Patents

Literature

261results about How to "Easy to center" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

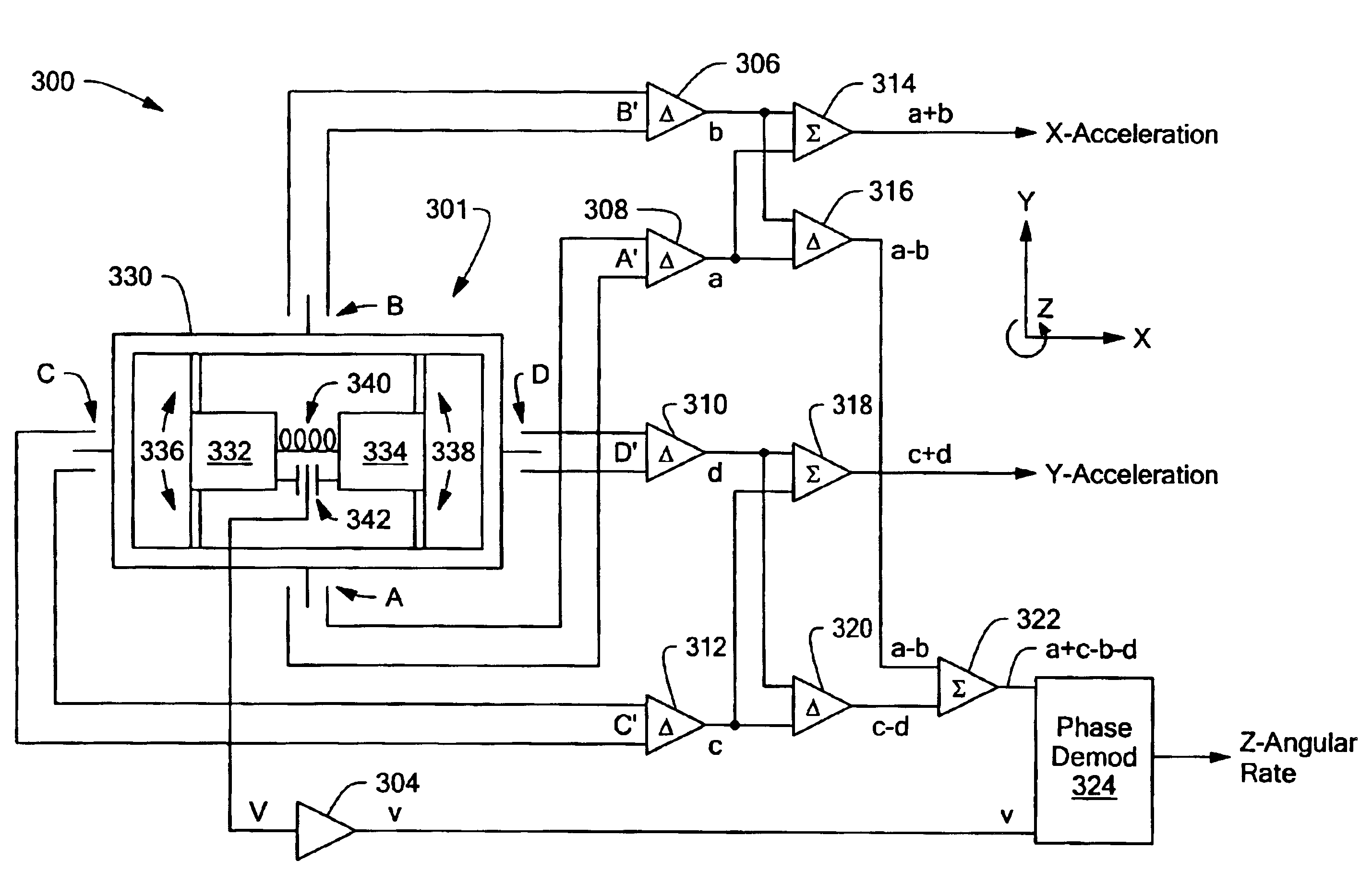

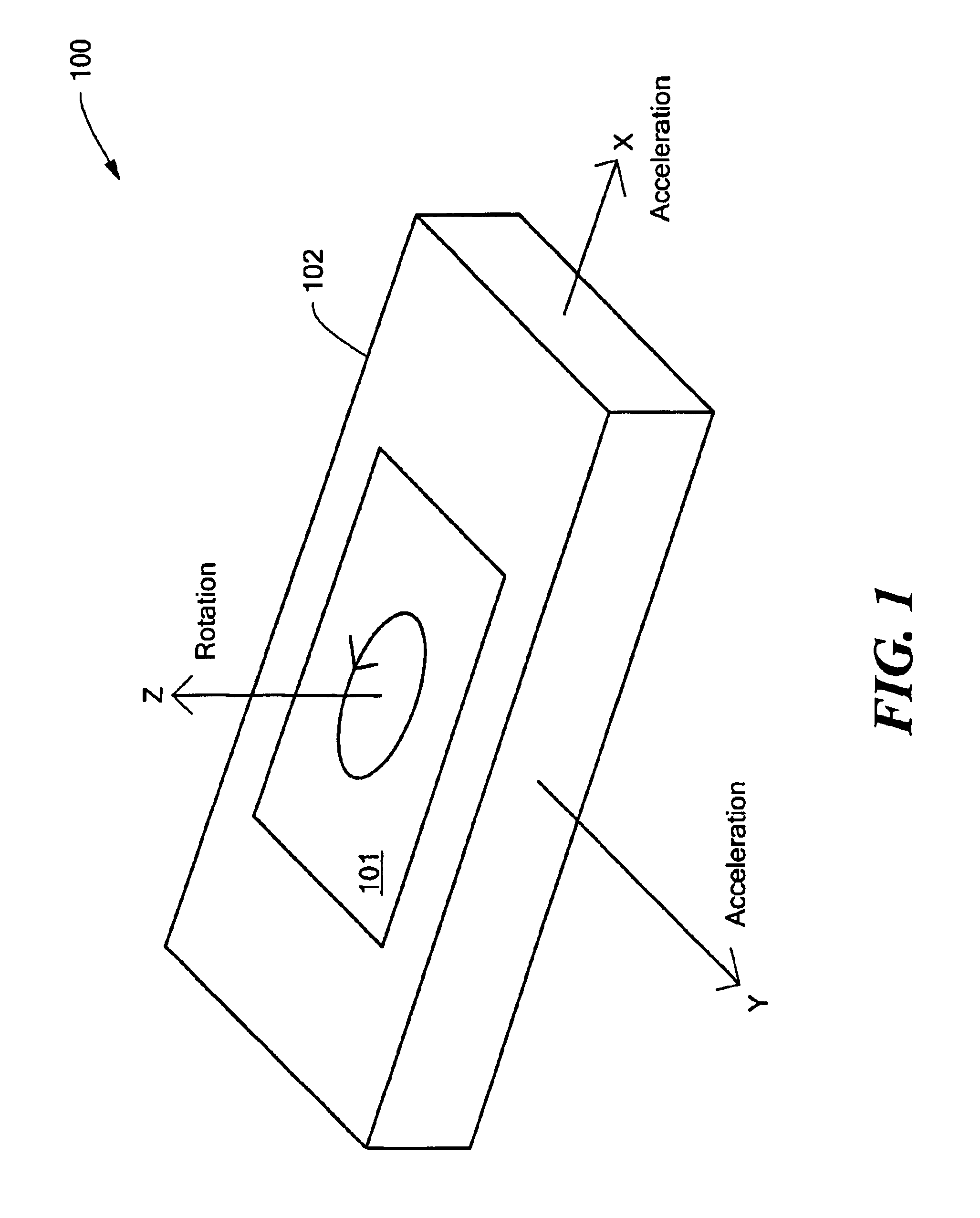

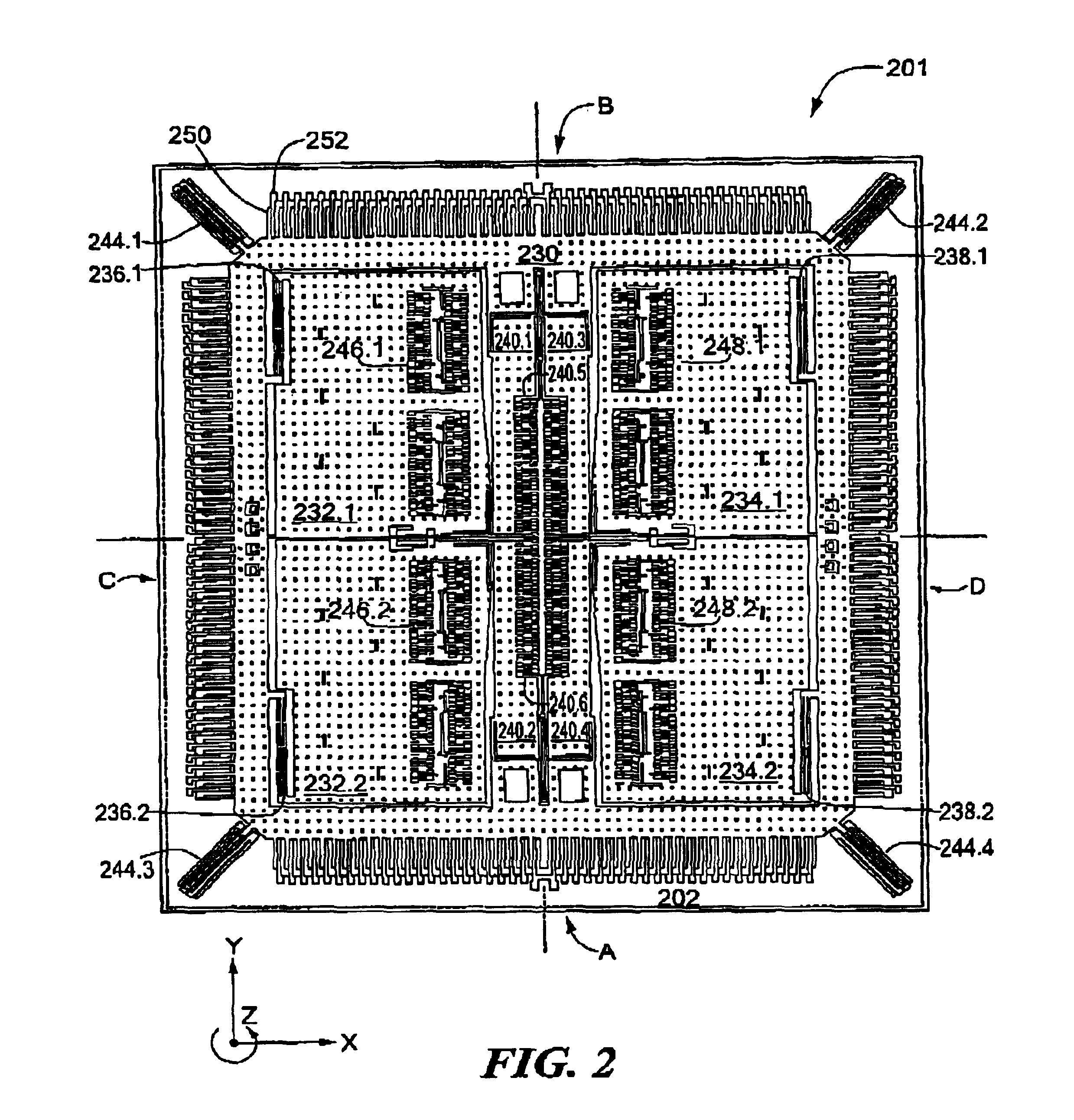

Micro-machined multi-sensor providing 2-axes of acceleration sensing and 1-axis of angular rate sensing

ActiveUS6845665B2Adverse effect of be reduceEasily centerAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsProof massElectrode pair

A micro-machined multi-sensor that provides 2-axes of acceleration sensing and 1-axis of angular rate sensing. The multi-sensor includes a rigid accelerometer frame, a first proof mass, and a second proof mass. The substrate has two associated acceleration axes in the plane of the substrate, and one associated rotation axis perpendicular to the acceleration axes. The proof masses have a common vibration axis, which is perpendicular to the rotation axis. The multi-sensor further includes a drive electrode structure for causing the proof masses to vibrate in antiphase, a first pair of acceleration sense electrode structures disposed along one of the acceleration axes, and a second pair of acceleration sense electrode structures disposed along the other acceleration axis. The multi-sensor adds the sense signals provided by the respective sense electrode pairs to extract information pertaining to acceleration sensing along the acceleration axes, and adds the differences of the sense signals provided by the respective sense electrode pairs to extract information pertaining to angular rate sensing relative to the rotation axis.

Owner:ANALOG DEVICES INC

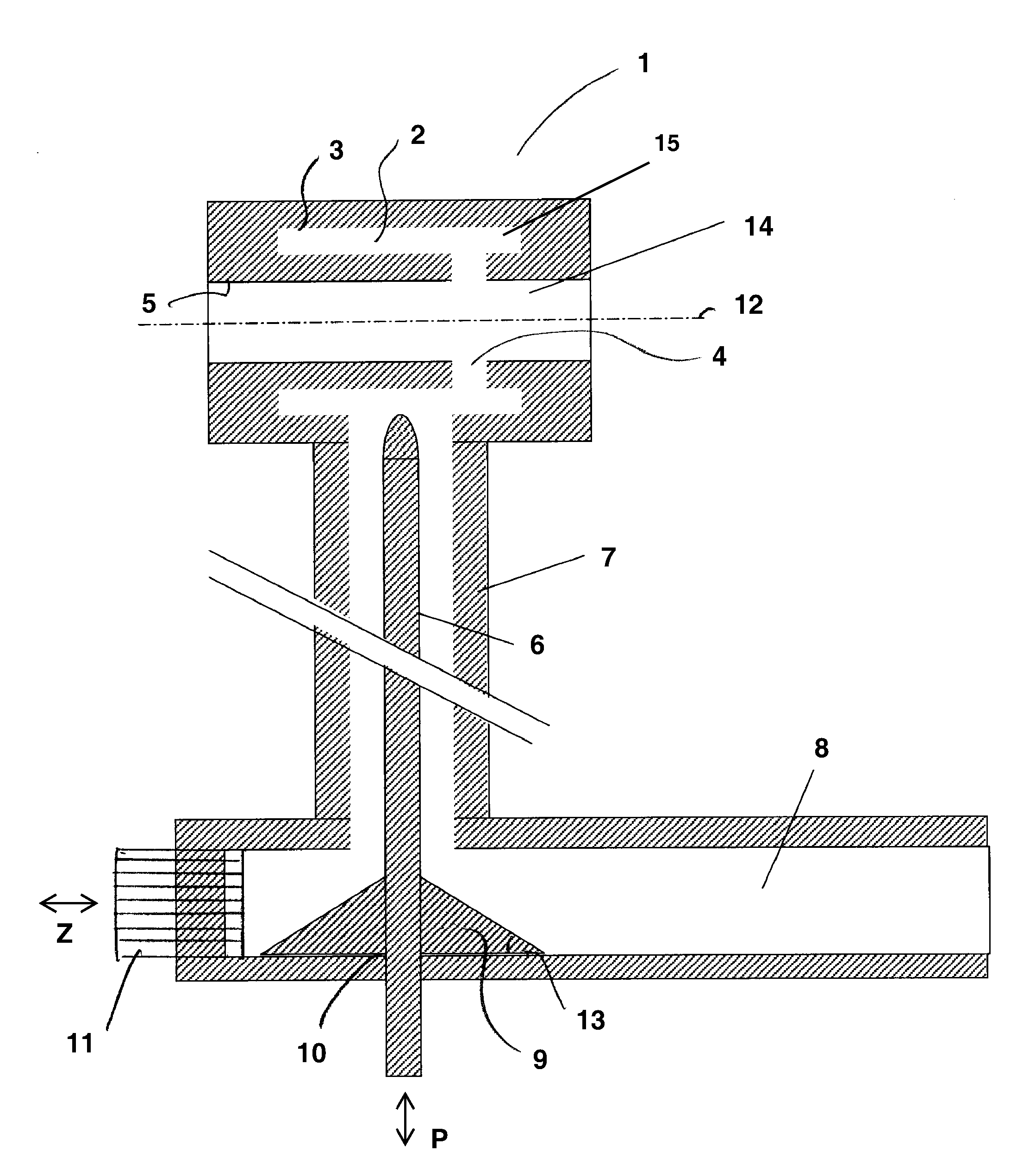

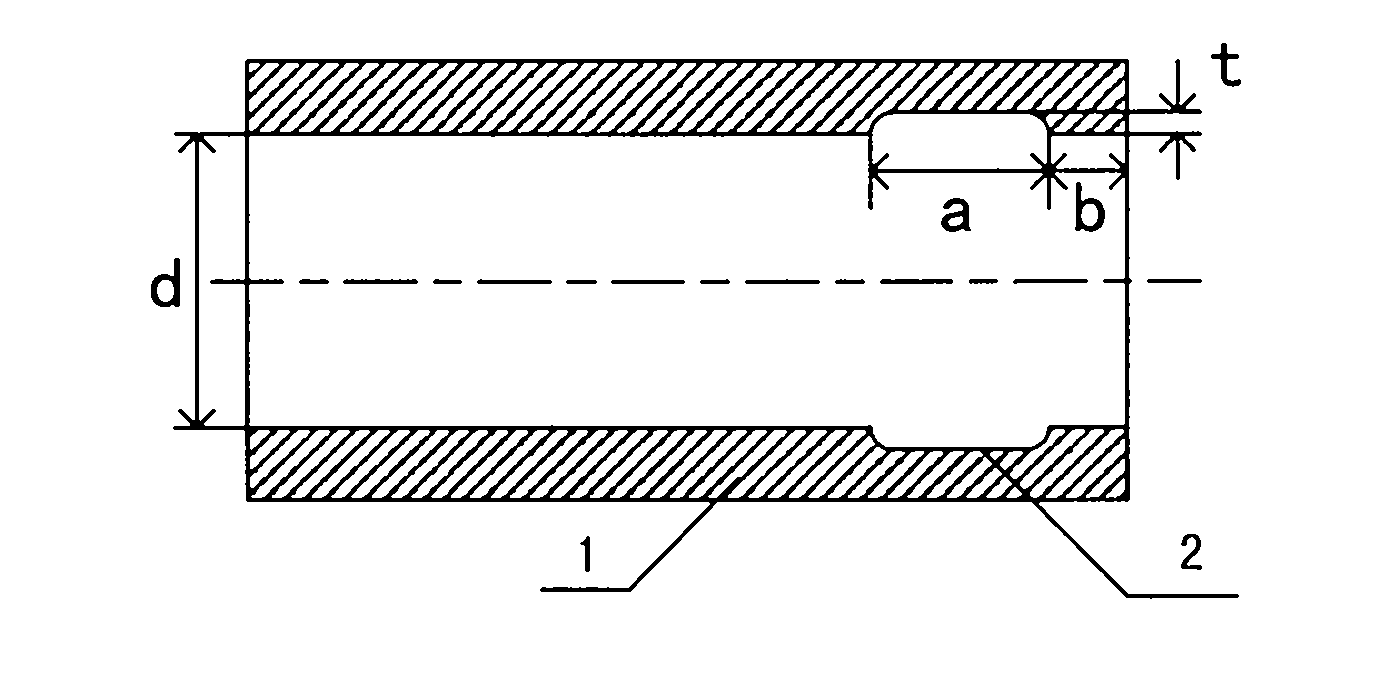

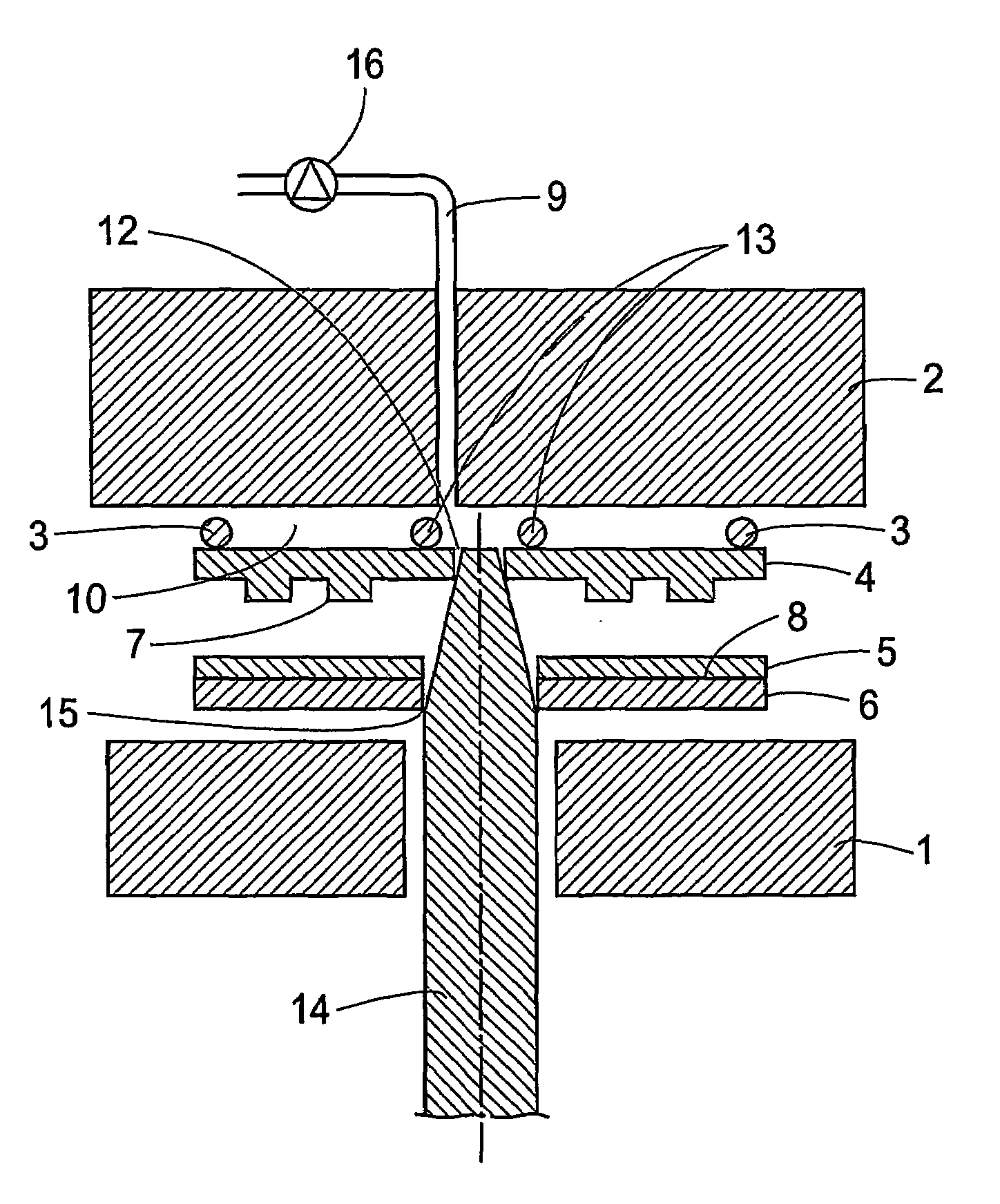

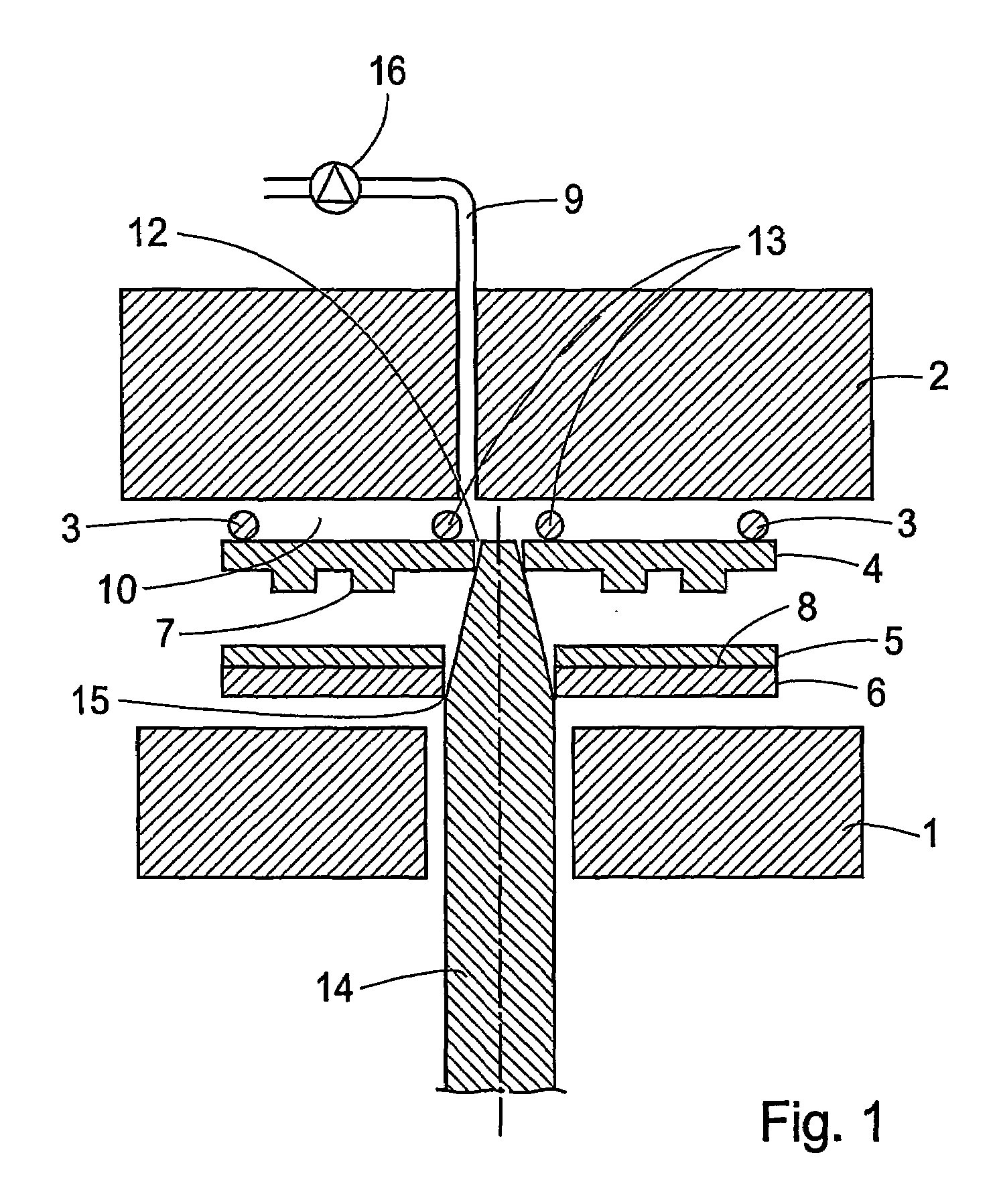

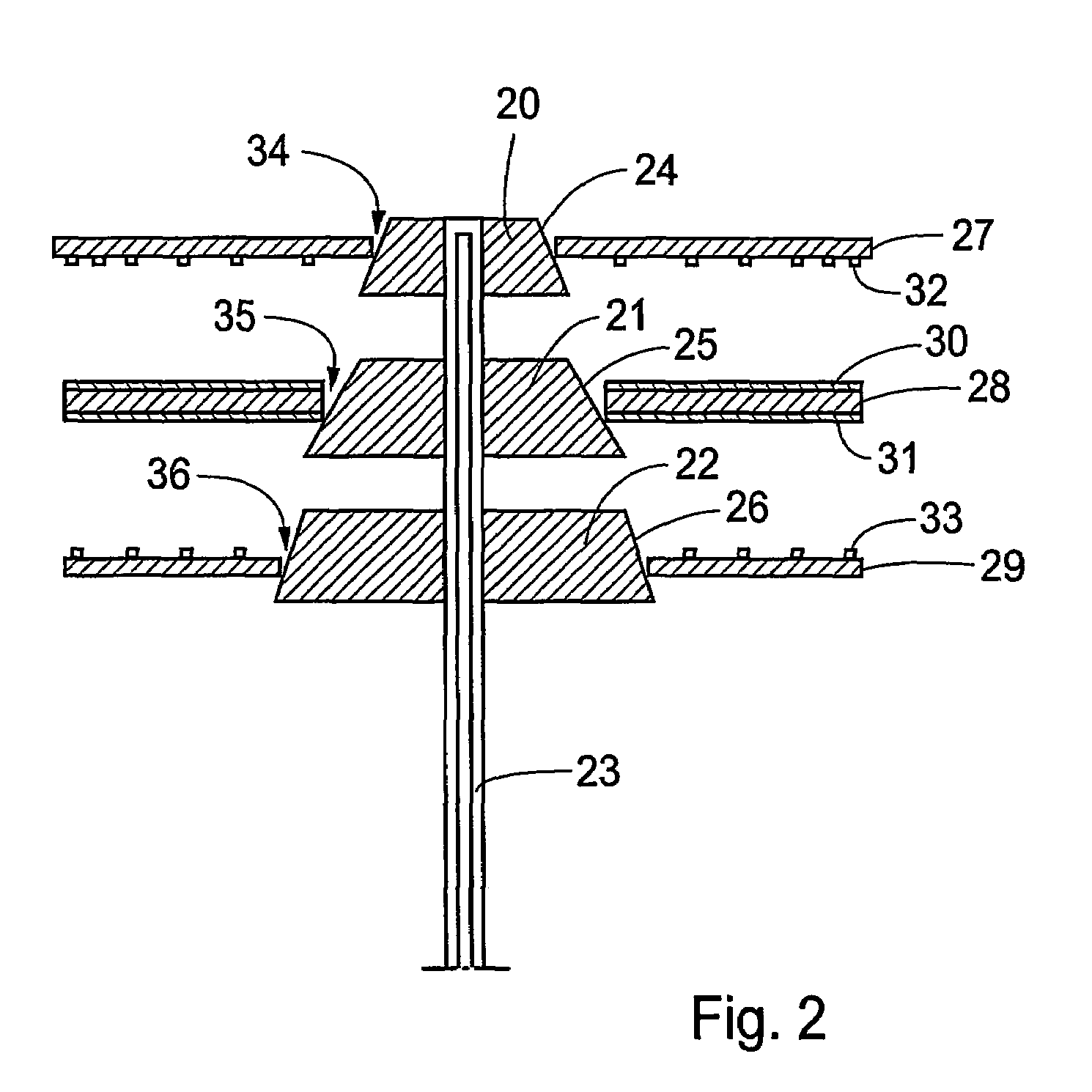

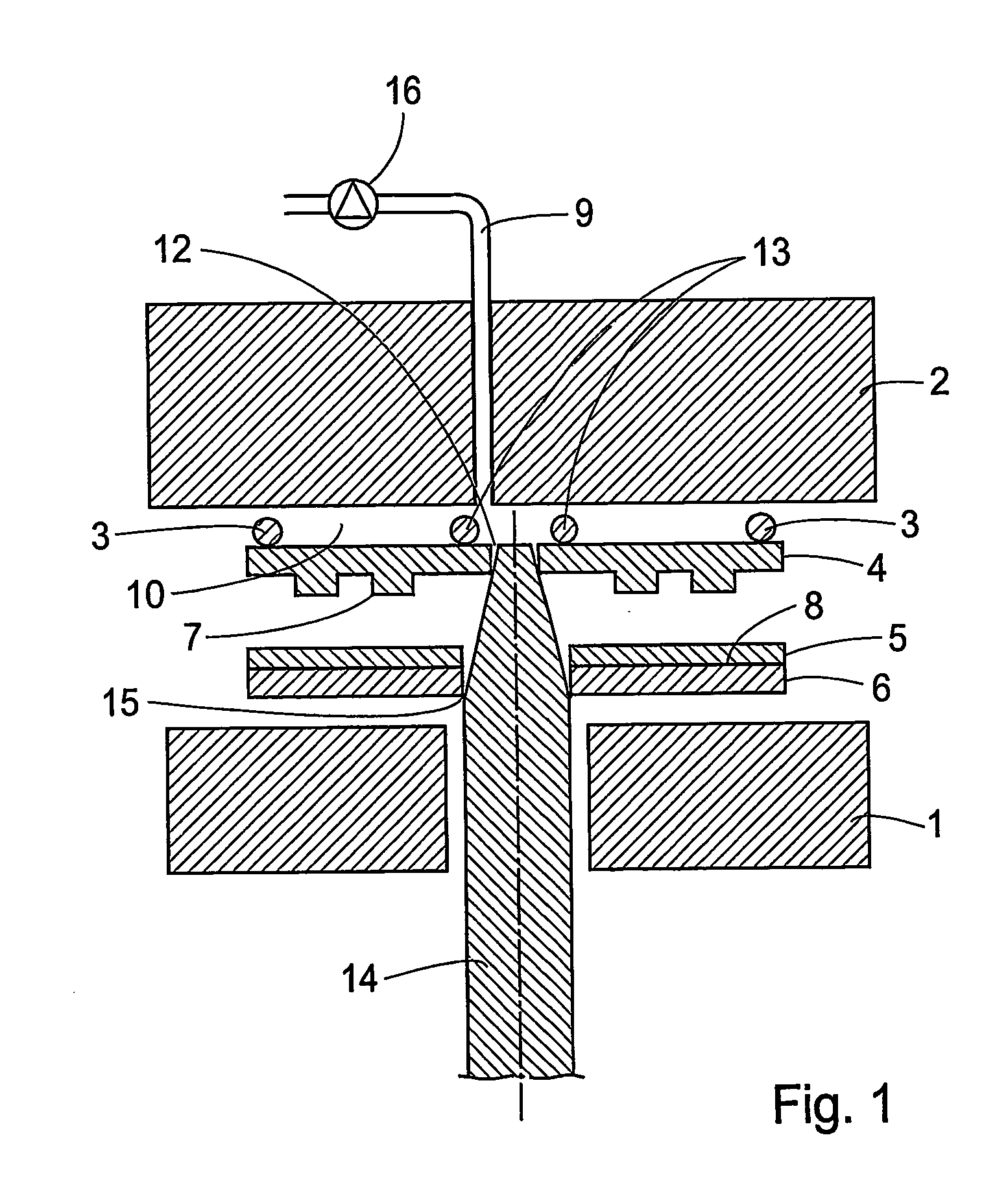

Apparatus for Effecting Plasma Chemical Vapor Deposition (PCVD)

ActiveUS20070289532A1Increase power levelIncrease deposition rateGlass making apparatusElectric discharge tubesChemical vapor depositionSilicon dioxide

The present invention relates to an apparatus for carrying out a plasma chemical vapor deposition process by which one or more layers of doped or undoped silica can be deposited on the interior of an elongated glass substrate tube. The present invention further relates to a method for manufacturing an optical fiber using such an apparatus.

