Patents

Literature

41results about How to "Accelerate liquid flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

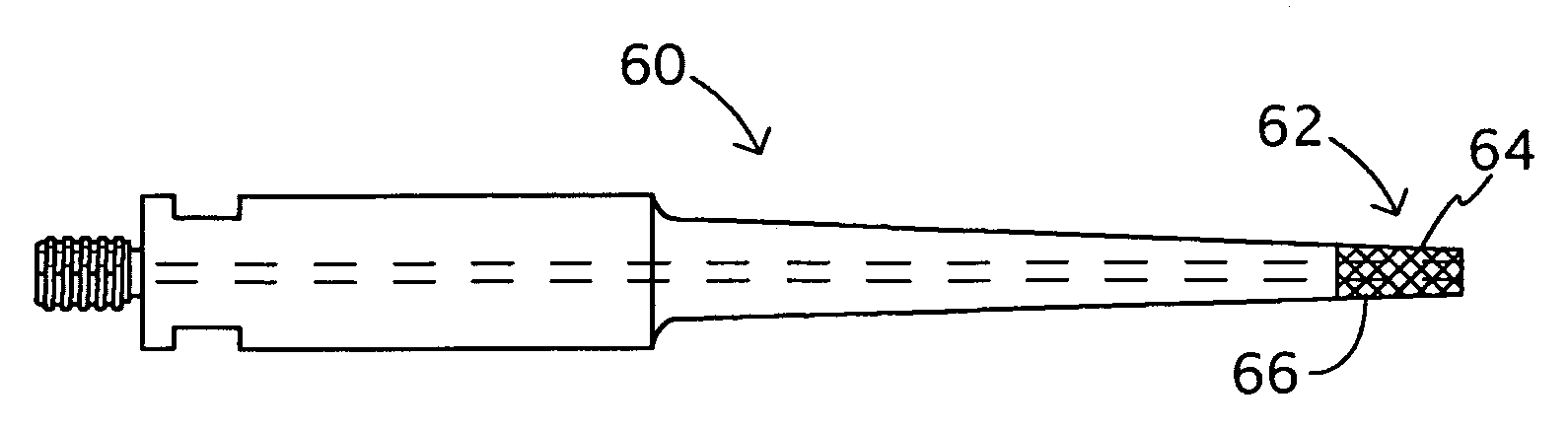

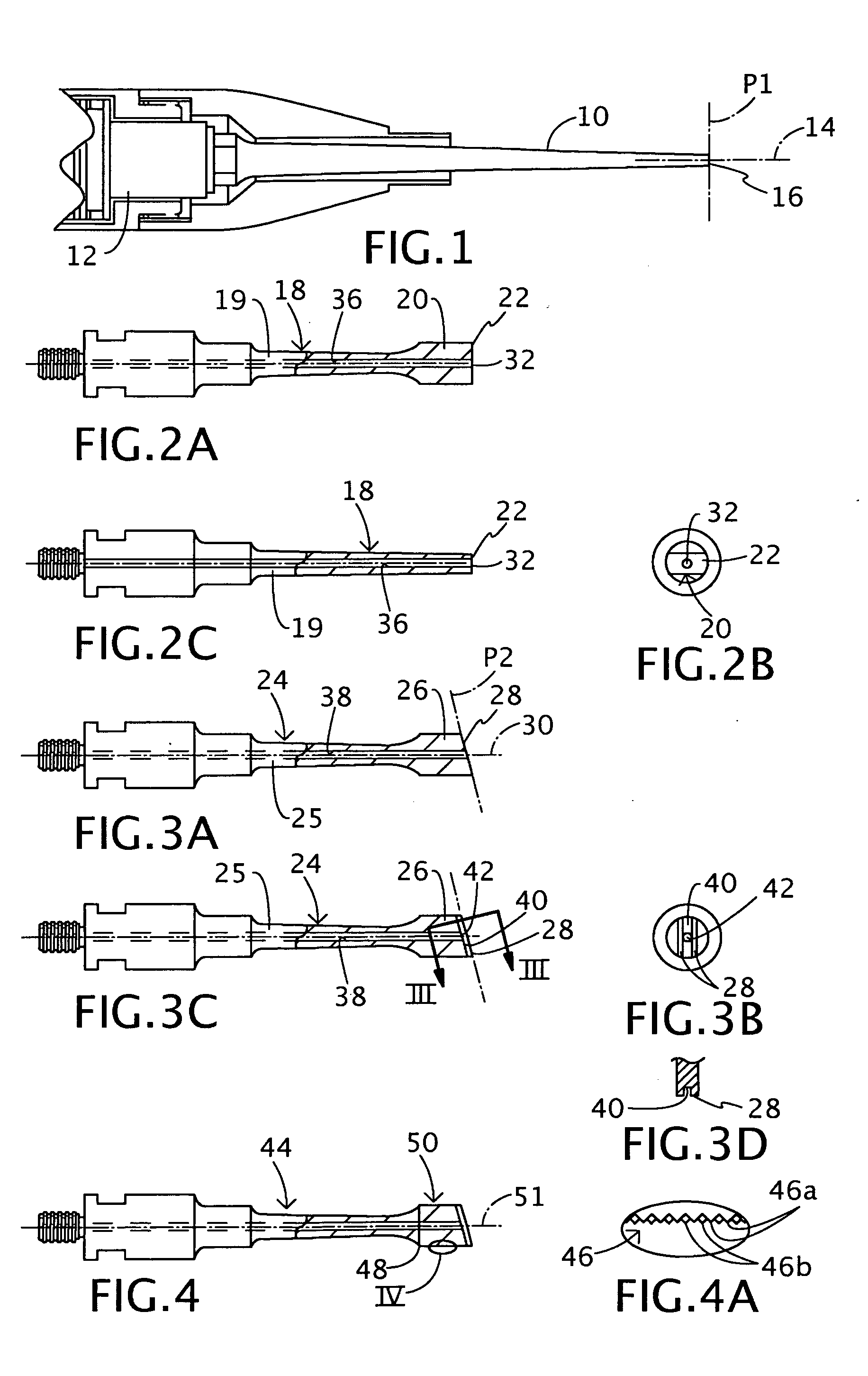

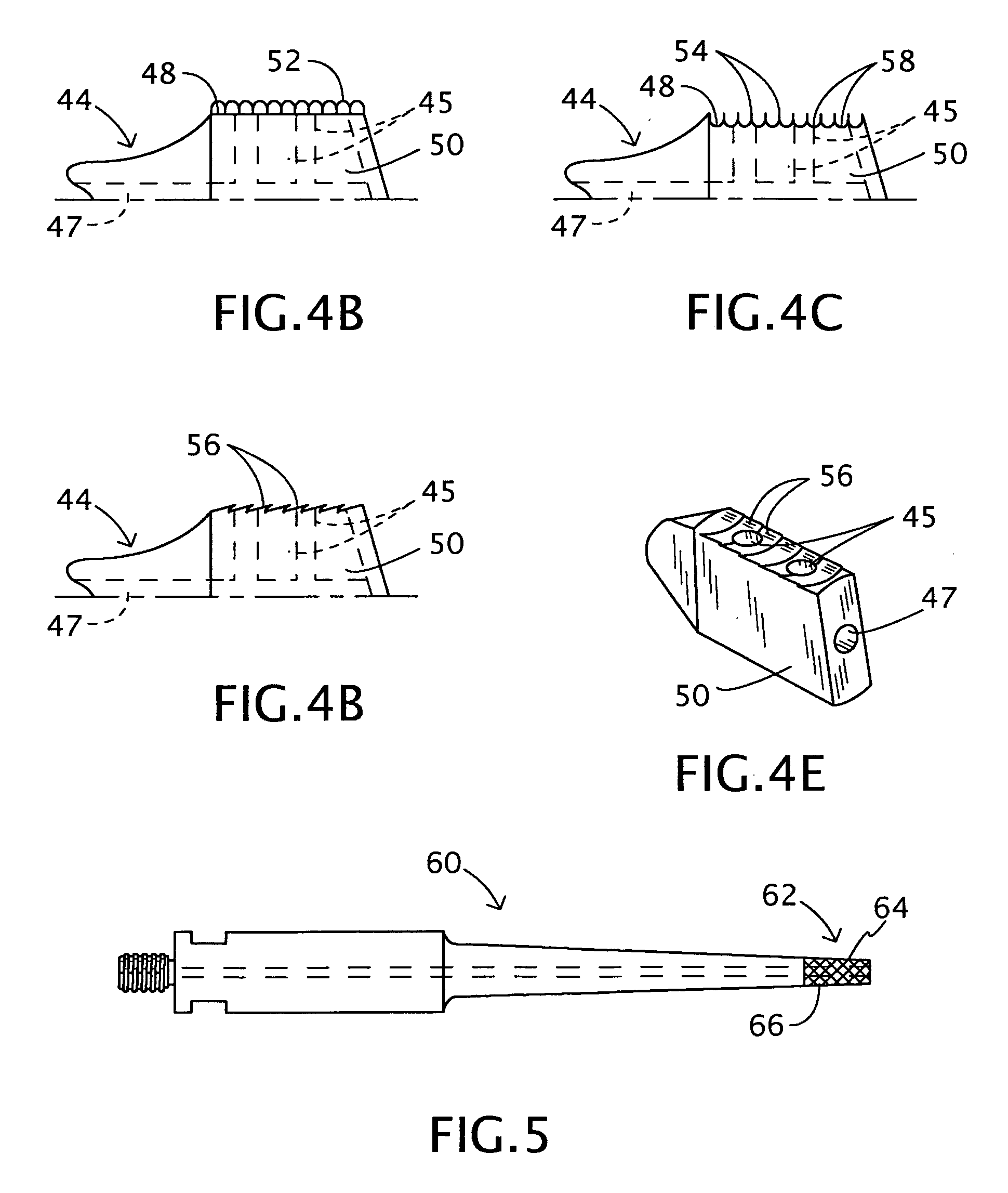

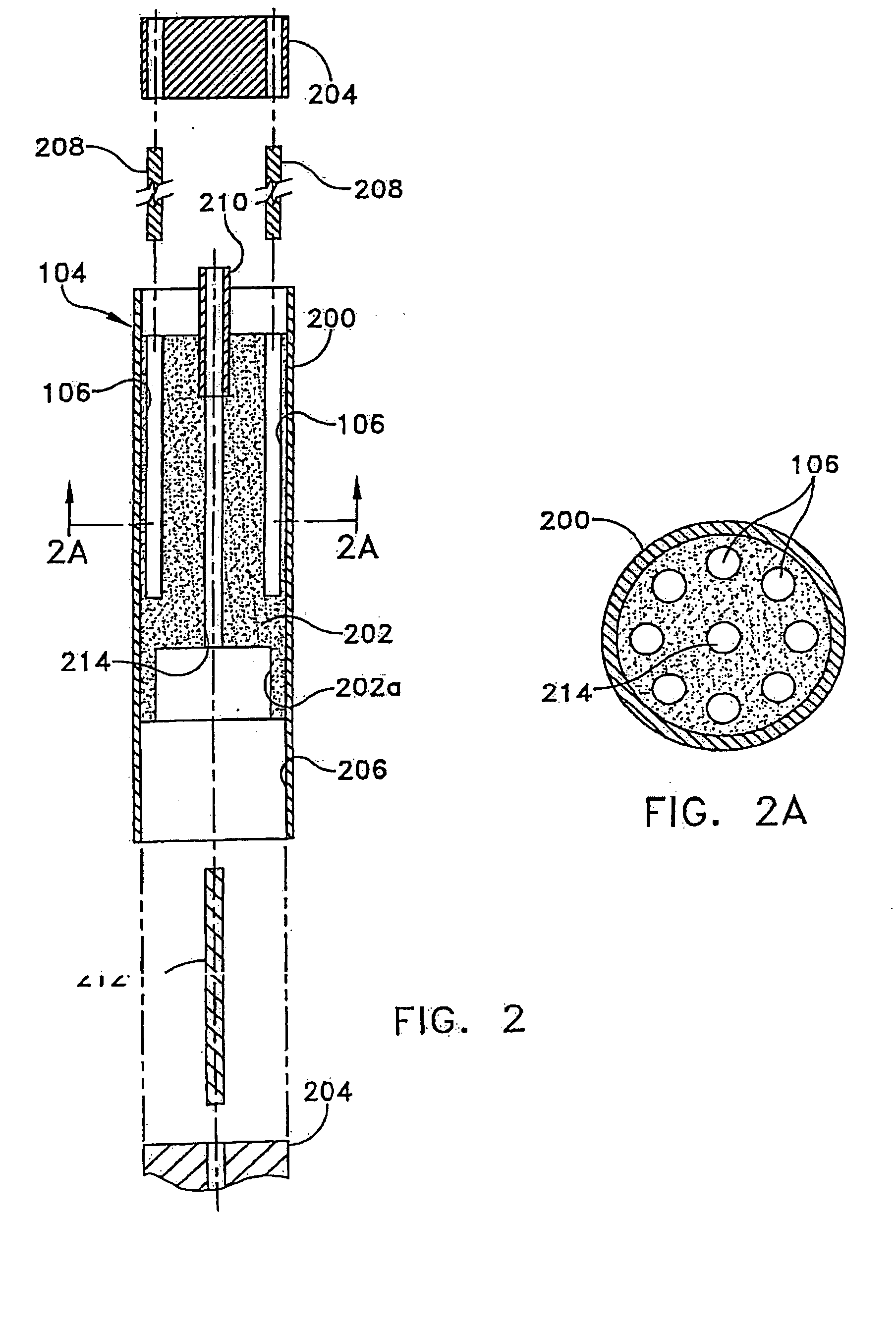

Ultrasonic debrider probe and method of use

InactiveUS20080058775A1Reduce temperature riseAvoid cloggingSurgical instrument detailsBiomedical engineeringMedical treatment

An ultrasonic medical probe has an elongate shaft with a head portion having a distal end face oriented at least partially transversely to a longitudinal axis of the shaft. The head portion has a lateral surface extending substantially parallel to the longitudinal axis, the lateral surface being provided with outwardly or radially extending projections. The shaft of the probe is provided with an internal longitudinal channel or bore and at least one ancillary or tributary channel communicating at an inner end with the longitudinal channel or bore and extending to the lateral surface. The ancillary or tributary channel has an outer end disposed in a region about the projections. The projections may be finely configured and distributed so as to form a knurled surface on the head portion.

Owner:MISONIX INC

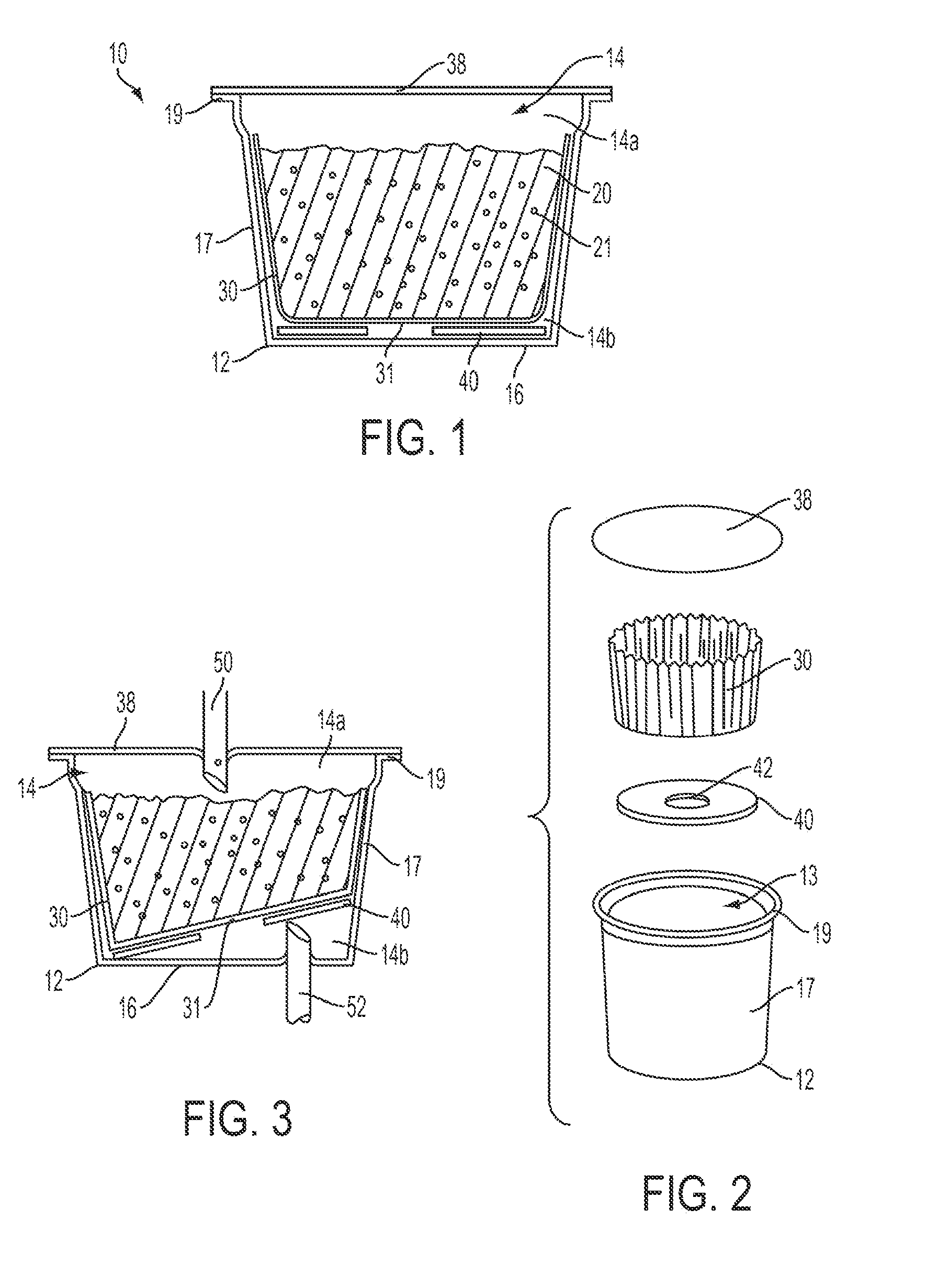

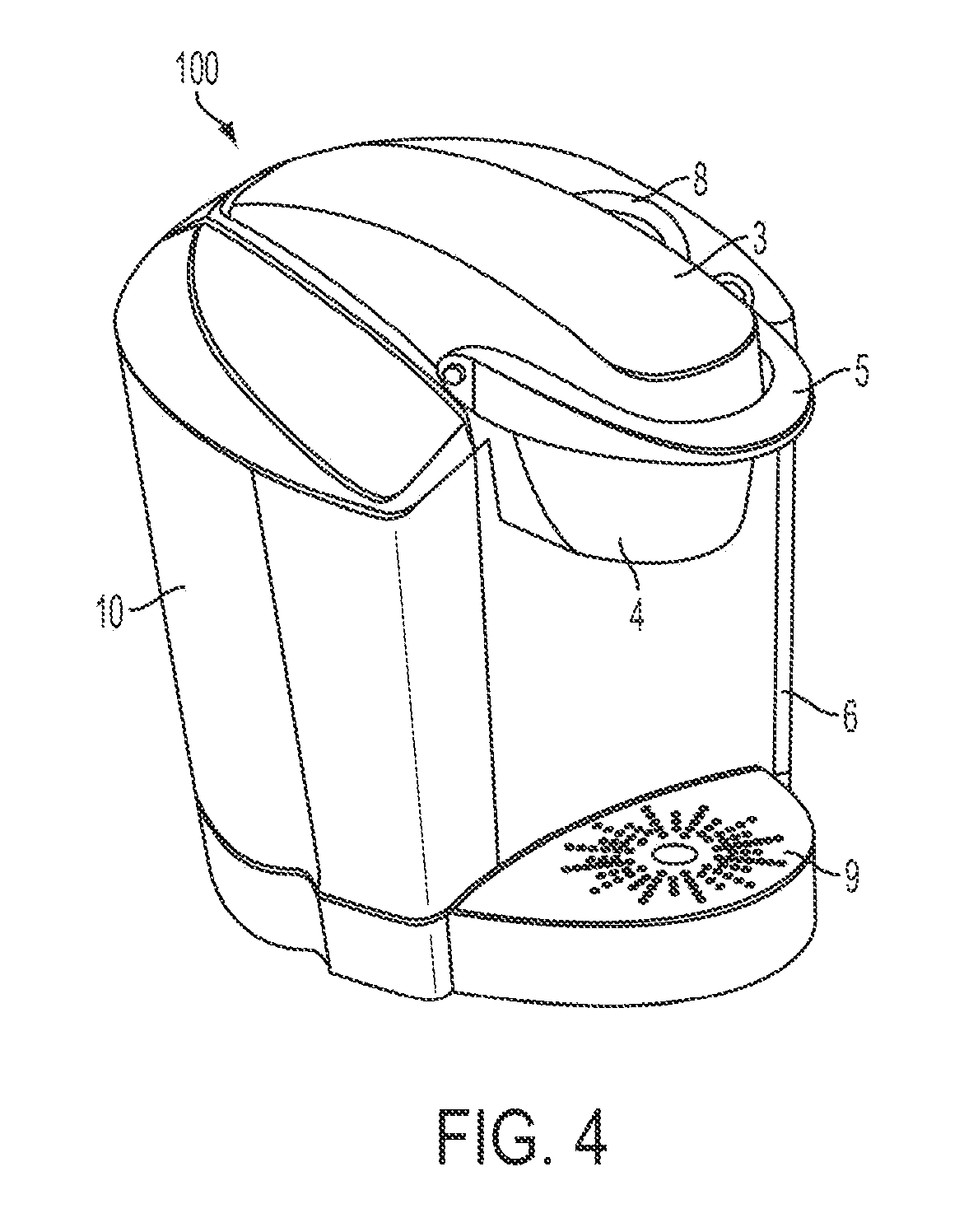

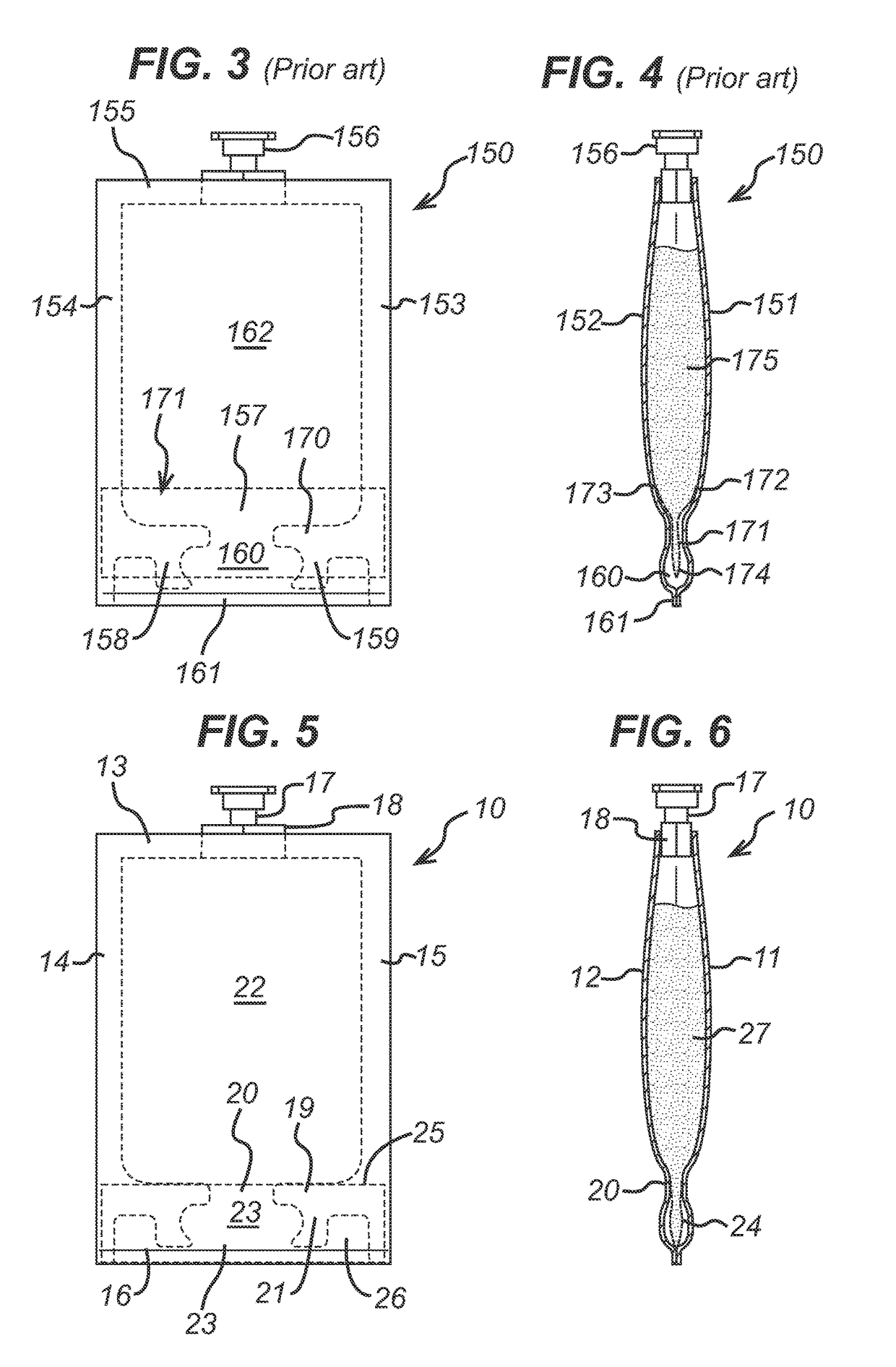

Beverage cartridge and method for beverage formation using filter aid

InactiveUS20110076361A1Speed up circulationReduce cloggingTea extractionBeverage vesselsParticulatesCellulose

A method and apparatus for forming a beverage involves the use of a filter aid, e.g., that is provided in a beverage cartridge with a beverage medium in a dry state. In one embodiment, a cartridge including a dried fruit material may also include a filter aid, such as perlite, diatomaceous earth or cellulose, that is mixed together with the fruit material. The filter aid may assist in flow through the beverage medium or through a filter, e.g., by helping prevent the clogging of pores of a filter used to remove particulate from a beverage formed by interaction of the beverage medium with water introduced into the cartridge. Thus, the filter aid may permit the use of some beverage media that would otherwise clog a filter and / or prevent proper dissolution of materials in the beverage media without the filter aid.

Owner:GREEN MOUNTAIN COFFEE ROASTERS INC

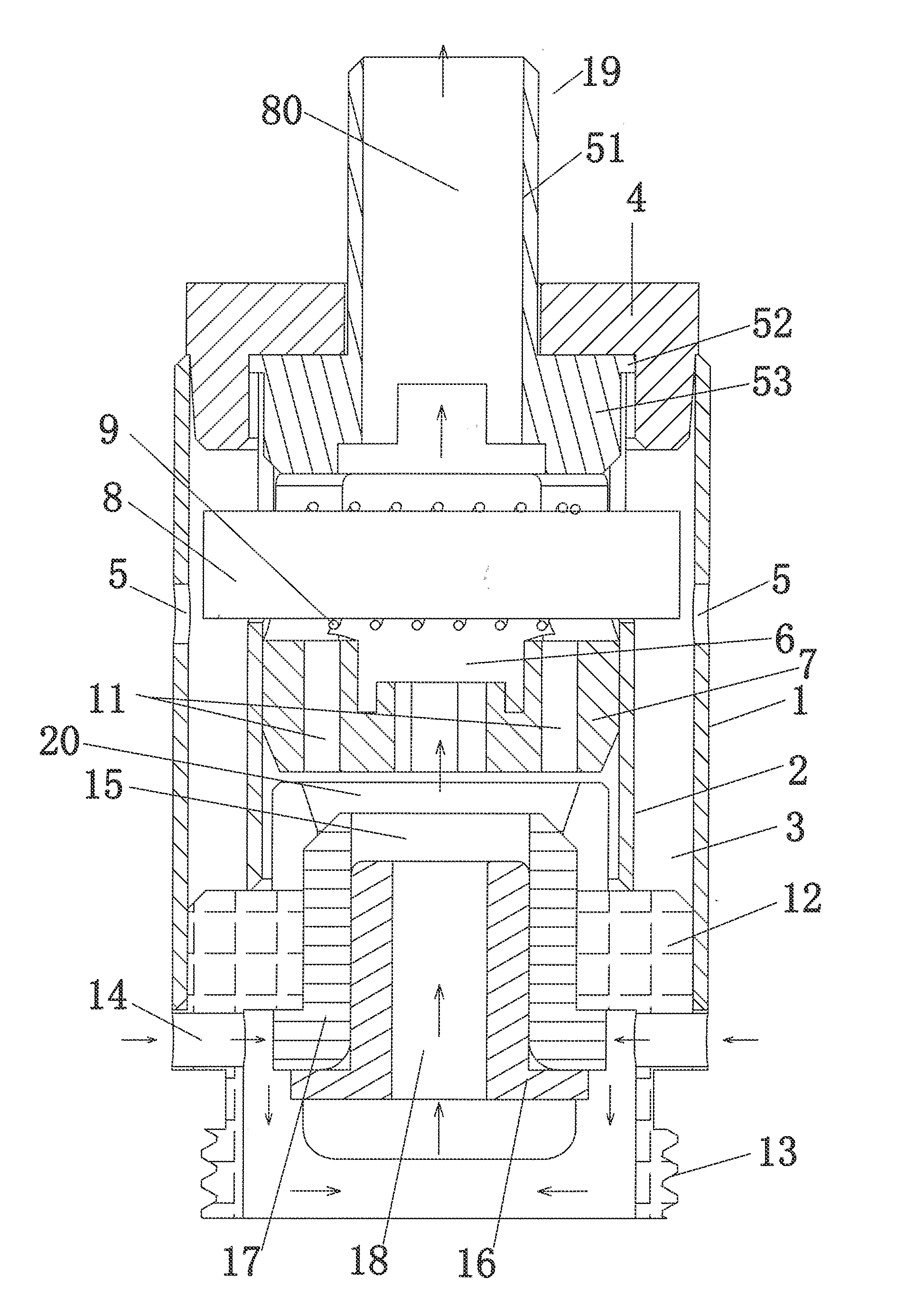

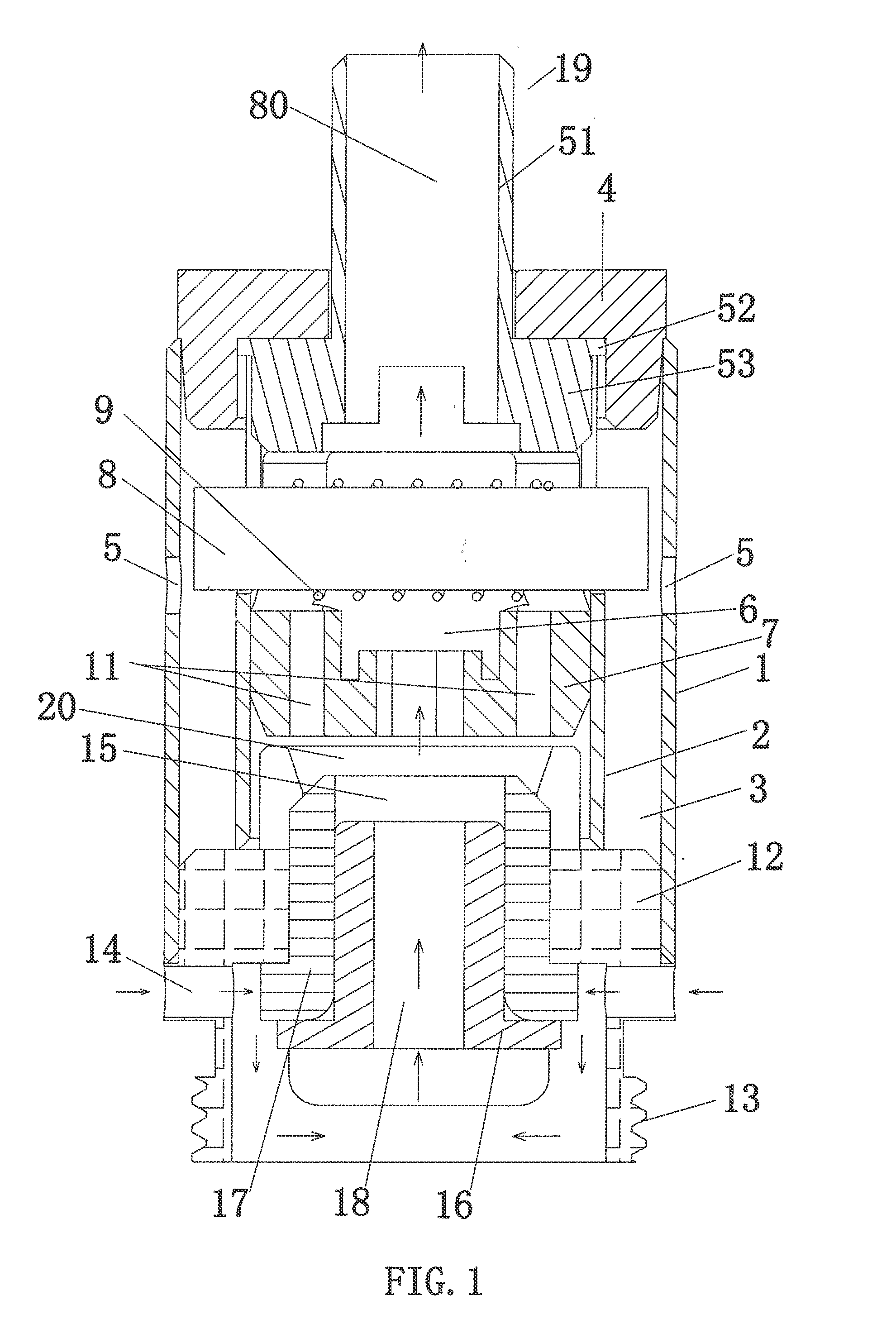

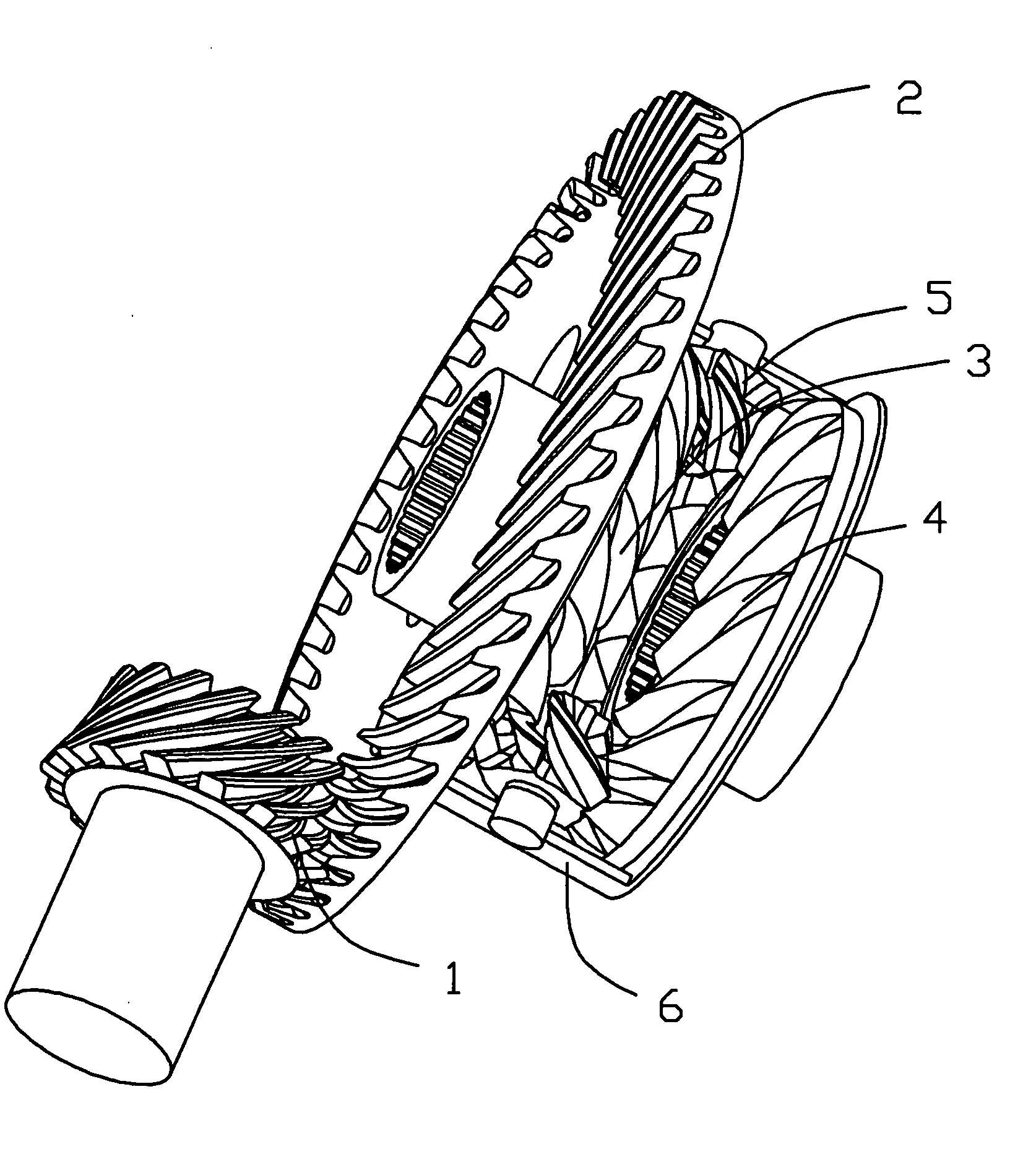

Atomizing Head

ActiveUS20150059787A1Simple structureAccelerate liquid flowLighting and heating apparatusTobacco pipesEngineeringVoltage

The present invention discloses an atomizer head assembly, comprising: an outer tube; an inner tube disposed in the outer tube, having a outer supporter openings formed on a lateral side of wall of the inner tube; a liquid storage chamber formed between the inner tube and the outer tube; a liquid inlet opening formed on a lateral side of wall of the outer tube; and an atomizing member having an end arranged in the one or more outer supporter openings. Moreover, the atomizing head assembly of the present invention comprises a plurality of atomizing members for atomizing liquid electrically connected in parallel and spatially arrange in various configurations, such that the atomizer head assembly can operated with an elevated voltage such that the heat generated per unit time by the atomizer head assembly is increased and the volume of atomized cigarette liquid in the atomizing chamber is increased accordingly.

