Patents

Literature

3647results about "Bark-zones/chip/dust/waste removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

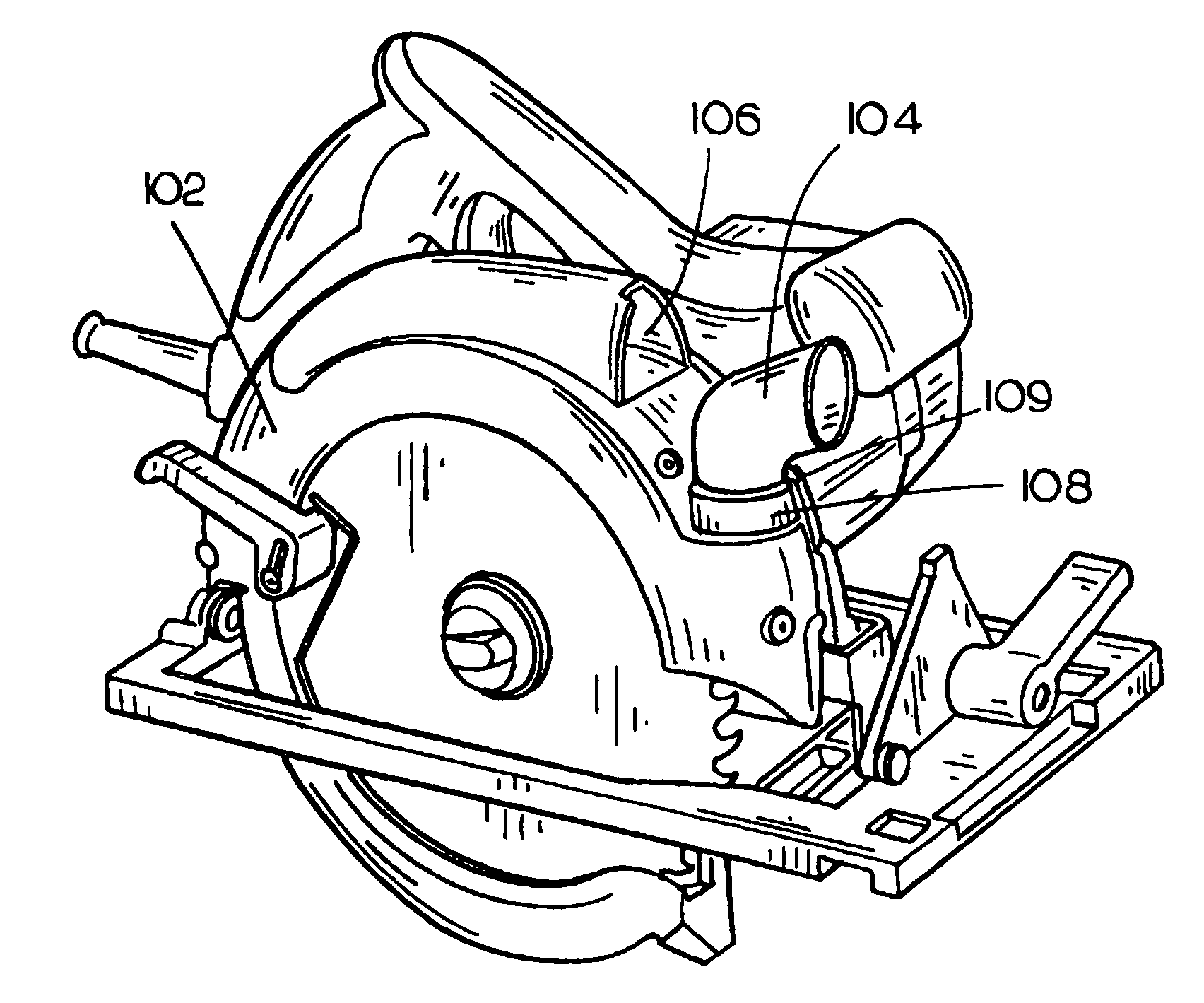

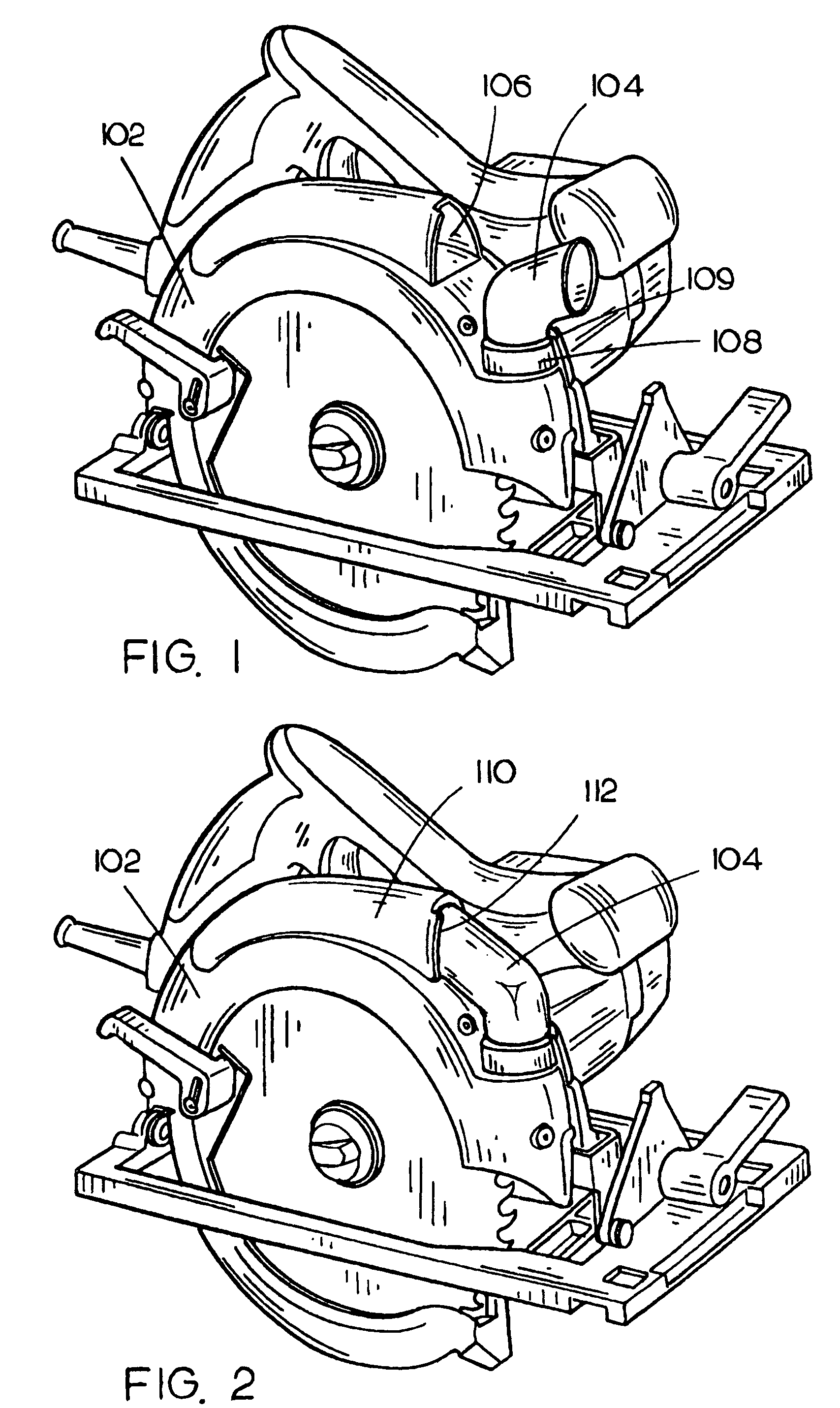

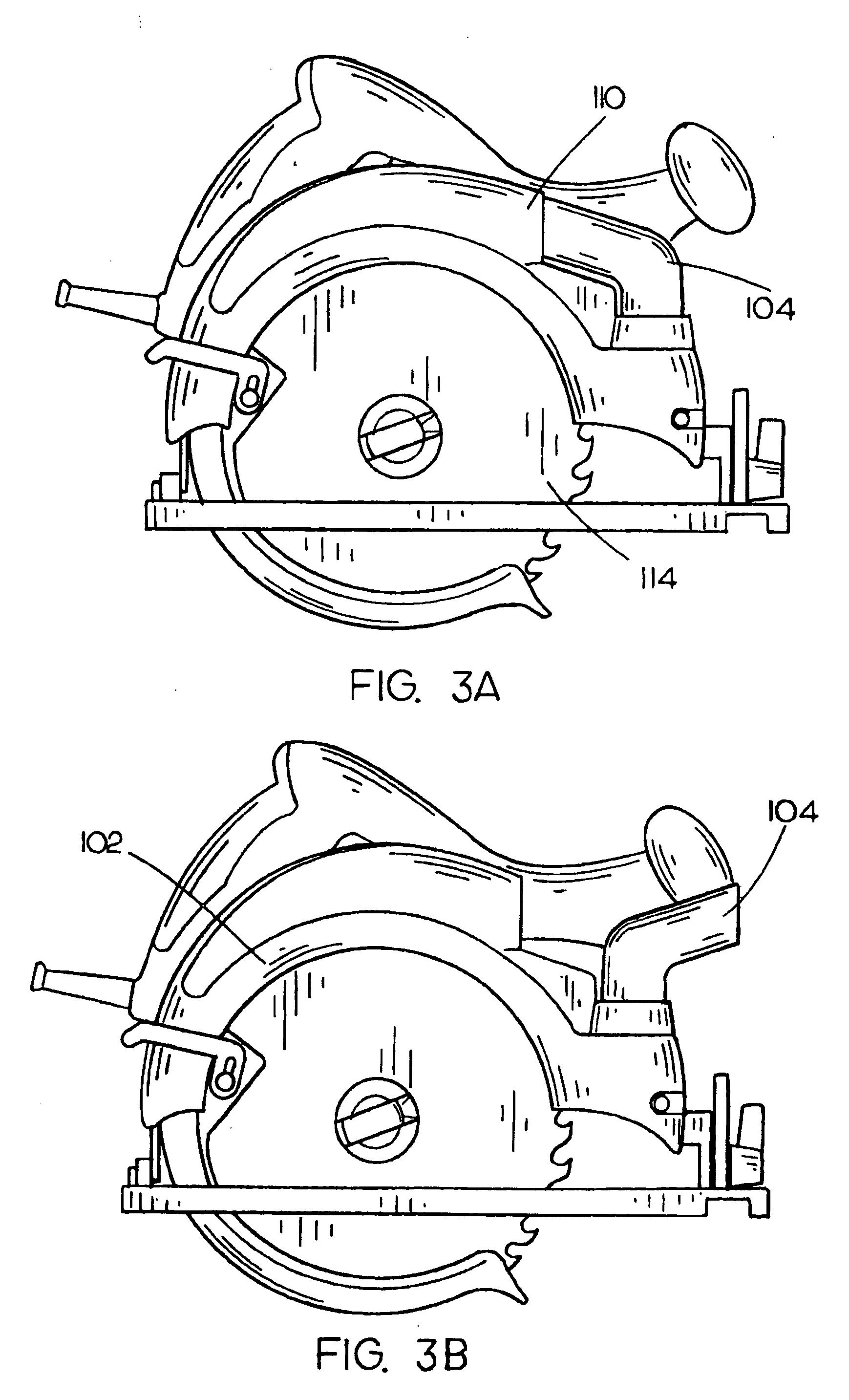

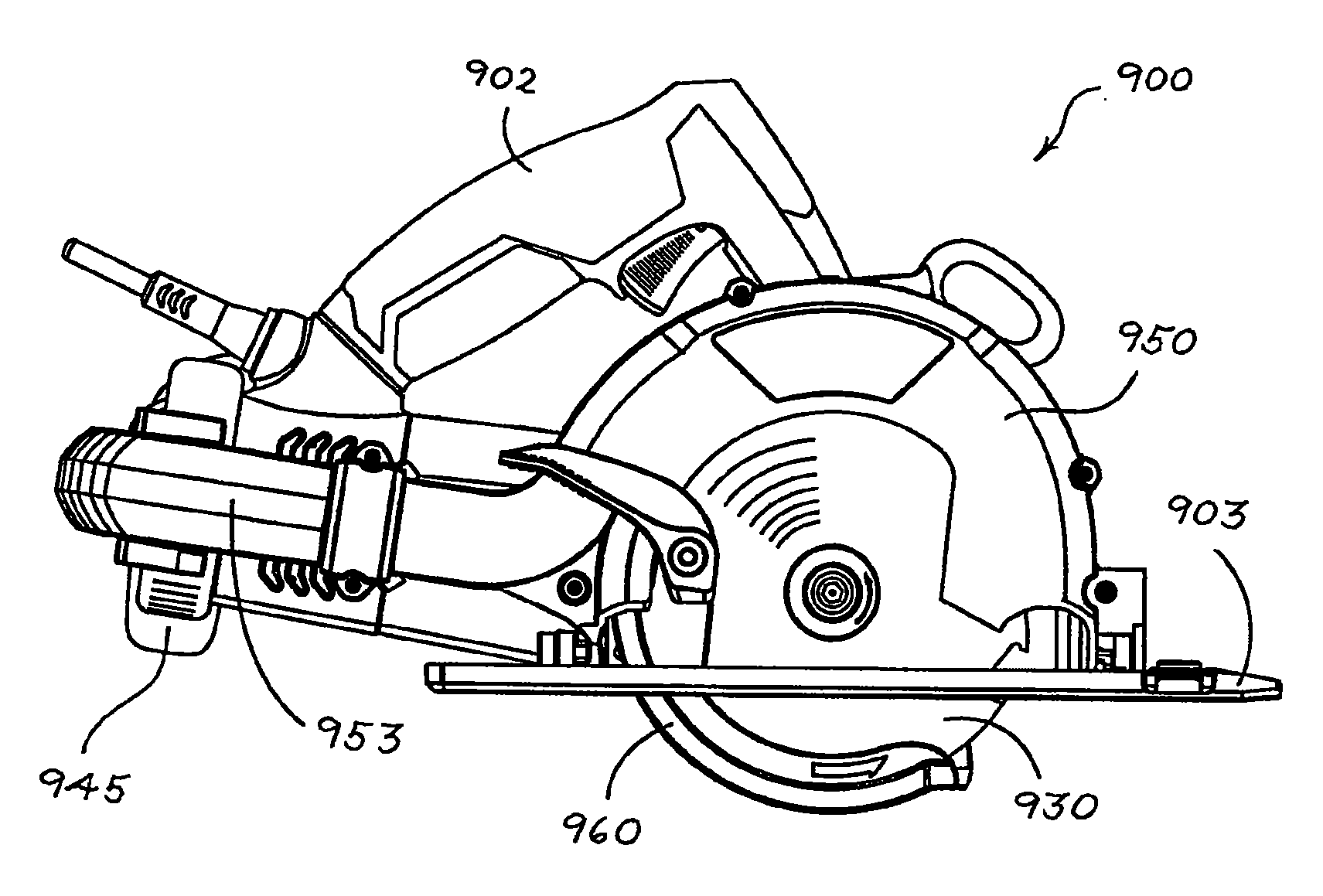

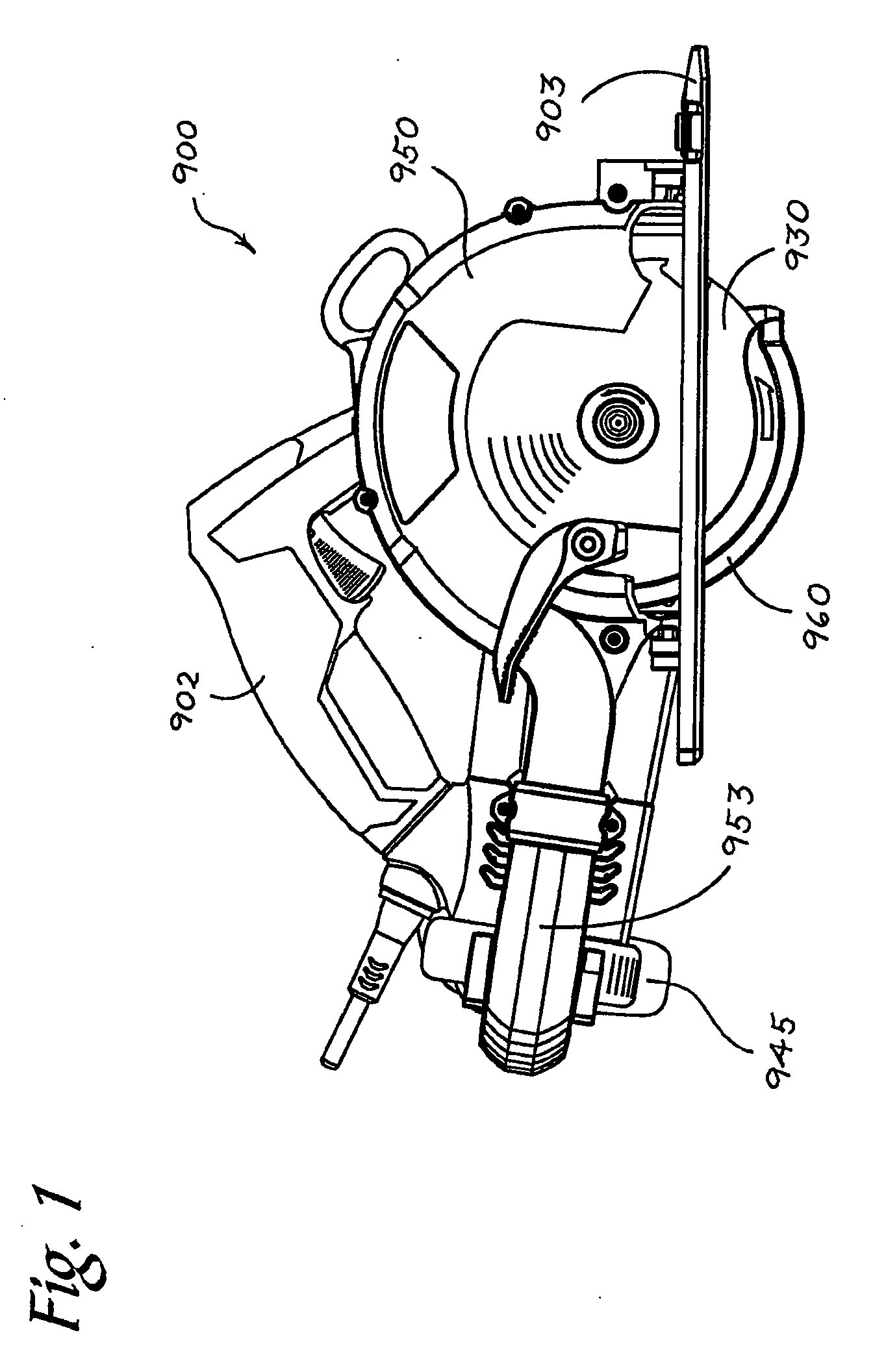

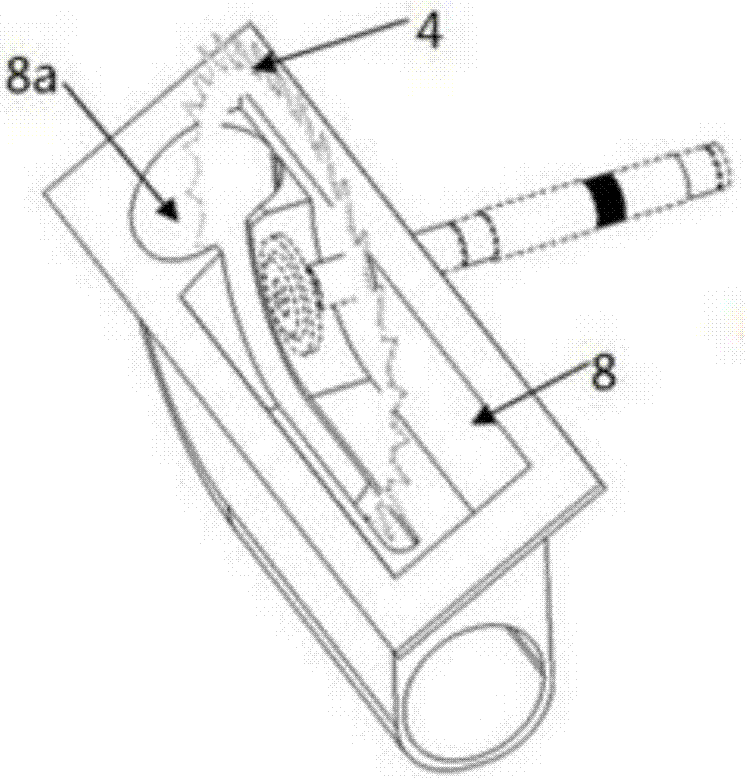

Variable dust chute for circular saws

The present invention is directed to a hand-held circular saw with an integrated dust collection system. Such saw may include an upper blade guard for protecting the user from a saw blade, the upper blade guard configured with a front region and a back region, the front region including a hollow channel to control the pathway of dust and debris and a dust collection system incorporated within the front region of the upper blade guard allowing dust and debris to be directed away from the user.

