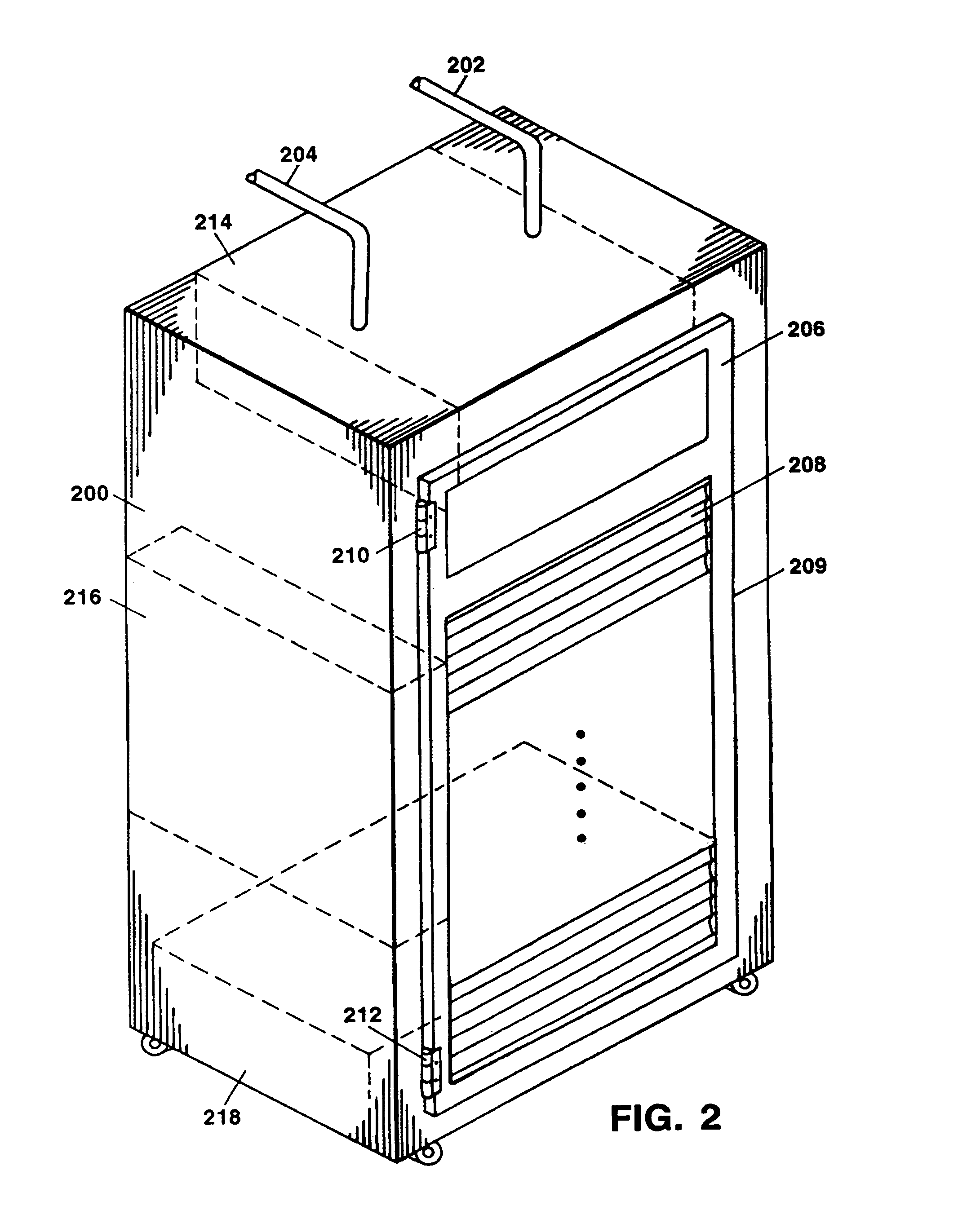

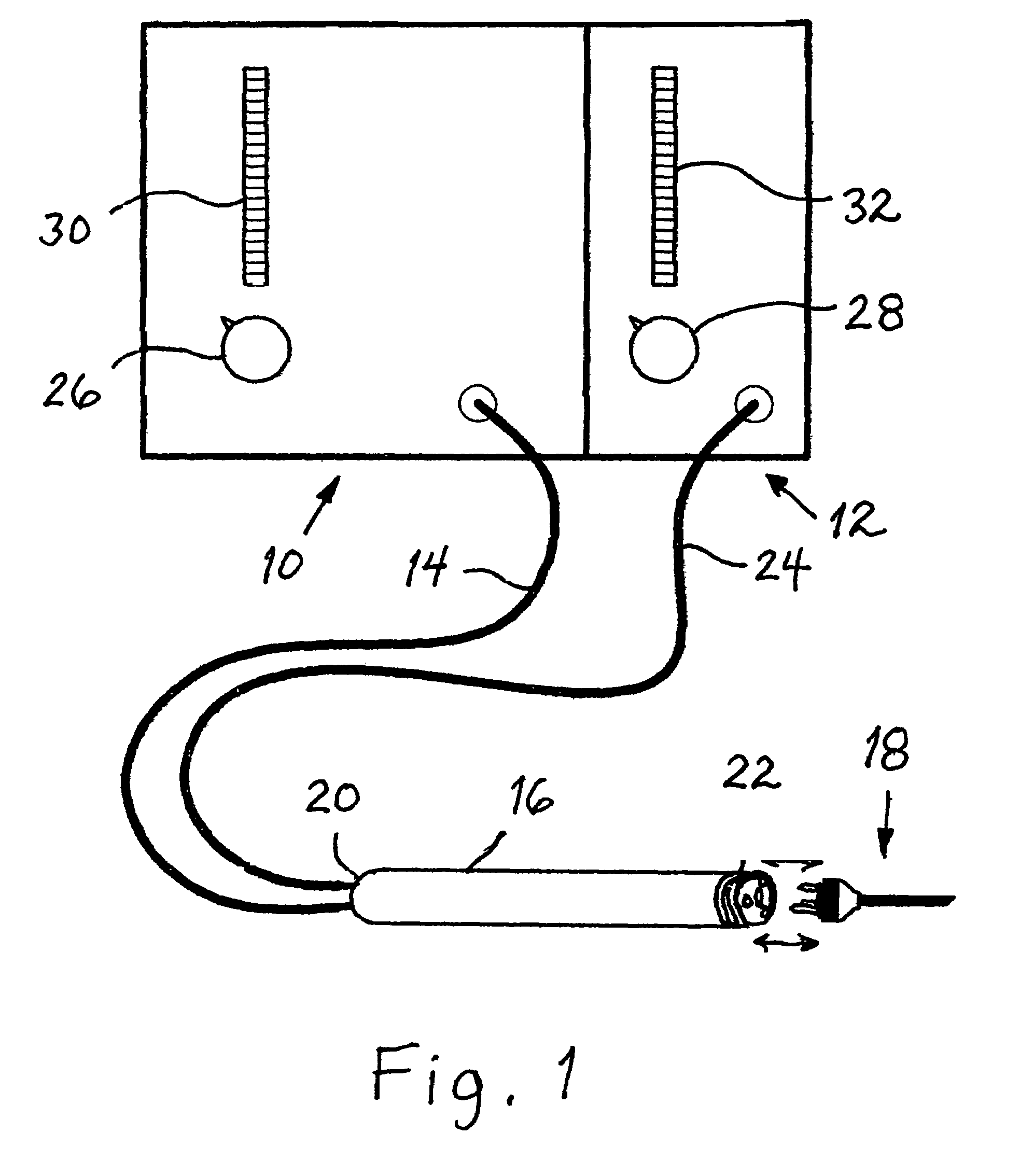

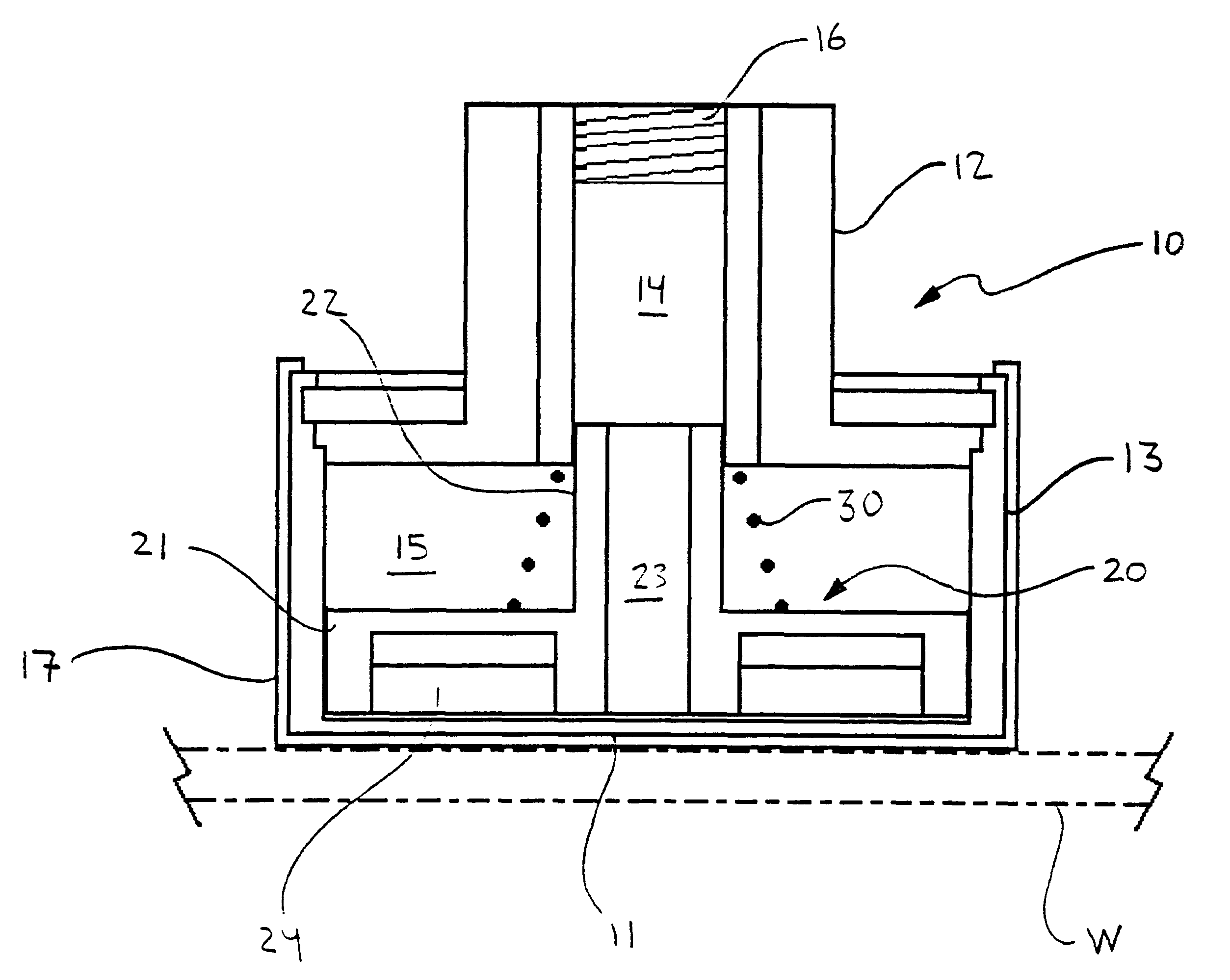

Self-cooled electronic equipment enclosure with failure tolerant cooling system and method of operation

ActiveUS6896612B1Reduce internal air pressureAvoid overall overheatingCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersEngineeringAtmospheric pressure

A sealed electronic equipment enclosure with a dedicated cooling system is fitted with movable louvers in the enclosure walls. During normal operation, air pressure developed by the dedicated cooling system keeps the louvers closed and maintains the enclosure sealed to the computer room environment. If the dedicated cooling system fails, the internal air pressure developed by the cooling system is reduced and air movers in the electronic equipment force the louvers open, thereby allowing the air movers to draw cooled air from the computer room into the enclosure. This cooled air prevents the equipment from overheating at least for a time period long enough to allow the dedicated cooling system to be replaced or repaired.

Owner:ORACLE INT CORP

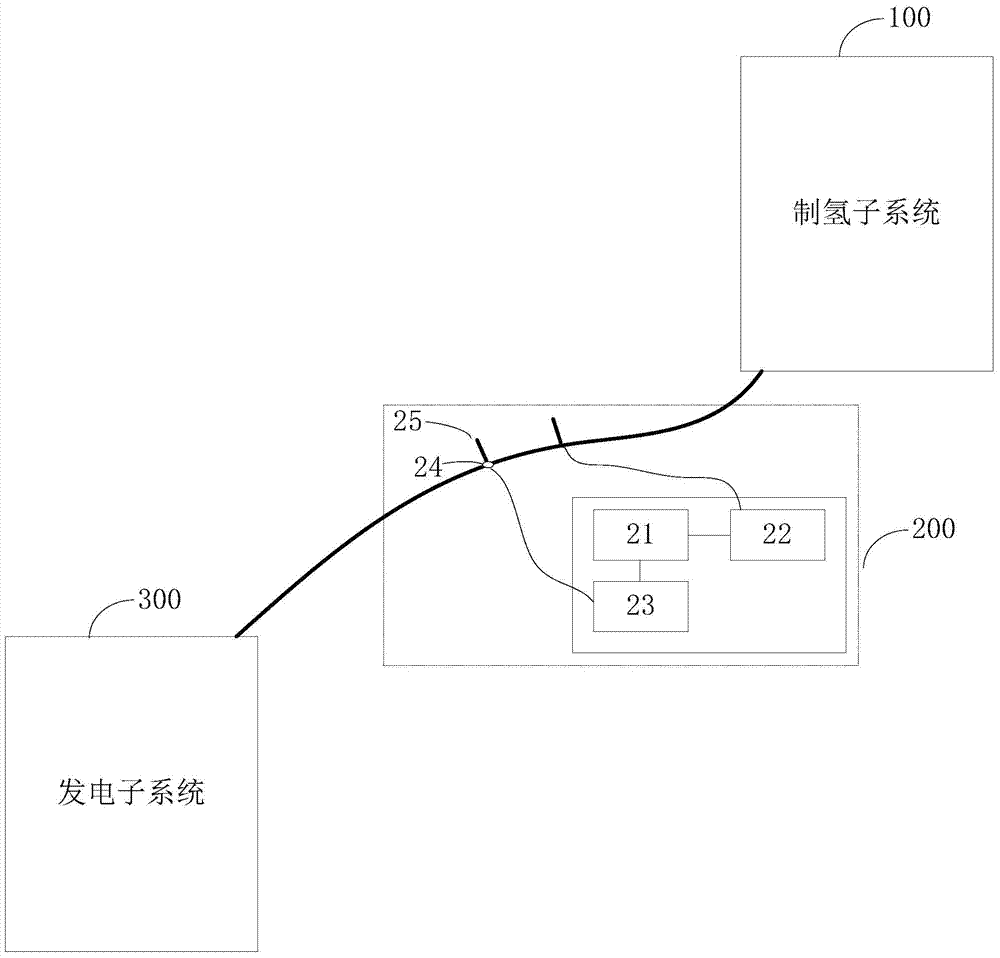

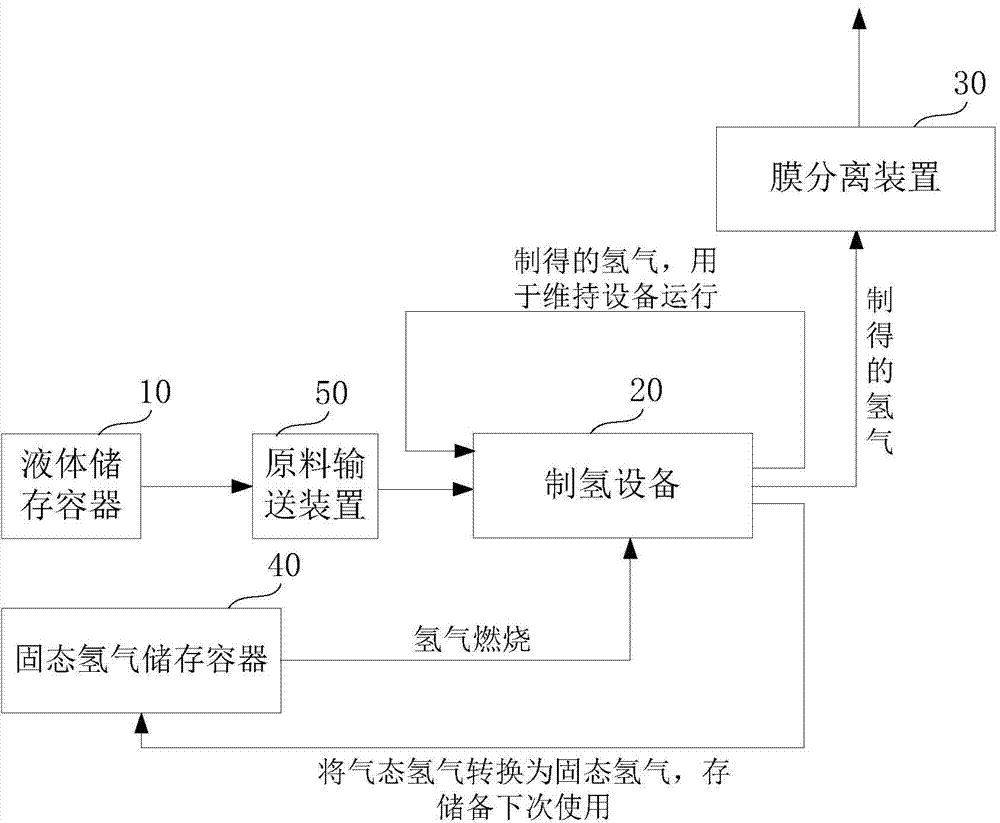

System and method for instant hydrogen production and power generation

The invention discloses a system and a method for instant hydrogen production and power generation. The system comprises a hydrogen production subsystem, an air pressure adjusting subsystem and a power generation subsystem, wherein the hydrogen production subsystem is used for preparing hydrogen from methanol water and transmitting the prepared hydrogen to the power generation subsystem in real time through a transmission pipeline; the transmission pipeline is provided with the air pressure adjusting subsystem for adjusting air pressure inside the transmission pipeline; the power generation subsystem is used for generating power by virtue of hydrogen prepared by the hydrogen production subsystem; the air pressure adjusting subsystem comprises a microprocessor, an air pressure sensor, a valve controller and an air outlet valve; the air pressure sensor is arranged in the transmission pipeline, and is used for sensing data of the air pressure inside the transmission pipeline and sending the data of the air pressure to the microprocessor; the microprocessor is used for controlling the on and off of the air outlet valve according to the data of the air pressure sensed by the air pressure sensor. Power can be generated by instantly prepared hydrogen, a hydrogen buffer tank is not required, and thus the portability and mobility of the hydrogen production and power generation system can be improved.

