Plate edge cutting machine

A technology of edge cutting machine and board, which is applied in the direction of wood processing equipment, circular saws, sawing components, etc. It can solve the problems of not running smoothly and accurately, the reliability of the whole machine is not high, and it is prone to operating failures. It is not easy to achieve The effects of failure, improved reliability and work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

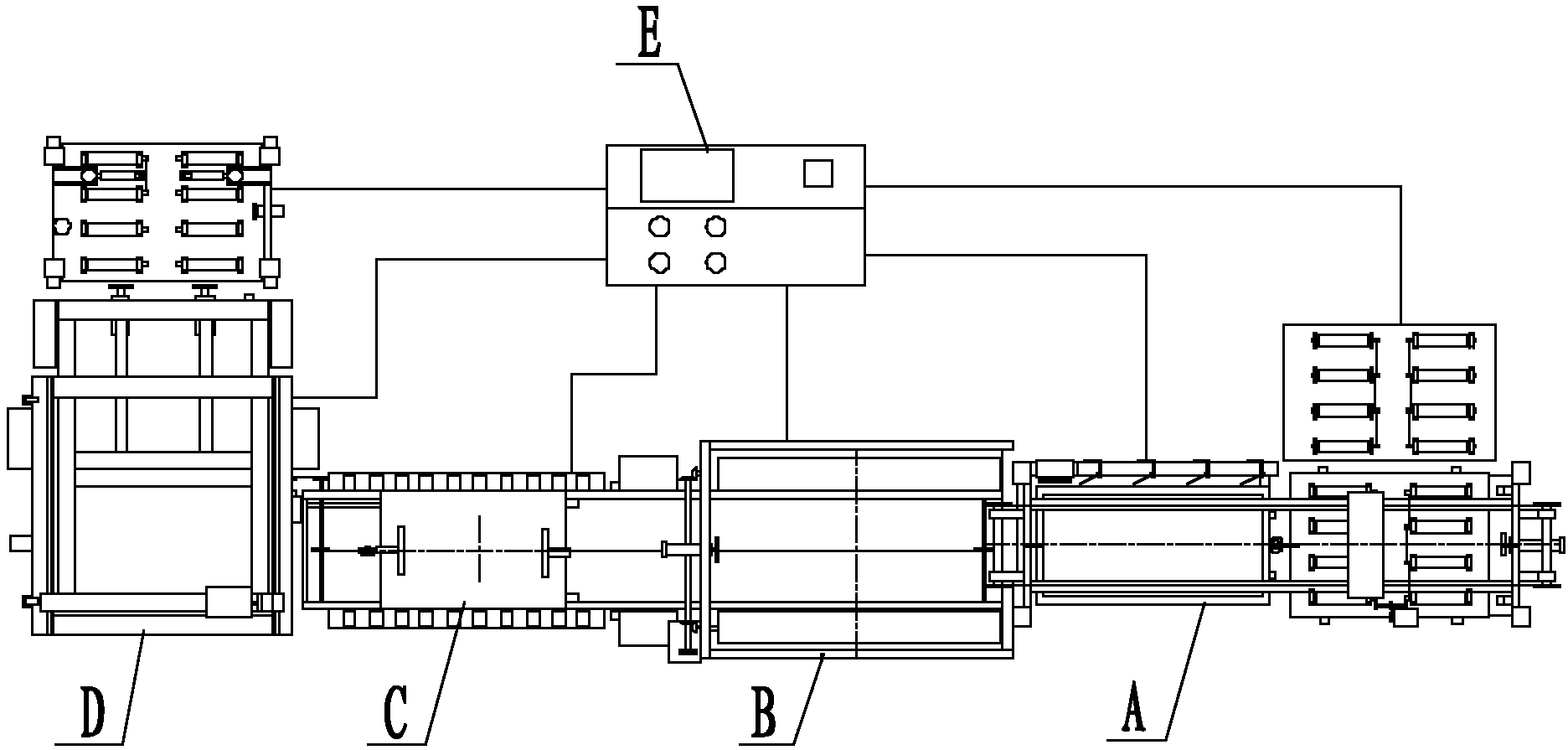

[0039] like figure 1 As shown, the plate edge trimmer includes a plate feeder A, a plate drop machine B, a longitudinal edge trimmer C, a horizontal edge trimmer D, and a control system E. The tail of the plate feeder A is connected to the head of the plate drop machine B , one end of the longitudinal trimming machine extends into the board dropper B to connect, and the other end is vertically connected to the horizontal trimmer D, and the control system E controls and connects the board feeder A, the board dropper B, the longitudinal trimmer C, and the board respectively. Horizontal trimming machine D.