Owner:JOYETECH CHANGZHOU ELECTRONICS

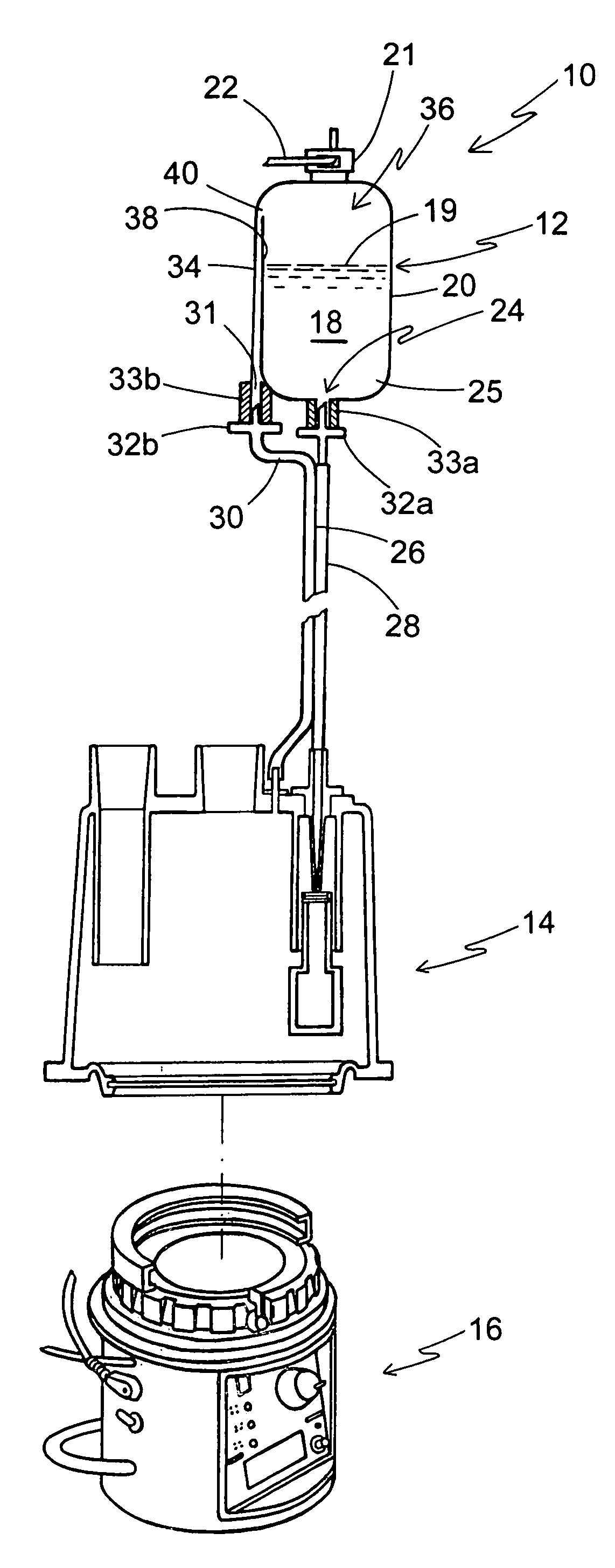

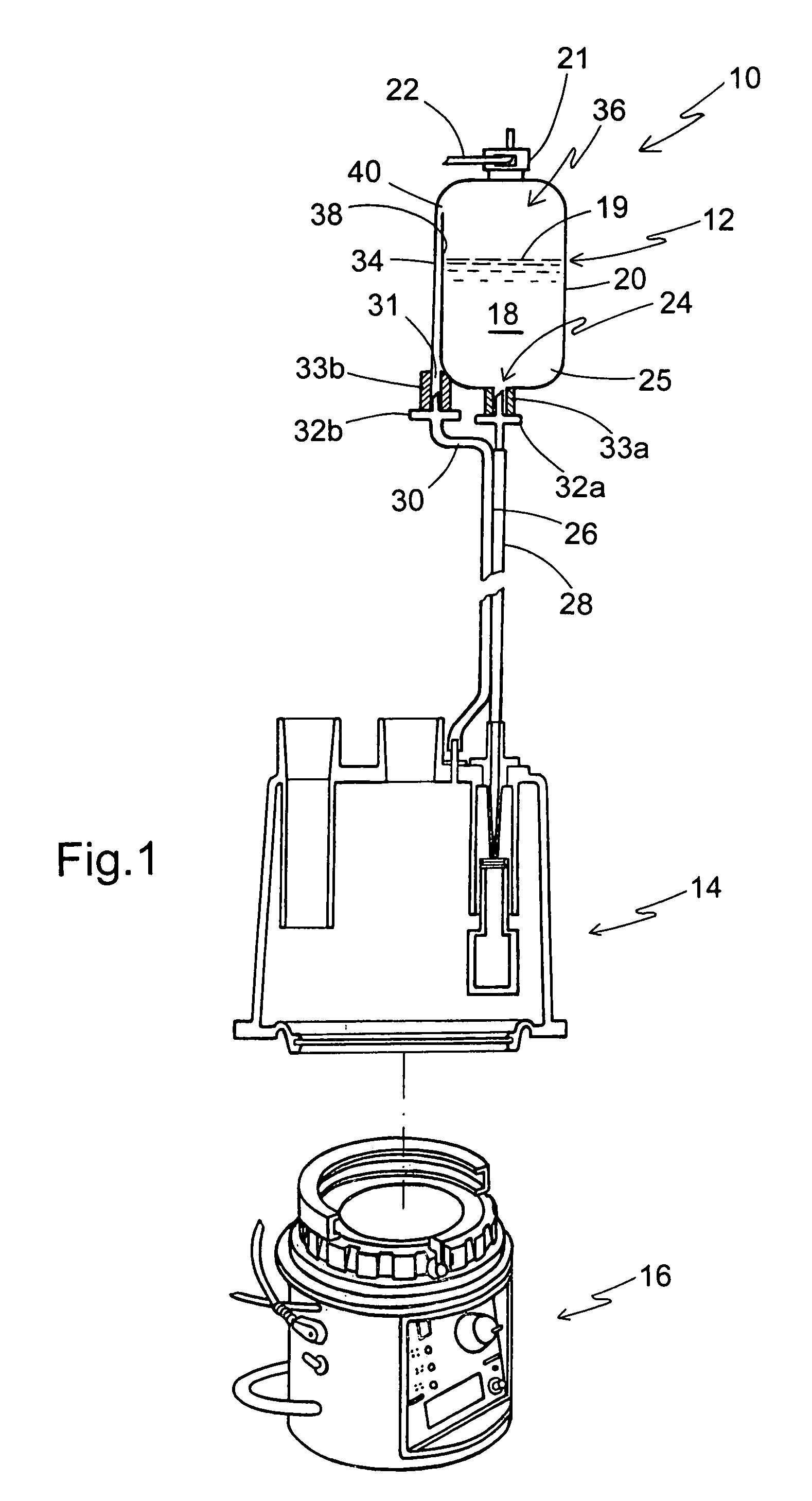

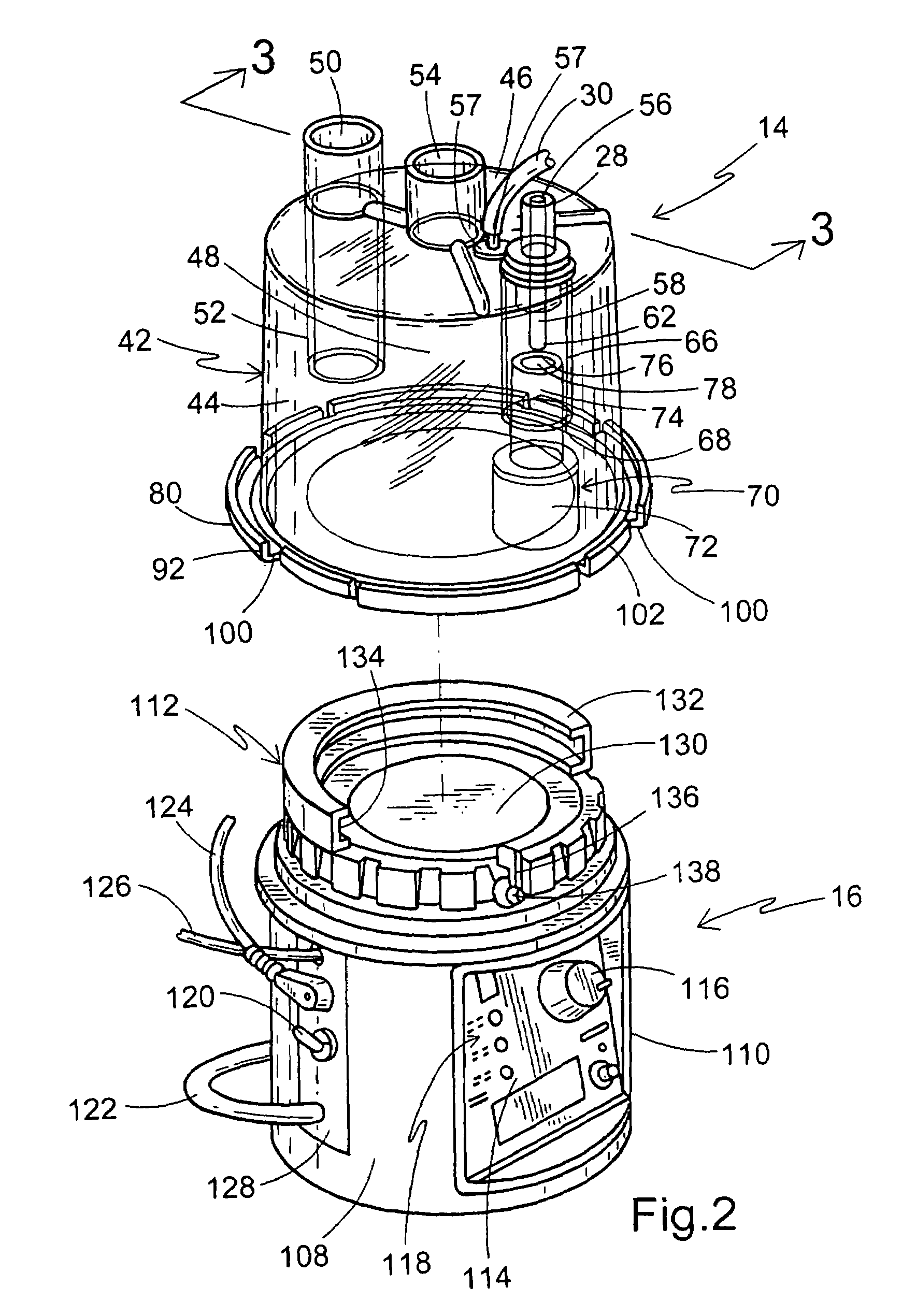

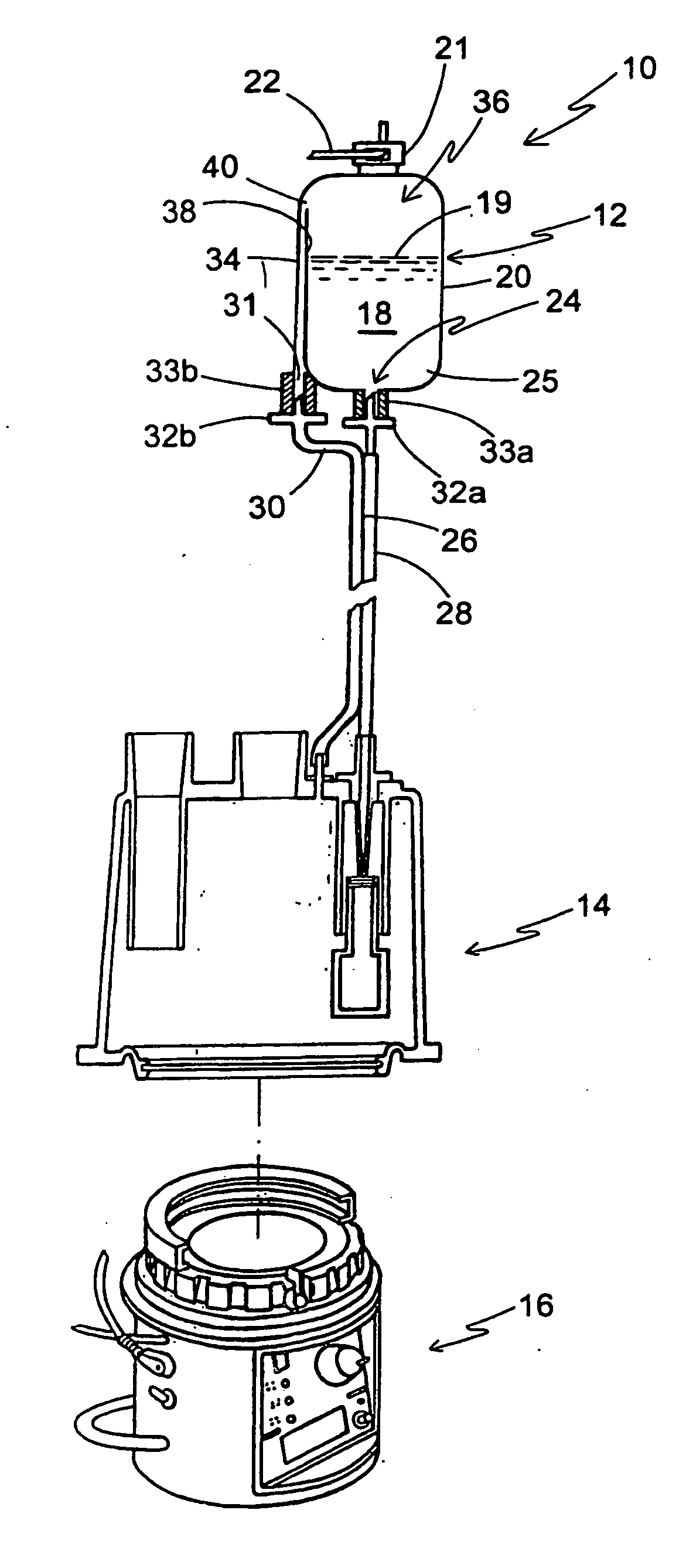

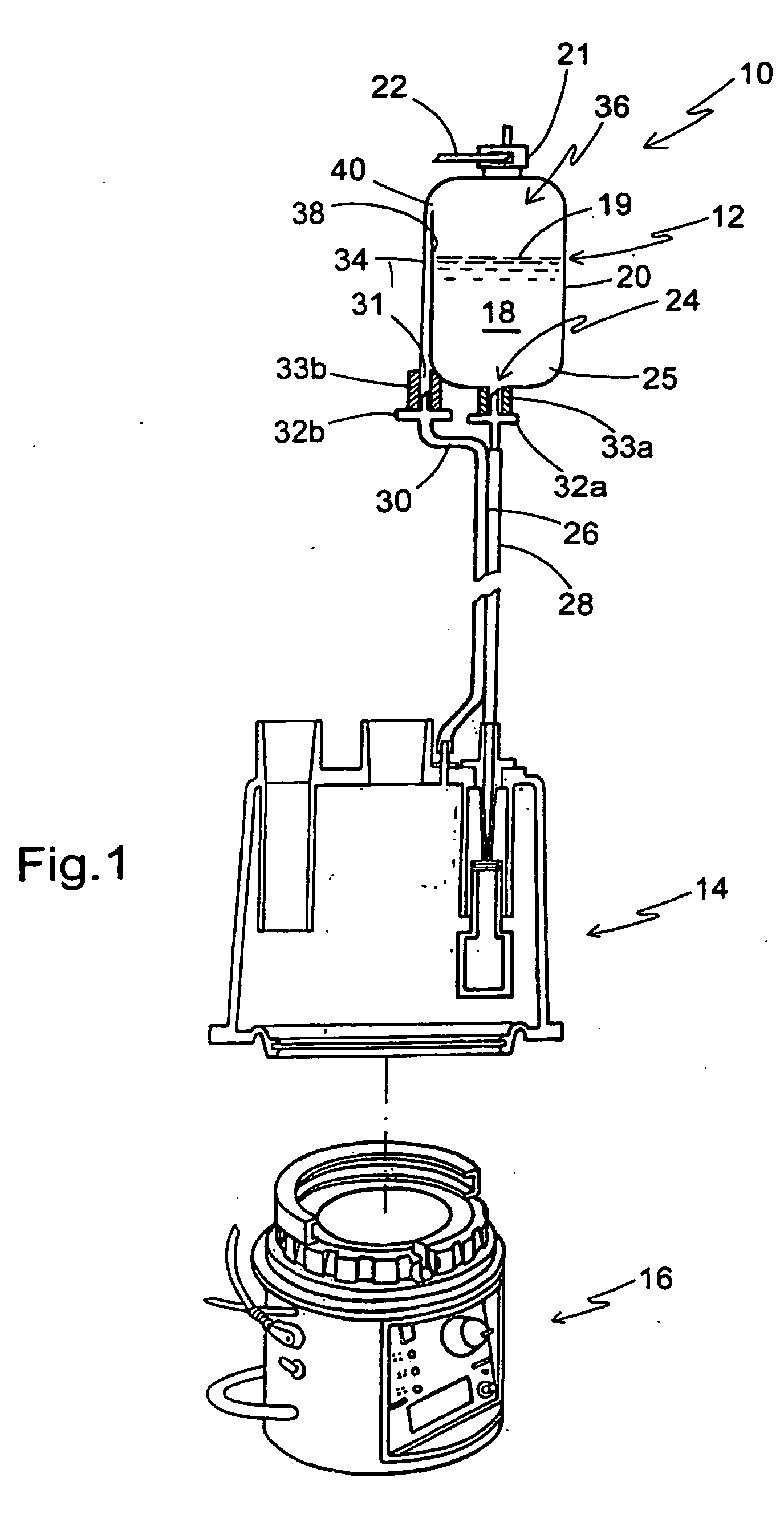

Apparatus for equalizing air pressure in air respiratory system

InactiveUS6988497B2Accelerate liquid flowBurnersOther heat production devicesHigh concentrationBreathing gas

A humidifier apparatus for operating at an air pressure is disclosed for use with a respiratory therapy breathing apparatus that provides a breathable gas supply to patients requiring higher concentrations of liquid vapor and gas pressure. The humidifier apparatus includes a feed liquid supply bag in fluid communication with a humidifier cartridge via a conduit. The conduit enables air to flow therethrough to equalize air pressure between the humidifier cartridge and the feed liquid supply bag in response to liquid being supplied to the humidifier cartridge.

Owner:MEZZANINE OPPORTUNITIES LLC AS AGENT

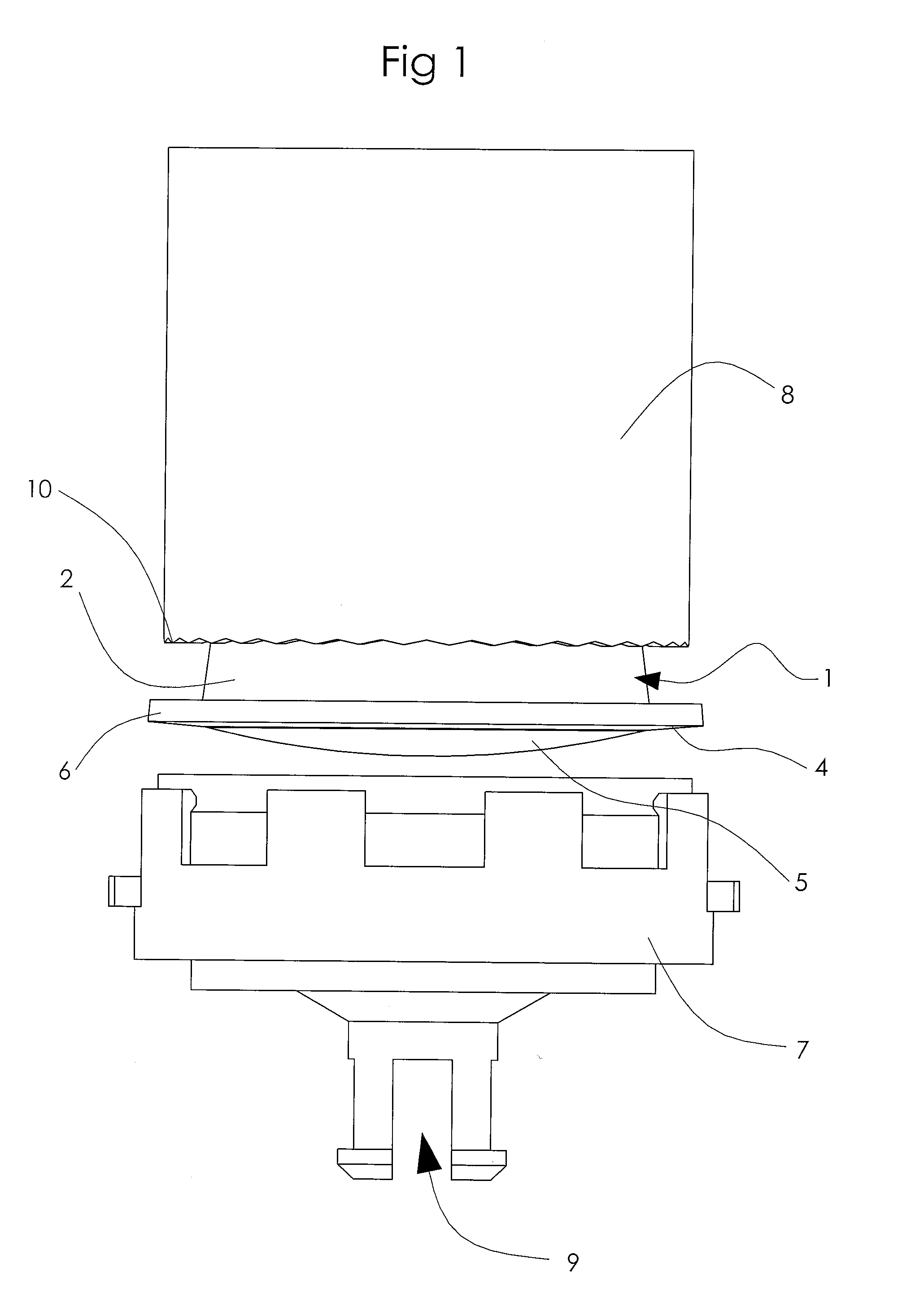

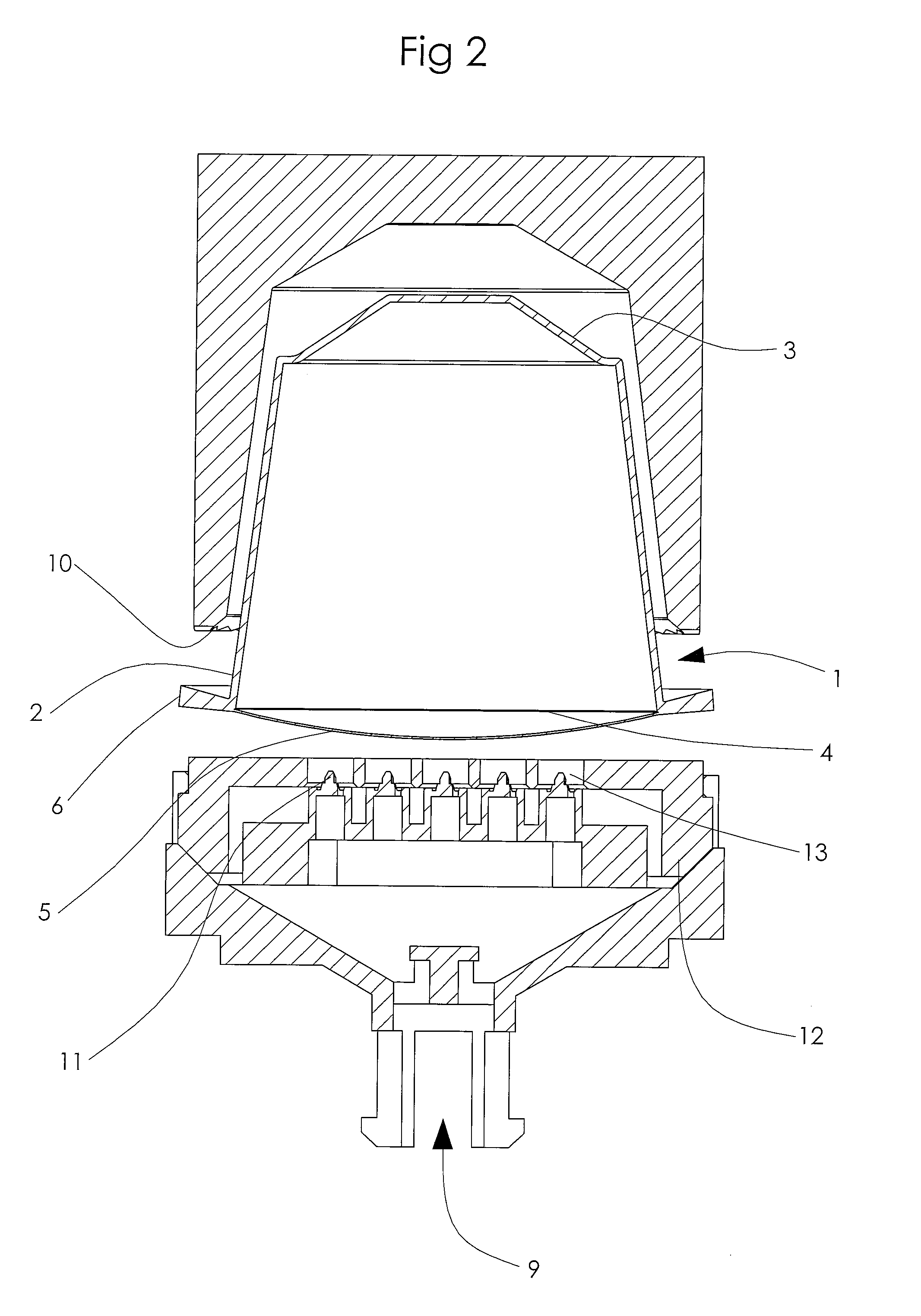

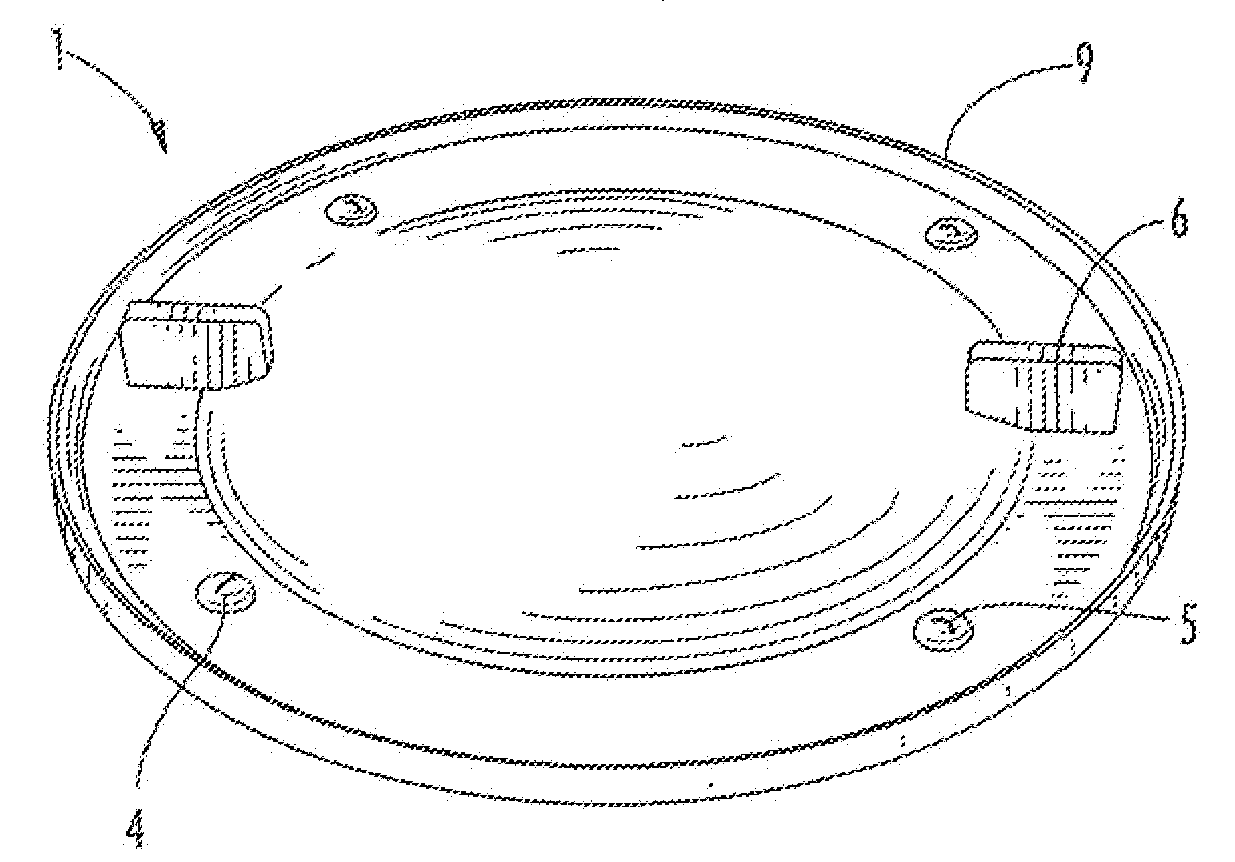

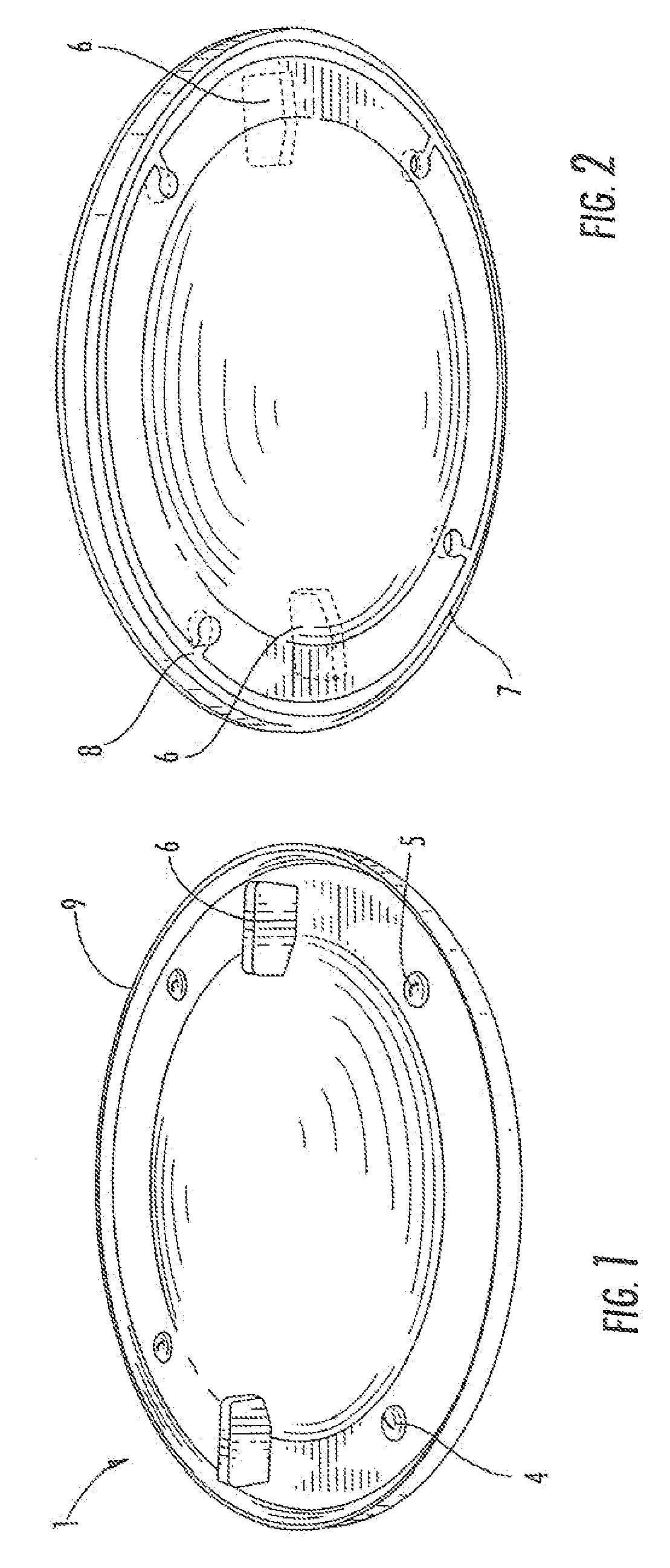

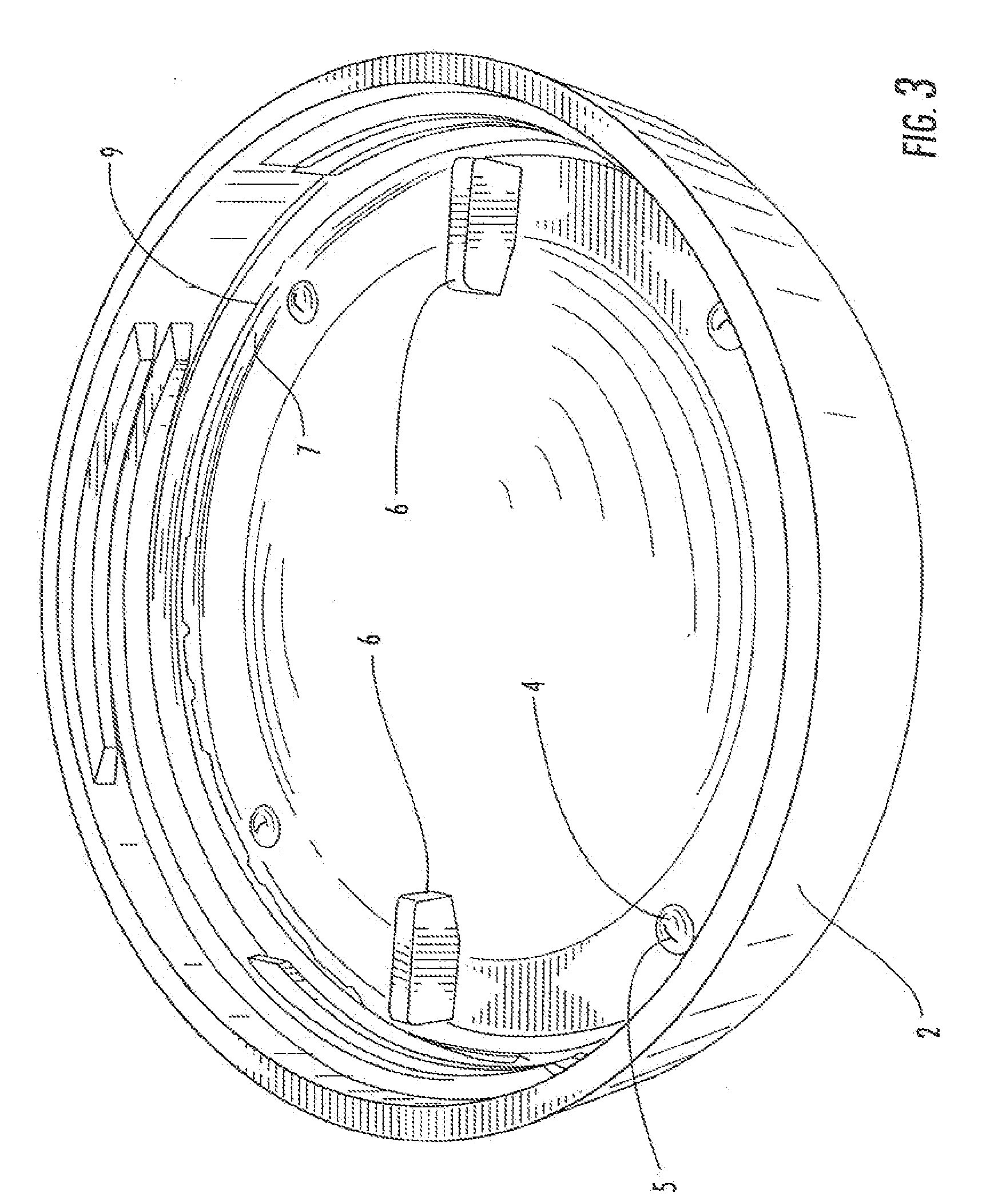

Capsule for preparing a drink

InactiveUS20110297005A1Easy to centerAccelerate liquid flowFlexible coversWrappersLower faceGround coffee

The invention relates to a capsule for preparing a drink, for example coffee, comprising a hollow element (1,1a,1b) for containing a dose, for example of ground coffee. Said hollow element (1,1a,1b) has a lateral wall (2, 2a, 2b), an upper face (3) and a lower face (4), the lower part of said lateral wall (2, 2a, 2b) extending in such a way as to create a rim (6, 3a, 3b) oriented along a plane cutting the lateral wall (2, 2a, 2b). The invention is characterised in that the thickness of the upper face (3) and / or the lateral wall (2, 2a, 2b) and / or the rim (6, 3a, 3b) is variable.

Owner:ETHICAL COFFEE COMPANY

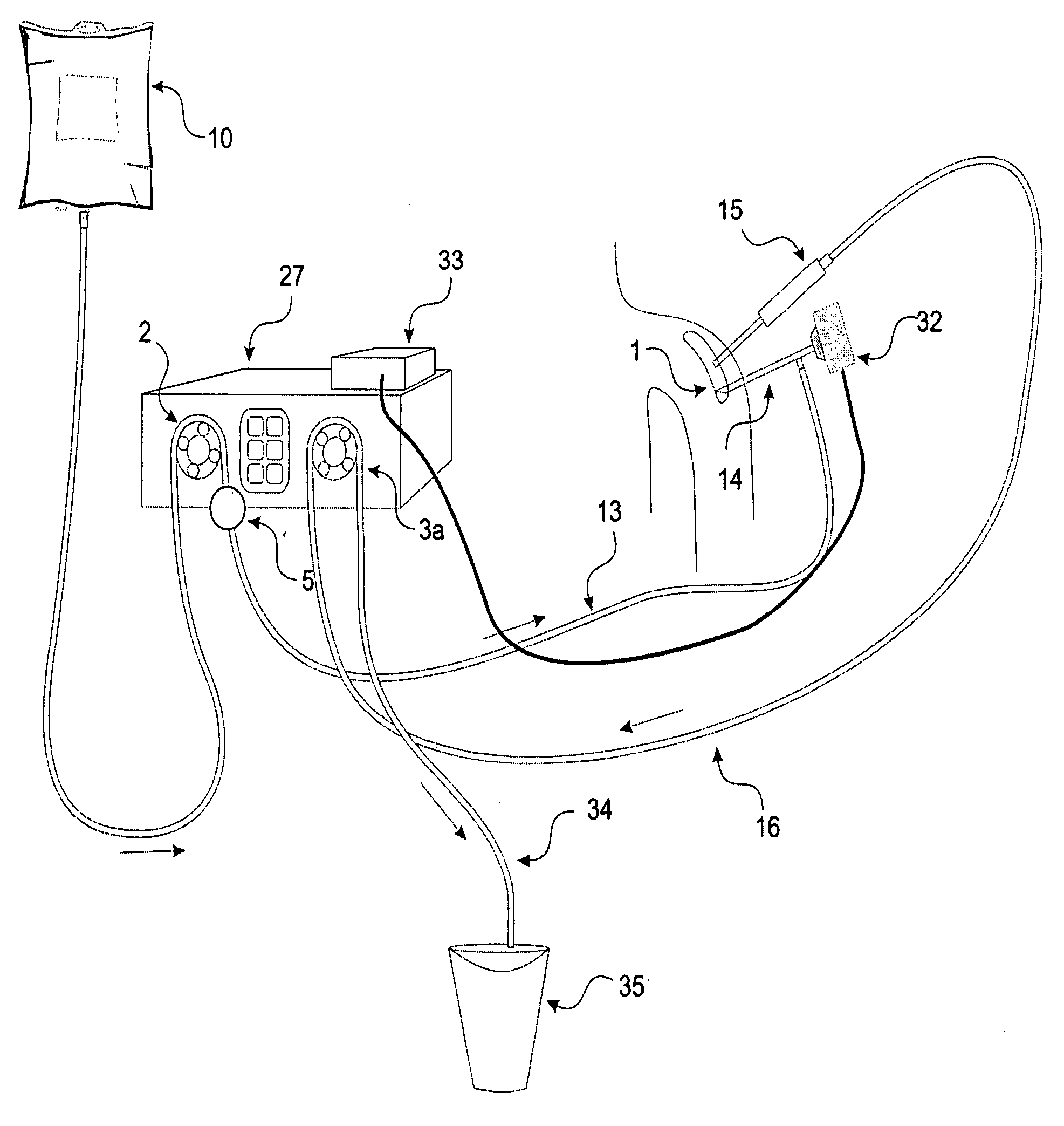

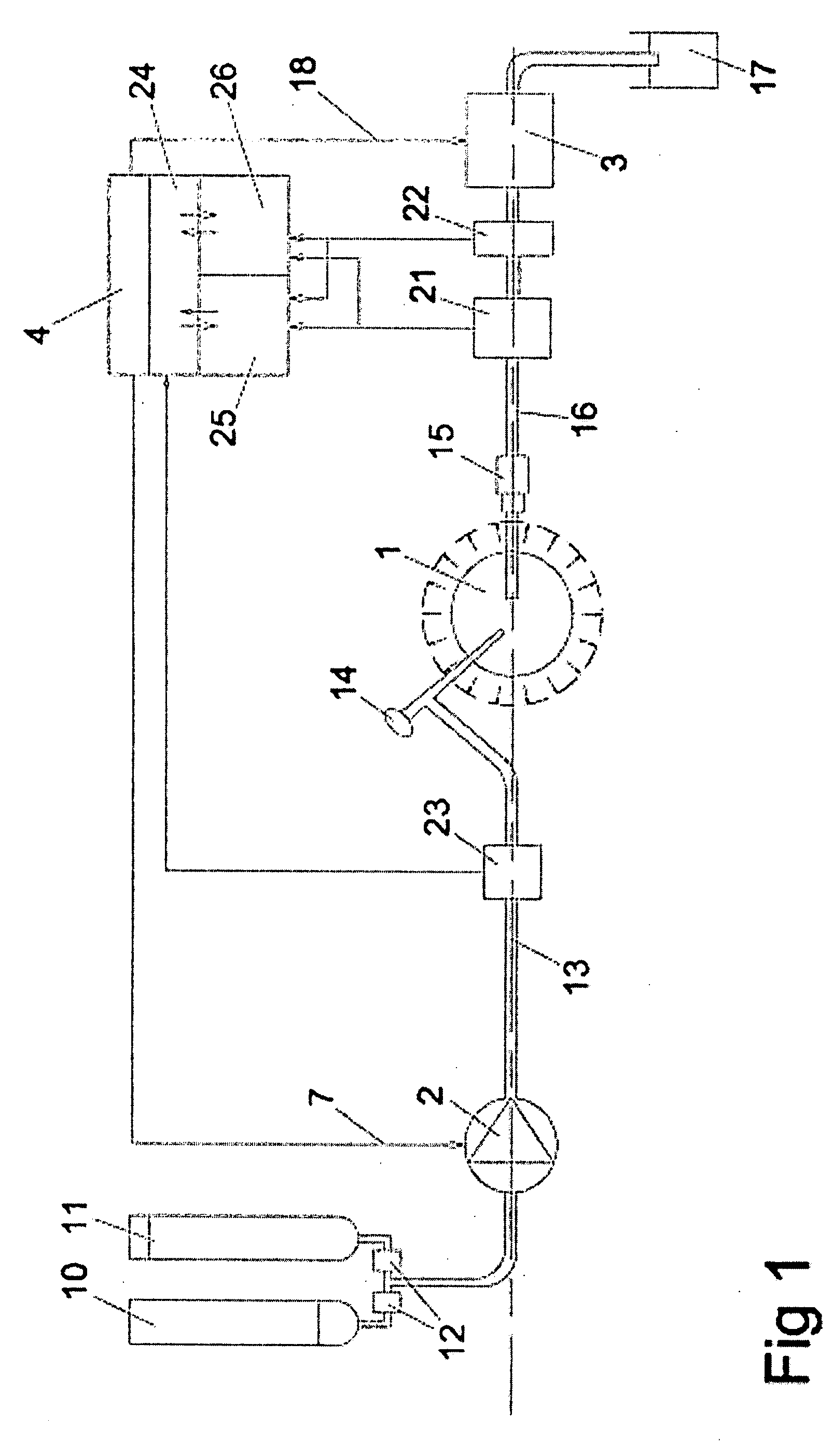

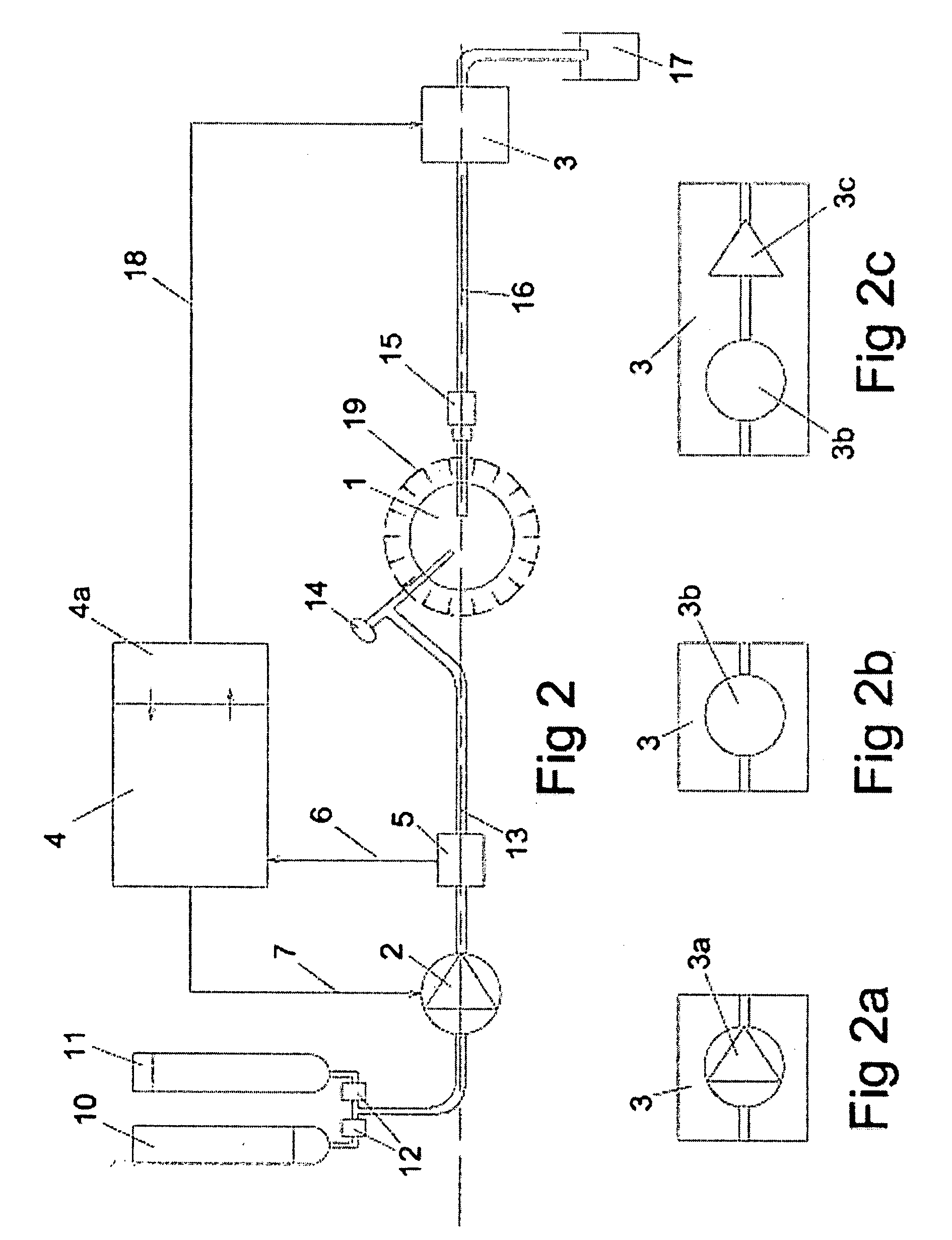

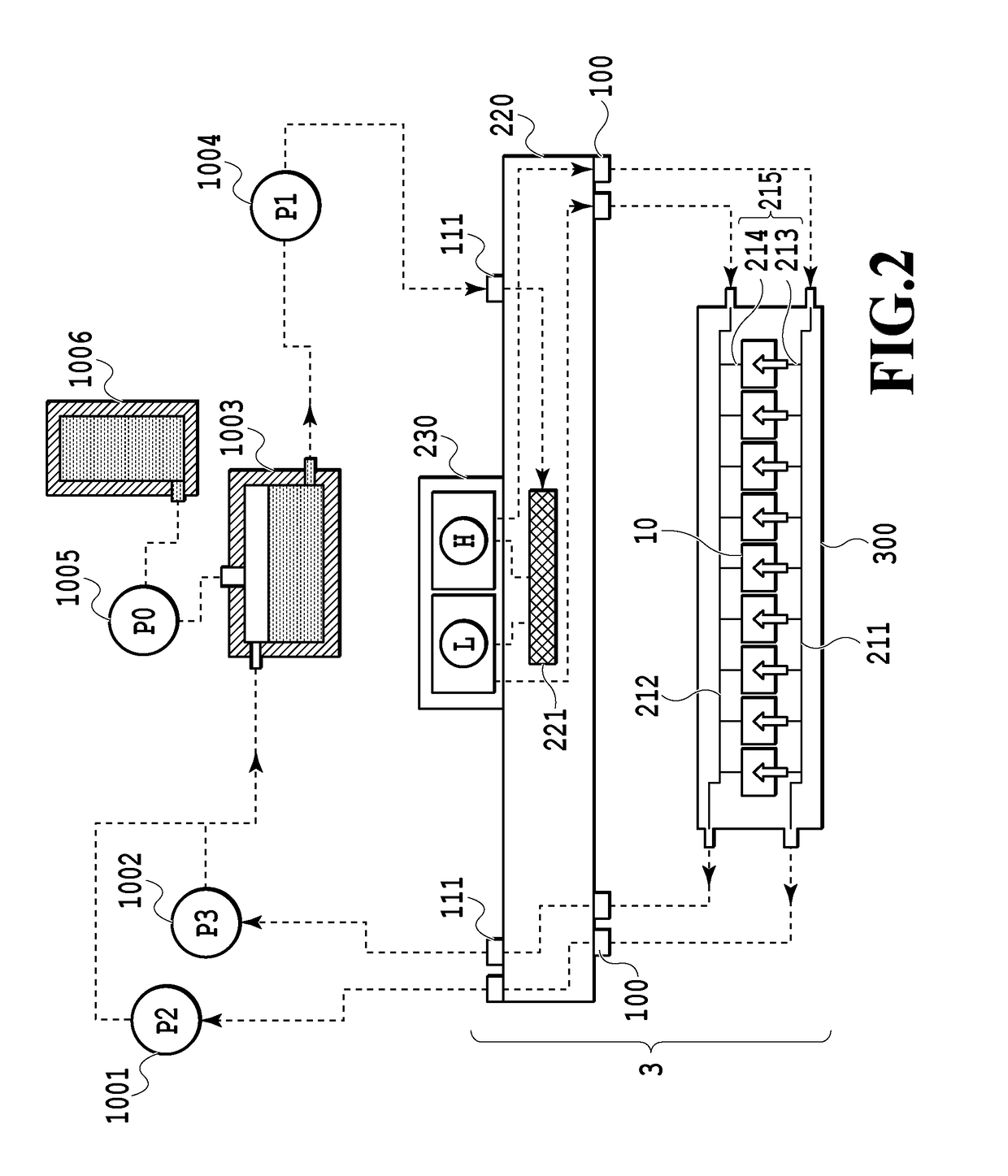

Method and device for irrigation of body cavities

ActiveUS20080243054A1Accelerate liquid flowGood blood pressureEndoscopesMedical devicesSurgical siteControl cell

A pressure and a vision regulation method and device for irrigation of a body cavity (1), in which method an inflow liquid pump (2) pressurizes the irrigation liquid in a feed line (13) and in which an outflow device (3) or an external suction source (20) drains the irrigation liquid from the body cavity (1) through a tubing (16) into a waste container (17) and in which a control unit (4) controls either the inflow liquid pump (2) only or both the inflow liquid pump (2) and the outflow device (3) depending on an inflow irrigation liquid pressure from a pressure sensor (5), where the first control unit (4) compares the inflow irrigation liquid pressure and flow with pressures calculated to correspond to pressure in the body cavity for the respective flow for a nominal surgical site and that a matching between the calculated values and the inflow irrigation liquid pressures is made by altering the effect of either the inflow liquid pump (2) only or the inflow liquid pump (2) and / or the outflow device (3) and / or the shut off valve. The above-mentioned pressure registration method and the device for irrigation of a body cavity is combined with an method for detecting blood cells, red blood cells, haemoglobin and / or debris in liquid coming from a surgical site so an automatically control and rinsing system is achieved keeping a clear vision in the viewing area of the operational site.