Owner:SHANGHAI HYDROGEN MOBILE REFRMER INSTR

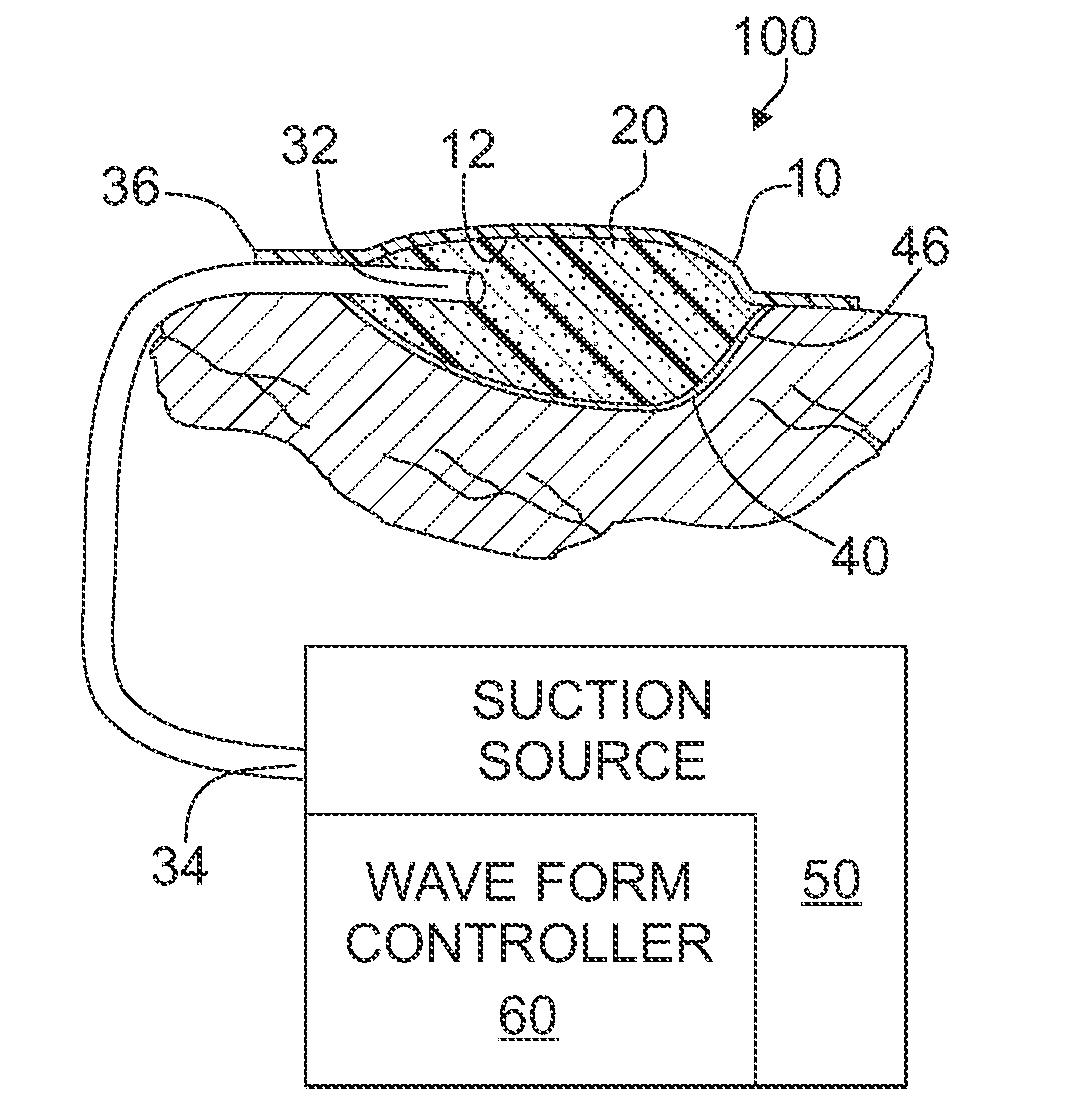

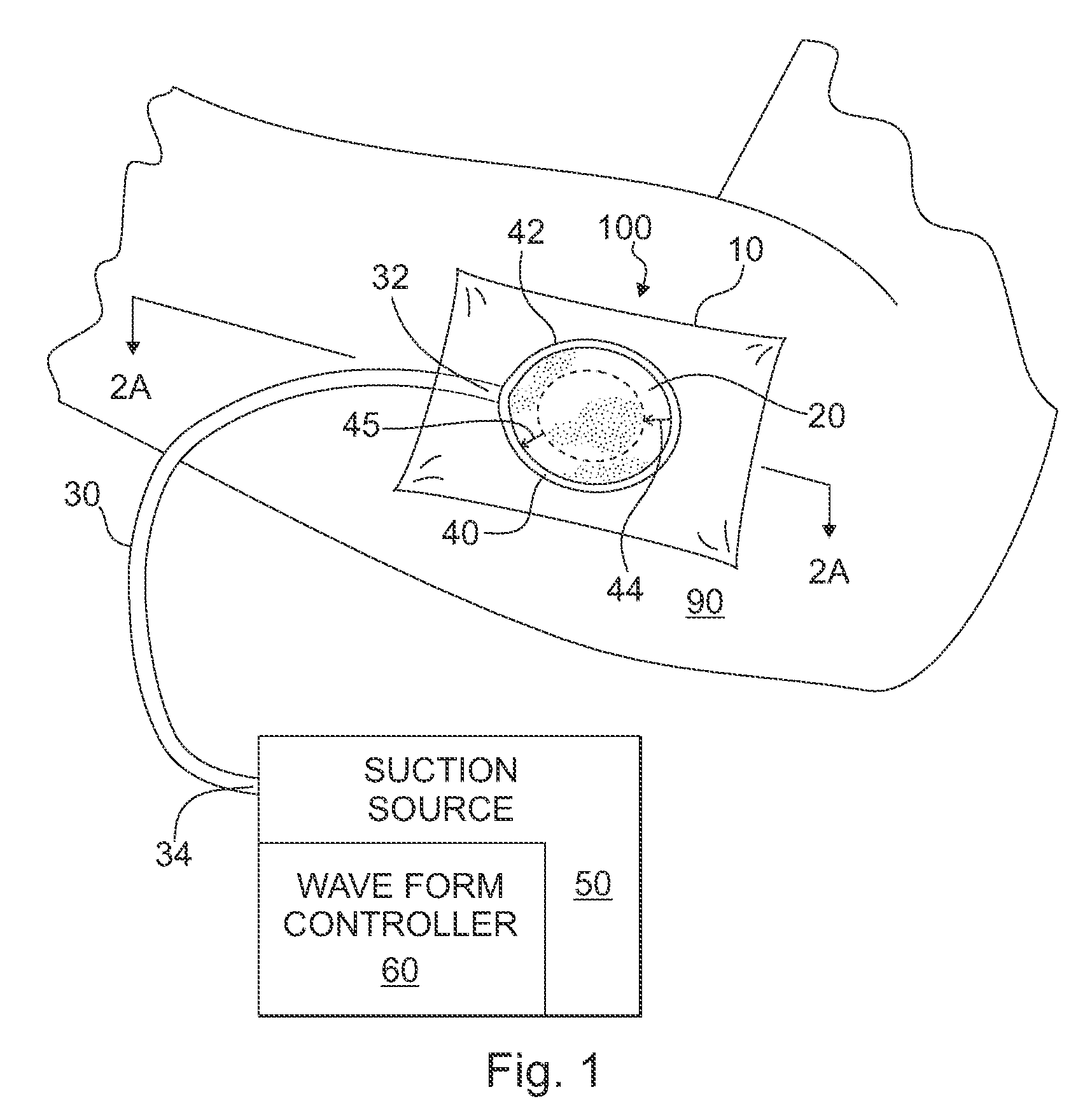

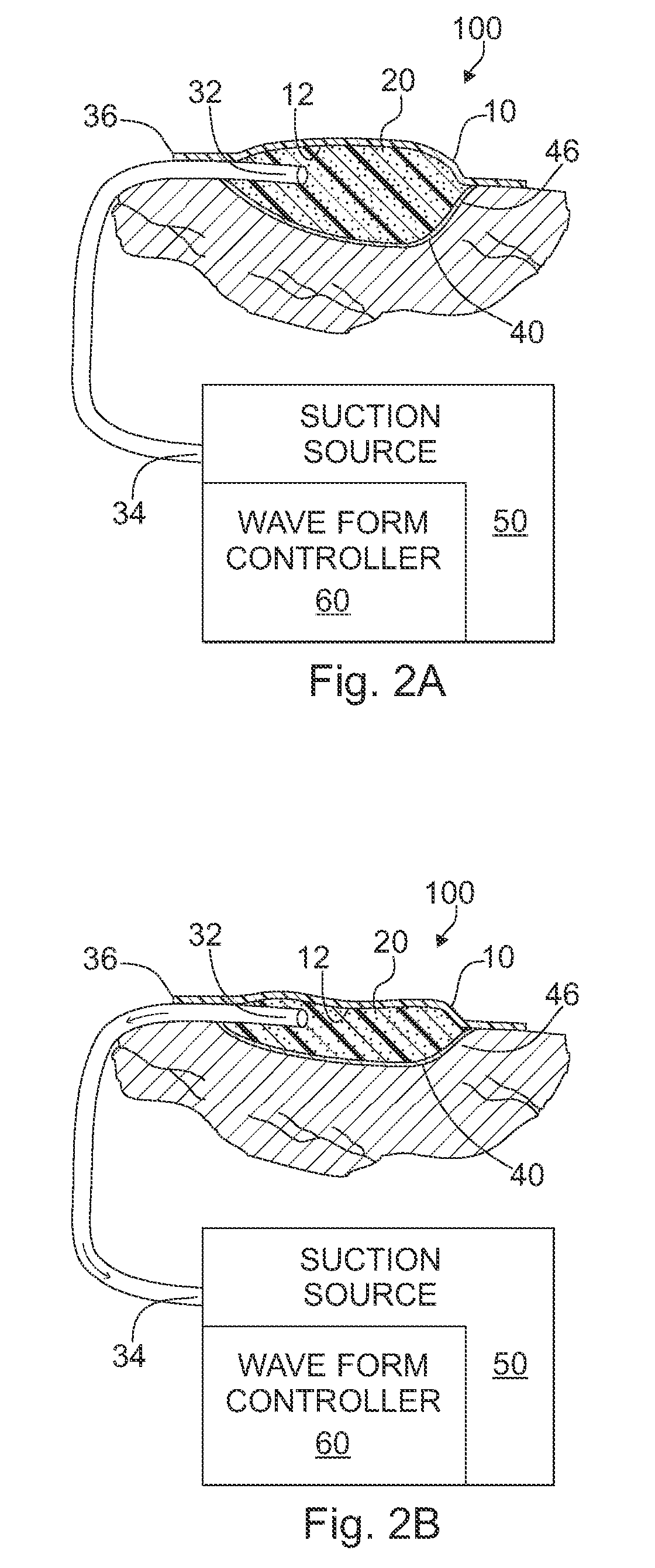

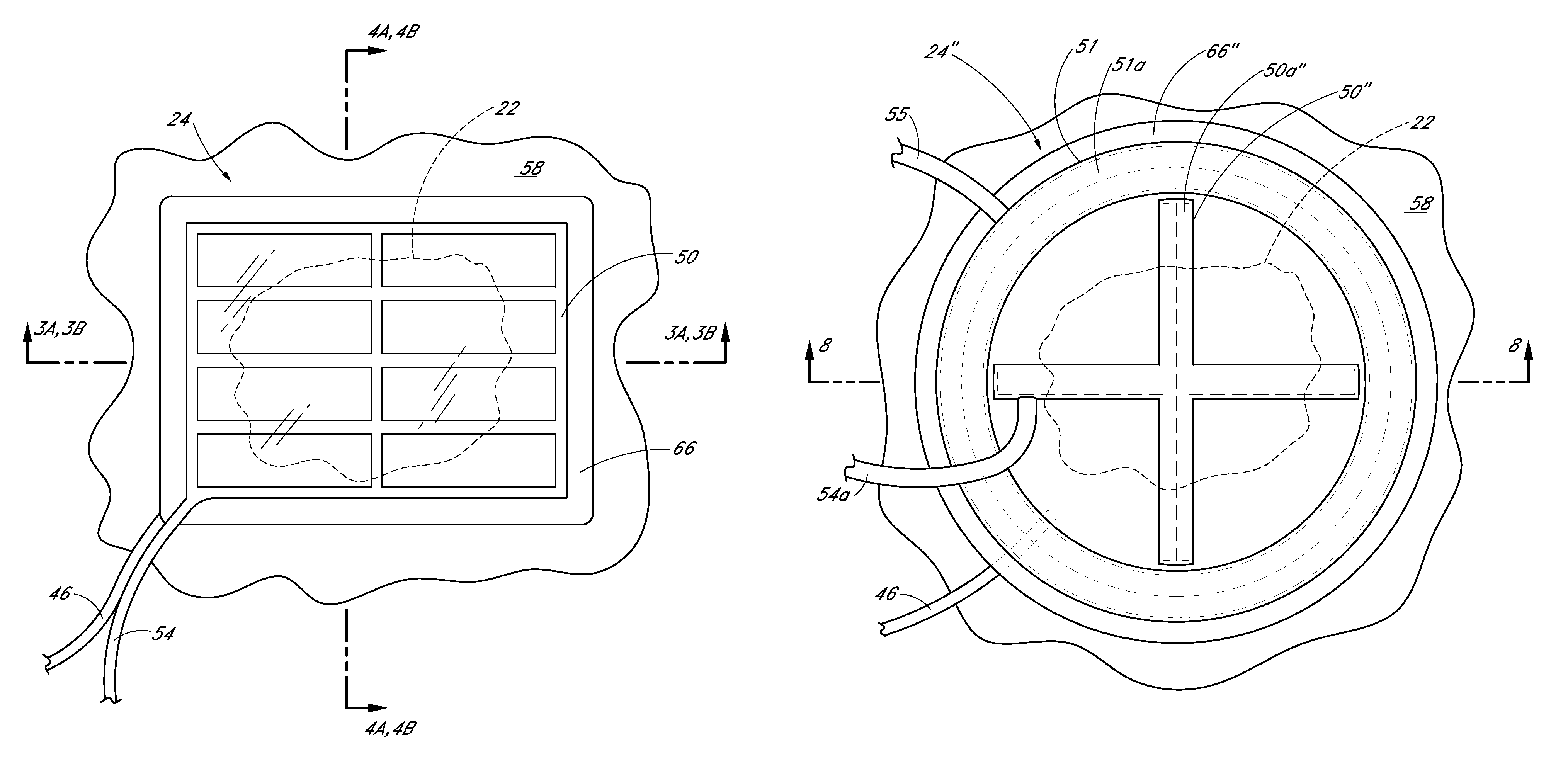

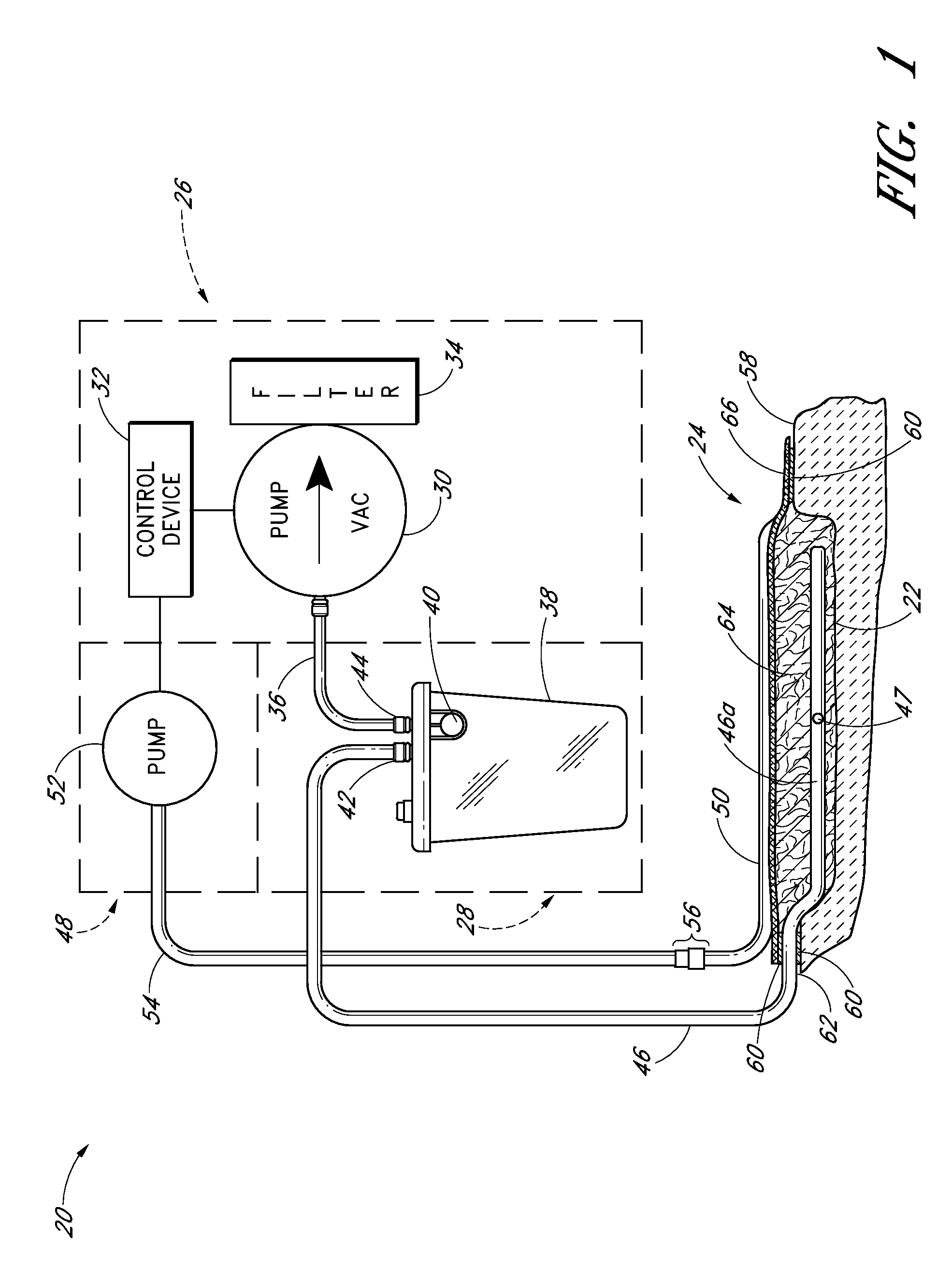

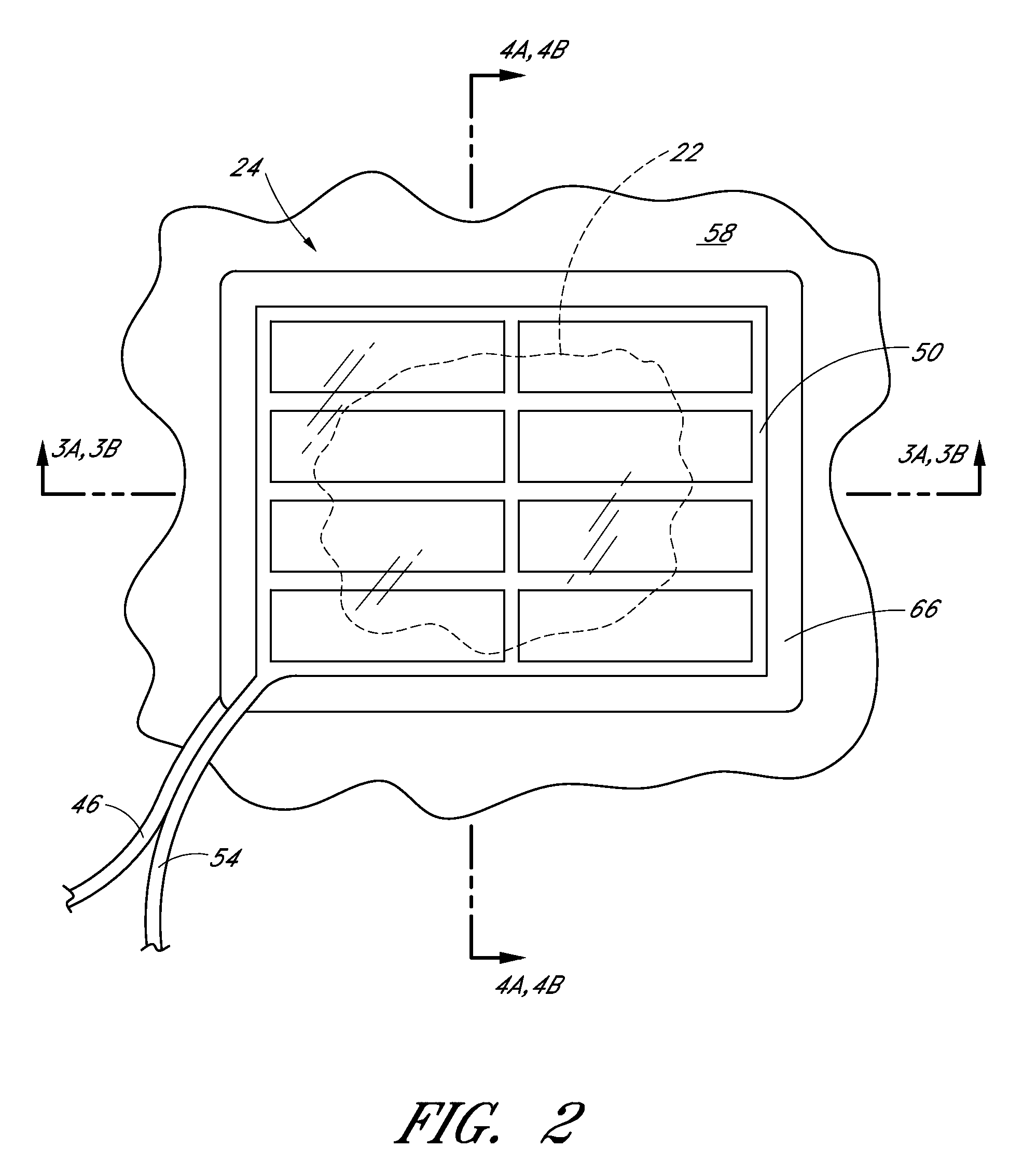

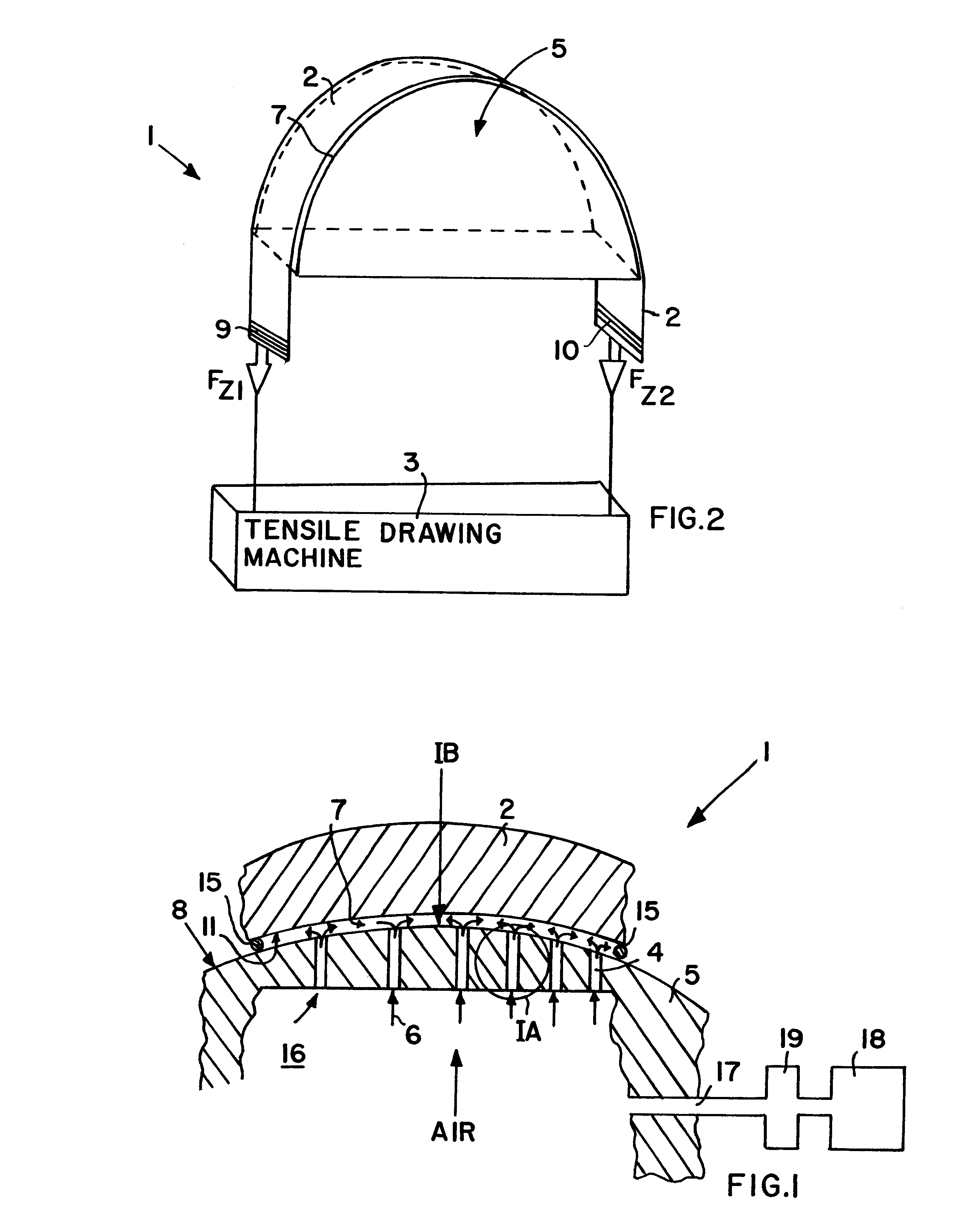

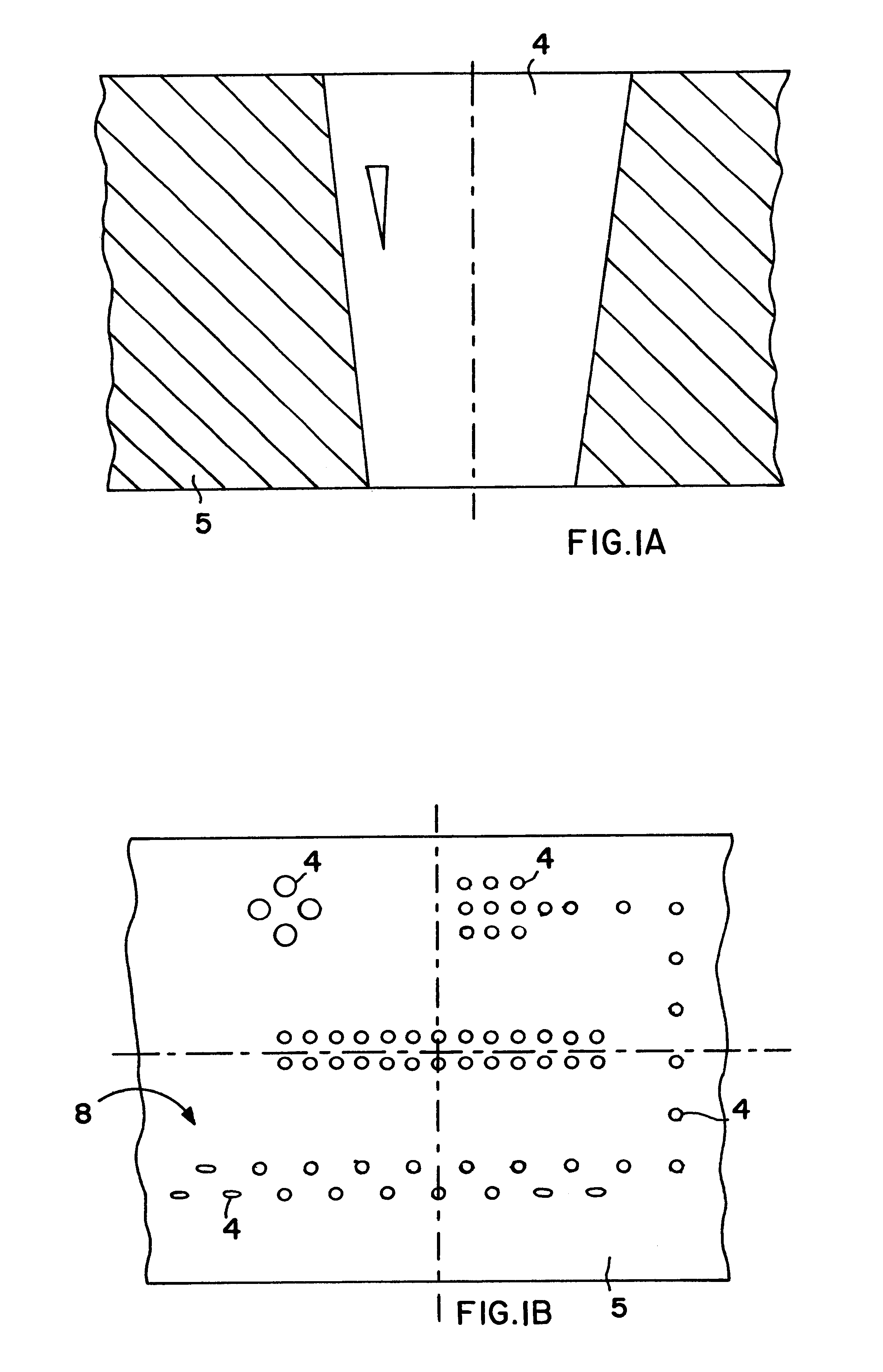

Apparatus and method for wound treatment employing periodic sub-atmospheric pressure

ActiveUS20080208147A1Promote tissue growthWound drainsAdhesive dressingsAtmospheric pressurePneumatic pressure

A tissue treatment apparatus and method are provided for treating tissue by the application of the time-varying sub-atmospheric pressure. The apparatus includes a cover adapted to cover a wound and adapted to maintain sub-atmospheric pressure the site of the wound. The apparatus further includes a source of suction configured to generate a time-varying sub-atmospheric pressure having a periodic waveform comprising a gradual change in pressure. The suction source cooperates with the cover to supply the time-varying sub-atmospheric pressure under the cover to the wound. The time-varying sub-atmospheric pressure may vary between a first pressure value below the inherent tissue tension of the wound tissue and a second pressure value above the inherent tissue tension of the wound tissue.

Owner:WAKE FOREST UNIV HEALTH SCI INC

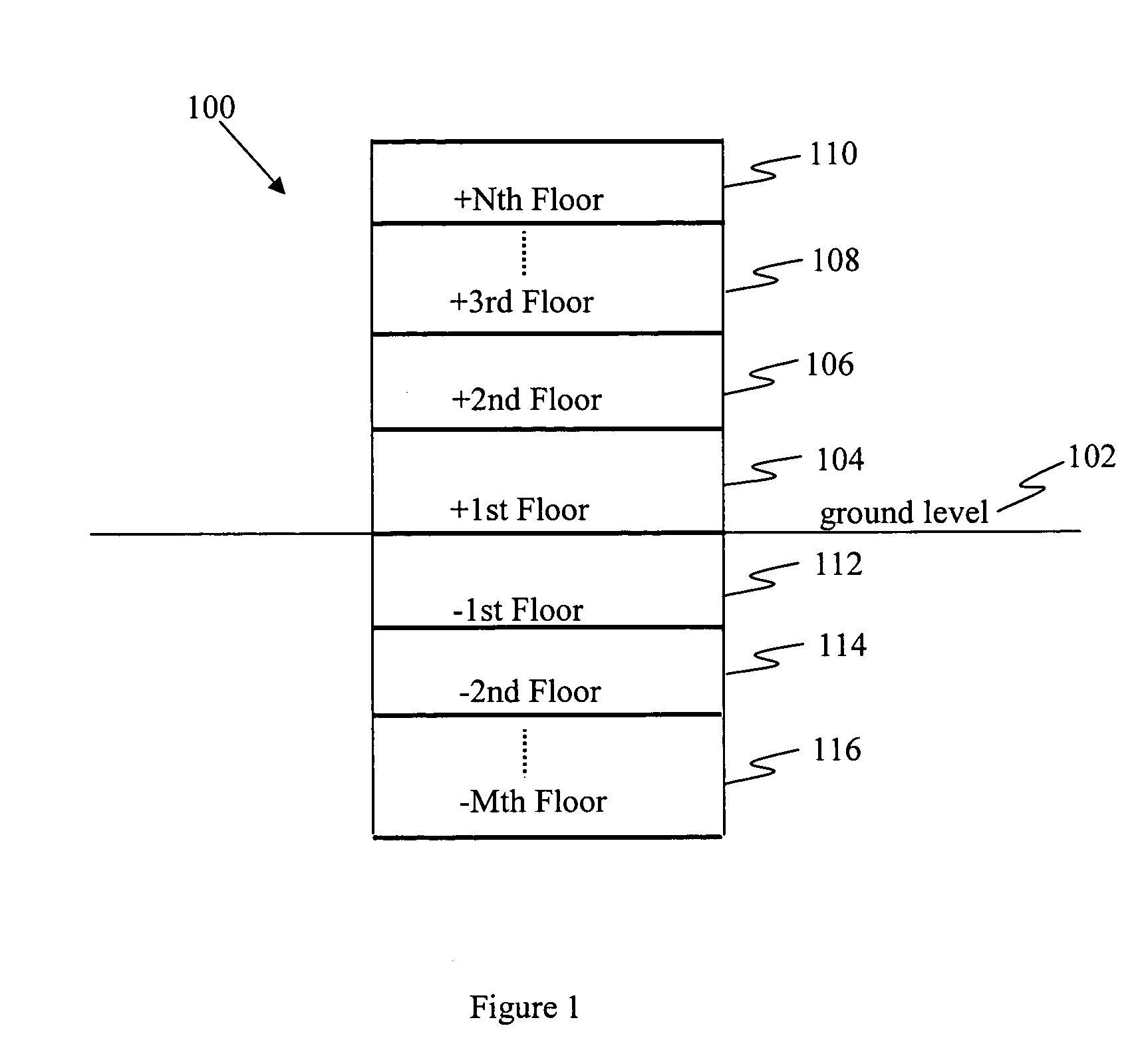

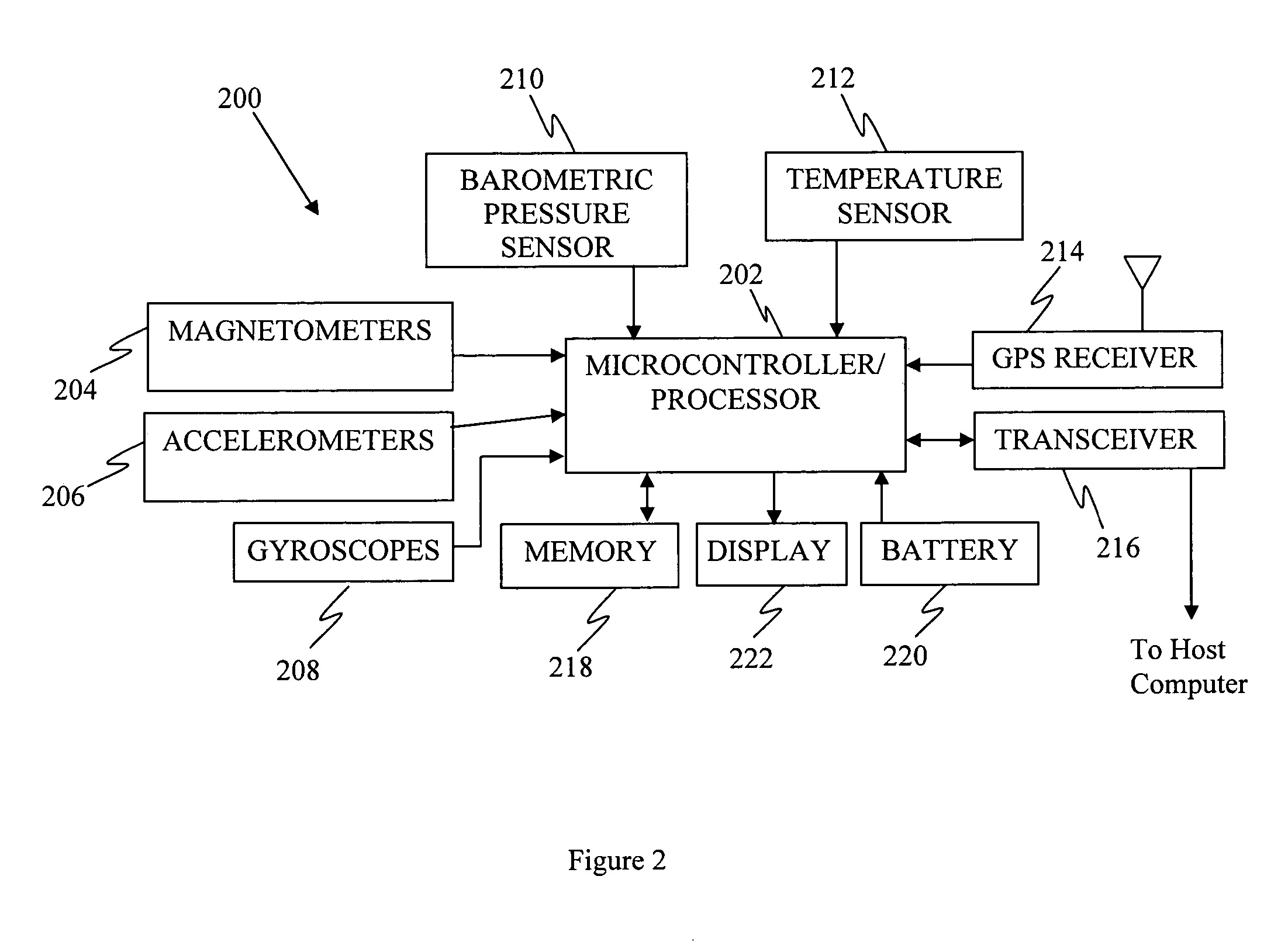

Barometric floor level indicator

InactiveUS7162368B2Instruments for road network navigationPosition fixationOperation modeEngineering

The invention relates to a device, system, and method for providing a multi-mode navigation device. In a first mode of operation, the navigation device provides position information based on a radio frequency navigation signals. If radio signals become unavailable, the navigation device enters a second mode of operation. In the second mode of operation the navigation device stores the most recent elevation and associates it with a reference elevation, the reference elevation is associated with an entry floor. The difference between a current elevation and the reference elevation is determined and this difference is divided by a floor height to obtain a floor number. The navigation device provides the floor number while reliable global position information is unavailable.

Owner:HONEYWELL INT INC

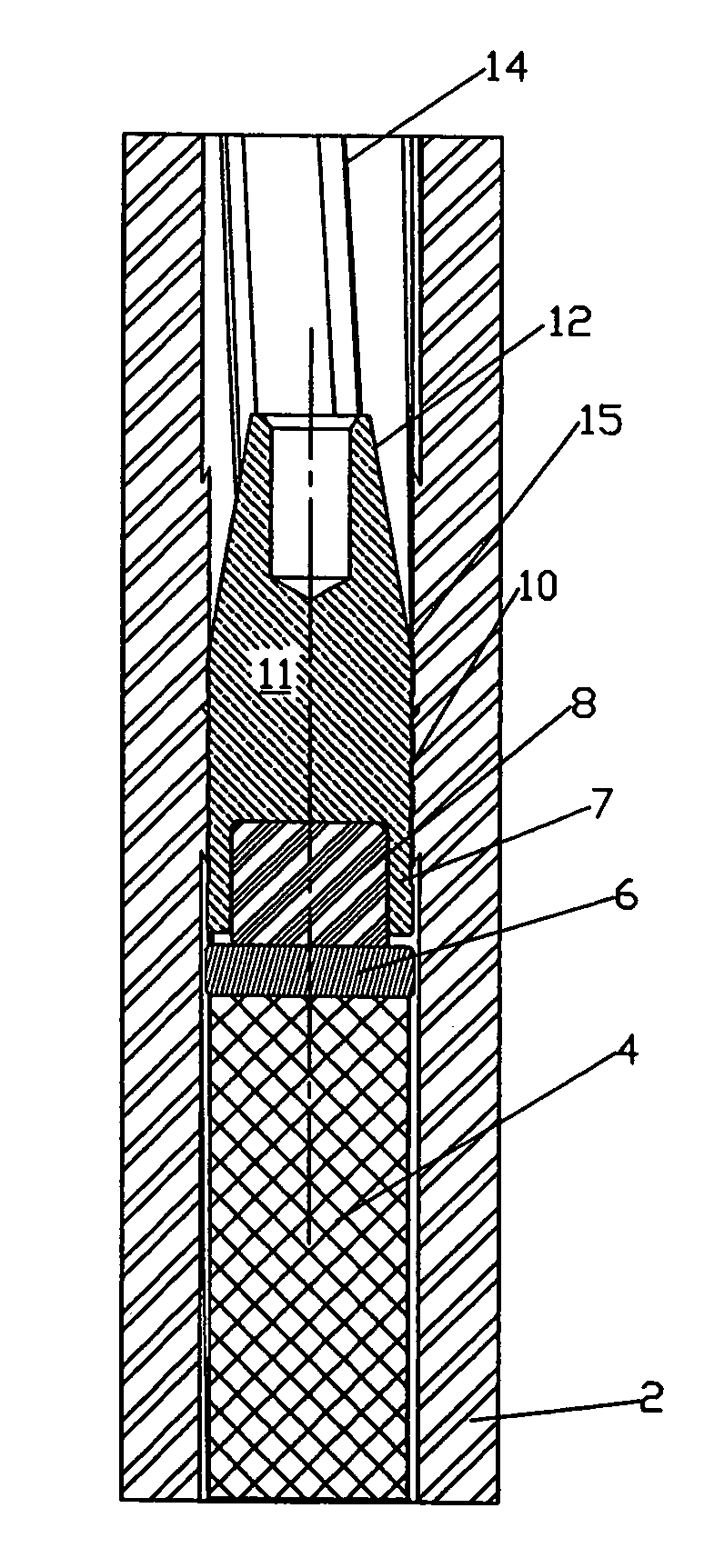

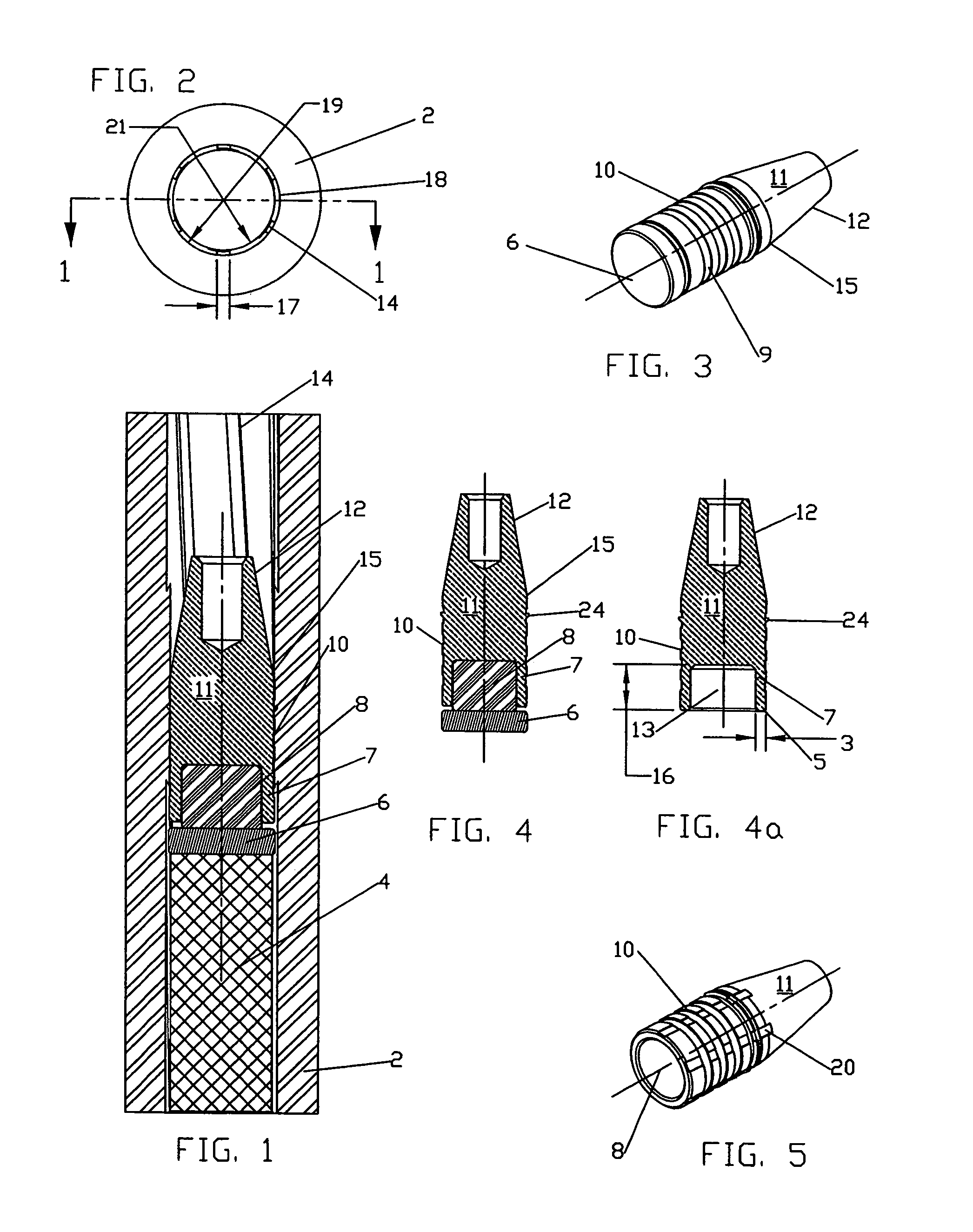

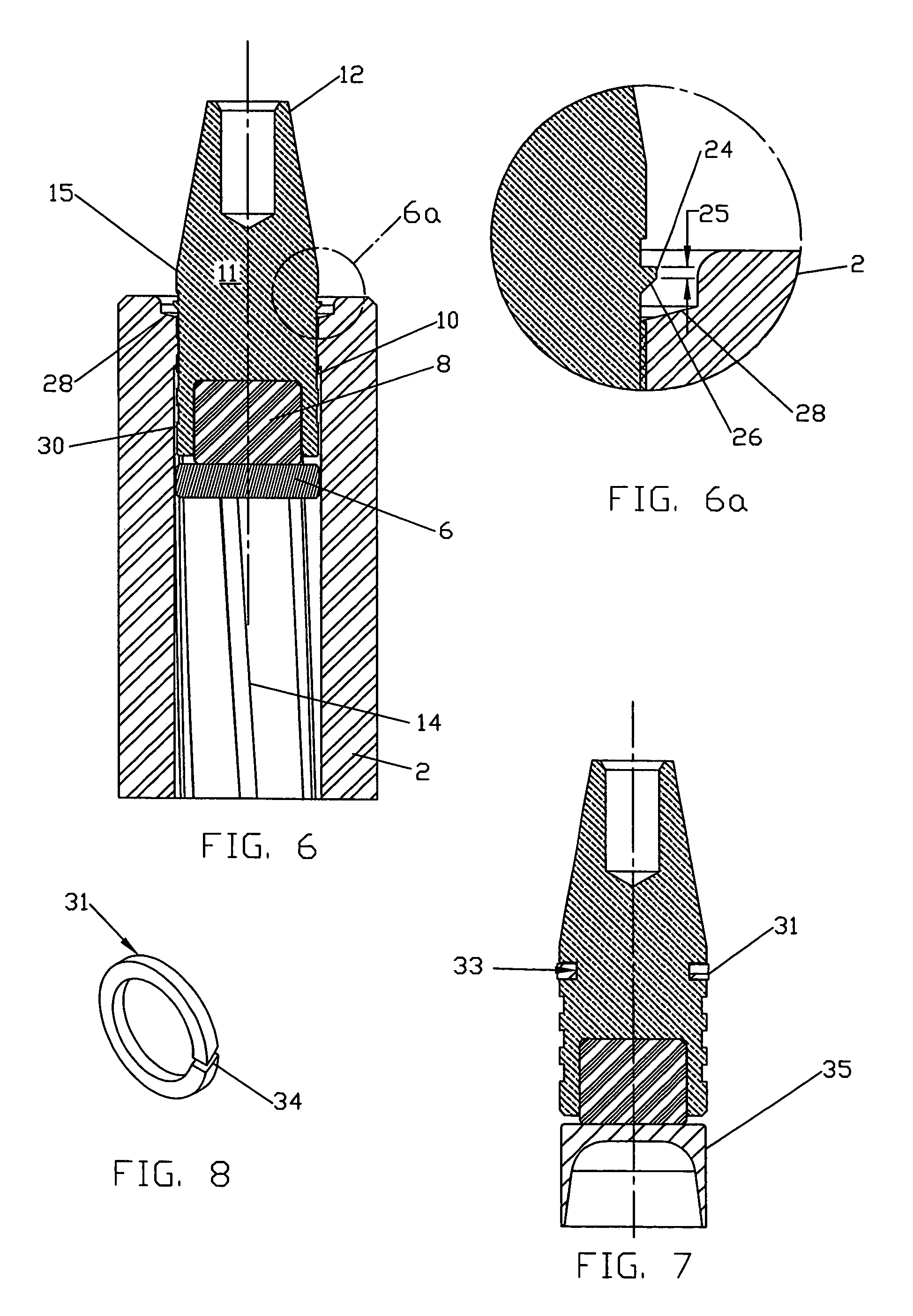

Muzzleloading firearm projectile

InactiveUS7380505B1Easy loadingReasonable alignmentAmmunition projectilesTraining ammunitionEngineeringCopper

A muzzle loading firearm projectile is disclosed that is composed of a multi diameter, hollow base solid copper bullet, the rear cavity filled with a material of low-density, and a gas pressure seal that separates the bullet from the powder charge. The majority of the bullet shank has a diameter less than the bore diameter of the firearm barrel to allow for ease of loading and alignment of the barrel and bullet axis; a narrow ring of material larger than the barrel bore diameter but less than the groove diameter is located at the junction of the bullet shank and nose profile that centers the bullet in the barrel and positively positions the bullet over the powder charge regardless of orientation of the firearm. The low-density material filling the rear cavity of the bullet acts as an expansion medium when impacted by the rear gas seal during the firing process causing the hollow shank of the bullet to expand and lock into the barrel rifling.

Owner:SHIERY JEFFREY C

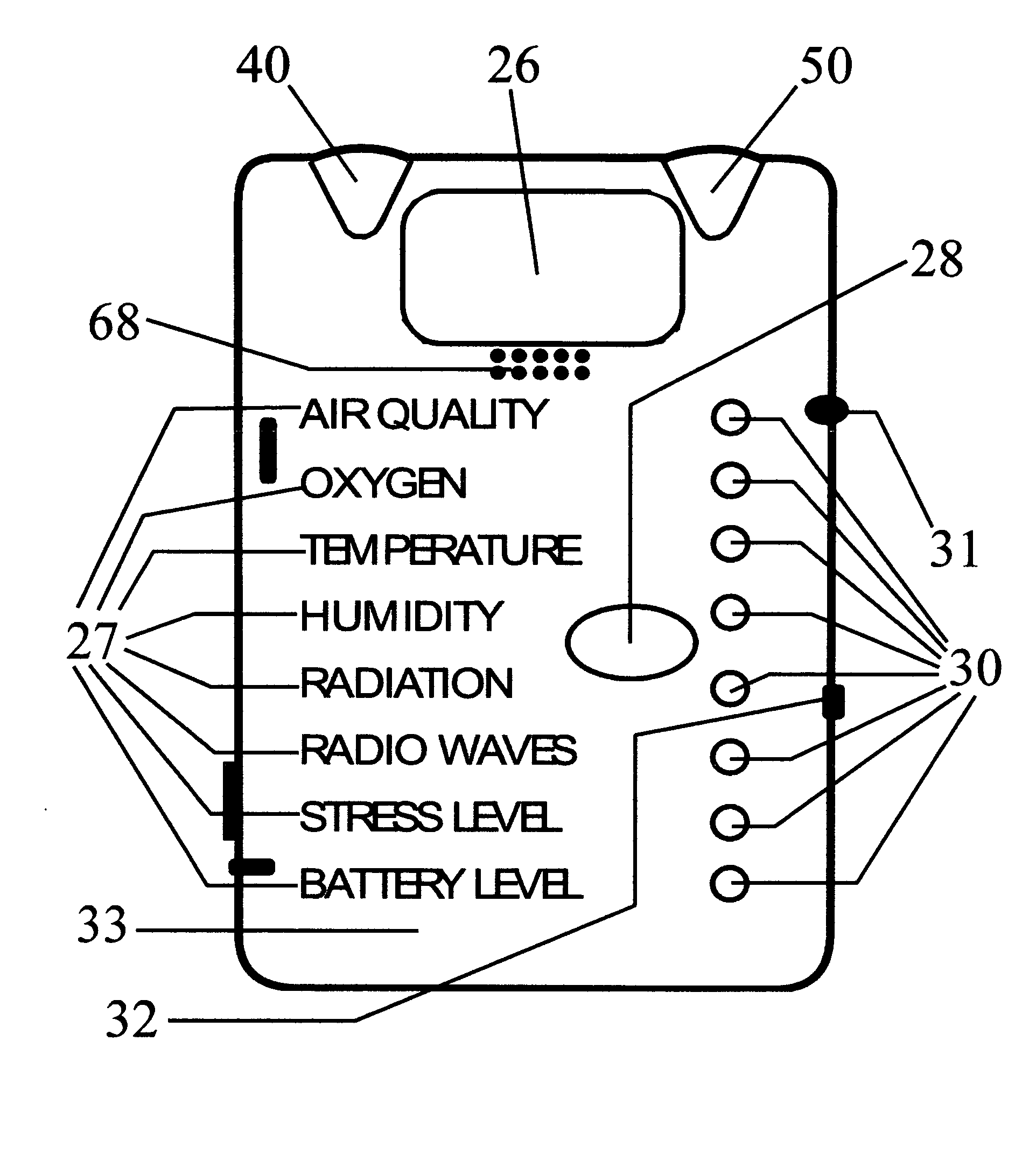

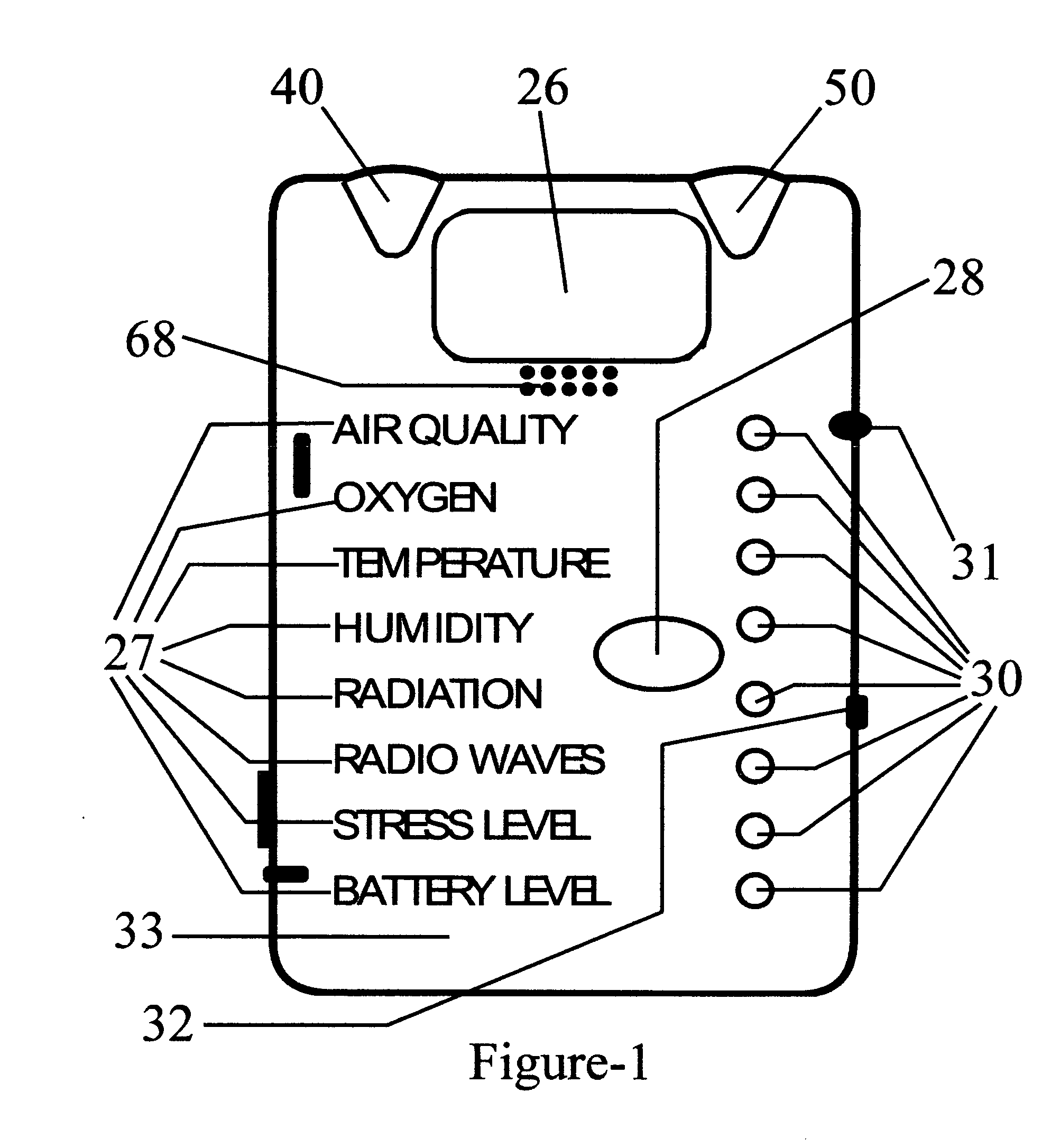

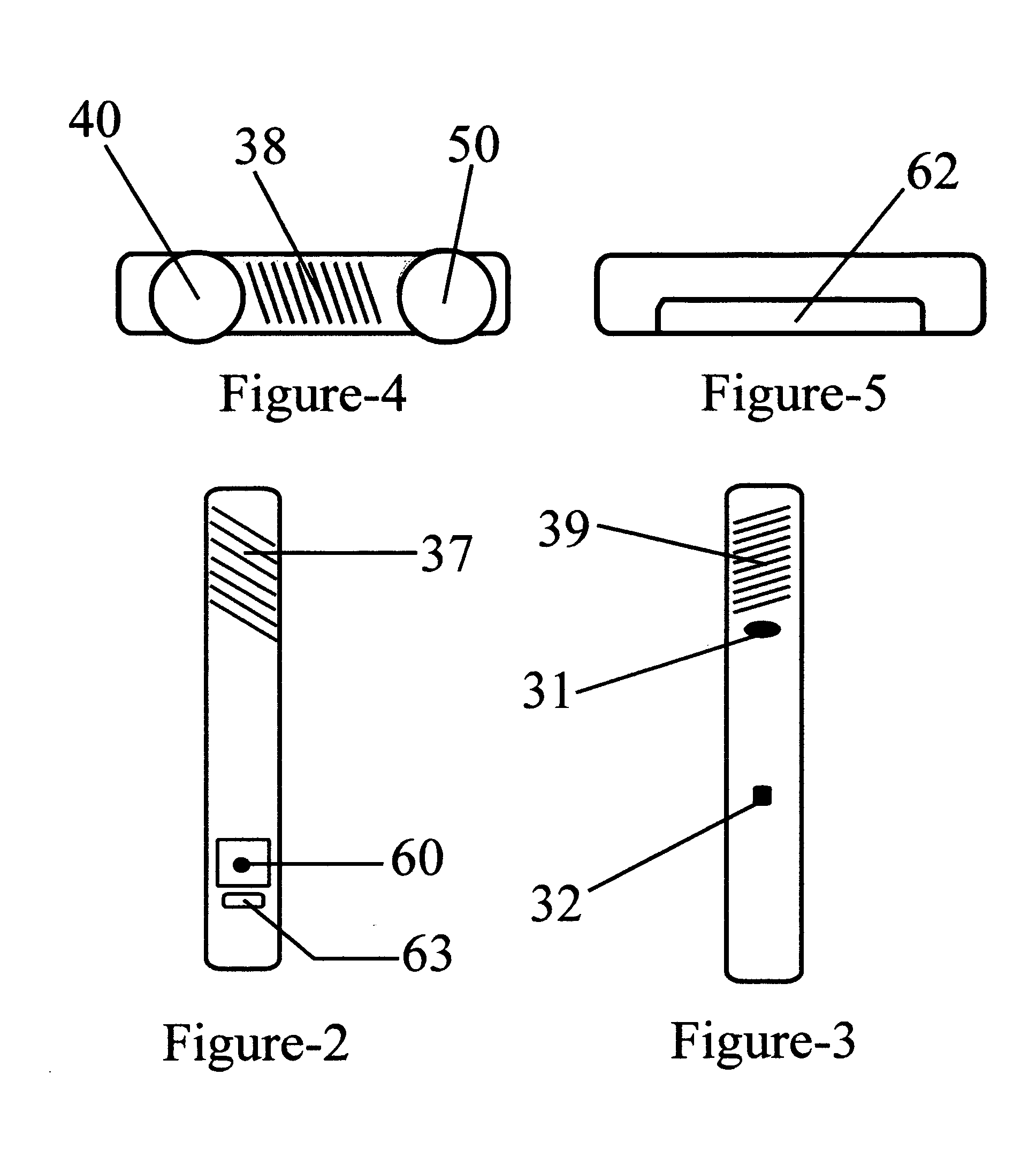

Safety indicator and method

InactiveUS20070241261A1Eliminate saturationImprove accuracyTelemedicineMaterial analysis by optical meansExposure durationRadiation exposure

A safety indicator monitors environment conditions detrimental to humans e.g., hazardous gases, air pollutants, low oxygen, radiation levels of EMF or RF and microwave, temperature, humidity and air pressure retaining a three month history to upload to a PC via infra red data interface or phone link. Contaminants are analyzed and compared to stored profiles to determine its classification and notify user of an adversity by stored voice messages from, via alarm tones and associated flashing LED, via vibrator for silent operation or via LCD. Environmental radiation sources are monitored and auto-scaled. Instantaneous radiation exposure level and exposure duration data are stored for later readout as a detector and dosimeter. Scans for EMF allow detection with auto scaling of radiation levels and exposure durations are stored for subsequent readout. Electronic bugs can be found with a high sensitivity EMF range setting. Ambient temperature measurements or humidity and barometric pressure can be made over time to predict weather changes. A PCS RF link provides wireless remote communications in a first responder military use by upload of alarm conditions, field measurements and with download of command instructions. The link supports reception of telemetry data for real time remote monitoring of personnel via the wrist band for blood pressure, temperature, pulse rate and blood oxygen levels are transmitted. Commercial uses include remote environmental data collection and employee assignment tasking. GPS locates personnel and reporting coordinates associated with alarm occurrences and associated environmental measurements.

