Patents

Literature

1314 results about "Short axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

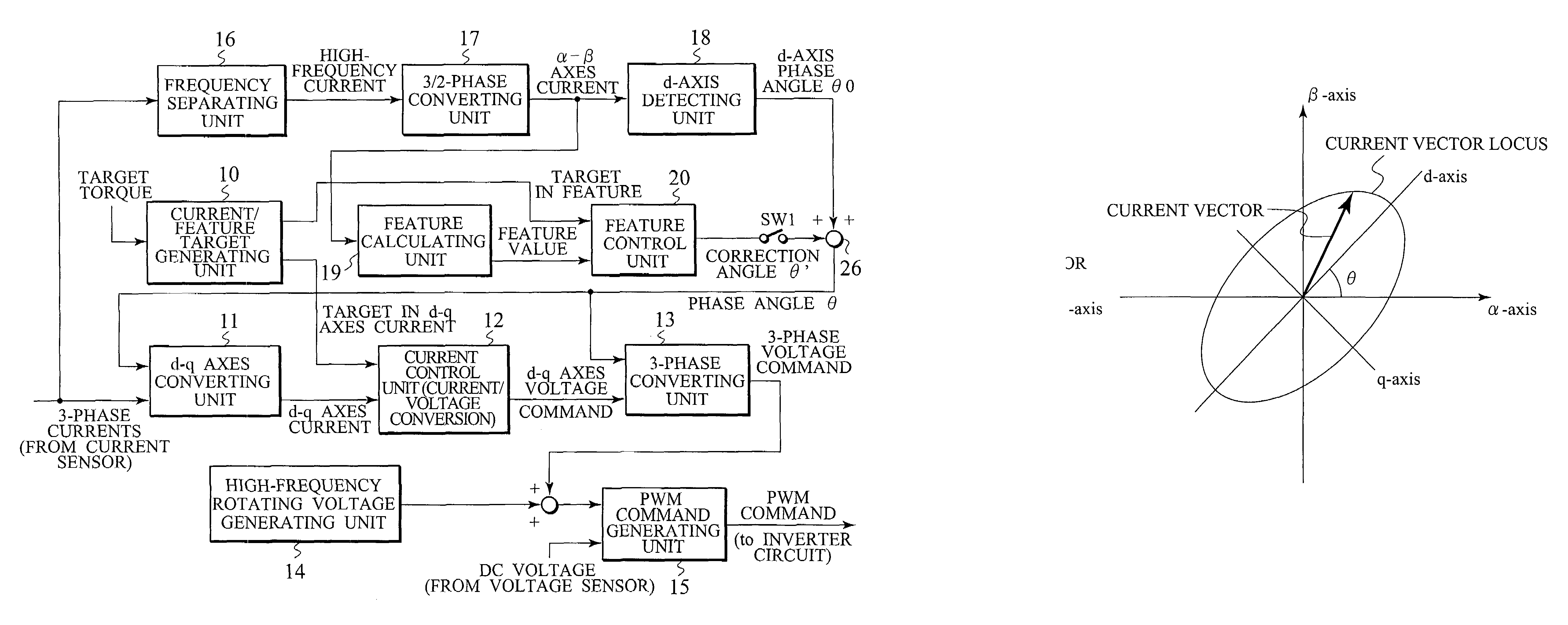

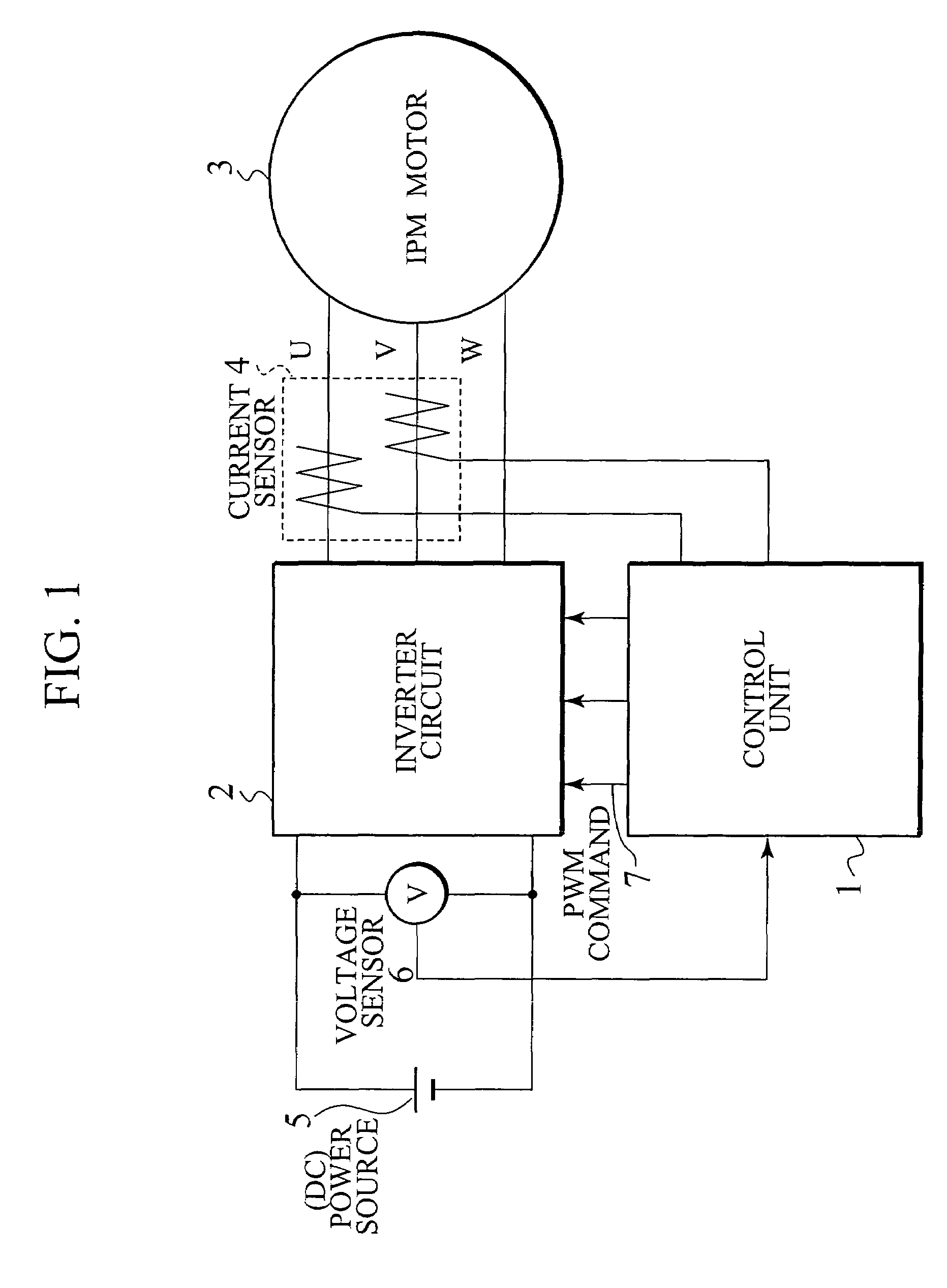

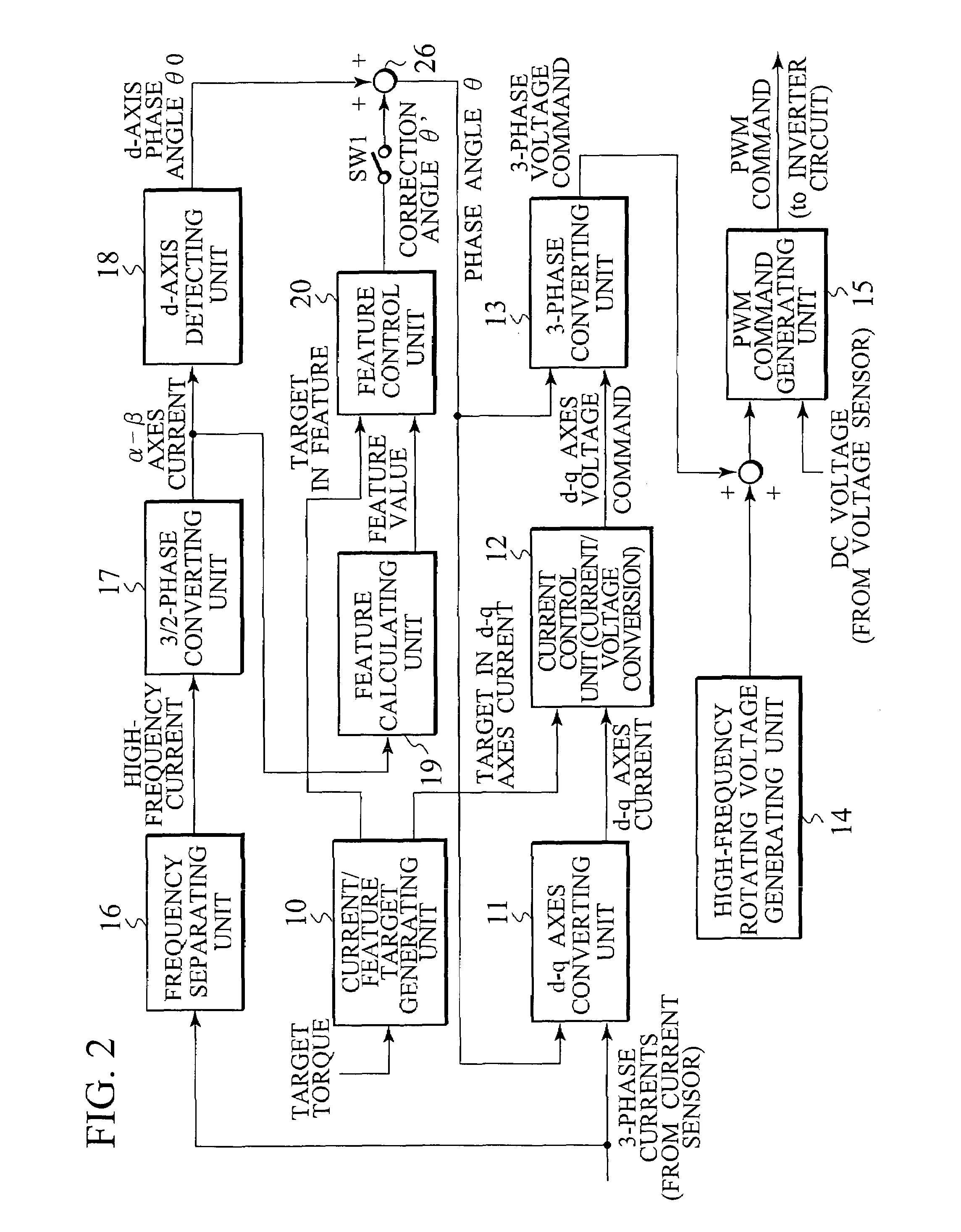

Control device for electric motor

ActiveUS7005828B2Improve artSingle-phase induction motor startersAC motor controlDriving currentAcquired characteristic

Corresponding to a target torque, the control device calculates a target value of a feature based on at least one of the length of a long axis of a current vector locus and the length of the short axis and further superimposes a superimposed current on a drive current for the motor, the superimposed current having a frequency different from the frequency of the drive current. Further, the control device detects an actual value of the feature based on at least one of the length of a long axis of a current vector locus of the superimposed current and the length of the short axis of the same and finally detects a phase angle of the motor based on the target value and the actual value for the feature. The manipulation of a detecting phase is performed by feedback of a feature obtained by the magnitude of the superimposed current. That is, when the actual feature is more than the target value, the detecting phase is advanced. Conversely, when the actual feature is less than the target value, the detecting phase is delayed.

Owner:NISSAN MOTOR CO LTD

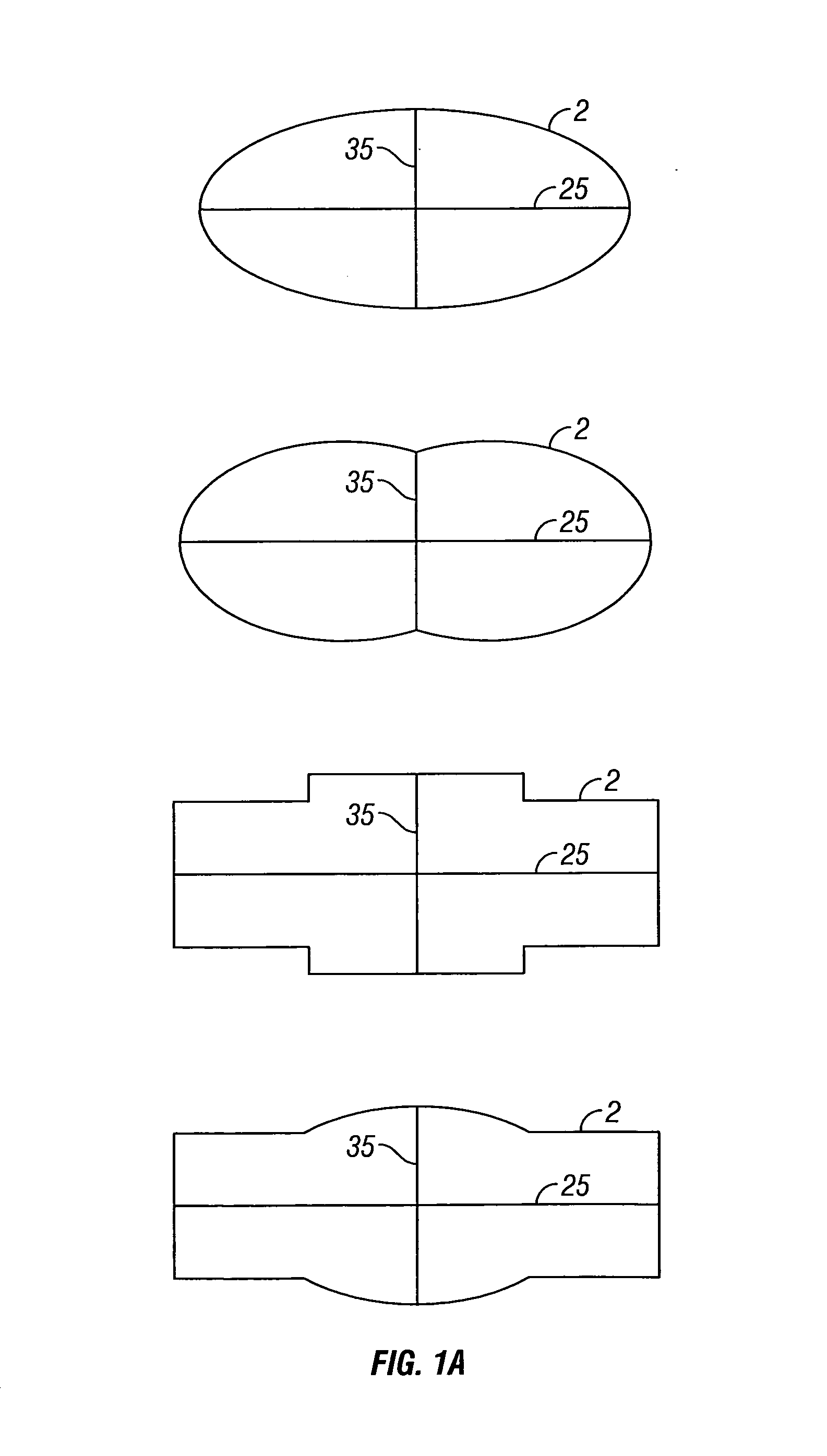

Method for automated analysis of apical four-chamber images of the heart

InactiveUS6708055B2Maximizes long axis lengthImage enhancementImage analysisBody organsCardiac muscle

A method for quantitatively analyzing digital images of approximately elliptical body organs, and in particular, echocardiographic images is provided. In particular, methods are disclosed for obtaining short-axis apical four-chamber views of a heart, and particularly for obtaining high-quality automated images of particular regions of the heart muscle, as viewed along its long axis.

Owner:FLORIDA UNIV OF A FLORIDA

Method for automated analysis of apical four-chamber images of the heart

InactiveUS20030153823A1Reduce brightnessAffect qualityImage enhancementImage analysisBody organsCardiac muscle

A method for quantitatively analyzing digital images of approximately elliptical body organs, and in particular, echocardiographic images is provided. In particular, methods are disclosed for obtaining short-axis apical four-chamber views of a heart, and particularly for obtaining high-quality automated images of particular regions of the heart muscle, as viewed along its long axis.

