Patents

Literature

43results about How to "Guarantee high efficiency and precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

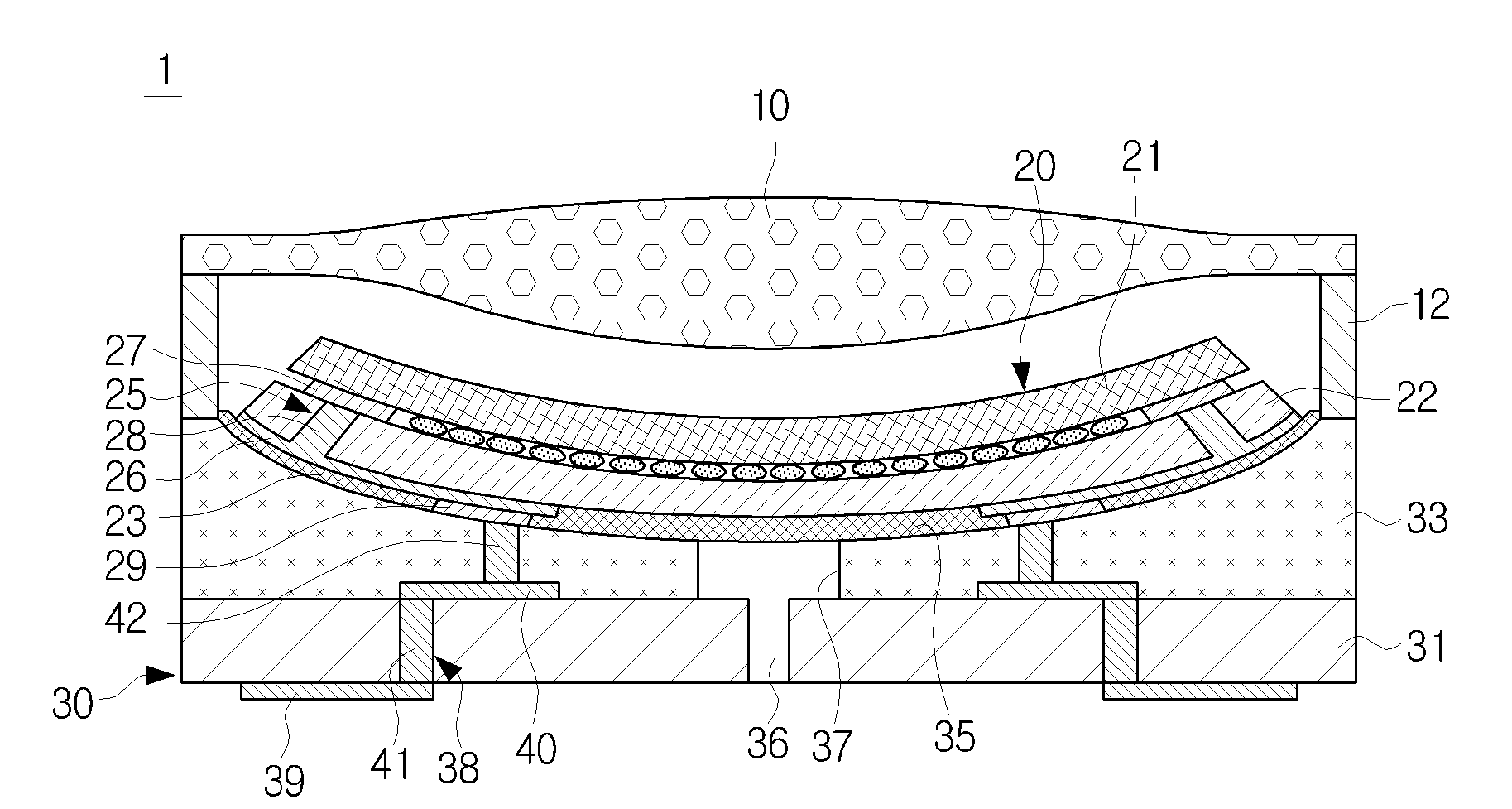

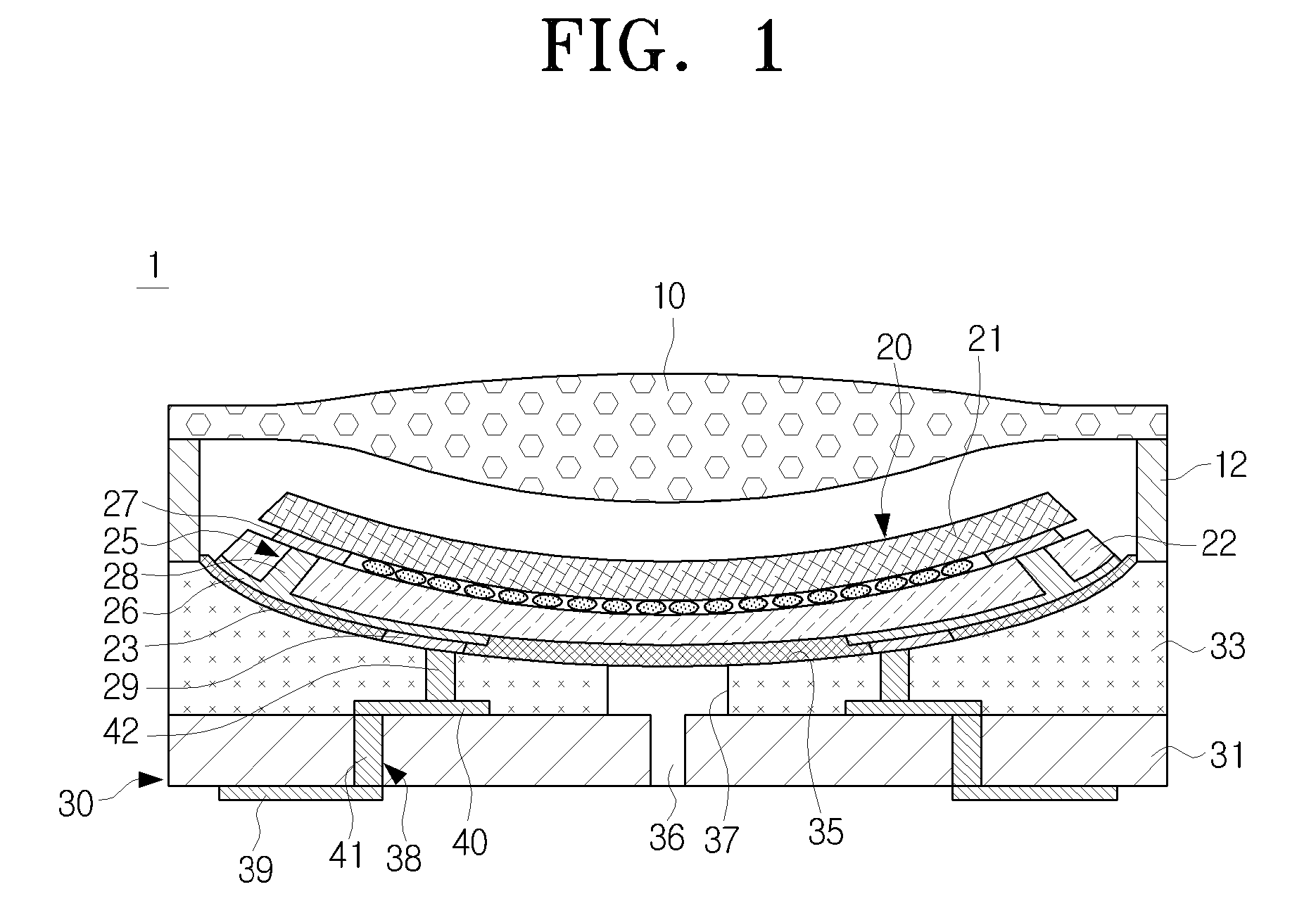

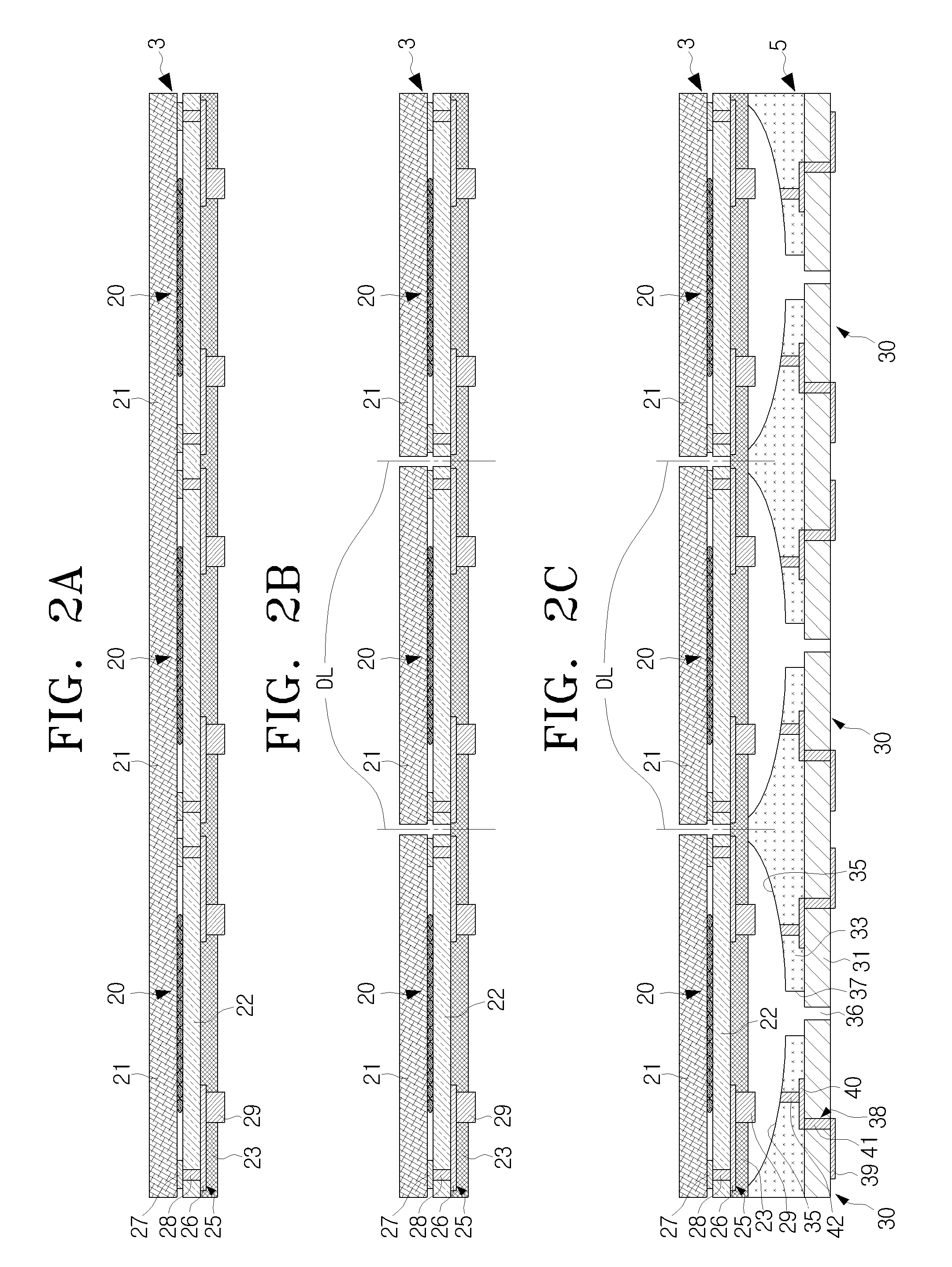

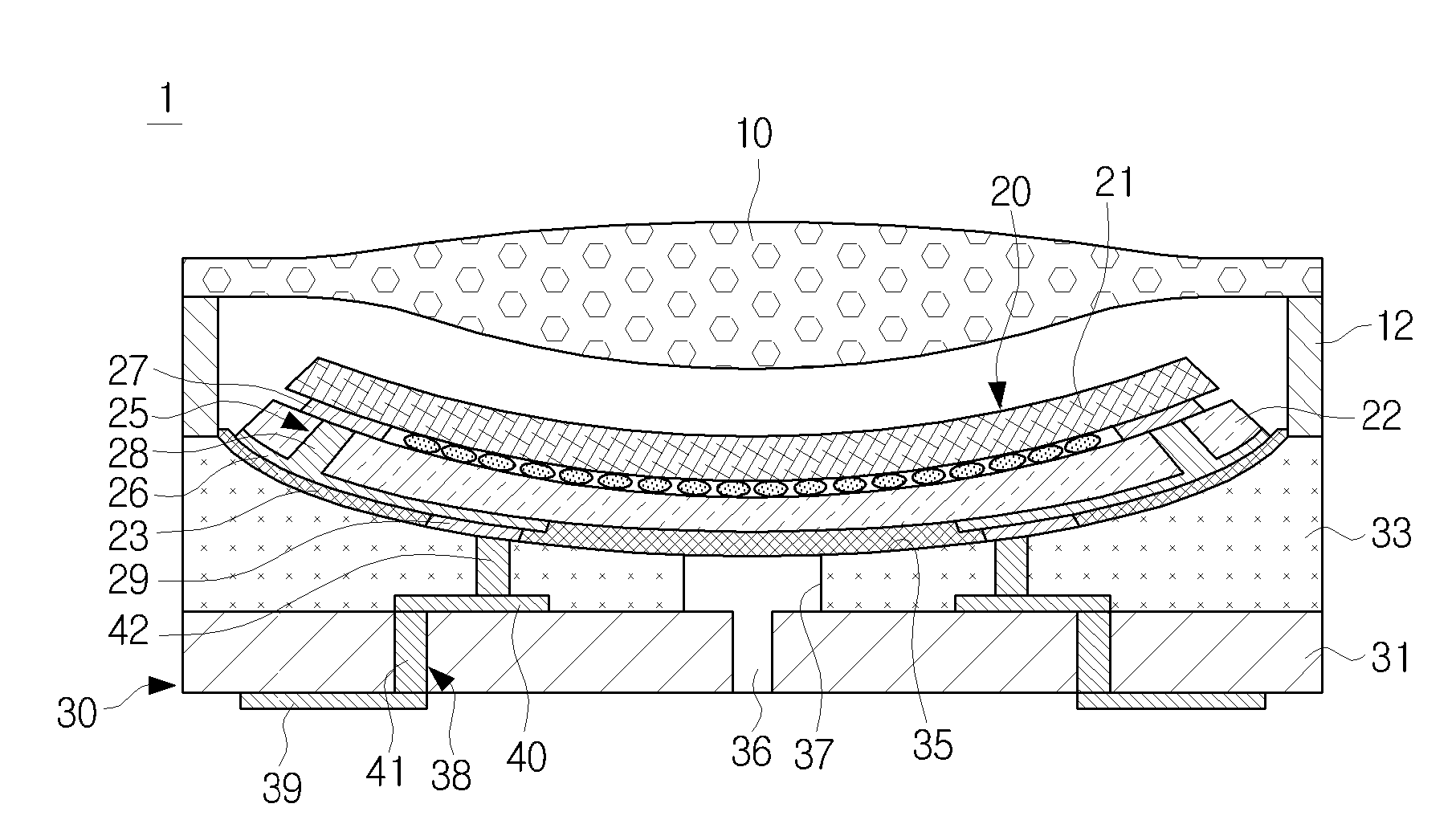

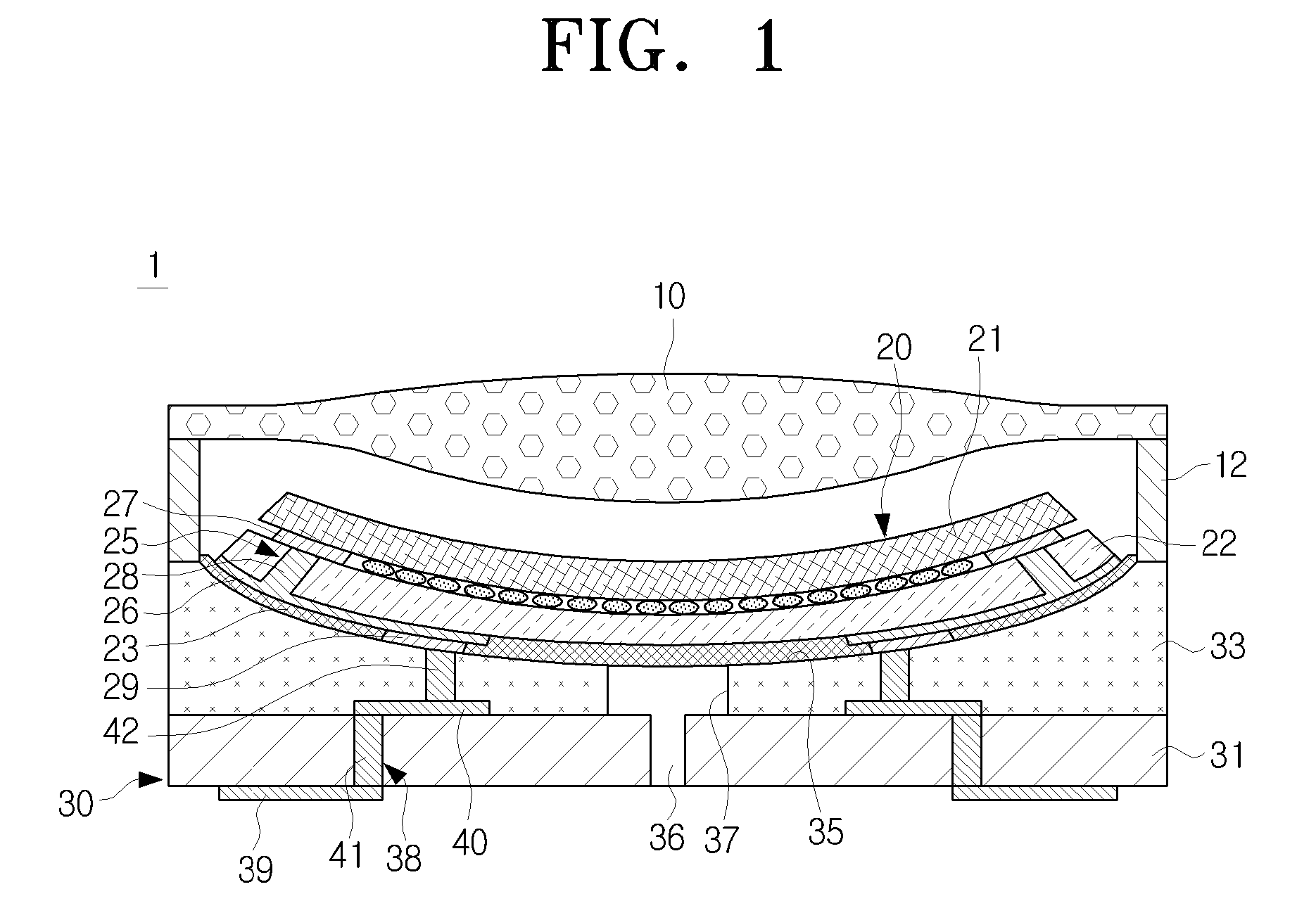

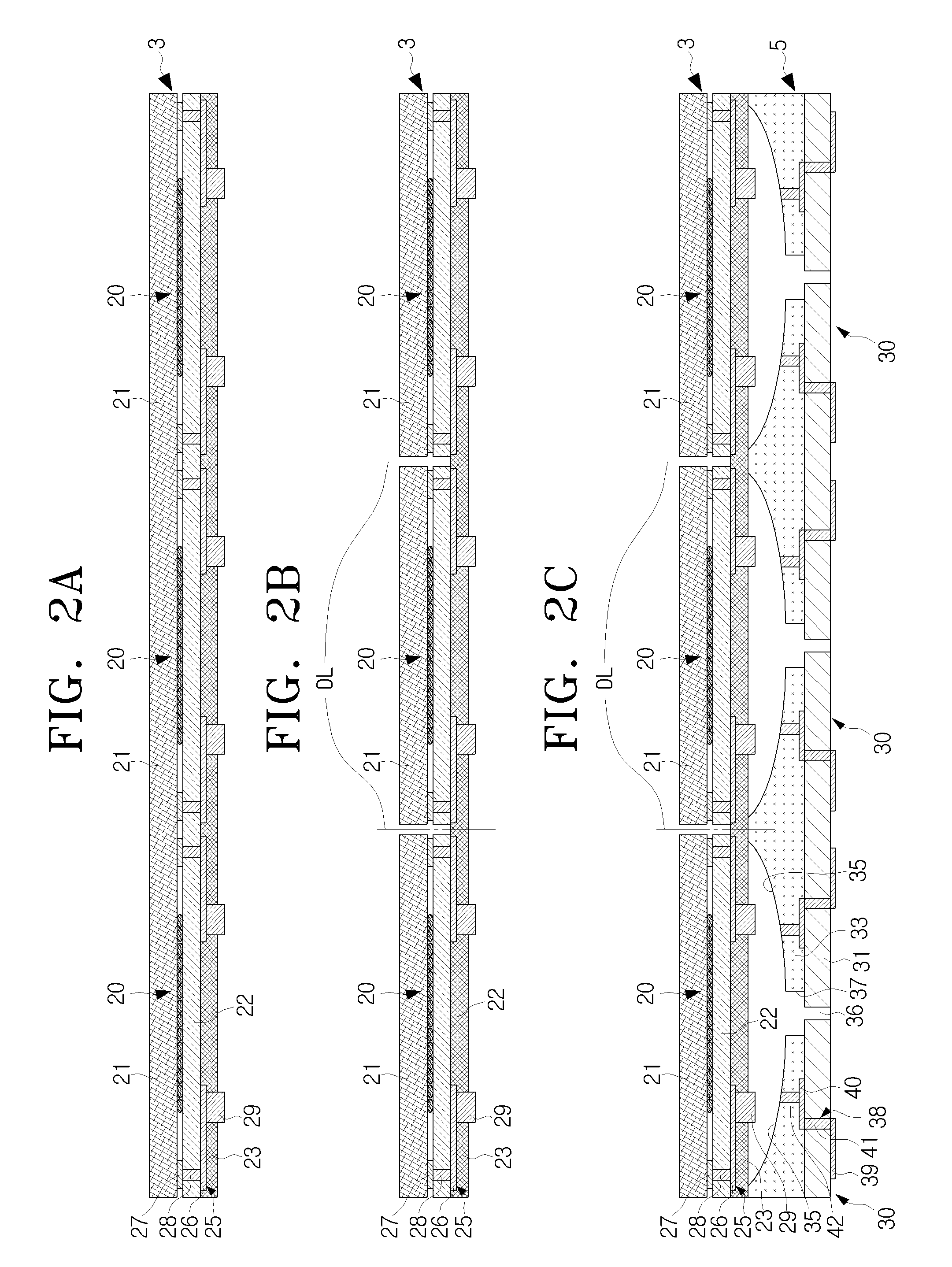

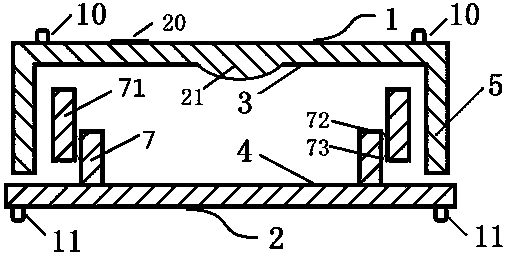

Image sensor module and fabrication method thereof

ActiveUS20090115875A1Improve efficiencyImprove precisionTelevision system detailsTelevision system scanning detailsPolymerElectrical and Electronics engineering

An image sensor module having a sensor chip closely adhered on a concave surface and a fabrication method thereof are disclosed. The image sensor module includes at least one sensor chip, at least one sensor chip-mounting structure comprising a substrate and a polymer layer formed on the substrate, the polymer layer having an concave surface formed on an upper part thereof by a polymer molding method, so that the sensor chip is bent and bonded on the concave surface, and at least one lens fixed on the at least one sensor chip-mounting structure above the sensor chip.

Owner:SAMSUNG ELECTRONICS CO LTD

Image sensor module and fabrication method thereof

ActiveUS7923793B2Guarantee high efficiency and precisionReduce manufacturing costTelevision system detailsForce measurement by measuring magnetic property varationEngineeringImage sensing

An image sensor module having a sensor chip closely adhered on a concave surface and a fabrication method thereof are disclosed. The image sensor module includes at least one sensor chip, at least one sensor chip-mounting structure comprising a substrate and a polymer layer formed on the substrate, the polymer layer having an concave surface formed on an upper part thereof by a polymer molding method, so that the sensor chip is bent and bonded on the concave surface, and at least one lens fixed on the at least one sensor chip-mounting structure above the sensor chip.

Owner:SAMSUNG ELECTRONICS CO LTD

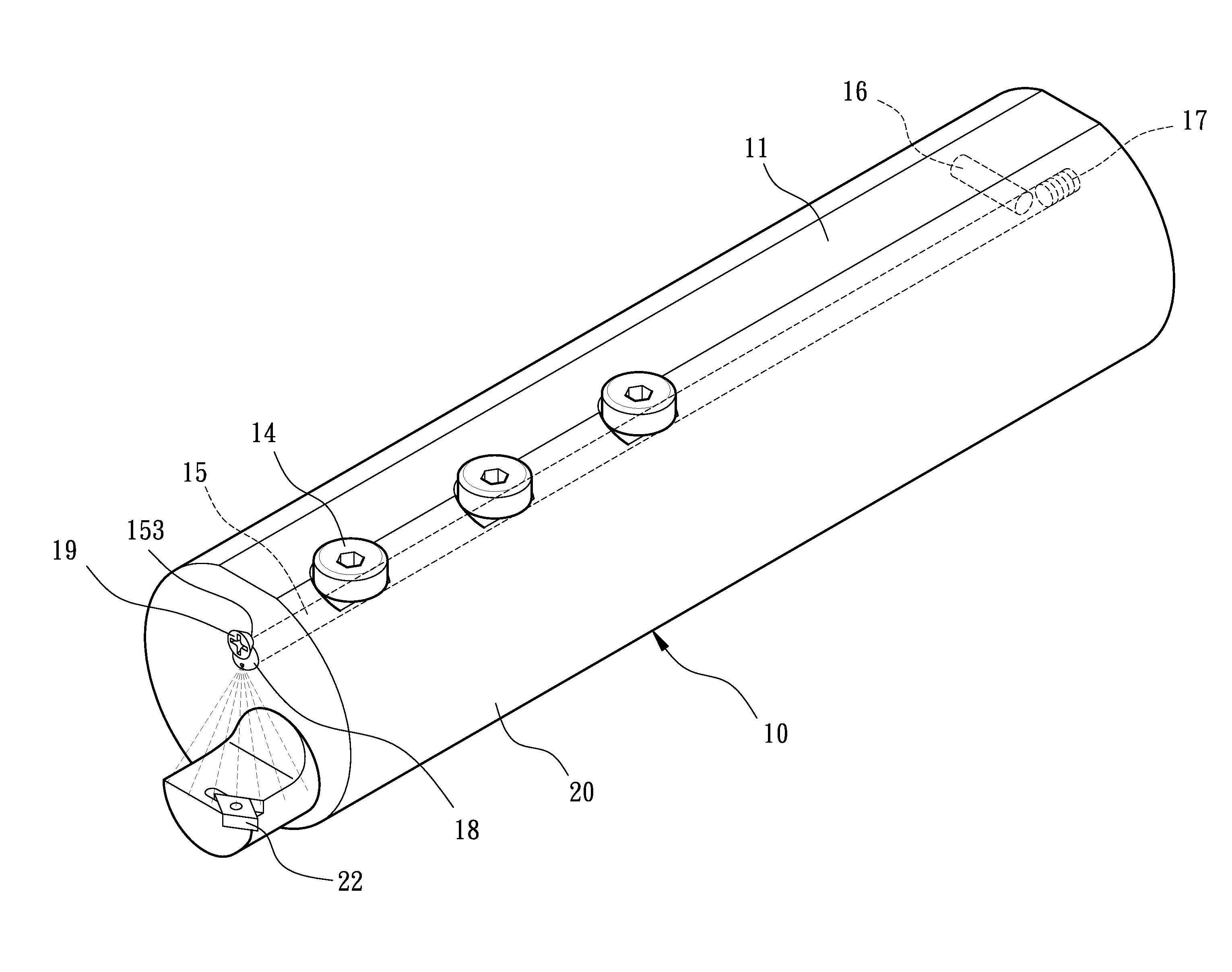

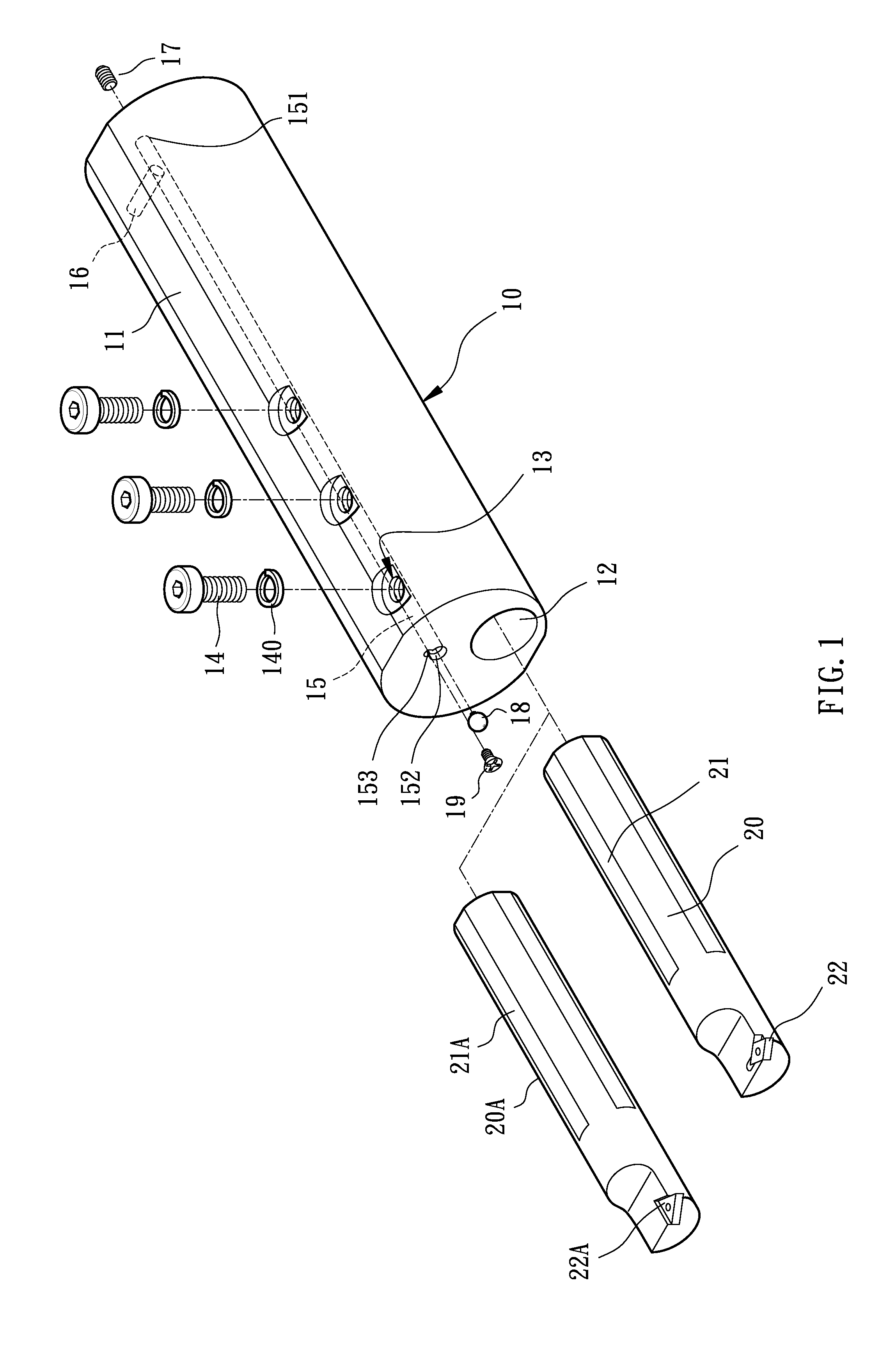

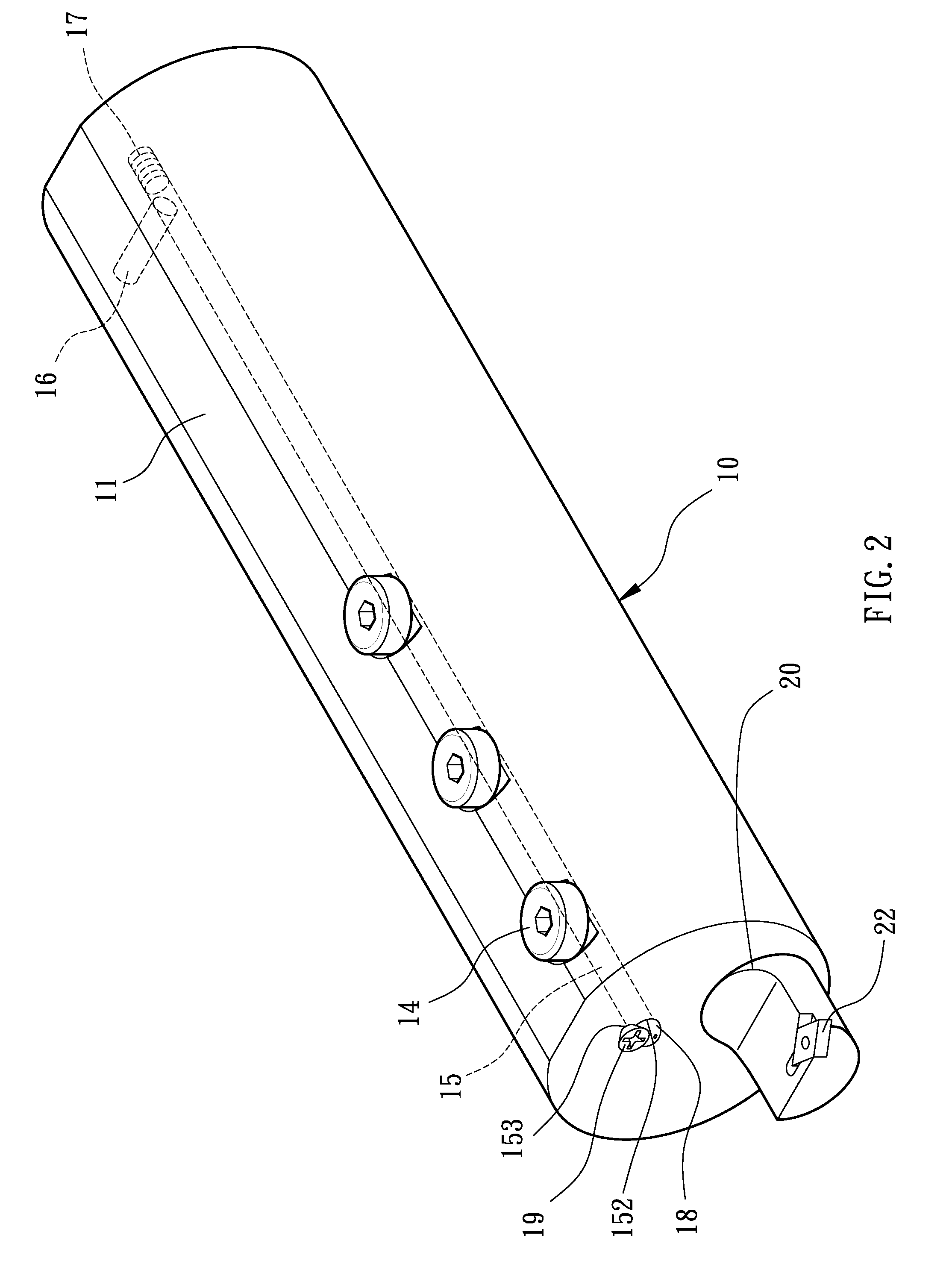

Combined-Type Lathe Tool

InactiveUS20100322722A1Easy to operateInexpensive combinativeTurning toolsTool holdersMechanical engineeringEngineering

