Patents

Literature

213results about How to "Improve test success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

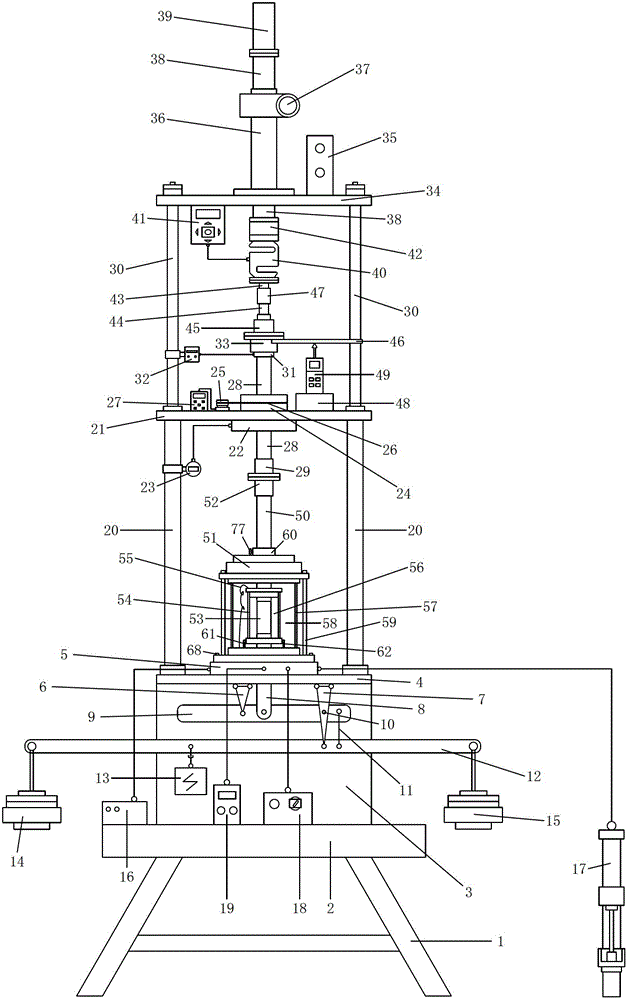

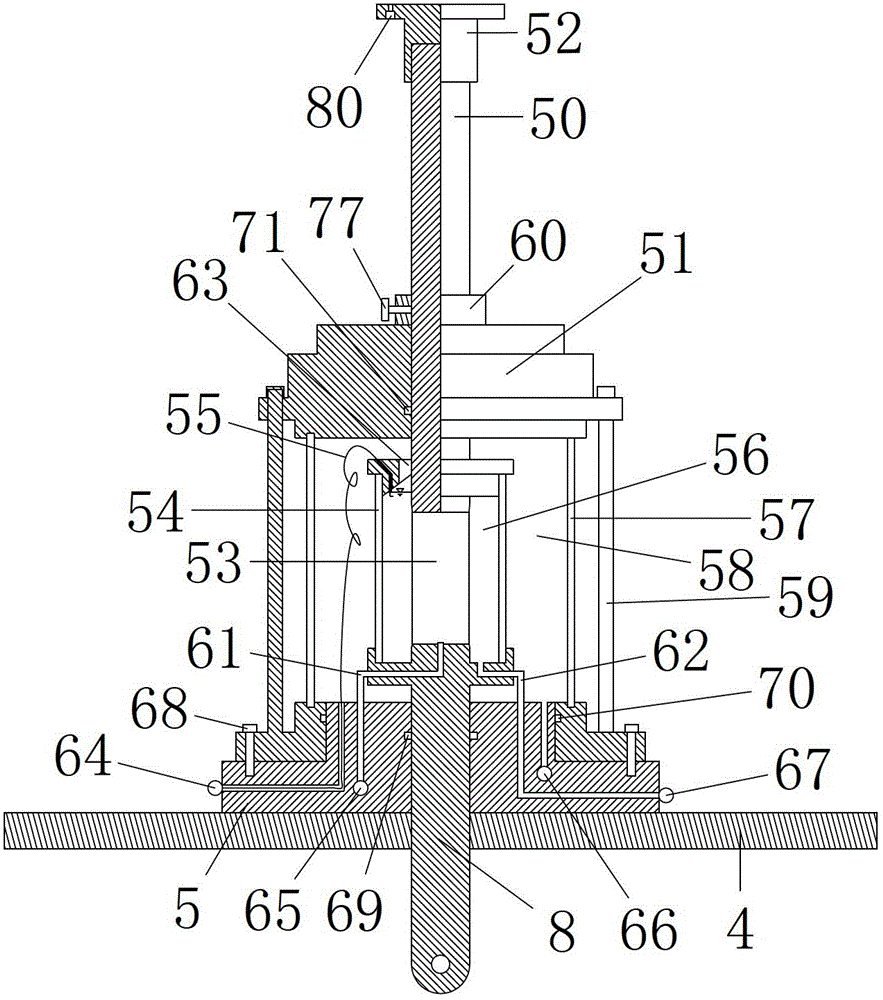

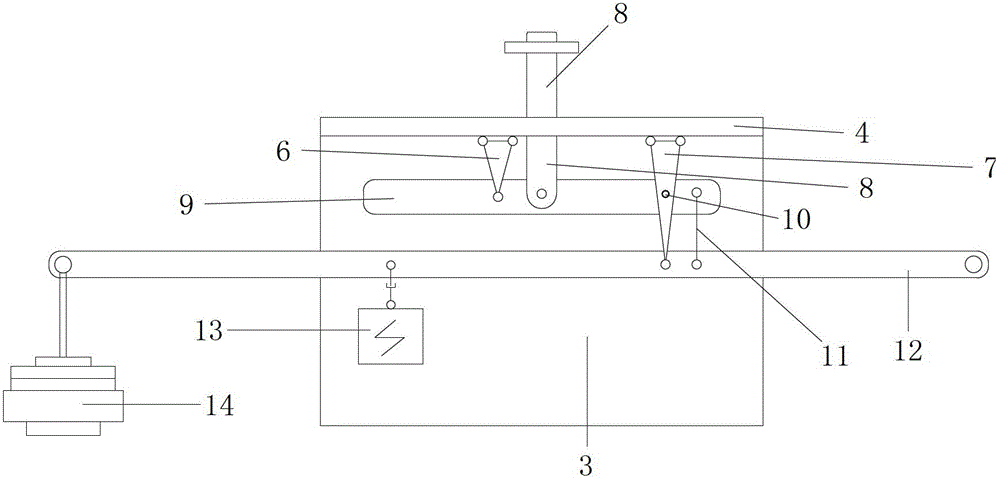

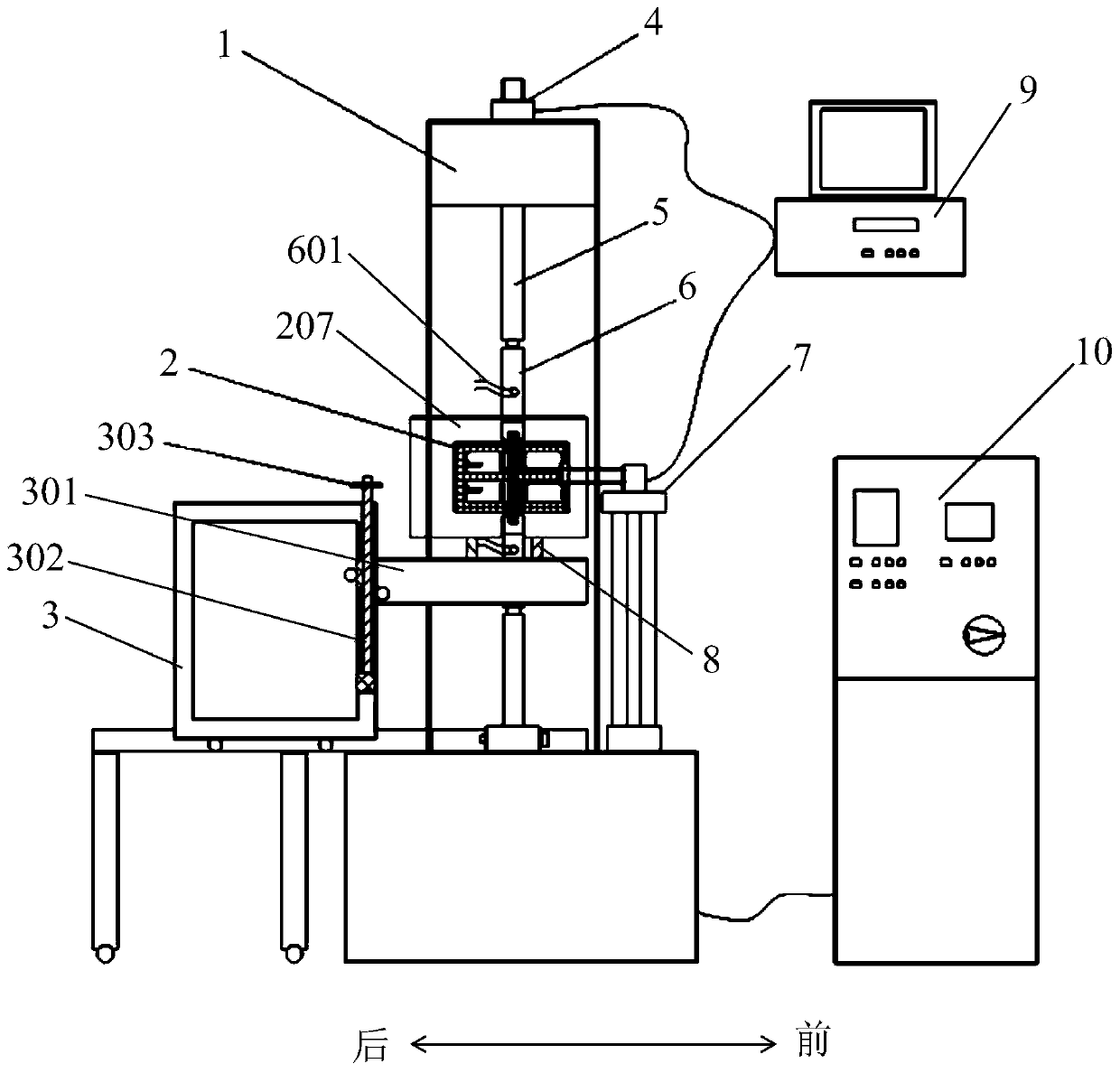

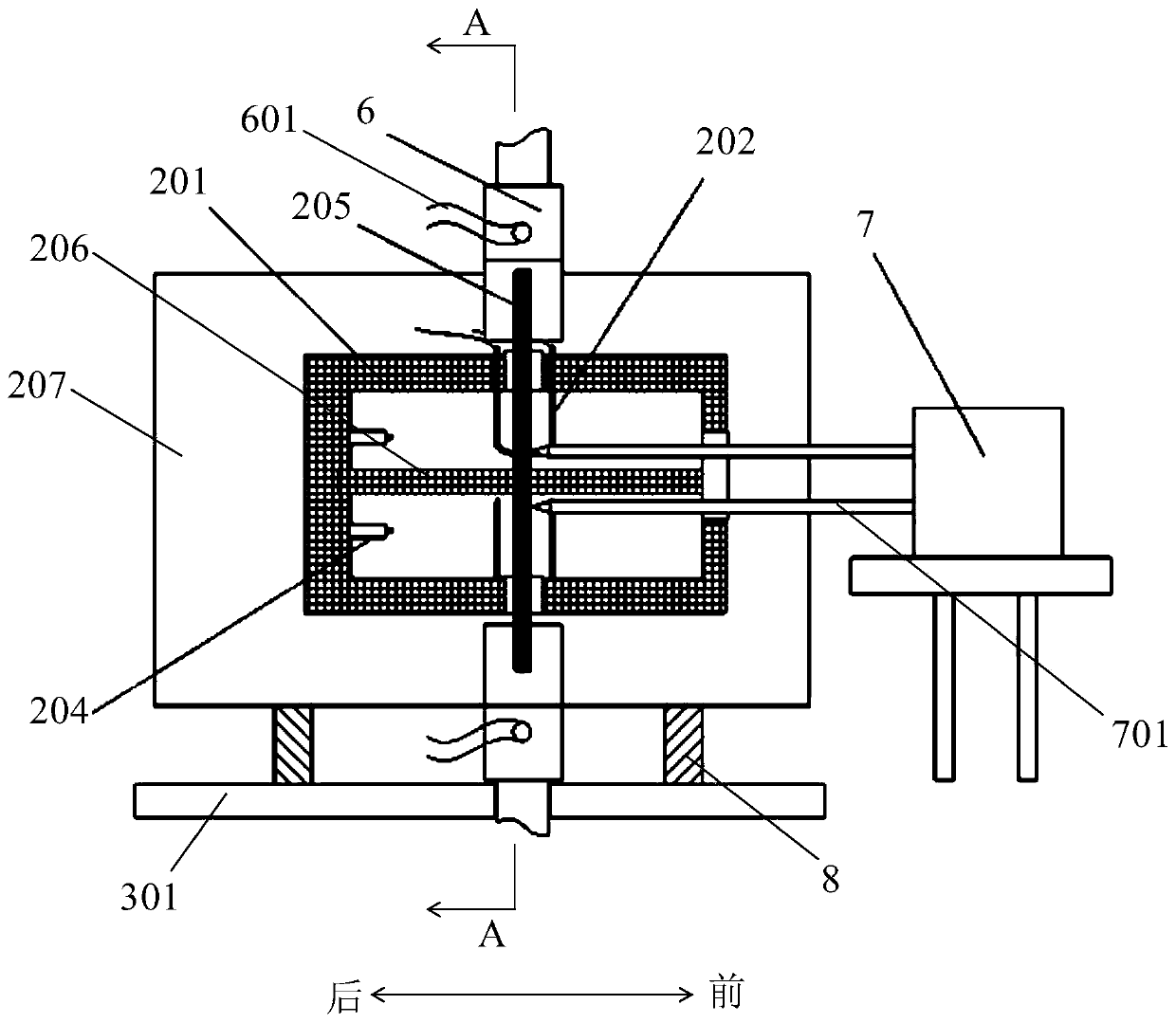

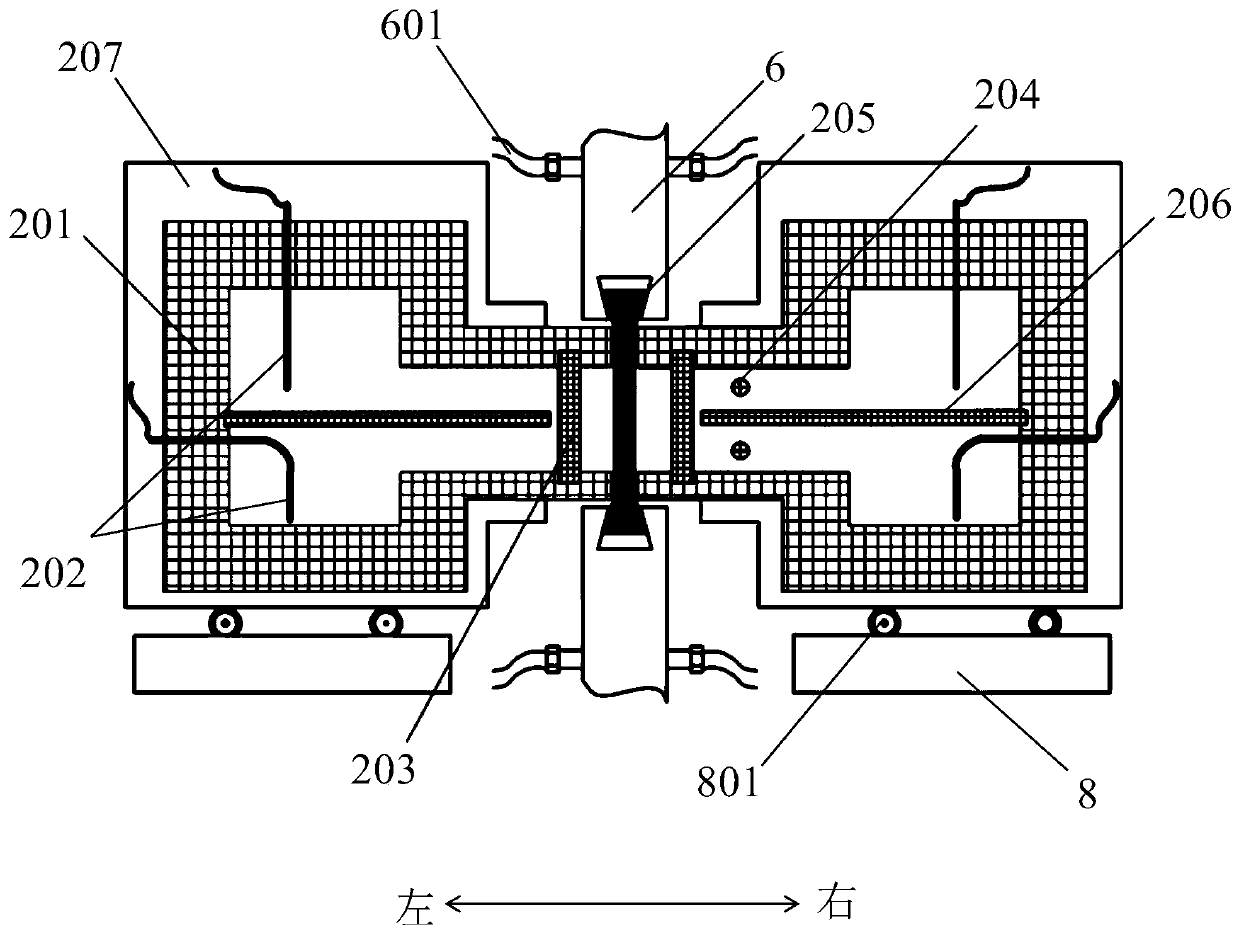

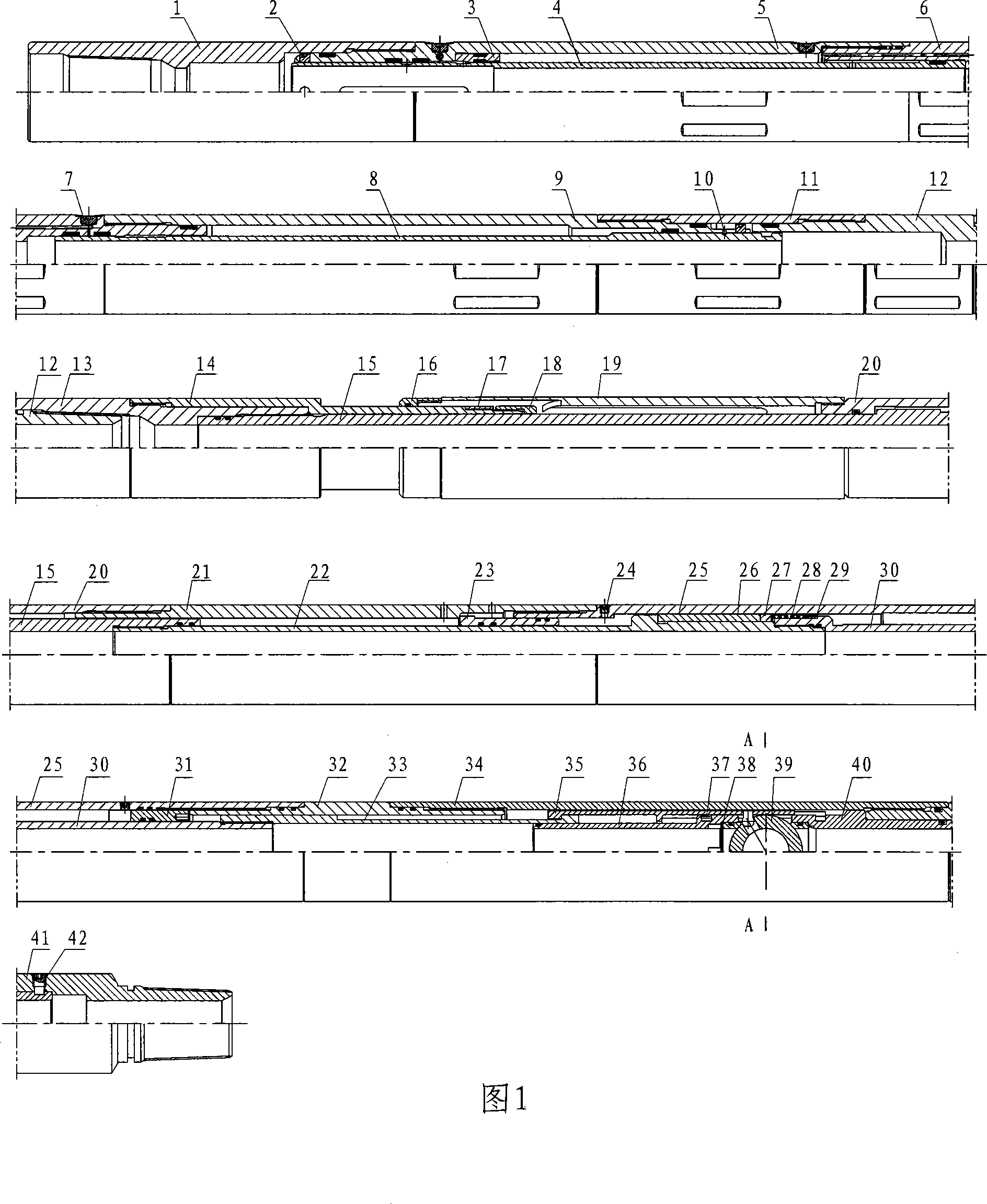

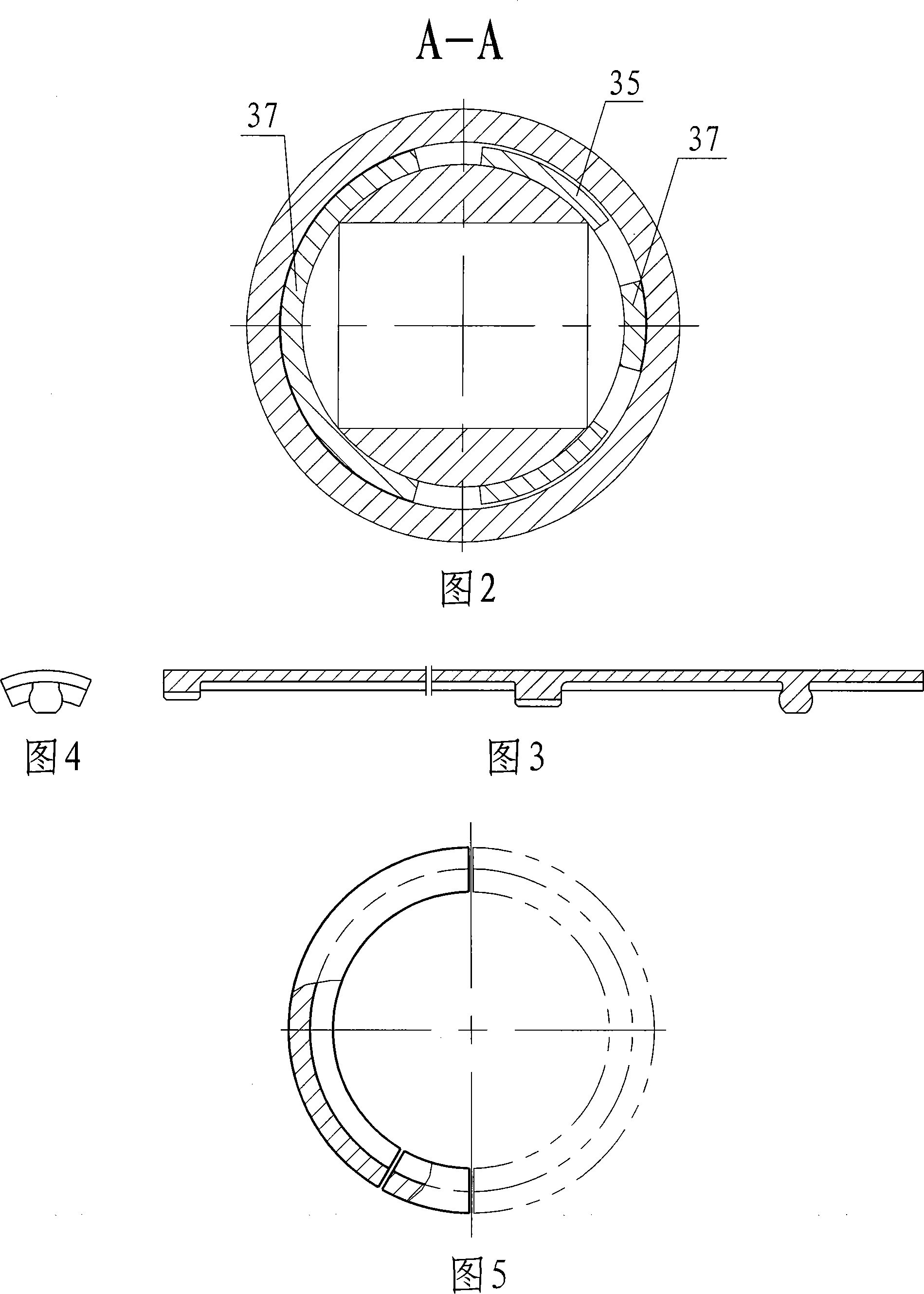

Multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions

InactiveCN103149101AStable controlCode of PracticeInvestigating material ductilityAxial displacementAmbient pressure

The invention discloses multifunctional triaxial creep testing machine with soil body pulling, pressing, twisting and shearing functions, which structurally comprises a main body part, power supply equipment, an axial loading and measuring mechanism, a torque loading and measuring mechanism, a volume-changed water level controlling and measuring mechanism, an ambient pressure loading and measuring mechanism, a pore pressure measuring mechanism, a creeping and loading mechanism, an axial displacement measuring mechanism and a lubricating mechanism. A torque separator can apply any combined axial action and torque action; a multifunctional lever part not only can apply a tension action to a sample through a lever, but also can apply a pressure action to the sample through the lever; and a detachable split volume-changed measuring water jacket structure is remarkably changed on the aspect of soil body sample body-changed measurement. The machine provided by the invention is simple in structure, convenient to operate and high in accuracy rate and success rate.