Owner:FLORIDA UNIV OF A FLORIDA

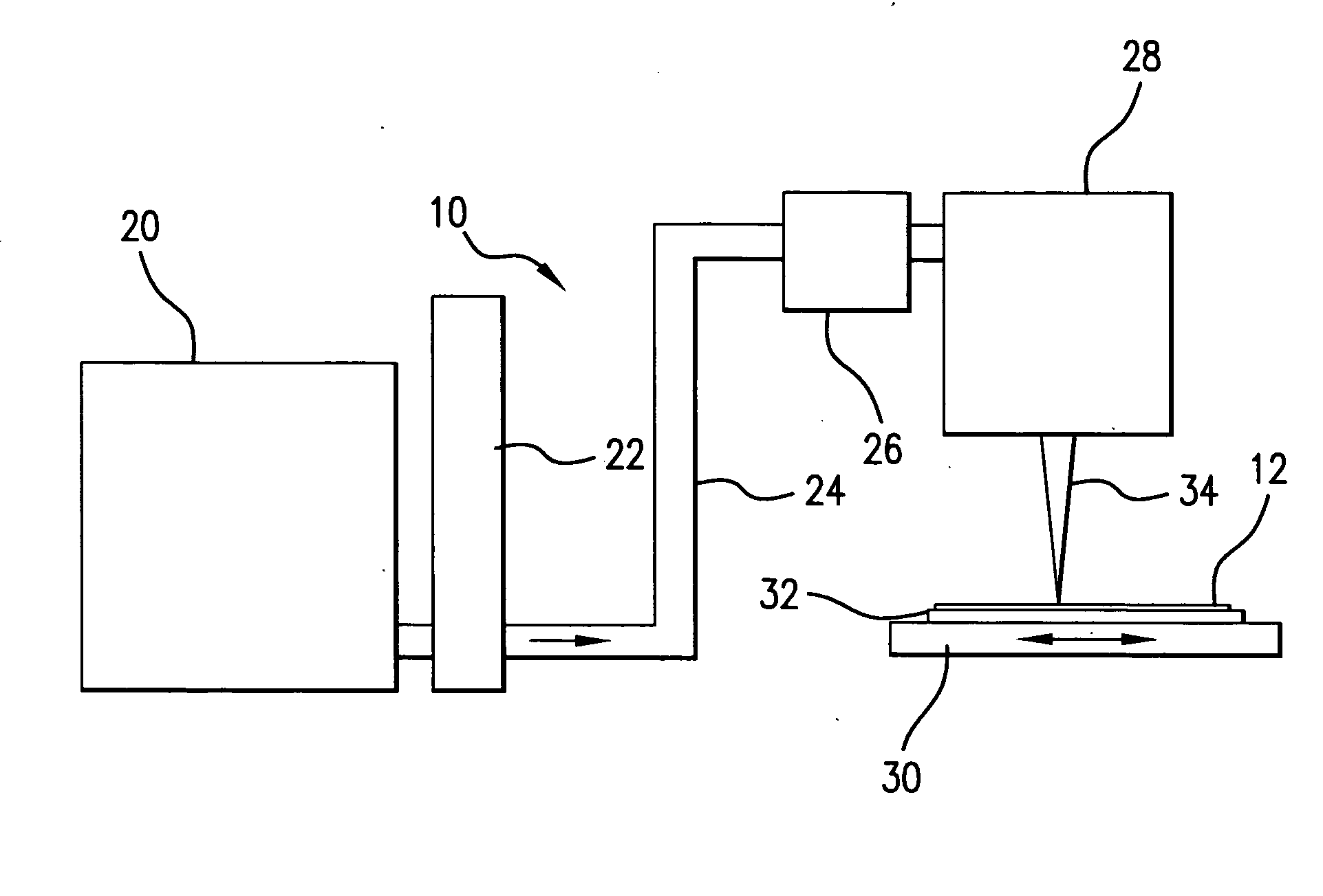

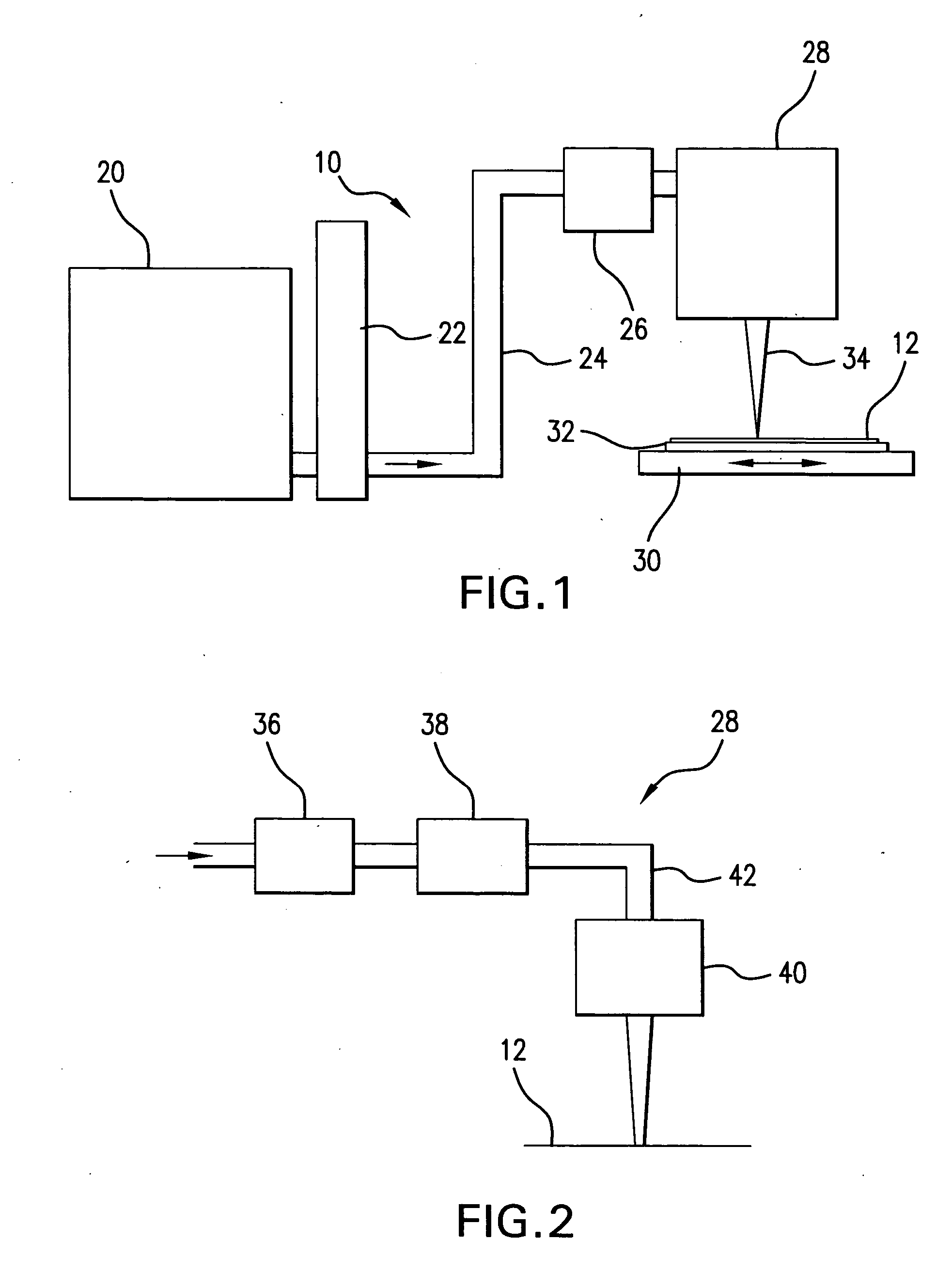

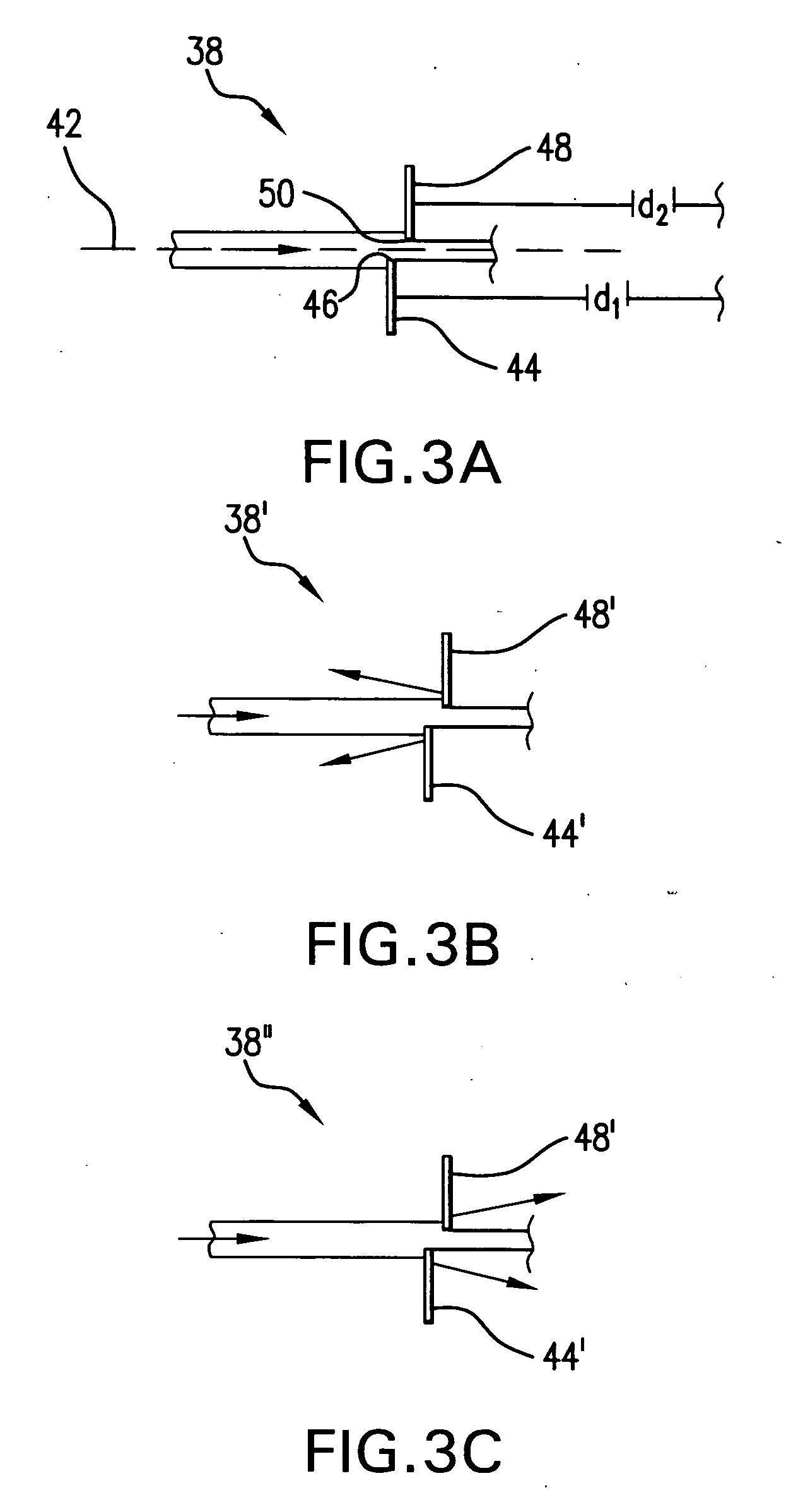

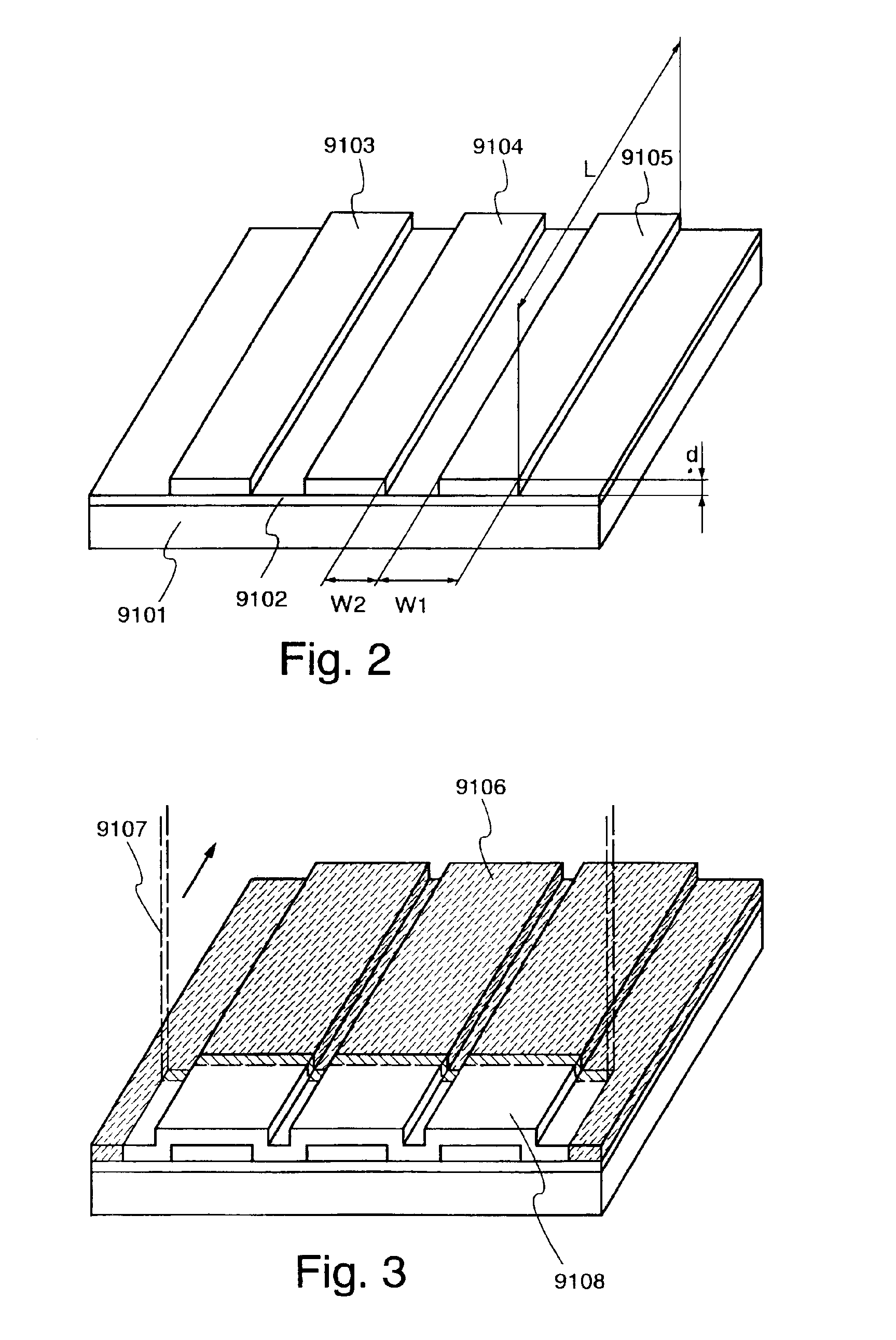

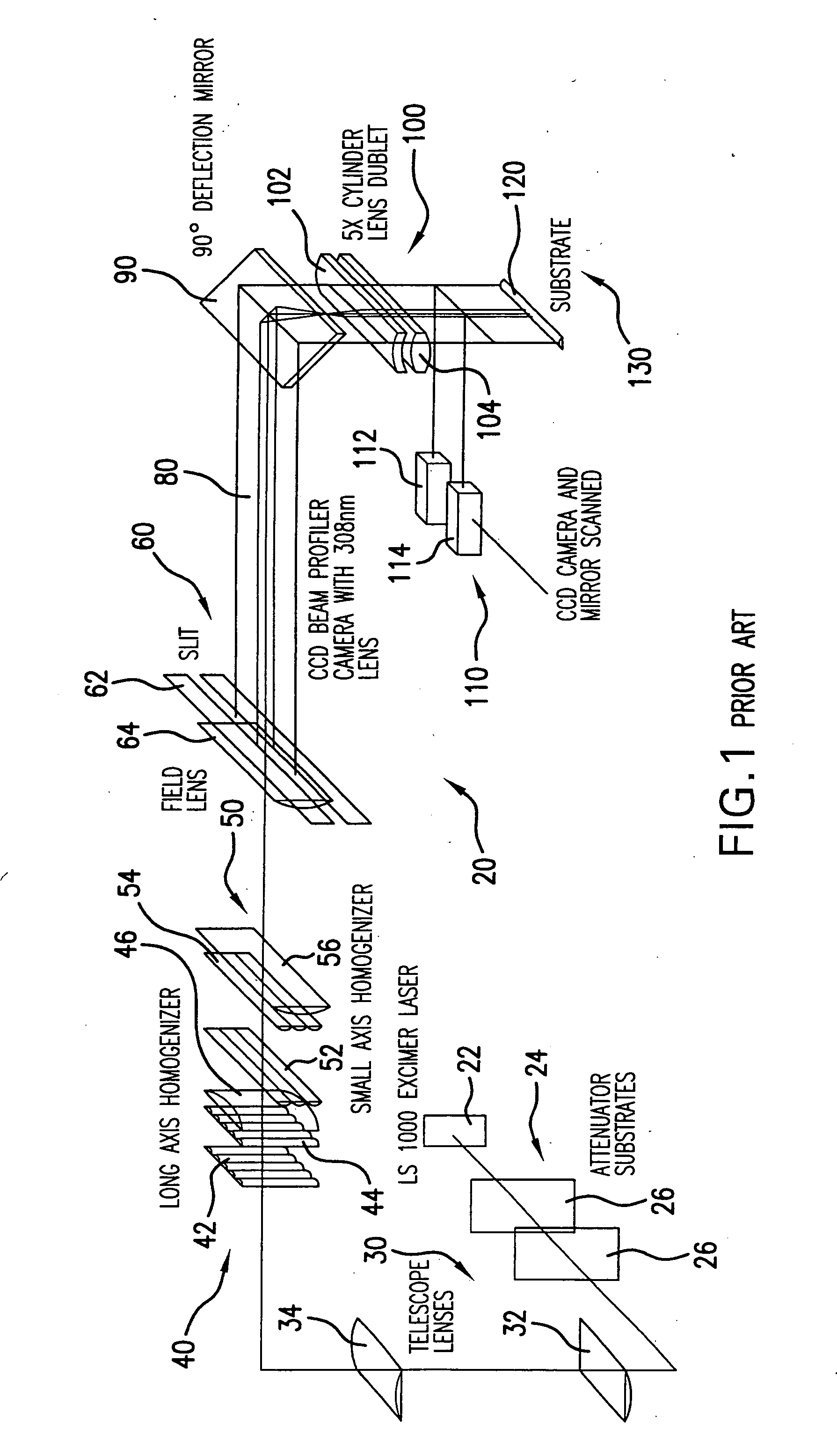

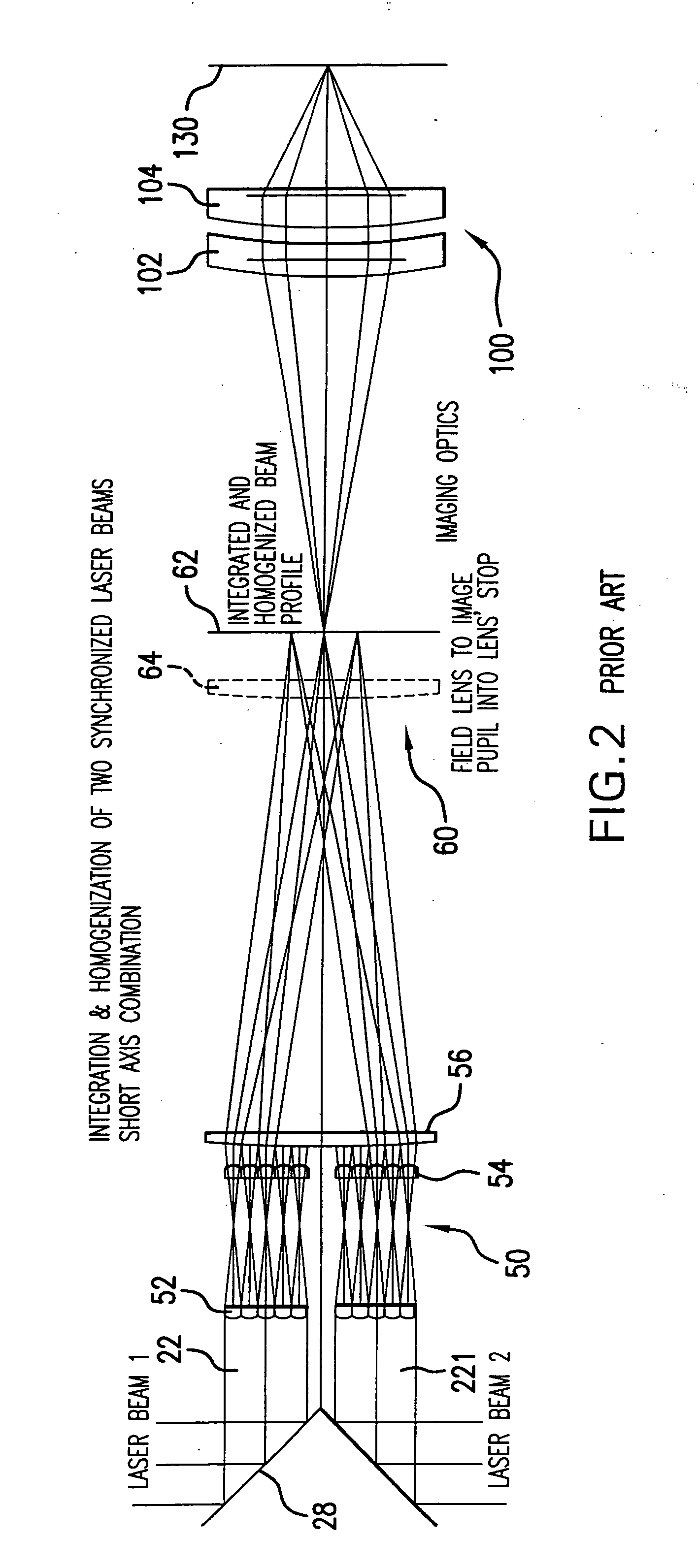

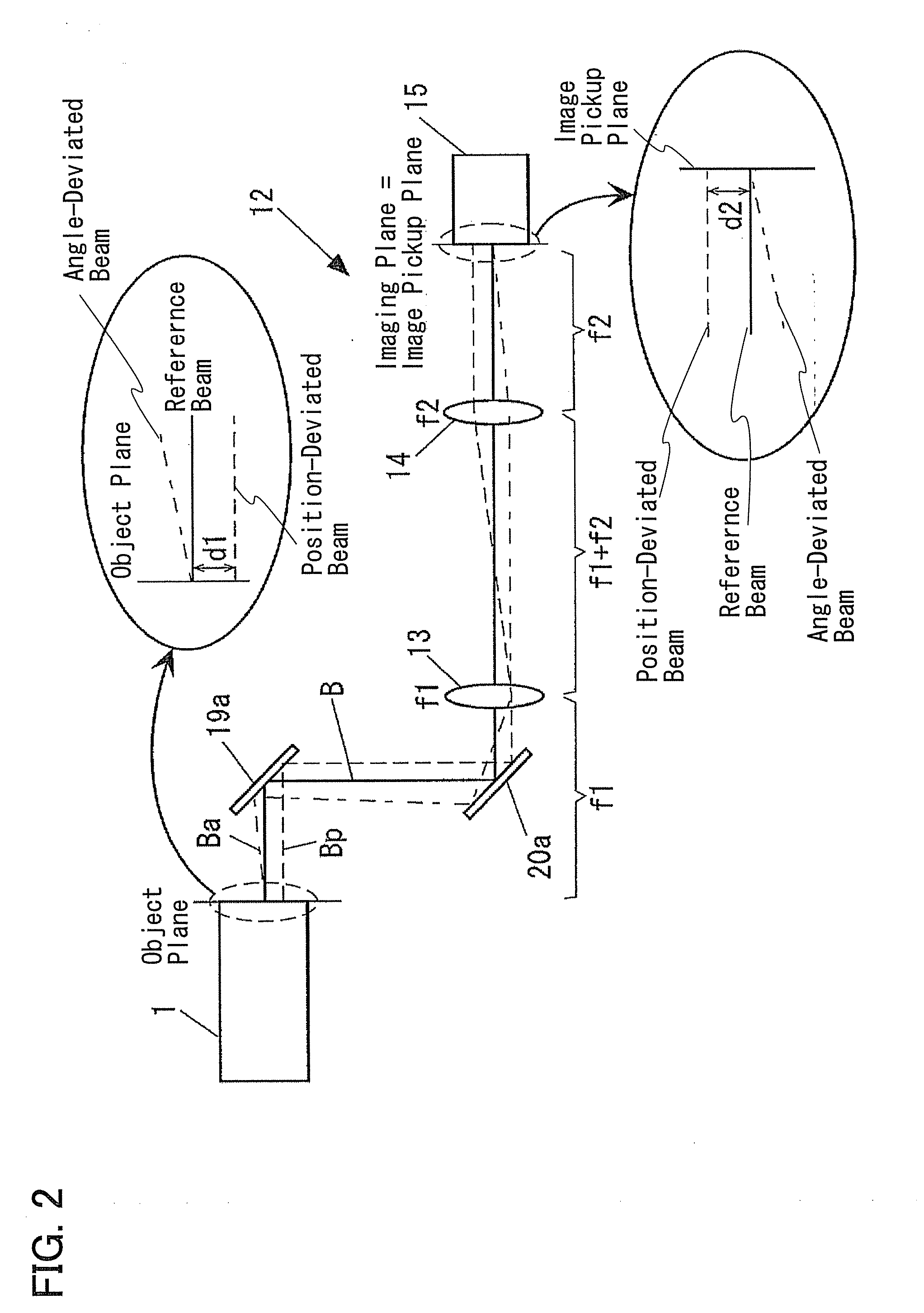

Systems and methods for generating laser light shaped as a line beam

Systems and methods are disclosed for shaping a laser beam for interaction with a film in which the laser beam travels along a beam path and defines a short-axis and a long-axis. In one aspect, the system may include a first short-axis element having an edge positioned at a distance, d1, along the beam path from the film and a second short-axis element having an edge positioned at a distance, d2, along the beam path from the film, with d2<d1. An optic may be positioned along the beam path between the second element and the film for focusing the beam in the short-axis for interaction with the film. In another aspect, a system may be provided having a mechanism operative to selectively adjust the curvature of one or both of the edges of the short-axis element.

Owner:CARL ZEISS SMT GMBH +1

Method for Automatic Segmentation of Images

InactiveUS20100215238A1Simplify the segmentation processSimple processImage enhancementImage analysisContour segmentationPattern recognition

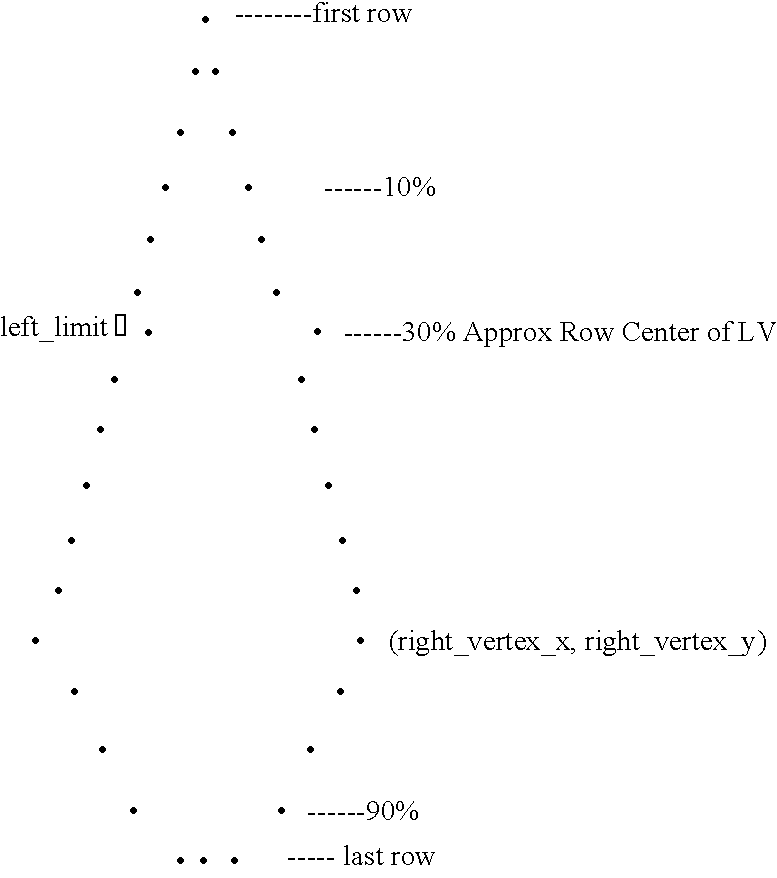

A method for automatic left ventricle segmentation of cine short-axis magnetic resonance (MR) images that does not require manually drawn initial contours, trained statistical shape models, or gray-level appearance models is provided. More specifically, the method employs a roundness metric to automatically locate the left ventricle. Epicardial contour segmentation is simplified by mapping the pixels from Cartesian to approximately polar coordinates. Furthermore, region growing is utilized by distributing seed points around the endocardial contour to find the LV myocardium and, thus, the epicardial contour. This is a robust technique for images where the epicardial edge has poor contrast. A fast Fourier transform (FFT) is utilized to smooth both the determined endocardial and epicardial contours. In addition to determining endocardial and epicardial contours, the method also determines the contours of papillary muscles and trabeculations.

Owner:SUNNYBROOK HEALTH SCI CENT

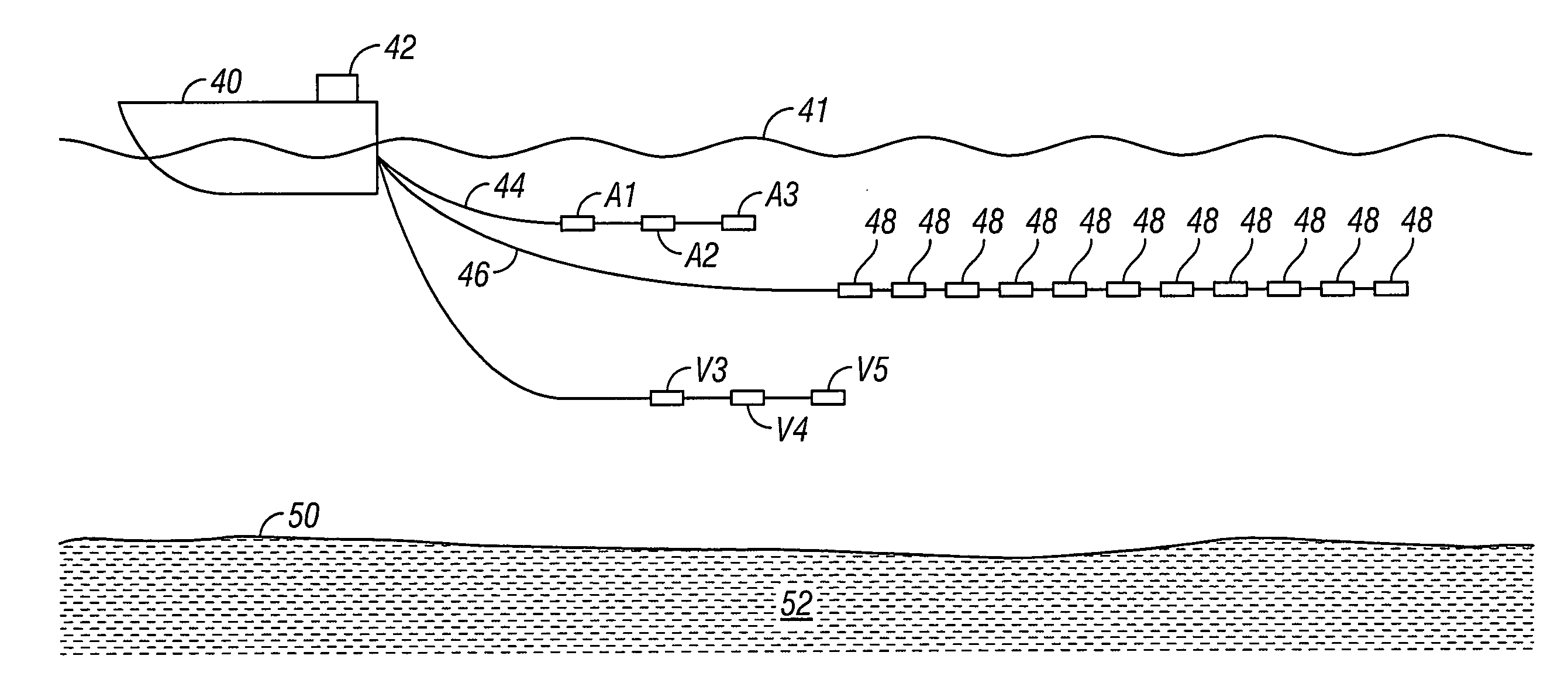

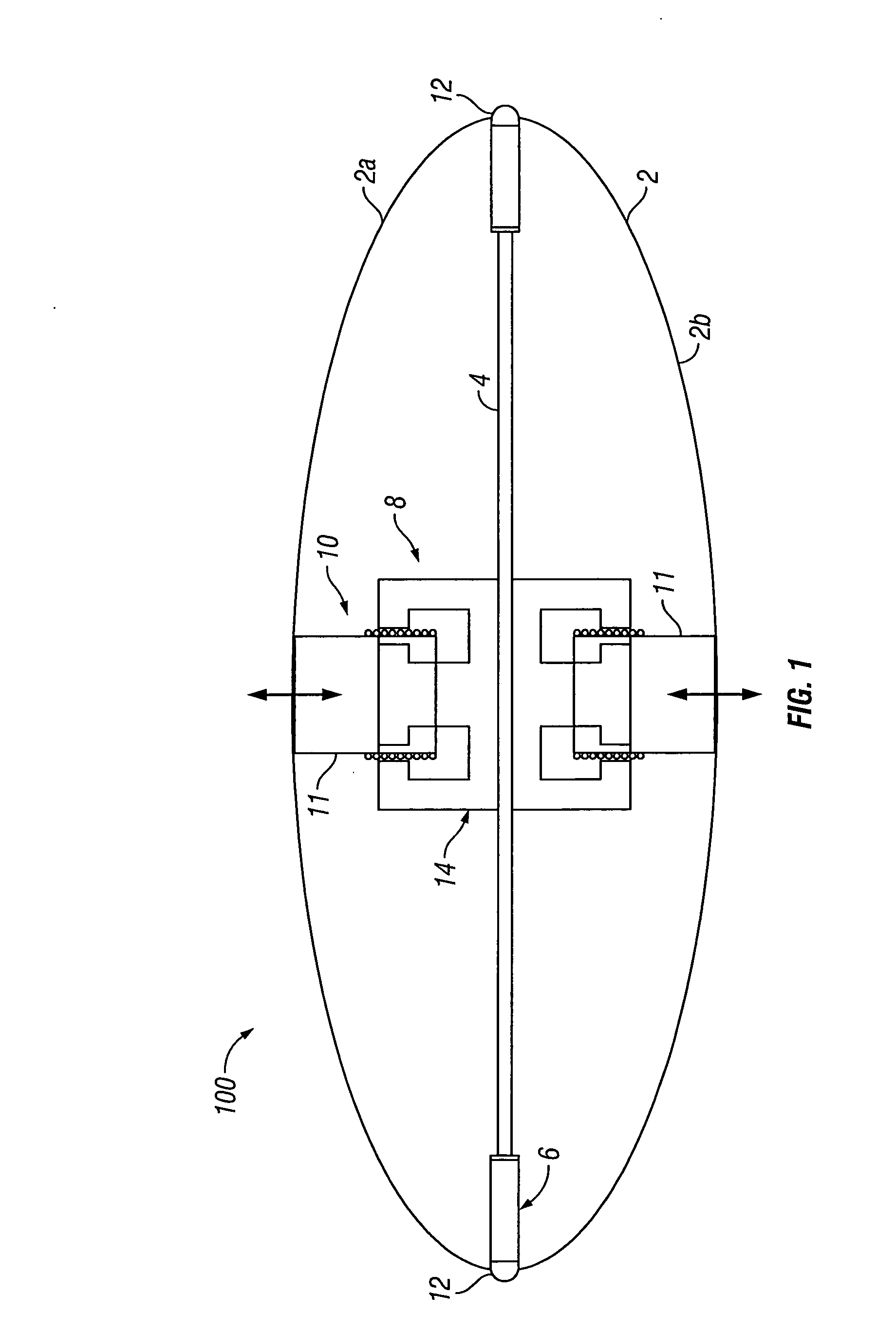

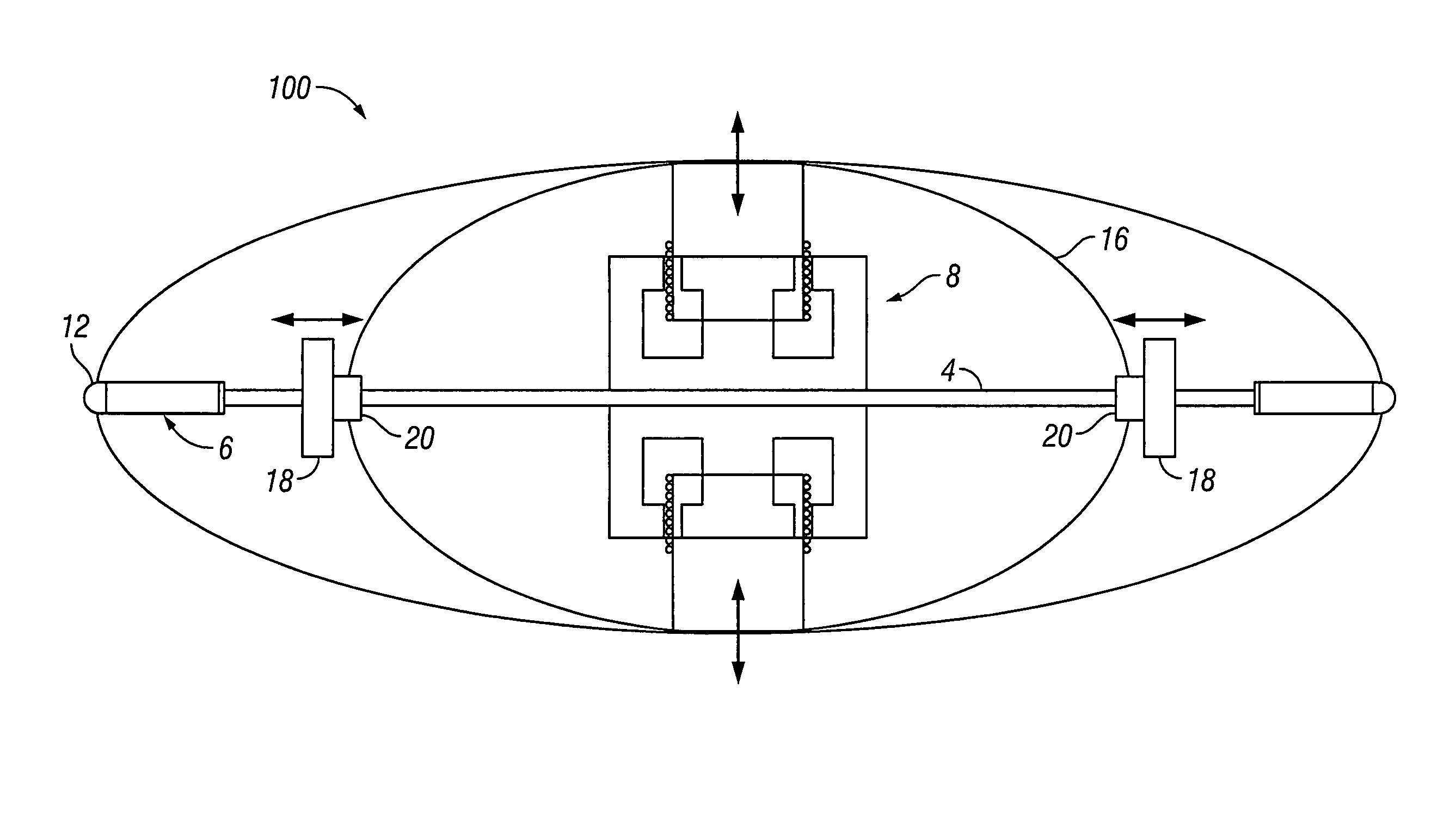

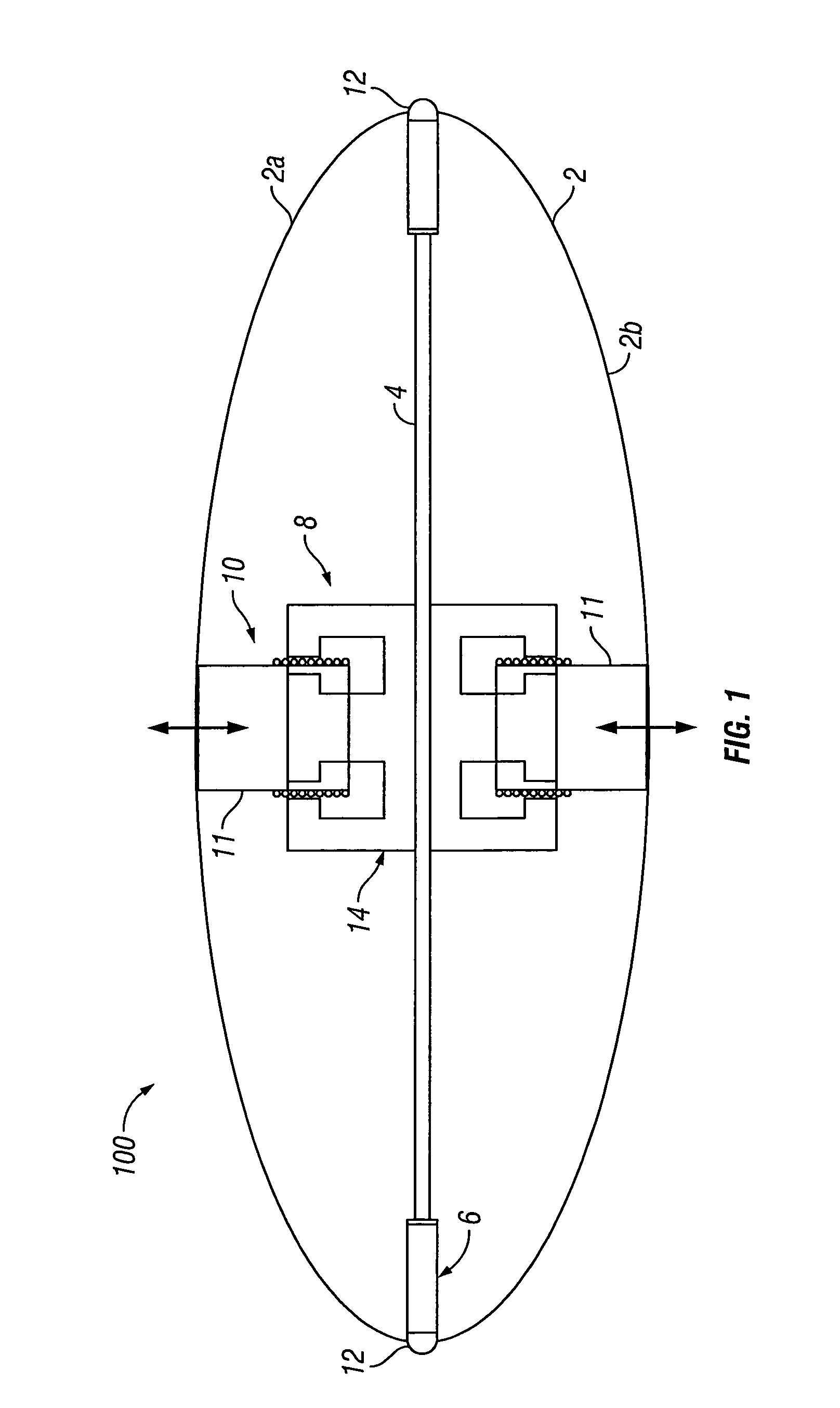

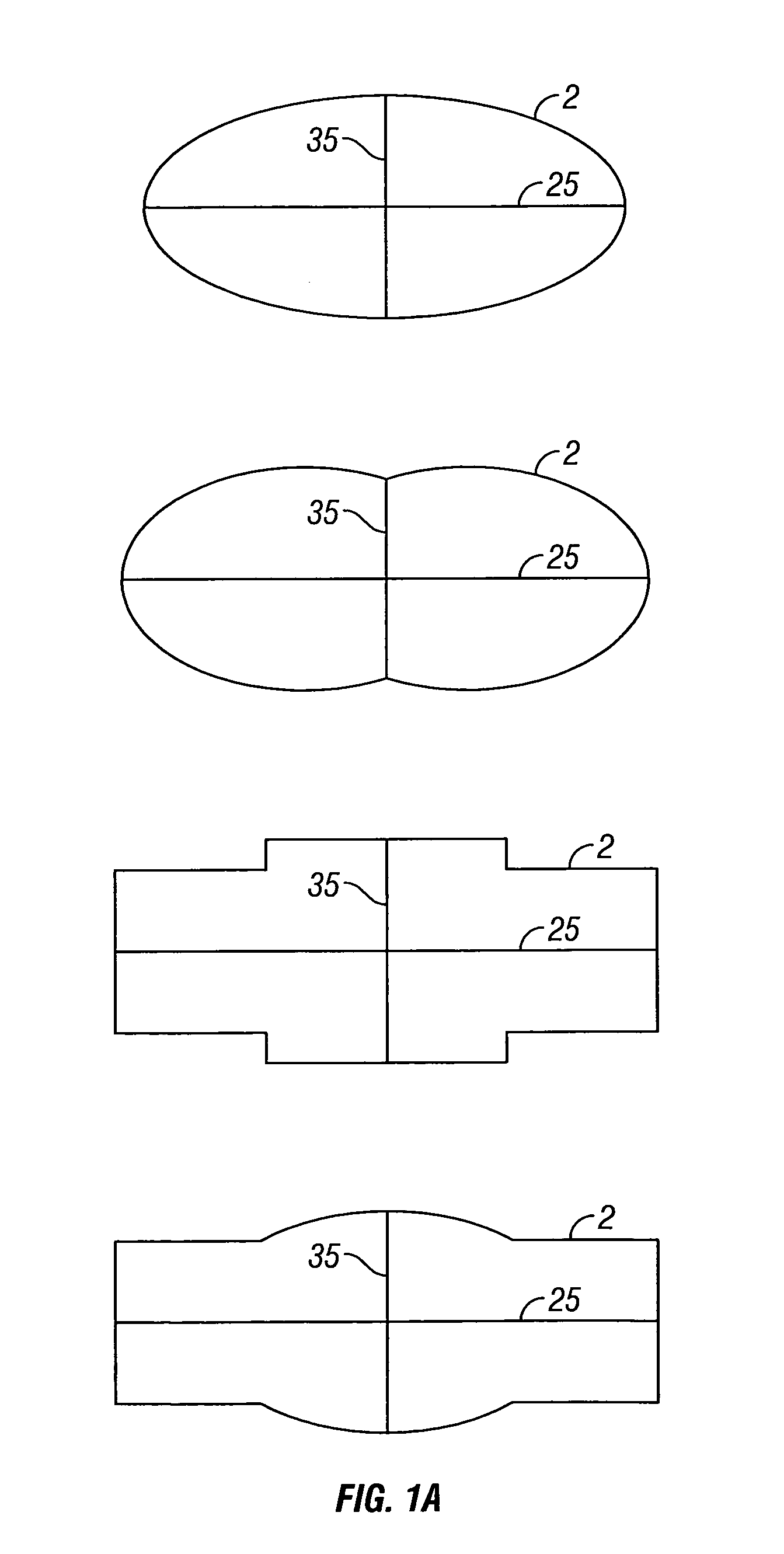

Marine acoustic vibrator having enhanced low-frequency amplitude

InactiveUS20110317515A1Seismic energy generationSound producing devicesVibration amplitudeSeismic survey

A seismic source includes a flextensional shell defining a longer axis and a shorter axis and at least one driver coupled to the flextensional shell proximate an end of the shorter axis. The seismic source may be a component of a marine seismic survey system. The marine seismic survey system may be utilized in a method of marine seismic surveying.