Owner:NTCG

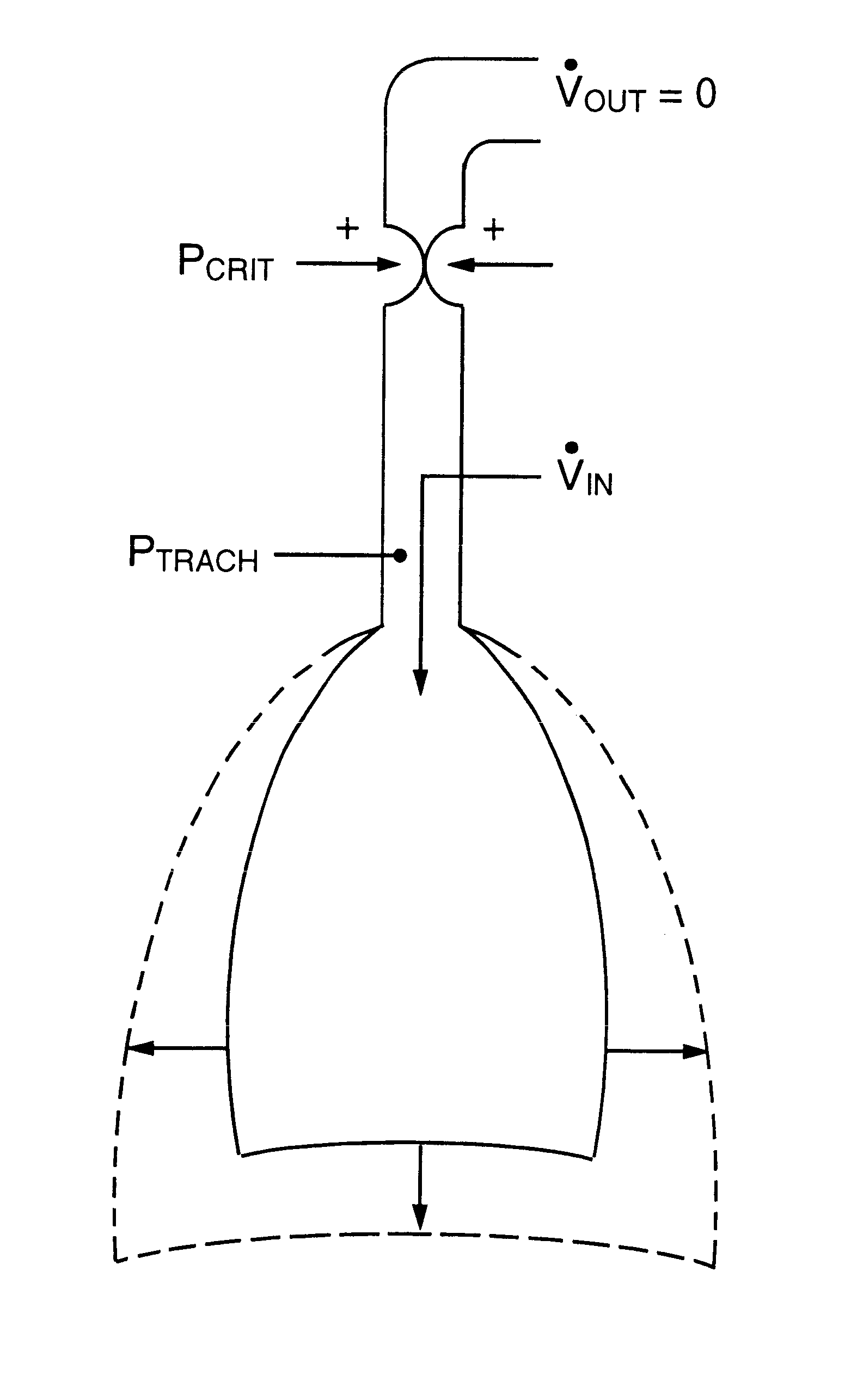

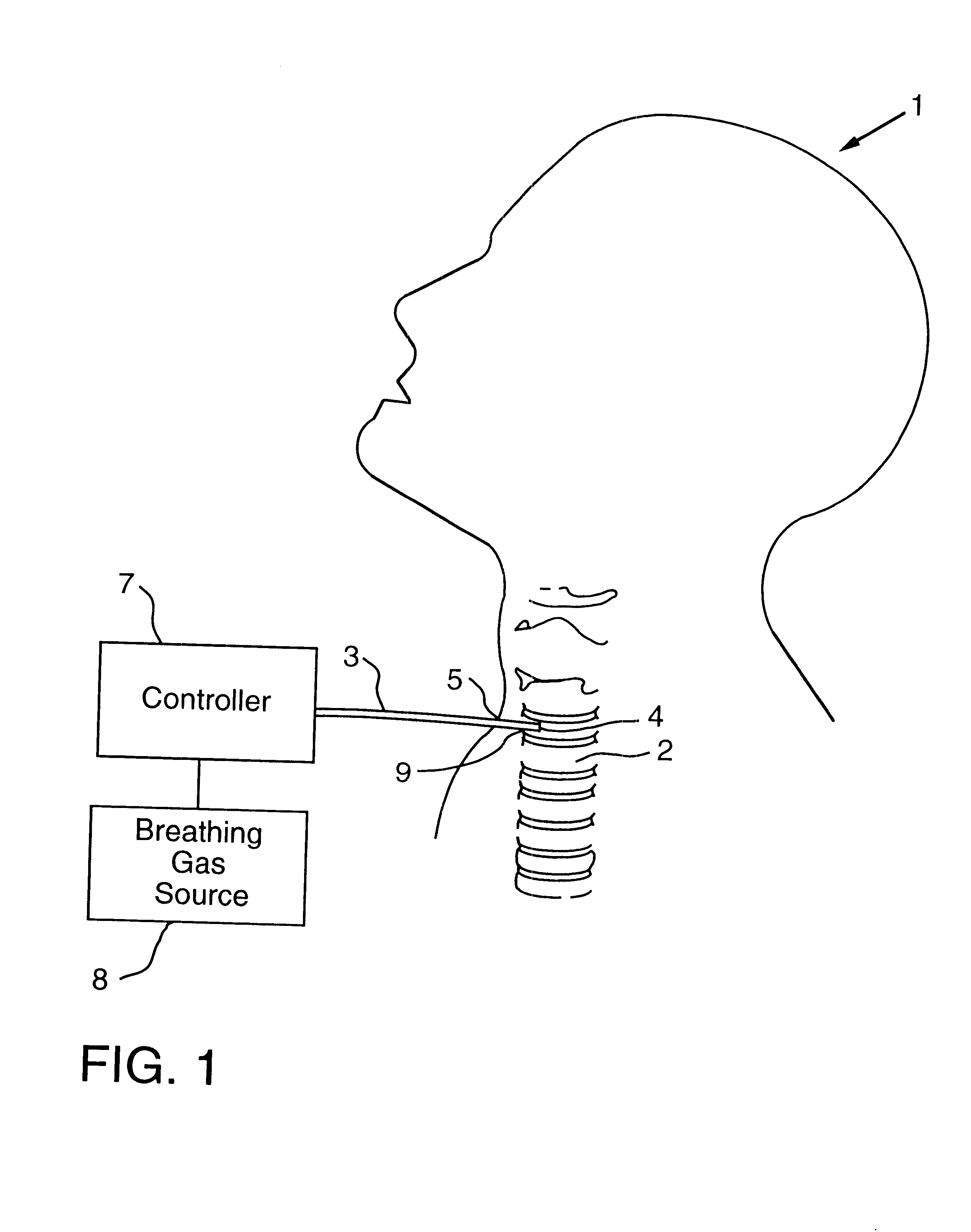

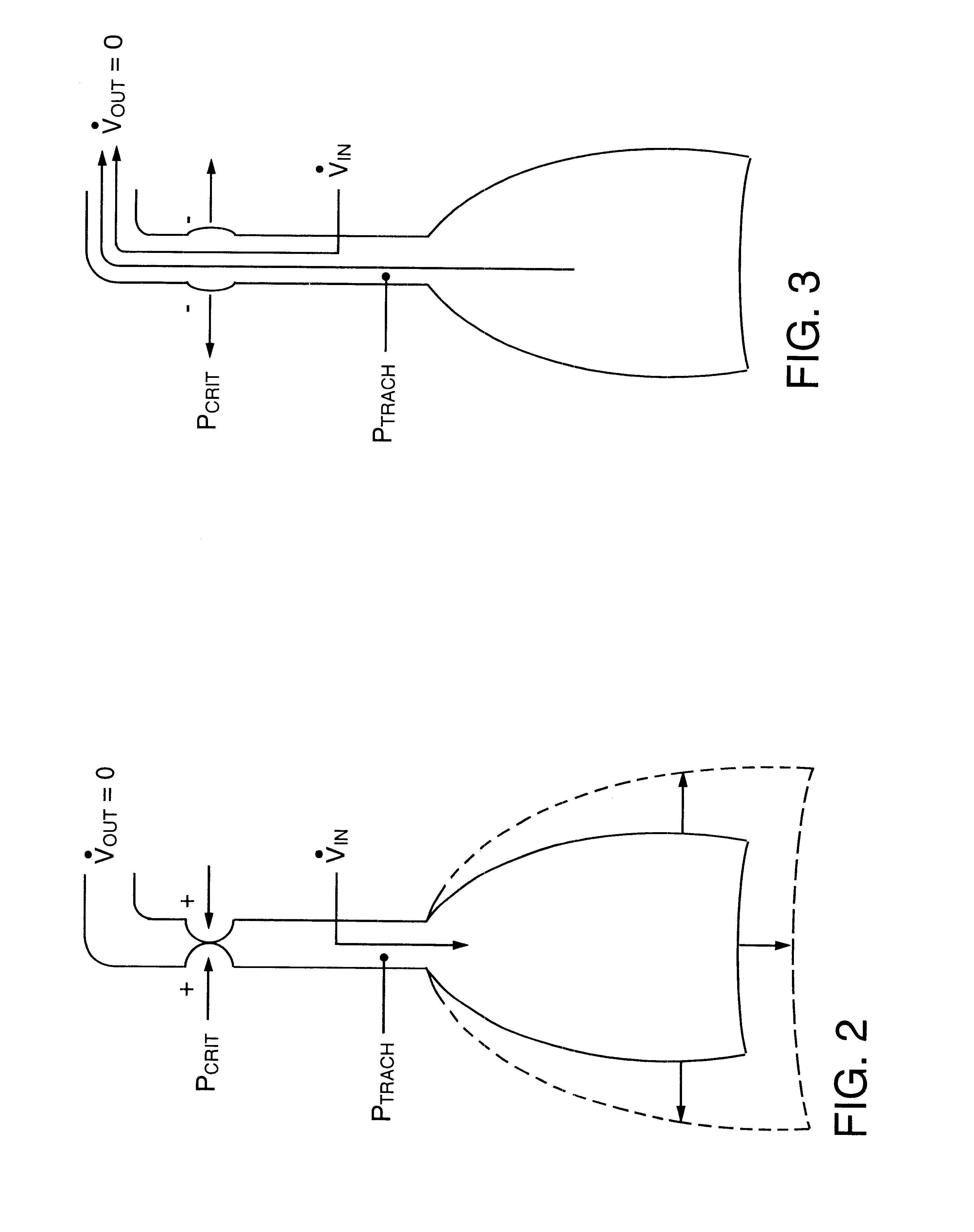

Method and apparatus for providing ventilatory support to a patient

InactiveUS6457472B1Easy to breatheReduce deliveryTracheal tubesElectrocardiographySupporting systemDelayed periods

A ventilatory support system which controls the flow of breathing gas to a patient based on the physiological requirements of the patient is disclosed. Gas pressure in the trachea of the patient is measured, and the delivery of breathing gas to the patient is controlled based on the sensed gas pressure. Depending on the physiological needs of the patient, a tracheal gas pressure limit and a breathing gas flow rate value are established. When the tracheal gas pressure limit is reached, the flow of breathing gas is reduced or terminated. The flow of breathing gas is resumed, for example, after a delay period, or after the tracheal gas pressure falls to a predetermined level.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

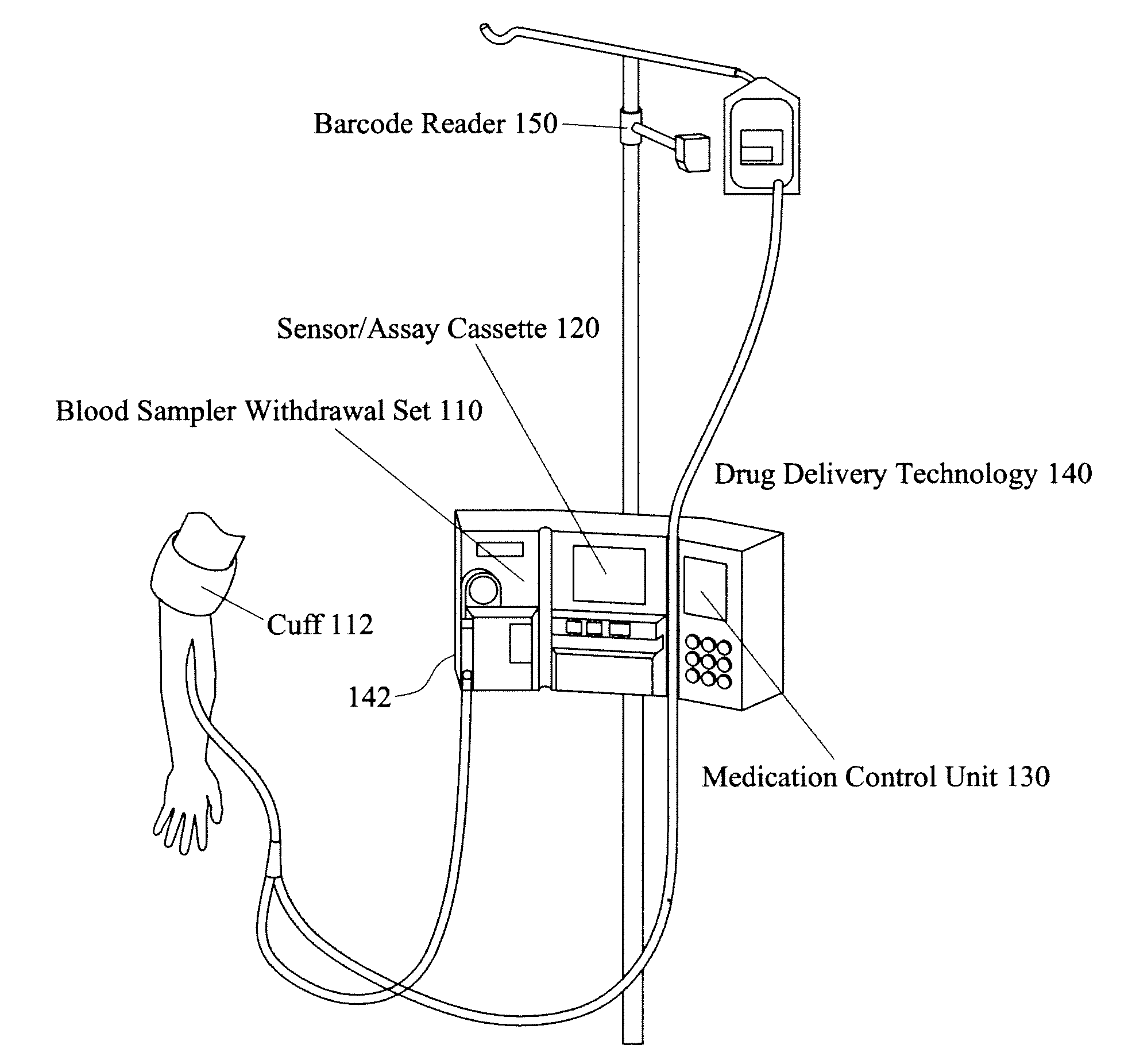

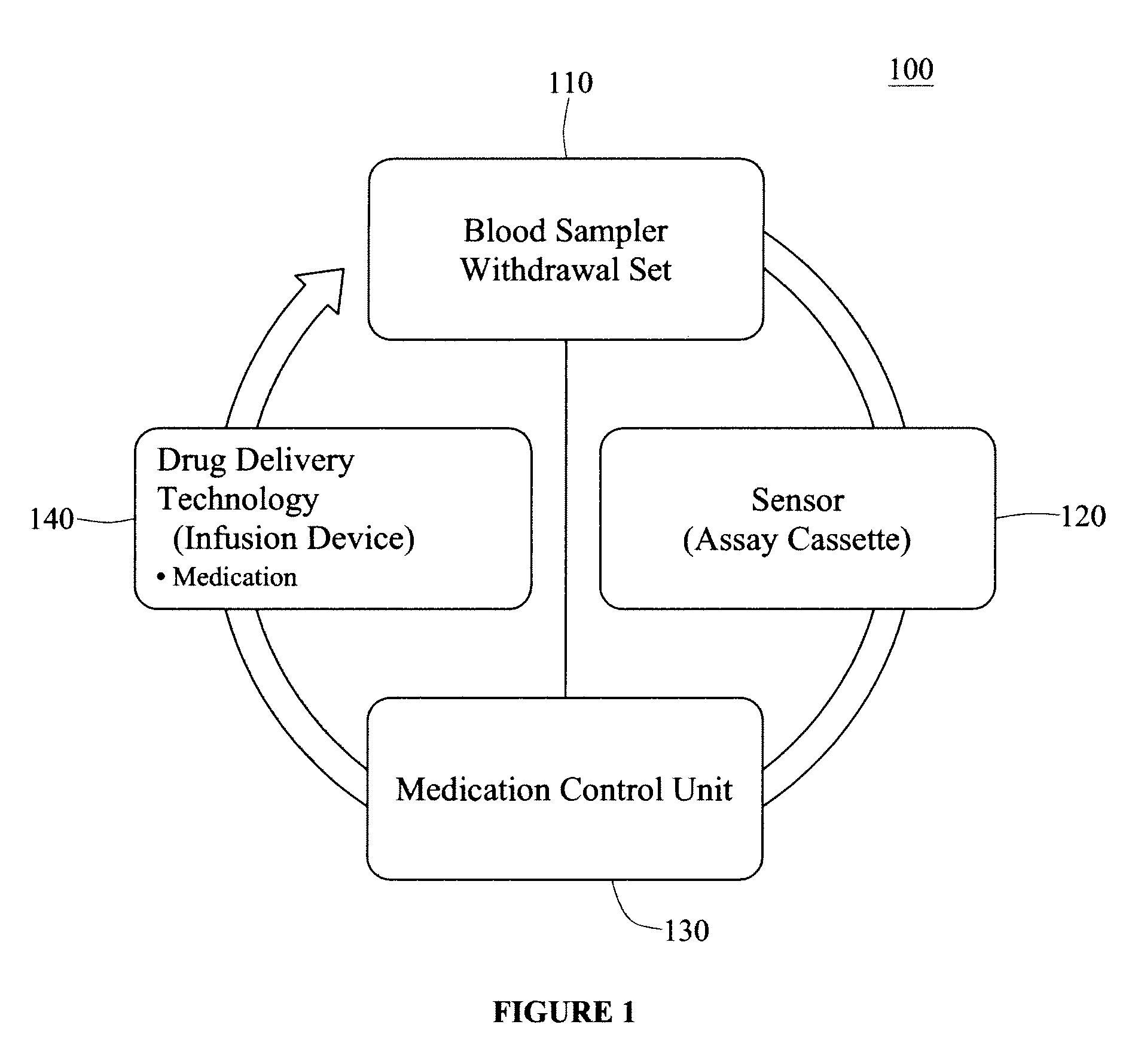

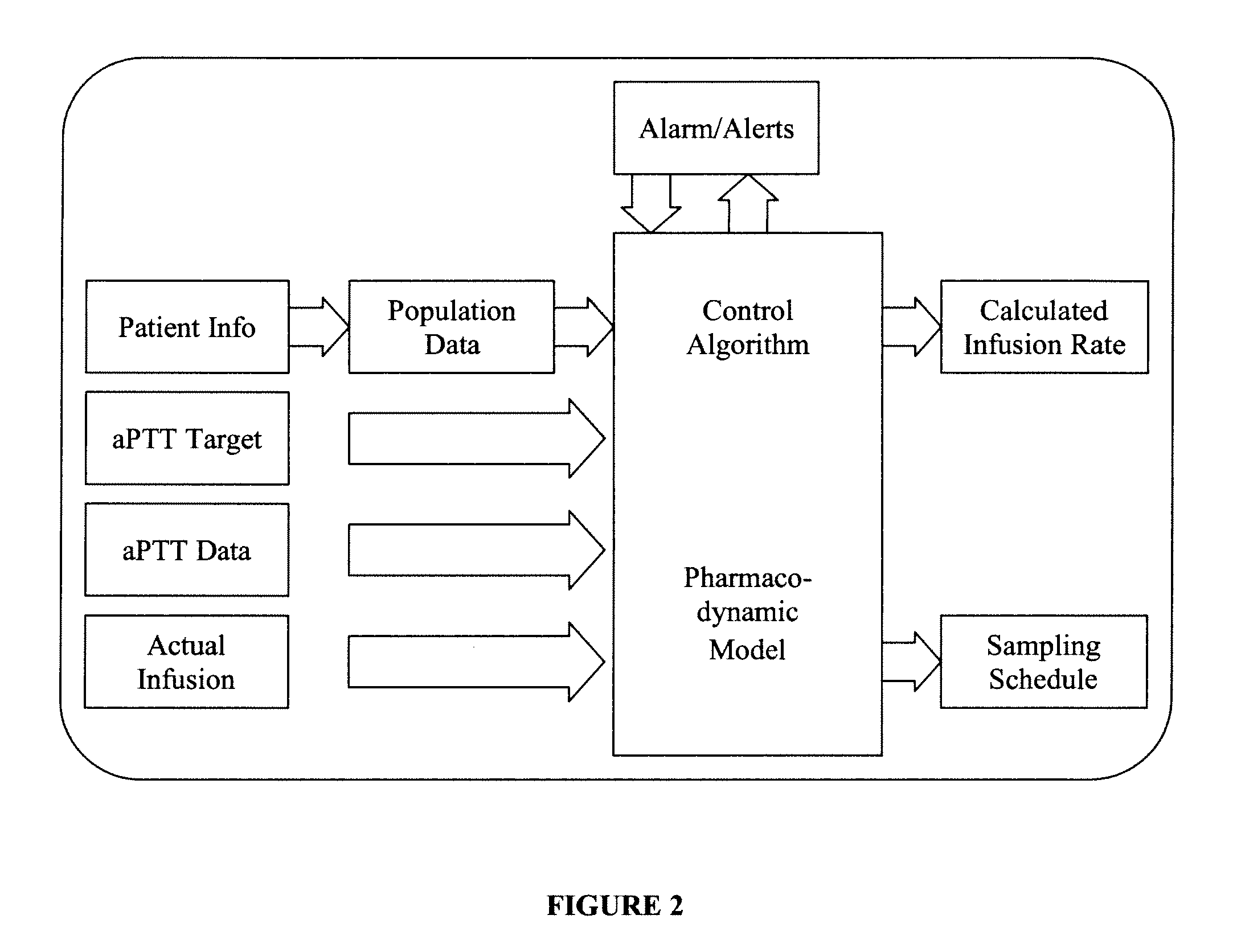

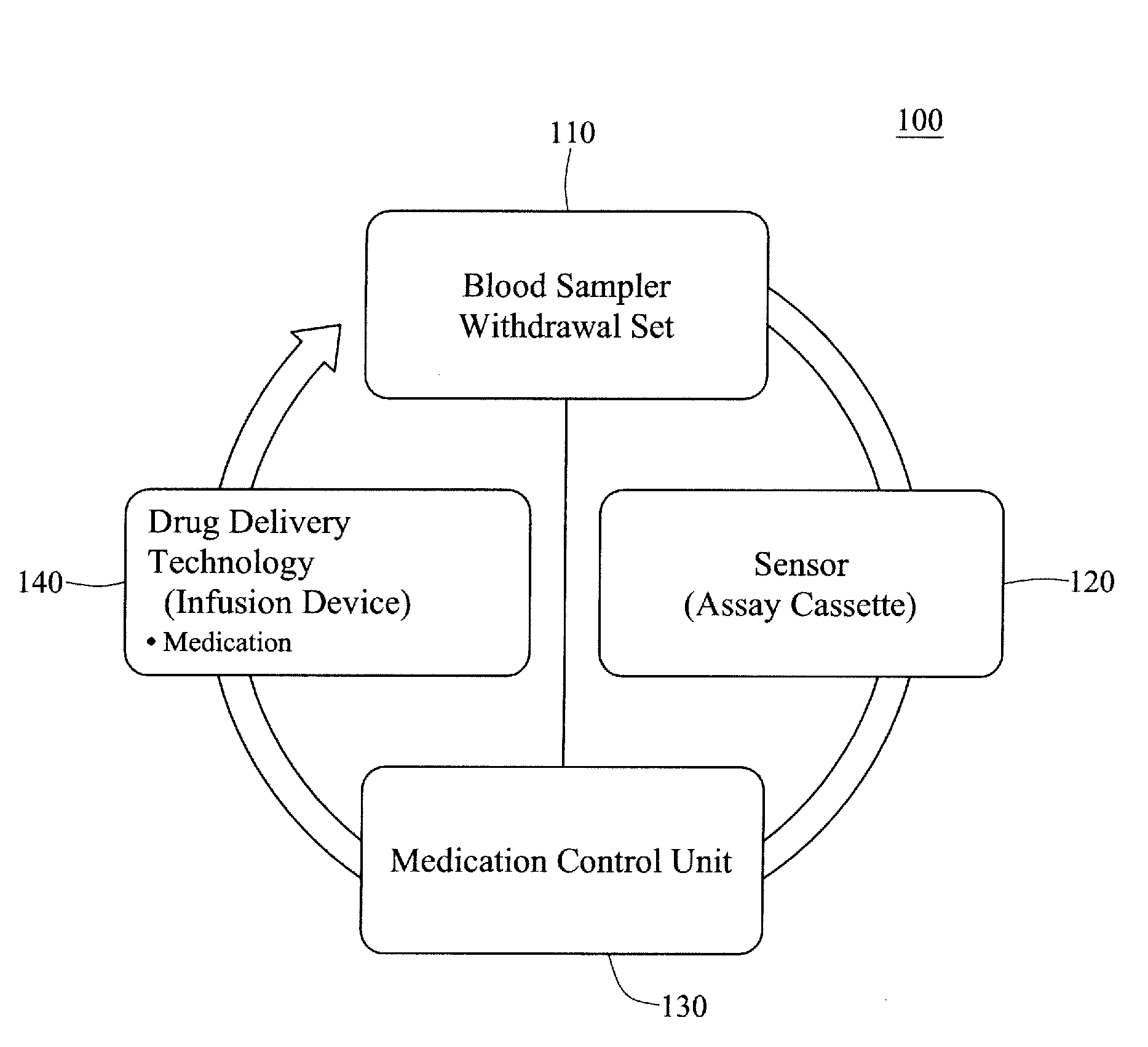

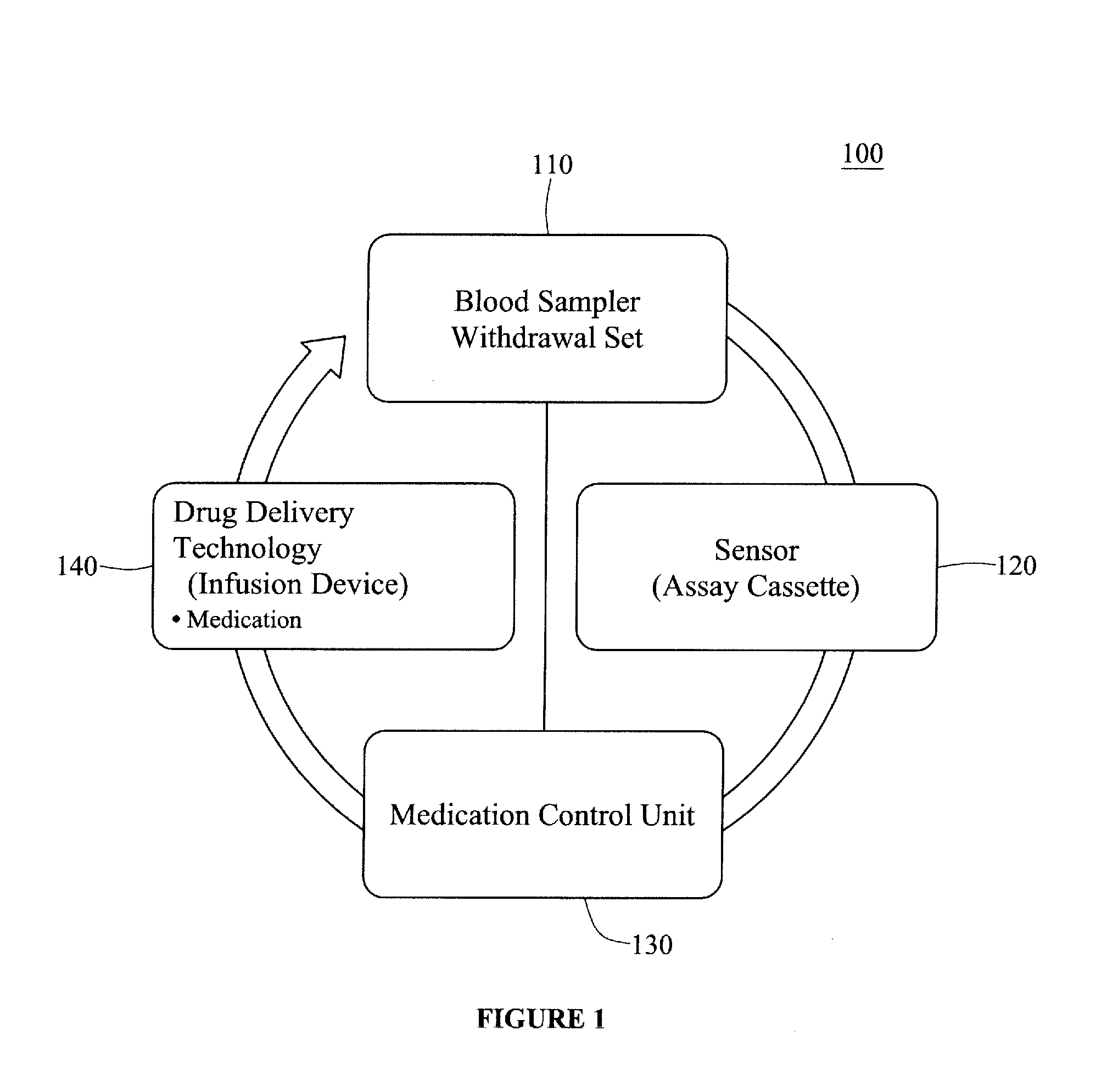

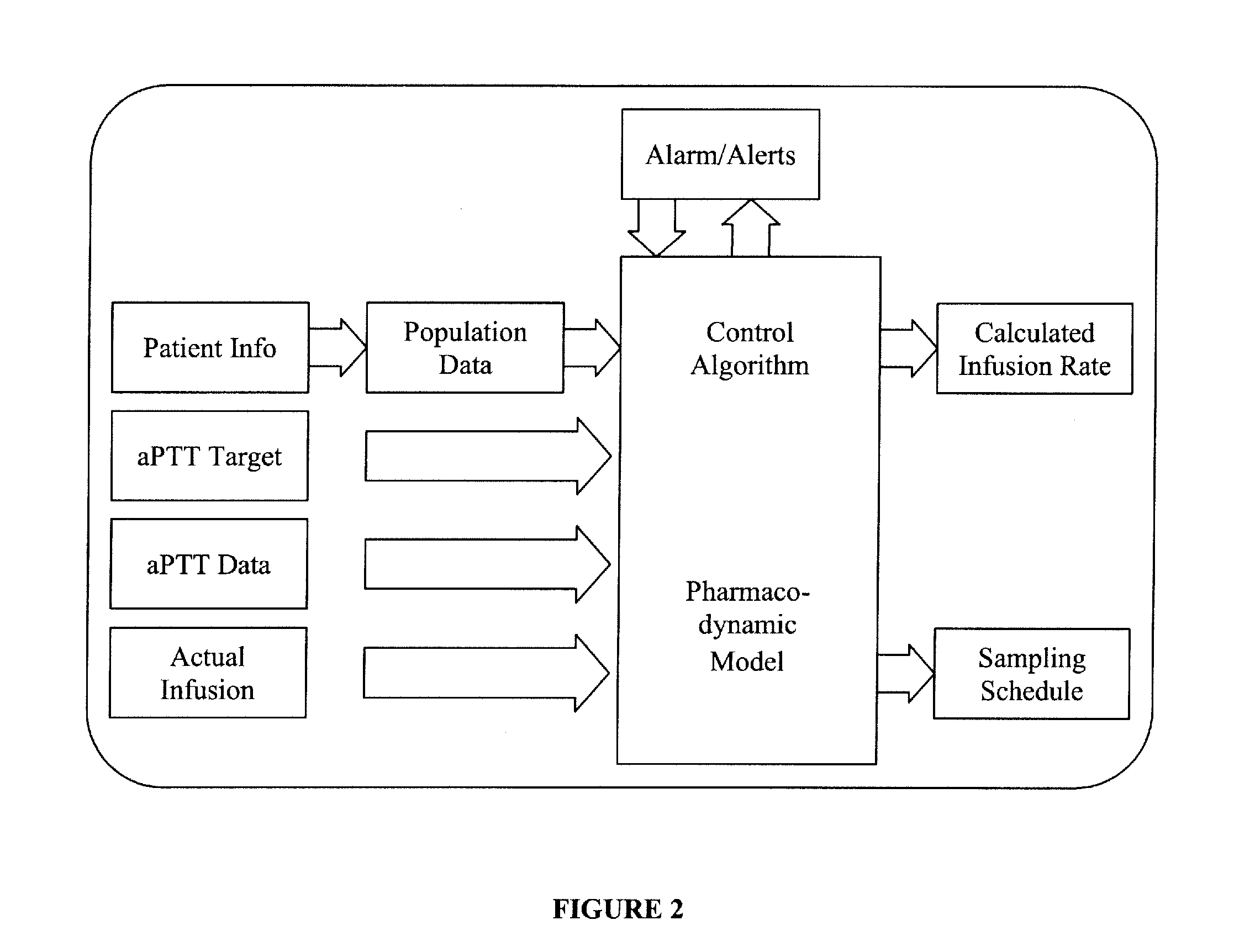

Integrated patient management and control system for medication delivery

InactiveUS20100036310A1Multiplex system selection arrangementsElectrotherapyPatient managementEmergency medicine

An integrated patient monitoring and control system is provided which includes a sample set, the sample set being adapted for coupling to the patient to obtain a specimen from the patient, a sensor, the sensor being adapted to receive the specimen from the sample set and to analyze the sample, a medication control unit, the medication control unit receiving information from the sensor, and utilizing that information to determine medication dosing information for the patient, and a medication administration system, the medication administration system receiving the dosing information from the medication control unit, and adapted to cause administration of the medication to the patient. If the sample set is adapted for blood draw, the system advantageously is performed in conjunction with a pneumatic pressure cuff, inflated so as to aid in blood draw.

Owner:AUTOMEDICS MEDICAL SYST

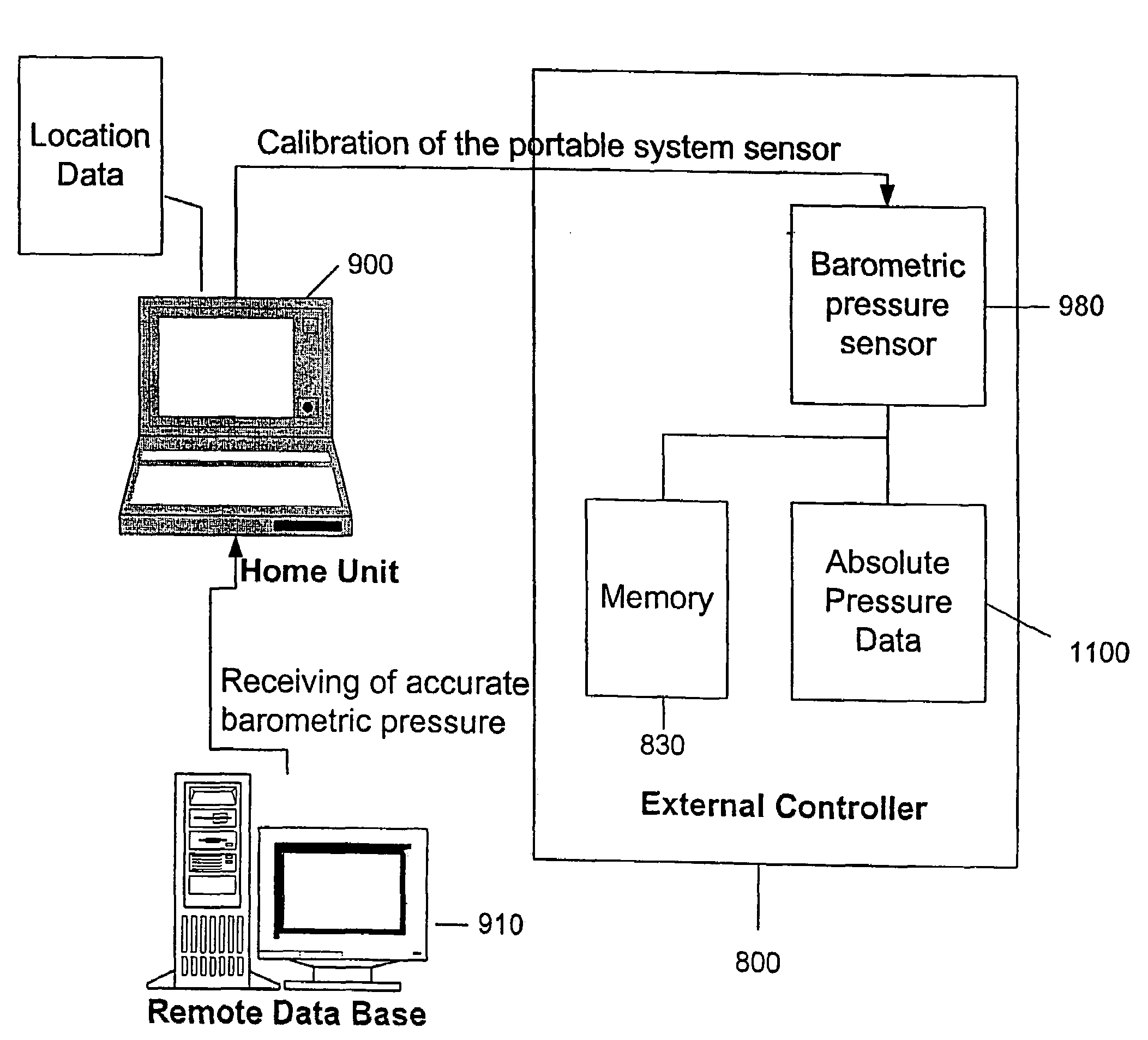

Barometric pressure correction based on remote sources of information

The invention includes systems and methods for converting absolute pressure data acquired in anatomical environments to gauge pressure data using an implant configured to monitor pressure. The implant is configured to communicate with an external controller, which is configured to communicate with a remote microprocessor that includes real-time barometric pressure data for one or more geographic locations.