Owner:BLACK & DECKER INC

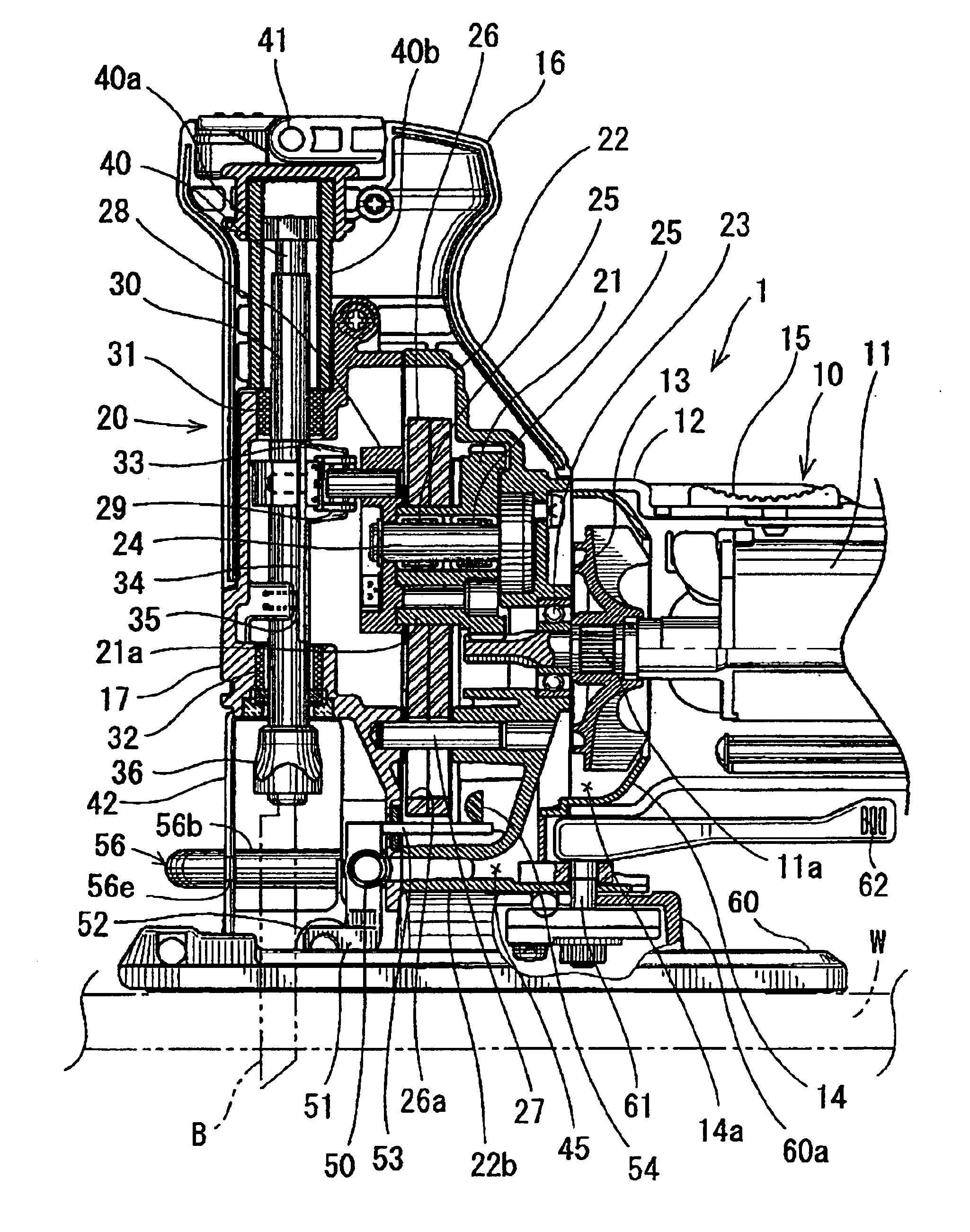

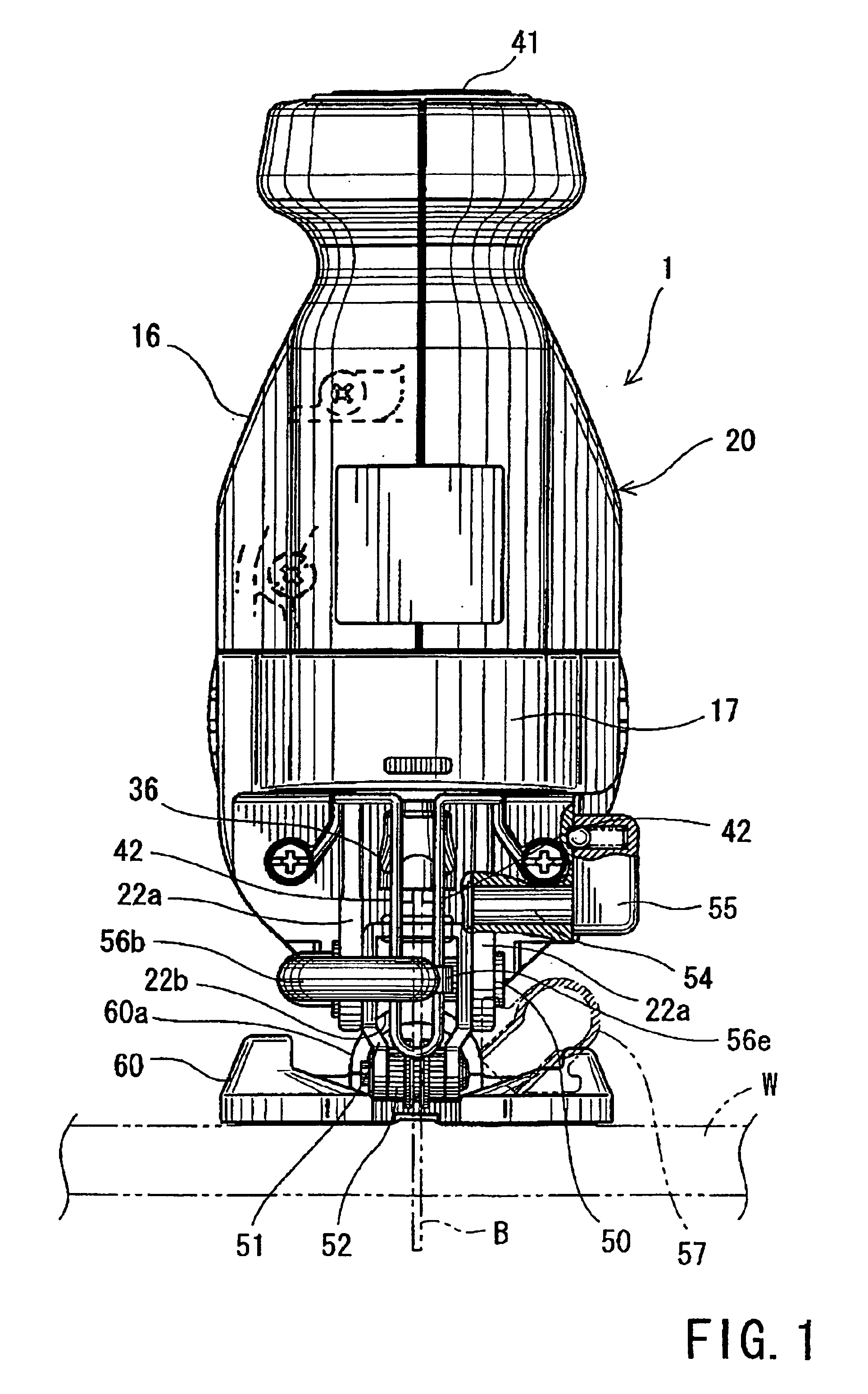

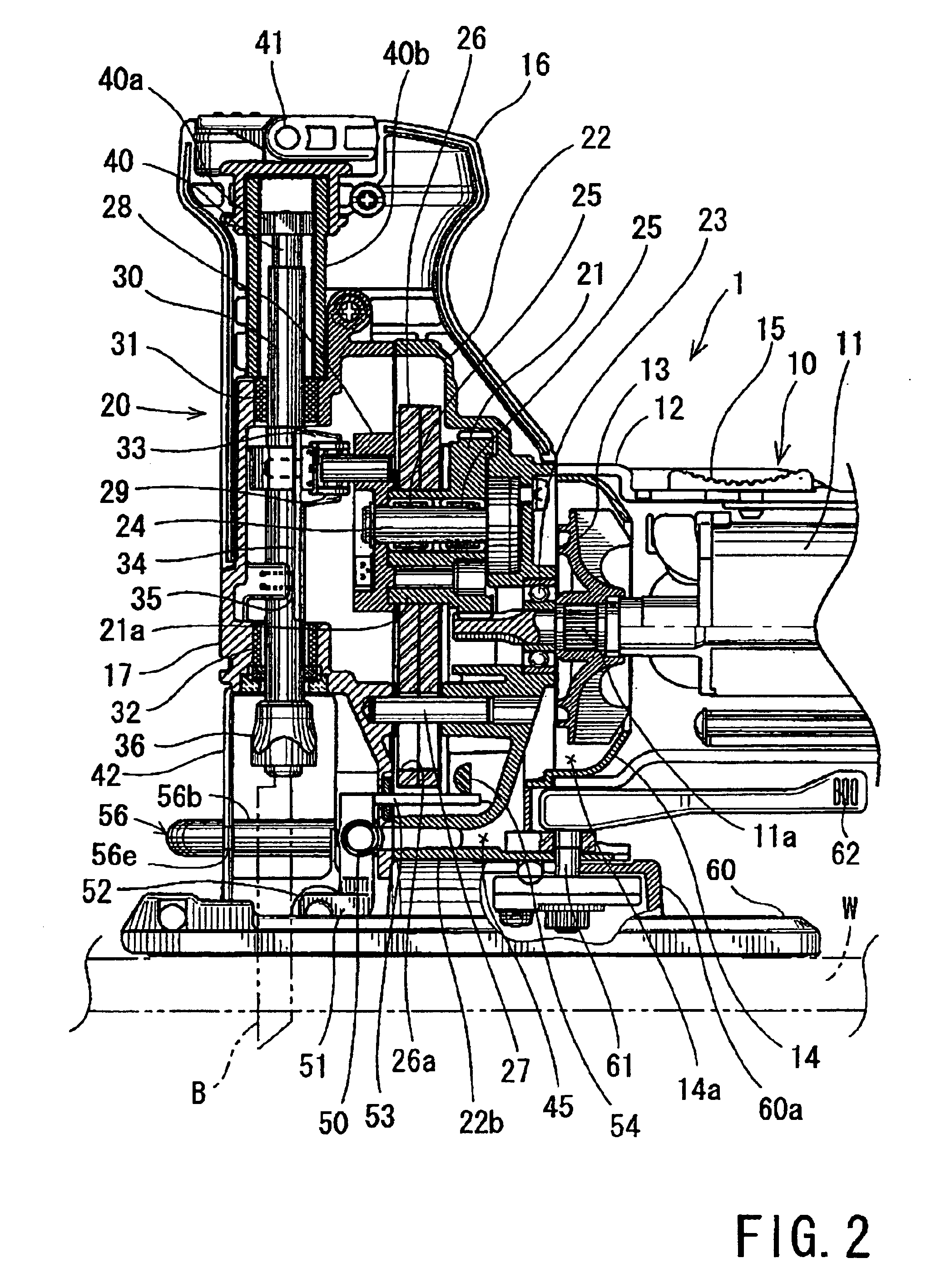

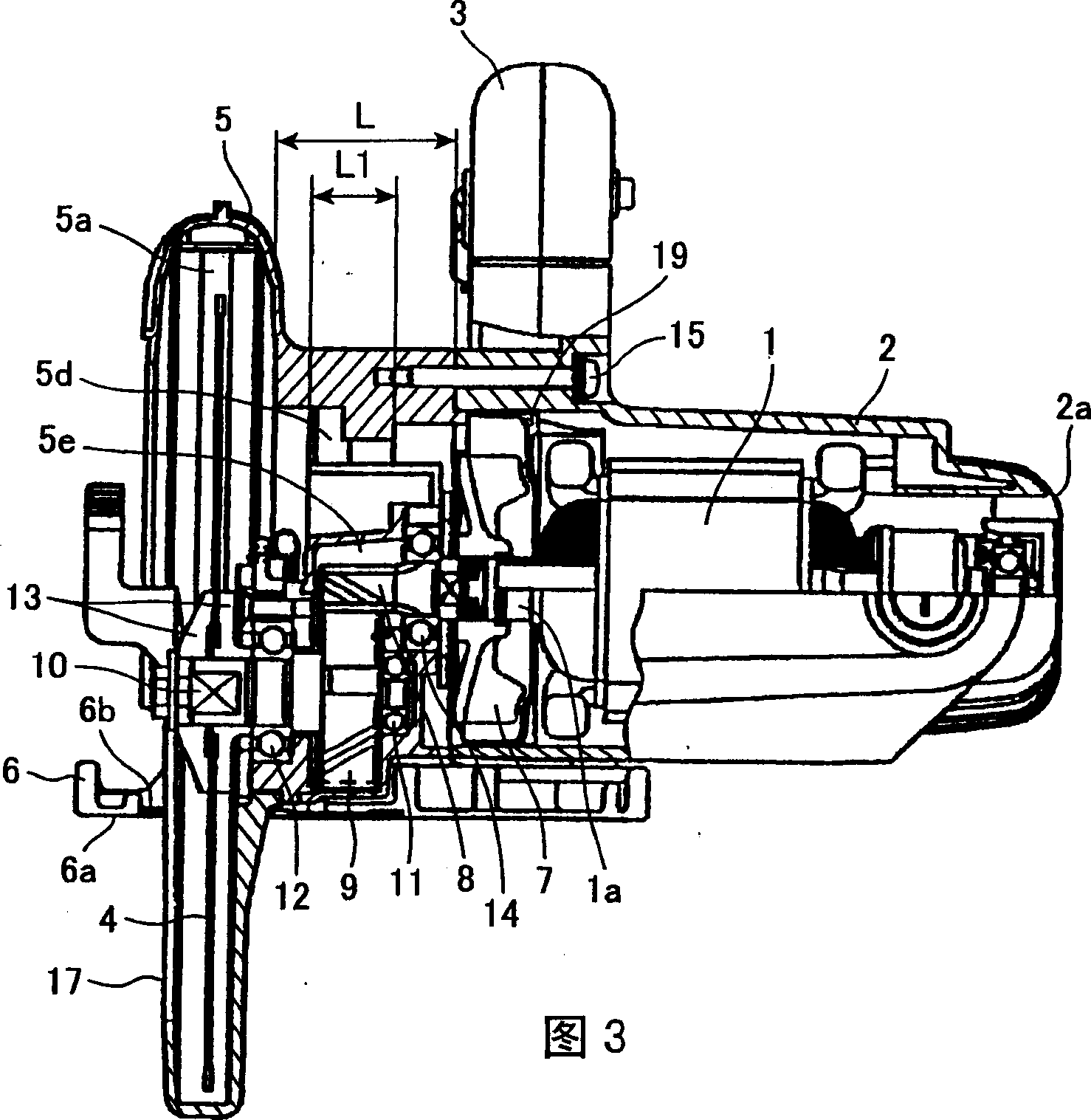

Reciprocating cutting tools having devices for limiting scattering of cutting chips

InactiveUS6892459B2Easy to operateEfficient collectionMetal sawing devicesMetal sawing accessoriesKnife bladesAir channel

Reciprocating cutting tools (1, 90, 100) may include a drive source (11) for reciprocally driving a blade (B). The drive source may also drive a blower (13) in order to generate an air stream. An air channel (50, 56, 50, 70, 85, 80) may guide the air stream to a position adjacent to the blade or a workpiece (W) that will be cut by the blade. Further, a chip collector nozzle (57) may draw or suction cutting chips away from the workpiece that has been cut by the blade.

