Patents

Literature

33768 results about "Ethylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene glycol (IUPAC name: ethane-1,2-diol) is an organic compound with the formula (CH₂OH)₂. It is mainly used for two purposes, as a raw material in the manufacture of polyester fibers and for antifreeze formulations. It is an odorless, colorless, sweet-tasting, viscous liquid. Ethylene glycol is toxic. Household pets are especially susceptible to ethylene glycol poisoning from vehicle antifreeze leaks.

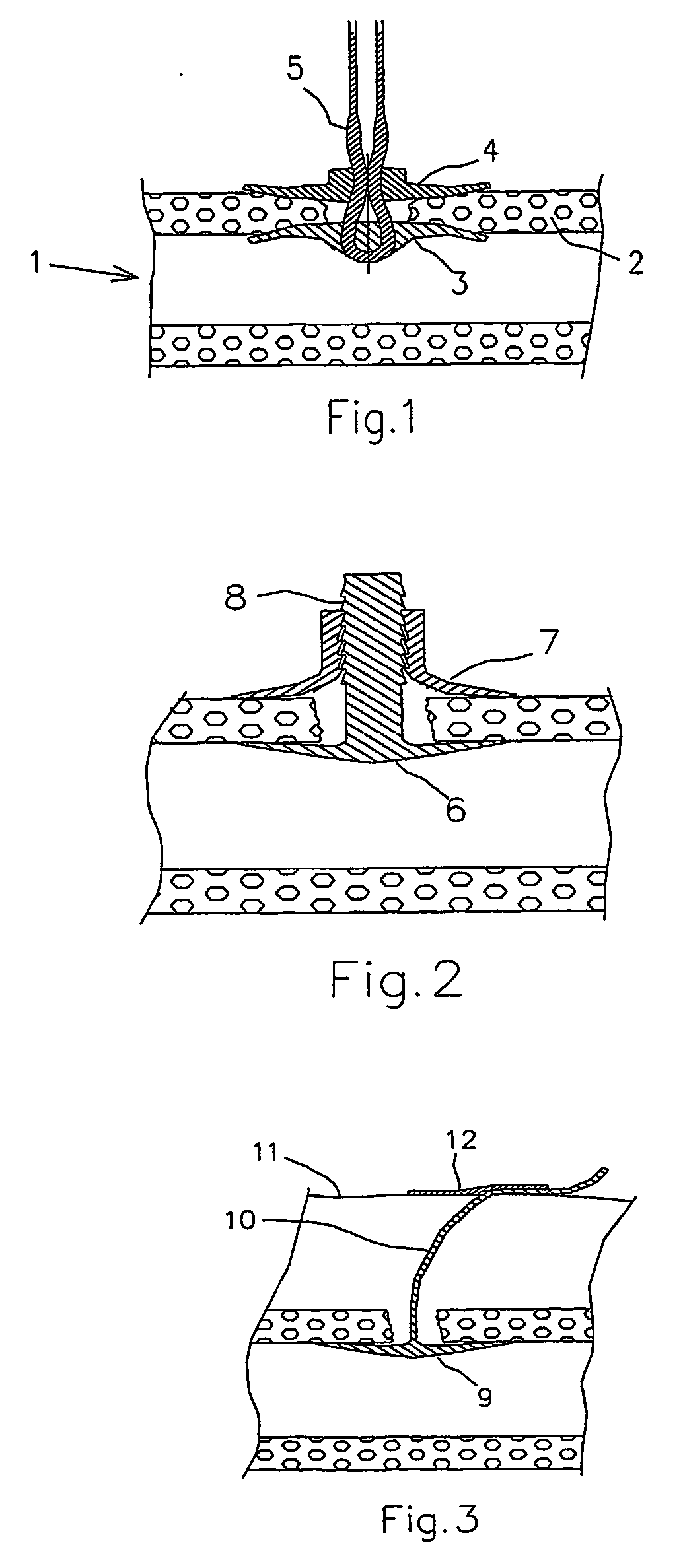

Dissolvable medical sealing device

ActiveUS20050169974A1Shorten the timeSuture equipmentsPharmaceutical delivery mechanismOrganismal ProcessPolyvinyl alcohol

The present invention provides a dissolvable medical sealing device (3, 4; 6, 7; 9) for closing a wound in vessel. A sealing device (3, 4, 6, 7, 9) according to the invention is made of a material that dissolves by means of physical processes, rather than by means of chemical or biological processes. Such a sealing device (3, 4; 6, 7; 9) can be made of polyethylene glycol, polypropylene glycol, copolymers containing ethylene glycol and propylene glycol, polyvinyl alcohol or polyvinyl pyrolidone, or any combinations thereof.

Owner:TERUMO MEDICAL CORP

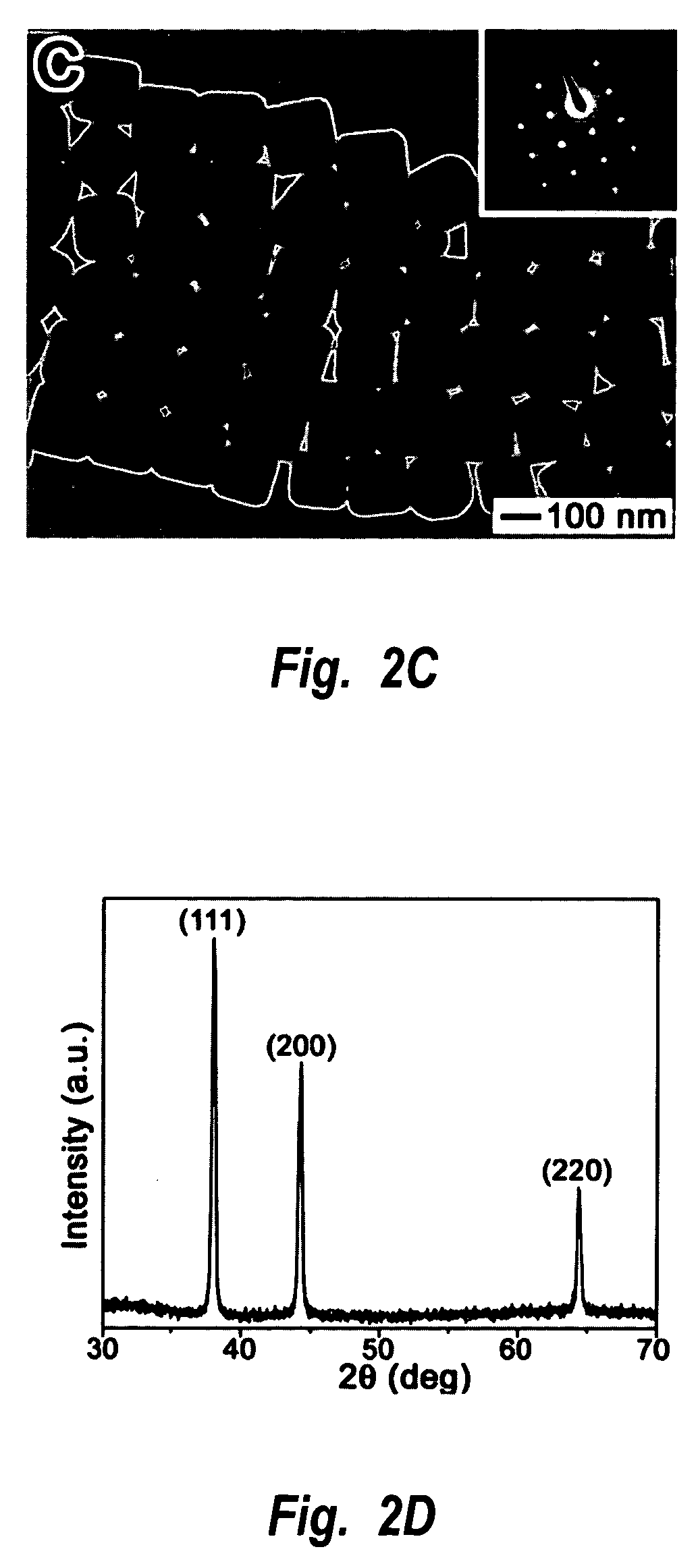

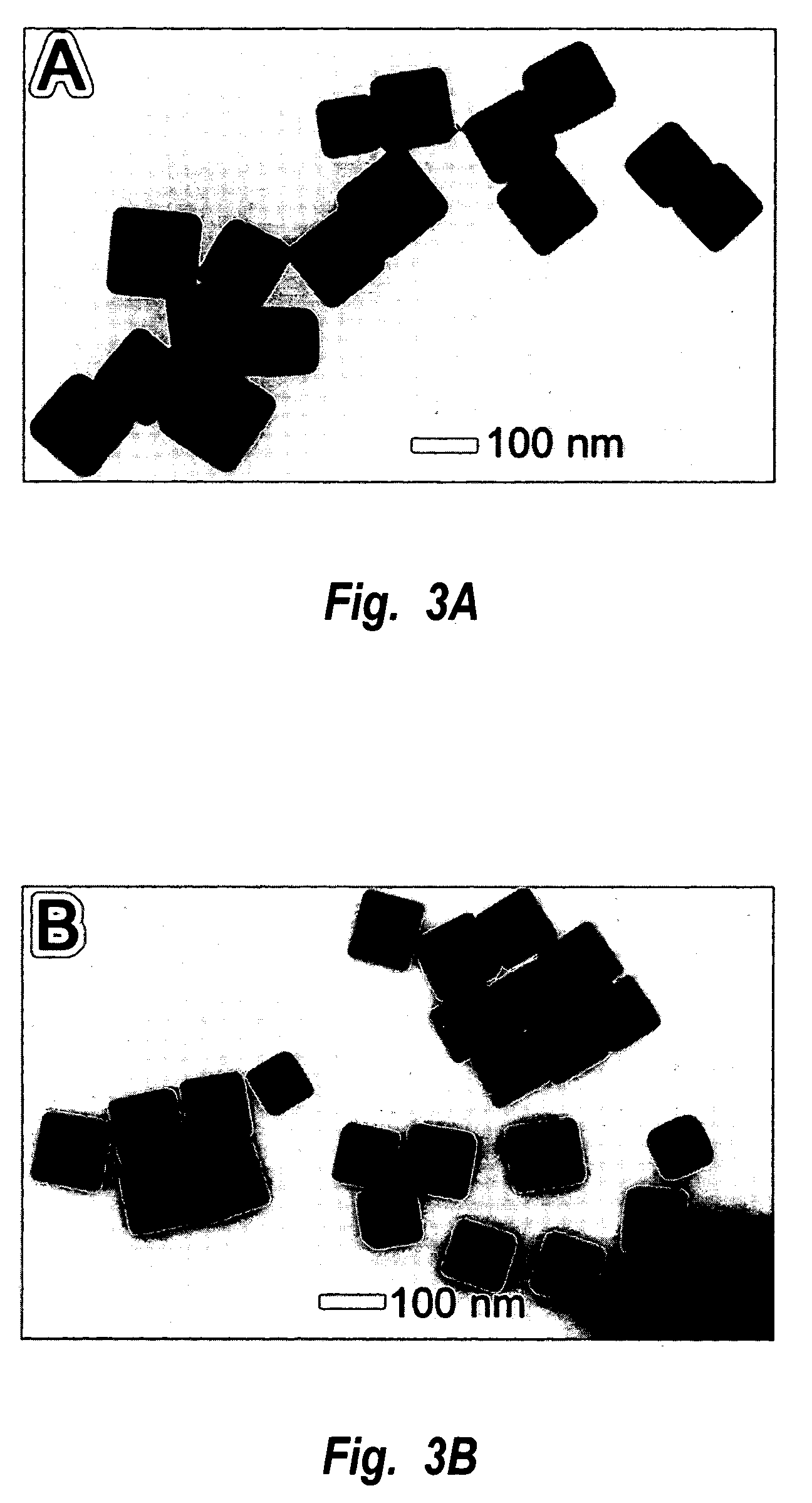

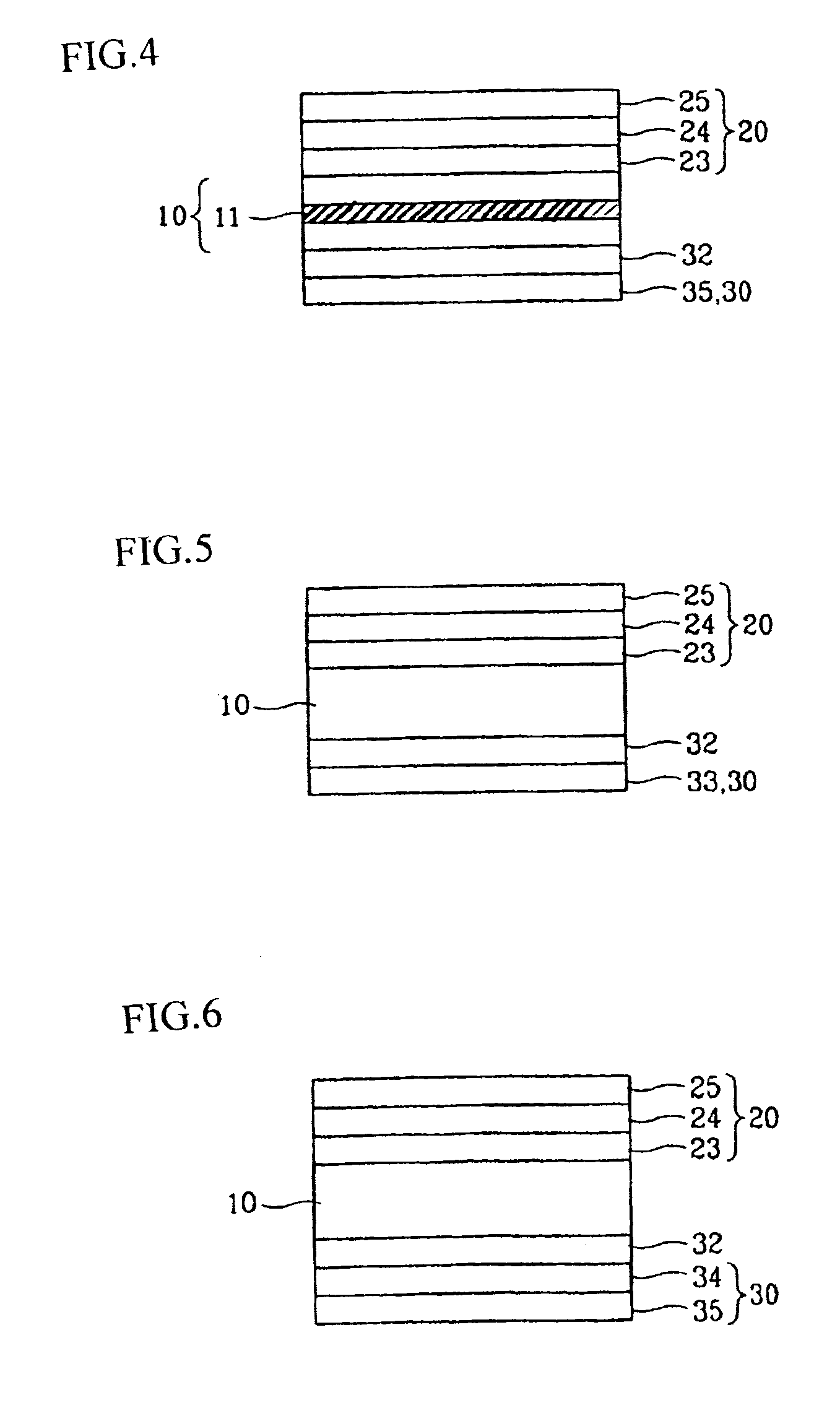

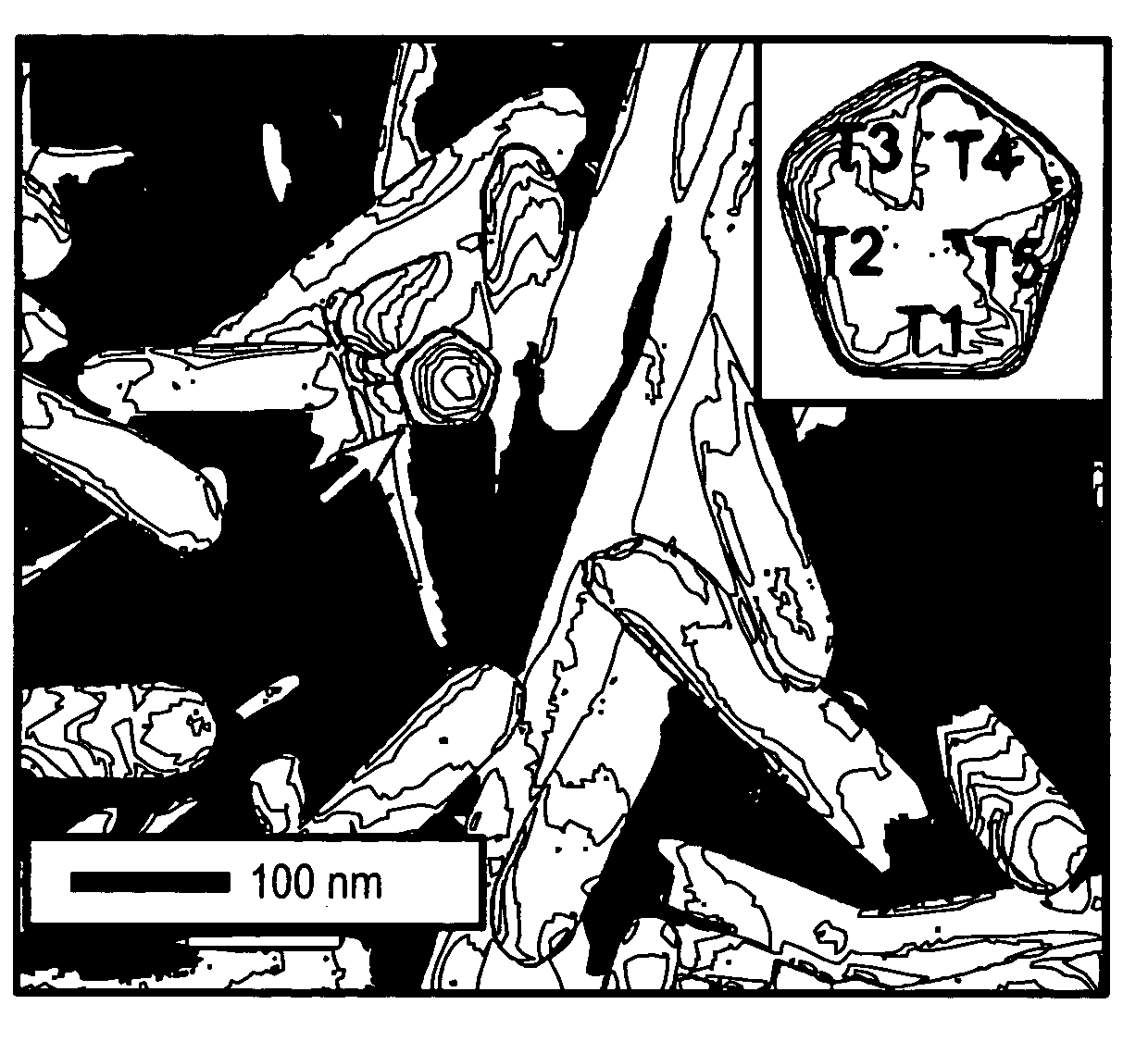

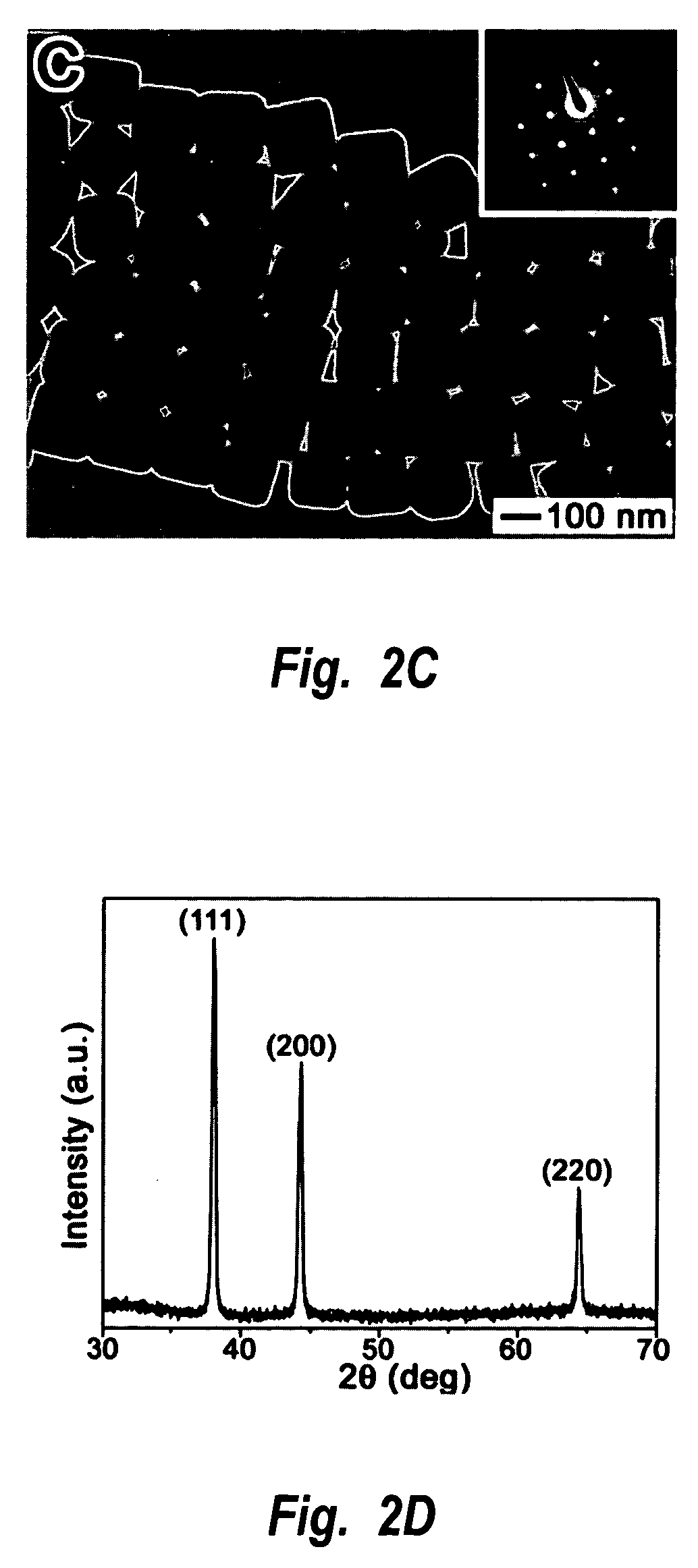

Methods of nanostructure formation and shape selection

Methods for forming nanostructures of various shapes are disclosed. Nanocubes, nanowires, nanopyramids and multiply twinned particles of silver may by formed by combining a solution of silver nitrate in ethylene glycol with a solution of poly(vinyl pyrrolidone) in ethylene glycol. Hollow nanostructures may be formed by reacting a solution of solid nanostructures comprising one of a first metal and a first metal alloy with a metal salt that can be reduced by the first metal or first metal alloy. Nanostructures comprising a core with at least one nanoshell may be formed by plating a nanostructure and reacting the plating with a metal salt.