Owner:PGS GEOPHYSICAL AS

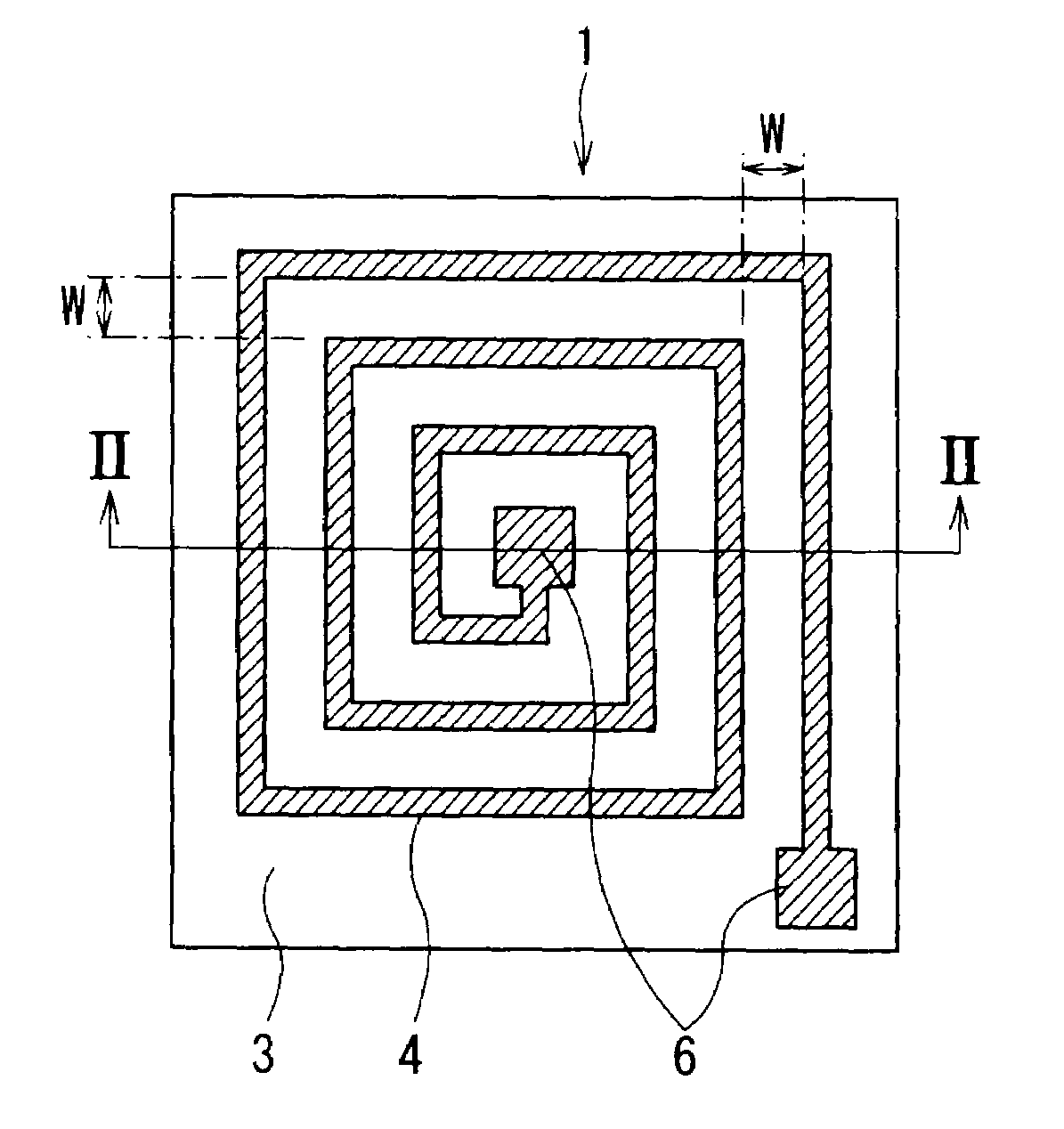

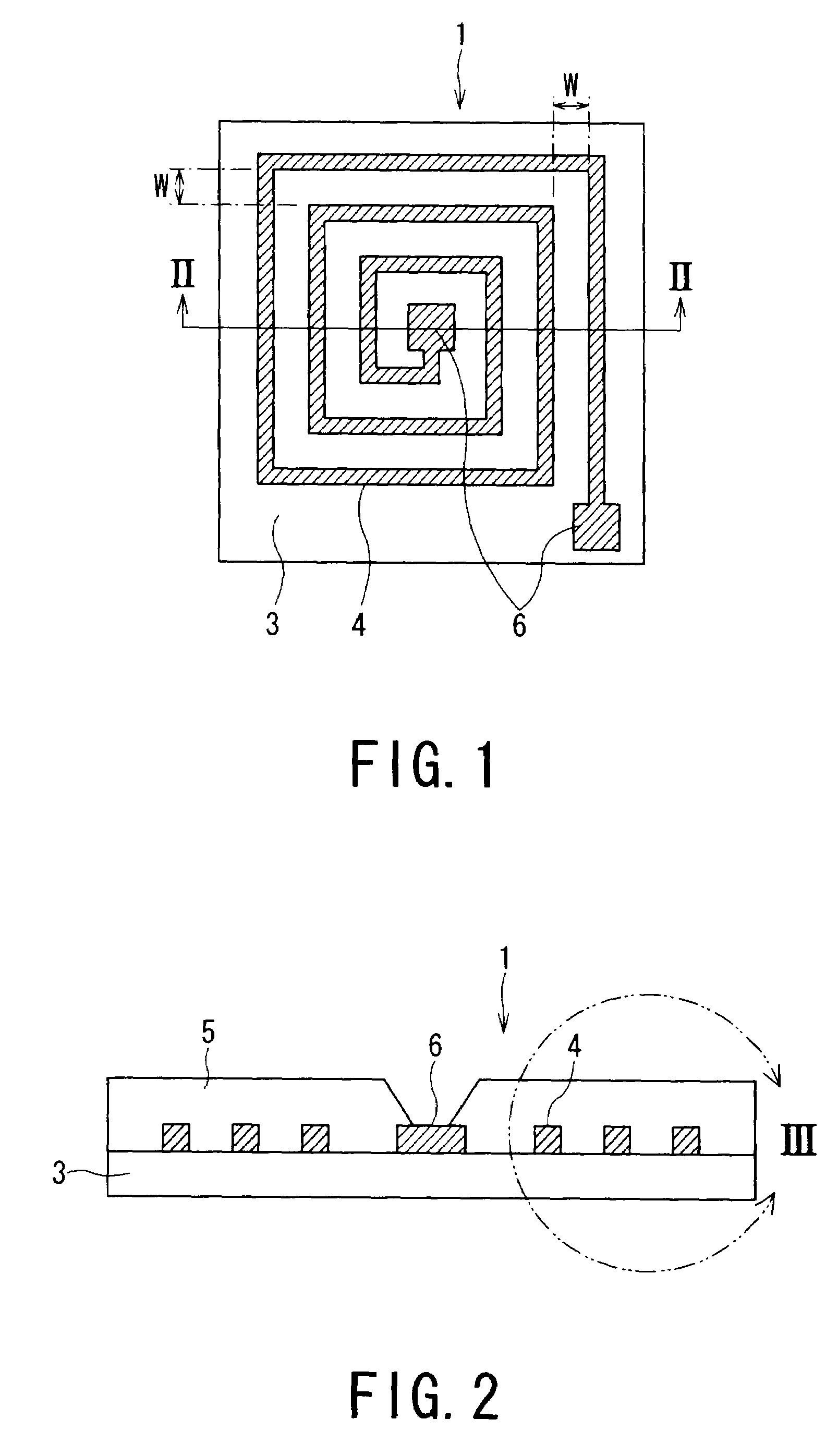

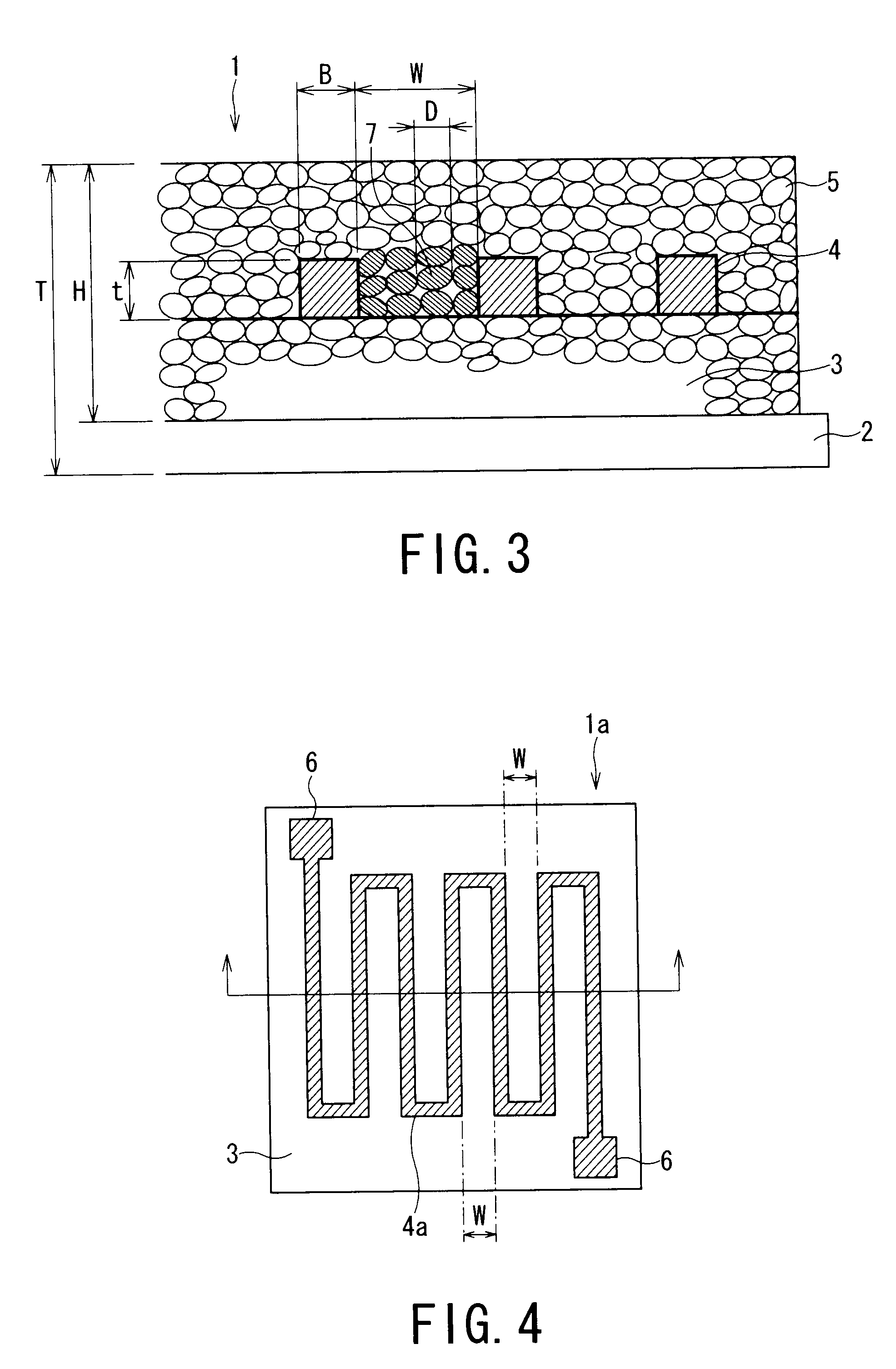

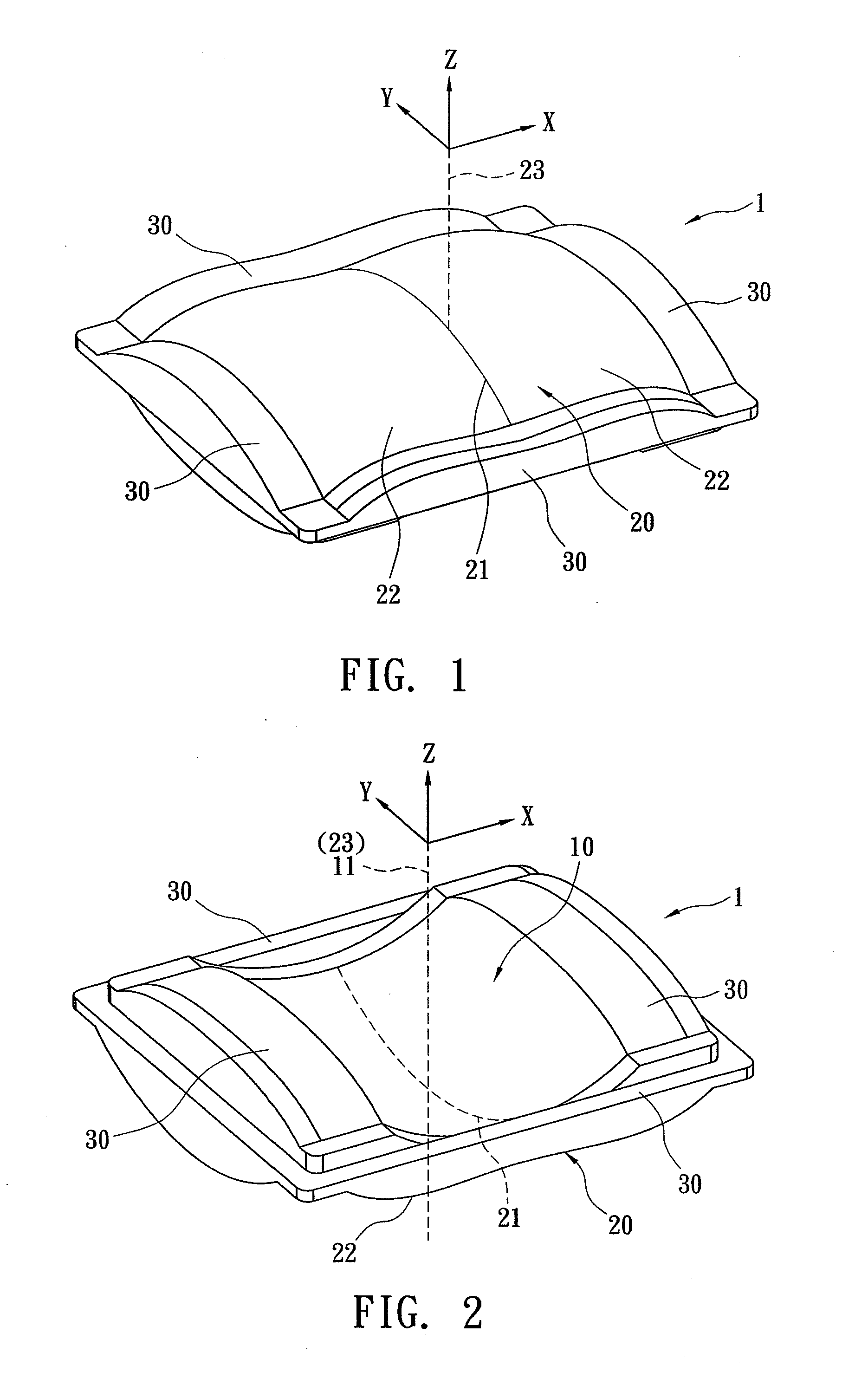

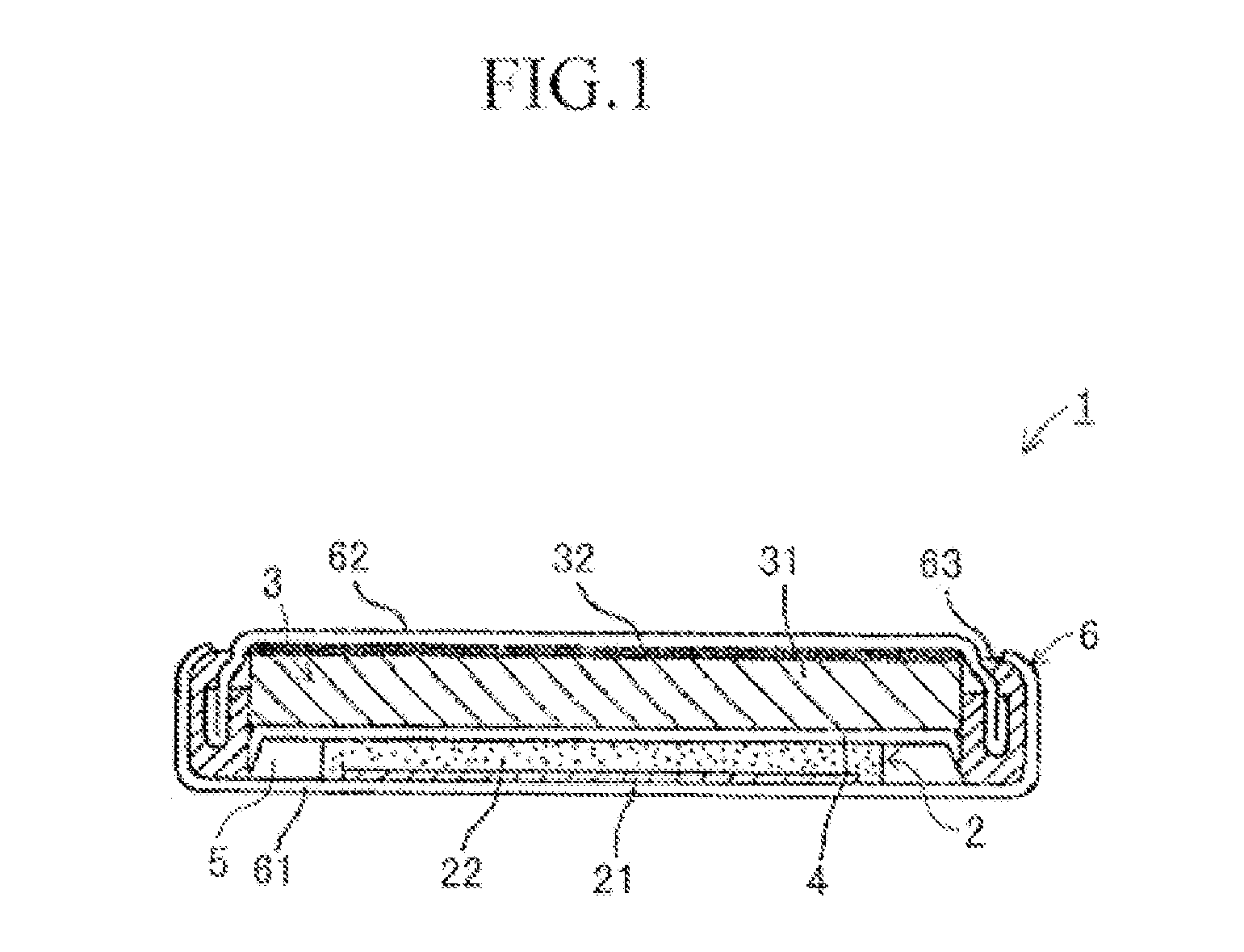

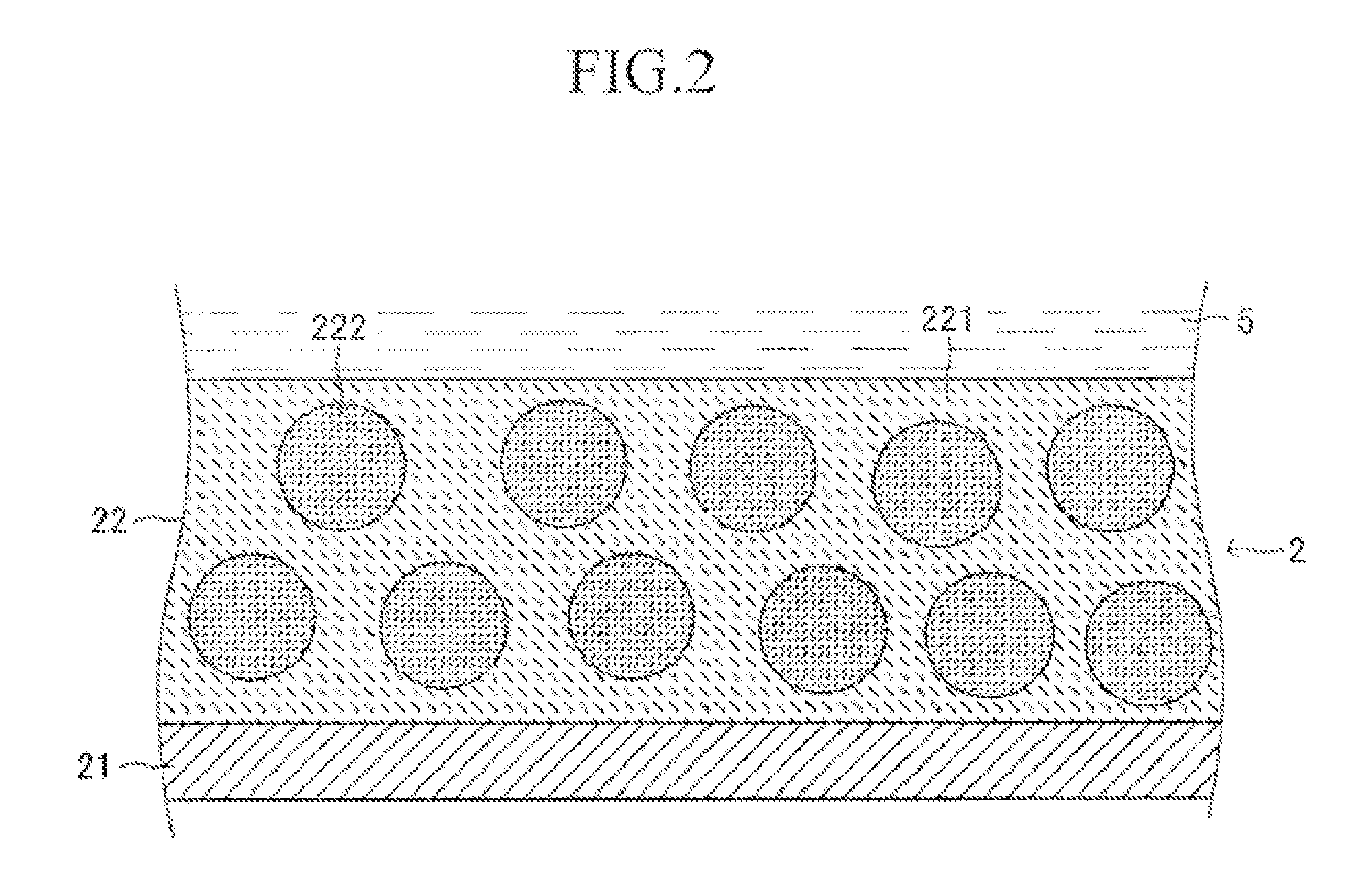

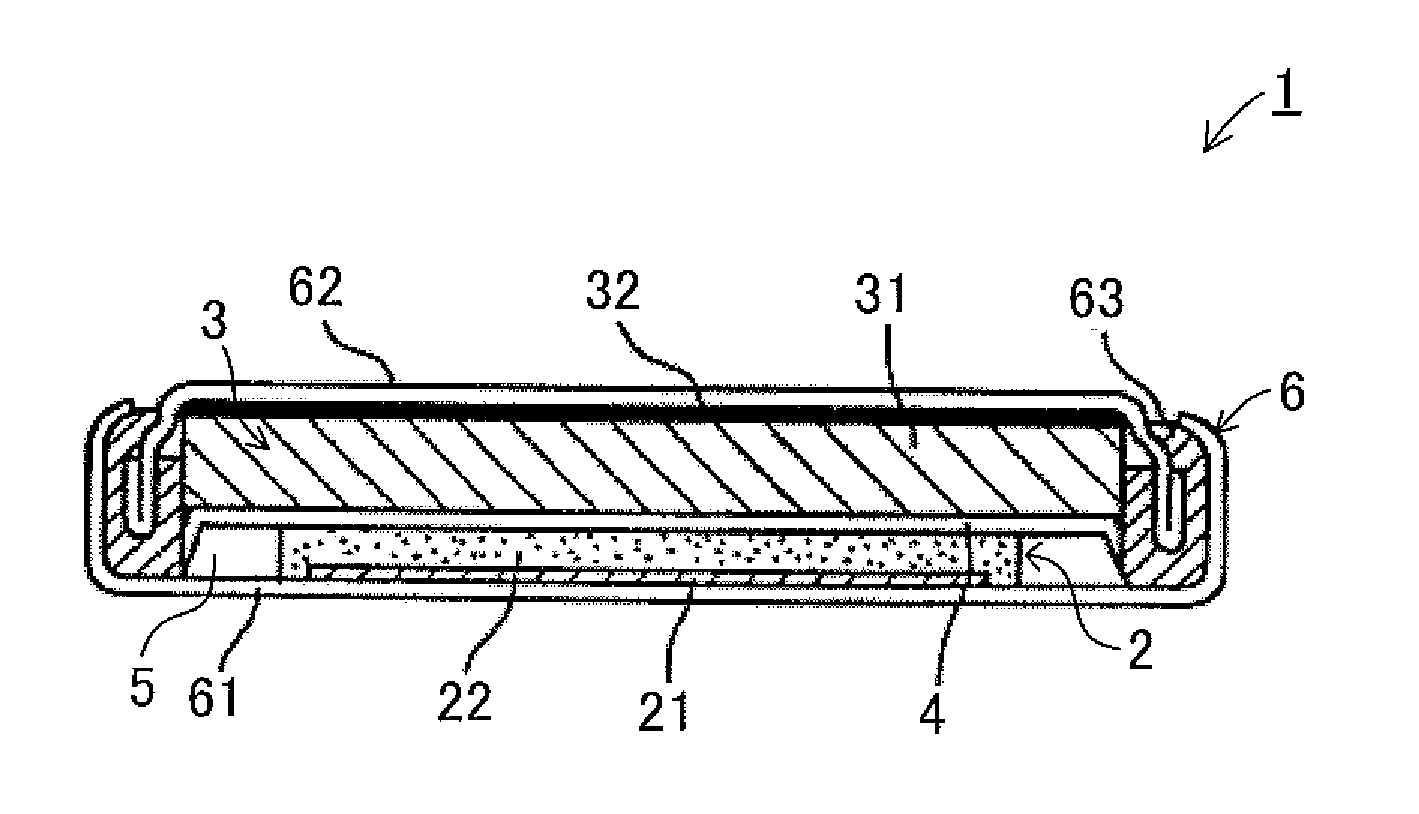

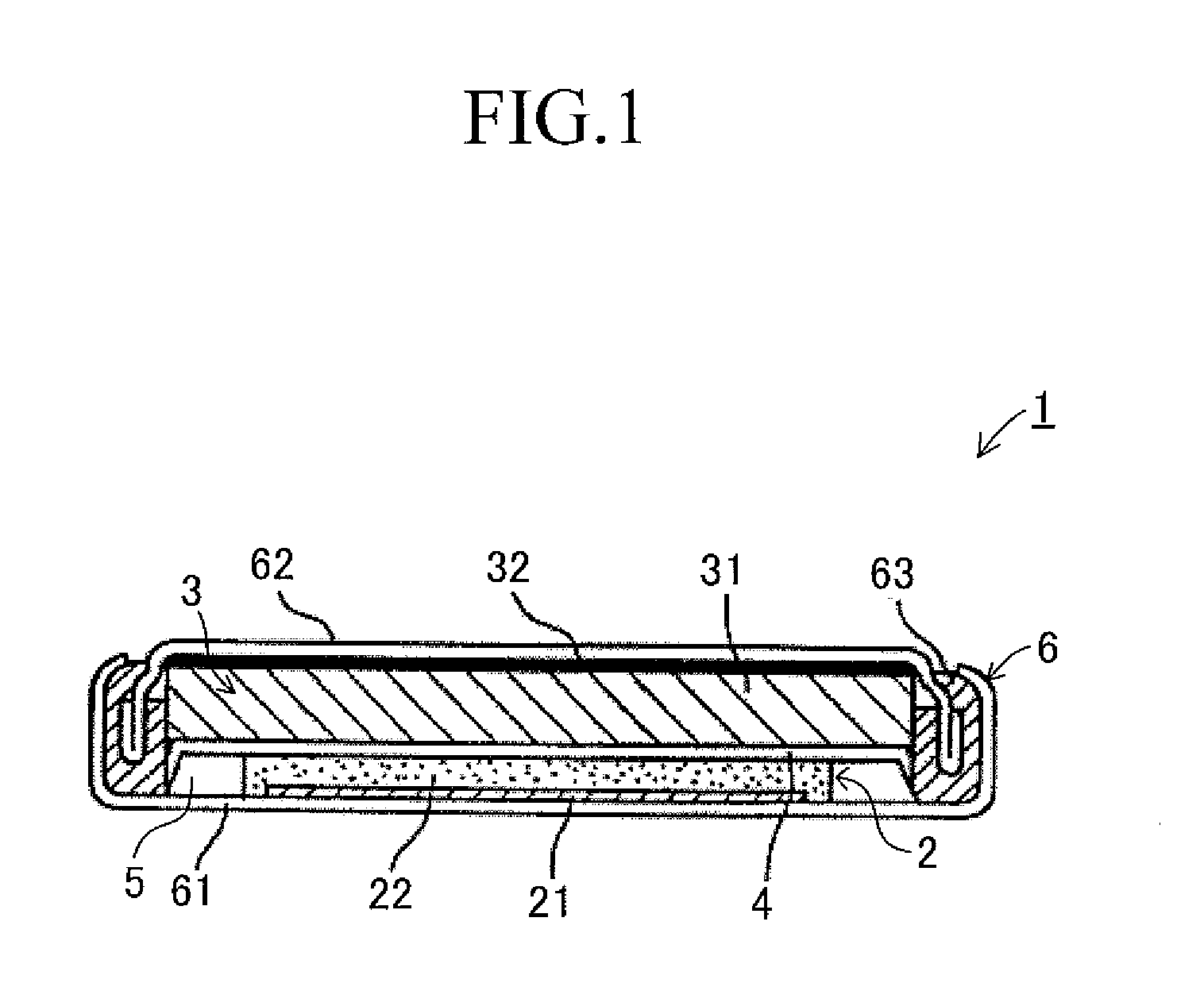

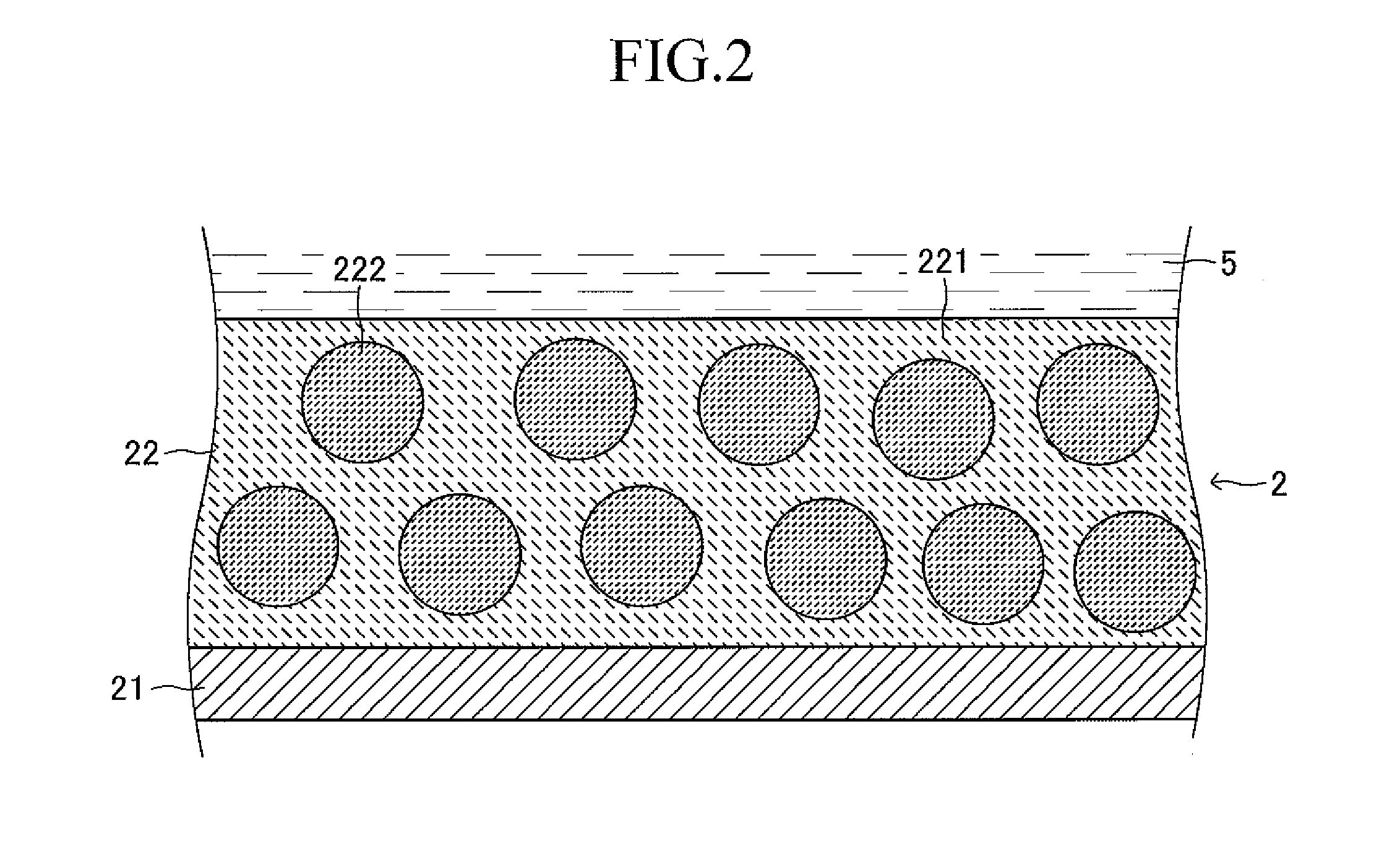

Flat magnetic element and power IC package using the same

ActiveUS20090243780A1Improve permeabilityIncrease inductanceSemiconductor/solid-state device detailsSolid-state devicesInductorInductance

A planar magnetic device 1 including a first magnetic layer 3, a second magnetic layer 5, and a planar coil 4 disposed between the first magnetic layer 3 and the second magnetic layer 5, wherein magnetic particles 7 having a shape ratio S / L of 0.7 to 1 when a length of a long axis is L and a length of a short axis orthogonal to the long axis is L are filled in a gap W between coil wirings of the planar coil 4. According to the planar magnetic device 1, it is possible to realize a planar magnetic device such as an inductor reduced in height by using fine particles that enable to effectively obtain a large inductance value.

Owner:KK TOSHIBA +1

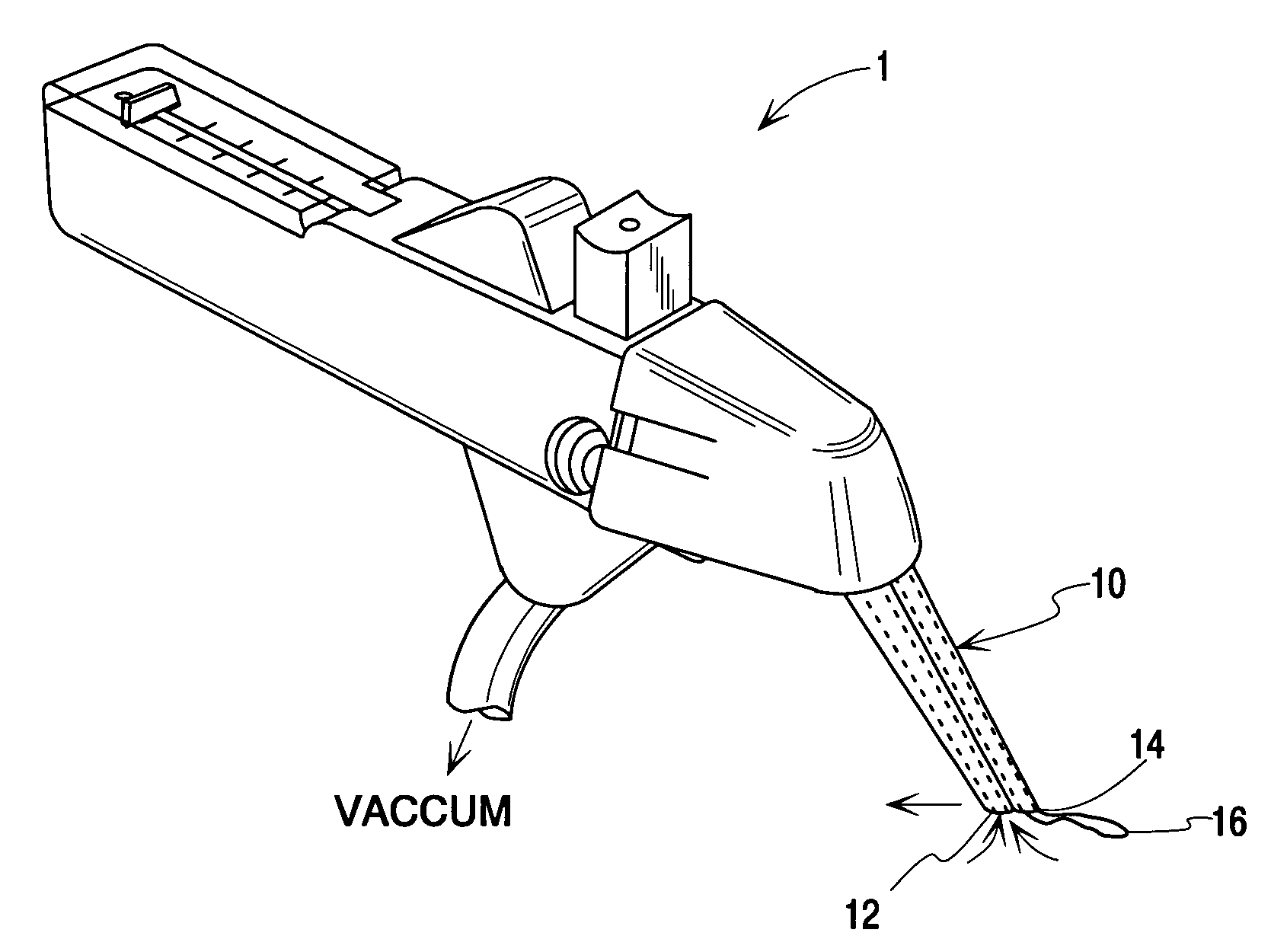

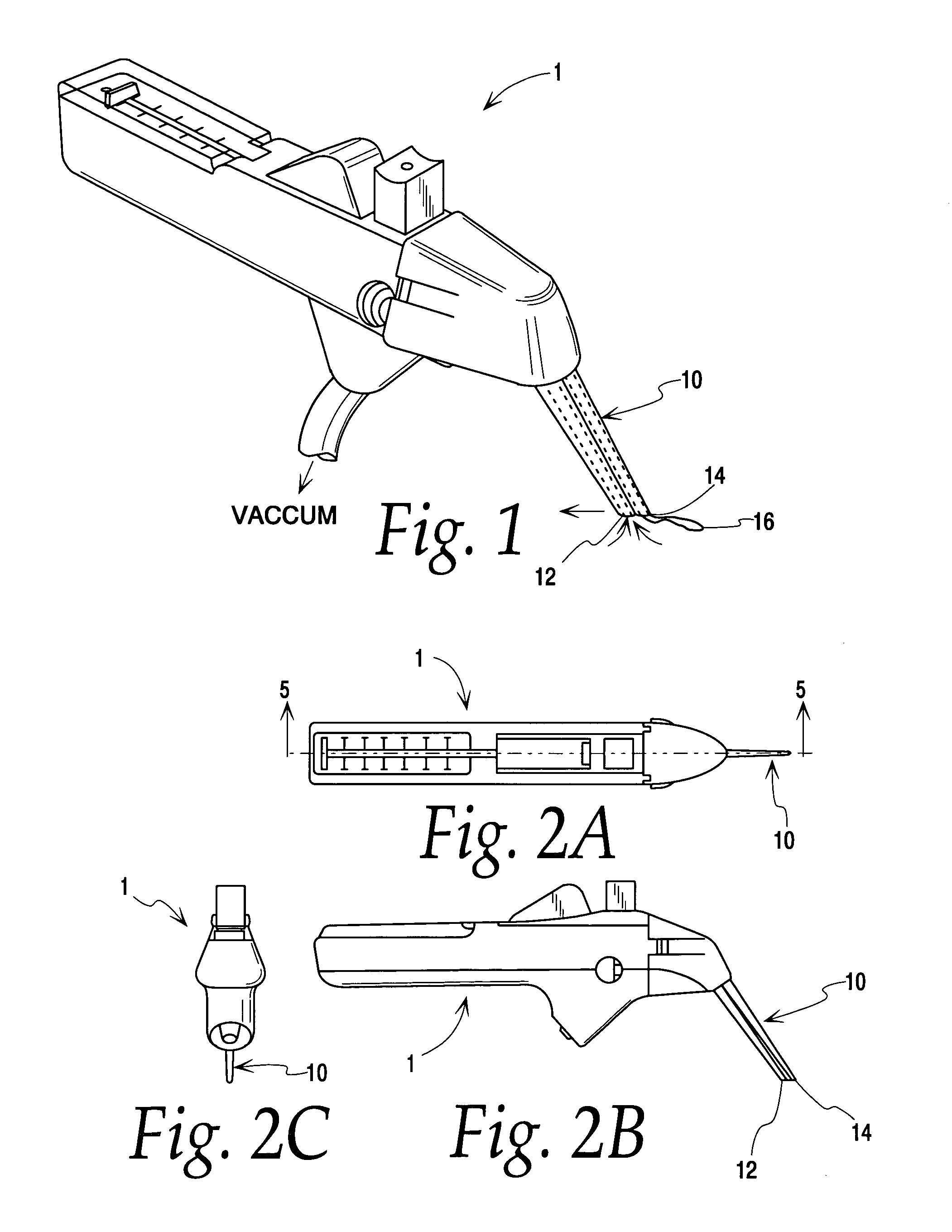

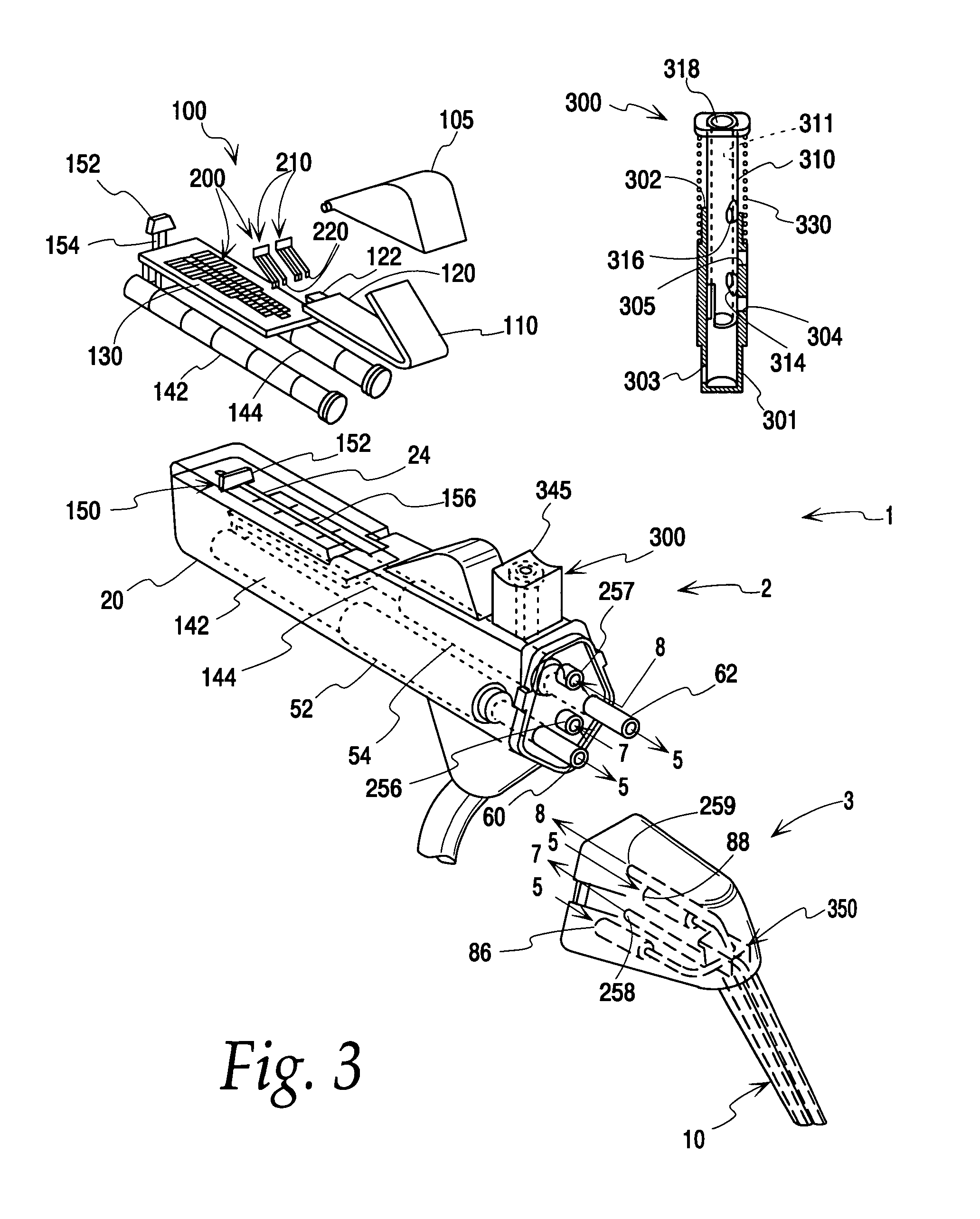

Medical suctioning apparatus and methods of use

A medical fluid suctioning device for selectively applying varied levels of suction pressure at a device-tissue interface includes a direct “trumpet”-type control mechanism in conjunction with a “venturi”-type control. A valve manifold is adapted to couple a vent pathway and a suction pathway simultaneously to the vacuum conduit adapted for connection to a vacuum source. The amount of resistance to flow due to vacuum pressure is adjusted simultaneously in both the vent pathway and the suction pathway in order to achieve controlled, selected levels of suction. Similarly shaped valve apertures are provided in inverse and reciprocal orientation along an axis of motion of a valve manifold. The apertures translate across ports to the suction and venting pathways simultaneously to vary applied suction to those pathways inversely. The shaped valve apertures preferably have diminished elliptical shapes having an elongate axis with an increasing cross-sectional area going from a transverse short axis to a transverse wide axis along the axis of motion of the valve manifold. The diminished elliptical shapes are inversely oriented relative to each other as regards the positioning of their wide and short transverse axis along the axis of motion.

