Patents

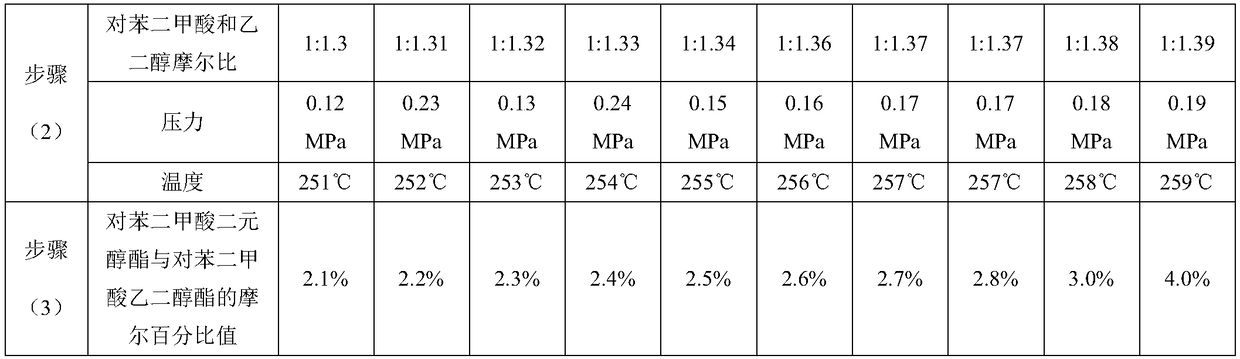

Literature

53results about How to "Increased access to polyester interior" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous super-bright trilobal profiled polyester fiber and production method thereof

ActiveCN106400166AImprove dyeing effectEasy to processFilament/thread formingMonocomponent copolyesters artificial filamentFiberYarn

