Patents

Literature

754results about "Force measurement by measuring magnetic property varation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

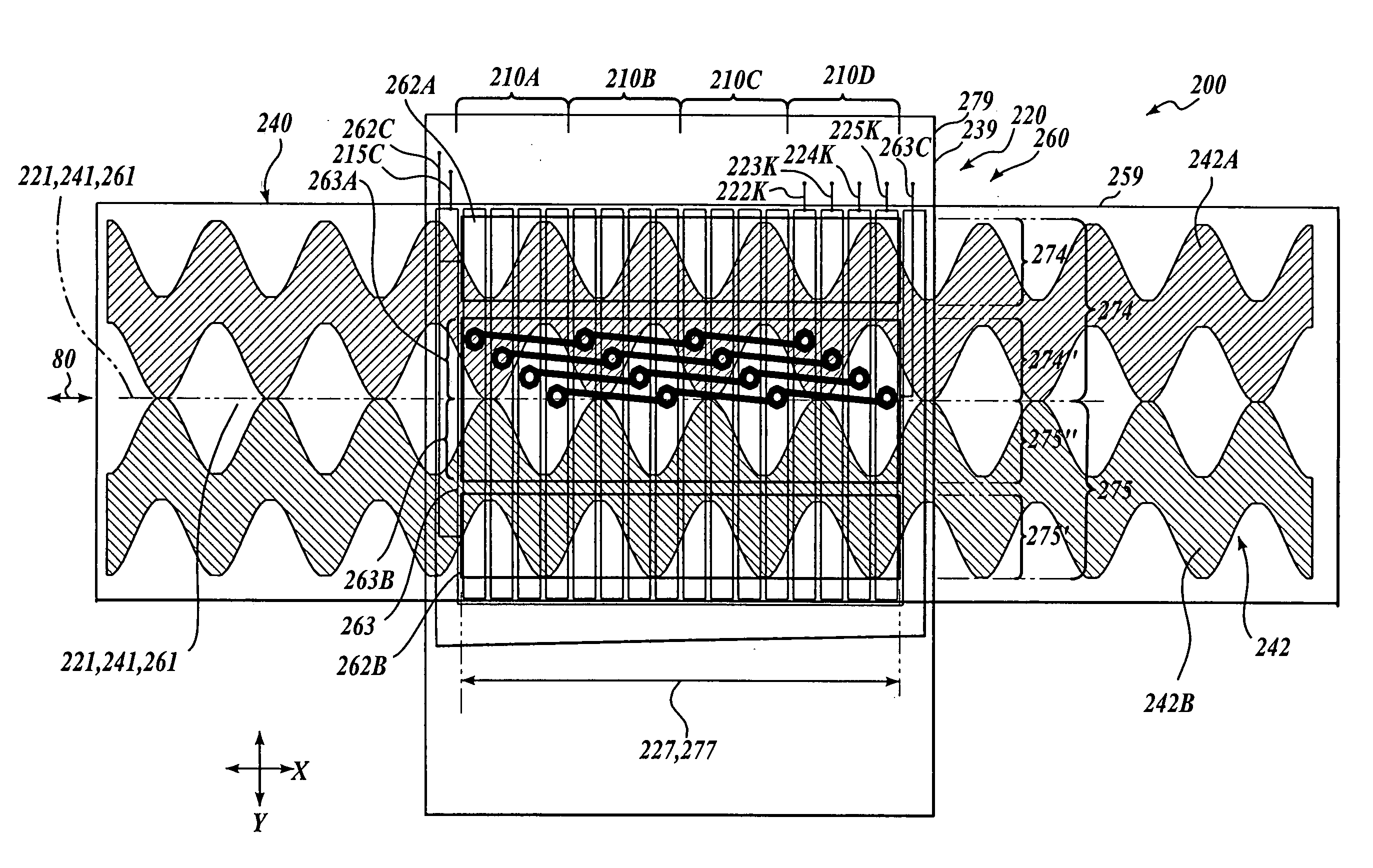

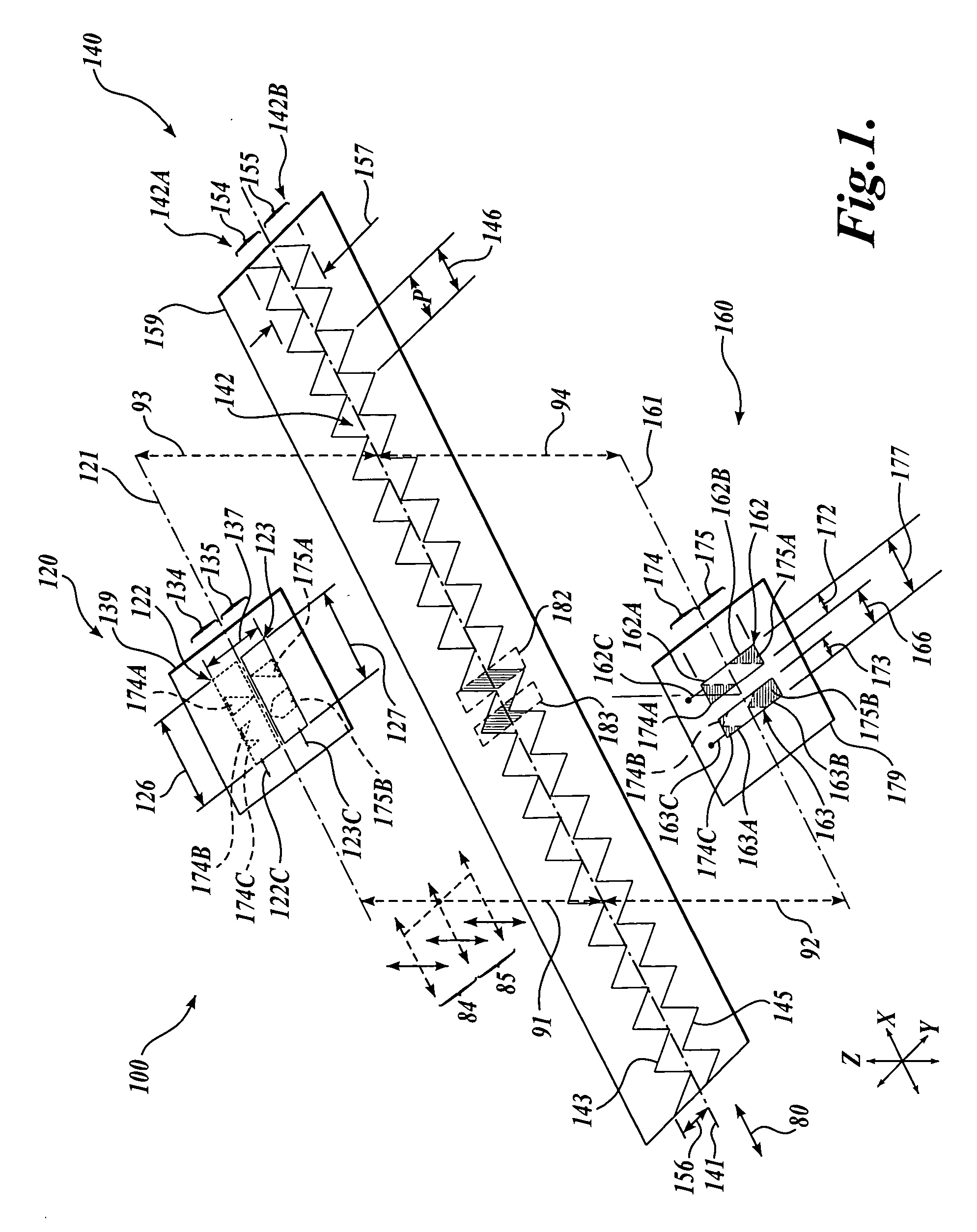

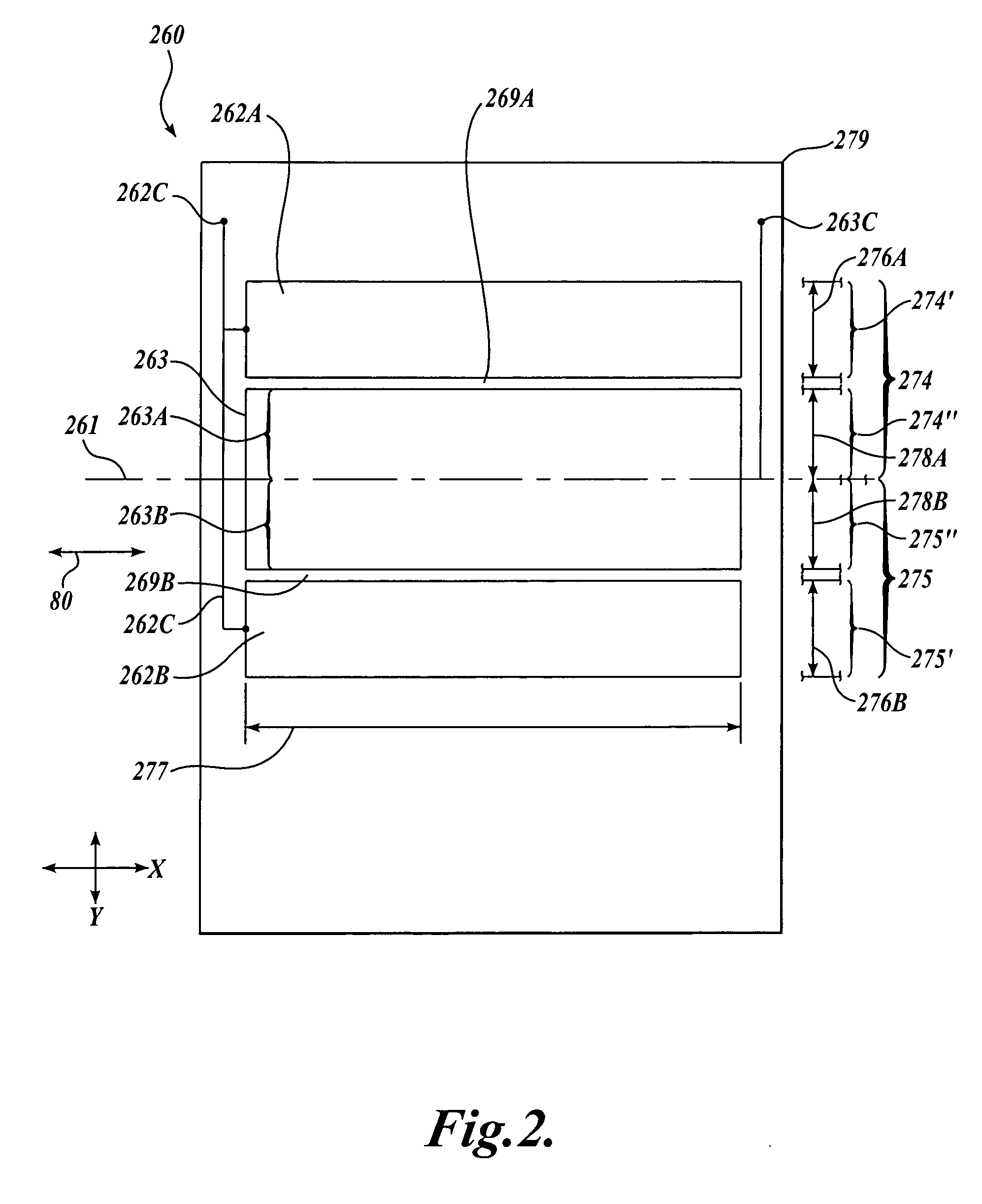

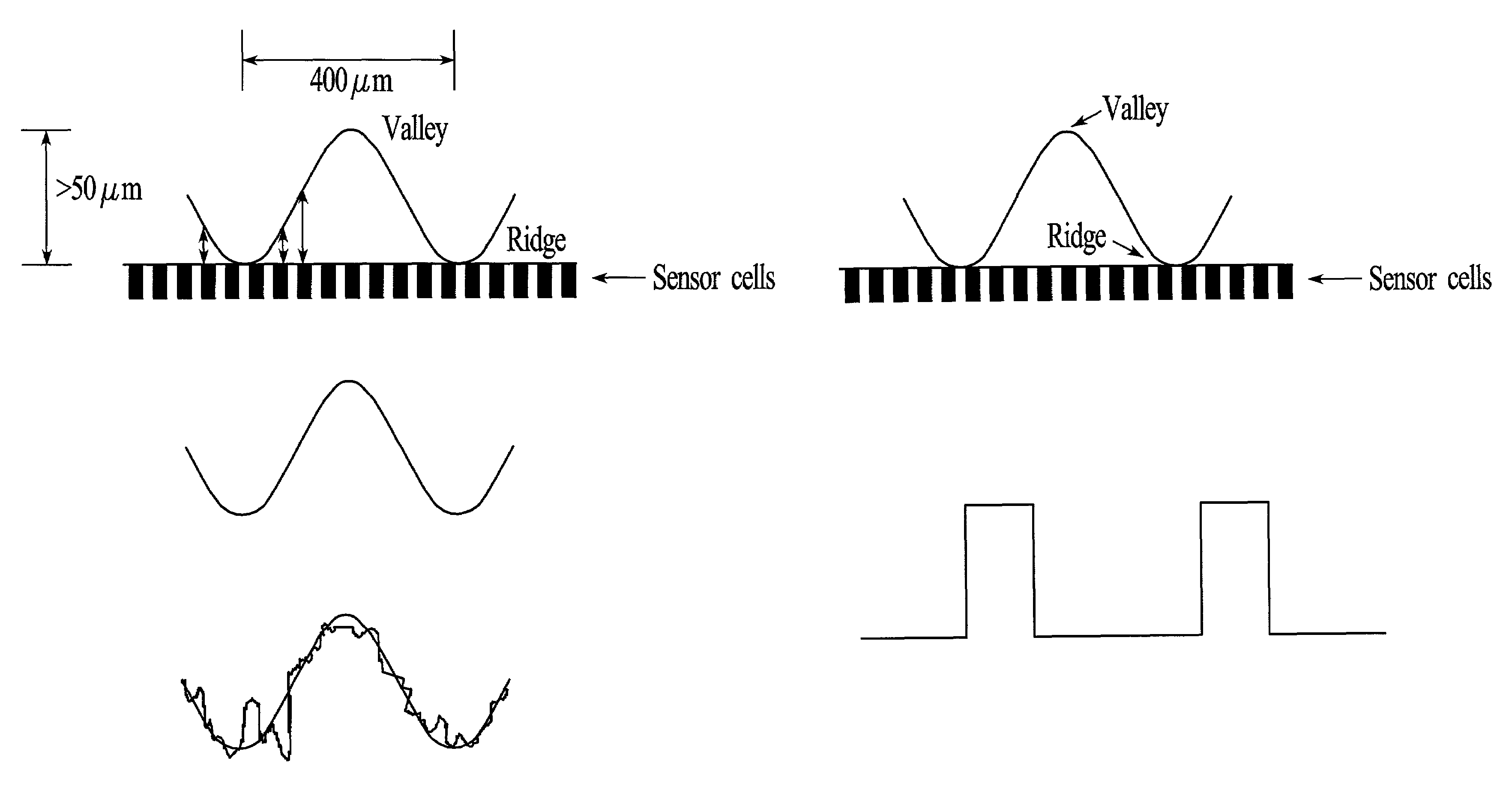

Signal-balanced shield electrode configuration for use in capacitive displacement sensing systems and methods

ActiveUS20050092108A1Convenient and economical and reliable and compactIncreased complexityForce measurement by measuring magnetic property varationWork measurementElectricityCapacitance

A capacitive encoder includes a signal-balanced shield electrode configuration that does not require electrical ground connection or active sensing and control in order to maintain the shield electrode(s) at a sufficiently constant voltage during capacitive position measurements. The shield electrode configuration is positioned in a capacitive coupling gap between transmitter electrodes and receiver electrodes during operation. The shield electrode configuration is patterned in a manner that complements the layout of the transmitter electrodes, such that the shield electrode configuration inherently floats at a nominally constant electrical potential when coupled to the signals present on the transmitter electrodes. The resulting capacitive encoder is thus more economical to build, convenient to install, and reliable during operation than capacitive encoders which use an electrical connection, compensation drive circuitry, or grounding in order to control the potential of a shield member that operates at a potential that is not inherently constant.

Owner:ANDERMOTION TECH

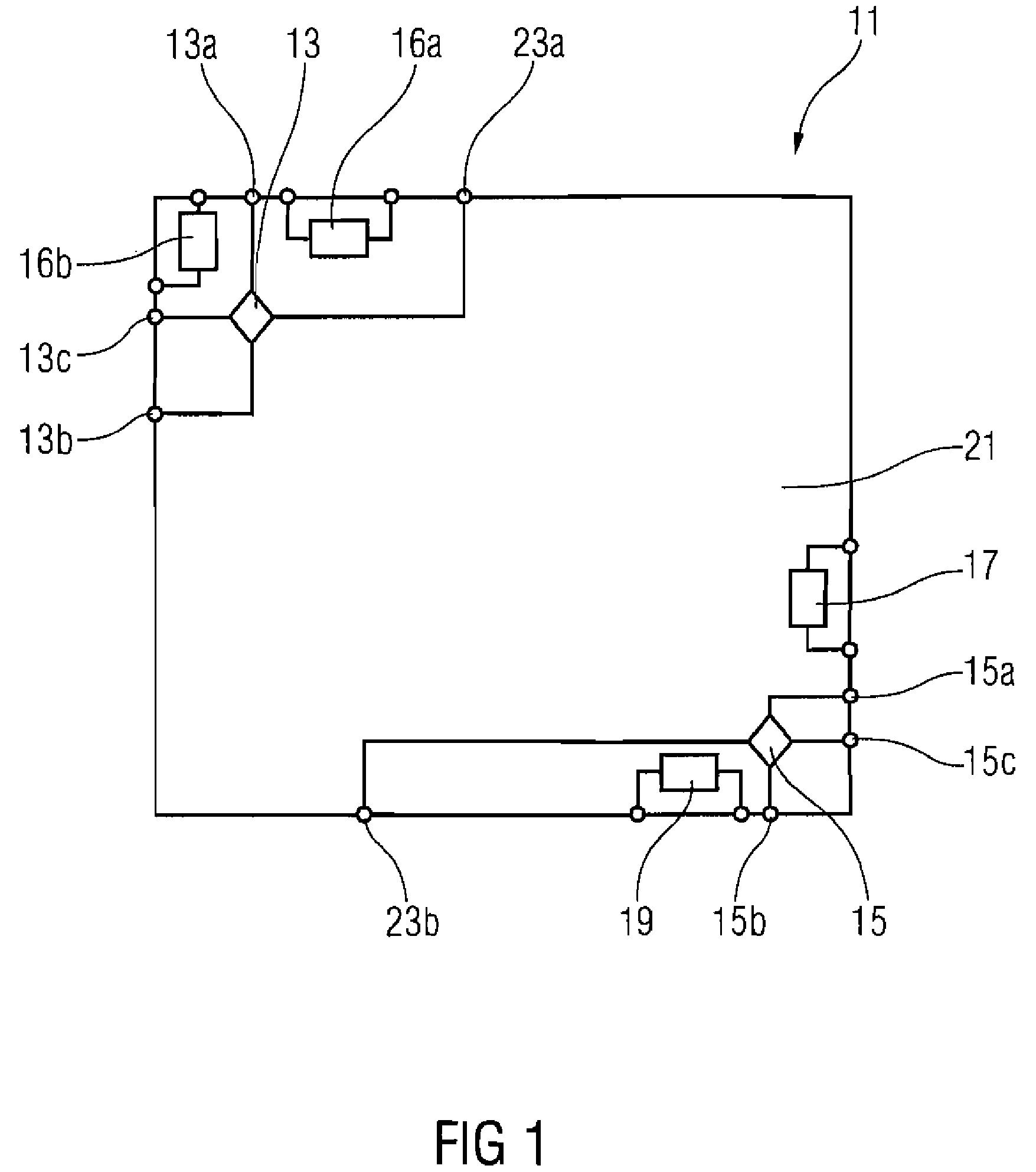

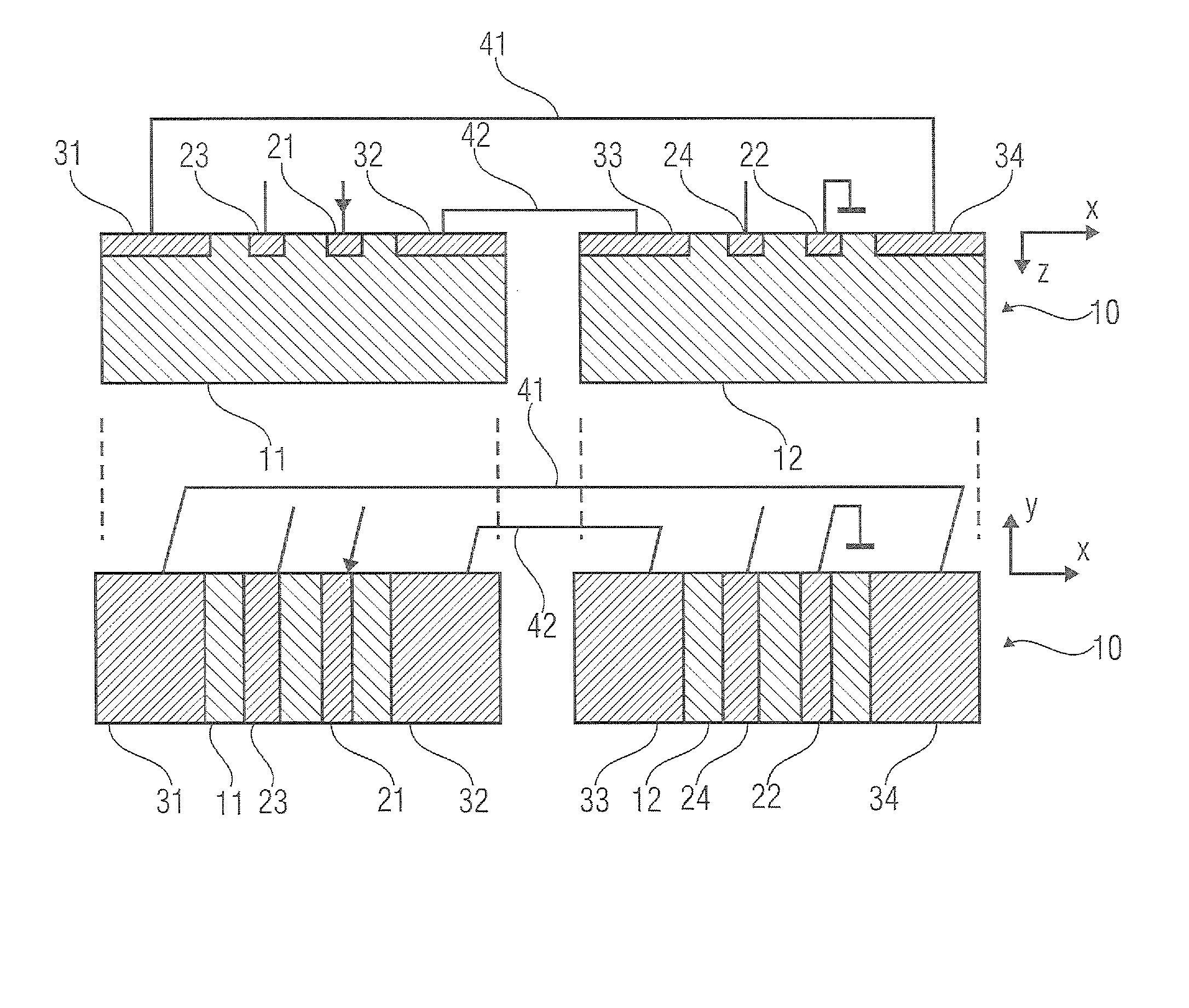

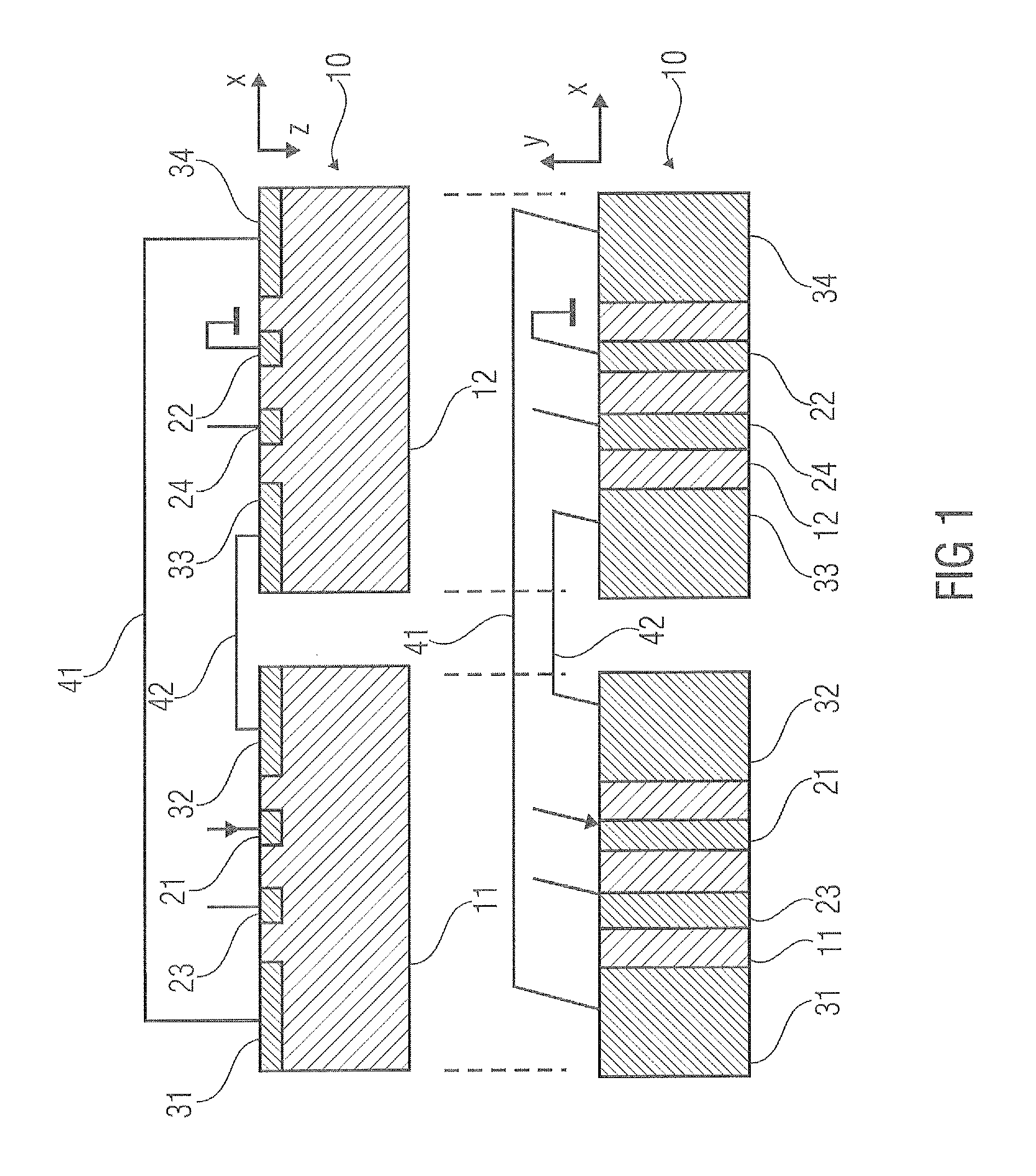

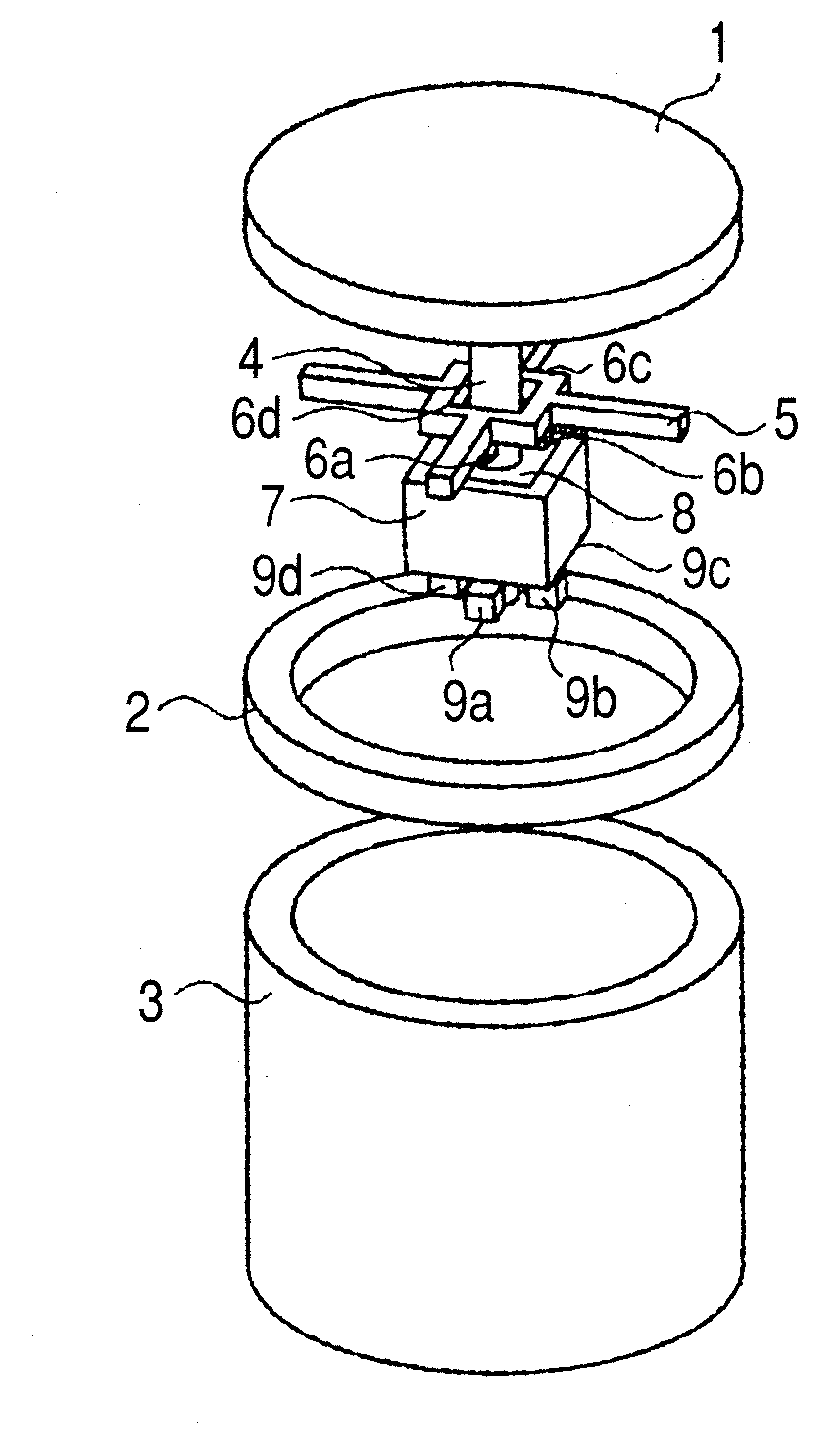

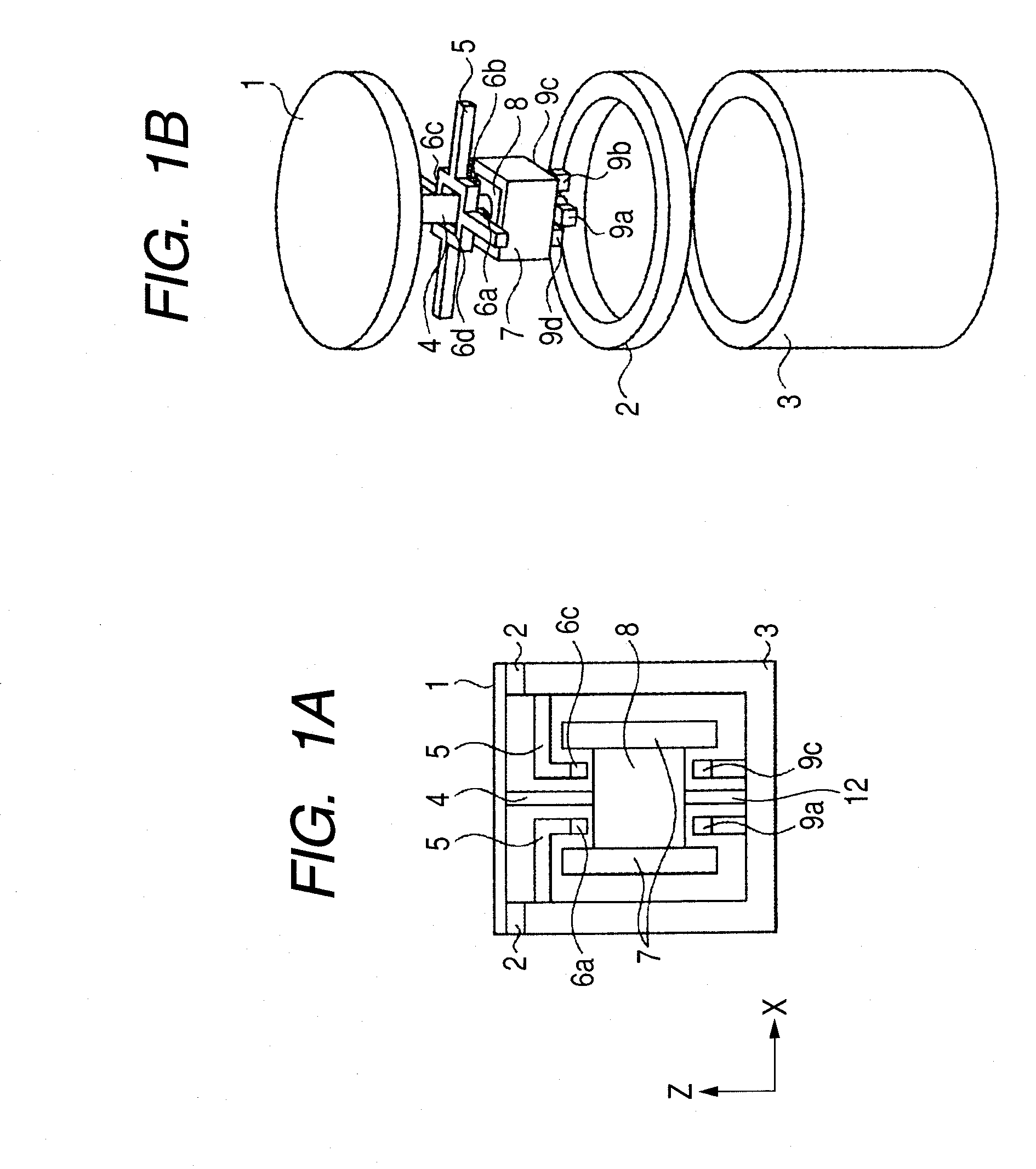

Magnetic field sensor apparatus

ActiveUS7474093B2Force measurement by measuring magnetic property varationAmplifier modifications to reduce noise influenceStress sensorAcoustics

A magnetic field sensor apparatus includes a first magnetic field sensor and a second magnetic field sensor, arranged on a substrate in a spaced manner from each other, a first temperature sensor with an output for a first temperature sensor signal, a second temperature sensor with an output for a second temperature sensor signal, a first stress sensor with an output for a first stress sensor signal, and a second stress sensor with an output for a second stress sensor signal, wherein the first temperature sensor and the first stress sensor are arranged more closely to the first magnetic field sensor or at a location identical with the first magnetic field sensor, and the second temperature sensor and the second stress sensor are arranged more closely to the second magnetic field sensor than to the first magnetic field sensor or at a location identical with the second magnetic field sensor.