Owner:BAXTER INT INC

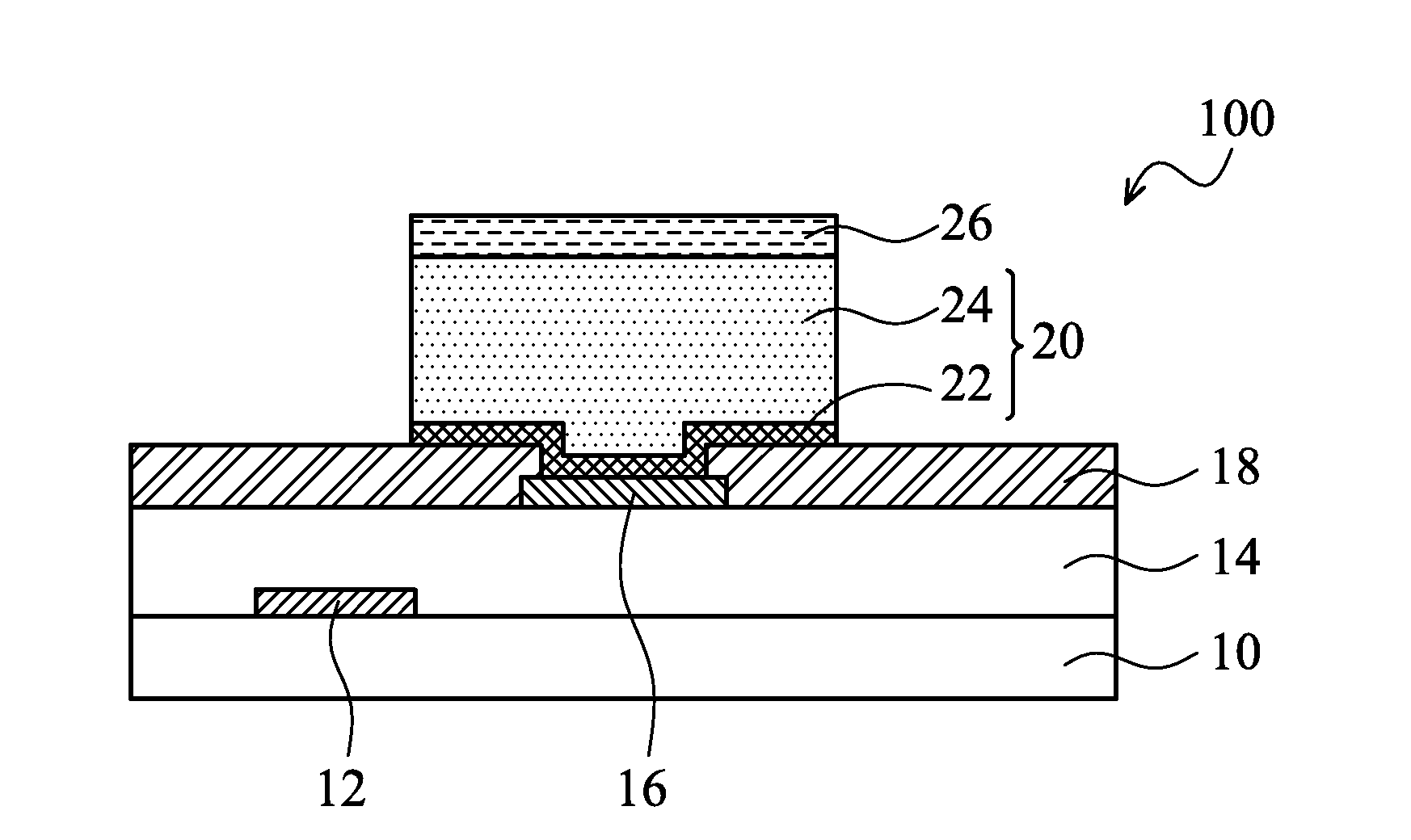

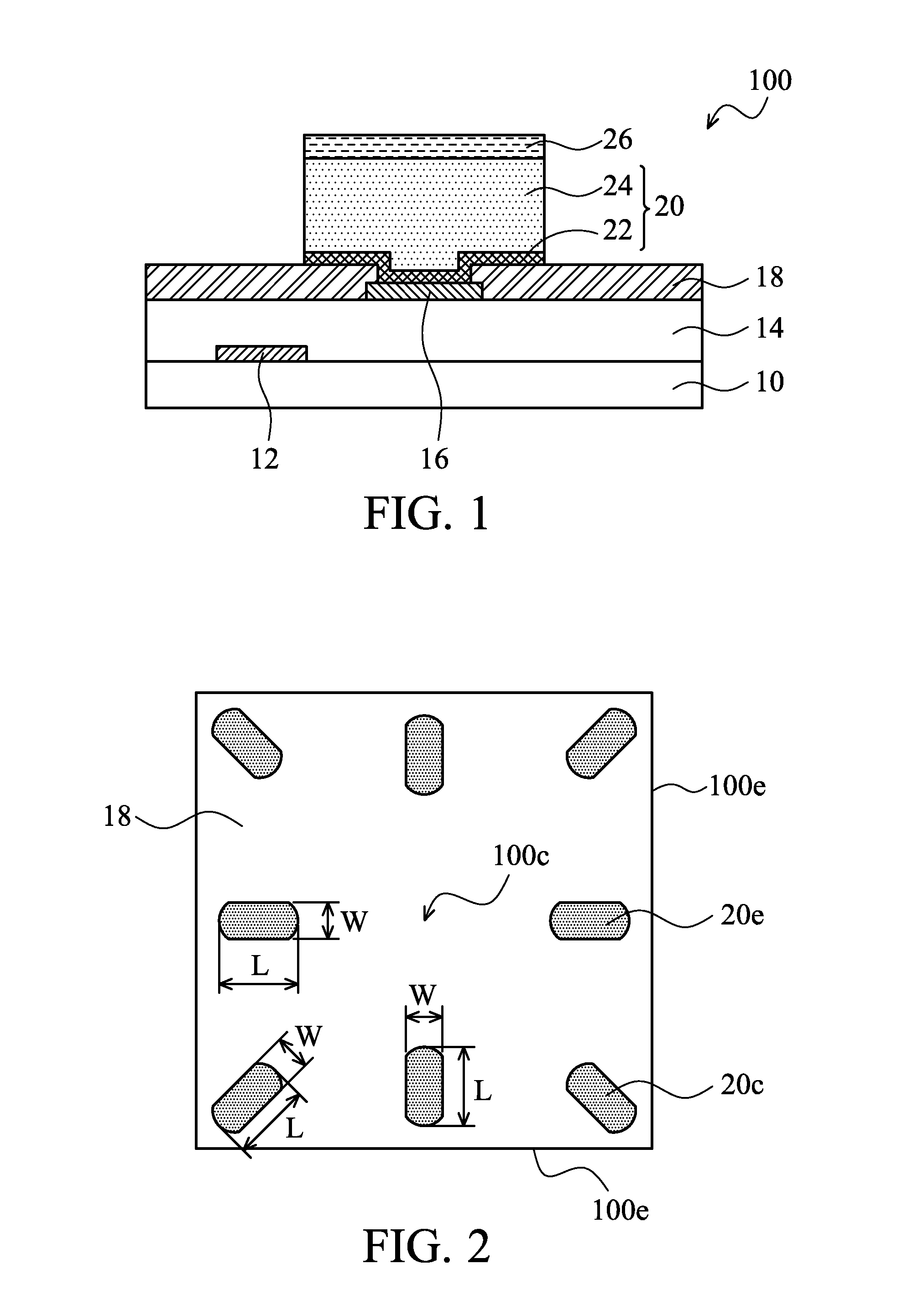

Elongated bump structure in semiconductor device

ActiveUS20130062755A1Heat resistantHigher-speed deviceSemiconductor/solid-state device detailsSolid-state devicesInterconnectionSemiconductor

A device includes a chip attached to a substrate. The chip includes a conductive pillar having a length (L) measured along a long axis of the conductive pillar and a width (W) measured along a short axis of the conductive pillar. The substrate includes a conductive trace and a mask layer overlying the conductive trace, wherein the mask layer has an opening exposing a portion of the conductive trace. An interconnection is formed between the conductive pillar and the exposed portion of the conductive trace. The opening has a first dimension (d1) measured along the long axis of the conductive pillar and a second dimension (d2) measured along the short axis of the conductive pillar. A ratio of L to d1 is greater than a ratio of W to d2.

Owner:TAIWAN SEMICON MFG CO LTD

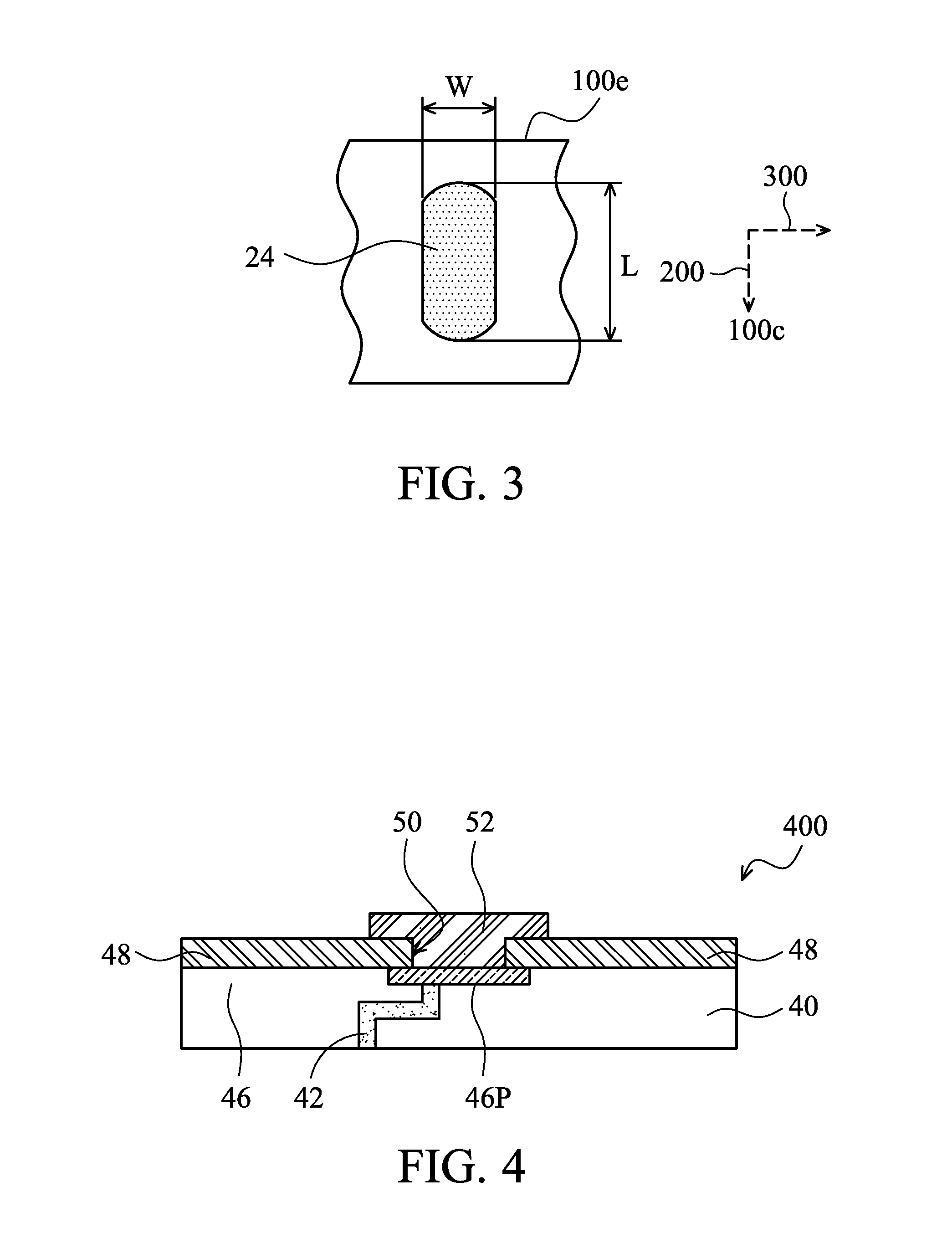

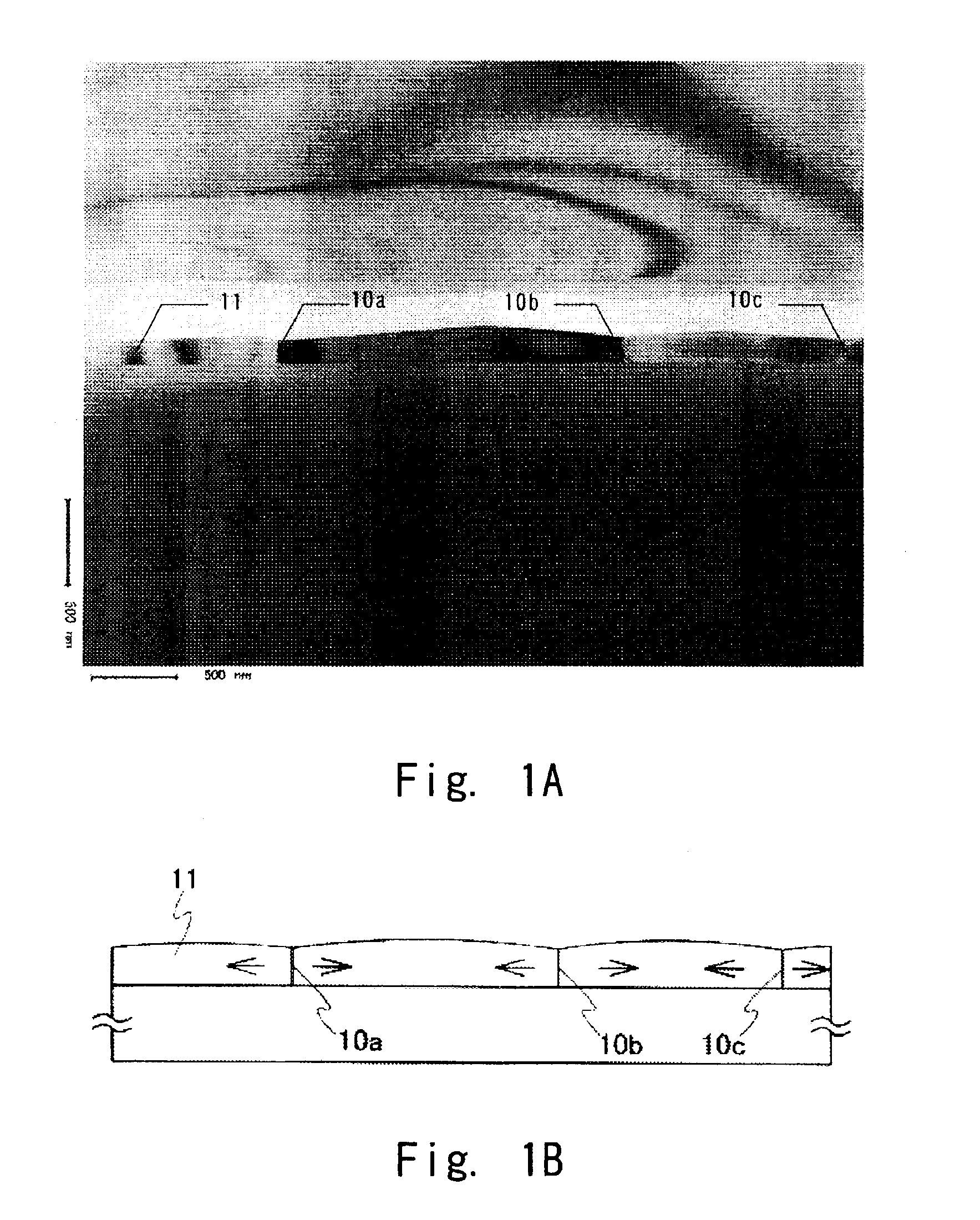

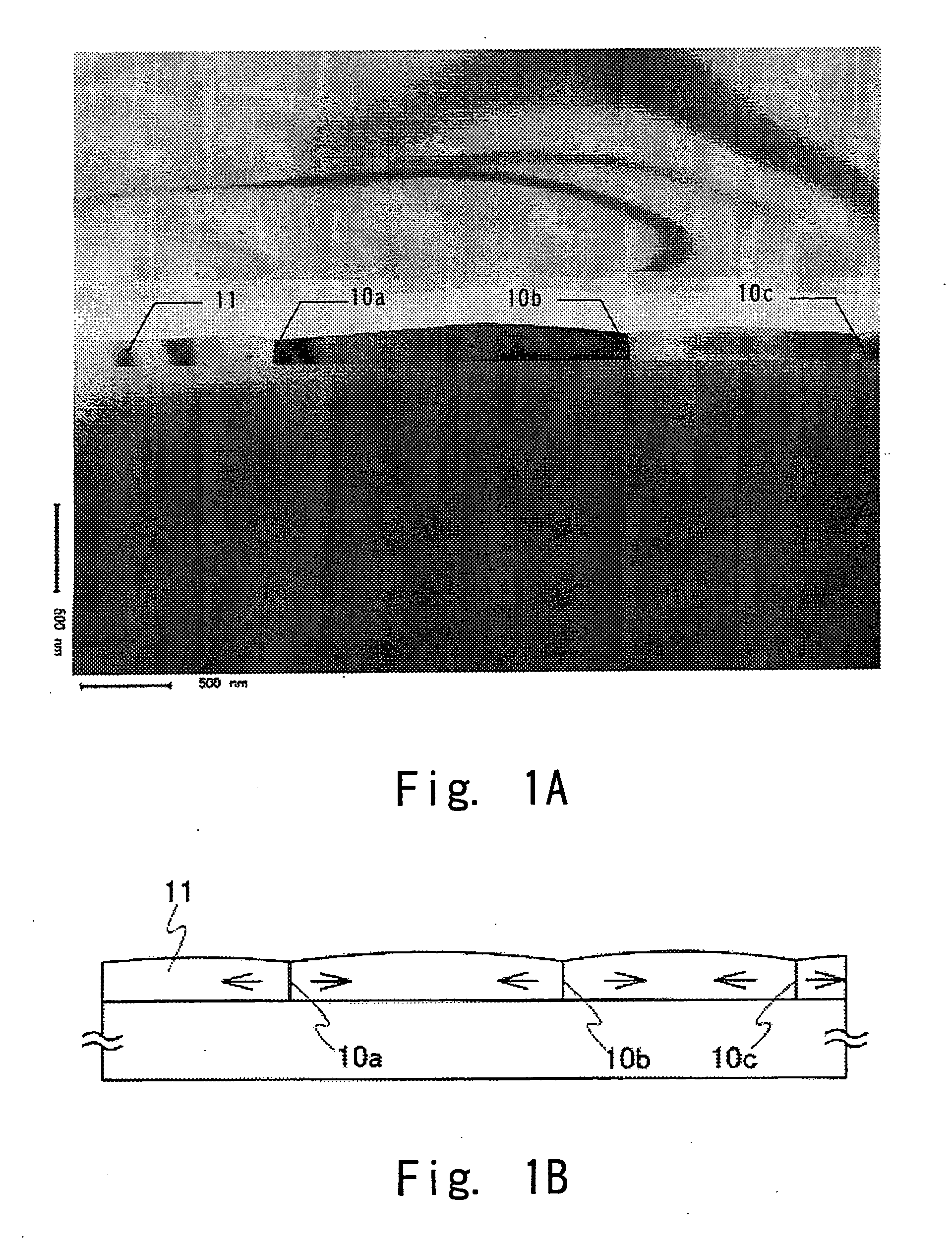

Semiconductor device and semiconductor device production system

InactiveUS6933527B2Improve barrier propertiesImprove stressTransistorSolid-state devicesStress concentrationLaser crystallization

It is a problem to provide a semiconductor device production system using a laser crystallization method capable of preventing grain boundaries from forming in a TFT channel region and further preventing conspicuous lowering in TFT mobility due to grain boundaries, on-current decrease or off-current increase. An insulation film is formed on a substrate, and a semiconductor film is formed on the insulation film. Due to this, preferentially formed is a region in the semiconductor film to be concentratedly applied by stress during crystallization with laser light. Specifically, a stripe-formed or rectangular concavo-convex is formed on the semiconductor film. Continuous-oscillation laser light is irradiated along the striped concavo-convex or along a direction of a longer or shorter axis of rectangle.

Owner:SEMICON ENERGY LAB CO LTD

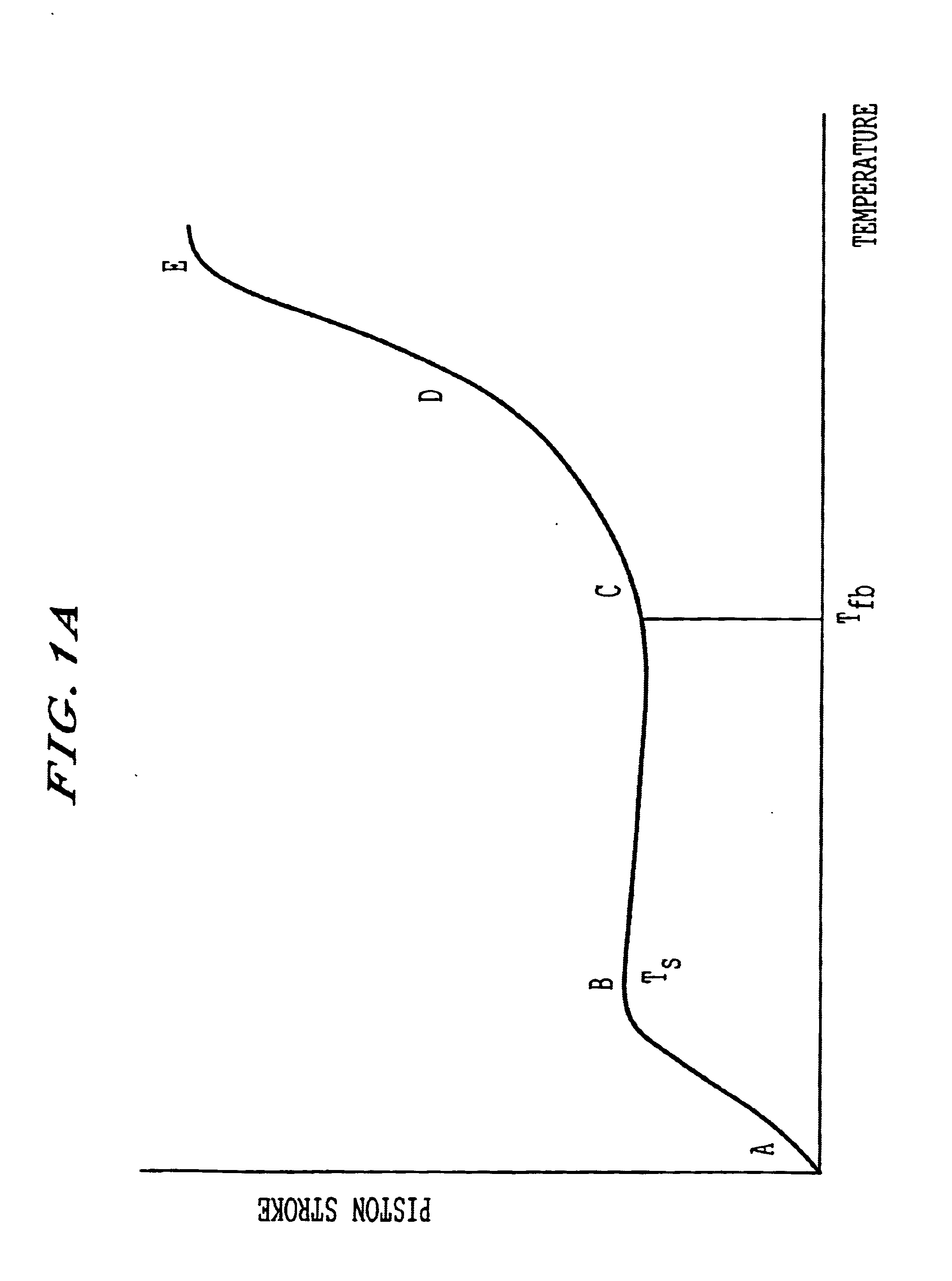

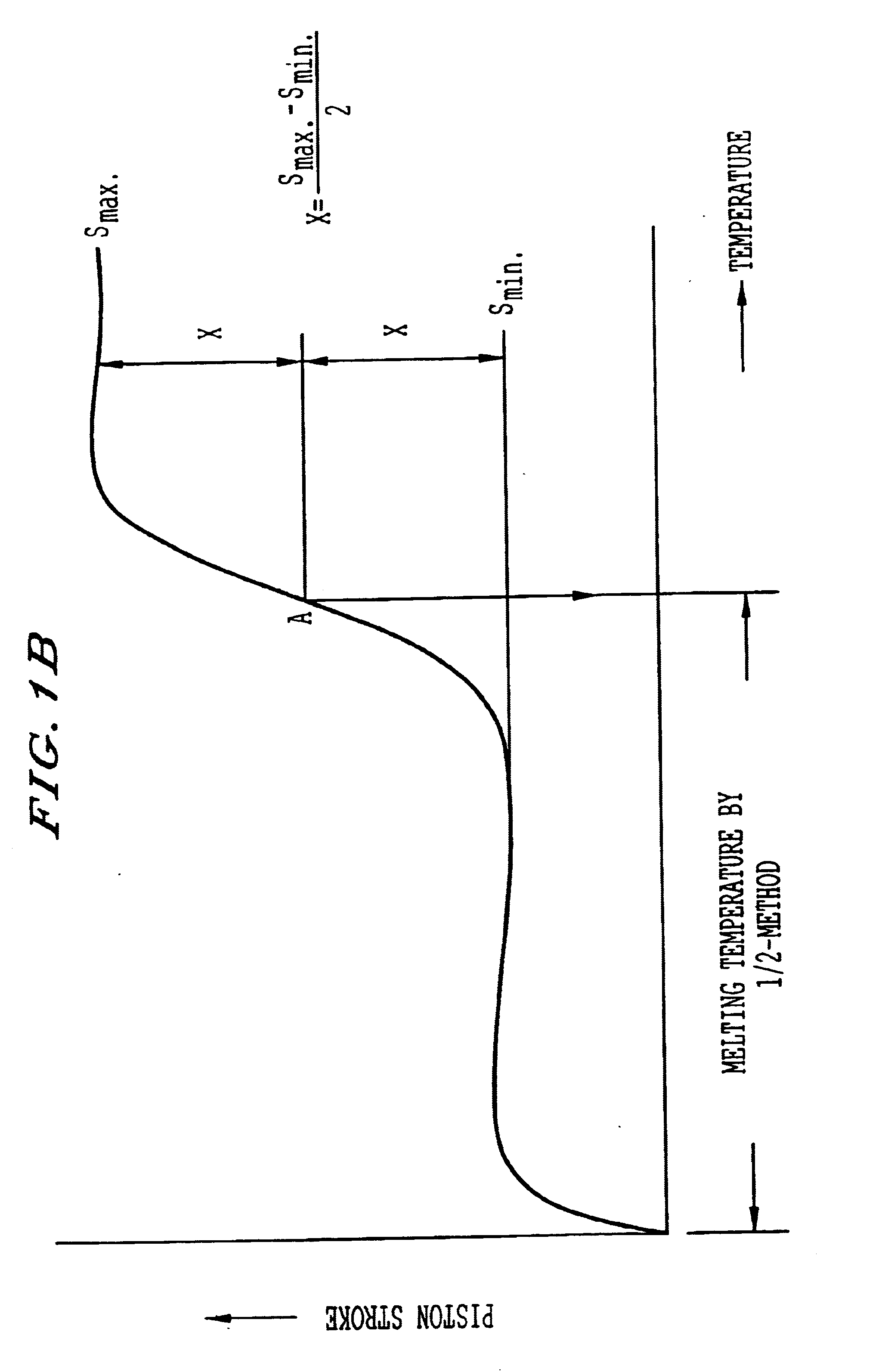

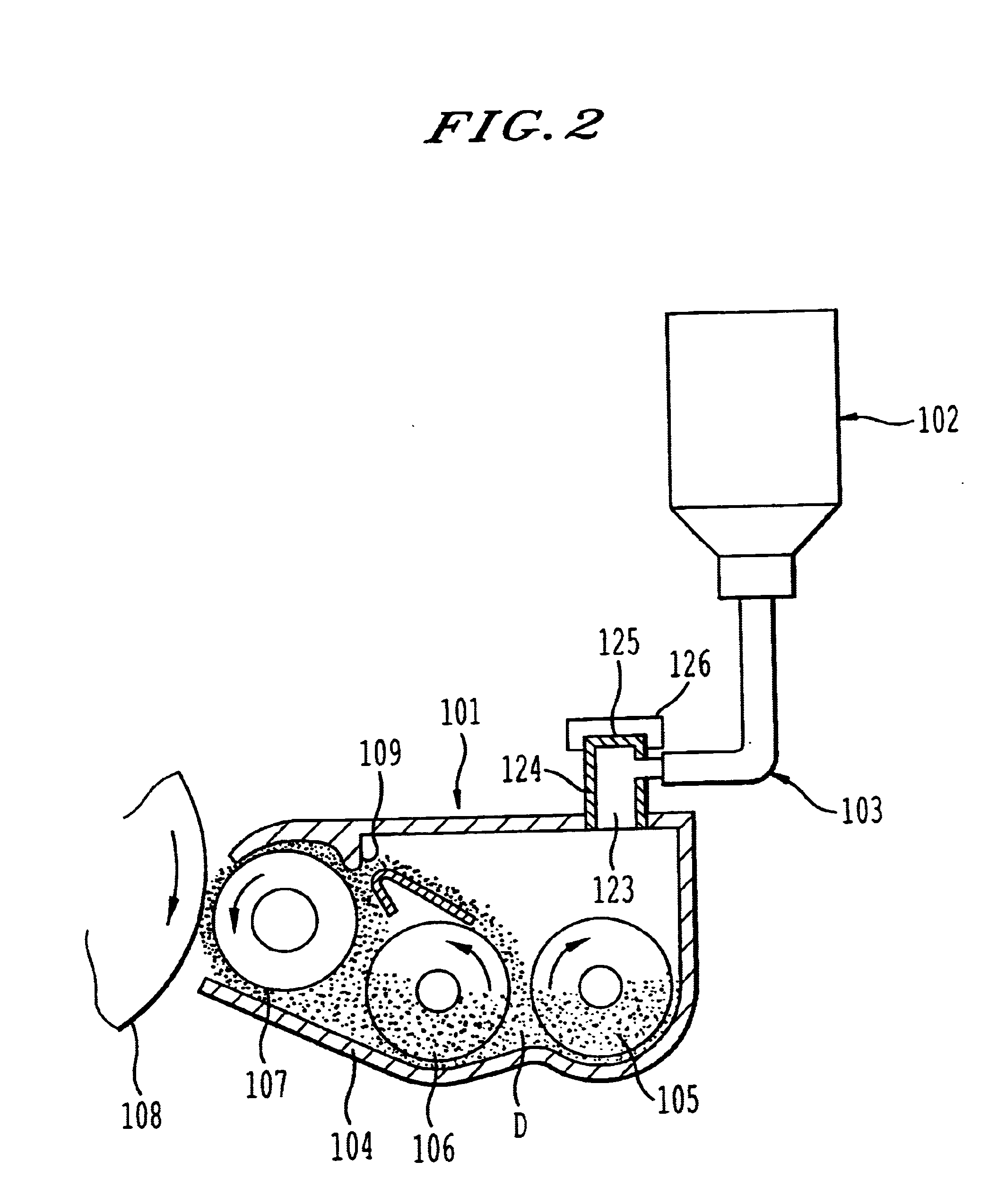

Toner for developing electrostatic latent image, developing method and developing apparatus

A toner, a developing method and apparatus is provided to satisfy both the low temperature fixation property and the hot offset property and that has a wide range of fixing temperature. The toner for an image formation comprises at least metal materials in a binding resin, wherein the toner is measured by a stand-alone type flow tester, and has a softening temperature of 65˜77.5° C., a flow beginning temperature of 100˜120° C., a melt temperature by a ½ method is 145˜195° C., and an average length of a short axis of a primary particle of the metal materials is 0.01˜0.4 μm.

