Method for testing pile shaft stress of static pressure high-strength pre-stressed concrete pipe pile

A technology of concrete pipe pile and stress testing, which is applied in foundation structure testing, construction, foundation structure engineering, etc., can solve problems such as low reliability and survival rate, great influence of environmental factors, and difficult testing and testing, and achieve easy accuracy The effect of distributed and automatic monitoring, strong anti-electromagnetic field interference ability, and simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

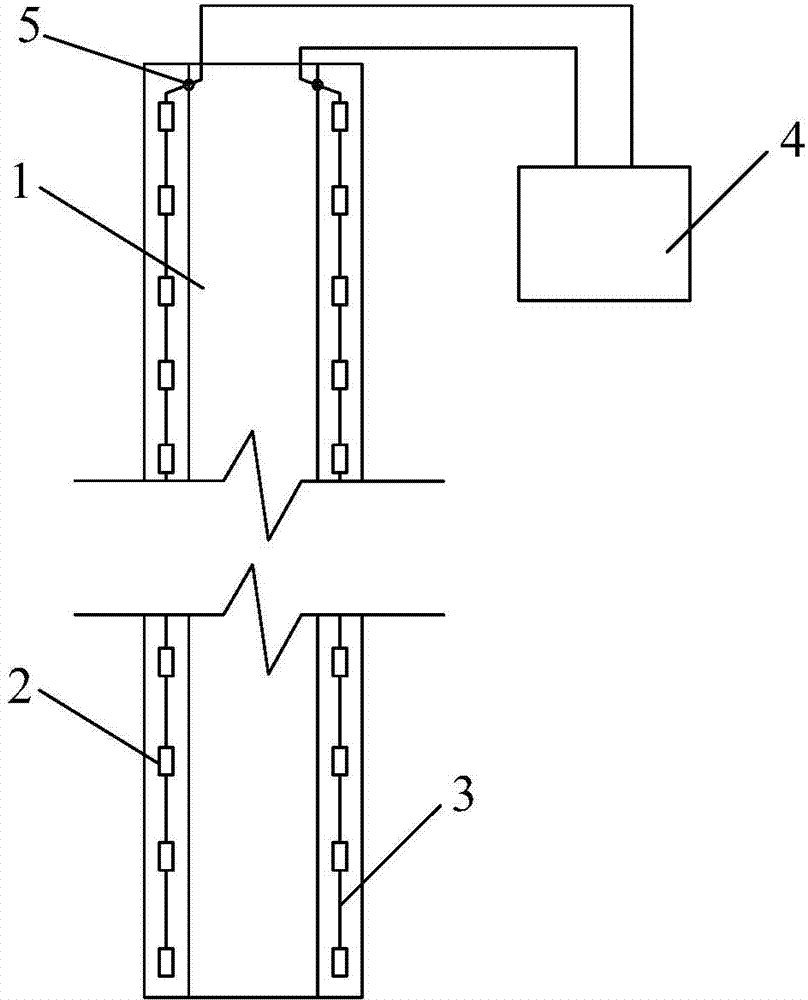

[0016] In this embodiment, the stress test is completed in the static pressure high-strength prestressed concrete pipe pile body stress test device, and the specific process is as follows:

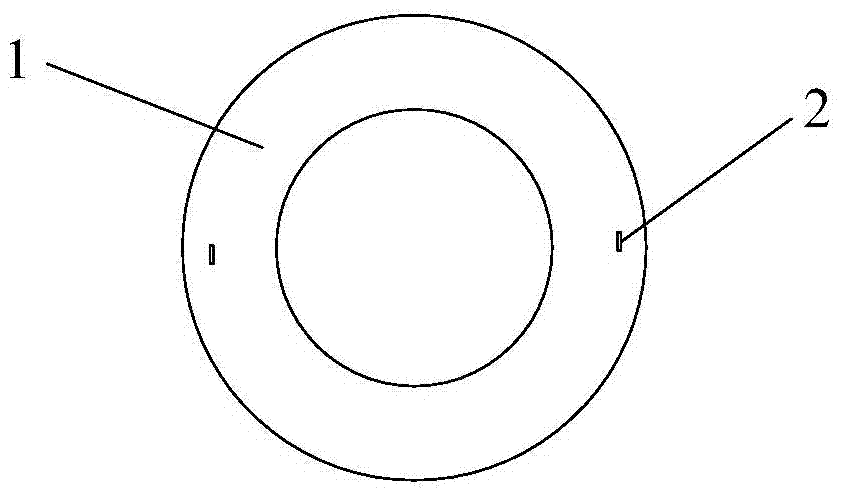

[0017] (1) Draw a straight line along the axis of the outer wall of the high-strength prestressed concrete (PHC) pipe pile 1, and then cut the shallow groove along the drawn straight line, and determine the fiber Bragg grating (FBG) in the shallow groove according to the position of the tested rock and soil. ) The implantation position of sensor 2, the fiber Bragg grating (FBG) sensor 2 is 25cm away from both ends of the high-strength prestressed concrete (PHC) pipe pile 1, avoiding the high-strength prestressed concrete (PHC) pipe pile 1. Metal end plate

[0018] (2) According to the position of the fiber Bragg grating (FBG) sensor 2, connect the fiber Bragg grating (FBG) sensor 2 and the armored optical cable 3 in a quasi-distributed fusion splicing series, and implant the series-connected fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com