Owner:XIAN UNIV OF TECH

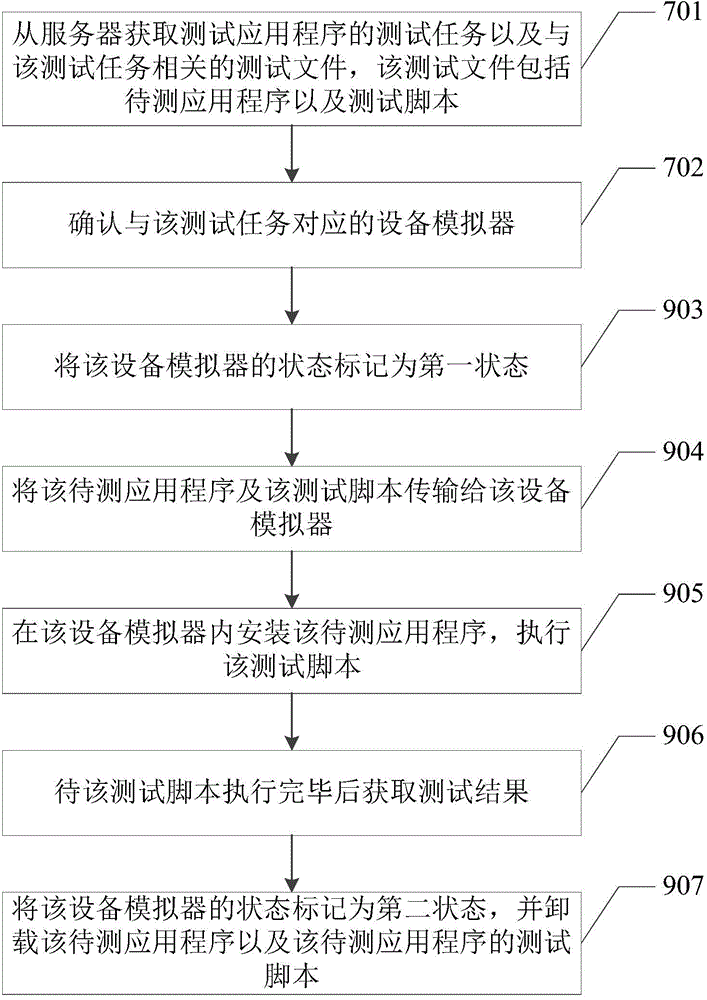

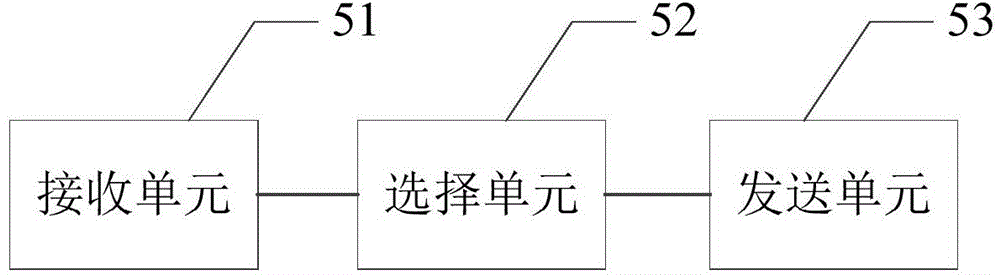

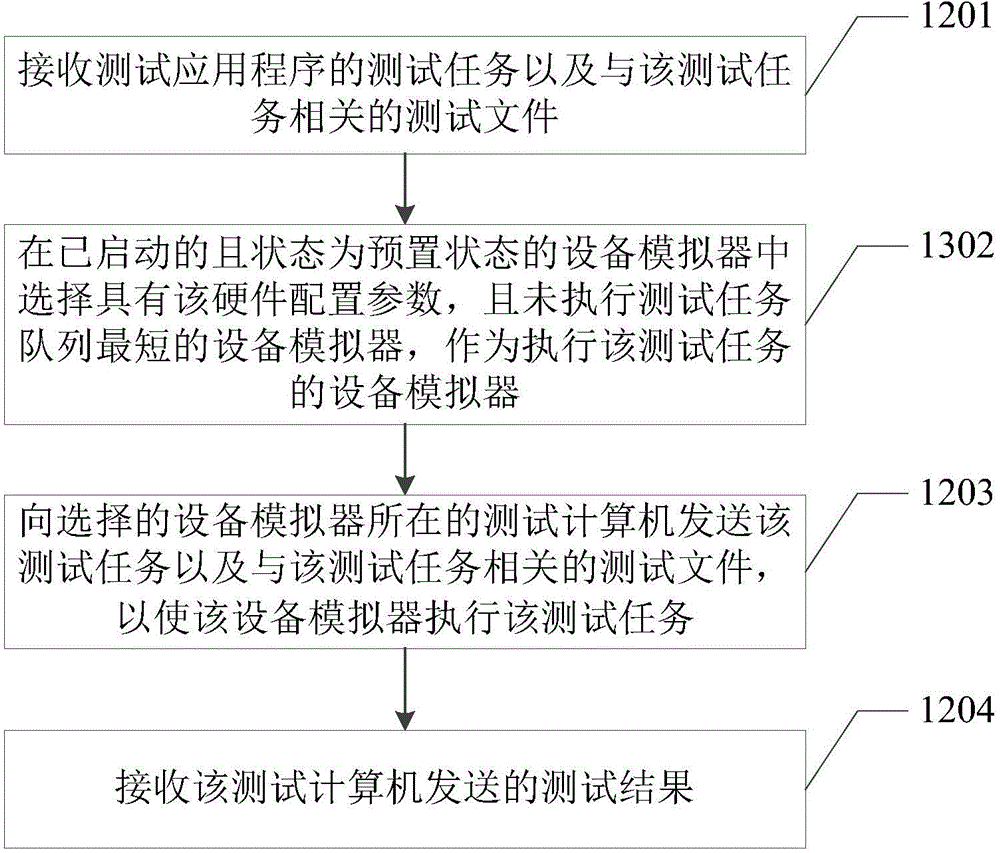

Mobile terminal application program test method and mobile terminal application program test system

ActiveCN104978263AImprove management efficiencyImprove test success rateSoftware testing/debuggingTest scriptSoftware engineering

The invention provides a mobile terminal application program test method, which comprises the following steps of: obtaining a test task of a test application program and a relevant test file from a server, wherein the test file comprises an application program to be tested and a test script; confirming a device simulator corresponding to the test task; installing the application program to be tested in the equipment simulator; executing the test script; and obtaining the test result after the execution of the test script is completed. The invention also provides a mobile terminal application program test system. The mobile terminal application program test method and the mobile terminal application program test system have the advantages that the test success rate can be improved, and the test cost is reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

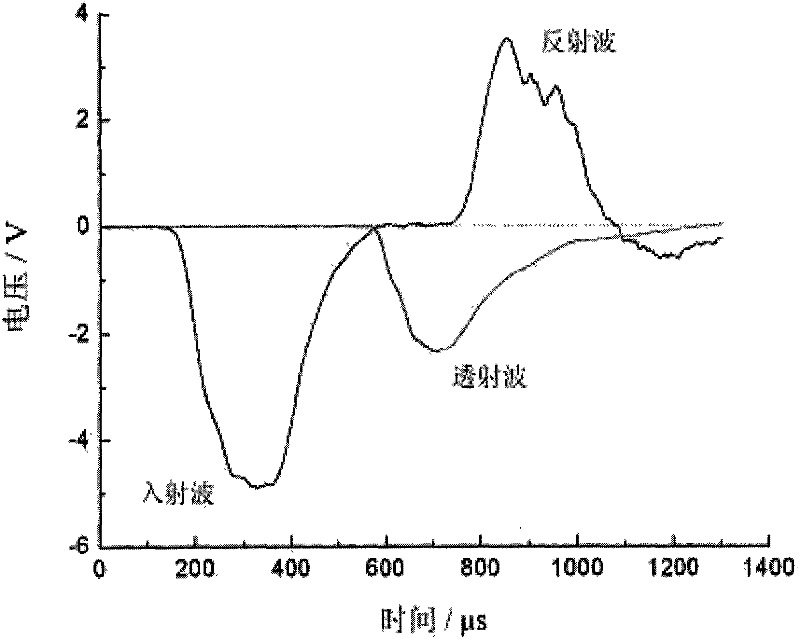

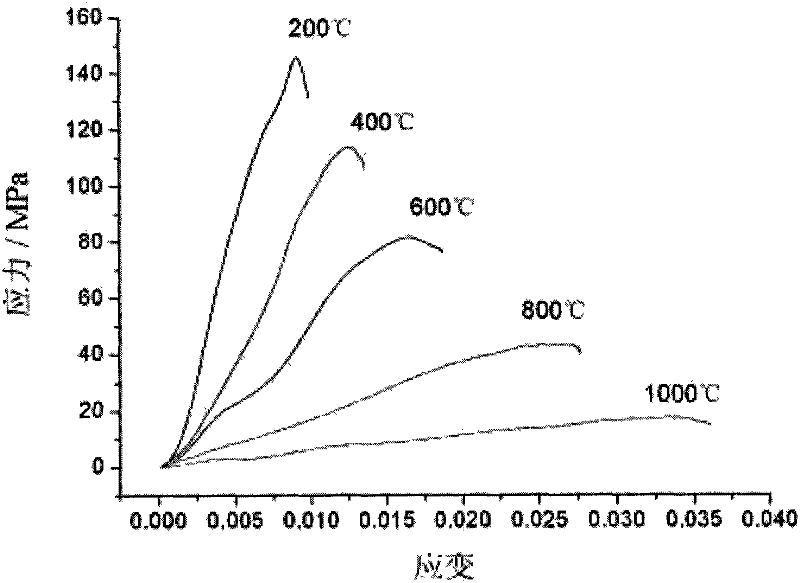

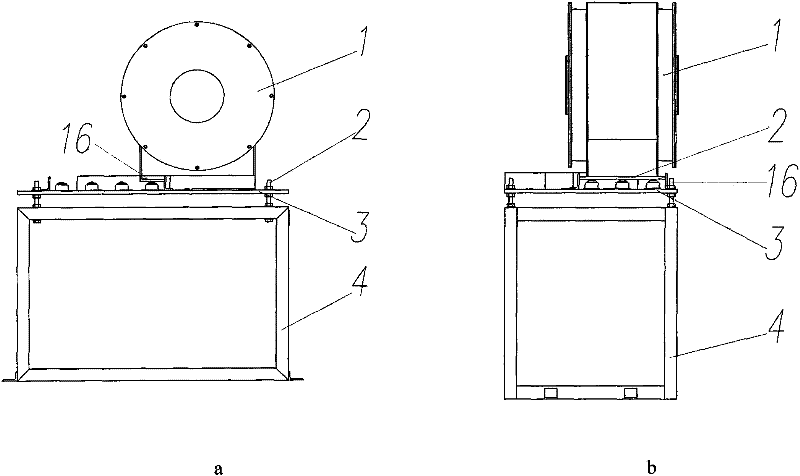

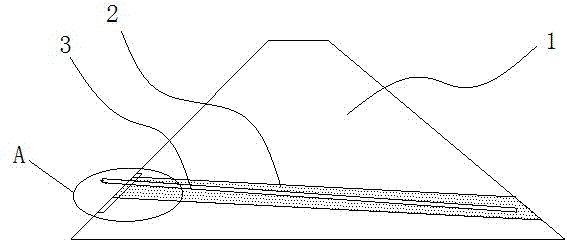

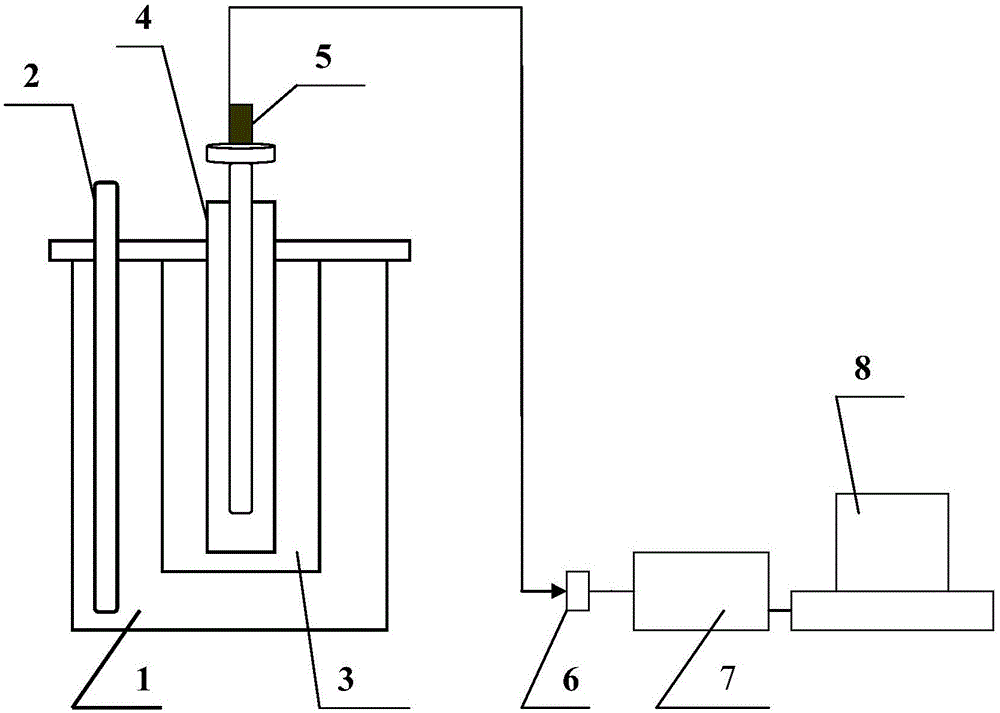

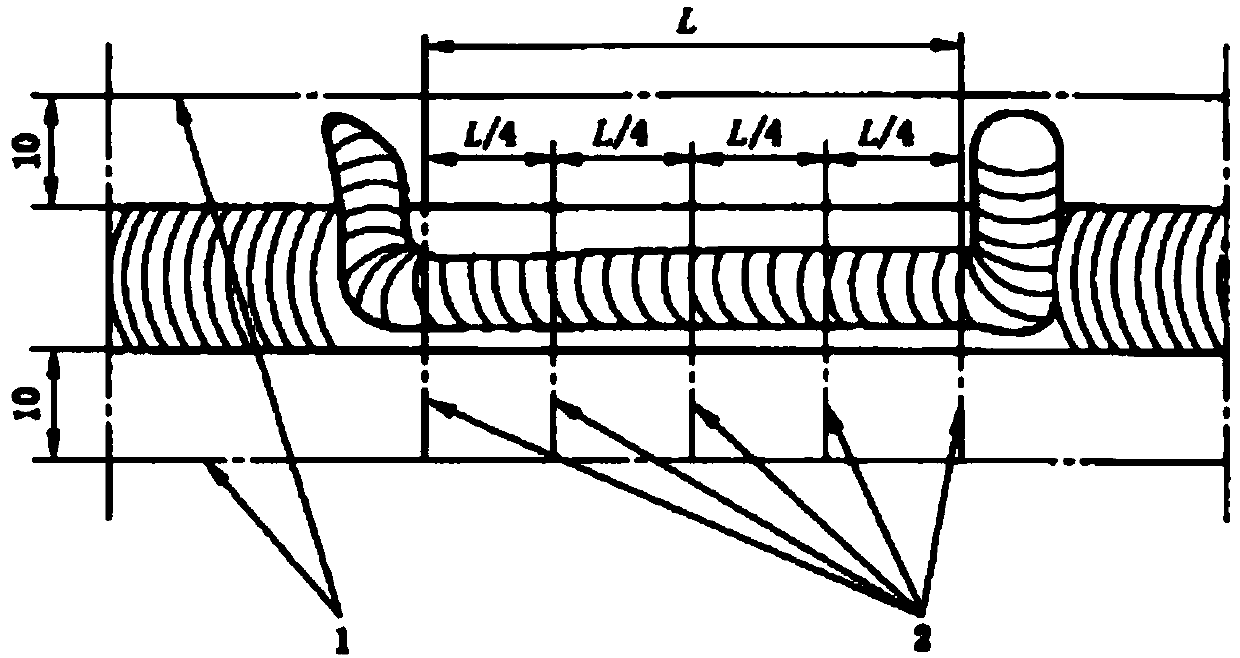

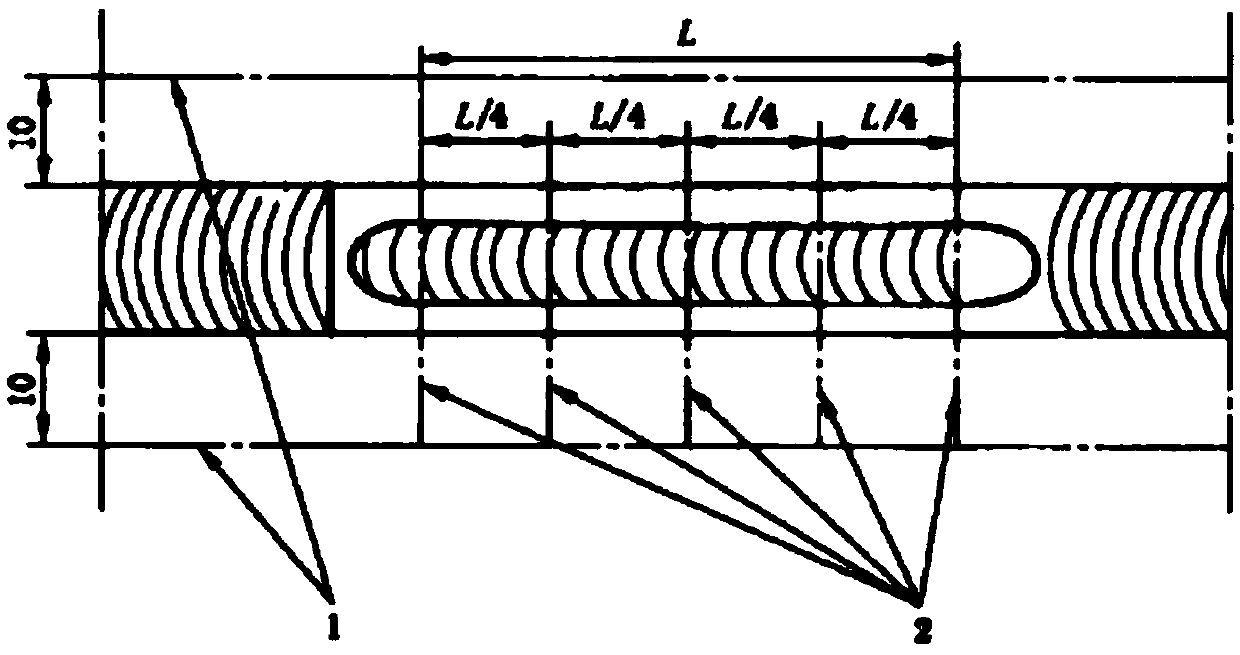

Heating device for Hopkinson compression bar test

InactiveCN102288497AEasy to adjustMeet heating needsMaterial strength using single impulsive forceBrickAluminum silicate

The invention discloses a heating device for a Hopkinson pressure bar test, which comprises a movable supporting platform, a tubular heating furnace and an electric control box. The tubular heating furnace is mounted on a sliding plate of the movable supporting platform. Two groups of sliding rails and a plurality of fixed sliding beads are arranged on the upper surface of the sliding plate. Two alundum tubes are symmetrically sleeved at two ends of a heat-resistant steel tube. Heat-resistant bricks are respectively built around the external surfaces of the joints of the two alundum tubes and the heat-resistant steel tube. The heat-resistant bricks are provided with through holes for mounting silicon carbide rods. Insulating linings are sleeved on the external surfaces of a hearth and the heat-resistant bricks. Positions where inner cavities of the insulating linings correspond to the through holes on the heat-resistant bricks are all provided with mounting holes of the silicon carbide rods. Aluminum silicate fibrous carpets package the external surfaces of the insulating linings. A furnace shell is packaged on the external surfaces of the aluminum silicate fibrous carpets and the insulating linings. A base is fixed on the furnace shell. Two heat-insulating covers are respectively mounted in the hearth from hearths at two ends, and end cover bolts are fixed at two ends of the furnace shell. In the invention, the tubular heating furnace can move in the up-and-down direction, the leftward-rightward direction and the frontward-backward direction of the platform, and the heating device has the characteristics of good heat-insulating performance and convenience in repair.