Owner:TENNESSEE MEDICAL INNOVATIONS INC

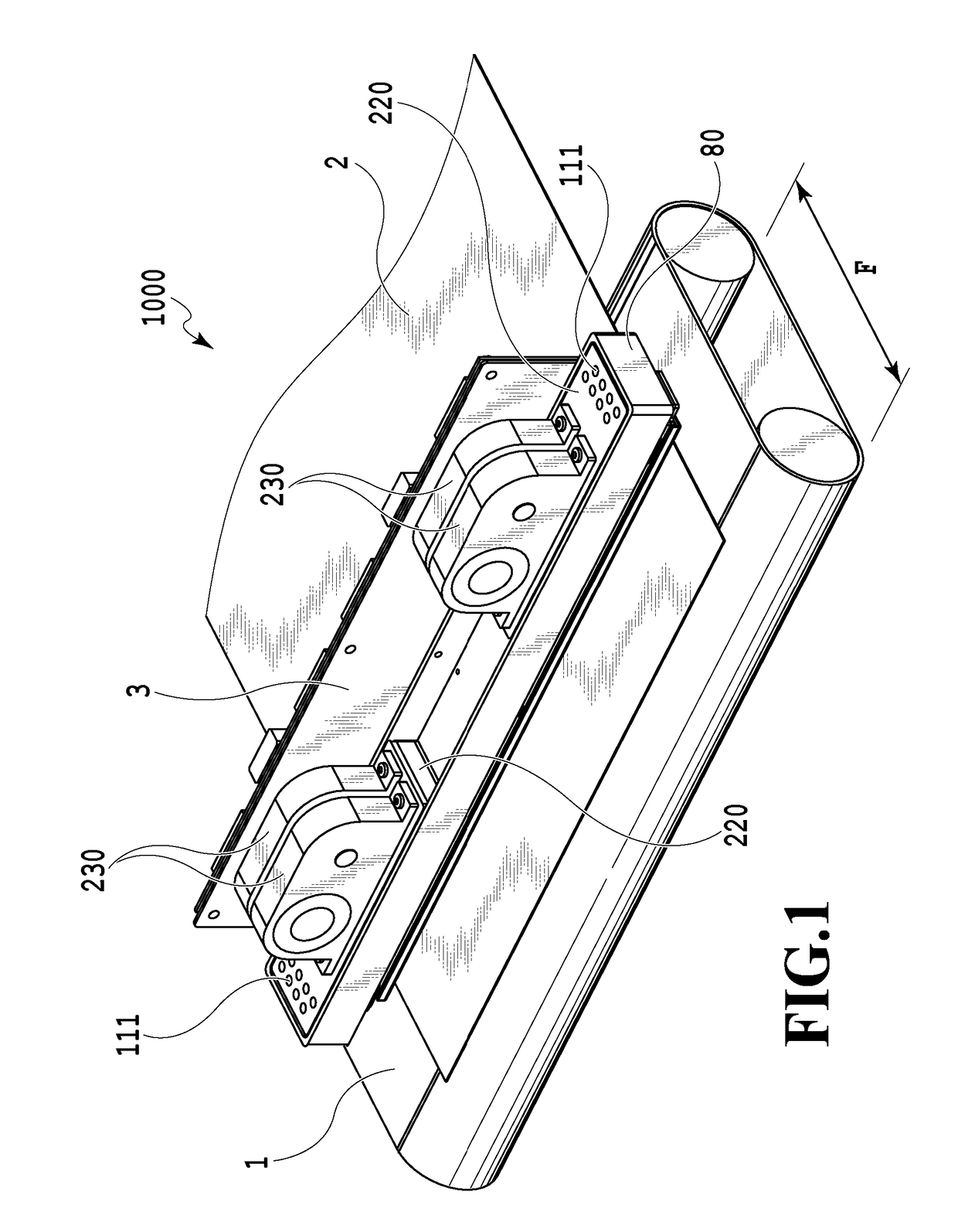

Liquid cooling device

InactiveUS20050082666A1Maximize heat exchange efficiencyAccelerate liquid flowSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringEngineering

Owner:HON HAI PRECISION IND CO LTD

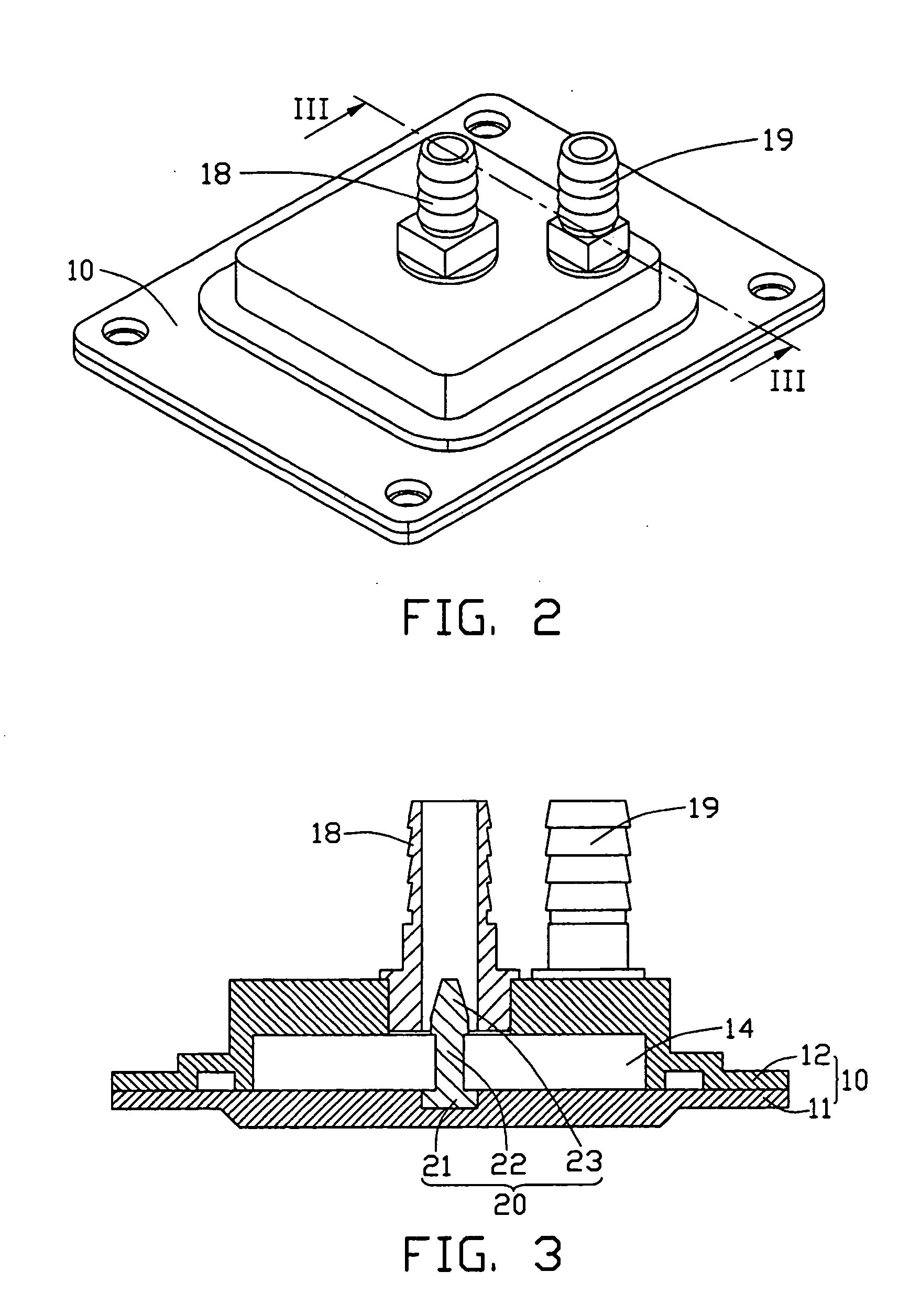

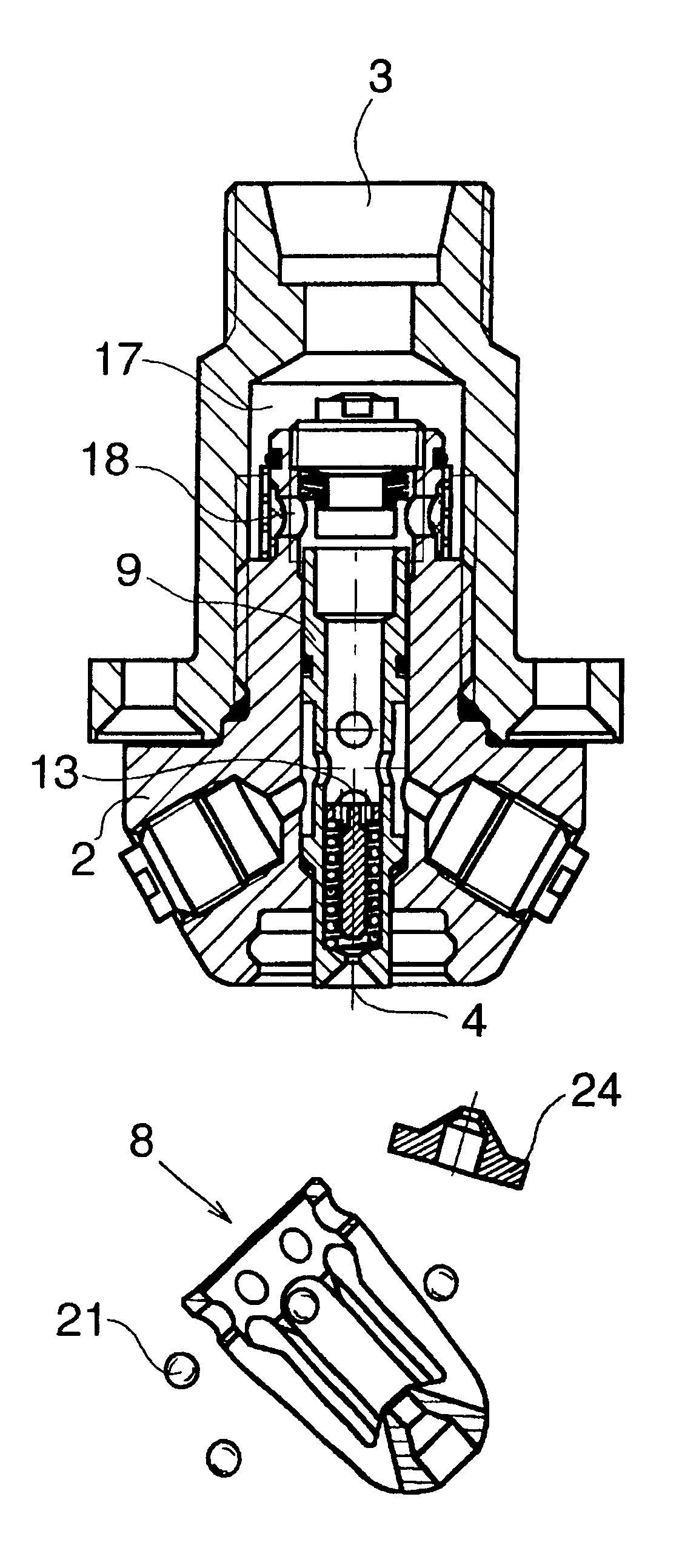

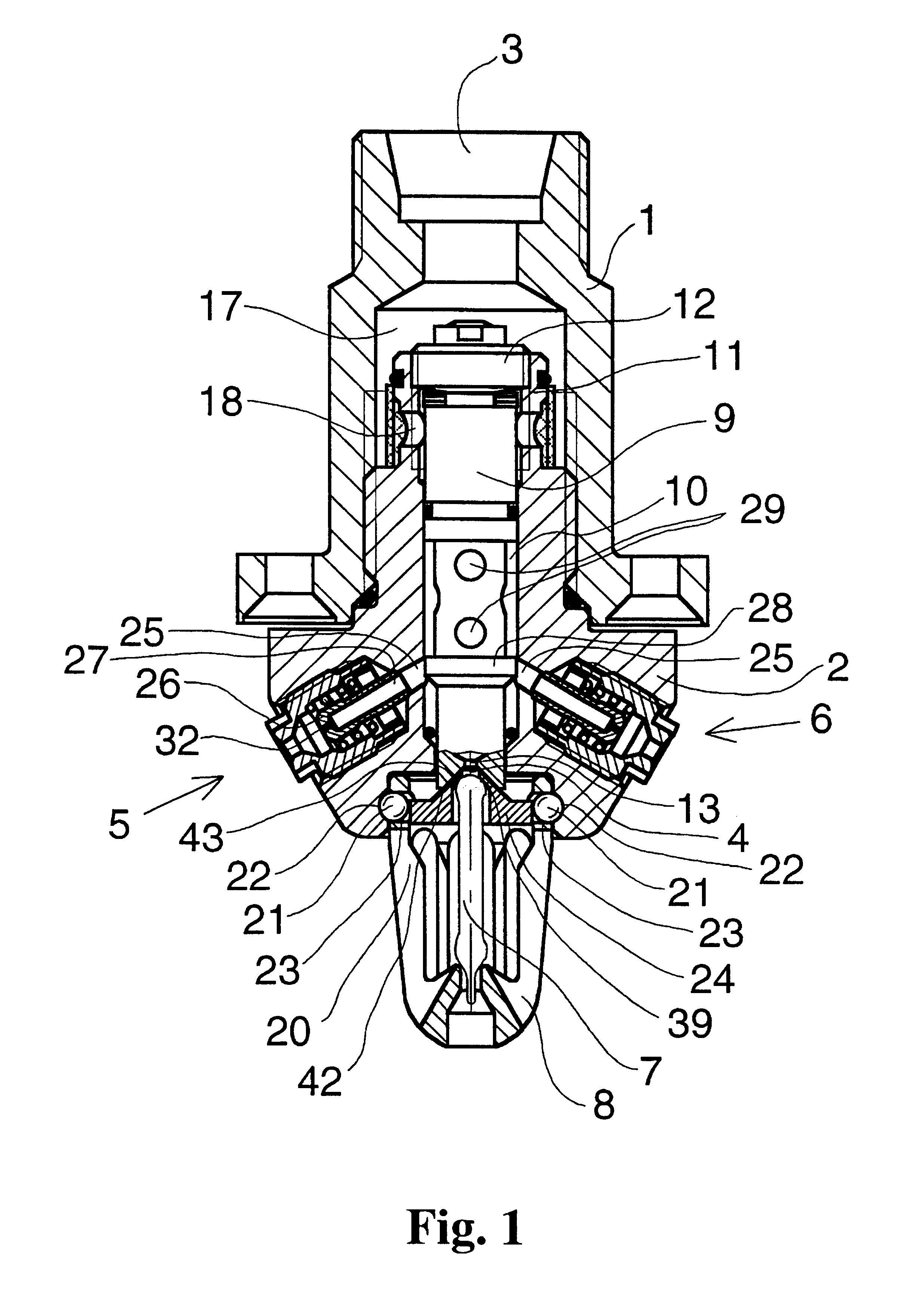

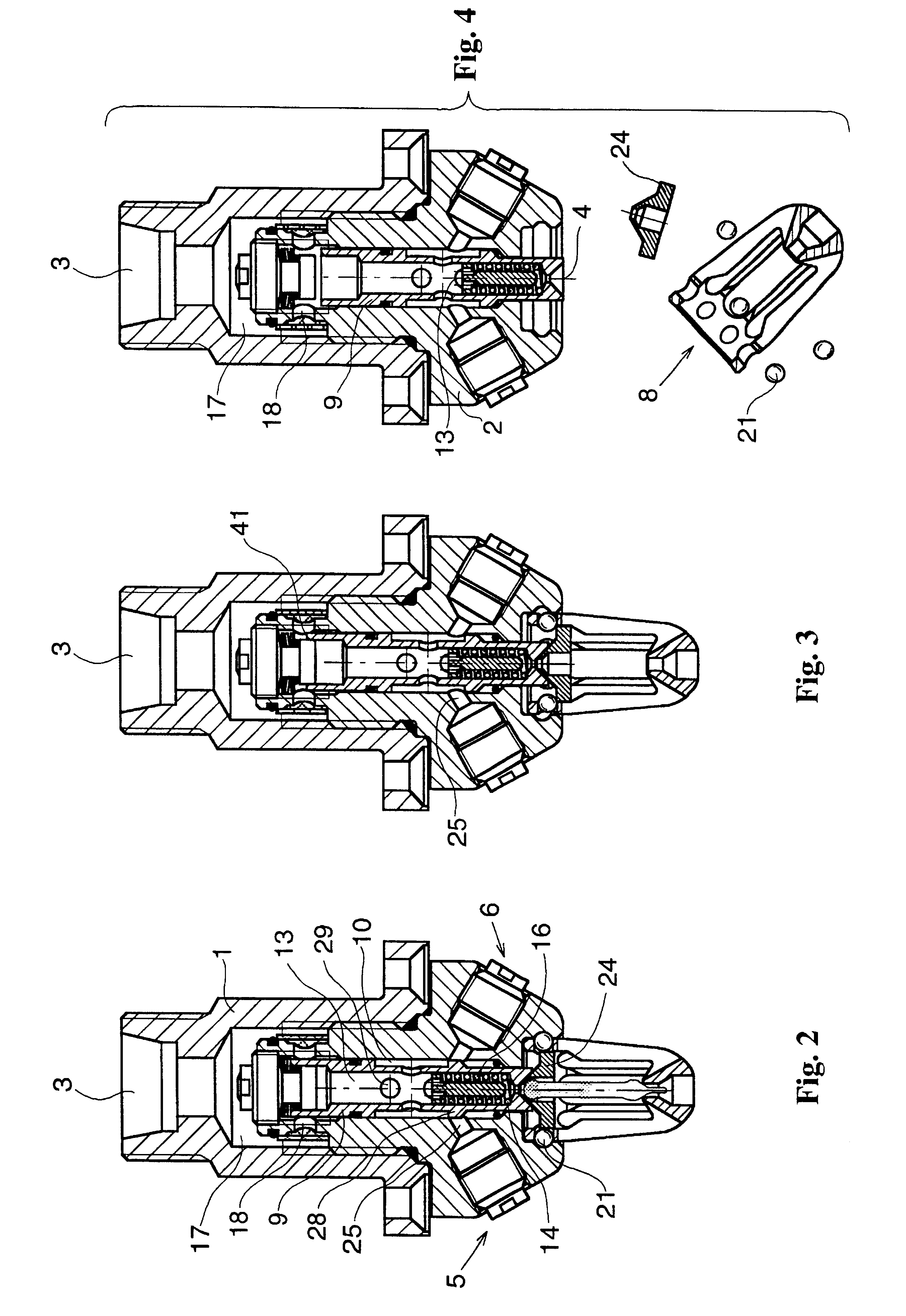

Sprinkler or spray head

InactiveUS6230815B1Increase the resistance valueAccelerate liquid flowFire rescueLocking mechanismPenetration force

The invention relates to a sprinkler or a spray head comprising a housing (2), an inlet (3), a nozzle (4) mounted in the housing, a passage (17-18-13) from the inlet to the nozzle, and a holder (8) for a release means, the holder being mounted in front of the nozzle so that it prevents the nozzle from spraying extinguishing medium forward without hindrance, the nozzle being arranged to spray extinguishing medium once the release means has been released. The holder (8) is mounted in the housing (2) by means of a locking mechanism, which is arranged to open and release the holder (8) from the housing once the release means (7) has been released. To allow efficient and forceful spraying of the extinguishing medium without that the holder stands in the way, reducing the momentum and penetration force of the jet, and to safeguard the operation, the spinkler or spray head comprises a spindle (9) which is arranged to move in the housing (2) from a first position, in which the spindle is arranged to close the passage (17-18-13) to keep the nozzle (4) closed, to a second position, in which the spindle is arranged to open the passage to keep the nozzle open, when the release means is being released, the spindle being arranged to exert a force on the locking mechanism and to open the locking mechanism when the spindle is moved toward the holder (8) into the second position, whereby the nozzle (4) can forcefully spray the extinguishing medium forward essentially without hindrance.

Owner:MARIOFF CORP OY

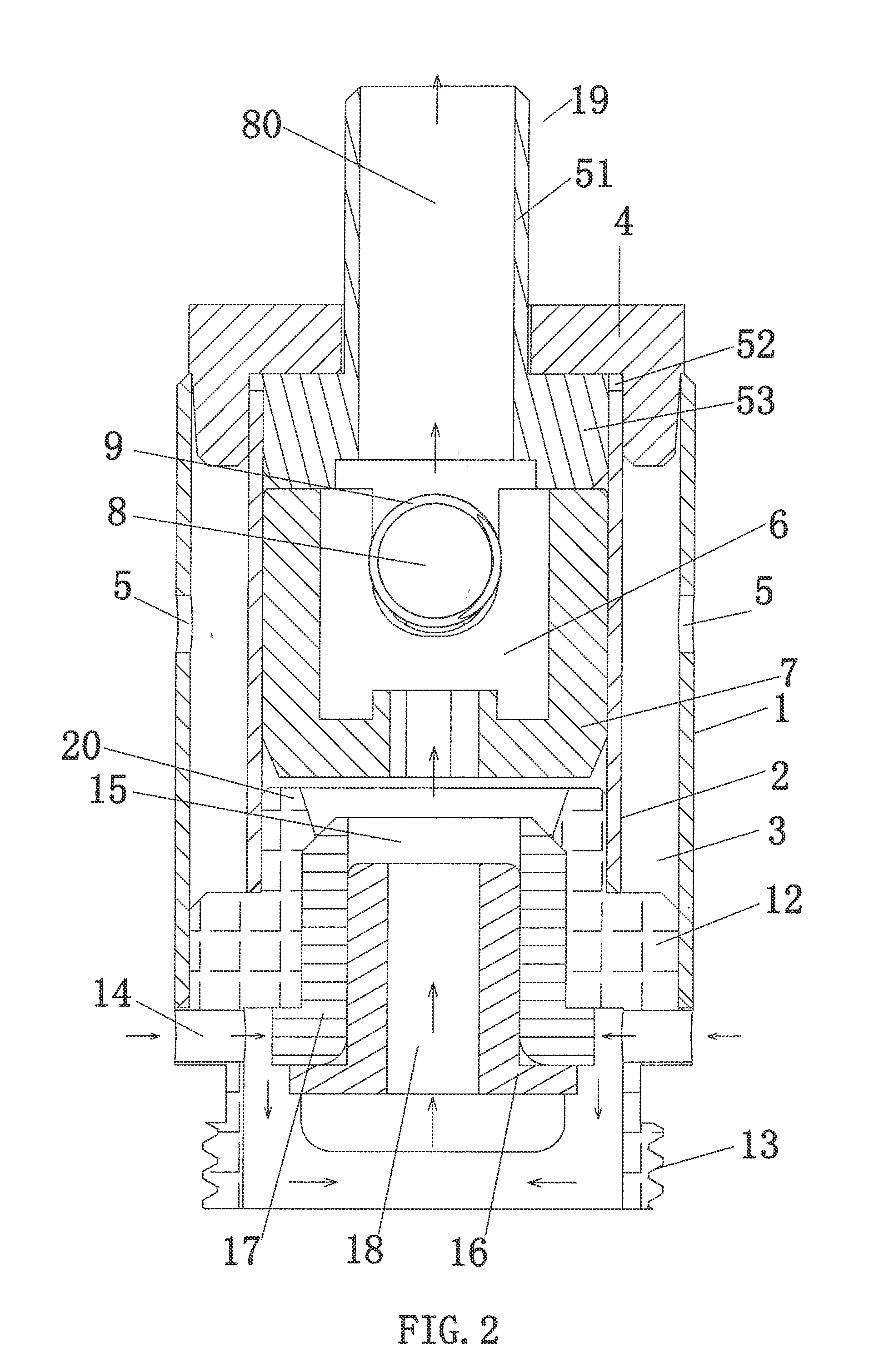

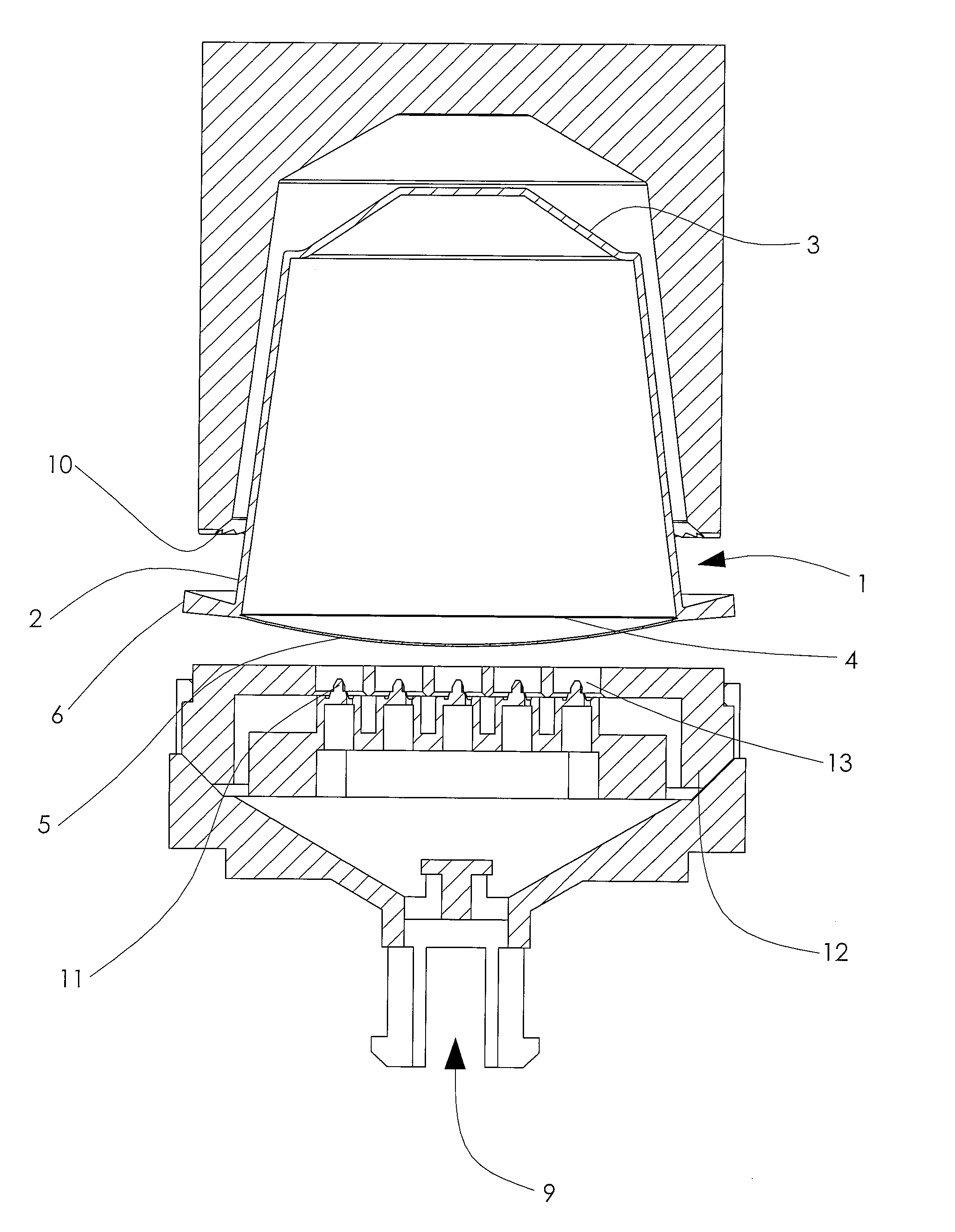

Nursing Bottle Air-Inlet Regulating Valve

InactiveUS20080237176A1Accelerate liquid flowAvoid creatingFeeding-bottlesTeatsAtmospheric airEngineering

A nursing bottle air-inlet regulating valve comprising a flat elastomeric valve (1) that lies on the inner part of a threaded base (2) of a nursing bottle body (3) and comprises small domes (4) on fee upper side (where the liquid is). The domes (4) have a slit (5), through which air flows to balance the pressure in the nursing bottle. Vent channels (8) are included on the Underside of the membrane, which is the side the membrane contacts the threaded base (2) of the nursing bottle. The membrane (1) has a perimeter wall or edge (9) that fits in the inner perimeter of the threaded base (2), continuing in a hollow perimeter channel (7) allowing air to circulate when the base (2) is unthreaded. The domes (4) are connected to the perimeter channel by the vent channels (8). Air-inlet flow is regulated by how much the vent channels (8) are squashed. The vent channels (8) allow the air to flow from outside the nursing bottle towards the domes, through the communicating channels that open to the outside when partially unthreading the threaded base (2) of the nursing bottle, the base (2) having a series of openings through which atmospheric air flows.

