Patents

Literature

1797results about How to "Simple test method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for testing net energy of electrical vehicle power battery

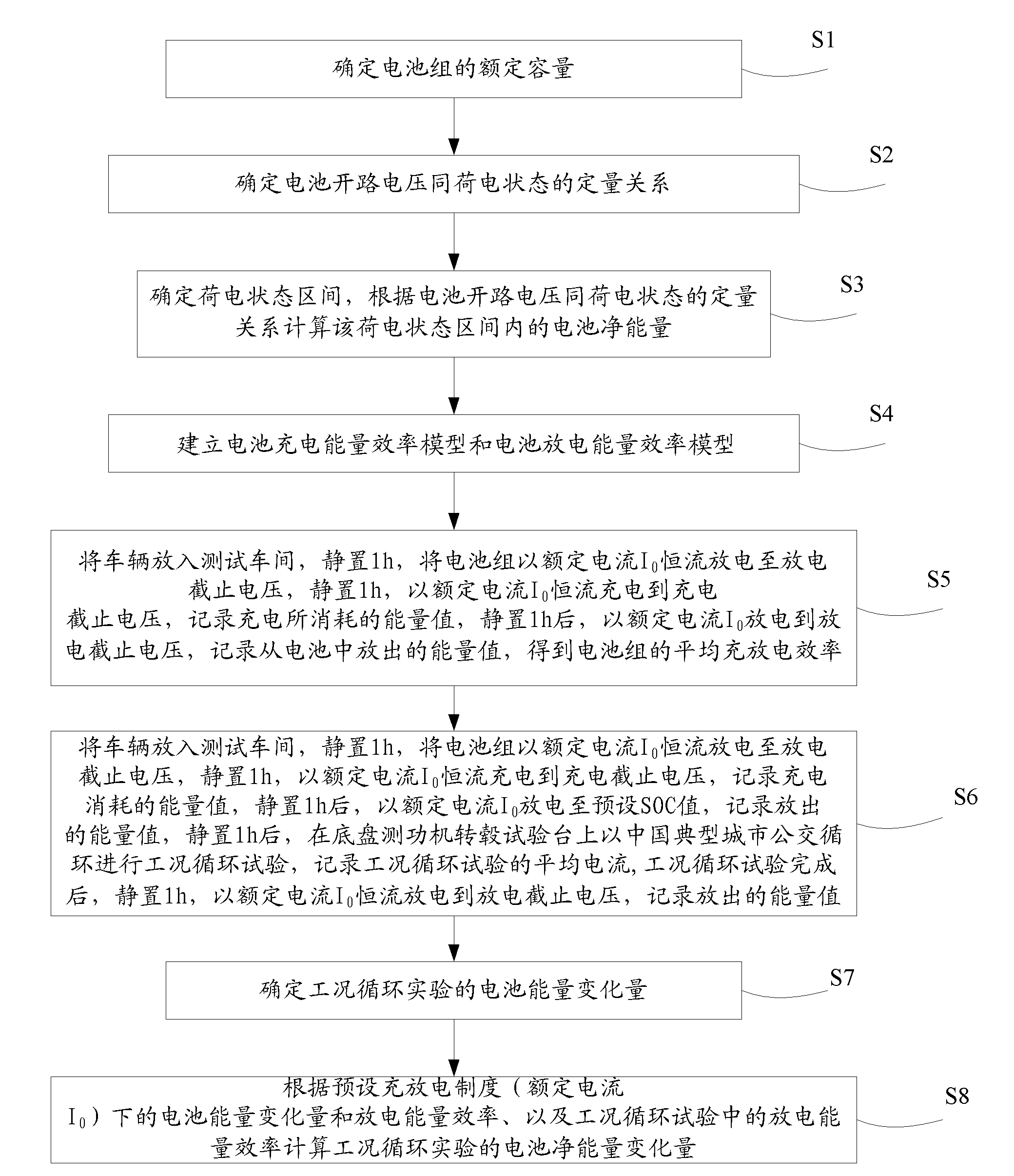

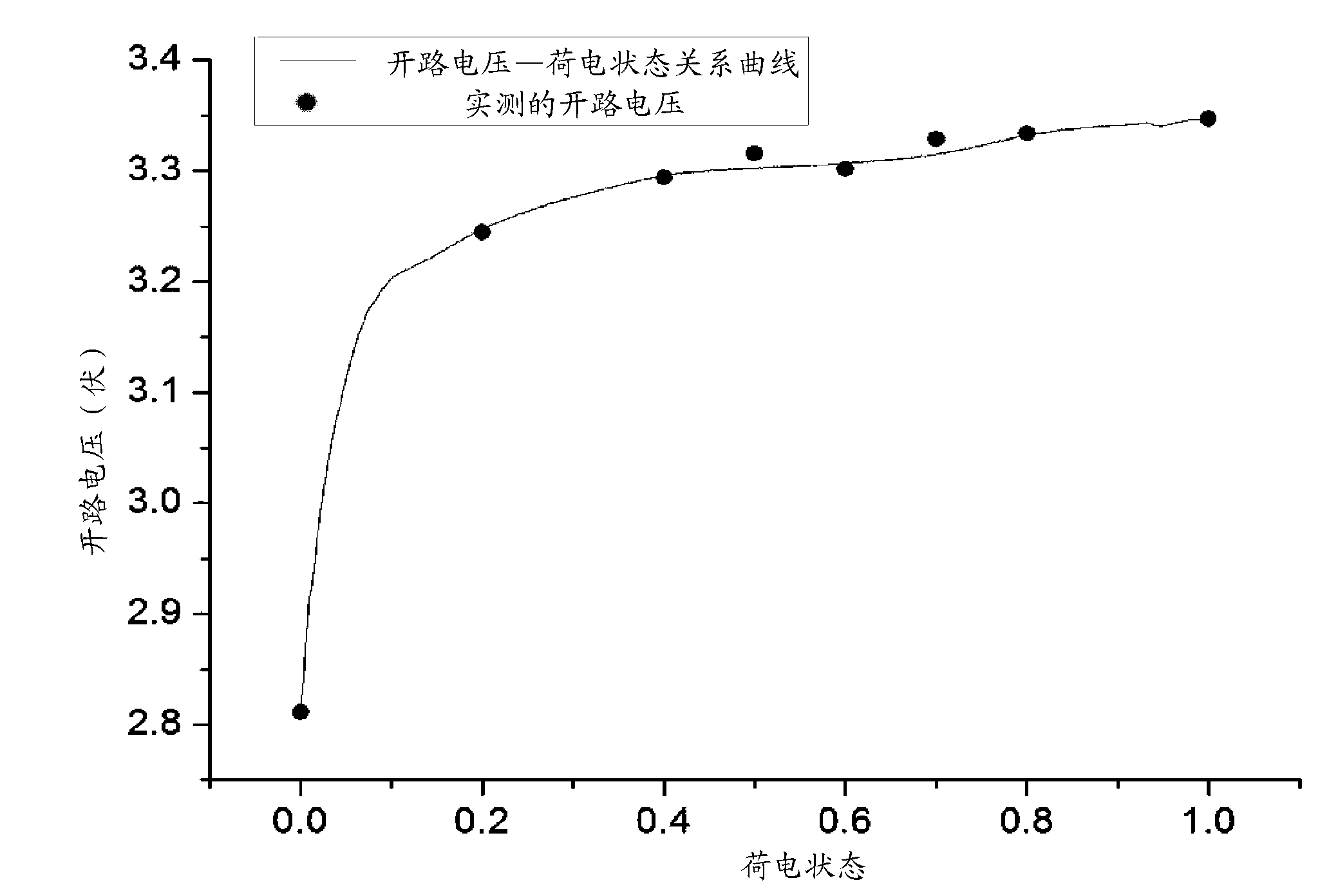

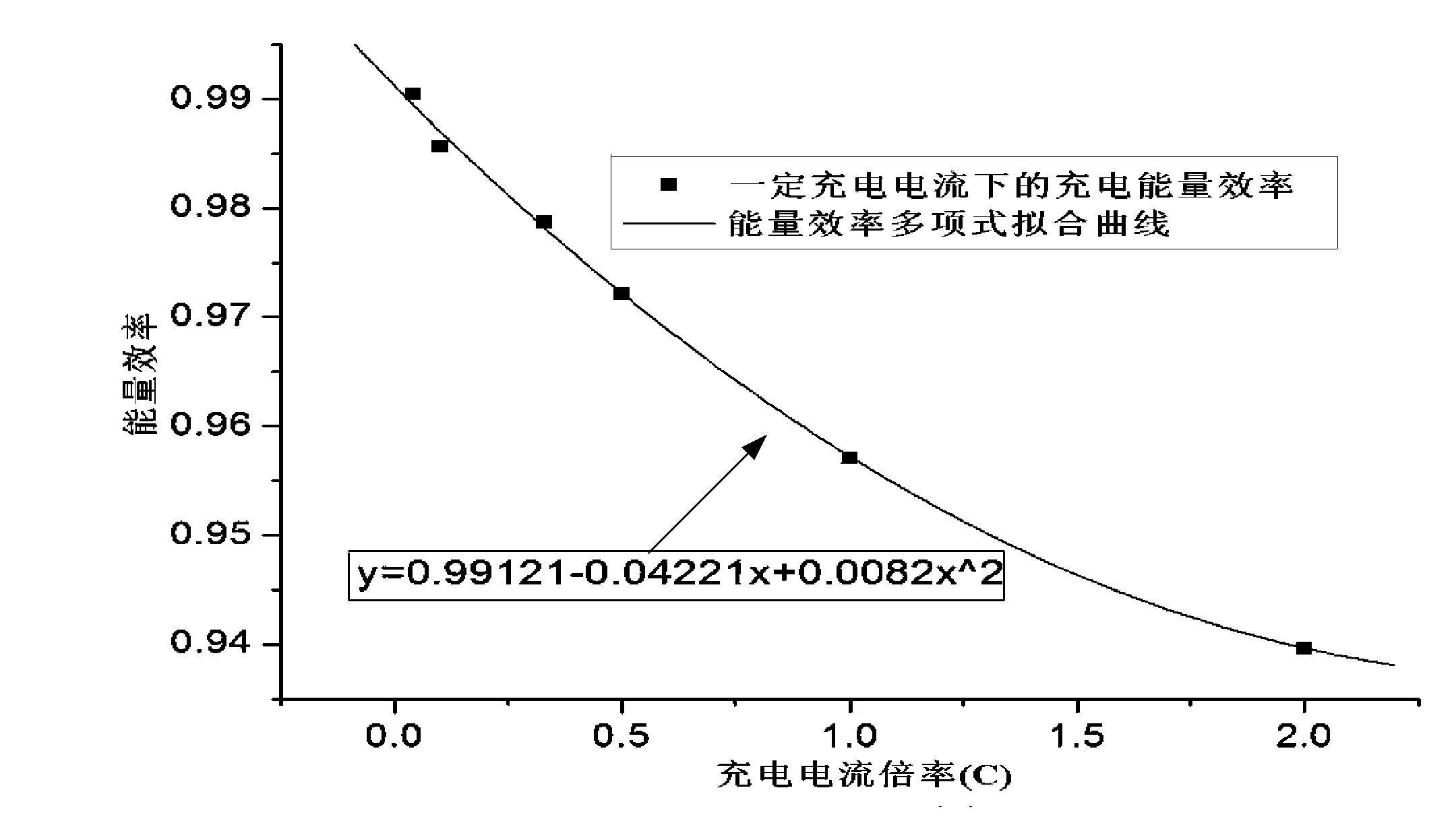

ActiveCN102121973AImprove accuracySimple test methodElectrical testingDischarge efficiencyEnergy variation

The invention discloses a method for testing net energy of an electrical vehicle power battery, which comprises the following steps of: charging a battery set in a state of discharging stop voltage to the state of charging stop voltage, recording the charged energy, discharging the battery set to a pre-set SOC by the stated current, recording the energy discharged at the first time, and then performing a working situation circulation test to the electrical vehicle, discharging the battery set to the discharging stop voltage by the stated current when the test is finished, recording the energy discharged at the second time, obtaining the energy change amount of the battery in the working situation circulation test according to the average charging and discharging efficiency of the battery set, correcting the energy change amount of the battery in the working situation circulation test according to the battery charging and discharging energy efficiency models, and obtaining the energy actually stored by the battery in the working situation circulation process, namely the battery net energy. The method considers the effect to battery net energy of charging and discharging efficiencies on one hand with high testing accuracy, and only tests the charging and discharging energies of the electrical vehicle before and after the test on the other hand, which is easy to be realized.

Owner:WUHAN UNIV OF TECH +1

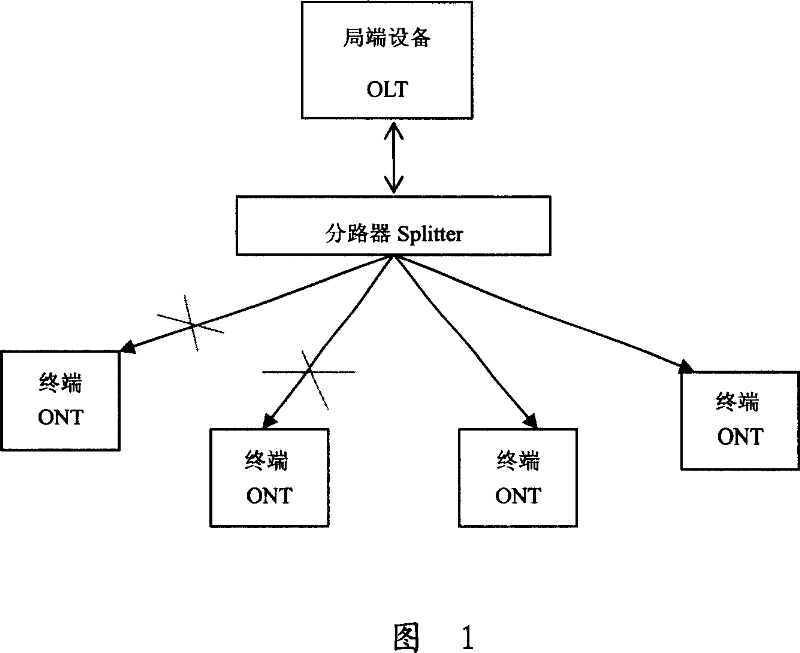

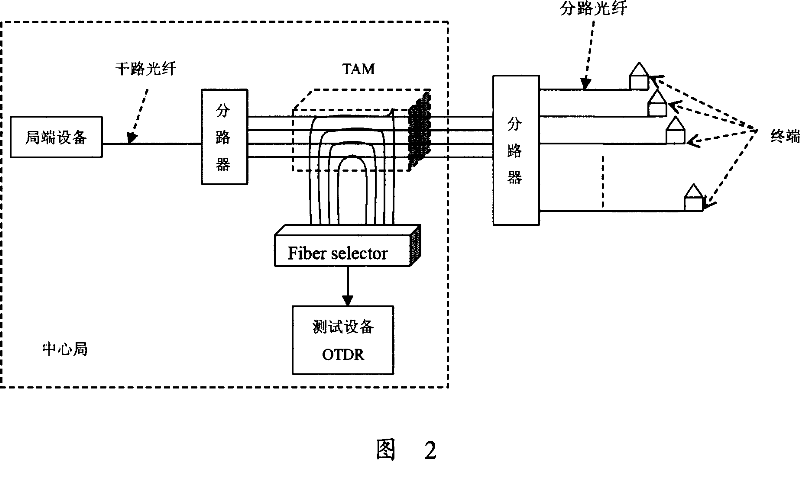

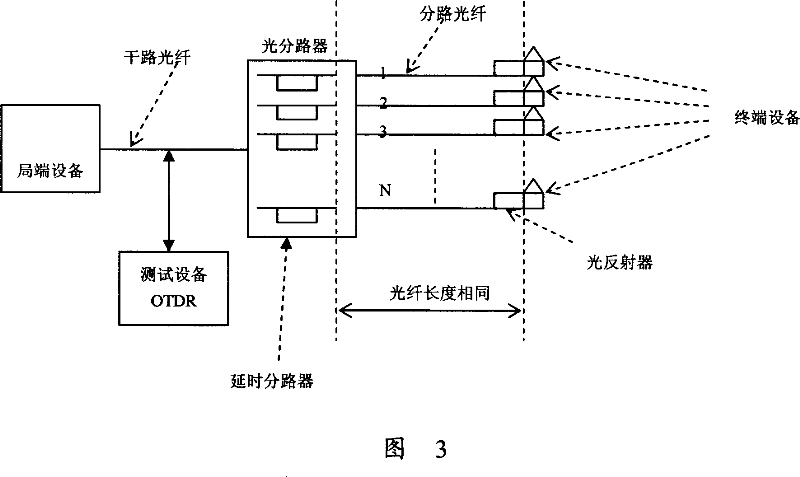

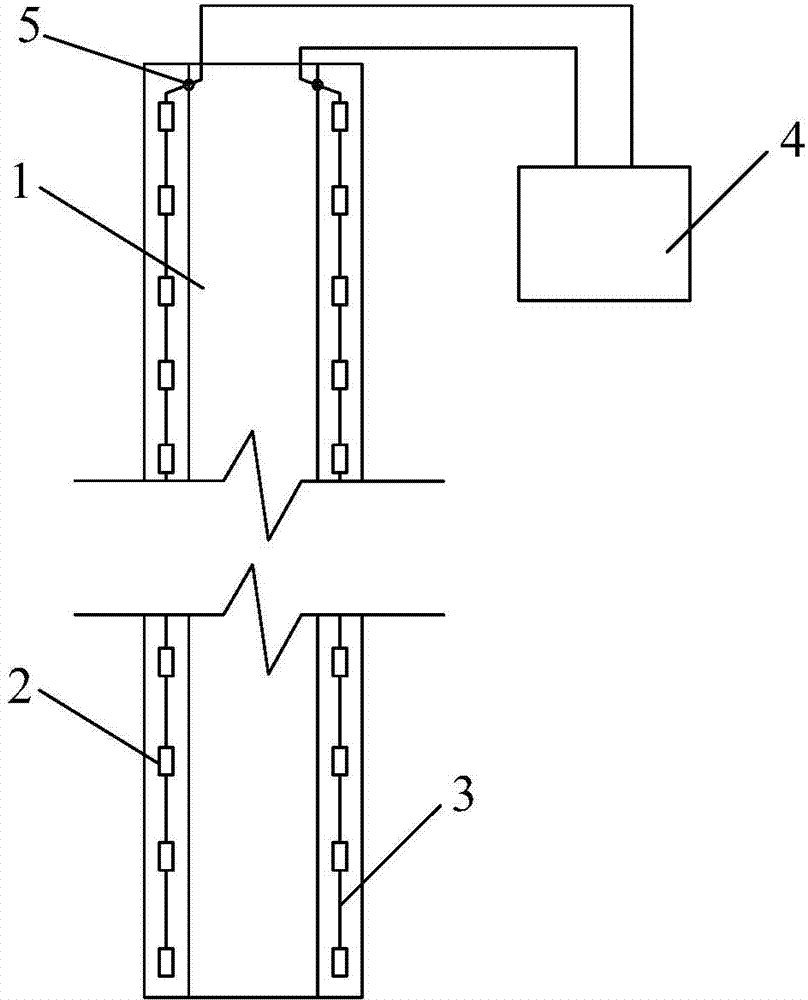

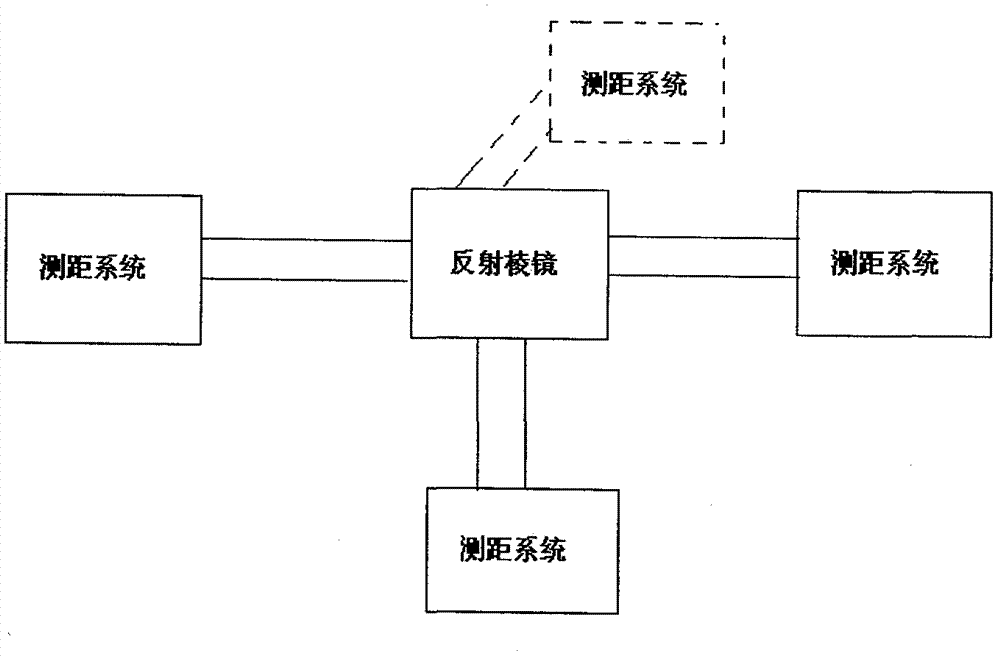

System and method for detecting optical fiber wiring troubles

InactiveCN101043272AReduce difficultySimple test methodElectromagnetic transmissionFiberDelayed time

The invention relates to fields of communication, specially a detecting system and method of optical fiber line fault. The detecting system includes: local equipment, terminal equipment, at least one light delay branching units which are between the local equipment and terminal equipment, test wavelength reflect device which is connected between the light delay branching units and terminal equipment and close to the spur track fiber of the terminal equipment, and test device OTDR of main circuit fiber which is between the light delay branching units and local equipment, said light delay branching units generate different delay time for light signal of different port branching light path, thereinto the length of branching fiber of said light delay branching units and terminal equipment is the same. The detecting method and system of the fiber line fault in this invention can simplify the test method of fiber line fault diagnosis, and decrease the cost of fiber construction.