Owner:INFINEON TECH AG

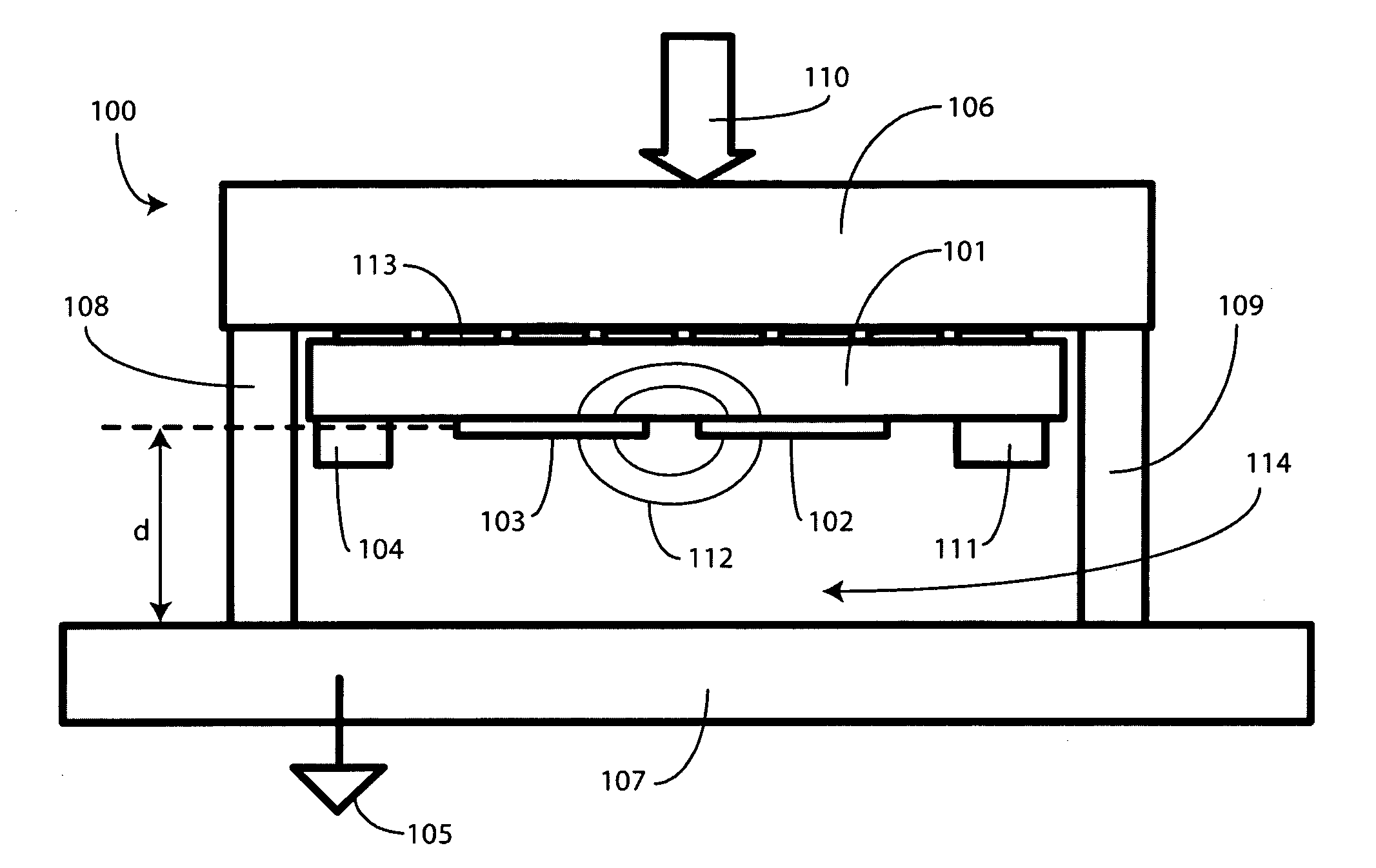

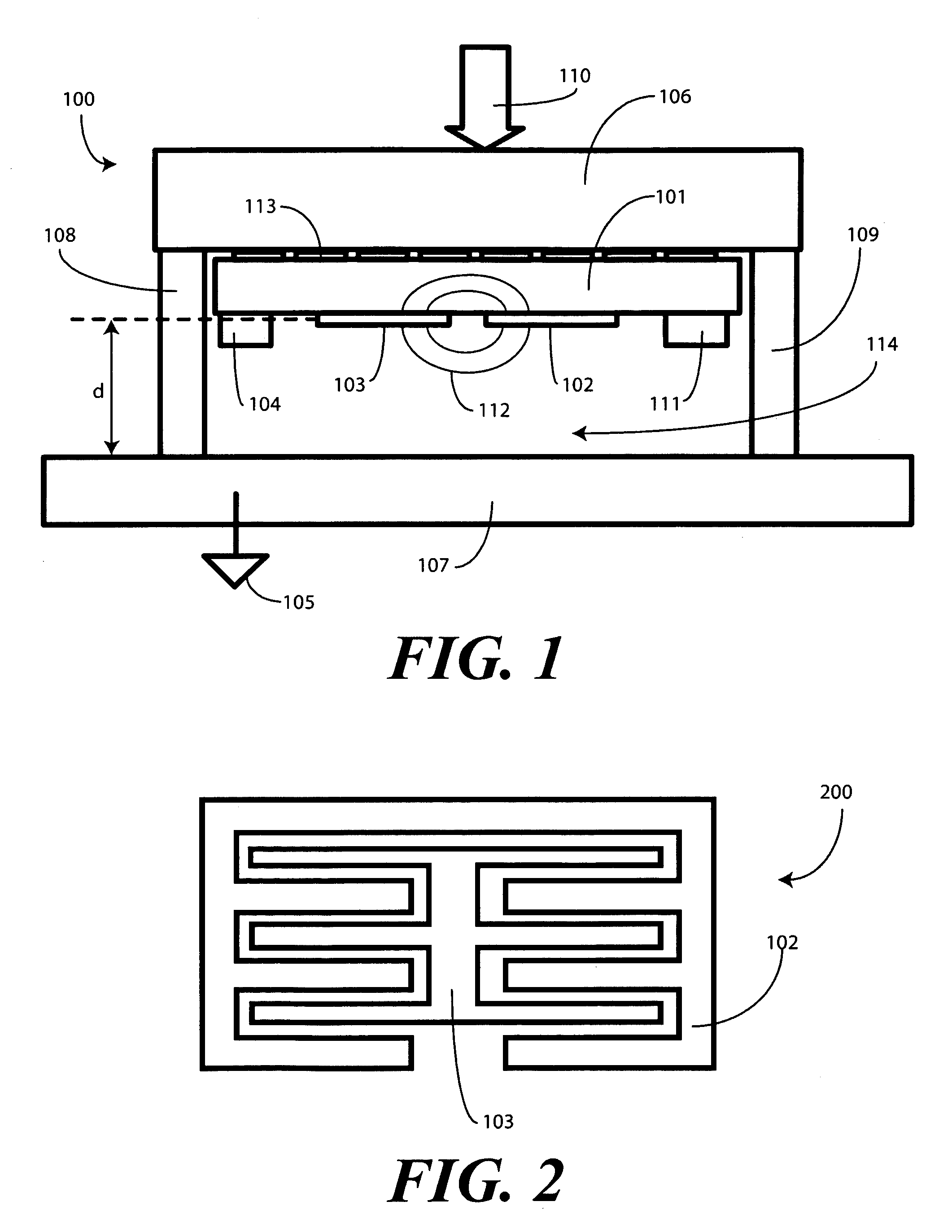

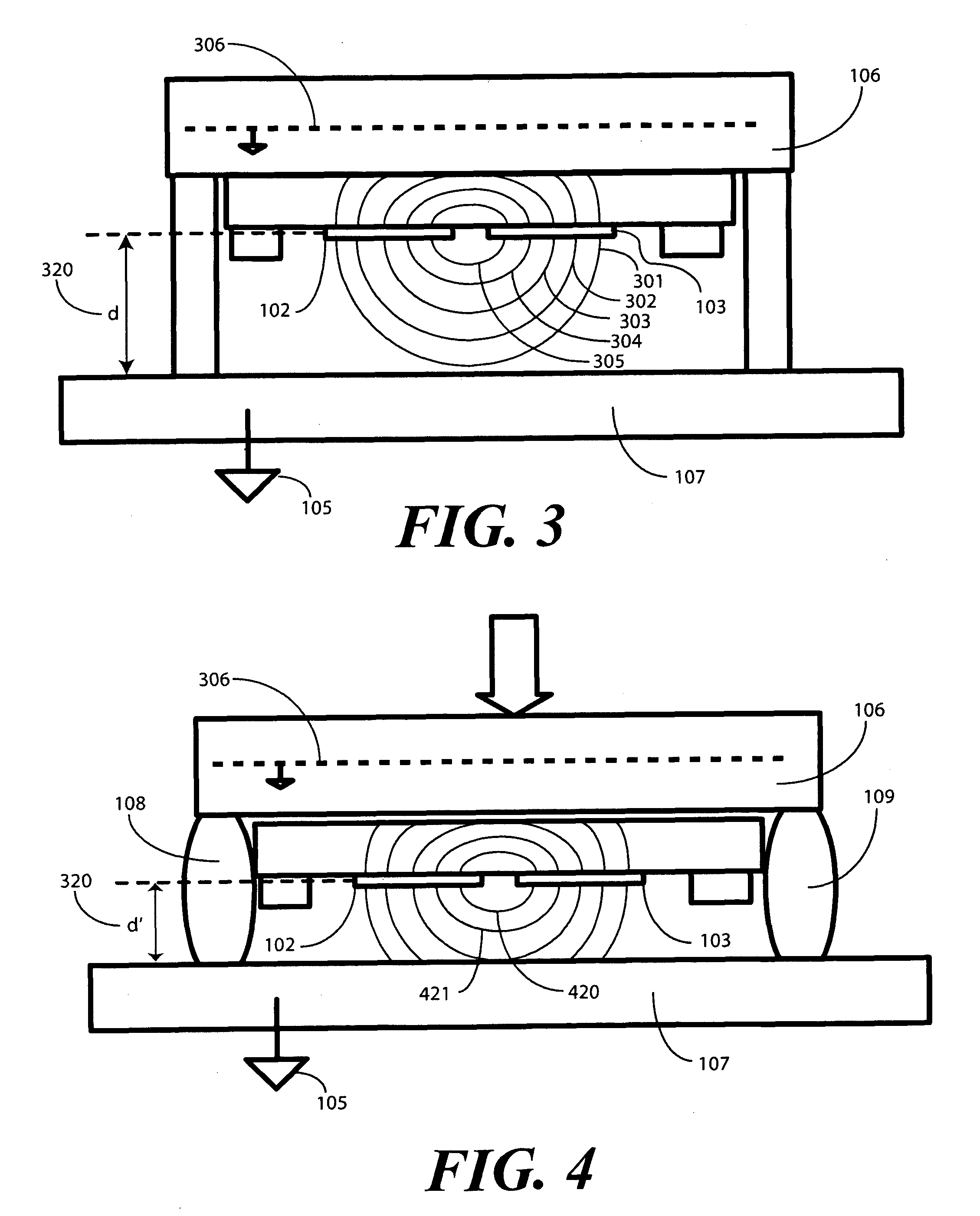

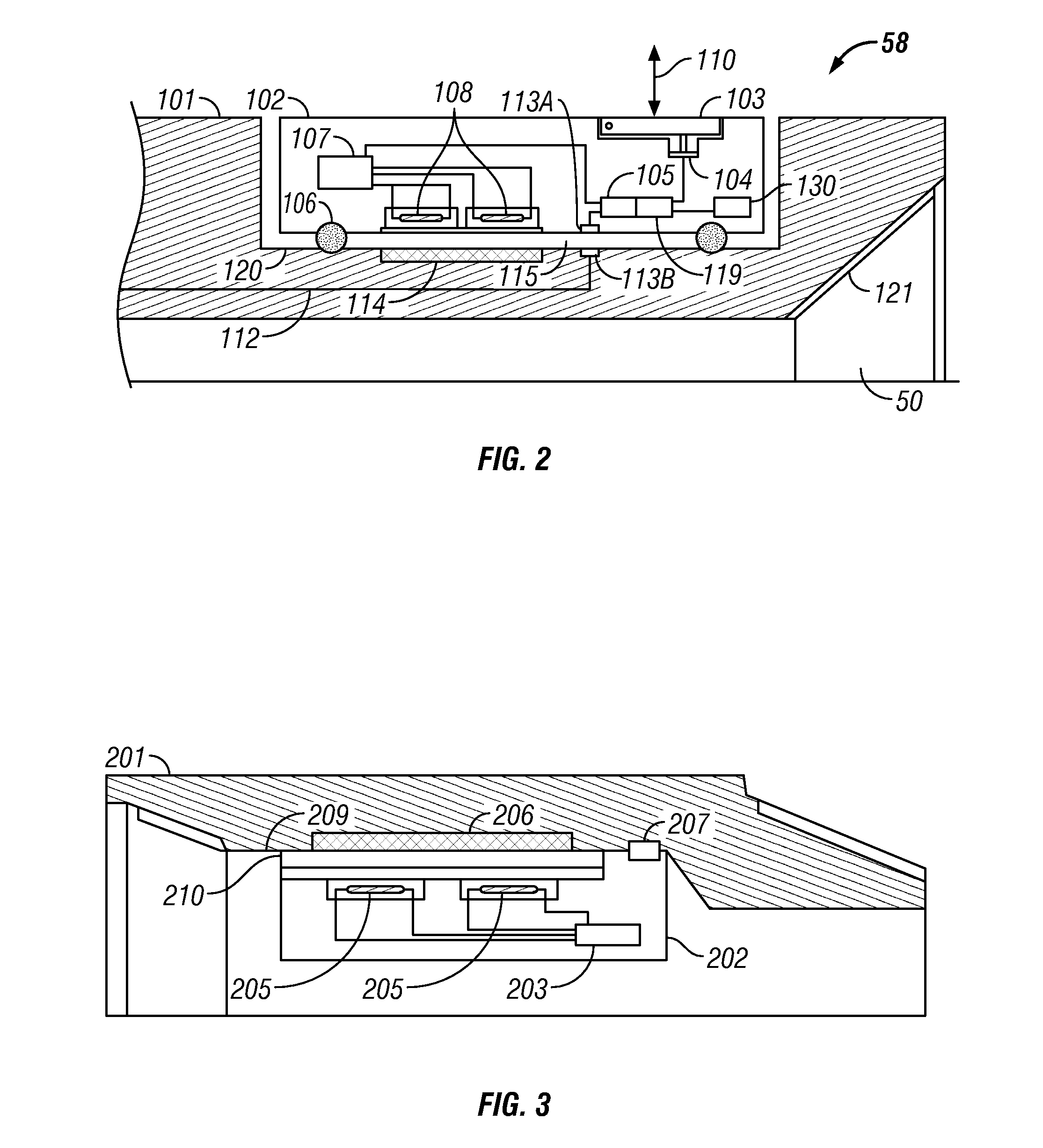

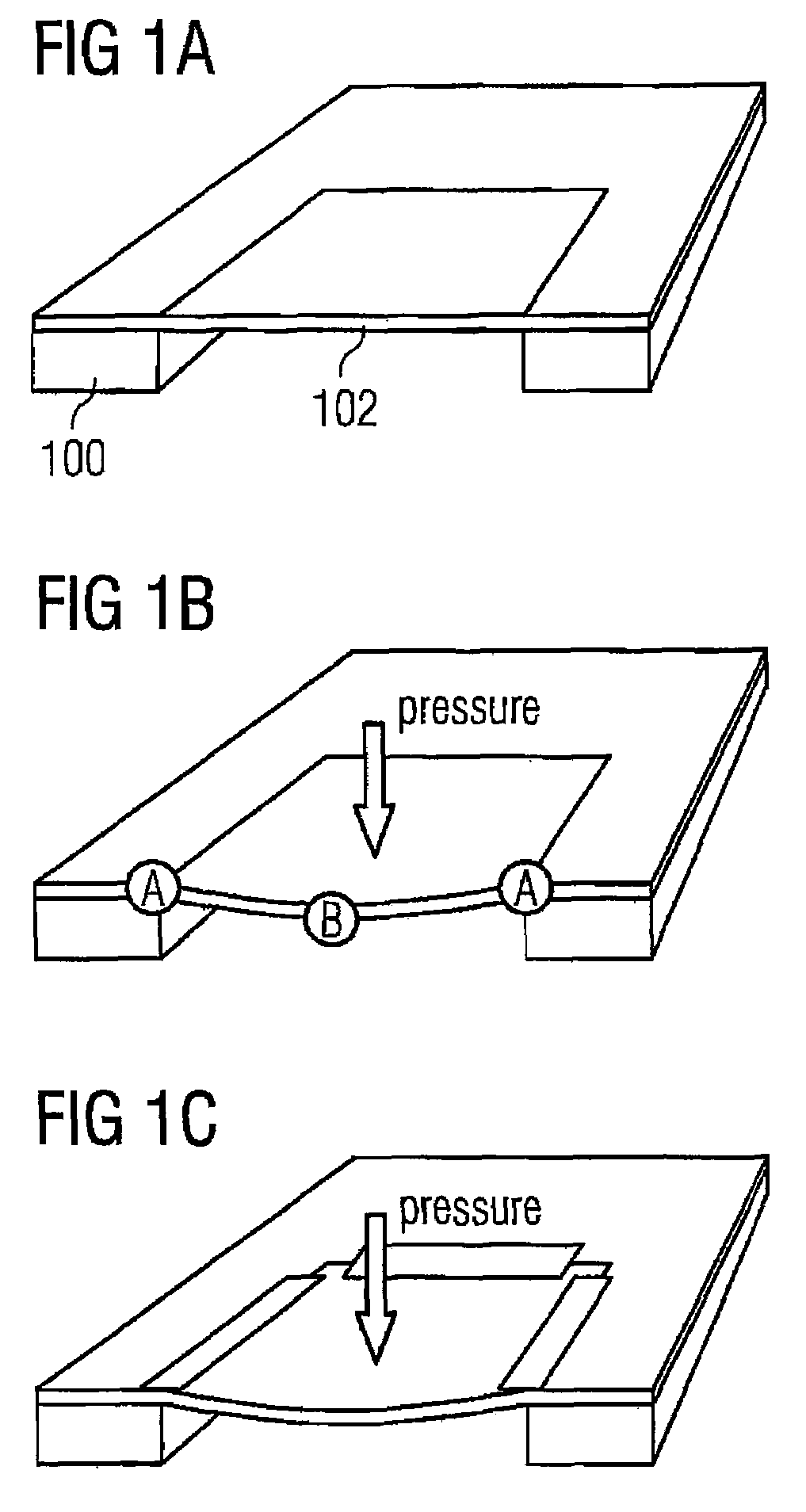

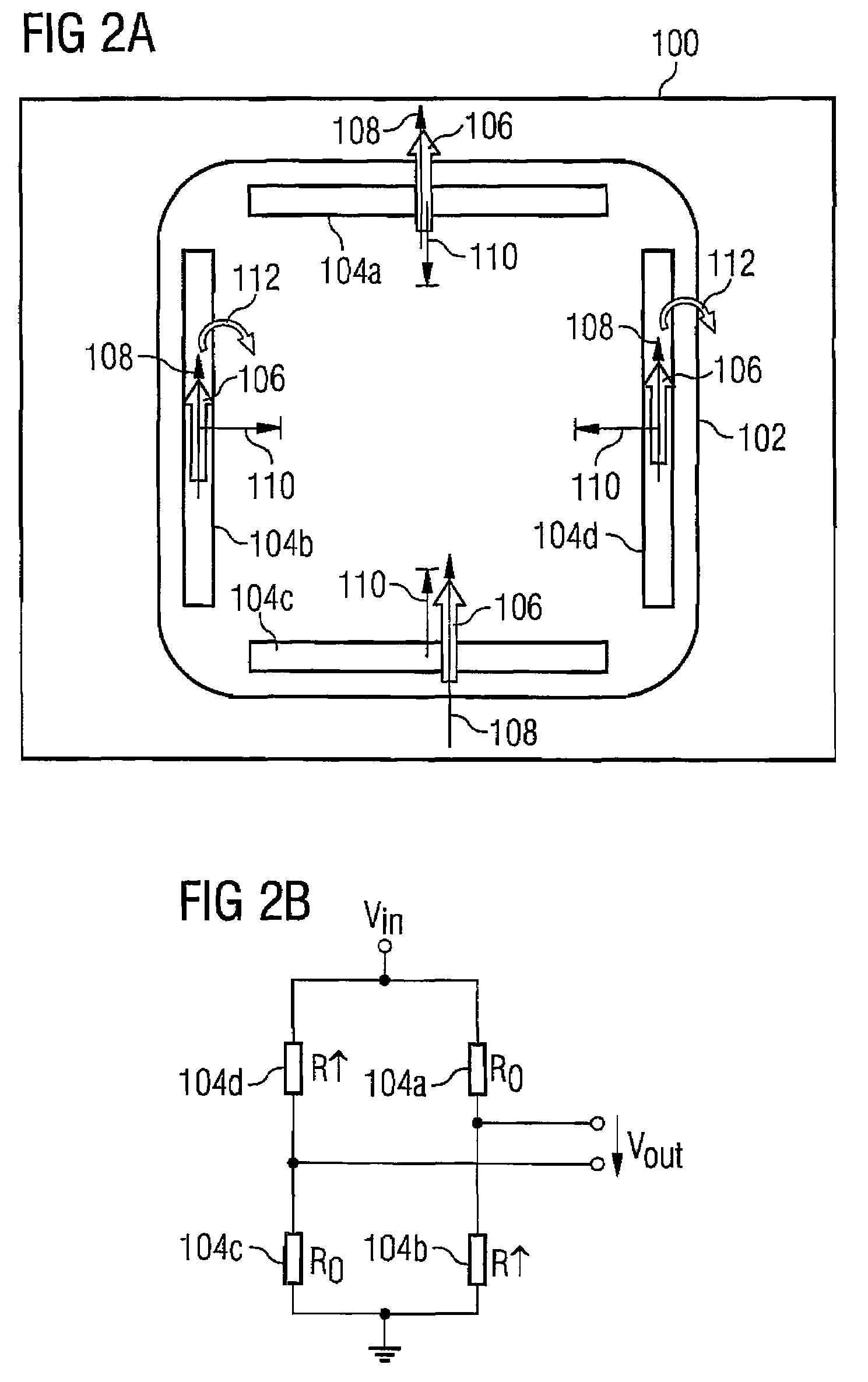

Single sided capacitive force sensor for electronic devices

ActiveUS7784366B2Force measurement by measuring magnetic property varationUsing electrical meansDriver circuitEngineering

A capacitive force sensor (100) includes a substrate (101) having at least one electrode pair (102,103) defining a capacitance disposed thereon. The substrate (101) is fixed relative to a first plate (106). A drive circuit (104) is configured to apply a voltage relative to a circuit ground (105) to the electrode pair (102,103). The first plate (106) is separated from a second plate (107) that is coupled to circuit ground (105) by a compliance member (108,109). The compliance member (108,109) is configured to oppose a compression force (110) while allowing the first plate (106) to physically move relative to the second plate (107). A capacitive detection circuit (111) is then configured to detect a change the capacitance when the compliance member (108,109) is compressed. The compression force (110) is then determined from the change in capacitance and the spring constant of the compliance member (108,109).

Owner:GOOGLE TECH HLDG LLC

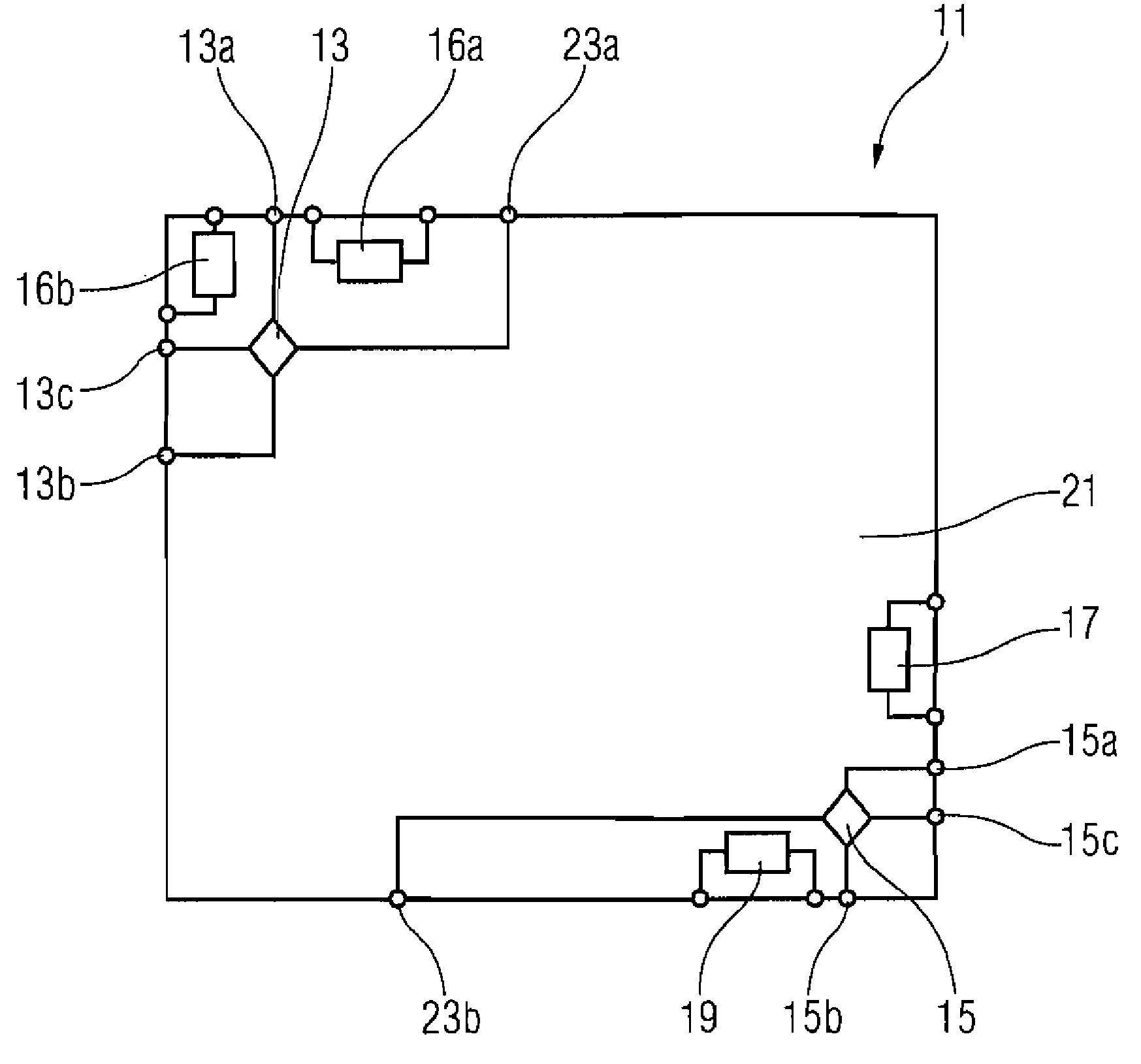

Electronic device with ring-connected hall effect regions

ActiveUS20130021026A1Force measurement by measuring magnetic property varationMagnetic field measurement using galvano-magnetic devicesElectronPhysics

An electronic device includes a number of n Hall effect regions with n>1, wherein the n Hall effect regions are isolated from each other. The electronic device also includes at least eight contacts in or on surfaces of the n Hall effect regions, wherein the contacts include: a first and a second contact of each Hall effect region. A first contact of the (k+1)-th Hall effect region is connected to the second contact of the k-th Hall effect region for k=1 to n−1, and the first contact of the first Hall effect region is connected to the second contact of the n-th Hall effect region. The at least eight contacts include at least two supply contacts and at least two sense contacts. Each Hall effect region includes at most one of the at least two supply contacts and at most one of the at least two sense contacts.

Owner:INFINEON TECH AG

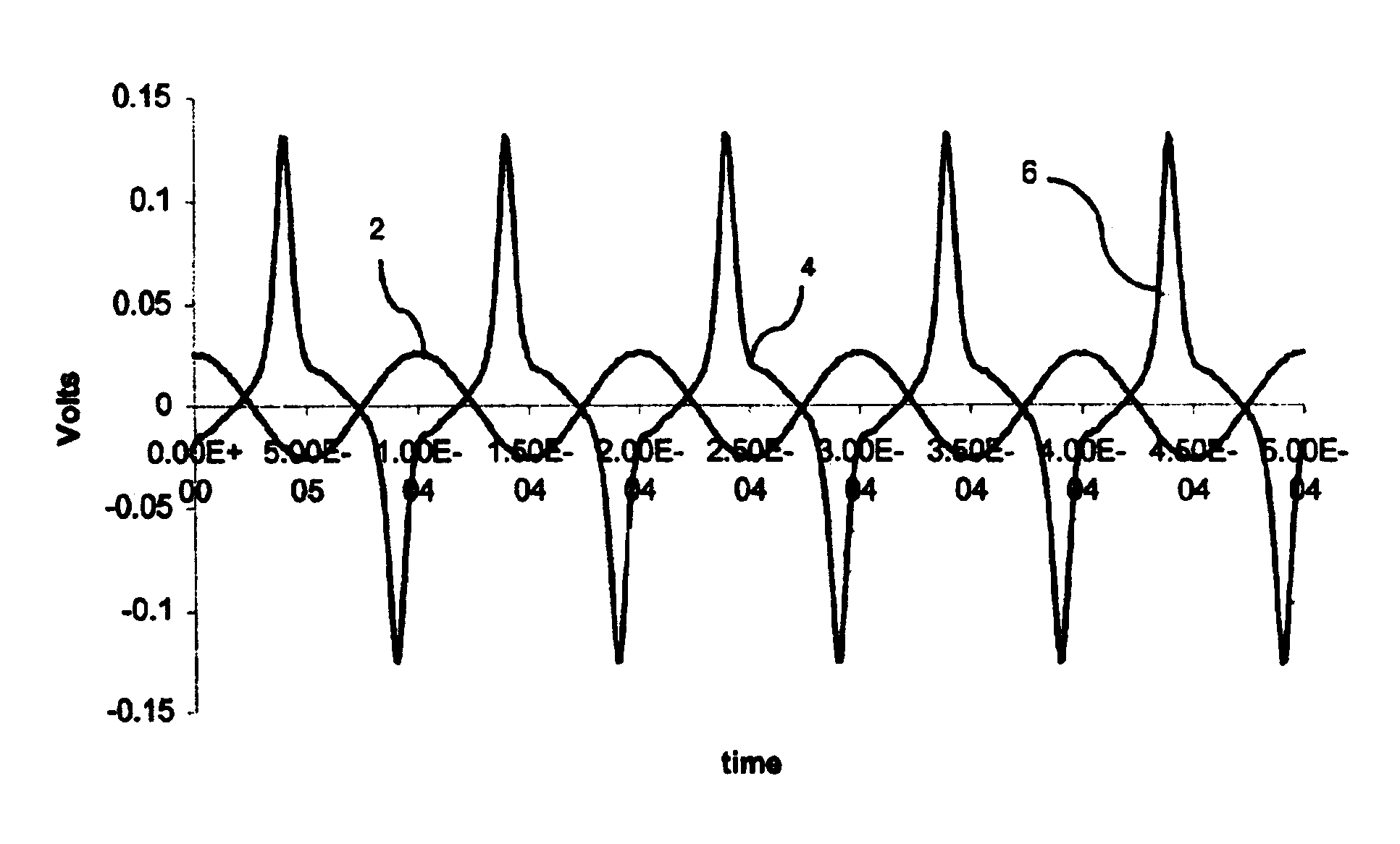

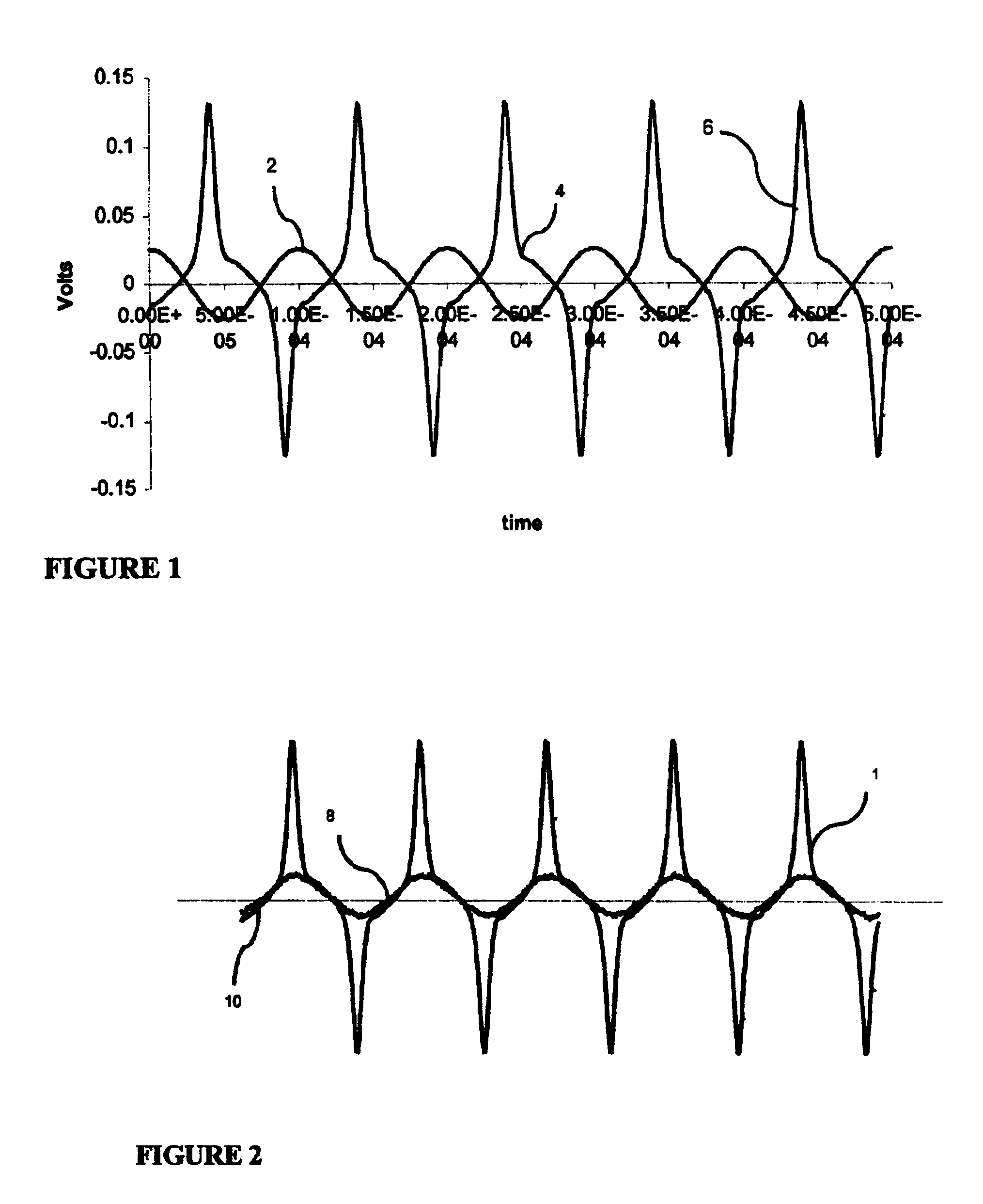

Inductively coupled stress/strain sensor

InactiveUS6912911B2Change relationshipForce measurement by measuring magnetic property varationWork measurementMagnetostrictionCouple stress

An improved method of sensing strain allows measurements of stress, torque, vibration and other loads imposed on a body without physical contact between the body / sensor and the monitoring equipment. An induction loop is at least partially comprised of a magnetostrictive material with a non-linear current-voltage relationship. An excitation device such as a coil is used to induce an AC response in the sensor. The non-linear response to the induced current is received by a sensing device such as a sensing coil, and the output thereof is filtered. The excitation device and sensing device are located in operative proximity to the sensor, but need not be in contact therewith, allowing easy measurement in small spaces, under harsh conditions, or of moving bodies such as drive shafts. The non-linear response of the sensor induces easily detectable harmonics of the base frequency of excitation. These harmonics may advantageously be measured as well.

Owner:SENSORTEX

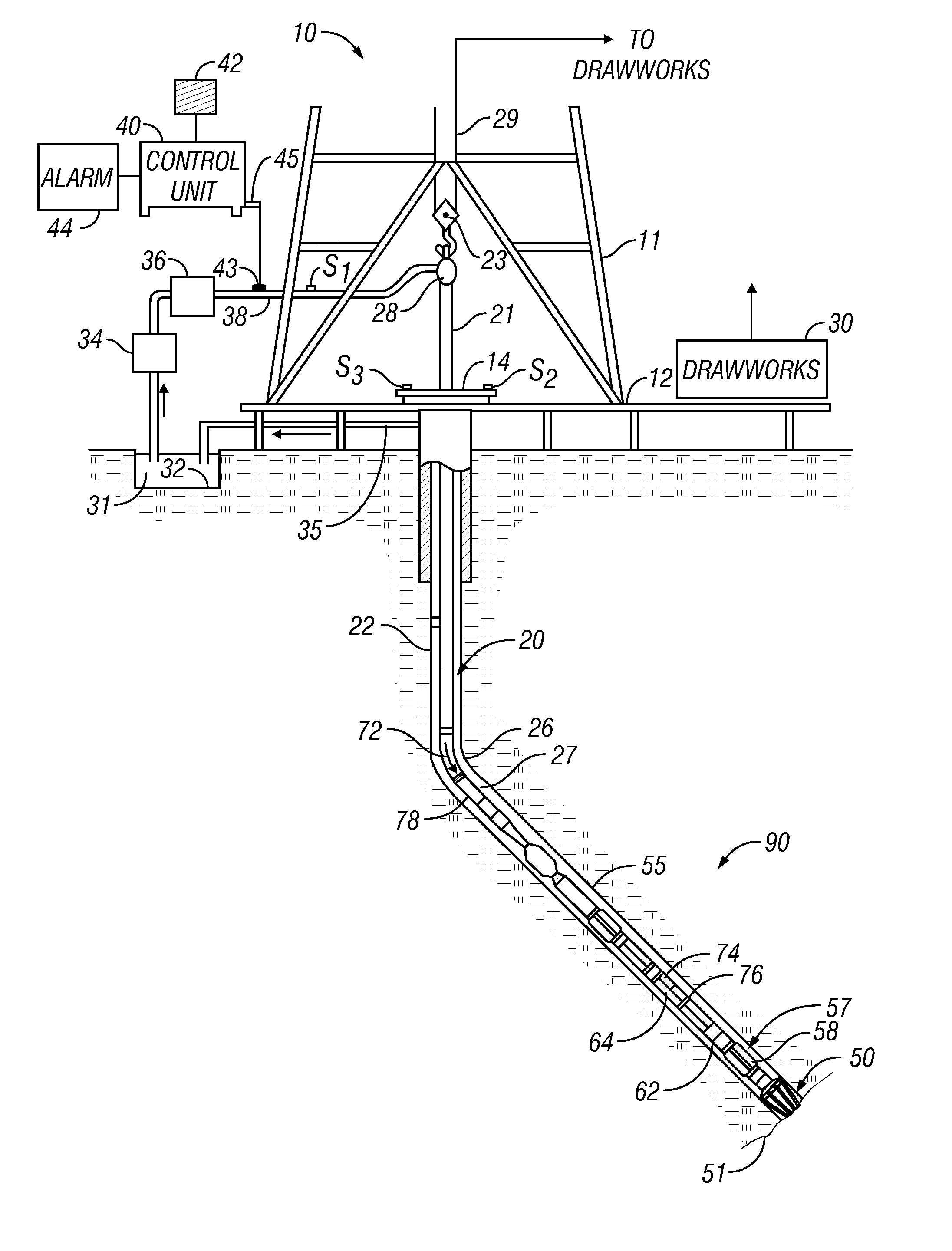

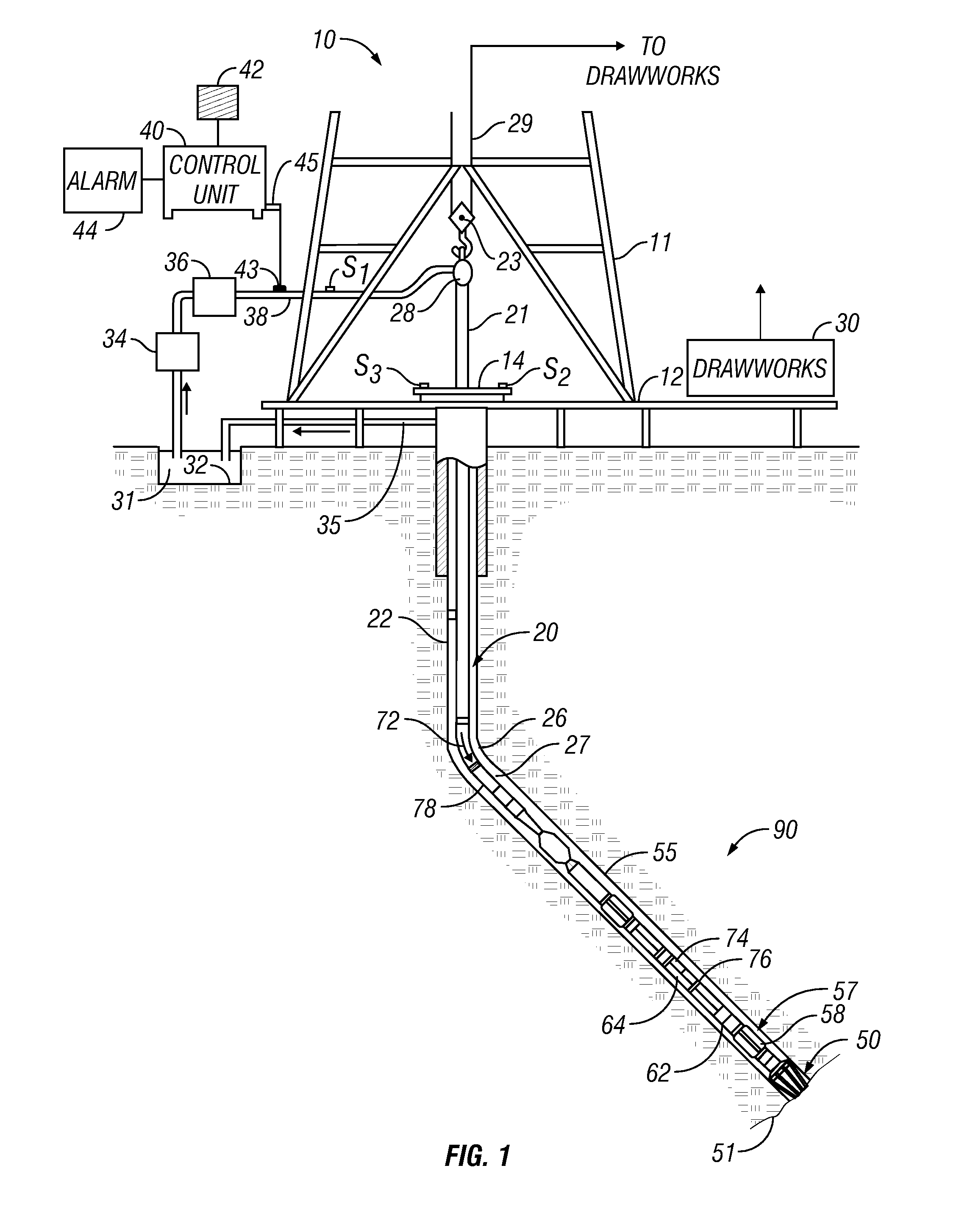

Apparatus and Methods for Estimating Loads and Movements of Members Downhole

InactiveUS20080035376A1Electric/magnetic detection for well-loggingEarth drilling toolsEngineeringWellbore