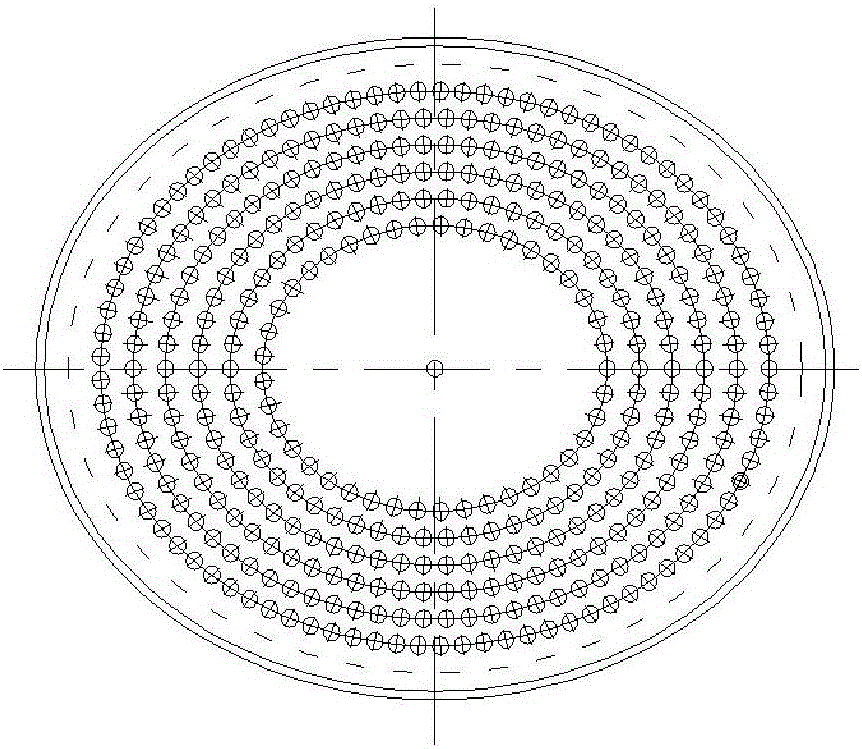

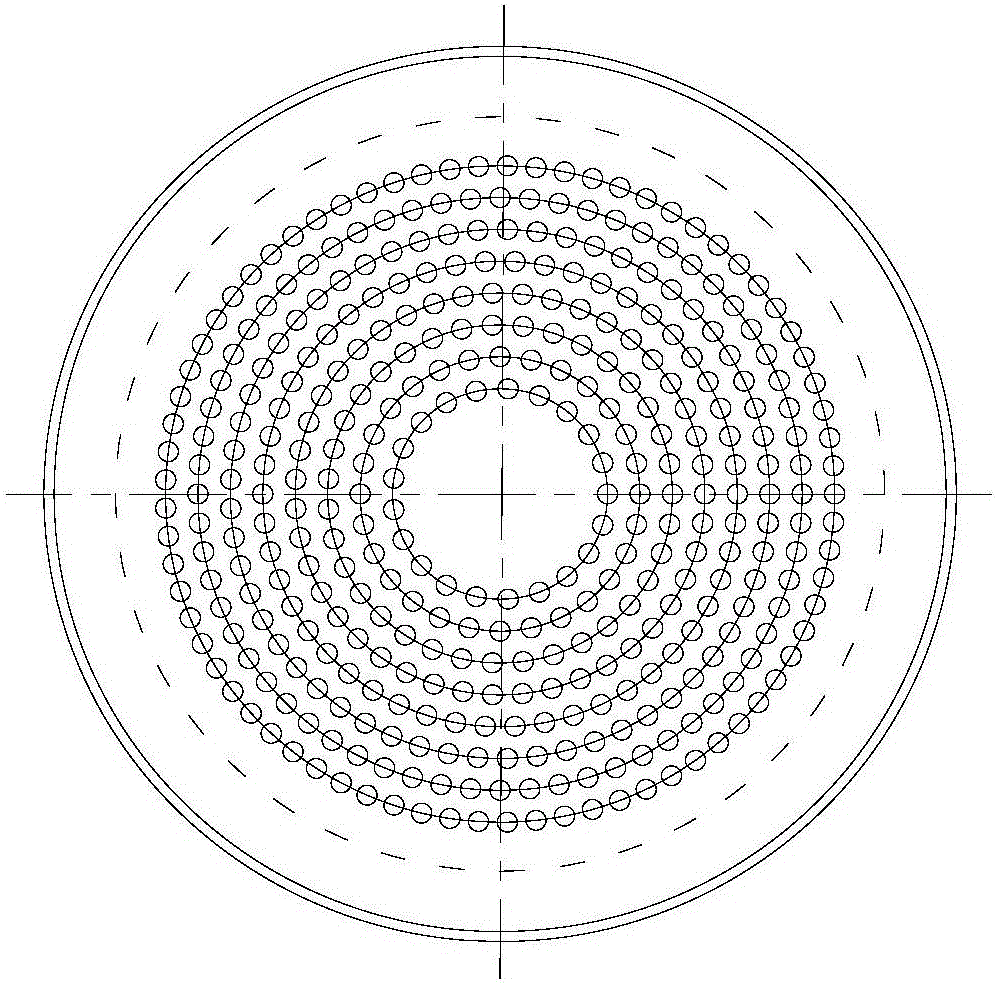

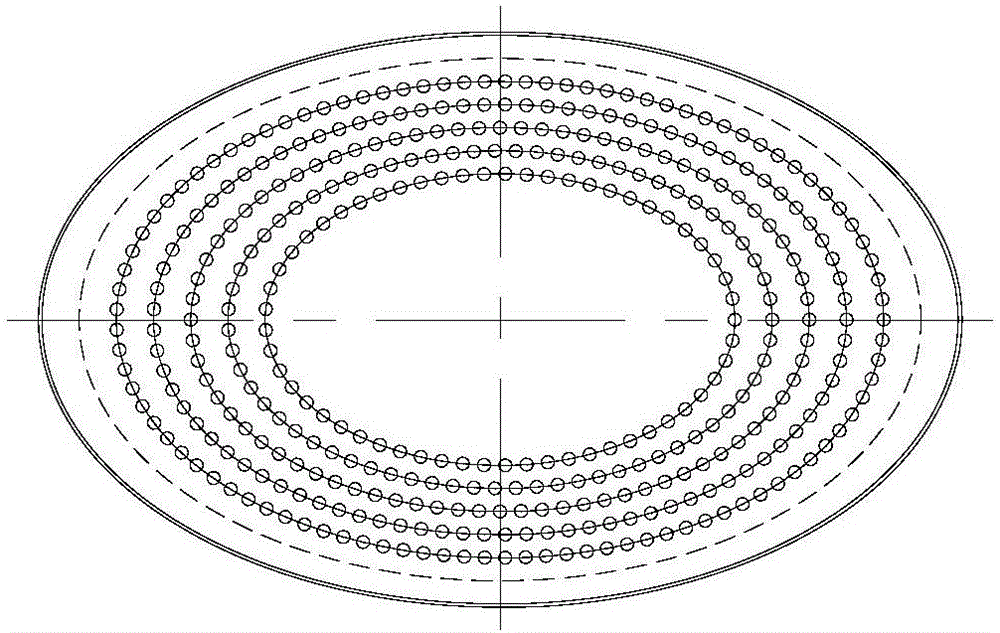

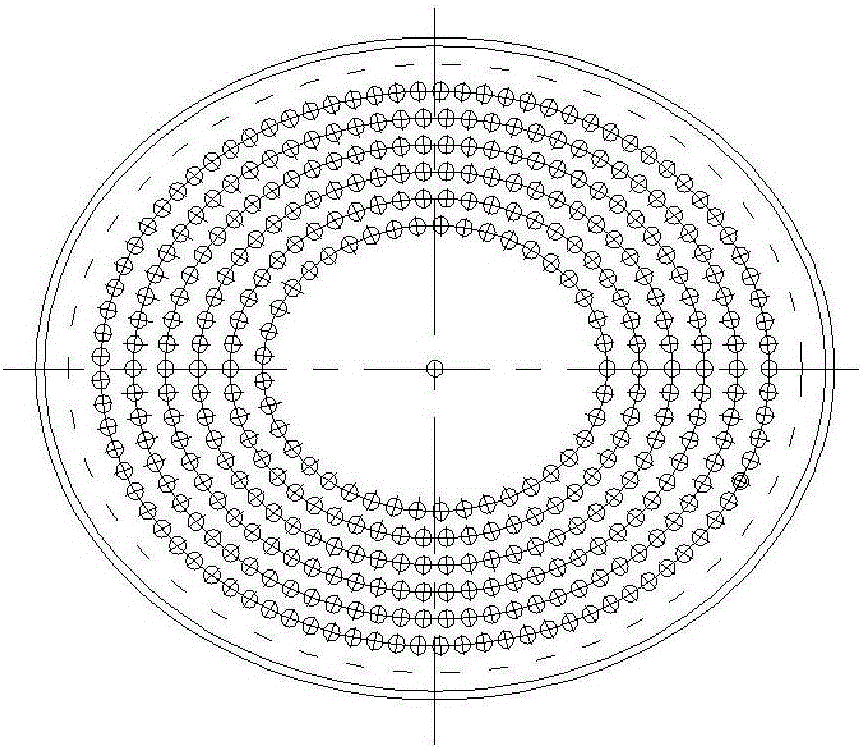

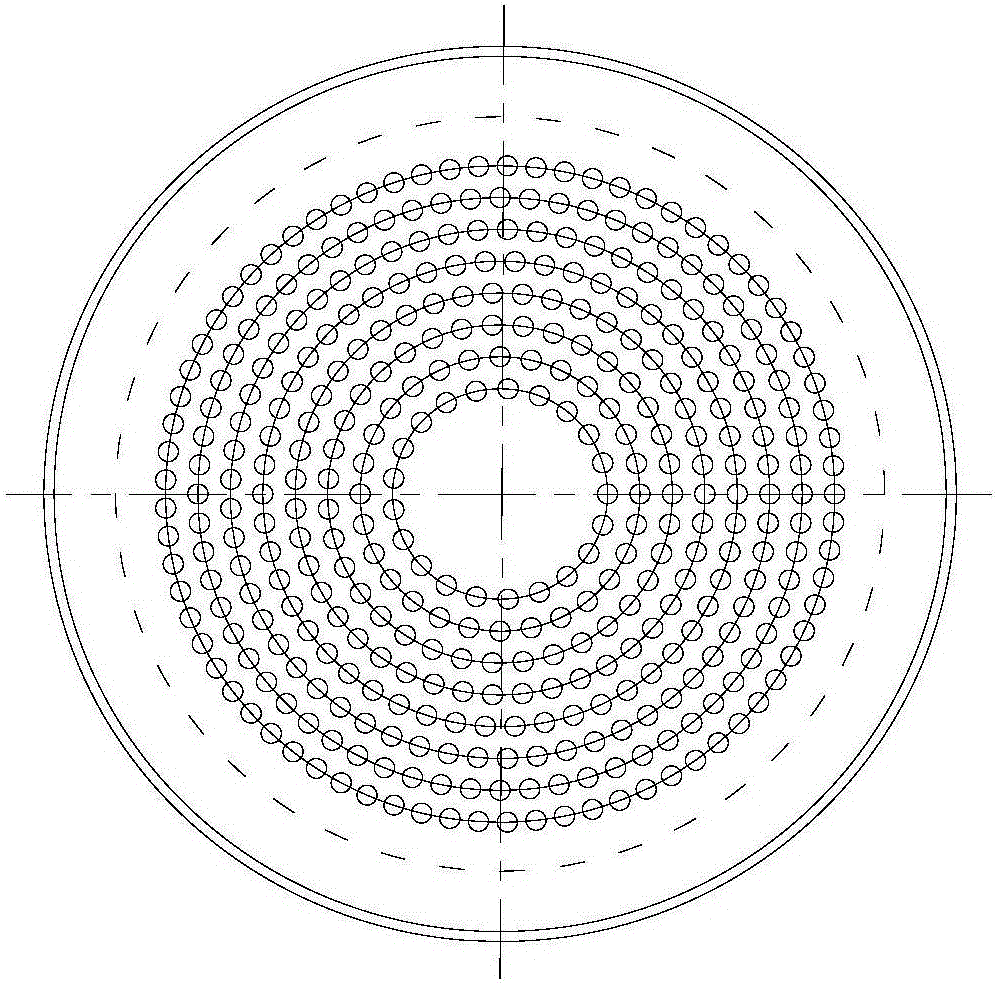

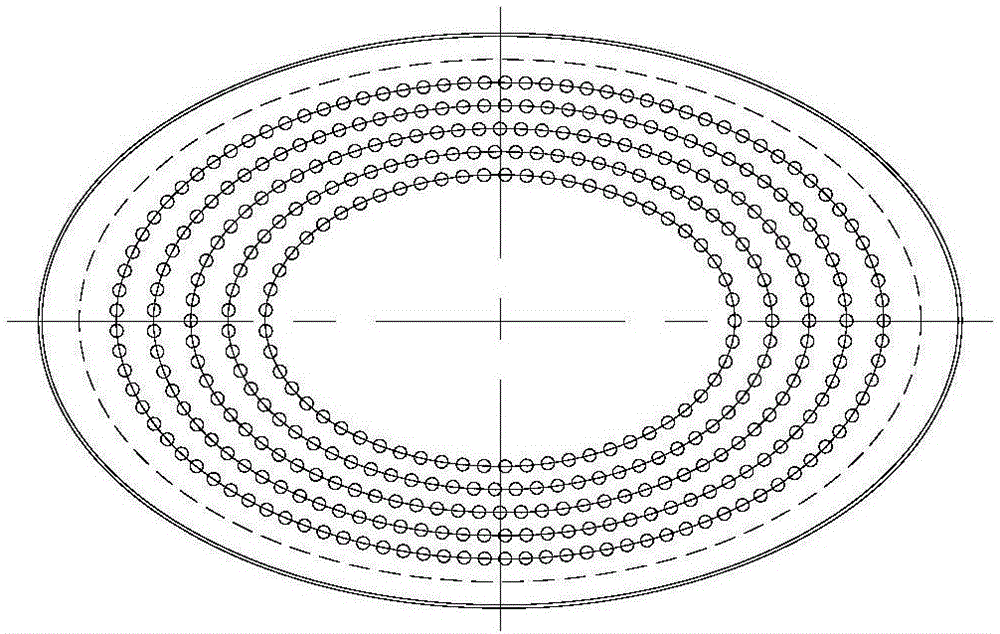

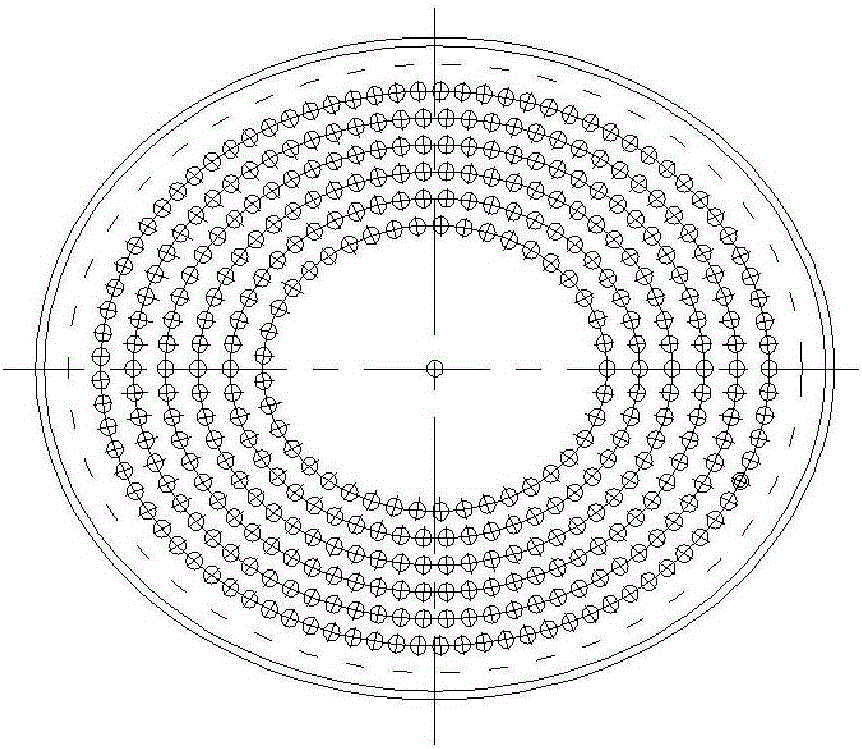

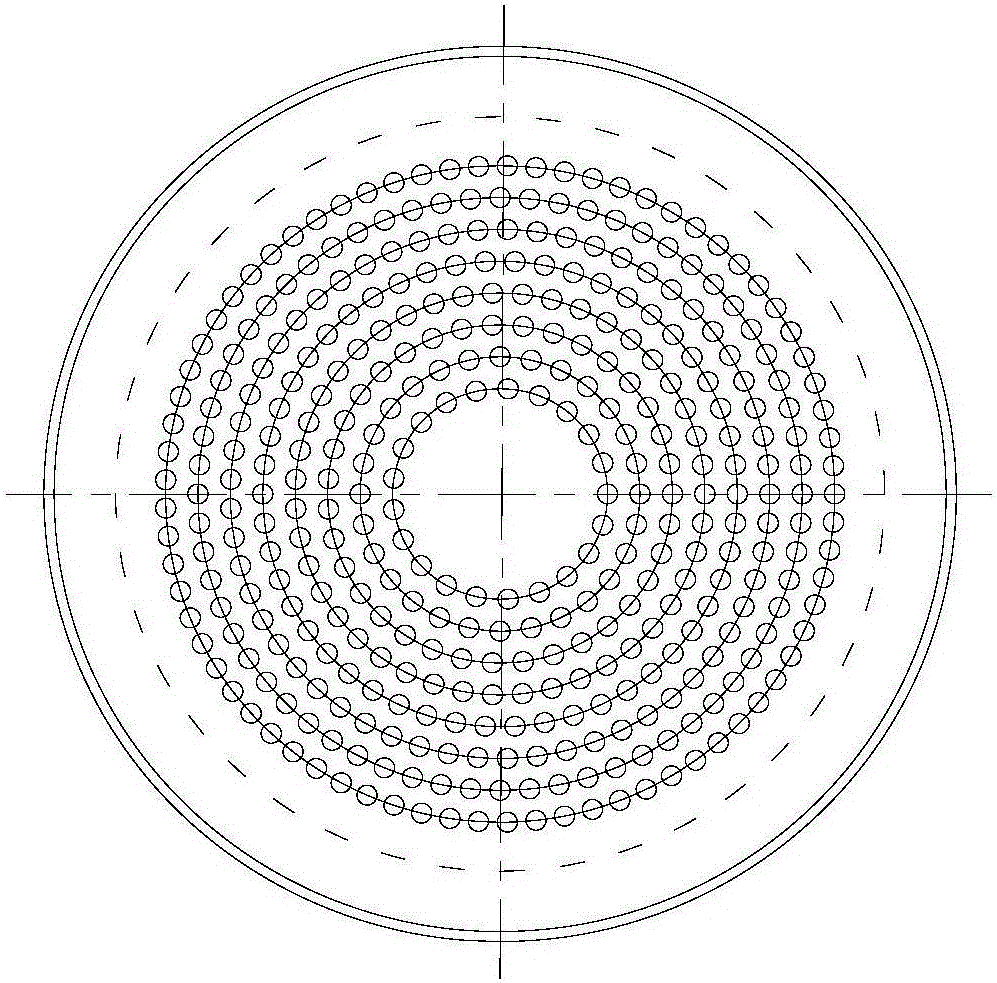

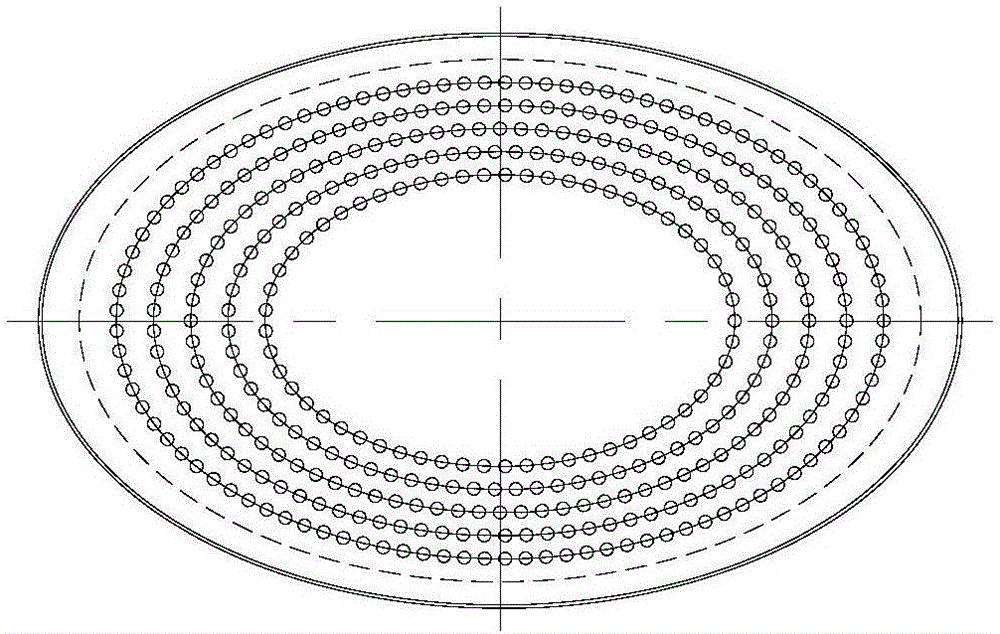

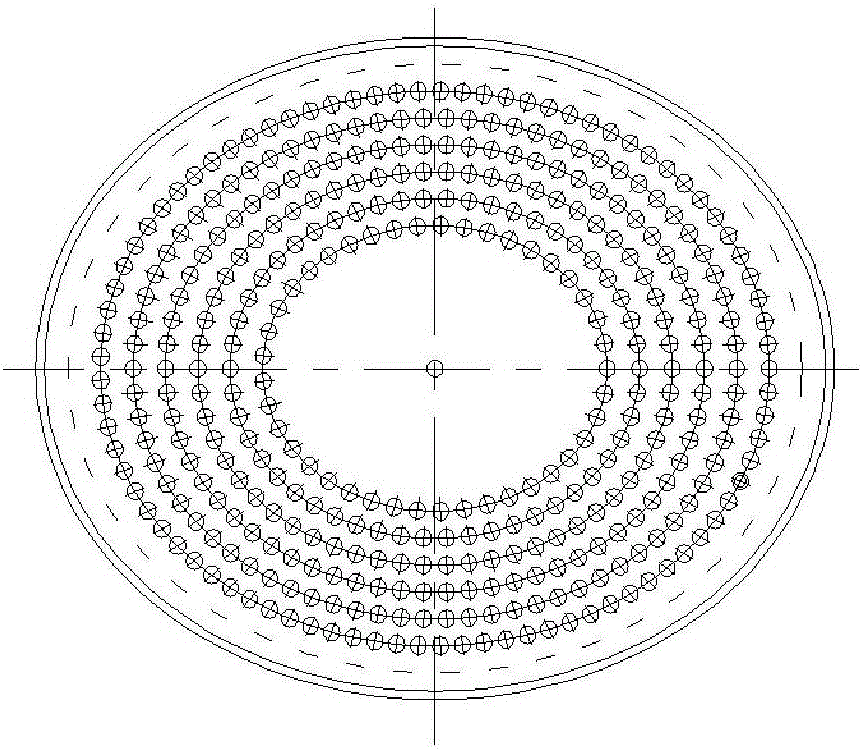

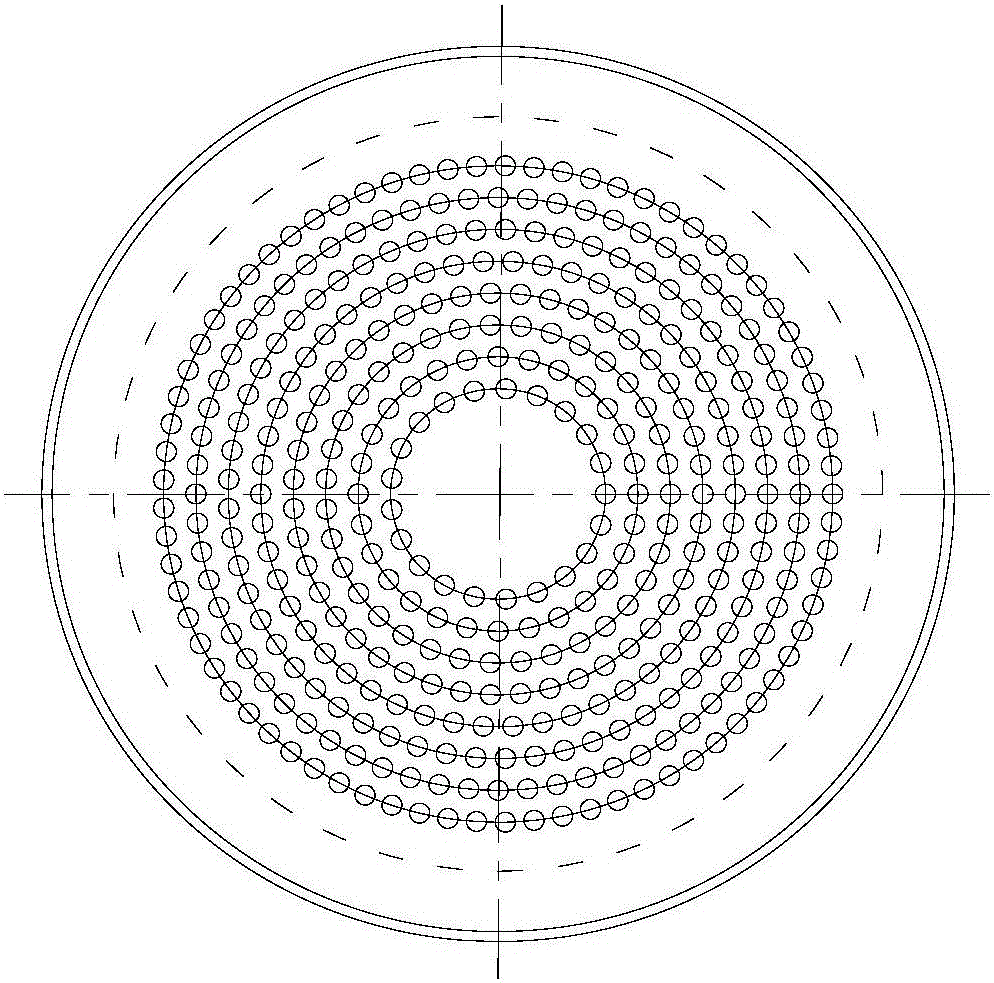

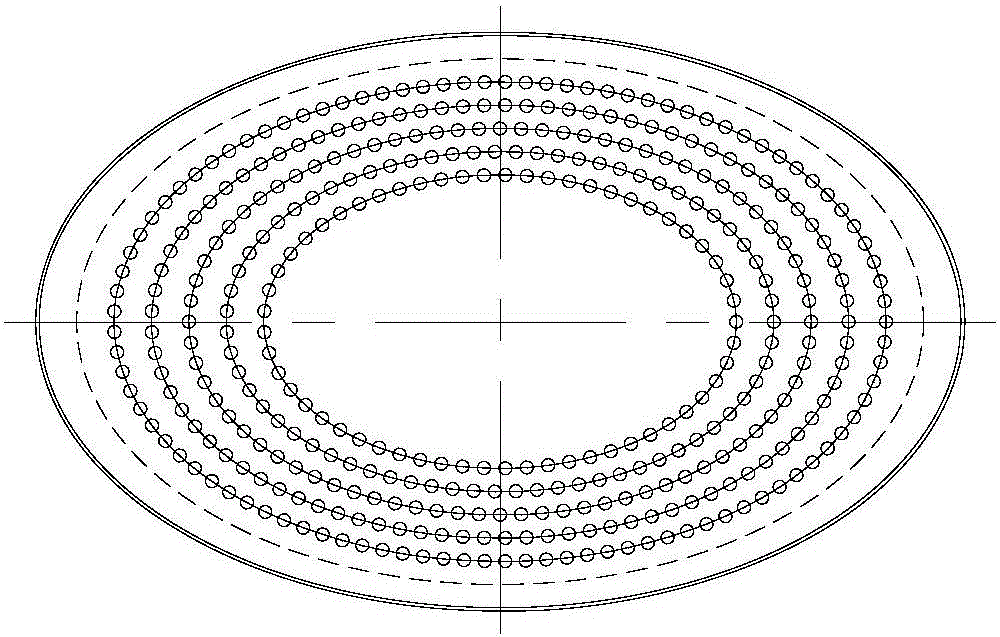

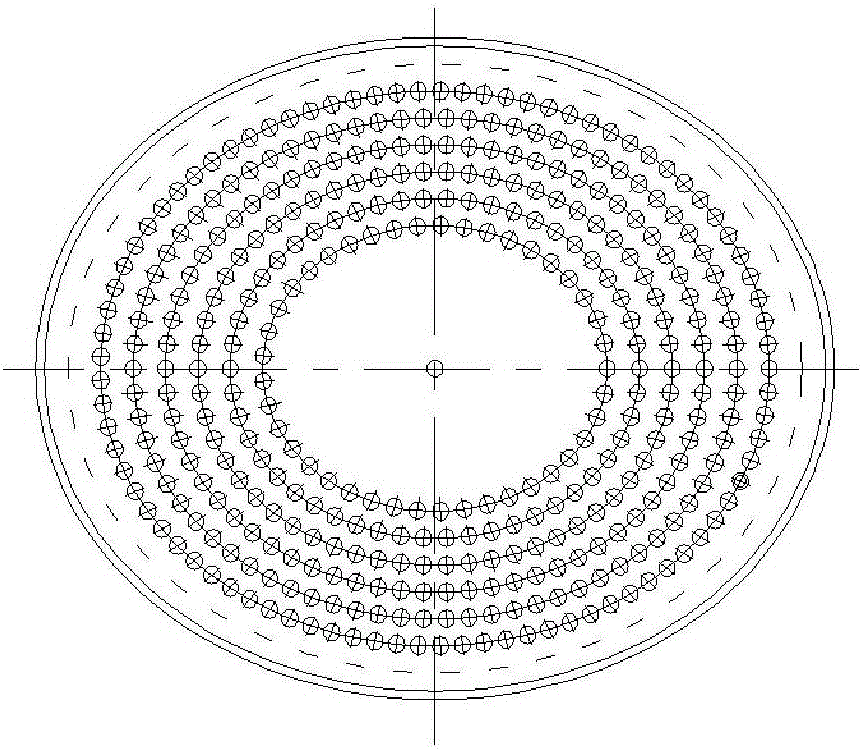

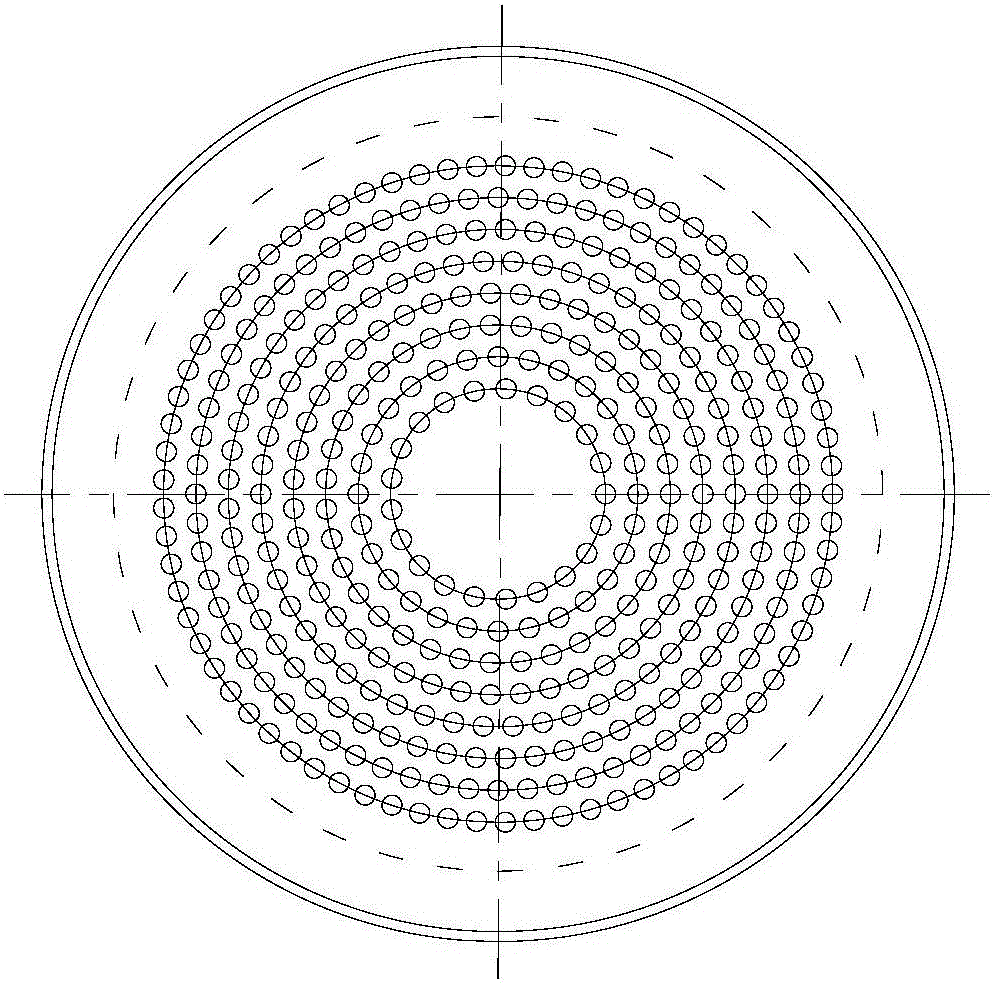

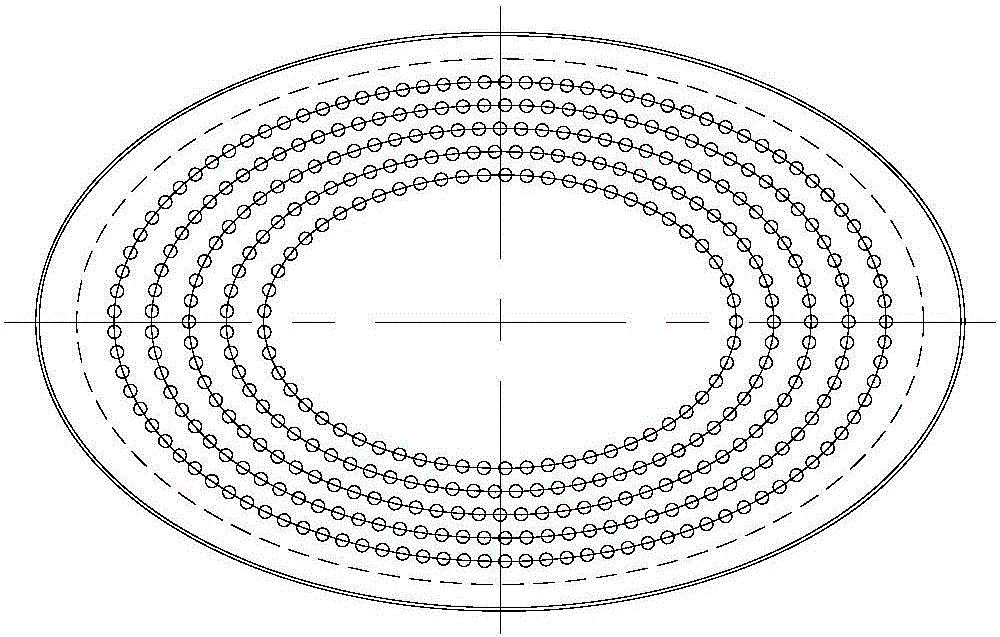

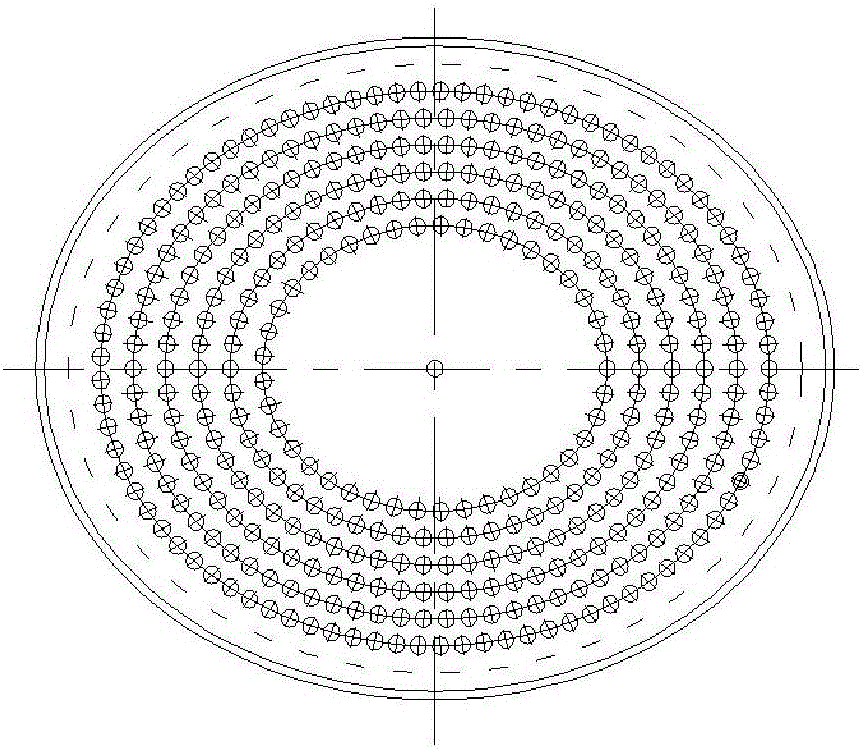

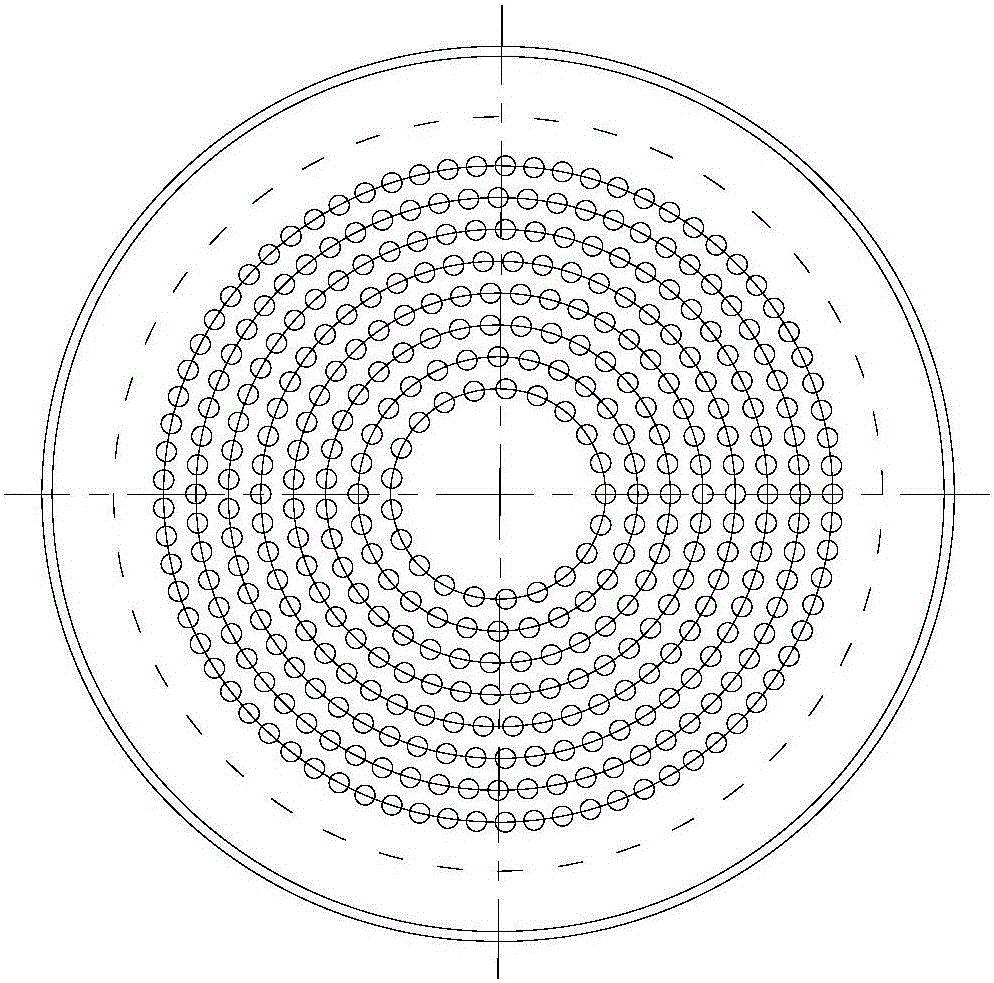

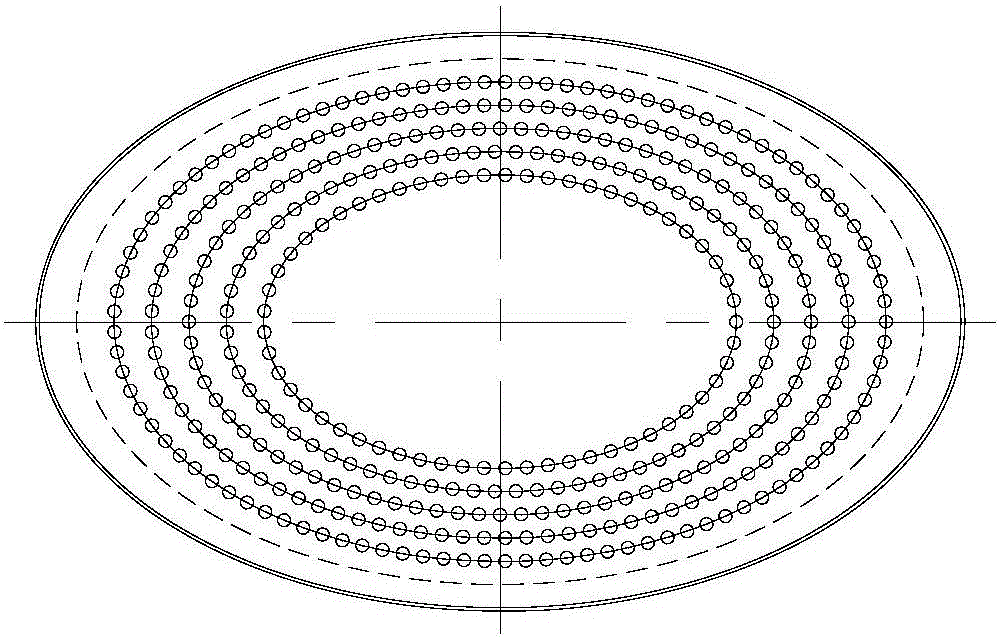

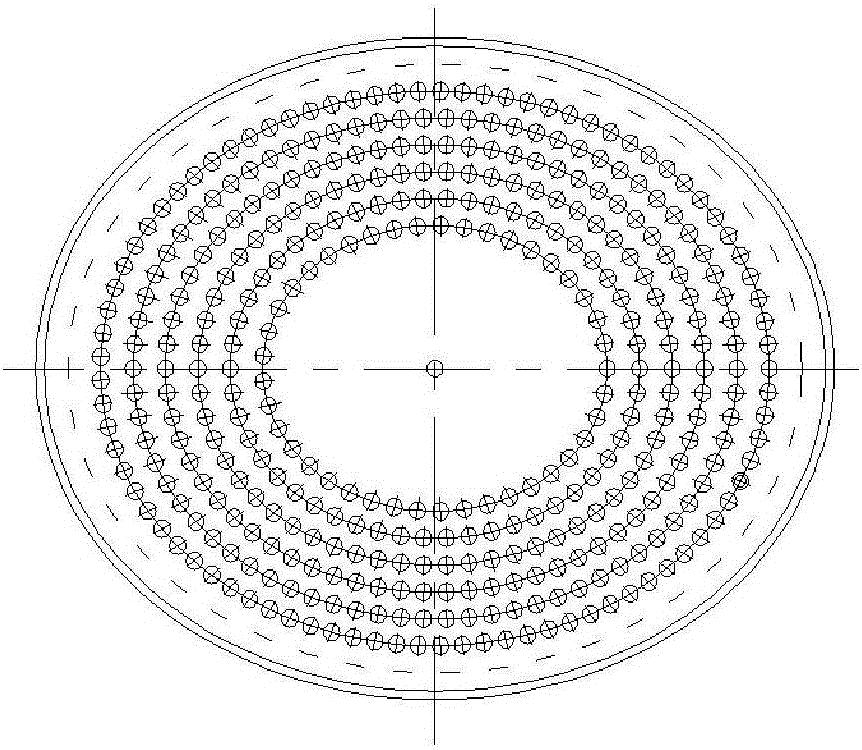

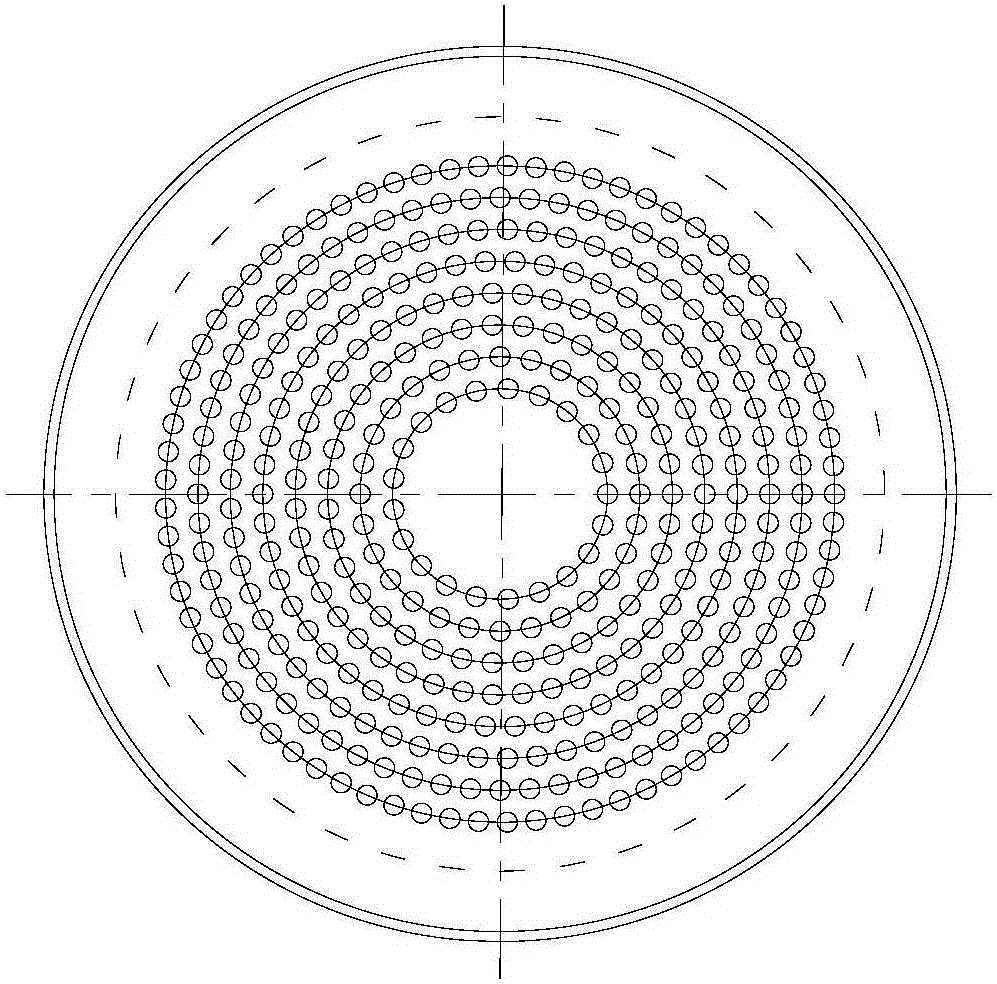

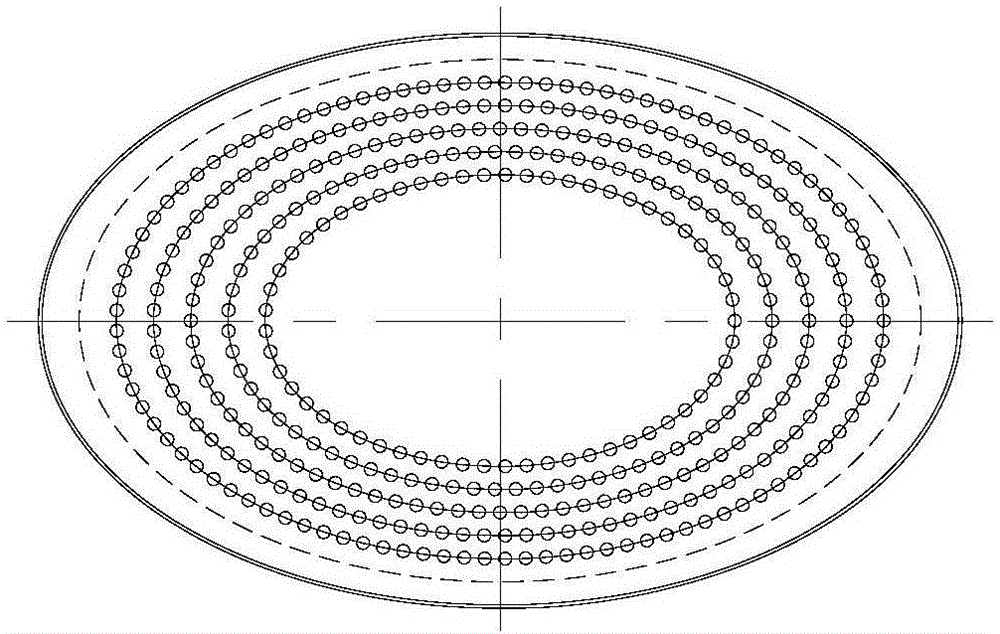

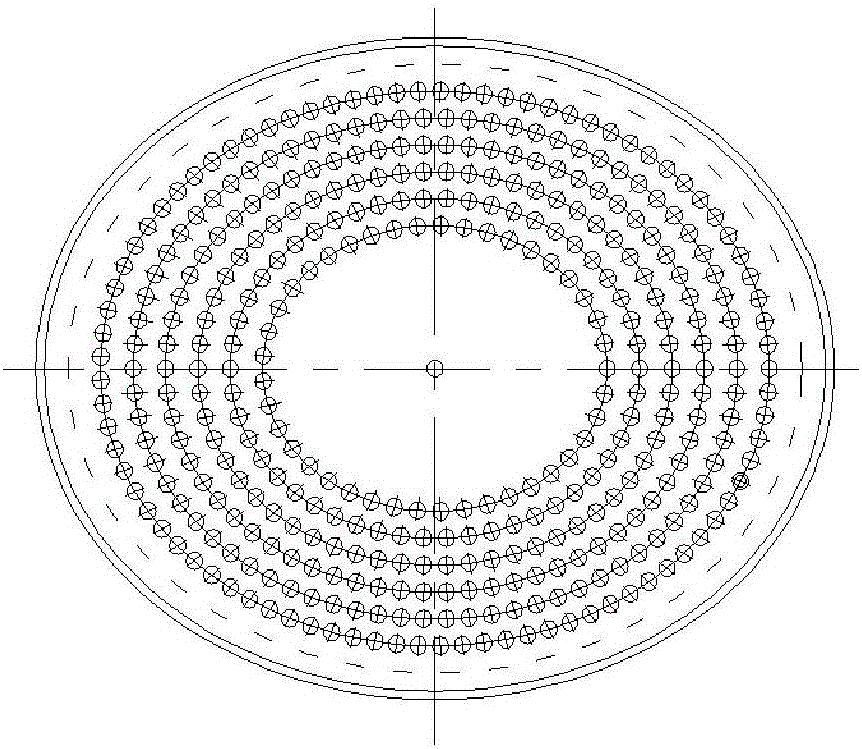

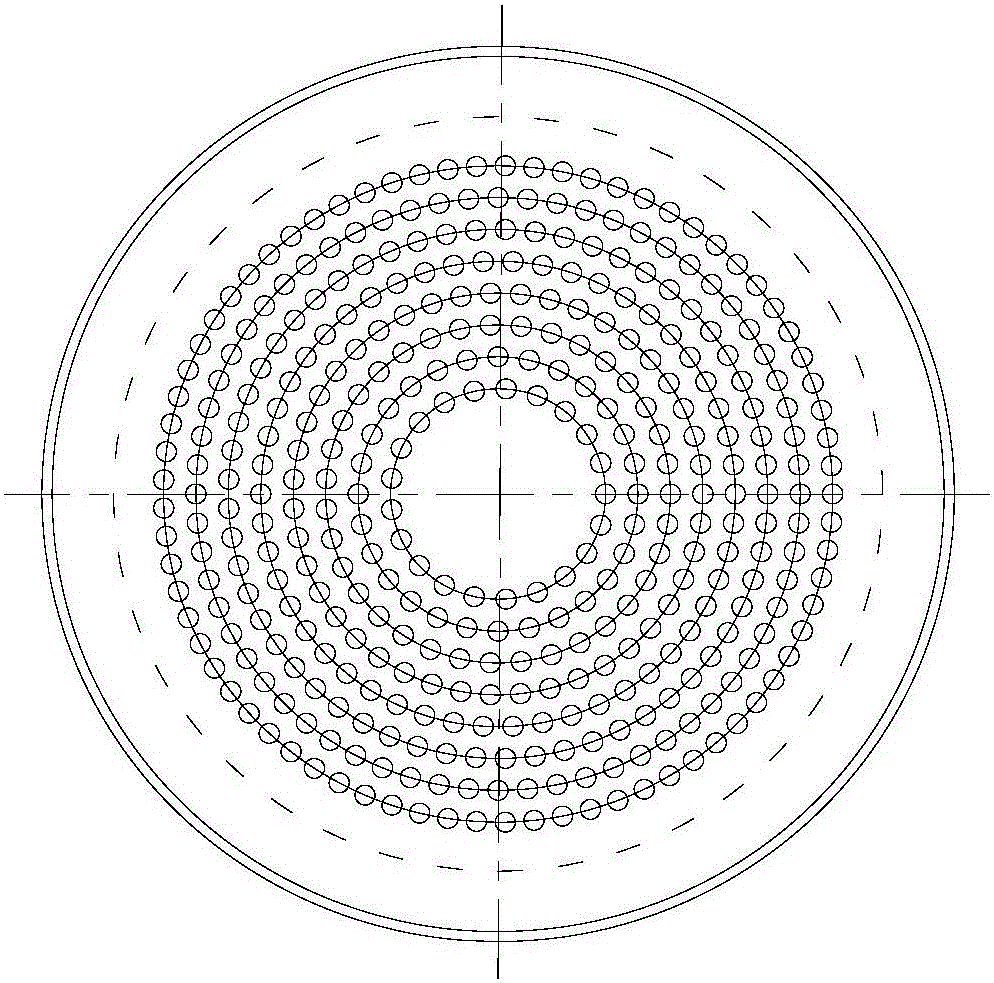

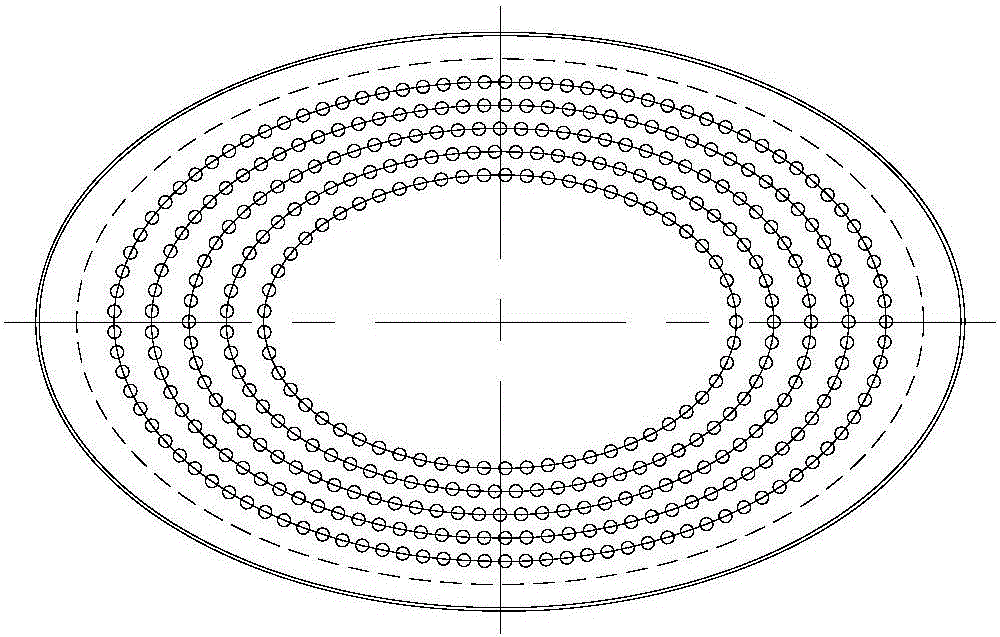

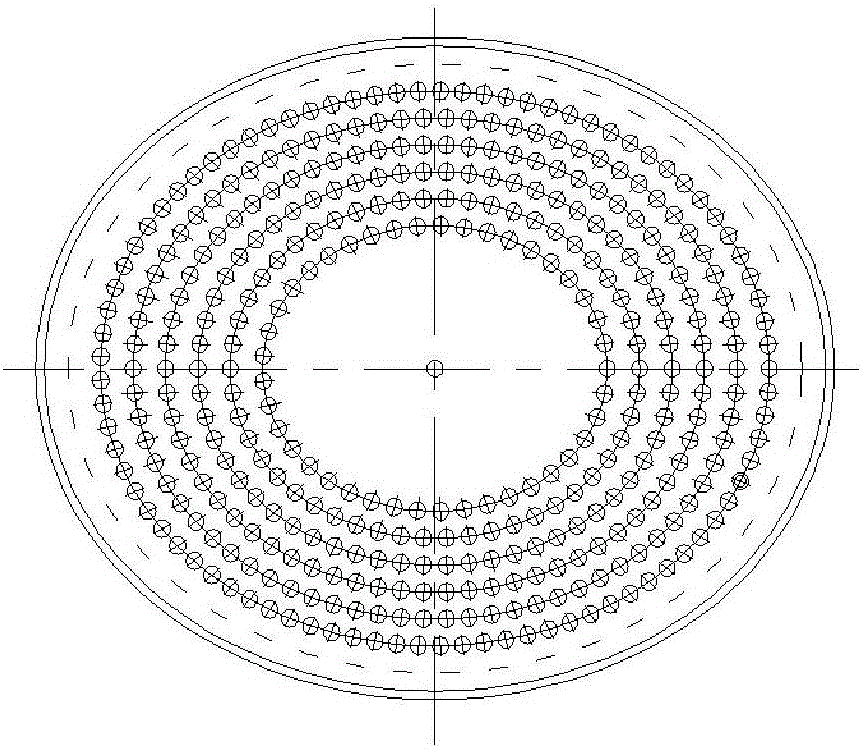

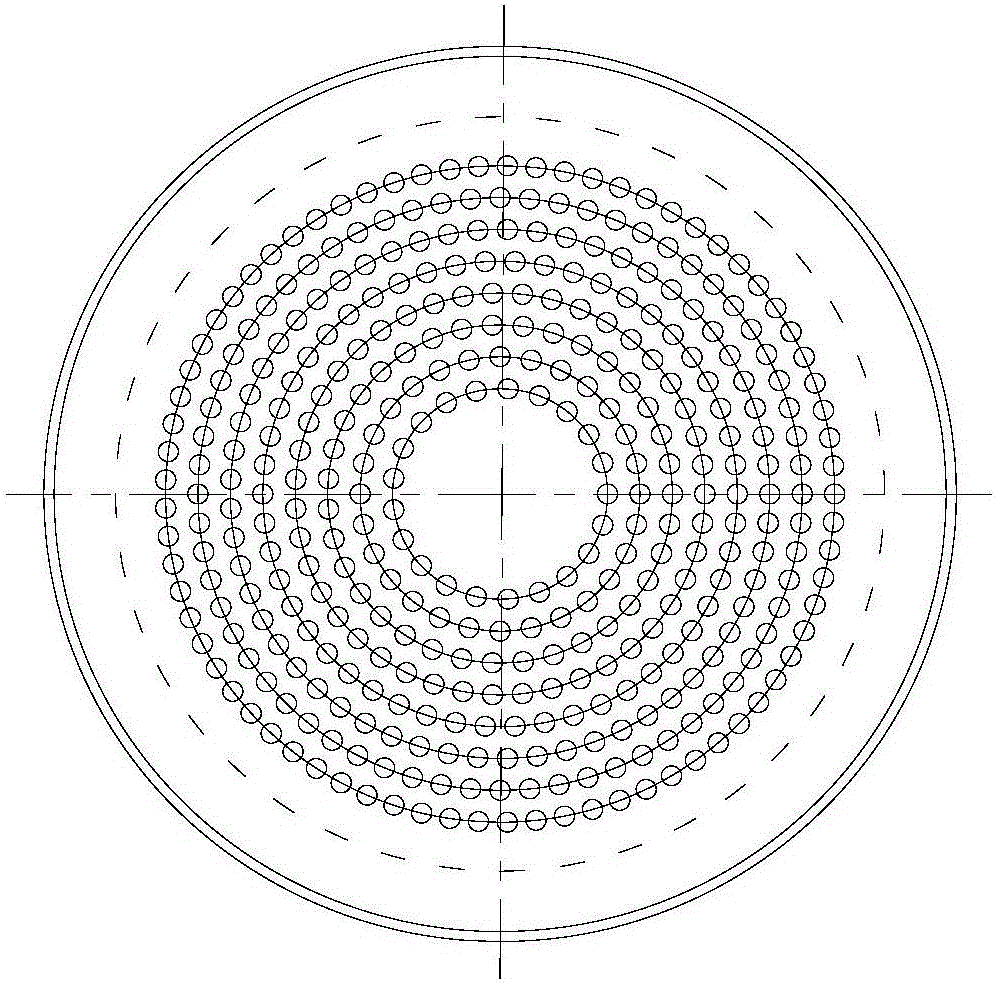

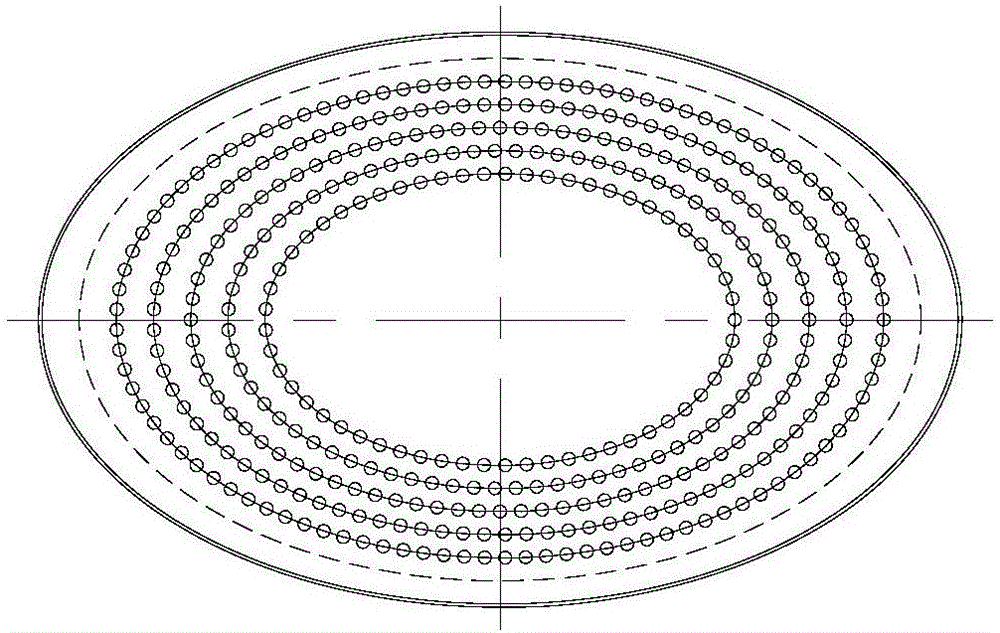

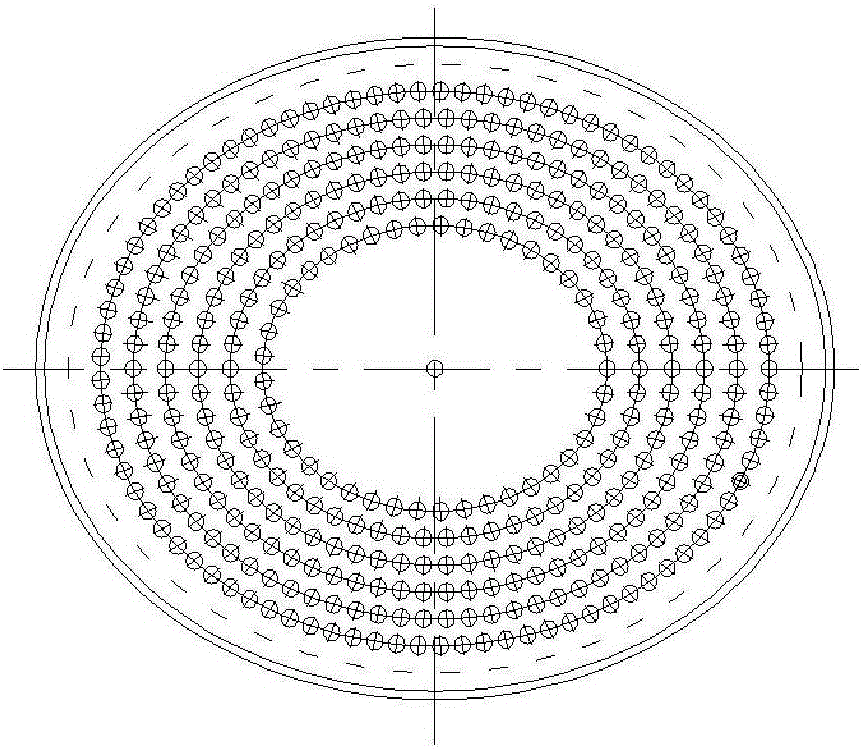

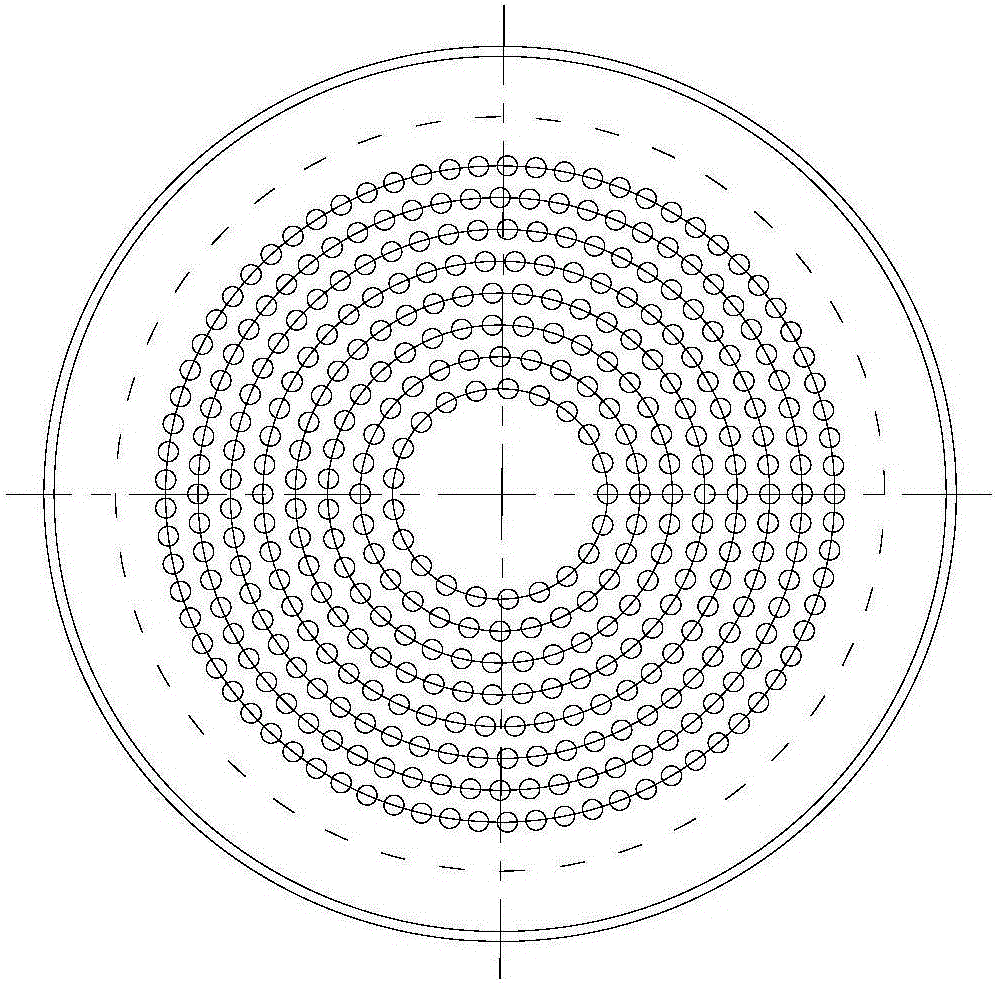

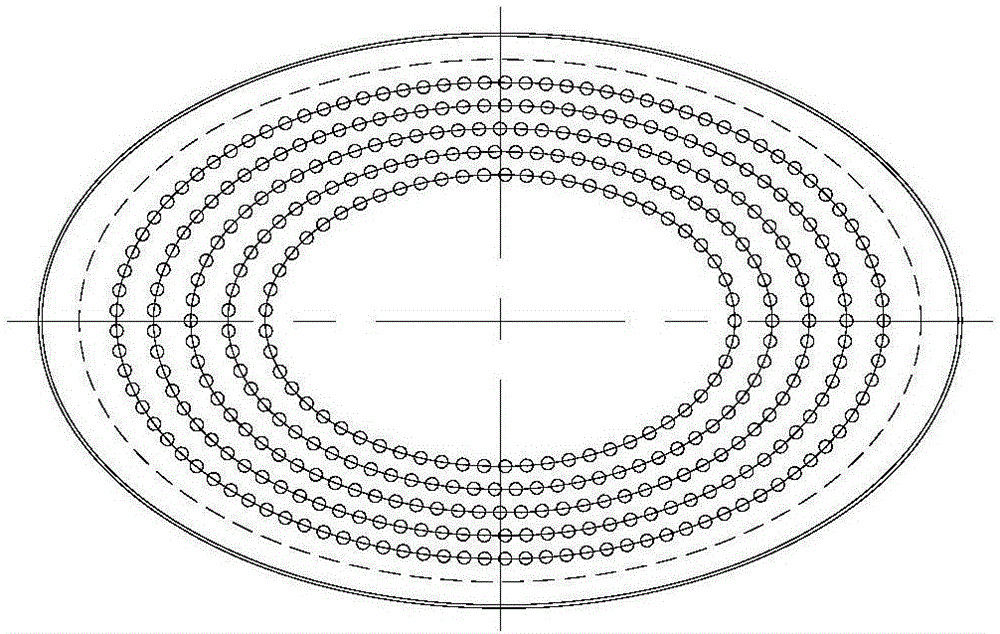

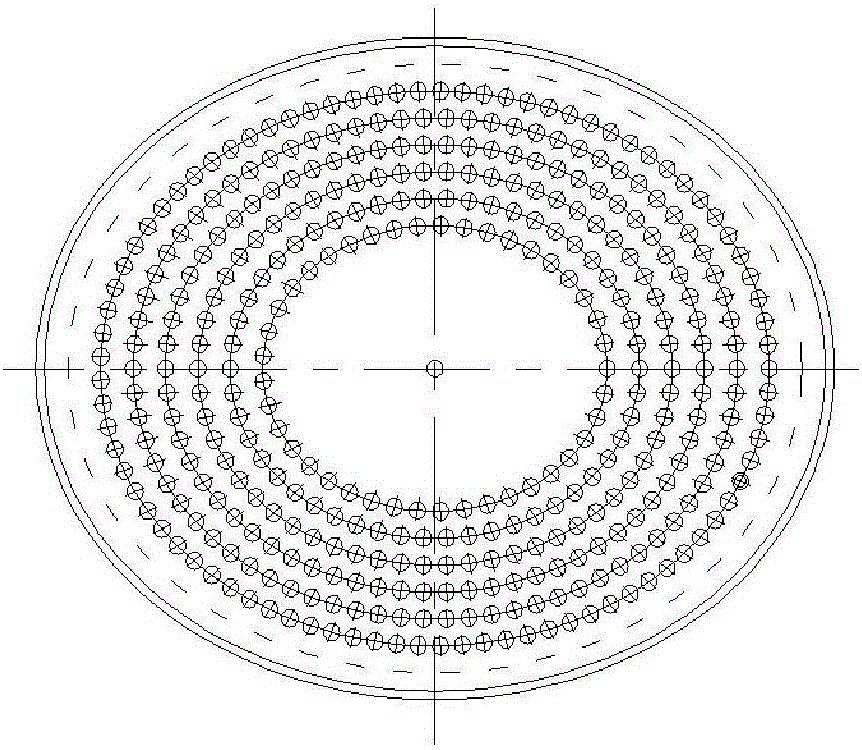

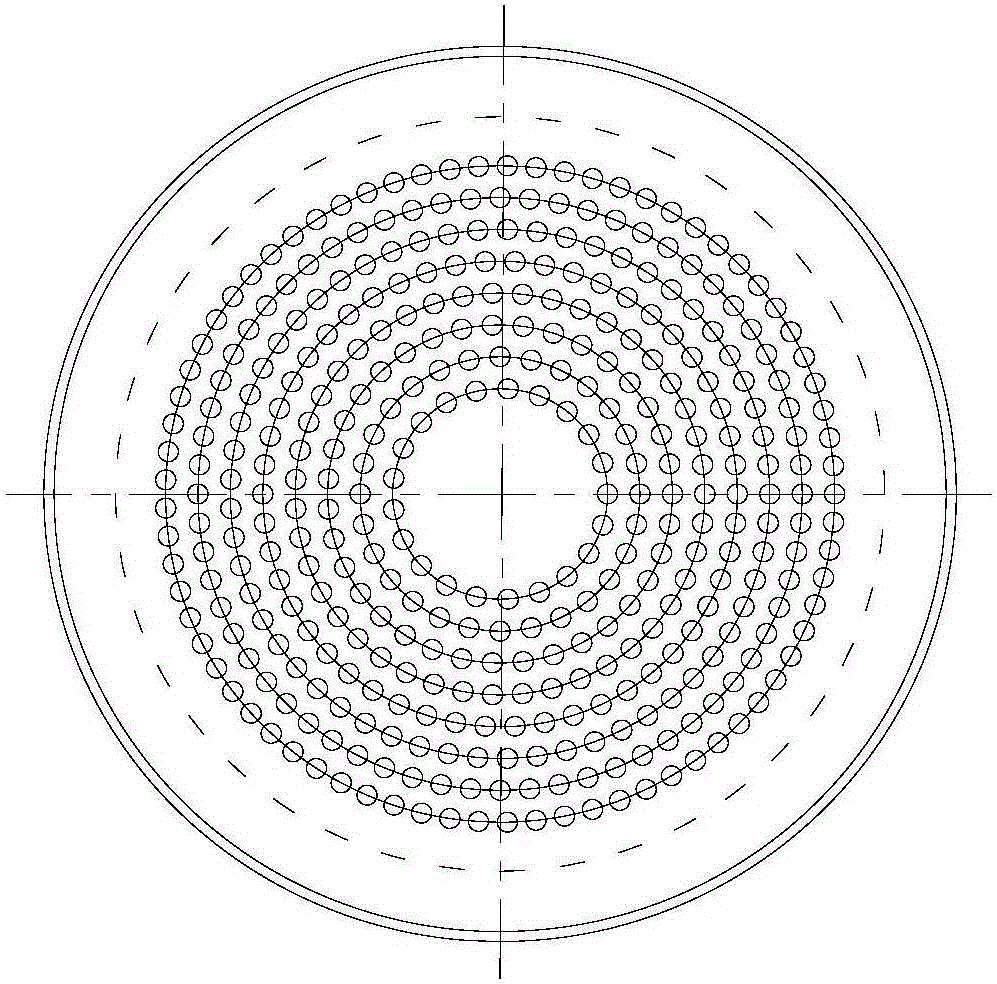

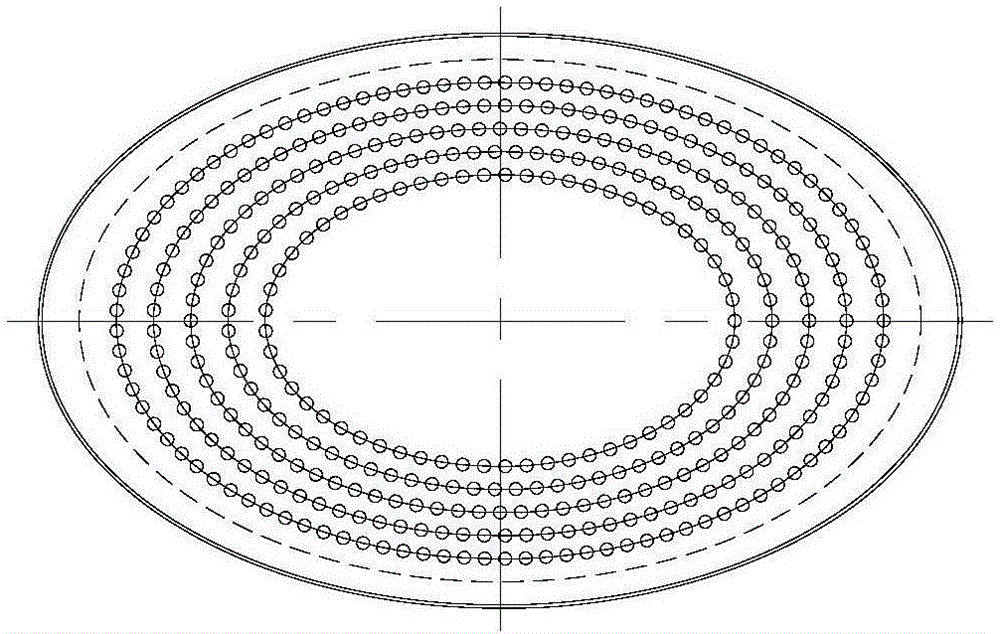

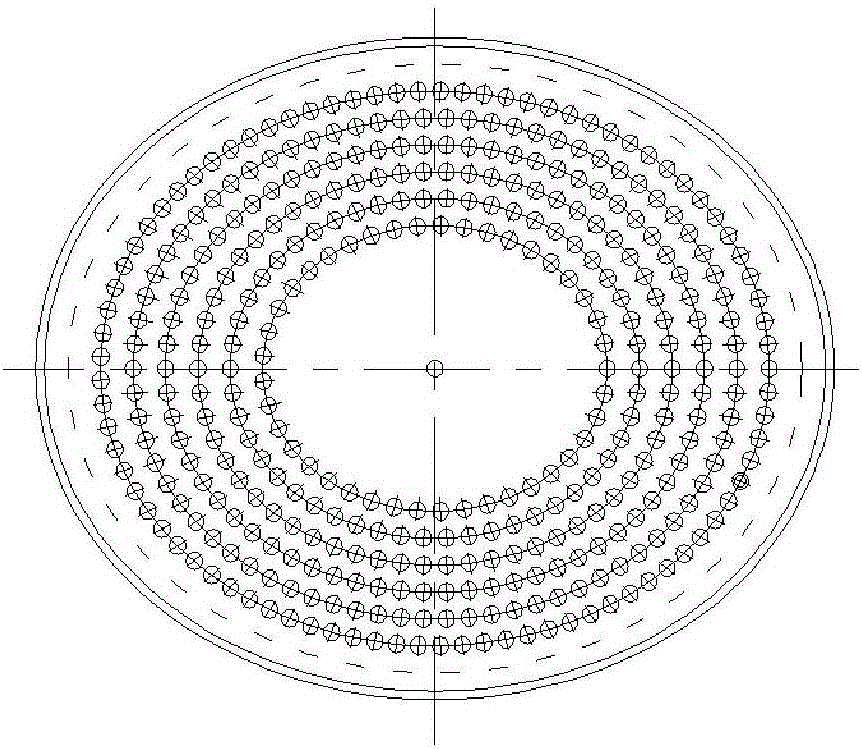

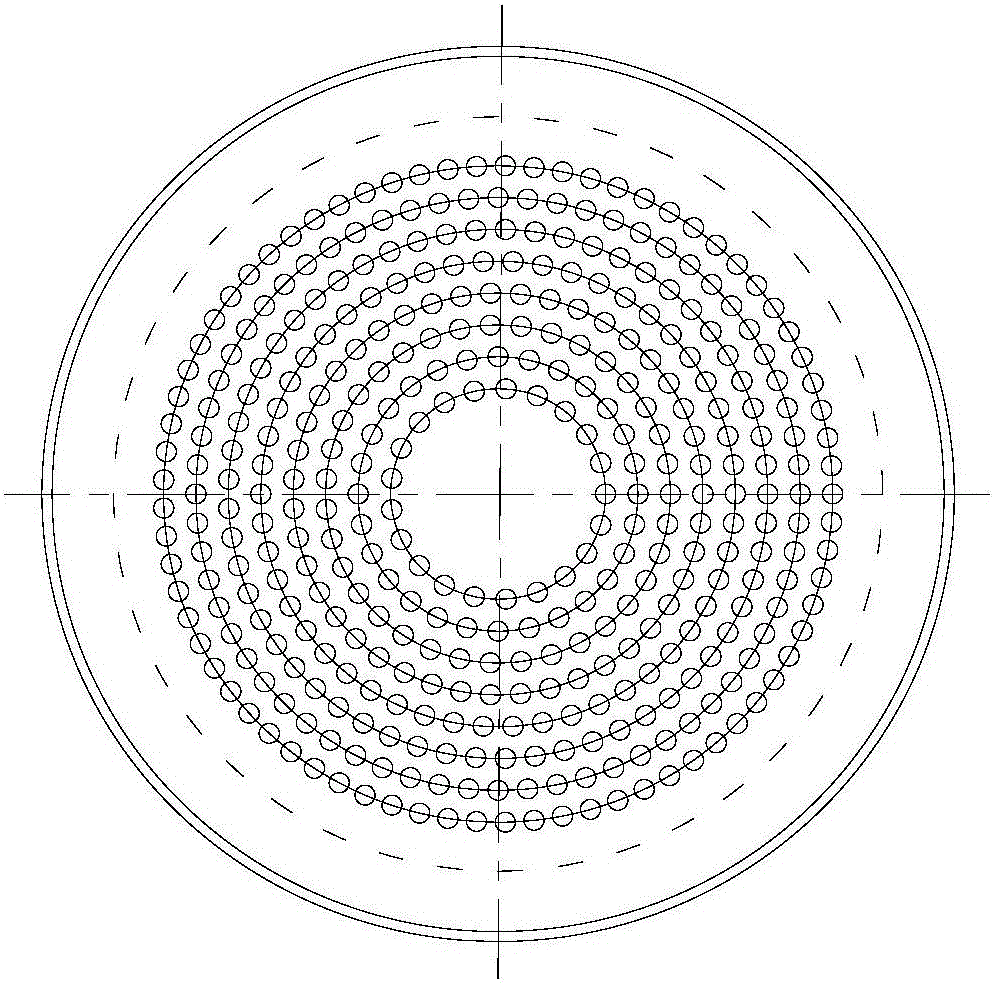

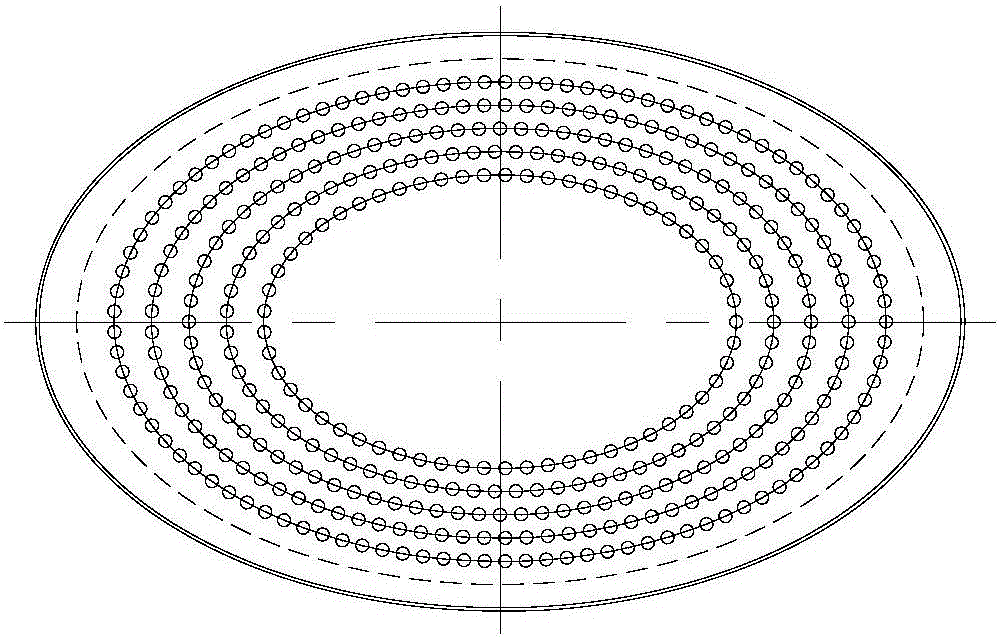

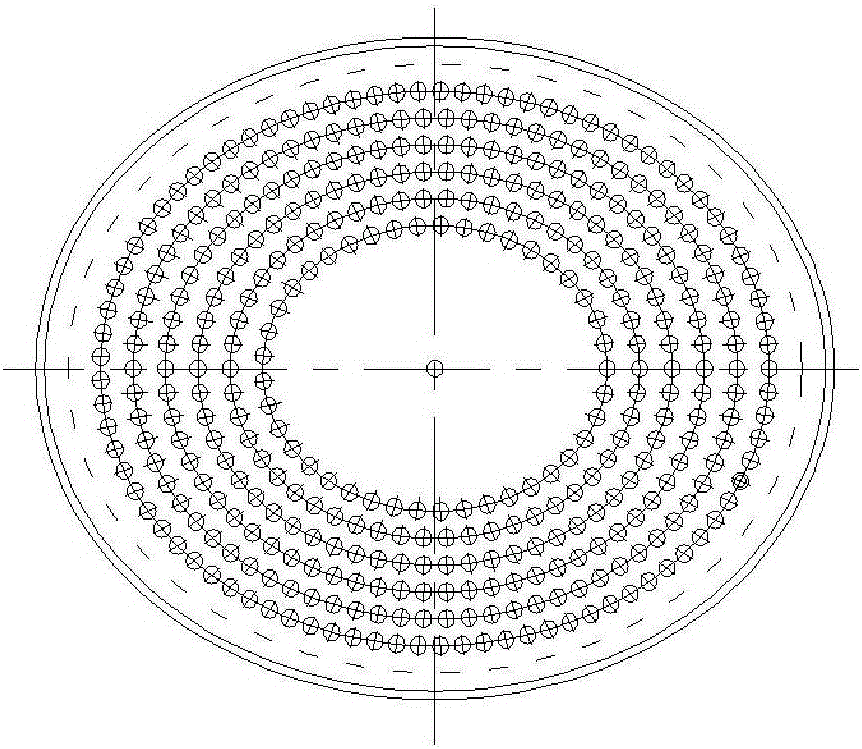

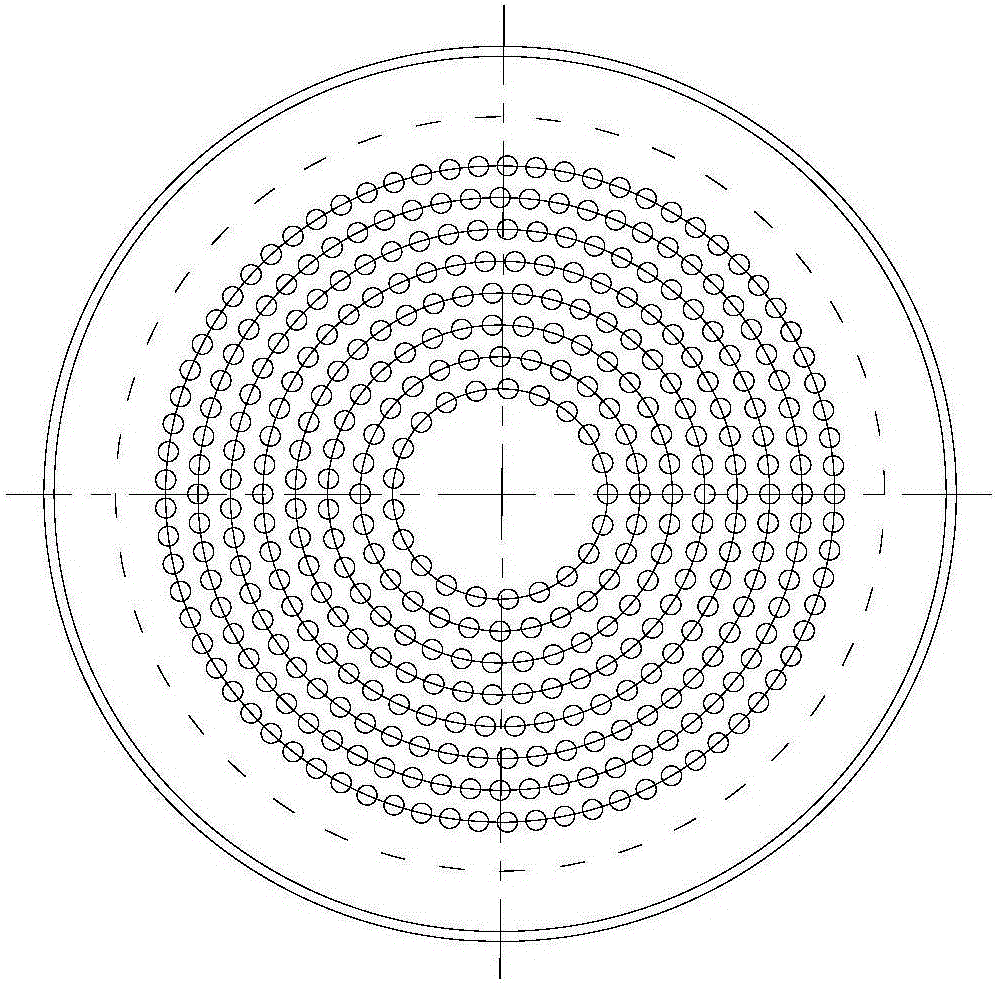

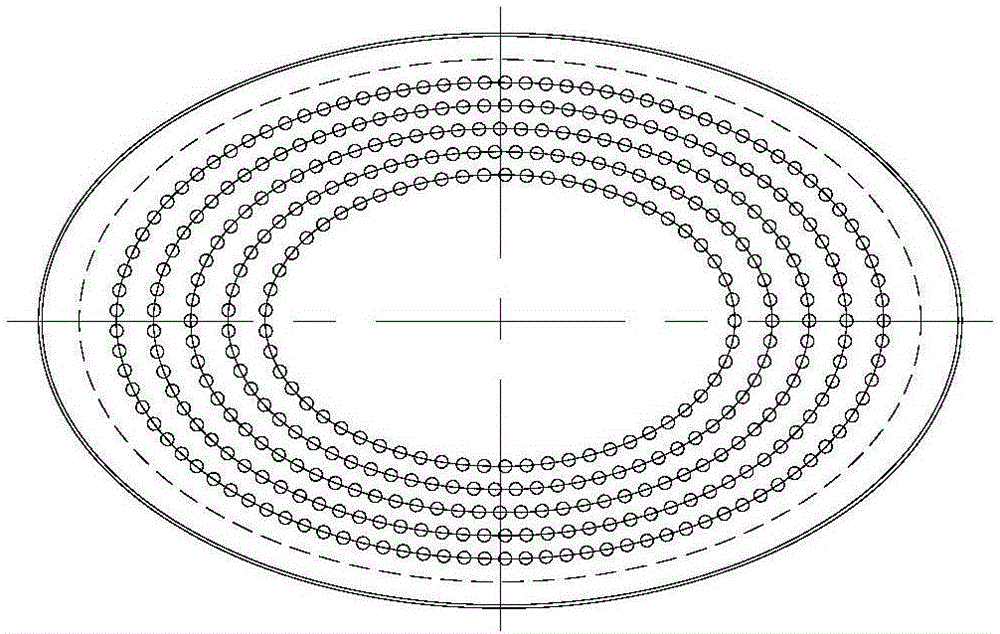

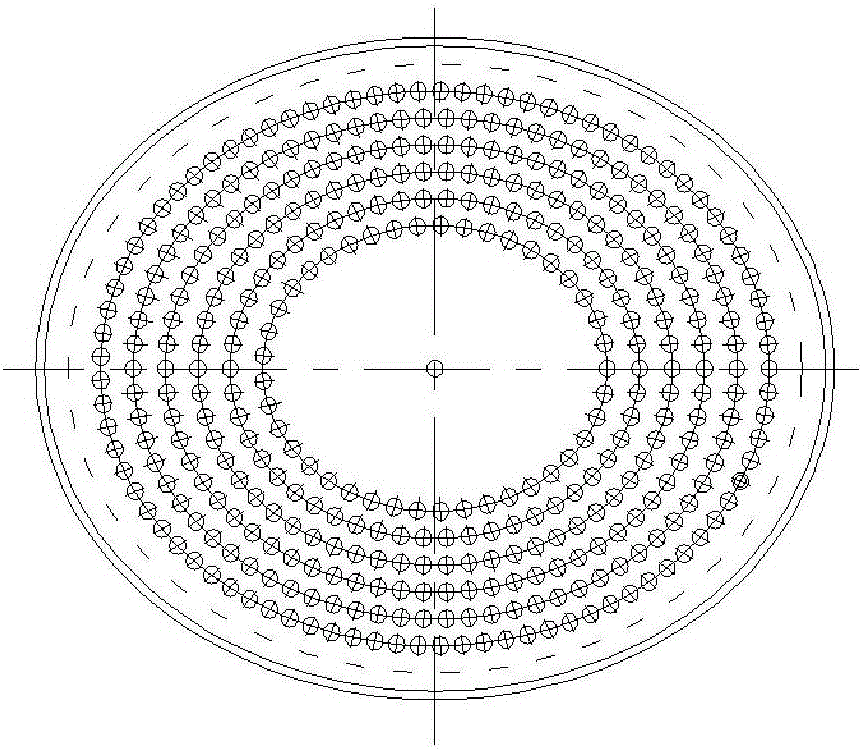

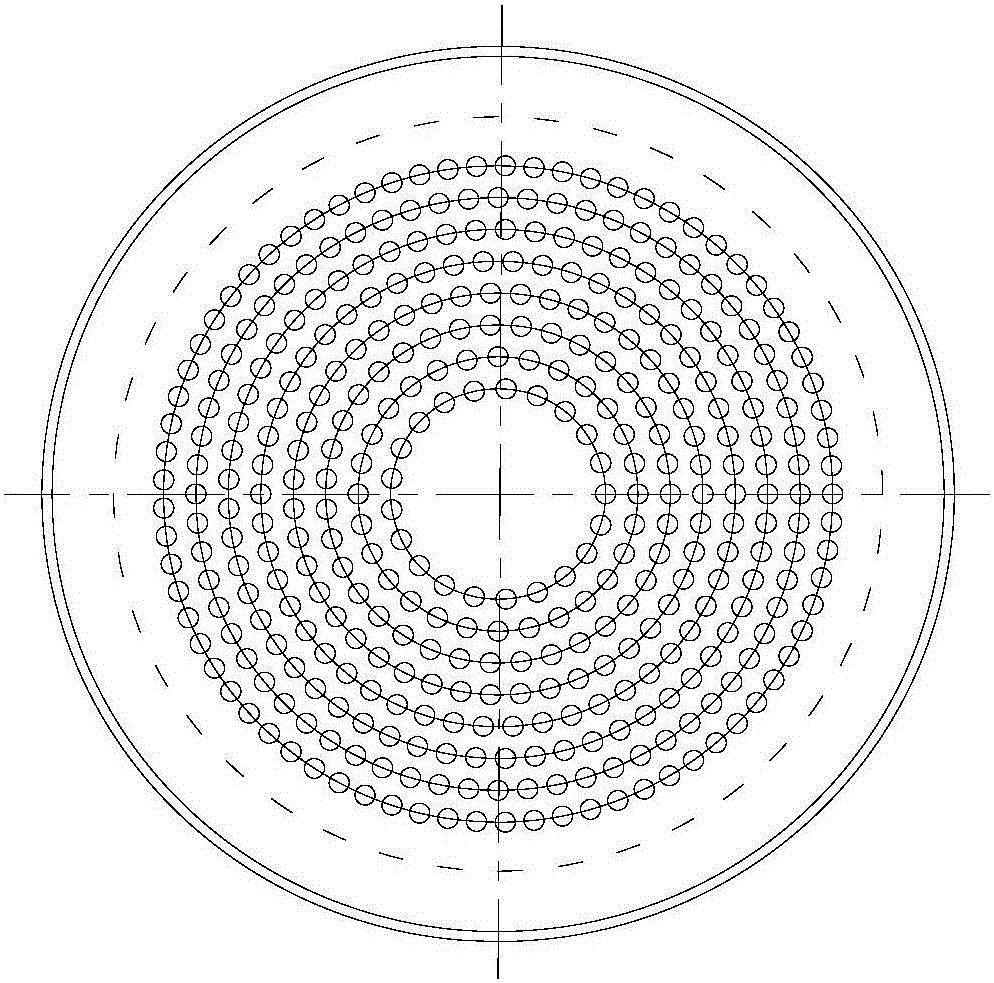

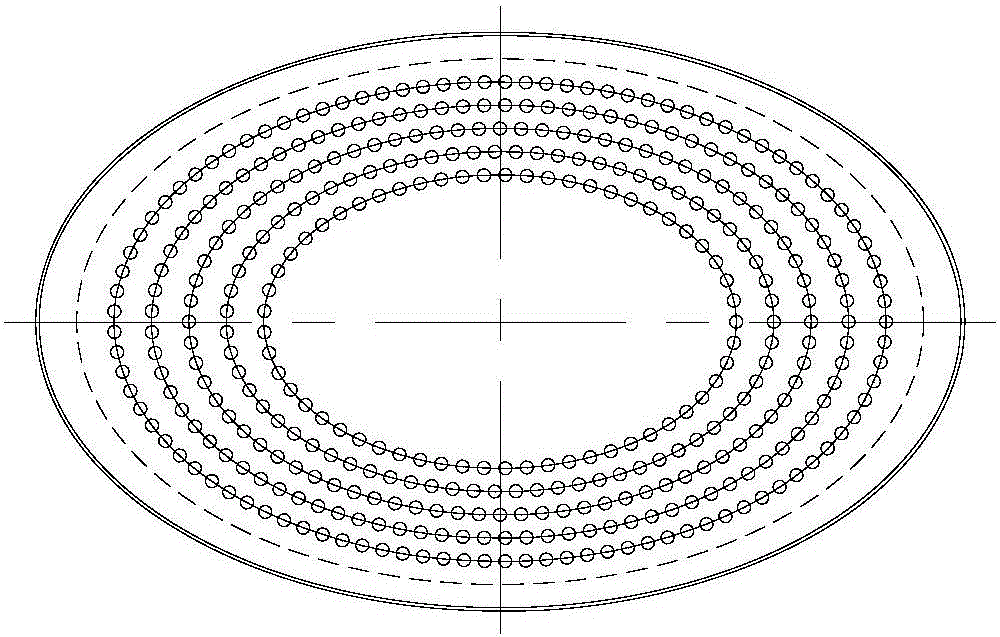

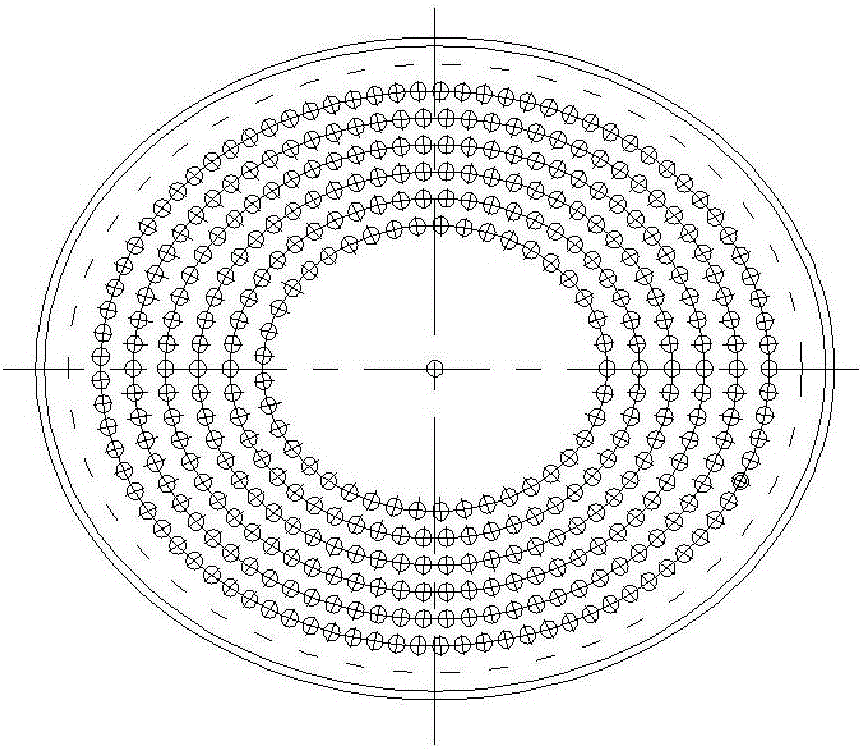

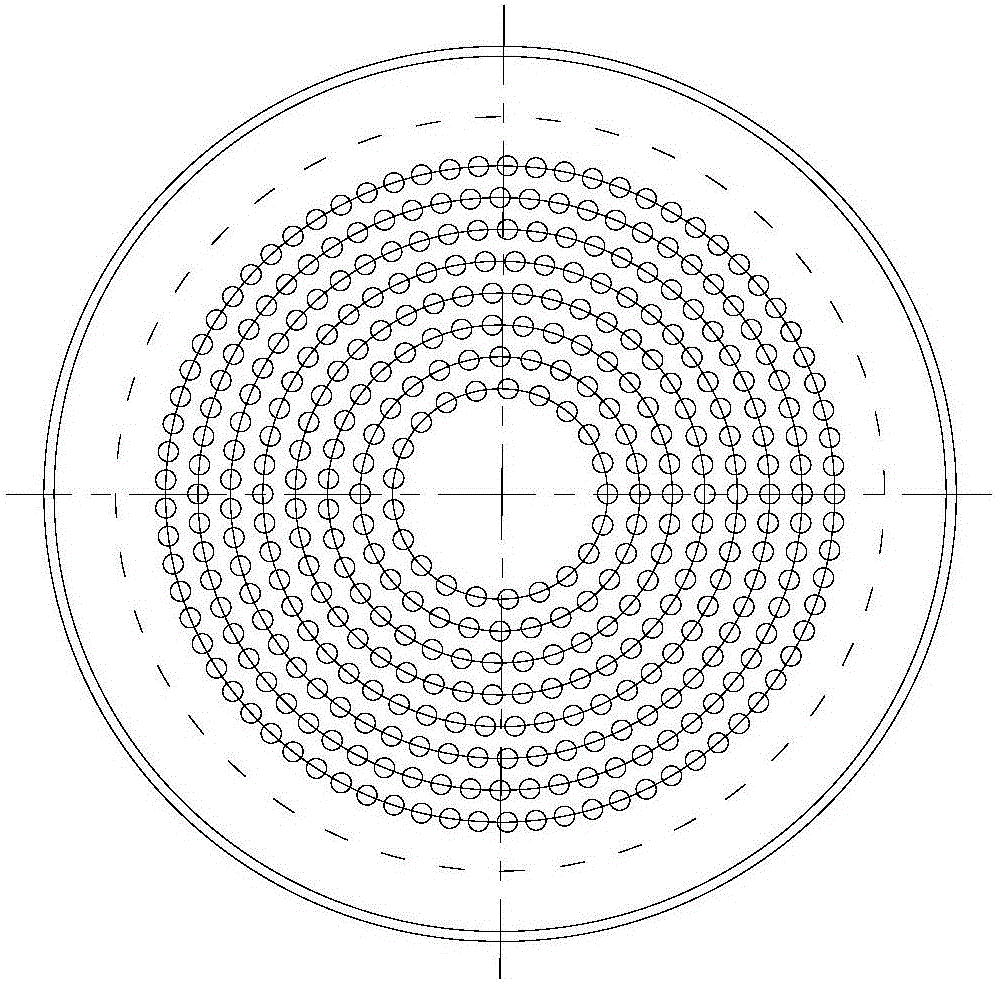

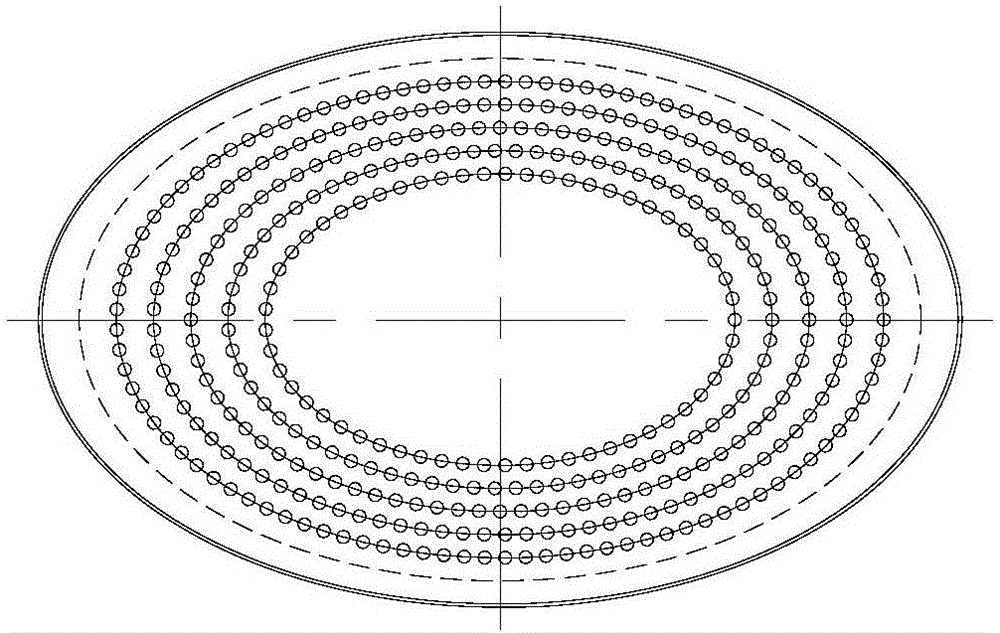