Owner:HUAWEI TECH CO LTD

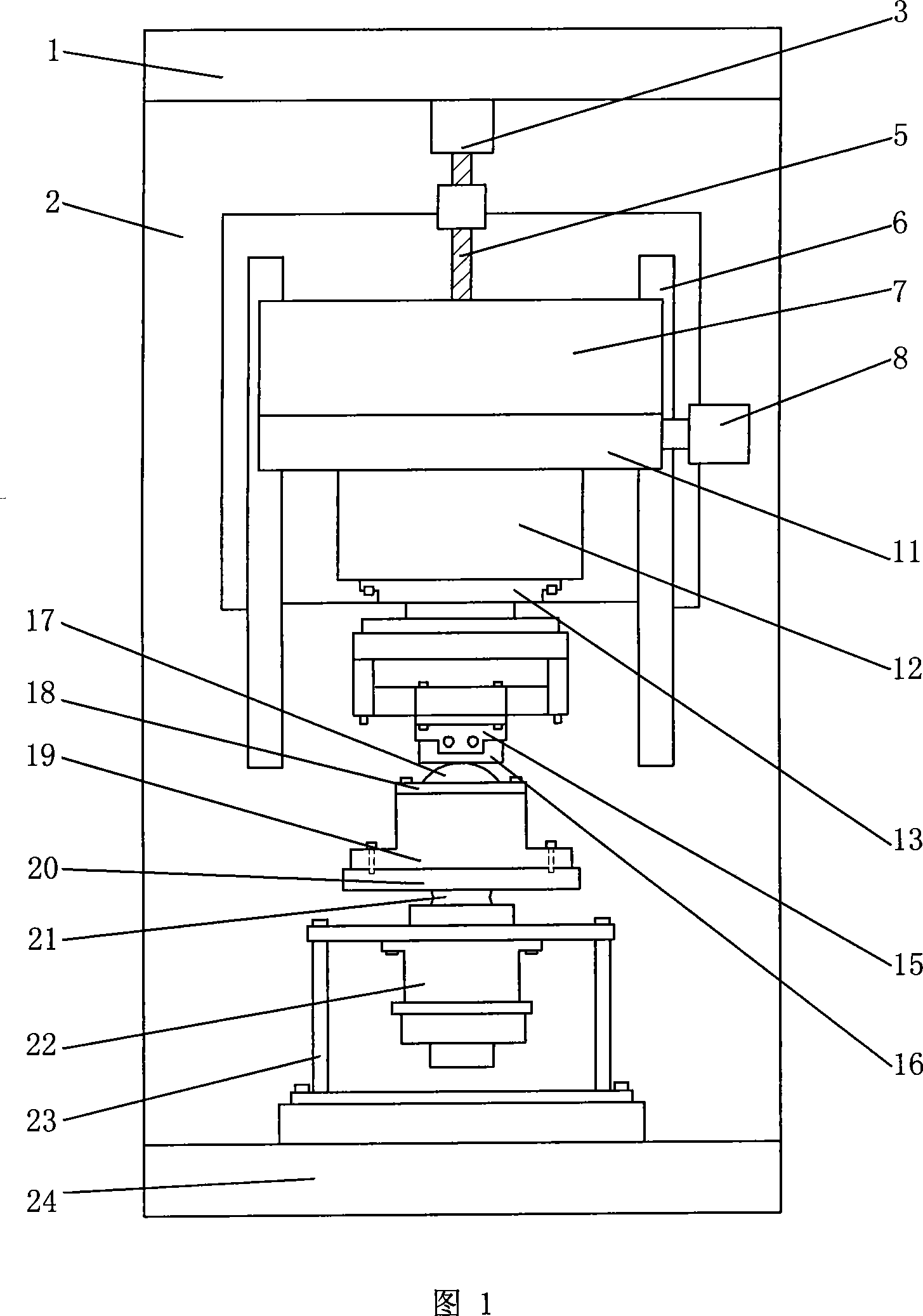

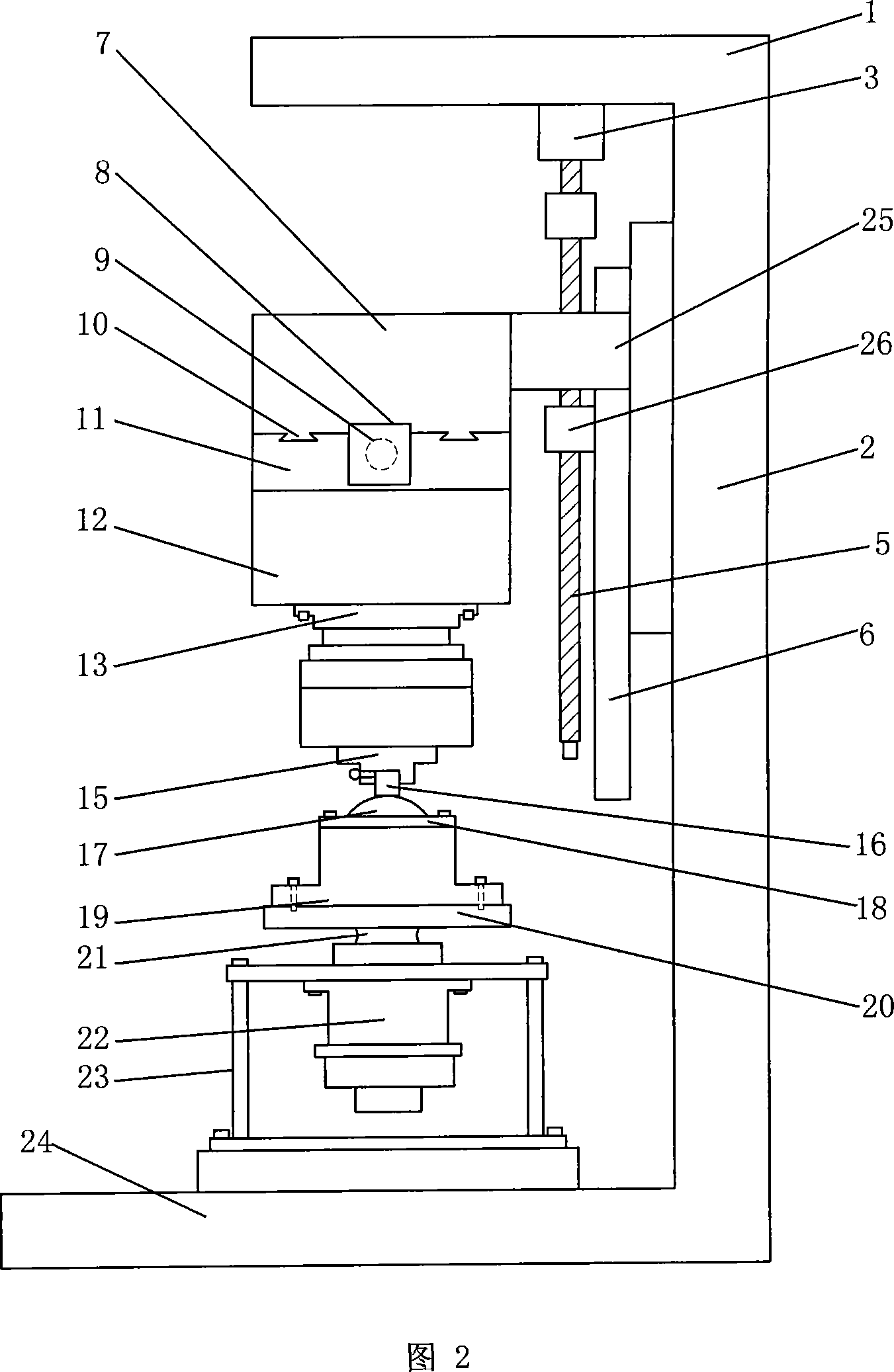

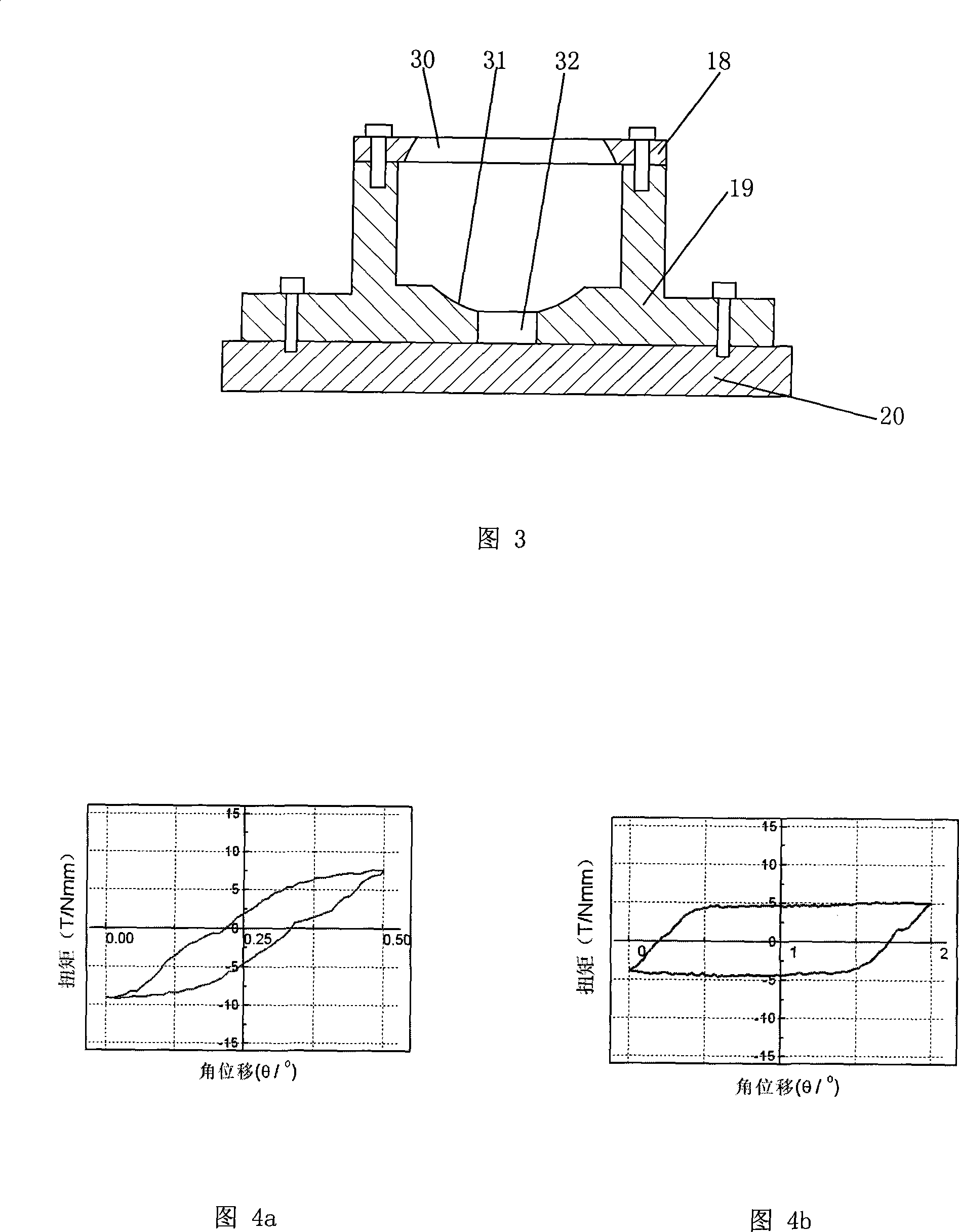

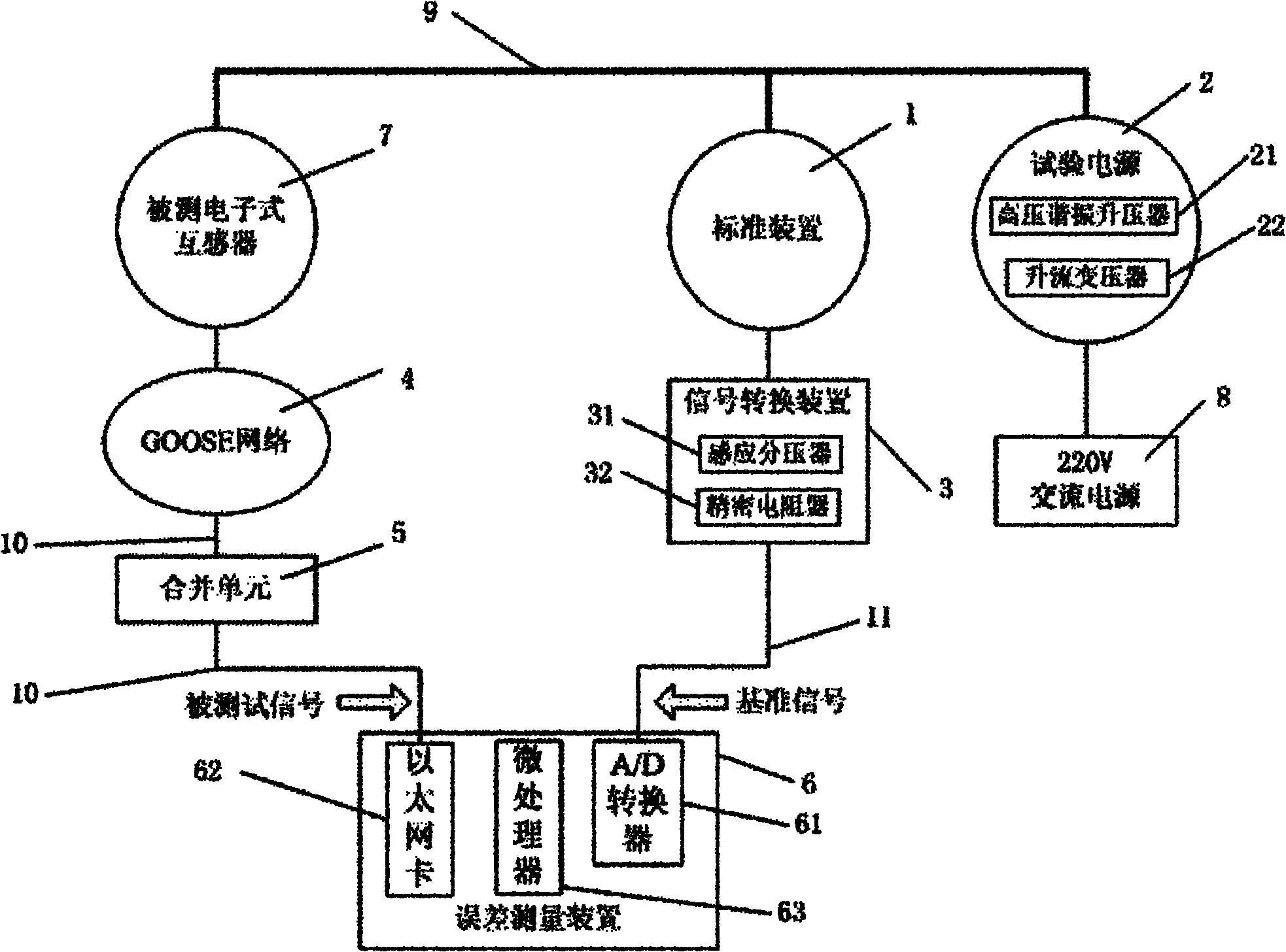

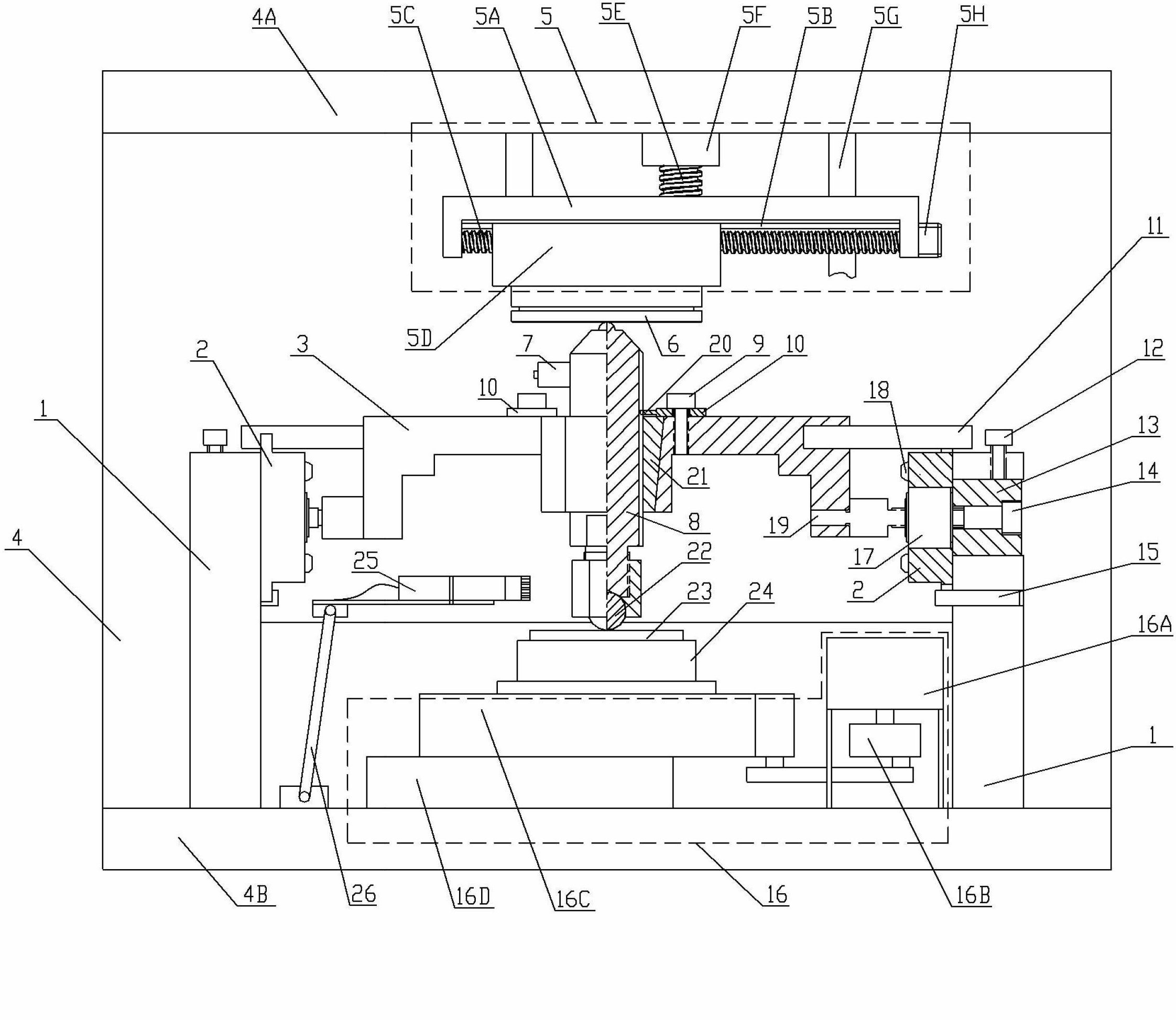

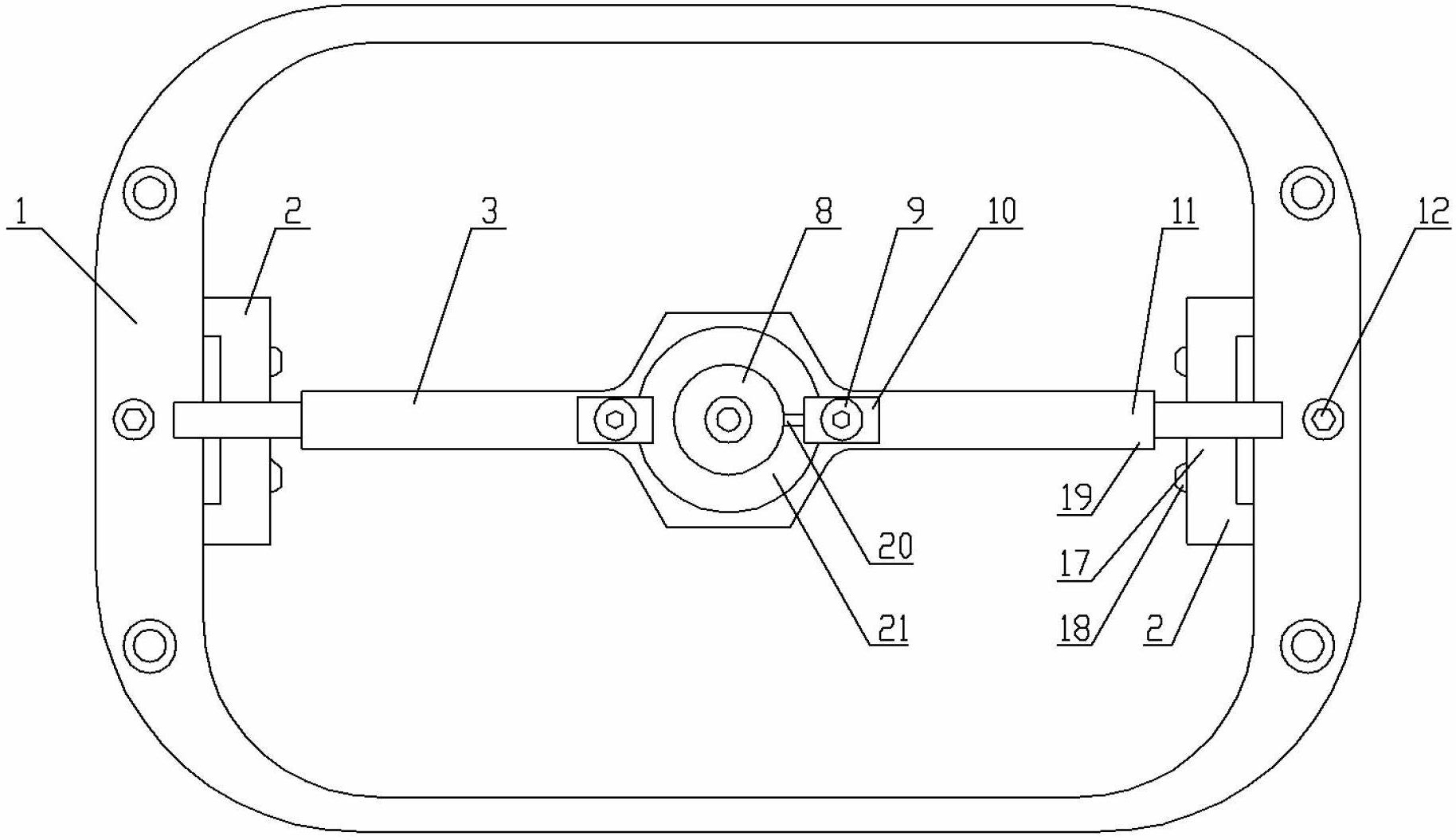

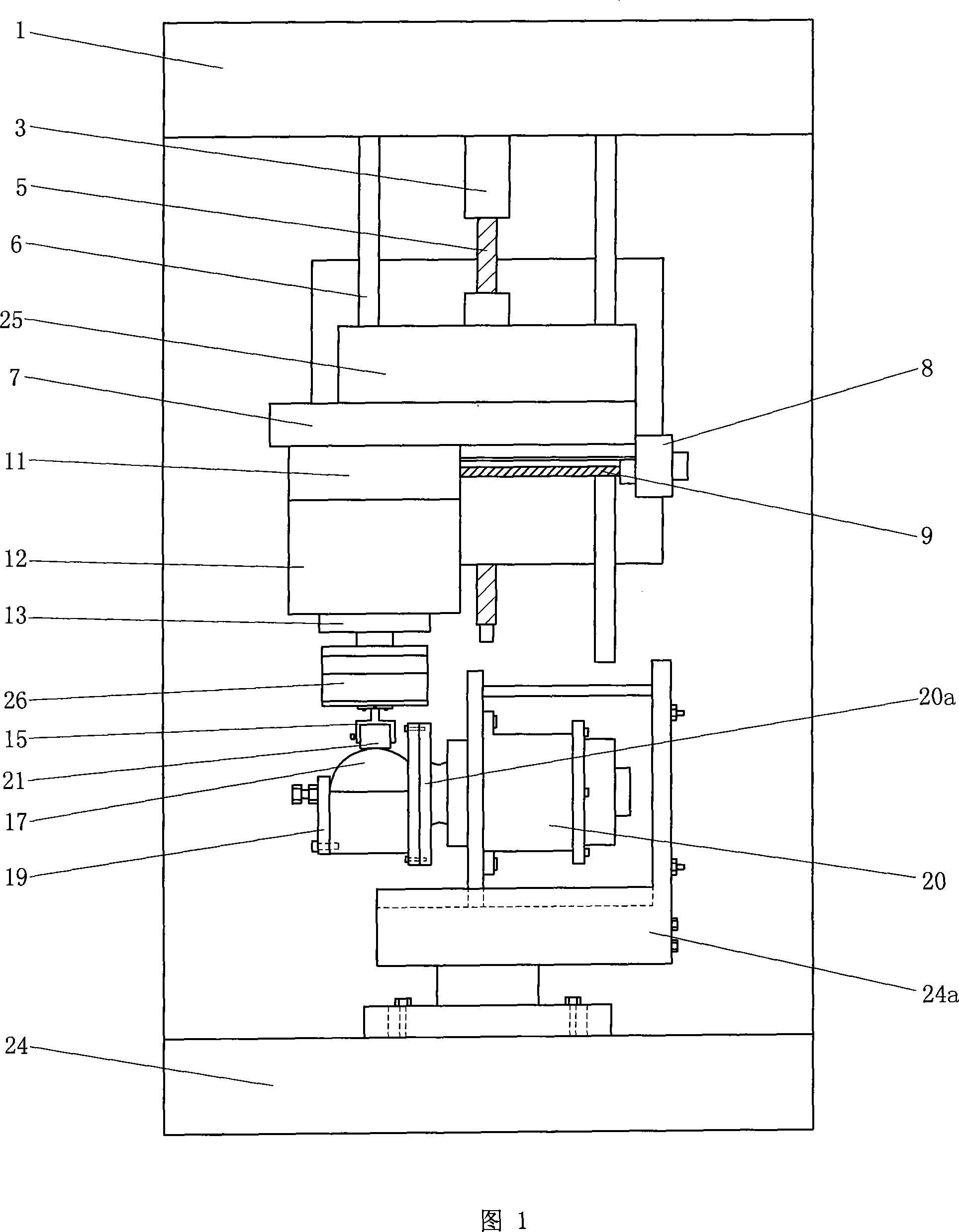

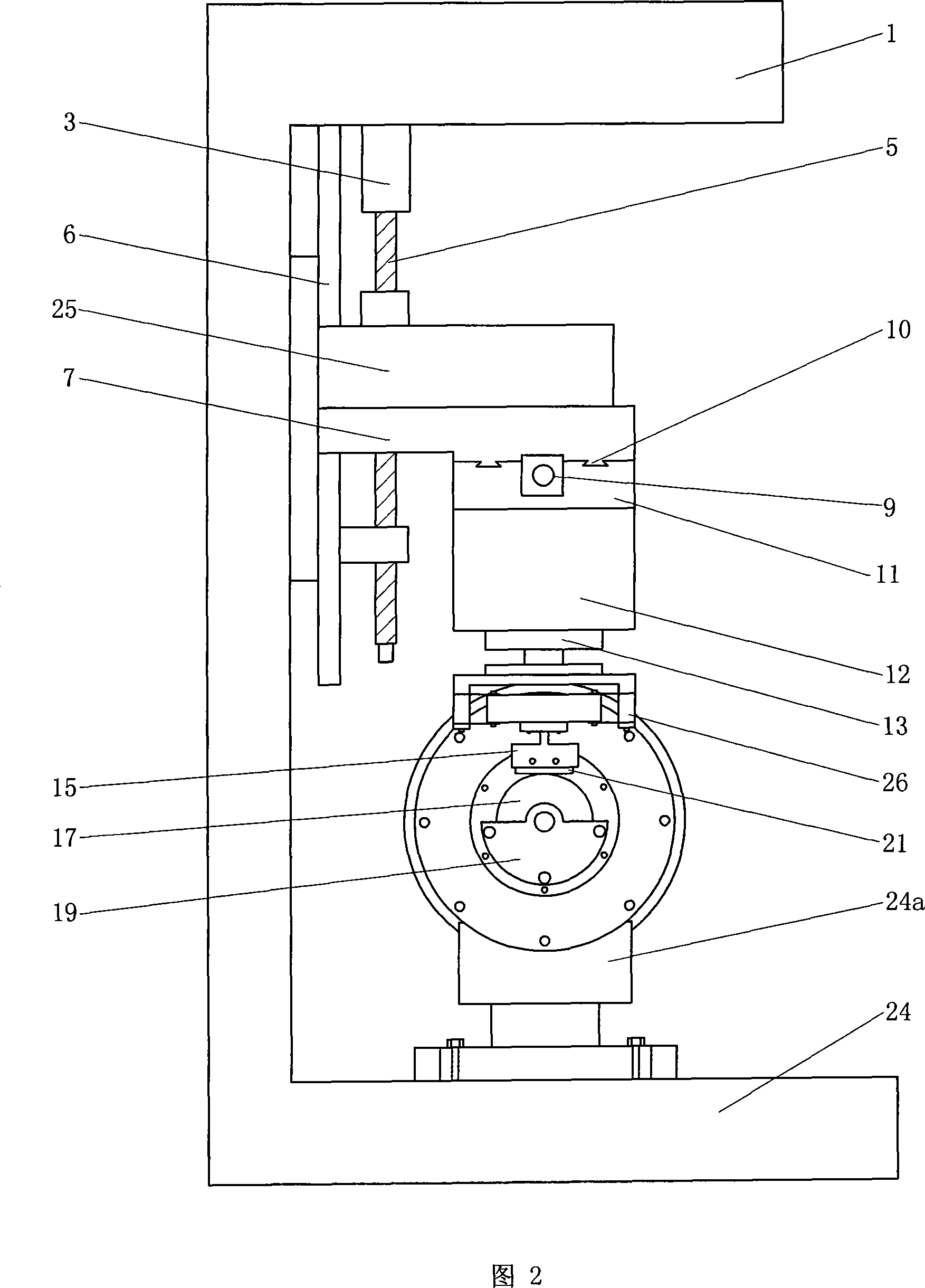

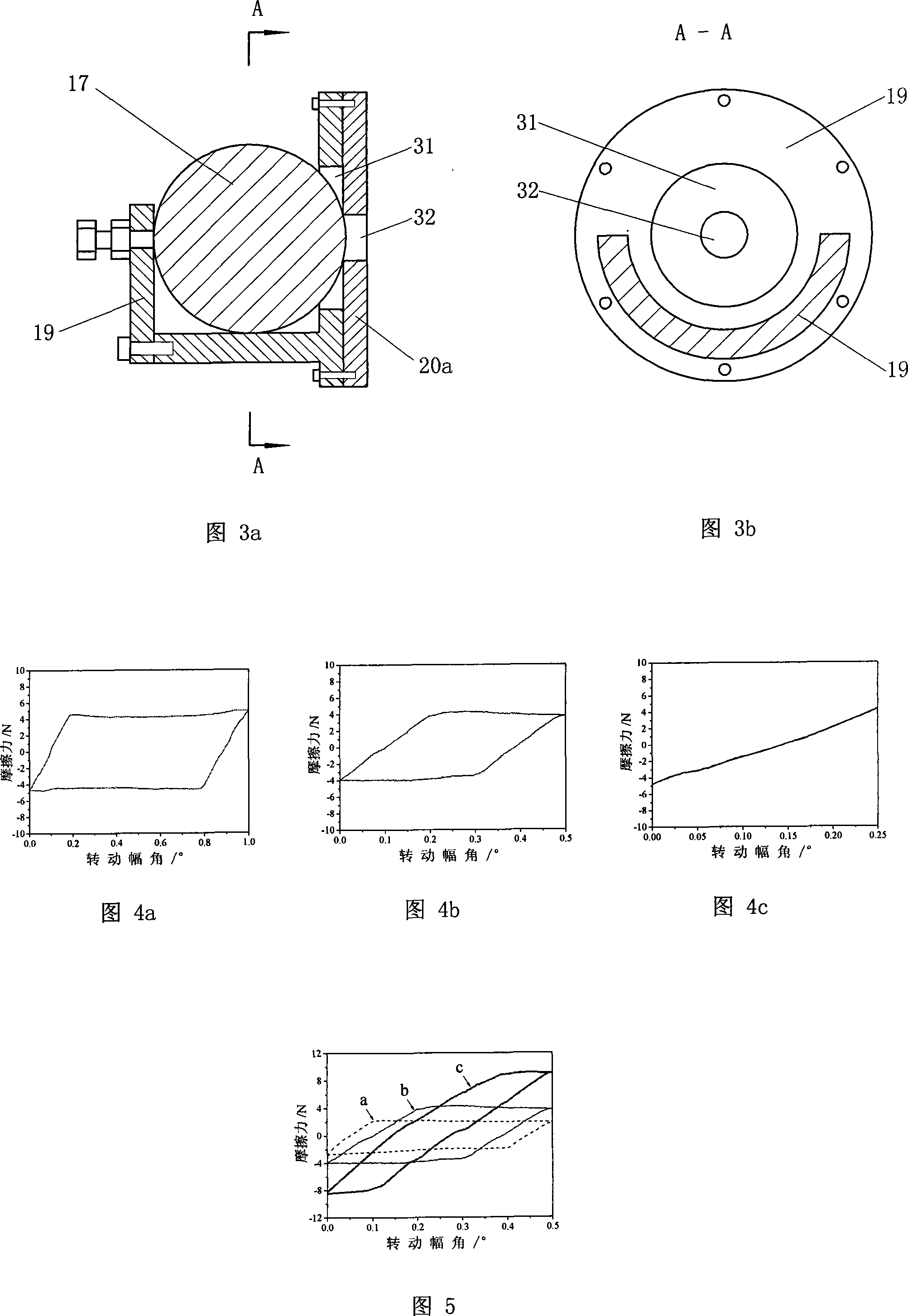

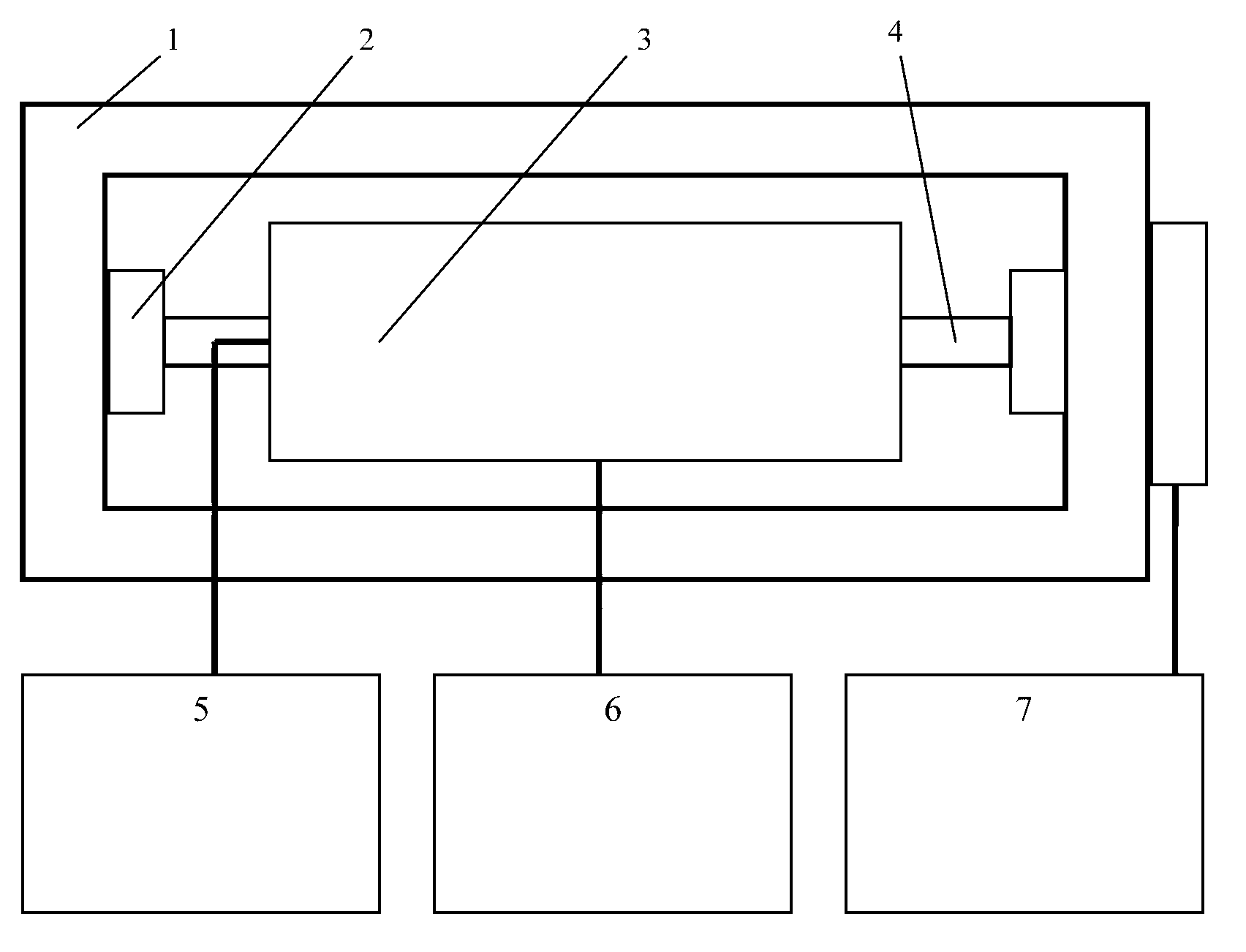

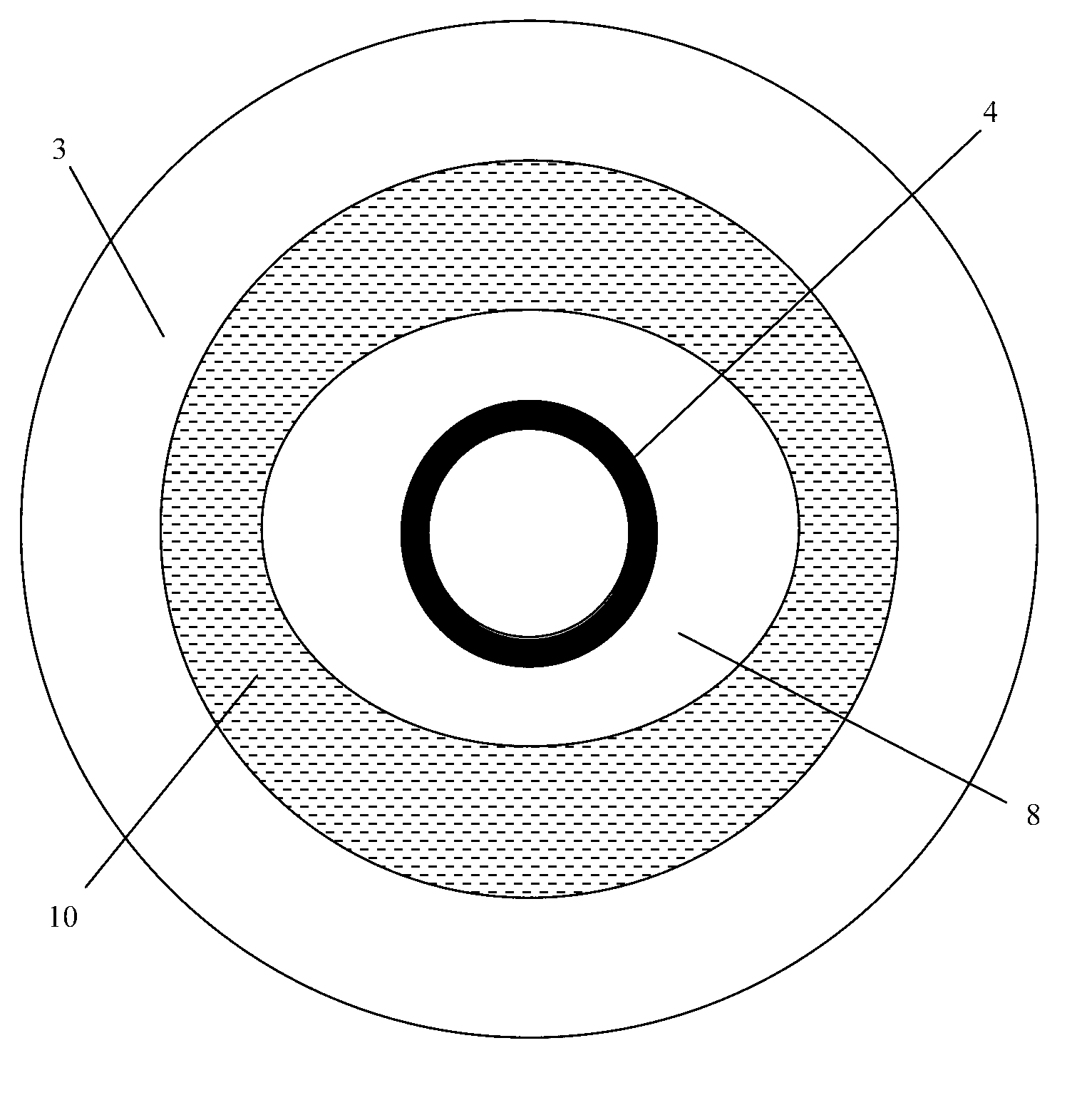

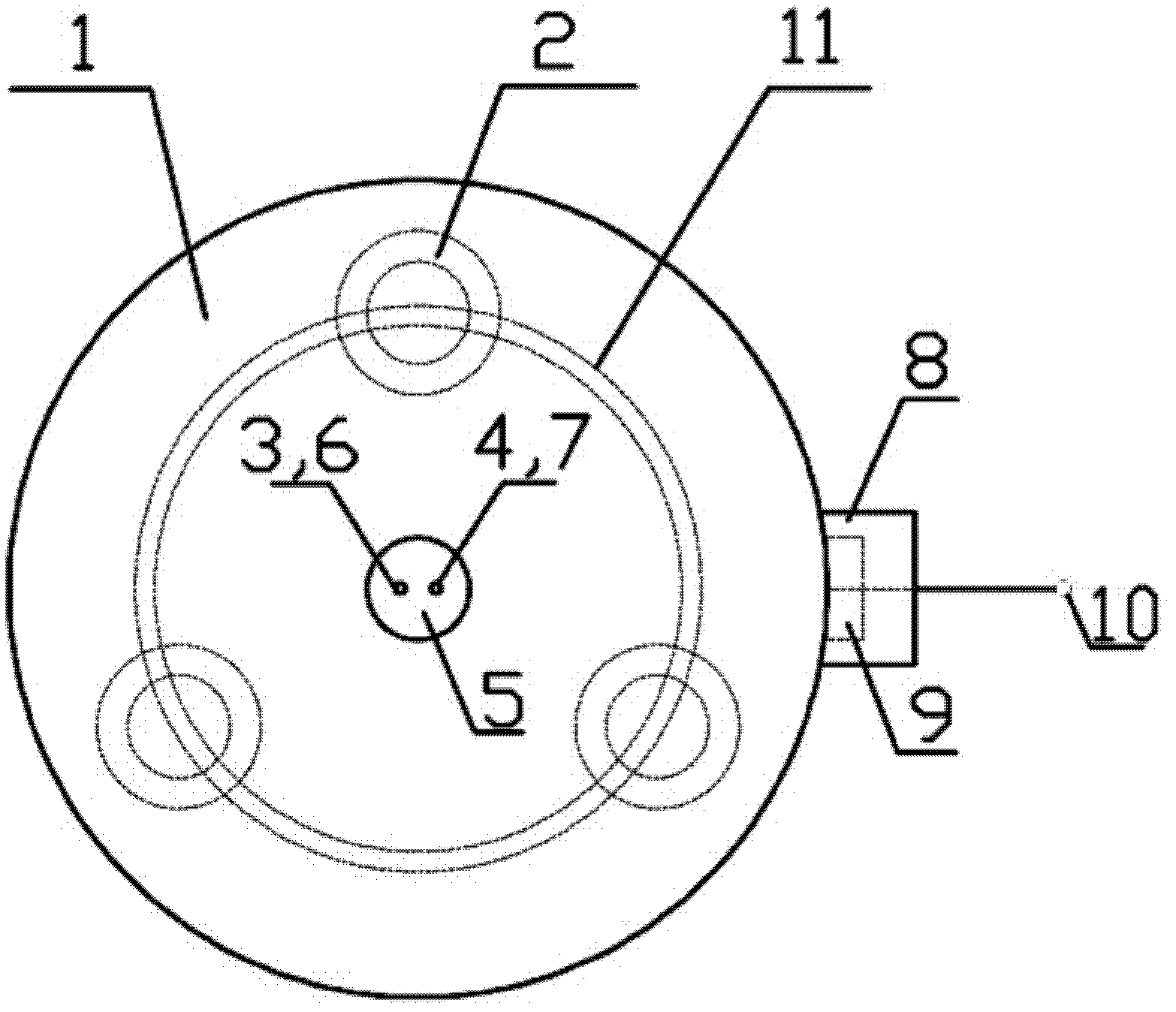

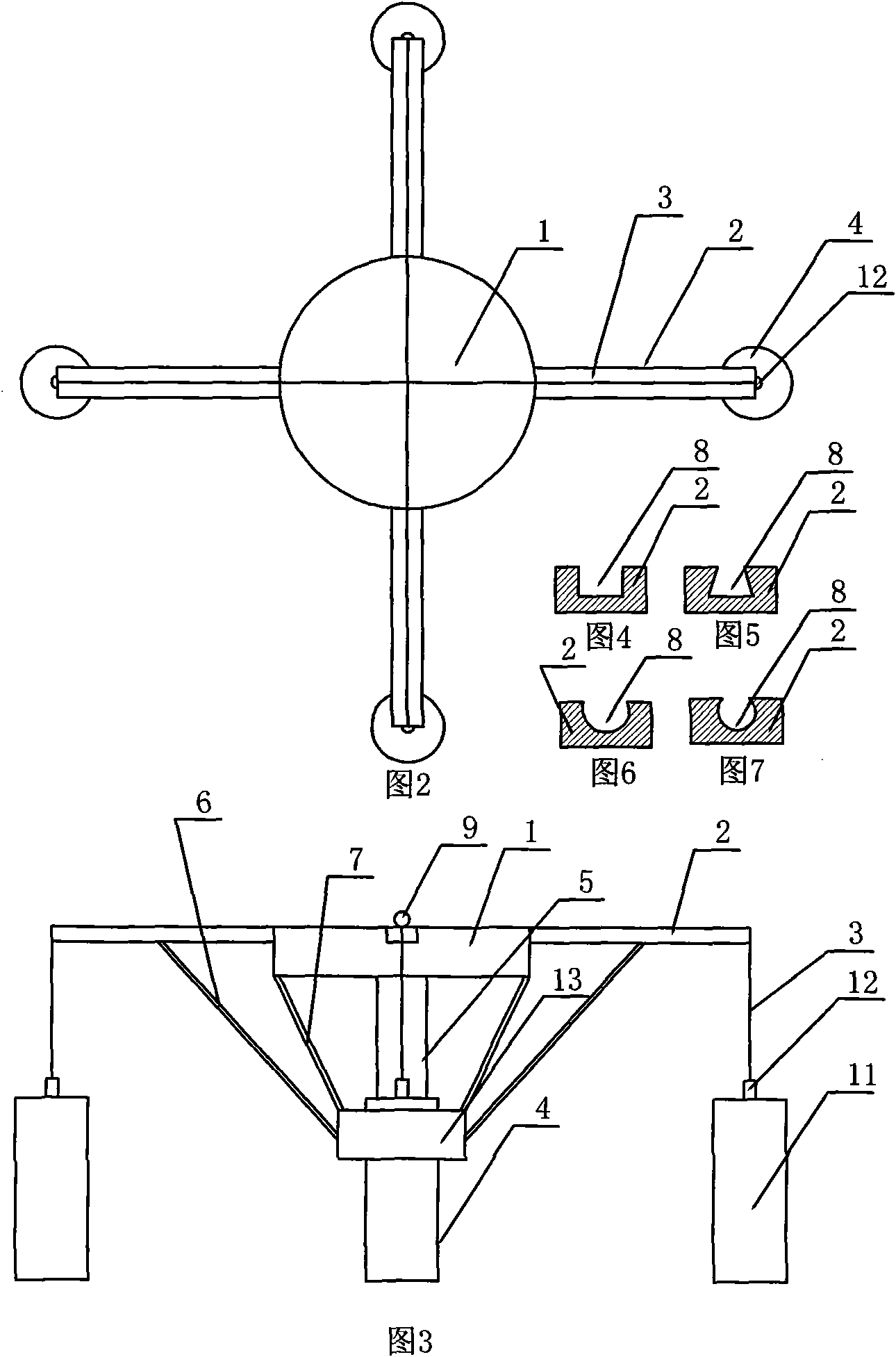

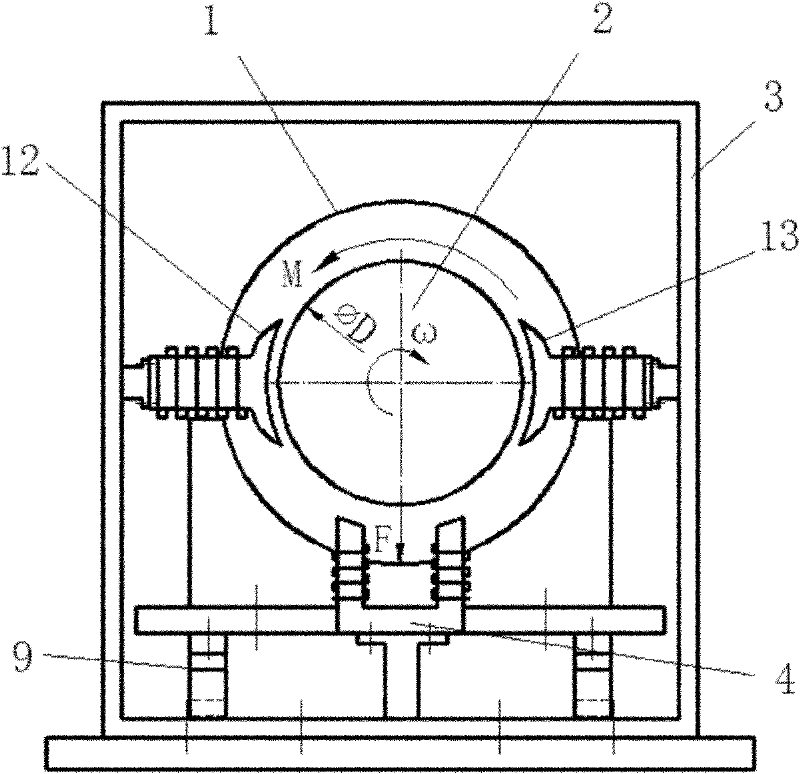

Twisting or micro-moving frictional wear test method and device thereof

InactiveCN101178345ANo wear and tearAccurately characterize kinetic propertiesStructural/machines measurementInvestigating abrasion/wear resistanceLow speedFriction torque

The invention relates to a torsional fretting friction wear test method, the method is that: an upper testing part is clamped in an upper clamp, a lower clamp is fixed with a high-precision low-speed rotation table by a thread, a vertical central line of a holding cavity of the lower clamp is aligned with a rotating shaft of the high-precision low-speed rotation table, a spherical lower testing part is clamped by the lower clamp; the upper clamp is controlled for up and down movements by a data collection control system, the upper and lower testing parts are contacted and are exerted by a set load, at the same time, the lower clamp and the lower testing part clamped by the lower clamp are controlled by the data collection control system to carry out a plurality of times of reciprocating rotations by a set rotation speed and a rotation angle; at the same time, the friction torque is measured by a six-dimension force / torque sensor which is connected with the upper clamp and is sent to the data collection control