Patents

Literature

45 results about "Fbg sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unbalanced interferometer based fiber bragg grating (FBG) demodulation system and method

InactiveCN102147552AResponsiveHigh sensitivityLight demodulationConverting sensor output opticallyGratingAcousto-optics

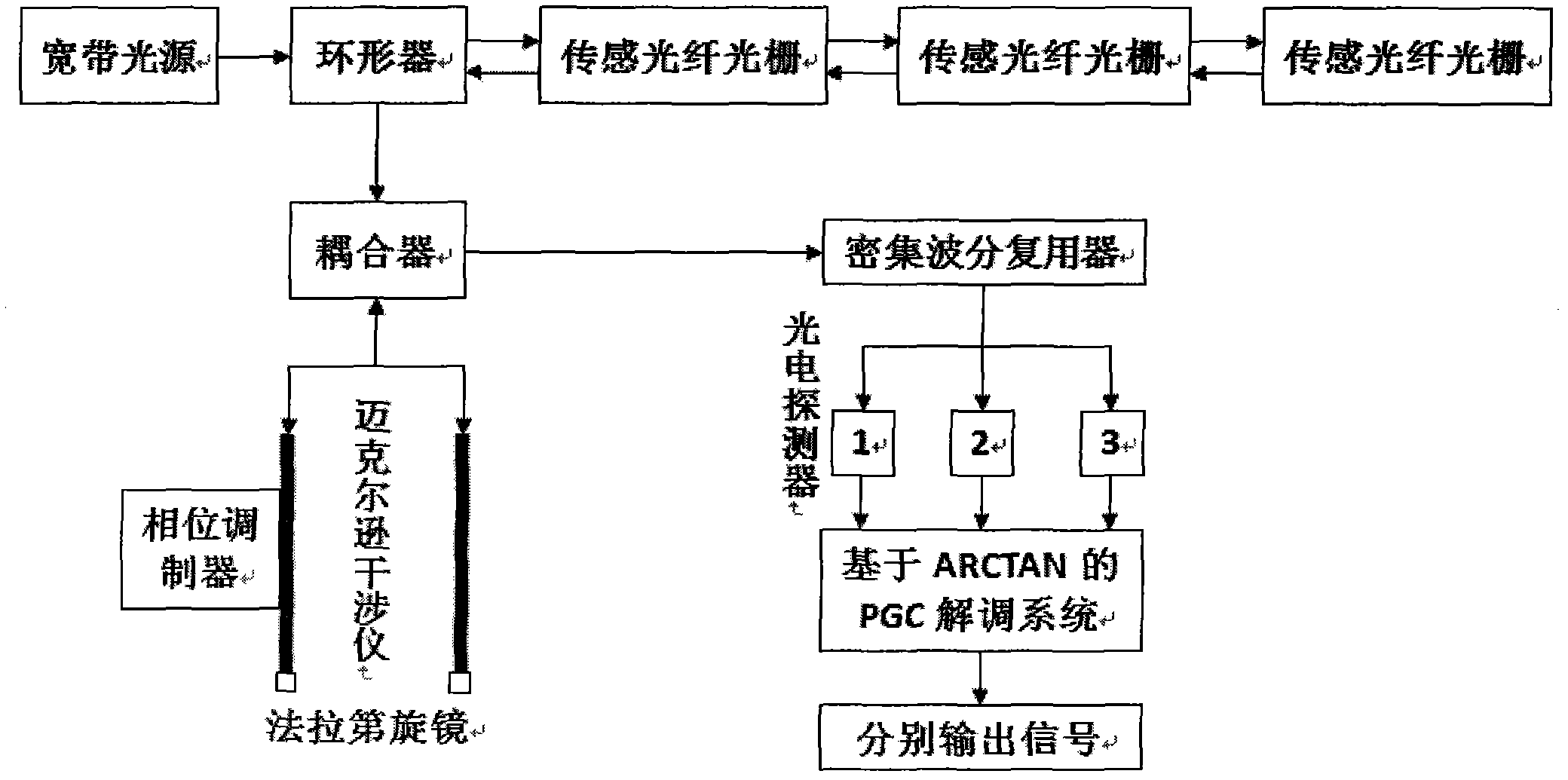

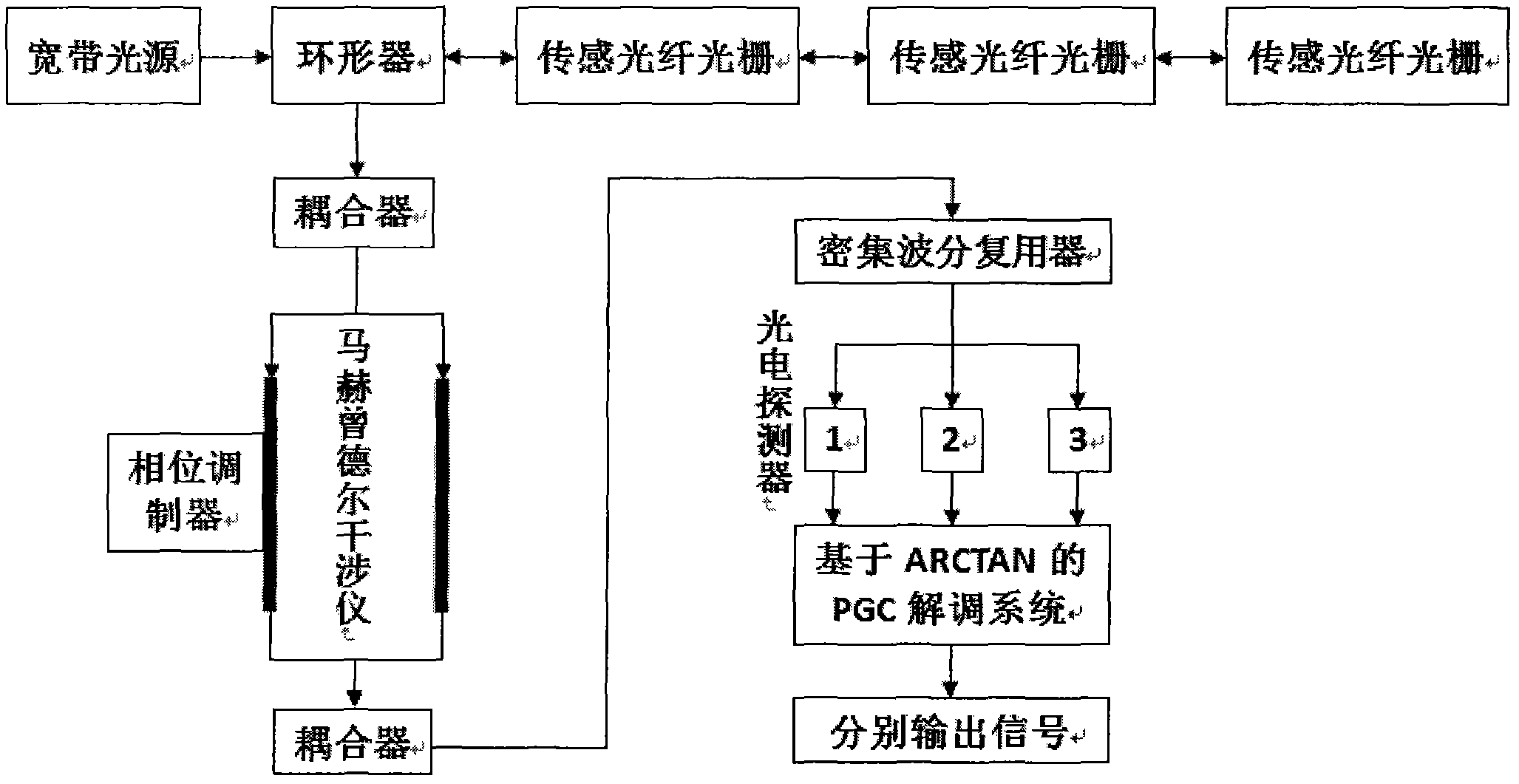

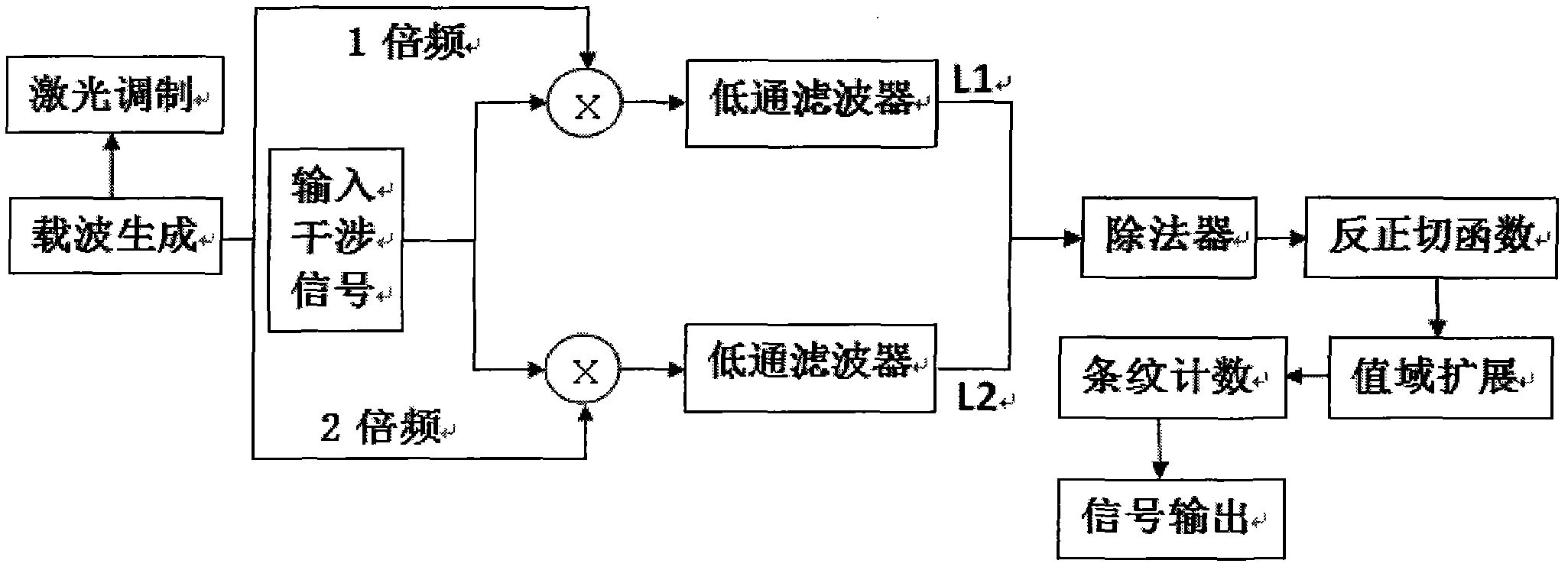

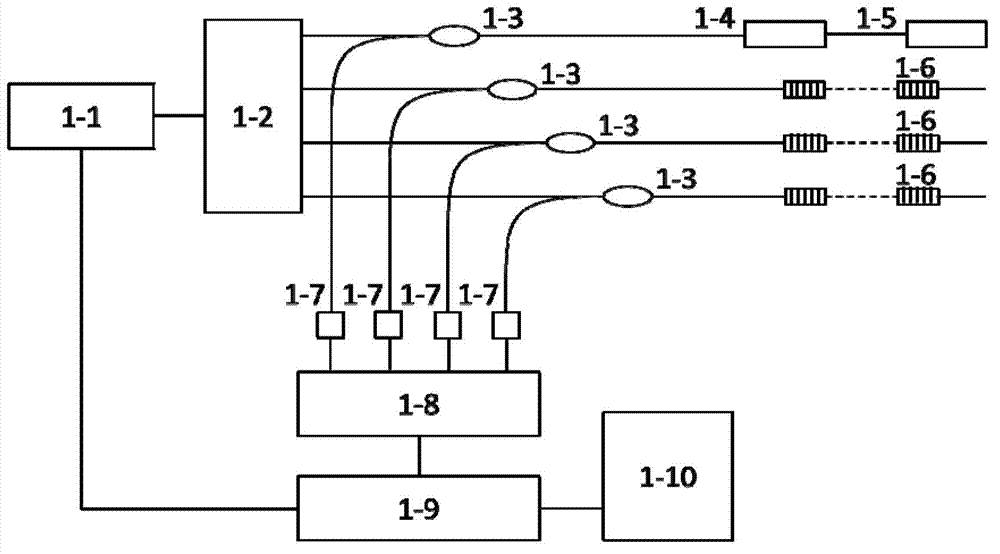

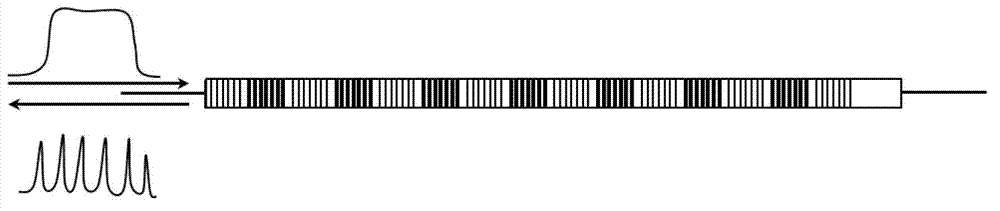

The invention relates to an unbalanced interferometer based fiber bragg grating (FBG) demodulation system and method, belonging to the technical field of fiber optic sensing. The system sequentially passes through a superluminescent diode (SLD) or an amplified spontaneous emission (ASE) broadband light source, an optic isolator, a circulator or a coupler, and a fiber bragg grating and returns back to the circulator or the coupler, and then passes through the coupler, an unbalanced Michelson interferometer with two channels and a Faraday rotator mirror and returns back to an interferometer and the coupler or passes through a Mach-Zehnder interferometer with two channels and the coupler, wherein one channel of the interferometer is wound around a piezoelectric ceramic or an electrooptical modulator, and an acousto-optic modulator, finally passes through a dense wave division multiplexer and a photoelectric detector and is connected with an ARCTAN based PGC (Phase Generation Carrier) signal response demodulation module. The invention has the advantages; by adopting the combination of the an FBG sensor and ARCTAN-based PGC phase modulation, the system has high sensitivity, large dynamic range and good linearity, good response to an abrupt signal and easiness of multiplexing, low cost and easiness of implementing.

Owner:DALIAN UNIV OF TECH

Method and device for demodulating fiber bragg grating (FBG) sensor

ActiveCN102879022ALow insertion lossReduce manufacturing difficultyConverting sensor output opticallyGratingPhotovoltaic detectors

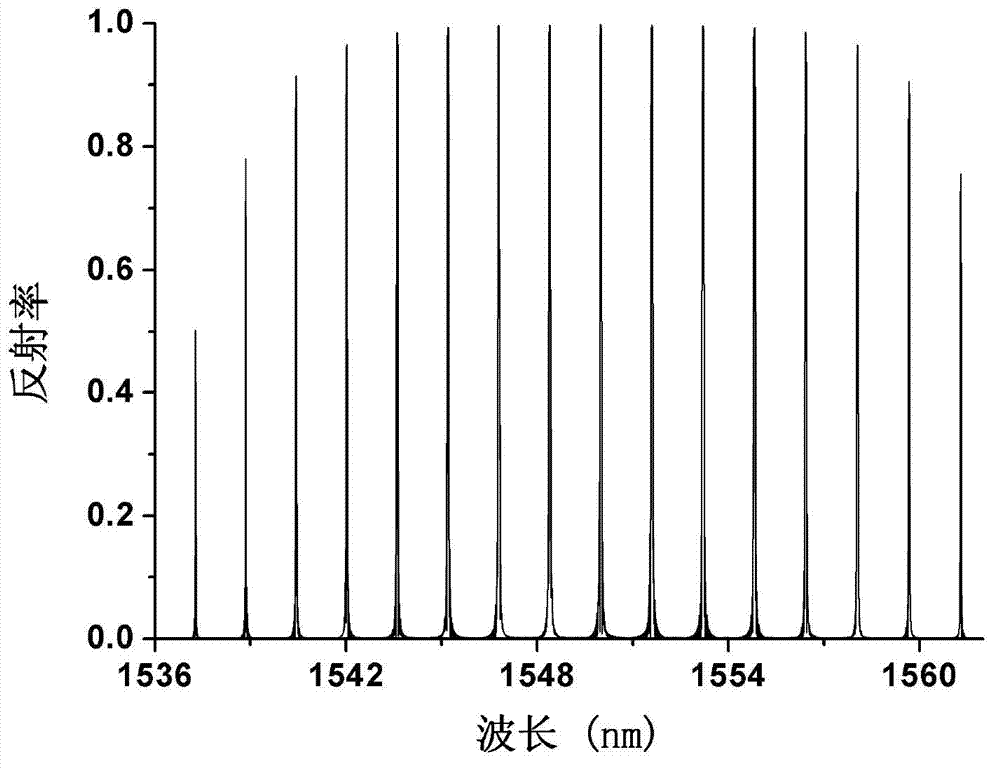

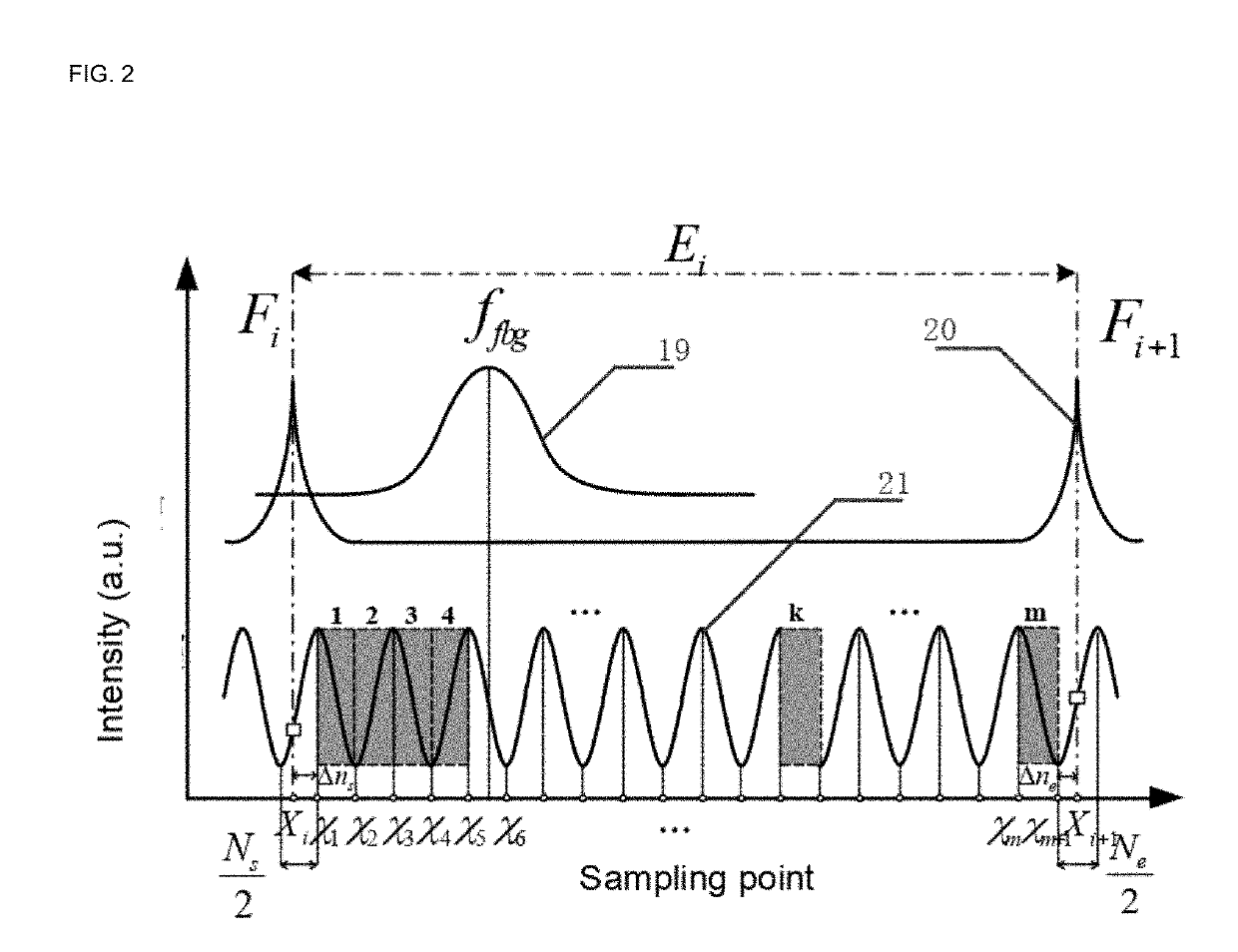

The invention discloses a method and a device for demodulating a fiber bragg grating (FBG) sensor. The method comprises the following steps of: controlling a wavelength scanning laser device to generate narrow-band scanning laser rays with continuously changed wavelengths by using a computer; splitting beams of the narrow-band scanning laser rays generated by the wavelength scanning laser device; enabling a generated reflection spectrum to enter a photoelectric detector again via an optical fiber coupler to be converted into electric signals after the beam-split narrow-band scanning laser rays respectively enter the FBG sensor to be measured and a reflecting FBG comb filter with a temperature compensation package function via the optical fiber coupler, and acquiring the electric signals by the computer after the electric signals are amplified; obtaining wavelengths of peaks of the reflecting FBG comb filter with the temperature compensation package function by the computer through a peak-detection algorithm; calibrating the reflection spectrum of the FBG sensor by the wavelengths; and calculating an absolute wavelength value of the FBG sensor.

Owner:杭州联光电子有限公司

Fiber bragg grating demodulation device capable of supressing fluctuations at variable ambient temperature and demodulation method thereof

ActiveUS20190178688A1Suppress fluctuationsImproved wavelength stabilityMitigation of undesired influencesConverting sensor output opticallyBeam splitterPhotovoltaic detectors

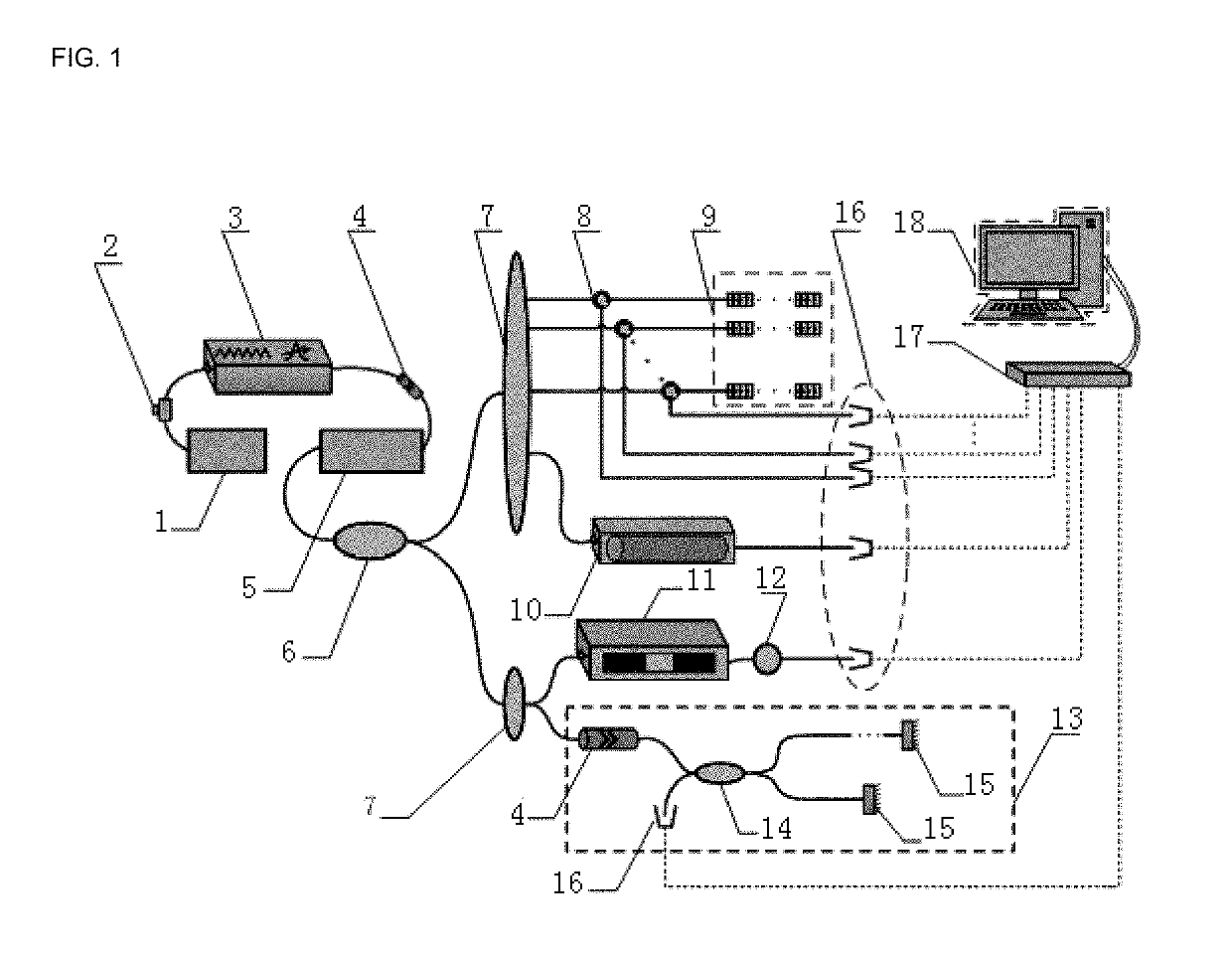

The present invention discloses a Fiber Bragg Grating demodulation device with a suppressed fluctuation at a variable ambient temperature and a demodulation method. The device comprises a broadband light source (1), an optical attenuator (2), a tunable F-P filter (3), a first optical fiber isolator (41), an erbium-doped optical fiber amplifier (5), an optical fiber first-stage beam splitter (6), a first optical fiber second-stage beam splitter (71), optical fiber circulators (8), FBG sensor arrays (9), a first photoelectric detector array (161), an optical fiber gas cell (10), a second optical fiber second-stage beam splitter (72), an optical fiber F-P etalon (11), a notch filter (12), an optical fiber assisted interferometer (13), a data acquisition card (17) and a processor (18).