Owner:REMON MEDICAL TECH

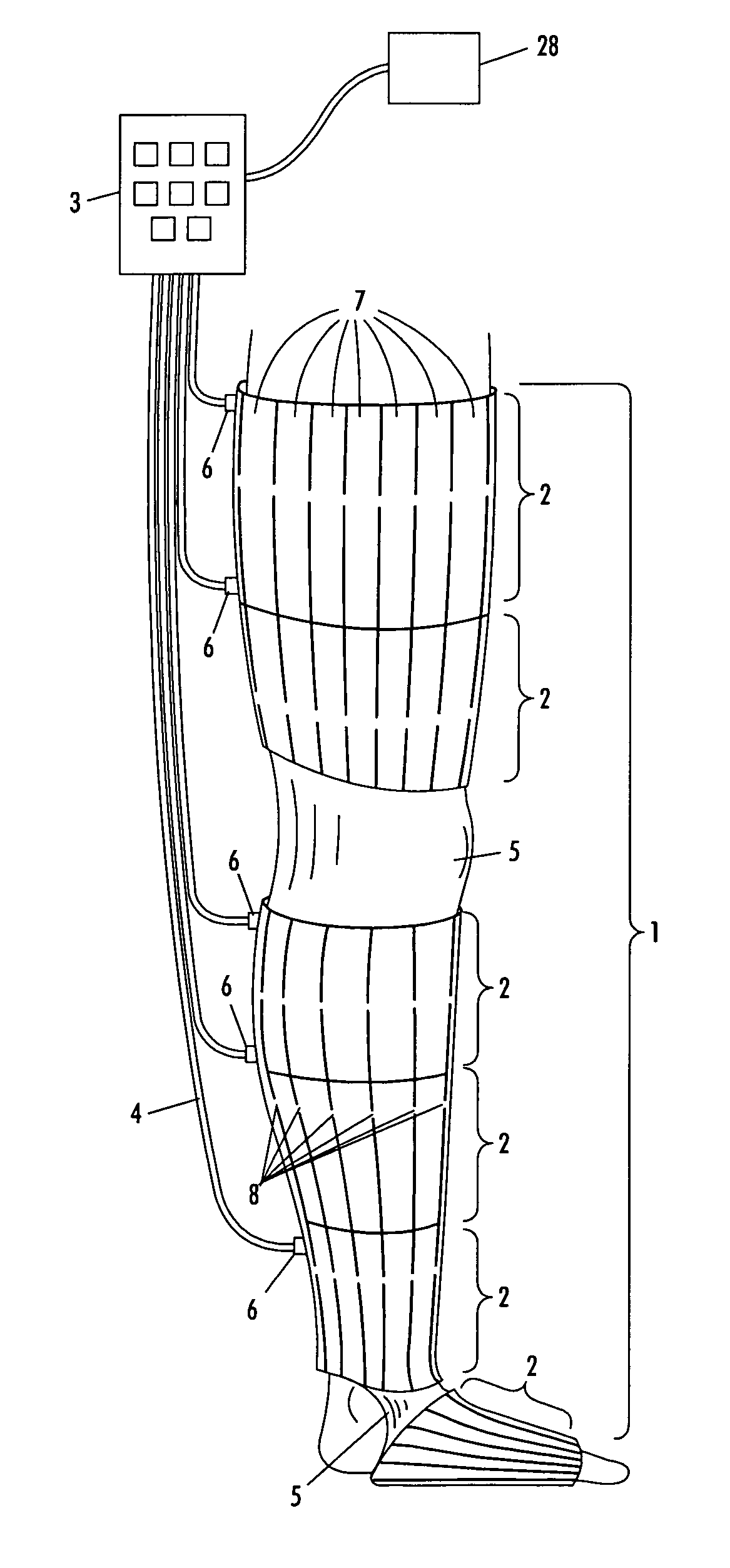

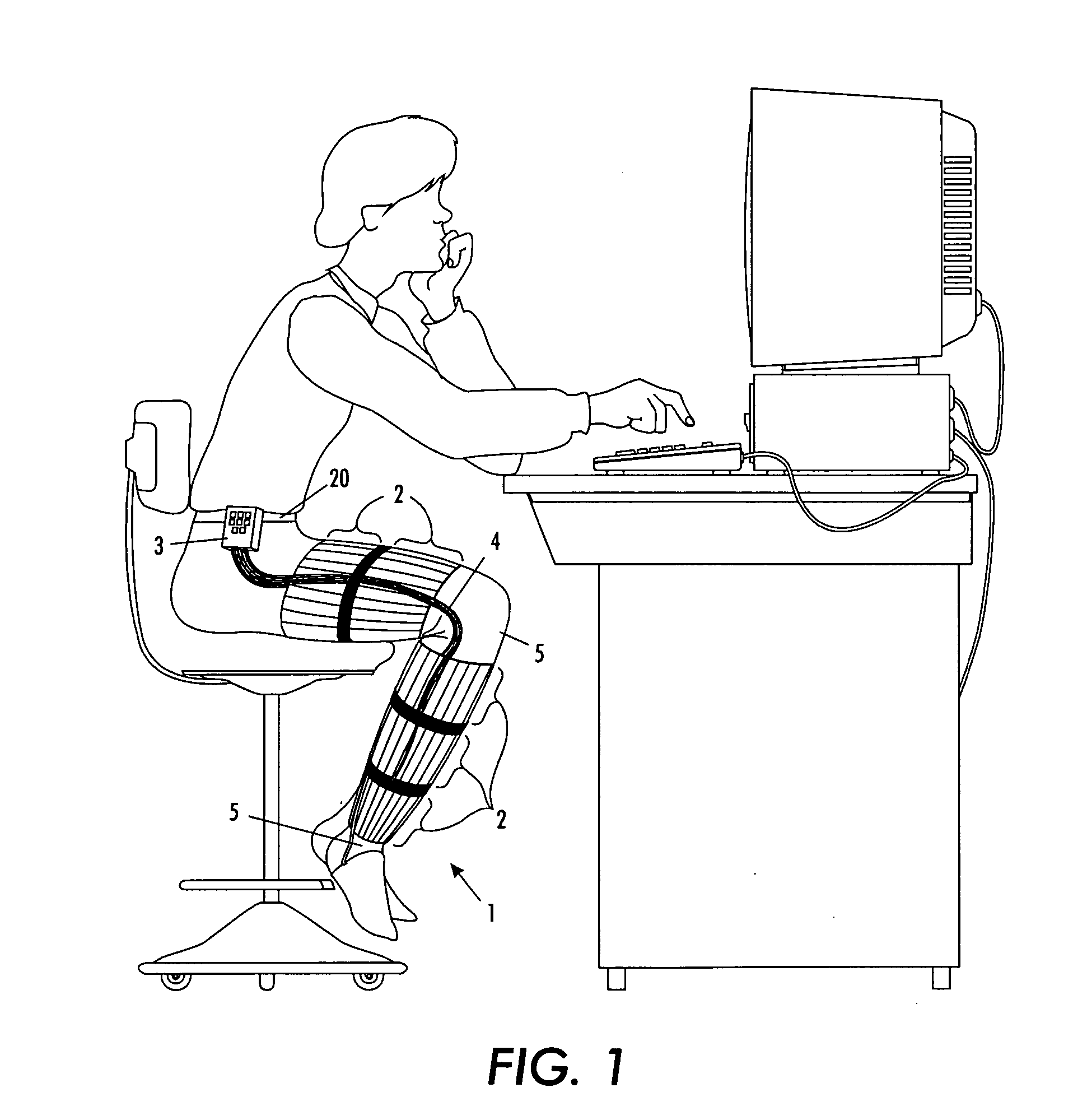

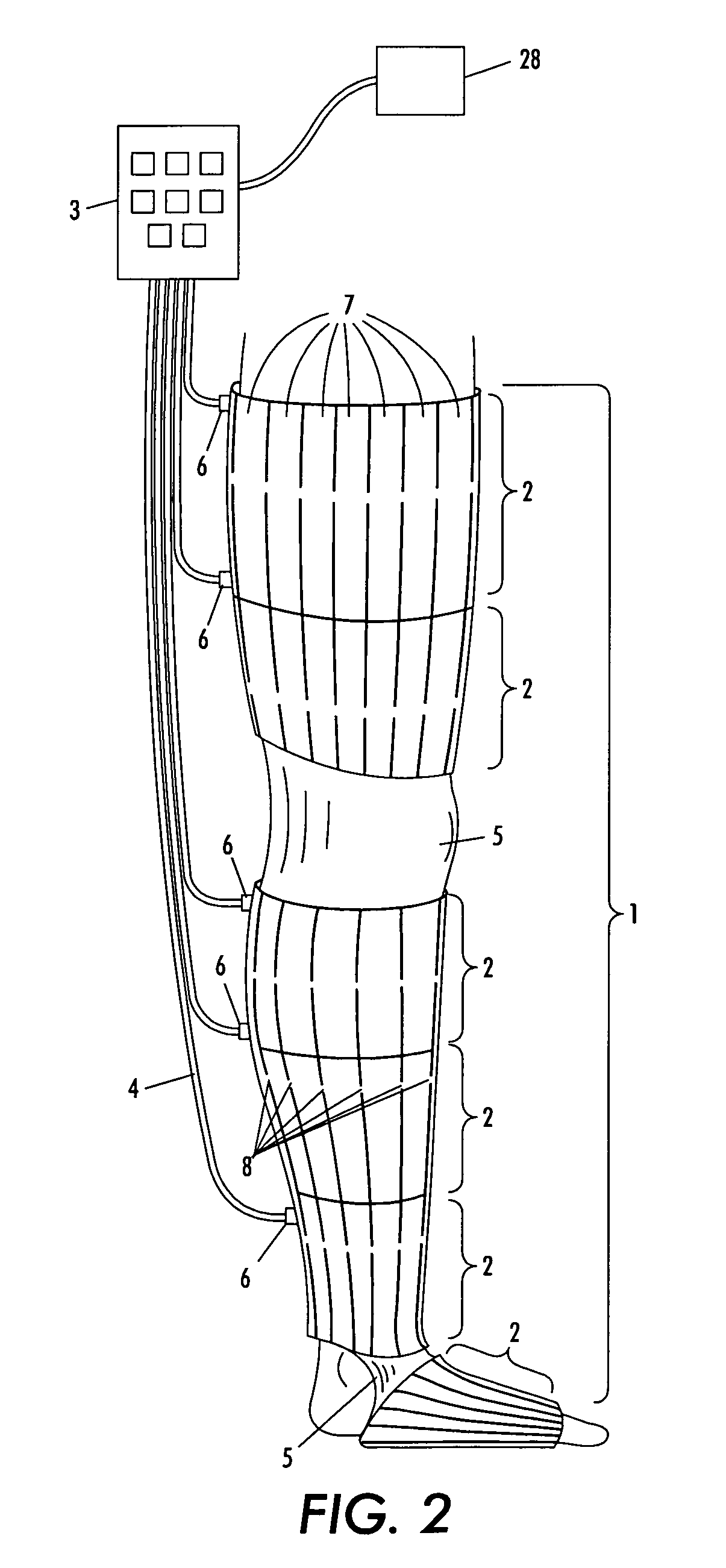

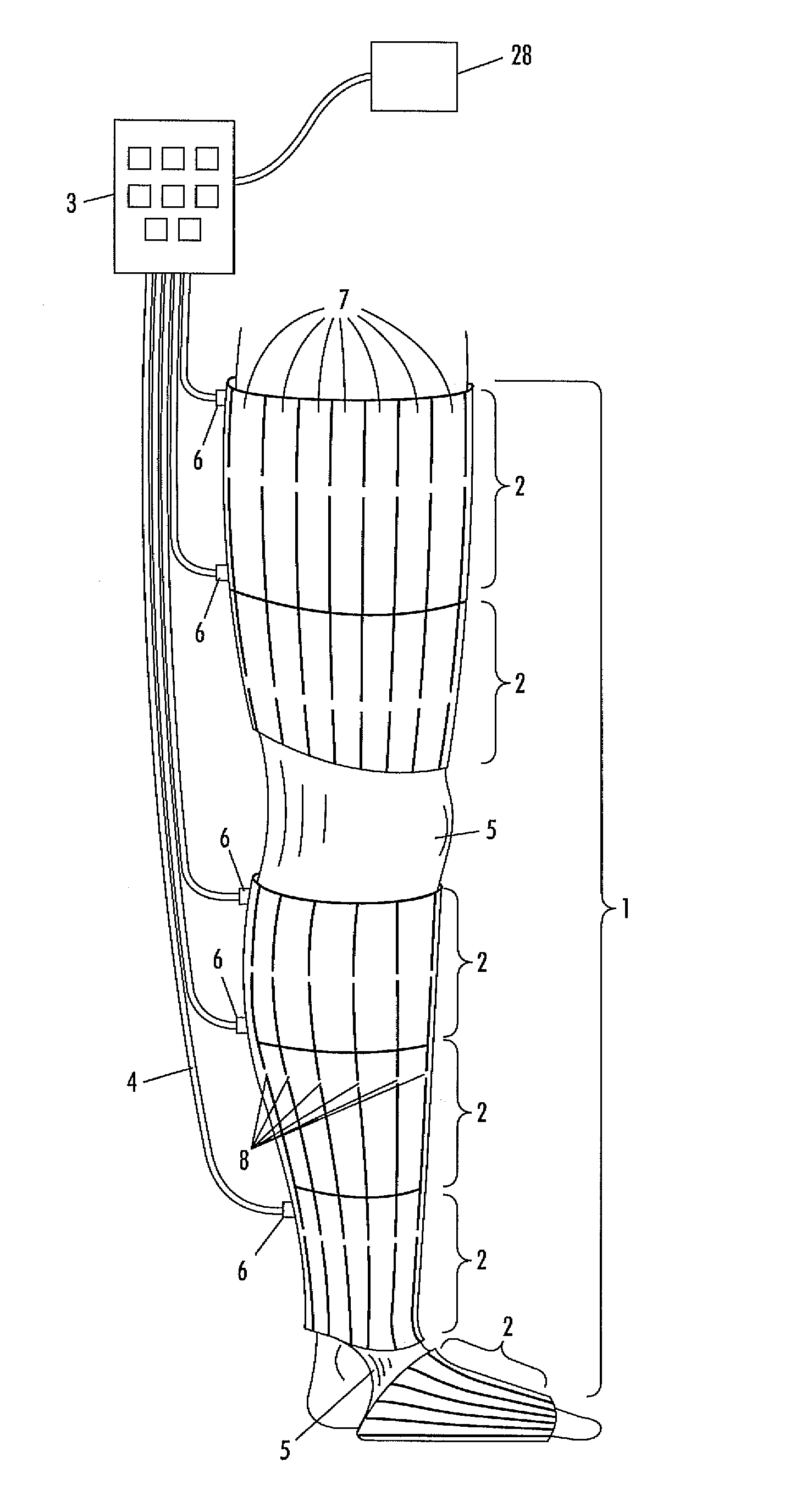

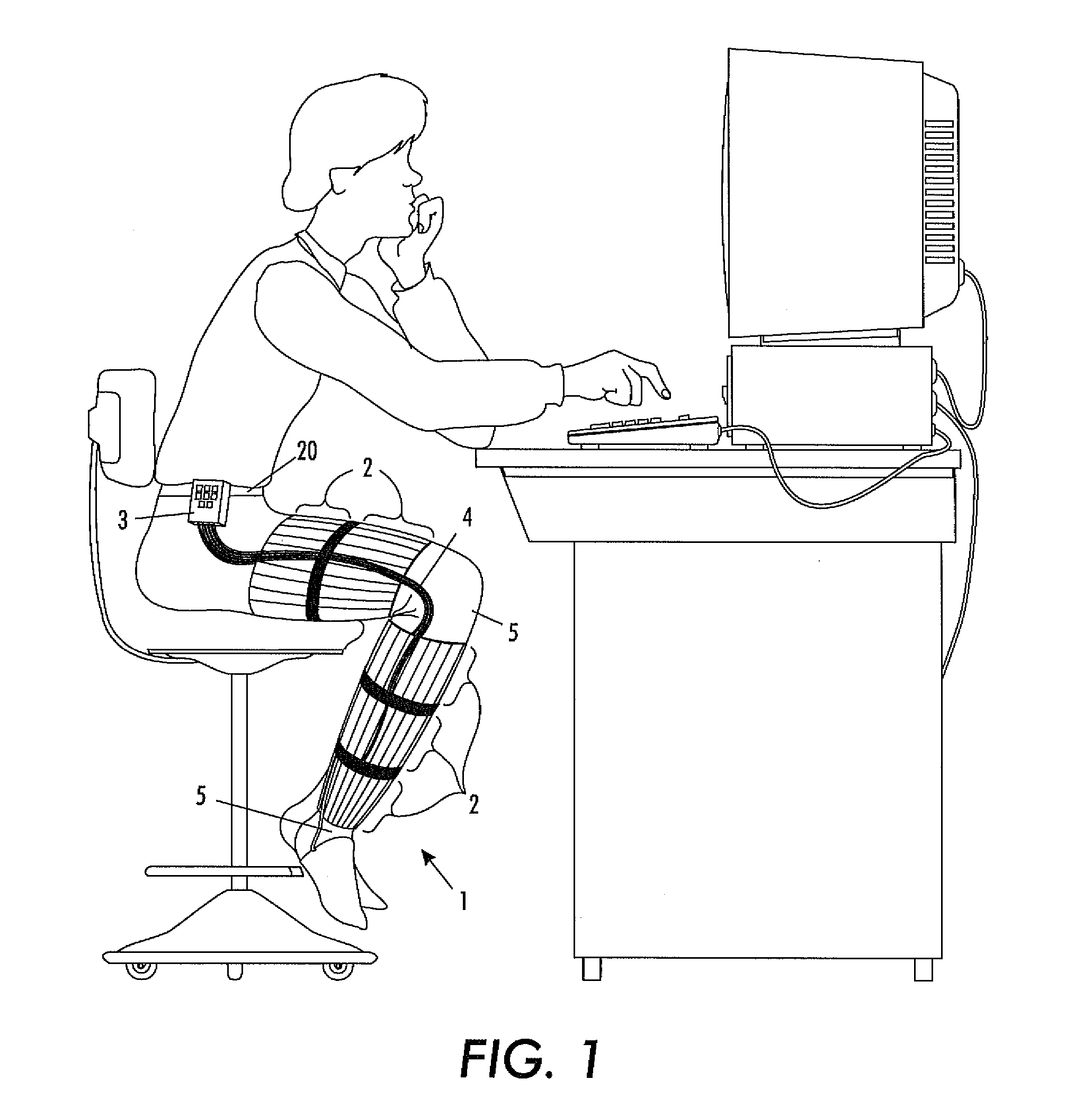

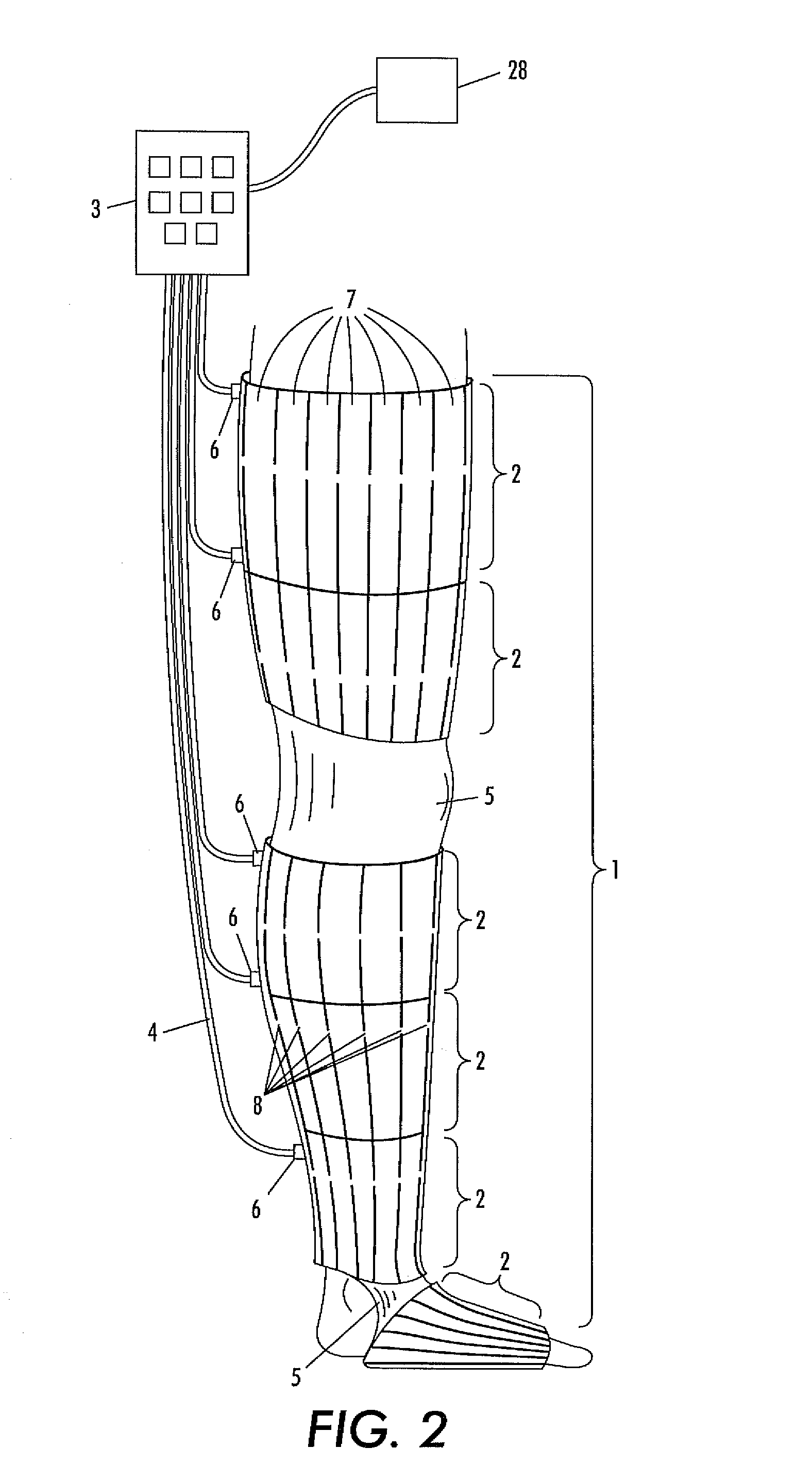

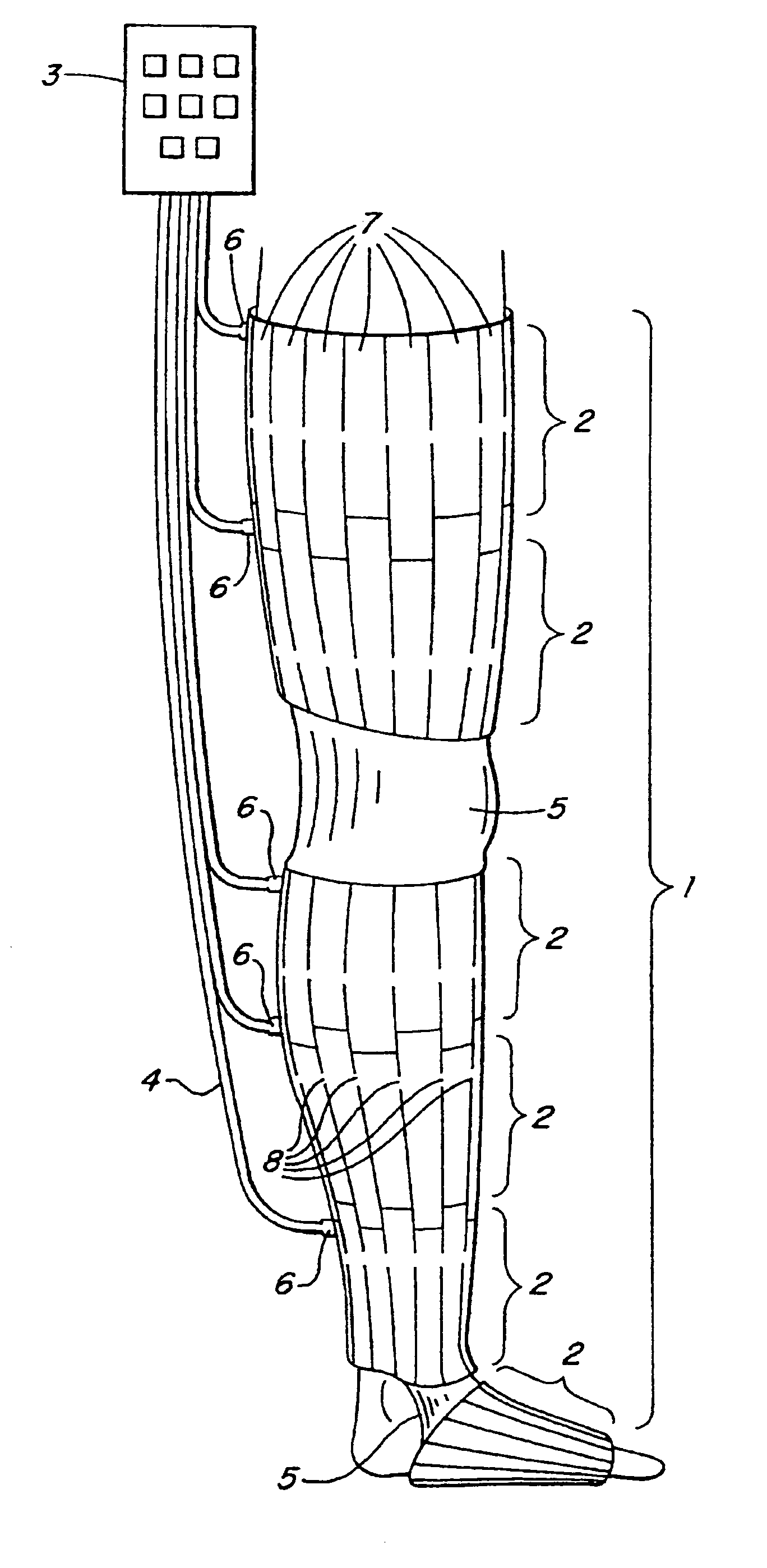

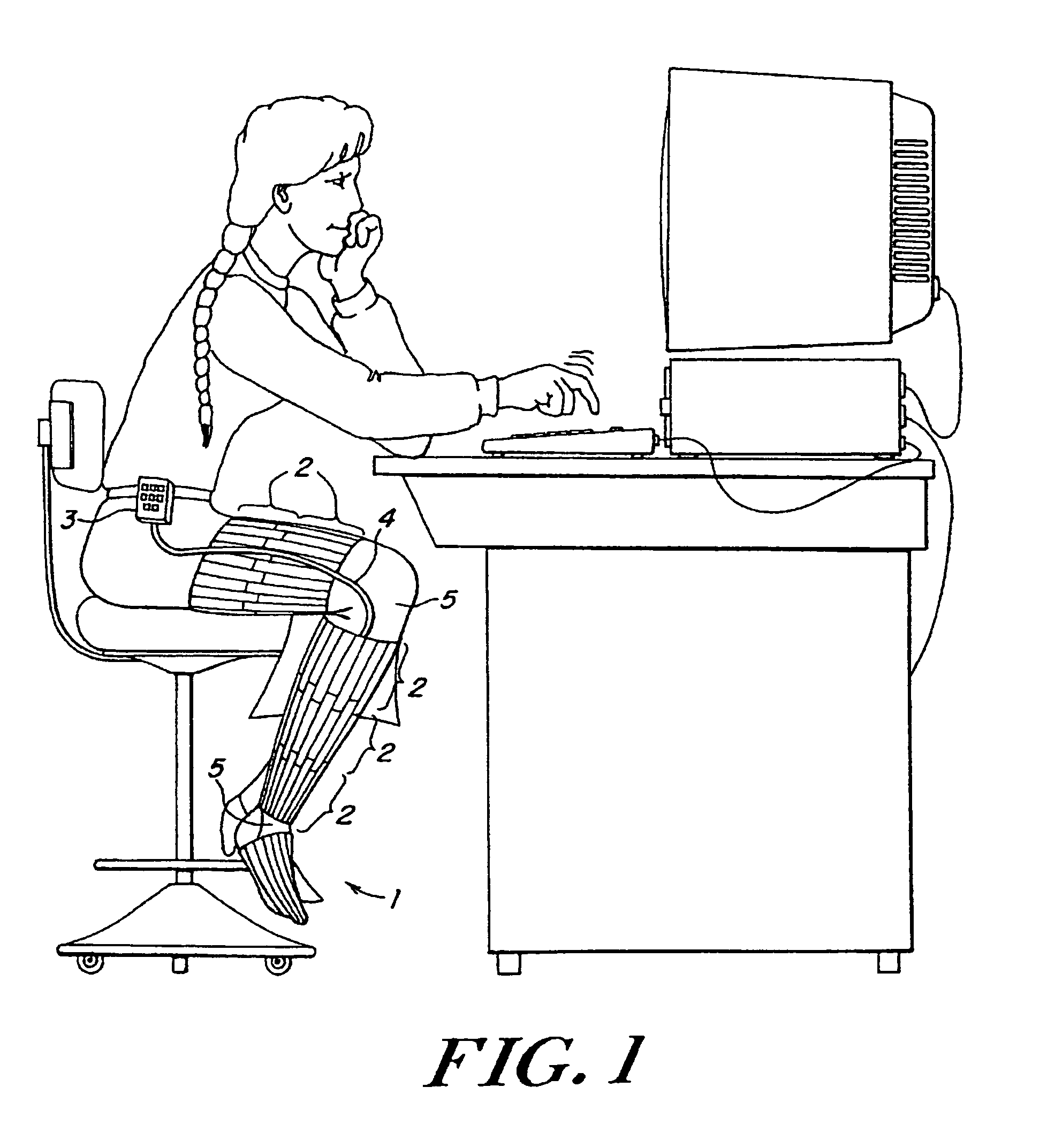

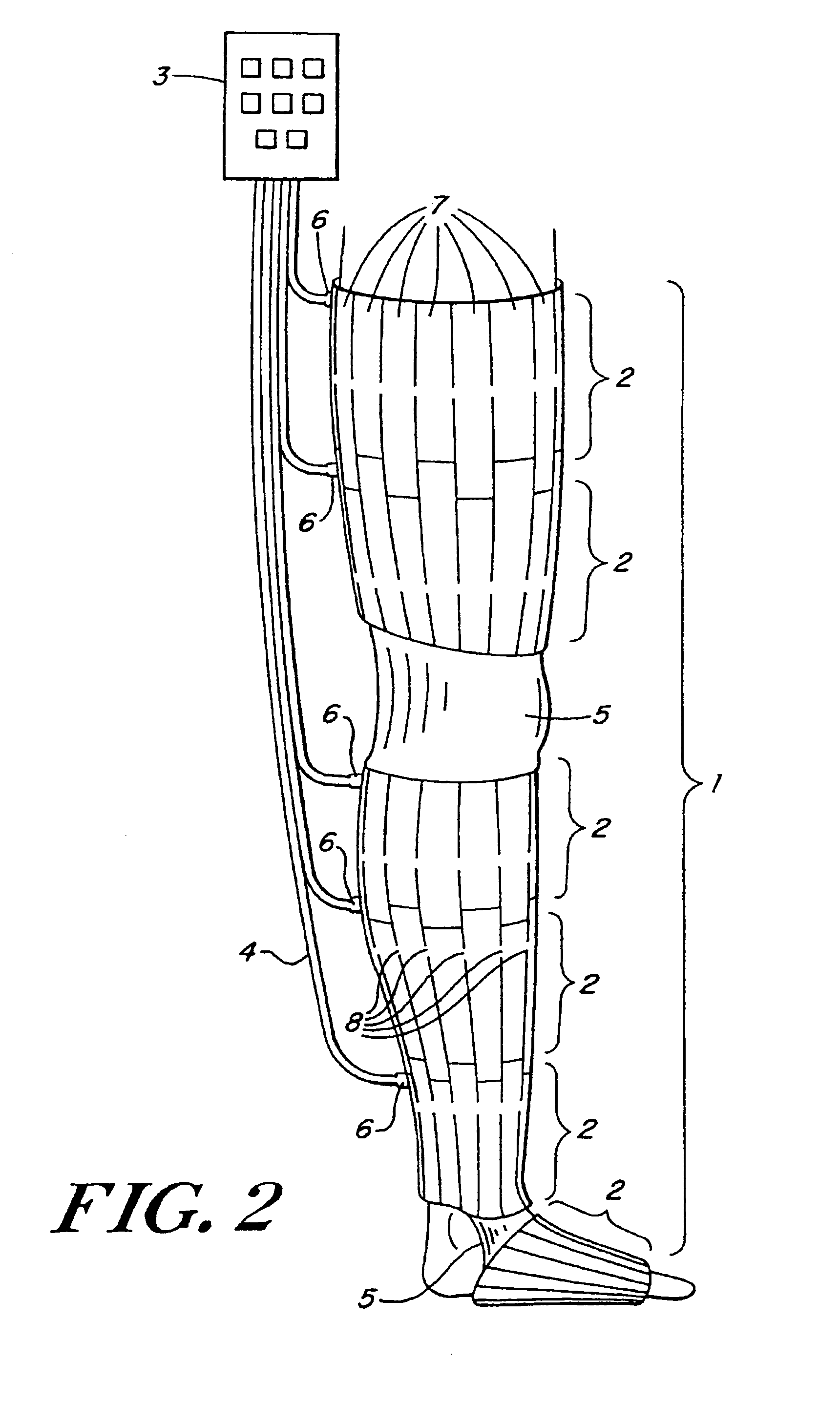

Method and apparatus for assisting vascular flow through external compression synchronized with venous phasic flow

An automatic portable ambulant miniaturized system for applying pneumatic pressure to a body limb including a portable ambulant hand-held fluid source unit, a conduit for delivering fluid generated by the unit, and a pressure sleeve coupled to the conduit and adapted to envelop a body limb. The pressure sleeve contains individually inflatable cells, each cell being subdivided into longitudinally extending confluent intra-cell compartments along the axis of the body limb. The intra-cell compartments are inflated and deflated essentially simultaneously by the portable fluid source unit. To increase the pick venous velocity generated by any kind of external compressive force on a limb with any kind of tempo-spatial regime, the venous phasic flow is monitored to determine so that the venous flow generated by the external compressive force can be synchronized with the in-phasic natural venous flow.

Owner:ZIMMER SURGICAL

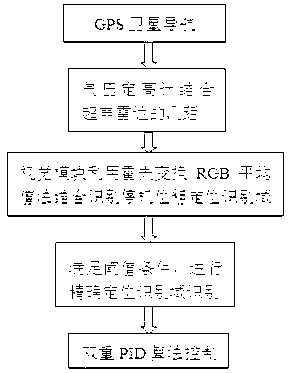

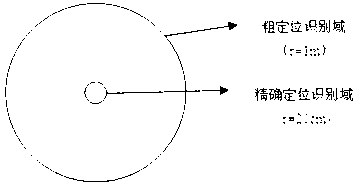

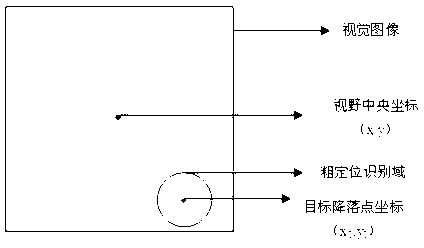

Image-processing-based unmanned plane accurate position landing method

InactiveCN103226356AHigh degree of intelligent controlAddressed bugs with missed landingsPosition/course control in three dimensionsVisual perceptionAND gate

The invention discloses an image-processing-based unmanned plane accurate position landing method, which comprises the following steps: (1) a GPS (global position system) satellite navigation system enables an unmanned plane to be located above a ground parking apron; (2) an air pressure height measurement gauge and a distance measurement module of an ultrasound radar are combined to control the ground clearance for the unmanned plane to land; (3) a vision module identifies a coarse positioning identification domain in real time, and combines Hough Transform and RGB mean value method and gate position identification to process a coordinate of a targeted landing point; (4) when landing of the unmanned plane meets the threshold condition of the coarse positioning identification domain, the algorithm in the step (3) is utilized to perform accurate positioning treatment on the accurate positioning identification domain; and (5) the unmanned plane is controlled for accurate landing by taking the treated deviation value as the input quantity and adopting the double PID algorithm. According to the invention, the defect that insufficient GPS accuracy of the unmanned plane causes a fault landing is overcome, the intelligence for the unmanned plane control is improved, and the cost for using an accurate sensor is greatly reduced.