Owner:BAKER HUGHES INC

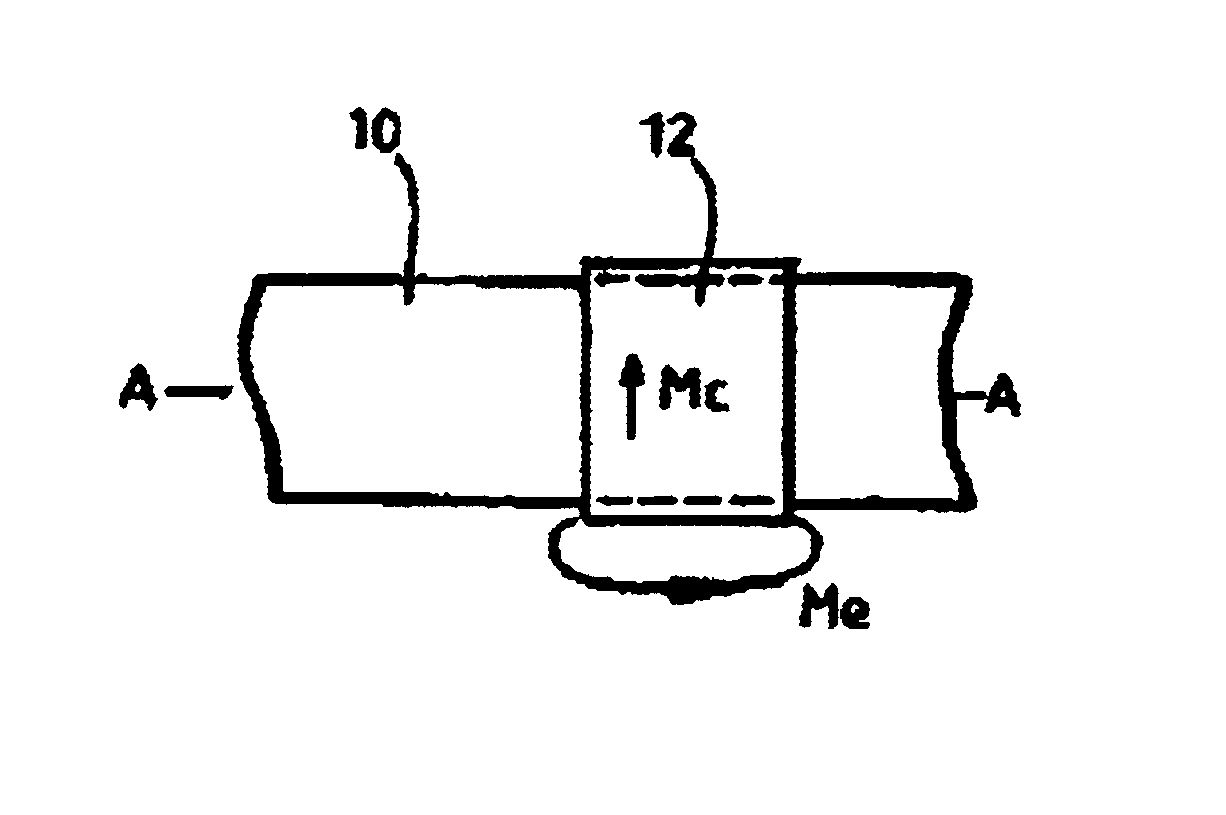

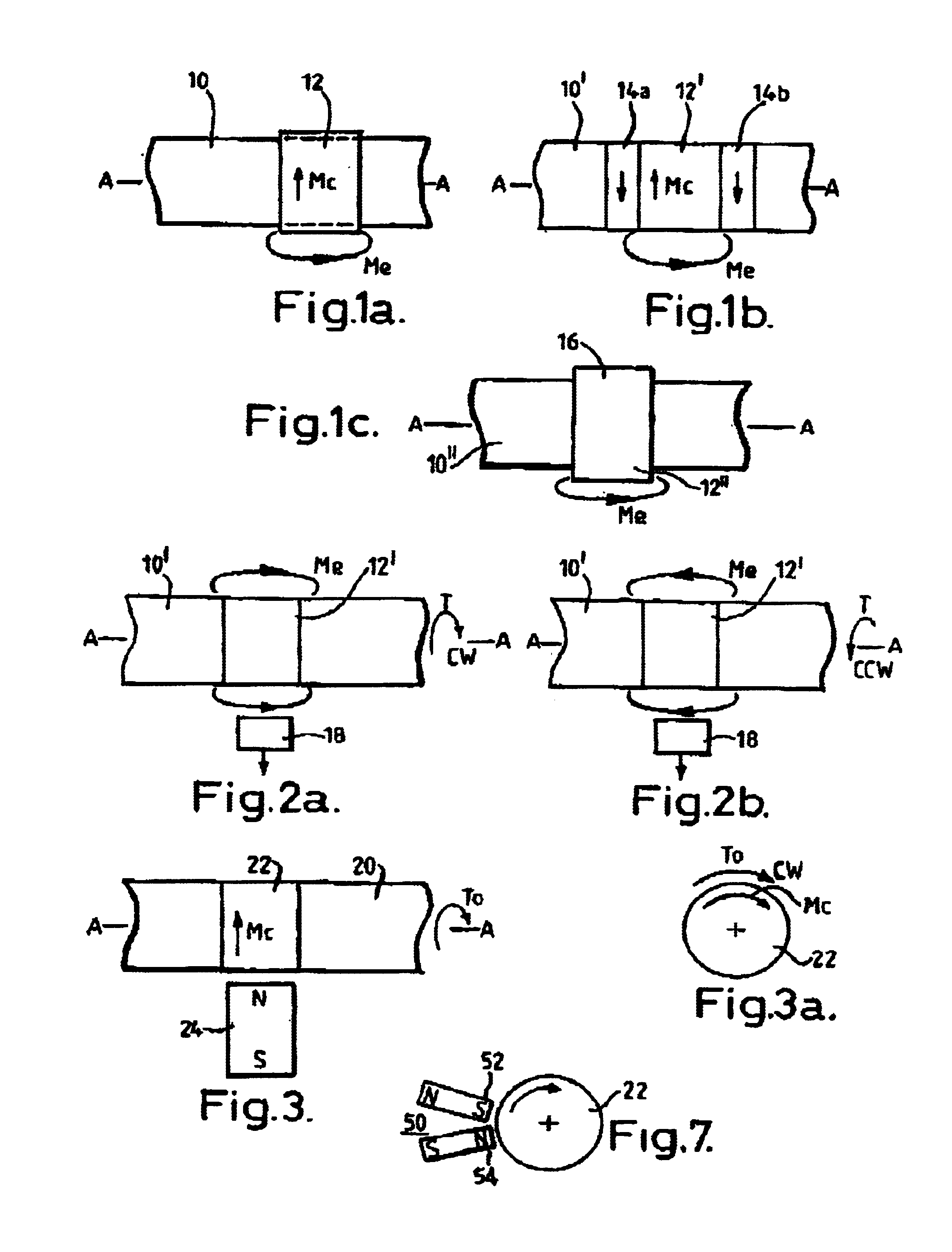

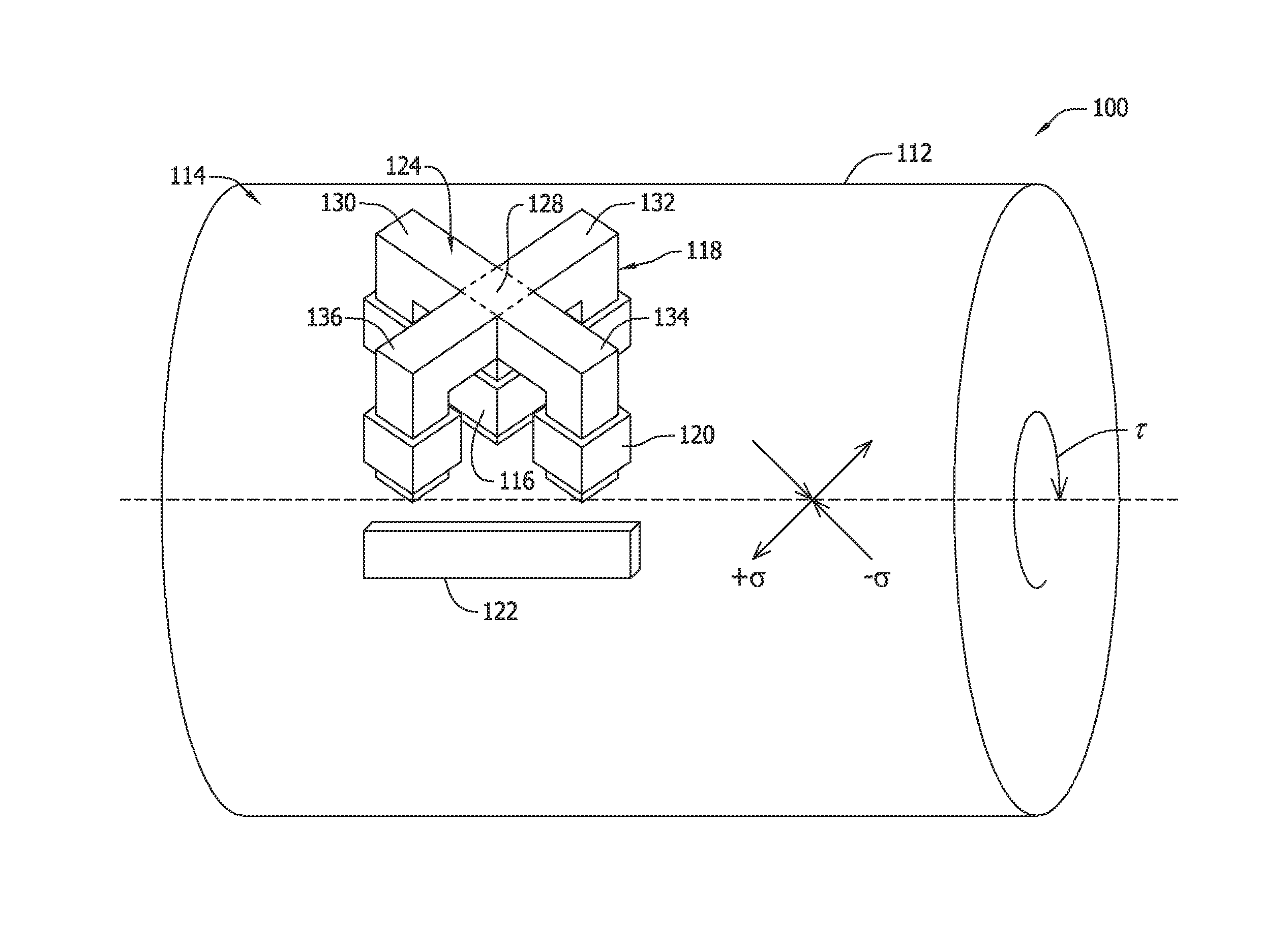

Magnetized torque transducer elements

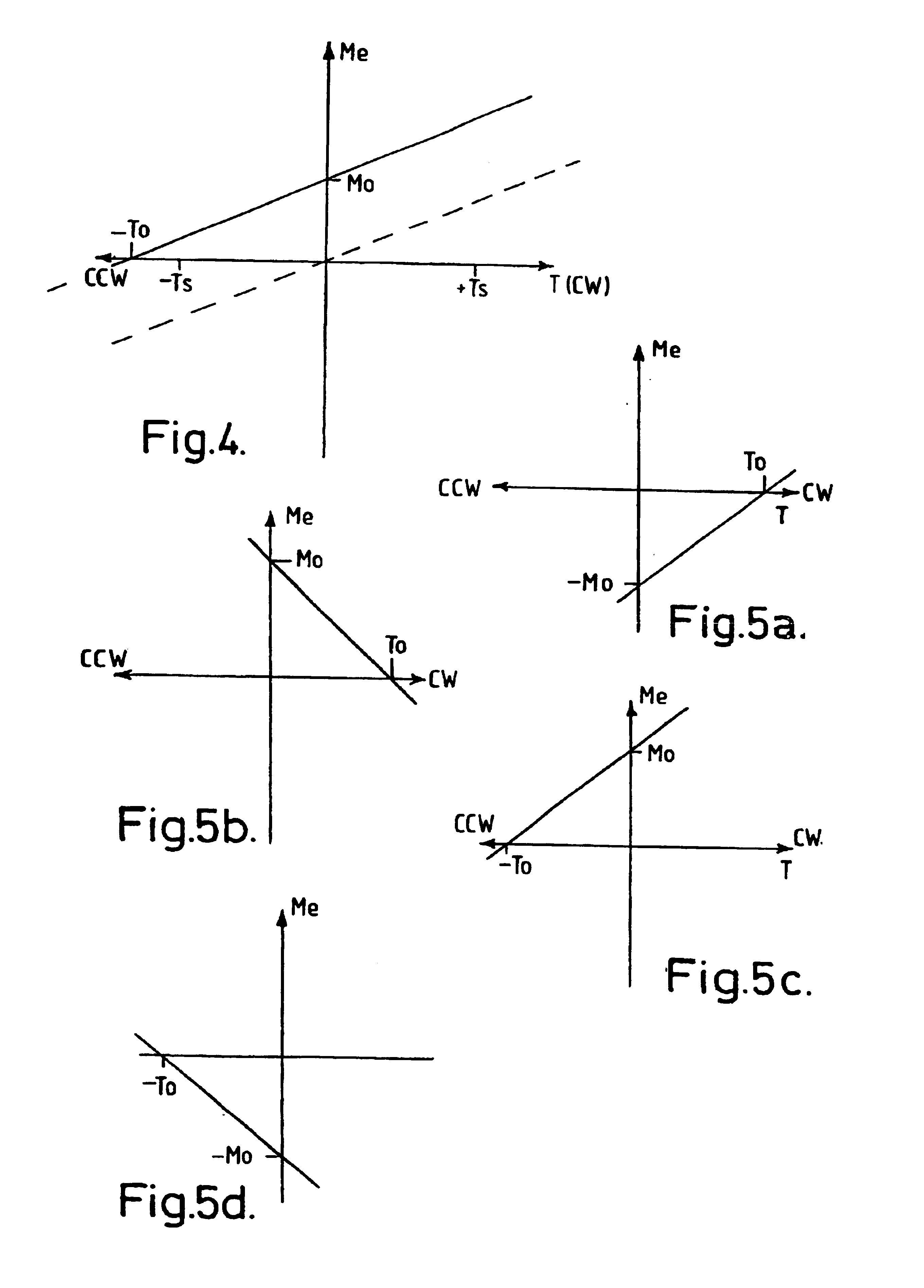

InactiveUS6910391B1Force measurement by measuring magnetic property varationWork measurementMagnetizationTransducer

The problem of magnetoelastic cirumferentially-magnetized torque transducers having a zero output magnetic field at zero torque is solved by pre-torqueing. This entails is circumferentially magnetizing the transducer element at a predetermined torque. The technique is advantageously applied to a pair of transducer elements (32, 34: 62, 64) whose outputs are combined (FIG. 6a: 76) to provide a range of measurement of torque (clockwise and counterclockwise) including zero torque. Various combinations of direction of pre-torque and direction of circumferential-magnetization are discussed. A circuit (FIG. 8) is disclosed for combining the signals to obtain a reference level (84) for gain control of the combined output signals V o from the two transducer elements (60, 62). Also disclosed is the application of the invention to other forms of torque transducer element in which a magnetic field is stored. One form is longitudinal magnetization (FIG. 10a). Another is radially spaced magnetization (FIG. 12a: FIG. 13).

Owner:ABAS

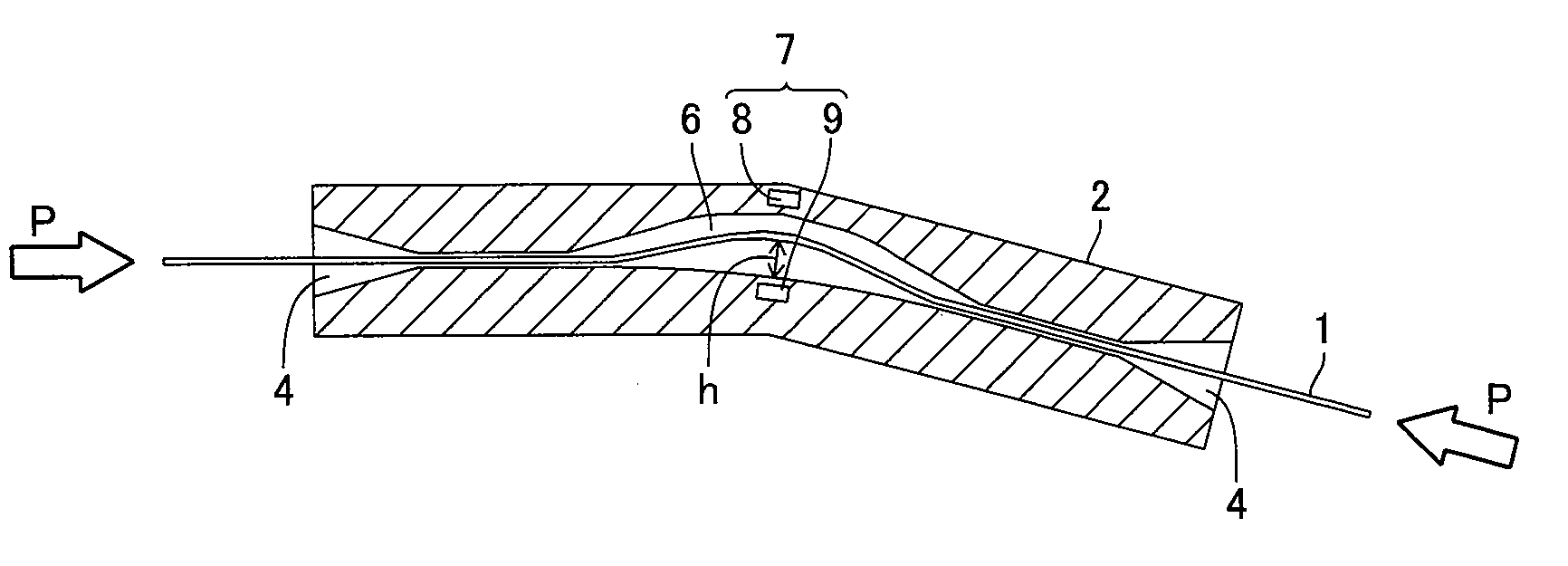

Device and method for measuring compressive force of flexible linear body

InactiveUS7984659B2Easy to compressCost effectivenessForce measurement by measuring magnetic property varationForce measurement by measuring optical property variationMeasurement deviceCost effectiveness

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

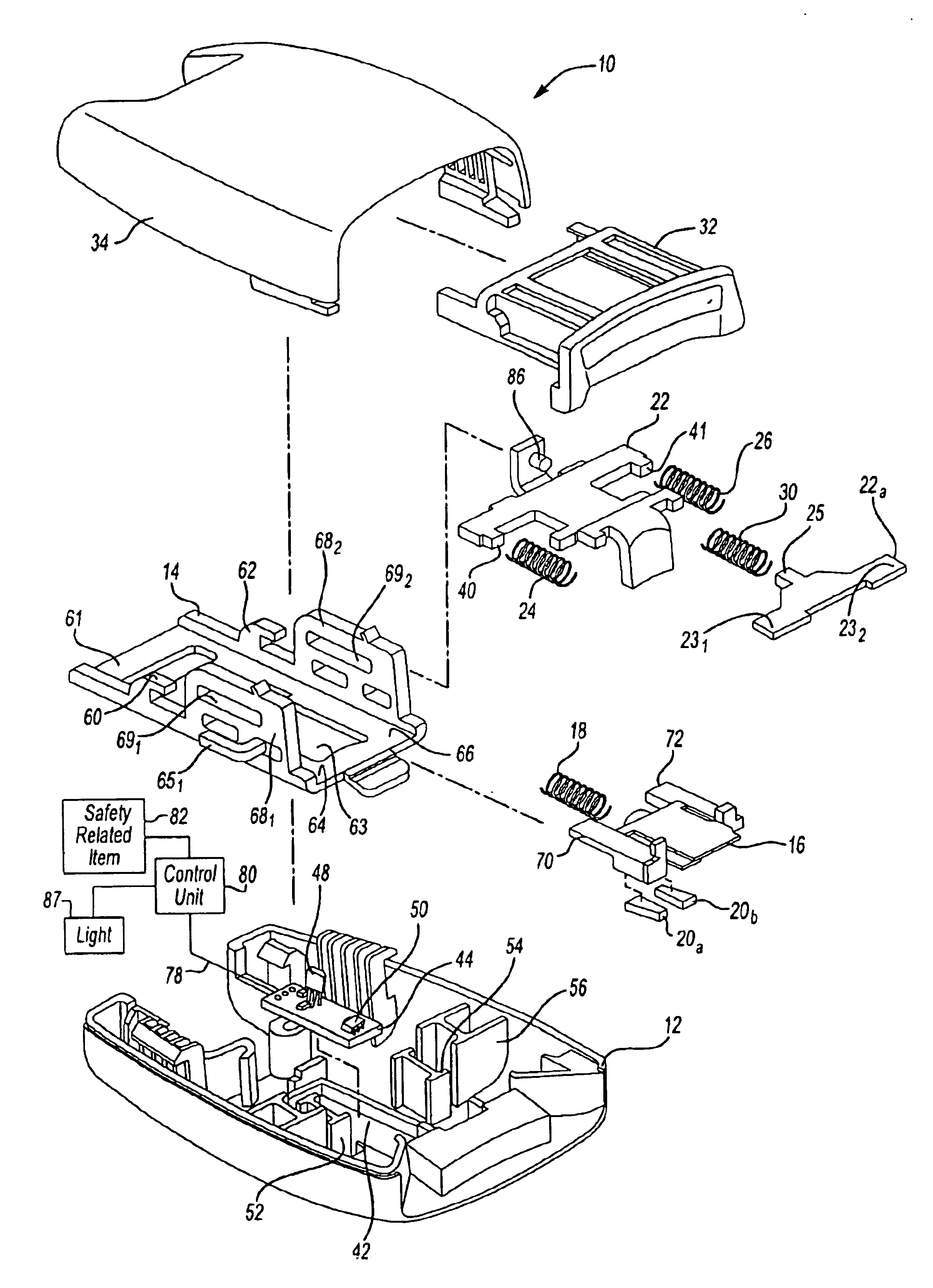

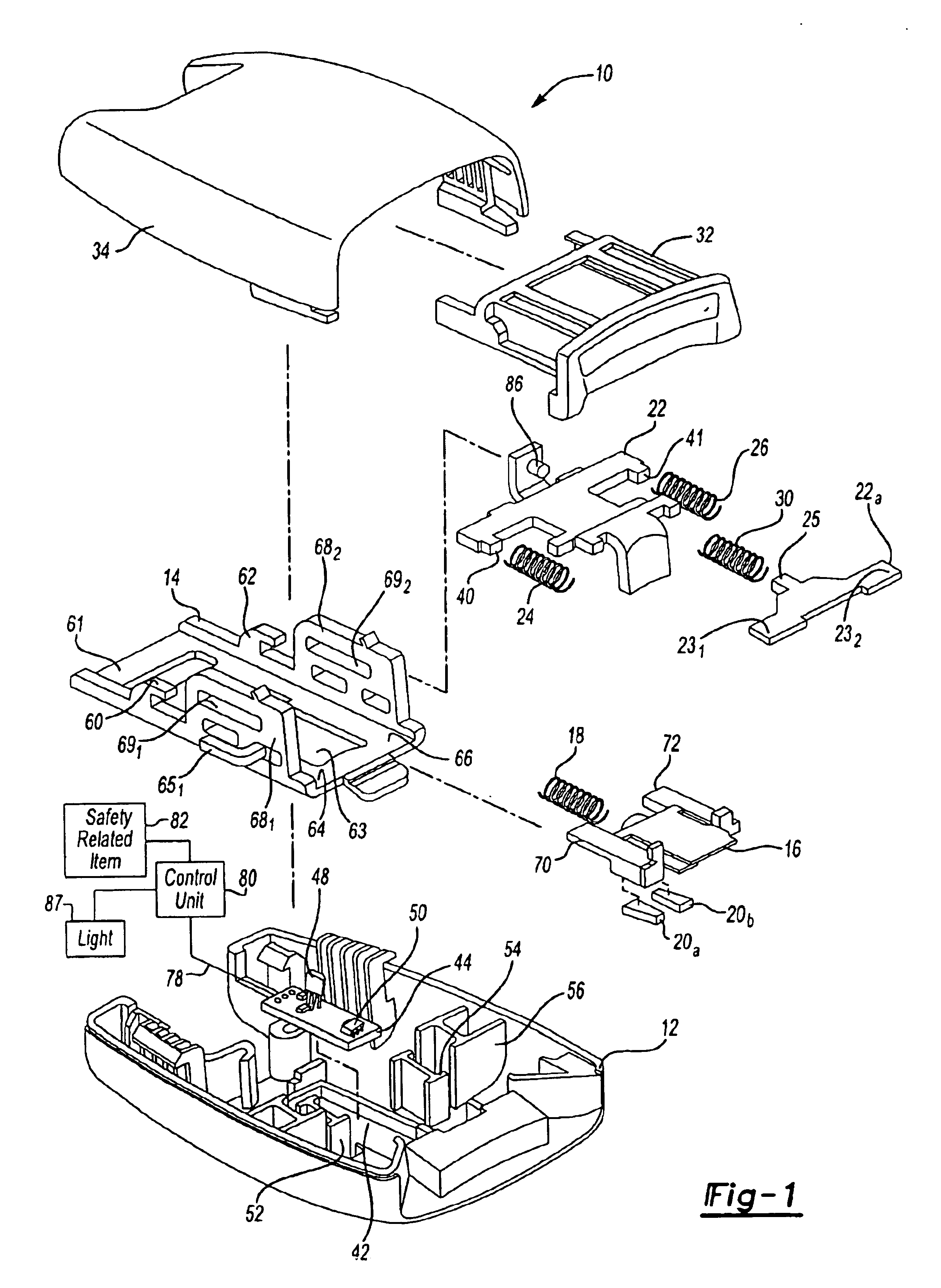

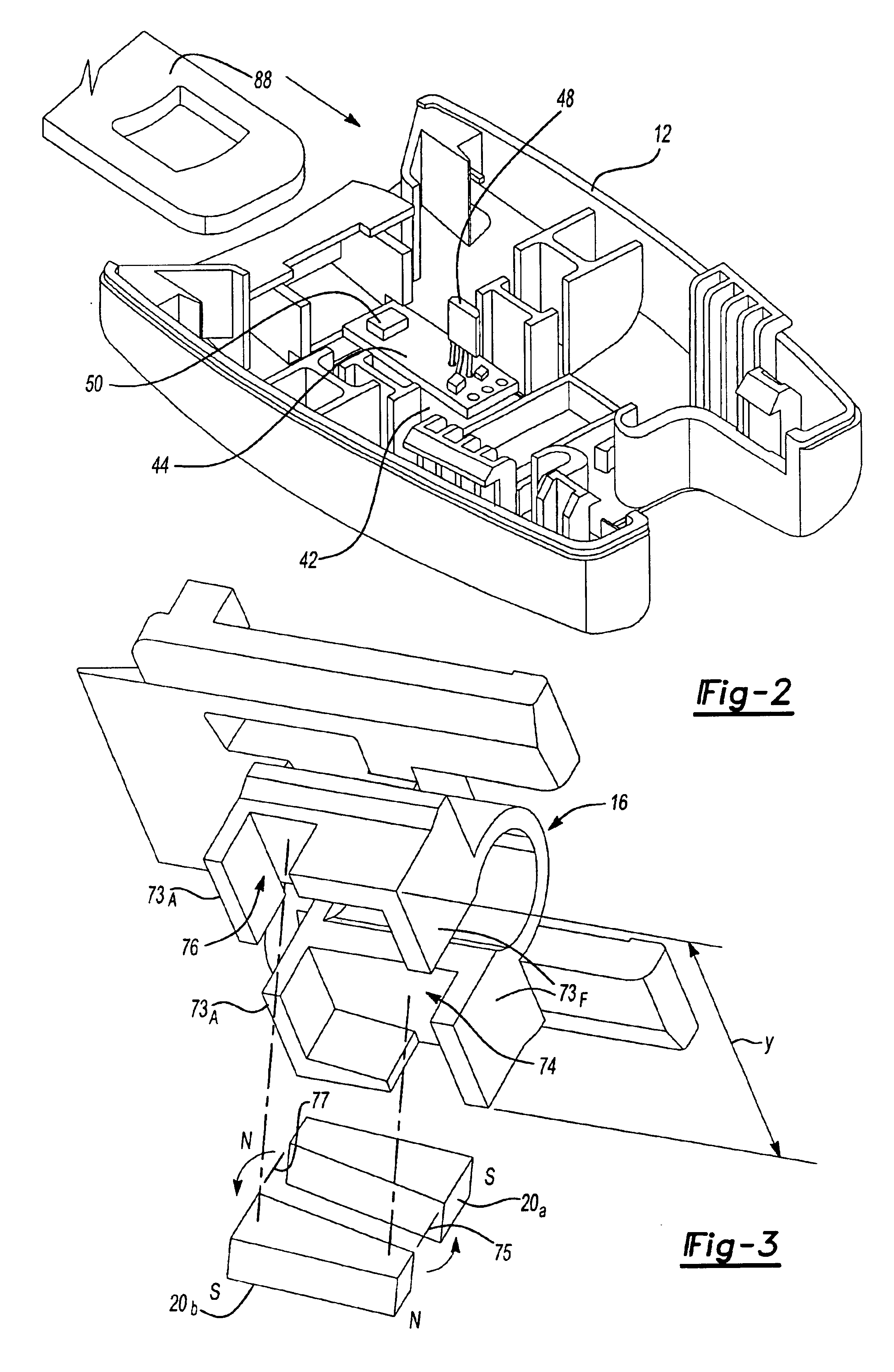

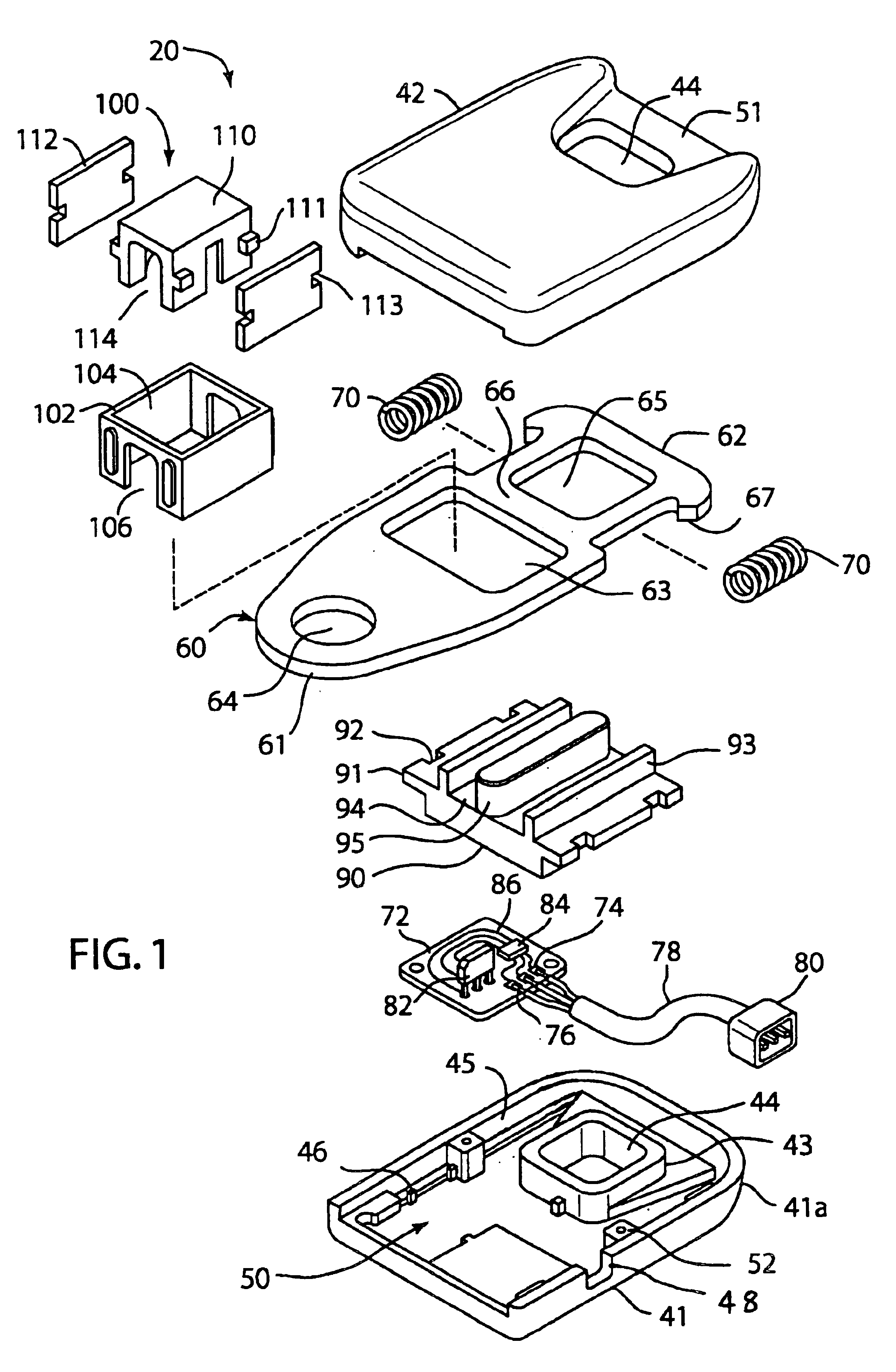

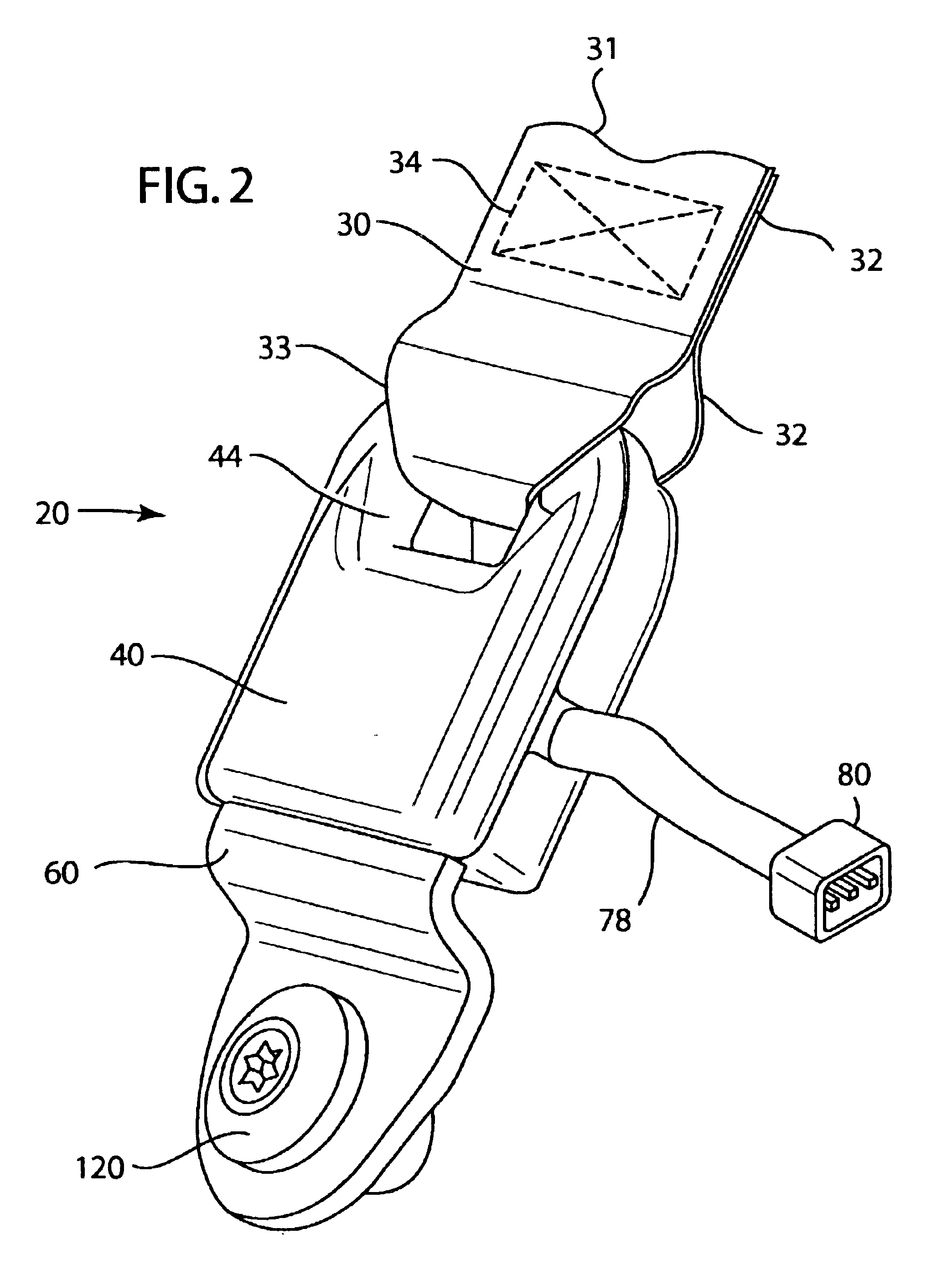

Seat belt tension sensor assembly

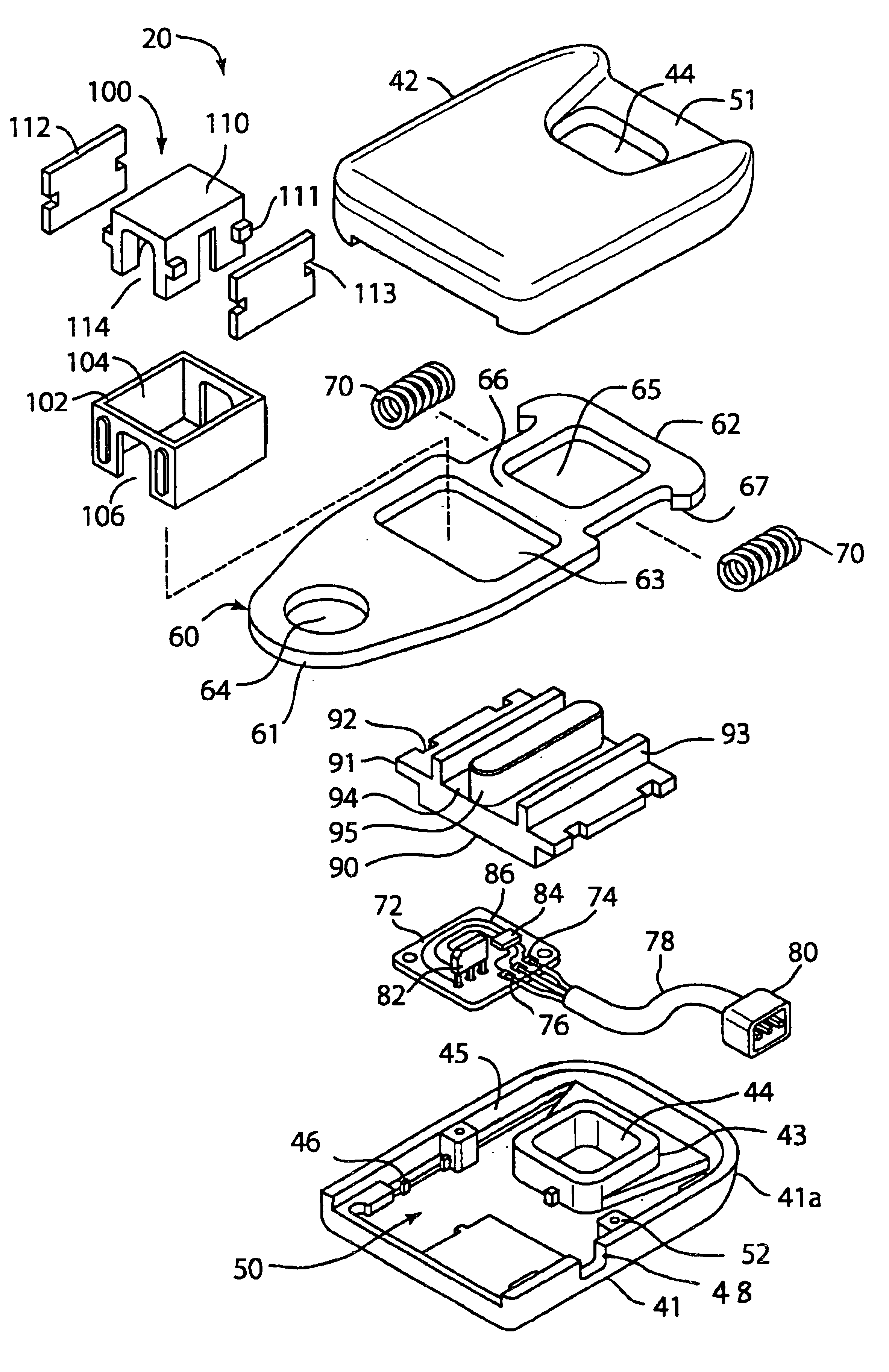

InactiveUS6851503B2Highly integratedIncrease the magnetic field strengthSnap fastenersForce measurement by measuring magnetic property varationSeat beltEngineering

A seat belt tension sensor assembly includes a housing, a slider slidably received within the housing, wherein the slider is configured for movement between a first position and a second position within the housing, and a first and second magnet associated with the slider for slidable movement therewith. The first and the second magnets are positioned side by side with opposite polarization. A hall effect device is fixed relative to the housing and protrudes between the first and the second magnets when the slider is in the second position. The hall effect device is configured to produce an output signal, the output signal being indicative of a seat belt tension of a seat belt as applied to the sensor assembly. A biasing member provides an urging force to the slider, the urging force urging the slider into the first position.