system, and a torque-angular displacement curve under the set rotation speed and the load conditions can be obtained by analysis. The method can conveniently allow the materials to generate the small angle torsional fretting friction wear, the degree of the automation is high, the precision of the control and the test is high and the reproducibility of the test data is good.

Owner:SOUTHWEST JIAOTONG UNIV

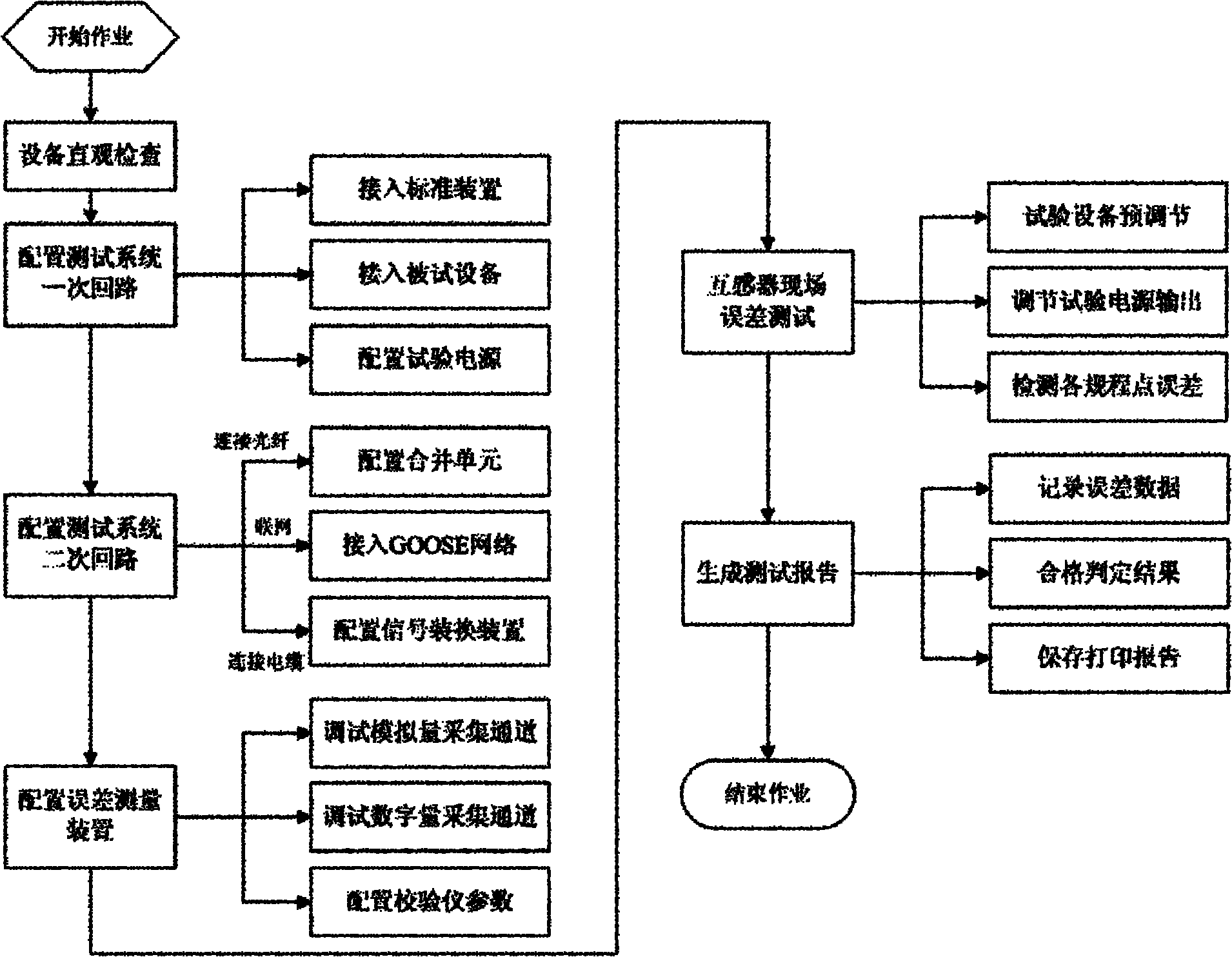

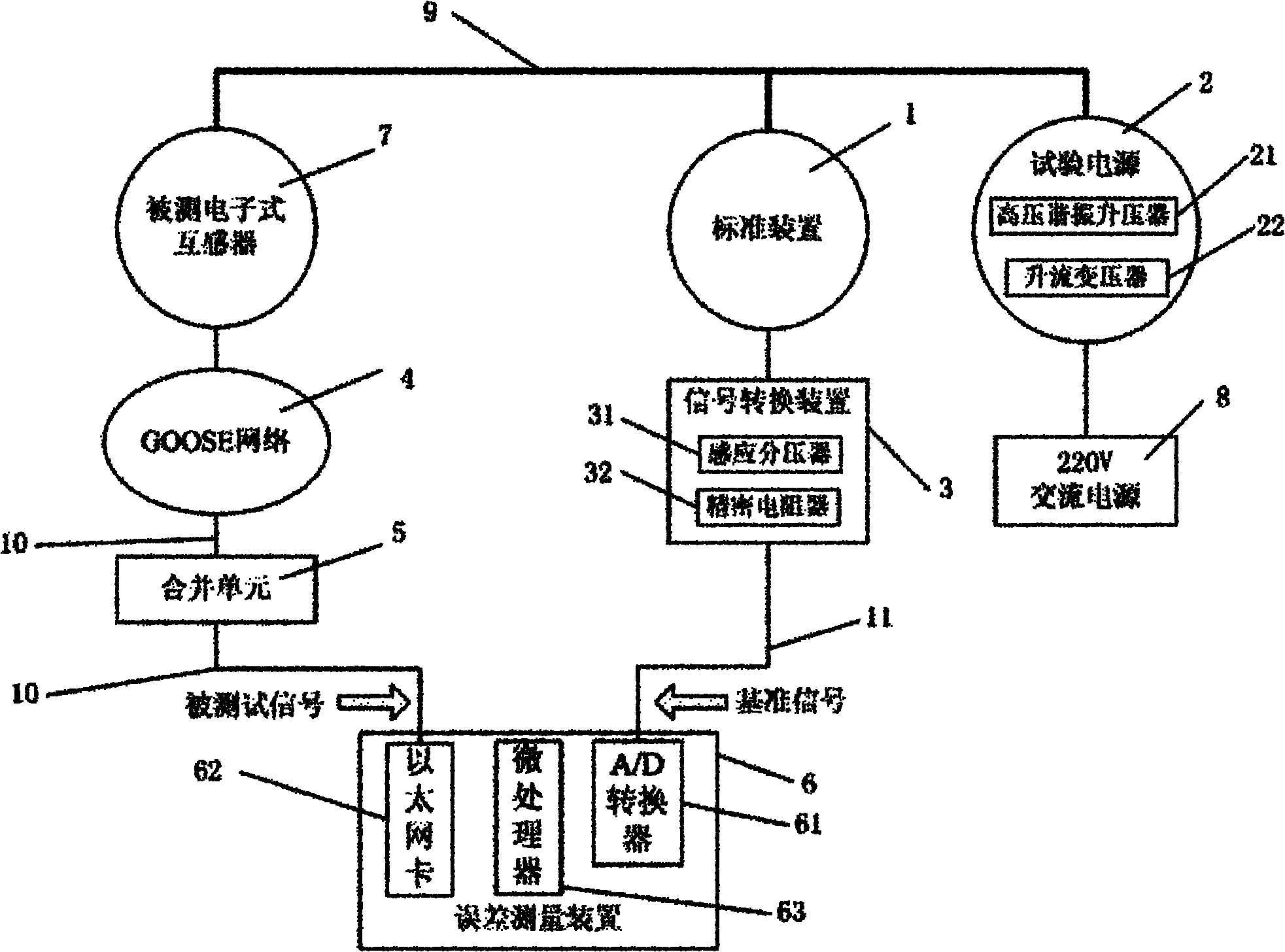

Electronic mutual inductor test system and test method

The invention discloses an electronic mutual inductor test system and a test method. The electronic mutual inductor test system comprises a standard device, a signal conversion device, an error measuring device, a test power supply, a merging unit and a tested electronic mutual inductor, wherein the standard device is used for providing a standard signal serving as a test reference; the signal conversion device is used for receiving the standard signal and converting the standard signal into an analog signal which can be acquired by the error measuring device; the test power supply is used for outputting a primary voltage and a primary current for test use; the merging unit is used for receiving a digital signal output by the tested electronic mutual inductor and processing the digital signal; and the error measuring device is used for receiving the standard signal output by the signal conversion device and the digital signal output by the merging unit, and acquiring the ratio difference and the phase difference of the tested electronic mutual inductor. The electronic mutual inductor test system is particularly suitable for a field error test of the electronic mutual inductor, andhas the advantages of convenient test work, high reliability, small equipment volume, light weight, high test result accuracy and the like.