Owner:TIANJIN UNIV

Optical fiber strain sensor device and strain detection method

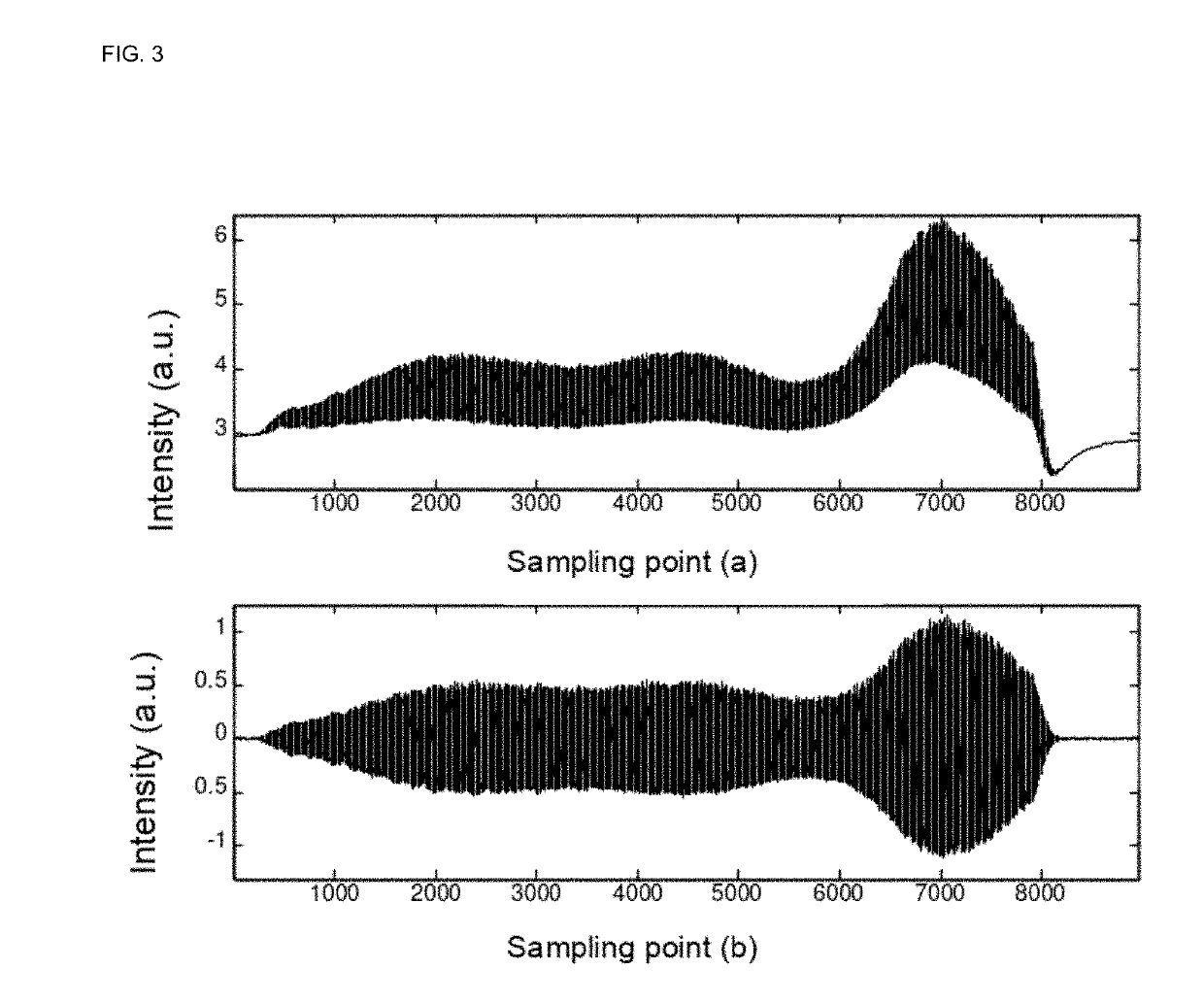

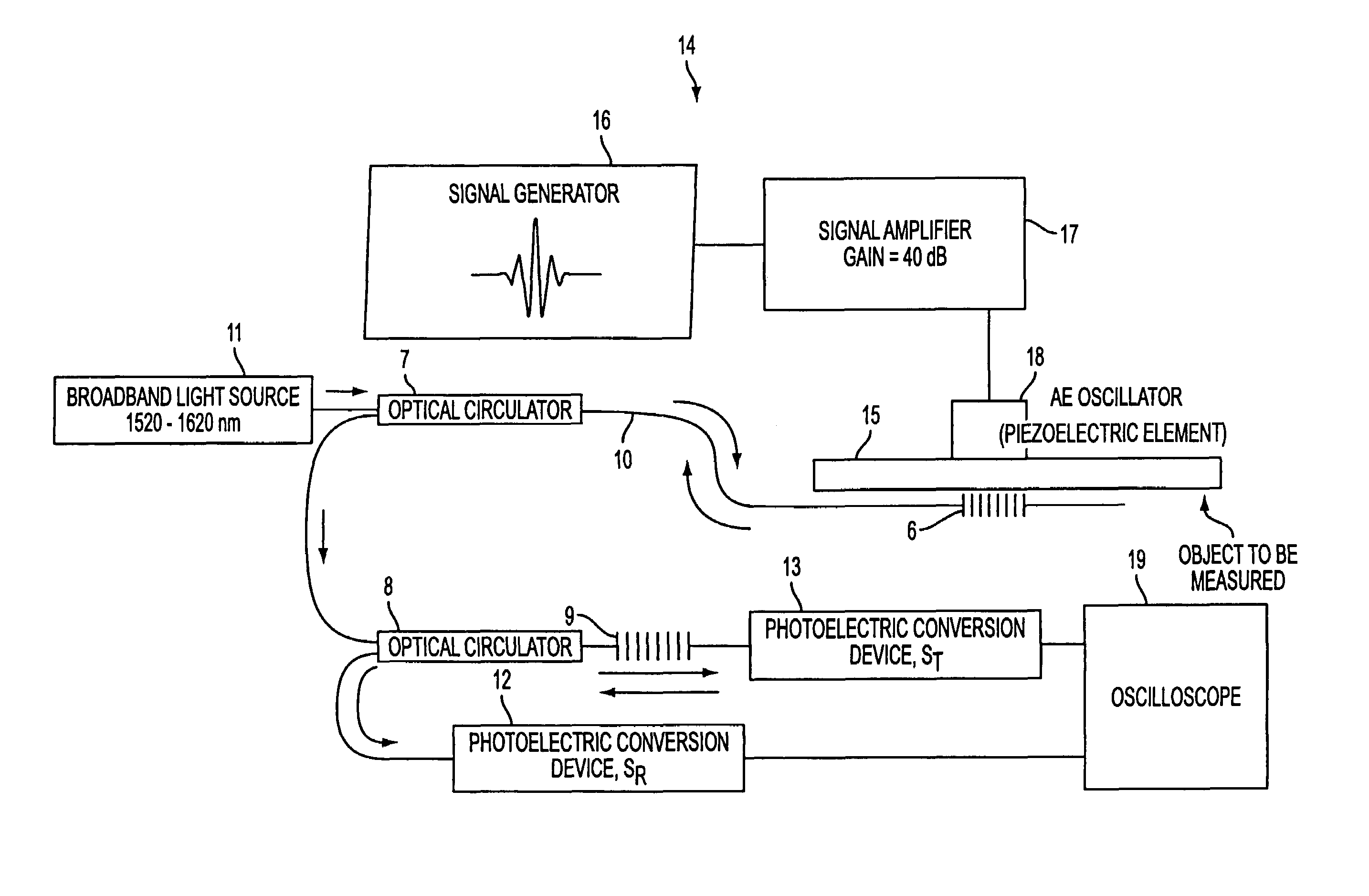

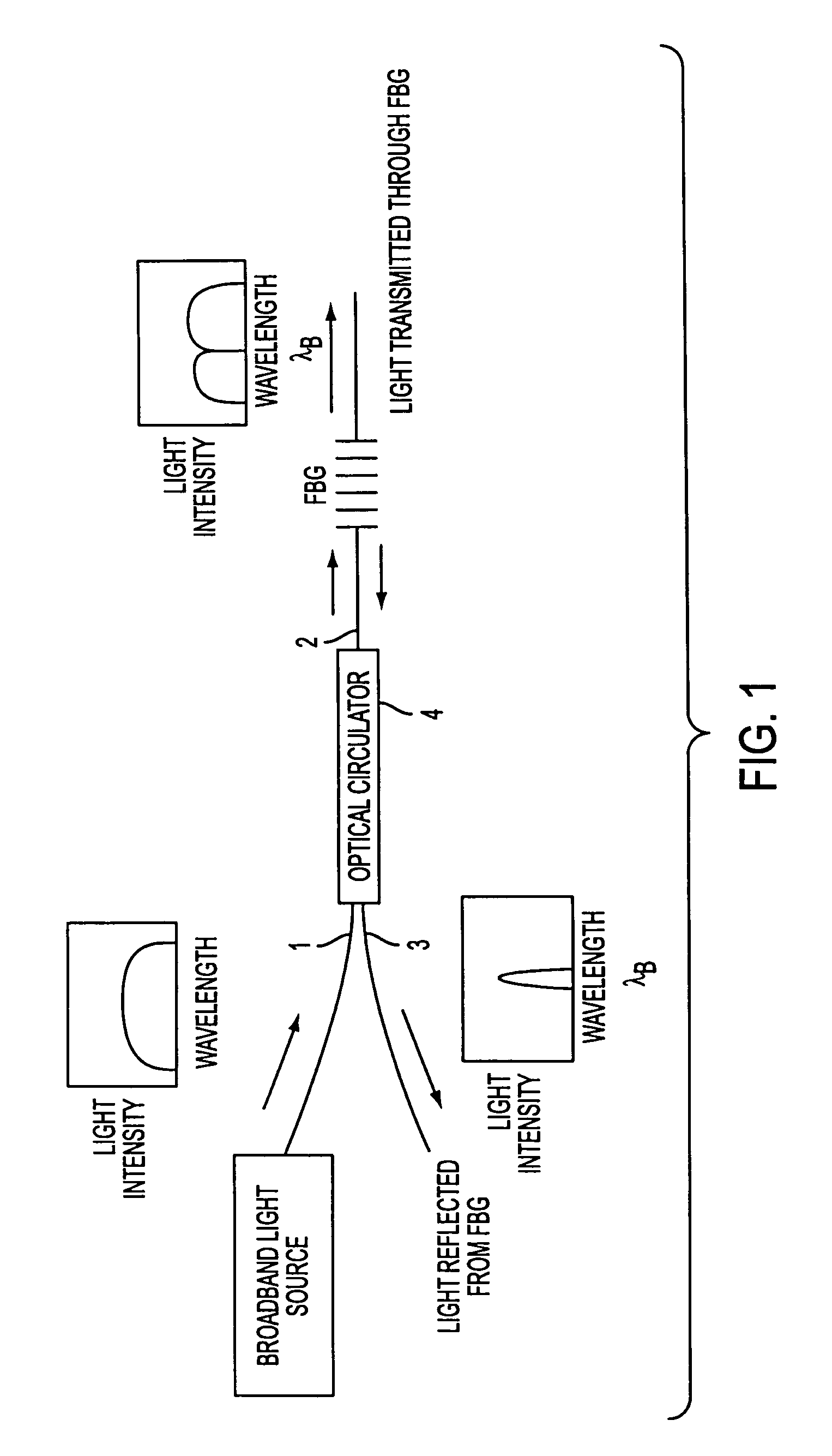

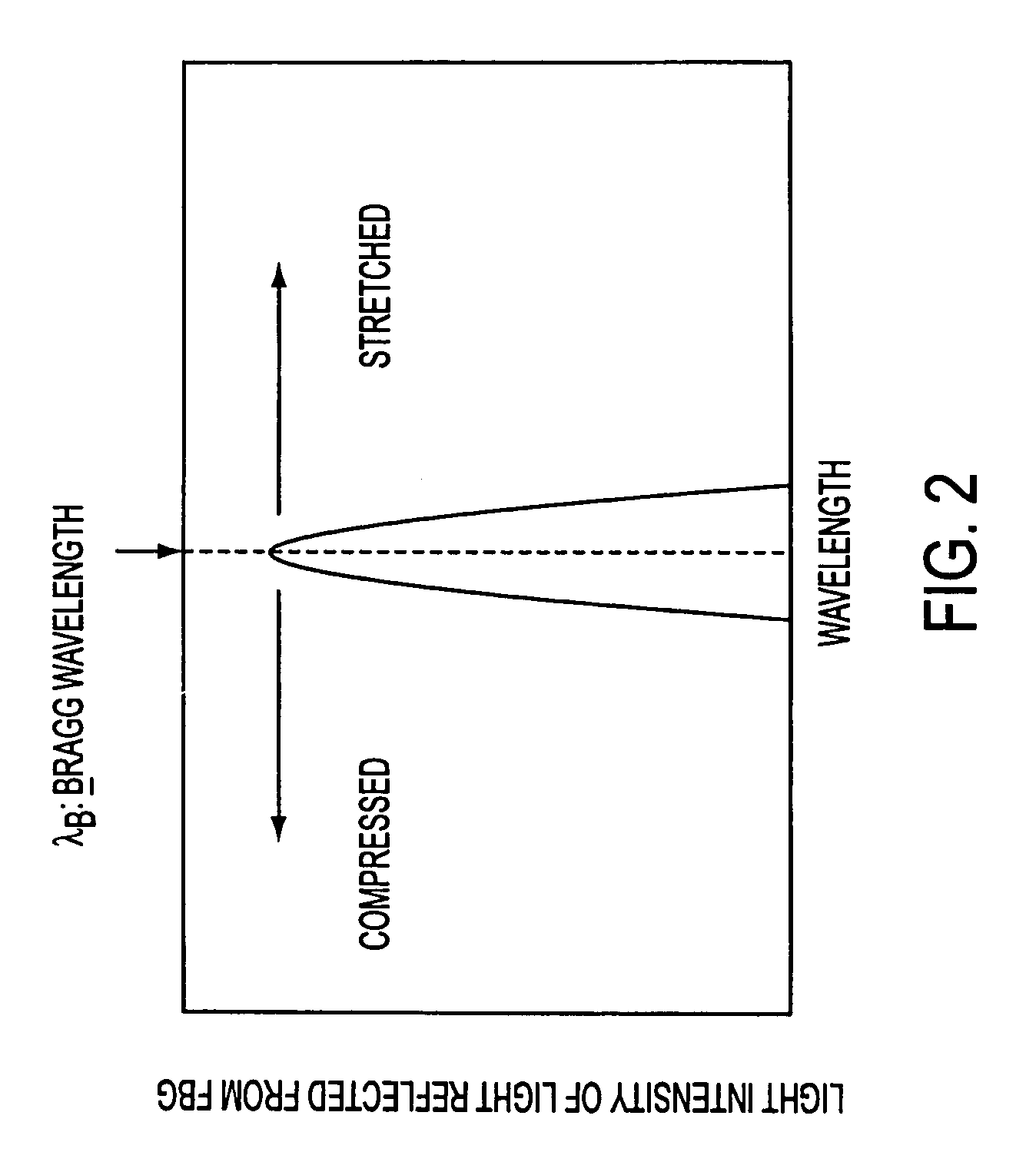

InactiveUS7002672B2Radiation pyrometryForce measurement by measuring optical property variationFiber Bragg gratingBroadband

To provide an optical fiber strain sensor device and a strain detection method, for measuring precisely AE and for detecting effectively a rapid strain change due to a shock load, an optical fiber strain sensor device includes an FBG sensor mounted on an object to be measured, a broadband light source for directing a broadband wavelength light ray to the FBG sensor, and an FBG filter that reflects or transmits a light ray reflected from the FBG sensor, and, using the FBG filter, the optical fiber strain sensor device processes and detects a change in the center wavelength of the light ray that has been incident from the broadband light source and then has been reflected from the FBG sensor.

Owner:NAT INST OF ADVANCED IND SCI & TECH

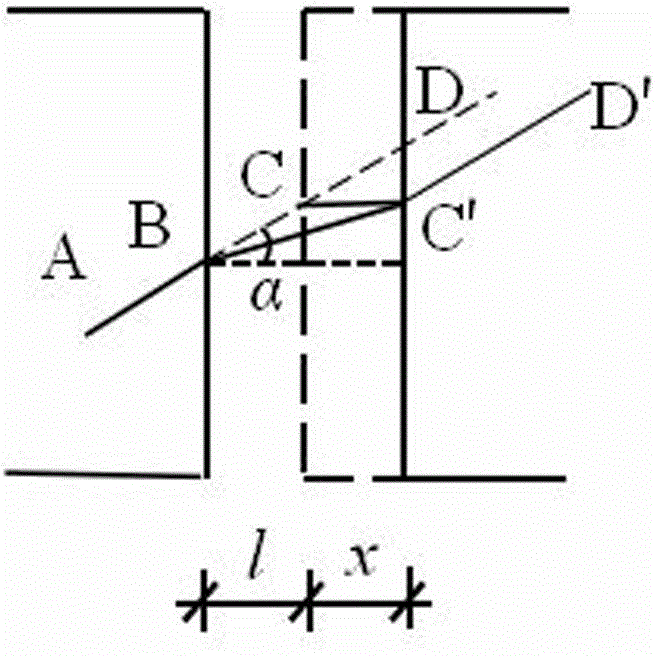

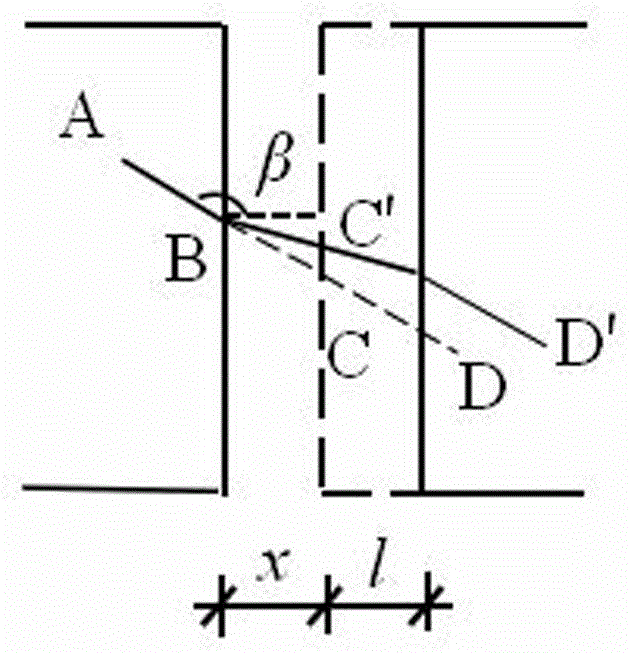

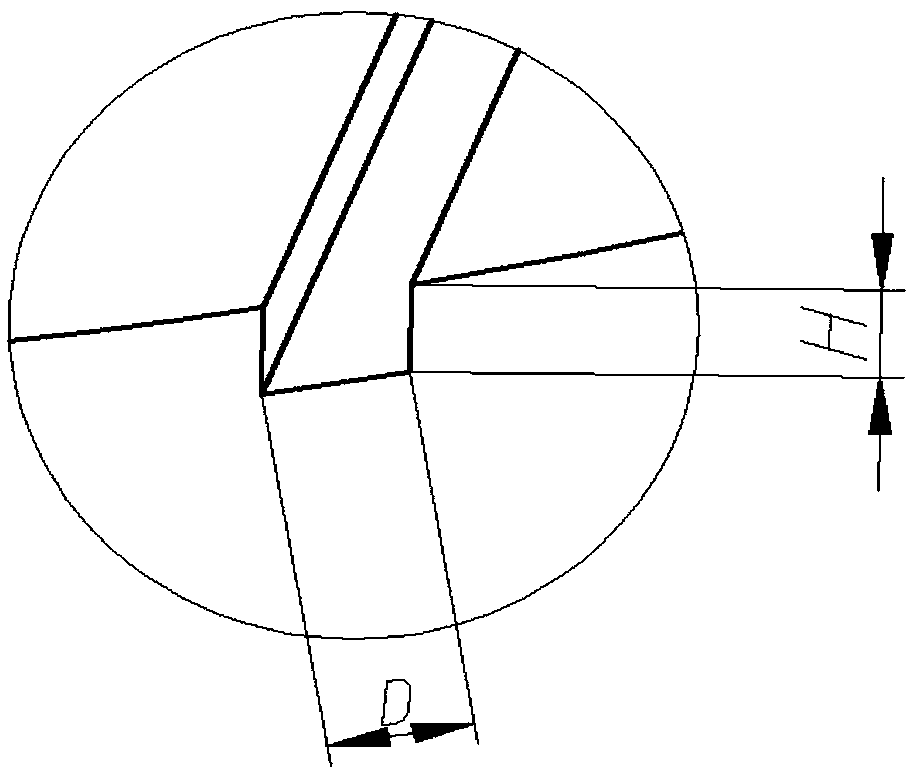

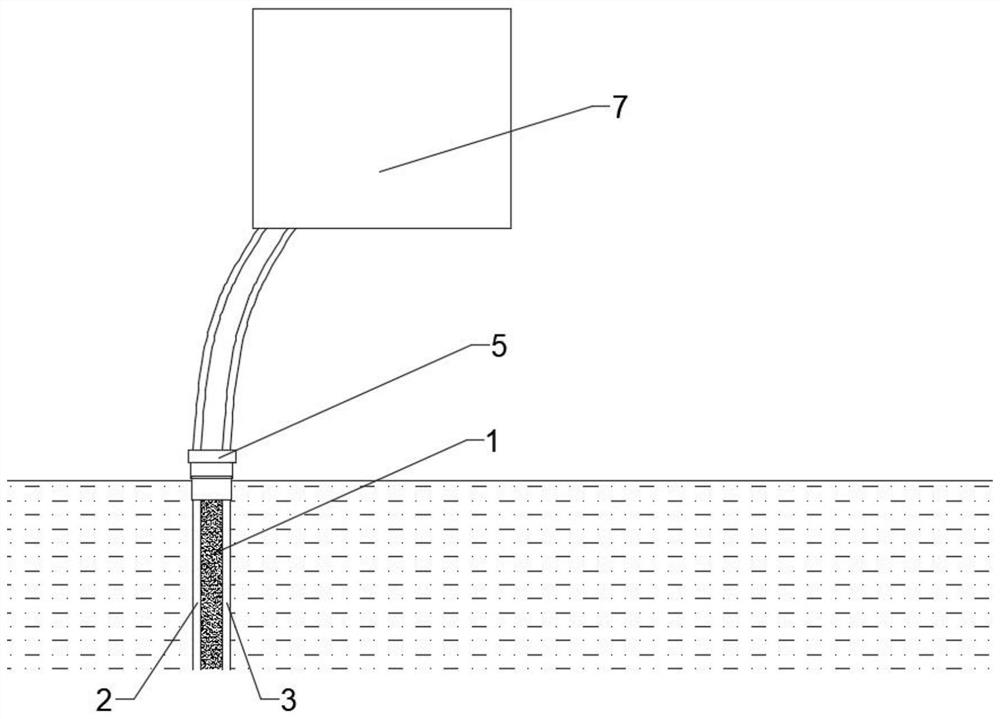

Long-gauge FBG (Fiber Bragg Grating) based settlement joint two-dimensional deformation and opposite inclination monitoring method

ActiveCN104613886AEasy to analyzeReal-time 2D deformationUsing optical meansFiber Bragg gratingEngineering

The invention relates to the settlement joint two-dimensional deformation detection technical field, particularly to a long-gauge FBG (Fiber Bragg Grating) based settlement joint two-dimensional deformation and opposite inclination monitoring method which aims at overcoming the defects that the deformation detection error is large and detection data are discontinuous in the actual use process of settlement joints in the prior art. A long-gauge FBG sensor is distributed and an average strain equation of the horizontal direction, the vertical direction and the two-dimensional deformation after the movement of a settlement joint is listed to solve the opening distance x of the settlement joint in the horizontal direction and the dislocation distance y of the settlement joint in the vertical direction. Compared with the traditional manual instrument monitoring, the long-gauge FBG based settlement joint two-dimensional deformation and opposite inclination monitoring method is high in test accuracy and continuous in data and can be popularized and utilized in engineering.

Owner:SHIJIAZHUANG TIEDAO UNIV

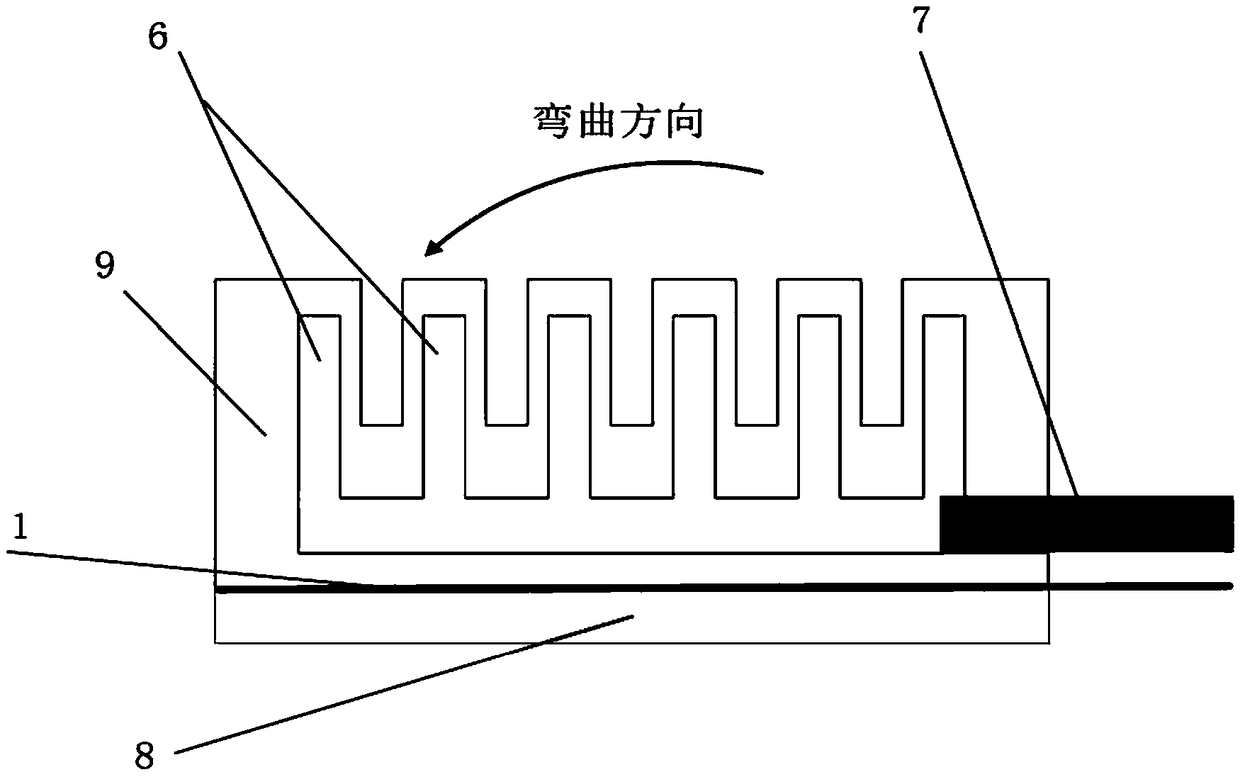

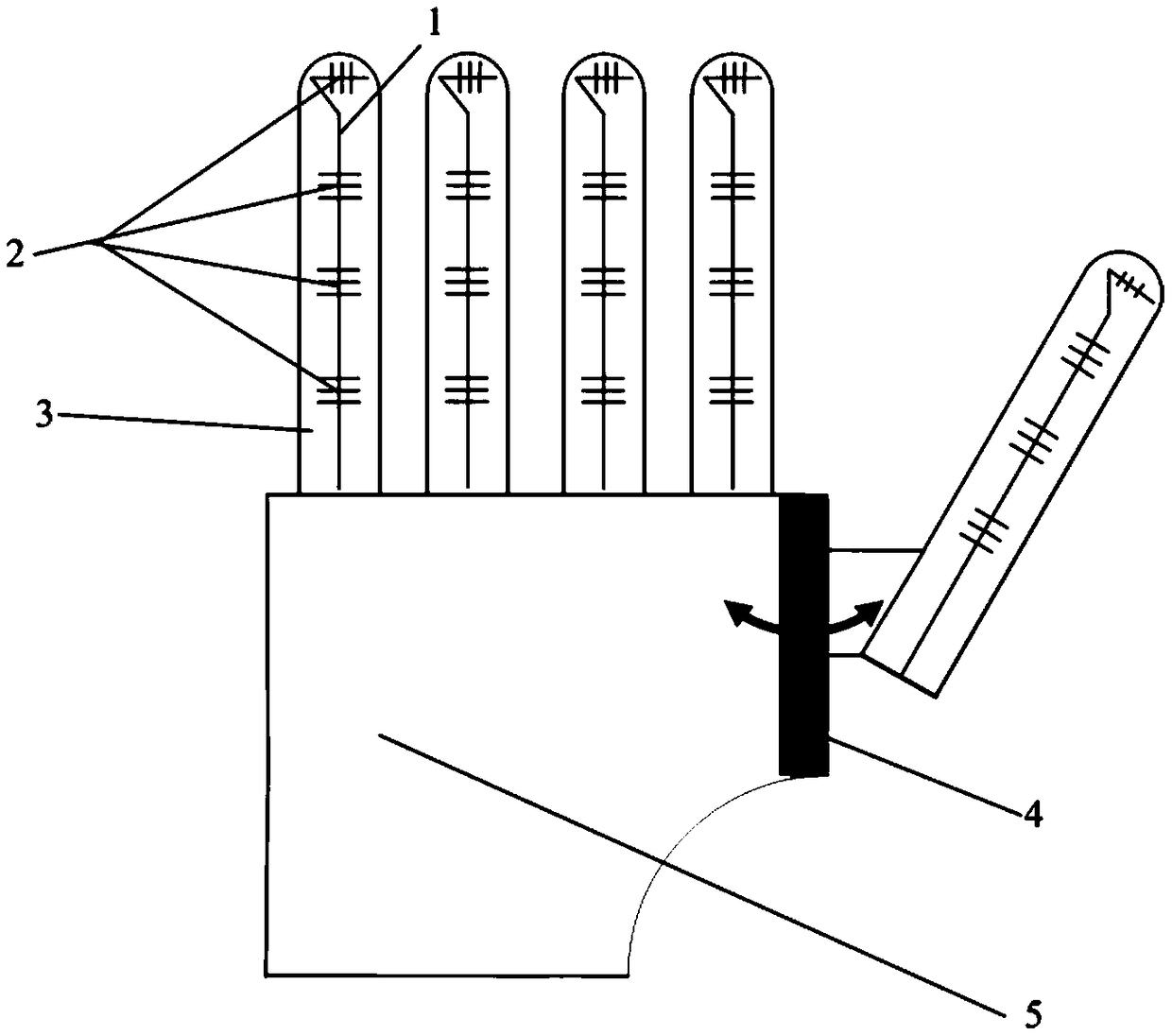

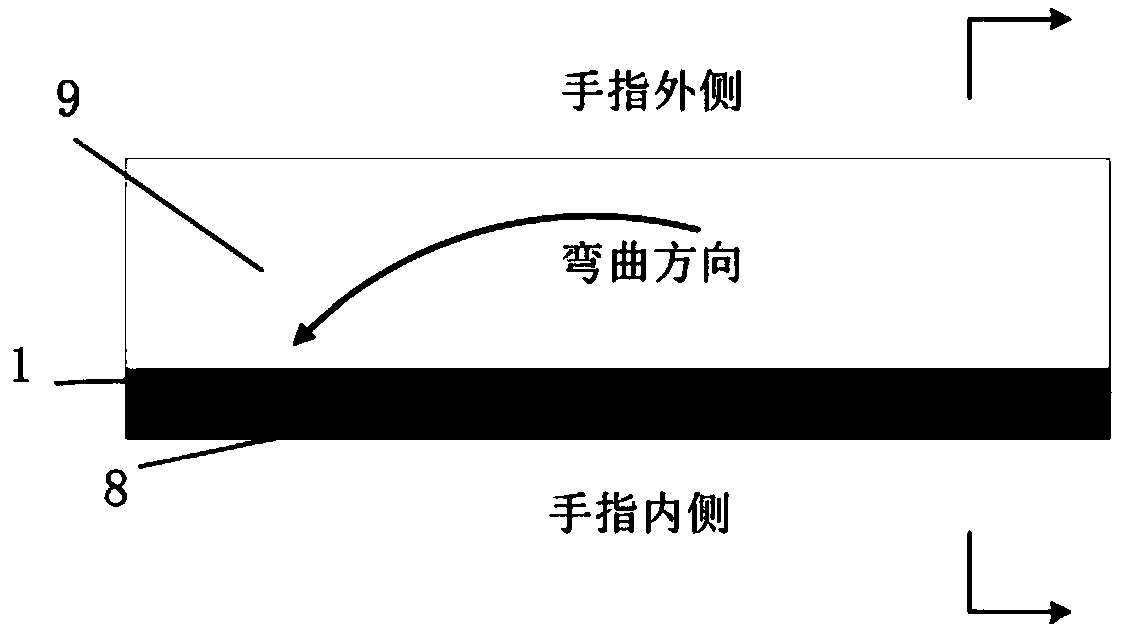

Flexible adaptive massage hand with FBG sensing

InactiveCN109431765AAdjustable positionMassage is safe and reliableProgramme-controlled manipulatorGripping headsFiber Bragg gratingMassage

The invention discloses a flexible adaptive massage hand with FBG sensing, which comprises a plurality of soft finger structures; the soft finger structures are connected to a palm base respectively,wherein one soft finger structure is connected to the palm base through a rotating structure; the soft finger structures are imbedded with a FBG sensor, which is used to sense the bending degree and massage strength of the finger and transmit the signal to a controller; the controller controls a pneumatic device to achieve the adjustment of the air pressure size in the soft finger structures. TheFBG sensor is implanted inside the finger, so that the sensing and feedback of the flexion degree of the finger and massage strength can be carried out, the safety and precision is improved. The jointof thumb and palm is a manual rotation axis, which can adjust the position of the thumb, thereby achieving three standard massages of pressing, pushing and kneading, and being important to achieve safe and reliable machine massage.