Owner:AIR FORCE UNIV PLA

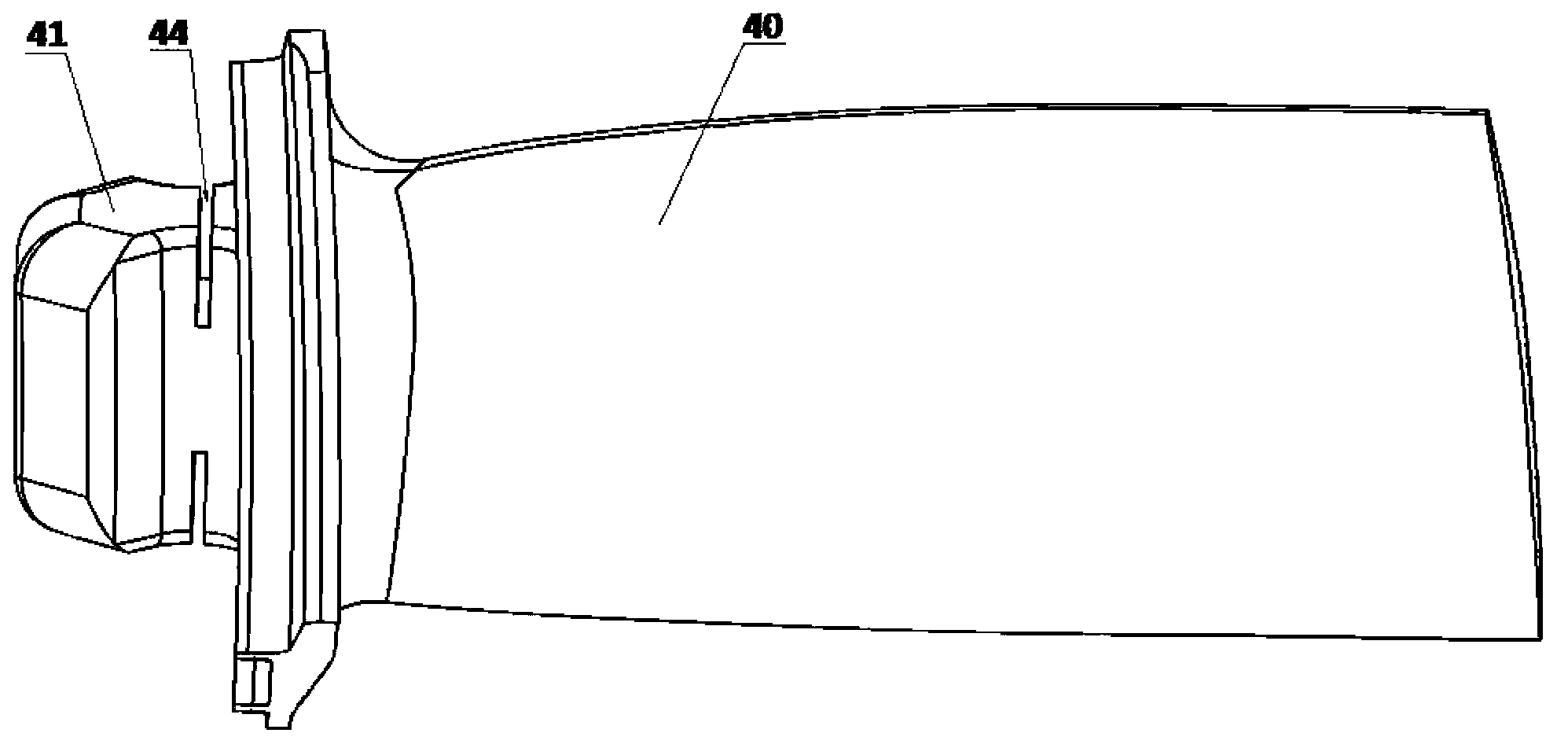

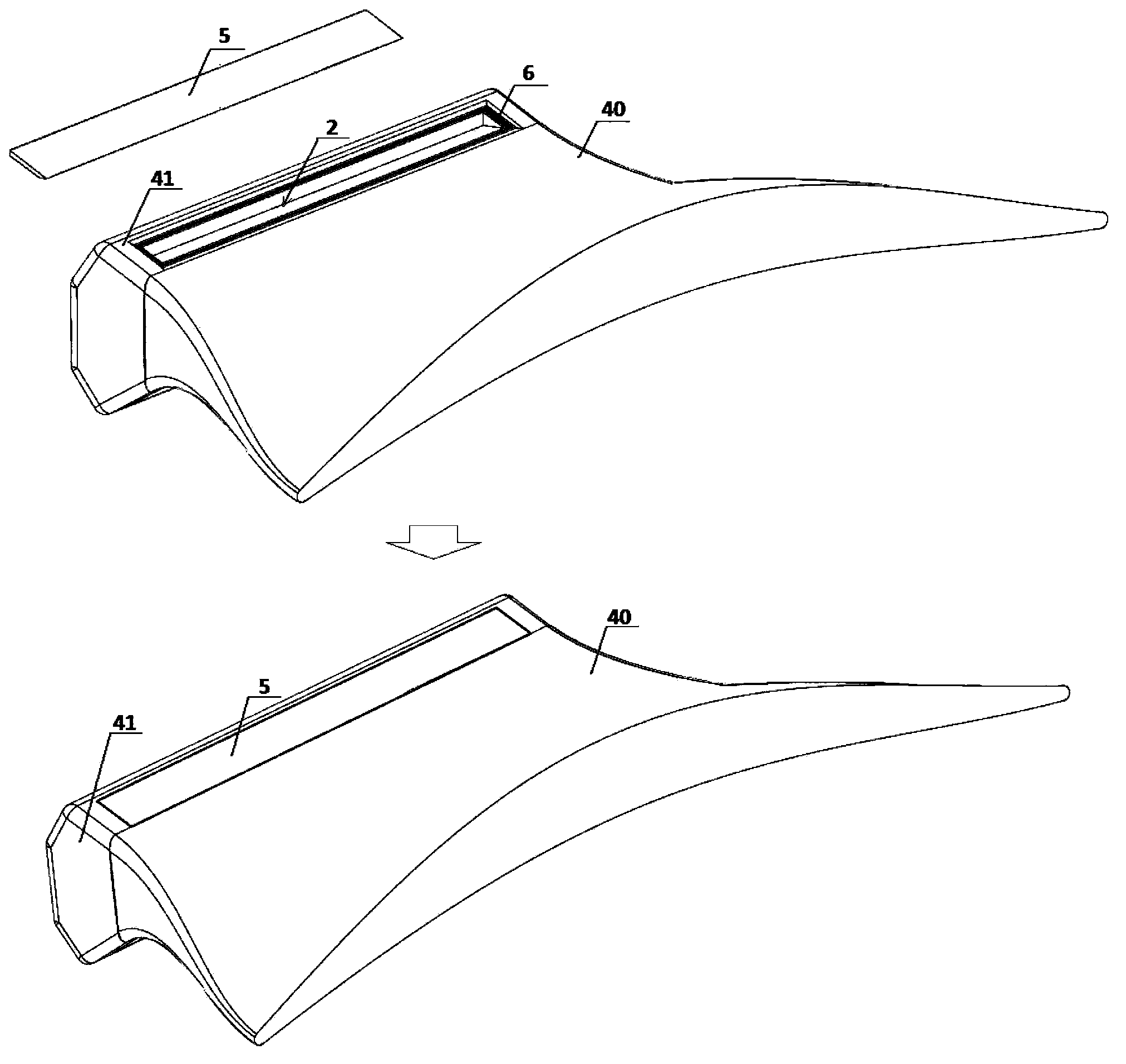

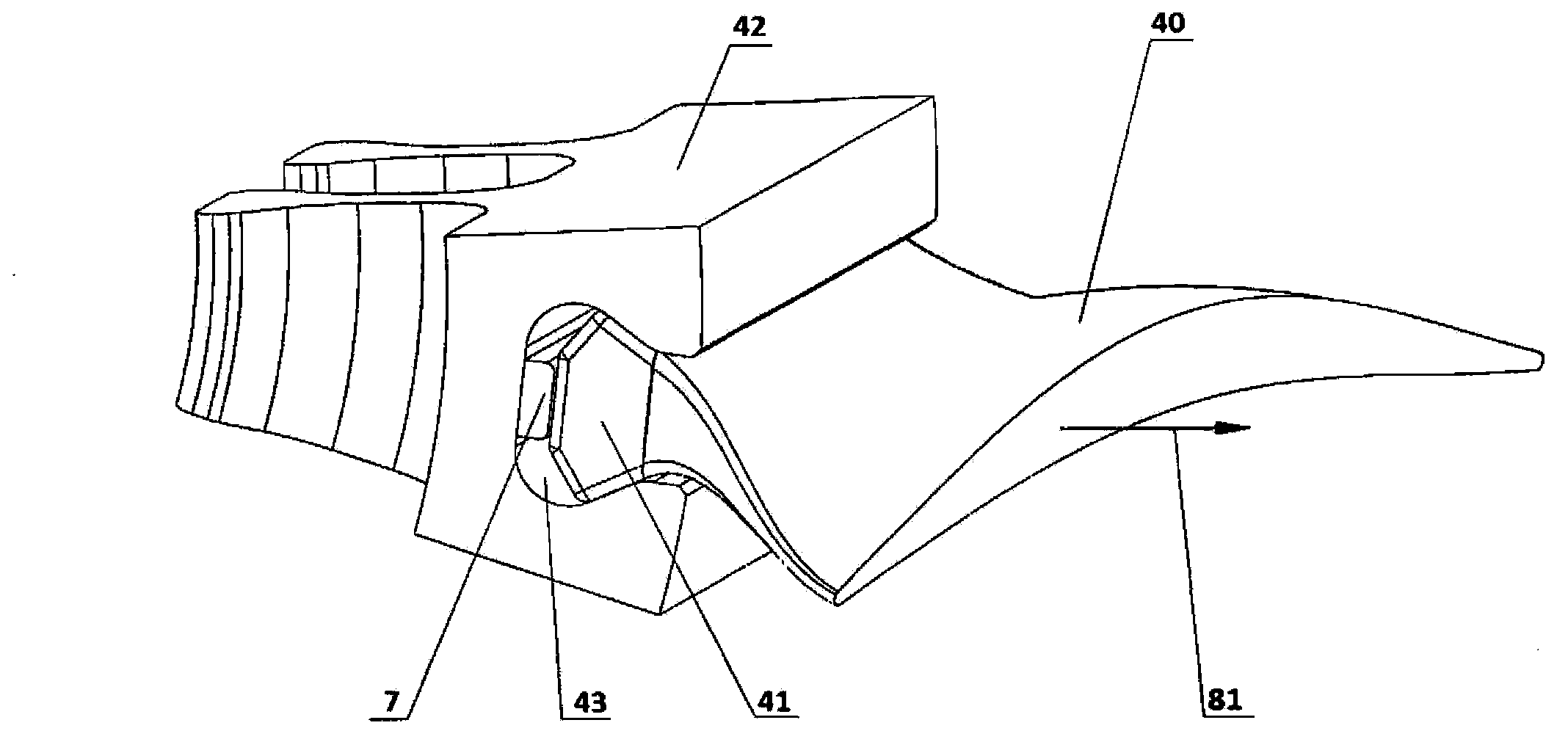

Blade separator and engine containment test device

ActiveCN103808515AInclusion Trial SuccessImprove test success rateEngine testingAviationExplosive material

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

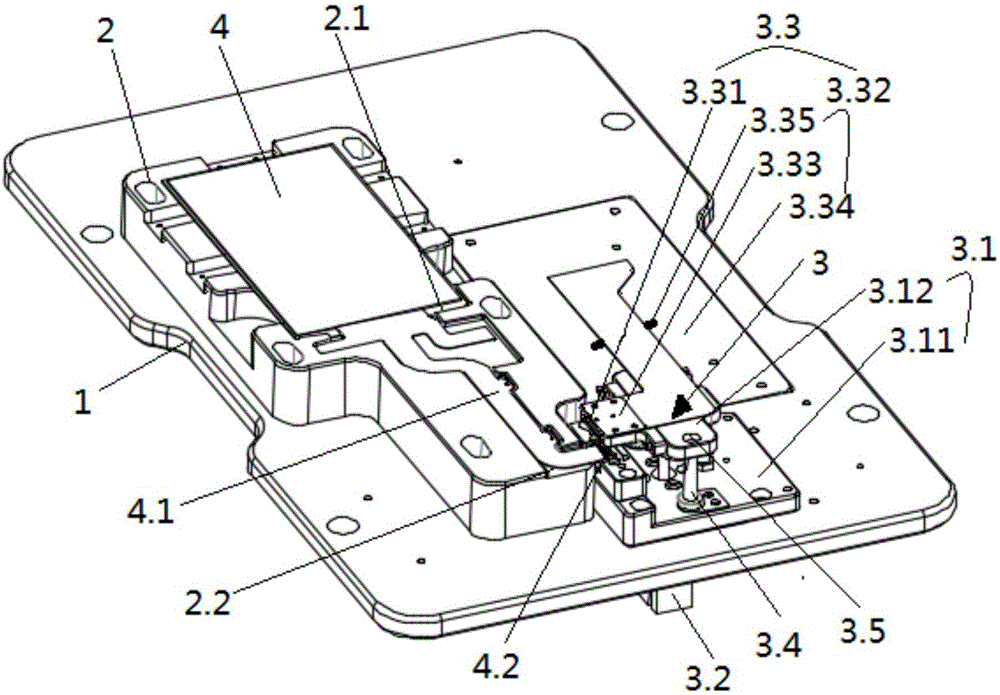

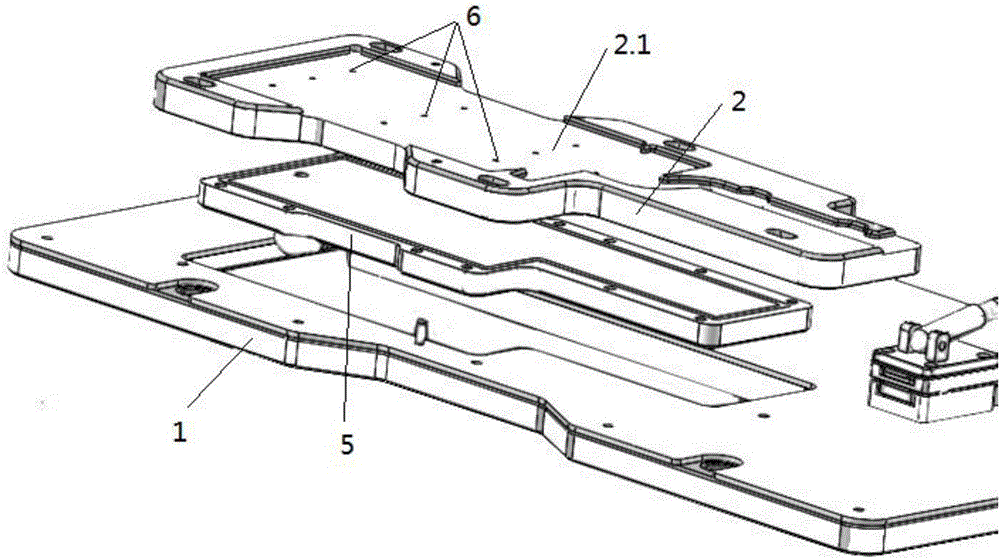

Automatic vertical press connecting structure for FOG liquid crystal screen

ActiveCN106683602APrecise positioningHigh precisionStatic indicating devicesTest efficiencyAutomatic control

The invention discloses an automatic vertical press connecting structure for an FOG liquid crystal screen. The automatic vertical press connecting structure comprises a bottom plate, a carrier and a press connecting device. A groove for containing and limiting a liquid crystal screen to be detected and a guide groove for guiding and limiting an FPC of the liquid crystal screen to be detected are formed in the surface of the carrier. The press connecting device comprises a clamping part, a driving part and a signal transmitting part; the clamping part comprises a clamping fixed part fixedly connected with the carrier and a clamping movable part movably connected with the clamping fixed part, and the signal transmitting part comprises a signal adaption probe and a signal line; the guide groove guides the FPC of the liquid crystal screen to be detected to the clamping part, and the driving part drives the clamping movable part to clamp or release a connector of the liquid crystal screen to be detected; the signal adaption probe is arranged on the clamping movable part and can be connected with the connector of the liquid crystal screen to be detected, one end of the signal line is connected with the signal adaption probe, and the other end of the signal line is electrically connected with a control terminal. The automatic vertical press connecting structure has the automatic control function and is accurate in location, high in precision and capable of lightening the liquid crystal screen during each time of connection, so that the testing efficiency is greatly improved, and the screen clicking success rate is greatly increased.

Owner:武汉精毅通电子技术有限公司 +1

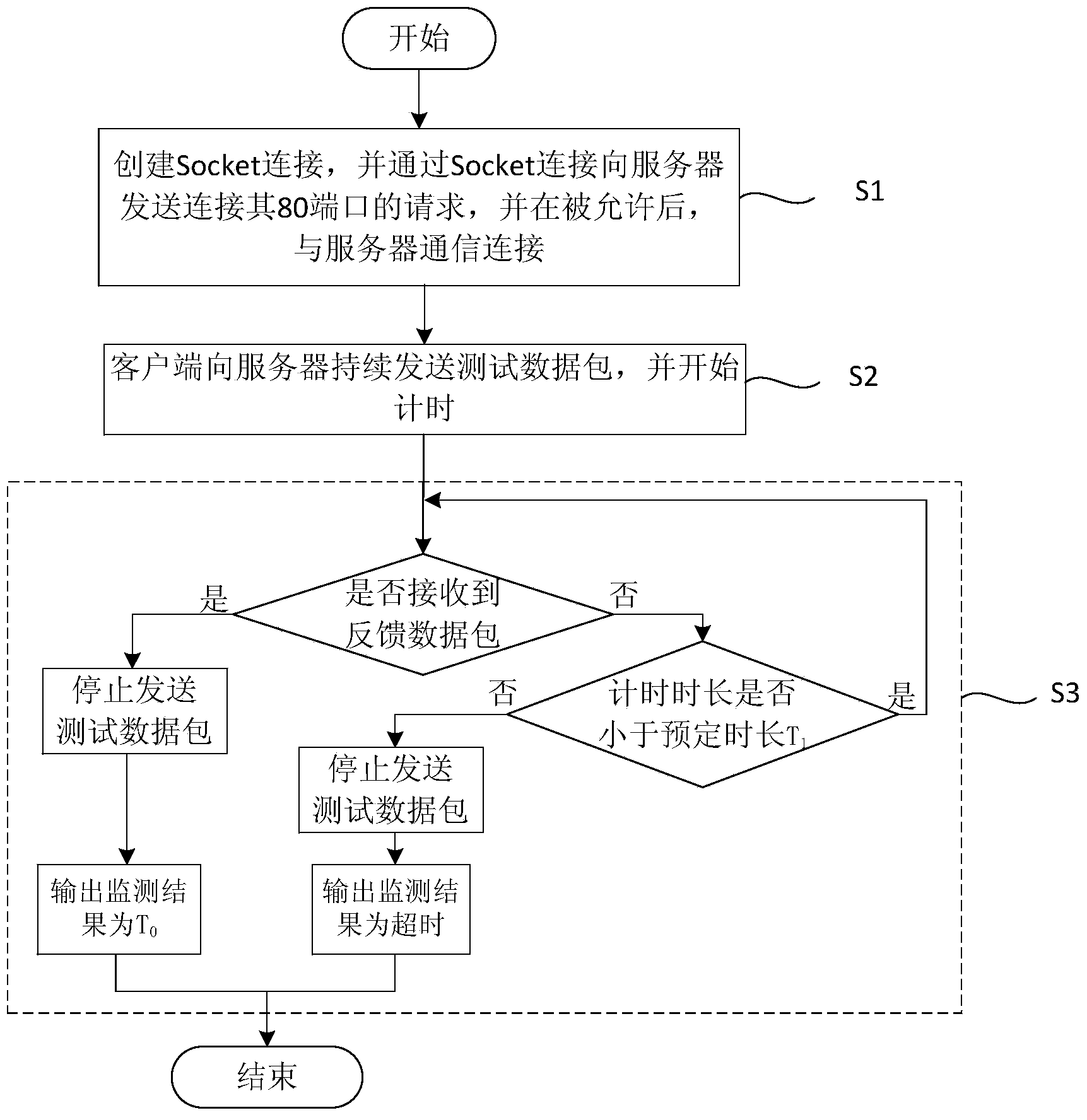

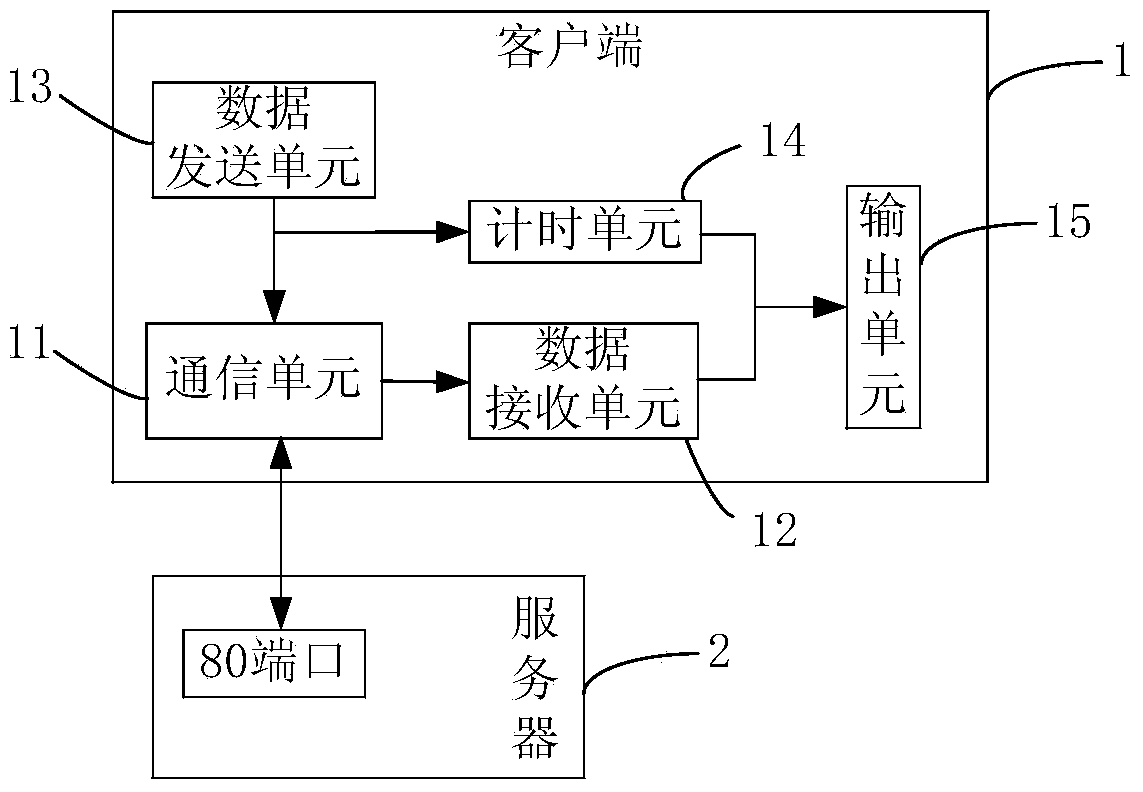

Network speed measurement method and system

InactiveCN103763156AImprove test success rateNot easy to failData switching networksClient-sideSpeed measurement

The invention provides a network speed measurement method used for measuring the network connection speed between a client side and a server. The method includes the following steps that a Socket connection is built on the client side, a request for connecting an 80 port of the server is sent to the server through the Socket connection, and after the request is automatically permitted by the server, the client side is in communication connection with the server through a three-way handshake mechanism based on a TCP / IP protocol; the client side sends a test data package to the server and starts timing at the moment; the client side outputs a corresponding speed measurement result according to whether a feedback data package returned by the server and timing duration are received or not, wherein the timing duration lasts to the time when the feedback data package is received. The invention further provides a network speed measurement system. The network speed measurement method and system have the advantages of being high in test success rate and not prone to failing.

Owner:中移信息技术有限公司

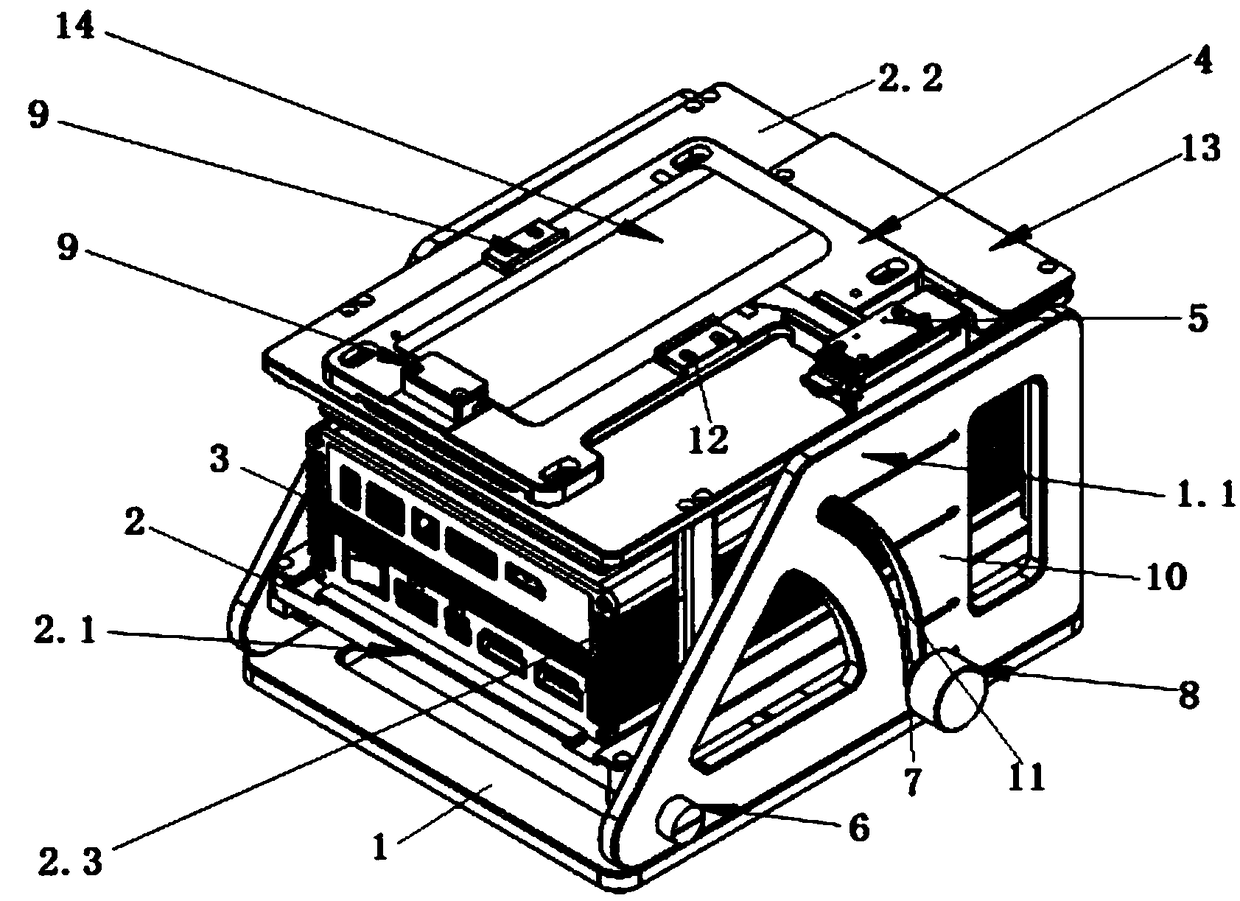

Mechanical tensile property testing device under high temperature environment and testing method

ActiveCN109696362AImplement testImprove test success rateMaterial strength using tensile/compressive forcesTest efficiencyTemperature control

The invention relates to a mechanical tensile property testing device under a high temperature environment and a testing method. The testing device comprises a tension load applying system, a high temperature atmosphere furnace, a temperature measuring and controlling system for carrying out temperature control on the high temperature atmosphere furnace, a regulating device for regulating the position of the high temperature atmosphere furnace and a high temperature deformation testing system for deformation measurement, wherein the tension load applying system comprises a main body structure,a support platform, a pair of connecting rods, a water-cooled fixture with a water-cooled structure and a pressure sensor; the high temperature atmosphere furnace comprises a first furnace body and asecond furnace body, the inner parts are heating areas, the getting close sides of the first furnace body and the second furnace body are inserted with a longitudinal heat insulation plate, and the first furnace body, the second furnace body and the longitudinal heat insulation plate are mutually cooperated to form a testing area for sample installation. The device and the method disclosed in theinvention break through the restriction of a high temperature chuck, the temperature field is more uniform, the oxidation time can be regulated more accurately, the modulus testing accuracy and the success rate are high, and the testing efficiency is high.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

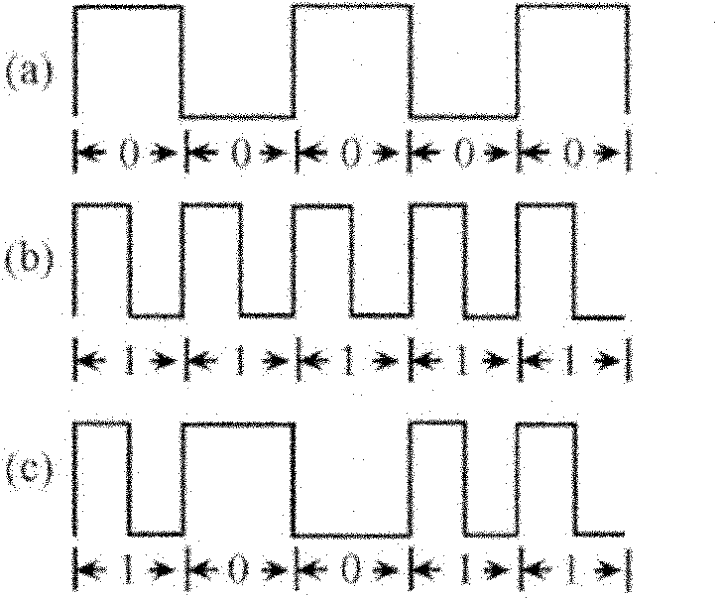

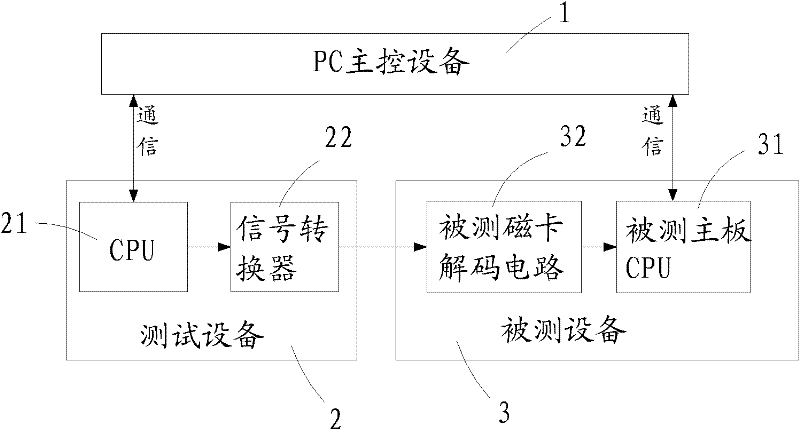

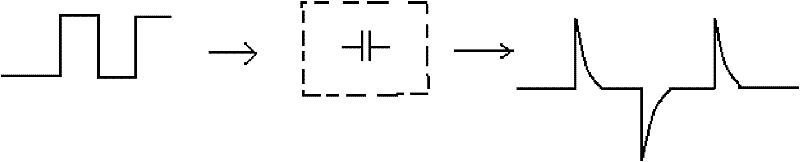

Automatic magnetic card decoding chip testing method

ActiveCN102175965AImprove test success rateFast testAnalog circuit testingPersonal computerAutomatic testing

The invention provides an automatic magnetic card decoding chip testing method. The method comprises the following steps: transmitting a command through a PC (personal computer) main control unit to request an apparatus to be tested in the state that the magnetic card is idle for card swiping test; re-transmitting a command through the PC main control unit to inform the CPU (central processing unit) of a testing apparatus to simulate signal jump with an F2F coding format so as to generate testing signals; processing the testing signals by a signal converter of the testing apparatus; transmitting the processed signal to the magnetic card decoding circuit of the apparatus to be tested to amplify, filter, shape and decode the signals; transmitting the signals to the CPU of the apparatus to be tested; and transmitting the test result to the PC main control unit by the CPU of the apparatus to be tested to achieve the test.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