Owner:DELPHI TECH INC

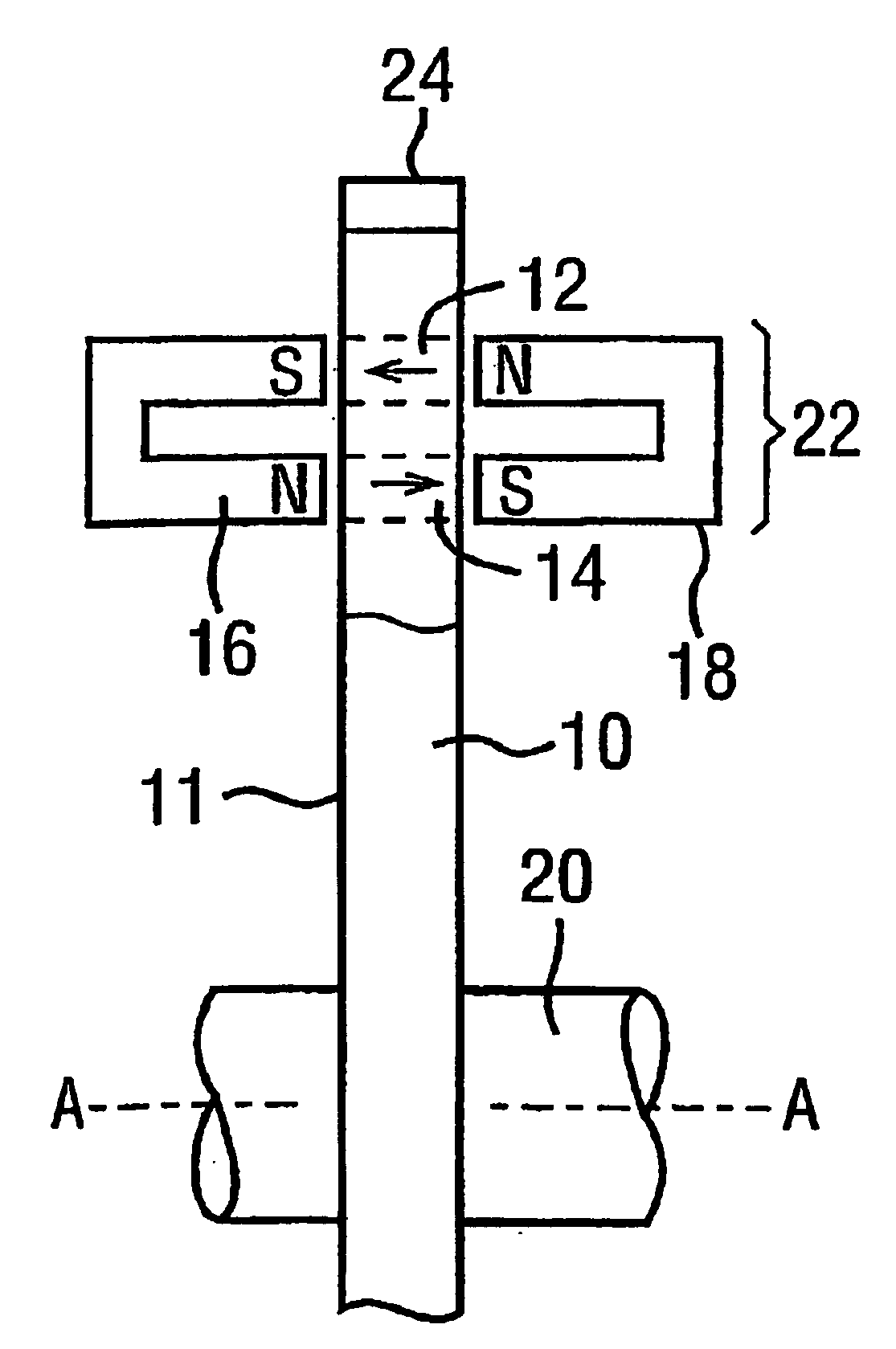

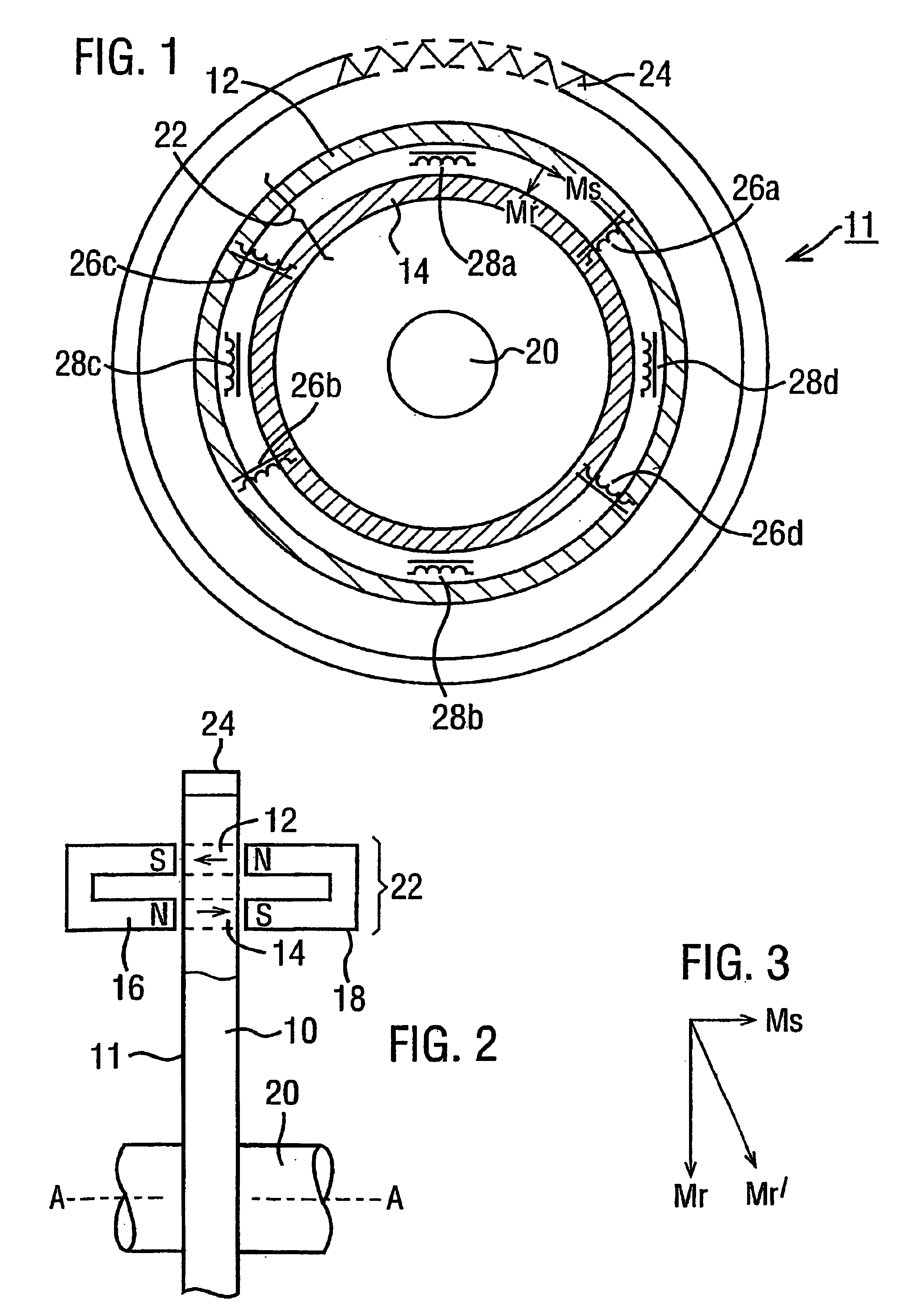

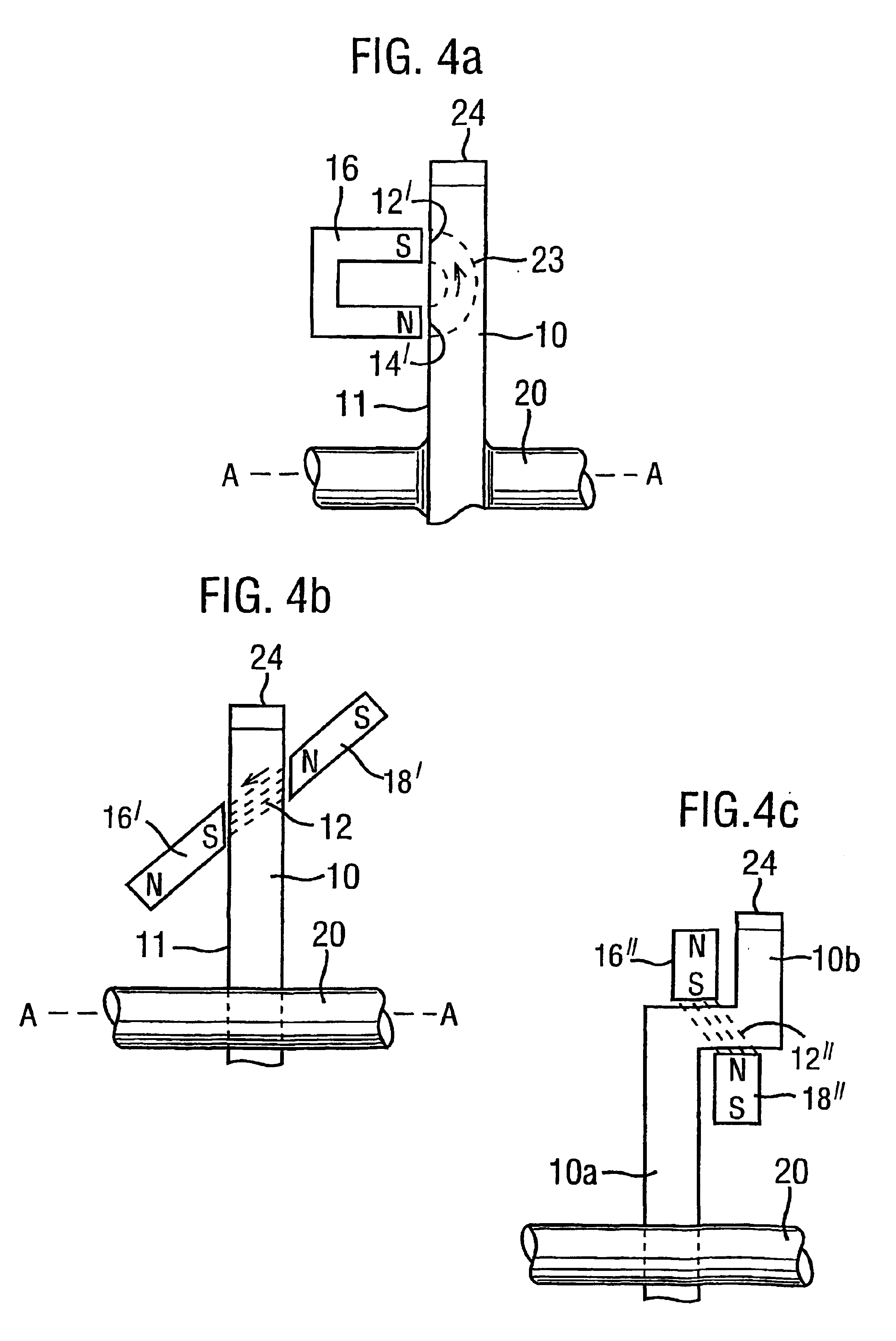

Magneto-elastic sensor, load pin, ball-joint and tow coupling comprising this sensor, method of determining a direction of a load vector

ActiveUS9347845B2Reduce measurementGuaranteed uptimeForce measurement by measuring magnetic property varationFluid pressure measurement by electric/magnetic elementsShear stressMagneto elastic

Owner:METHODE ELECTRONICS MALTA LTD

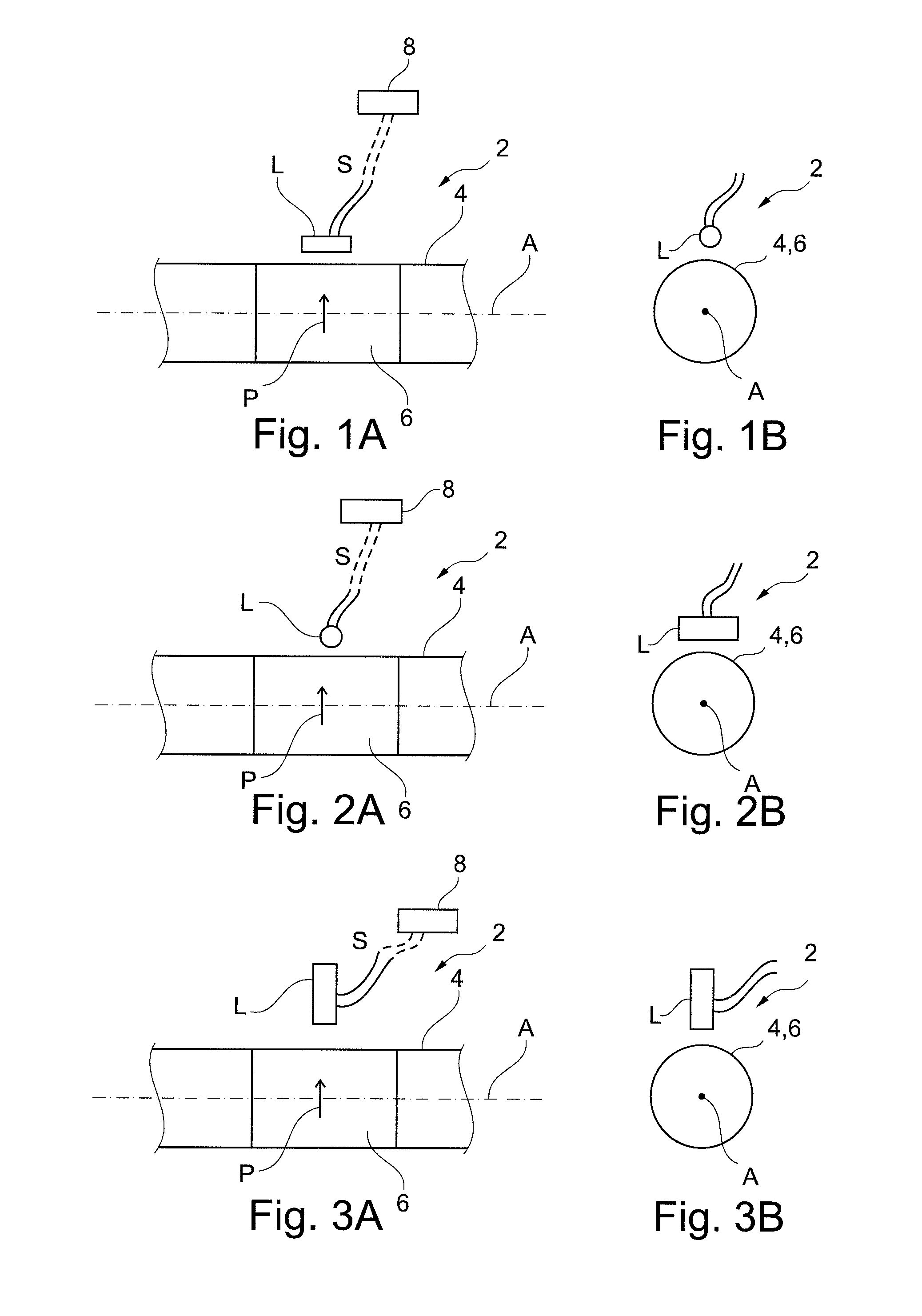

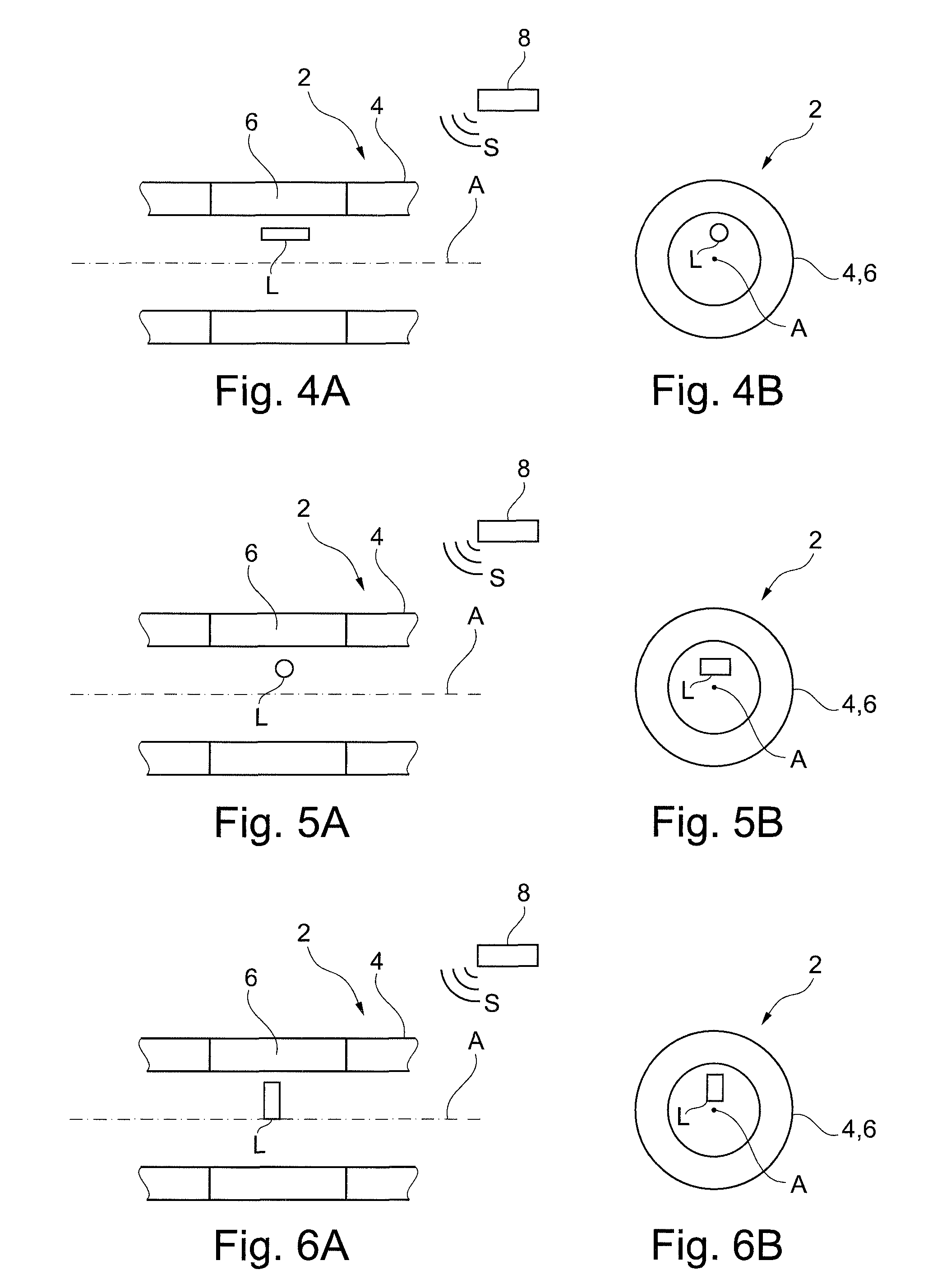

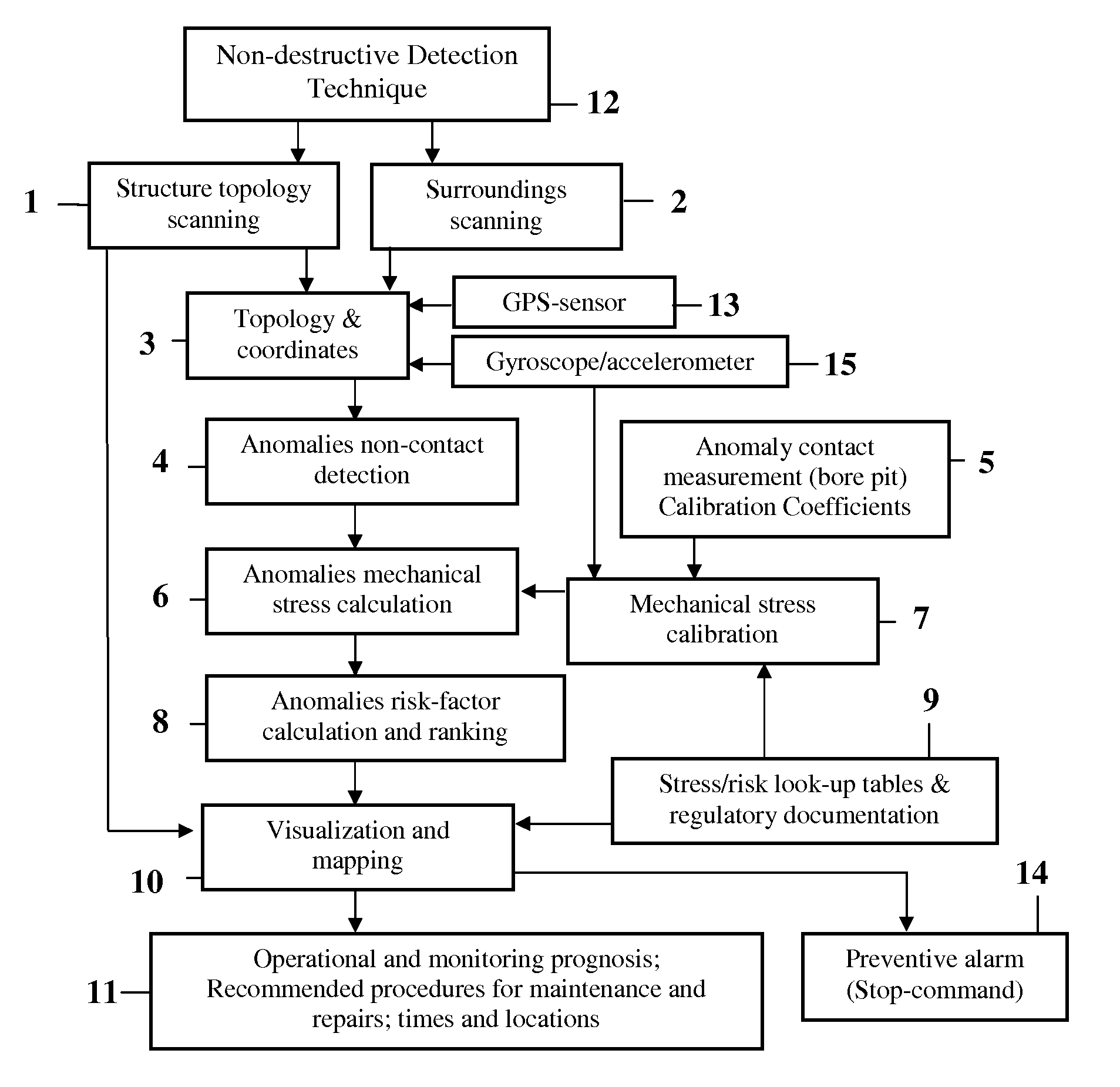

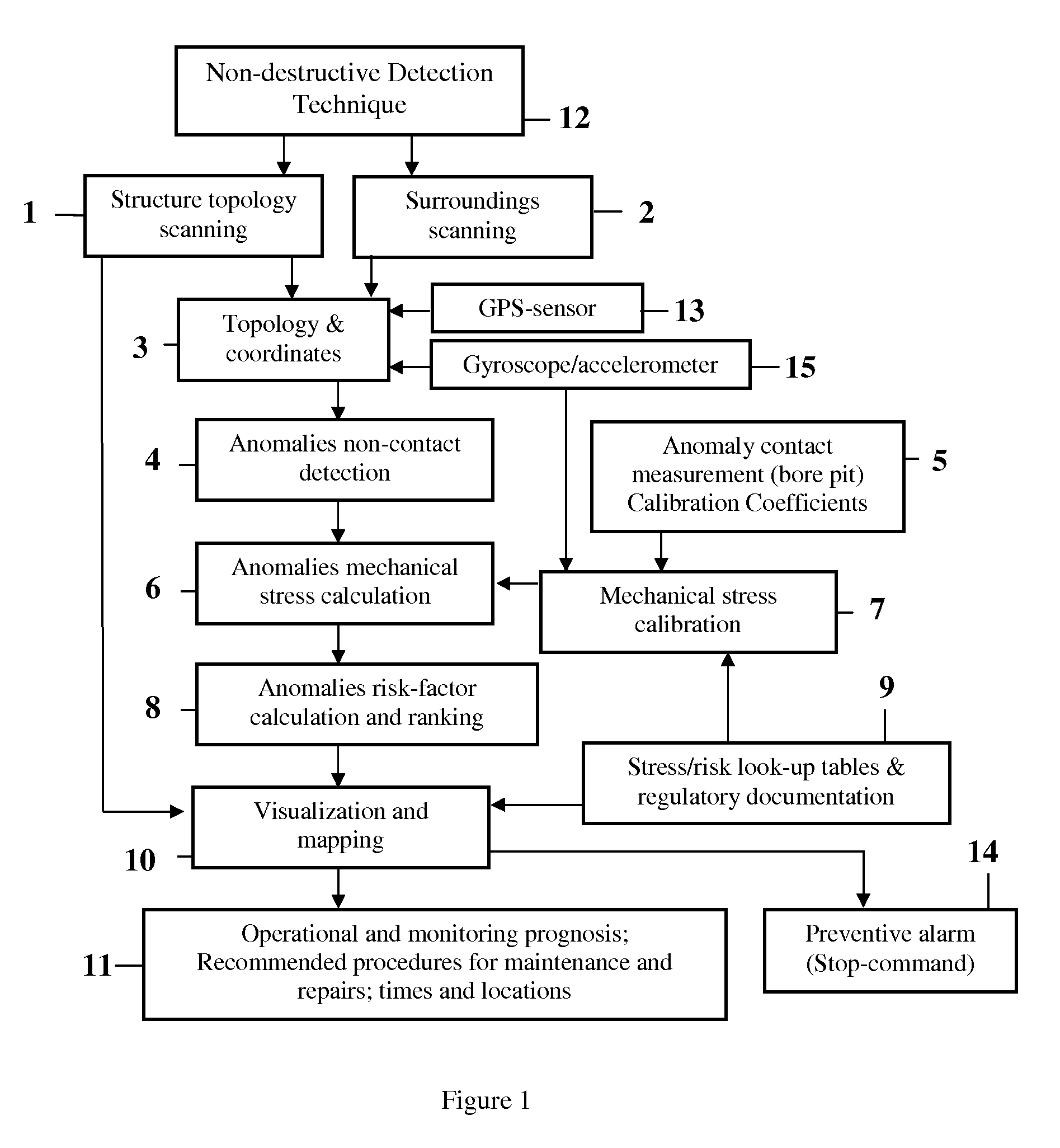

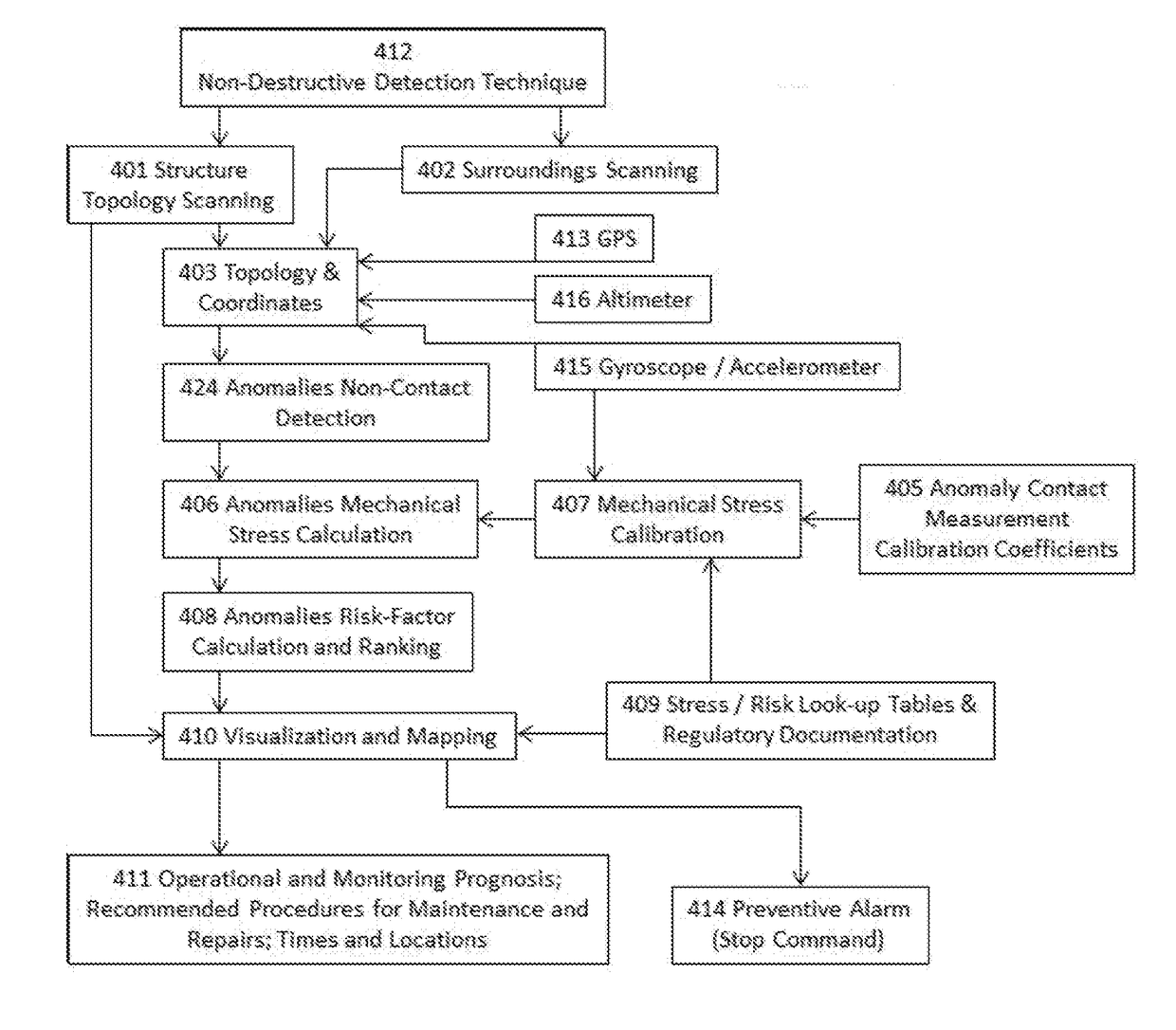

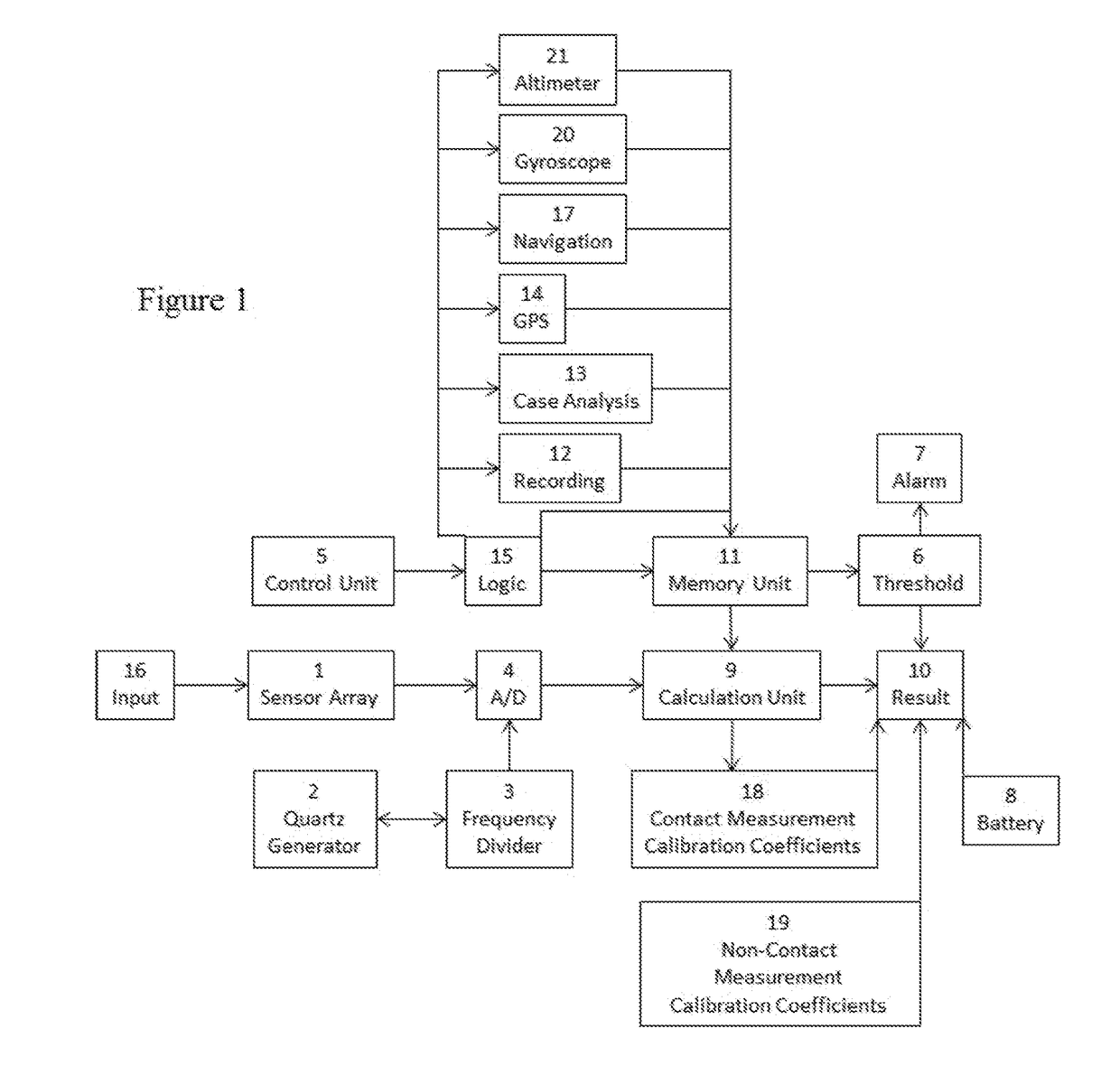

Metallic constructions integrity assessment and maintenance planning method

ActiveUS8447532B1Easy maintenancePromote repairPlug gaugesForce measurement by measuring magnetic property varationMaintenance planningHeavy duty

A method for metallic structure maintenance is disclosed. The method includes a magneto-graphic / Magnetic Tomography technique to identify stress-related defects. The method is specifically optimized for extended, non-accessible underground and underwater metallic structures in providing quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the method implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

