Patents

Literature

1489results about "Galvano-magnetic hall-effect devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

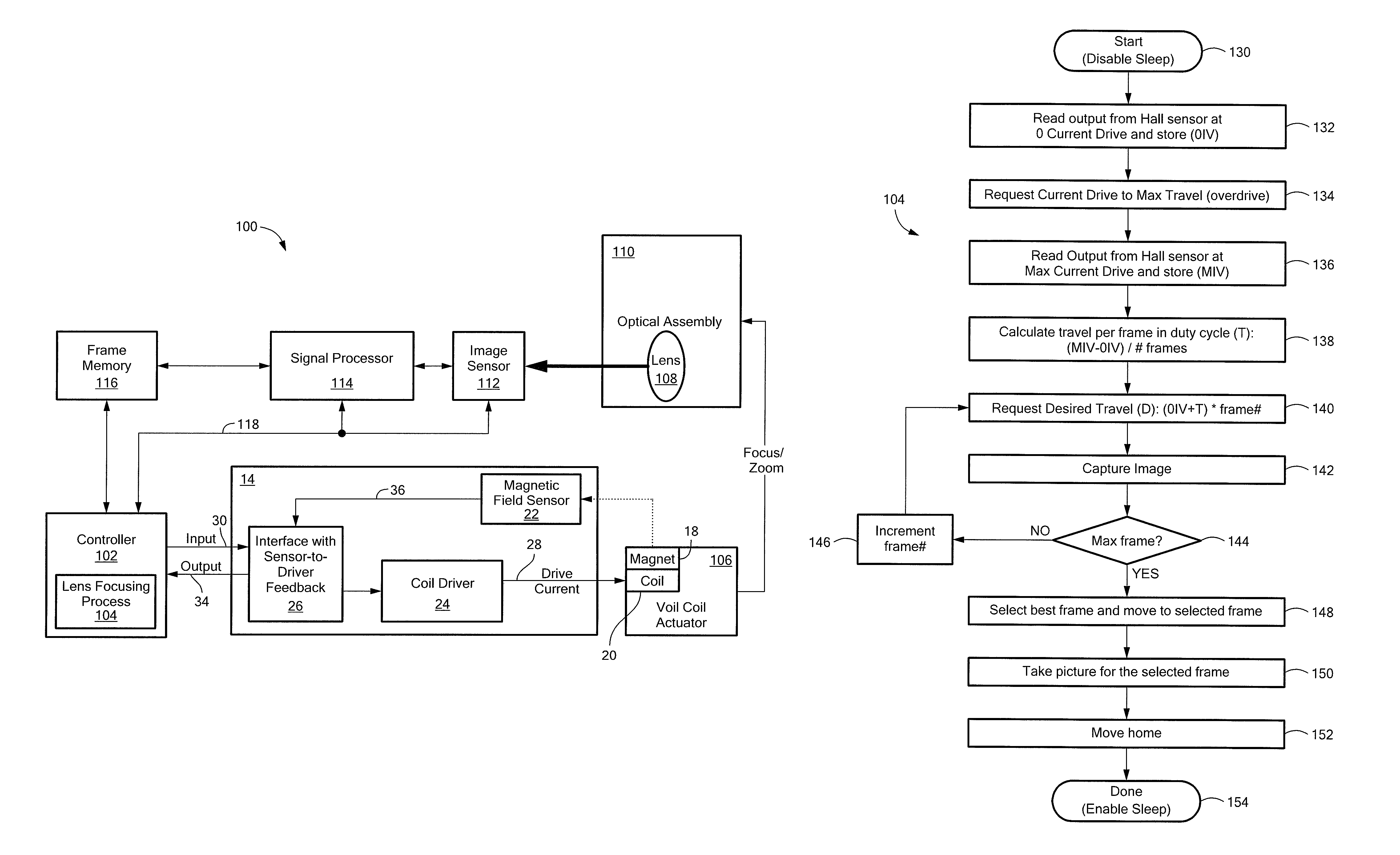

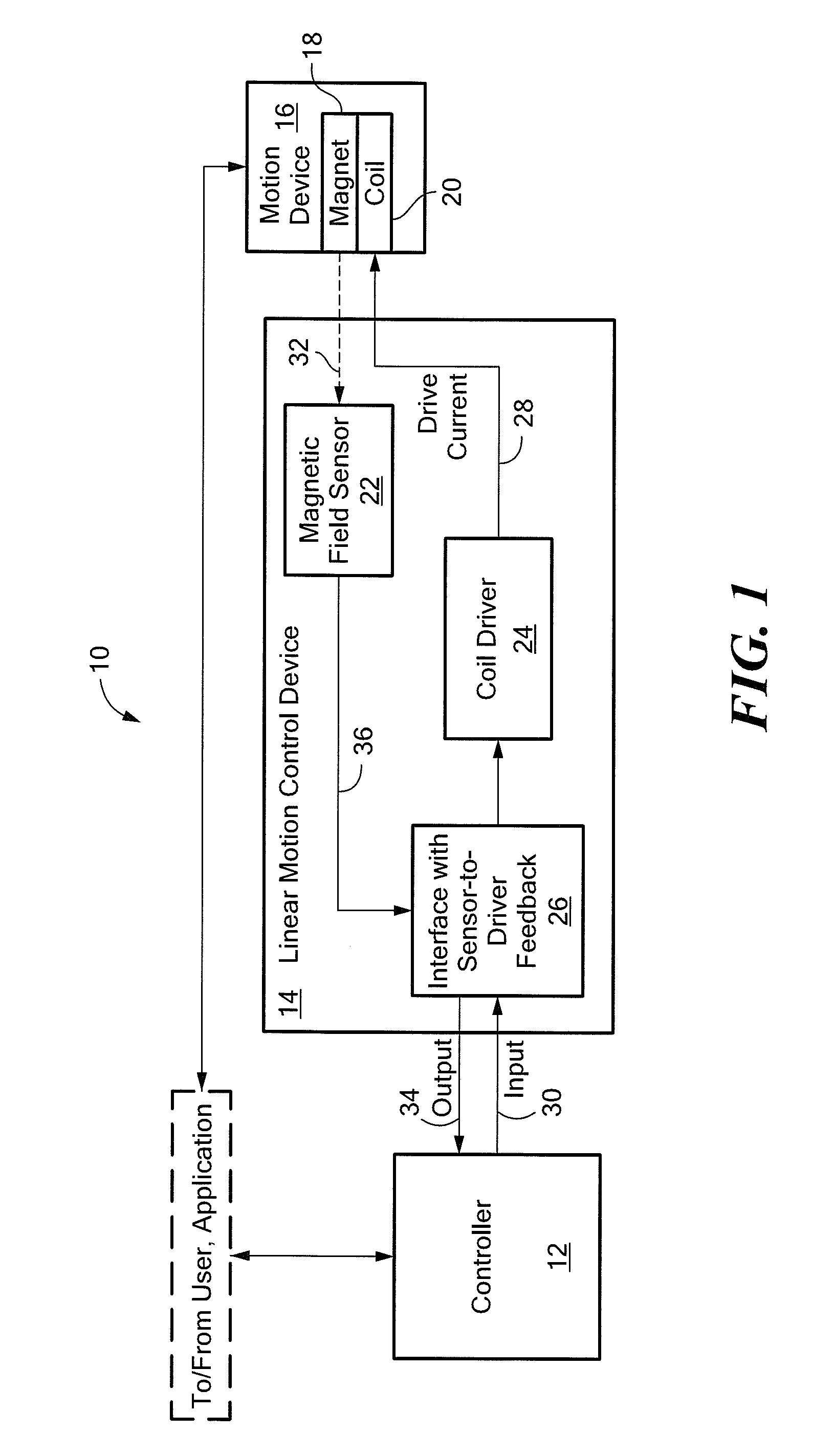

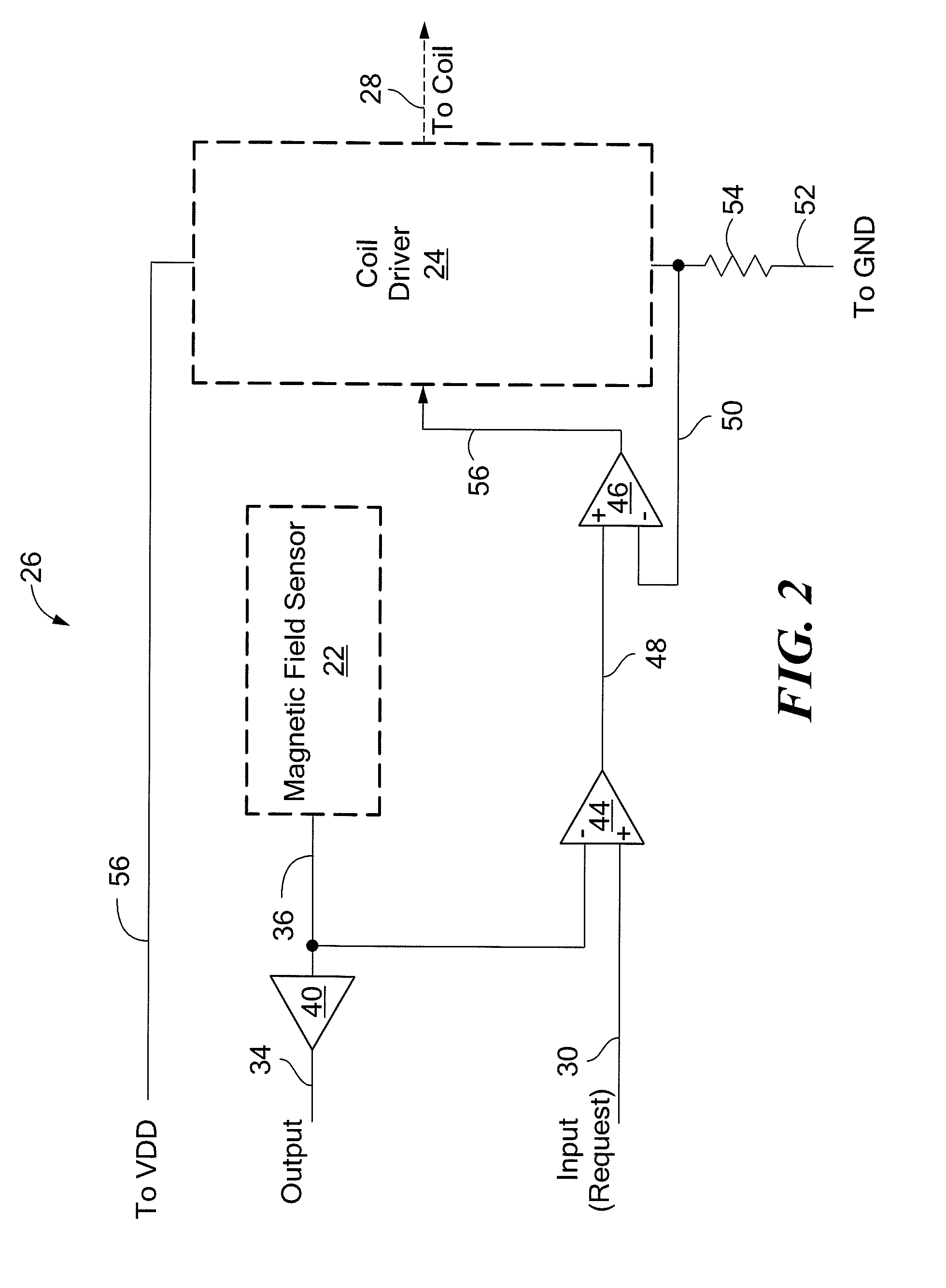

Hall-effect based linear motor controller

Owner:ALLEGRO MICROSYSTEMS INC

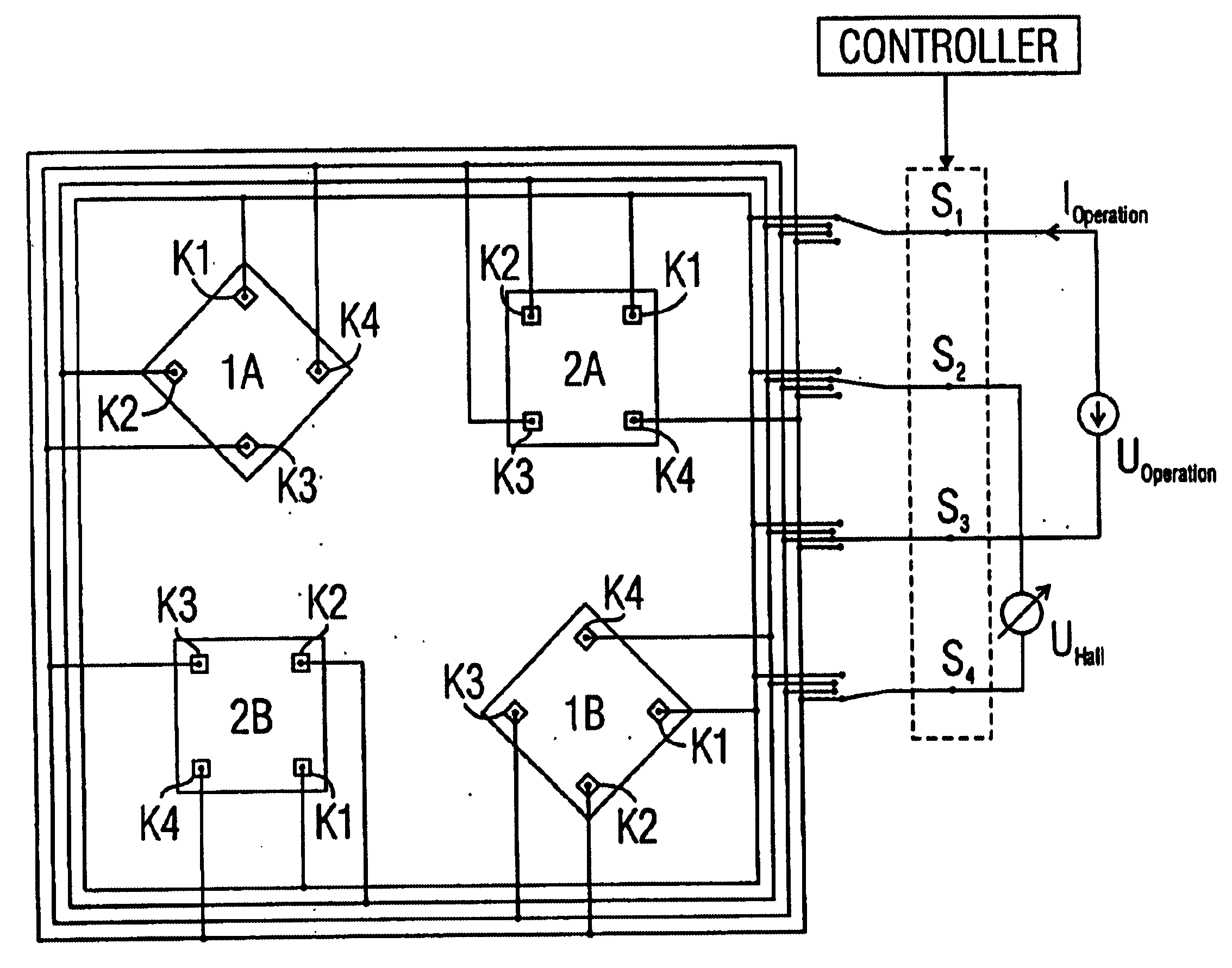

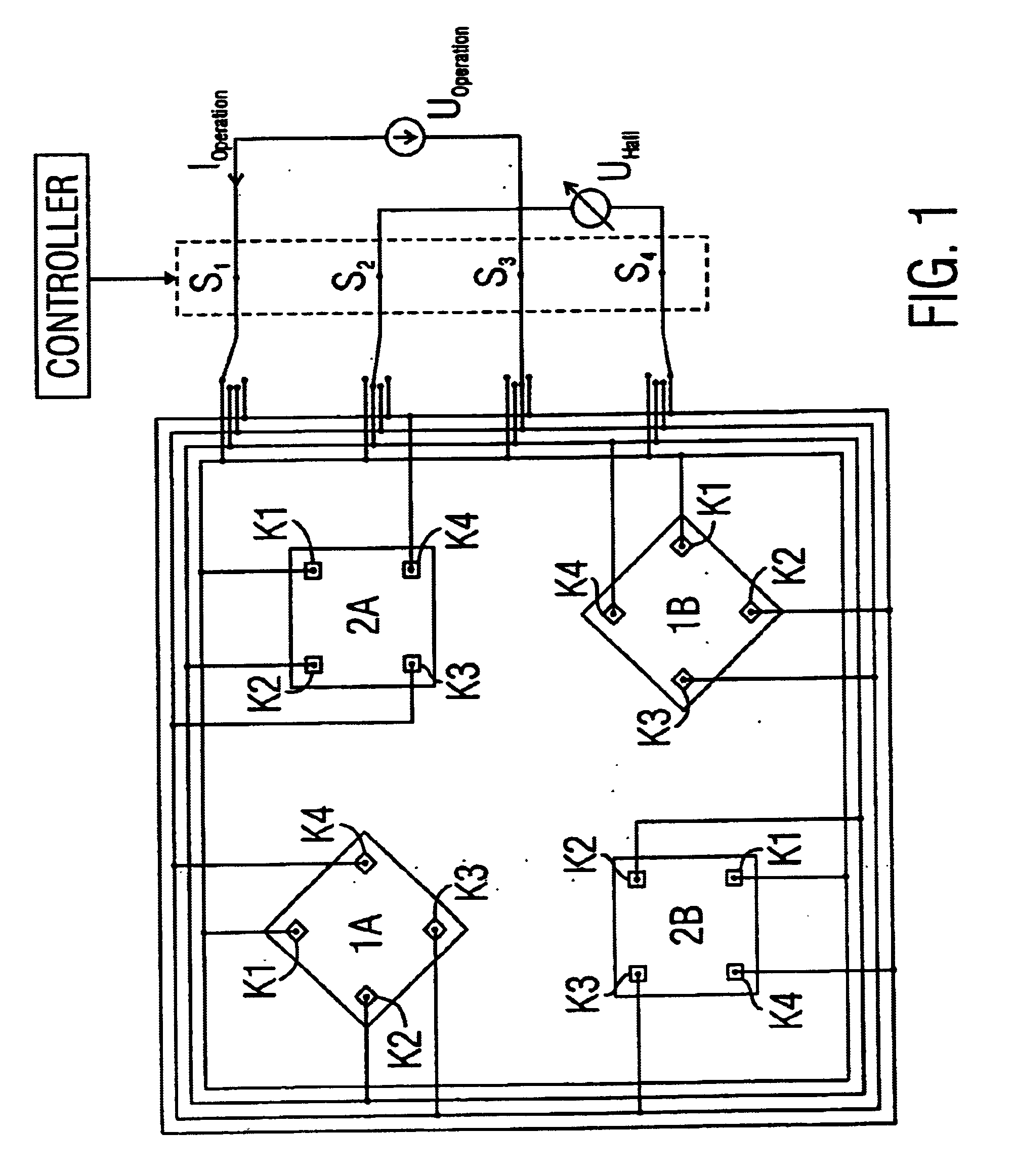

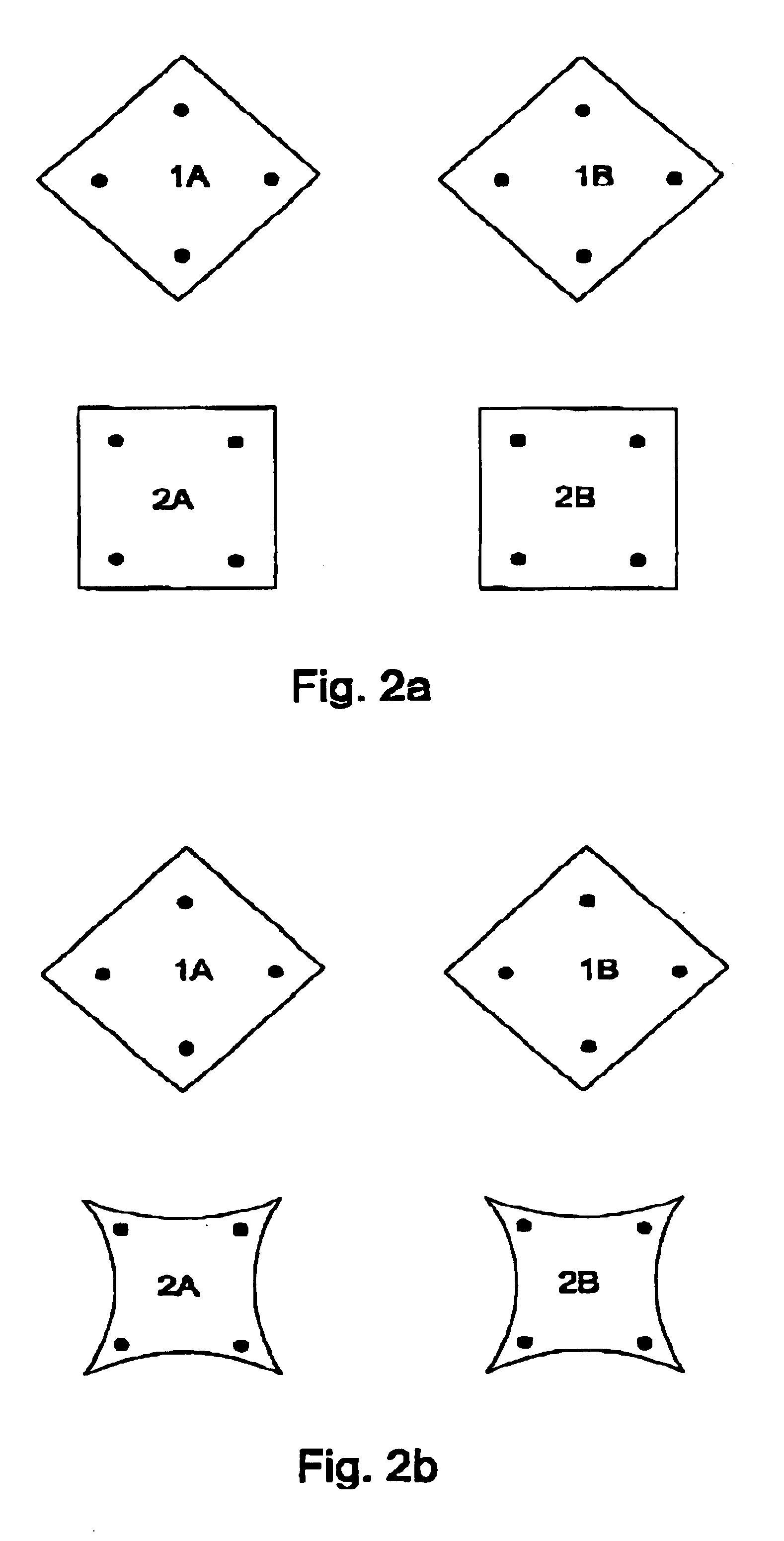

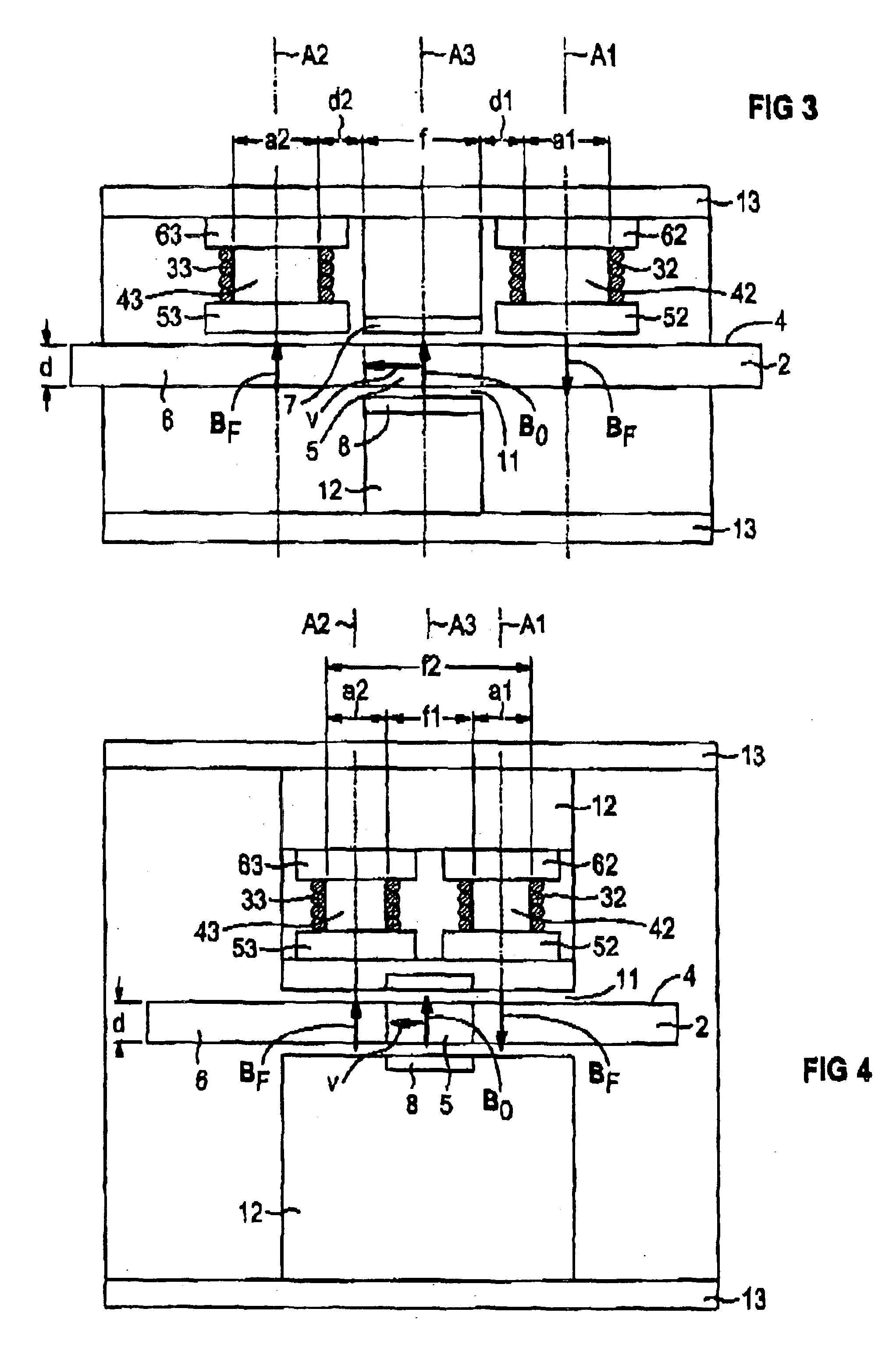

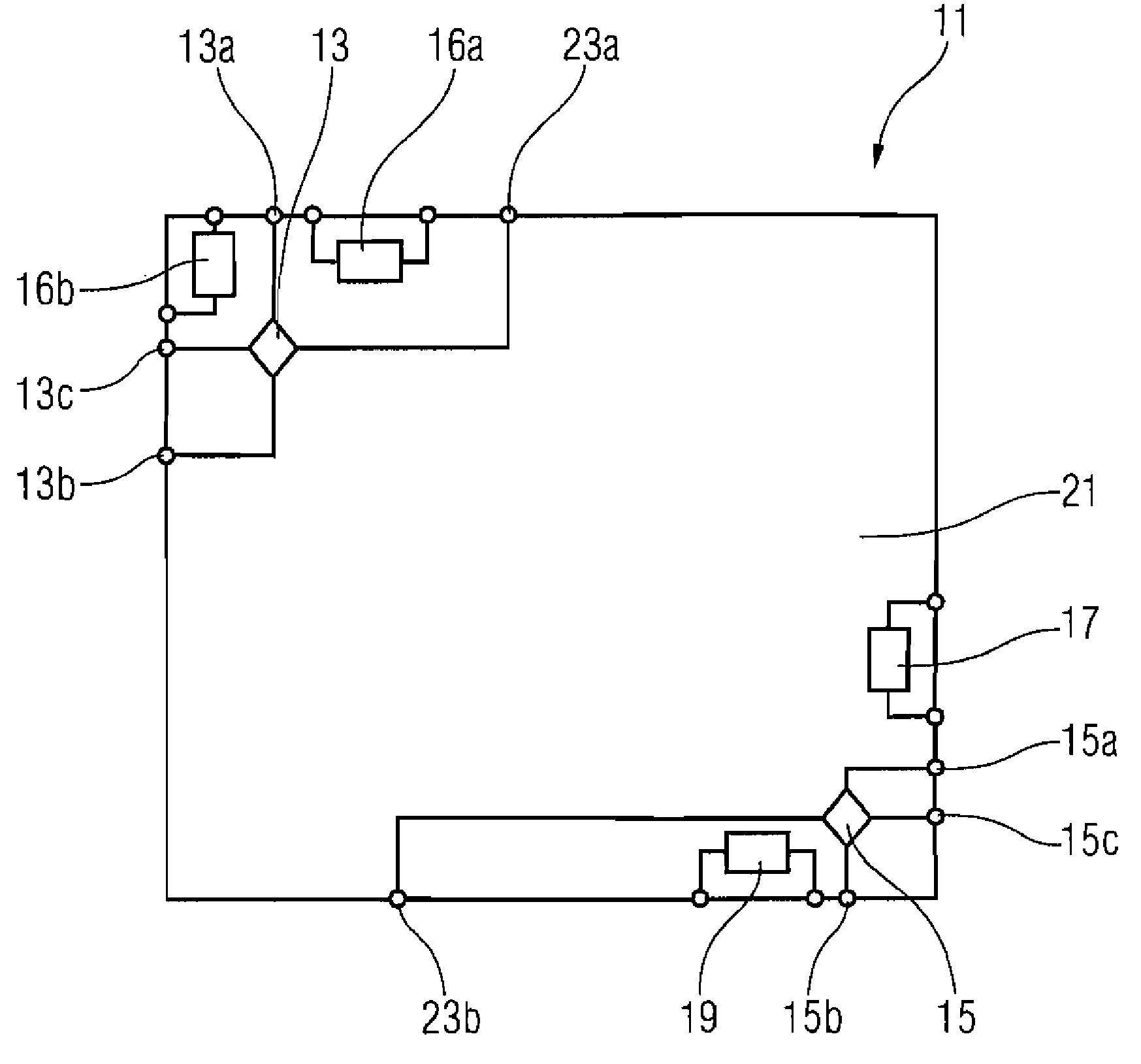

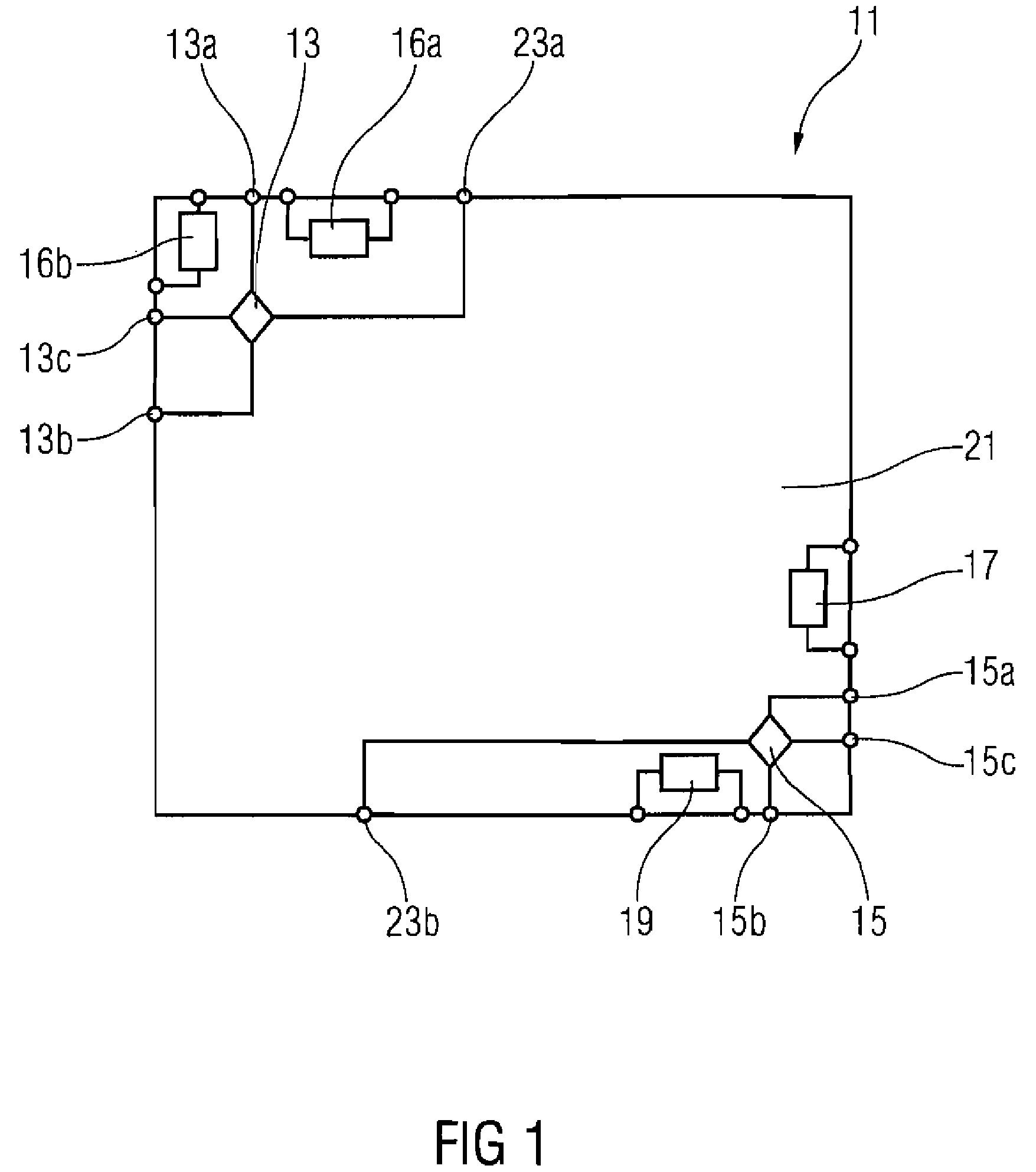

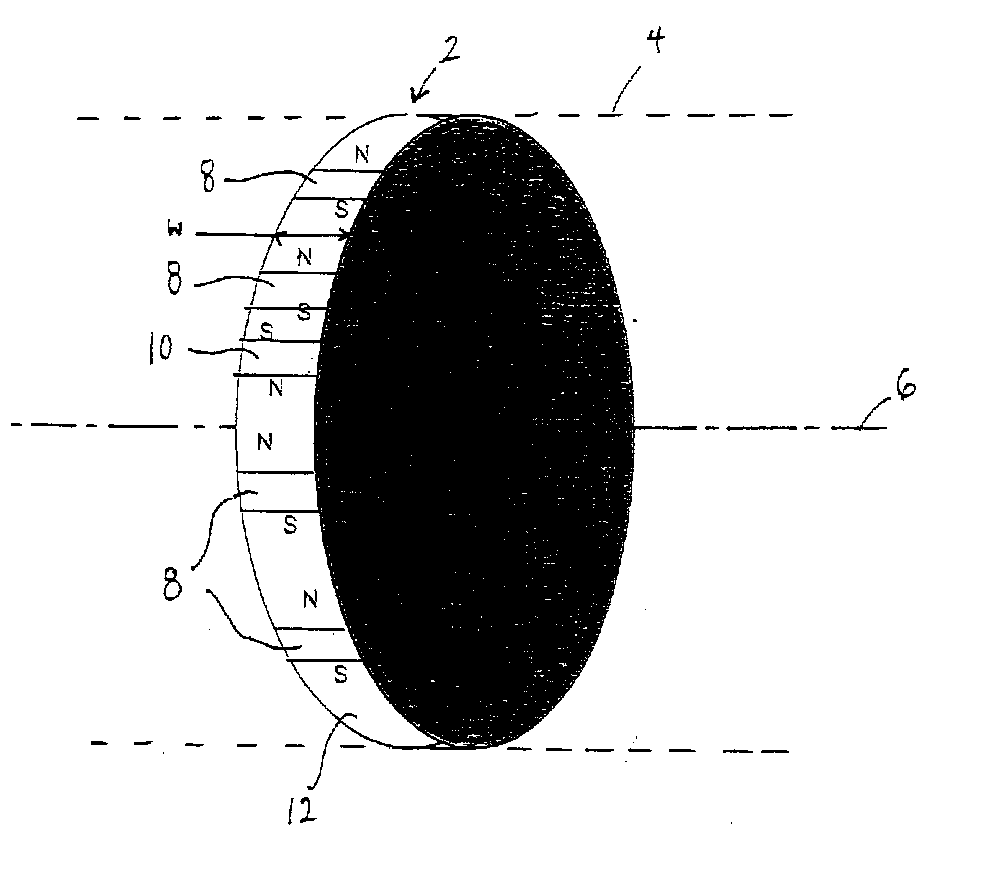

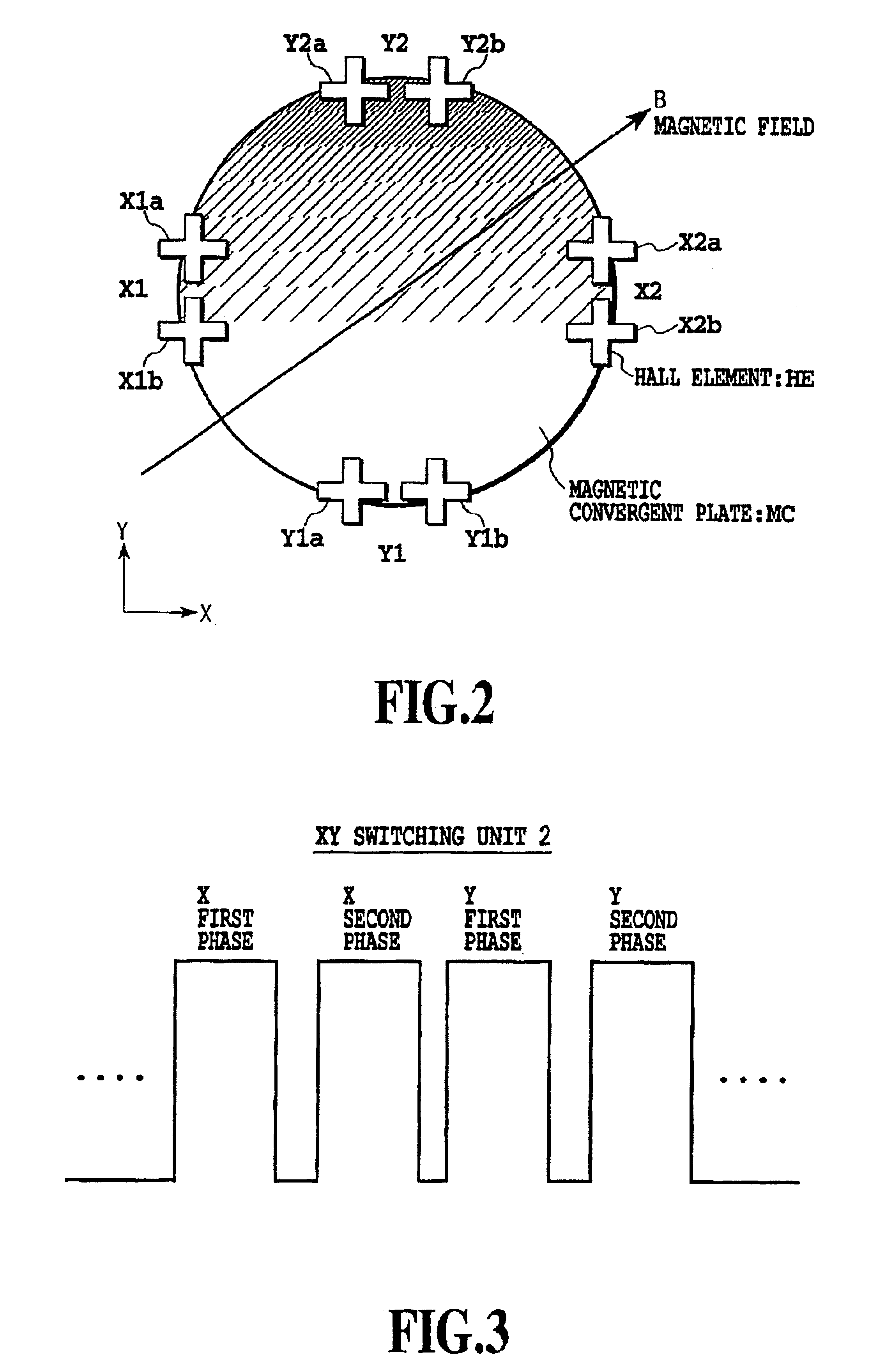

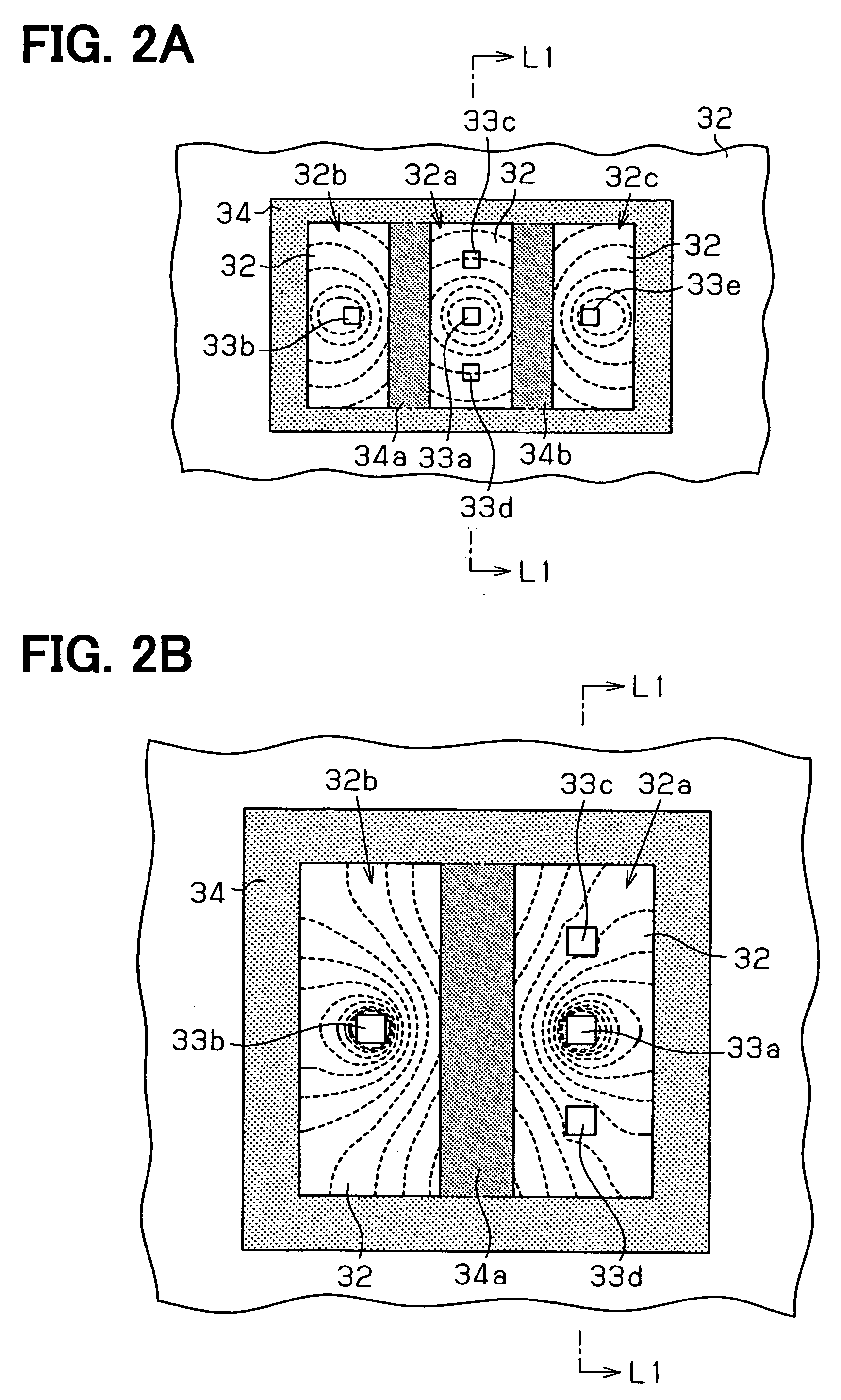

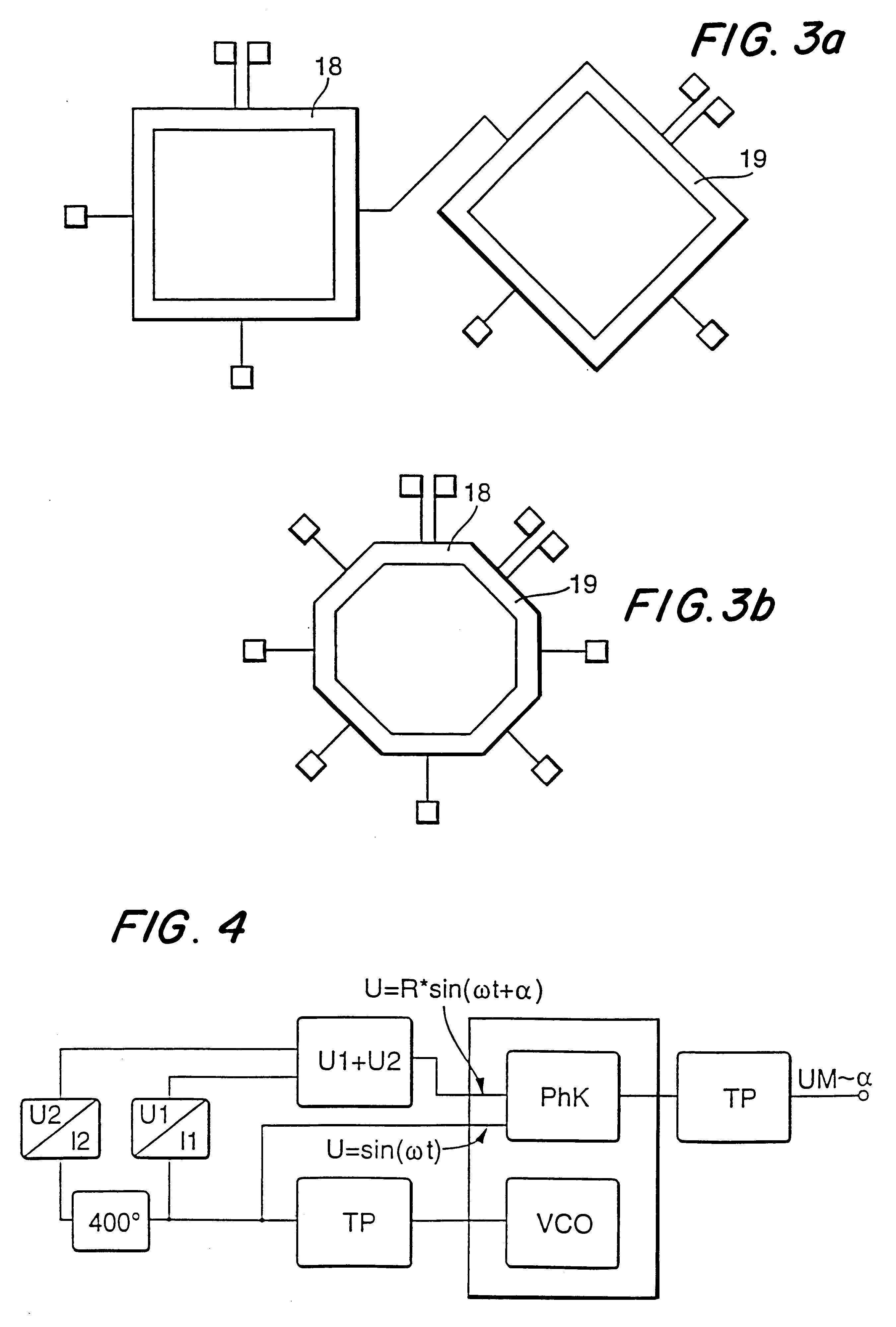

Hall sensor array for measuring a magnetic field with offset compensation

InactiveUS6768301B1Less complicated to manufactureReduce signalingSolid-state devicesMagnetic field measurement using galvano-magnetic devicesSensor arrayVoltage source