Owner:UNIV OF WASHINGTON

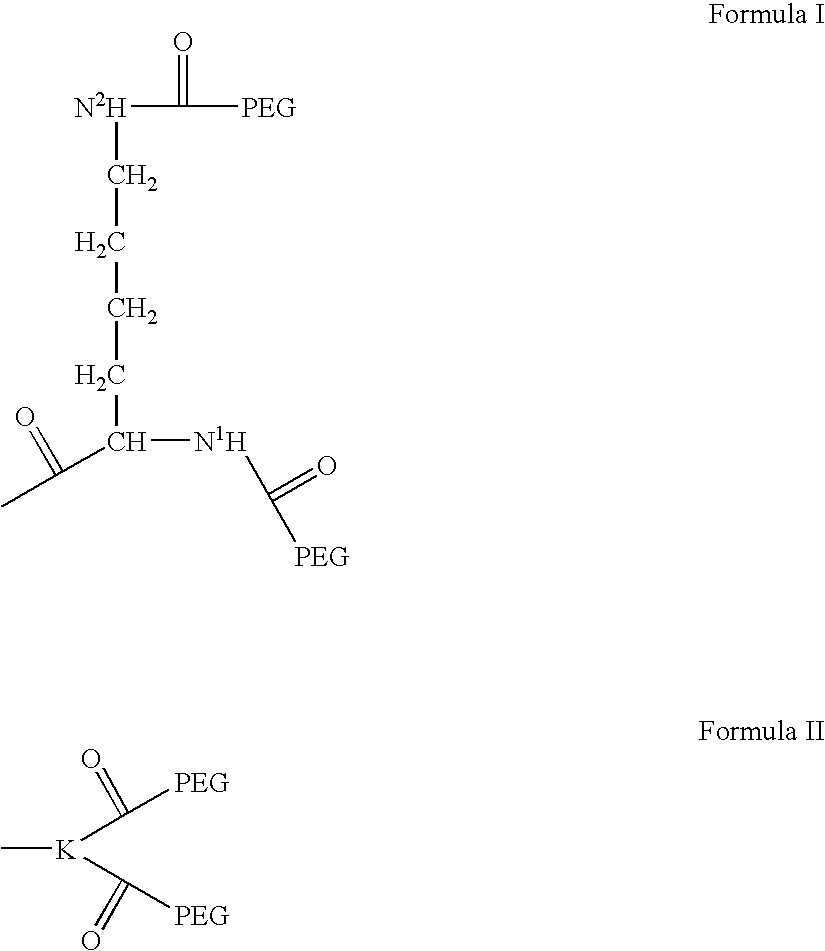

Novel poly(ethylene glycol) modified compounds and uses thereof

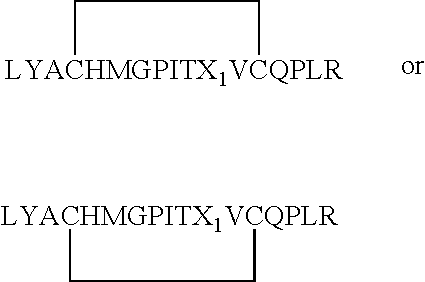

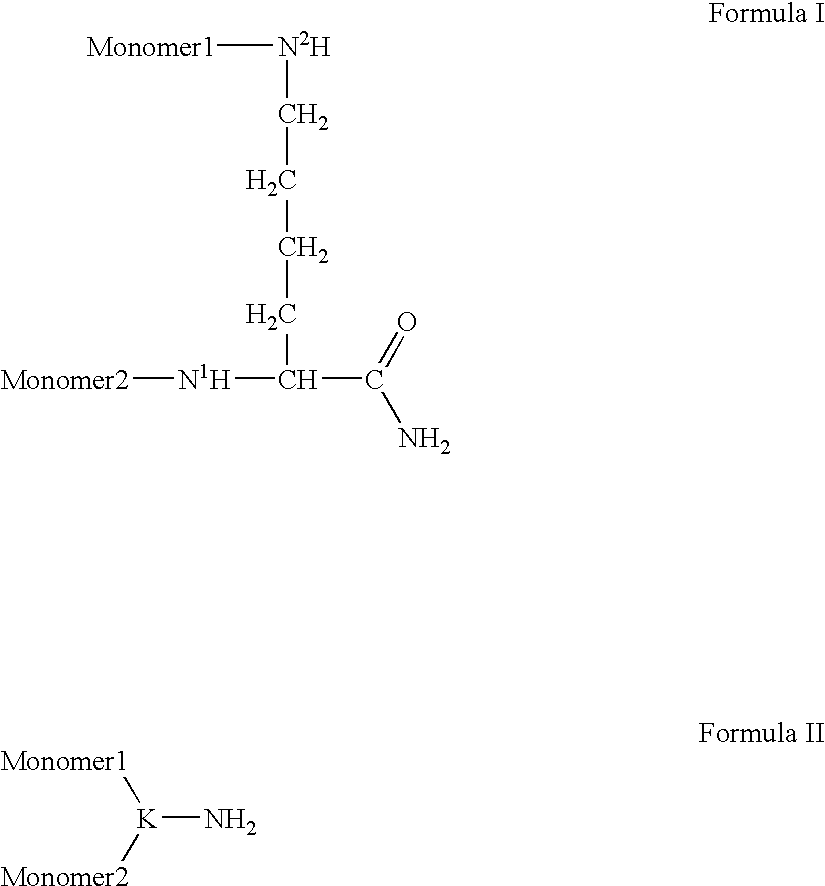

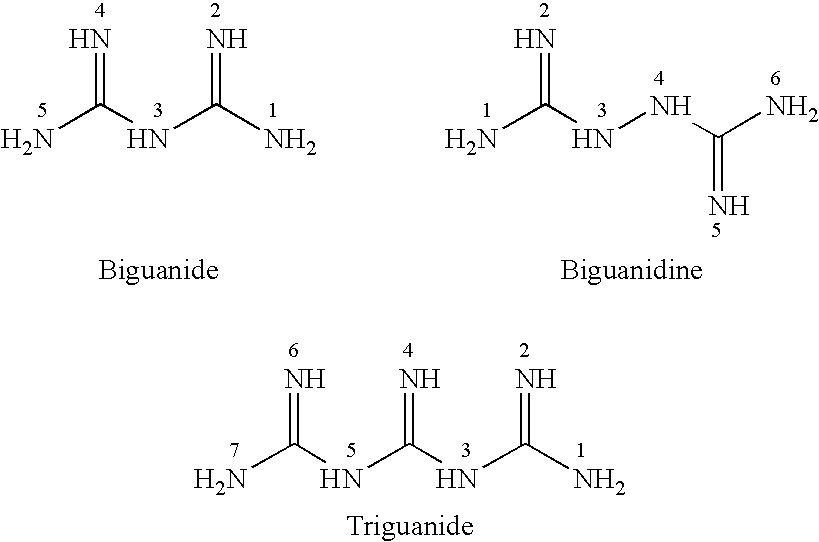

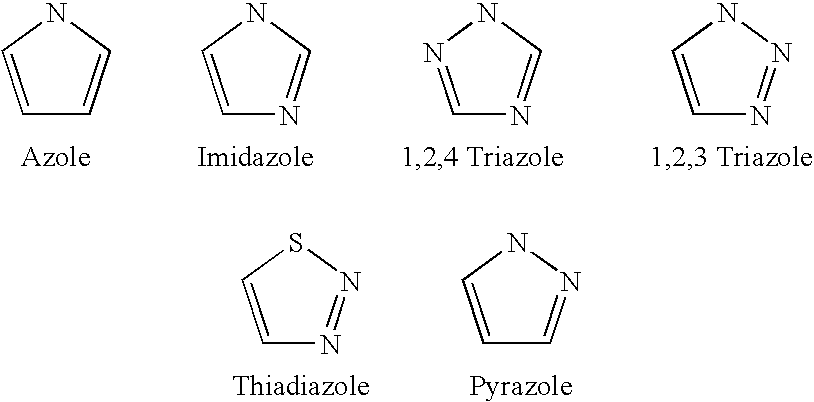

InactiveUS20050107297A1Good antigenicityIncreased durabilityPeptide/protein ingredientsDepsipeptidesPolyethylene glycolGlycol synthesis

The present invention relates to a peptide-based compound comprising a peptide moiety and a poly(ethylene glycol) moiety wherein the poly(ethylene glycol) moiety (preferably linear) has a molecular weight of more than 20 KDaltons (preferably from 20 to 60 KDaltons). The peptide moiety may be monomeric, dimeric or oligomeric. Such peptide-based compounds may optional include a linker moiety and / or a spacer moiety.

Owner:AFFYMAX

Oleaginous pharmaceutical and cosmetic foam

InactiveUS20070292461A1Pleasant and easy to spreadPatient compliance is goodCosmetic preparationsMetabolism disorderActive agentPolyethylene glycol

The invention relates to stable pharmaceutical or cosmetic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent comprising polyethylene glycol (PEG) or PEG derivative and mixtures thereof, or comprising propylene glycol, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Sheets formed from polyesters including isosorbide

InactiveUS6025061AImprove low temperature impact strengthIncrease the maximum use temperatureLayered productsAnimal housingPolyesterInherent viscosity

A sheet made of a polyester which includes monomer units of terephthaloyl moieties, ethylene glycol moieties and isosorbide moieties is described. The polyester has an inherent viscosity of at least about 0.35 dL / g when measured as a 1% (weight / volume) solution of said polyester in o-chlorophenol at a temperature of 25 DEG C. The present invention also relates to a method of making the polyester sheet described above and a method of thermoforming the sheet into articles.

Owner:EI DU PONT DE NEMOURS & CO

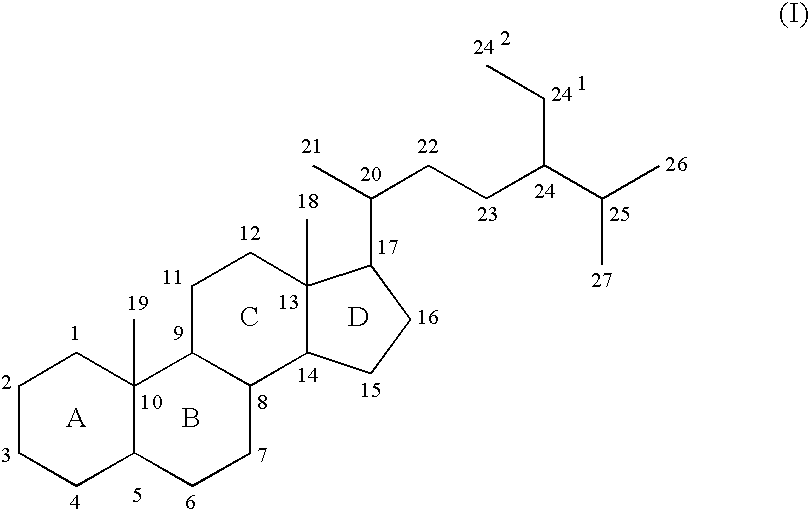

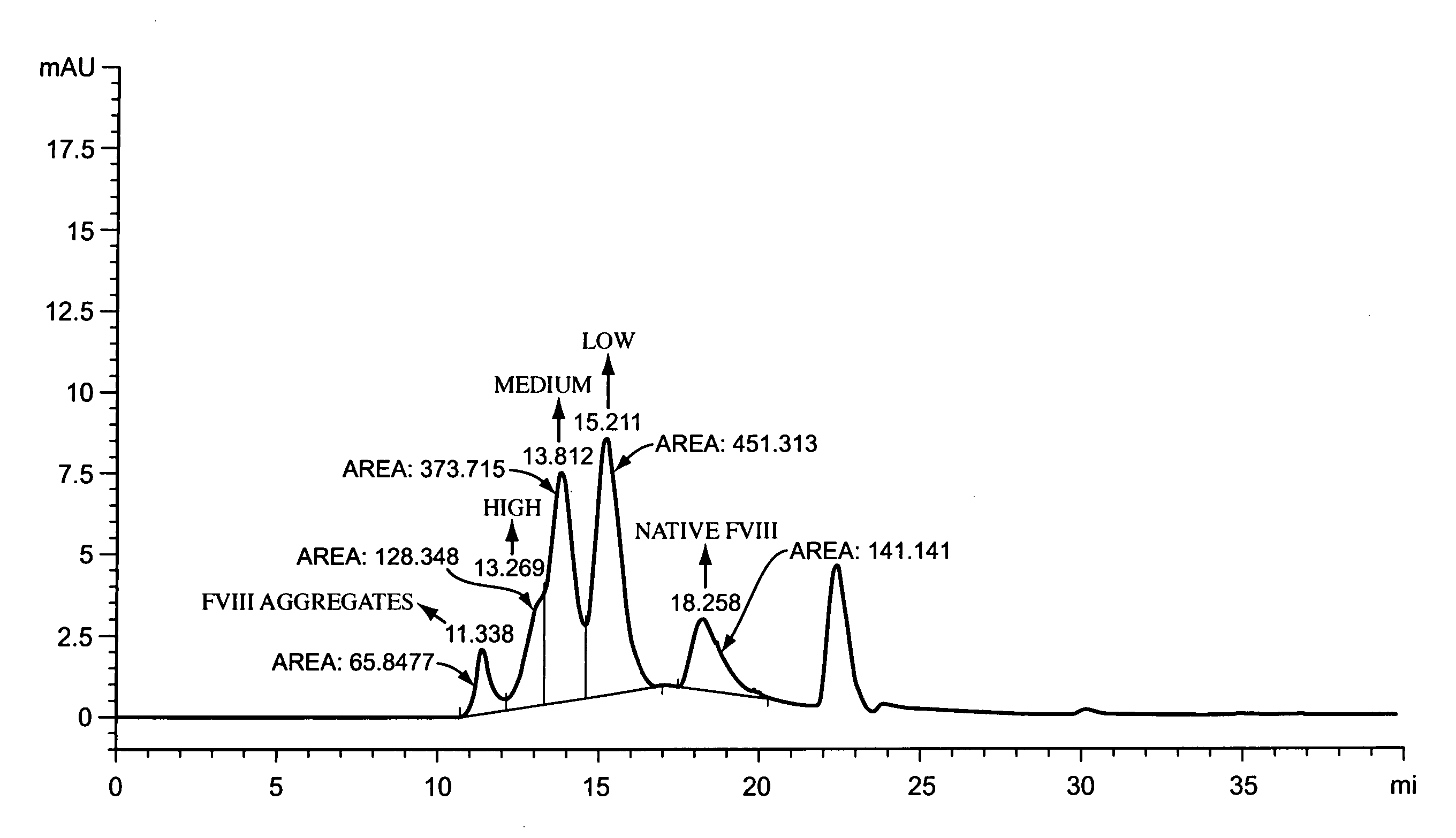

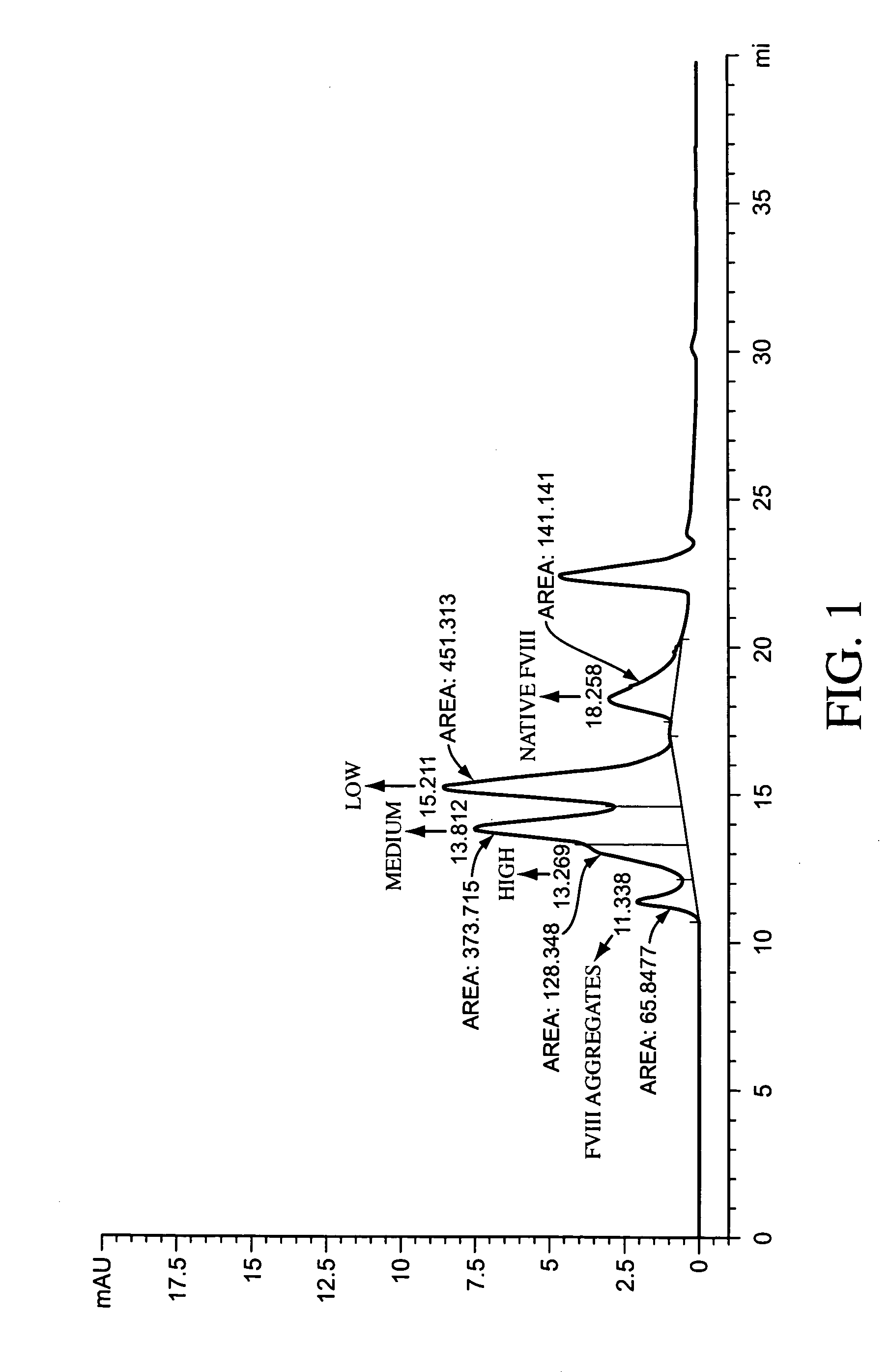

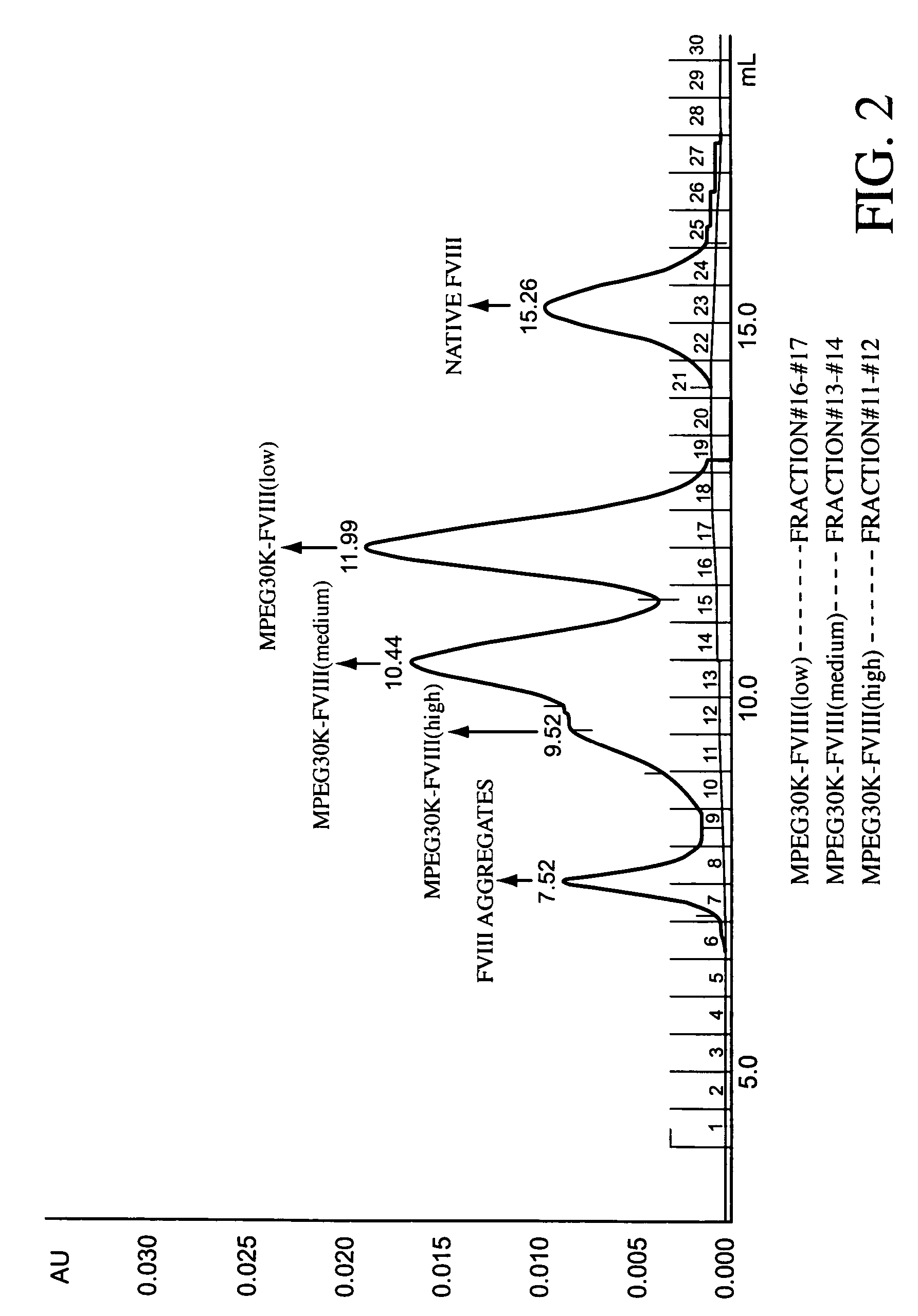

Polymer-factor VIII moiety conjugates

ActiveUS7199223B2Low immunogenicityReduce dosing frequencyPeptide/protein ingredientsMammal material medical ingredientsWater solubleEthylene glycol

Conjugates of a Factor VIII moiety and one or more water-soluble polymers are provided. Typically, the water-soluble polymer is poly(ethylene glycol) or a derivative thereof. Also provided are compositions comprising the conjugates, methods of making the conjugates, and methods of administering compositions comprising the conjugates to a patient.