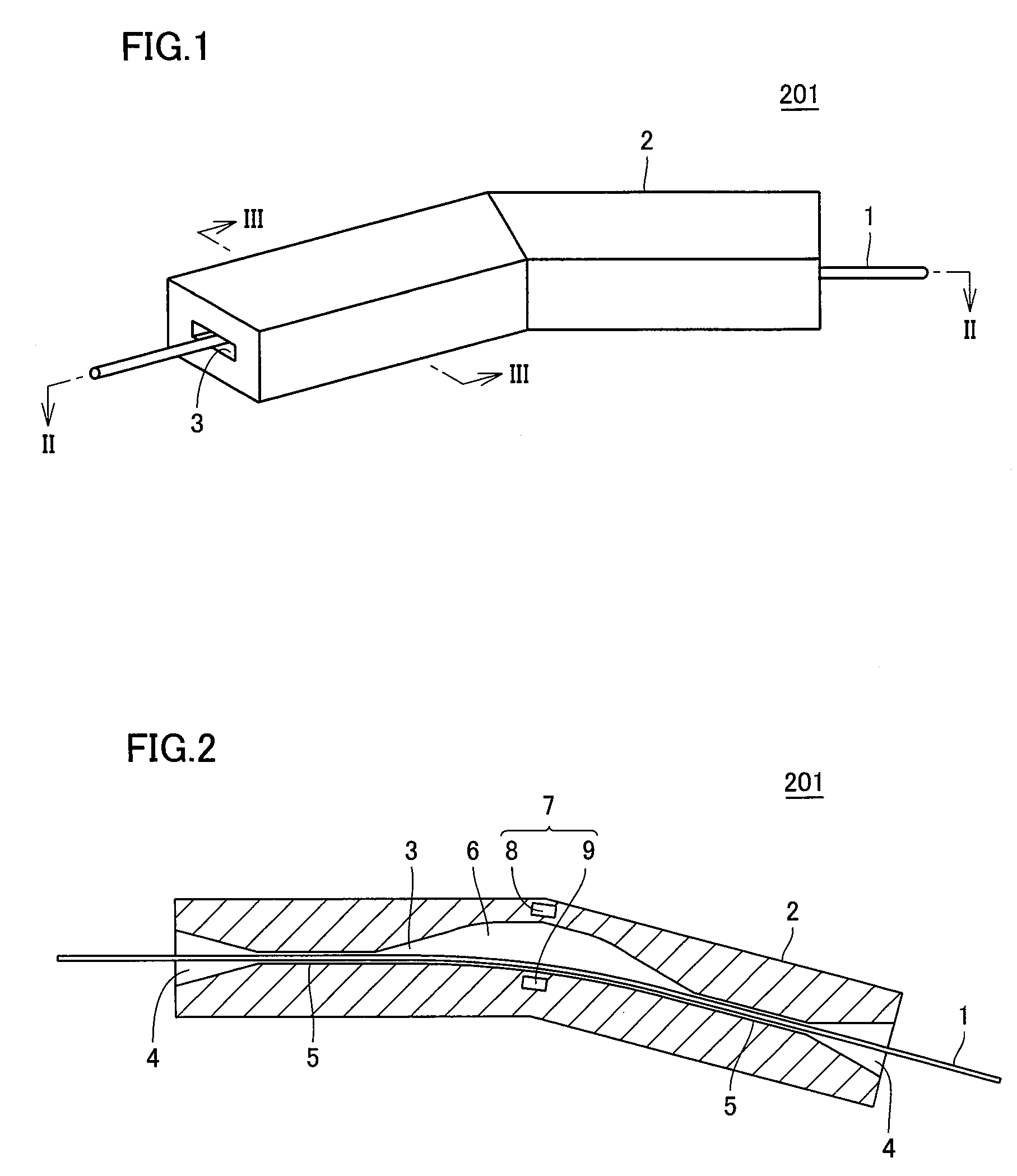

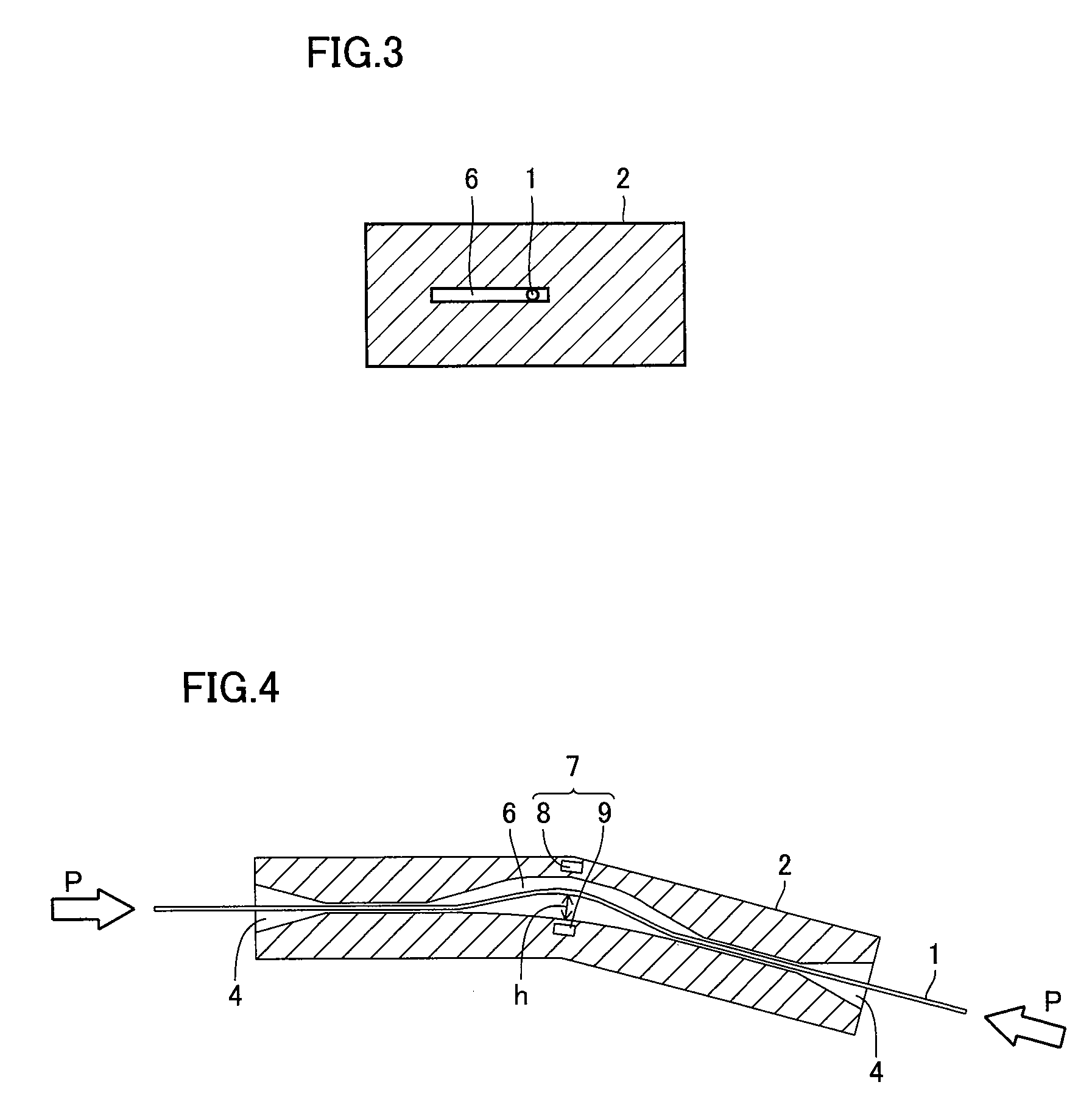

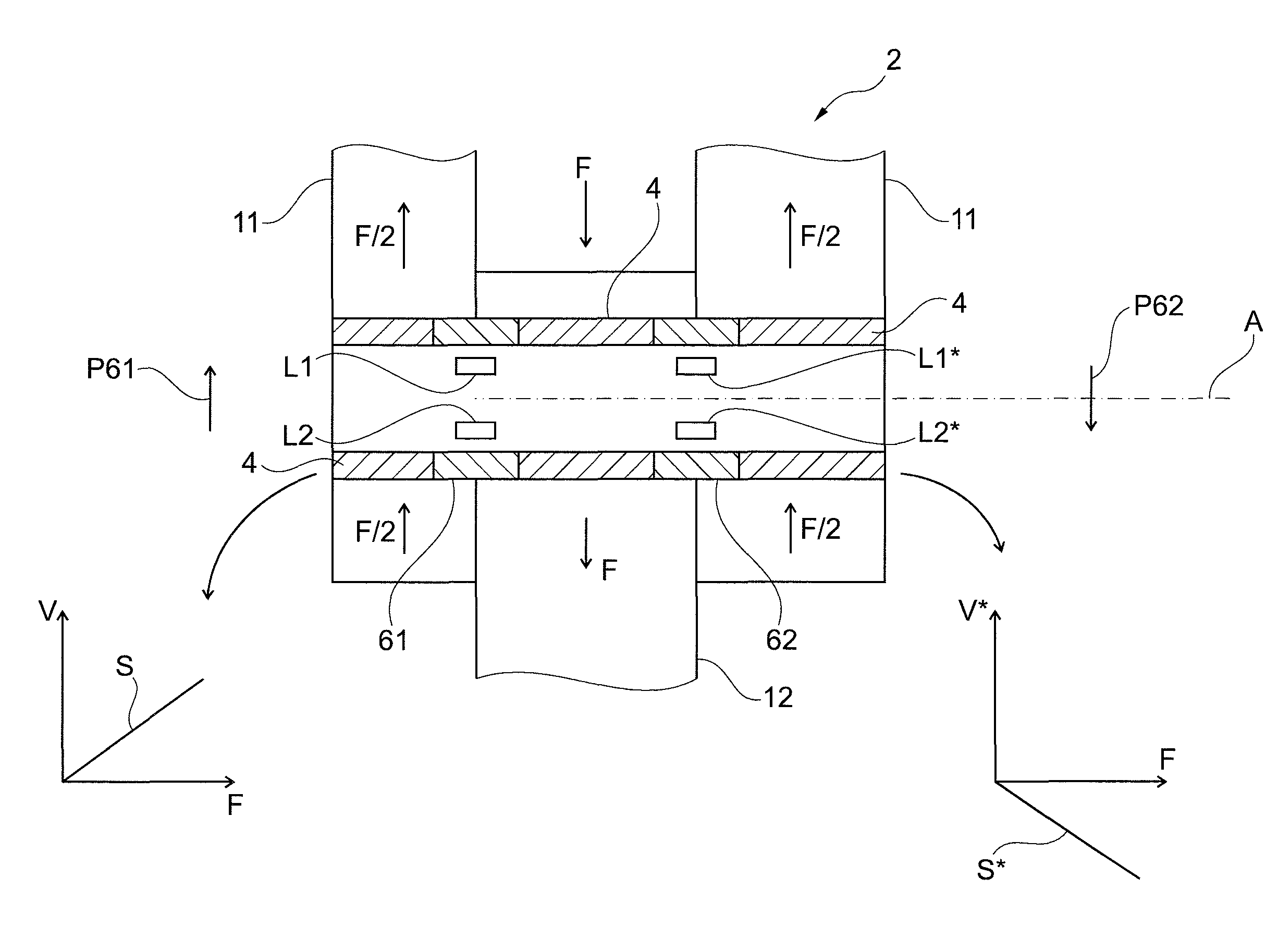

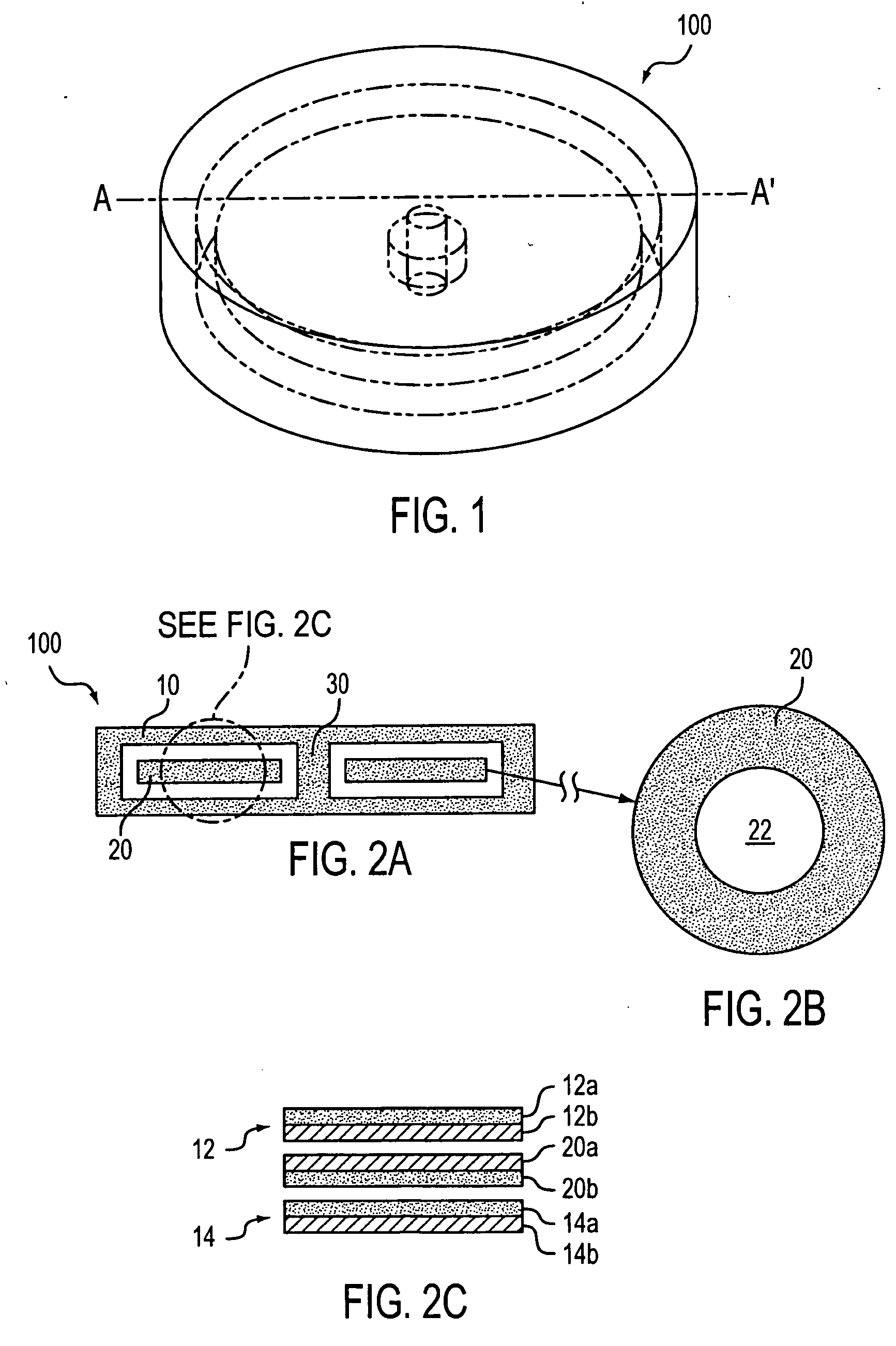

Capacitive sensor

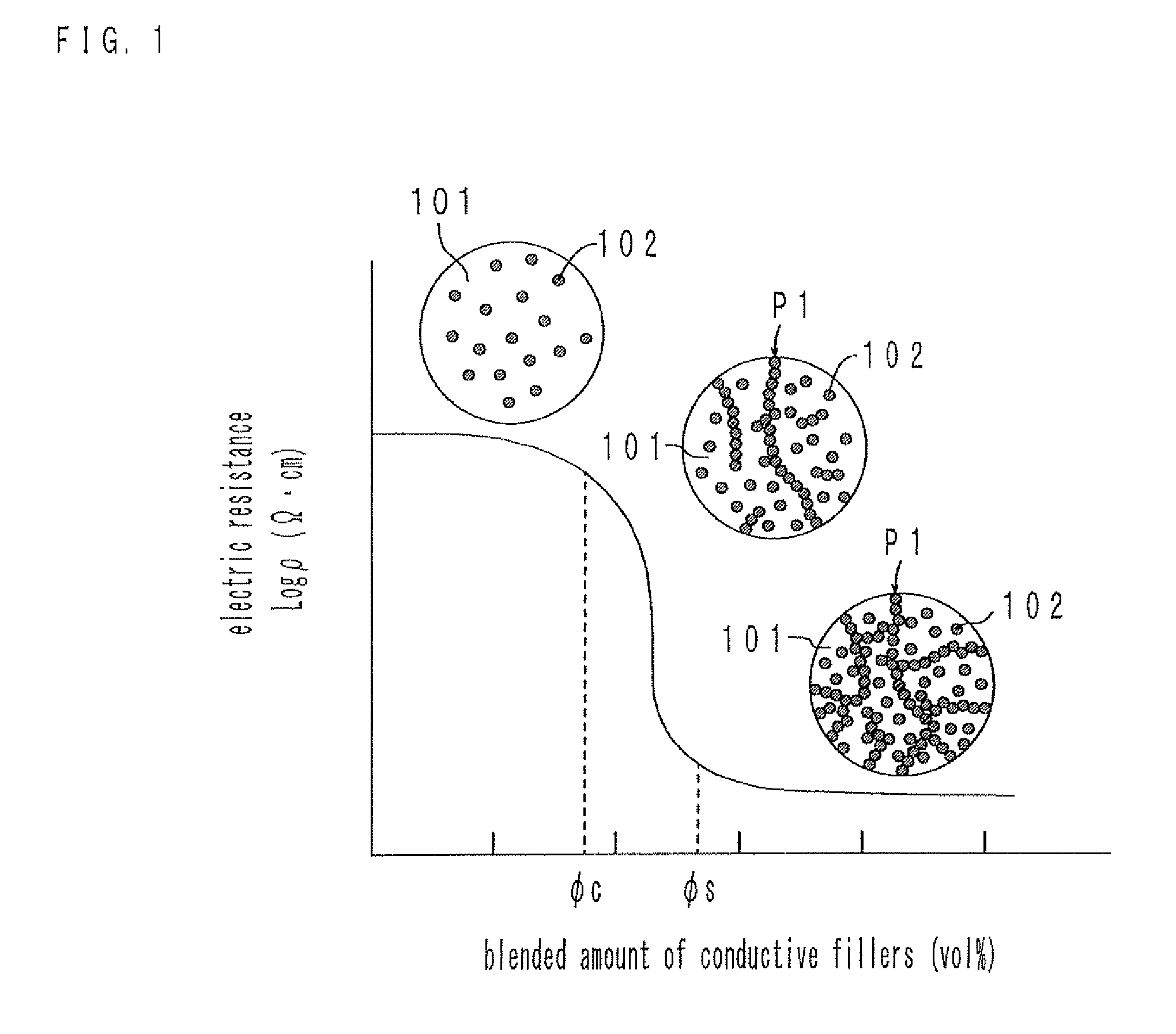

ActiveUS7958789B2Great electrostatic capacity variationEasy to integrateForce measurement by measuring magnetic property varationResistance/reactance/impedenceElastomerCapacitive sensing

A capacitive sensor includes a dielectric layer made of an elastomer and a pair of electrodes arranged via the dielectric layer, and detects deformation on the basis of electrostatic capacity variation between the pair of electrodes. The pair of electrodes contain an elastomer and conductive fillers filled into the elastomer, are expandable and contractible in accordance with deformation of the dielectric layer, and exhibit little conductivity variation even when the pair of electrodes expand and contract. At least one of the dielectric layer and the electrodes is formed by a printing method using a dielectric layer coating containing a formation component of the dielectric layer or an electrode coating containing a formation component of the electrode.

Owner:SUMITOMO RIKO CO LTD

Measurement apparatus and method

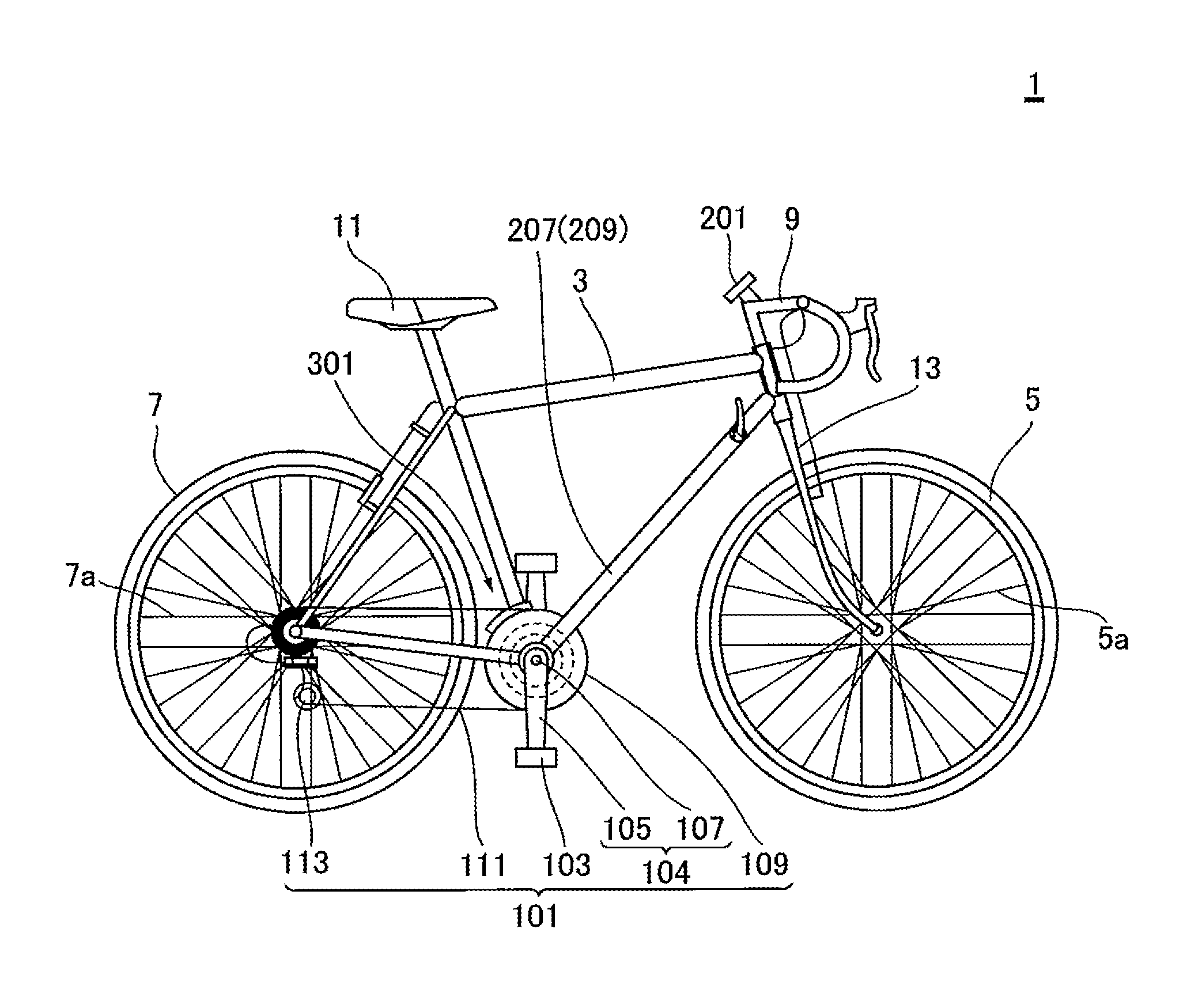

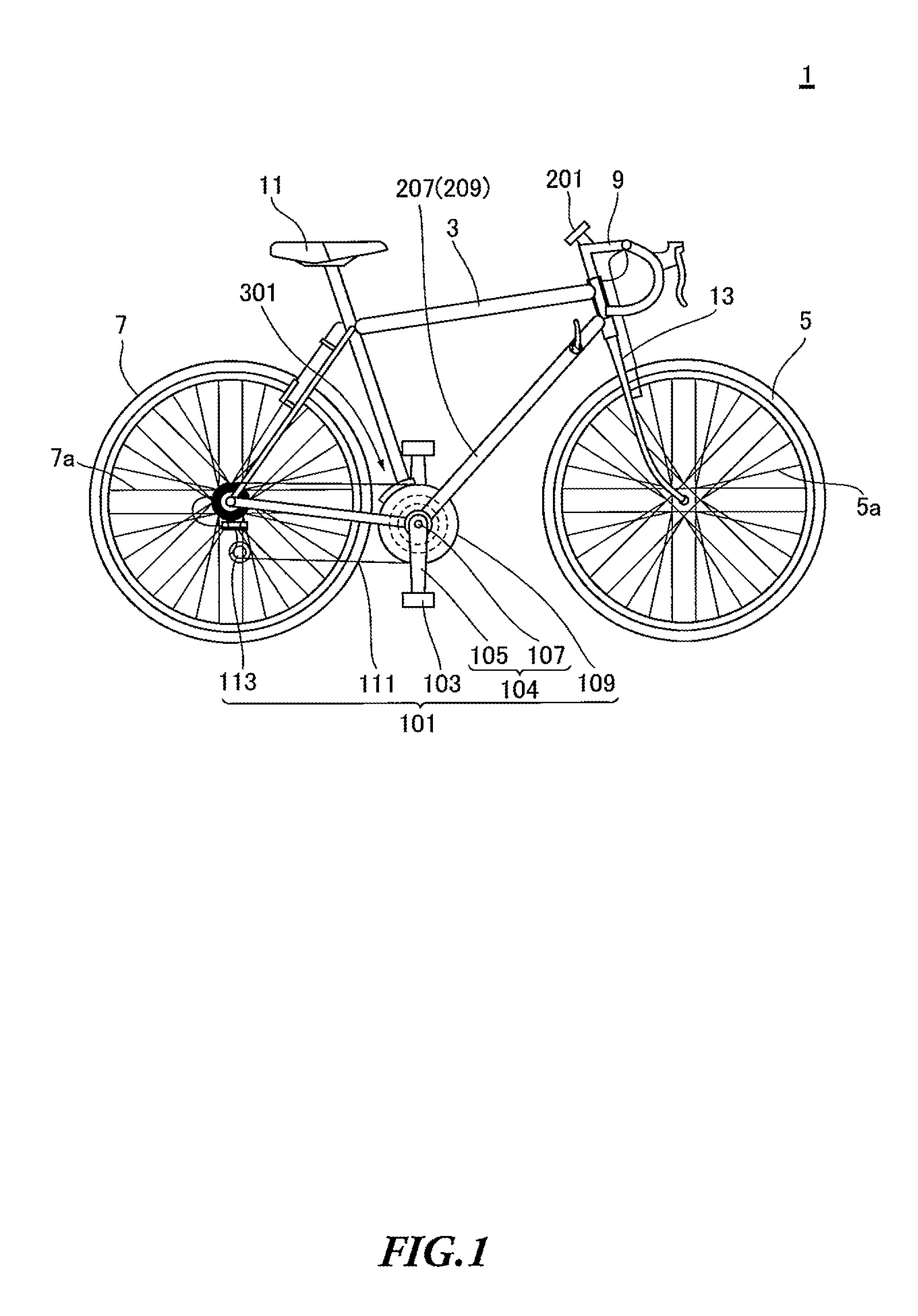

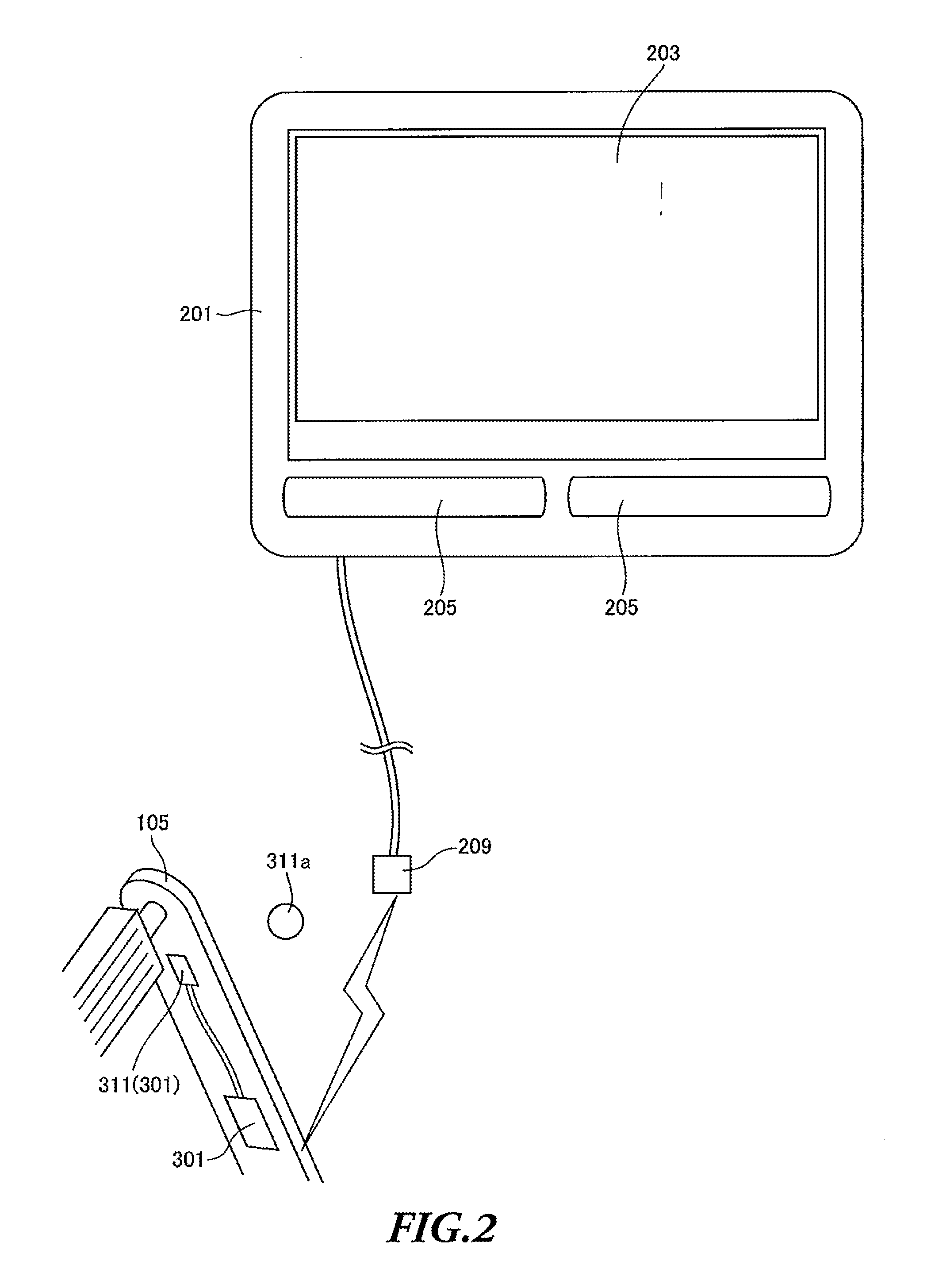

ActiveUS20130205916A1Vehicle cranksForce measurement by measuring magnetic property varationAngular degreesEngineering

A measurement module that measures force being applied to a man-powered machine includes: a strain sensor that detects strain of a crank of the bicycle configured to transmit force being applied from a user through the crank and one front gear selected among one or more front gears; an MM magnetic sensor that detects the crank passing through a predetermined position; and an MM control part. The MM control part calculates a rotation angle of the crank based on an elapsed time from a time the crank passes through the predetermined position that the sensor has detected, calculates force applied to the crank based on a strain amount of the crank that the strain sensor has detected, associates the rotation angle with the force applied to the crank to calculate distribution of the force applied from the user.

Owner:SHIMANO INC

Magnetostrictive multilayer sensor and method for producing a sensor

InactiveUS7490522B2Force measurement by measuring magnetic property varationFluid pressure measurement by electric/magnetic elementsElectrical resistance and conductanceMechanical engineering

Owner:INFINEON TECH AG

Magnetic force sensor

InactiveUS20100175487A1Suppresses noise generationImprove permeabilityForce measurement by measuring magnetic property varationApparatus for force/torque/work measurementMagnetic tension forceTransducer

A magnetic force sensor includes: an action portion on which an external force acts; a sensing unit converting a force working on the action portion into an electric signal; and an outer frame having an elastic body elastically supporting the action portion and storing the sensing unit therein. The sensing unit includes a magnetic flux generation source connected with the action portion and a magnetoelectric transducer fixed on the outer frame and the magnetic flux generation source has a magnetic body therewith that controls flow of magnetic fluxes generated by the magnetic flux generation source.