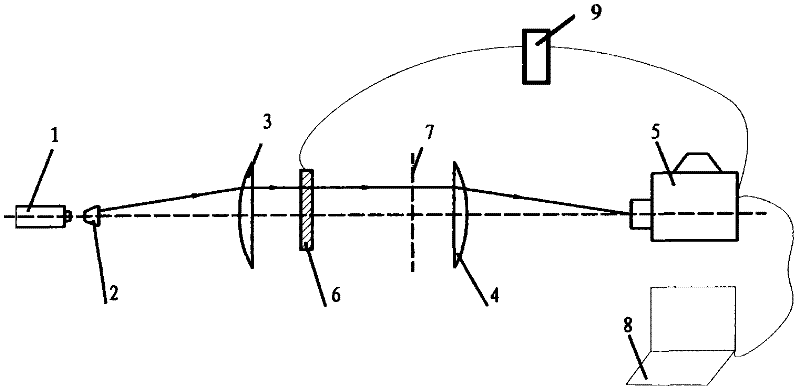

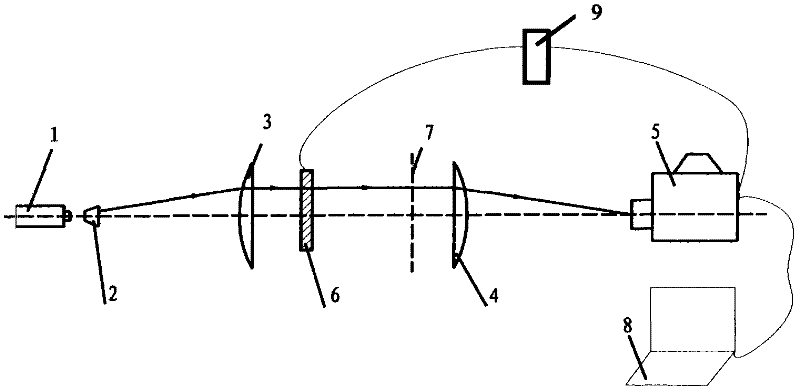

Digital laser dynamic caustics experiment method and system thereof

InactiveCN102539254AImprove controllabilityHigh precisionMaterial strength using single impulsive forceCamera lensSynchronous control

The invention discloses a digital laser dynamic caustics experiment method and a system thereof. The system comprises a laser device, a beam expanding mirror, a field lens assembly, an uploading device, a synchronous control switch, a digital high speed camera and a computer. A continuous line beam is emitted by the laser device, converted into plane beam through the beam expanding mirror, converted into parallel beams through the field lens to shoot on the surface of a test piece and finally converged to be conveyed in a camera lens of the digital high speed camera. With starting of the uploading device, the digital high speed camera is synchronously controlled to be started to finish dynamic record of crack expanding processes on the test piece, namely, digital dynamic caustics record is finished. The system can be used for optical measurement mechanics analysis in dynamic broken experiment processes like impact, explosion and the like and is simple in light path system, convenient to operates, low in experiment cost, short in period and capable of continuously detecting the whole broken processes and improving experiment accuracy.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