Owner:HEFEI POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

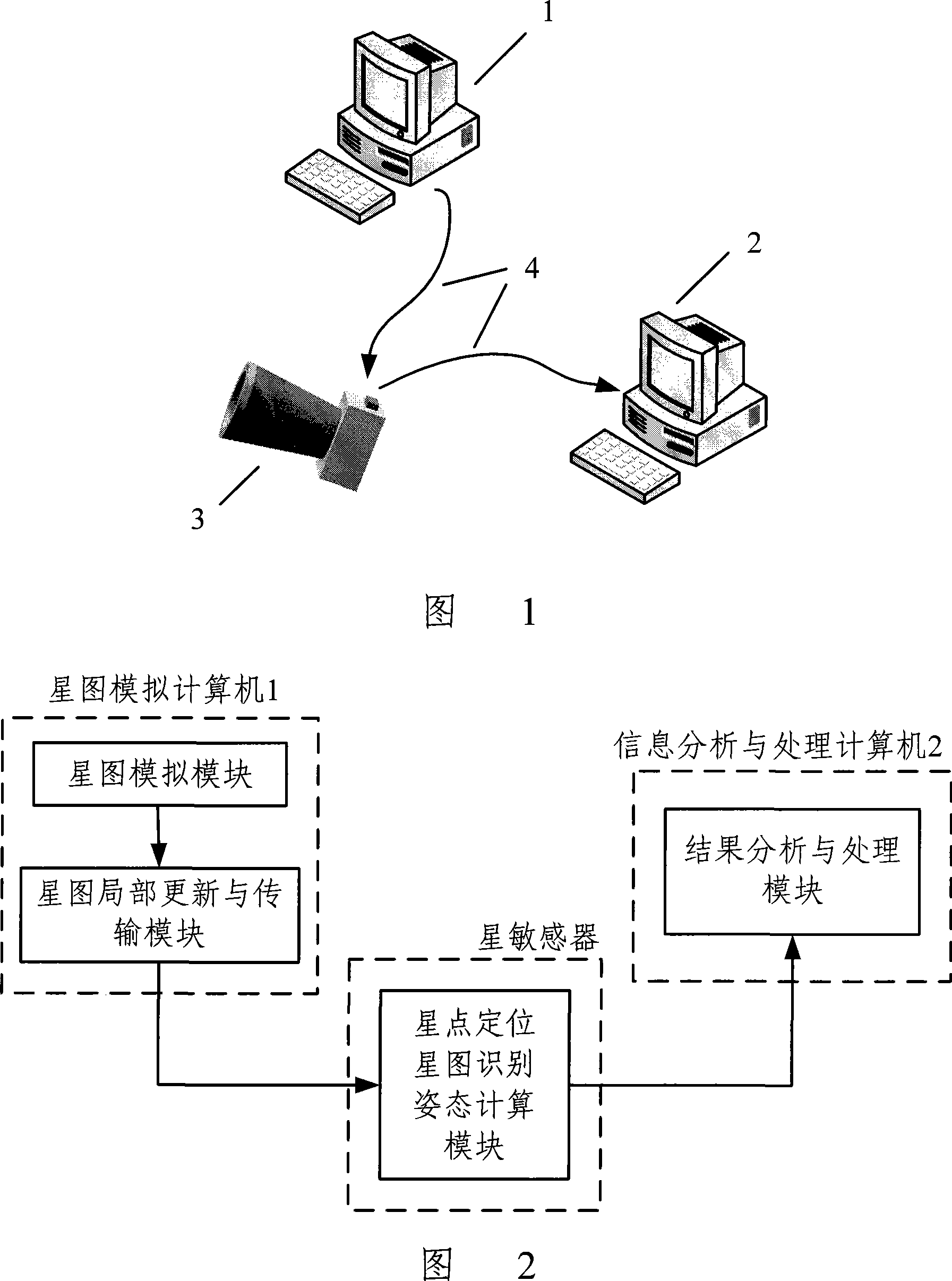

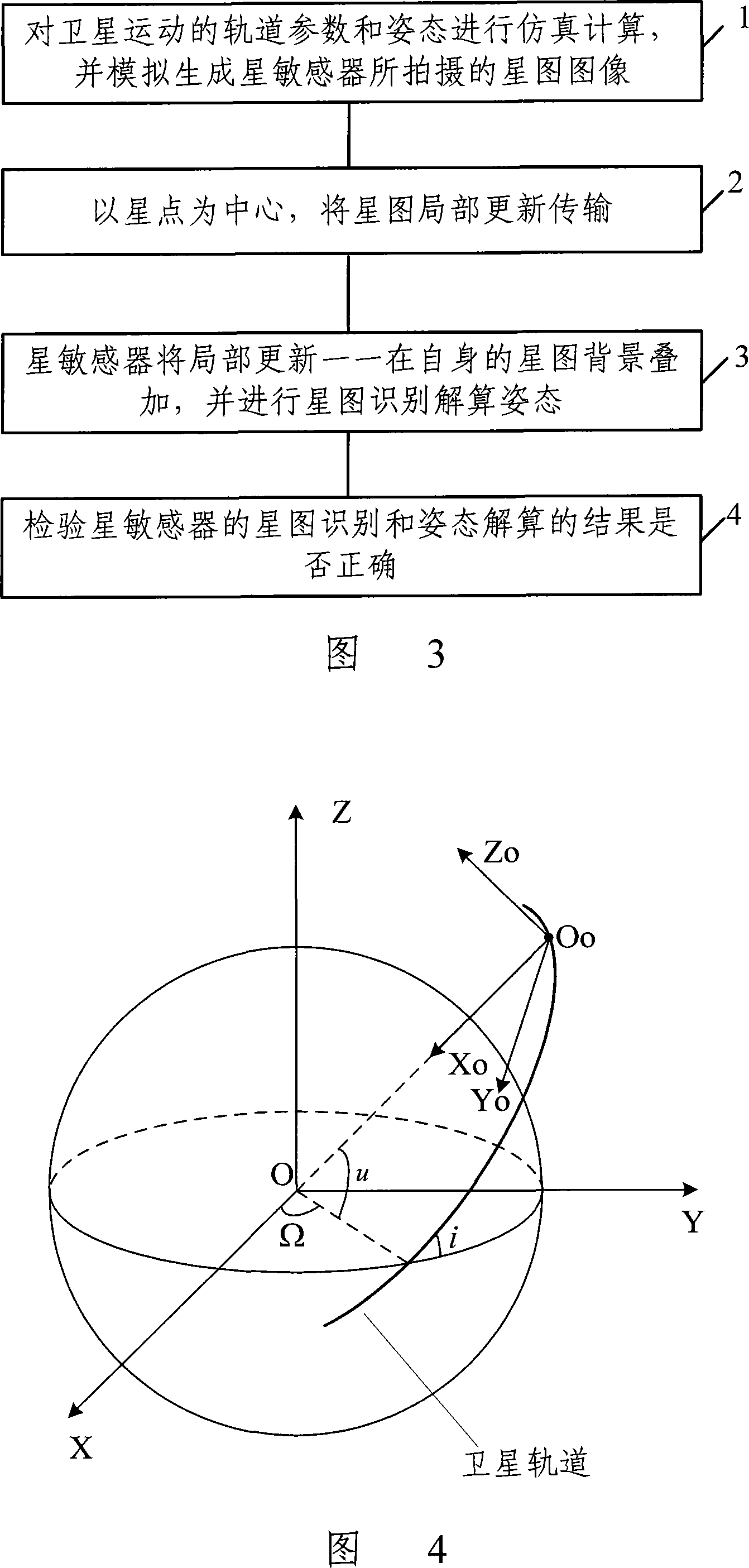

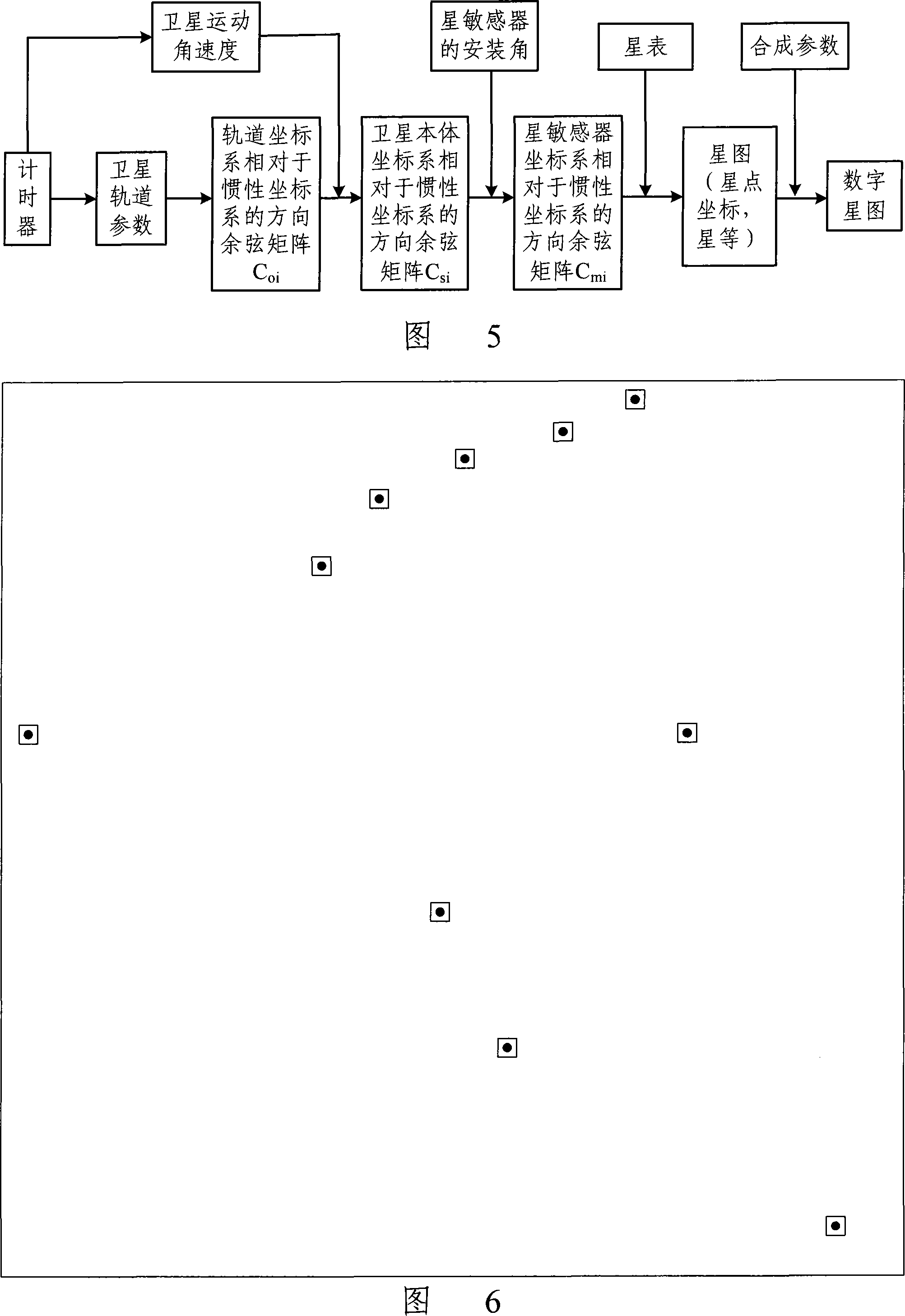

Method and apparatus for testing star sensor function based on electric injection star map

InactiveCN101226113AComprehensive testImplement testStructural/machines measurementNavigation by astronomical meansElectricityFunctional testing

The invention discloses a star sensor function test method based on electric injection star map, which comprises simulating the track parameter and attitude of satellite motion and simulating a star map shot by a star sensor, using the star point center to refresh and transmit part of the star map, laminating the part refreshes in the star map background of the star sensor, positioning star point, recognizing star map and calculating altitude, checking the results of the star map recognition and altitude calculation of the star sensor. The invention discloses a relative device. The invention has high refresh rate of star map, which can simulate the track altitude of star sensor and can process ground simulation test with whole star system, without additional external devices and special application condition demand, but with strong versatility.

Owner:BEIHANG UNIV

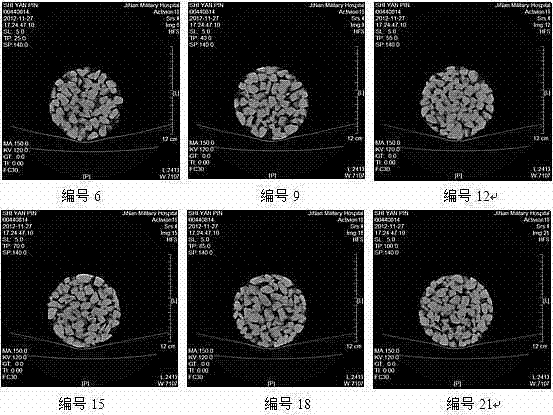

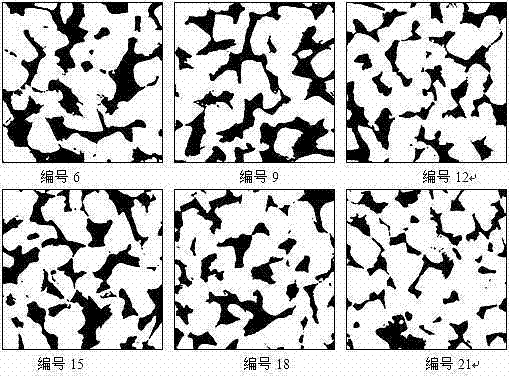

Characterization method of pore structure of porous concrete based on CT (Computerized Tomography) technology

InactiveCN103575751ASimple test methodShort detection timePermeability/surface area analysisMaterial analysis by transmitting radiationPore distributionImaging processing

The invention discloses a characterization method of a pore structure of porous concrete based on a CT (Computerized Tomography) technology. Pore structure parameters such as the plane porosity, the effective aperture and the aperture distribution of the porous concrete are obtained by analyzing a CT-scanned two-dimensional cross-sectional image through an image processing method. The characterization method specifically comprises the following steps: firstly, acquiring the two-dimensional cross-sectional image of the porous concrete by a CT scanner, and acquiring a clear pore distribution map by white and black binarization of the image by a computer; then, calculating the area representing a pore region by image processing software and converting the region into a circle with equal area; and finally, carrying out statistic analysis on data with pore grater than 1mm to obtain the pore structure parameters such as the plane porosity, the effective aperture and the aperture distribution of the porous concrete. By adopting the characterization method of the pore structure of the porous concrete, not only is the test method simple, but also the precision is high and the error is small.

Owner:UNIV OF JINAN

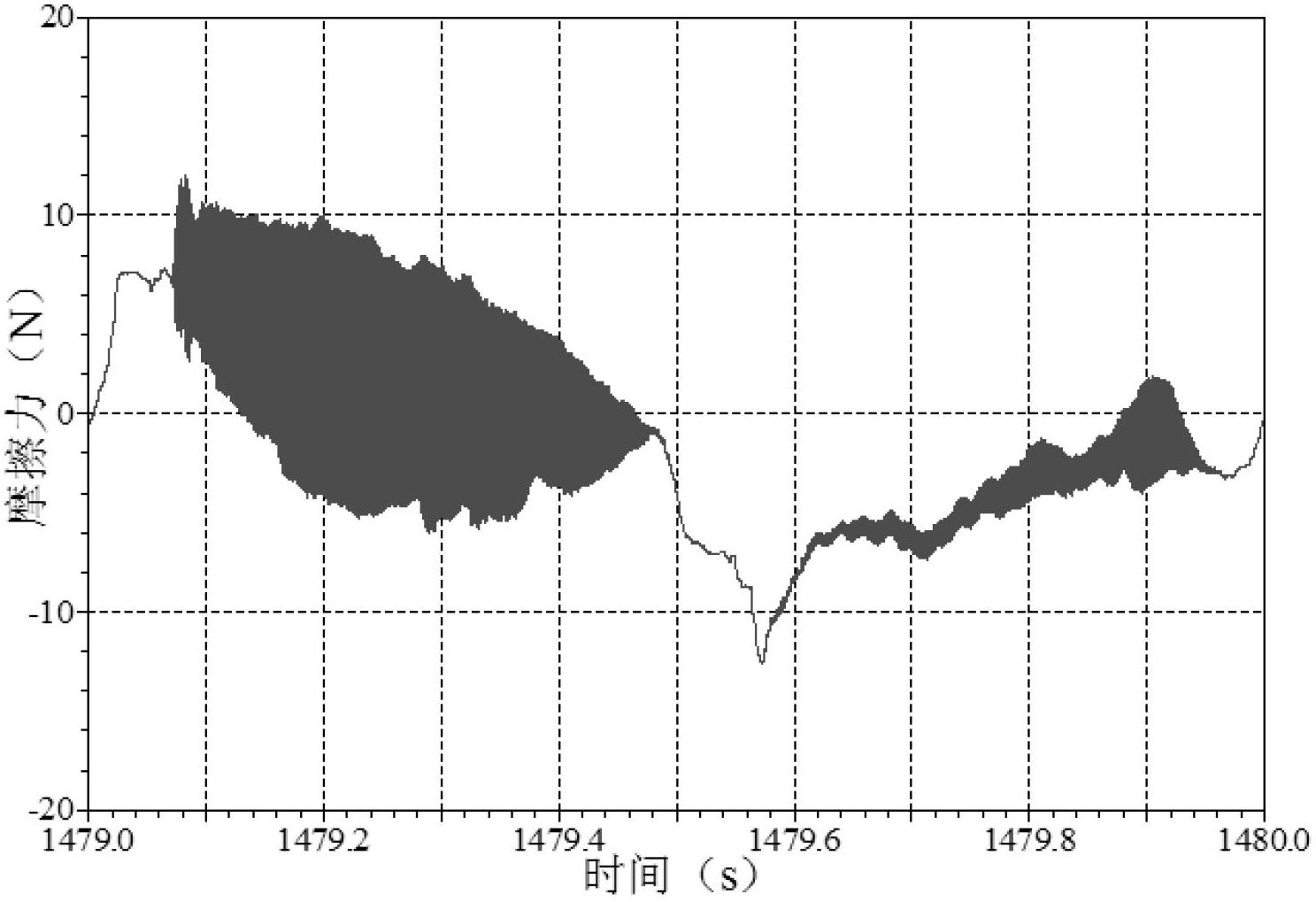

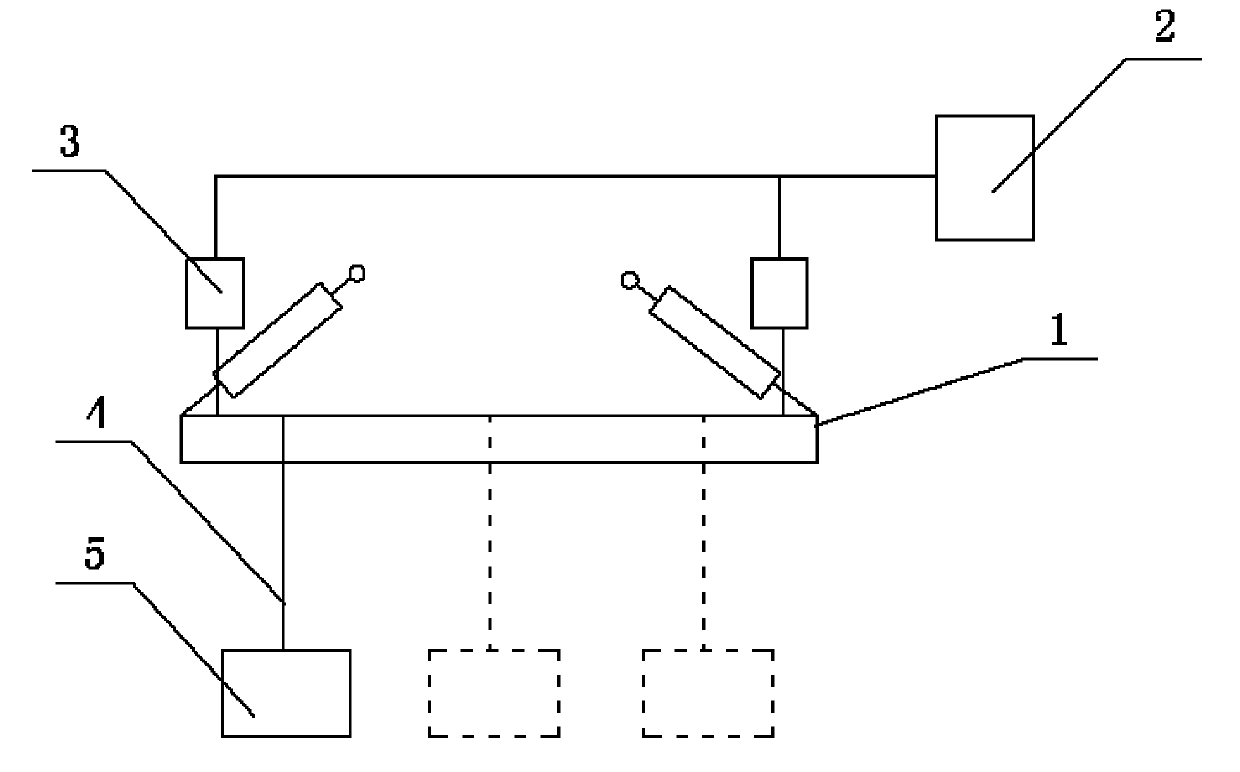

Method for testing and analyzing frictional noise and test device for method

InactiveCN102680083ASimple designEasy to useAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementVibration accelerationEngineering

The invention discloses a method for testing and analyzing frictional noise and a test device for the method. The method comprises that: a lower fixture clamping a lower friction part is fixed onto a reciprocating device; an upper fixture clamping an upper friction part penetrates through a horizontal support to contact with the bottom of a strain force sensor; a three-dimensional acceleration sensor is mounted on the upper fixture; two ends of the horizontal support are fixed onto support bases by piezoelectric force sensors; and the strain force sensor is fixed to the bottom of a two-dimensional moving table. A sensing end of an acoustic sensor is close to a contact interface of the upper friction part and the lower friction part, and the two-dimensional moving table is controlled so that the upper friction part and the lower friction part are controlled to do reciprocating friction motion, and the three sensors accurately, synchronously and dynamically acquire the frictional noise,vibration acceleration and frictional force and analyze the frictional noise, the vibration acceleration and the frictional force in real time. Therefore, mutual relation and influencing law of the frictional noise, the interface and characteristics of a system are accurately analyzed, a mechanism of production of the frictional noise is disclosed, and a more accurate and reliable test basis is provided for realizing noise-reduction design for mechanical equipment, improving performance of the mechanical equipment and prolonging the service life of the mechanical equipment.

Owner:SOUTHWEST JIAOTONG UNIV

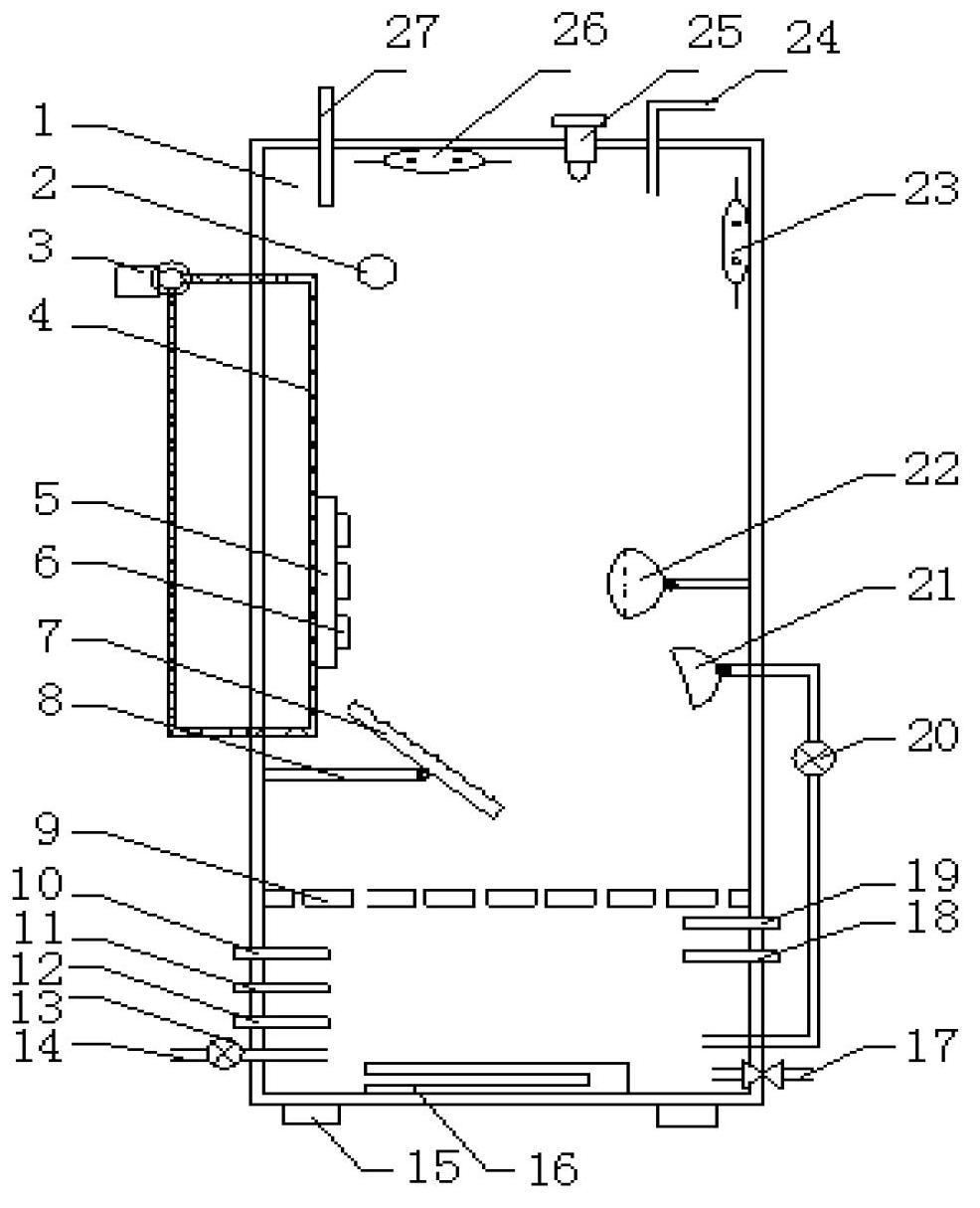

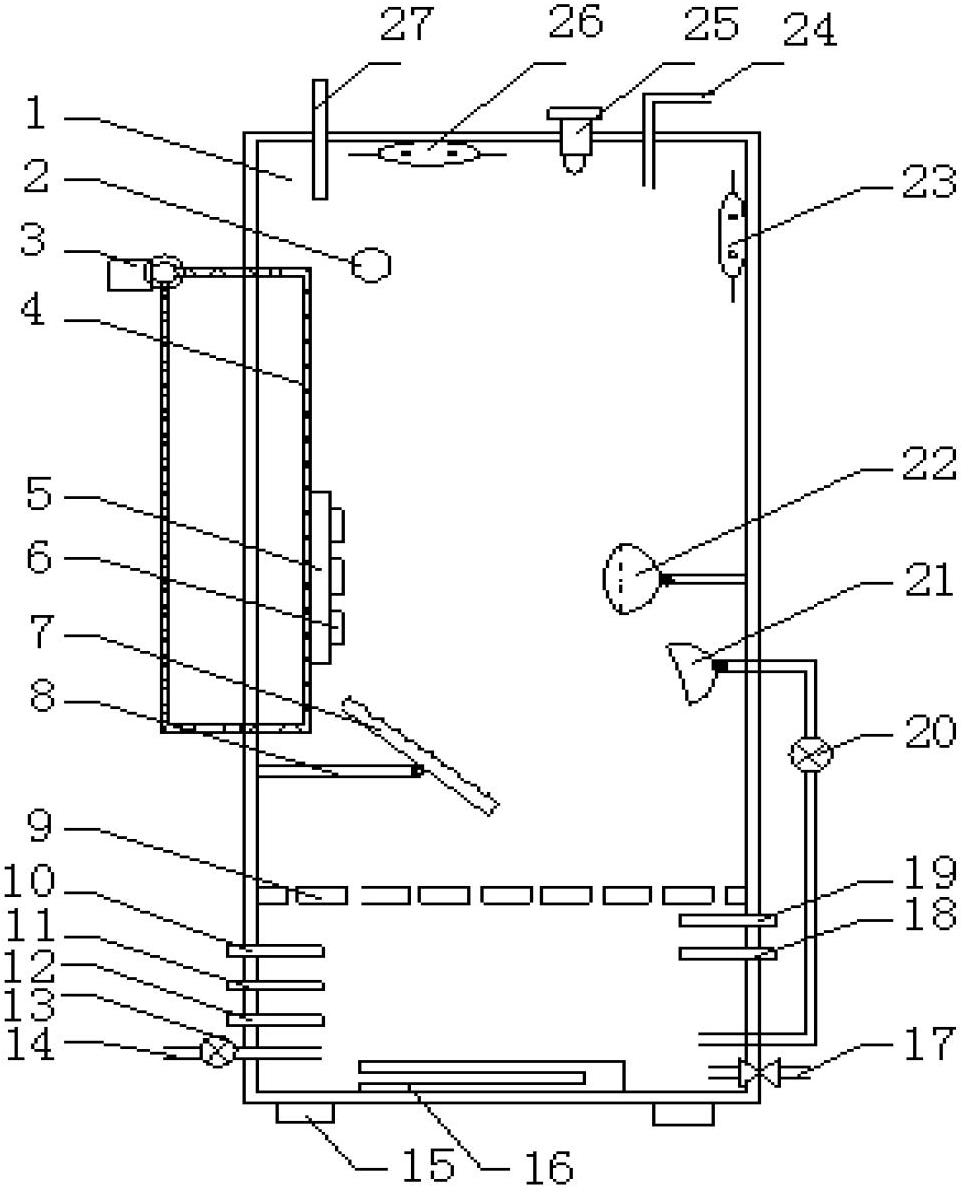

Marine splash environment simulation test device

ActiveCN102680385AImprove the simulation effectComprehensive monitoring of water qualityWeather/light/corrosion resistanceEngineeringMarine equipment