A Hall sensor array for offset-compensated magnetic field measurement comprises a first and at least one additional pair of Hall sensor elements. Each Hall sensor element has four terminals, of which two act as power supply terminals for supplying an operating current and two act as measurement terminals for measuring a Hall voltage. Respective first supply terminals of each Hall sensor element are connected together and to a first terminal of a common voltage source and respective second supply terminals of each Hall sensor element are connected together and to a second terminal of the common voltage source so that the common voltage source supplies an operating current for the Hall sensor elements. The Hall sensor elements are operated in the spinning current mode so that the offset voltages of the Hall sensor elements approximately cancel one another out in a revolution so that the Hall signal contributions which actually depend on the magnetic field remain.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

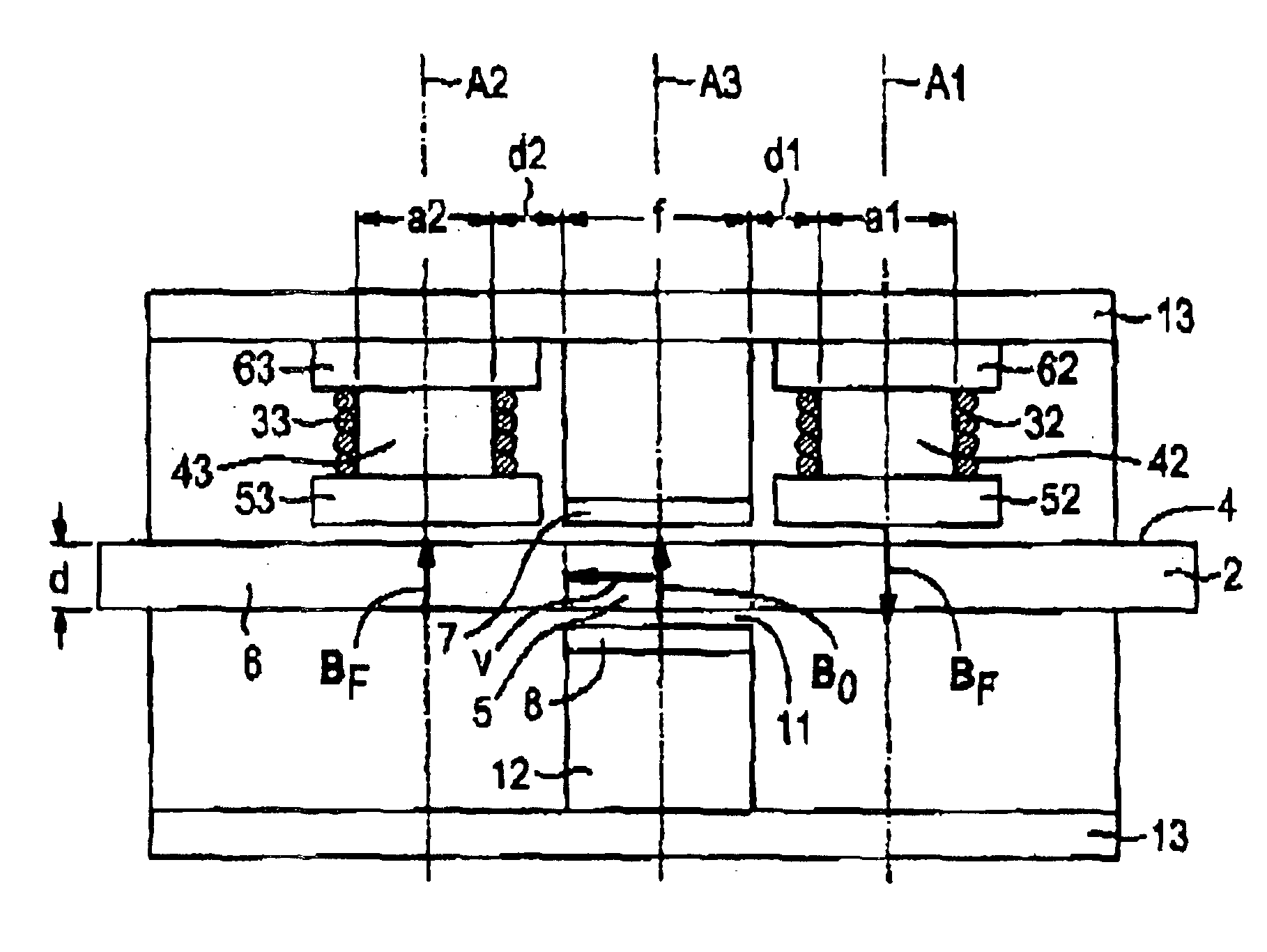

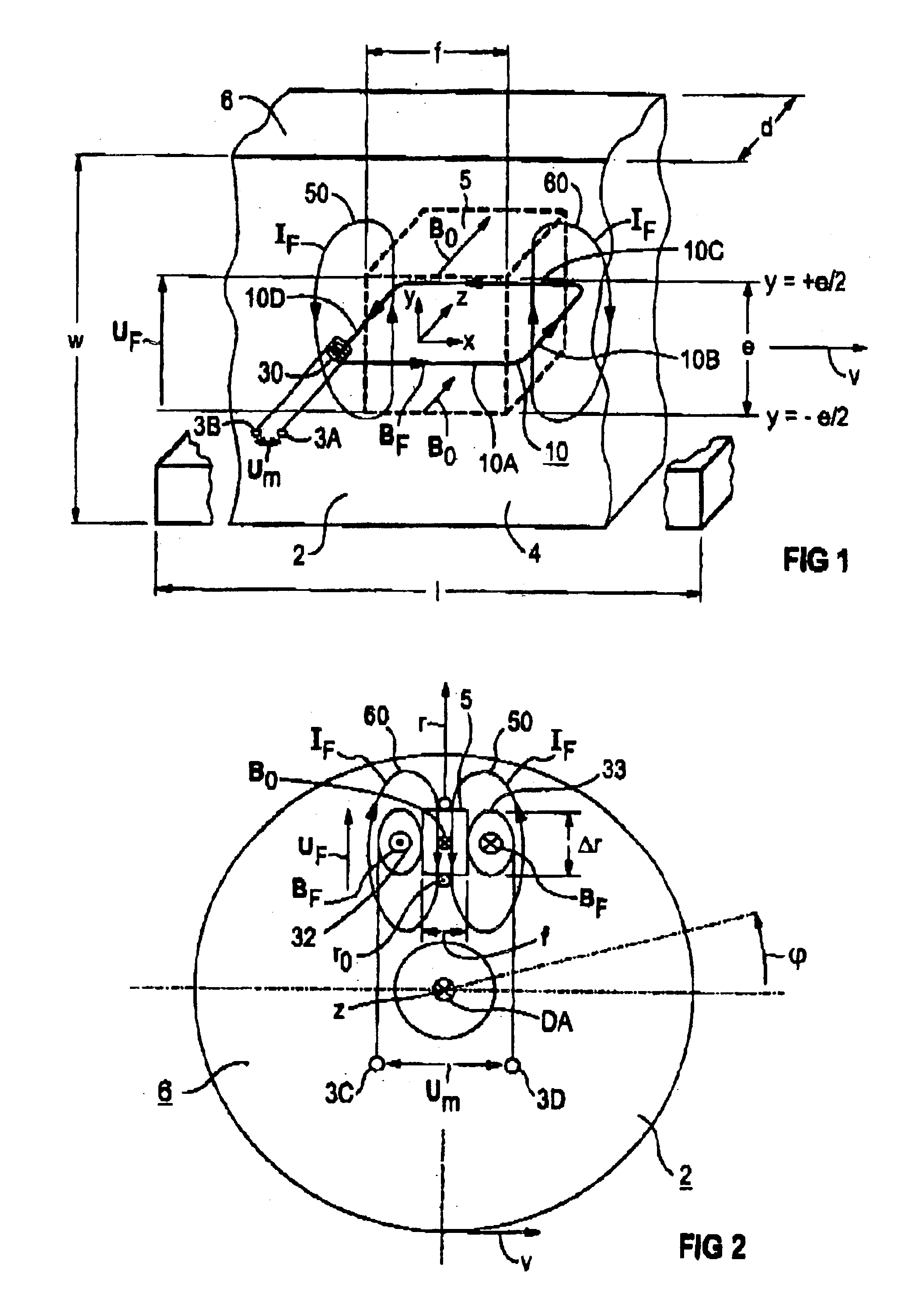

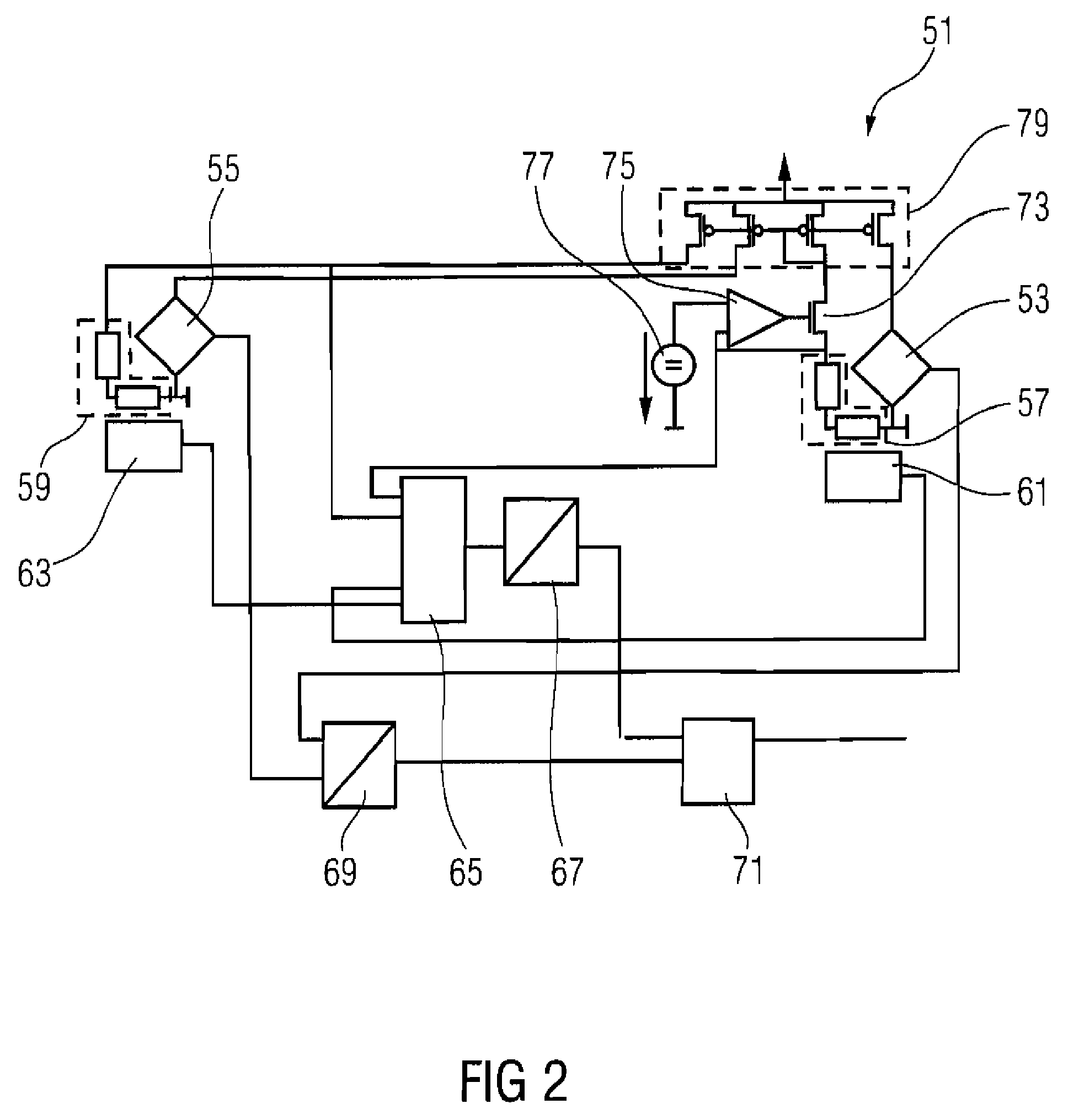

Device for measuring the motion of a conducting body through magnetic induction

InactiveUS6850053B2Improve cooling effectReduce thermal noiseAcceleration measurement using interia forcesMagnetic-field-controlled resistorsMeasurement deviceClassical mechanics

A device for measuring a motion of a moving electrically conducting body is disclosed. A magnetic field generated by, for example, electromagnets or permanent magnets, penetrates at least a partial area of the moving body. Two or more measuring devices are arranged outside the magnetic field to measure a measurement magnetic field that is induced by electrical currents in the moving body. The measuring devices are arranged essentially symmetrically with respect to the magnetic field generating means or the moving body. The measurement magnetic field represents at least one motion variable of the moving body. The measuring device is thereby no longer subjected to the temperature-dependent variations of the exciting field.

Owner:SIEMENS AG

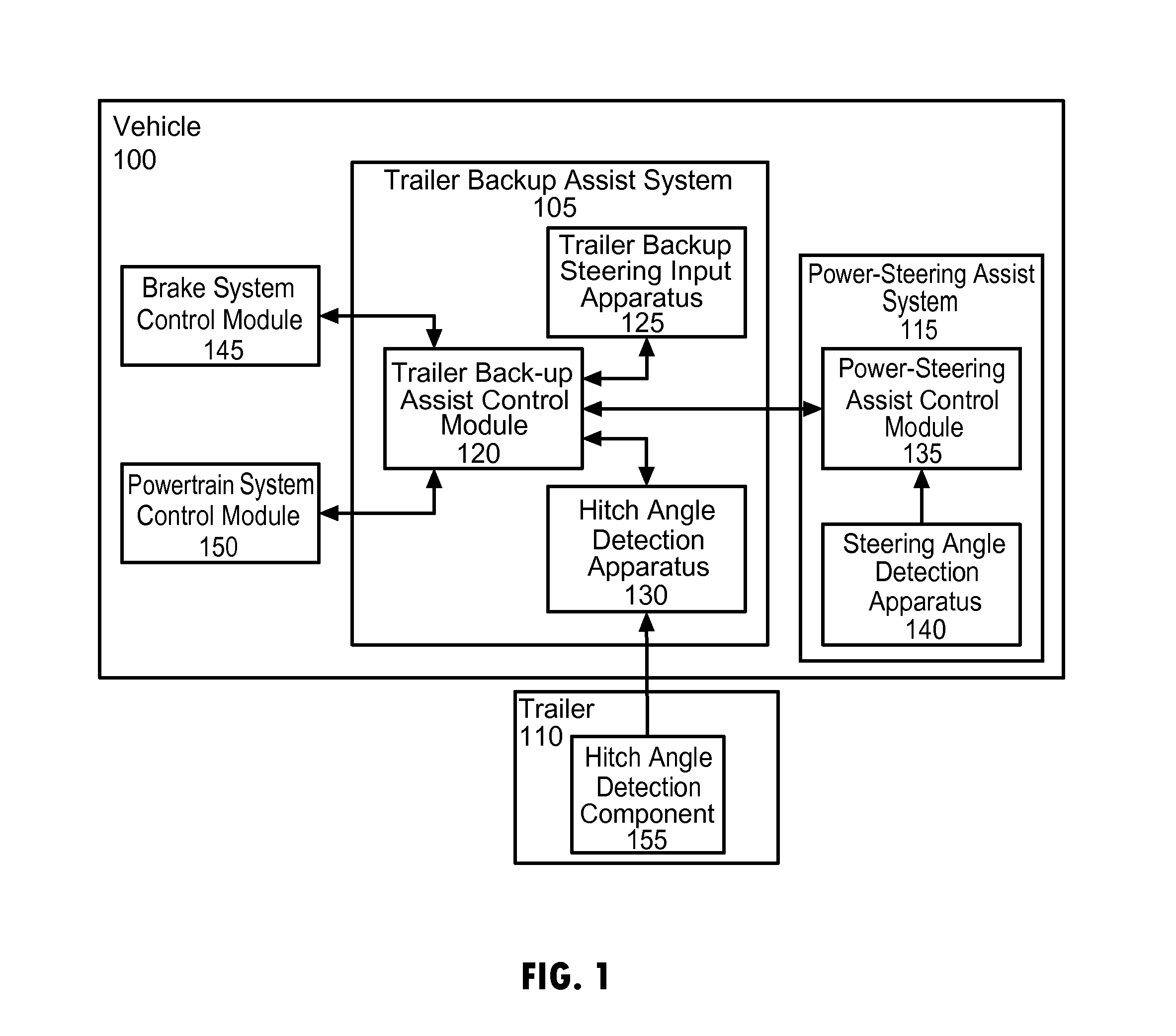

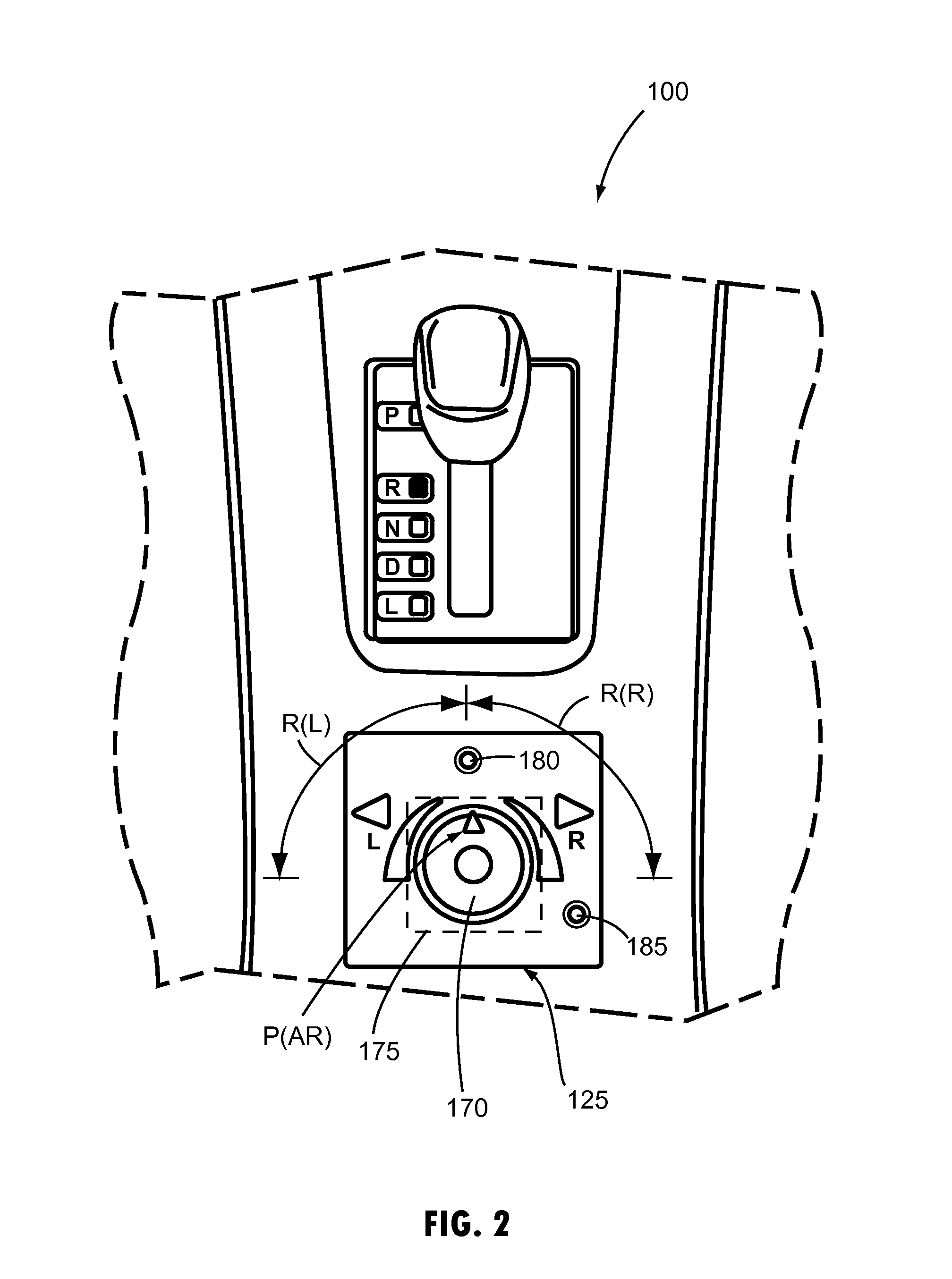

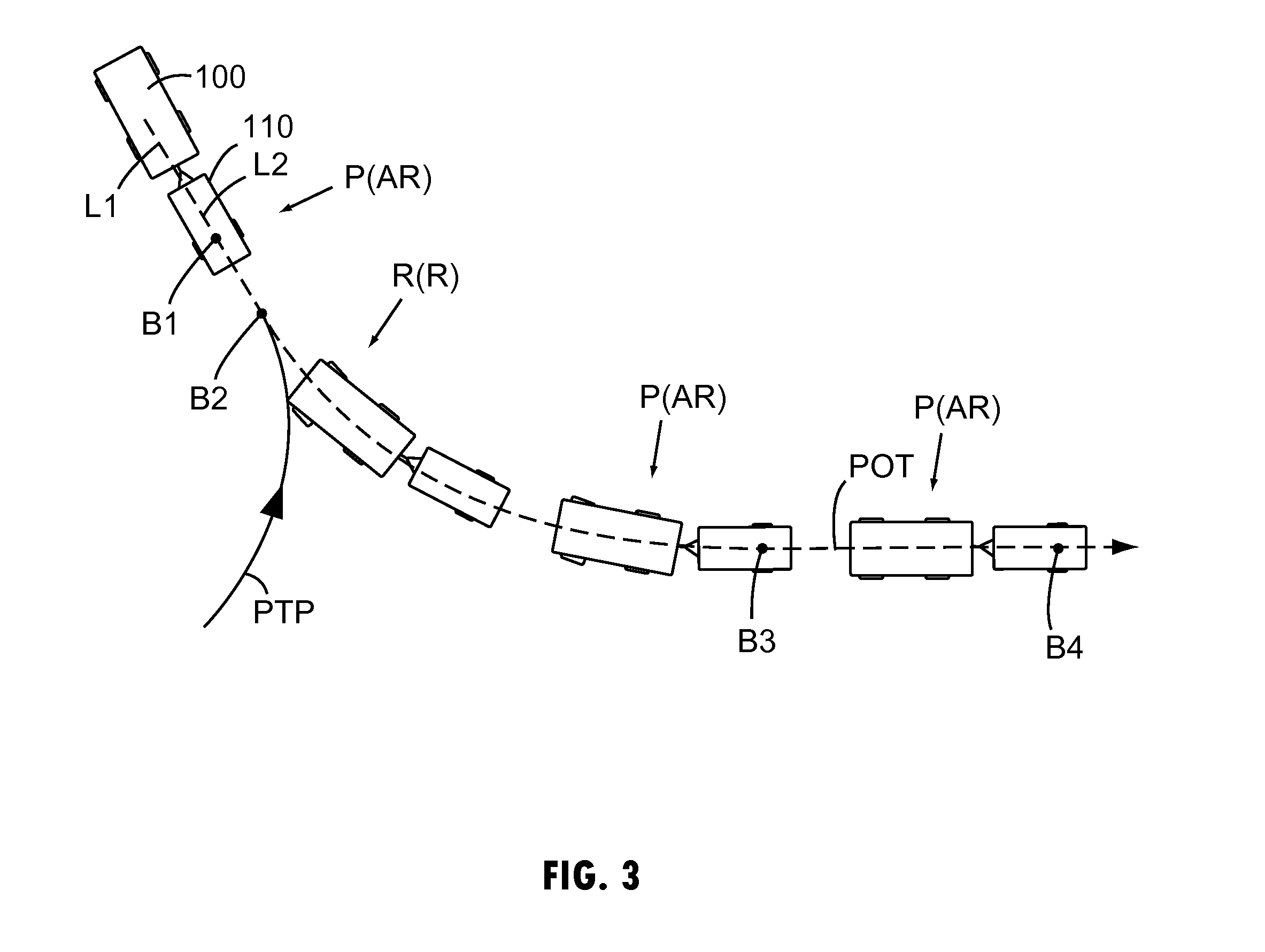

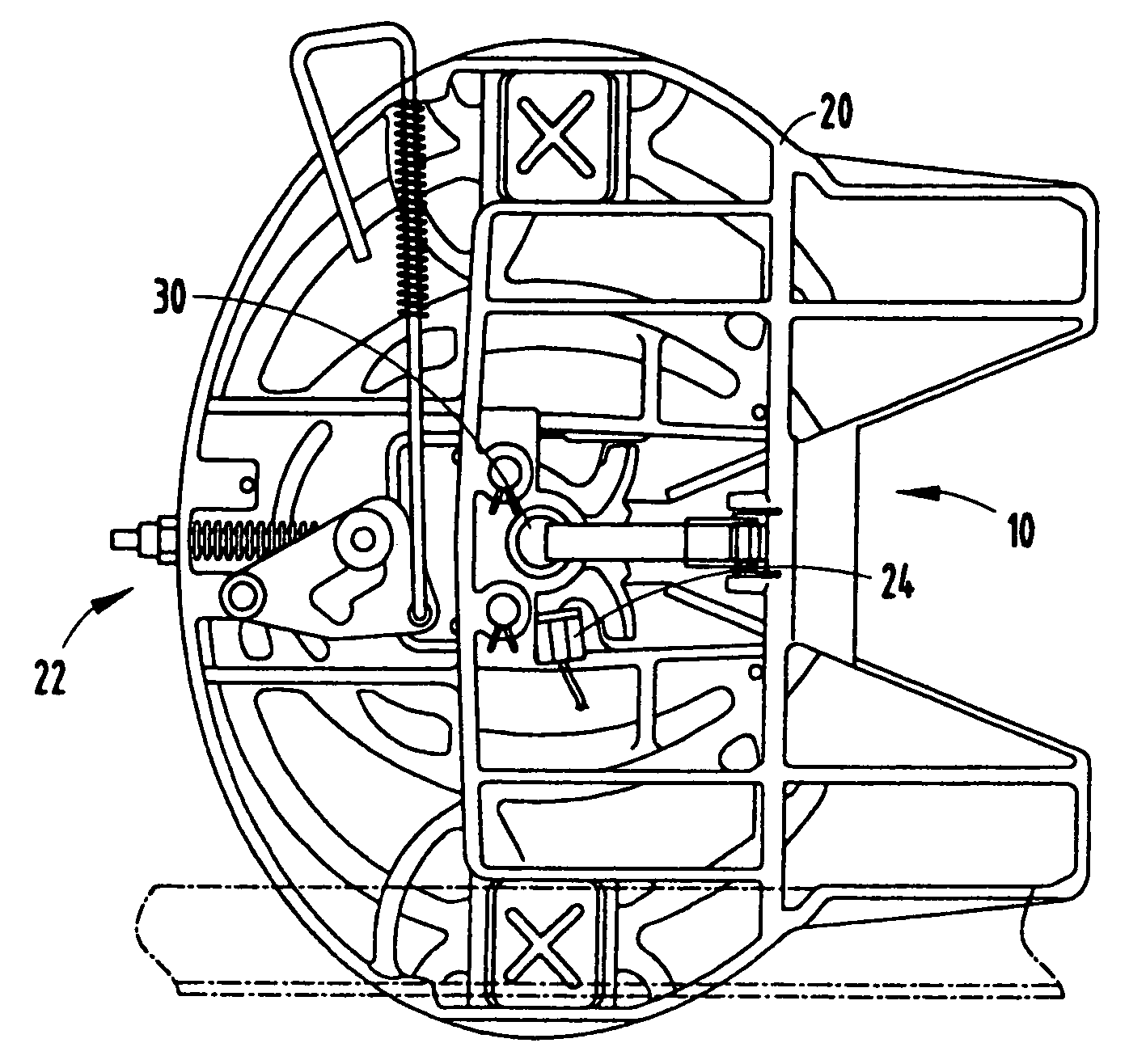

Hitch angle sensor assembly

ActiveUS20140210456A1Solid-state devicesMagnetic field measurement using galvano-magnetic devicesEngineeringVertical axis

In one embodiment, a hitch angle sensor assembly includes a spacer fixed between a hitch ball and a mounting surface on a vehicle. An element is rotatably coupled with the spacer about a vertical axis defined by the hitch ball, and connecting member secures the element to a trailer. A hall sensor is coupled with the spacer and senses a magnetic portion of the element to determine a hitch angle between the vehicle and trailer. This and other embodiments of the hitch angle sensor assembly may be used independently or in combination with other hitch angle sensors or systems to estimate the hitch angle between the vehicle and trailer, which may be advantageously used for operation of the vehicle with a trailer backup assist system.