Owner:DRAKA COMTEQ BV

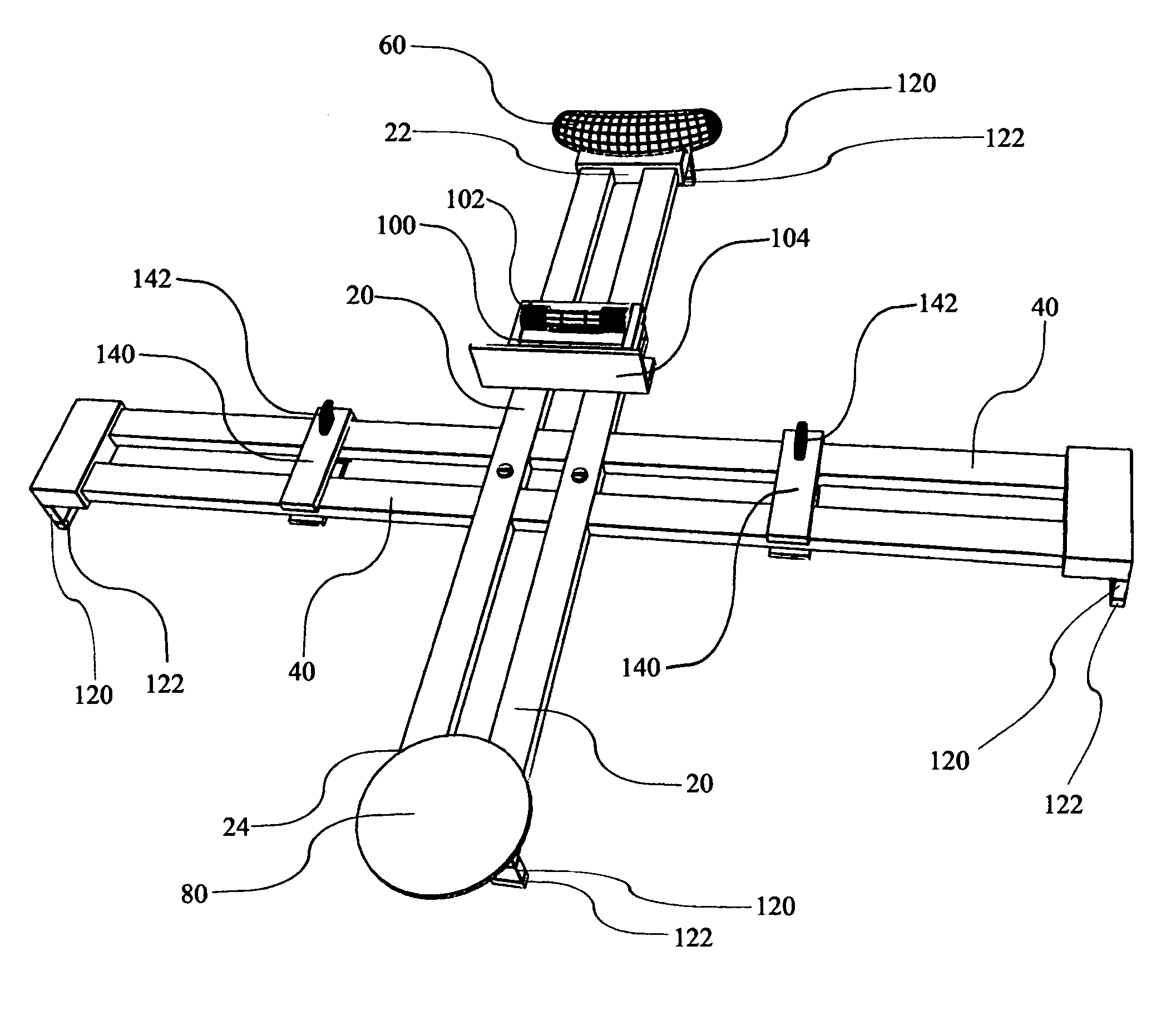

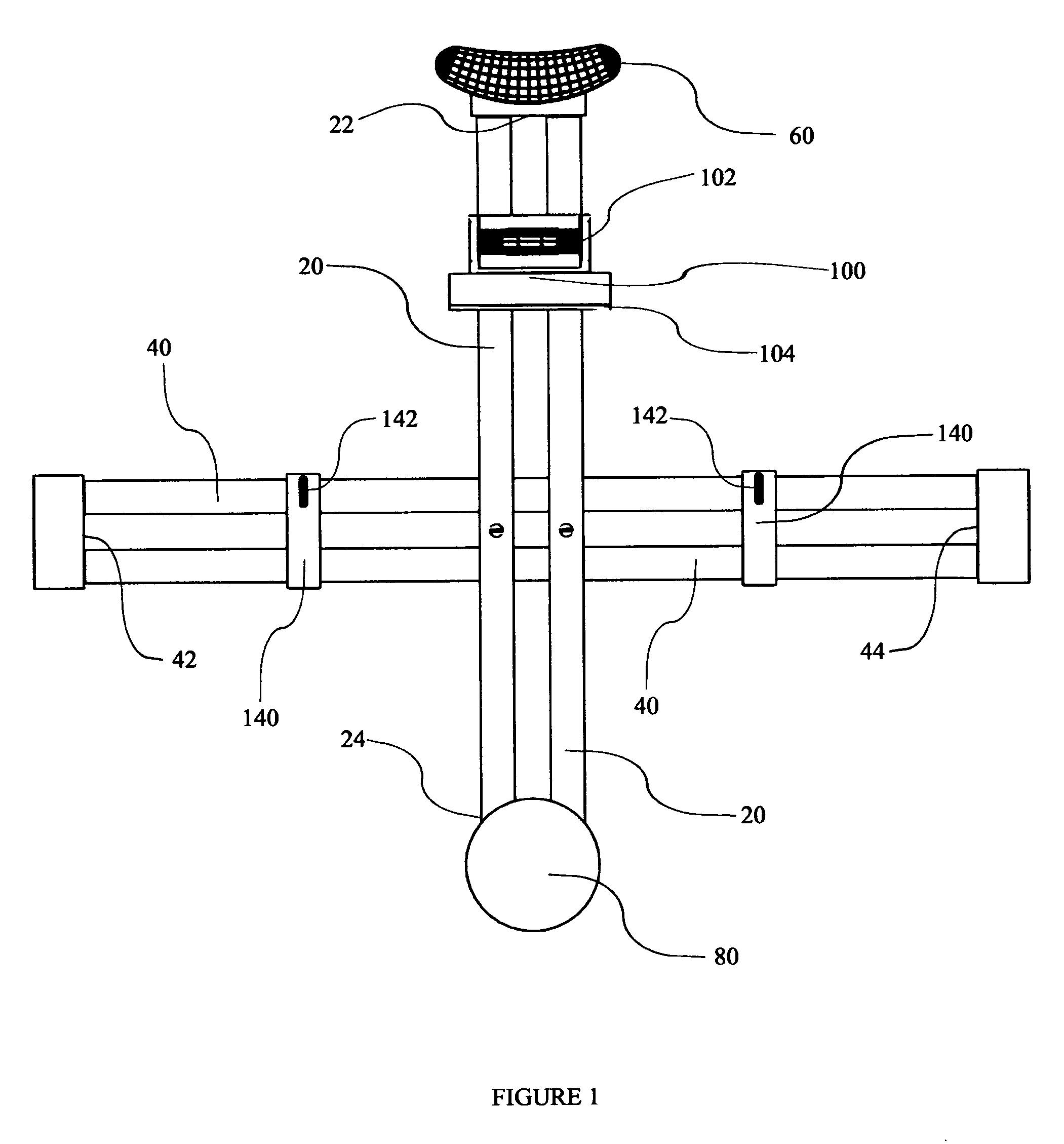

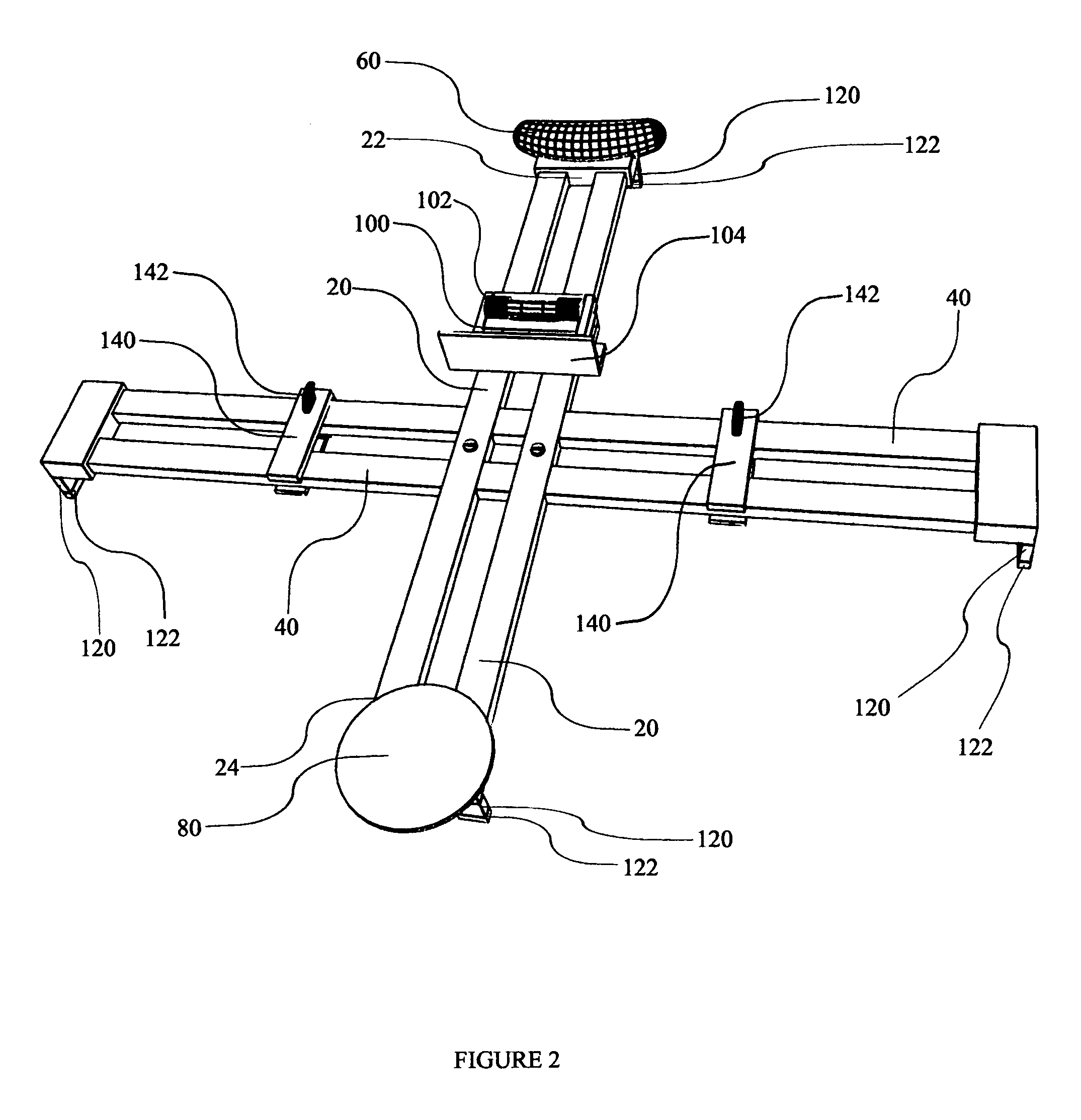

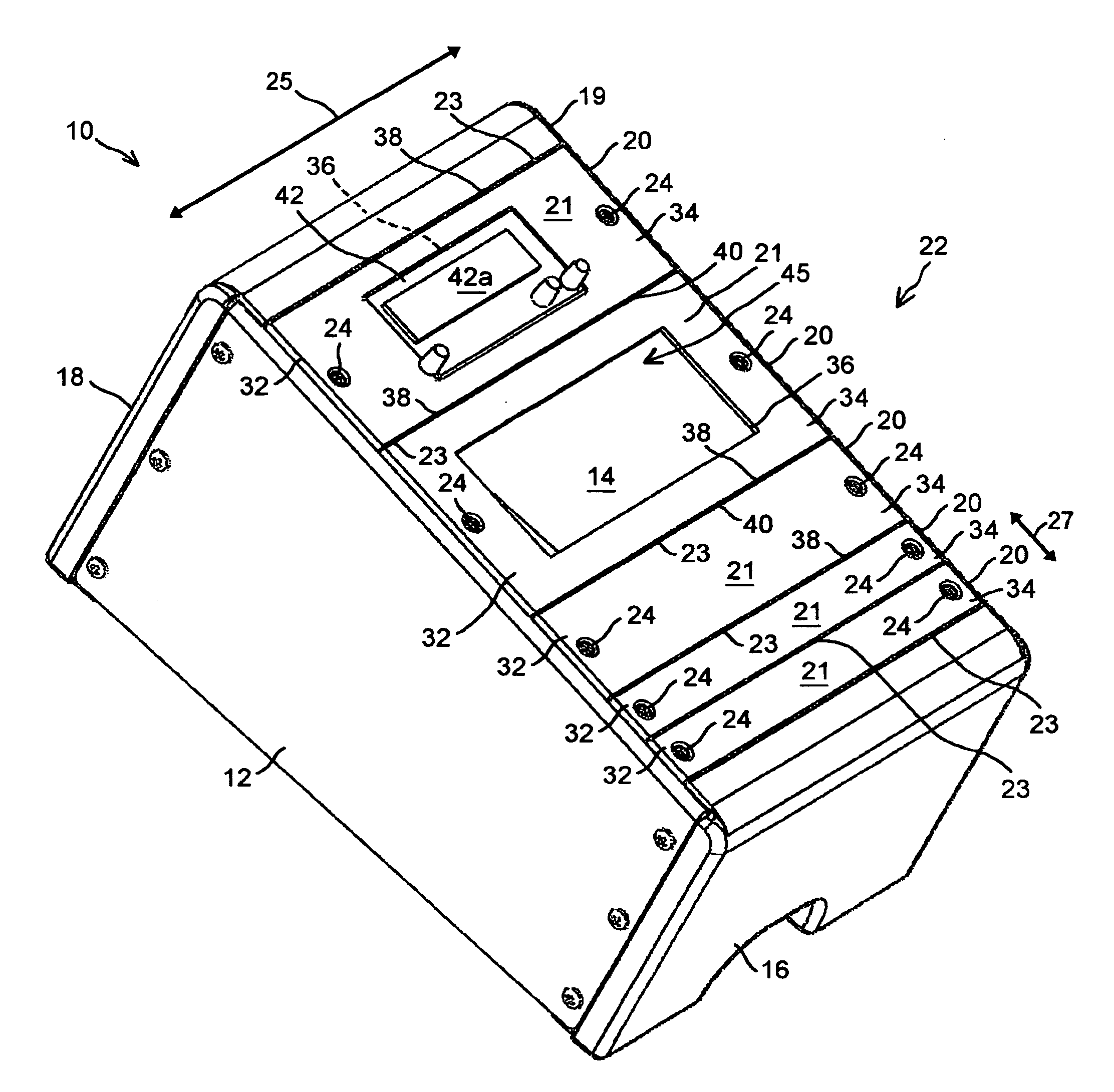

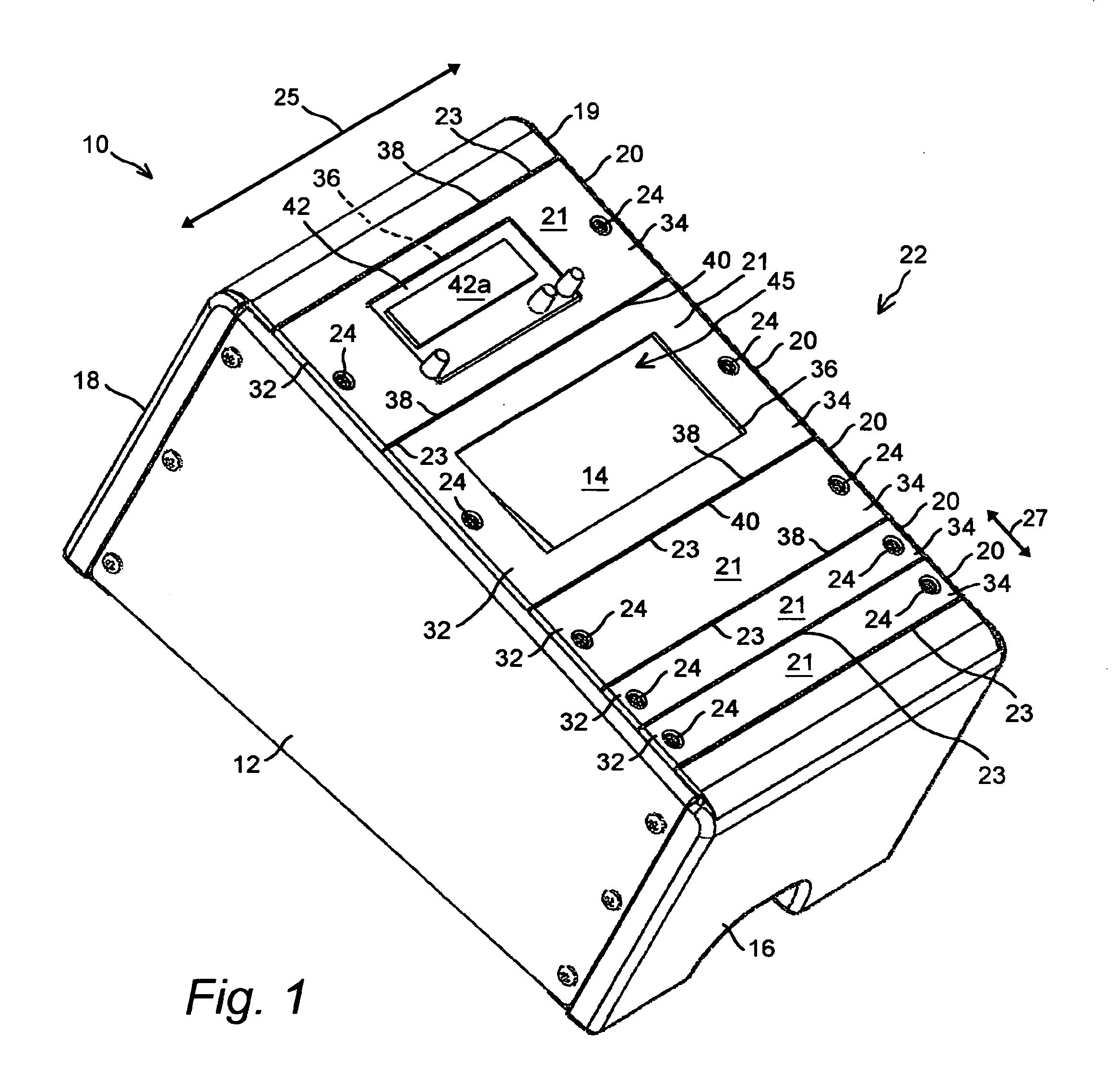

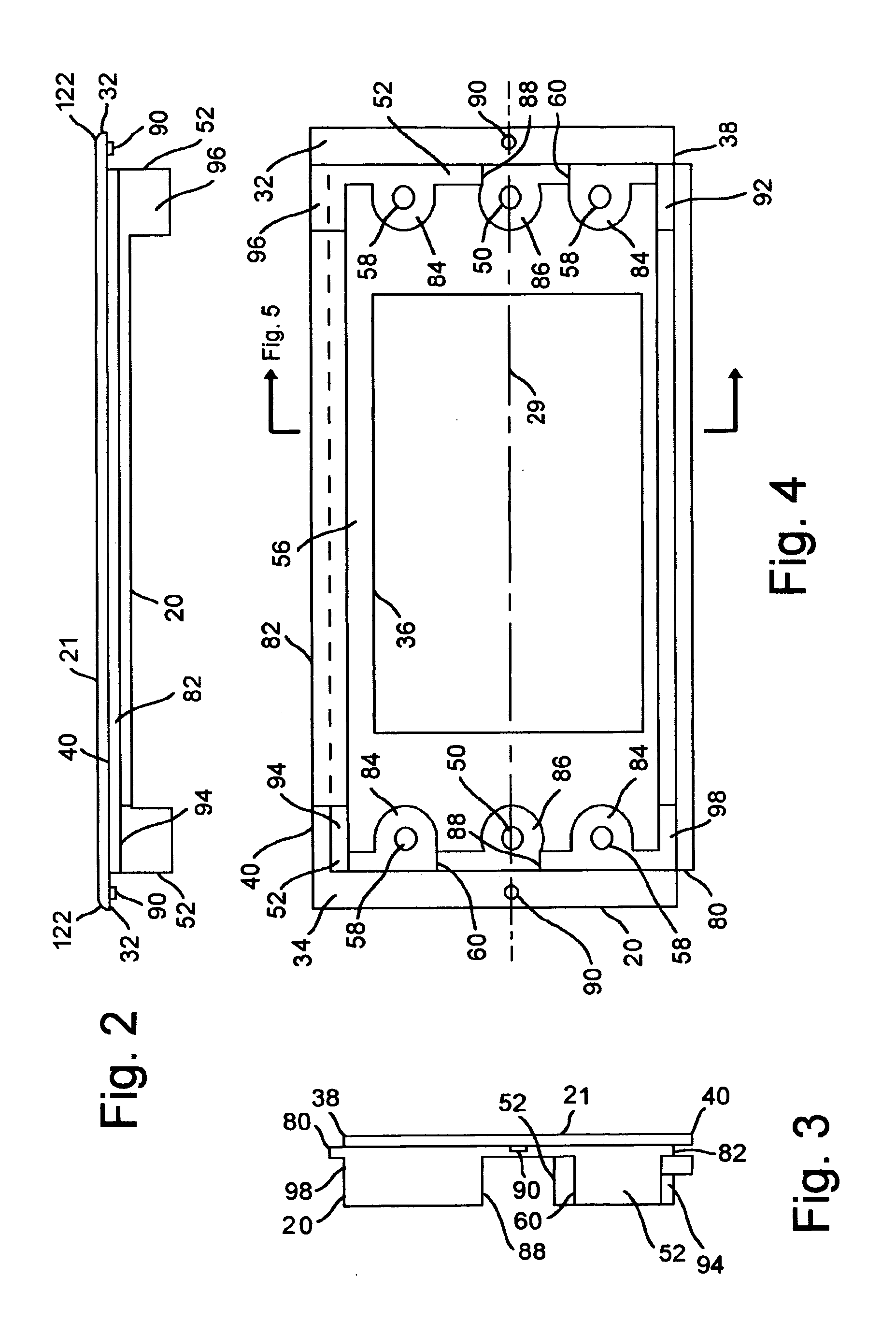

Device for mounting decorative and functional items

A device for easy positioning, leveling, marking and hanging of all types of pictures, sconces, decorative shelves, mirrors, and other devices to be mounted on a support surface. It has elongated vertical and horizontal support members attached together, each preferably with resilient legs. The vertical support has a handle at one end, a surface rest at its other end, and a rotatable sliding level. Sliding hook clips are positioned along the horizontal support, each having a front hook for holding an item to be hung while positioning and marking with an opposed marking implement take place. One or more hook clips can be used simultaneously. Flexing or compression of legs, soft pads, vertical support member, and / or horizontal support member reduces the wall stand-off distance of the device and causes the aligned marking implements to contact and mark the wall exactly where the held item should be permanently mounted.

Owner:CARBONARO GREGORY S

Method of resin sealing permanent magnets in laminated rotor core

ActiveUS20090189309A1Decrease in temperatureEasy to cleanMagnetic circuitManufacturing stator/rotor bodiesMagnetEngineering

Owner:MITSUI HIGH TEC INC

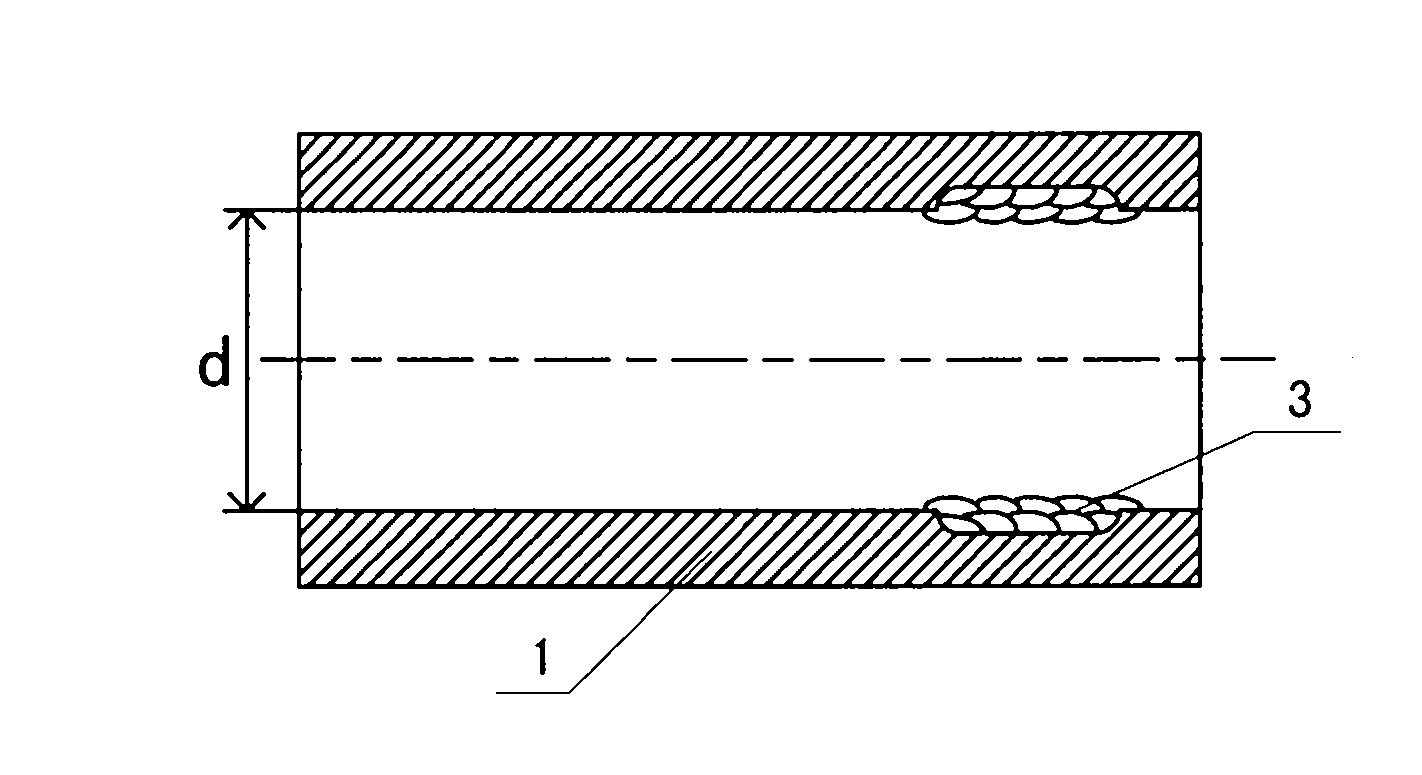

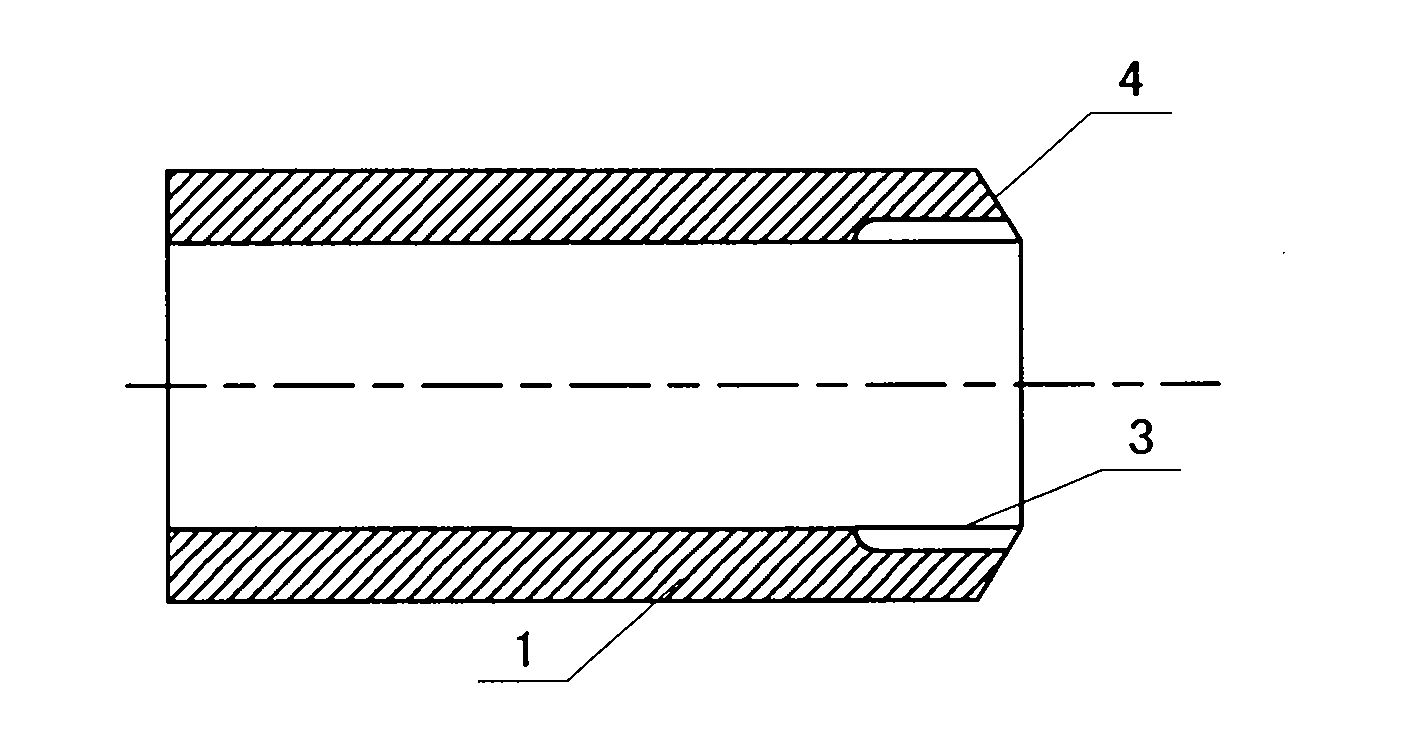

Method for welding anticorrosion steel pipeline with no internal repaired mouth

InactiveCN103008988AReduce the chance of welding defectsRigid enoughArc welding apparatusChemical industryAlloy

The invention provides a method for welding an anticorrosion steel pipeline with no internal repaired mouth, which is applicable to the anticorrosion treatment of a steel pipeline welding connector with an anticorrosion coating in the petroleum industry and the chemical industry. The method is characterized in that a groove with a certain length and depth is machined on a position which is at a certain distance from the end part of the steel pipe, an anticorrosion alloy material is surfaced on the groove, the end part of the surfaced steel pipe is machined into a V-shaped groove, an anticorrosion coating with sufficient thickness is coated on the inner wall of the steel pipe, the anticorrosion coating covers sufficient length of the anticorrosion alloy surfacing layer, then two steel pipes are in butt connection with each other, layering welding is carried out after the two steel pipes are fixed on one point, an argon tungsten-arc welding method is adopted, the anticorrosion alloy material which is identical to that of the surfacing is selected as the filling material, and argon is filled into the pipe to protect the pipe in the welding process. Due to the adoption of the novel technology for welding the anticorrosion steel pipeline with no internal repaired mouth, the corrosion resistance of the inner wall and a weld mouth of the pipeline can be guaranteed, the internal mouth repairing technology on the spot after the welding can be avoided, characteristics such as simplicity in construction and reliability in performance can be realized, and the method is suitable for the real engineering application of the petroleum and chemical industry fields.

Owner:HARBIN INST OF TECH

Combined pressure and temperature sensor

InactiveUS7434470B2Produced cost-effectivelyReliable measurementMeasurement apparatus componentsFluid pressure measurementEngineeringPressure sensor

A combined pressure and temperature sensor for recording the pressure and the temperature of a medium. A sensor element of the combined pressure and temperature sensor includes a through-hole to a diaphragm and a bore for accommodating a temperature sensor. The diaphragm cooperates with a pressure sensor. At an end face of the sensor element, on the side of the medium, a cover is fastened, in which a hollow space is developed to accommodate the temperature sensor.