Owner:YING FAN ENTERPRISE

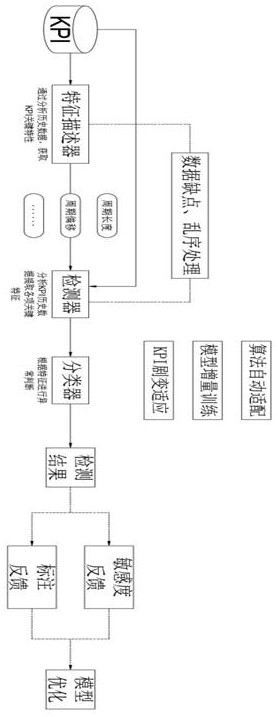

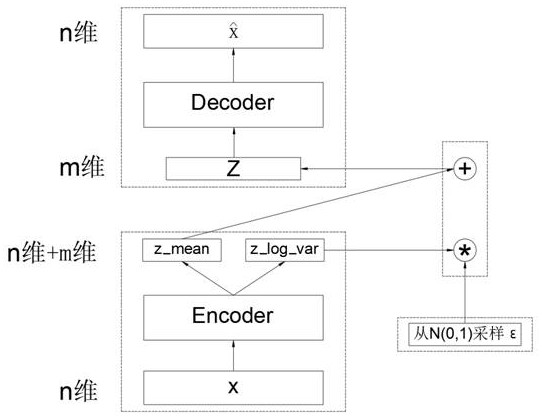

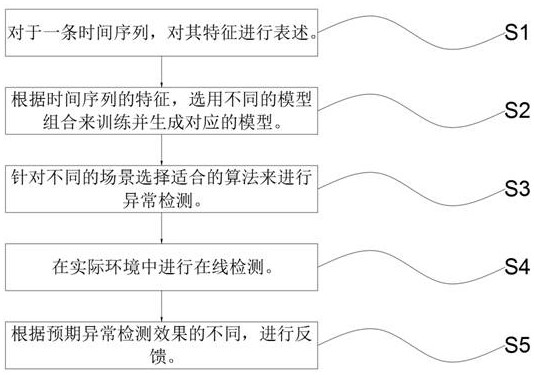

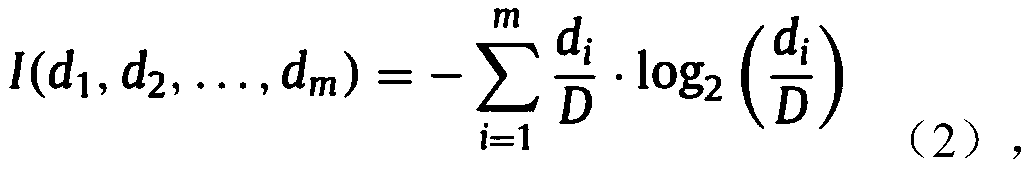

Single-index anomaly detection method based on operation and maintenance monitoring

PendingCN111858231AHigh speedImprove the efficiency and accuracy of anomaly detectionHardware monitoringCharacter and pattern recognitionFeature descriptorData science

The invention discloses a single-index anomaly detection method based on operation and maintenance monitoring. The anomaly detection system carries out KPI anomaly detection on time series data collected and stored by operation and maintenance monitoring, the time series data comprises time and index values collected by the operation and maintenance monitoring through a technical tool, and the anomaly detection system comprises a feature descriptor, a detector and a classifier. The invention is scientific and reasonable, safe and convenient in use; appropriate algorithms are selected for different scenes to carry out anomaly detection, abnormity detection efficiency and accuracy can be effectively improved, a problem of true value missing caused by false alarm and missing alarm can be avoided, so the algorithm is made to have enough fast speed to process the online real-time data, and the algorithm is made to automatically detect abnormity without dependence on annotation.

Owner:北京必示科技有限公司

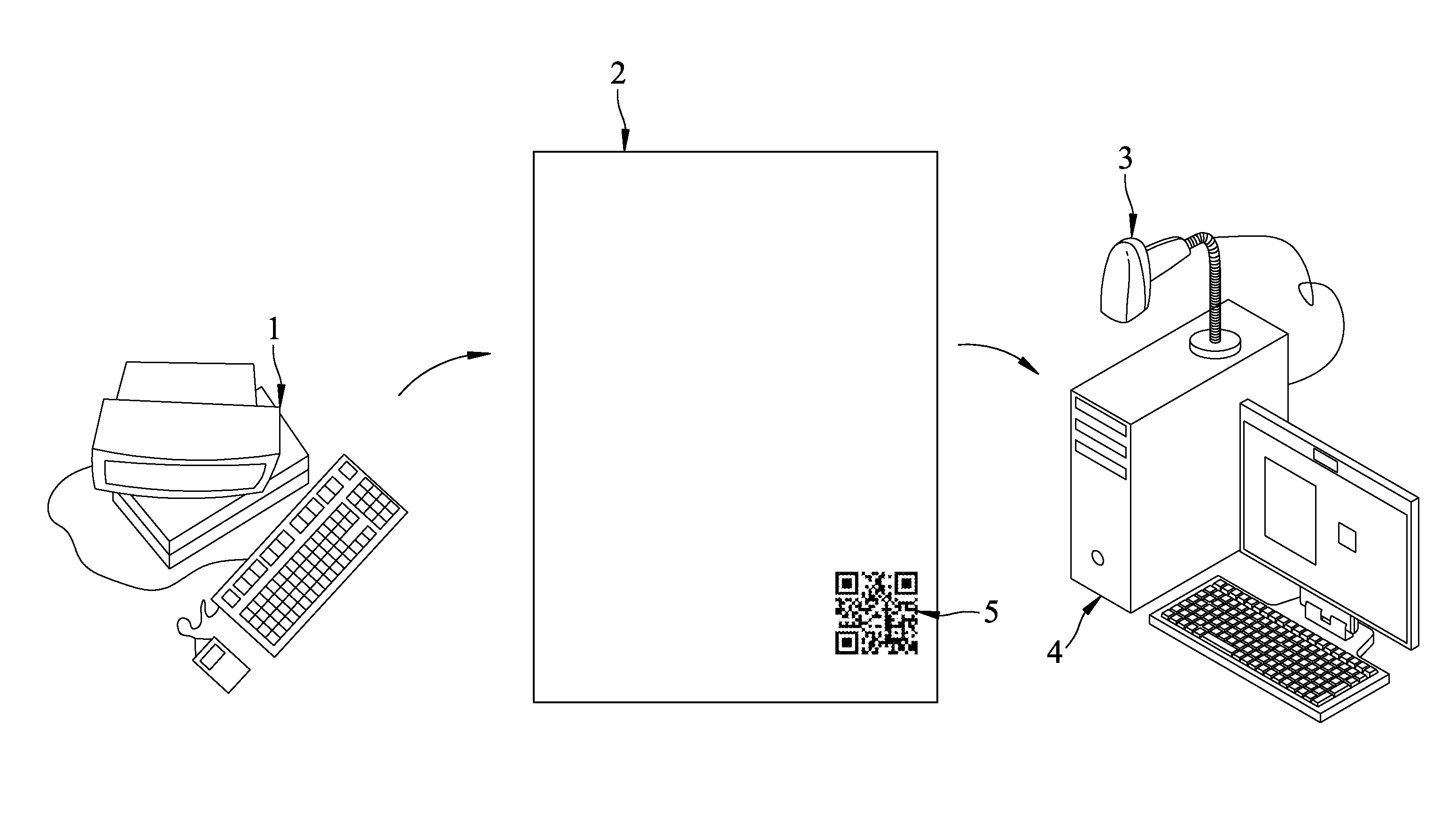

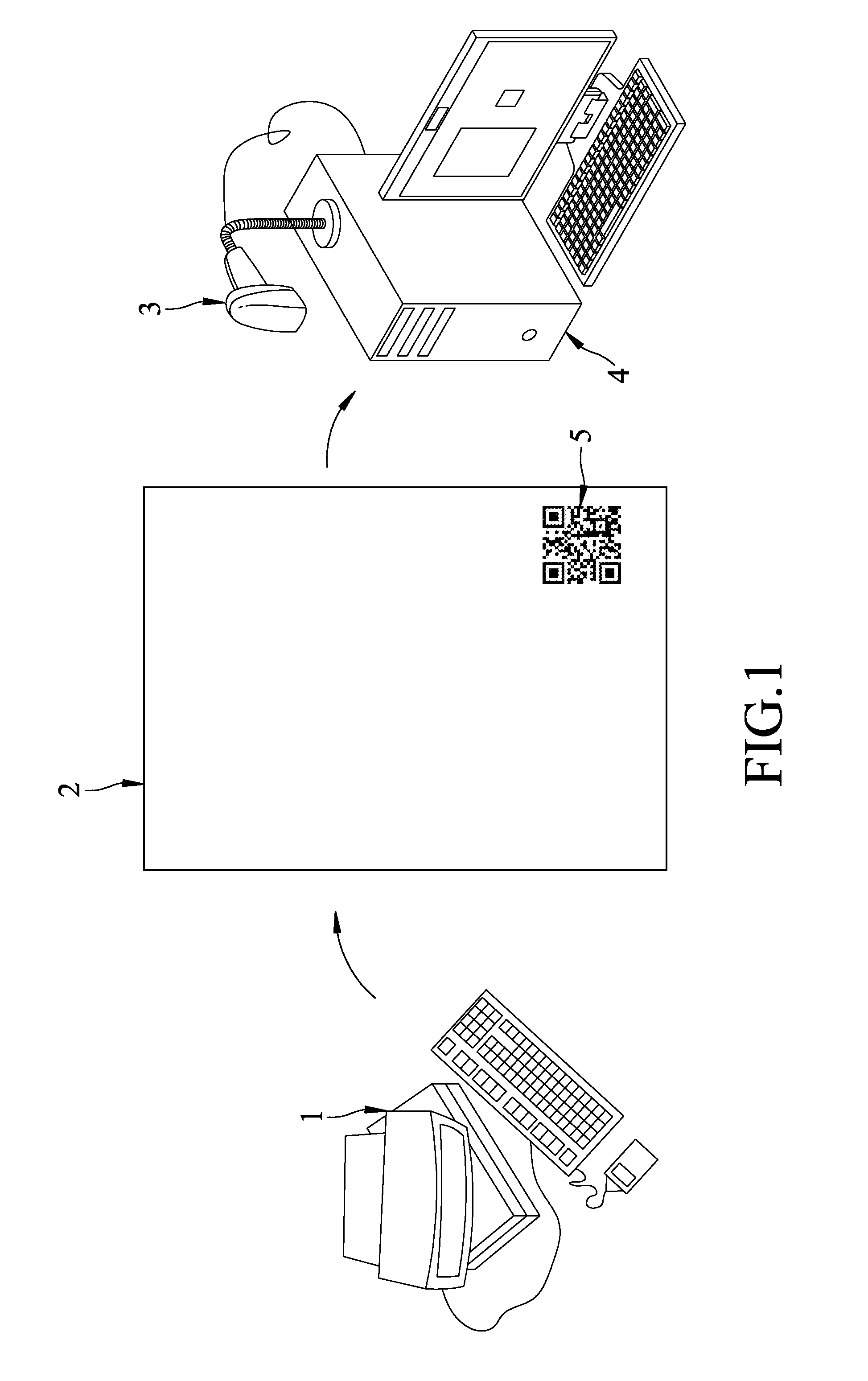

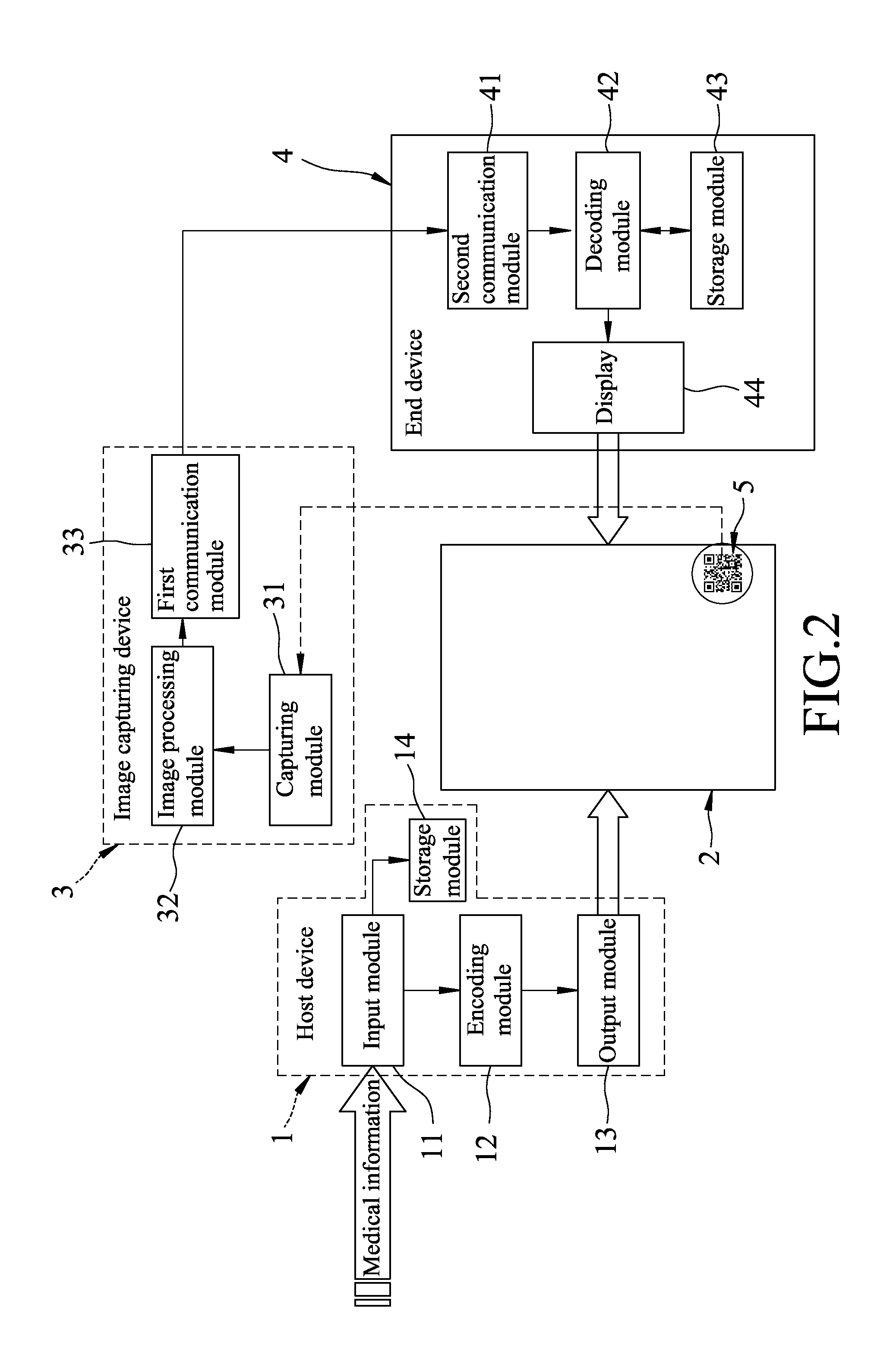

System and Method for Managing Medical Information

InactiveUS20150100334A1Improve efficiencyImprove precisionDigital data information retrievalFinanceTerminal equipmentBarcode

A system for managing medical information includes a host device for installation at a first location, an image capturing device, and an end device for installation at a second location. The host device encodes medical information into a barcode, and outputs the barcode to an information carrier. The image capturing device captures an image of the barcode on the information carrier so as to create a barcode image. The end device decodes the barcode image for obtaining the medical information encoded by the host device.

Owner:LIN CHI HUNG +2

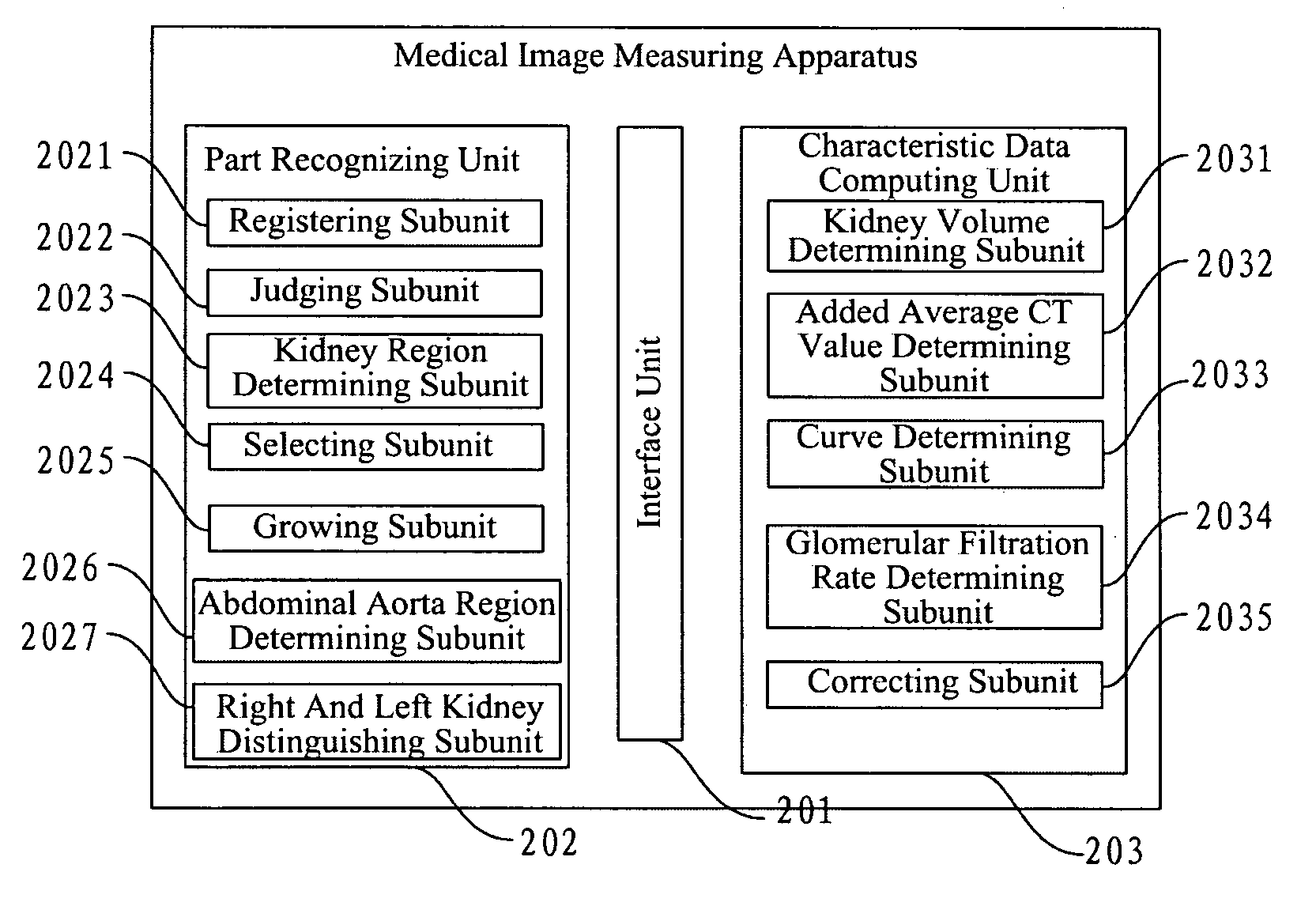

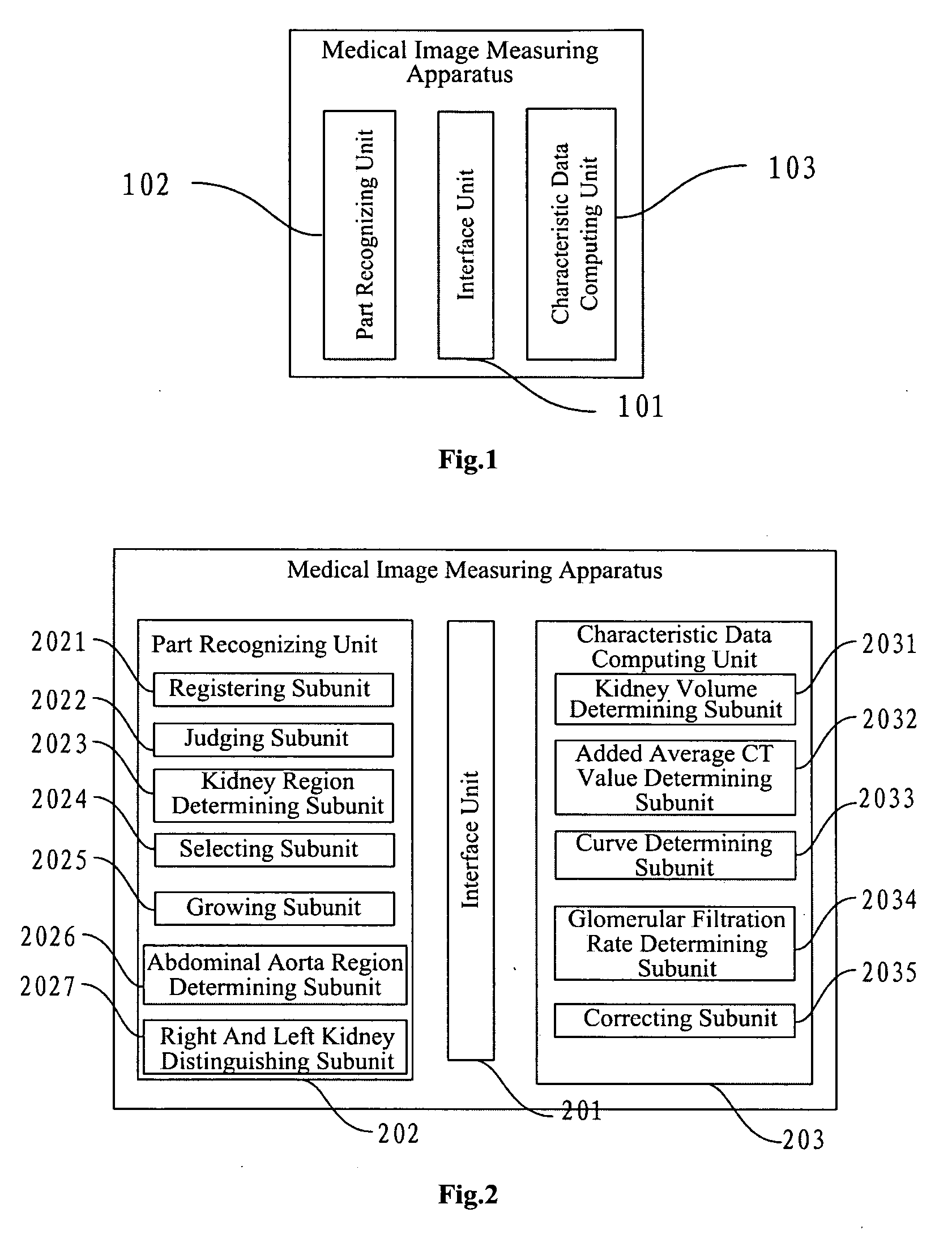

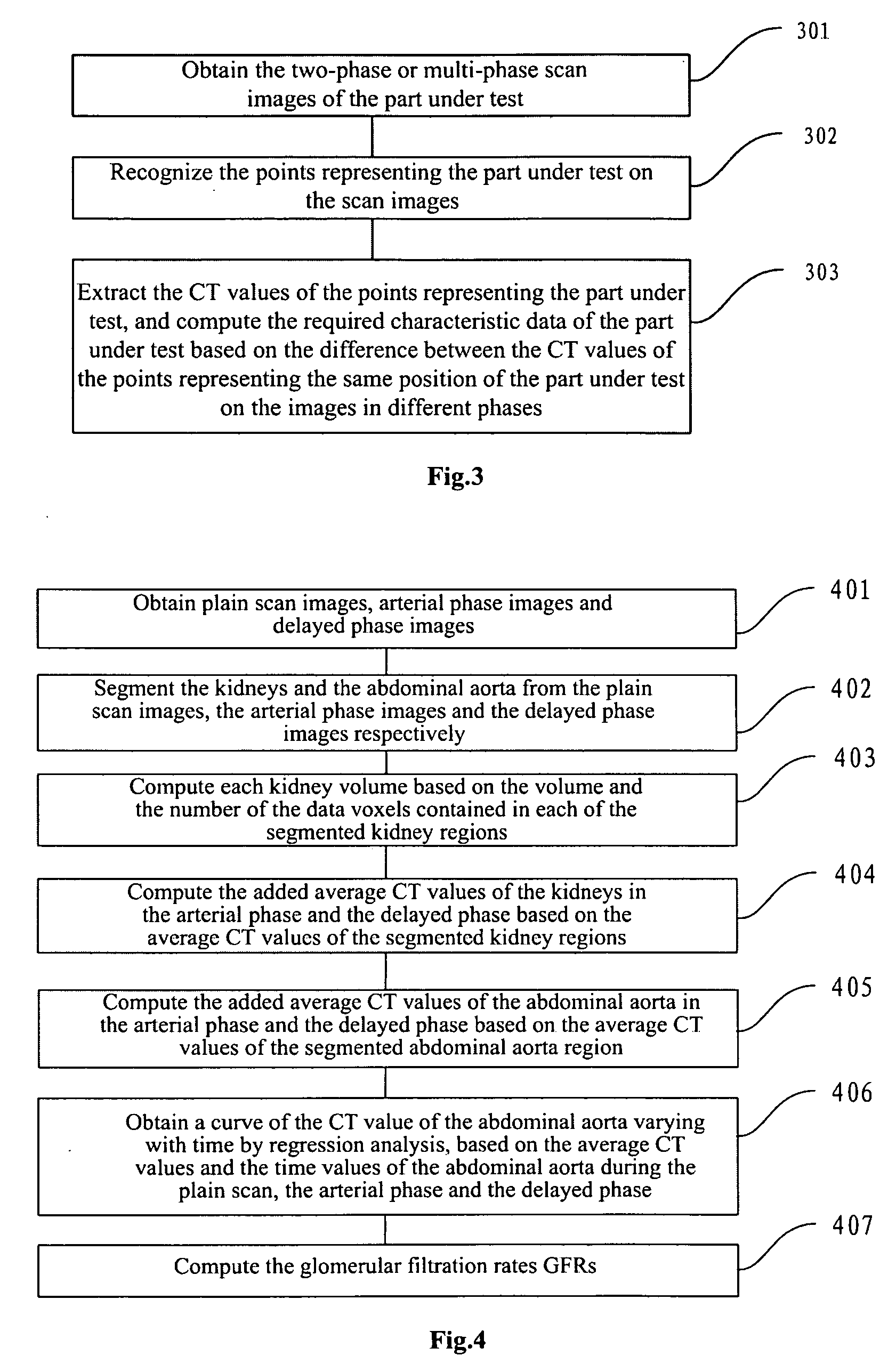

Image measuring apparatus and method, and image measuring system for glomerular filtration rate