Owner:GUANGDONG UNIV OF TECH

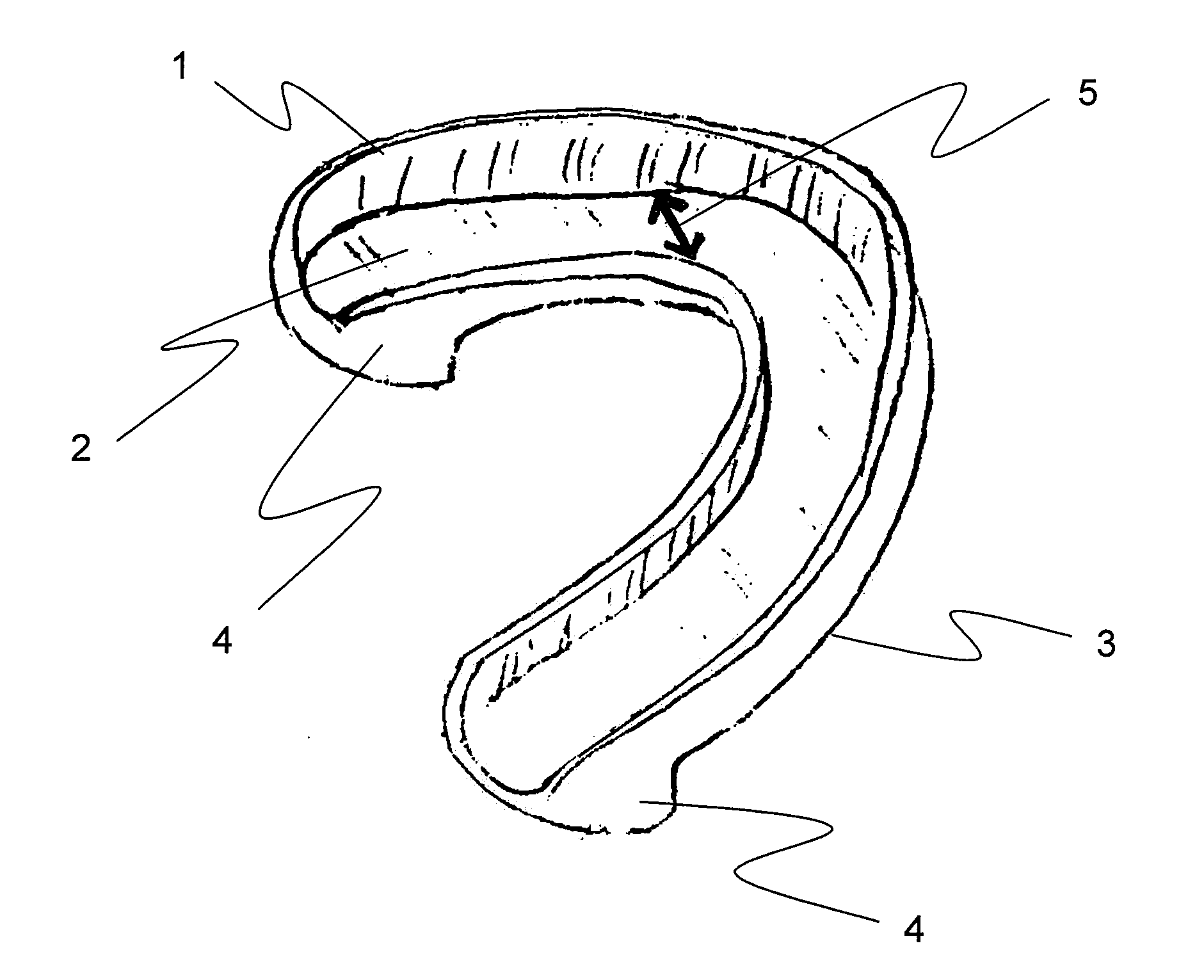

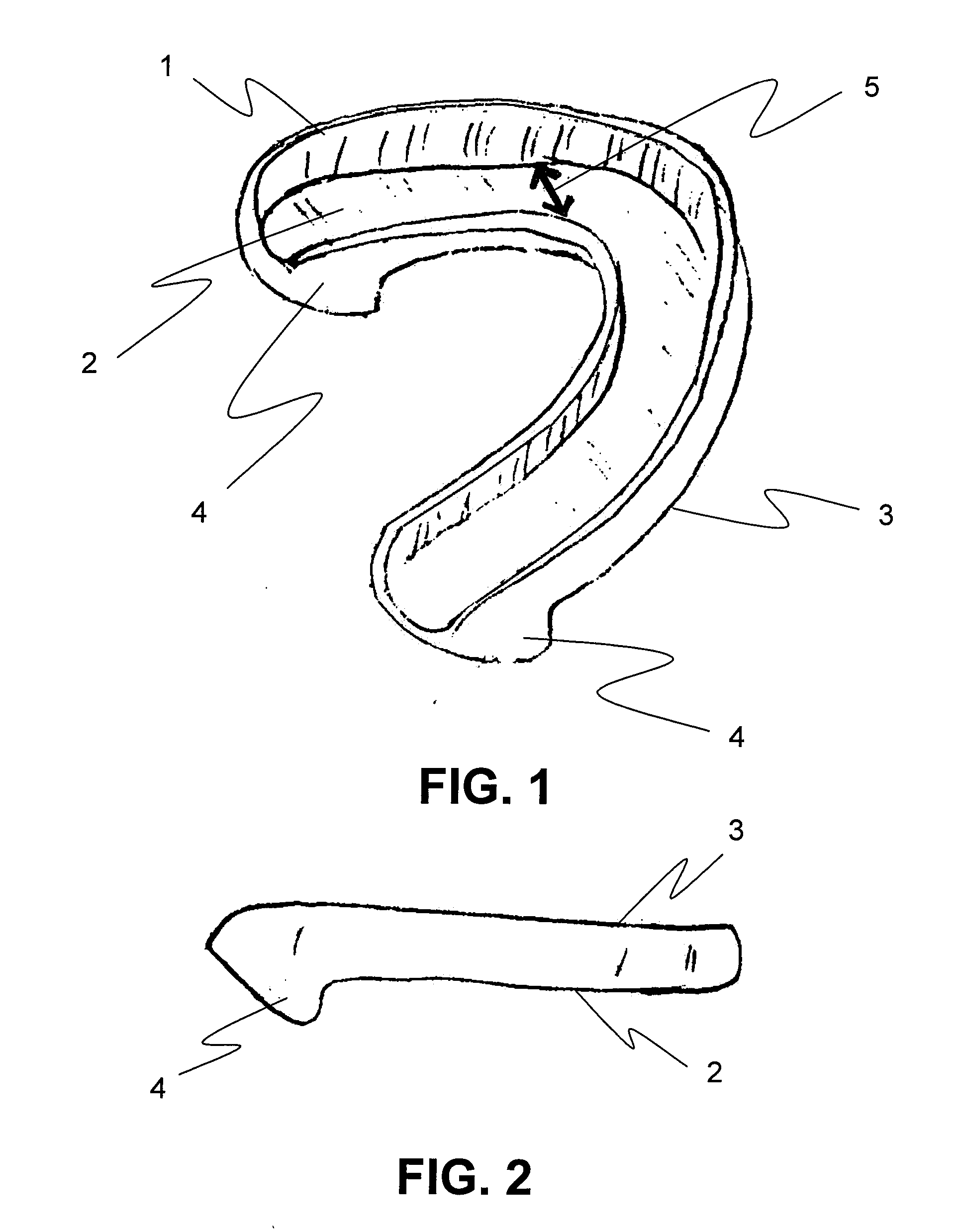

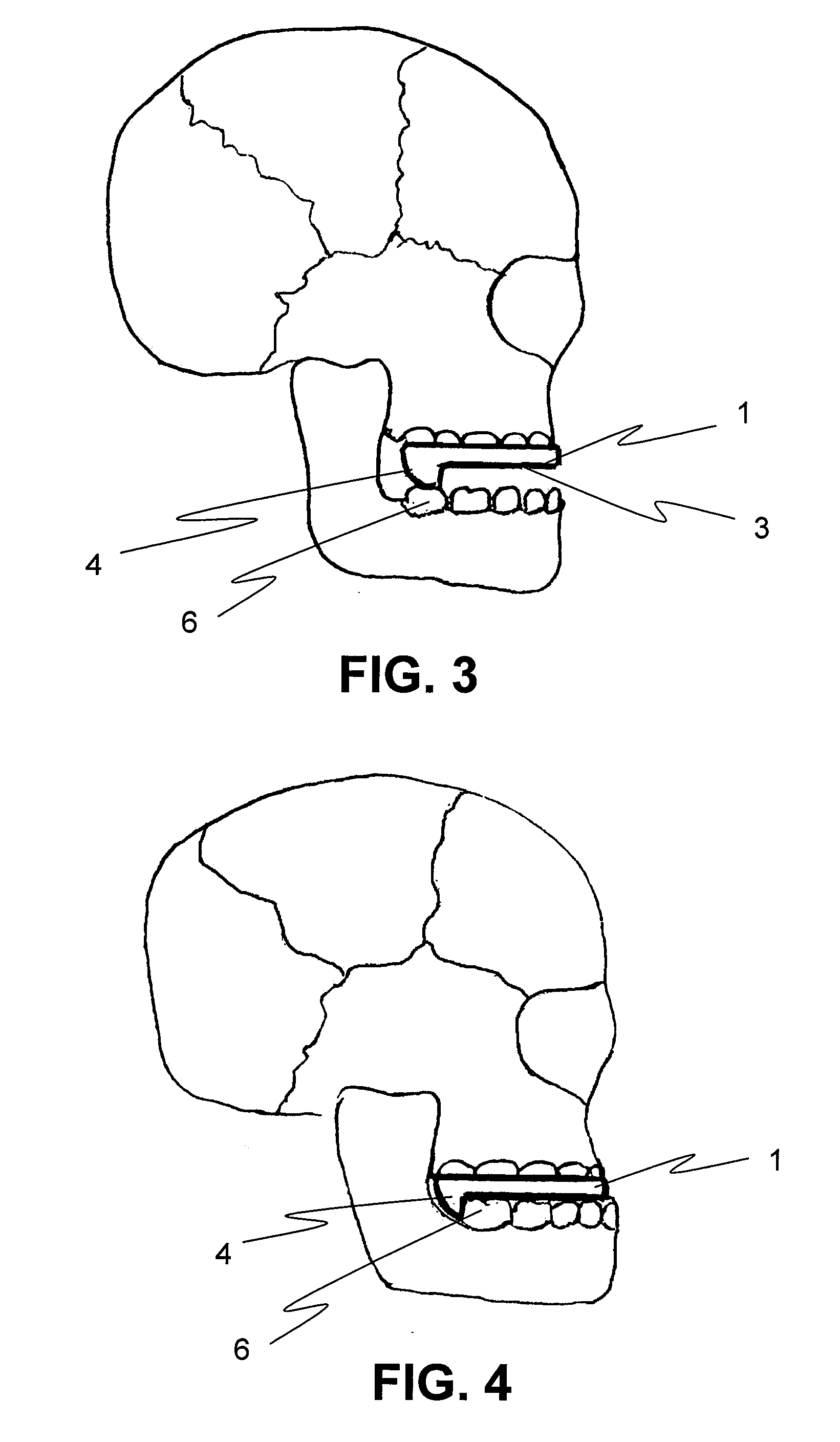

Mandibular Advancement Mouthpiece, An Intraoccusal Removable Improved Device For Eliminating Or Reducing Snoring

When there is an obstruction to the passage of air through the back of the mouth and nose, the soft palate and the bell collide, producing a vibration called snoring. There are various ways of reducing or eliminating snoring, nasal masks introducing air pressure to the throat (CPAP), surgery of the throat (OPPBA) and devices that are introduced into the mouth to cause a mandibular advancement what increases the oropharyngeal area, improving ventilation, among other solutions. The present invention disclosure an intraocclusal removable device in the form of a “U” that is placed covering all of the upper jaw teeth, wherein two steps, one in each extreme of the lower part of the element, which impede the mandible be closed completely on its normal occlusion, forcing it to produce a forward displacement of the lower jaw.

Owner:HEINE ANDRES

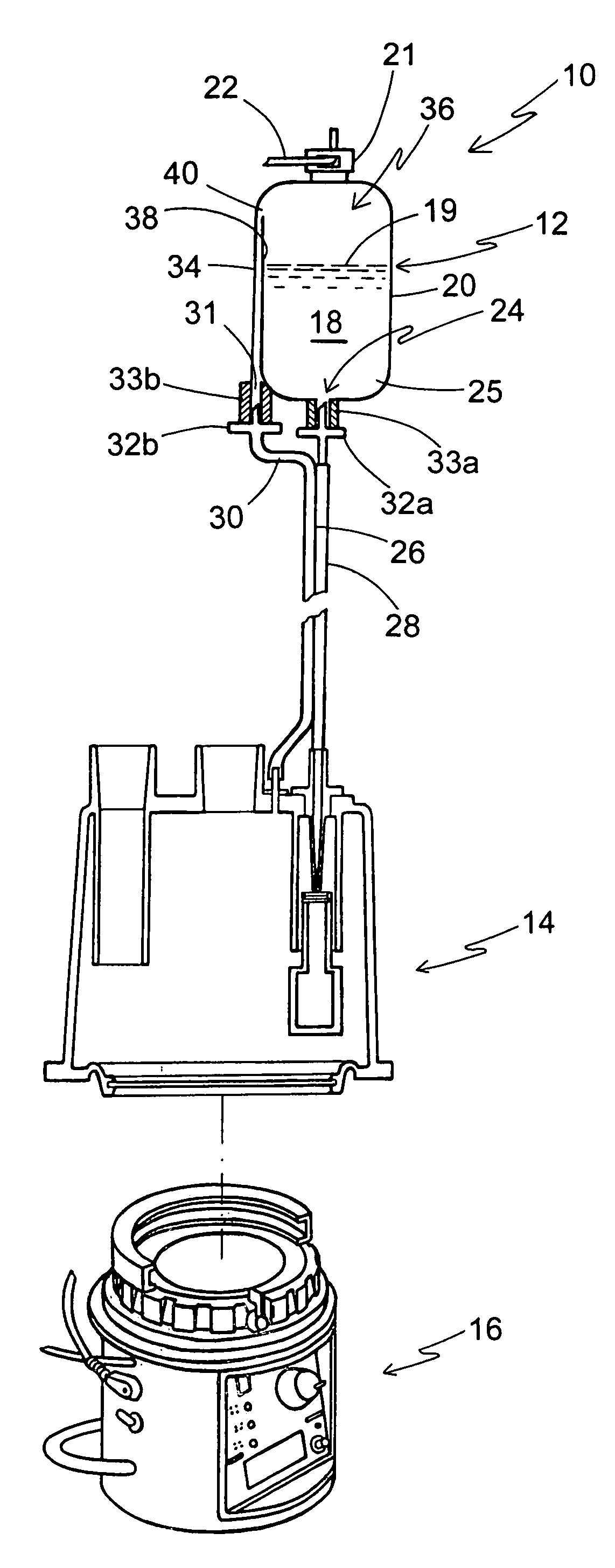

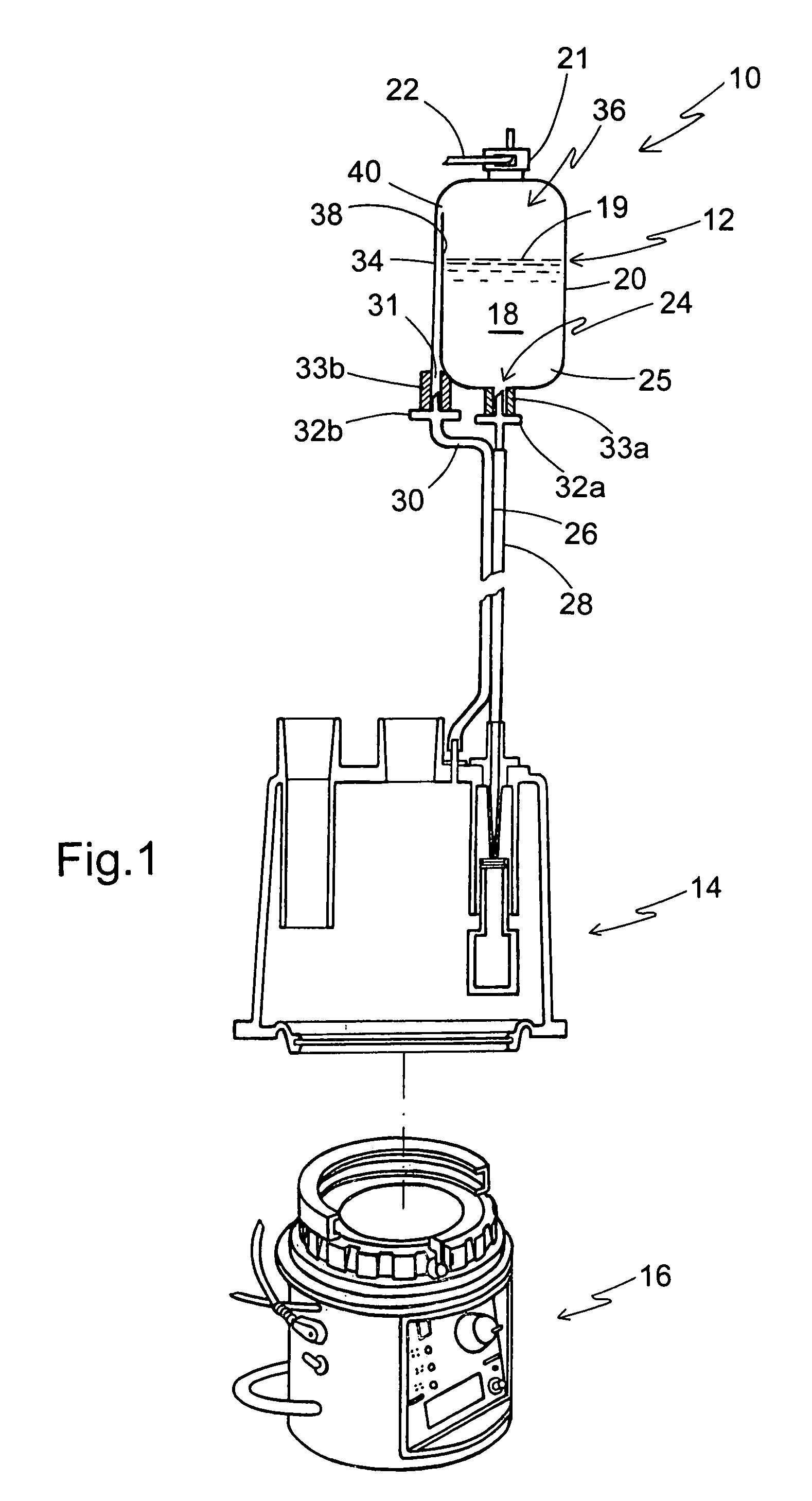

Apparatus for equalizing air pressure in air respiratory system

InactiveUS6988497B2Accelerate liquid flowBurnersOther heat production devicesHigh concentrationBreathing gas

A humidifier apparatus for operating at an air pressure is disclosed for use with a respiratory therapy breathing apparatus that provides a breathable gas supply to patients requiring higher concentrations of liquid vapor and gas pressure. The humidifier apparatus includes a feed liquid supply bag in fluid communication with a humidifier cartridge via a conduit. The conduit enables air to flow therethrough to equalize air pressure between the humidifier cartridge and the feed liquid supply bag in response to liquid being supplied to the humidifier cartridge.

Owner:MEZZANINE OPPORTUNITIES LLC AS AGENT

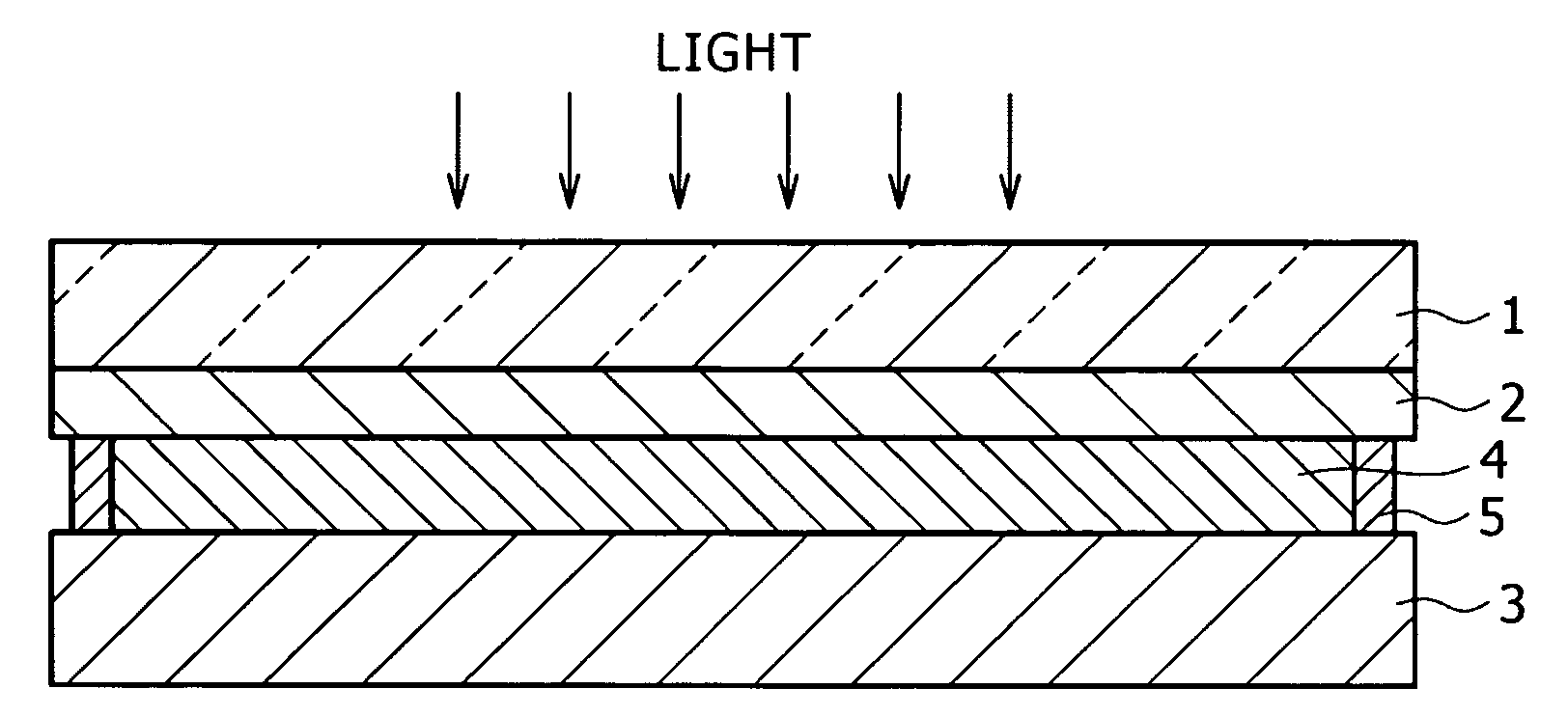

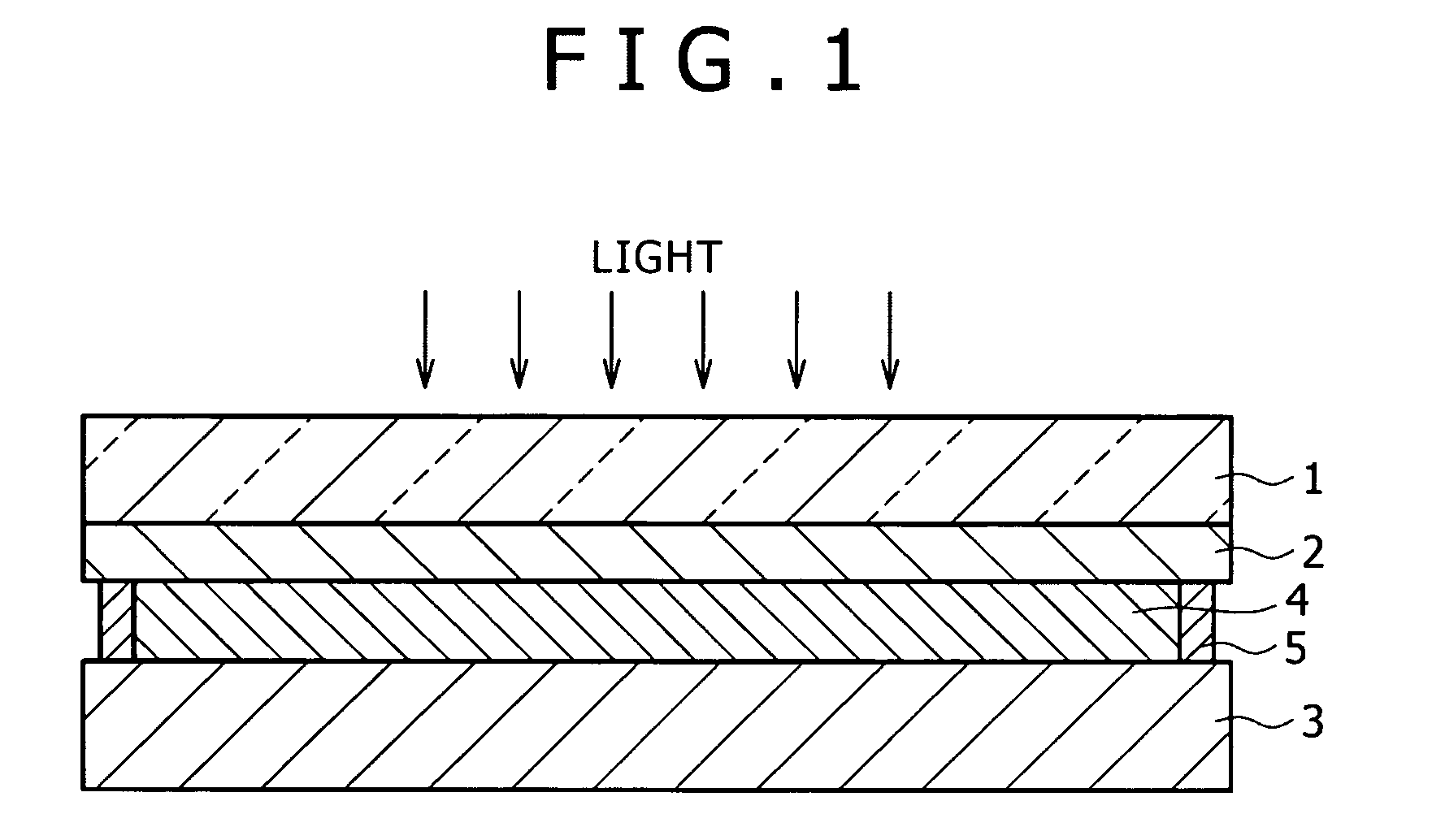

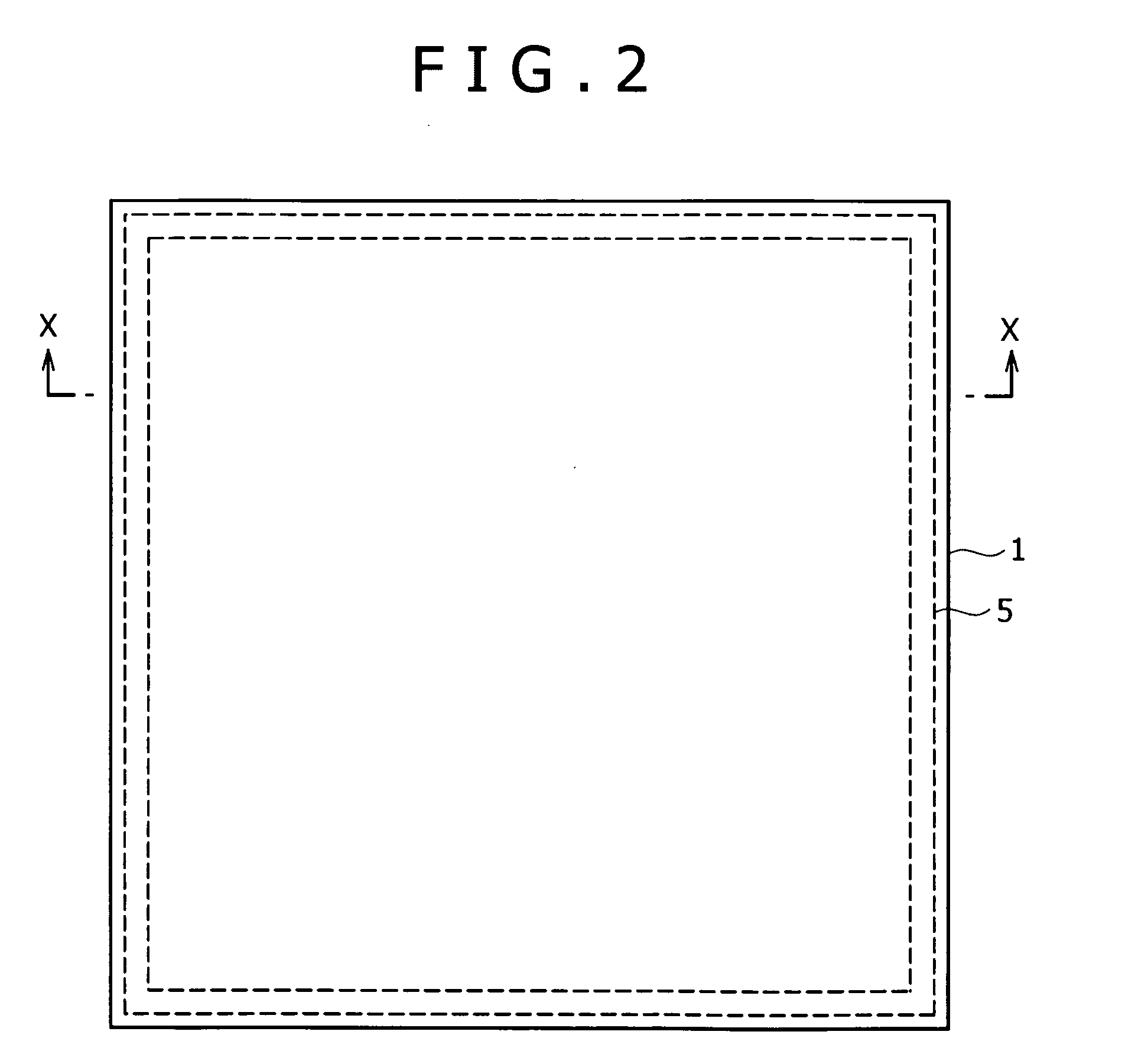

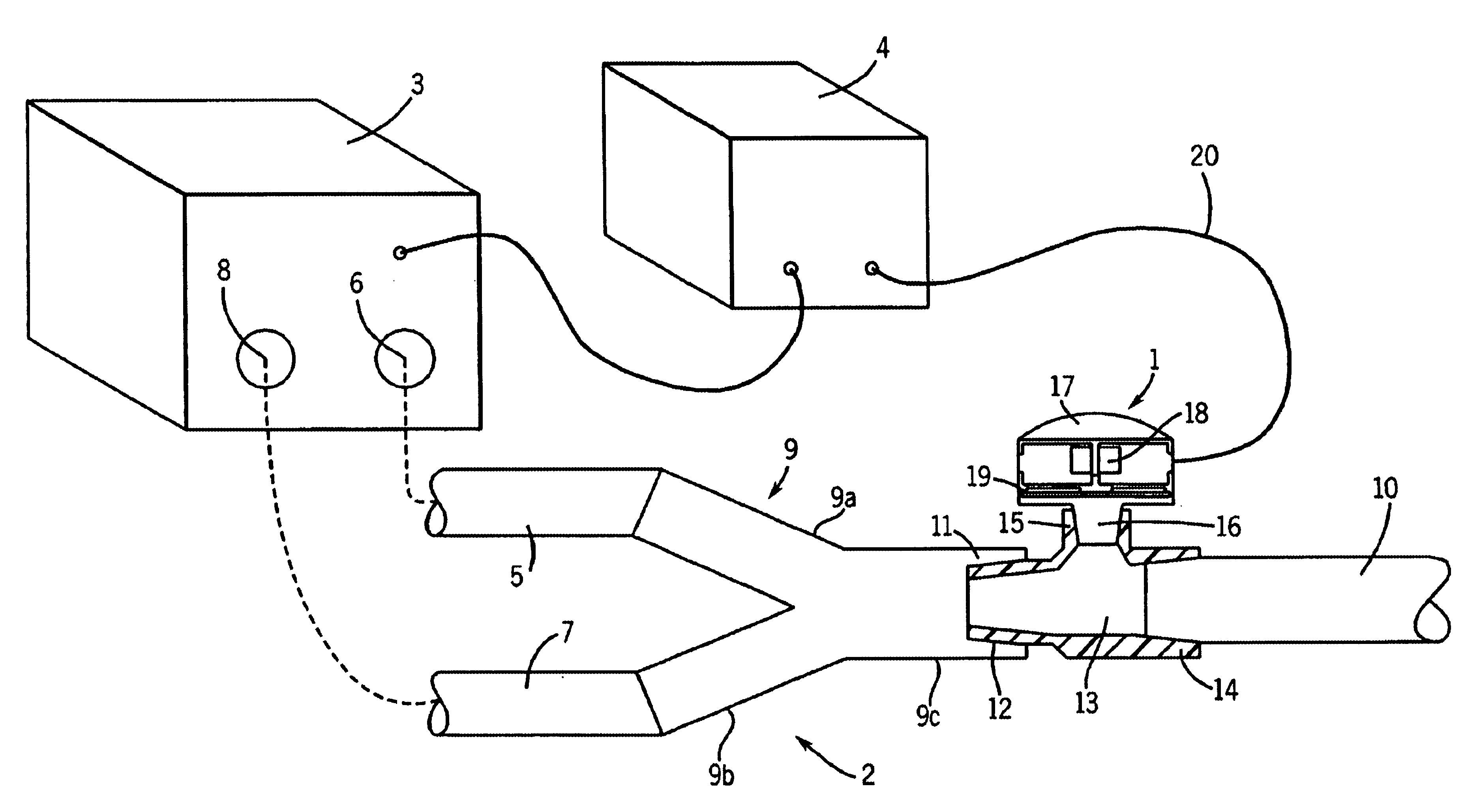

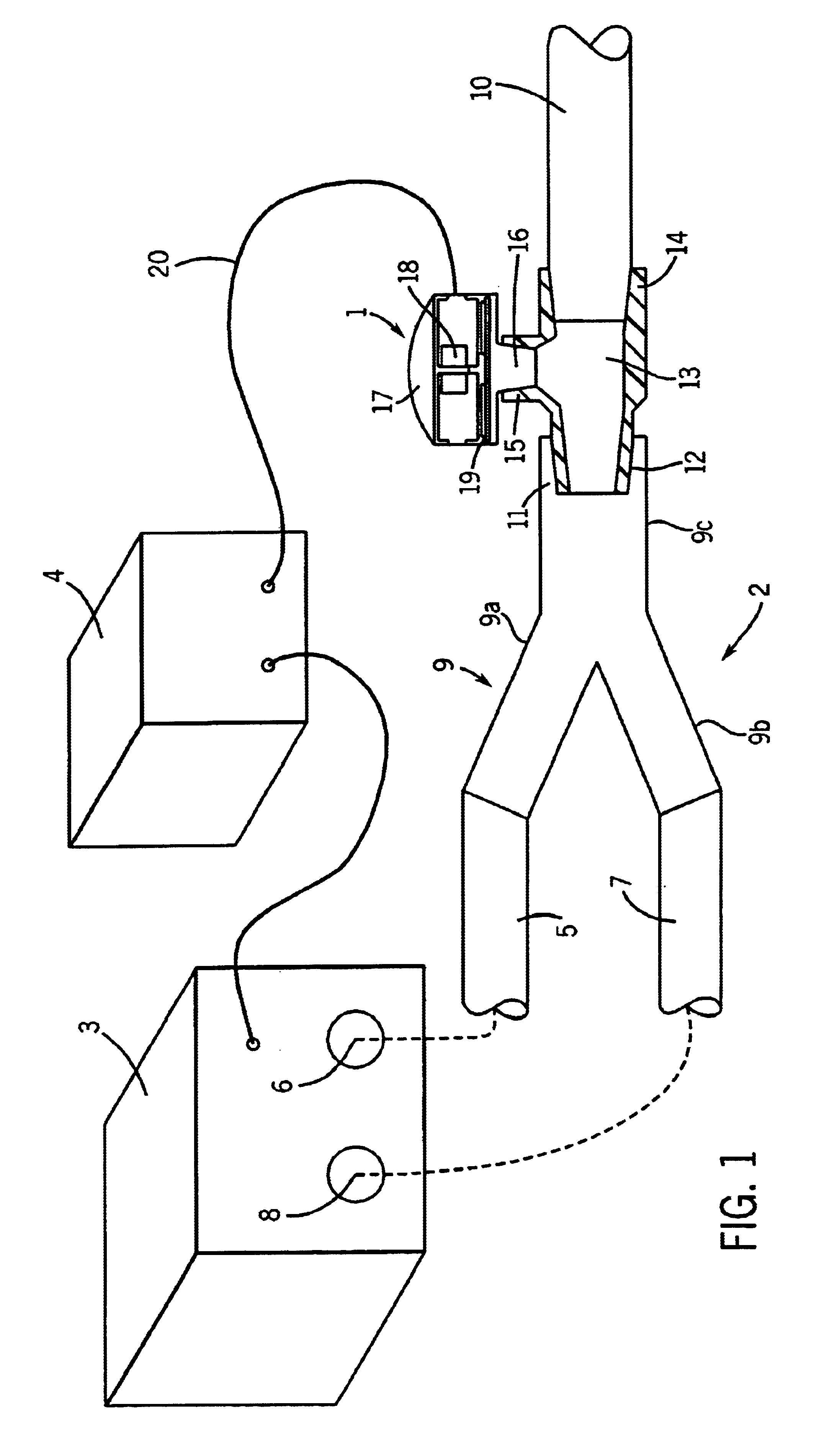

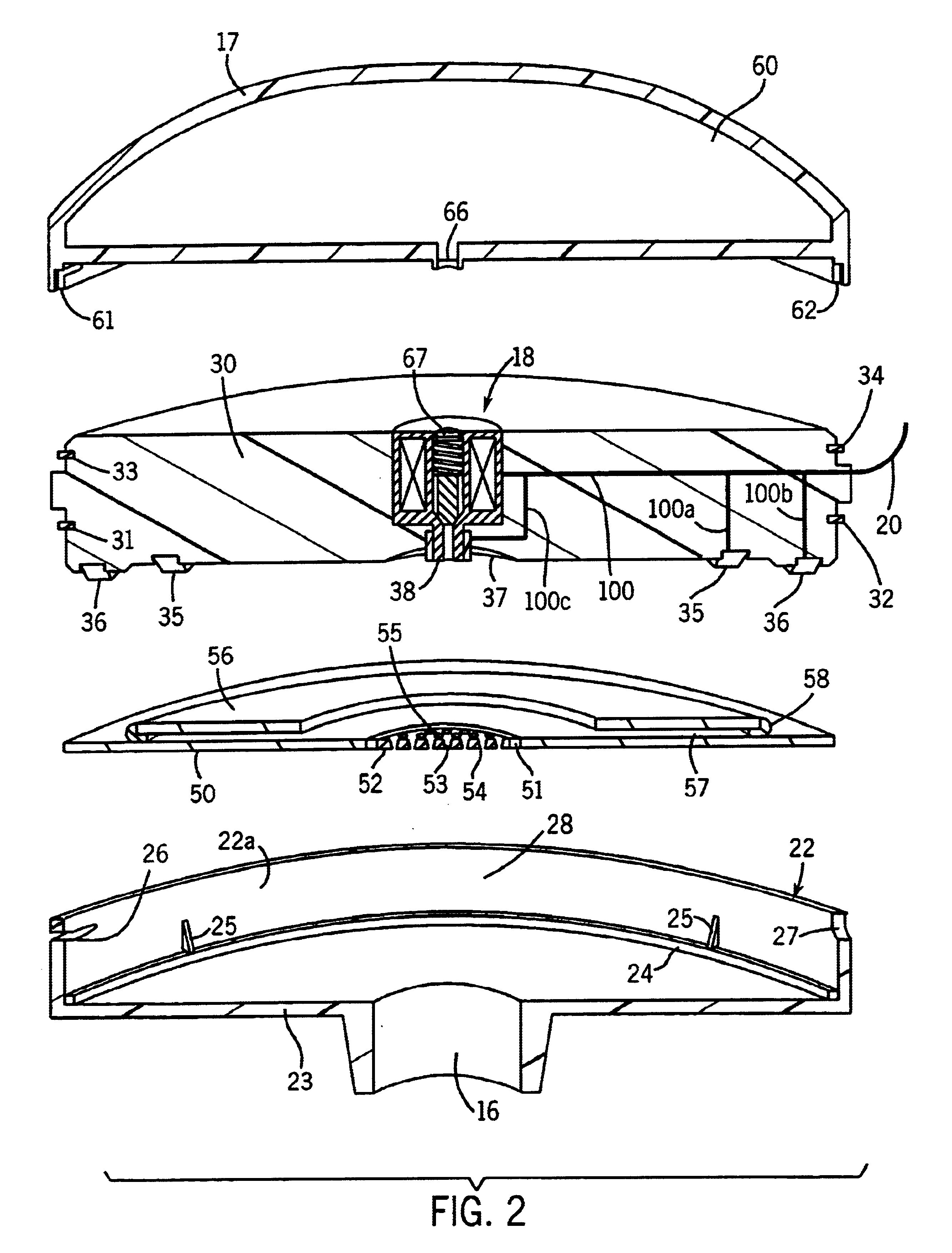

Dye-sensitized photoelectric conversion device and method of manufacturing the same

InactiveUS20100101648A1Reduced durabilityReduced strengthElectrolytic capacitorsFinal product manufactureAtmospheric airPhotoelectric conversion

A method of manufacturing a dye-sensitized photoelectric conversion device is provided by which a dye-sensitized photoelectric conversion device being excellent in strength and durability and free of any projection, as a result of the absence of need for an end seal, can be fabricated through simple manufacturing steps. In manufacturing a dye-sensitized photoelectric conversion device which has an electrolyte between a dye-sensitized semiconductor layer and a counter electrode and which also has a first armor member provided on the outside of the dye-sensitized semiconductor layer and a second armor member provided on the outside of the counter electrode, a sealing material and the electrolyte are formed at predetermined locations of one or both of the first armor member and the second armor member, thereafter the first armor member and the second armor member, with the sealing material and the electrolyte sandwiched therebetween, are adhered to each other with the sealing material under a gas pressure of not higher than the atmospheric air pressure and not lower than the vapor pressure of the electrolyte.

Owner:SONY CORP

Negative pressure dressing and method of using same

ActiveUS8945030B2Reduce spacingIncrease volumeMedical devicesAdhesive dressingsElectricityEngineering

Apparatuses and methods for treating a wound by applying reduced or negative pressure to the wound can include a wound cover, a fluid collection container, a vacuum pump, an inflation pump, and one or more conduits. The wound cover can be configured to move between at least a relatively rigid, generally raised position and a relatively flexible, generally collapsed position according to a predetermined program or in response to input from a user or one of more sensors. In some embodiments, the wound cover can be configured to move between at least the relatively rigid, generally raised position and the relatively flexible, generally collapsed position by adjusting the air pressure in one or more channels in the wound cover or by adjusting or by adjusting the length of piezoelectric or other length changing material supported by the wound cover.

Owner:SMITH & NEPHEW INC

Integrated patient management and control system for medication delivery

An integrated patient monitoring and control system is provided which includes a SITS, the SITS being adapted for coupling to the patient to obtain a specimen from the patient, a sensor, the sensor being adapted to receive the specimen from the SITS and to analyze the sample, a medication control unit, the medication control unit receiving information from the sensor, and utilizing that information to determine medication dosing information for the patient, and a medication administration system, the medication administration system receiving the dosing information from the medication control unit, and adapted to cause administration of the medication to the patient. If the SITS is adapted for blood draw, the system advantageously is performed in conjunction with a pneumatic pressure cuff, inflated so as to aid in blood draw.