Owner:CANON KK

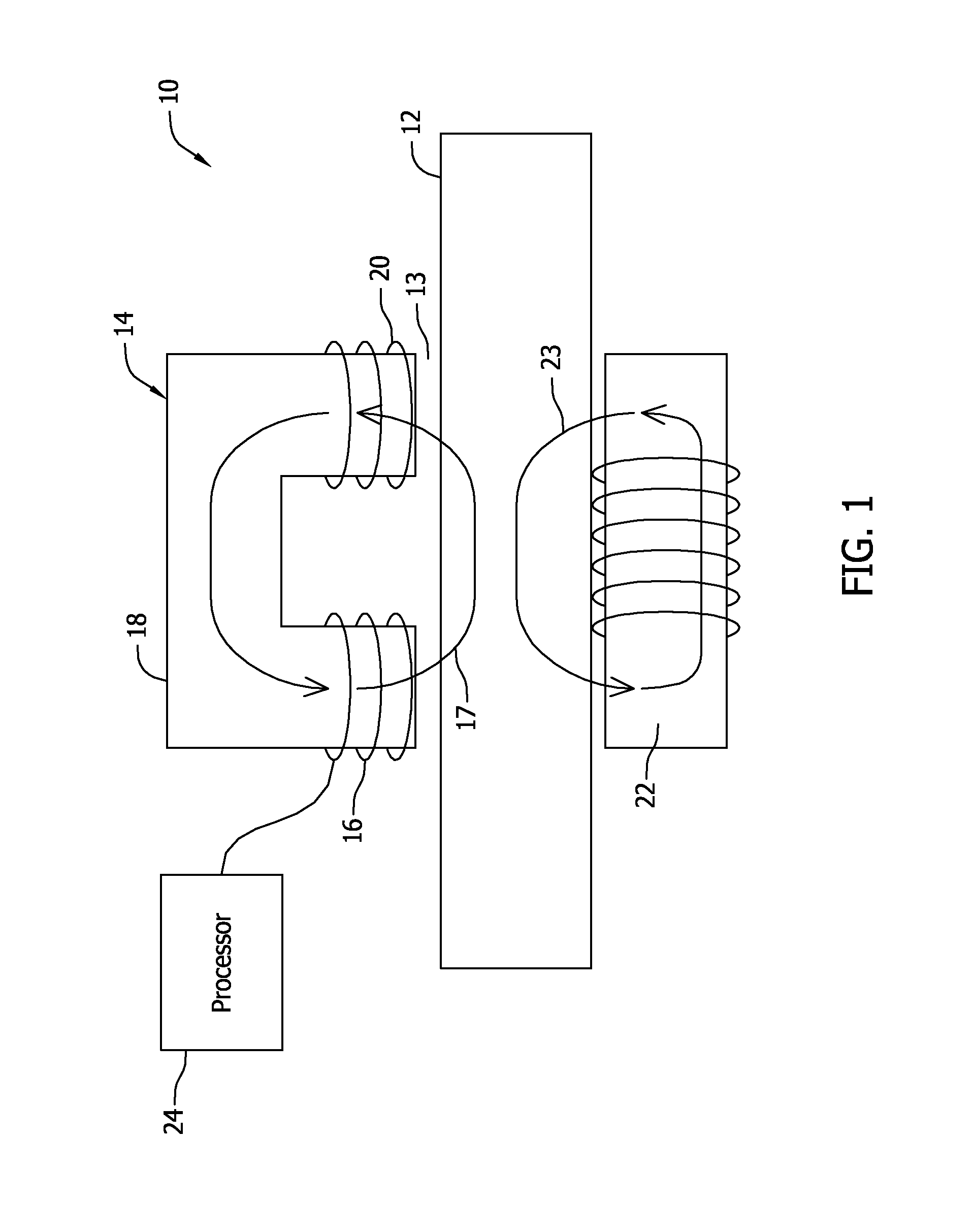

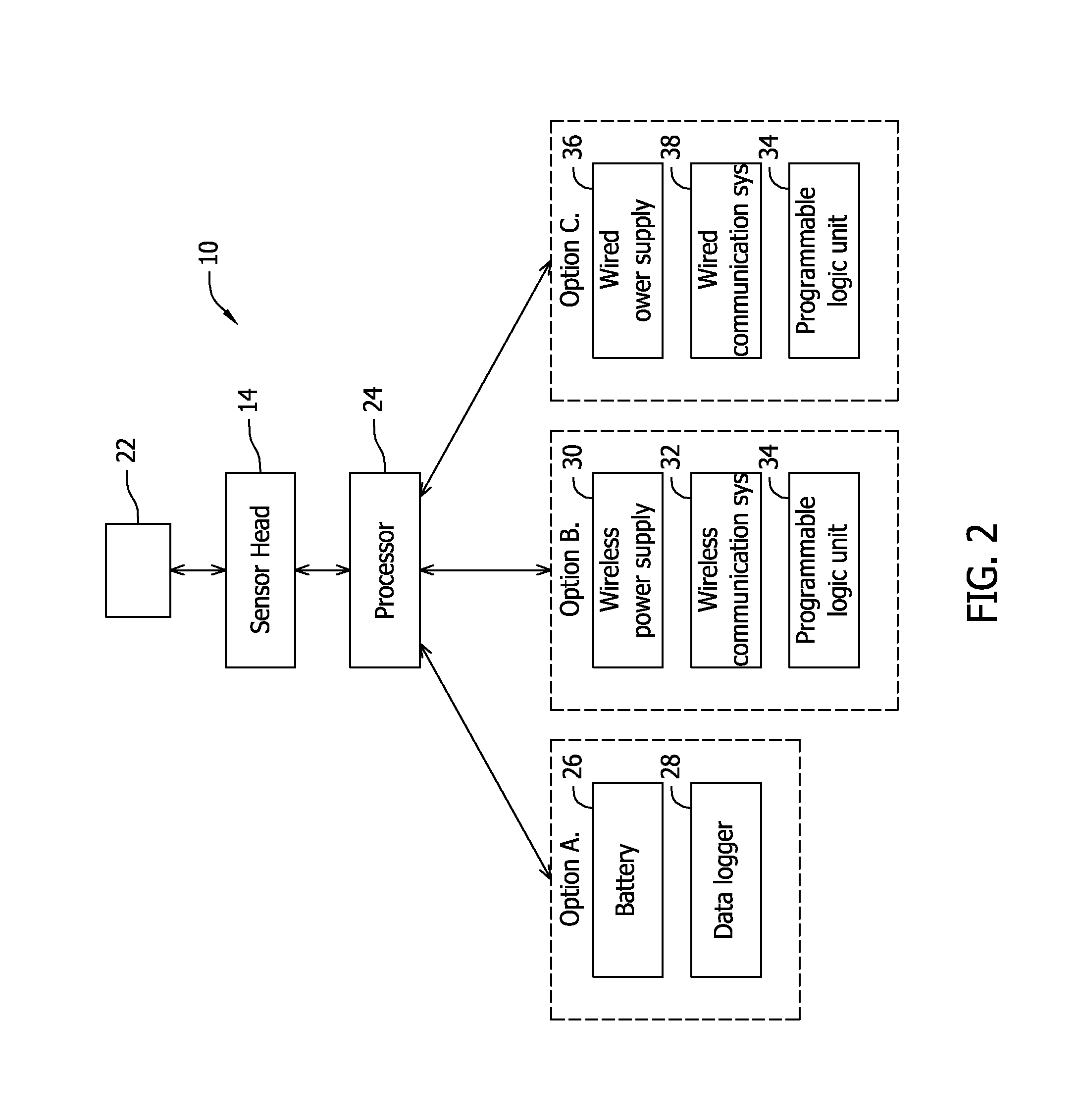

Non-contact magnetostrictive sensing systems and methods

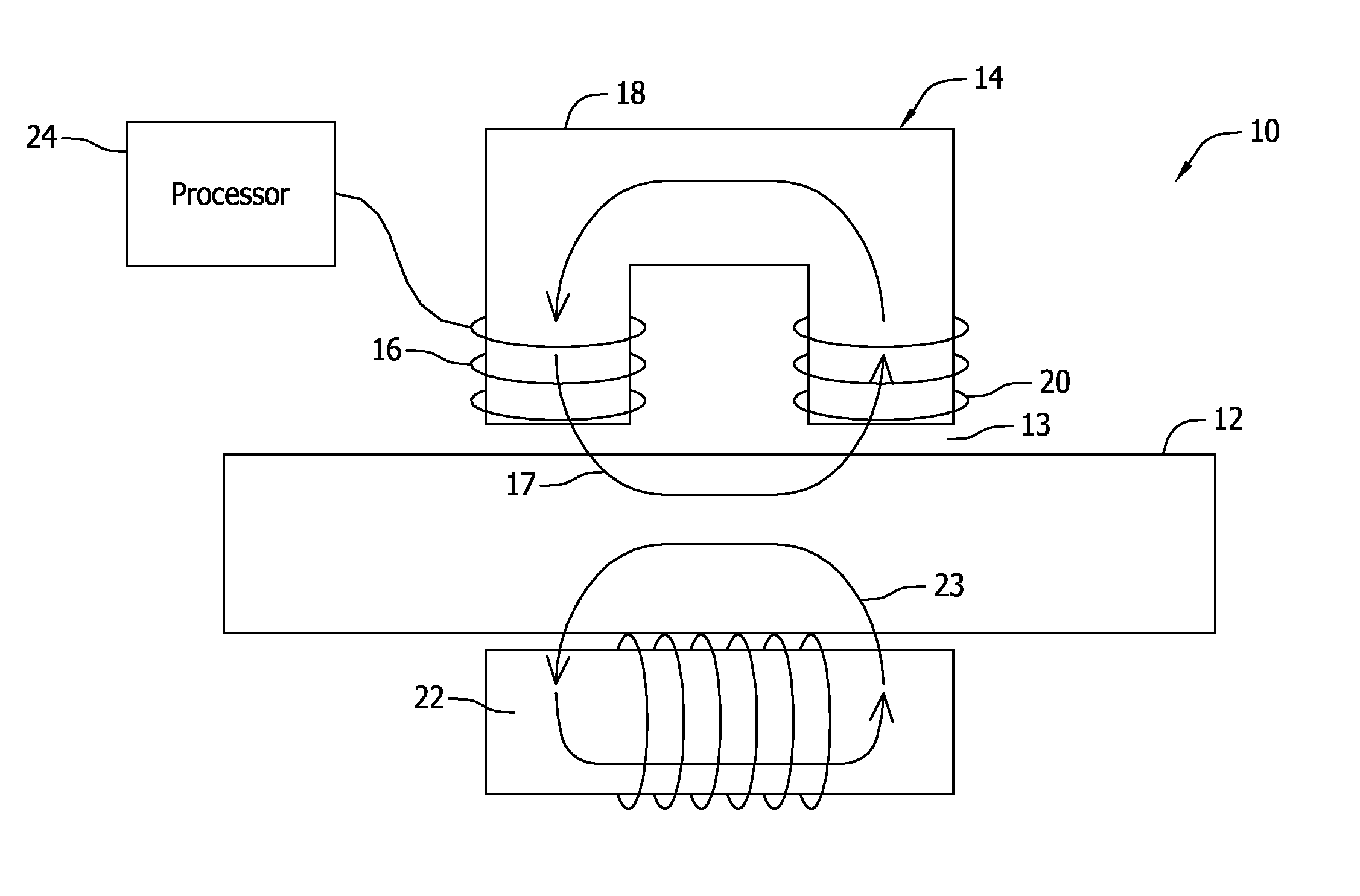

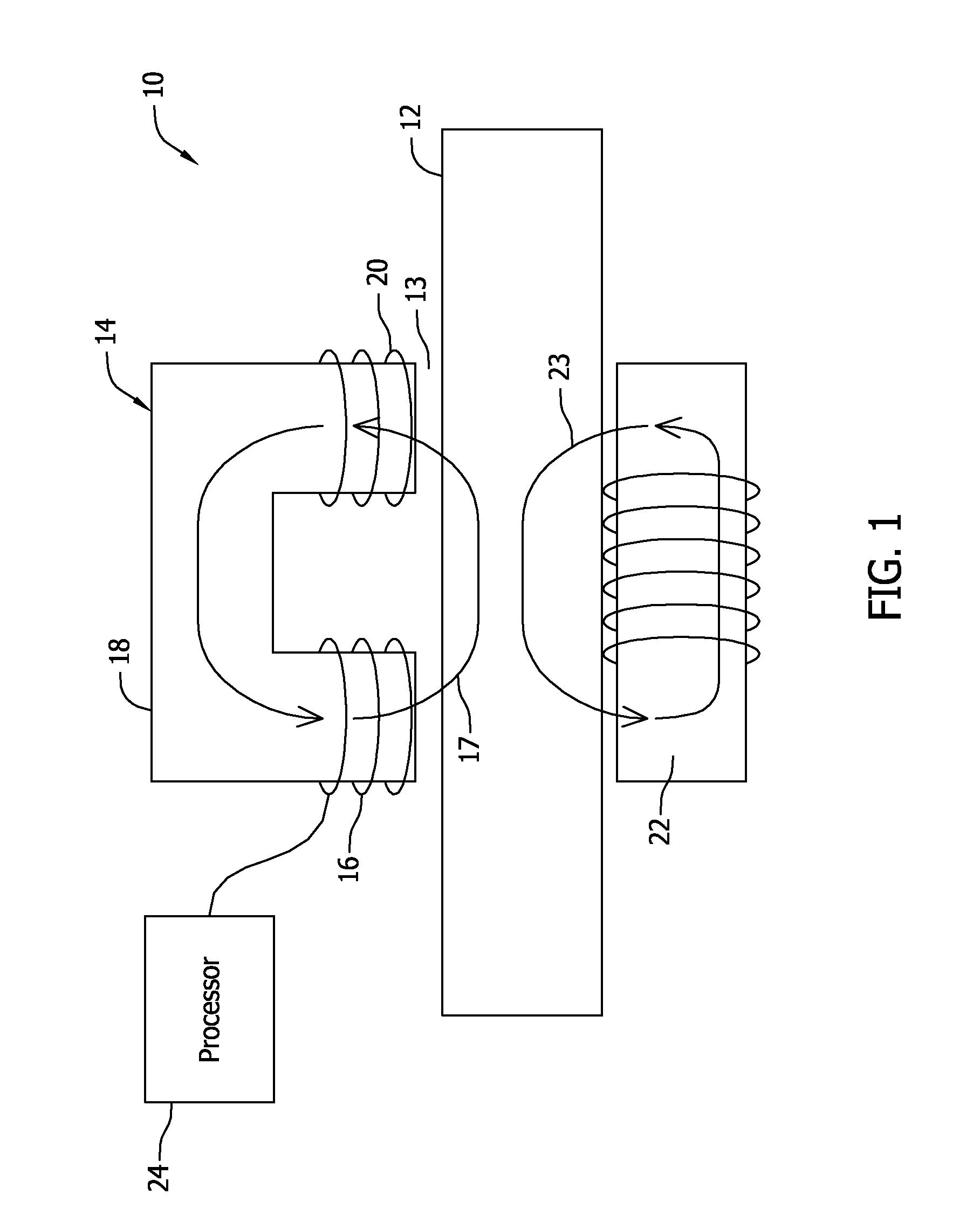

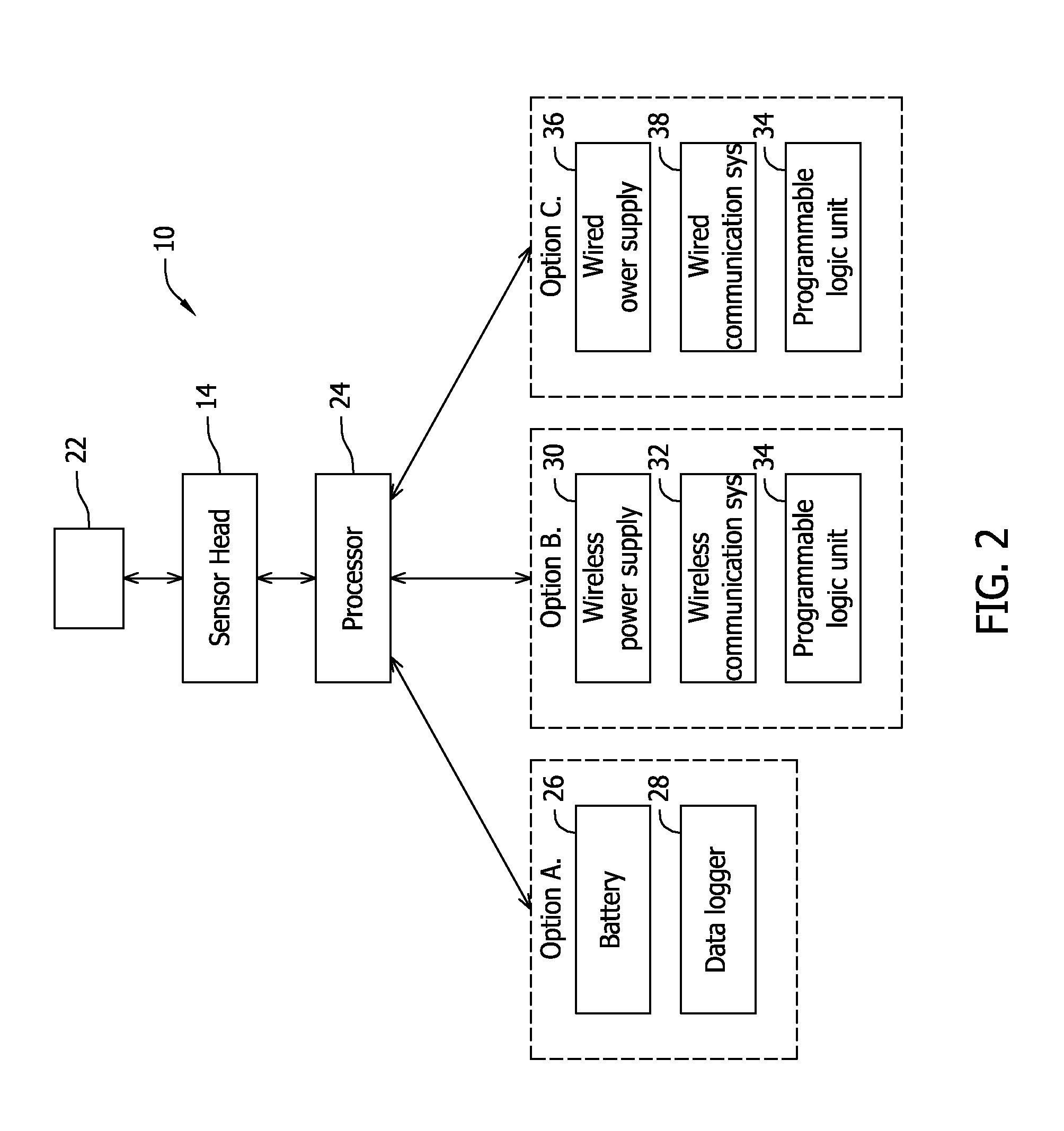

ActiveUS20140184210A1Force measurement by measuring magnetic property varationWork measurementMagnetic fluxExcitation coil

A system for sensing stress in a ferromagnetic material is provided. The system includes at least one magnetic flux device configured to induce a conditioning magnetic flux in the ferromagnetic material. The system also includes a sensor positioned proximate to the ferromagnetic material. The sensor includes a core, at least one excitation coil configured to induce a second magnetic flux in the ferromagnetic material, and at least one detector configured to detect changes in the second magnetic flux.

Owner:BAKER HUGHES INC

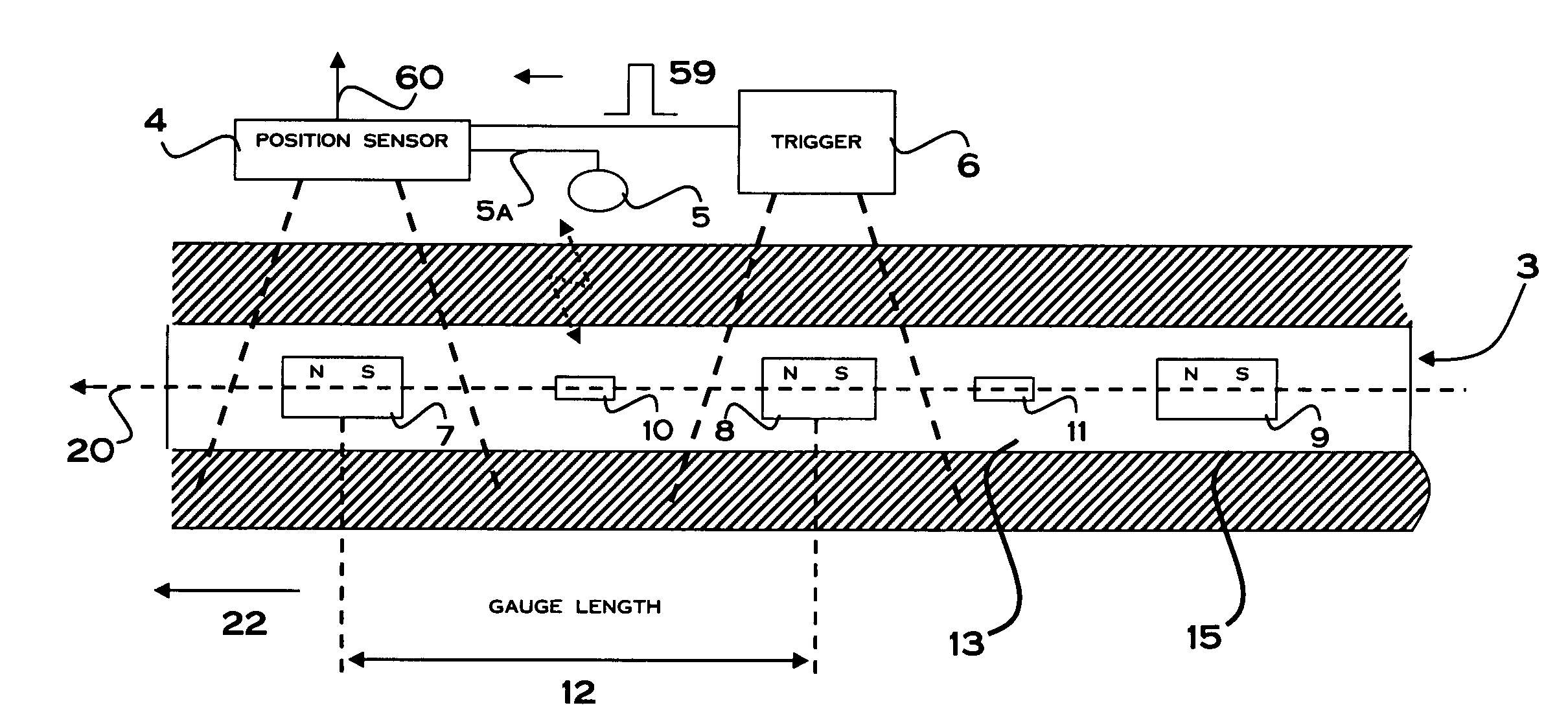

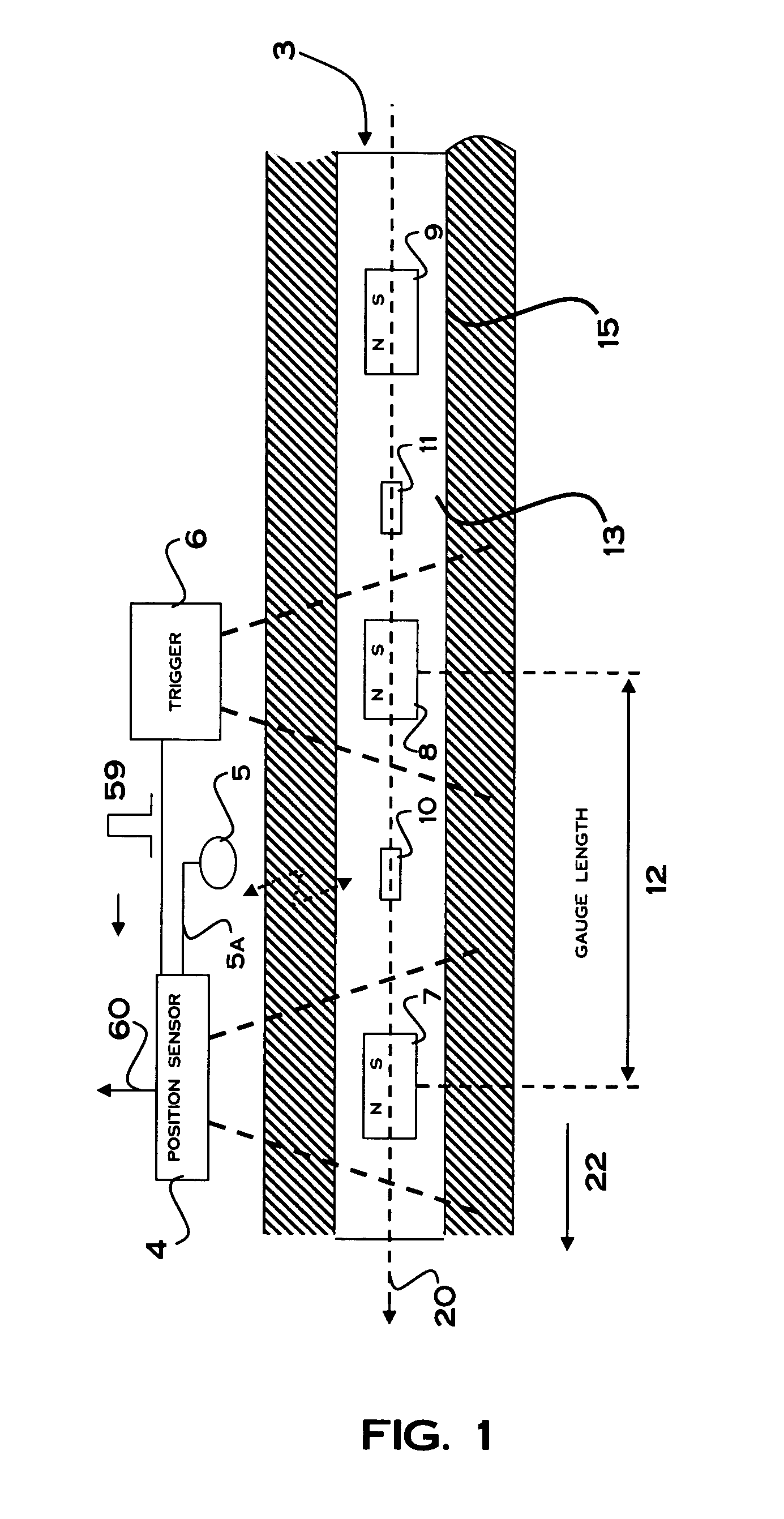

Strain gauge sensor system and method

InactiveUS7441464B2Unlimited measurement rangeGood strain measurement resolution and reliabilityForce measurement by measuring magnetic property varationUsing electrical meansFiberStrain gauge

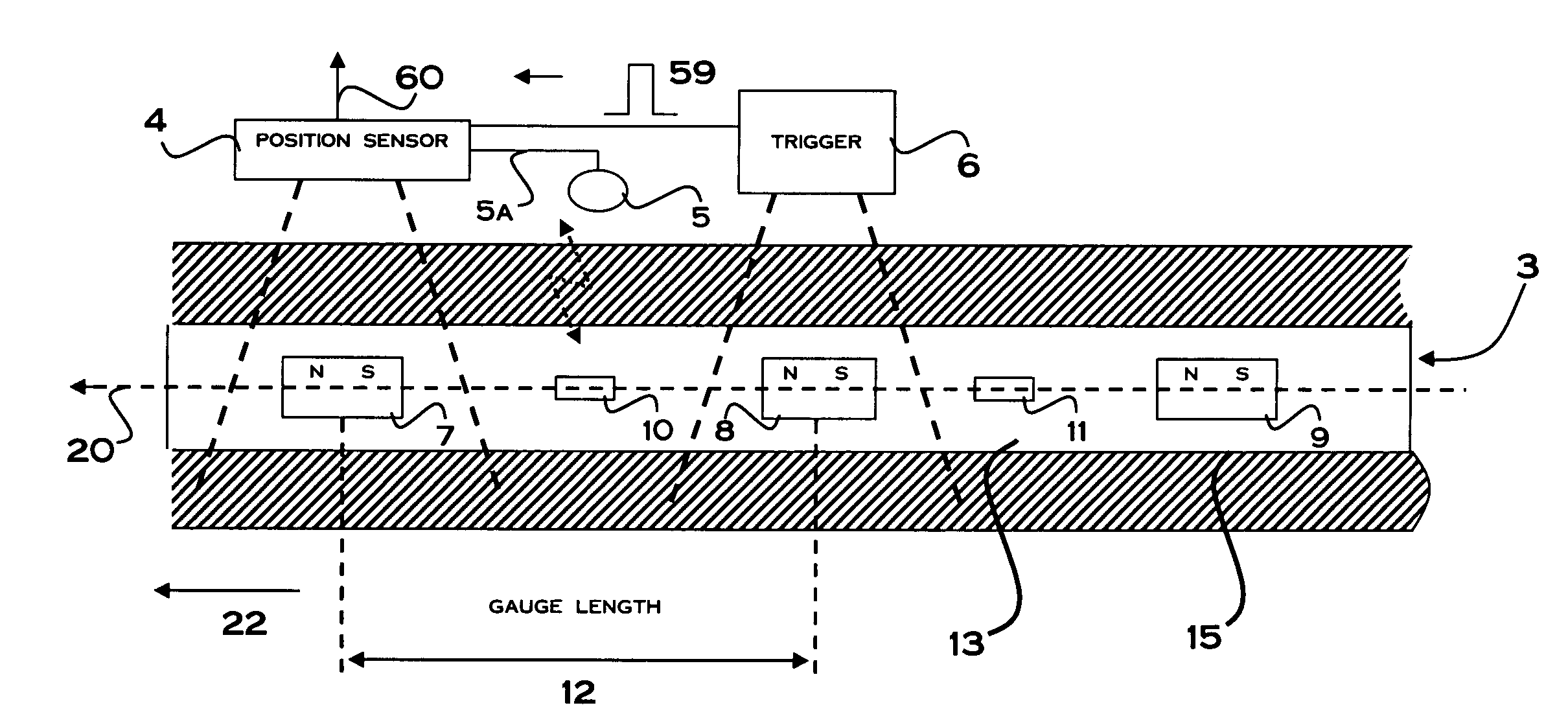

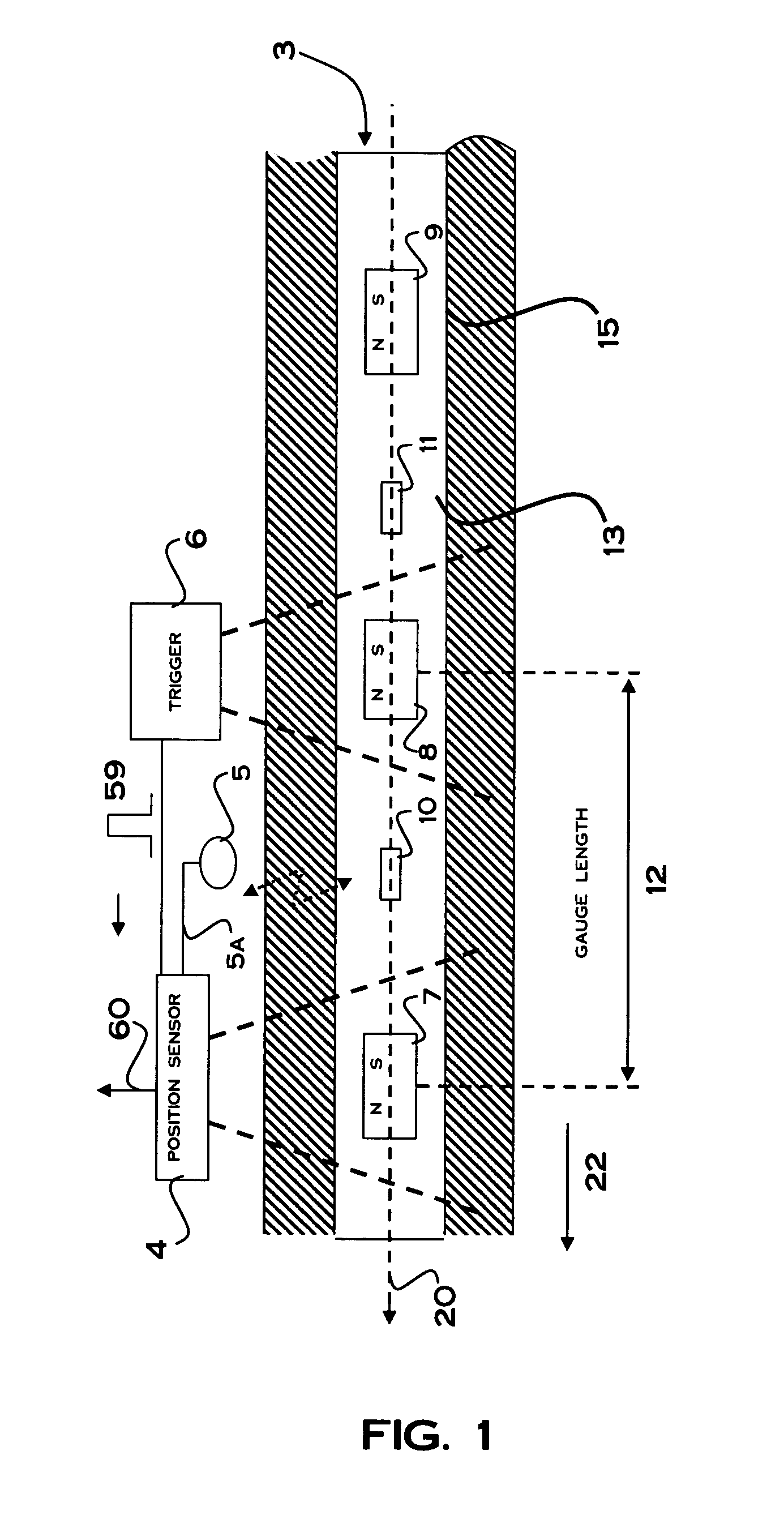

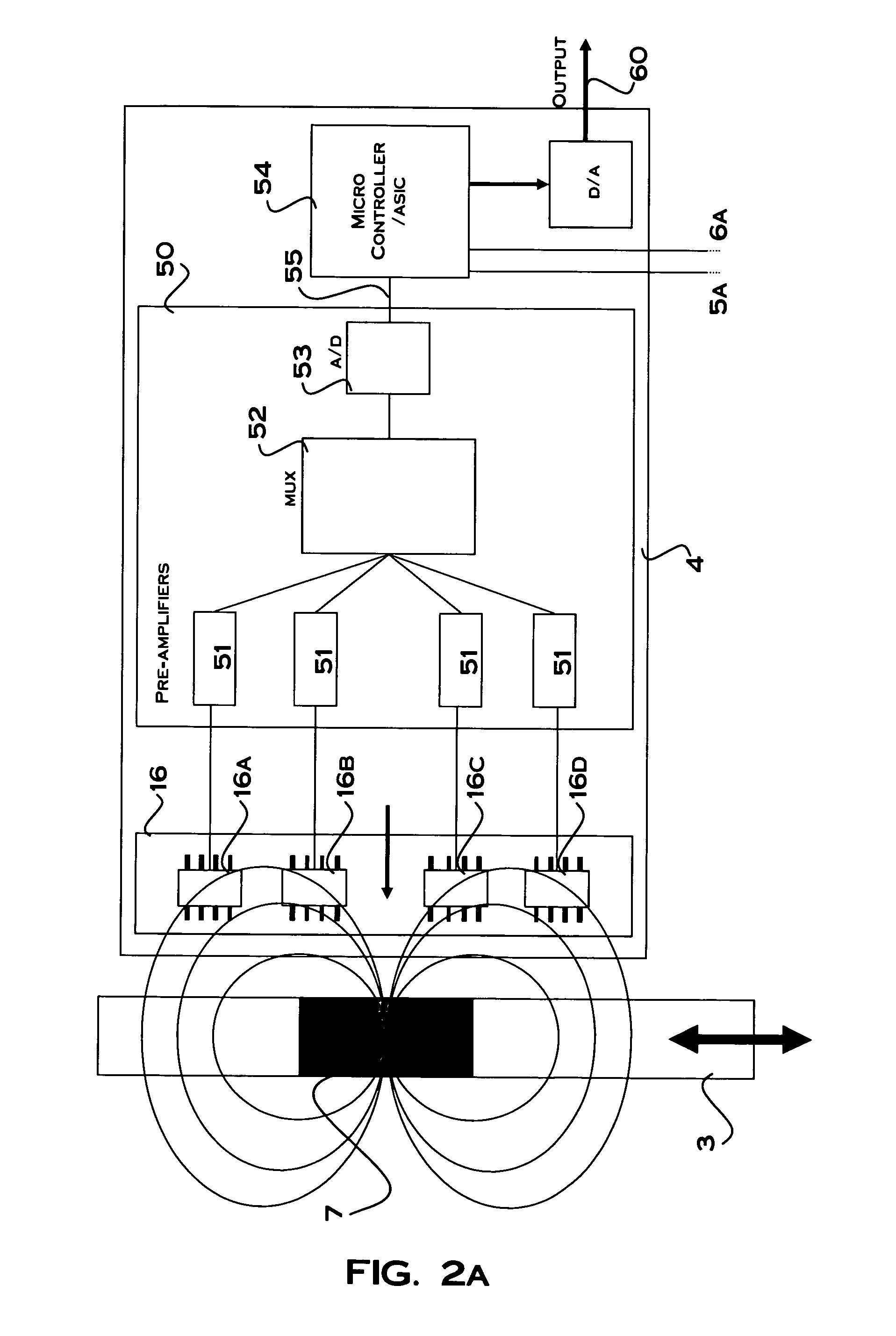

A strain gauge sensor system and method for measuring the strain in a member, such as a fiber rope, has a sensor target assembly having a plurality of magnets carried spaced apart by individual gauge lengths along the member. Position and trigger sensor devices are configured spaced apart along side a desired path of travel of the member. When the member is fed along the desired path of travel, the trigger sensor device, in response to magnetically sensing a passing magnet, triggers the position sensor device to read the position of an adjacent passing magnet. The strain in the gauge length is determined from the read position. RFID tags placed on the member between the magnets can be identified by an RF reader to identify a particular gauge length being measured. The system can include a deployment device for feeding the member along the desired path.

Owner:HONEYWELL INT INC

Hall effect seat belt tension sensor

InactiveUS6729194B2Force measurement by measuring magnetic property varationPedestrian/occupant safety arrangementSeat beltEngineering

A hall effect seat belt tension sensor for a vehicle. The sensor has a housing mounted to a seat belt. An anchor plate is mounted between the seat belt and a fixed point on a vehicle. The anchor plate is partially mounted in housing. A spring is mounted between the housing and the anchor plate. Tension on the seat belt causes the anchor plate to move relative to the housing. A magnetic field generator is mounted to the anchor plate. The magnetic field generator moves as the anchor plate moves. A magnetic field sensor is mounted to the housing. The sensor generates an electrical signal in response to movement of the magnetic field generator.

Owner:CTS CORP ELKHART

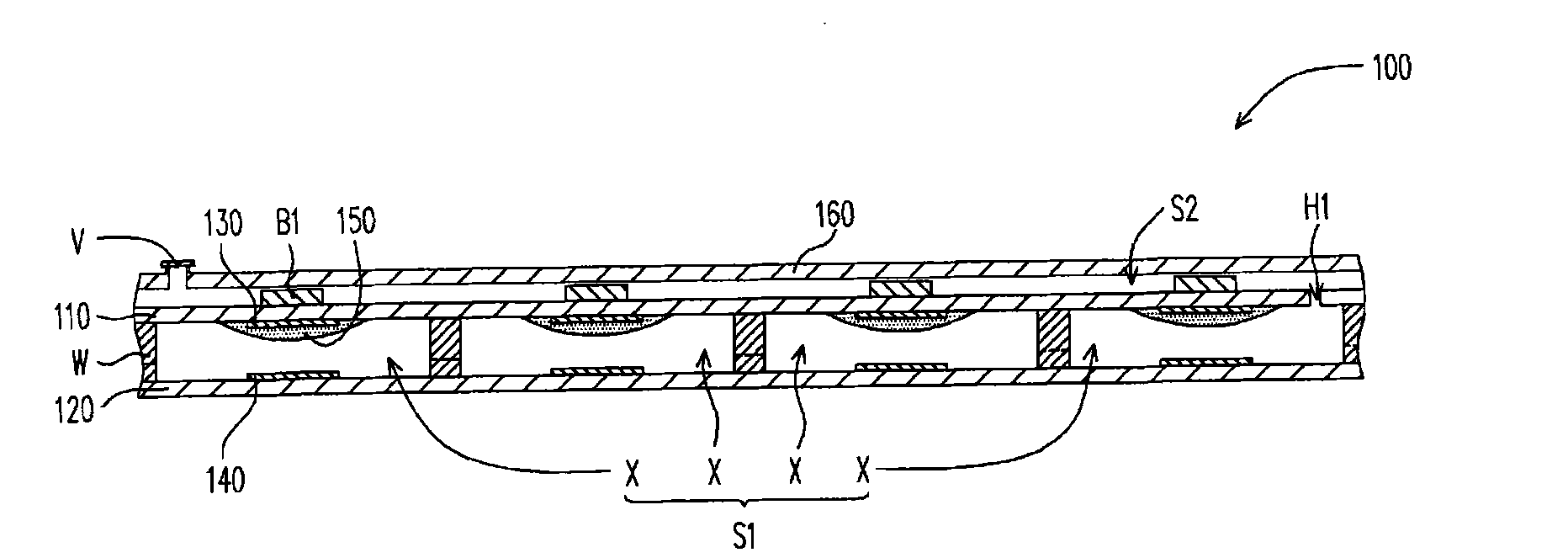

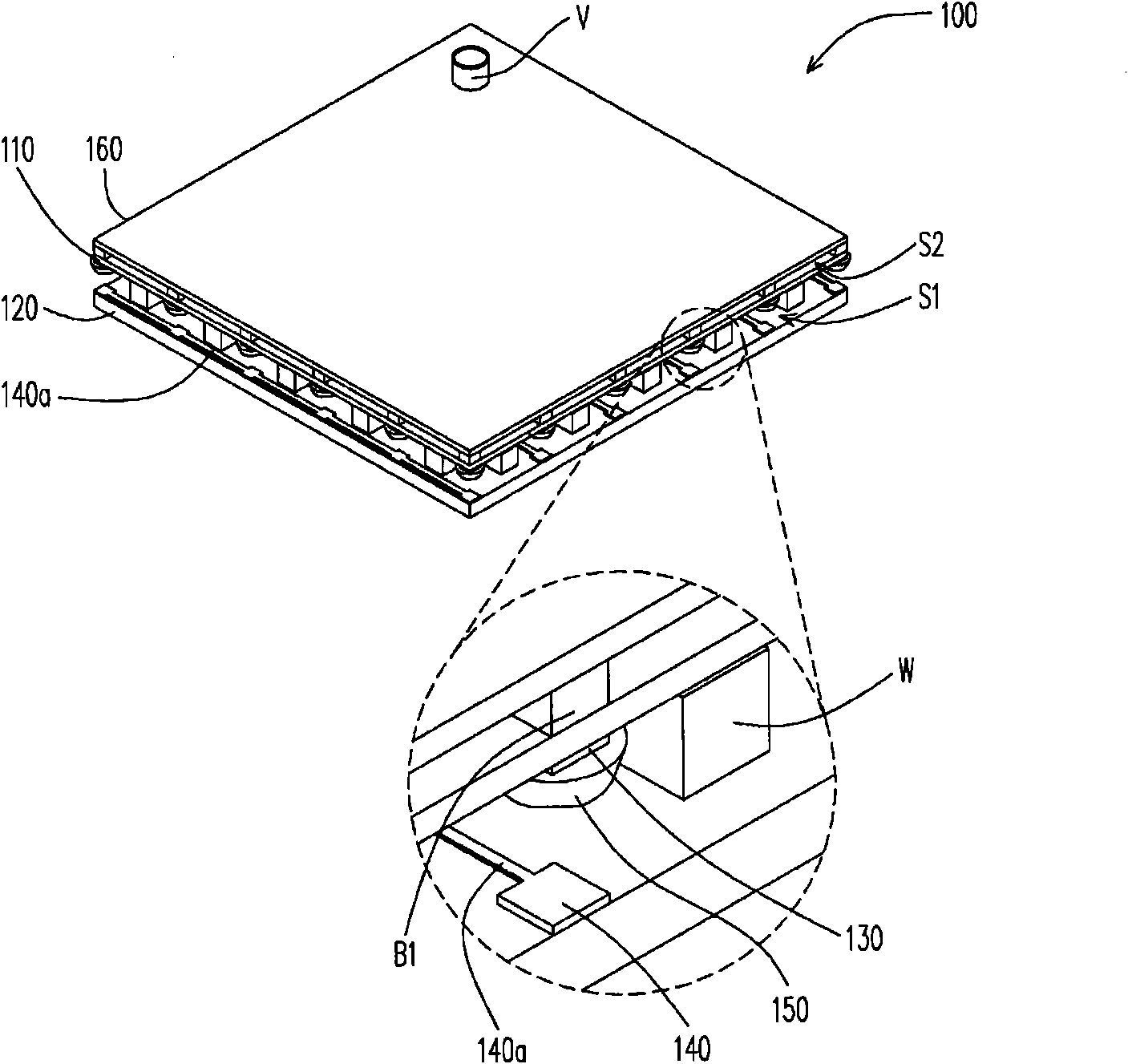

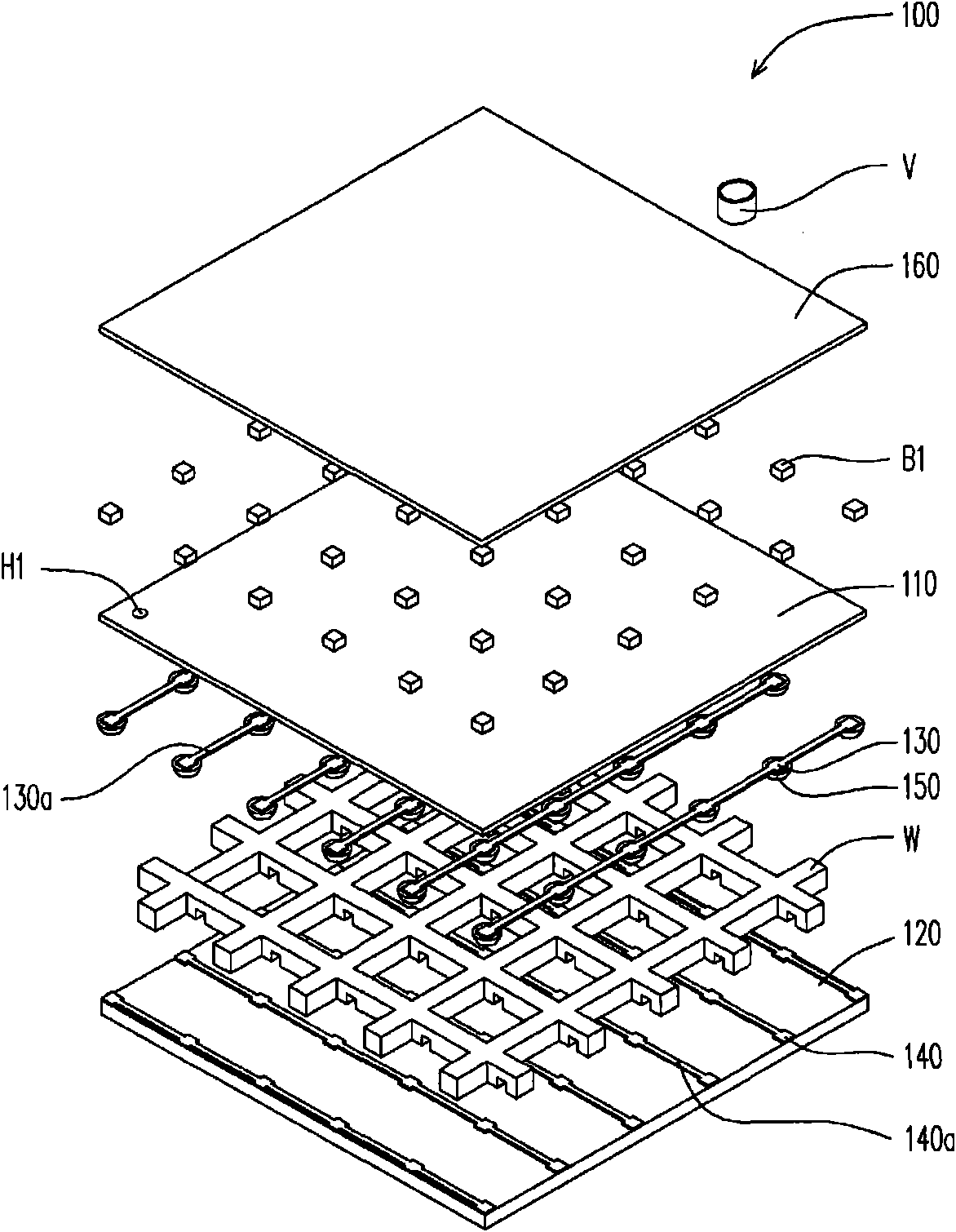

Flexible electronic pressure sensing device and manufacturing method thereof

InactiveCN101776496AReduce technology requirementsLow costForce measurement by measuring magnetic property varationForce measurement using piezo-electric devicesPressure senseEngineering

The invention relates to a flexible electronic pressure sensing device capable of sensing a large area and being manufactured at low cost and a manufacturing method thereof. The device comprises multiple layers of flexible films, a plurality of electrodes, a plurality of sensing blocks and a plurality of bumps, wherein the flexible films are arranged at intervals to define two spaces; the electrodes and the sensing blocks are arranged on the flexible films and positioned in one space; and the bumps are arranged on the flexible films and positioned in the other space. The air in the spaces maintains a relative distance between two flexible films which are provided with the electrodes and the sensing blocks. In case of deformation, the flexible electronic pressure sensing device can avoid error sensing signals caused by the mutual contact of the sensing block and the electrode or two sensing blocks respectively arranged on different flexible films. In addition, the invention also relates to the method for manufacturing the flexible electronic pressure sensing device.