Owner:RICOH KK

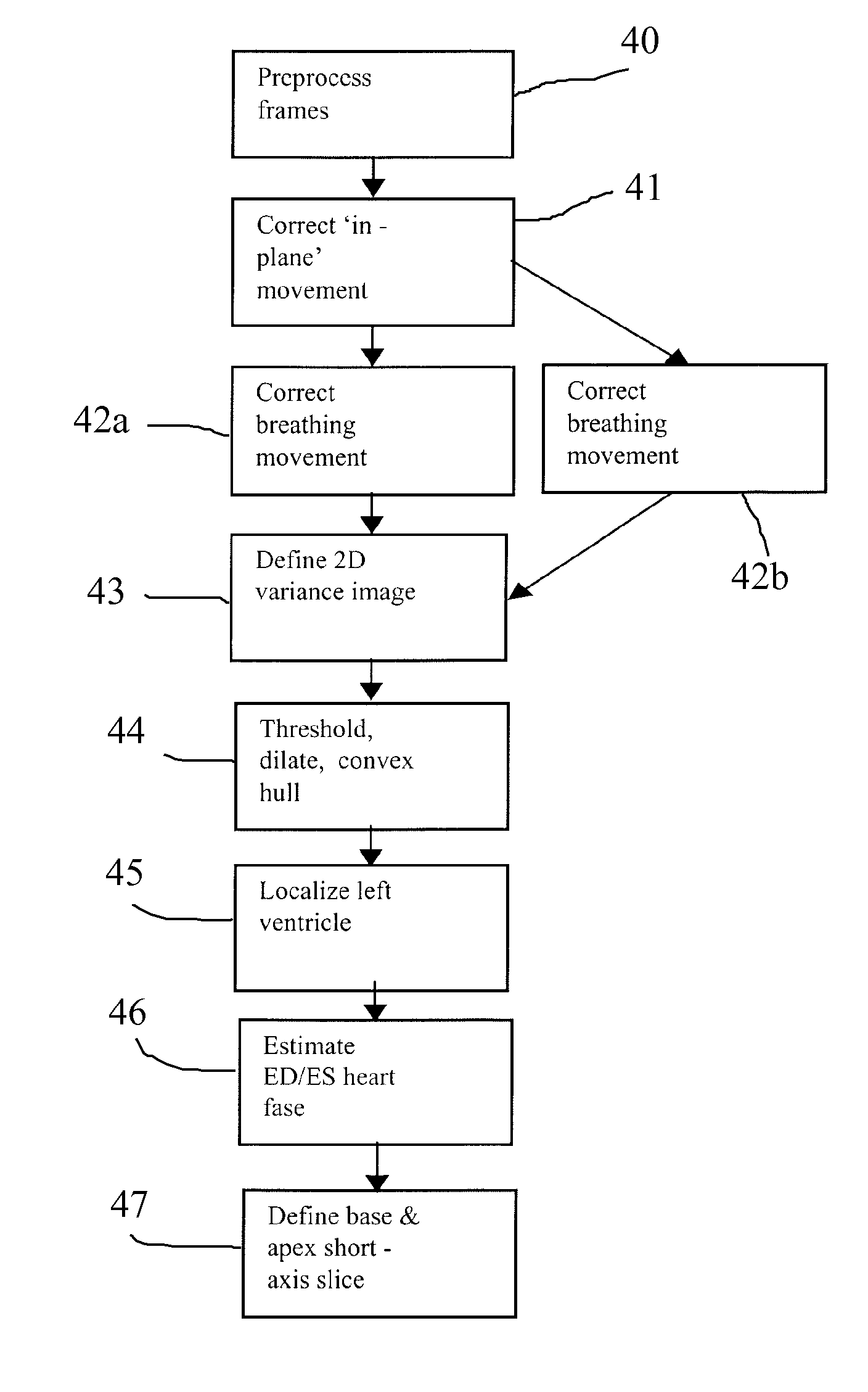

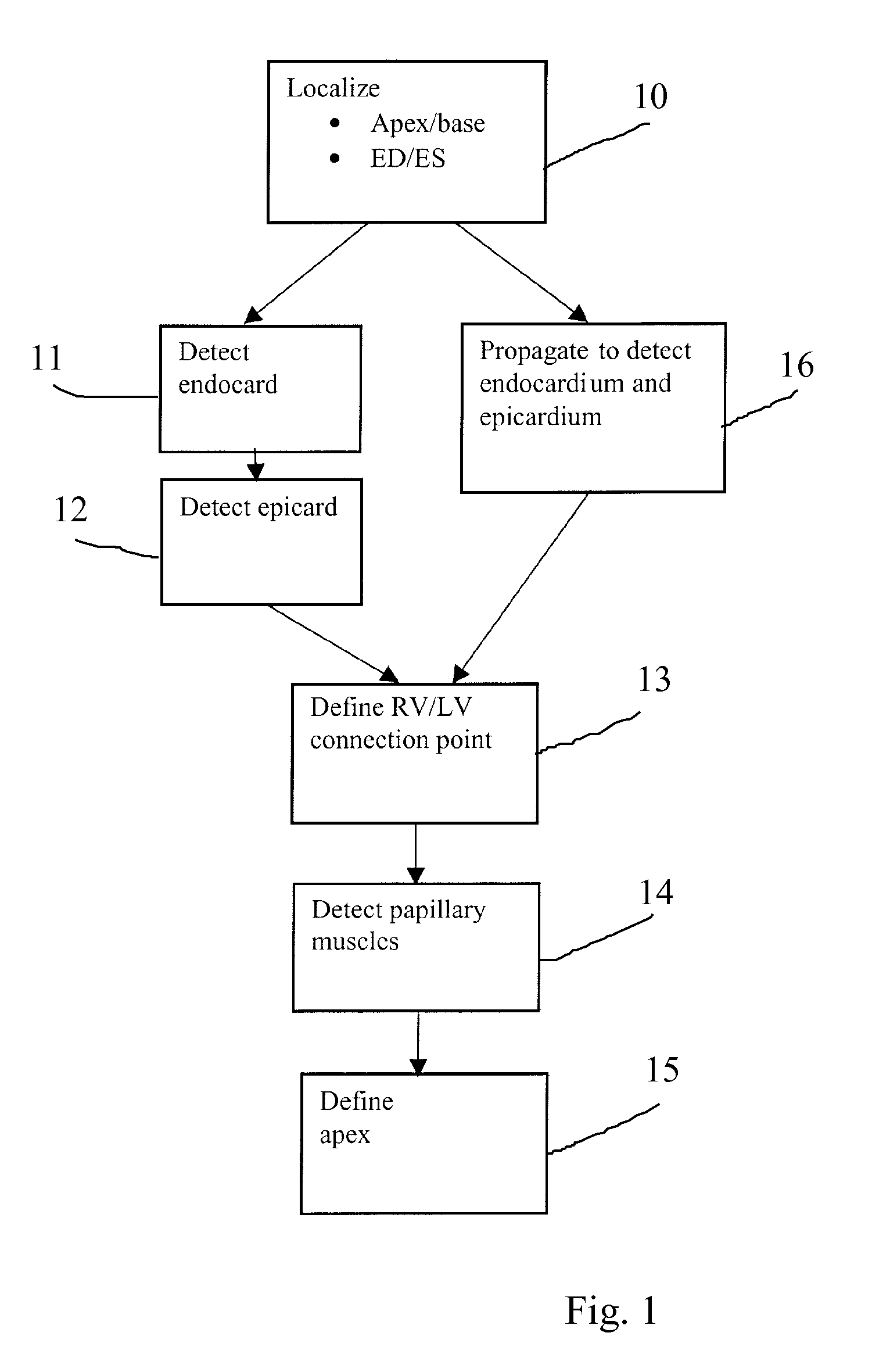

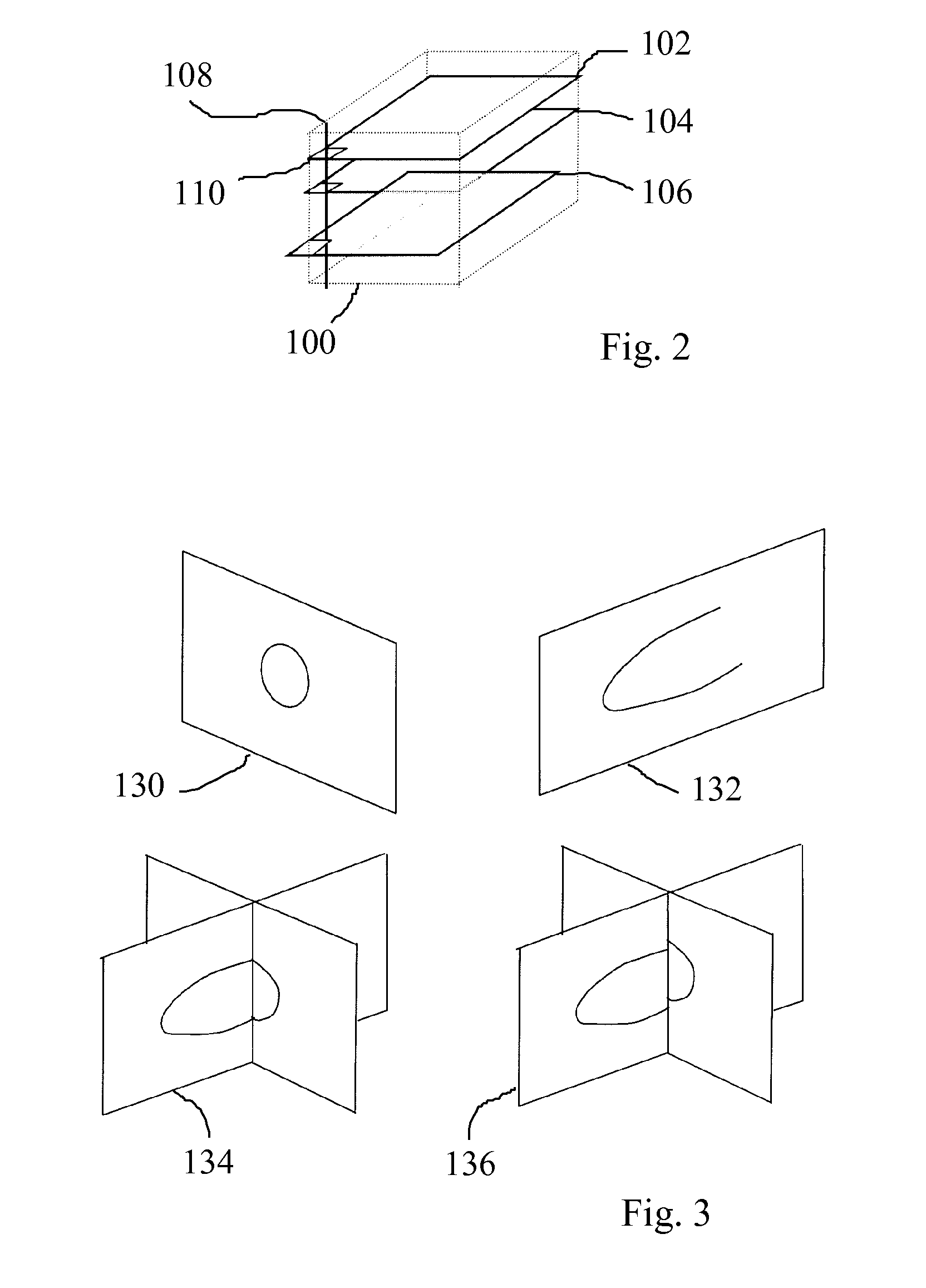

Method, Apparatus and Computer Program Product for Automatic Segmenting of Cardiac Chambers

ActiveUS20070253609A1Improve accuracyGood reproducibilityUltrasonic/sonic/infrasonic diagnosticsImage enhancementData setResonance

A method, apparatus and computer program product for machine-based segmentation of the cardiac chambers in a four-dimensional magnetic resonance image data that contains at least short-axis cine sequences. The segmenting is based on temporal variations in the data set and on features extracted from the image data. In particular, the method and apparatus process the image data to automatically segment an endocard based on fuzzy object extraction and to automatically segment an epicard through finding a radial minimum cost with dynamic sign definition and tissue classification. In addition, image data is preferably preprocessed to eliminate high local image variances and inhomogeneity. The image data is also preferably processed to identify positions of a base slice, an apex slice, an end-diastole, an end-systole and an LVRV connection.

Owner:PIE MEDICAL IMAGING

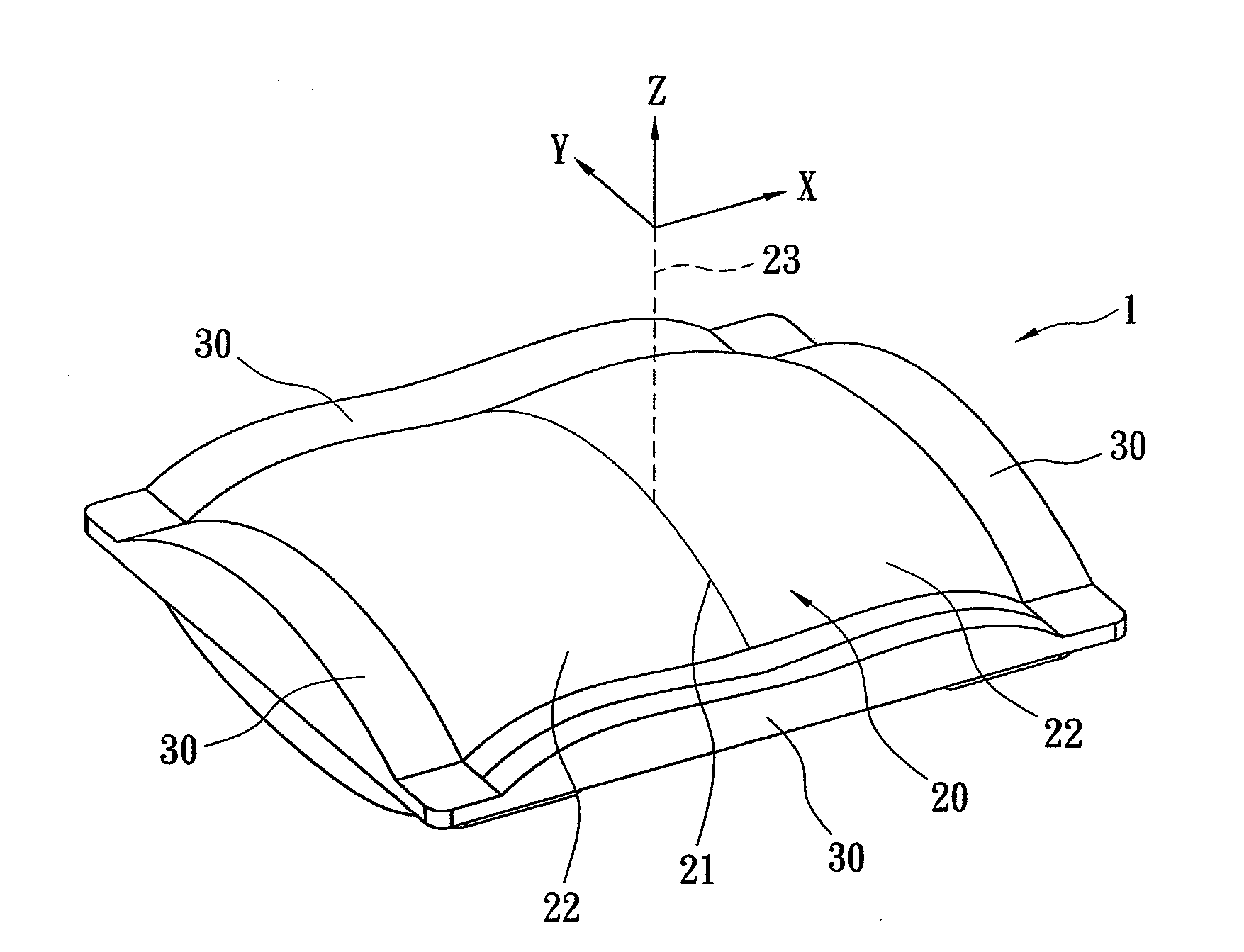

Light distribution lens

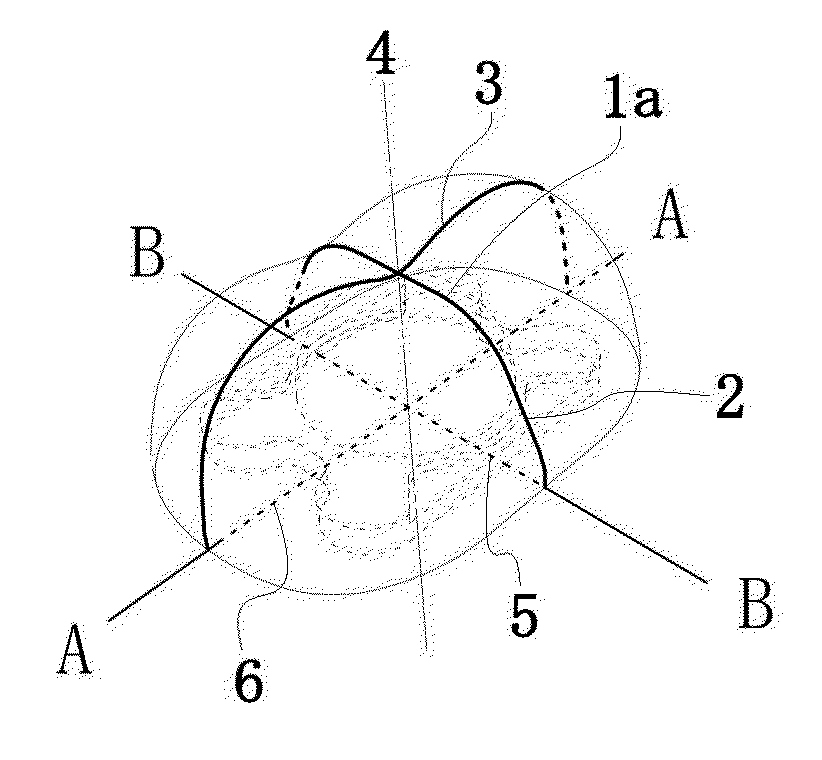

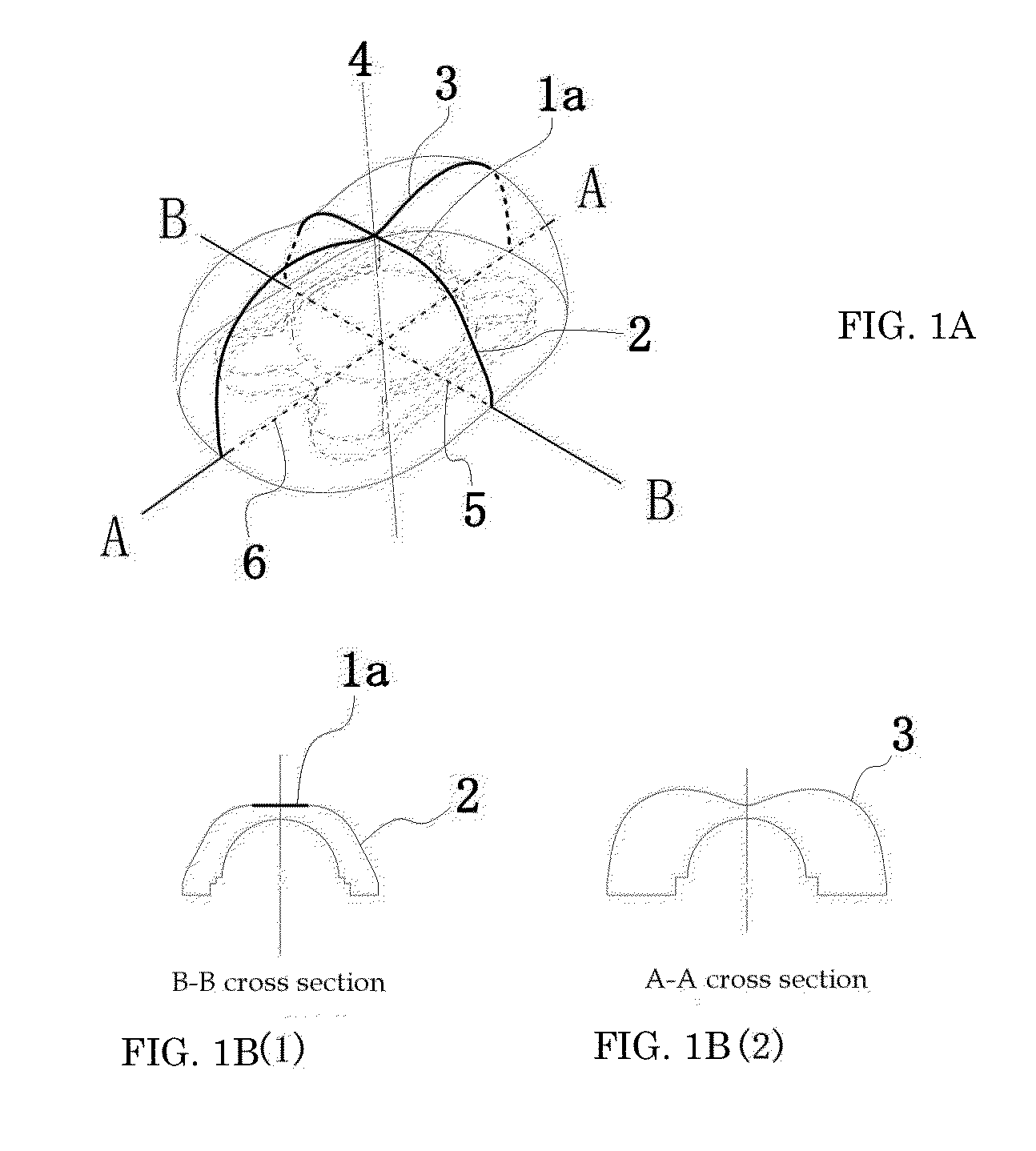

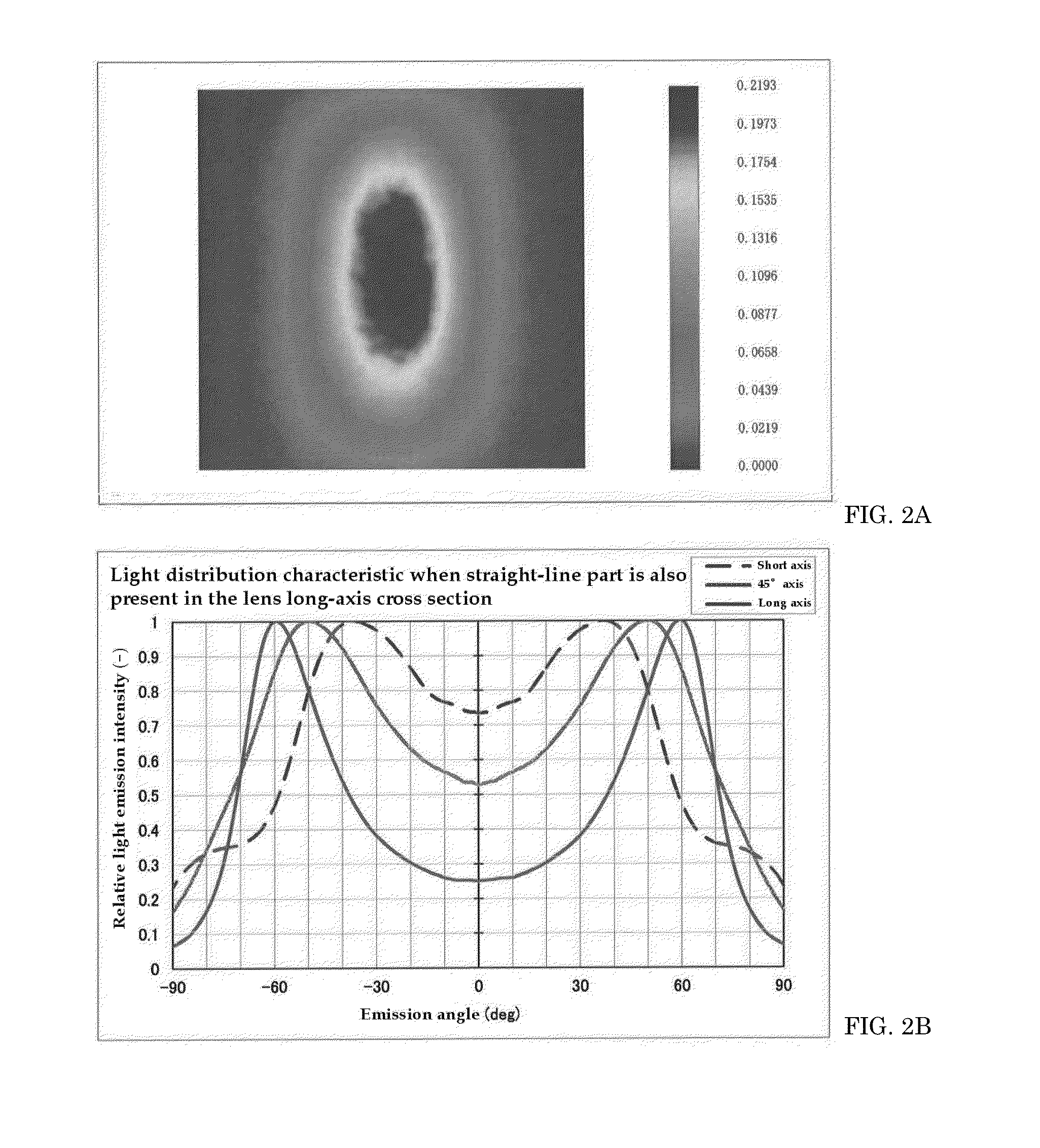

ActiveUS20150276170A1Wide light distributionSmoothly-diffused light distributionPrinted circuit assemblingPoint-like light sourceCamera lensDistribution control

A lens for light emitting lamps that use light emitting elements such as LEDs, etc., is provided. The lens has a specific surface shape for light-distribution control to achieve desired light distributions, as well as a light emitting device using said lens. On the lens surface of the light emitting side which has a double-peak shape to obtain a light distribution characteristic having long and short two axes, by possessing a straight-line part in the surface shape of the light emitting side viewed on the lens short-axis cross section, a desired smoothly-diffused light distribution having a longitudinal direction with a certain width is obtained. The lens may be designed to have a surface of the light emitting side comprising a collection of straight lines parallel to the lens short-axis cross section, or to have a continuous curved surface comprising a collection of straight lines parallel to the lens short axis.

Owner:NICHIA CORP +1

Dual antenna capable of transmitting and receiving circularly polarized electromagnetic wave and linearly polarized electromagnetic wave

InactiveUS6879294B2Improve reliabilityLess susceptibleSimultaneous aerial operationsAntenna supports/mountingsClassical mechanicsBand-pass filter

A direction of a power feed patch relative to a rod-shaped antenna is set so that a short axis thereof substantially orthogonally crosses a plane containing an intersection between the short axis and a long axis of the power feed patch of a patch antenna and an axis of the rod-shaped antenna. As a plane of polarization of a linearly polarized electromagnetic wave radiated from the rod-shaped antenna is thereby caused to substantially coincide with a direction of the long axis of the power feed patch and to substantially orthogonally cross a direction of the short axis, even if a powerful wave of a higher frequency than a desired frequency to be received by the patch antenna and difficult to be removed by a band pass filter of a low-noise amplifier circuit is radiated from the rod-shaped antenna, field components of the high frequency electromagnetic wave in the direction of the short axis will become virtually zero.