Owner:SHANDONG UNIV

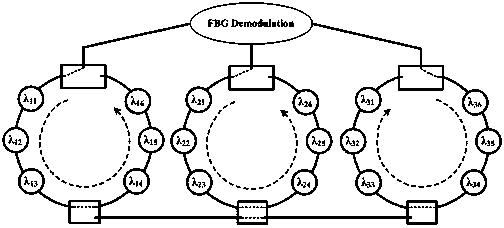

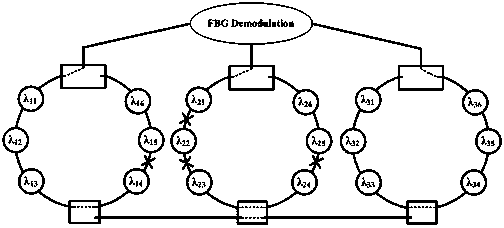

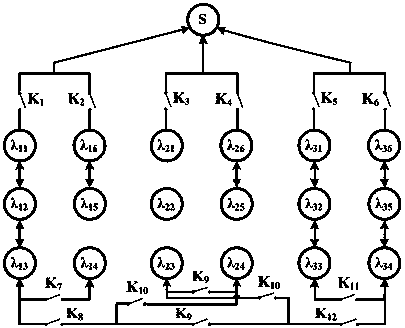

Repairing method for optical fiber sensing network based on ring topology structure

ActiveCN103873140AAchieve self-healingImprove reliabilityTransmission monitoring/testing/fault-measurement systemsNetwork structureEngineering

The invention discloses a repairing method for an optical fiber sensing network based on a ring topology structure. The method is based on an optical fiber sensing network comprising an fiber bragg grating interrogator and at least two ring subnets, wherein each ring subnetwork comprises a first light path switcher, a second light path switcher and M FBG (fiber bragg grating) sensors; during repairing, the position with the link fault in an optical fiber sensing network is firstly judged; then, an adjacent element linked list for representing the structure of the optical fiber sensing network after the link fault appears is established; then, according to the SPFA (shortest path faster algorithm), the demodulation path of each FBG sensor is obtained; finally, the switching path of the light switcher is calculated; according to the switching path, the corresponding light path in the optical fiber sensing network is switched. According to the repairing method for the optical fiber sensing network based on the ring topology structure, which is disclosed by the invention, an affected FBG sensor with the intact function in the optical fiber sensing network can be demodulated to the largest extent, the optical fiber sensing network can be repaired by self, and the reliability of the whole optical fiber sensing network can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

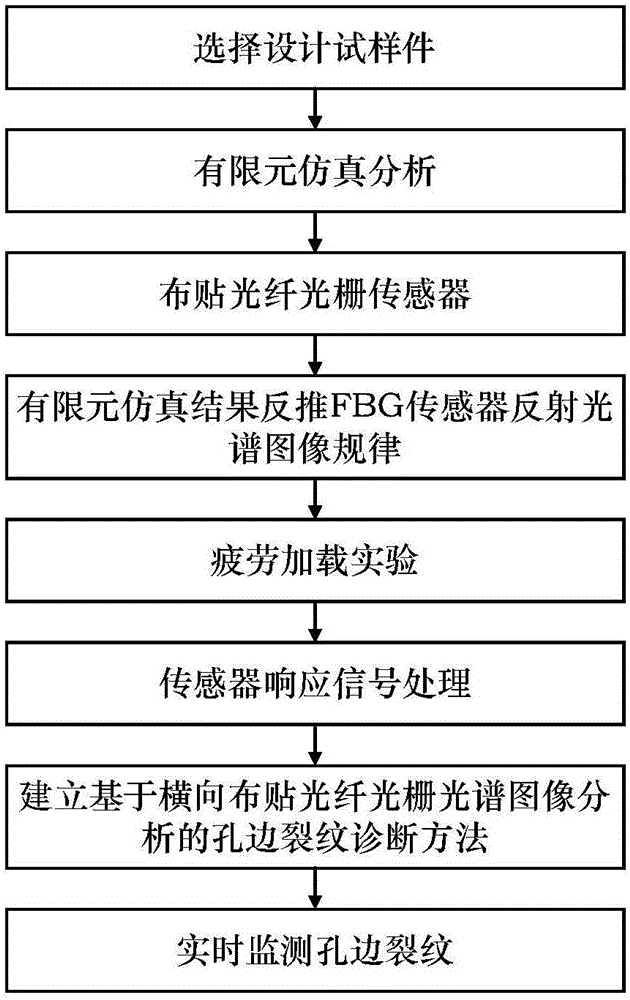

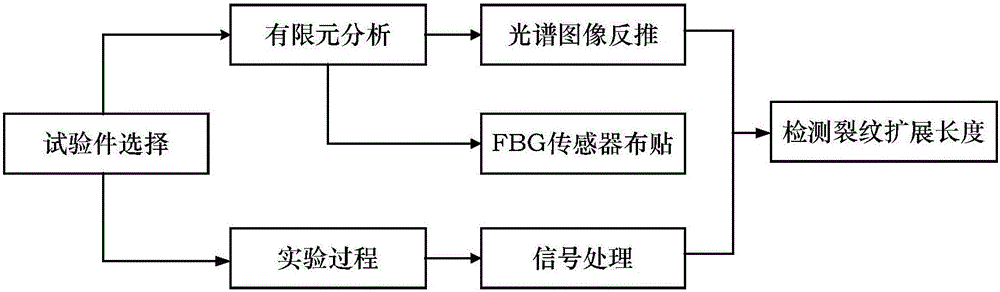

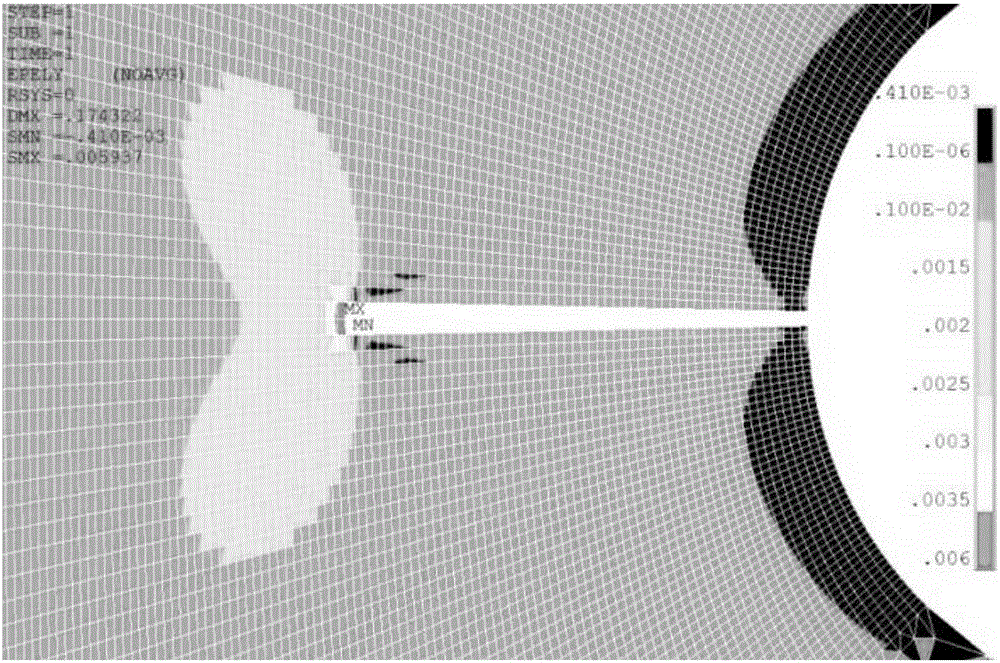

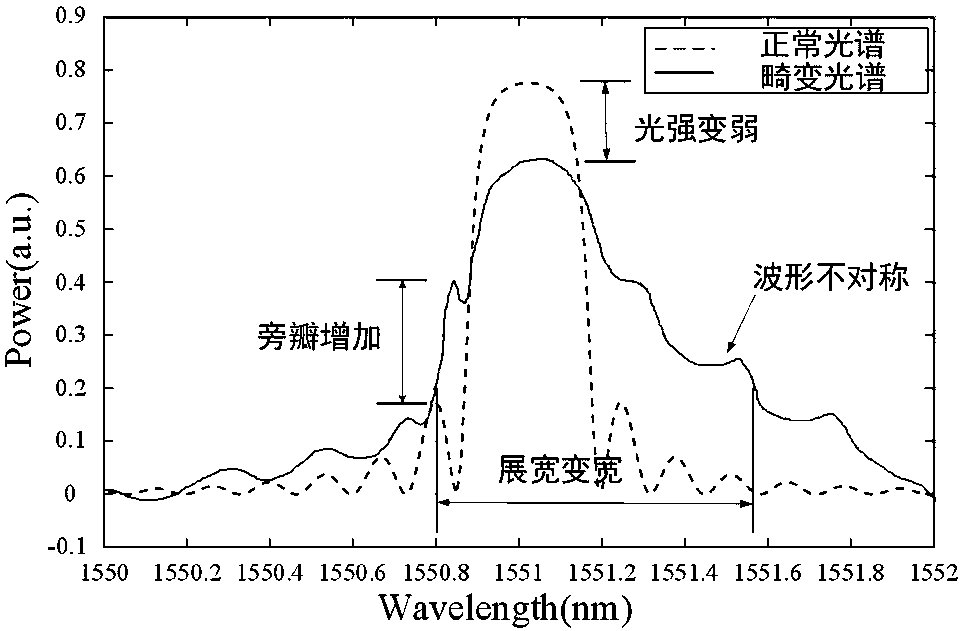

Hole-edge crack diagnosis method based on optical fiber spectrum image analysis

InactiveCN106596255ASolve the positioning problemAchieve research resultsStrength propertiesFiberGrating

A hole-edge crack diagnosis method based on optical fiber spectrum image analysis includes the following steps: (1) selecting a test sample and designing the test sample; (2) performing structural mechanics analysis to the test sample; (3) pasting fiber Bragg grating sensors on an aluminum alloy thin board; (4) according to finite element simulation results, backstepping the principle of a reflective spectrum image of the FBG sensors; (5) installing the aluminum alloy thin board, on which the FBG sensors are pasted, on a fatigue test machine to perform fatigue crack propagation test; (6) processing signals collected by the FBG sensors; and (7) repeating the steps (1) - (5) to verify the method established in the step (6); and (8) completing real-time monitoring of the cracks. By means of the steps, the hole-edge crack diagnosis method based on transversal-arranged FBG spectrum analysis is achieved, thereby achieving the researching effect of diagnosis on length of a hole-edge crack. The method solves the positioning problem of length of the hole-edge crack in the aluminum alloy board in engineering application.

Owner:BEIHANG UNIV

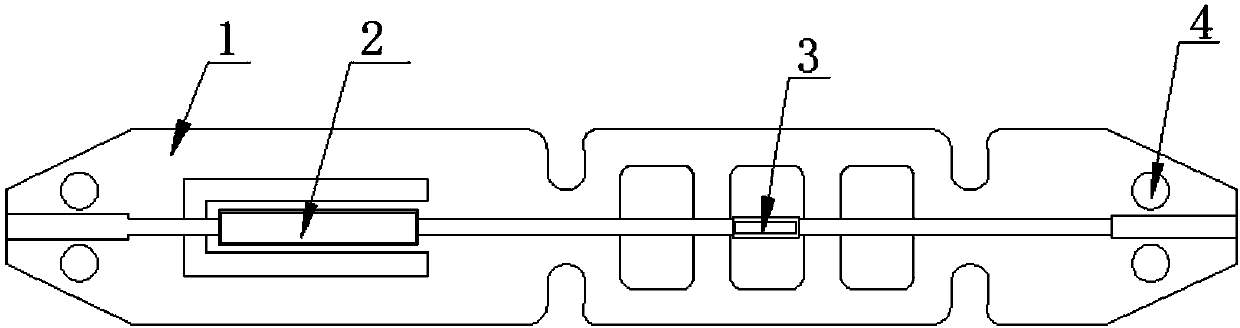

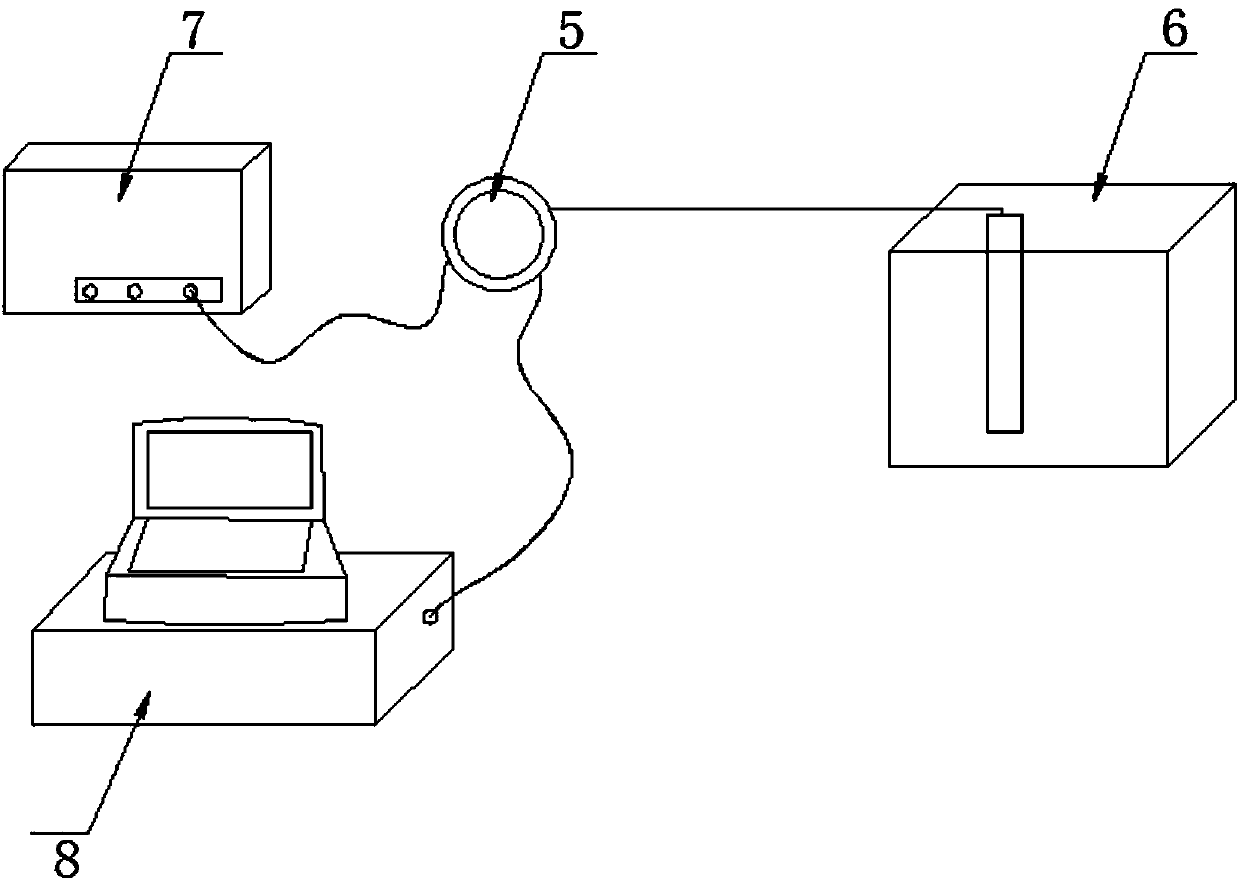

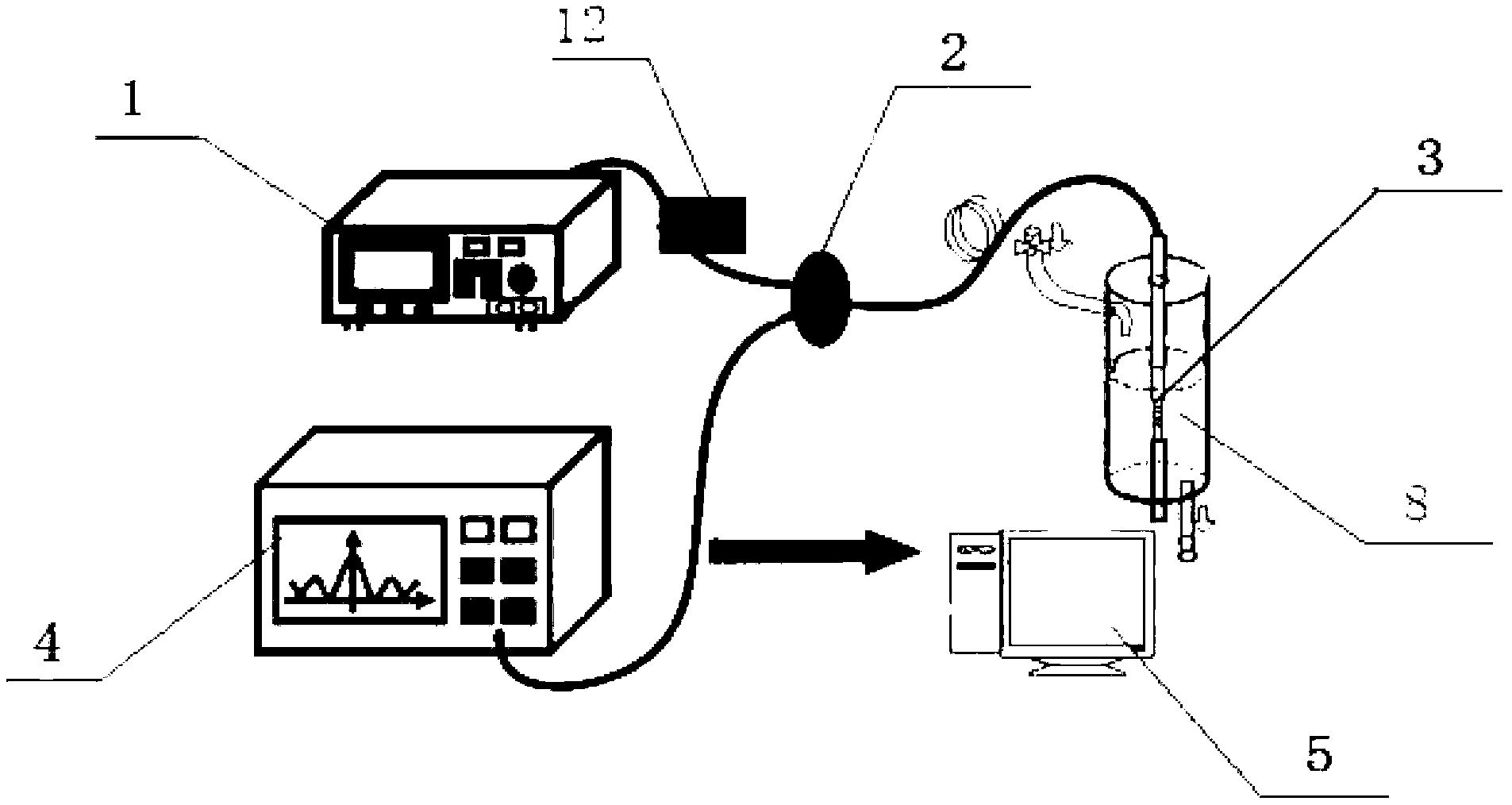

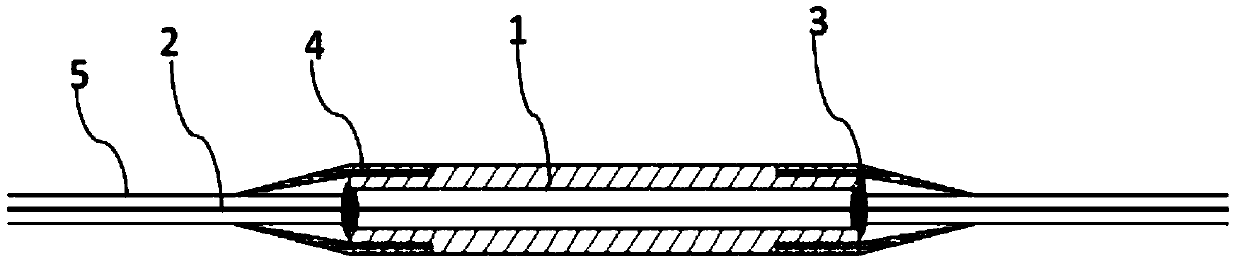

Substrate type temperature-strain measurement FBG (Fiber Bragg Grating) sensor and performance testing method

InactiveCN107907069AIncreased strain sensitivityAchieving temperature-strain decouplingThermometers using physical/chemical changesThermometer testing/calibrationWater bathsSubstrate type

The invention discloses a substrate type temperature-strain measurement FBG (Fiber Bragg Grating) sensor, which is characterized by comprising a substrate, a first FBG and a second FBG, wherein the first FBG and the second FBG are sequentially arranged on the substrate from left to right; the first FBG and the substrate are adhered through DP420 glue, and the second FBG and the substrate are adhered through 353ND glue; and the substrate is uniformly provided with fixing holes. A testing system in the step S1 comprises a circulator, a Fluke water bath, a broadband light source and a demodulation instrument, wherein an output end of the broadband light source is electrically connected with an input end of the circulator; an FBG sensor placed in the Fluke water bath is electrically connectedwith the circulator through a wire. The substrate type temperature-strain measurement FBG sensor and the performance testing method not only perform decoupling on the temperature and the strain, but also achieve an effect of performing decoupling on the temperature and the strain simultaneously; and the sensor can simultaneously measure the temperature and the strain, and the strain sensitivity isimproved.

Owner:BEIJING INFORMATION SCI & TECH UNIV

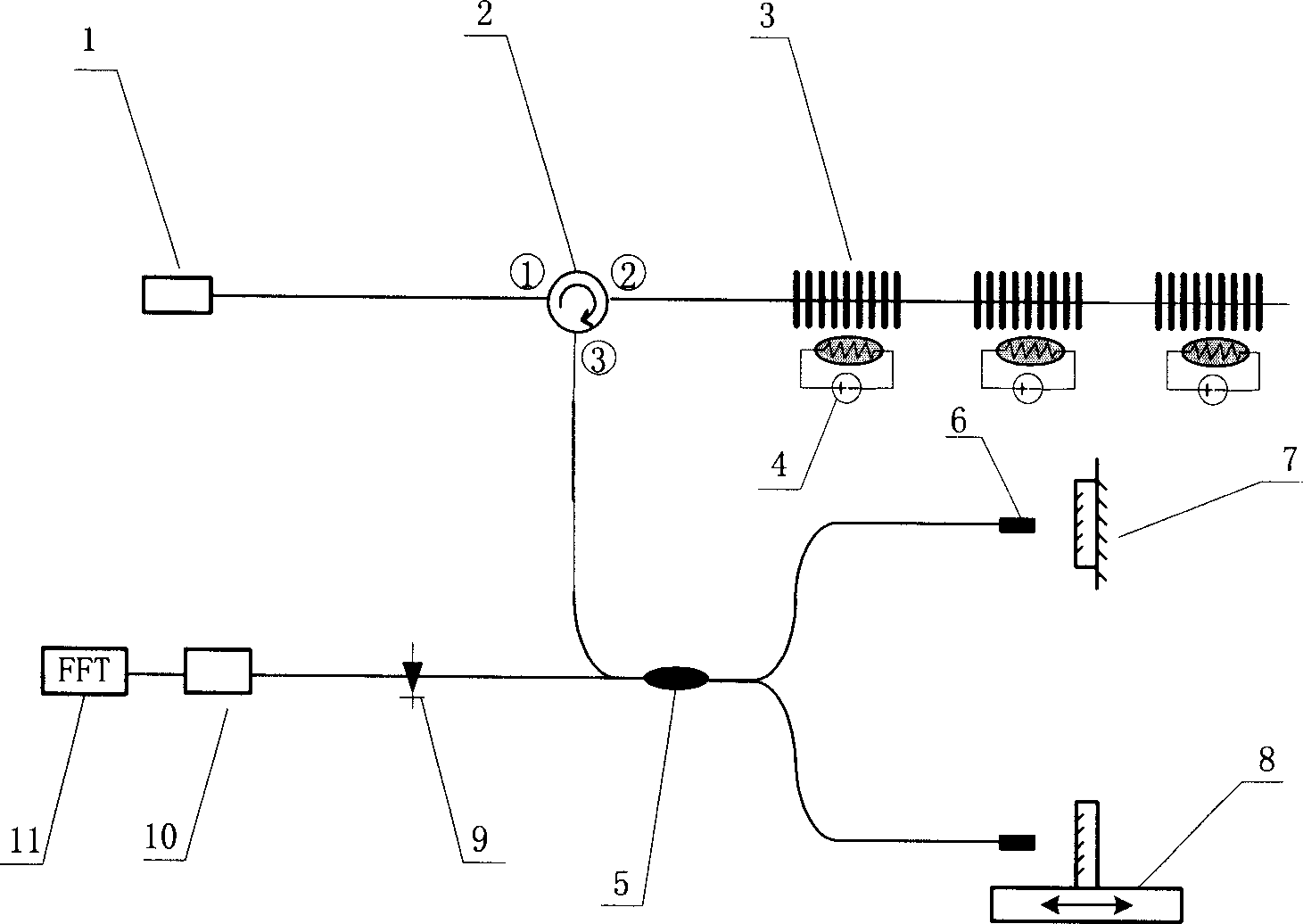

Method and apparatus for sensing methane concentration based on optical fiber Bragg raster

InactiveCN1904659ARealize multiplexingResolve interferenceMaterial analysis by optical meansCoupling light guidesGratingFiber Bragg grating

The invention relates to a method for optical fiber Prague grating used in methane thickness sensor and the device to realize the method. The FBG sensor connects to broad band light source through optical fiber circulator, and reflecting light connects to optical fiber coupler through optical fiber circulator. The input of photodiode connects to one end of 3-dB optical fiber coupler, and the output end of photodiode connects to data acquisition card that is connected to FFT analyzer. The other end of 3-dB optical fiber coupler connects to two optical fiber collimator. Two reflecting mirrors are set corresponding to two optical fiber collimators and one could control the movement by step motor. The invention is suited for multiple spot methane thickness high accuracy measurement.