The invention belongs to the technical field of marine equipment, and particularly relates to a marine splash environment simulation test device, wherein stringed testing cable holes are arranged in the upper part of one side surface of the box-structured test box, a frame-structured drive pull rod is arranged on the other side, a splash plate angle adjusting rod is arranged at the lower part, and a splash plate is formed at the inner end of the splash plate angle adjusting rod; sensors and water inlets are arranged on the side surface of a liquid area from top to bottom; a gas exhaust opening, a ventilating and moisture exhausting device, an infrared heating lamp and a box temperature sensor are fixedly and sequentially arranged on the top side surface of the test box body from right to left; and a ultraviolet lamp, an air blower, a nozzle, a water spray pump, a liquid level controller, a dissolved oxygen sensor and a water drain opening are arranged on the opposite side of the test box corresponding to the side surface provided with the drive pull rod. The marine splash environment simulation test device has simple structure and higher automation degree, is convenient to operate, needs no staff attendance, and can simulate marine splash environment in a laboratory, so as to analyze and evaluate the corrosion and aging of the material.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

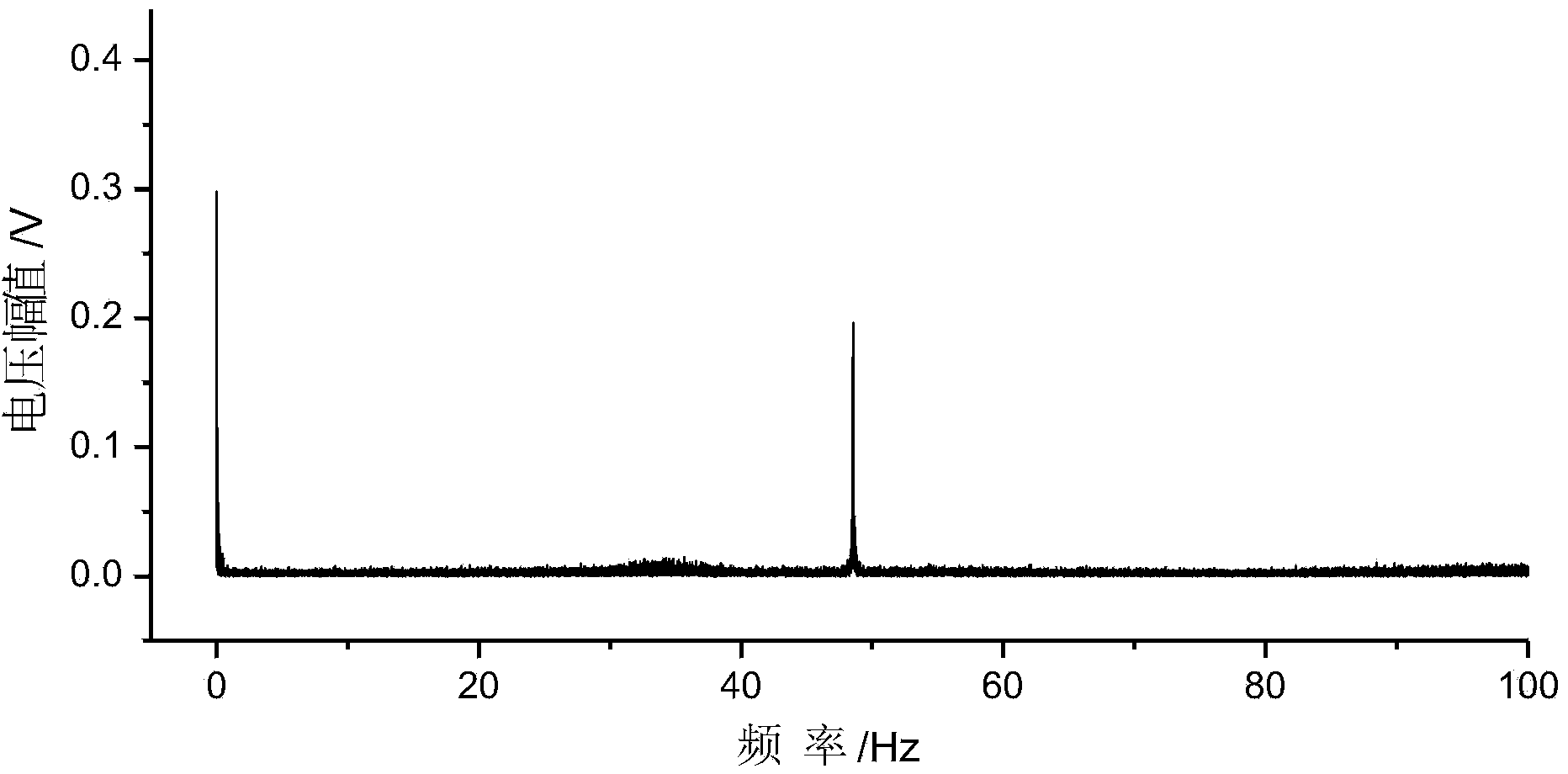

Frequency domain test and analysis system and method for cable overall ageing life evaluation

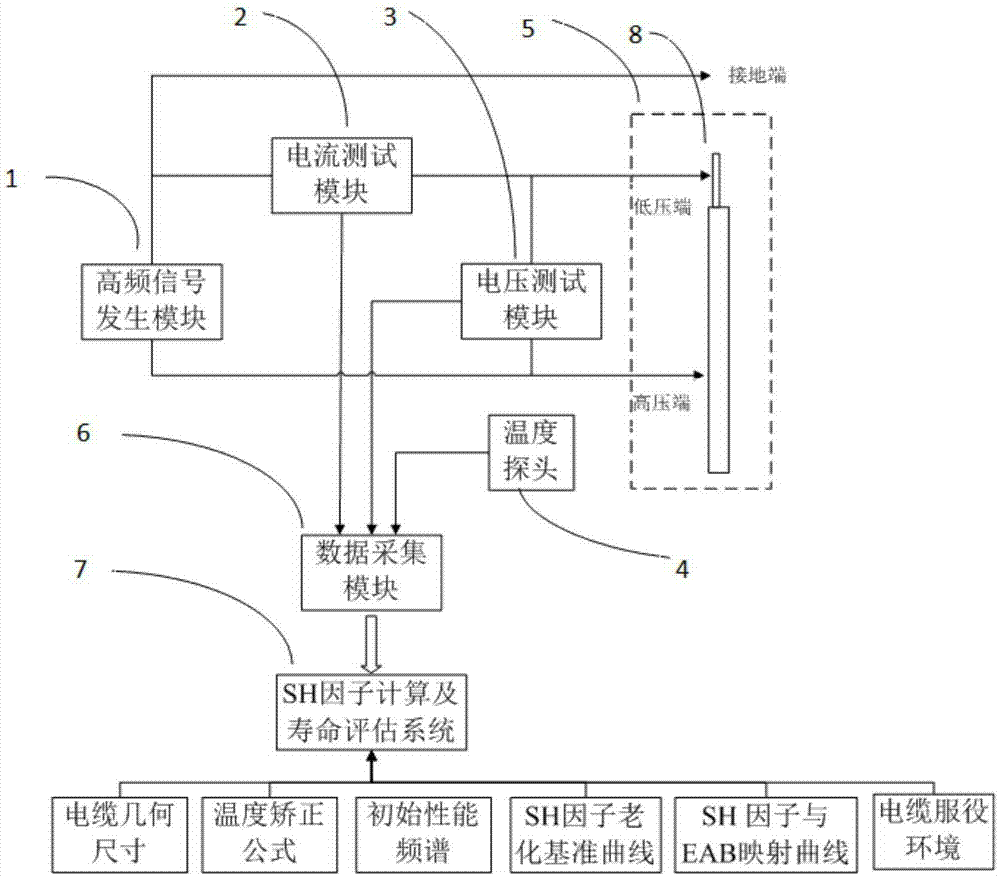

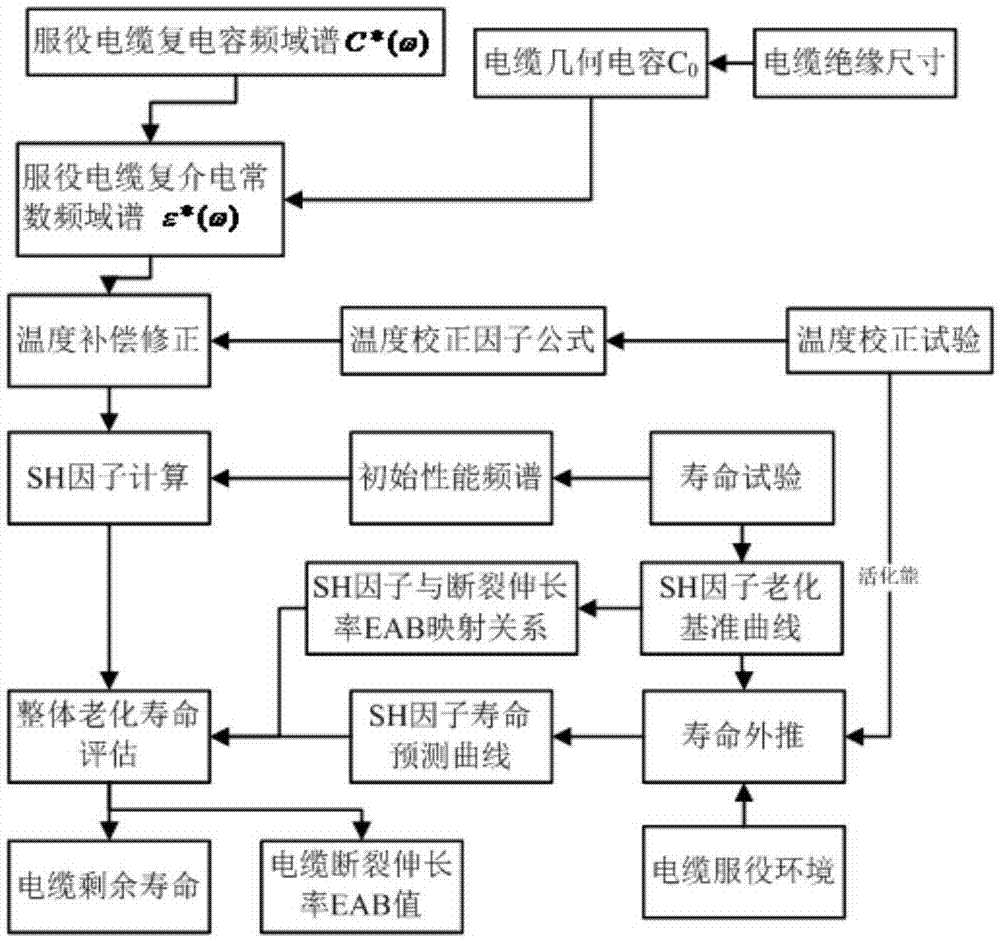

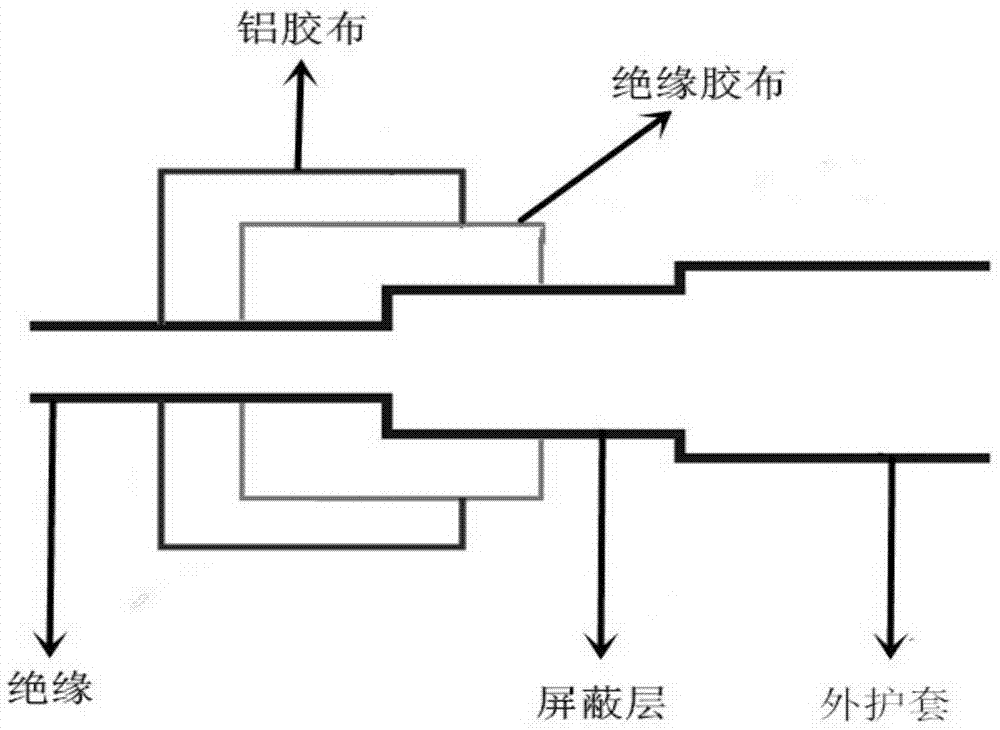

ActiveCN106855605AAccurate aging stateSolve the problem of longevityTesting dielectric strengthResistance/reactance/impedenceCapacitanceFrequency spectrum

The invention belongs to the technical field of cable nondestructive test and life evaluation and specifically relates to frequency domain test and analysis system and method for cable overall ageing life evaluation. A data acquisition module collects voltage and current response of a cable under actions of AC signals in different frequencies, and calculates cable complex capacitance spectrum and dielectric spectrum; according to temperature signals measured by a temperature probe, the dielectric spectrum calculated based on the test data is subjected to temperature correction treatment by calling temperature compensation factor of the cable in such material stored in the system to obtain a corrected frequency domain curve under a reference temperature; and an SH factor calculation and life evaluation system calculates an SH factor value for reflecting a current state of the cable according to the corrected dielectric spectrum curve, and extrapolates residual life of the cable under the current service condition and a current EAB (elongation at break ) value according to curve information recorded in the system. The system can realize in-service inspection and life evaluation of the on-site in-service cable.

Owner:RES INST OF NUCLEAR POWER OPERATION +1

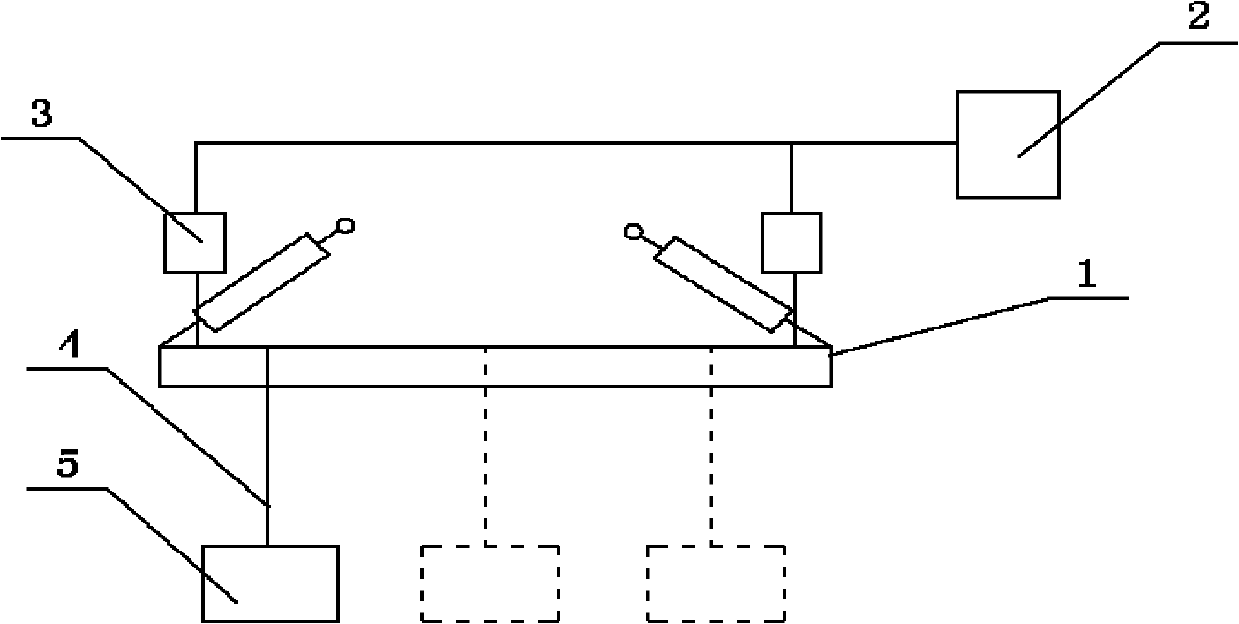

Rotary micromotion friction wear test method and device thereof

InactiveCN101226122AHigh degree of automationHigh precision of control and testingMachine part testingInvestigating abrasion/wear resistanceTorque sensorLow speed

The invention relates to a rotary inching friction abrasion test method and a relative device, wherein the method comprises clamping a plane upper sample on an upper clamp, fixing a lower clamp on the horizontal rotation shaft of a high-precision ultra-low speed rotation motor, clamping a spherical lower sample via a lower clamp, aligning the horizontal central line of the lower sample with the rotation shaft of the rotation motor, using a data acquisition and control system to control the up-and-down and left-and-right motions of the upper clamp to contact the upper and lower samples and apply a preset normal load, at the same time, using the data acquisition and control system to control the rotation motor to reciprocally rotate the lower clamp and lower sample at preset rotation argument, rotation speed and times, to realize the rotary inching friction between the upper and lower samples, using a six-dimension force / torque sensor to test and feed the friction force to the data acquisition and control system to be analyzed to obtain a friction force-angle displacement curvature. The inventive method can simply realize small angle rotary inching friction abrasion of material, with high automatic degree, high control and test accuracy and better test data reappearance.

Owner:SOUTHWEST JIAOTONG UNIV

Method for testing pile shaft stress of static pressure high-strength pre-stressed concrete pipe pile

The invention belongs to the technical field of building construction stress testing and relates to a method for testing the pile shaft stress of a static pressure high-strength pre-stressed concrete pipe pile. When tensile force or pressure is received by a fiber Bragg grating sensor, the optical fiber grating period is changed due to the extension or the compression of the sensor, and therefore the effective refraction rate of the FBG sensor is changed. According to the axial strain of one section of the high-strength pre-stressed concrete pipe pile, the pile shaft stress of the static pressure high-strength pre-stressed concrete pipe pile is obtained, and therefore the axial force of a pile shaft, the side friction and the pile tip resistance are obtained. The method for testing the pile shaft stress of the static pressure high-strength pre-stressed concrete pipe pile is simple, convenient to operate, high in measuring accuracy, high in sensitivity, strong in electromagnetic field interference resistance, high in rate of survival, and capable of achieving quasi-distributed and automatic monitoring easier compared with a method of a traditional force testing element.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