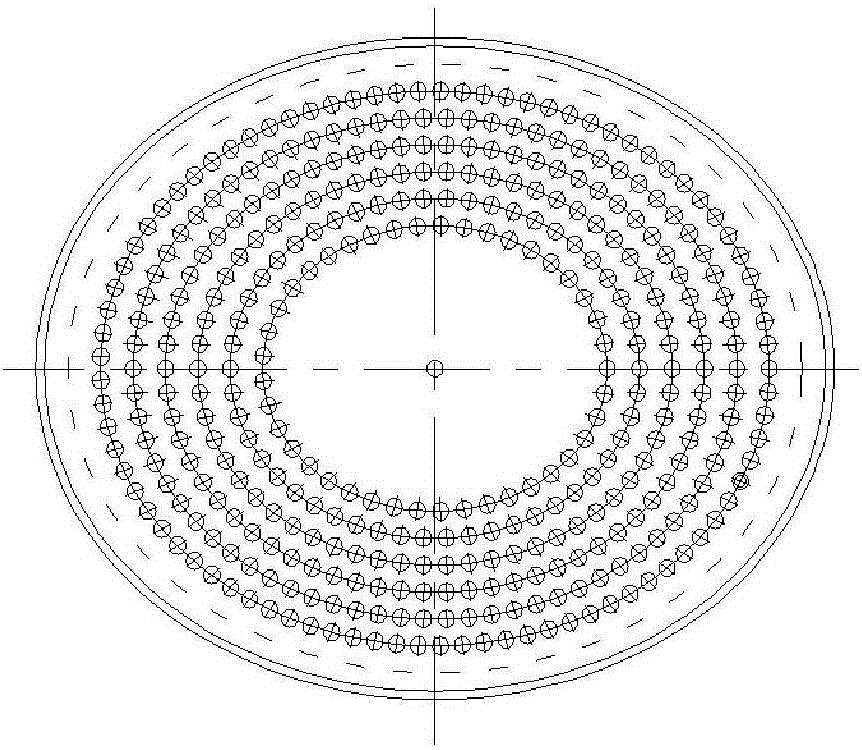

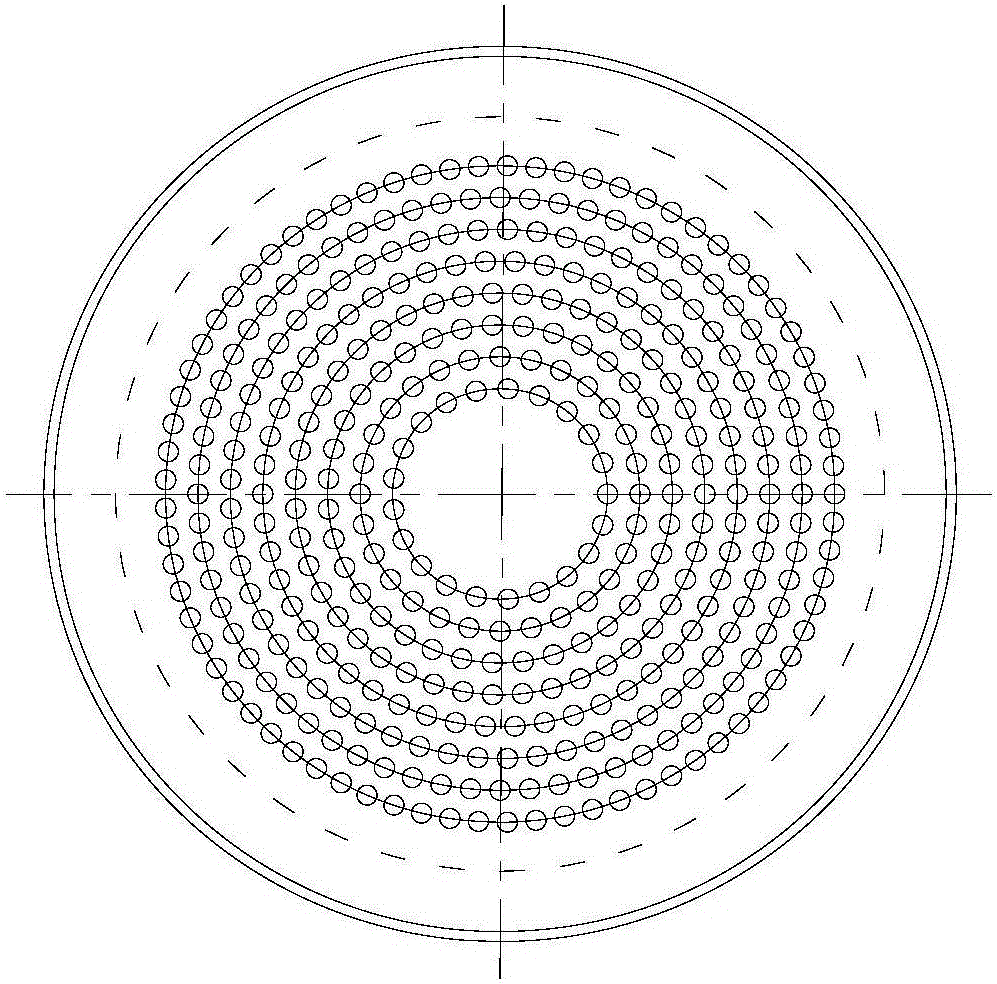

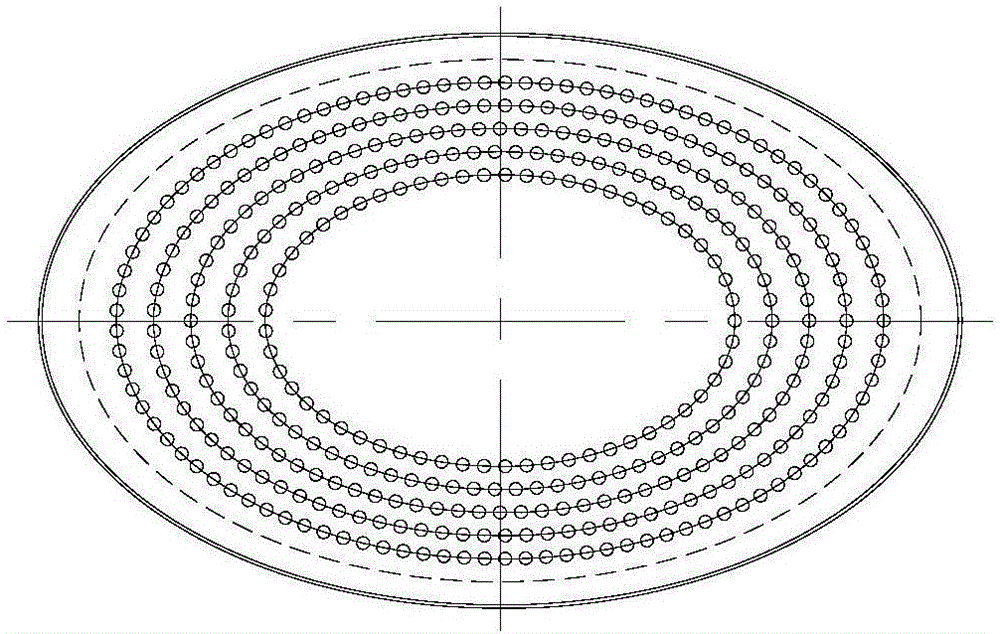

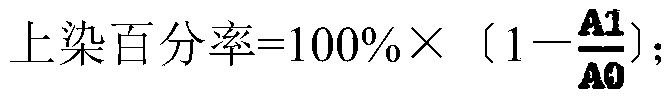

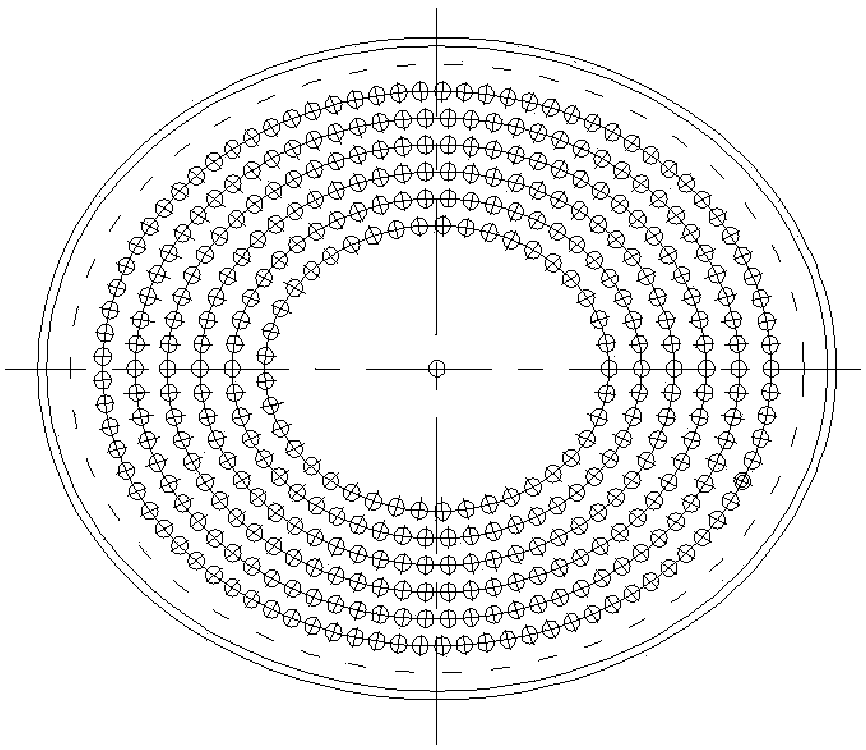

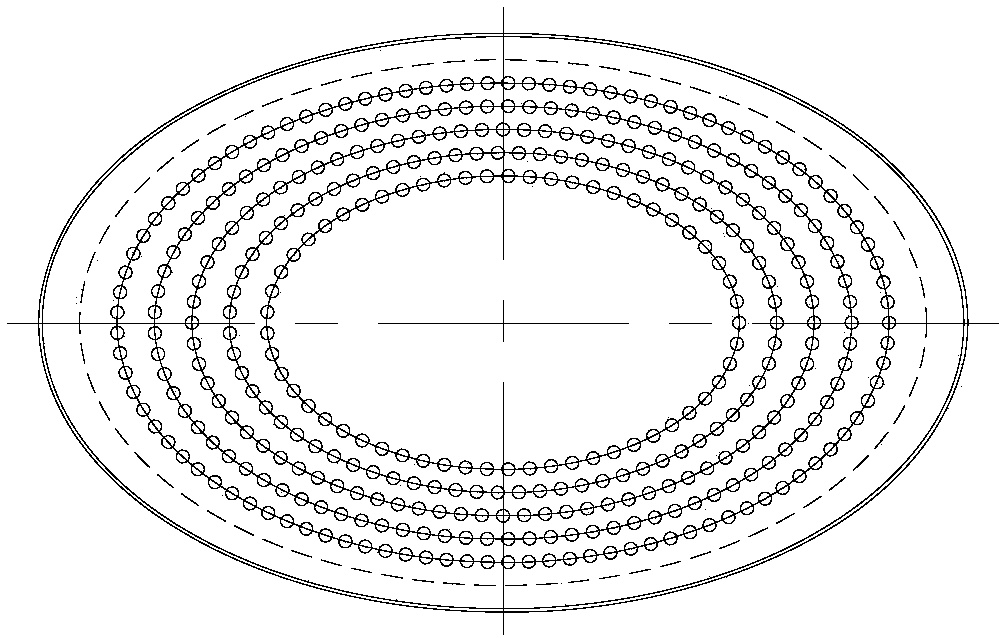

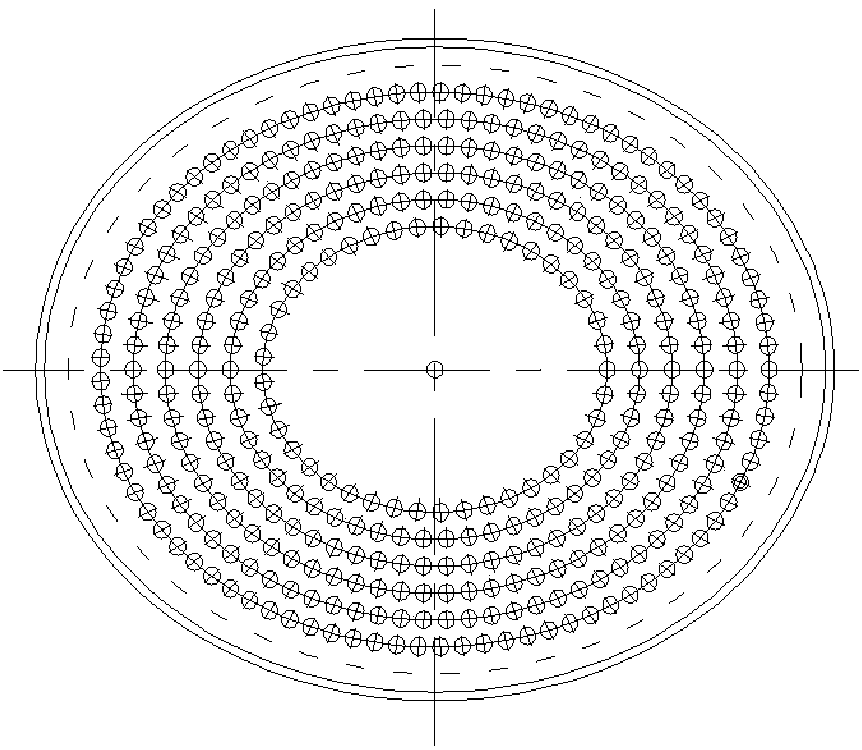

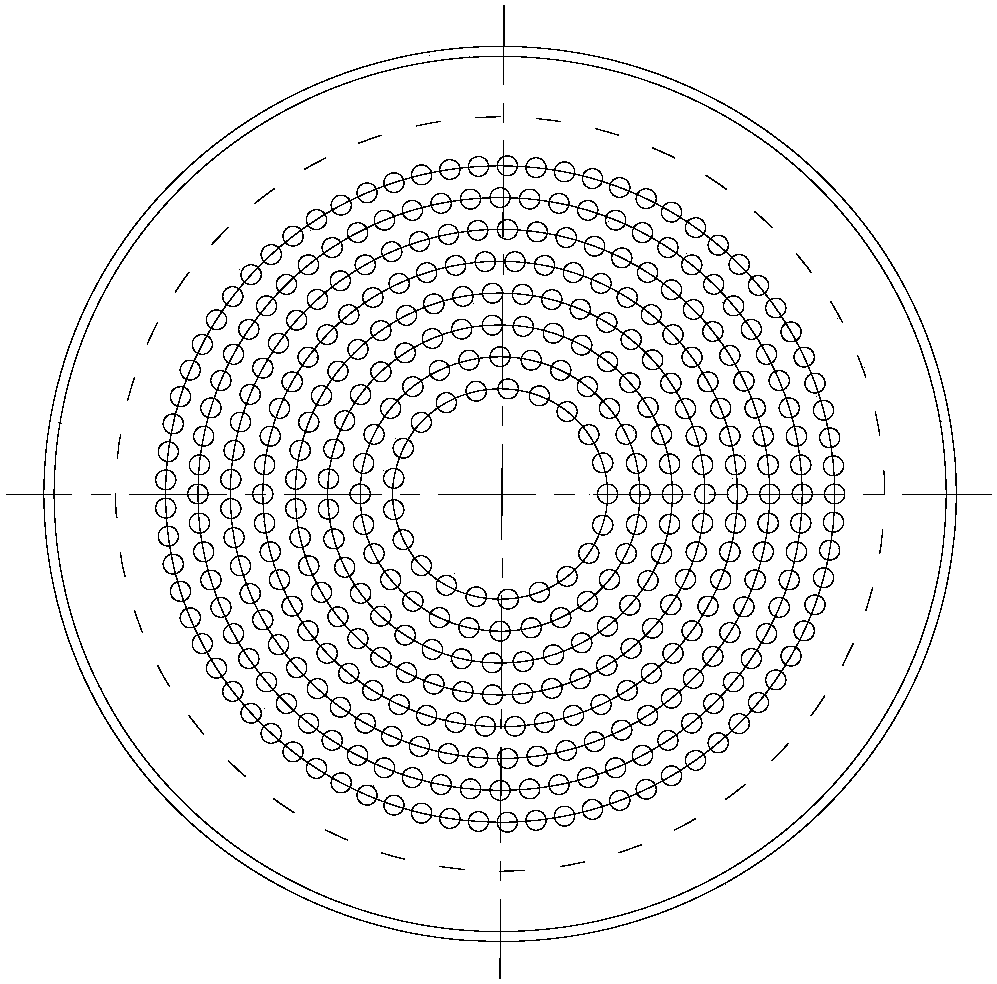

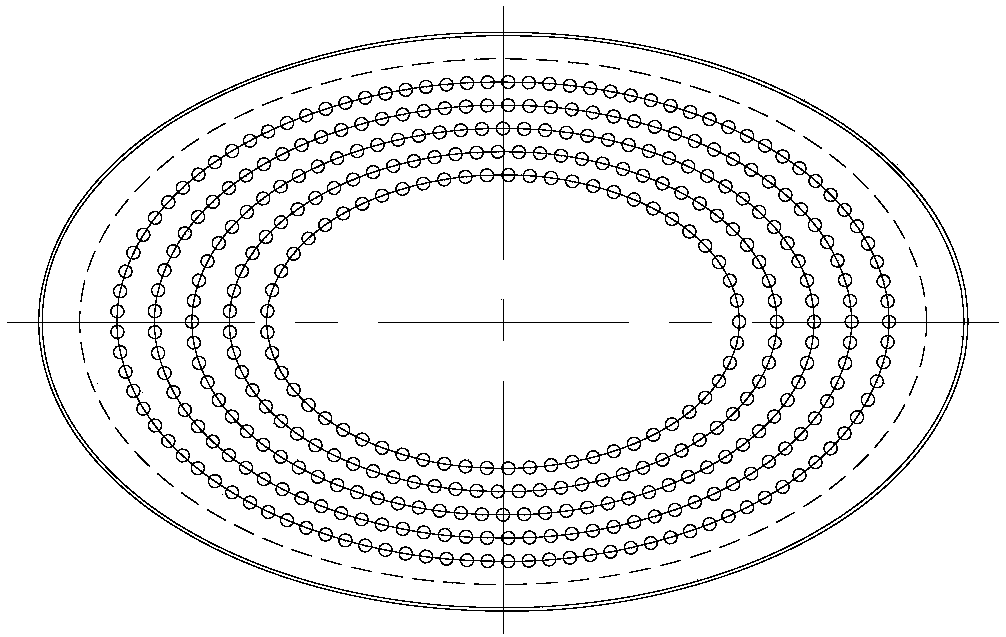

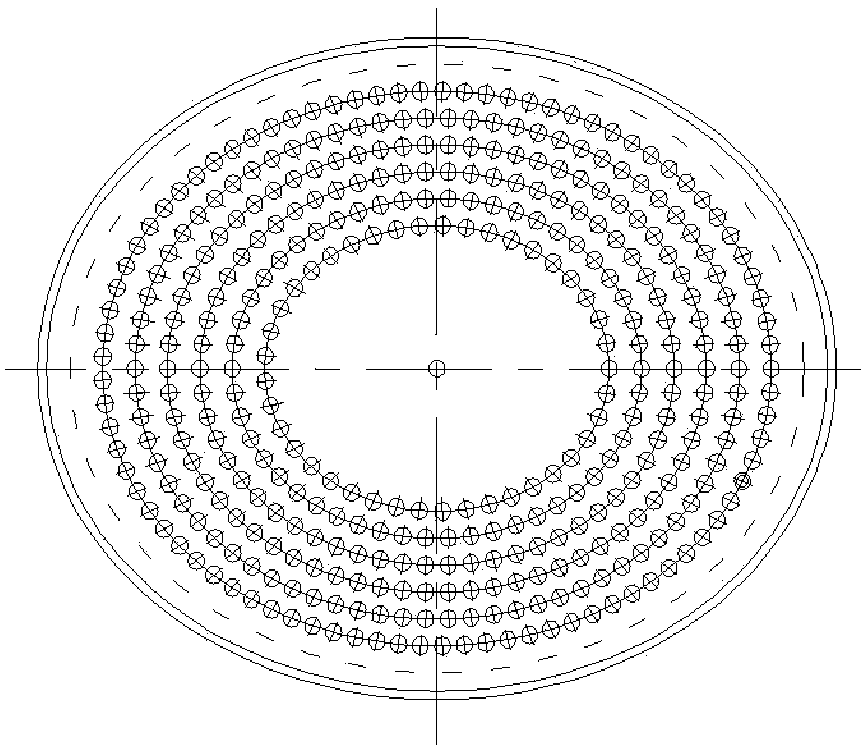

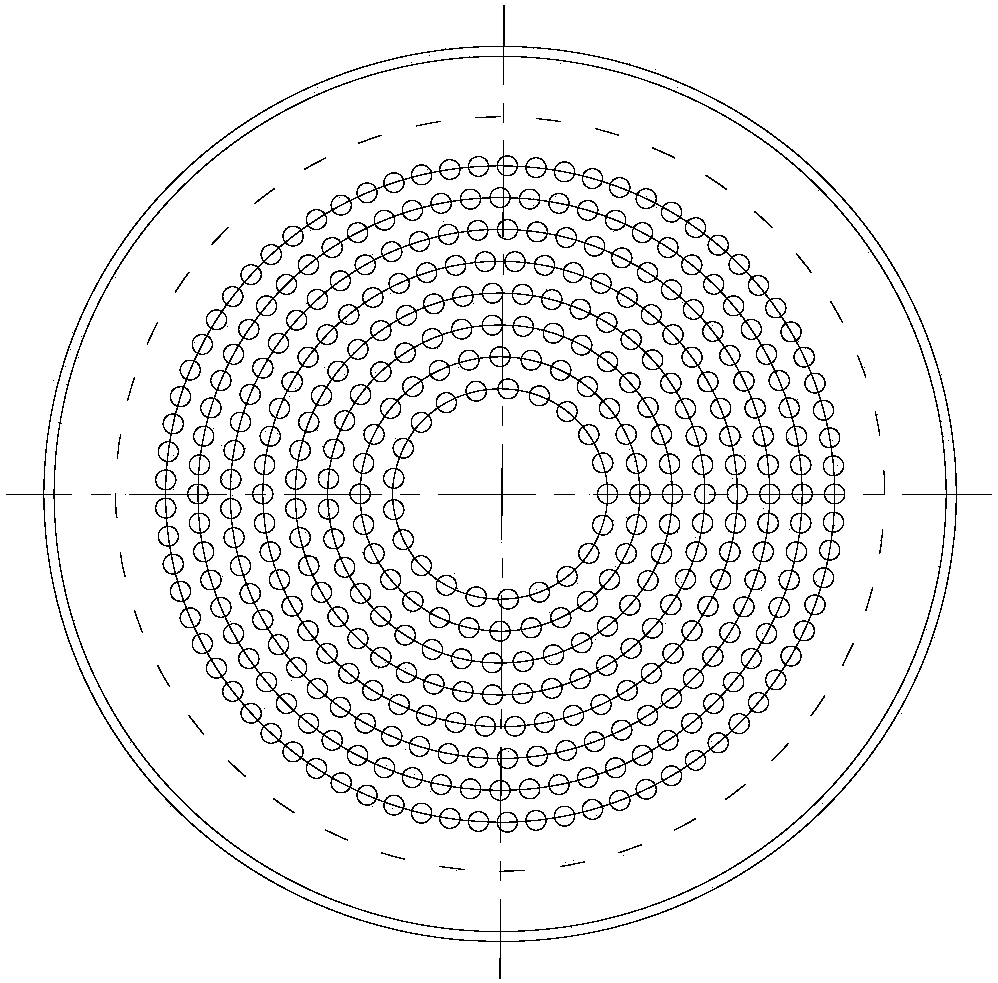

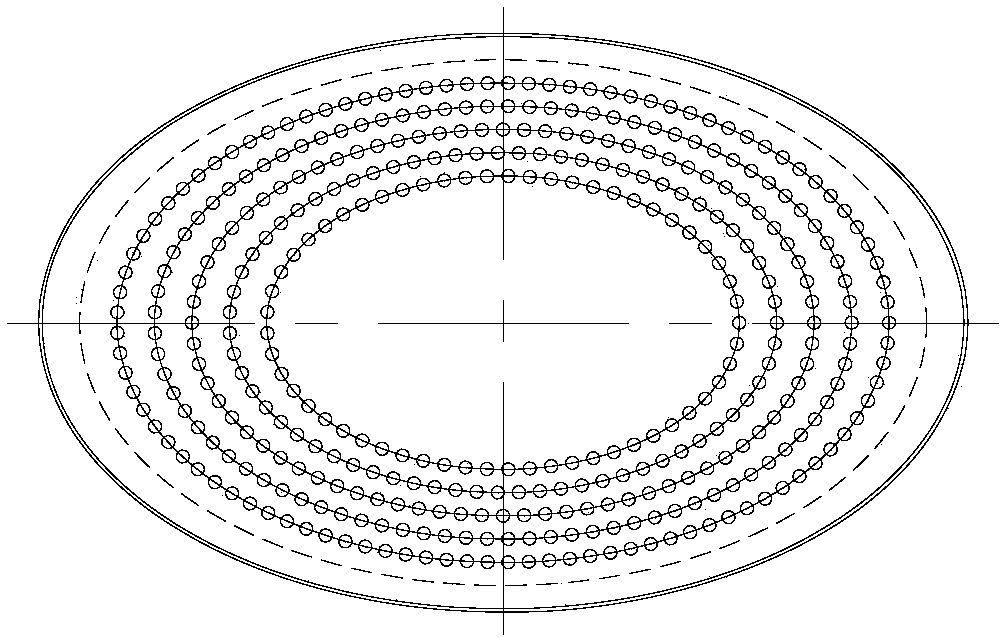

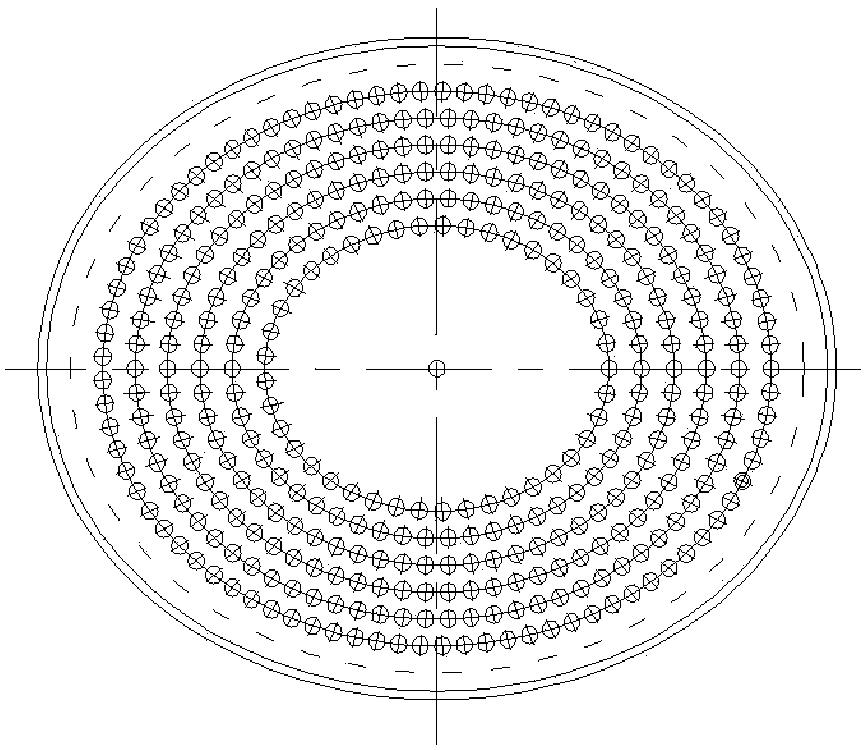

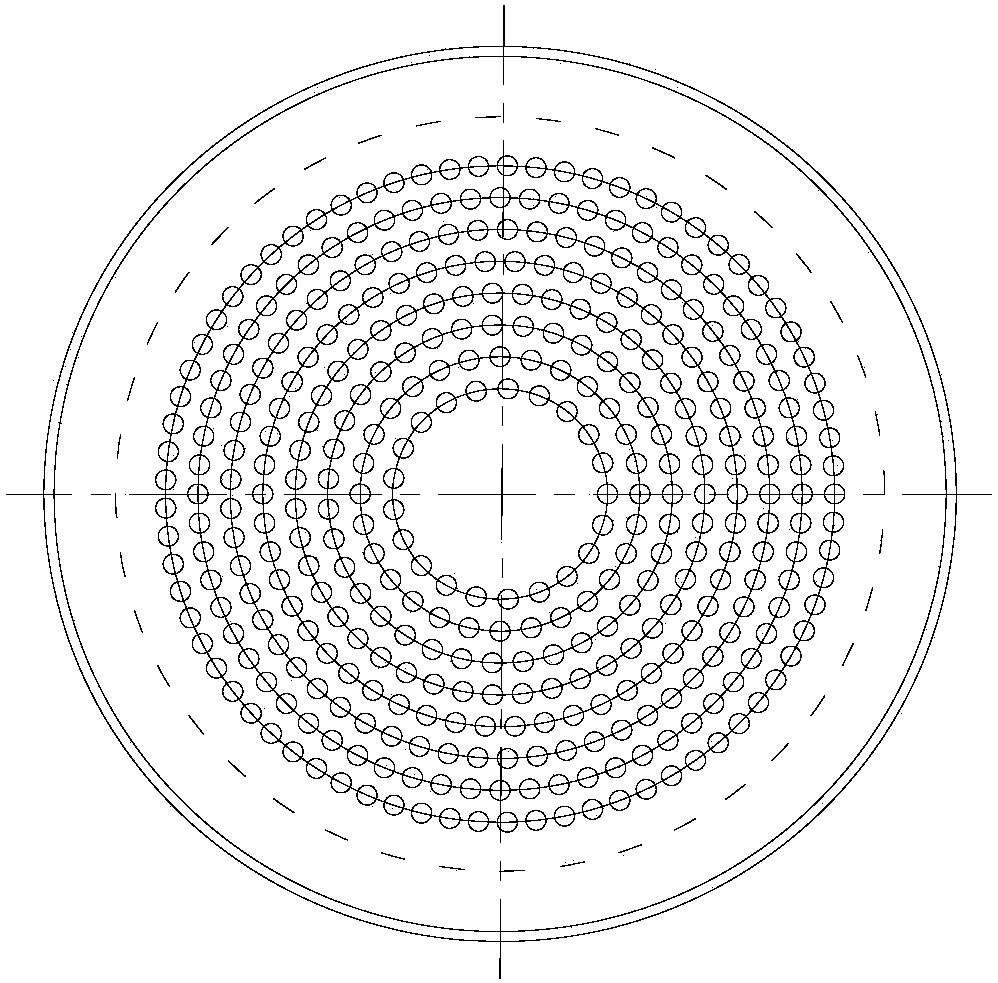

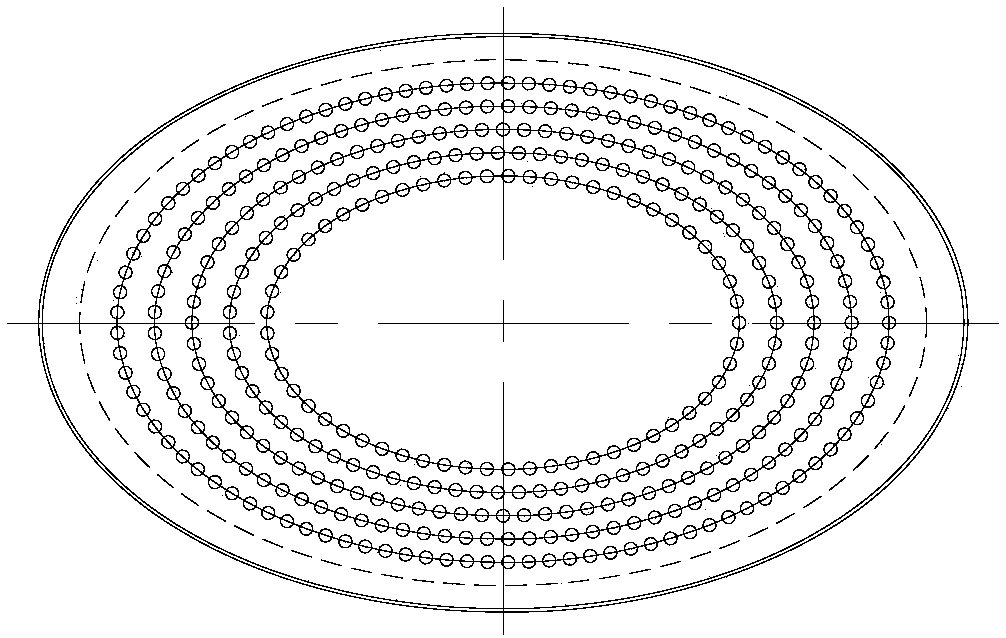

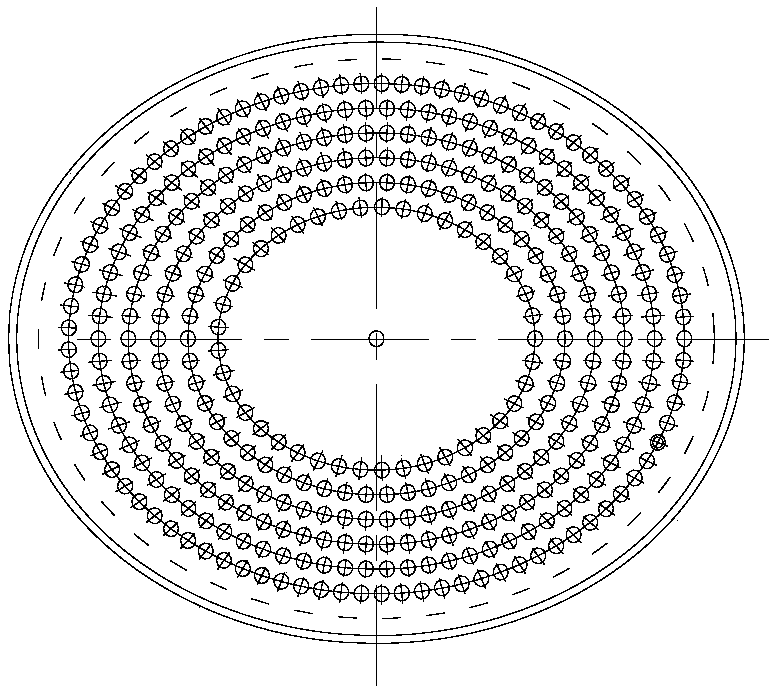

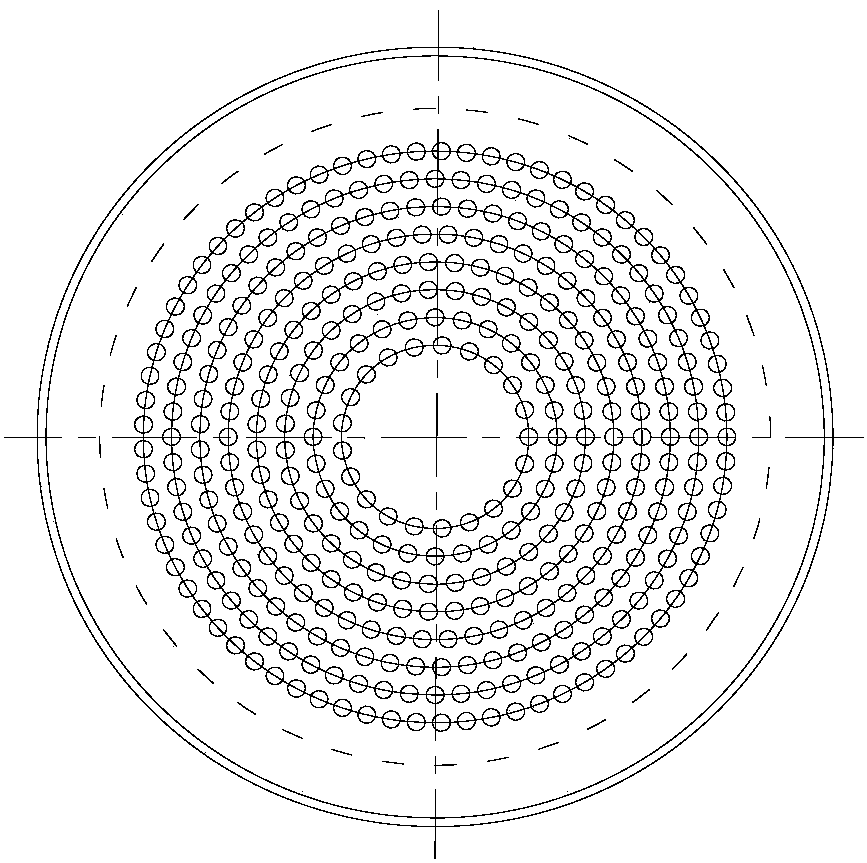

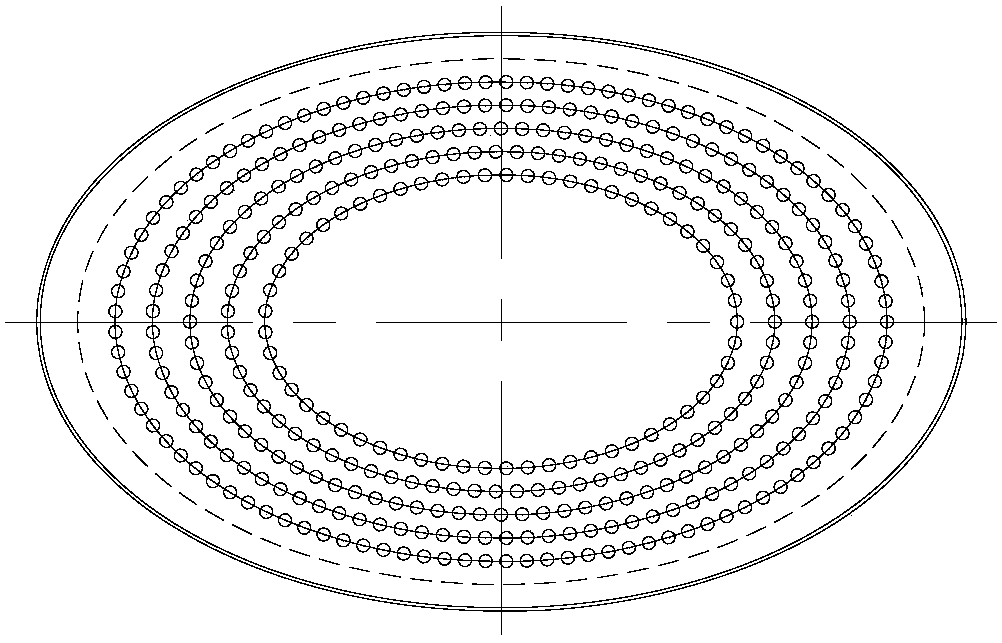

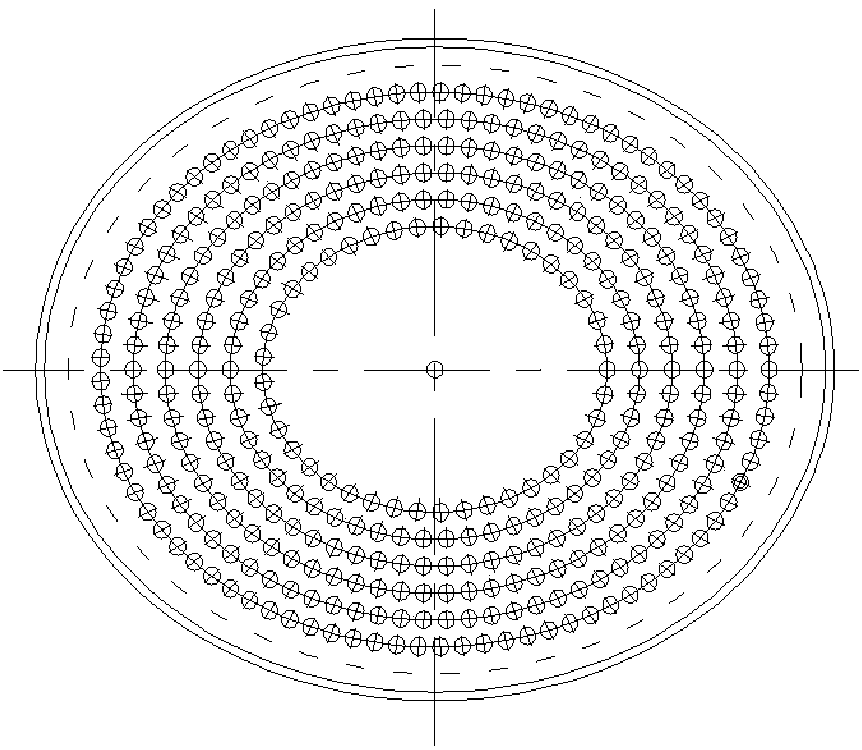

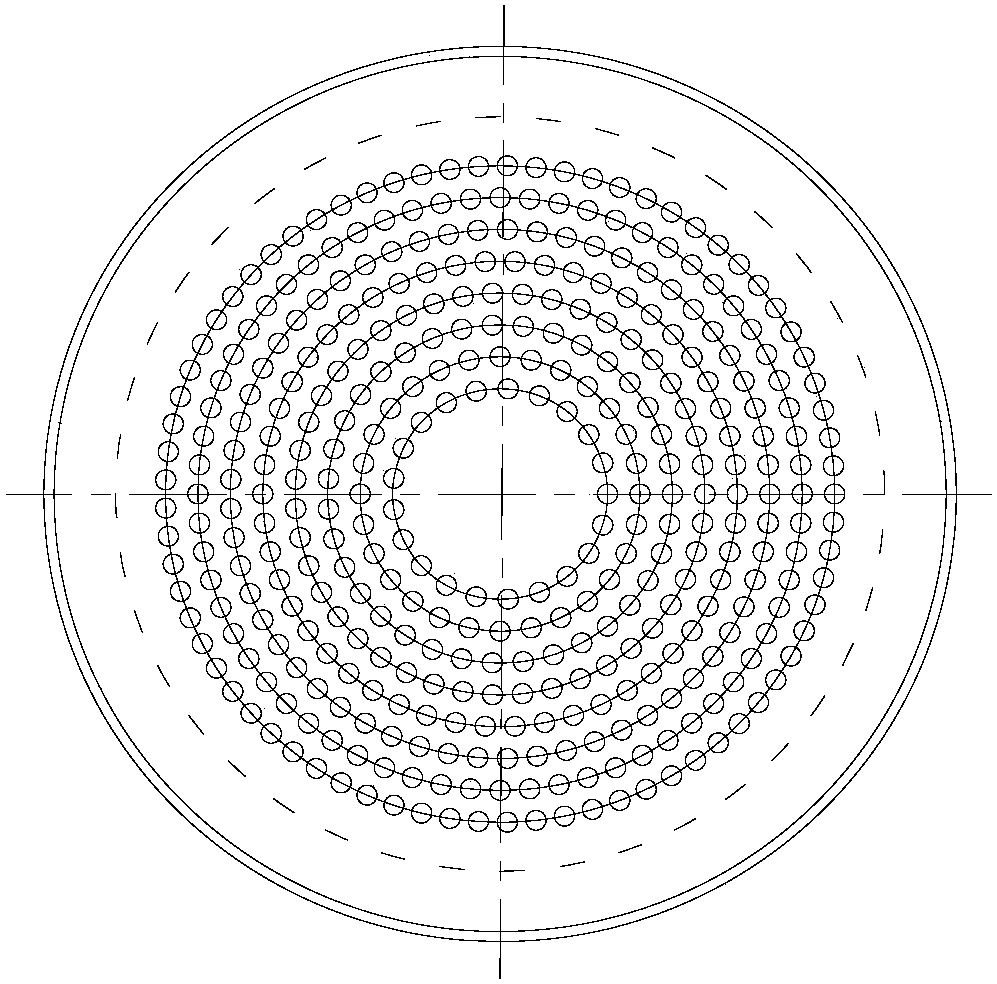

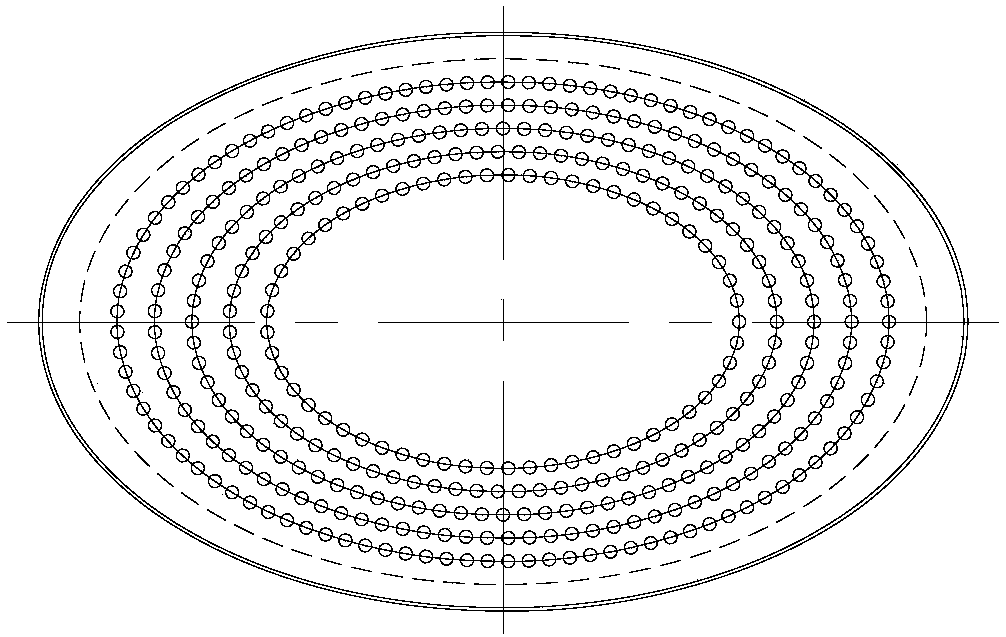

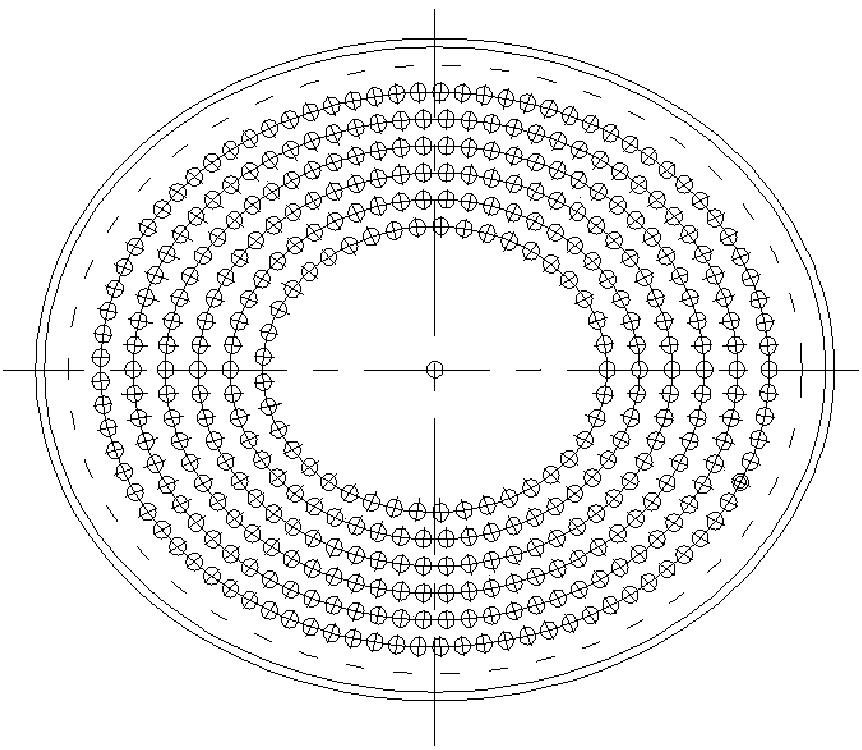

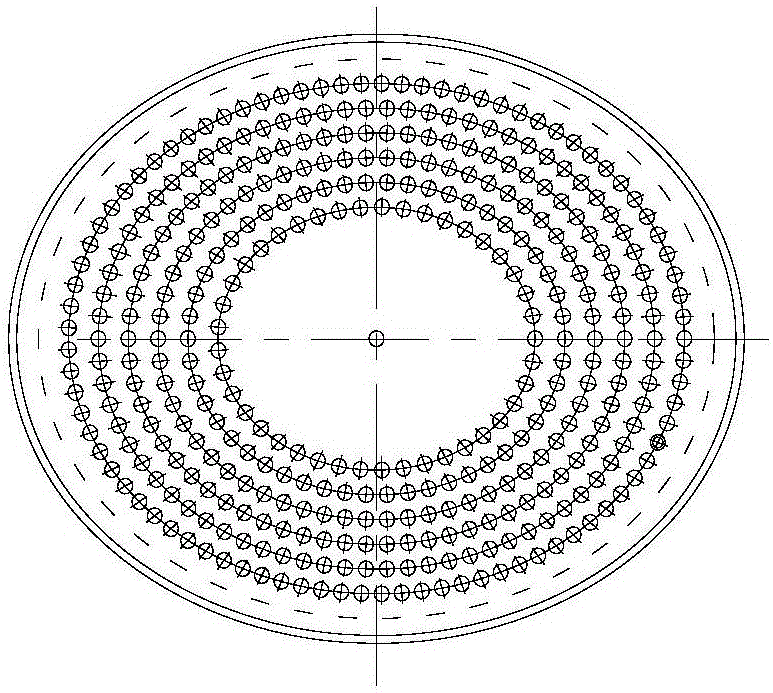

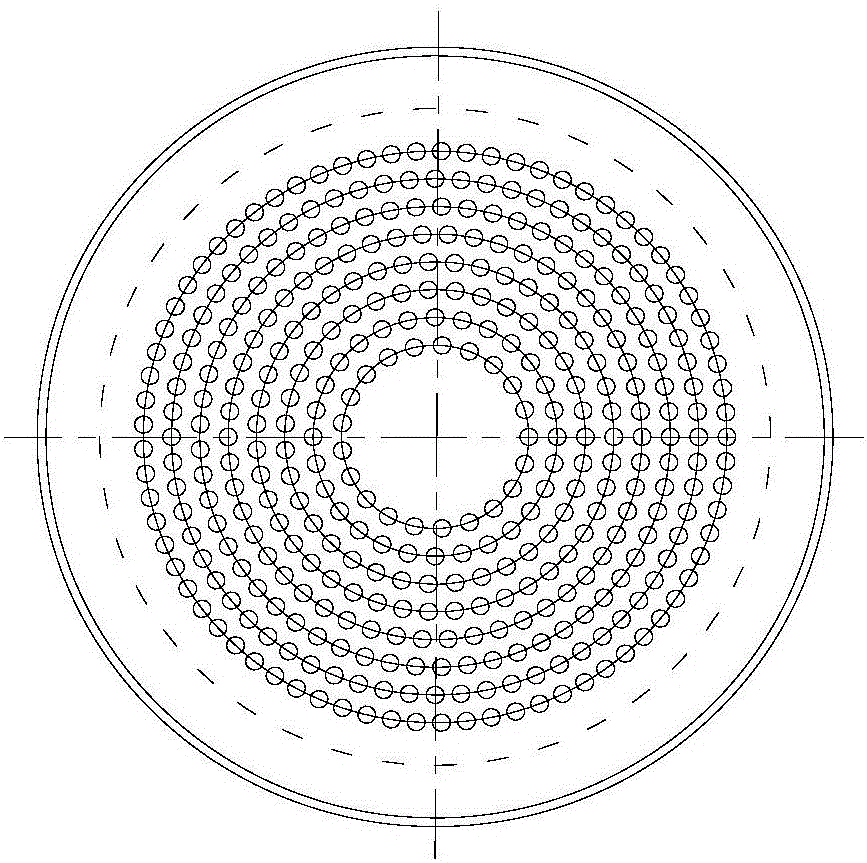

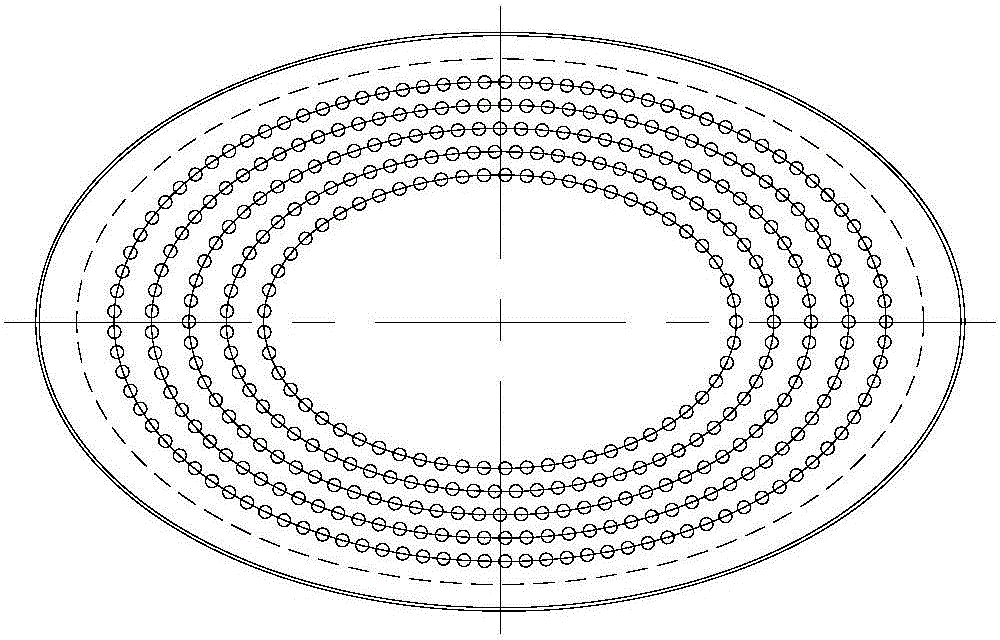

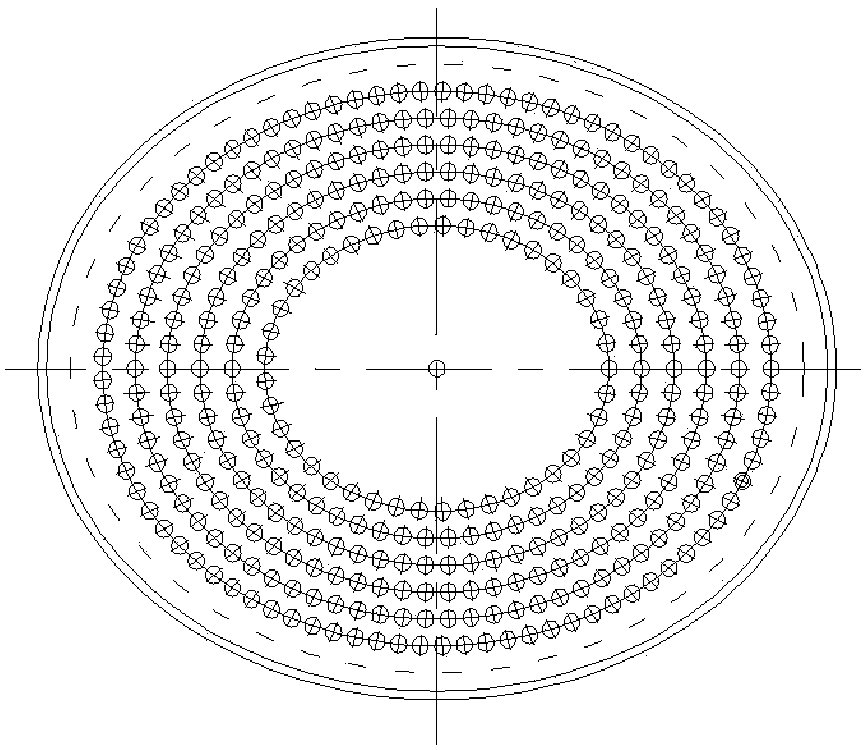

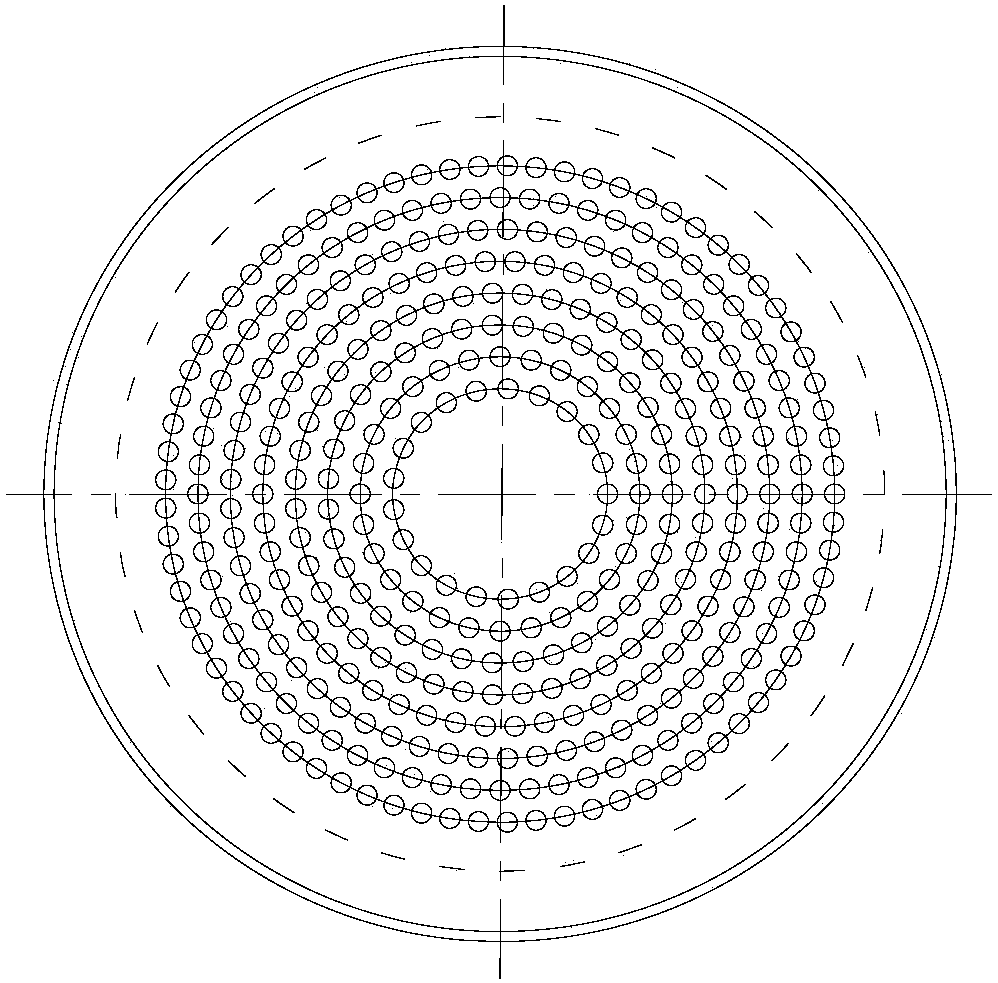

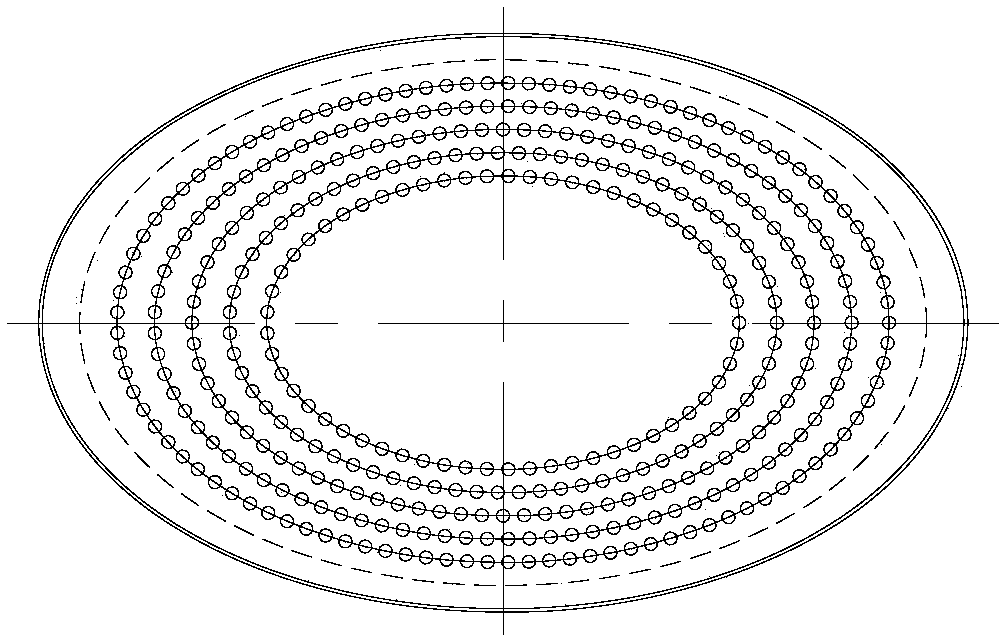

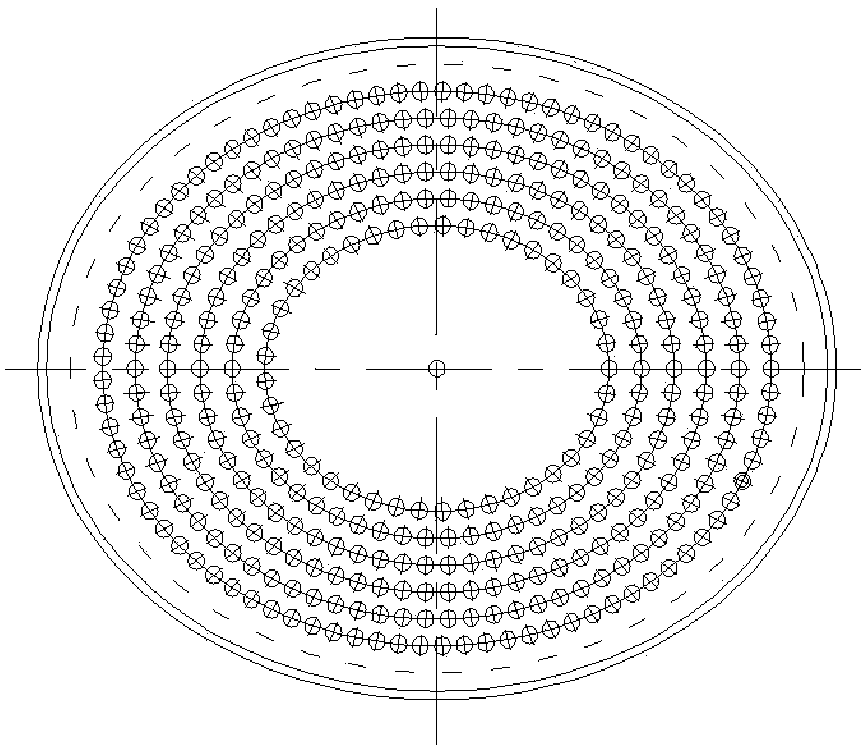

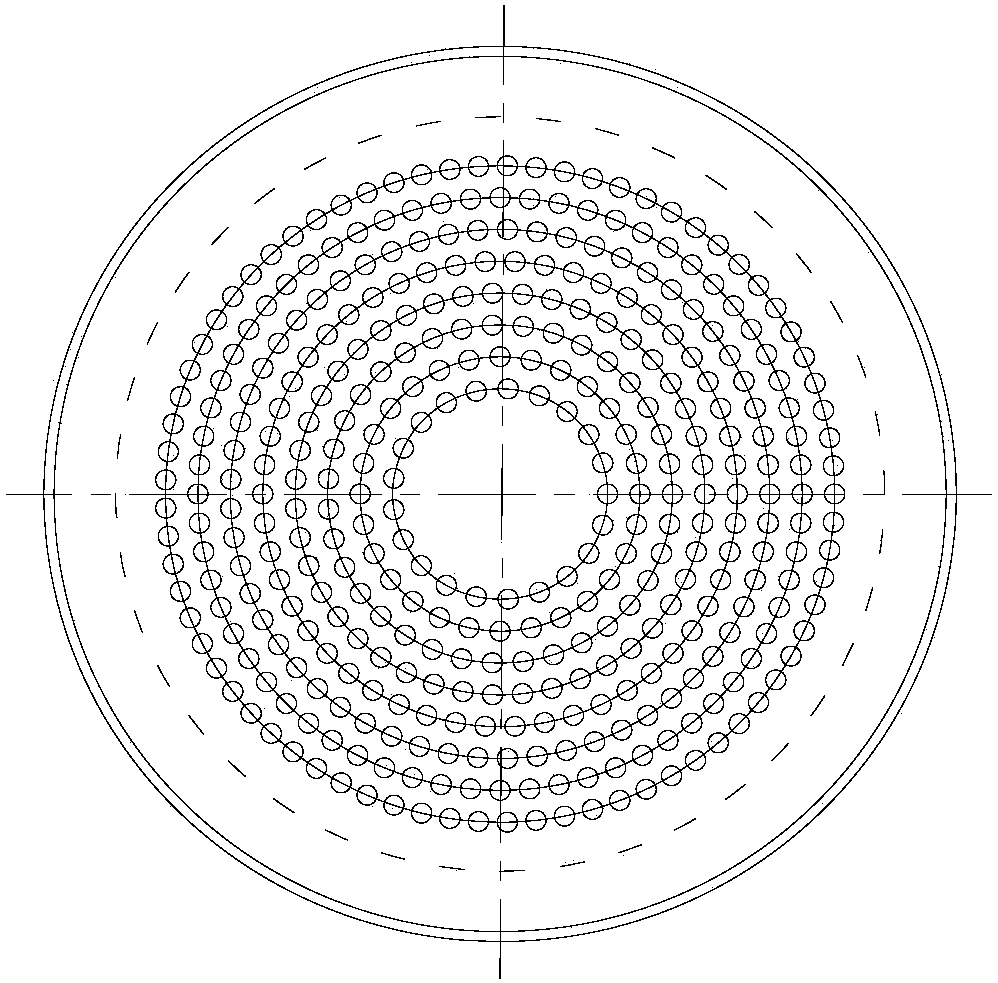

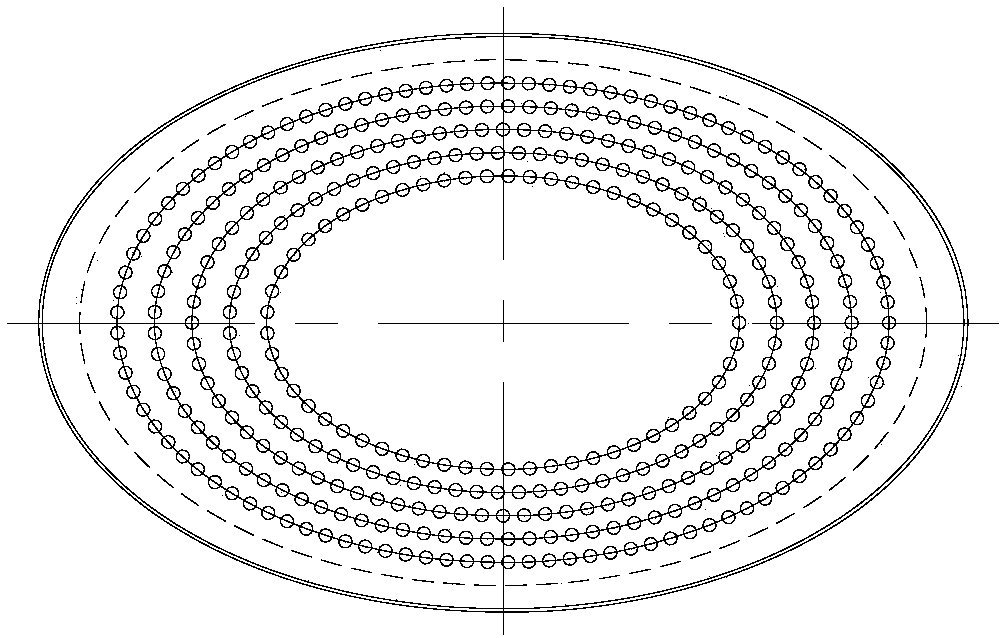

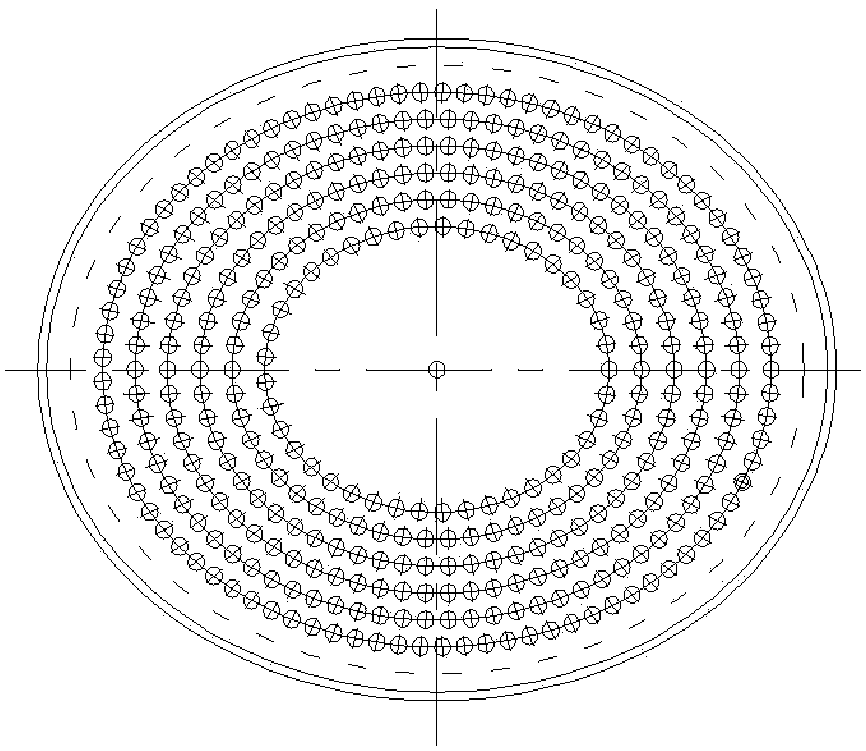

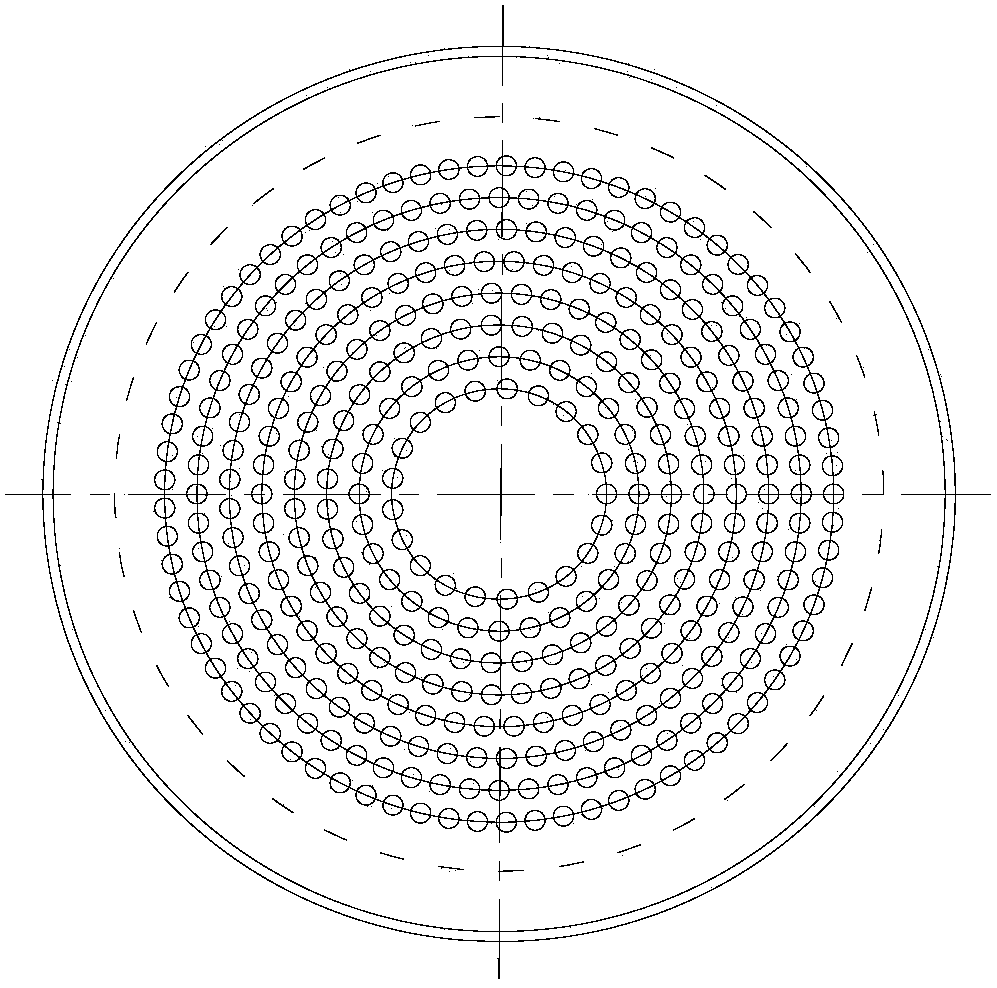

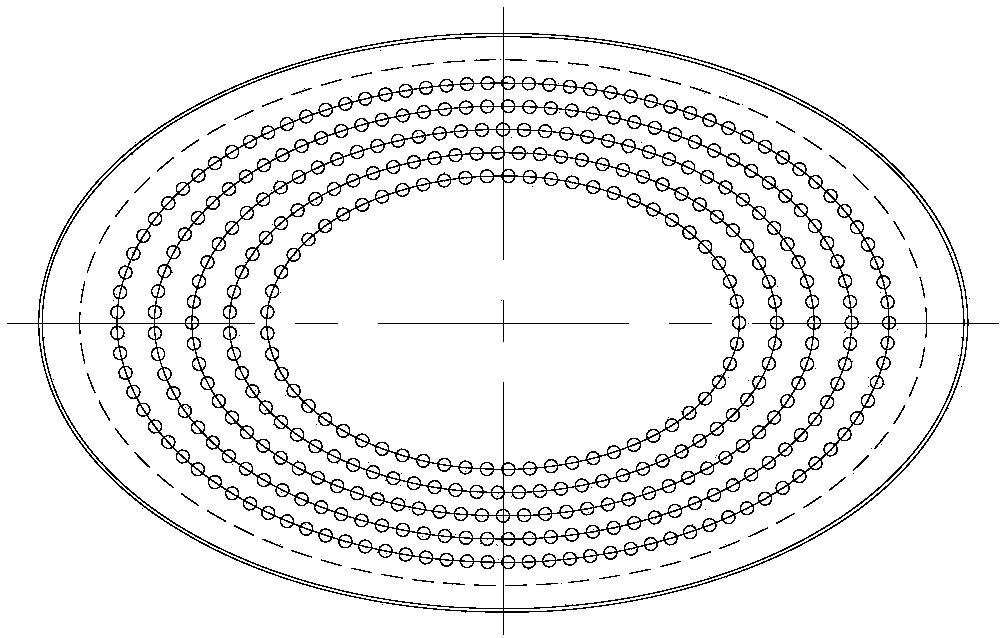

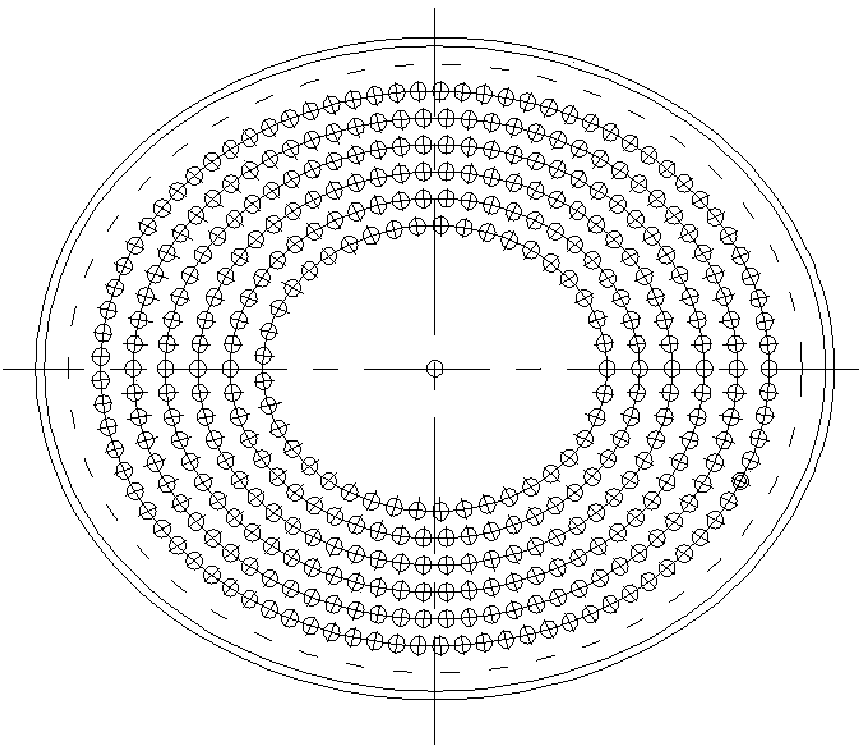

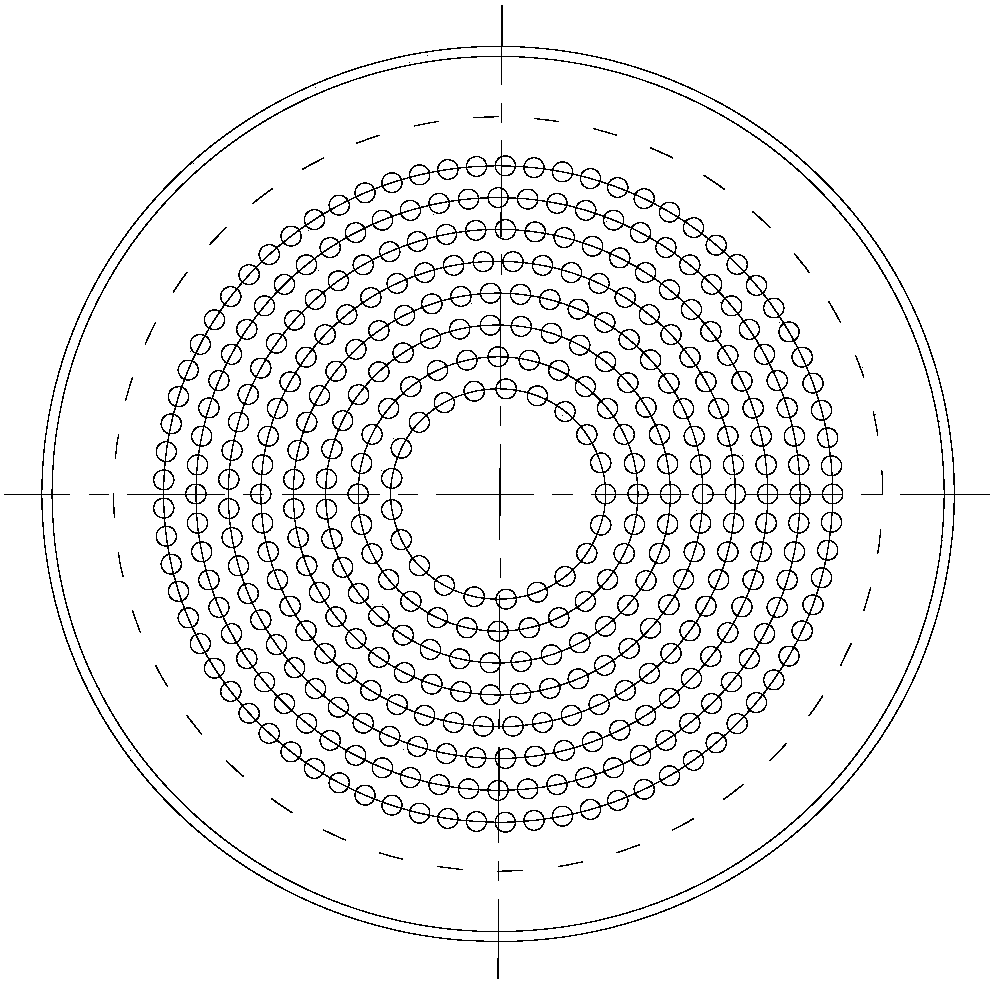

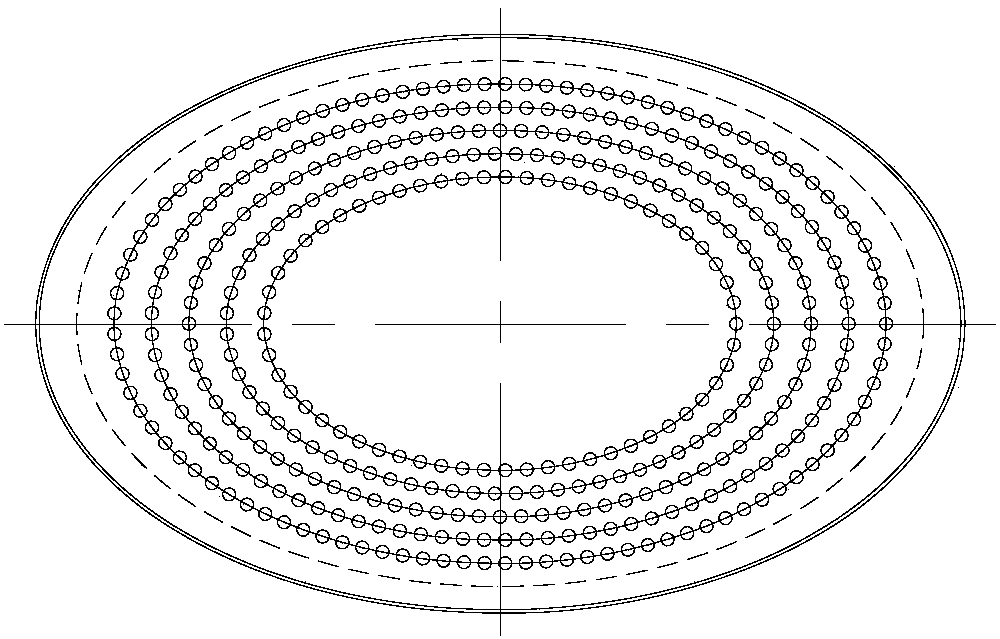

The invention relates to a porous super-bright trilobal profiled polyester fiber and a production method thereof. Modified polyester is spun by adopting a porous spinneret with the cross section shape of spinneret micro-pores being trilobal in order to produce the porous super-bright trilobal profiled polyester fiber; the