Owner:MAKITA CORP

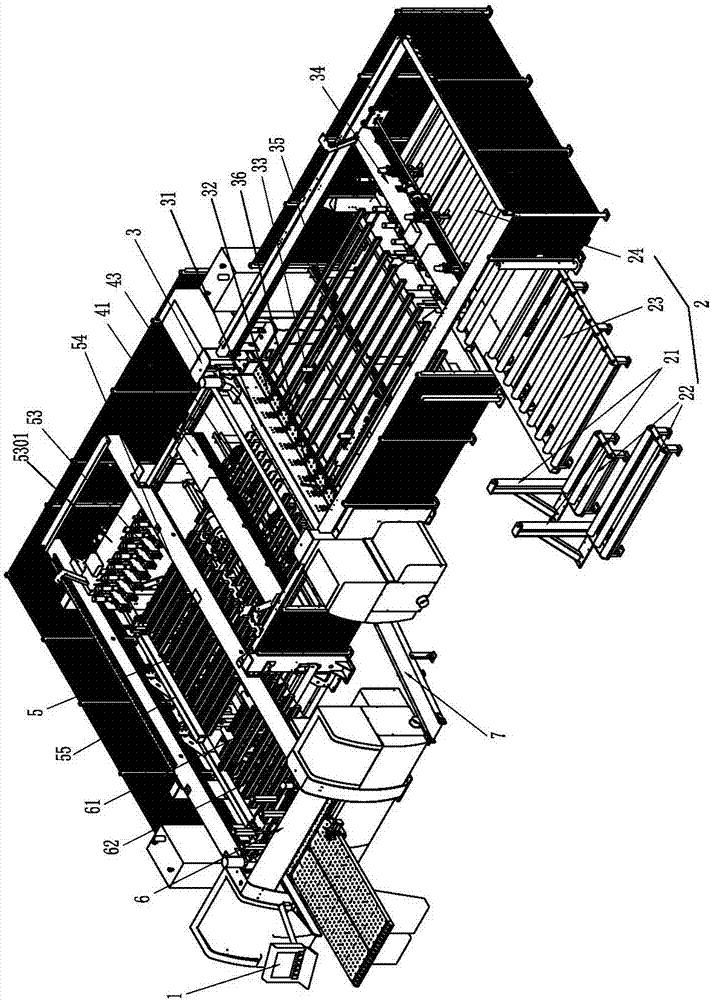

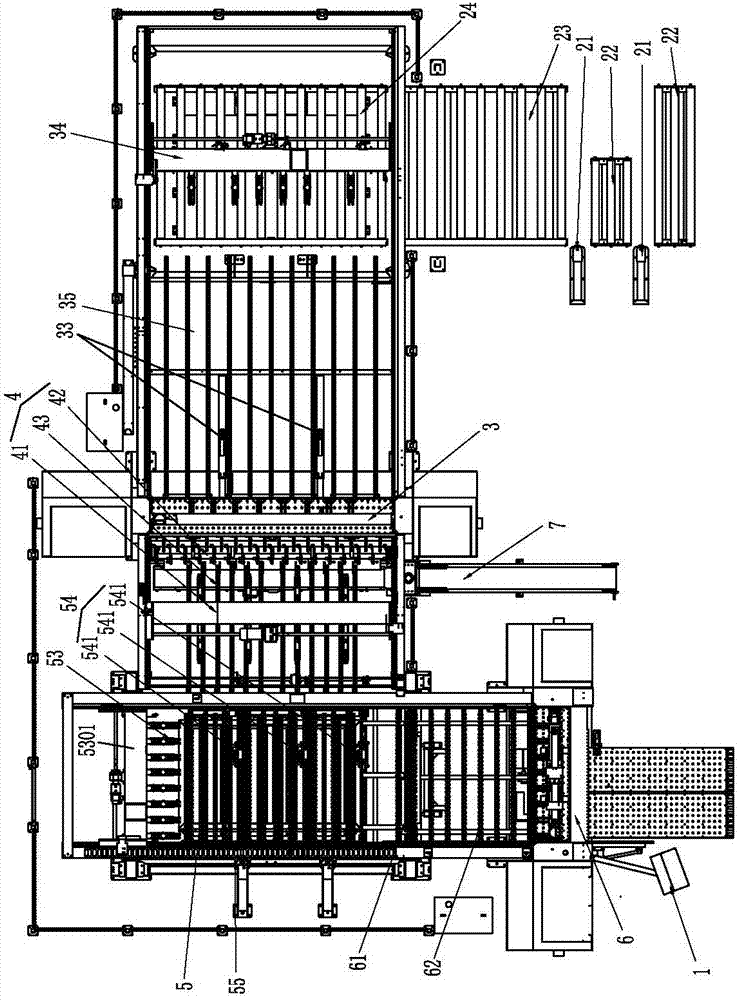

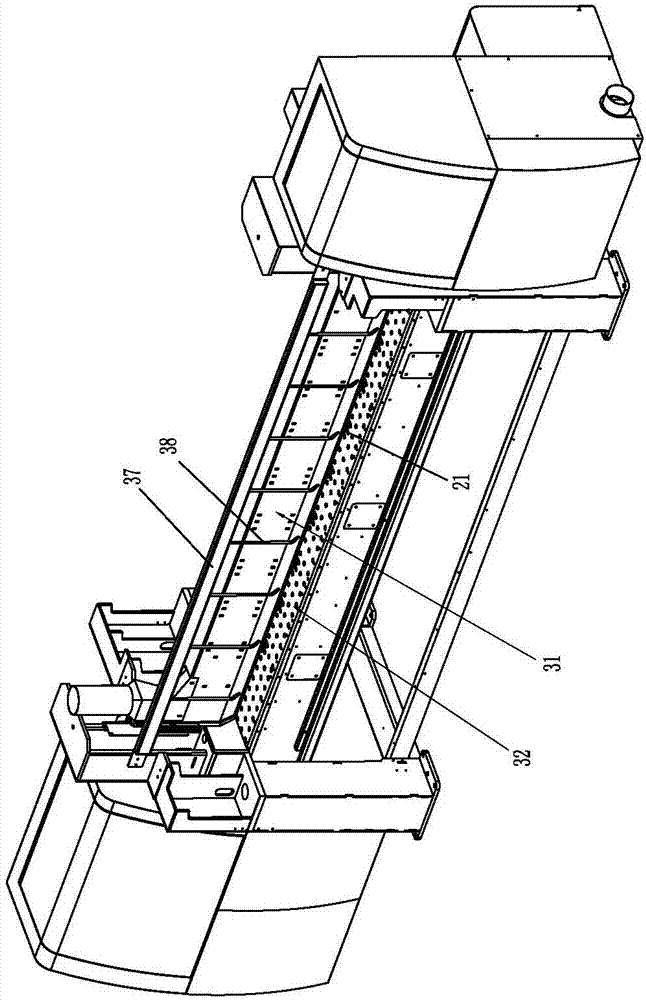

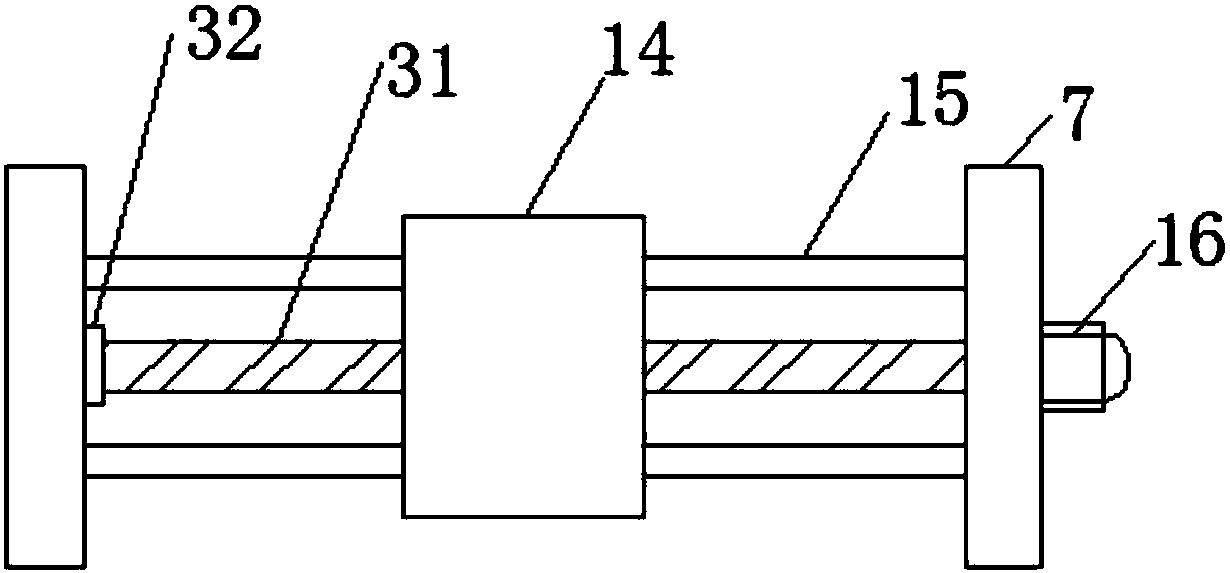

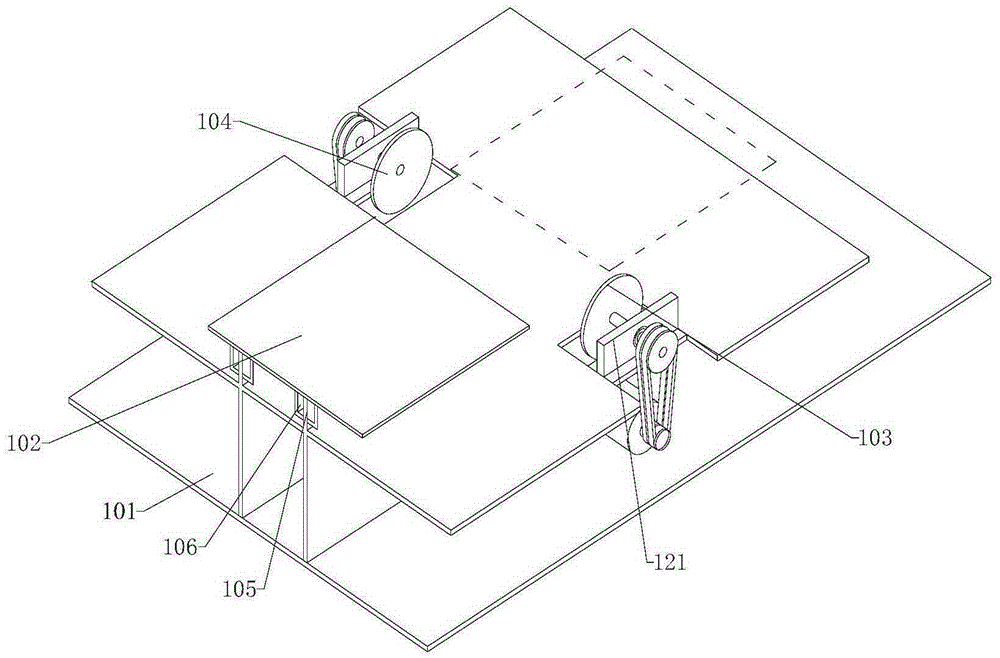

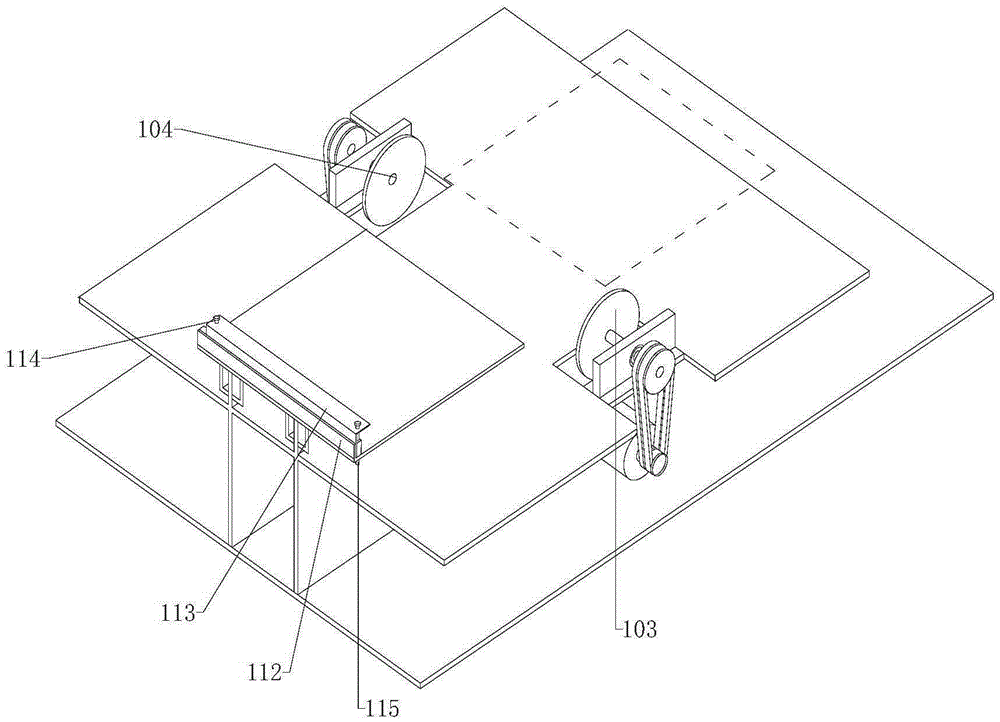

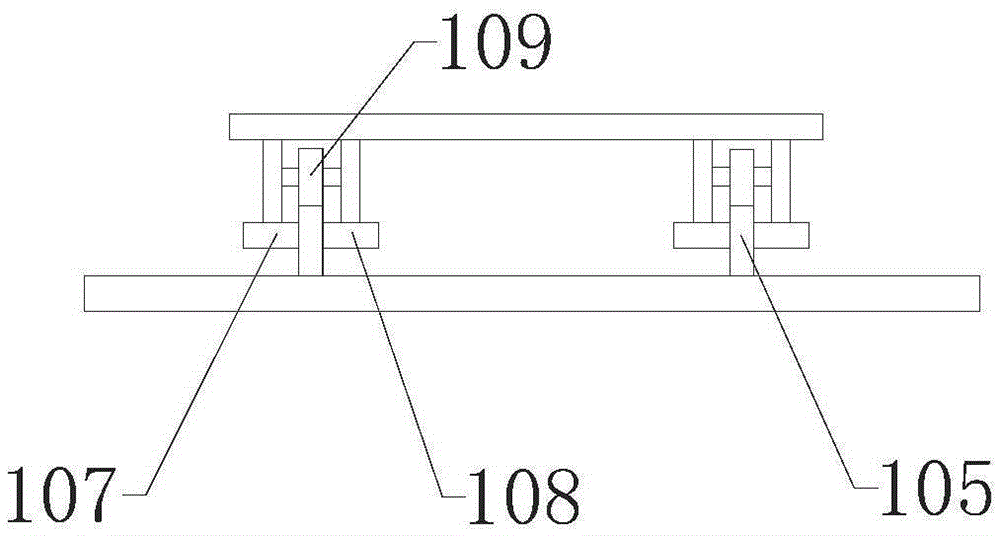

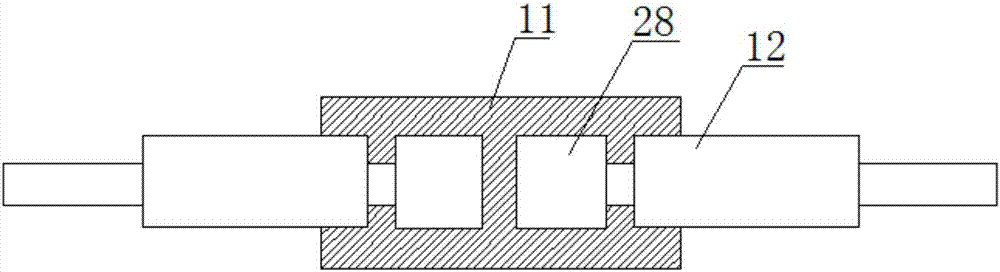

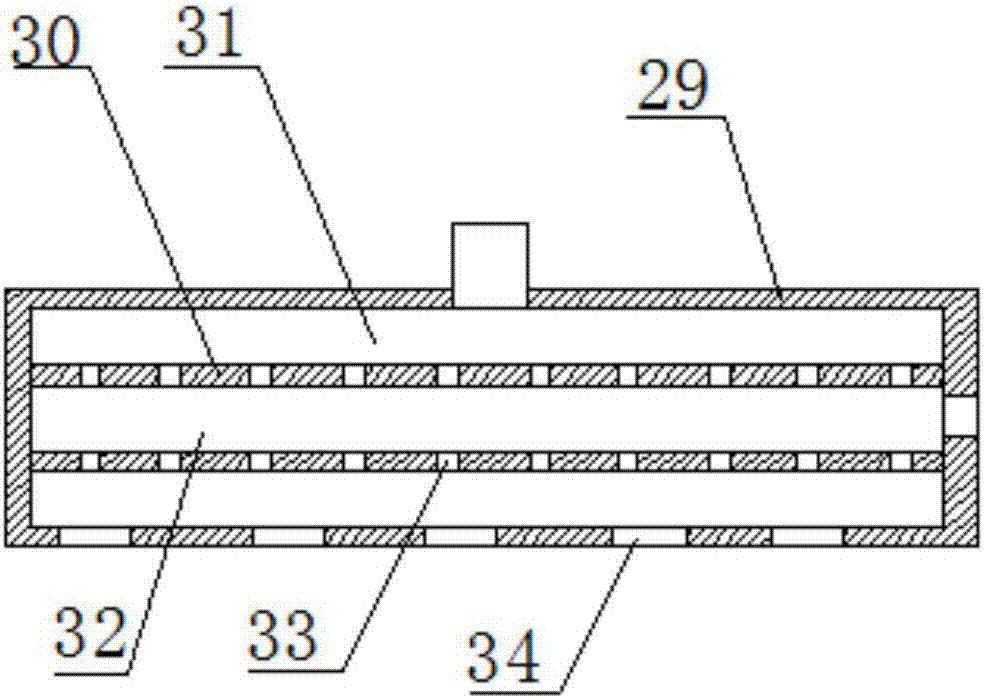

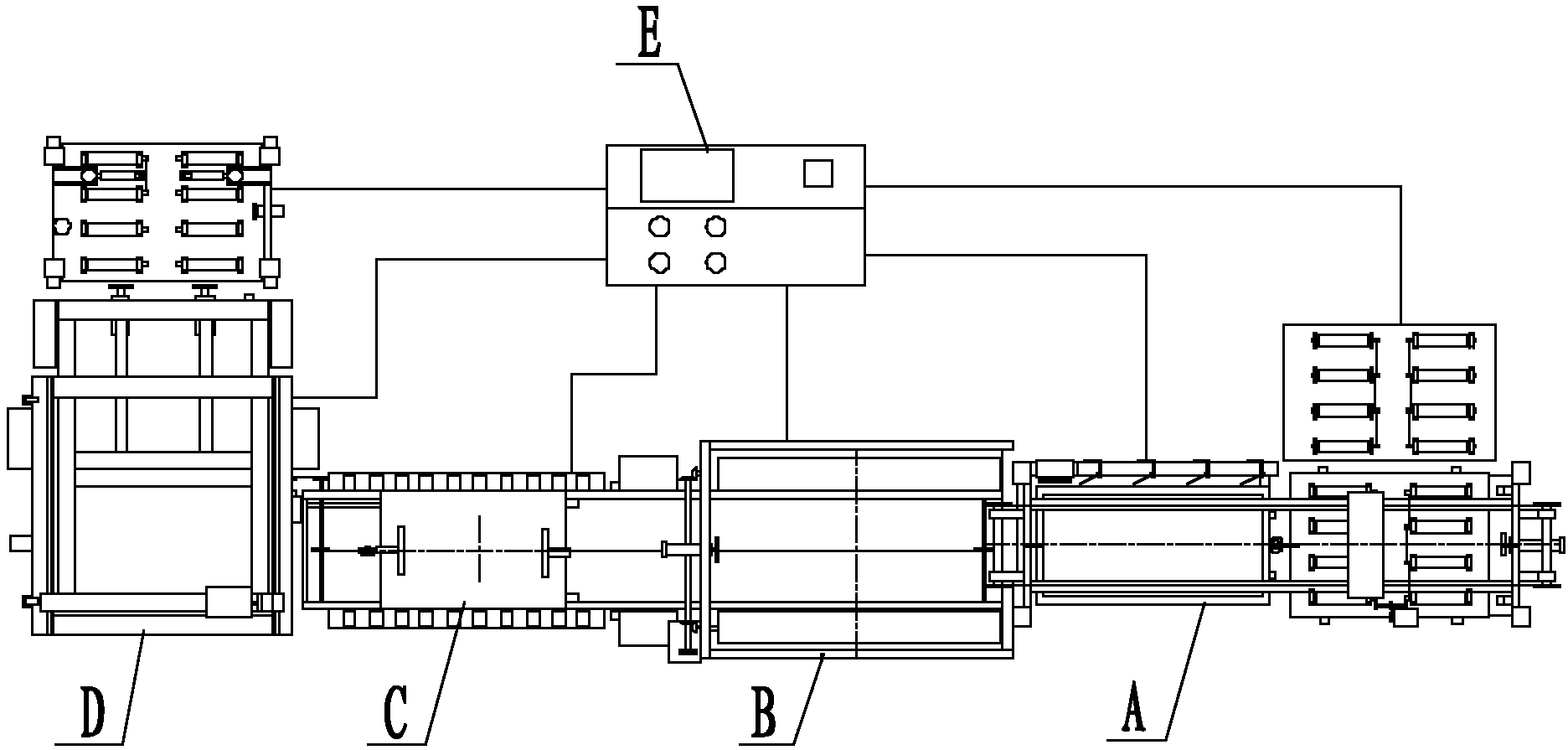

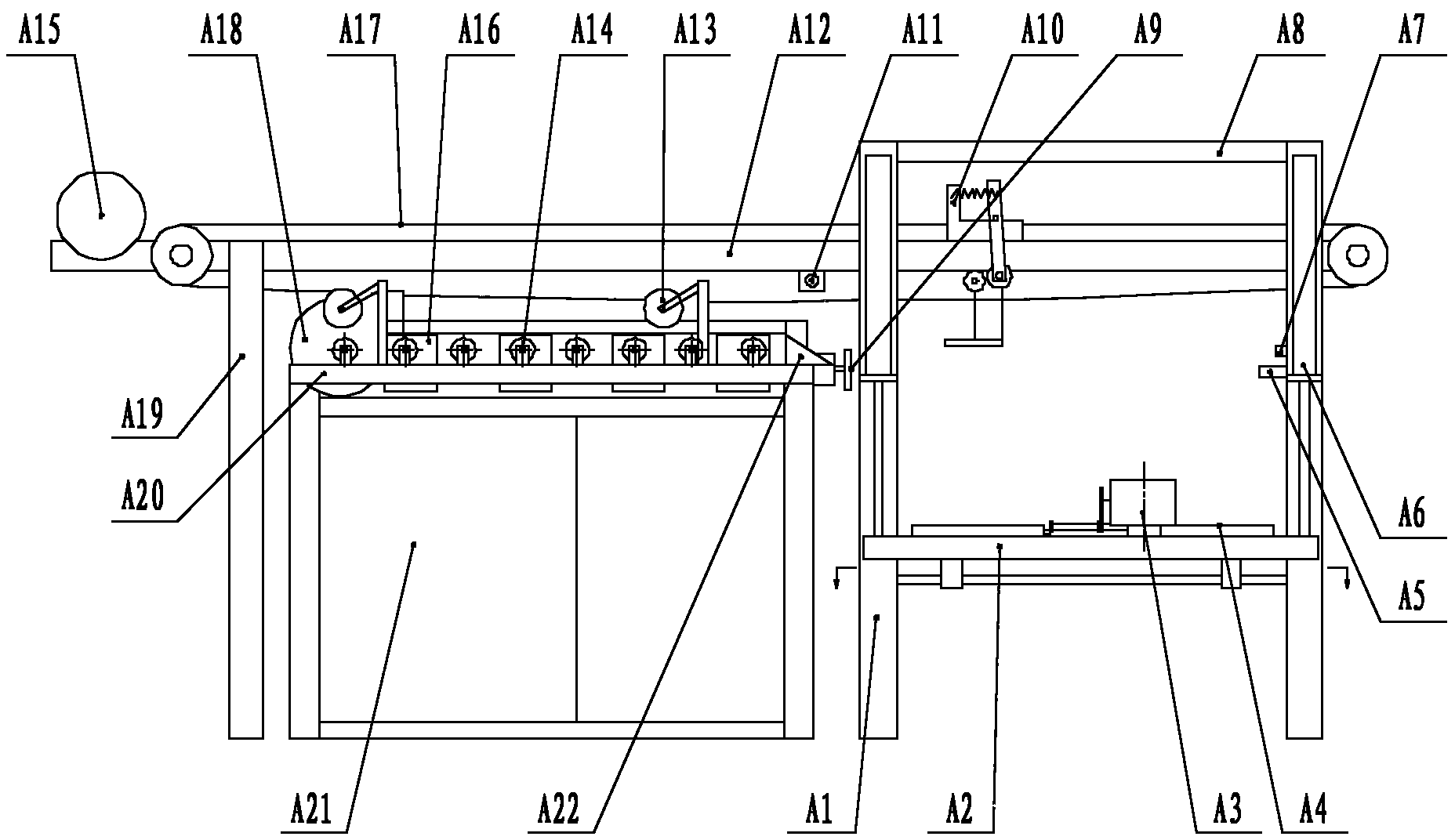

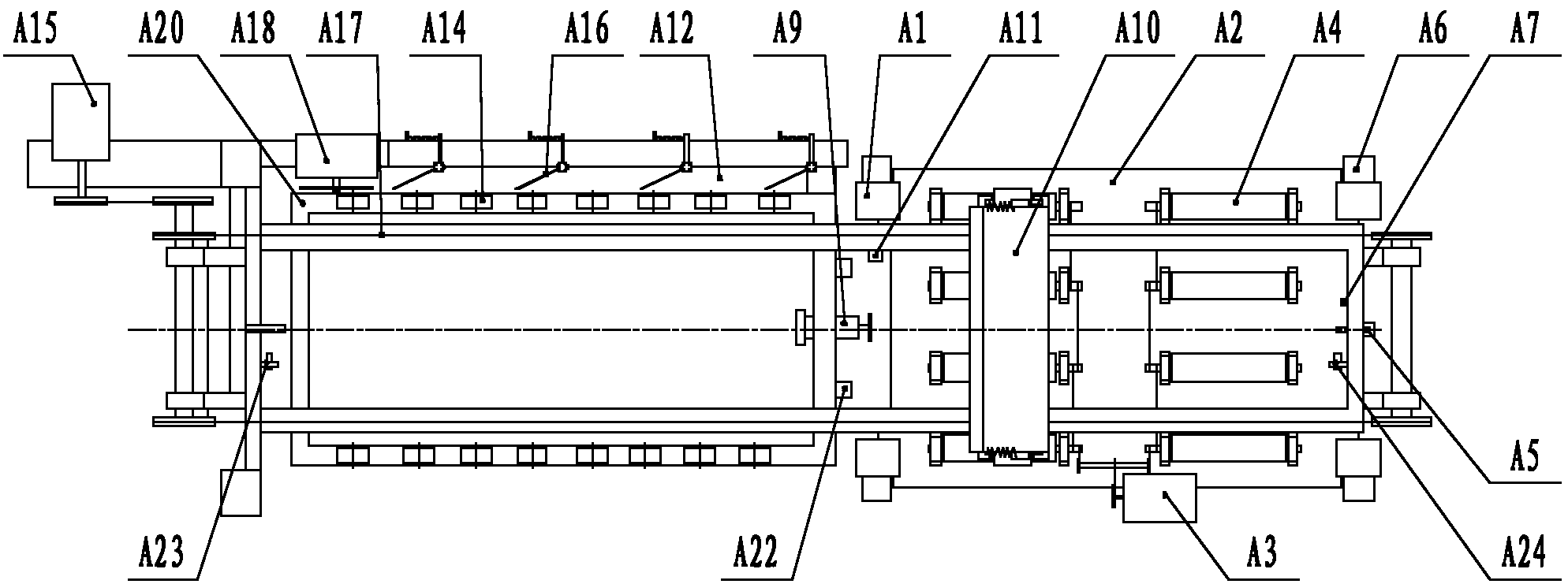

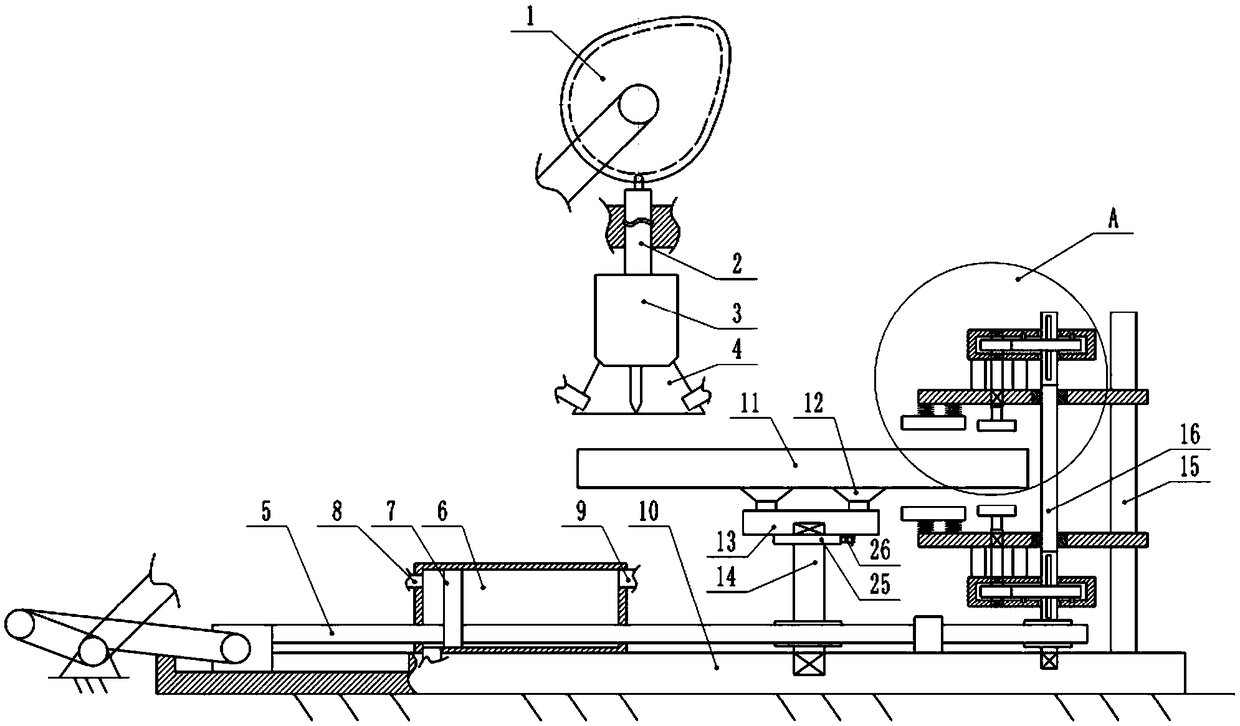

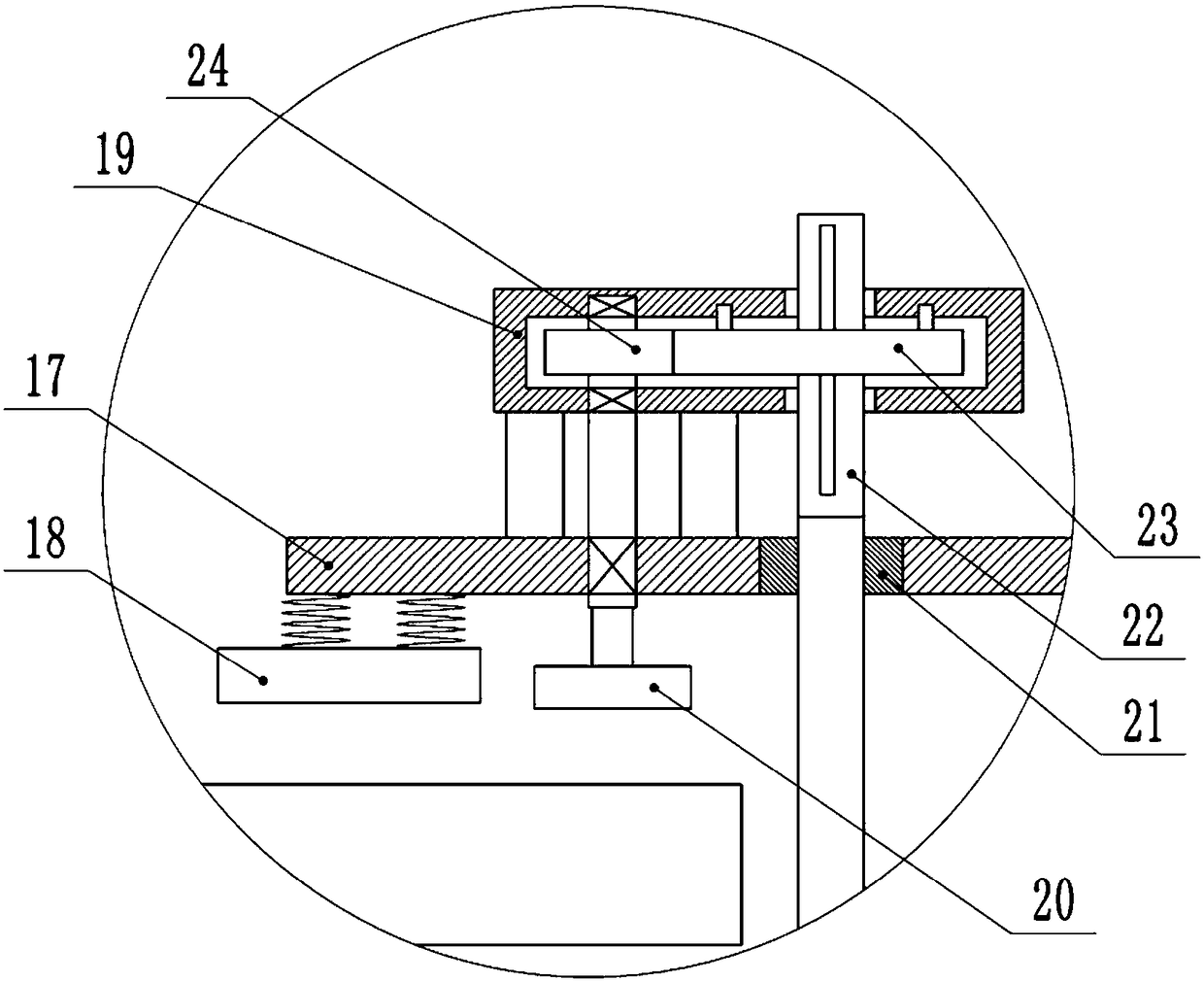

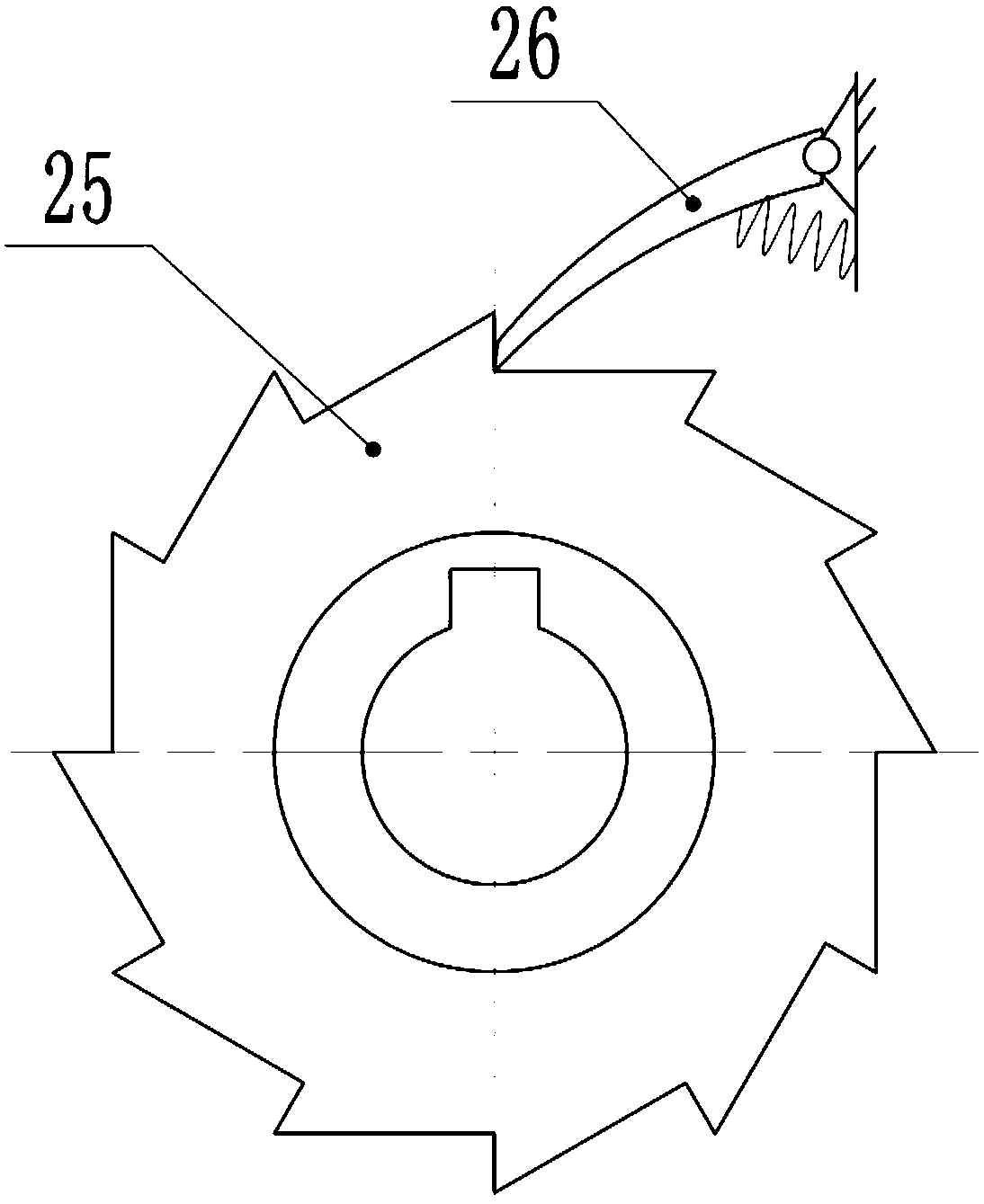

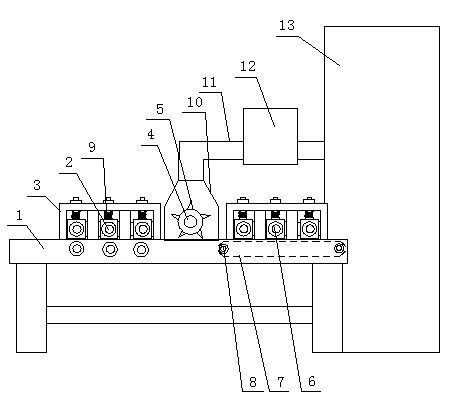

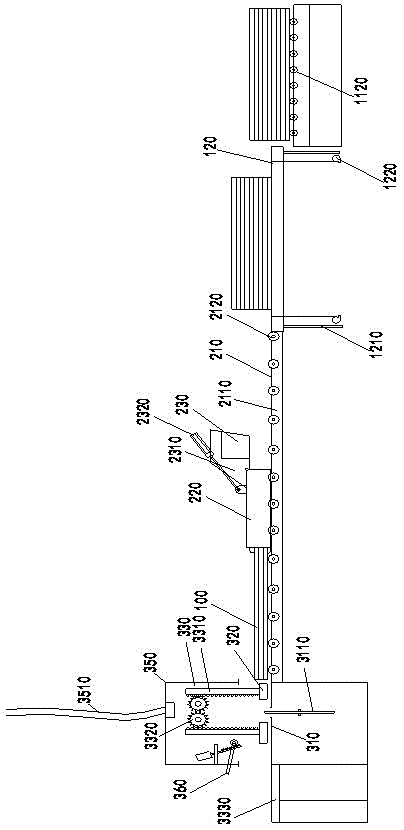

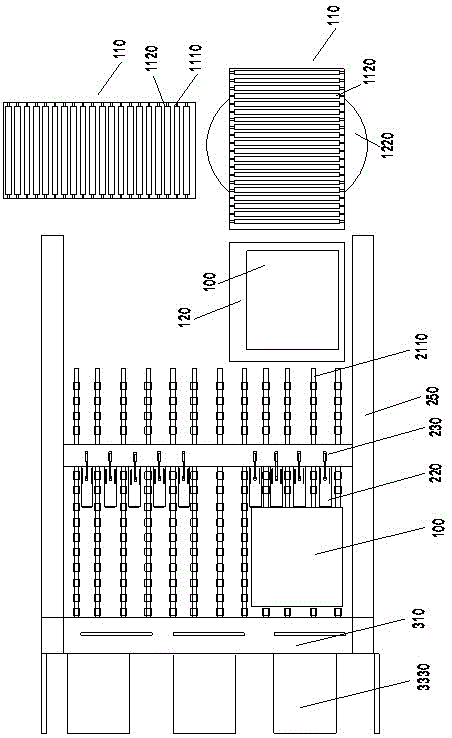

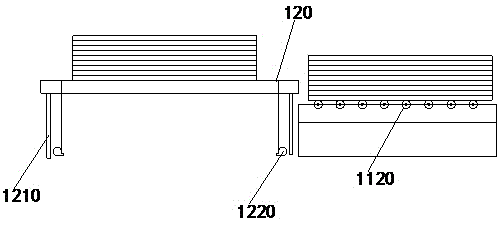

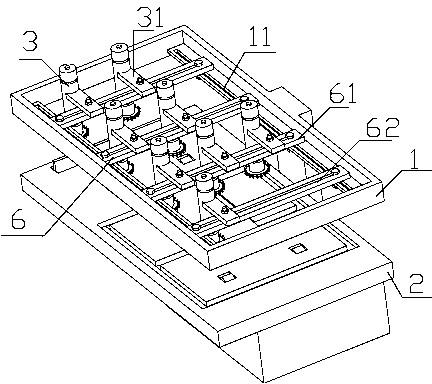

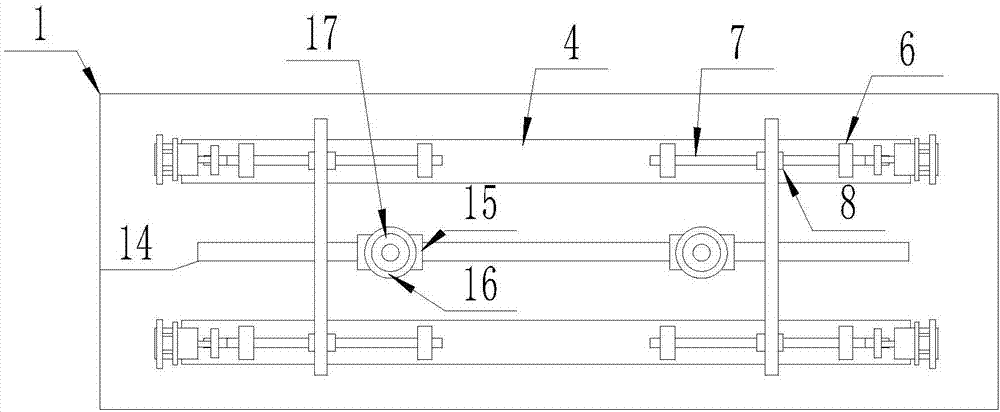

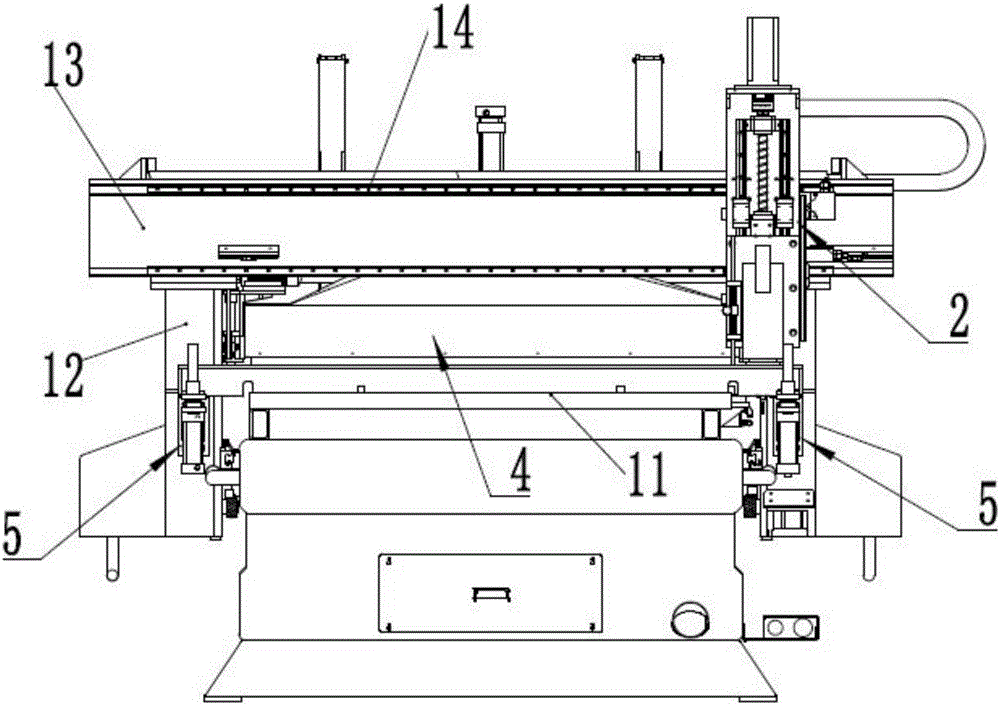

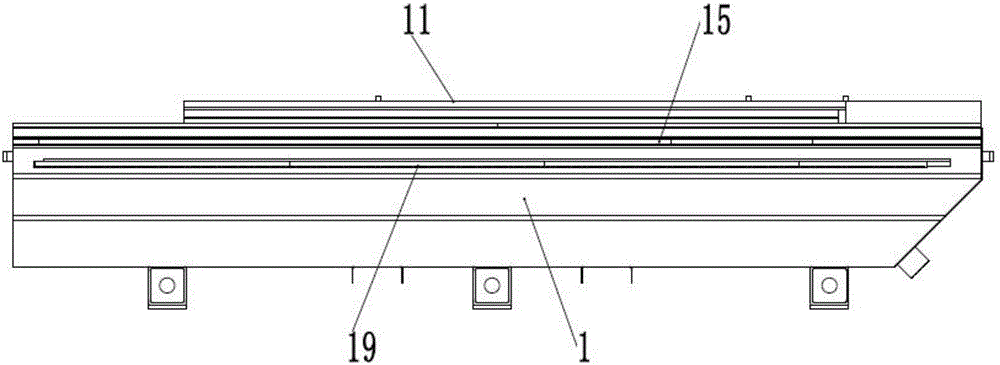

Longitudinal and transverse cutting computer cut-to-size saw equipment

ActiveCN106965261ARealize automatic feeding processImprove processing efficiencyFeeding devicesBark-zones/chip/dust/waste removalEngineeringWaste treatment

The invention discloses longitudinal and transverse cutting computer cut-to-size saw equipment which comprises a control unit, a feed unit, a longitudinal sawing unit, a transition feed unit, a lift type longitudinal and transverse bidirectional conveying platform, a transverse sawing unit and an excess material and waste treatment unit. The longitudinal sawing unit comprises a longitudinal sawing main machine rack, a longitudinal sawing saw carriage, a longitudinal sawing pressure cross beam, a longitudinal sawing plate front alignment device, a longitudinal sawing feed pushing rod cross beam assembly and a first conveying platform. The transition feed unit comprises a feed hooking hand mechanism, an excess material discharge mechanism and a second conveying platform. The lift type longitudinal and transverse bidirectional conveying platform comprises a transverse conveying unit and a longitudinal conveying unit which are arranged in a staggered mode. The transverse sawing unit comprises a transverse sawing main machine rack, a transverse sawing saw carriage, a transverse sawing pressure cross beam, a transverse sawing plate front alignment device and a third conveying platform. By adoption of the longitudinal and transverse cutting computer cut-to-size saw equipment, plate automatic feeding, automatic longitudinal cutting and automatic transverse cutting are achieved, trimming excess materials can be automatically treated, processing efficiency is greatly improved, and labor force is saved.

