Double-end cross saw device

A horizontal saw, double-end technology, applied in feeding devices, clamping devices, circular saws, etc., can solve the problems of inconvenient automatic feeding and discharging of large plates, inefficient and accurate positioning, limited use range, etc., to ensure high efficiency. Accuracy, guaranteed timeliness and smoothness, versatility and highly adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

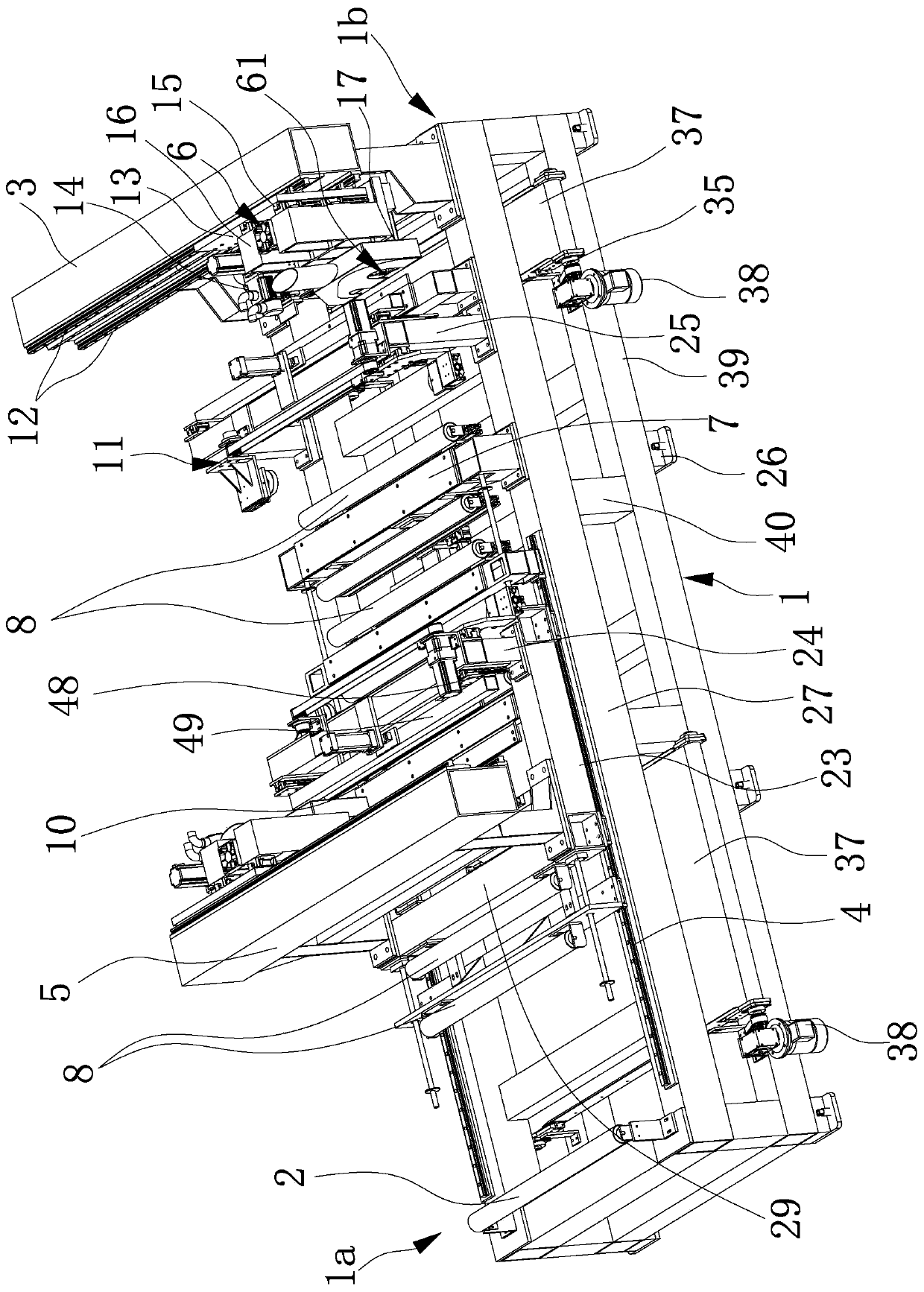

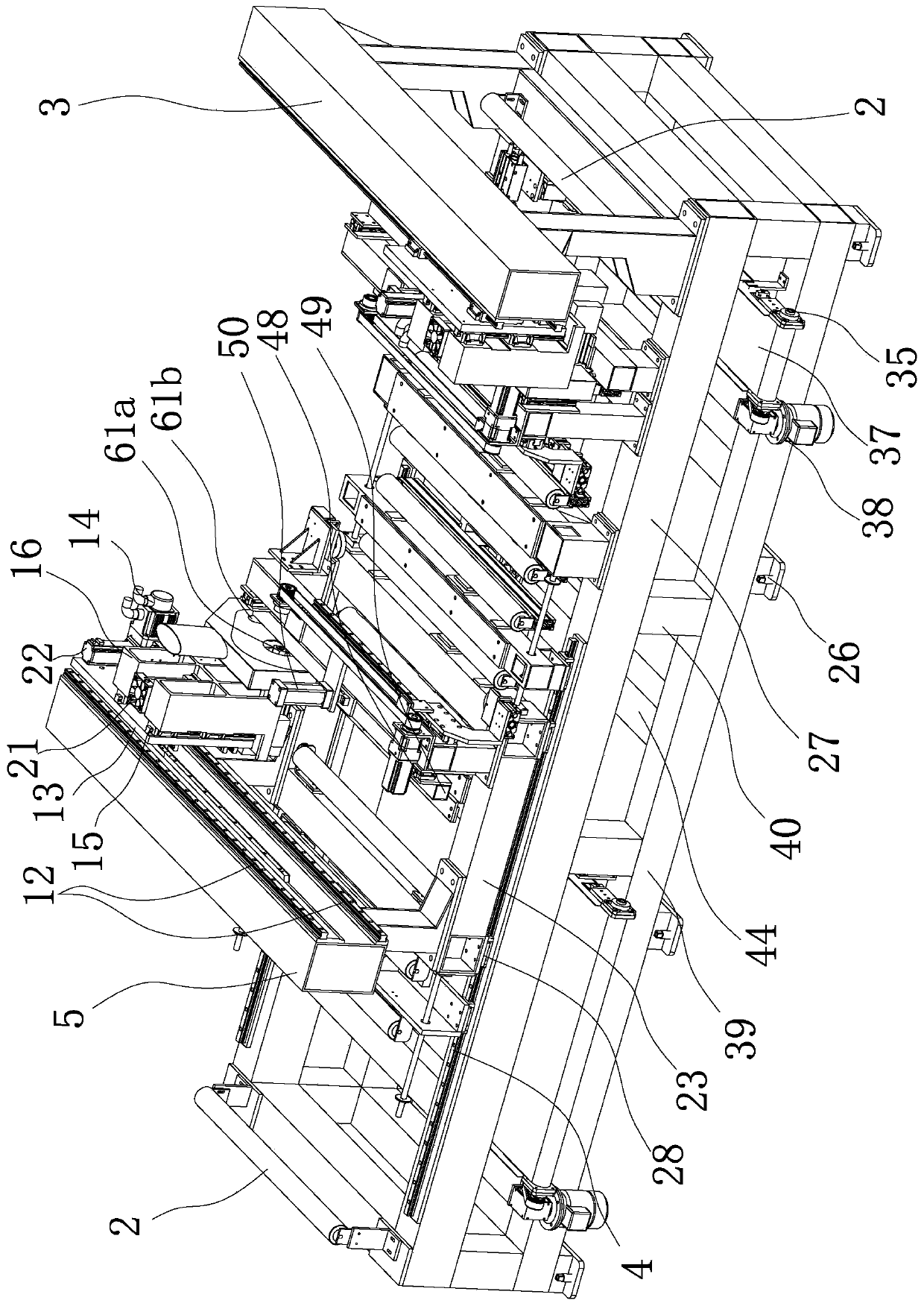

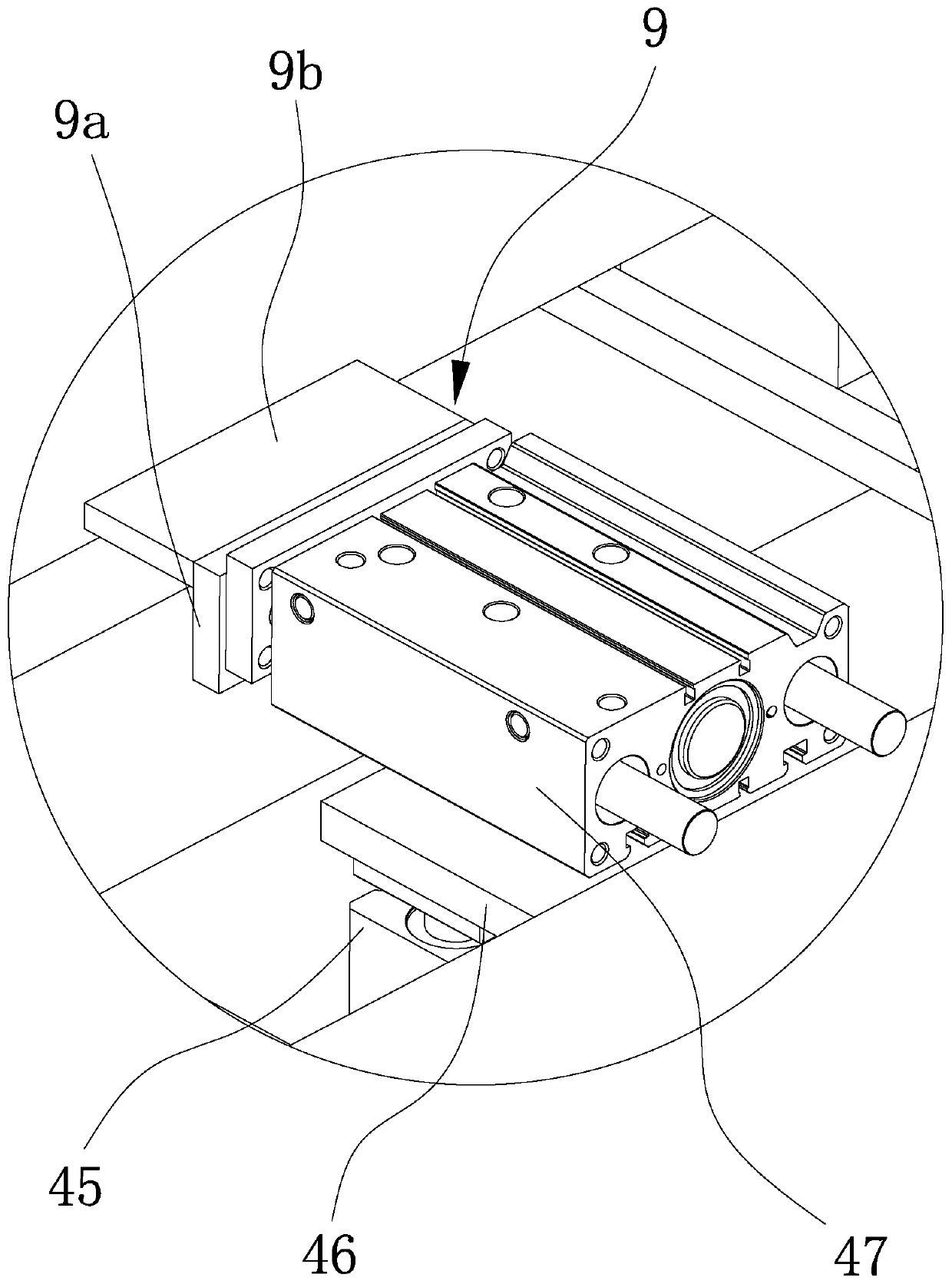

[0032] Such as Figure 1 to Figure 7 As shown, the double-end cross saw device includes a frame 1, one end of the frame 1 is an input end 1a, and the other end is an output end 1b, and the input end 1a and the output end 1b of the frame 1 are provided with a first roller 2 , the output end 1b of the frame 1 is fixed with a fixed gantry 3, and the two sides of the frame 1 close to the input end 1a are provided with slide rails 4, and the slide rails 4 are slidably provided with activities that can move toward the fixed gantry 3. The gantry 5, the fixed gantry 3 and the movable gantry 5 are all equipped with a processing head assembly 6 with a saw disc 61; the frame 1 is provided with several groups of workbenches 7 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com