Owner:ROBERT BOSCH GMBH

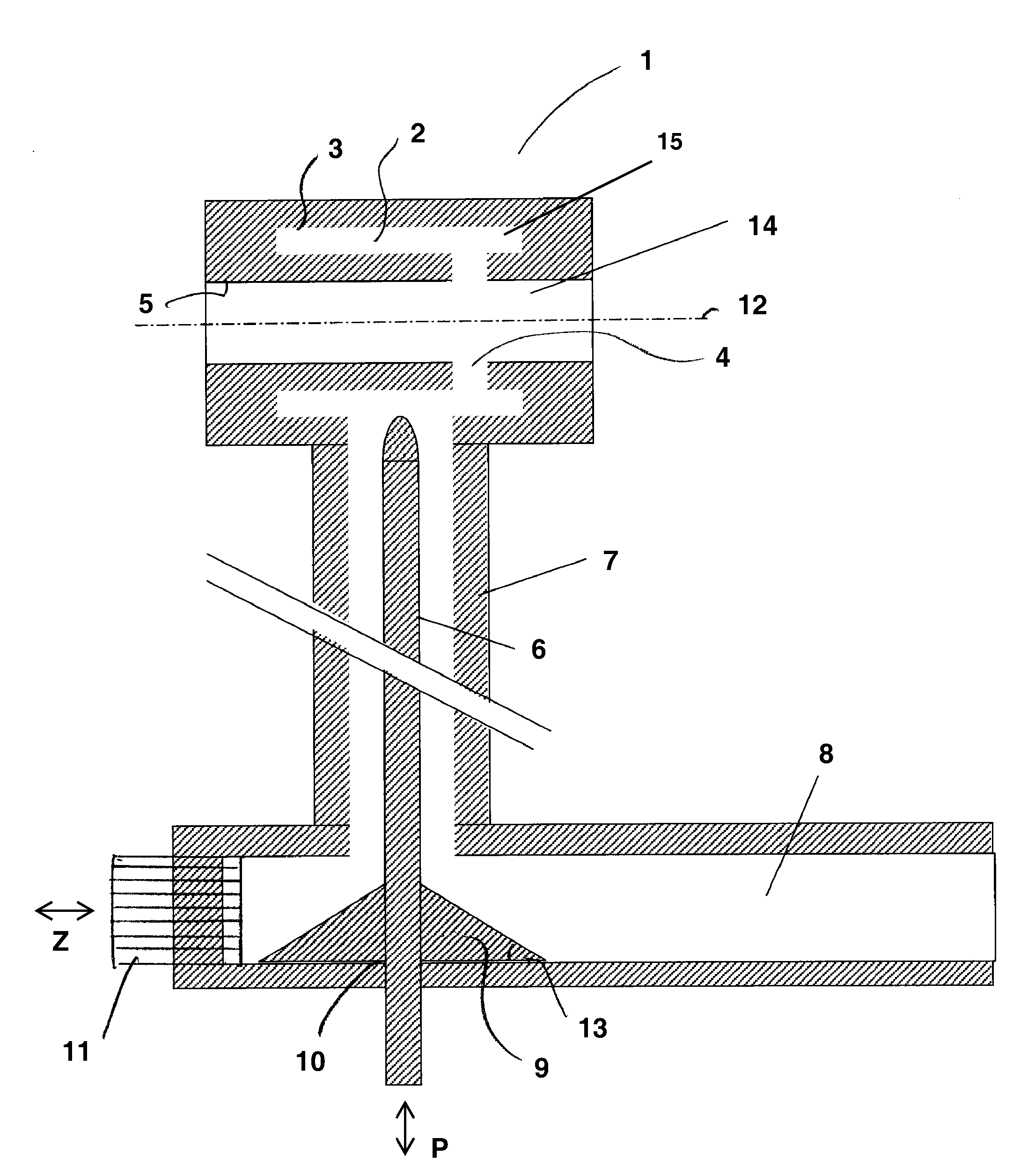

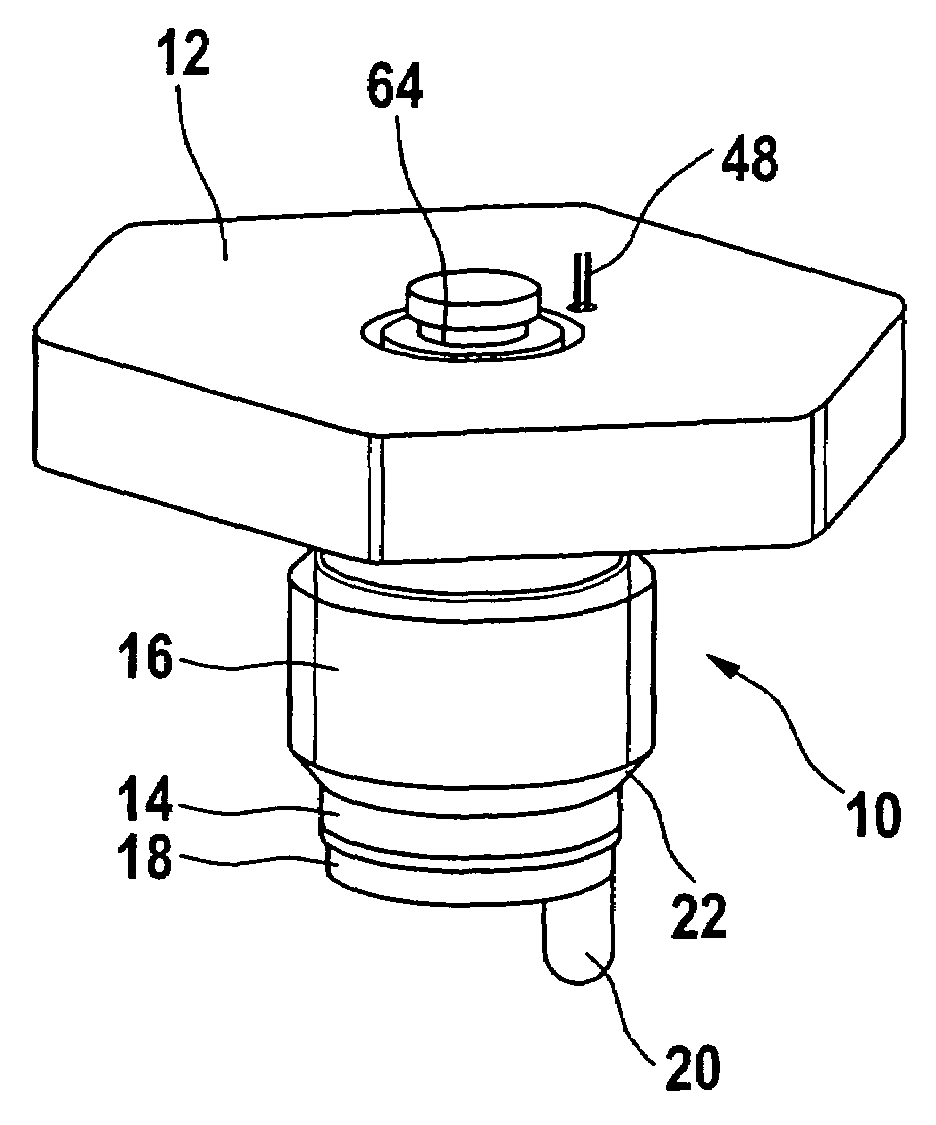

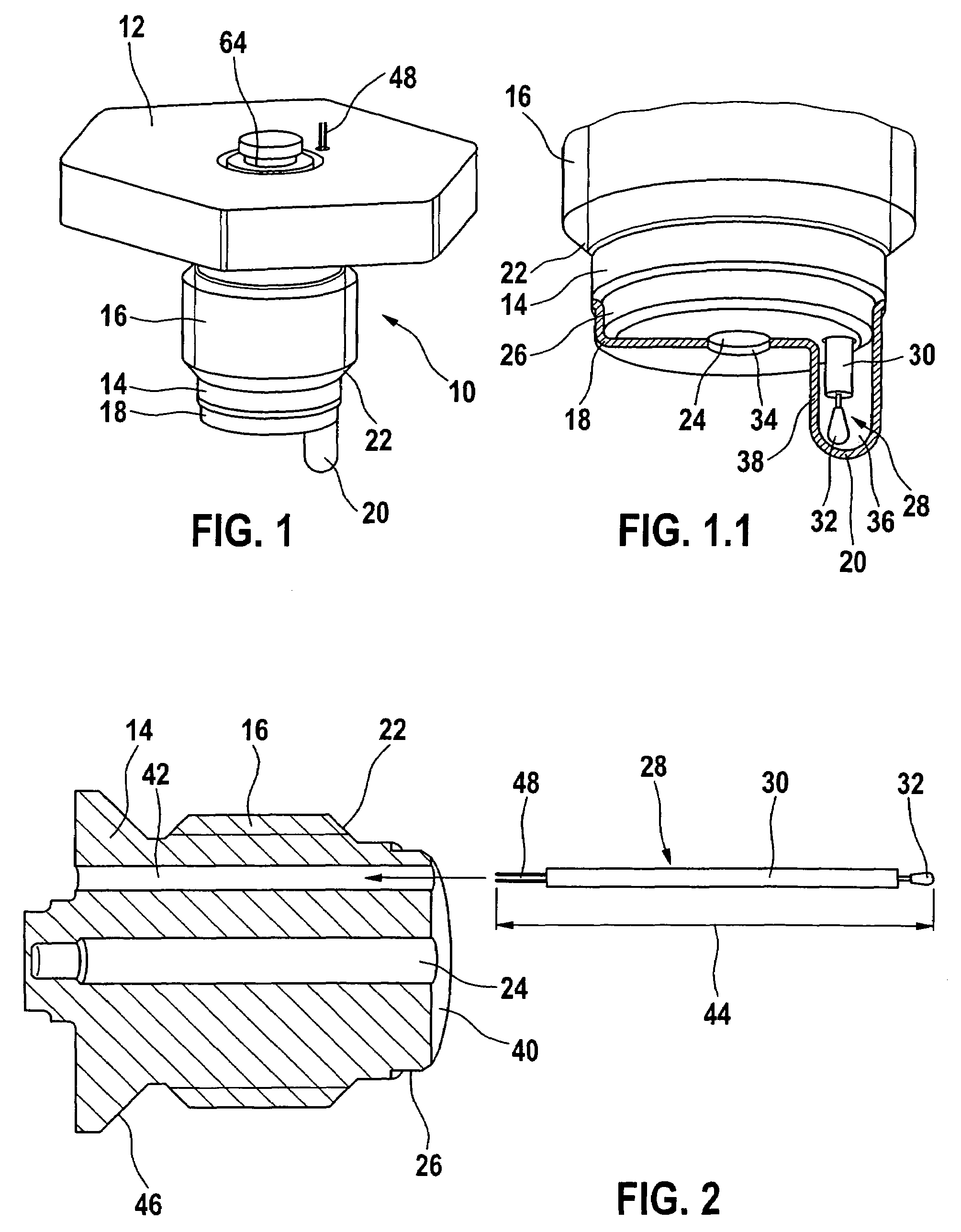

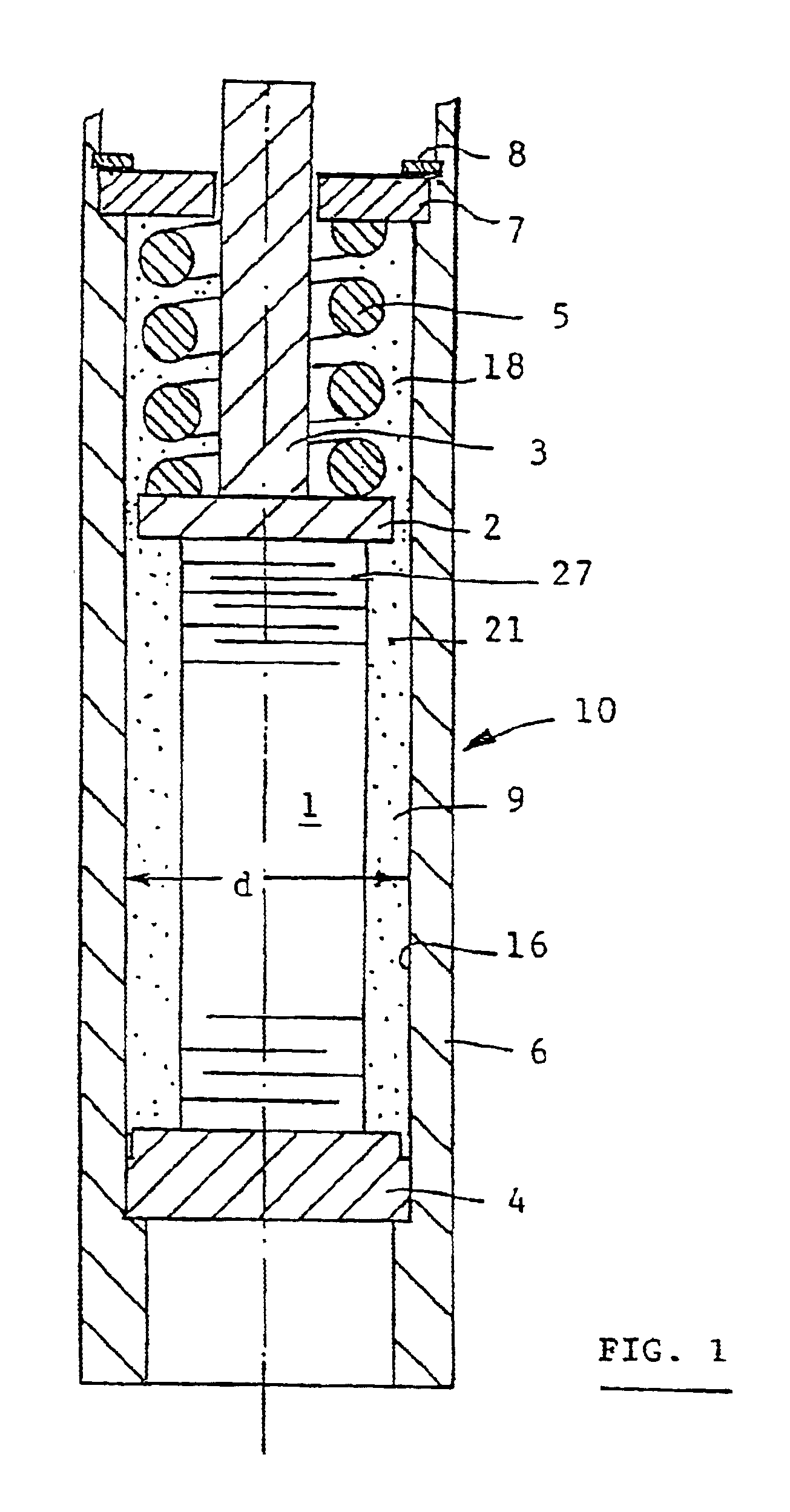

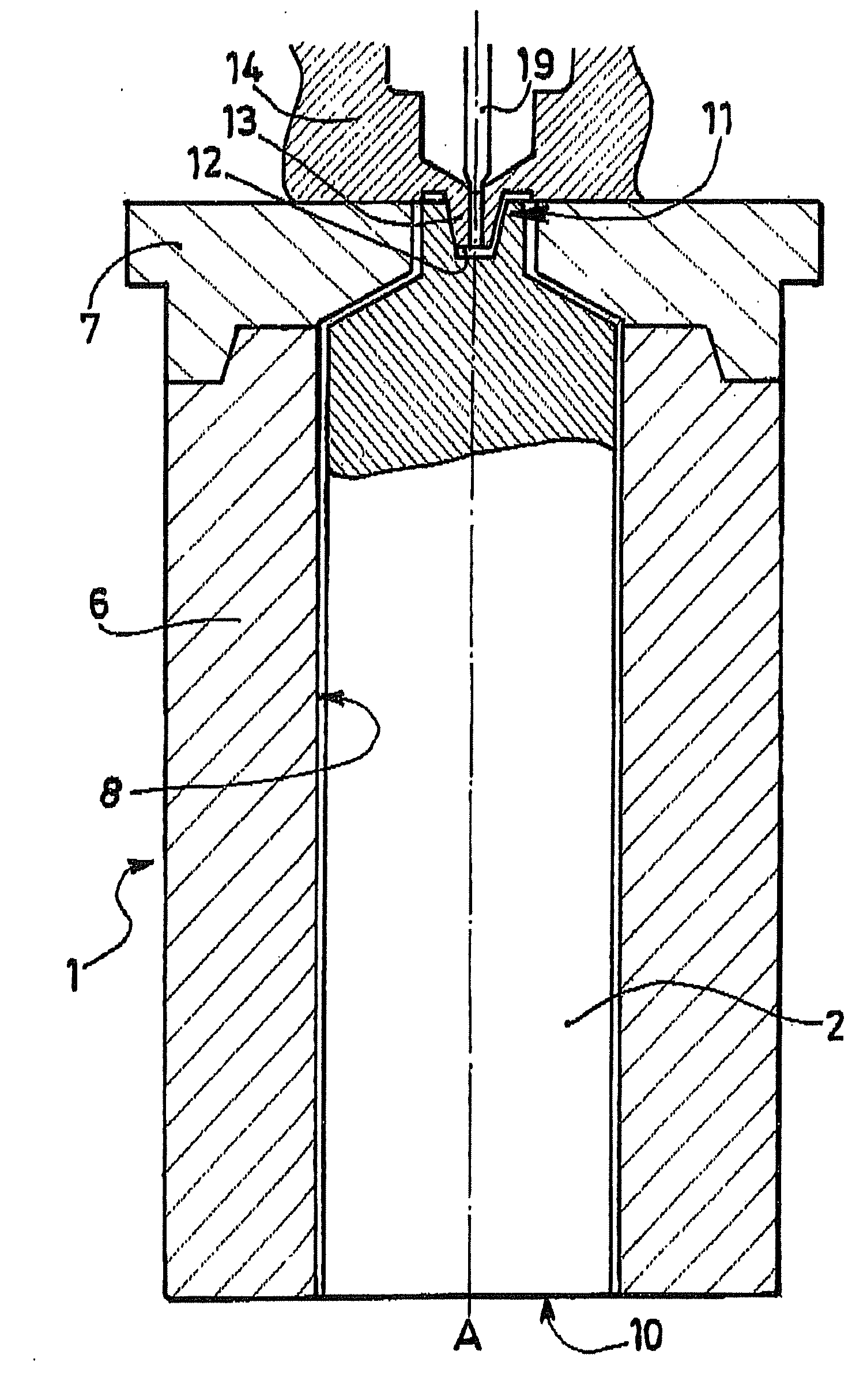

Piezoelectric actuator

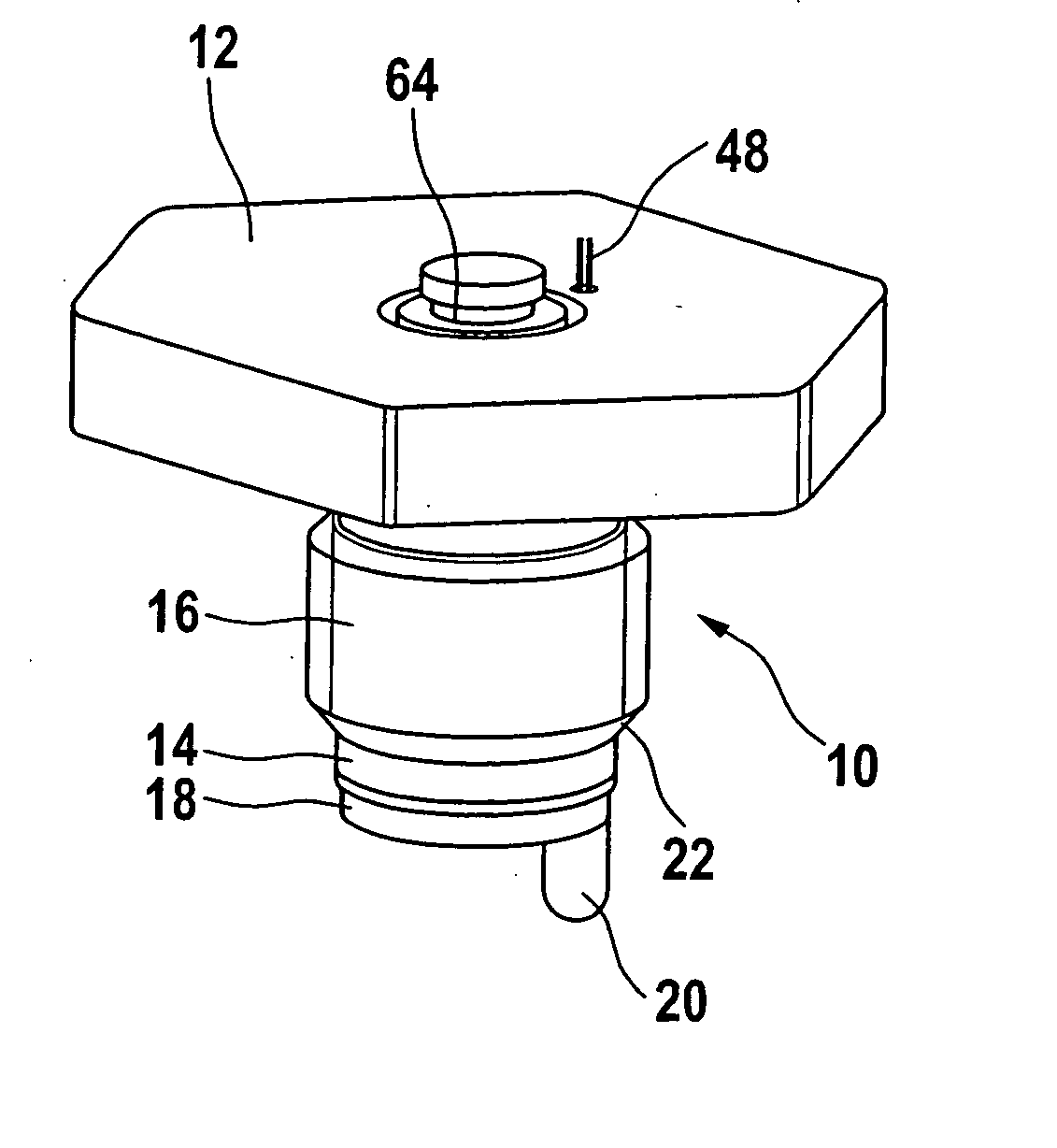

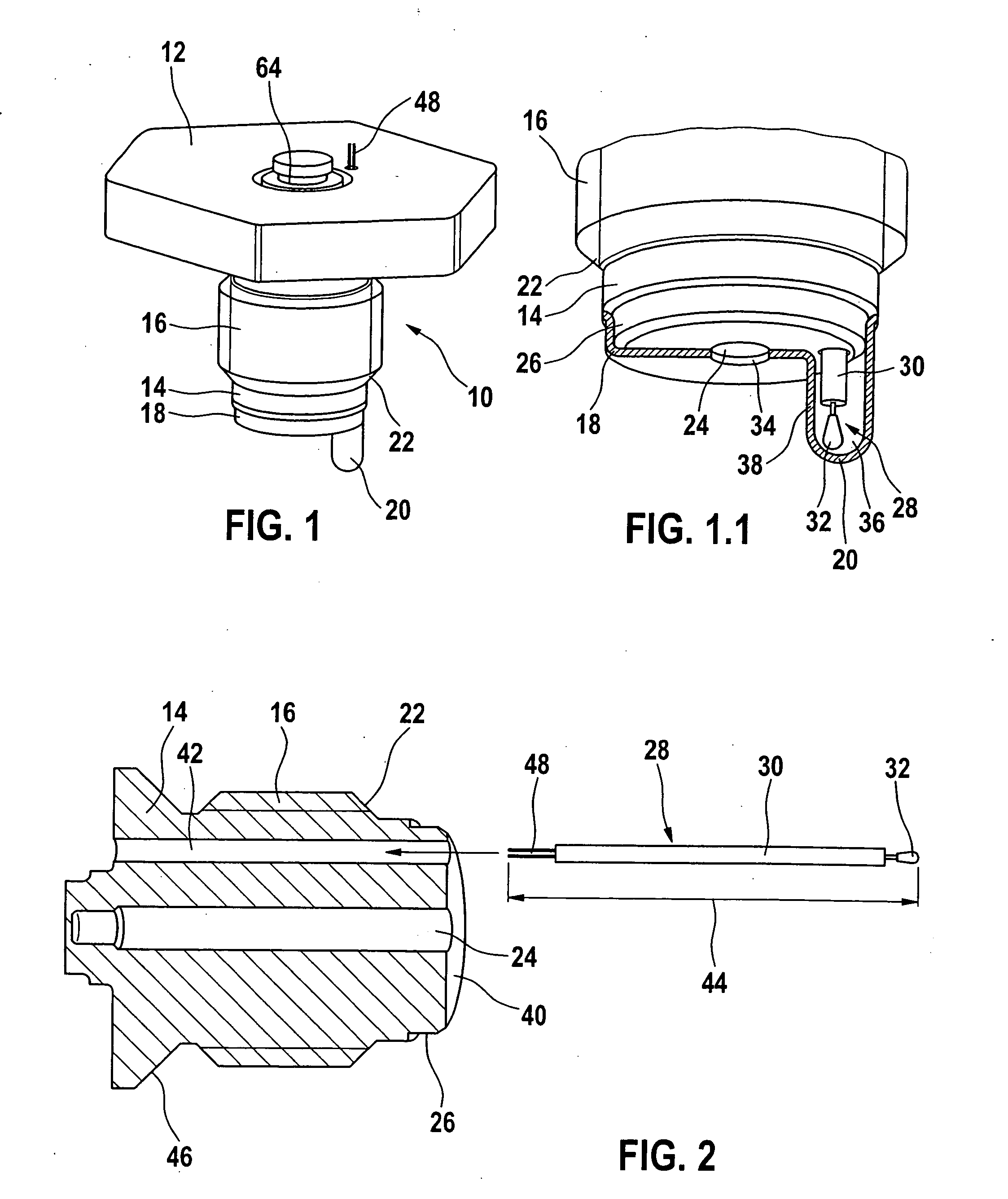

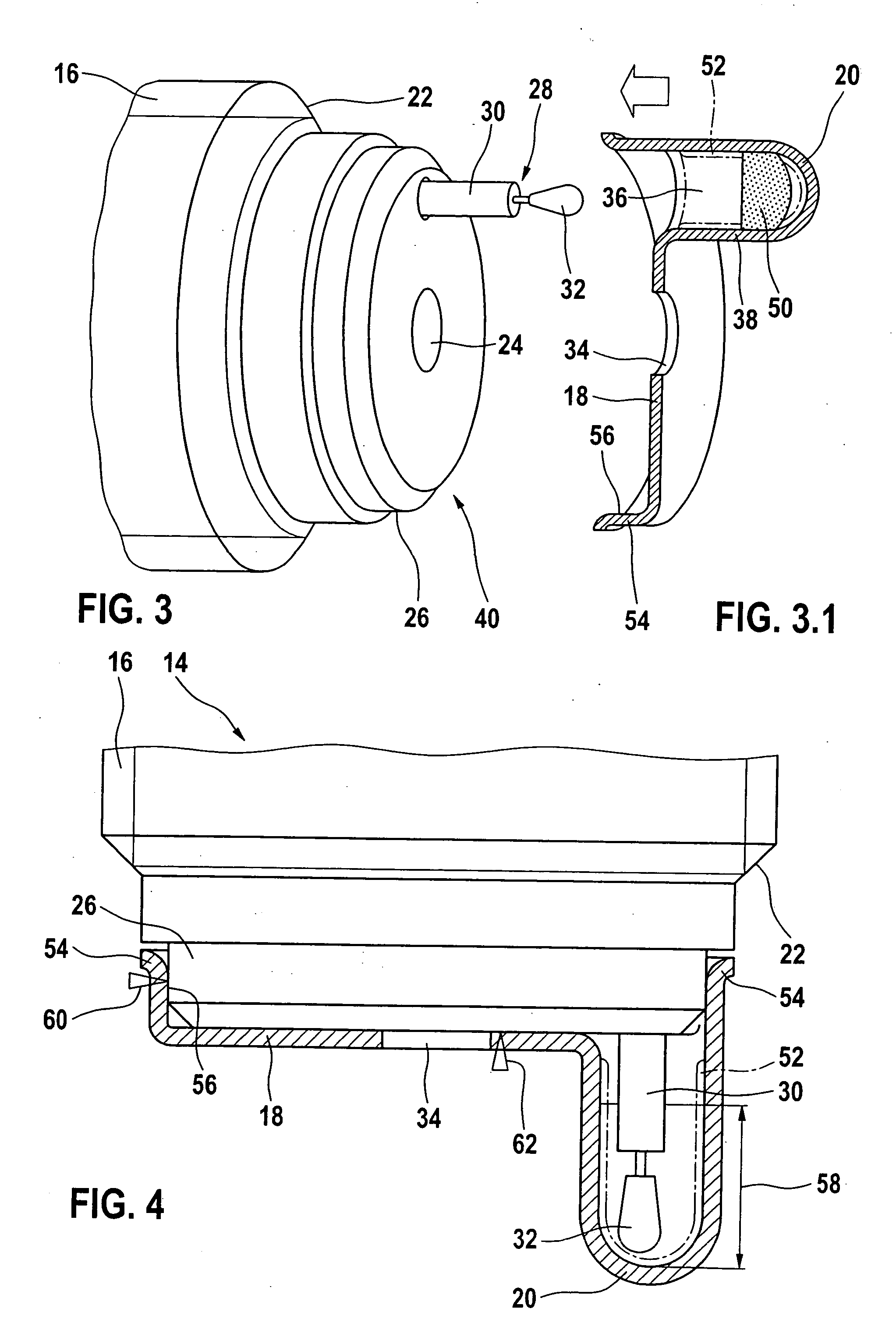

InactiveUS6700308B2Easy to centerImprove heat transfer performanceOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesElastomerMobile vehicle

The invention relates to a piezoelectric actuator, in particular for actuating control valves or injection valves in motor vehicles, having an actuator body in the form of a multilayered laminate made up of stacked layers of piezoelectric material with intervening metallic or electrically conductive layers that function as electrodes, and the end faces of this actuator body are respectively contacted by a top plate oriented toward the valve having an axially protruding valve tappet and a bottom plate at the opposite end, wherein the actuator rests in an axial bore of a valve housing and is prestressed at the ends in the axial direction between the top plate and the bottom plate by means of a spring element. According to the invention, the actuator-at least including the top plate-is enclosed by an electrically insulating elastomer sleeve so that when installed, the actuator with the elastomer sleeve rests snugly against the inner wall of the axial bore of the valve housing in the vicinity of the actuator.

Owner:ROBERT BOSCH GMBH

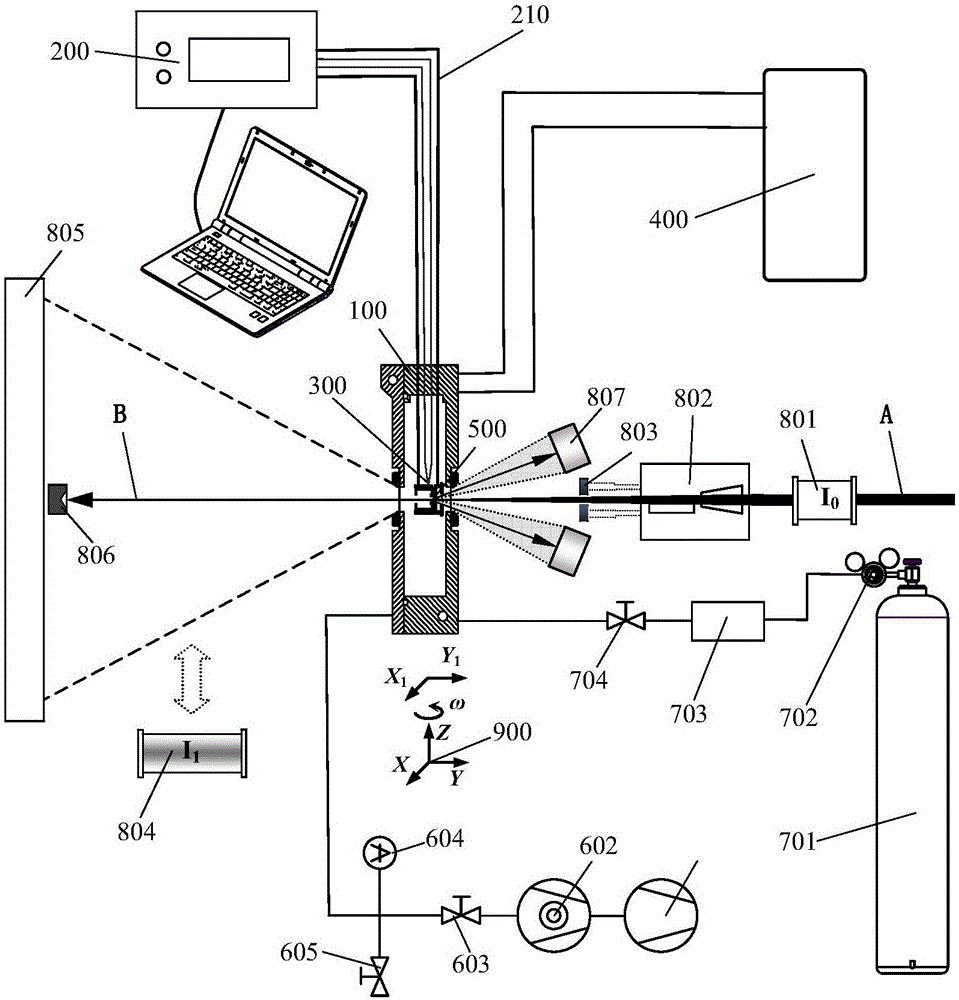

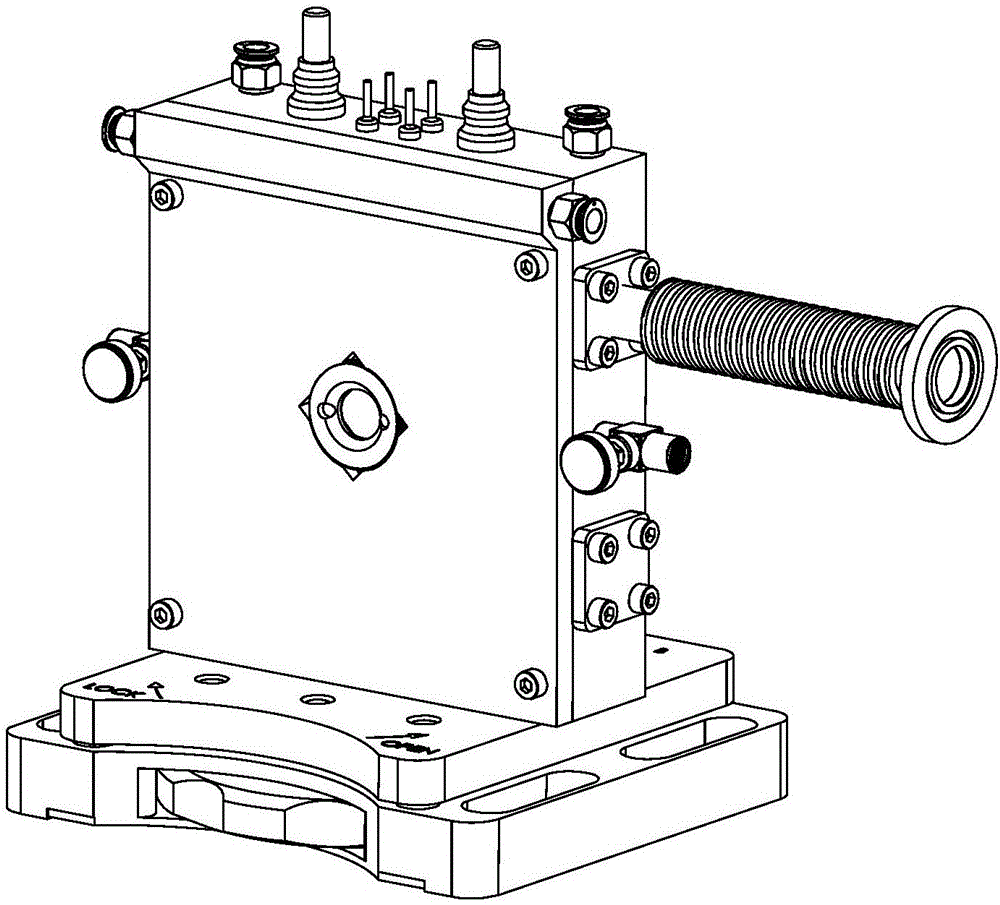

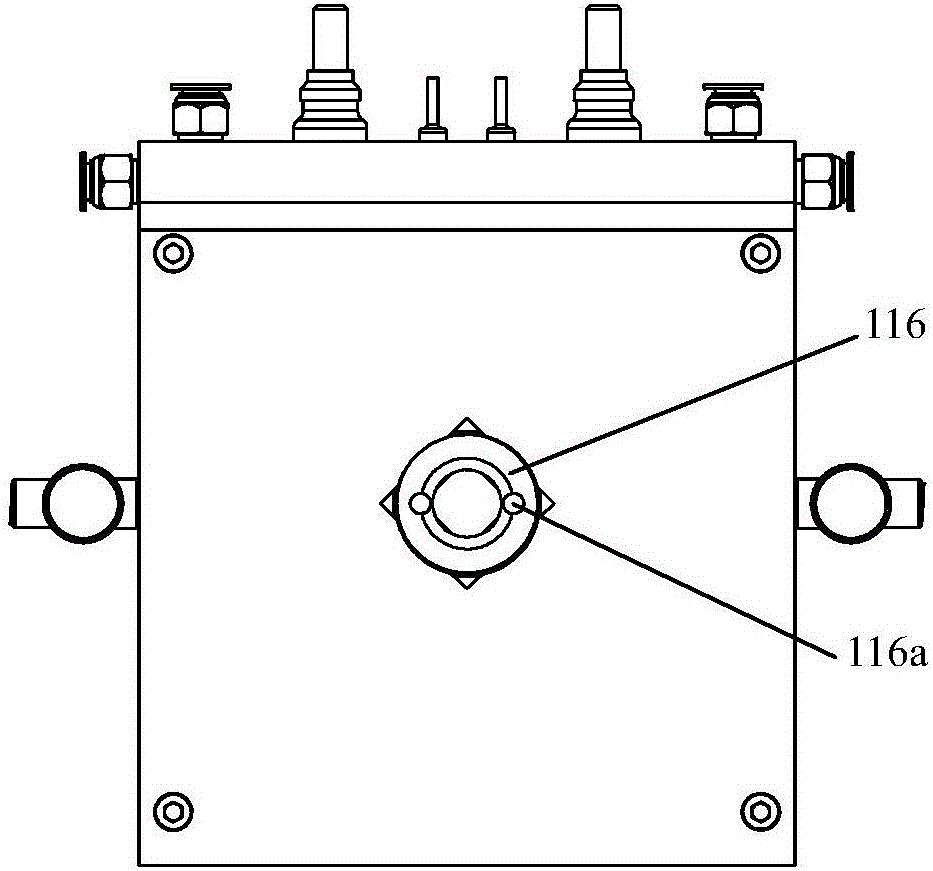

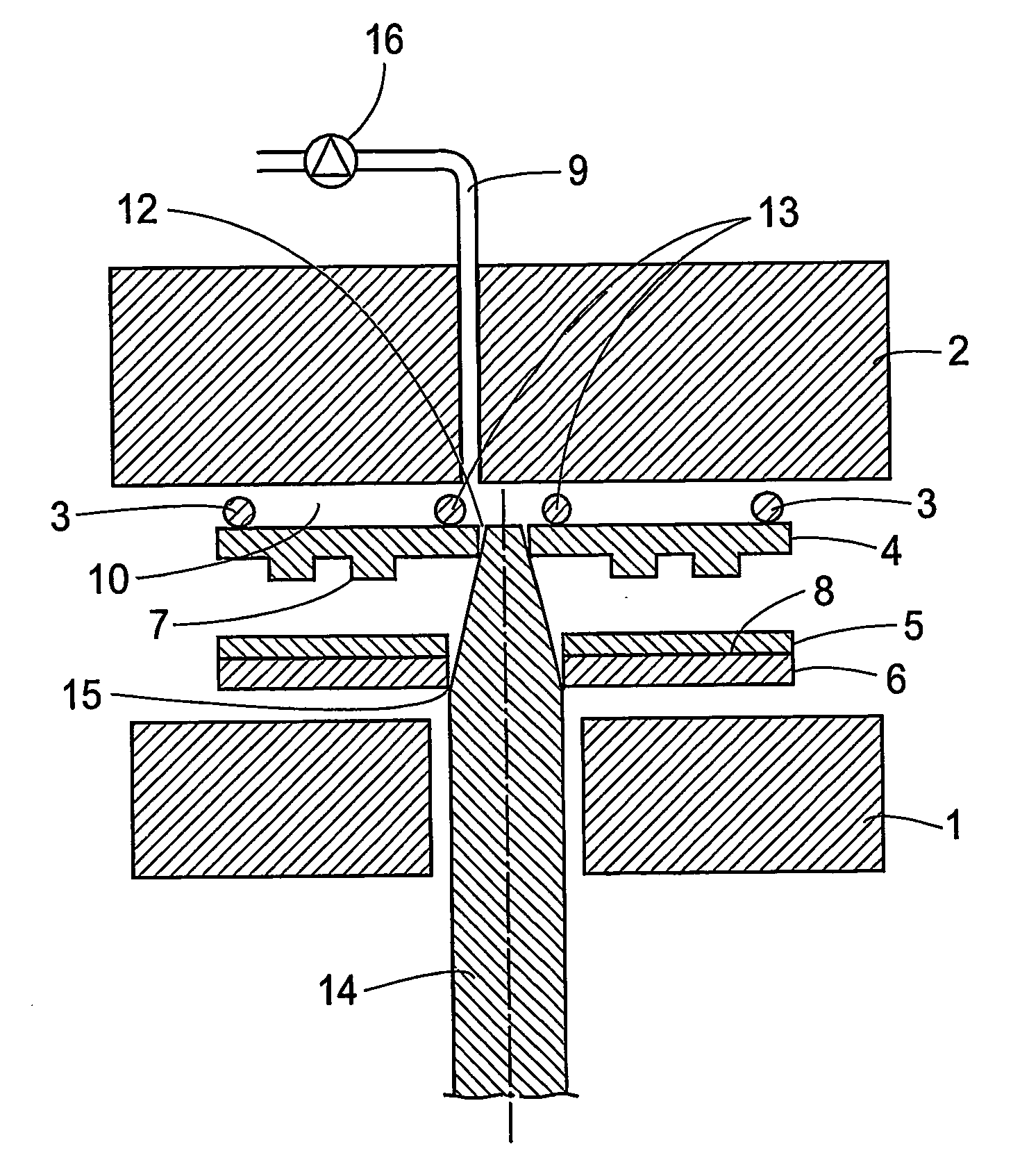

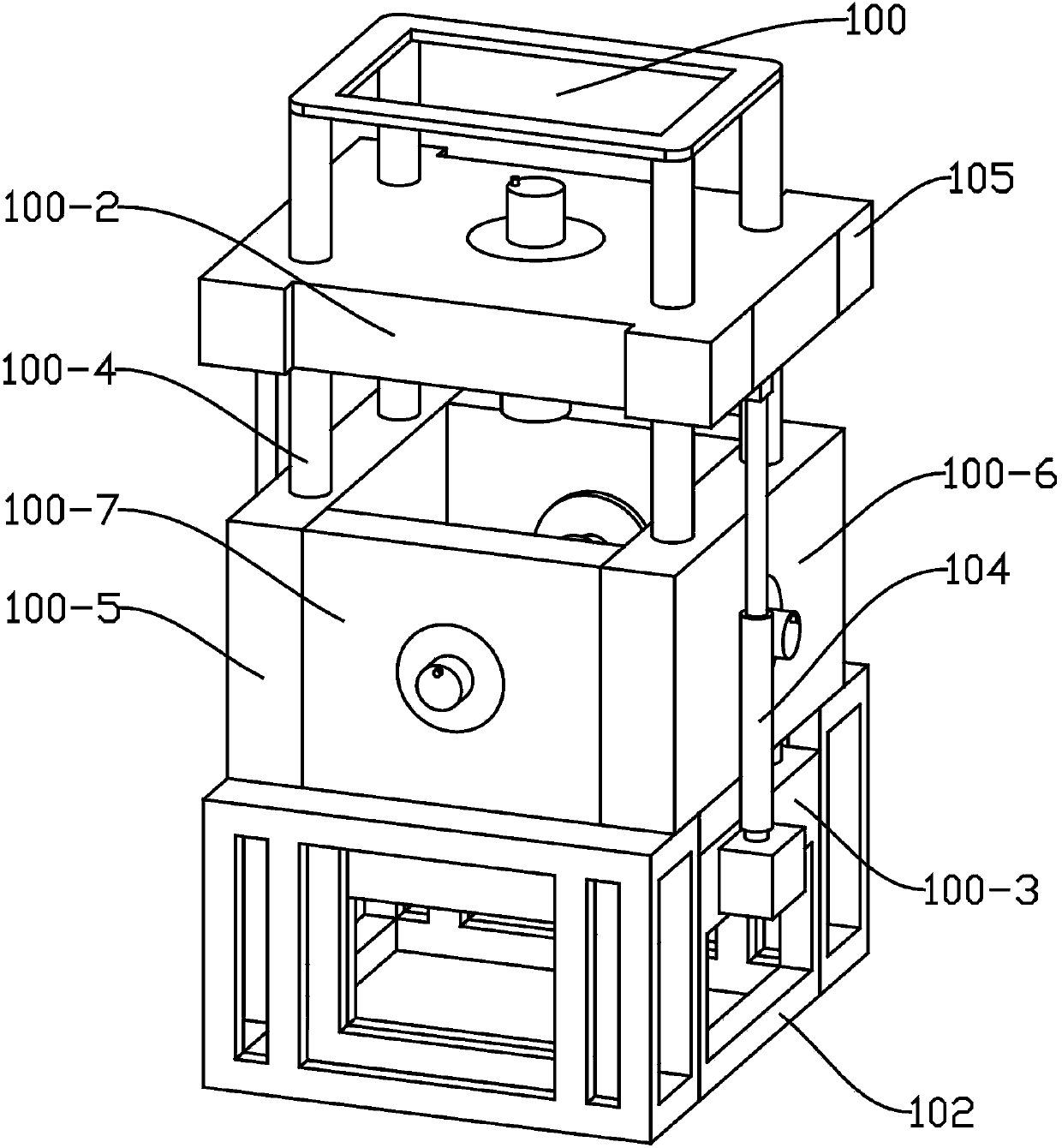

Heating stage and heating stage device for X-ray microprobes and experimental method of heating stage device

ActiveCN106483148AEasy to centerHeating evenlyMaterial analysis using wave/particle radiationX ray microprobeHard X-rays

The invention discloses a heating stage for X-ray microprobes. The heating stage comprises a heating stage body, a heater and a sample holder; an incident window and a transmitting window are coaxially and correspondingly arranged on the front wall and the rear wall of the heating stage body respectively, and the bottom of the heating stage body can be mounted on a sample positioning platform; the sample holder is sleeved in the heater in high heating area ratio; each of the heater and the sample holder is provided with a light transmission hole, and the light transmission hole is coaxial with the incident window and the transmitting window. The heating stage for the X-ray microprobes can be operated vertically, and temperature gradient of samples is small; in addition, the heating stage has the advantages of high light transmission, vacuum chamber, easiness in alignment, good temperature uniform of the samples, wide sample type and shape adaptability, high operation temperature limit and the like. In addition, the invention further discloses a heating stage device and an experimental method thereof. The heating stage device is high in back-scattered fluorescent detection efficiency, sufficient rotatable angle and detection angle, overall atmosphere protection and vacuum environment are provided for the samples. The heating stage, the heating stage device and the experimental method are especially suitable for hard X-ray microprobes.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for transferring a pattern

InactiveUS7082876B2Less complicatedEasy to manufactureRecord carriersPlaten pressesMechanical engineering

Owner:OBDUCAT AB SE

Device for injection molding a tubular element from synthetic material

InactiveUS20090004324A1Compensation for shrinkageConstant wall thicknessFood shapingTubular articlesSynthetic materialsBiomedical engineering