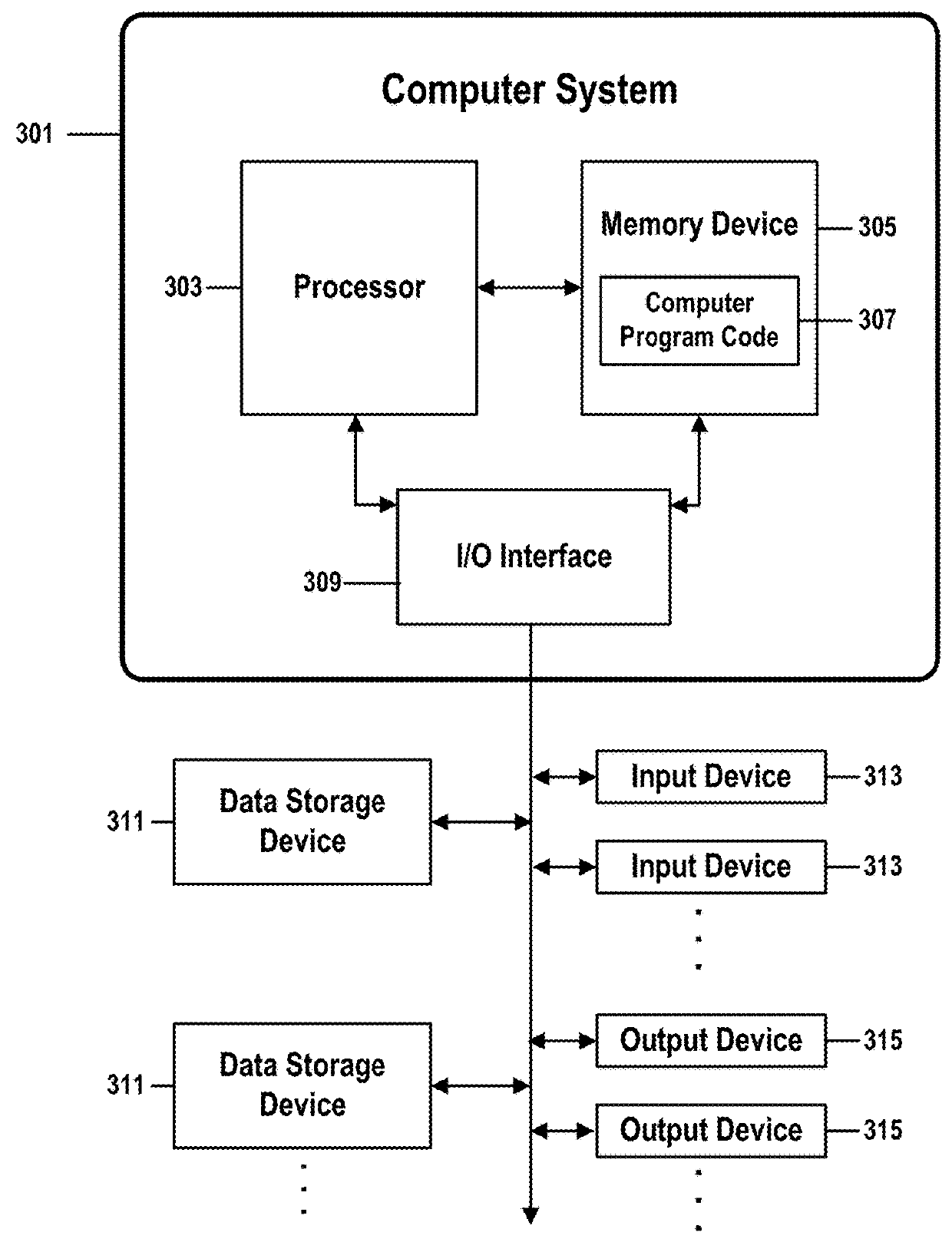

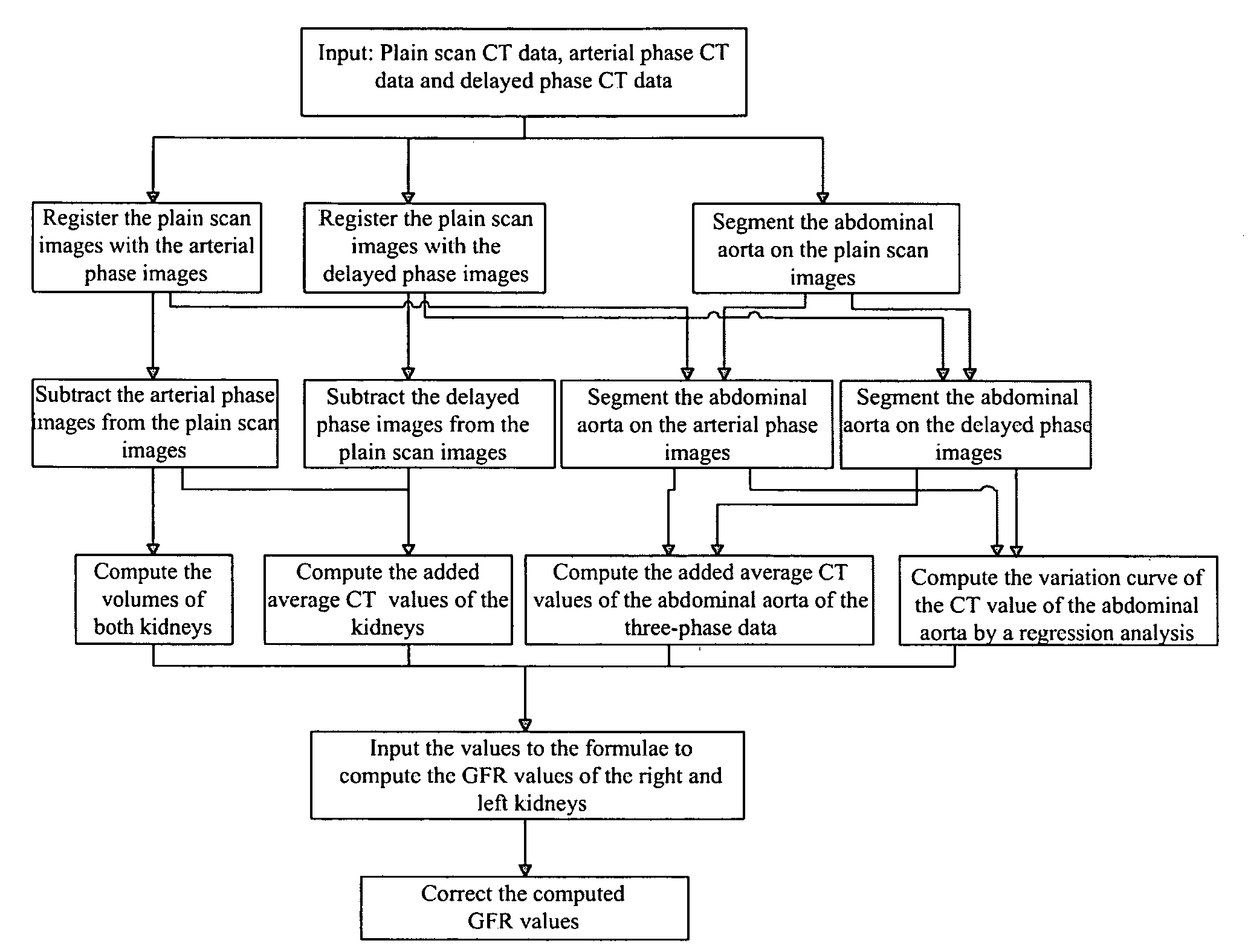

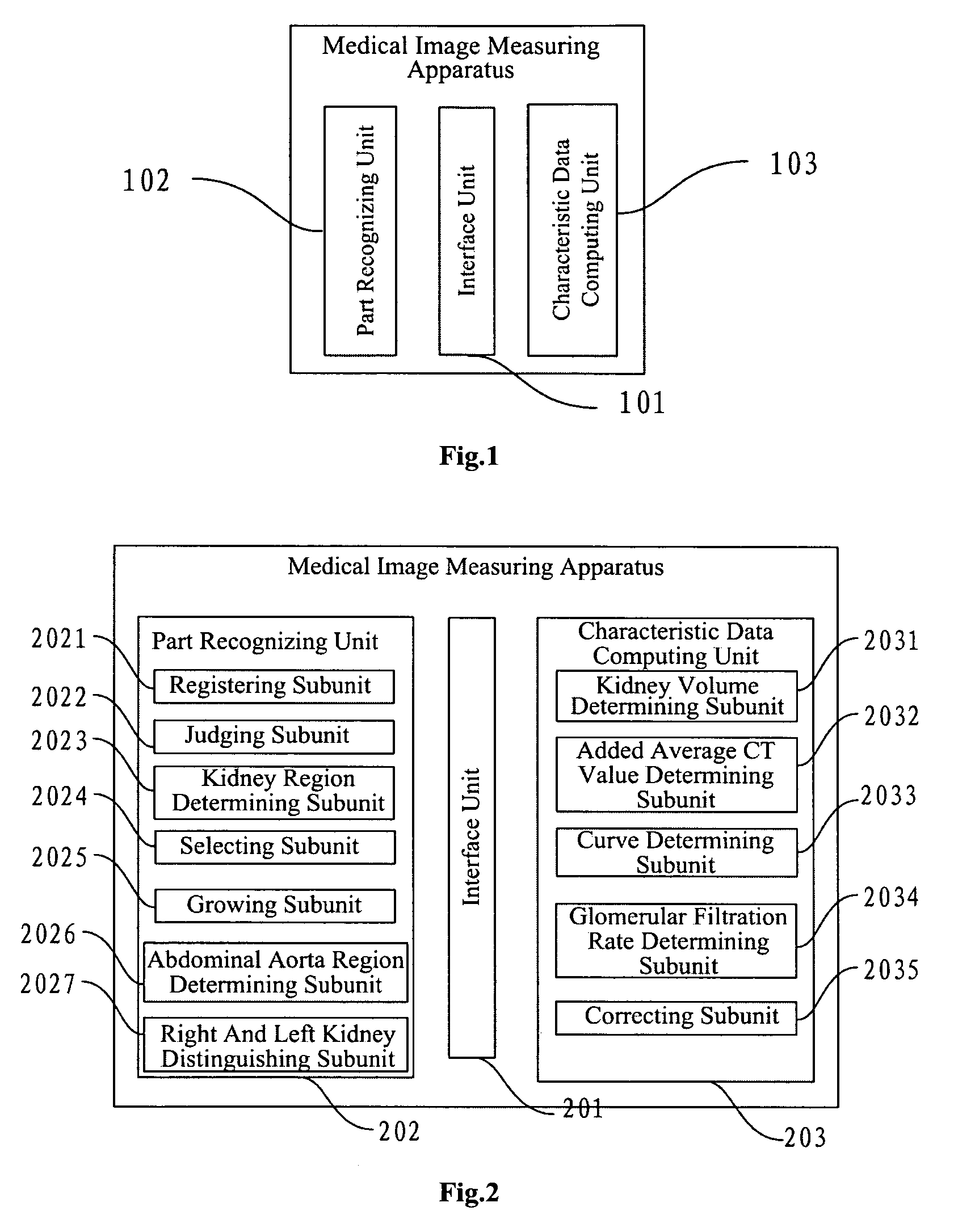

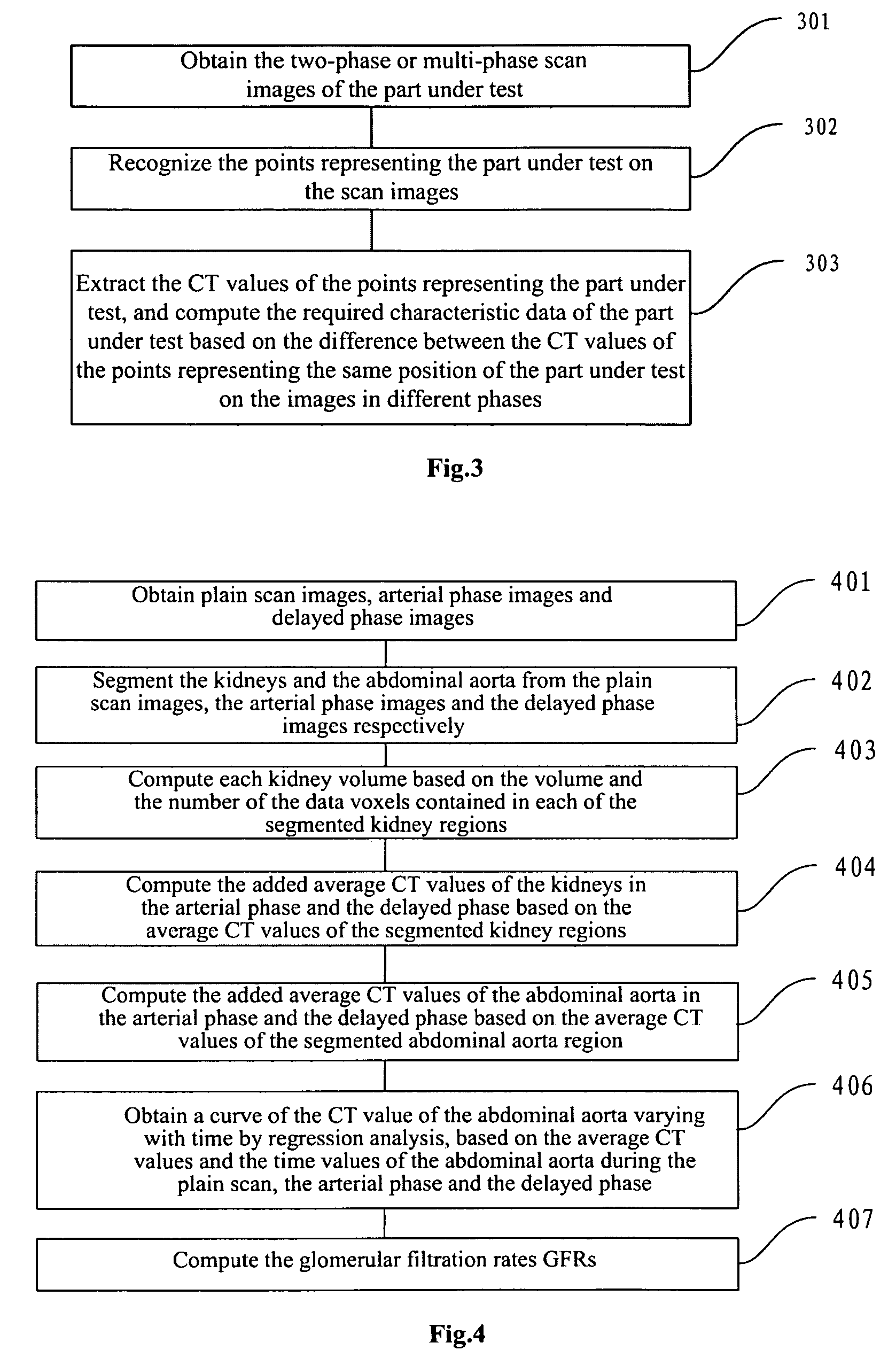

ActiveUS20080025589A1Guarantee high efficiency and precisionImprove accuracyImage enhancementImage analysisMeasurement deviceFiltration

The present invention discloses an abdominal CT image measuring apparatus and method. The abdominal CT image measuring apparatus includes: an interface unit; a part recognizing unit and a characteristic data computing unit. The present invention can determine the specific region of the part under test with a little amount of computation, by registration and subtraction operation on the two-phase scan images. This is easy to be carried out in computers, thus the computing speed of the characteristic data can be guaranteed and the efficiency can be improved. By the recognizing of the kidney regions and the abdominal aorta region in the present invention, the glomerular filtration rates obtained by applying the key concept of the present invention to the image measuring of glomerular filtration rate can meet the clinical application requirements in both precision and speed.

Owner:NEUSOFT MEDICAL SYST CO LTD

Database-management system with artificially intelligent virtual database administration

ActiveUS20180096252A1Guarantee high efficiency and precisionMachine learningInference methodsEngineeringData mining

A method and associated systems for a database-management system with artificially intelligent database administration. The DBMS includes one or more databases, each of which is monitored by sensors that detect conditions indicative of database performance. An operational engine receives input from the sensors, translates it into a form understandable by an artificially intelligent decision engine, and forwards the translated input to the decision engine. The decision engine uses preloaded knowledge elements stored in a knowledgebase to infer whether the sensor input identifies an issue that must be resolved by a database-administration activity. If so, the decision engine attempts to select a best solution, optionally seeks confirmation of its selection from an outside source, and directs the operational engine to implement the selected solution. The relative success of the solution is fed back to the knowledgebase, allowing the system, by means of machine learning, to continuously improve accuracy and effectiveness.

Owner:KYNDRYL INC

Image measuring apparatus and method, and image measuring system for glomerular filtration rate

ActiveUS7813536B2Guarantee high efficiency and precisionImprove accuracyImage enhancementImage analysisMeasurement deviceFiltration

The present invention discloses an abdominal CT image measuring apparatus and method. The abdominal CT image measuring apparatus includes: an interface unit; a part recognizing unit and a characteristic data computing unit. The present invention can determine the specific region of the part under test with a little amount of computation, by registration and subtraction operation on the two-phase scan images. This is easy to be carried out in computers, thus the computing speed of the characteristic data can be guaranteed and the efficiency can be improved. By the recognizing of the kidney regions and the abdominal aorta region in the present invention, the glomerular filtration rates obtained by applying the key concept of the present invention to the image measuring of glomerular filtration rate can meet the clinical application requirements in both precision and speed.

Owner:NEUSOFT MEDICAL SYST CO LTD

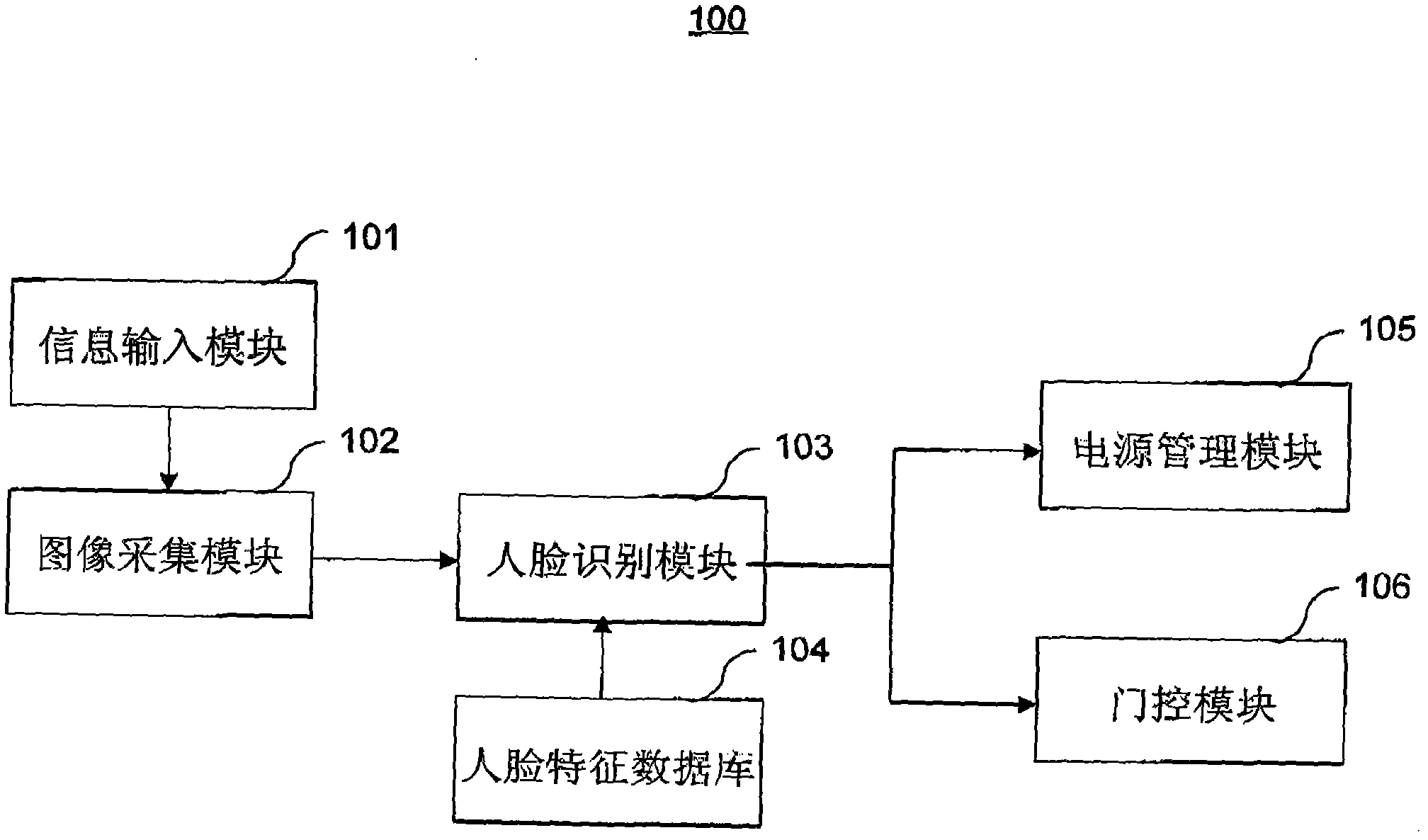

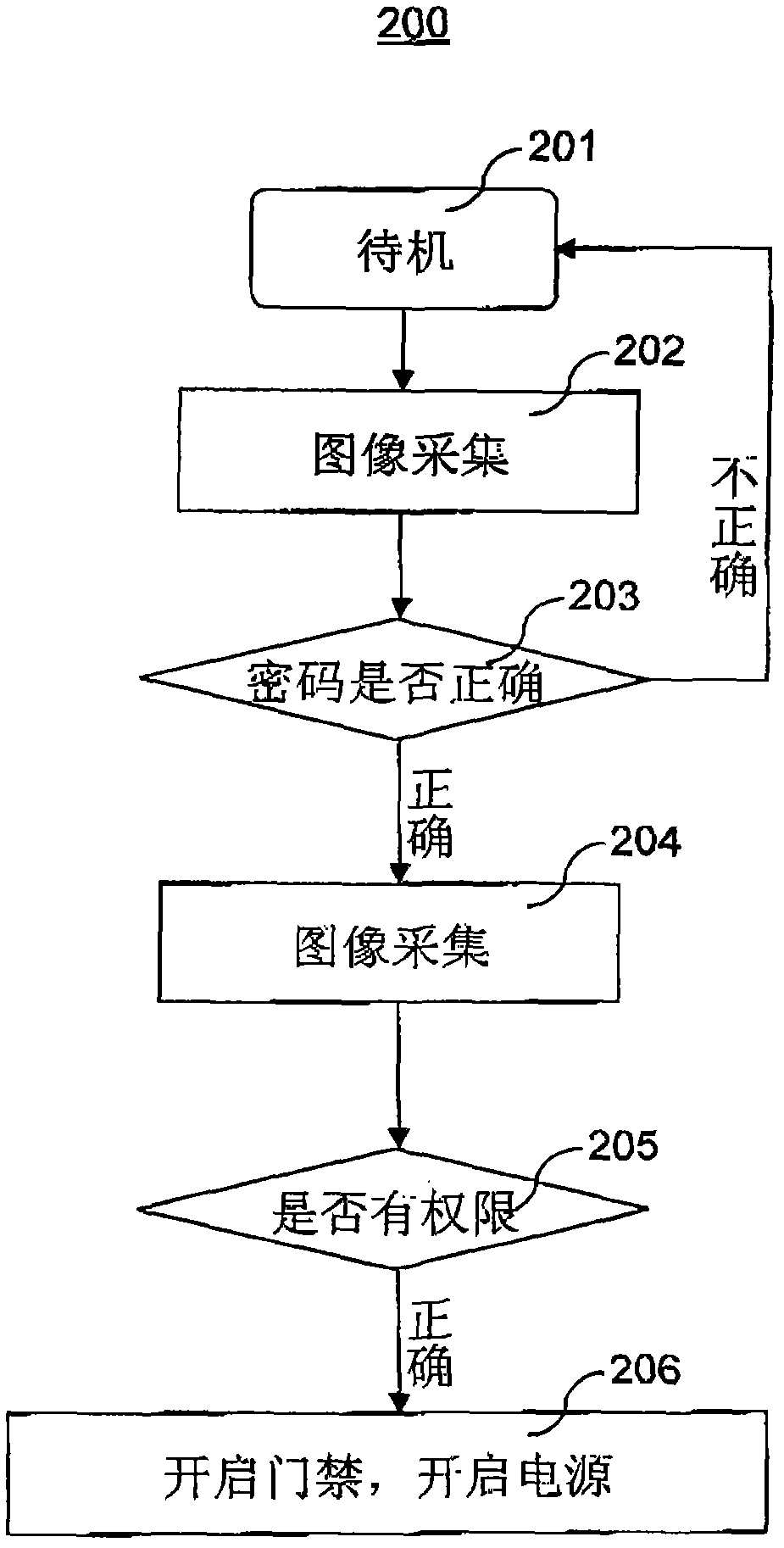

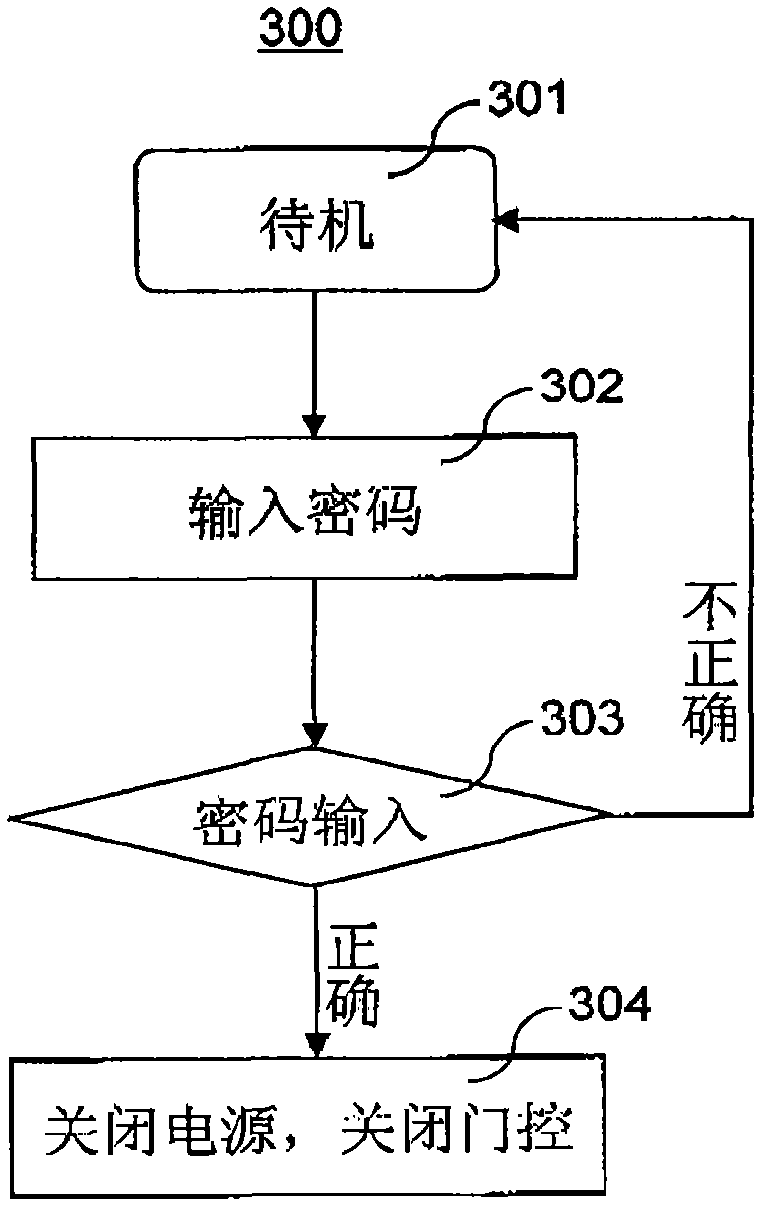

Door control lock comprising power supply management

InactiveCN102465636AEfficient managementTo achieve the effect of confidentialityNon-mechanical controlsCharacter and pattern recognitionSupply managementComputer module

The invention discloses a door control lock comprising power supply management. The door control lock comprises a face feature database, an image acquisition module, a face recognition module and a power supply management module, wherein the face feature database is used for storing face feature data of users with the authority entering a management area; the image acquisition module is used for acquiring face images of the users and judging whether the acquired face images of the users are of the face feature data of the users with the authority entering the management area, if so, a power supply in the power supply management area is turned on, otherwise, the users of the face images are not those with the authority entering the management area; and the power supply management module is used for turning on the power supply and a door control module in the management area and opening a door guard in the management area. The door control lock has efficient safety, accuracy and high awareness, and effectively manages the access users.

Owner:WUXI MEIWANG NETWORK INFORMATION TECH

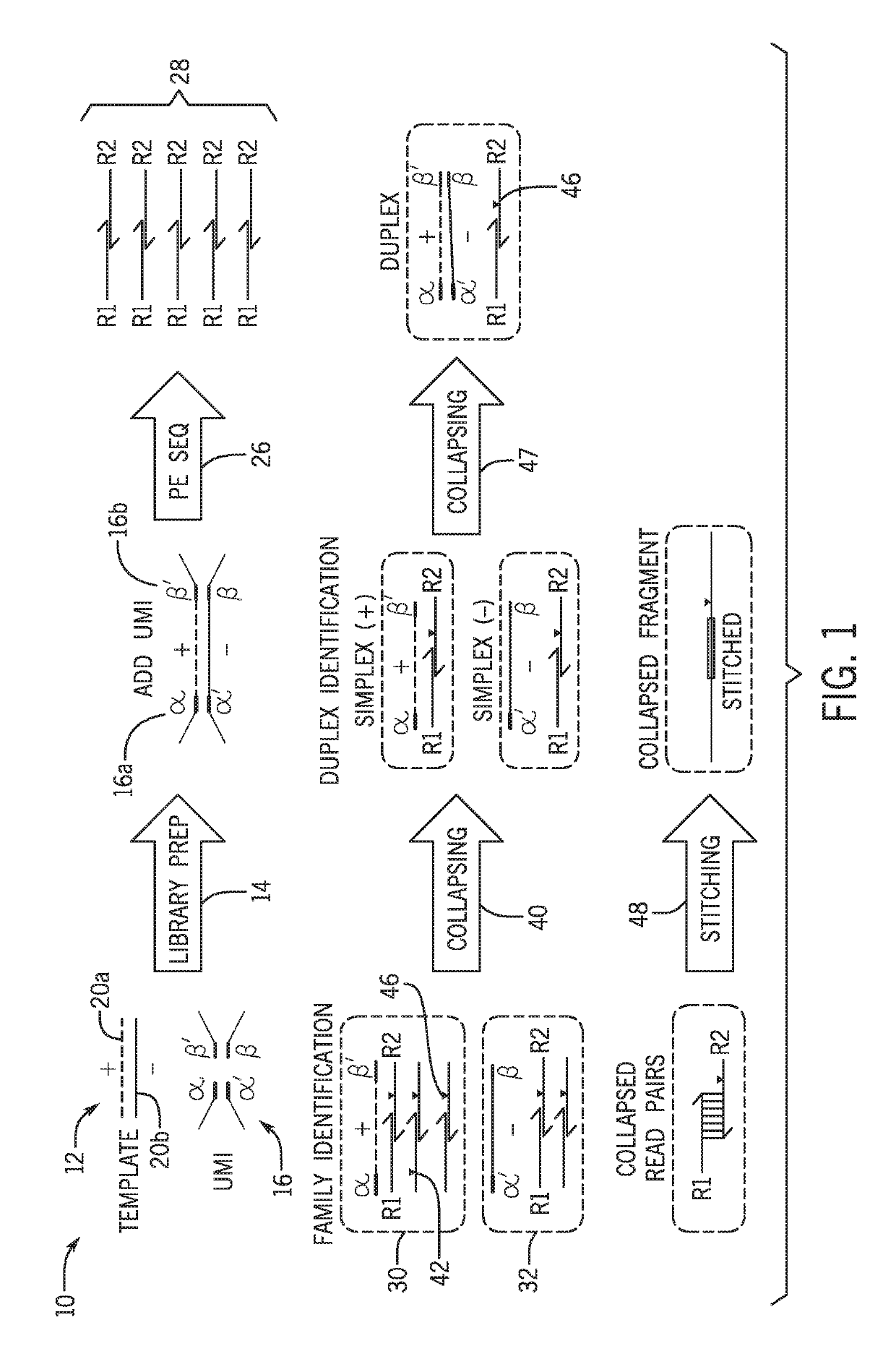

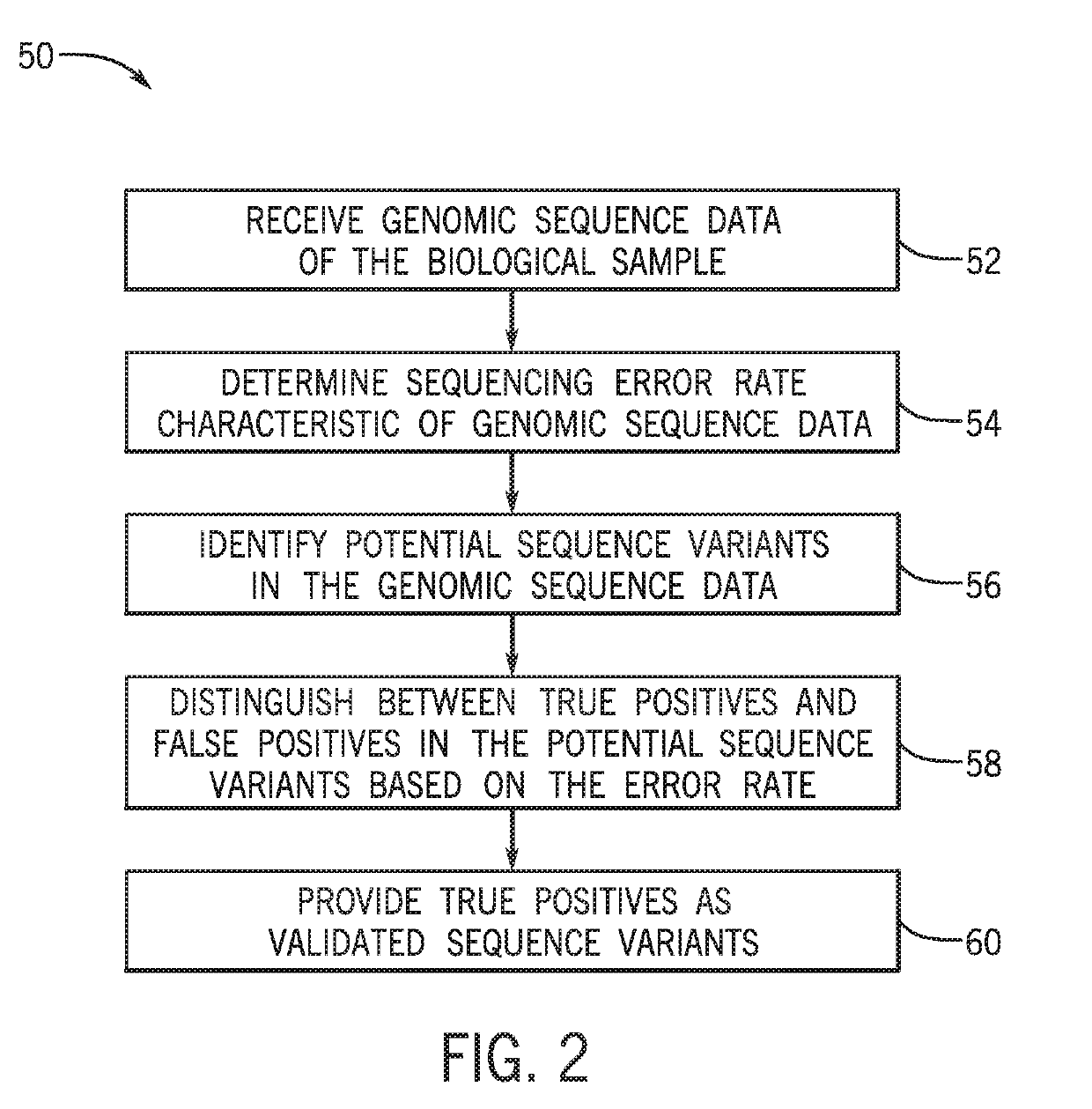

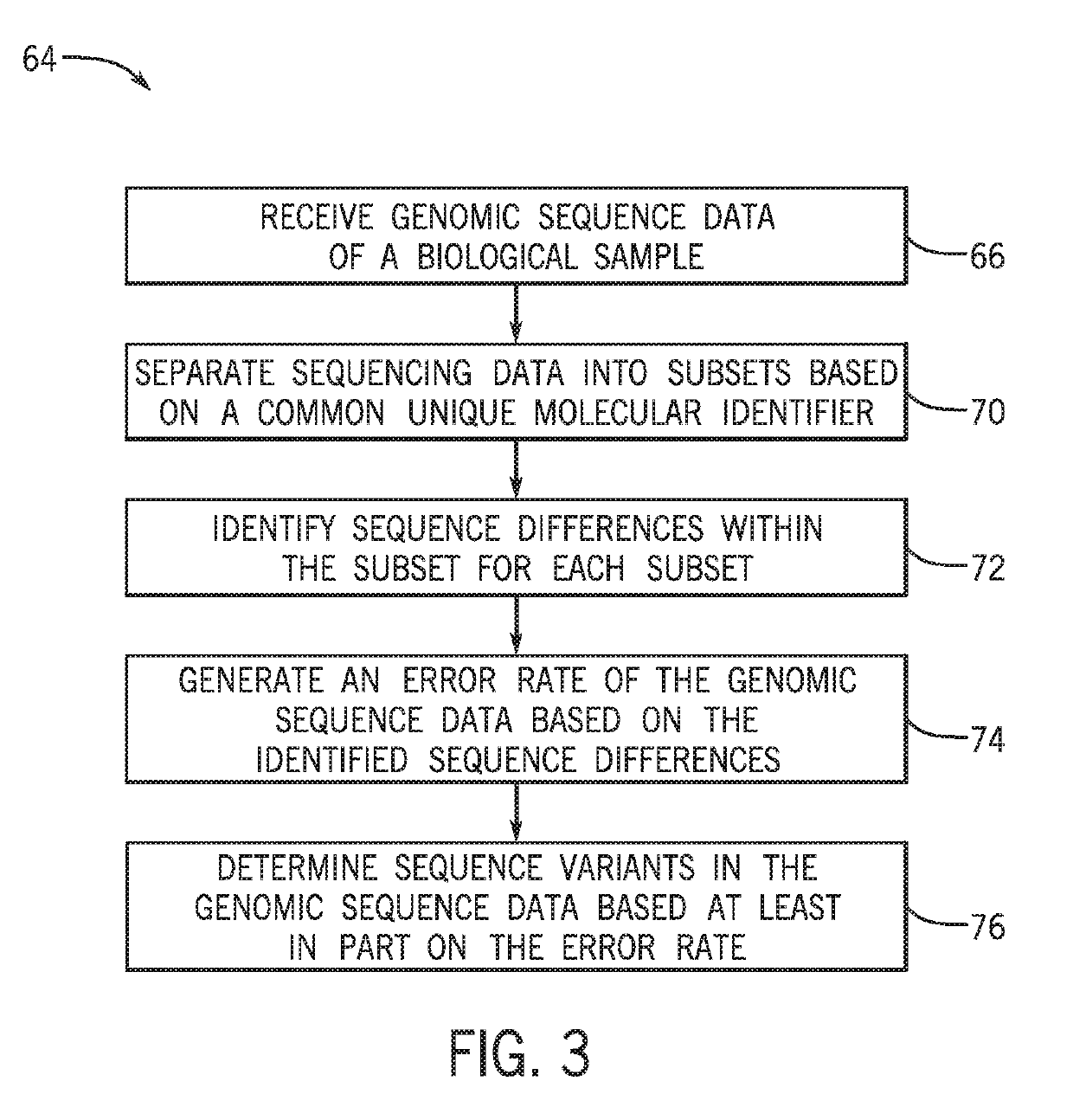

Validation methods and systems for sequence variant calls

PendingUS20190206510A1Improve accuracyImprove efficiencyBiostatisticsProteomicsValidation methodsComputer science

Presented herein are techniques for identifying and / or validating sequence variants in genomic sequence data. The techniques include generating an error rate reflective of sequence errors present in the genomic sequence data. The error rate may be used to validate potential sequence variants. The error rate may be based on errors identified during consensus sequence confirmation for sequence reads associated with individual unique molecular identifiers.