Owner:FORD GLOBAL TECH LLC

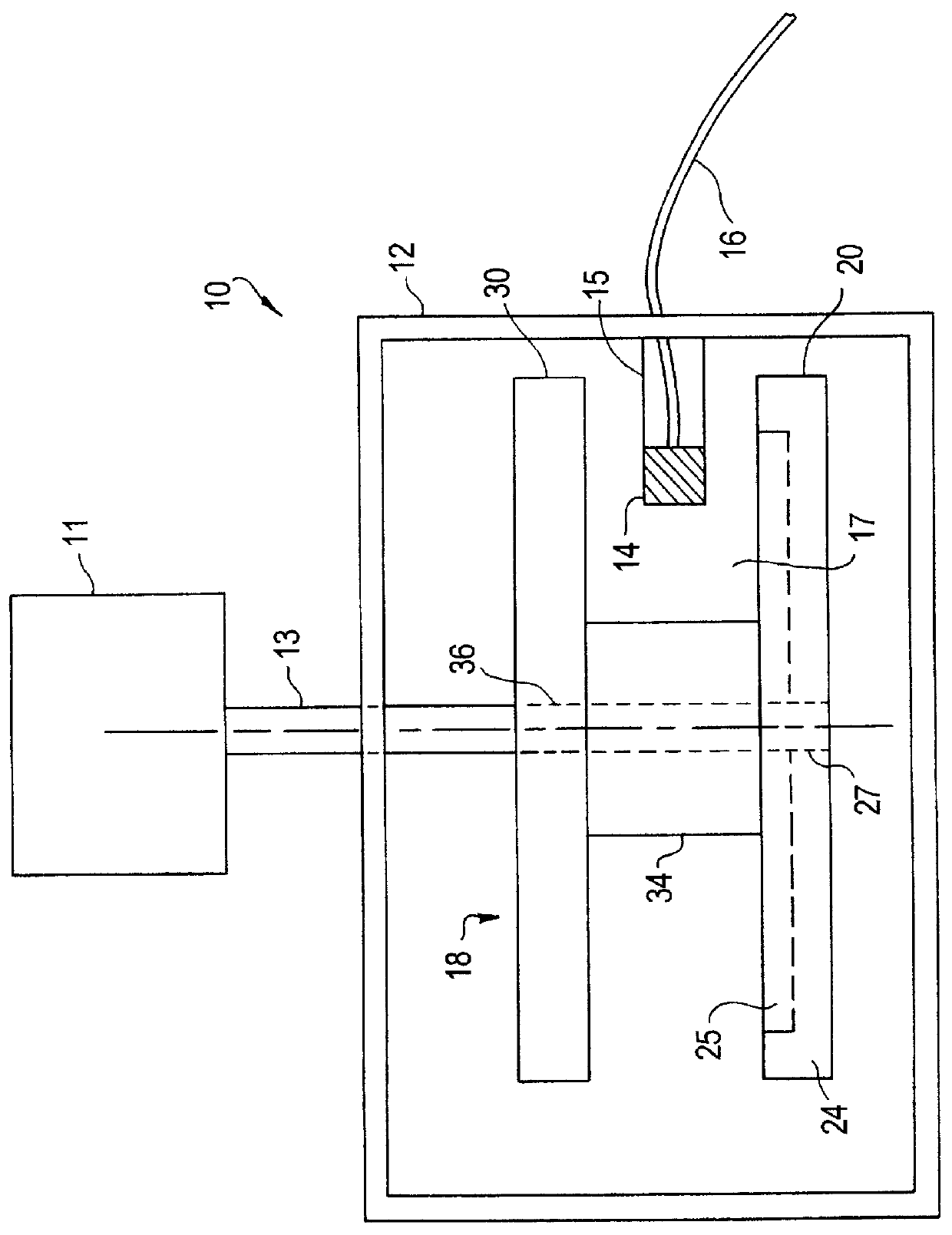

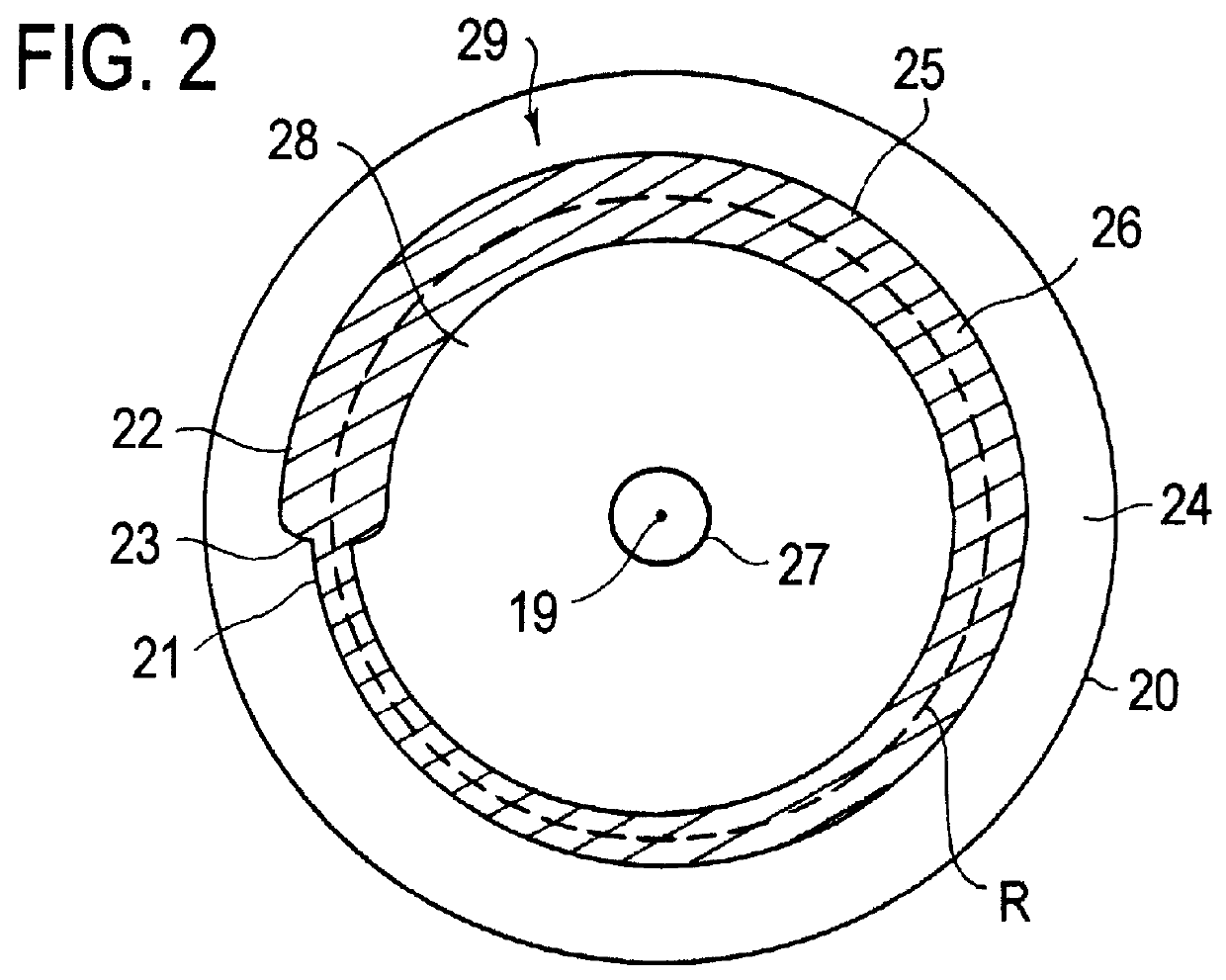

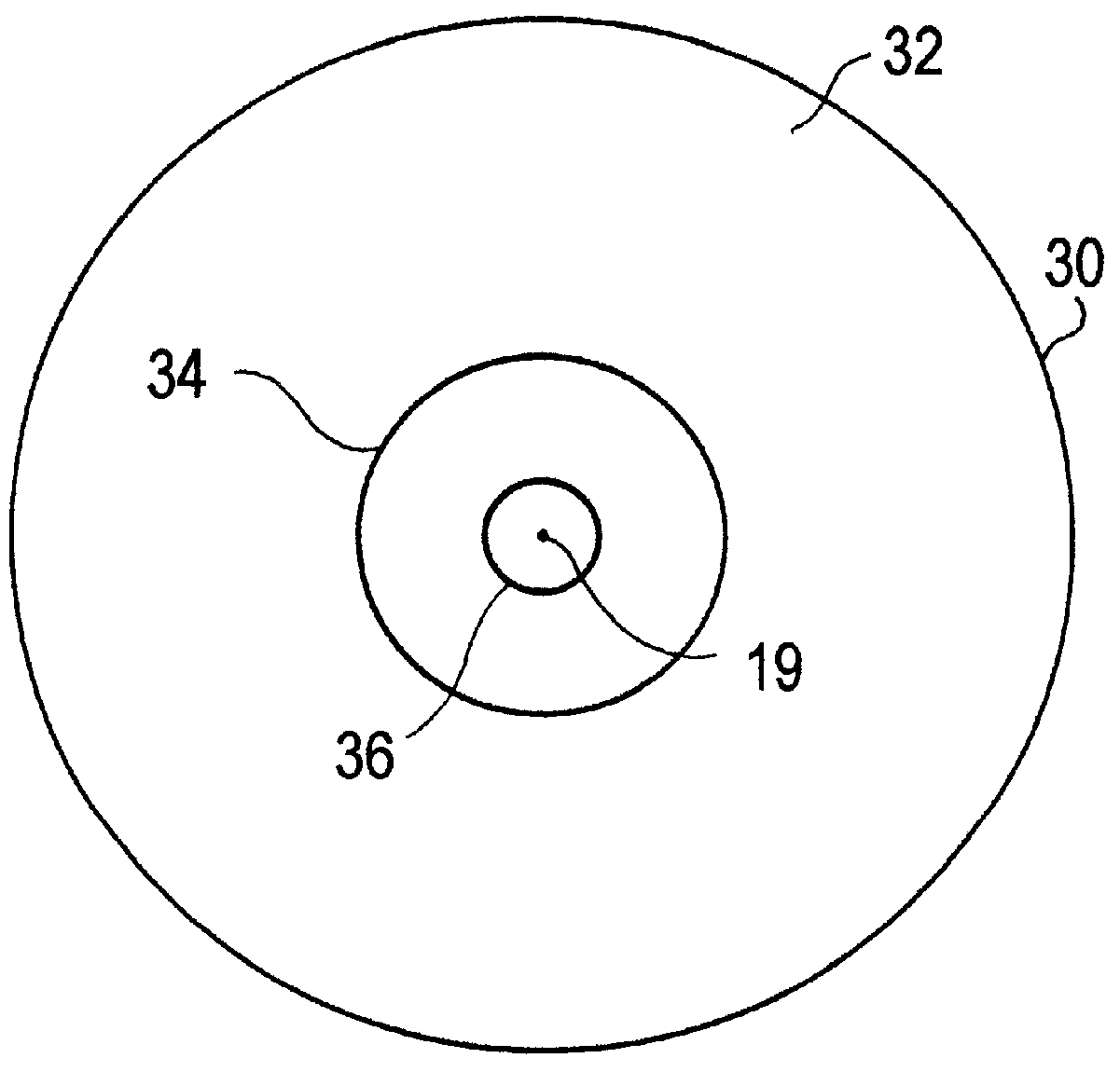

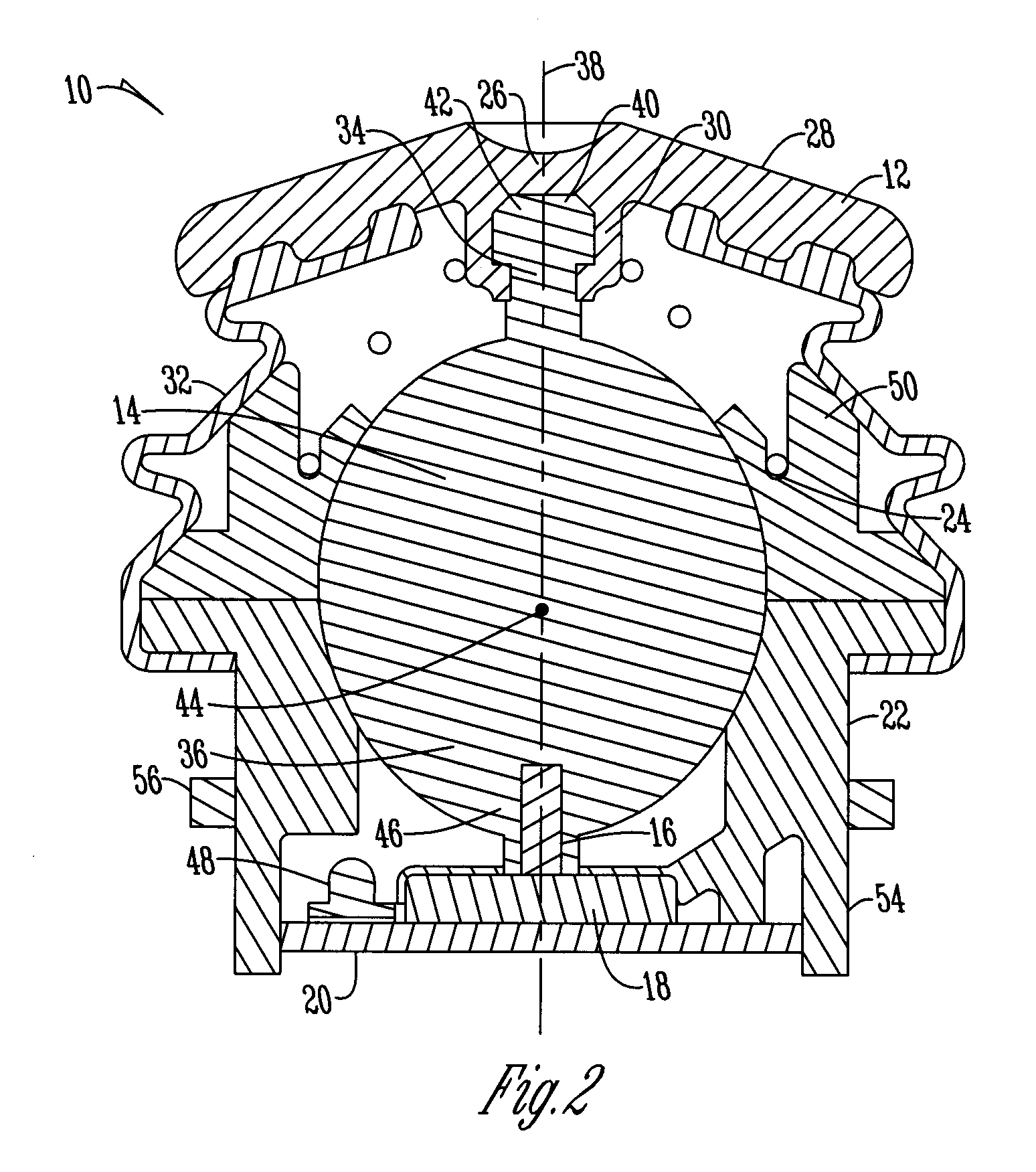

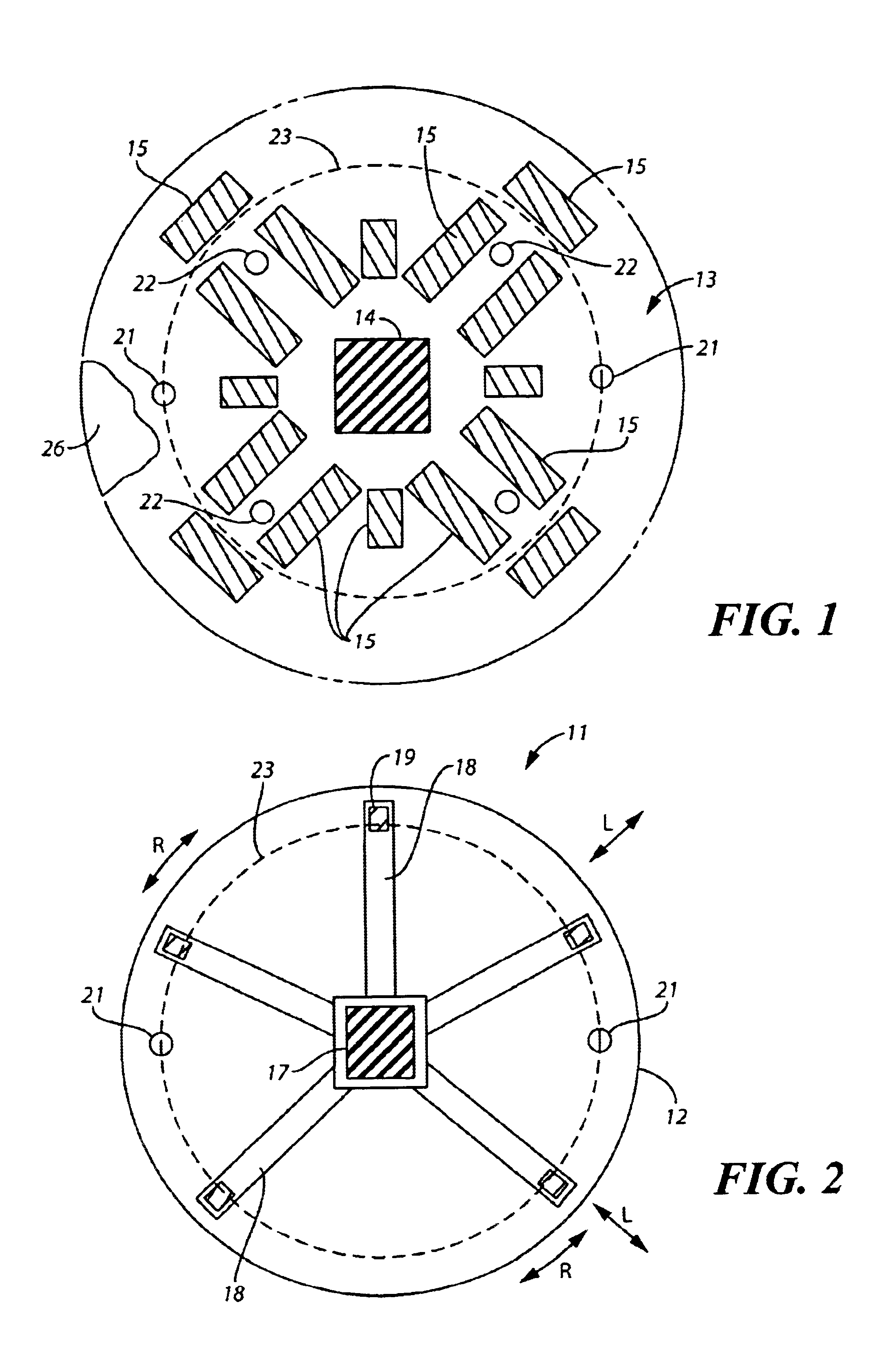

Magnetic position sensor having a variable width magnet mounted into a rotating disk and a hall effect sensor

InactiveUS6124709AEddy current effect is minimized and eliminatedMagnetic-field-controlled resistorsSolid-state devicesPosition sensorPhysics

A linear analog rotary 360 degree magnetic position sensor assembly for sensing the position of rotating objects. A magnet having a varying width is mounted to a magnet disc. A flux return disc is mounted on a shaft opposed to the magnet disc. The magnet generates a magnetic field in an air gap between the discs. A magnetic field sensor such as a hall effect sensor is positioned in the gap and operates to provide an output signal representative of the magnetic field density as the shaft and disc rotate. The output signal changes magnitude in relation to the relative position of the magnet with respect to the magnetic field sensor.

Owner:CTS CORP ELKHART

Magnetic field sensor apparatus

ActiveUS7474093B2Force measurement by measuring magnetic property varationAmplifier modifications to reduce noise influenceStress sensorAcoustics

A magnetic field sensor apparatus includes a first magnetic field sensor and a second magnetic field sensor, arranged on a substrate in a spaced manner from each other, a first temperature sensor with an output for a first temperature sensor signal, a second temperature sensor with an output for a second temperature sensor signal, a first stress sensor with an output for a first stress sensor signal, and a second stress sensor with an output for a second stress sensor signal, wherein the first temperature sensor and the first stress sensor are arranged more closely to the first magnetic field sensor or at a location identical with the first magnetic field sensor, and the second temperature sensor and the second stress sensor are arranged more closely to the second magnetic field sensor than to the first magnetic field sensor or at a location identical with the second magnetic field sensor.

Owner:INFINEON TECH AG

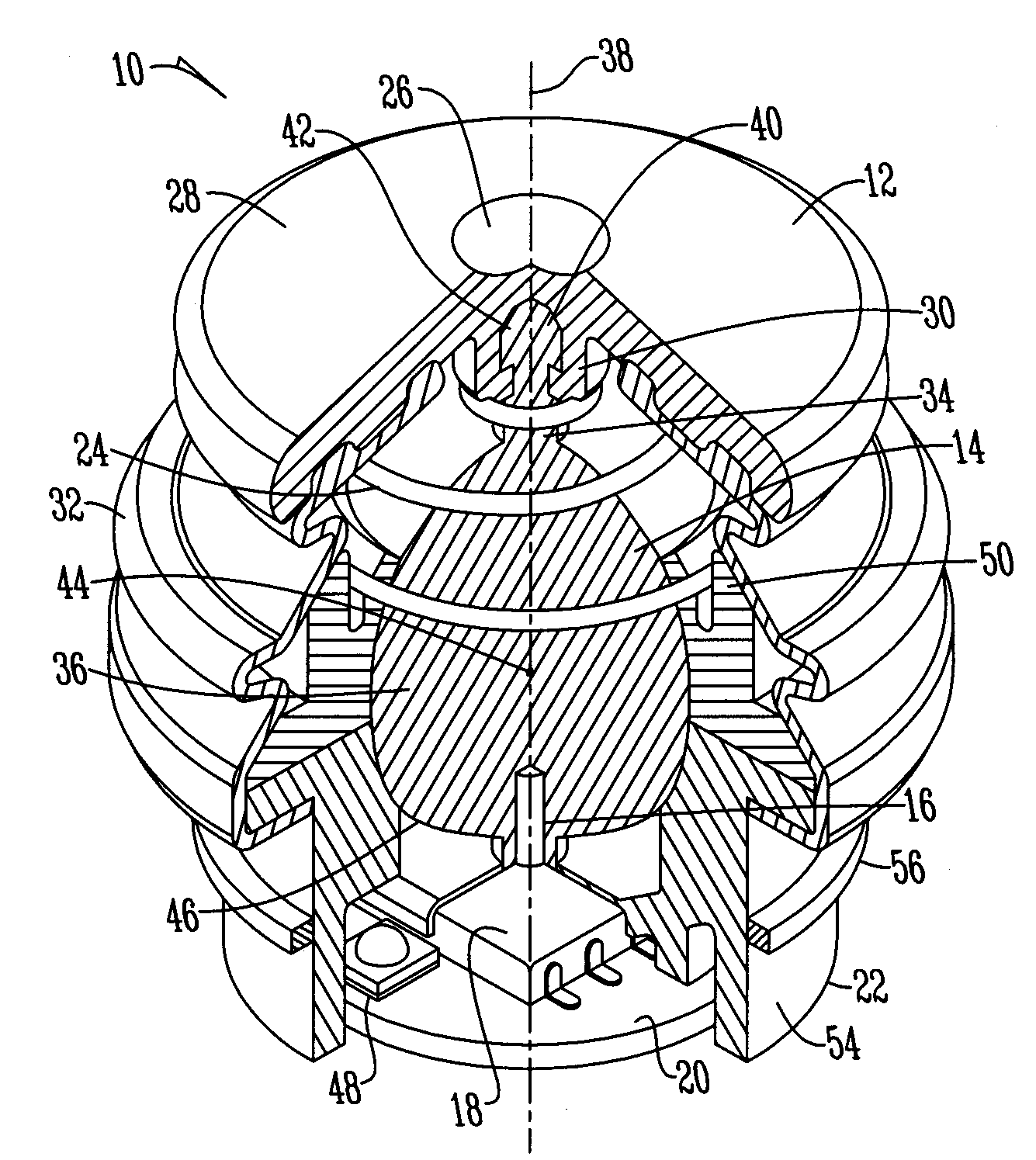

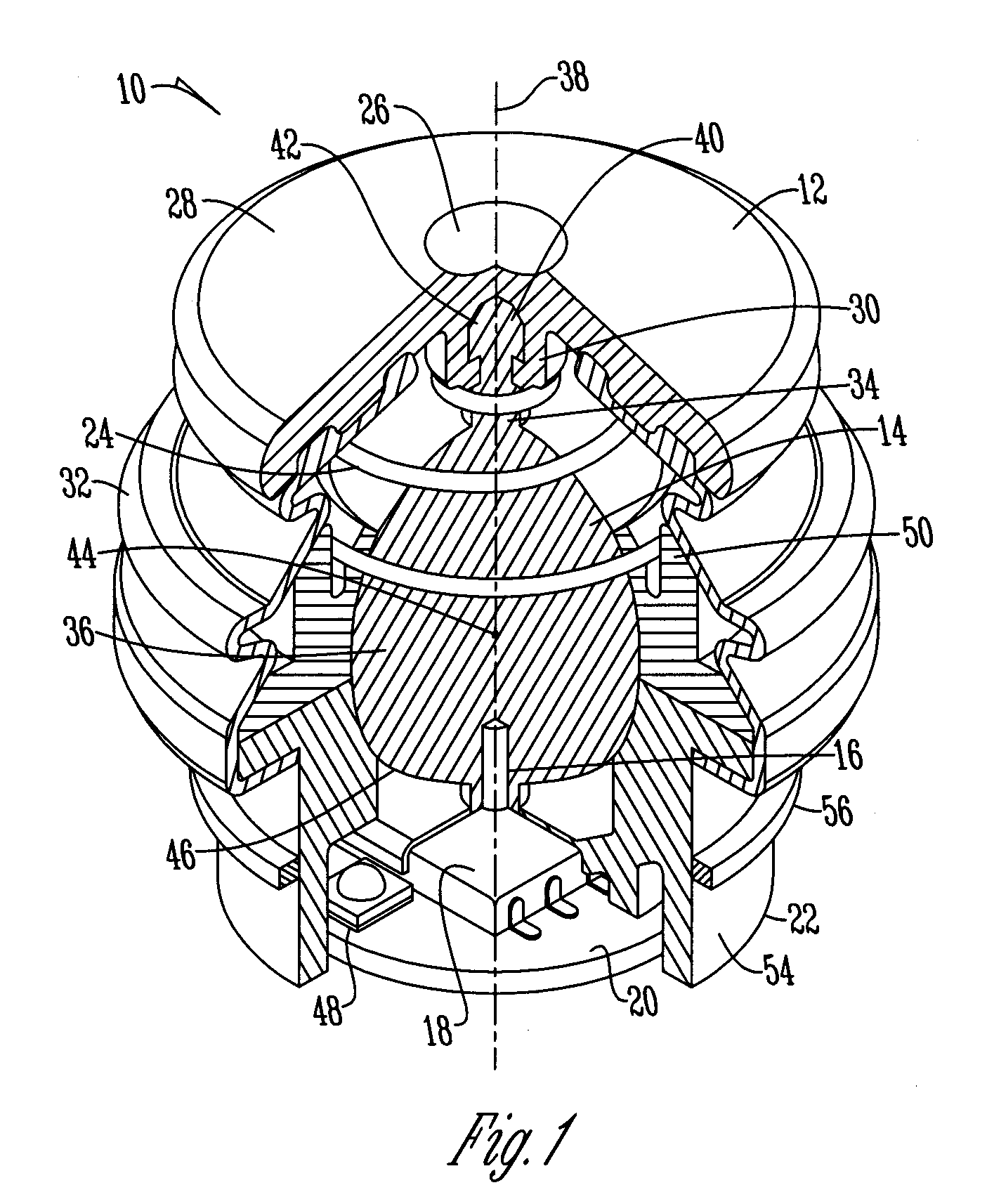

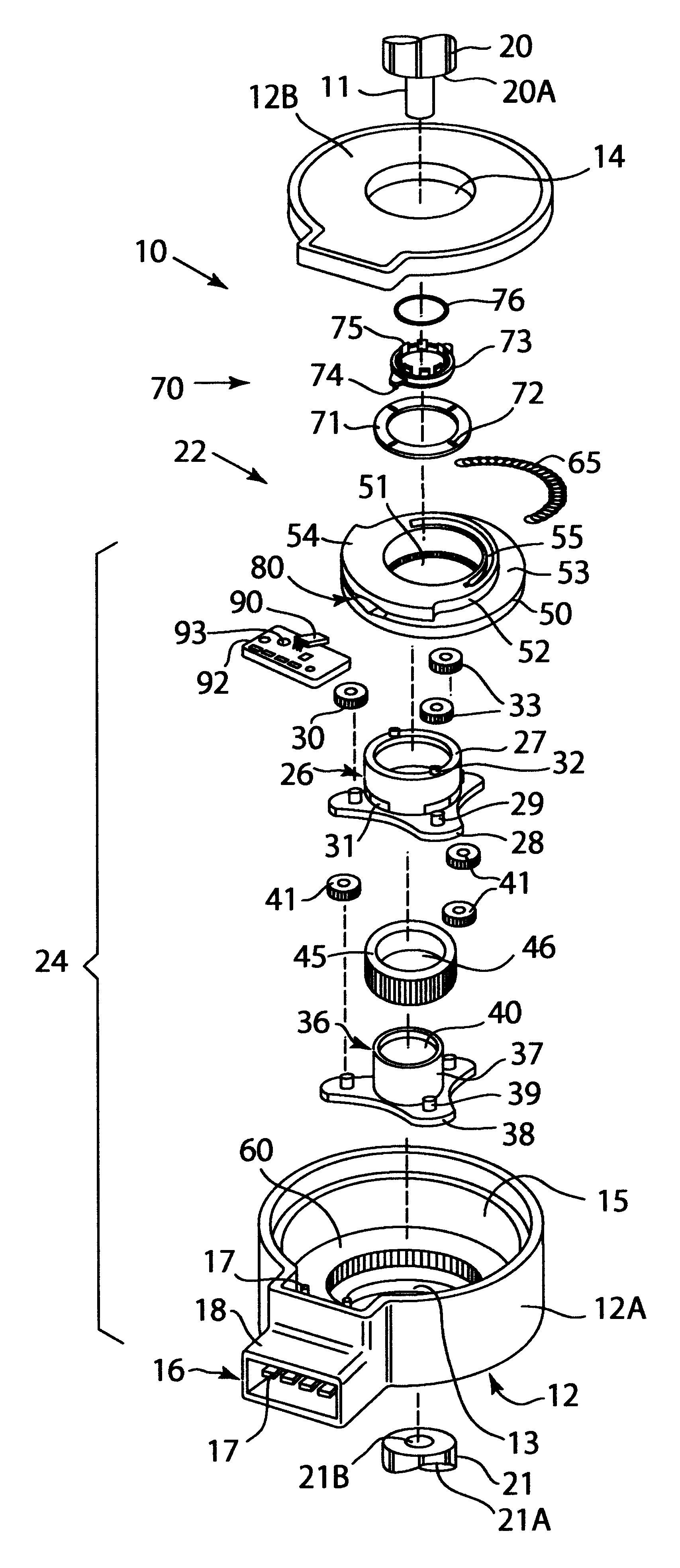

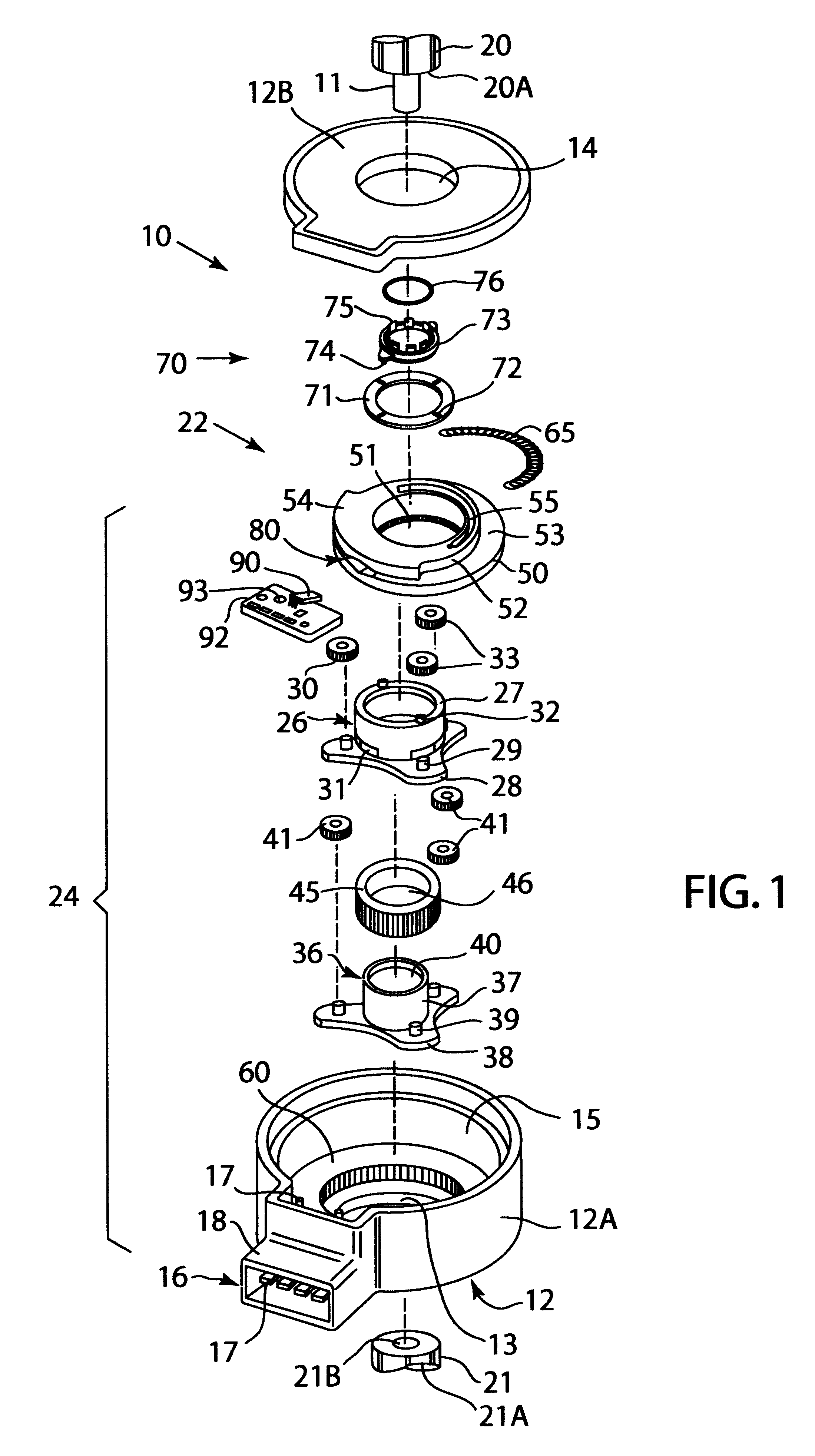

Joystick and method of manufacturing the same

ActiveUS20090212766A1Manual control with multiple controlled membersControlling membersJoystickEngineering

A joystick having a movable member that includes a shaft portion and a spherical portion wherein the shaft portion has a diameter less than the spherical portion. An actuating member is secured to the shaft portion of the movable member to provide actuation of the movable member. A magnet is disposed within the spherical portion of the movable member and positioned adjacent a three axis sensor such that the magnet moves in a hemispherical pattern along the three axis sensor to operate a device.

Owner:DANFOSS POWER SOLUTIONS INC

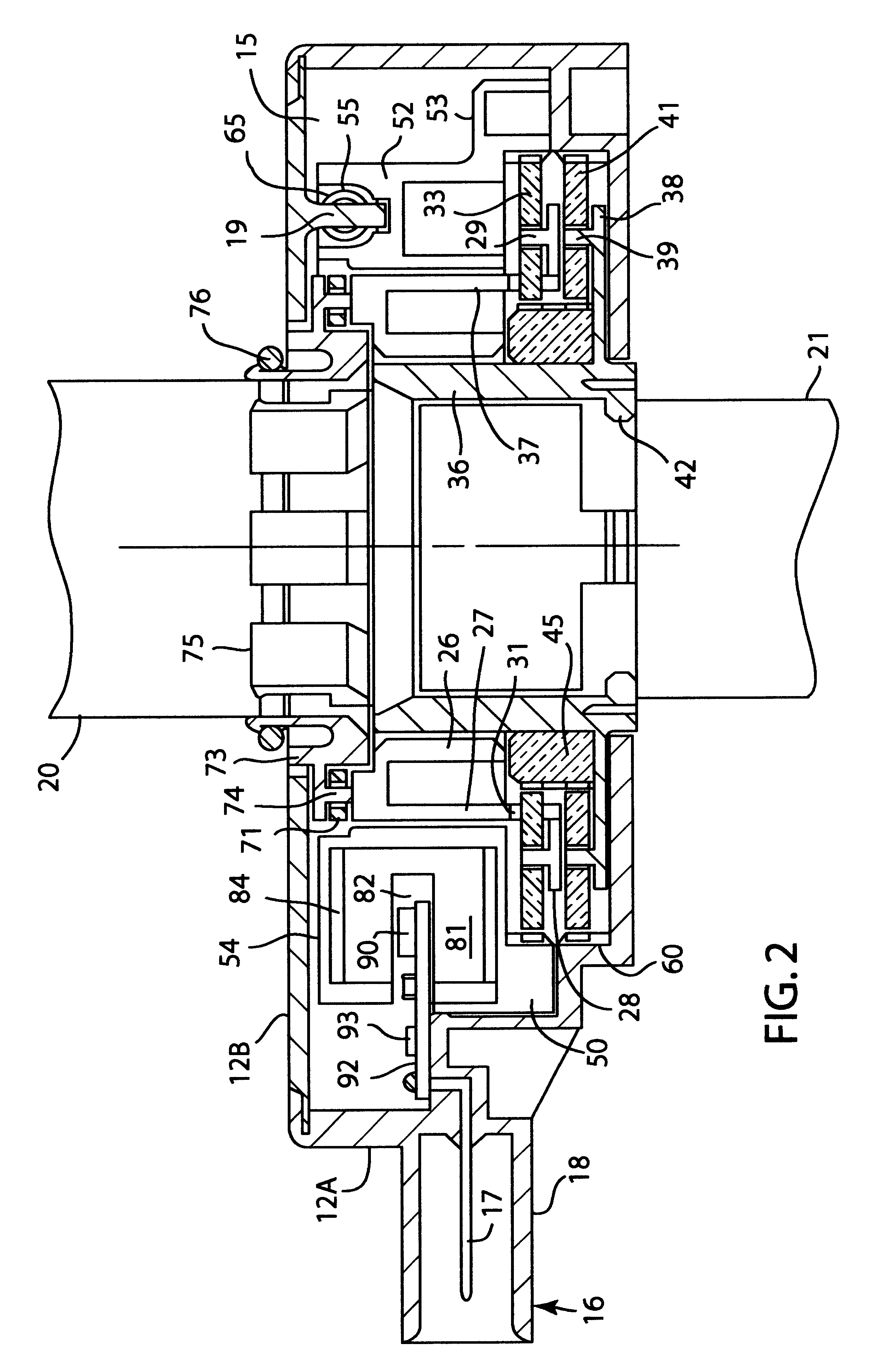

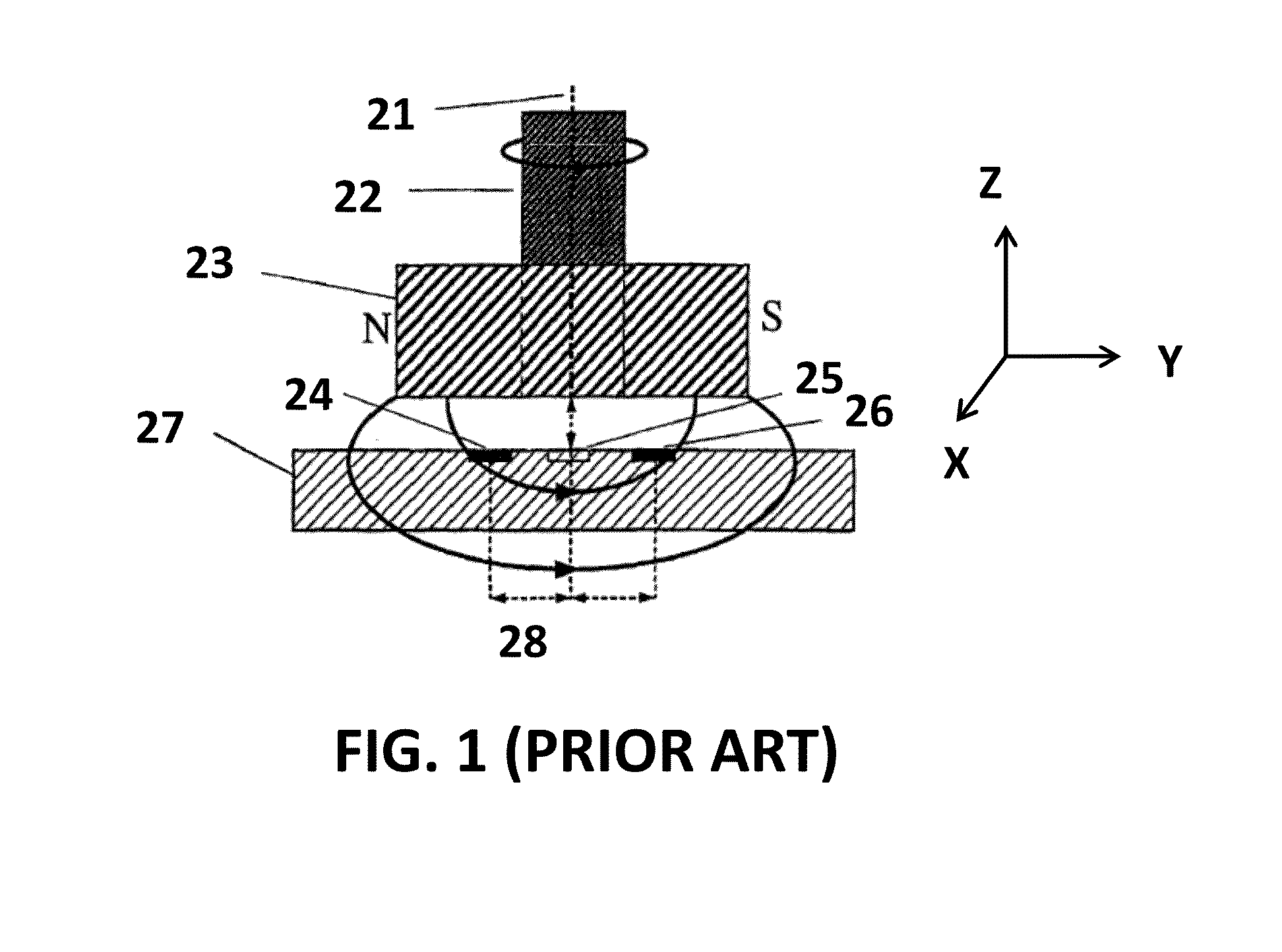

Non-contacting sensor for measuring relative displacement between two rotating shafts

A sensor for measuring the relative displacement between two rotating shafts. The sensor can sense a torque applied to the steering wheel of a vehicle. The sensor has a housing that has apertures at each end. The rotating shafts pass into the housing. A sensor assembly is located in the housing and connected to the shafts. The sensor assembly generates an electrical signal that is proportional to the relative rotational displacement between the shafts. An electrical connector is located in the housing and electrically connects with the sensor assembly. The sensor assembly has a planetary gear assembly that is connected to the shafts. A variable magnetic field generator is connected to the planetary gear assembly and moves proportional to the relative rotational displacement of the shafts. A magnetic field sensor is located adjacent the variable magnetic field generator and generates the electrical signal as the variable magnetic field generator moves.

Owner:CTS CORP ELKHART

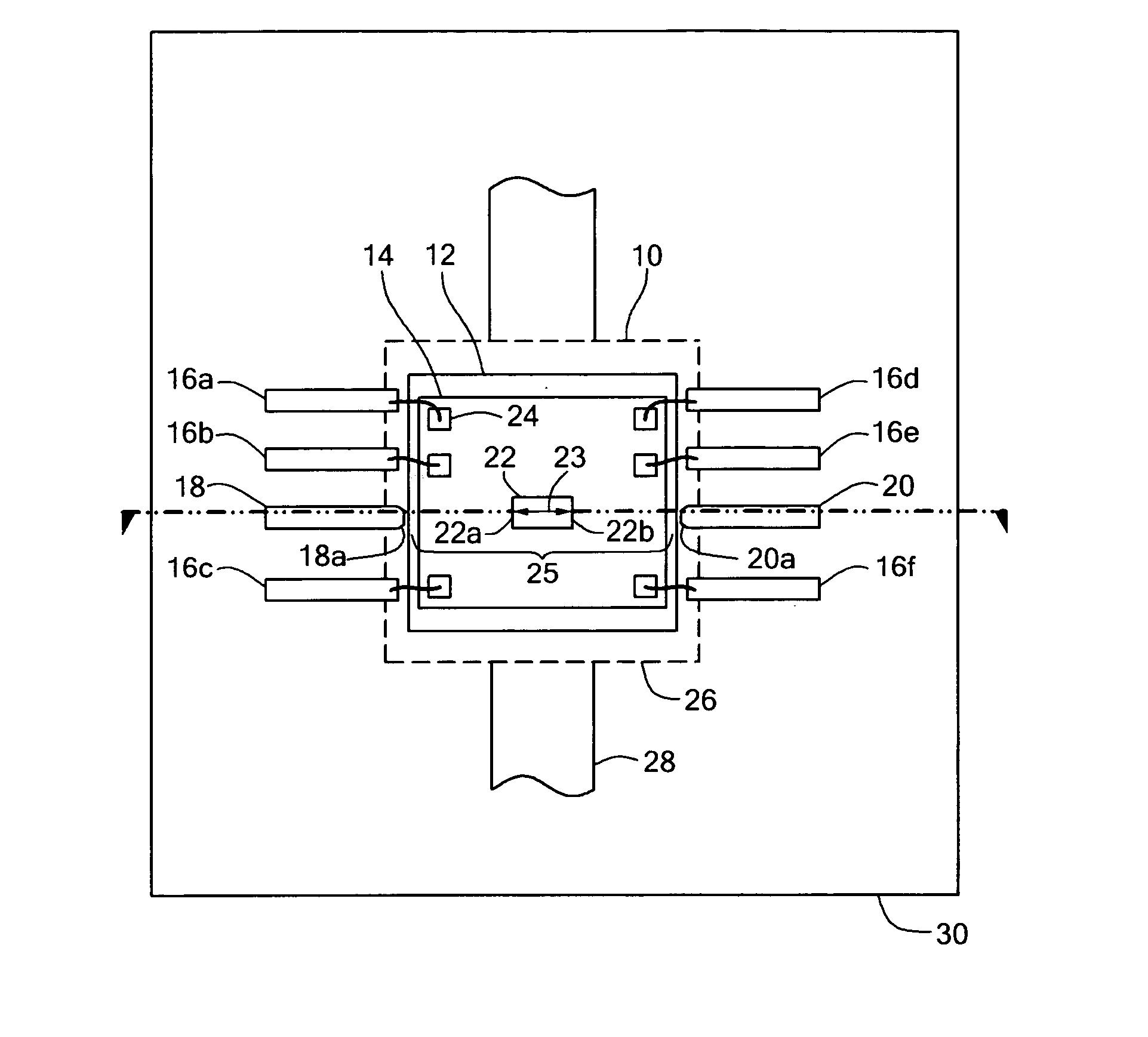

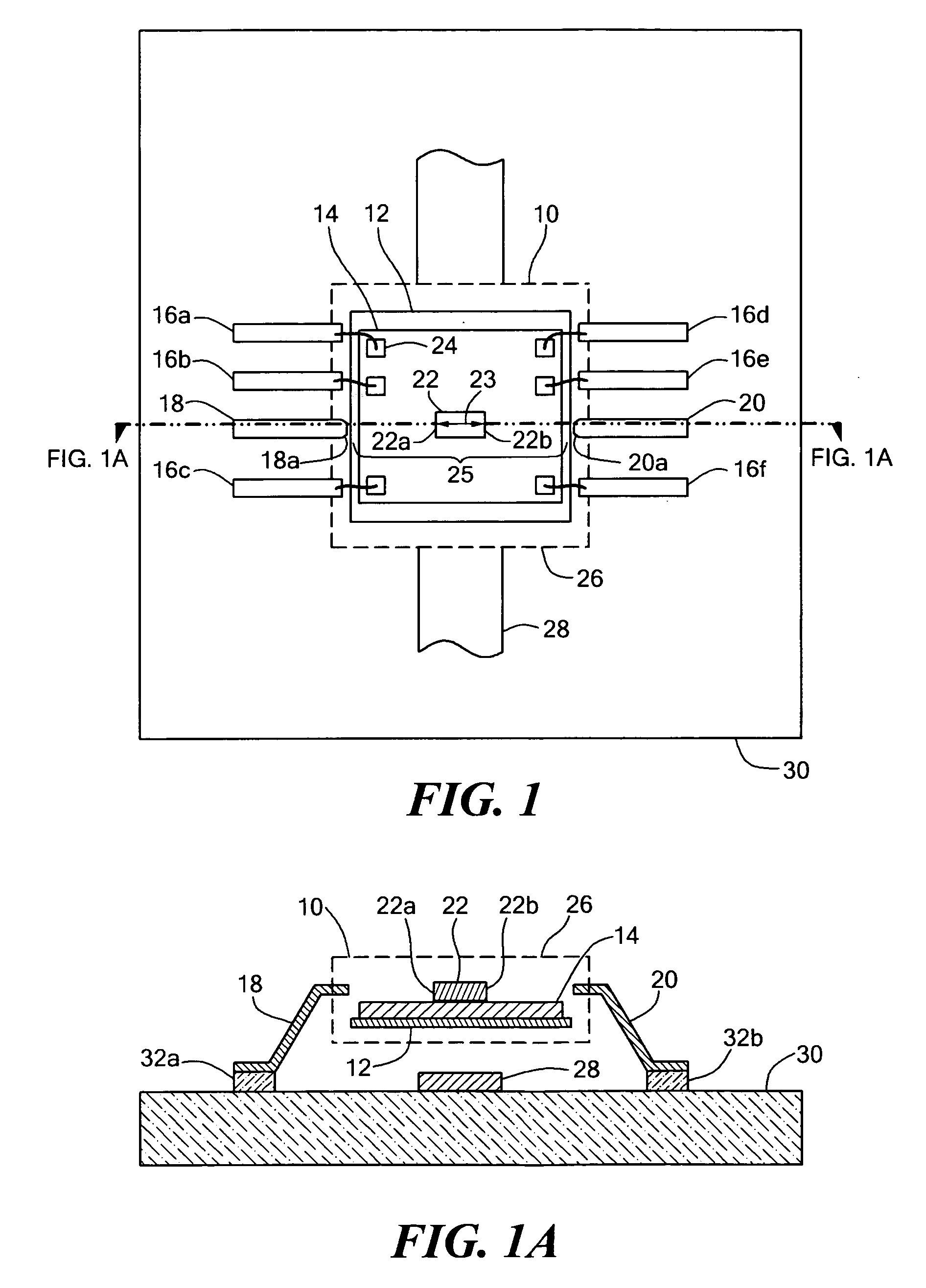

Integrated sensor having a magnetic flux concentrator

ActiveUS20060175674A1High sensitivitySolid-state devicesGalvano-magnetic hall-effect devicesCurrent sensorMagnetic flux

An integrated sensor has a magnetic field sensing element and first and second relatively high magnetically permeable members forming a gap, wherein the magnetic field element is disposed within the gap. The magnetically permeable members provide an increase in the flux experienced by the magnetic field sensing element in response to a magnetic field. The integrated sensor can be used as a current sensor, a proximity detector, or a magnetic field sensor.