Owner:NANXING MACHINERY CO LTD

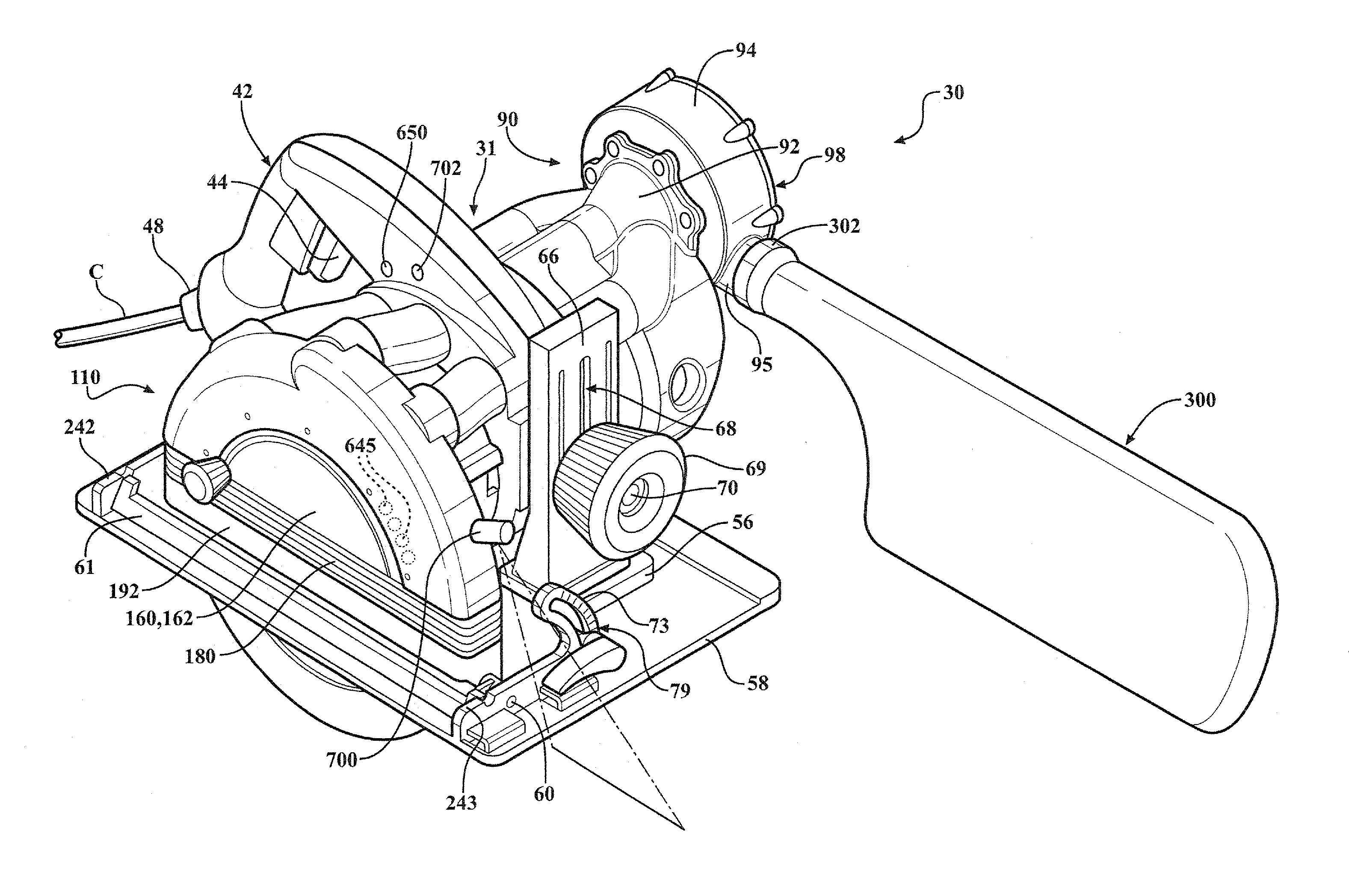

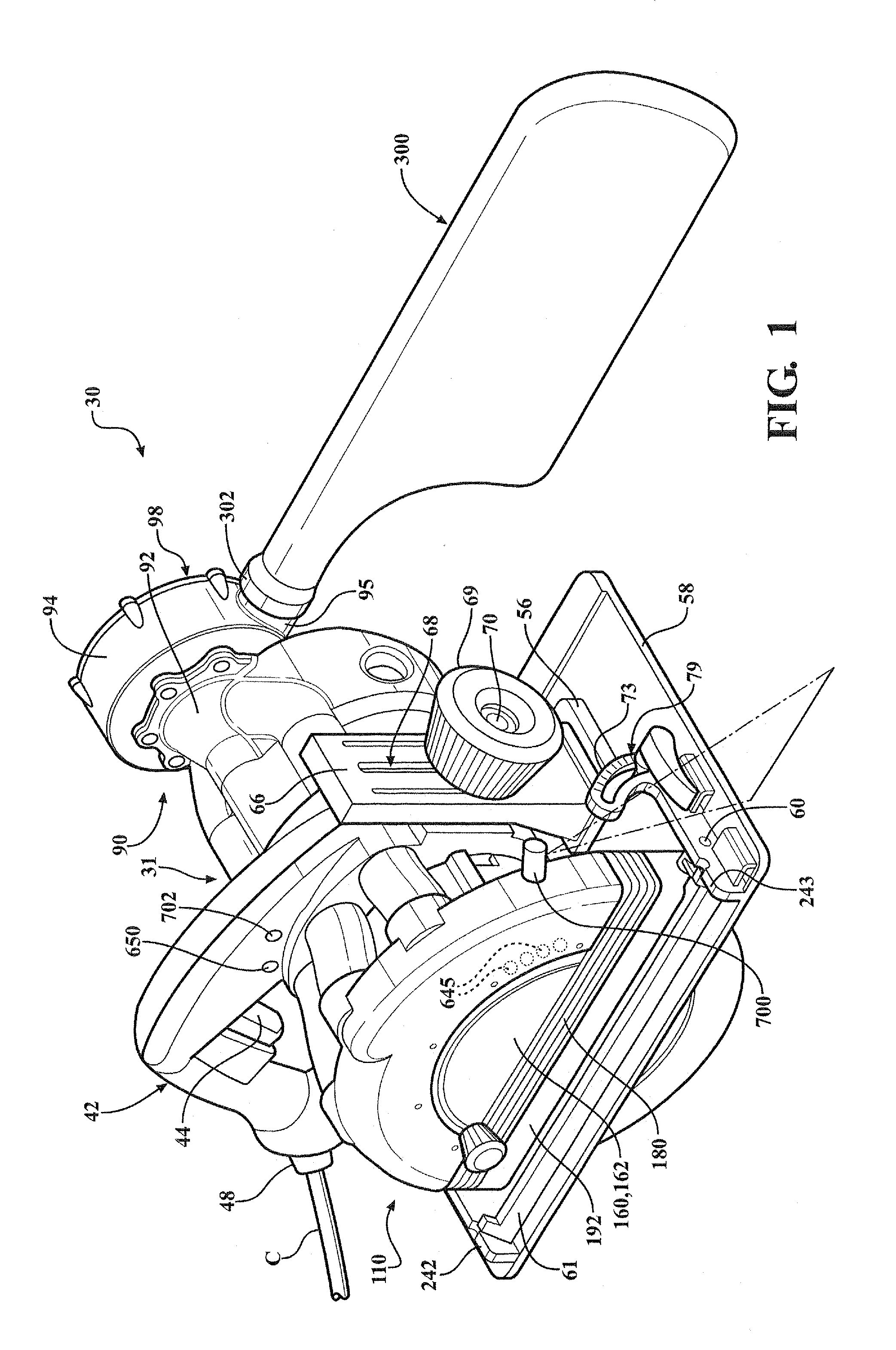

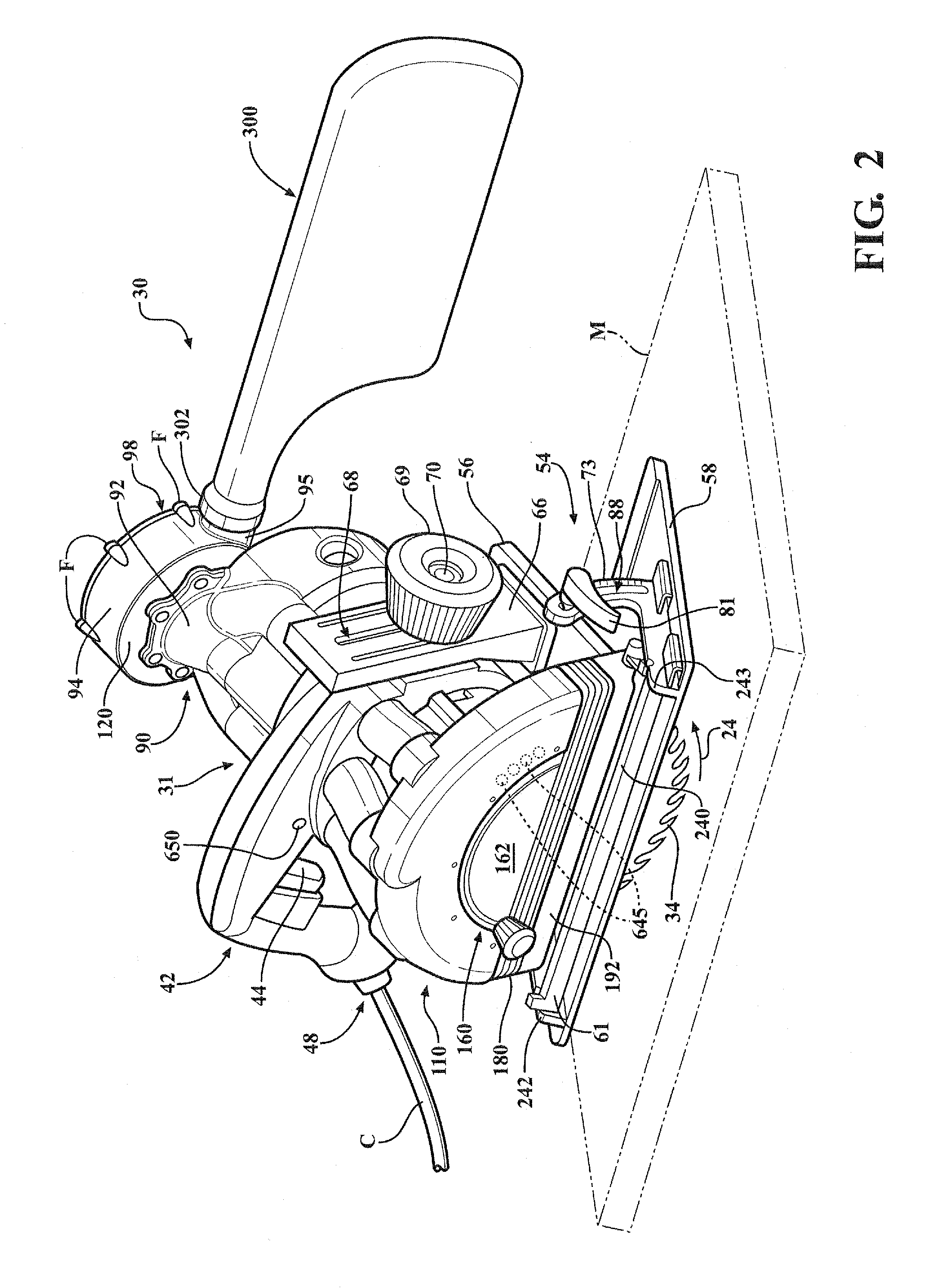

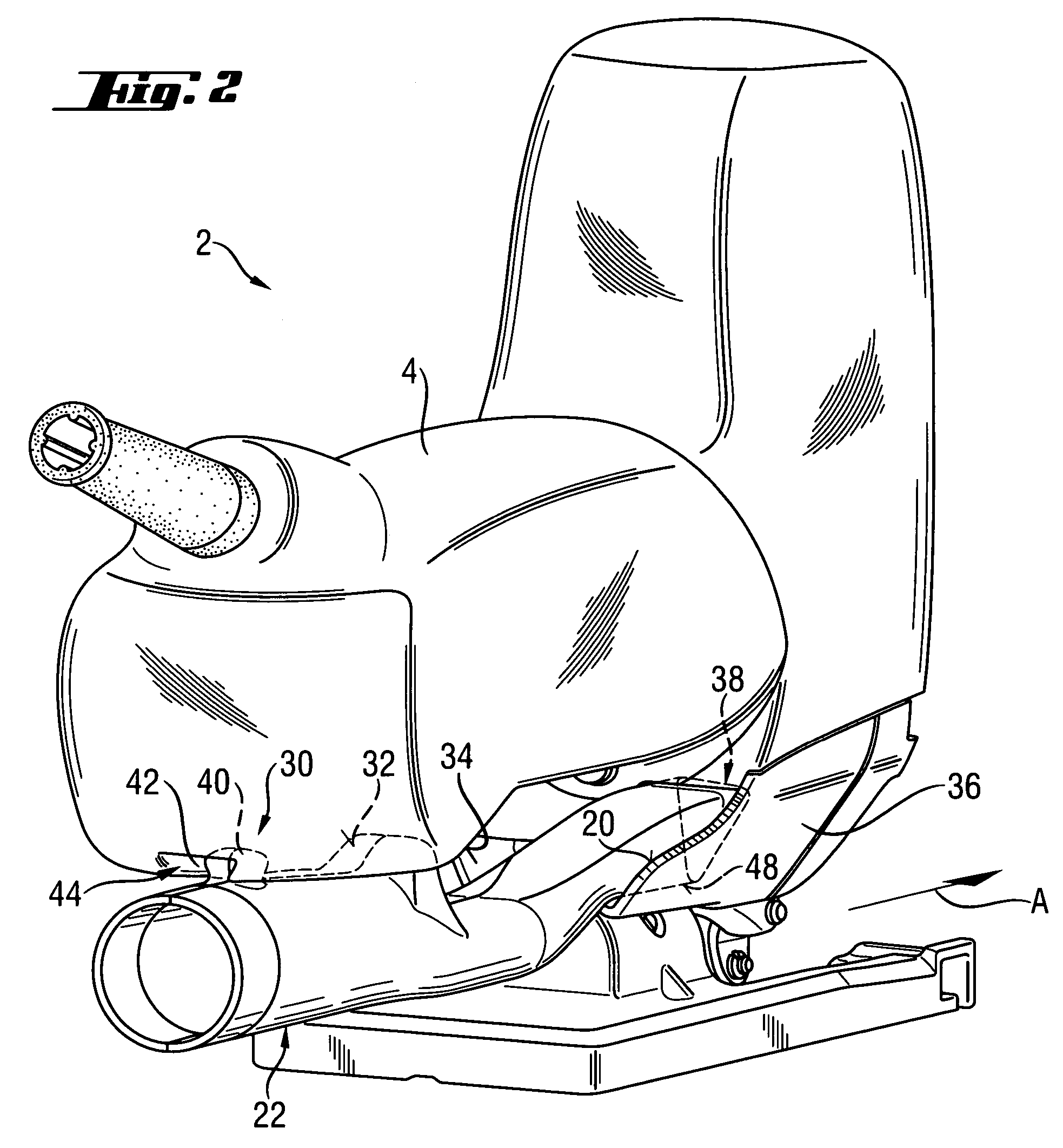

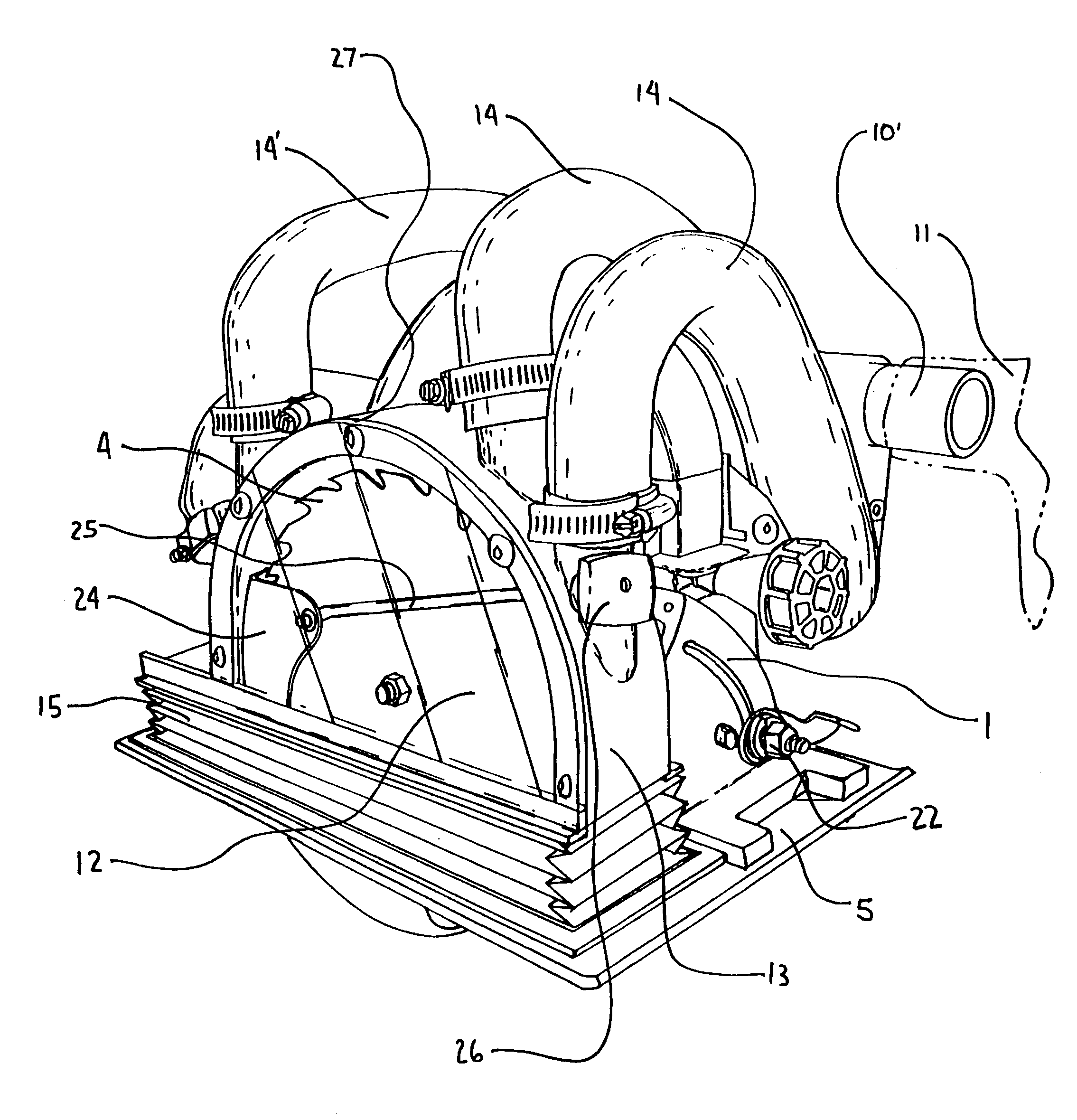

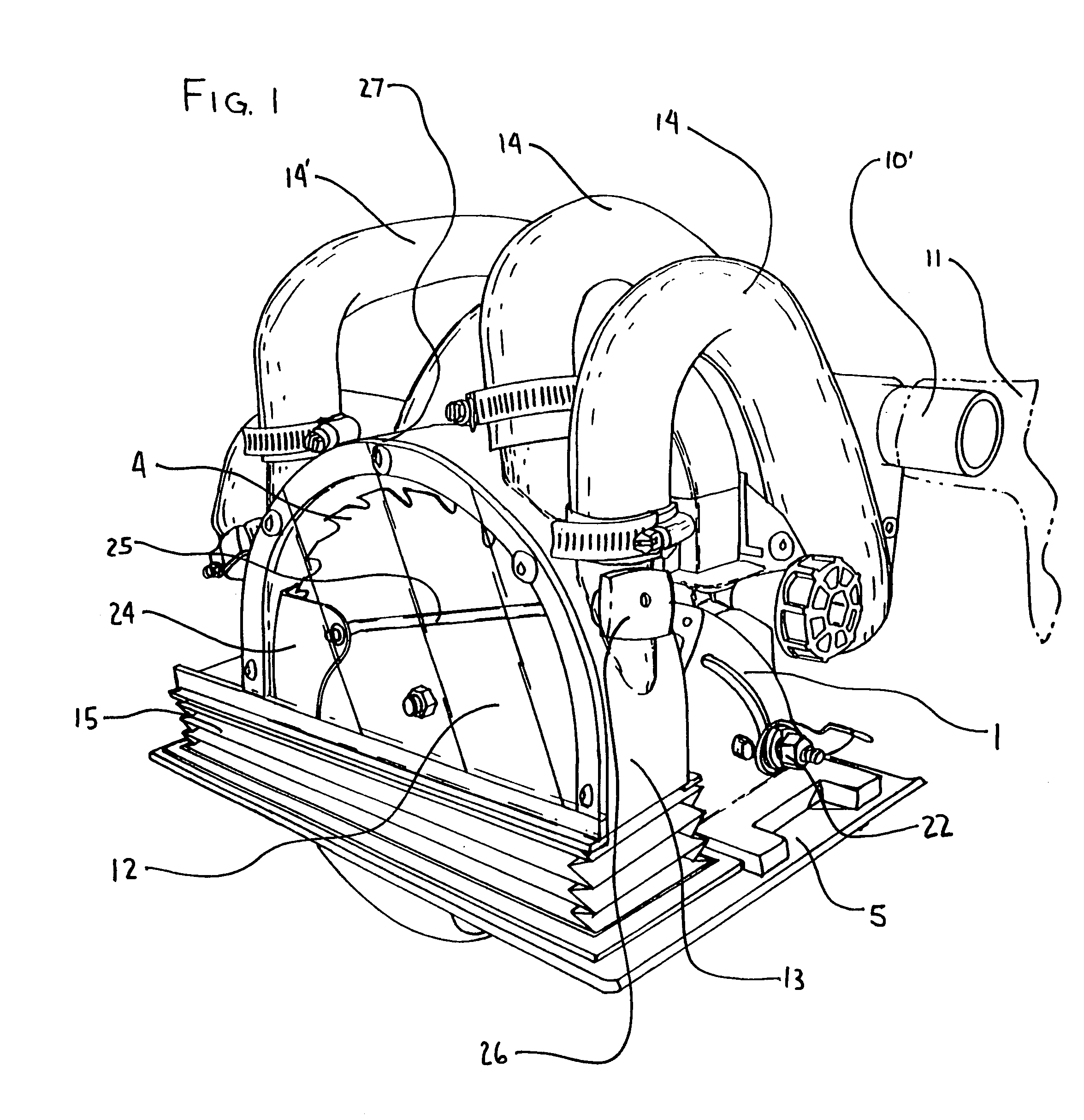

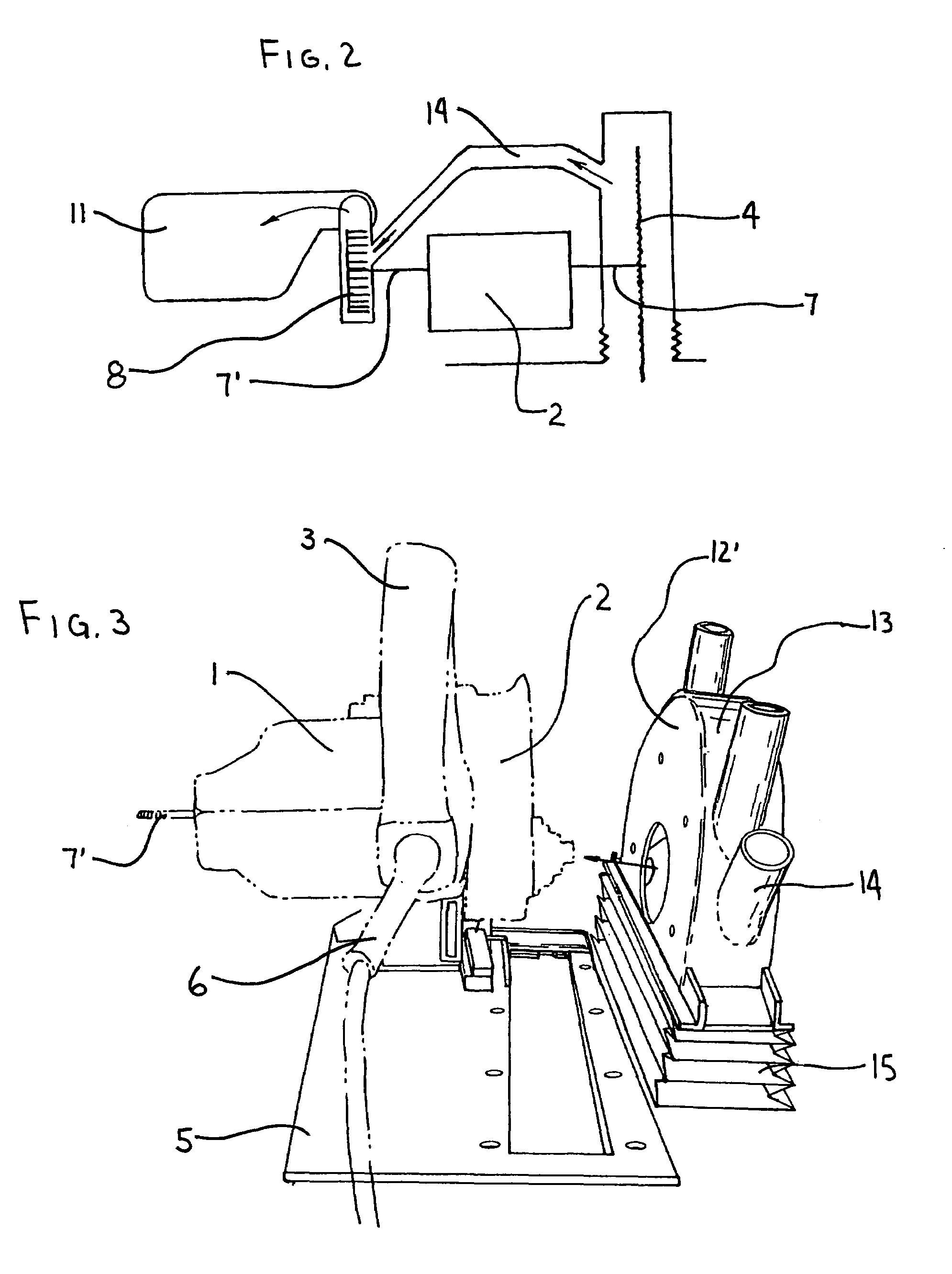

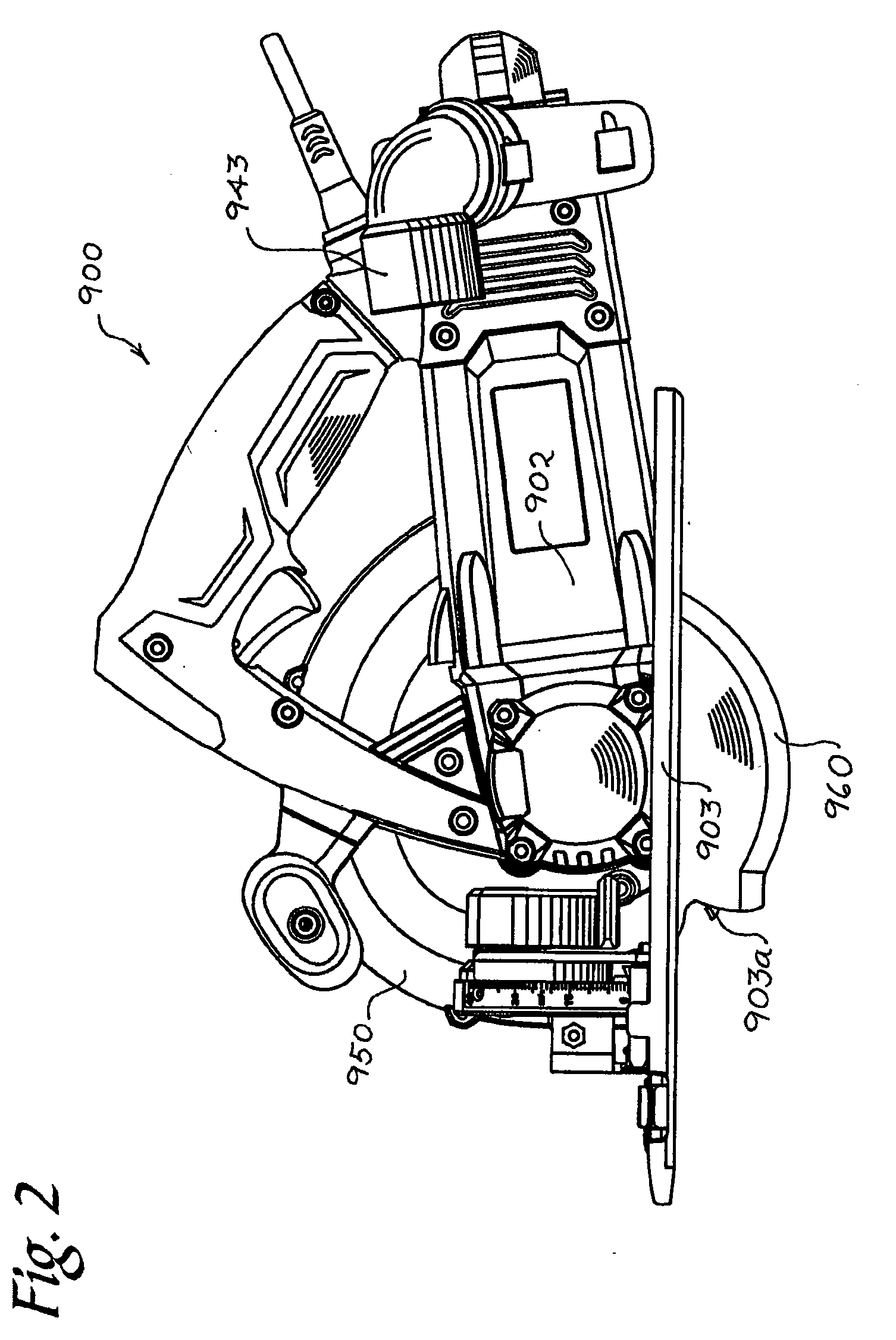

Portable cutting device with on-board debris collection

InactiveUS20100269353A1Eliminate needMetal sawing devicesMetal sawing accessoriesImpellerMotor drive

A portable cutting device having a cutting tool for cutting a material. The cutting device includes a motor driving the cutting tool and a shroud at least partially enclosing the cutting tool. The shroud defines a debris accumulation chamber for gathering debris created by the cutting tool cutting the material. An impeller is operatively coupled to the motor and driven by the motor to create suction pressure to draw the debris out of the debris accumulation chamber and into a collection bag.