Owner:NEKTAR THERAPEUTICS INC

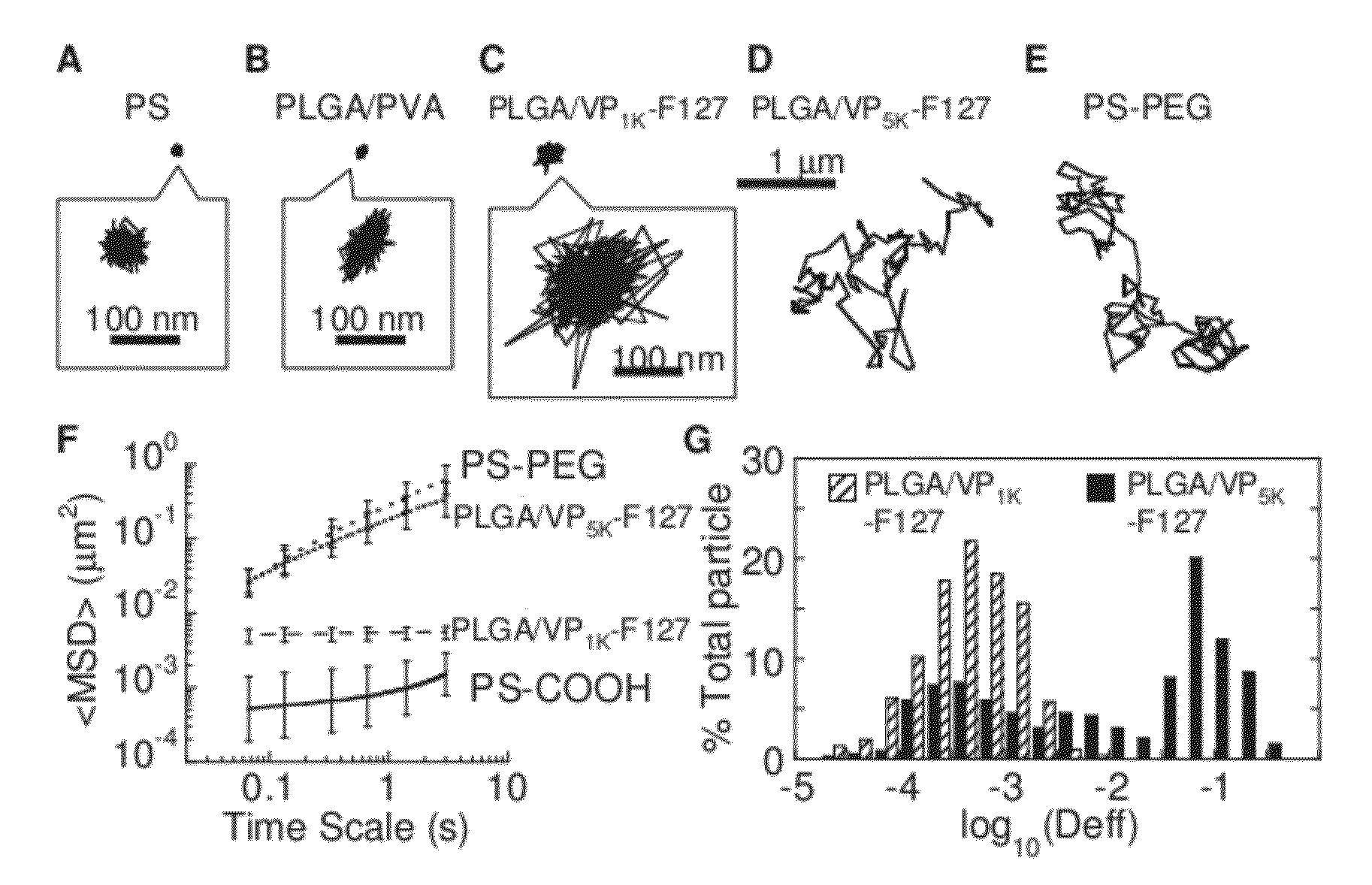

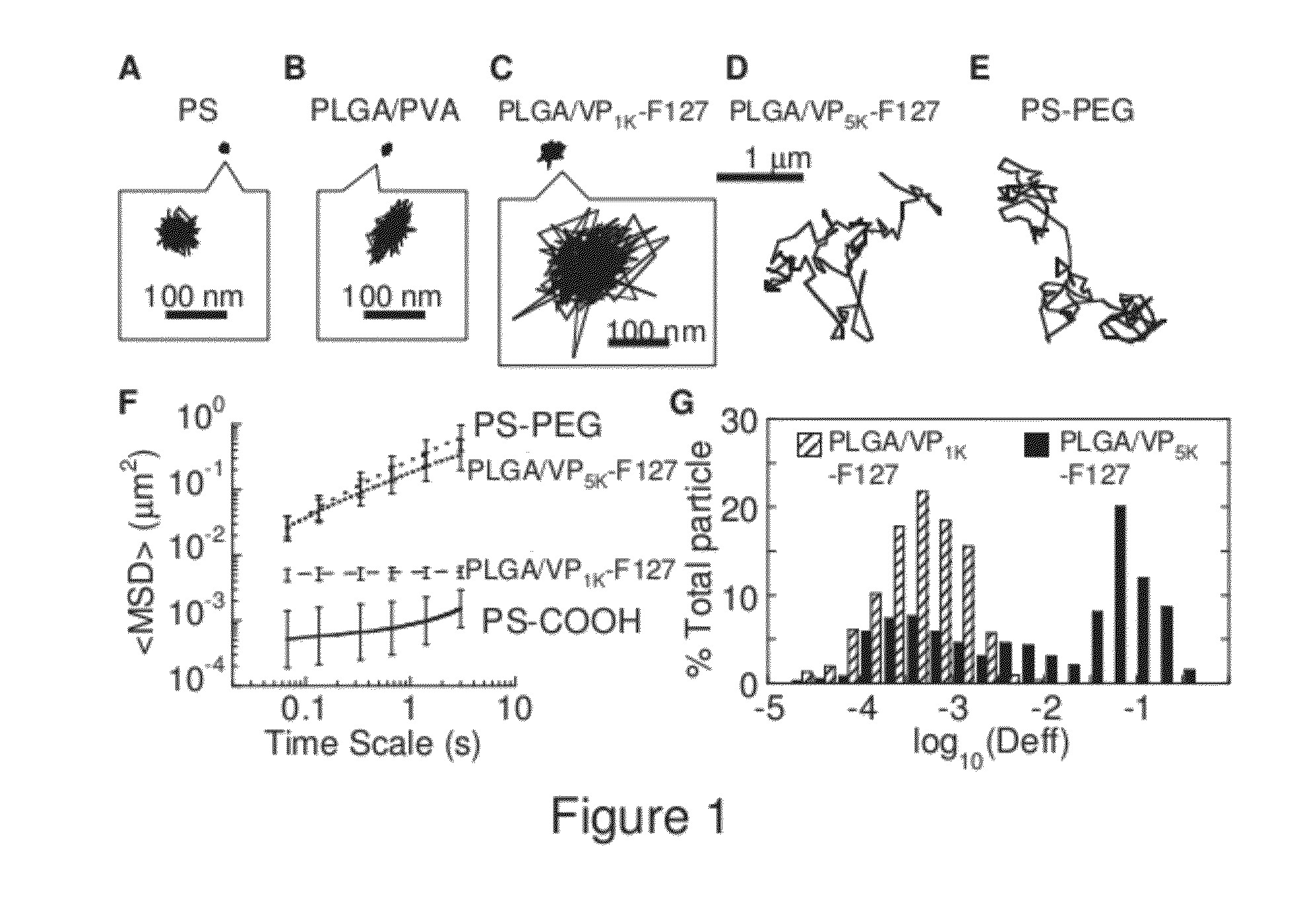

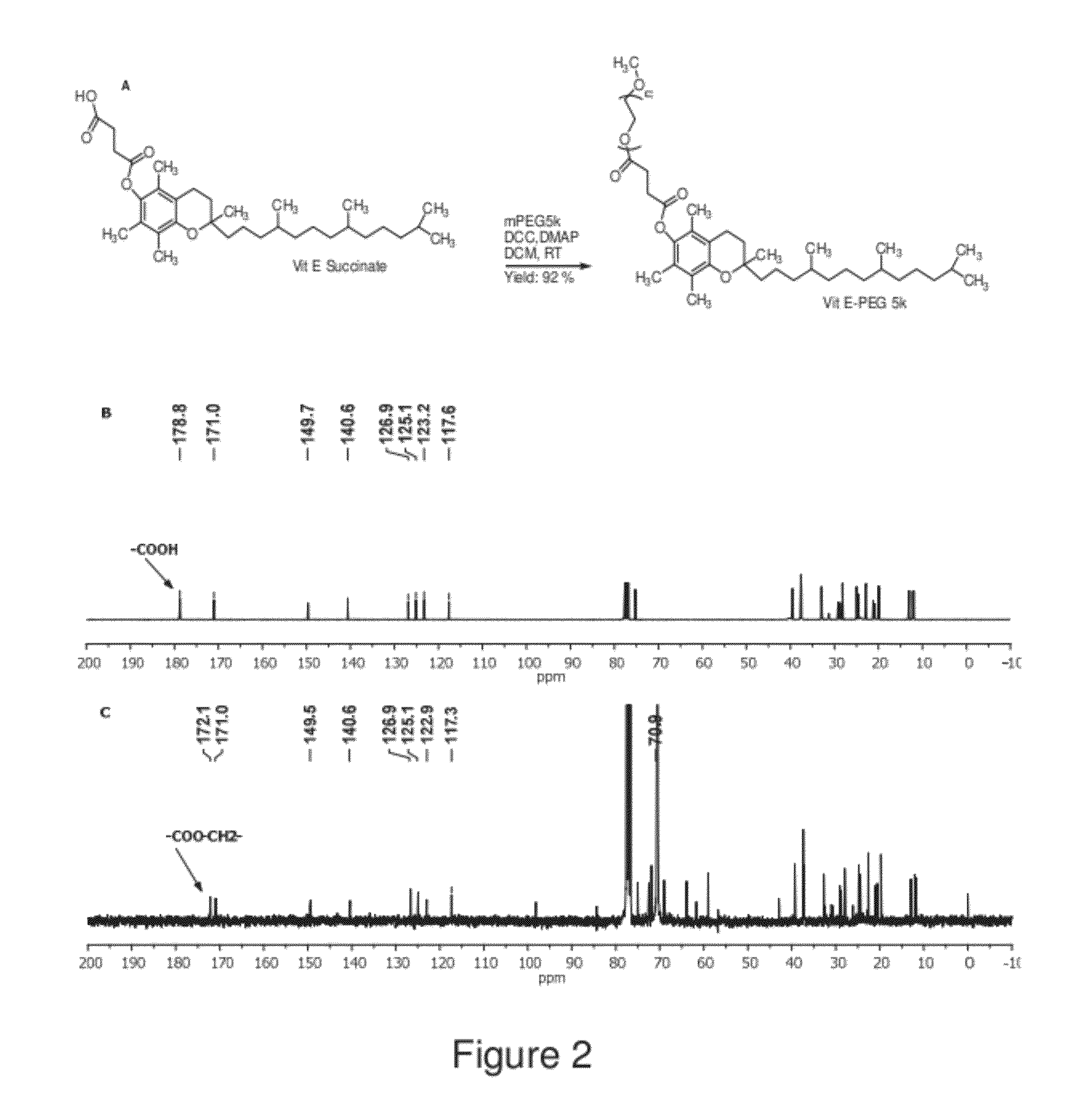

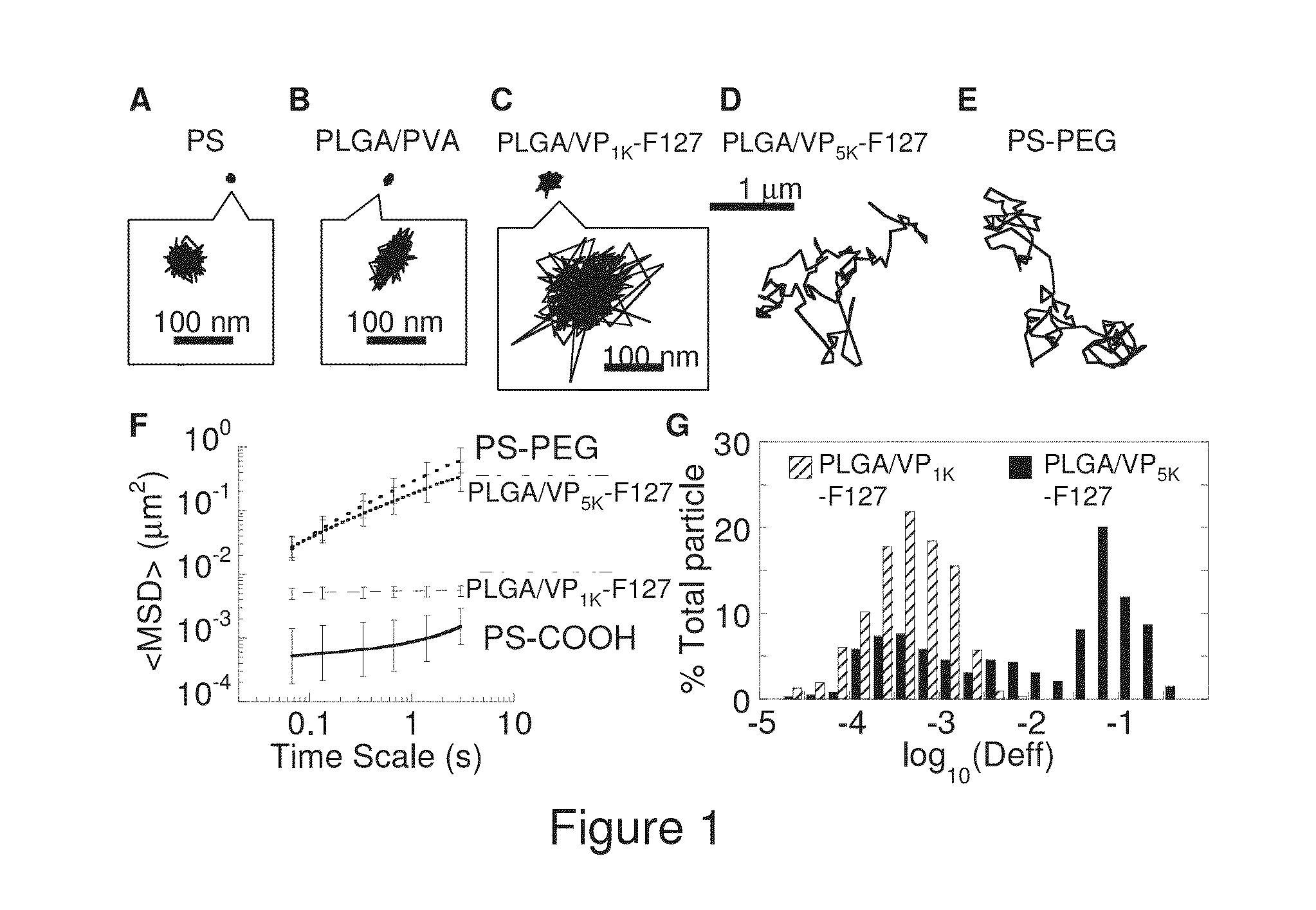

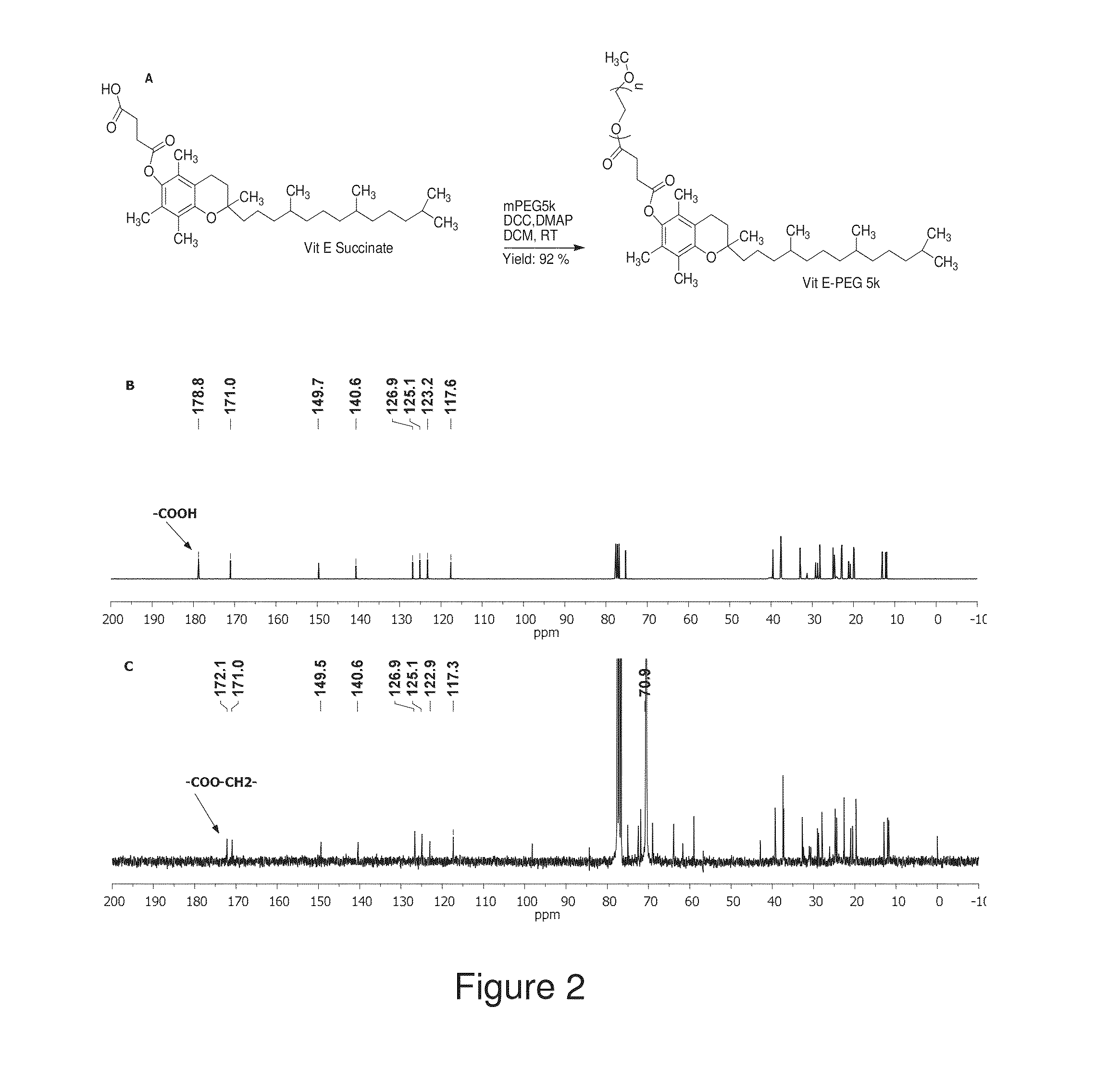

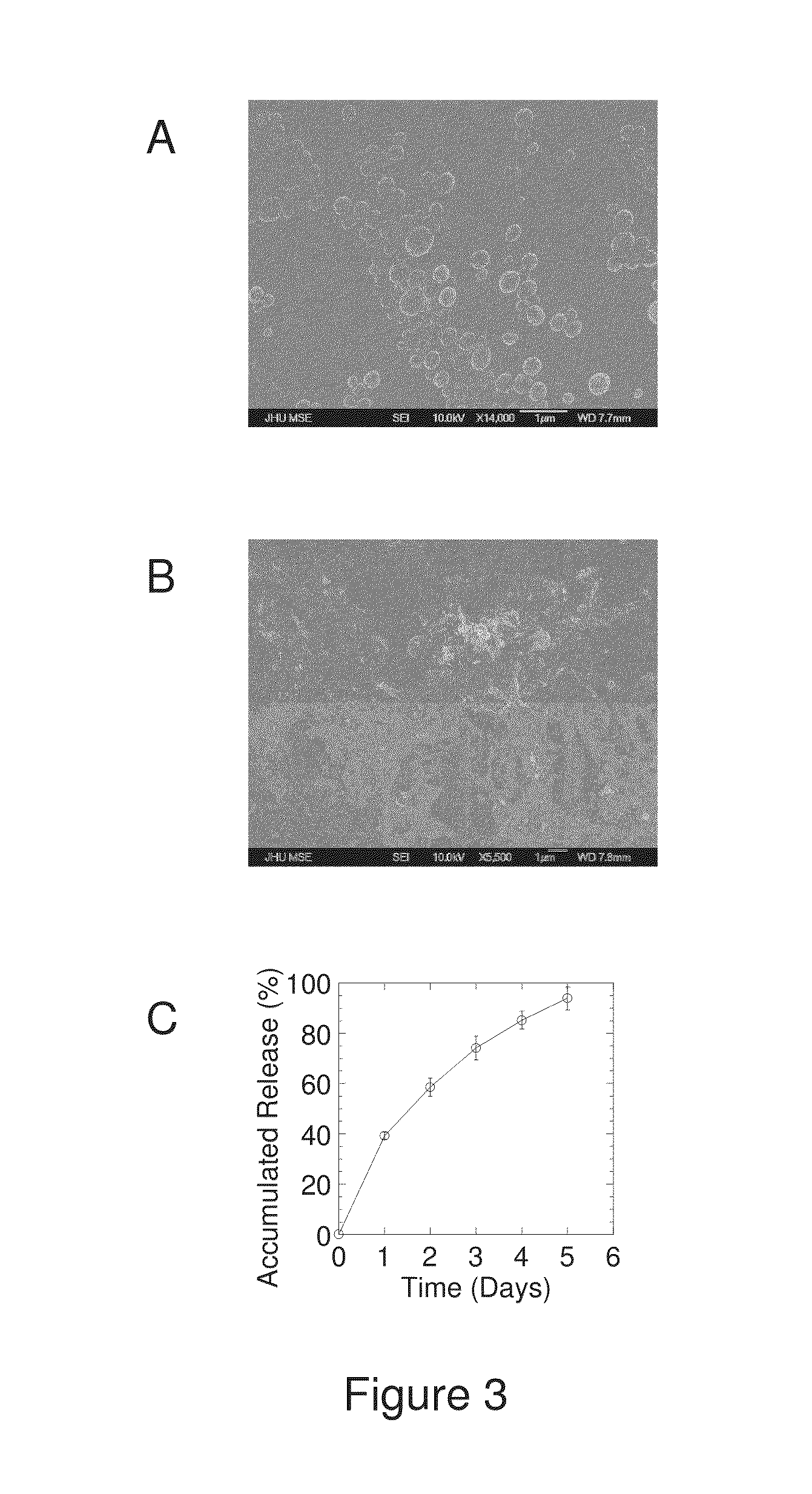

Compositions and methods relating to reduced mucoadhesion

InactiveUS20120121718A1Reduced mucoadhesionDiffusion fastOrganic active ingredientsPowder deliveryMedicineParticle composition

The present invention generally relates to reducing the mucoadhesive properties of a particle. In some embodiments, the particle is coated with and / or associated with a (poly(ethylene glycol))-(poly(propylene oxide))-(poly(ethylene glycol)) triblock copolymer. Methods for preparing inventive particles using a poly(ethylene glycol)-vitamin E conjugate as a surfactant are also provided. In some embodiments, methods are provided comprising administering to a subject a composition of particles of the present invention. Such particles with reduced mucoadhesive properties are useful in delivering agents to mucosal tissues such as oral, ophthalmic, gastrointestinal, nasal, respiratory, and genital mucosal tissues.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

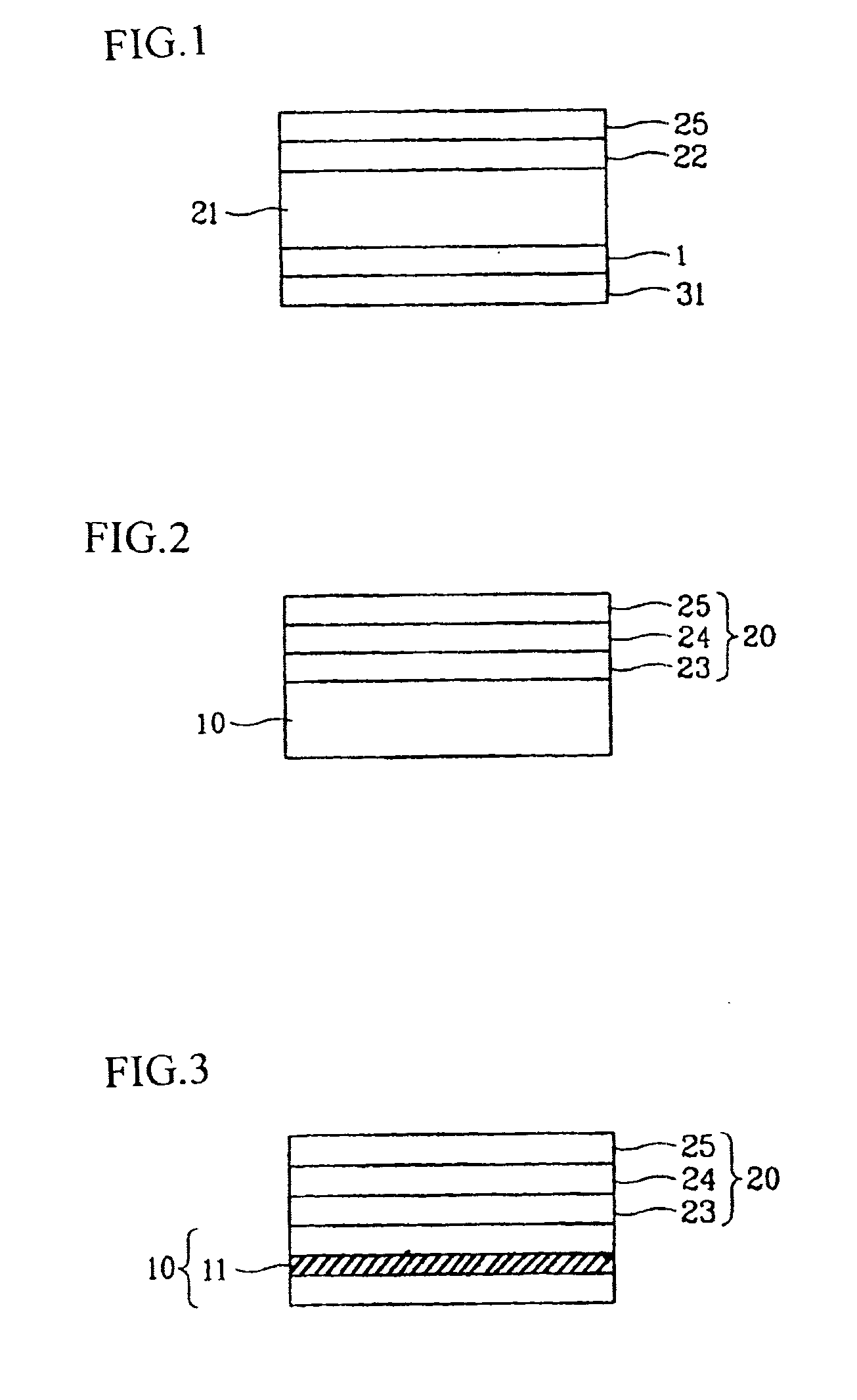

Decorative floor covering comprising polyethylene terephthalate film layer in surface layer and manufacturing method of the same

InactiveUS6933043B1Superior surface printing sharpness and realismEasy to installSynthetic resin layered productsPaper/cardboard layered productsSurface layerPolyethylene terephthalate

The present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein the surface layer comprises a polyethylene terephthalate film layer, and a method for preparing the same. Furthermore, the present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein a light weight back layer is further comprised under the substrate layer, and a method for preparing the same. A decorative floor covering of the present invention is a decorative floor covering which has superior surface heat resistance, printing sharpness and realism, and it can be installed conveniently since not only can non-foamed polyvinyl chloride resin be used as a substrate layer, but also the weight of a floor covering is light when a light weight back layer is comprised under the substrate layer.

Owner:LG CHEM LTD

Methods of nanostructure formation and shape selection

Methods for forming nanostructures of various shapes are disclosed. Nanocubes, nanowires, nanopyramids and multiply twinned particles of silver may by formed by combining a solution of silver nitrate in ethylene glycol with a solution of poly(vinyl pyrrolidone) in ethylene glycol. Hollow nanostructures may be formed by reacting a solution of solid nanostructures comprising one of a first metal and a first metal alloy with a metal salt that can be reduced by the first metal or first metal alloy. Nanostructures comprising a core with at least one nanoshell may be formed by plating a nanostructure and reacting the plating with a metal salt.

Owner:UNIV OF WASHINGTON

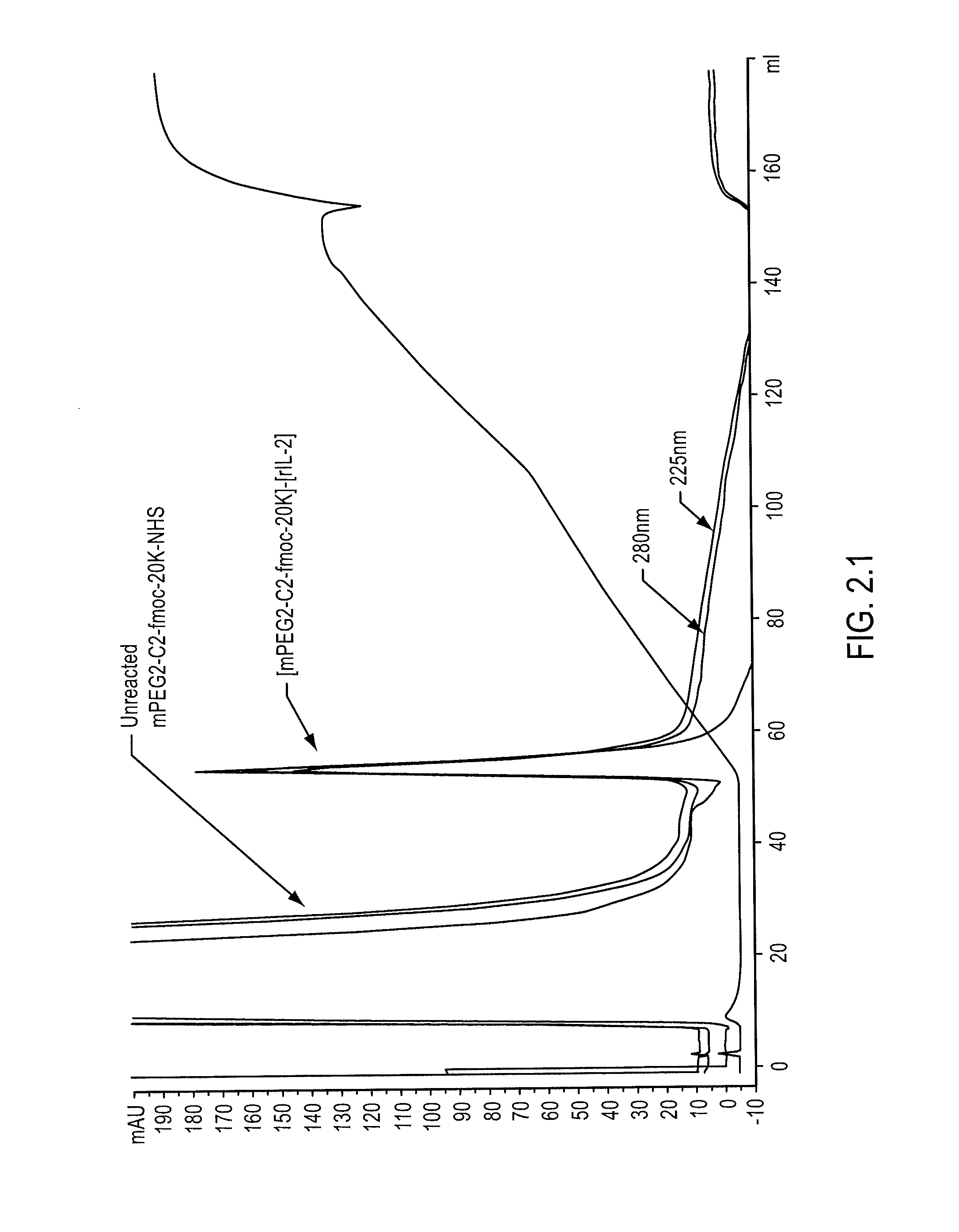

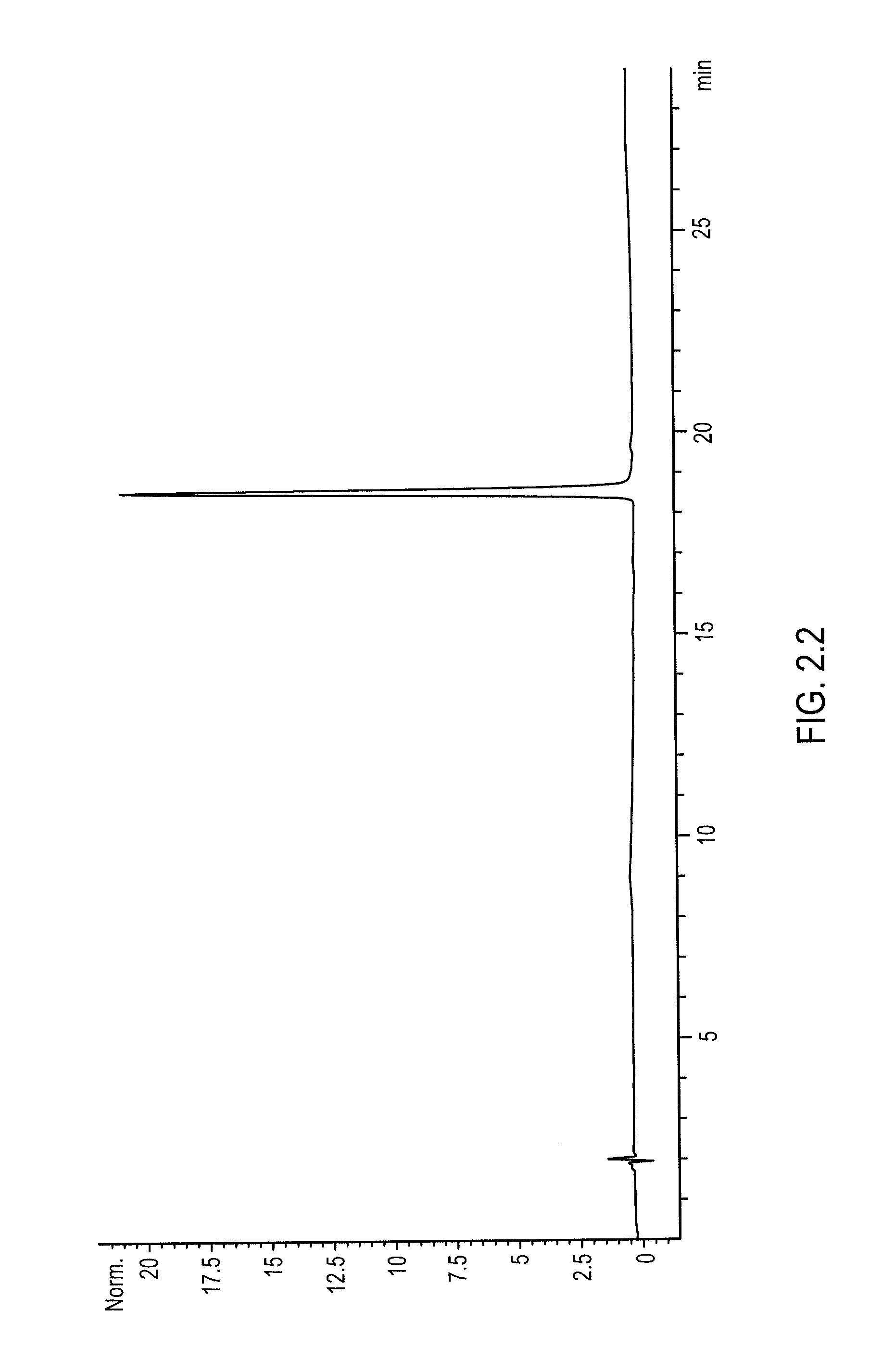

Conjugates of an IL-2 Moiety and a Polymer

Conjugates of an IL-2 moiety and one or more nonpeptidic, water-soluble polymers are provided. Typically, the nonpeptidic, water-soluble polymer is poly(ethylene glycol) or a derivative thereof. Also provided, among other things, are compositions comprising conjugates, methods of making conjugates, methods of administering compositions to an individual, nucleic acid sequences, expression systems, host cells, and methods for preparing IL-moieties.

Owner:NEKTAR THERAPEUTICS INC