Owner:ALLEGRO MICROSYSTEMS INC

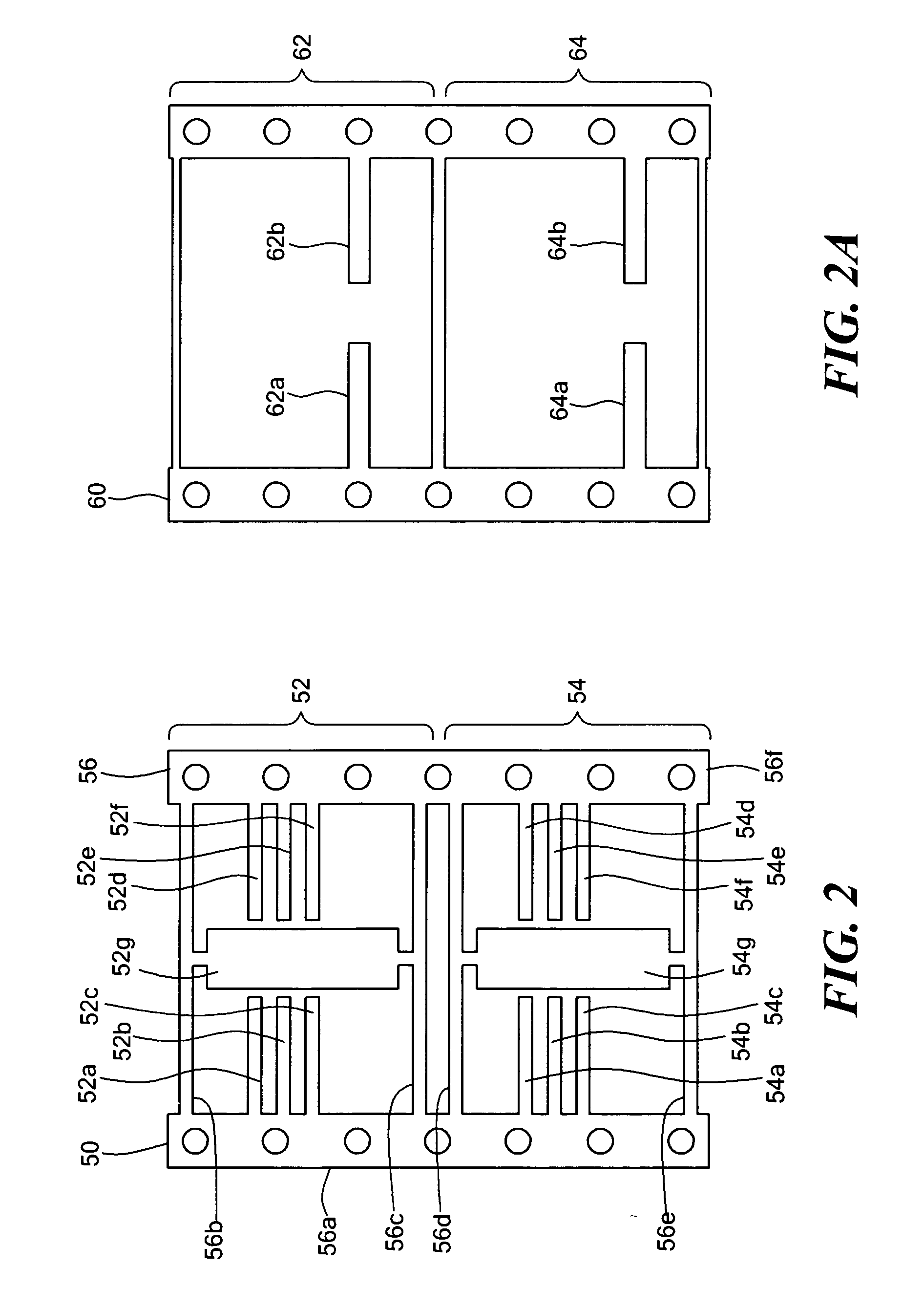

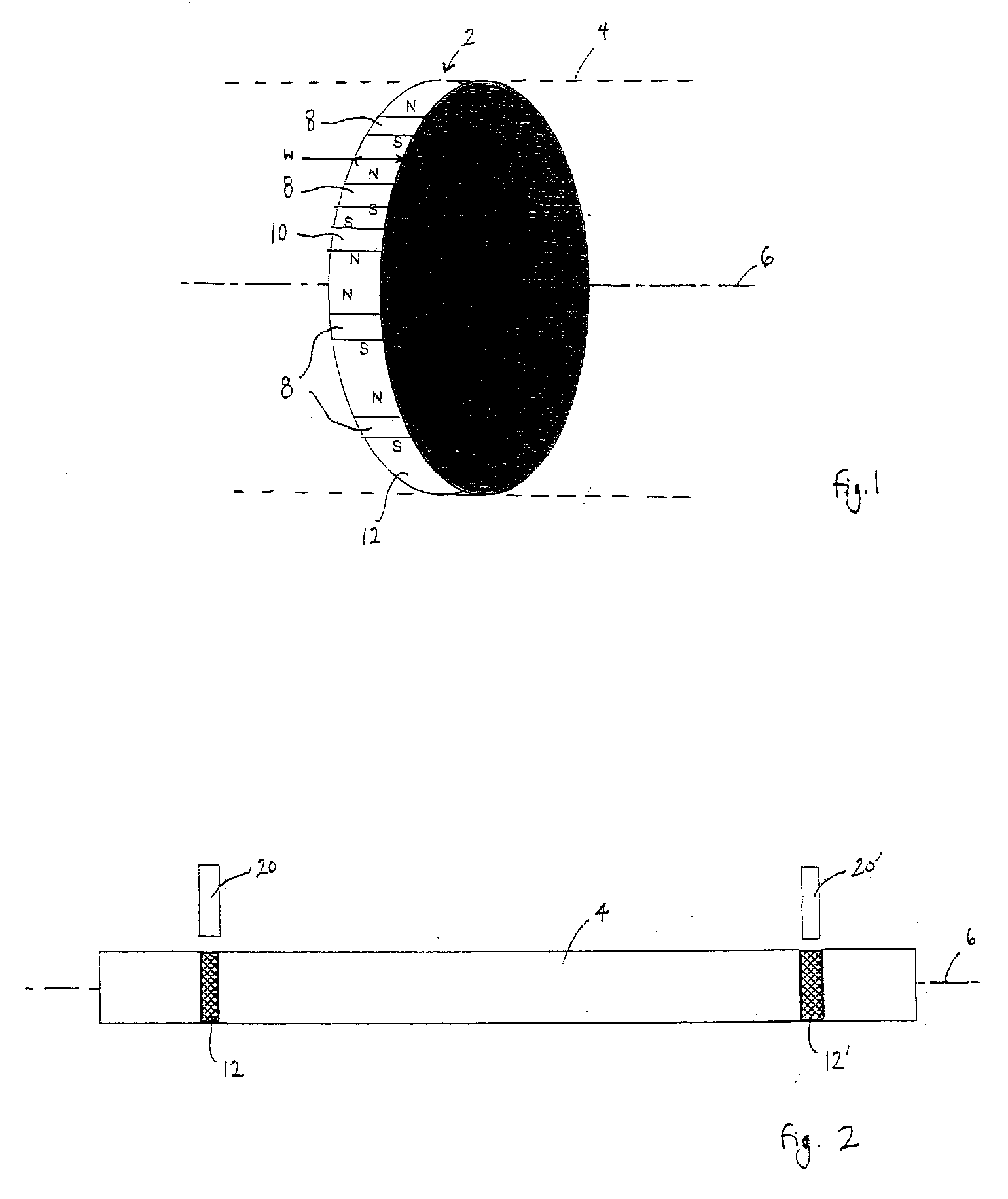

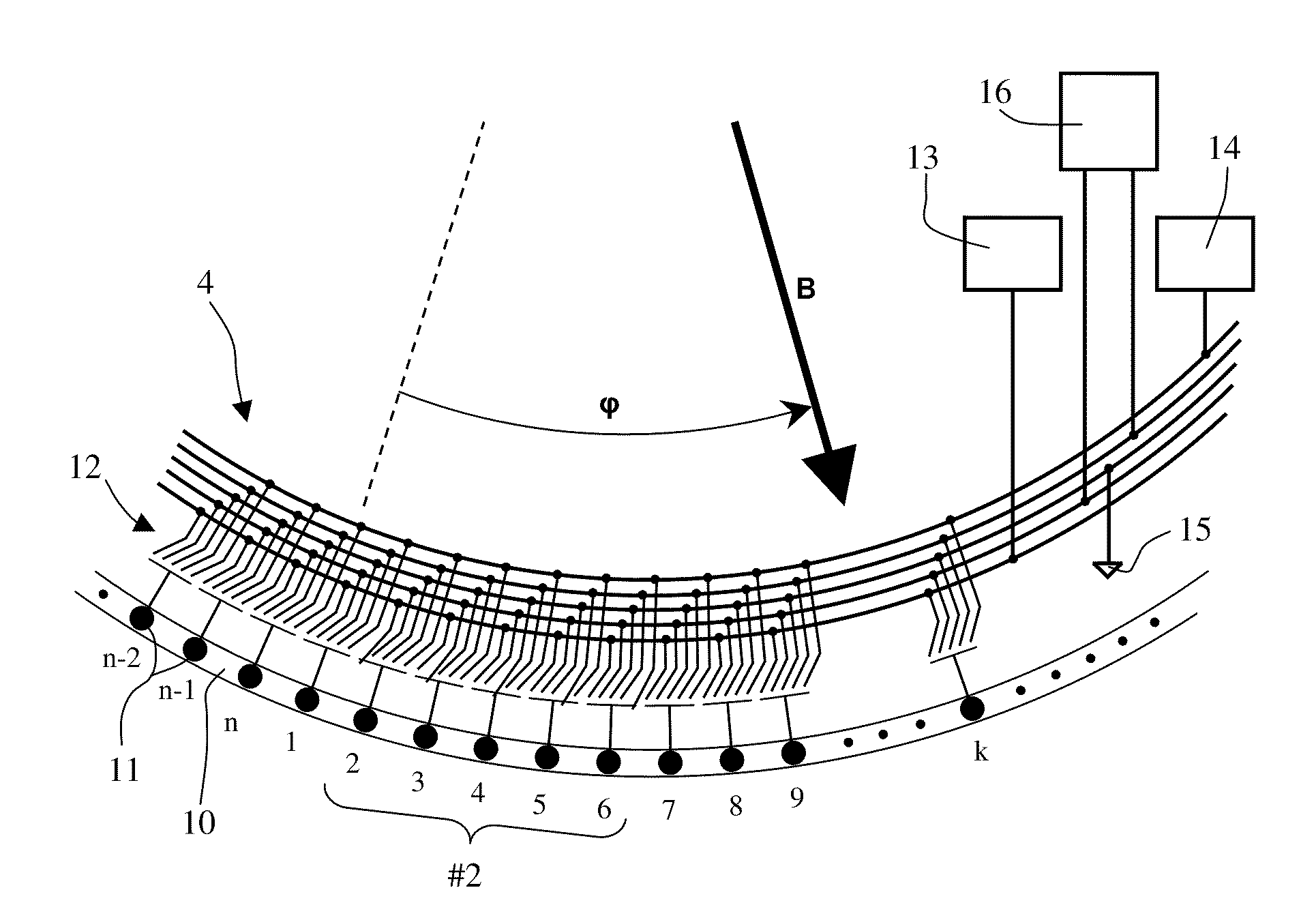

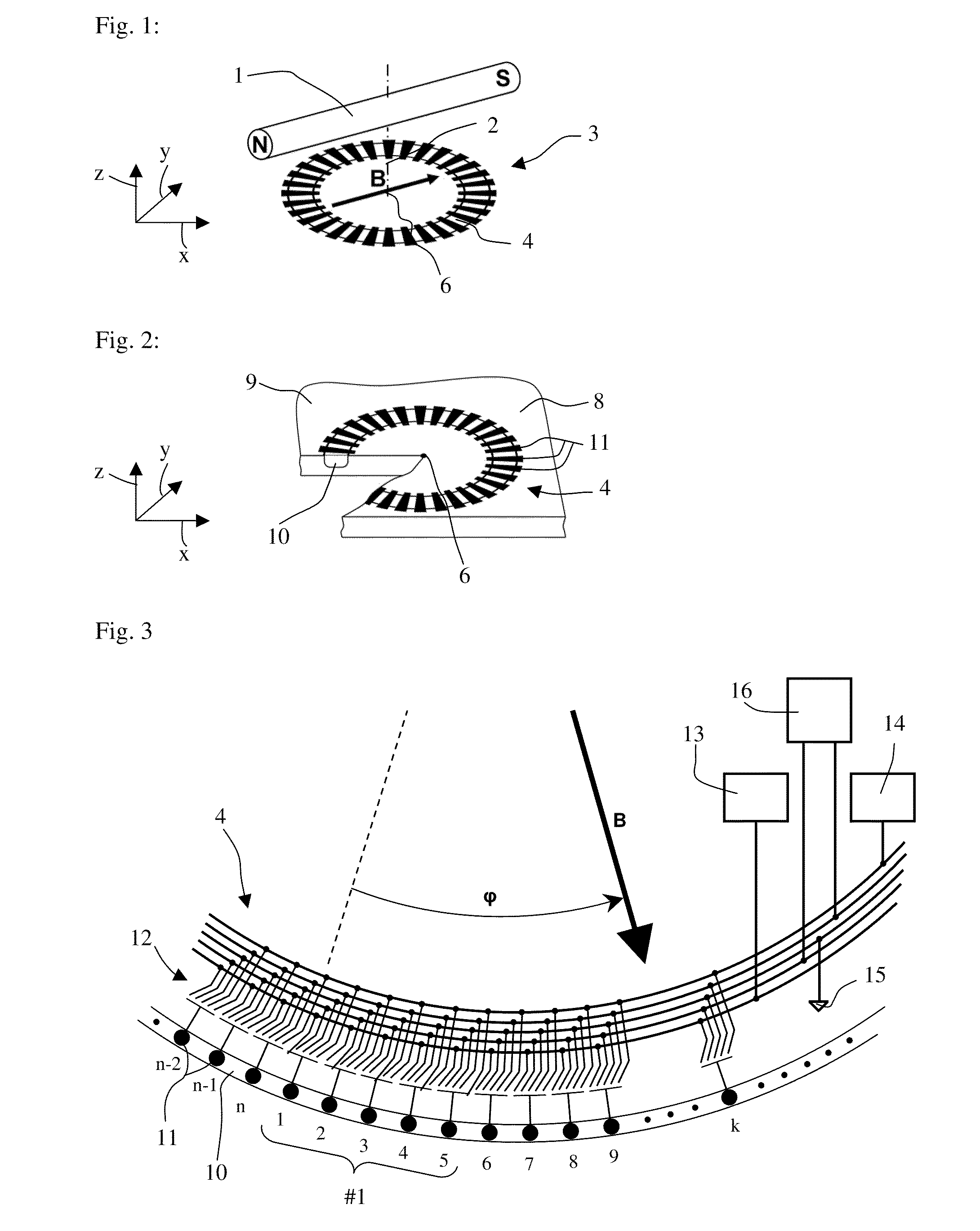

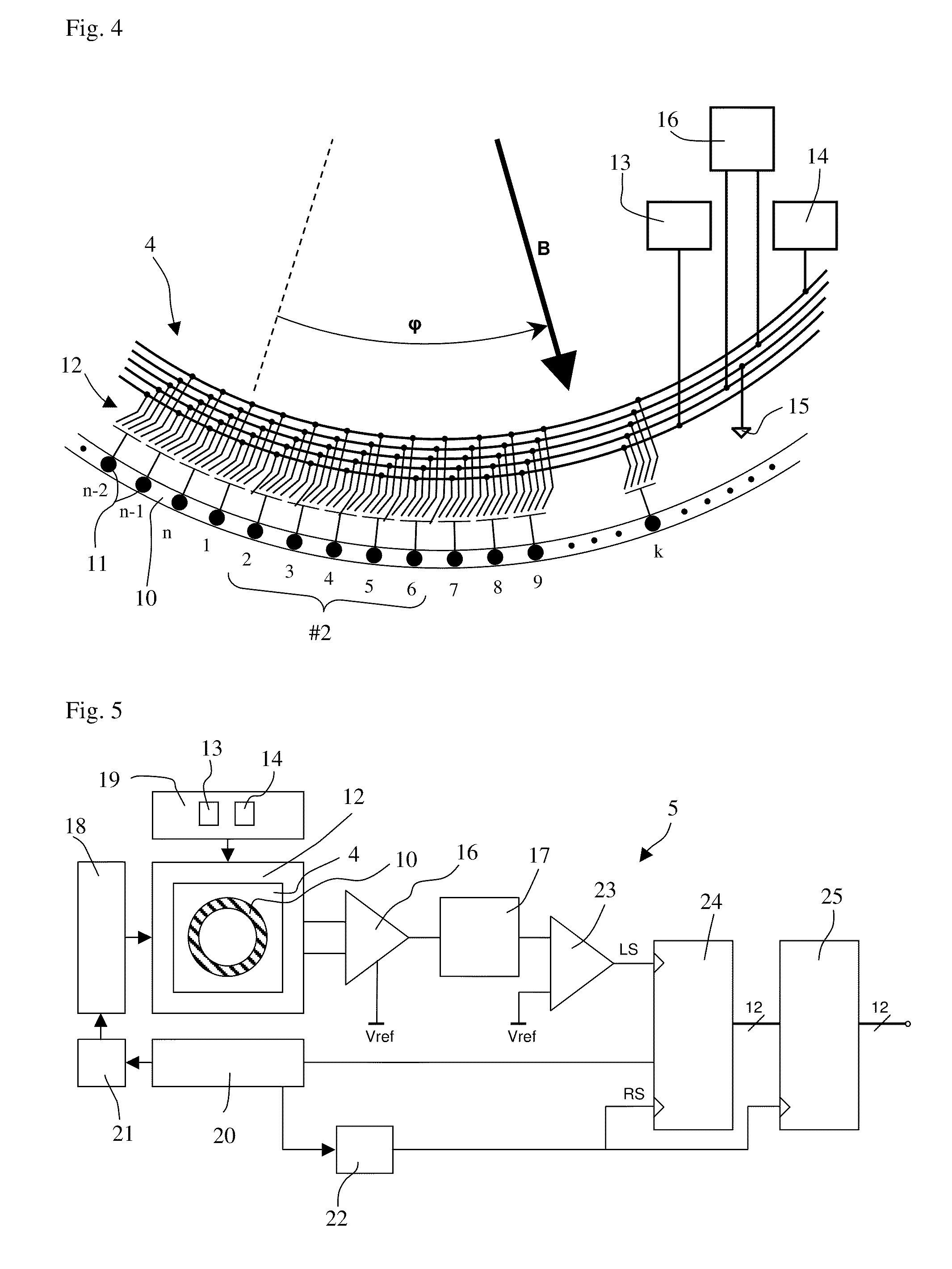

Rotation Sensing

A compact arrangement which enables rotation of a component (4) of an apparatus to be sensed is provided. A component adapted for use in such an arrangement comprises a body having an axis of rotation (6) and a plurality of discrete magnetised regions (8) thereon, each formed in a layer of material (12) on the surface of the body, the magnetised regions being circumferentially distributed at substantially the same axial position to enable rotation of the component relative to a sensor (20, 20′) to be monitored. Methods for manufacturing a suitable component are also described. The arrangement disclosed enables the rotational position of component, such as a shaft for example, to be sensed using a Hall effect sensor, and a component may be modified in accordance with the invention without substantially increasing its volume.

Owner:EQUIPMAKE

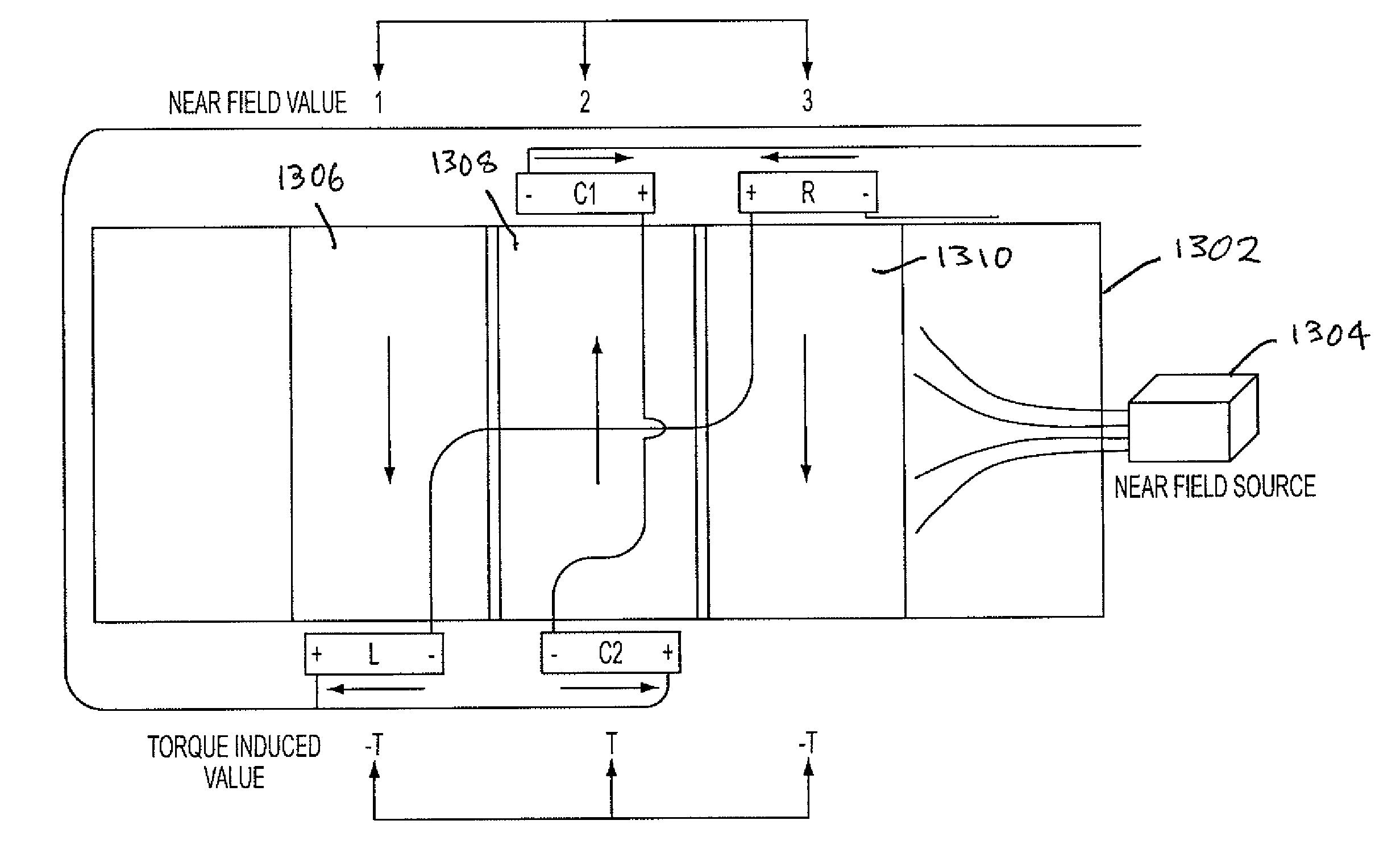

Magnetoelastic torque sensor with ambient field rejection

ActiveUS8087304B2Cancellation effectEliminate the effects ofSolid-state devicesWork measurementCondensed matter physicsTorque sensor

Owner:METHODE ELETRONICS INC

Magnetic Field Sensor For Measuring A Direction Of A Magnetic Field In A Plane

ActiveUS20100164491A1Solid-state devicesMagnetic field measurement using galvano-magnetic devicesControl signalElectronic switch

A magnetic field sensor for measuring a direction of a magnetic field in a plane comprises a sensing structure comprising a ring-shaped well, a plurality of contacts of equal size placed at equal distance from each other along the ring-shaped well, and an electronic circuit comprising a plurality of electronic switches associated with the contacts of the sensing structure, a logic block for controlling the electronic switches, at least one current source, a means for measuring a difference between a first voltage and a second voltage, a timing circuit providing a control signal for controlling the logic block and providing a reference signal, wherein the logic block is adapted to close and open the electronic switches under the control of the control signal according to a predetermined scheme such that a predetermined number of contacts of the plurality of contacts form a vertical Hall element that is supplied with current from the at least one current source and that has two contacts connected to the means for measuring, and such that the vertical Hall element is moved in steps along the ring-shaped well, and a means for measuring a phase shift between the reference signal and an output signal of the voltage measuring means.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

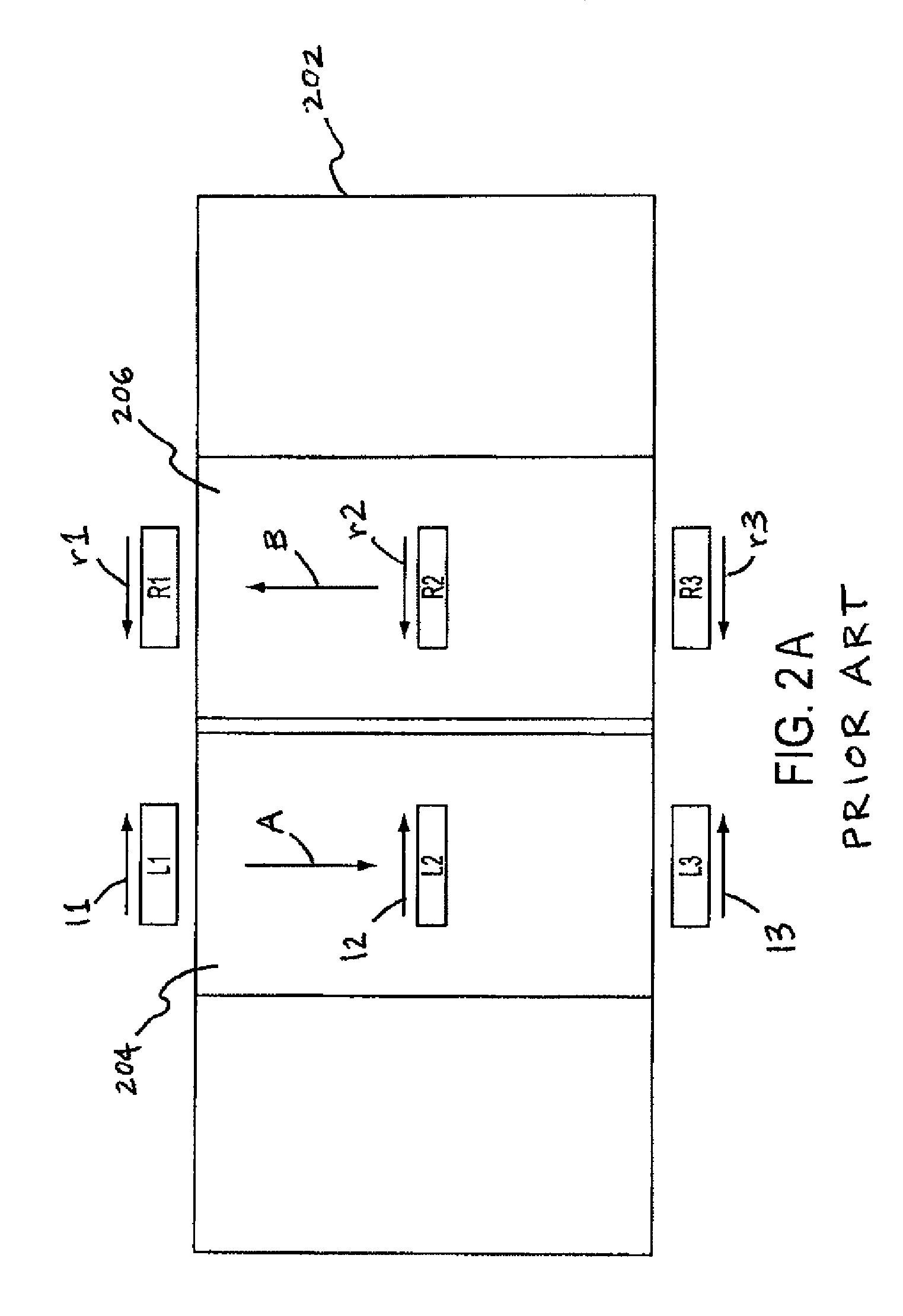

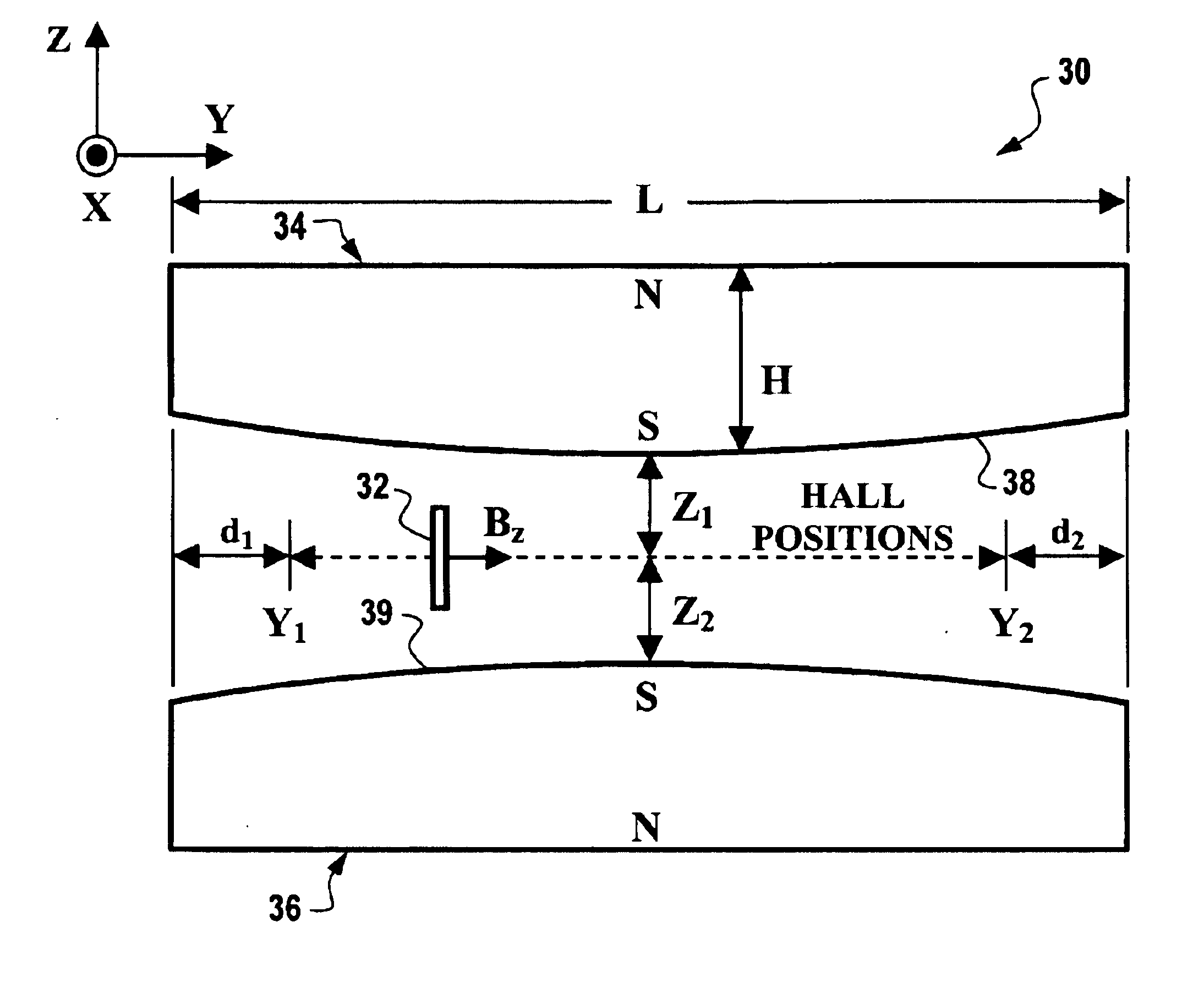

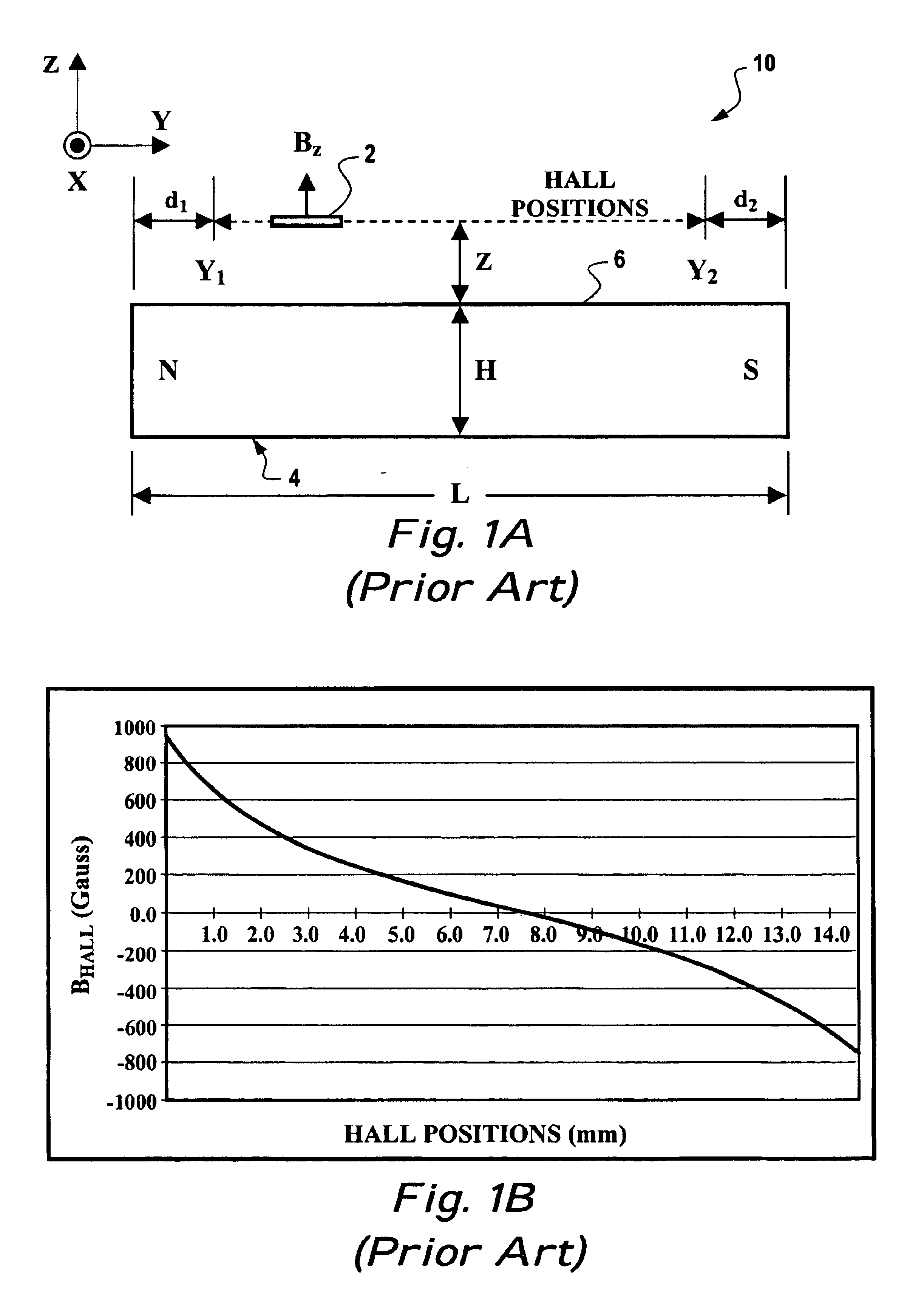

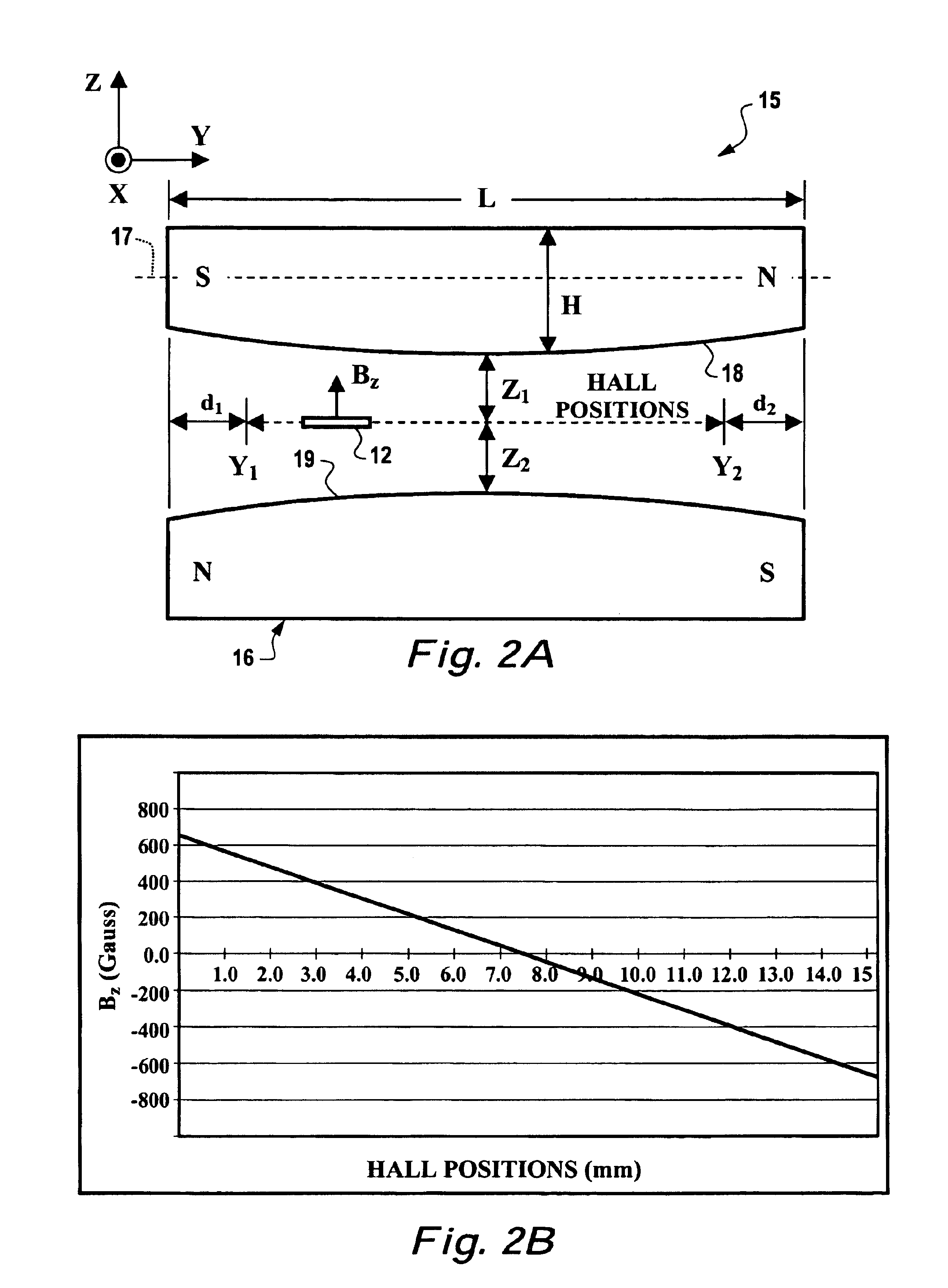

Balanced magnetic linear displacement sensor

ActiveUS7088095B1Easy to understandSolid-state devicesMagnetic field measurement using galvano-magnetic devicesHall elementTransducer

A magnetic linear displacement sensor. In accordance with one embodiment, the displacement sensor includes a Hall transducer element having a sensor plate surface and at least one magnet having a lengthwise dimension along which said Hall element detects a magnetic field component orthogonal to the sensor plate surface during displacement sensing. The magnet includes first and second pole faces disposed on opposite lengthwise sides thereof and a polarization axis aligned orthogonally with respect to the lengthwise dimension. The first pole face opposes the Hall, element and is characterized as having a non-planar surface contoured to generate a substantially linear orthogonal magnetic field component sensed by said Hall element during linear displacement sensing.