spinneret micro-pores are arranged in the porous spinneret in an elliptical manner, the pore center of every spinneret micro-pore is positioned in a concentric ellipse, concentric ellipses are serial ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. A preparation method of the modified polyester comprises the following steps: reacting terephthalic acid with ethylene glycol to prepare ethylene terephthalate, adding diol terephthalate prepared from terephthalic acid and branched chain-containing diol, and continuously reacting to obtain the modified polyester. The porous super-bright trilobal profiled polyester fiber produced in the invention has excellent performances, the liner density deviation ratio is not greater than 0.5%, the breaking strength CV value is not greater than 4.0%, the fracture elongation CV value is not greater than 8.0%, and the yarn unevenness CV value is not greater than 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Differential shrinkage composite filament and preparing method thereof

ActiveCN106381558AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberAlcohol

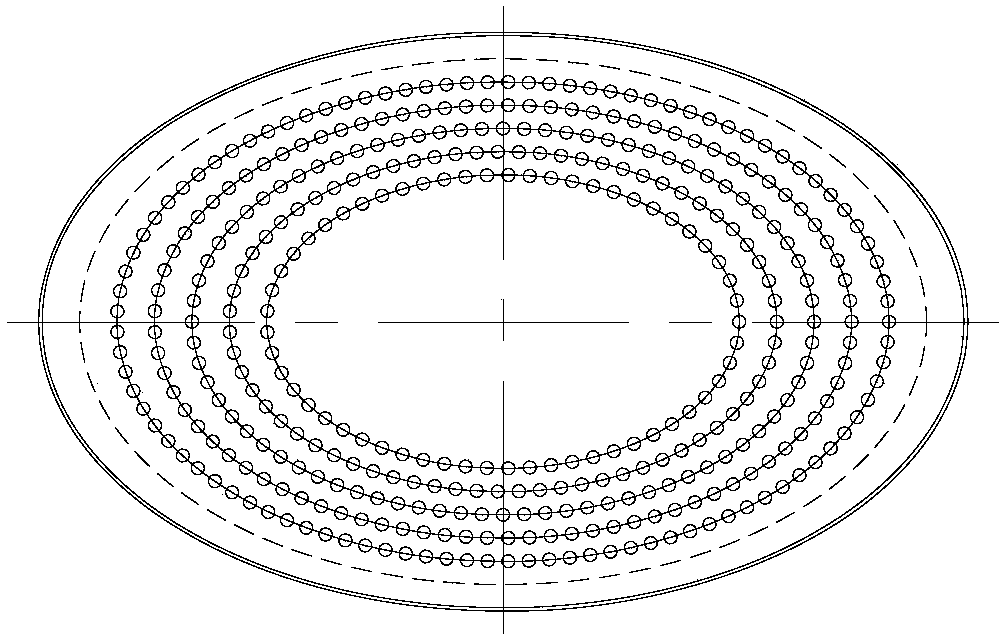

The invention relates to a differential shrinkage composite filament and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the differential shrinkage composite filament; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. The differential shrinkage composite filament is subjected to plying and doubling by modified polyester POY filament and FDY filament, then is composited through network, and finally reeled. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing dihydric alcohol are subjected to a reaction to obtain terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The filament has excellent fiber performance, the linear density deviation ratio is less than or equal to 2.0%, a breaking tenacity CV value is less than or equal to 4.0%, a breaking elongation CV value is less than or equal to 8.0%, and a crimp contraction variation coefficient CV value is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and preparation method thereof