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

Soluble, degradable poly(ethylene glycol) derivatives for conrollable release of bound molecules into solution

InactiveUS20050171328A1Reduce rateEnhance solubility and circulation lifetimePharmaceutical non-active ingredientsSynthetic polymeric active ingredientsSolubilityIncreased sizes

PEG and related polymer derivatives having weak, hydrolytically unstable linkages near the reactive end of the polymer are provided for conjugation to drugs, including proteins, enzymes, small molecules, and others. These derivatives provide a sufficient circulation period for a drug-PEG conjugate, followed by hydrolytic breakdown of the conjugate and release of the bound molecule. In some cases, drugs that demonstrate reduced activity when permanently coupled to PEG maintain a therapeutically suitable activity when coupled to a degradable PEG in accordance with the invention. The PEG derivatives of the invention can be used to impart improved water solubility, increased size, a slower rate of kidney clearance, and reduced immunogenicity to a conjugate formed by attachment thereto. Controlled hydrolytic release of the bound molecule into an aqueous environment can then enhance the drug's delivery profile by providing a delivery system which employs such polymers and utilizes the teachings provided herein.

Owner:NEKTAR THERAPEUTICS INC

Nano carbon materials for enhancing thermal transfer in fluids

InactiveUS6695974B2Improve thermal conductivityImprove heat transfer performanceMaterial nanotechnologyNanostructure manufactureOrganic groupElectrical polarity

A novel fluid heat transfer agent suitable for use in a closed heat transfer system, for example, wherein energy is transferred between an evaporator and a condenser in heat exchange relationship with the heat transfer agent that is caused to flow from one to the other. The novel heat transfer agent is a complex comprising a body of heat transfer fluid, for example, ethylene glycol or water, having suspended therein carbon nanoparticles in a quantity sufficient to enhance the thermal conductivity of the body of heat transfers fluid, per se. The carbon nanoparticles are selected from carbon in the form of sp<2 >type and sp<3 >type bonding and preferably comprise nanotubes or fullerenes and may have a coupling agent bonded thereto or enclosed therein when the nanotube or fullerene forms a hollow capsule. The coupling agent may be a polar organic group covalently bonded to the carbon nanoparticles and miscible in the fluid medium.

Owner:MATERIALS & ELECTROCHEM RES

Catalyzer for the oxalic ester hydrogenation synthesizing of ethylene glycol and method of preparing the same

A catalyst for hydrogenated synthesis of glycol with oxalate and a preparation method for the catalyst belong to the glycol preparation technical field. The catalyst of the present invention uses the copper metal as the main active component, and zinc as the promoter, and is manufactured with the method of deposition. A carrier of the catalyst is the modified silica sol. The select content of the copper metal is 5 to 45 percent of the carrier weight, and the optimal content of the copper metal is 10 to 40 percent. The content of zinc metal is 0.1 to 15 percent of the carrier weight, and the optimal content of zinc metal is 1 to 8.0 percent. The select specific surface area of the carrier is 90-350m2 / g, and the optimal is 150-300m2 / g. Proven by experiments, the catalyst is provided with the very high reaction activity and glycollate selectivity in the reaction to synthesize glycollate with oxalate and hydrogen Moreover, the catalyst is provided with the long usable life and the stable reaction performance, and can be easily controlled.