Owner:SENSATA TECHNOLOGIES INC

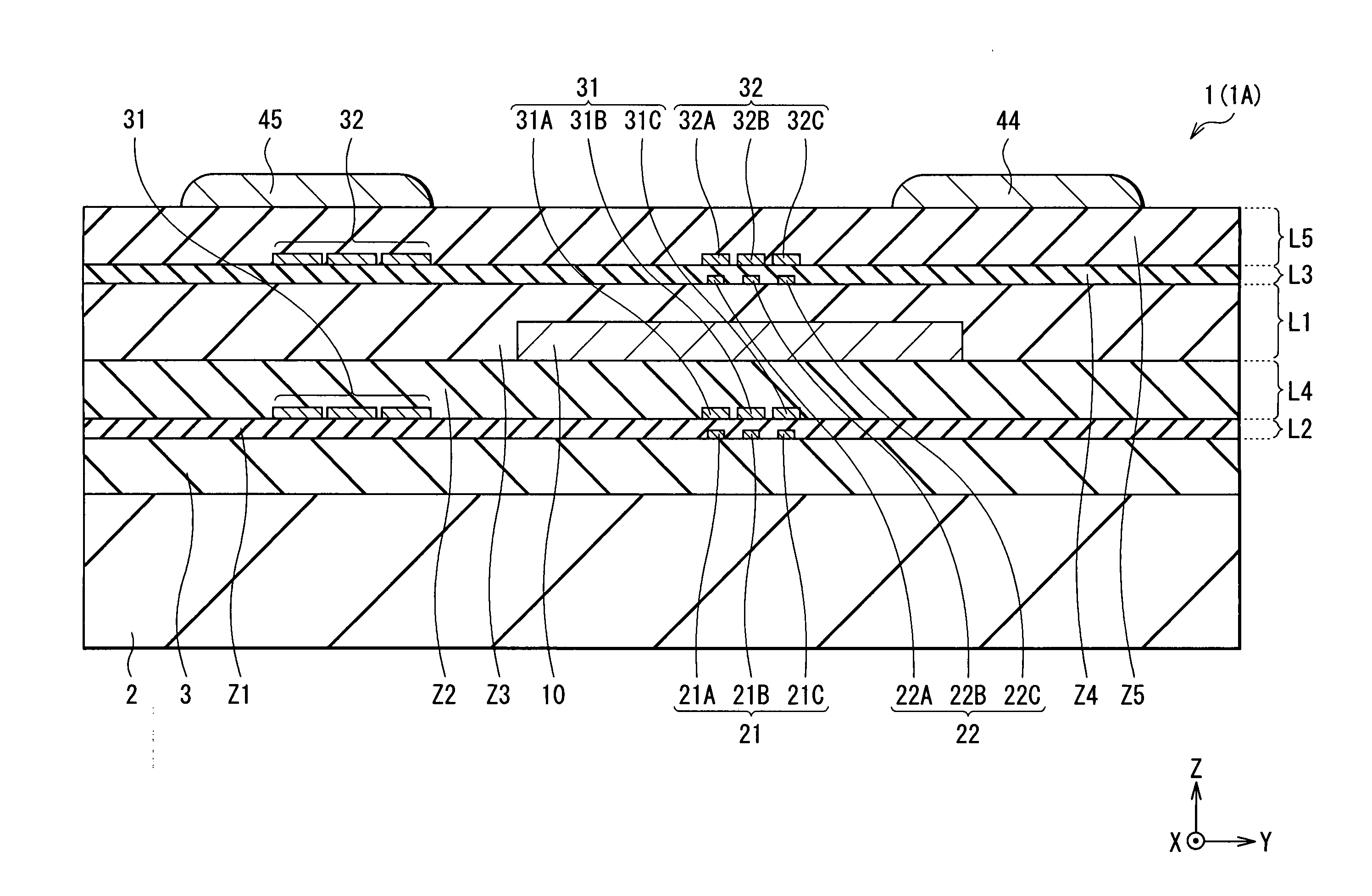

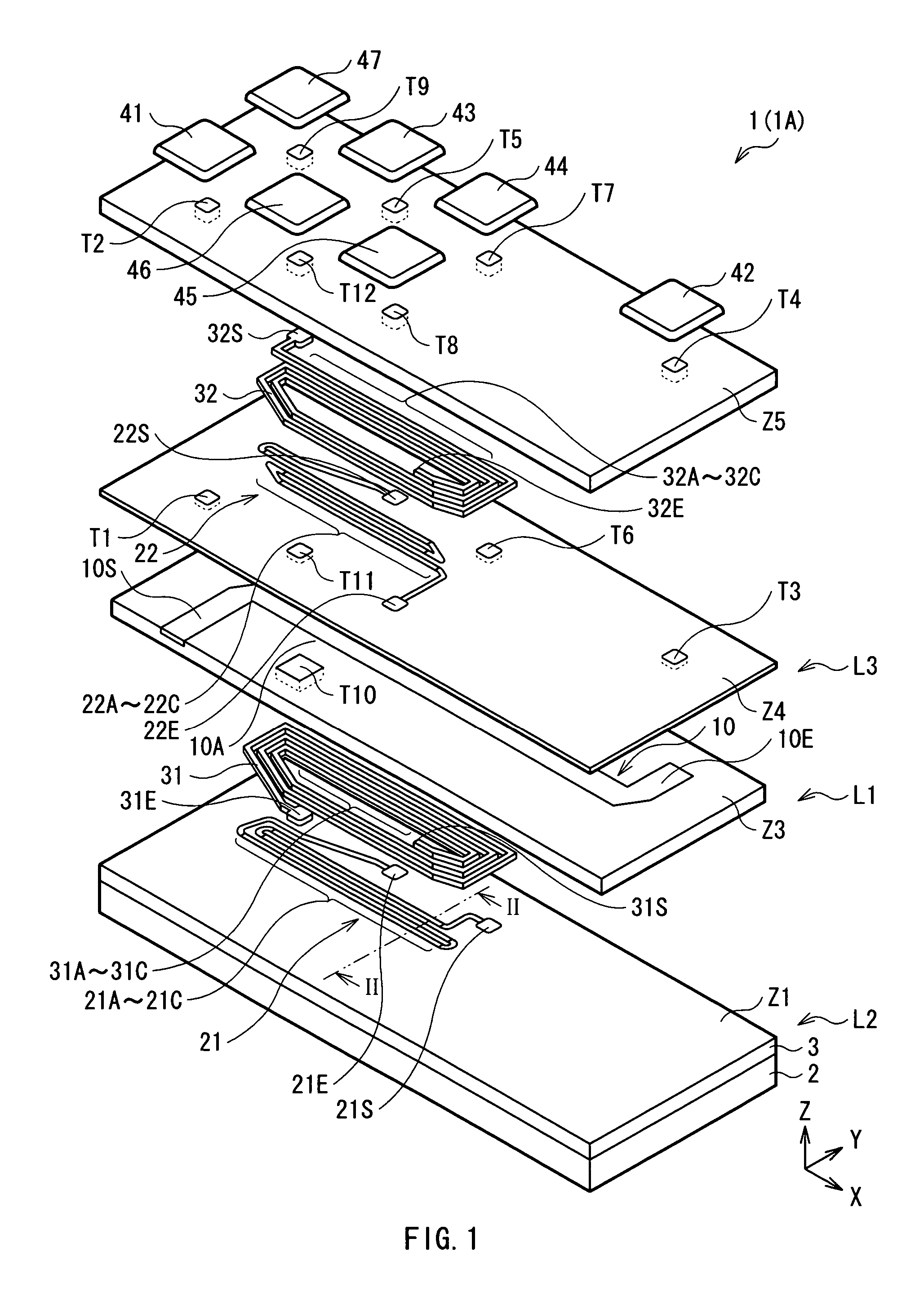

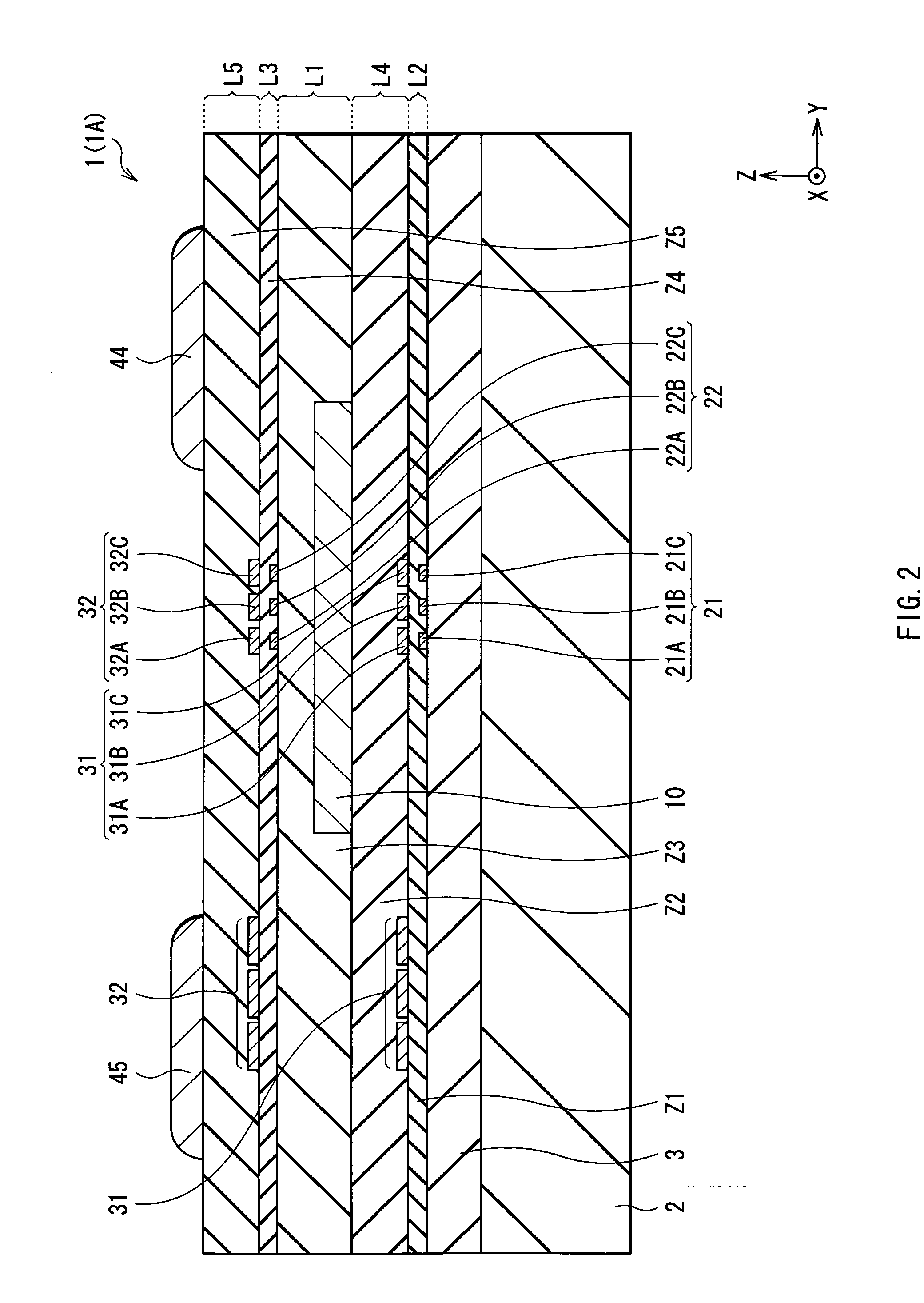

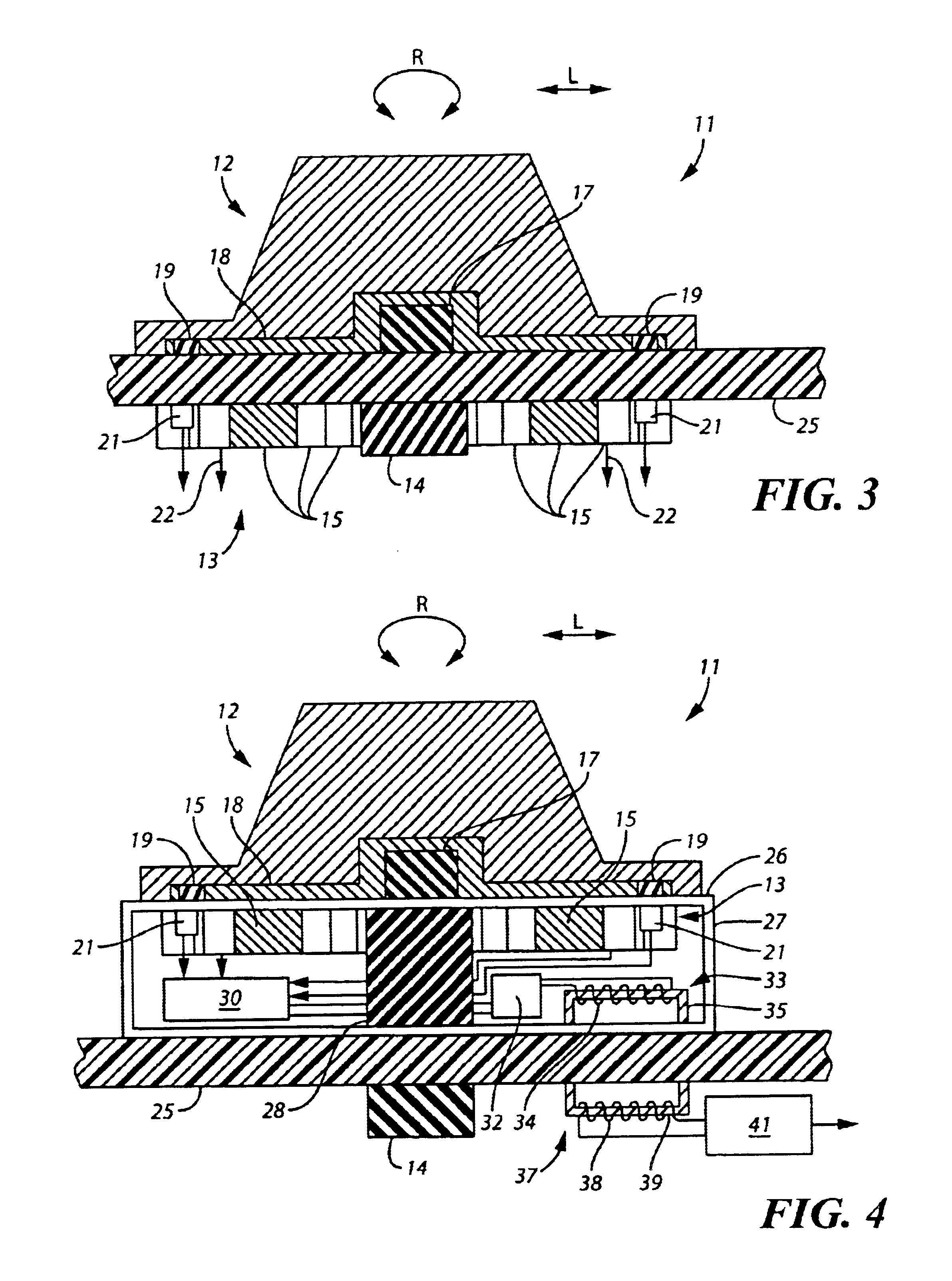

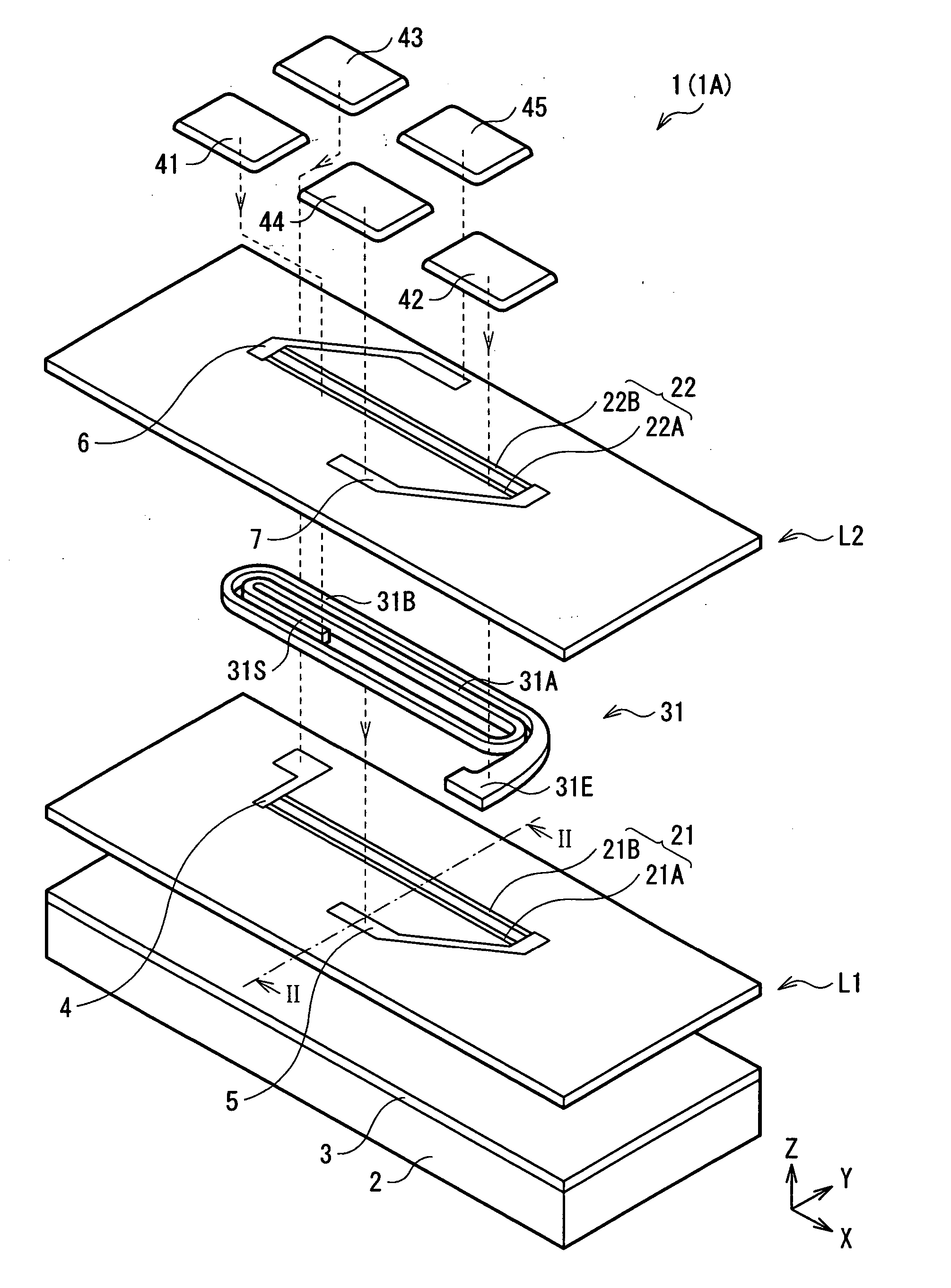

Current sensor

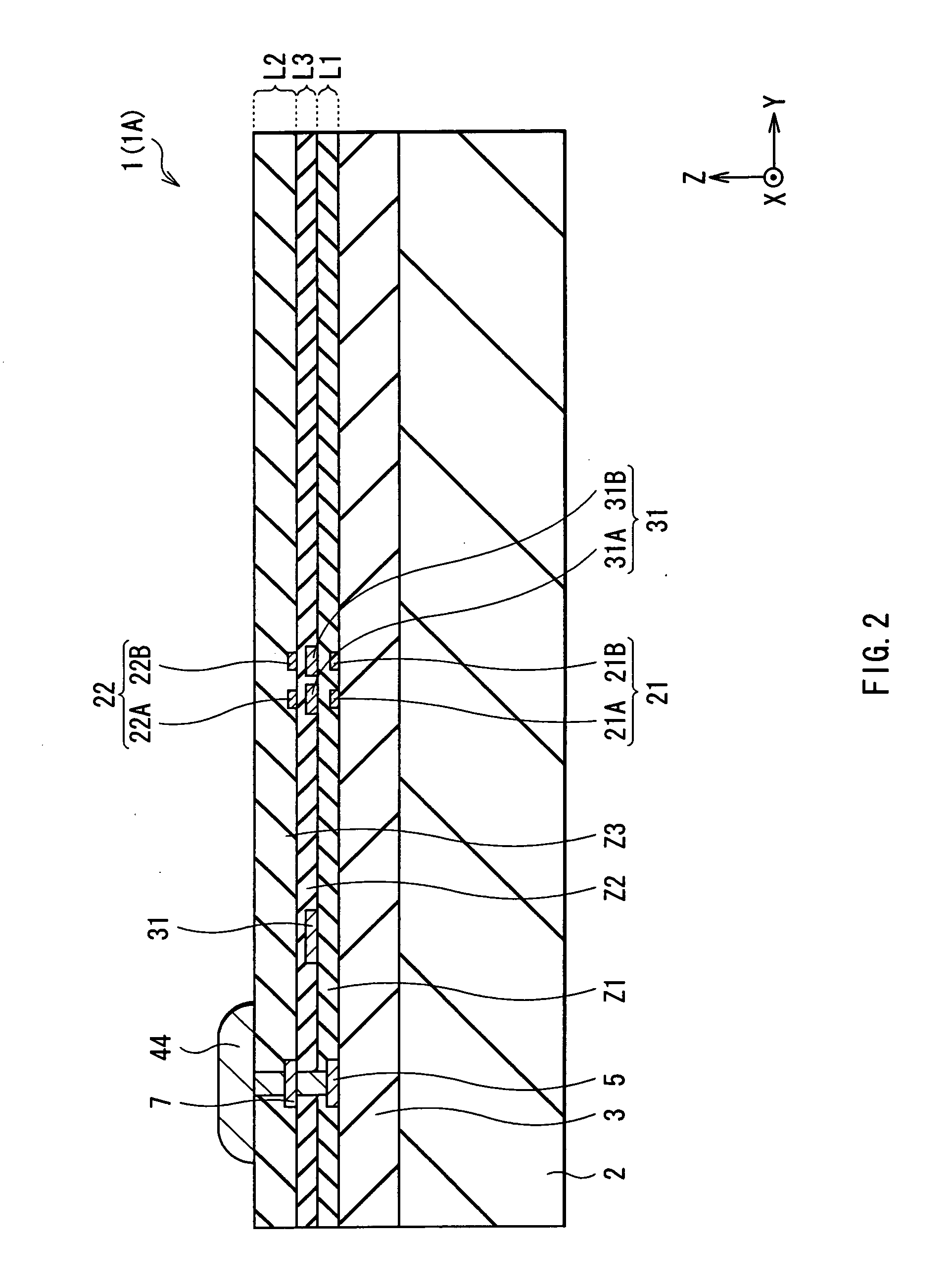

ActiveUS20060091993A1High sensitivityImprove accuracyMagnetic-field-controlled resistorsSolid-state devicesElectrical resistance and conductanceMagnetic reluctance

The present invention provides a current sensor capable of sensing a current to be detected with high precision. The current sensor includes a bus line which extends in an X direction at a first level and to which a current to be detected is supplied, a first magnetoresistive element extending in the X direction in a region corresponding to the bus line at a second level, and a second magnetoresistive element extending in the X direction in a region corresponding to the bus line at a third level. The resistance value of the first magnetoresistive element and that of the second magnetoresistive element change in directions opposite to the second level in accordance with a current magnetic field generated by the current to be detected. With the configuration, the first and second magnetoresistive elements and the bus line can be disposed close to each other. While realizing compactness, the current magnetic field can be detected with high sensitivity.

Owner:TDK CORPARATION

Apparatus and method for the determination of a direction of an object

InactiveUS20050258820A1Advanced conceptMagnetic-field-controlled resistorsSolid-state devicesMagnetic fieldNuclear magnetic resonance

An apparatus for the determination of a momentary relative direction of an indicator object depending on a magnetic field influenced or generated by the indicator object includes first means for sensing a course of a first magnetic field component of the magnetic field, second means for sensing a course of a second magnetic field component of the magnetic field, and means for evaluating the course of the first magnetic field component and the second magnetic field component in order to determine the momentary, relative direction of the indicator object, the first magnetic field component and the second magnetic field component being offset in angle with respect to each other.

Owner:INFINEON TECH AG

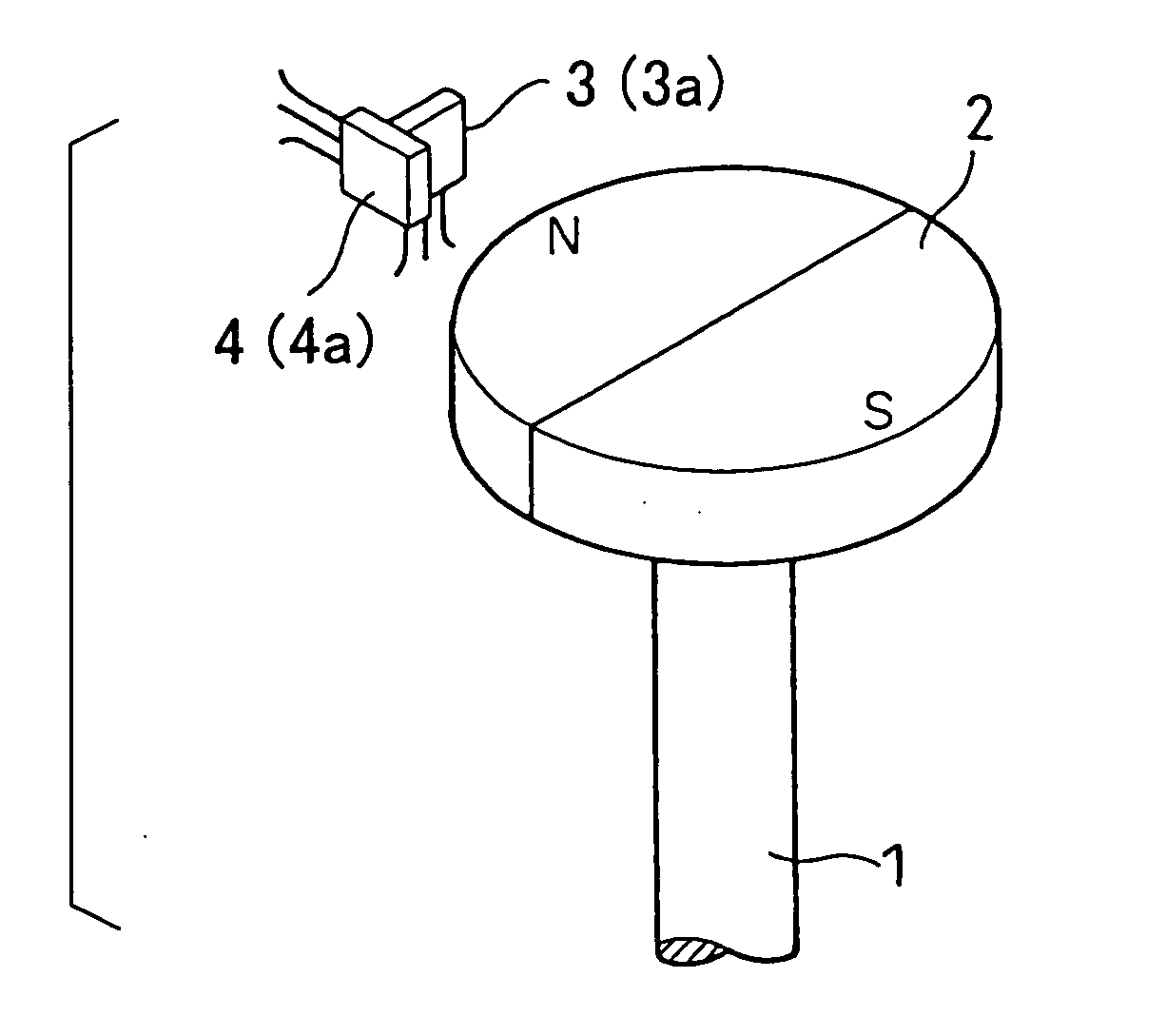

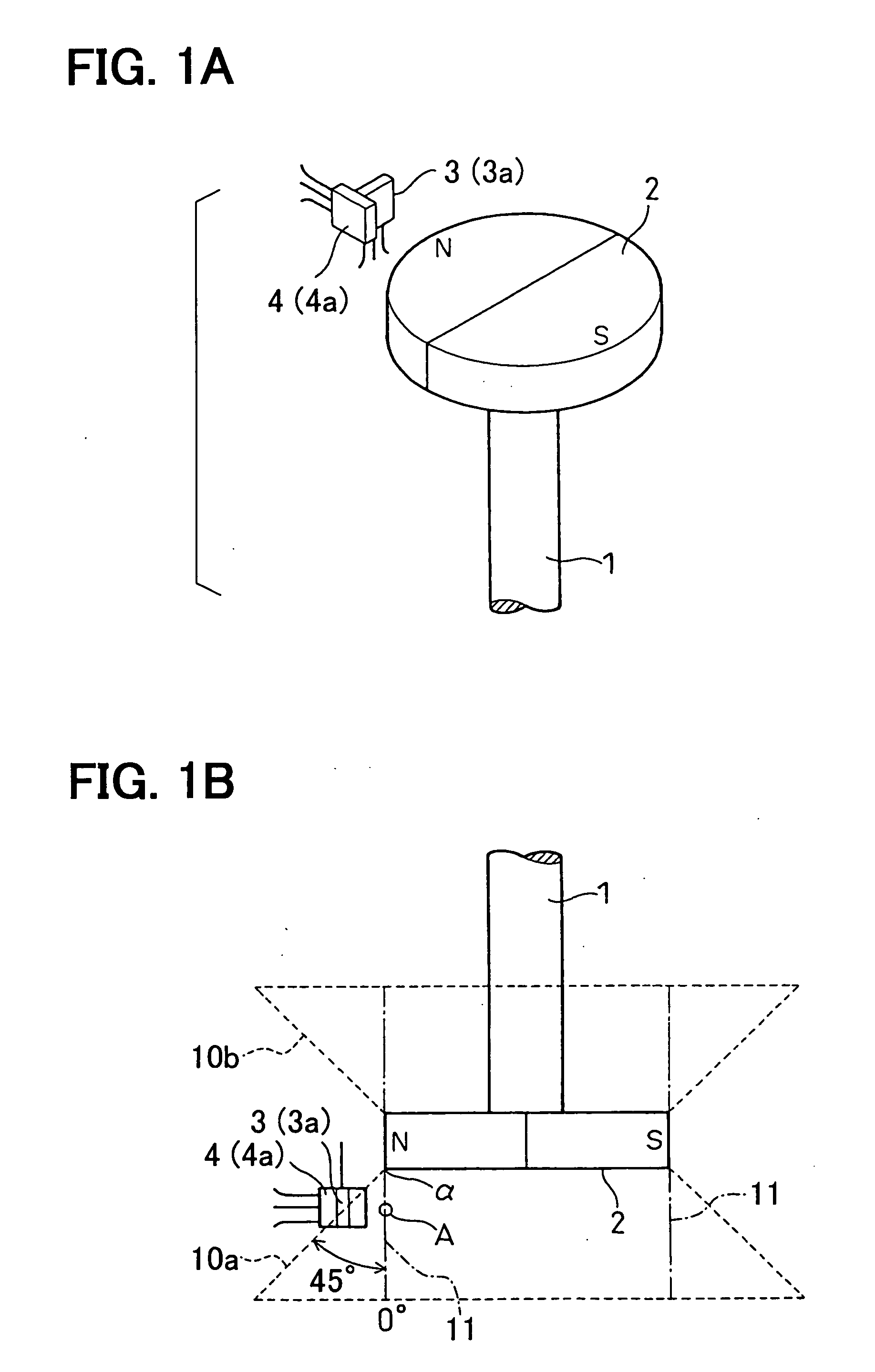

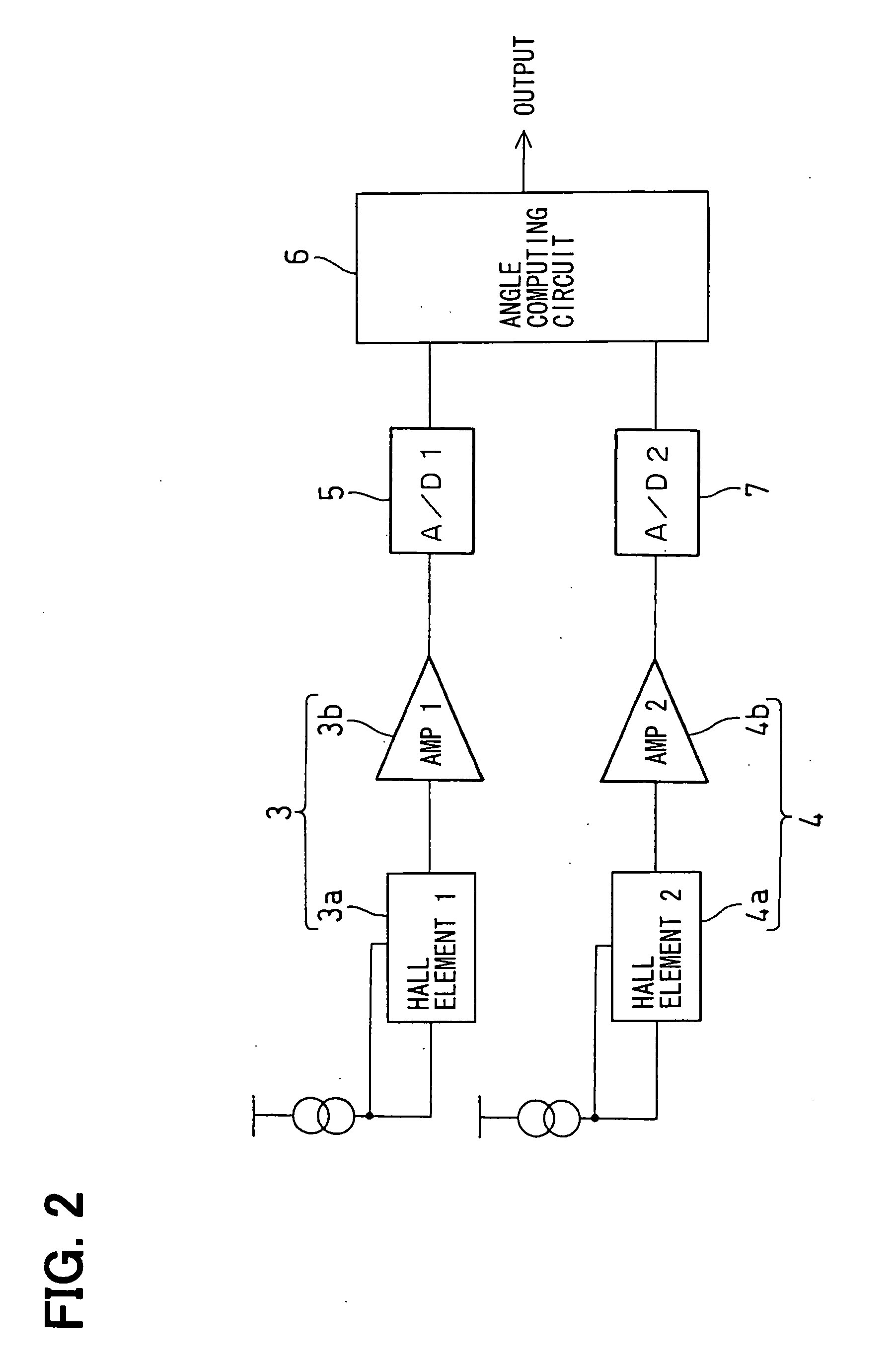

Angle determining apparatus and angle determining system

InactiveUS6969988B2Solid-state devicesMagnetic field measurement using galvano-magnetic devicesEngineeringElectrical and Electronics engineering

Owner:ASAHI KASEI ELECTRONICS CO LTD +1

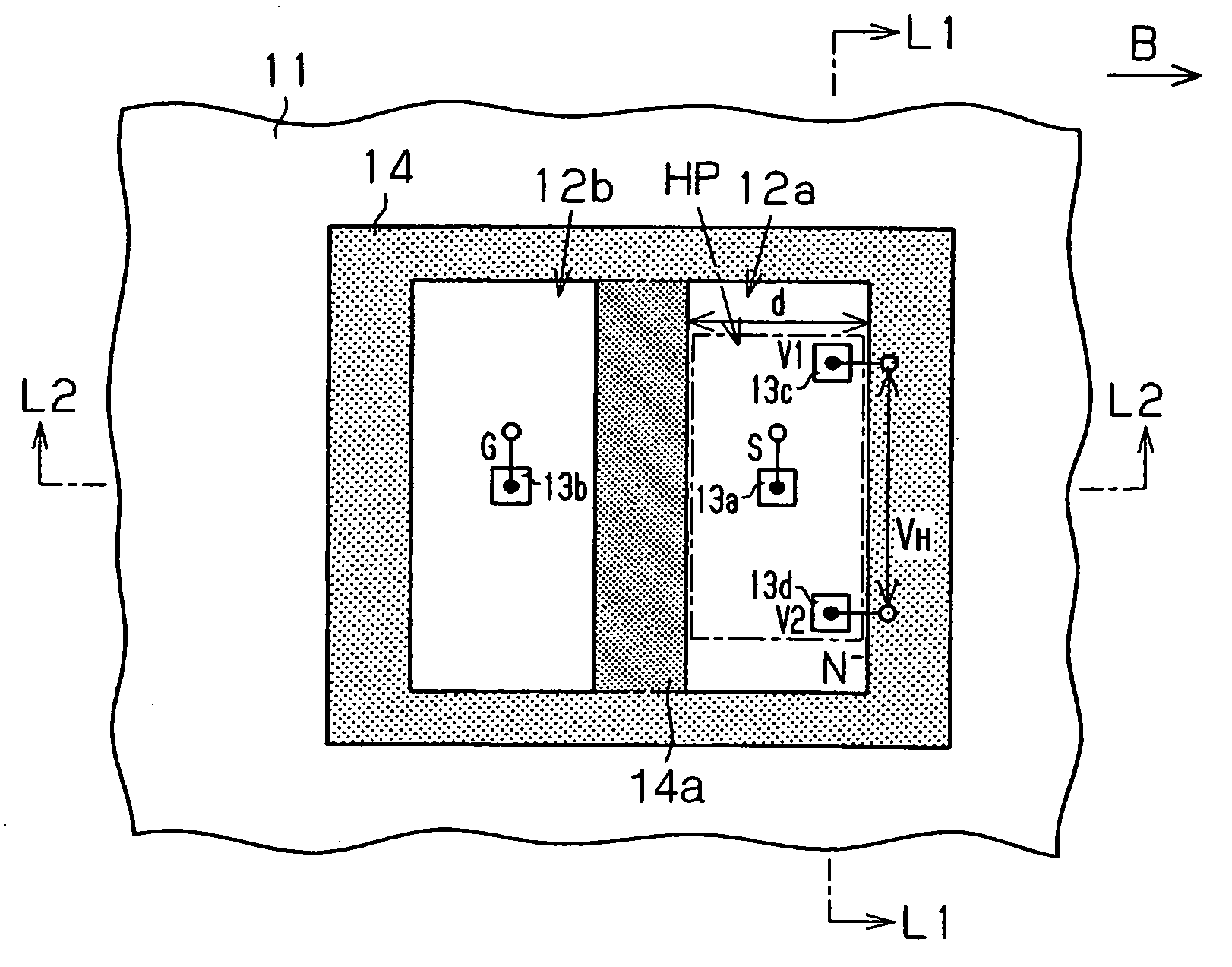

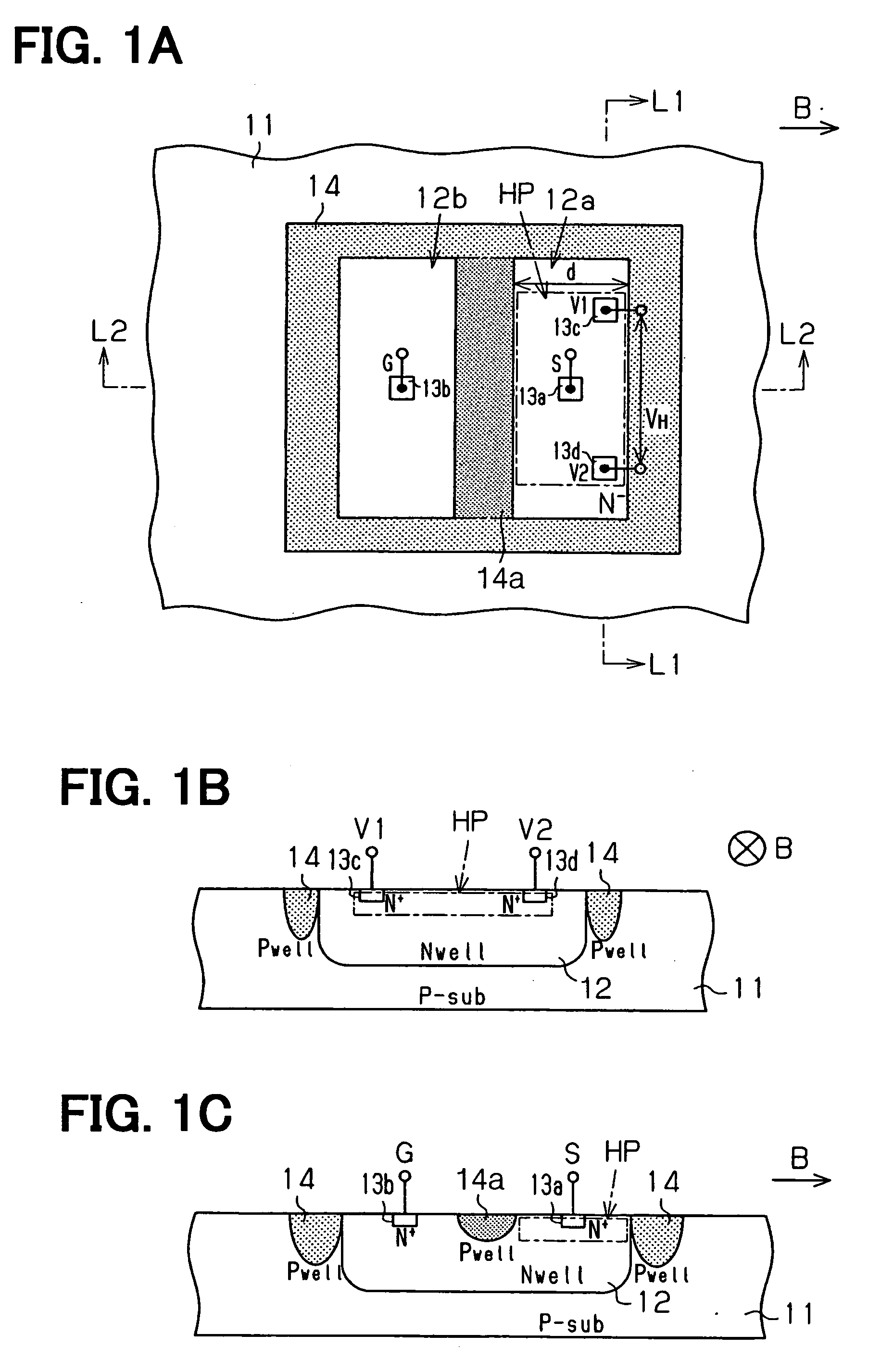

Vertical Hall device and method for adjusting offset voltage of vertical Hall device

InactiveUS20060097715A1Easily and accurately determinedReduce device voltageSolid-state devicesMagnetic field measurement using galvano-magnetic devicesEngineeringSemiconductor

A vertical Hall device includes: a semiconductor substrate including a magnetic field detection portion, a current portion and an output portion. The output portion includes a pair of output terminals. The current portion is capable of supplying the current to the magnetic field detection portion and retrieving the current from the magnetic field detection portion. The current portion is sandwiched between a pair of the output terminals in such a manner that the current portion is disposed apart from a line connecting between a pair of the output terminals.