Owner:PILLADO RAMIRO

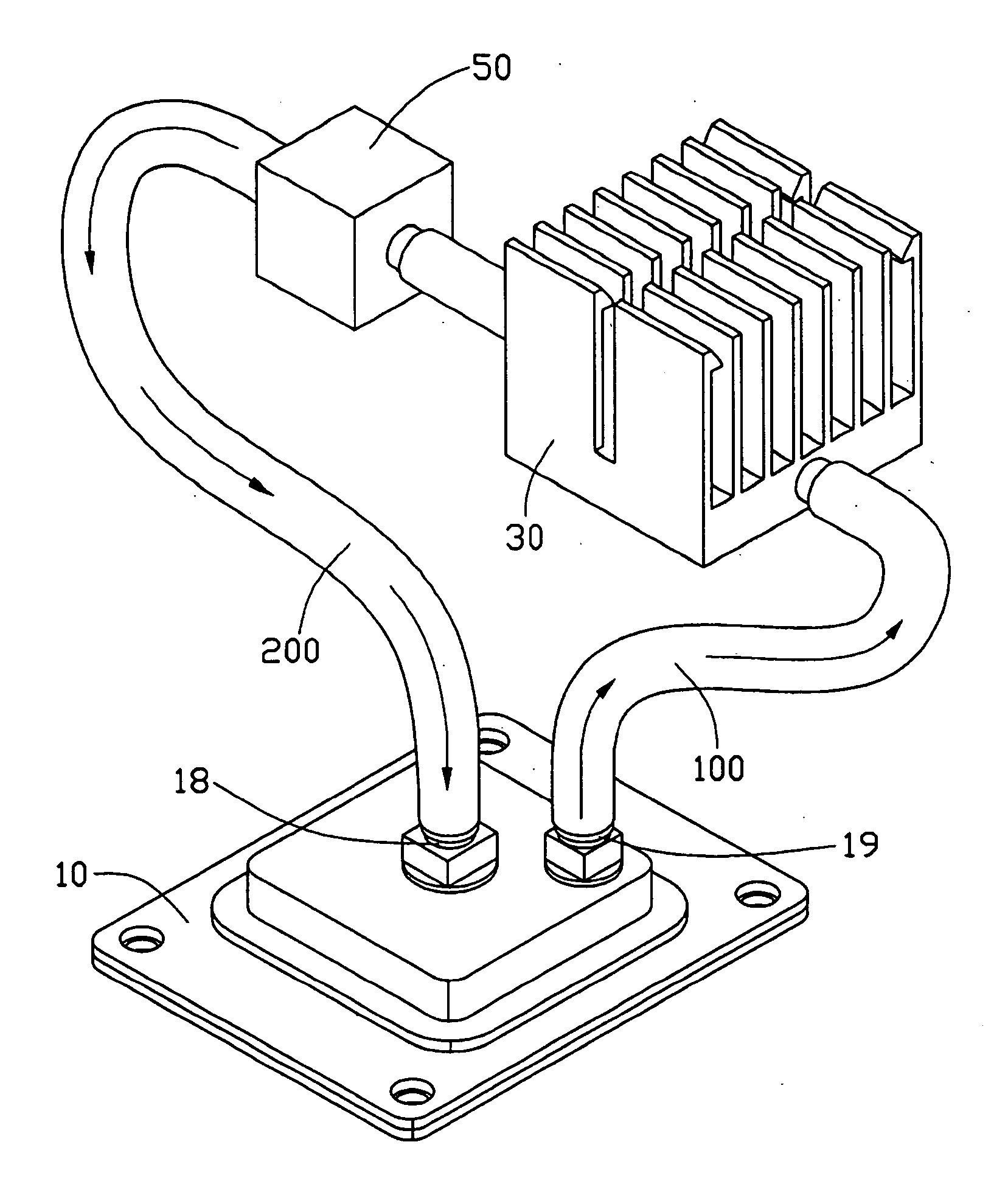

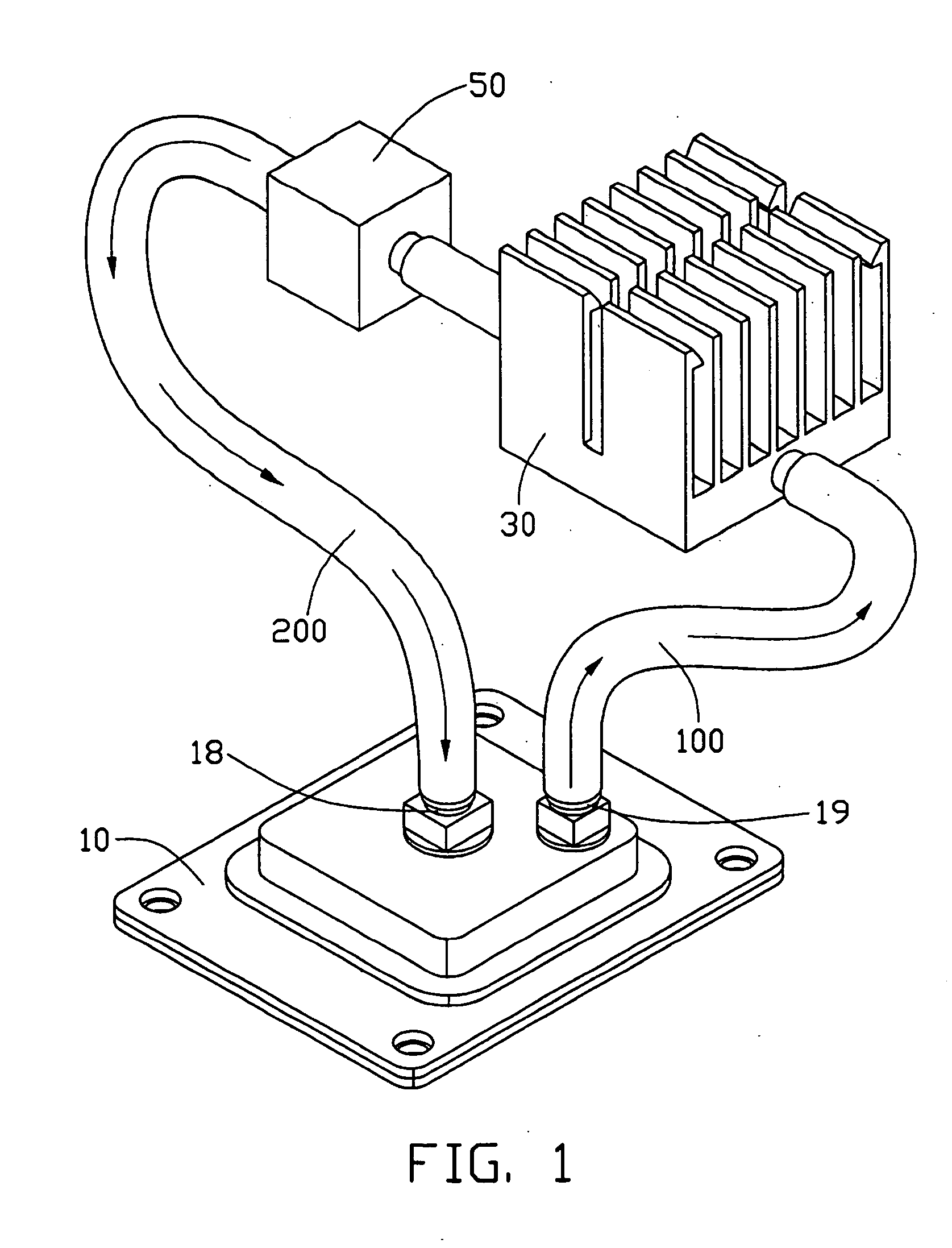

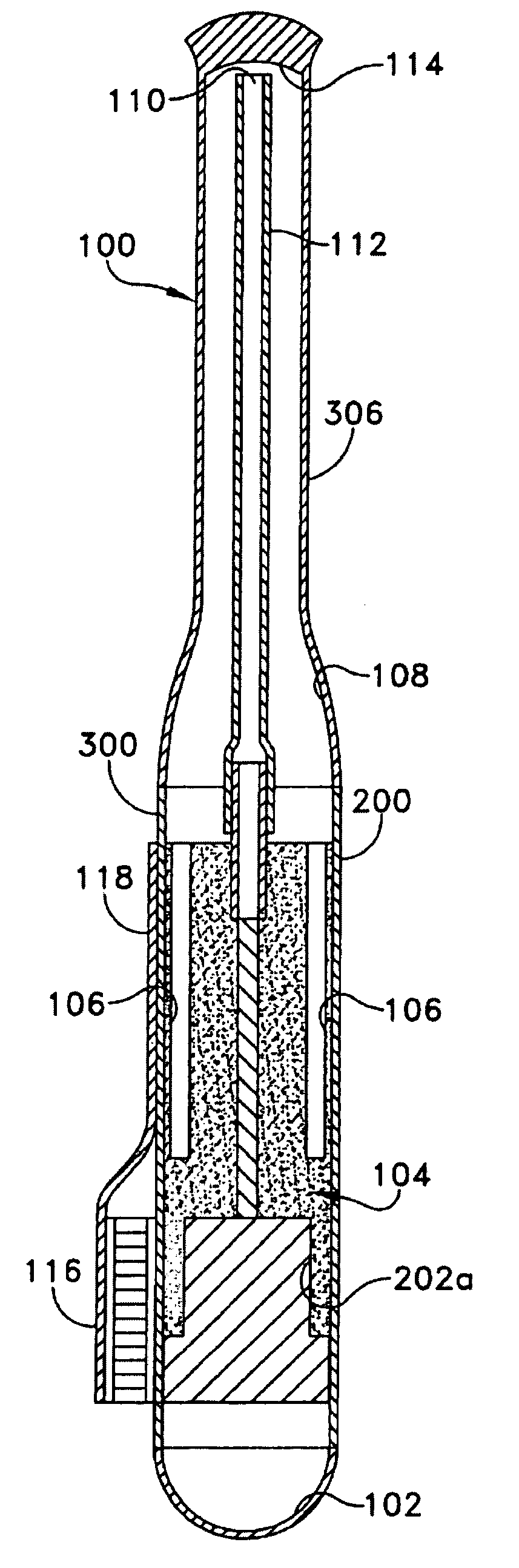

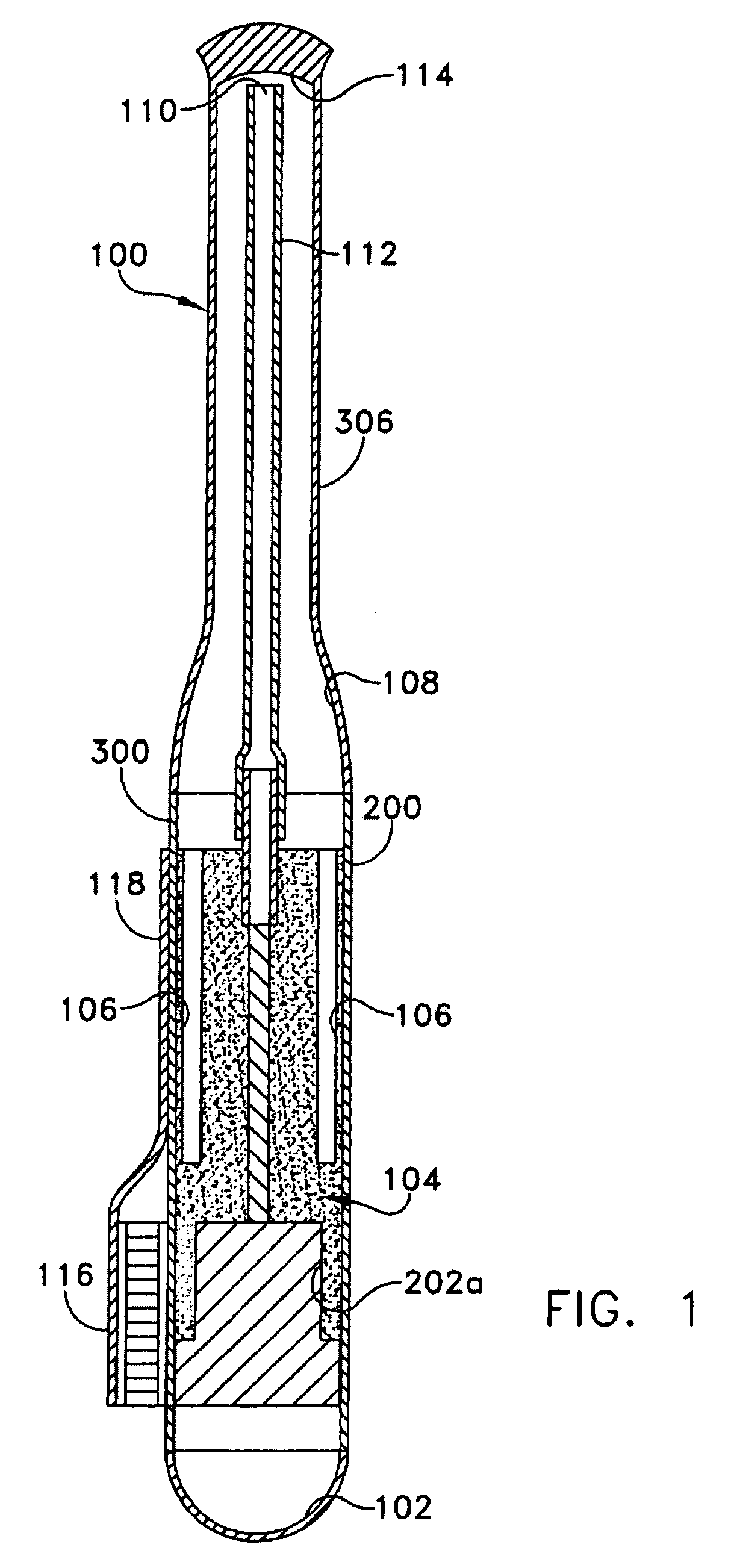

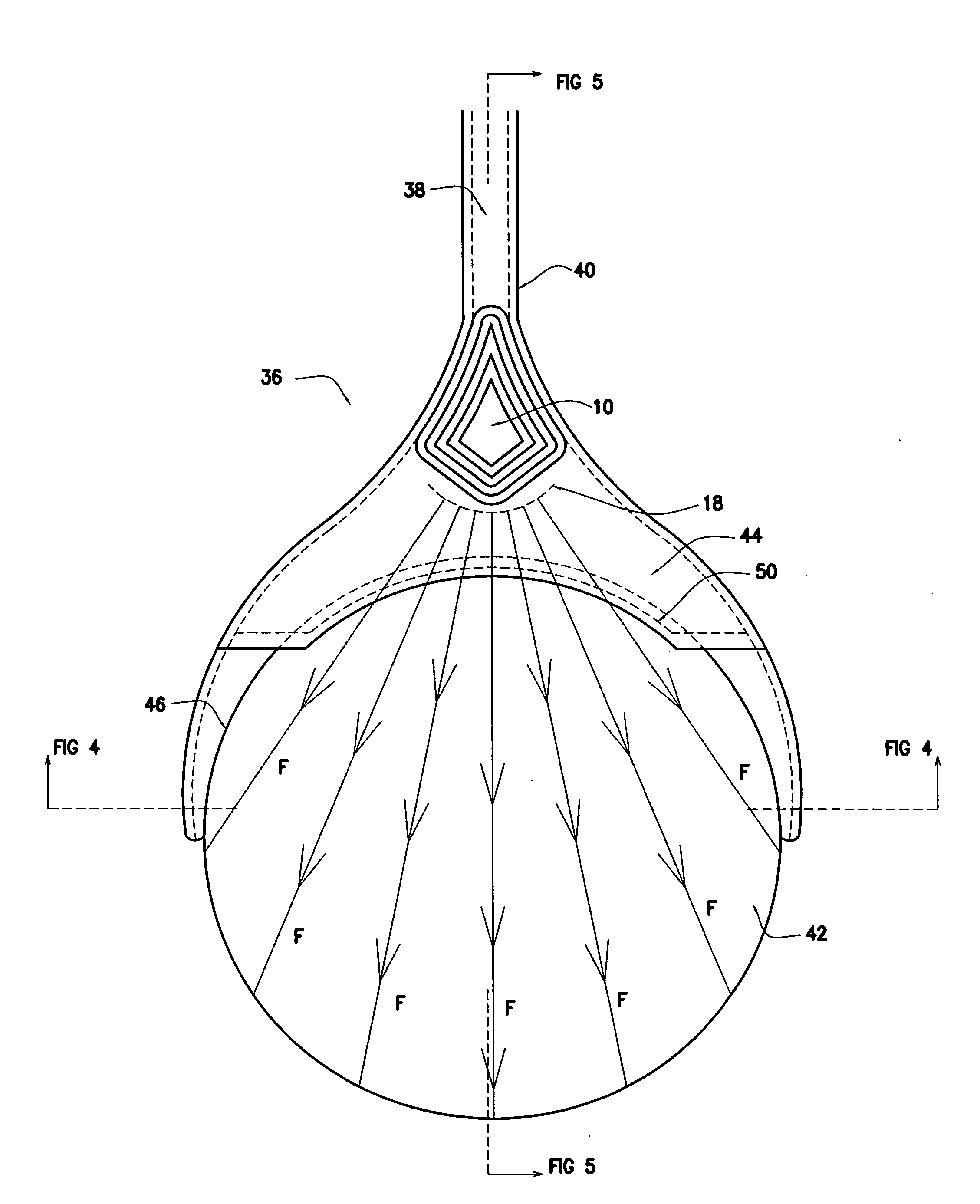

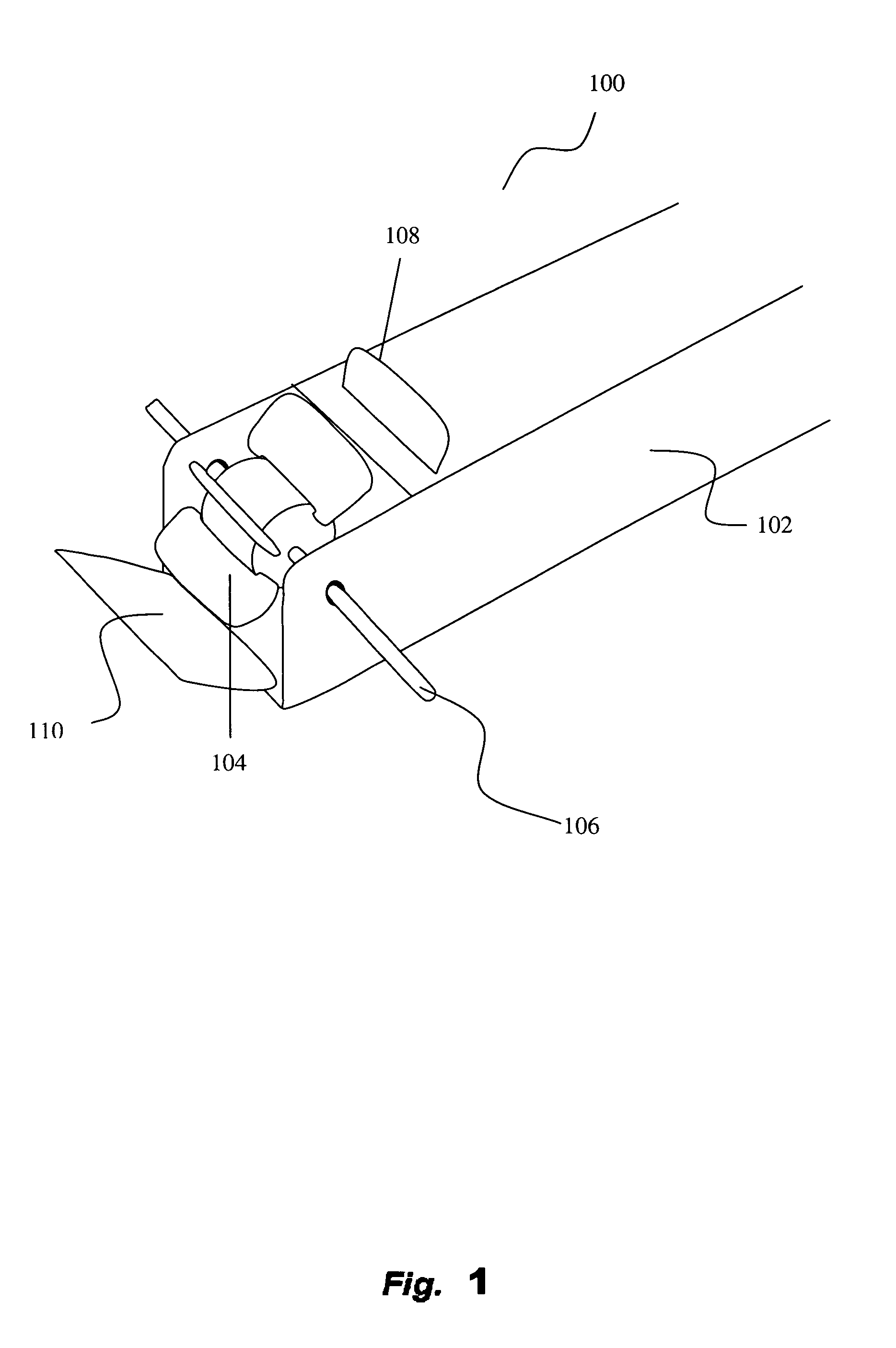

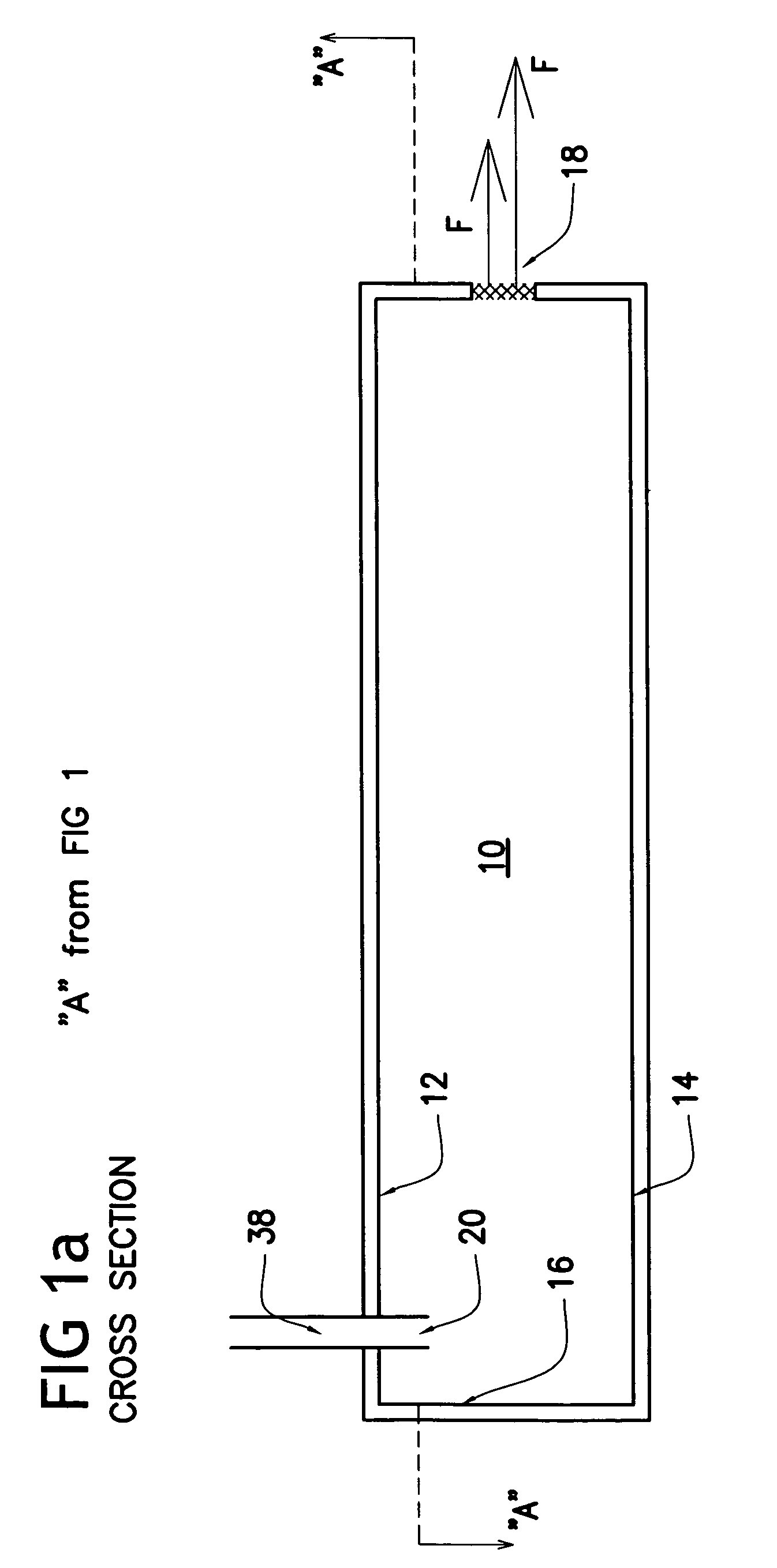

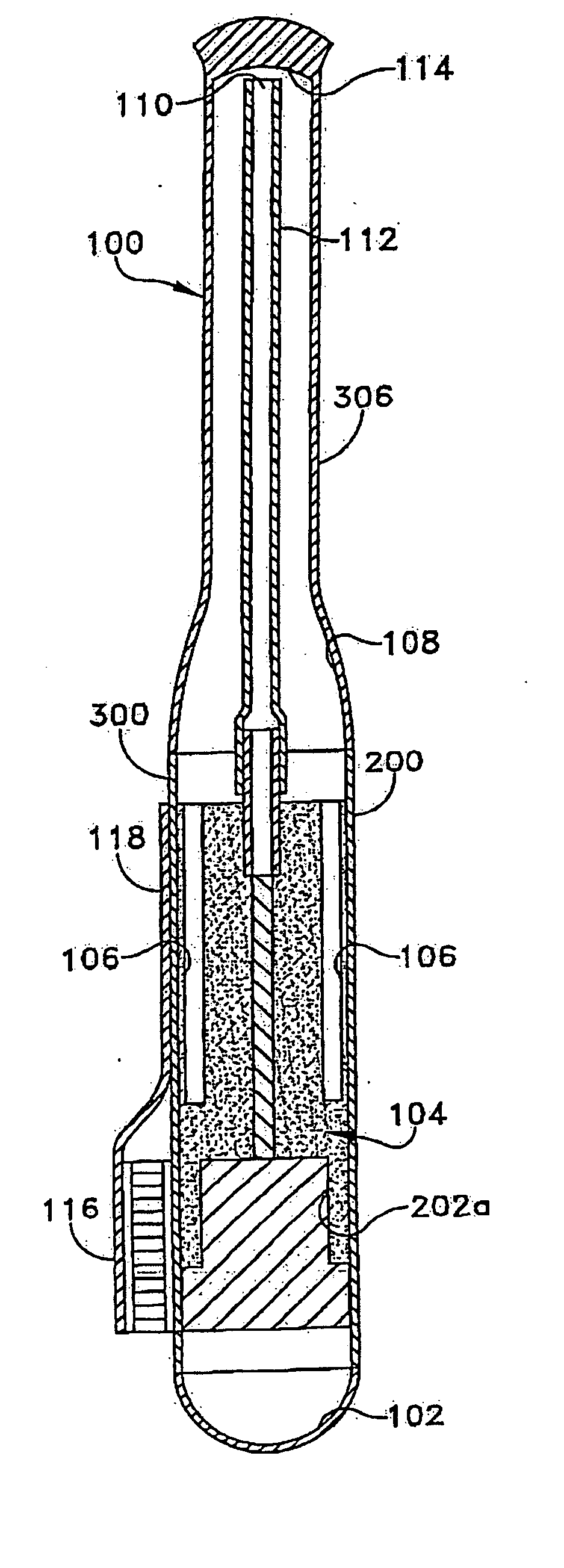

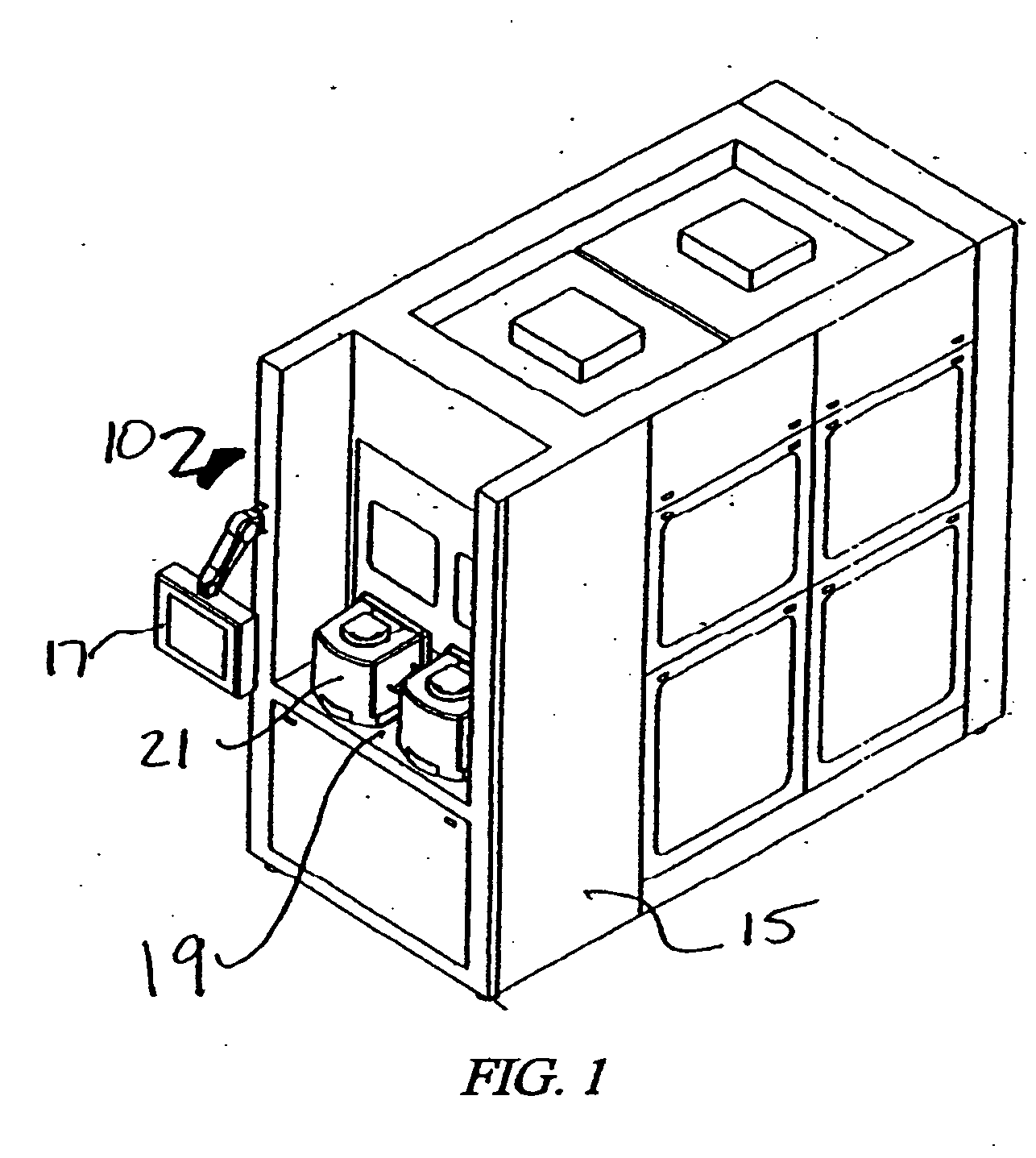

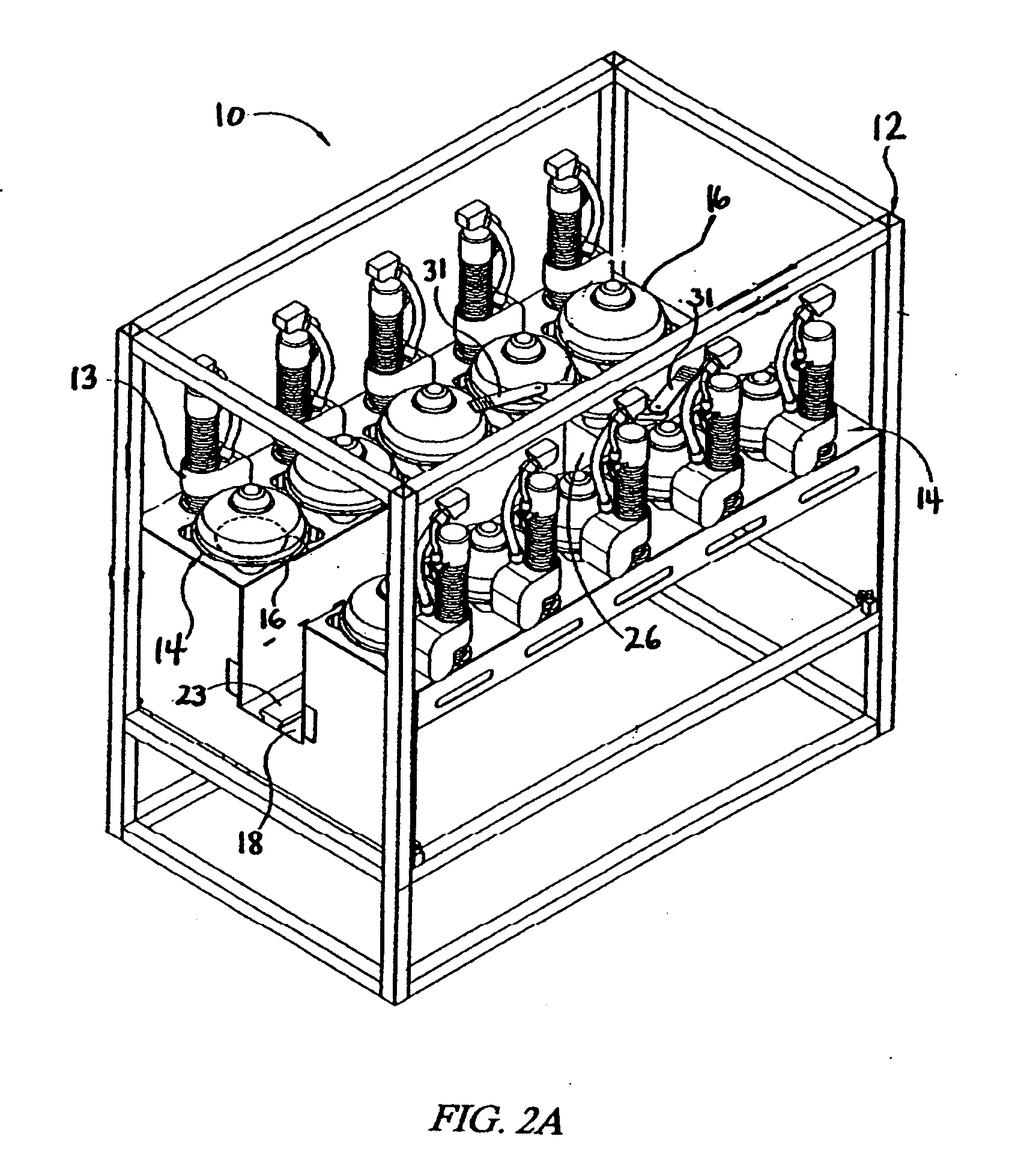

Hybrid loop heat pipe

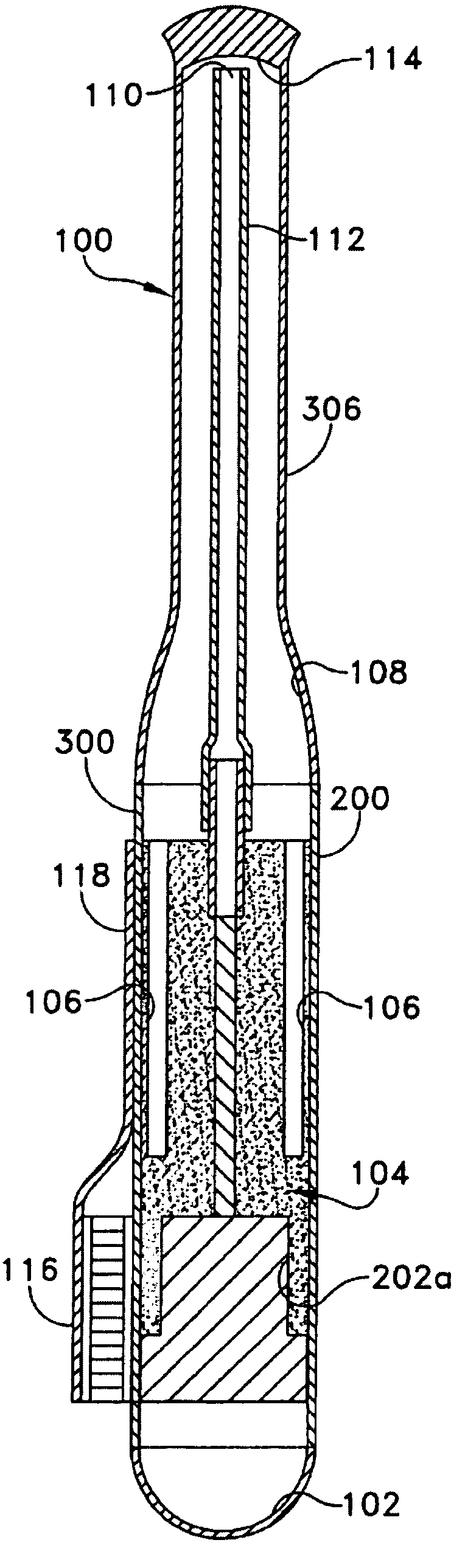

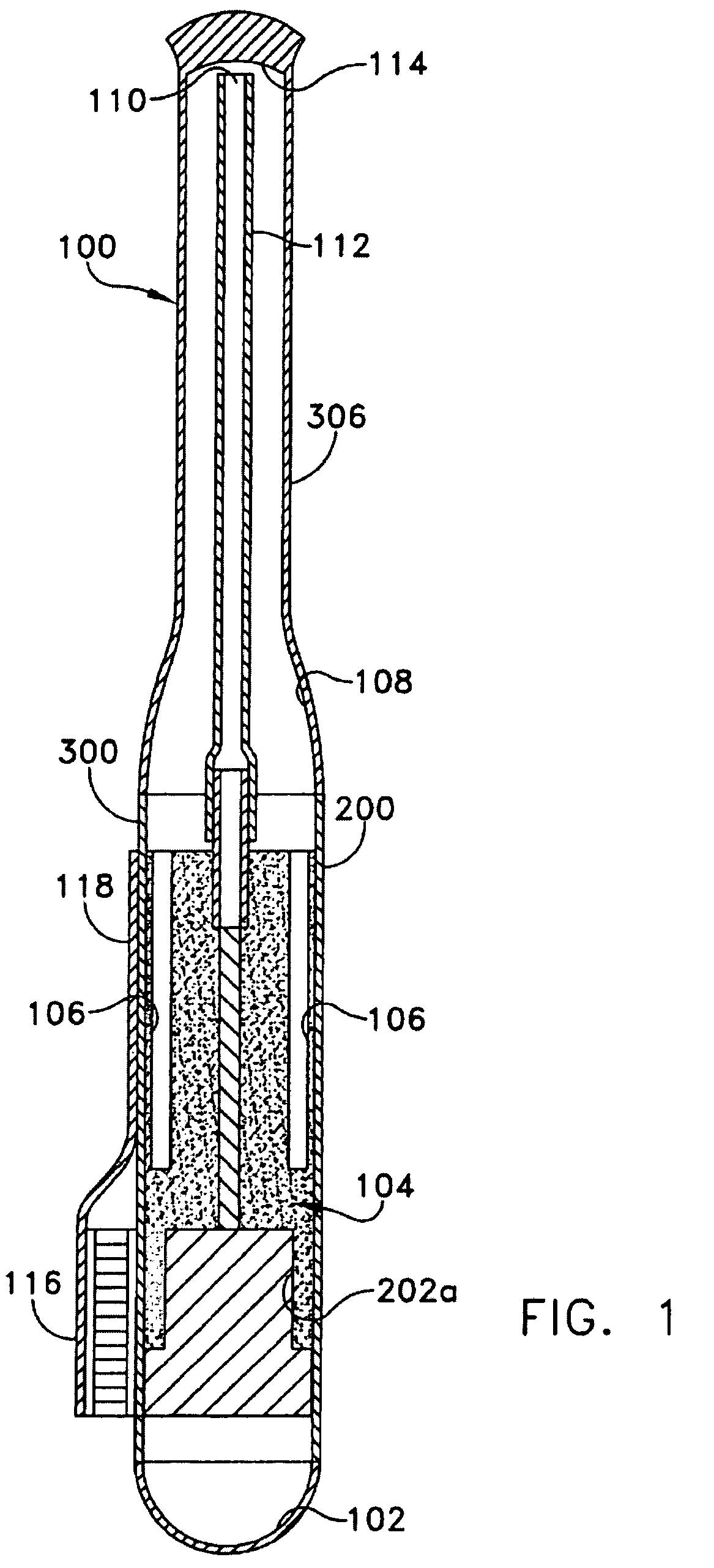

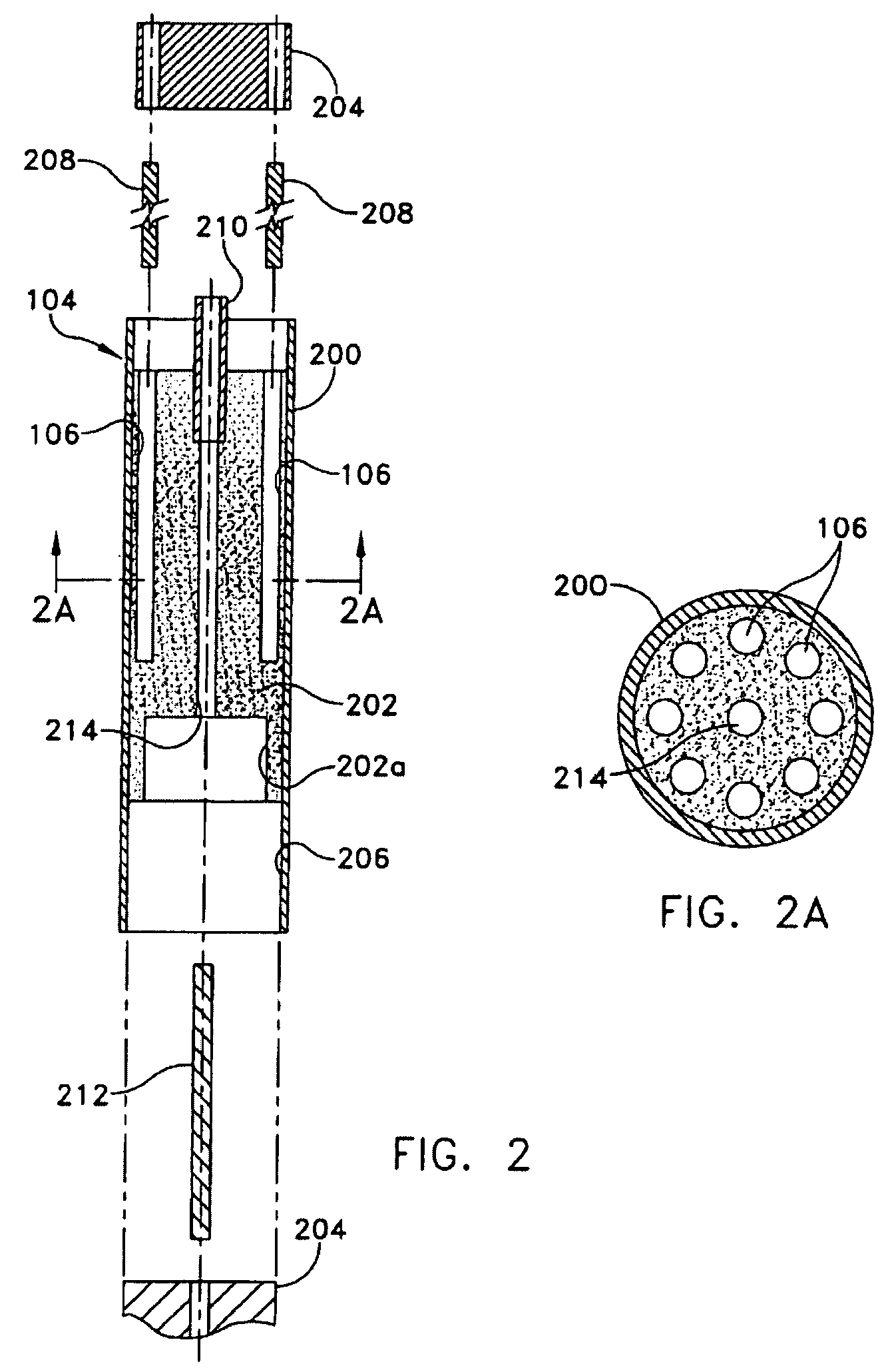

InactiveUS6926072B2Avoids slow down and oppositionAccelerate liquid flowDomestic stoves or rangesThermal insulationEngineeringLoop heat pipe

A heat pipe assembly (100) has a combined reservoir (102) and evaporator (104), the evaporator (104) having ducts of a vapor manifold (106) that exhausts vapor toward the condenser (108) instead of opposing the flow of liquid condensate to the reservoir (102), and the evaporator (104) having a wick passage that impels the condensate toward the reservoir (102) instead of opposing the flow of vapor.