Owner:VIEL +1

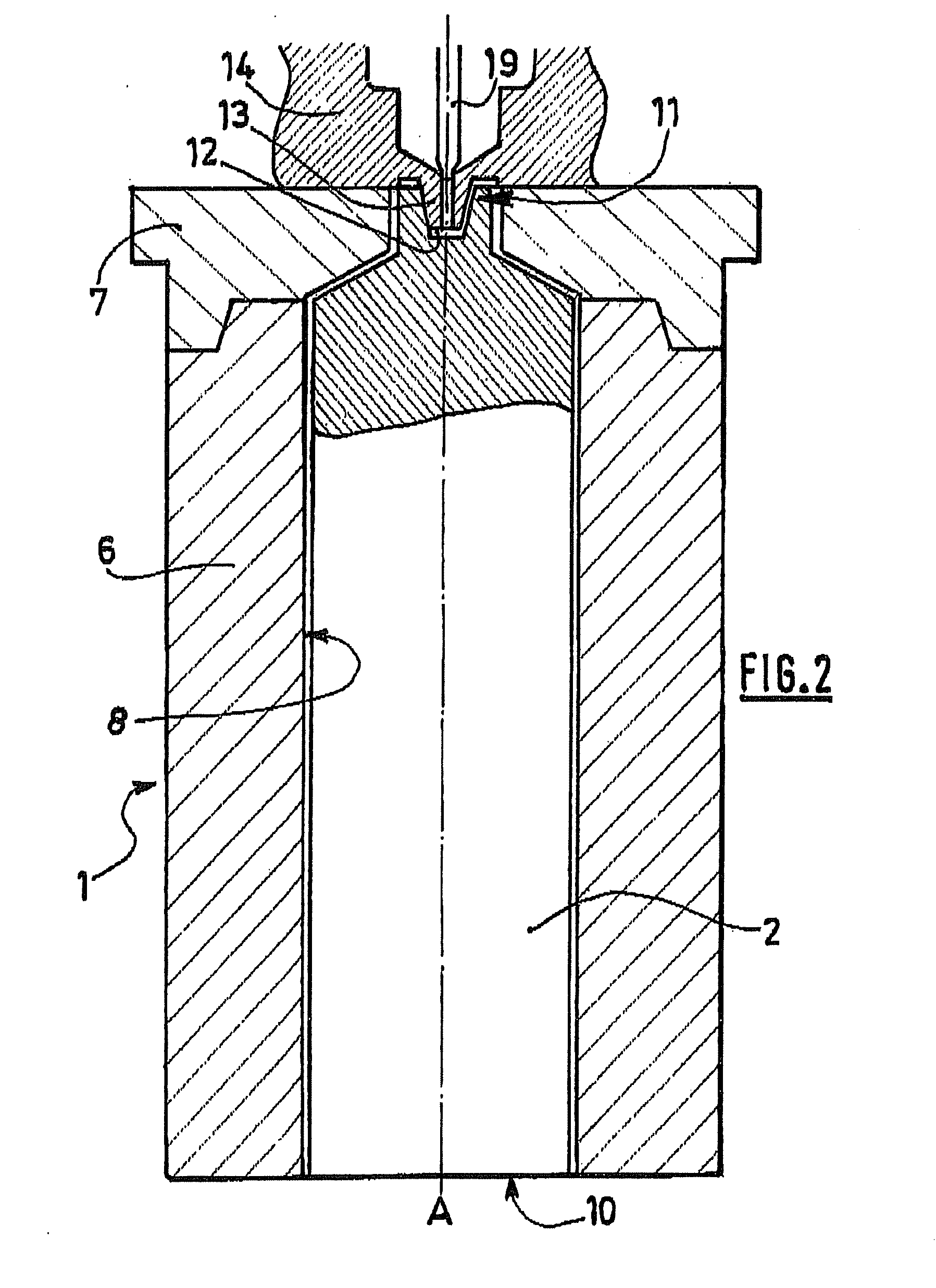

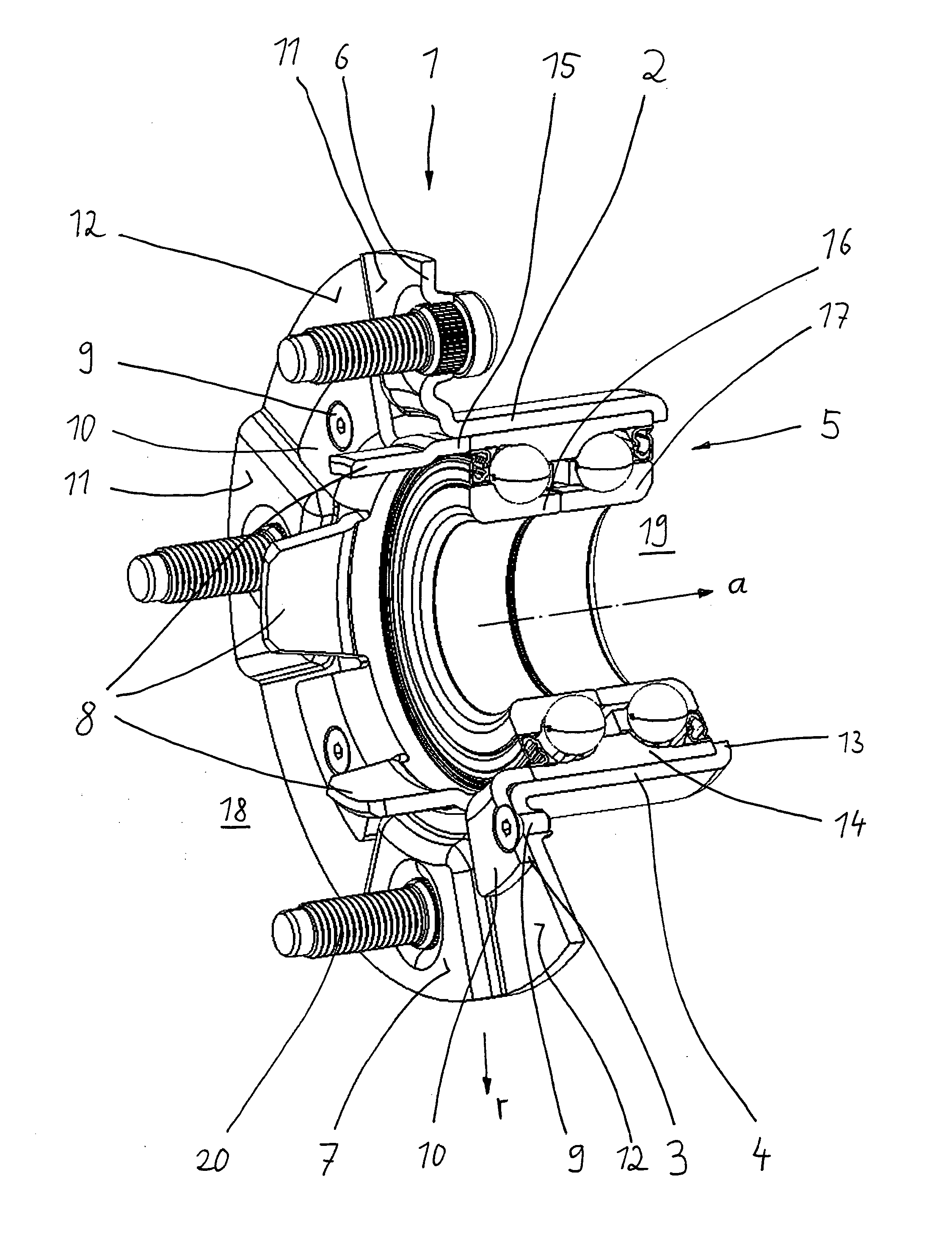

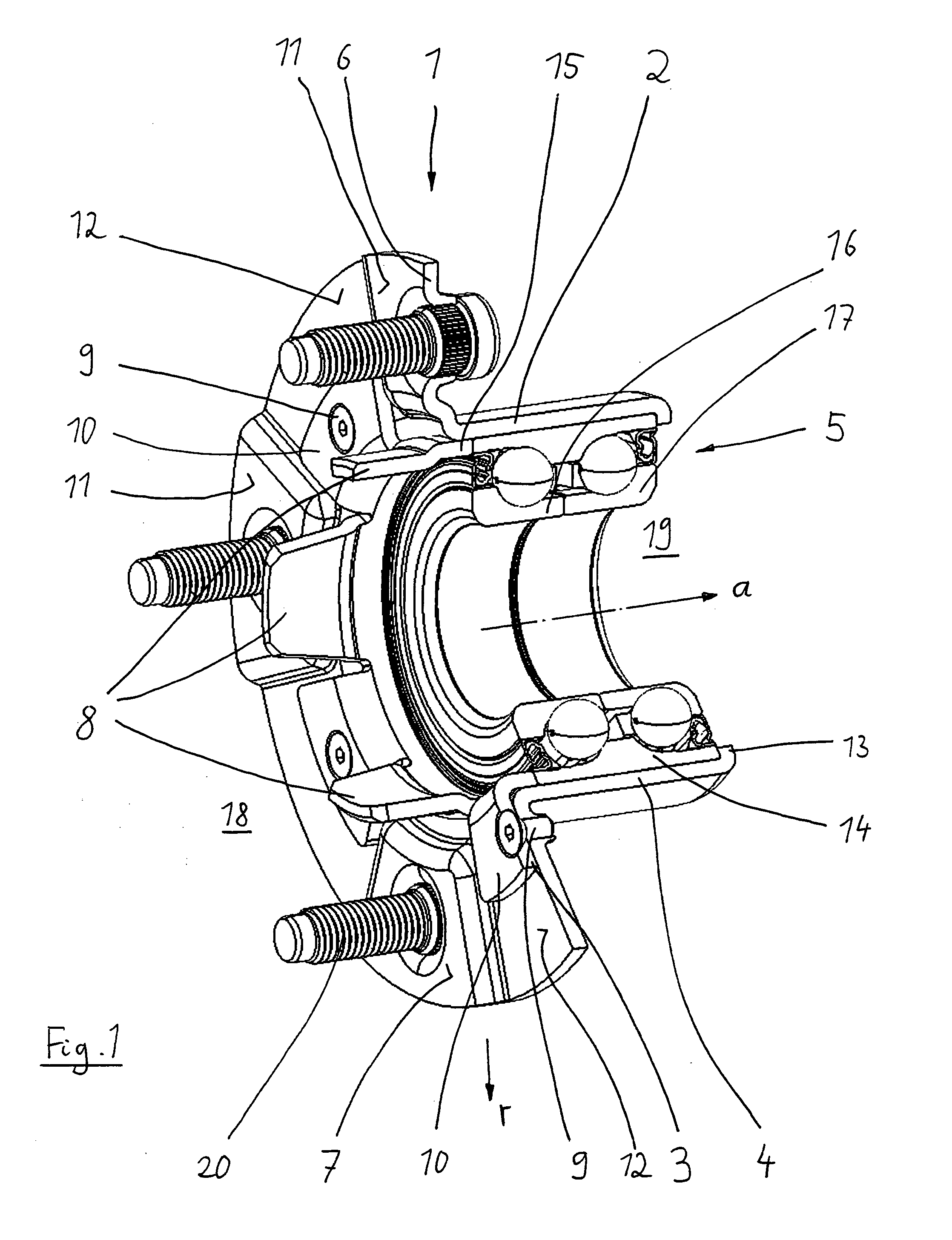

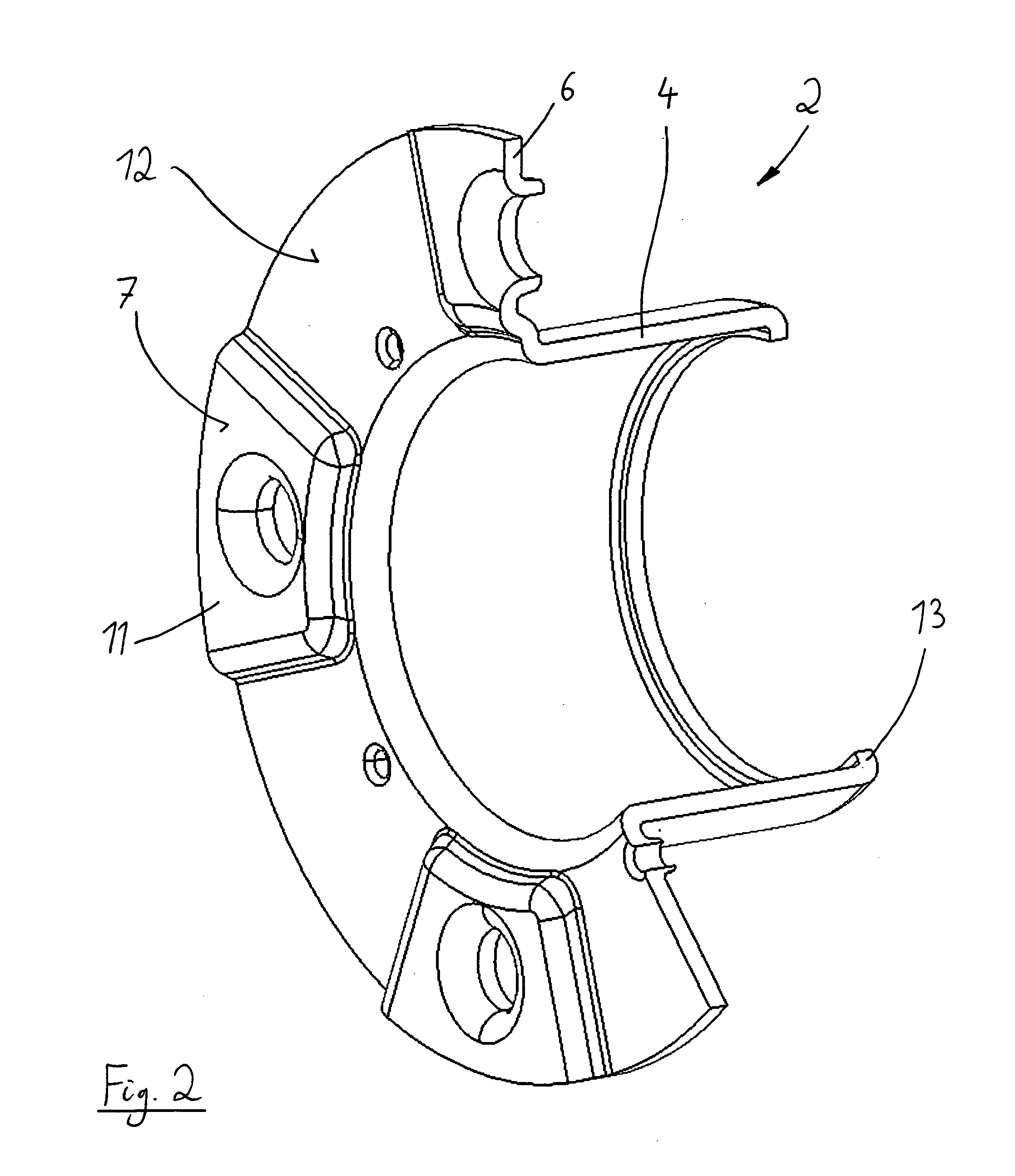

Wheel Bearing Unit

ActiveUS20110187179A1Avoid corrosionEasy to manufactureRotary/oscillating piston combinations for elastic fluidsRolling contact bearingsEngineeringFlange

The invention relates to a wheel bearing unit (1) for a vehicle wheel, comprising a hub element (2, 3) which has a axially (a) extending cylindrical section (4) to be supported by a bearing arrangement (5) and which has a radially (r) extending flange section (6) for fixing the vehicle wheel and / or a brake disk at a face side (7) of the flange section (6). To ensure a simple design with high stability the invention is characterized in that the hub element (2, 3) consists of a first part (2) comprising the cylindrical section (4) and the flange section (6) and of a second part (3), wherein the second part (3) has means (8) for centering a wheel rim of the vehicle wheel and / or the brake disk and wherein the first part (2) and the second part (3) are connected by connection means (9).

Owner:AB SKF

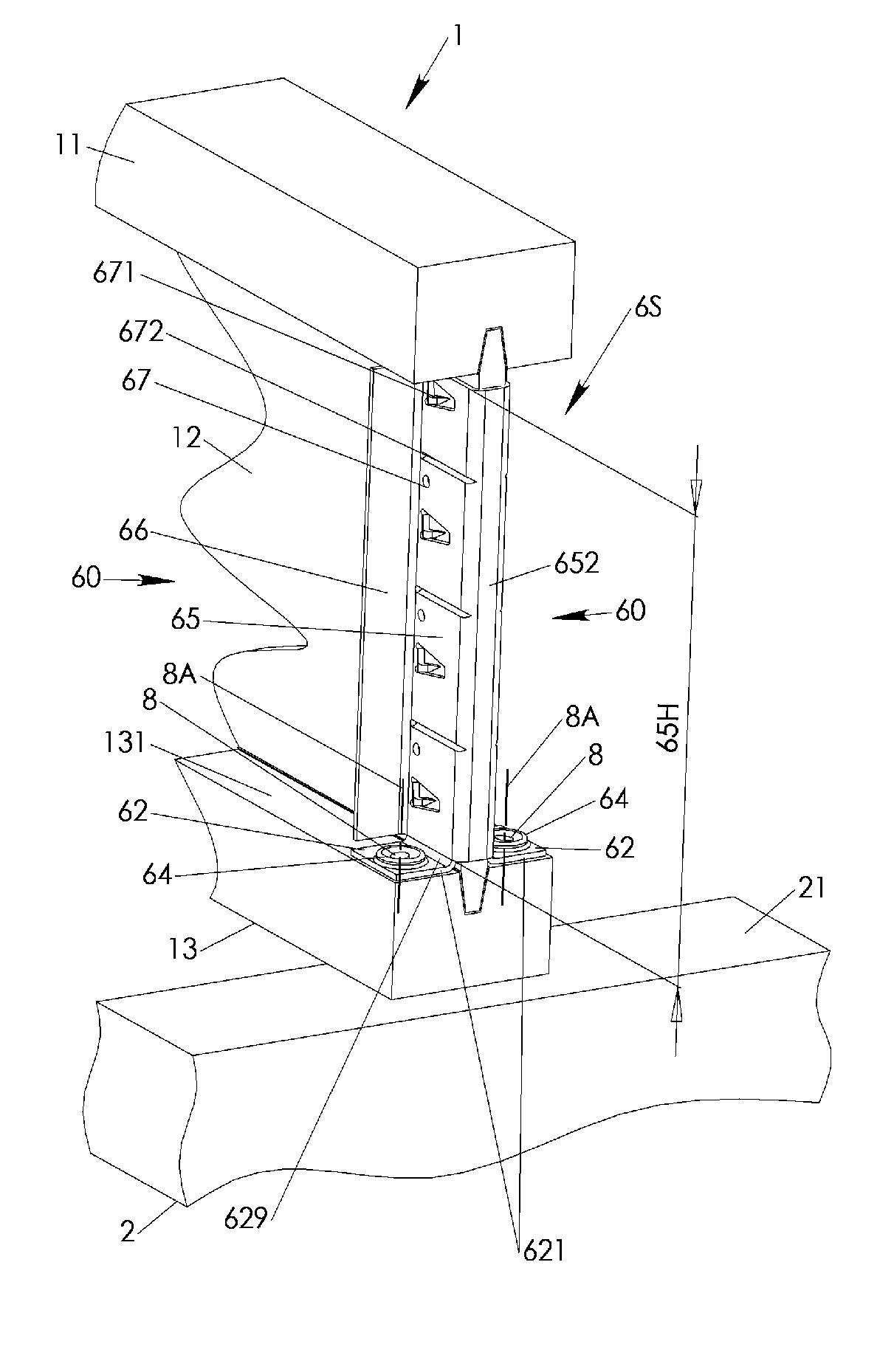

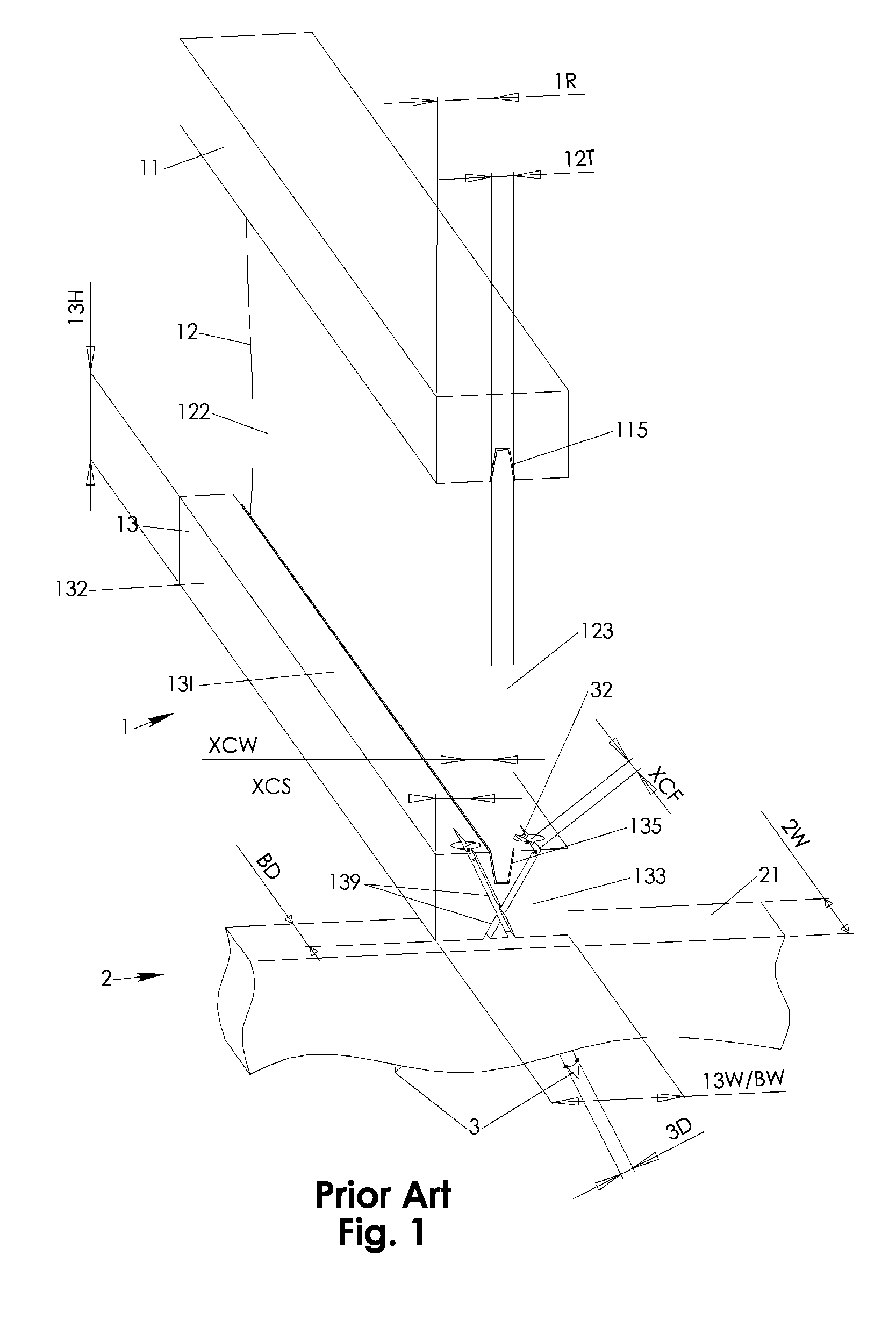

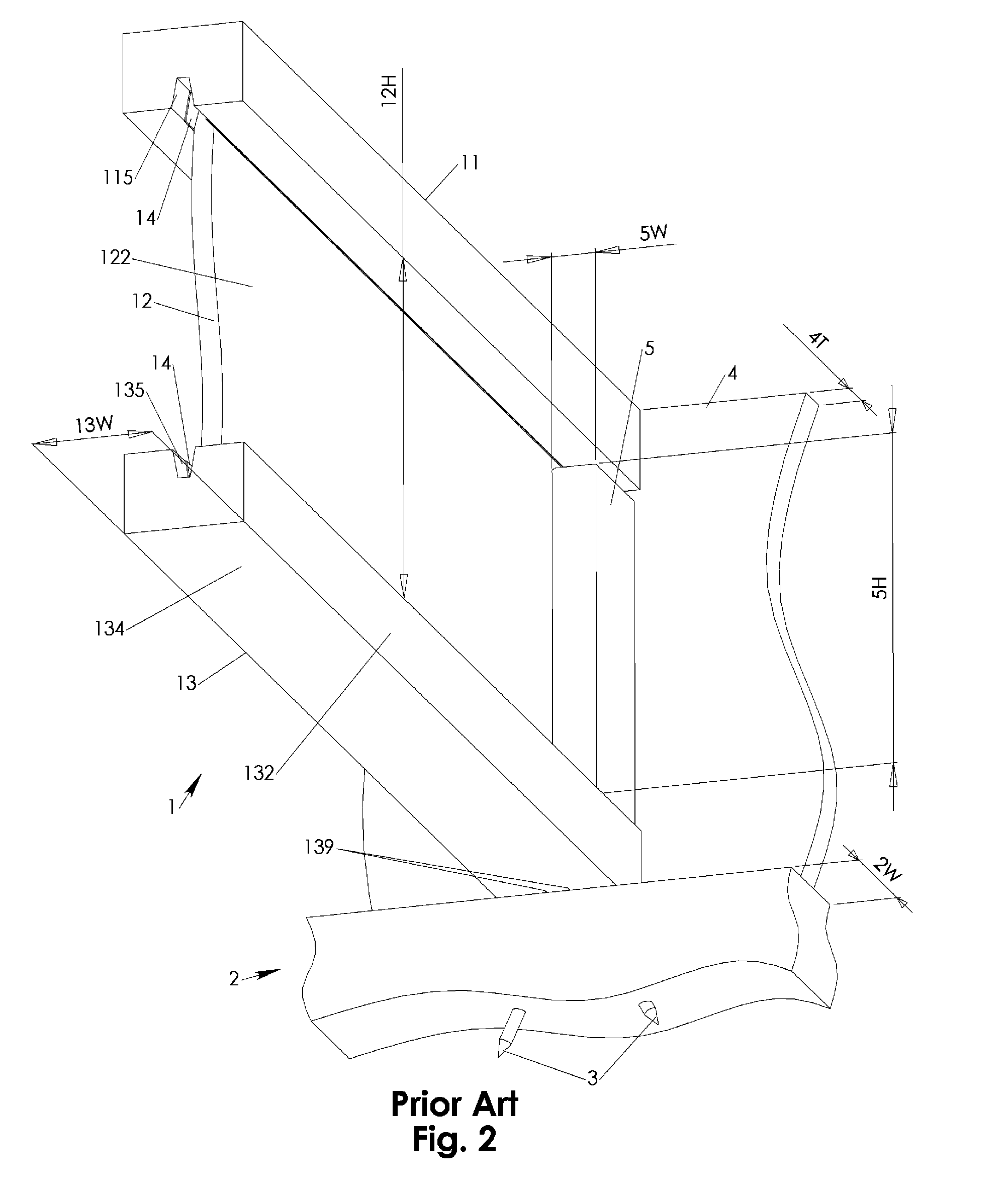

Sheet Metal Web Stiffener And Chord Nailing Restrictor For Wooden I-Joist

A monolithic sheet metal chord nailing restricting and web stiffening device features a chord plate combined with a web stiffening structure configured for lateral attachment to the web of a wooden I-joist. The chord plate is positioned on the bottom of the web stiffening structure and features a nail restricting hole having a diameter that corresponds to a predetermined diameter of a chord nail as defined by wooden I-joist manufacturers. The web stiffening structure has a web plate for attachment to the web and a buckling opposing web stiffening rib. Once the web stiffening structure is attached to the web above the bearing rest the nail restricting hole restricts chord nailing position and nail shaft diameter to manufacturer defined limits. Two devices may be combined by a web front bridge plate for simultaneous attachment of two opposite devices along an I-joist end.

Owner:DAVIS JOHN D

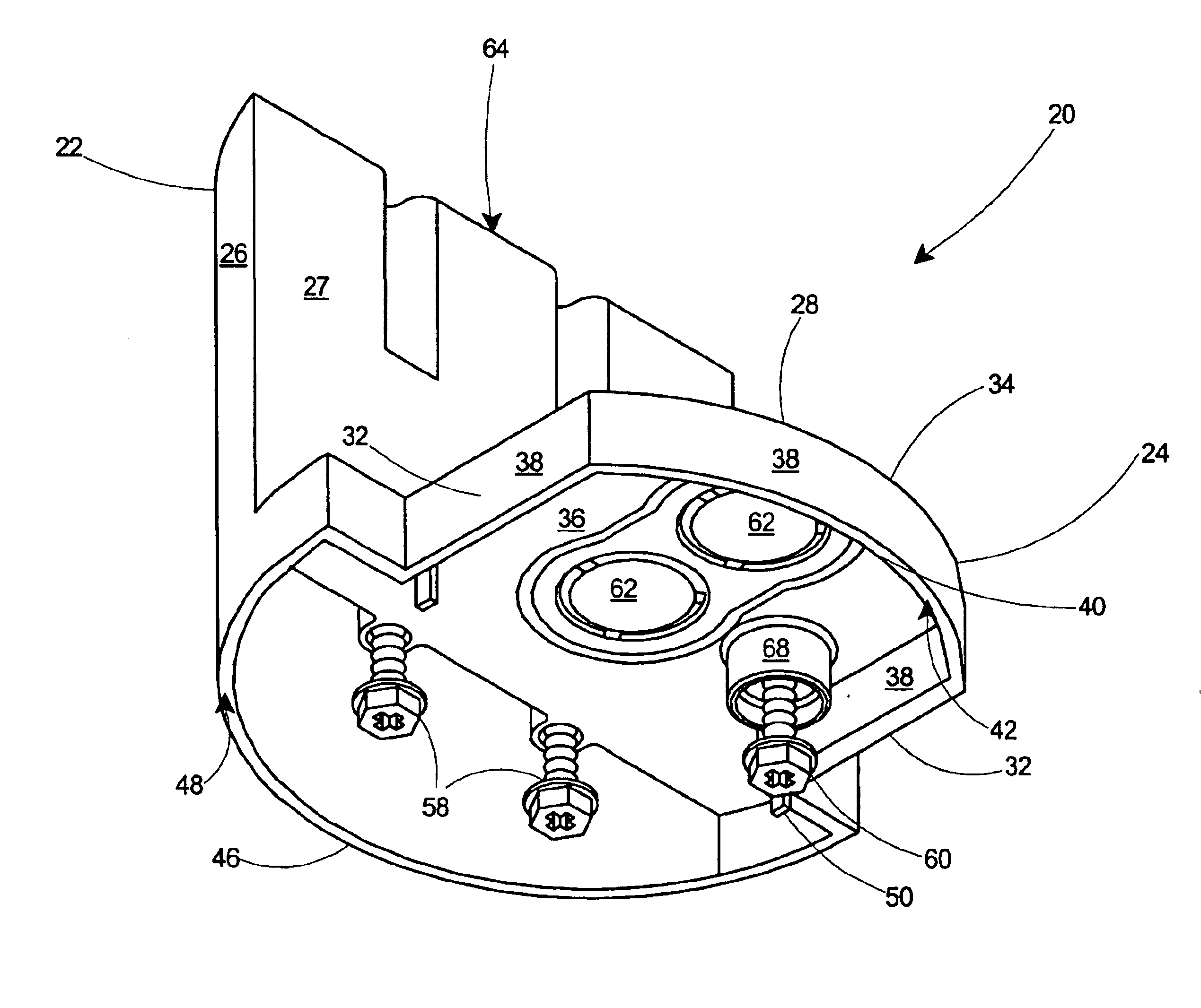

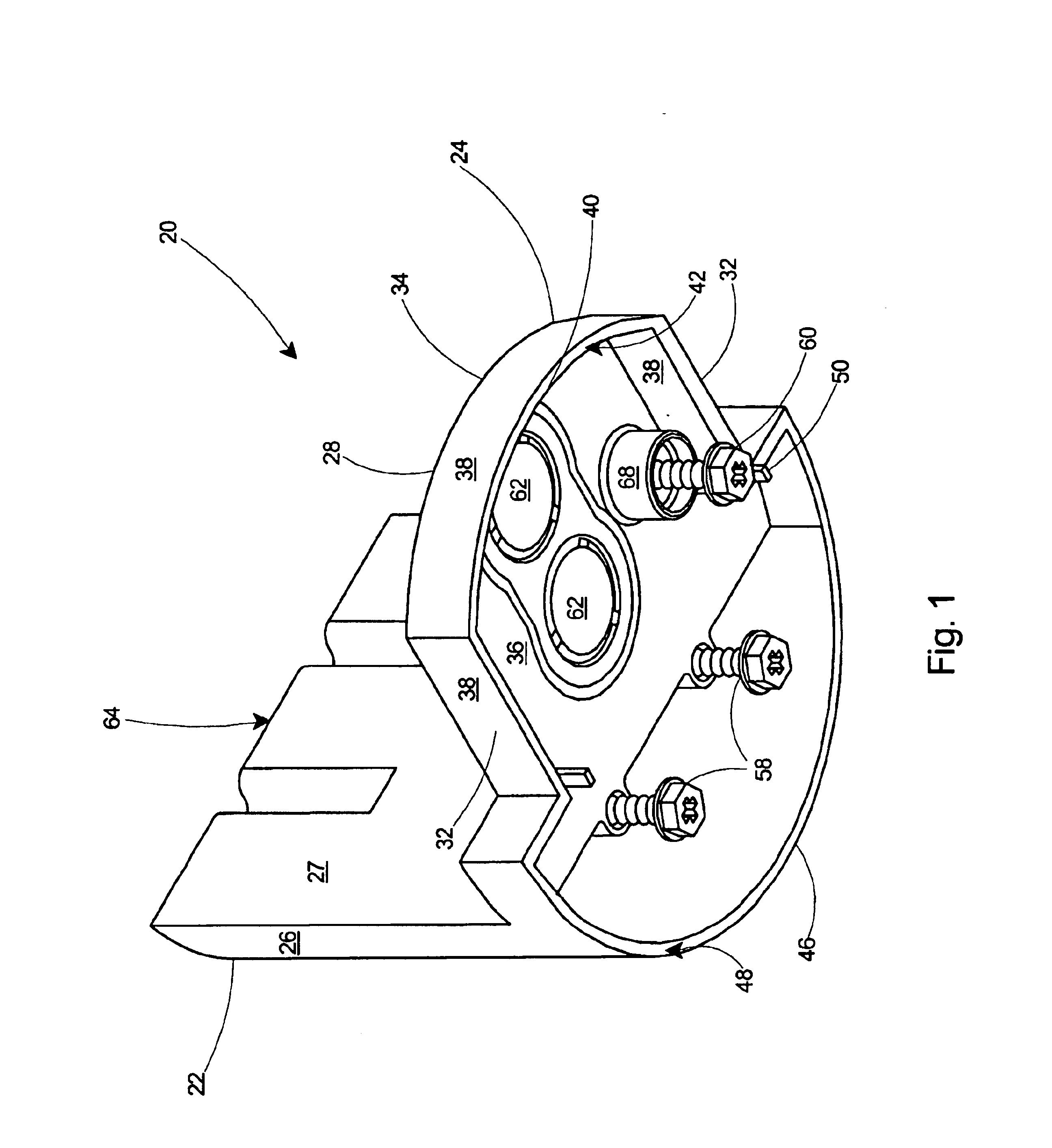

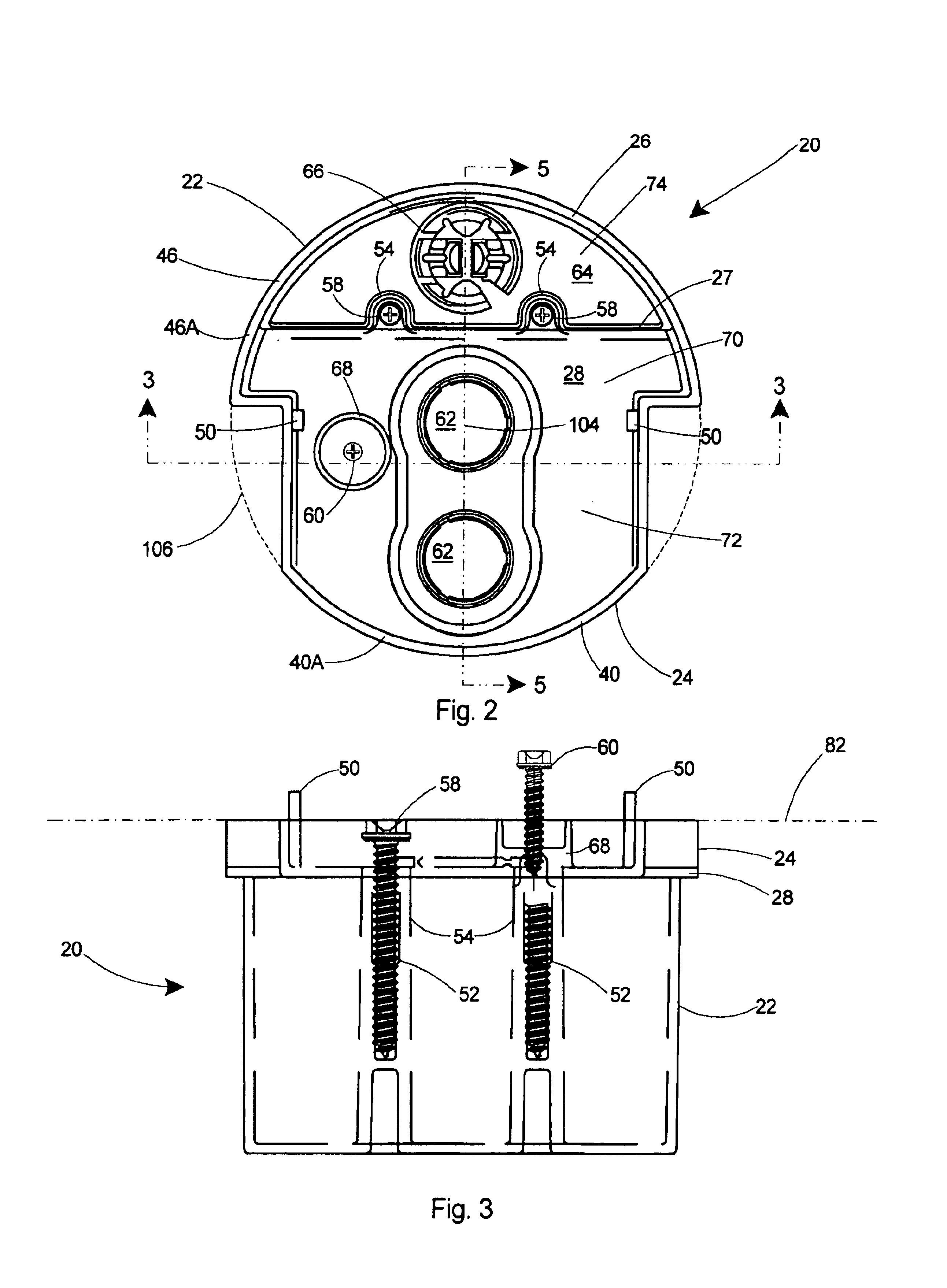

Prepackaged mounting assembly

A prepackaged mounting assembly for securing a device, such as a ceiling fan, light fixture, or similar device to an overhead beam. The mounting assembly includes an L-shaped mounting box that includes a first and a second junction box. Each junction box includes an integral arcuate flange portion that cooperate to accept a separately supplied bracket thereon. The bracket includes slots therein and the integral flange portion includes downward extending alignment posts to enable easy centering of the bracket under the mounting box and the overhead beam. All hardware required to complete installation of the device is temporarily secured to the L-shaped box for shipment and storage, including an initial fastener and load bearing fasteners. The L-shaped mounting assembly is especially useful for mounting an electrical device to an existing ceiling.