ActiveCN106283251AImprove cooling effectImprove fiber propertiesSpinnerette packsMonocomponent copolyesters artificial filamentYarnBreaking strength

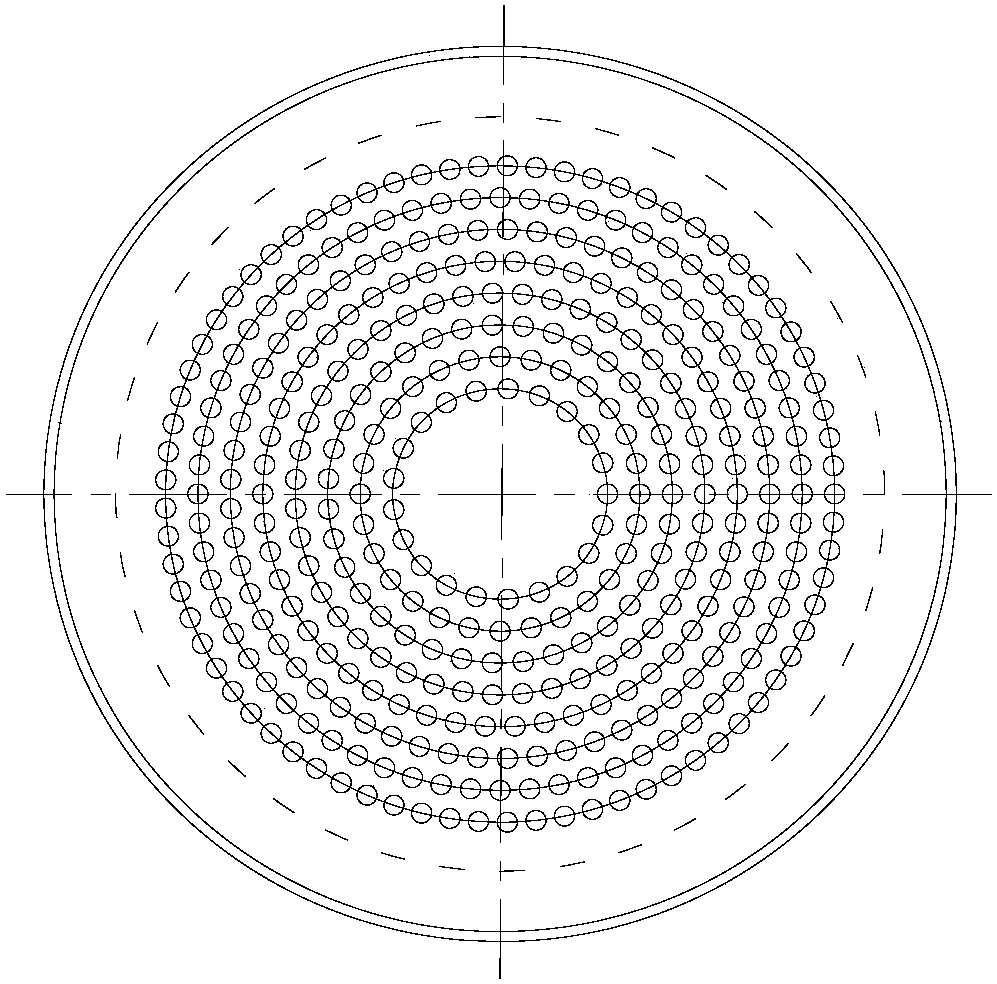

The invention relates to porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and a preparation method thereof. According to the preparation method, the porous PTT-fiber HOY is prepared from modified PTT by spinning with a porous spinneret; spinneret orifices in the porous spinneret are arranged in an oval shape, that is, the centers of the spinneret orifices are located on concentric ellipses adopting series ellipses, major axes of all the ellipses are collinear, and minor axes of all the ellipses are collinear. The porous PTT-fiber HOY is prepared from modified PTT through measurement, extrusion, cooling, oiling and winding. A preparation method of modified PTT comprises the steps as follows: terephthalic acid and 1,3-propanediol react, trimethylene terephthalate is prepared, diol terephthalate prepared from terephthalic acid and branched-chain-containing diol through a reaction is added, reaction is continued, and modified PTT is obtained. The prepared HOY has excellent fiber performance, the deviation rate of linear density is lower than or equal to 0.2%, the breaking strength CV value is lower than or equal to 2.5%, and the breaking elongation CV value is lower than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous soft polyester fiber FDY yarn and preparing method thereof

ActiveCN106381547AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureYarnFiber

The invention relates to a porous soft polyester fiber FDY yarn and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the porous soft polyester fiber FDY yarn; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. the porous soft polyester fiber FDY yarn is prepared by metering modified polyester slices, extruding, cooling, oiling, stretching, thermoforming and reeling the material. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing hexanediol are subjected to a reaction to obtain the terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The yarn has excellent fiber performance, the linear density deviation ratio is less than or equal to 0.5%, the breaking tenacity CV value is less than or equal to 4.0%, breaking elongation CV value is less than or equal to 8.0%, and a yarn unevenness CV value is less than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

Porous super-soft cotton-like polyester fiber, and preparation method thereof

ActiveCN106400168AImprove cooling effectImprove fiber propertiesNew-spun product collectionHollow filament manufactureBreaking strengthYarn

The invention relates to a porous super-soft cotton-like polyester fiber, and a preparation method thereof. According to the preparation method, the porous super-soft cotton-like polyester fiber is prepared from modified polyester via porous spinneret plate spinning; spinneret orifices on a porous spinneret plate are arranged in an elliptical manner, wherein the orifice centers of the spinneret orifices are arranged in a series of concentration ellipses, the long axes of the concentration ellipses are collinear, and the short axes are collinear. The porous super-soft cotton-like polyester fiber is prepared from modified polyester POY yarn and modified polyester FDY yarn. A preparation method of the modified polyester comprises following steps: terephthalic acid is reacted with ethanediol so as to obtain ethanediol terephthalate, terephthalic