Owner:ALPS ALPINE CO LTD

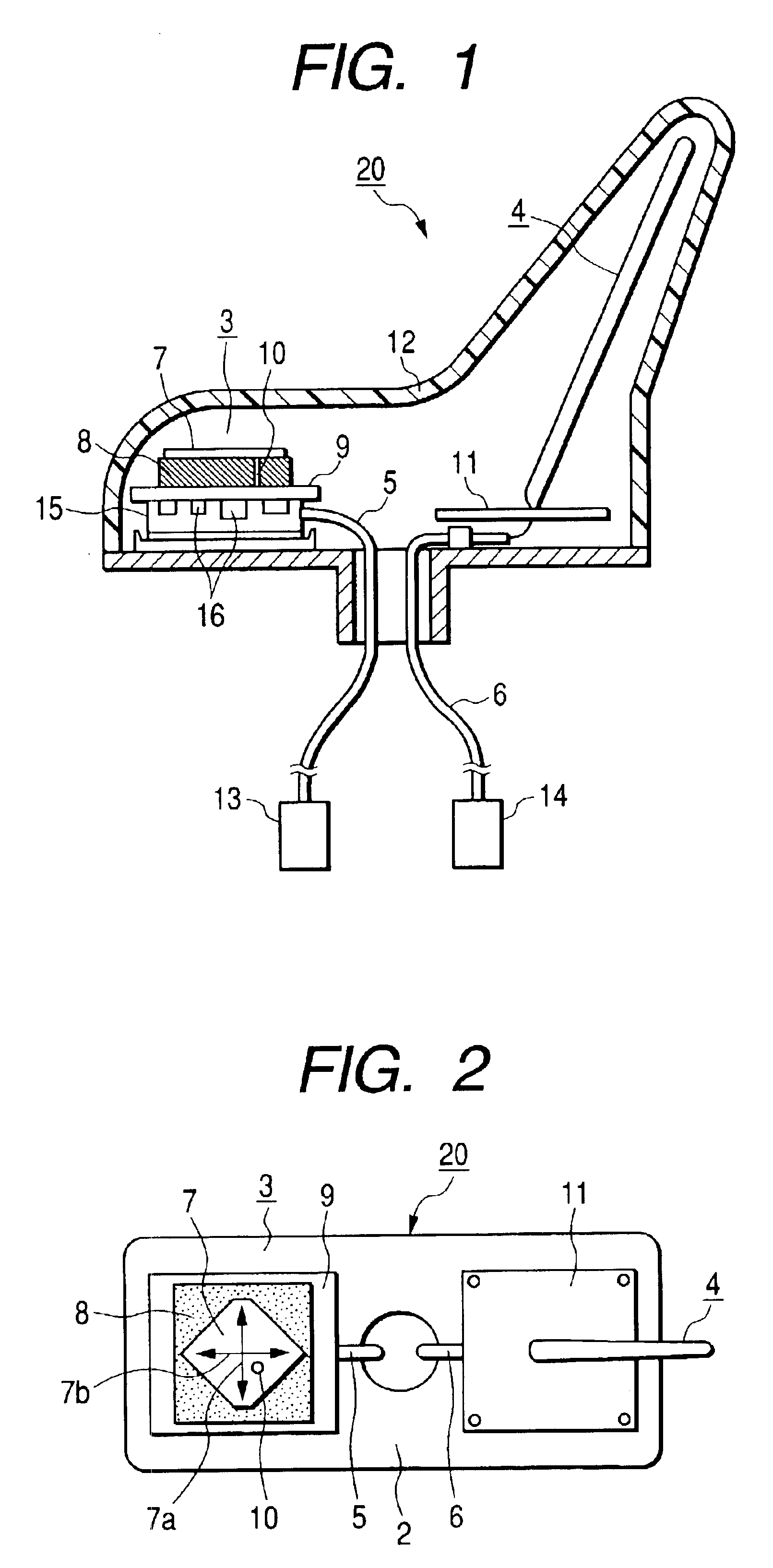

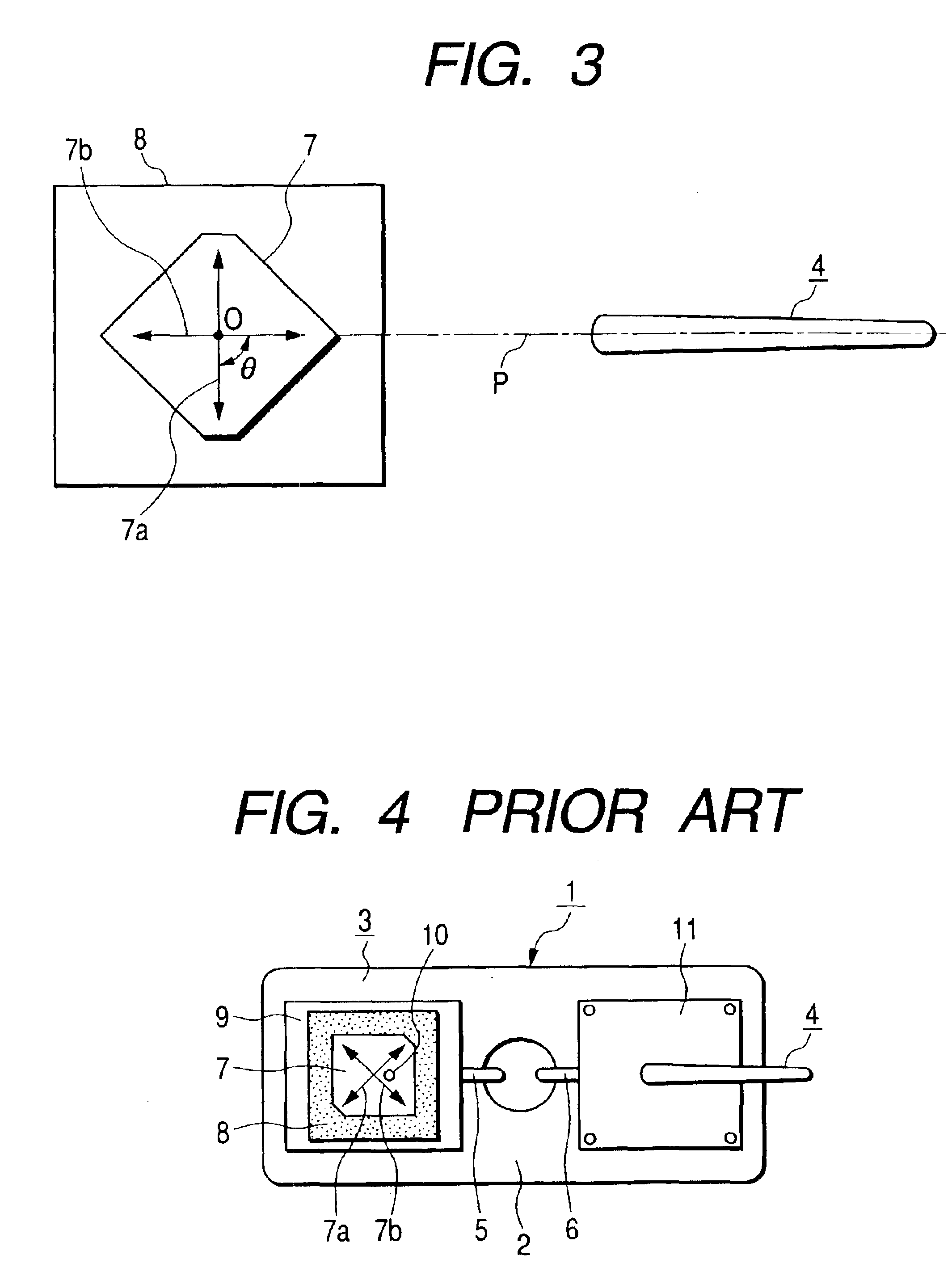

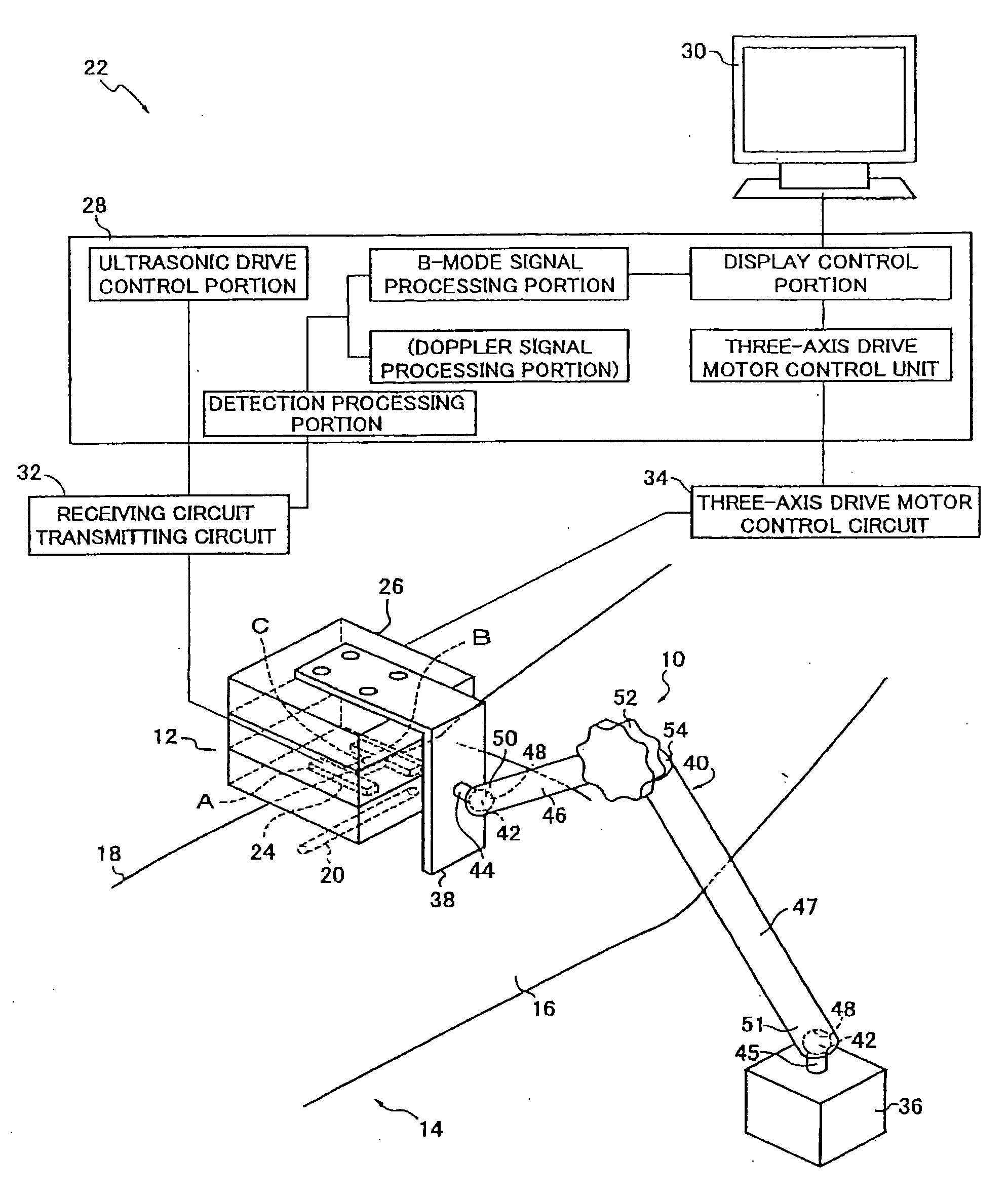

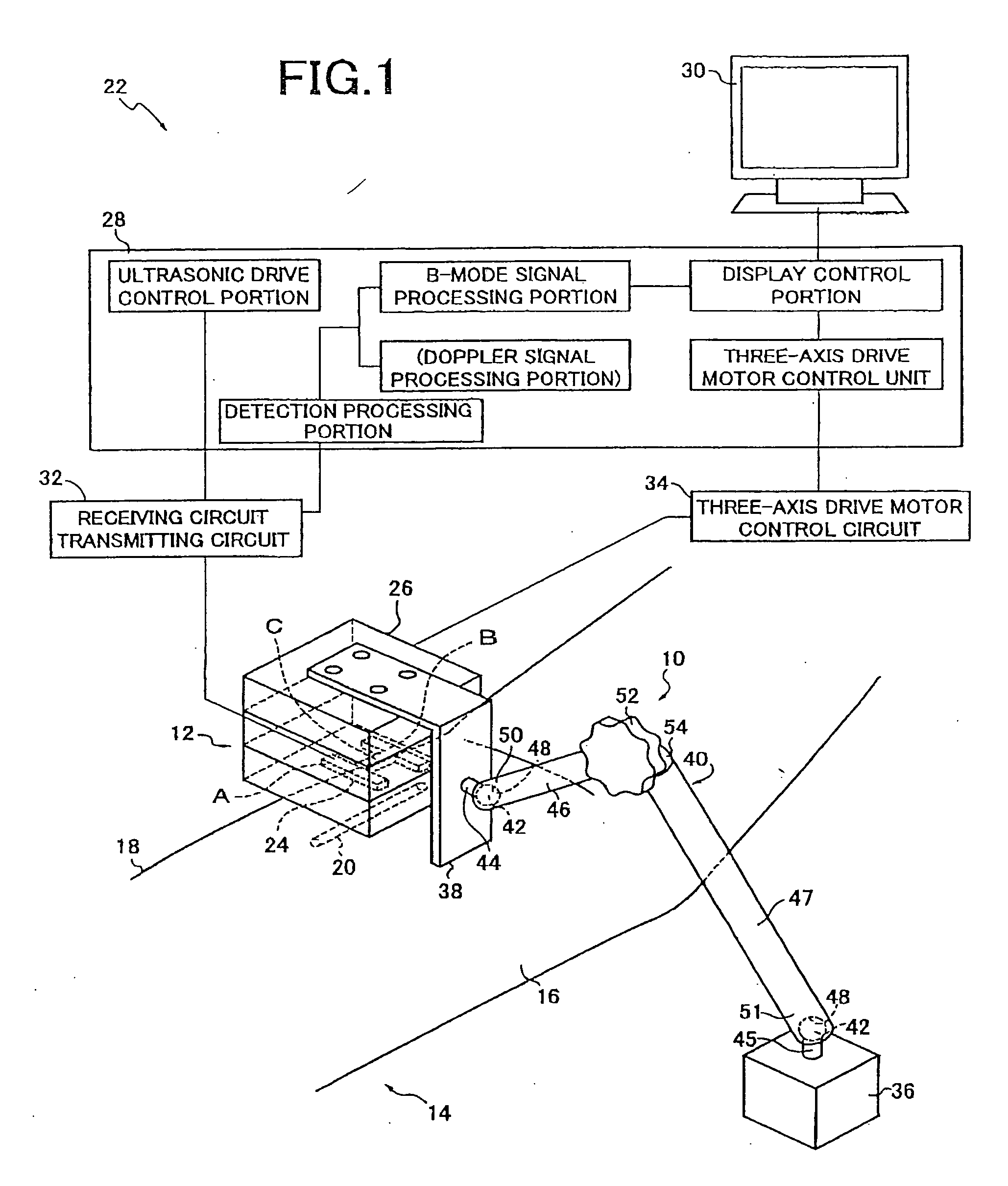

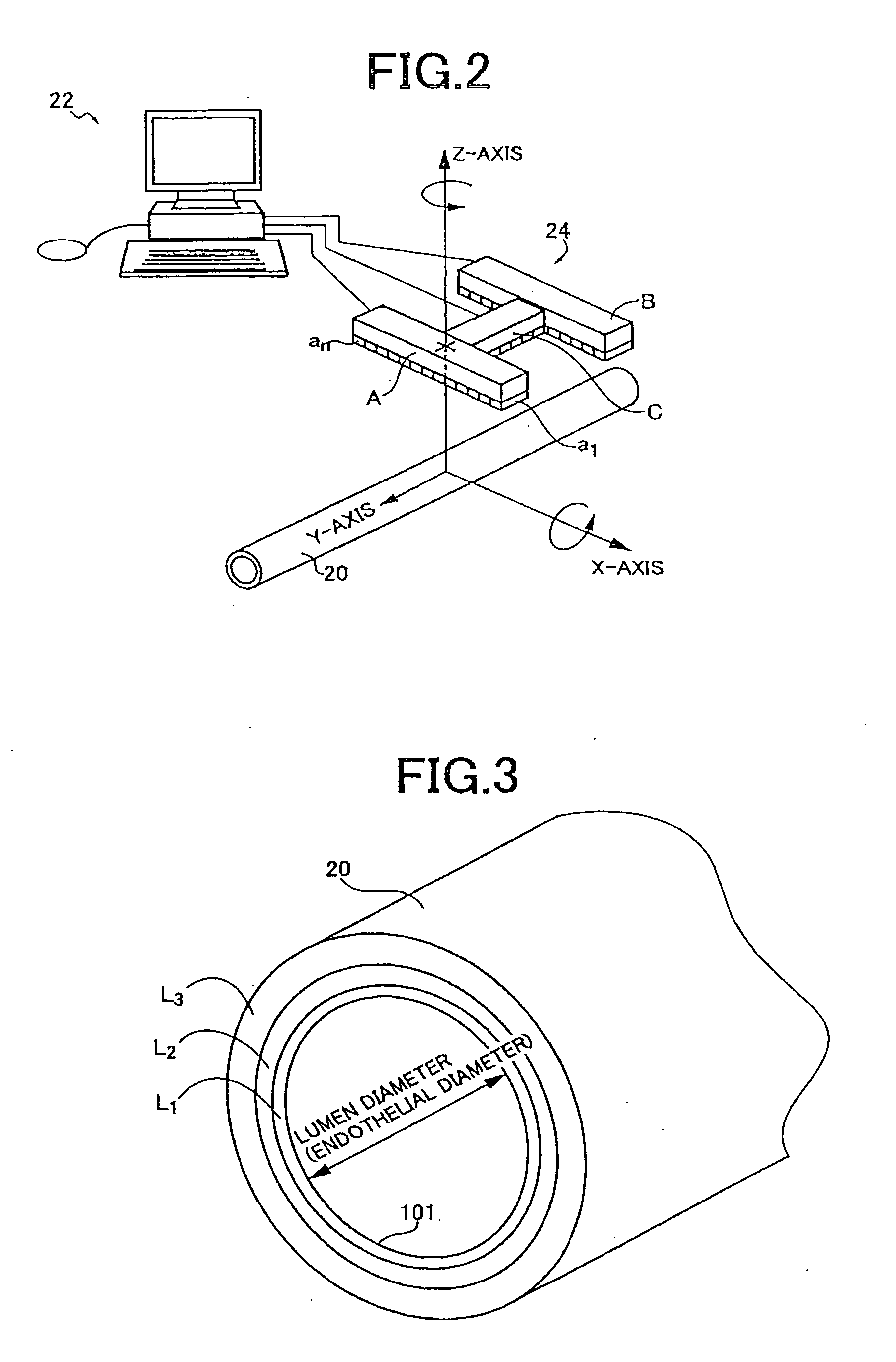

Blood vessel ultrasonic image measuring method

ActiveUS20100210946A1Simply and easily be positionedImprove accuracyUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsThree vesselsLiving body

A blood vessel ultrasonic image measuring method capable of facilitating the positioning of an ultrasonic probe and acquiring sufficient positioning accuracy is provided. Because of inclusion of an around-X-axis positioning step of causing a multiaxis driving device 26 to position an ultrasonic probe such that distances from respective ultrasonic array probes to the center of a blood vessel are equalized, and an X-axis direction positioning step and an around-Z-axis positioning step of causing the multiaxis driving device to position the ultrasonic probe such that the image of the blood vessel is positioned at the center portion in the width direction of the first short axis image display area G1 and the second short axis image display area G2, the positioning may be performed by using the positions in the longitudinal direction of the ultrasonic array probes relative to the blood vessel or the distances of the ultrasonic array probes to the blood vessel and, therefore, the ultrasonic probe may simply and easily be positioned on the blood vessel of a living body with higher accuracy.

Owner:UNAX CORP

LED optical lens and illumination device thereof

A LED optical lens and an illumination device thereof are revealed. The optical lens includes a light-source side surface and an image side surface of the LED optical lens that both are designed respectively according to mathematical expressions of freeform surfaces such as Anamorphic formula and Toric formula Thus the optical lens has different curvatures along different axes. After light from LED emitting into the optical lens at a fixed incident angle, emergent light with different divergence angles along different axes is generated. For example, the divergence angle along the long axis is larger than that along the short axis. Therefore a uniform and near rectangular distribution pattern is formed on the target area Moreover, a plurality of optical lenses aligned along the same axes is arranged at a holder to form a lens array. The lens array is used together with a LED array so as to form a LED illumination device.

Owner:CREATE ELECTRONICS OPTICAL

Marine acoustic vibrator having enhanced low-frequency amplitude

InactiveUS8446798B2Seismic energy generationSound producing devicesVibration amplitudeSeismic survey

Owner:PGS GEOPHYSICAL AS

Semiconductor device and semiconductor device production system

InactiveUS20050161742A1Improve barrier propertiesImprove stressTransistorSolid-state devicesStress concentrationDevice material

It is a problem to provide a semiconductor device production system using a laser crystallization method capable of preventing grain boundaries from forming in a TFT channel region and further preventing conspicuous lowering in TFT mobility due to grain boundaries, on-current decrease or off-current increase. An insulation film is formed on a substrate, and a semiconductor film is formed on the insulation film. Due to this, preferentially formed is a region in the semiconductor film to be concentratedly applied by stress during crystallization with laser light. Specifically, a stripe-formed or rectangular concavo-convex is formed on the semiconductor film. Continuous-oscillation laser light is irradiated along the striped concavo-convex or along a direction of a longer or shorter axis of rectangle.

Owner:SEMICON ENERGY LAB CO LTD

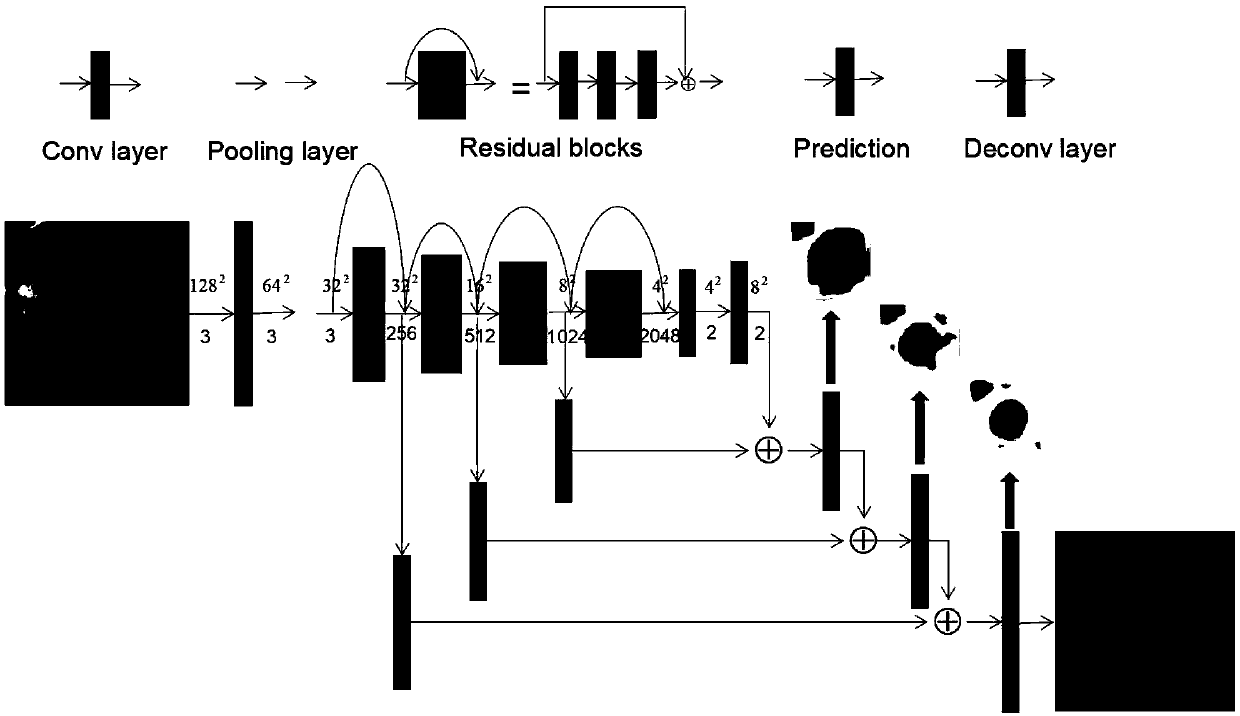

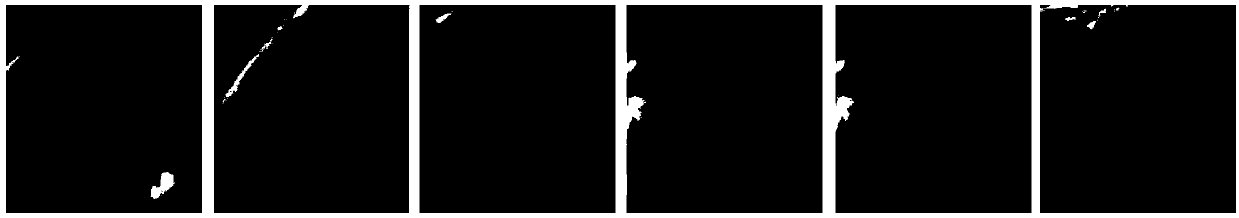

A heart left ventricle segmentation method based on a deep full convolutional neural network

ActiveCN109584254AHigh precisionImprove robustnessImage enhancementImage analysisAlgorithmImage segmentation algorithm

The invention discloses a heart left ventricle segmentation method based on a deep full convolutional neural network. According to the method, a deep learning idea is introduced into heart magnetic resonance short-axis image left ventricle segmentation; The process is mainly divided into a training stage and a prediction stage, in the training stage, a preprocessed 128 * 128 heart magnetic resonance image serves as input, a manually processed label serves as a label of a network to be used for calculating errors, and along with increase of training iteration times, the error of a training setand the error of a verification set are gradually reduced; And in the test stage, inputting data in the test set into the trained model, and finally outputting prediction of each pixel by the networkto generate a segmentation result. According to the method, segmentation of the heart magnetic resonance short-axis image is achieved from the perspective of data driving, the problem that manual outline drawing is time-consuming and labor-consuming is effectively solved, the defects of a traditional image segmentation algorithm can be overcome, and high-precision and high-robustness left ventricle segmentation is achieved.

Owner:ZHEJIANG UNIV

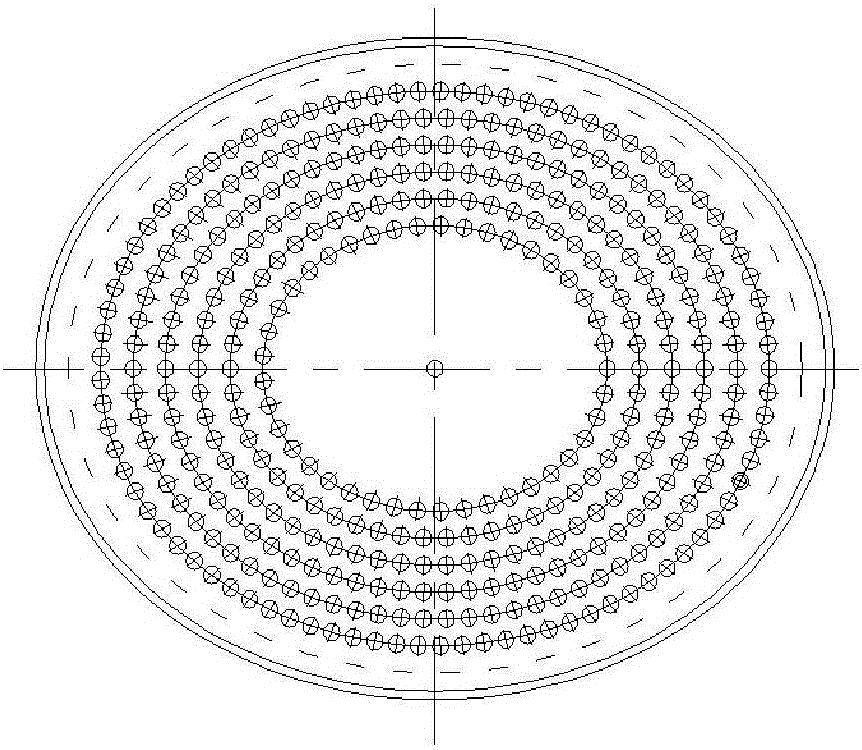

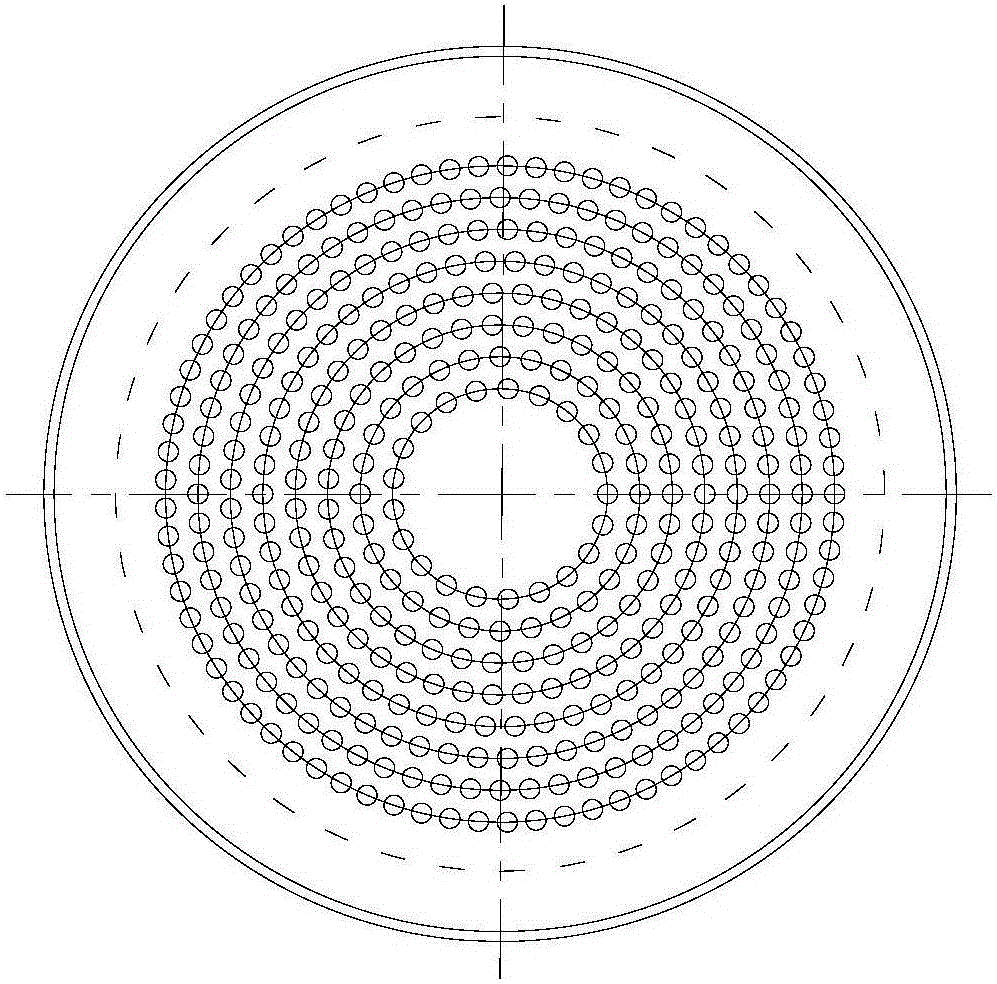

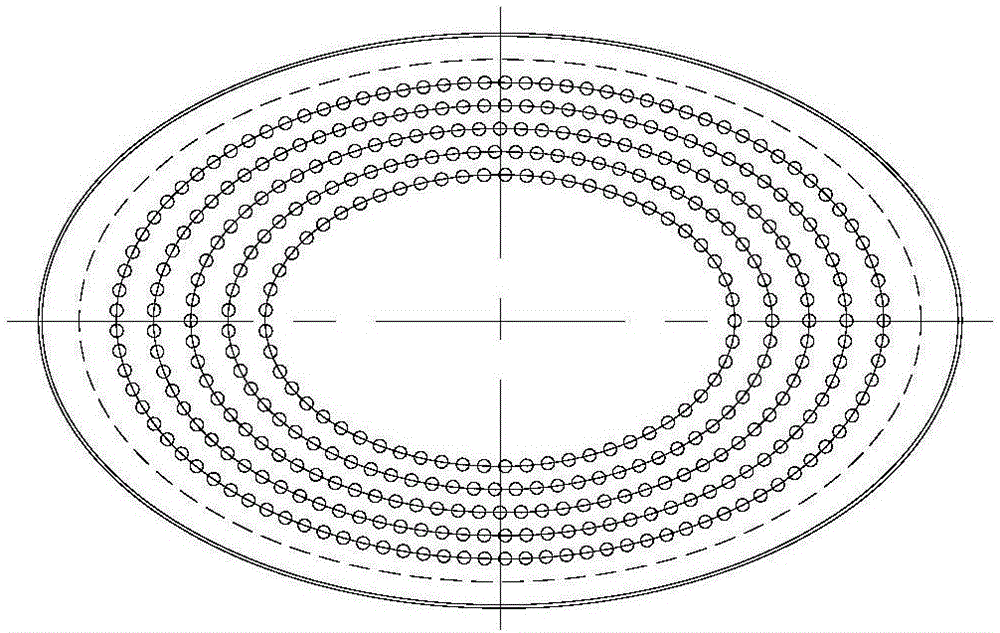

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

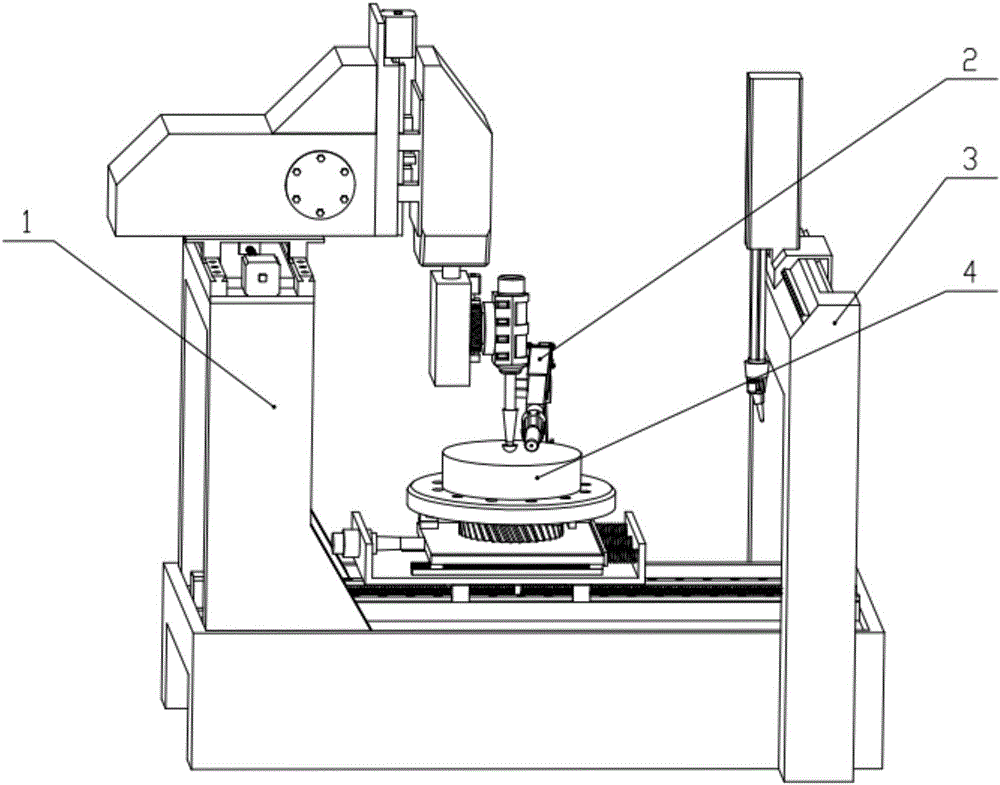

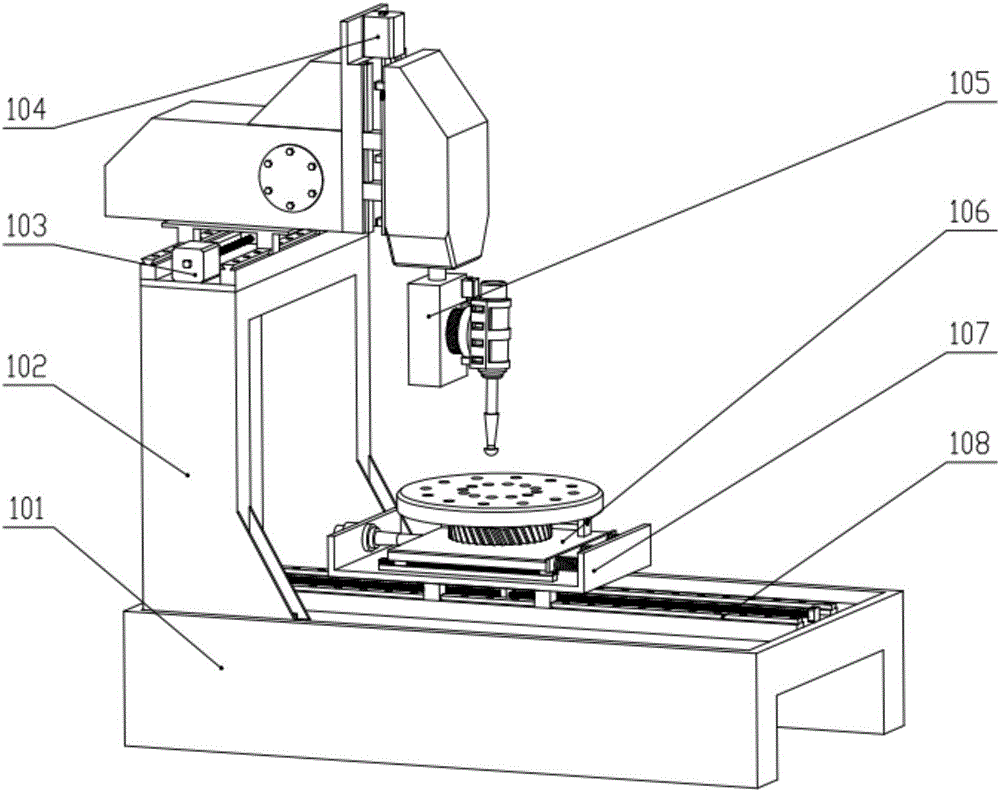

Five-axis three-dimensional ultrasonic polishing machine tool for optical curved surface machining and use method of five-axis three-dimensional ultrasonic polishing machine tool

ActiveCN106736992AGood removal effectImprove efficiencyGrinding carriagesOptical surface grinding machinesUltrasonic vibrationEngineering

The invention discloses a five-axis three-dimensional ultrasonic polishing machine tool for optical curved surface machining. The five-axis three-dimensional ultrasonic polishing machine tool comprises a machine tool, an ultrasonic atomization device for applying polishing liquid and a workpiece on-line detection device. An X-direction travel mechanism, a Z-direction travel mechanism and a Y-direction travel mechanism are arranged on the machine tool; a spindle ultrasonic vibration polishing device is arranged on the Z-direction travel mechanism; a Y-direction ultrasonic vibration device is arranged on the Y-direction travel mechanism; a C-direction rotating work table is arranged on the Y-direction ultrasonic vibration device; the machine tool can enable the axis line direction of a polishing head parallel to the normal line of a polishing point of a workpiece through five-axis linkage; when the polishing head rotates, the ultrasonic wave of the Y-direction ultrasonic vibration device and the ultrasonic wave of the ultrasonic vibration polishing device which swings around the Z direction are vertically coupled in a plane; when the amplitude A1 of the Y-direction ultrasonic vibration device is greater than the amplitude A2 of the ultrasonic vibration polishing device, the polishing head and the workpiece can form an elliptic machining track where a long axis is in the Y-direction and a short axis is in the normal line position of the polishing point of the workpiece, so that the contact area between the polishing head and the workpiece is increased, and the curved surface removal rate and the polishing machining efficiency can be greatly improved.

Owner:NORTHEASTERN UNIV

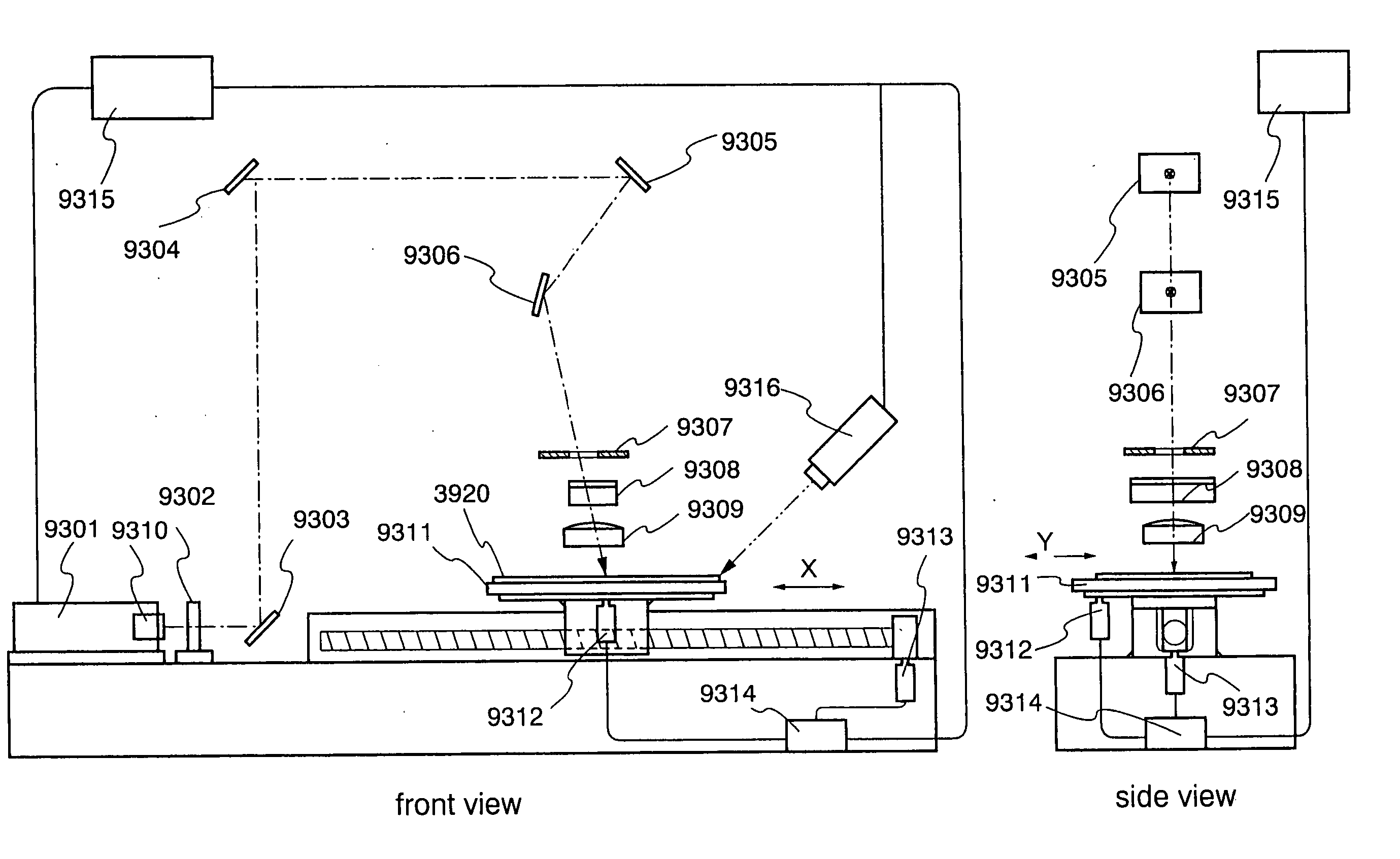

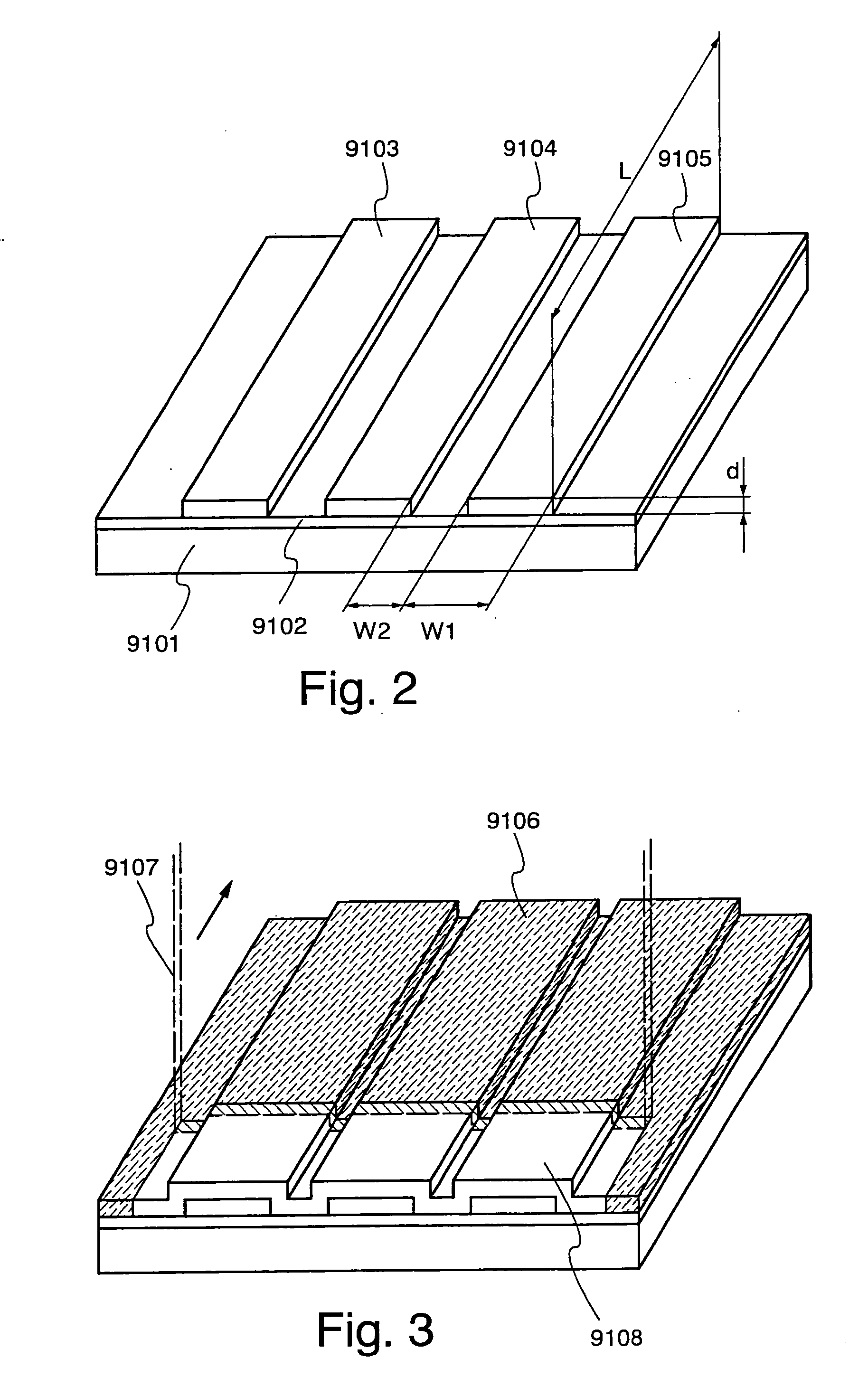

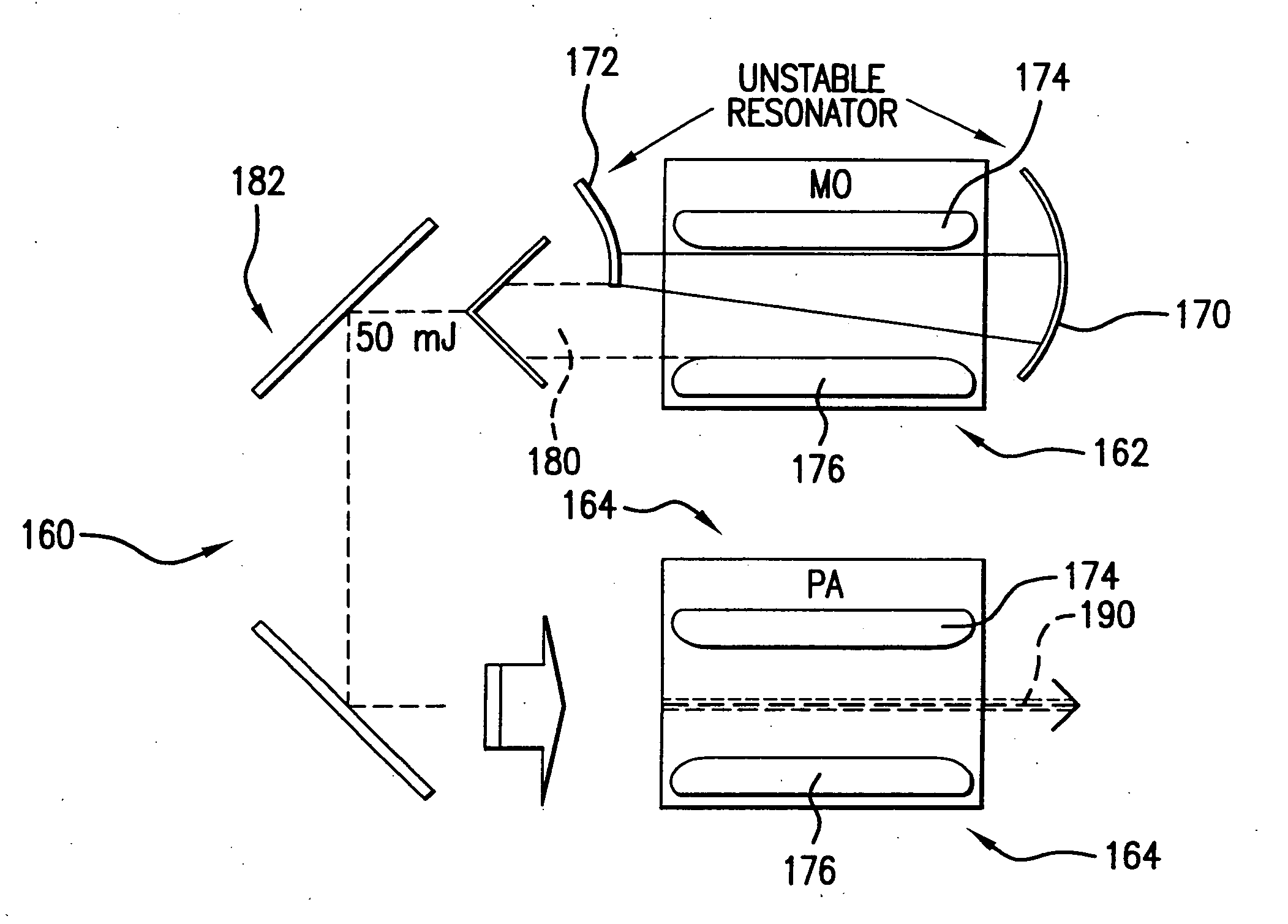

Laser thin film poly-silicon annealing optical system

A high energy, high repetition rate workpiece surface heating method and apparatus are disclosed which may comprise a pulsed XeF laser operating at or above 4000 Hz and producing a laser output light pulse beam at a center wavelength of about 351 nm; an optical system narrowing the laser output light pulse beam to less than 20 μm in a short axis of the laser output light pulse beam and expanding the laser output light pulse beam to form in a long axis of the beam a workpiece covering extent of the long axis; the optical system including a field stop intermediate the laser and the workpiece; the workpiece comprising a layer to be heated; wherein the optical system focuses the laser output light pulse beam at a field stop with a magnification sufficient to maintain an intensity profile that has sufficiently steep sidewalls to allow the field stop to maintain a sufficiently steep beam profile at the workpiece without blocking the beam profile at too high an intensity level. 2. The apparatus may also have a high average power in the laser output light pulse beam as delivered to the workpiece and a a line bow correction mechanism in a short axis optical assembly. The line bow correction mechanism may comprise a plurality of weak cross cylinders. The system may comprise a catadioptric projection system. The linewidth due to laser diffraction and divergence may be less than geometric limitations. The system may project adjacent peaks of the nominal XeF spectrum to improve overall depth of focus through the separate center wavelengths of each respective adjacent peak having a different focal plane at the workpiece. The system may comprise a line bow is correction mechanism within a field stop optical assembly correcting line bow at the field stop plane and within a workpiece projection optical assembly correcting line bow at the workpiece plane.

