Hole-edge crack diagnosis method based on optical fiber spectrum image analysis

A technology of image analysis and optical fiber spectroscopy, applied in the field of hole edge crack diagnosis, which can solve the problems of missed detection and false alarms of intelligent coating sensors, statistical models that do not explain the relationship between crack propagation and reflection spectrum, and characteristic parameters that have no physical meaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

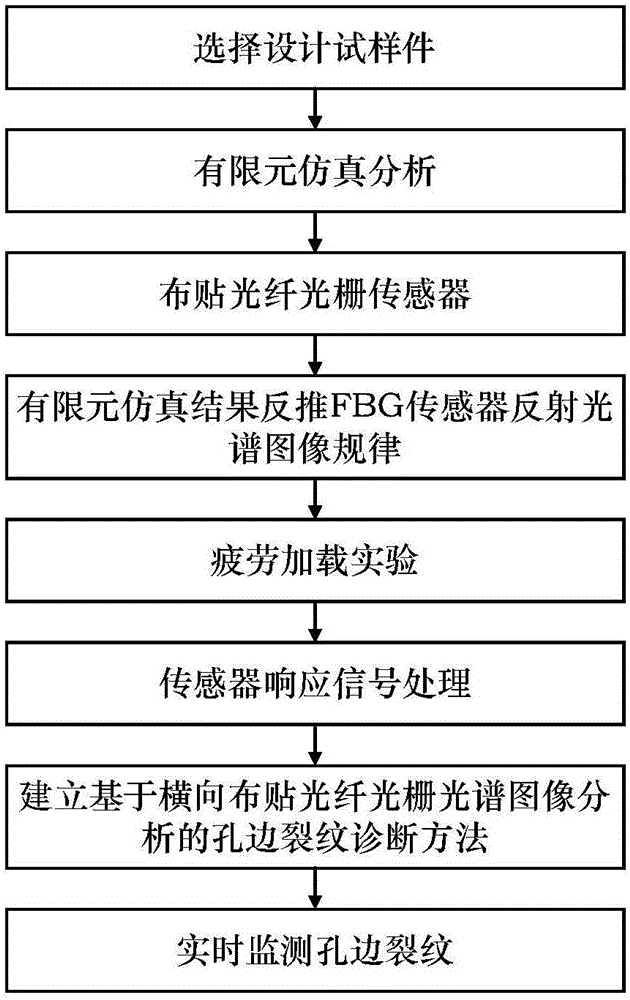

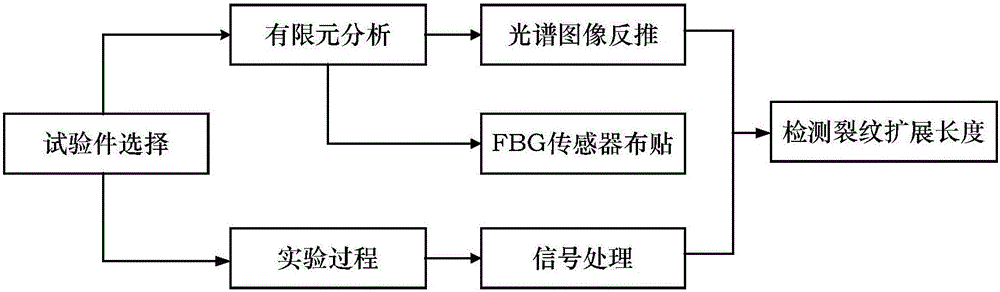

[0033] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The invention provides a method for diagnosing cracks at the edge of a hole based on optical fiber spectral image analysis. The overall process schematic diagram of the method is as follows figure 2 shown.

[0034] A method for diagnosing cracks at the edge of a hole based on optical fiber spectral image analysis of the present invention, see figure 1 , 2 As shown, it is realized through the following steps:

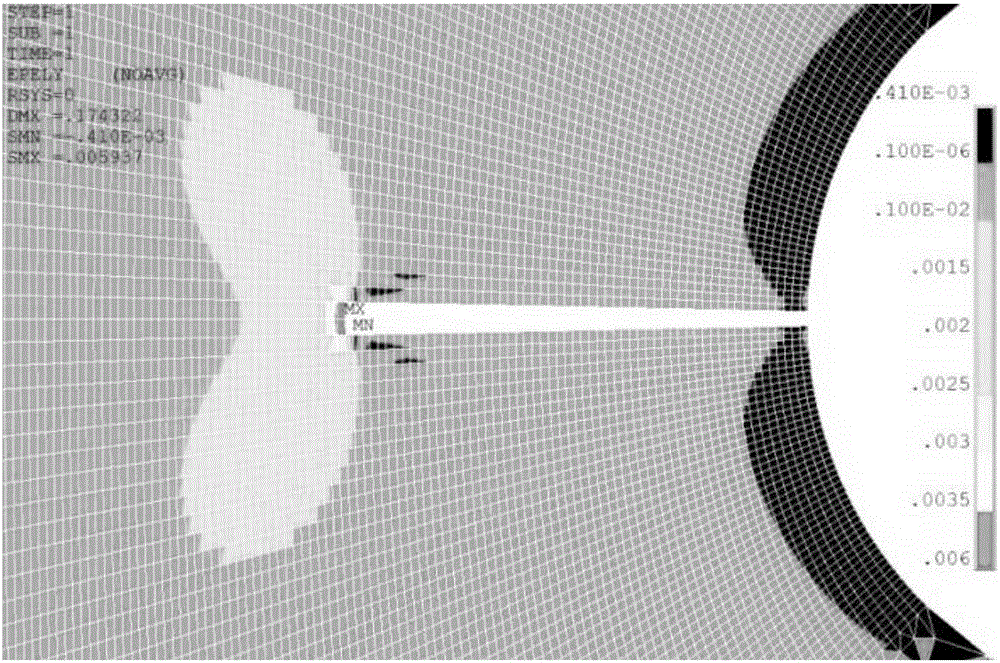

[0035] The first step is to select the sample aluminum alloy sheet such as image 3 As shown, its brand specification: aluminum alloy 2024-T3, 300*100*2 (mm). In order to appear fatigue crack growth faster, a circular hole with a diameter of Φ10mm is opened in the center of the aluminum alloy sheet, and a small crack with a length of 3mm is prefabricated on the right side of the hole parallel to the short axis.

[0036]The second step is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com