Owner:MARTIN CHARLES B

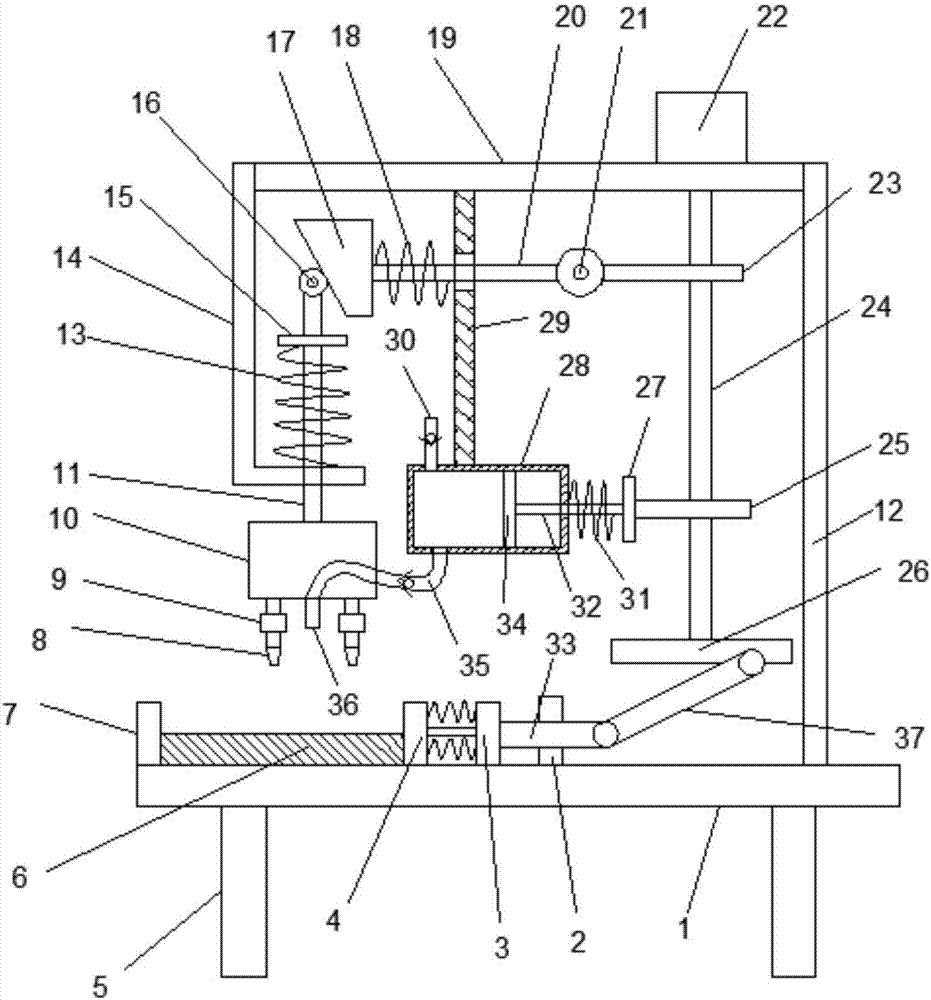

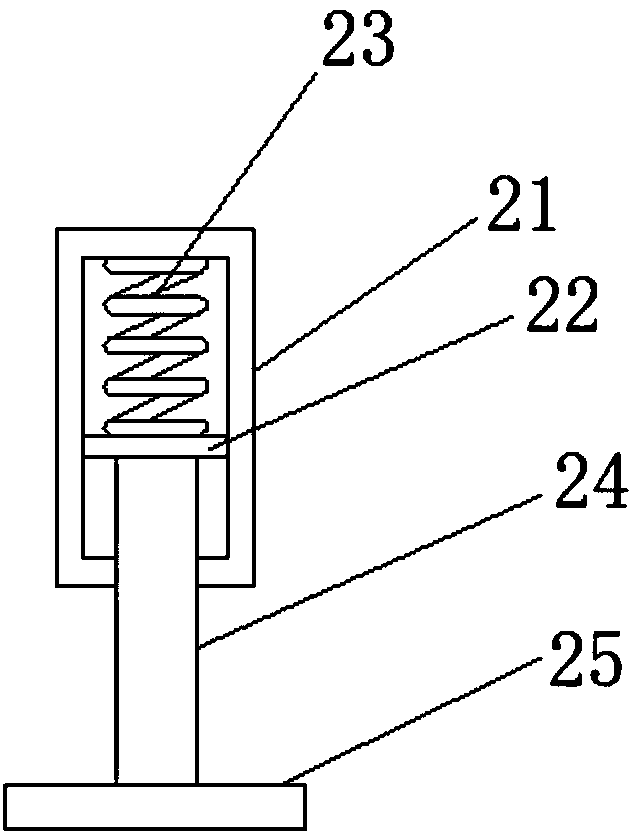

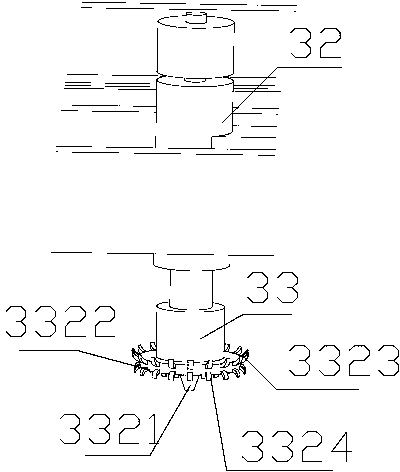

Self-cleaning type building timber equally-spaced punching device

InactiveCN107186825AReasonable structureInnovative designStationary drilling machinesBark-zones/chip/dust/waste removalPunchingDrive wheel

The invention discloses a self-cleaning equidistant punching device for building timber, which comprises a workbench, a support frame is connected to the upper end of the right side of the workbench, a top plate is connected to the left side of the upper end of the support frame, and a driving motor is arranged on the right side of the top plate to drive The lower end of the motor is connected to the drive shaft, the middle part of the upper end of the drive shaft is connected to the first cam, the left end of the first cam is in contact with the roller, the left end of the roller is connected to the push rod, the left end of the push rod is connected to the push block, and the left lower end of the push block contacts There is a pulley, the lower end of the pulley is connected with a lifting rod, the middle part of the upper end of the lifting rod is connected with a limit plate, the lower end of the limit plate is connected with a second spring, the lower end of the lifting rod is connected with a driving box, the middle part of the lower end of the drive shaft is connected with a second cam, and the bottom of the drive shaft The end is connected with a driving wheel, and the middle part of the driving wheel is connected with a crank. The present invention realizes the efficient punching effect on wood pieces, improves the working efficiency of wood punching, and at the same time avoids the accumulation of sawdust on the wood pieces, thereby increasing the processing quality of the wood pieces.

Owner:阮霞伟

Building panel drilling device with waste recycling function

InactiveCN108189158AReduce pollutionStationary drilling machinesBark-zones/chip/dust/waste removalHydraulic cylinderPiston rod

The invention discloses a building panel drilling device with a waste recycling function. The building panel drilling device comprises a supporting platform. Hydraulic cylinder devices are arranged atthe left end and the right end below a beam plate. Piston rods are arranged below the hydraulic cylinder devices. A lifting plate is fixedly welded to the lower portions of the left piston rod and the right piston rod. Sleeve bases which are in cup joint to a front stand column and a rear stand column are arranged on the left side wall and the right side wall of the lifting plate. Fixing tables are arranged at the left end and the right end below the lifting plate. A material collecting hopper is arranged below the supporting platform. Waste suction pipes are evenly arranged above the material collecting hopper and penetrate the upper end face of the supporting platform. A dust suction device is fixedly arranged at the left end above the supporting base, and the right side of the dust suction device is connected with the material collecting hoper through a dust guiding pipe. According to the building panel drilling device with the waste recycling function, the dust suction device canbe started in the drilling process for collecting dust waste in the drilling process into the material collecting hopper through the waste suction pipes, and accordingly environment pollution in the work process is reduced.

Owner:冯瑞芳

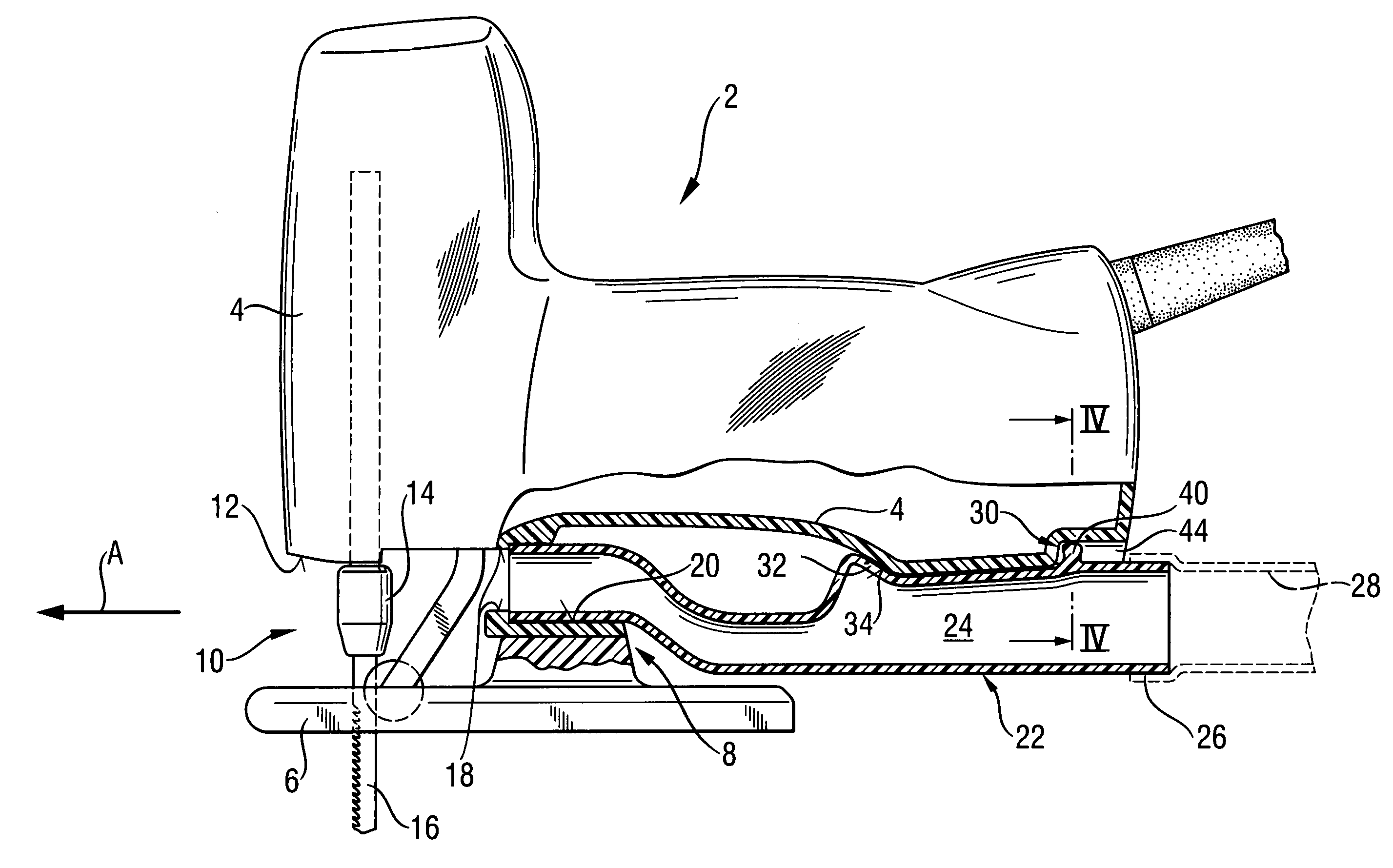

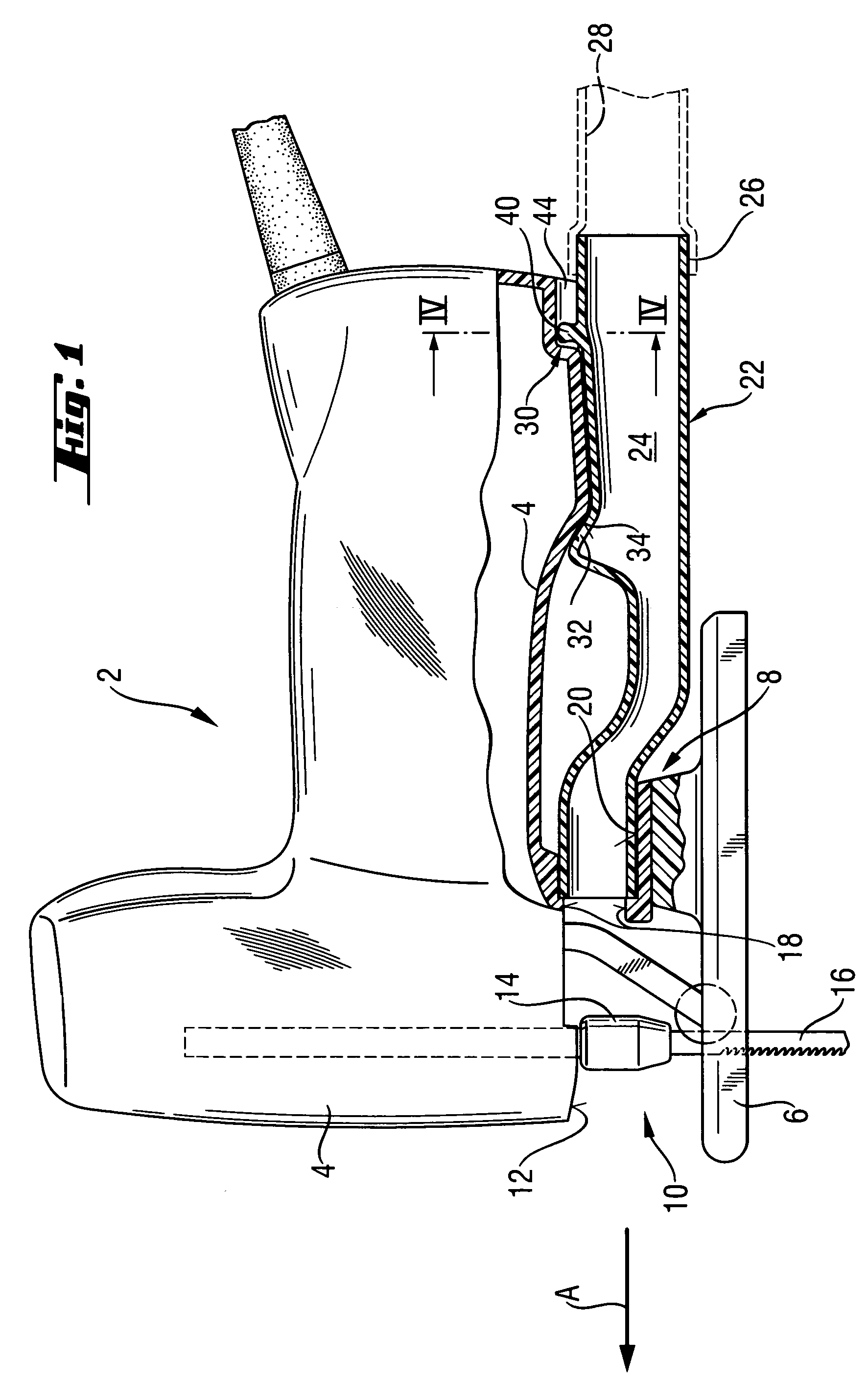

Compass saw with a suction connection arrangement

ActiveUS7197826B2Easy to handleGood lookingMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

Owner:HILTI AG

Cutting machine

InactiveCN105291198AReduce frictionReduce wearEdge grinding machinesSawing componentsEngineeringWood plank

The invention provides a cutting machine and belongs to the field of mechanical devices. The cutting machine comprises a rack body, a workbench, a drive device and a cutting part, wherein the rack body is provided with a first guide rail; the workbench is in sliding connection with the first guide rail; the drive device is connected with the workbench and the cutting part; the cutting part comprise a first longitudinal cutting part body and a second longitudinal cutting part body which are arranged symmetrically; the first longitudinal cutting part body and the second longitudinal cutting part body are connected with the rack body; the first longitudinal cutting part body is located on one side of the workbench in the direction of the first guide rail; the second longitudinal cutting part body is located on the side, away from the first longitudinal cutting part body, of the workbench. According to the cutting machine, the drive device drives the workbench to slide along the first guide rail, so that cutting machining of planks is automatic, the cutting precision of the planks can be ensured without experienced operators, work intensity of the operators is also relieved, and the plank machining efficiency is improved.

Owner:CHONGQING AIBUTE FURNITURE

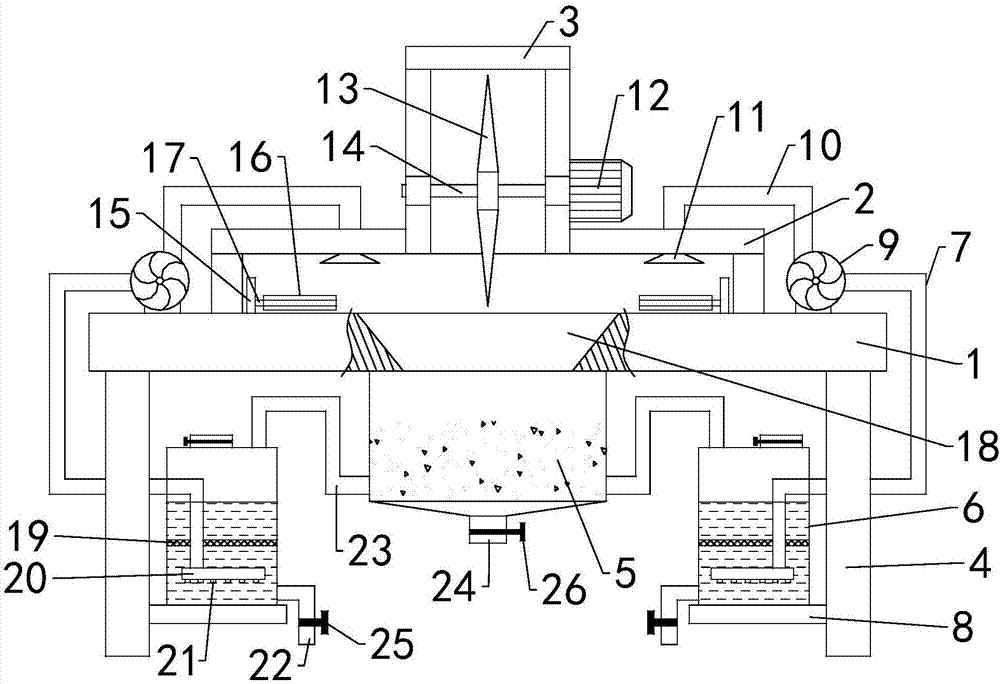

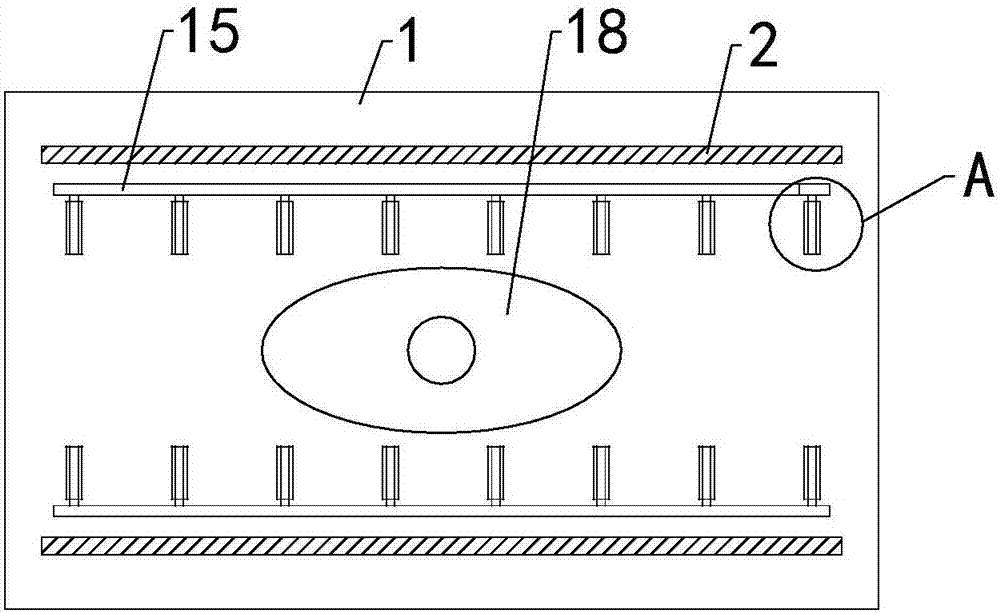

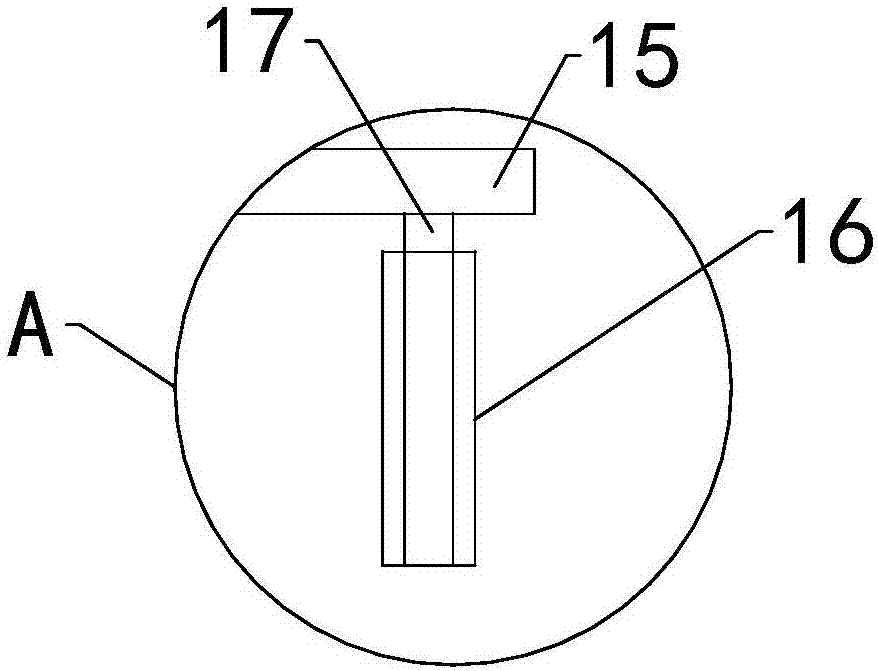

Dust sucking type wood processing cutting device

InactiveCN107214777APrevent accidental touchEasy to processProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningPulp and paper industry

The invention discloses a vacuum-type wood processing and cutting device, which comprises a working table, a protective box, a protective cover, a sawdust collection box and a water tank. The upper surface of the working table is symmetrically fixed and welded. There are a number of rotating shafts on the inner wall of the plate, each rotating shaft is equipped with a conveying roller, and two fans are symmetrically arranged on the upper surface of both ends of the workbench, and the air inlet of each fan is connected. There is an air intake pipeline, the air intake end of the air intake pipeline is connected with the dust collection hood, the lower part of the inner cavity of the water tank is provided with an annular exhaust pipe, and the annular exhaust pipe is connected with the outlet end of the ventilation pipeline, and the inlet of the ventilation pipeline The gas end is connected with the gas outlet of the blower fan, and the upper part of the inner cavity of the water tank is connected with the lower inner cavity of the sawdust collection box through a connecting pipe. The invention has simple structure, high safety, is convenient for processing and cutting wood boards, can effectively absorb dust and collect sawdust, and is suitable for popularization and use.

Owner:张翔

Efficient wood plate processing equipment

InactiveCN107336292AReduce difficultyReduce pollutionProfiling/shaping machinesBark-zones/chip/dust/waste removalArchitectural engineeringSlide plate

The invention discloses a high-efficiency wood board processing equipment, which comprises a workbench. A protective cover is arranged on the upper side of the workbench. A horizontal first sliding rail is arranged on the inner upper end of the protective cover, and a longitudinally arranged sliding plate is arranged on the first sliding rail. , the lower side of the skateboard is provided with a longitudinal second slide rail, the second slide rail is provided with a second electric telescopic rod, the lower end of the second electric telescopic rod is provided with a first motor, and the output end of the first motor is provided with a mounting seat , the inside of the mounting seat is left and right symmetrically provided with a second motor, the output ends of the two second motors are provided with a fourth electric telescopic rod, the outer end of the fourth electric telescopic rod is provided with a mounting plate, and the upper side of the mounting plate is provided There is a grinding device, a cutting device is arranged on the lower side of the mounting plate, a supporting plate is arranged on the lower part of the legs, and a dust collection box is arranged on the upper side of the supporting plate. The invention has the advantages of simple structure, convenient use, high processing efficiency, reduced work intensity and reduced dust pollution.

Owner:侯添有

Plate edge cutting machine

InactiveCN103213173ANot easy to failImprove reliabilityFeeding devicesCircular sawsControl systemAgricultural engineering

The invention discloses a plate edge cutting machine, which belongs to the field of plate processing machinery. The plate edge cutting machine has the technical scheme that the plate edge cutting machine comprises a plate conveying machine, a plate falling machine, a longitudinal edge cutting machine, a horizontal edge cutting machine and a control system, wherein the tail part of the plate conveying machine is connected with the head part of the plate falling machine, the longitudinal edge cutting machine is connected with the plate falling machine, the other end of the longitudinal edge cutting machine is vertically connected with the horizontal edge cutting machine, the control system is respectively connected with the plate conveying machine, the plate falling machine, the longitudinal edge cutting machine and the horizontal edge cutting machine in a control mode, the plate conveying machine comprises an elevator I, a plate conveying machine rack and a positioning platform, and a push head is fixedly arranged above the plate conveying machine rack; and the push head comprises a sliding plate and a positioning and connecting device, the sliding plate is provided with a glare shield and a hook plate, and a plate propping air cylinder is arranged at the right side of the plate conveying machine rack. The invention provides the plate edge cutting machine which has better entire machine performance and higher automation degree, and is mainly used for cutting rough edges of plates.