Owner:CYMER INC

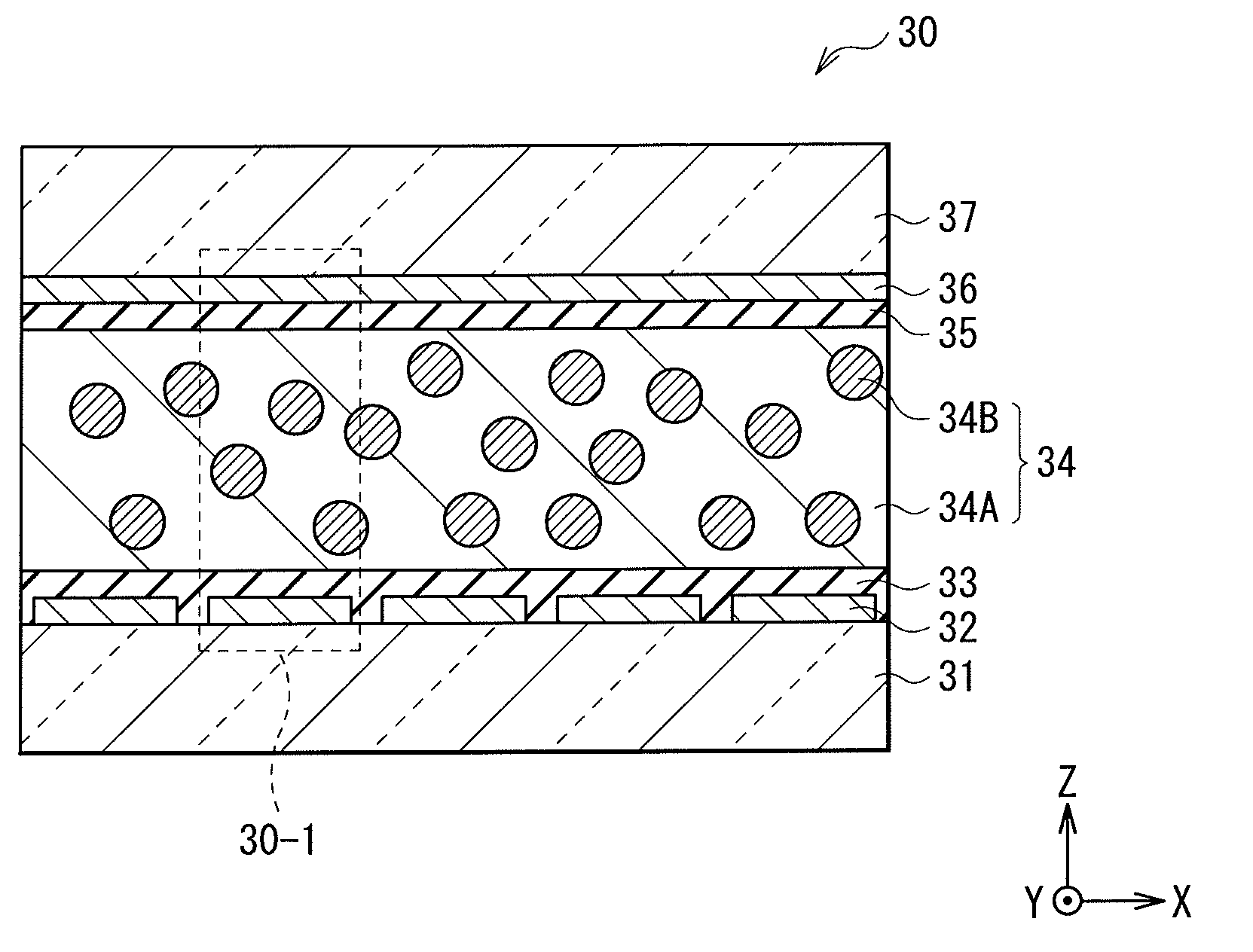

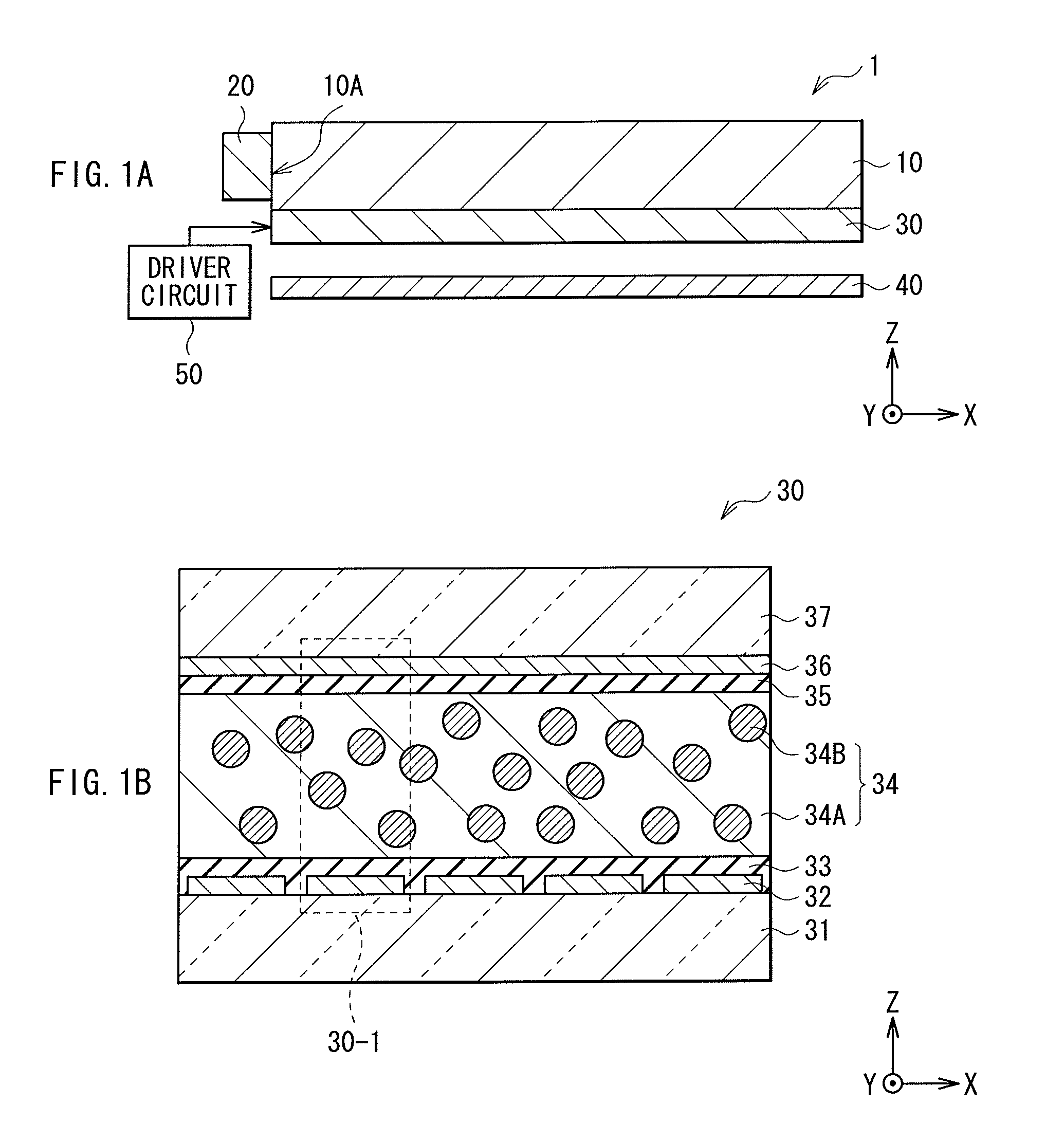

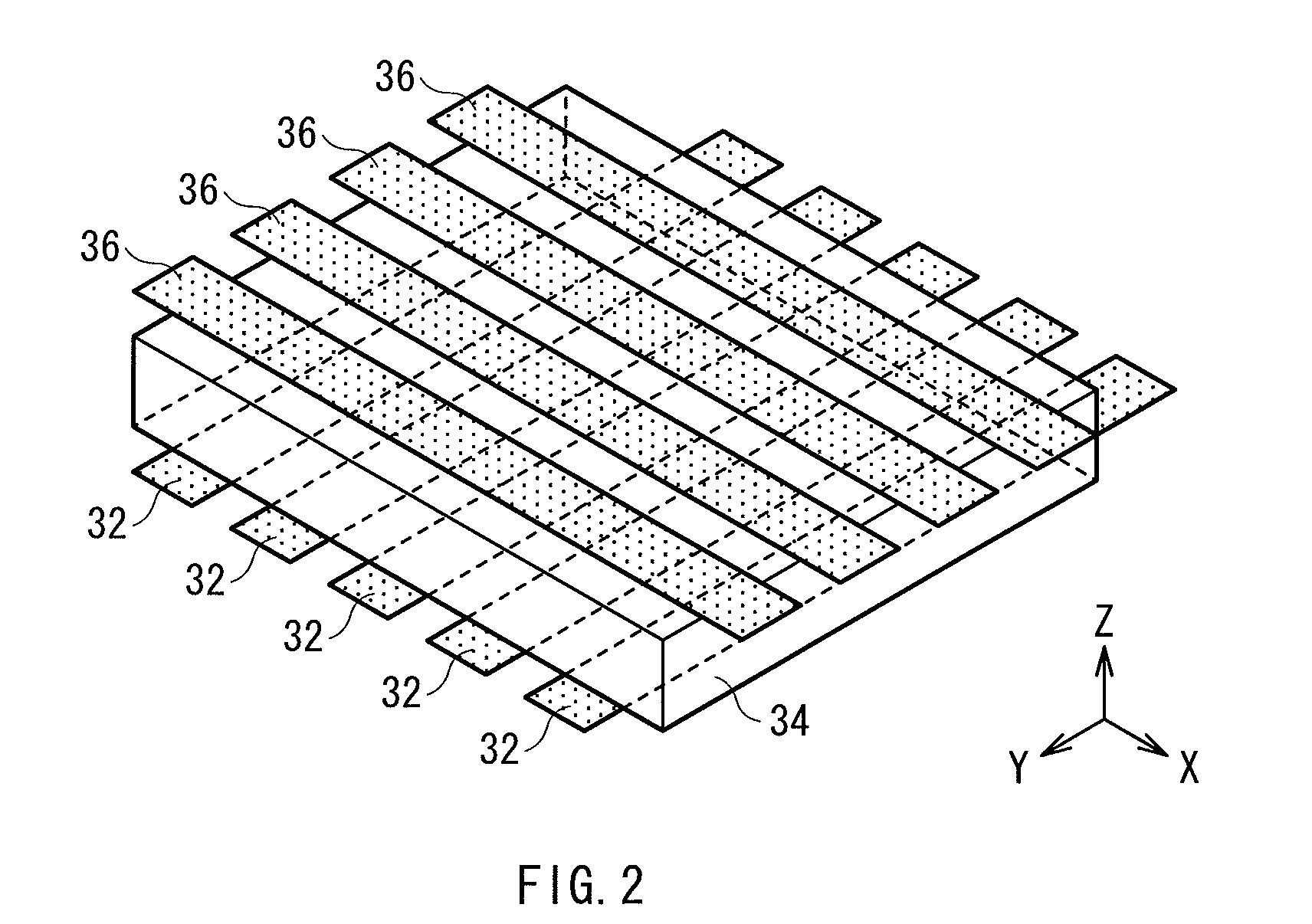

Lighting device and display device

ActiveUS20110249221A1Reduce variationIncrease distanceMechanical apparatusPlanar/plate-like light guidesLight guideEffect light

A lighting device includes: a light guide plate; a light source disposed on a side face of the light guide plate; and a light modulation element disposed on a surface or in the inside of the light guide plate and adhered to the light guide plate. The light modulation element has a pair of transparent substrates disposed separately and oppositely, a pair of electrodes provided on respective surfaces of the pair of transparent substrates, and a light modulation layer provided in a gap between the pair of transparent substrates. The light modulation layer includes a first region, having optical anisotropy, responsive to an electric field, and a second region, having optical anisotropy, unresponsive to an electric field. The second region has a striped structure with average striped texture size of 0.05 μm to 10 μm both inclusive in a short axis direction.

Owner:SONY CORP +1

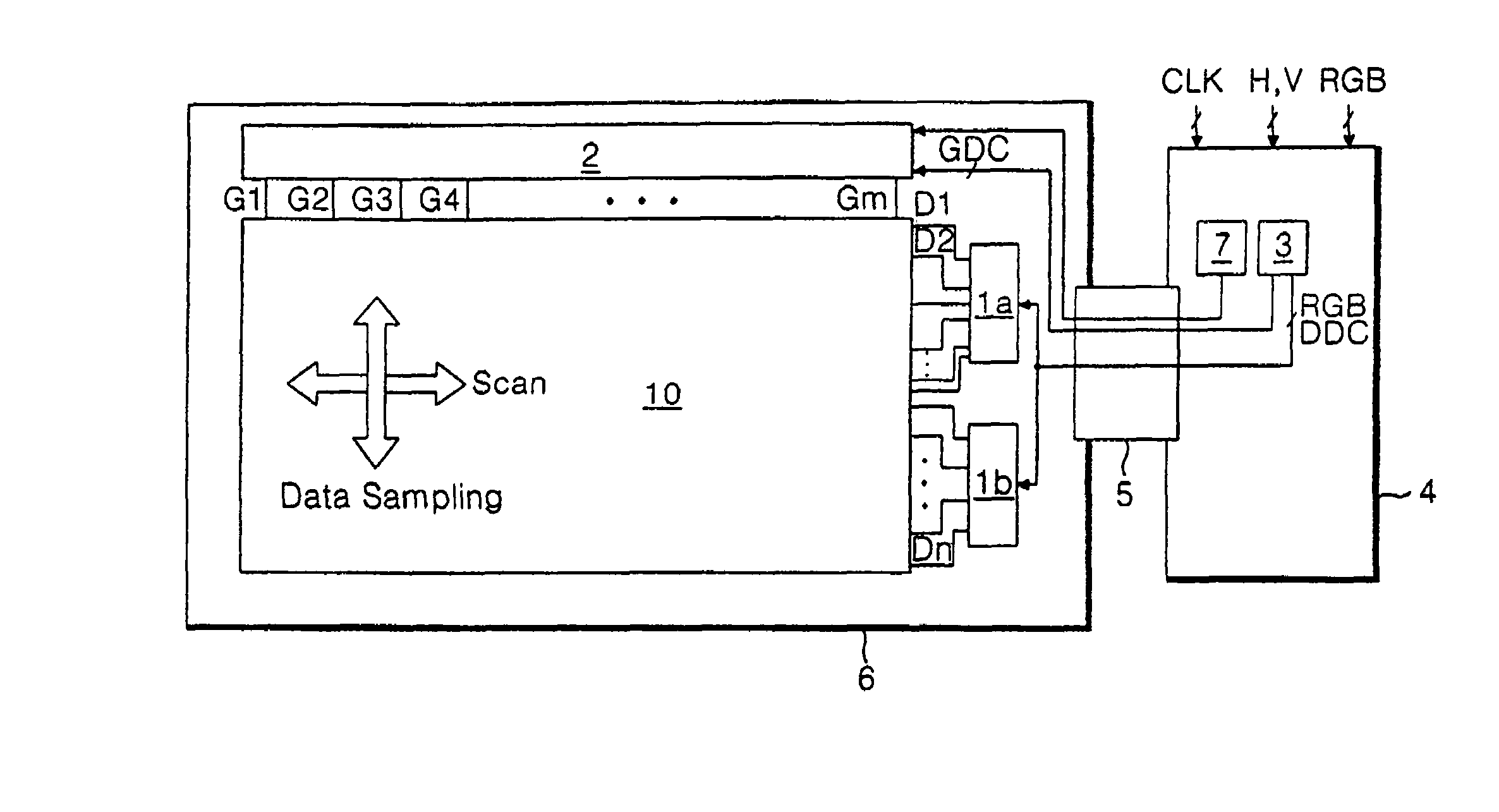

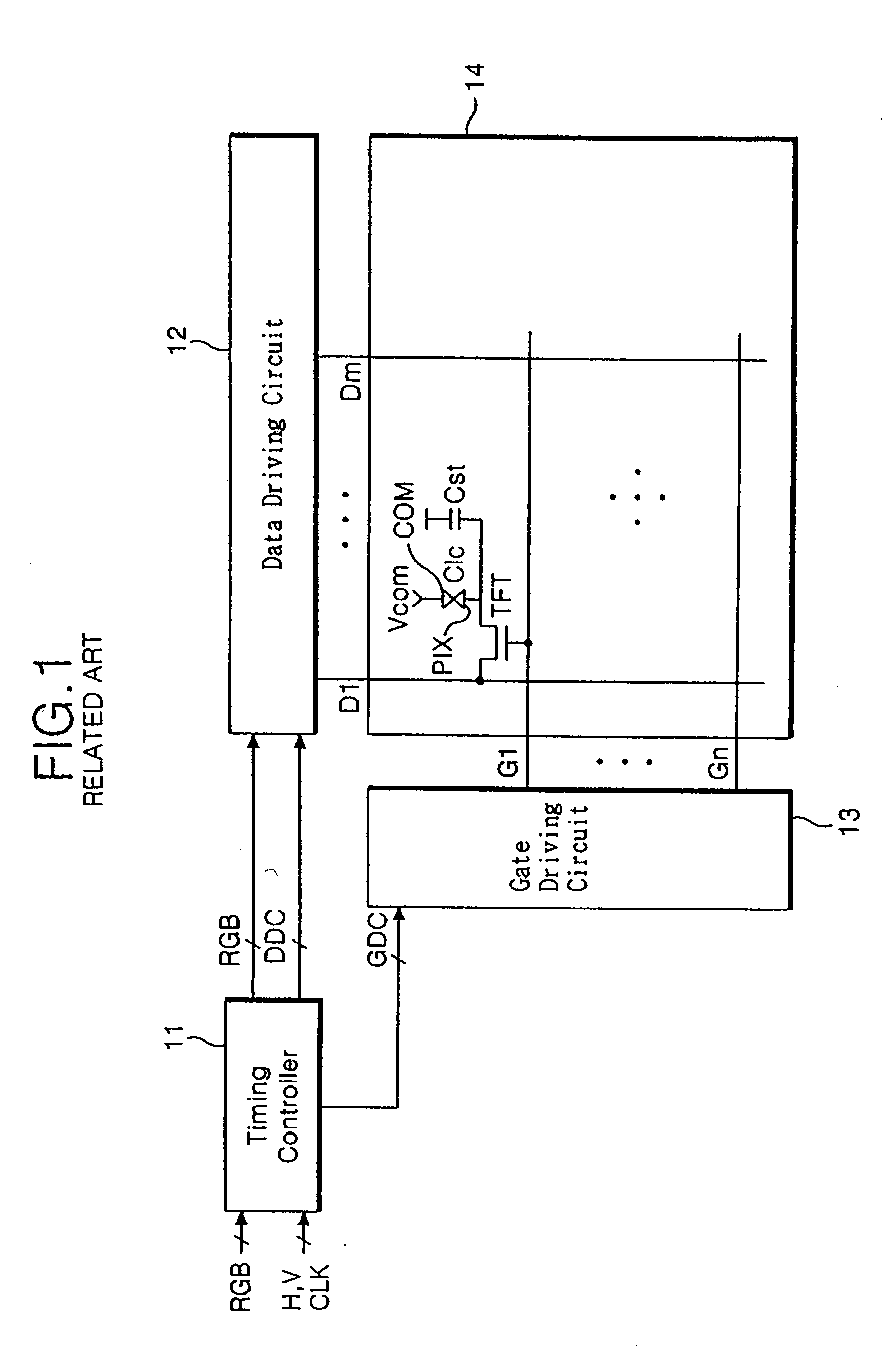

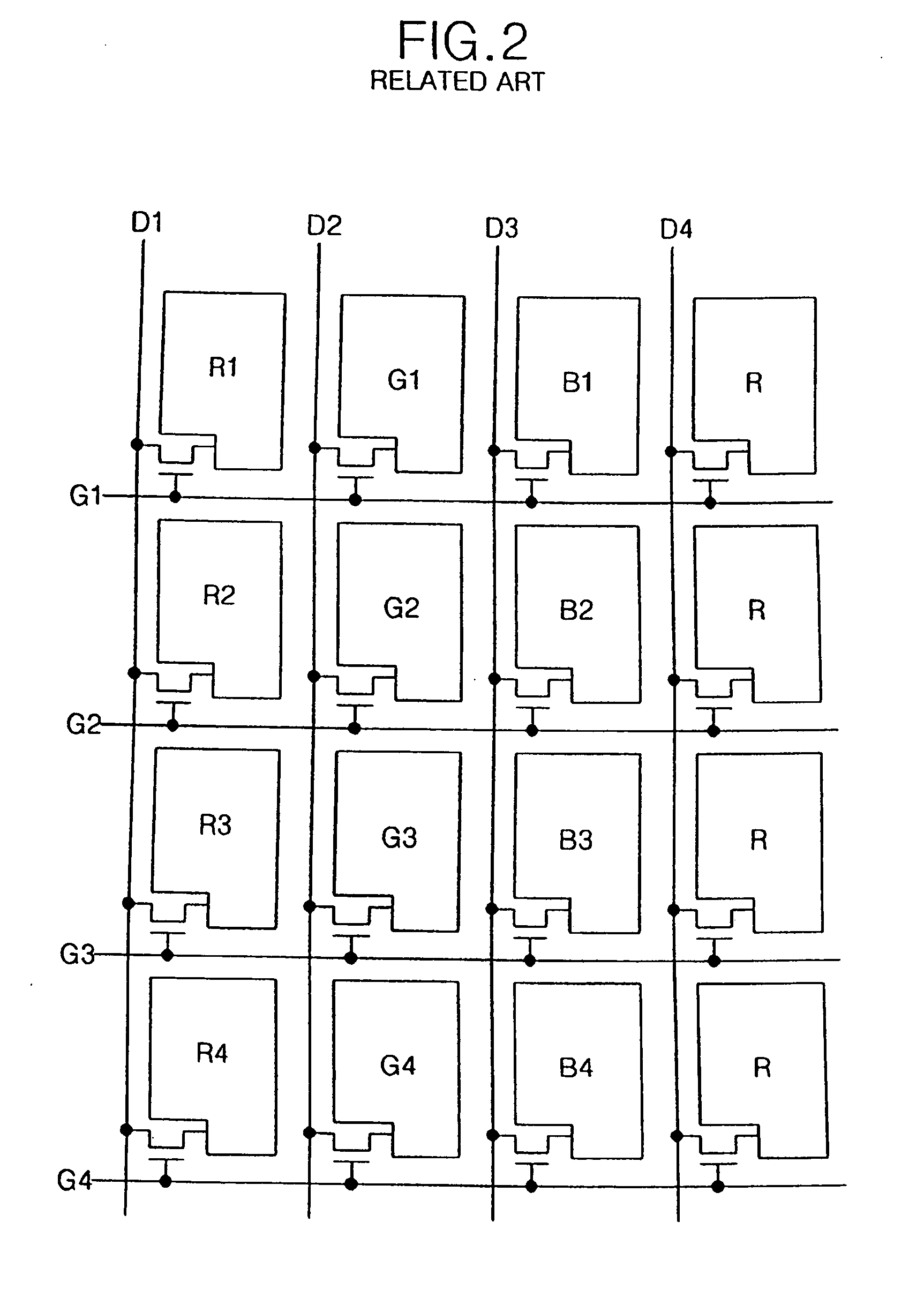

Liquid crystal display device and method of driving the same

ActiveUS20080106535A1Cathode-ray tube indicatorsInput/output processes for data processingDigital videoLiquid-crystal display

A liquid crystal display device and a method of driving the same is disclosed, which can decrease the number of source drive integrated circuits ICs used to supply data, and can also decrease a flexible printed circuit and a printed circuit board to supply signals to the source drive integrated circuits ICs in size. The liquid crystal display device comprises a liquid crystal panel including a plurality of data lines formed along a long-axis direction of substrate, and a plurality of gate lines formed along a short-axis direction of substrate, wherein each gate line is orthogonal to each data line; a data driving circuit to supply data voltages to the data lines; a gate driving circuit to supply scan pulses to the gate lines; and a timing controller to supply digital video data to the data driving circuit, and to control the data driving circuit and the gate driving circuit