Owner:ILLUMINA INC

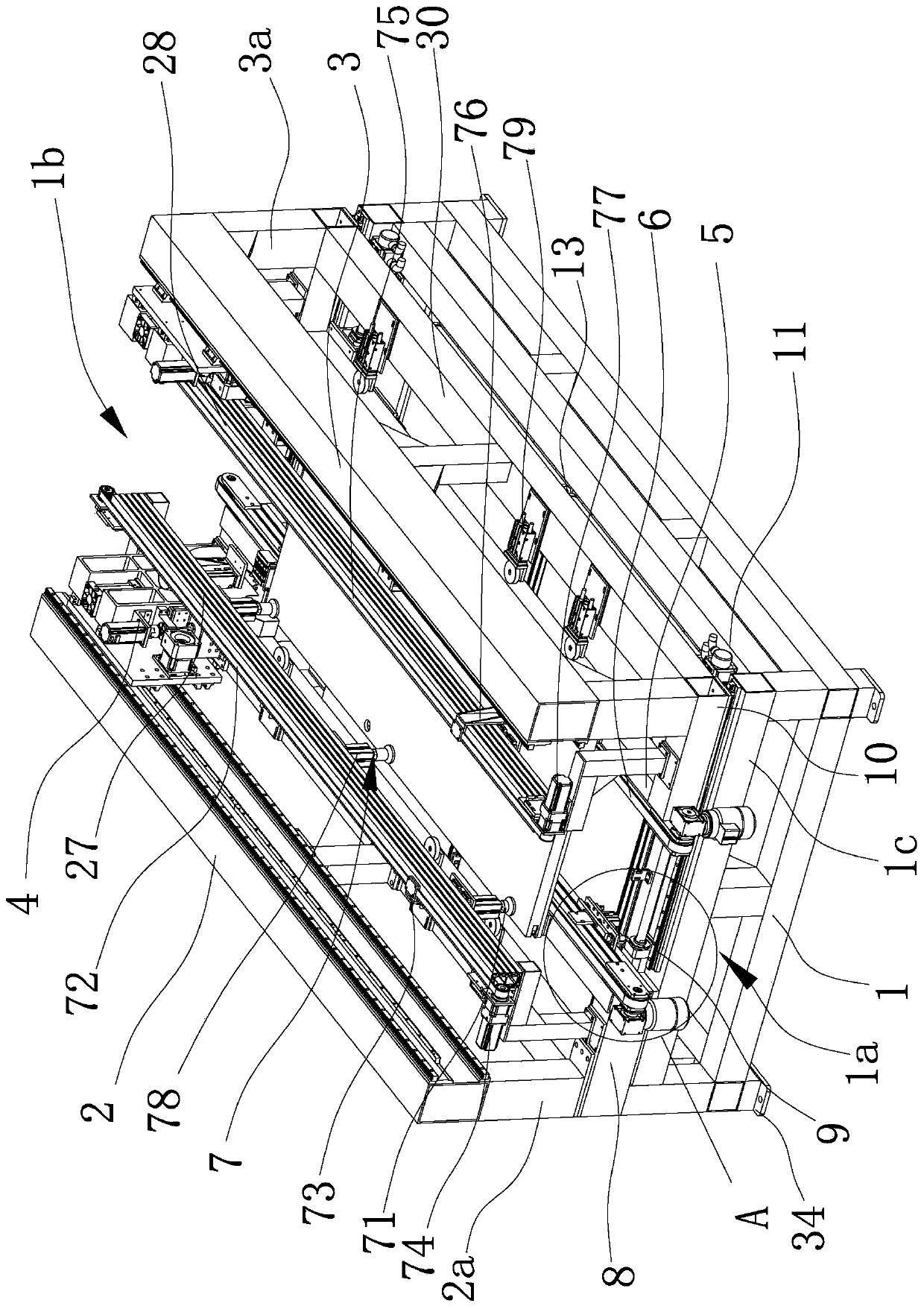

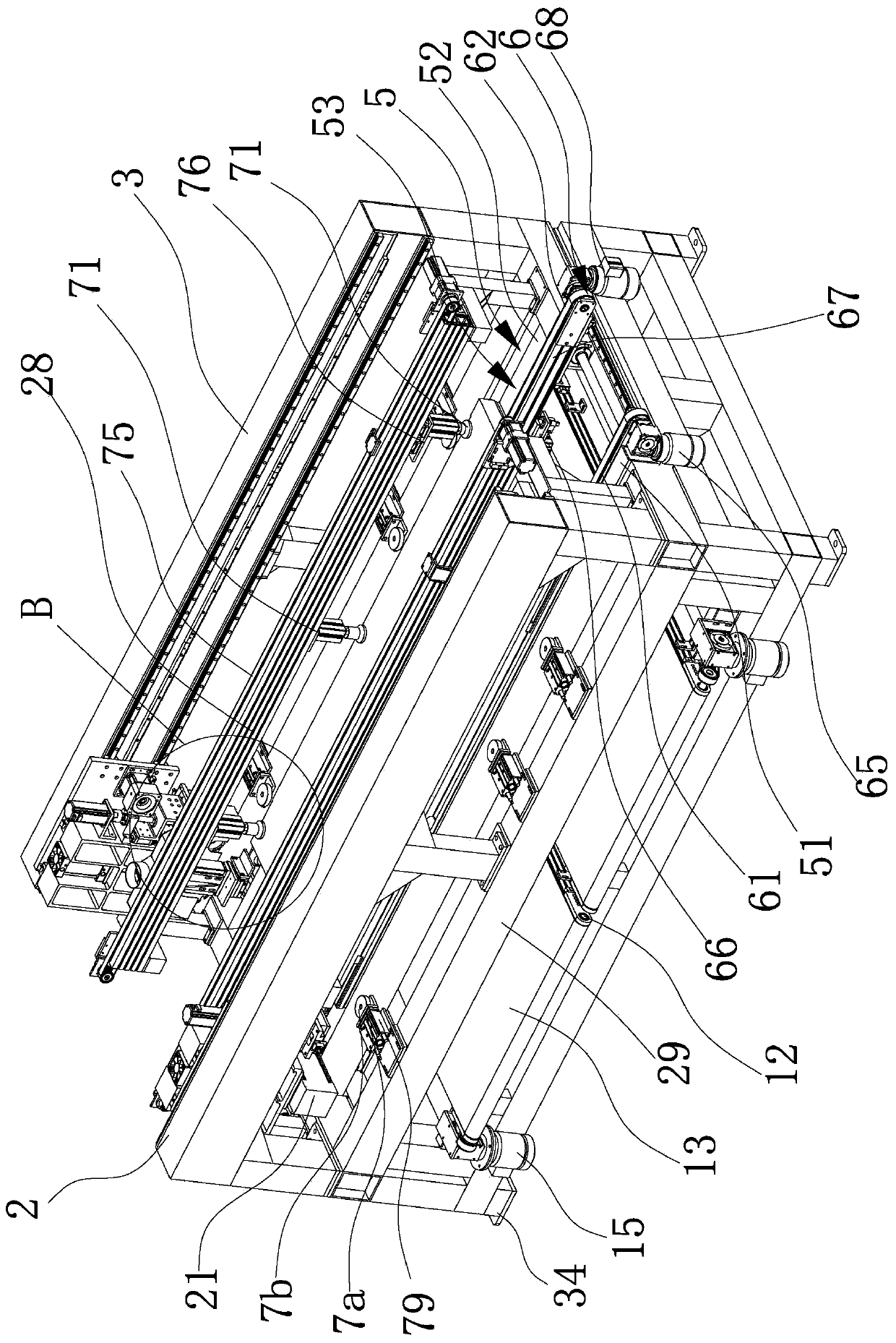

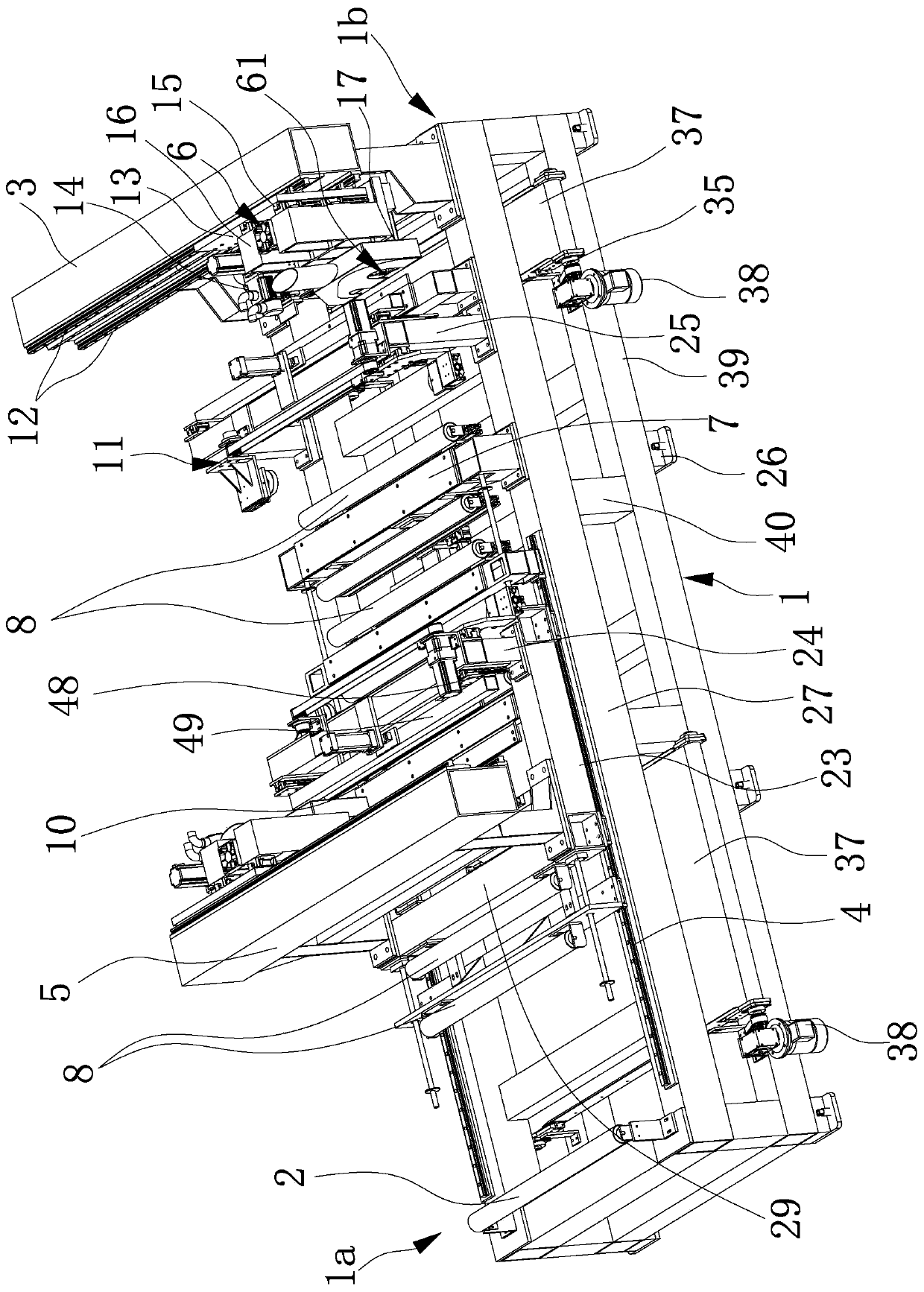

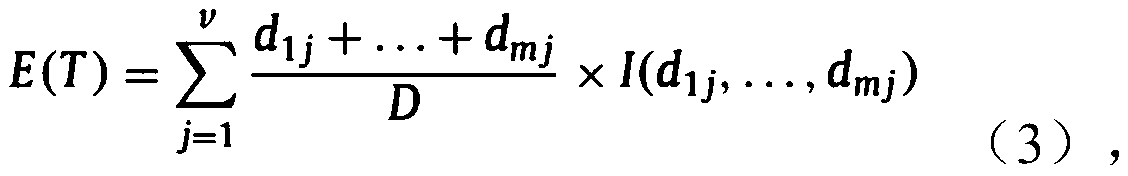

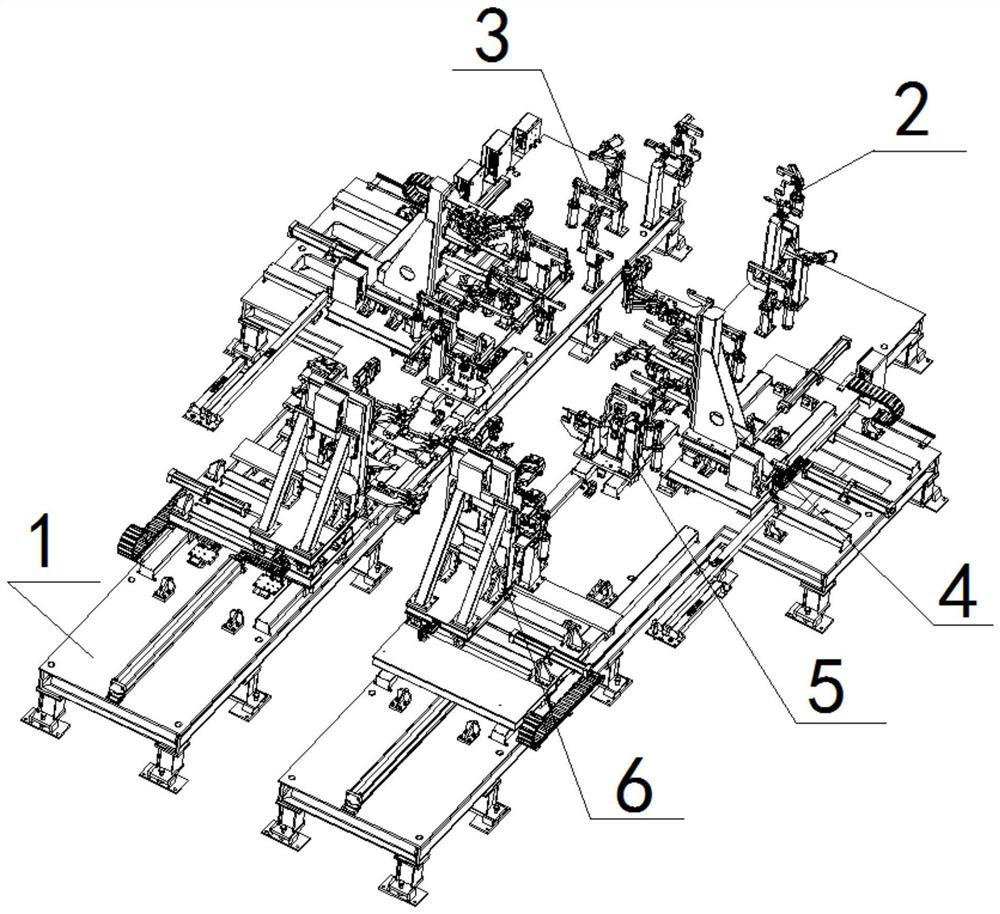

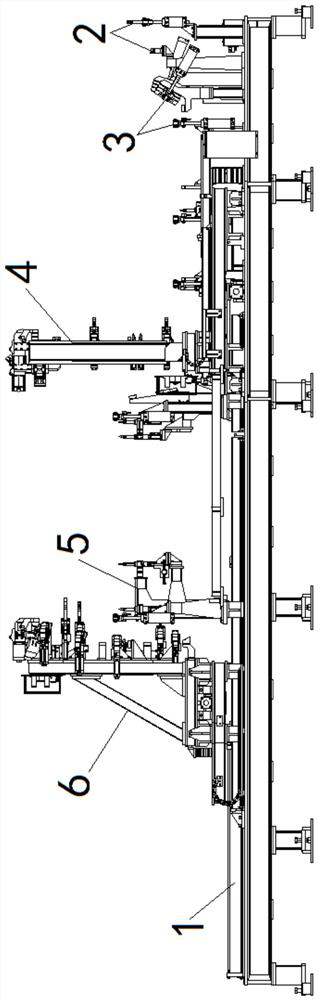

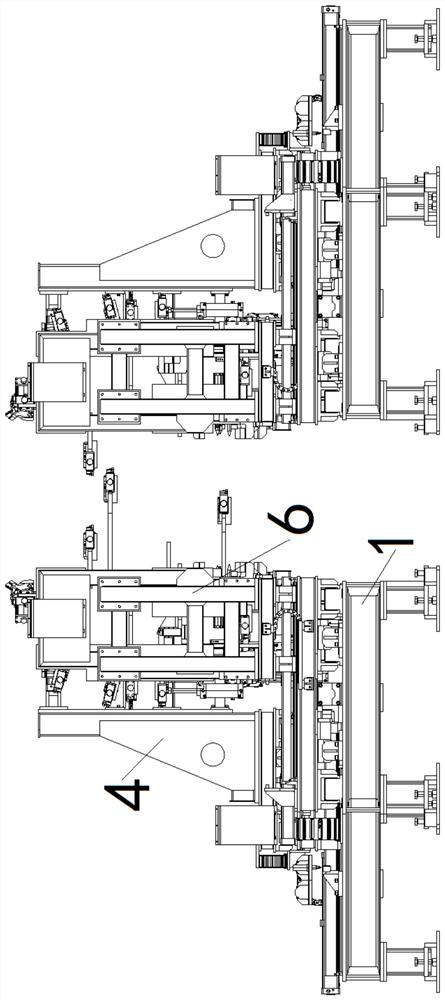

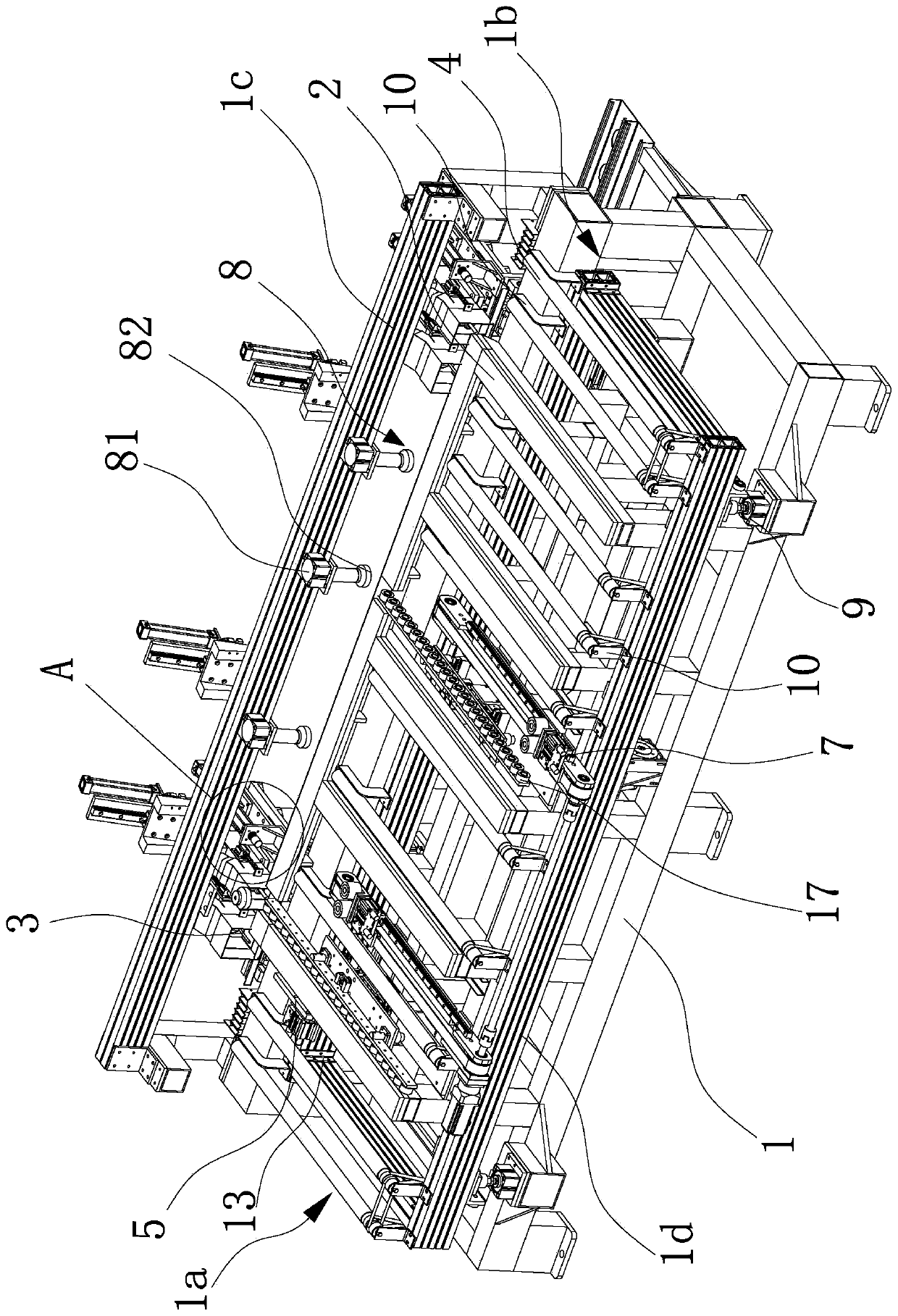

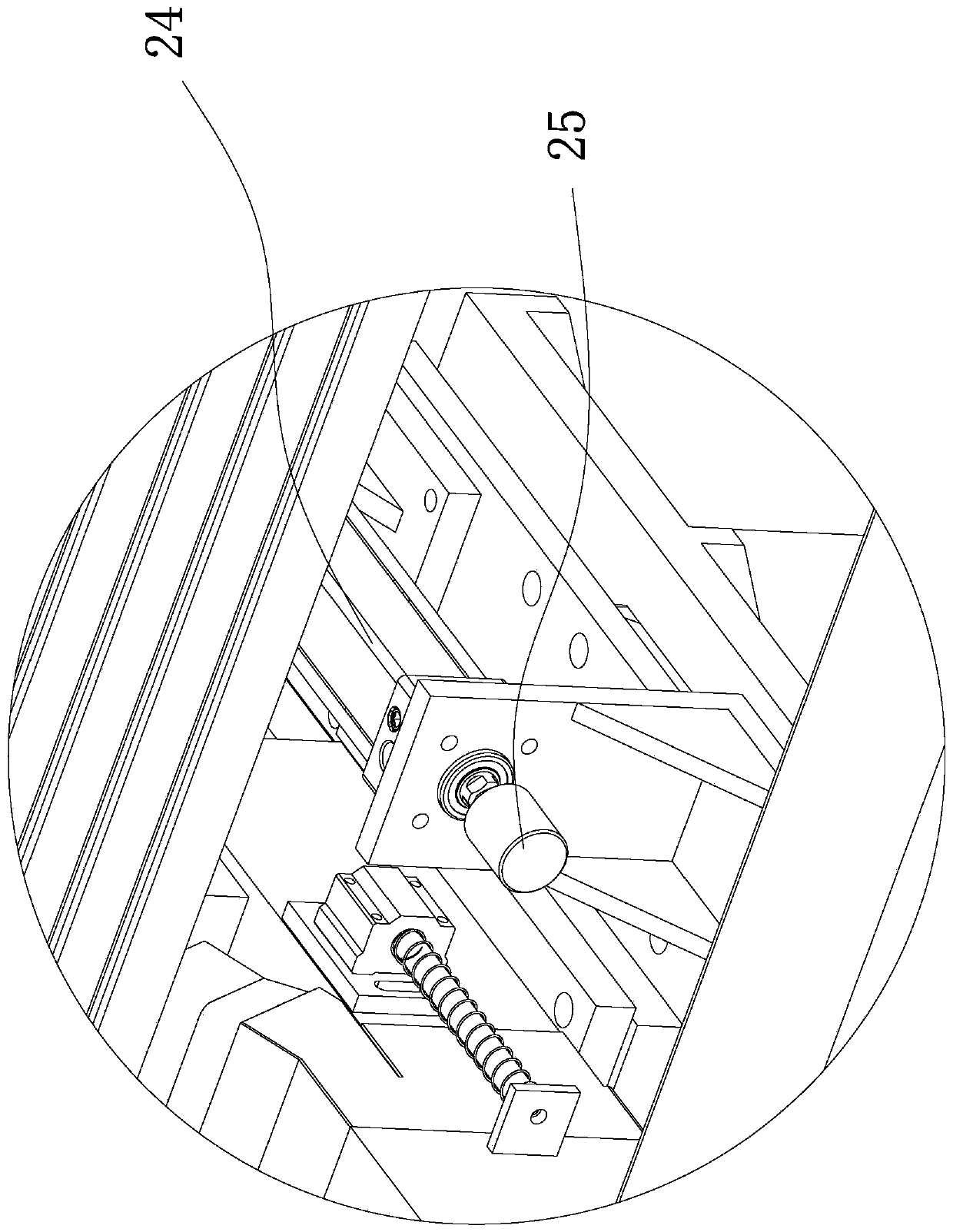

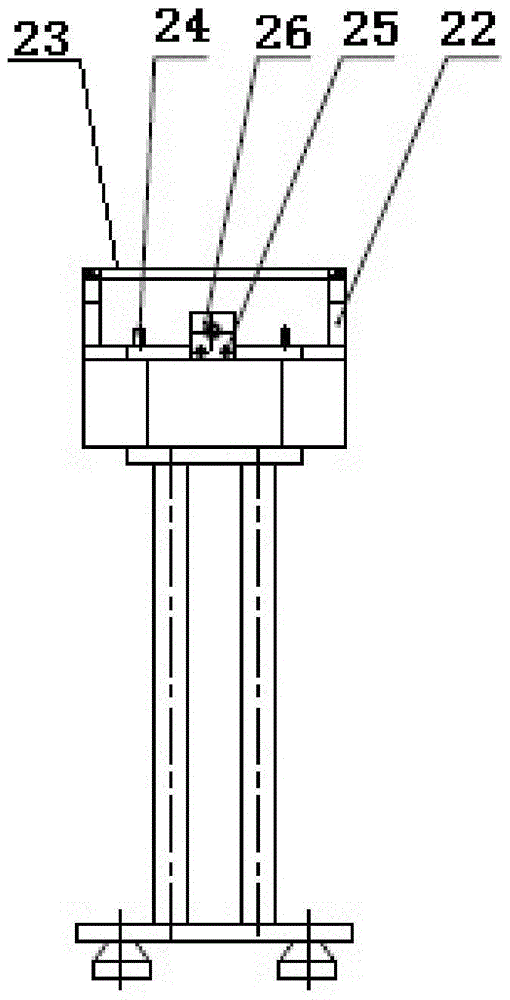

Double-end rip sawing device

PendingCN110696099AGuaranteed timelinessGuaranteed smoothnessFeeding devicesGripping devicesAutomatic controlReciprocating motion

The invention provides a double-end rip sawing device and belongs to the technical field of automatic mechanical equipment. The technical problems that in the prior art, automatic feeding and discharging of large plates are inconvenient, and the double-end rip sawing device is not suitable for plates needed by large door and window furniture and the other products are solved. The double-end rip sawing device comprises a rack, one end of the rack is an input end, and the other end of the rack is an output end. A fixed frame is fixedly arranged on one side of the rack, and a movable frame capable of moving in the width direction of the rack is arranged on the other side of the rack. Machining head assemblies with saw discs are arranged on the fixed frame and the movable frame, and the machining head assemblies can do reciprocating motion on the fixed frame or the movable frame in the length direction. According to the double-end rip sawing device, automatic conveying, positioning and machining are carried out after feeding is carried out, full-automatic control is achieved, and the timeliness and smoothness of feeding and discharging can be guaranteed; and the two sides of a door plate are machined and cut at the same time through the machining head assemblies on the fixed frame and the movable frame, and therefore the machining efficiency is greatly improved.