Owner:ZHEJIANG UNIV

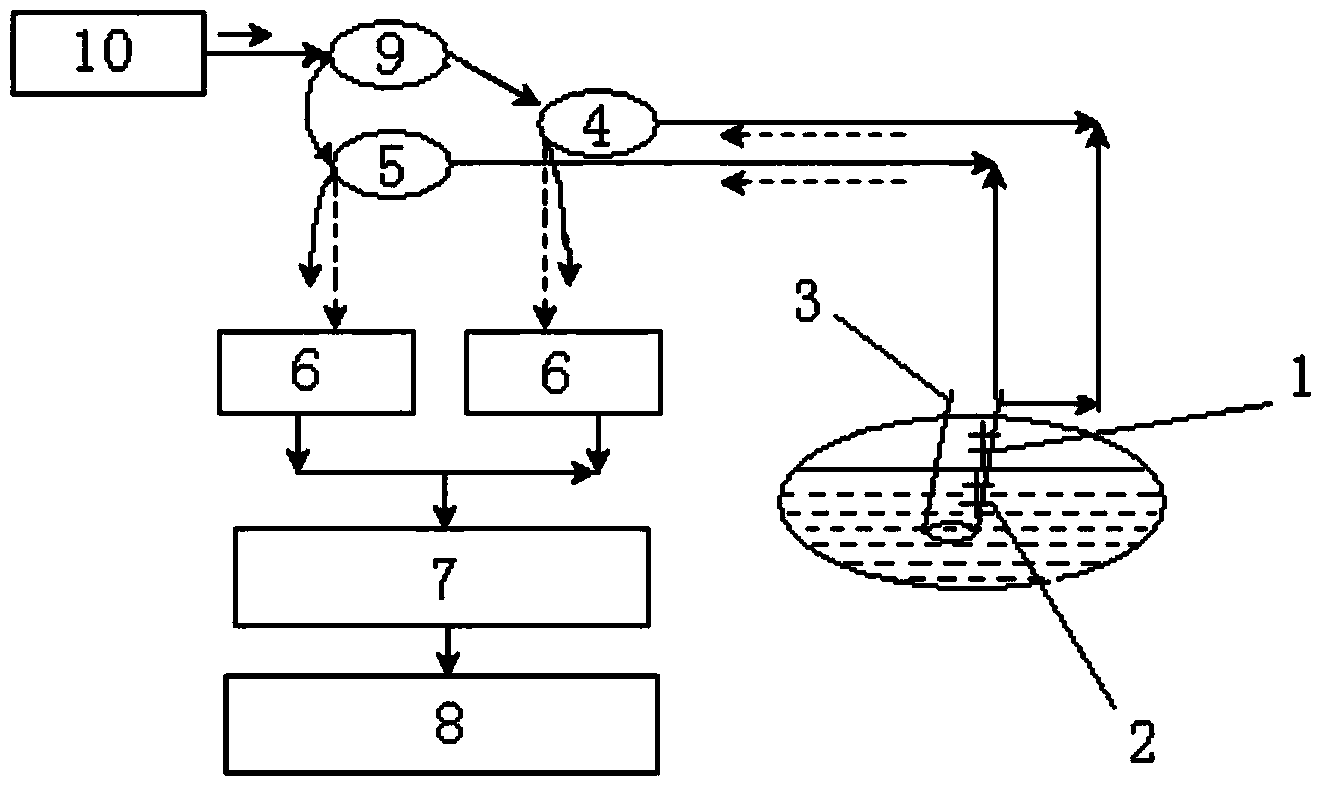

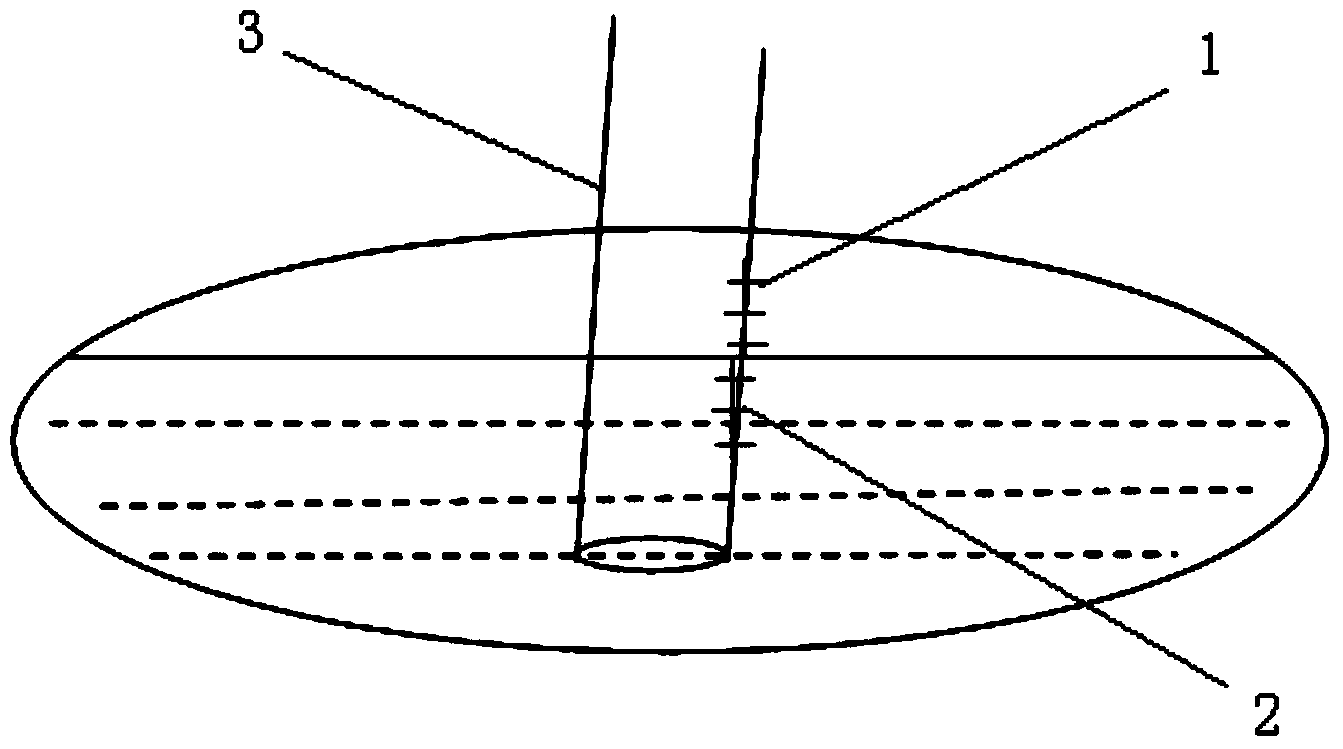

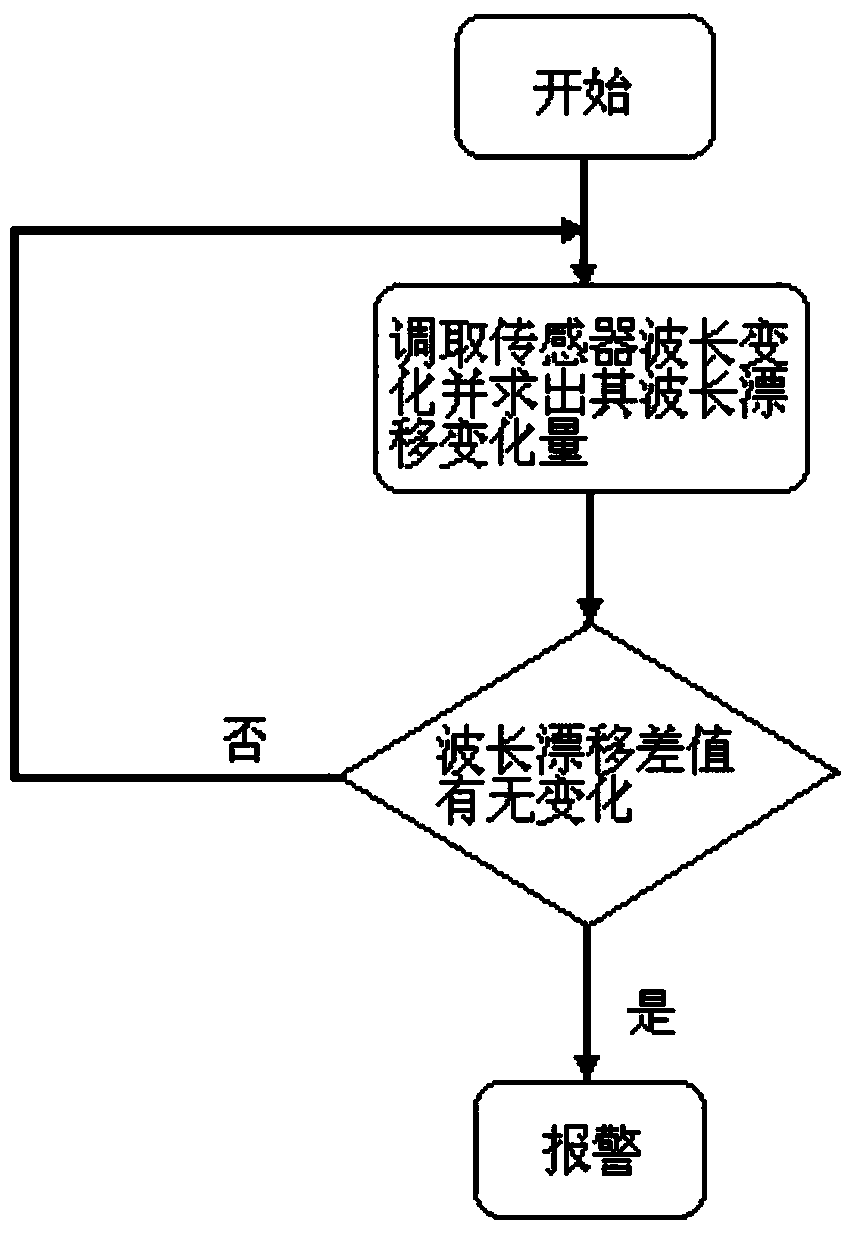

Oil tank truck oil leakage early-warning device based on FBG sensors

ActiveCN103852220ATimely processingTimely judgmentFluid-tightness measurement using fluid/vacuumTruckFbg sensor

An oil tank truck oil leakage early-warning device based on FBG sensors comprises a hose, wherein one end of the hose is inserted into liquid, the other end of the hose extends outside the liquid level, the inner wall of the hose outside the liquid level and the inner wall of the hose inside the liquid are respectively provided with one FBG sensor in an attaching mode, the two FBG sensors are electrically connected with a first coupler and a second coupler respectively, the first coupler and the second coupler are respectively connected with an photoelectric detector respectively, the photoelectric detector is electrically connected with a signal processing module, the signal processing module is electrically connected with an alarm, wavelength shift change amount caused by oil leakage of the two FBG sensors is resolved through analysis of the signal processing module, if wavelength shift difference values change, it can be judged that oil leakage accidents are happening, the alarm is started immediately to give an alarm, real-time detection and alarming on an oil tank truck and other dangerous areas can be achieved, potential safety hazards are eliminated, and the device has the advantages of being high in accuracy and high in instantaneity.

Owner:SHAANXI UNIV OF SCI & TECH

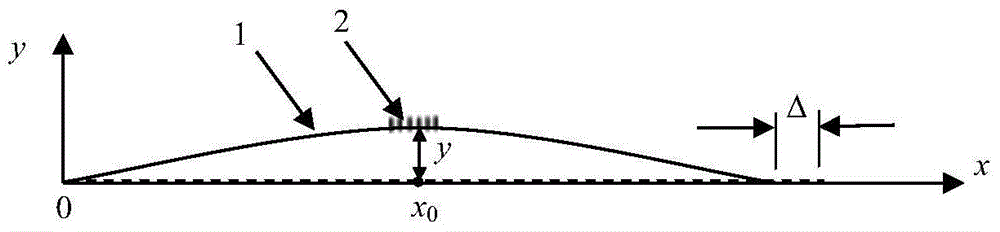

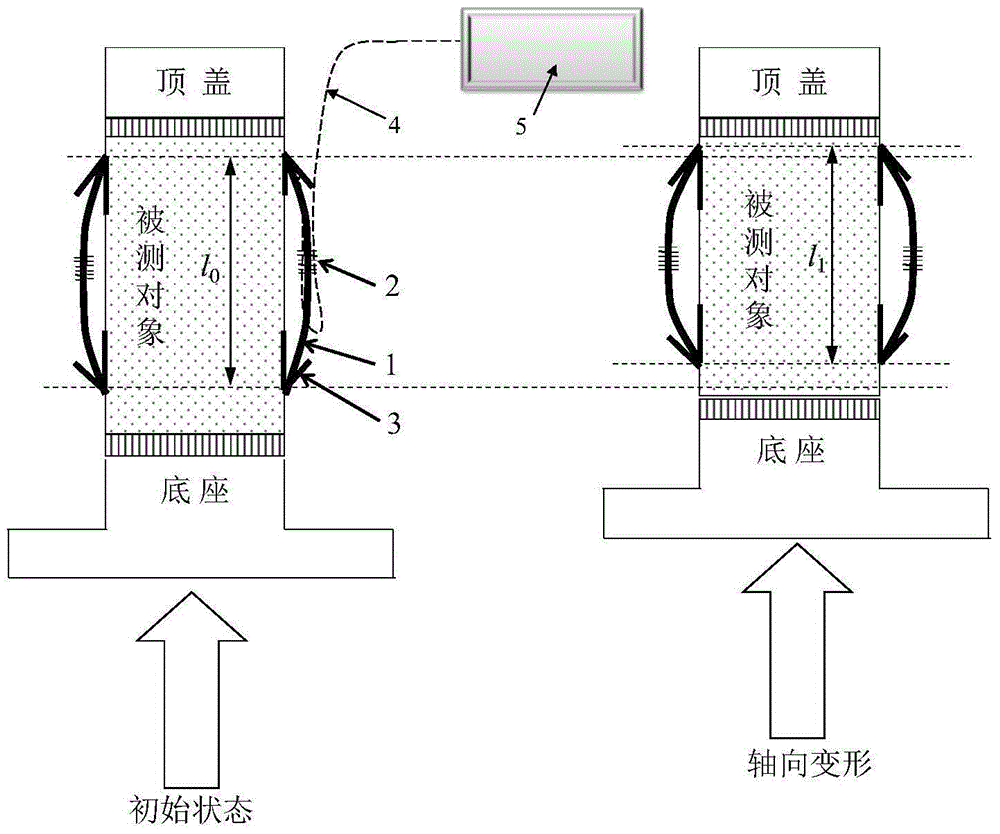

Partial displacement measurement method based on fiber grating sensor

ActiveCN105115440ASolving Precision Measurement ProblemsMeet measurement needsUsing optical meansElastomerGrating

The invention provides a partial displacement measurement method based on a fiber bragg grating sensor. The method comprises the steps of elastomer structure and size selecting, FBG sensor mounting and fixing, and calculating of the local displacement of a measured object. According to the main principle, when the measured object is compressed, the deformation of the measured object leads to the deformation of an elastomer, and a fiber grating deforms. According to the invention, a formula shows that a unique corresponding formula is provided for the deformation of the grating and the local displacement of the measured object; the deformation of the measured object can be acquired; and the local displacement of the measured object can be precisely measured.

Owner:HUAZHONG UNIV OF SCI & TECH

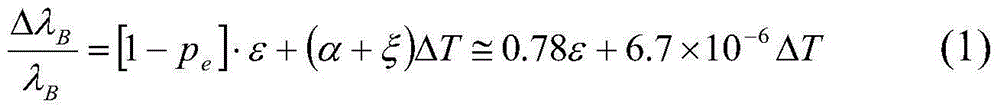

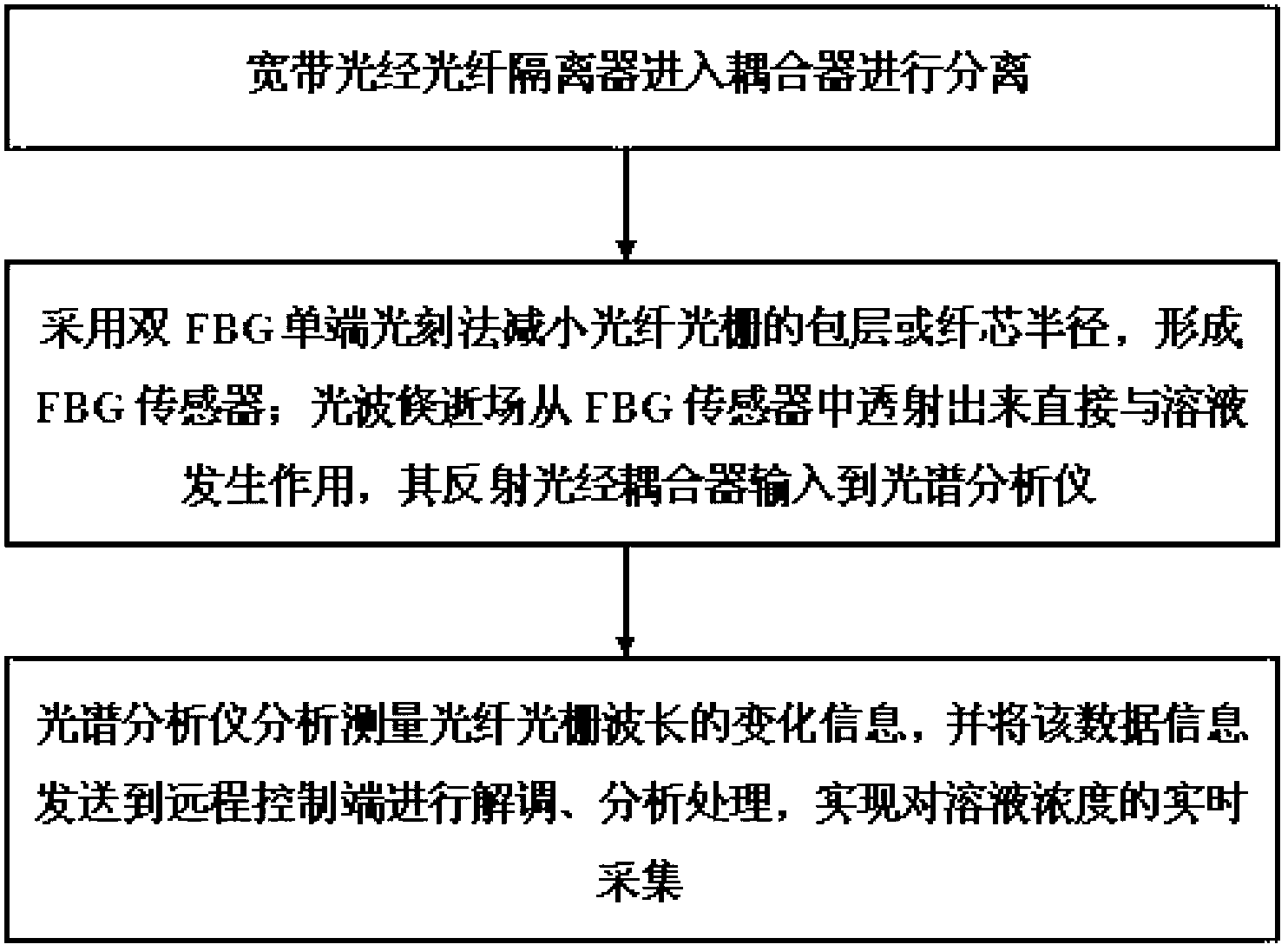

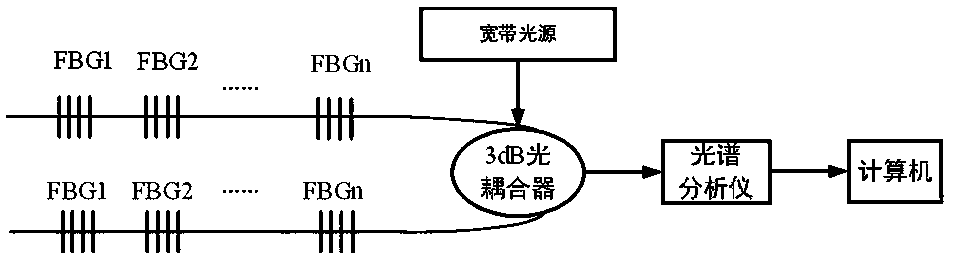

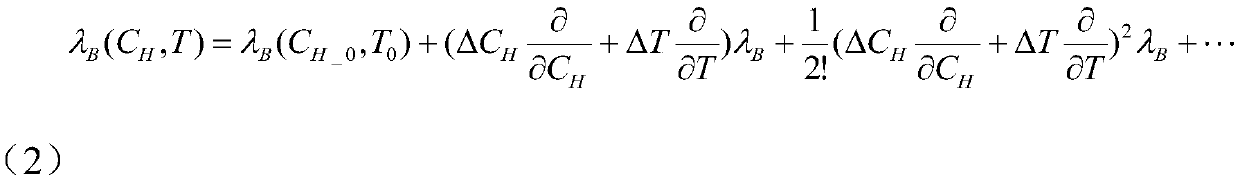

Method and system for measuring concentration of chemical solution by fiber bragg gratings (FBG)

InactiveCN102706825AImprove securityReduce cross-sensitivity effectsColor/spectral properties measurementsFiberChemical solution

The invention discloses a method and system for measuring the concentration of a chemical solution by fiber bragg gratings (FBG). The system comprises a broadband light source 1, a fiber isolator 12, a coupler 2, an FBG sensor 3, a spectrum analyzer 4 and a computer control end 5, wherein the fiber isolator 12 is respectively connected with the broadband light source 1 and a coupler 2, the coupler 2 is respectively connected with the FBG sensor 3 and the spectrum analyzer 4, and the spectrum analyzer 4 is connected with the computer control end 5. According to the invention, a double FBG single-end photoetching method is used to reduce the radius of claddings or fiber cores of fiber bragg gratings, so as to obtain a double fiber bragg grating structure which is sensitive to the external refractive index, and thus the FBG sensor is formed so that the FBG propagation mode is sensitive to the change of concentration of a solution outside, and therefore the on-ling and real-time acquisition and remote control for the concentration of the solution can be realized through detection on the change of reflection wavelength of fiber bragg gratings under the support of equipment such as the coupler, the FBG sensor, the spectrum analyzer.

Owner:东北大学秦皇岛分校

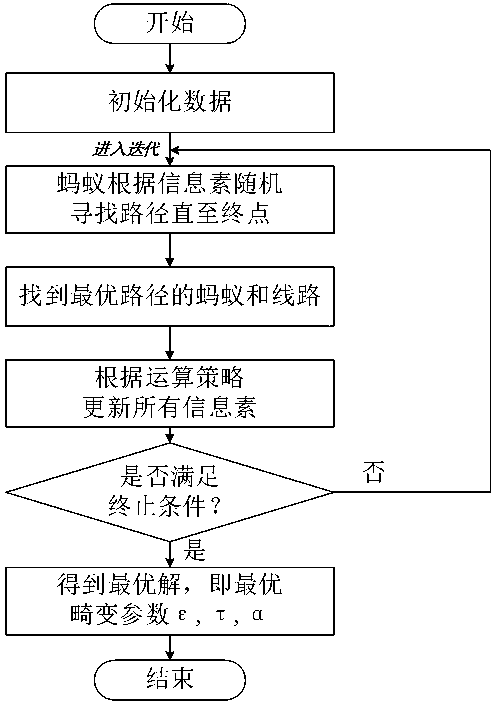

Distributed multi-node cooperative fiber bragg grating sensor fault positioning method

The invention relates to a distributed multi-node cooperative fiber bragg grating sensor fault positioning method. For abnormal state of fault data in the FBG sensor network, a distributed multi-nodeFBG network fault node is accurately positioned in combination with anant colony algorithm and a support vector machine.

Owner:FUZHOU UNIV

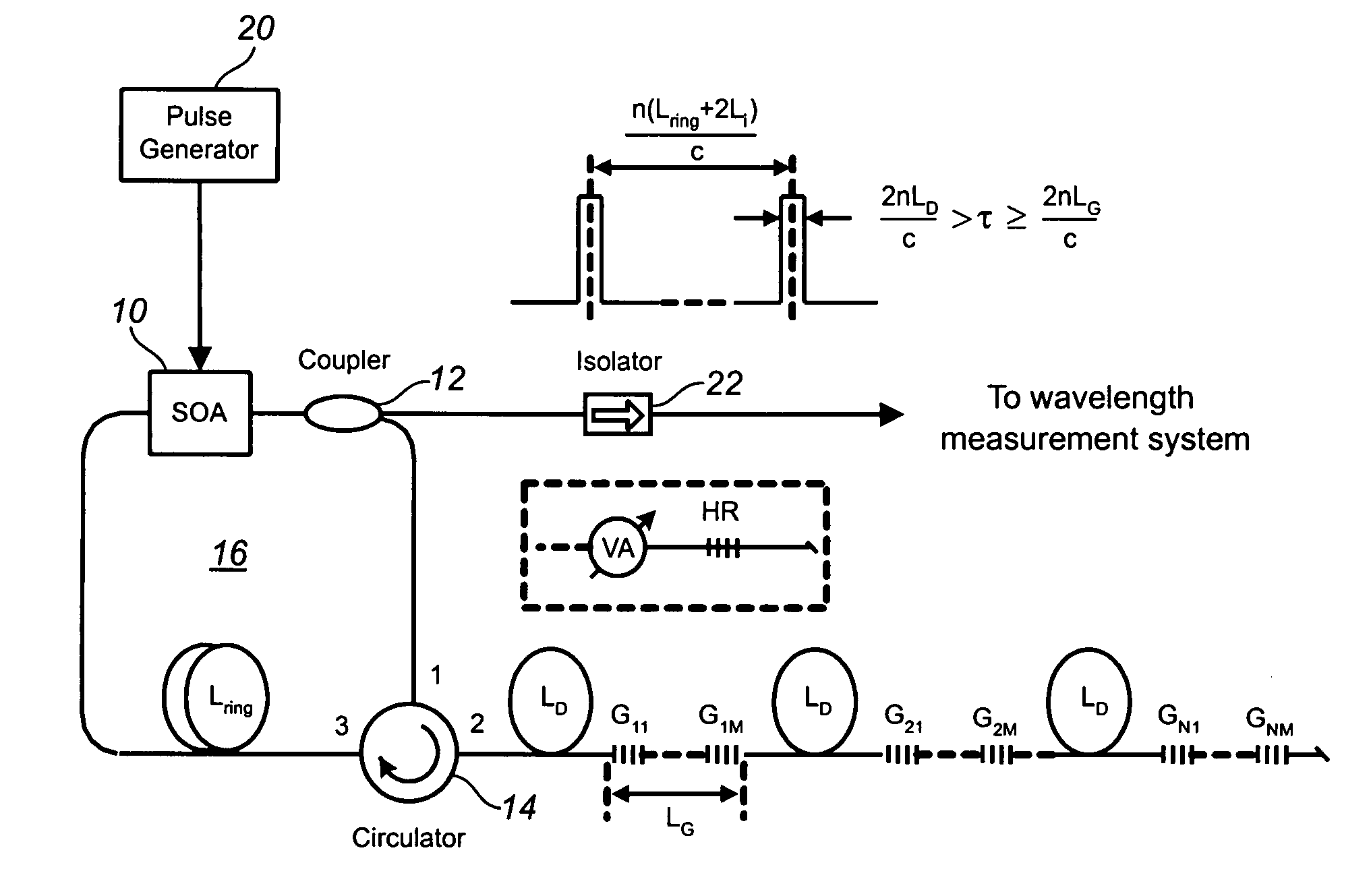

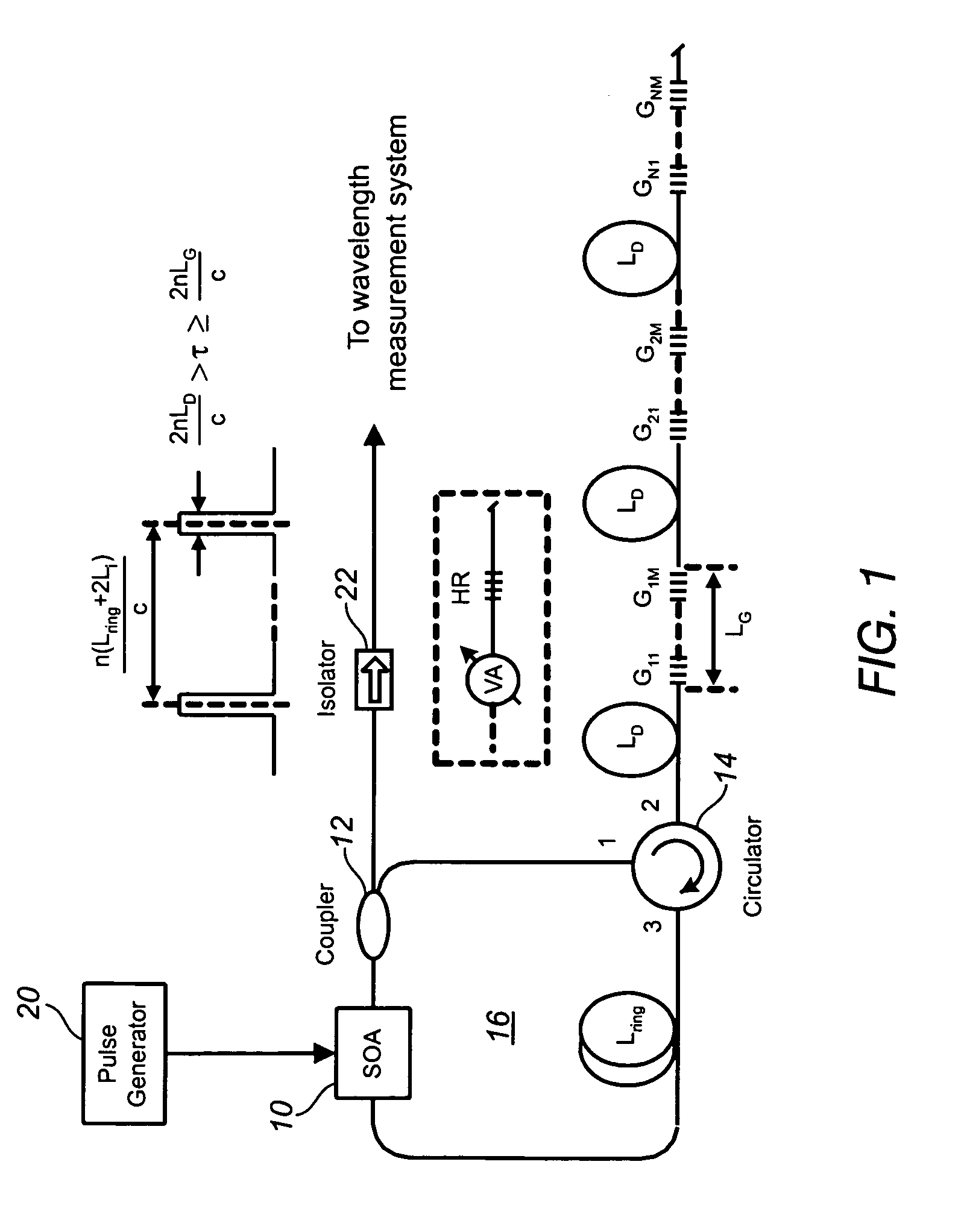

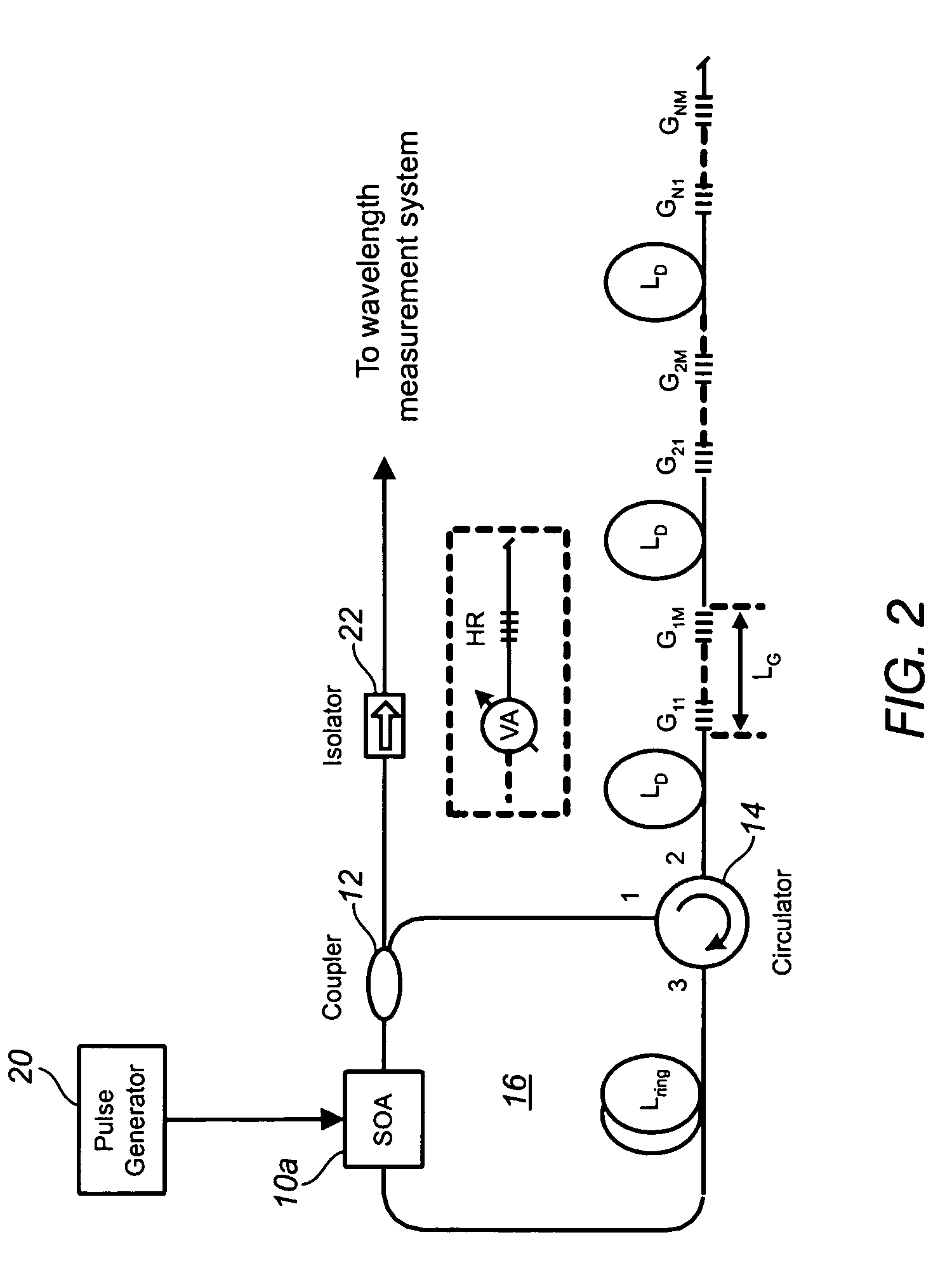

FBG sensor interrogation method using semiconductor optical amplifier in ring cavity configuration

ActiveUS7266260B2Improve performanceSimple interrogationOptical measurementsTime-division optical multiplex systemsMultiplexingGrating

A sensor device that uses a number of bragg grating (FBG) sensors and novel interrogation system with a ring cavity configuration for simultaneous time-division-multiplexex (TDM) and wavelength-division-multiplexed (WDM) interrogation of FBG sensors. The ring cavity includes an amplifier, and output coupler and an optical circulator. The coupler is connected to a wavelength measuring system and the optical circulator is connected to the FBG sensors. The FBG sensors can be in a number of groups. TDM interrogation is applied to each group of FBG sensors while WDM interrogation is applied to each FBG sensors within each group.

