Encoder system and method of assembling an encoder system

a technology of encoder system and encoder, which is applied in the field of encoder system, can solve the problems of high cost of encoder system and high cost of prior art production method, and achieve the effect of high degree of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

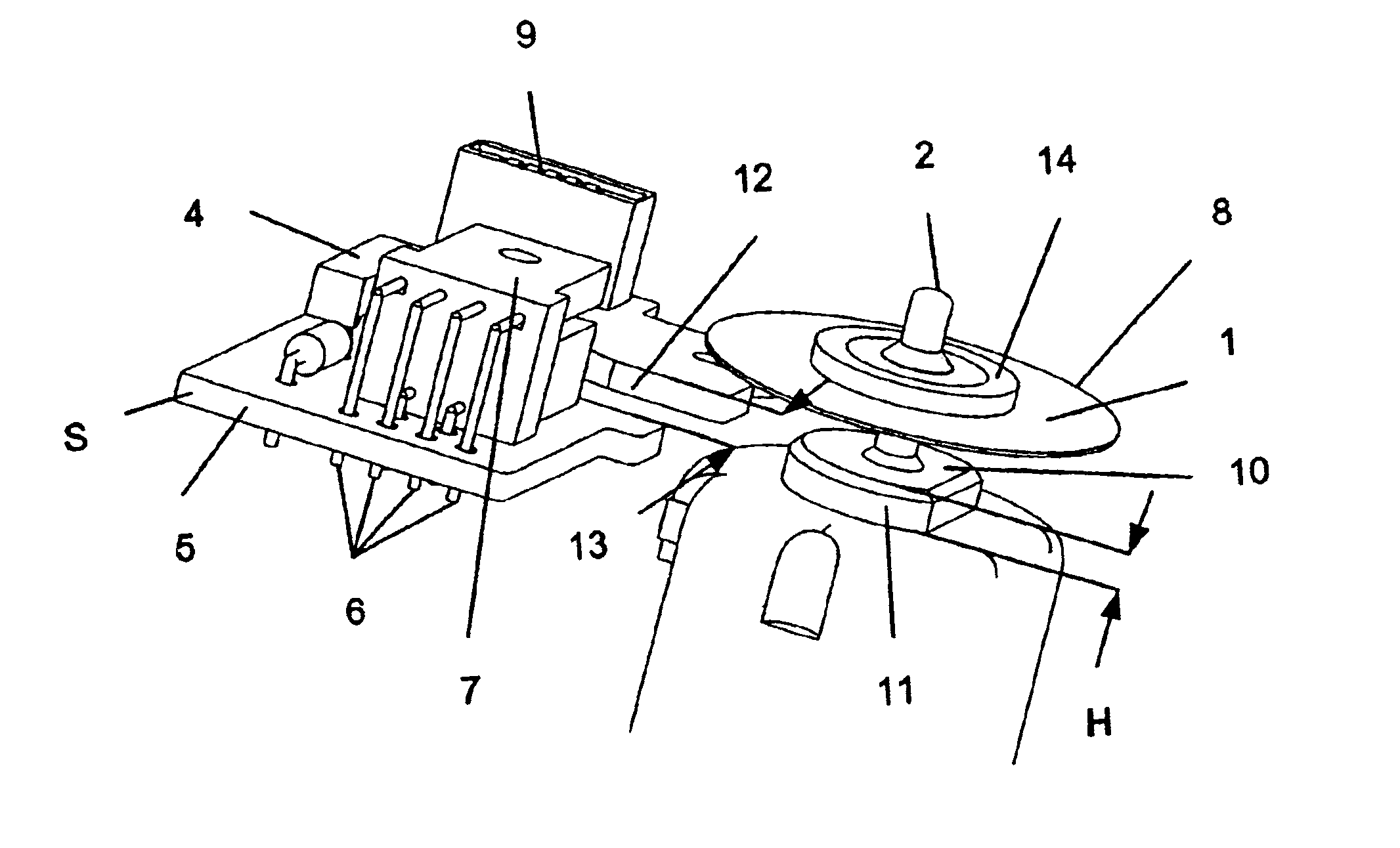

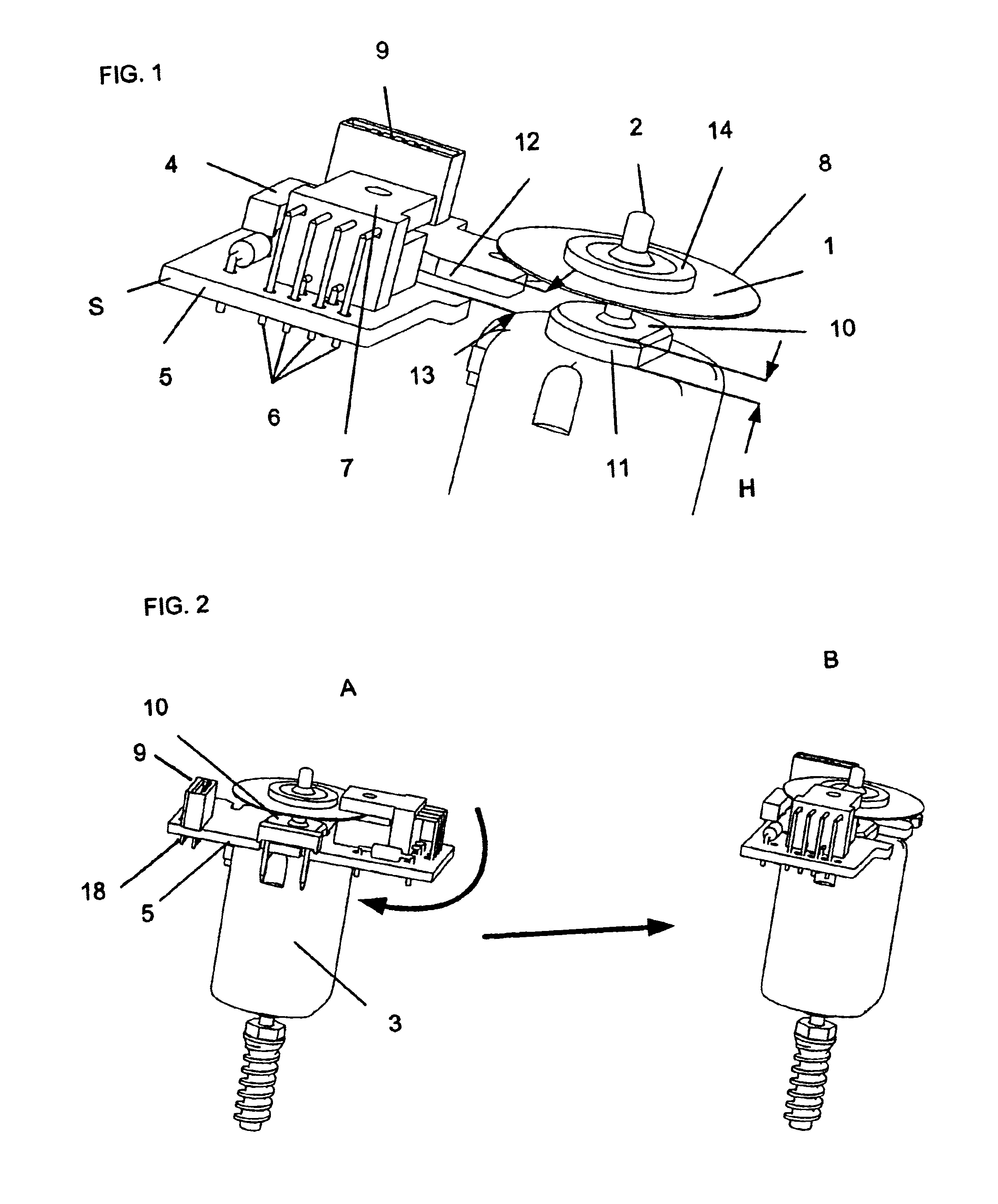

[0024]FIG. 1 shows an encoder system according to the invention. The timing disc 1 has a timing disc hub 14 for centering purposes and is designed so that it can be mounted on a motor shaft 2. The circuit board 5 has a sensor-emitter unit 7 and a plug-in connector 9.