Owner:TAIZHOU EVOK MASCH CO LTD

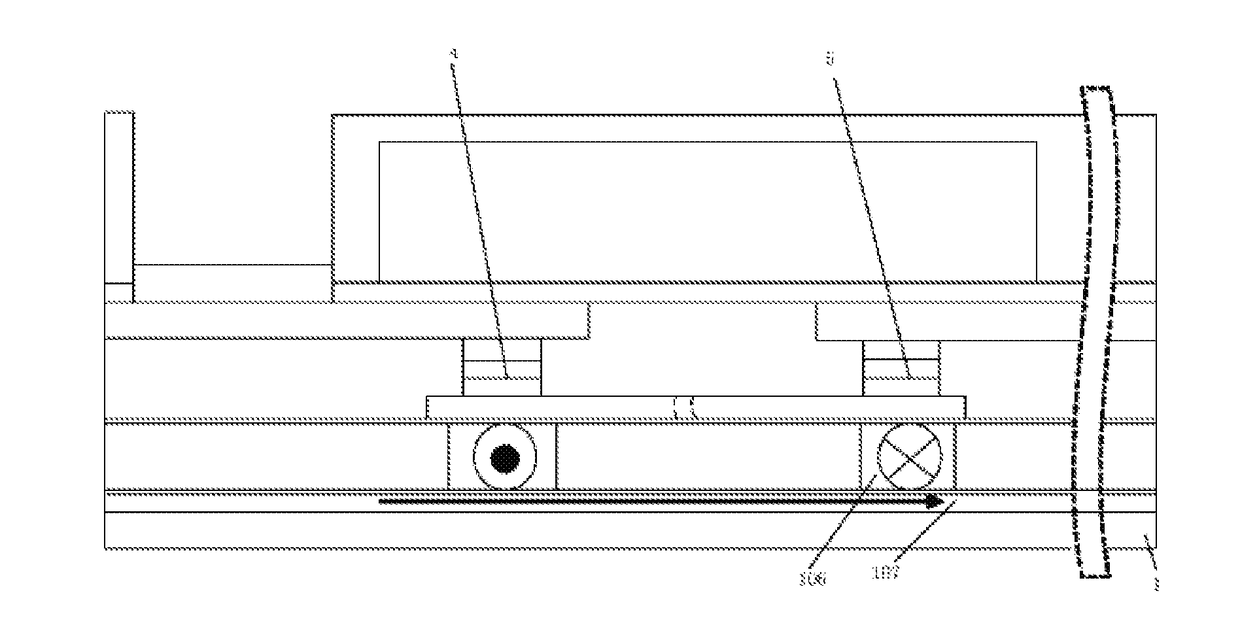

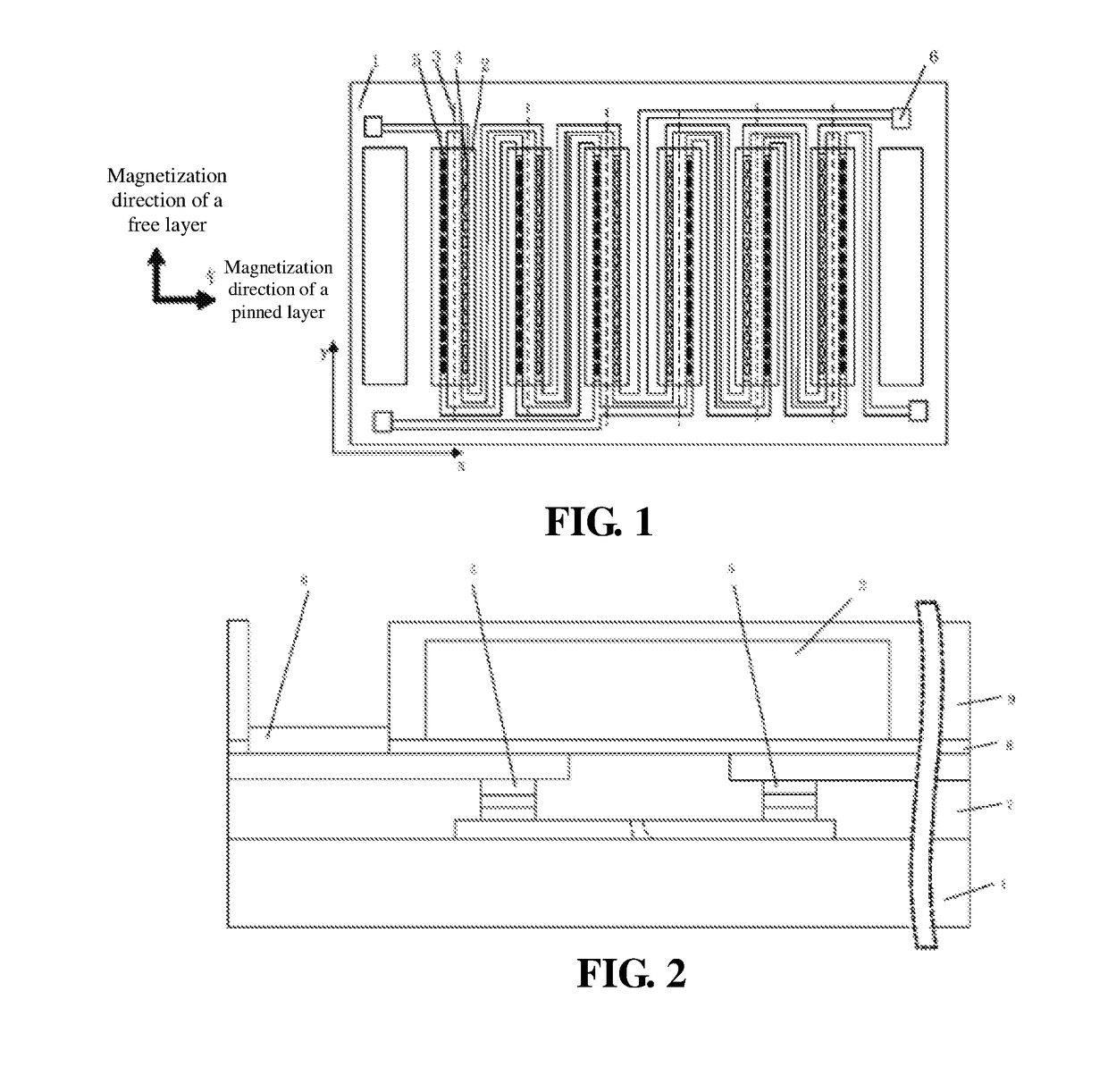

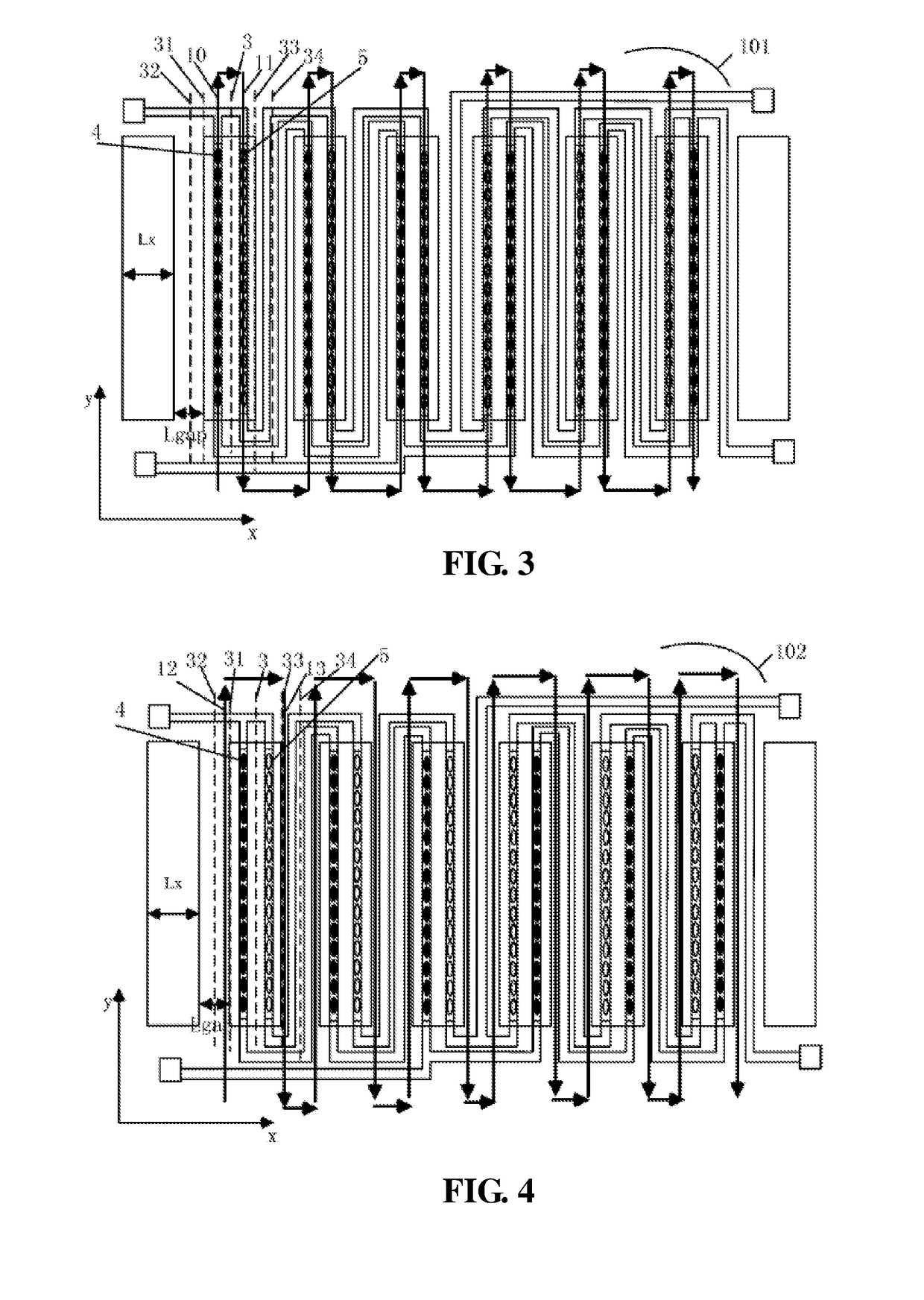

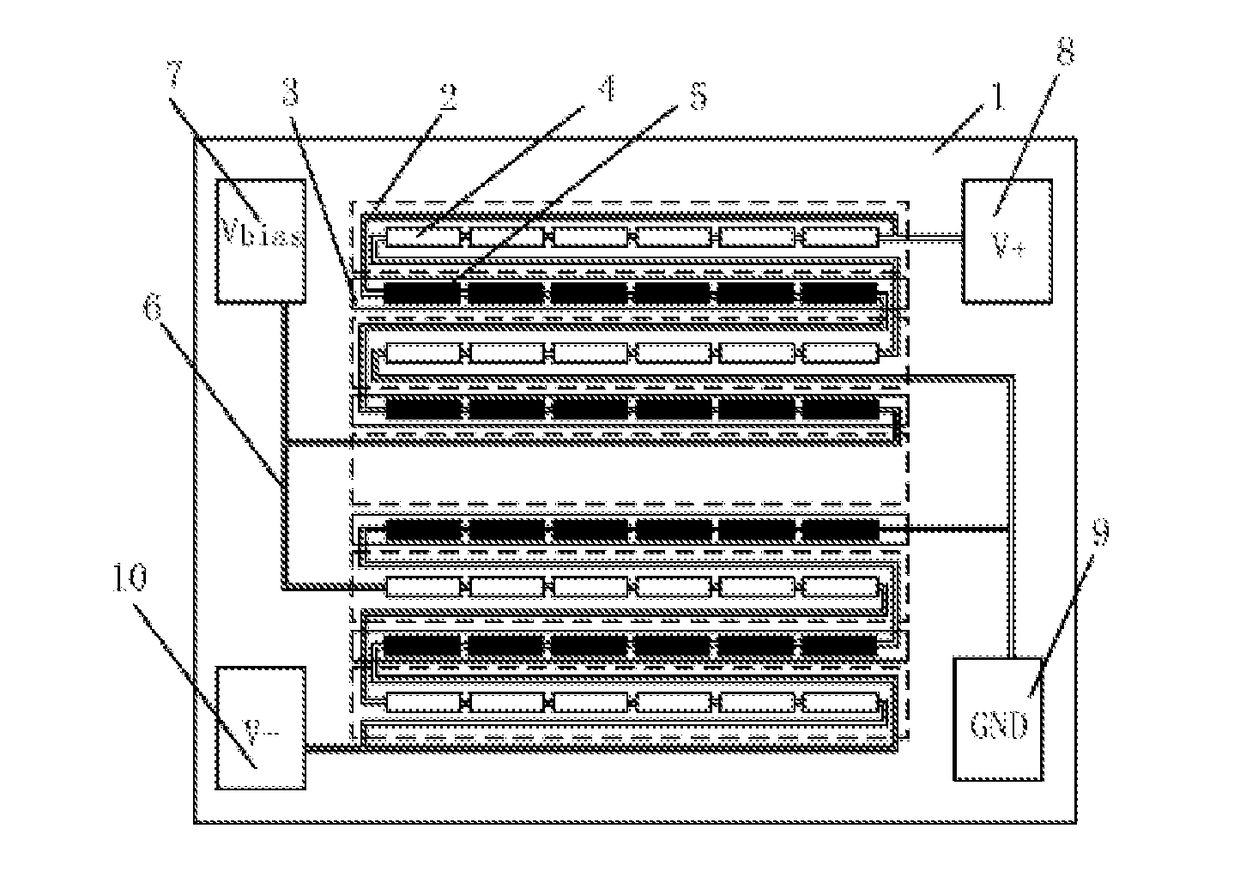

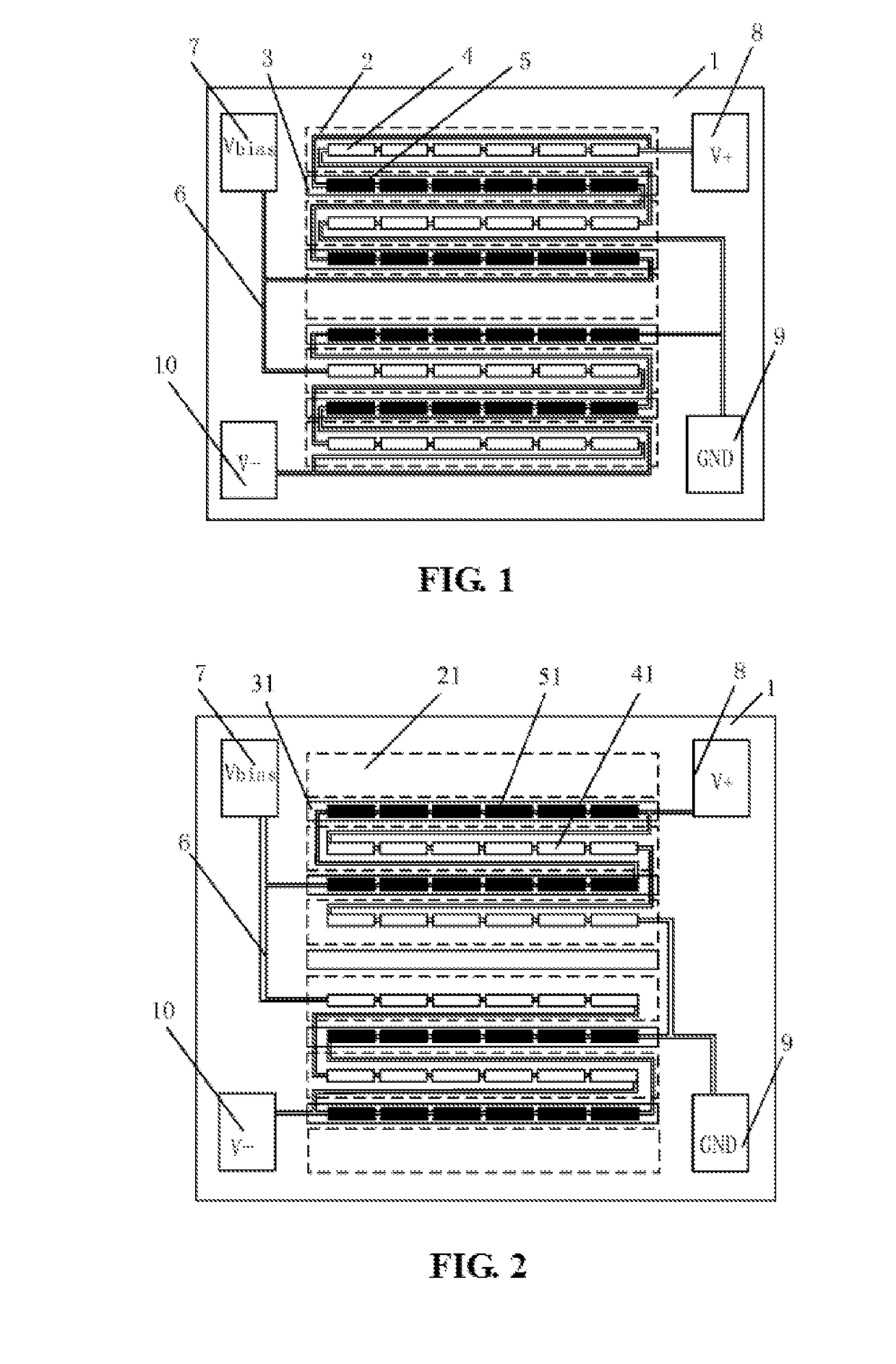

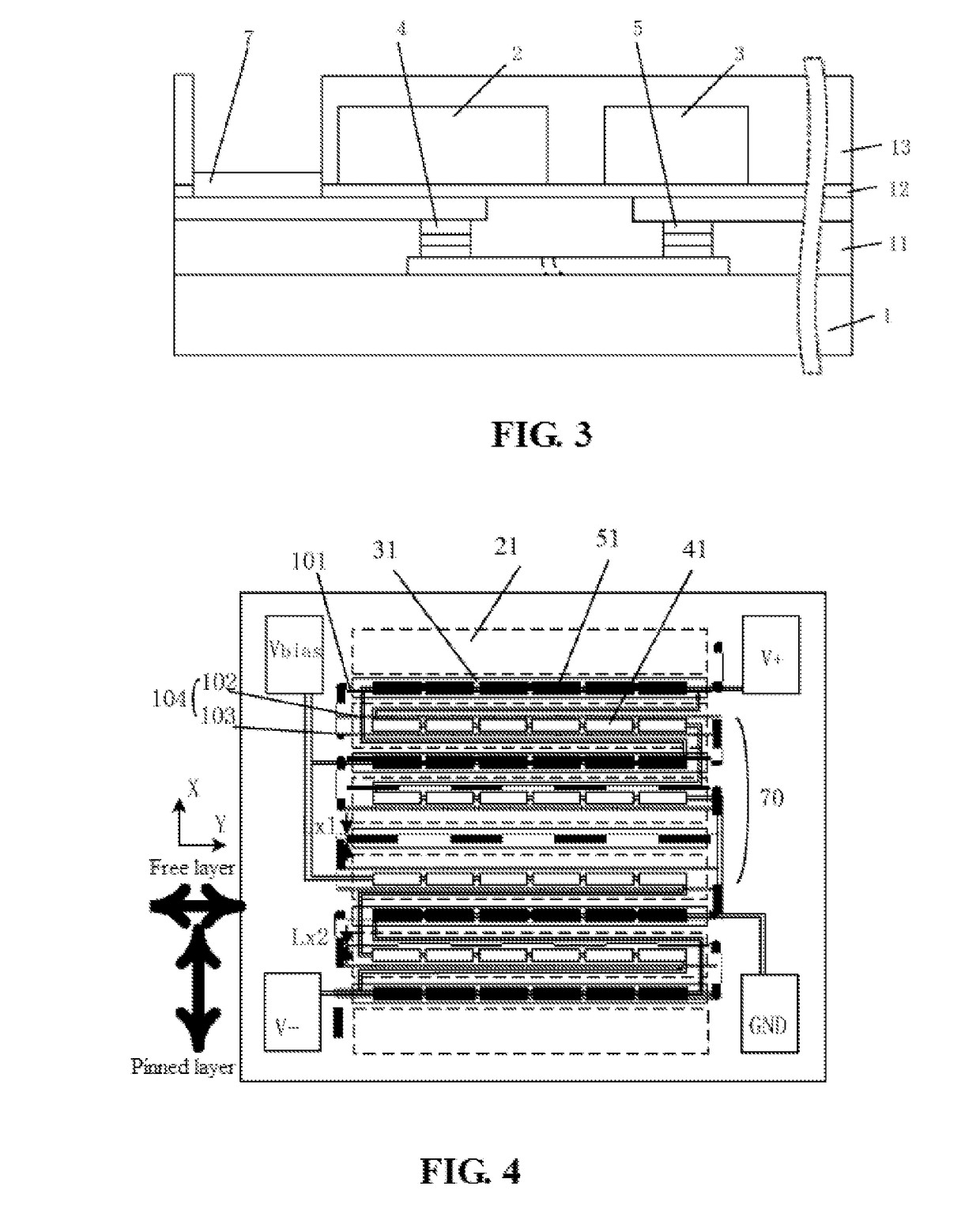

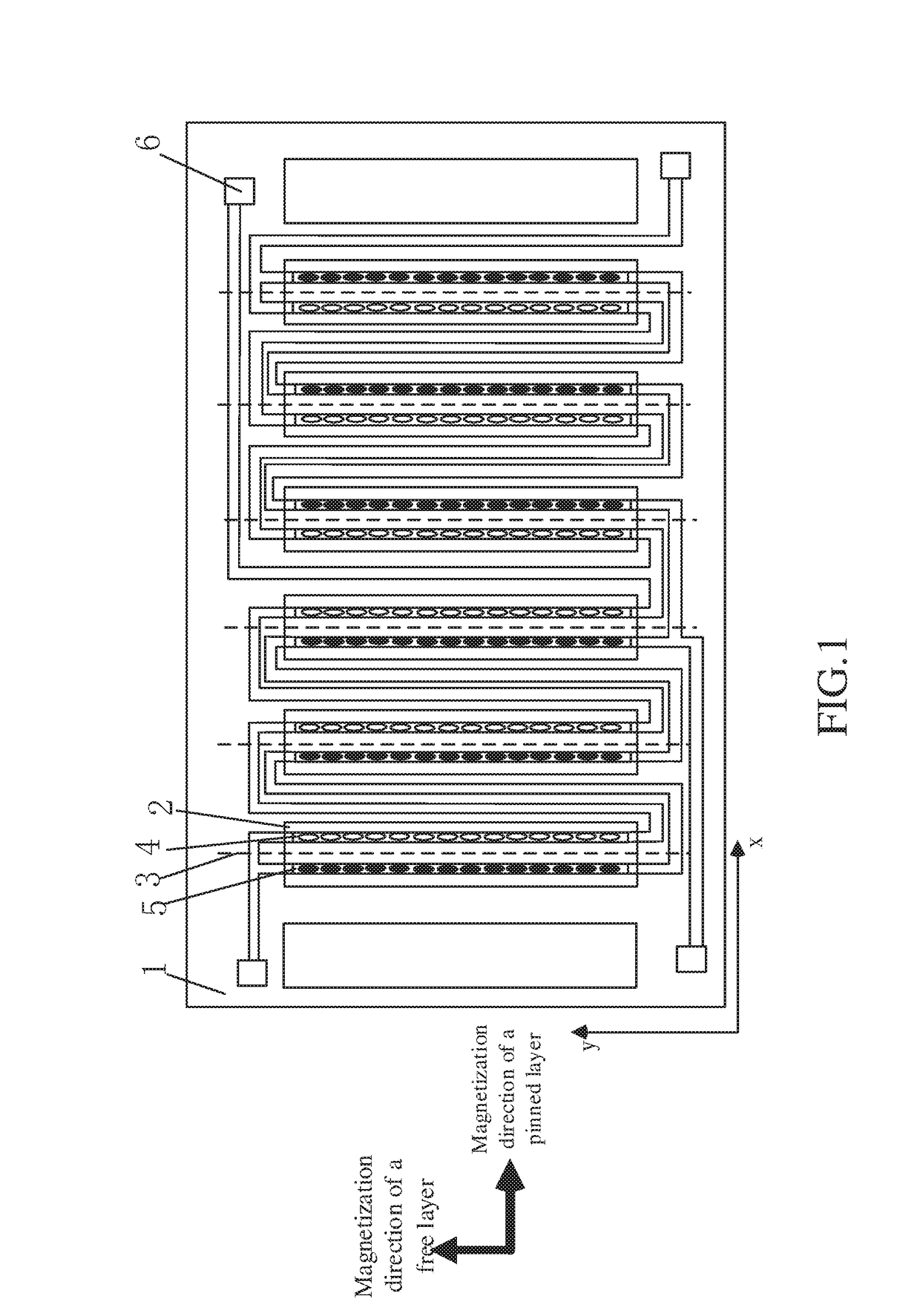

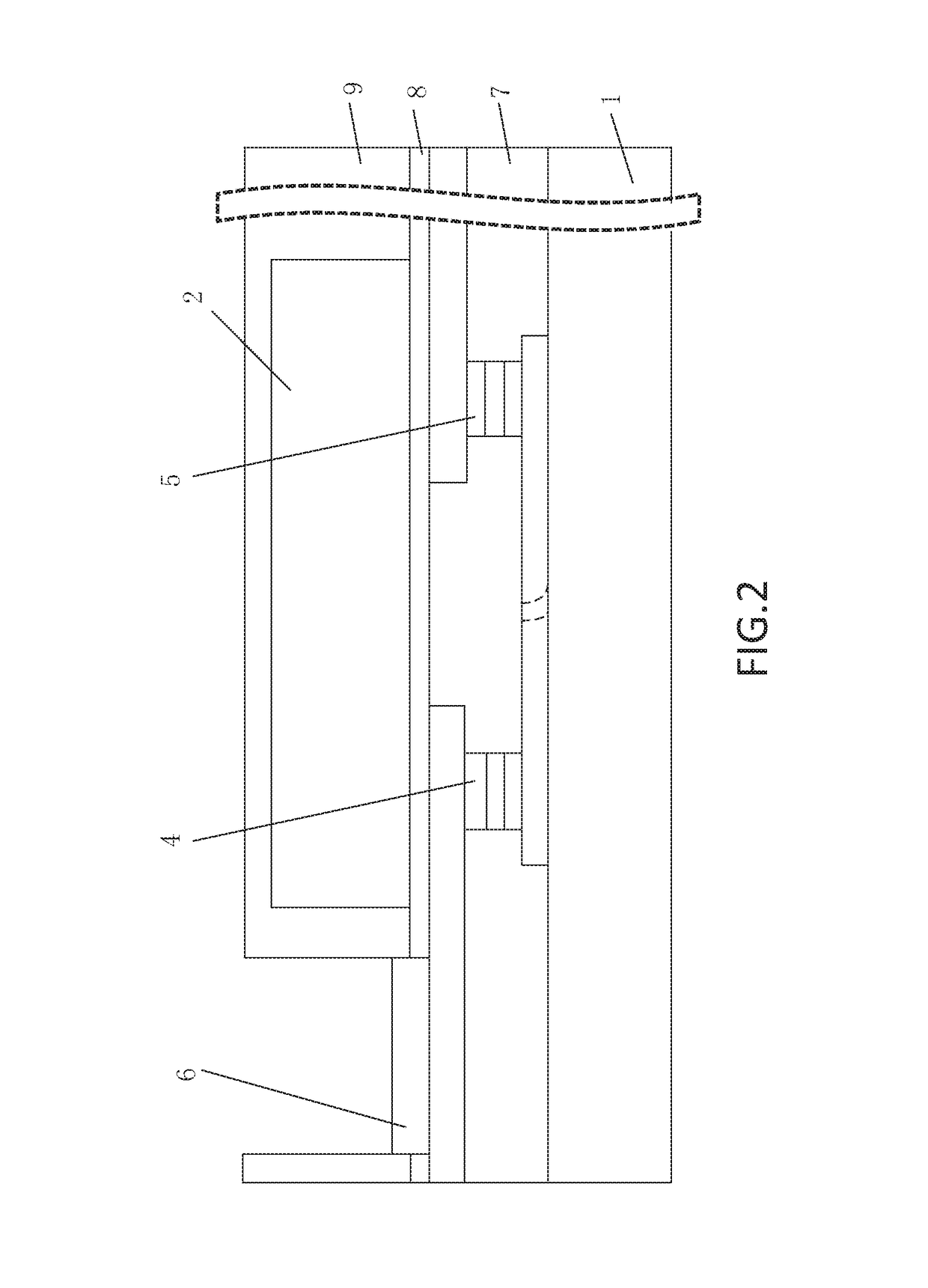

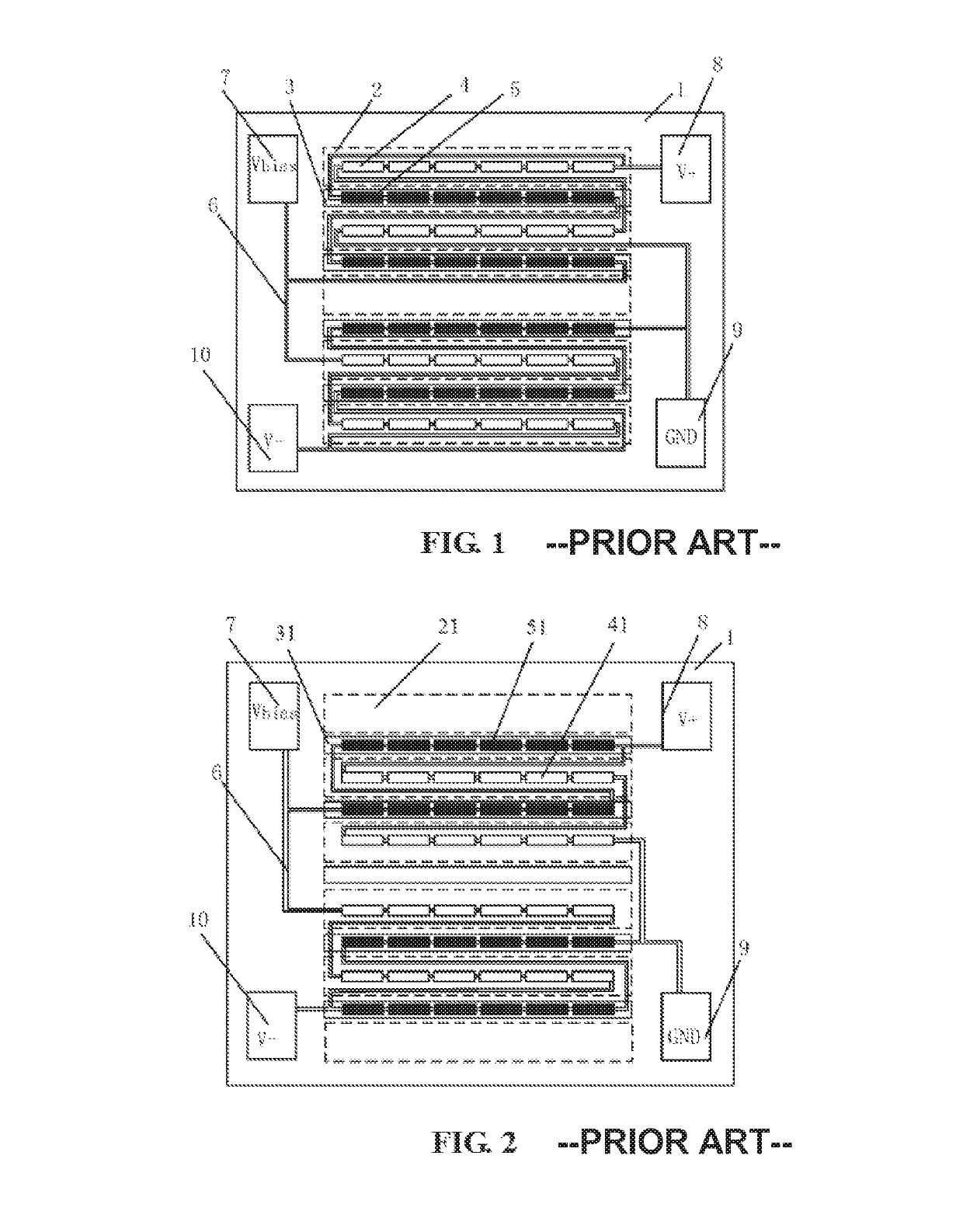

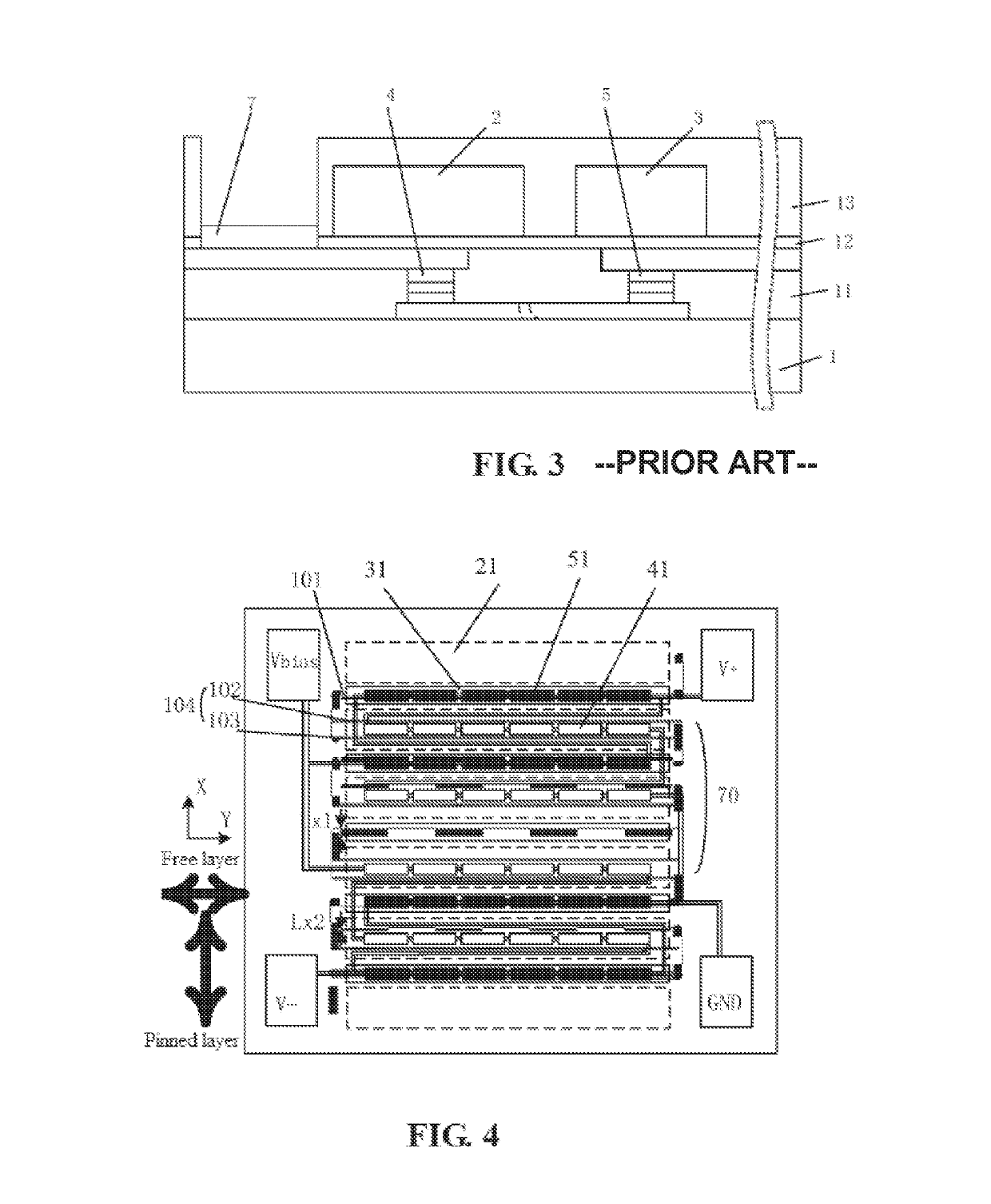

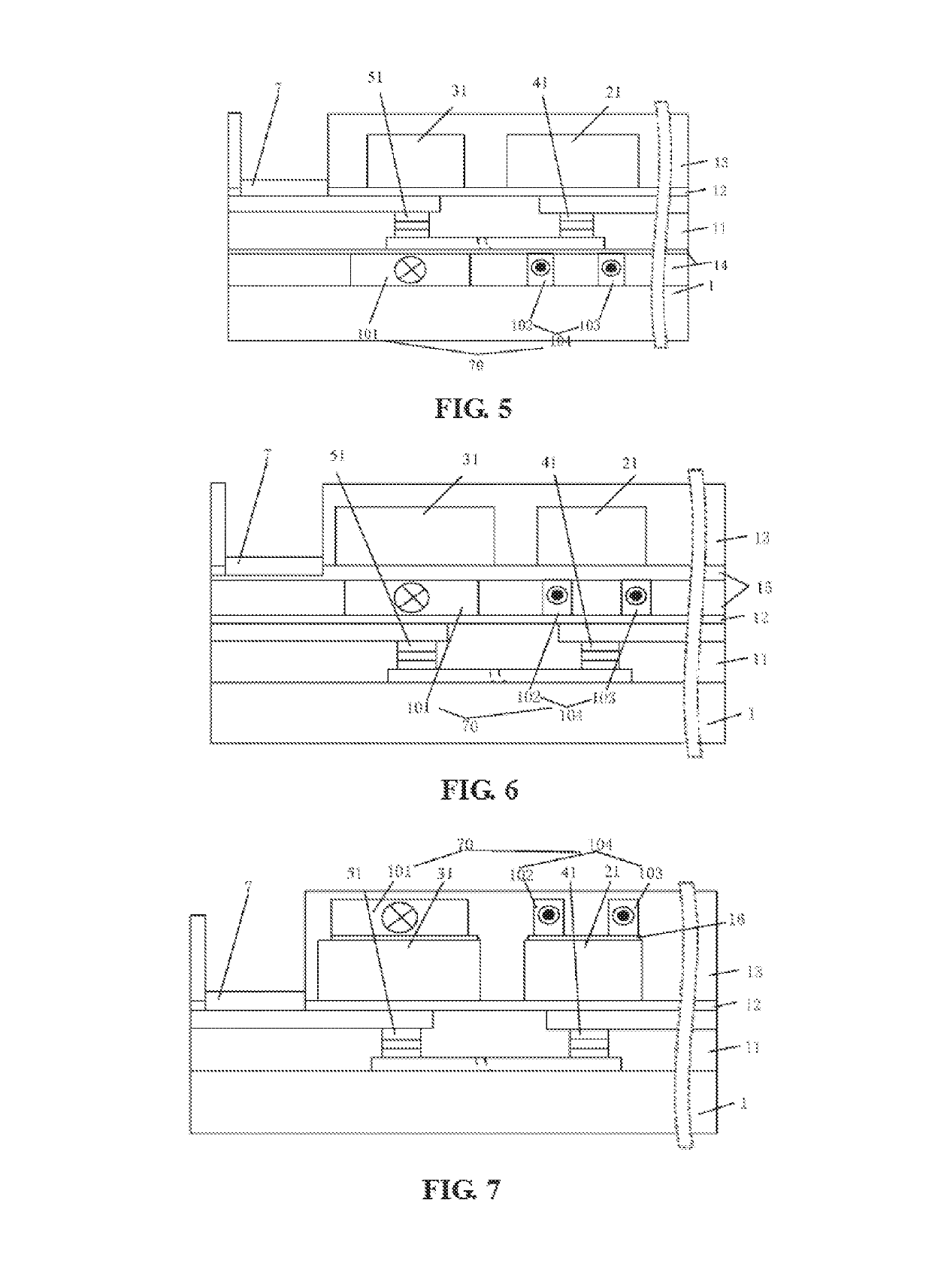

Single chip z-axis linear magnetoresistive sensor with calibration/initialization coil

ActiveUS20180081000A1Improve efficiencyImprove precisionMagnetic field offset compensationMagnetic sensor geometrical arrangementsMagnetic reluctanceMagnetization

A single chip Z-axis linear magnetoresistive sensor with a calibration / initialization coil comprises a single chip Z-axis linear magnetoresistive sensor, and a calibration coil and / or an initialization coil. The calibration coil and the initialization coil are planar coils or three-dimensional coils. The planar coils are located above a substrate and below a magnetoresistive sensing unit, between a magnetoresistive sensing unit and a soft ferromagnetic flux concentrator, above a soft ferromagnetic flux concentrator, or in a gap of the soft ferromagnetic flux concentrator. The three-dimensional coil is wound around the soft ferromagnetic flux concentrator and the magnetoresistive sensing unit. The calibration coil and the initialization coil respectively comprise straight wires which are parallel to a magnetization direction of a pinned layer / free layer, wherein the calibration coil generates an equivalent calibration magnetic field parallel / anti-parallel to the direction of the pinned layer of a push or a pull magnetoresistive unit string, and the initialization coil generates a uniform initializing magnetic field in the direction of the free layer at all magnetoresistive sensing units. By controlling the current in the calibration coil / initialization coil, calibration and magnetic state initialization of the single chip Z-axis linear magnetoresistive sensor can be achieved. The sensor has advantages of being highly efficient, quick, and convenient.

Owner:MULTIDIMENSION TECH CO LTD

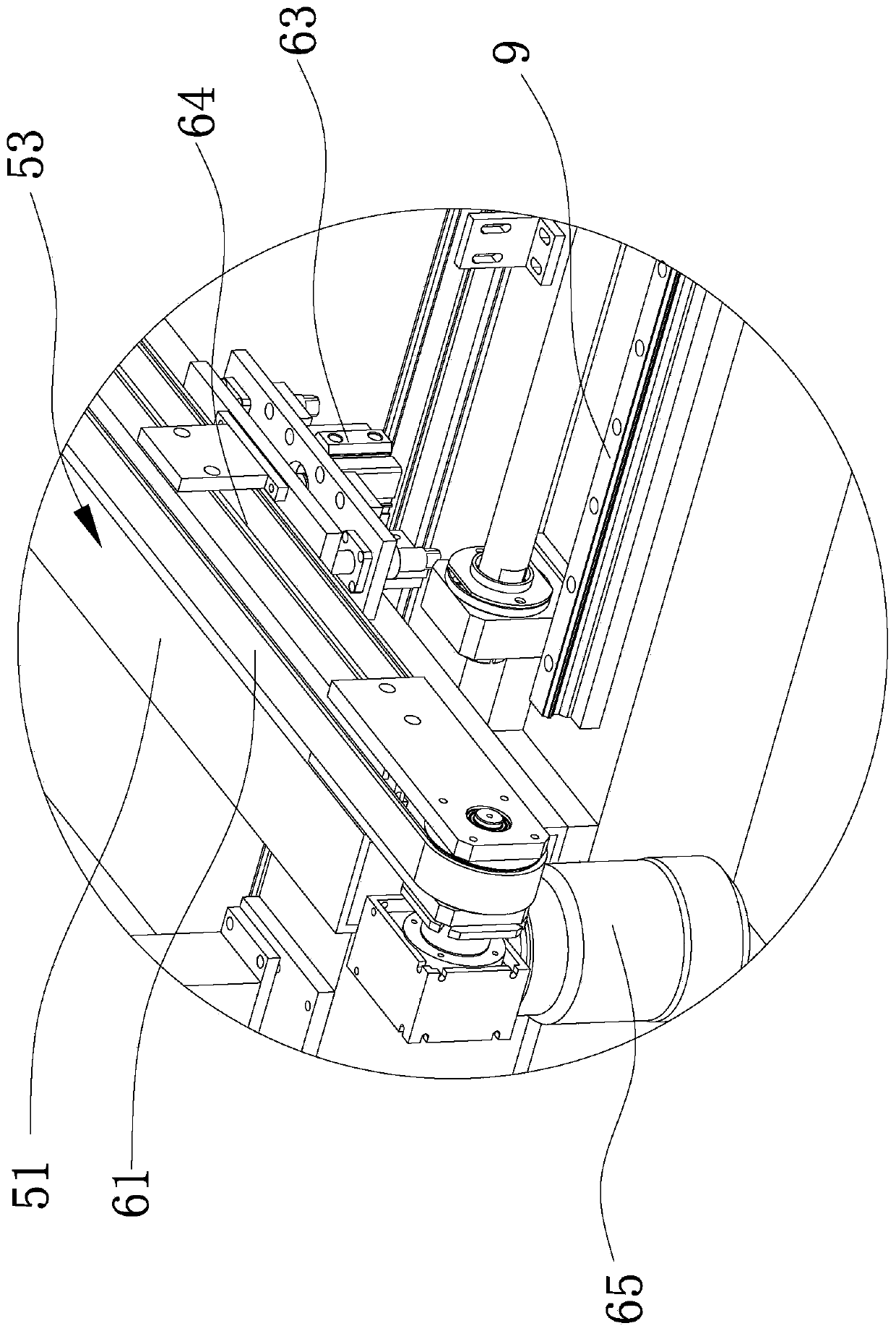

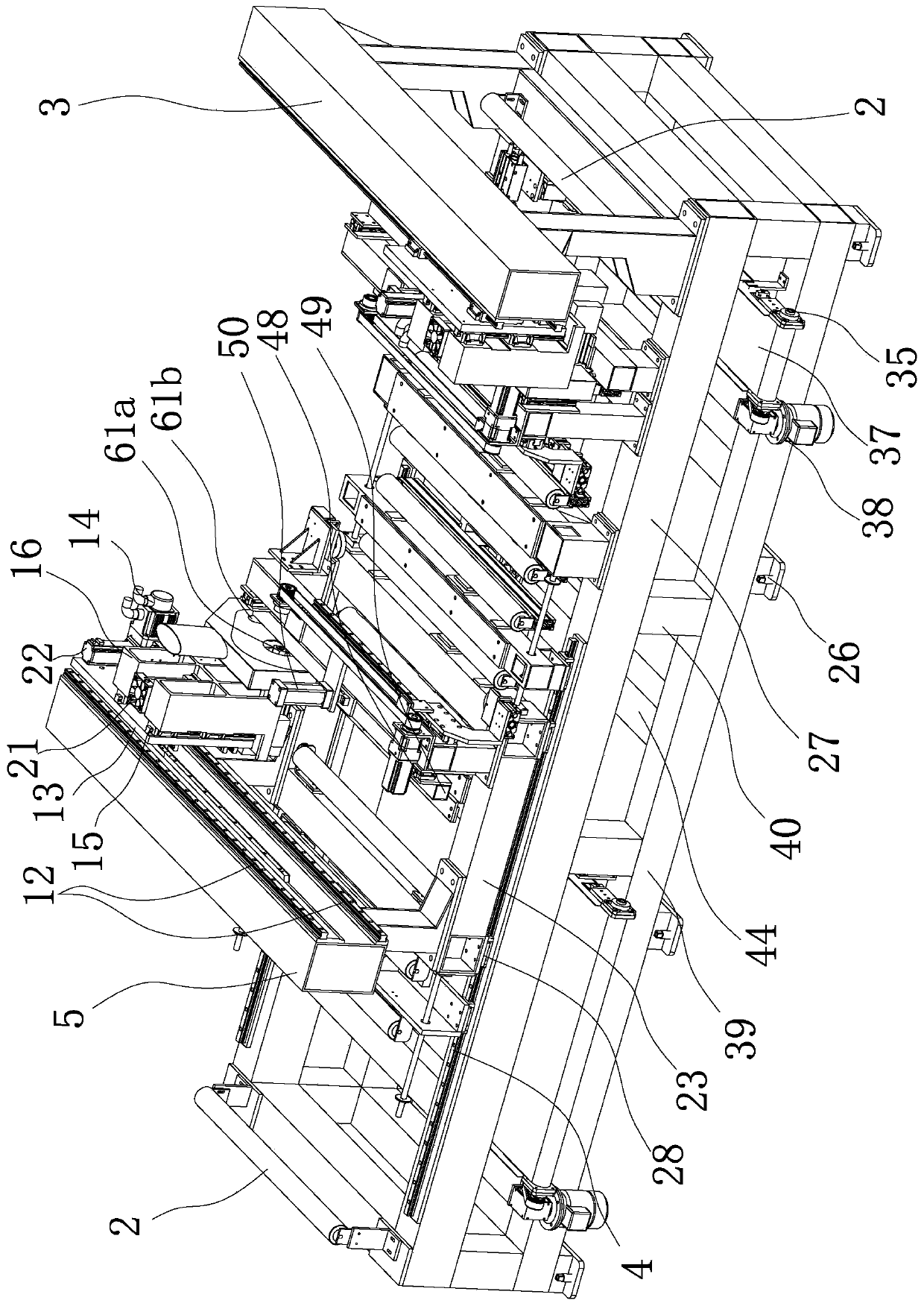

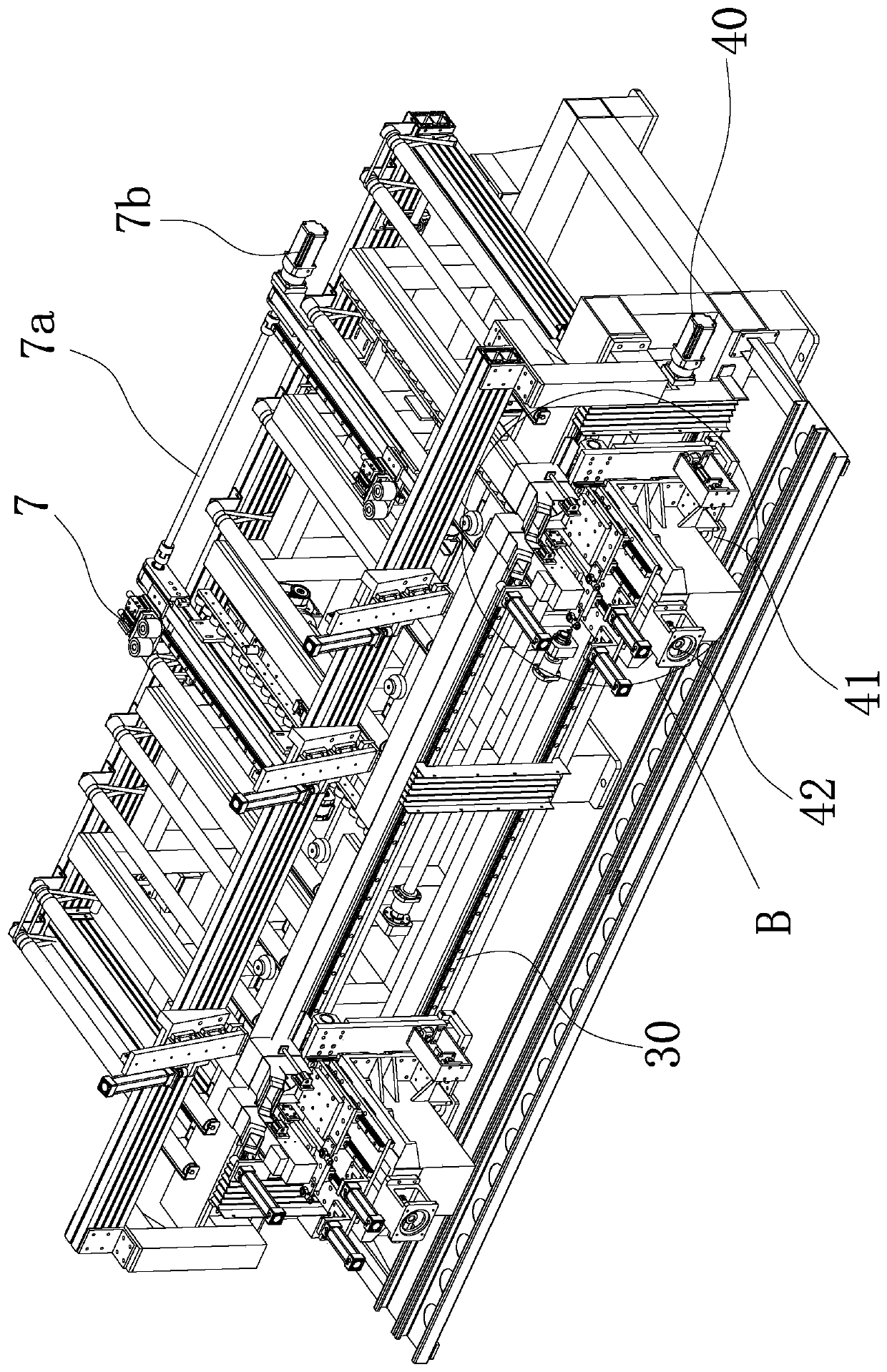

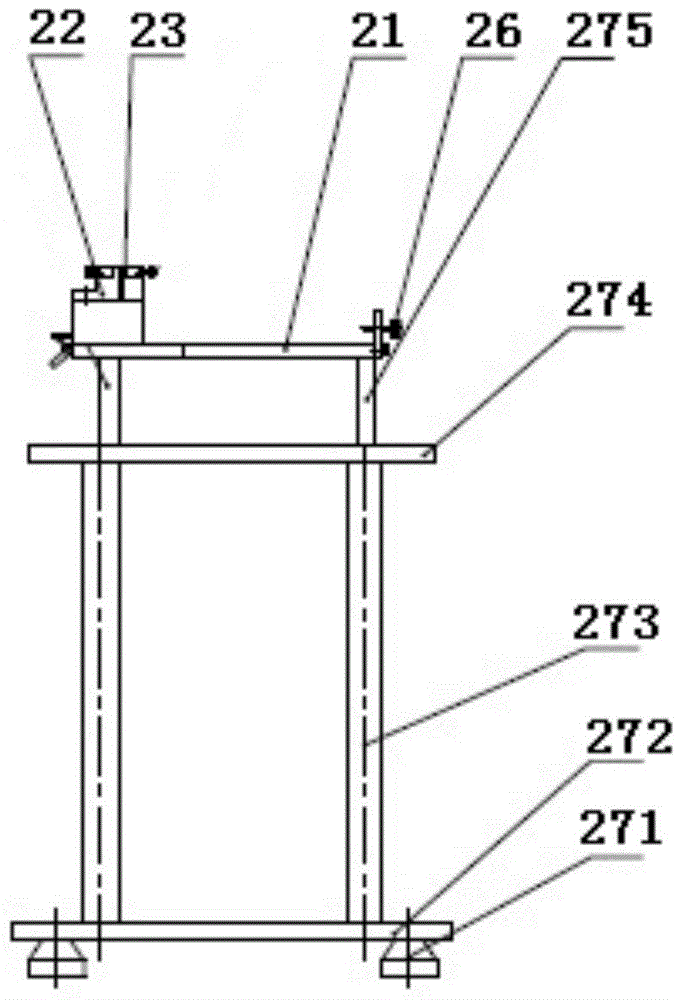

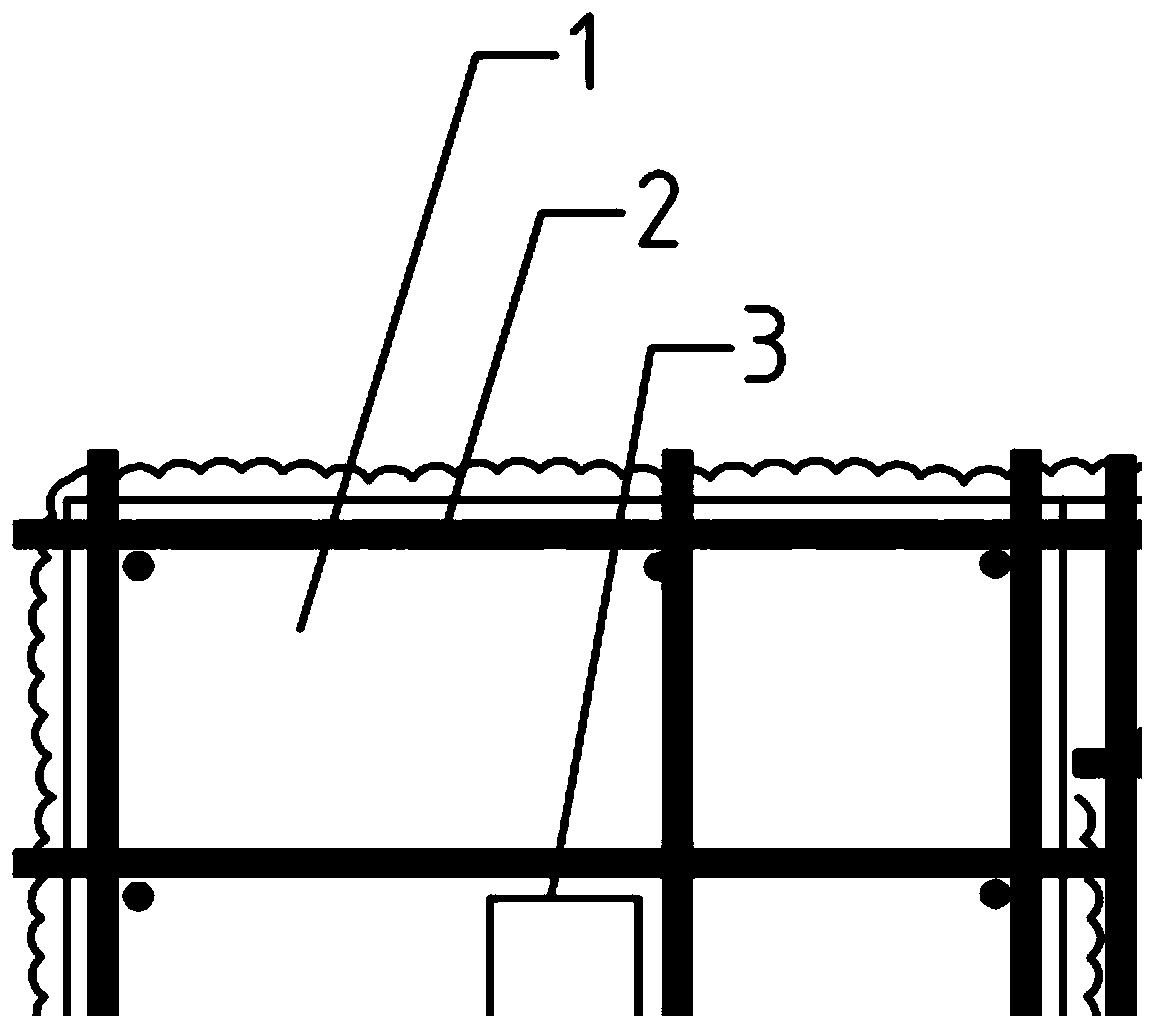

Double-end cross saw device

PendingCN110722640ARealize fully automatic controlGuaranteed timelinessFeeding devicesGripping devicesAutomatic controlMechanical equipment

The invention provides a double-end cross saw device, and belongs to the technical field of automatic mechanical equipment. The double-end cross saw device solves the technical problems that in the prior art, automatic feeding and discharging of large plates are not convenient, and the double-end cross saw device is not suitable for plates needed by large door and window furniture and other products. The double-end cross saw device comprises a rack, wherein the input end and the output end of the rack are each provided with a first roller; a fixed portal frame is fixedly arranged at the outputend of the rack; sliding rails are arranged at the positions, close