Owner:IND TECH RES INST

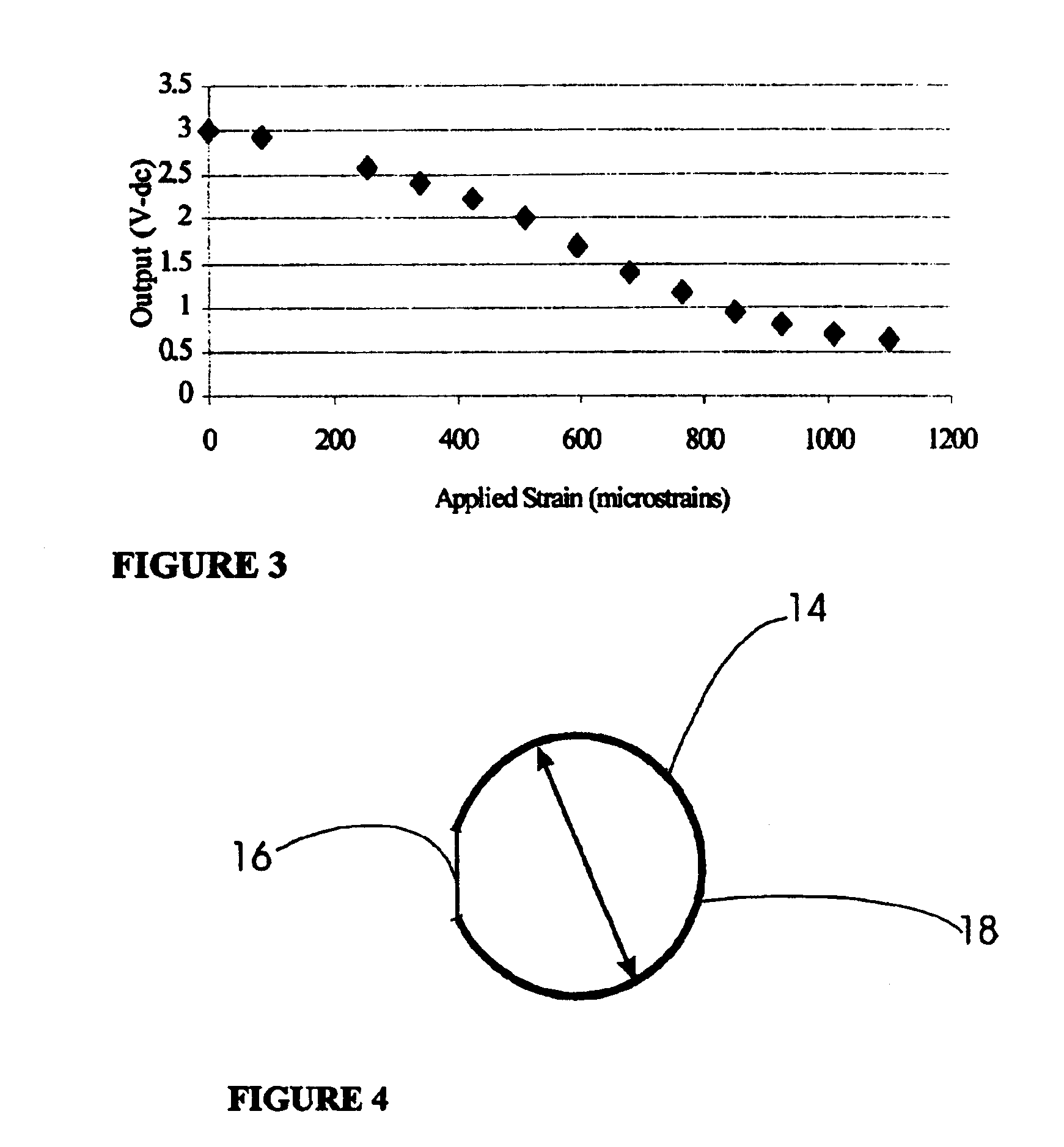

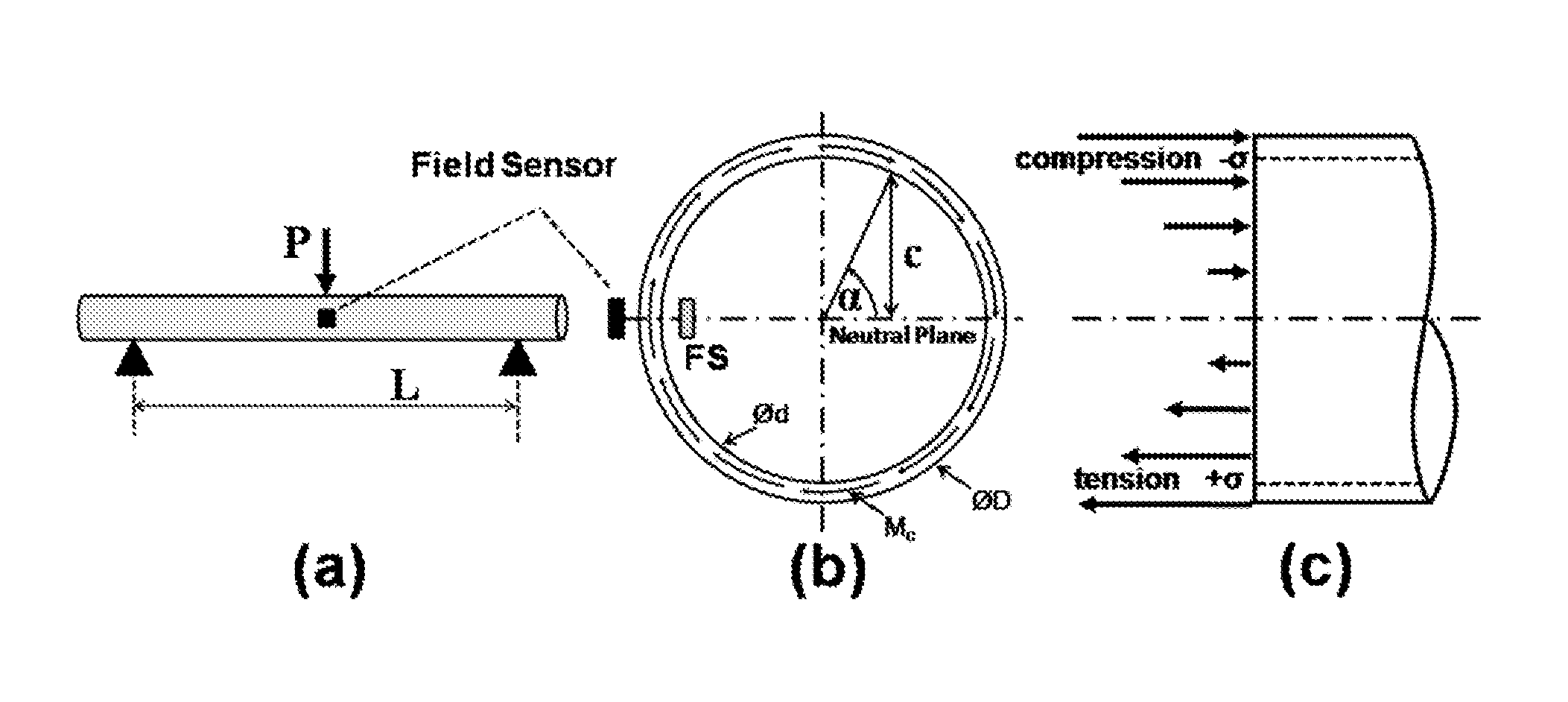

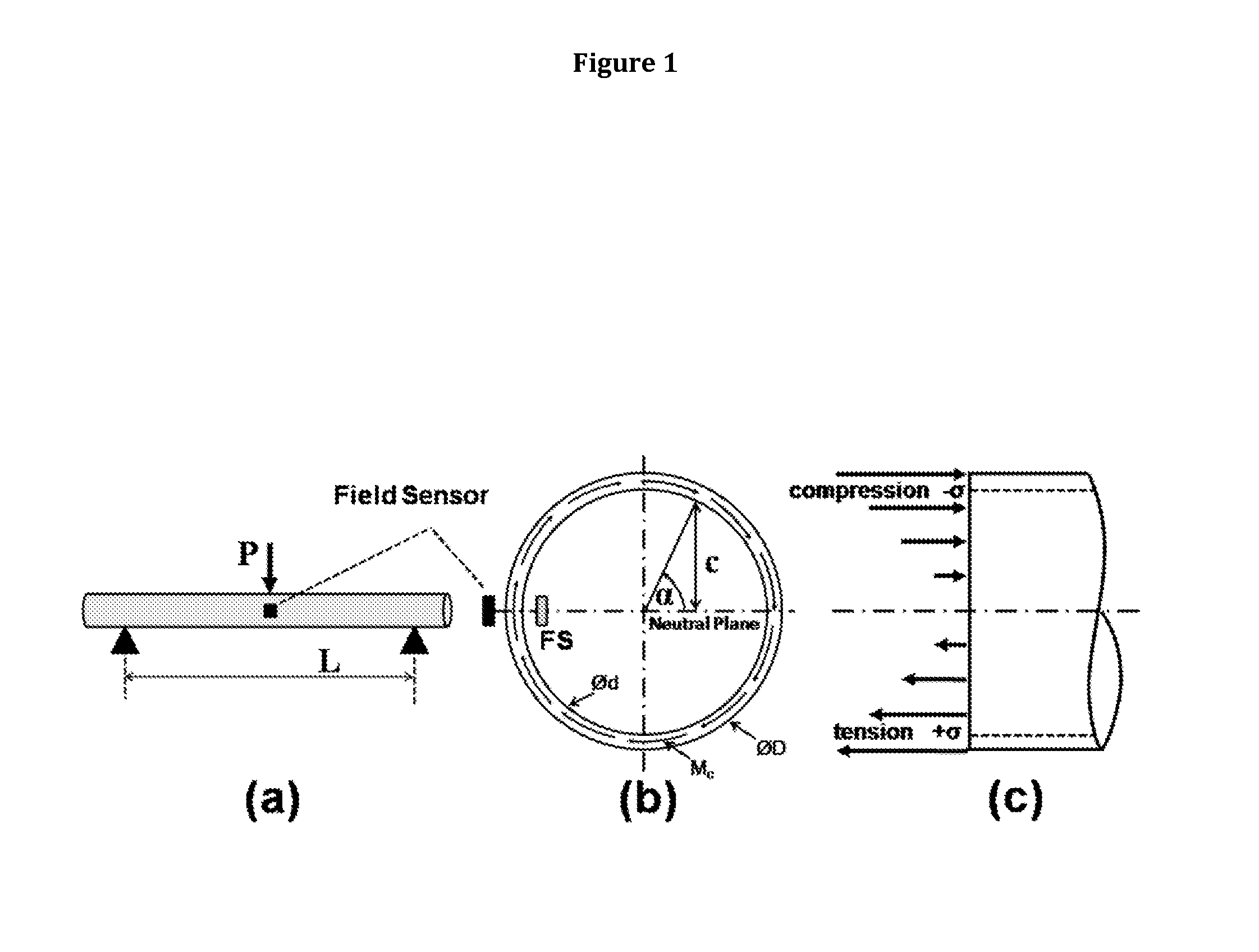

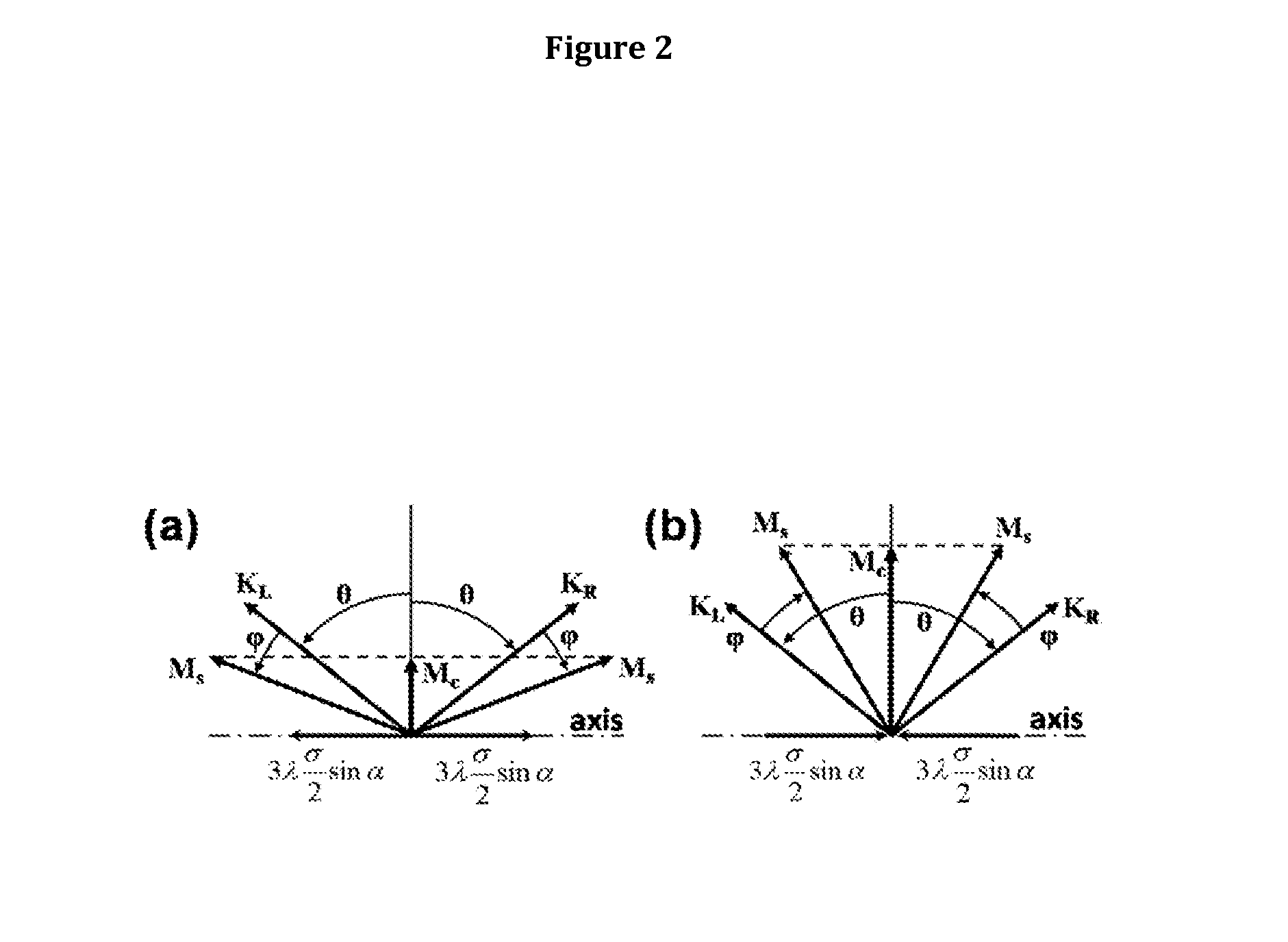

Magnetoelastic force sensors, transducers, methods, and systems for assessing bending stress

InactiveUS20120296577A1Force measurement by measuring magnetic property varationWork measurementPush and pullPull force

A new type of magnetoelastic device for sensing force is described. It comprises of two elements: a circumferentially magnetized member comprised of magnetoelastically active material mounted as a beam and loaded by the force to be sensed, and a magnetic field sensor mounted at or near the member's surface, preferentially at or near a longitudinal location where the bending moment is maximum and at a circumferential location where the bending stress is zero. Flexural loading causes a variation of the circumferential magnetization with angular position. This variation is the source of free poles, the field from which is a measure of the applied force. Testing demonstrates that the field intensity is a linear analog of the experienced bending stress over a significant range of applied push and pull forces.

Owner:MAGCANICA

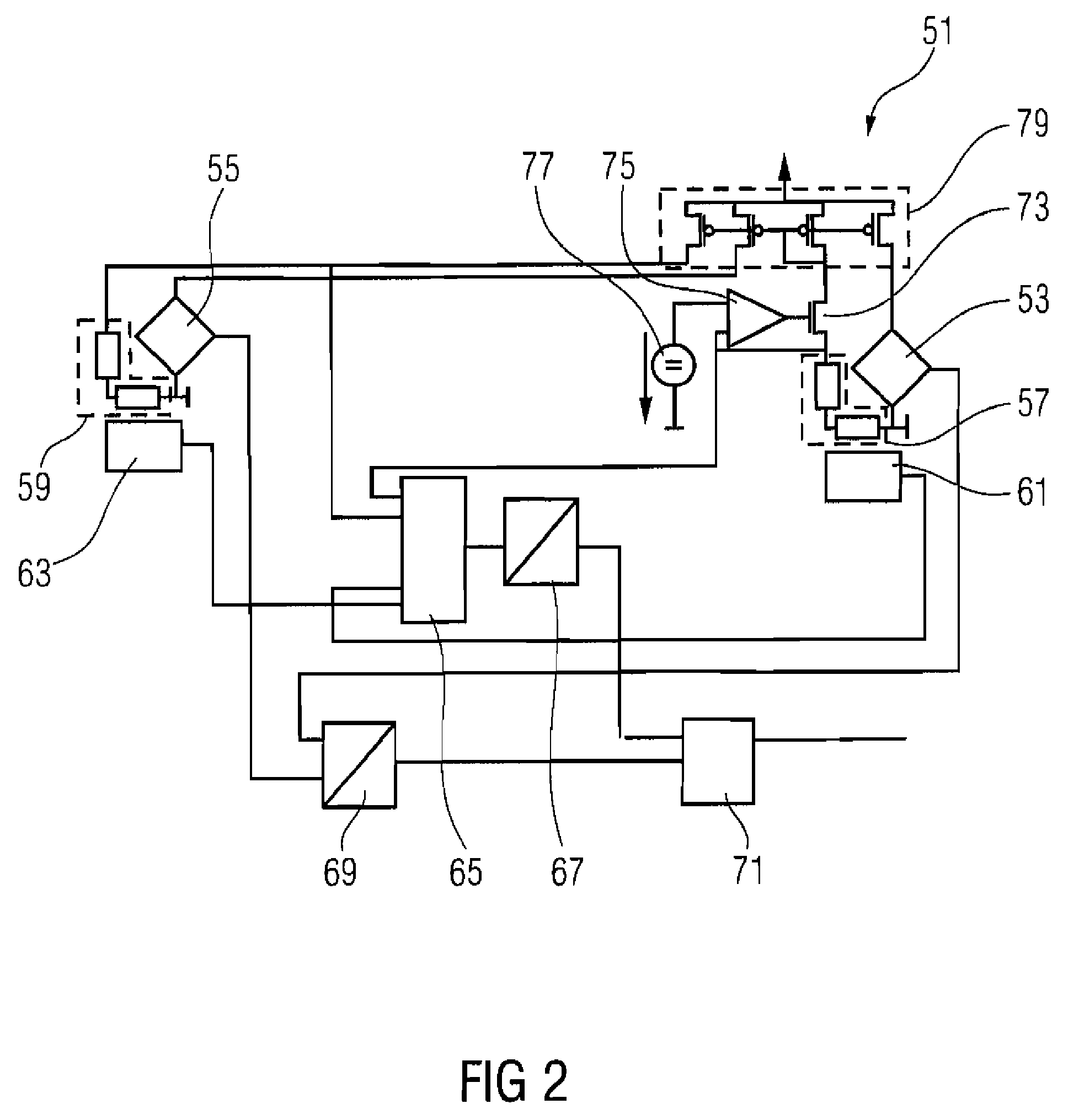

Magnetic-based torque/speed sensor

InactiveUS6959612B2Force measurement by measuring magnetic property varationWork measurementGear wheelTransducer

Torque is measured in the chain wheel (50) of a pedal cycle by a non-contacting magnetic-based transducer. A magnetising source (70), a D.C. type of source such as a permanent magnet is positioned adjacent the chain wheel (50) to induce an arcuate magnetised zone (72) in the wheel (50) as it rotates. The zone emanates a torque-dependent magnetic-field component that is detectable by a sensor (74) that follows the source (70) in the direction of rotation. By having the magnetising source (70) continually in position the arcuate tranducer zone (72) is refreshed on each rotation of the chain wheel. The nature of the pulsating torque in the chain wheel due to the exertion of the rider and its relationship to the angle of the pedal cranks is discussed with a preference for positioning the source (70) and sensor (74) at positions of minimum and maximum exerted torque respectively. If the induced arcuate magnetisation is interrupted (76) pulses for measuring rotational speed are obtainable. The torque measurement is of general application to torque in sprocket wheels or gear wheels.

Owner:ABAS

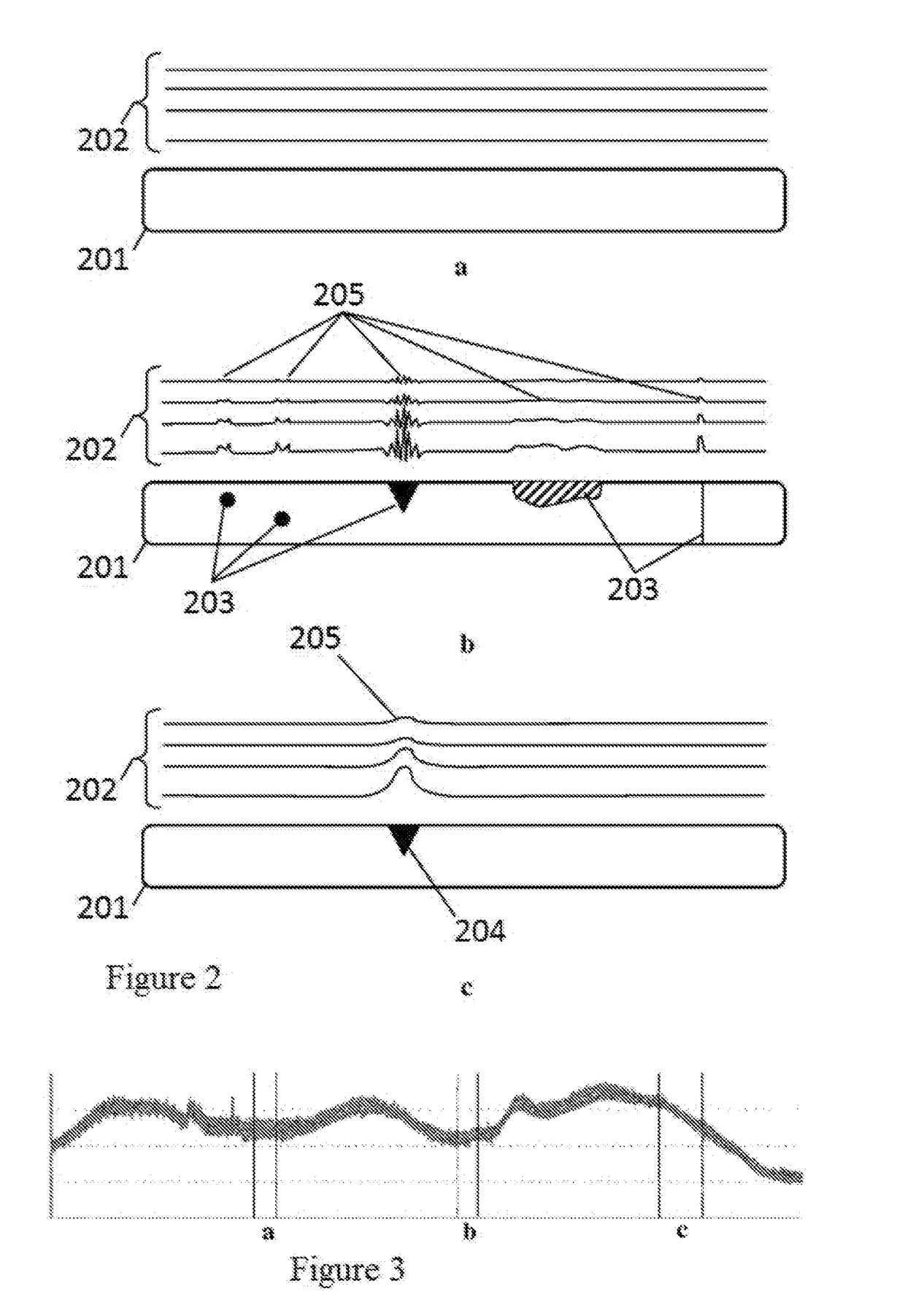

Non-destructive system and method for detecting structural defects

ActiveUS20170122909A1Stable positionImprove accuracyForce measurement by measuring magnetic property varationUnmanned aerial vehiclesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device can determine the position of the defect or stress including depth information. The device includes registration means that optimized for use with metallic structures of various types, shapes, and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in roiled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, bridges, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

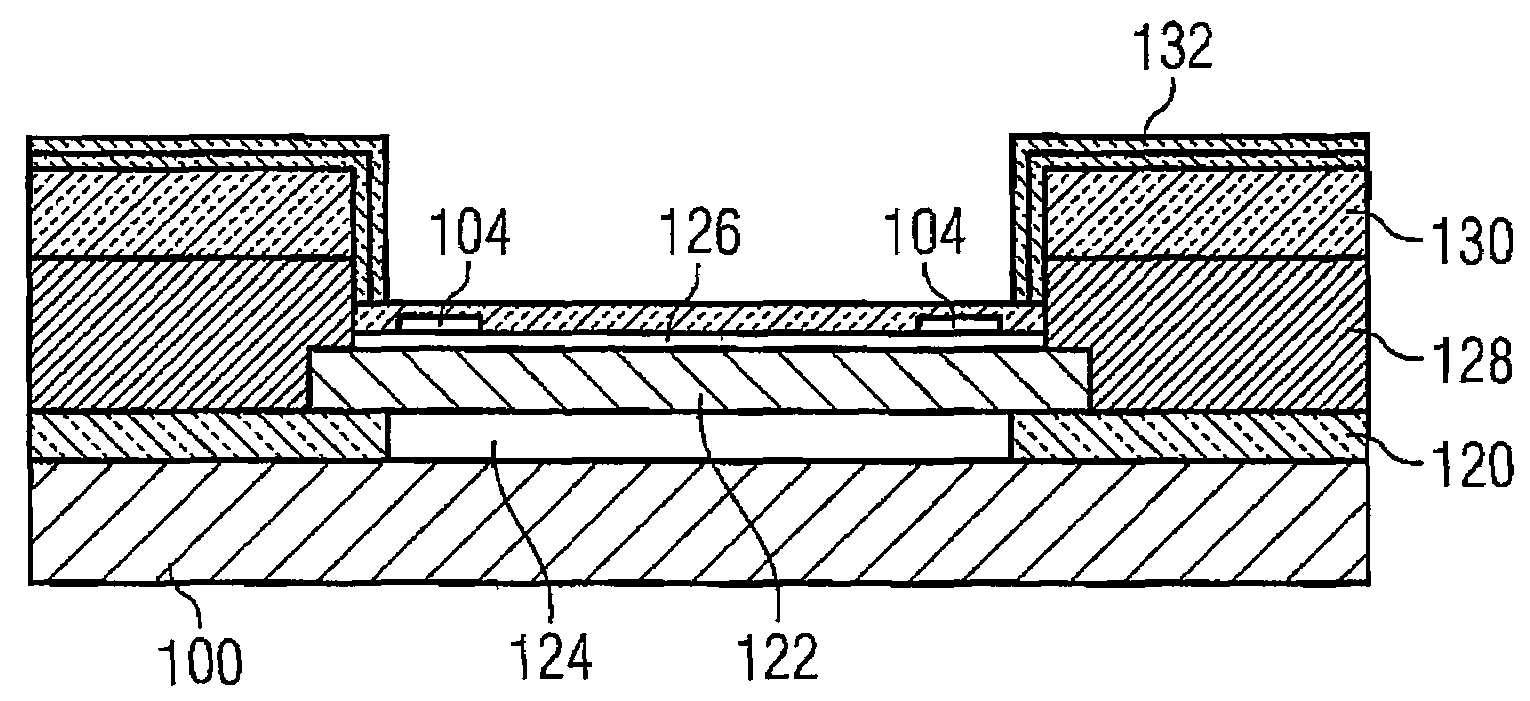

Magnetic MEMS device and method of forming thereof

InactiveUS20050252293A1Accurate measurementTelevision system detailsForce measurement by measuring magnetic property varationEngineeringMems sensors

A microelectromechanical system (MEMS) sensor and method for measuring the motion of an intermediate member and a method for making the MEMS sensor. The MEMS sensor includes a substrate, a lower magnetic member disposed on the substrate, a layer disposed over the substrate, an upper magnetic member disposed at a side of the layer facing the lower magnetic member, an intermediate magnetic member magnetically levitated between the lower magnetic member and upper magnetic member; and a component measuring at least one of motion, forces acting on, and a displacement of the intermediate magnetic member.

Owner:SAMSUNG ELECTRONICS CO LTD

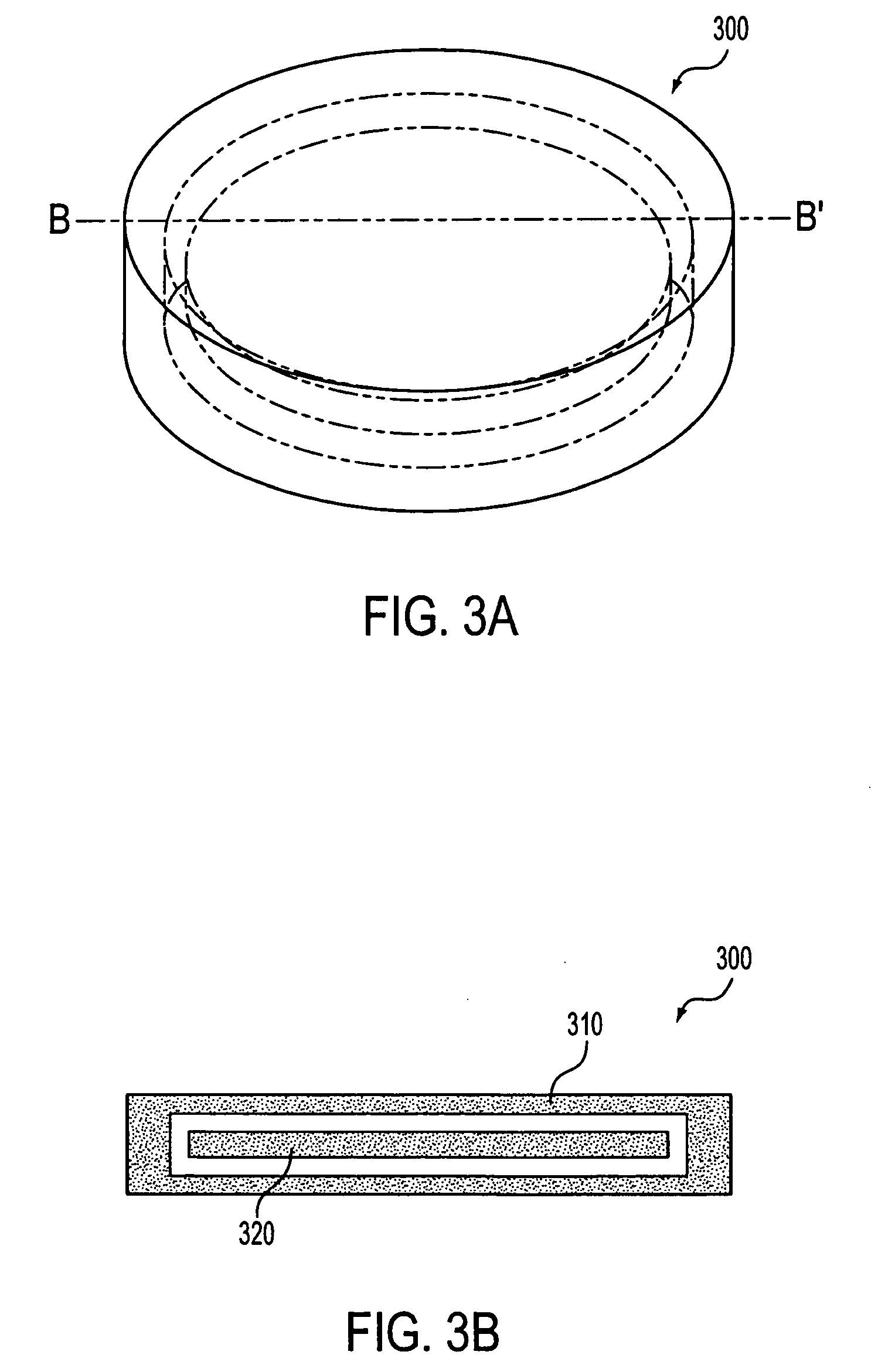

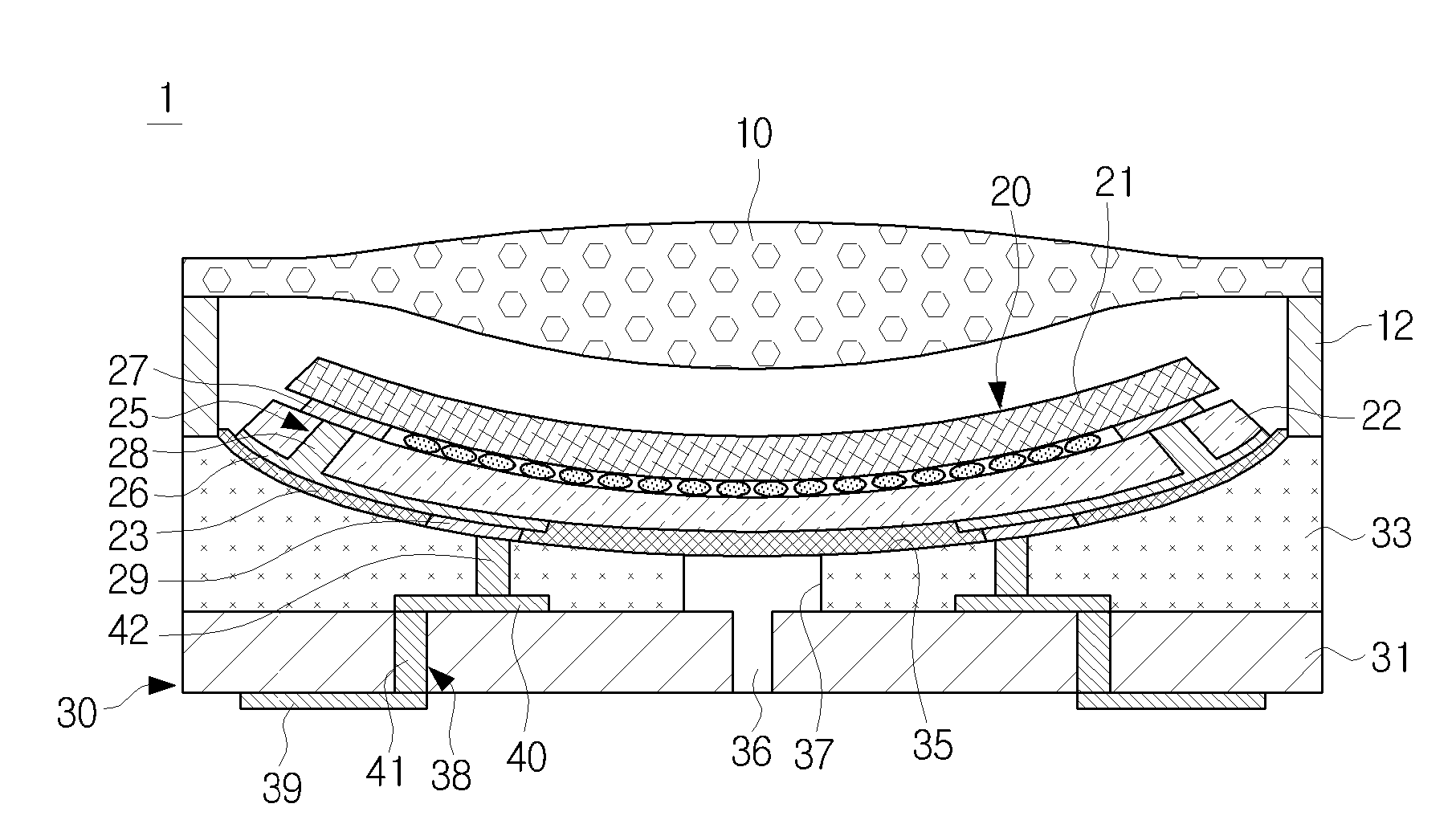

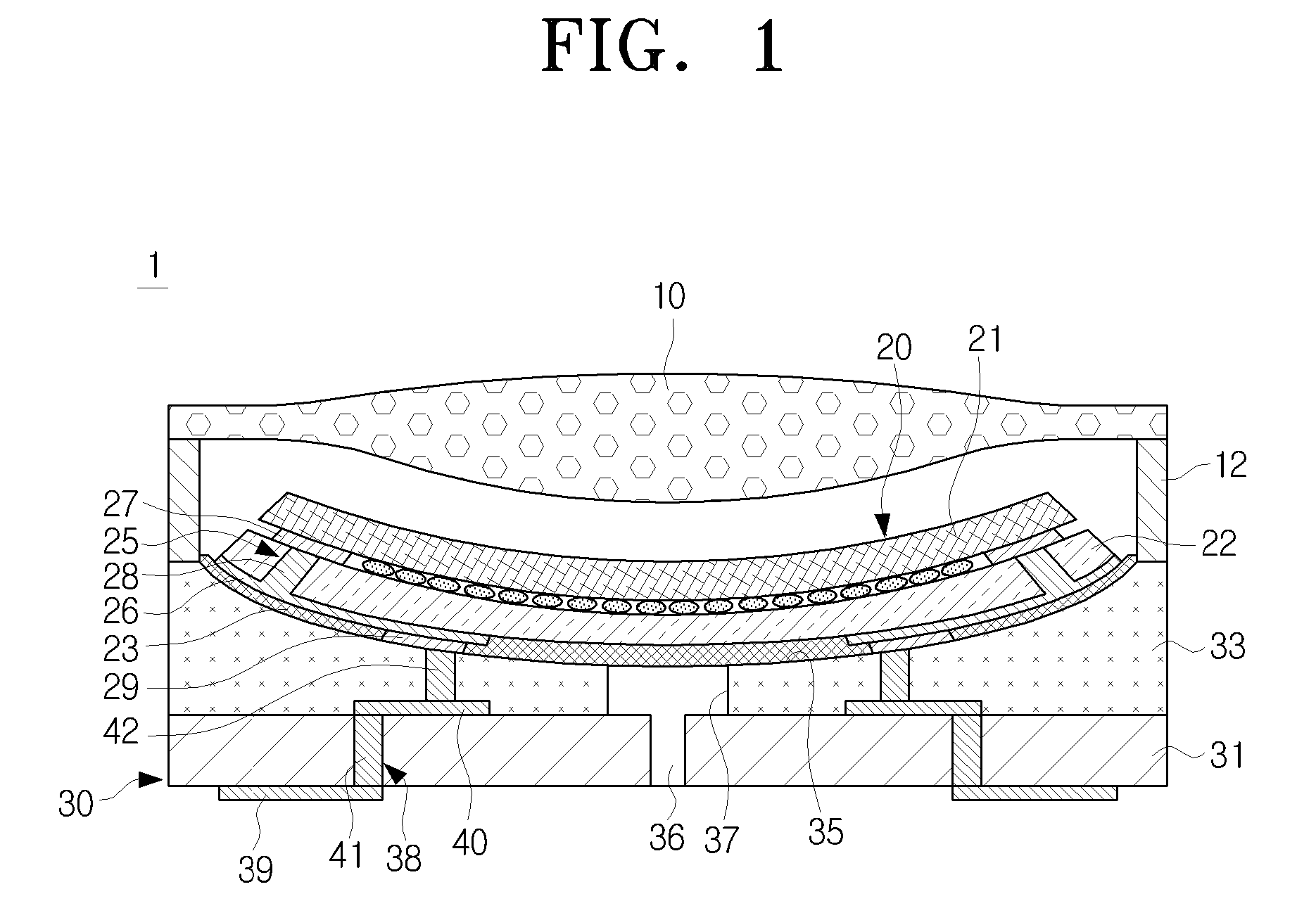

Image sensor module and fabrication method thereof

ActiveUS7923793B2Guarantee high efficiency and precisionReduce manufacturing costTelevision system detailsForce measurement by measuring magnetic property varationEngineeringImage sensing

An image sensor module having a sensor chip closely adhered on a concave surface and a fabrication method thereof are disclosed. The image sensor module includes at least one sensor chip, at least one sensor chip-mounting structure comprising a substrate and a polymer layer formed on the substrate, the polymer layer having an concave surface formed on an upper part thereof by a polymer molding method, so that the sensor chip is bent and bonded on the concave surface, and at least one lens fixed on the at least one sensor chip-mounting structure above the sensor chip.