Owner:TIANJIN UNIV +1

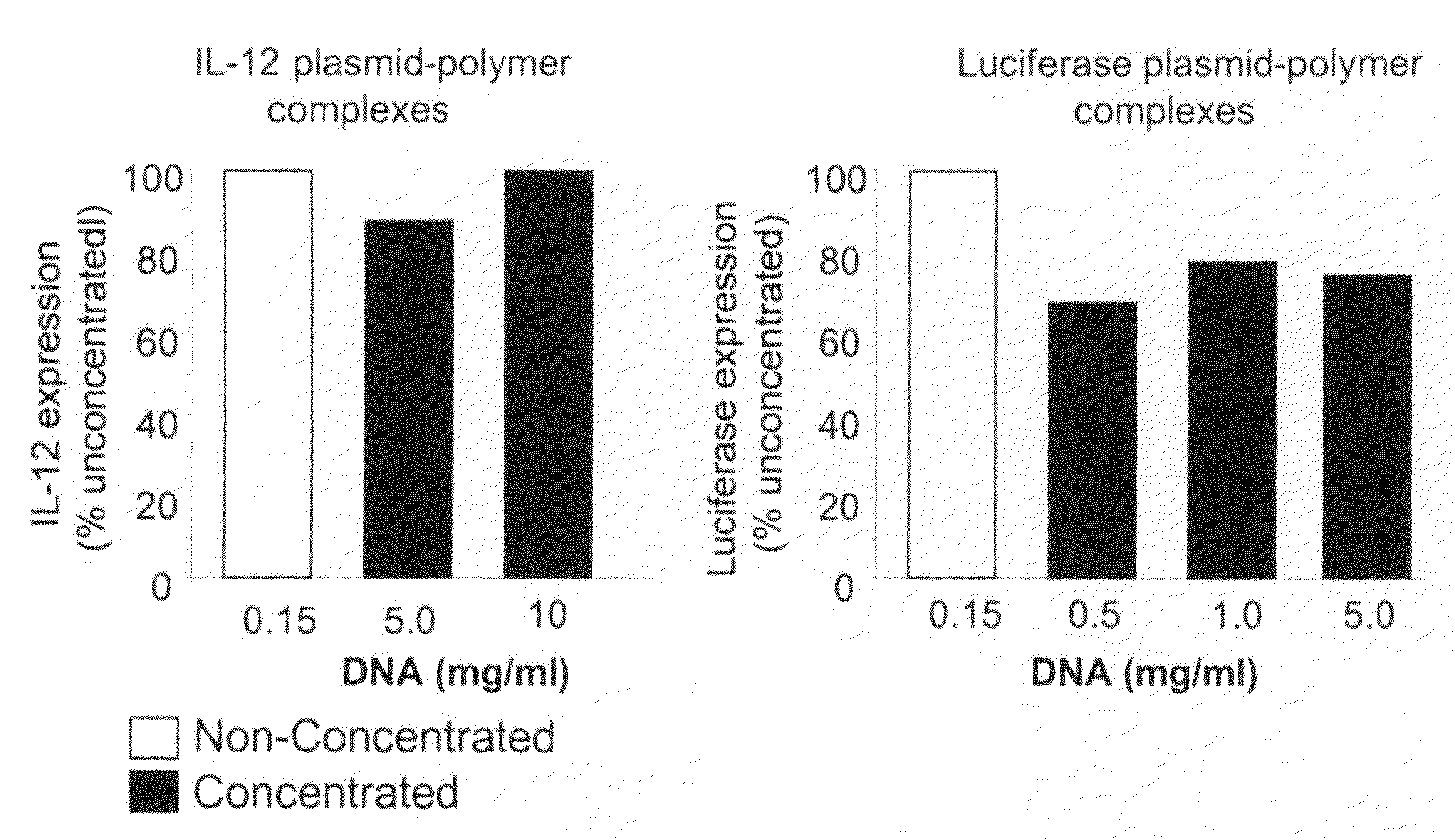

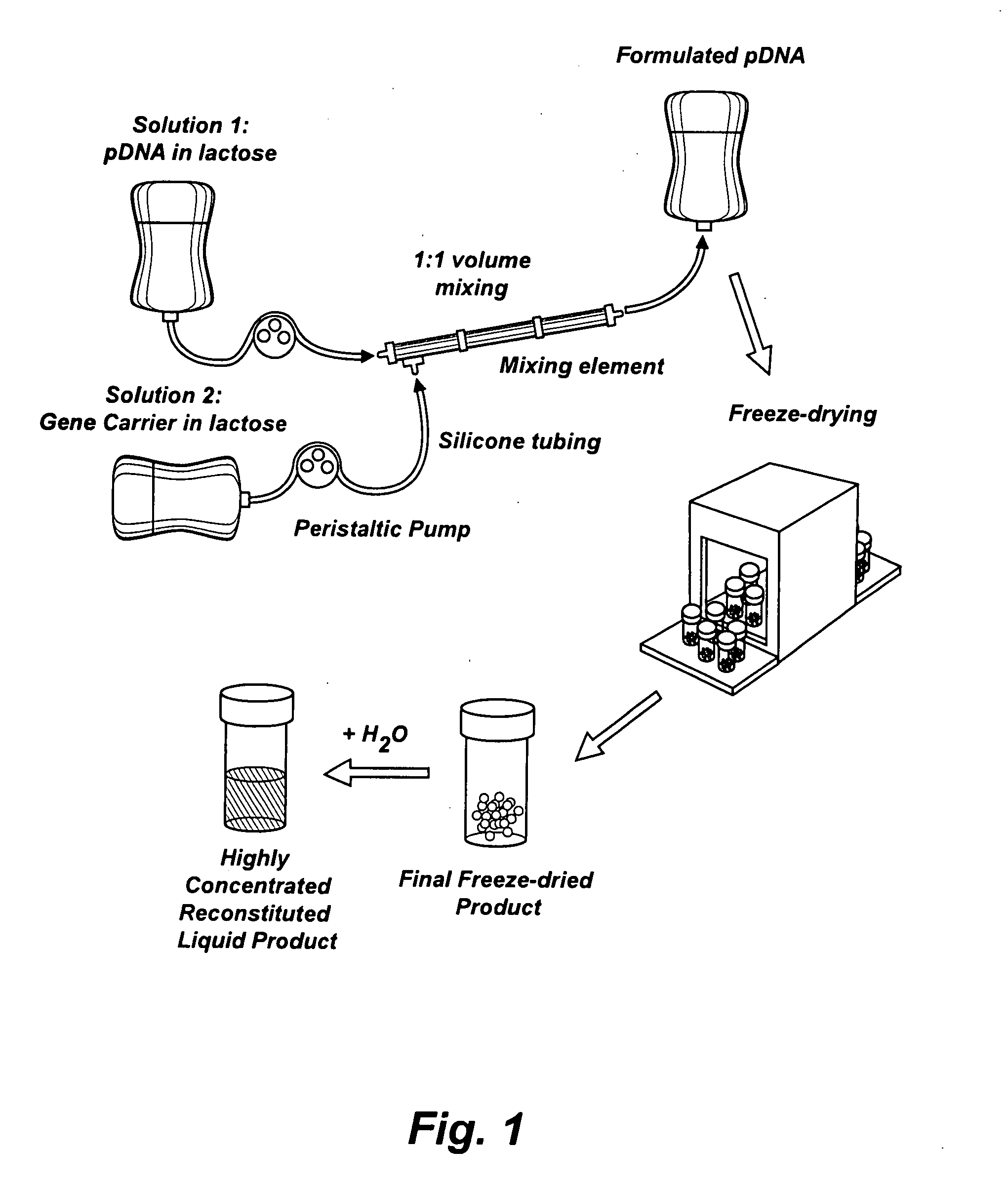

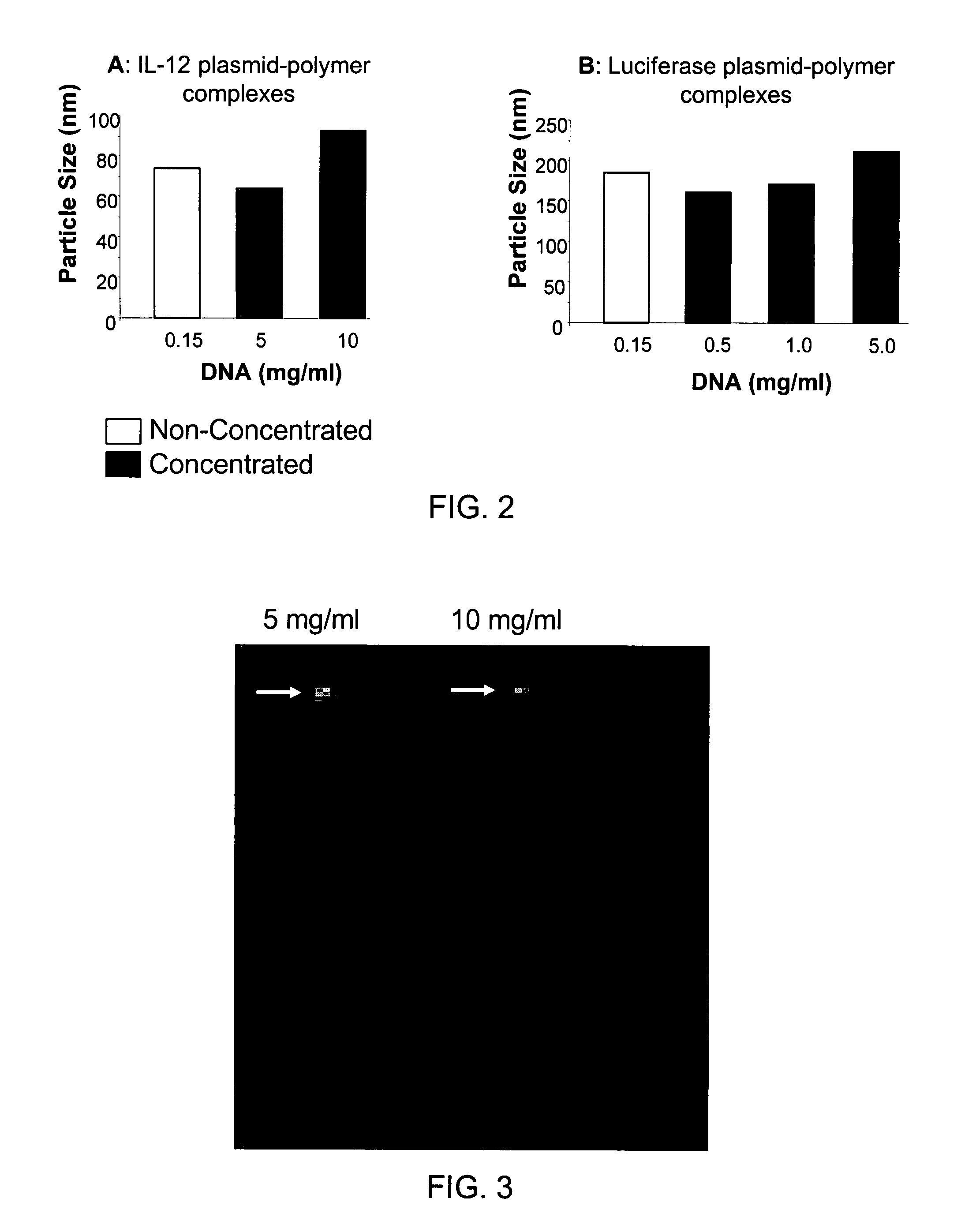

Composition, method of preparation & application of concentrated formulations of condensed nucleic acids with a cationic lipopolymer

UndeterminedUS20090042825A1Increase efficiency and dosing flexibilitySpecial deliveryPeptide/protein ingredientsFiller ExcipientCholesterol

Compositions, methods, and applications that increase the efficiency of nucleic acid transfection are provided. In one aspect, a pharmaceutical composition may include at least about 0.5 mg / ml concentration of a nucleic acid condensed with a cationic lipopolymer suspended in an isotonic solution, where the cationic lipopolymer includes a cationic polymer backbone having cholesterol and polyethylene glycol covalently attached thereto, and wherein the molar ratio of cholesterol to cationic polymer backbone is within a range of from about 0.1 to about 10, and the molar ratio of polyethylene glycol to cationic polymer backbone is within a range of from about 0.1 to about 10. The composition further may include a filler excipient.

Owner:EXPRESSION GENETICS INC

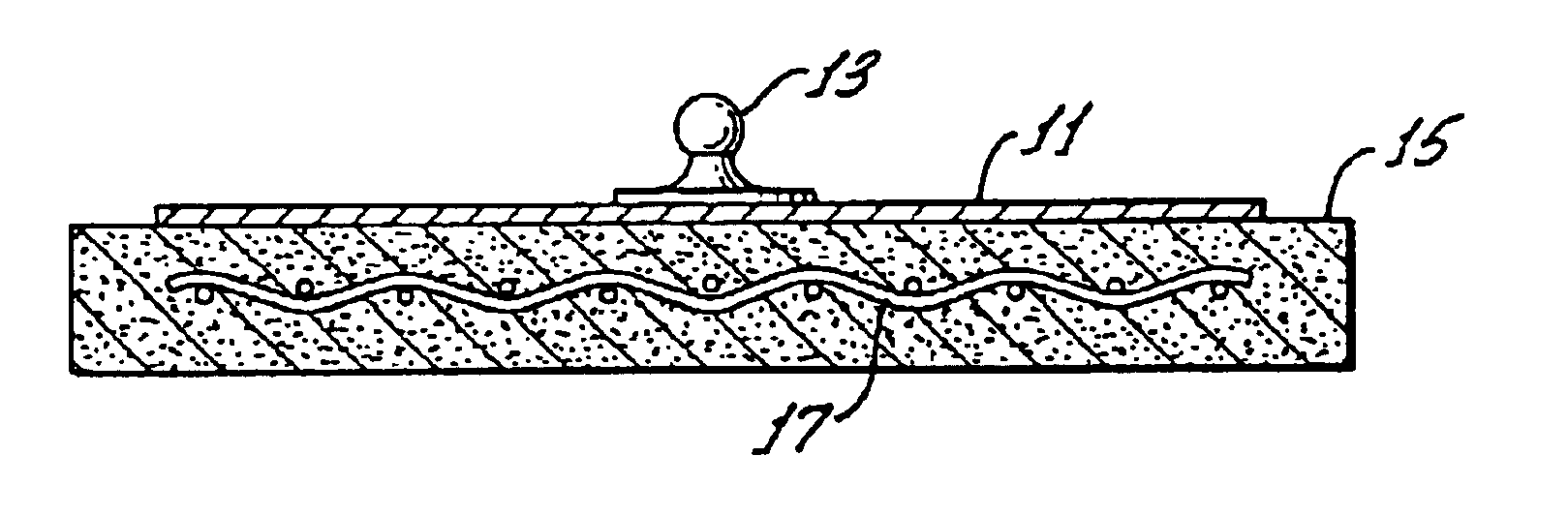

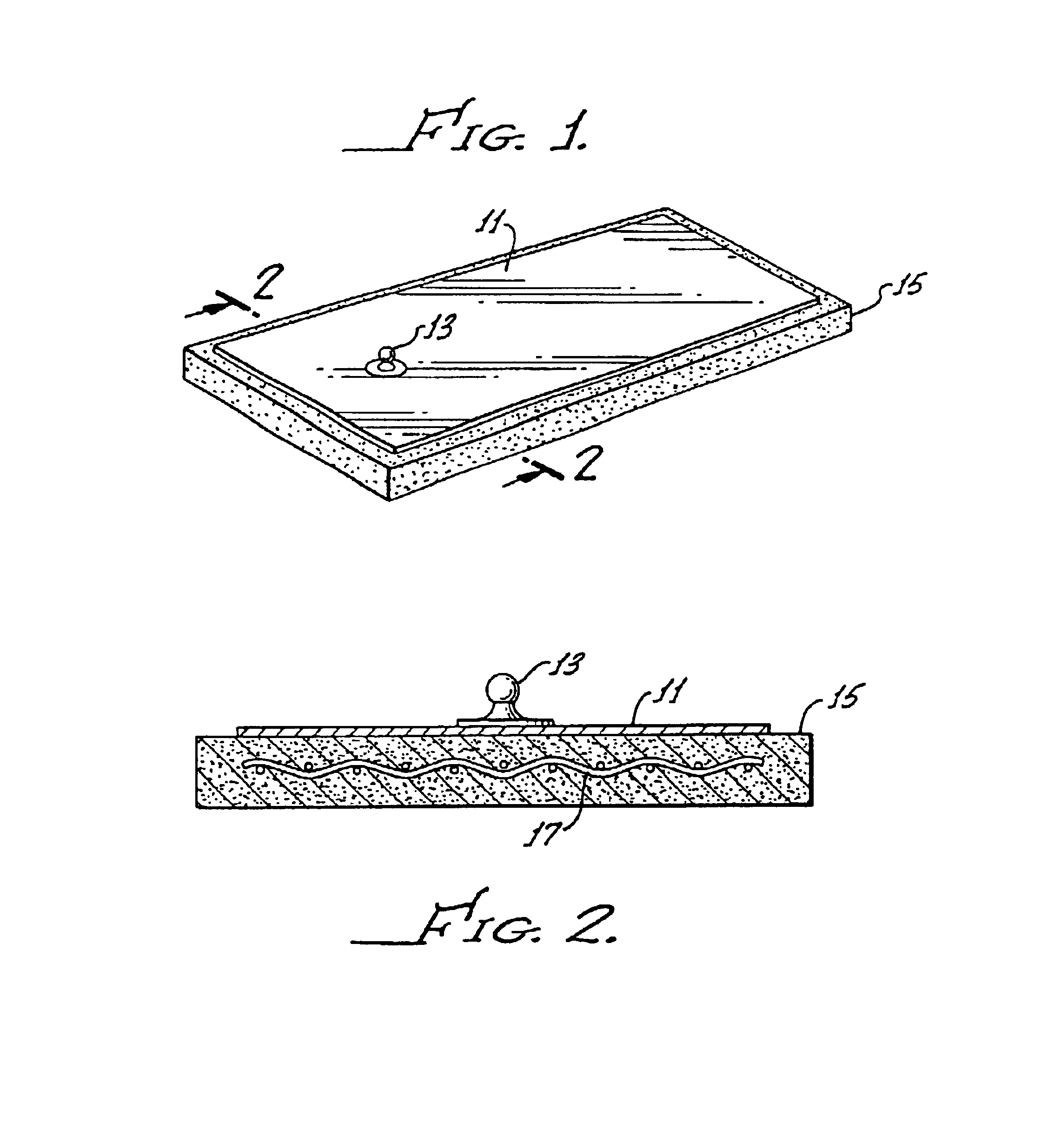

Medical electrode

An electrode providing electrical contact with a patient's skin includes a conductive member adapted for connection to an external electrical apparatus and a non-liquid water containing film for electrically interfacing to said patient's skin, the non-liquid film being electrically and mechanically connected to said conductive member. The non-liquid water containing film includes an electrically conductive organic polymer plasticized with a polyhydric alcohol with said organic polymer being derived from a monomeric mixture comprising from about 2 to 30 pph acrylic acid, 2 to 30 pph of a glycolvinylether and 0.01 to 1.5 pph of a crosslinking agent. Preferably the polyhydric alcohol is glycerol.