Owner:THE HONG KONG POLYTECHNIC UNIV

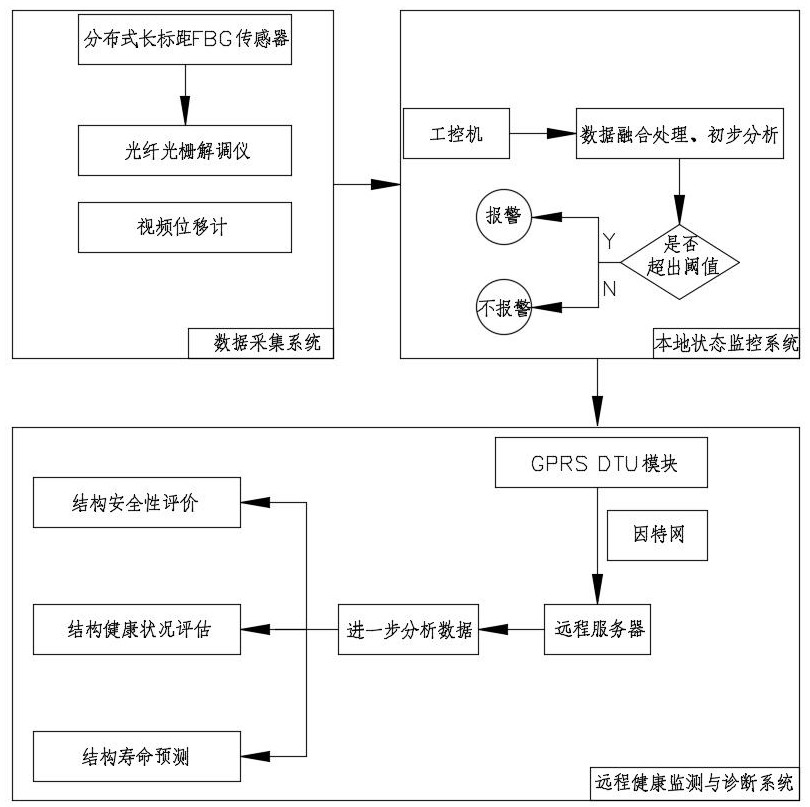

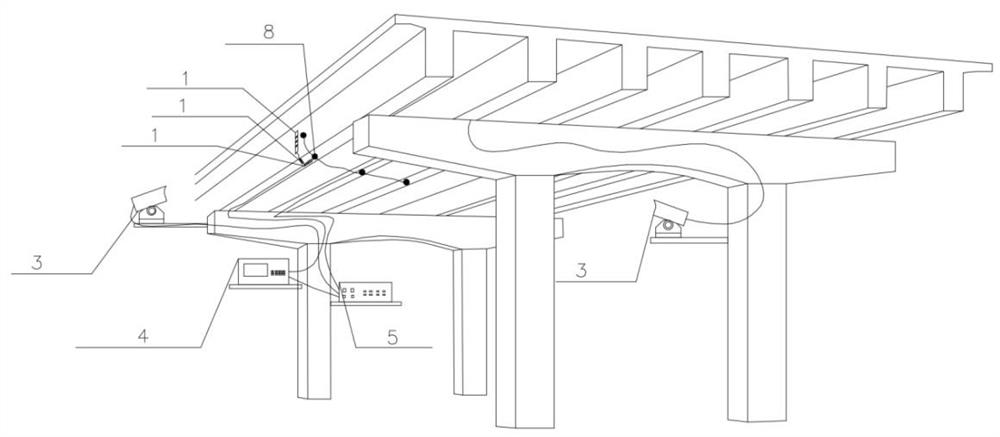

Bridge displacement monitoring system based on regional distribution sensing and DIC technology fusion

ActiveCN113532290AMake up for the lossIncrease credibilityUsing optical meansMonitoring systemFiber gratings

Owner:江苏中云筑智慧运维研究院有限公司 +1

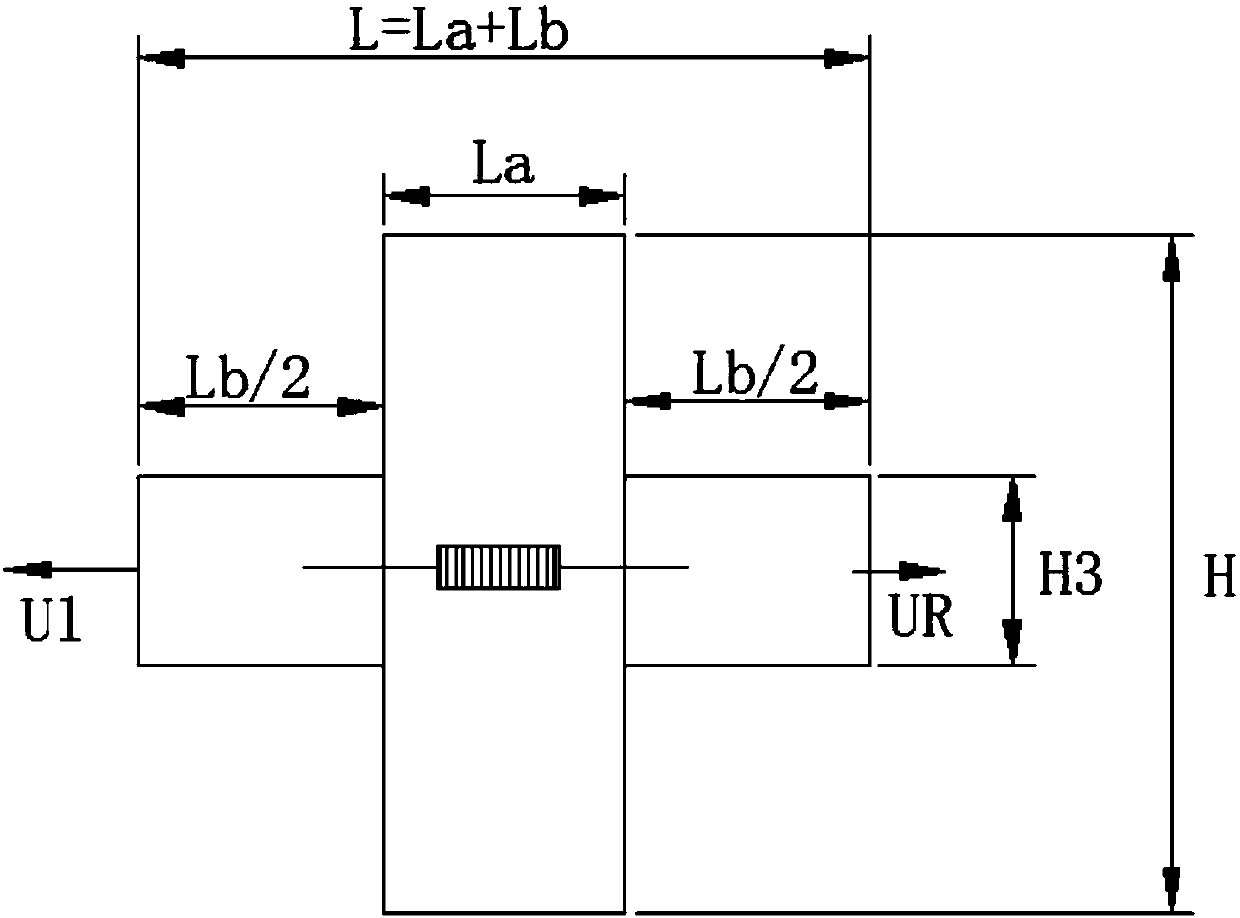

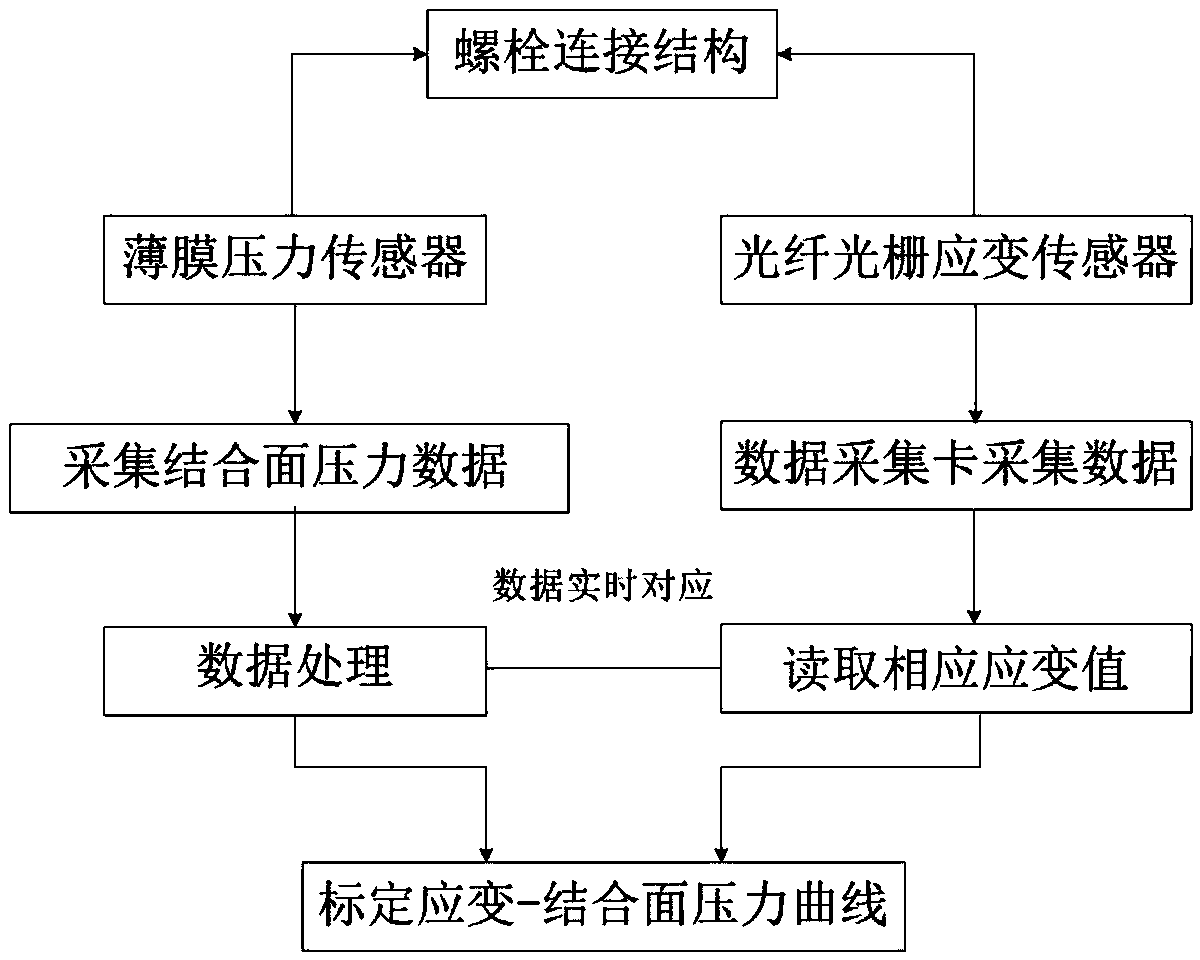

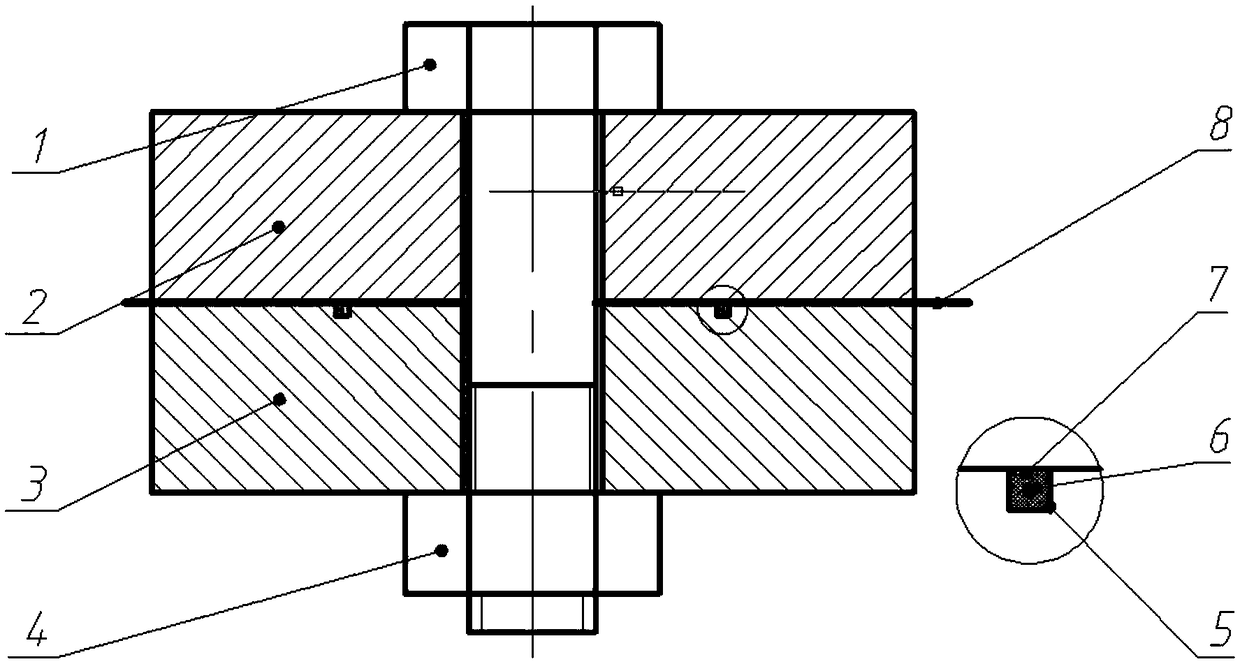

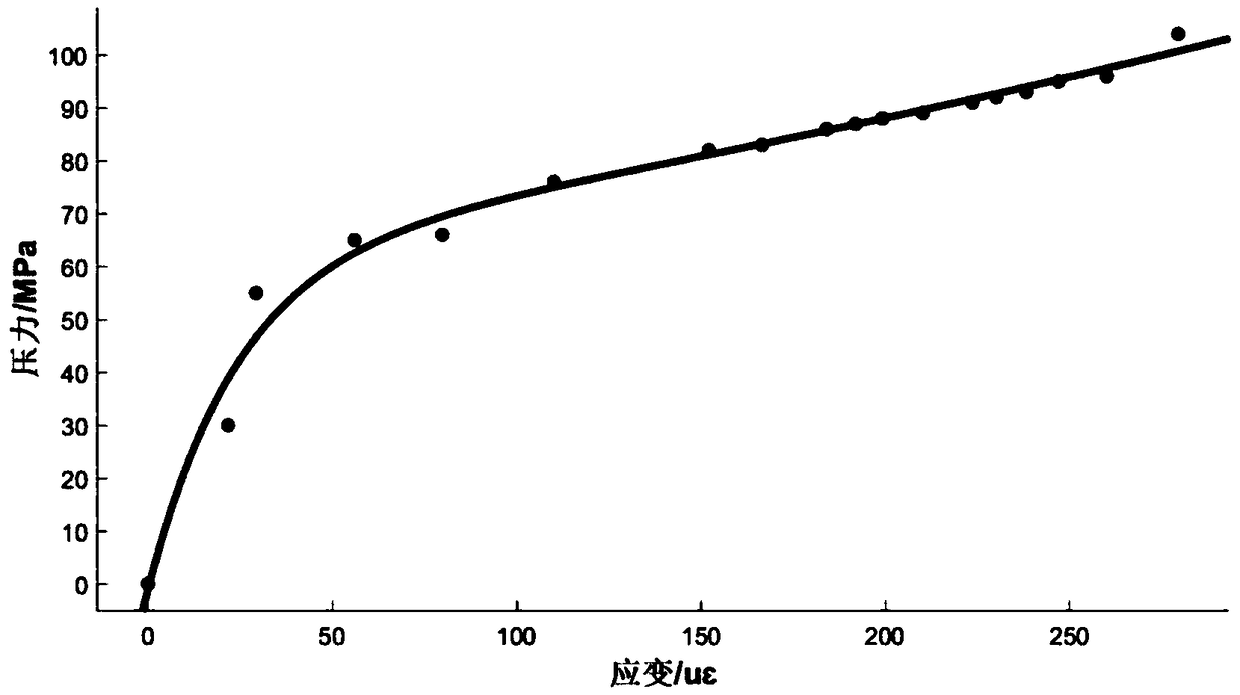

Method for detecting bolt fastening joint surface pressure based on FBG sensor

ActiveCN109186822ASolving difficult problems that cannot be directly detectedAccurate Strain-Joint Surface Pressure CurveForce measurement by measuring optical property variationApparatus for force/torque/work measurementPressure curveFiber Bragg grating

The invention belongs to the technical field of pressure detection of a connecting piece joint surface, and provides a method for detecting a bolt fastening joint surface pressure based on an FBG sensor, wherein the method converts the joint surface pressure to the strain of the FBG sensor. The method comprises the steps of: determining the size and the position of the embedding groove of the FBGsensor based on a strain transferring theory of embedded FBG sensor; and determining the pressure of the detecting point of the joint surface based on a single-bolt connection joint surface pressure distribution theory, thereby realizing the calibration of the strain and the pressure value corresponding to each other, and realizing the accurate detection of the joint surface pressure. According tothe method for detecting the bolt fastening joint surface pressure based on the FBG sensor, the method determines the size and the position of the embedding groove of the FBG sensor, thereby ensuringthe reliability and the accuracy of the strain information, obtaining an accurate strain-joining surface pressure curve combined with the determination of the joint surface pressure, and providing apractical and feasible method for studying bolt connection joint surface pressure.

Owner:DALIAN UNIV OF TECH

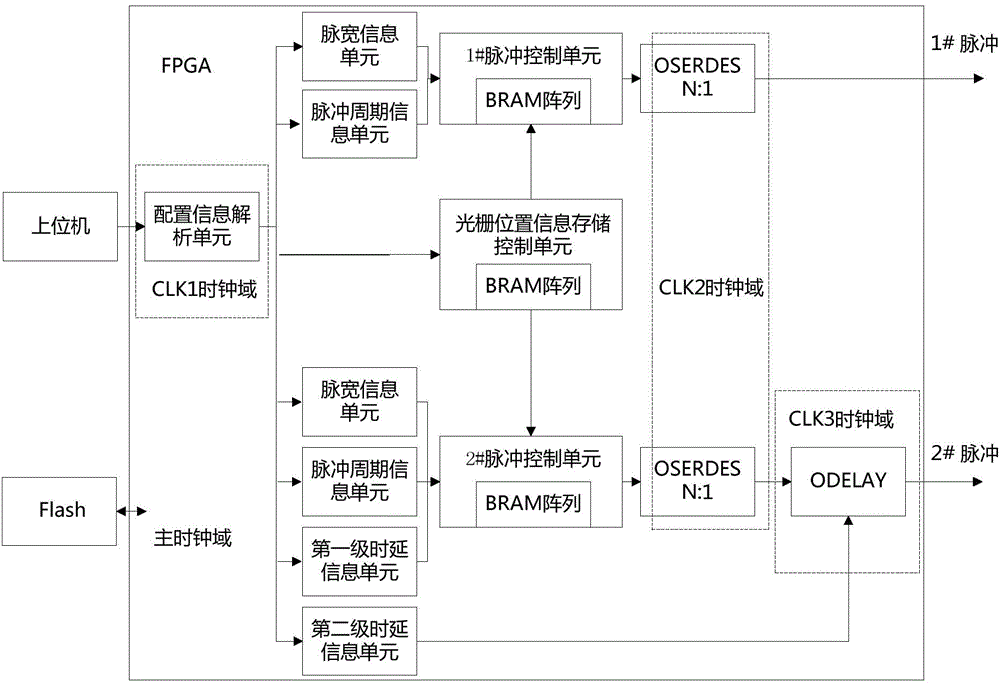

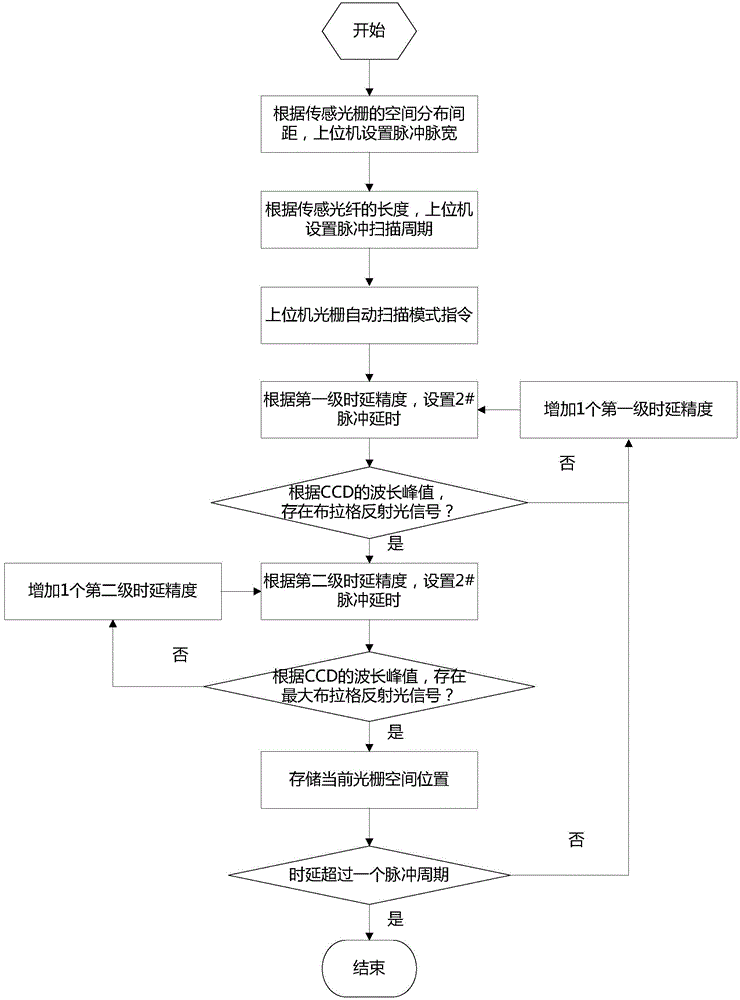

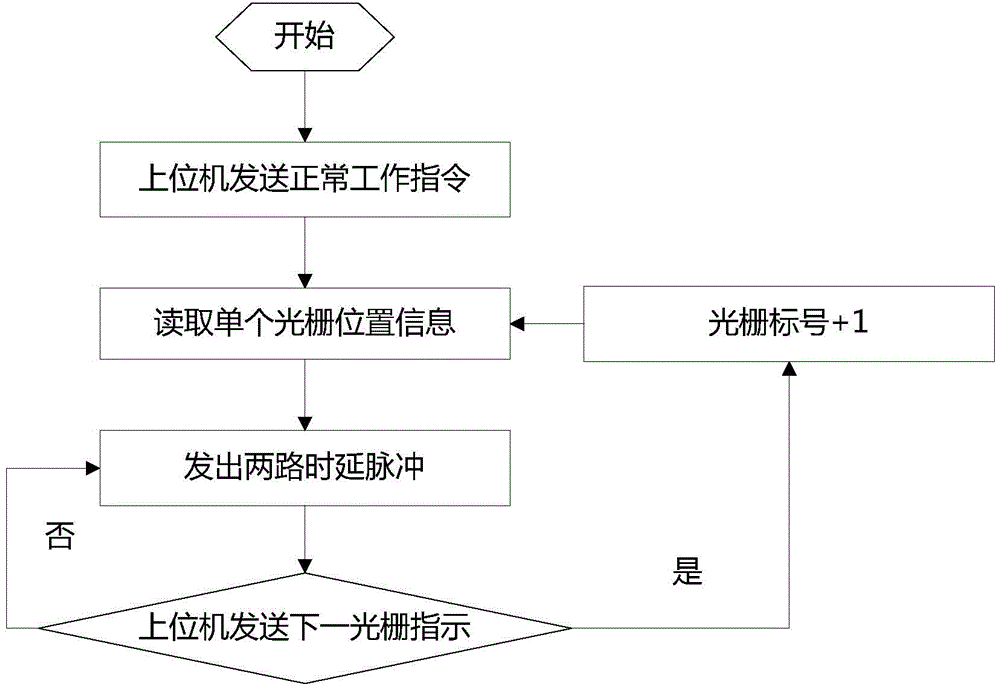

Phase-shift pulse generation device for time division multiplexing FBG sensor network

InactiveCN104596553AAccurate location in spaceFlexible access to statusConverting sensor output opticallyGratingTime delays

The invention discloses a phase-shift pulse generation device for a time division multiplexing FBG sensor network. The device is characterized in that an FBG on the sensor network is elected through a high-precision phase-shift electric pulse signal controlling an optical signal so as to finish the time division multiplexing of large-scale optical fibers. The device comprises a configuration information analyzing unit, a pulse width information unit, a pulse width cycle information unit, a first-stage time delay control unit, a second-stage time delay control unit, a pulse control unit, a FBG position information storing control unit and an OSERDES parallel-serial conversion unit which are connected through electric signals. According to the pulse-shift pulse generation device and method, the problem that the FBG cannot be automatically scanned through a commercial signal generator can be solved; in addition, the pulse phase shift precision can be greatly improved; the cost is low; the integrity is high; the system structure is simple; the reliability is high; the time division multi-way FBG array expansion can be carried out conveniently.