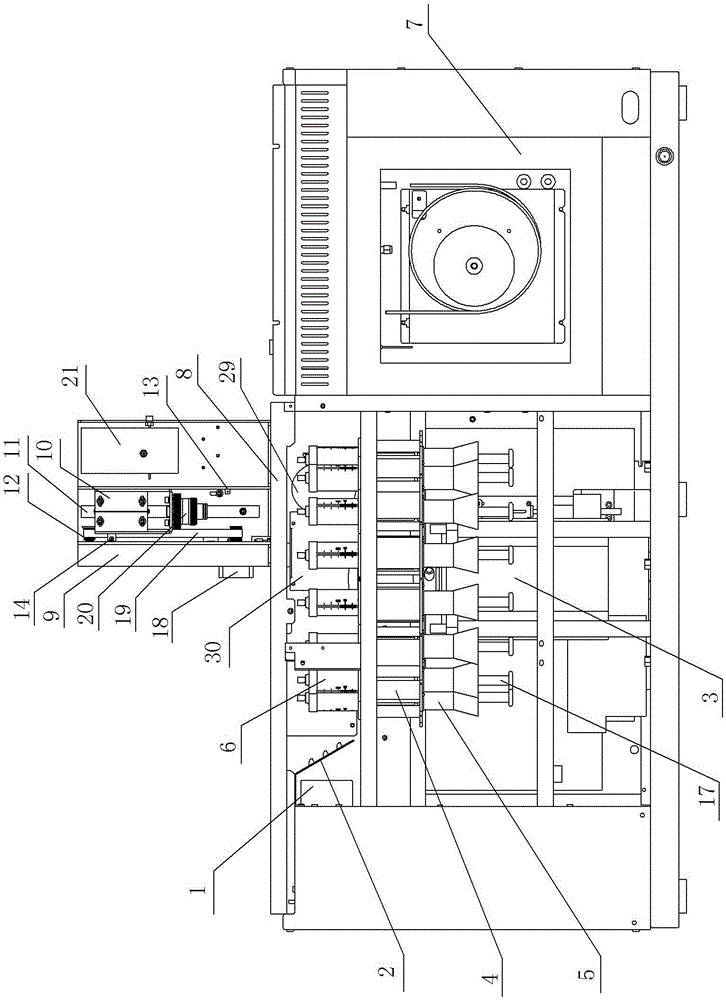

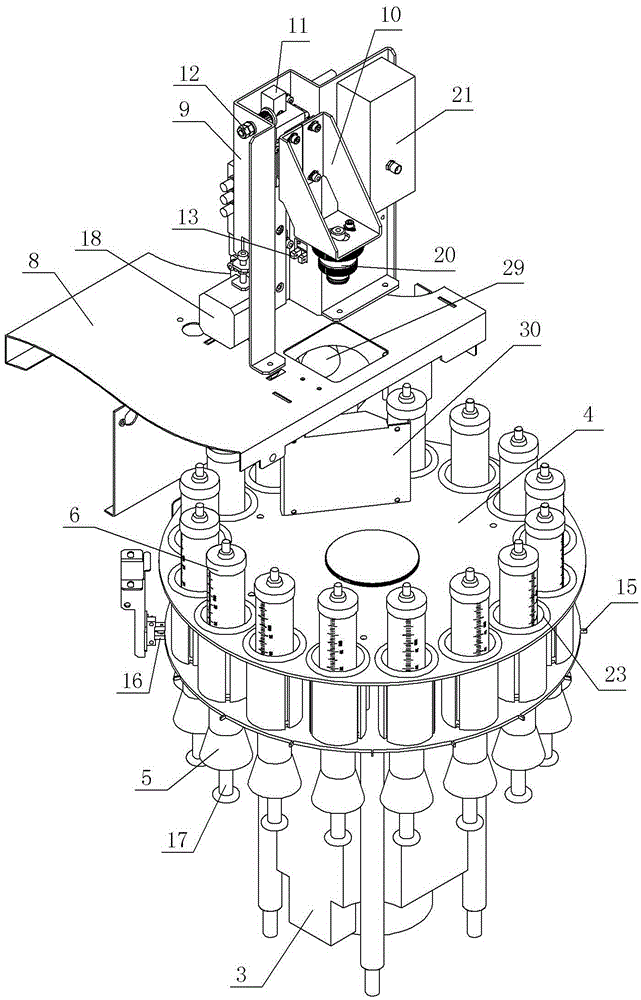

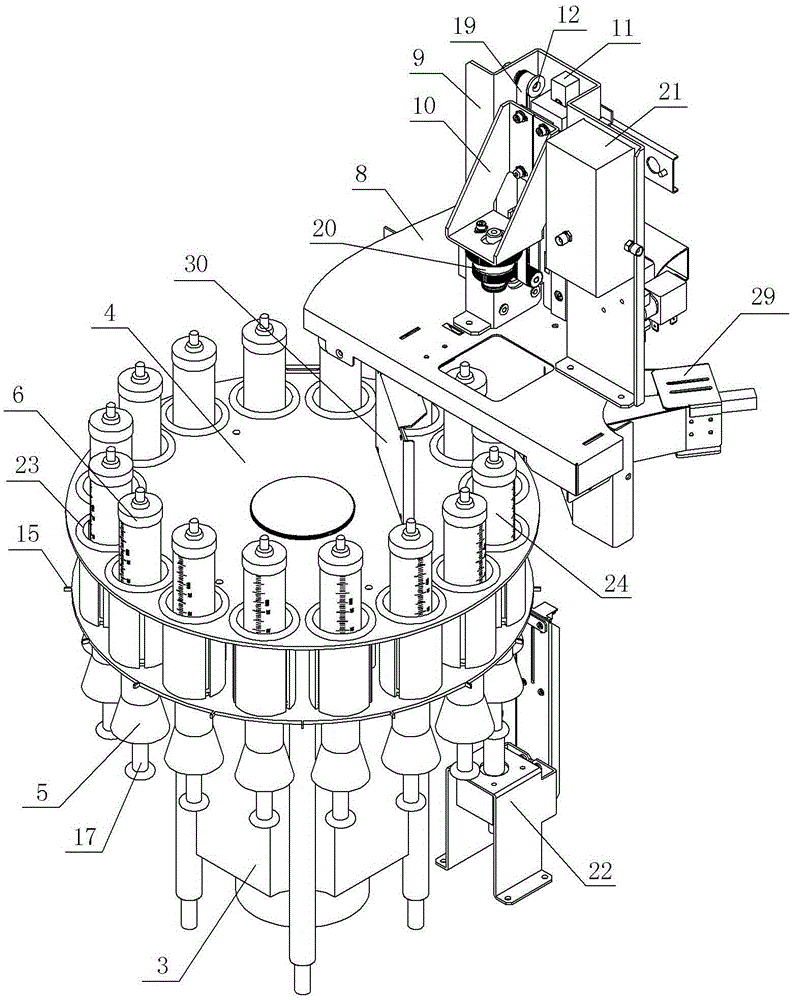

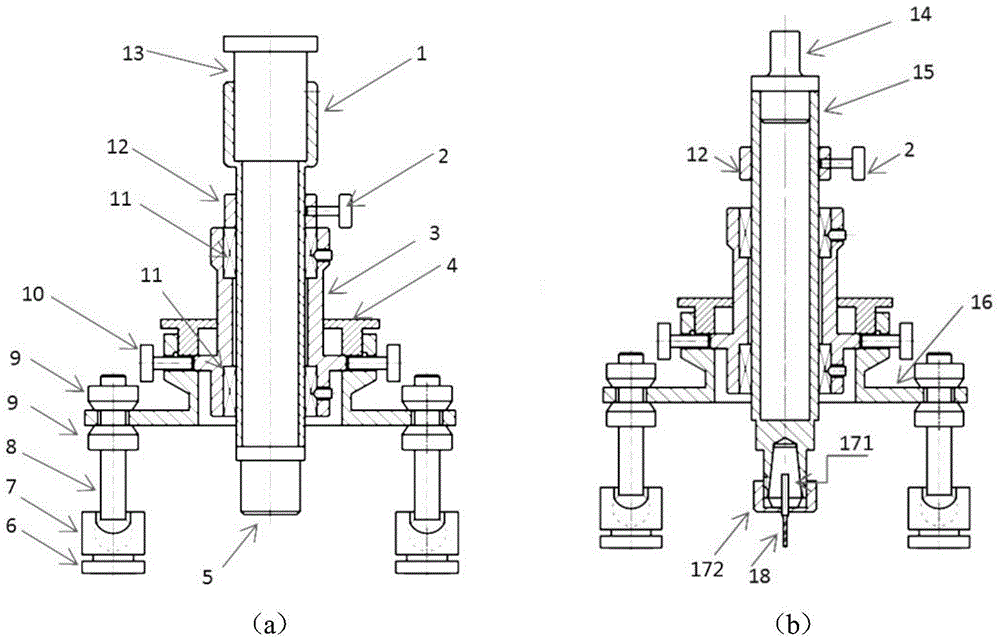

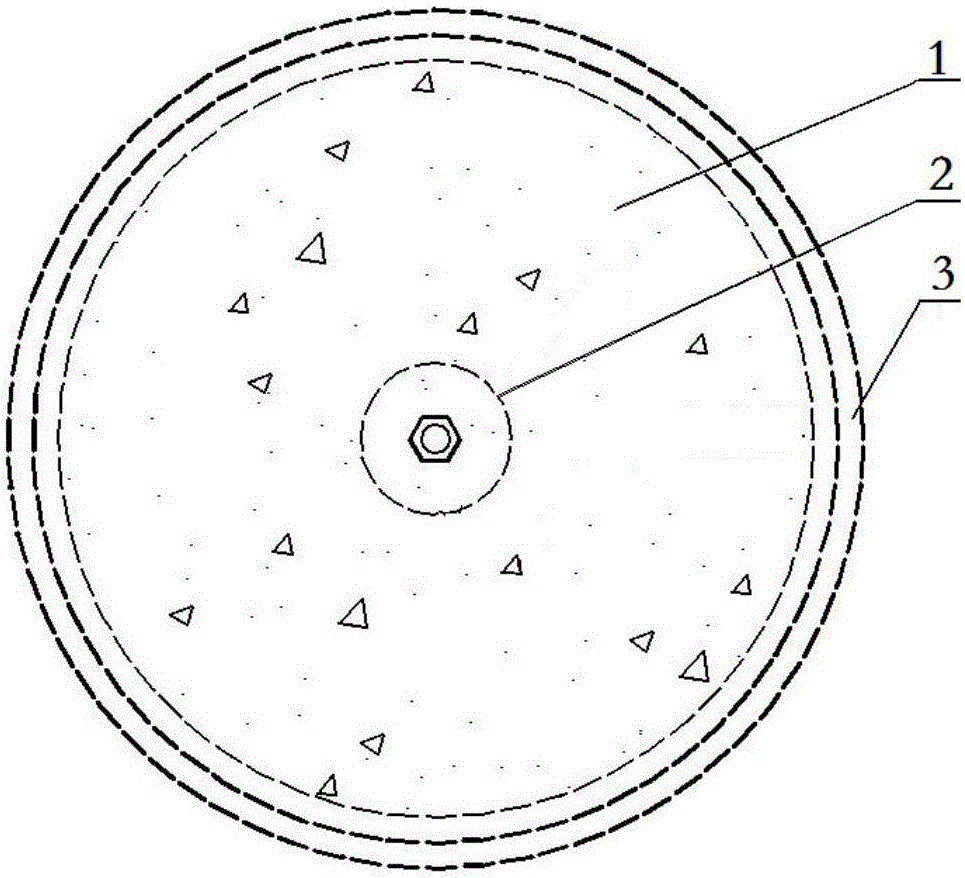

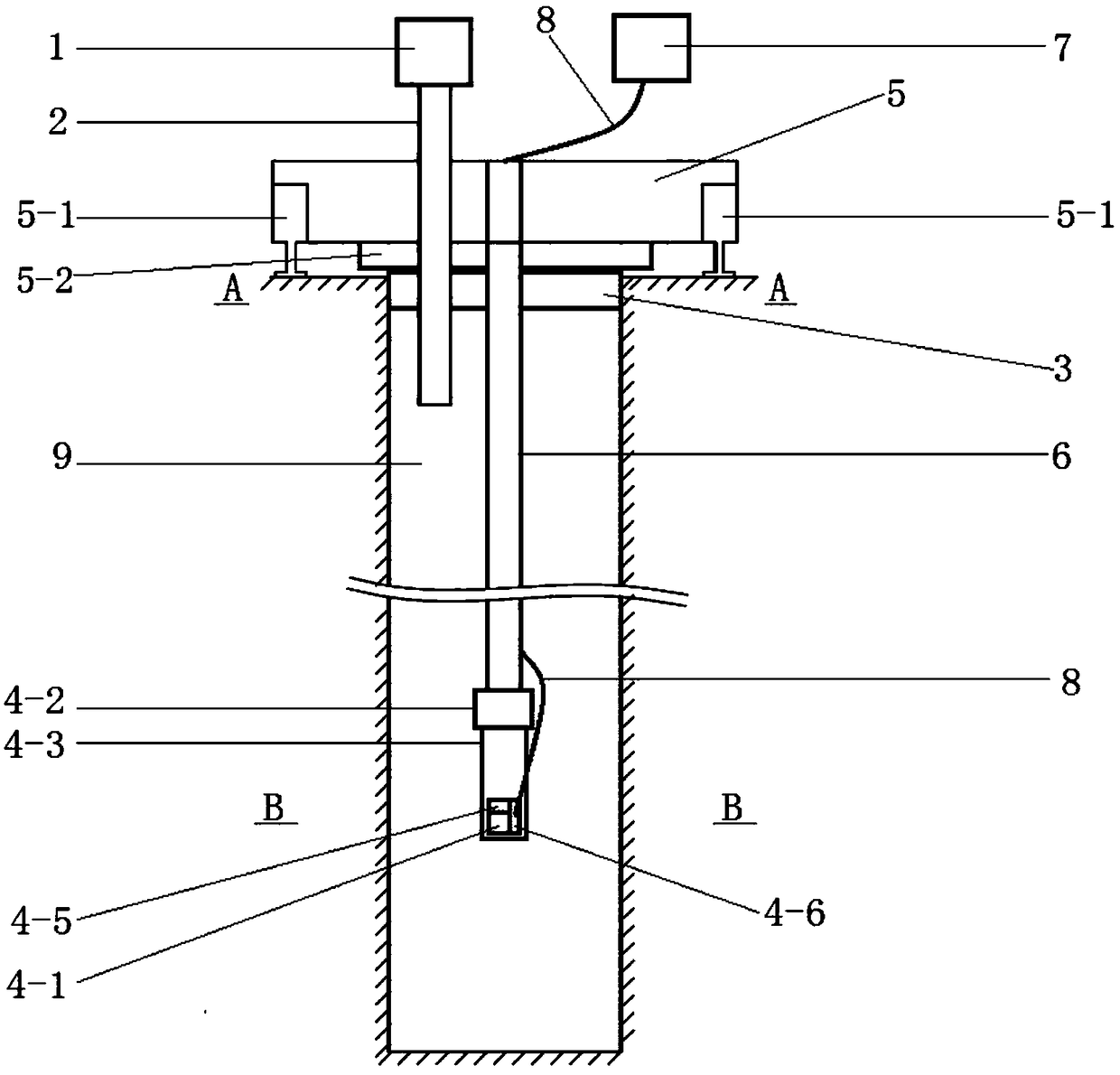

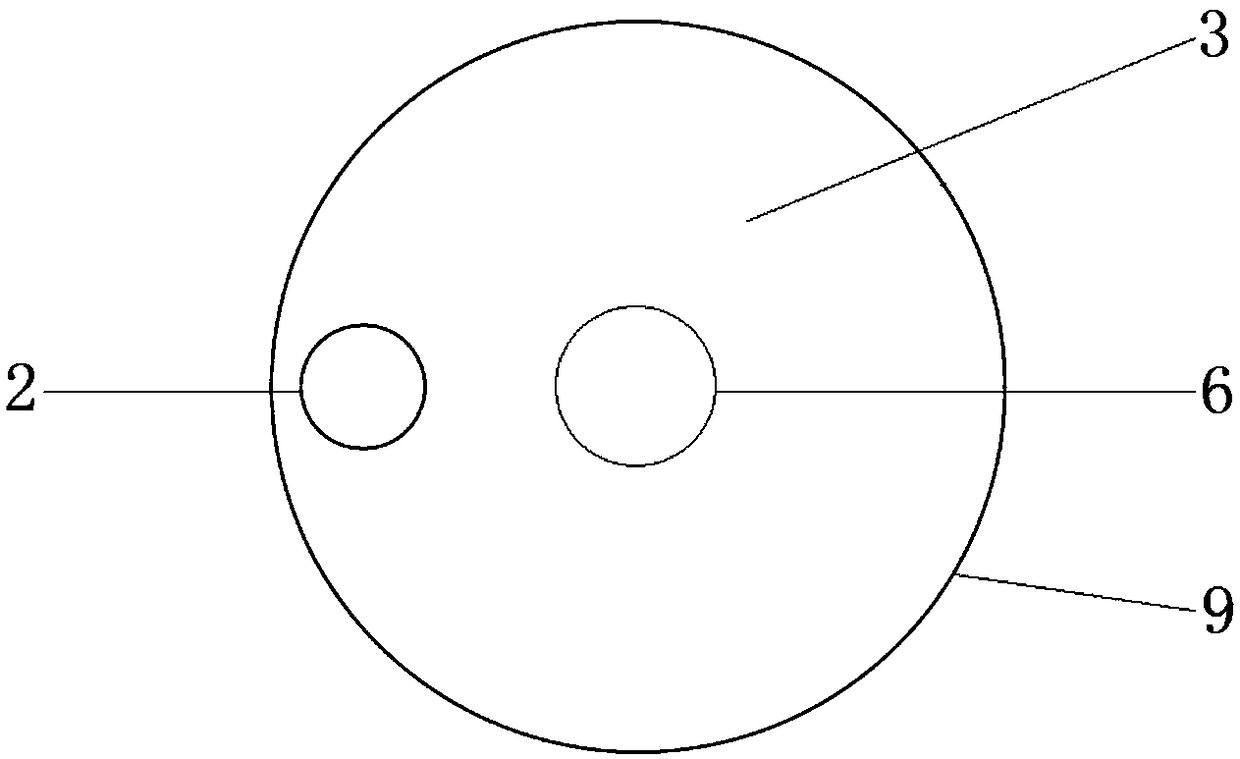

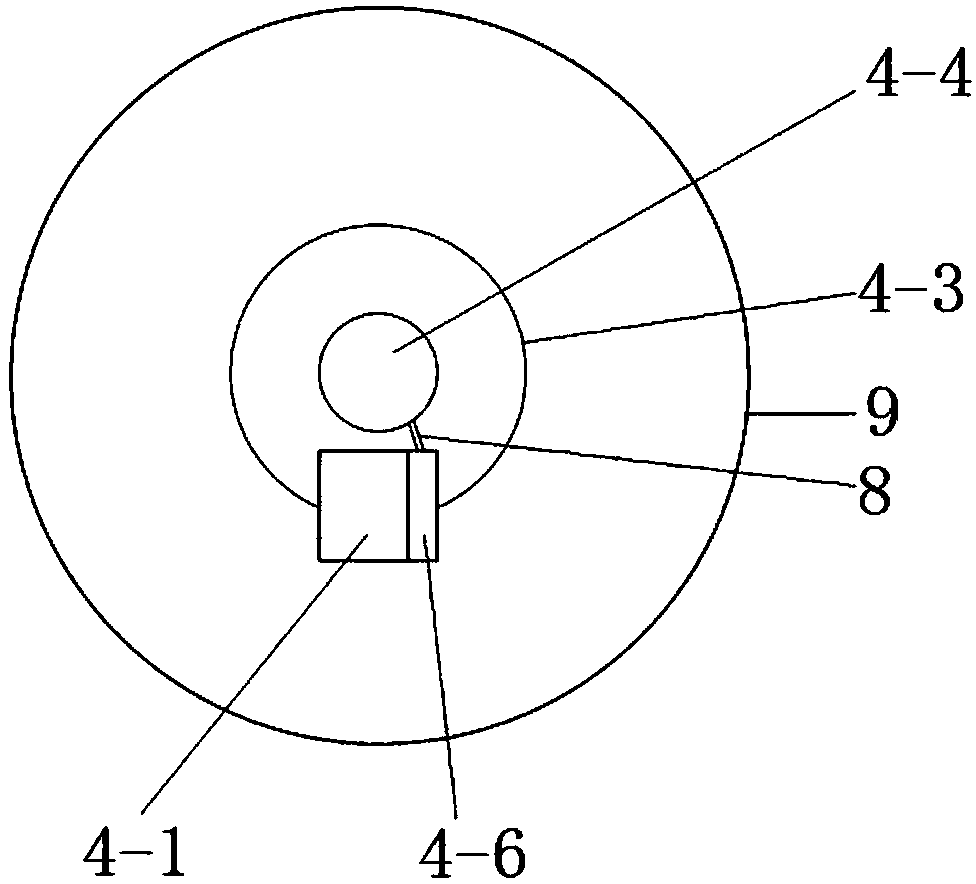

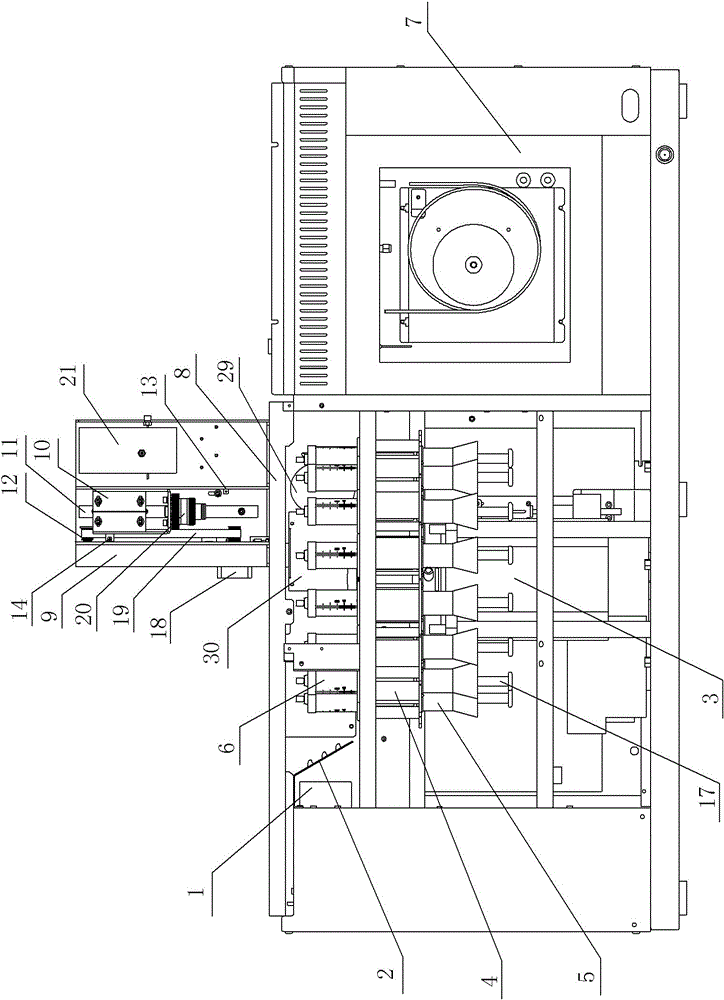

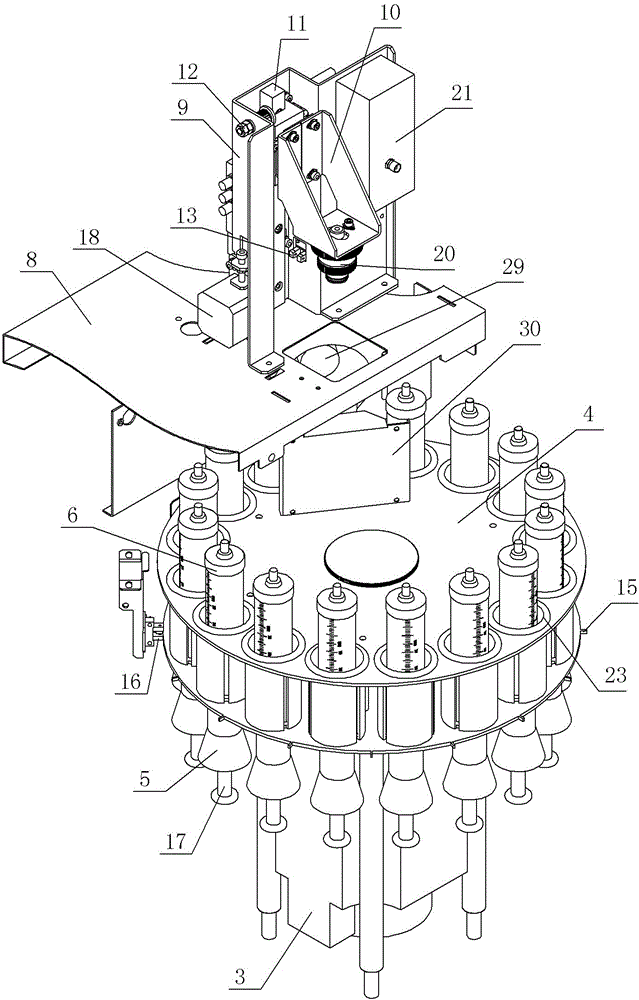

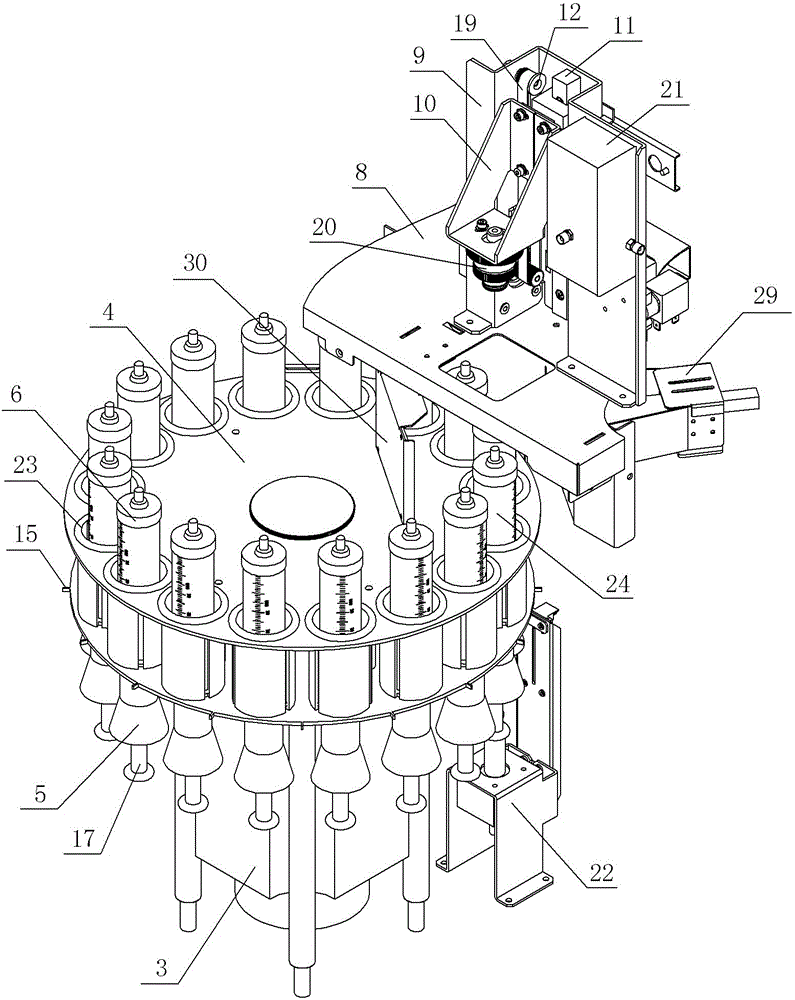

Automatic analyzer for dissolved gas in insulating oil

The invention relates to an automatic analyzer for dissolved gas in insulating oil. The gas analyzer comprises a degassing mechanism, an autoinjection mechanism, a chromatogram mechanism and a circuit control part, wherein the autoinjection mechanism comprises a degassing disc, a degassing motor, a background light source and a camera, the degassing motor drives the degassing disc to rotate, N vertical syringe mounting through holes are uniformly arranged in the circumference of the upper surface of the degassing disc, and the background light source and the camera are used for detecting the volume of insulating oil in syringes; the autoinjection mechanism comprises a gas feeding motor, a belt, a gas feeding head support, a gas feeding head and a push rod motor, the gas feeding motor drives the gas feeding head support to move up and down via the belt, and the gas feeding head is mounted on the gas feeding head support; and when the degassing disc rotates to a set position, the upper end of a to-be-detected syringe on the degassing disc just corresponds to the gas feeding head, the lower end of the to-be-detected syringe just corresponds to the upper end part of a push rod of the push rod motor, and a hollow syringe needle in the gas feeding head is connected with the chromatogram mechanism. The automatic analyzer has a high automation degree and small errors.

Owner:HENAN ZHONGFEN INSTR

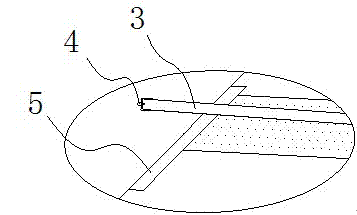

Residual stress measurement system through hole-drilling method

The invention discloses a residual stress measurement system through a hole-drilling method, and belongs to the technical field of material processing and experimental stress analysis. The system comprises two parts: a drilling device and stress calculation software. The drilling device is formed by a speed-adjustable electric hand drill, a tool microscope, a drill rod, a guide cylinder and a magnetic support base and the like; and the calculation software is programmed through C language, and can give residual stress in an assigned direction, or principal stress and included angle in real time. Since a drilling guide device adopts an embedded ball bearing mode, an rotary friction effect of the drill rod is totally prevented; since the support adopts permanent magnetic bases and lock nuts each having a breach, site positioning and fillet weld stress measurement are realized greatly; and since the calculation program takes features of change of hole edge plastic deformation and processing strain with the stress value into consideration, a stress calculation formula of any two vertical directions is given to enable welding residual stress measurement to become much easier and accurate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

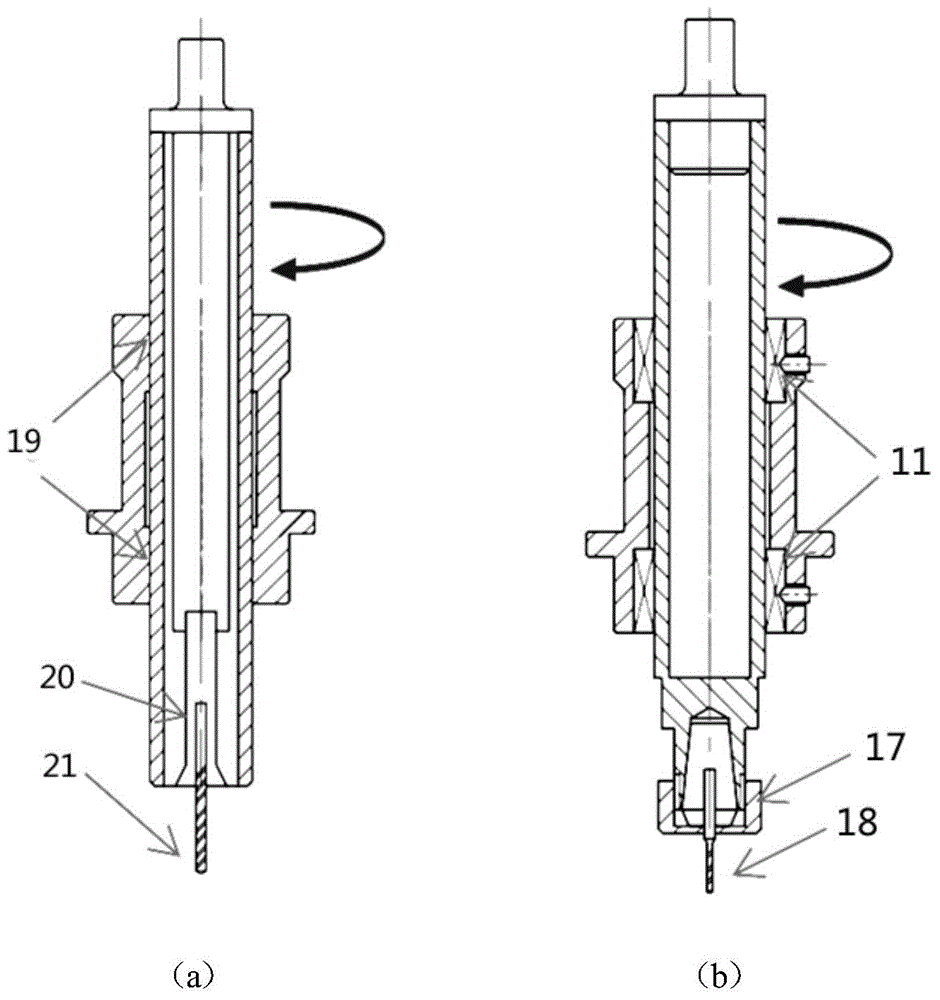

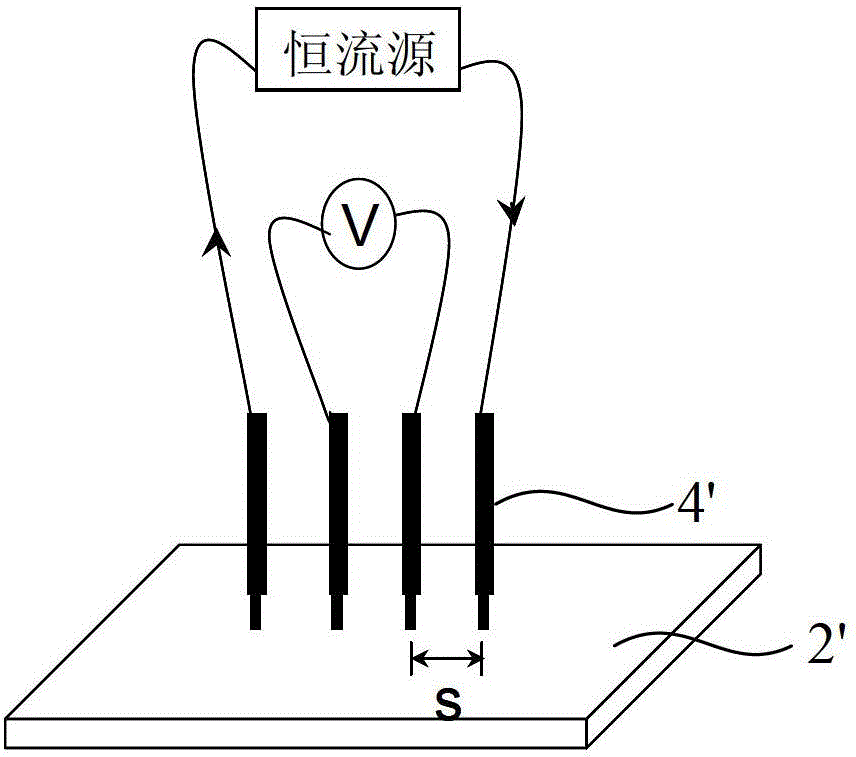

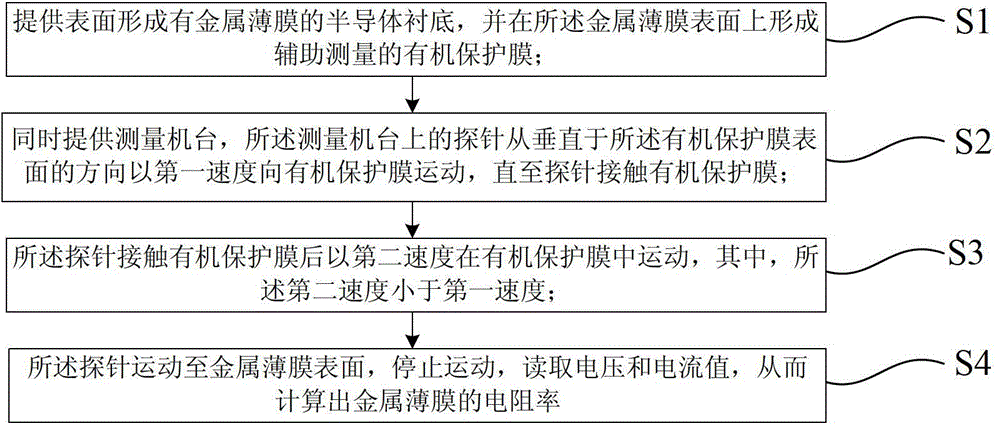

Method for measuring resistivity of metal film

ActiveCN104422824AReduce the chance of punctureImprove test success rateResistance/reactance/impedenceElectric resistivitySemiconductor

The invention provides a method for measuring resistivity of a metal film. The measuring method comprises the following steps: providing a semiconductor substrate on the surface of which the metal film is formed, and making an organic protection film; providing a measurement platform, wherein a probe on the measurement platform moves toward the organic protection film at a first speed; allowing the probe to move in the organic protection film at a second speed after the probe is in contact with the organic protection film, and the second speed is smaller than the first speed; stopping movement of the probe when the probe moves to the surface of the metal film, reading a voltage value and a current value, and calculating the resistivity of the metal film. According to the method, a layer of organic protection film is made on the surface of the metal film, the probe rapidly descends to the surface of the organic protection film at the first speed, pricks the organic protection film at the second speed and slowly descends to the surface of the metal film, and two different probe speeds are adopted, so that the probability of pricking of the metal film is lowered greatly, the success rate of a product test is increased, and the measurement period is shortened.

Owner:SEMICON MFG INT (SHANGHAI) CORP

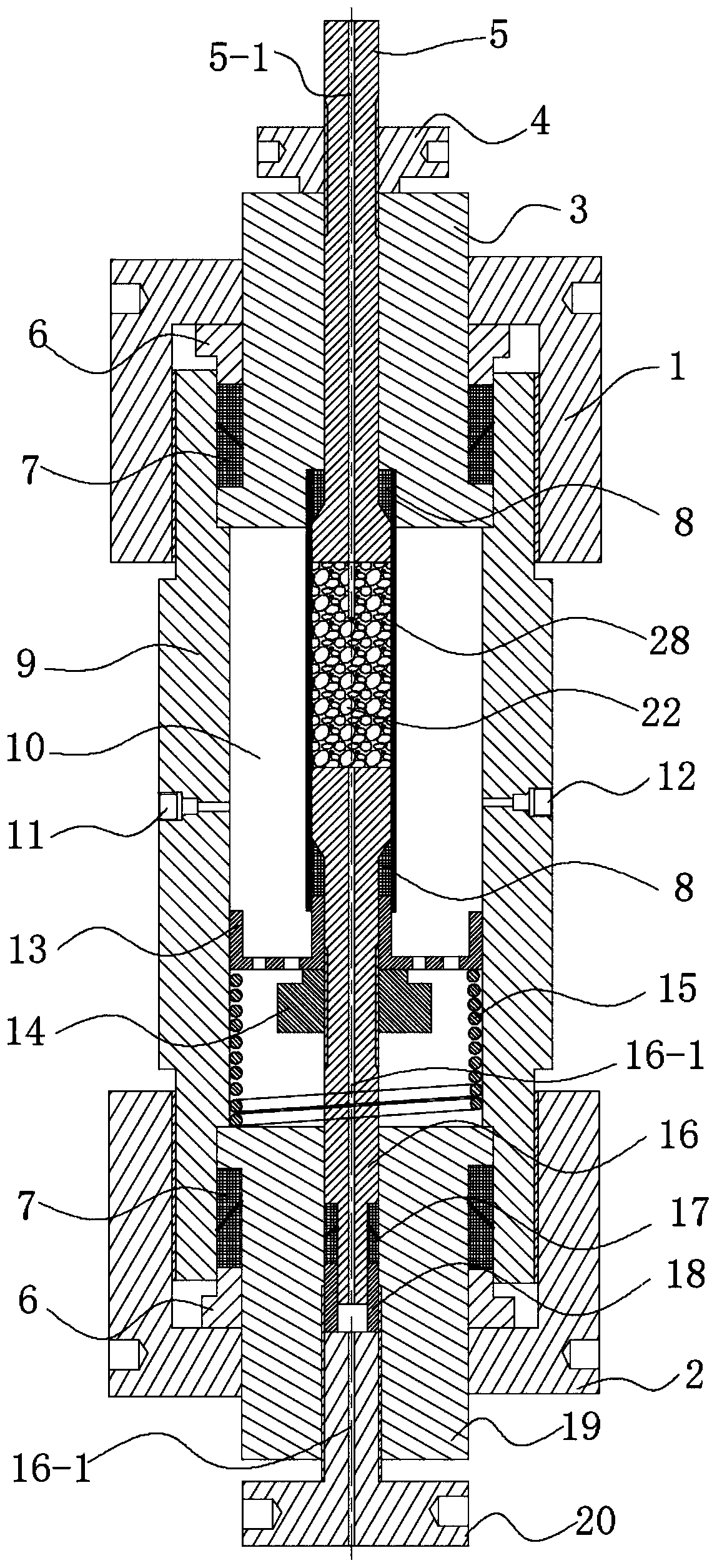

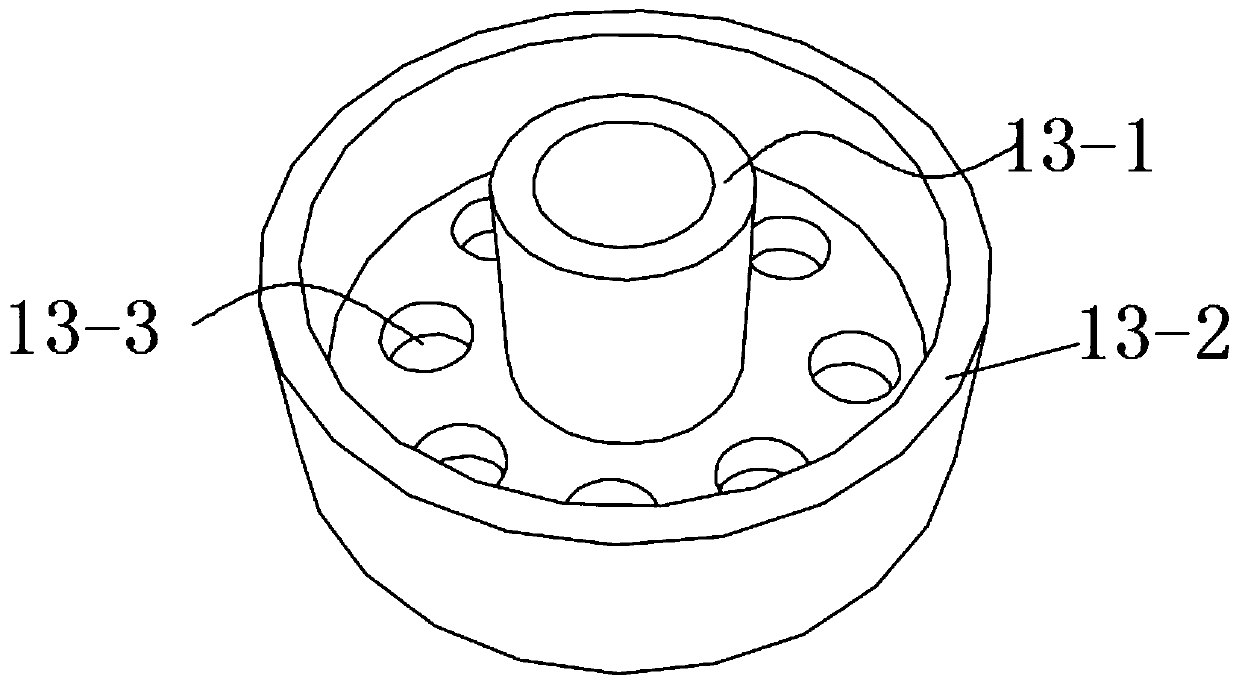

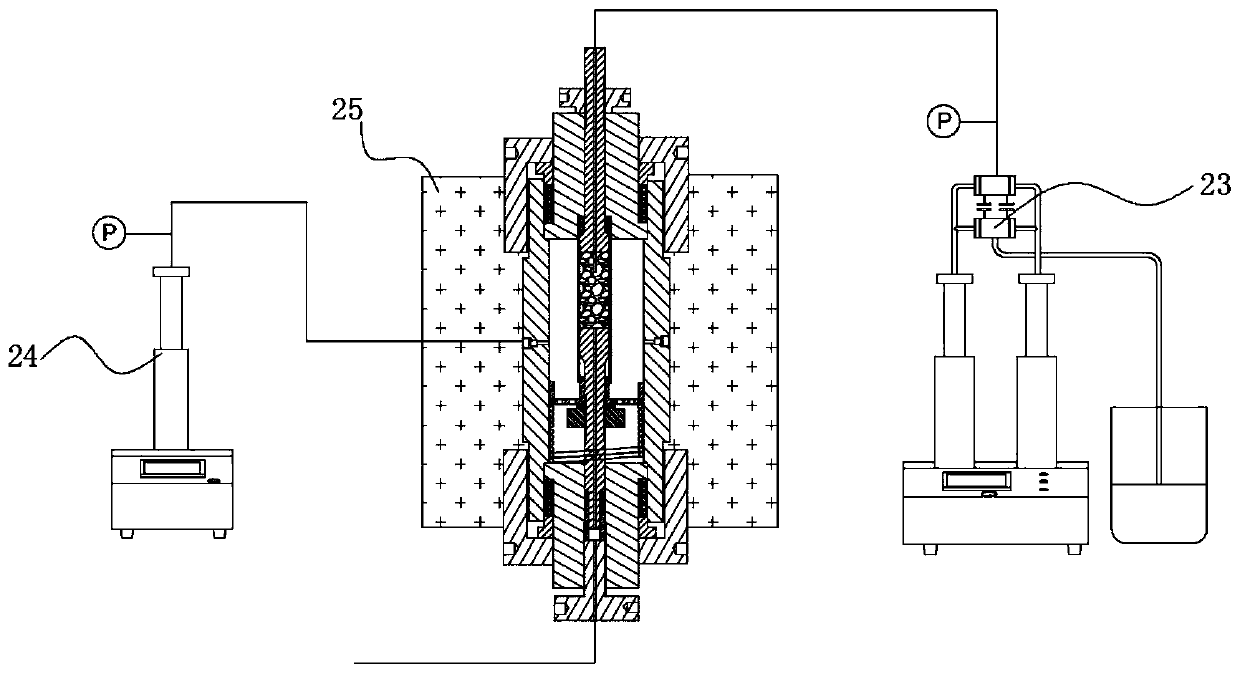

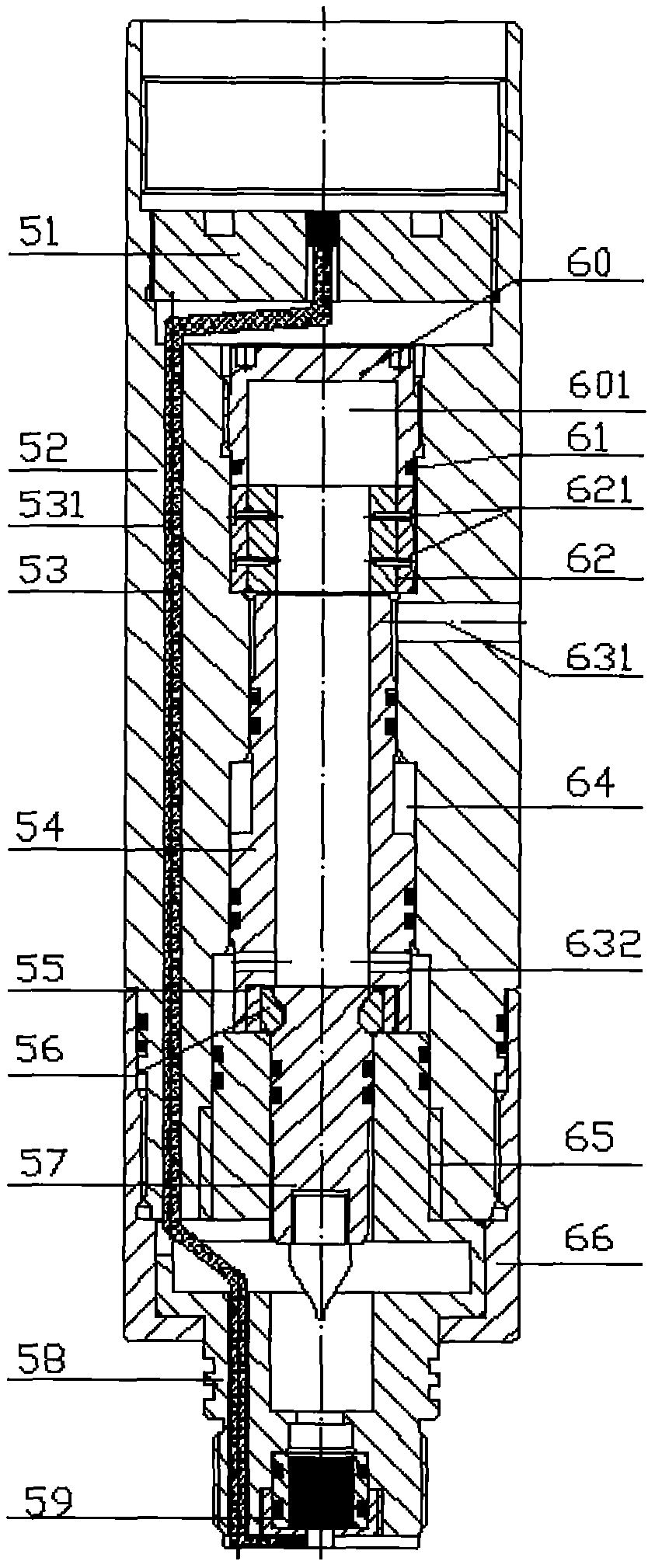

High-temperature and high-pressure hydrofracturing clamp holder and test method thereof

PendingCN109870349AImprove test success rateEasy to operateMaterial strength using tensile/compressive forcesEngineeringHigh pressure

The invention discloses a high-temperature and high-pressure hydrofracturing clamp holder and a test method thereof. The high-temperature and high-pressure hydrofracturing clamp holder comprises a test barrel, a barrel upper mounting part, a barrel lower mounting part and a barrel inner mounting part. A hydrofracturing test can be carried out for a small rock sample; a single test can be carried out by one person; the operation is convenient; the test success rate is high; and the single test cost is relatively low. The clamp holder has five seal designs in total, so that test failure caused by liquid leakage in a test process can be effectively avoided; seal parts are sealed in a related part compressing mode, and in a heating process or the test process, the seal parts can be continuously compressed; and a seal pre-tightening force application and provision part is specially designed in the barrel inner mounting part, so that expansion force after heating of the part in the test process can be resisted, research on a fracture mechanical behavior of a high-temperature and high-pressure rock mass under a thermal-mechanical coupling effect is facilitated, and theoretical basis and guidance can be provided for construction engineering of reservoir layers in high-temperature rock mass geothermal exploitation engineering.