Owner:阎育华

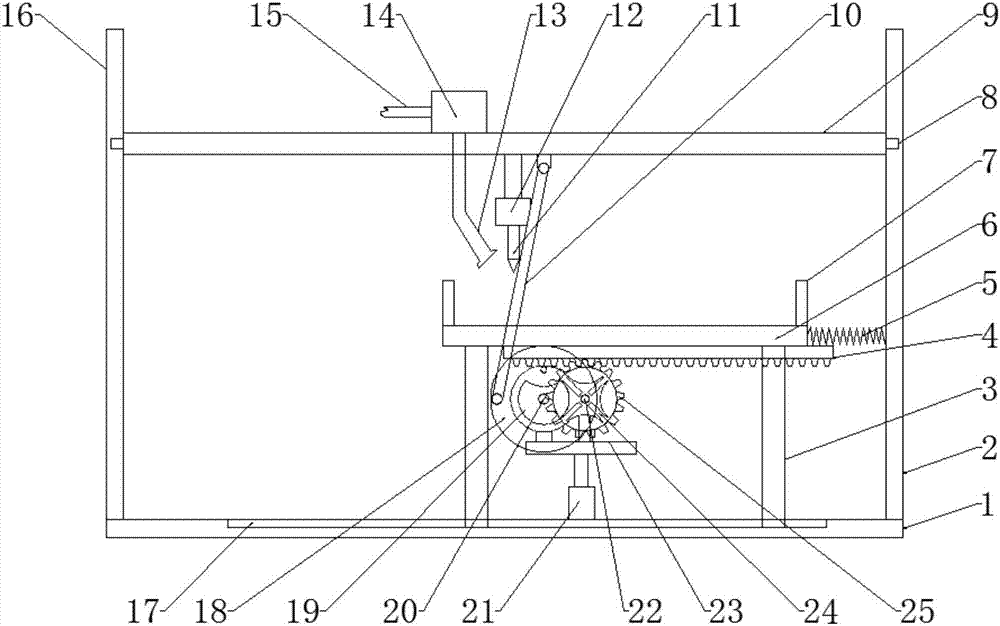

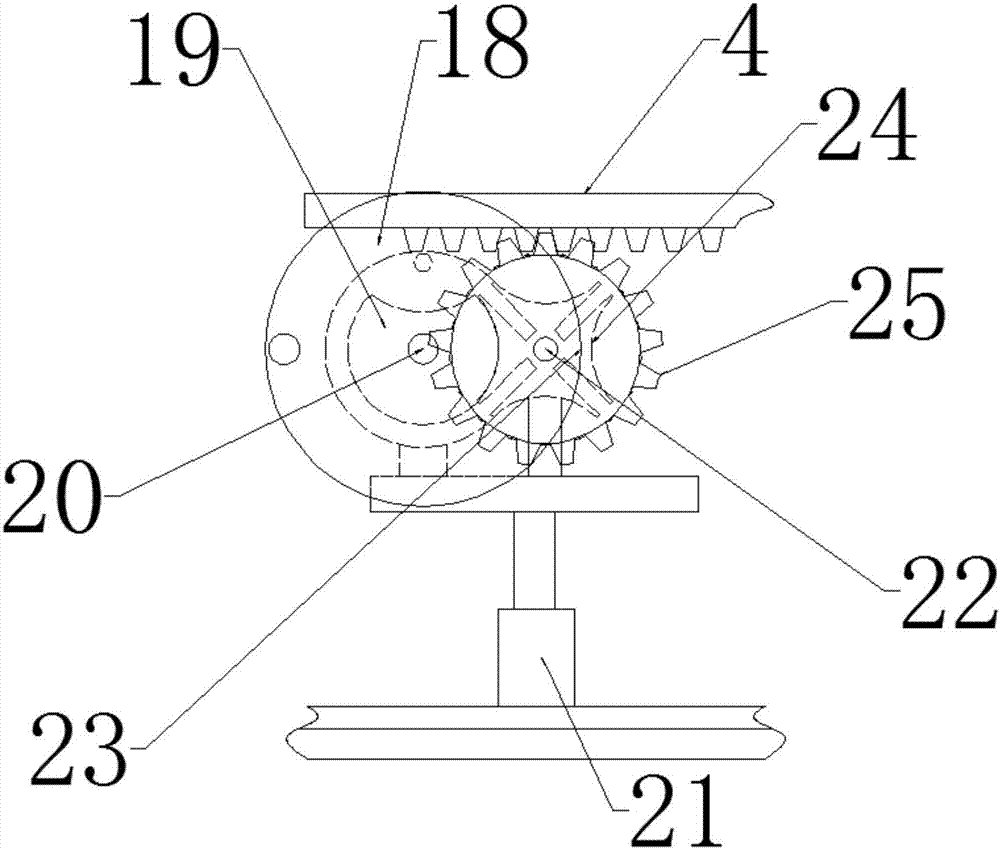

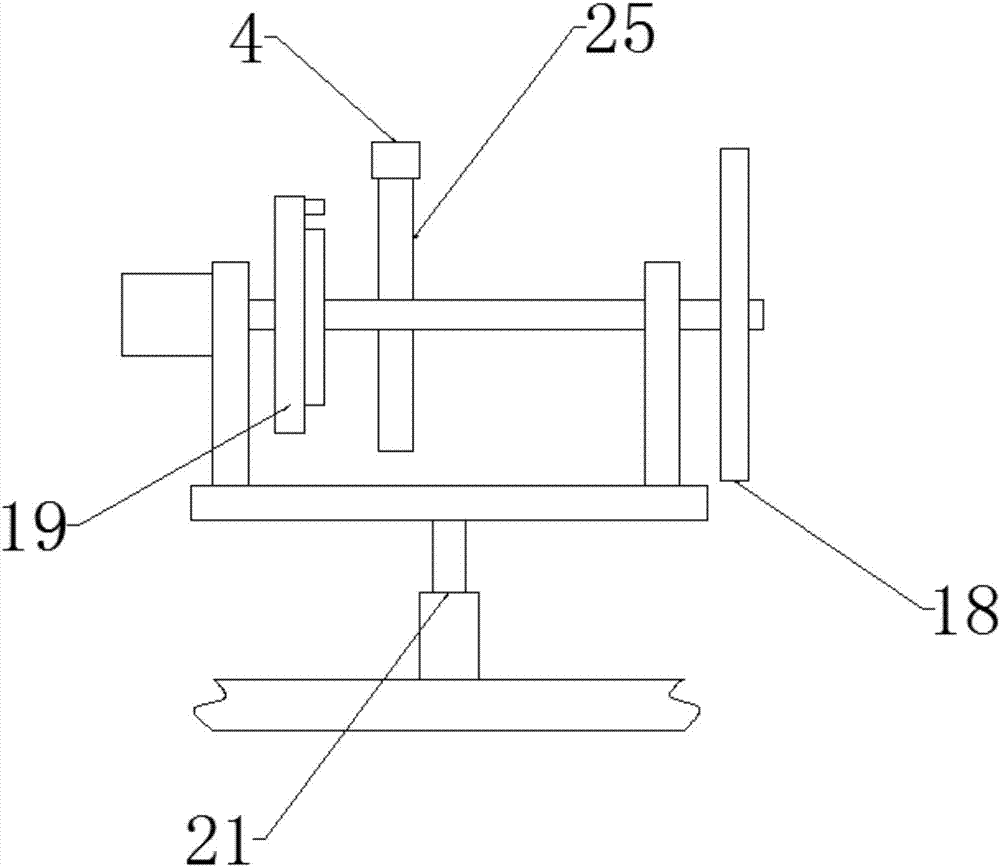

Board punching device

PendingCN108638225AEvenly punchedRealize Angle SwitchingEdge grinding machinesGrinding carriagesPunchingGear wheel

The invention belongs to the technical field of wood processing equipment, and particularly discloses a board punching device. The board punching device comprises a machine frame. A rotary table is arranged on the machine frame, a punching mechanism and a power mechanism are arranged on the upper portion of the machine frame, and the power mechanism drives the punching mechanism to ascend and descend. A crank and sliding block mechanism is arranged on the machine frame, a push rod which is fixedly connected with a sliding block is connected to the machine frame in a sliding mode, and an intermittent mechanism which drives the rotary table to conduct one-way intermittent rotation is connected between the push rod and the rotary table. A clamping mechanism is further arranged on the machineframe, and comprises a supporting rod. Two supporting plates are connected to the supporting rod in a sliding mode. A two-way lead screw is connected to the machine frame in a rotating mode, the two supporting plates are matched with the two-way lead screw through nuts, and the two-way lead screw and the push rod are connected through a gear and rack pair. Clamping plates and polishing discs are arranged on the inner sides of the two supporting plates, and transmission mechanisms which are used for driving the polishing discs to rotate are connected between the polishing discs and the two-waylead screw. By the adoption of the scheme, automatic rotation and clamping of a board are achieved in the drilling process, the working efficiency is high, and the labor intensity of workers is reduced.

Owner:重庆哲骁装饰工程有限公司

Self-contained vacuum saw

Owner:MARTIN CHARLES B

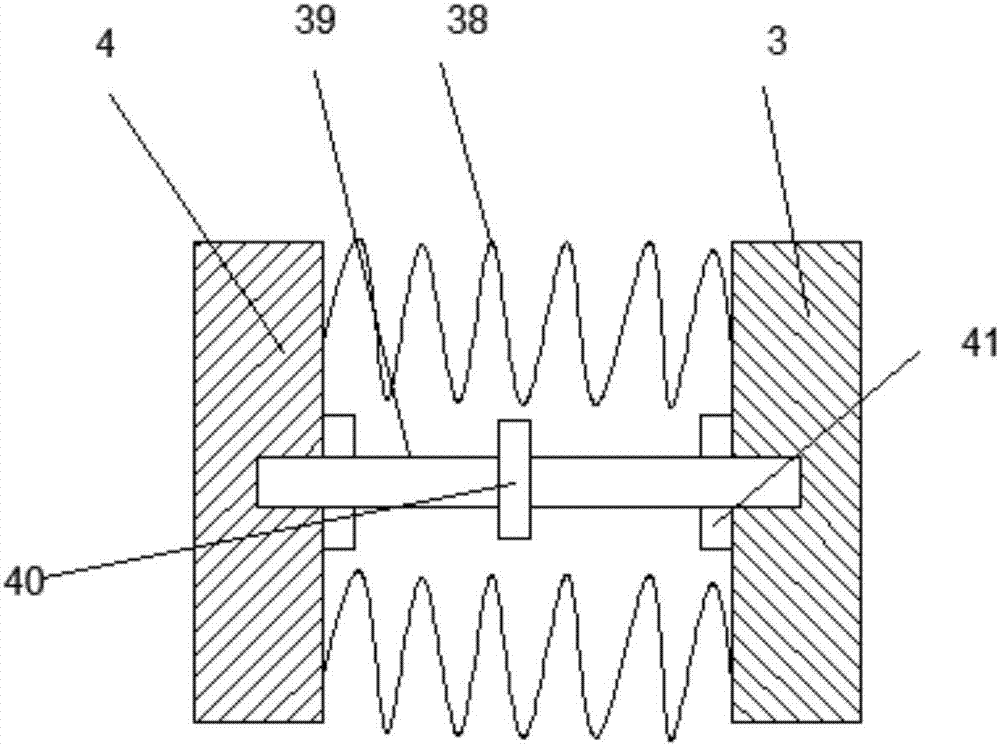

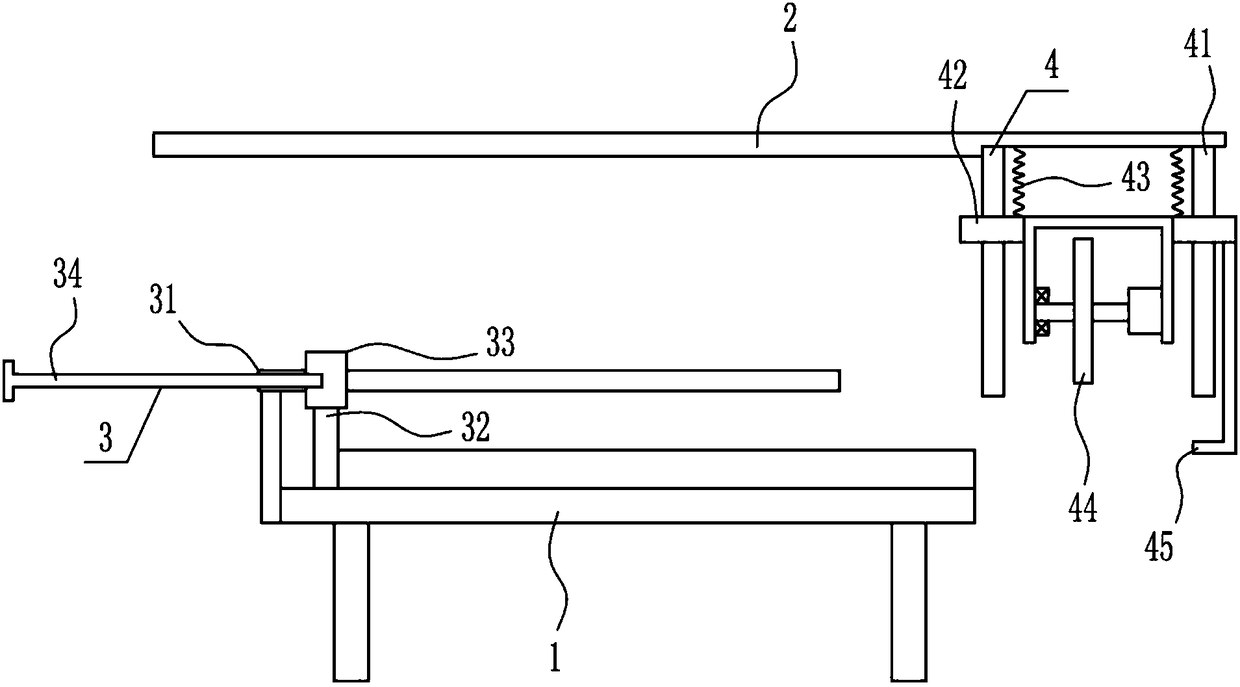

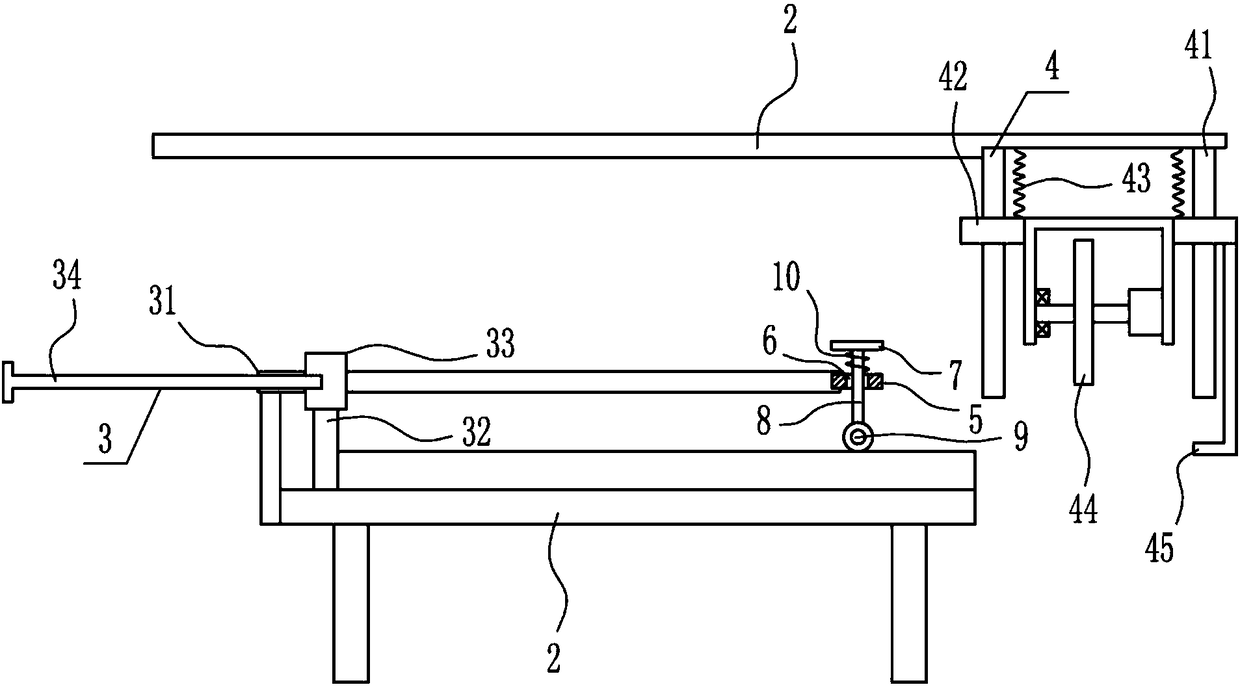

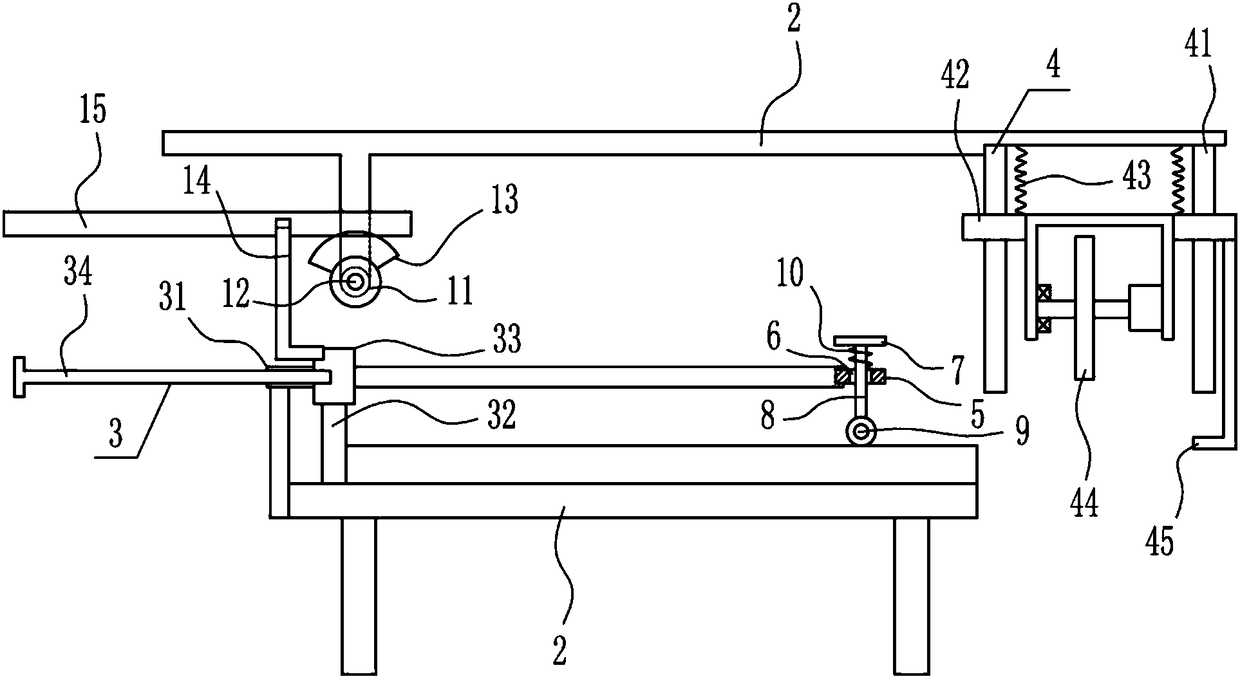

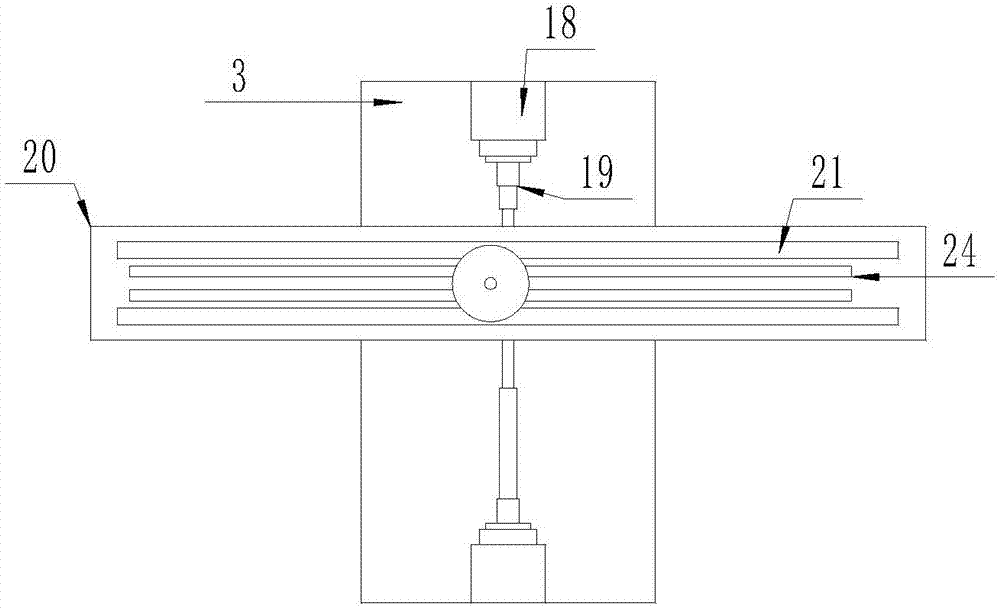

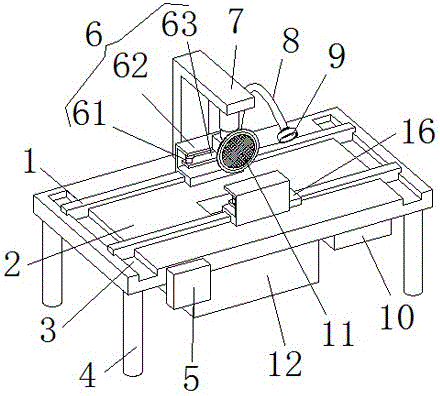

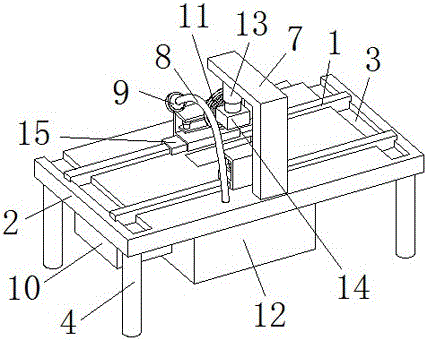

Automatic conveying and cutting device for building wood board

InactiveCN108177200ARealize cut-to-lengthAvoid cutsProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringIdler-wheel

The invention relates to a cutting device, in particular to an automatic conveying and cutting device for a building wood board. The technical problem to be solved by the invention is to provide the automatic conveying and cutting device for the building wood board, wherein the automatic conveying and cutting device can be used for automatically pushing the wood board and can realize fixed-lengthcutting. The automatic conveying and cutting device for the building wood board comprises a worktable and the like; the top of the worktable is connected with a moving mechanism; a top plate is arranged above the worktable; and the right side of the top plate is connected with a cutting mechanism. The automatic conveying and cutting device for the building wood board, provided by the invention, isprovided with the moving mechanism, a first guide rail, a push plate, a first guide sleeve, a push rod and the cutting mechanism, so an electric saw wheel can be moved without manpower, and efforts of a worker can be saved; by arranging a fixing block, a check block, a lifting rod, an idler wheel and a second spring, the wood board is prevented from being warped when the wood board is cut, so steady cutting of the electric saw wheel is not affected.

Owner:周远桂

Blade Guard for Power Tool Having an Evacuation System

A blade guard is configured to surround a rotatable cutting blade. The blade guard includes an arcuate body mounted to surround a portion of an outer circumferential edge of the cutting blade, wherein the arcuate body is fixed with respect to the rotatable blade. A plenum is disposed upon the body and configured to provide fluid communication between a cutting zone within the body and a suction source. An aperture is defined in the body proximate the cutting blade, the aperture disposed proximate a location where the cutting blade exits a workpiece being cut.

Owner:EASTWAY FAIR

Wood cutting device

InactiveCN103659940AEasy feedingGuaranteed to proceed normallyProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringWood cutting

The invention provides a wood cutting device, which comprises a frame, a plurality of feeding rollers, a bracket, a spindle, cutting knives and a plurality of discharge rollers. The feeding rollers are arranged on the bracket, the bracket is fixed on the frame, the spindle is uniformly provided with a plurality of cutting knives, a discharging end of the frame is provided with a belt conveyor for conveying wood, both ends of the belt conveyor are provided with rollers for driving the conveyer belt to rotate, the discharge rollers are arranged above the belt conveyor, the feeding rollers are provided with damping springs, and the damping springs are arranged between the feeding rollers and the bracket. The wood cutting device can guarantee the stability of feeding and avoid influence of vibration of wood on cutting accuracy in the cutting process. During the whole cutting process, the device can realize automatic feeding, cutting and discharging; and the spindle is evenly provided with the plurality of cutting knives, so as to effectively improve the cutting efficiency.

Owner:简厚诚

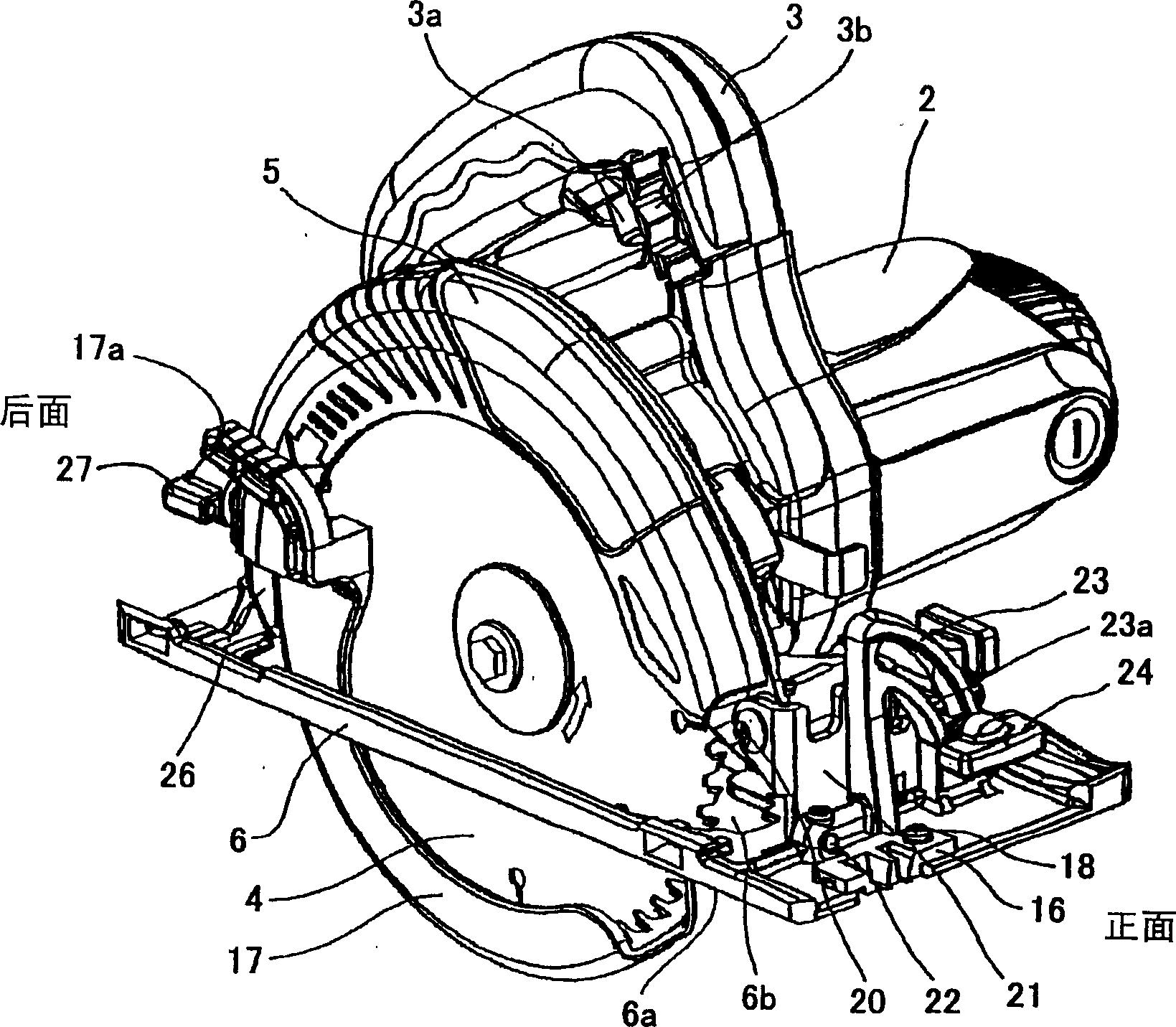

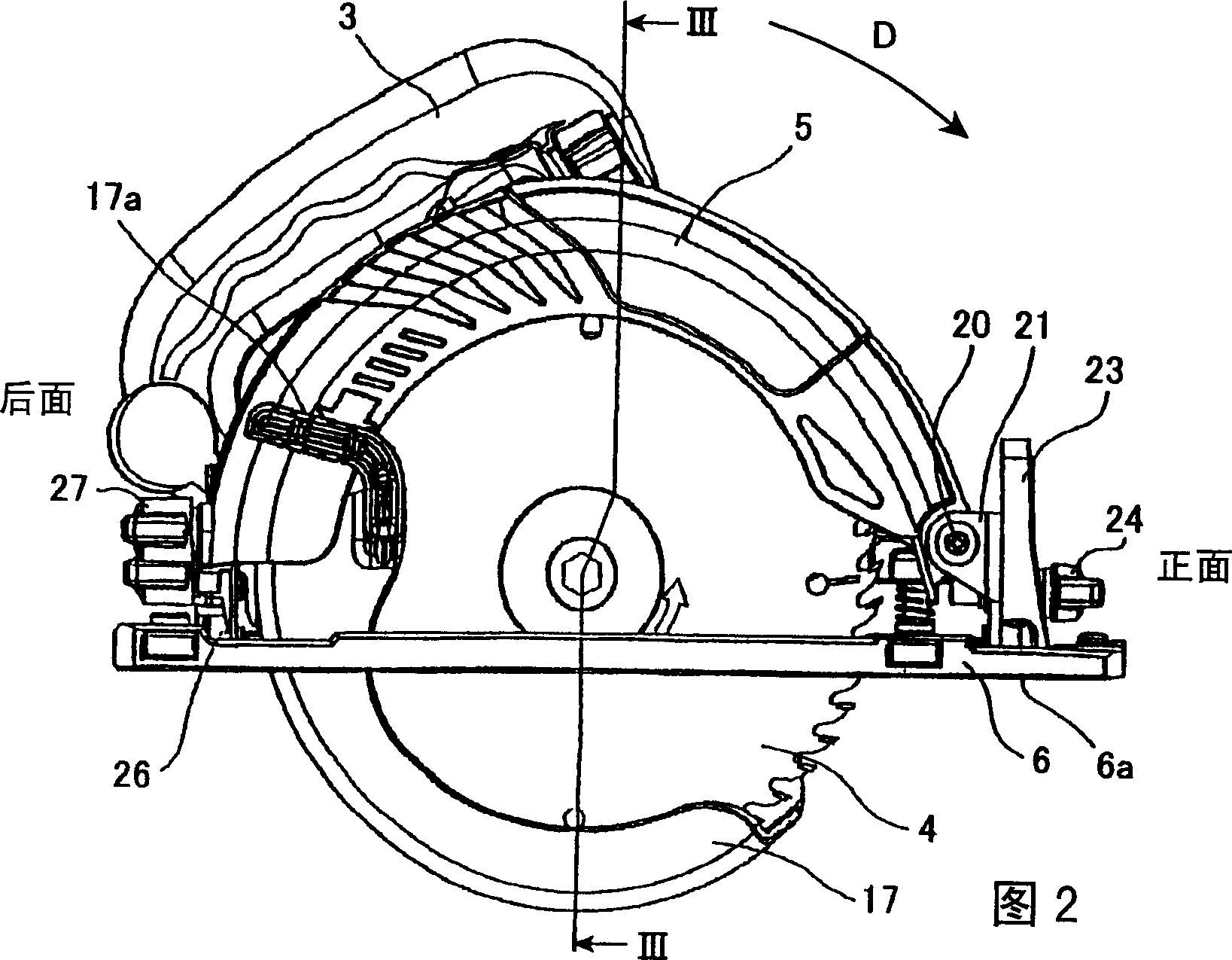

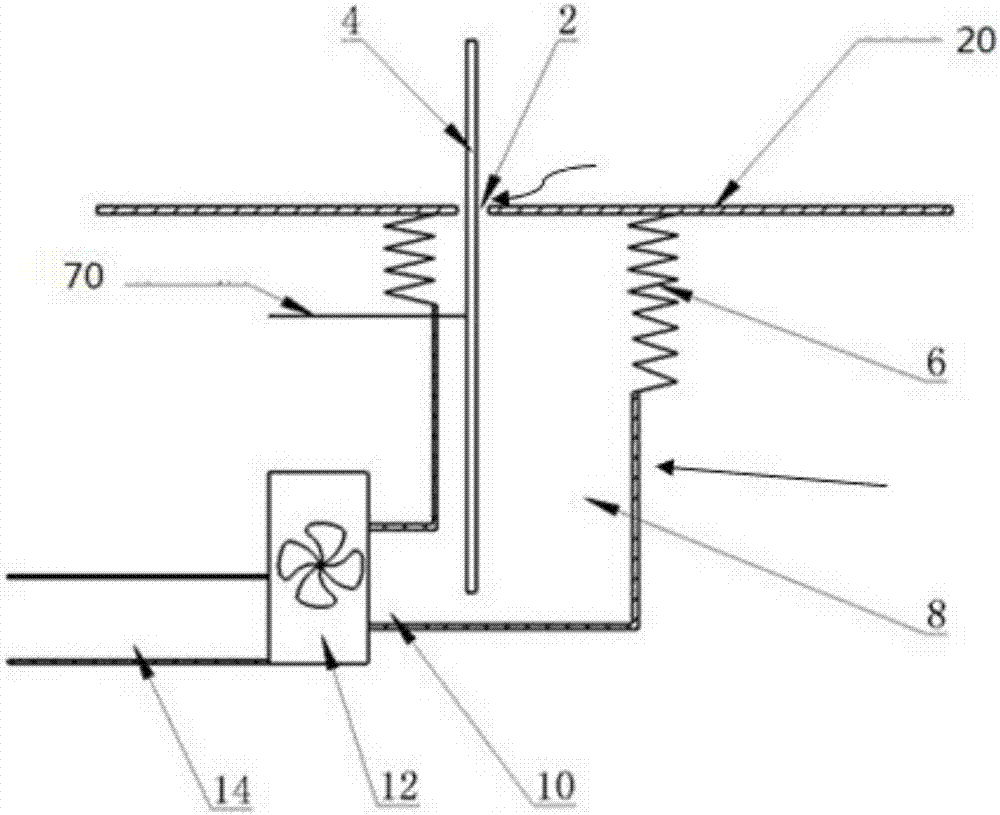

Portable electric cutting device with blower mechanism

ActiveCN1496800AAvoid accumulationImprove cutting accuracyPortable power driven sawsBark-zones/chip/dust/waste removalEngineeringMechanical engineering

Fanned air generated by a fan to cool a motor is discharged from a housing through fanned air discharge ports toward an opening formed in a base. The fanned air discharged toward the opening is then introduced into a groove in fluid communication with the opening. The groove is formed in a bottom surface of the base and has an open side at a front side of the base. The fanned air is then discharged from the front side of the base, blowing off saw dust on a cutting object so as to prevent dust from accumulating on a marking line on the cutting object.