Owner:WUHAN UNIV OF TECH

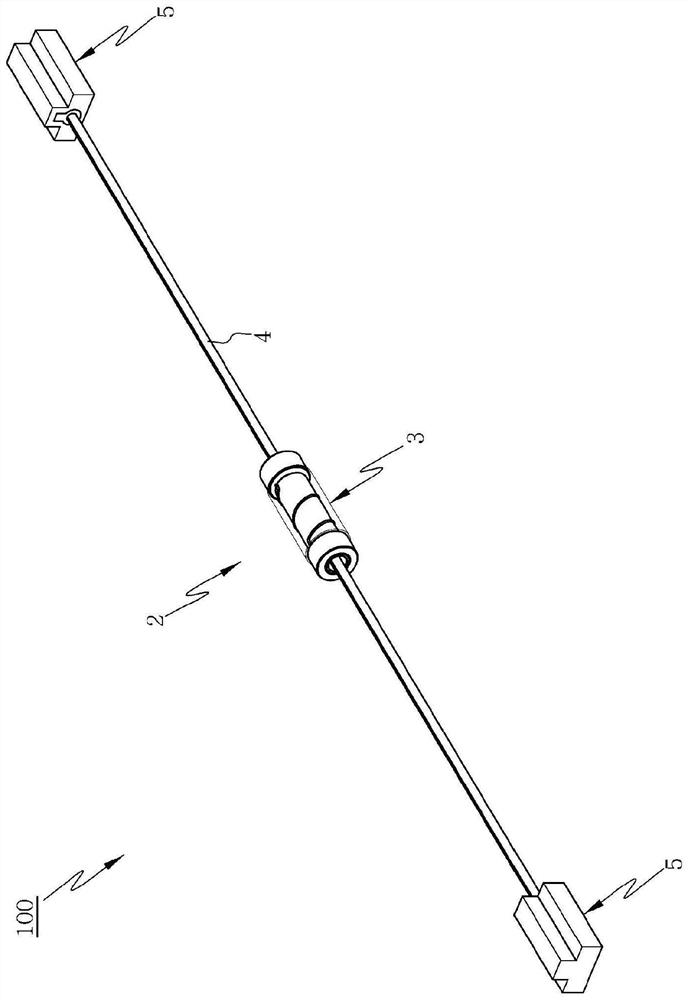

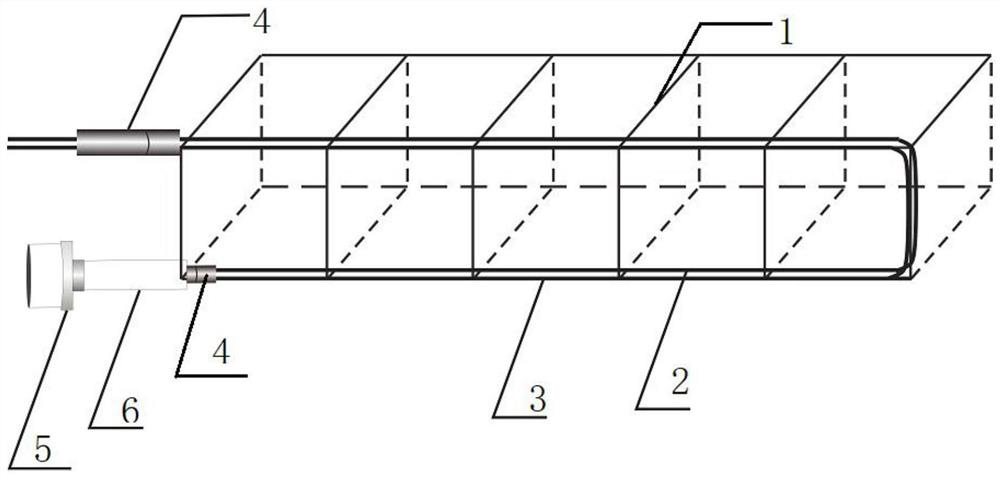

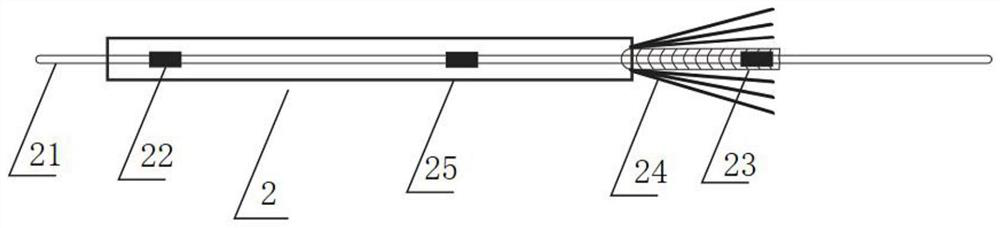

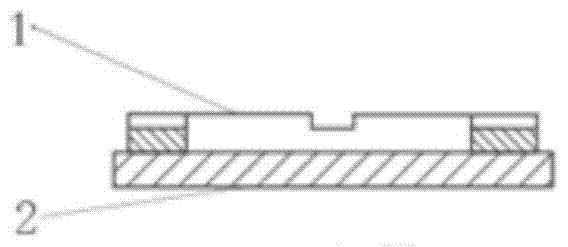

Novel FBG temperature sensor based on low-melting glass, and packaging process of the same

ActiveCN107817061AGood repeatabilityImprove reliabilityThermometers using physical/chemical changesInterference fitFiber Bragg grating

The invention discloses a novel FBG (Fibber Bragg Gratting) temperature sensor based on low-melting glass, and a packaging process of the same. The novel FBG temperature sensor based on low-melting glass includes an alumina ceramic tube (1), a polyimides FBG (2), low-melting glass (3), rubber tail sleeves (4) and high temperature protective sleeves (5), wherein the polyimides FBG (2) penetrates through the alumina ceramic tube (1), is arranged at the central position of the alumina ceramic tube (1), and is in parallel with the alumina ceramic tube (1); the low-melting glass (3) is used to enable the alumina ceramic tube (1) and the polyimides FBG (2) to form a ceramic tube-FBG assembly; the rubber tail sleeves (4) respectively sleeve two ends of the ceramic tube in an interference fit mode; the high temperature protective sleeves (5) respectively sleeve respectively two segments of polyimides tail fibre portions outside the ceramic tube-FBG assembly; and interference fit is performed between the high temperature protective sleeves (5) and the rubber tail sleeves (4). The novel FBG temperature sensor based on low-melting glass has the advantages of being simple in the packaging process, being high in repeatability of the sensor after packaging, and being high in reliability, and is significant for solving the FBG sensor packaging process problem.

Owner:TIANJIN UNIV

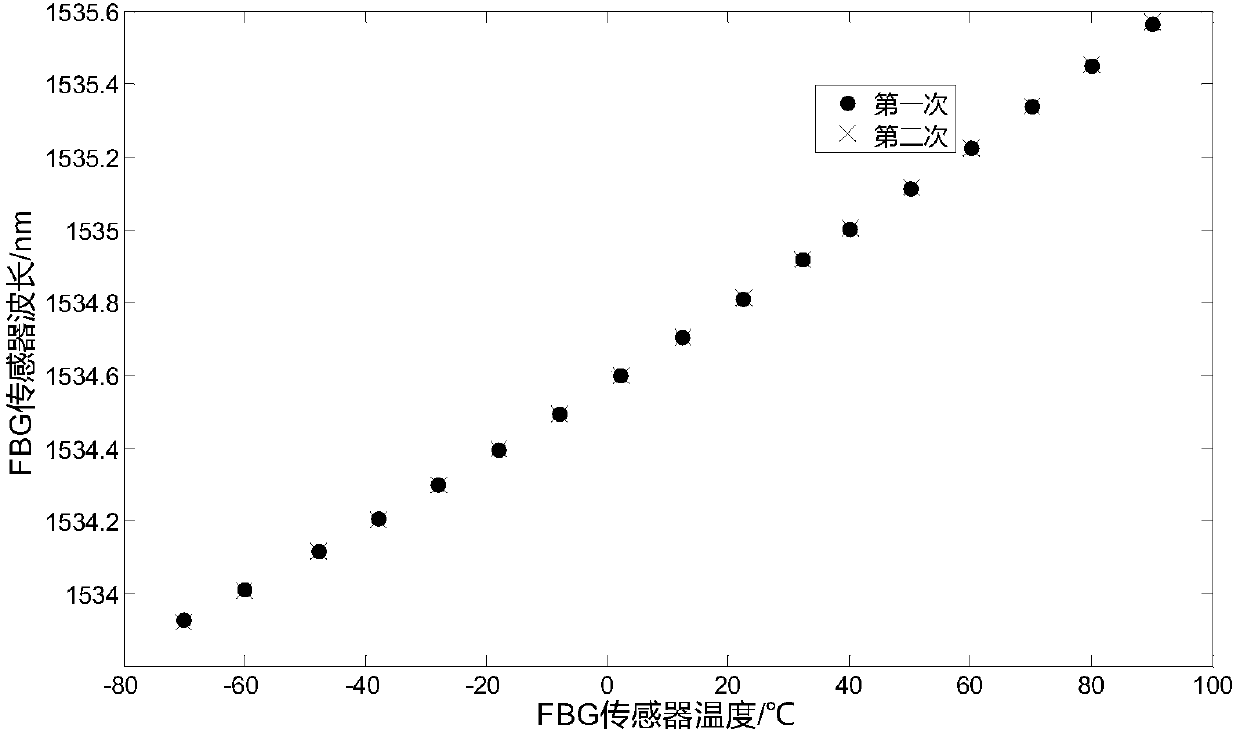

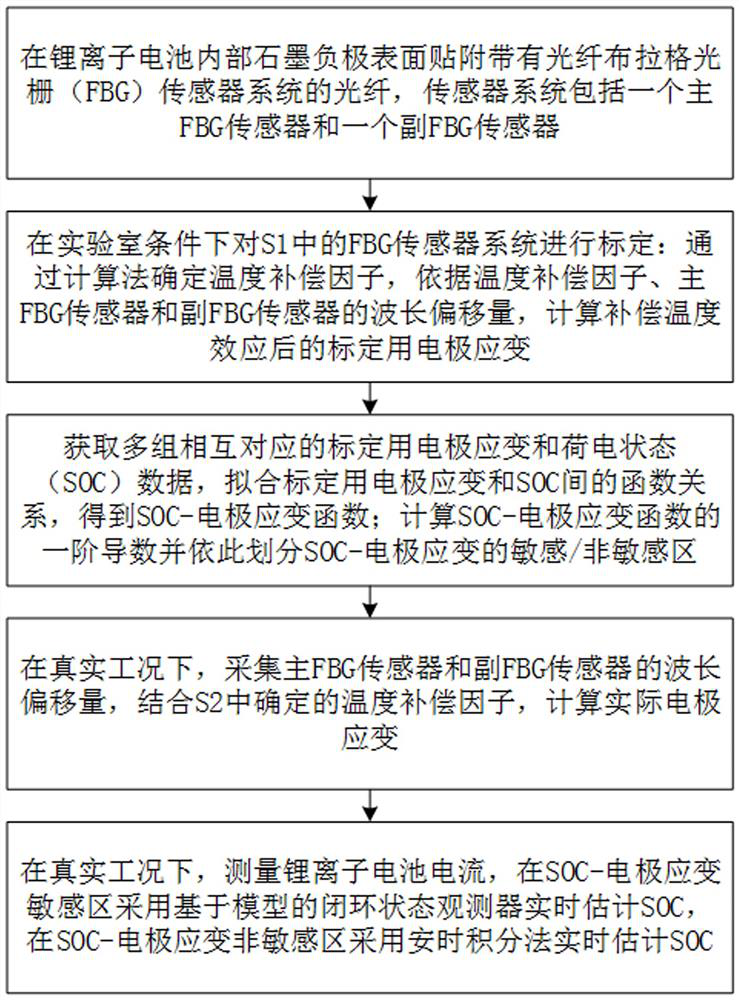

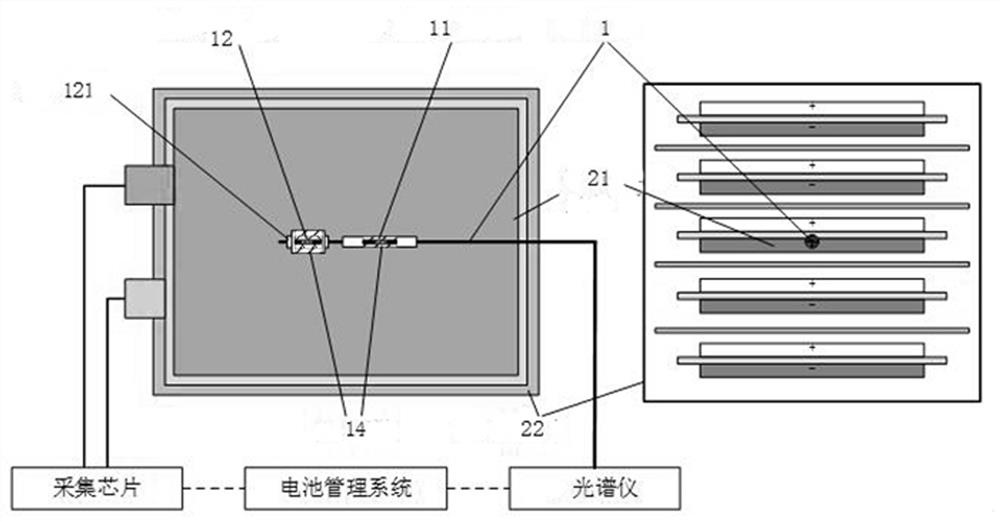

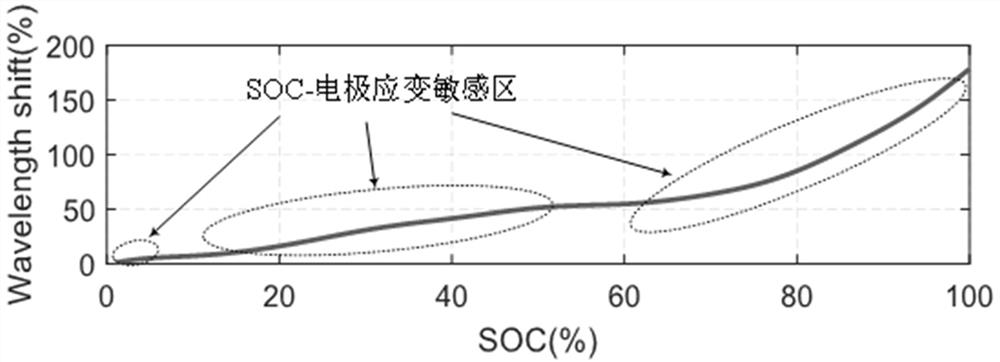

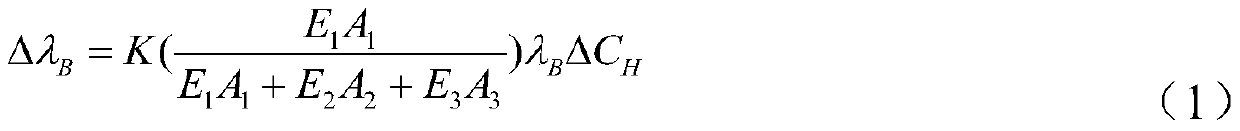

Lithium ion battery state-of-charge estimation method based on embedded optical fiber sensor

ActiveCN112014738AImprove estimation accuracyAccurate measurementElectrical testingUsing optical meansEngineeringLithium-ion battery

The invention discloses a lithium ion battery state-of-charge estimation method based on an embedded optical fiber sensor. The lithium ion battery state-of-charge estimation method comprises the following steps that: S1, attaching an optical fiber with an FBG sensor system to the surface of a graphite negative electrode in a lithium ion battery; S2, calibrating the FBG sensor system in the step S1under laboratory conditions; S3, fitting a function relationship between a calibration electrode strain and an SOC to obtain an SOC-electrode strain function, and calculating a first-order derivativeof the SOC-electrode strain function and dividing sensitive / non-sensitive regions of SOC-electrode strain according to the first-order derivative; S4, under a real working condition, calculating actual electrode strain; and S5, under a real working condition, measuring the current of the lithium ion battery, and estimating the SOC in real time. According to the lithium ion battery state-of-chargeestimation method, the FBG sensor system is embedded into the lithium ion battery to acquire internal electrode strain data, SOC estimation based on internal state information of the lithium ion battery is realized, and the SOC-electrode strain function relationship and an ampere-hour integral algorithm are fused, so that the accuracy of the algorithm is ensured, and the lithium ion battery state-of-charge estimation method has an application value of a battery management system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

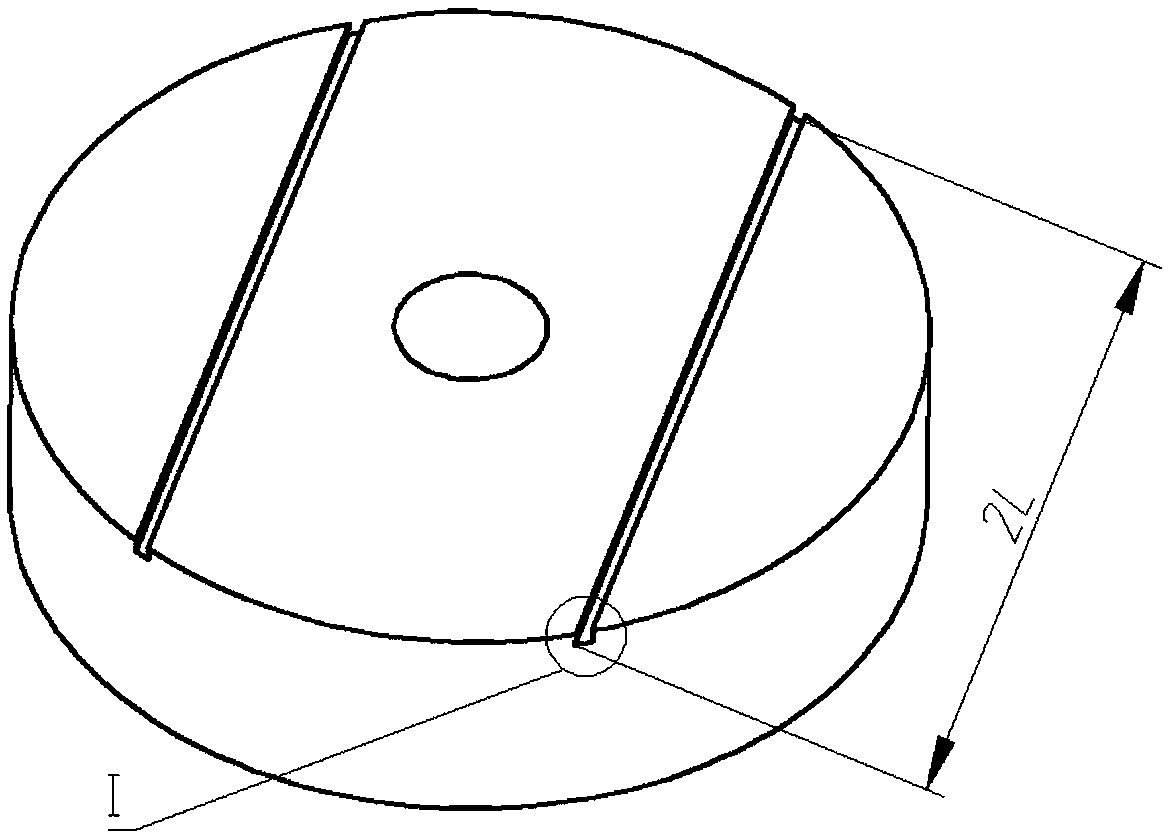

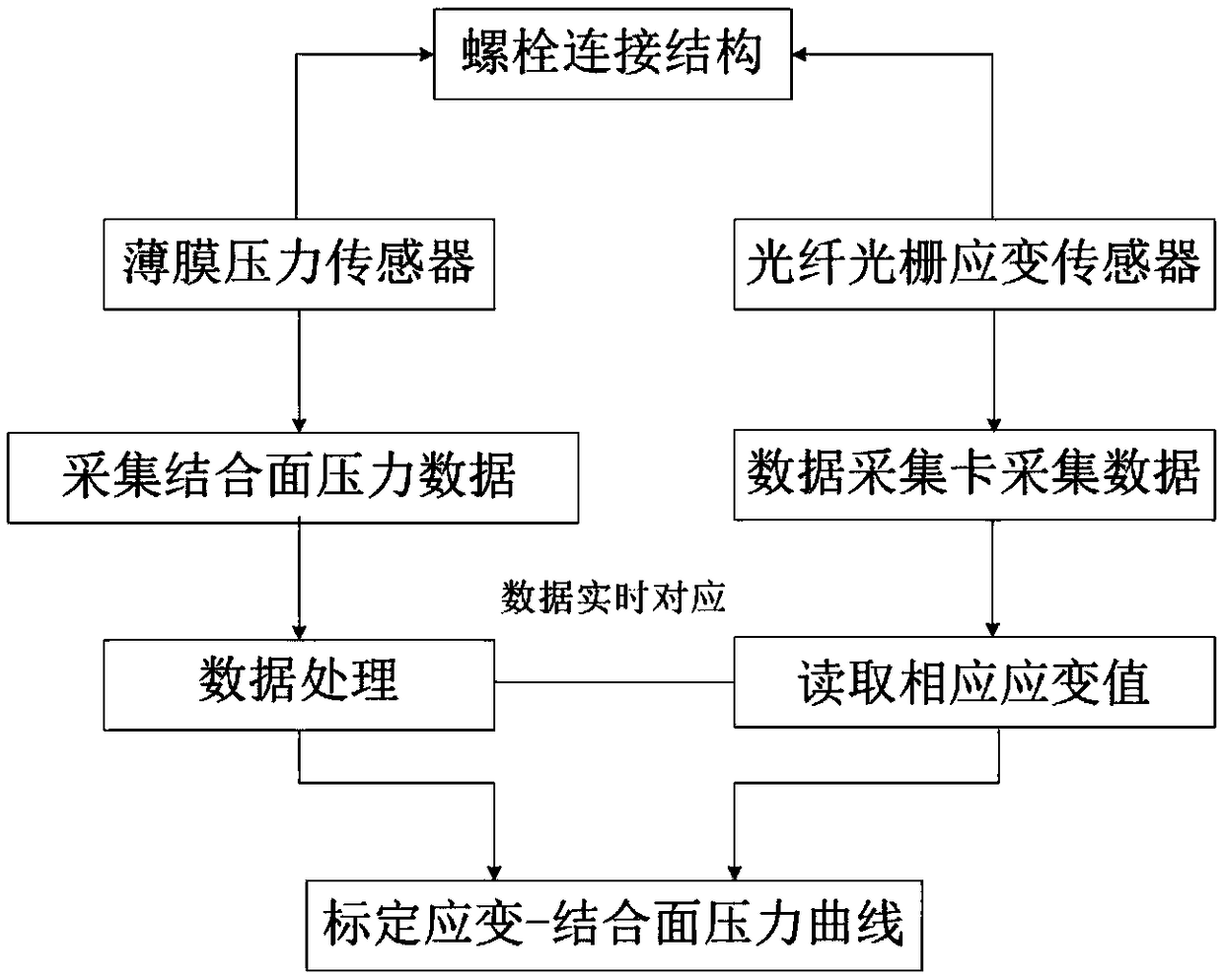

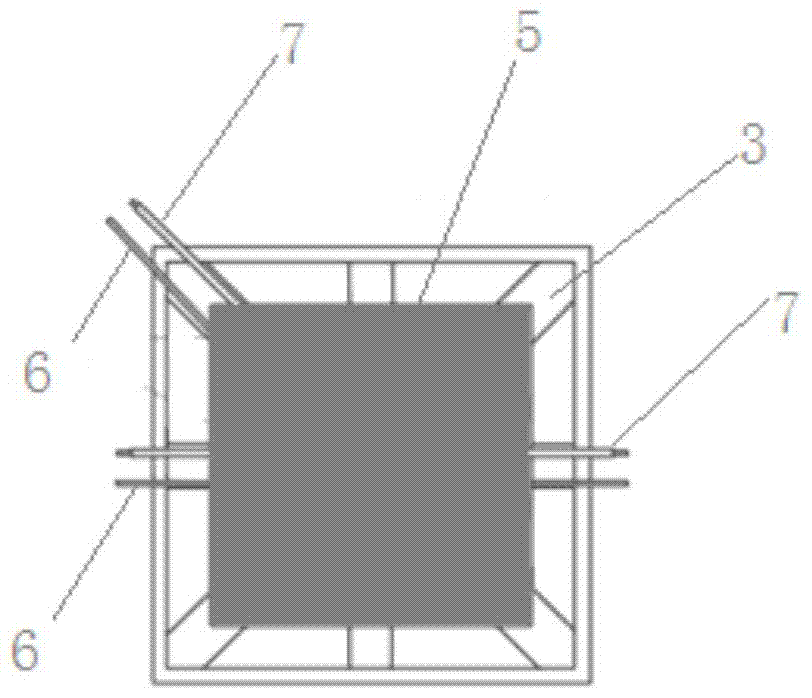

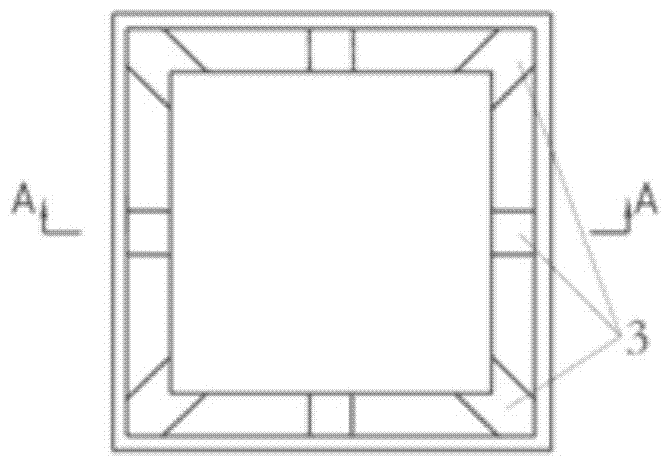

Calibration method for detecting pressure of bolted connection joint surfaces based on FBG sensors

ActiveCN109186823AA Convenient and Reliable Strain-Joint Surface Pressure Calibration MethodSolving the calibration process is relatively cumbersomeForce measurement by measuring optical property variationFluid pressure measurement by optical meansJoint surfaceFbg sensor

The invention belongs to the technical field of pressure detection of the joint surfaces of connected parts, and discloses a calibration method for detecting the pressure of the bolted connection joint surfaces based on FBG sensors. On the basis of using the method for detecting the pressure of the bolted fastening joint surfaces based on the FBG sensors, the set of complete calibration method isdesigned by combining with specific experimental parameters, and the calibration method comprises design of the equivalent annular connected parts, FBG sensor burying grooves in the connected parts and the whole calibration process. The problems that the calibration process is cumbersome and difficult to control under the conditions that the surface pressure at multiple points of the joint surfaces is detected simultaneously or the situation of the joint surfaces is complex are solved; and the calibration process is simpler, the calibration efficiency is greatly improved, and thus the method for detecting the pressure of the joint surfaces is applied more widely.