Owner:CHINA UNIV OF MINING & TECH

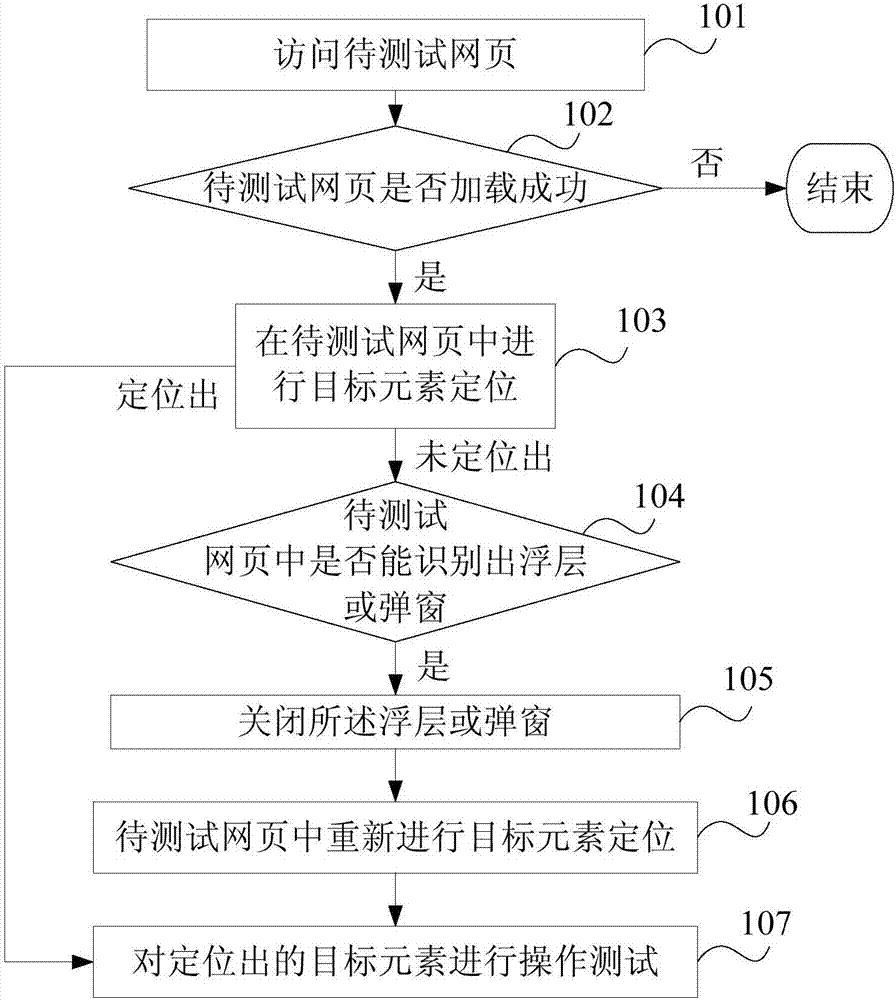

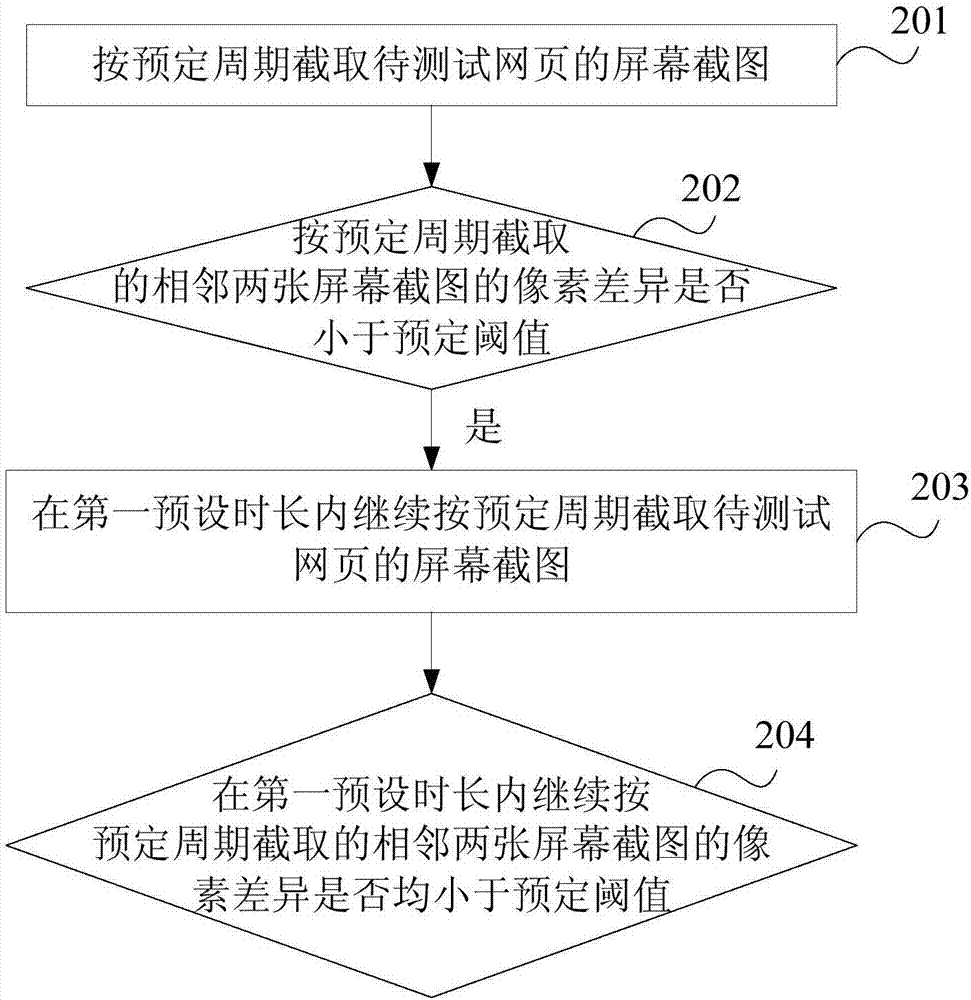

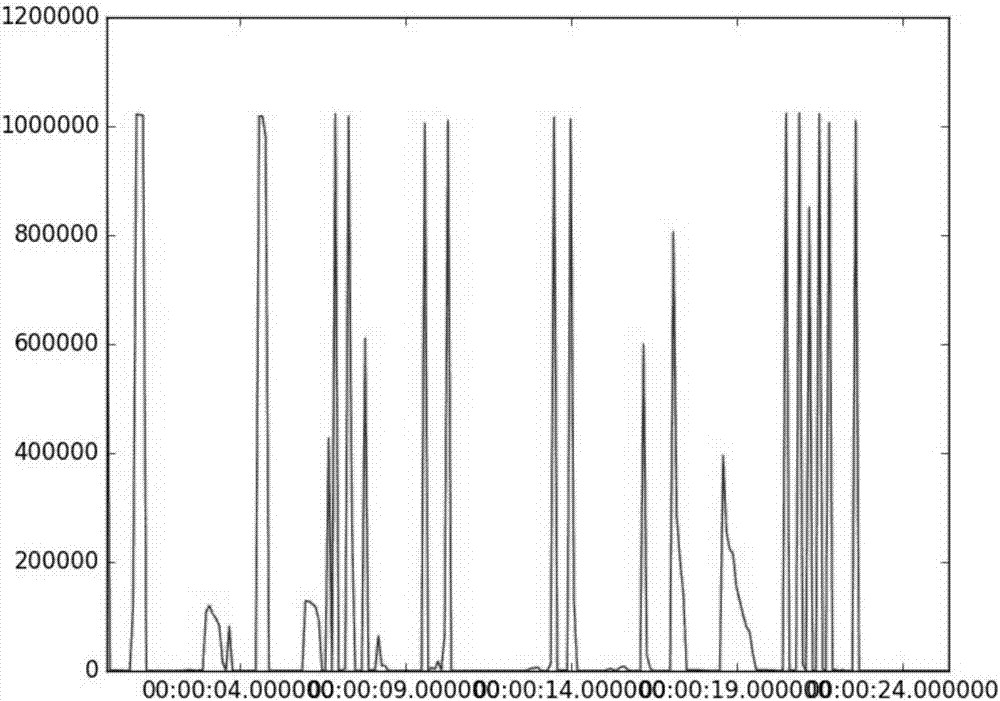

Web automation testing method and electronic device

InactiveCN107239397ATroubleshoot non-functional failuresImprove test success rateSoftware testing/debuggingComputer hardwareOperational system

The embodiment of the invention discloses a Web automation testing method and an electronic device, and relates to the field of automation testing. The web automation testing method promotes the success rate of Web testing execution. The testing method comprises the steps that a web page to be tested is accessed, whether or not the loading of the web page to be tested is successful is judged, if the loading of the web page to be tested is successful, the positioning of a target element is conducted on the web page to be tested; if the target element is not located, whether or not the presence of a floating layer or a popup window is in the web page to be tested is judged, if the floating layer or the popup window is present in the web page to be tested, after the floating layer or the popup window is closed, the positioning of the target element is re-conducted in the web page to be tested; if the target element is located again from the web page to be tested, an operational test is conducted on the target element. The Web automation testing method is applied to webpage testing in various operating systems.

Owner:BEIJING WEIYING TIMES TECH CO LTD

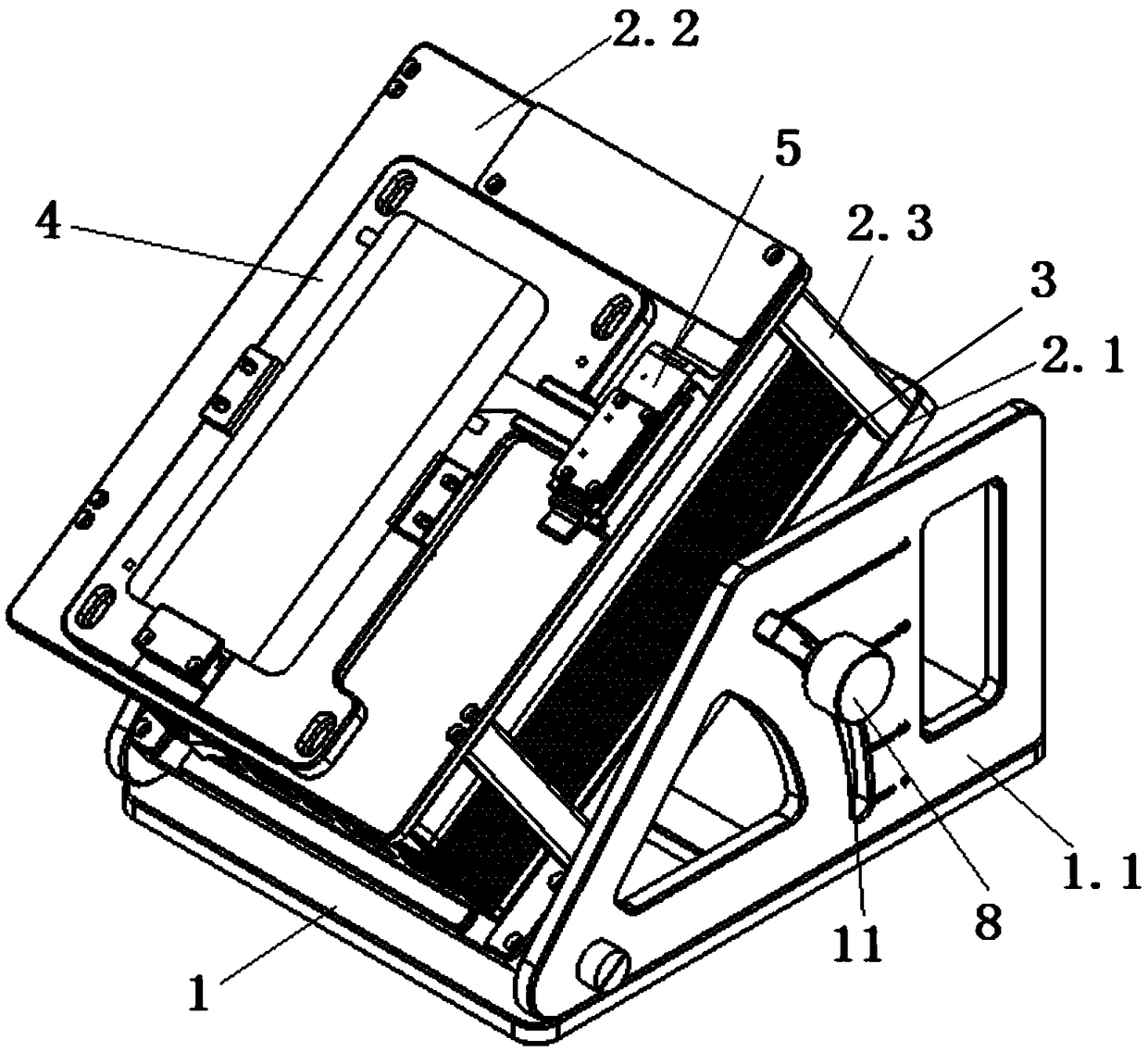

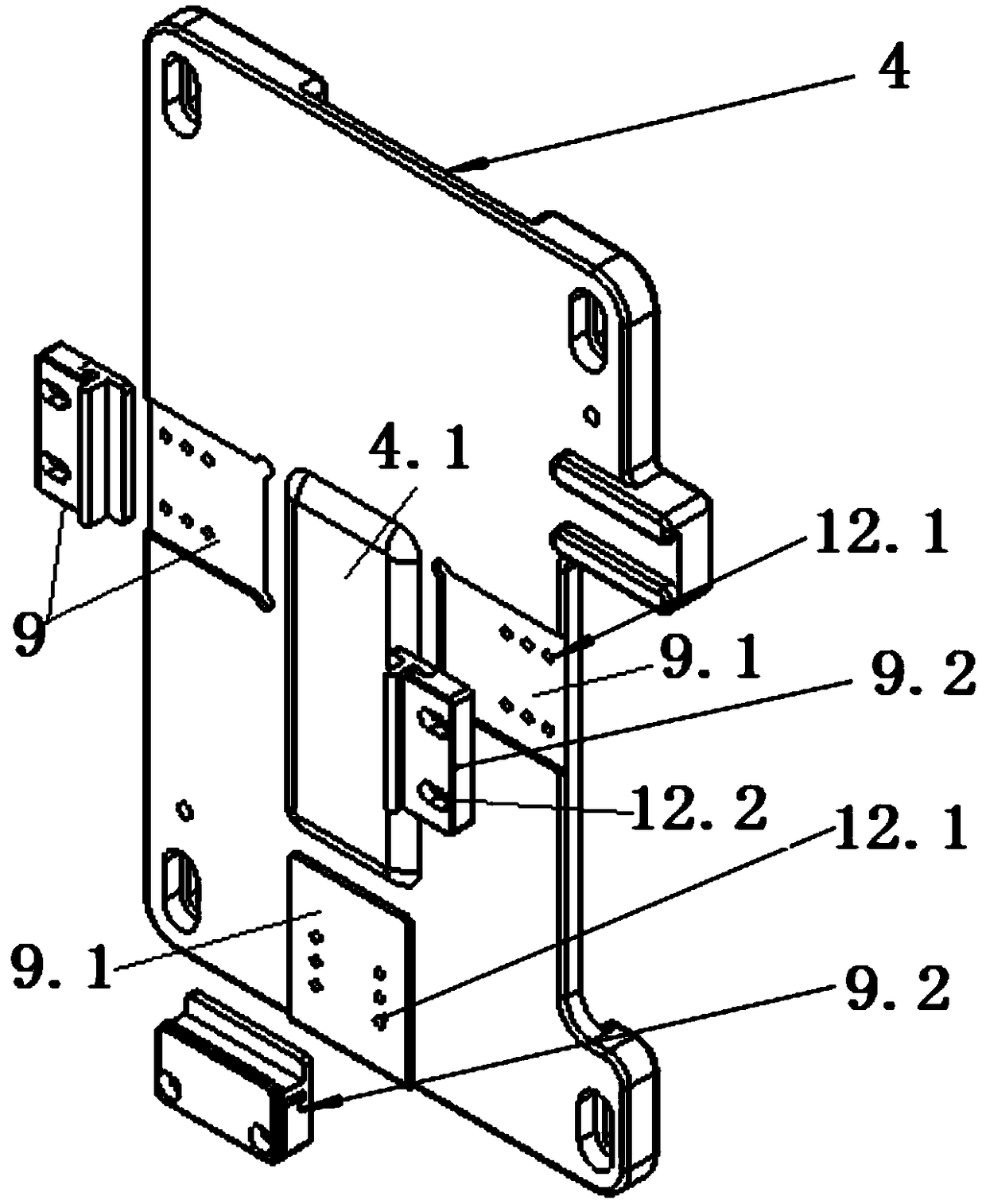

Portable angle-adjustable type electronic screen test fixture

PendingCN108776400AEasy to fixEffective positioning fixedElectrical testingNon-linear opticsEngineeringElectrical and Electronics engineering

The invention discloses a portable angle-adjustable type electronic screen test fixture. The portable angle-adjustable type electronic screen test fixture comprises a mounting seat and a rack, whereinthe rack is hinged with the mounting seat through a hinged shaft; an angle adjusting device is arranged between the mounting seat and the rack; a PG test box, a carrier and a POGO conduction device are arranged on the rack; the PG test box is electrically connected with the POGO conduction device; the carrier is of an integrated plate-shaped structure; a support boss and limiting structures are arranged on one side surface of the carrier; the limiting structures are arranged on the periphery of the support boss; each limiting structure comprises a guiding groove formed in the surface of the carrier and a limiting block connected into the guiding groove in a sliding fit manner, and the limiting block is connected with the carrier through a positioning structure. The fixture is simple in structure and convenient to carry, and can be applicable to lighting tests of electronic screens with various sizes on the premise that the carrier is not replaced integrally.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

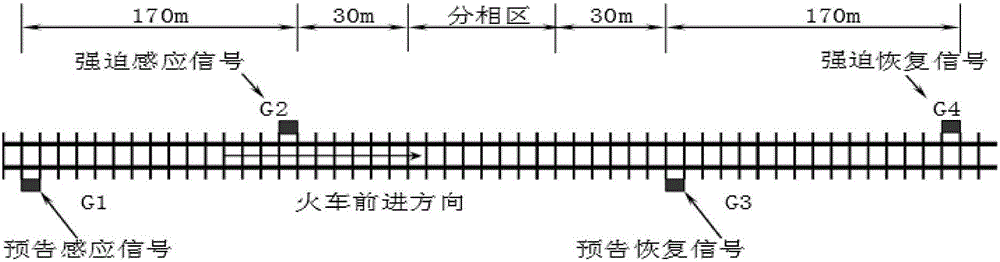

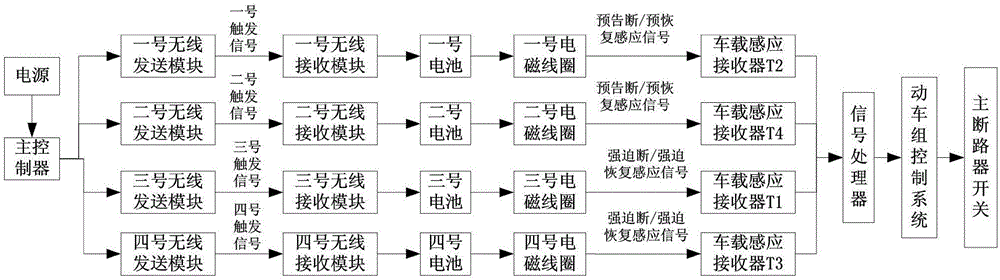

Motor train unit neutral section passing system dynamic simulation testing system and testing method

ActiveCN106556757ASimple test methodEasy to operateTesting electric installations on transportRailroad industrySystem testing

The invention discloses a motor train unit neutral section passing system dynamic simulation testing system and testing method, and belongs to the field of railroad industry automatic neutral section passing system testing technology. The system includes a control apparatus, a triggering apparatus and 4 U-shaped fixing racks. The control apparatus includes a power supply, a master controller, a No.1 wireless transmitting module, a No.2 wireless transmitting module, a No.3 wireless transmitting module and a No.4 wireless transmitting module. The triggering apparatus includes a No.1 triggering apparatus, a No.2 triggering apparatus, a No.3 triggering apparatus and a No.4 triggering apparatus. Each triggering apparatus is mounted at a corresponding onboard sensing receiver through one U-shaped fixing rack. According to the invention, the system can conduct neutral section passing test on any region of a railway line, is no longer restricted by the conditions of the railway line, and can finish the dynamic neutral section passing test. The testing method is simple and easy to operate, has a success rate as high as 100 percent, and has low cost.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

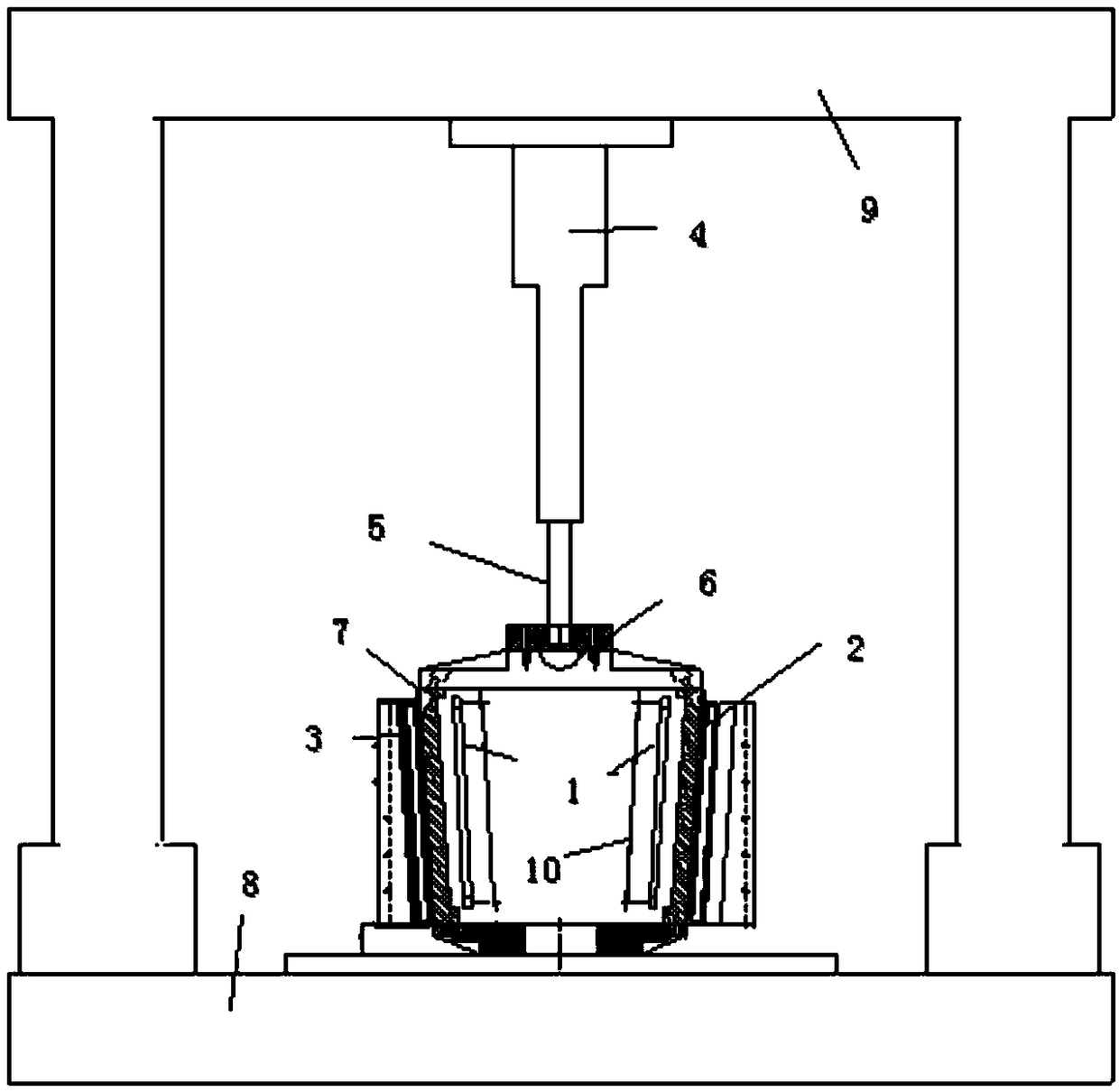

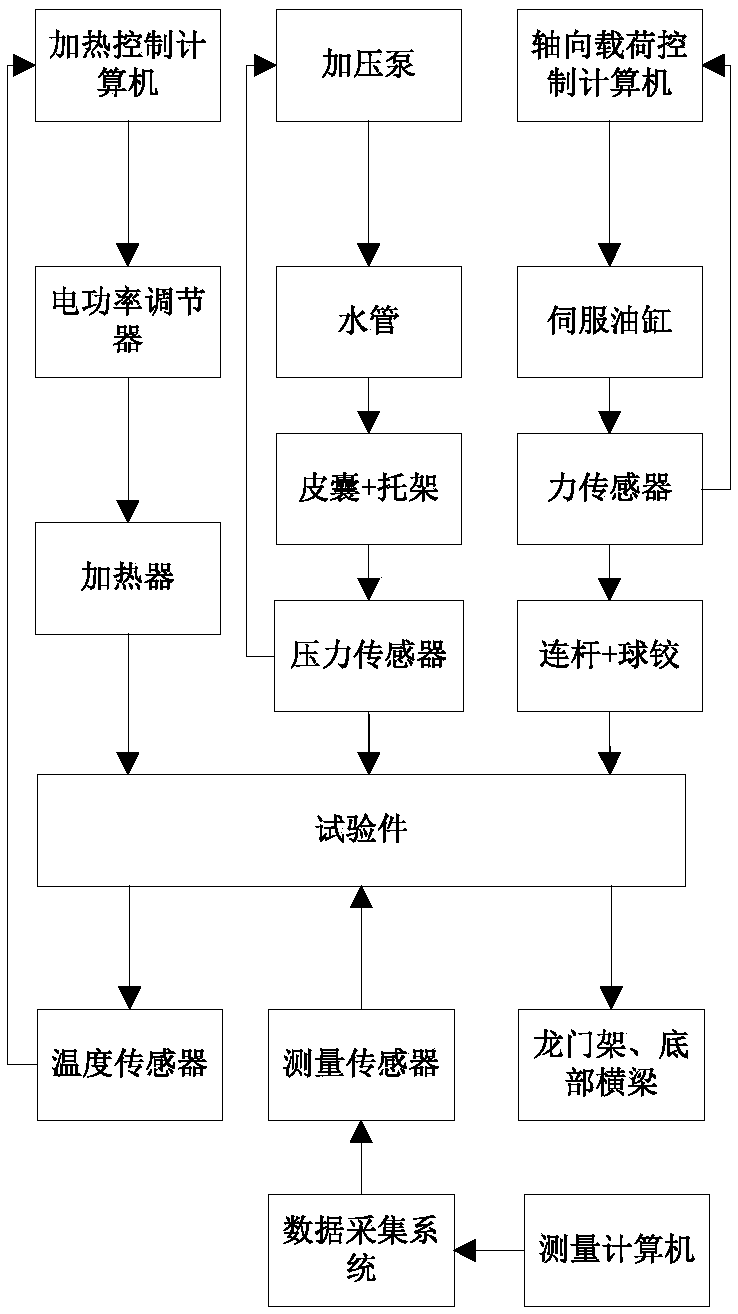

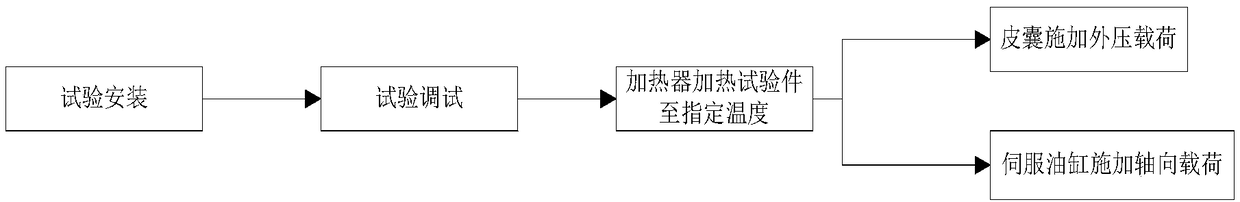

Structural thermal external pressure test system of aircraft cabin sections and method thereof