Owner:SAMSUNG ELECTRONICS CO LTD

Strain gauge sensor system and method

InactiveUS20080105059A1Unlimited measurement rangeGood strain measurement resolution and reliabilityForce measurement by measuring magnetic property varationUsing electrical meansFiberStrain gauge

A strain gauge sensor system and method for measuring the strain in a member, such as a fiber rope, has a sensor target assembly having a plurality of magnets carried spaced apart by individual gauge lengths along the member. Position and trigger sensor devices are configured spaced apart along side a desired path of travel of the member. When the member is fed along the desired path of travel, the trigger sensor device, in response to magnetically sensing a passing magnet, triggers the position sensor device to read the position of an adjacent passing magnet. The strain in the gauge length is determined from the read position. RFID tags placed on the member between the magnets can be identified by an RF reader to identify a particular gauge length being measured. The system can include a deployment device for feeding the member along the desired path.

Owner:HONEYWELL INT INC

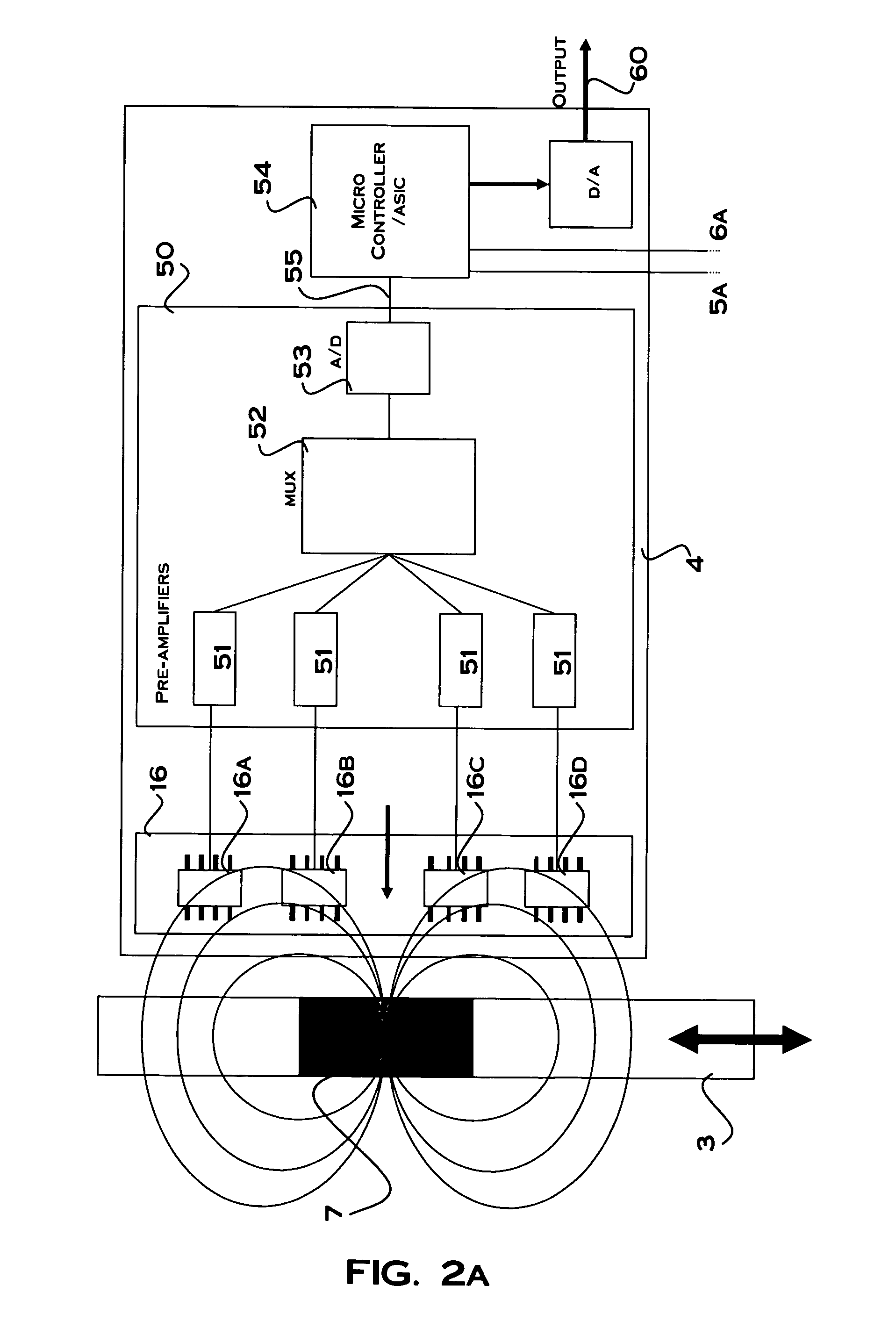

Measuring device and measuring method for alternating stress of ferromagnetic component

ActiveCN103499404ATo achieve the purpose of stress identificationWide application backgroundForce measurement by measuring magnetic property varationMaterial magnetic variablesMeasurement deviceSignal conditioning

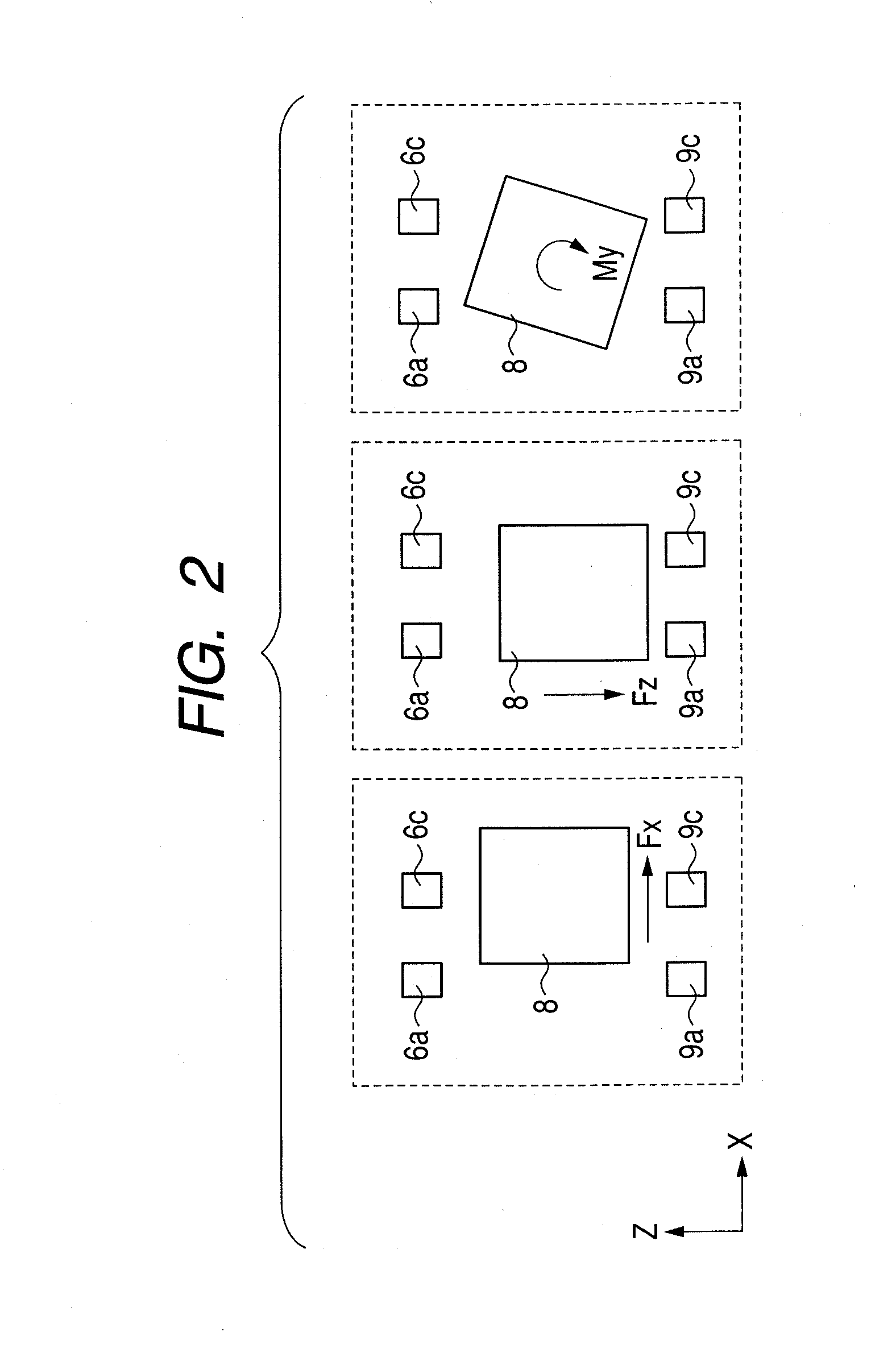

The invention discloses a measuring device and a measuring method for alternating stress of a ferromagnetic component, is used for measuring the stress direction and the stress intensity of the ferromagnetic component, and belongs to the field of nondestructive measuring technologies and devices. The measuring device comprises a signal excitation module, an excitation probe, a detecting coil, a signal conditioning module, a signal acquisition module and a computer signal processing analysis module. The measuring device and the measuring method disclosed by the invention have the substantial characteristics that a to-be-detected component is magnetized by utilizing a U-shaped probe with an alternating signal, so that stress area is enough in secondary induced magnetic field, and then, an induced magnetic field of representing stress information is picked up by the detecting coil, and therefore, the goal of identifying the stress is achieved. According to the measuring method, by utilizing a set of detecting systems, not only can the stress degree of the surface and the near surface of the ferromagnetic component be evaluated but also the major stress direction in the component can be determined. The measuring device and the measuring method for the alternating stress of the ferromagnetic component are wider in application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

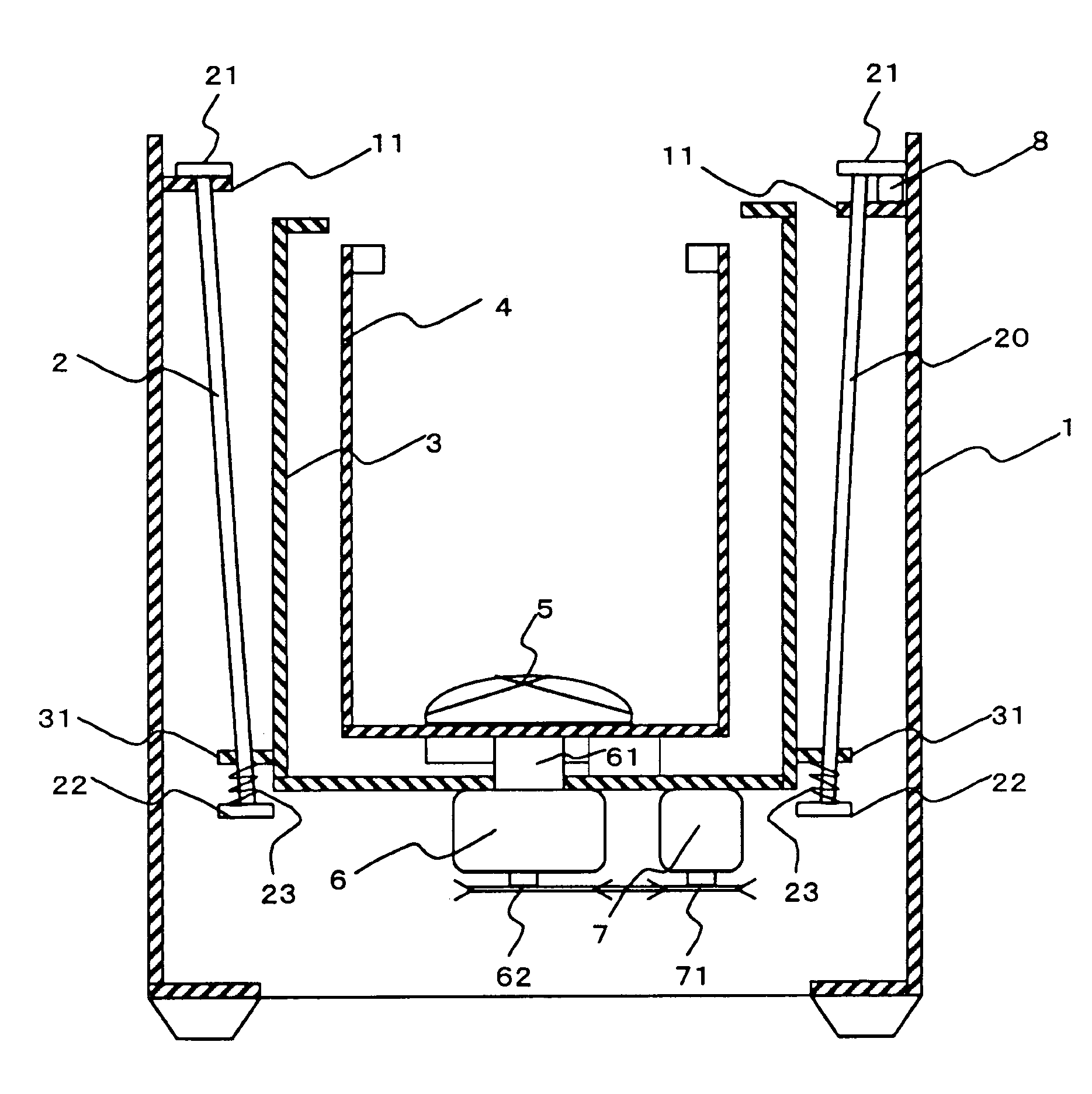

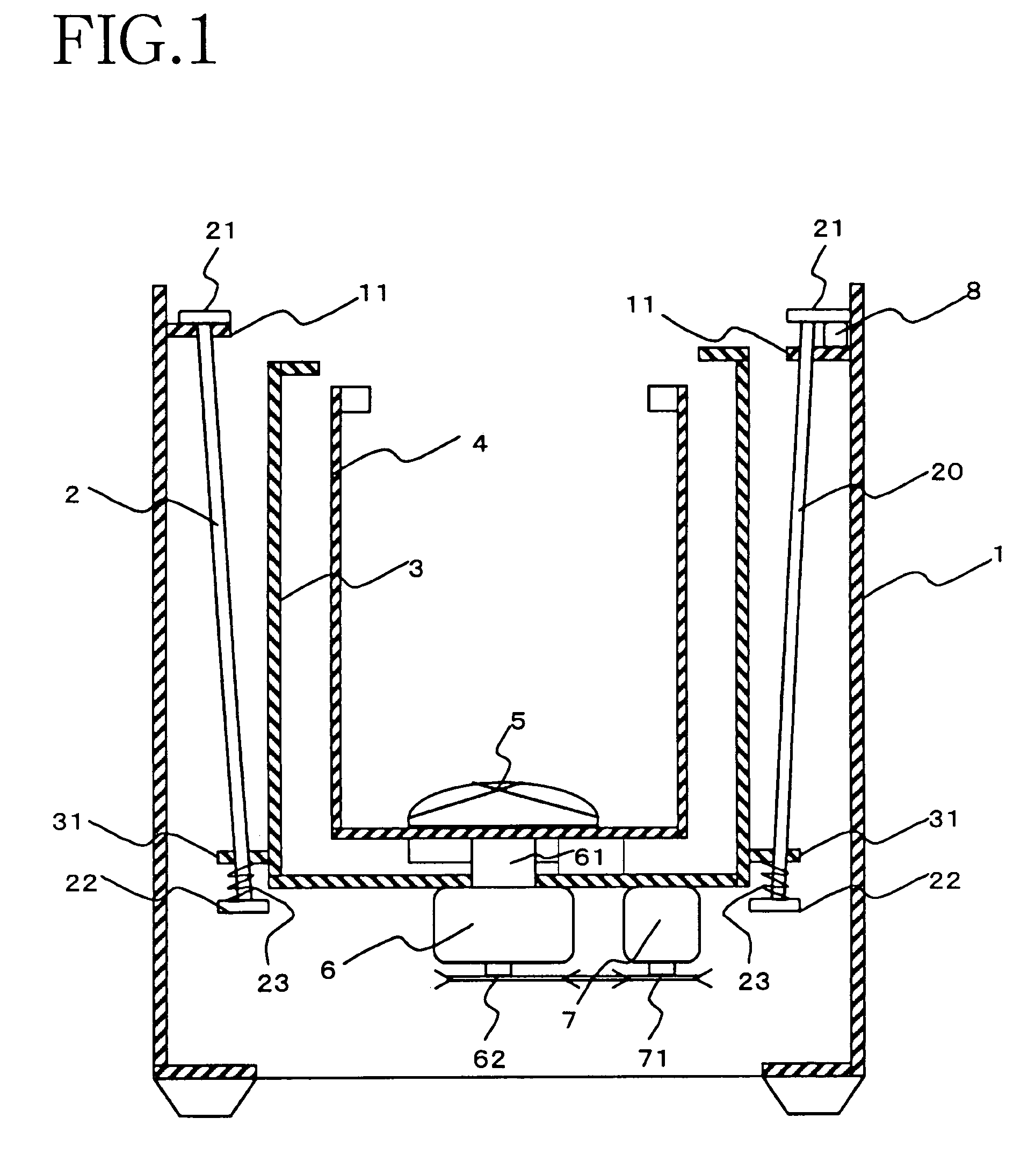

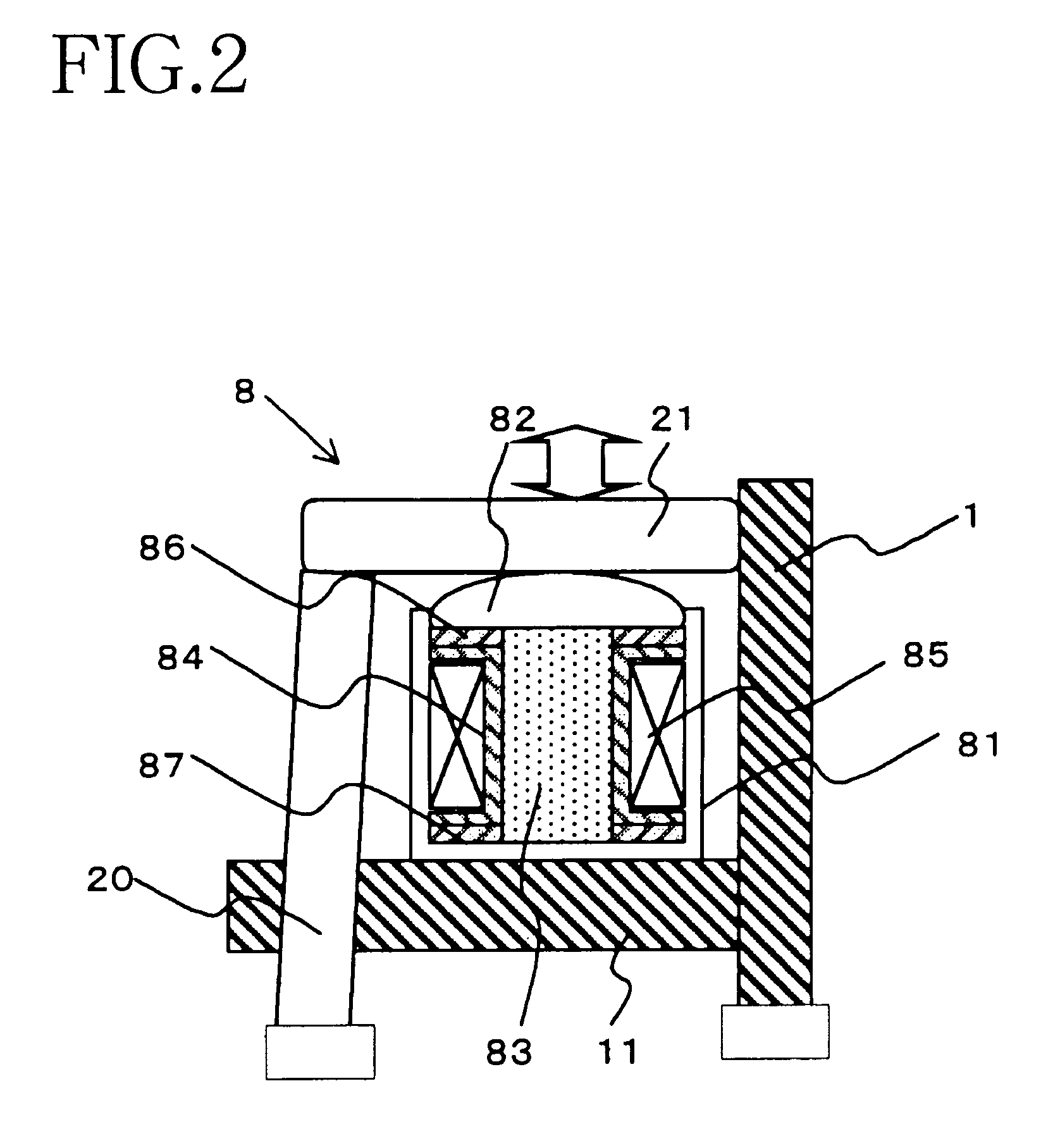

Load detecting system and automatic washing machine equipped with a system for detecting the magnitude of the load acting on a magnetostrictive element

InactiveUS6983657B1Accurate detectionAccurately load actingForce measurement by measuring magnetic property varationOther washing machinesMicrocomputerEngineering

The invention provides a load detecting system comprising a core (83) of magnetostrictive material, a coil (85) disposed in the vicinity of the core, and a load detecting circuit (10) connected to the coil (85) for detecting the magnitude of a load acting on the core (83). The load detecting circuit (10) comprises an exciting circuit (102) for passing an a.c. detecting current through the coil (85), a pulse current generating circuit (103) for passing through the coil a detection preparing current having a current value greater than the maximum value of the detecting current, a change-over circuit (104) for effecting a change-over between the exciting circuit (102) and the pulse current generating circuit (103) to pass the detecting current through the coil after passing the detection preparing current therethrough, and a microcomputer (100) for deriving the magnitude of the load acting on the magnetostrictive element based on an impedance variation produced in the coil during the period of passage of the detecting current through the coil.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

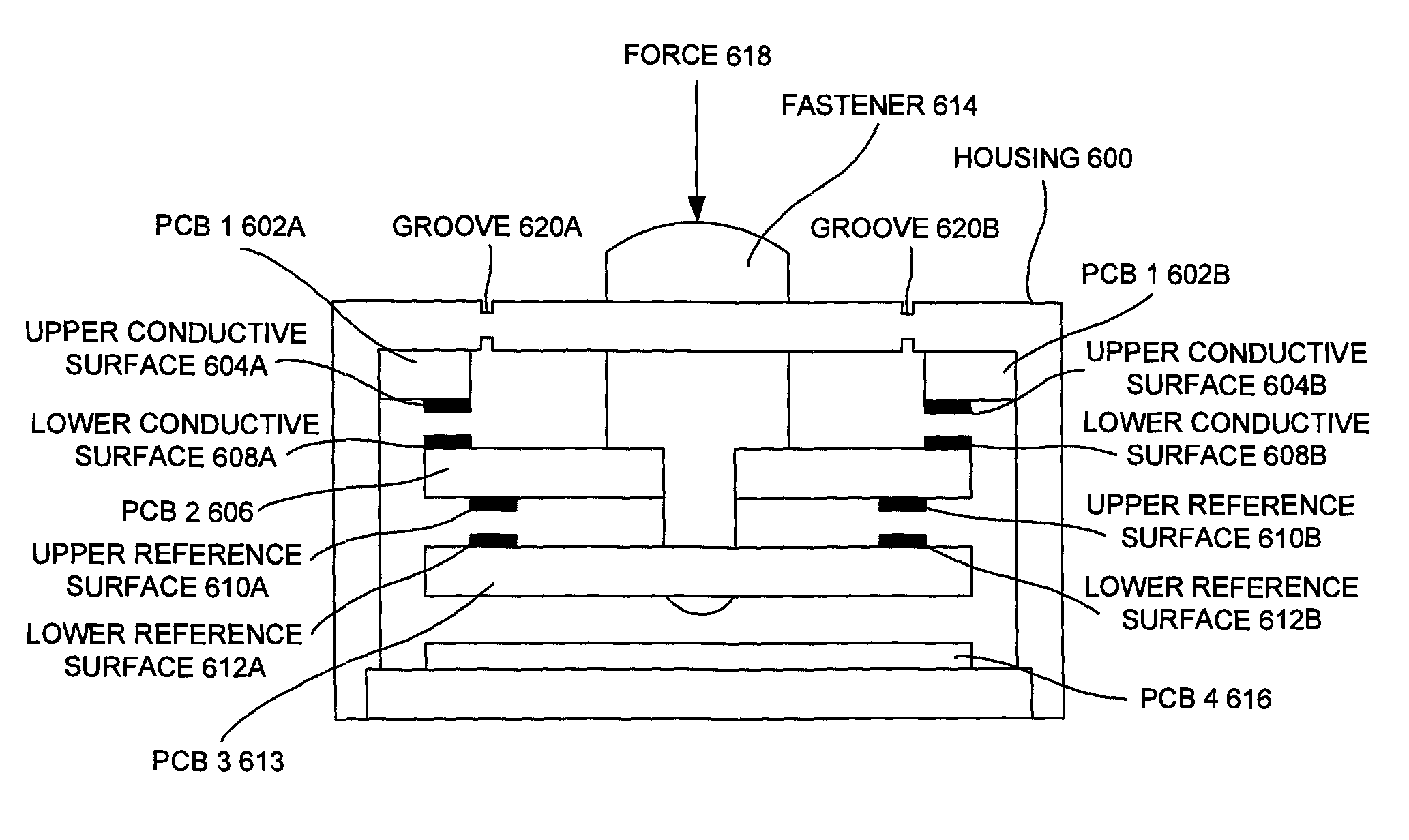

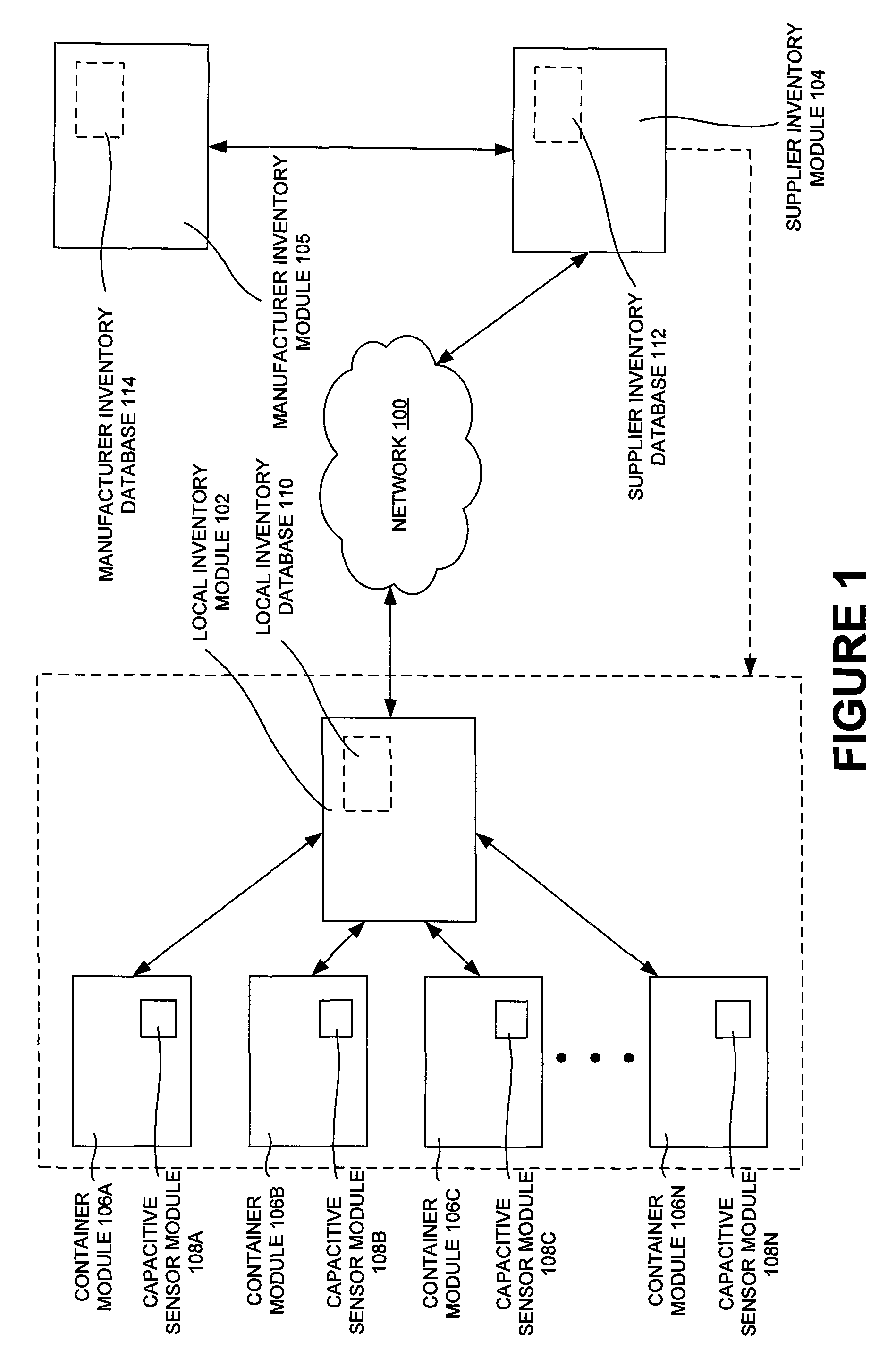

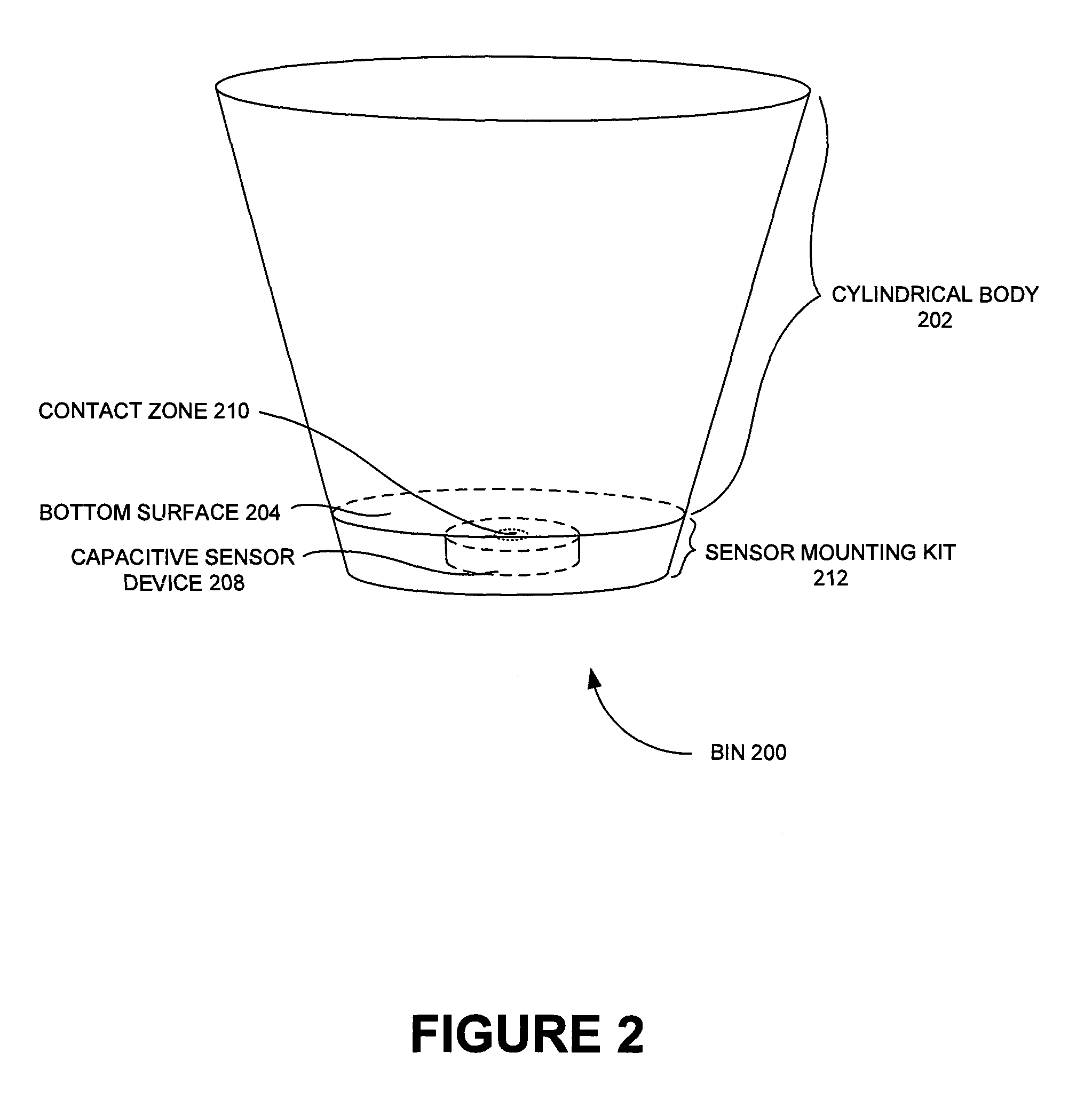

Capacitive sensor based inventory control

ActiveUS7775130B2Minimize impactReduce the amount requiredForce measurement by measuring magnetic property varationUsing electrical meansMechanical engineeringCapacitance transducer

A method, apparatus and system of capacitive sensor based inventory control is disclosed. In one embodiment, an inventory management system includes a first conductive surface and a second conductive surface substantially parallel to the first conductive surface, a sensor to generate a measurement based on a change in a distance between the first conductive surface and the second conductive surface, a scale formed with a set of plates having inserted between the set of plates the first conductive surface and the second conductive surface and a container placed above the scale such that an item (e.g., a liquid, a solid, a discrete part, a powder and / or a gas, etc.) of the container is weighed through the measurement. The inventory management system may further include a reference capacitor associated with the apparatus to enable the sensor to adjust the measurement based on the environmental condition.

Owner:YPOINT CAPITAL

Non-contact magnetostrictive sensing systems and methods

ActiveUS9212958B2Force measurement by measuring magnetic property varationWork measurementMagnetic fluxExcitation coil

A system for sensing stress in a ferromagnetic material is provided. The system includes at least one magnetic flux device configured to induce a conditioning magnetic flux in the ferromagnetic material. The system also includes a sensor positioned proximate to the ferromagnetic material. The sensor includes a core, at least one excitation coil configured to induce a second magnetic flux in the ferromagnetic material, and at least one detector configured to detect changes in the second magnetic flux.

Owner:BAKER HUGHES HLDG LLC

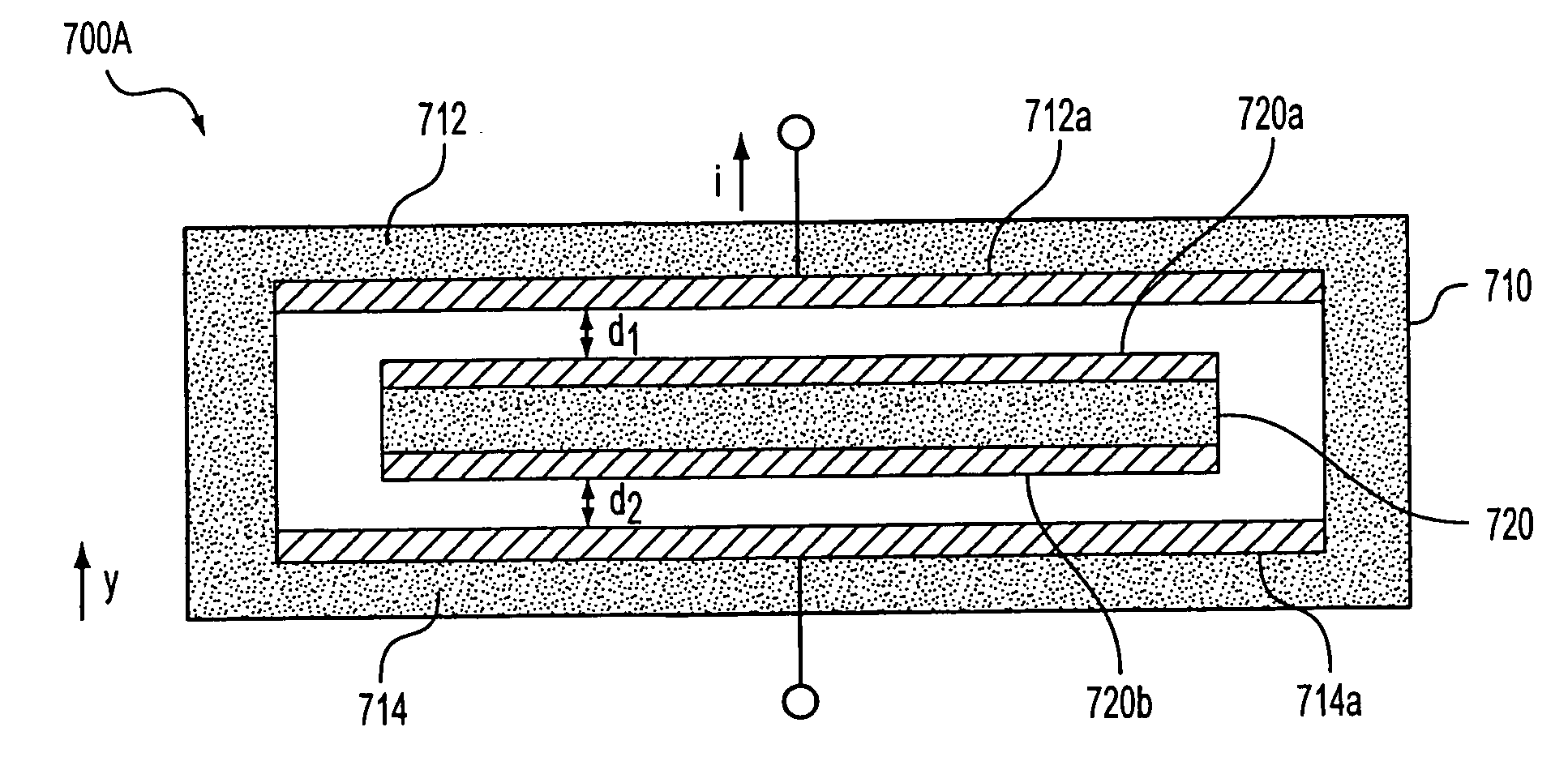

Use of multi-layer thin films as stress sensors

InactiveUS7059201B2Reduce torqueLess sensitiveForce measurement by measuring magnetic property varationPrint image acquisitionElectrical resistance and conductanceMagnetization

The present invention provides a pressure sensing device that includes at least one TMR sensor, and preferably an array of TMR sensors, with each TMR sensor having an insulating spacer layer interposed between a pinned and a free ferromagnetic layer. In an unbiased state, the magnetization vector of each of the ferromagnetic layers is preferably parallel to each other. Upon application of a small voltage, the magnetization vectors remain unchanged. Upon application of stress, the magnetization vector of the free magnetic layer will rotate, thus causing a corresponding and proportionally related change in the resistance of the sensor. This change in resistance can be sensed and used to calculate the stress applied thereto.

Owner:LENOVO PC INT

Popular searches

Torque measurement Converting sensor output electrically/magnetically Solid-state devices Digital computer details Galvano-magnetic hall-effect devices Electrical/magnetic solid deformation measurement Transmission noise suppression Electric digital data processing Electronic switching Input/output processes for data processing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com