Owner:GRETZ THOMAS J +1

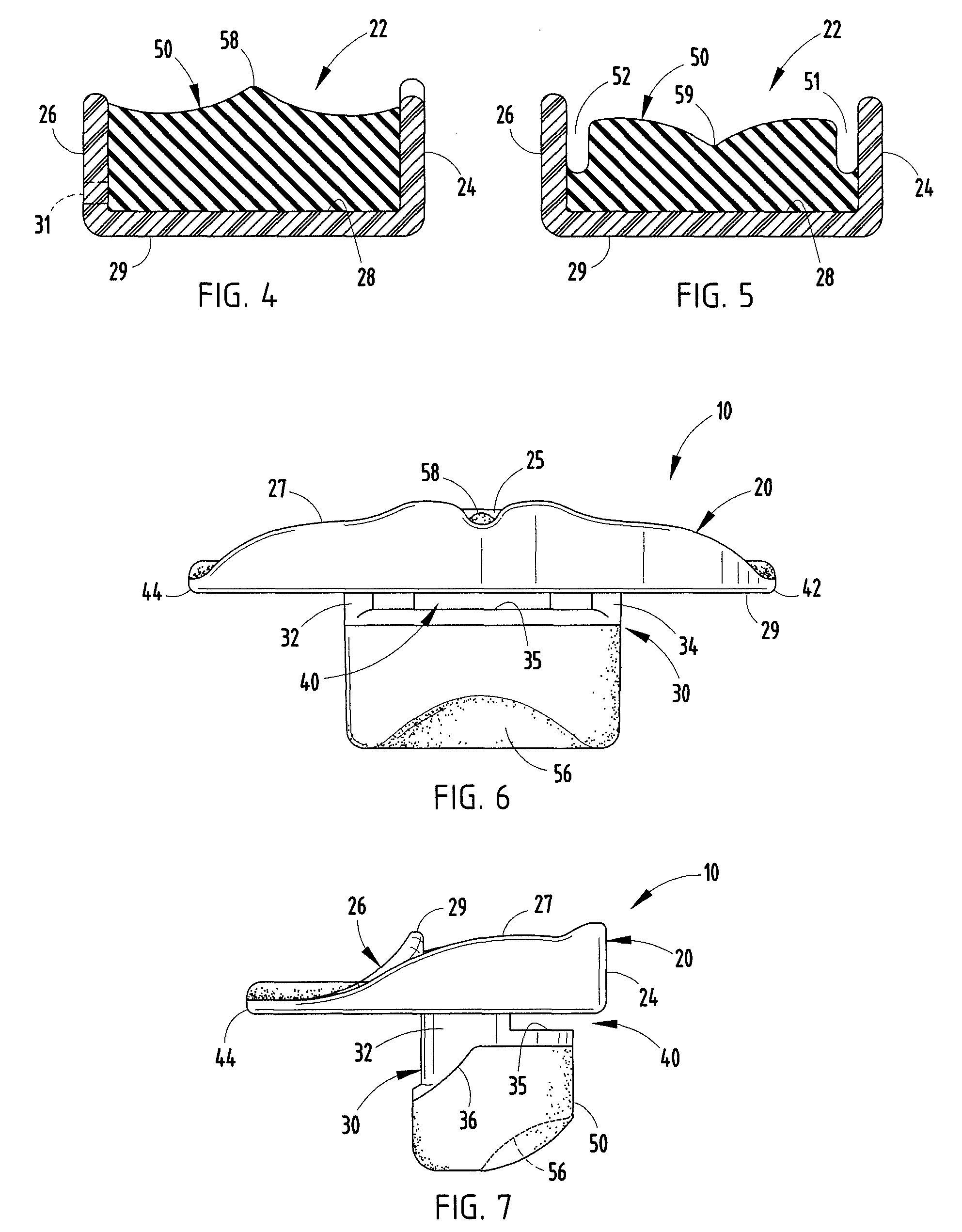

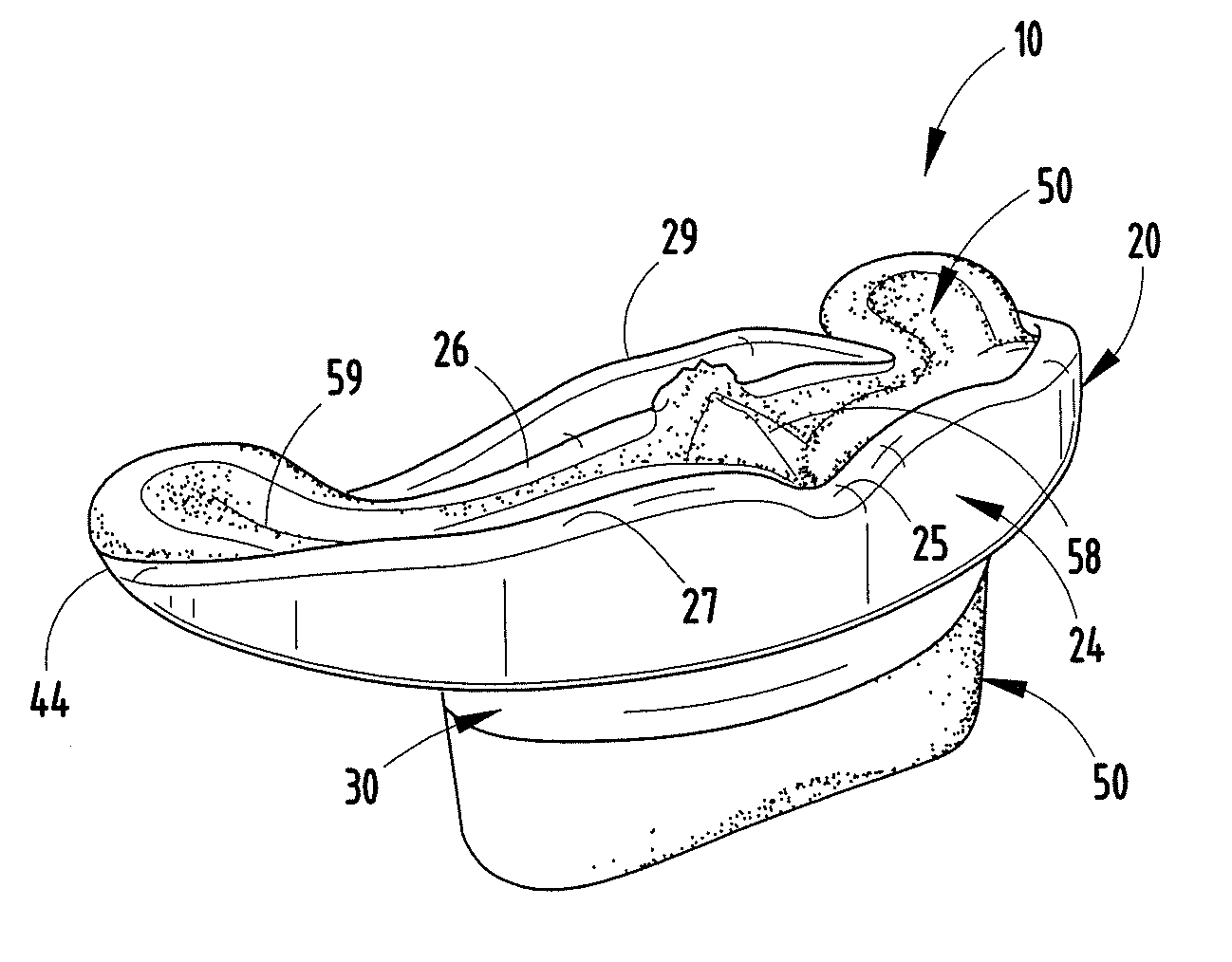

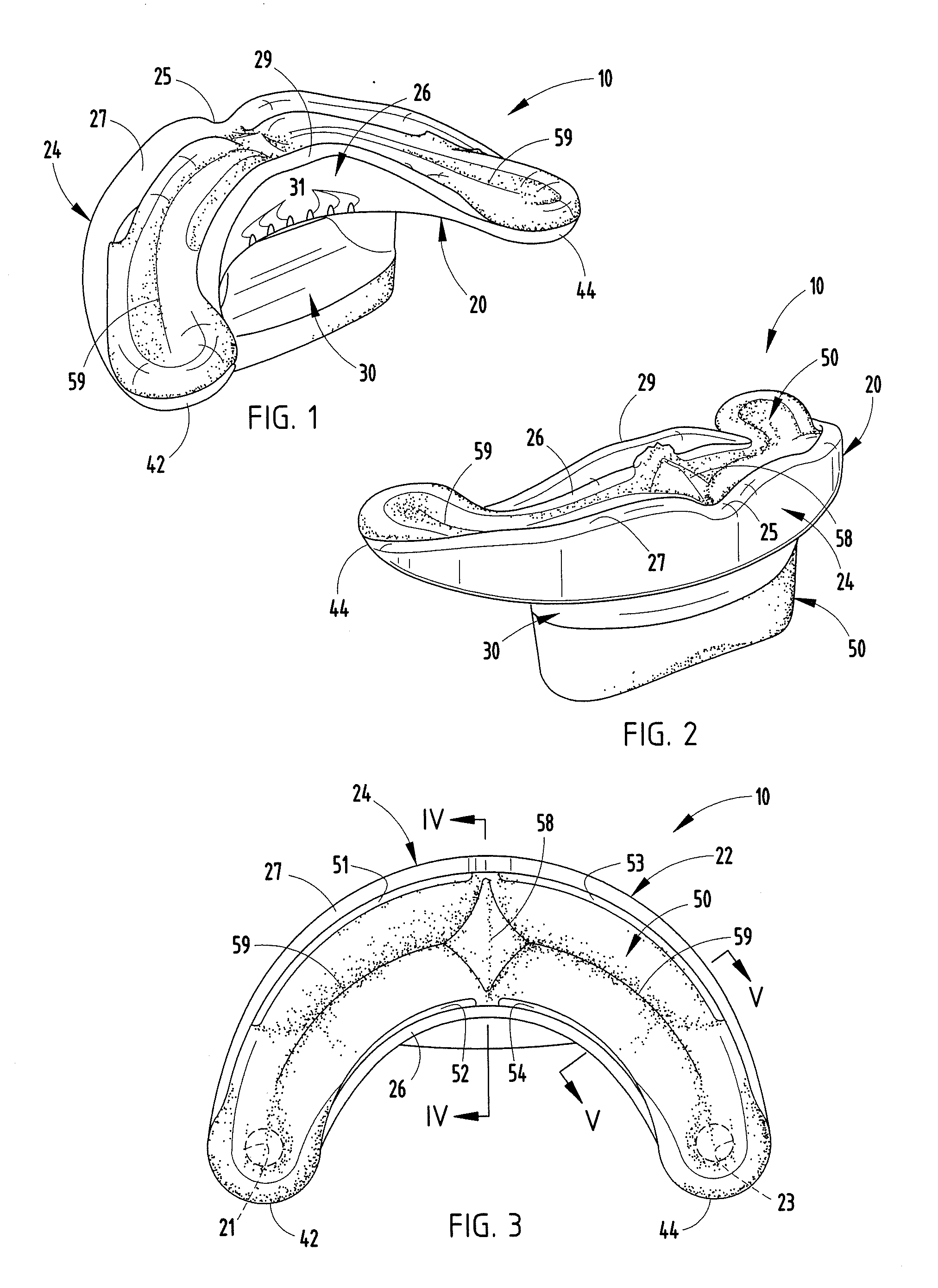

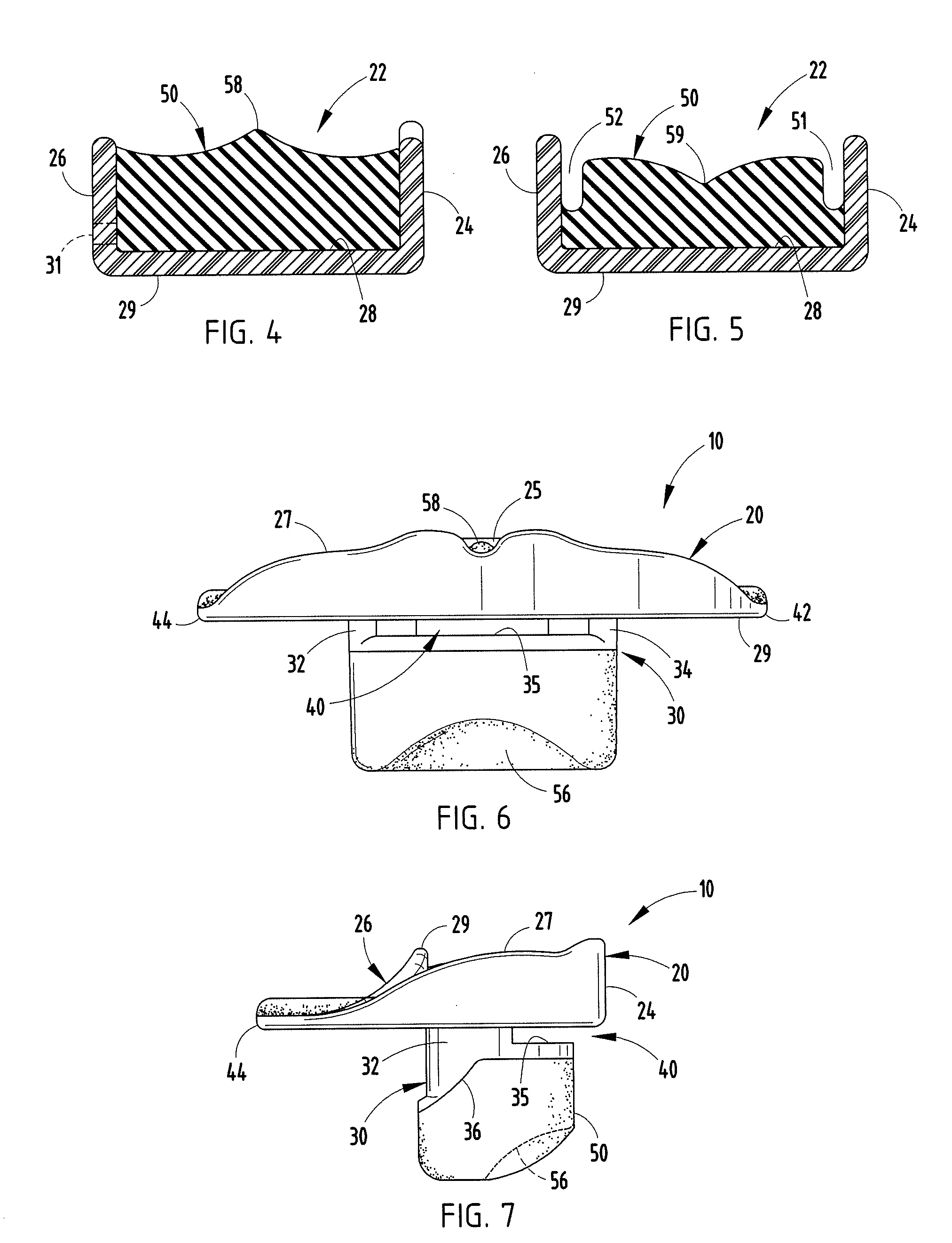

Oral orthosis

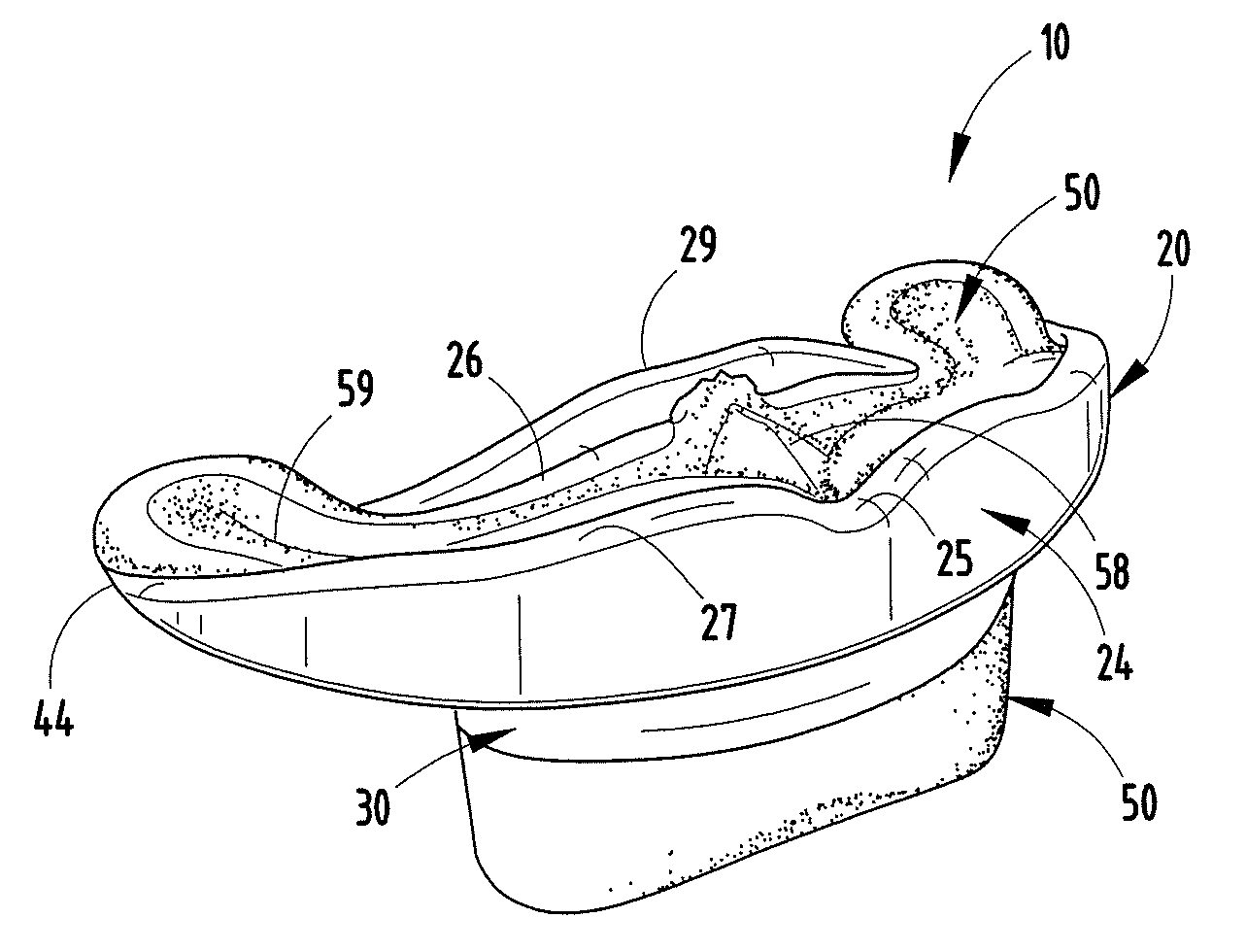

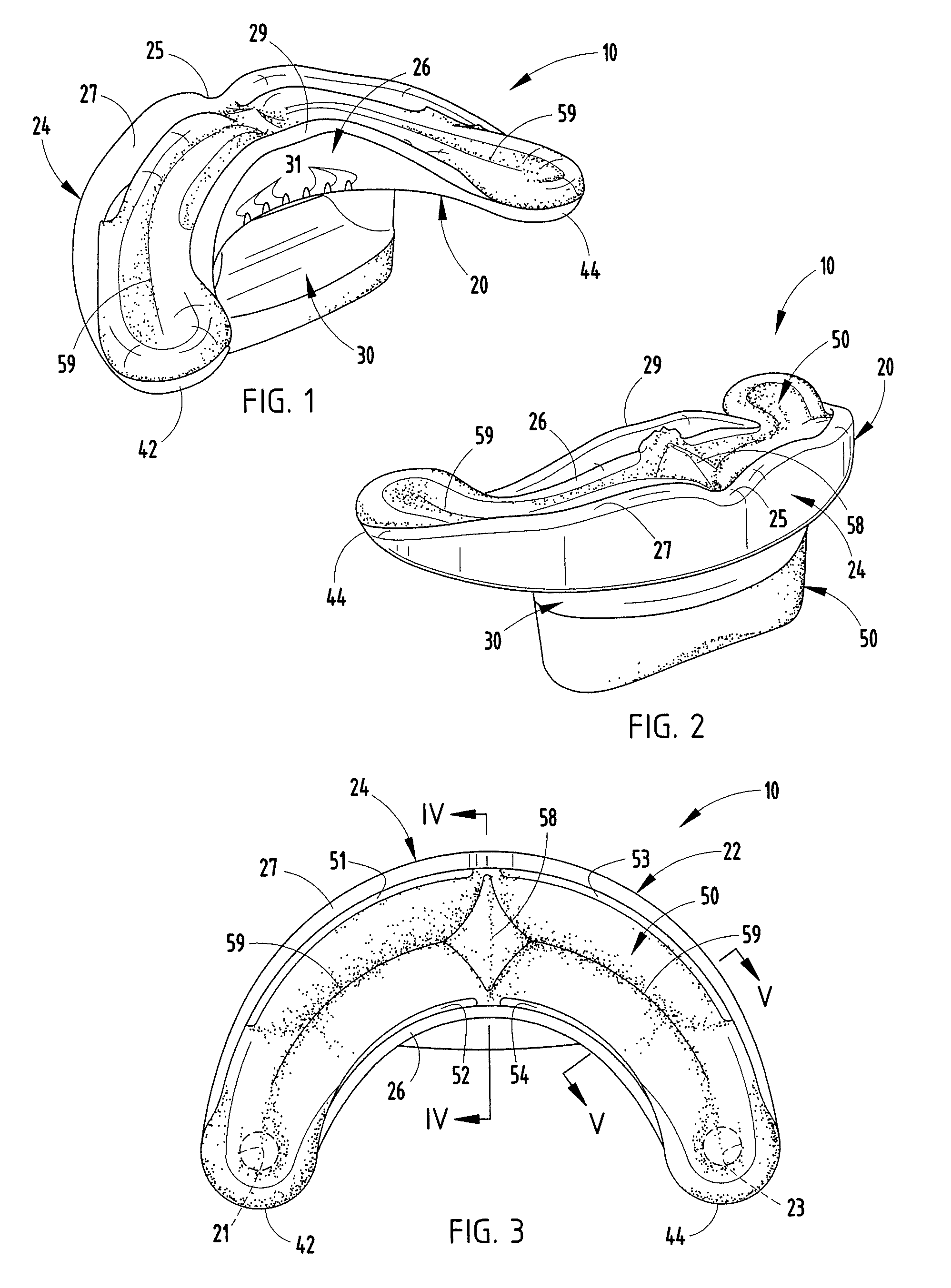

ActiveUS8322344B2More materialAccurate fitImpression capsTeeth fillingCompressible materialEngineering

An oral orthosis includes a holder in the shape of a mouthpiece, including a curved arcuate trough-like upper section which receives a formable material. The formable material does not occupy the entire trough but rather includes voids between the formable material and the inner surfaces of trough of the holder to allow expansion of the formable material into the voids during the molding process when tooth pressure is placed on the formable material. This design results in elimination of the excess formable material which otherwise would require removal by trimming. Additionally, the formable material is placed in the trough in a configuration which includes indexing indentations along the centerline of the material, such that, during the molding process, the mouthpiece containing the formable material is easily centered along the edges of the user's teeth to provide a precise fitting.

Owner:RANIR LLC

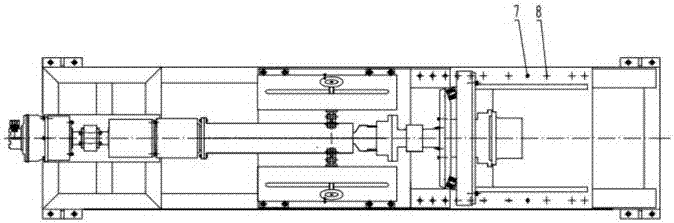

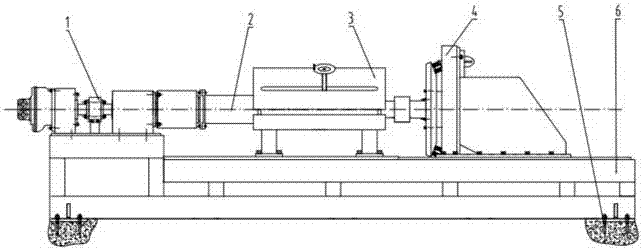

Test stand for testing performance of dynamic directional rotary steering drilling tool

ActiveCN107219084AMeet loadingReduce frictionStructural/machines measurementExperimental researchTest performance

The invention discloses a test stand for testing the performance of a dynamic directional rotary steering drilling tool. The test stand comprises a frame body, a rotating device, a clamping device and a loading device, can simulate the steering process of the directional rotary steering drilling tool in actual well conditions, and can realize random adjustment for the angle of a controllable bent joint within an operating range thereof while the directional rotary steering drilling tool bear the axial pressure torque at the same time. Experimental research on the aspects such as verification for the steering performance, the reliability and a control principle of the directional rotary steering drilling tool through loading the axial pressure and torque, and research on simulated well drilling can also be carried out. The test stand can be used for performance testing and principle verification for the directional rotary steering tool.

Owner:XI'AN PETROLEUM UNIVERSITY

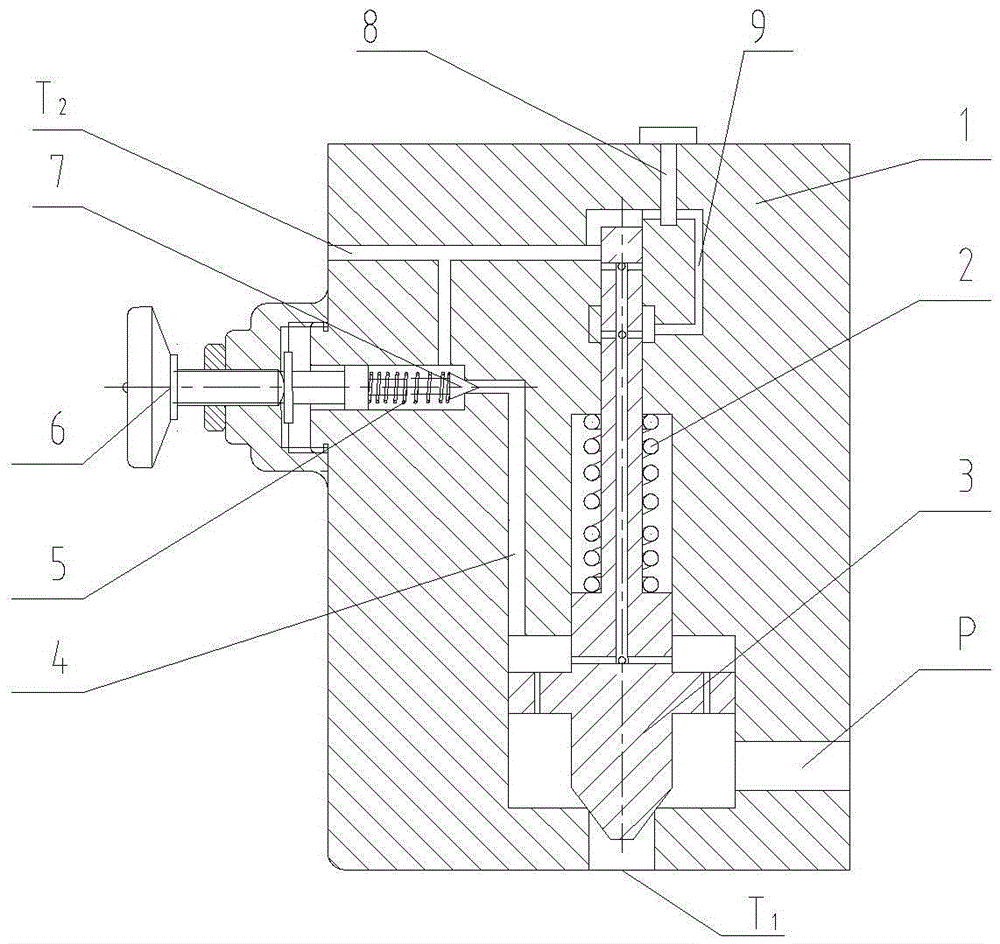

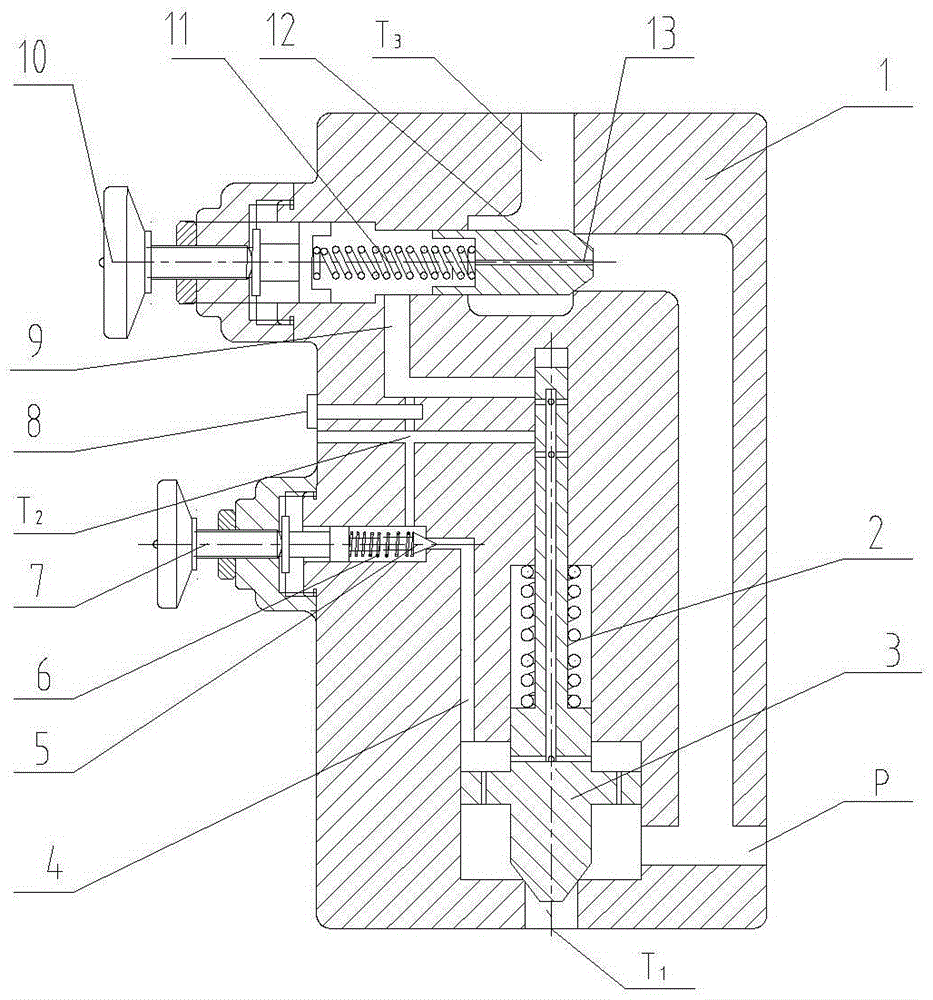

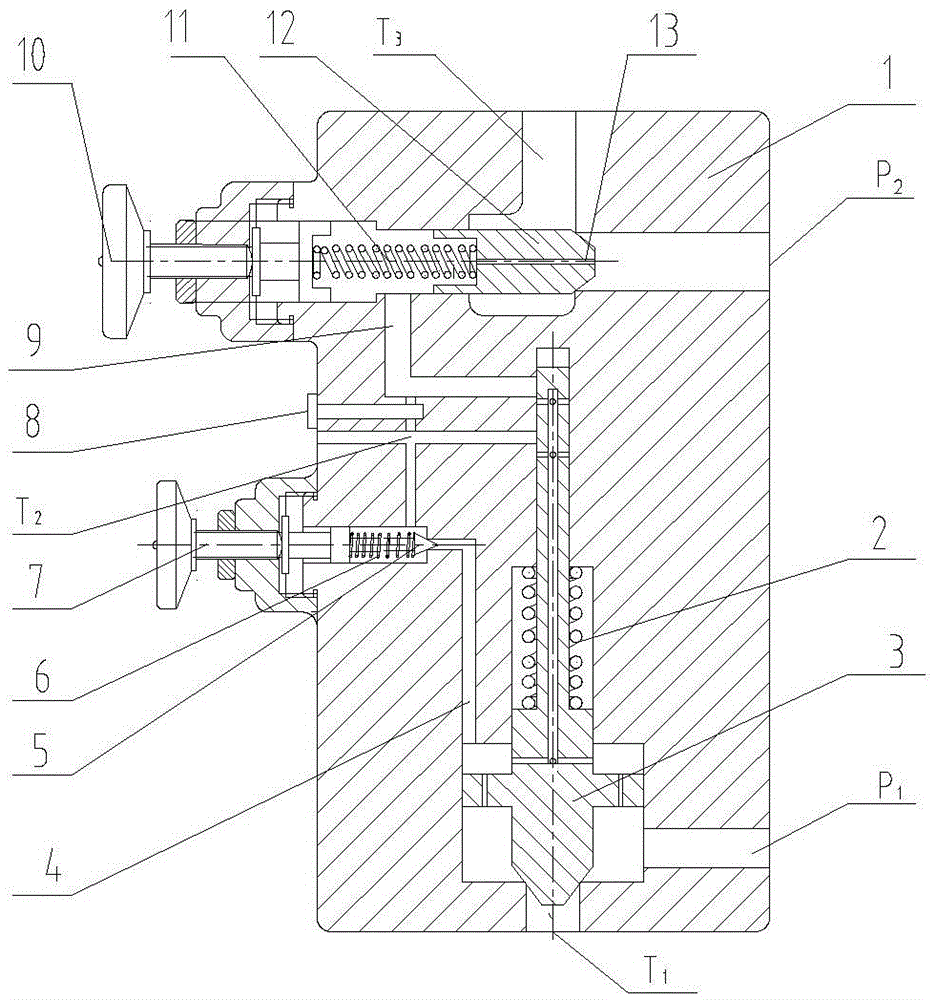

Overflow valve with pressure regulating and safety functions

The invention discloses an overflow valve with pressure regulating and safety functions, and relates to the technical field of hydraulic control valves. The overflow valve comprises a valve body, a main valve, a pilot valve and an emergency pin; the valve body is provided with a runner, a drainage hole, a liquid inlet, a first liquid outlet and a second liquid outlet; one side of the main valve is communicated with the liquid inlet, the other side of the main valve is connected with the pilot valve through the runner, the lower end of the main valve is communicated with the first liquid outlet, and the upper end of the main valve is communicated with the second liquid outlet through the drainage hole; and the emergency pin is connected with the drainage hole. The problem that resonance is caused by a traditional dual overflow valve is effectively solved; the stability of a main valve element is improved; centering of the main valve element is facilitated, and clamping of the valve element is prevented; the balance of the safety valve element is achieved through hydraulic pressure at the two ends, once the pressure is released from one end, the safety valve element can be rapidly opened, and the pressure of the safety valve element is released; when emergency circumstances occur in a system, one end of a pressure limiting valve element is opened to be subject to pressure releasing by rotating a safety pin, and safety and stability of the pressure of the system are guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

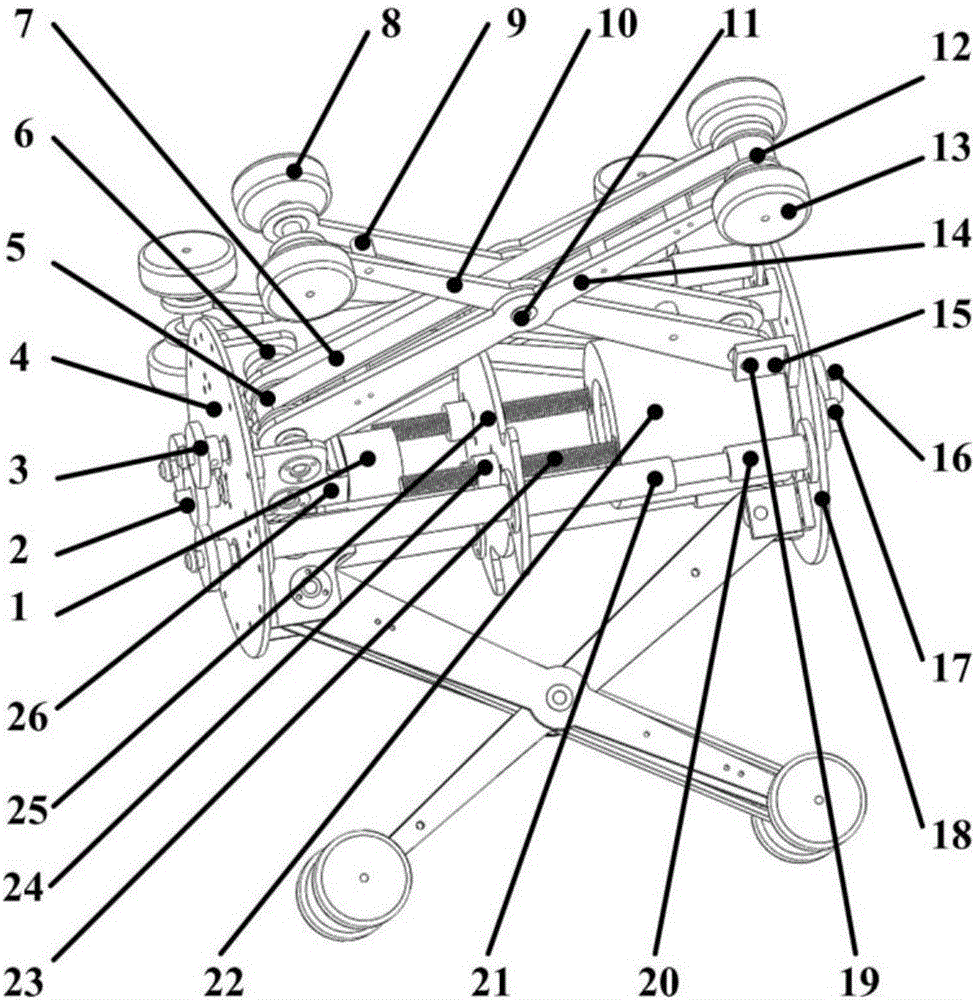

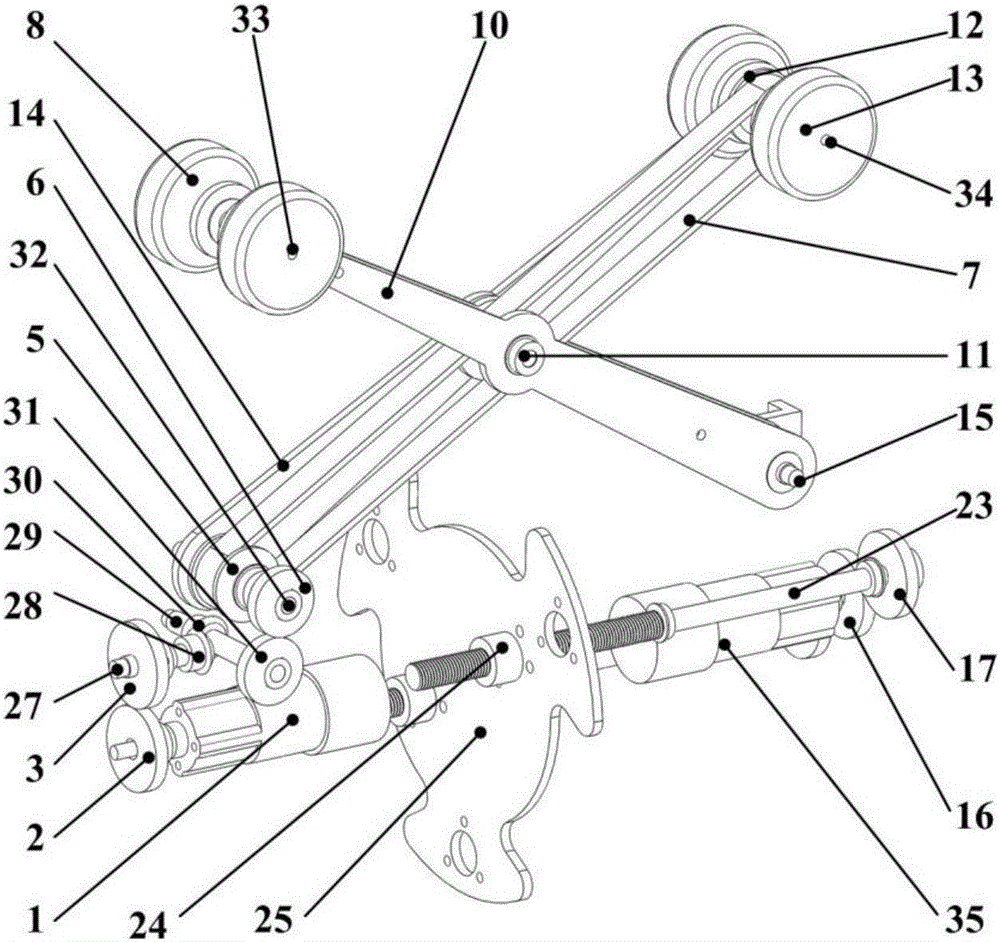

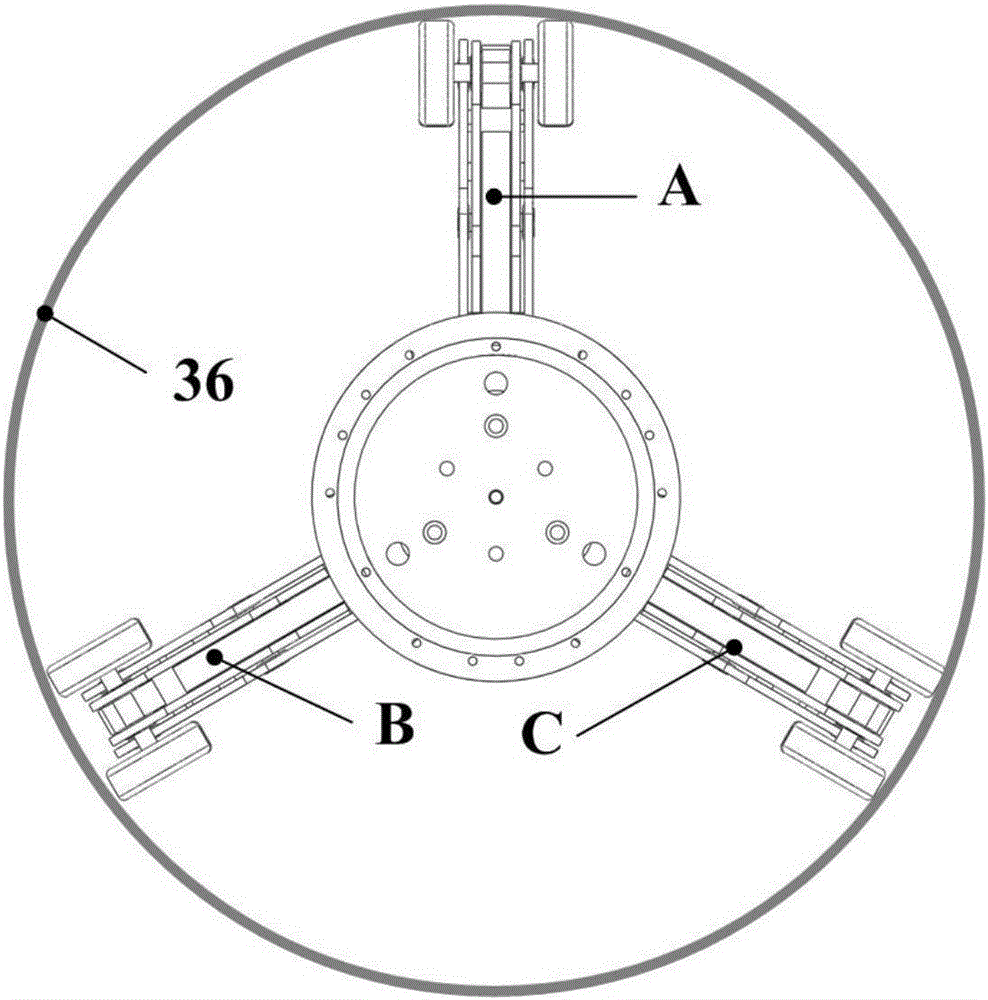

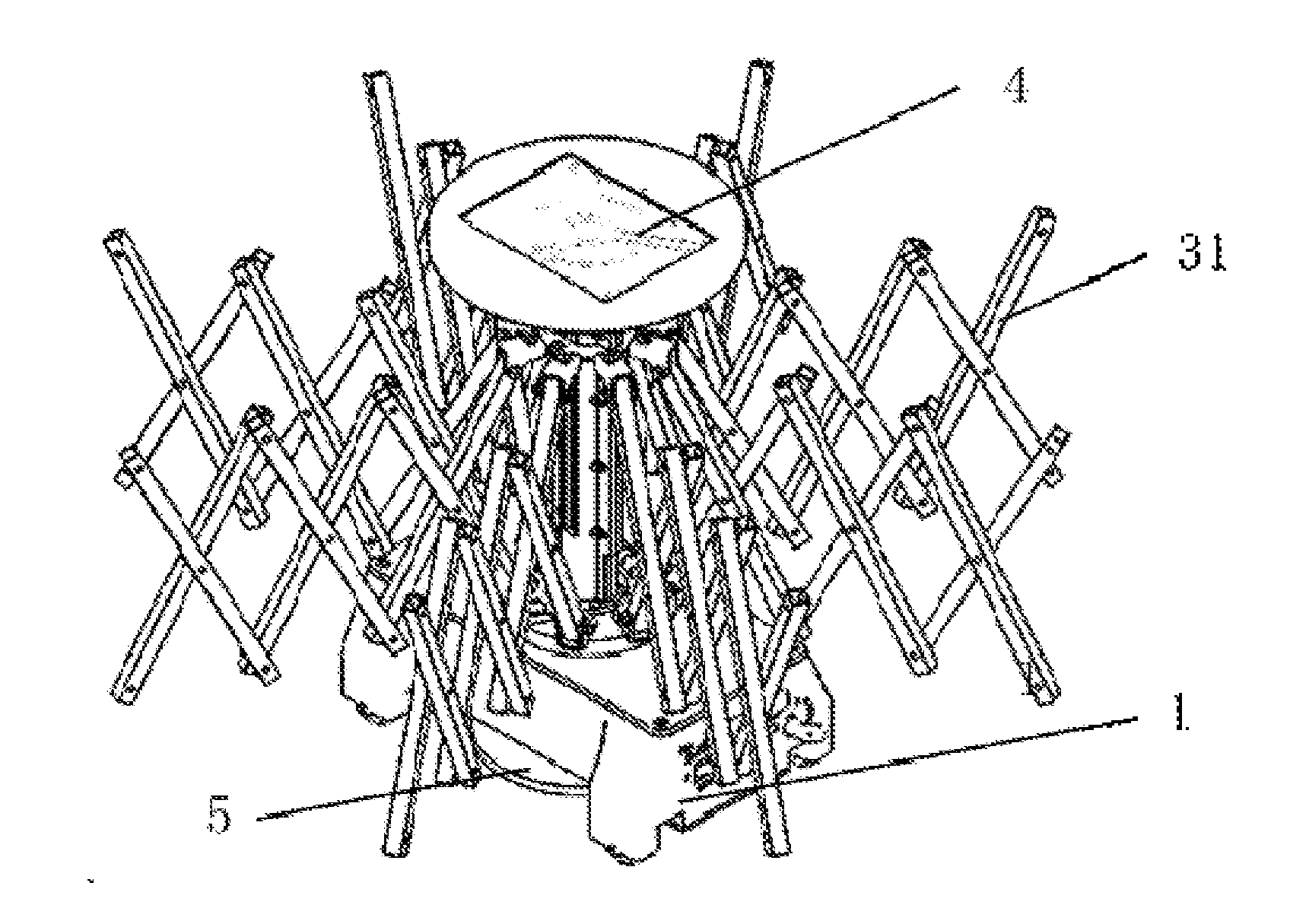

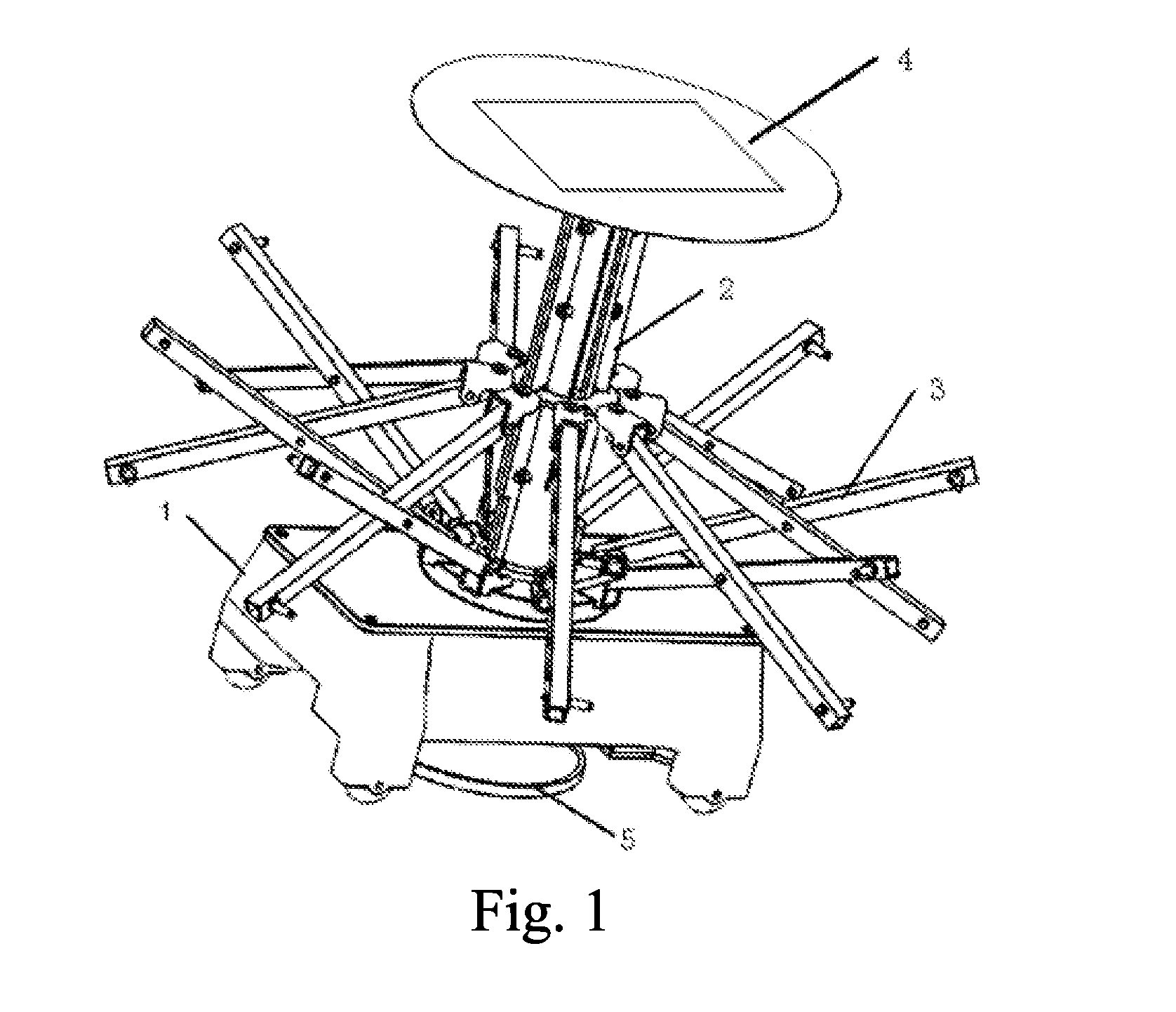

Portable type large-variable-diameter all-wheel-drive type pipeline robot

The invention provides a portable type large-variable-diameter all-wheel-drive type pipeline robot which comprises a front end plate, a rear end plate, a front rocker arm, a rear rocker arm, a scissor-type reducing mechanism and a positioning all-wheel-drive mechanism, wherein the positioning all-wheel-drive mechanism is arranged on the front end plate; the scissor-type reducing mechanism is arranged on the rear end plate; one end of the front rocker arm is hinged with the front end plate; the rear rocker arm is hinged with the rear end plate; the front rocker arm is hinged with the rear rocker arm to form a shears-fork structure; the scissor-type reducing mechanism is connected with the positioning all-wheel-drive mechanism; and the scissor-type reducing mechanism can slide relative to the positioning all-wheel-drive mechanism to drive the front rocker arm and the rear rocker arm to form shears-fork motion. According to the portable type large-variable-diameter all-wheel-drive type pipeline robot provided by the invention, when the reducing motor rotates, a nut pulls the front end plate to get close to a guide post or get away from the guide post, and scissor-type rocker arms which are synchronously fixedly arranged on the front end plate and the rear end plate open and close, so that a supporting radius of the robot is changed.