Owner:LG DISPLAY CO LTD

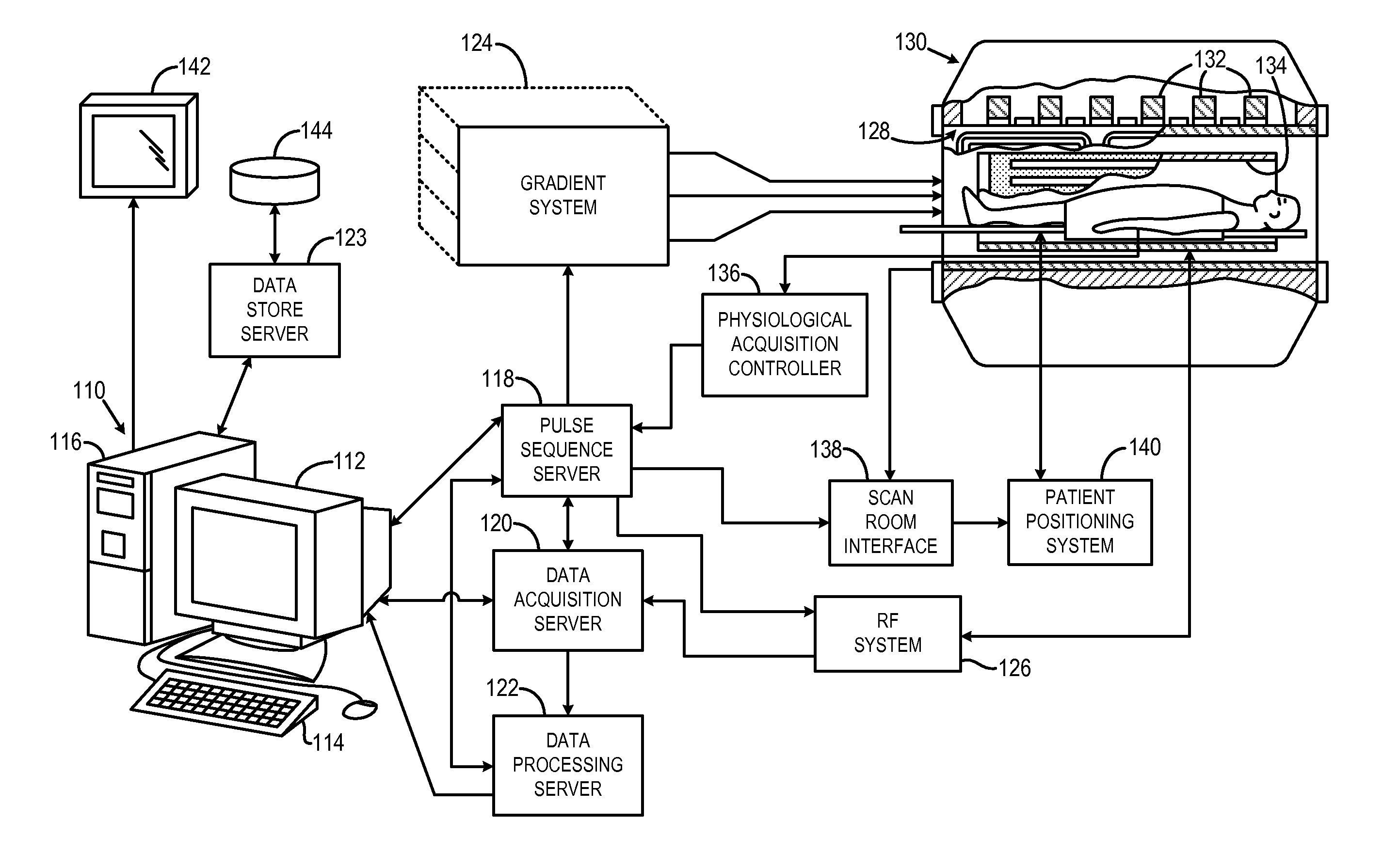

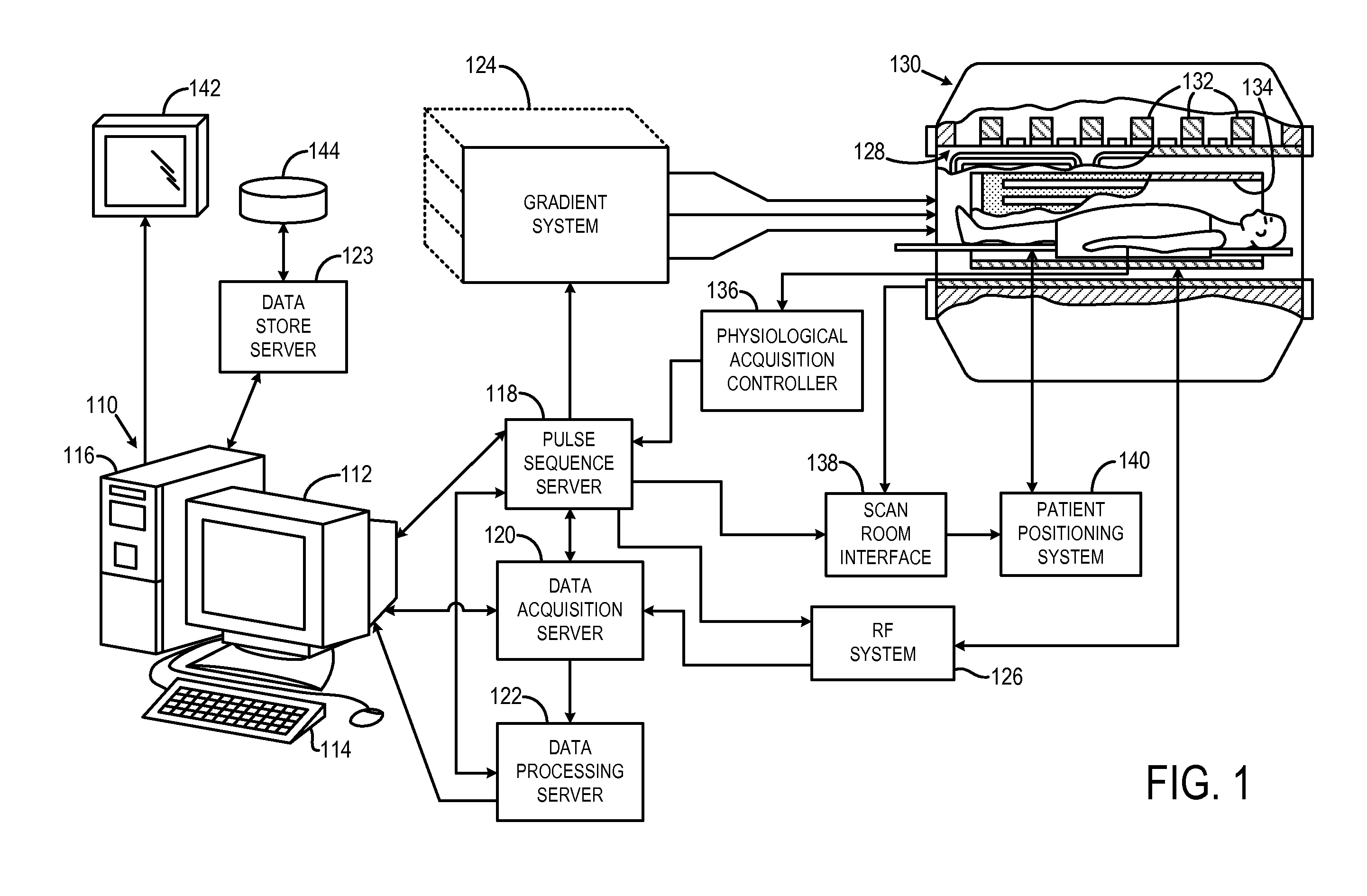

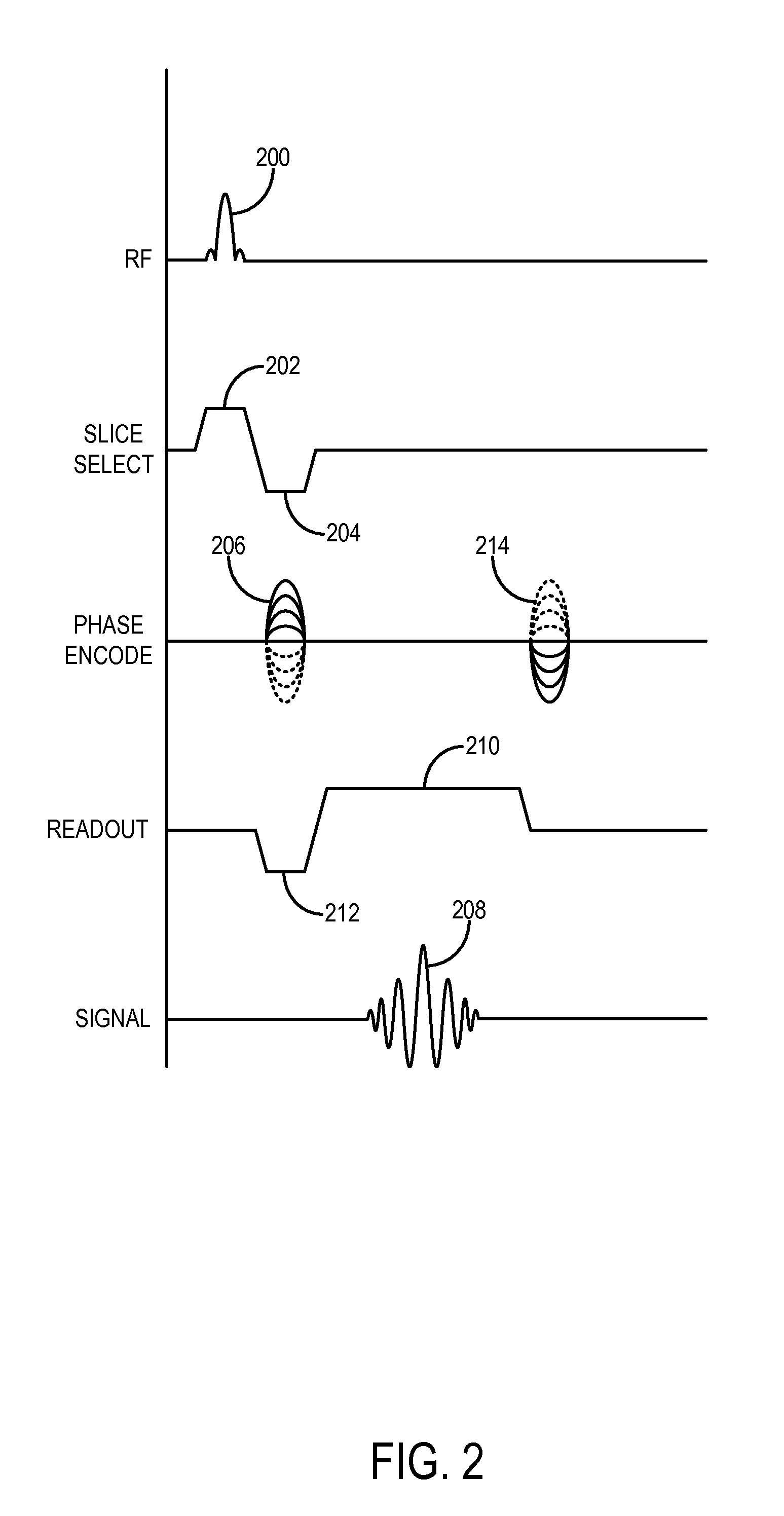

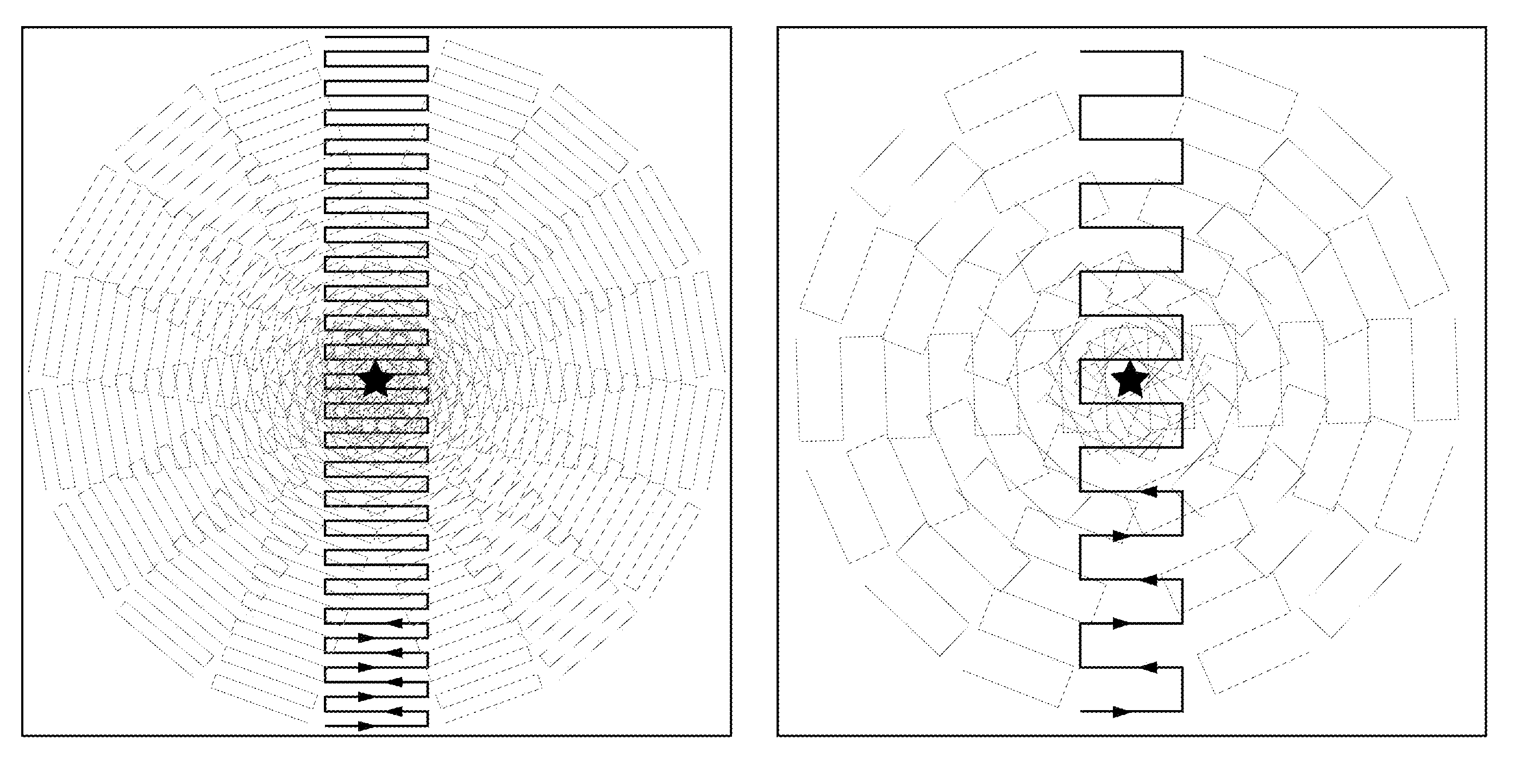

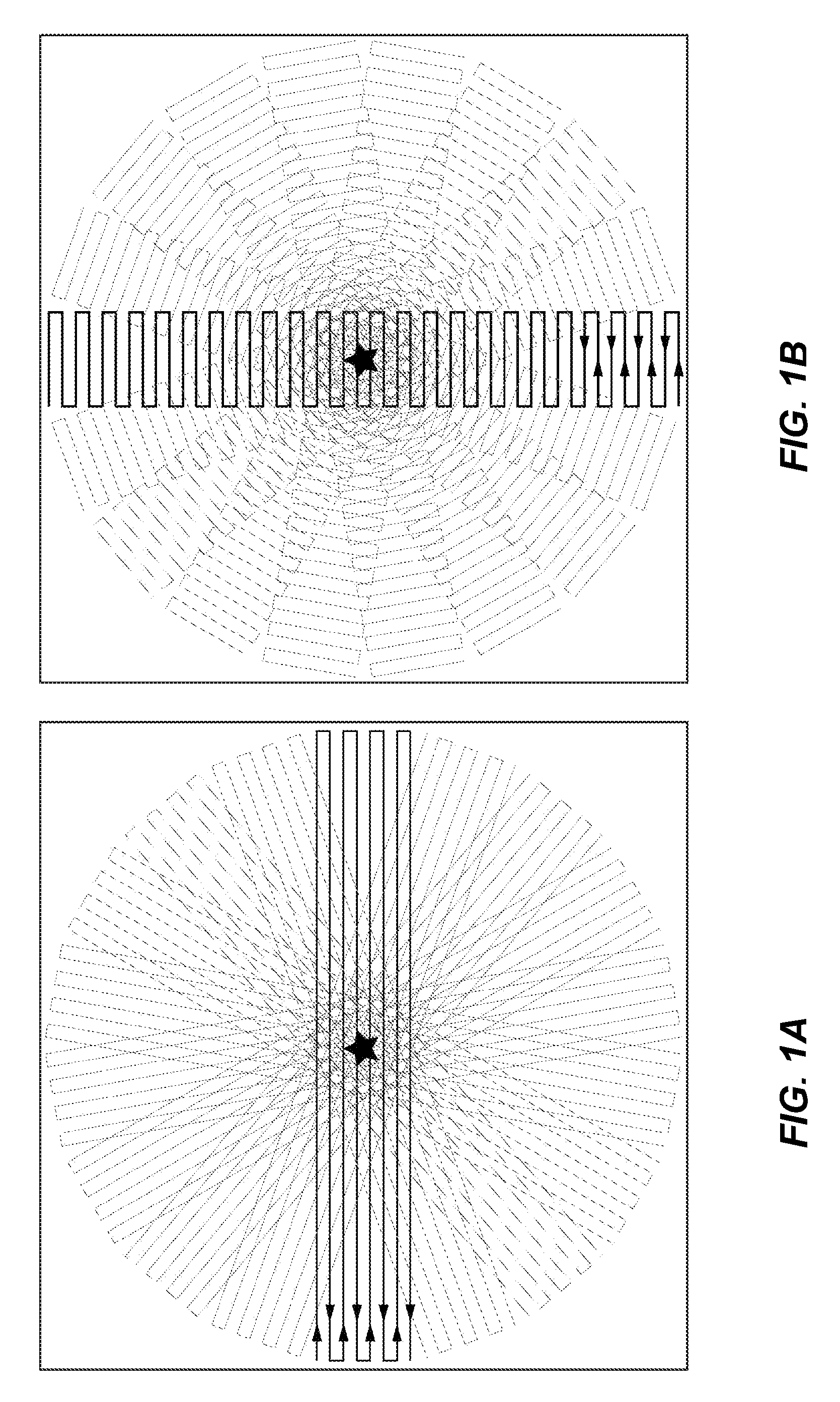

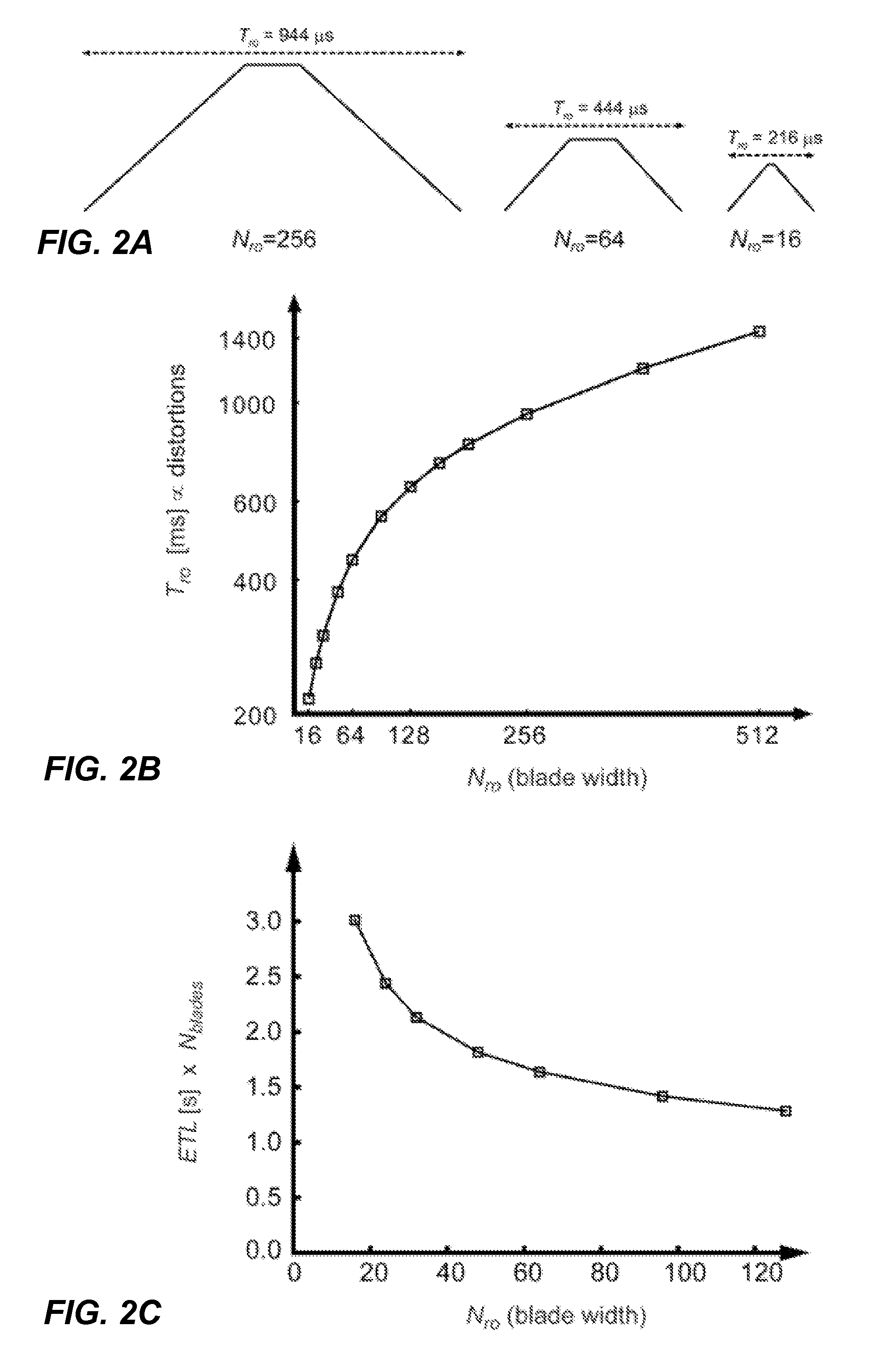

MRI data acquisition using propeller k-space data acquisition

ActiveUS7535222B2Increase speedReduce spacingMagnetic measurementsCharacter and pattern recognitionMagnetic susceptibilityPropeller

Disclosed is a new propeller EPI pulse sequence with reduced sensitivity to field inhomogeneities is proposed. Image artifacts such as blurring due to Nyquist ghosting and susceptibility gradients are investigated and compared with those obtained in previous propeller EPI studies. The proposed propeller EPI sequence uses a readout that is played out along the short axis of the propeller blade, orthogonal to the readout used in previous propeller methods. In contrast to long-axis readout propeller EPI, this causes the echo spacing between two consecutive phase-encoding (PE) lines to decrease, which in turn increases the k-space velocity in this direction and hence the pseudo-bandwidth.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

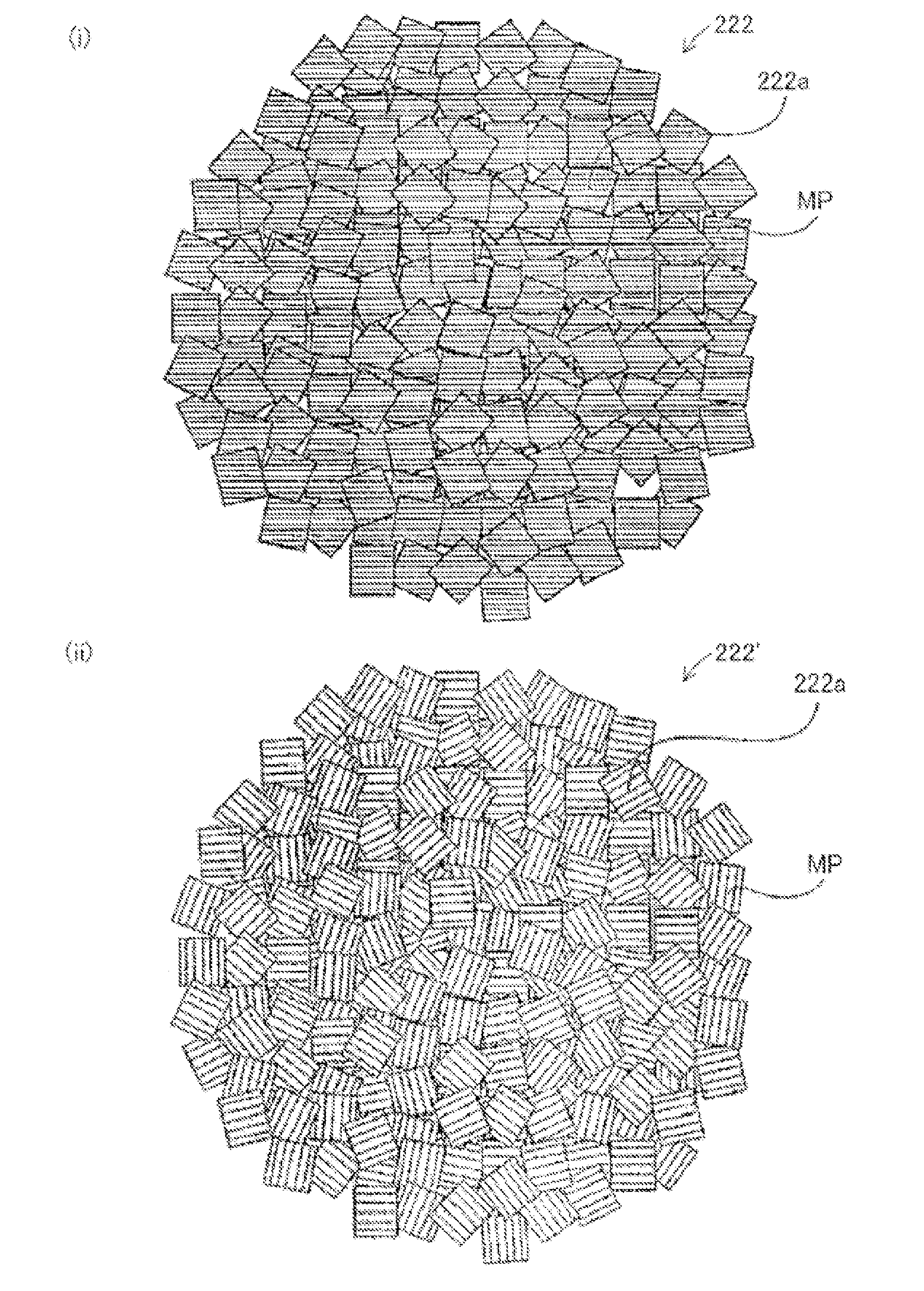

Cathode active material precursor particle, method for producing thereof and method for producing cathode active material for lithium secondary battery

InactiveUS20120256337A1Enhanced electron-conductivityEnhanced lithium-ion-conductivityCell electrodesFinal product manufactureLithiumMaterials science

The cathode active material precursor particle, which forms, through incorporation of lithium thereinto, a cathode active material particle for use in a lithium secondary battery, the cathode active material particle containing a lithium complex oxide having a layered rock salt structure, is characterized in that the precursor particle has an aspect ratio, which is a ratio of long axis diameter to short axis diameter, of 1.0 or more and less than 2 and is formed so that the (003) planes of the lithium-incorporated cathode active material particle are substantially uniaxially oriented.

Owner:NGK INSULATORS LTD

Lithium secondary battery and cathode active material therefor

InactiveUS20120258369A1Enhanced electron-conductivityEnhanced lithium-ion-conductivityConductive materialActive material electrodesLithiumPlane orientation

The lithium secondary battery cathode active material having a layered rock salt structure is characterized in that the material is formed of a plurality of primary particles having a mean particle size of 0.01 to 5 μm, and contains secondary particles having a mean particle size of 1 to 100 μm and an aspect ratio, which is a ratio of long axis diameter to short axis diameter, of 1.0 or more and less than 2; and that the primary particles forming the secondary particles have a (003) plane orientation degree of 50% or higher.

Owner:NGK INSULATORS LTD

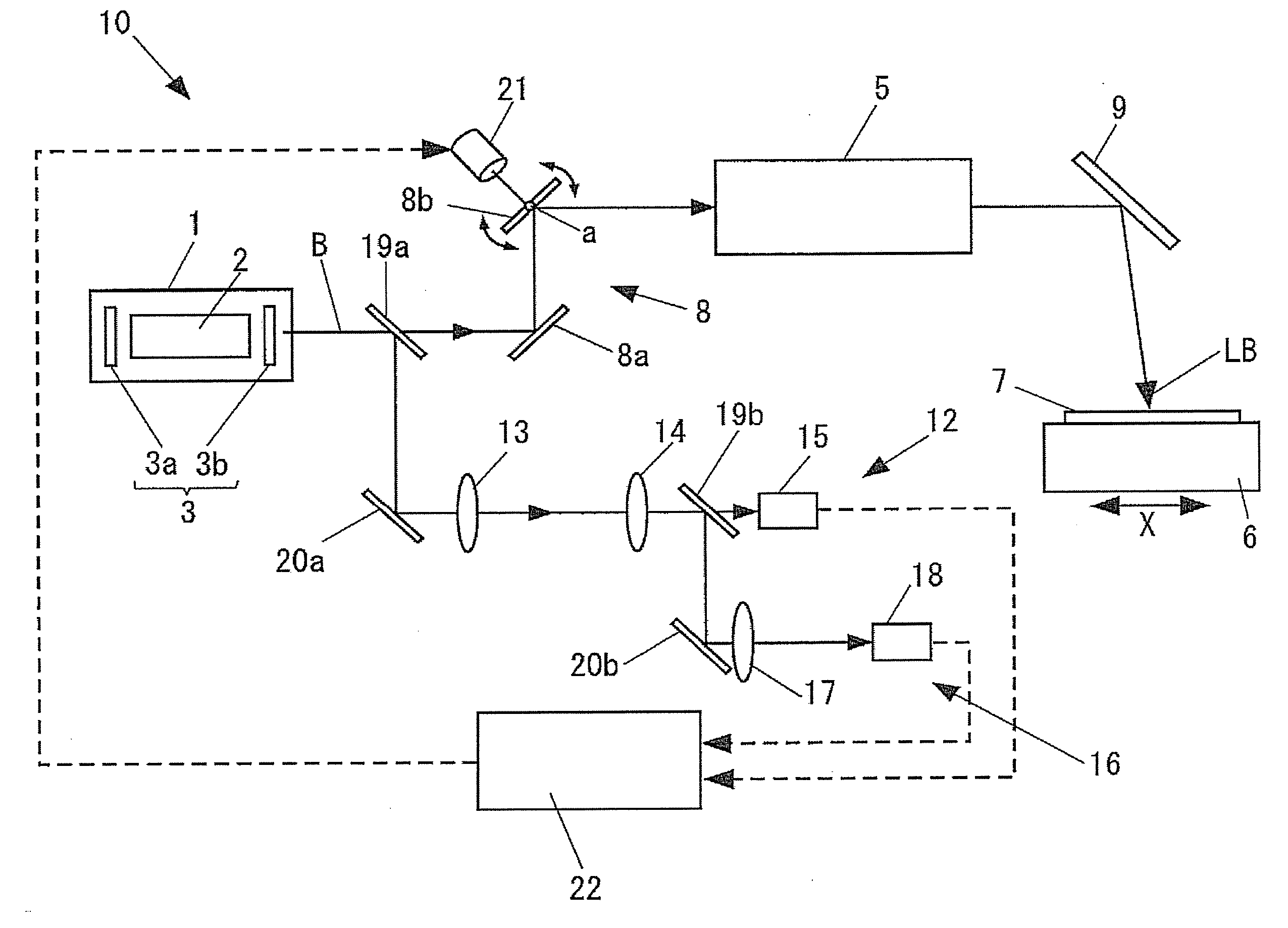

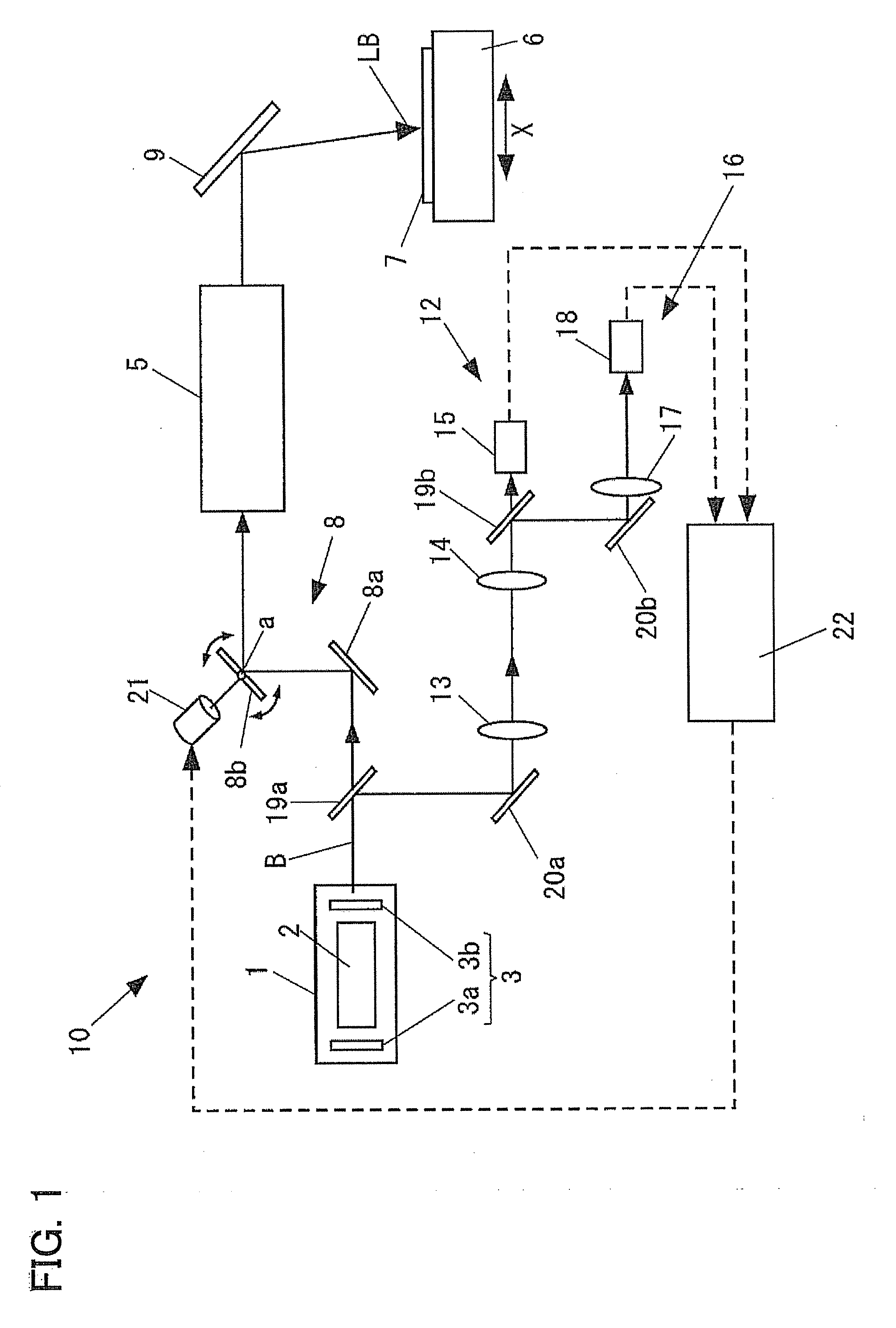

Laser Annealing Apparatus and Method

ActiveUS20090218475A1Reduce uneven exposureReduce unevennessPhotometry using reference valueMaterial analysis by optical meansLight beamIrradiation

The irradiation unevenness caused by drift occurring in a beam short-axis direction is reduced without adding a new beam shaping unit and affecting the propagation characteristic of a beam in an optical resonator. A position deviation detector for detecting a position deviation of a laser beam before passing through a beam shaping optical system, an angle deviation detector for detecting an angle deviation of the laser beam before passing through the beam shaping optical system, a deflection mirror for deflecting the laser beam, which is disposed in an optical path between a laser and an object (substrate), and a mirror controller for controlling orientation of the deflection mirror, based on detection data obtained using the position deviation detector and the angle deviation detector so as to eliminate the position deviation from a reference irradiation position in the short-axis direction of a linear beam on a surface to be irradiated.

Owner:SEMICON ENERGY LAB CO LTD

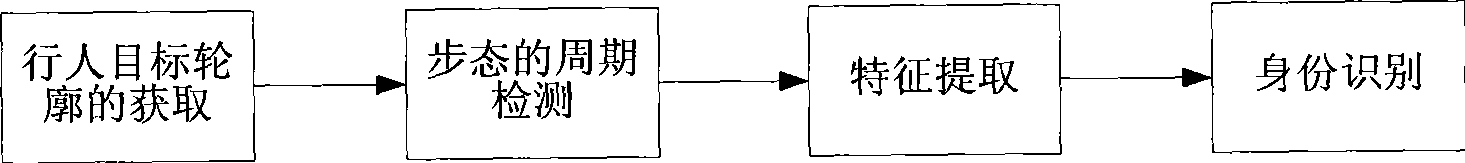

Partitioned matrix-based gait recognition method

InactiveCN101488185AEfficient determinationReduce complexityCharacter and pattern recognitionPrincipal component analysisVideo sequence

The invention provides a gait recognition method based on a partitioned matrix. Firstly, extracting single-frame images from a video, then carrying out grey scale transformation on the single-frame images, using the background subtraction method to extract person body targets, using mathematical morphology to fill the holes of binary images, and extracting profiles of the person by means of single connection analysis so that the person bodies are positioned in the middle and are uniformly in the size of 64 * 64 pixels; observing the periodic change of the gait according to elliptical short axis and eccentricity fitted in image regions after the standard centralization of each frame image in a gait video sequence; using a gait energy diagram to extract the integral characteristic of the gait in the one period, dividing GEI into sub-blocks by means of the partitioned matrix, eliminating the sub-blocks which are useless to classification in a self-adapting manner, and adopting the method, which combines the two-dimensional principal component analysis of a sub-block mode with the two-dimensional linear discriminant analysis, to further extract local characteristics; and integrating the characteristics of each effective sub-block into a whole during the classification recognition, and adopting a nearest neighbor classifier to perform identification judgment. The method is effective for the recognition of the gait of knapsack change.

Owner:HARBIN ENG UNIV

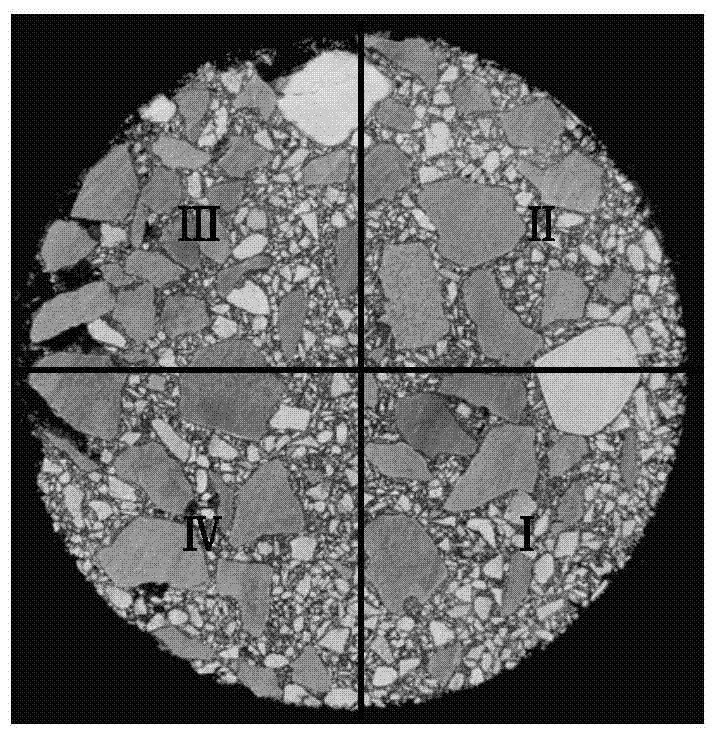

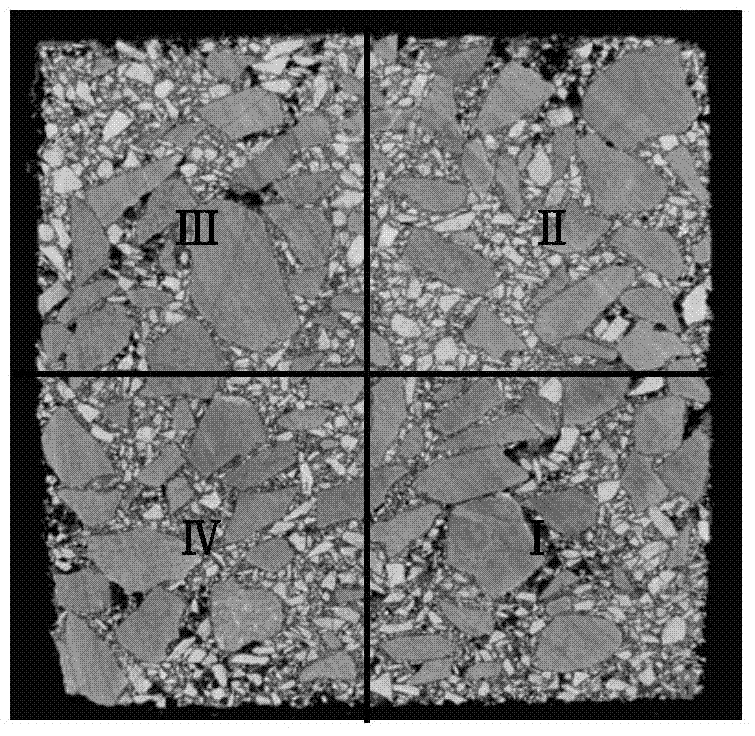

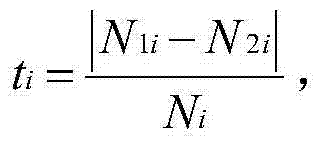

Method for evaluating uniformity of asphalt mixture

InactiveCN103575752AThe evaluation result is accurateMaterial analysis by optical meansMaterial analysis by transmitting radiationEngineeringDigital image

The invention discloses a method for evaluating the uniformity of an asphalt mixture. The method comprises the following steps: firstly, providing a cylindrical asphalt mixture test piece required by analysis through indoor molding or field sampling; secondly, acquiring a sectional image of the asphalt mixture test piece through an industrial computed tomography (CT) machine or a digital camera, wherein the asphalt mixture test piece is cut through a saw-tooth cutting machine when the digital camera is adopted; thirdly, converting the image into a black-and-white image in a bitmap (BMP) format, and analyzing the black-and-white image to obtain information of each aggregate and each hole in the sectional image of the asphalt mixture test piece, wherein the information comprises perimeter, area, equivalent diameter, coordinates of a long axis and a short axis, position coordinates of a center of mass and the like; and finally, respectively calculating the distribution states of aggregates and holes on the section of the mixture in terms of position distribution, quantity distribution and long axis azimuth distribution of the aggregates and the holes in the mixture so as to evaluate the uniformity of the mixture. On the basis of a digital image technology, the uniformity of the asphalt mixture is directly and quantitatively evaluated. Compared with other methods, the method has the advantage that an evaluation result is more accurate.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com