Owner:AUTOMEDICS MEDICAL SYST

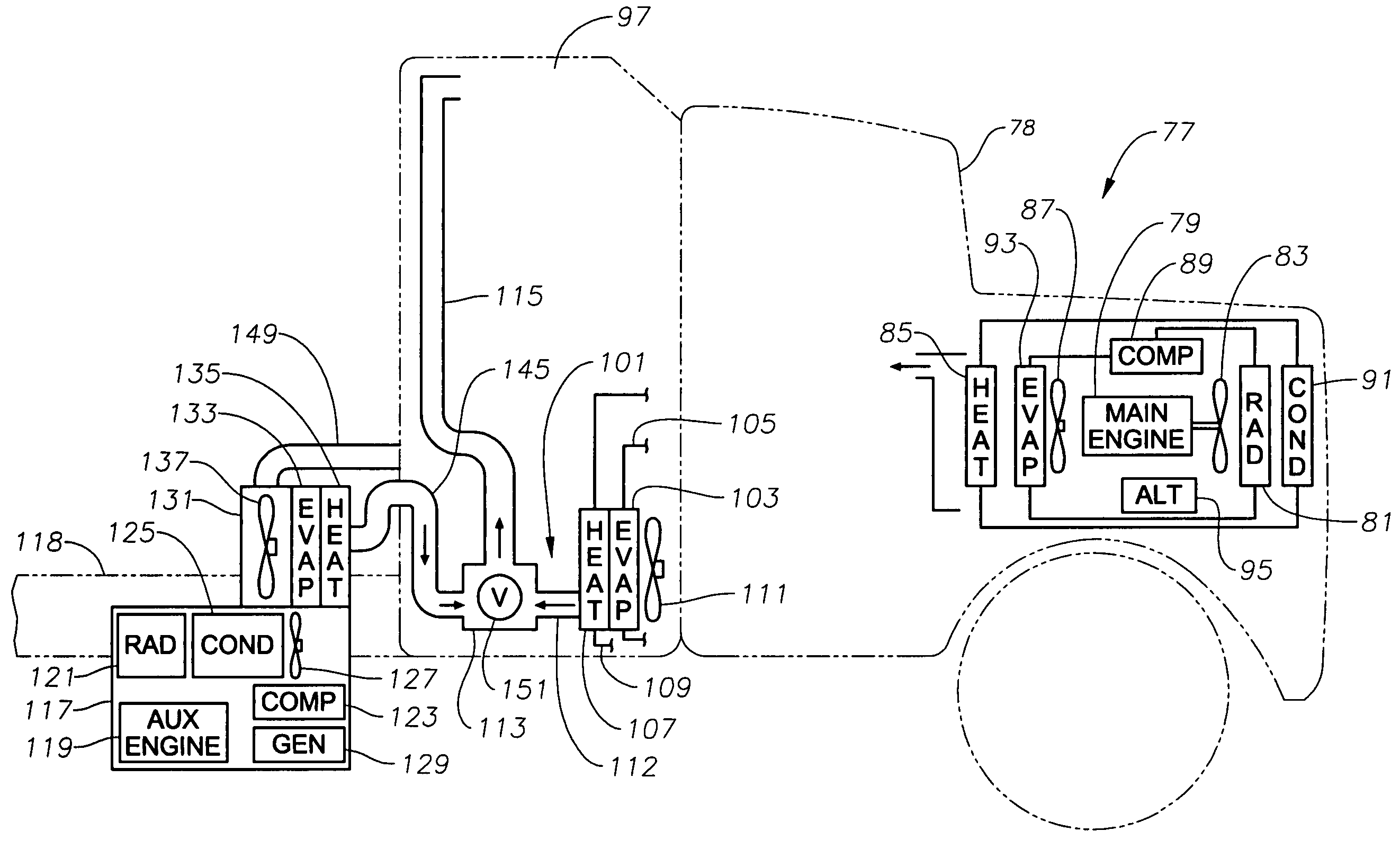

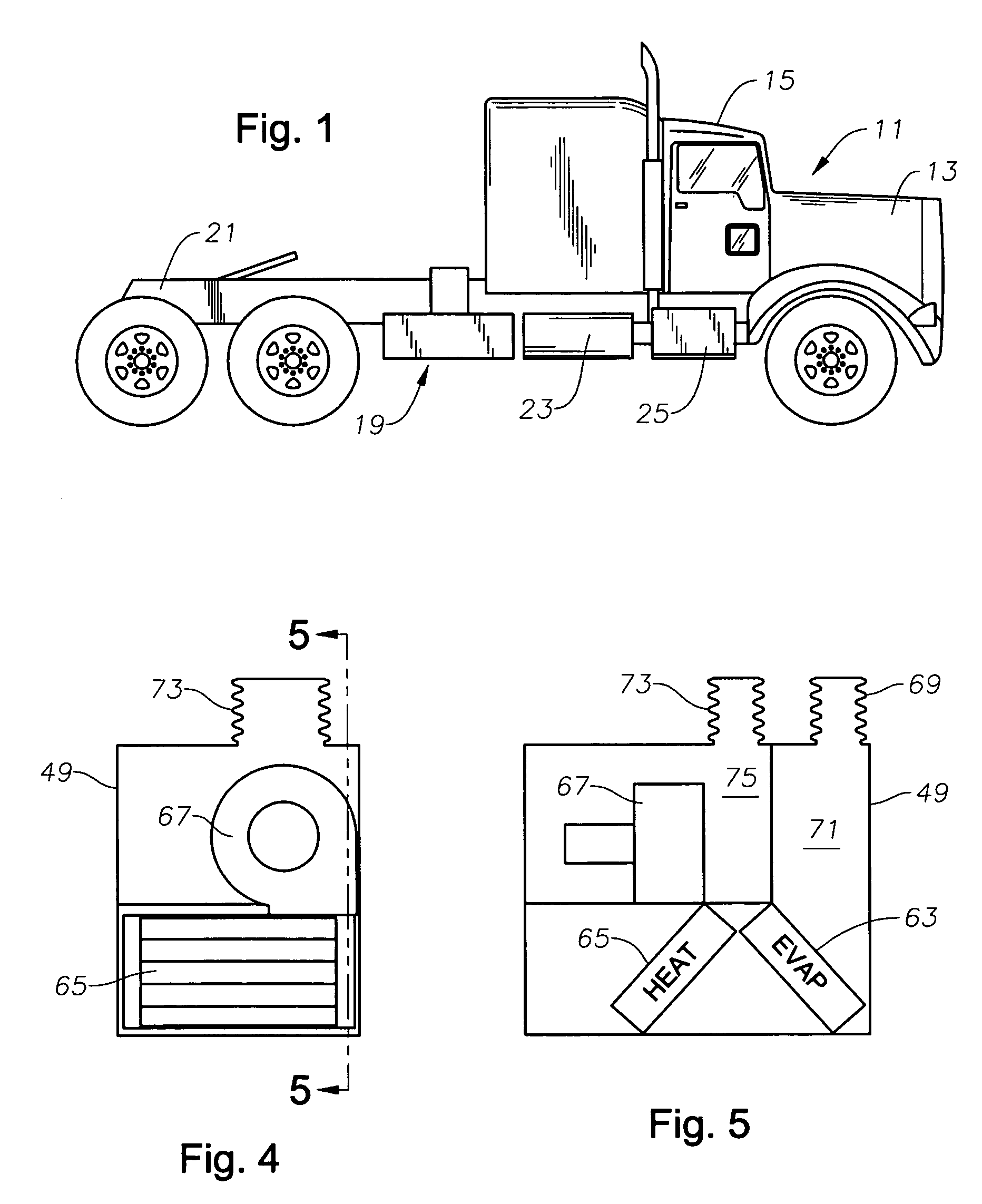

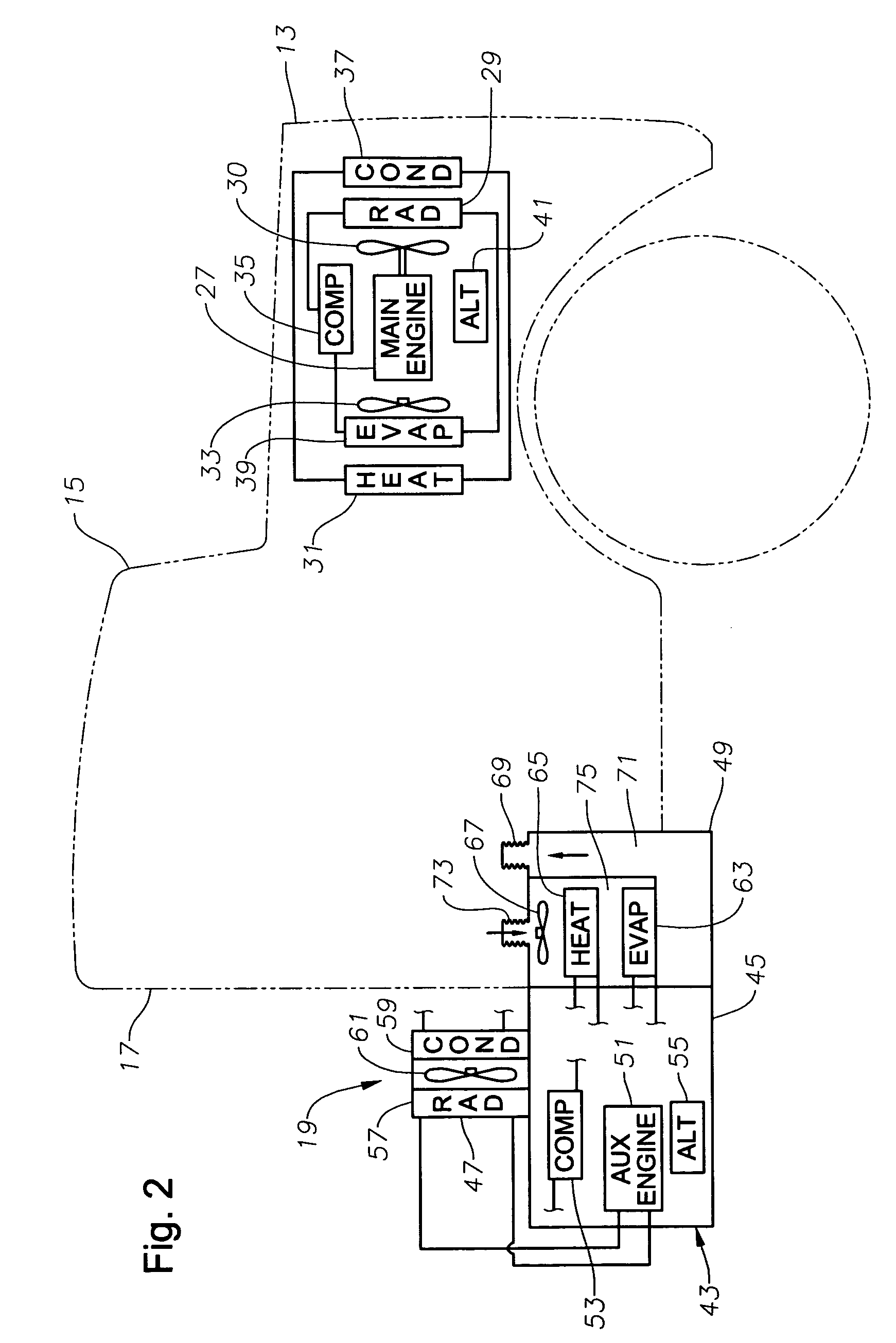

Vehicle heating and cooling system

A heating and air-conditioning system has an auxiliary engine for heating and cooling of a vehicle while the primary engine of the vehicle is not operating. The vehicle has a sleeper compartment with a sleeper compartment air conditioning unit powered by the main engine. An auxiliary air conditioning system located exterior of the sleeper compartment is powered by the auxiliary engine. An auxiliary supply duct extends into the sleeper compartment and joins the duct of the sleeper compartment air conditioning unit. A valve operated by air pressure blocks air flow from the sleeper compartment air conditioning unit into the auxiliary duct while in the main position. In the auxiliary position, the valve blocks air flow from the auxiliary duct into the sleeper compartment air conditioning unit.

Owner:LONGHORN SCSF LTD

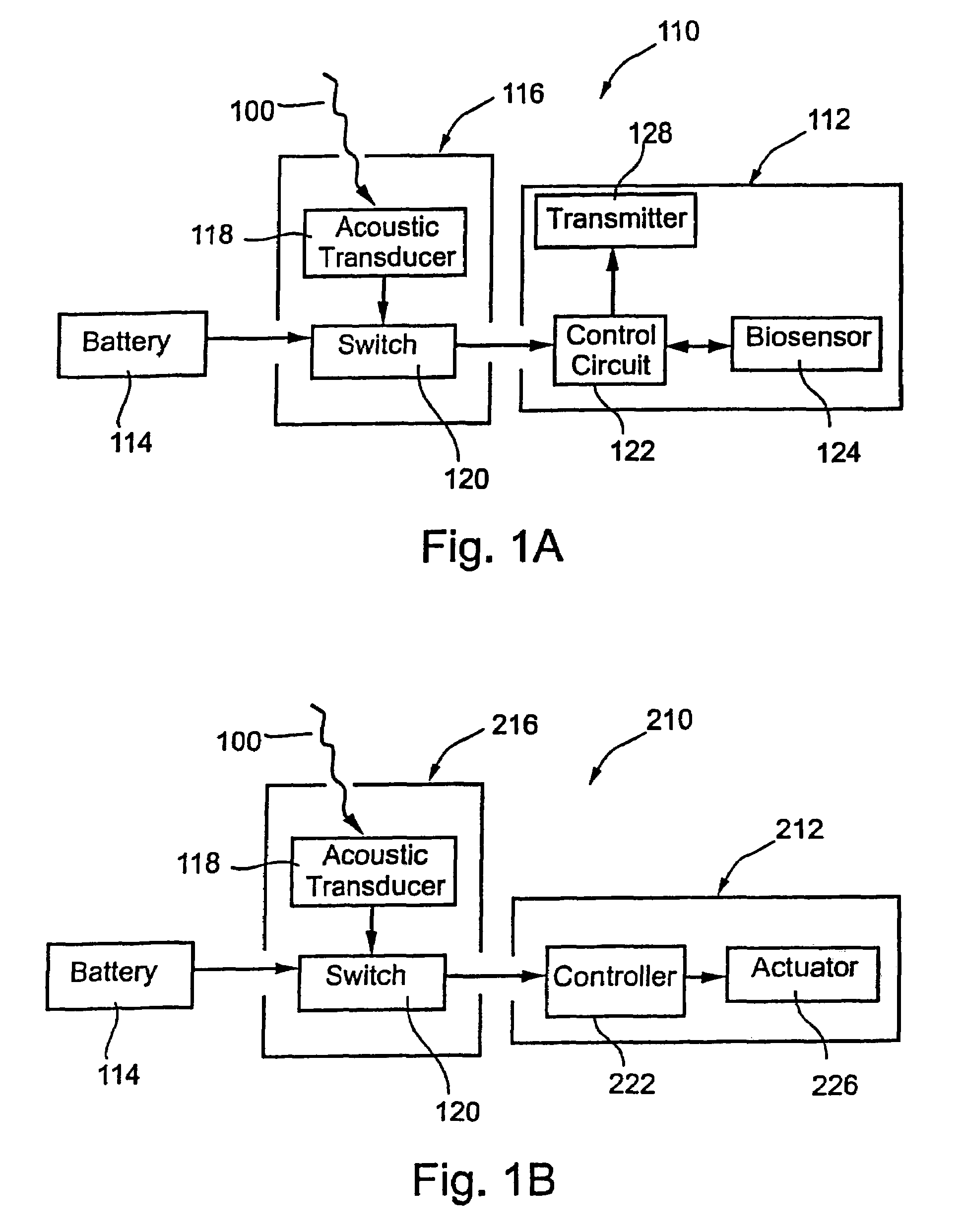

Vibrating element liquid discharging apparatus having gas pressure sensing

InactiveUS6978779B2Avoid the needOutput maximizationRespiratorsOperating means/releasing devices for valvesElectricityPneumatic pressure

A nebulizer determines the pressure and flow direction of the receiving gas for atomized liquid. A member of the apparatus is subjected to pressure exerted by the gas. The member is coupled to a bi-directional mechanical-electrical conversion element, such as a piezoelectric element, to form a pressure transducer. The member exerts a mechanical loading on the element responsive to the gas pressure to which it is subjected. In one embodiment, the element mechanically vibrates responsive to alternating electrical energization to discharge the liquid into the gas. The electrical admittance of the element is alterable by the mechanical loading applied to the element by the member. The difference between admittances measured in the loaded condition of the element and in an unloaded condition at the selected energization frequency is an indication of the pressure of the gas. By observing whether the magnitude of the admittance in the loaded state is greater or less than that in the unloaded state, the flow direction of the gas may also be determined. Or the flow direction may be determined by observing the changes in admittance as the frequency of the electrical energization is varied. In another embodiment, the piezoelectric element is not energized. The electrical output of the element, when subjected to a mechanical loading from the gas pressure, is used to detect gas pressures and / or as an indication of the gas pressure.

Owner:INSTRUMENTARIUM CORP

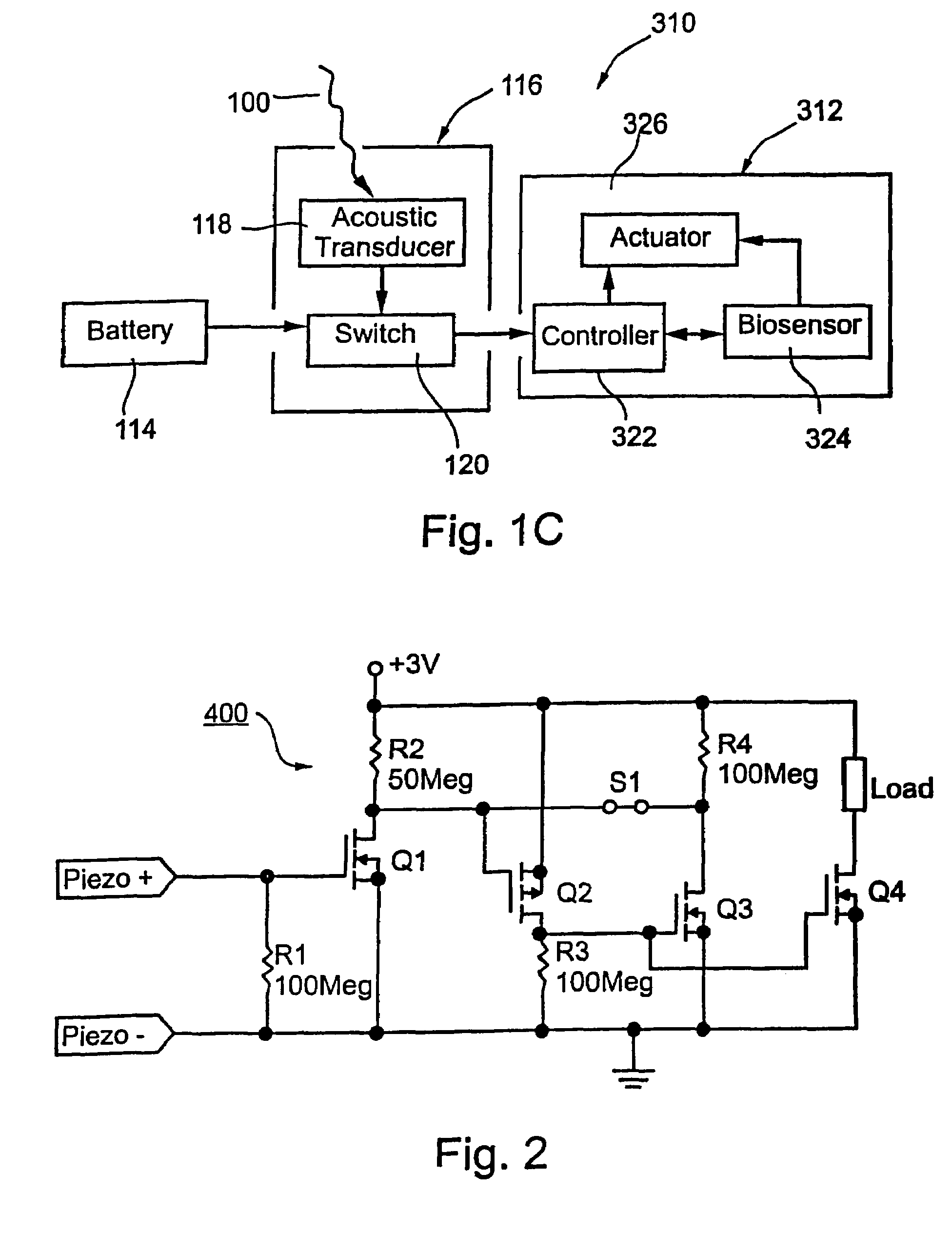

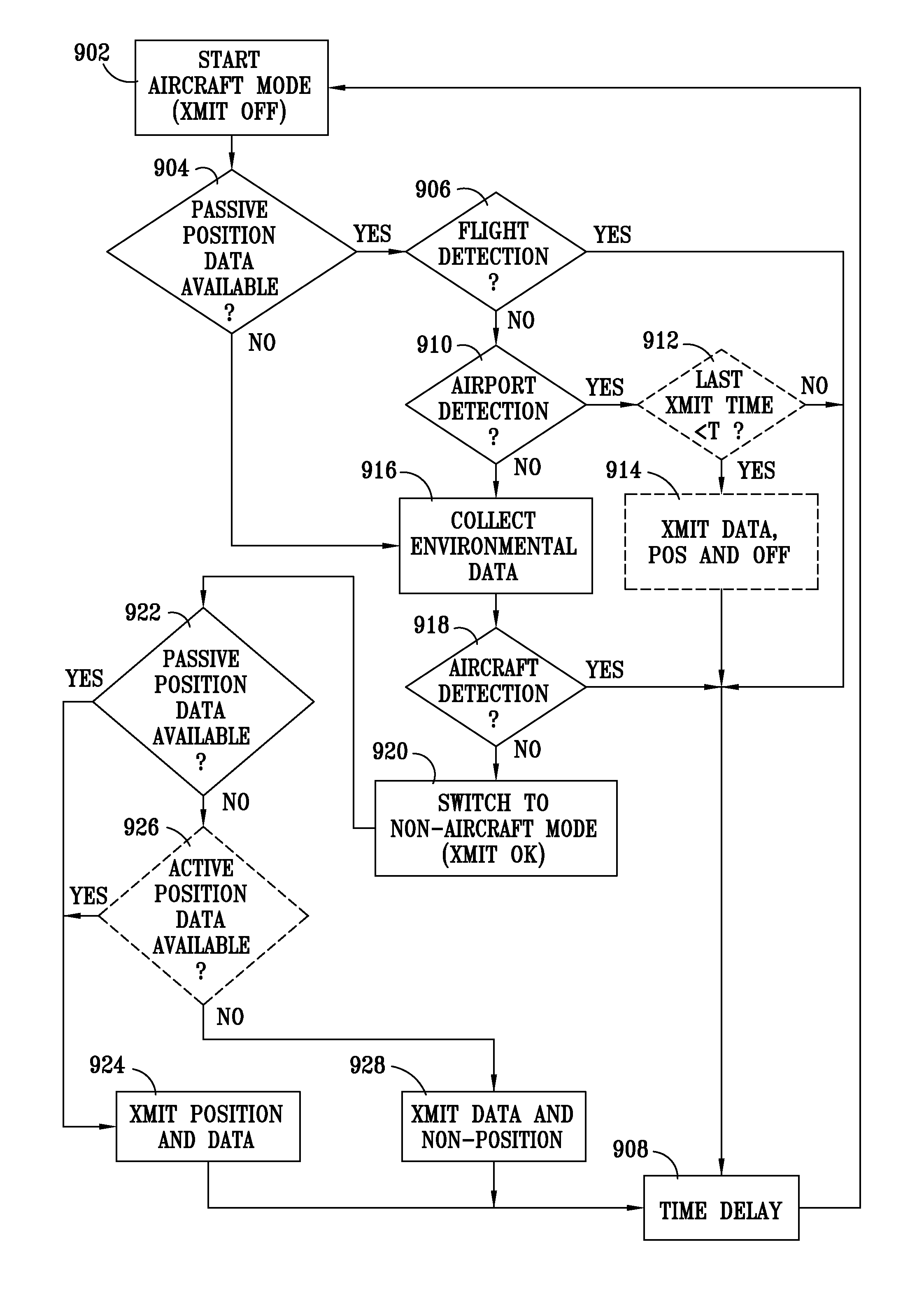

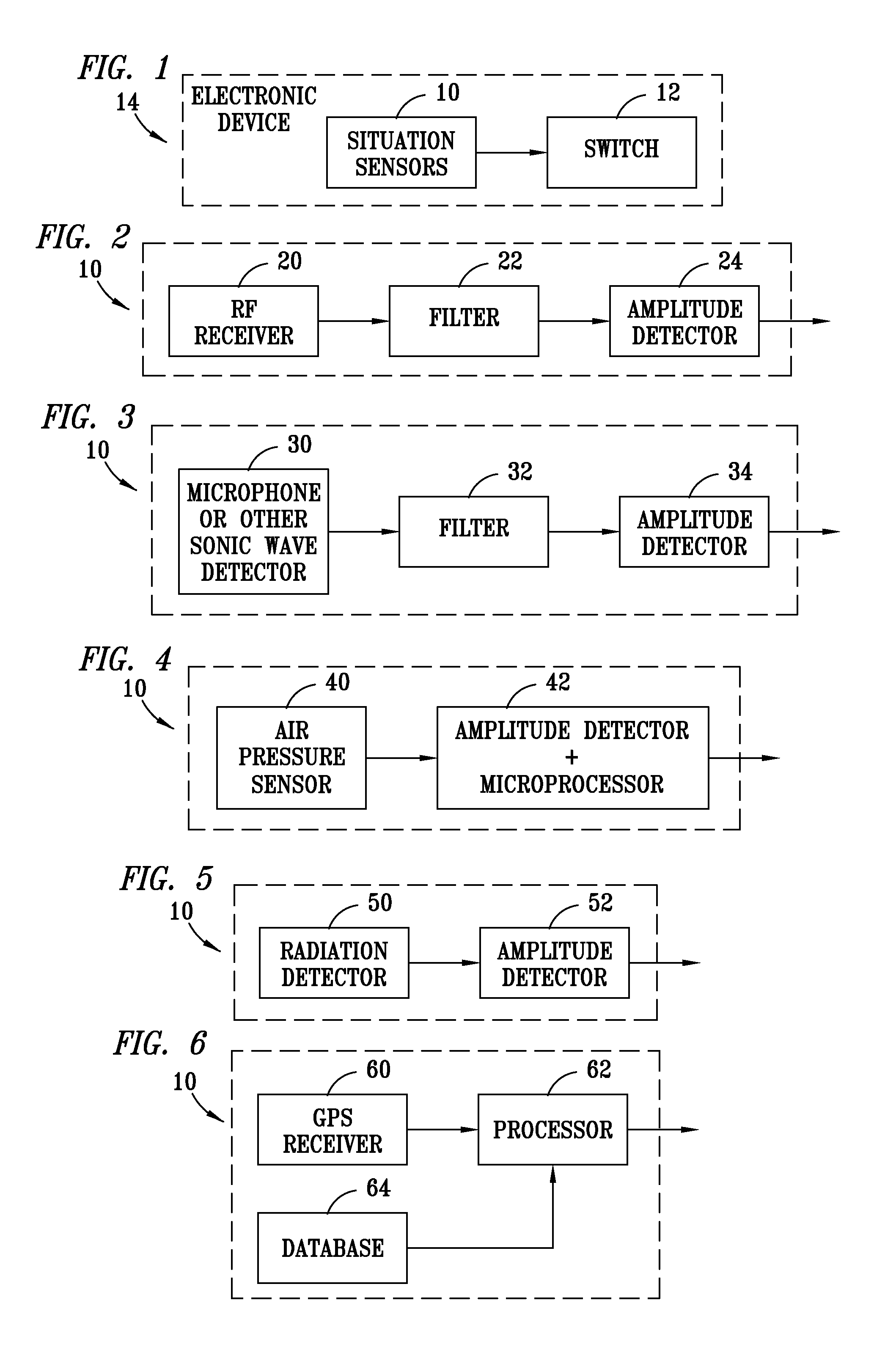

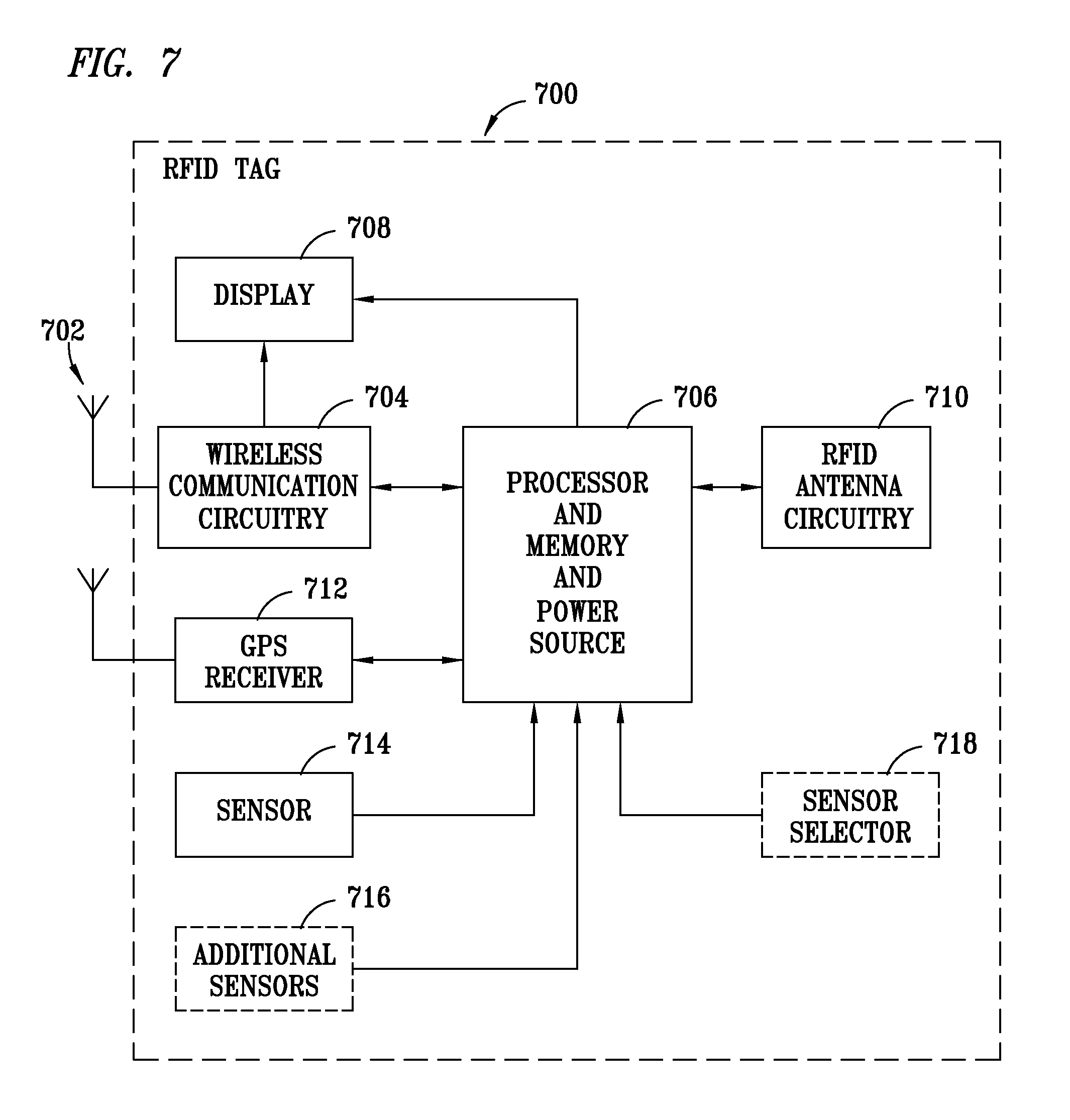

Method and apparatus for autonomous detection of a given location or situation

ActiveUS7791455B1Electric signal transmission systemsMultiple keys/algorithms usageFlight vehicleAtmospheric pressure

A method and apparatus is provided for sensing a given situation such as the presence of operational aircraft for deactivation, or other modification, of a device such as wireless communication circuitry signal transmission circuitry while in the presence of the operational aircraft. The sensing of a situation may be by the presence of a predetermined signal, the arrival at a given location, a measurable change in air pressure and so forth. The sensor circuitry, upon detecting conditions suggestive of operational aircraft, operates to activate, deactivate or otherwise modify the performance of a device while in the presence or immediate vicinity of aircraft or other predetermined situation.

Owner:INTELLECTUAL TECH LLC

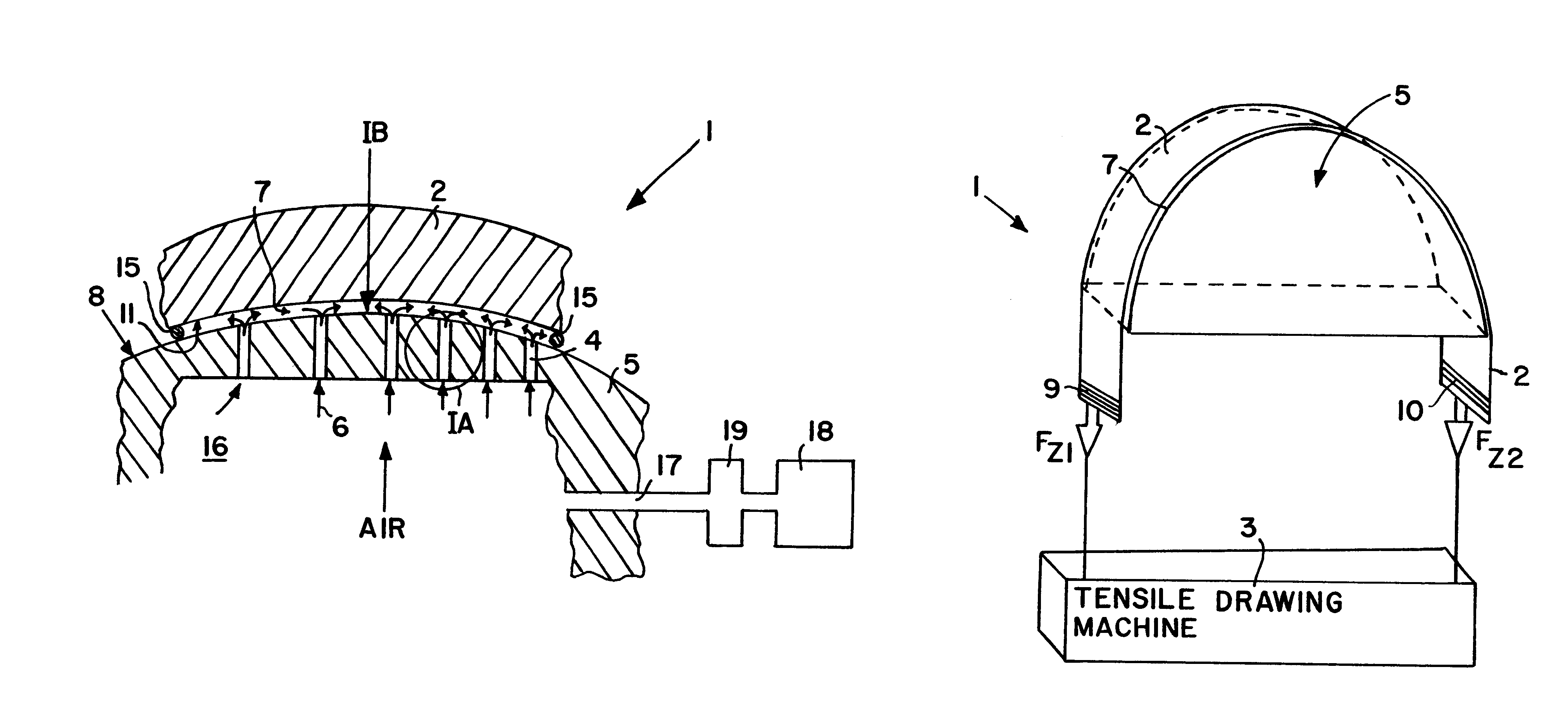

Method and apparatus for forming a metal sheet under elevated temperature and air pressure