Owner:DENSO CORP

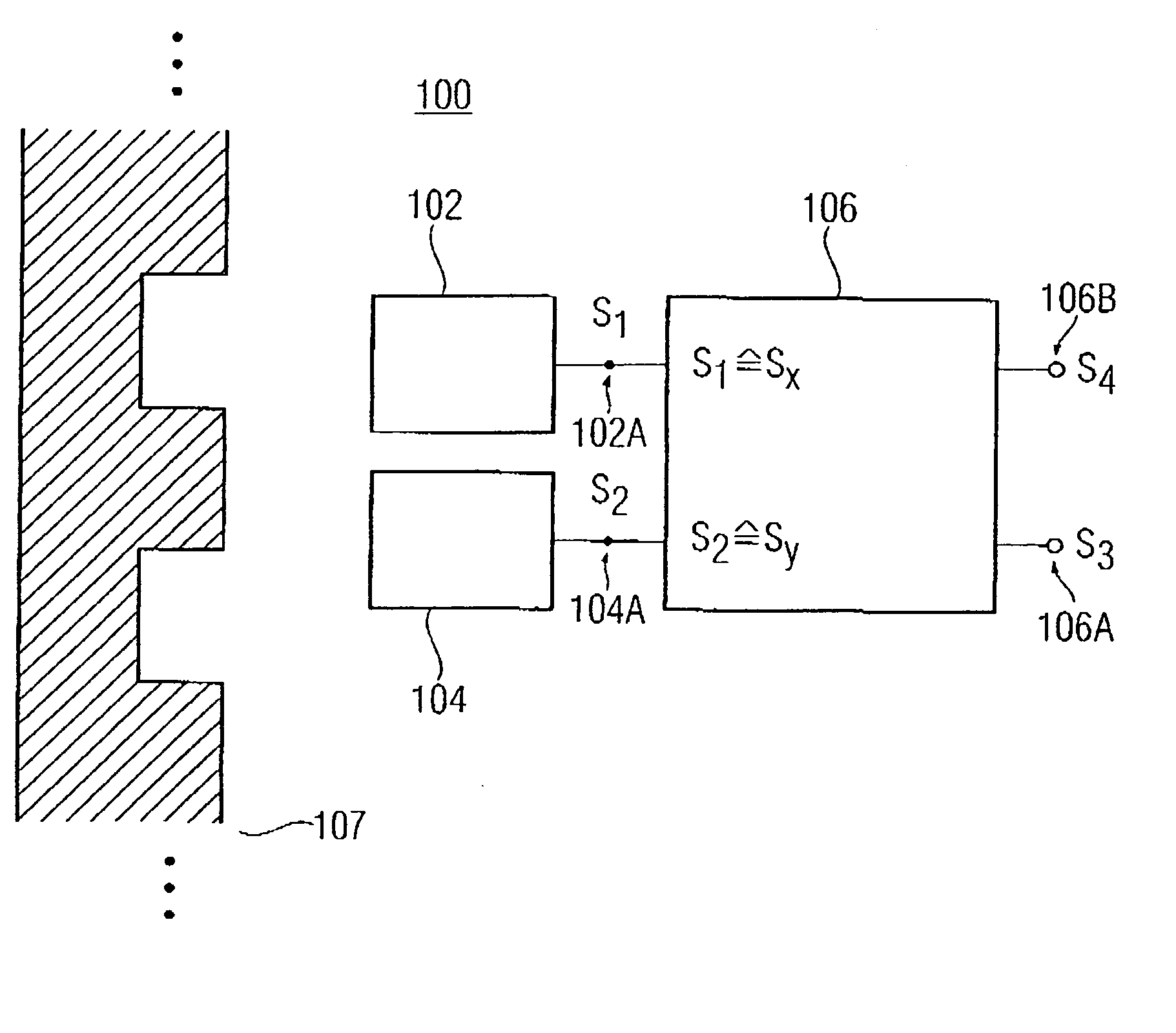

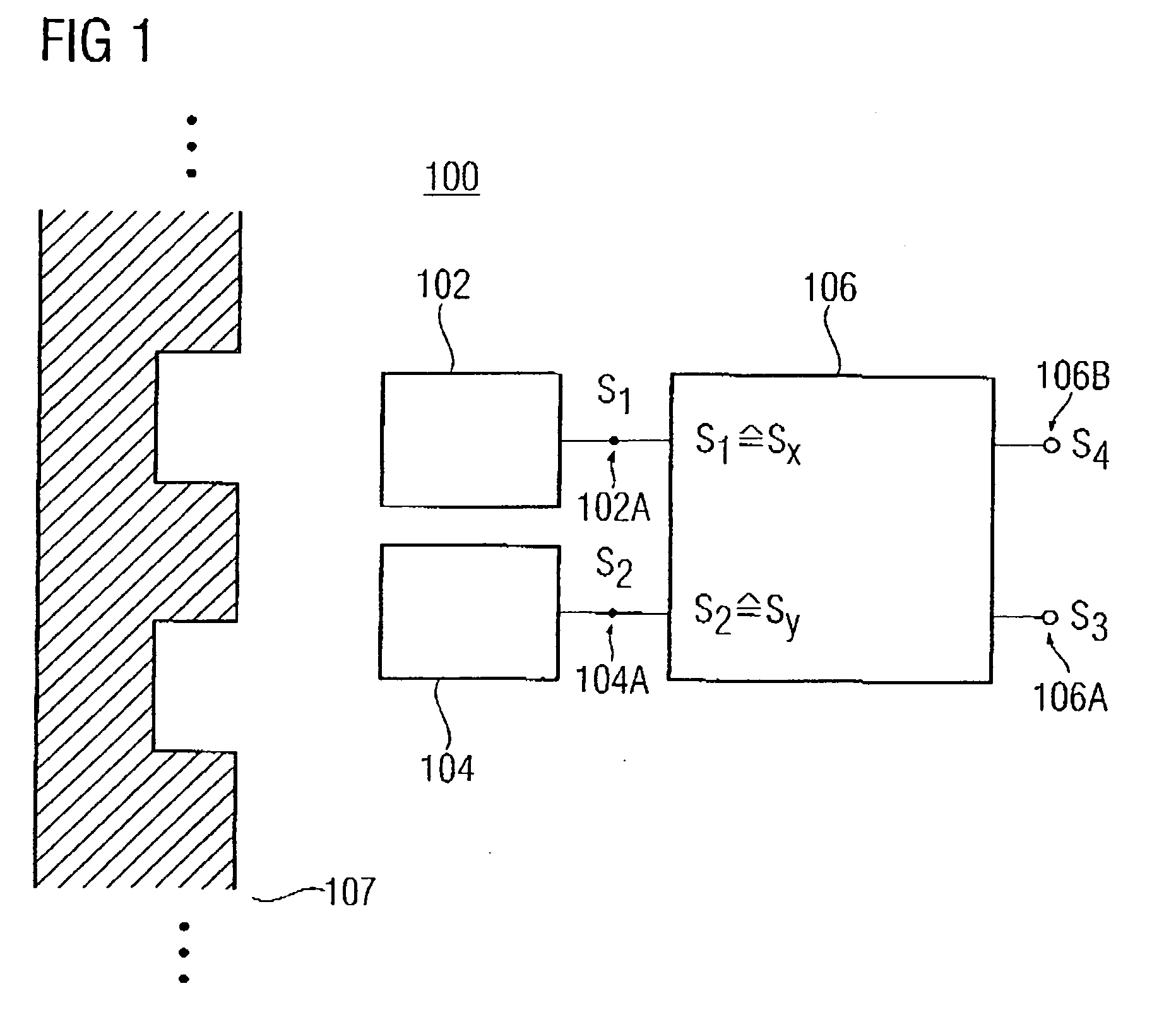

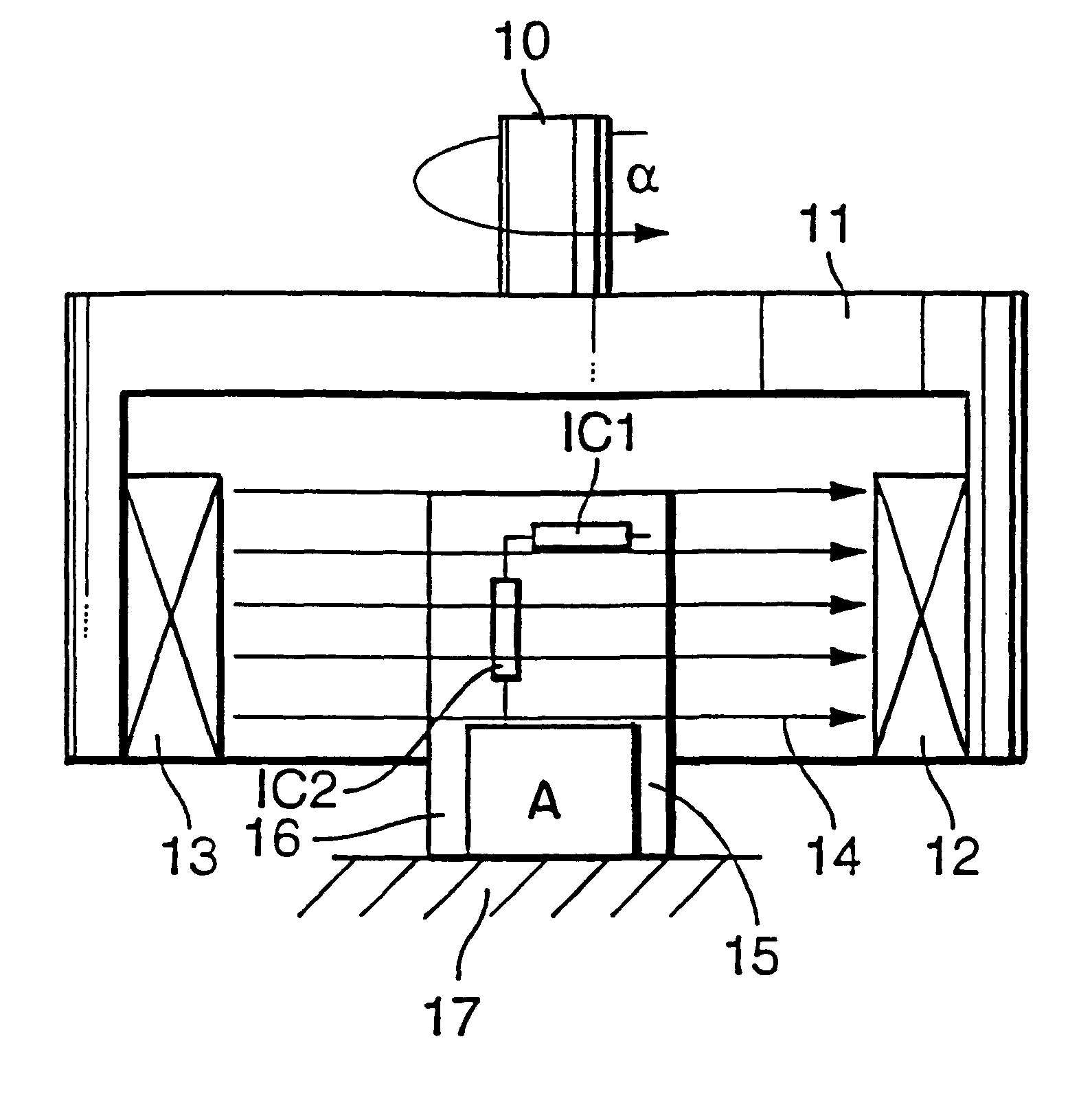

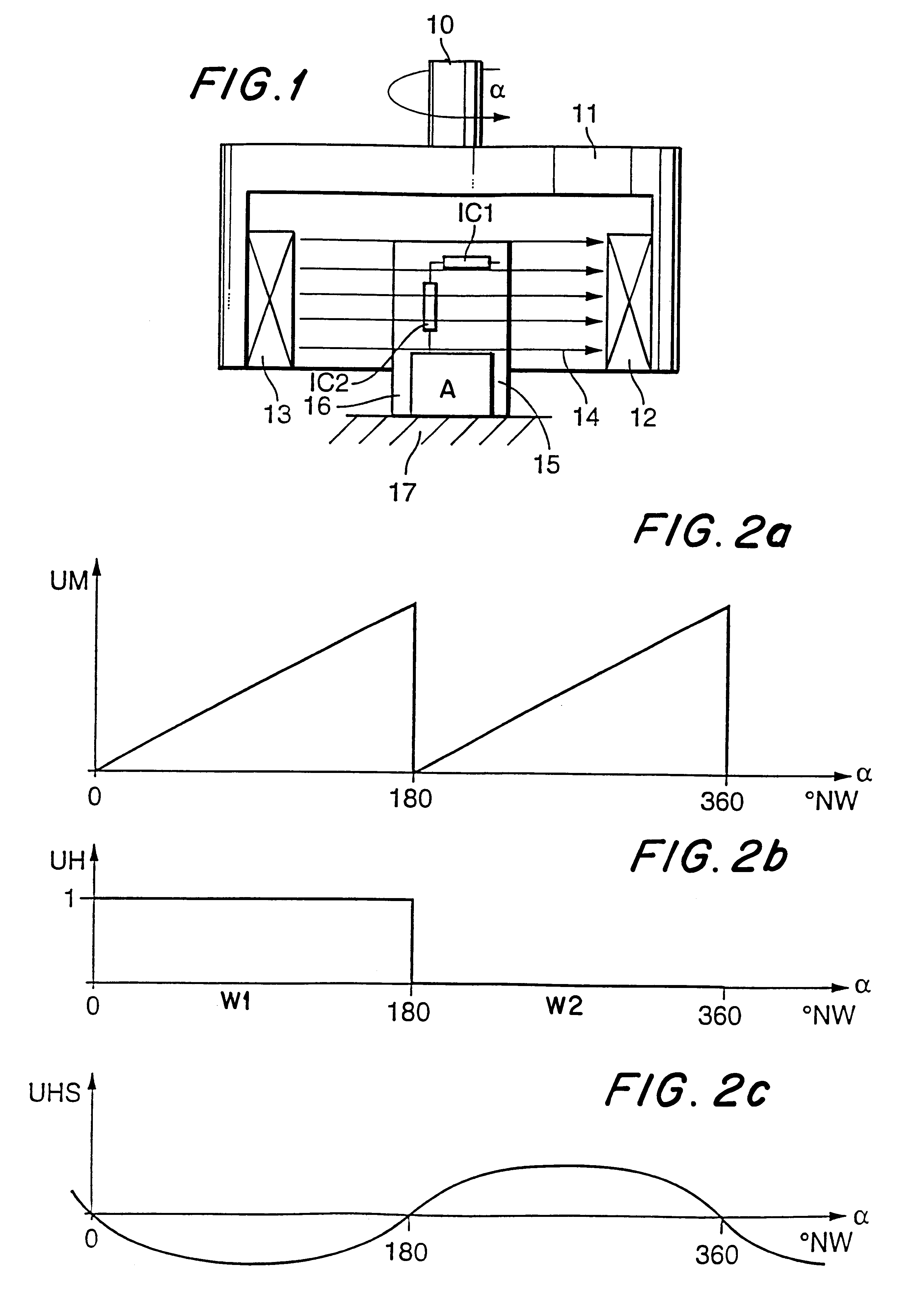

Non-contact system for detecting an angle of rotation

InactiveUS6212783B1Angles/taper measurementsElectric ignition installationAngular orientationInternal combustion engine

The arrangement for contactless determination of an angular position of a rotatable element, such as a camshaft of an internal combustion engine, which includes a magnet arranged to rotate with the rotatable element; a magnetic field sensor stationary in relation to the rotatable element and including a first sensor element (IC1) and a second sensor element (IC2), wherein the first sensor element generates a first output signal linearly dependent on an angle between the magnetic field and the magnetic field sensor according to a magnetoresistive effect, whereby the first output signal has respective values between 0° and 180° that repeat between 180° and 360°, and the second sensor element generates a second output signal having a high value between 0° and 180° and a low value between 180° and 360° according to a Hall effect; and an evaluation circuit (A) for analyzing output signals of both sensor elements to determine the angular position of the rotatable element between 0° and 360°. The evaluating circuit finds that the absolute angular position is either of two angular orientations spaced 180° from each other only from the signal from the first sensor element and selects one of them as the absolute angular position according to the second output signal.

Owner:ROBERT BOSCH GMBH

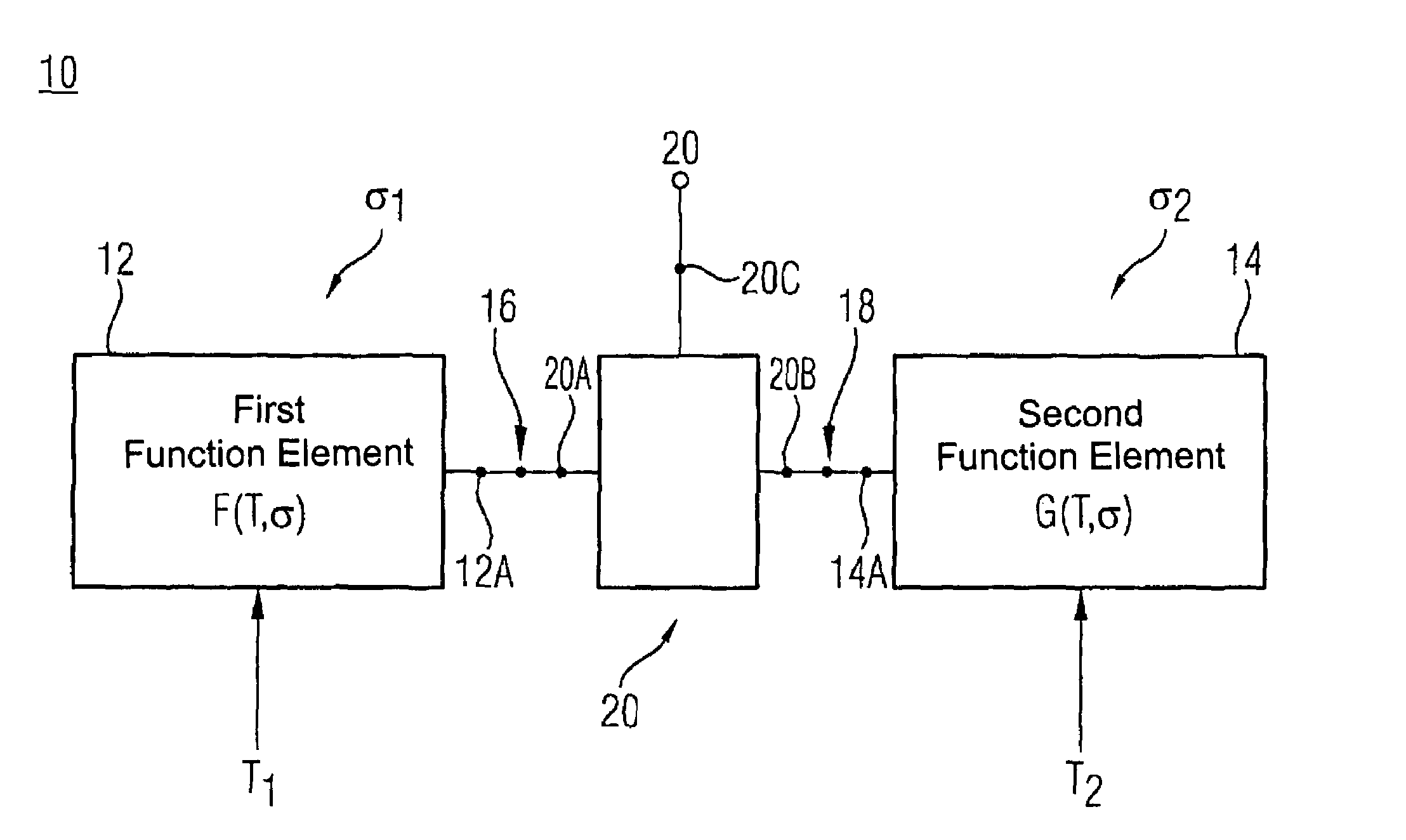

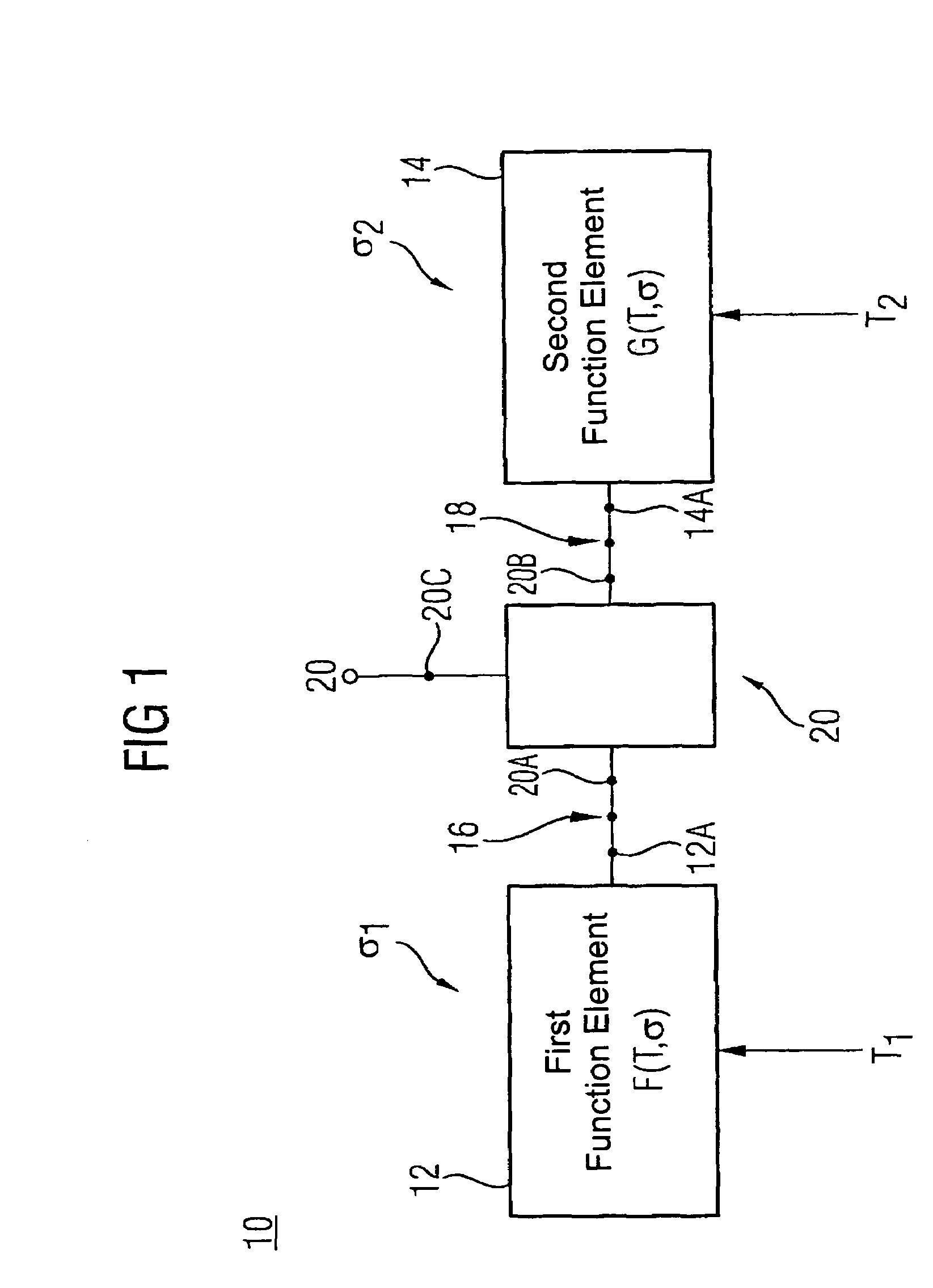

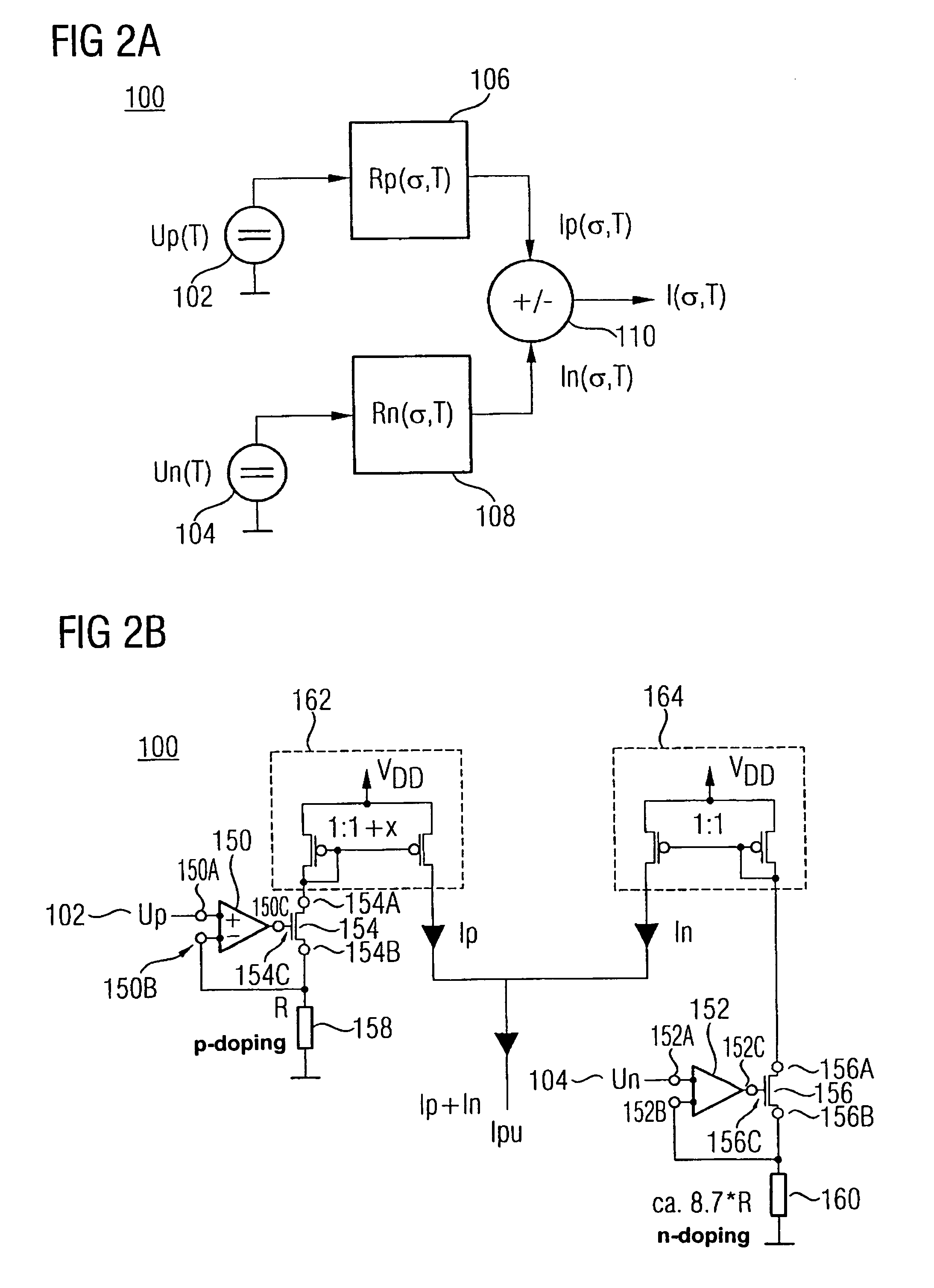

Concept of compensating for piezo influences on integrated circuitry

ActiveUS7437260B2Quality improvementFluid pressure measurement by electric/magnetic elementsSolid-state devicesElectricitySemiconductor chip

A semiconductor chip includes a first functional element having a first electronic functional-element parameter exhibiting a dependence relating to the mechanical stress present in the semiconductor circuit chip, and being configured to provide a first output signal, a second functional element having a second electronic functional-element parameter exhibiting a dependence in relation to the mechanical stress present in the semiconductor circuit chip, and being configured to provide a second output signal in dependence on the second electronic functional-element parameter and the mechanical stress, and a combination means for combining the first and second output signals to obtain a resulting output signal exhibiting a predefined dependence on the mechanical stress present in the semiconductor circuit chip, the first and second functional elements being integrated on the semiconductor circuit chip and arranged, geometrically, such that that the first and second functional-element stress influence functions are identical within a tolerance range.

Owner:INFINEON TECH AG

Rotational angle sensing device and assembling method thereof

ActiveUS20050253578A1Convenient ArrangementMagnetic-field-controlled resistorsSolid-state devicesHall elementMagnetic flux

A magnet is provided to one of two members, which make relative rotation therebetween. First and second Hall elements are arranged adjacent to each other and are provided to the other one of the two members. A magnetic sensing surface of the first Hall element is generally perpendicular to a magnetic sensing surface of the second Hall element, and a relative rotational angle between the two members is determined through the first and second Hall elements based on a magnetic flux, which is generated by a magnetic flux generating portion of the magnet and passes through the first and second Hall elements toward a magnetic flux attracting portion of the magnet.

Owner:DENSO CORP

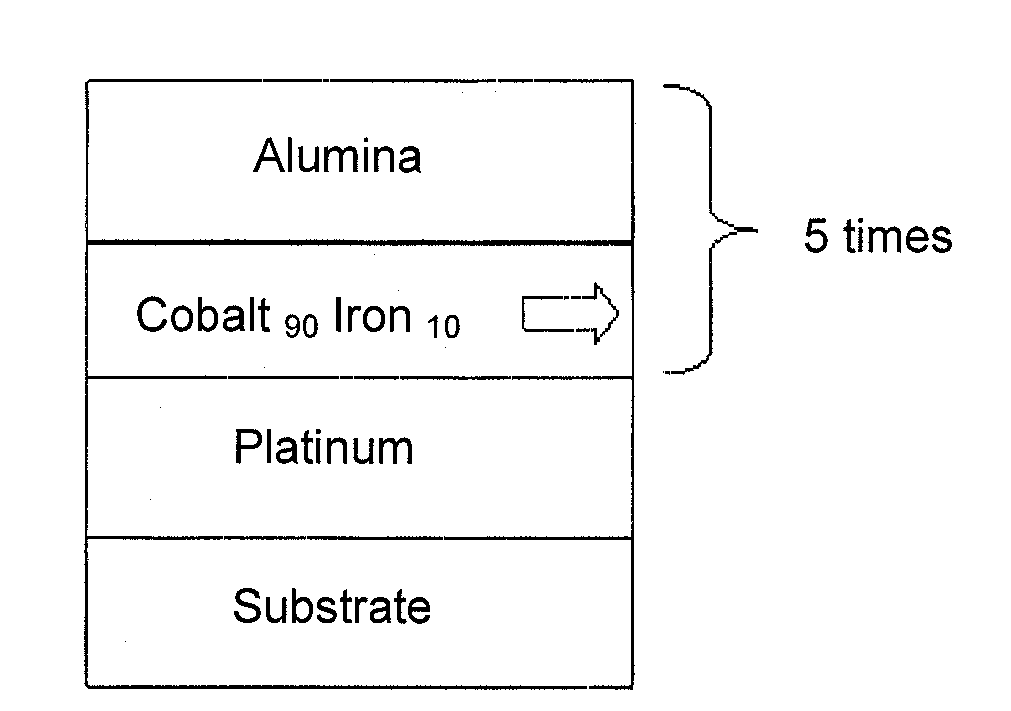

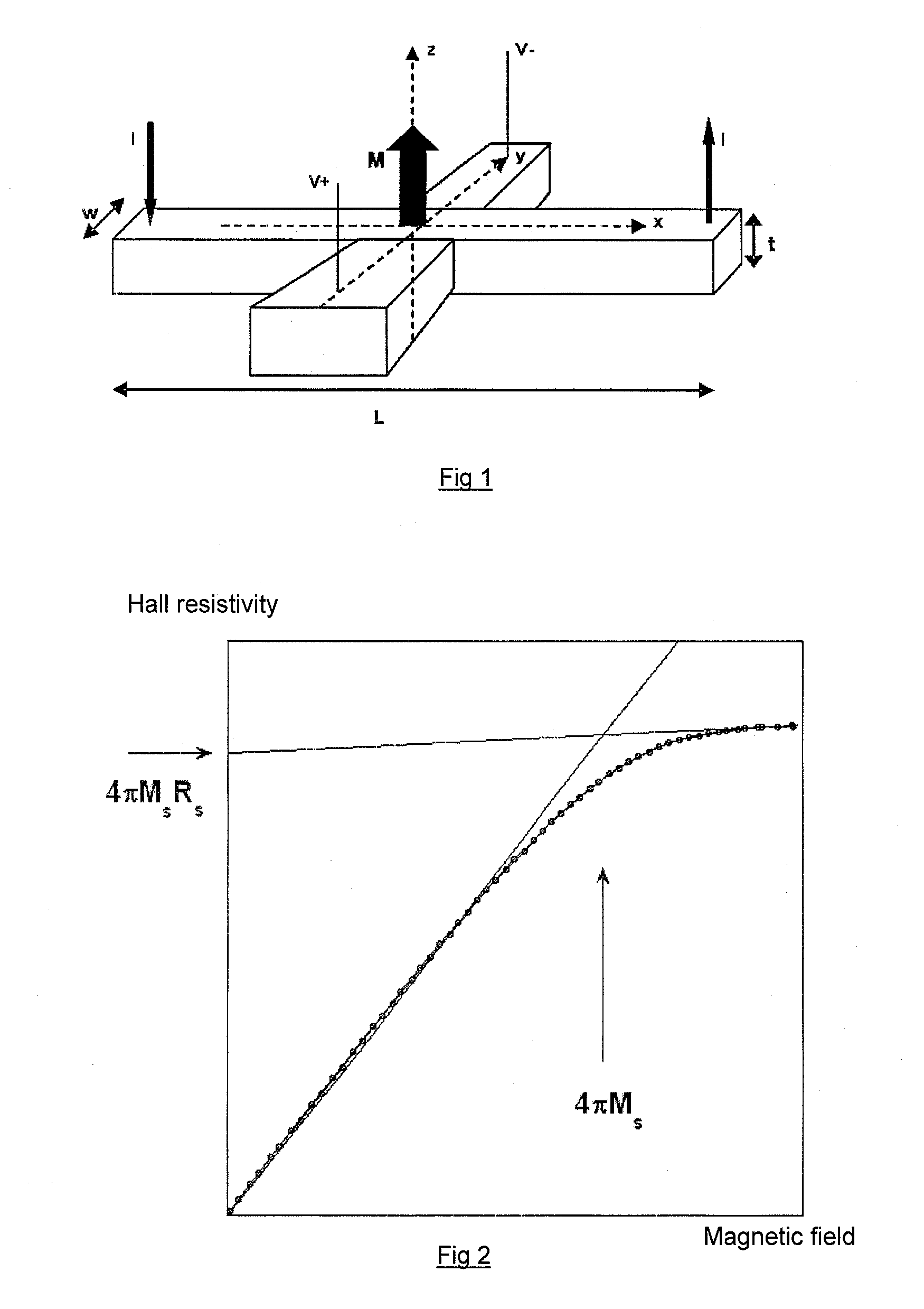

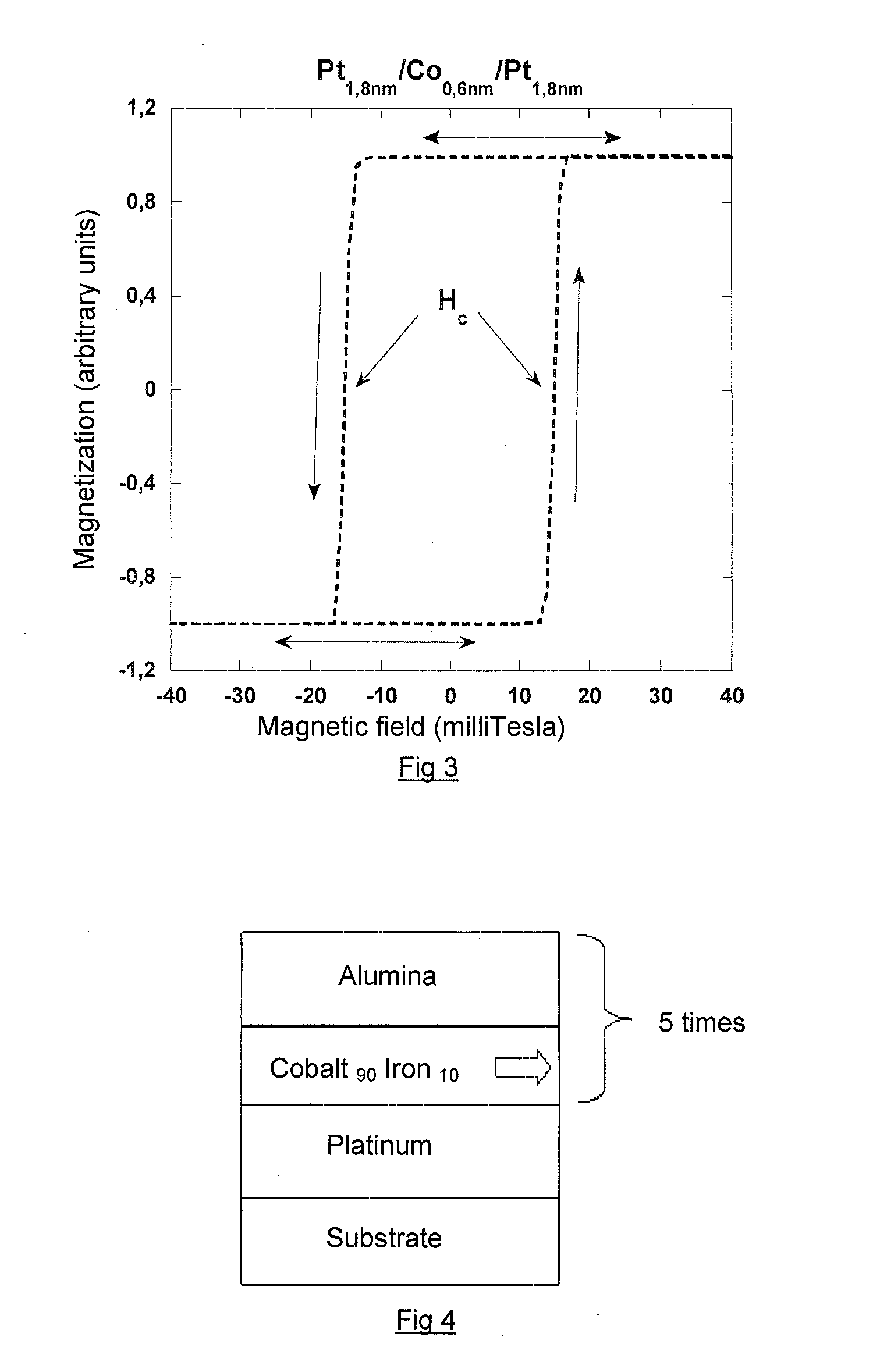

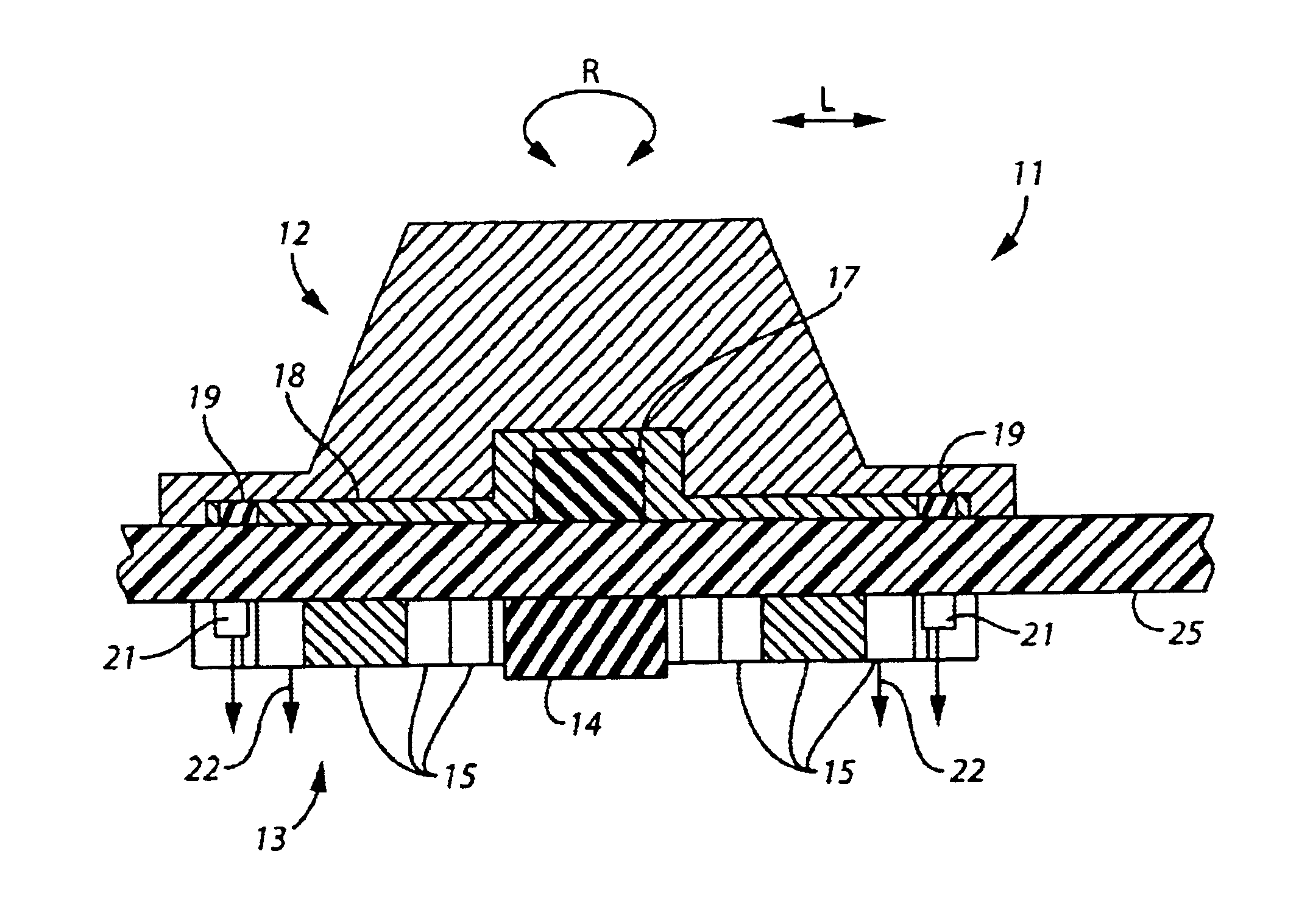

Magnetic multilayer device, method for producing such a device, magnetic field sensor, magnetic memory and logic gate using such a device

ActiveUS20080151615A1High perpendicular anisotropyHigh resistivityNanostructure applicationNanomagnetismMagnetic anisotropyMagnetic memory

This magnetic multilayer device comprises, on a substrate, an alternating sequence of magnetic metallic layers M and oxide, hydride or nitride layers O. The number of layers M equals at least two. The layers M are continuous. There is interfacial magnetic anisotropy perpendicular to the plane of the layers at the level of the M / O interfaces.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Operating device for an electrical appliance

InactiveUS6812435B2Easy constructionIncrease contactDomestic stoves or rangesLighting and heating apparatusLinear motionEngineering

Owner:E G O ELEKTRO GERAETEBAU GMBH

Current sensor

ActiveUS20060145690A1Easy to optimizeGuaranteed current efficiencyNanomagnetismMagnetic-field-controlled resistorsCurrent sensorElectrical current

The present invention provides a current sensor capable of sensing a current to be detected with high precision while realizing a compact configuration. The current sensor includes a first MR element including element patterns disposed at a first level, a second MR element including element patterns disposed at a second level, and a thin film coil which winds at a third level provided between the first and second levels while including winding body portions extending in an X axis direction in correspondence with the element patterns of the first and second MR elements, and which applies a current magnetic field to each of the element patterns when a current to be detected is supplied. Therefore, by using both of the first and second MR elements, the current magnetic field can be detected with high sensitivity and high precision.