Owner:SHANGHAI SUJIE ROBOT TECH

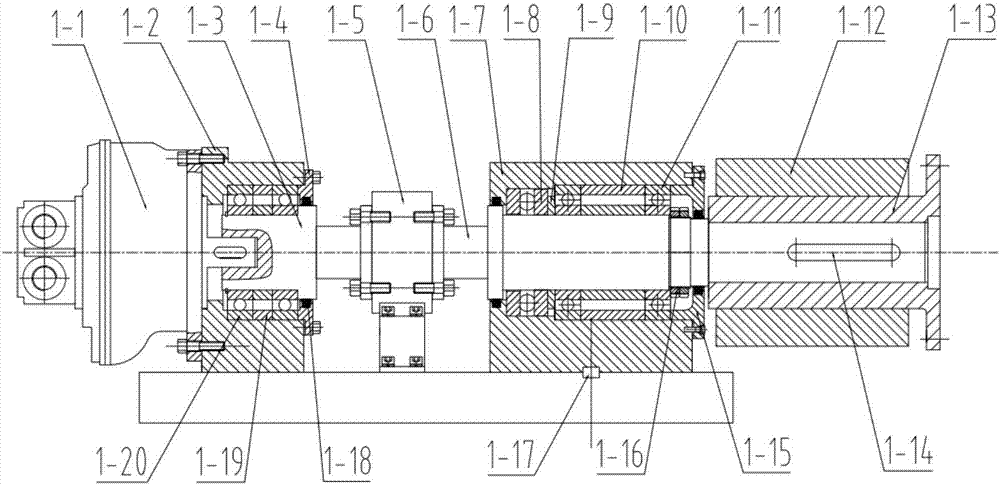

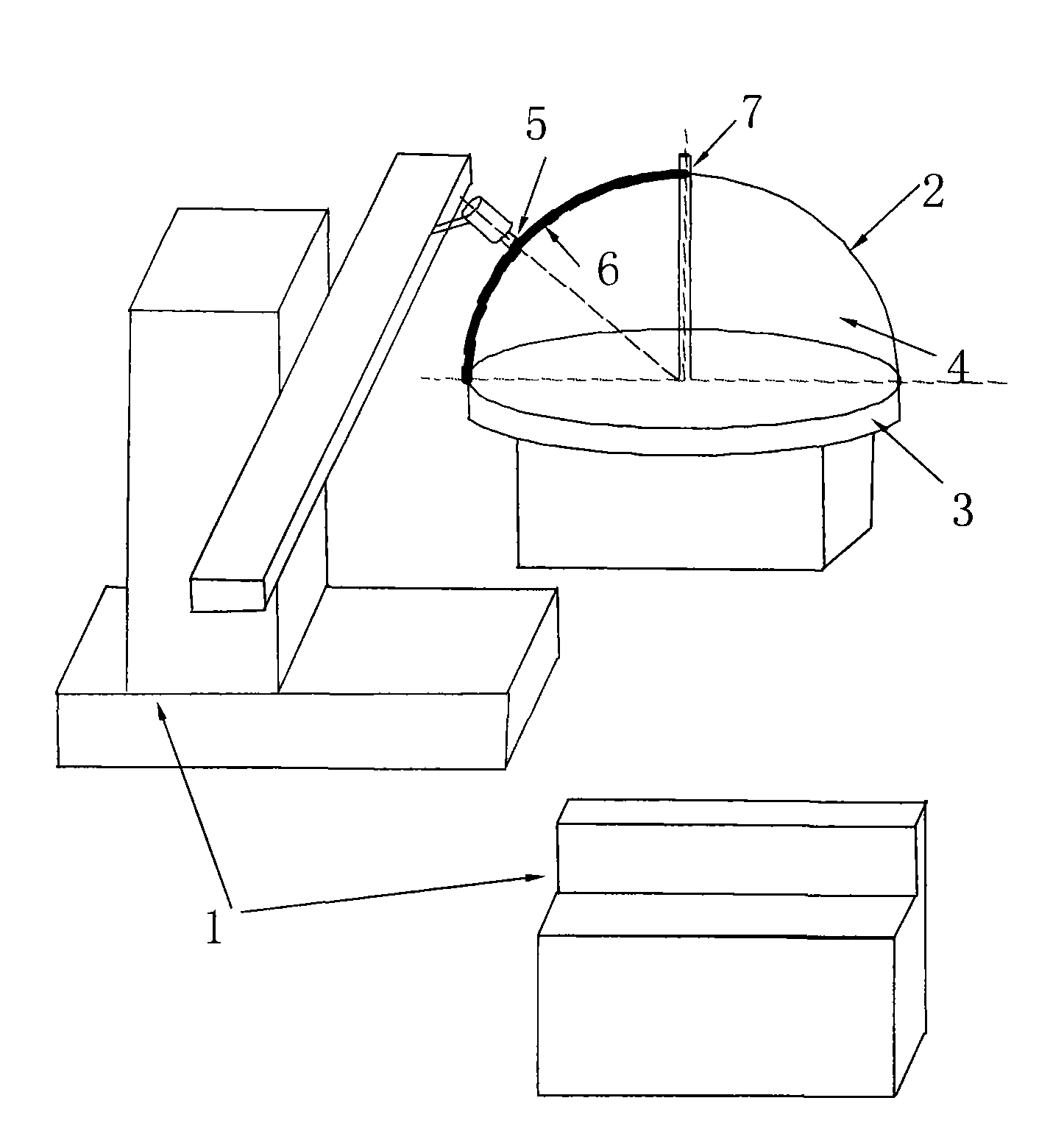

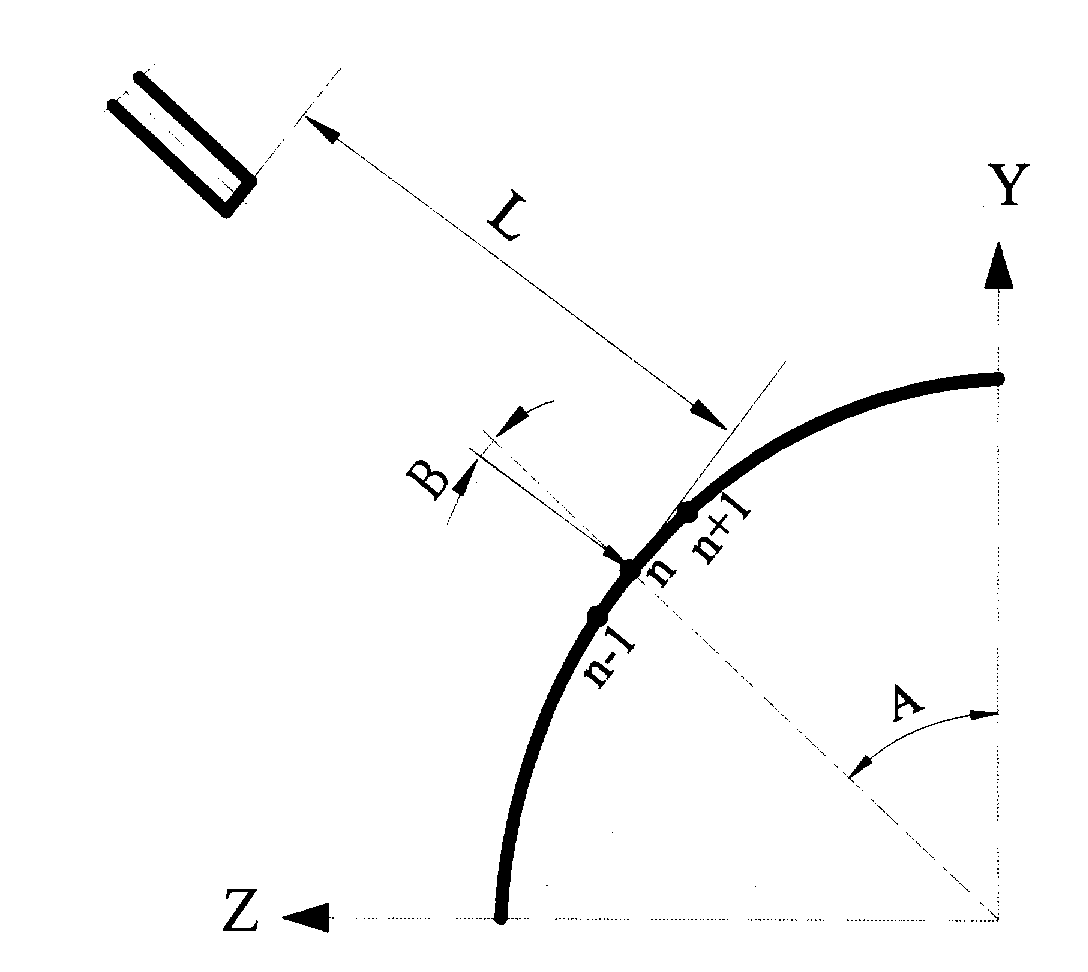

Numerical control stirring friction welding system and welding method thereof

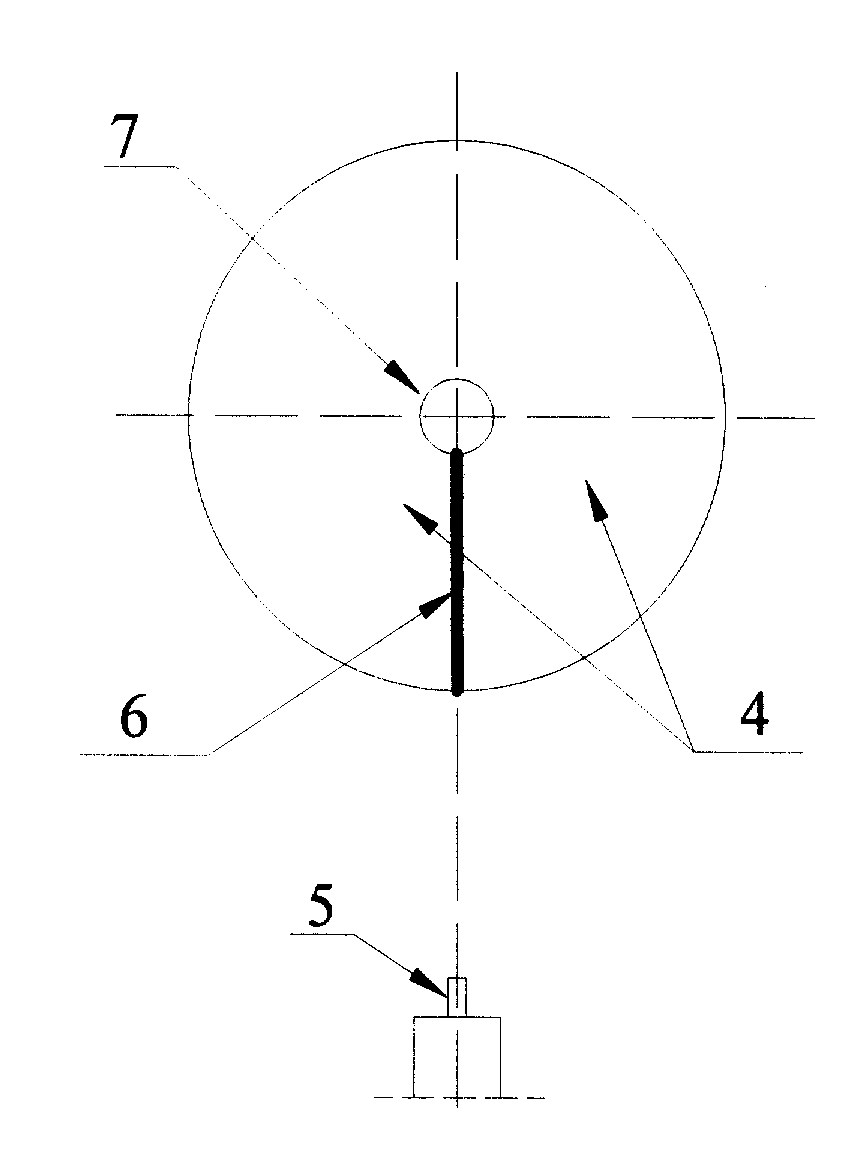

InactiveCN101612689AImprove welding precisionEasy to centerNumerical controlNon-electric welding apparatusEngineeringFriction stir welding

The invention discloses a numerical control stirring friction welding system, which comprises a numerical control stirring friction welder [1] provided with control software, wherein a main shaft of the numerical control stirring friction welder [1] is provided with a stirring head [5]; a welding fixture [2] is arranged on a rotating platform [3]; the shaft center of the welding fixture is the same as that of a central shaft [7] of the rotating platform [3]; and a welding structure member [4] is arranged on the welding fixture [2]. The invention also discloses a welding method for the system, which comprises the following steps: 1, the compiling of numerical control programs; 2, system debugging; 3, assembly; 4, system centration; 5, the set of welding parameters; and 6, system zero restoring. The numerical control stirring friction welding system solves the problems of the welding of space curve welding seams and plane two-dimensional welding seams, and has the advantages of high welding precision, simple and convenient operation, and the like.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Combined pressure and temperature sensor

InactiveUS20070186659A1Improve temperature measurement accuracyEasy constructionMeasurement apparatus componentsFluid pressure measurementEngineeringPressure sensor

A combined pressure and temperature sensor for recording the pressure and the temperature of a medium. A sensor element of the combined pressure and temperature sensor includes a through-hole to a diaphragm and a bore for accommodating a temperature sensor. The diaphragm cooperates with a pressure sensor. At an end face of the sensor element, on the side of the medium, a cover is fastened, in which a hollow space is developed to accommodate the temperature sensor.

Owner:ROBERT BOSCH GMBH

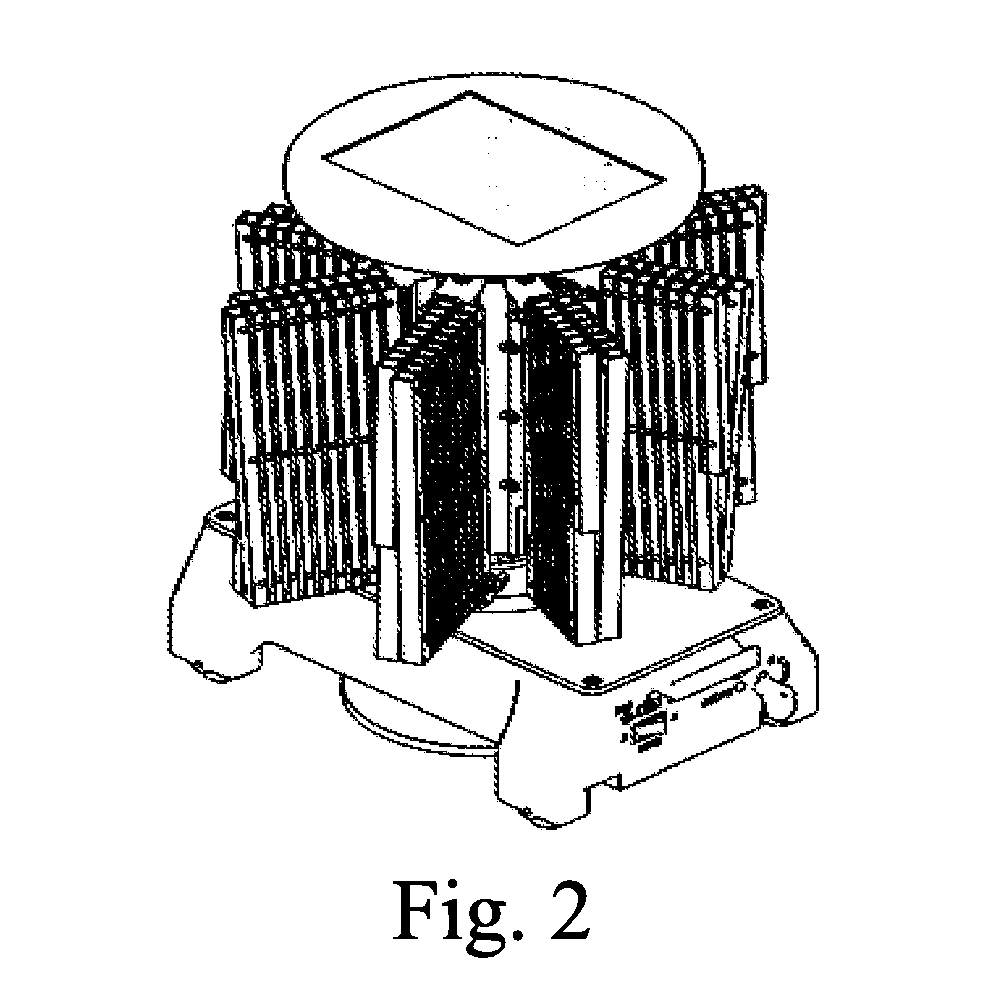

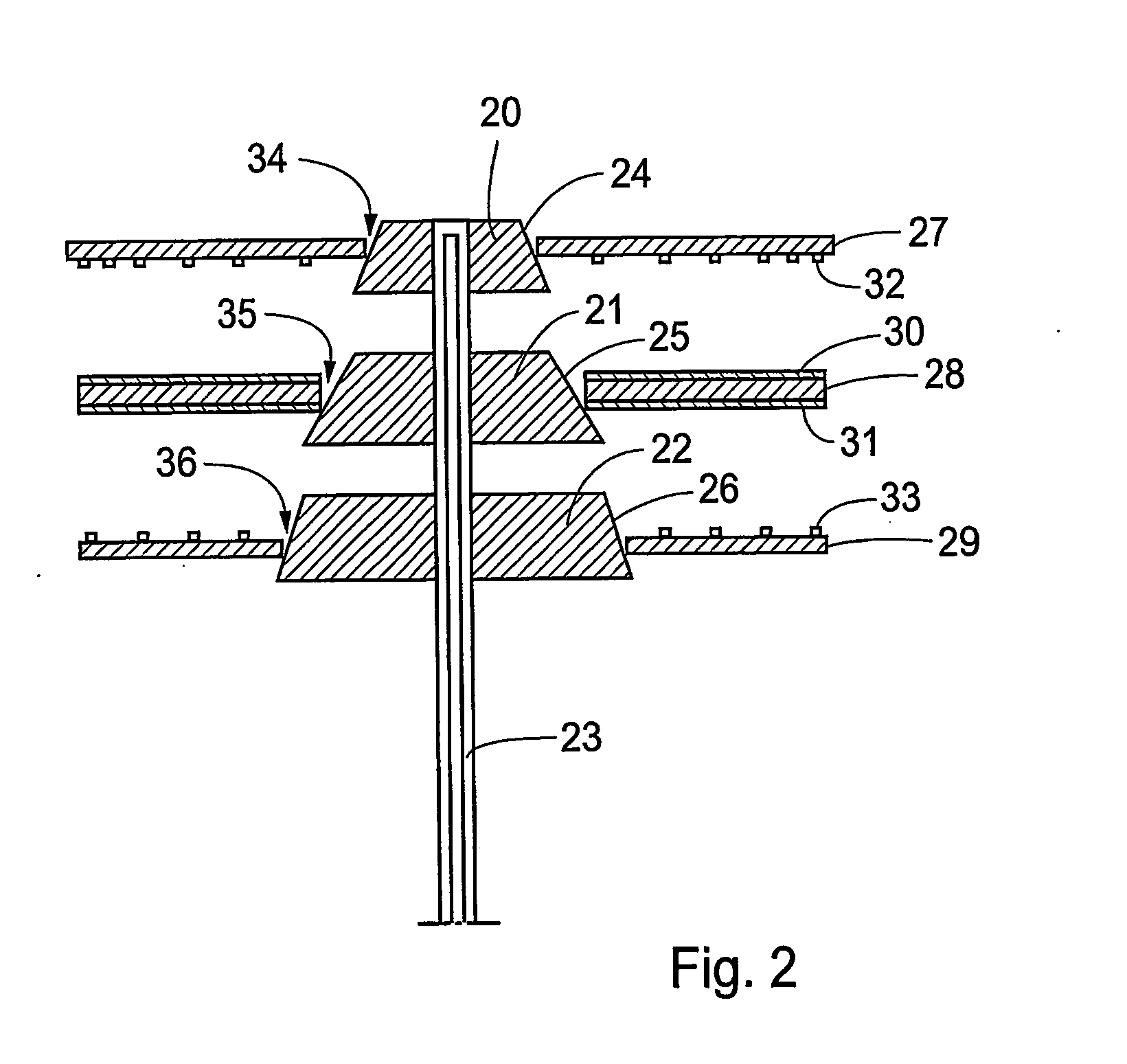

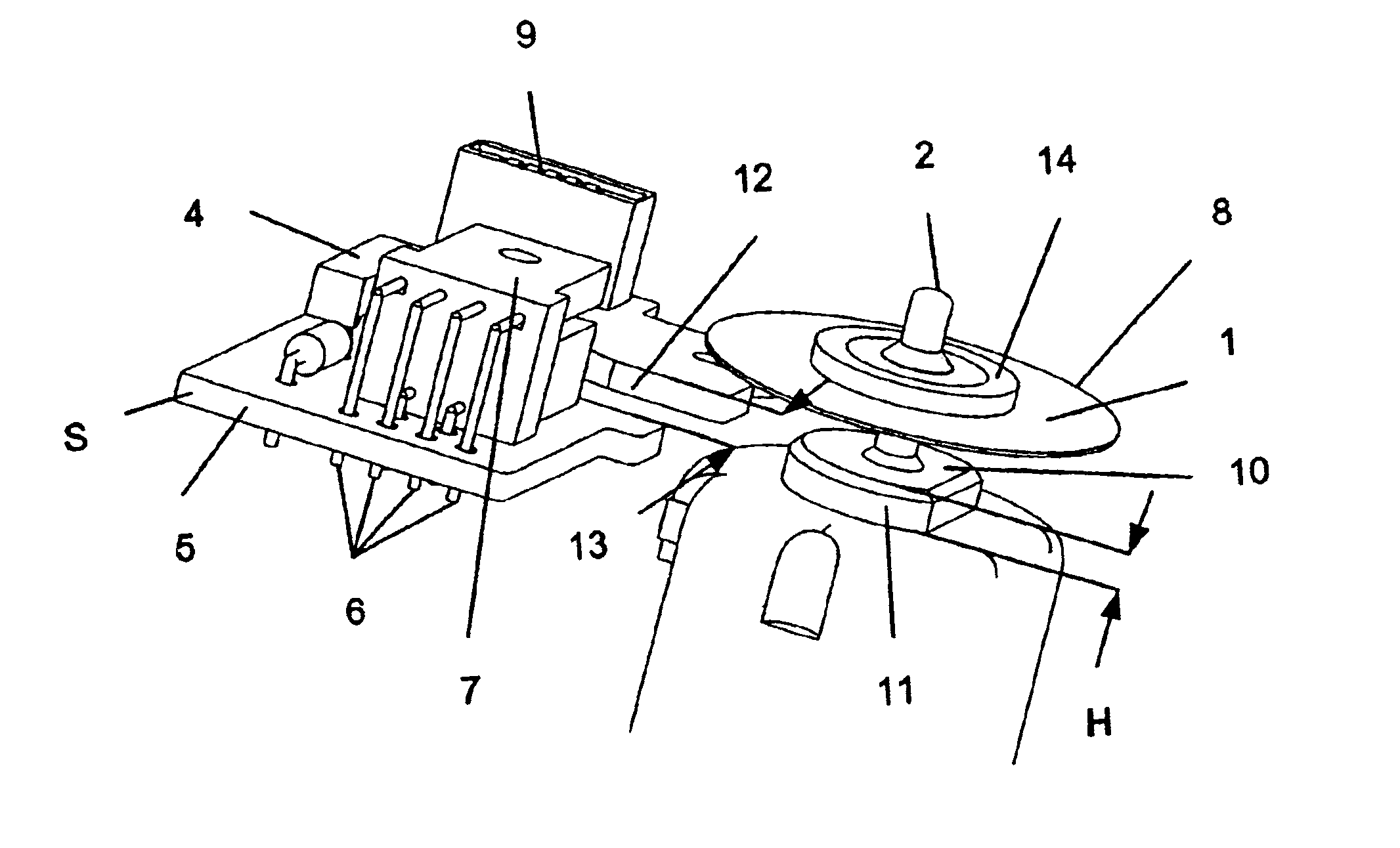

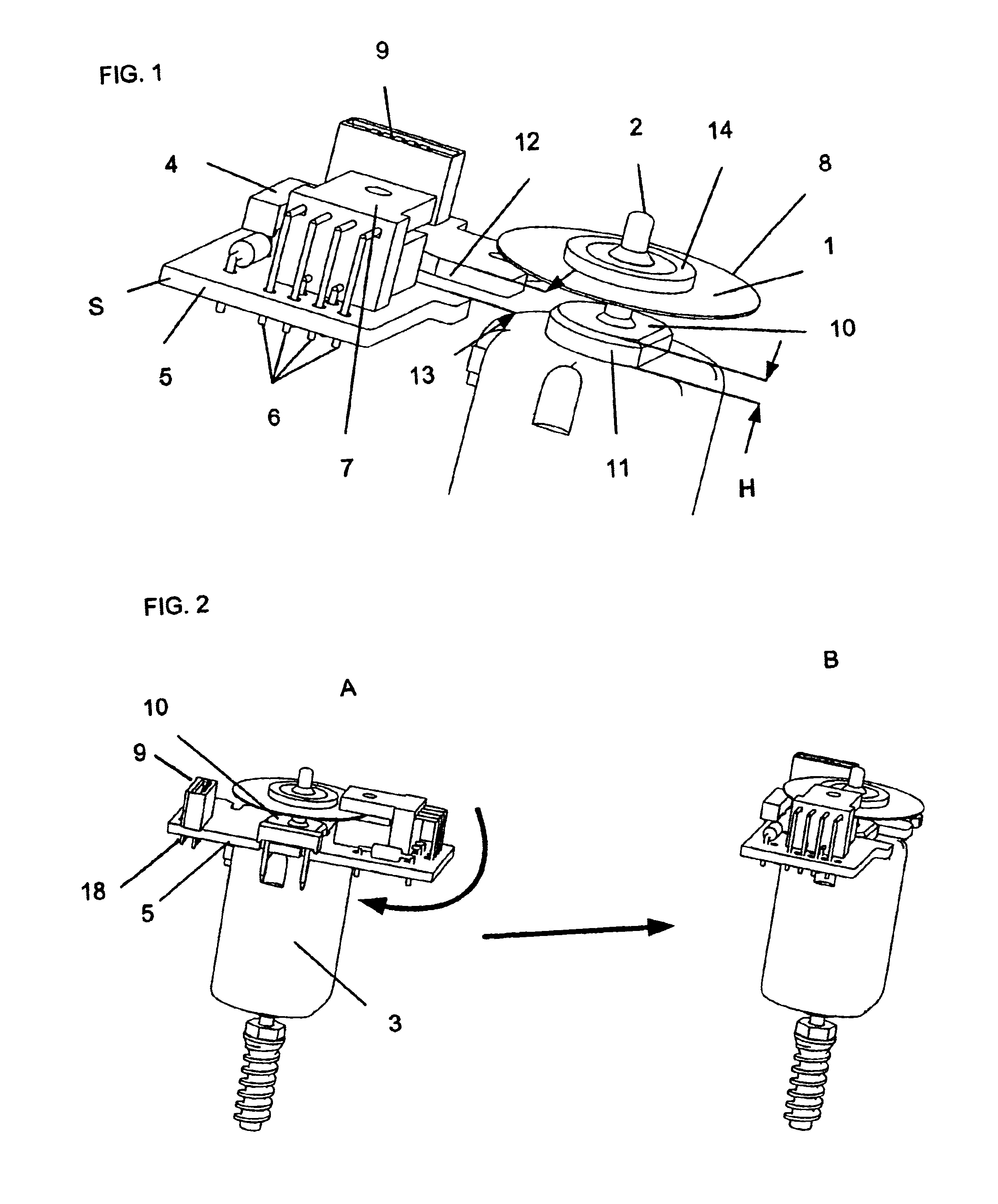

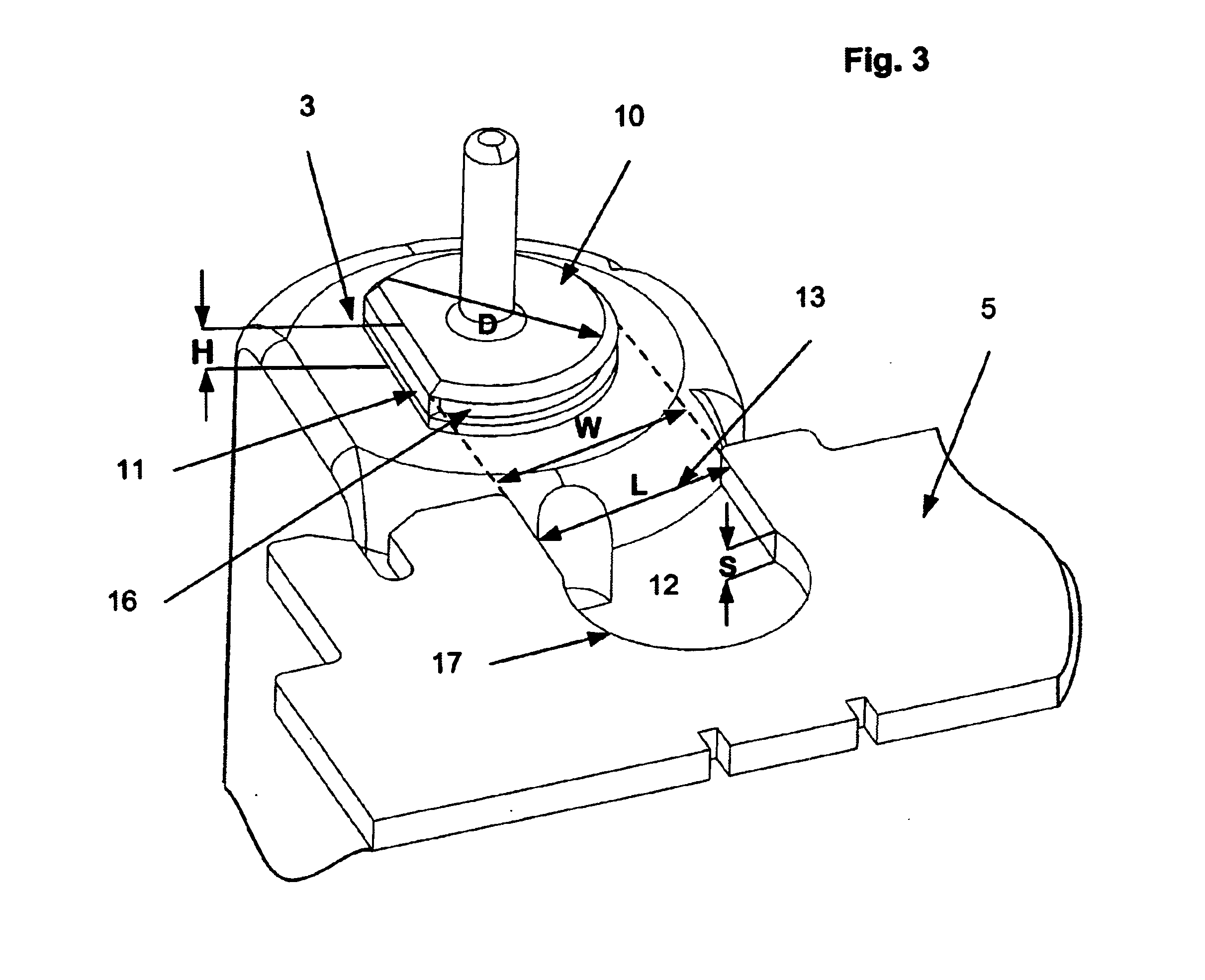

Multi-functional Sunshade

A multi-functional sunshade is provided, including housing (1), raising and lowering mechanism (2) and folding mechanism (3), in which raising and lowering mechanism (2) connects to housing (1), and raising and lowering mechanism (2) drives folding mechanism (3) for spreading and drawing in. Housing (1) comprises housing body (11), motor. Raising and lowering mechanism (2) comprises: raising and lowering rod (21), raising and lowering platform (22) and raising and lowering seat (23), in which: motor set up in housing body (11) drives raising and lowering platform (22) to move along the axial direction of raising and lowering rod (21), which is installed in housing body (11) via raising and lowering seat (23). In case of equipment failure, it can draw in the sunshade cloth through an emergency mechanism and uses a plug-in buckle to increase the assembly efficiency substantially. It has a broad market prospect.