Owner:THERMAL

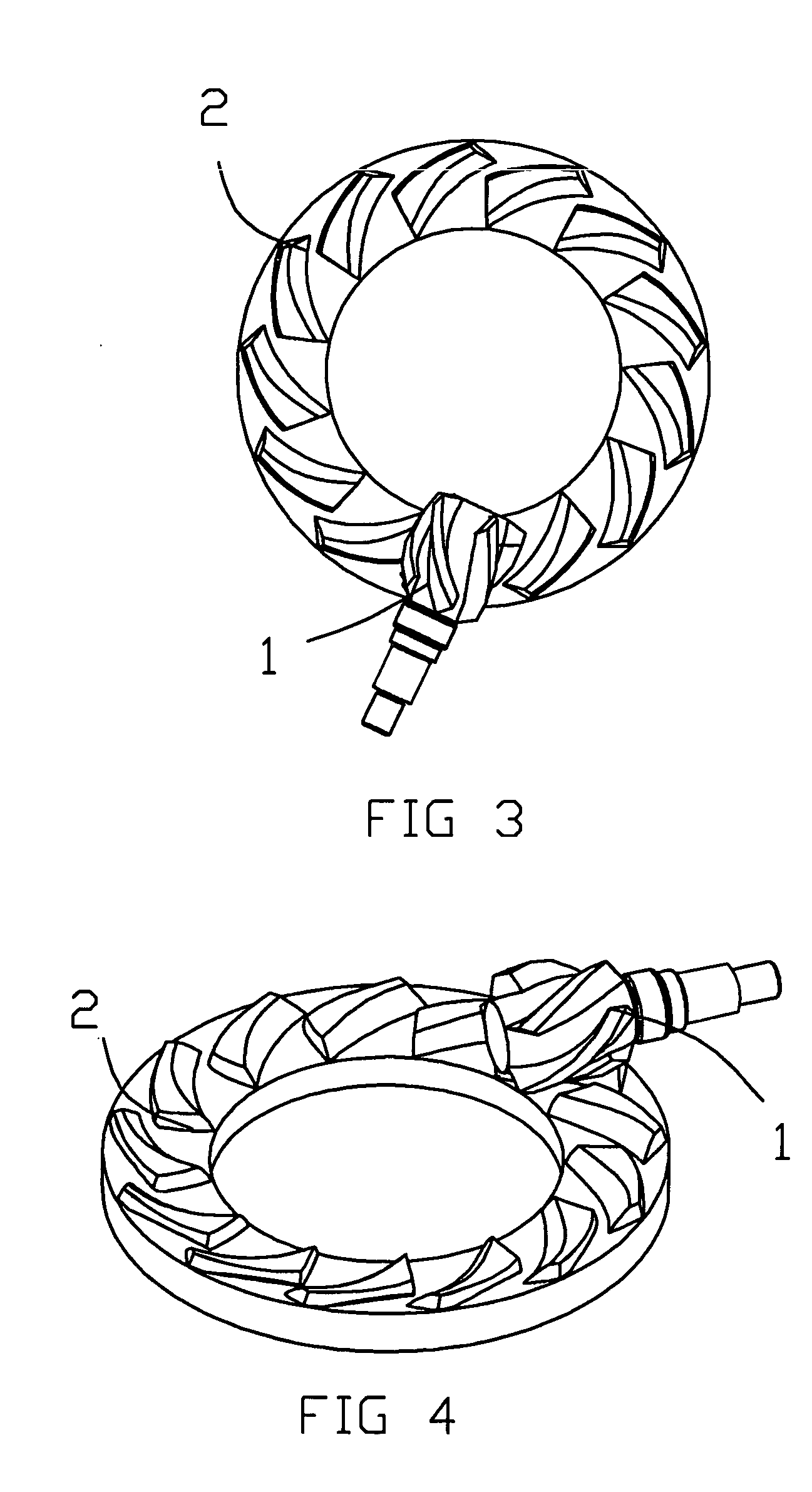

Drive axle assembly and differential

InactiveUS20050054471A1Improve the lubrication effectAccelerate liquid flowToothed gearingsPortable liftingEngineeringMechanical engineering

Owner:FLEYTMAN YAKOV

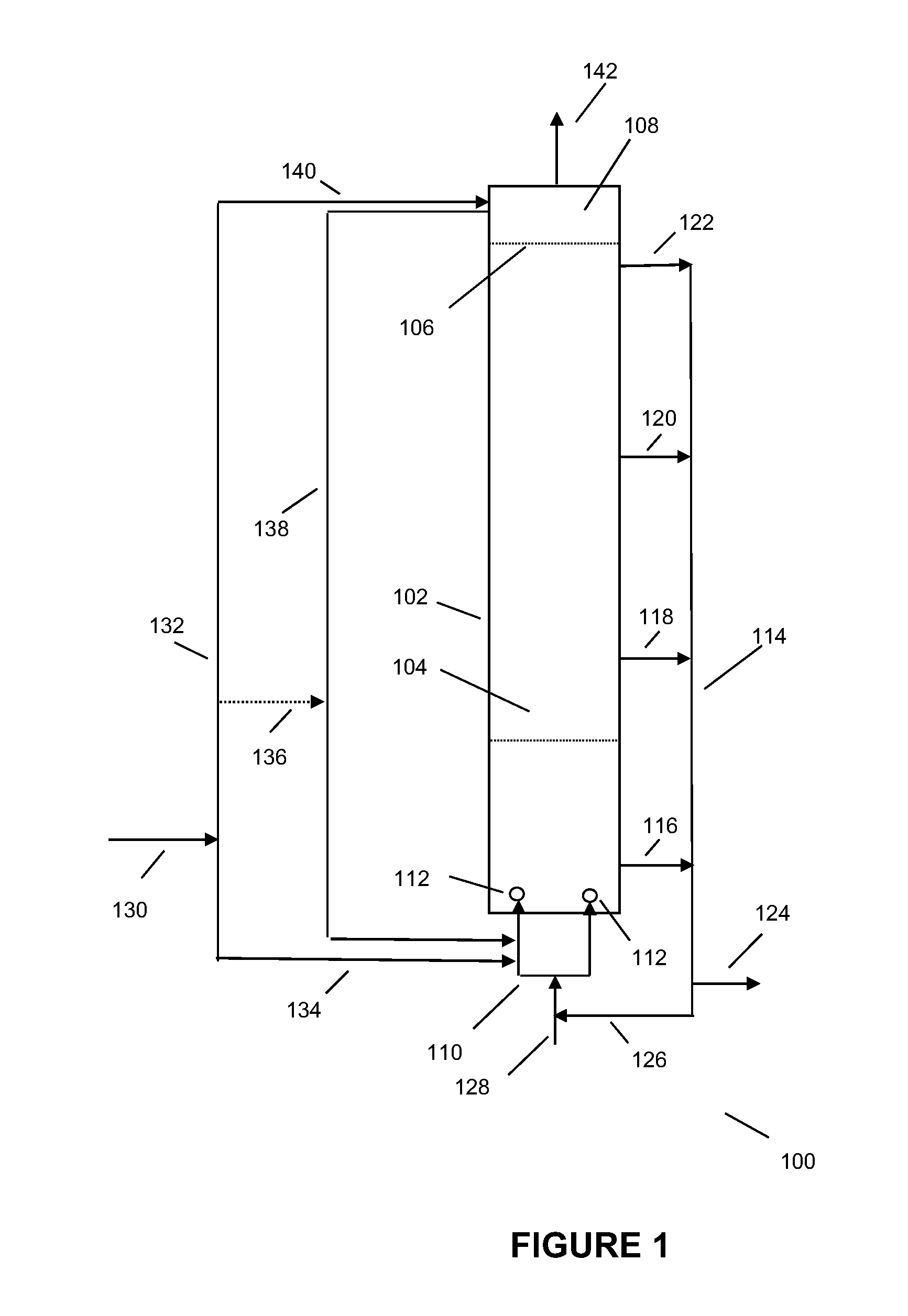

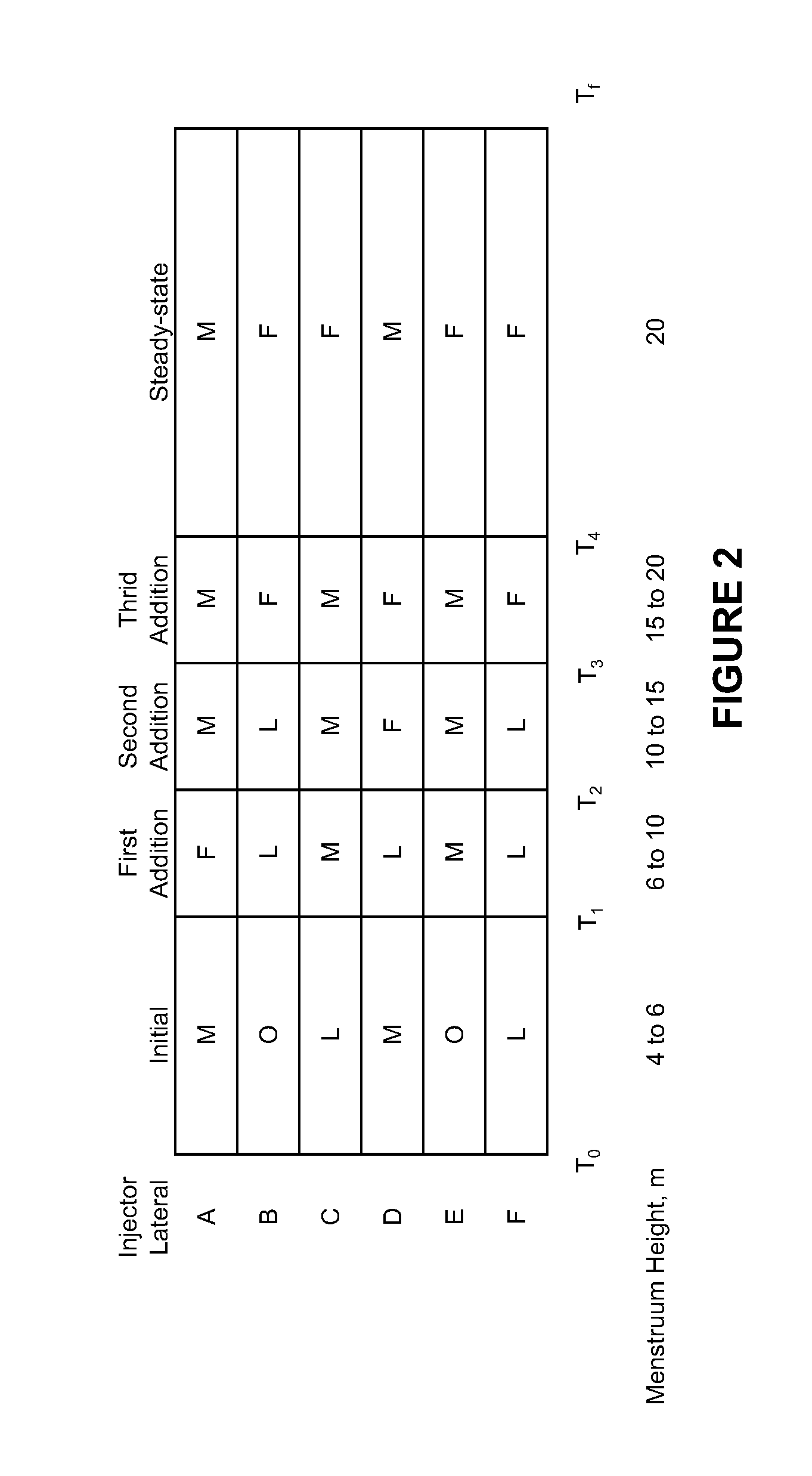

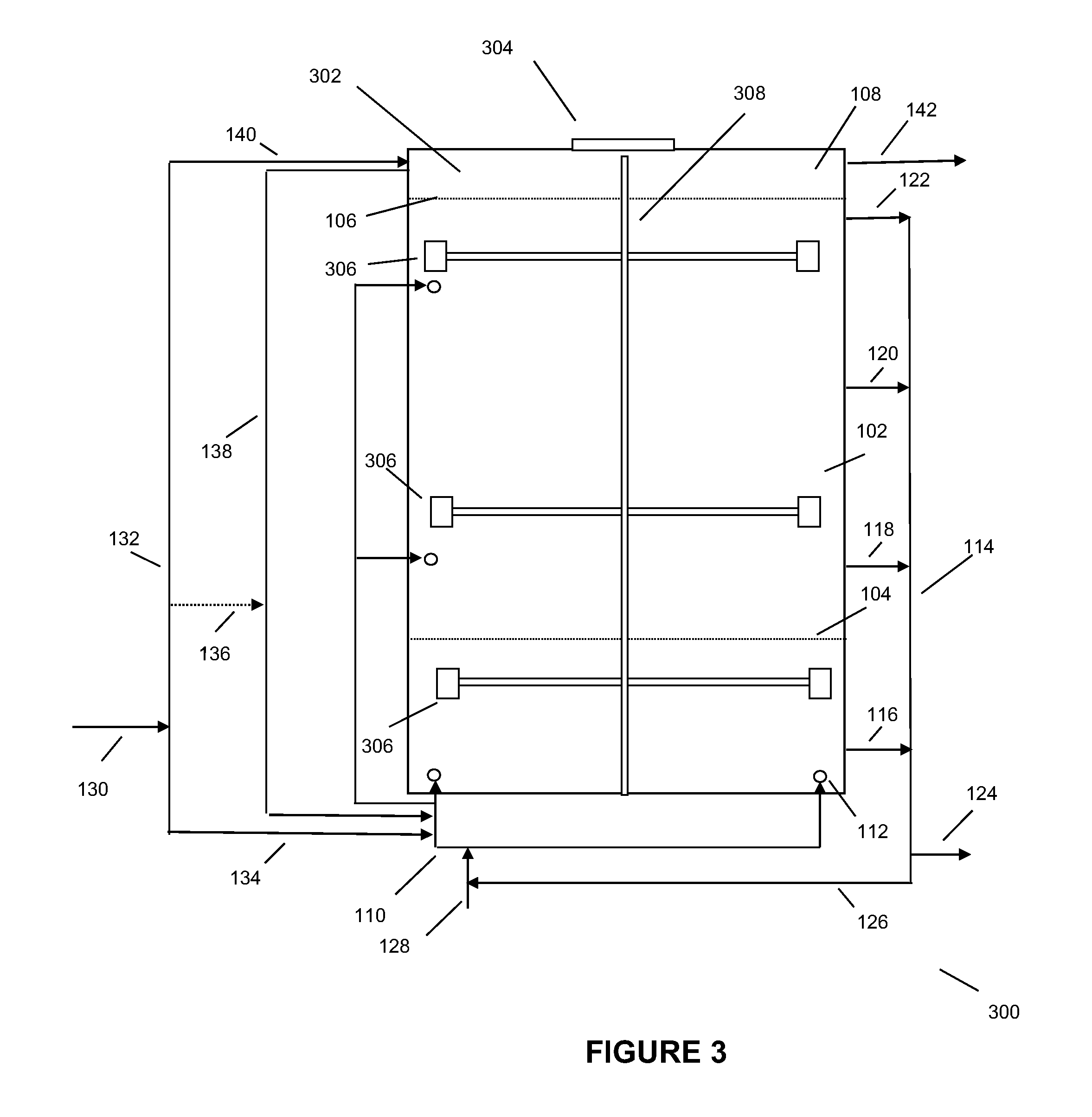

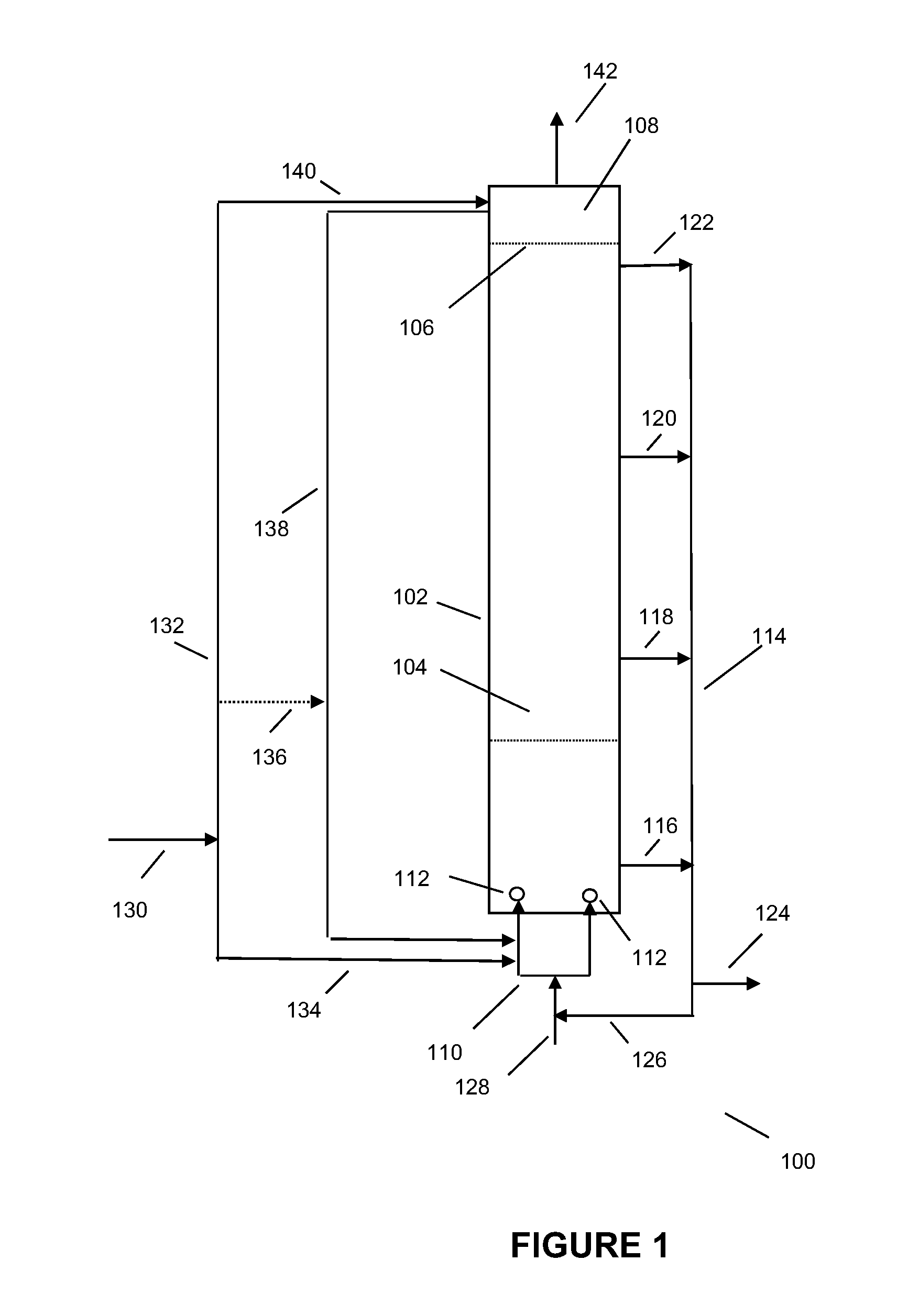

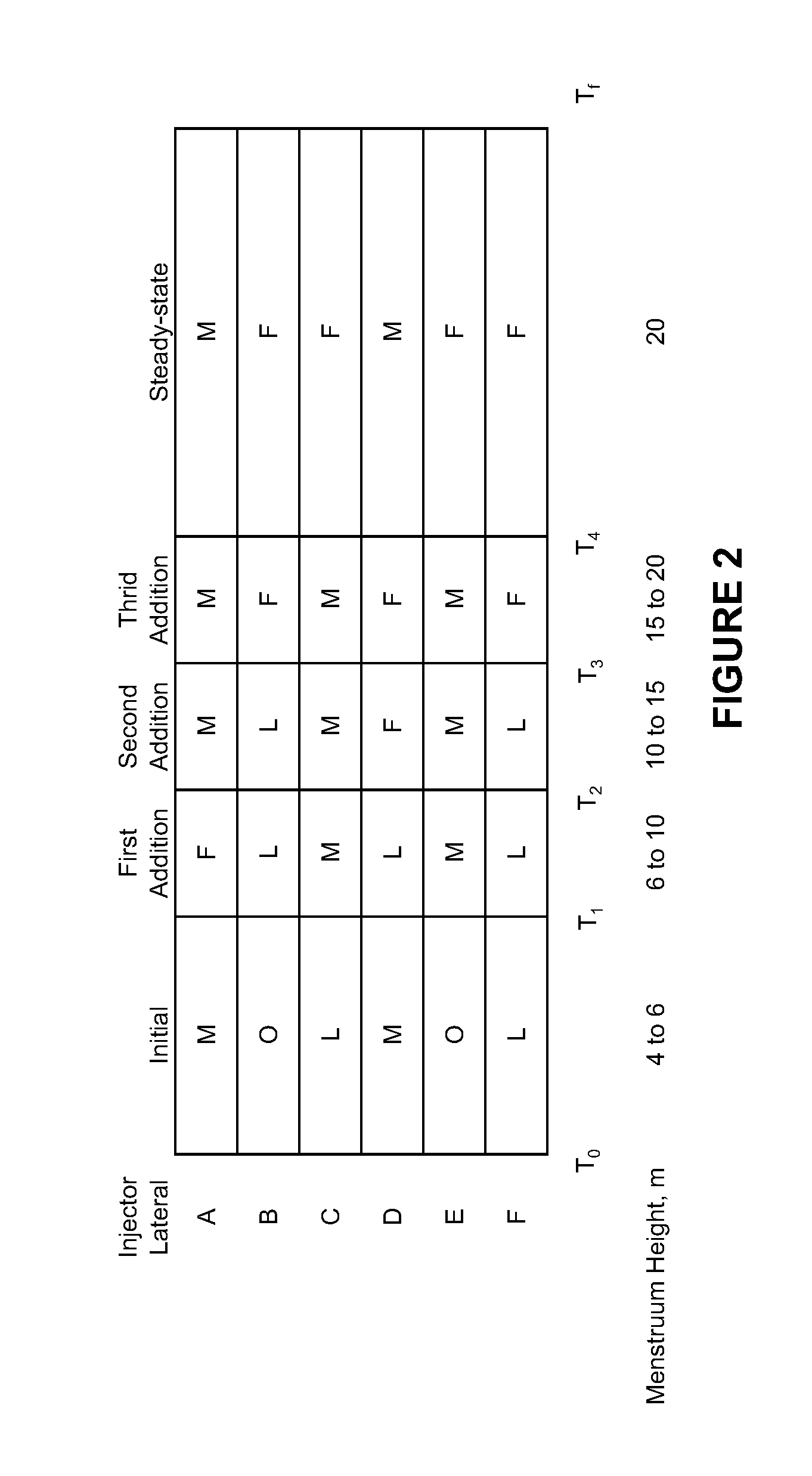

Processes for starting up deep tank anaerobic fermentation reactors for making oxygenated organic compound from carbon monoxide and hydrogen

ActiveUS20130078693A1Reduce riskPromotes robust growthBiochemistry apparatusBiofuelsOxygenOrganic compound

Processes are provided for starting up of anaerobic, deep tank fermentation systems used in the anaerobic bioconversion of hydrogen and carbon monoxide in a gaseous substrate stream to oxygenated organic compounds such as ethanol. In the processes injectors using a motive liquid are used to introduce gas substrate into the deep tank fermentation reactor where at least one of:(i) adjusting the gas to liquid flow ratio through an injector,(ii) changing the rate of liquid flow through an injector, and(iii) adjusting the carbon monoxide mole fraction in the gas feed by admixture with at least one other gas,wherein the mass transfer of carbon monoxide to an aqueous menstruum in the reactor is controlled to obtain the robust growth of the microorganism while maintaining the carbon monoxide concentration below that amount which is unduly adverse to the microorganism. In preferred aspects of the invention, recycled gas from the head space of the reactor is used to modulate the supply of carbon monoxide to the aqueous menstruum.

Owner:SYNATA BIO INC

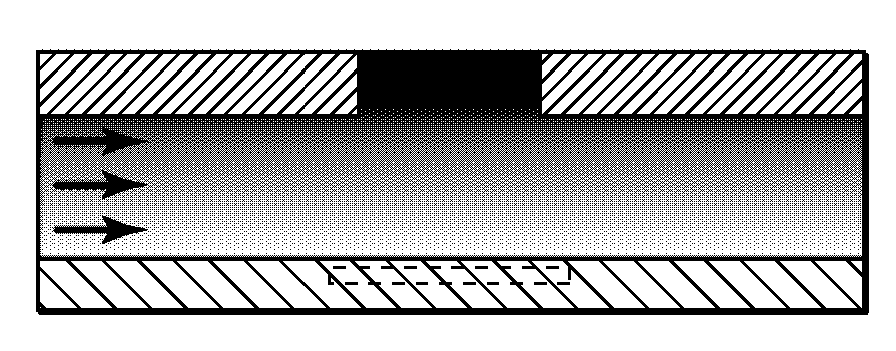

System and method for removing surface contamination

InactiveUS20100261132A1Preventing and removing biofilmsReduce turbulenceDental toolsSomatoscopeProduct gasEnvironmental engineering

A system and method are provided in which a laminar flow of pressurized gas from a curved slit in a chamber is directed across a surface to propel a laminar flow of a liquid, below the laminar flow gas, across the surface to prevent surface contamination or remove contaminants from the surface. In a particular application, the system and method are employed in a self-cleaning dental mirror tool including a dental mirror attached to a handle, wherein the gas is air, the liquid is water, and the surface is the reflective surface of the dental mirror.

Owner:WIDEN RANDY MILES

Portable turbine systems

InactiveUS8129855B1Easy to transportAccelerate liquid flowHydro energy generationMachines/enginesTurbineElectric generator

Novel apparatus and techniques for harnessing wind and / or moving-liquid energy using one or more portable turbine systems are disclosed. One embodiment includes a portable stream turbine system having a hub with many paddles, held by an axle in a housing. The system further includes a disk fixed to the hub and extended out of the housing to be also fixed to a gear structure, which is connected to a generator. The output of the generator can be connected to electronics to perform different functions. Another embodiment includes a number of portable turbine systems removably attached together to form an array. In one example, the number of portable turbine systems in an array can be adjustable, depending on needs. The different embodiments regarding a stream turbine system can further include a floatation mechanism to keep the different embodiments afloat or partially afloat in a fluid. The different embodiments regarding a stream turbine system or an array of stream turbine systems can also include a drifting prevention mechanism to prevent the embodiments from being drifted away, and to substantially maintain the orientation of the embodiments in a fluid.

Owner:TONG LUCAS +1

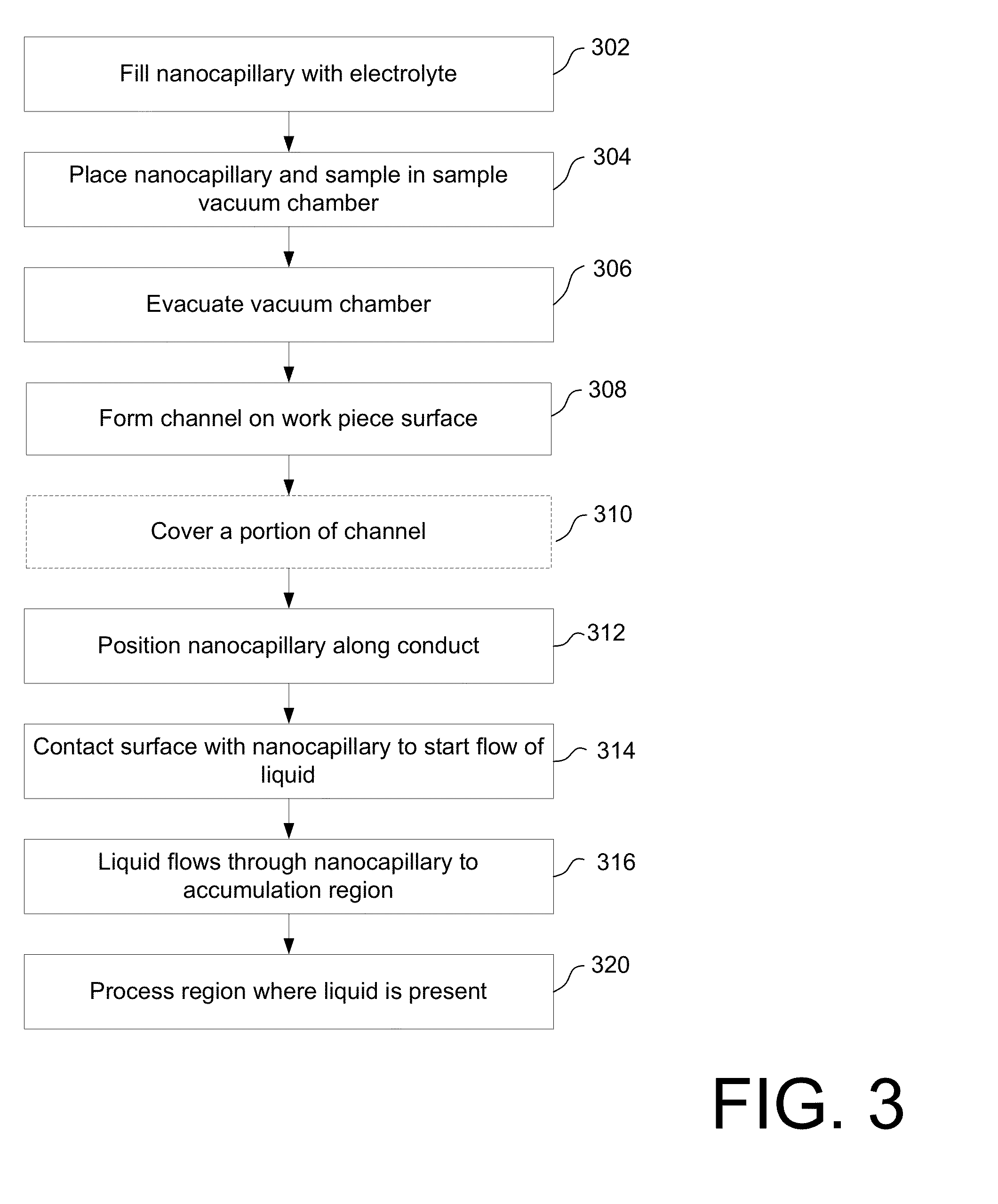

Microfluidics Delivery Systems

ActiveUS20140151335A1Accelerate liquid flowMaterial analysis using wave/particle radiationElectrolysis componentsMicrofluidicsEngineering

Methods of dispensing a small amount of liquid onto a work piece includes in some embodiments known providing a microscopic channel for the liquid to flow from the nanodispenser. In some embodiments, dispensing the liquid includes dispensing the liquid using a nanodispenser have at least one slit extending to the tip. Some methods include controlling the rate of evaporation or the rate of liquid flow to establish an equilibrium producing a bubble of a desired size.

Owner:FEI CO

Vapor-liquid contacting apparatuses with vortex contacting stages

InactiveUS20100258427A1Narrow downReduction in stage efficiencyCombination devicesTransportation and packagingVapor liquidReactive distillation

Vapor-liquid contacting apparatuses, for example reactors and distillation columns (as well as reactive distillation apparatuses), comprising a vessel with one or more vortex contacting stages, are described. The one or more stages provide high interfacial area for the effective contacting of the different phases, in addition to the effective disengagement of these phases after contacting.

Owner:UOP LLC

Printing apparatus, printing method, and medium

ActiveUS20170197407A1Accelerate liquid flowIncrease costInking apparatusEngineeringLiquid circulation

In a printing apparatus including a circulation system circulating a liquid, a volatile component included in the liquid evaporates from an ejection opening and thus characteristics of the liquid involving with concentration or viscosity change. The invention provides a printing apparatus that uses a liquid ejection head including an ejection opening ejecting a liquid, a print element generating energy for ejecting a liquid, and a pressure chamber having the print element provided therein, the printing apparatus including: a circulator configured to circulate the liquid so that the liquid passes through the pressure chamber; and a concentration adjustment unit configured to adjust a concentration of a liquid inside a liquid circulation system by discharging the liquid from the inside of the liquid circulation system and replenishing the liquid into the liquid circulation system from the outside of the liquid circulation system in response to the amount of the discharged liquid.

Owner:CANON KK

System and method for removing surface contamination

InactiveUS8282393B2Preventing and removing biofilmsReduce turbulenceDental toolsSomatoscopeEnvironmental engineeringContamination

A system and method are provided in which a laminar flow of pressurized gas from a curved slit in a chamber is directed across a surface to propel a laminar flow of a liquid, below the laminar flow gas, across the surface to prevent surface contamination or remove contaminants from the surface. In a particular application, the system and method are employed in a self-cleaning dental mirror tool including a dental mirror attached to a handle, wherein the gas is air, the liquid is water, and the surface is the reflective surface of the dental mirror.

Owner:WIDEN RANDY MILES

Hybrid loop heat pipe

ActiveUS20050086806A1Avoids slow downAvoids oppositionThermal insulationIndirect heat exchangersEngineeringLoop heat pipe

A heat pipe assembly (100) has a combined reservoir (102) and evaporator (104), the evaporator (104) having ducts of a vapor manifold (106) that exhausts vapor toward the condenser (108) instead of opposing the flow of liquid condensate to the reservoir (102), and the evaporator (104) having a wick passage that impels the condensate toward the reservoir (102) instead of opposing the flow of vapor.