to the two sides of the input end, of the rack; a movable portal frame capable of moving in the direction of the fixed portal frameis arranged on the sliding rails in a sliding manner; and the fixed portal frame and the movable portal frame are each provided with a machining head assembly with a saw disc. The double-end cross saw device achieves automatic conveying, positioning and machining after feeding, full-automatic control is achieved, timeliness and smoothness of feeding and discharging can be ensured, the machining head assemblies on the fixed portal frame and the movable portal frame are used for machining and cutting the two ends of a door plate at the same time, and therefore the machining efficiency is greatly improved.

Owner:TAIZHOU EVOK MASCH CO LTD

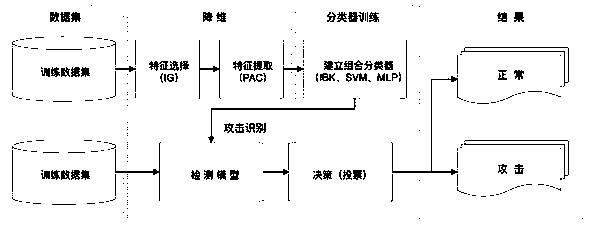

Network-oriented intrusion data detection method

ActiveCN110602120AReduce dimensionalityGuarantee high efficiency and precisionData switching networksData miningFalse alarm

The invention discloses a network-oriented intrusion data detection method, which comprises the following steps of: firstly, performing attribute dimension reduction on network flow data, and then inputting the data into a data detection model; and enabling the detection model to process the network flow data according to a decision rule and detects intrusion data. According to the invention, high-efficiency, high-precision and low-false-alarm intrusion detection can be realized, and the detection efficiency is improved.

Owner:INFORMATION & COMM BRANCH OF STATE GRID JIANGSU ELECTRIC POWER

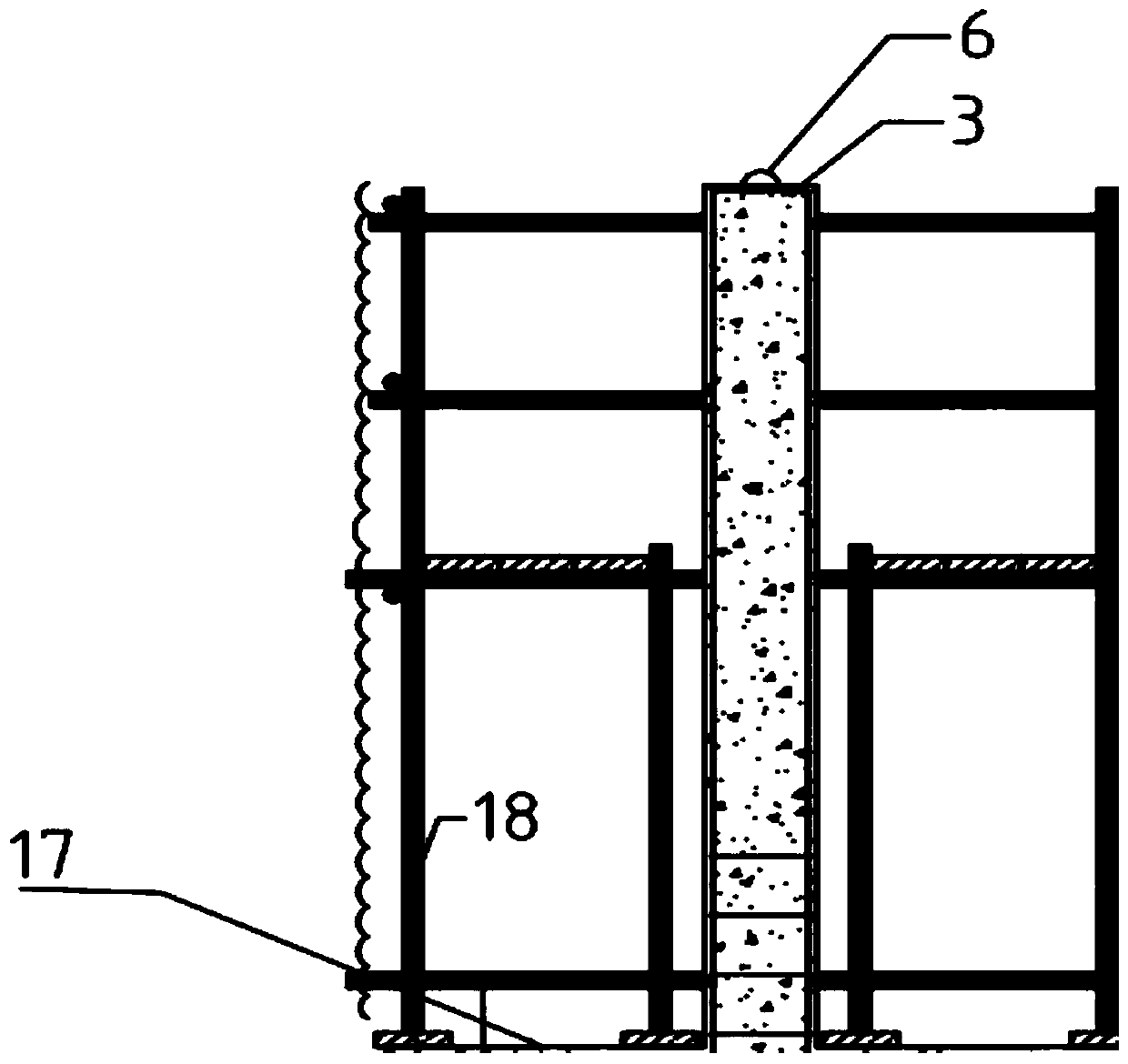

Bearing type and non-bearing type body-in-white lower vehicle body mixed flow tool and method

ActiveCN112958976AInnovative ideasIngenious structureInternal combustion piston enginesWelding/cutting auxillary devicesMixed flowControl system

The invention discloses a bearing type and non-bearing type body-in-white lower vehicle body mixed flow tool and method. The mixed flow tool comprises a split type clamp mounting plate, a front longitudinal beam positioning unit, a front wall assembly positioning unit, a non-bearing type rear wall translation gable wall, a rear wheel cover sliding table positioning unit, a bearing type rear wall translation gable wall and a control system. According to the vehicle body types of bearing type and non-bearing type body-in-white lower vehicle bodies, the control system controls the front longitudinal beam positioning unit, the front wall assembly positioning unit, the rear wheel cover sliding table positioning unit and the bearing type rear wall translation gable wall to position and assemble the bearing type body-in-white lower vehicle body; or the front wall assembly positioning unit and the non-bearing type rear wall translation gable wall are used for positioning and assembling the non-bearing type body-in-white lower vehicle body. The bearing type and non-bearing type body-in-white lower vehicle body mixed flow tool is novel in thought, ingenious in structure, high in automation degree and capable of meeting the mixed flow production requirements of various bearing type and non-bearing type military off-road vehicle body-in-white lower vehicle bodies.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