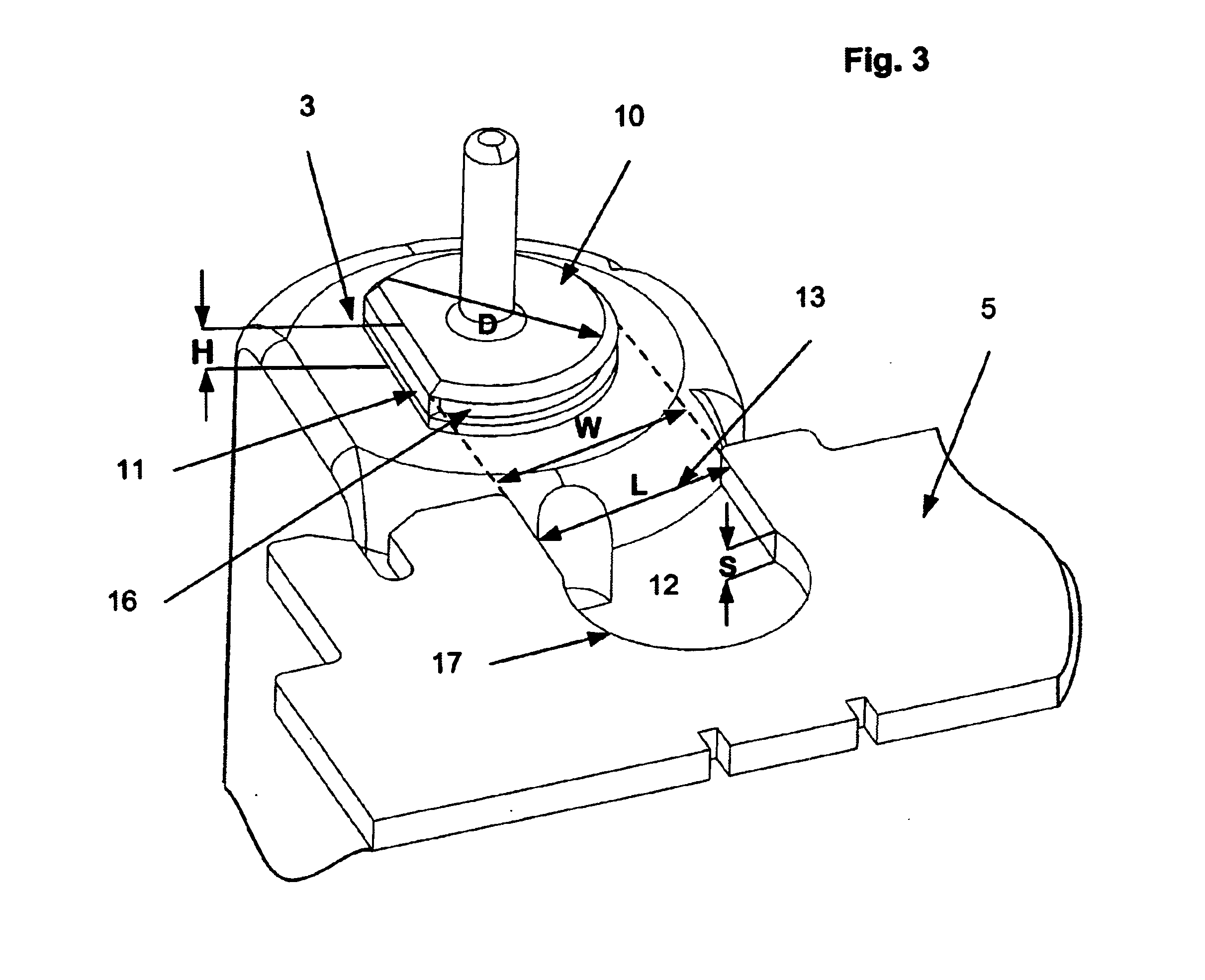

[0025]The motor shaft 2 forms part of an electric motor 3. At the upward end of the motor 3, in the flange plane where the motor shaft 2 protrudes through an opening, the motor flange has a centering collar 10 with a flattened portion 11. The shape of the centering collar 10 is designed to permit centering of the motor 3 in the flange plane with reference to the sensor-emitter unit 7 and the timing disc 1. The circuit board 5 has an opening 13 so that the circuit board can be slid over the centering collar into a position where the centering collar is seated in a correspondingly shaped recess 12.

[0026]The circuit board 5 carries all the connections required for the supply of power to the connecting leads 6 of the sensor-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

| mechanical | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com