Owner:AIRBUS OPERATIONS GMBH

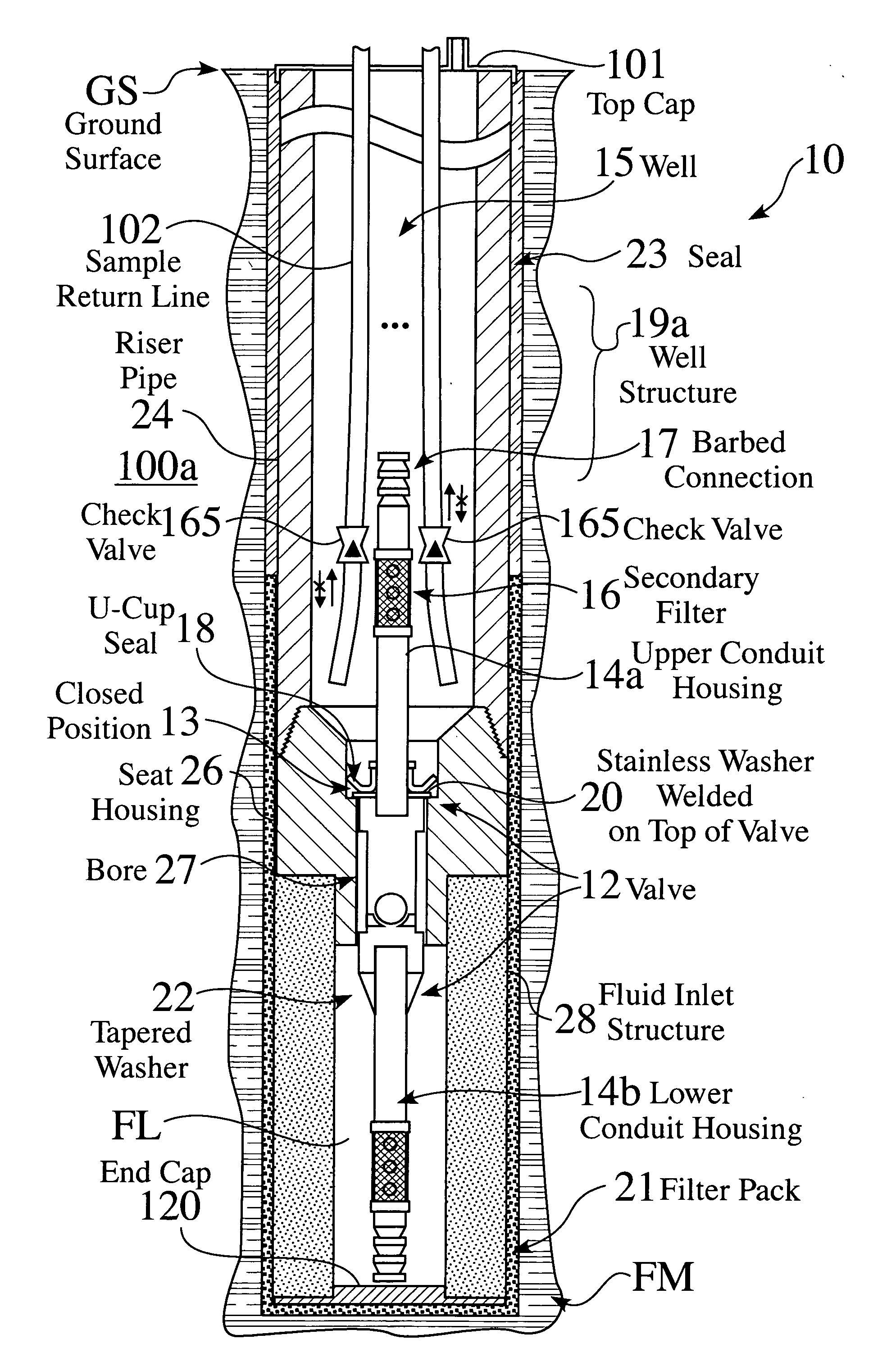

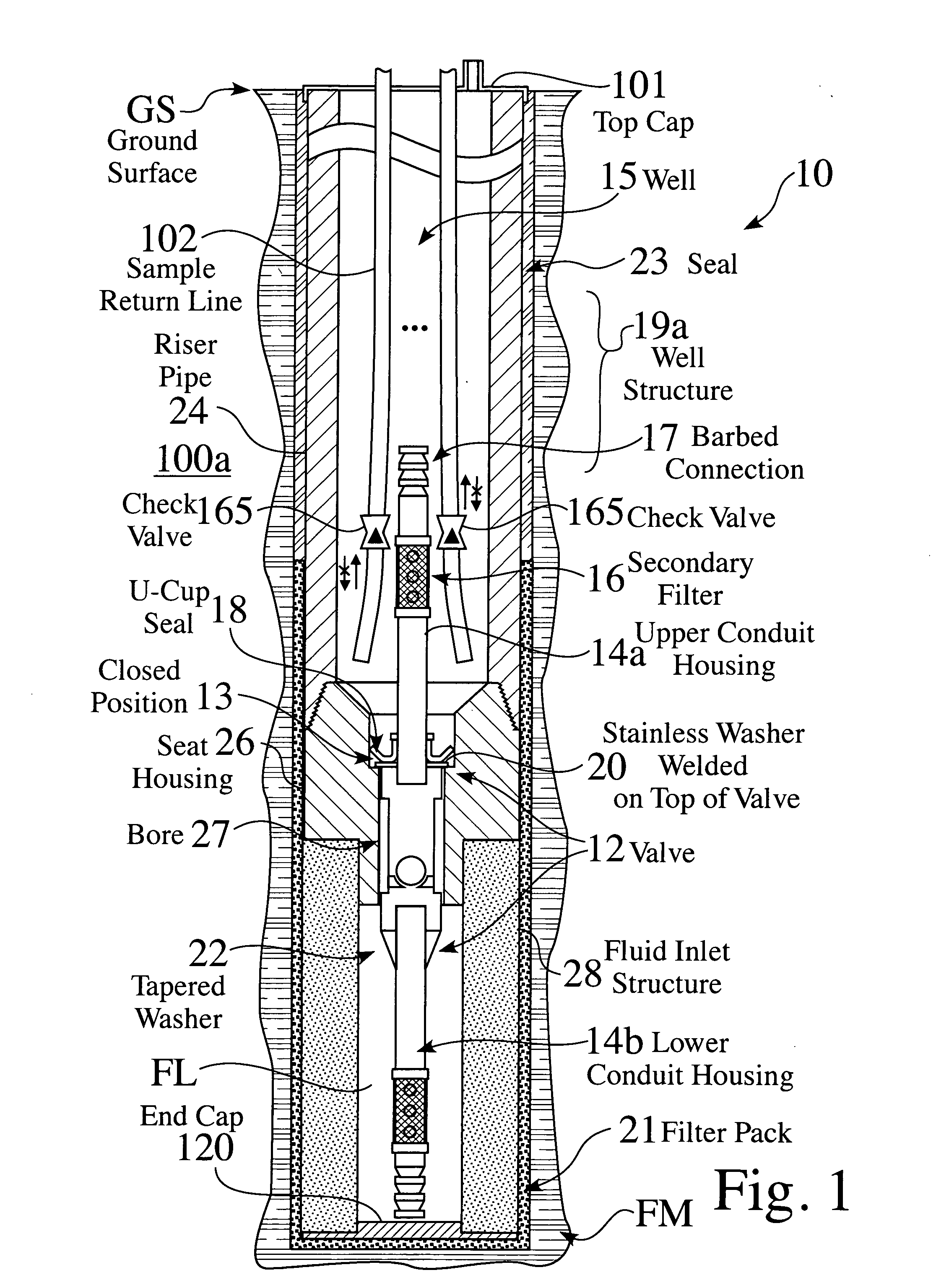

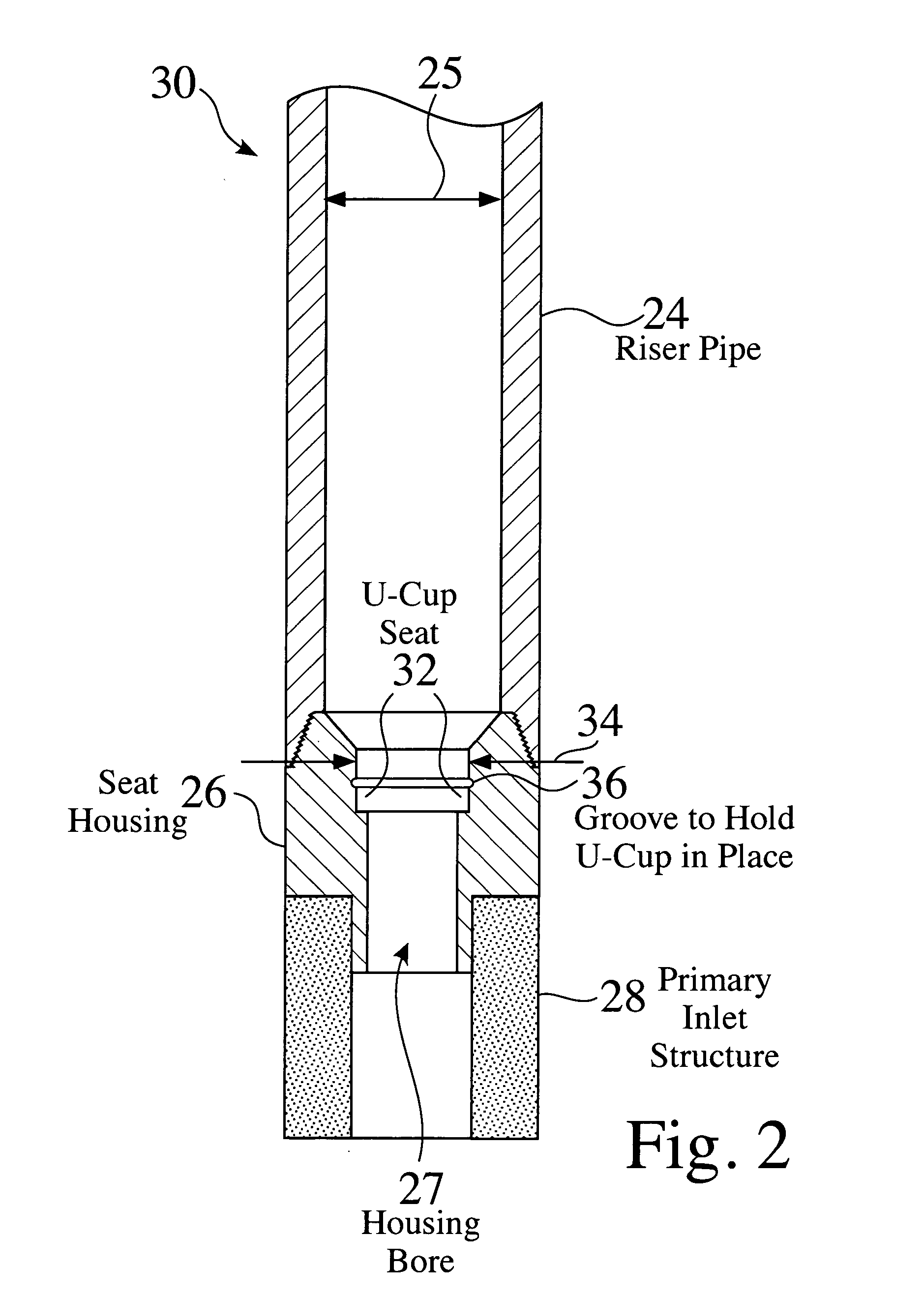

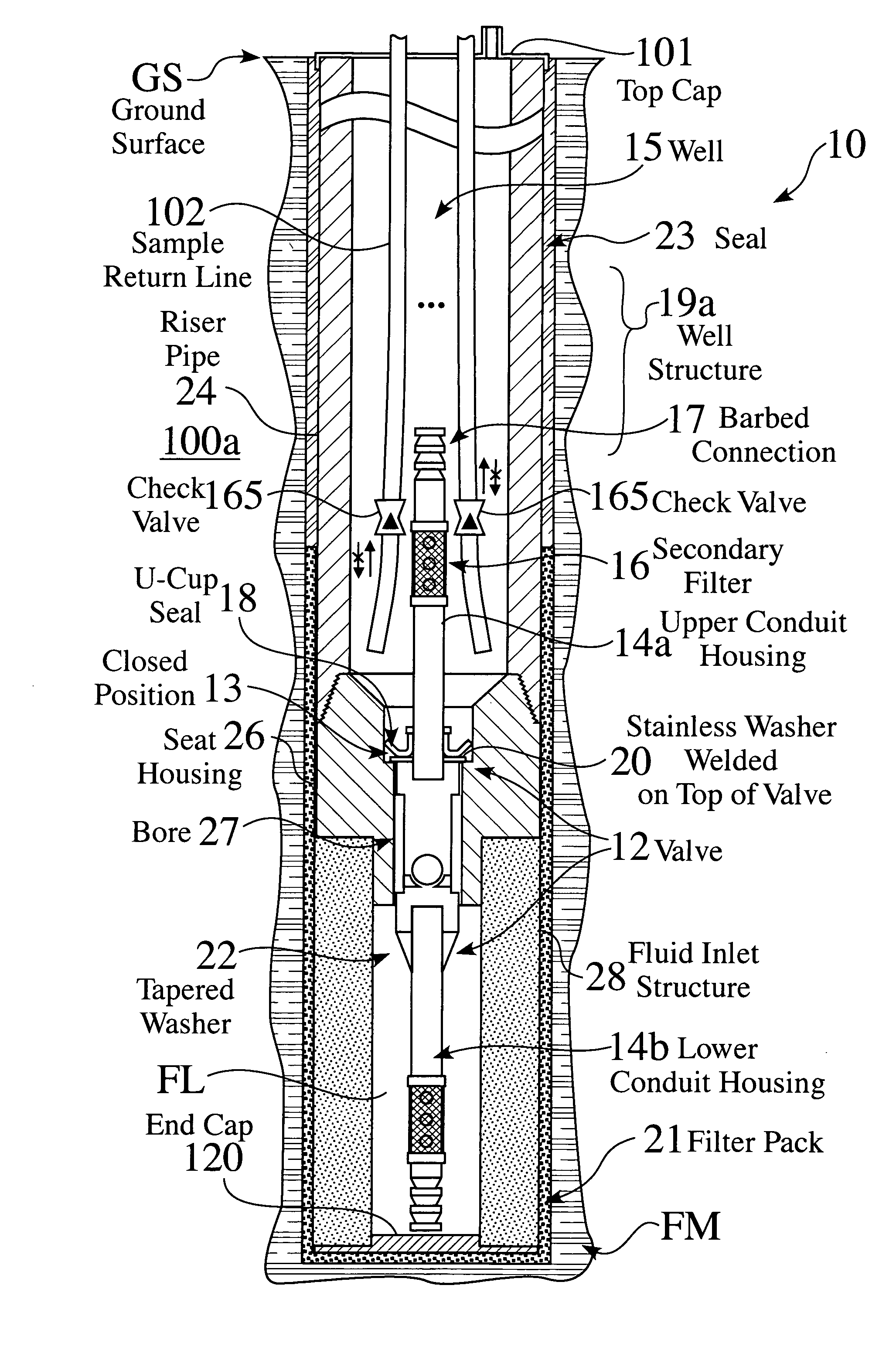

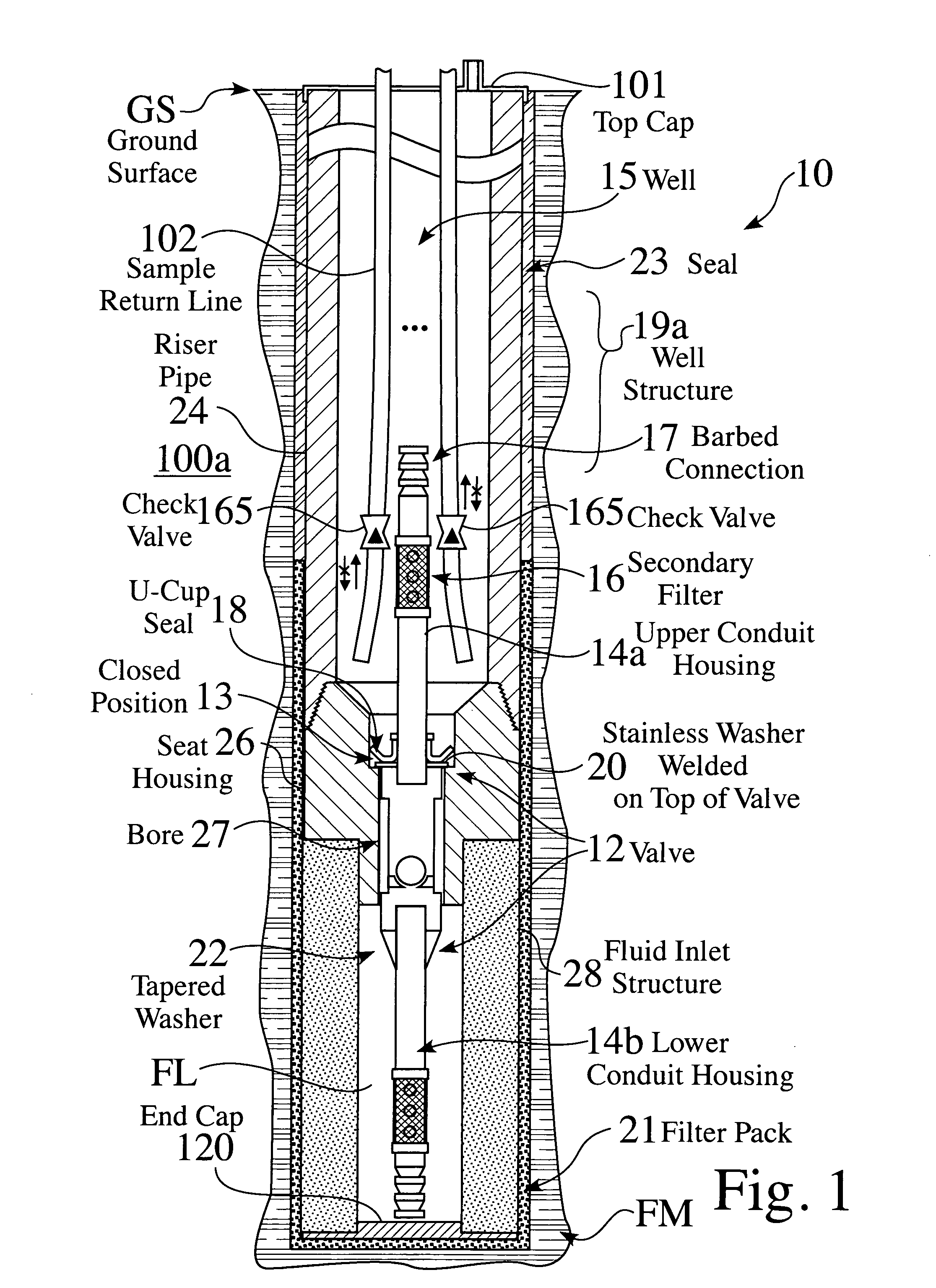

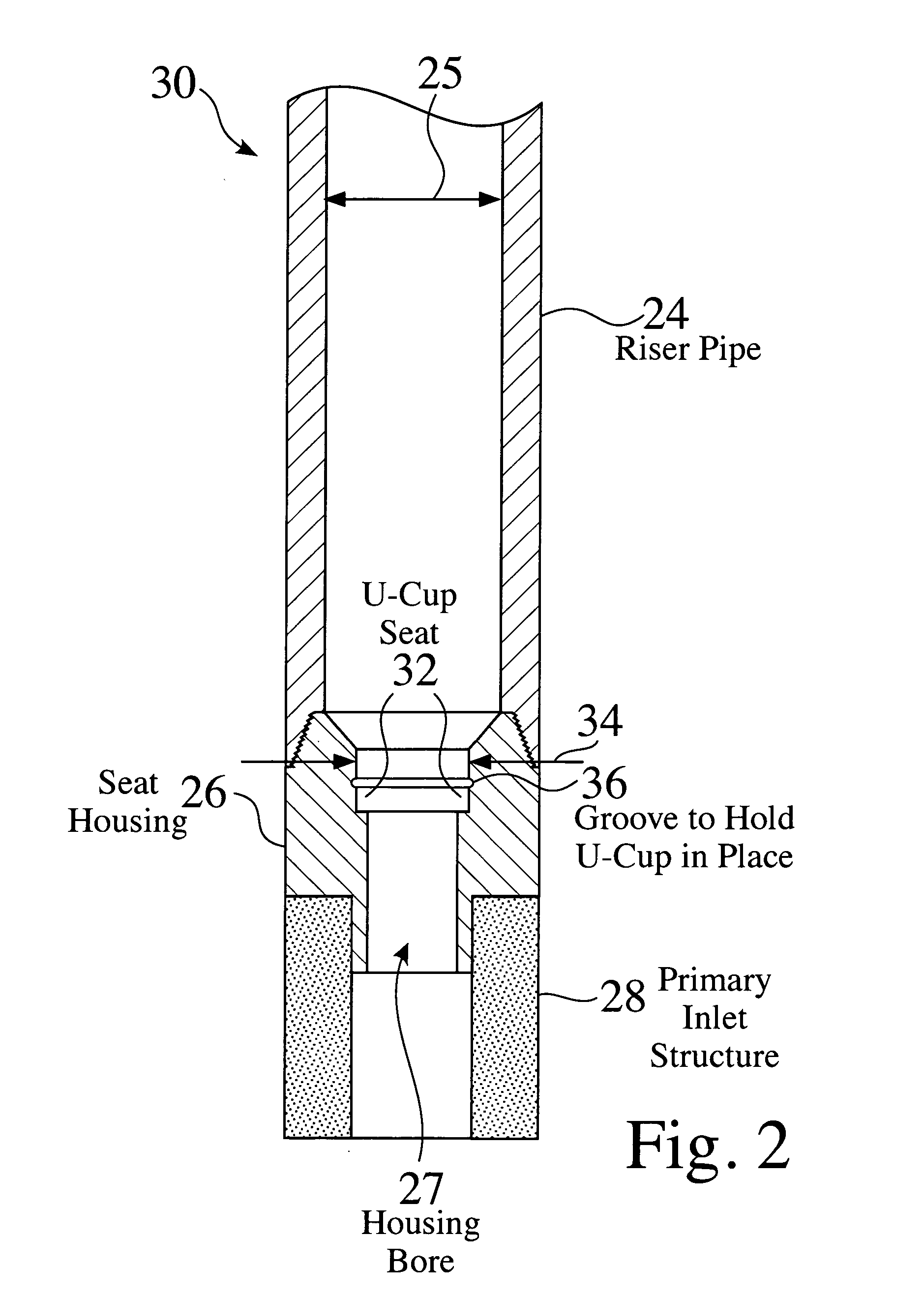

Method and apparatus for gas displacement well systems

A method and apparatus is provided for reducing the purge volume of a well during purging and sampling operations. In some system embodiments, the apparatus can be retrofitted to existing small diameter wells. A further embodiment provides a method and apparatus for using direct pneumatic pressure to purge and sample small diameter wells using a removable valve. This aspect of the invention allows a direct pneumatic pressure pump with a primary valve to be withdrawn through the top of the inside to the pump's pressure holding structure without removing a riser pipe or the system's fluid inlet structure. The invention allows fitting or retrofitting small diameter wells with valves for direct pneumatic pressure purging and sampling. Other embodiments include sealing a removable valve at or above the bottom of a riser pipe, remotely attaching a tool at the top of a removable valve, withdrawing a direct pneumatic pressure pump system's primary valve through the inside of the inside pump's pressure holding structure without removing the riser pipe, and attaching a direct pneumatic pressure pump system's sample return line to its primary valve. Further embodiments include a multiple return line pneumatic pump / well, which allows the use of multiple return lines on a pneumatic pump when used to pump water from very deep wells where piezometric surface of the water is also deep, as well as other uses for direct pressure pneumatic pumping and sampling.

Owner:BLAISDELL MARK KEVIN

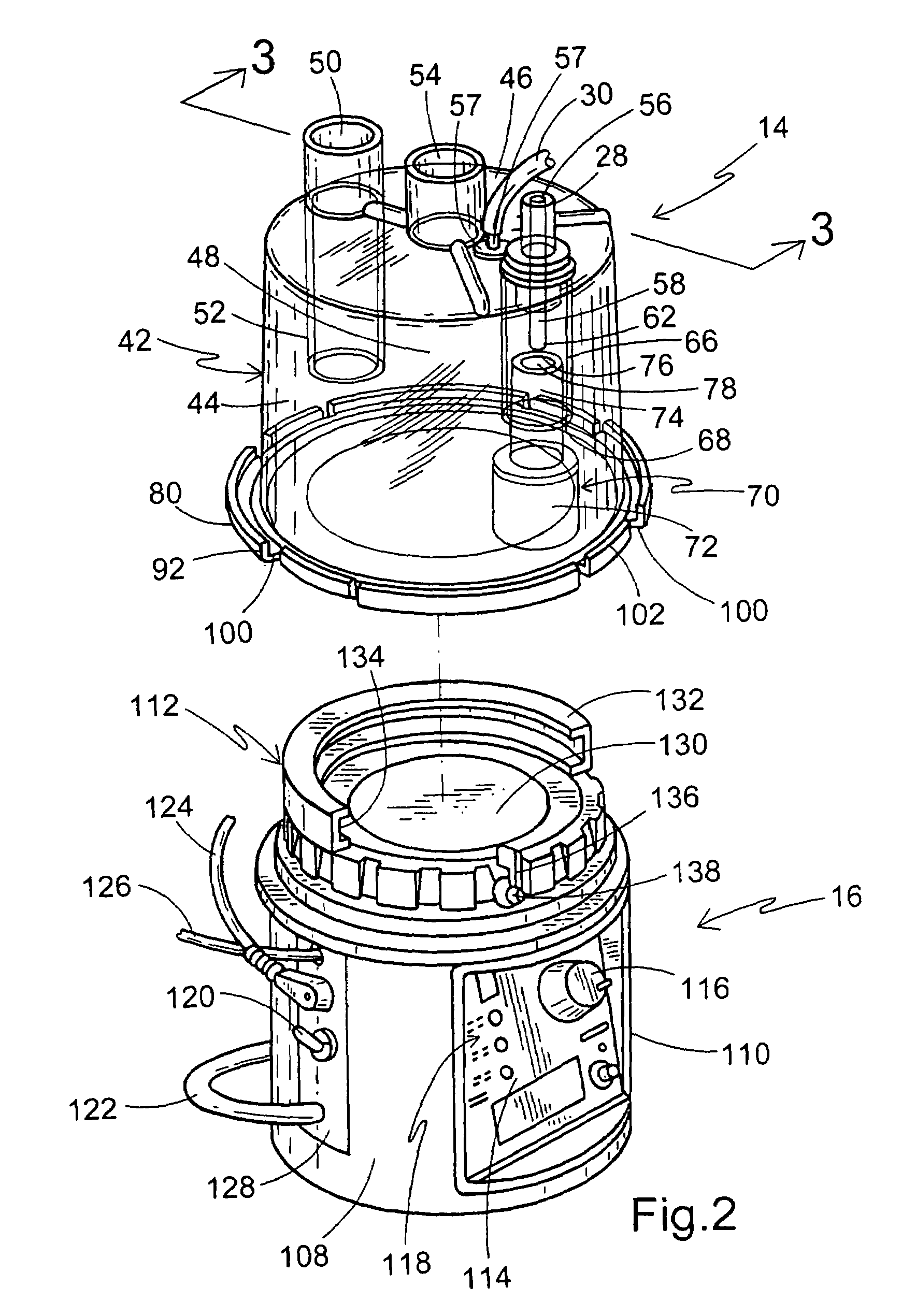

Method and apparatus for assisting vascular flow through external compression synchronized with venous phasic flow

An automatic portable ambulant miniaturized system for applying pneumatic pressure to a body limb including a portable ambulant hand-held fluid source unit, a conduit for delivering fluid generated by the unit, and a pressure sleeve coupled to the conduit and adapted to envelop a body limb. The pressure sleeve contains individually inflatable cells, each cell being subdivided into longitudinally extending confluent intra-cell compartments along the axis of the body limb. The intra-cell compartments are inflated and deflated essentially simultaneously by the portable fluid source unit. To increase the peak venous velocity generated by any kind of external compressive force on a limb with any kind of tempo-spatial regime, the venous phasic flow is monitored to determine so that the venous flow generated by the external compressive force can be synchronized with the in-phasic natural venous flow.

Owner:ZIMMER SURGICAL

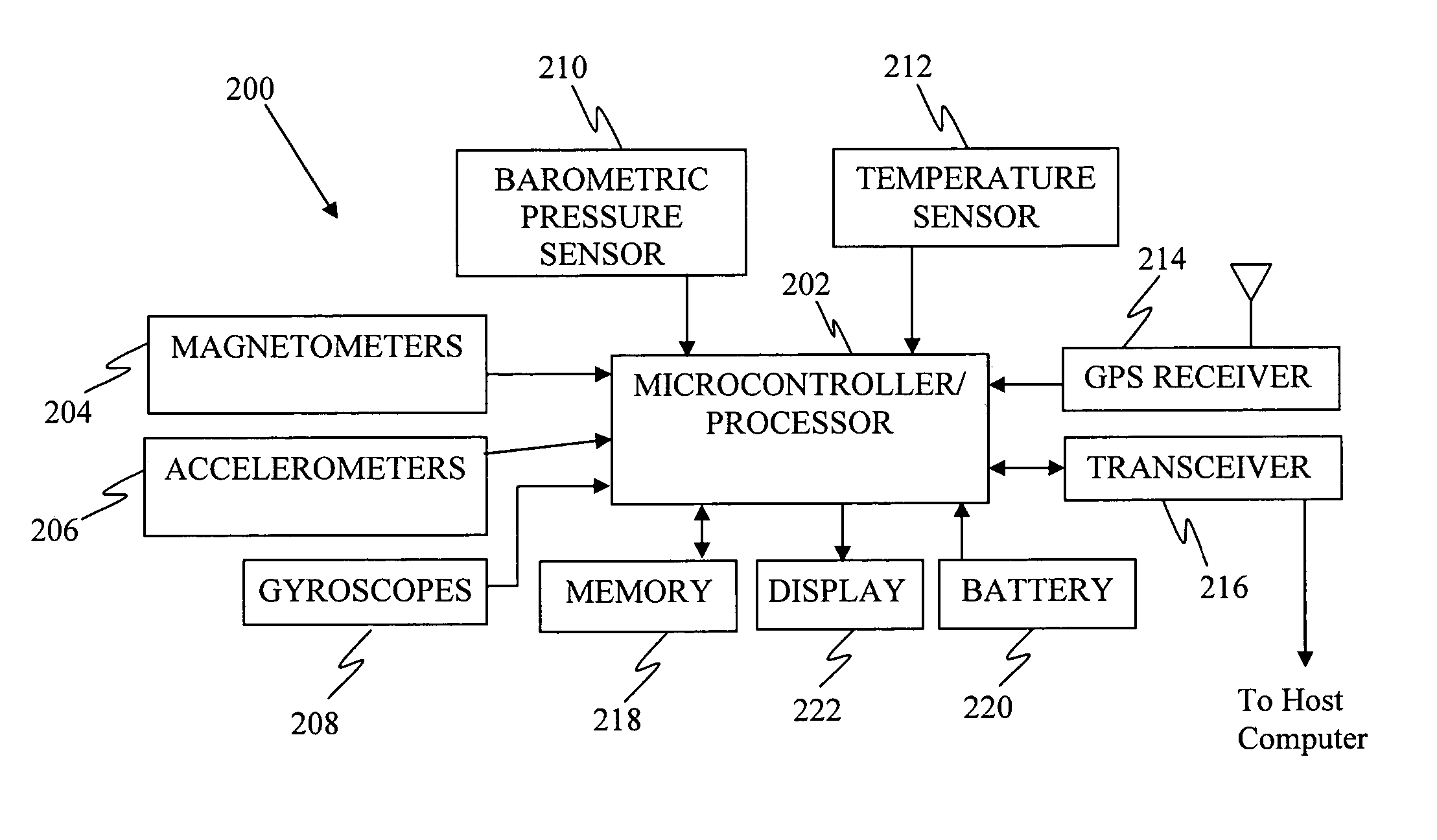

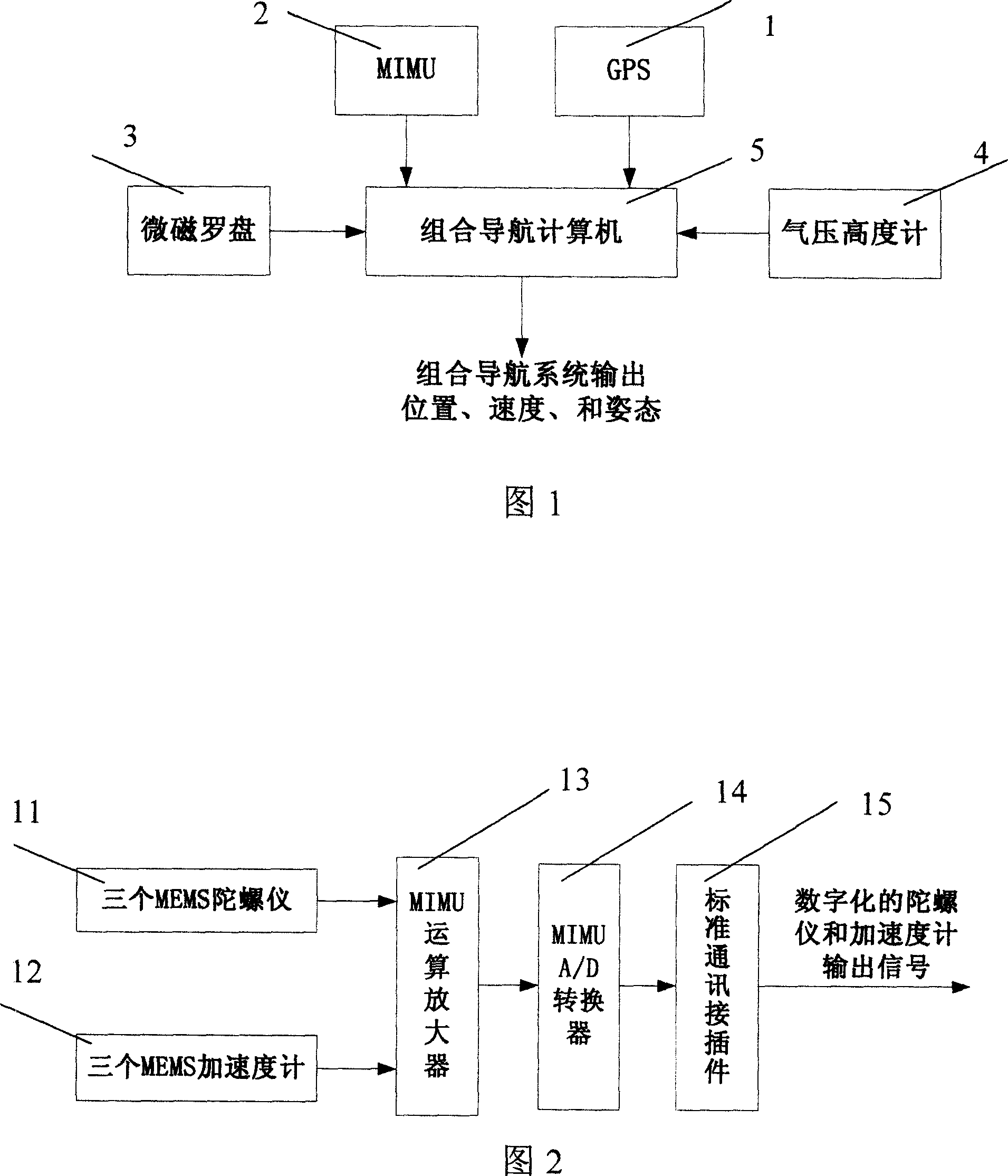

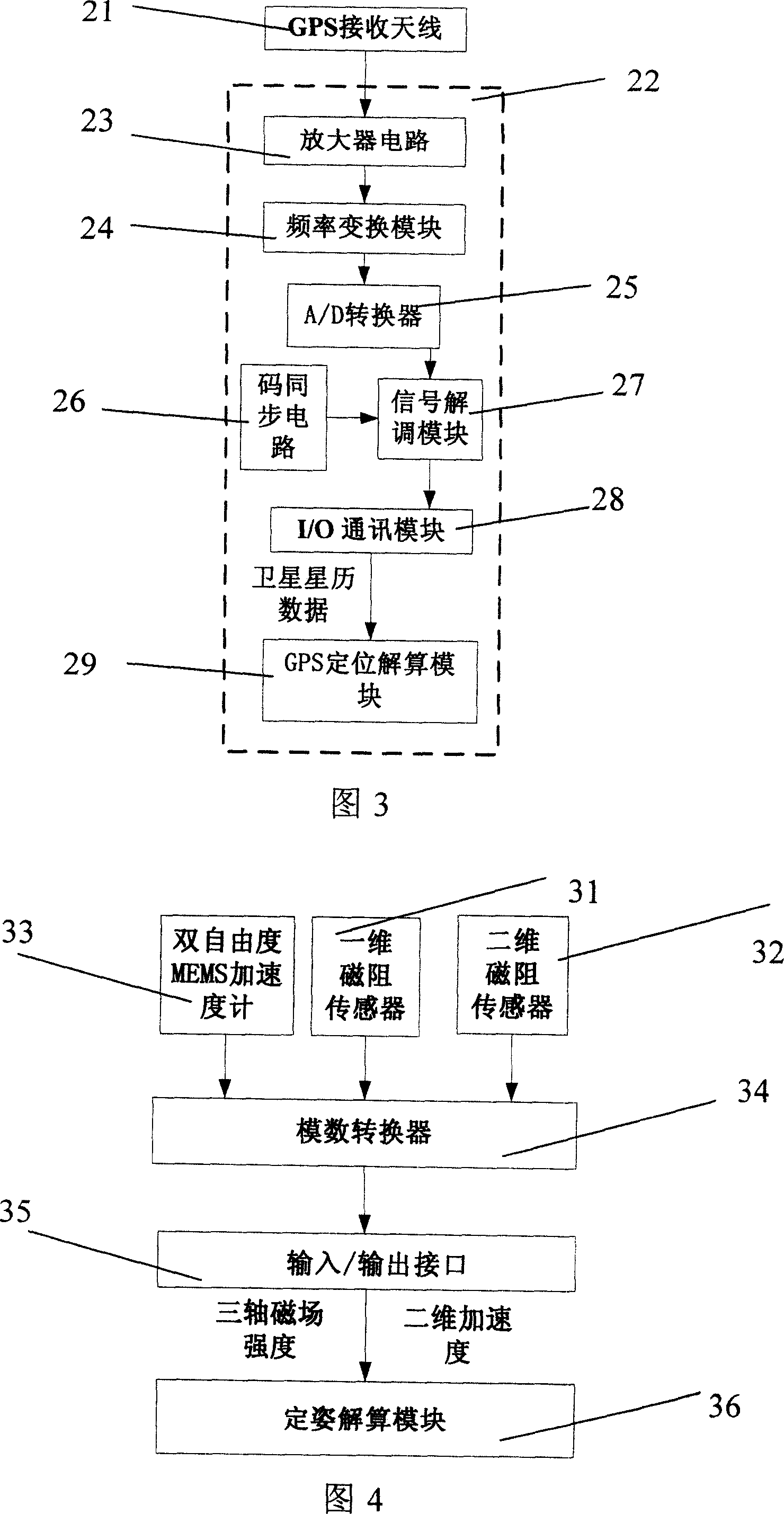

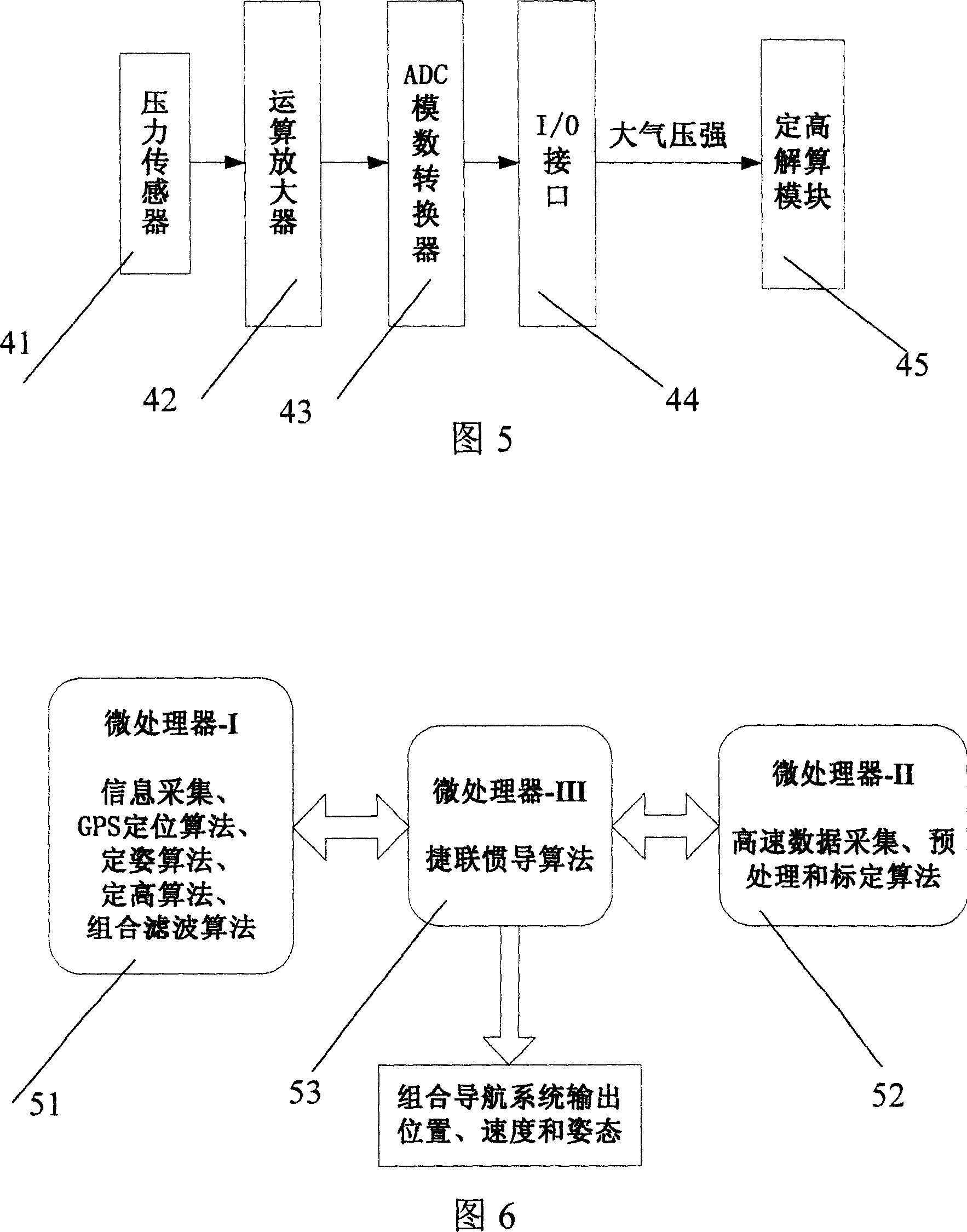

High integral navigation device combined by MIMU/GPS/micromagnetic compass/barometric altimeter

InactiveCN101000244AHigh precisionImprove fault toleranceInstruments for road network navigationNavigational calculation instrumentsFilter algorithmEngineering

The invention relates to high integrity MIMU / GPS / micro magnetic compass / pressure altitude gage integrated navigation system. It is made up MIMU subsystem, GPS subsystem, micro magnetic compass subsystem, pressure altitude gage subsystem, and integrated navigation computer used to process subsystem output data and inosculate information to output carrier position, speed, and attitude information. The four subsystems adopt hard ware integrative high grade integration technique. The navigation computer adopts three embedding type microprocessor and has the feature of redundancy multiplexing. The GPS, micro magnetic compass, pressure altitude gage use one microprocessor together to process their algorithm. Navigation algorithm is made up of strap down inertial navigation algorithm, multi velocity model combined filtering algorithm. The invention has the advantages of small volume, low cost, high reliability, fast response speed and high precision. Thus it can be used in micro-miniature flyer precise navigation.