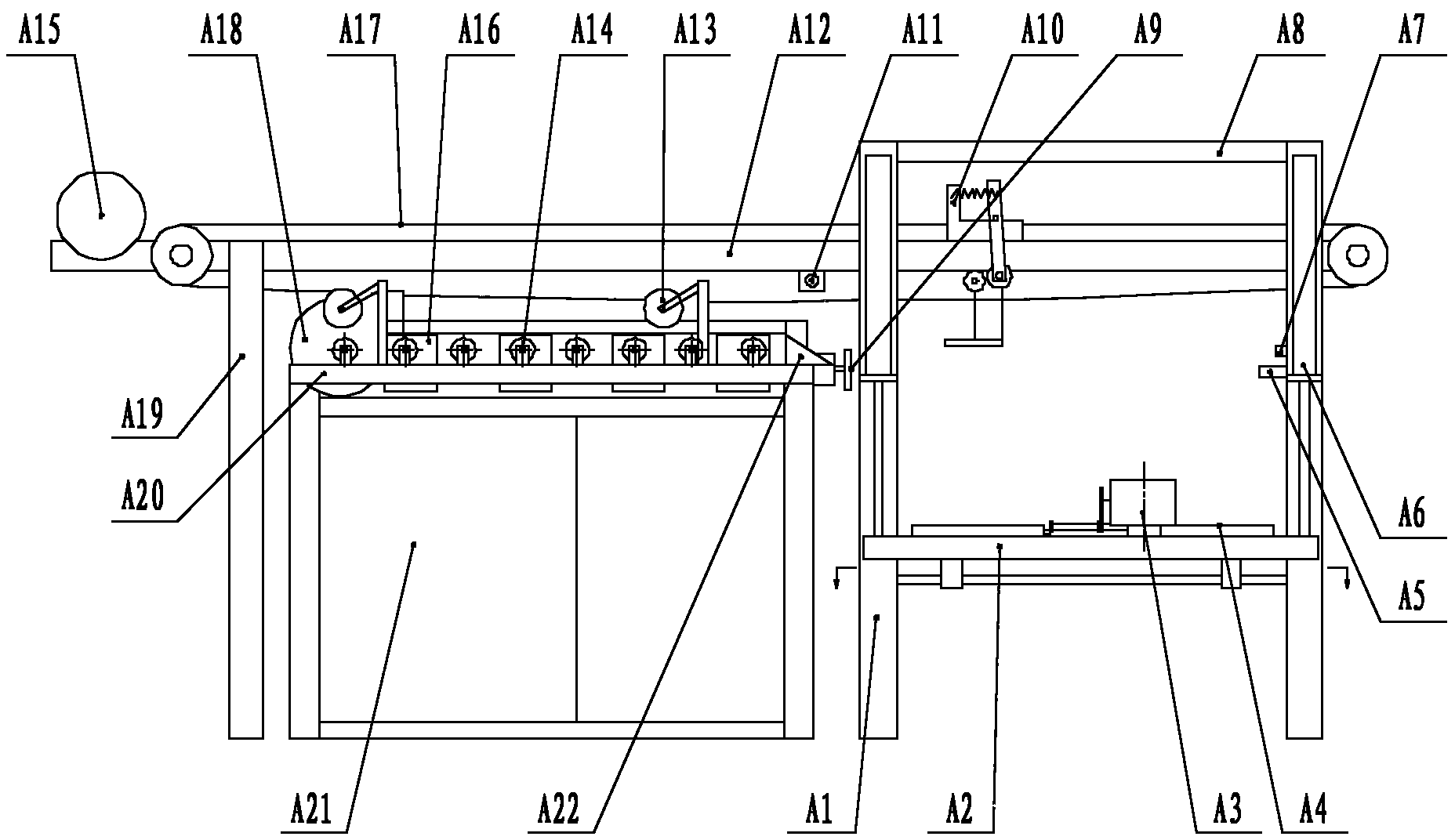

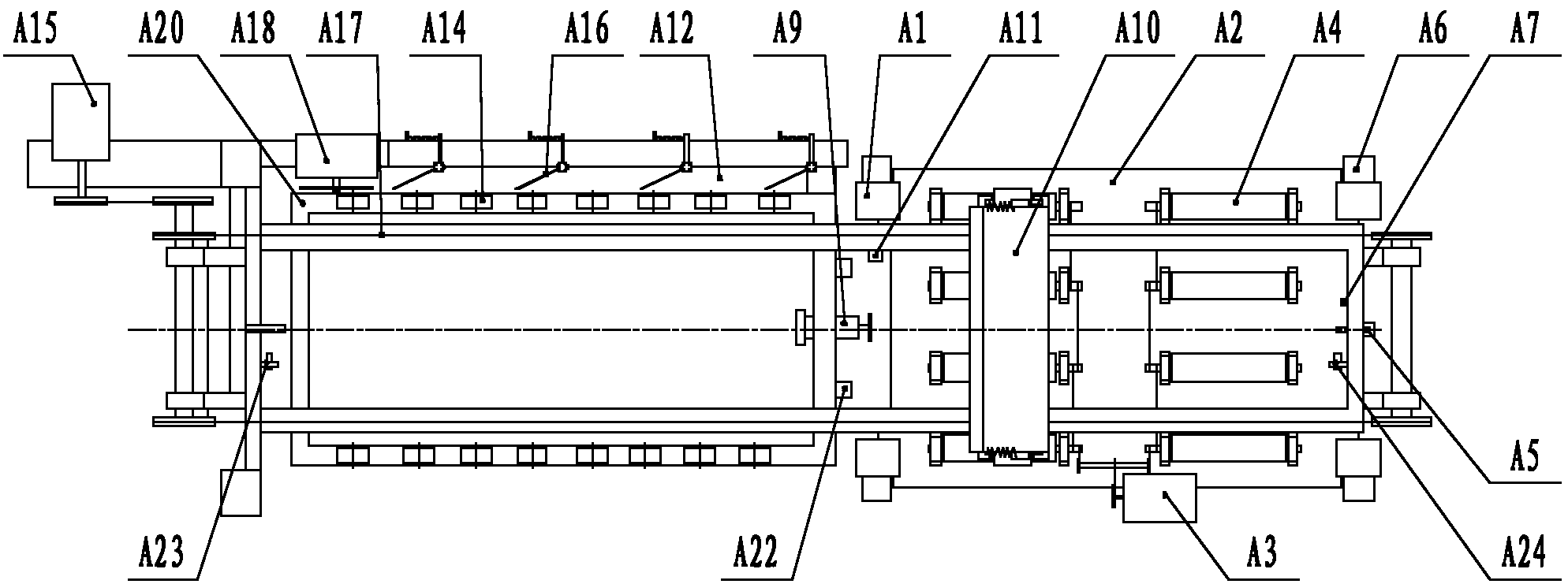

[0040] like Figure 2 to Figure 6 As shown, the plate feeder A includes an elevator IA8, a plate feed frame A19 and a positioning platform A20, and above the plate feed frame A19, a plate feed guide rail A12, a push head A10, and a push head transmission device are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com