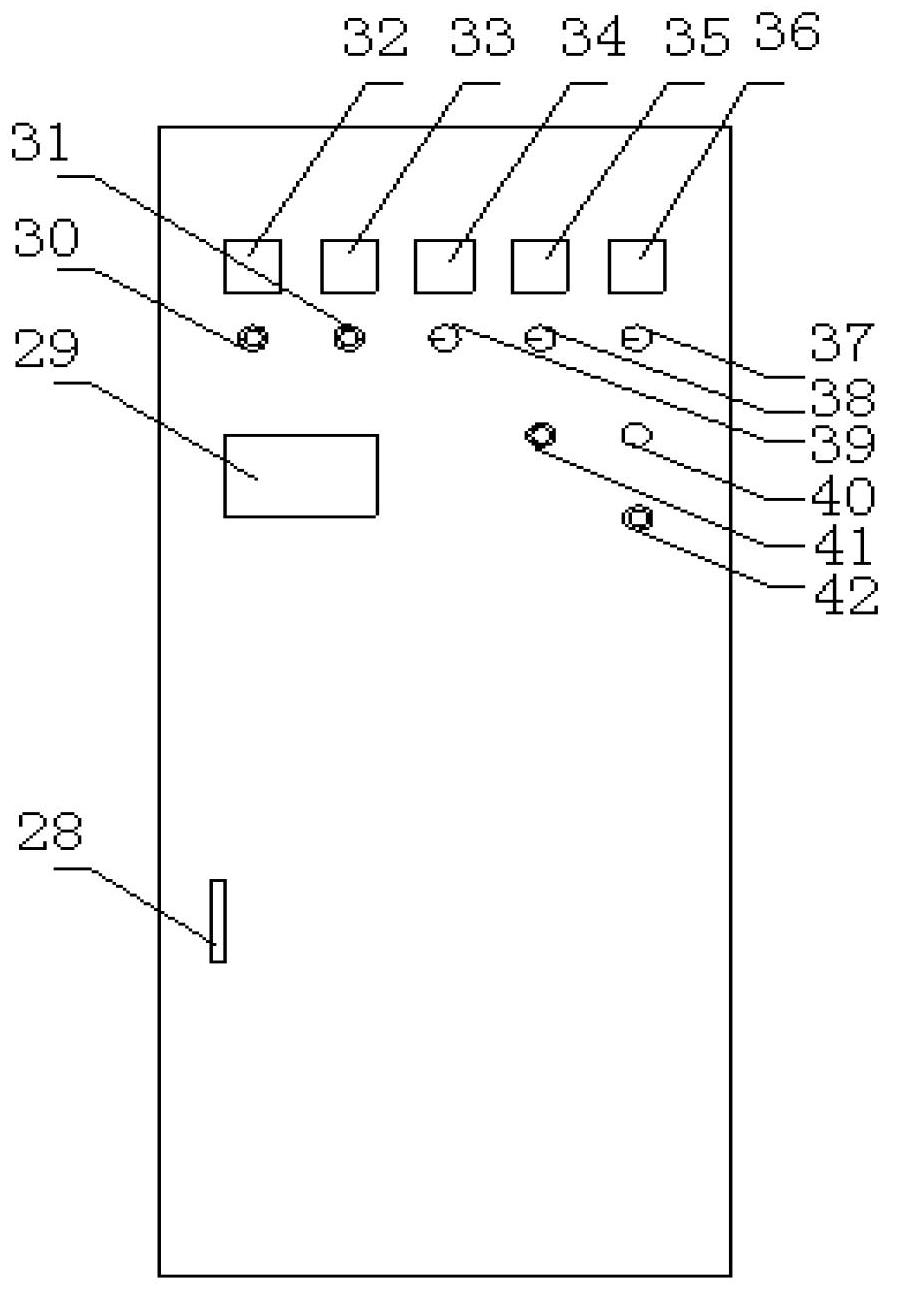

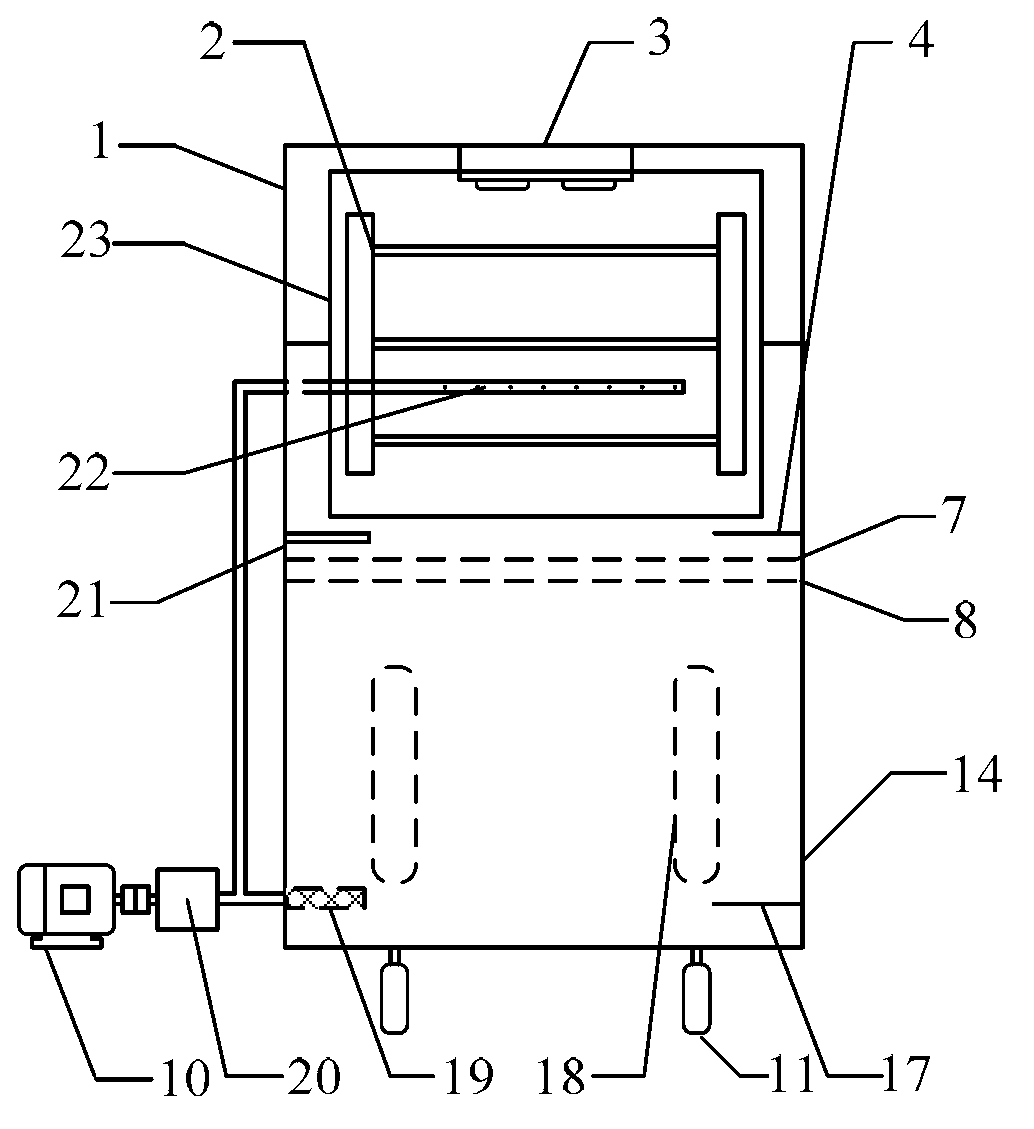

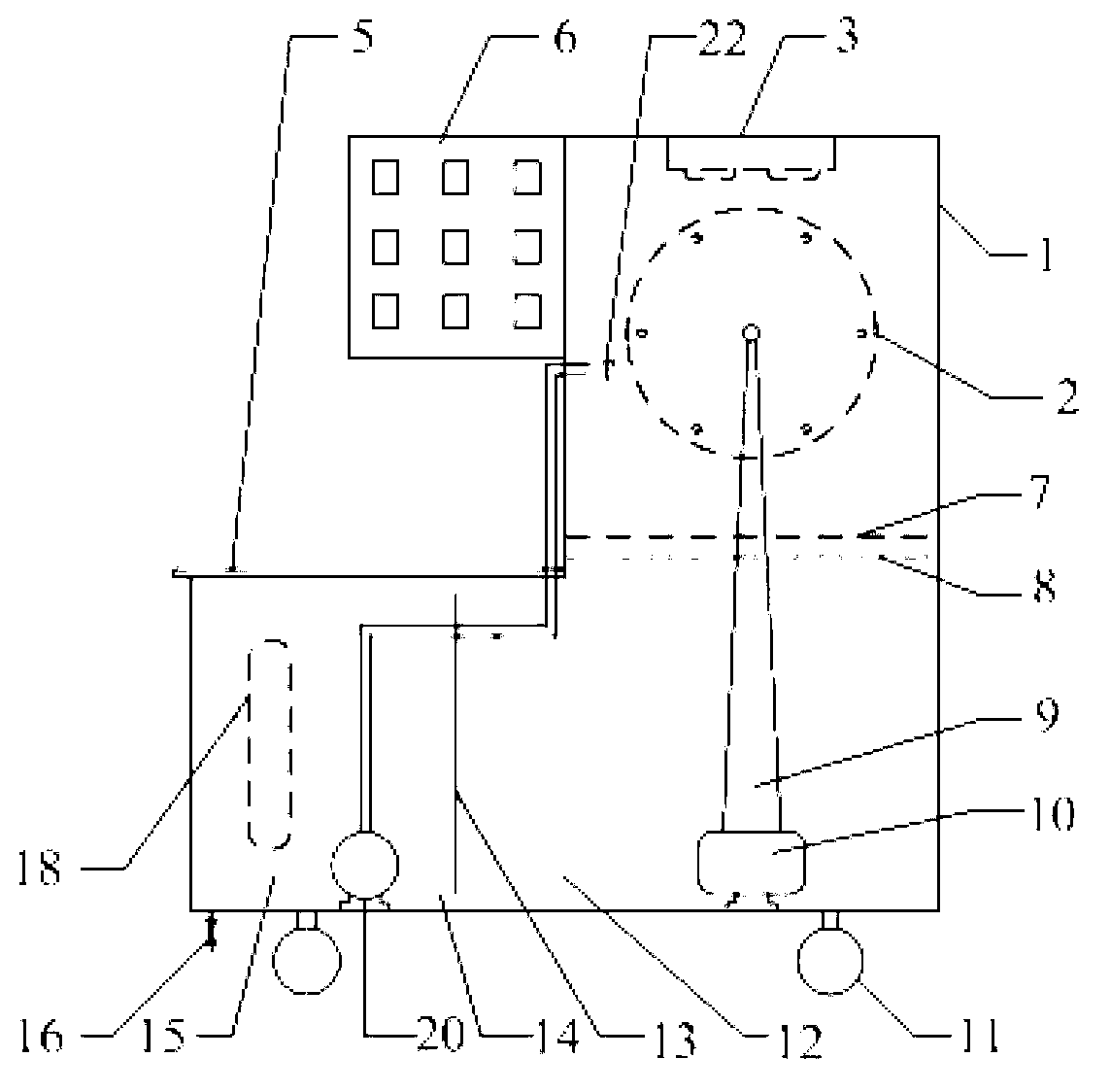

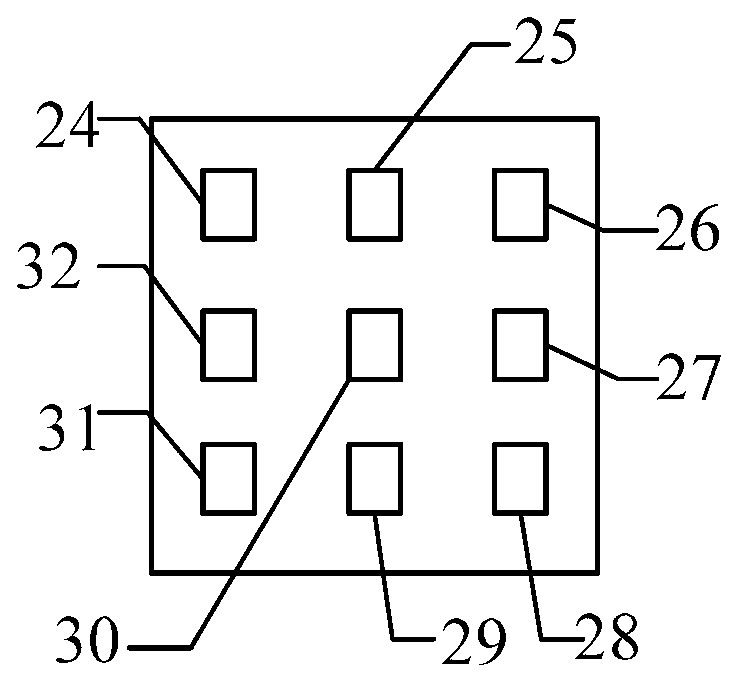

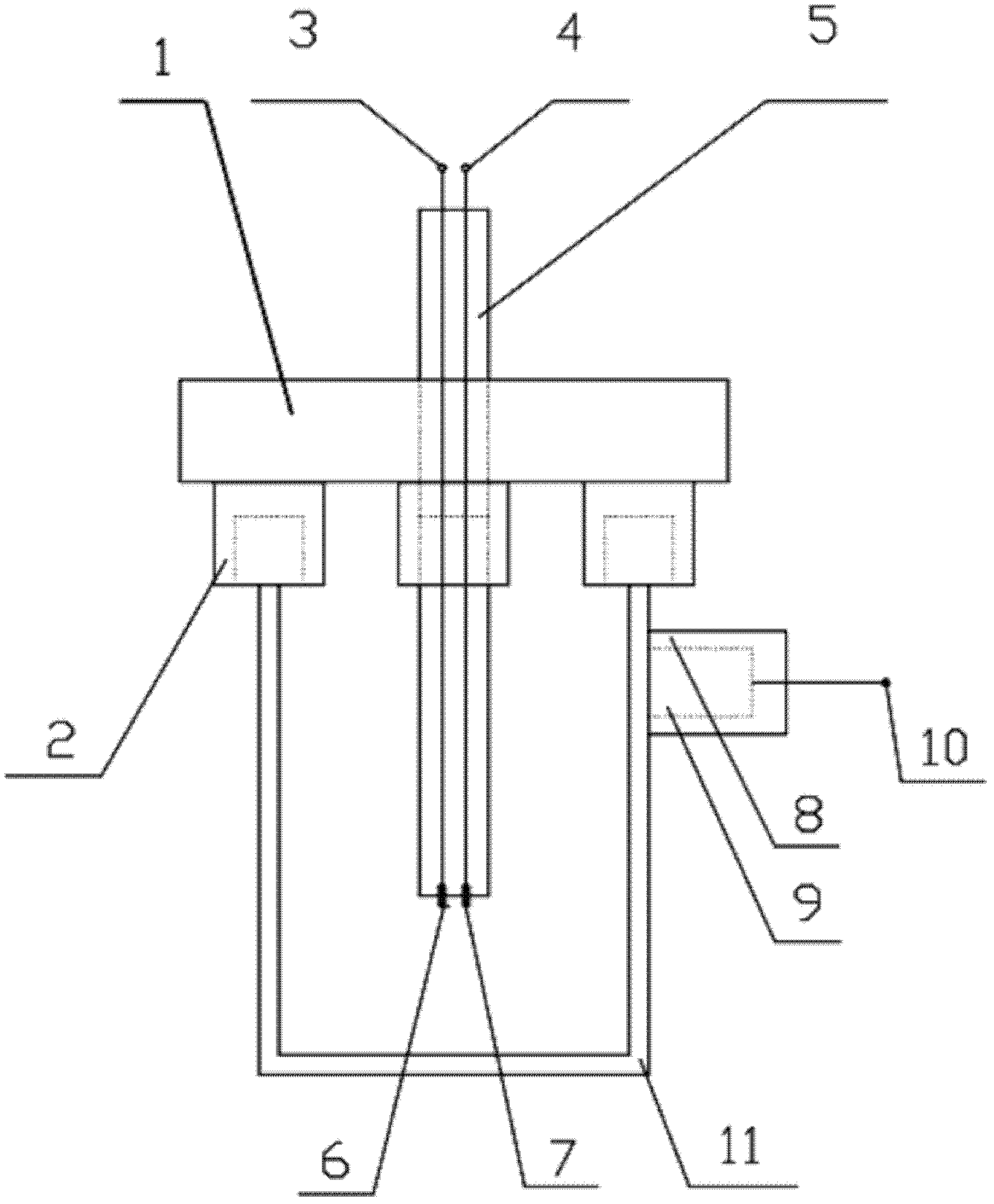

Marine-splash-zone-simulating corrosion test device and testing method

ActiveCN102937565ASimple structureSimple and fast operationWeather/light/corrosion resistanceAutomatic controlFiltration

The invention discloses a marine-splash-zone-simulating corrosion test device and a marine-splash-zone-simulating corrosion testing method. The device comprises a box, liquid storage tank, a rotary sample rack, a transmission system, a spraying system, an illumination system, a temperature control system, a filtration system, a time control system and an automatic control system panel. The rotary sample rack, the spraying system, the illumination system, and the temperature control system are arranged in the box. The transmission system is arranged on the outside of the box, and is connected with the rotary sample rack. The liquid storage tank is arranged below the box. An overflow plate is arranged in the liquid storage tank, and divides the liquid storage tank into two parts, which are a sedimentation tank and a supernatant tank. The automatic control system panel is arranged above the liquid storage tank. The spraying system, the illumination system, the temperature control system, and the time control system are respectively connected with the automatic control system panel.

Owner:ANGANG STEEL CO LTD

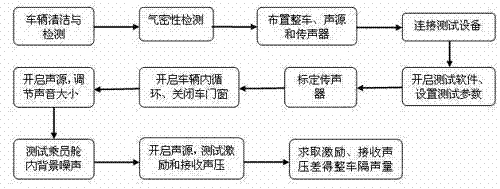

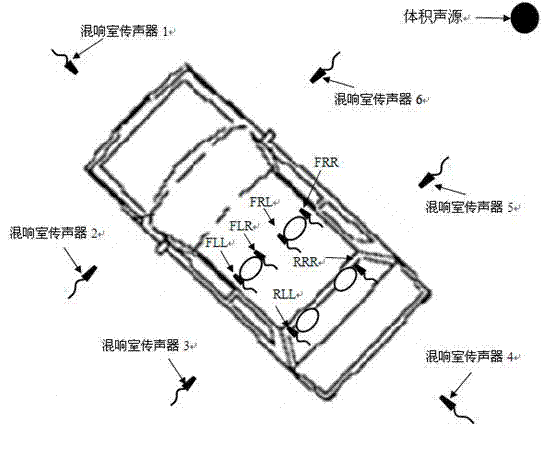

Method of testing and evaluating sound insulation property of finished automobile based on reverberation room

InactiveCN103115666AReflects the level of sound insulation performanceSimple test methodVehicle testingSubsonic/sonic/ultrasonic wave measurementMean squareEngineering

The invention provides a method testing and evaluating sound insulation property of a finished automobile based on a reverberation room. Stimulating sound pressure sources are arranged at random multiple positions inside the reverberation room. Sound pressure testers are arranged at multiple positions inside the sealed finished automobile. A sound pressure mean square value outside an automobile body inside the reverberation room is calculated to obtain a stimulating sound pressure. A sound pressure mean square value inside the finished automobile is calculated to obtain a receiving sound pressure. A difference between the stimulating sound pressure and the receiving sound pressure is a sound decay. Thus the sound insulation property of the finished automobile is judged.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

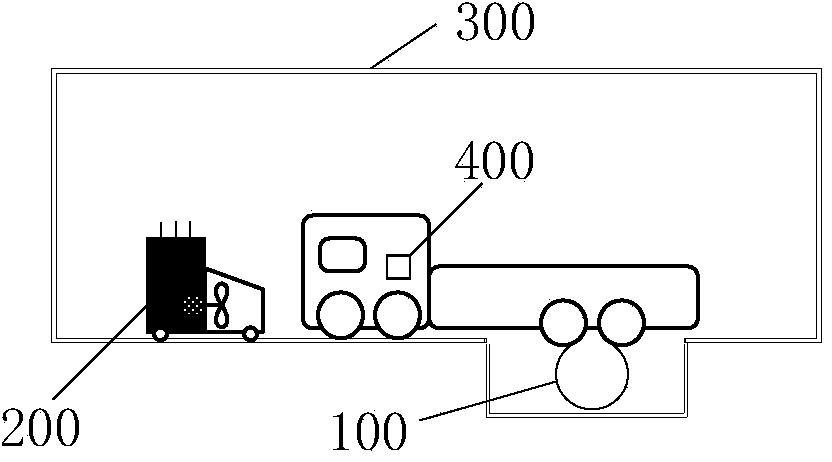

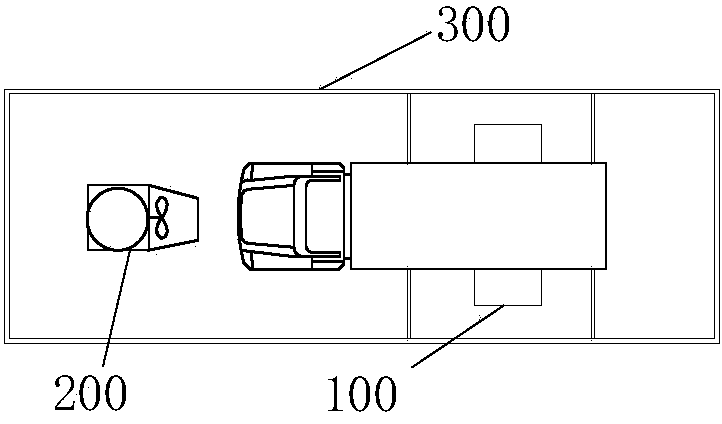

Indoor testing device and method for vehicle heat balance ability

ActiveCN104180997AEasy to operateSimple heat balance capabilityVehicle testingEngine testingMaximum torqueTemperature control

The invention discloses an indoor testing device and method for the vehicle heat balance ability, and belongs to the field of vehicle cooling system heat balance technologies. The device comprises a chassis dynamometer, an environment bin with a temperature control system, a cooling fan and a temperature data collection system. The chassis dynamometer is arranged in the environment bin. The cooling fan is arranged in front of a vehicle to be tested in the environment bin and used for simulating the air speed. The temperature data collection system is arranged in the vehicle to be tested and used for measuring the temperature of a vehicle water way and the environment. According to the indoor testing device and method, the heat balance ability of an engine and a cooling system of the vehicle are tested fast and effectively, the maximum power point of an external characteristic curve of the engine, the water inlet and outlet temperature, at the maximum torque point, of the engine and the water inlet and outlet temperature of a radiator are tested, matching and requirements of the engine and the cooling system of the vehicle can be judged in real time, and the state of the sample vehicle to be tested can be adjusted for research and development.

Owner:NANJING AUTOMOBILE GROUP CORP

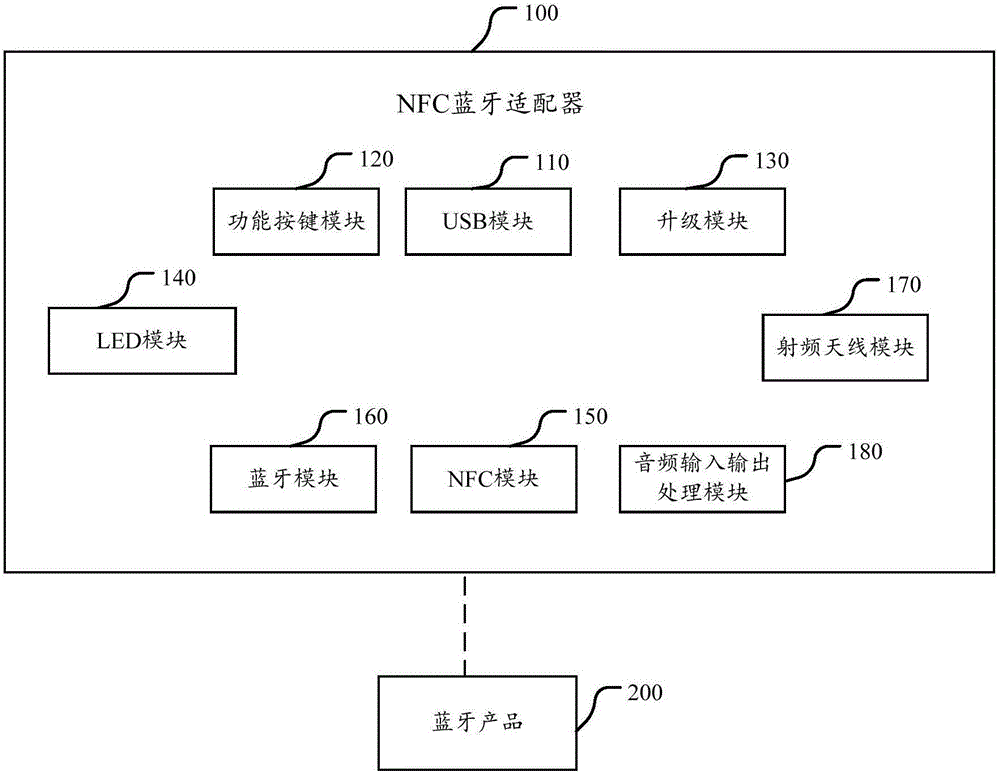

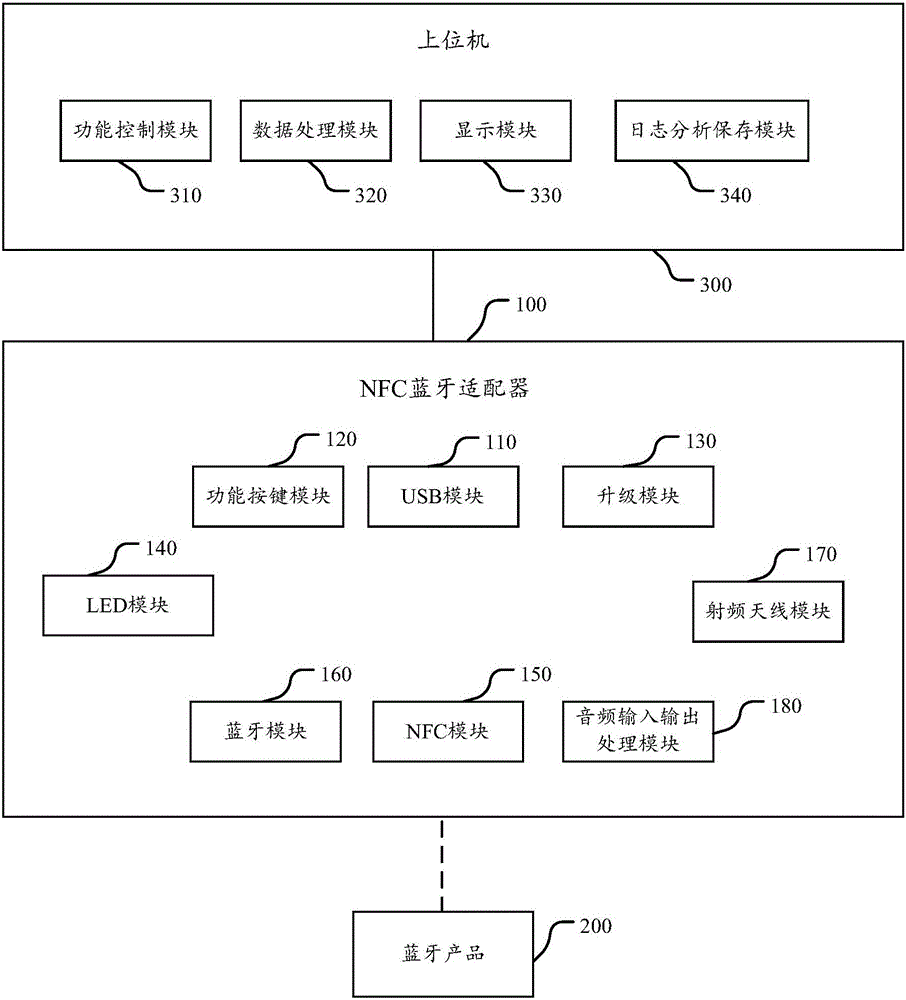

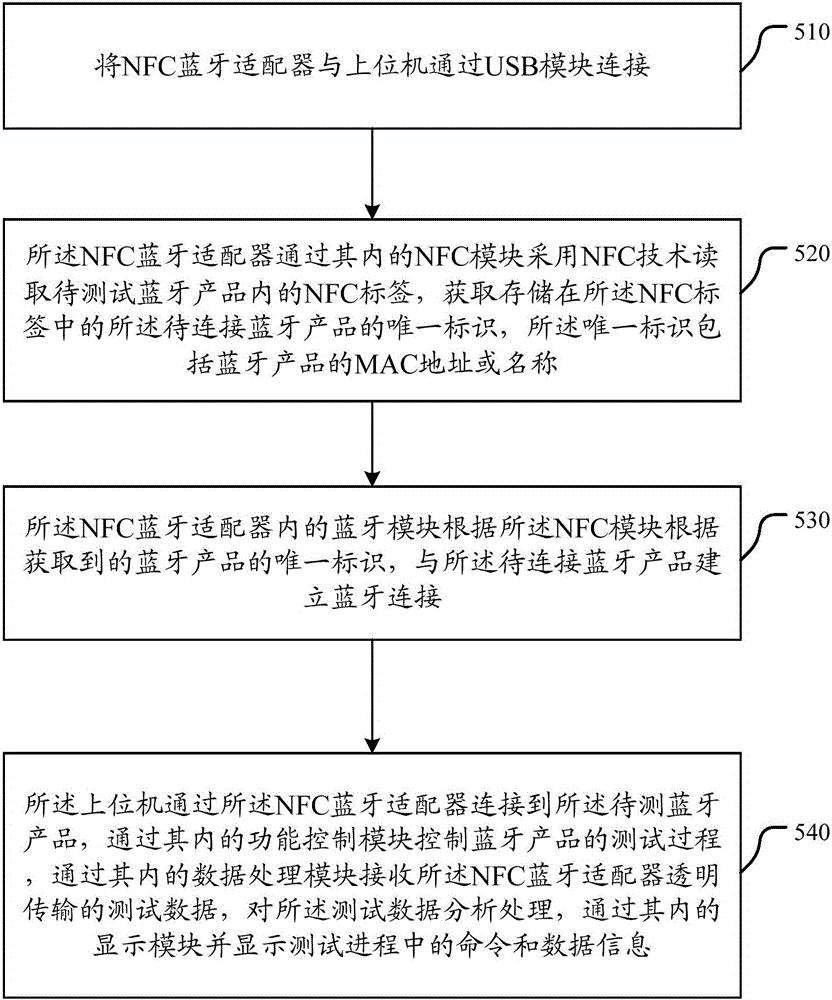

NFC bluetooth adapter and bluetooth product test system and test method

InactiveCN105848196AUniqueness guaranteedHigh speedNear-field systems using receiversWireless communicationUnique identifierBluetooth

The invention discloses an NFC bluetooth adapter and a bluetooth product test system and test method. The NFC bluetooth adapter comprises an NFC module which adopts an NFC technology to read an NFC tag arranged in a bluetooth product under connection and acquires a unique identifier of the bluetooth product under connection stored in the NFC tag; and a bluetooth module which establishes bluetooth connection with the bluetooth product under connection according to the unique identifier of the bluetooth product under connection acquired by the NFC module. The bluetooth product test system comprises an upper computer and the NFC bluetooth adapter. The bluetooth adapter guarantees the uniqueness of connection of the bluetooth product so that speed and accuracy of connection of the bluetooth adapter and the bluetooth product can be effectively enhanced. According to the bluetooth product test system, the NFC bluetooth adapter is combined with the upper computer with no requirement for additional complex special test equipment or complex manual operation so that various tests of the bluetooth product can be simply and rapidly controlled, and thus the bluetooth product test system has the advantages of being simple in test method and easy to operate.