Owner:BEIHANG UNIV

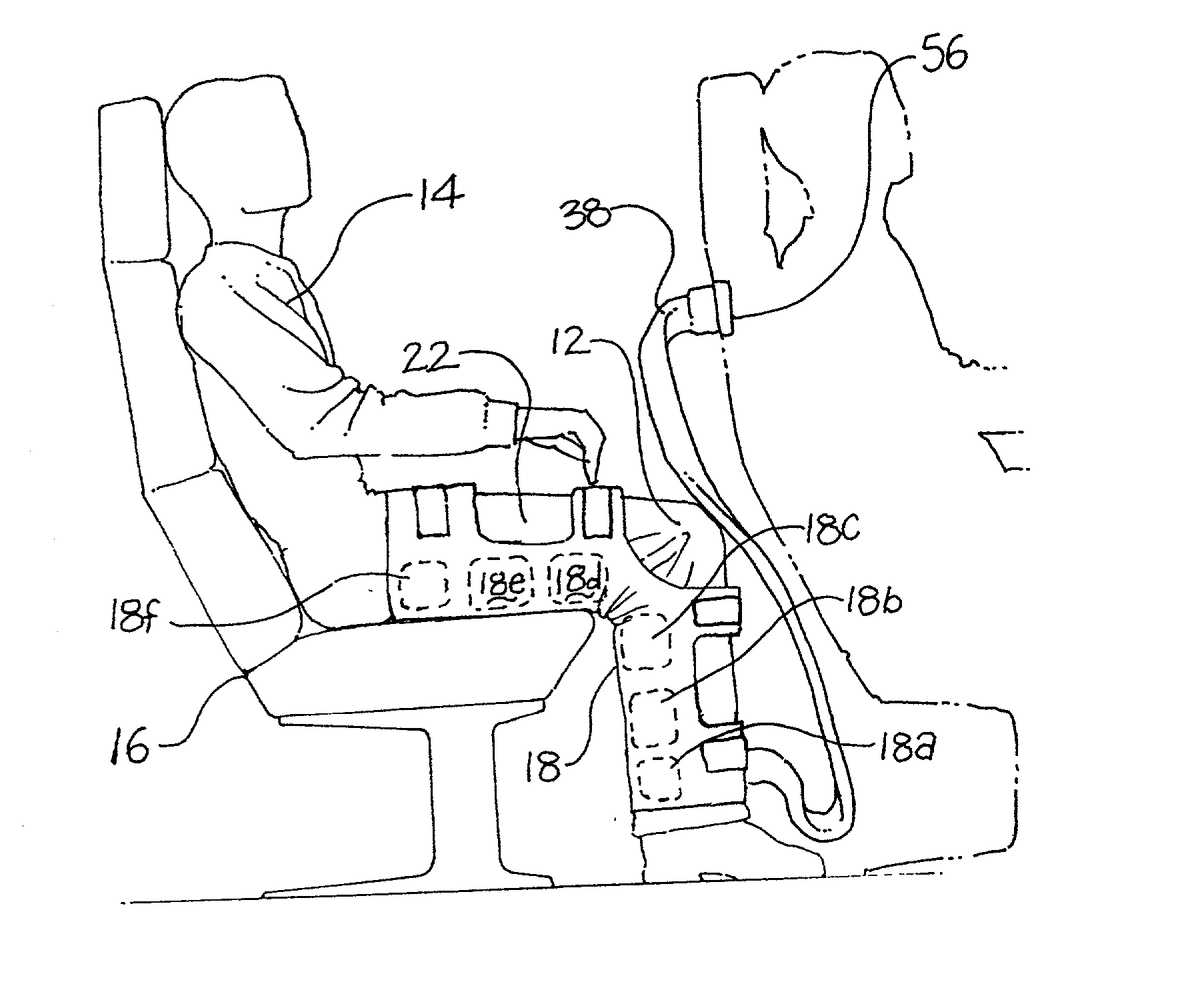

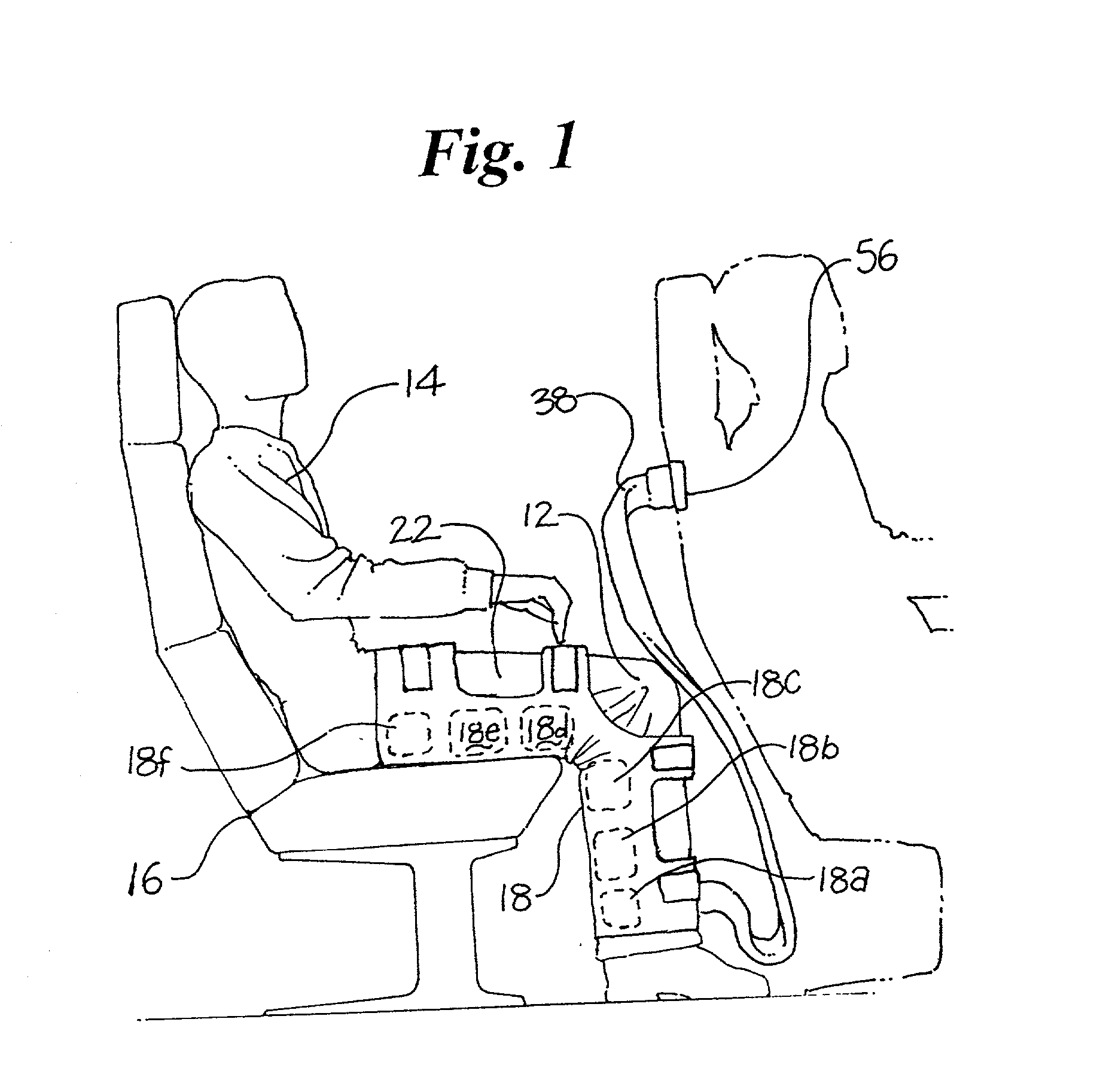

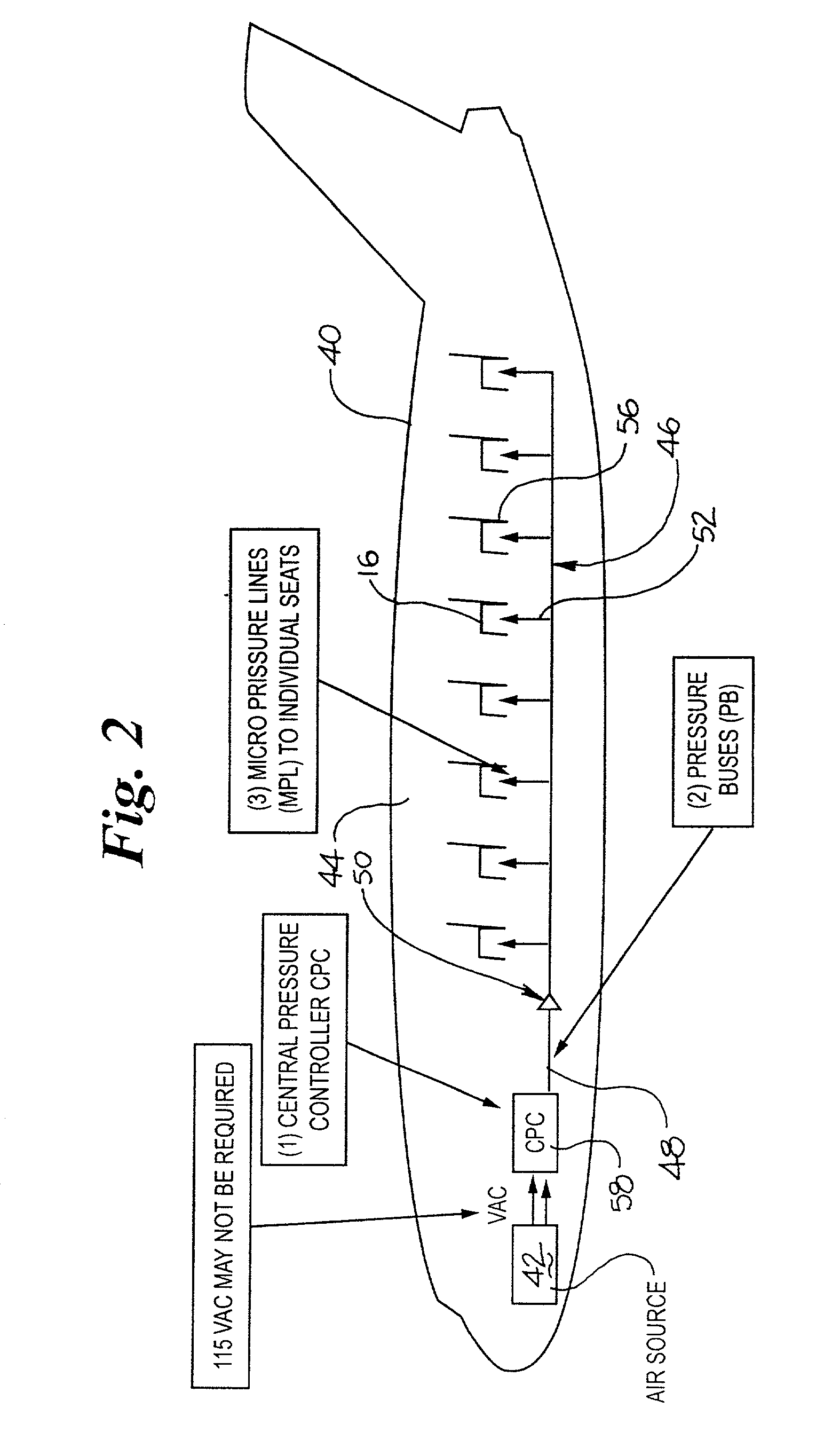

Pressure device and system for preventing thrombosis

A system for providing prophylaxis against thrombosis comprises in combination a vehicle and a plurality of inflatable compression sleeves. The vehicle has a pneumatic pressure source for supplying a predetermined flow of pneumatic fluid to a plurality of passenger positions. The pneumatic pressure source has a plurality of leads, which extend to a connection port located in each of the passenger positions. Each of the inflatable compression sleeves has a plurality of inflatable chambers therein. The sleeves are constructed to be engaged to a connection port, thereby providing fluid communication between the pneumatic pressure source and the plurality of chambers. The sleeves may be worn by a passenger to help prevent the occurrence of deep vein thrombosis. Individual sleeves comprise at least two inflatable chambers wherein a second inflatable chamber is subsequent to the inflation of a first inflatable chamber.

Owner:KUSLICH STEPHEN D +1

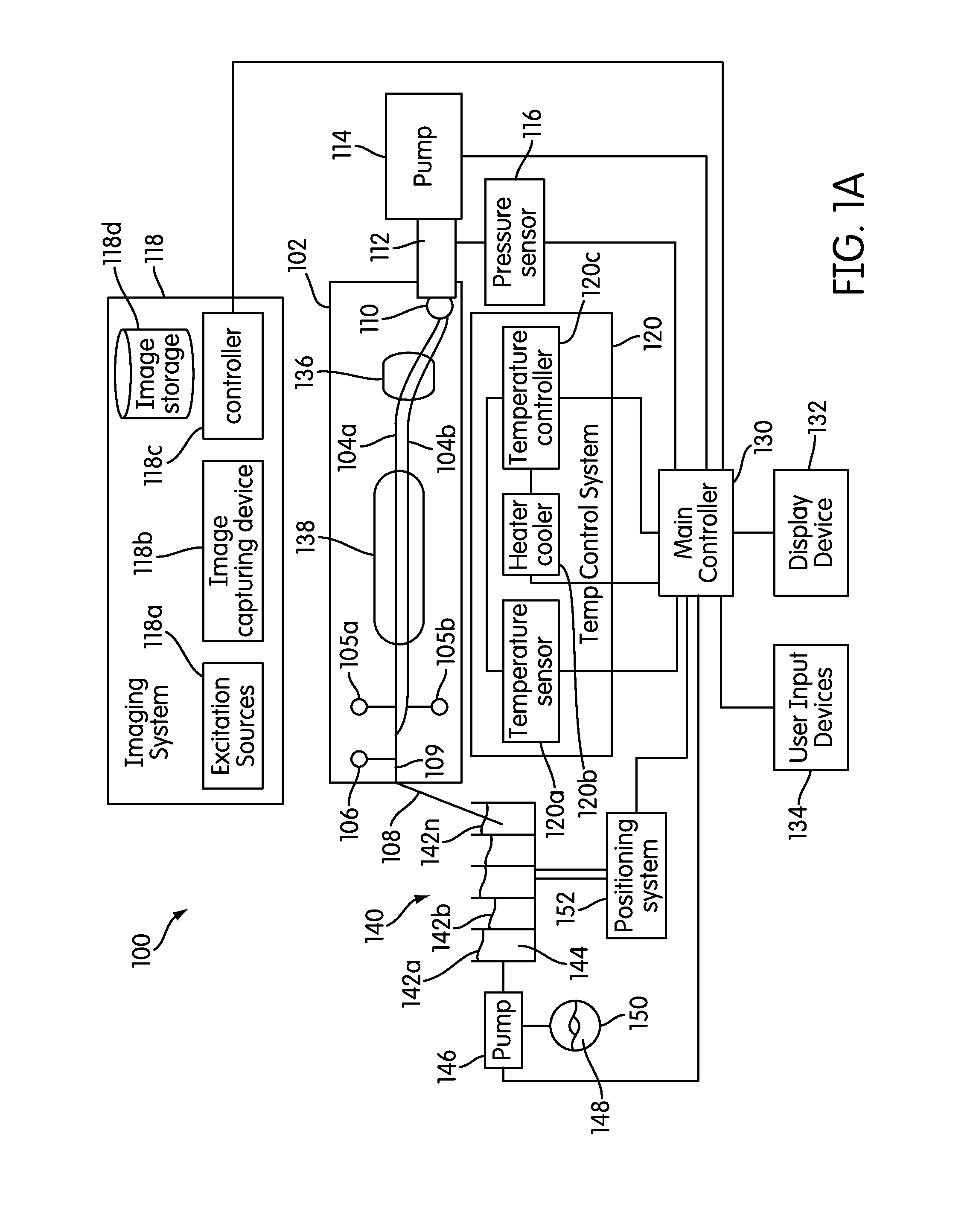

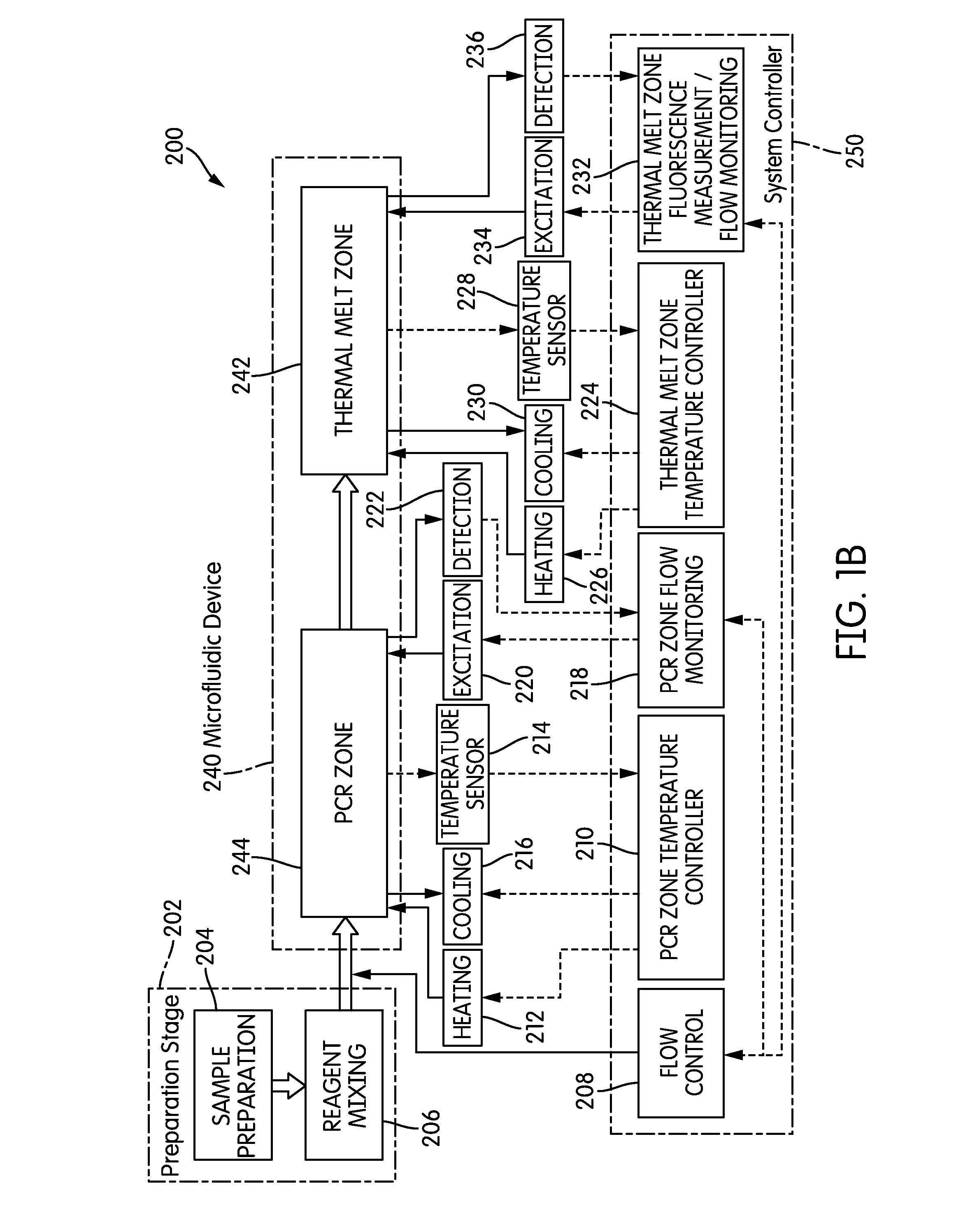

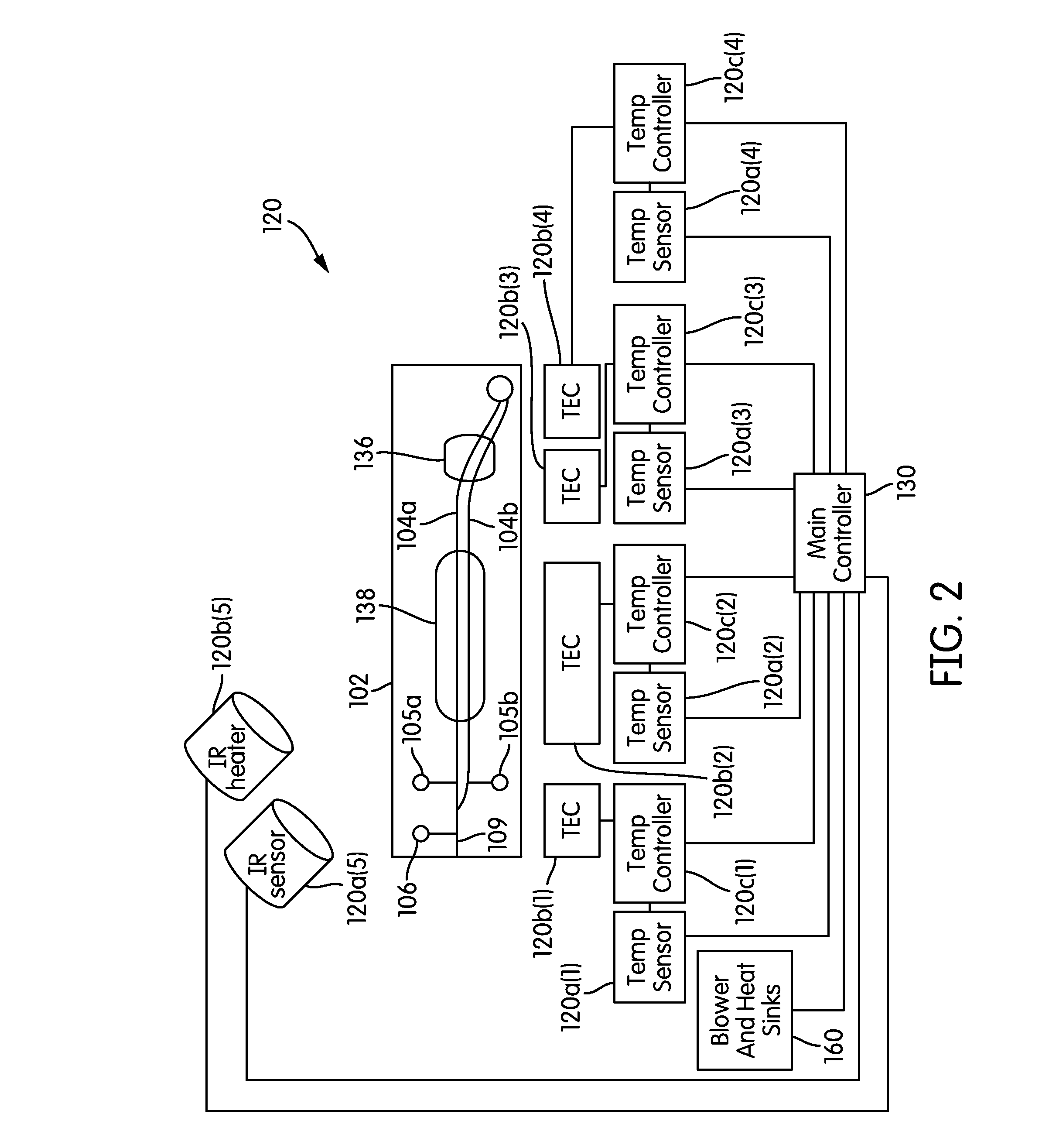

System and method for serial processing of multiple nucleic acid assays

ActiveUS20120052560A1Rapid serial processingBioreactor/fermenter combinationsBiological substance pretreatmentsHandling systemData store

The present invention relates generally to systems and methods for the rapid serial processing of multiple nucleic acid assays. More particularly, the present invention provides for the real time processing of nucleic acid during polymerase chain reaction (PCR) and thermal melt applications. According to an aspect of the invention, a system for the rapid serial processing of multiple nucleic acid assays is provided. In one embodiment, the system includes, but is not limited to: a microfluidic cartridge having microfluidic (flow-through) channels, a fluorescence imaging system, a temperature measurement and control system; a pressure measurement and control system for applying variable pneumatic pressures to the microfluidic cartridge; a storage device for holding multiple reagents (e.g., a well-plate); a liquid handling system comprising at least one robotic pipettor for aspirating, mixing, and dispensing reagent mixtures to the microfluidic cartridge; systems for data storage, processing, and output; and a system controller to coordinate the various devices and functions.

Owner:CANON USA

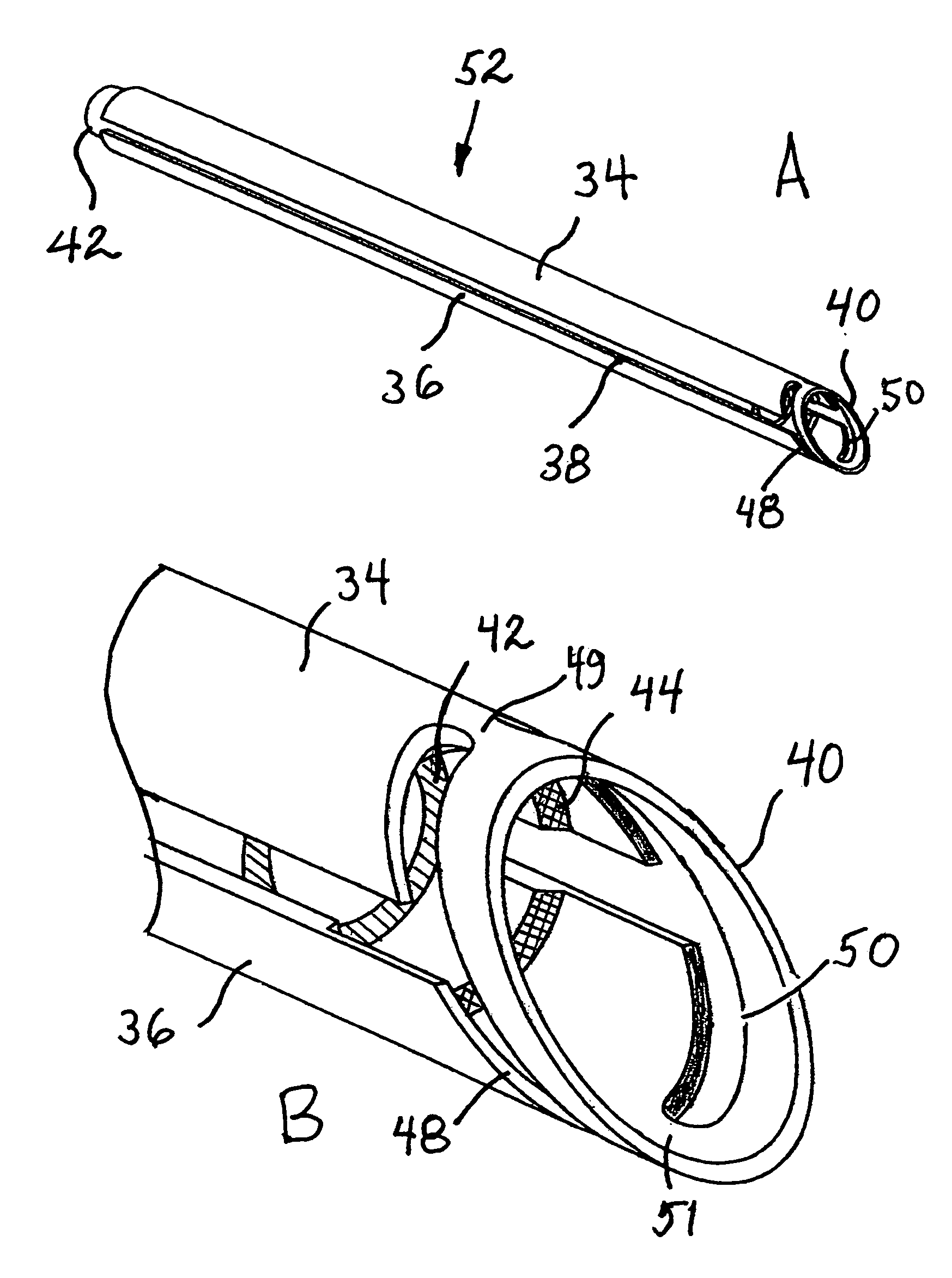

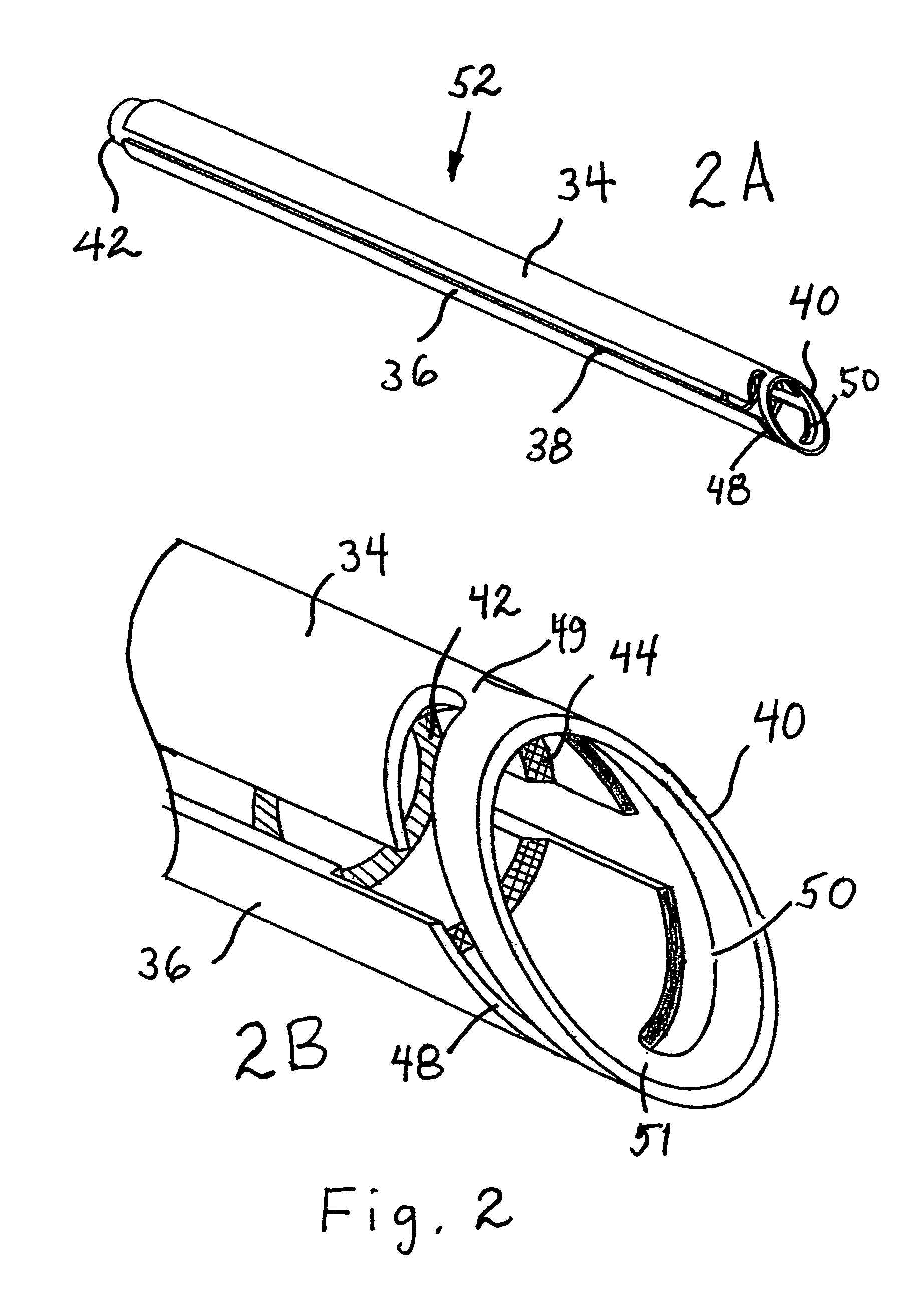

Automatic portable pneumatic compression system

InactiveUS7063676B2Improve compactnessReduce power consumptionPneumatic massageChiropractic devicesHand heldCatheter

An automatic portable ambulant miniaturized system for applying pneumatic pressure to a body limb including a portable ambulant hand-held fluid source unit, a conduit for delivering fluid generated by the unit, and a sleeve coupled to the conduit and adapted to envelop a body limb. The sleeve contains one or more individually inflatable cells, each cell being subdivided into two or more longitudinally extending confluent compartments along the axis of the body limb. The compartments are inflated and deflated essentially simultaneously by the portable fluid source unit.

Owner:ZIMMER SURGICAL

Thermal airflow tool and system

A combination pressurized airflow and thermal cutting tool constructed as a dual-use thermal airflow tool for directed heating and drying of a specific area in surgical procedures, such as, by way of example, in eye cataract surgery where it is primarily used for needs related to the operation of a thermal cutting tool. The thermal airflow tool comprises a probe having an elongated, hollow body adapted to provide electrical power to a burning ring formed at a distal end thereof, and an air channel for conducting pressurized airflow to the distal end of the probe, with at least two apertures radially disposed at the distal end of the probe. The thermal airflow tool is in physical and electrical connection with an air pressure unit and thermal power unit, respectively, for directing and concentrating at least one of the pressurized airflow and heat at the distal end of the thermal airflow tool onto a surgical area when electrical power is applied to the thermal airflow tool.

Owner:VALENS ASSOC INC

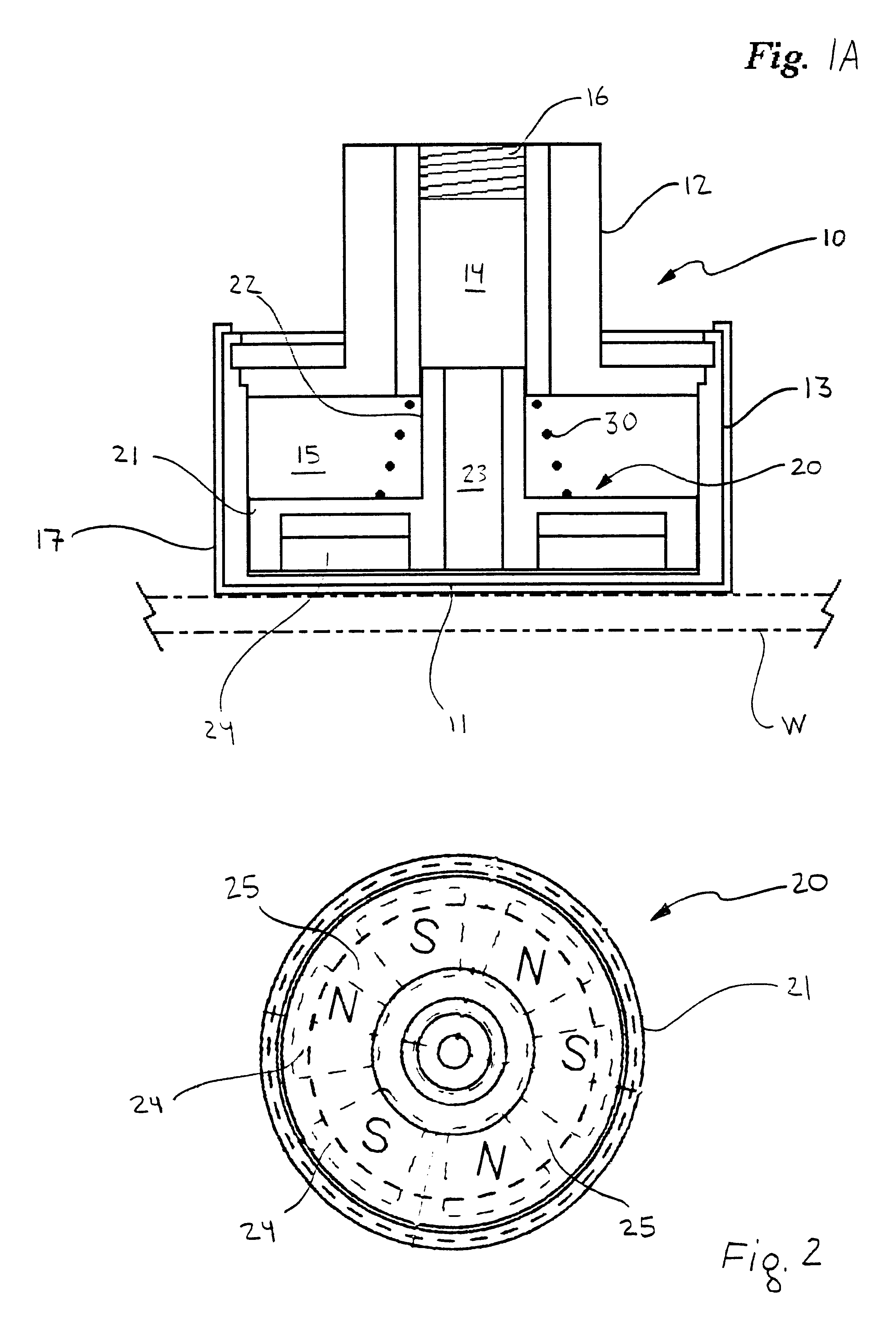

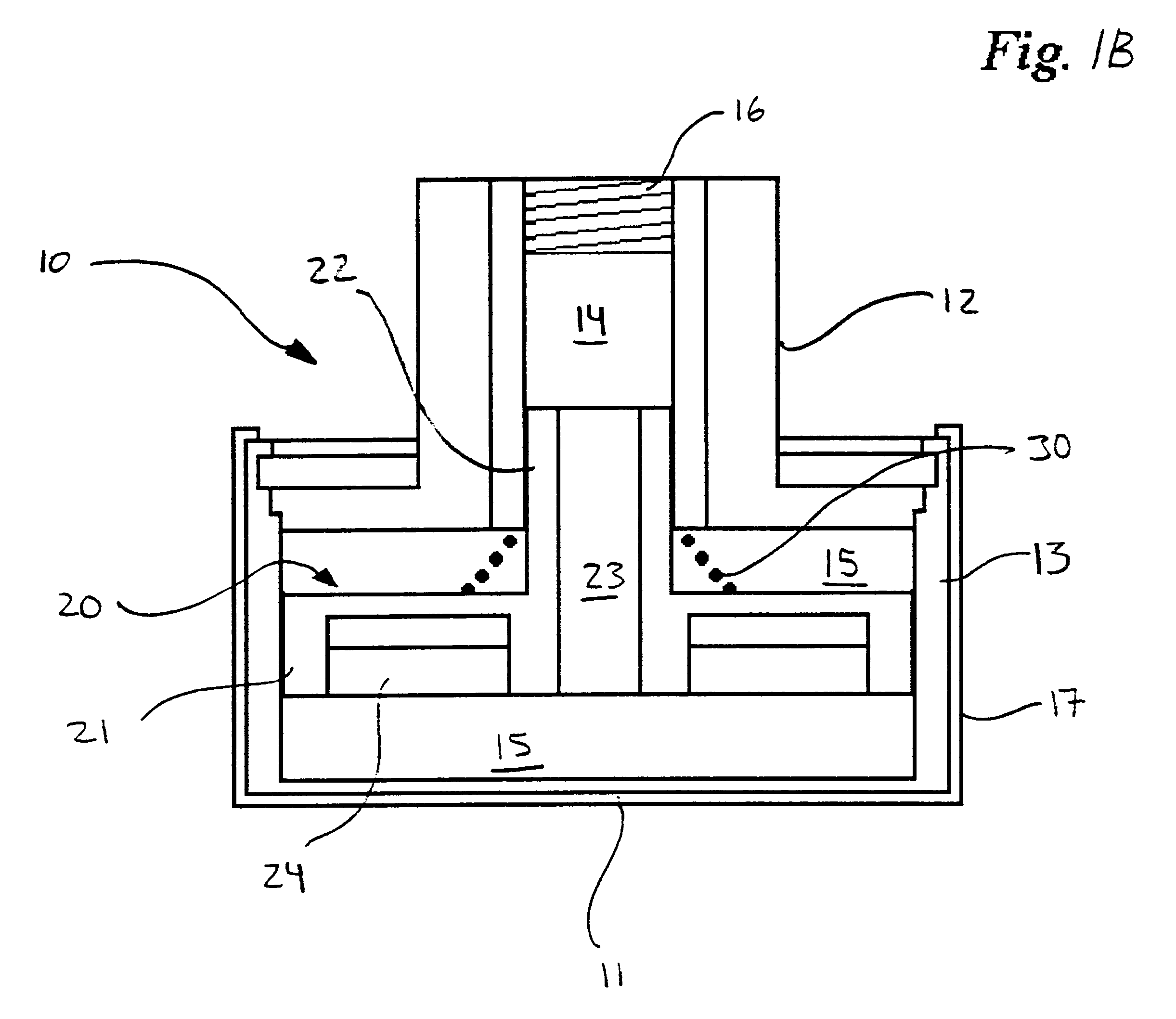

Pneumatically actuated magnetic workpiece holder

A pneumatically actuated magnetic workpiece holder comprising a housing having a contact surface for contacting a workpiece to be held, and a magnet assembly translationally disposed in the housing, the magnet assembly comprising a plurality of permanent magnets arranged so that adjacent magnets are of opposite polarities. The housing is adapted for fluid communication with a pneumatic supply. The magnet assembly is biased towards an operative position, according to which the magnet assembly is sufficiently near the contact surface to exert on a workpiece an attractive force sufficient for holding the workpiece in contact with the workpiece holder, and is translationally positionable by pneumatic pressure towards an inoperative position, according to which the magnet assembly is sufficiently distant from the contact surface so as to be unable to exert on the workpiece an attractive force sufficient for holding the workpiece in contact with the workpiece holder. The invention is adapted for replacing suction-cup workpiece holders in conventional vacuum lifting devices, and a method of utilizing the present invention in this fashion is taught to comprise providing the workpiece holder with a coupling complimentary to the coupling for such conventional suction-cup workpiece holders, so that the magnetic workpiece holder may be substituted for the conventional suction-cup holder in the vacuum lifting device. According to this method, the vacuum supply of the conventional vacuum lifting device is adapted to provide such positive air pressure for employing the magnetic workpiece holder of this invention.

Owner:INDAL MAGNETICS

Method and apparatus for gas displacement well systems

A method and apparatus is provided for reducing the purge volume of a well during purging and sampling operations. In some system embodiments, the apparatus can be retrofitted to existing small diameter wells. A further embodiment provides a method and apparatus for using direct pneumatic pressure to purge and sample small diameter wells using a removable valve. This aspect of the invention allows a direct pneumatic pressure pump with a primary valve to be withdrawn through the top of the inside to the pump's pressure holding structure without removing a riser pipe or the system's fluid inlet structure. The invention allows fitting or retrofitting small diameter wells with valves for direct pneumatic pressure purging and sampling. Other embodiments include sealing a removable valve at or above the bottom of a riser pipe, remotely attaching a tool at the top of a removable valve, withdrawing a direct pneumatic pressure pump system's primary valve through the inside of the inside pump's pressure holding structure without removing the riser pipe, and attaching a direct pneumatic pressure pump system's sample return line to its primary valve. Further embodiments include a multiple return line pneumatic pump / well, which allows the use of multiple return lines on a pneumatic pump when used to pump water from very deep wells where piezometric surface of the water is also deep, as well as other uses for direct pressure pneumatic pumping and sampling.

Owner:BLAISDELL MARK KEVIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com