Owner:THERMAL

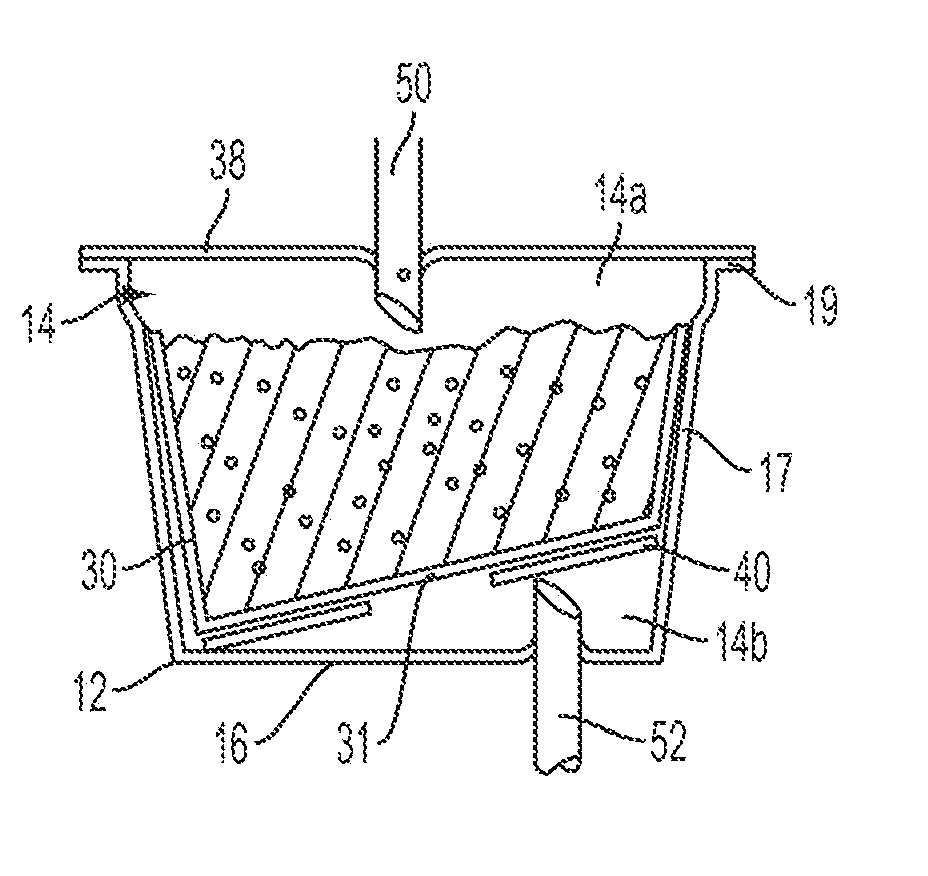

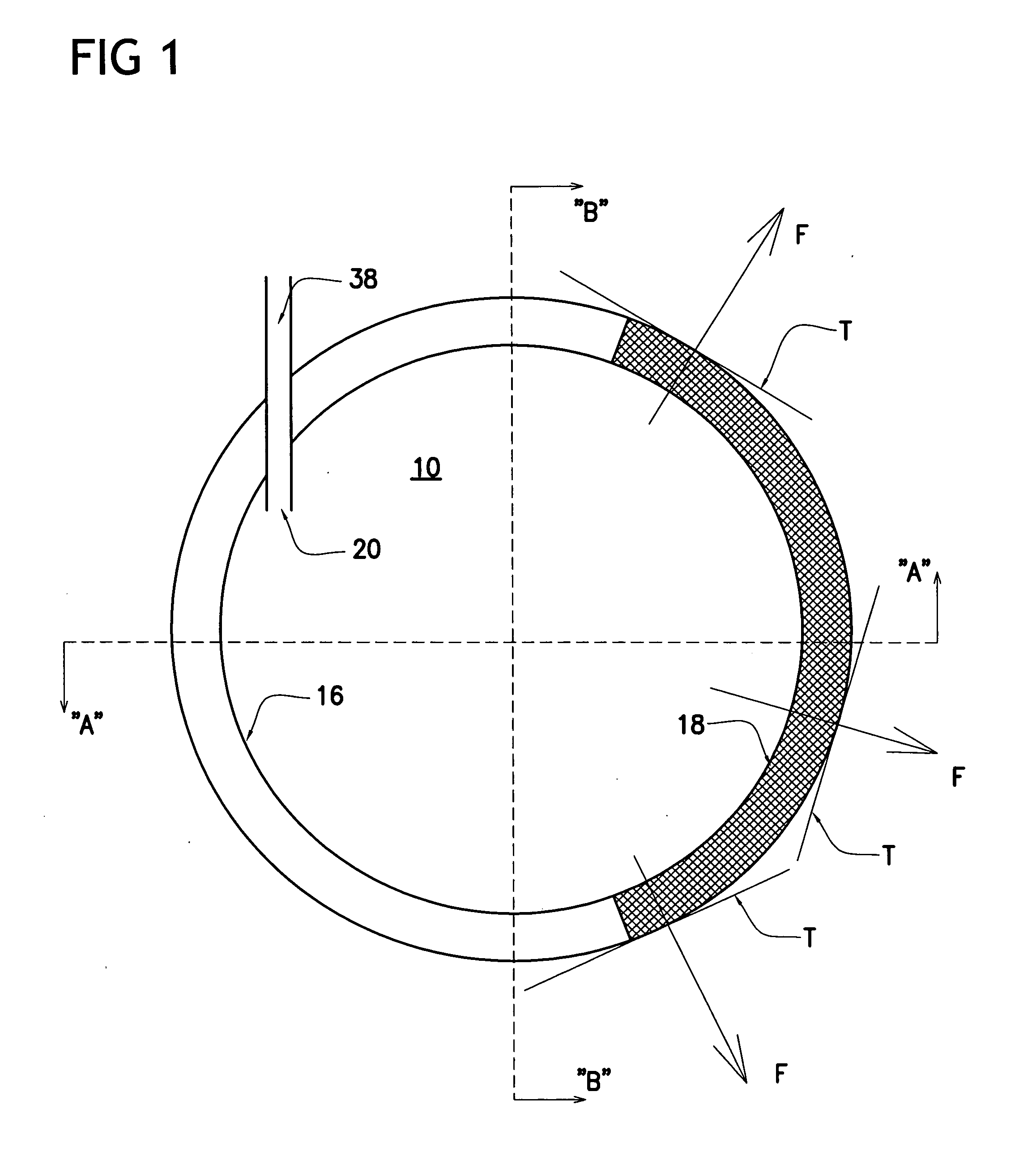

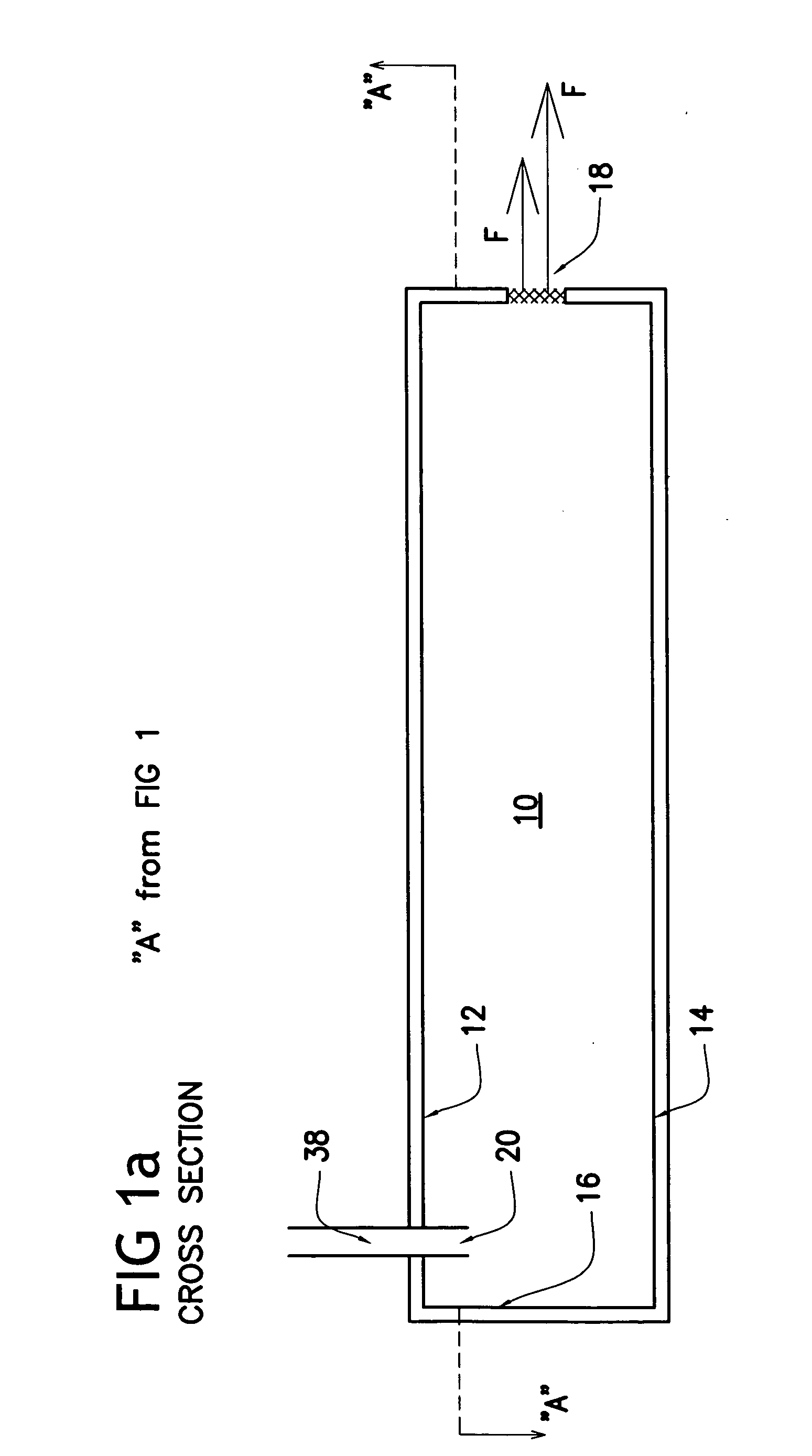

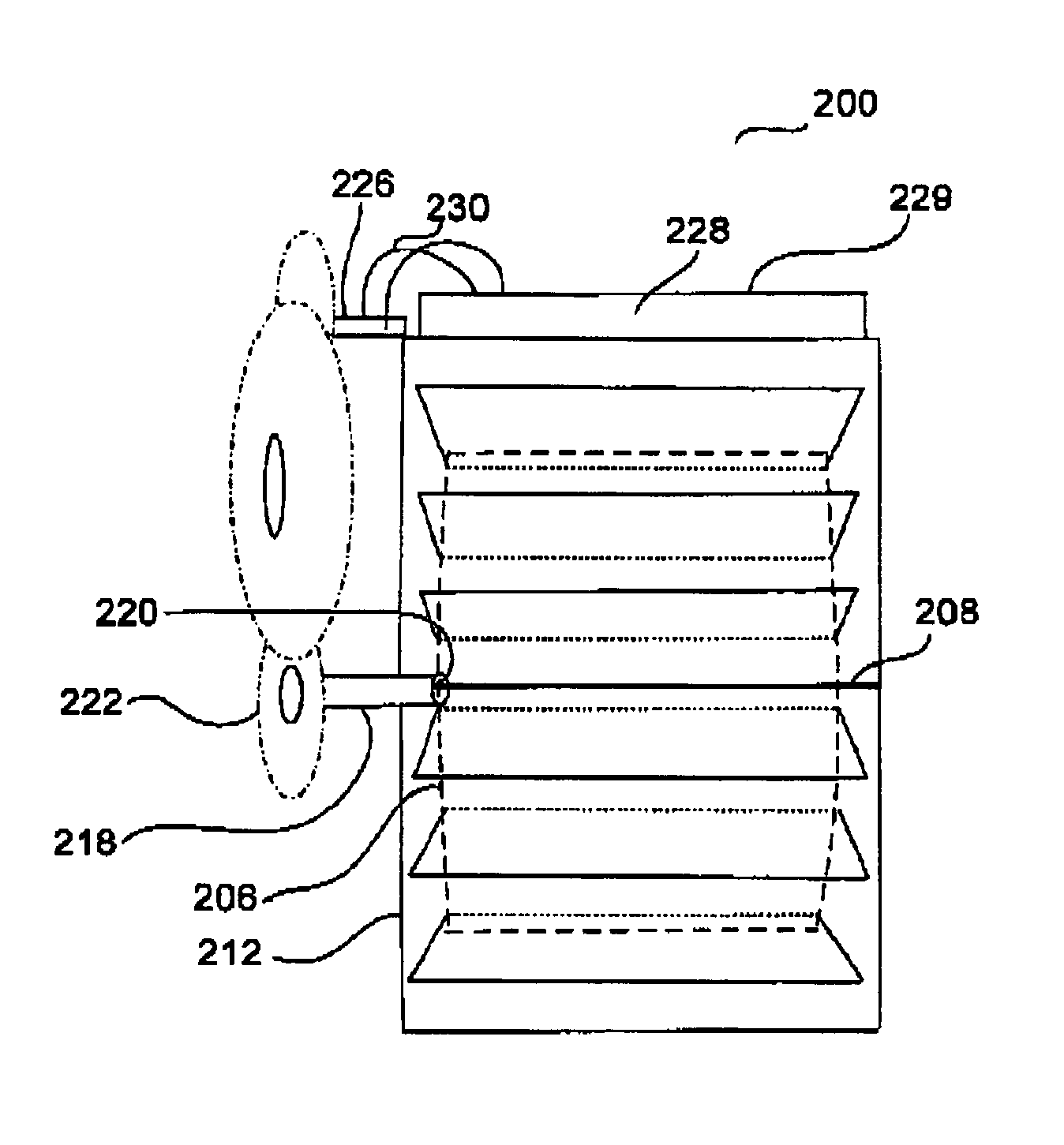

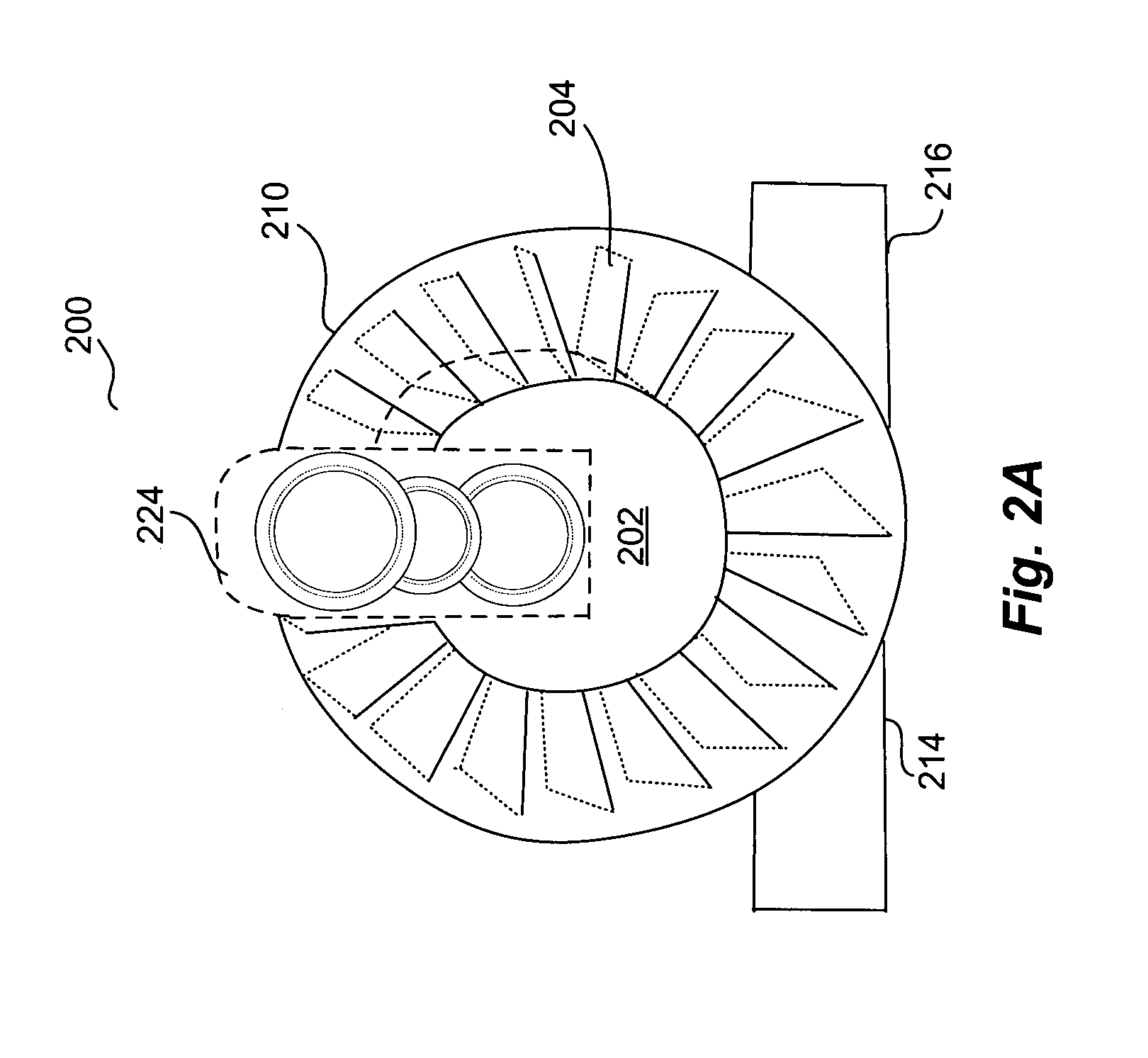

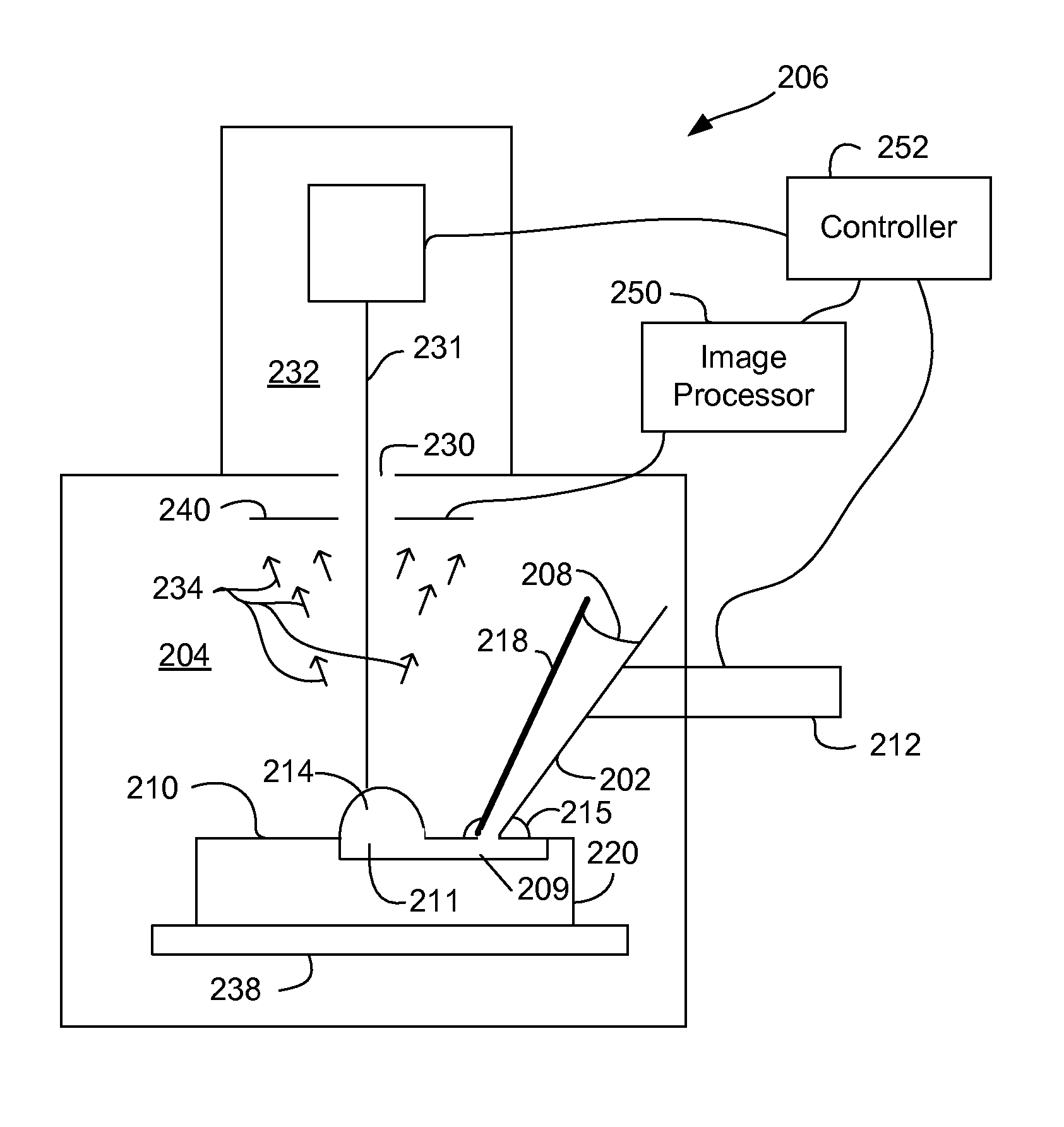

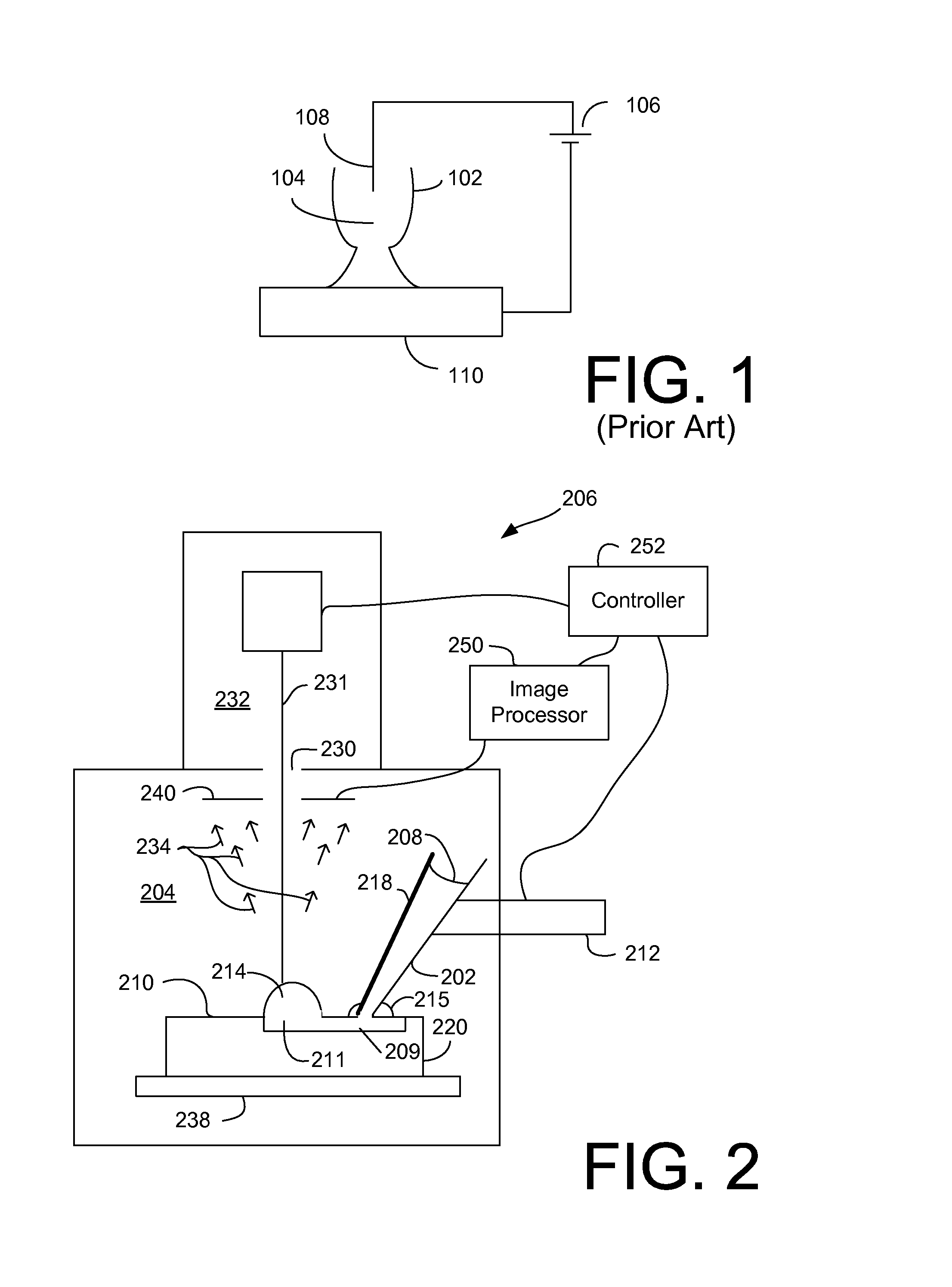

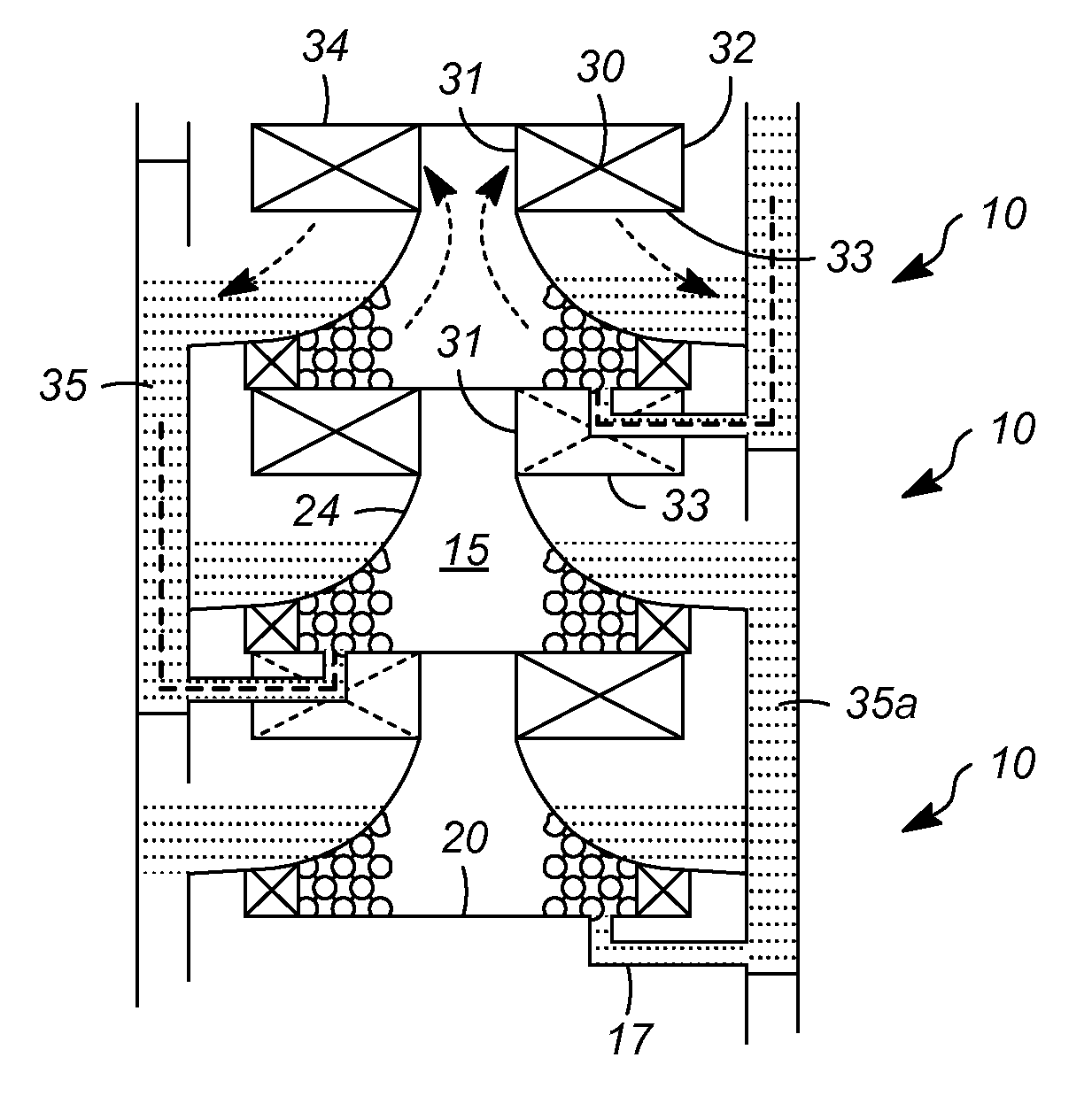

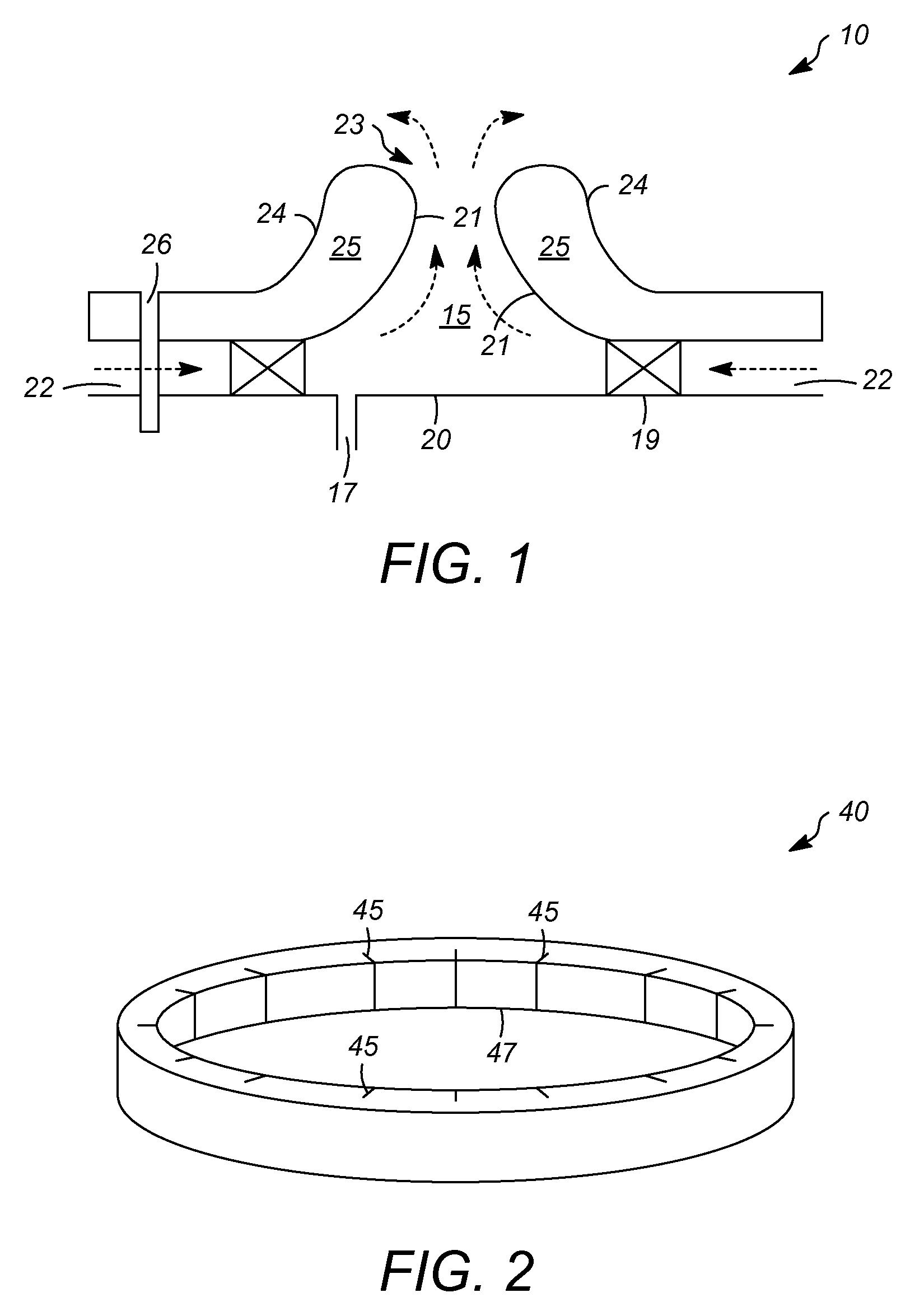

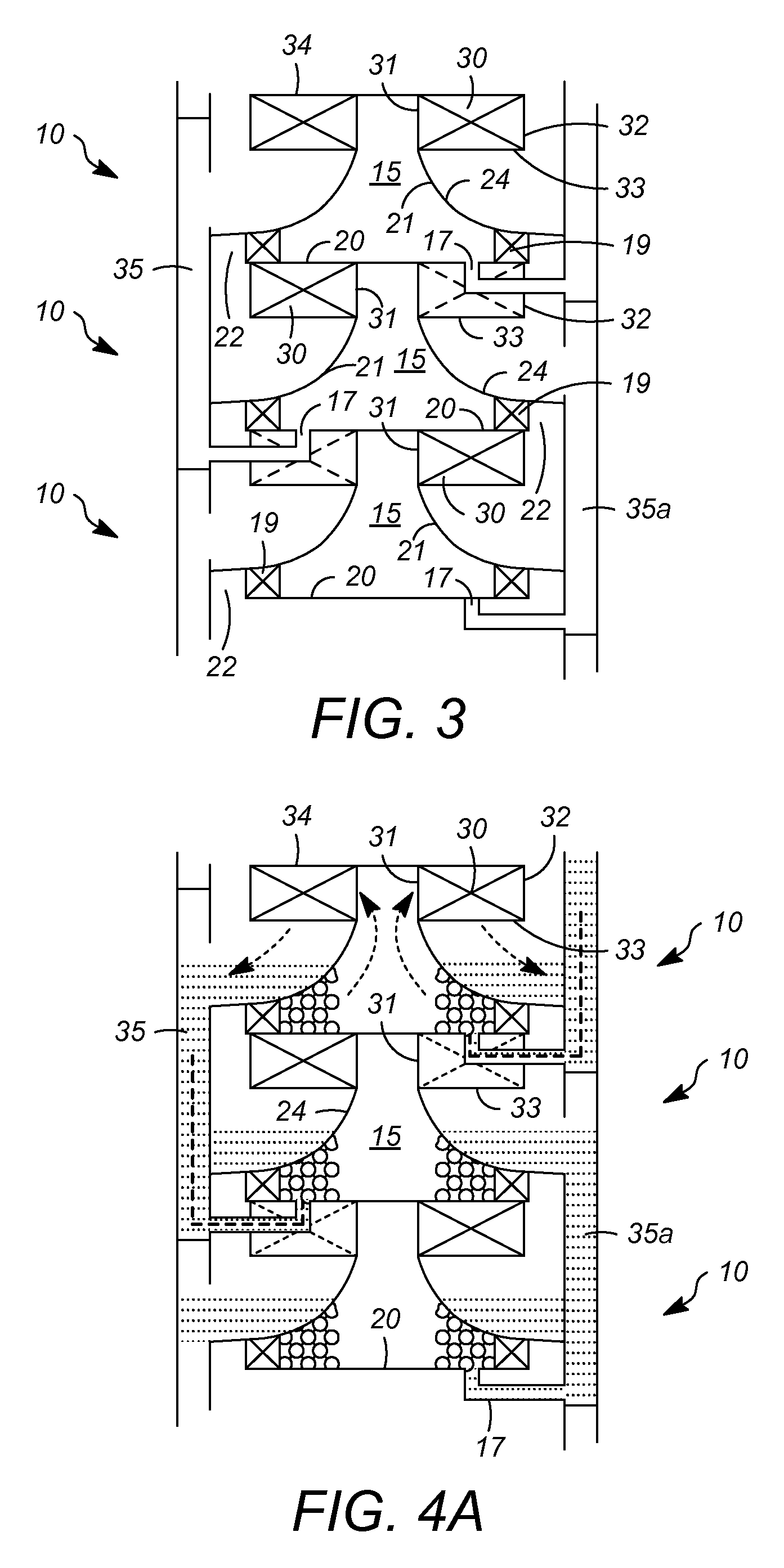

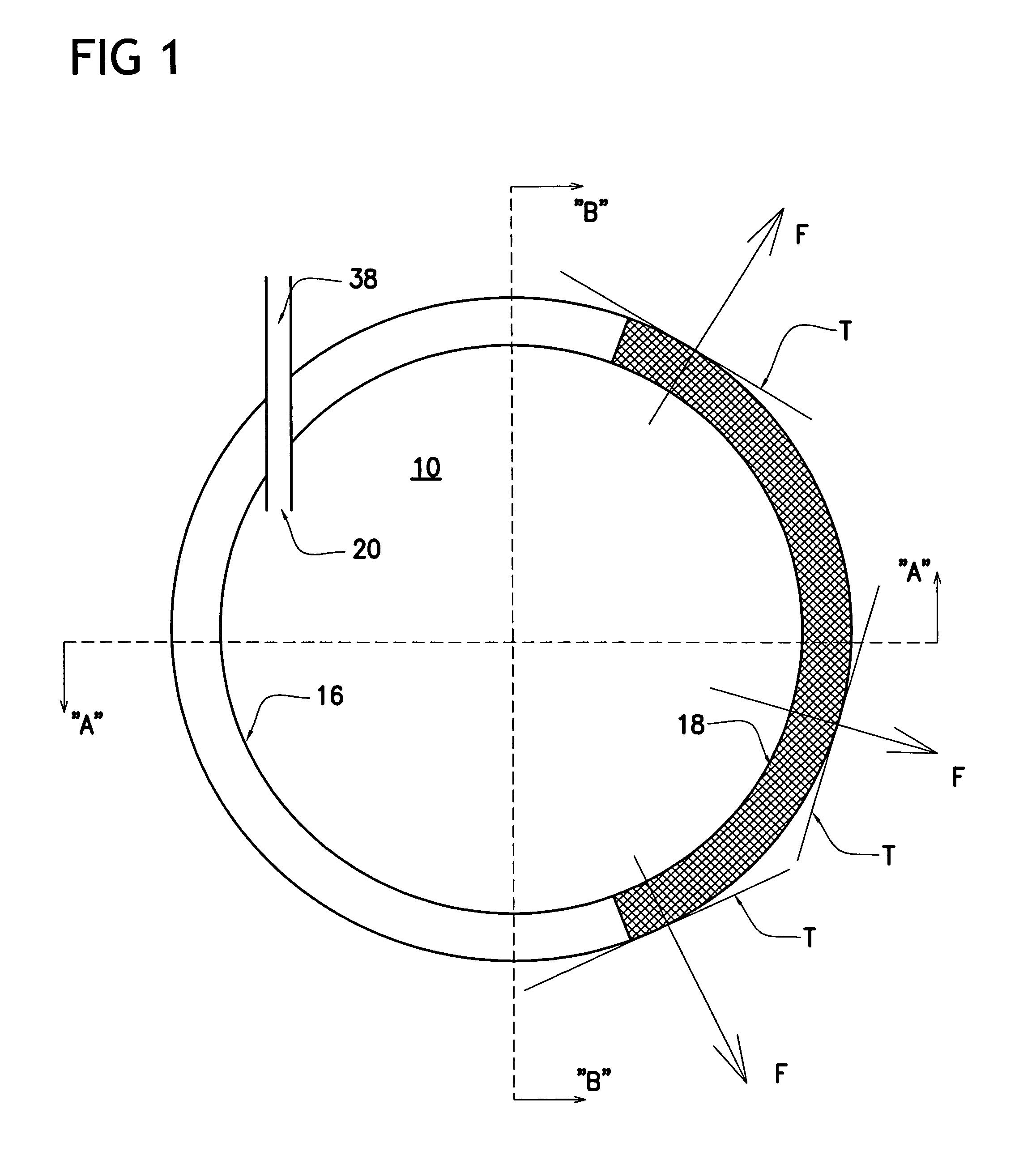

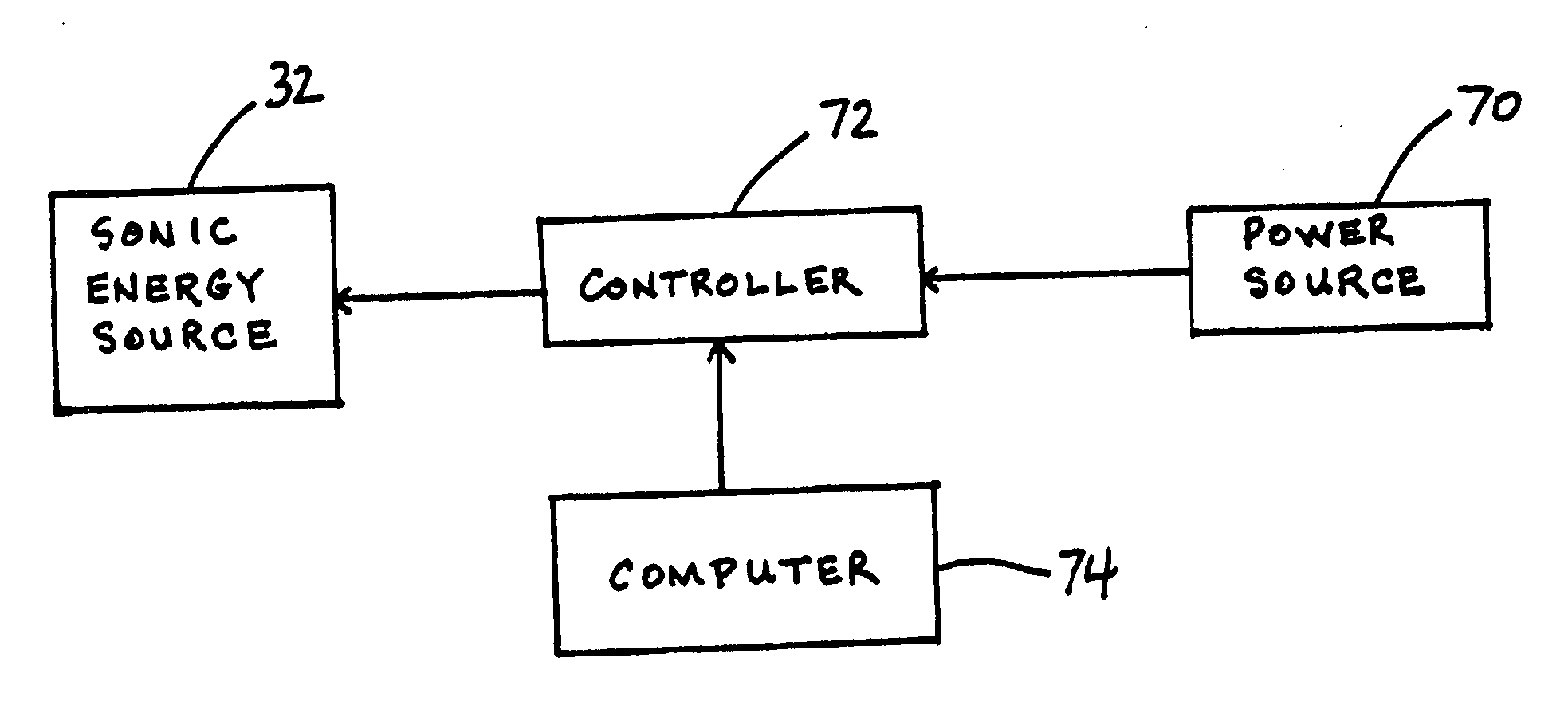

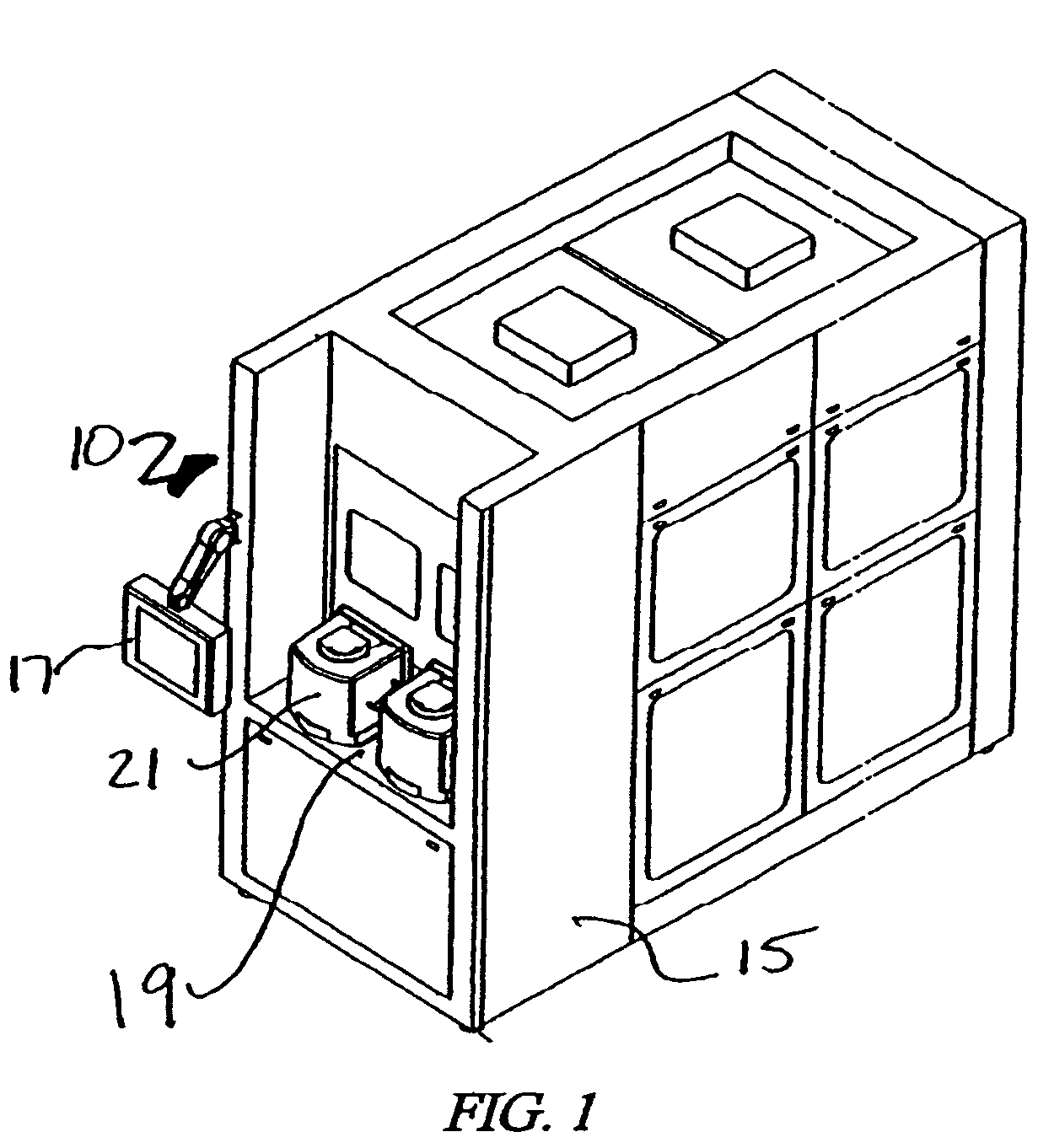

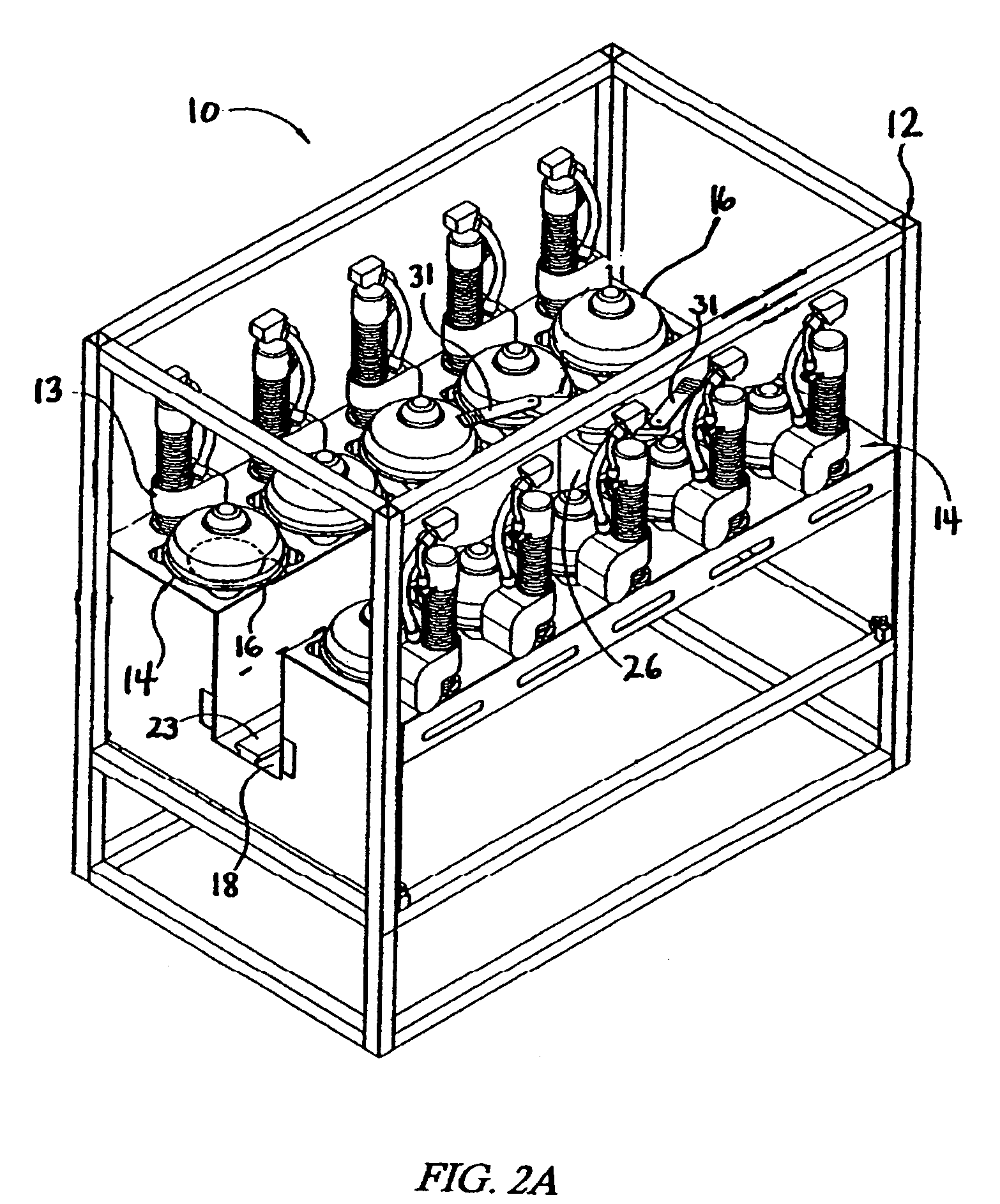

Sonic energy process chamber

InactiveUS20050199066A1Reduced boundary layer thicknessUniform processingRadiation pyrometryAnalysing solids using sonic/ultrasonic/infrasonic wavesHEAD SPINNINGTransducer

A system for processing a workpiece includes a base having a bowl or recess for holding a processing fluid. A sonic energy source, such as a megasonic transducer, provides sonic energy into a processing fluid in the bowl. A process head holds a workpiece. A process head lifter lowers the head holding the workpiece into the processing fluid in the bowl. Sonic energy is provided to the workpiece through the processing fluid, optionally while the processing head spins the workpiece. The processing fluid may include de-ionized water and an etchant.