Owner:TDK CORPARATION

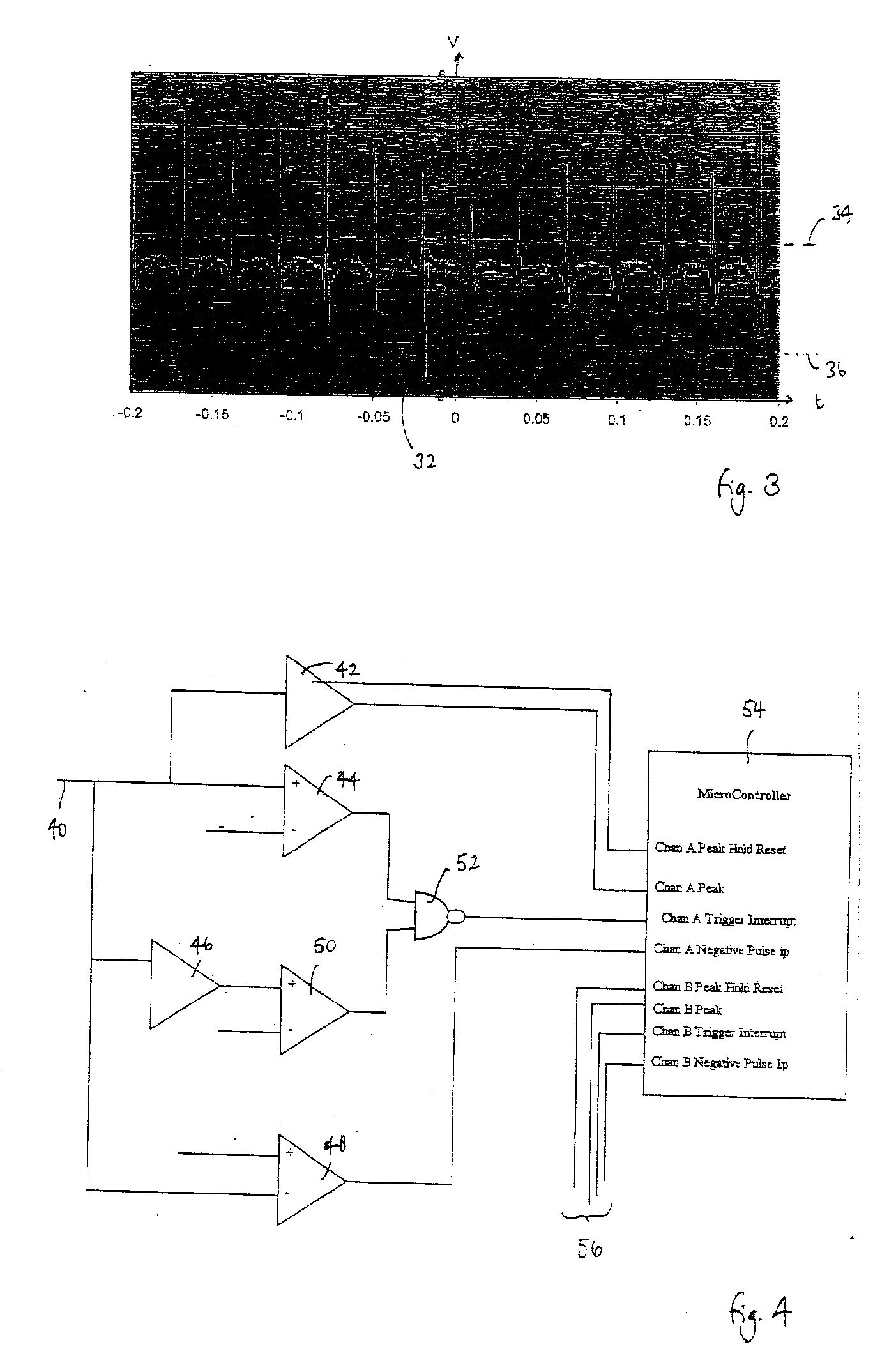

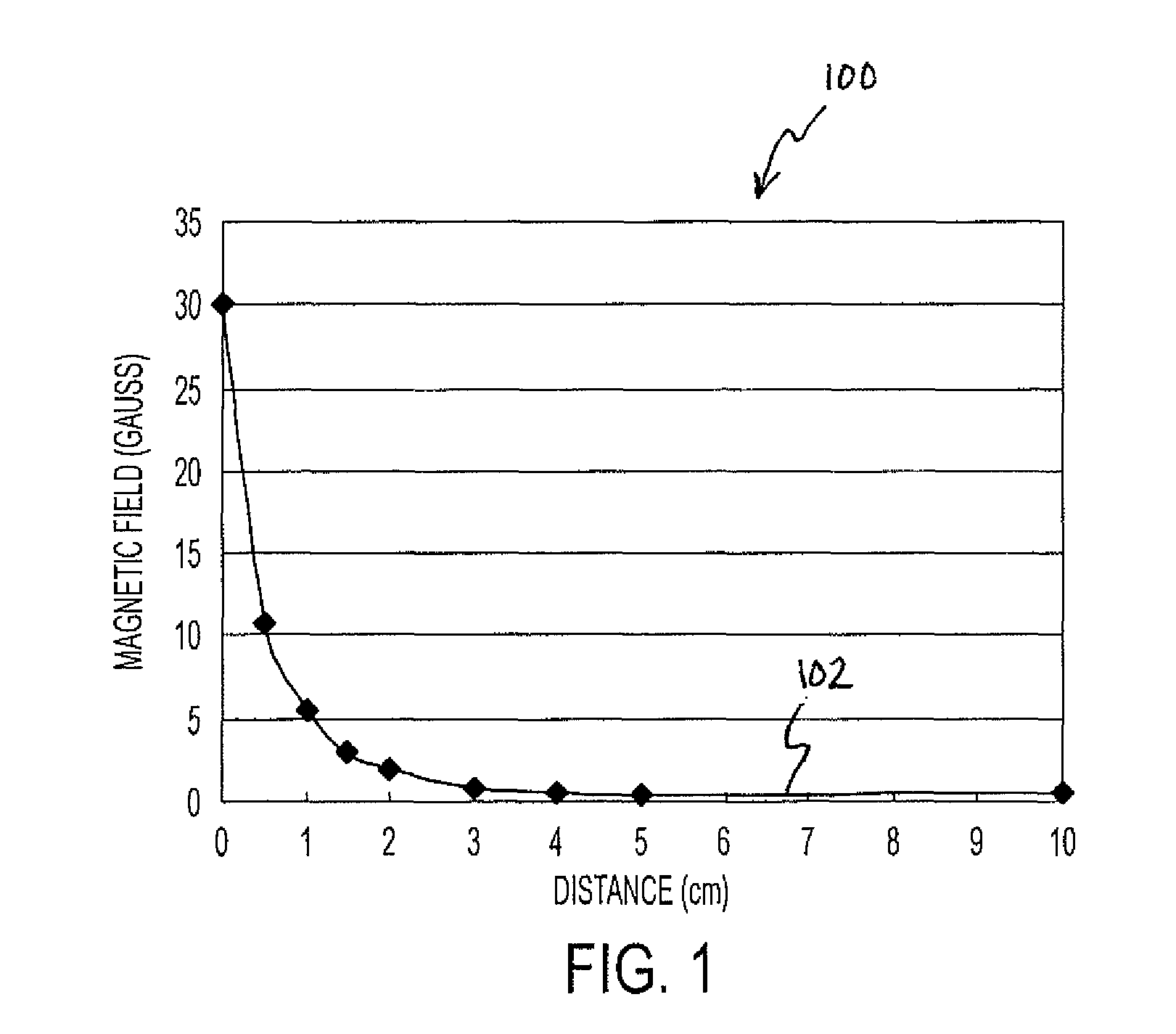

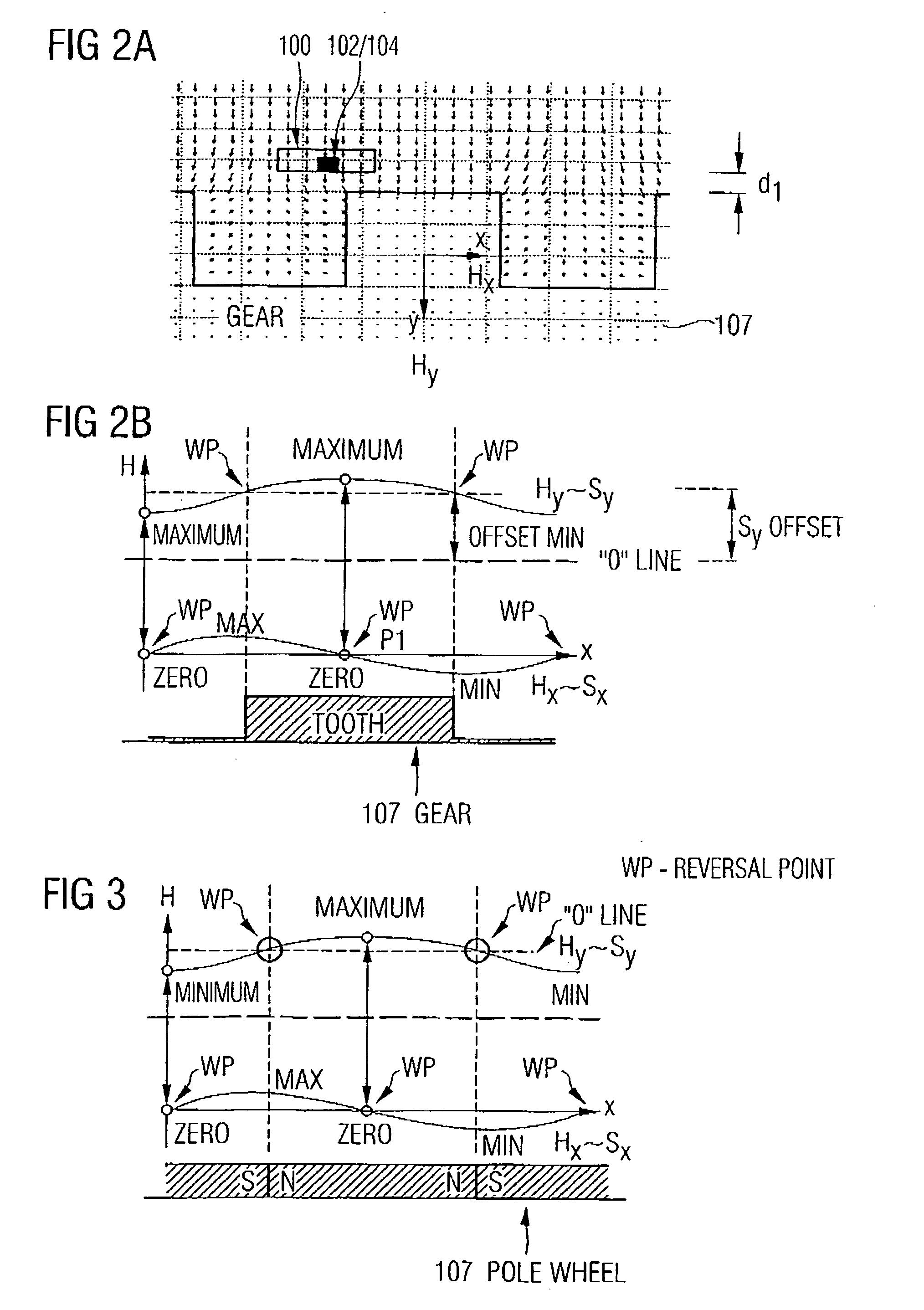

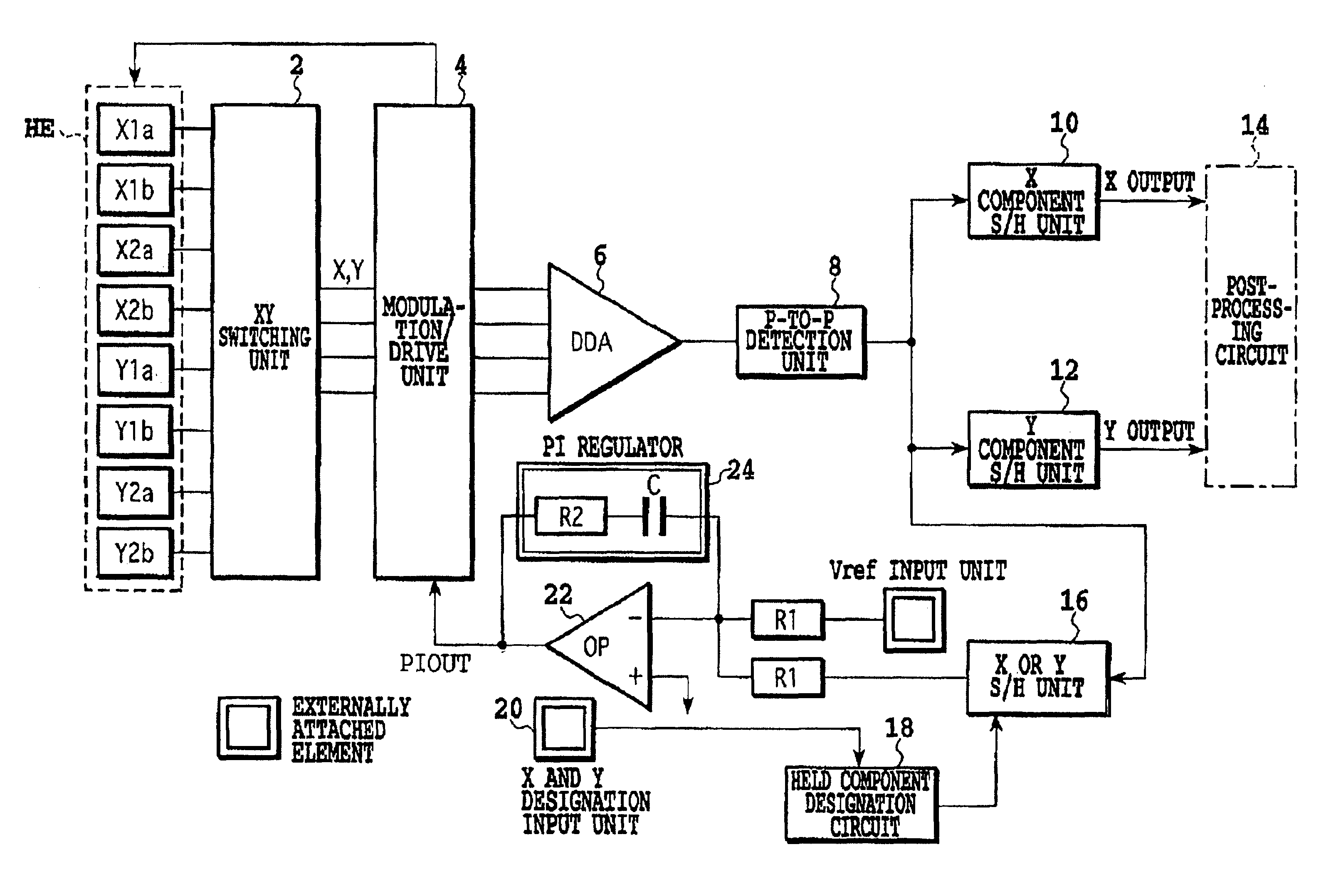

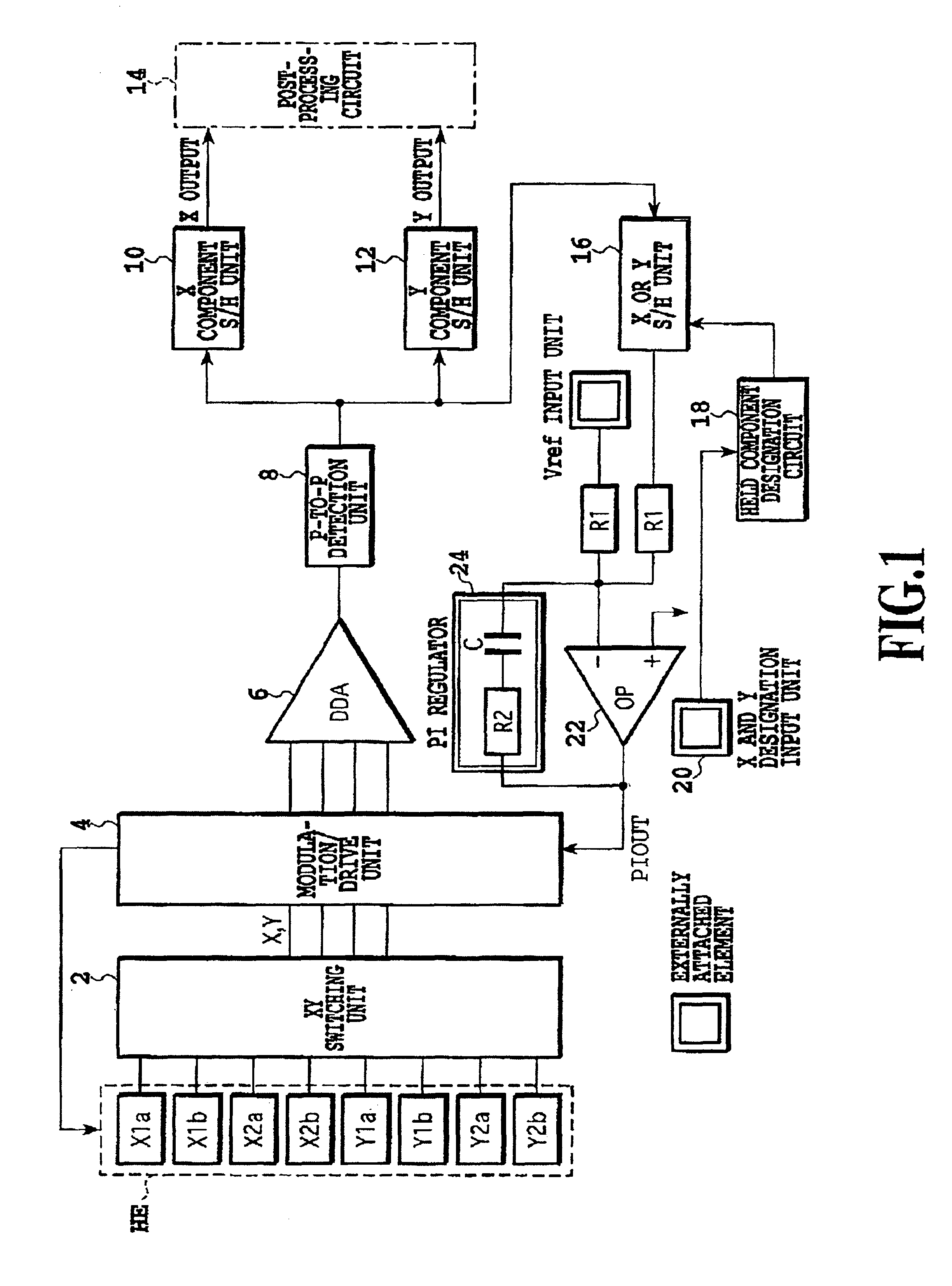

Calibration circuits and methods for proximity detector

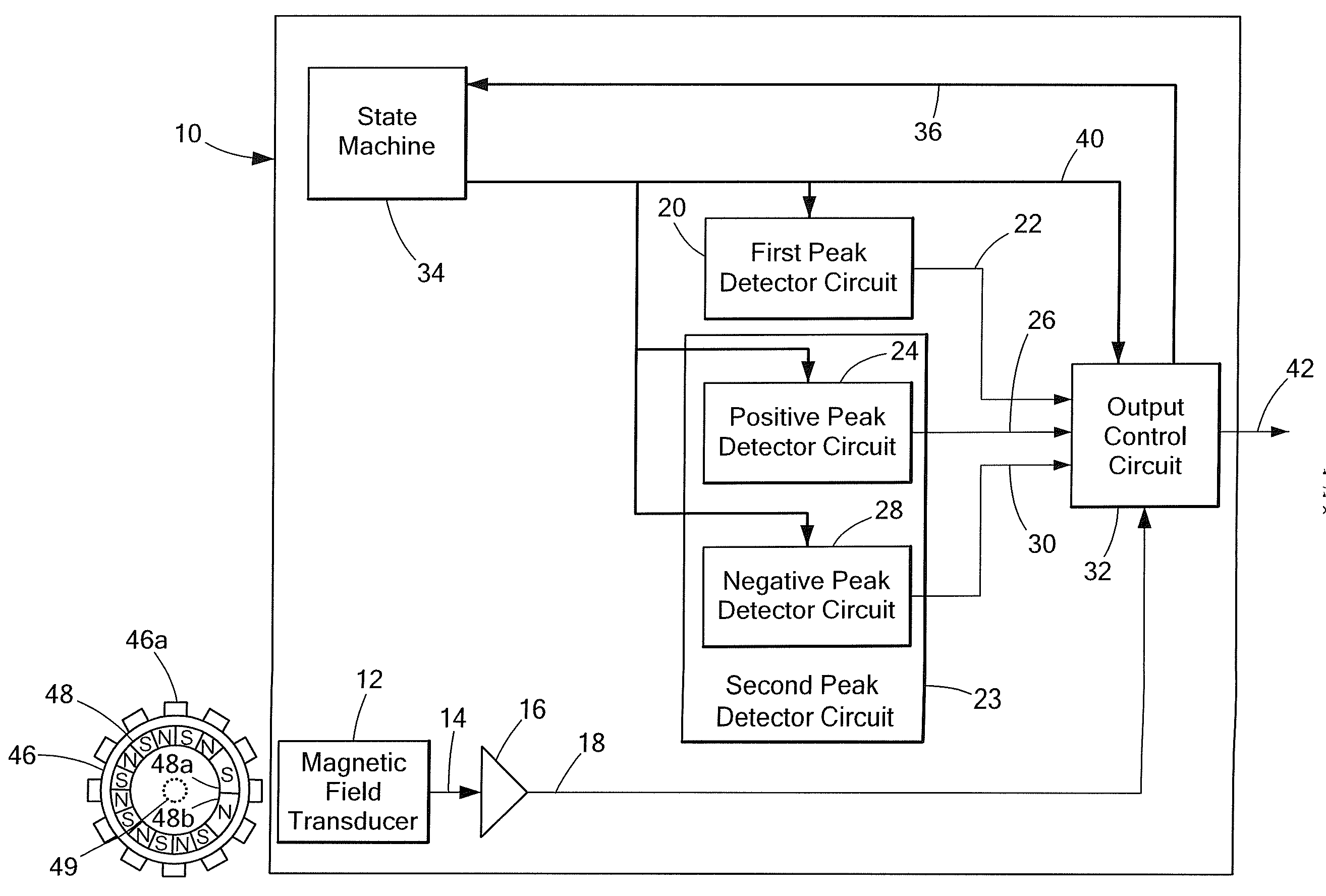

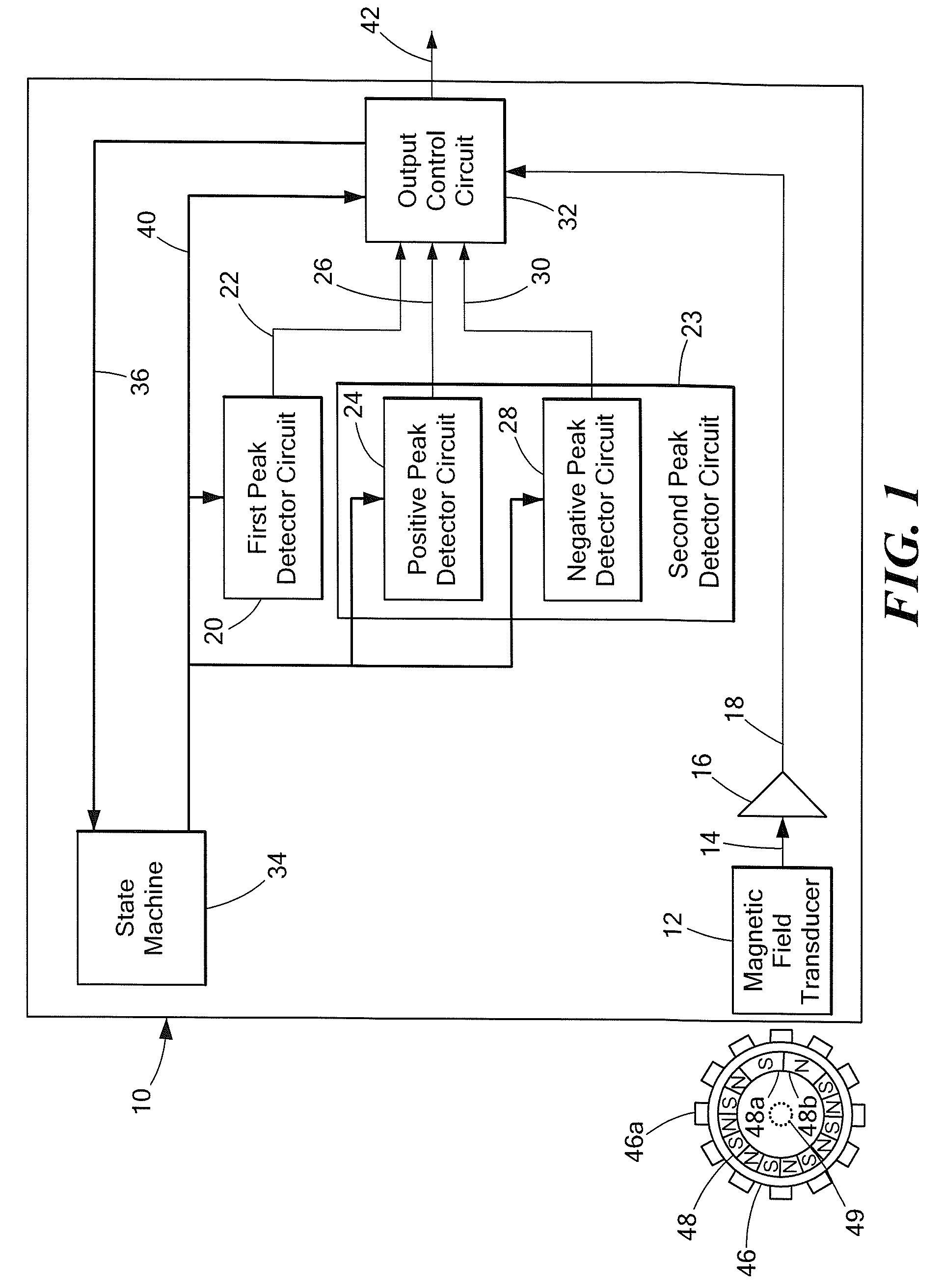

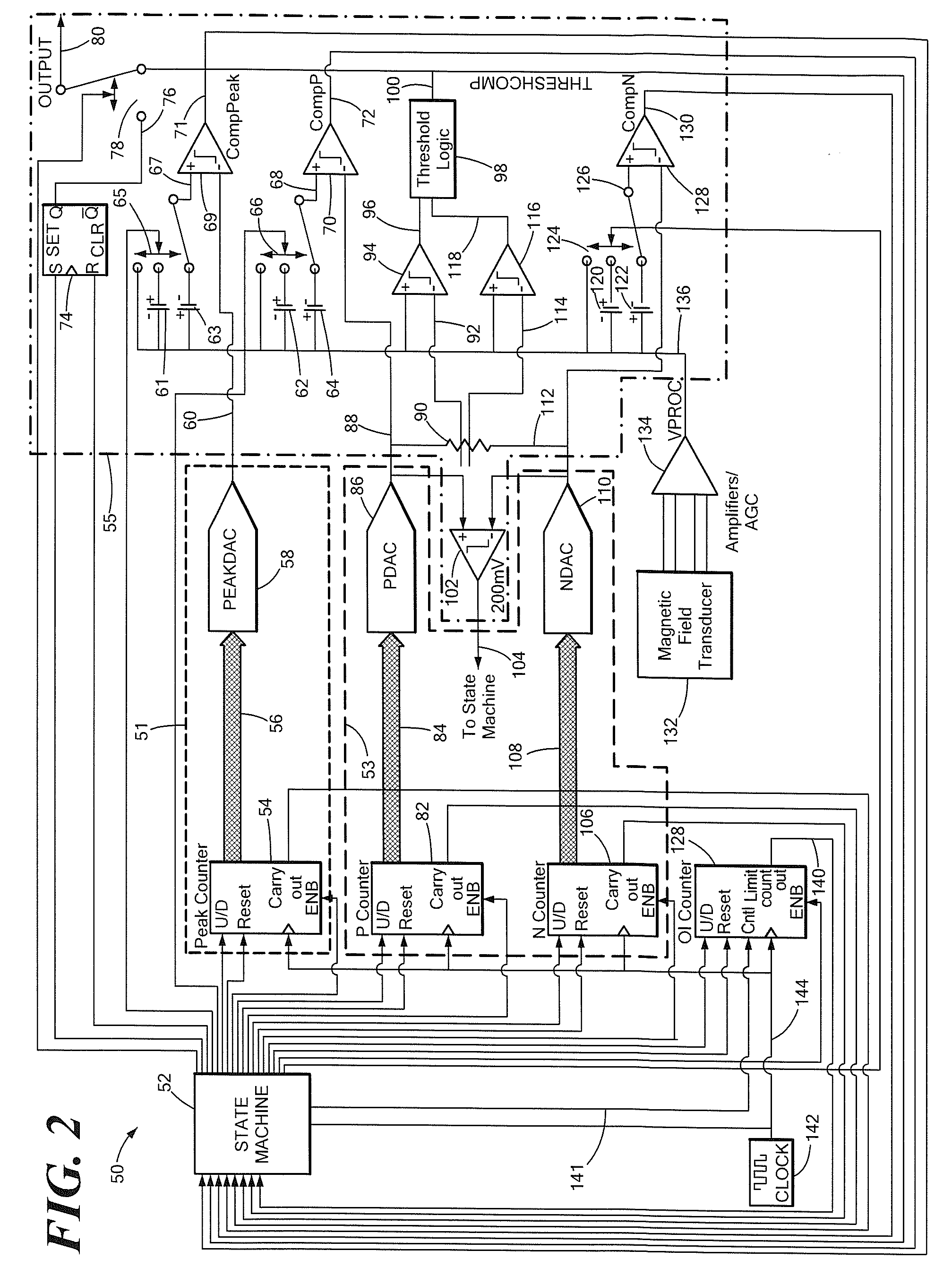

ActiveUS20090001972A1Magnetic-field-controlled resistorsSolid-state devicesDetector circuitsPeak value

A proximity detector employs a first peak detector circuit and a second peak detector circuit, both responsive to a magnetic field signal. The second peak detector circuit includes a positive peak detector circuit and a negative peak detector circuit, each of which have a predetermined excursion limit in an outward direction away from a center voltage of the magnetic field signal so as to be less affected by a large signature region in the magnetic field signal. The proximity detector also includes an output control circuit. The output control circuit is configured to provide an output signal, which, during a determined time period, changes state in response to the first peak detector circuit, and which, after the determined time period, changes state in response to the second peak detector circuit.

Owner:ALLEGRO MICROSYSTEMS INC

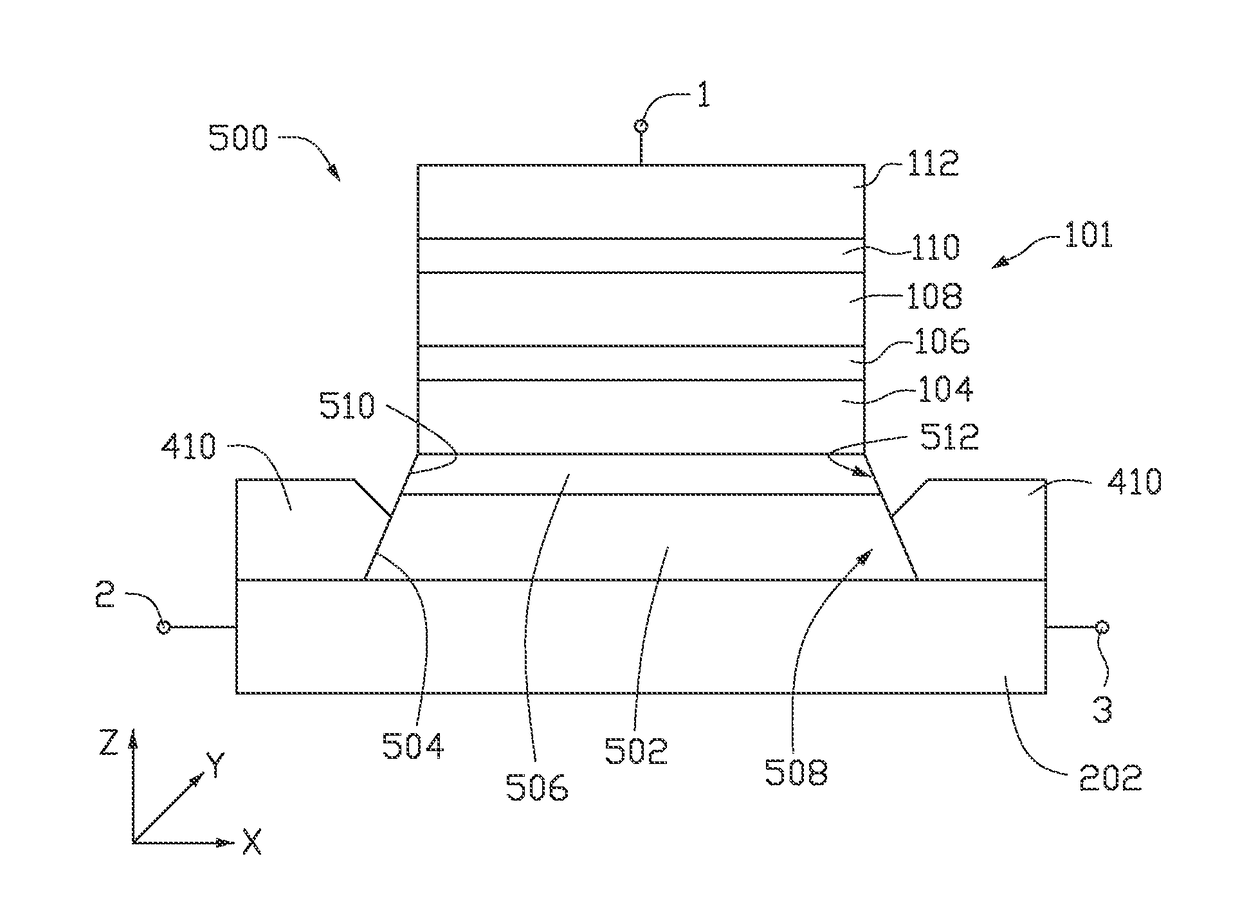

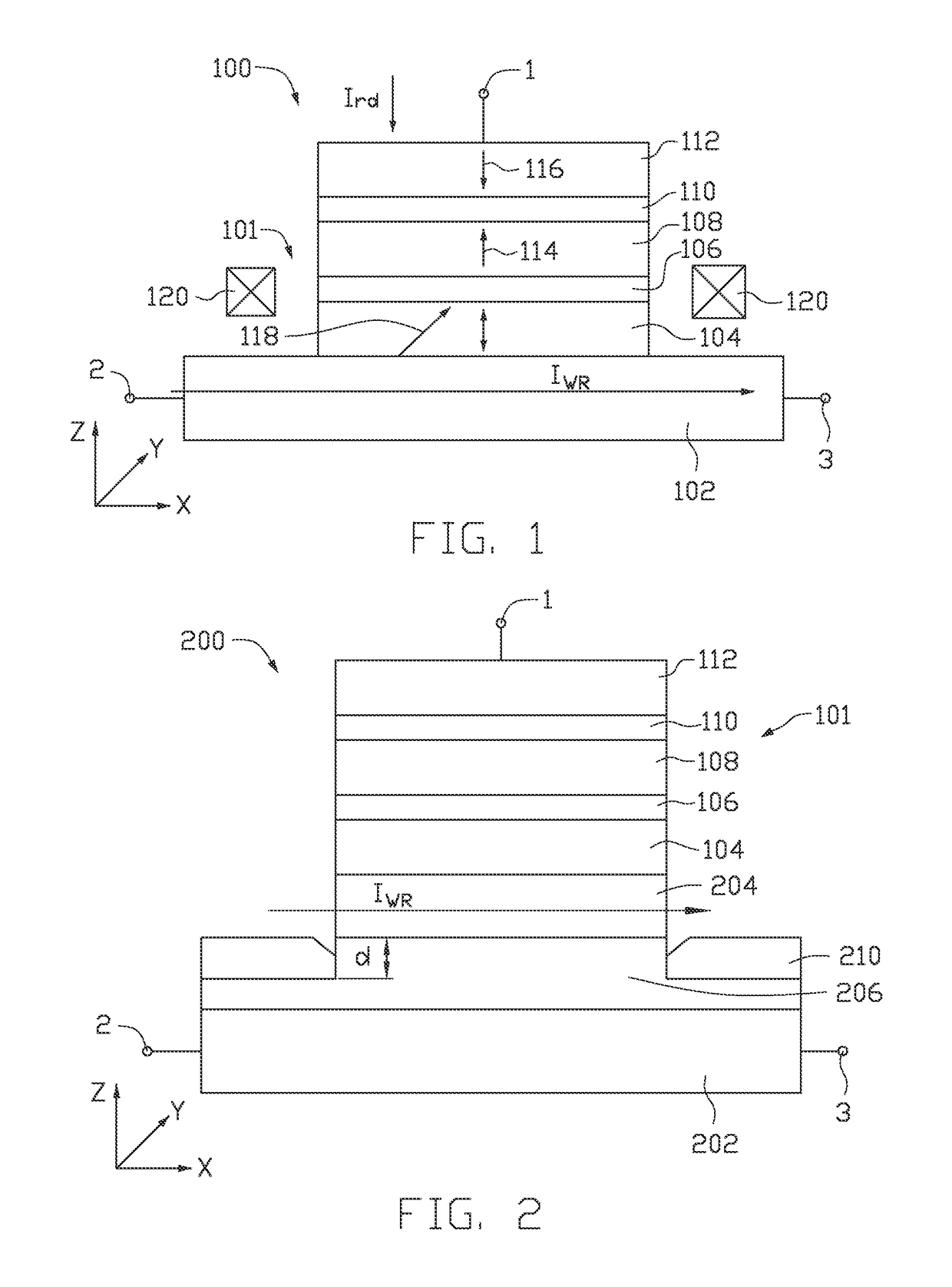

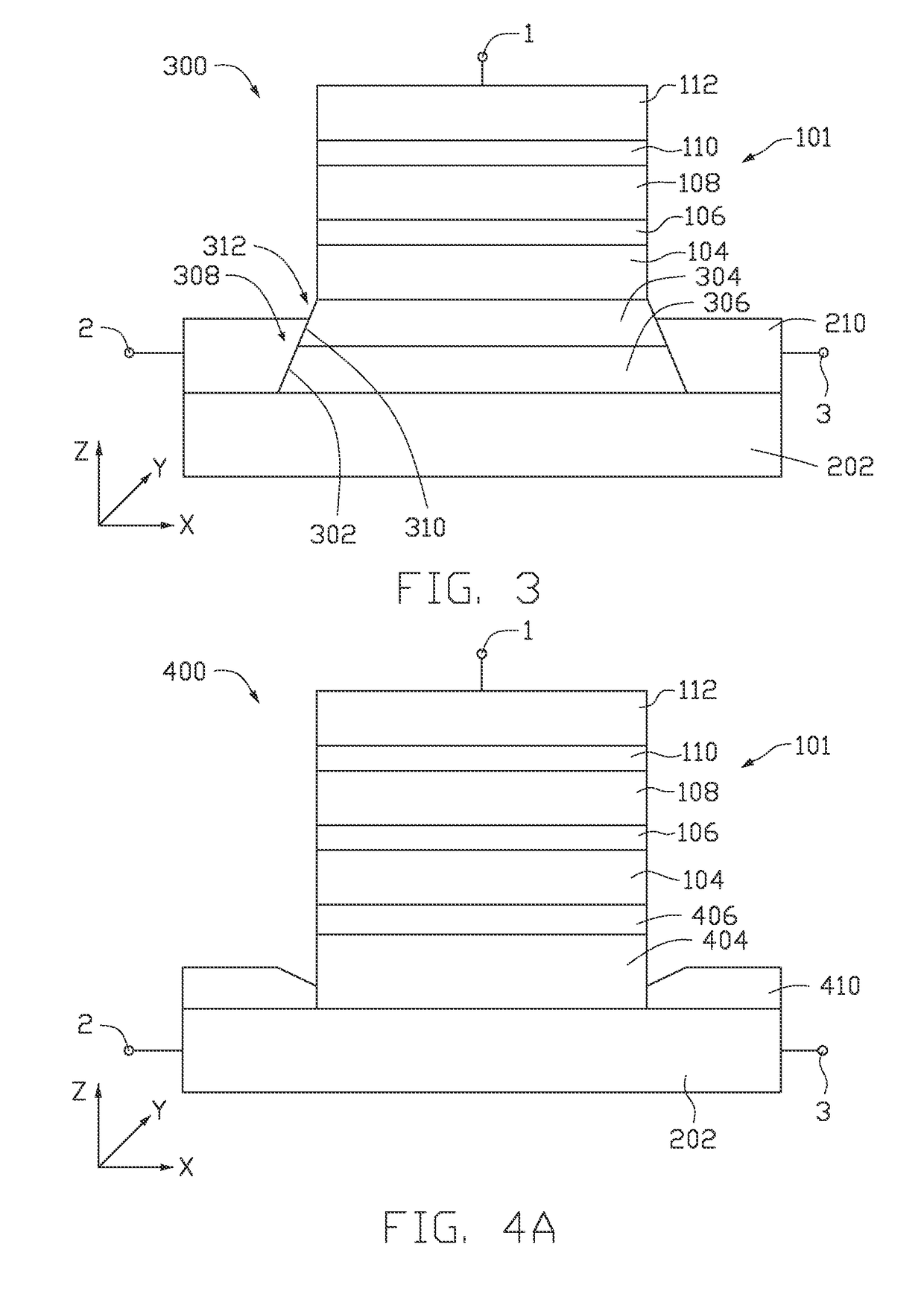

Three Terminal Spin Orbit Torque Memory Cell with In-Stack MAGNETIC LAYER THAT PROVIDES Magnetic Bias Field AND SPIN ORBIT TORQUE VIA Anomalous Hall Effect

ActiveUS20170125078A1Remarkable effectMagnetic-field-controlled resistorsSolid-state devicesSpin orbit torqueBias field

A method and apparatus for deterministically switching a free layer in a spin orbit torque magnetoresistive random access memory (SOT-MRAM) cell is disclosed herein. In one embodiment, an SOT-MRAM memory cell is provided. The SOT-MRAM memory cell includes a magnetic tunnel junction, a ferromagnetic bias layer, and an antiferromagnetic layer. The magnetic tunnel junction includes a free layer having primarily two bi-stable magnetization directions, a reference layer having a fixed magnetization direction, and an insulating tunnel barrier layer positioned between the free layer and the reference layer. The ferromagnetic bias layer is configured to provide spin orbit torque via anomalous Hall effect and simultaneously configured to provide a magnetic bias field on the free layer to achieve deterministic switching. The antiferromagnetic layer is positioned below the ferromagnetic bias layer and is configured to pin a magnetization direction of the ferromagnetic bias layer in a predetermined direction.

Owner:WESTERN DIGITAL TECH INC

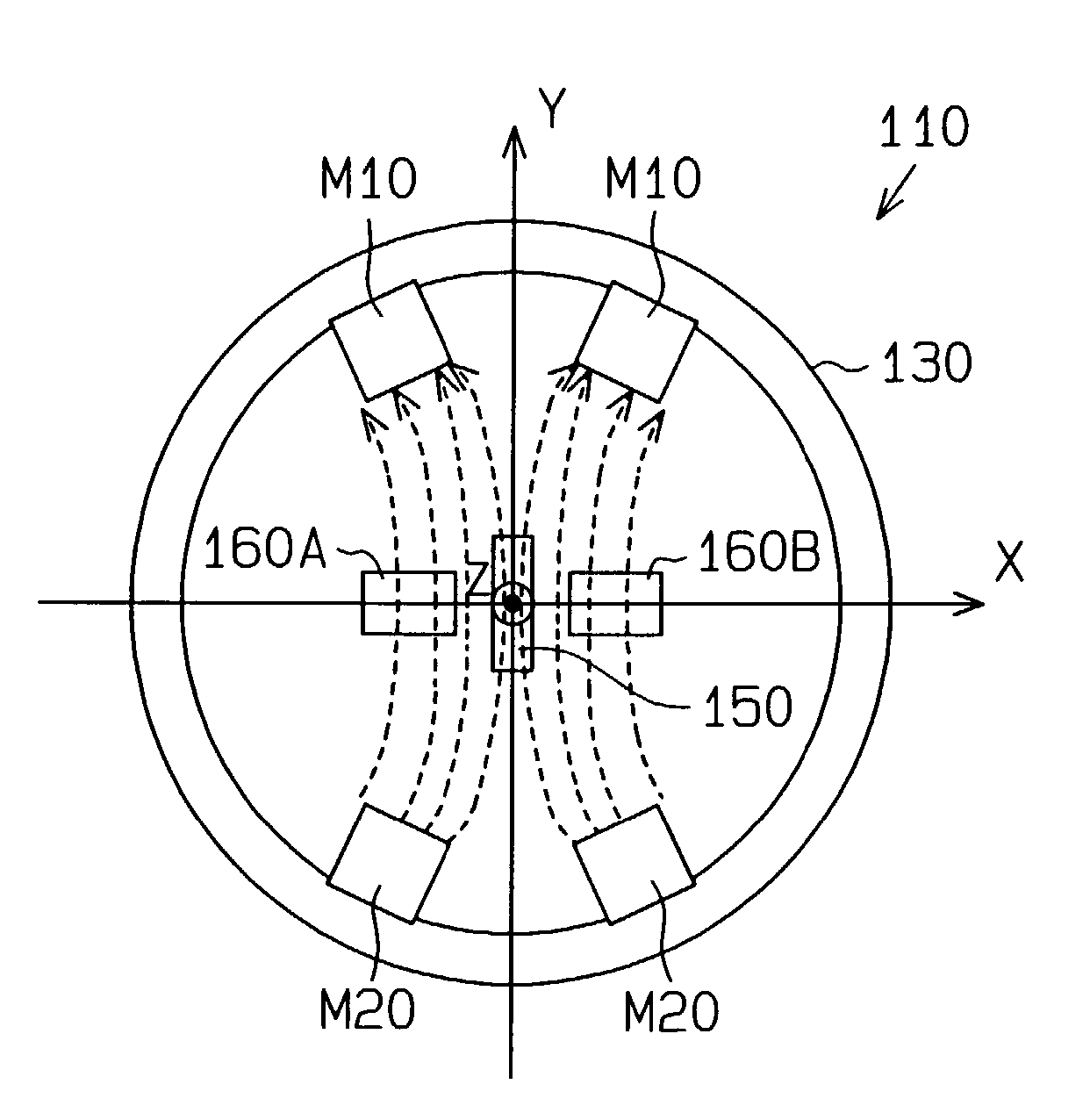

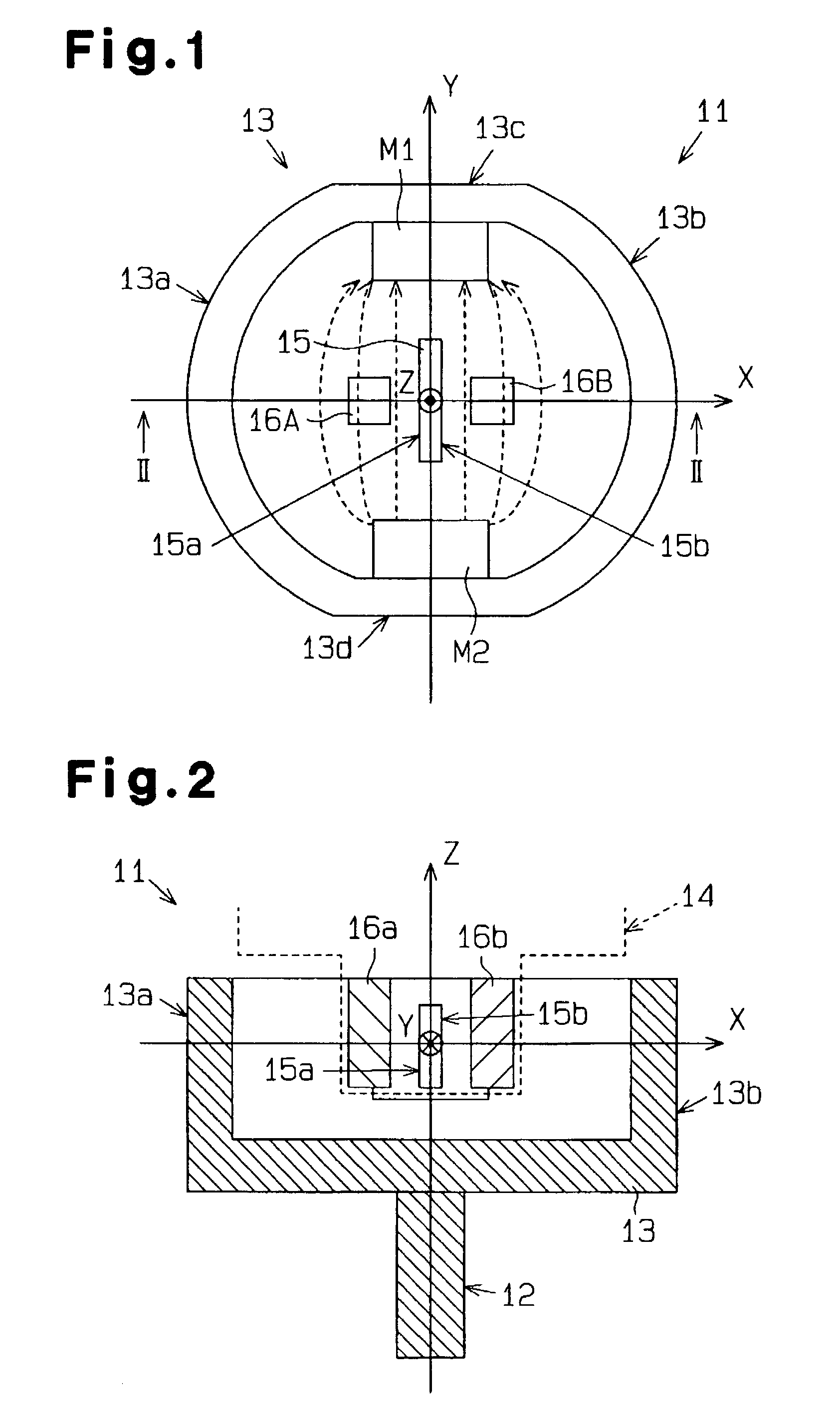

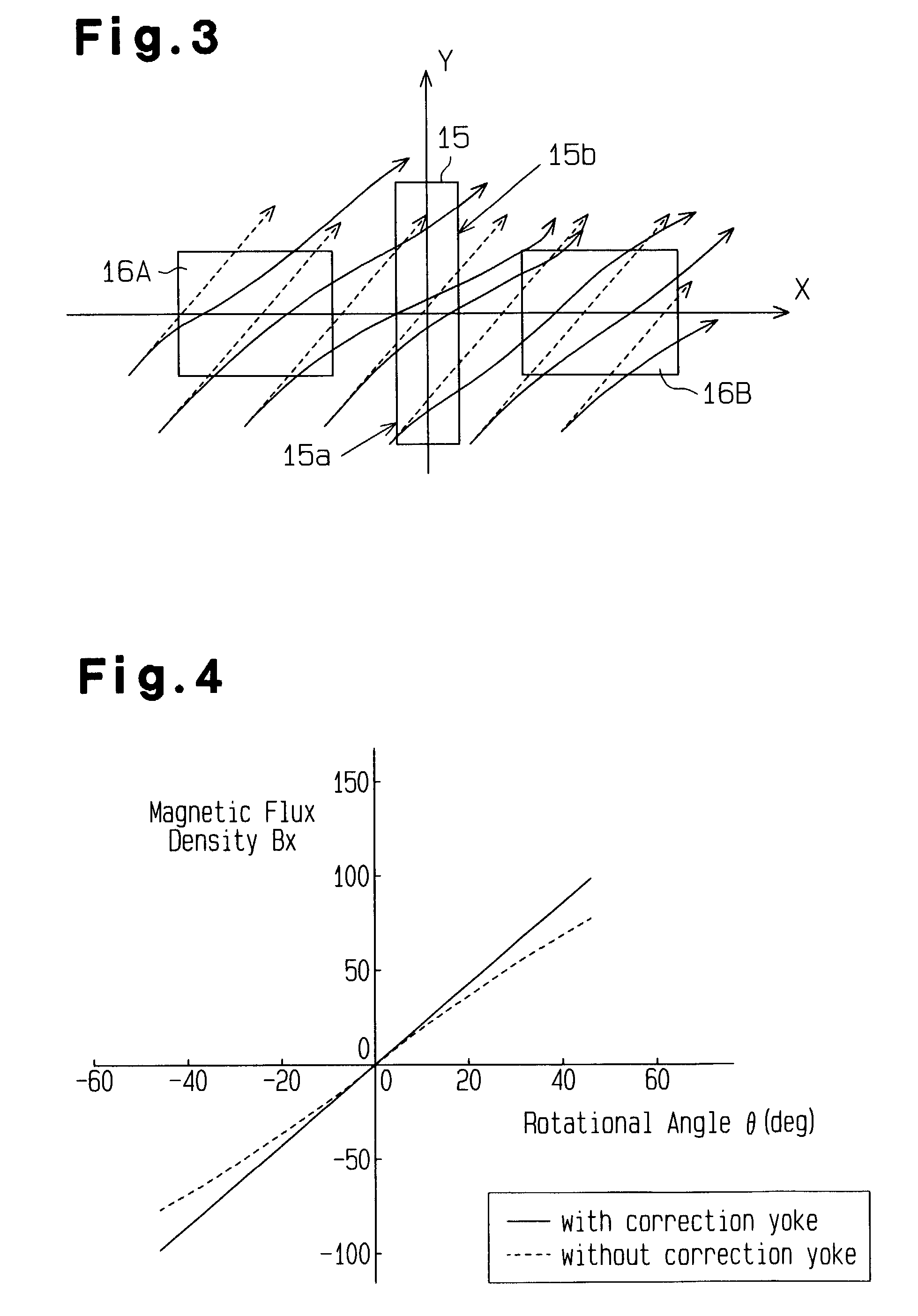

Angular sensor with a magneto-electric transducer and a magnetic deflection device

InactiveUS7030606B2Magnetic-field-controlled resistorsSolid-state devicesUltrasonic sensorTransducer

An angular sensor which enables to obtain an output signal proportional to a relative rotational angle with low manufacturing cost and with miniaturized size. An angular sensor which includes a first magnet and a second magnet fixed to a rotation body, magnetic flux sensing surface is fixed to the stator to be positioned in magnetic field between the first magnet and the second magnet and perpendicular to magnetic sensing direction for sensing a magnetic flux, a magneto-electric transducer element for outputting an electric signal corresponding to a magnetic sensing direction element of the magnetic density, deflection yokes. The deflection yokes are positioned facing the magnetic flux sensing surfaces. The deflection yokes are positioned within a range of three quarters of a distance between the first magnet and the second magnet in X-axis direction and one half of a distance between the first magnet and the second magnet in Y-axis direction.