Owner:HITACHI KOKI CO LTD

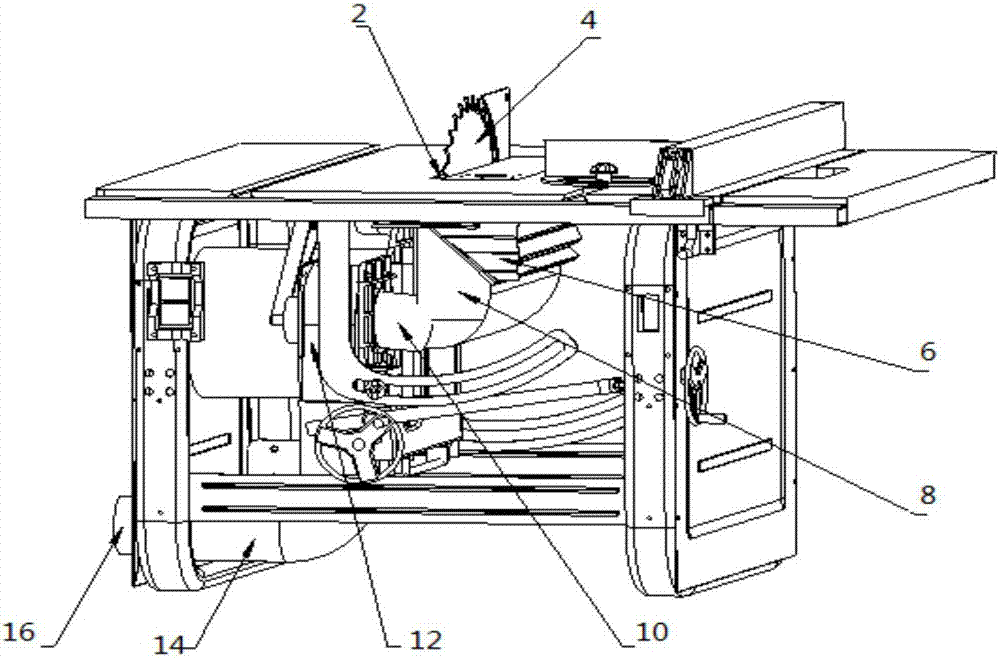

Dustless Table Saw

ActiveCN107150378AMetal sawing devicesMetal sawing accessoriesMechanical engineeringDust collection system

A dustless table saw with a built-in dust collection system is disclosed. The table saw uses a soft foldable seal to seal the gap between the blade slot and the blade housing, the blade housing has an internal extraction channel to maximize the dust collection. Another variation of the table saw utilizes a U-shaped blade housing with a divider. The table saw has a built-in raising / lowering mechanism to raise / lower the blade, and a built-in tilting mechanism to tile the blade. The table saw also utilizes an anti-dust blade guard to optimize the dust extraction.

Owner:SIROCCO DUSTLESS LLC

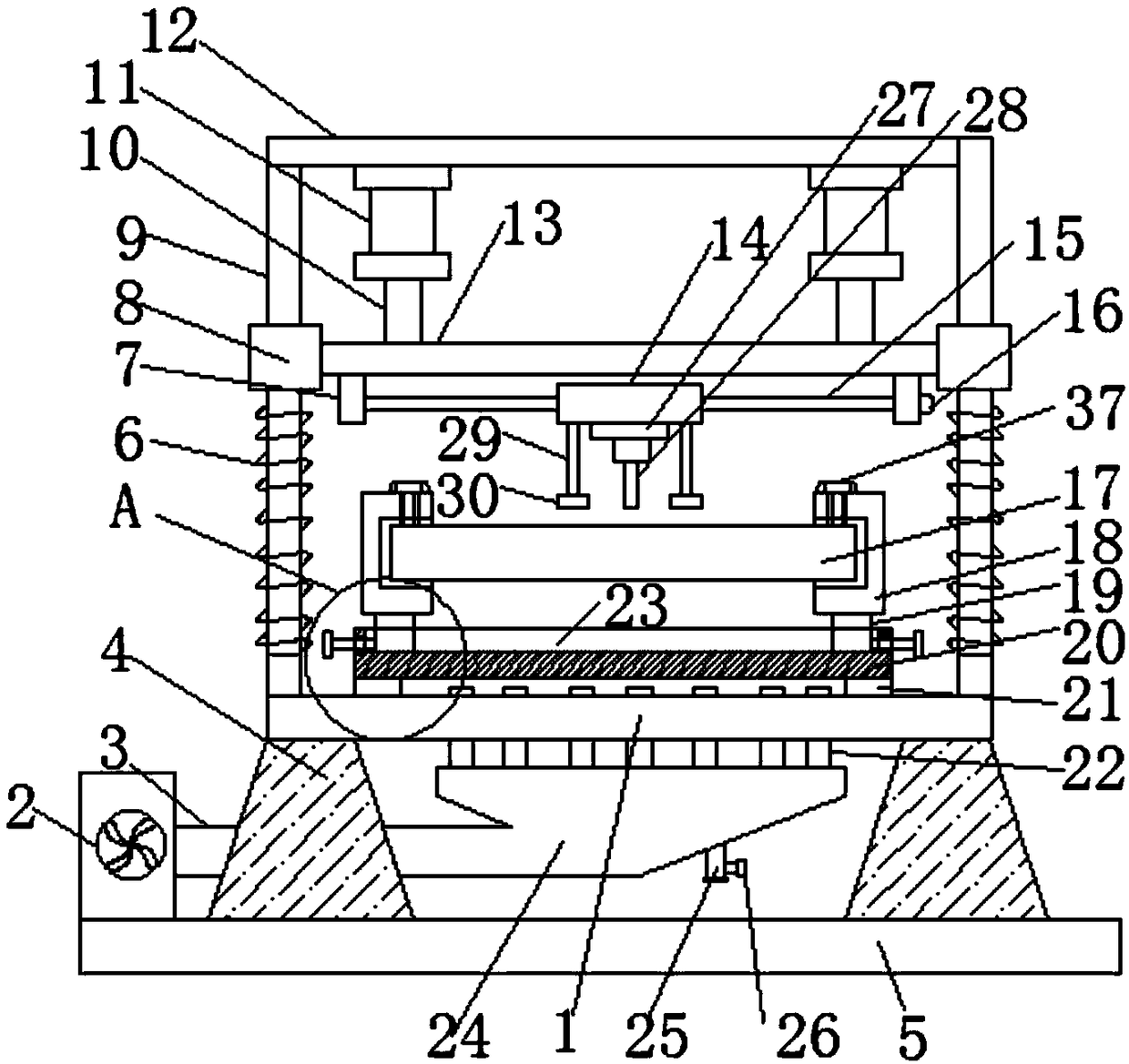

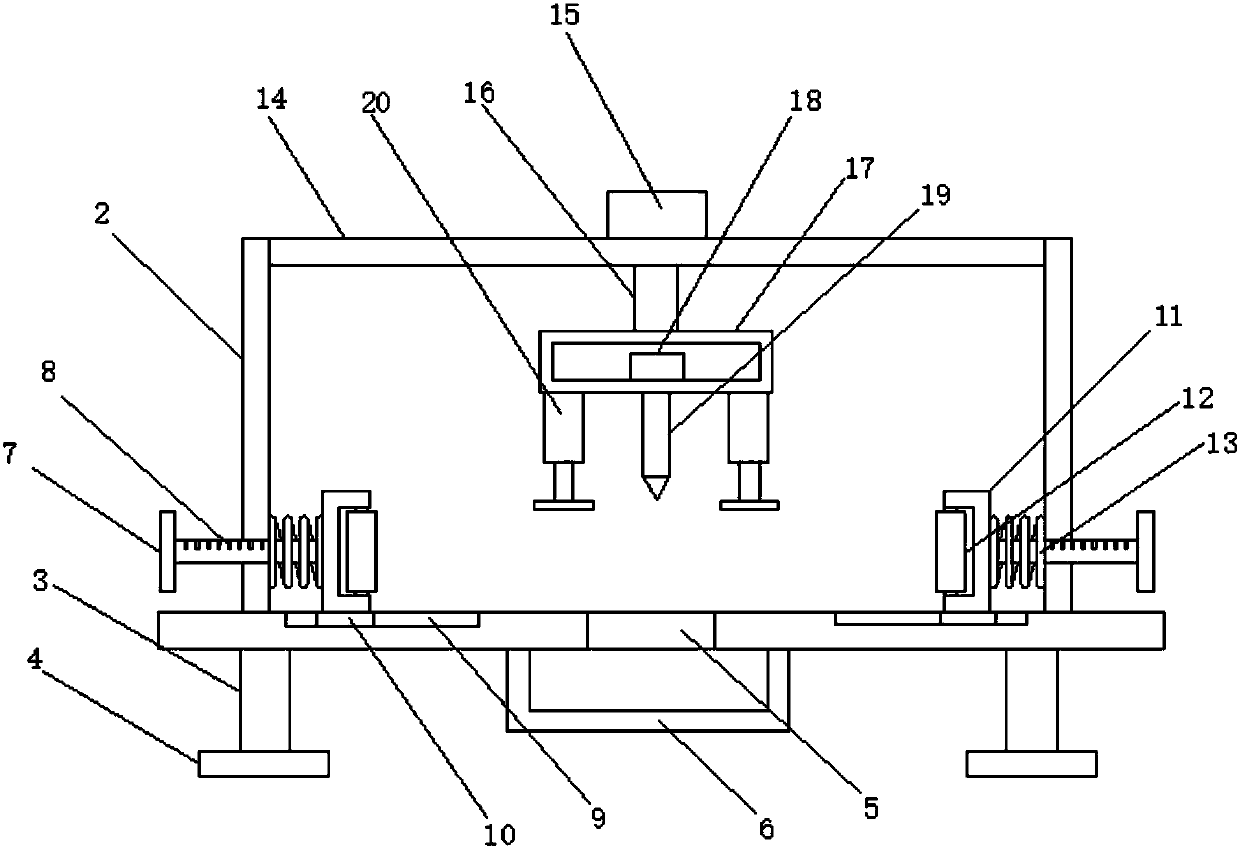

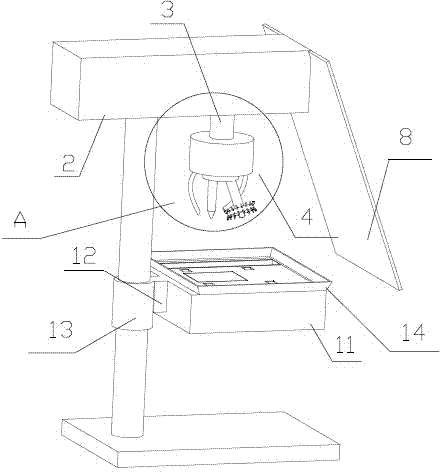

Equal-distance and efficient hole drilling device for building wood

InactiveCN107234678ASimple structureEasy to operateStationary drilling machinesBark-zones/chip/dust/waste removalMotor driveArchitectural engineering

The invention discloses an equidistant high-efficiency drilling device for building timber, comprising a bottom plate, a left side plate is fixed on the upper left part of the bottom plate, a right side plate is fixed on the upper right part of the bottom plate, a workbench is arranged above the bottom plate, and the workbench and the bottom plate Sliding connection, a power mechanism is provided under the worktable, clamping devices are provided on both sides of the upper part of the worktable, a mounting plate is slidably connected between the left side plate and the right side plate, and a second motor is fixed in the middle of the bottom of the mounting plate. The second motor drives and connects the drill bit, and a dust-absorbing device is installed on the mounting plate. The present invention is provided with a power mechanism, which includes a first electric push rod, a first motor, an active dial, a driven sheave, a gear, a rack and The disc, through the cooperation of the above components, realizes equidistant drilling, high drilling efficiency, equipped with a clamping device, which can clamp or loosen the board, easy to operate, reliable clamping, equipped with a vacuum device to avoid dust in the working area Scattered, the working environment is extremely poor, affecting the health of the staff.

Owner:杜鑫

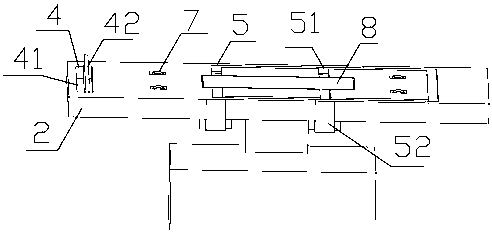

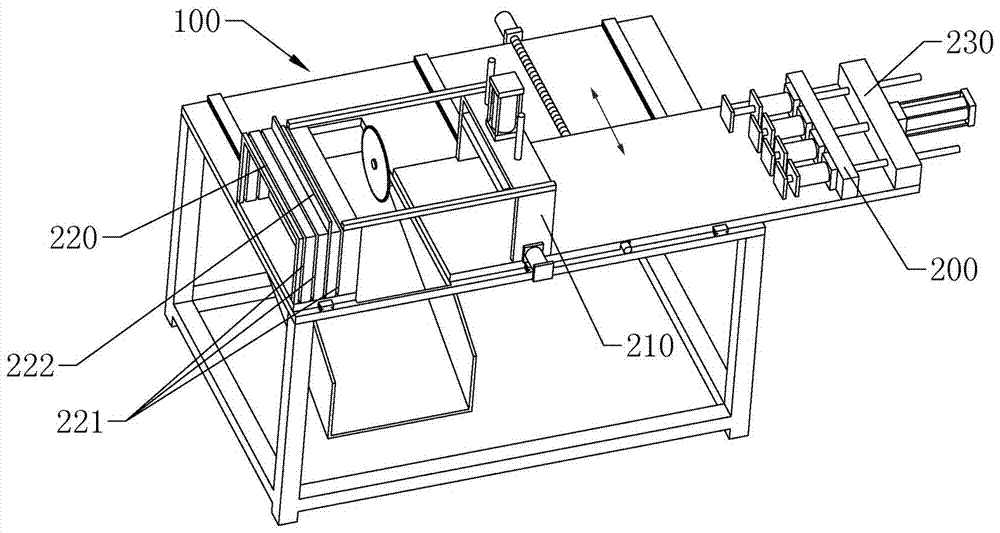

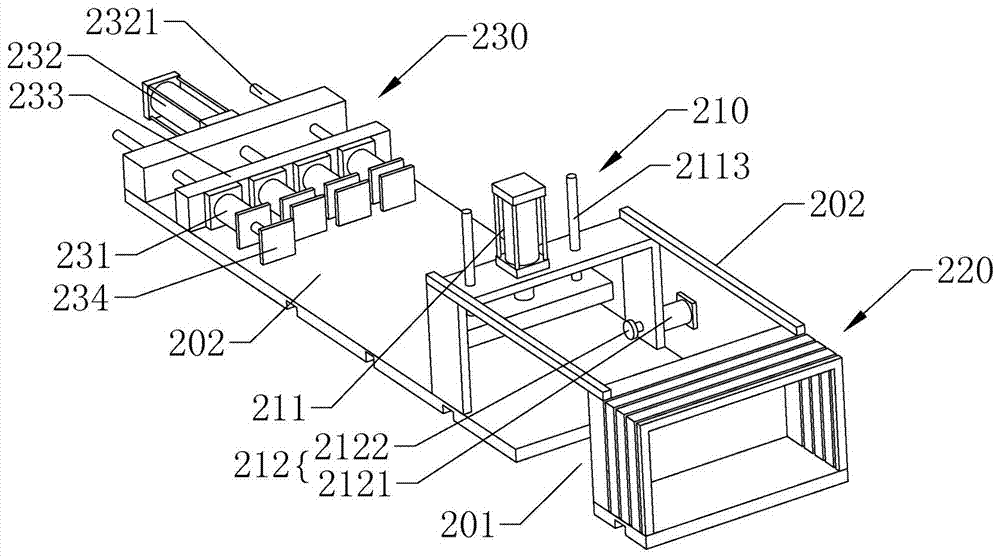

Automatic feeding and cutting process for artificial board

ActiveCN105583911ARealize pushStable recyclingFeeding devicesGripping devicesEngineeringMechanical engineering

The invention provides an automatic feeding and cutting process for an artificial board, comprising a feeding device, a pushing device and a cutting device, wherein the pushing device is arranged between the cutting device and the feeding device and comprises support rods arranged transversely and feeding mechanical arms arranged between adjacent support rods, a transverse moving rack is arranged above the support rods, the feeding mechanical arms are hinged to a fixed seat fixed on the transverse moving rack, a pulling arm cylinder is hinged to the fixed seat, and a telescopic rod of the pulling arm cylinder is hinged to the middle of the mechanical arm. The automatic feeding and cutting process is simple in structure, and the mechanical arms for pushing boards are provided, so that integrated conveying of the cut boards can be realized, and efficiency and safety are greatly improved. Pushing of boards can be well achieved by utilizing the structure of the feeding mechanical arms. Meanwhile, a clamping mechanism is designed to ensure stability in recovery and cutting of the board, and due to the arrangement of a feeding mechanism, working efficiency is greatly improved and manpower needed for conveying is greatly reduced.

Owner:FUTIAN FUZHOU ARTS & CRAFTS

Plank drilling device for furniture product

InactiveCN108115770AGuaranteed to move in a straight linePrevent tamperingStationary drilling machinesBark-zones/chip/dust/waste removalDrive motorEngineering

The invention discloses a plank drilling device for a furniture product. The plank drilling device comprises a working table and two side plates, a top plate is arranged at the top end of the side plate, a plurality of support columns are arranged on the lower end face of the working table, a bottom plate is arranged at the bottom end of the support column, two symmetric mounting racks are arranged on the upper end face of the working table, a positioning press roll is arranged on the mounting rack, an adjusting screw rod is arranged on each of the two side plates, scales are further arrangedon the adjusting screw rod, one side of the mounting rack is connected with the side plate through a reset spring, an air cylinder is arranged on the top plate, a pneumatic push rod is arranged at thelower end of the air cylinder, an outer frame is fixedly connected at the bottom end of the pneumatic push rod, a drill bit is installed on the lower end face of the outer frame, the upper end of thedrill bit is connected with a drive motor arranged in the outer frame, and compressing devices are symmetrically arranged on the two sides of the lower end of the outer frame. The plank drilling device is simple in structure, the drilling accuracy is higher, the efficiency is higher, the plank drilling device can continuously drill by being adaptive to planks of different widths, the operation issimple and convenient, and the practicality is stronger.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