Owner:APPLIED MATERIALS INC

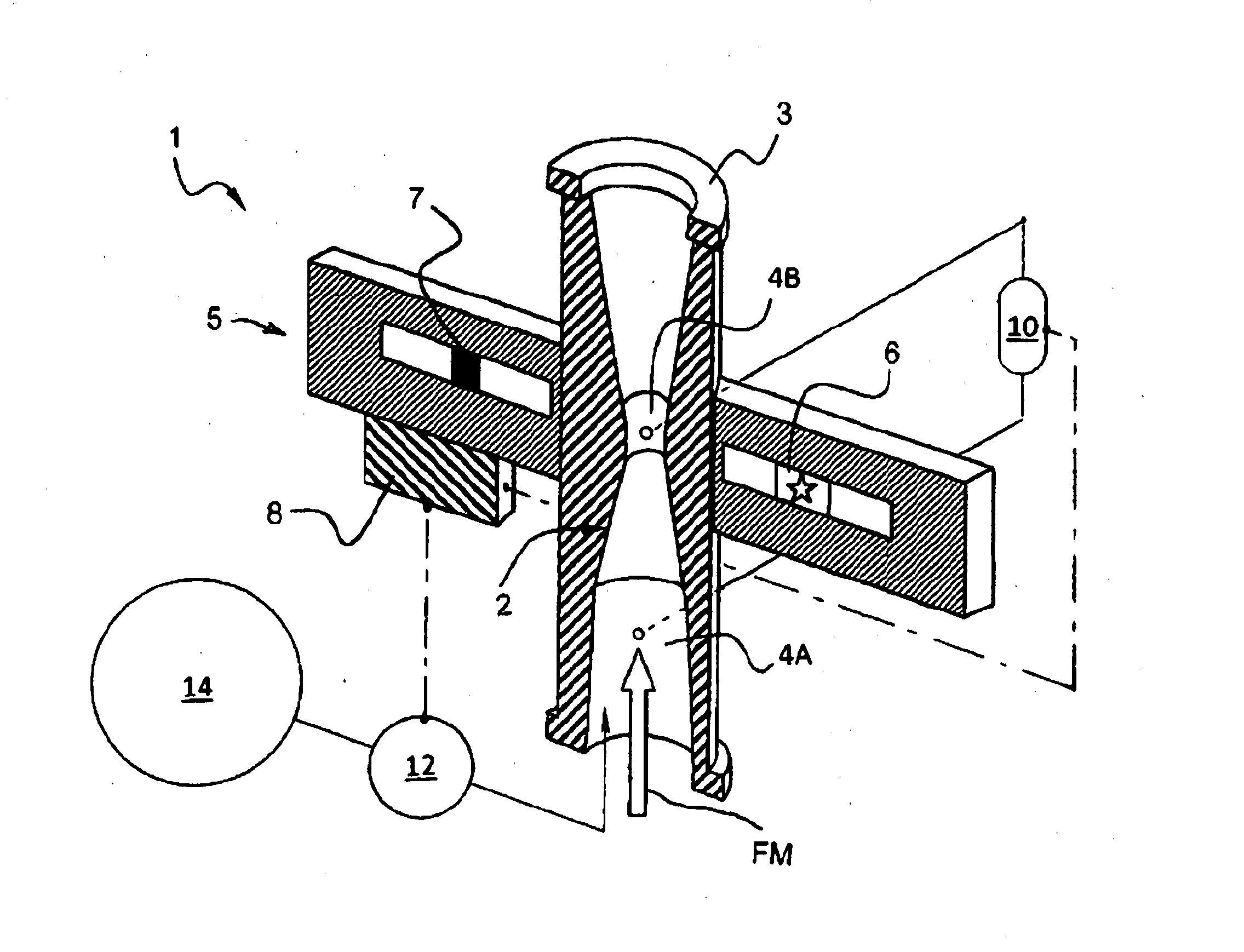

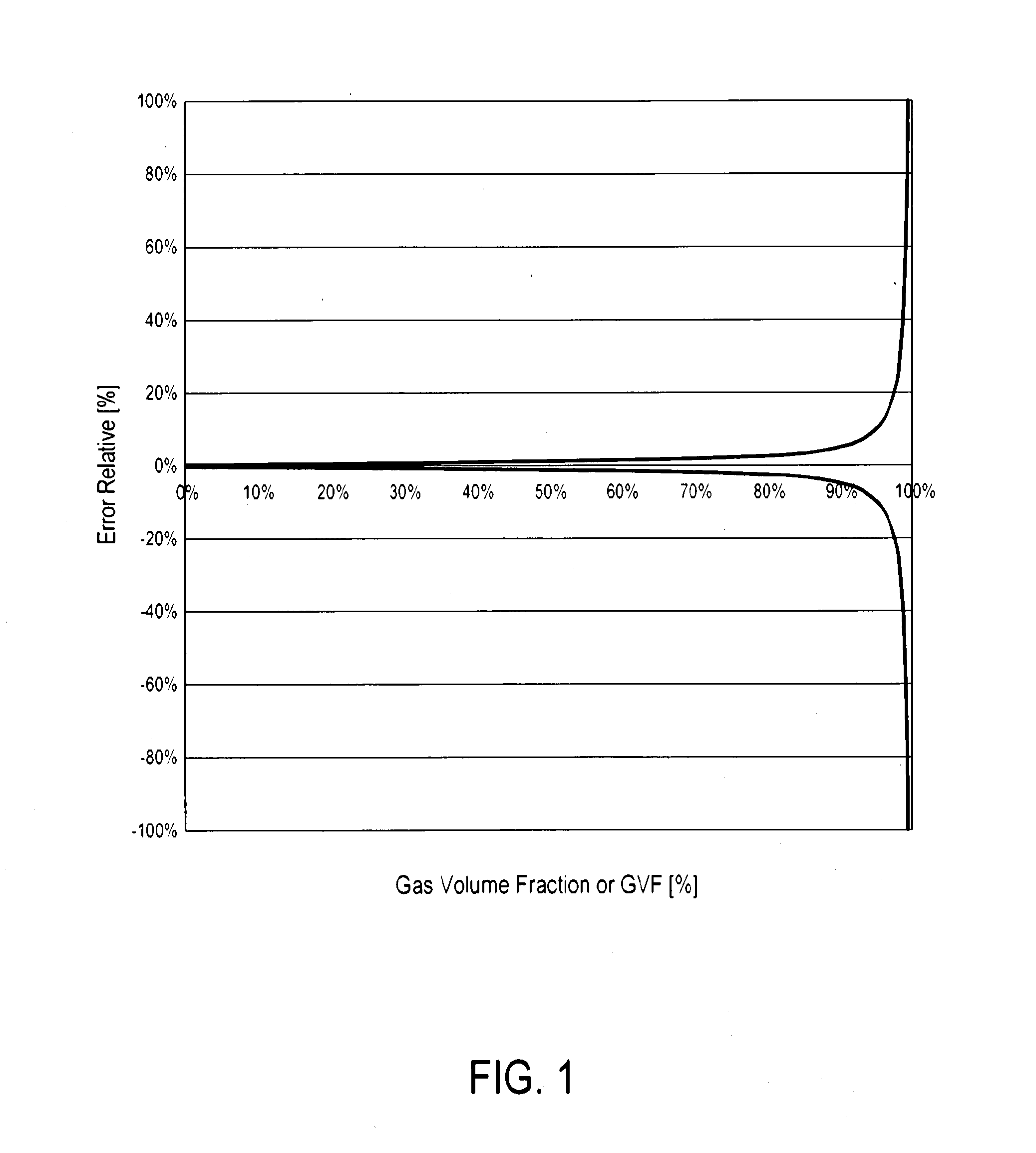

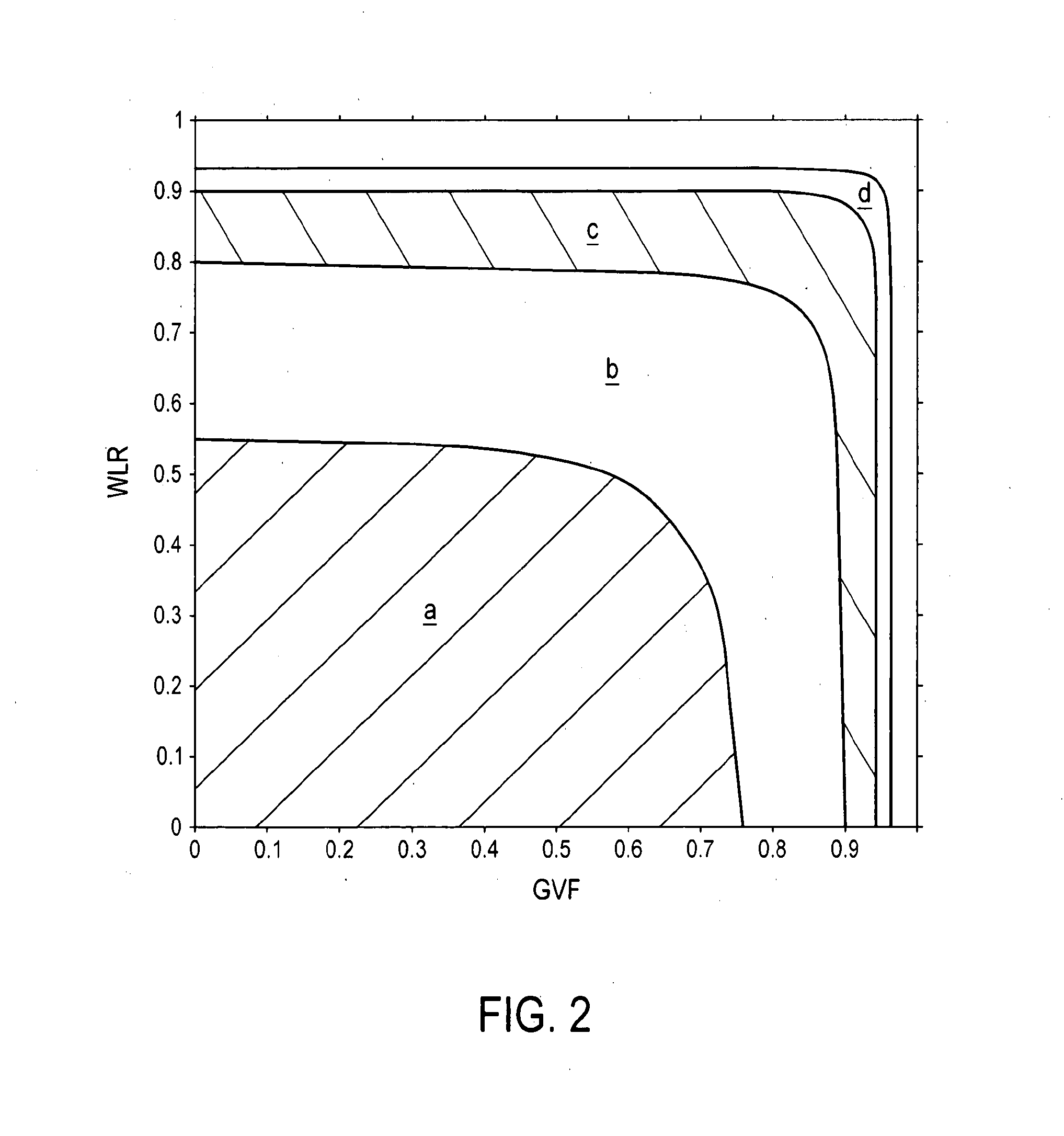

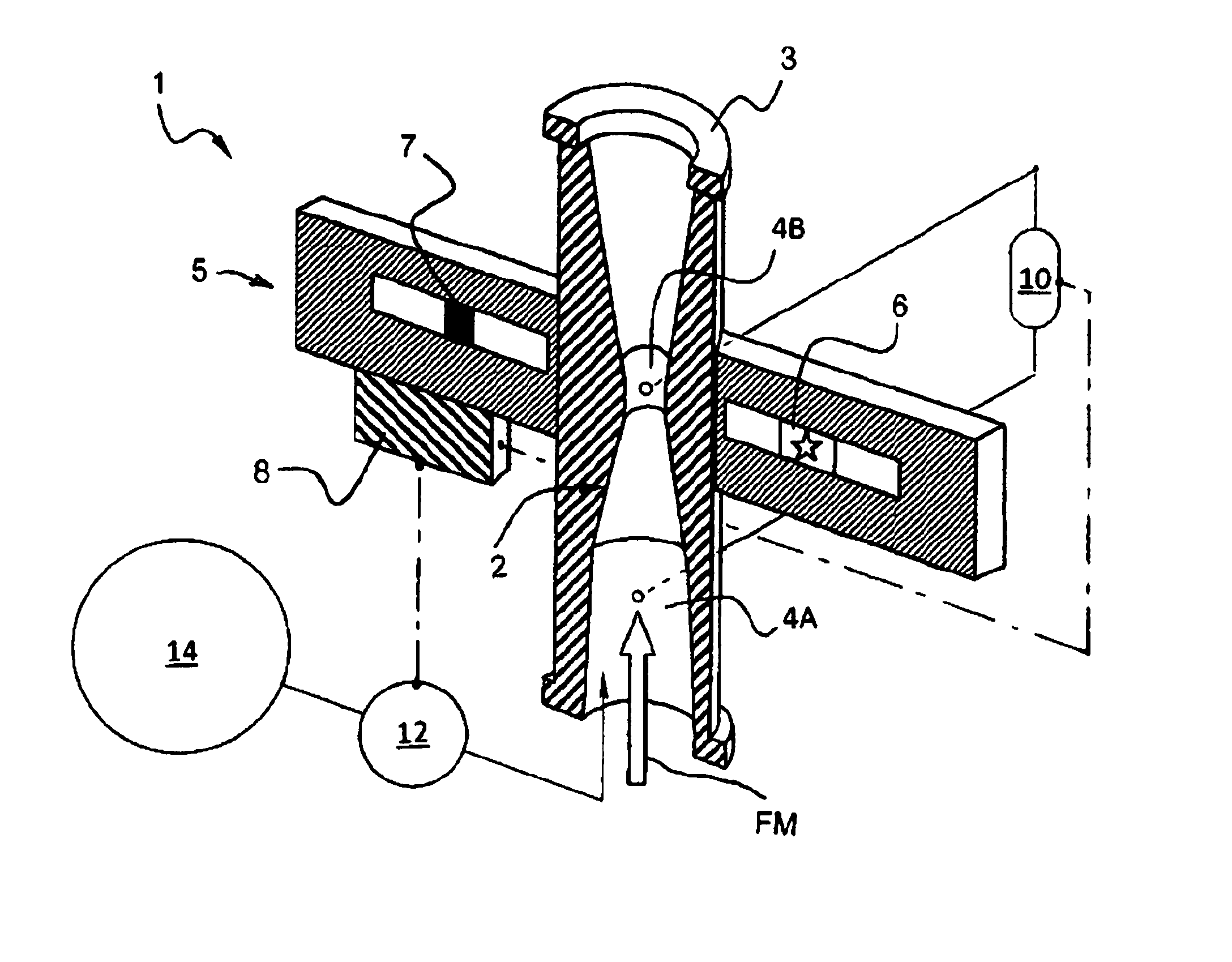

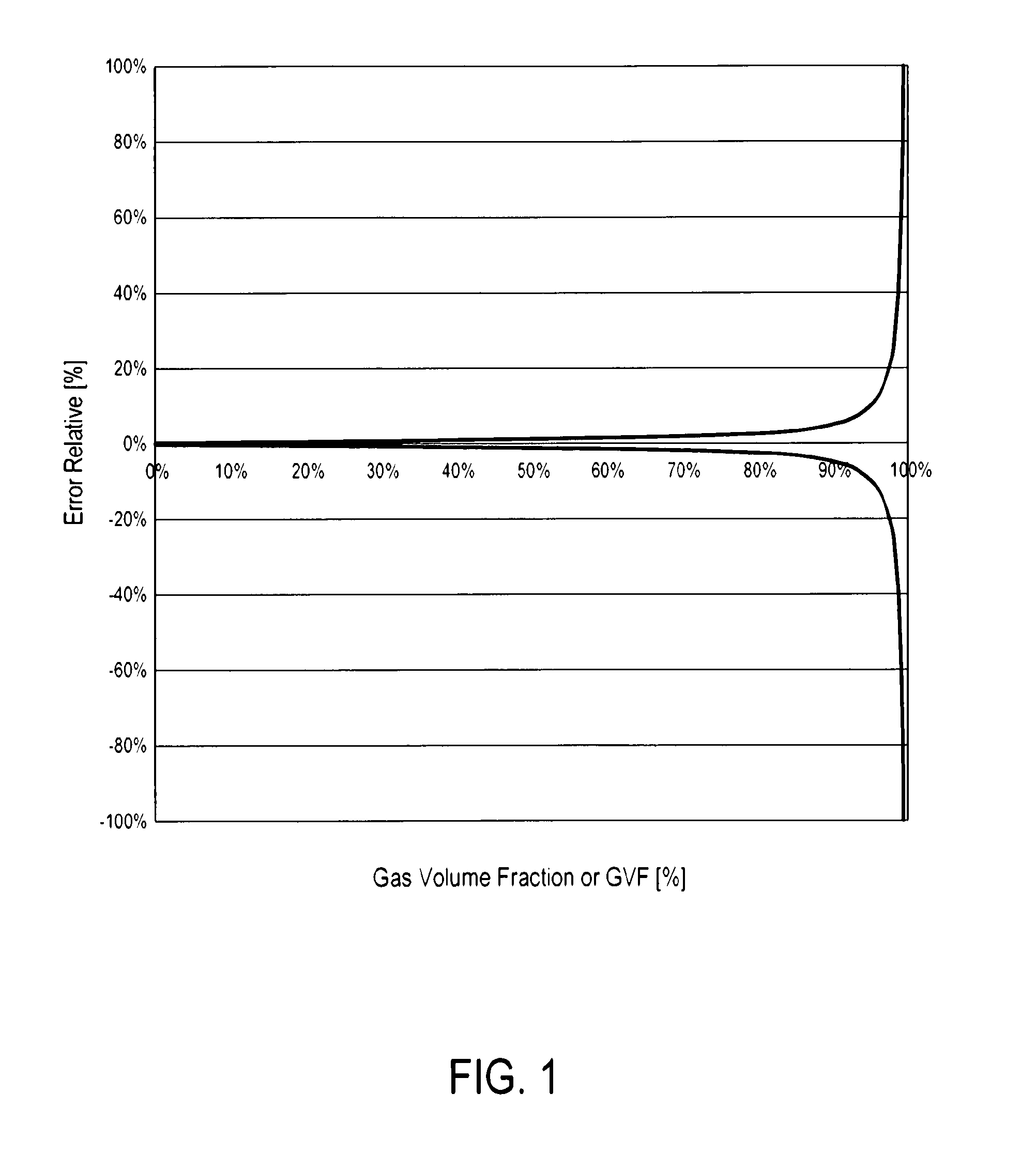

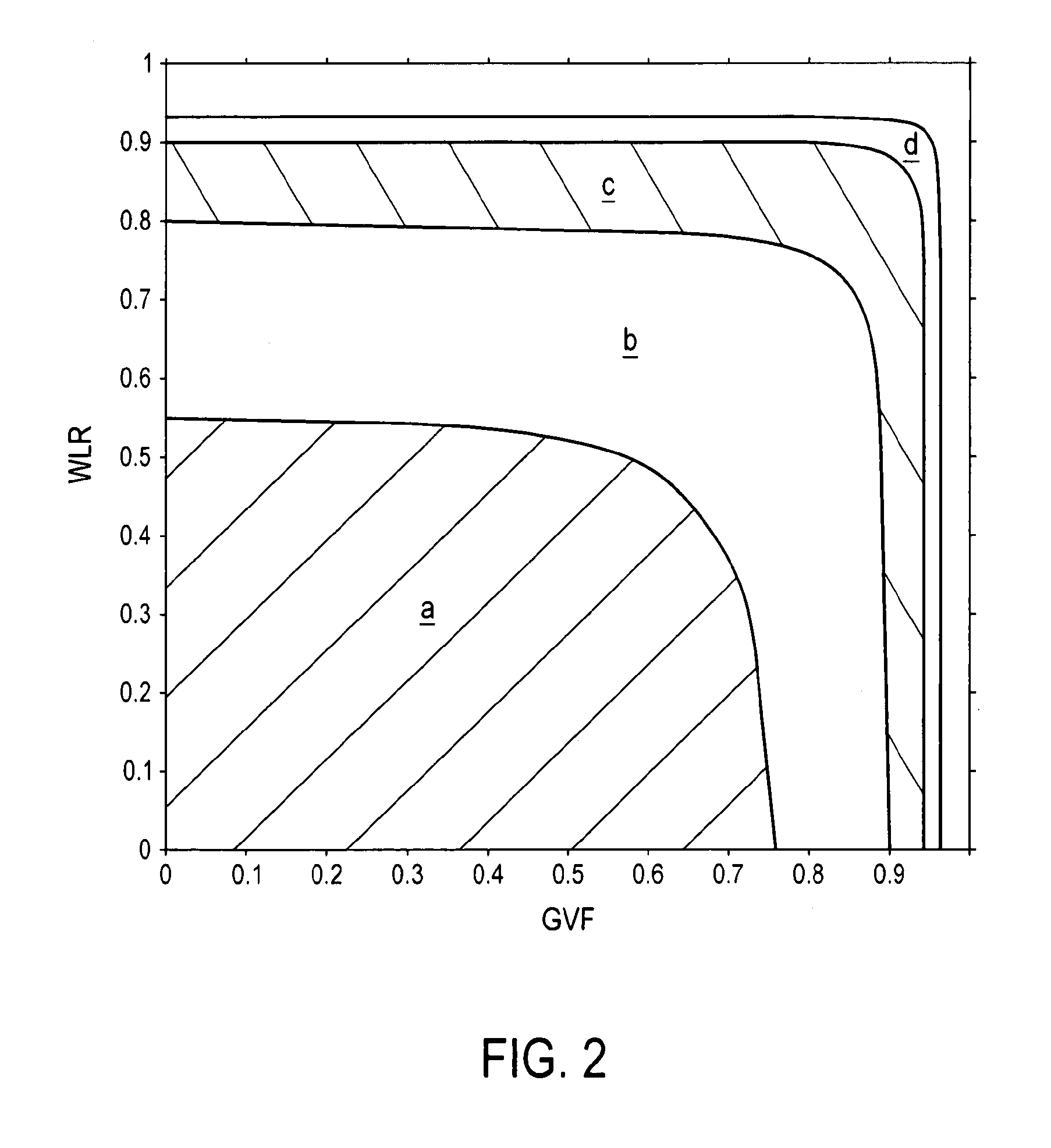

Flow Meter System and Method for Measuring An Amount of Liquid in A Largely Gaseous Multiphase Flow

InactiveUS20130174668A1Accurate measurementBig increaseTesting/calibration for volume flowVolume/mass flow by differential pressureDifferential pressureGas phase

Both a flow meter system and method are provided for accurately measuring the percentage amounts of liquid and gas phases in a multiphase flow through a conduit when the liquid phase constitutes a small minority portion (e.g., less than about 20%) of the multiphase flow. The system includes a flow meter that includes a differential pressure sensor connected across a Venturi in the conduit, and a dual energy fraction meter, each of which is operably connected to a digital processor. The system further includes a pump connected to the conduit upstream of the flow meter that introduces at least one pulse of a known quantity of liquid, the pulse being sufficient in volume to temporarily increase the liquid phase by a detectable amount. After the liquid pulse is introduced into the multi-phase flow, the digital processor computes the changes in the percentage amounts of the liquid and gas phases which should have occurred as a result of the pulse, and compares the computed changes with the actual changes measured by the flow meter in order to calibrate the flow meter. The measured increase in the liquid flow is then subtracted from the total measured liquid flow to determine the actual percentage of liquid flow.

Owner:SCHLUMBERGER TECH CORP

Sonic energy process chamber

InactiveUS7337663B2Reduced boundary layer thicknessUniform processingRadiation pyrometryAnalysing solids using sonic/ultrasonic/infrasonic wavesHEAD SPINNINGTransducer

A system for processing a workpiece includes a base having a bowl or recess for holding a processing fluid. A sonic energy source, such as a megasonic transducer, provides sonic energy into a processing fluid in the bowl. A process head holds a workpiece. A process head lifter lowers the head holding the workpiece into the processing fluid in the bowl. Sonic energy is provided to the workpiece through the processing fluid, optionally while the processing head spins the workpiece. The processing fluid may include de-ionized water and an etchant.

Owner:APPLIED MATERIALS INC

Processes for starting up deep tank anaerobic fermentation reactors for making oxygenated organic compound from carbon monoxide and hydrogen

ActiveUS8936927B2Reduce riskPromotes robust growthBioreactor/fermenter combinationsBiological substance pretreatmentsSimple Organic CompoundsMicroorganism

Processes are provided for starting up of anaerobic, deep tank fermentation systems used in the anaerobic bioconversion of hydrogen and carbon monoxide in a gaseous substrate stream to oxygenated organic compounds such as ethanol. In the processes injectors using a motive liquid are used to introduce gas substrate into the deep tank fermentation reactor where at least one of:(i) adjusting the gas to liquid flow ratio through an injector,(ii) changing the rate of liquid flow through an injector, and(iii) adjusting the carbon monoxide mole fraction in the gas feed by admixture with at least one other gas,wherein the mass transfer of carbon monoxide to an aqueous menstruum in the reactor is controlled to obtain the robust growth of the microorganism while maintaining the carbon monoxide concentration below that amount which is unduly adverse to the microorganism. In preferred aspects of the invention, recycled gas from the head space of the reactor is used to modulate the supply of carbon monoxide to the aqueous menstruum.

Owner:SYNATA BIO INC

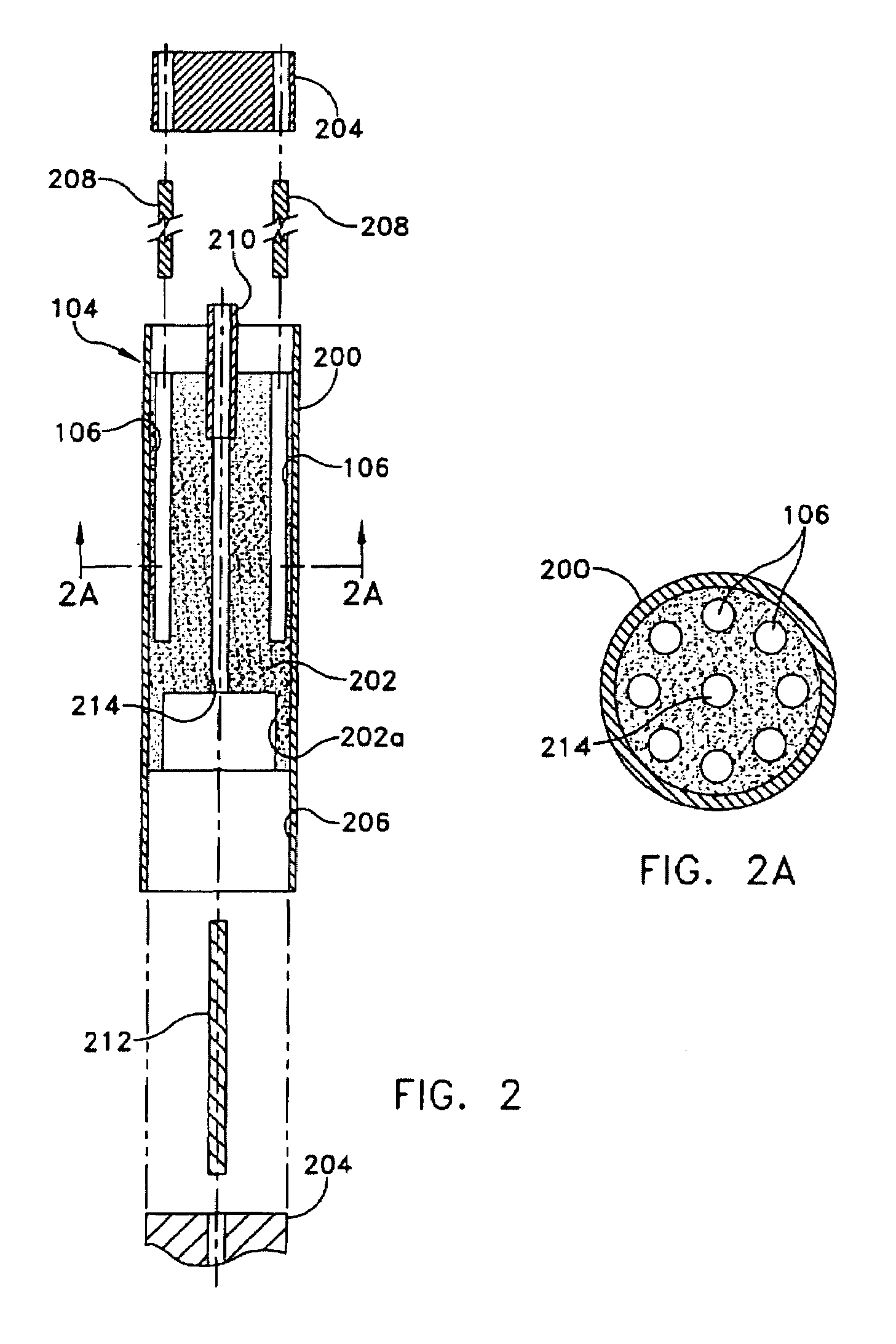

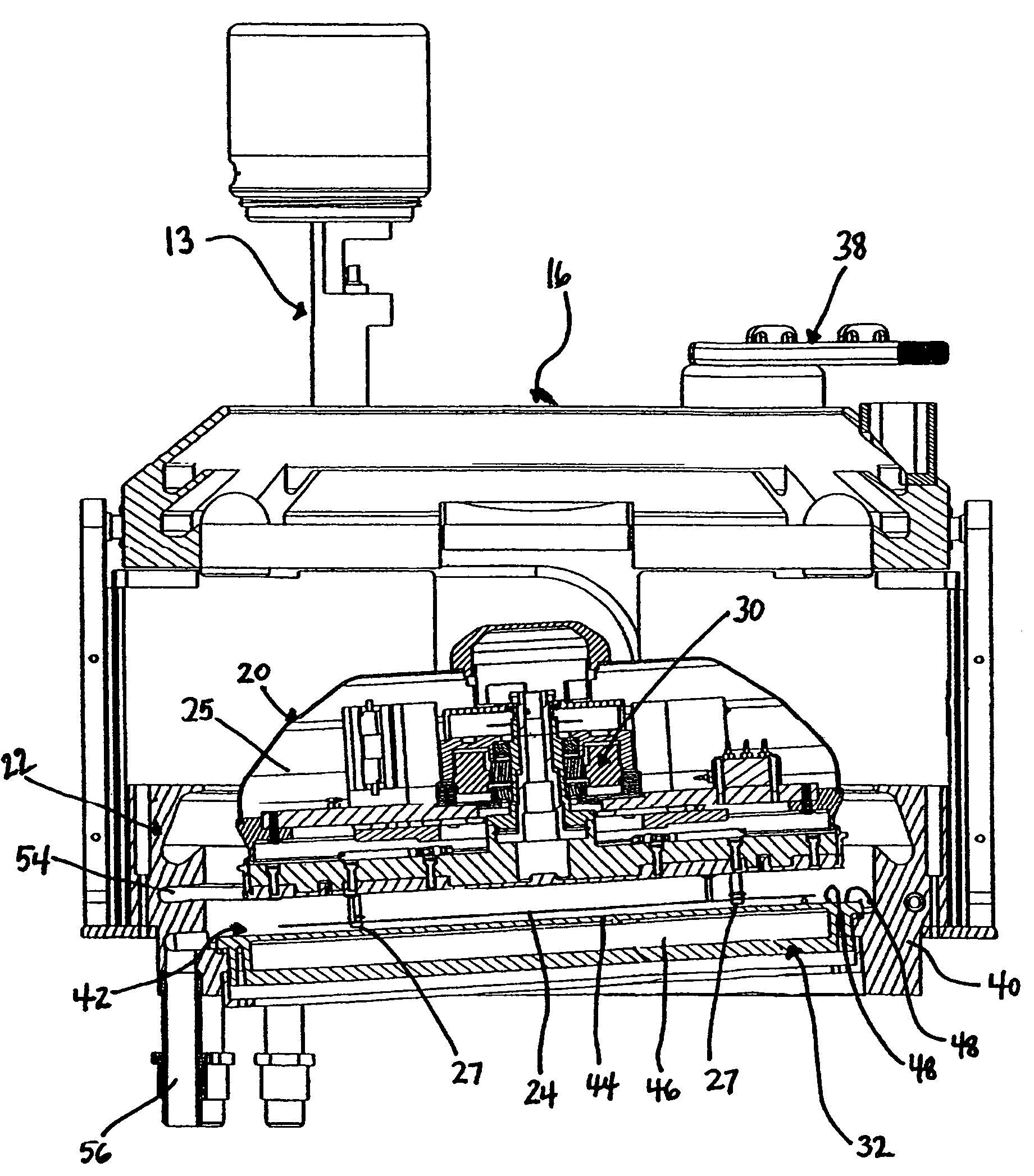

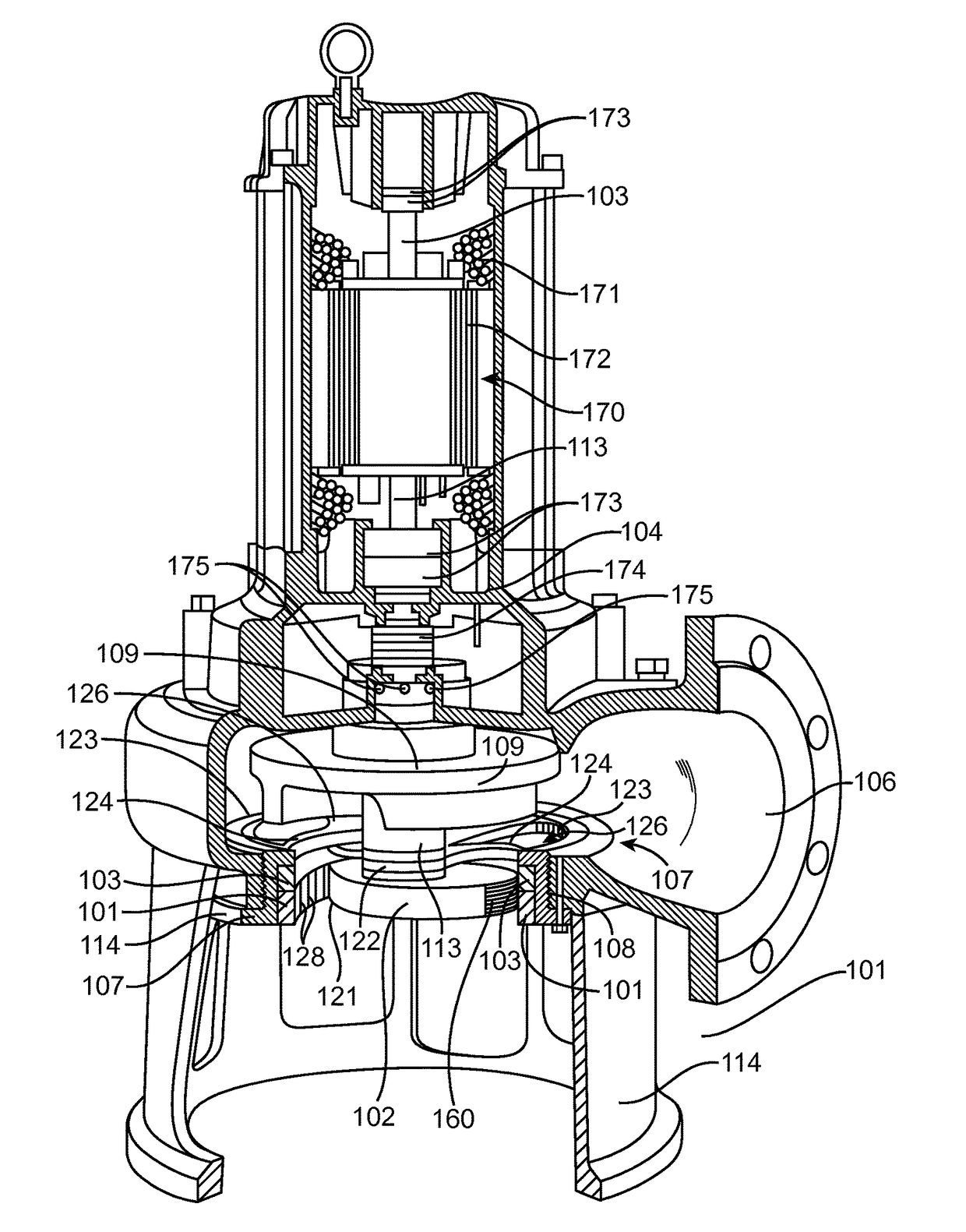

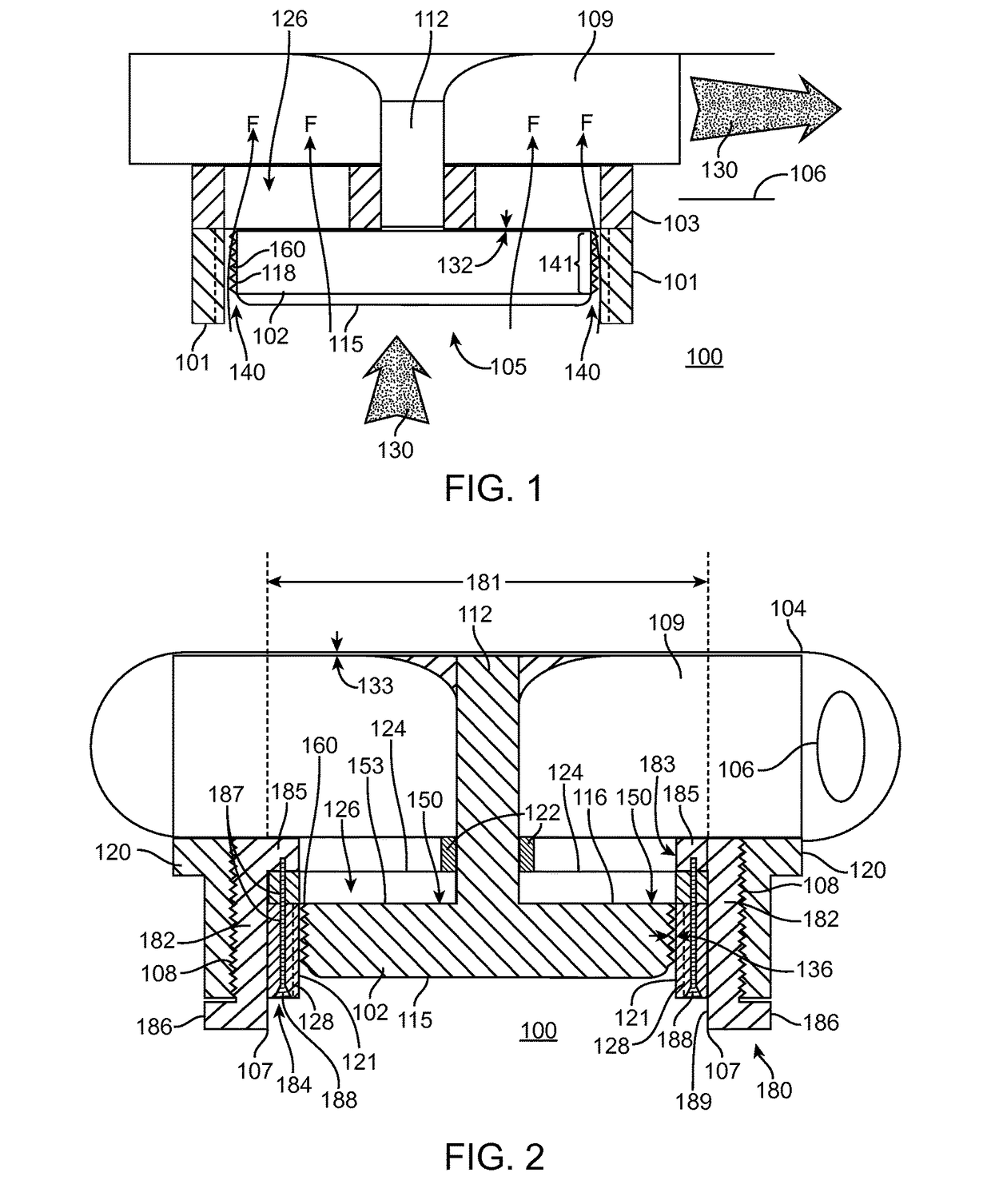

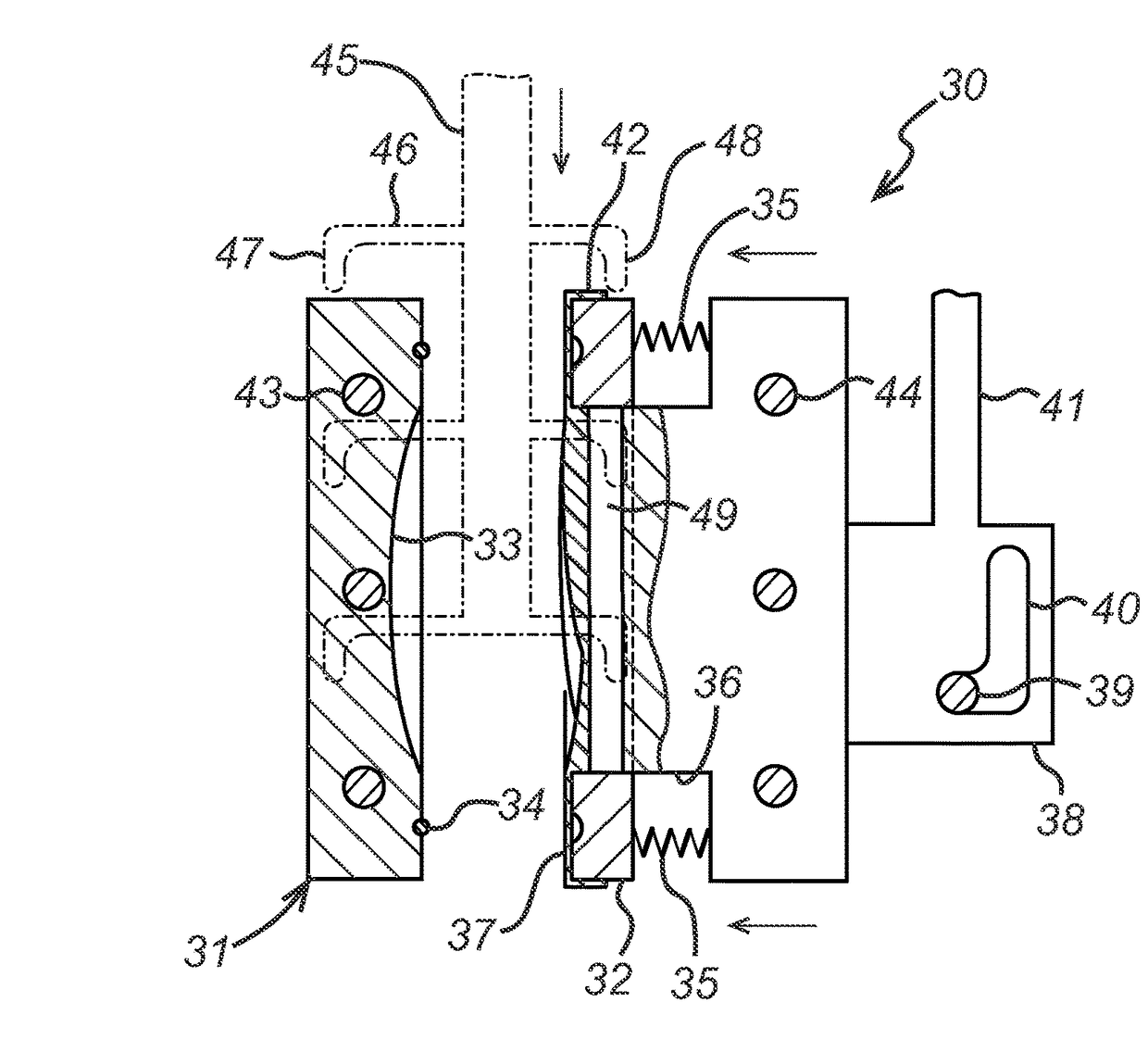

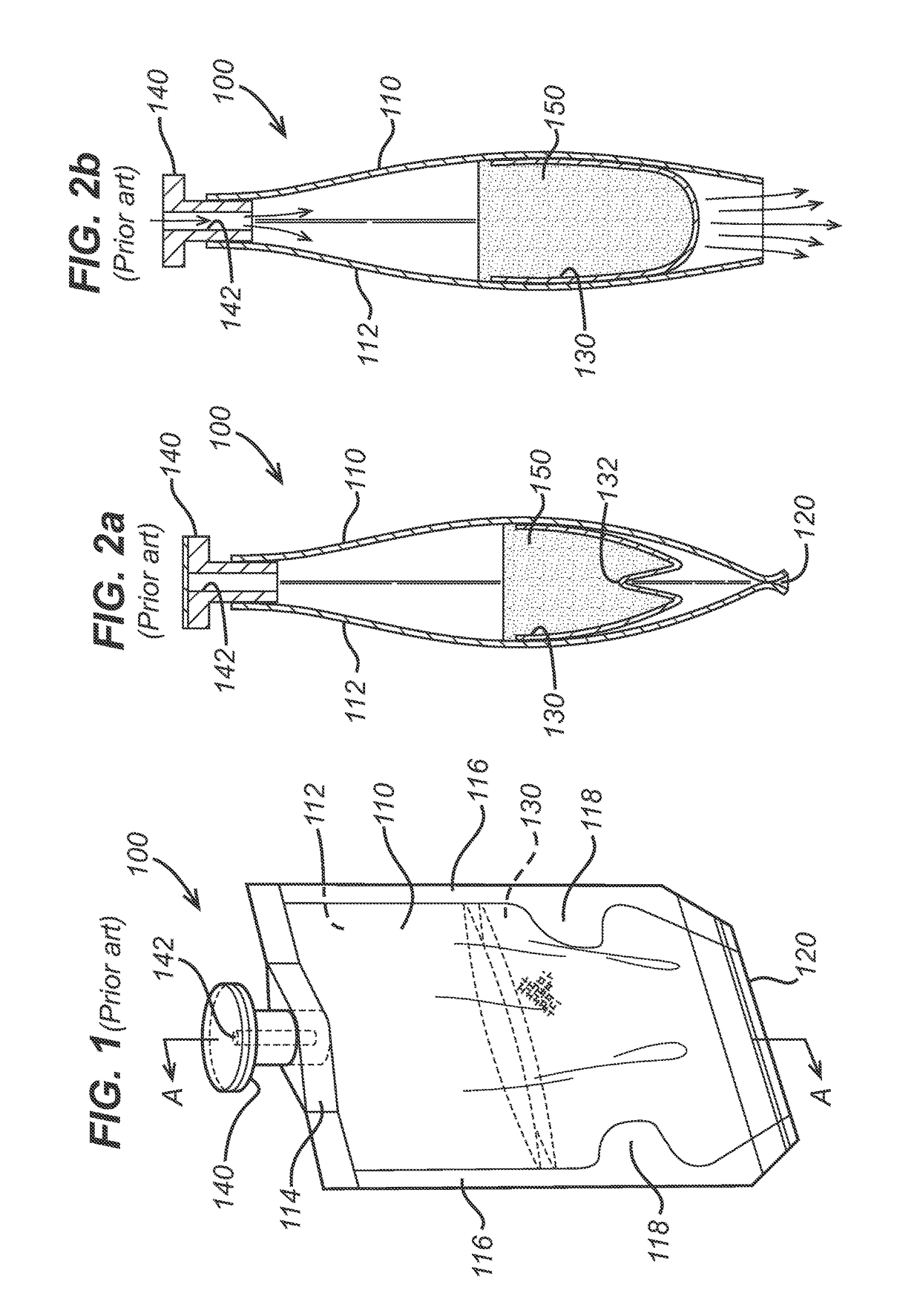

Shred and shear pump

ActiveUS20150377255A1Increase heightLong serviceSpecific fluid pumpsPump componentsImpellerWastewater