Owner:AXELGAARD MANUFACTURING COMPANY INC

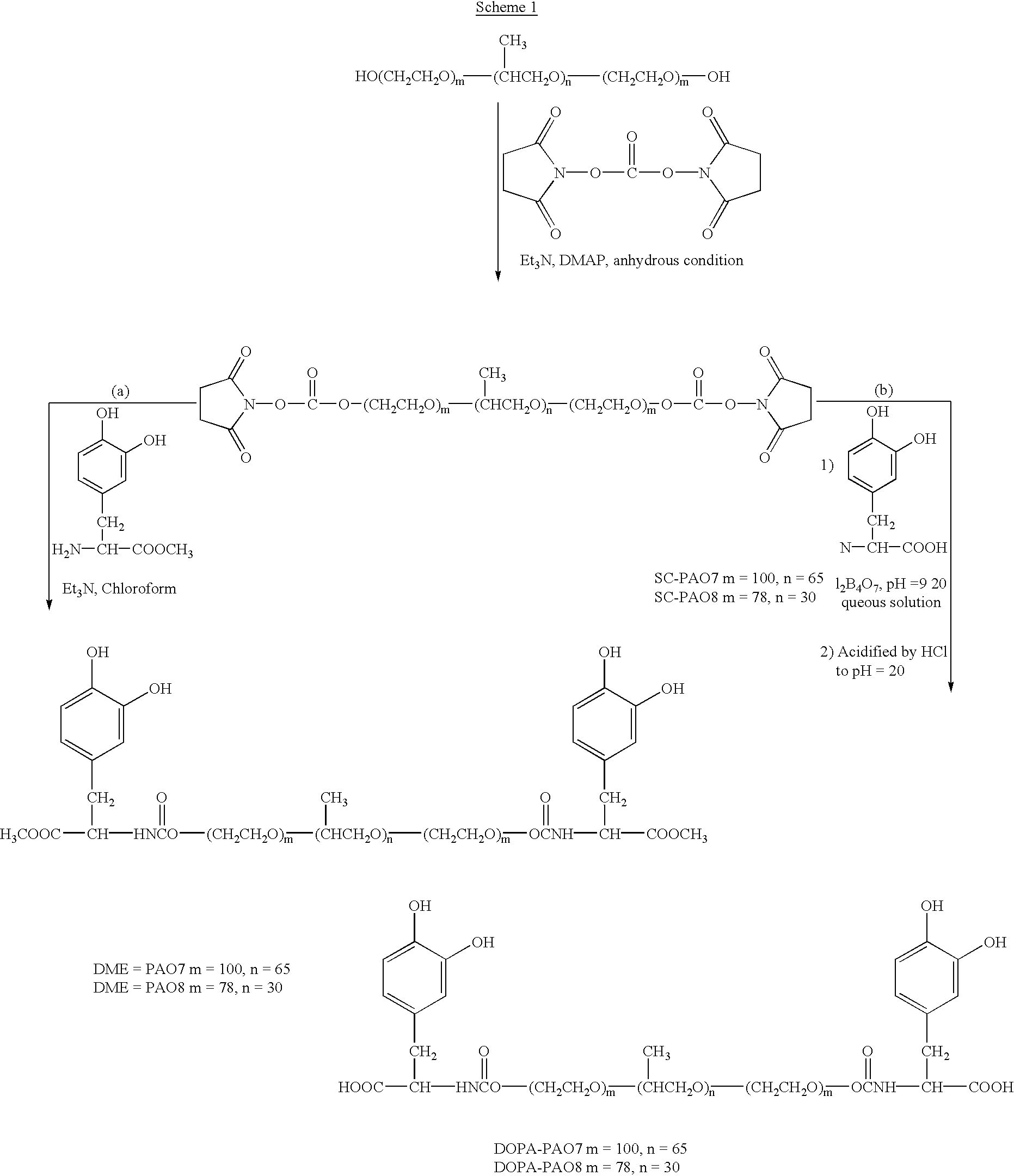

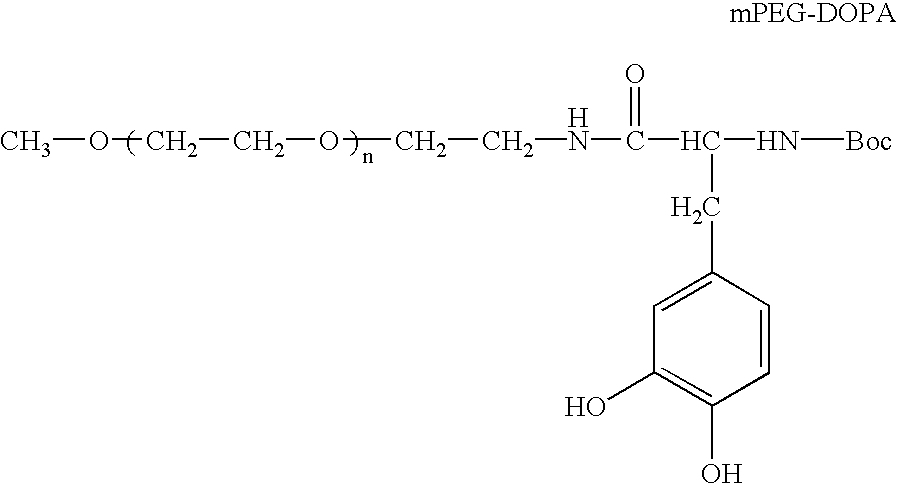

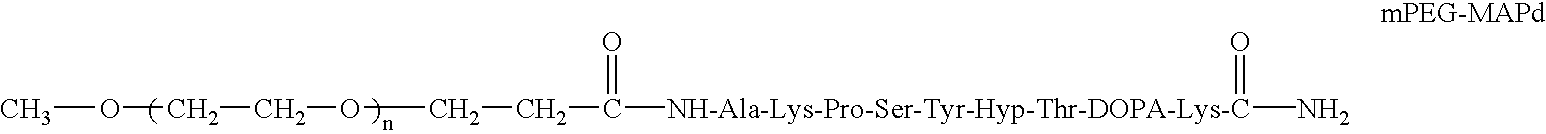

Adhesive DOPA-containing polymers and related methods of use

3,4-Dihydroxyphenyl-L-alanine (DOPA) is an unusual amino acid found in mussel adhesive proteins (MAPs) that form tenacious bonds to various substrates under water. DOPA is believed to be responsible for the adhesive characteristics of MAPs. This invention relates to a route for the conjugation of DOPA moieties to various polymeric systems, including but not limited to poly(ethylene glycol) or poly(alkylene oxide) systems such as poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) (PEO-PPO-PEO) block copolymers.

Owner:NORTHWESTERN UNIV

Isolatable, water soluble, and hydrolytically stable active sulfones of poly(ethylene glycol) and related polymers for modification of surfaces and molecules

A poly(ethylene glycol) derivative is disclosed that is activated with a sulfone moiety for selective attachment to thiol moieties on molecules and surfaces. The activated PEG is water soluble, hydrolytically stable for extended periods, and forms hydrolytically stable linkages with thiol moieties. The linkages generally are not reversible in reducing environments. The PEG derivative is useful for modifying the characteristics of substances including modifying biologically active molecules and surfaces for biocompatibility. Methods for synthesizing the active PEG and for preparing conjugates of the active PEG and other substances, including biologically active substances, are also disclosed.

Owner:NEKTAR THERAPEUTICS INC

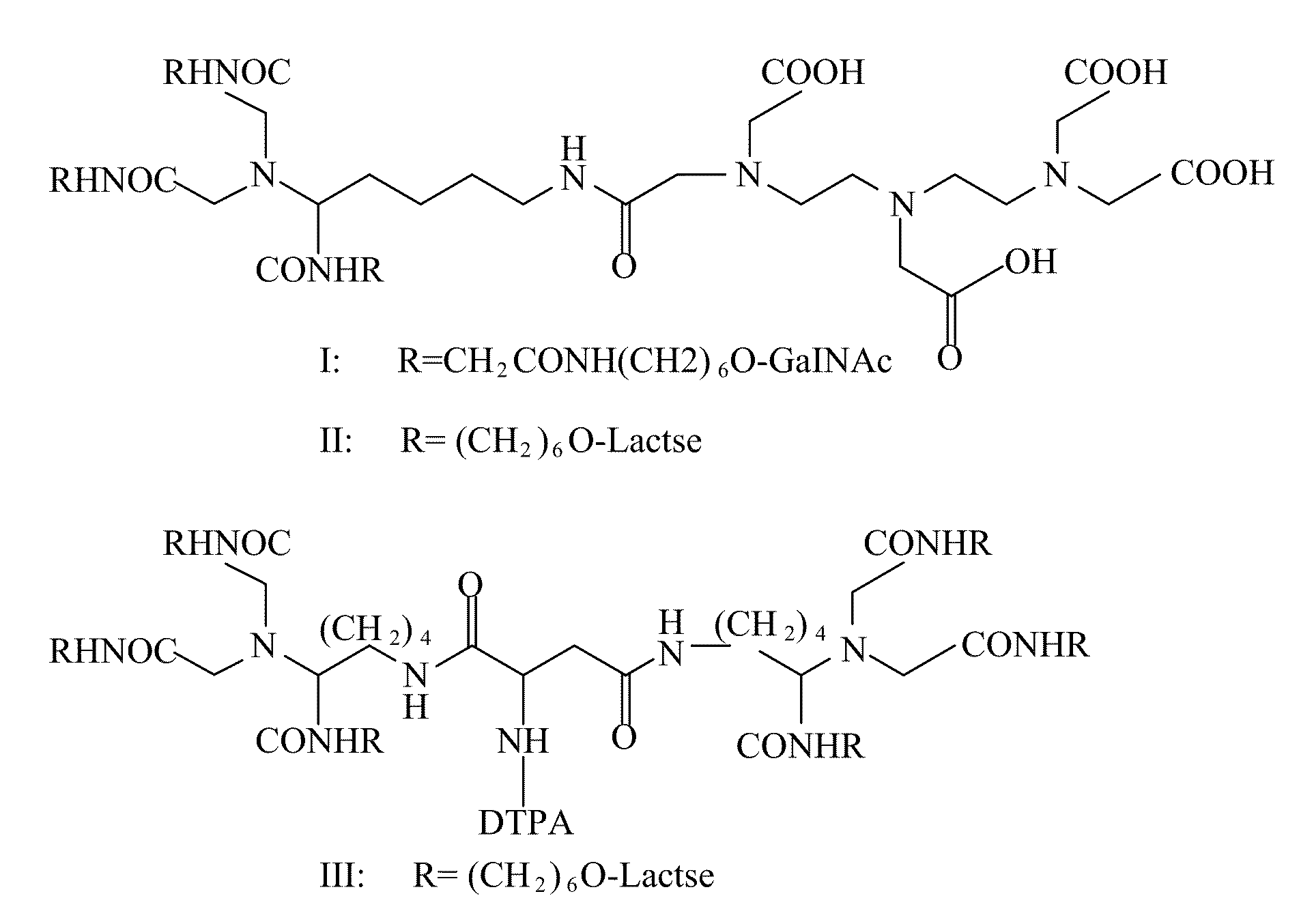

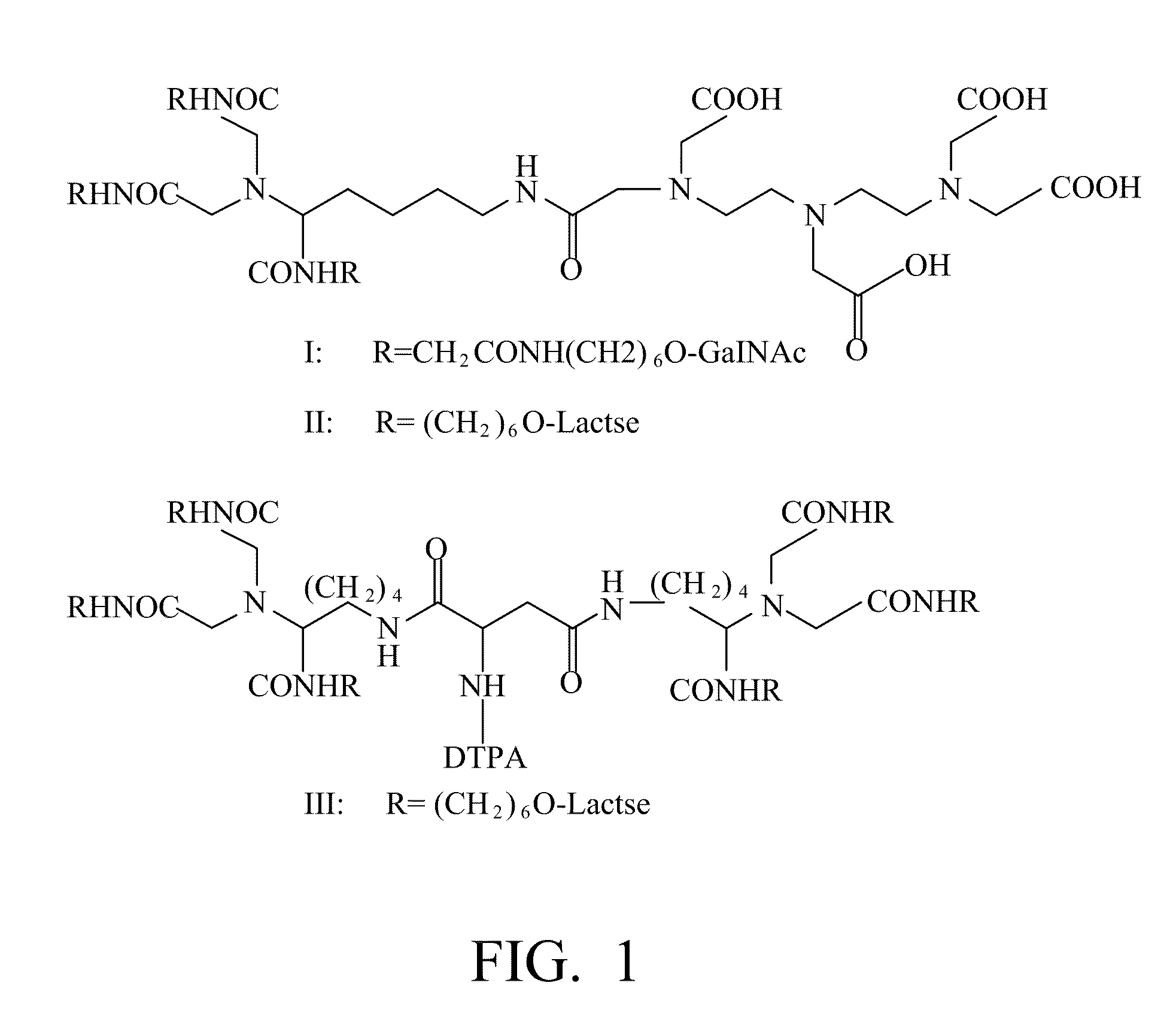

Radiolabeling method using multivalent glycoligands as hepatic receptor imaging agent

InactiveUS20110097264A1Low toxicityImprove securityRadioactive preparation carriersSaccharide peptide ingredientsImaging agentClinical trial

A radiolabeling method using a multivalent glycoligand as hepatic receptor imaging agent is provided. The multivalent glycoligand-DTPA derivatives (In-111-DTPA-hexa lactoside and In-111-DTPA-tri-galactosamine glycoside) labeled with In-111 are used as hepatic receptor imaging agent. The effects of imaging of a hepatic receptor in different species are evaluated, the lowest specific radioactivity values of hepatic receptor imaging required in different species are discovered. Since the specificity of the human ASGPR closely resembles that of the mouse. This kind of radiolabelling method, agent and related study about specific radioactivity could be used in clinical trial in the future.