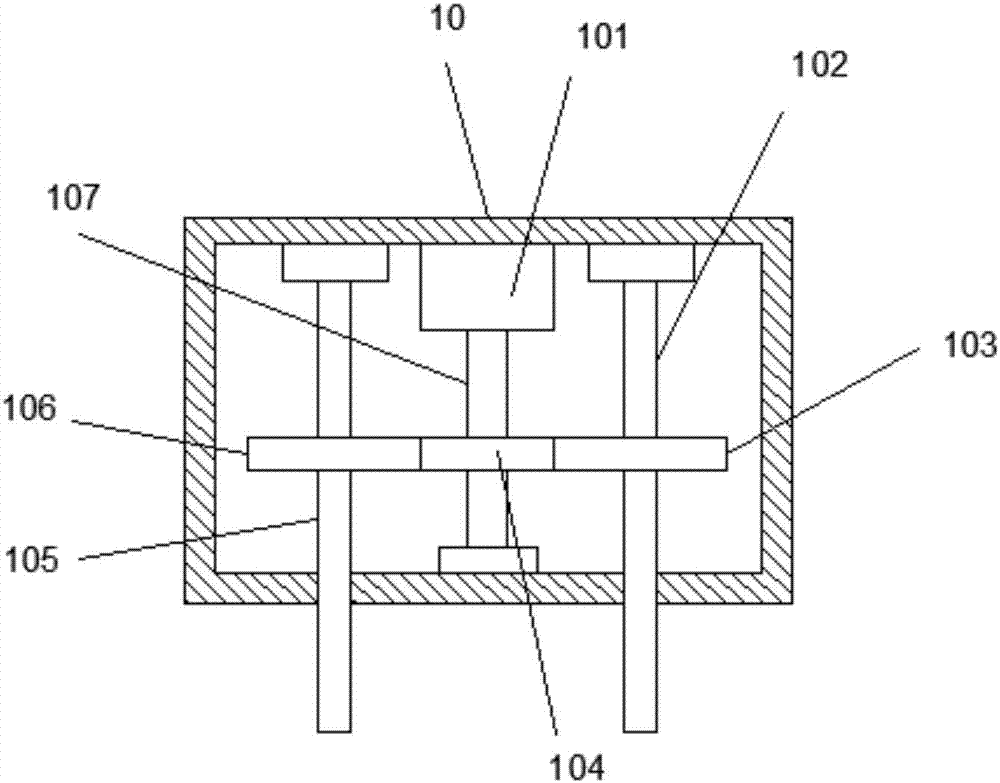

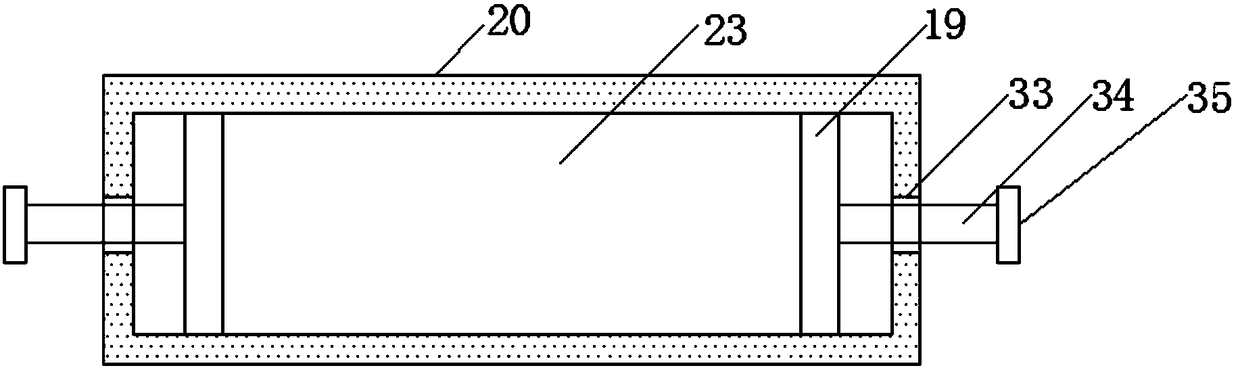

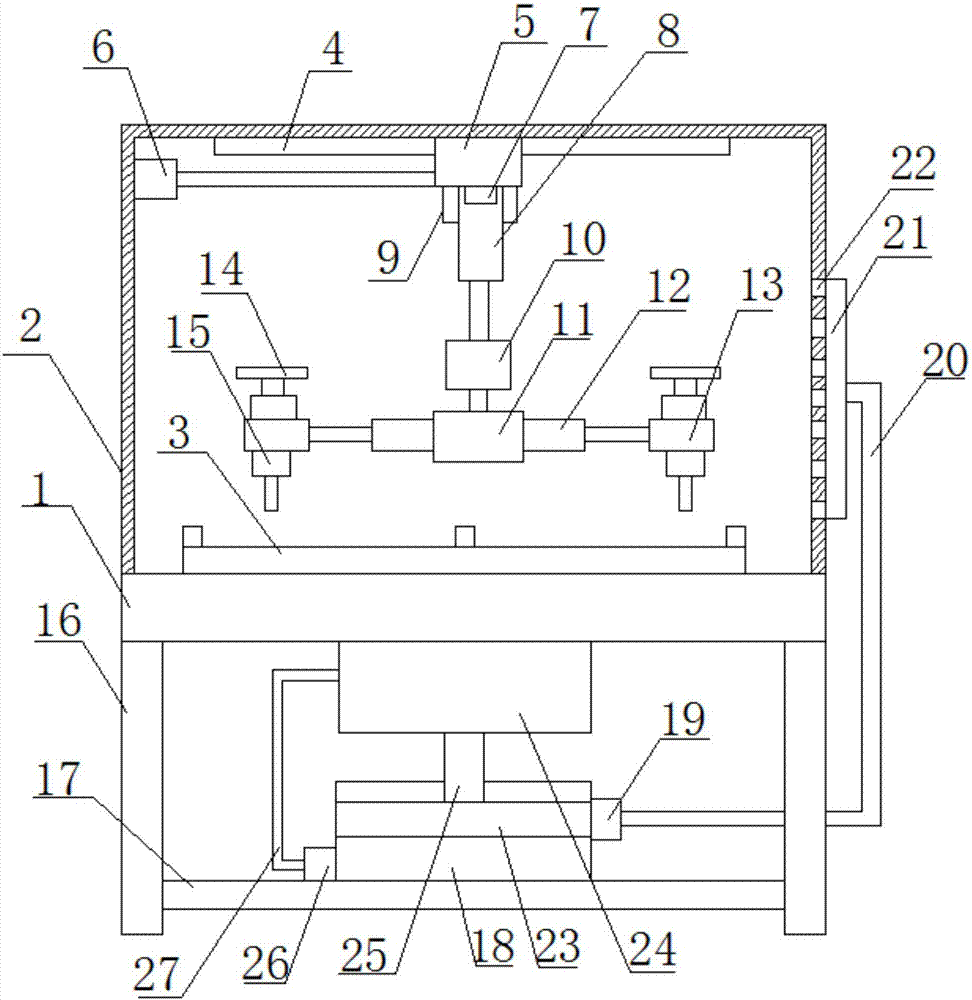

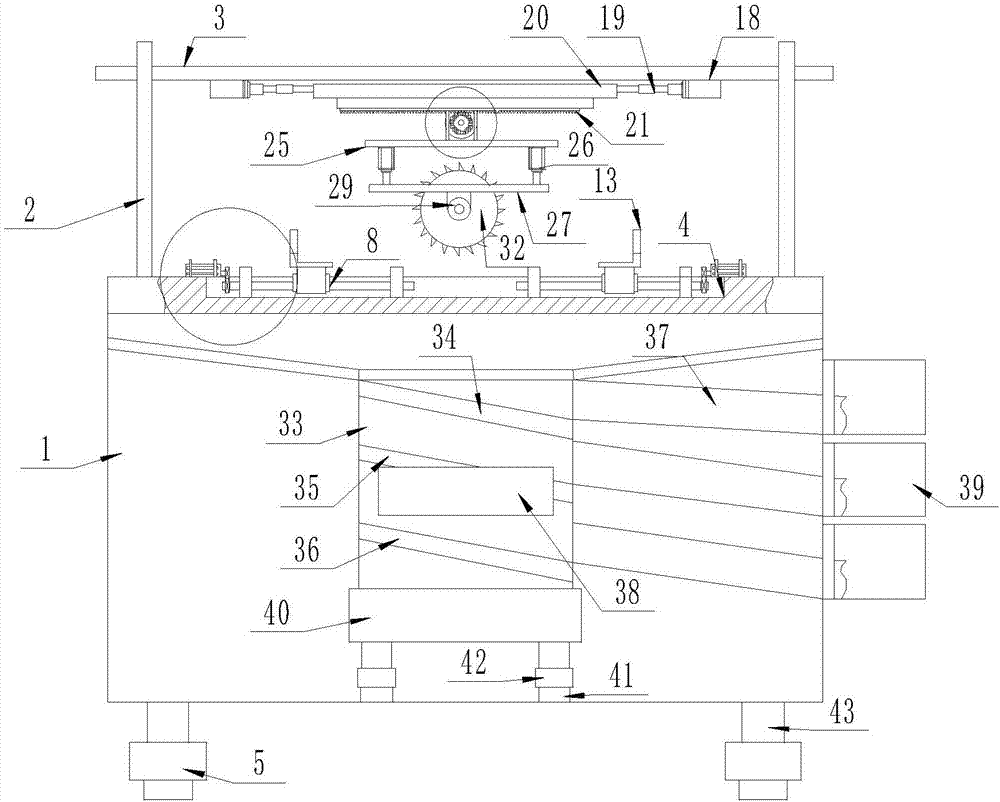

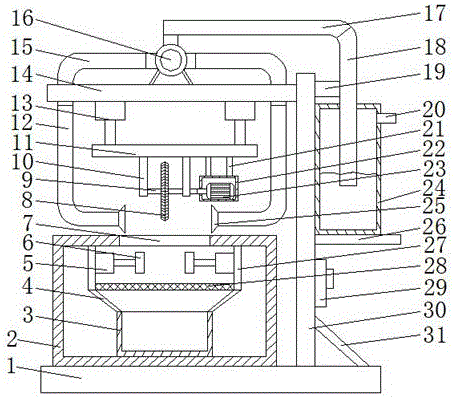

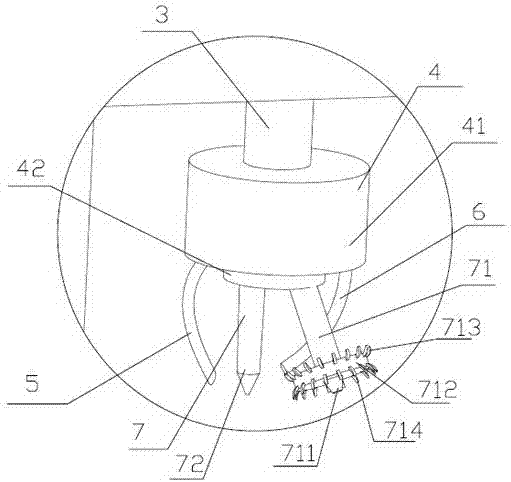

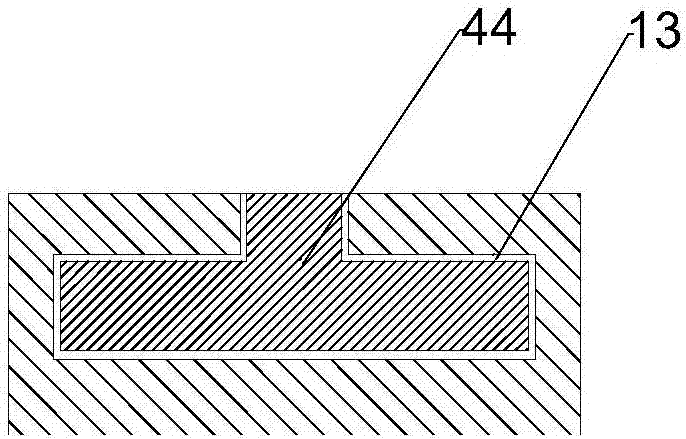

Drilling machine for furniture board material

ActiveCN104339423AEasy and effective removalProtection cleanStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringDrilling machines

The invention relates to the field of furniture processing equipment, and particularly relates to a drilling machine for a furniture board material. The invention is realized by the following technical scheme: the drilling machine for the furniture board material comprises a drilling device, a lower-site machine platform, an upper-site machine platform, a sliding device and a clearing device, wherein the lower-site machine platform is used for placing a board material; the upper-site machine platform is parallel to the lower-site machine platform, arranged above the lower-site machine platform and connected with the drilling device; the sliding device is connected with the drilling device so that the drilling device can move along X axis and Y axis on the plane of the upper-site machine platform, and the clearing device is arranged on the lower-site machine platform and used for clearing board material scraps. The invention aims to provide the drilling machine for the furniture board material, the drilling device can be arranged flexibly, a plurality of holes of the board material are drilled once only at preset positions, the drilling machine also has the function of clearing the scraps, and the cleanness of the processing environment is improved.

Owner:ZHEJIANG BOTAI FURNITURE

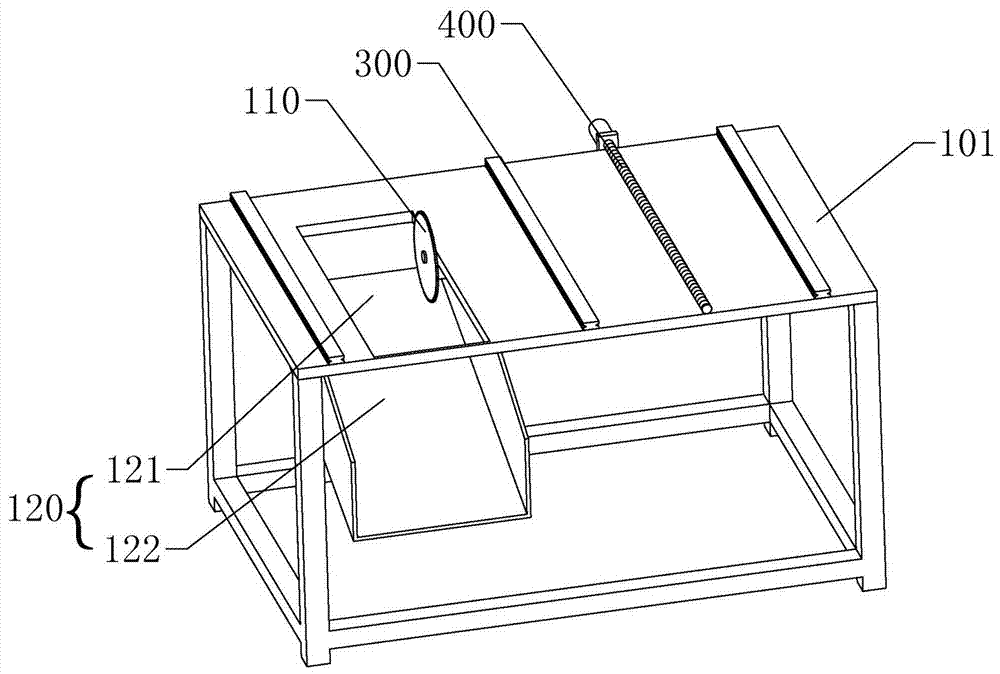

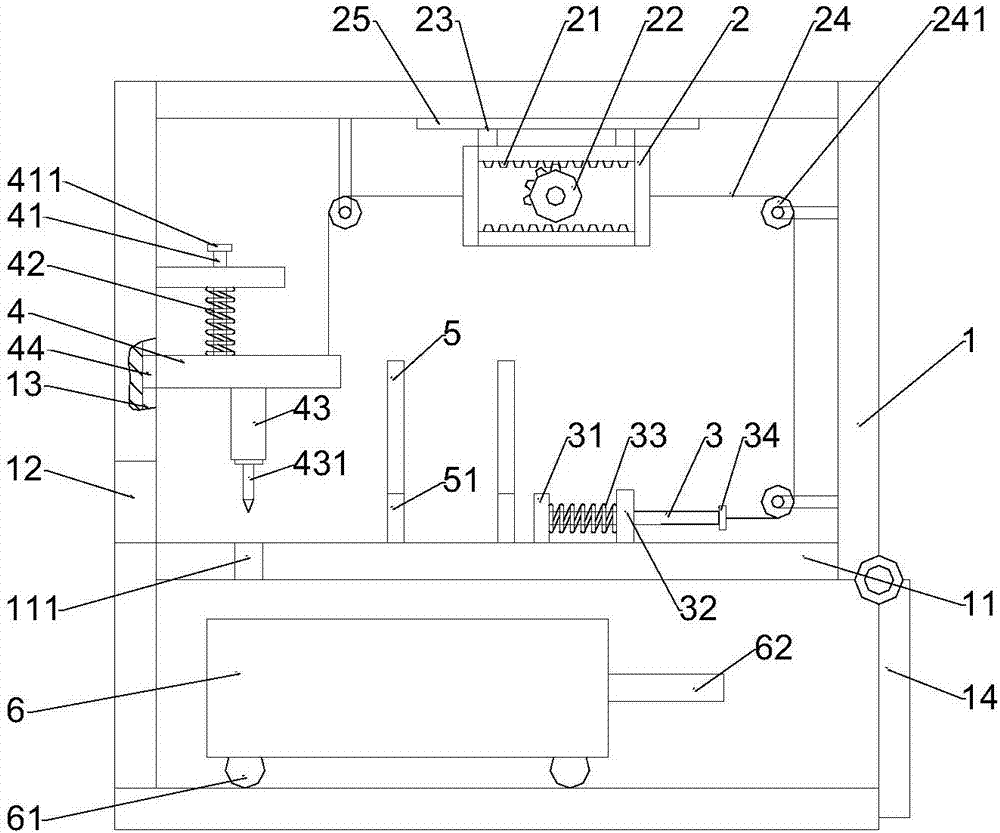

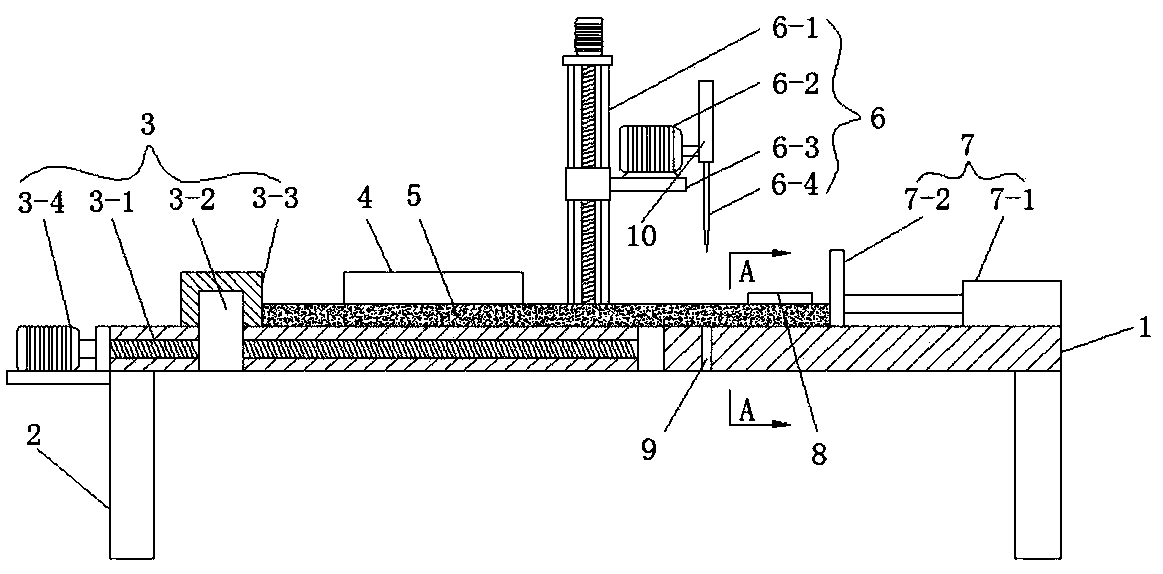

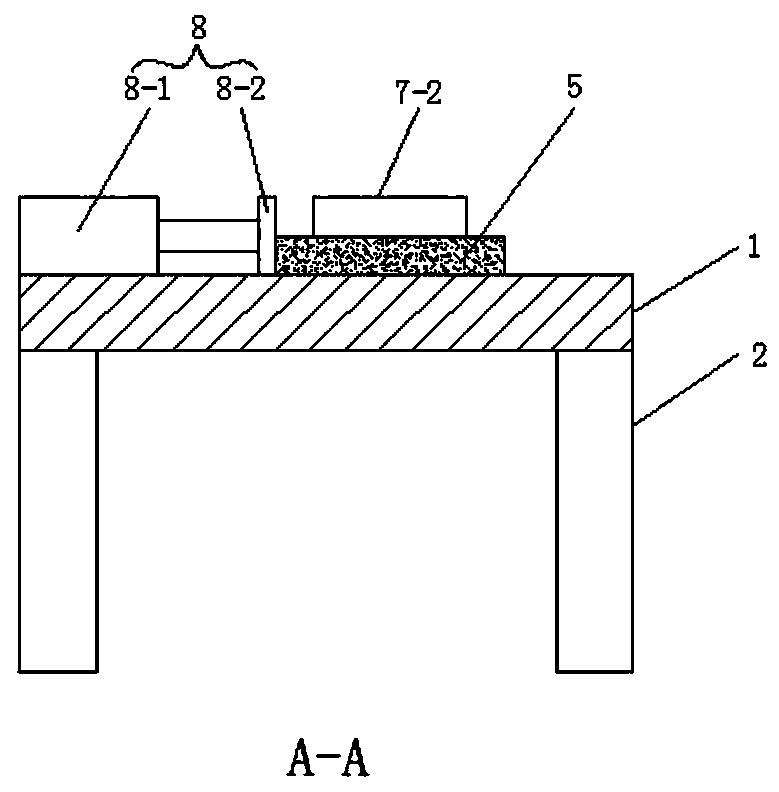

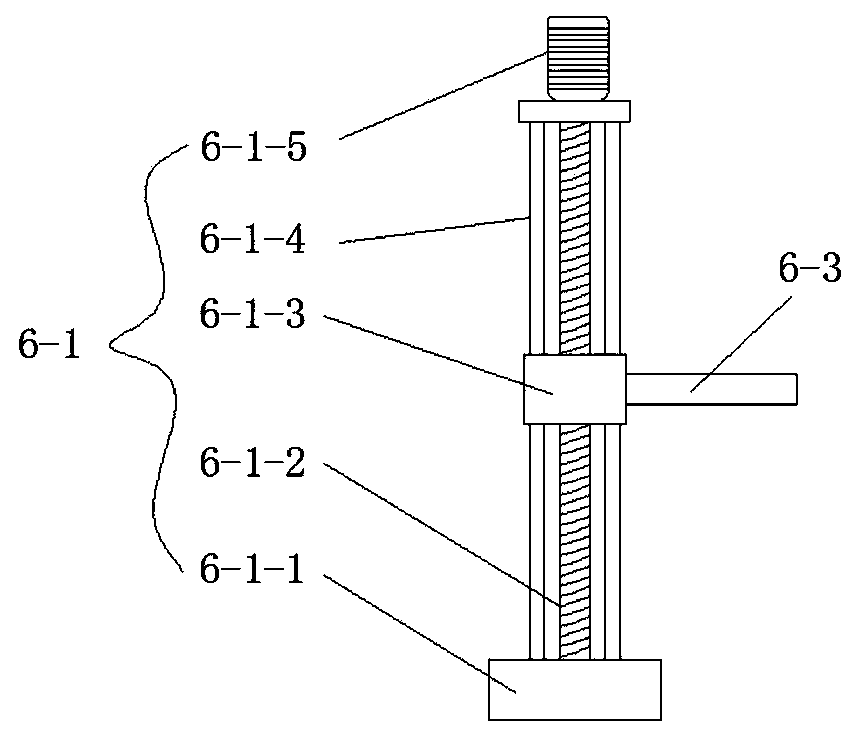

Wood fixed-dimension high-precision cutting and waste recycling integrated equipment

The invention discloses wood fixed-dimension high-precision cutting and waste recycling integrated equipment which comprises a base. The interior of the base is of a hollow structure, and the exterior of the base is of a rectangular structure. A plate feeding mechanism is arranged on the upper surface of the base. A clamping mechanism is arranged on the plate feeding mechanism. A pair of guide rods is fixed to the base. A cross beam is fixed to the guide rods. A transverse feeding mechanism is arranged on the cross beam. A longitudinal feeding mechanism is arranged on the transverse feeding mechanism. A lifting mechanism is arranged on the longitudinal feeding mechanism. A cutting mechanism is arranged on the lifting mechanism. The equipment has the beneficial effects that after a PLC series controller is installed in a spare position of the equipment, automatic cutting can be achieved completely, the equipment can help workers stay away from wood chips effectively, and meanwhile, the wood chips can be recycled into the equipment through a waste recycling mechanism for wood forming next time.

Owner:DONGGUAN POLYTECHNIC

Building material cutting device with dust removal effect

InactiveCN106584684APrevent fallingEasy to fixWorking accessoriesBark-zones/chip/dust/waste removalEngineeringExhaust pipe

Disclosed is a building material cutting device with a dust removal effect. The building material cutting device with the dust removal effect comprises a bearing plate. A working box is fixedly connected with the top of the bearing plate, a cut material opening is formed in the top of the working box, and separating plates are fixedly connected with the two sides of the top of the inner wall of the working box. First air cylinders are fixedly connected with the tops of the face-to-face sides of the separating plates, clamping blocks are fixedly connected with the output ends of the first air cylinders, a screen plate is fixedly connected with the bottoms of the face-to-face sides of the separating plates, and inclined plates are fixedly connected with the bottoms of the separating plates. A waste material collecting box is arranged at the bottom of the inner wall of the working box. According to the building material cutting device with the dust removal effect, due to the fact that a controller, the working box, the cut material opening, the first air cylinders, the clamping blocks, the screen plate, the waste material collecting box, dust hoods, dust suction pipes, second connecting pipes, an exhaust fan, a first connecting pipe, an air outlet pipe, a purifying box and an exhaust pipe are arranged, the effect that particle dust and large-particle waste materials can be processed at the same time is achieved.

Owner:王万森

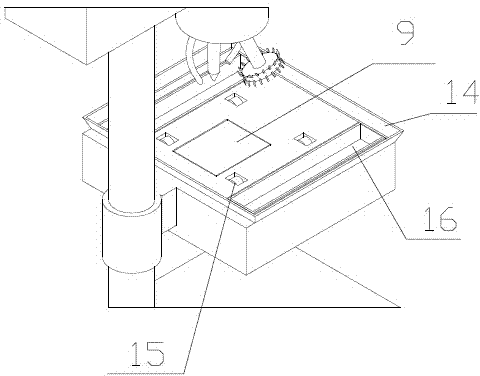

High-efficiency punching device suitable for furniture board

ActiveCN104325519AImprove work efficiencyAvoid wear and tearDrilling machinesDrilling toolsPunchingInjection device

The invention relates to the field of furniture processing equipment, and in particular relates to a high-efficiency punching device suitable for a furniture board. The device is realized by the following technical scheme: the high-efficiency punching device suitable for the furniture board comprises a stand, a drilling device, an operating board, a lifting device, an oil injection device and a cleaning device, wherein the drilling device is used for punching the furniture board; the operating board is connected with the stand, can move along the vertical direction of the stand and is used for containing the furniture board; one end of the lifting device is connected with the stand, the other end of the lifting device is connected with the drilling device, and the lifting device is capable of adjusting the vertical distance of the drilling device relative to the stand; the oil injection device is used for injecting engine oil at the drilled position; the cleaning device is used for cleaning the drilled position by spraying water. The invention aims at providing the high-efficiency punching device suitable for the furniture board, a drill bit does not need to be manually replaced, and the high-efficiency punching device has the functions of lubricating by injecting oil and cleaning by spraying water.

Owner:ZHEJIANG BOTAI FURNITURE

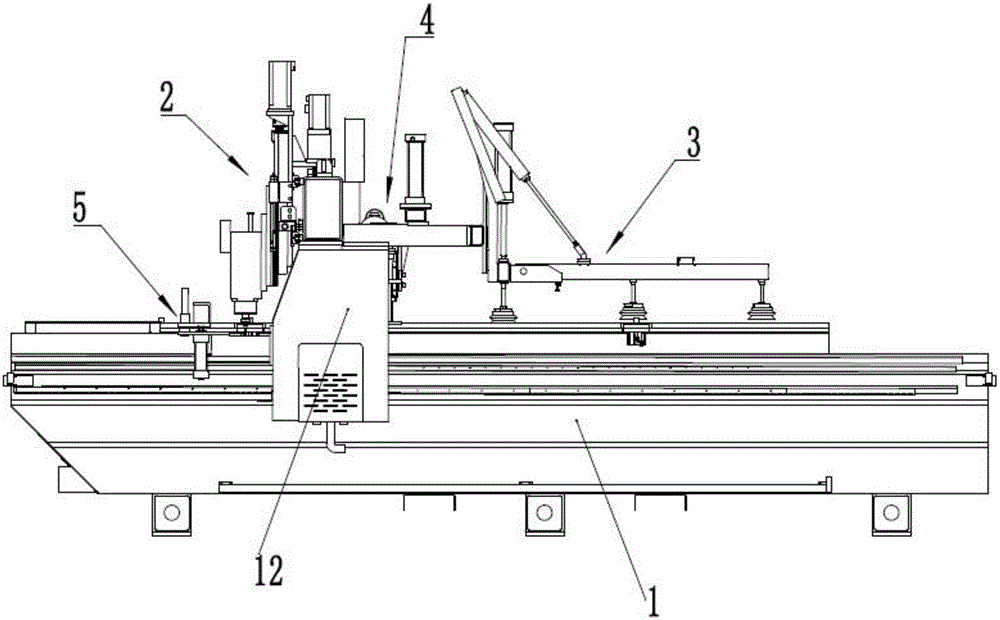

Novel numerical control cutting machine

InactiveCN105773734AImprove processing efficiencyImprove machining accuracyProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlEngineering

The invention discloses a novel numerical control cutting machine which comprises a rack, wherein a working table used for supporting a workpiece is arranged on the rack. The novel numerical control cutting machine further comprises a cross beam capable of moving on the rack, a processing component used for processing the workpiece on the working table, a material sucking device used for loading materials, a dust collection device used for cleaning chips on the surface of the workpiece on the working table, and a material pushing device used for pushing the processed workpiece away from the working table. According to the novel numerical control cutting machine, the processing efficiency is high, the processing accuracy is high, the automation degree is high, the operation is convenient, a straight line edge can be processed on the workpiece, an arc edge can be processed, the processing range is wide, and the processing flexibility is high.

Owner:GUANGDONG SANDAR CNC MACHINERY CO LTD

Automatic wood cutting machine

InactiveCN107053344AImprove securityImprove clamping effectFeeding devicesGripping devicesFixed frameSlide plate

The invention relates to the field of furniture manufacturing, in particular to an automatic wood cutting machine. The automatic wood cutting machine comprises a fixed frame and a movable frame. The movable frame is arranged above the fixed frame. A guide rail and a lead screw are arranged between the fixed frame and the movable frame. The fixed frame comprises a top plate, a cutting mechanism and a discharging mechanism. The discharging mechanism comprises a discharging outlet formed in the top plate and a discharging slide. The cutting mechanism is a cutting machine body fixed to the lower portion of the top plate. The top of a cutting blade of the cutting machine body is higher than the top of the top plate. The movable frame comprises a cutting area located above the discharging outlet, a clamping mechanism, a length positioning mechanism and a pushing mechanism. The clamping mechanism, the length positioning mechanism and the pushing mechanism are sequentially arranged. The cutting area is arranged between the clamping mechanism and the length positioning mechanism. The clamping mechanism is connected with the top of the length positioning mechanism through a connecting rod. The clamping mechanism is connected with the bottom of the pushing mechanism through a sliding plate.

Owner:ZOY HOME FURNISHING CORP

Cutting device for fiberboard

InactiveCN106738072ASimple structureSimple and fast operationGuide fencesFeeding devicesLinear motorFiberboard

The invention discloses a cutting device for a fiberboard. The cutting device for the fiberboard comprises a cutting table; an L-shaped bracket is arranged on the rear side of the upper surface of the cutting table; the lower end of the L-shaped bracket is connected with a first electric telescopic rod through a bolt; the telescopic end of the first electric telescopic rod is connected with a motor through a bolt; a cutting blade is arranged at the end part of the output shaft of the motor; the cutting blade is driven to rotate through the motor, so that the fiberboard is more convenient to cut; a fixed plate is driven to move vertically through a second electric telescopic rod, so that the fiberboard is more convenient to fix; the fiberboard can be driven to move horizontally through a linear motor, so that the fiberboard is more convenient to cut; waste materials produced when the fiberboard is cut can be collected through a dust collector, so that the cutting table is cleaner and tidier. The cutting device for the fiberboard is simple in structure and convenient to operate; manual cutting can be replaced, and a cut edge is tidier; a large amount of manpower is saved; the cutting table can be kept clean all the time.

Owner:昭平县科学技术指导站

Furniture wood drilling device capable of drilling continuously

InactiveCN107263618AAchieve continuous drillingGuaranteed continuityStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringWood flour

The invention discloses a furniture wood drilling device capable of drilling continuously. The furniture wood drilling device comprises a frame body; the middle lower portion of an inner cavity of the frame body is provided with a partition plate; the upper portion of the right side of the inner cavity of the frame body is provided with a movable frame, steel wires are connected to the left side and the right side of the movable frame correspondingly, and the steel wire on the right side is connected with a transverse push rod through a right-side guide wheel; the left side of the transverse push rod is provided with a wood storing frame, ejection openings are symmetrically formed in the two sides of the bottom of the wood storing frame, and the length of the ejection openings is the same as that of the push plate; the steel wire on the left side of the movable frame is connected with a moving seat through a left-side guide wheel, and a drilling mechanism is installed at the bottom of the moving seat; and the partition plate is provided with a discharging hole, and a wood flour collecting frame is arranged below the discharging hole. Through the furniture wood drilling device, continuous drilling operation can be conducted on a plurality of pieces of wood, the wood drilling efficiency is improved, and meanwhile, the drilling device is ingenious in design, easy to operate and worth of application and popularization.

Owner:佛山市顺德区渝鸿塑料制品有限公司

Adjustable wood board cutting processing device

InactiveCN107839021ASimple structureEasy to operateGuide fencesFeeding devicesConnection tableAgricultural engineering

The invention discloses an adjustable wood board cutting processing device and relates to the technical field of board processing equipment. The adjustable wood board cutting processing device comprises a workbench, the four corners of the lower end of the workbench are provided with supports correspondingly, a push mechanism, two side plates for positioning boards, a cutting mechanism and a limiting mechanism are sequentially arranged on the workbench from left to right, the push mechanism comprises a lead screw arranged inside the workbench, the lead screw is provided with a nut base, the nut base is sleeved with a push block which can slide on the workbench, the lead screw is connected with a stepping motor arranged on the outer side of the workbench, the cutting mechanism comprises a lifting mechanism arranged on the workbench, the lifting mechanism is connected with a supporting plate capable of moving on the lifting mechanism, the supporting plate is provided with a motor, the motor is connected with a saw blade, the limiting mechanism comprises an air cylinder arranged on the workbench, and a piston rod of the air cylinder is connected with a baffle. The adjustable wood board cutting processing device has the advantages of being simple in structure, convenient to operate and easy to adjust.

Owner:SICHUAN GUANTENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com