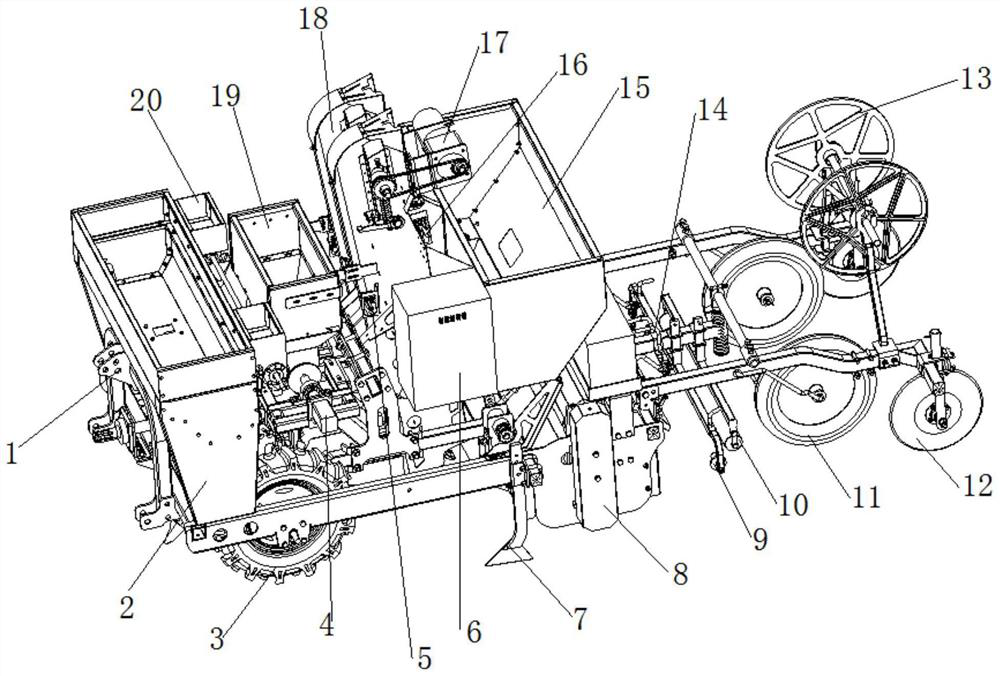

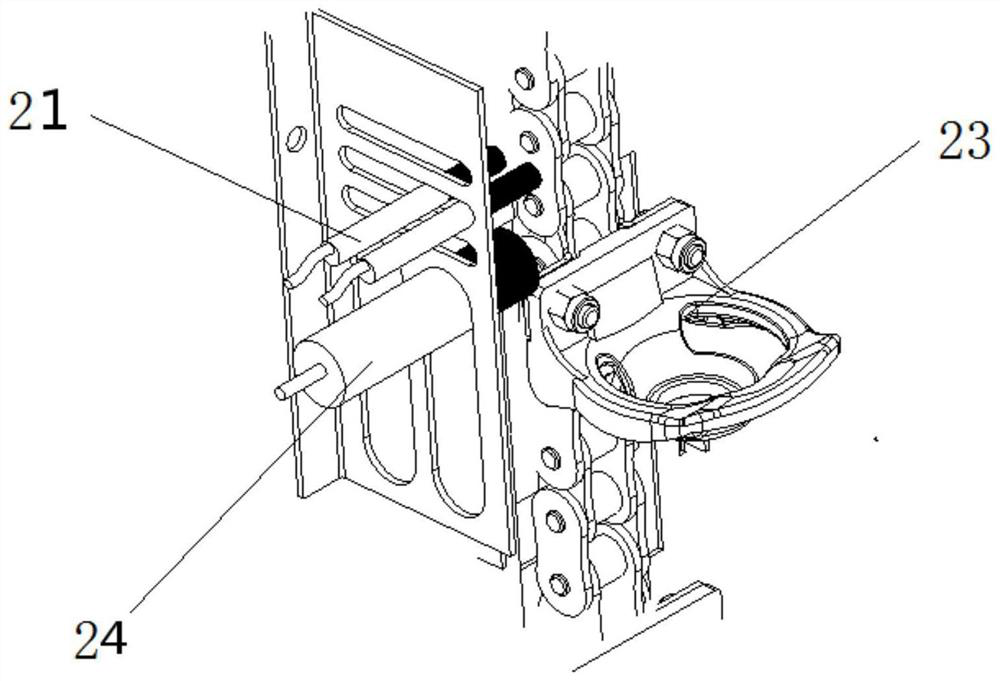

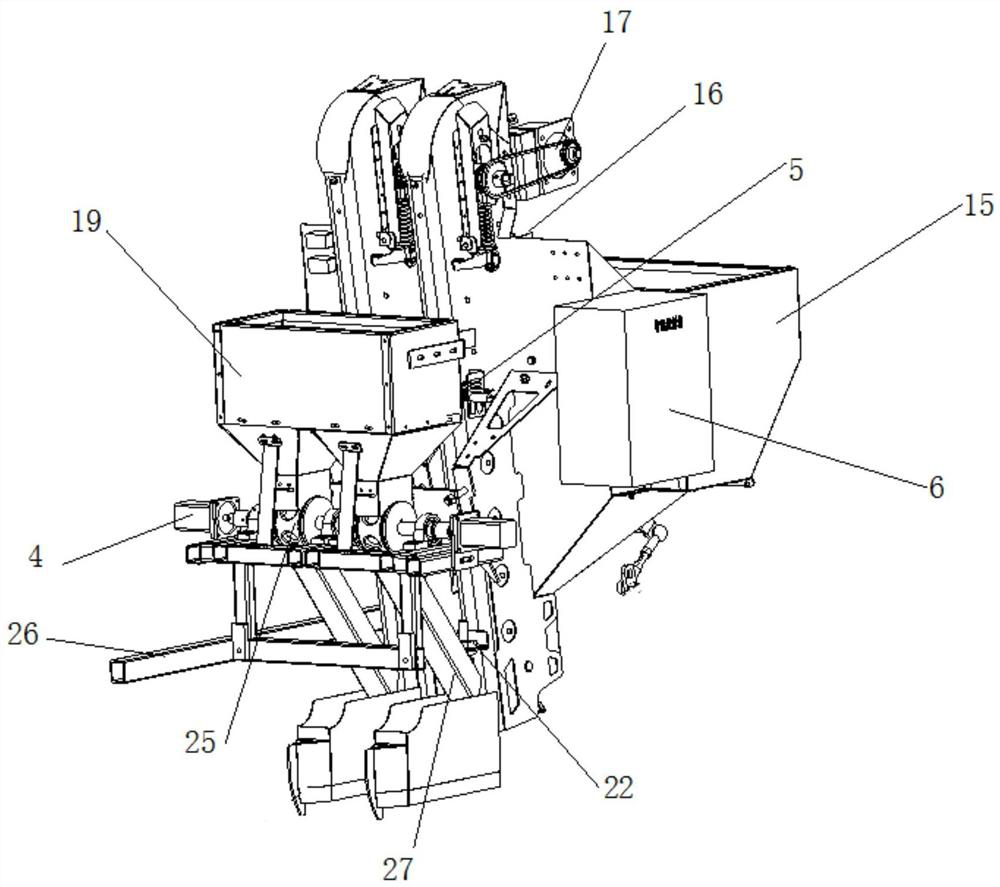

Potato miss-seeding reseeding machine capable of realizing high efficiency precision and low miss-seeding

PendingCN111771442ASolve the shortcomings of low efficiency, low seeding accuracy and high cost of artificial reseedingImprove seeding accuracySpadesFertiliser distributersAgricultural engineeringDrip irrigation

The invention belongs to the technical field of agricultural machinery, and particularly relates to a potato miss-seeding reseeding machine capable of realizing high efficiency precision and low miss-seeding. The potato miss-seeding reseeding machine comprises fixed racks, a fertilizing device, a granular pesticide seeding device, a reseeding device, a seed metering device, a miss-seeding detection device, a rotary tillage ridging device, a weeding and pesticide spraying device and a film mulching and soil covering device, wherein a cross beam is arranged in front of the two fixed racks, a suspension bracket is mounted on the cross beam, a fertilization ditching shovel is mounted in the middle of the cross beam, a traveling wheel is mounted on each of the two fixed racks, the rotary tillage ridging device is mounted behind the fixed racks, and a drip irrigation belt laying device and a film mulching and soil covering device are arranged behind the rotary tillage ridging device. The potato miss-seeding reseeding machine capable of realizing high-efficiency precision and low miss-seeding is compact in mechanical structure, simple in structure and stable in operation, and capable of realizing accurate seeding of potatoes and reducing the miss-seeding rate.

Owner:QINGDAO AGRI UNIV

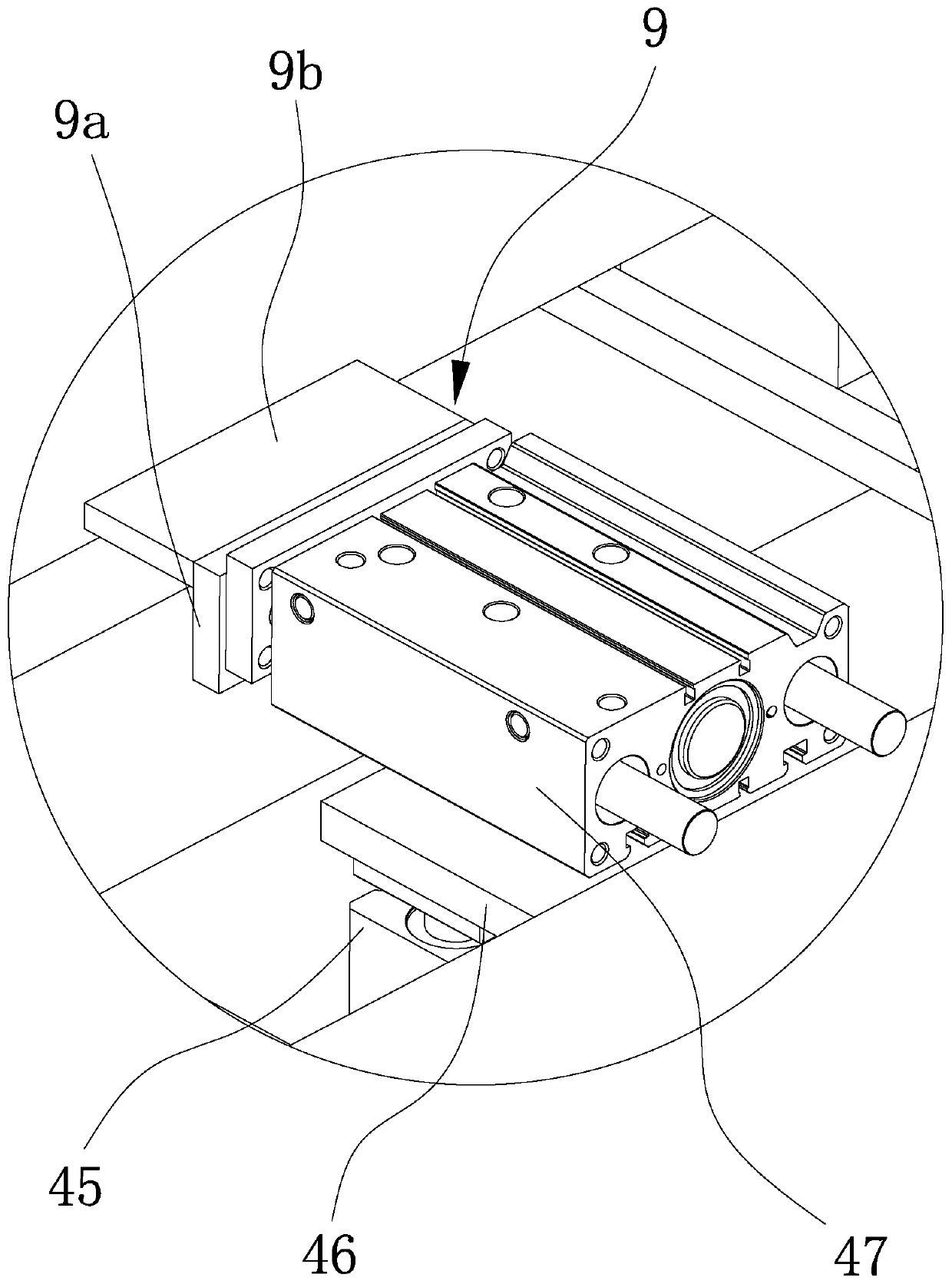

Device used for machining plate side face hole groove

PendingCN111421622AGuarantee high efficiency and precisionGuaranteed timelinessStationary drilling machinesMulti-purpose machinesEngineeringMechanical equipment

The invention provides a device used for machining a plate side face hole groove, and belongs to the technical field of automatic mechanical equipment. The technical problems that in the prior art, positioning machining is not efficient and accurate, stability is poor, and in the plate conveying process, wear is easily caused can be solved. The device comprises a rack, an input end is arranged atone end of the rack, an output end is arranged at the other end of the rack, and the device is characterized in that multiple work platforms are fixedly mounted on the rack, at least one set of working heads facing the work platform is mounted on one side of the rack, a set of rollers capable of lifting is arranged on the rack from the input end to the output end of the rack, a baffle which can lift and move towards the conveying direction of the rollers is arranged between the rollers, a mounting cross beam is fixedly mounted at the position, above the work heads, of the rack, and the mounting cross beam is provided with a driving part inclining downwards to face the side of the rack from the outer side of the rack. Timeliness and smoothness of loading and discharging can be ensured, themultiple work heads carry out machining at the same time, and machining efficiency is greatly improved.

Owner:TAIZHOU EVOK MASCH CO LTD

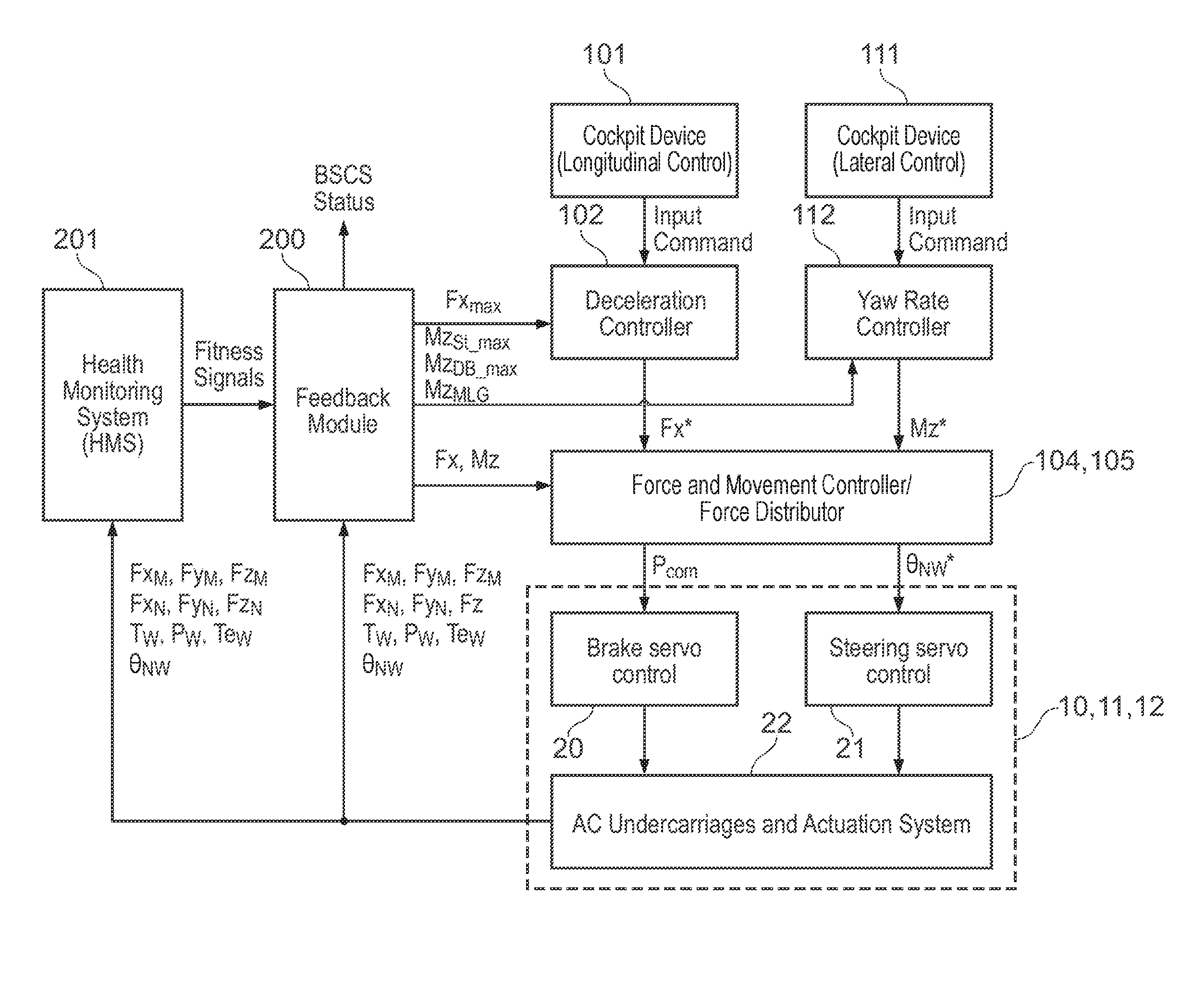

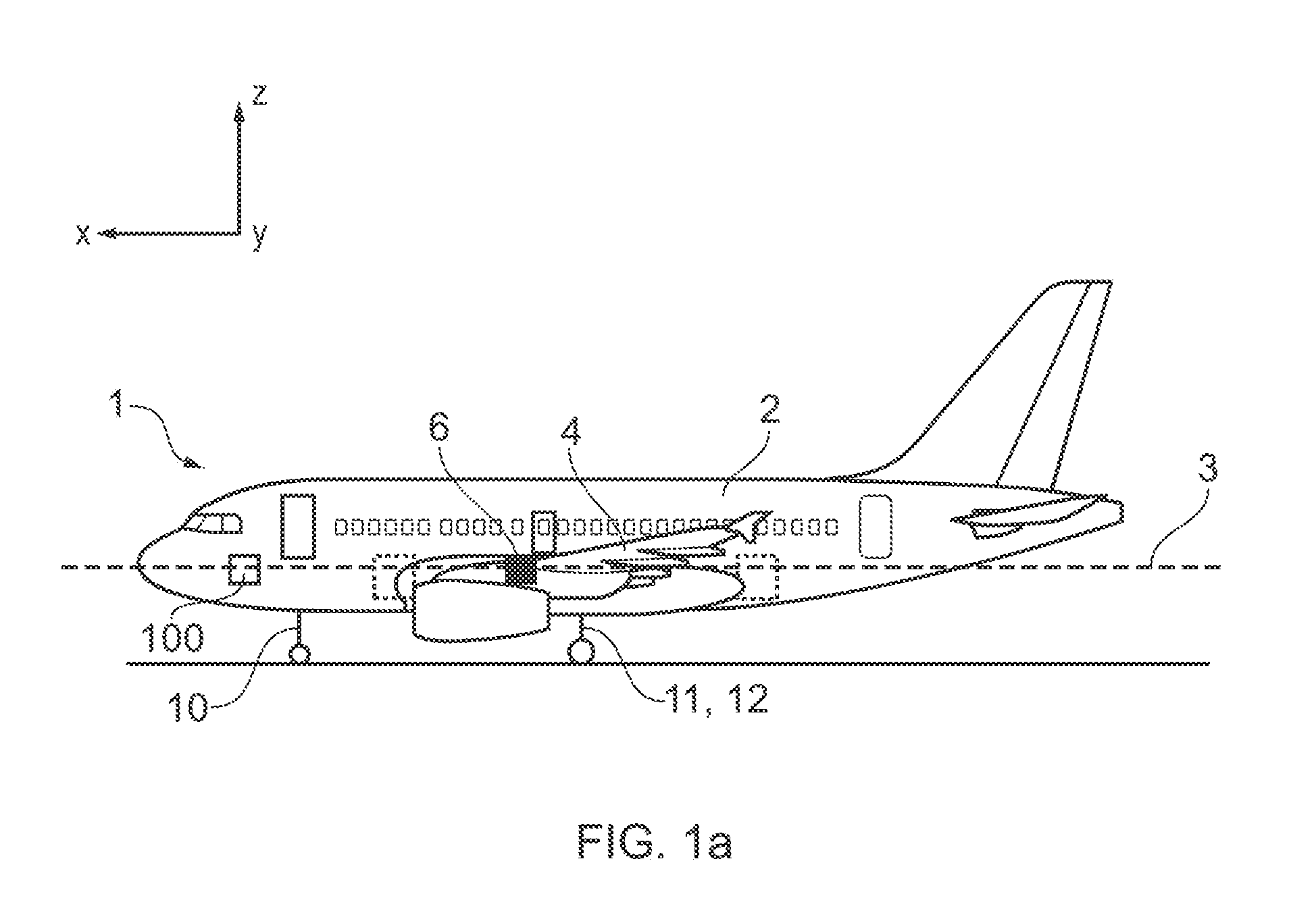

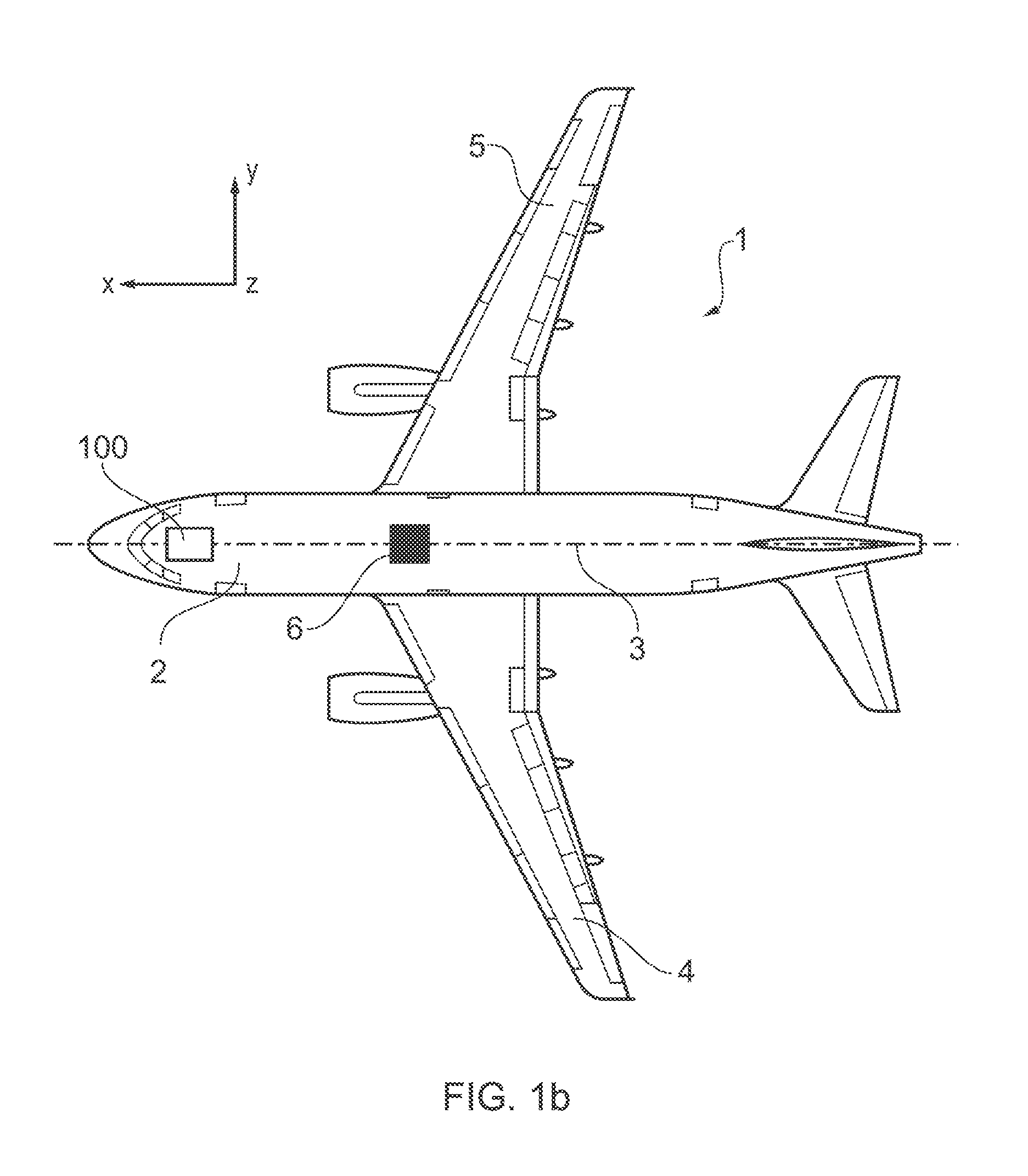

Data processing unit for aircraft undercarriage performance monitoring

ActiveUS20170011568A1Increase heightAffect performanceAircraft health monitoring devicesRegistering/indicating working of vehiclesFlight vehicleAirplane

A data processing unit for monitoring the performance of at least one undercarriage which is used for braking and / or steering an aircraft, wherein the data processing unit is configured to: receive data representative of operating characteristics of the undercarriage(s) and use that data to calculate a maximum achievable braking force and / or yaw moment to be generated by the undercarriage(s). Also a method for monitoring the performance of at least one aircraft undercarriage which is used for braking and / or steering an aircraft, the method including: receiving data representative of operating characteristics of the undercarriage(s); and using that data to calculate a maximum achievable braking force and / or yaw moment to be generated by the undercarriage(s).

Owner:AIRBUS OPERATIONS LTD +1

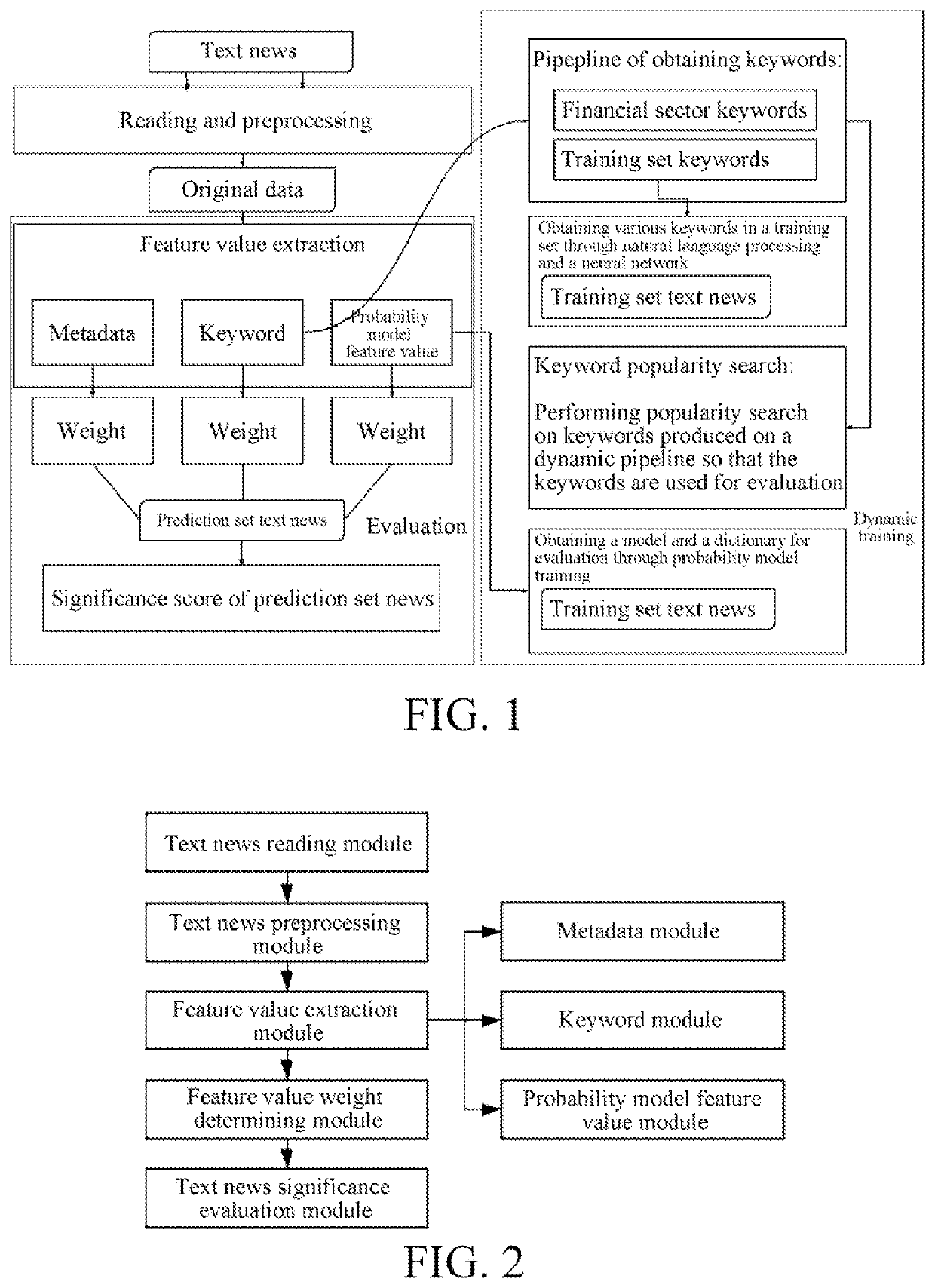

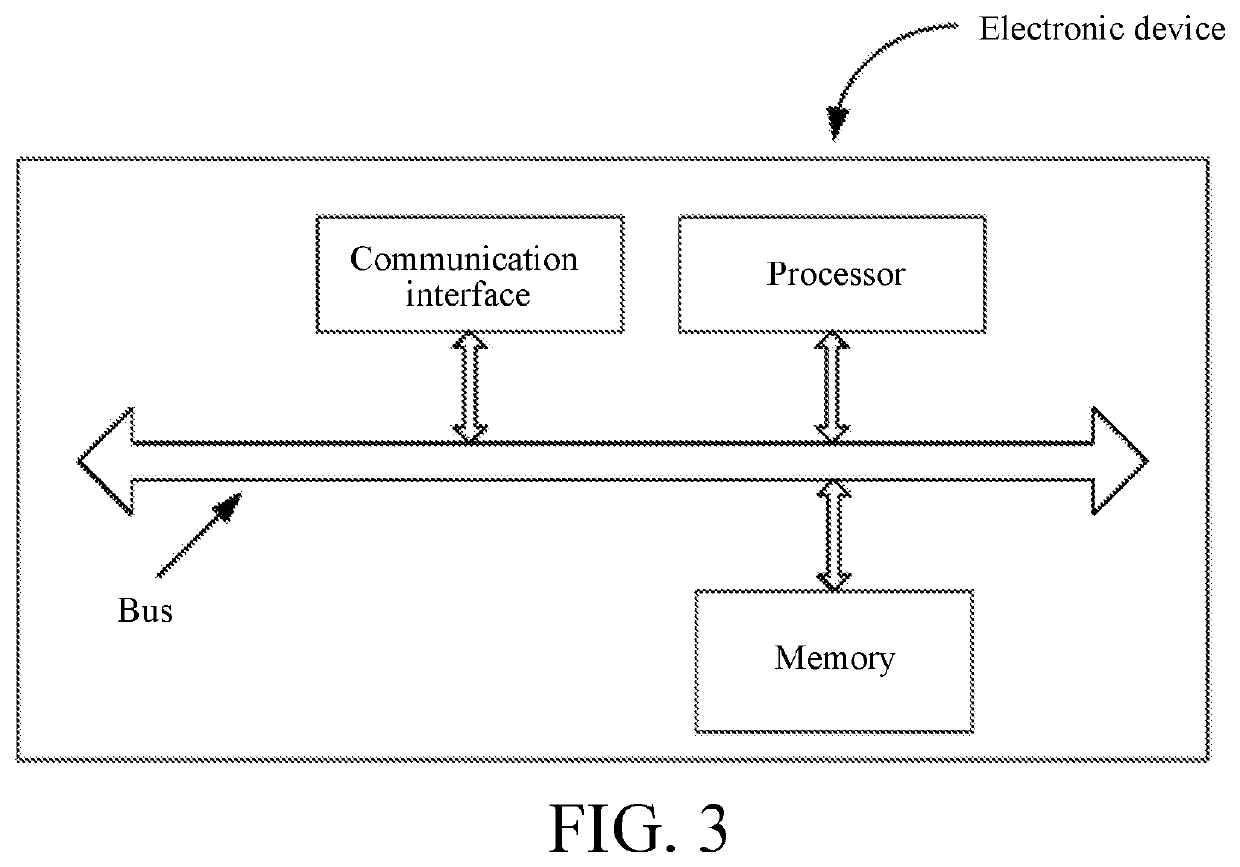

Text-Based News Significance Evaluation Method, Apparatus, and Electronic Device

PendingUS20220075938A1Guarantee high efficiency and precisionImprove accuracyNatural language data processingProbabilistic networksOriginal dataEngineering

The present invention provides text-based news significance evaluation methods, apparatuses, and electronic devices for improving efficiency and accuracy of news significance evaluation, and implementing real-time dynamic evaluation on text news. The method comprises: reading text news; preprocessing the text news to obtain original data; extracting feature values from the original data, which comprises metadata, a keyword, and a probability model feature value; and obtaining a score of each feature value according to a weight ratio corresponding to each feature value. The apparatus comprises: a text news reading module, a text news preprocessing module, a feature value extraction module, a feature value weight determining module, and a text news significance evaluation module. The electronic device comprises a memory and a processor. The memory stores a computer program that can run on the processor. When executing the computer program, the processor implements the text-based news significance evaluation method.

Owner:BUSINESS MANAGEMENT ADVISORY LLC

Single-chip high-magnetic-field x-axis linear magnetoresistive sensor with calibration and initialization coil

ActiveUS20180246177A1Accurate supervisionGuarantee high efficiency and precisionMagnetic field offset compensationMagnetic sensor arraysSingle chipAcoustics

A single-chip high-magnetic-field X-axis linear magnetoresistive sensor with a calibration and an initialization coil, comprising a high magnetic field single-chip referenced bridge X-axis magnetoresistive sensor, a calibration coil, and an initialization coil, wherein the calibration coils are planar coils, and the initialization coils are planar or three-dimensional coils. The planar calibration coils and the planar initialization coils can be placed above a substrate and below the magnetoresistive sensor units, between the magnetoresistive sensor units and the soft ferromagnetic flux guides, above the soft ferromagnetic flux guides, or at gaps between the soft ferromagnetic flux guides. The three-dimensional initialization coil is wound around the soft ferromagnetic flux guides and magnetoresistive sensor units. The calibration coils and the initialization coils generate a calibration magnetic field paralleled the direction of pinned layer and a uniform initialization magnetic field in the direction of the free layer respectively at the location of the magnetoresistive sensor units. Through controlling the current of the calibration coils and the initialization coils, the calibration and initialization of the magnetic state of the single-chip X-axis linear magnetoresistive sensor can be performed.