Owner:INST NUCLEAR ENERGY RES ROCAEC

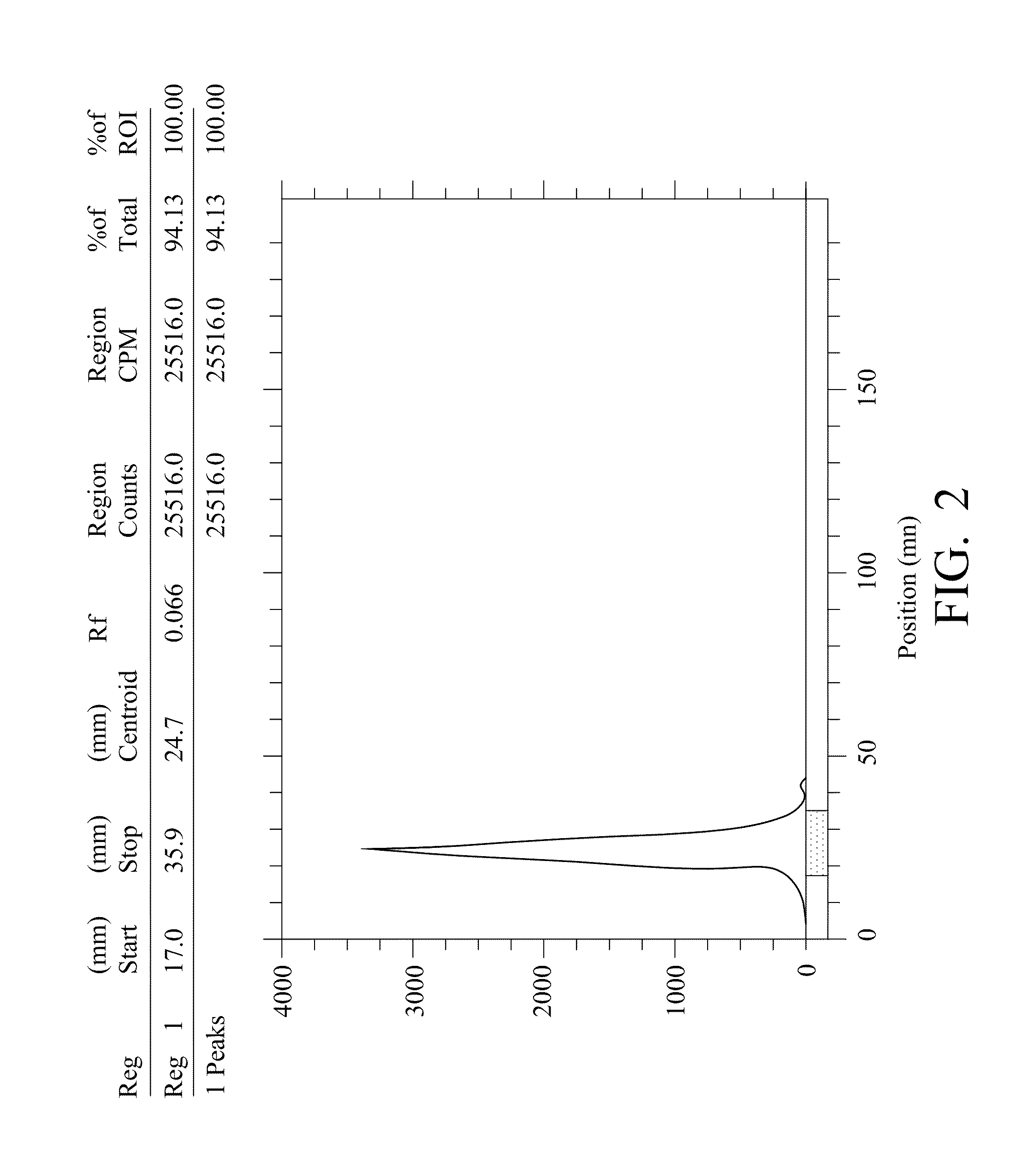

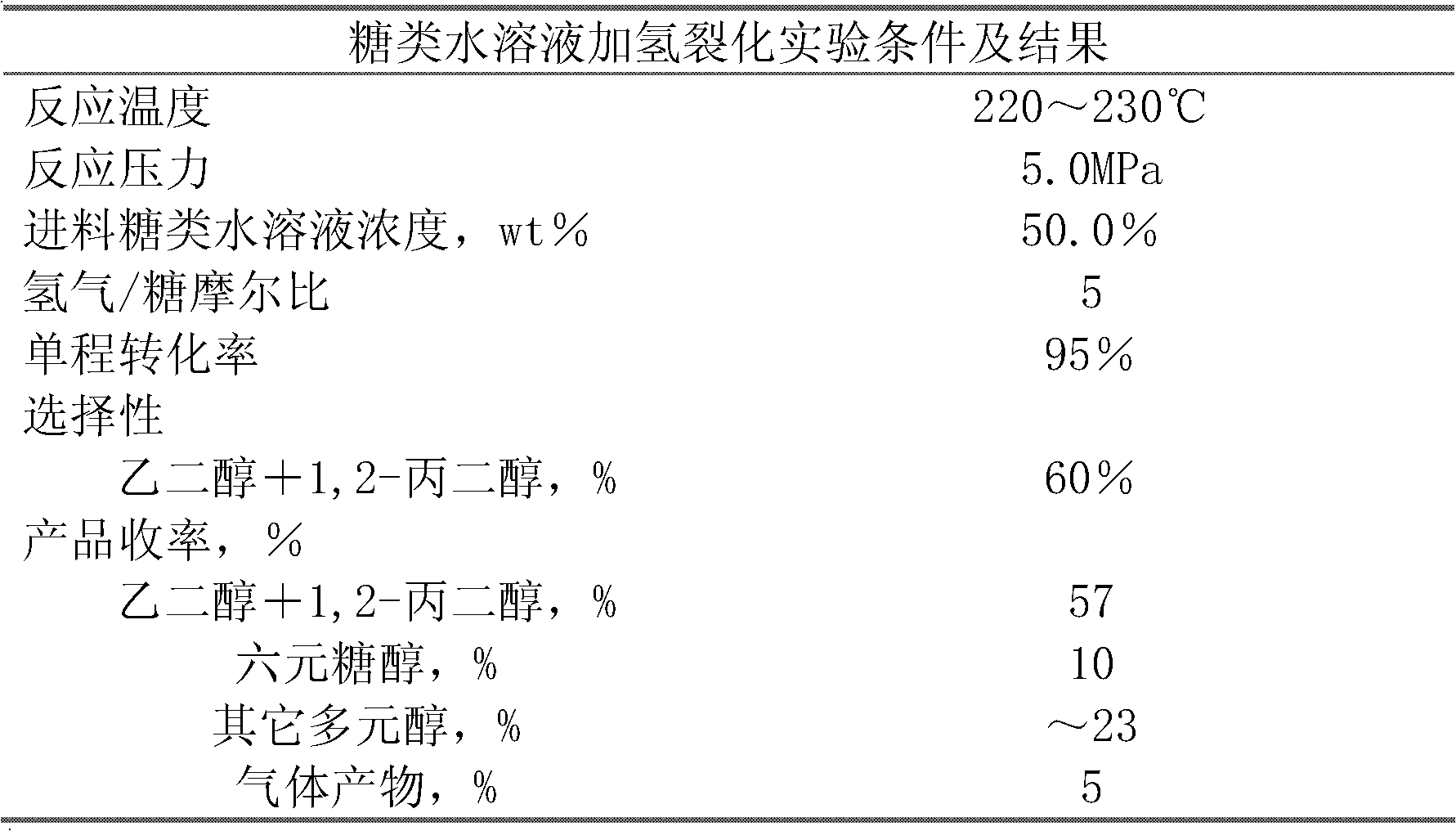

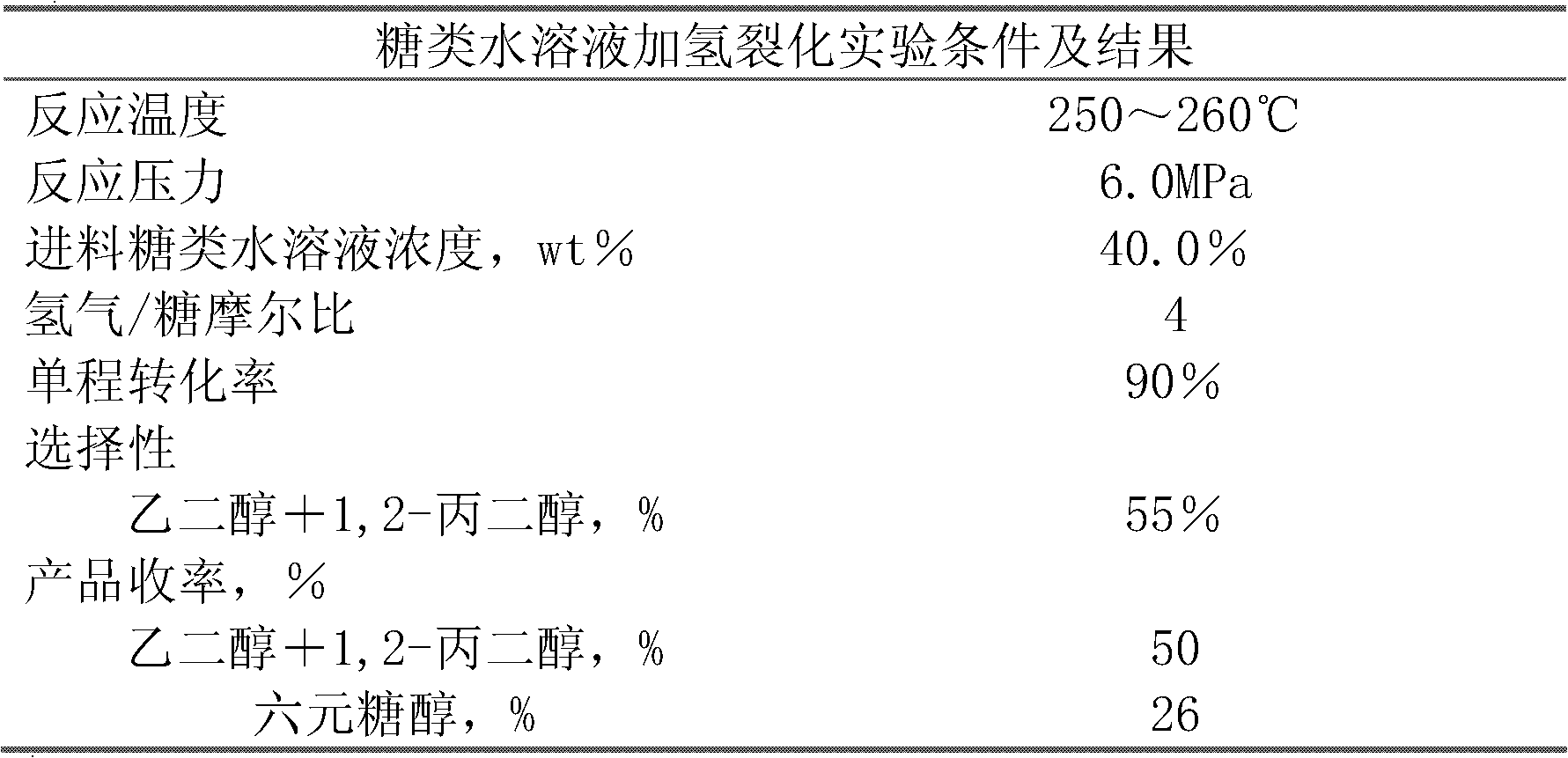

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

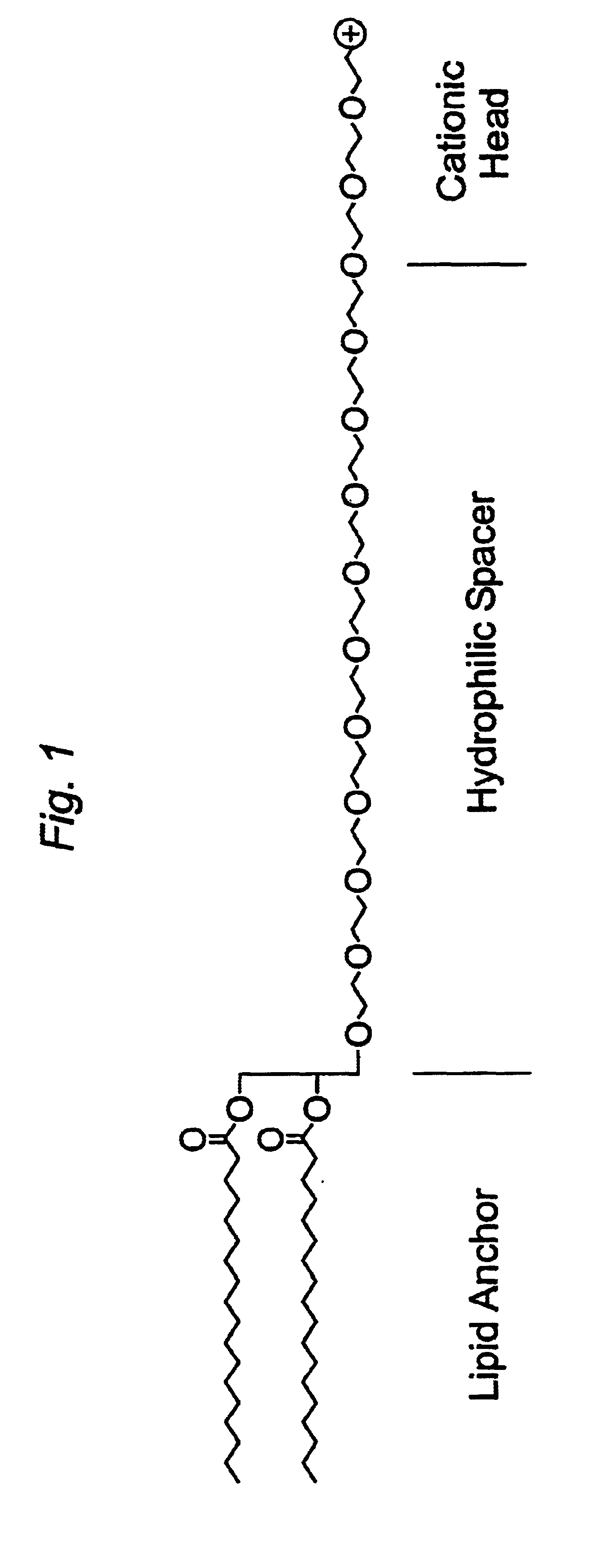

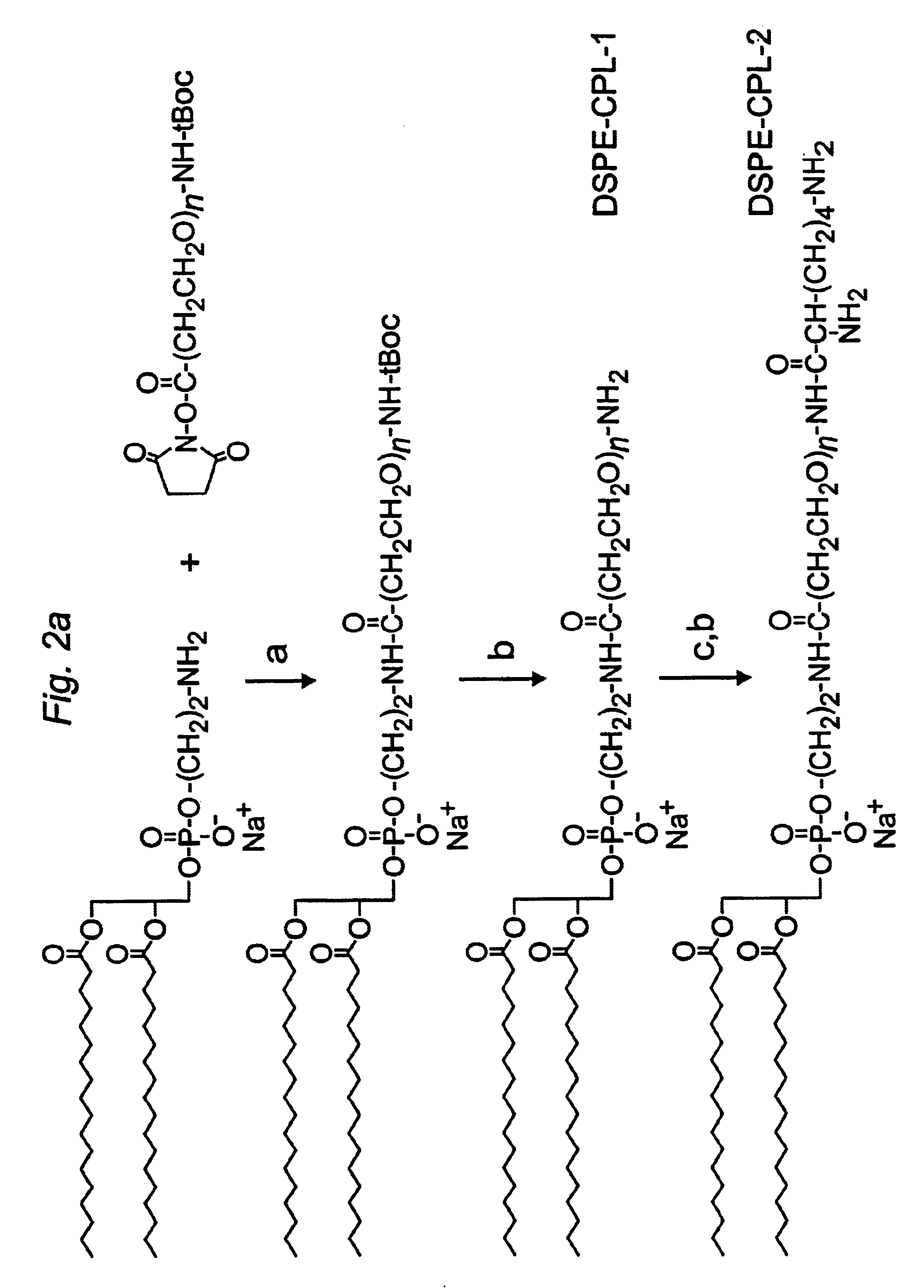

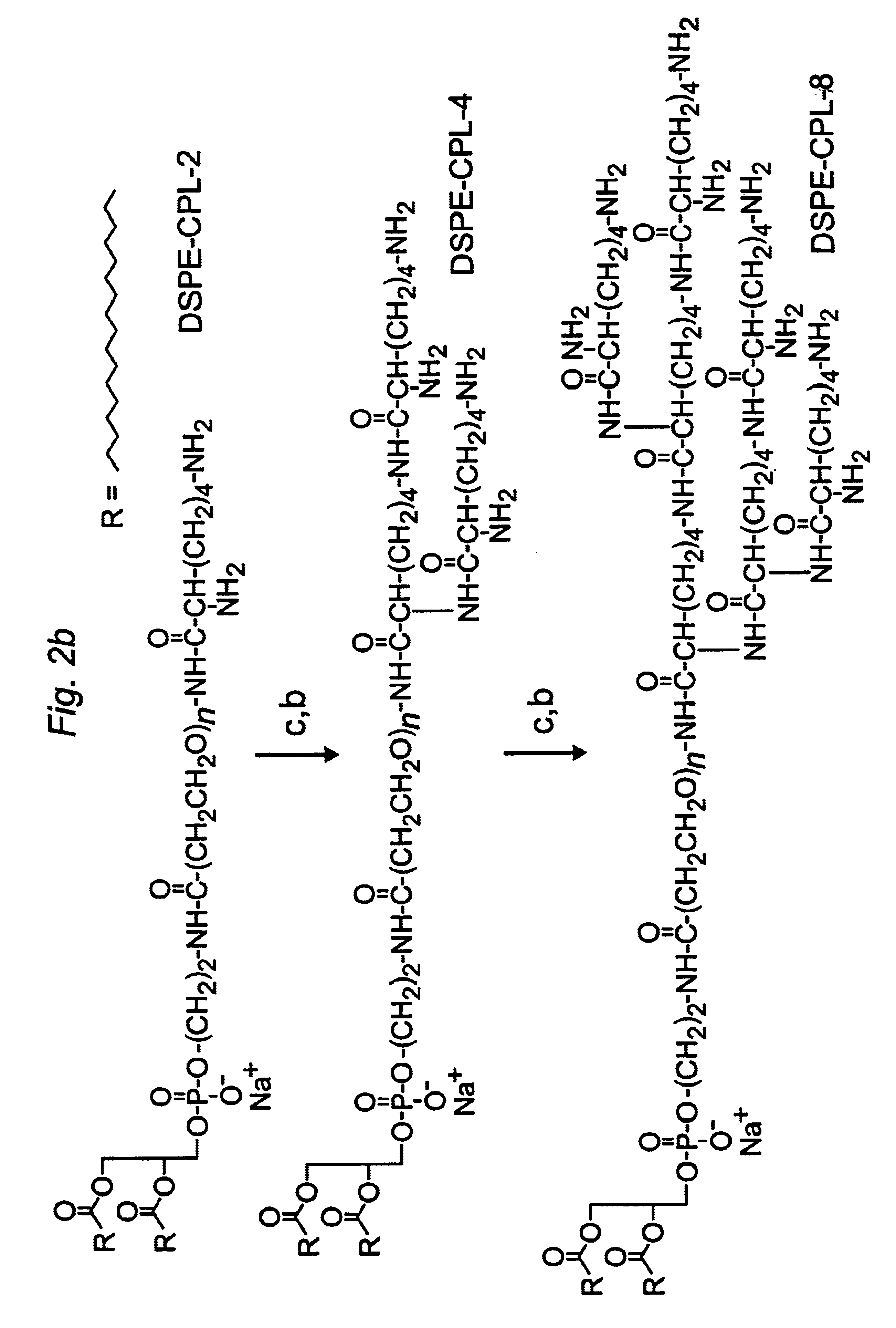

Cationic peg-lipids and methods of use

InactiveUS6852334B1High transfection efficiencyMicroencapsulation basedGenetic material ingredientsLipid formationHydrophilic polymers

The present invention provides cationic-polymer-lipid conjugates (CPLs) such as distal cationic-poly(ethylene glycol)-lipid conjugates which can be incorporated into conventional and stealth liposomes or other lipid-based formulation for enhancing cellular uptake. The CPLs of the present invention comprise a lipid moiety; a hydrophilic polymer; and a polycationic moiety. Method of increasing intracellular delivery of nucleic acids are also provided.

Owner:THE UNIV OF BRITISH COLUMBIA

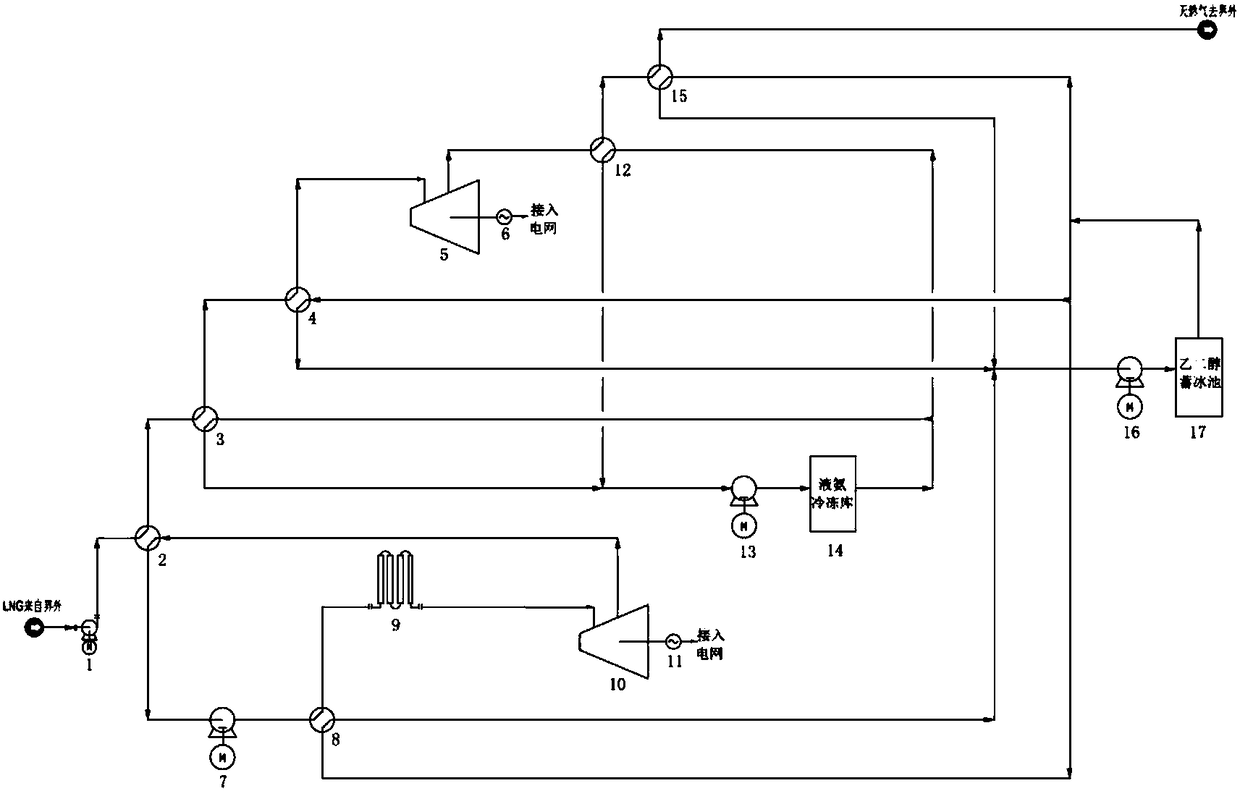

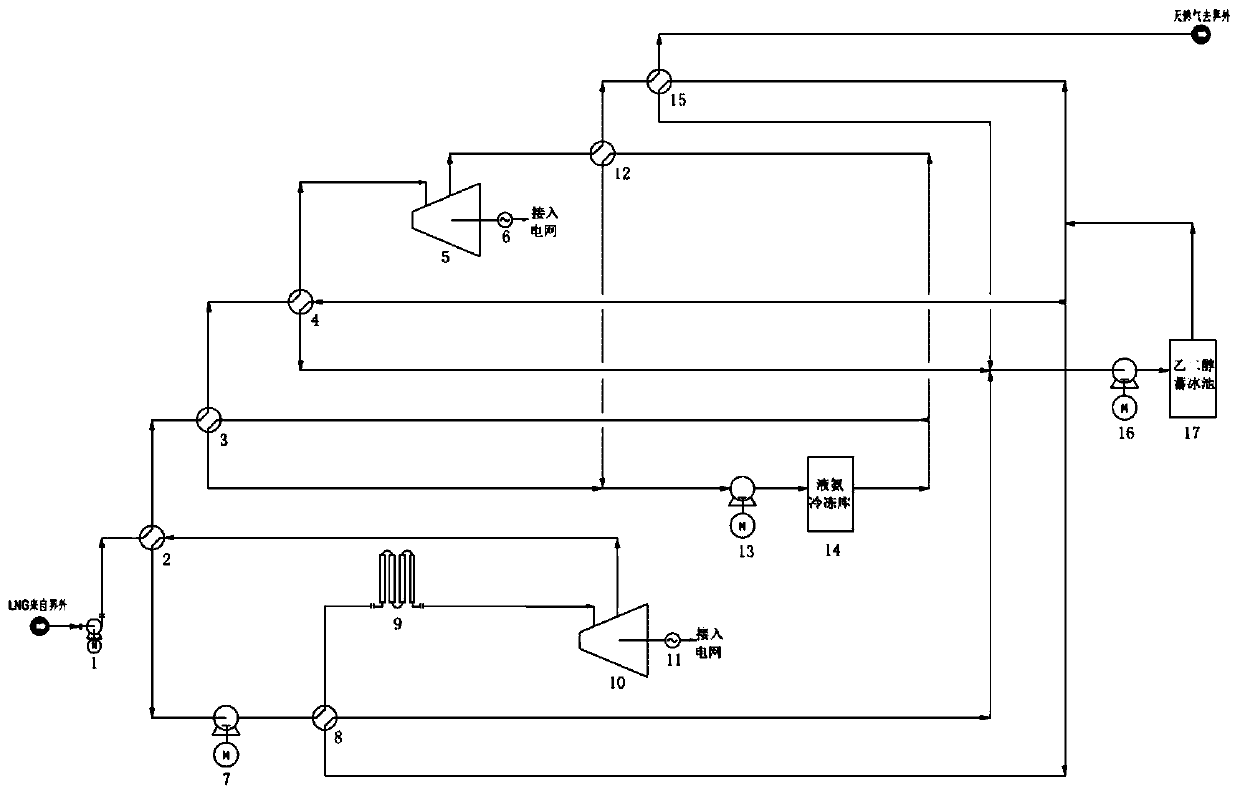

System for comprehensively utilizing LNG cold energy for power generation and cold supply

ActiveCN108087050AImprove utilization efficiencyClimate change adaptationCompression machines with several condensersIce storageRefrigeration

The invention relates to a system for comprehensively utilizing LNG cold energy for power generation and cold supply. The system comprises a LNG supercharging gasification direct expansion power generation system, a mixed working medium Rankine cycle power generation system, a liquid ammonia refrigeration house cold supply system and an ethylene glycol ice storage bath air conditioner cold supplycirculation system. The cold energy released in the LNG gasification process is utilized; high-grade electric energy is generated through LNG supercharging gasification direct expansion power generation and mixed working medium Rankine cycle power generation; cold is supplied to a refrigeration house through the cold energy released in the LNG gasification process for ammonia recycling; and cold is supplied to an air conditioner through the cold energy released in the LNG gasification process for ethylene glycol ice storage bath recycling. By means of the system, gradient utilization of the LNG cold energy is achieved, and the cold energy utilization efficiency is high.