Owner:H&J GRP L L C

Method for transferring a pattern

InactiveUS20050167847A1Less complicatedEasy to manufactureRecord carriersPlaten pressesMechanical engineeringEngineering

Owner:OBDUCAT AB SE

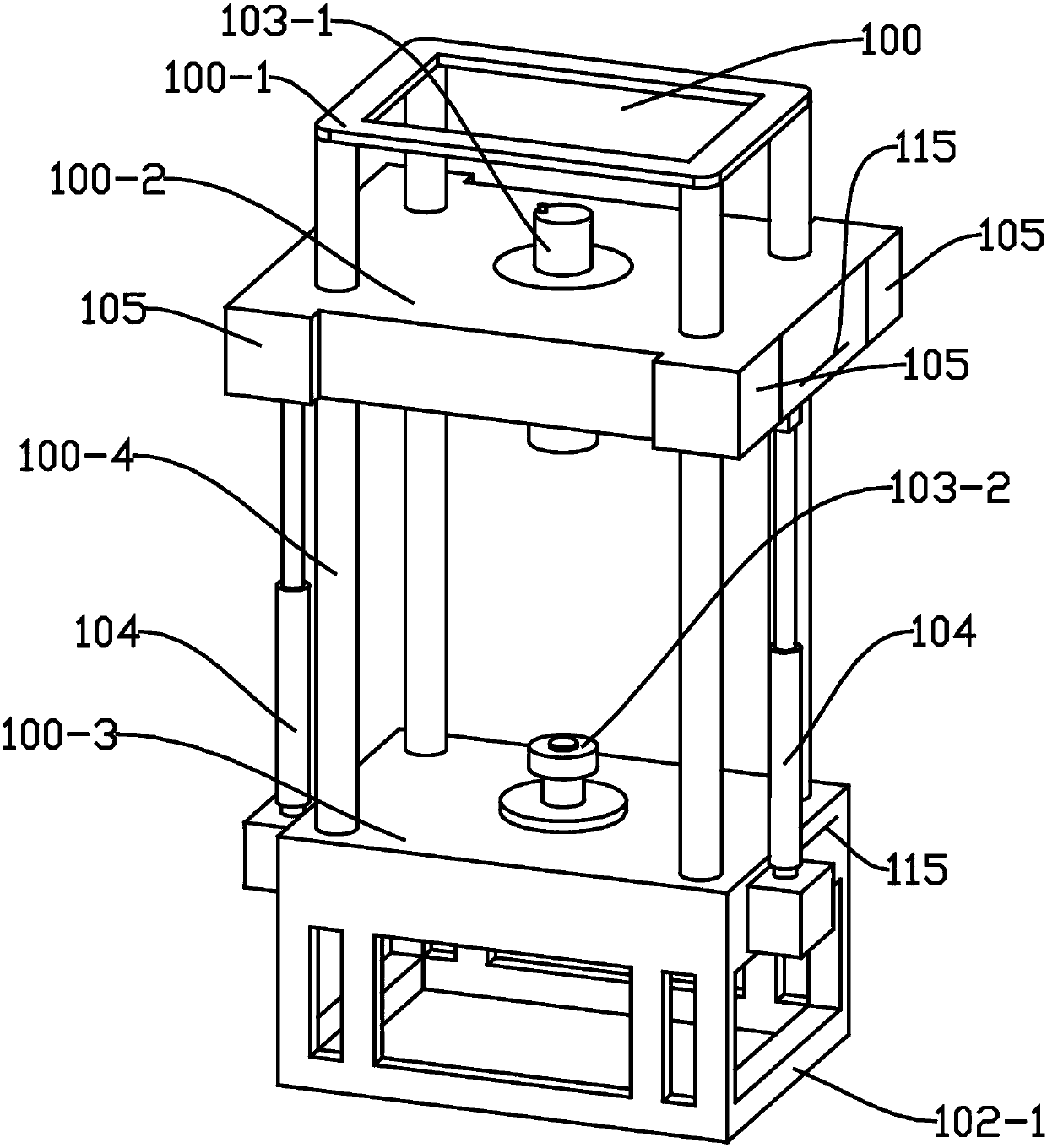

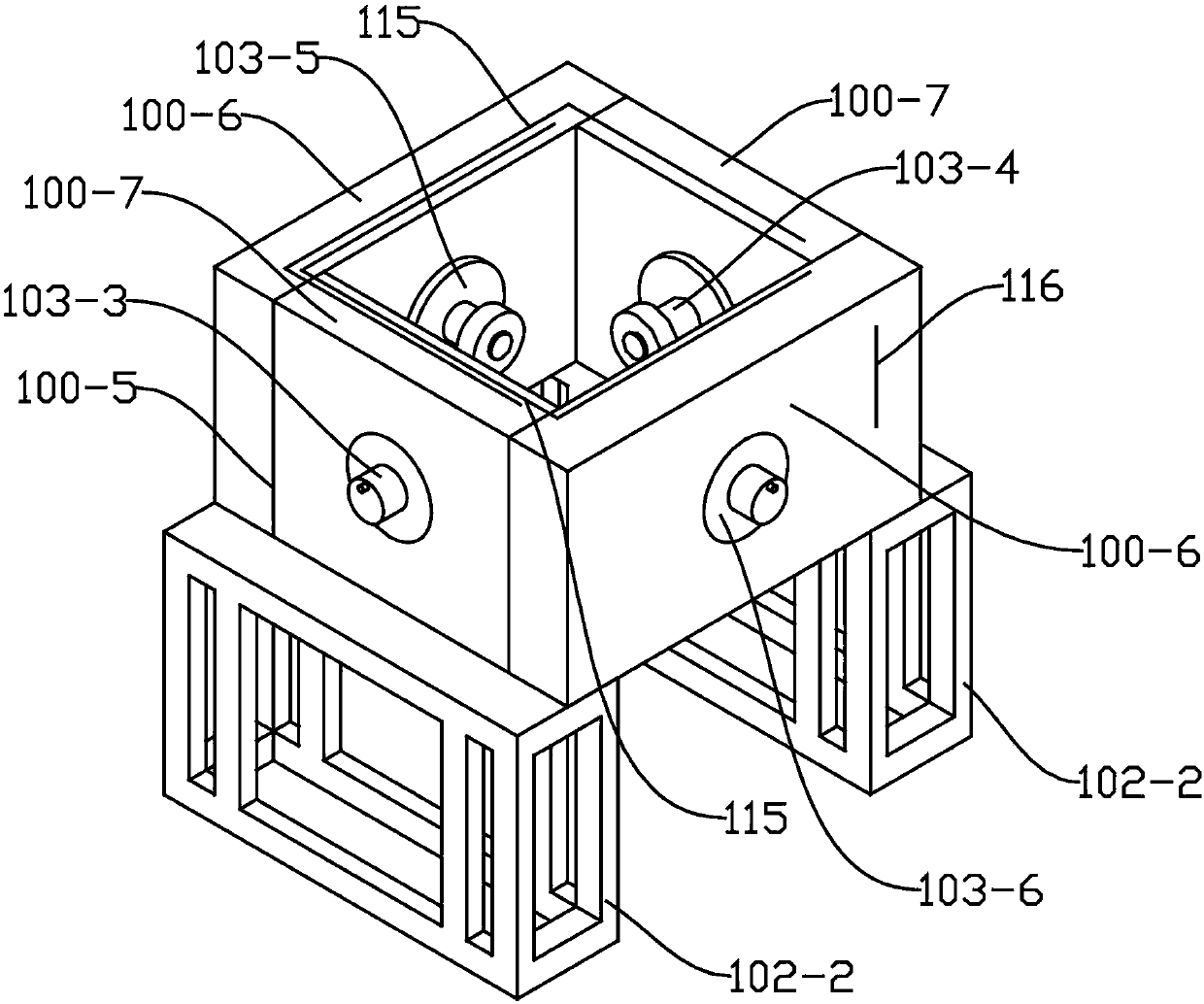

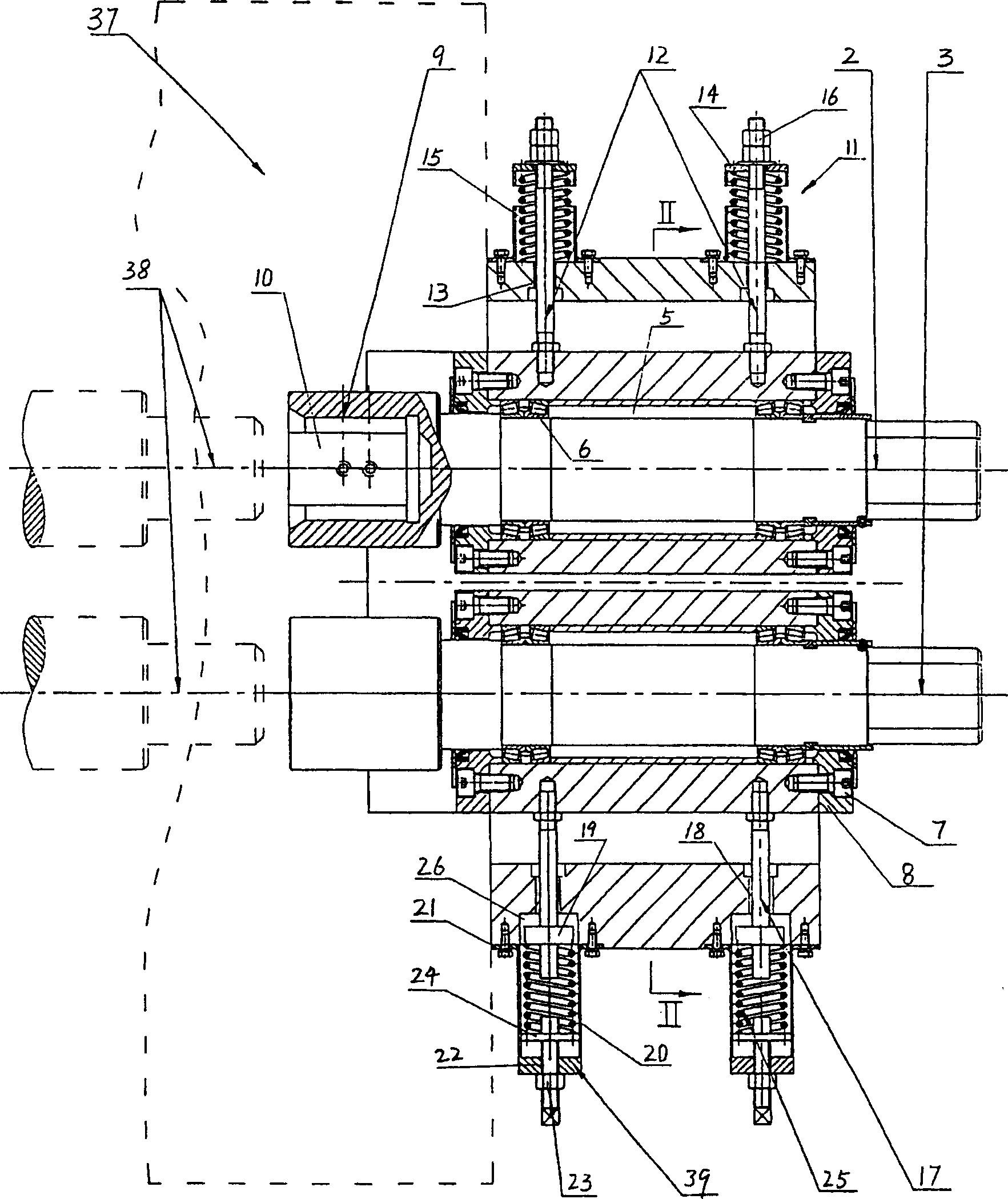

Triaxial test machine and testing system

PendingCN107941615AAccurate Mechanical Properties ParametersAccurateMaterial strength using tensile/compressive forcesTriaxial shear testVertical alignment

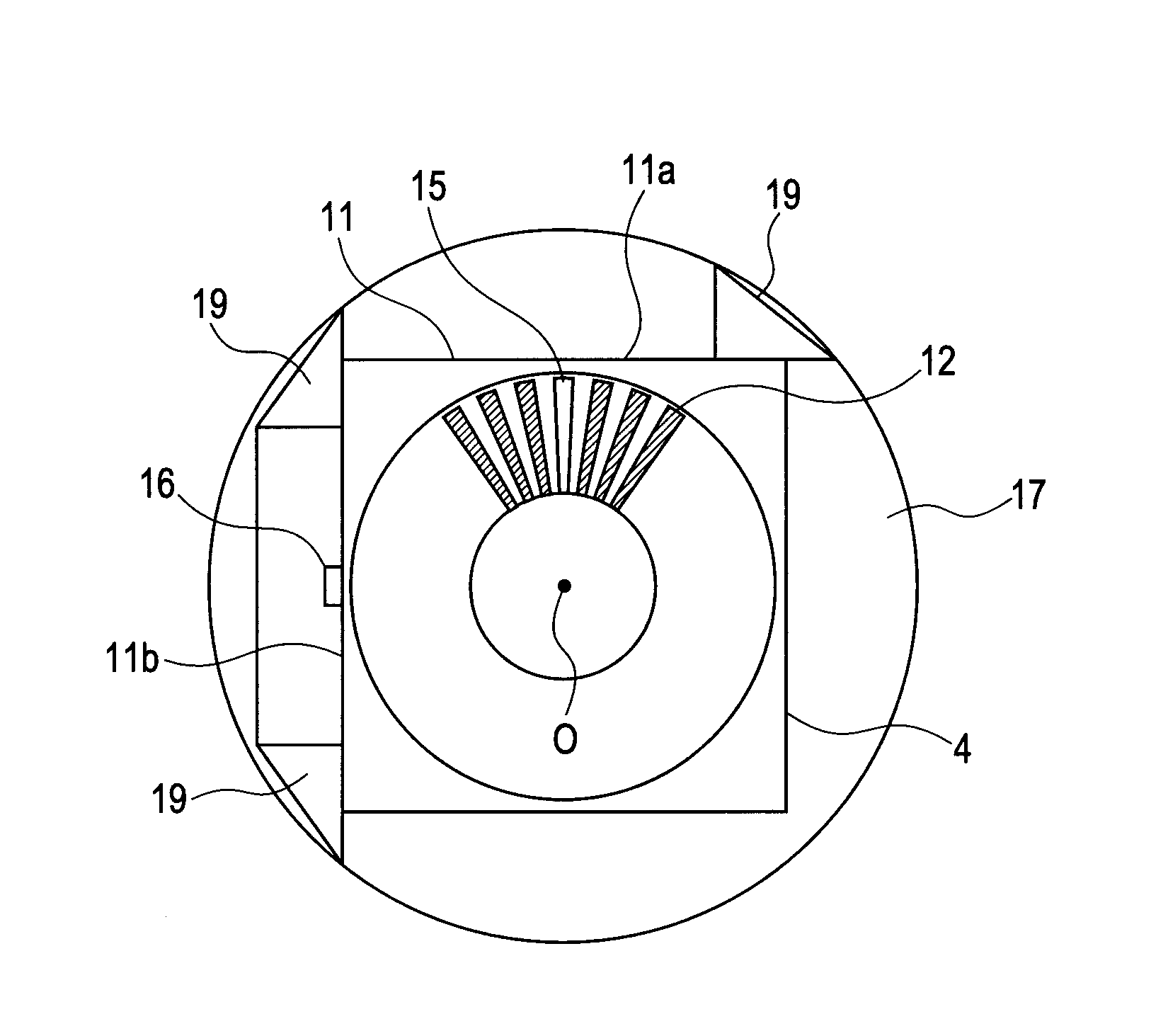

The invention relates to a triaxial testing machine and a testing system. The triaxial testing machine comprises a loading frame, a specimen box, a base, six actuators, a lifting oil cylinder and a locking oil cylinder, wherein the axes of the six actuators intersect at a point O. The actuators are used to provide six loads perpendicular to the six surfaces of a test piece to the test piece in a test piece box, so that three directions perpendicular to the surfaces of the test piece have independent load / unload capability; the test piece box is used to install and position the test piece, so that the geometric center 0'' of the test piece coincides with the geometric center 0' of the test piece box, and the geometric center O' of the test piece box coincides with the point O, and any faceof the test piece is perpendicular to the axis of any actuator. The triaxial testing machine and the testing system can conveniently and quickly complete the centering process of the test piece, the three-direction six-surface loading of the test piece can be performed, true triaxial tests can be completed, and in the three-direction six-surface loading process, one-direction sudden unloading canalso be achieved to complete rock burst tests.

Owner:SICHUAN DEXIANG KECHUANG INSTR

Oral orthosis

ActiveUS20110162658A1Excess materialPrecise fitImpression capsTeeth fillingEngineeringCompressible material

An oral orthosis includes a holder in the shape of a mouthpiece, including a curved arcuate trough-like upper section which receives a formable material. The formable material does not occupy the entire trough but rather includes voids between the formable material and the inner surfaces of trough of the holder to allow expansion of the formable material into the voids during the molding process when tooth pressure is placed on the formable material. This design results in elimination of the excess formable material which otherwise would require removal by trimming. Additionally, the formable material is placed in the trough in a configuration which includes indexing indentations along the centerline of the material, such that, during the molding process, the mouthpiece containing the formable material is easily centered along the edges of the user's teeth to provide a precise fitting.