Owner:AISIN SEIKI KK

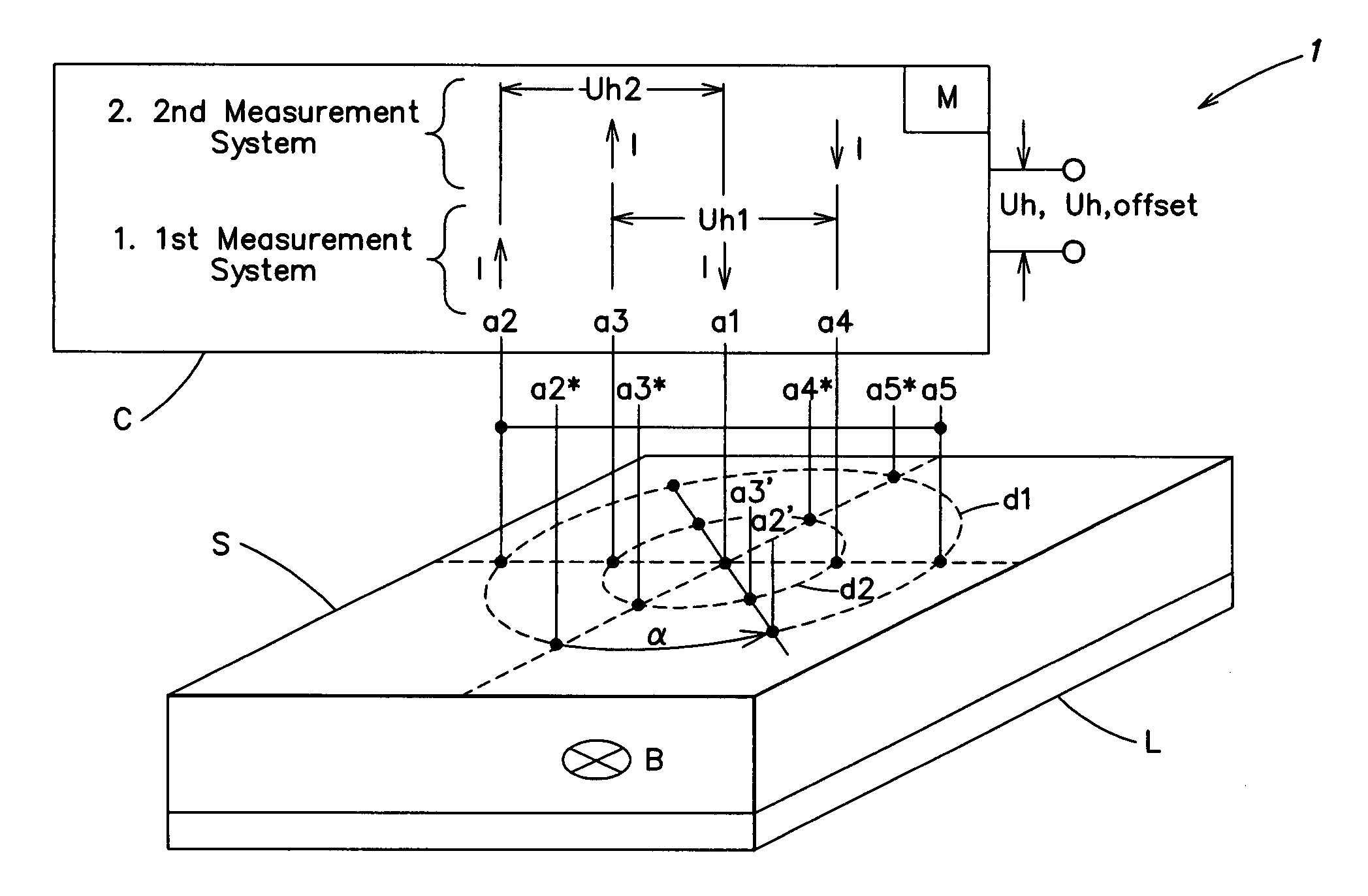

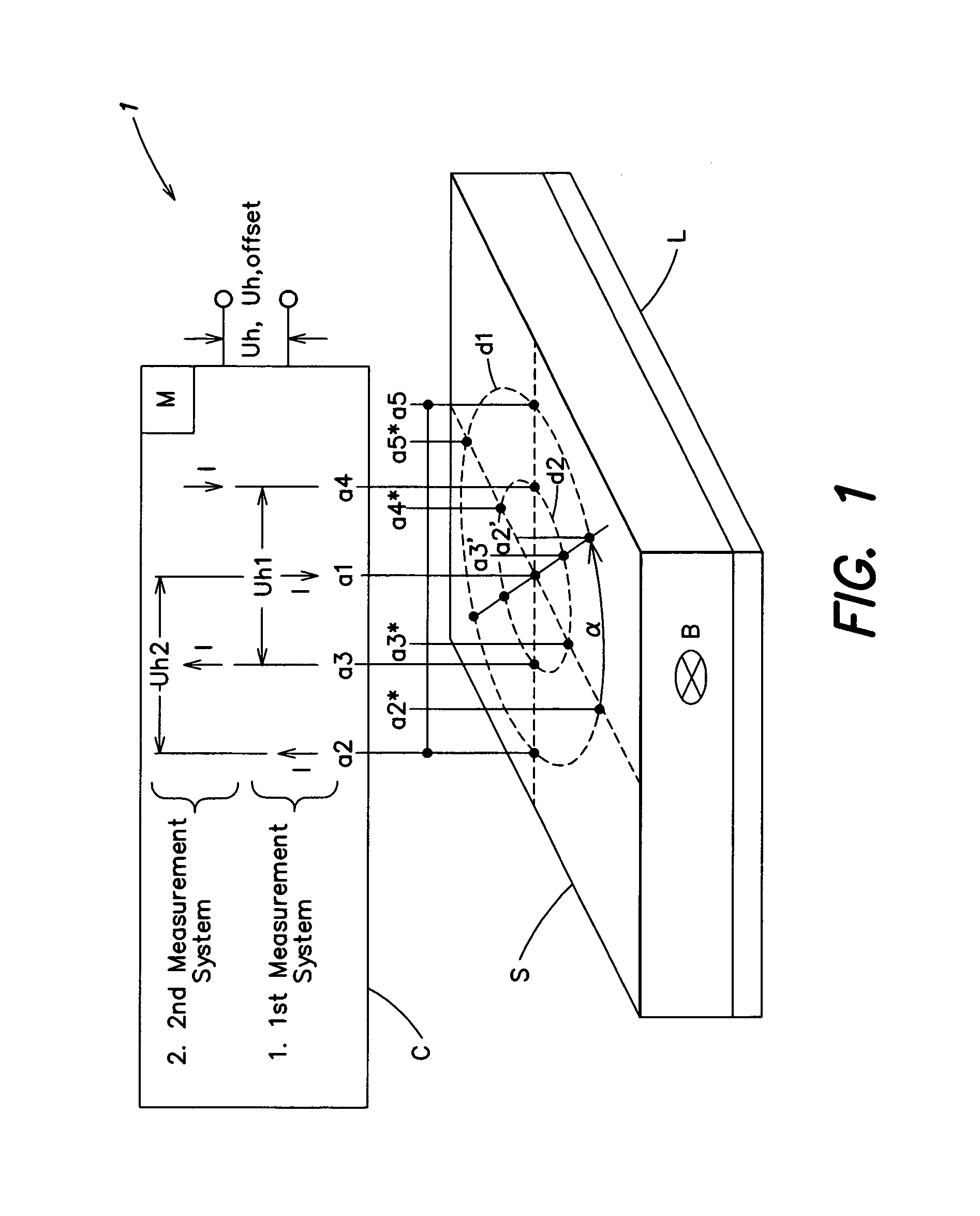

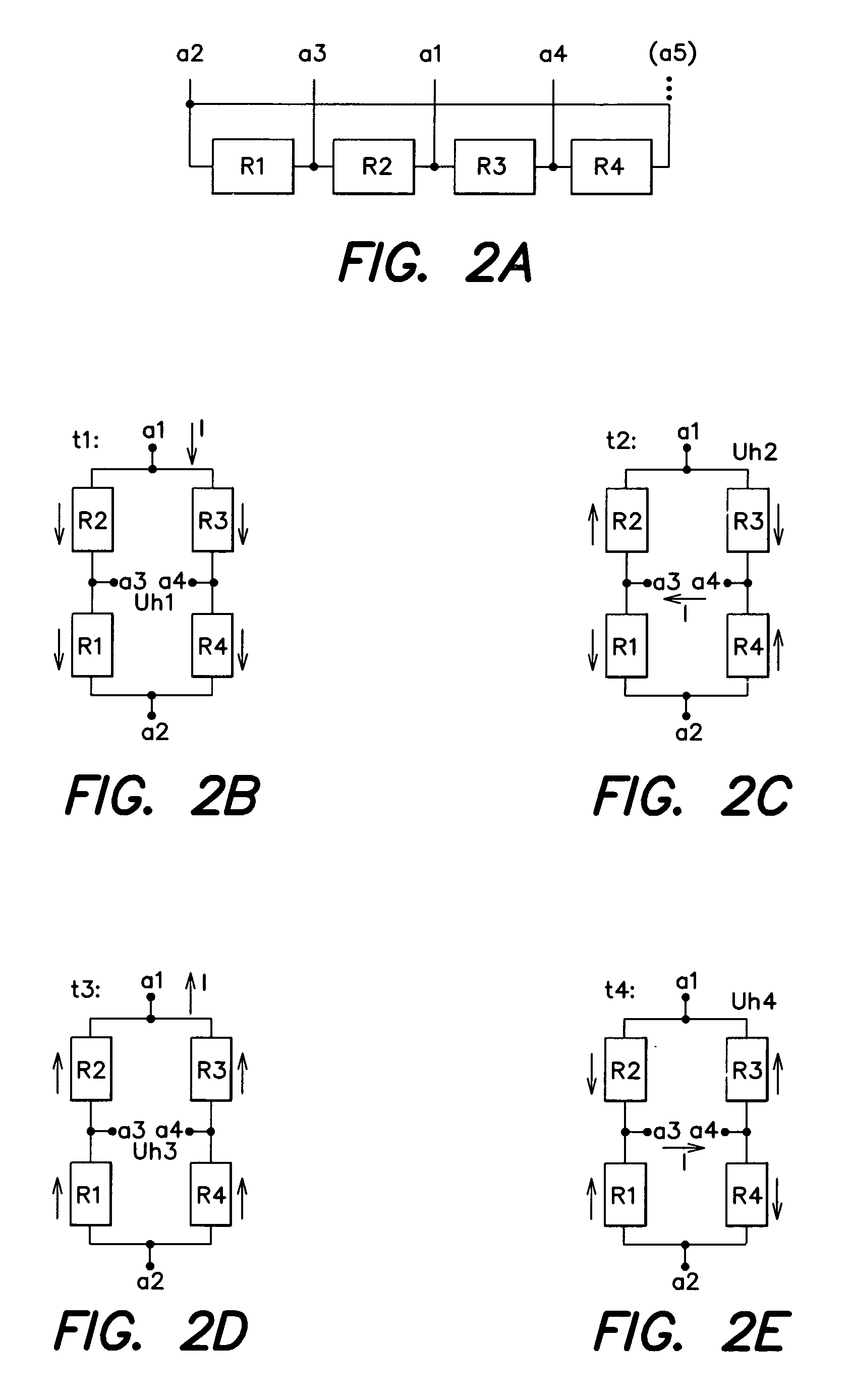

Offset-reduced hall sensor

ActiveUS7119538B2Easy to switchSolid-state devicesMagnetic field measurement using galvano-magnetic devicesVoltagePhysics

A technique for determining an offset-reduced Hall voltage (Uh), and / or an offset voltage (UH, offset) of a Hall sensor (1) includes applying a Hall sensor current (I) at first and second taps (a1, a2, a3) of the Hall sensor (1), and determining a first Hall voltage (Uh1) at third and fourth taps (a3, a4) displaced from the first and second taps (a1, a2, a5). A second Hall sensor current is applied modified relative to the first, and a second Hall voltage (Uh2) is determined. The Hall voltage (Uh) and / or Hall voltage offset (Uh,offset) are determined from the first and second Hall voltages. To compensate any offset present, a second measurement applies the second Hall sensor current I at taps (a3, a4) that are spatially displaced relative to the first and / or second taps.

Owner:TDK MICRONAS GMBH

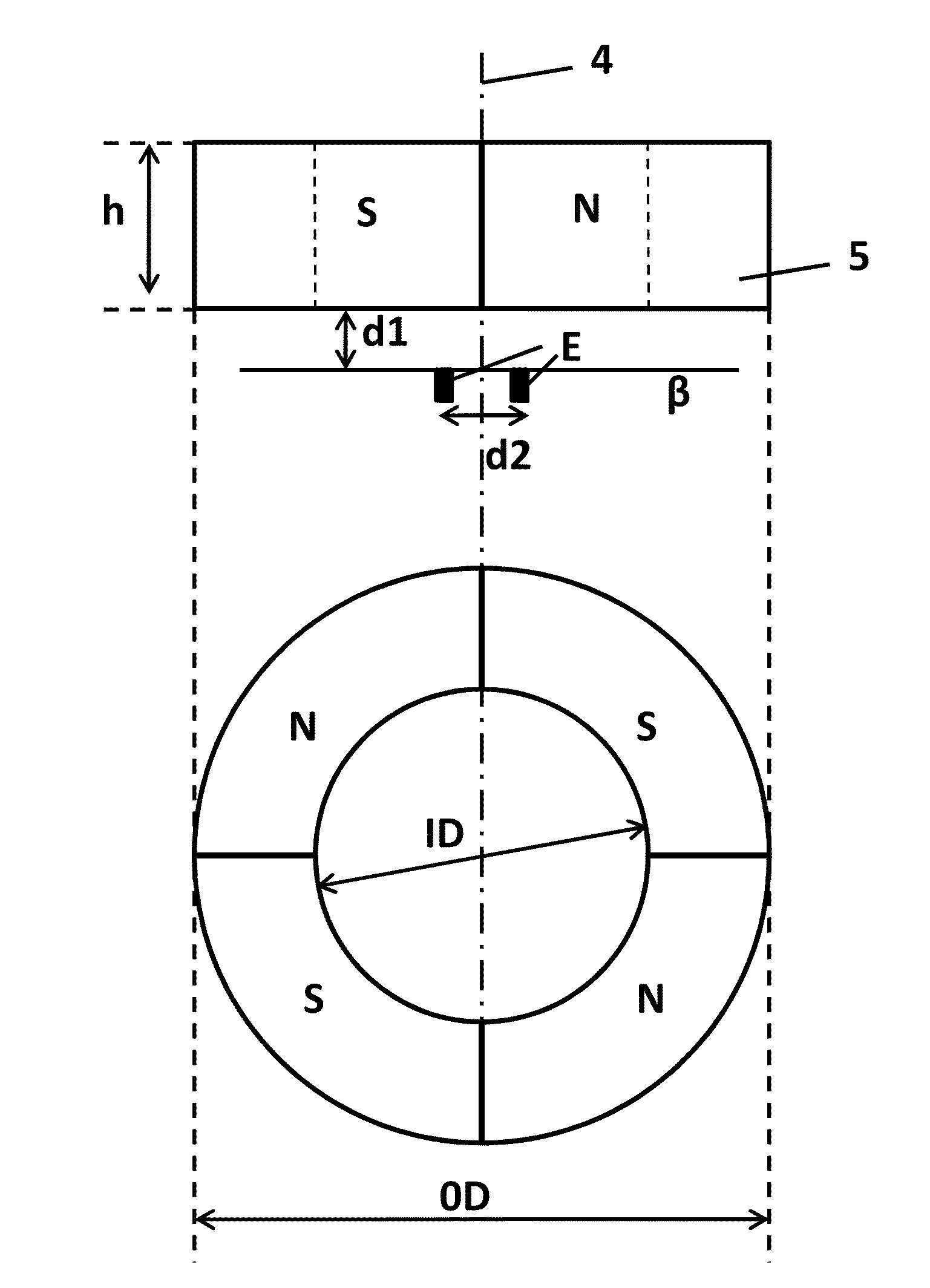

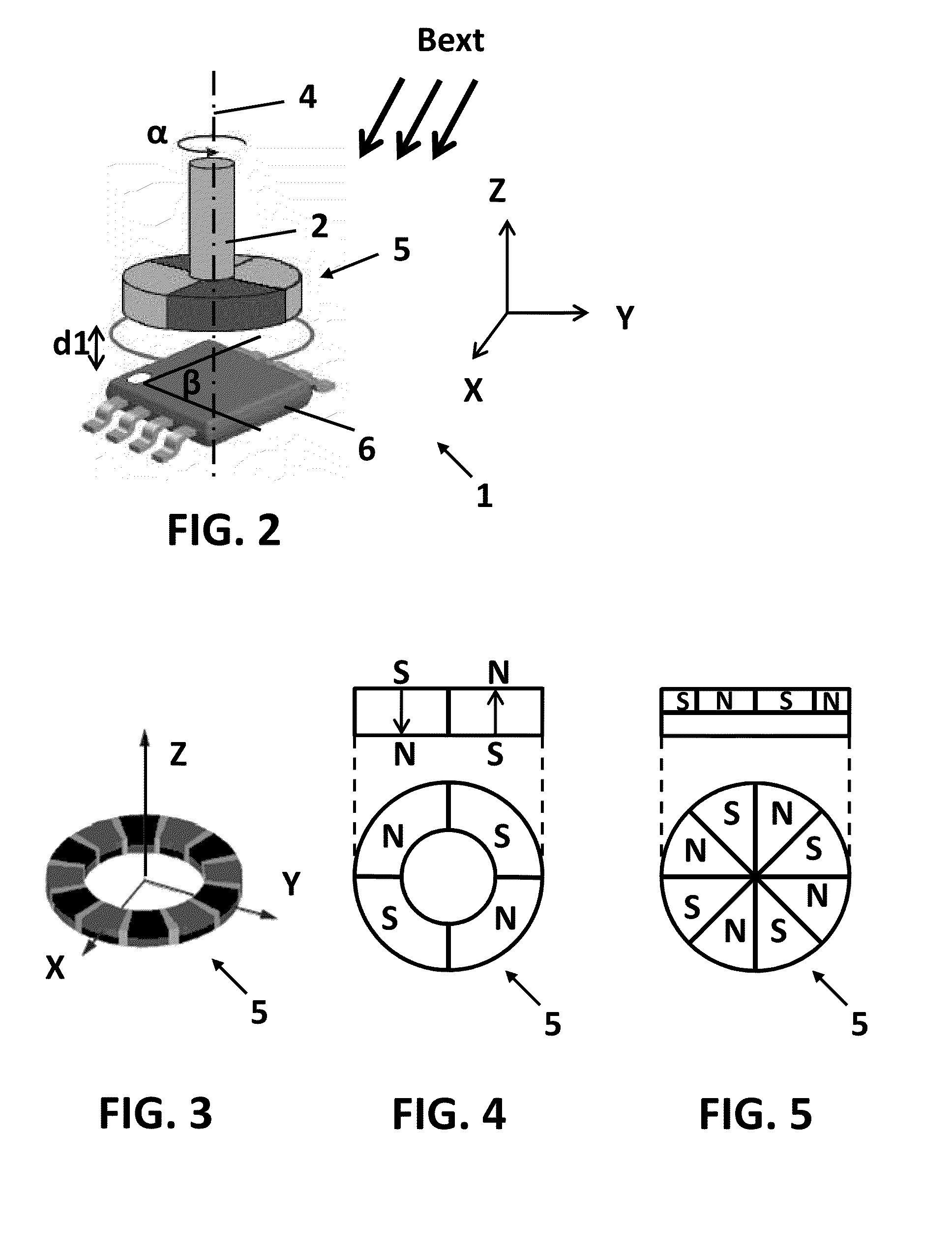

Arrangement, Method and Sensor for Measuring an Absolute Angular Position Using a Multi-Pole Magnet

ActiveUS20150226581A1Reduce sensitivityHigh sensitivitySolid-state devicesMagnetic field measurement using galvano-magnetic devicesAcousticsMagnet

An arrangement for measuring an angular position of a rotor with respect to a stator, comprises a multi-pole magnet mounted on the rotor, and a sensor mounted on the stator and a plurality of sensor elements organized in two groups or four groups for measuring a magnetic field component. A method for calculating the angular position comprises making a sum of signals of the elements of each group, a ratio of the two sums, and an arctan function. Alternatively the method may comprise making a sum of signals, the difference of sums, a ratio of the differences, and an arctan function. An integrated sensor, and the use of such arrangement or sensor in an automotive environment.

Owner:MELEXIS TECH NV

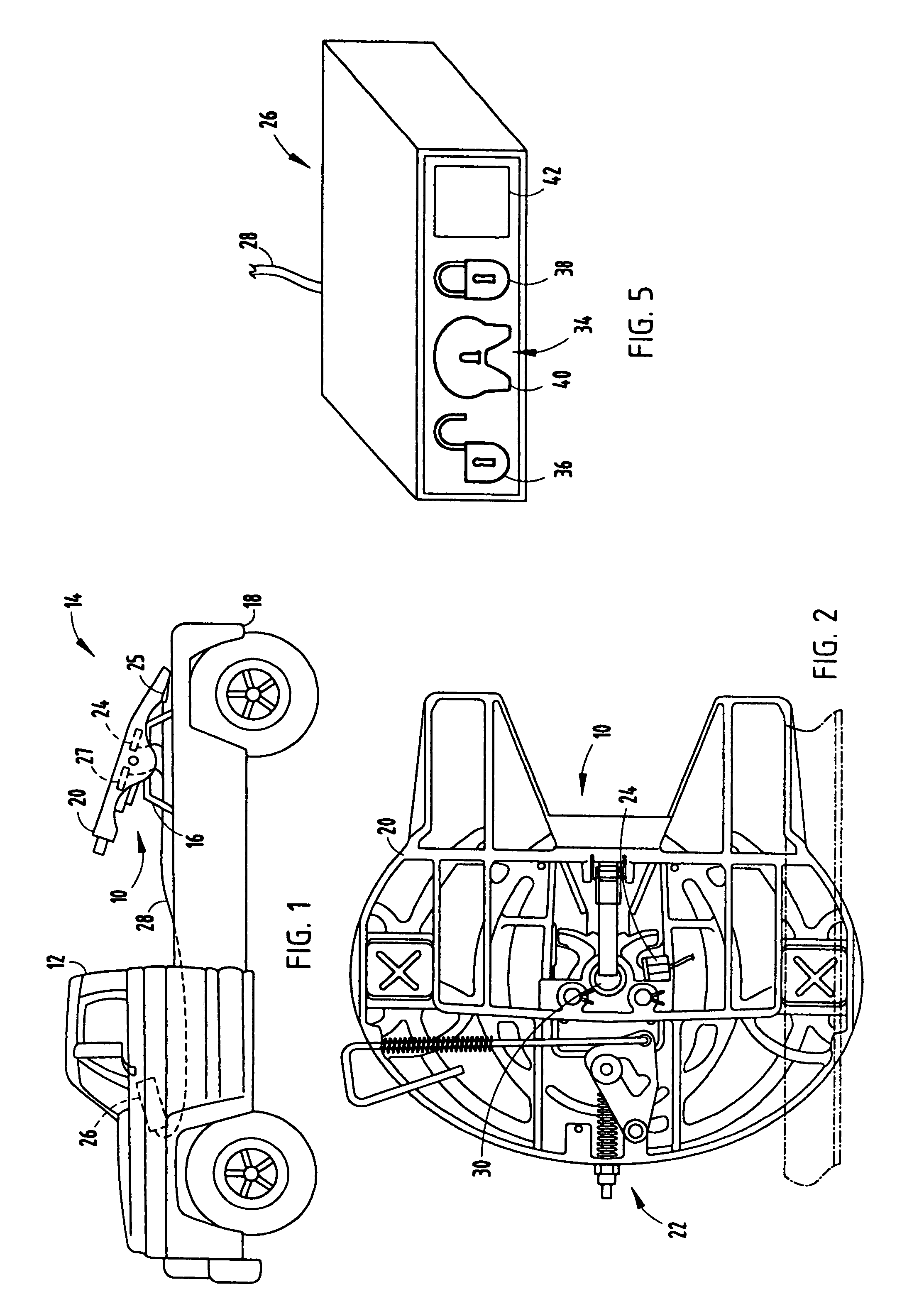

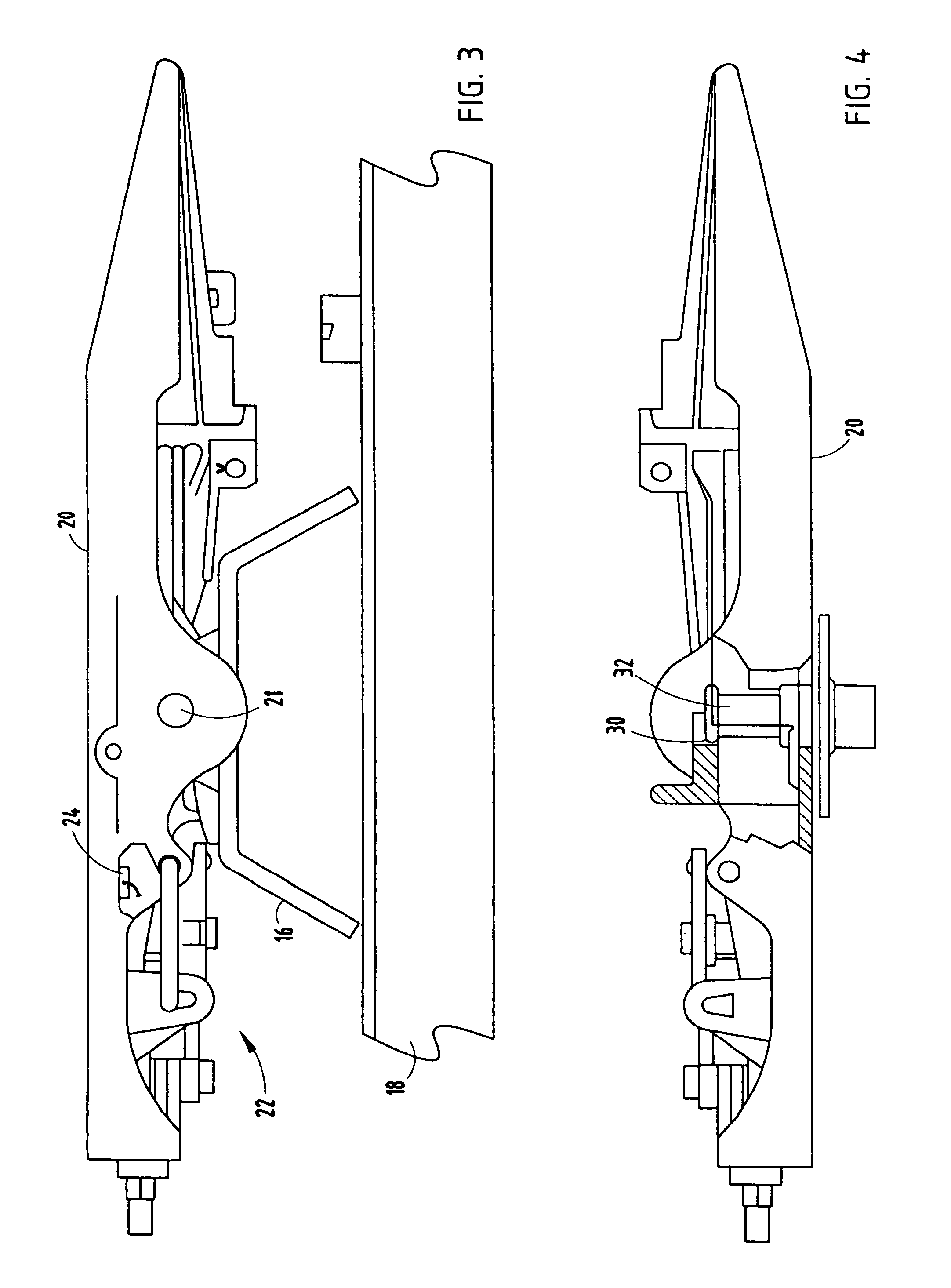

Fifth wheel sensor assembly

ActiveUS7548155B2Increased operating lifeReliable distinctionVehicle seatsSolid-state devicesElectronic systemsLocking mechanism

An electronic system that monitors a trailer hitch assembly having a plate hitch with a throat for receiving a kingpin of a trailer and a locking mechanism for locking the kingpin within the throat. The electronic system determines whether the trailer hitch assemblies is properly coupled to the trailer, and comprises a first magnet creating a first magnetic flux, and a first Hall-effect sensor for sensing the position of the kingpin of the trailer relative to the throat of the hitch plate by measuring the first magnetic flux. The system further comprises a control circuit operably coupled with the first Hall-effect sensor in determining whether the first magnetic flux indicates a proper location of the kingpin of the trailer relative to the throat of the hitch plate. The electronic system discriminates between the kingpin and foreign materials, thereby assuring proper locking of the locking mechanism.

Owner:THE HOLLAND GROUP

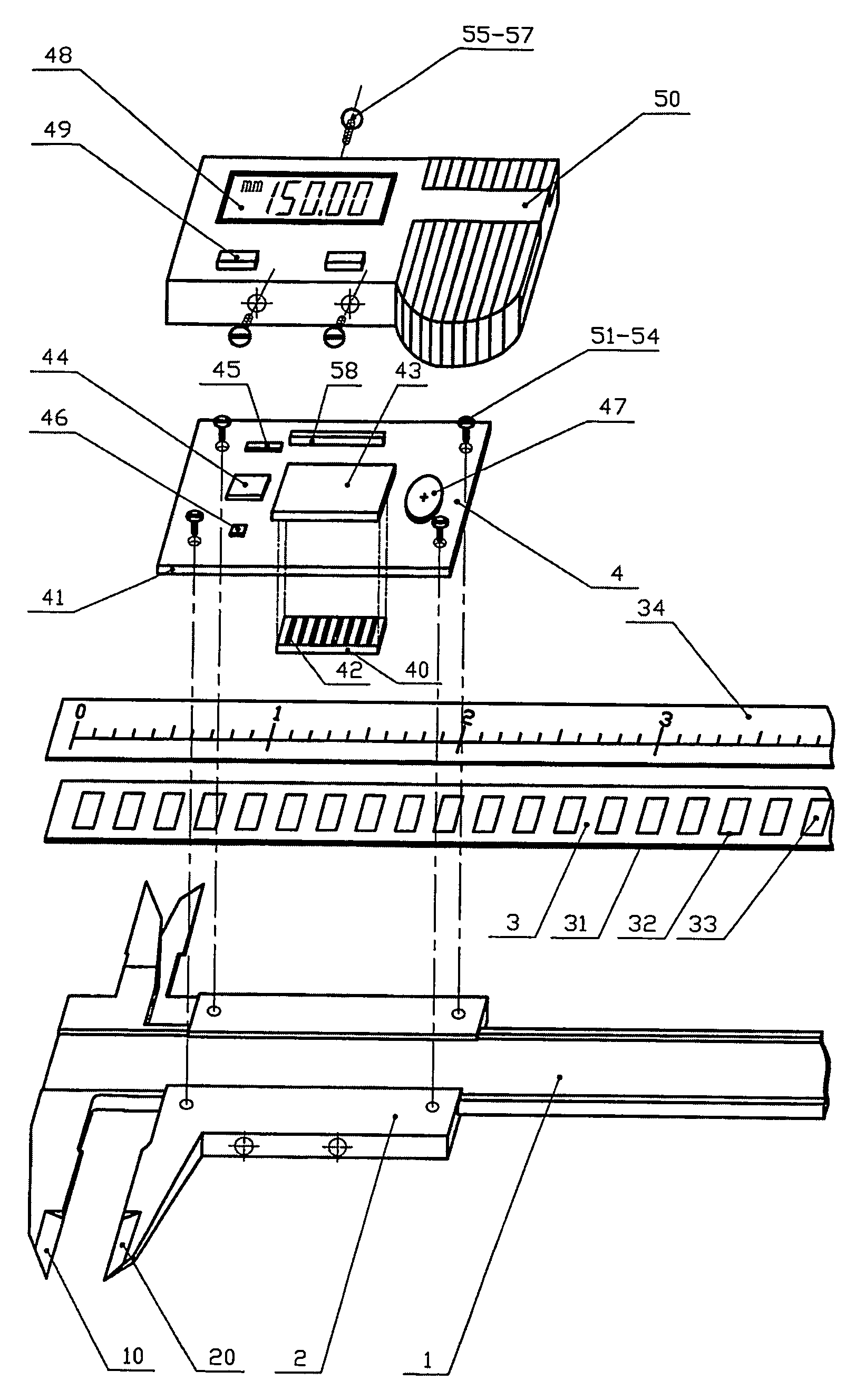

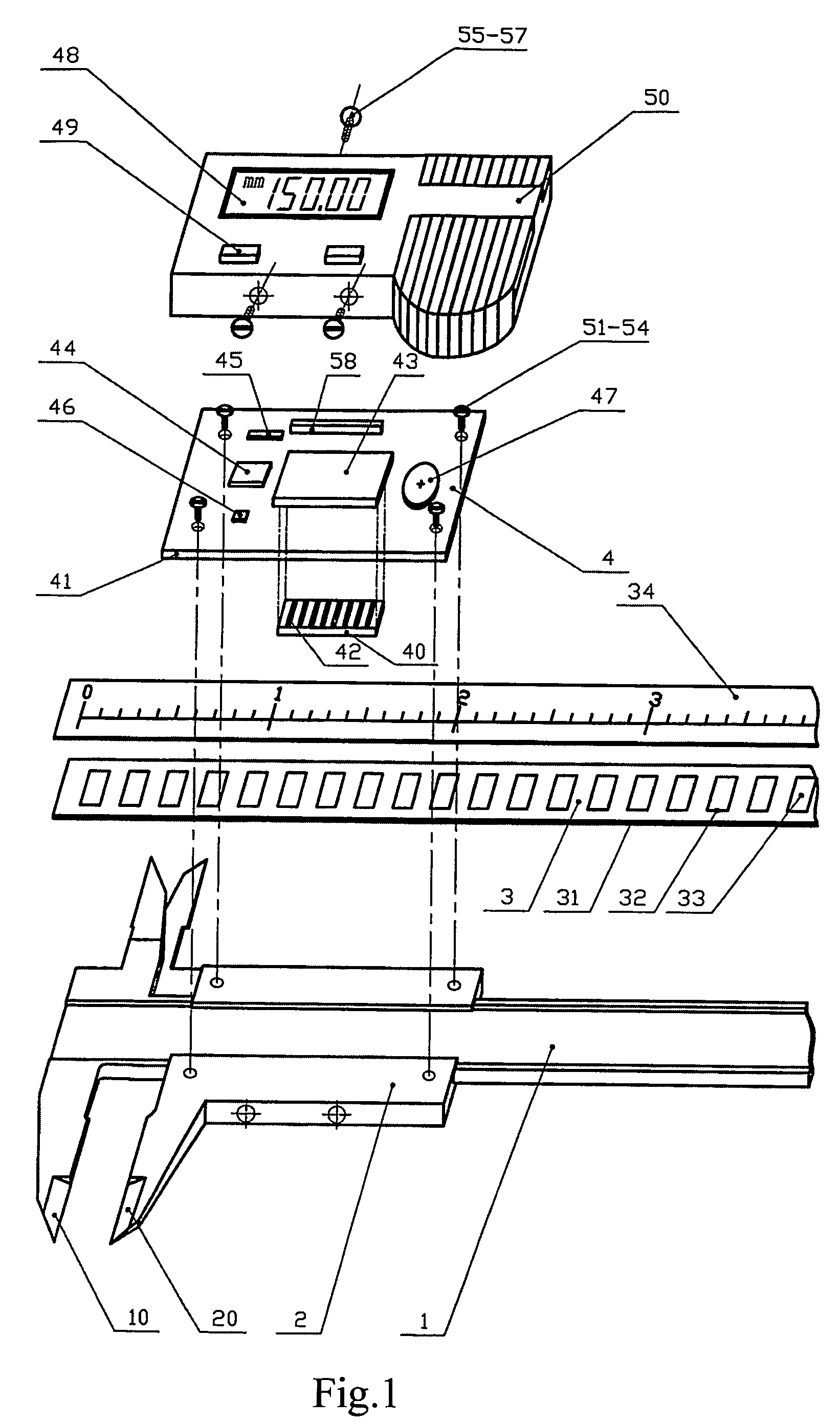

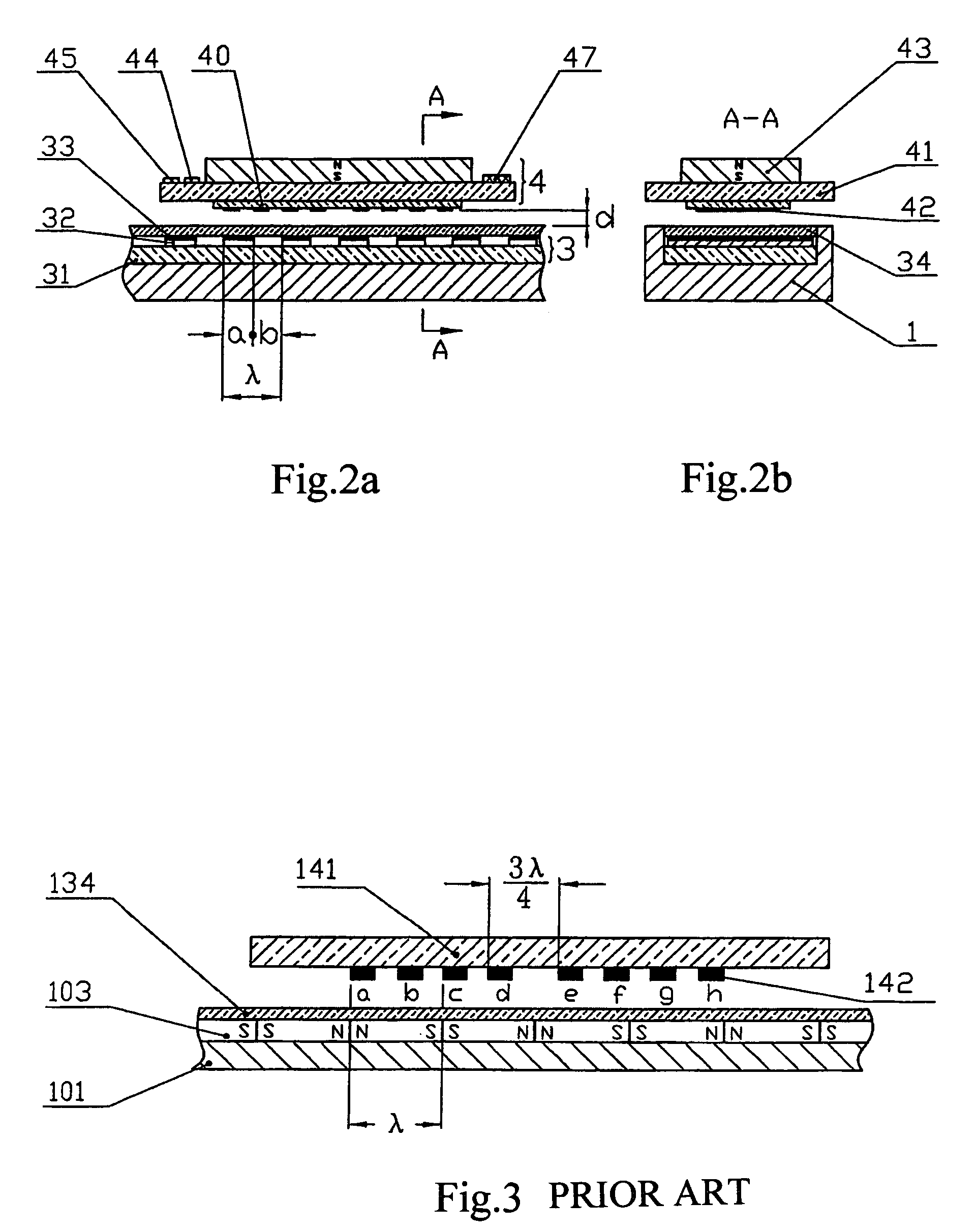

Magnetic displacement ruler

InactiveUS7253611B2Simple structureEasy to manufactureWalking sticksSlide gaugesMeasurement deviceMagnetic reluctance

This invention relates to a magnetic displacement measurement device, which comprises a ruler body and a vernier, wherein a magnetic main ruler is fixed on the ruler body, and a secondary ruler is fixed on the vernier; the secondary ruler comprises a magnetic sensor and a measurement circuit thereon; said magnetic sensor is composed of magnetoresistances; said measurement circuit comprises at least two measurement bridges composed of magnetoresistances; the movement distance of the vernier is displayed on the display screen of the device after being detected by the magnetic sensor and being processed by the measurement circuit. The magnetic displacement measurement device provided by the invention not only can normally work in the wet and oil polluted environment, but also has the advantages of simple structure, convenient manufacture, low price, low power consumption and high precision.

Owner:BEIJING AEROSPACE FENG GUANG ELECTRONICS TECHN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com