Owner:DALIAN UNIV OF TECH

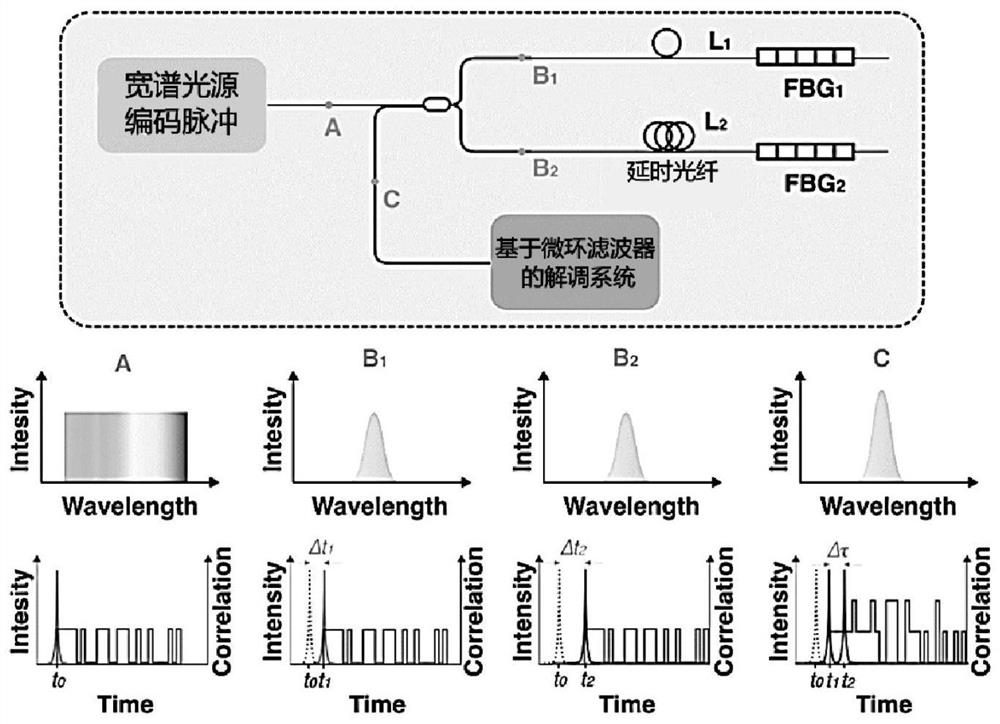

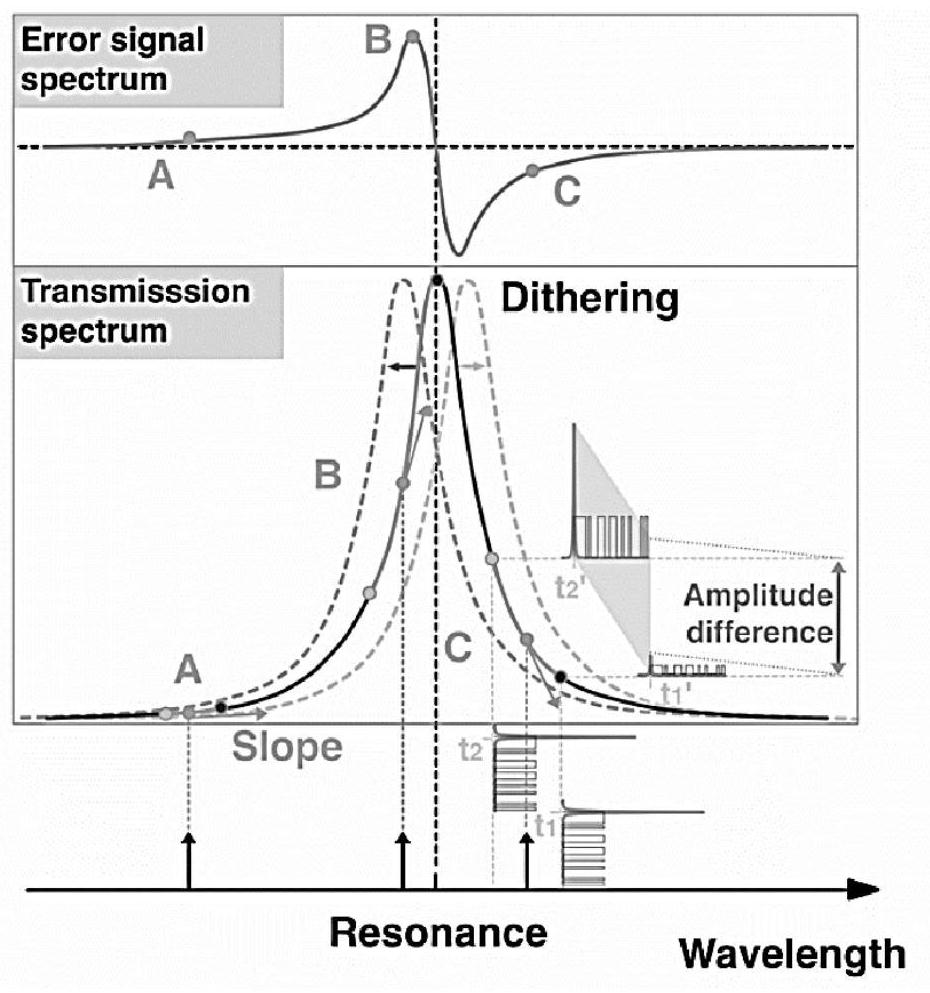

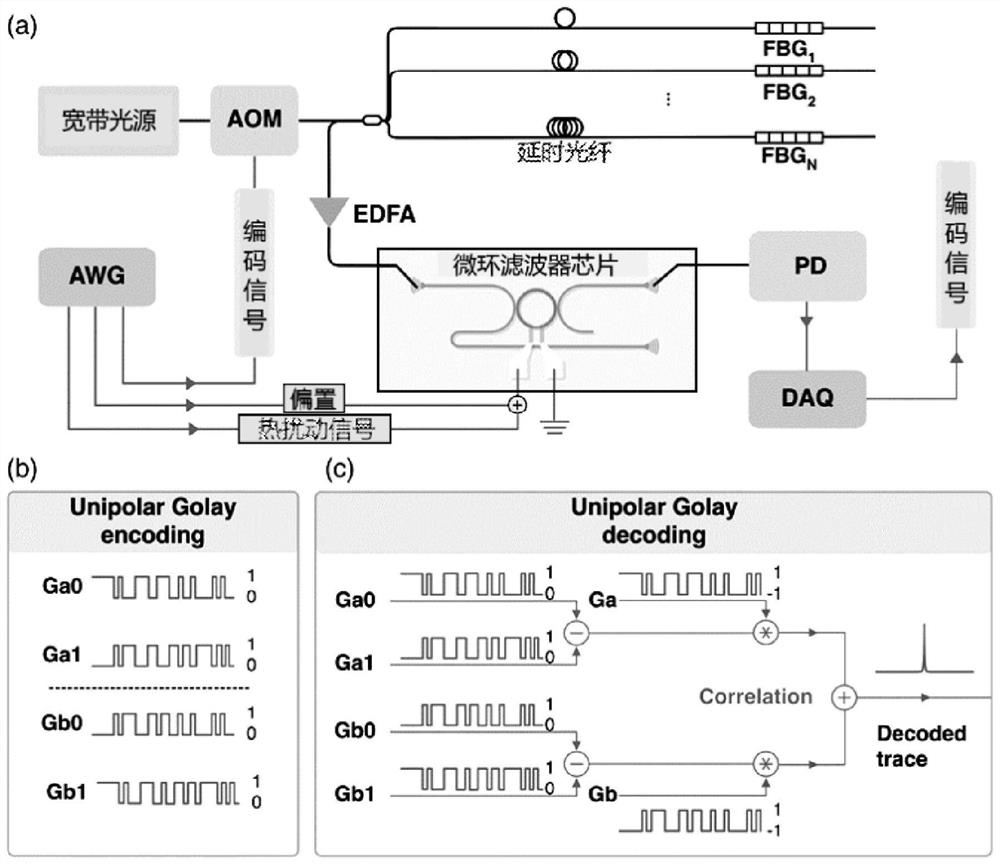

Silicon-based micro-ring pulse coding time division multiplexing dynamic wavelength demodulation method

ActiveCN112325911AHigh precisionConverting sensor output opticallyFiber Bragg gratingSoftware engineering

The invention relates to a silicon-based micro-ring pulse coding time division multiplexing dynamic wavelength demodulation method, which comprises the following steps: performing pulse coding on wide-spectrum light by adopting acousto-optic modulation, sending the processed light to an FBG sensor, coupling an FBG reflection signal to a micro-ring filter chip through an optical fiber coupler, andperforming modulating by applying a thermal disturbance signal to the micro-ring filter chip; and enabling a receiving terminal to extract a sensing signal through an electric signal obtained by photoelectric detection by adopting a slope-assisted micro-ring filtering demodulation algorithm. According to the invention, the micro-ring filter is used for detecting the Bragg wavelength drift of the FBG sensor, thereby achieving the signal demodulation of the silicon-based integrated time division multiplexing FBG sensor.

Owner:SHANGHAI JIAO TONG UNIV

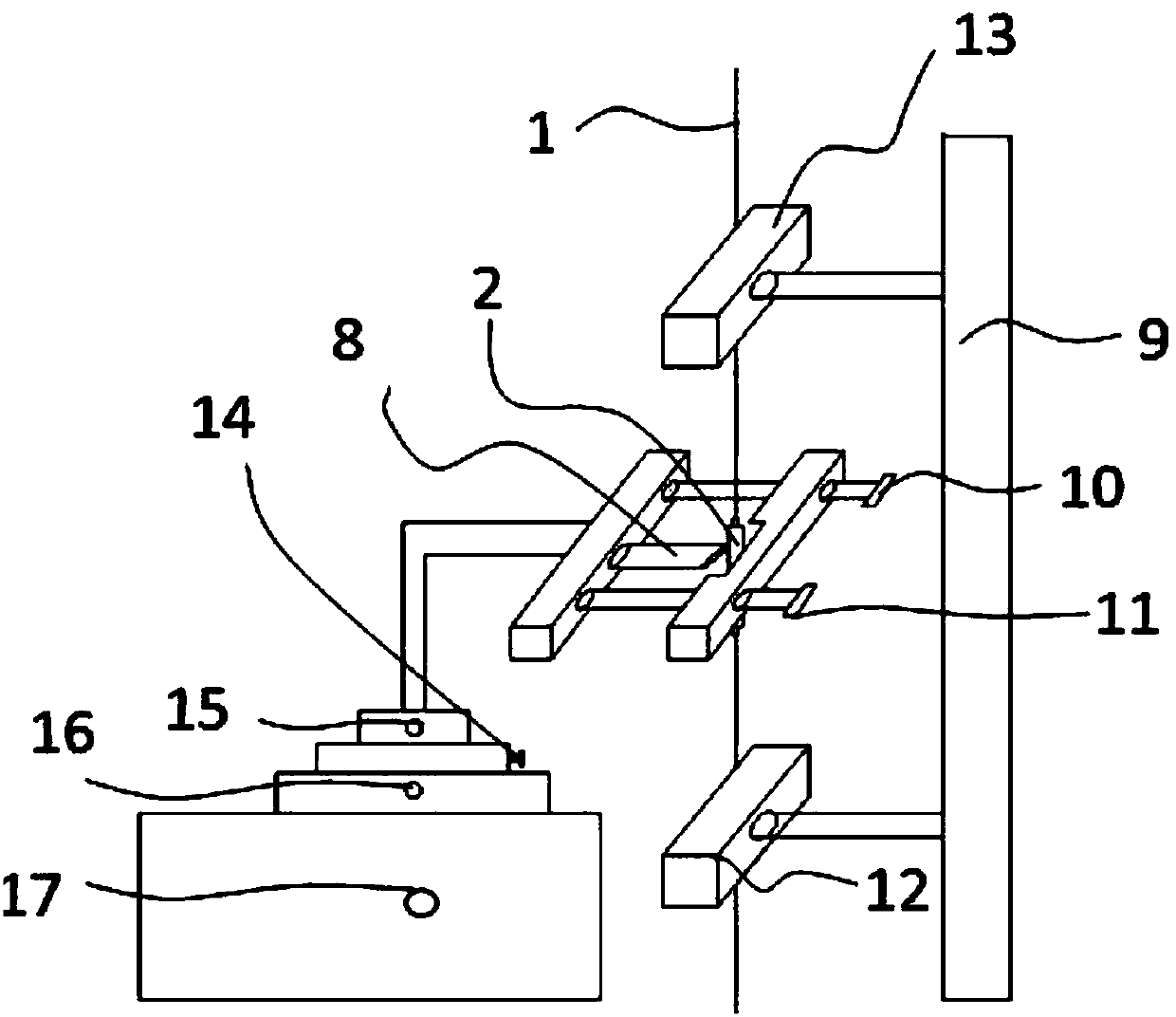

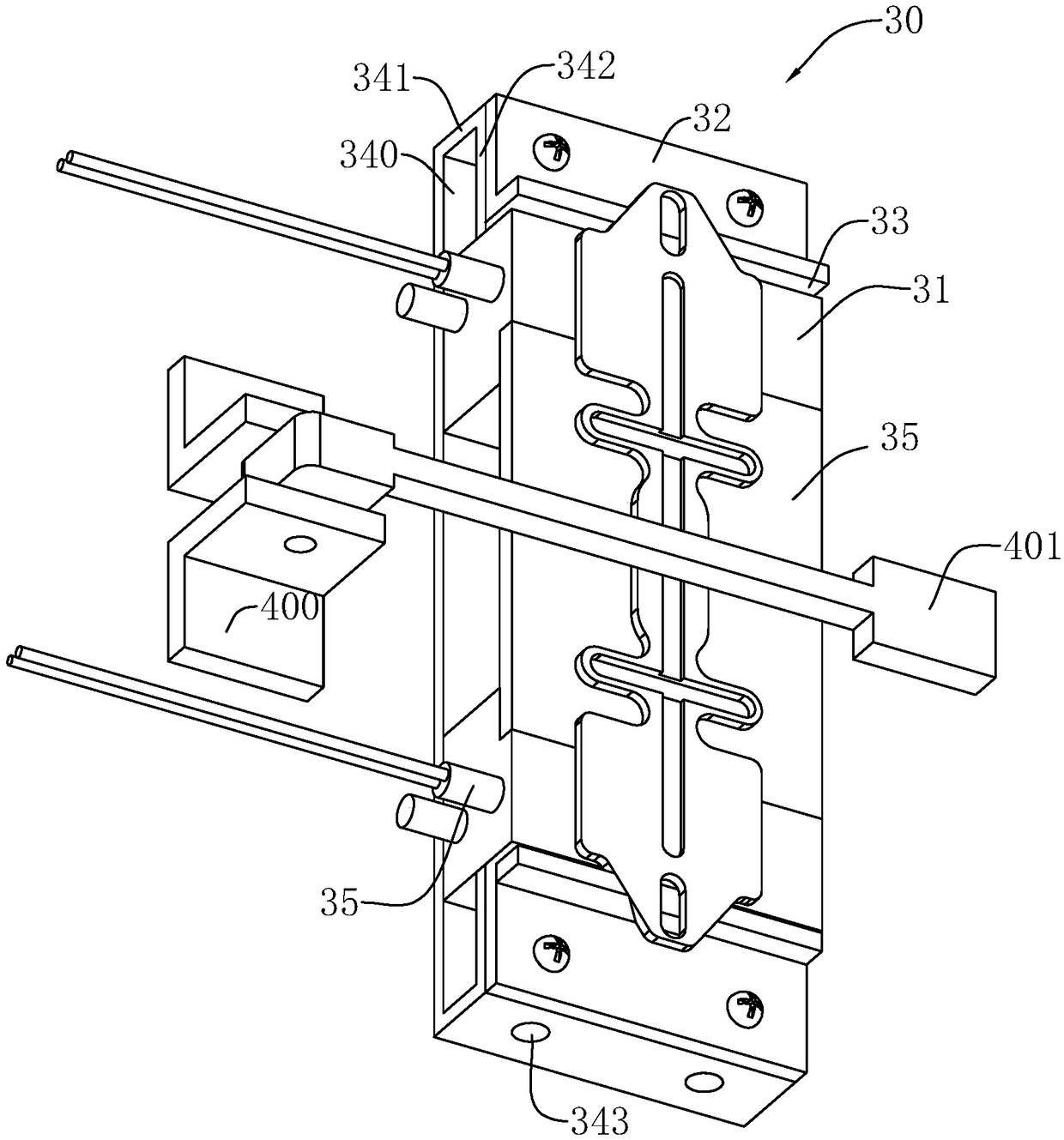

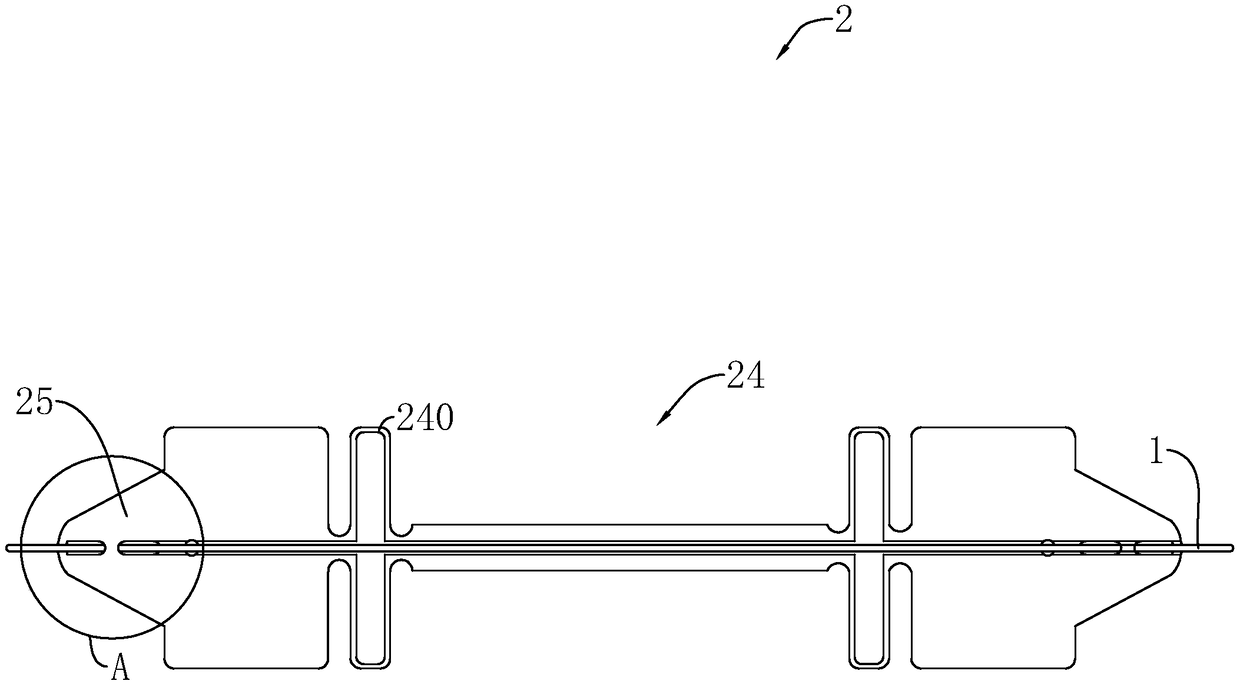

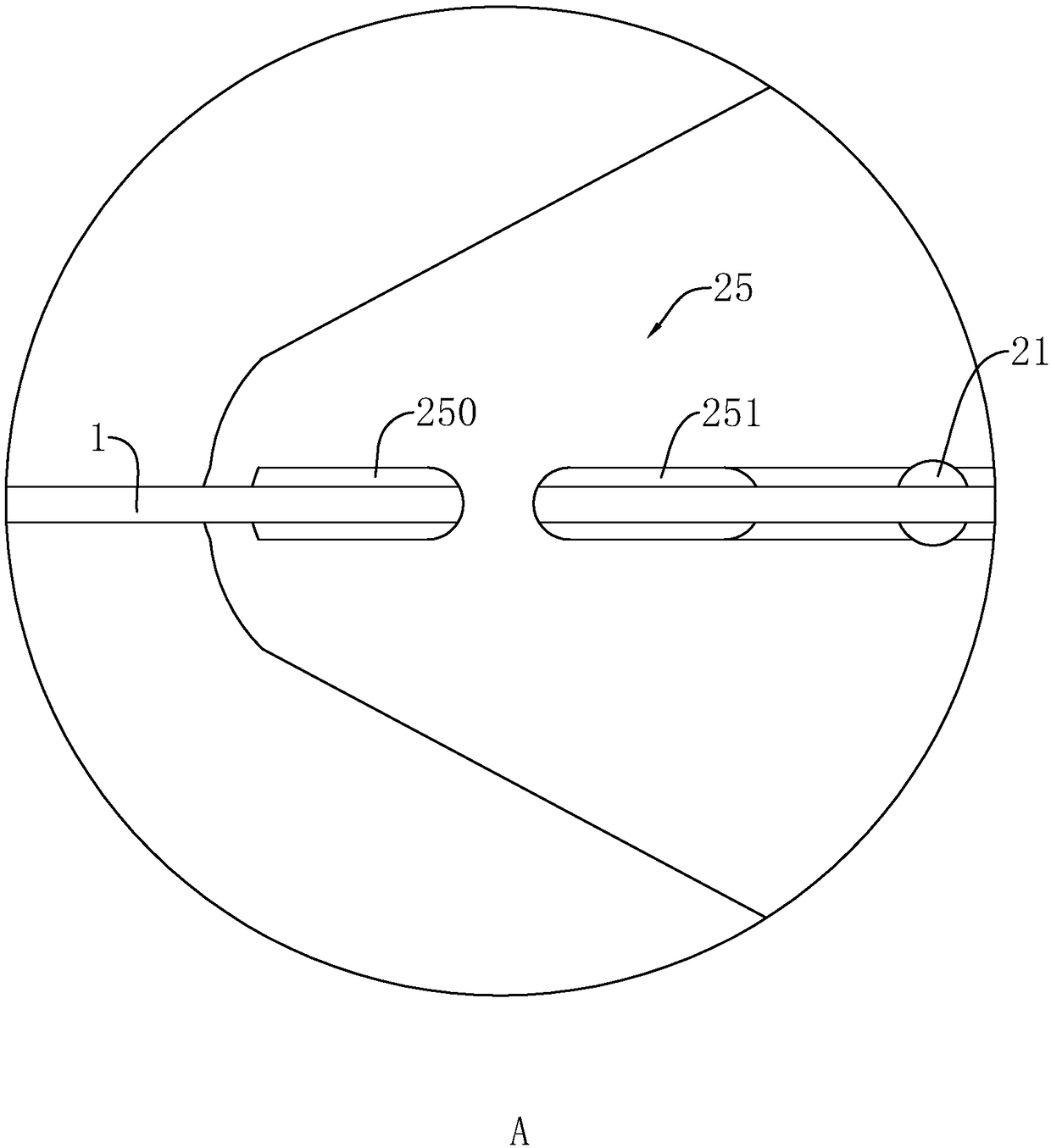

Calibration platform of FBG sensor

PendingCN108844482AEasy to operateImprove calibration accuracyUsing optical meansFbg sensorEngineering

The invention discloses a calibration platform of an FBG (Fiber Bragg Grating) sensor and relates to calibration of the FBG sensor. The key points of the technical scheme are that the calibration platform includes a calibration table, a fixed fixing table fixed on the calibration table, a movable fixing table connected to the calibration table in a sliding manner and having an upper surface beingcoplanar with the upper surface of the fixed fixing table, a stretching device used for adjusting the movable fixing table to be away from the fixed fixing table, and a distance measuring rule used for measuring the distance between the movable fixing table and the fixed fixing table, wherein the movable fixing table fits the fixed fixing table and abuts against the fixed fixing table and two endsof the FBG sensor are fixed on the movable fixing table and the fixed fixing table. According to the invention, the calibration platform has a characteristic of improving calibration precision through facilitating quantitative deformation of the FBG sensor.

Owner:北京通为科技有限公司

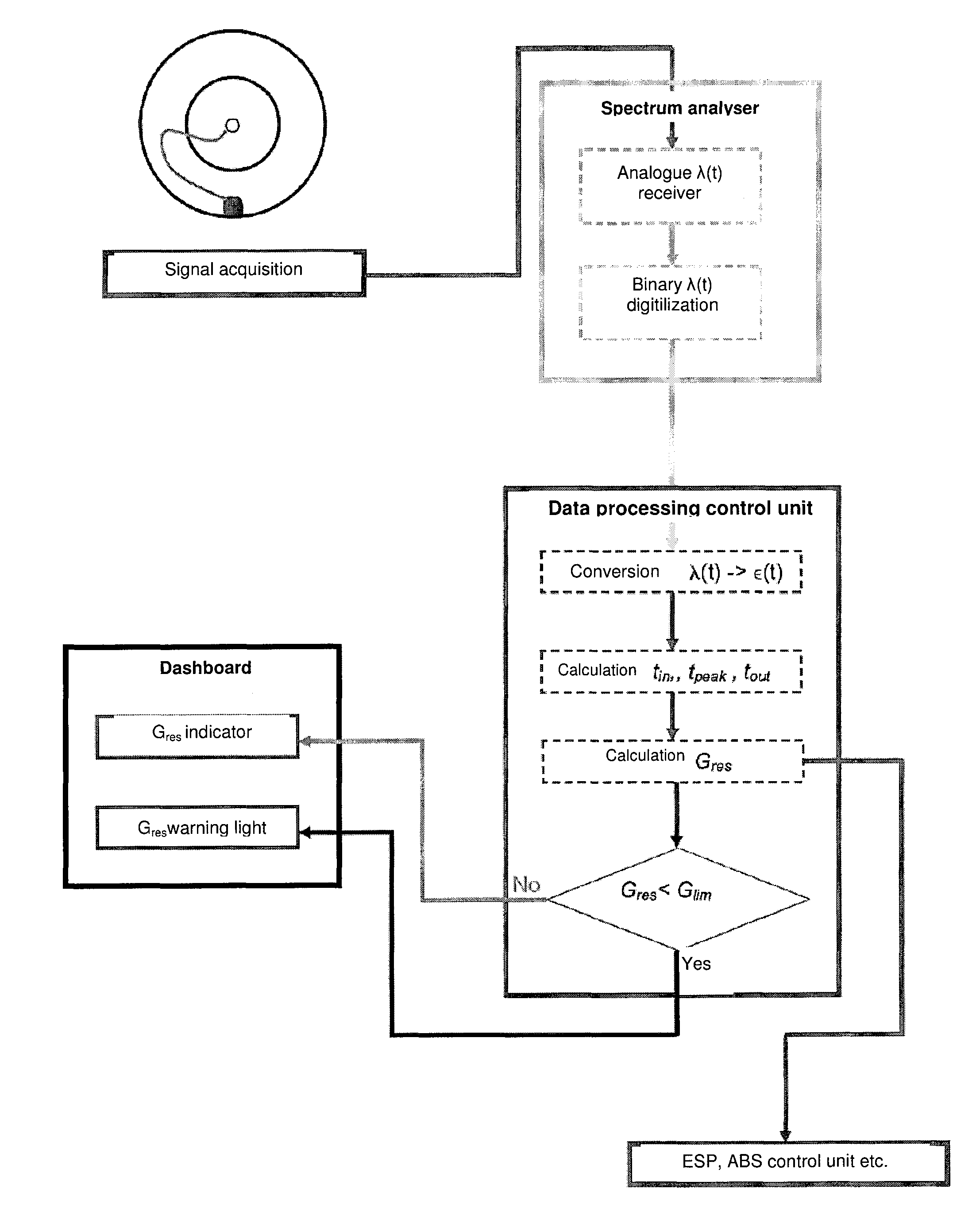

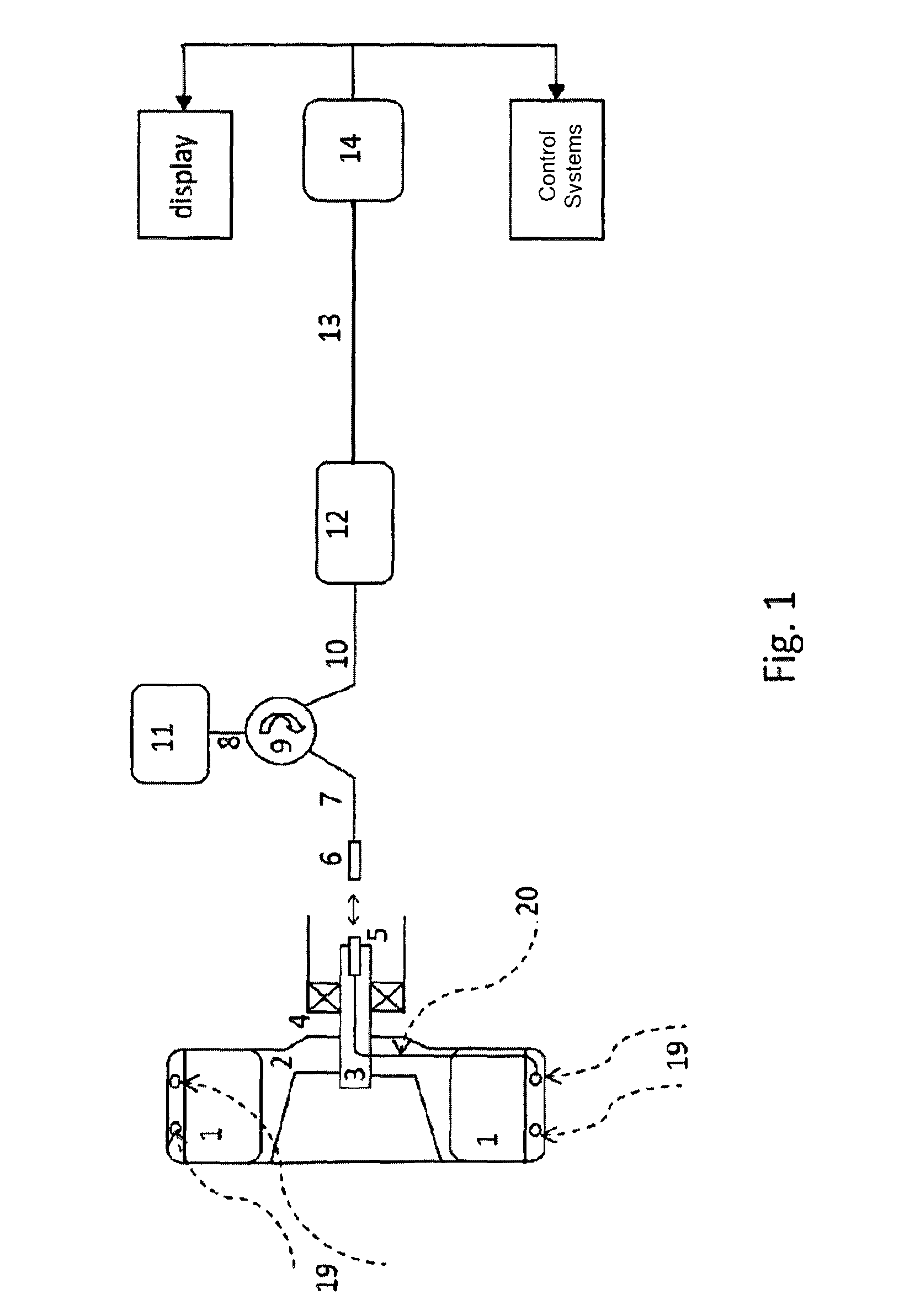

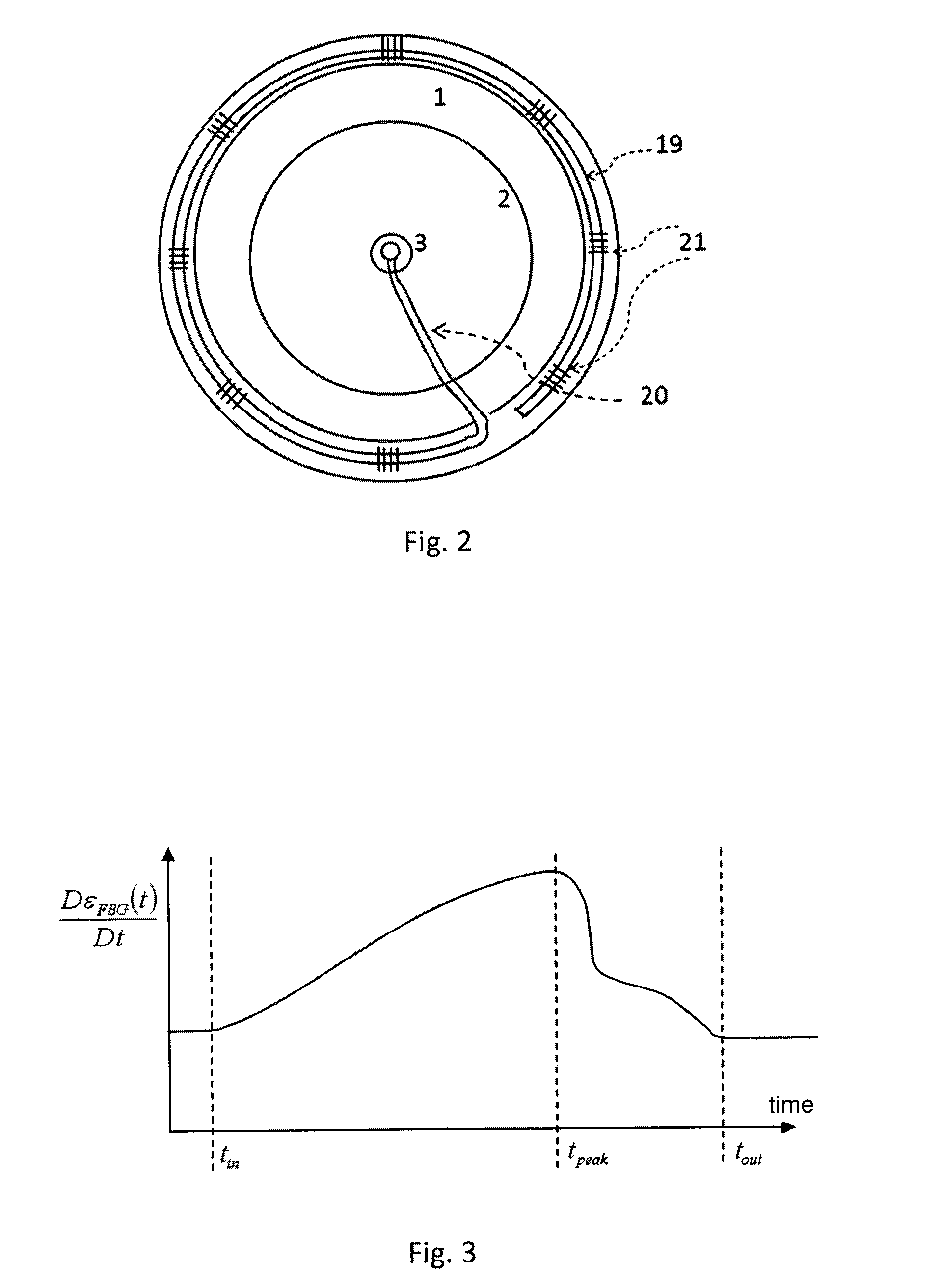

System and method for optical measuring of tire adhesion and tire suitable for such measurement

ActiveUS9370973B2Running safety of the vehicle to be increasedImprove securityTyre partsWheelsFiberFrequency spectrum

A system for measuring the grip between a vehicle wheel tire and a road surface comprising a fiber optic (19) provided with FBG sensors (21) affixed to the internal surface of the tire, which record data regarding the state of state of residual grip Grs of the tire to the road. The fiber optic (19) has an end part (20) which, through an optical joint (5, 6) transmits the data to an instrumentation of the vehicle, making it pass through a spectrum analyzer (12), a data processing system (14), which implements the residual grip identification algorithm Grs. The residual grip information is sent to a display that is visible by the driver and / or to active control systems for driving the vehicle.