acid and hexanediol containing branch chains are added are reacted so as to obtain dihydric alcohol terephthalate, and continuous reaction is carried out so as to obtain the modified polyester. The performance of the obtained porous super-soft cotton-like polyester fiber is excellent; linear density deviation ratio is equal to or less than 2.0%; breaking strength CV value is equal to or less than 4.0%; breaking elongation CV value is equal to or less than 8.0%; and crimp contraction variable coefficient CV value is equal to or less than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous PBT fiber DTY (drawn textured yarn) and preparation method thereof

ActiveCN106283258AImprove cooling effectImprove fiber propertiesHollow filament manufactureMelt spinning methodsFiberBreaking strength

The invention relates to porous PBT fiber DTY (drawn textured yarn) and a preparation method thereof. The porous PBT fiber DTY is prepared from modified PBT through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged in an ellipse, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The porous PBT fiber DTY is prepared from the modified PBT through metering, extruding, cooling, oiling and winding; a preparation method of the modified PBT comprises the following steps: terephthalic acid and 1,4-butanediol react to prepare butanediol 1,4-terephthalate, terephthalic acid and diol containing branched chains are added for a reaction, diol terephthalate is prepared and continuously subjected to a reaction, and modified PBT is obtained. The prepared DTY has excellent performance, the linear density deviation is lower than or equal to 0.2%, the breaking strength CV value is smaller than or equal to 2.5%, and the breaking elongation CV value is smaller than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous flax-like polyester fiber and preparation method thereof