InactiveCN108918582AImprove test success rateShorten the preparation cycleMaterial heat developmentMaterial strength using tensile/compressive forcesHinge angleExternal pressure

The invention discloses a structural thermal external pressure test system of aircraft cabin sections. The structural thermal external pressure test system comprises a thermal load loading system, anexternal pressure loading system and an axial loading system, wherein the thermal load loading system comprises a heater for heating a test part; the external pressure loading system comprises a leather bag; the shape of the leather bag is as same as that of the outer wall of the test part; the leather bag is coated on the periphery of the test part according to the shape; liquid is added into theleather bag so as to control the pressure; the axial loading system comprises a servo oil cylinder, a connection rod and a spherical hinge; the servo oil cylinder is fixed above the test part; one end of the connection rod is connected with the servo oil cylinder; the other end of the connection rod is connected with the spherical hinge; the servo oil cylinder is started to drive the connection rod move up or down so as to drive the spherical hinge to axially apply axial tension or pressure to the direction of the test part. Through the structural thermal external pressure test system and themethod thereof, the problem of applying the thermal load, the axial tensile load and the external pressure load to the test part when carrying out thermal external pressure test and especially applying the axial tensile load when applying the thermal load and the external pressure load is solved.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

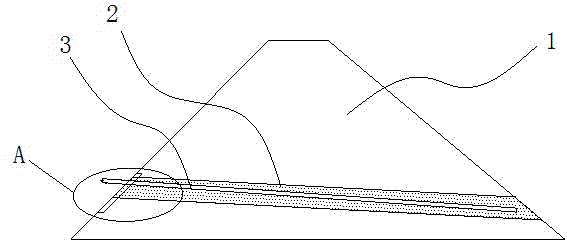

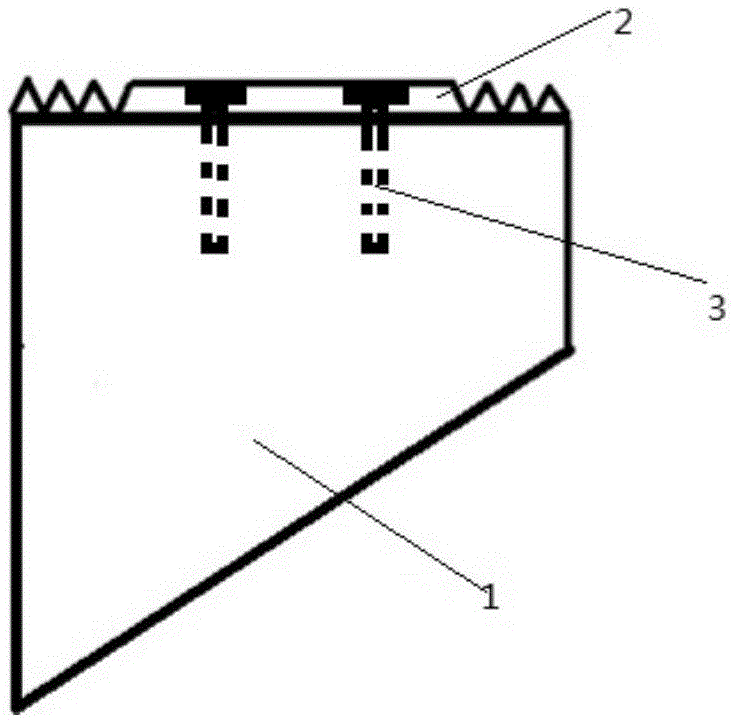

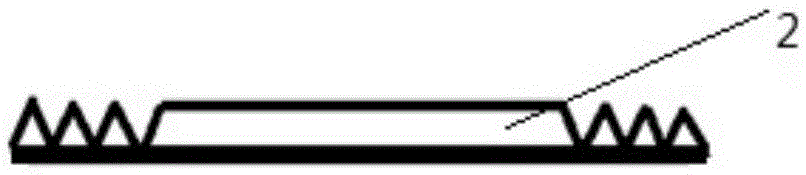

Earth and rockfill dam for simulating piping dam break test

The invention relates to an earth and rockfill dam for simulating a piping dam break test. The earth and rockfill dam comprises a dam body which is built by rock materials, wherein a weak layer capable of generating a piping channel is laid at a set position of the dam body according to the test requirement; a water pipe which penetrates through the dam body is arranged in the weak layer; through holes which are distributed along the axial direction at intervals are formed in a pipe wall of the water pipe; and the water pipe which is positioned at the upstream end of the dam body is provided with a valve. During test, water is injected into the water pipe so as to wash the weak layer, so that the formation of piping channel inside the dam body is simulated and accelerated. The field piping test development time can be controlled, and the phenomena that the field test fails even an unexpected sudden dam break event occurs and losses of life and property are caused because the piping channel formation time cannot be controlled are avoided.

Owner:NANJING HYDRAULIC RES INST

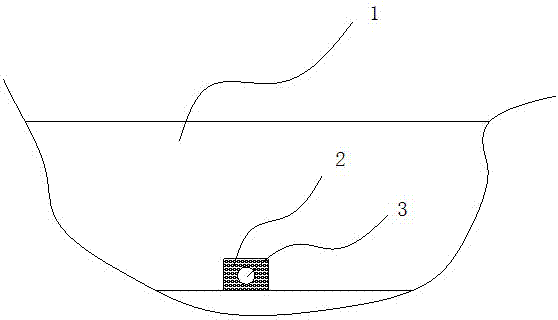

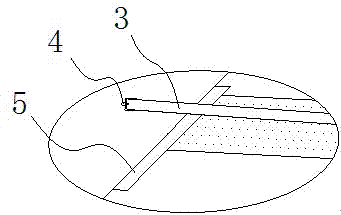

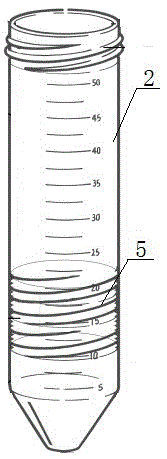

Density gradient centrifugal tube with position-adjustable porous diaphragm and application of centrifugal tube

ActiveCN105567556AAvoid premixingAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCentrifugal separation

The invention provides a density gradient centrifugal tube with a position-adjustable porous diaphragm. The density gradient centrifugal tube comprises a centrifugal tube body, a centrifugal tube cover is arranged at the upper end of the centrifugal tube body, a diaphragm layer is arranged in the centrifugal tube body, an internal thread is formed in the inner wall of the centrifugal tube body, an external thread is formed in the outer wall of the diaphragm layer, the internal thread of the centrifugal tube body is matched with the external thread of the diaphragm layer, and multiple small pores are formed in the diaphragm layer. The centrifugal tube is divided into the portion for containing a separating solution and the portion for being added with a sample to be detected through the diaphragm layer, premixing of the sample and the separating solution is effectively avoided, sample pollution caused during centrifuging and sampling is reduced, and the quality of centrifugal separation is greatly improved; meanwhile, a diaphragm layer rotary knob can be made to adjust the diaphragm layer up and down according to differences of the types and volumes of samples to be treated, so that optimal separation solution volume exists at the lower end of the diaphragm layer, and the application range is widened.

Owner:武汉海吉力生物科技有限公司

Earth and rockfill dam piping burst field test method

ActiveCN103114553AIntegrity guaranteedImprove test success rateEarth-fill damsHydraulic modelsEngineeringDam break

The invention relates to an earth and rockfill dam piping burst process field test method. According to the method, a weak layer is preset in a dam body, a porous pipe is buried in the weak layer to form a piping channel, and the dam is facilitated to form piping burst. According to the method, the phenomenon that a stable seepage channel cannot be formed in the dam and the piping burst cannot be formed is effectively avoided during test, and the phenomena that the field test fails even an unexpected sudden dam break event occurs and losses of life and property are caused because the piping channel formation time cannot be controlled are avoided. The test success rate is improved, and complete test data is ensured. According to the related method, the field piping test development time can be controlled, and the method has important values for improving the large-scale field piping test success rate and mastering the earth and rockfill dam piping burst mechanism and has important significance for pushing the development of the domestic dam break hydraulics discipline.

Owner:NANJING HYDRAULIC RES INST

Automated testing system of freezing point, melting point or crystallization point

InactiveCN106814099ARealize automated detectionImprove test success rateMaterial crystallisationInvestigating phase/state changePlatinumData display

The invention discloses an automated testing system of a freezing point, a melting point or a crystallization point, comprising a heat insulation sleeve pipe, an air sleeve pipe, a sample filling test pipe, a platinum resistor temperature sensor, a collecting card, a temperature data display instrument and a PC terminal; the air sleeve pipe is arranged at the inner part of the heat insulation sleeve pipe; the sample filling test pipe is inserted to the air sleeve pipe; the platinum resistor temperature sensor is inserted to the sample filling test pipe; the collecting card is connected with the platinum resistor temperature sensor; the a temperature data display instrument is connected with the collecting card; the PC terminal is connected with the a temperature data display instrument. The system realizes the automatic detection of the freezing point (crystallization point and melting point) test; the test success rate is improved from 70% to 100%; two samples can be detected synchronously by one person, the analysis efficiency is improved by over 1 time, thereby providing technical support for releasing the contradiction between the saturated detection task and the intense human resource; meanwhile, the system removes the artificial bias of temperature collection; the measurement result uncertainty is better than the manual analysis; the measurement accuracy is improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

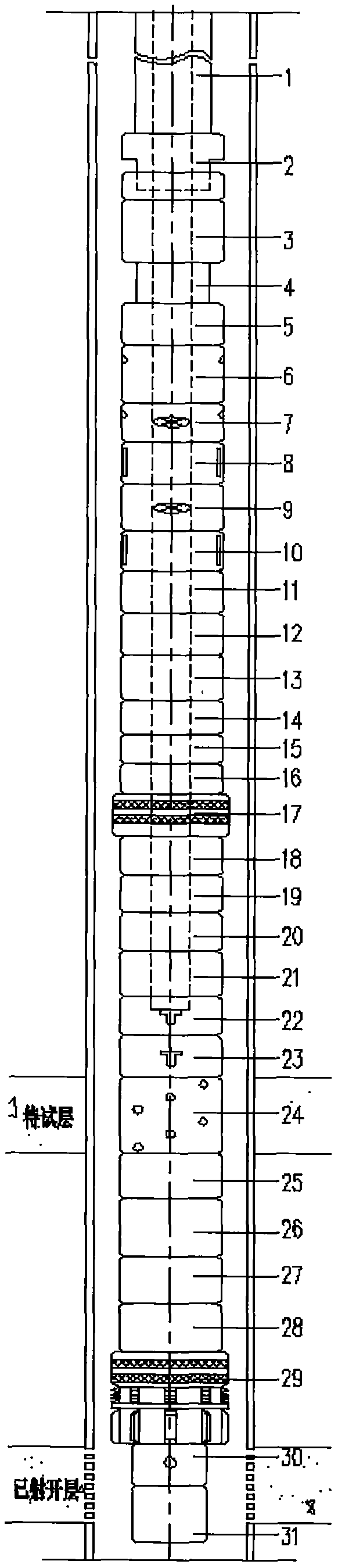

Full-bore straddling perforation-test combination tubular column and operating method thereof

ActiveCN109083625AReduced Chances of ContaminationConducive to obtaining complete and accurate formation parametersSurveyFluid removalEngineeringHigh pressure

The invention provides an efficient, reliable and multifunctional full-bore straddling perforation-test combination tubular column and an operating method thereof aiming at the situation that perforated well opening sections exist below a to-be-tested oil layer. The tubular column is provided with a full-bore straddling perforation part, a JJ-1 carrier, an RD sampler and other multiple tool systems, straddling perforation, testing, reservoir transformation, testing after transformation and other technology combinations can be conducted, testing before and after transformation, JJ-1 well testing, calculation of production volume and sampling are conducted, and stratum parameters are fully and precisely obtained; besides, on the premise that a decompression cavity is reserved, two ignition modes of bar dropping ignition and parallel explosion-propagation pressure delay ignition are simultaneously set for the tubular column above a perforating gun, the damage of instantaneous high pressure of perforations to down-hole instruments and apparatuses can also be reduced, and fishing, bar dropping and other complicated work after bar dropping ignition fails can also be avoided. By means ofthe technology, the technological process can be simplified, the labor intensity is lowered, the construction period is saved, the construction efficiency is improved, and the success rate is increased.

Owner:营口市双龙射孔器材有限公司

Treatment method for preventing fracture melting of tensile sample

ActiveCN105651617APrevent fracture meltingChange the situation of frequent meltingMaterial strength using tensile/compressive forcesHigh resistanceNeck parts

The invention relates to a treatment method for preventing fracture melting of a tensile sample, in particular to a high-temperature plate and strip tensile test performed on a thermal simulation test machine. The treatment method comprises the following steps: sleeving a thermocouple wire with a quartz tube for protection; arranging a set of fixture at the two ends of the plate and strip tensile sample respectively; starting tension under a protection atmosphere; when a necking part occurs on the sample and a power angle fluctuation range delta is greater than 30 degrees, turning a thermal button off to manually stop a heating loop; meanwhile, manually controlling a stroke to tension the sample until breaking. According to the treatment method, power-off treatment is performed when the sample is fractured, so that the phenomenon that topographic characteristics cannot be observed due to fracture melting of the sample caused by a large amount of Joule heat generated at a high-resistance moment in the case of fracture of the sample is prevented, the situation of frequent fracture melting of the sample under a high-temperature condition in an original test is changed, the test success rate is increased, the test cost is lowered, and operation is easy, convenient and feasible.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

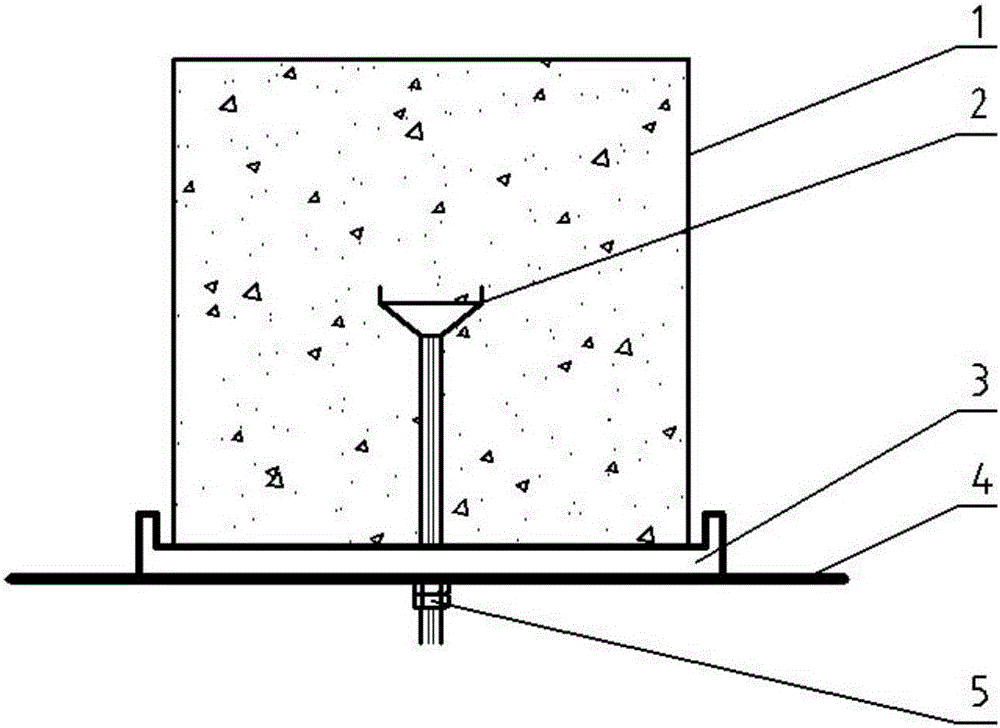

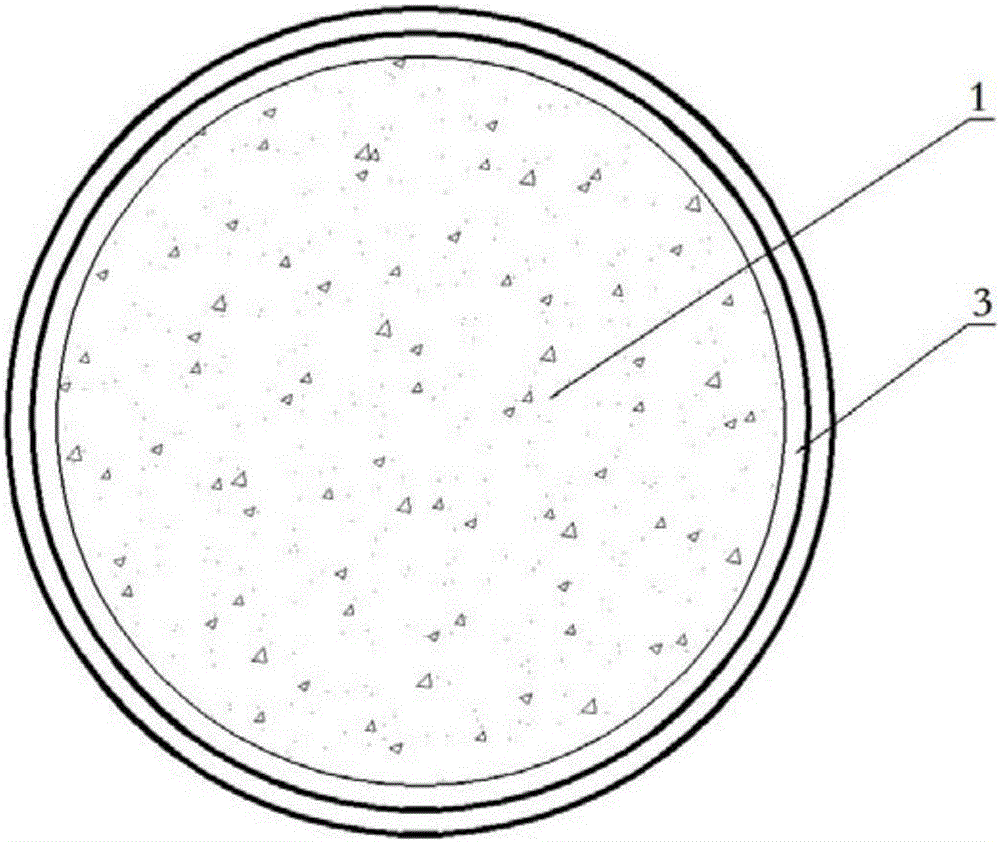

Concrete impermeability test method and test apparatus thereof

InactiveCN105910970AImprove sealingOmit sealing procedurePermeability/surface area analysisEngineeringTested time

The invention provides a concrete impermeability test method and a test apparatus thereof. The test method comprises the following steps: fixedly connecting one end of a pre-embedded pressure leading tube with a concrete sample through pouring, connecting the other end of the pre-embedded pressure leading tube with a water tube, allowing pressure water to go through the pre-embedded pressure leading tube and to enter test concrete, and determining the water pressure of the water tube, which is the test pressure, when water infiltrates from the periphery of the concrete sample. The invention also relates to the concrete impermeability test apparatus. The method and the apparatus are adopted to carry out concrete sample impermeability test without sealing the sample, so the problem of difficult sealing between the sample and a frame test mold in the concrete sample impermeability test process is solved, the success rate of impermeability tests is improved, the operating flow is simplified, the test time is shortened, the water seepage path is visually reflected, and the practicality of an impermeability tester in engineering is improved.

Owner:黄显彬

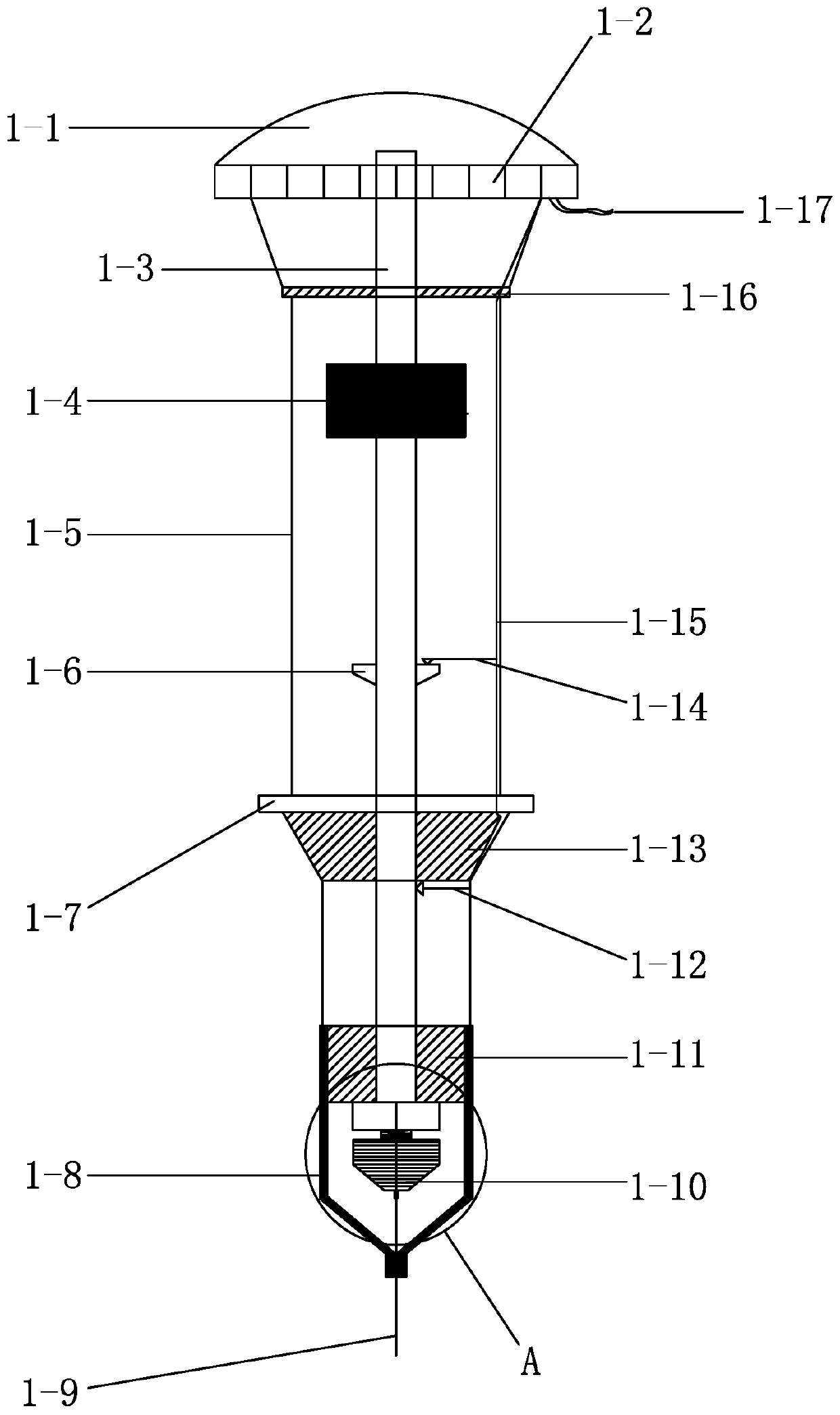

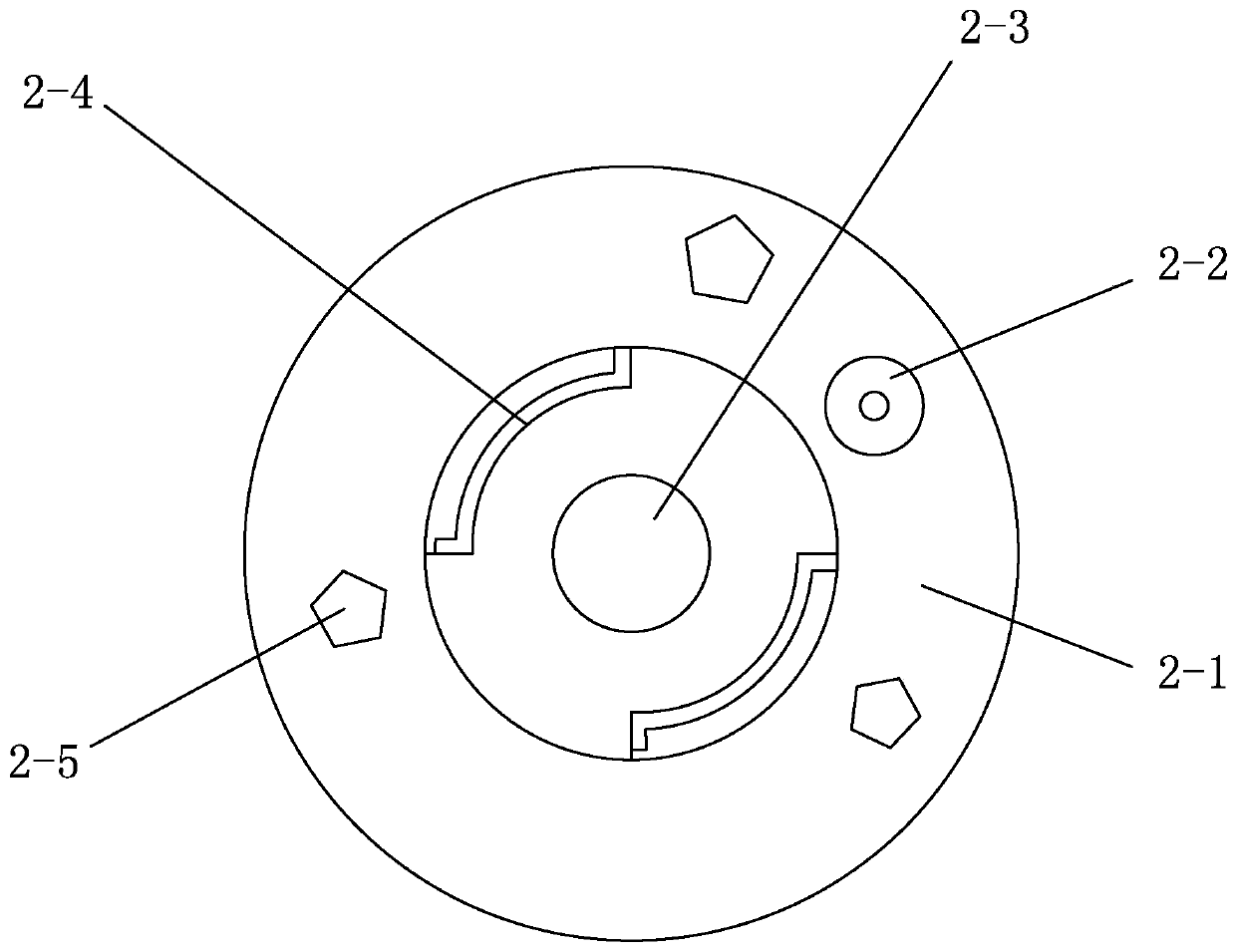

Whole pass sampling tester

InactiveCN101126315AEasy to operateFlexible and reliable operationBorehole/well accessoriesTime delaysChoked flow

The invention relates to a testing and sampling tool used in well of the oilfield, specifically speaking, an all-size sampling tester which comprises a sampling mechanism, an inversion mechanism, a time-delay mechanism and a ball valve mechanism. The ball valve mechanism is connected with the lower end of a mandrel; the sampling mechanism, the inversion mechanism and the time-delay mechanism are sequentially from top to bottom sleeved at the outer side of the mandrel, the mechanisms are all sequentially connected with each other, the mandrel can move up and down in each mechanism to actuate the switch of the ball valve mechanism. The invention can realize the operation and control on the switch and sampling of the ball valve of the downhole tool under the actuation of the up-down movement of a drill stem or an oil tube. the operation is convenient and the actuation is flexible and reliable; the invention adopts the large-size, large-flow and all-size design and can resist high pressure, which can effectively avoid the choked flow, enlarges the operation scope of the tool, considerably improves the utilization ratio of the tool and the success rate of the test; the ball valve can be repeatedly opened or closed by raising or lowering the drill stem or the oil tube, and thus a plurality of open flow periods and shut-in pressure survey periods can be obtained.