Owner:SICHUAN HENGRI GAS ENG CO LTD

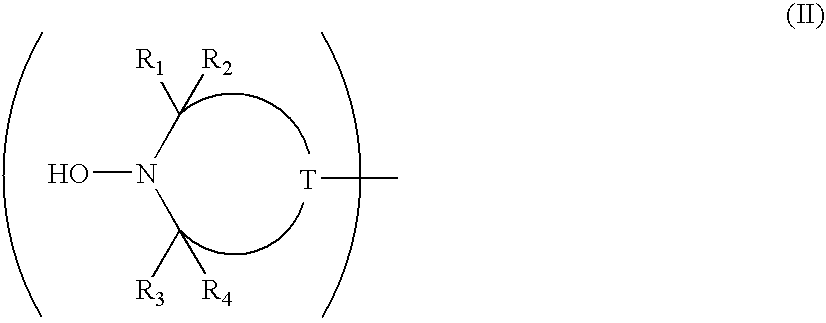

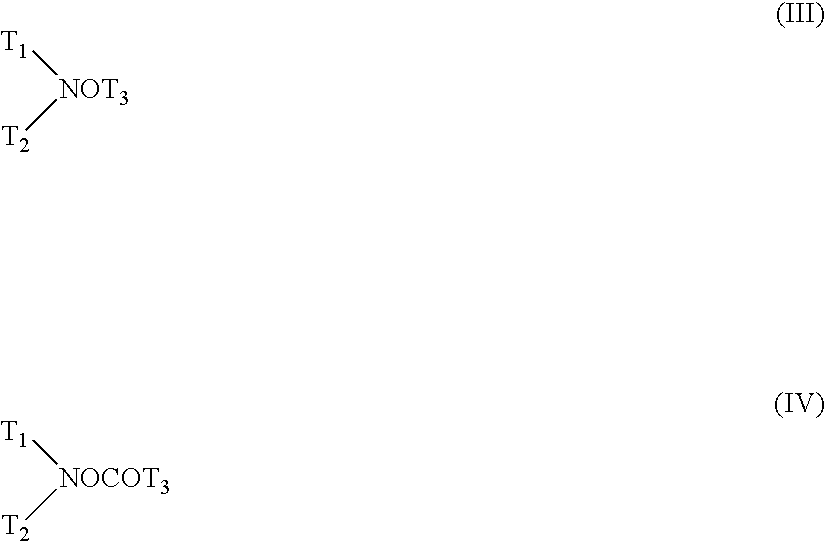

Polyester and polyamide compositions of low residual aldehyde content

A mixture of a polyester, such as poly(ethylene terephthalate) PET, or a polyamide, and a suitable stabilizer selected from the group consisting of hydroxylamine stabilizers, substituted hydroxylamine stabilizers, nitrone stabilizers and amine oxide stabilizers, when extrusion compounded exhibits a lower residual acetaldehyde content than does polyester or polyamide alone when similarly treated. The invention pertains to any polyester or polyamide used in the manufacture of molded articles, fibers or films, for instance bottles or containers which are used to store consumer materials, for example food, beverages and water.

Owner:CIBA SPECIALTY CHEM CORP

A system for comprehensive utilization of lng cold energy for power generation and cooling

ActiveCN108087050BImprove utilization efficiencyClimate change adaptationCompression machines with several condensersIce storageEngineering

The invention relates to a system for comprehensively utilizing LNG cold energy for power generation and cold supply. The system comprises a LNG supercharging gasification direct expansion power generation system, a mixed working medium Rankine cycle power generation system, a liquid ammonia refrigeration house cold supply system and an ethylene glycol ice storage bath air conditioner cold supplycirculation system. The cold energy released in the LNG gasification process is utilized; high-grade electric energy is generated through LNG supercharging gasification direct expansion power generation and mixed working medium Rankine cycle power generation; cold is supplied to a refrigeration house through the cold energy released in the LNG gasification process for ammonia recycling; and cold is supplied to an air conditioner through the cold energy released in the LNG gasification process for ethylene glycol ice storage bath recycling. By means of the system, gradient utilization of the LNG cold energy is achieved, and the cold energy utilization efficiency is high.

Owner:SICHUAN HENGRI GAS ENG CO LTD

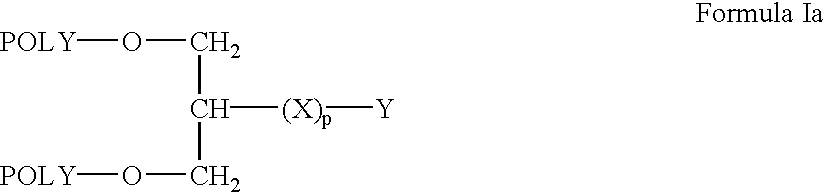

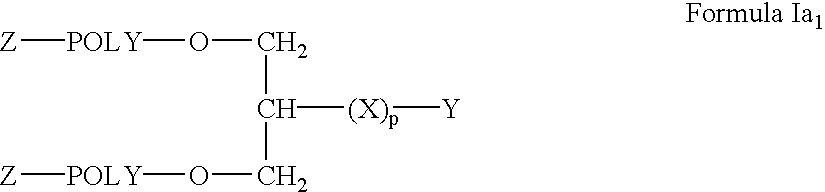

Branched polymers and their conjugates

ActiveUS7026440B2PreparationEasy to synthesizeBiocideMicrobiological testing/measurementArylActive agent

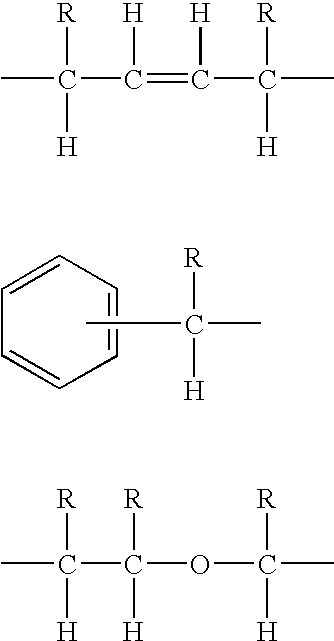

The present invention is directed to branched reactive water-soluble polymers comprising at least two polymer arms, such as poly(ethylene glycol), attached to a central aliphatic hydrocarbon core molecule through heteroatom linkages. The branched polymers bear at least one functional group for reacting with a biologically active agent to form a biologically active conjugate. The functional group of the branched polymer can be directly attached to the aliphatic hydrocarbon core or via an intervening linkage, such as a heteroatom, -alkylene-, —O-alkylene-O—, -alkylene-O-alkylene-, -aryl-O—, —O-aryl-, (—O-alkylene-)m, or (-alkylene-O—)m linkage, wherein m is 1–10.

Owner:NEKTAR THERAPEUTICS INC

Polyester/polyamide blend having improved flavor retaining property and clarity

InactiveUS7375154B2High oxygen barrierImprove performanceConductive materialSpecial tyresPolyesterPolymer science

This invention relates to a polyester / polyamide blend having an excellent gas barrier property. More particularly, the present invention relates to combinations of a polyethylene terephthalate polymer and a polyamide polymer having an excellent gas barrier property and short oxygen scavenging induction periods, where the polyamide polymer has a C:A terminal group concentration ratio of 2:1 or more and a C+A terminal group concentration of at least 0.17 meq / g of polyamide polymer, wherein C represents a cumulative total of a terminal carboxyl group concentration and a terminal hydrocarbyl group concentration expressed in meq / g of polyamide, and A represents a terminal amine group concentration expressed in meq / g of polyamide.

Owner:EASTMAN CHEM CO

Tocopheryl polyethylene glycol succinate powder and process for preparing same

InactiveUS20070184117A1Without compromising handling characteristicPowder deliveryOrganic active ingredientsPolymer scienceTocopherol polyethylene glycol succinate

A powdered tocopheryl polyethylene glycol succinate (TPGS™) having an average particle size of less than about 1000 microns. In one embodiment, the powdered tocopheryl polyethylene glycol succinate is prepared by a process that includes atomizing a fluidic tocopheryl polyethylene glycol succinate into an environment suitable for solidifying the atomized tocopheryl polyethylene glycol succinate. In another embodiment, the powdered tocopheryl polyethylene glycol succinate is prepared by a process of applying a force to a solid tocopheryl polyethylene glycol succinate starting material that is sufficient to produce a powdered product.

Owner:EASTMAN CHEM CO

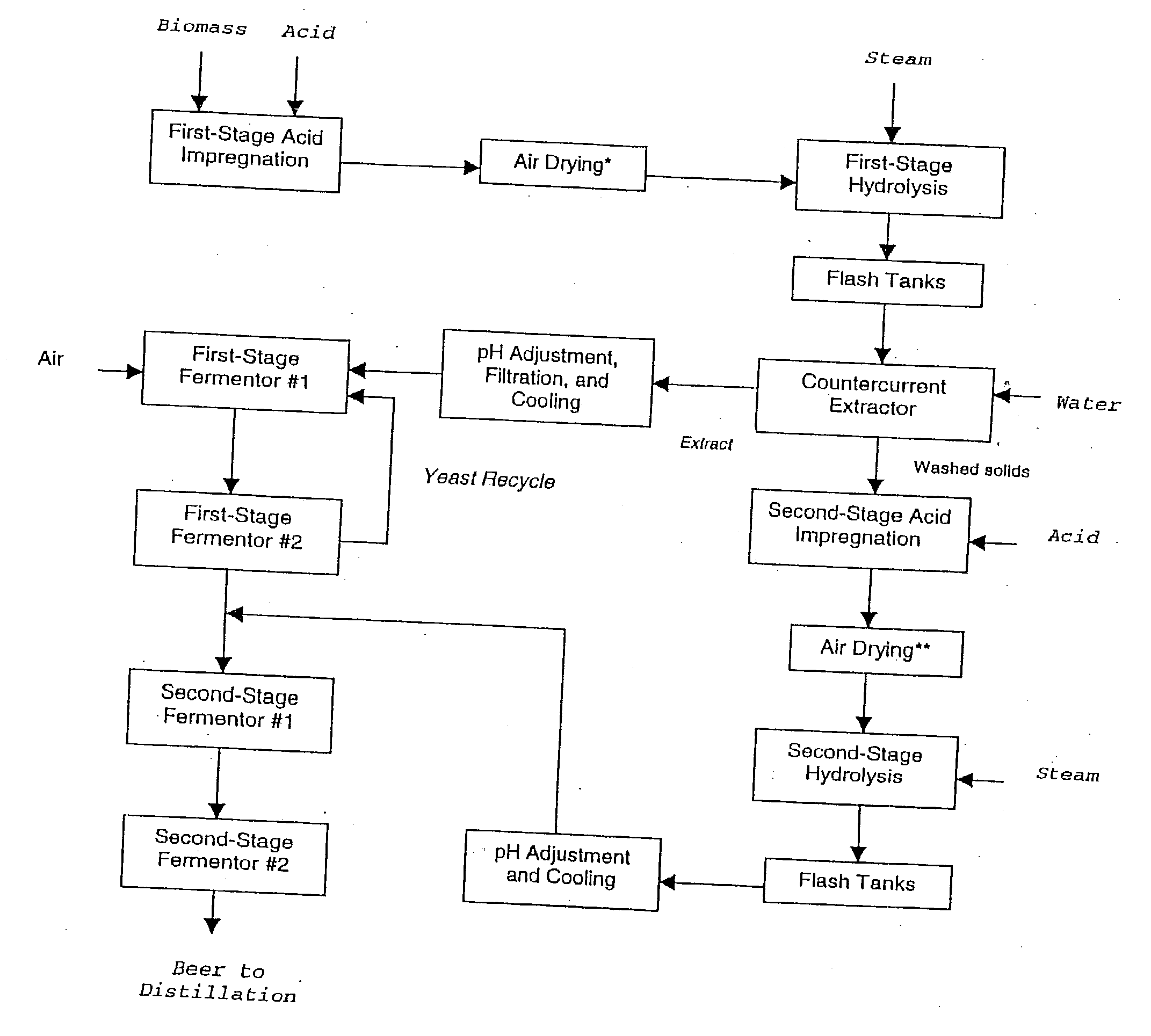

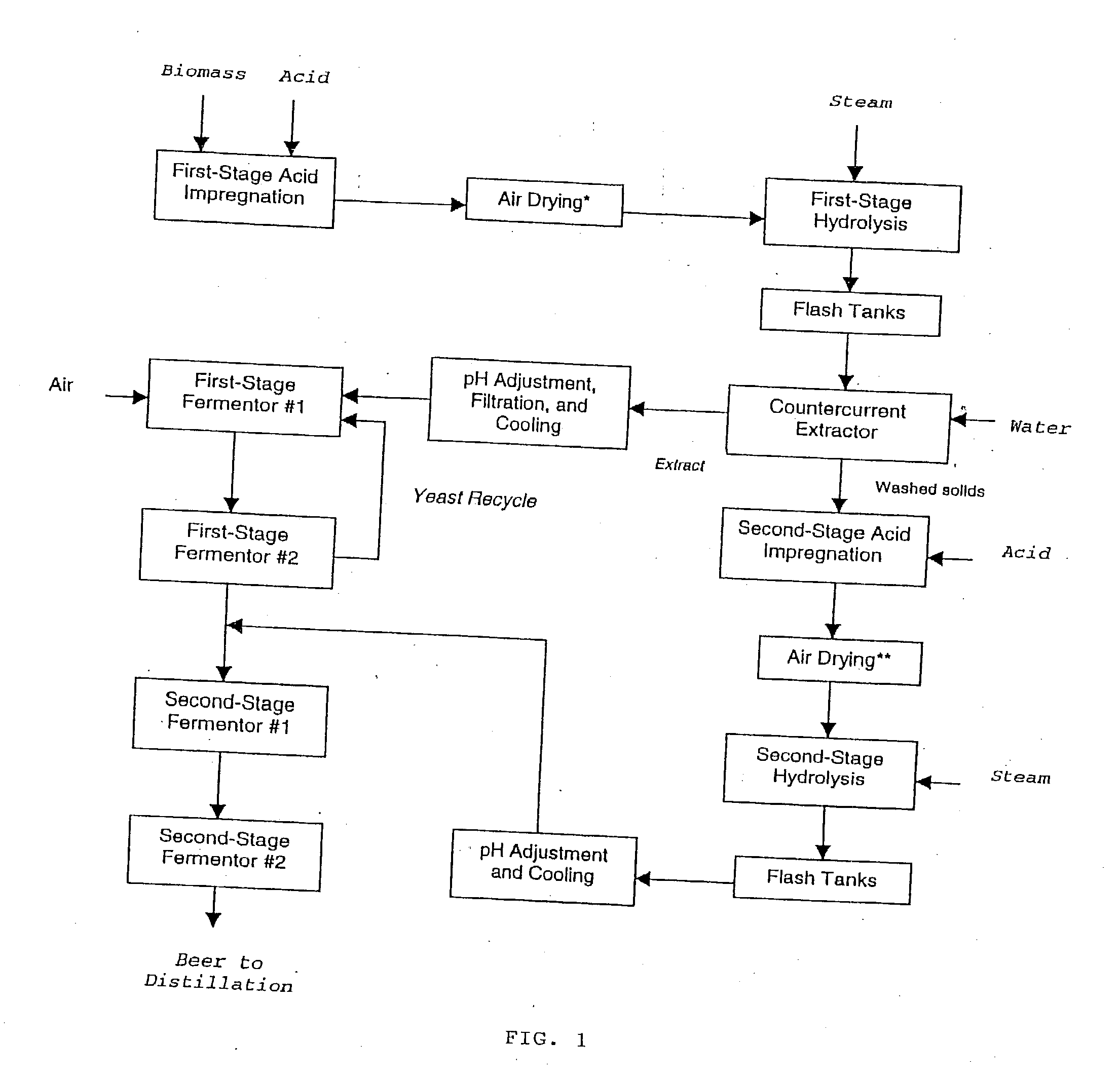

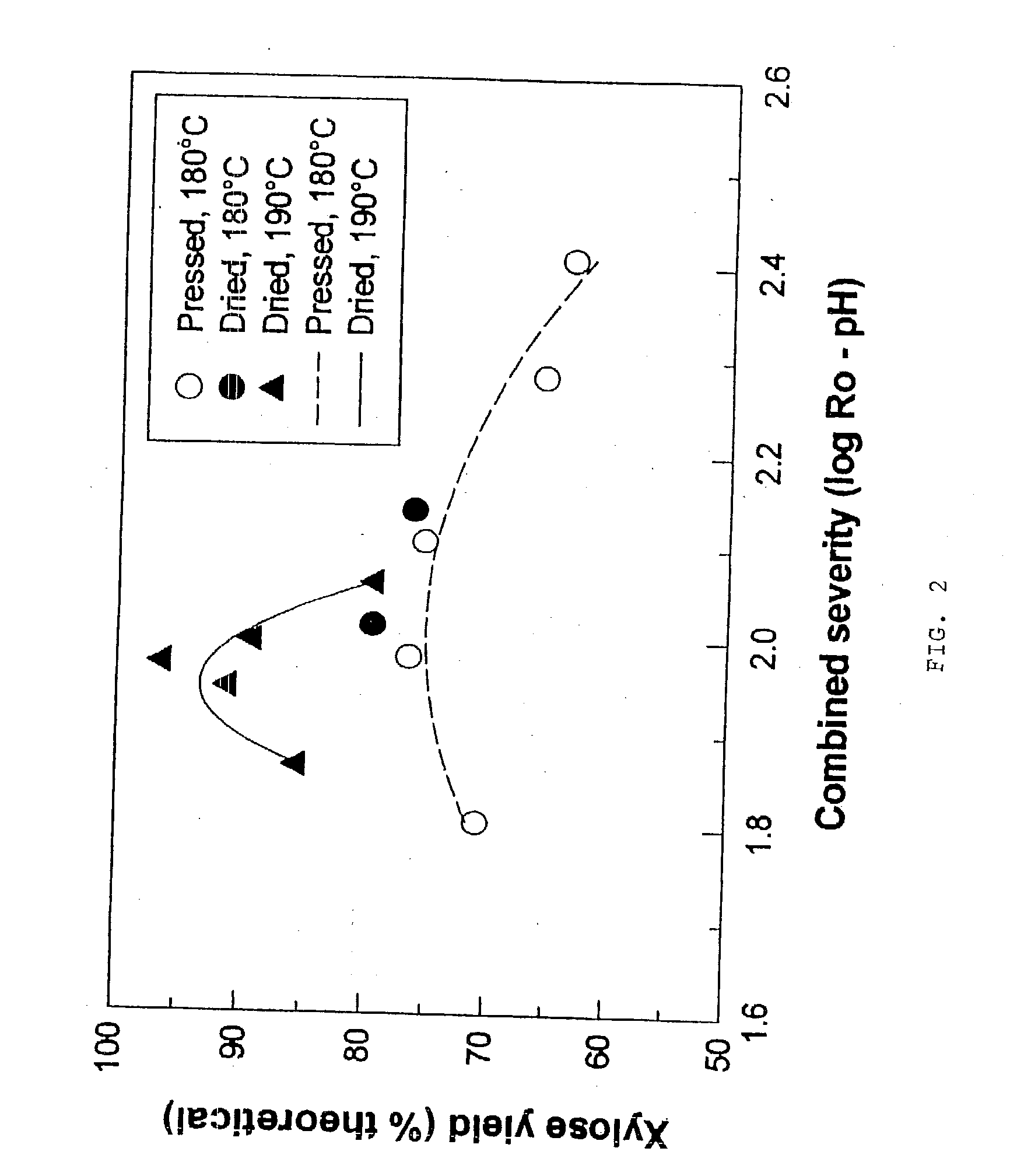

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

Medicine for preventing and treating coronary heart disease and angina pectoris and its prepn and other use

InactiveCN1348815AGood curative effectLess frequent seizuresNervous disorderMetabolism disorderSalvia miltiorrhizaCoronary artery disease

The present invention relates to traditional Chinese medicine for treating coronary heart disease and stenocardia is made from (by wt.%) salvia root 50-97%, notoginseng 2-48% and borneol 0.2-3%, in which the salvia root and notoginseng and hot extracted with water, then filtering, concentrating, alcohol precipitating, standing still, recovering ethyl alcohol, concentrating, into extractum, further blended with borneol and adjuvant polyglycol-6000 to form into product.

Owner:TIANJIN TASLY PHARMA CO LTD

Compositions and methods relating to reduced mucoadhesion

InactiveUS20130236556A1Reduced mucoadhesionDiffusion fastBiocidePowder deliveryMedicineParticle composition

The present invention generally relates to reducing the mucoadhesive properties of a particle. In some embodiments, the particle is coated with and / or associated with a (poly(ethylene glycol))-(poly(propylene oxide))-(poly(ethylene glycol)) triblock copolymer. Methods for preparing inventive particles using a poly(ethylene glycol)-vitamin E conjugate as a surfactant are also provided. In some embodiments, methods are provided comprising administering to a subject a composition of particles of the present invention. Such particles with reduced mucoadhesive properties are useful in delivering agents to mucosal tissues such as oral, ophthalmic, gastrointestinal, nasal, respiratory, and genital mucosal tissues.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com