ActiveCN106400164AIncrease the degree of diffusionImprove dyeing performanceFilament/thread formingMonocomponent copolyesters artificial filamentPropylene glycolLinear density

The invention relates to a porous flax-like polyester fiber and a preparation method thereof. The porous flax-like polyester fiber is prepared by spinning modified polyester by using a porous spinneret plate, wherein spinneret holes in the porous spinneret plate are elliptically arrayed; i.e., the centers of the spinneret holes are located on concentric ellipses which are series ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are also collinear. The porous flax-like polyester fiber is prepared from modified polyester POY yarns and modified polyester FDY yarns through process. A preparation method for the modified polyester comprises the following steps: reacting terephthalic acid with glycol to prepare ethylene terephthalate; adding dihydric alcohol terephthalate prepared through reaction of terephthalic acid with propylene glycol containing a branched chain; and continuing reaction so as to obtain the modified polyester. The fiber prepared in the invention has following excellent properties: a linear density deviation ratio of no more than 2.0%, a breaking tenacity CV value of no more than 4.0%, a breaking elongation CV value of no more than 8.0%, and a crimp contraction variation coefficient CV value of no more than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Super-soft wool-like porous polyester and preparation method thereof

ActiveCN106319678AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentWoolPropylene glycol

The invention relates to super-soft wool-like porous polyester and a preparation method thereof. The super-soft wool-like porous polyester is prepared from modified polyester through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The super-soft wool-like porous polyester is prepared from modified polyester POY and modified polyester FDY through processing; a preparation method of the modified polyester comprises the following steps: terephthalic acid and ethylene glycol react to prepare ethylene glycol terephthalate, terephthalic acid and propylene glycol containing branched chains are added for a reaction, glycol terephthalate is prepared and continuously subjected to a reaction, and modified polyester is obtained. The prepared fiber has excellent performance, the linear density deviation is lower than or equal to 2.0%, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, and the crimp contraction variation coefficient CV value is lower than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Modified polyester and preparation method thereof

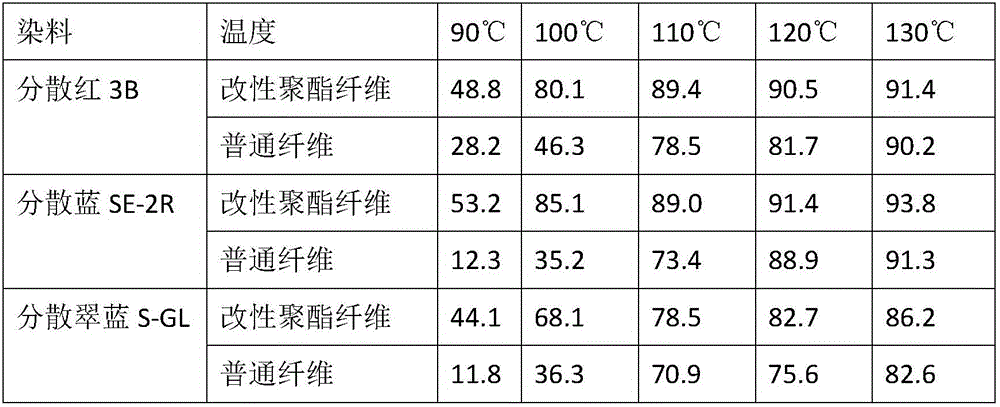

ActiveCN106380580AIncrease the degree of diffusionImprove dyeing performanceMonocomponent copolyesters artificial filamentDyeing processChemistryDyeing

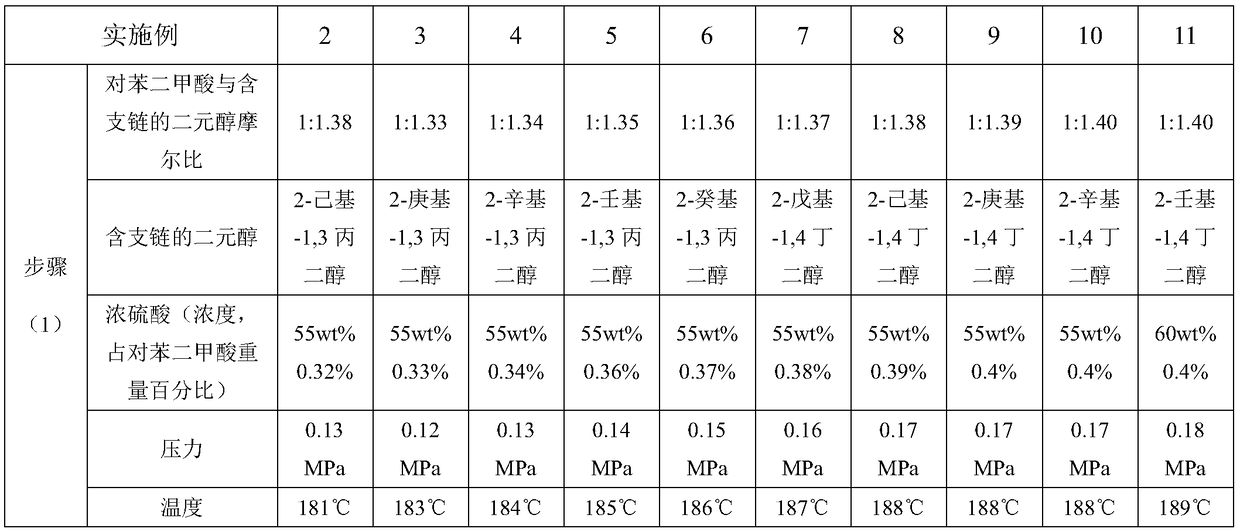

The invention relates to a modified polyester and a preparation method thereof. The modified polyester is composed of a terephthalic acid segment, a glycol segment, and a branch chain containing dihydric alcohol segment. The branch chain of the branch chain containing dihydric alcohol segment is positioned on one non-terminal carbon of the branch chain containing dihydric alcohol segment, is a straight carbon chain, and contains 5 to 10 carbon atoms. The preparation method comprises the following steps: carrying out esterification reactions between terephthalic acid and branch chain containing dihydric alcohol in the presence of concentrated sulfuric acid to obtain dihydric alcohol terephthalate; then carrying out esterification reactions between terephthalic acid and glycol to obtain ethylene terephthalate; stirring and mixing dihydric alcohol terephthalate and ethylene terephthalate, in the presence of a catalyst and a stabilizing agent, and carrying out condensation reactions in a low vacuum stage and a high vacuum stage to obtain modified polyester. The increased space between the gaps among molecular chains in polyester is far greater than that of branch chain free polyester at a same temperature, so small particles such as dye can more easily enter the interior of modified polyester, and the dyeing speed is increased.

Owner:JIANGSU HENGLI CHEM FIBER

Porous polyester fiber FDY and preparation method thereof

ActiveCN106283262AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentBreaking strengthYarn

The invention relates to porous polyester fiber FDY and a preparation method thereof. The porous polyester fiber FDY is prepared by spinning modified polyester through a porous spinneret plate; spinneret holes formed in the spinneret plate are arranged in an oval shape, that is to say, hole centers of the spinneret holes are located on concentric ellipses which are series ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. The porous polyester fiber FDY is prepared from modified polyester slices through metering, extruding, cooling, oiling, stretching, heat setting and winding; a preparation method of modified polyester comprises the steps that terephthalic acid reacts with ethylene glycol to obtain ethylene terephthalate, terephthalic acid dihydroxy alcohol ester which is prepared through a reaction of terephthalic acid and terephthalic acid containing is added, reacting is conducted continuously, and porous polyester is obtained. The fiber prepared through the method is excellent in performance, the linear density deviation rate is smaller than or equal to 0.5%, the breaking strength CV value is smaller than or equal to 4.0%, the breaking elongation CV value is smaller than or equal to 8.0%, and the yarn unevenness CV is smaller than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

Porous PTT (polytrimethylene terephthalate) fiber FDY (fully drawn yarn) and preparation method thereof

ActiveCN106319677AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnBreaking strength

The invention relates to porous PTT (polytrimethylene terephthalate) fiber FDY (fully drawn yarn) and a preparation method thereof. The porous PTT fiber FDY is prepared from modified PTT through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The porous PTT fiber FDY is prepared from the modified PTT through processing; a preparation method of the modified PTT comprises the following steps: terephthalic acid and 1,3-propanediol react to prepare 1,3-propanediol terephthalate, terephthalic acid and diol containing branched chains are added for a reaction, diol terephthalate is prepared and continuously subjected to a reaction, and modified PTT is obtained. The prepared fiber has excellent performance, the linear density deviation is lower than or equal to 0.5%, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, and the yarn unevenness CV is lower than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

Soft wool-like porous polyester and preparation method thereof

ActiveCN106319679AImprove cooling effectImprove fiber propertiesSpinnerette packsMelt spinning methodsFiberTerephthalic acid

The invention relates to soft wool-like porous polyester and a preparation method thereof. The soft wool-like porous polyester is prepared from modified polyester through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The soft wool-like porous polyester is prepared from modified polyester POY and modified polyester FDY through processing; a preparation method of the modified polyester comprises the following steps: terephthalic acid and ethylene glycol react to prepare ethylene terephthalate, terephthalic acid and propylene glycol containing branched chains are added for a reaction, glycol terephthalate is prepared and continuously subjected to a reaction, and modified polyester is obtained. The prepared fiber has excellent performance, the linear density deviation is lower than or equal to 2.0%, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, and the crimp contraction variation coefficient CV value is lower than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous super-soft linen-like polyester fiber and preparation method thereof

ActiveCN106400170AImprove cooling effectImprove fiber propertiesFilament/thread formingMonocomponent copolyesters artificial filamentYarnFiber

The invention relates to a porous super-soft linen-like polyester fiber and a preparation method thereof. Modified polyester is spun by a porous spinneret plate to prepare the porous super-soft linen-like polyester fiber. The spinneret orifices in the spinneret plate are arranged in an oval shape. The center of the spinneret orifices is positioned on the center of concentric ellipses; the concentric ellipses are a series of ellipses, long axes of all ellipses are collinear, and moreover, short axes of all ellipses are collinear. The porous super-soft linen-like polyester fiber is prepared from modified polyester POY yarns and modified polyester FDY yarns. The modified polyester preparation method comprises the following steps: reacting terephthalic acid with glycol to obtain ethylene glycol terephthalate, reacting ethylene glycol terephthalate with added branch chain containing hexylene glycol to generate dihydric alcohol terephthalate, and keeping on reactions to obtain modified polyester. The prepared fiber has excellent performances: the linear density deviation ratio is not more than 2.0%, the breaking strength CV value is not more than 4.0%, the breaking elongation CV value is not more than 8.0%, and the crimp contraction variable coefficient CV value is not more than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous soft flax-like polyester fiber and preparation method thereof

ActiveCN106381551AImprove cooling effectImprove fiber propertiesSpinnerette packsHollow filament manufactureFiberBreaking strength

The invention relates to a porous soft flax-like polyester fiber and a preparation method thereof; the porous soft flax-like polyester fiber is prepared by spinning modified polyester through a porous spinneret plate; an arrangement way of spinneret holes in the porous spinneret plate is in oval arrangement, that is to say, a hole center of the spinneret holes is located in concentric ellipses, the concentric ellipses are a series of ellipses, the long axes of all the ellipses are collinear, and the short axes are collinear. The porous soft flax-like polyester fiber is prepared by processing modified polyester POY filaments and modified polyester FDY filaments, wherein a preparation method for the modified polyester comprises the steps: carrying out a reaction of terephthalic acid and ethylene glycol to prepare ethylene glycol terephthalate, adding terephthalic acid and branched chain-containing dihydric alcohol, carrying out a reaction to prepare dihydric alcohol terephthalate, and continuing to carry out reaction to obtain the modified polyester. The prepared fiber is excellent in properties, the linear density deviation rate is less than or equal to 2.0%, the CV value of breaking strength is less than or equal to 4.0%, the CV value of elongation at break is less than or equal to 8.0%, and the CV value of the crimp shrinking percentage variation coefficient is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous superfine denier polyester fiber and preparation method thereof

ActiveCN106381549AIncrease the degree of diffusionImprove dyeing performanceSpinnerette packsHollow filament manufactureChemistryIsopropylene glycol

The invention relates to porous superfine denier polyester fiber and a preparation method thereof. Modified polyester undergoes spinning by a porous spinneret plate to prepare porous superfine denier polyester fiber. The arrangement mode of spinneret orifices on the porous spinneret plate is elliptical arrangement. That is to say, the centers of the spinneret orifices are positioned at concentric ellipses which are series ellipses. Long axis of all the ellipses is collinear, and minor axis is collinear. The porous superfine denier polyester fiber is prepared by metering of modified polyester chip, extrusion, cooling, oiling, cooling, oiling and high-speed winding. A preparation method of modified polyester comprises the following steps: letting terephthalic acid and glycol react to prepare ethylene glycol terephthalate, adding terephthalic acid and propylene glycol containing branched chain and reacting to prepare terephthalic dibasic alcohol ester, and continuously reacting to obtain modified polyester. The prepared fiber has excellent properties. Deviation ratio of linear density is less than or equal to 0.5%; breaking strength CV value is less than or equal to 4.0%; breaking elongation CV value is less than or equal to 8.0%; and yarn unevenness CV value is less than or equal to 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous soft polyester fiber POY and preparation method thereof

ActiveCN106381548AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberBreaking strength

The invention relates to porous soft polyester fiber POY and a preparation method thereof. Modified polyester undergoes spinning by a porous spinneret plate to prepare porous soft polyester fiber POY. The arrangement mode of spinneret orifices on the porous spinneret plate is elliptical arrangement. That is to say, the centers of the spinneret orifices are positioned at concentric ellipses which are series ellipses. Long axis of all the ellipses is collinear, and minor axis is collinear. According to the porous soft polyester fiber POY, modified polyester undergoes grain-sized dicing to obtain modified polyester chip; and the modified polyester chip undergoes metering, extrusion, cooling, oiling and winding so as to prepare the product. A preparation method of the modified polyester comprises the following steps: letting terephthalic acid and glycol react to prepare ethylene glycol terephthalate, adding terephthalic acid and dihydric alcohol containing branched chain and reacting to prepare terephthalic dibasic alcohol ester, and continuously reacting to the modified polyester. The prepared fiber has excellent properties. Deviation ratio of linear density is less than or equal to 0.2%; breaking strength CV value is less than or equal to 2.5%; and breaking elongation CV value is less than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Porous soft cottonlike polyester fiber and preparation method thereof

ActiveCN106381550AImprove cooling effectImprove fiber propertiesSpinnerette packsHollow filament manufactureBreaking strengthFiber

The invention relates to porous soft cottonlike polyester fiber and a preparation method thereof. Modified polyester undergoes spinning by a porous spinneret plate to prepare porous soft cottonlike polyester fiber. The arrangement mode of spinneret orifices on the porous spinneret plate is elliptical arrangement. That is to say, the centers of the spinneret orifices are positioned at concentric ellipses which are series ellipses. Long axis of all the ellipses is collinear, and minor axis is collinear. The porous soft cottonlike polyester fiber is prepared by processing of modified polyester POY and modified polyester FDY. A preparation method of the modified polyester comprises the following steps: letting terephthalic acid and glycol react to prepare ethylene glycol terephthalate, adding terephthalic acid and hexanediol containing branched chain and reacting to prepare terephthalic dibasic alcohol ester, and continuously reacting to modified polyester. The prepared fiber has excellent properties. Deviation ratio of linear density is less than or equal to 2.0%; breaking strength CV value is less than or equal to 4.0%; breaking elongation CV value is less than or equal to 8.0%; and variable coefficient CV value of crimp contraction is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyester fiber and preparation method thereof

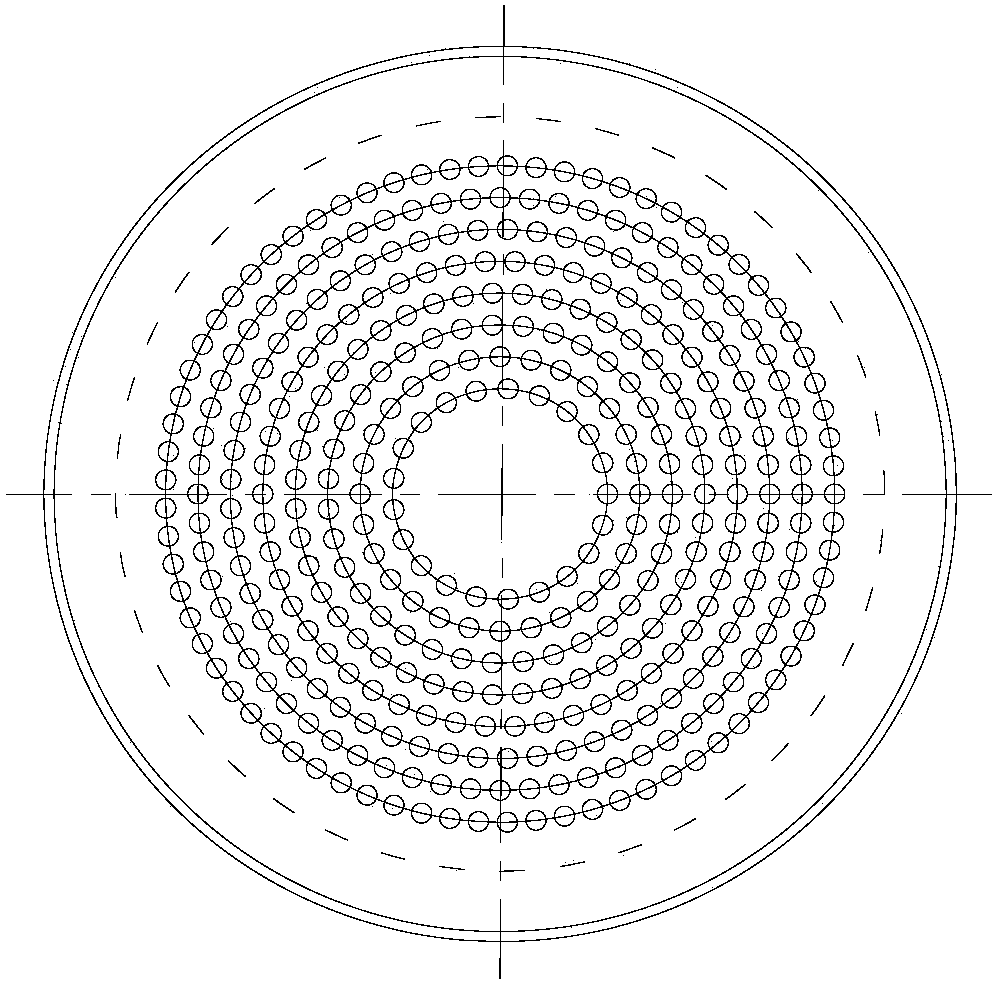

ActiveCN106367835BImprove dyeing effectIncreased access to polyester interiorSpinnerette packsMonocomponent copolyesters artificial filamentSlurryLow vacuum

The invention relates to polyester fibres and a preparation method thereof. The raw material of the polyester fibres is modified polyester which consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The preparation method of the polyester fibres comprises the following steps: performing esterification reaction on terephthalic acid and branched chain-containing dihydric alcohol under the catalysis of concentrated sulphuric acid to obtain terephthalic acid dihydric alcohol ester; then, preparing the terephthalic acid and the ethylene glycol into slurry, and performing the esterification reaction on the slurry to obtain the terephthalic acid ethylene glycol ester; finally, stirring and mixing the terephthalic acid dihydric alcohol ester and the terephthalic acid ethylene glycol ester, and performing condensation polymerization in a low vacuum stage and a high vacuum stage under the action of a catalyst and a stabilizing agent to obtain modified polyester; metering, extruding, cooling, oiling, stretching, heat-setting and winding the polyester to prepare the polyester fibres. The increasing amplitude of the spatial gaps of the polyester fibres is much higher than that of branched chain-free polyester fibres at the same temperature, which is beneficial to the degree of micro particles, such as a dye, that enter the polyester; the dyeing rate is improved.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of different shrinkage composite yarn and its preparation method

ActiveCN106381558BImprove cooling effectImprove fiber propertiesSpinnerette packsHollow filament manufactureFiberDiol

The invention relates to a different shrinkage composite yarn and a preparation method thereof. The modified polyester is spun through a porous spinneret to obtain a different shrinkage composite yarn; the arrangement of the spinneret holes on the porous spinneret is elliptical, namely The hole centers of the spinneret holes are located on concentric ellipses, and the concentric ellipses are a series of ellipses. The major axes of all ellipses are collinear, and the minor axes are collinear. Different shrinkage composite yarn is obtained by plying and plying modified polyester POY yarn and FDY yarn, through network compounding, and finally winding. The preparation method of modified polyester is: terephthalic acid and ethylene glycol react to prepare terephthalic acid Ethylene glycol diformate is added with diol terephthalate obtained by reacting terephthalic acid with branched diols, and the reaction is continued to obtain modified polyester. The fiber prepared by the invention has excellent properties, the linear density deviation rate of the different shrinkage composite yarn is ≤2.0%, the breaking strength CV value is ≤4.0%, the breaking elongation CV value is ≤8.0%, and the crimp shrinkage rate variation coefficient CV value is ≤8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous soft polyester fiber poy yarn and preparation method thereof

ActiveCN106381548BImprove cooling effectImprove fiber propertiesSpinnerette packsHollow filament manufactureFiberBreaking strength

The invention relates to porous soft polyester fiber POY and a preparation method thereof. Modified polyester undergoes spinning by a porous spinneret plate to prepare porous soft polyester fiber POY. The arrangement mode of spinneret orifices on the porous spinneret plate is elliptical arrangement. That is to say, the centers of the spinneret orifices are positioned at concentric ellipses which are series ellipses. Long axis of all the ellipses is collinear, and minor axis is collinear. According to the porous soft polyester fiber POY, modified polyester undergoes grain-sized dicing to obtain modified polyester chip; and the modified polyester chip undergoes metering, extrusion, cooling, oiling and winding so as to prepare the product. A preparation method of the modified polyester comprises the following steps: letting terephthalic acid and glycol react to prepare ethylene glycol terephthalate, adding terephthalic acid and dihydric alcohol containing branched chain and reacting to prepare terephthalic dibasic alcohol ester, and continuously reacting to the modified polyester. The prepared fiber has excellent properties. Deviation ratio of linear density is less than or equal to 0.2%; breaking strength CV value is less than or equal to 2.5%; and breaking elongation CV value is less than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous soft linen-like polyester fiber and its preparation method

ActiveCN106381551BImprove cooling effectImprove fiber propertiesSpinnerette packsHollow filament manufactureFiberBreaking strength

The invention relates to a porous soft flax-like polyester fiber and a preparation method thereof; the porous soft flax-like polyester fiber is prepared by spinning modified polyester through a porous spinneret plate; an arrangement way of spinneret holes in the porous spinneret plate is in oval arrangement, that is to say, a hole center of the spinneret holes is located in concentric ellipses, the concentric ellipses are a series of ellipses, the long axes of all the ellipses are collinear, and the short axes are collinear. The porous soft flax-like polyester fiber is prepared by processing modified polyester POY filaments and modified polyester FDY filaments, wherein a preparation method for the modified polyester comprises the steps: carrying out a reaction of terephthalic acid and ethylene glycol to prepare ethylene glycol terephthalate, adding terephthalic acid and branched chain-containing dihydric alcohol, carrying out a reaction to prepare dihydric alcohol terephthalate, and continuing to carry out reaction to obtain the modified polyester. The prepared fiber is excellent in properties, the linear density deviation rate is less than or equal to 2.0%, the CV value of breaking strength is less than or equal to 4.0%, the CV value of elongation at break is less than or equal to 8.0%, and the CV value of the crimp shrinking percentage variation coefficient is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous polyester fiber poy yarn and preparation method thereof

ActiveCN106400169BImprove cooling effectImprove fiber propertiesSpinnerette packsHollow filament manufactureFiberBreaking strength

Owner:JIANGSU HENGLI CHEM FIBER

A kind of preparation method of porous modified polyester fiber

ActiveCN106319675BImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnBreaking strength

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous ultra-bright three-lobed special-shaped polyester fiber and its preparation method

ActiveCN106400166BImprove cooling effectImprove fiber propertiesFilament/thread formingMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a porous super-bright trilobal profiled polyester fiber and a production method thereof. Modified polyester is spun by adopting a porous spinneret with the cross section shape of spinneret micro-pores being trilobal in order to produce the porous super-bright trilobal profiled polyester fiber; the spinneret micro-pores are arranged in the porous spinneret in an elliptical manner, the pore center of every spinneret micro-pore is positioned in a concentric ellipse, concentric ellipses are serial ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. A preparation method of the modified polyester comprises the following steps: reacting terephthalic acid with ethylene glycol to prepare ethylene terephthalate, adding diol terephthalate prepared from terephthalic acid and branched chain-containing diol, and continuously reacting to obtain the modified polyester. The porous super-bright trilobal profiled polyester fiber produced in the invention has excellent performances, the liner density deviation ratio is not greater than 0.5%, the breaking strength CV value is not greater than 4.0%, the fracture elongation CV value is not greater than 8.0%, and the yarn unevenness CV value is not greater than 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous polyester fiber hoy yarn and preparation method thereof

ActiveCN106400161BImprove cooling effectImprove fiber propertiesFilament/thread formingMonocomponent copolyesters artificial filamentFiberBreaking strength

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of modified porous polyester

ActiveCN106319675AImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnBreaking strength

The invention relates to a preparation method of modified porous polyester. The modified porous polyester is prepared from modified polyester through spinning by a porous spinneret plate; spinneret holes in the porous spinneret plate are arranged elliptically, that is, the centers of the spinneret holes are located on concentric ellipses which are a series of ellipses, major axes of the ellipses are collinear, and minor axes of the ellipses are collinear. The modified porous polyester is prepared from modified polyester through metering, extruding by the porous spinneret plate, cooling, oiling, drawing, heat setting and winding; a preparation method of the modified polyester comprises the following steps: terephthalic acid and ethylene glycol react to prepare ethylene terephthalate, terephthalic acid and glycol containing branched chains are added for a reaction, glycol terephthalate is prepared and continuously subjected to a reaction, and modified polyester is obtained. The prepared fiber has excellent performance, the breaking strength CV value is lower than or equal to 4.0%, the breaking elongation CV value is lower than or equal to 8.0%, the yarn unevenness CV value is lower than or equal to 2.0%, and the boiling water shrinkage is 7.5% plus or minus 0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous superfine denier flat yarn and its preparation method

ActiveCN106400167BImprove cooling effectImprove fiber propertiesMonocomponent copolyesters artificial filamentMelt spinning methodsYarnFiber

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous PTT fiber hoy silk and preparation method thereof

ActiveCN106283251BImprove cooling effectImprove fiber propertiesSpinnerette packsMonocomponent copolyesters artificial filamentBreaking strengthYarn

The invention relates to porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and a preparation method thereof. According to the preparation method, the porous PTT-fiber HOY is prepared from modified PTT by spinning with a porous spinneret; spinneret orifices in the porous spinneret are arranged in an oval shape, that is, the centers of the spinneret orifices are located on concentric ellipses adopting series ellipses, major axes of all the ellipses are collinear, and minor axes of all the ellipses are collinear. The porous PTT-fiber HOY is prepared from modified PTT through measurement, extrusion, cooling, oiling and winding. A preparation method of modified PTT comprises the steps as follows: terephthalic acid and 1,3-propanediol react, trimethylene terephthalate is prepared, diol terephthalate prepared from terephthalic acid and branched-chain-containing diol through a reaction is added, reaction is continued, and modified PTT is obtained. The prepared HOY has excellent fiber performance, the deviation rate of linear density is lower than or equal to 0.2%, the breaking strength CV value is lower than or equal to 2.5%, and the breaking elongation CV value is lower than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous supersoft polyester fiber fdy yarn and preparation method thereof

ActiveCN106283260BImprove cooling effectImprove fiber propertiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnBreaking strength

Owner:JIANGSU HENGLI CHEM FIBER

A kind of porous supersoft linen-like polyester fiber and its preparation method

ActiveCN106400170BImprove cooling effectImprove fiber propertiesFilament/thread formingMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a porous super-soft linen-like polyester fiber and a preparation method thereof. Modified polyester is spun by a porous spinneret plate to prepare the porous super-soft linen-like polyester fiber. The spinneret orifices in the spinneret plate are arranged in an oval shape. The center of the spinneret orifices is positioned on the center of concentric ellipses; the concentric ellipses are a series of ellipses, long axes of all ellipses are collinear, and moreover, short axes of all ellipses are collinear. The porous super-soft linen-like polyester fiber is prepared from modified polyester POY yarns and modified polyester FDY yarns. The modified polyester preparation method comprises the following steps: reacting terephthalic acid with glycol to obtain ethylene glycol terephthalate, reacting ethylene glycol terephthalate with added branch chain containing hexylene glycol to generate dihydric alcohol terephthalate, and keeping on reactions to obtain modified polyester. The prepared fiber has excellent performances: the linear density deviation ratio is not more than 2.0%, the breaking strength CV value is not more than 4.0%, the breaking elongation CV value is not more than 8.0%, and the crimp contraction variable coefficient CV value is not more than 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com