Owner:刘淑娟

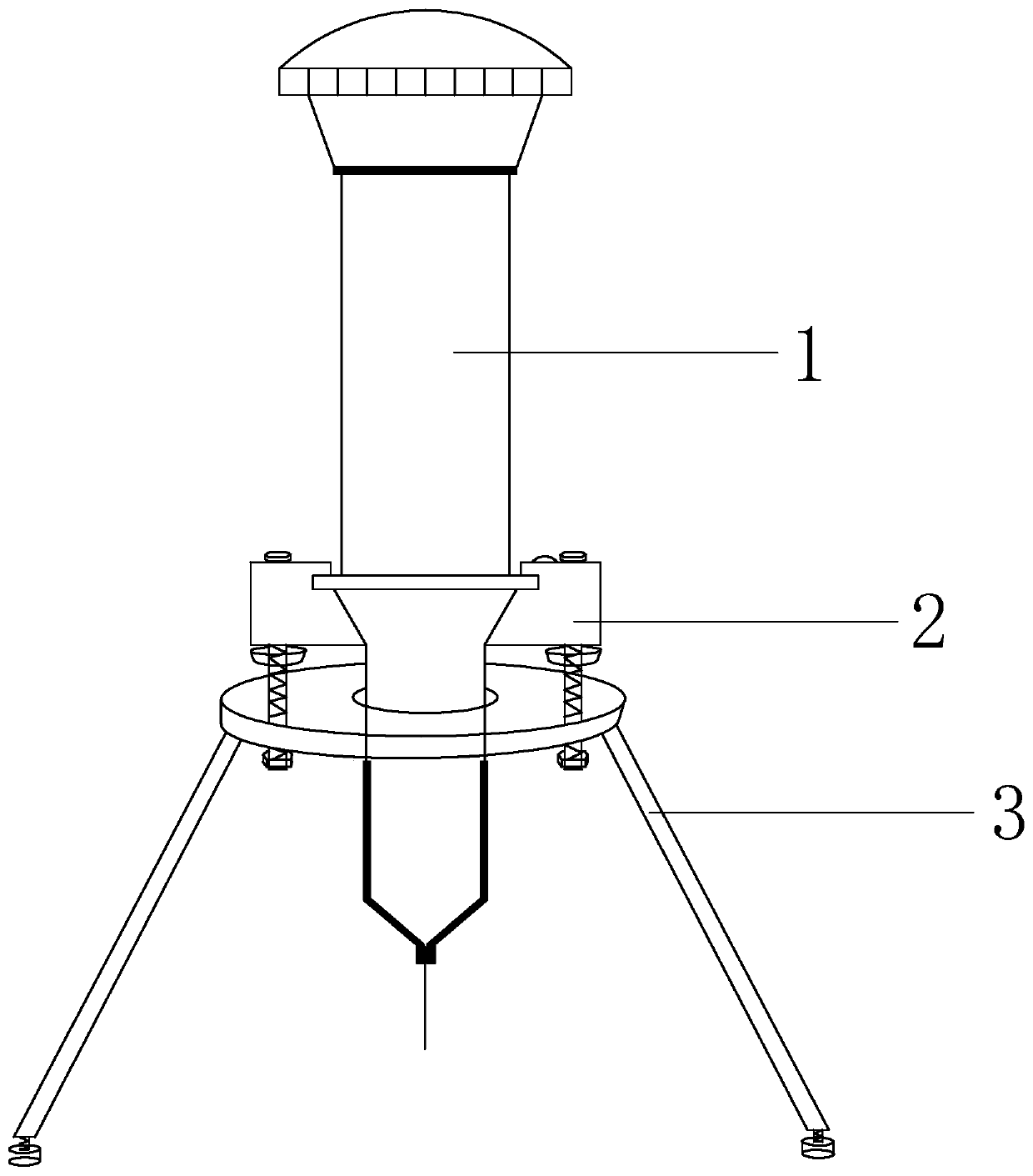

Soft rock strength test needle penetration instrument and use method thereof

PendingCN109708985AEven by forceImprove the leveling effectMaterial strength using repeated/pulsating forcesFree fallingNeedle penetration

The invention, which belongs to the technical field of geotechnical engineering detection, provides a soft rock strength test needle penetration instrument and a use method thereof. The soft rock strength test needle penetration instrument comprises a needle penetration instrument body, a connection buckle and a tripod that are connected. An electromagnetic coil is electrified; a center penetration hammer moves upward under the effect of the electromagnetic field to accumulate potential energy; after power interruption, the center penetration hammer makes free falling body movement and the potential energy is converted into kinetic energy, so that the penetration needle is hammered to apply pressures on the soft rock; and the falling distance of the center penetration hammer is controlledbased on the currents and thus the instrument can reach balancing every time in force applying. With a tripod leveling instrument, circular leveling bubble observation is carried out, so that the leveling performance of the instrument in operation is improved; the experimental success rate is further increased; a pressure sensor and a displacement sensor are used for replacing the manual countingmethod of the traditional penetration instrument, so that the result accuracy is improved; with an external device, the hammer number of times of the center penetration hammer is controlled and data are read; and the intelligent degree is increased and data are collected conveniently and precisely.

Owner:YANGZHOU UNIV

Horizontal effective ground stress testing method and device

ActiveCN108691536ALow costEasy to implementBorehole/well accessoriesLaser rangingPressure measurement

The invention provides a horizontal effective ground stress testing method. The method is established on the basis of a formula of a plane circular hole displacement elastic solution and a thick-wallcylinder, and the principle of the method is that in-situ ground stress is deduced reversely by restoring hole edge displacement deformation under the action of ground stress. The invention further provides a horizontal effective ground stress testing device. The device comprises a grouting device, a grouting pipe, a drilling sealing element, a drilled hole form and pressure measuring system, a supporting fixing frame, a connecting rod and a computer processing system. The drilled hole form and pressure measuring system comprises a multi-optical-scale phase laser range finder, a motor, a detection shaft, a three-dimensional electronic compass, a pressure sensor and a data integration chip. The computer processing system is connected with the data integration chip through a data line; a drilled hole is perpendicular to the horizontal plane, the grouting pipe is used for making the grouting device communicated with the drilled hole, the drilling form and the pressure measuring system isfixed to the supporting fixing frame through the connecting rod, the axis of the detection shaft coincides with the axis of the drilled hole, and a drilling opening is sealed through the drilling sealing element.

Owner:SICHUAN UNIV

Automatic Dissolved Gas Analyzer in Insulating Oil

ActiveCN105241987BImprove test success rateIncrease success rateComponent separationMotor driveEngineering

The invention relates to an automatic analyzer for dissolved gas in insulating oil. The gas analyzer comprises a degassing mechanism, an autoinjection mechanism, a chromatogram mechanism and a circuit control part, wherein the autoinjection mechanism comprises a degassing disc, a degassing motor, a background light source and a camera, the degassing motor drives the degassing disc to rotate, N vertical syringe mounting through holes are uniformly arranged in the circumference of the upper surface of the degassing disc, and the background light source and the camera are used for detecting the volume of insulating oil in syringes; the autoinjection mechanism comprises a gas feeding motor, a belt, a gas feeding head support, a gas feeding head and a push rod motor, the gas feeding motor drives the gas feeding head support to move up and down via the belt, and the gas feeding head is mounted on the gas feeding head support; and when the degassing disc rotates to a set position, the upper end of a to-be-detected syringe on the degassing disc just corresponds to the gas feeding head, the lower end of the to-be-detected syringe just corresponds to the upper end part of a push rod of the push rod motor, and a hollow syringe needle in the gas feeding head is connected with the chromatogram mechanism. The automatic analyzer has a high automation degree and small errors.

Owner:HENAN ZHONGFEN INSTR

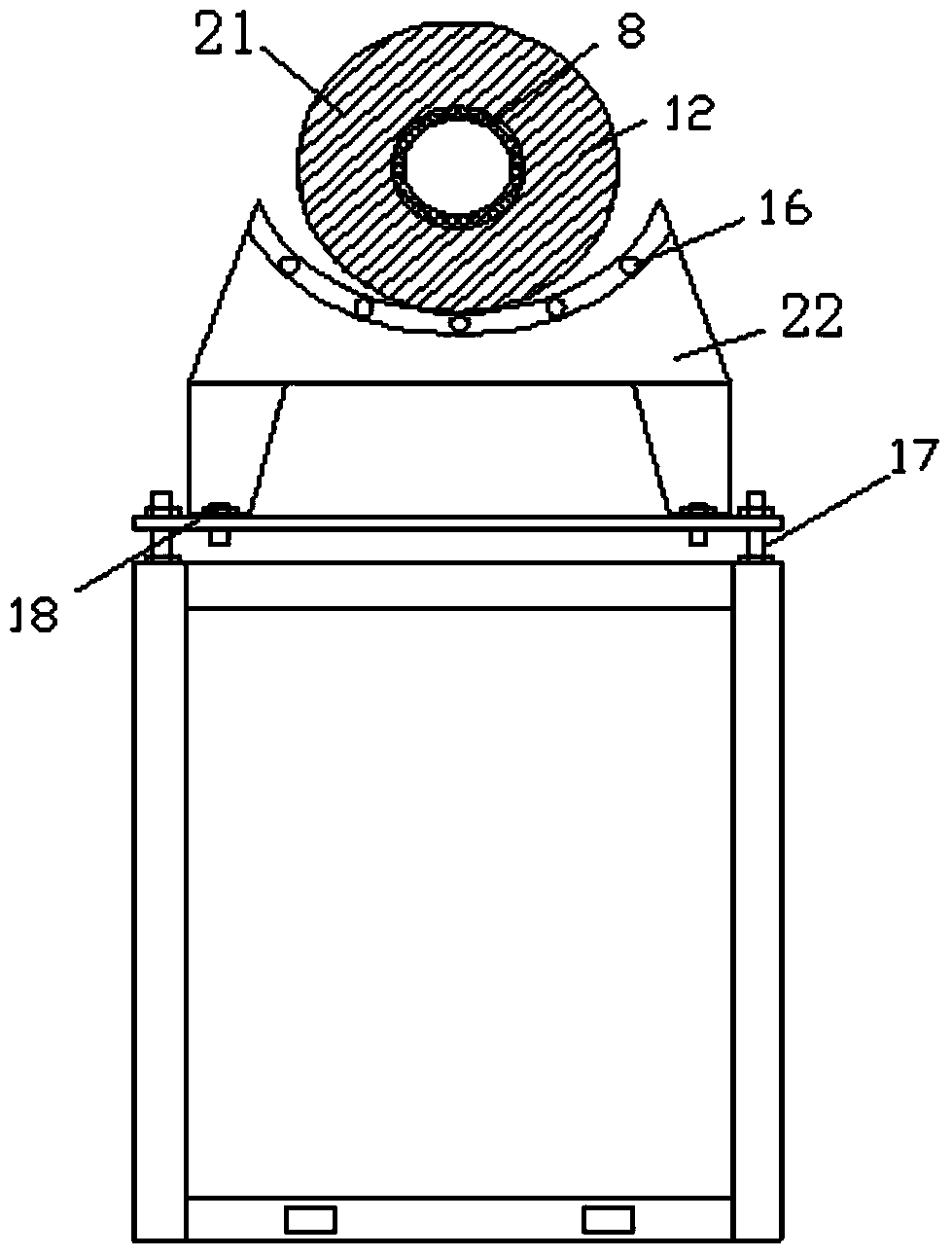

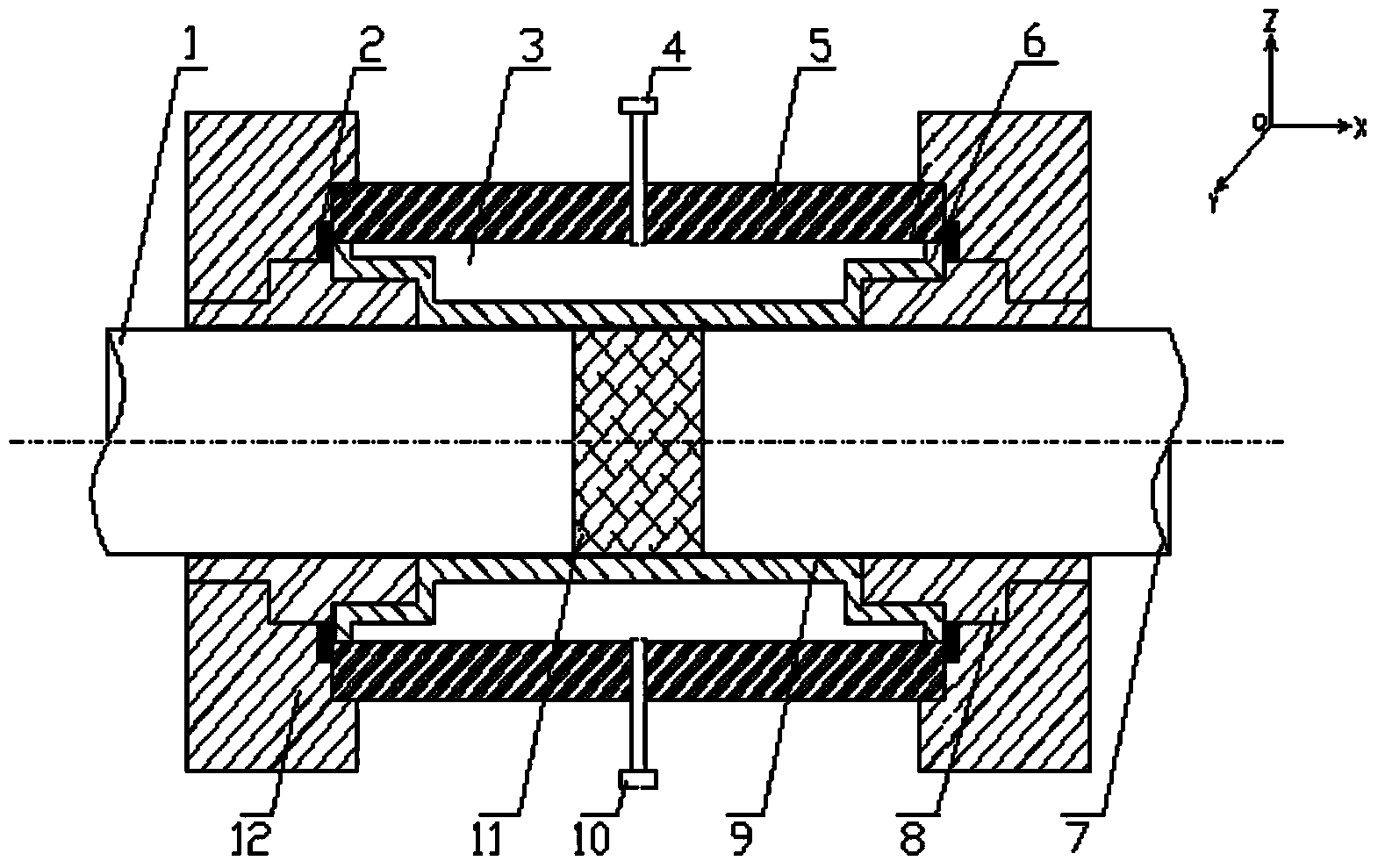

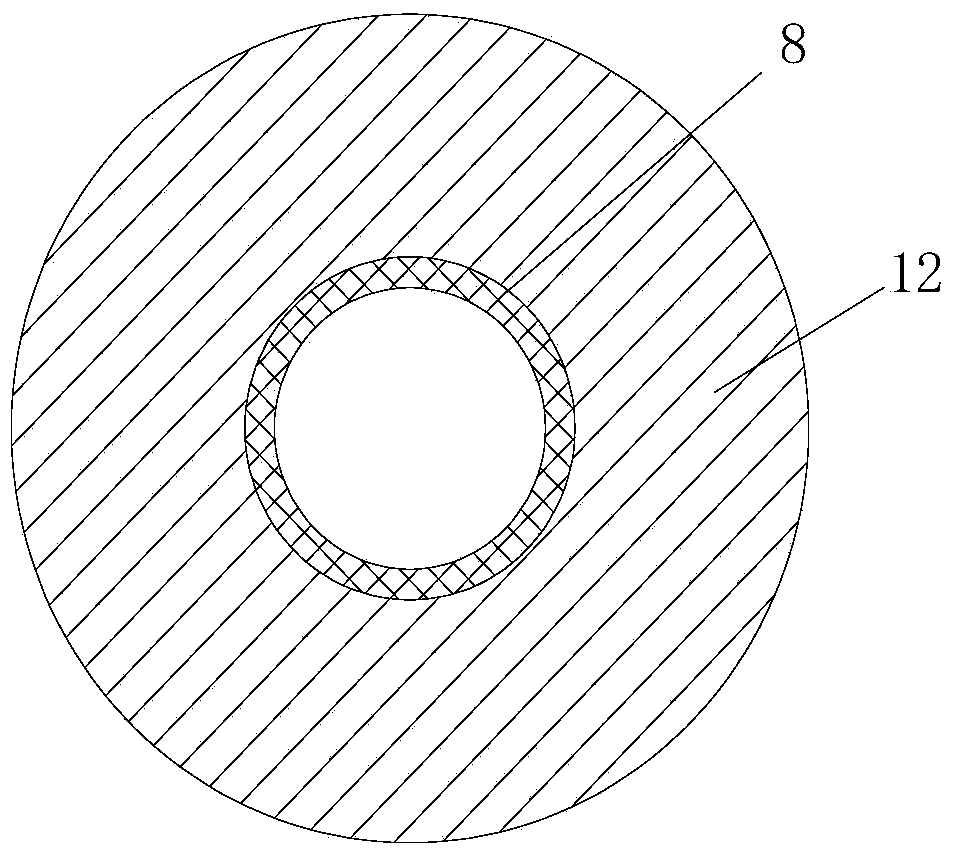

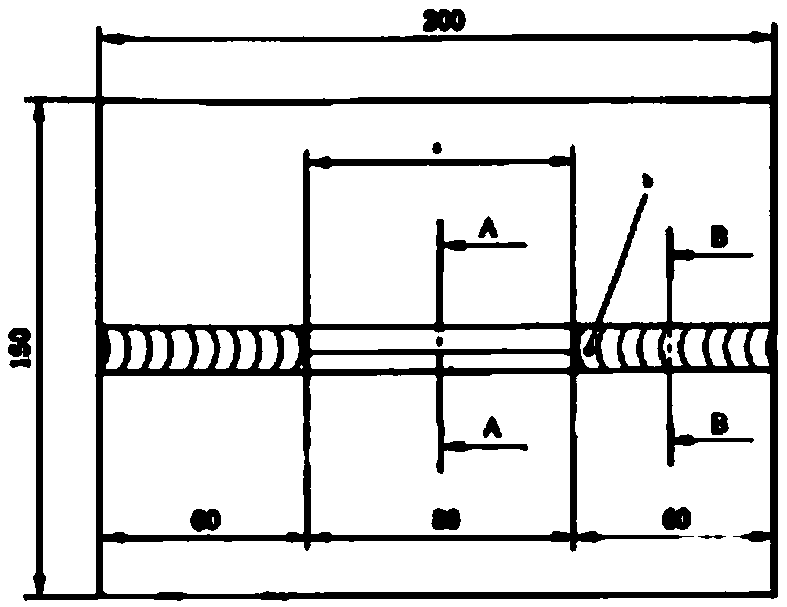

Circumferential pressurizing device for large-diameter Hopkinson pressure bar

InactiveCN103616279AEasy to adjustMeet pressurizationMaterial strength using tensile/compressive forcesEngineeringCylinder block

The invention discloses a circumferential pressurizing device for a large-diameter Hopkinson pressure bar. The circumferential pressurizing device is characterized in that a moving platform is arranged on the upper surface of a bracket and can move along the Z direction and the Y direction. A pressurizing cylinder body is arranged on the upper surface of the moving platform and can move along the X direction. One end of each of two inner bushings is arranged in each inner hole in the two ends of an oil-separating rubber sleeve; the other ends of the two inner bushings are respectively arranged in inner holes of two outer sleeves. The two inner bushings, an oil cylinder and the oil-separated rubber sleeve are fixed tightly by one pair of outer sleeves. A hydraulic oil chamber is formed between the inner surface of the oil cylinder and the outer surface of the oil-separated rubber sleeve. The circumference of the oil cylinder is provided with an oil inlet / pressure meter interface and an exhaust hole. The circumferential pressurizing device disclosed by the invention can be widely applied in indoor static-dynamic combined loading test of the Hopkinson pressure bar made of rock and concrete materials in the fields of civil air-defense engineering, geotechnical engineering and underground engineering and the like, and has the characteristics that the pressure application is accurate and uniform, the stability is high, the positioning of a test piece is accurate, the success ratio of the test is high and the service life is long and the like.

Owner:AIR FORCE UNIV PLA

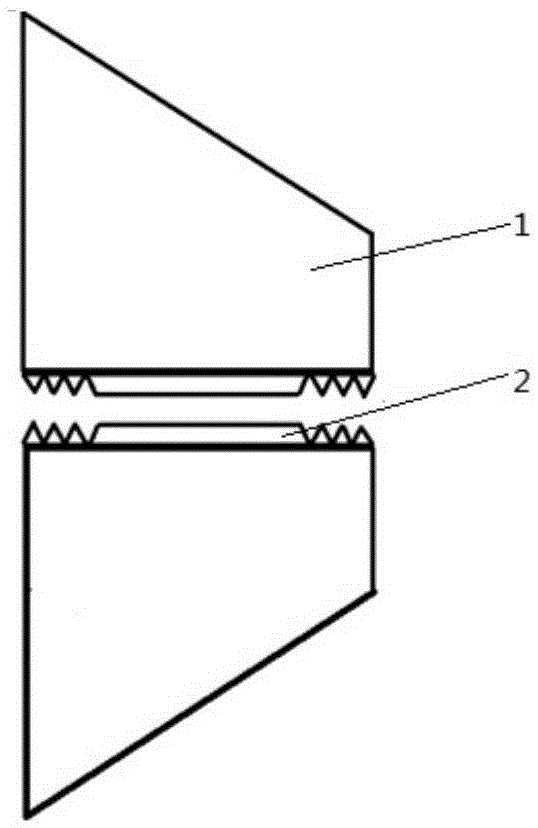

Method for detecting welding cracks of inclined Y-shaped groove

InactiveCN109520858AReduce the risk of oversizingImprove efficiencyPreparing sample for investigationArc welding apparatusEngineeringAssembly structure

The invention relates to a method for detecting welding cracks of an inclined Y-shaped groove. The method comprises the following steps: (1) selecting an appropriate welding material; (2) optimizing processing morphology of the groove; (3) performing preweld cleaning; (4) test piece splicing; (5) welding and restraining the weld joint; (6) preheating a testing weld before welding; (7) welding thetesting weld; (8) post-weld treatment; (9) performing weld coloring; and (10) assessment of the crack. The step (2) comprises the following sub-step: preparing samples 1 and 2, wherein the assembly structure of the sample 1 is a wedge surface which is in a longitudinal symmetry manner and mutually presents a tip top, and the assembly structure of the sample 2 is as follows: the two sides are in the shape of a wedge surface which is in a longitudinal symmetry manner and mutually presents a tip top, the middle is a slope extending up and down, the relatively upper wedge surface of the slope wholly sinks in parallel, and the sinking depth is consistent with the standard required post-weld inclined Y root gap. In addition, the method disclosed by the invention directly adopts a coloring snap or bend breaking method, and the surface crack rate, root crack rate and section crack rate can be intuitively measured.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com