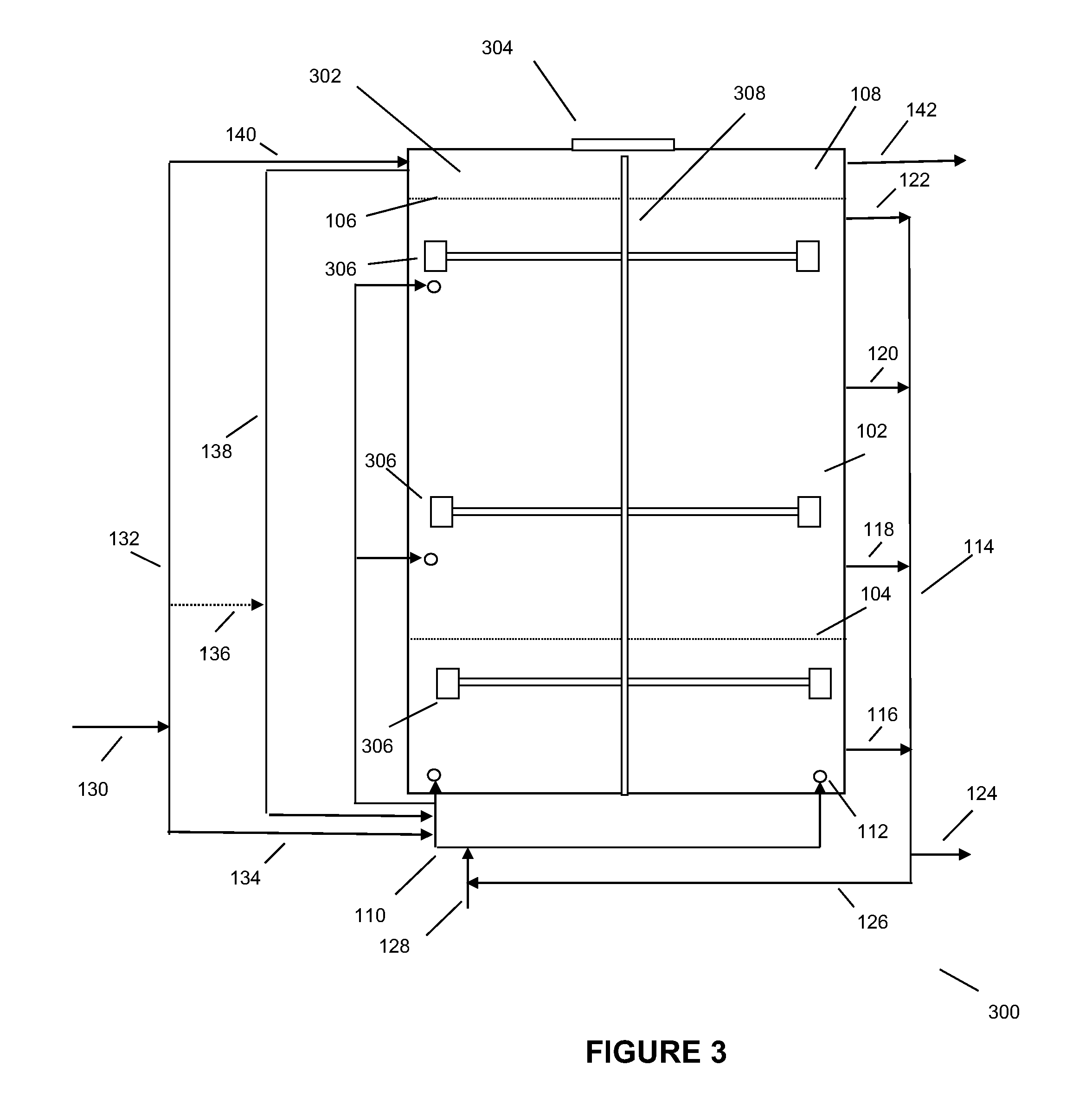

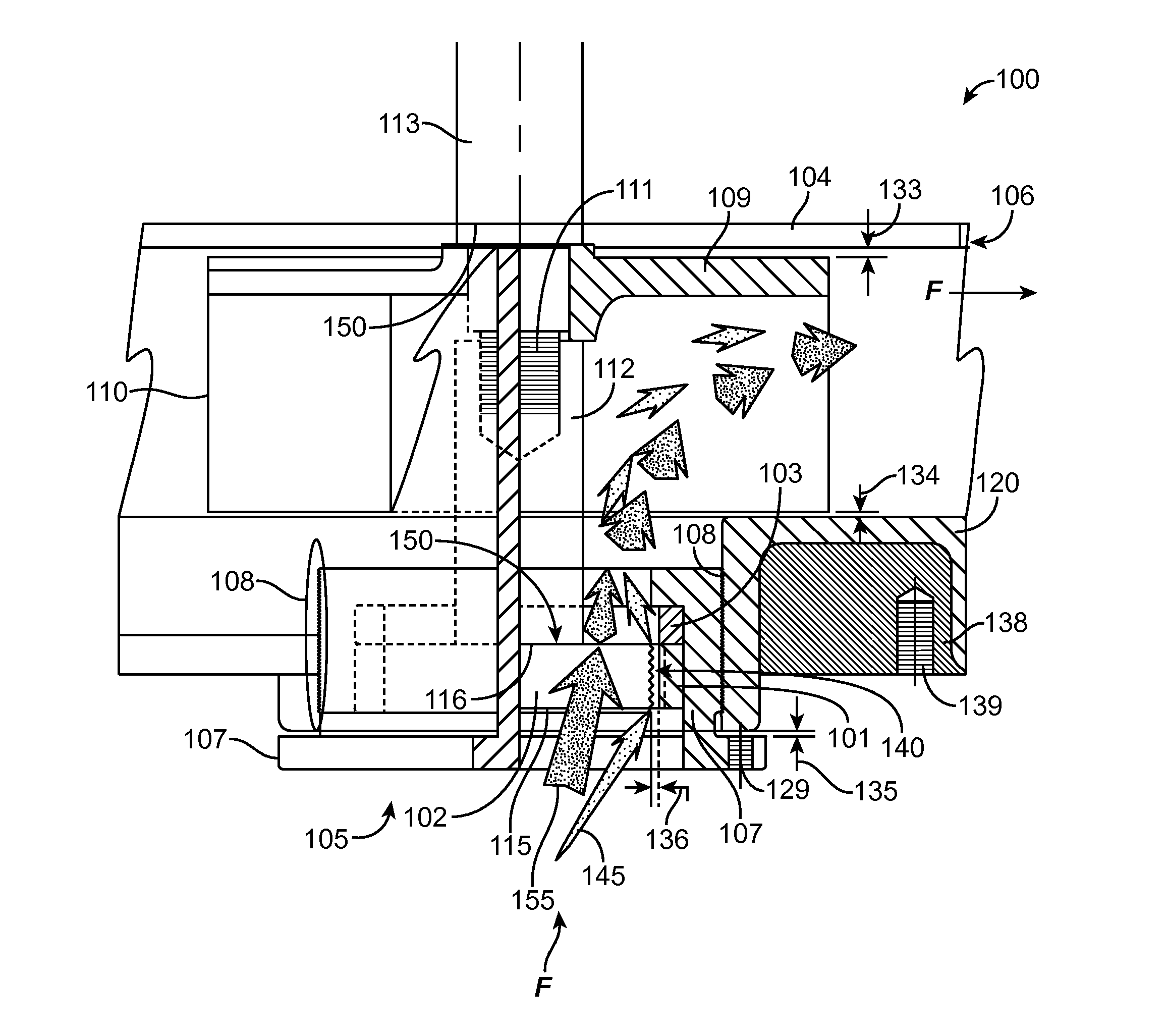

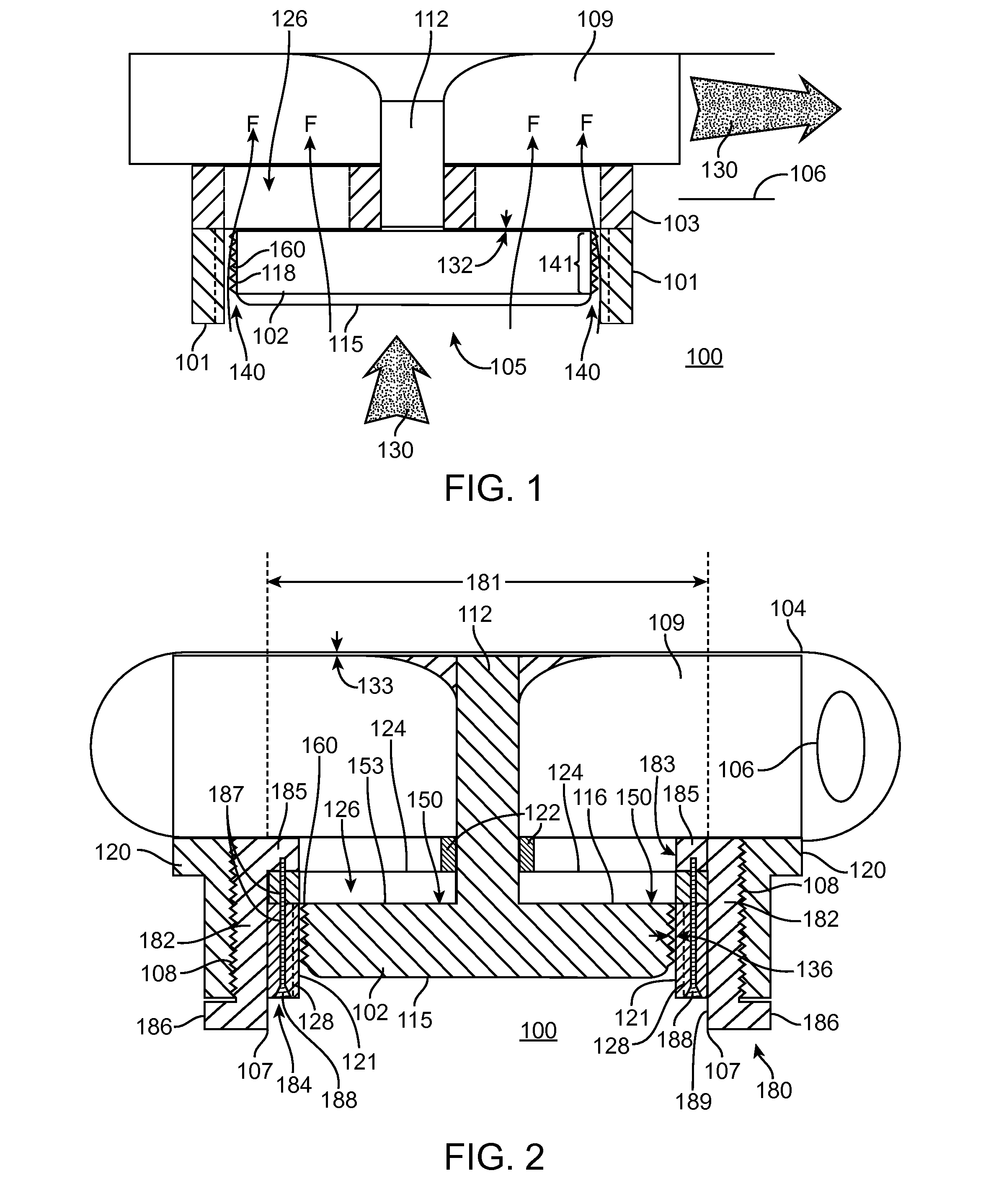

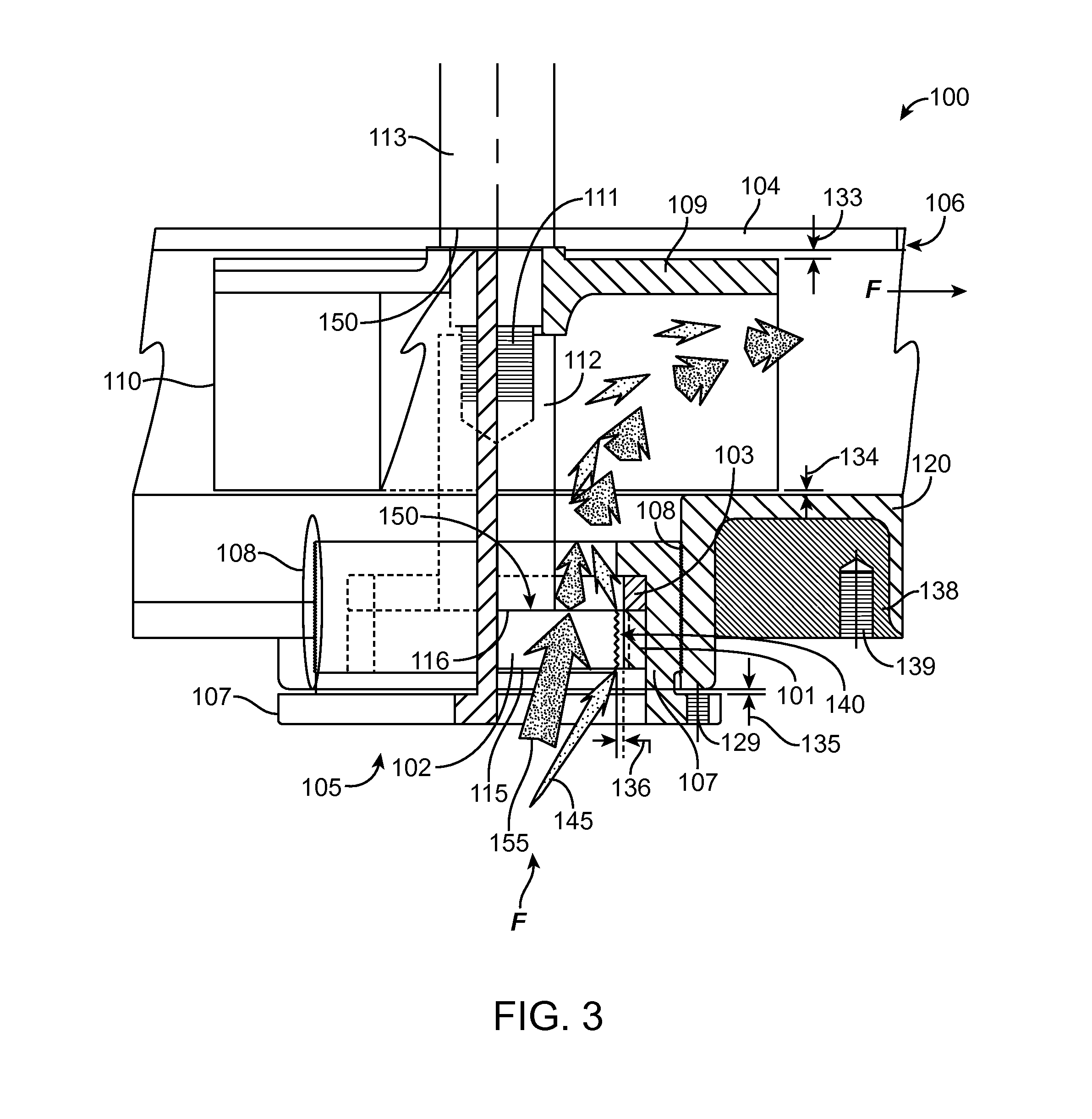

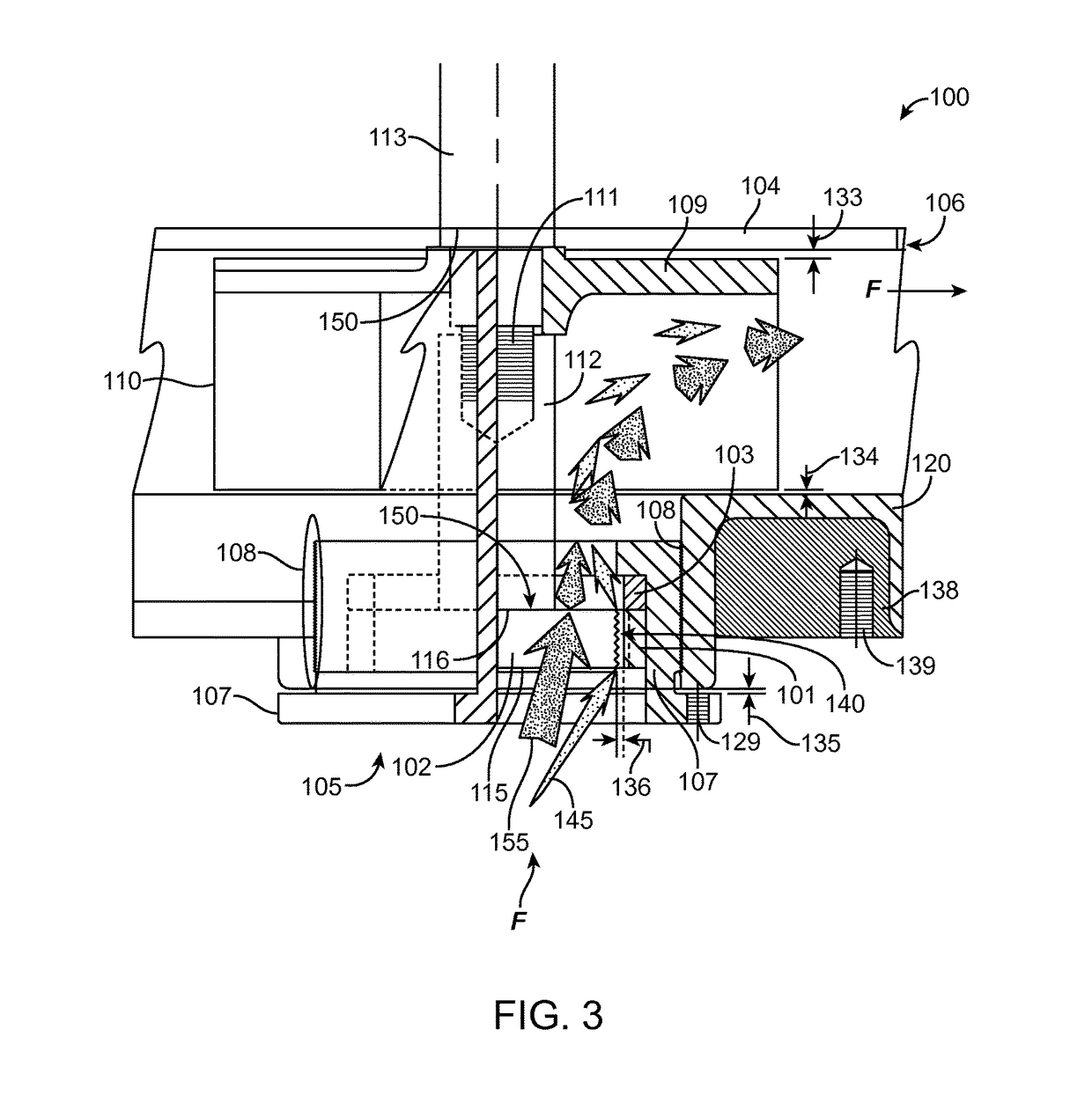

The present invention is a pump (100) used for applications where a solid (130) is present in wastewater and other liquids that requires cutting and reduction in size so as to pass the solid (130) through the inlet (105) to the outlet (106) of the pump (100). The pump (100) has a pump casing (104) with an inlet (105) and an outlet (106) formed therein. A drive unit (170) rotates a drive shaft (113) extending axially through the pump casing (104) to an impeller (109) and a cutter bar (102). The pump (100) is further configured with a radial cutter ring assembly (101) positioned adjacent the cutter bar (102) and the inlet (105) providing a shredding cutting action (140) of solids (145) between the rotating cutter bar (102) sliding past a radial cutter ring assembly (101) held stationary, e.g. cutting blades (160) formed in an edge (118) of the cutter bar (102) rotate across an internal surface (121) of the radial cutter ring assembly (101). The pump (100) also has an axial cutter ring assembly (103) with one or more blades (124) forming openings (126) adapted for the passage of solids (155) from the inlet (105) to the outlet (106) to provide a shearing cutting action (150) of solids (155) by a rotation of an upper surface (116) of the cutter bar (102) sliding past an axial cutting surface (153) of the blades (124) of the axial cutter ring assembly (103). The shred and shear pump (100) may be configured with a plurality of slots (128) on the internal surface (121) of the radial cutter ring assembly (101) to hold woven fibrous material for the shredding cutting action (140). The pump (100) also features improved optimized flow, cutting and reducing solids in the form of woven fibrous materials, and adjustability of the cutter housing (107) for precision and wear adjustment.

Owner:IND FLOW SOLUTIONS OPERATING LLC

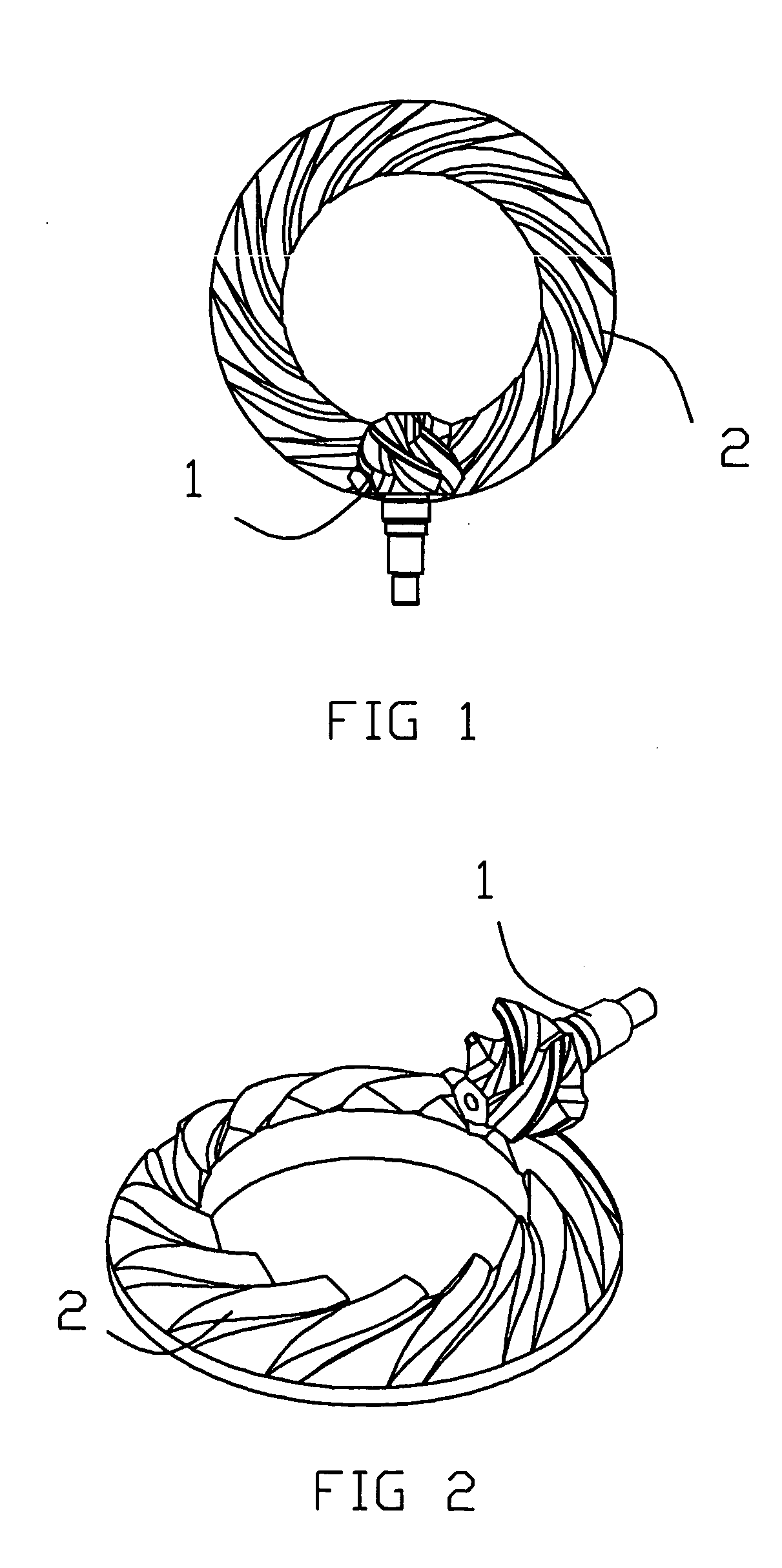

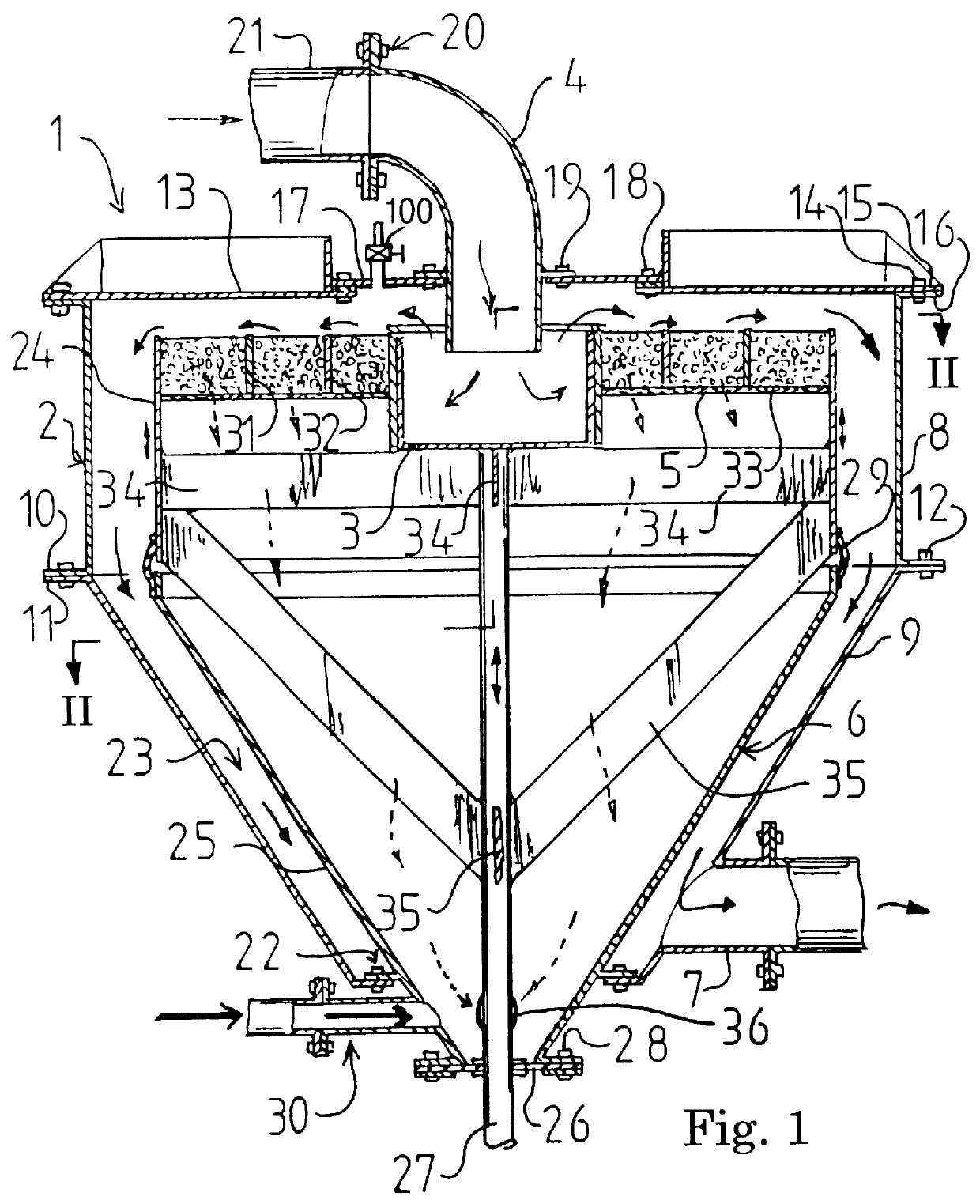

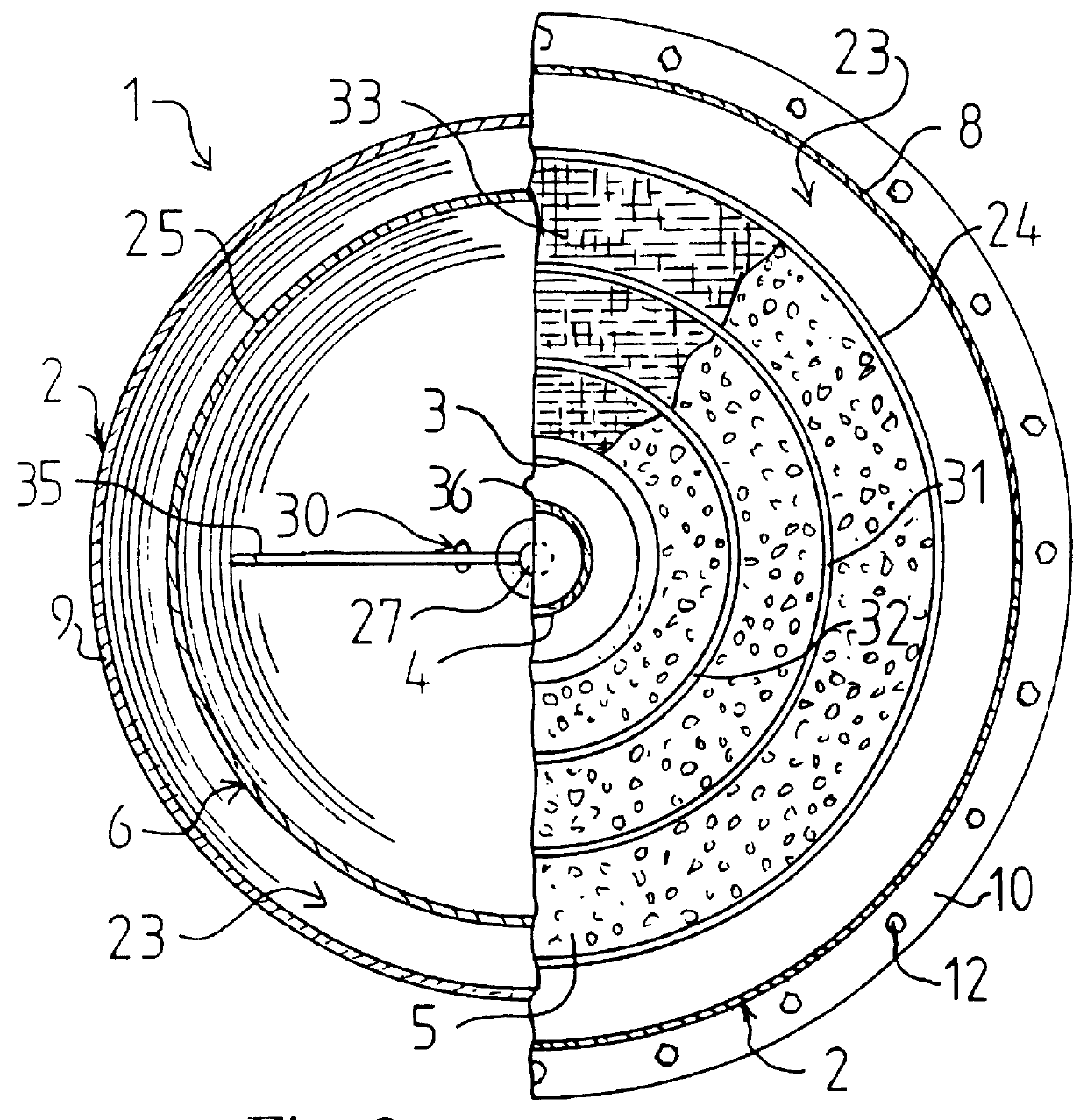

Separator for separating particles from a slurry

InactiveUS6079567ASuitable for useEasy to separateGas current separationWater/sewage treatmentParticulatesSlurry

PCT No. PCT / AU95 / 00137 Sec. 371 Date Jul. 15, 1998 Sec. 102(e) Date Jul. 15, 1998 PCT Filed Mar. 15, 1995 PCT Pub. No. WO95 / 26232 PCT Pub. Date Oct. 5, 1995A separator (1) for separating dense particulates from slurry includes a sealed housing (2) enclosing a submerged screen bed (33) which allows dense particulates to fall into a hutch (6) from which they may be discharged. The housing has a slurry inlet (4) arranged to deliver slurry to a sump (3) which directs slurry to flow radially over the bed. An annular cavity (23) formed between the housing and bed receives tailings flowing off of the top of the bed. An outlet (7) from the annular cavity allows discharge of the tailings, and a liquid inlet (30) to the hutch provides an upward flow of liquid through the bed. The bed is agitated to assist passage of dense particulates.

Owner:GRAY ALEXANDER HAMILTON

Shred and shear pump

ActiveUS9719527B2Long serviceImprove cutting effectSpecific fluid pumpsPump componentsImpellerDrive shaft

The present invention is a pump used for applications where a solid is present in wastewater and other liquids that requires cutting and reduction in size so as to pass the solid through the inlet to the outlet of the pump. The pump has a pump casing with an inlet and an outlet formed therein. A drive unit rotates a drive shaft extending axially through the pump casing to an impeller and a cutter bar. The pump is further configured with a radial cutter ring assembly positioned adjacent the cutter bar and the inlet providing a shredding cutting action of solids between the rotating cutter bar sliding past a radial cutter ring assembly held stationary, e.g. cutting blades formed in an edge of the cutter bar rotate across an internal surface of the radial cutter ring assembly. The pump also has an axial cutter ring assembly with one or more blades forming openings adapted for the passage of solids from the inlet to the outlet to provide a shearing cutting action of solids by a rotation of an upper surface of the cutter bar sliding past an axial cutting surface of the blades of the axial cutter ring assembly. The shred and shear pump may be configured with a plurality of slots on the internal surface of the radial cutter ring assembly to hold woven fibrous material for the shredding cutting action. The pump also features improved optimized flow, cutting and reducing solids in the form of woven fibrous materials, and adjustability of the cutter housing for precision and wear adjustment.

Owner:IND FLOW SOLUTIONS OPERATING LLC

Hybrid loop heat pipe

InactiveUS20050087328A1Avoids slow down and oppositionAccelerate liquid flowDomestic stoves or rangesThermal insulationEngineeringLoop heat pipe

A heat pipe assembly (100) has a combined reservoir (102) and evaporator (104), the evaporator (104) having ducts of a vapor manifold (106) that exhausts vapor toward the condenser (108) instead of opposing the flow of liquid condensate to the reservoir (102), and the evaporator (104) having a wick passage that impels the condensate toward the reservoir (102) instead of opposing the flow of vapor.

Owner:THERMAL

Flow meter system and method for measuring an amount of liquid in a largely gaseous multiphase flow

InactiveUS8939033B2Accurate measurementEfficient calibrationTesting/calibration for volume flowVolume/mass flow by differential pressureDifferential pressureGas phase

Both a flow meter system and method are provided for accurately measuring the percentage amounts of liquid and gas phases in a multiphase flow through a conduit when the liquid phase constitutes a small minority portion (e.g., less than about 20%) of the multiphase flow. The system includes a flow meter that includes a differential pressure sensor connected across a Venturi in the conduit, and a dual energy fraction meter, each of which is operably connected to a digital processor. The system further includes a pump connected to the conduit upstream of the flow meter that introduces at least one pulse of a known quantity of liquid, the pulse being sufficient in volume to temporarily increase the liquid phase by a detectable amount. After the liquid pulse is introduced into the multi-phase flow, the digital processor computes the changes in the percentage amounts of the liquid and gas phases which should have occurred as a result of the pulse, and compares the computed changes with the actual changes measured by the flow meter in order to calibrate the flow meter. The measured increase in the liquid flow is then subtracted from the total measured liquid flow to determine the actual percentage of liquid flow.

Owner:SCHLUMBERGER TECH CORP

Apparatus for equalizing air pressure in an air respiratory system

InactiveUS20060076009A1Accelerate liquid flowRespiratorsLighting and heating apparatusHigh concentrationBreathing gas

A humidifier apparatus for operating at an air pressure is disclosed for use with a respiratory therapy breathing apparatus that provides a breathable gas supply to patients requiring higher concentrations of liquid vapor and gas pressure. The humidifier apparatus includes a feed liquid supply bag in fluid communication with a humidifier cartridge via a conduit. The conduit enables air to flow therethrough to equalize air pressure between the humidifier cartridge and the feed liquid supply bag in response to liquid being supplied to the humidifier cartridge.

Owner:MEDEX CARDIO PULMONARY INC

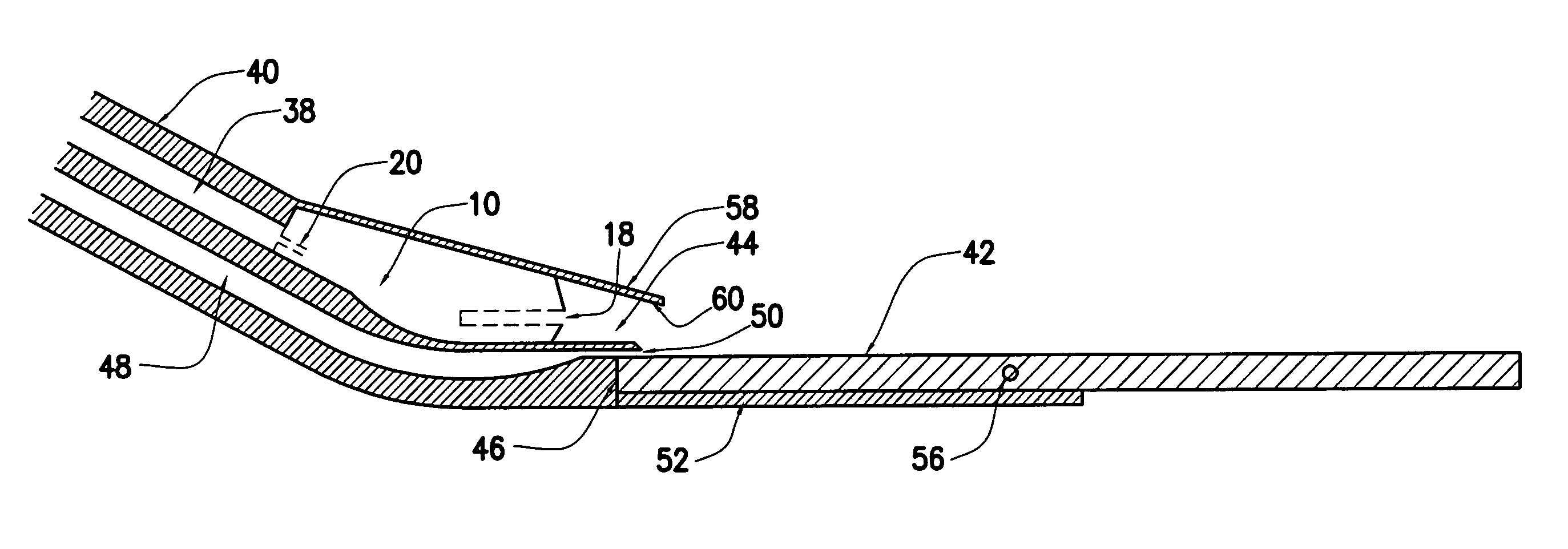

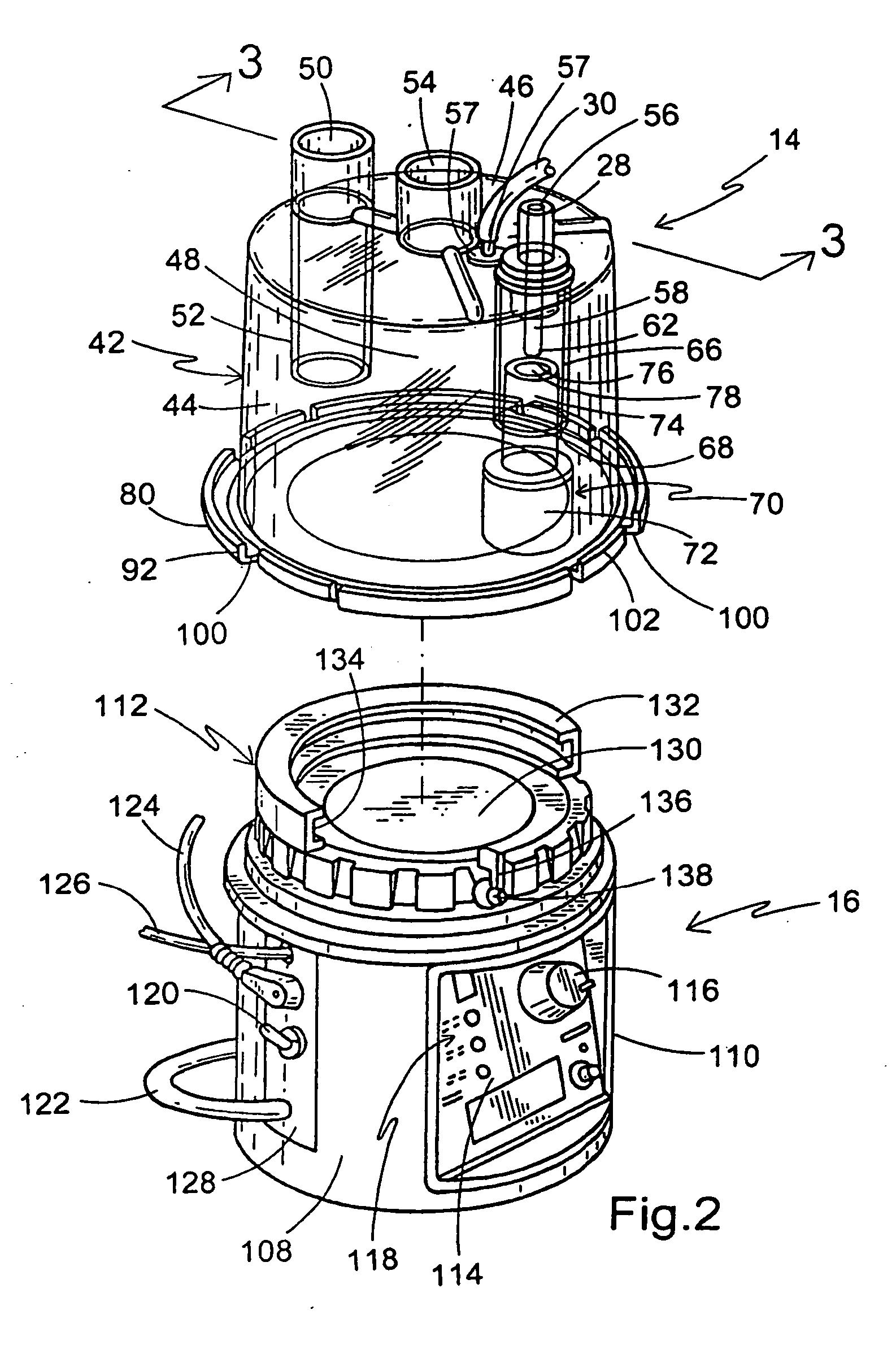

Beverage preparation with pressurized liquid

ActiveUS20170340160A1Accelerate liquid flowIncrease openingBeverage vesselsPistonBiomedical engineering

A beverage preparation apparatus for preparation of a beverage from a capsule in a clamp assembly (30). The clamp assembly has a first clamp member (31) and a second clamp member, where the inner surfaces of the first clamp member and the second clamp member form a clamp chamber (33) for substantially enclosing and supporting a capsule (10) during beverage preparation. The second clamp member comprises a rigid peripheral frame (32) having a central void and a resilient layer (37) extending across said central void. There is a piston (36) positioned in the central void and resiliently coupled to the peripheral frame (32) to allow limited resilient movement of the rigid peripheral frame (32) relative to the piston (36).

Owner:LAVAZZA PROFESSIONAL NORTH AMERICA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com