Owner:QINGDAO GOERTEK

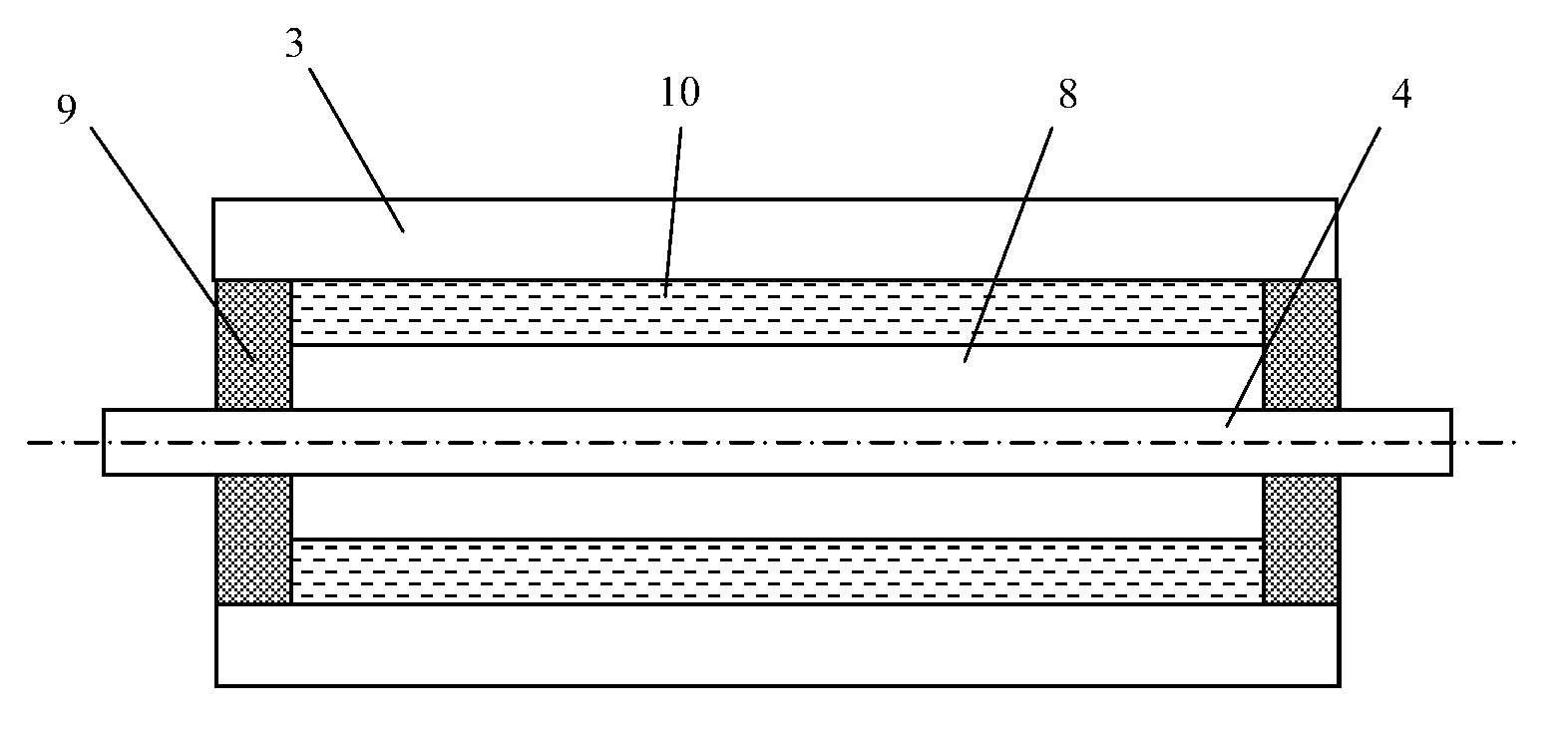

Bushing non-uniform external pressure loading test device and bushing non-uniform external pressure loading test method

ActiveCN103308390AThe test method is simpleImprove loading efficiencyMaterial strength using tensile/compressive forcesTest frameEngineering

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

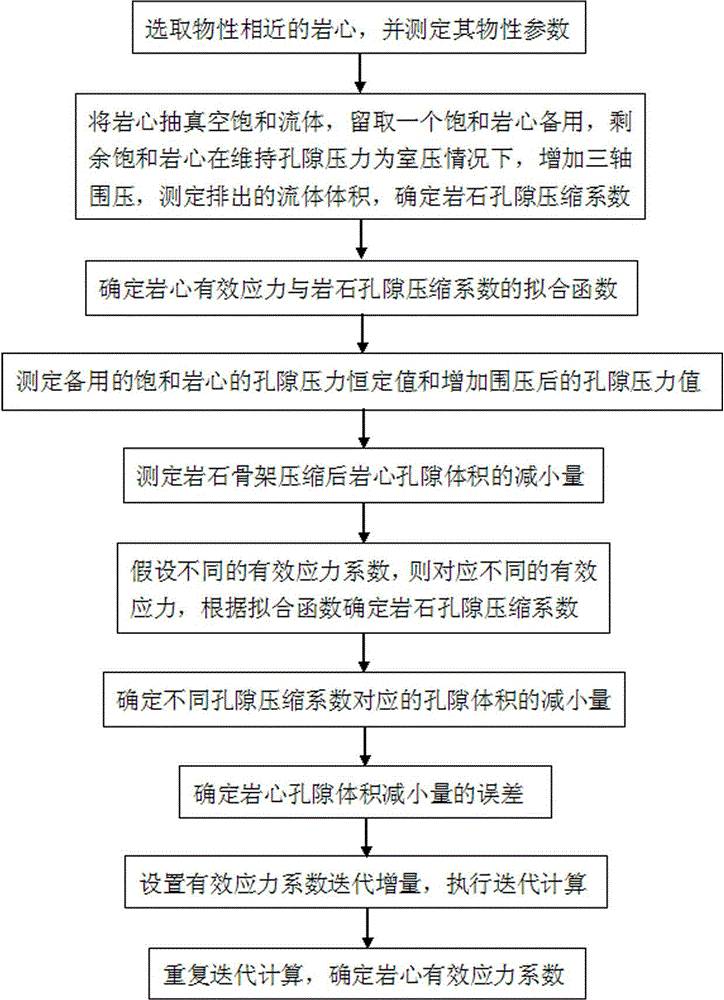

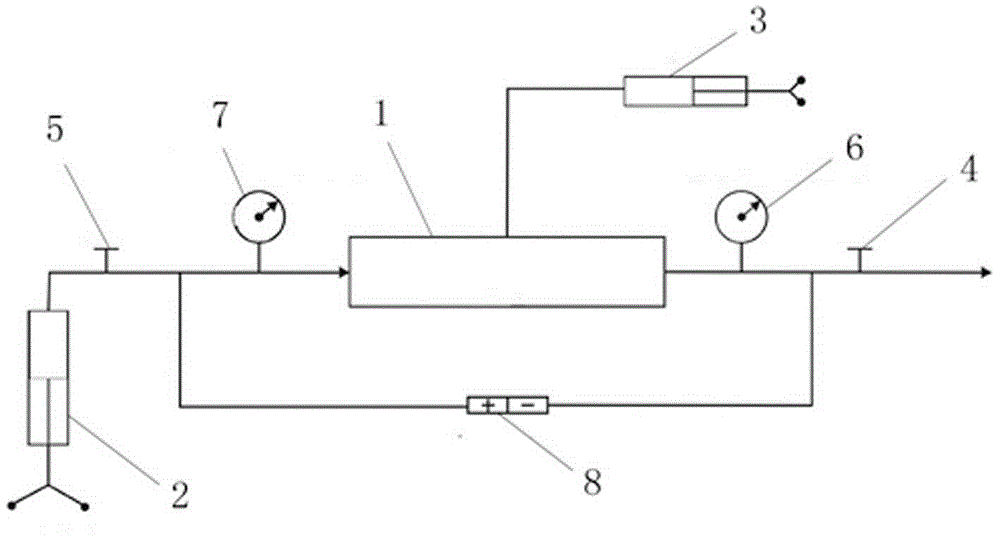

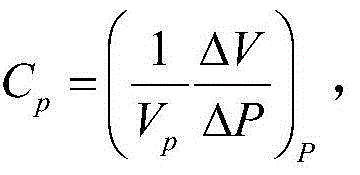

Method for determining effective rock stress coefficient based on pore compression experiment

ActiveCN104089823AThe principle of the test is clearSimple test methodMaterial strength using tensile/compressive forcesPermeability/surface area analysisPhysical propertyEffective stress

The invention discloses a method for determining an effective rock stress coefficient based on a pore compression experiment. The method comprises the following steps: selecting cores with similar physical properties in the same direction of the same rock, vacuumizing saturated fluid, gradually increasing triaxial confining pressure under the condition that the pore pressure is maintained to be room pressure, measuring the volume of fluid discharged from pores in the pressurization process, determining the rock pore compression coefficient, fitting a fitting function between the effective stress and the pore compression coefficient, measuring a pore pressure constant value of the saturated core and the pore pressure value after the confining pressure is increased, determining core pore volume reduction, and finally determining the effective rock stress coefficient value according to a calculation formula of the effective stress born by a rock matrix and the rock pore compression coefficient. The method is applied to low-permeability and ultralow-permeability reservoir stress research, the testing equipment is simple, the principle is clear, and the method is simple and accurate in measurement result.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for testing content of magnetic substances in lithium ion battery anode material

InactiveCN103884571AHigh precisionContent Accurate TestComponent separationPreparing sample for investigationSolventAmount of substance

The invention discloses a method for testing the content of magnetic substances in a lithium ion battery anode material. The method comprises the following steps: ultrasonically dispersing a lithium ion battery anode material to be tested into a solvent, adding a polymer cladded magnet, ultrasonically adsorbing the magnetic substances, thereby obtaining the polymer cladded magnet adsorbed with the magnetic substances; adding the polymer cladded magnet adsorbed with the magnetic substances into a cleaning solution for performing ultrasonic cleaning; dissolving the cleaned polymer cladded magnet adsorbed with the magnetic substances by using an acidic reagent, thereby obtaining a dissolution solution; and testing the content of the magnetic substances in the dissolution solution. According to the method, the content of the magnetic substances in the lithium ion battery anode material can be accurately tested, particularly the content of the magnetic substances contained in micron order materials and nanoscale materials can be accurately detected. The testing method is simple, easy to operate and high in precision, and the precision can reach a ppb level.

Owner:SHENZHEN DYNANONIC +1

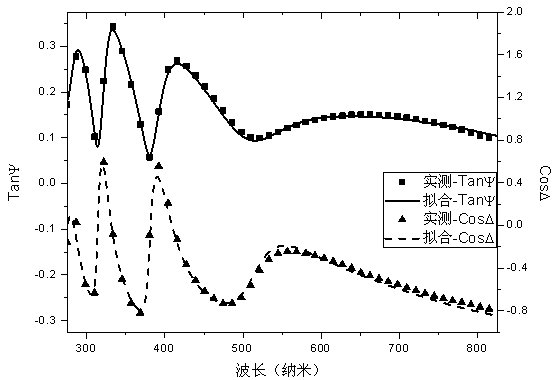

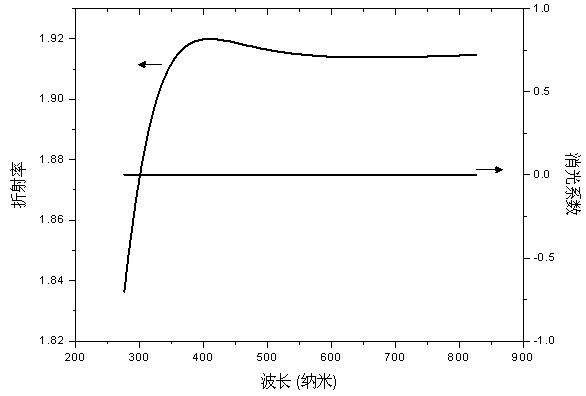

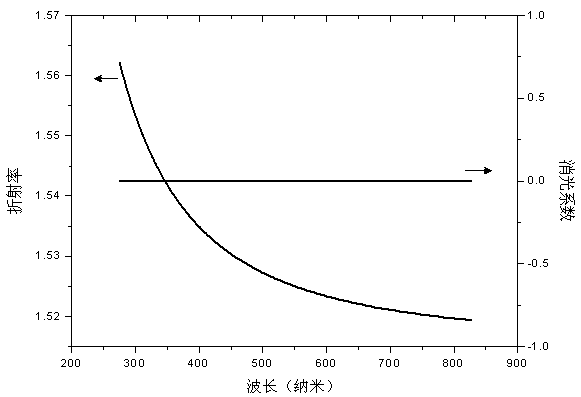

Optical parameter detection method of low-radiation coated glass

ActiveCN103323403APrecise structureNo damagePhase-affecting property measurementsColor/spectral properties measurementsOptical testSpectroscopic ellipsometry

The invention relates to an optical parameter detection method of low-radiation coated glass, wherein the low-radiation coated glass is SnO2:F / SiCxOy, 0<x<1, and 1<y<4. The invention belongs to a coated glass detection field. On basis of obtaining a spectroscopic ellipsometry of SnO2:F / SiCxOy energy saving coated glass, the method introduces a five-layer film structure and an optical dispersion equation, returns an actually-measured spectroscopic ellipsometry by iteration, and finally obtains a film structure of the SnO2:F / SiCxOy coated glass and optical parameters of each layer. By the method, on-line real time monitor of optical performances of the coated glass can be implemented. The method can obtain an accurate film structure and the optical parameters only by optical test means, has advantages of no damage on a sample, small time consuming for measuring, simple measuring method, and no special requirement on a sample surface to be measured, and is very suitable for performance detection of the SnO2:F / SiCxOy energy saving coated glass.

Owner:中玻(陕西)新技术有限公司

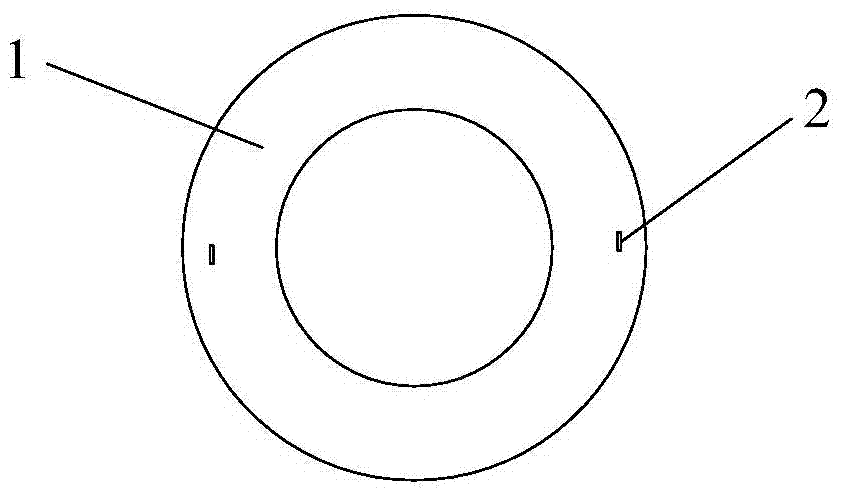

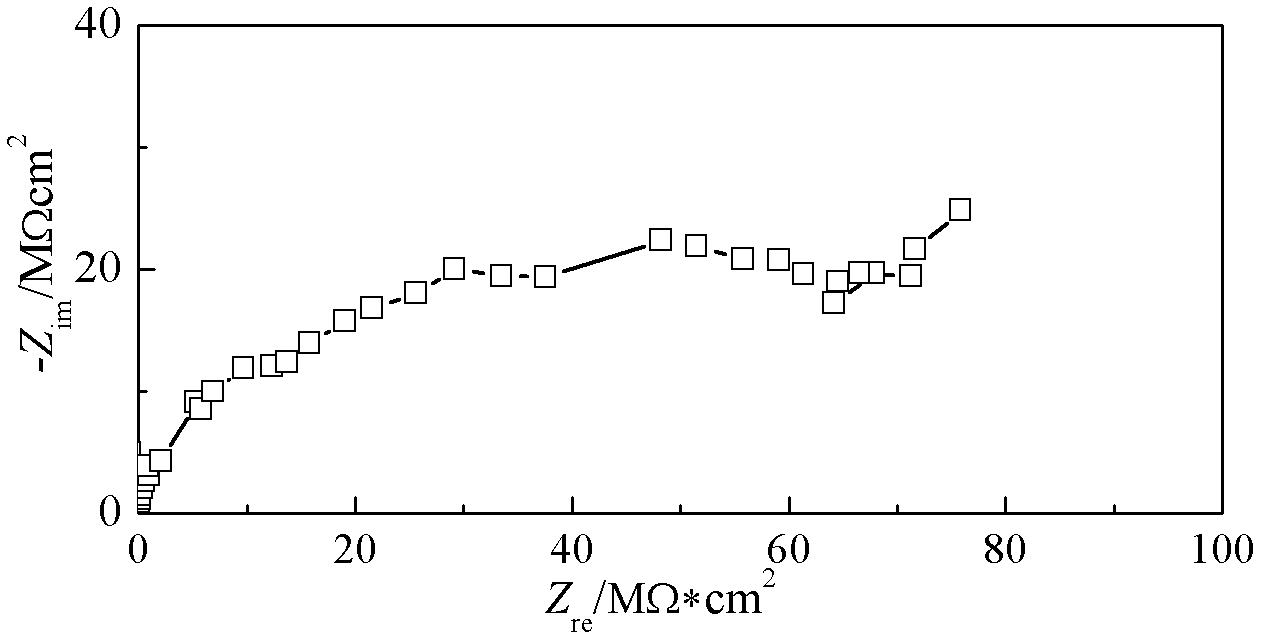

Sensor for measuring corrosion of inner wall of metal tank body and monitoring method

ActiveCN102494990AJudgment integrityDetermine the type of damageWeather/light/corrosion resistanceSpectroscopyAuxiliary electrode

The invention discloses a sensor for measuring the corrosion of the inner wall of a metal tank body and a monitoring method. The sensor is of the following structure that the sensor comprises a fixing device, a sleeve, a reference electrode, an auxiliary electrode and a working electrode; and in the measuring process, the sensor is arranged at the top of a metal tank, the metal tank and the sensor are fixed and are tightly contacted through magnets, the electrodes partly extend into the tank to be in contact with a solution for performing an electrochemical detection, and a contact of the working electrode is attracted by the magnets to be fixed on the outer surface of the tank body. In the monitoring process, the corrosion behavior and degree of the inner wall of the metal tank are tested by utilizing an electrochemical low-frequency impedance spectroscopy technology. In the technical scheme disclosed by the invention, the sensor has simple manufacturing process, is sensitive to response, is convenient to carry and is simple to operate; the monitoring method is simple and convenient and has high data resolvability; the breakage condition, the breakage type and the corrosion degree of a coating on the inner wall of the metal tank can be rapidly judged in the service environment by the monitoring method; and the monitoring method is suitable for carrying out rapid detection andevaluation on the corrosion degree of the coatings on the inner walls of the metal tanks with various sizes.

Owner:TIANJIN UNIV

System and method for tunnel deformation monitoring

InactiveCN103090812AReal-time monitoring of deformationSimple test methodTransmission systemsUsing optical meansOperational systemWireless transmission

The invention provides a system and a method for tunnel deformation monitoring. The system and the method for tunnel deformation monitoring comprise the following steps: distance meters and prisms with proper numbers and types are selected; positions are designated on a line needing measuring, and reflecting prisms are arranged on each monitoring point. According to dimensionality measured according to actual need, different numbers of distance meters are arranged on stable reference points with known coordinates, the reflecting prisms are measured in real time, and a plurality of formulas are composed by utilizing measurement formulas to solve the three-dimension space coordinates of each reflecting prism on the monitoring points. The monitoring frequencies of the distance meters are set through a computer operation system, and data obtained by the distance meters is accurately and timely transmitted to a software analysis system through a wireless transmission device. The software analysis system can calculate the deformation value and the change rate of the tunnel monitoring point at a certain time interval through the way that the software analysis system compares three-dimensional coordinates of different time intervals on a monitoring point of the reflecting prisms.

Owner:BEIJING DIGSUR SCI & TECH +1

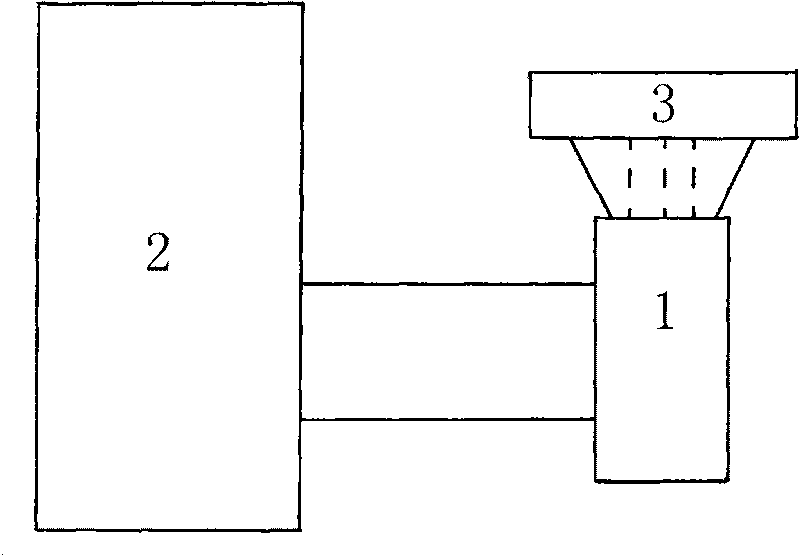

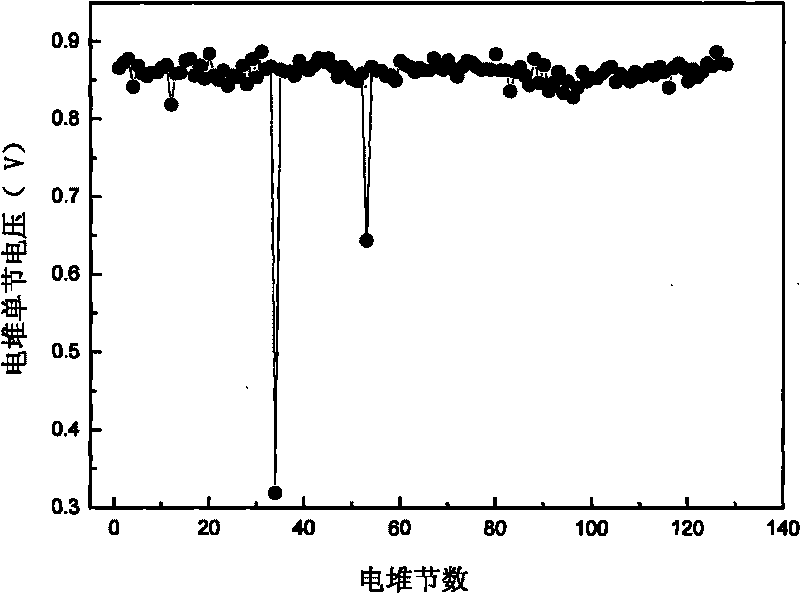

Method for detecting blow-by of hydrogen and oxygen in fuel cell stack quickly

ActiveCN101697005AAvoid safety hazardsQuality improvementFuel cells groupingCurrent/voltage measurementFuel cellsHydrogen

The invention relates to a method for detecting the blow-by of hydrogen and oxygen in a fuel cell stack quickly, which comprises the following steps: mounting the stack on a detection platform to connect the stack and a gas pipeline of a test platform and a circuit of a voltage routing inspection system; introducing hydrogen cavity detection gas into a hydrogen cavity of the stack, introducing oxygen cavity detection gas to an oxygen cavity, and enabling the stack to enter the generating state; and after voltages of cells in the stack are in an open circuit state of over 0.9 V, stopping introducing the oxygen cavity detection gas, continuing to introduce the hydrogen cavity detection gas to the hydrogen cavity, keeping pressure and recording the change of the cell voltages of the fuel cell stack under the state. Thus, a position in which the cell that the voltage of a single cell in the fuel cell stack drops quickly is positioned is a specific position of the blow-by of an oxy-hydrogen cavity. The method can detect the specific position of the blow-by of the hydrogen and oxygen in the fuel cell stack quickly, has the characteristics of novel and simple structure, quick test time, accurate test and the like, and belongs to the method for detecting the blow-by of the hydrogen and oxygen in the fuel cell stack which integrates economy and practicability into a whole.

Owner:SUNRISE POWER CO LTD

Rigid body mode testing method for powertrain mounting system under loading condition

ActiveCN101907523AShorten test timeReduce test costsVehicle suspension/damping testingVibration testingPowertrainEngineering

The invention discloses a rigid body mode testing method for a powertrain mounting system under the loading condition. In the method, a heavy object is hung on a powertrain mounting device under the loading condition; and a rope for hanging the heavy object is cut to suddenly release the force acted on the powertrain mounting device so as to excite the free vibration of the powertrain mounting device and immediately trigger a data acquisition unit to record and store the data on a vibration transducer at the moment. A rigid body mode of the mounting system is tested by the method and the obtained each-order natural frequency and decoupling rate are the actual and real natural frequency and decoupling rate of a tested vehicle, so that the method tests the performance of the vehicle most directly, really and reliably. The testing method can be performed on any entire vehicle, only a proper number of heavy objects is needed, and the design and processing of a test bench are avoided, so that the testing cost is basically avoided. Obviously, the testing time and the testing cost are greatly saved.

Owner:常熟市知识产权运营中心有限公司

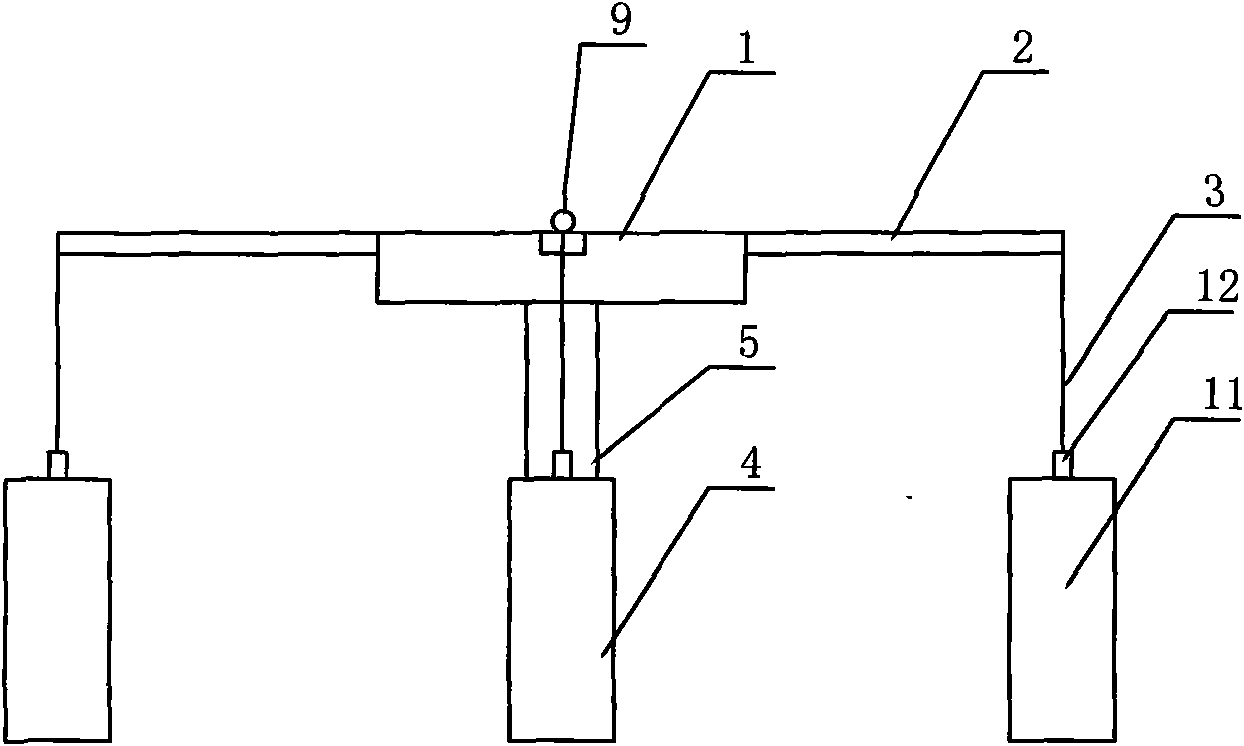

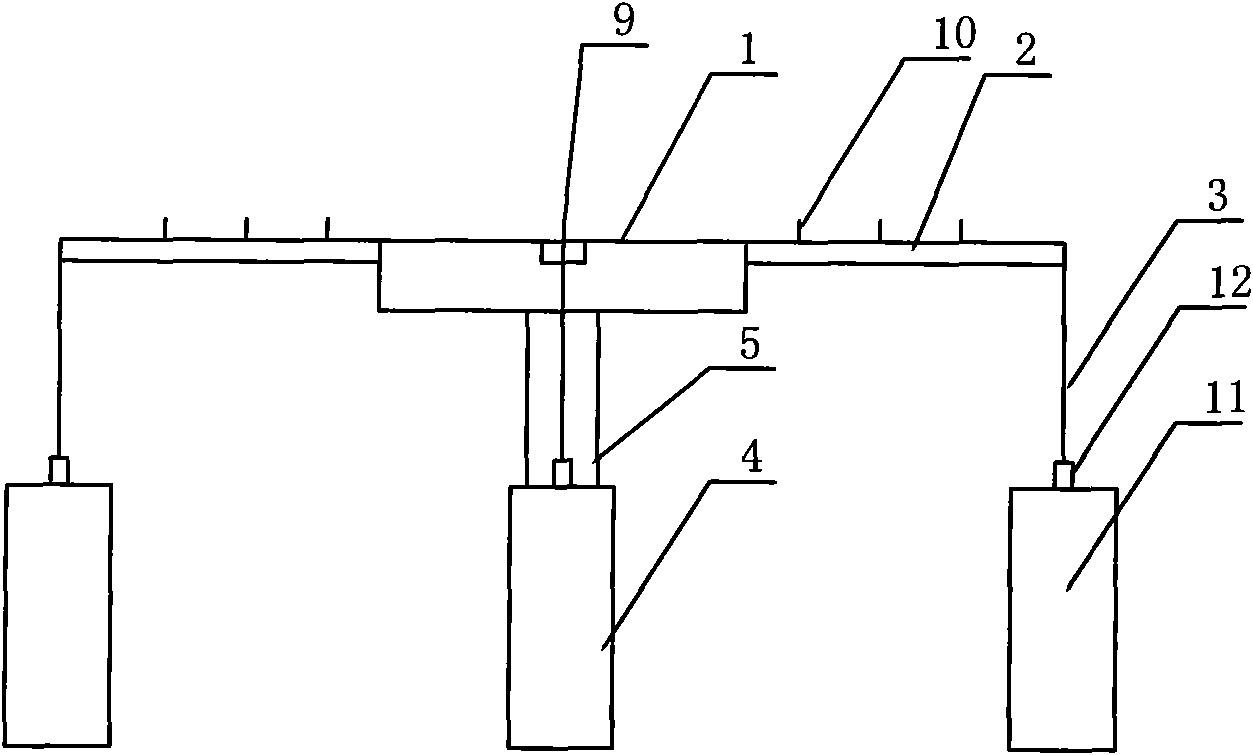

Compressive pile load detection device and method

The invention discloses a compressive pile load detection device and method. The device comprises a jack and a counterforce device, wherein the jack is arranged on the compressive pile to be detected, the upper surface of the jack contacts with the lower surface of the counterforce device; the counterforce device comprises a force transferring chuck, a force-transferring guide rod arranged on the force transferring chuck, a steel wire rope and a pile rope connecting mechanism; the upper surface of the jack contacts with the lower surface of the force transferring chuck, the steel wire rope penetrates through the force transferring chuck and the pile rope connecting mechanism along the force-transferring guide rod, the pile rope connecting mechanism is fixedly connected with auxiliary pile of the compressive pile to be detected, and the two ends of the steel wire rope are fixed together. By using the detection device exerting uplift loading evenly on the auxiliary piles surrounding the compressive pile to be detected, the mechanical parameters of the compressive pile to be detected can be detected accurately. The device of the invention has simple structure and convenient operation, and can meet the requirements of compressive pile vertical stationary load test.