Owner:UNIV DEGLI STUDI DI ROMA LA SAPIENZA

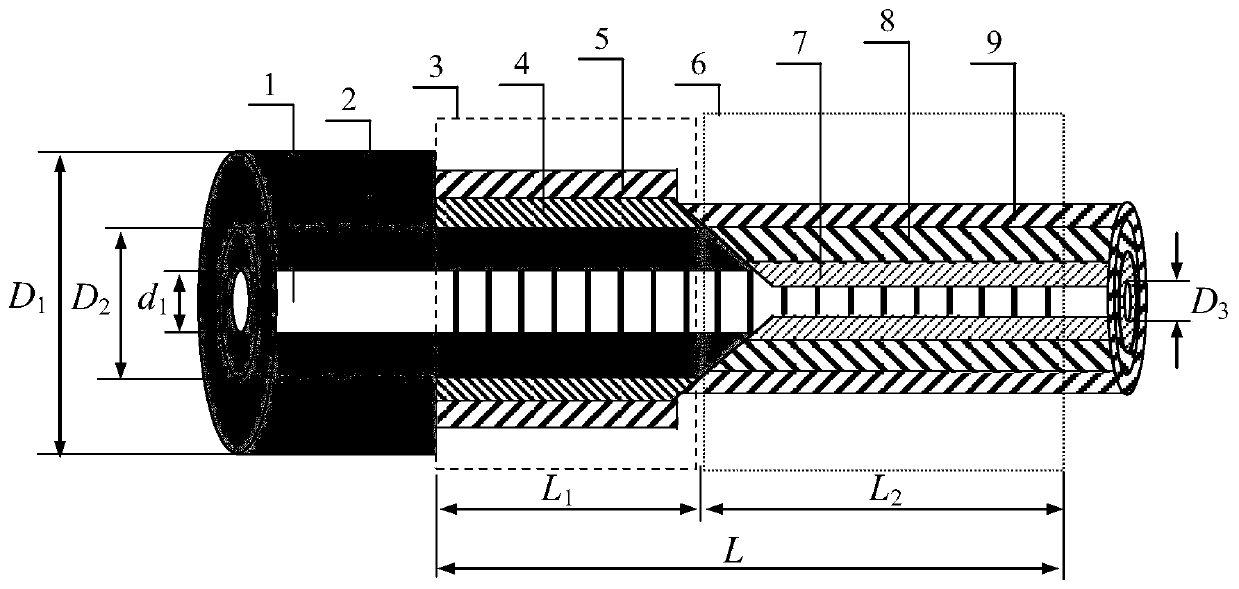

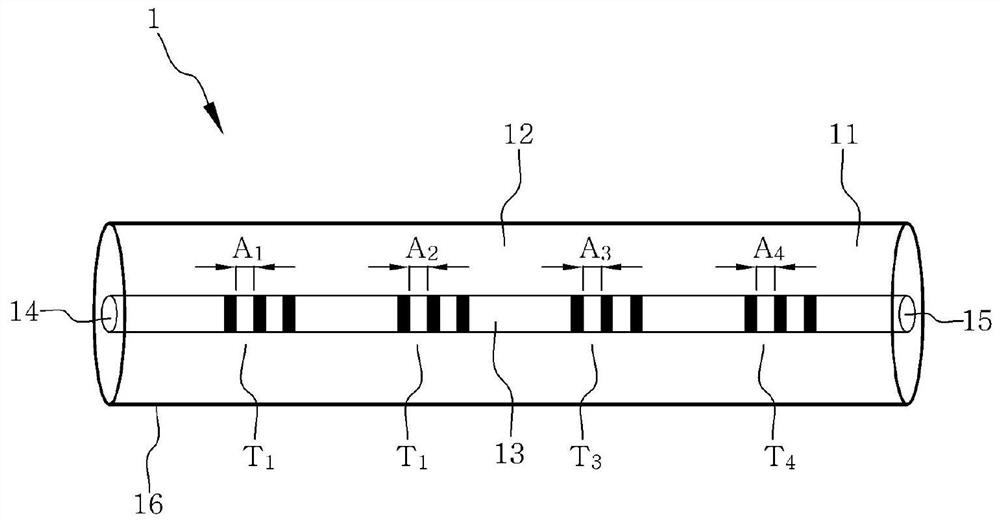

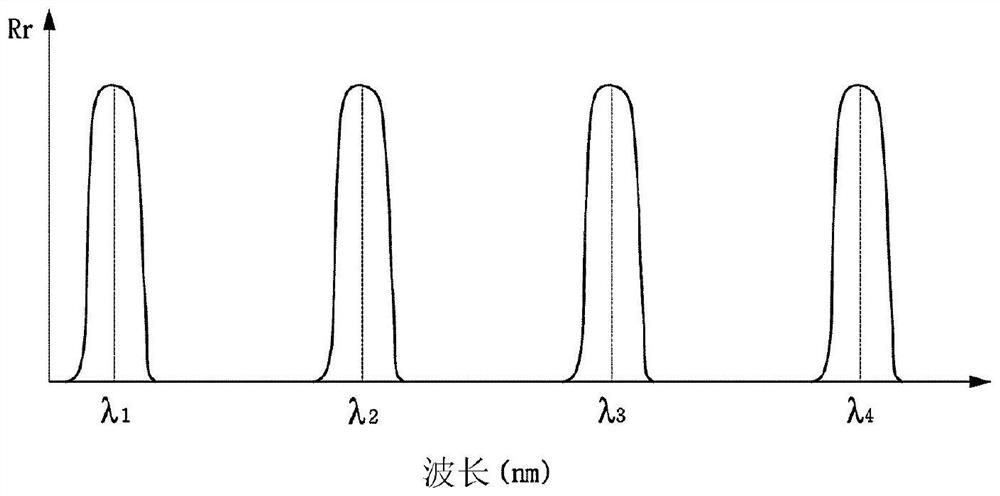

FBG hydrogen sensor for simultaneous measurement of temperature and concentration and preparation method thereof

ActiveCN107607218BHigh sensitivityImprove stabilityMaterial analysis by optical meansThermometers using physical/chemical changesFiberPhysical chemistry

The present invention relates to an optical fiber gas sensor, in particular to a FBG hydrogen sensor for simultaneously measuring temperature and concentration and a preparation method thereof; comprising an optical fiber core, an optical fiber cladding, and an optical fiber protective layer, the optical fiber is provided with not less than A FBG area, the FBG area is provided with a measurement area coaxial with the fiber core, including a length L 1 The temperature measurement area and the length is L 2 Temperature and hydrogen concentration measurement area, the temperature measurement area is composed of fast-corroded FBG, gold film and PTFE film layer arranged sequentially from the inside to the outside; the temperature measurement and hydrogen concentration area is composed of slow-corroded Composed of FBG, polydopamine film layer, hydrogen-sensitive film layer and PTFE film layer, the FBG sensor adopting the technical solution of the present invention has high sensitivity, stable performance and can simultaneously acquire hydrogen concentration and temperature change information online.

Owner:重庆黄葛树智能传感器研究院有限公司

Fbg-based torsion sensor device

ActiveCN113015892AMeasurement of torque/twisting force while tighteningForce measurement by measuring optical property variationFiberGrating

Embodiments relate to a torsion sensor device which measures a degree of torsion of a measurement object by using a fiber Bragg gratings (FBG) sensor, the sensor device comprising: an FBG sensor including a sensing unit formed in one section of an elongated optical fiber; and a fixing device for fixing and supporting the FBG sensor to cause displacement of the FBG sensor according to motion of the measurement object, wherein the fixing device includes a bending prevention member to enable the sensing unit to have torsion displacement without bending displacement, according to the motion of the measurement object.

Owner:KOREA INST OF SCI & TECH

Method and device for demodulating fiber bragg grating (FBG) sensor

ActiveCN102879022BLow insertion lossReduce manufacturing difficultyConverting sensor output opticallyEngineeringOptical fiber coupler

The invention discloses a method and a device for demodulating a fiber bragg grating (FBG) sensor. The method comprises the following steps of: controlling a wavelength scanning laser device to generate narrow-band scanning laser rays with continuously changed wavelengths by using a computer; splitting beams of the narrow-band scanning laser rays generated by the wavelength scanning laser device; enabling a generated reflection spectrum to enter a photoelectric detector again via an optical fiber coupler to be converted into electric signals after the beam-split narrow-band scanning laser rays respectively enter the FBG sensor to be measured and a reflecting FBG comb filter with a temperature compensation package function via the optical fiber coupler, and acquiring the electric signals by the computer after the electric signals are amplified; obtaining wavelengths of peaks of the reflecting FBG comb filter with the temperature compensation package function by the computer through a peak-detection algorithm; calibrating the reflection spectrum of the FBG sensor by the wavelengths; and calculating an absolute wavelength value of the FBG sensor.

Owner:杭州联光电子有限公司

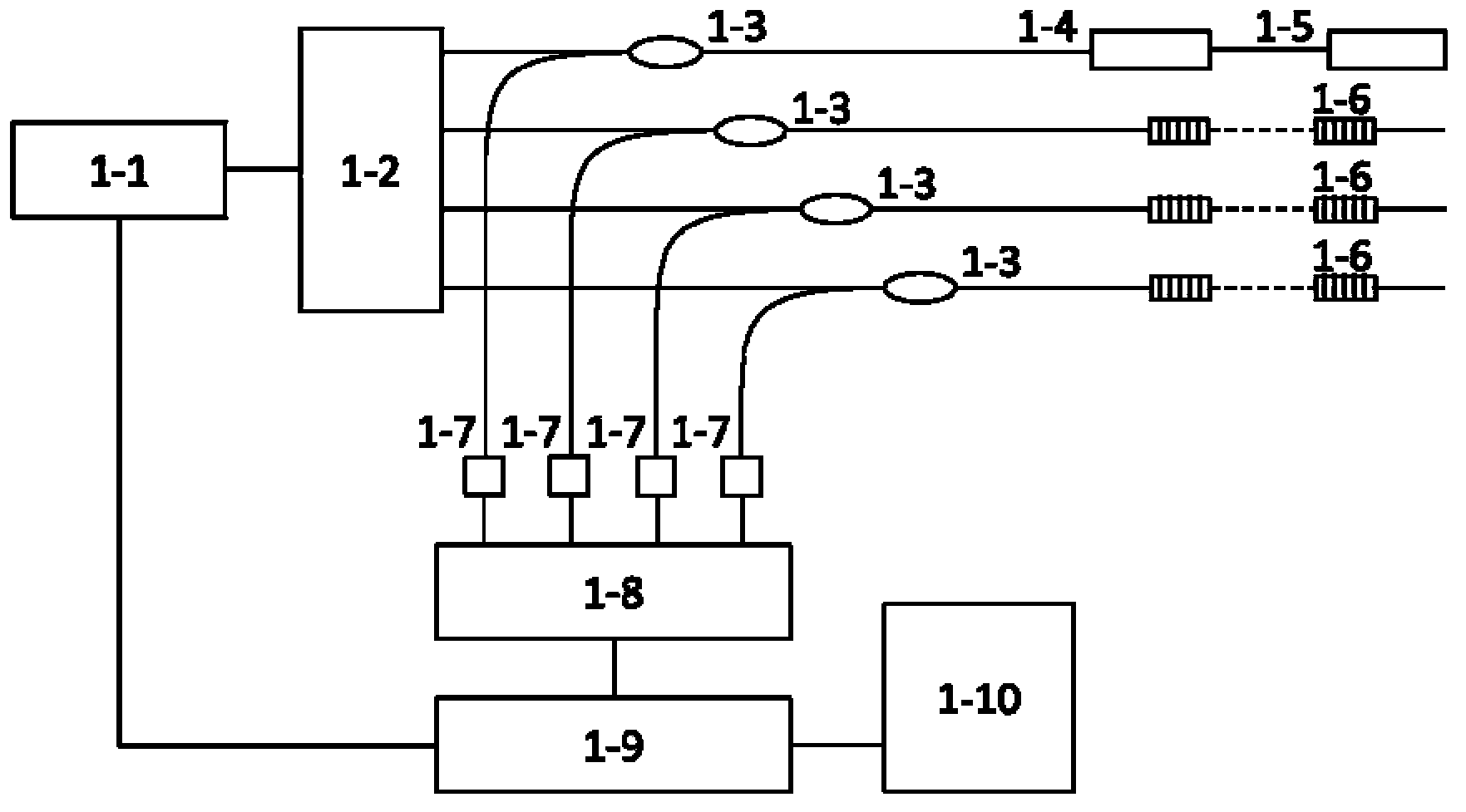

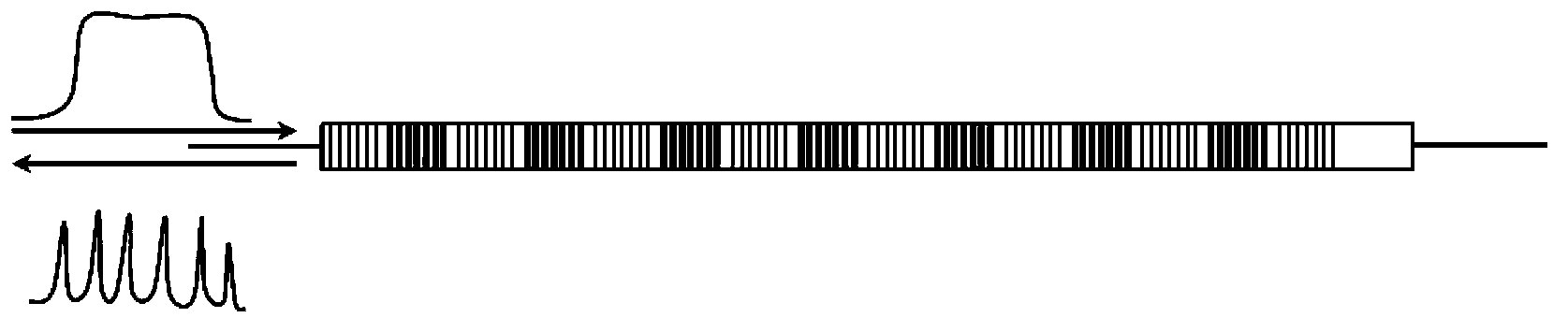

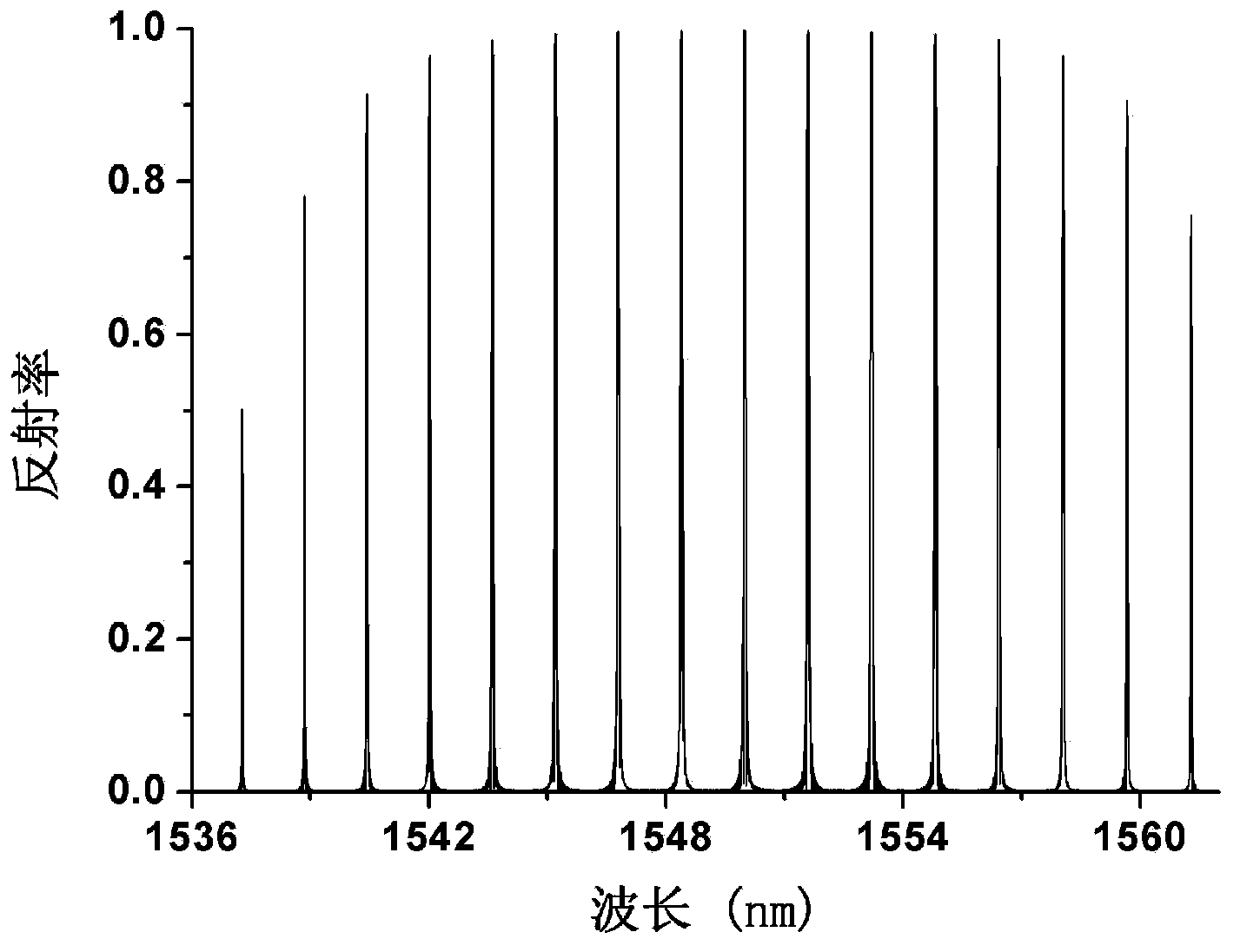

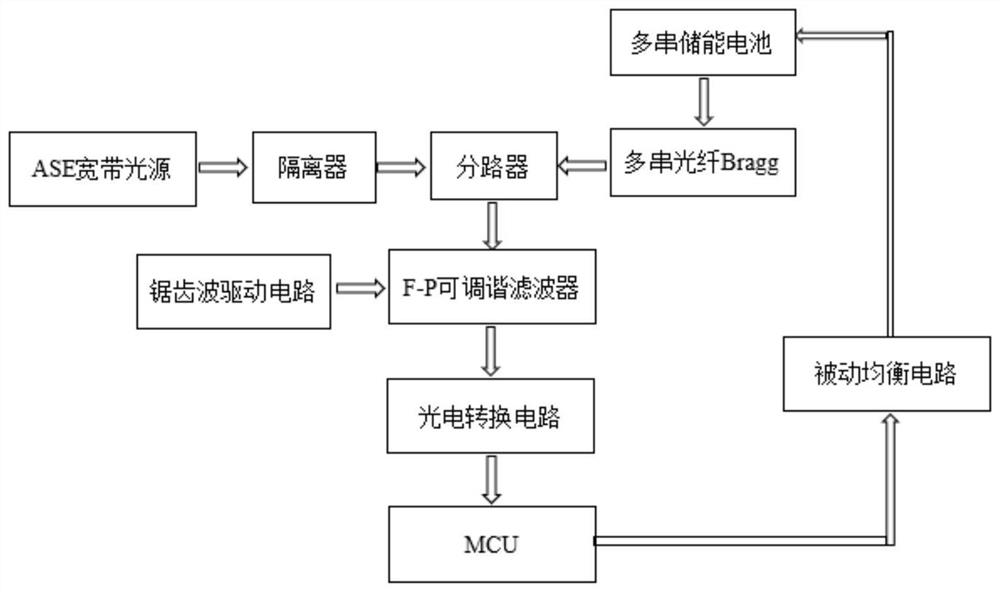

Optical fiber Bragg voltage measuring method suitable for energy storage battery

ActiveCN113009214AReasonable designCorrosion resistanceMeasurement using digital techniquesElectrical batteryHemt circuits

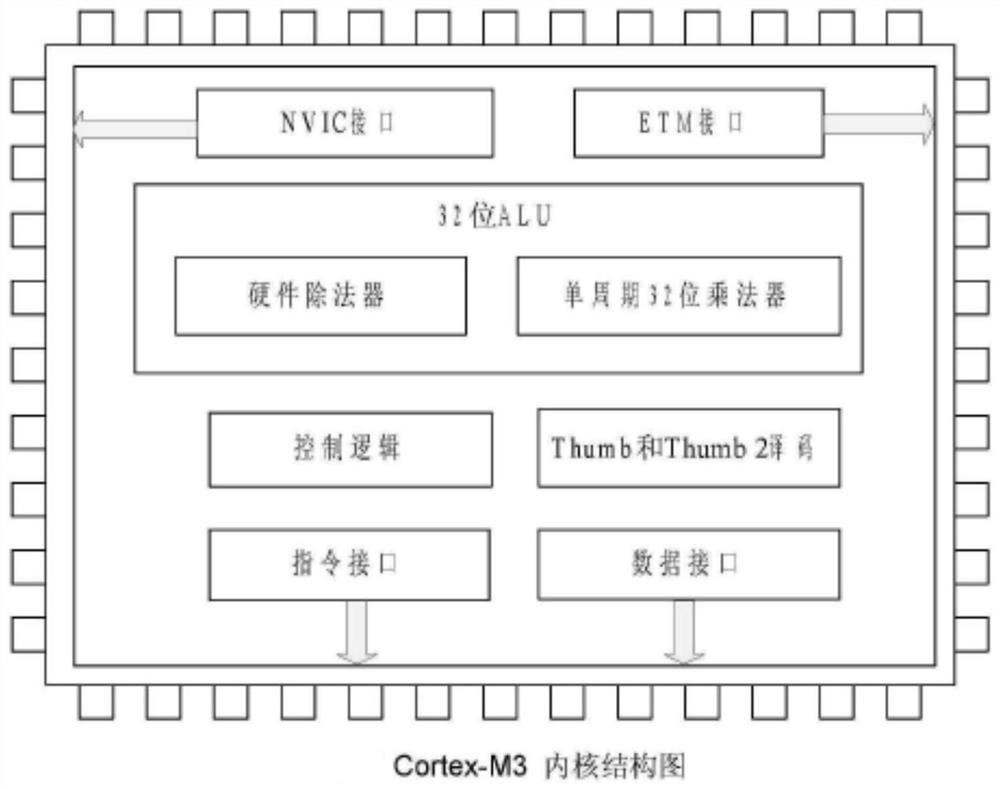

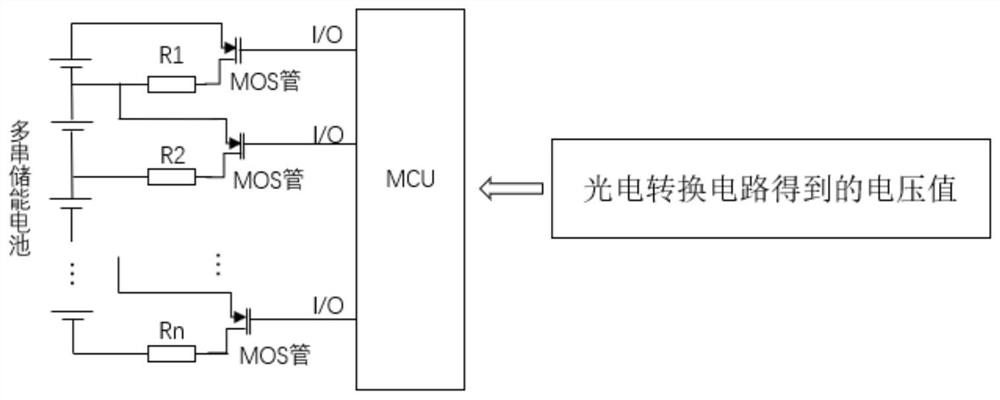

The invention discloses an optical fiber Bragg voltage measuring method suitable for an energy storage battery. An ASE broadband light source, an isolator, a splitter, a plurality of optical fiber Bragg strings, an F-P tunable filter, a sawtooth wave driving circuit, a photoelectric conversion circuit, an MCU and a passive equalization circuit are included. The BMS voltage measuring system has corrosion resistance, can be conveniently used at any position of various chemical batteries, such as the exterior and interior of a common lithium iron phosphate battery in the energy storage industry or the exterior and interior of a flow battery, and has the advantages of high precision, electromagnetic interference resistance and the like; STM32F103ZET6 is used as a main control chip, and a tunable F-P filter demodulation technology is combined to realize the voltage measuring system of the FBG sensor; the system is portable, small and exquisite, low in price and high in cost performance. The system can be conveniently integrated with an existing BMS system to replace a battery front-end acquisition chip AFE monopolized abroad for a long time.

Owner:SHANGHAI YUYUAN POWER TECH CO LTD

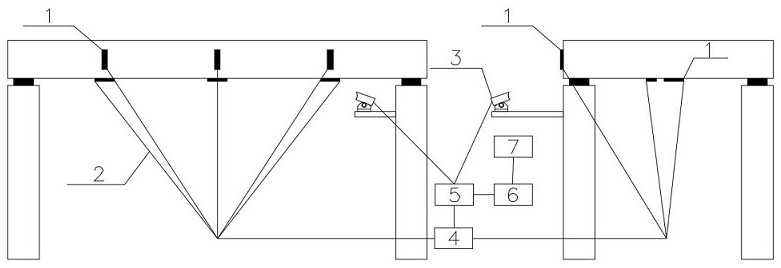

Large-span concrete beam multi-point continuous measurement device and measurement method

PendingCN112033461AGuaranteed flexibilityAvoid construction damageForce measurement by measuring optical property variationWork measurementContinuous measurementFiber Bragg grating

The invention discloses a large-span concrete beam multi-point continuous measurement device and a measurement method. The device comprises an inner fixed point type strain optical cable, a reinforcement cage and an optical fiber and optical cable demodulator, wherein the inner fixed point type strain optical cable is bound on a main reinforcement of the reinforcement cage and is poured into the concrete beam; the inner fixed point type strain optical cable is connected to the optical fiber and optical cable demodulator; the internal fixed point type strain optical cable comprises an optical cable inner core, internal fixed point FBG sensors, an optical cable sheath, an armor tube and a steel strand. The plurality of internal fixed point FBG sensors are uniformly distributed in the opticalcable inner core and are wrapped in the armor tube; the optical cable sheath wraps the armor tube wound with the plurality of strands of steel strands; the number of the inner fixed point FBG sensorsof a single inner fixed point type strain optical cable reaches 2000, and multi-point dense continuous testing of a large-span concrete structure is achieved. The temperature sensing optical cable and the inner fixed point type strain optical cable are symmetrically distributed up and down along the main reinforcements of the reinforcement cage; the optical fiber and optical cable demodulator canobtain a plurality of data at the same time, thereby achieving the monitoring of the internal force, bending moment and deflection of the concrete beam.

Owner:THE 4TH ENG OF CHINA RAILWAY 5TH ENG GROUP +2

A test device for thermal molding and curing deformation of resin-based composite materials and the preparation and use method of the device

ActiveCN104315990BReduce difficultyImprove survival rateUsing optical meansSpecial purpose recording/indication apparatusPolymer scienceResin matrix

The invention relates to a testing device for resin matrix composite material hot mold pressing curing deformation and a manufacturing and using method thereof. The testing device comprises resin matrix composite material prepreg and FBG sensors arranged in the prepreg. The method comprises the steps that the FBG sensors are laid on the nth layer in the fiber axial direction to be used as strain sensors, reference sensors for temperature compensation are laid on the nth layer or the (n+1)th layer or the (n-1)th layer, lead grooves are formed in a mold side wall frame board, the mold side wall frame board is coated with a high temperature resistance polymer film, leads of the sensors are led out of the lead grooves and connected with a signal receiver, a mold is closed, hot press molding is carried out, and curing forming on-line real-time monitoring is achieved. The problems that during composite material heat mold pressing curing deformation monitoring, grid regions are fragile and prone to breakage, and monitoring signals cannot be effectively transmitted if leading is inappropriate in a closed full-rigid hot mold pressing mold are solved, and meanwhile the problem that a composite material structure part with built-in FBG sensors is hard to break away from the full-rigid mold is solved.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com