Owner:MULTIDIMENSION TECH CO LTD

Single chip Z-axis linear magnetoresistive sensor with calibration/initialization coil

ActiveUS10228426B2Guarantee high efficiency and precisionExclude influenceMagnetic field offset compensationMagnetic sensor geometrical arrangementsMagnetic reluctanceMagnetization

Owner:MULTIDIMENSION TECH CO LTD

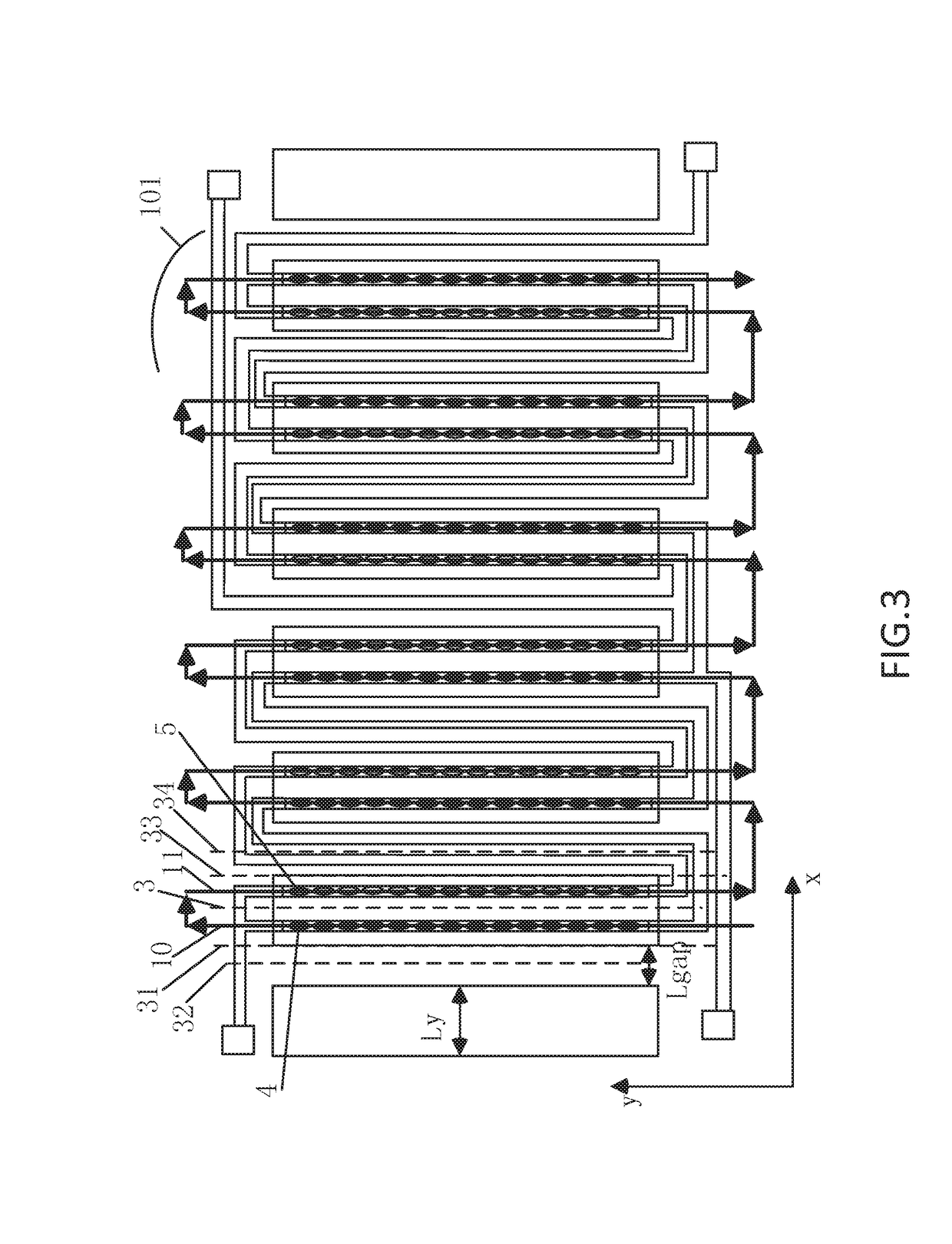

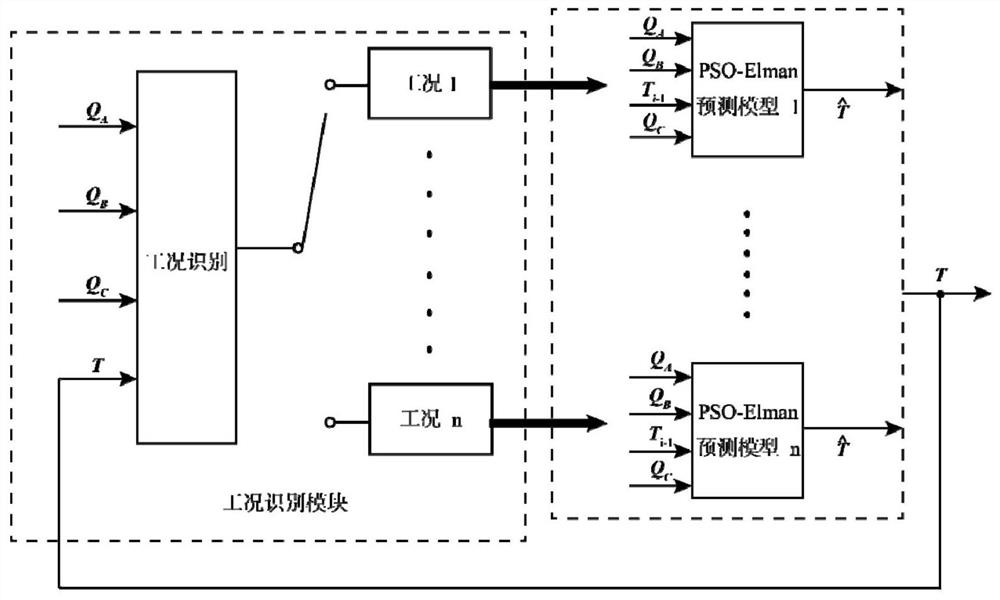

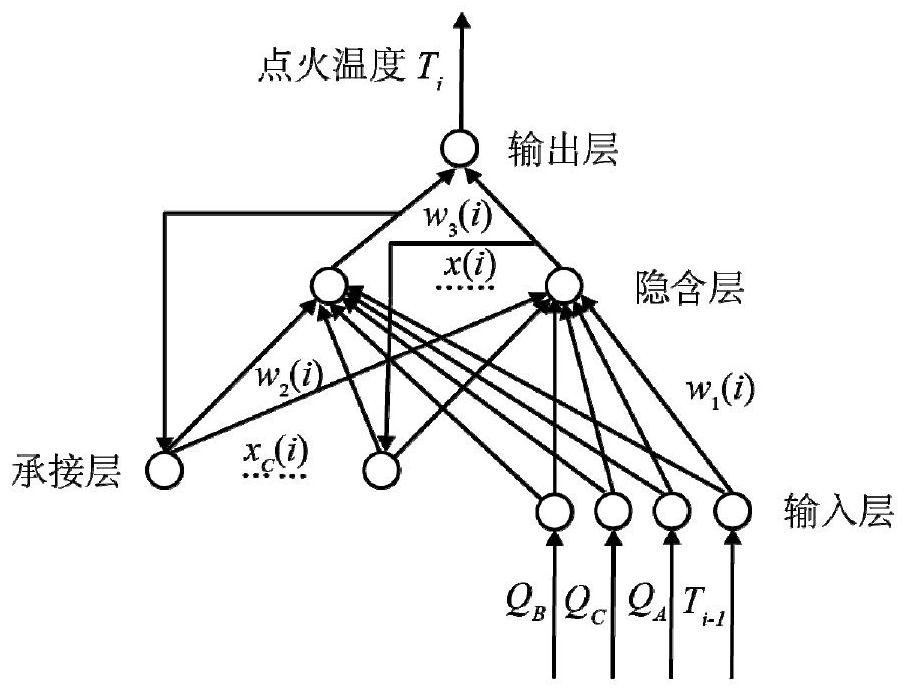

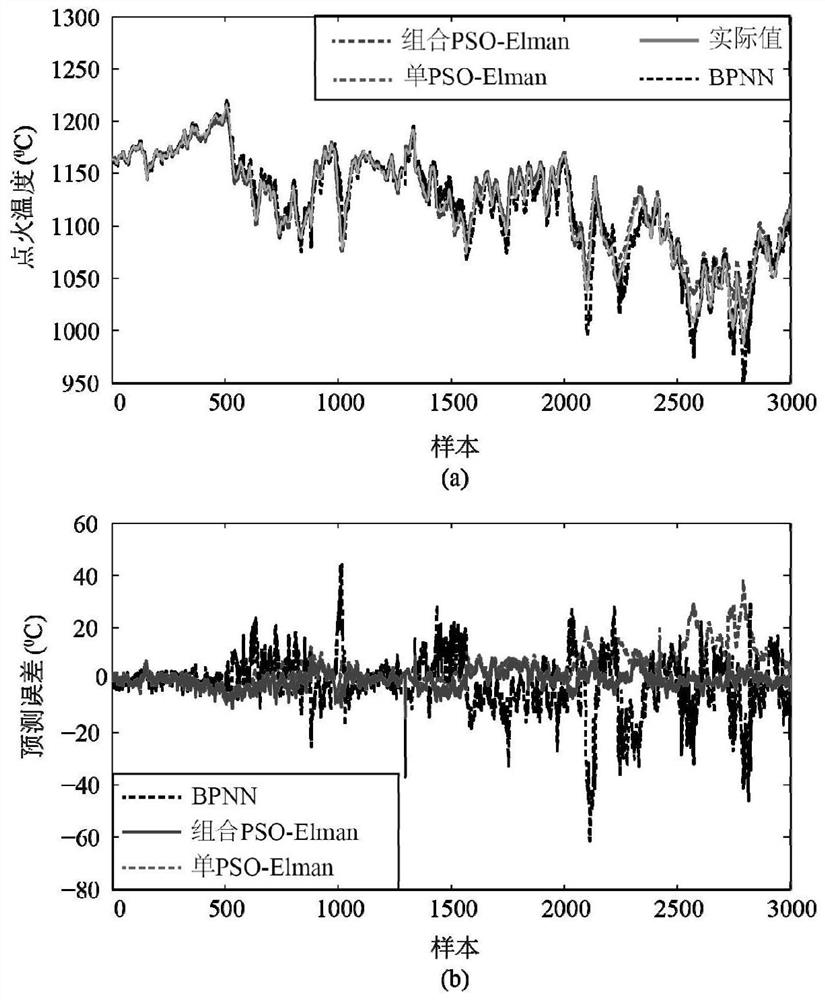

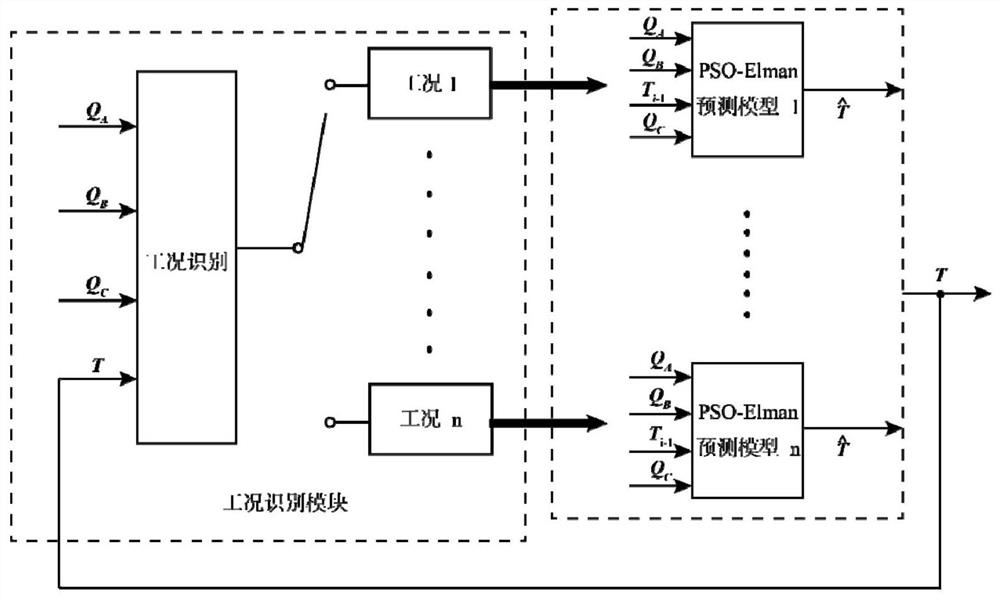

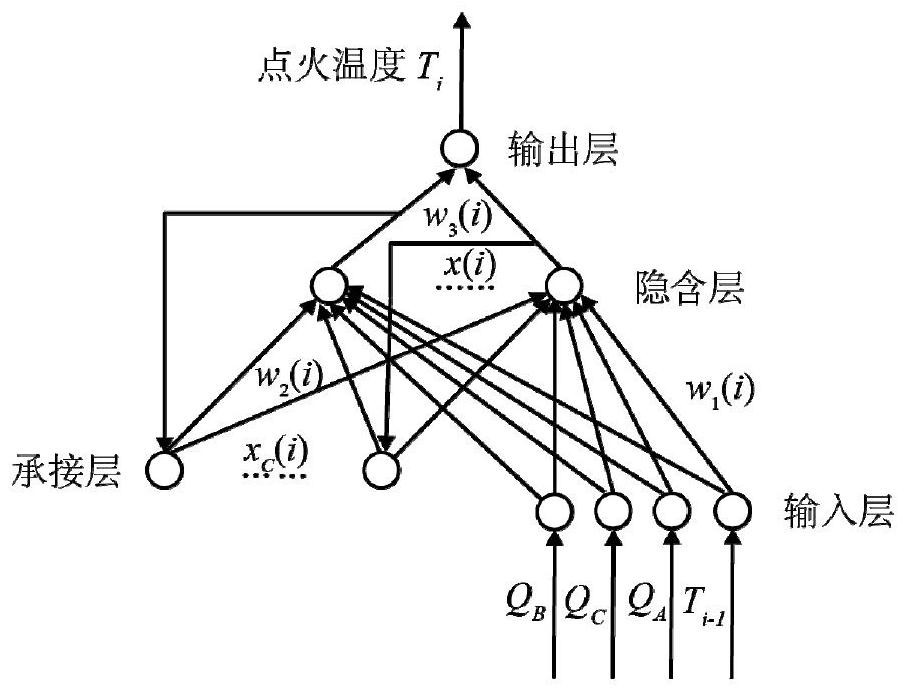

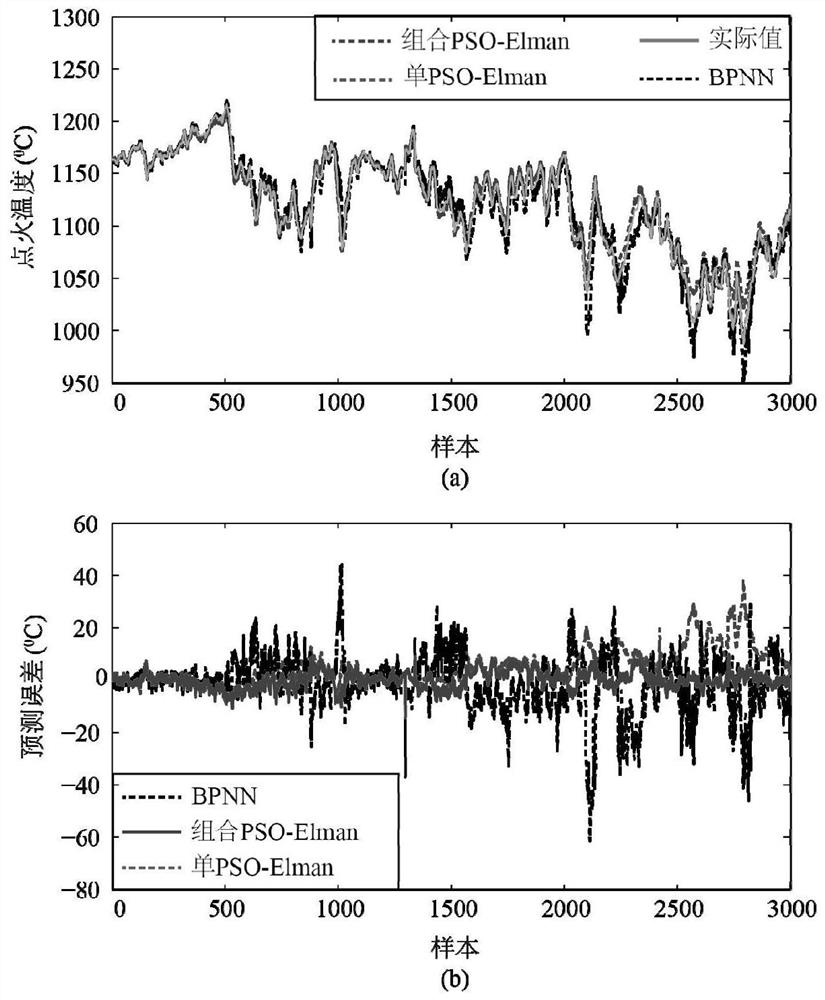

Sintering ignition temperature modeling prediction method based on working condition recognition

ActiveCN112329269APredicted ignition temperatureAchieve ignition temperatureDesign optimisation/simulationSpecial data processing applicationsProcess engineeringFcm clustering

The invention provides a sintering ignition temperature modeling prediction method based on working condition recognition. The method comprises the following steps: carrying out the clustering of a plurality of working conditions in an ignition process through an FCM clustering method, and determining the types of the working conditions; carrying out DBI index calculation on the determined workingcondition category, and determining the working condition number of the sintering ignition process; and then based on different groups of actual data obtained after clustering, establishing the determined ignition temperature prediction model PSOElman under each specific working condition. According to the invention, the defect that the precision of a single prediction model becomes poor when theworking condition in the ignition process changes is overcome, whether the working condition in the ignition process changes or not can be judged according to real-time feedback data, and if yes, thecurrent working condition can be recognized and switched to the corresponding prediction model for prediction; therefore, it is guaranteed that the ignition temperature can be predicted by the most suitable PSO-Elman prediction model under various working conditions for a long time scale, and therefore long-term and efficient prediction precision is kept.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

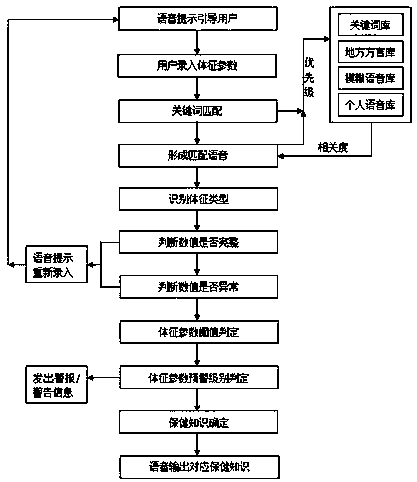

Sign monitoring method through voice inputting

InactiveCN110136831AAvoid troubleGuarantee high efficiency and precisionHealth-index calculationSpeech recognitionComputer networkOlder people

The invention relates to a sign monitoring method through voice inputting. The method facilitates voice parameter inputting by an old person who is an important target in household sign monitoring andis not familiar with an operation mode and has a high age. Furthermore the sign monitoring method performs matching identification on the input voice through priority and correlation and has advantages of high precision, and high result accuracy.

Owner:JIANGSU ETOWN DIGITAL TECH CO LTD

Auxiliary tooling and detection method for detecting the accuracy of adhesive tooling

ActiveCN104101276BGuarantee high efficiency and precisionImprove inspection efficiencyMechanical clearance measurementsTest efficiencyEngineering

Owner:SINO MAGNETICS TECH

Single-chip high-magnetic-field X-axis linear magnetoresistive sensor with calibration and initialization coil

ActiveUS10379176B2Accurate supervisionGuarantee high efficiency and precisionMagnetic field offset compensationMagnetic sensor arraysSingle chipAcoustics

A single-chip high-magnetic-field X-axis linear magnetoresistive sensor with a calibration and an initialization coil, comprising a high magnetic field single-chip referenced bridge X-axis magnetoresistive sensor, a calibration coil, and an initialization coil, wherein the calibration coils are planar coils, and the initialization coils are planar or three-dimensional coils. The planar calibration coils and the planar initialization coils can be placed above a substrate and below the magnetoresistive sensor units, between the magnetoresistive sensor units and the soft ferromagnetic flux guides, above the soft ferromagnetic flux guides, or at gaps between the soft ferromagnetic flux guides. The three-dimensional initialization coil is wound around the soft ferromagnetic flux guides and magnetoresistive sensor units. The calibration coils and the initialization coils generate a calibration magnetic field paralleled the direction of pinned layer and a uniform initialization magnetic field in the direction of the free layer respectively at the location of the magnetoresistive sensor units. Through controlling the current of the calibration coils and the initialization coils, the calibration and initialization of the magnetic state of the single-chip X-axis linear magnetoresistive sensor can be performed.

Owner:MULTIDIMENSION TECH CO LTD

A Modeling and Prediction Method of Sintering Ignition Temperature Based on Working Condition Recognition

ActiveCN112329269BOvercome the defect of poor accuracyGuarantee high efficiency and precisionDesign optimisation/simulationSpecial data processing applicationsProcess engineeringFcm clustering

The invention provides a method for modeling and predicting sintering ignition temperature based on working condition identification, which comprises the following steps: using FCM clustering method to cluster multiple working conditions in the ignition process to determine the category of working conditions; to determine the category of working conditions Carry out DBI index calculation, determine the number of working conditions of the sintering ignition process; Based on the different groups of actual data obtained after clustering, set up the ignition temperature prediction model PSO-Elman under each specific working condition determined, the present invention overcomes the ignition process engineering When the conditions change, the accuracy of the single prediction model becomes poor. It can judge whether the ignition process has changed according to the real-time feedback data. If it changes, it can identify the current conditions and switch to the corresponding prediction model for prediction, ensuring long-term The ignition temperature under various working conditions on the time scale can be predicted by the most suitable PSO-Elman prediction model, so as to maintain long-term high-efficiency prediction accuracy.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

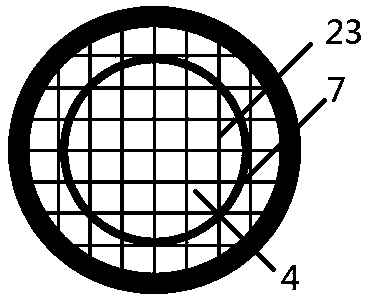

Press-out-type antiskid visual easy-to-mark grid counting surface sampling culture dish

InactiveCN108913572ASimple structureEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsMarking outEngineering

Owner:韩德礼

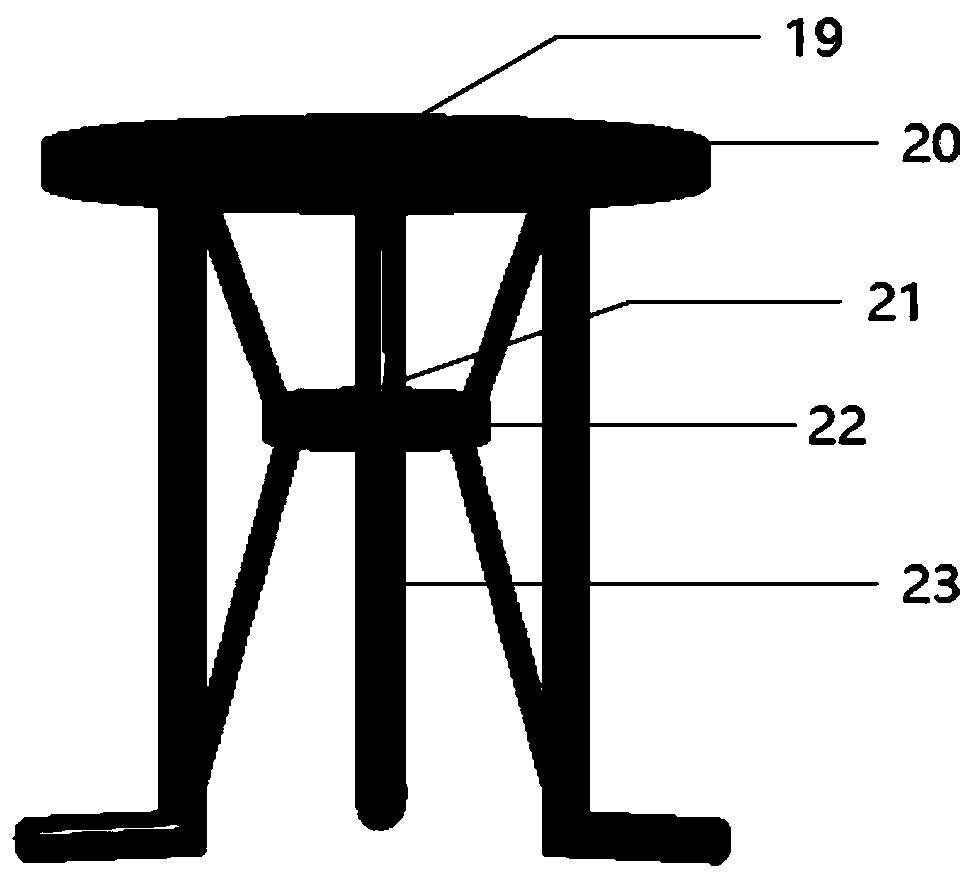

Stable forced centering disc and measuring method thereof

InactiveCN111089571AImprove controllabilityImprove visibilitySurveying instrumentsEngineeringManagement support

The invention provides a stable forced centering disc. The stable forced centering disc comprises a centering disc body arranged at the top of a centering disc frame, an instrument mounting hole is formed in the center of the centering disc body, a limiting base is arranged right under the centering disc body and fixedly connected with the centering disc body through an inverted triangular support, and a limiting hole in the center of the limiting base and the instrument mounting hole are kept to allow a pre-buried frame body to pass through; and the limiting base is fixedly connected with a supporting plane through a triangular support. The stable forced centering disc is better in precision control, stability and visibility, excellent in comprehensive performance and remarkable in systemeffective control effect, and powerful technical and management support is provided for fine management and operation of building construction in measurement related work.

Owner:SHANGHAI CONSTRUCTION GROUP

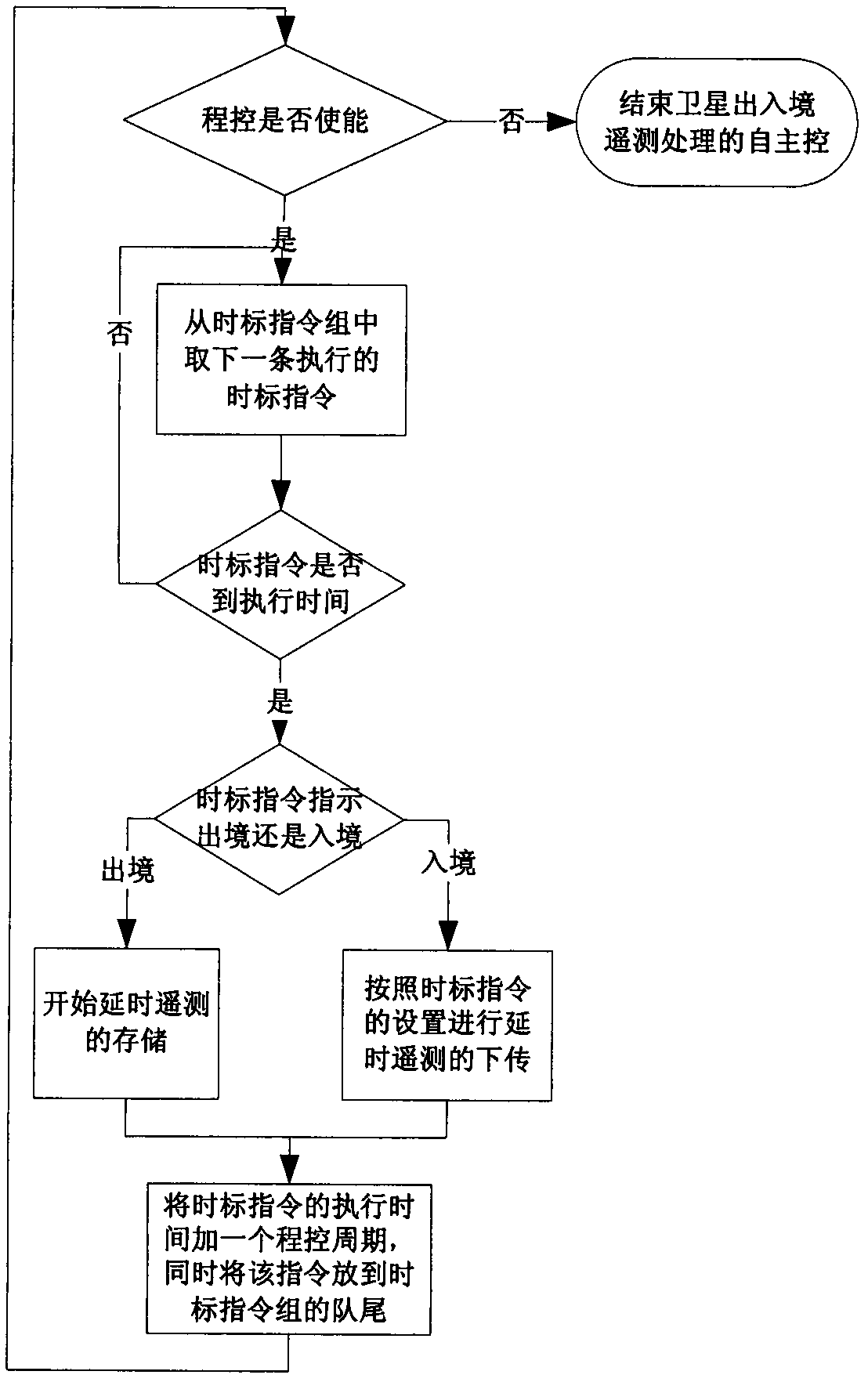

Satellite entry-exit independent telemetry processing control method

InactiveCN102436394BEasy to controlReduce workloadMultiprogramming arrangementsTime markSatellite orbit

A satellite entry-exit independent telemetry processing control method sets a time mark instruction group for each satellite mission. Each time mark instruction group is composed of time mark instructions with time marks, and the execution time of the time mark instructions is the time indicated by corresponding time marks. A program control cycle is set according to a satellite orbit cycle, timemark instruction groups required by one program control cycle are injected on the ground in one time, a satellite retrieves corresponding time mark instruction groups according to the current executing mission, then corresponding instructions in the time mark instruction groups are executed according to the current satellite time, and all the time mark instructions are executed sequentially according to the time marks. After one instruction is completed, the instruction is automatically arranged at the rears of the time mark instruction groups, and one program control cycle is added on an original execution time so as to serve as the next execution time. If overtime occurs in the time mark instruction execution process, the instruction is executed at once or given up. The method can achieve satellite entry-exit independent telemetry management.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

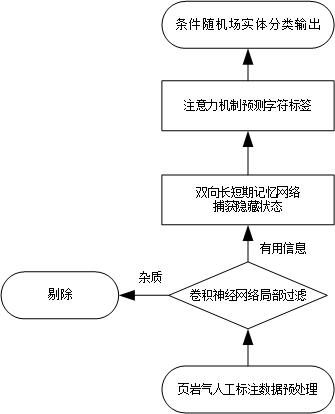

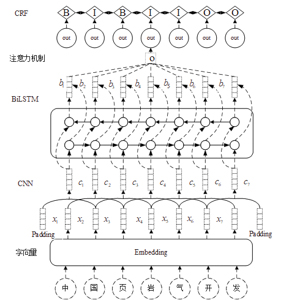

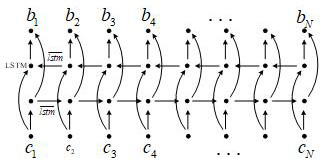

Shale gas entity recognition method based on improved neural network

PendingCN114580421ACommand global semantic featuresGuarantee high efficiency and precisionSemantic analysisNeural architecturesConditional random fieldManual annotation

The invention provides a shale gas entity recognition method based on an improved neural network, and belongs to the field of shale gas and natural language processing. The method comprises the following steps: firstly, preprocessing shale gas manual annotation data, mapping characters into a dense vector sequence with context semantics, and transmitting the dense vector sequence to a convolutional neural network to filter the influence of local contexts in sentences on entity recognition; then, the hidden state of the context at the shale gas labeling position is captured through a bidirectional long-short-term memory network, labels in sentences are concerned through an attention mechanism, character labels are predicted through similar information, and the problem of labeling inconsistency is solved; and finally, uploading to a conditional random field, and further constraining the result to achieve the effect of entity classification. According to the method, the names of related entities in the shale gas field can be quickly and efficiently identified, and the first shale gas high-precision entity identification method is provided for a shale gas intelligent analysis system.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com