Owner:RANIR LLC

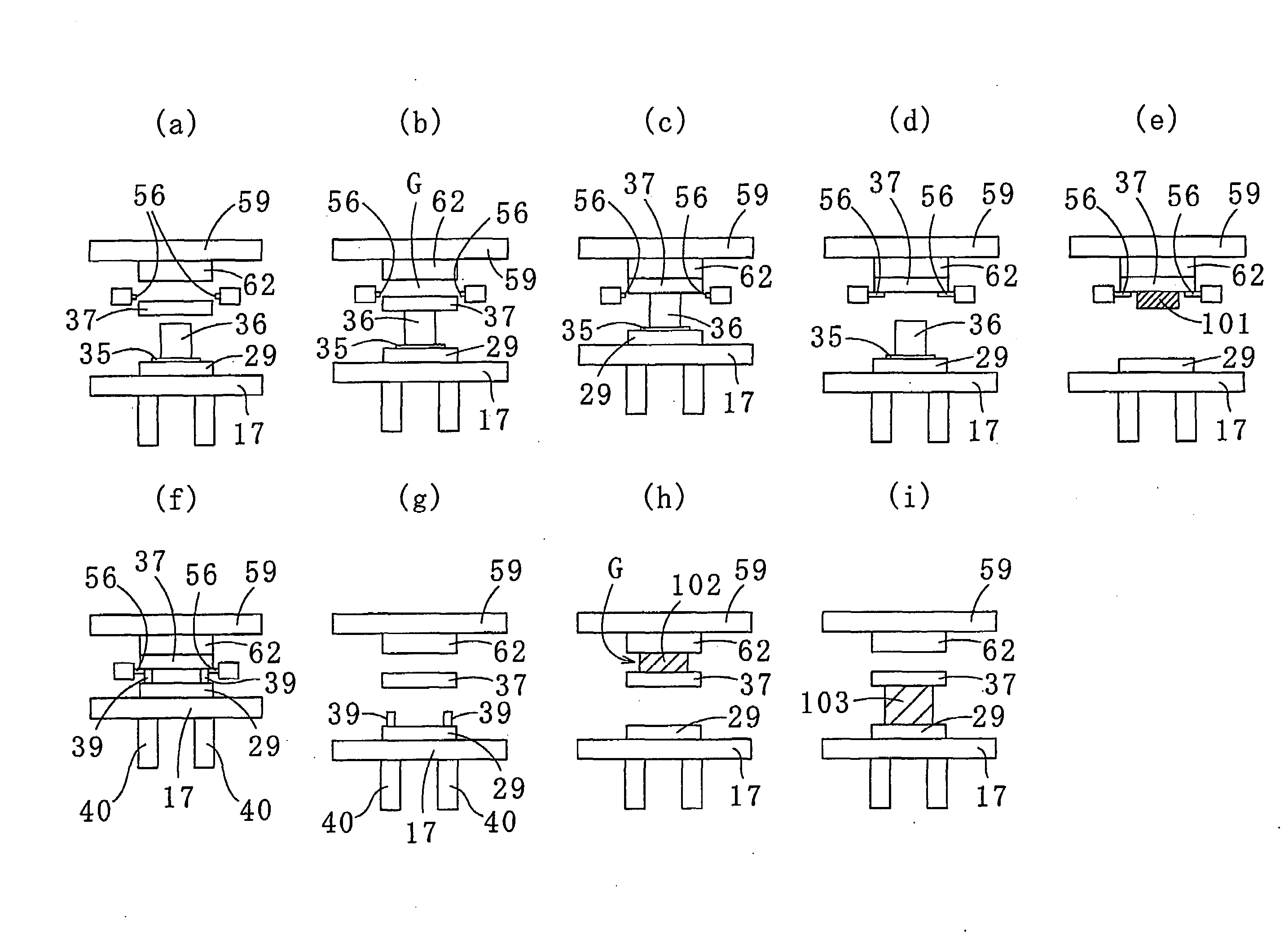

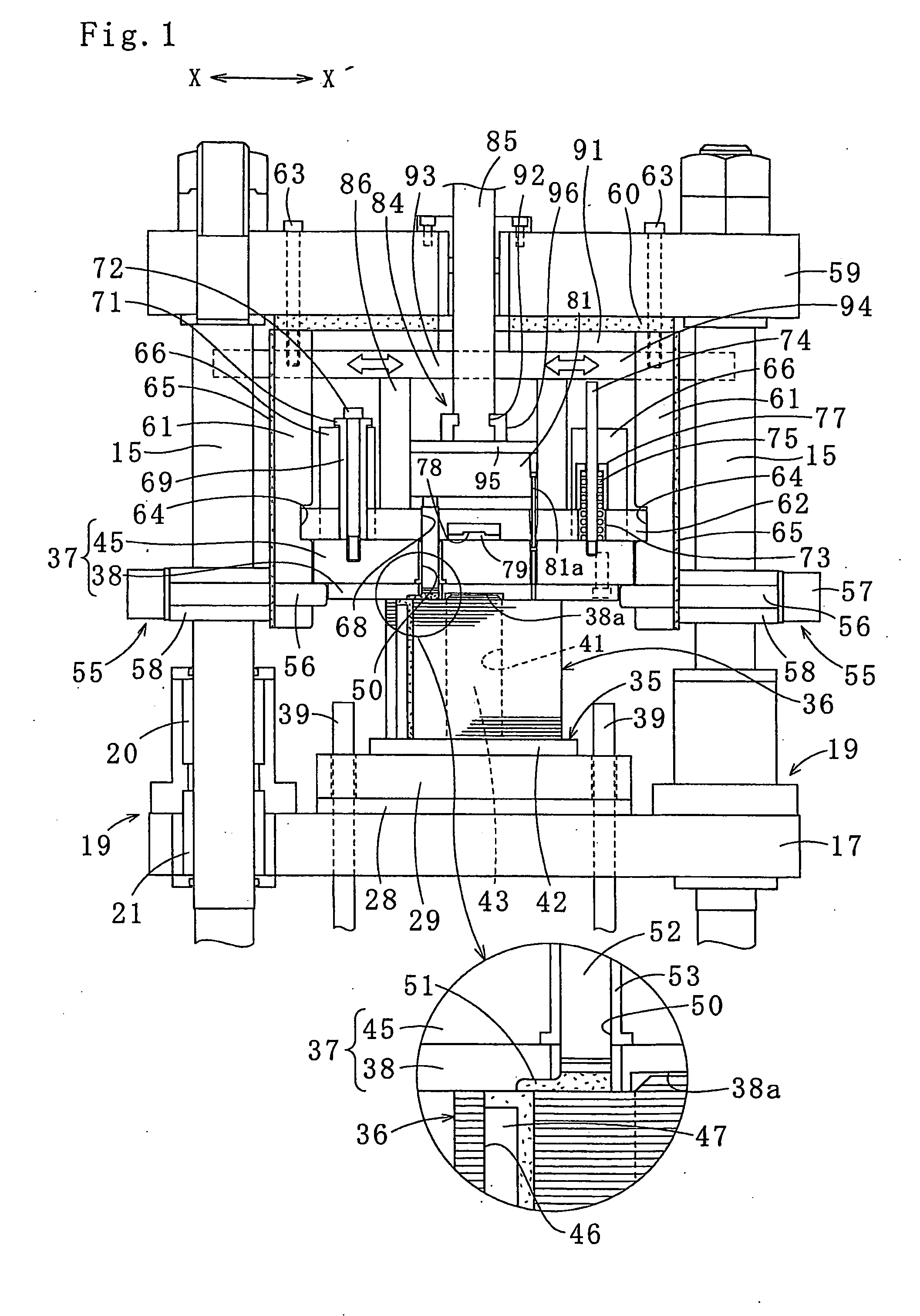

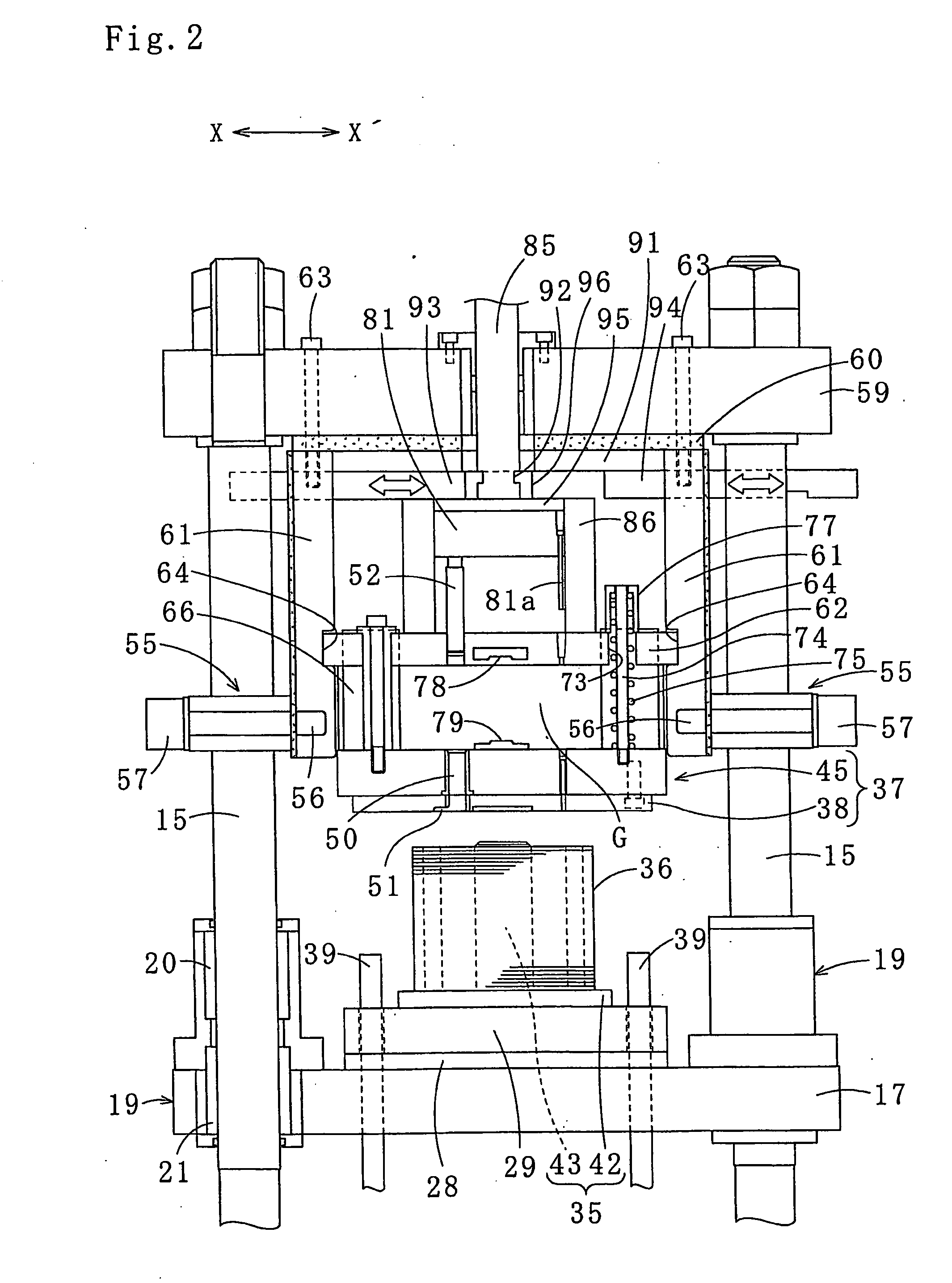

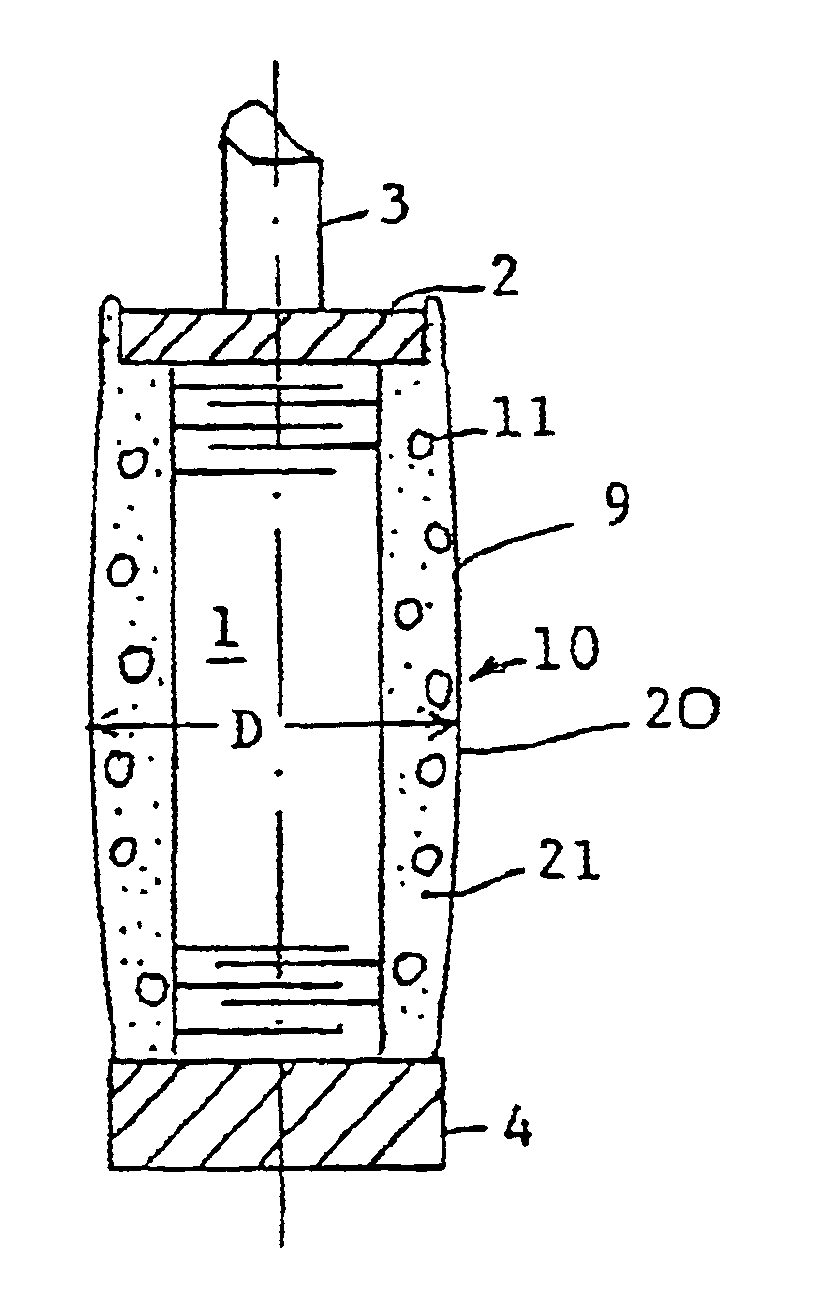

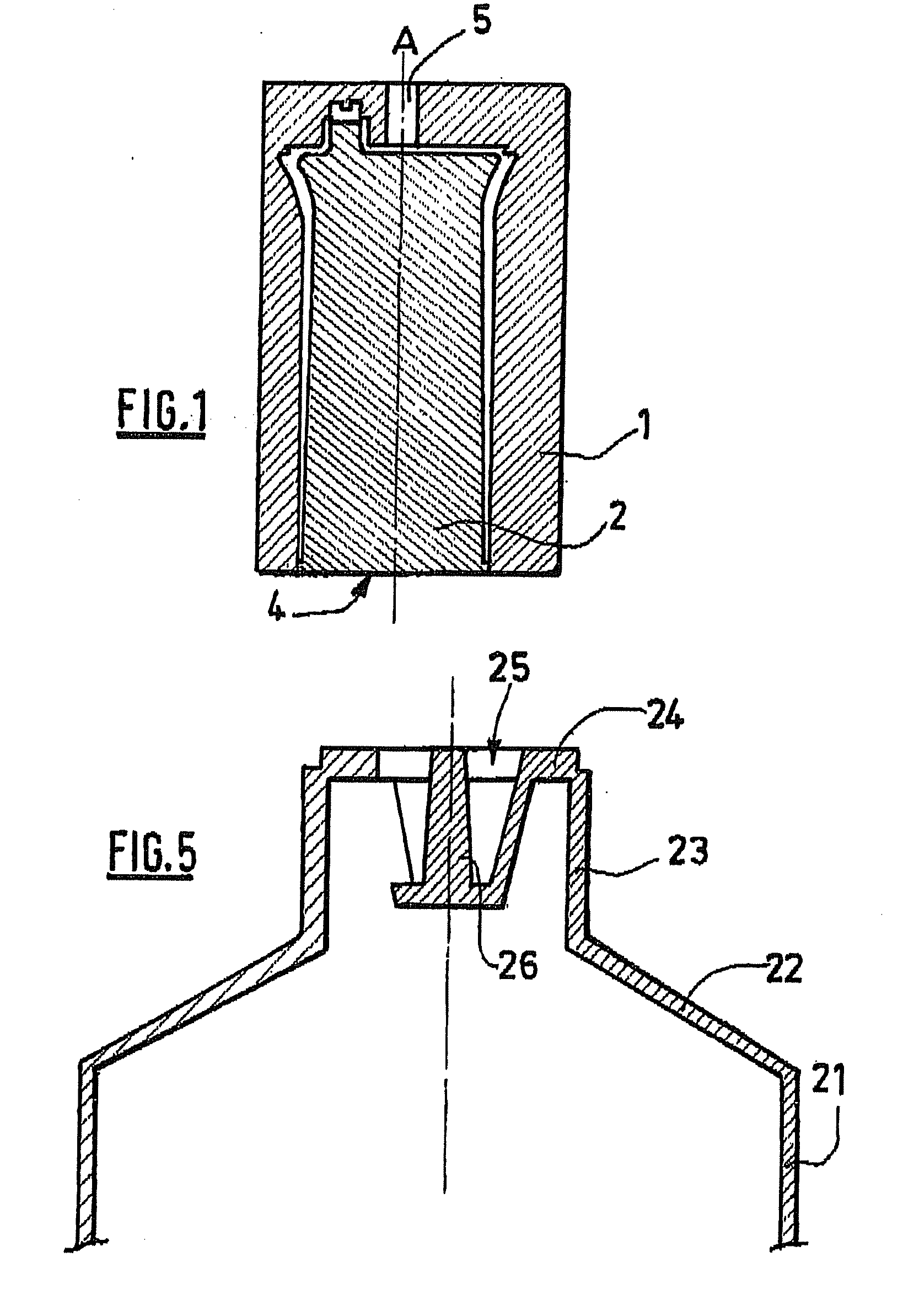

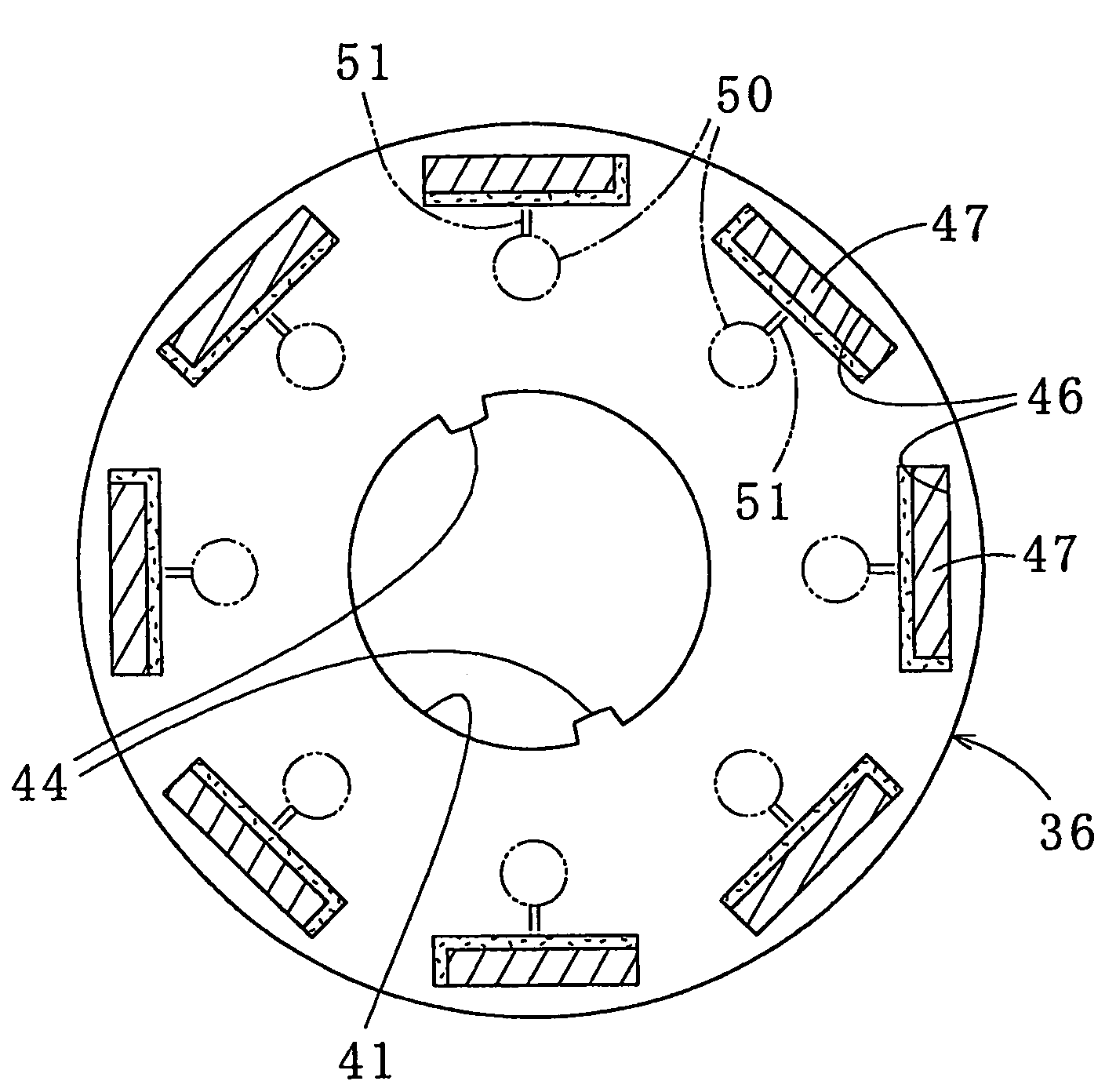

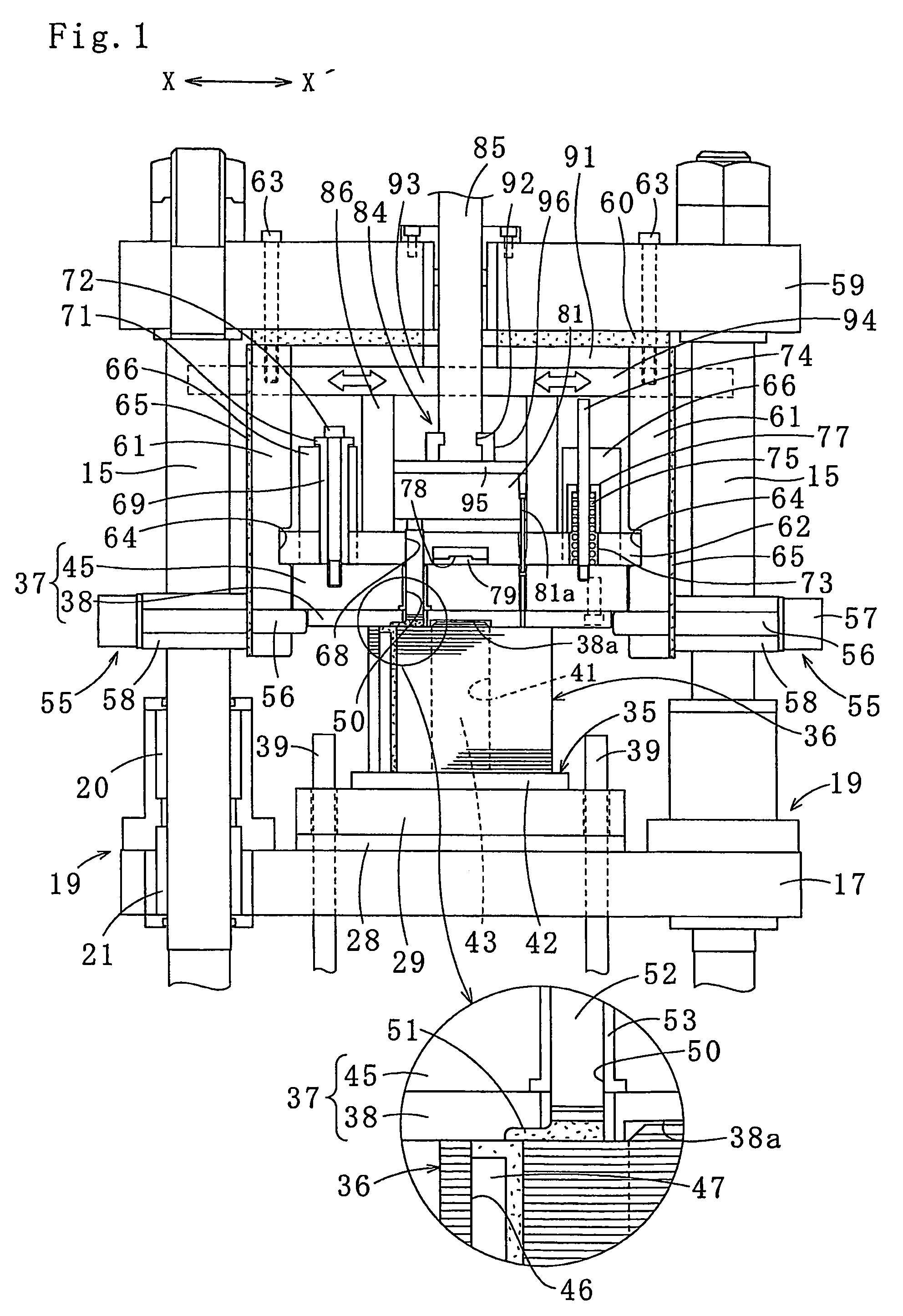

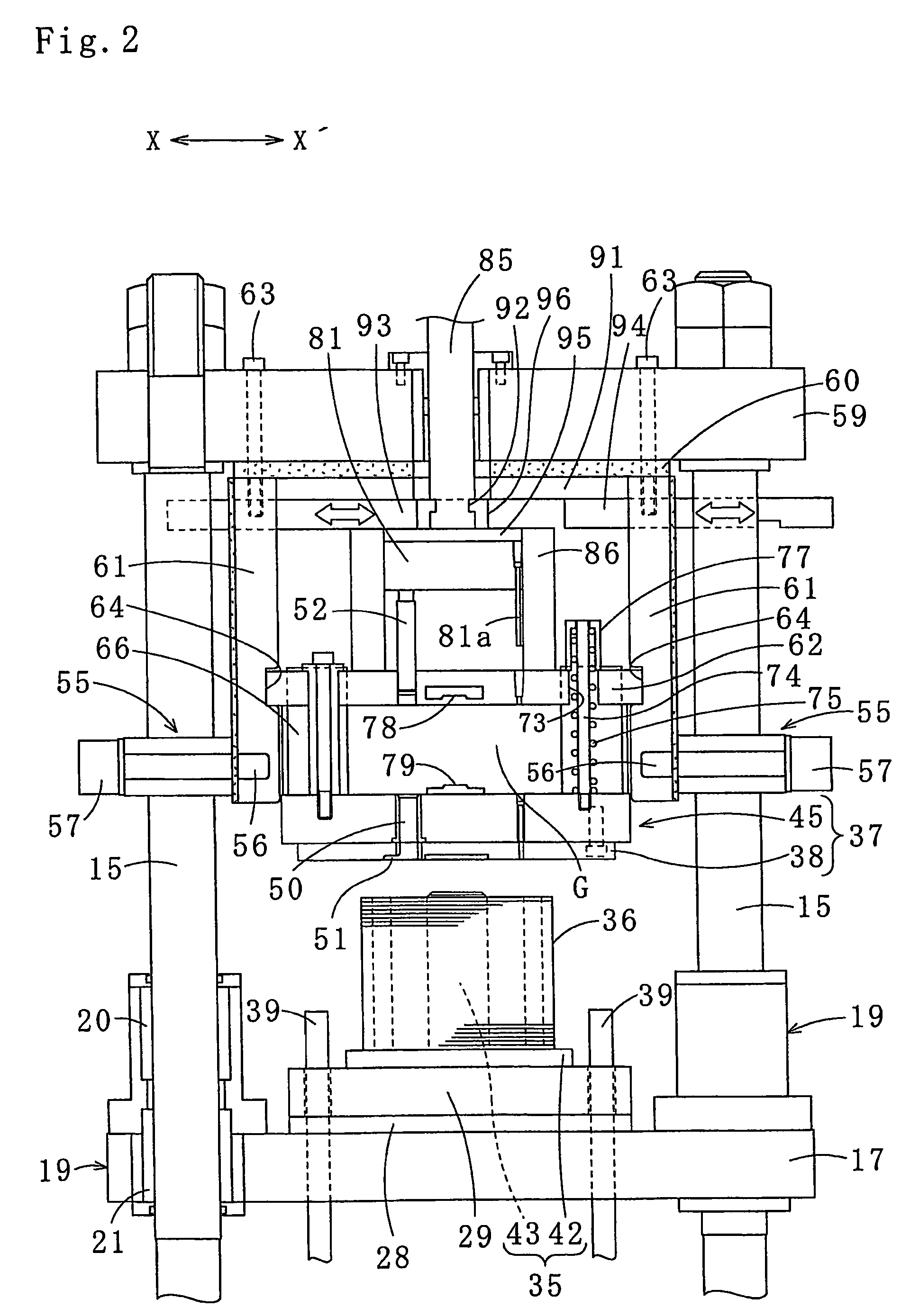

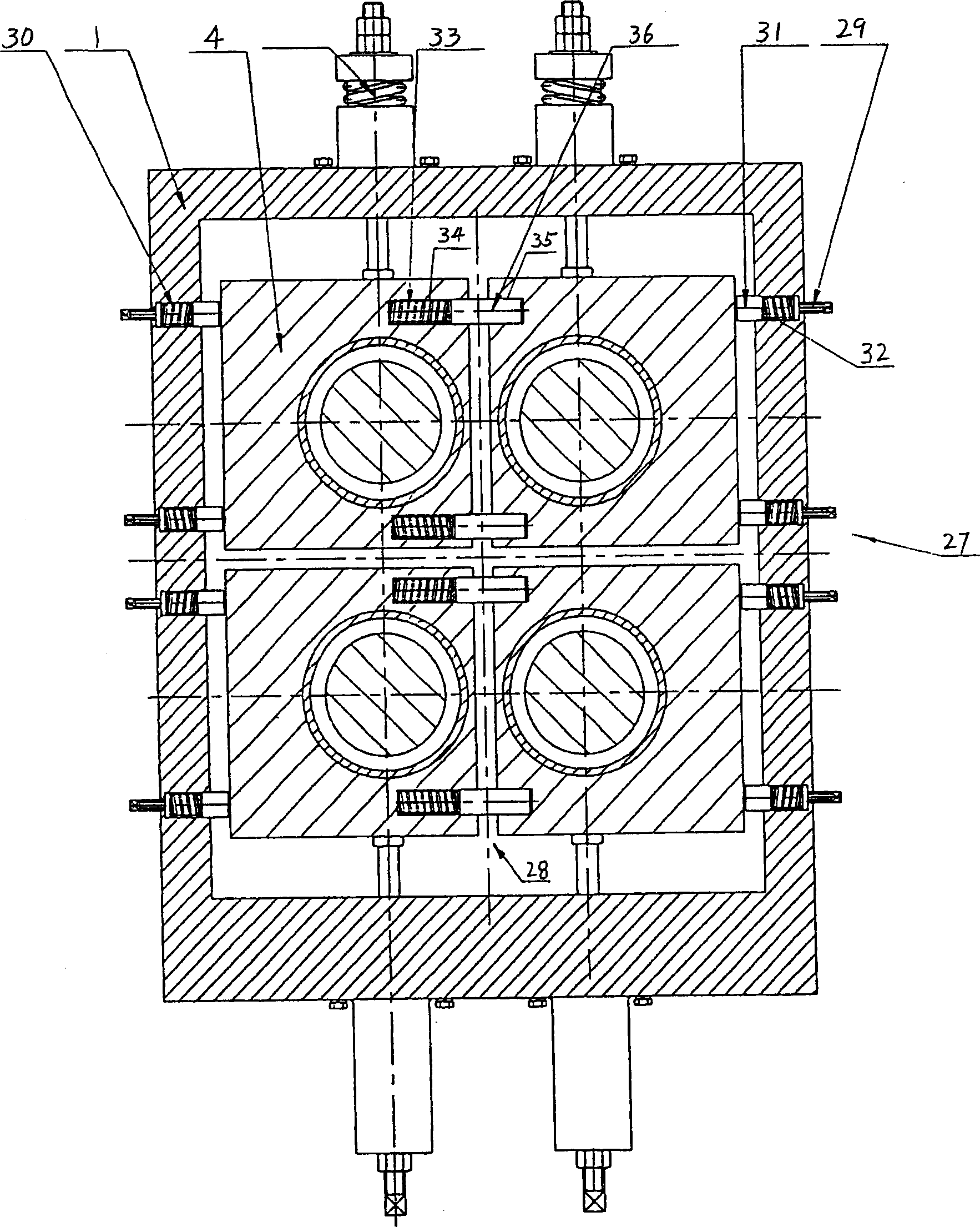

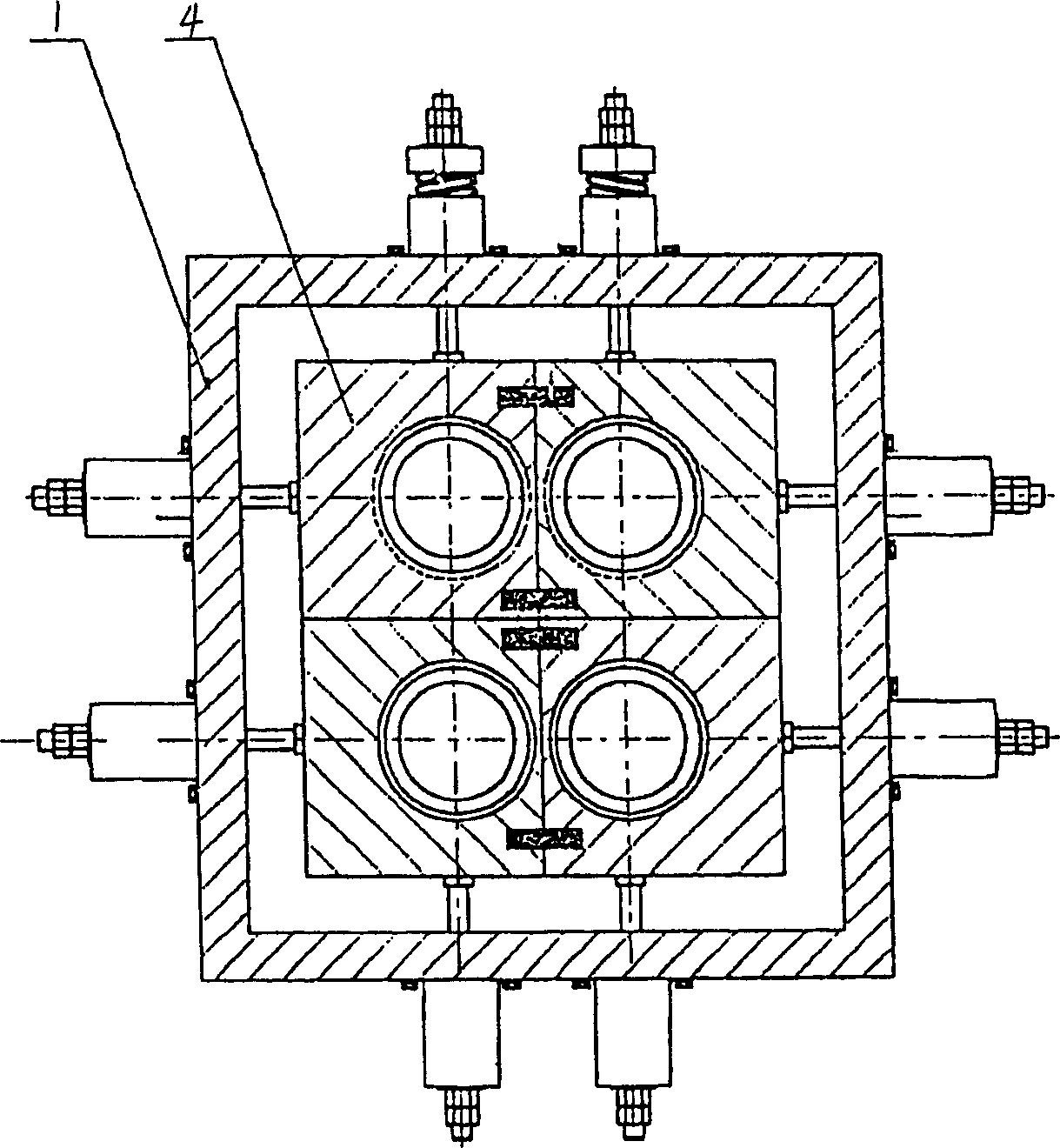

Method of resin sealing permanent magnets in laminated rotor core

ActiveUS7897089B2Easy to cleanEasy to disassembleMagnetic circuitManufacturing stator/rotor bodiesEngineeringPlunger

A laminated rotor core (36) wherein permanent magnets (47) are inserted in respective magnet insertion holes (46) is disposed between and pressed by an upper die (37) and a lower die (29). The upper die (37) has resin reservoir pots (50) provided above the laminated rotor core (36) and at positions corresponding to the respective magnet insertion holes (46). Raw resin material put in the resin reservoir pots (50) is heated by the upper die (37). Subsequently, the resin material in a liquefied state is ejected from the resin reservoir pots (50) by plungers (52) that are inserted and moves vertically in the resin reservoir pots (50) and is directly filled in the magnet insertion holes (46). Consequently, the respective magnet insertion holes (46) are filled with the resin material more evenly and highly reliable products can be supplied at low cost.

Owner:MITSUI HIGH TEC INC

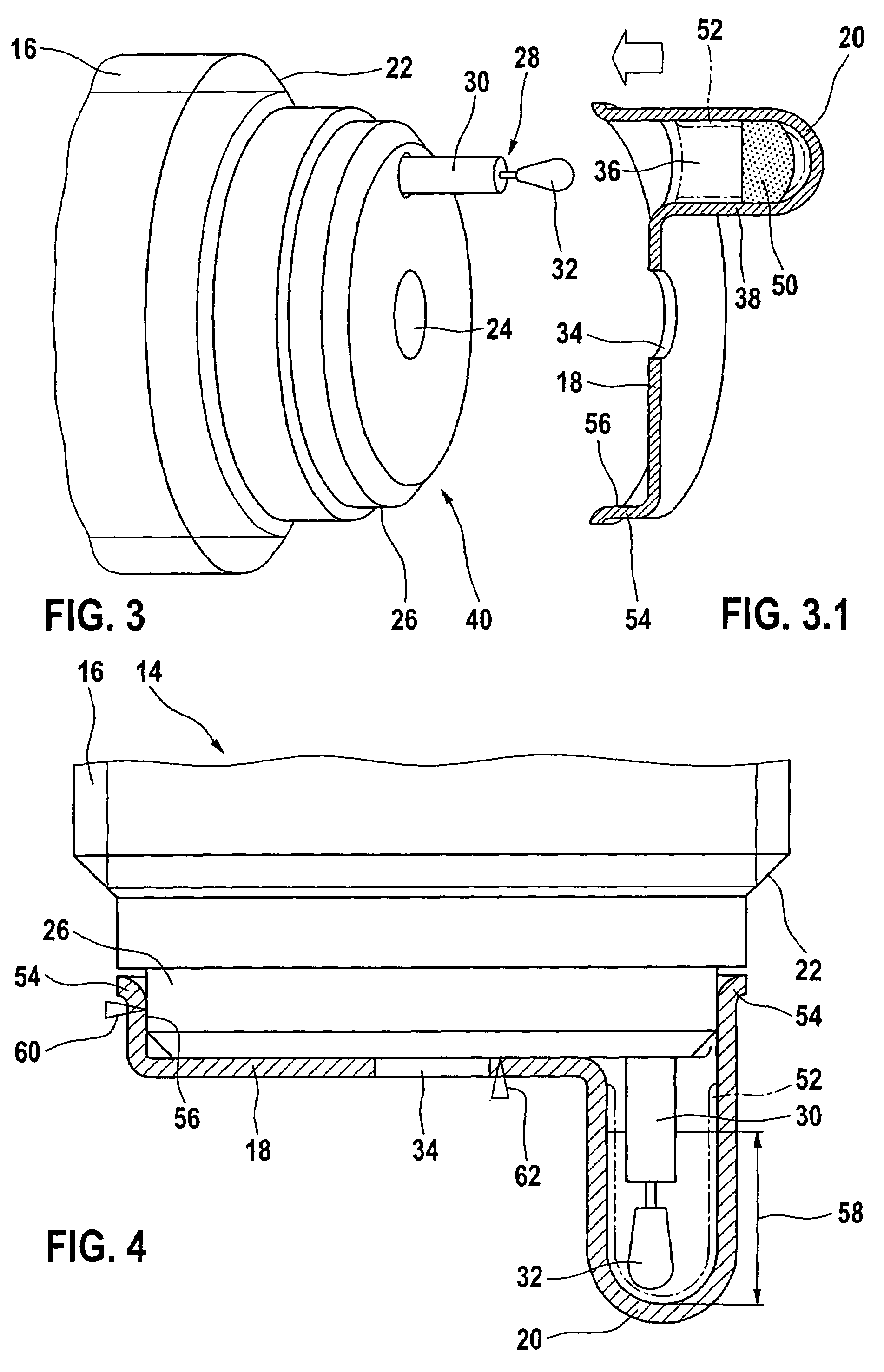

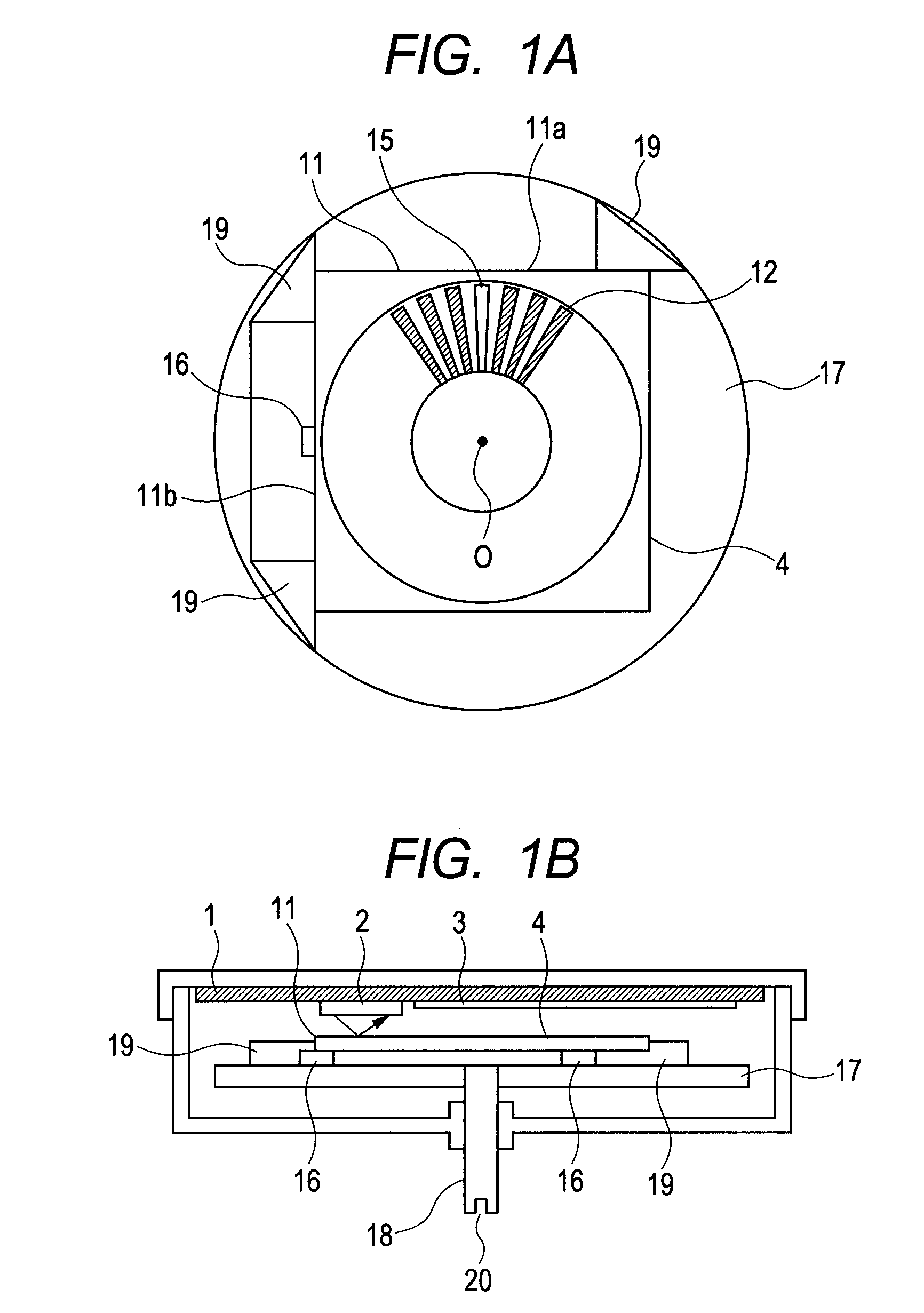

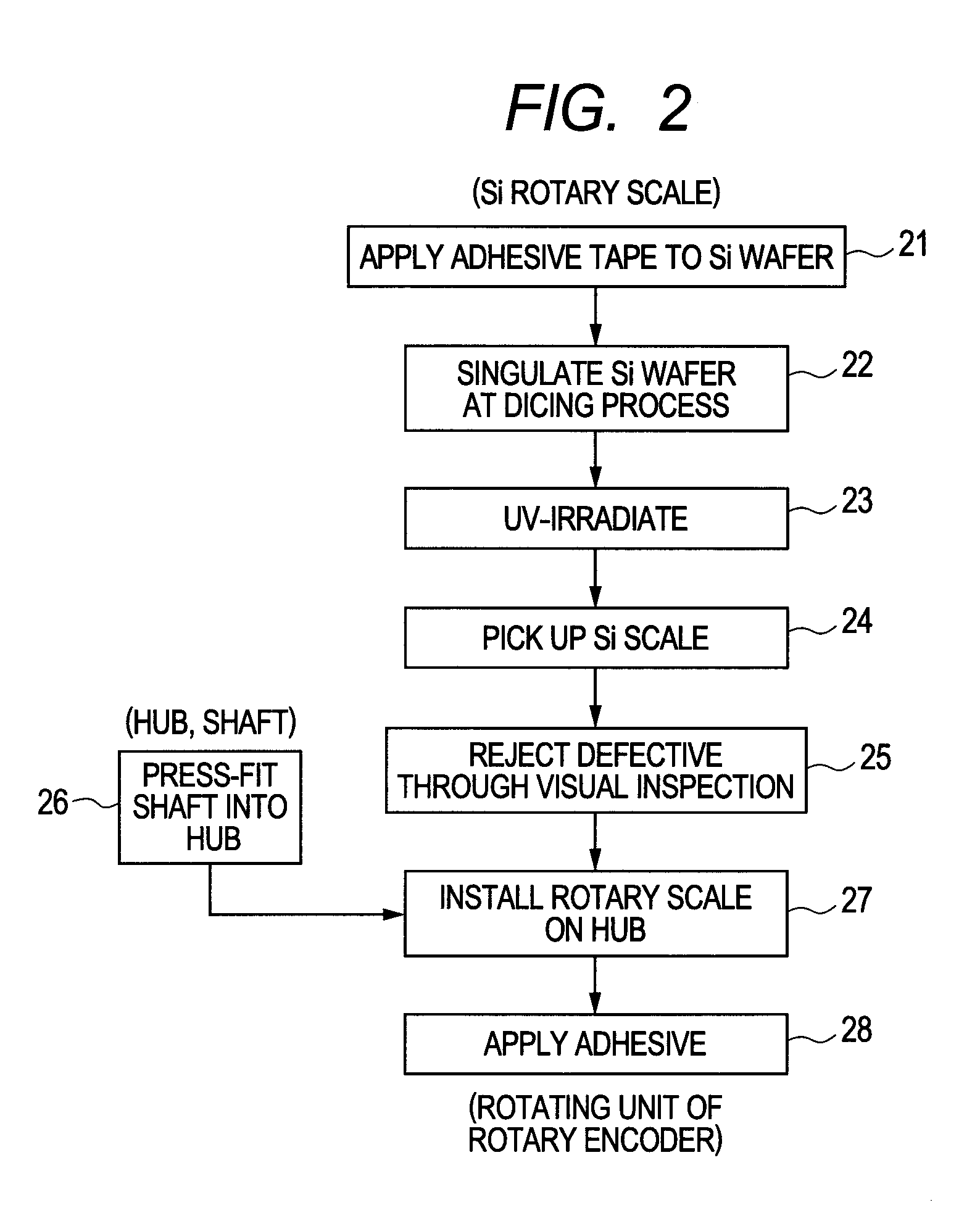

Rotary encoder and method of assembling the same

ActiveUS8487237B2Easy to centerEasy to assembleOptical measurementsMaterial analysis by optical meansMechanical engineeringRotary dial

Provided is a rotary encoder, including: a rotary scale, which has a predetermined pattern including continuous patterns and a rotational angle original point formed thereon with reference to a pattern center, has a polygonal outer shape, and has the rotational angle original point defined with reference to at least one side of sides of the polygonal outer shape; a hub, which includes projections for abutting the sides of the polygonal outer shape of the rotary scale and positioning the rotary scale; a rotating shaft, which is press-fitted into the hub and rotates coaxially with the pattern center of the rotary scale; and detecting units for irradiating the rotary scale with light and detecting the light reflected by the rotary scale.

Owner:CANON KK +1

Reconfigurable console mount

ActiveUS20100090489A1Easy to centerEasy to placeLaminationLamination apparatusLap jointTongue and groove

Owner:CARNEVALI JEFFREY D

Roller changer for multiple roller rolling mill

InactiveCN1647866AQuick roll changeProvide work efficiencyMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The roller changer for multiple roller rolling mill includes frame, two-layer connecting shaft seats, rotary connecting shafts supported with the connecting shaft seat, and sleeves in one end of the connecting shafts. Under the support of the frame, the connecting shaft seats and thus the connecting shafts may be shifted vertically and / or horizontally, while the sleeves are relatively fixed. The present invention is favorable to the centering of driving rollers and the automatic centering of the sleeves to realize fast roller change in high efficiency.

Owner:郑红专 +1

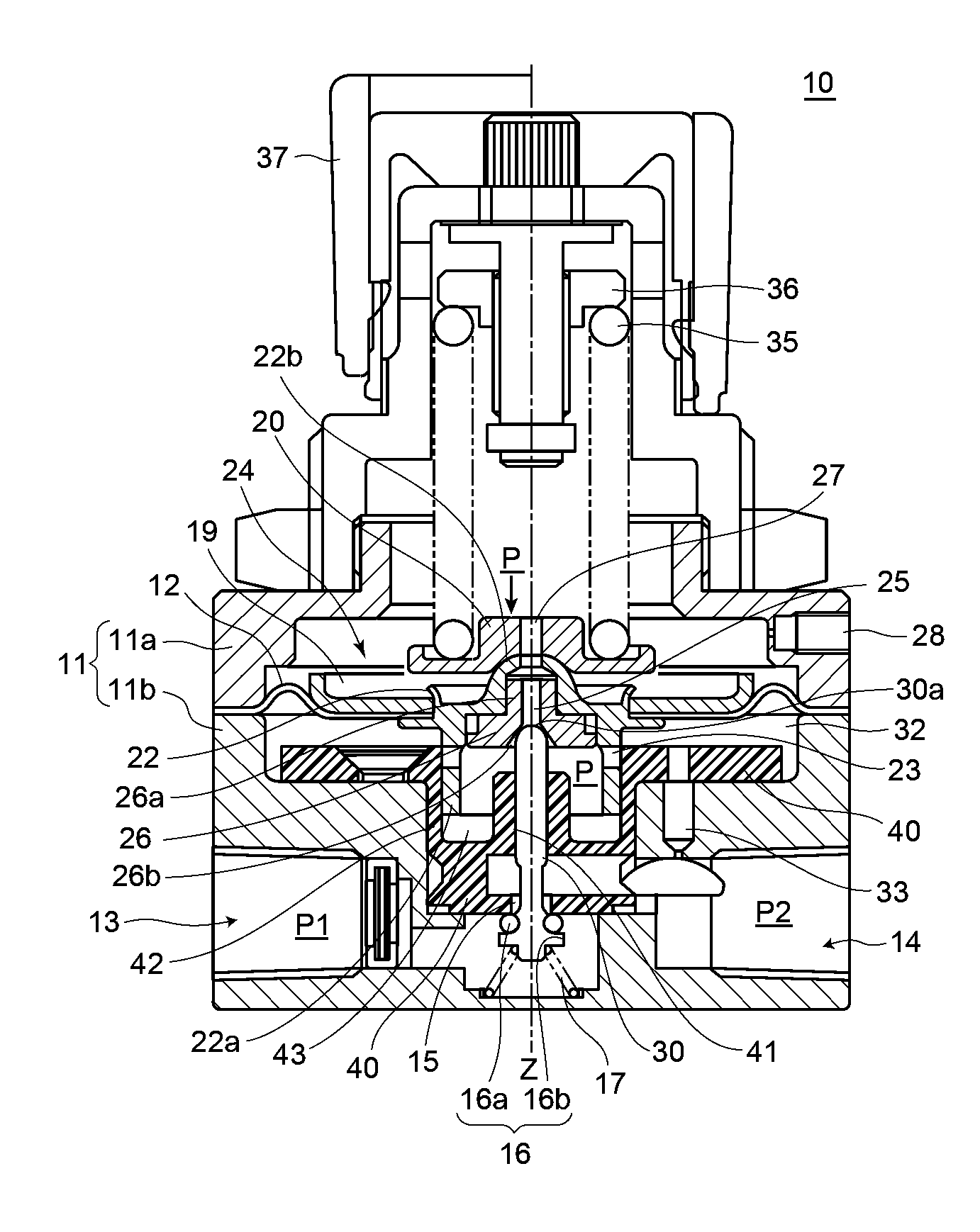

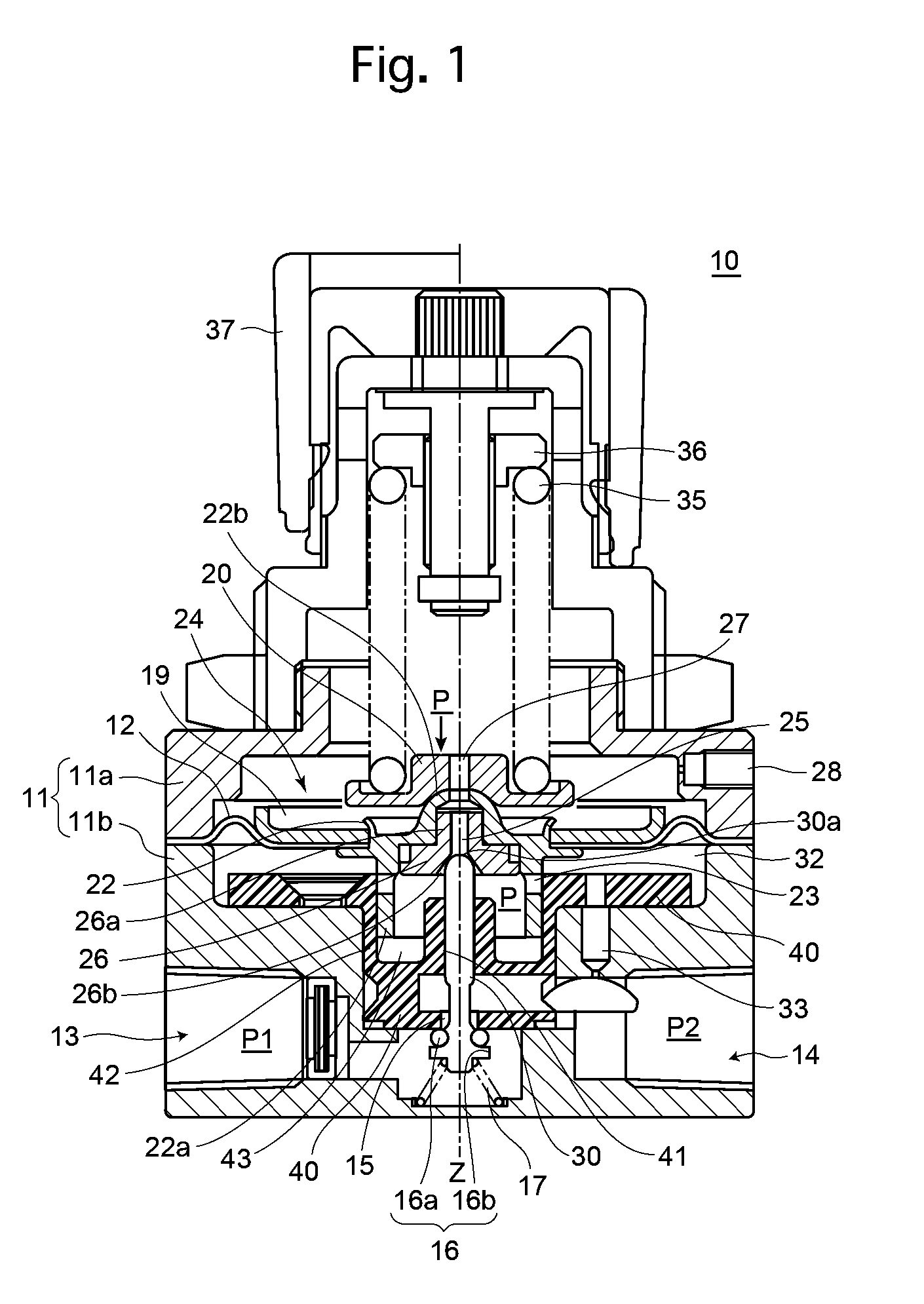

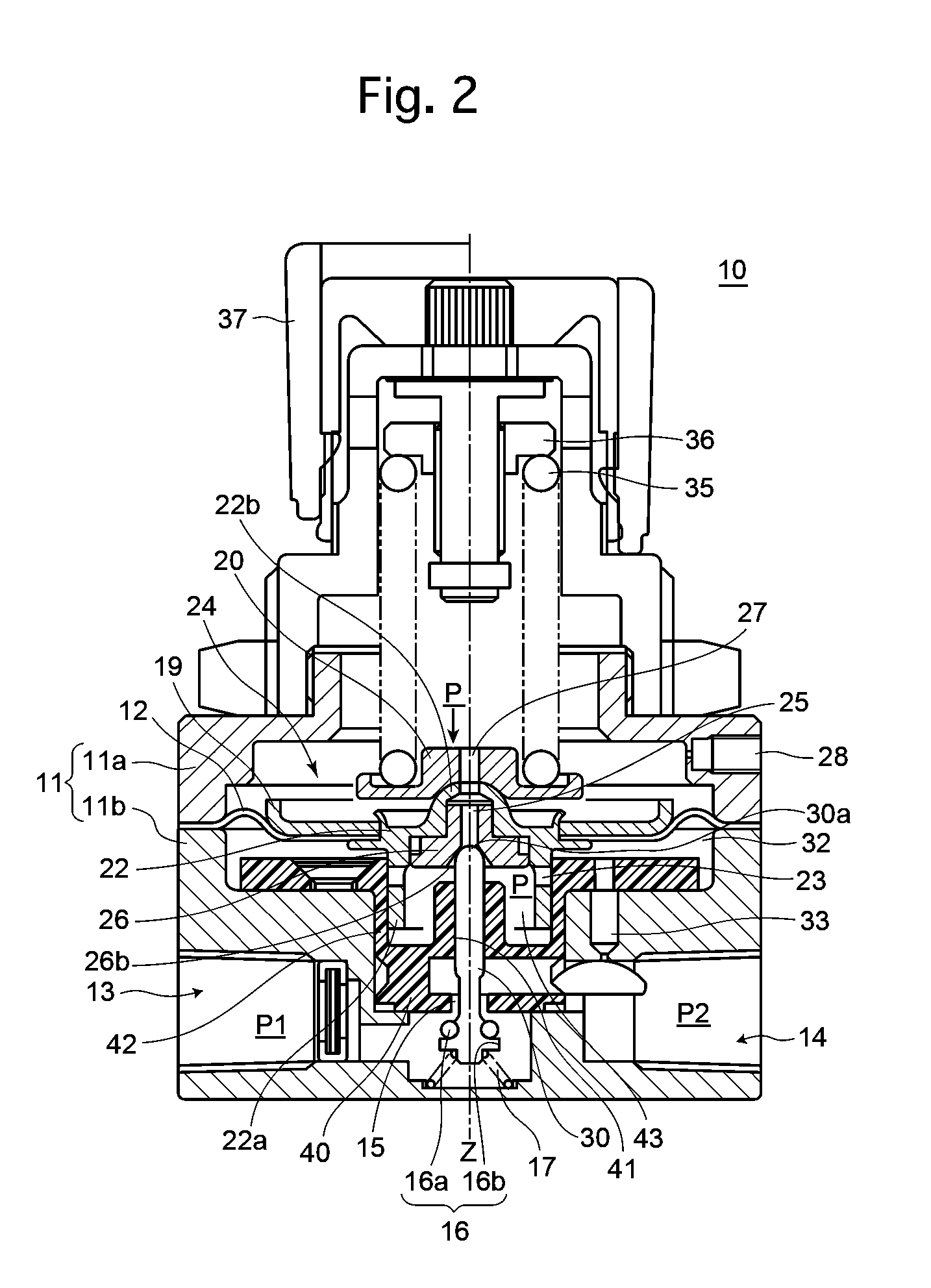

Pressure reducing valve

ActiveUS8342201B2Reduce in quantityEasy to centerOperating means/releasing devices for valvesFluid pressure controlSafety valveValve guide

A pressure reducing valve includes a opening / closing valve between primary and secondary pressure chambers, a diaphragm body, a valve hole through which the secondary pressure chamber is communicatively connected with the atmosphere, a relief valve which opens / closes the valve hole, and a linkage member which links the opening / closing valve with the relief valve so as to open / close in association with each other. The linkage member includes a valve guide having a valve passage through which the primary and secondary pressure chambers are communicatively connected, and a pintle inserted into a pintle hole and guided thereby. The opening / closing valve and the relief valve are provided on lower and upper ends of the pintle, respectively. The valve hole has a common axis with those of the valve passage and the pintle hole. One and the other of the valve guide and the pintle are made of resin and metal.

Owner:FUJIKURA COMPOSITES INC

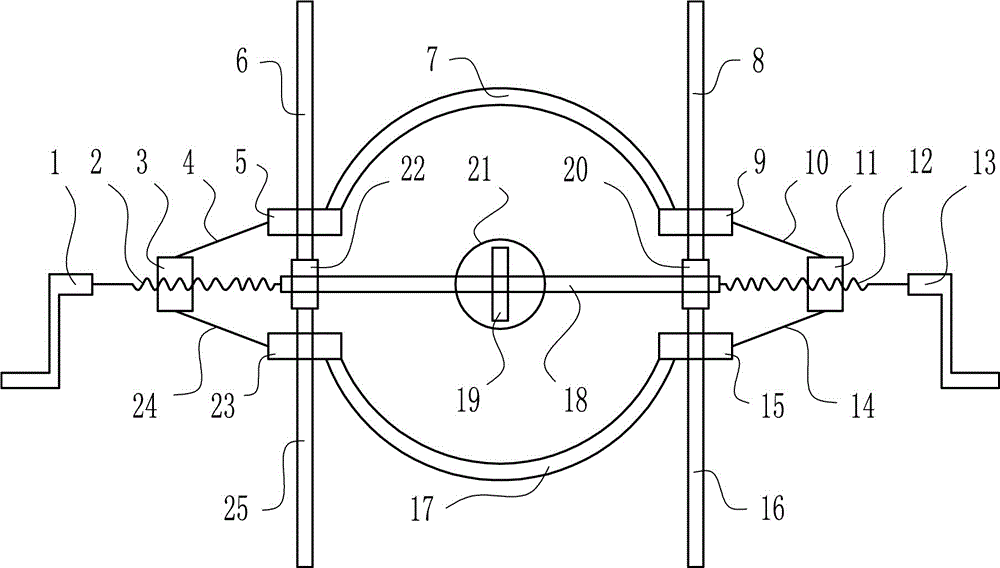

Lathe chuck capable of preventing axial sliding of workpiece

The invention relates to a chuck, in particular to a lathe chuck capable of preventing axial sliding of a workpiece. According to the technical aim, the lathe chuck capable of preventing axial sliding of the workpiece comprises a left rocking handle, a left lead screw, a left nut, a connecting rod III, a sliding block III, a sliding rod III, an upper arc fixed plate, a sliding rod II, a sliding block II, a connecting rod II, a right nut, a right lead screw, a right rocking handle, a connecting rod I, a sliding block I, a sliding rod I, a lower arc fixed plate, a cross rod, a fixed block, a right bearing, a connecting shaft, a left bearing, a sliding block IV, a connecting rod IV and a sliding rod IV. The right lead screw is arranged on the left side of the right rocking handle. According to the lathe chuck capable of preventing axial sliding of the workpiece, by means of the structure of the vertically symmetric arc fixed plates and cooperation of the nuts and the lead screws, the center of the workpiece can be located conveniently.

Owner:西安朋邦工贸有限公司

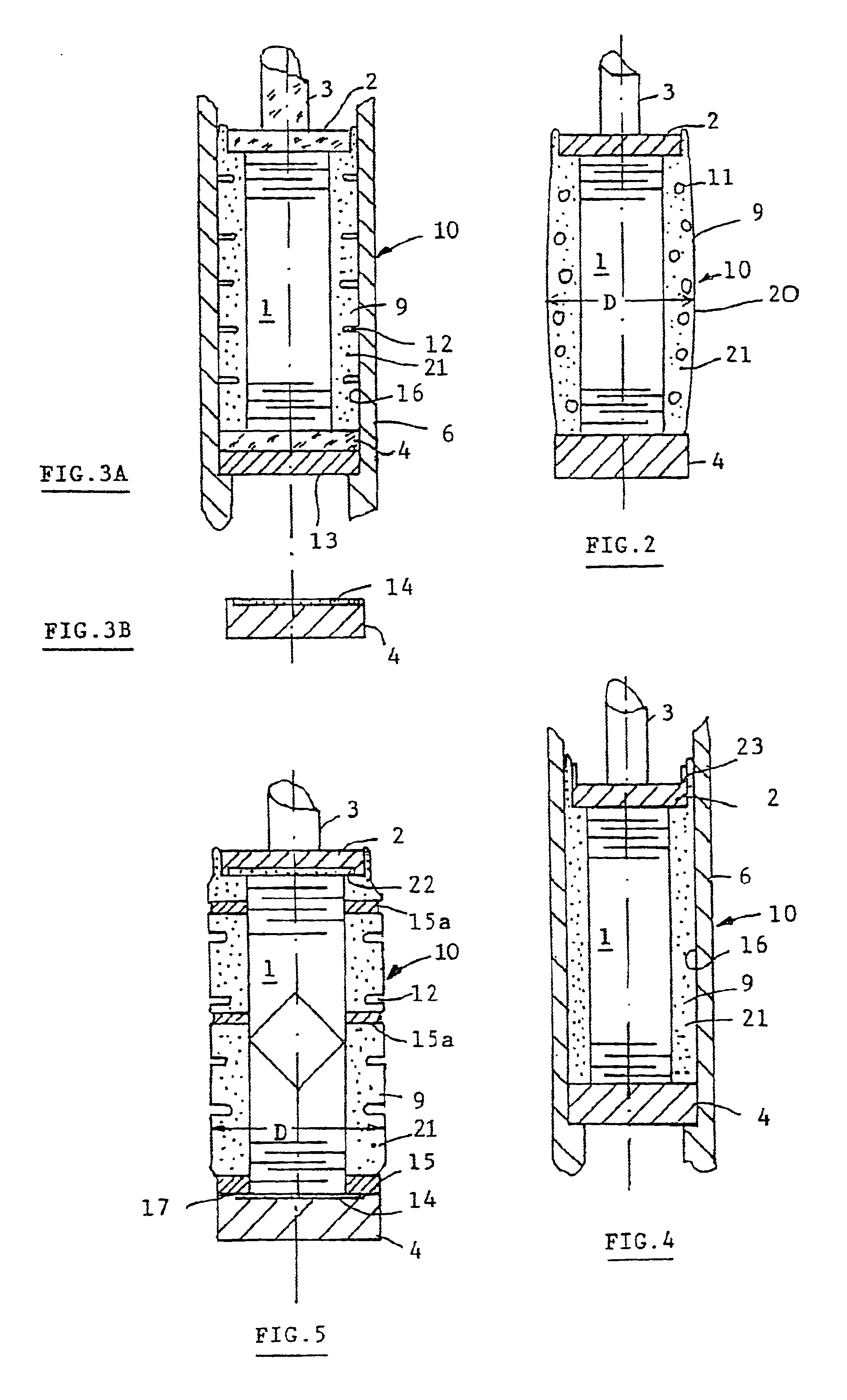

Encoder system and method of assembling an encoder system

InactiveUS6960758B2High precisionEasy to centerAssociation with control/drive circuitsElectronic circuit testingEngineeringMotor shaft

An encoder system with a timing disc includes a preassembled circuit board with a U-shaped sensor / emitter embracing the edge of the timing disc. The timing disc is configured to be slipped onto a motor shaft at the flange end of an electric motor, and the circuit board is designed to be mounted on the flange of the motor by mechanical, thermal, and / or adhesive means of attachment. The motor flange is equipped with a centering collar that has a flattened portion on its otherwise circular circumference. The circuit board has a cutout opening that receives the centering collar in a form-fitting way when the circuit board is slid onto the flange of the motor. By rotating the circuit board 90° about the centering collar, the circuit board is secured in a defined position on the motor flange.

Owner:PWB RUHLATEC INDPROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com