Owner:河南省水利基本建设工程质量检测中心站

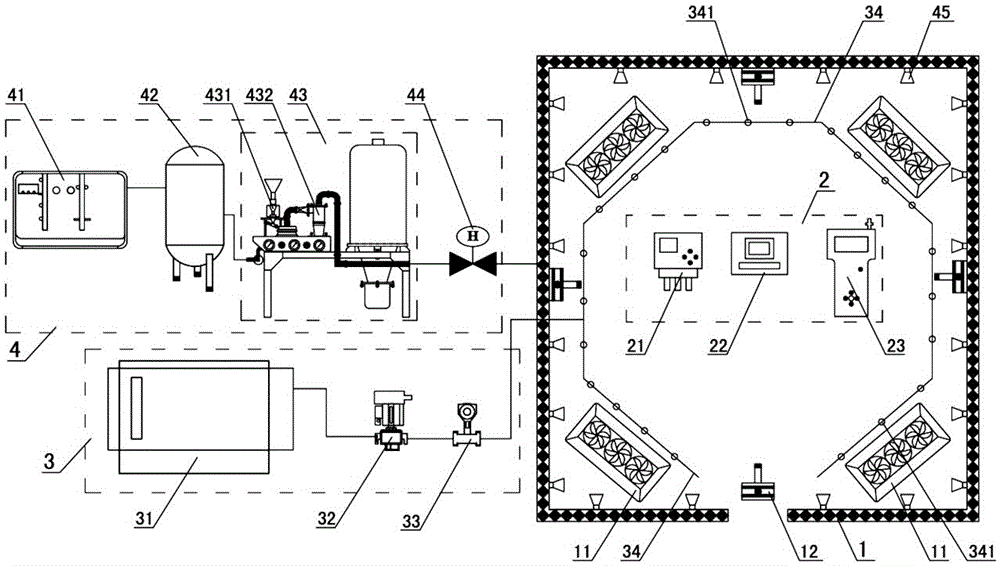

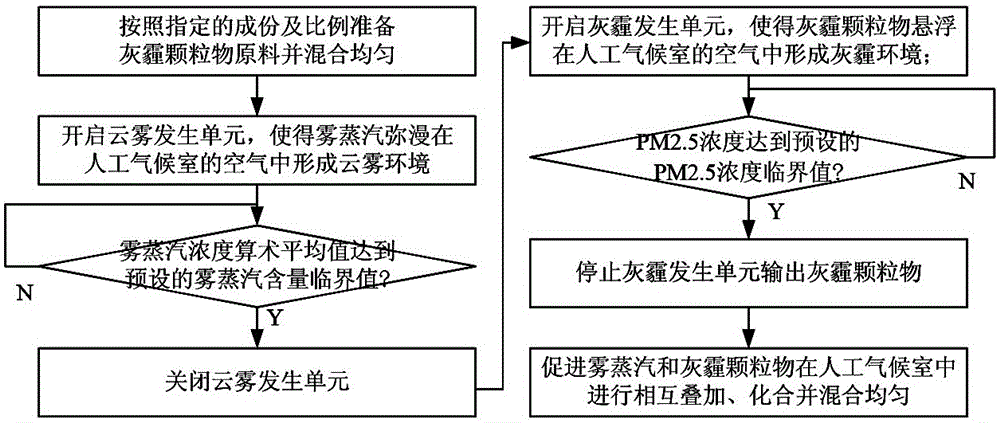

Phytotron haze environment simulating device and haze environment simulating method thereof

InactiveCN105115863ASame physical and chemical propertiesSimple test methodMaterial analysisParticulatesEngineering

The invention discloses a phytotron haze environment simulating device and a haze environment simulating method thereof. The device comprises a phytotron, a haze parameter detection unit, a cloud mist generation unit and a dust-haze generation unit, the haze parameter detection unit is arranged in the phytotron, and the output end of the cloud mist generation unit and the output end of the dust-haze generation unit are communicated with the interior of the phytotron. The simulating method comprises the steps that dust-haze particle raw materials are prepared and evenly mixed, the clout mist generation unit is started to form a cloud mist environment, the dust-haze generation unit is started to form a dust-haze environment, and mutual superposition, chemical combination and even mixing of mist steam and dust-haze particles are facilitated to form a haze environment. According to the phytotron haze environment simulating device and the haze environment simulating method thereof, PM2.5 particles and the stable haze environment of which the cloud mist concentration, chemical components of dust-haze particles and particle size distribution can be freely controlled and adjusted can be formed in the phytotron, and a safe and reliable experiment support is provided for researching the influence of the haze environment on human body health, outdoor traffic and electrical external insulation equipment.

Owner:STATE GRID CORP OF CHINA +2

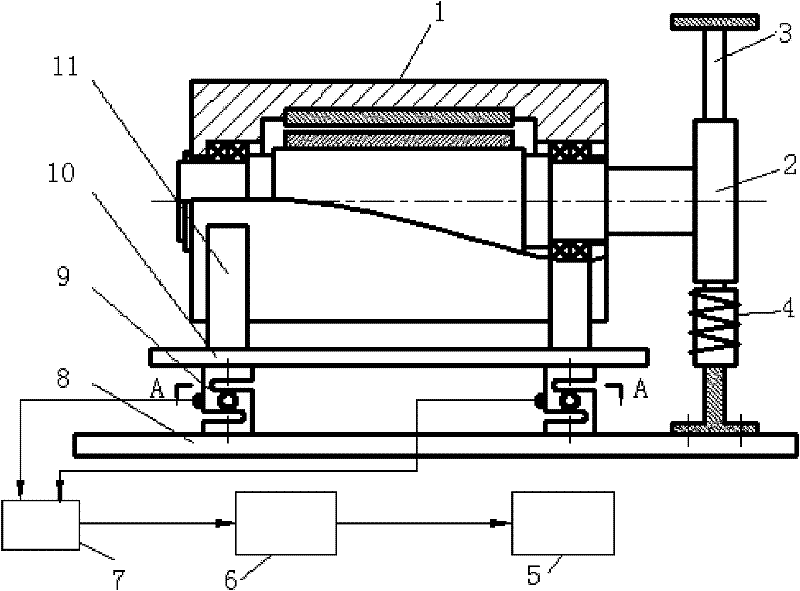

High-speed motorized spindle non-contact loading force and torque testing device and method

InactiveCN102128697ASolve complexitySolve the costForce measurementWork measurementElectricityCircular disc

The invention discloses a high-speed motorized spindle non-contact loading force and torque testing device. A fixed seat and an entire support are arranged on a working platform, the fixed seat is installed on the working platform through four pull pressure sensors which are distributed at the four corners of the lower surface of the fixed seat, a support seat is fixed on the upper surface of the fixed seat and is provided with a motorized spindle, and one axial end of the motorized spindle is sleeved with a loading disk; and the four pull pressure sensors are simultaneously connected with an amplified filter circuit, the amplified filter circuit is connected with a data acquisition card, the data acquisition card is connected with an industrial personal computer, and the industrial personal computer is connected with a displaying, printing and keyboard input device. The invention also discloses a radial loading force and loading torque testing method by utilizing the device. The problem of difficult testing of loading capacity in a high-speed motorized spindle characteristic analysis test is solved by using the device and method disclosed by the invention.

Owner:XIAN UNIV OF TECH

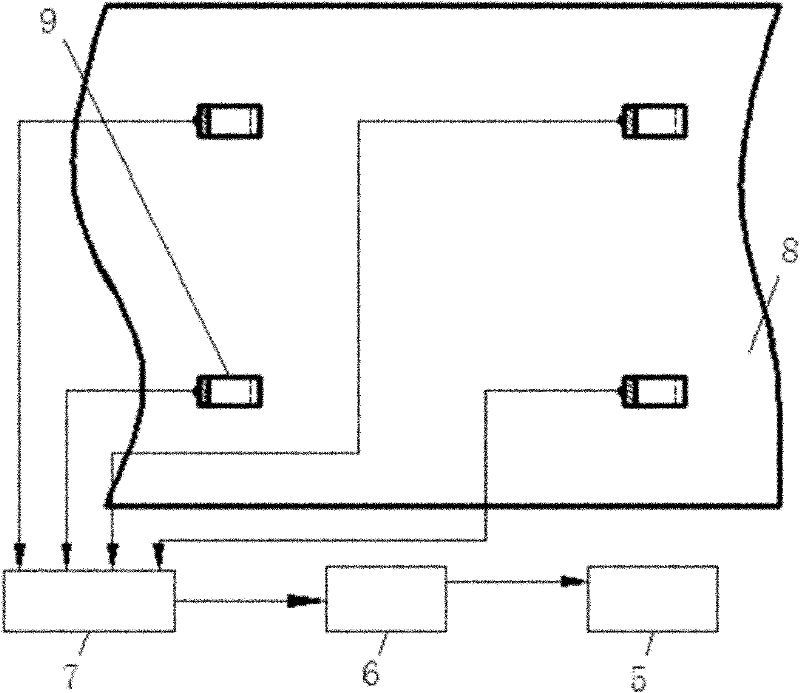

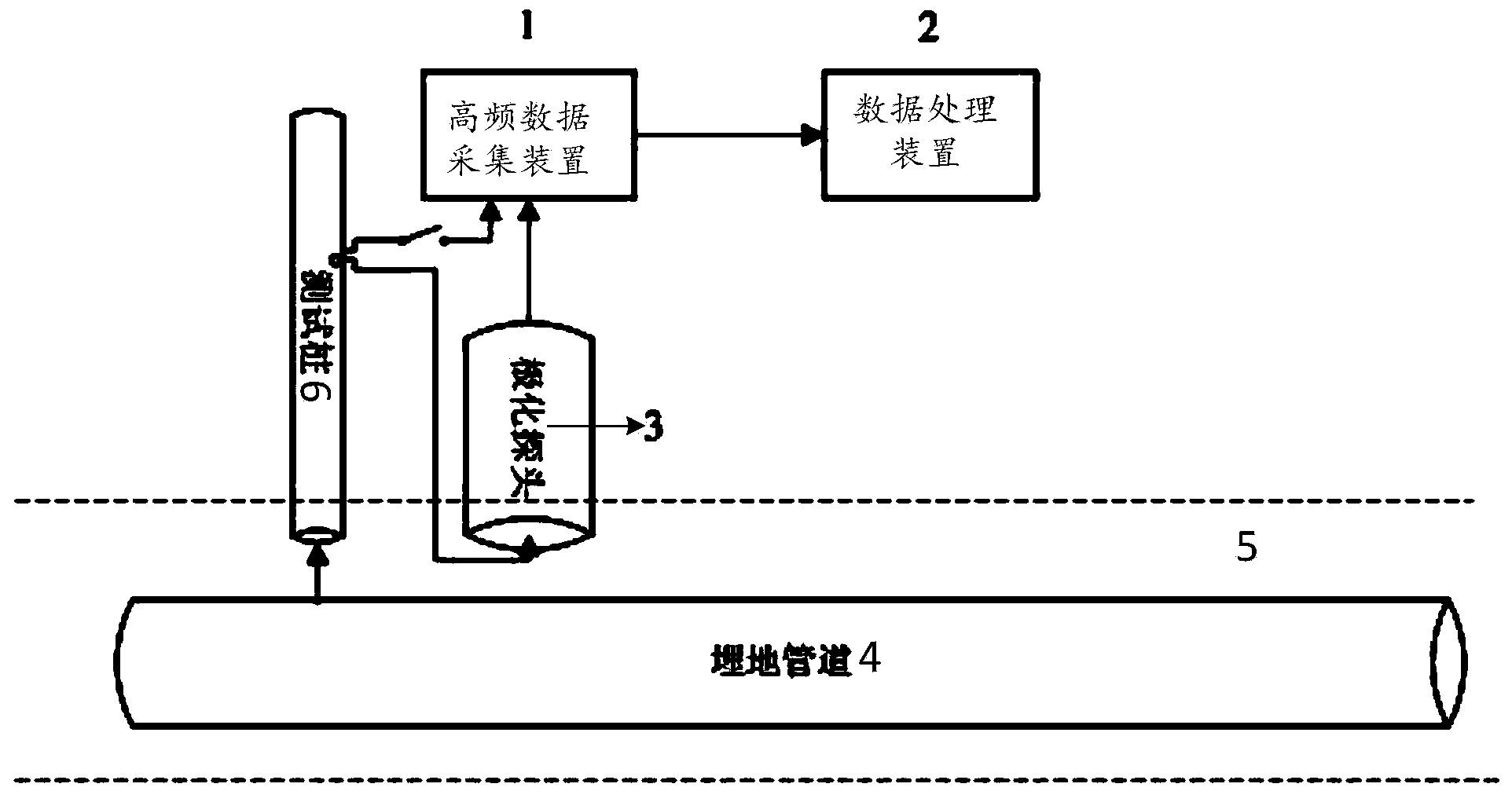

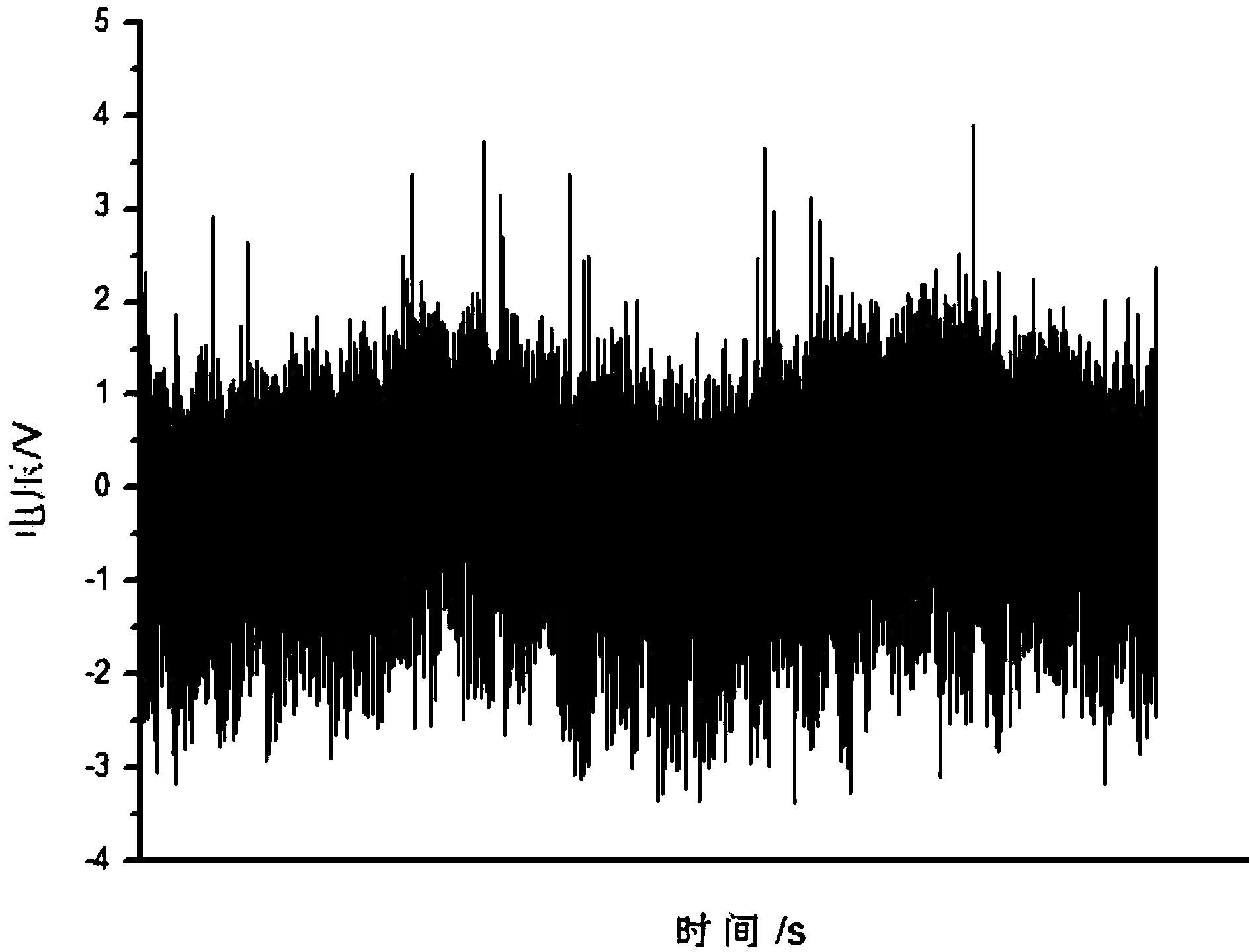

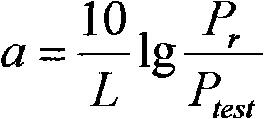

Dynamic interference potential test system for buried pipeline

The invention discloses a dynamic interference potential test system for a buried pipeline. The dynamic interference potential test system comprises a polarized probe, a high-frequency data acquisition device and a data processing device. As the polarized probe replaces a traditional copper sulfate reference electrode, valid data can be provided for corrosion risk assessment of a pipeline at a defect point of the corrosion protection layer of a simulating pipeline, and at the same time potential errors brought by the placement position of the traditional copper sulfate reference electrode are avoided; excavation and measurement for soil electric resistance around the buried pipeline are not needed, a test method is simplified, and further errors brought by orientation of measurement for soil electric resistance are eliminated. The high-frequency data acquisition device is used for acquiring data, and then the data is transmitted to the data processing device for Fourier transform, so that conversion from time domain to frequency domain of the AC-DC superimposed dynamic potential can be obtained, the frequency component of stray current can be accurately judged, and the size of DC potential and the source and size of AC interference can be accurately obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

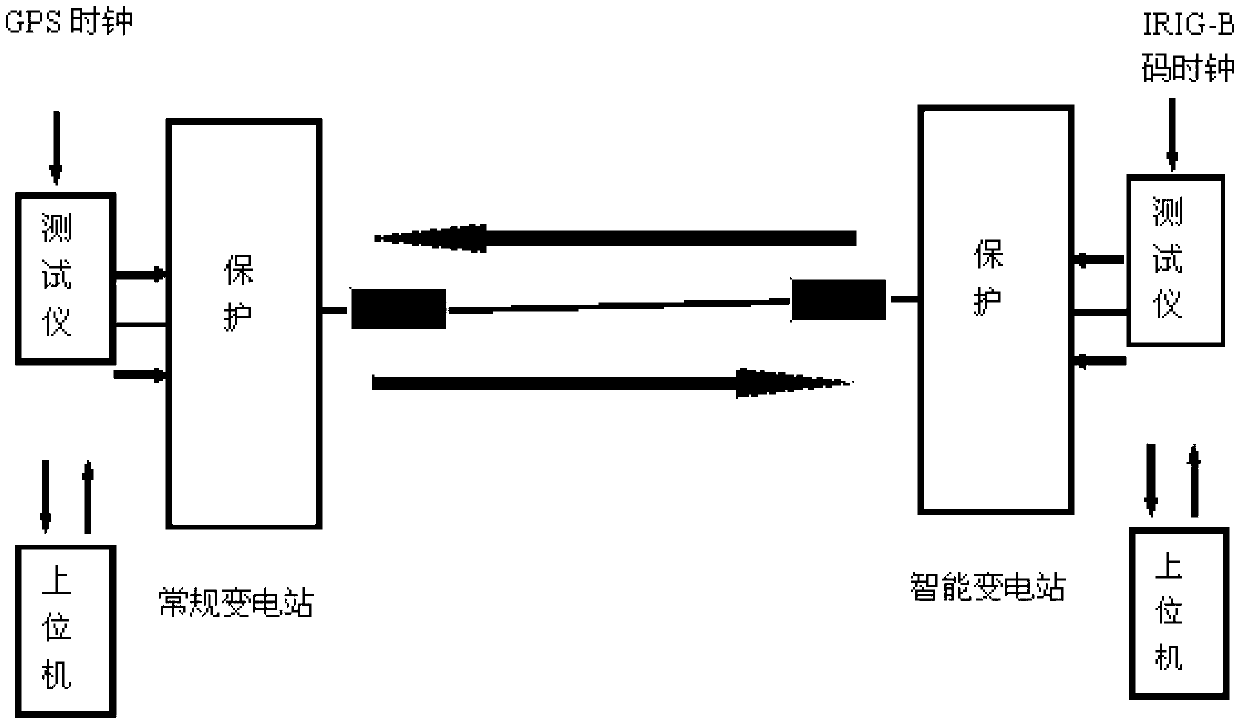

Intelligent and conventional transformer substation optical fiber longitudinal difference protection channel joint debugging test method

InactiveCN102721882AGuaranteed correctnessGuaranteed action settingElectrical testingTime informationTransformer

The invention discloses an intelligent and conventional transformer substation optical fiber longitudinal difference protection channel joint debugging test method which is characterized in that the intelligent transformer substation adopts a light inter-range instrumentation group (IRIG)-B code synchronous time tick mode, and the conventional transformer substation adopts a global positioning system (GPS) time tick mode, so that a plurality of points can be subjected to synchronous acquisition and trigger test; during test, relay protection testers on two sides are respectively connected to a GPS clock and an IRIG-B code clock; and time information comprising date, hour, minute, second and the like is sent at the frequency of one time per second. The intelligent and conventional transformer substation optical fiber longitudinal difference protection channel joint debugging test method has the advantages that the intelligent transformer substation adopts the light IRIG-B code synchronous time tick mode, and the conventional transformer substation adopts the GPS time tick mode, so that protection synchronous sampling and synchronous sampling of the testers on two sides are completed by using the two clocks, and a plurality of points can be subjected to synchronous acquisition and trigger test; therefore, the test on dual-end optical fiber current longitudinal difference protection is realized; and the test method is simple, and the data is accurate.

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

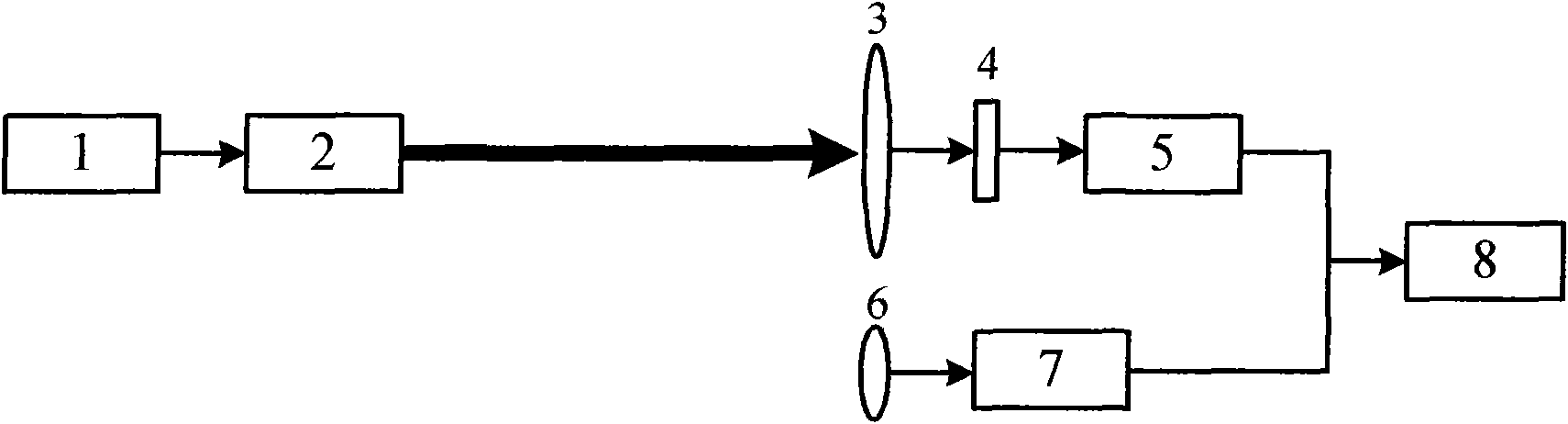

Method for testing lightwave transmission characteristics in atmospheric channel

InactiveCN101814952AReduce in quantityReduce testing costTransmission monitoring/testing/fault-measurement systemsOptical communicationPhysics

The invention relates to a method for testing lightwave transmission characteristics in an atmospheric channel, which belongs to the technical field of optics and is used in fields such as wireless optical communication, optical radar and the like. A testing system which comprises a laser emission subsystem, a receiving subsystem and a data processing subsystem is set up, wherein the receiving subsystem comprises two independent receiving light paths: one is a Fresnel screen receiving light path which consists of a Fresnel lens, a field lens and a No. I digital camera and is used for testing attenuation, drift and extension; and the other is an arrival angle fluctuation receiving light path which consists of a receiving lens and a No. II digital camera and is used for testing arrival angle fluctuation. The invention only adopts one set of testing system to carry out the testing of four types of turbulence effects and an attenuation effect, thus having great significance in reducing the number of hardwares needed by the testing of the atmospheric turbulence effects and the attenuation effect, reducing the number of testers, expenditure and period, realizing the miniaturization, light weight and low power consumption of the testing system and implementing quick, convenient and overall lightwave transmission characteristic tests.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

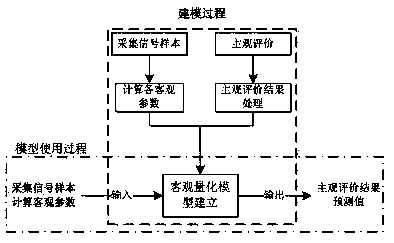

Objective quantitative evaluation method for idle noise in automobile

InactiveCN108663115AEffective Testing and Evaluation MethodsThe test method is simpleSubsonic/sonic/ultrasonic wave measurementMultivariable linear regressionLinear regression

The invention discloses an objective quantitative evaluation method for idle noise in an automobile. The objective quantitative evaluation method comprises the steps of acquiring objective parametersand processing of subjective parameters, carrying out correlation analysis on the subjective evaluation result and the objective parameters, establishing a correlation model by using a multi-element linear regression, and obtaining an objective quantitative mathematical model of the subjective evaluation of idle speed noises. According to the method, the subjective evaluation condition of the idling noise performance of the automobile can be obtained. The objective quantitative evaluation method is a comprehensive, direct, rapid and effective testing and evaluating method. The test method applied by the method is simple, clear in idea and very high in universality, can be suitable for testing and evaluating the idle speed noise performance of various types of vehicles, and is low in cost.

Owner:BRILLIANCE AUTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com