Patents

Literature

80 results about "Glycolates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Derivatives of ACETIC ACID which contain an hydroxy group attached to the methyl carbon.

Catalyzer for the oxalic ester hydrogenation synthesizing of ethylene glycol and method of preparing the same

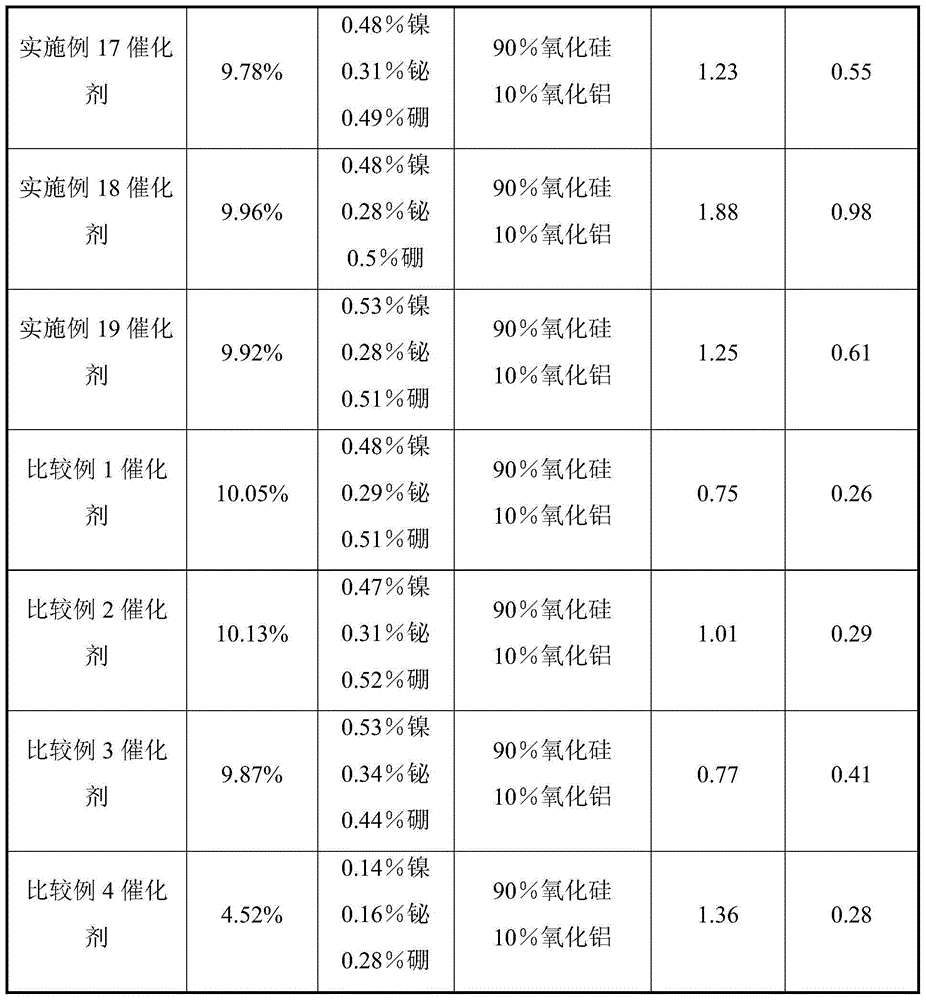

A catalyst for hydrogenated synthesis of glycol with oxalate and a preparation method for the catalyst belong to the glycol preparation technical field. The catalyst of the present invention uses the copper metal as the main active component, and zinc as the promoter, and is manufactured with the method of deposition. A carrier of the catalyst is the modified silica sol. The select content of the copper metal is 5 to 45 percent of the carrier weight, and the optimal content of the copper metal is 10 to 40 percent. The content of zinc metal is 0.1 to 15 percent of the carrier weight, and the optimal content of zinc metal is 1 to 8.0 percent. The select specific surface area of the carrier is 90-350m2 / g, and the optimal is 150-300m2 / g. Proven by experiments, the catalyst is provided with the very high reaction activity and glycollate selectivity in the reaction to synthesize glycollate with oxalate and hydrogen Moreover, the catalyst is provided with the long usable life and the stable reaction performance, and can be easily controlled.

Owner:TIANJIN UNIV +1

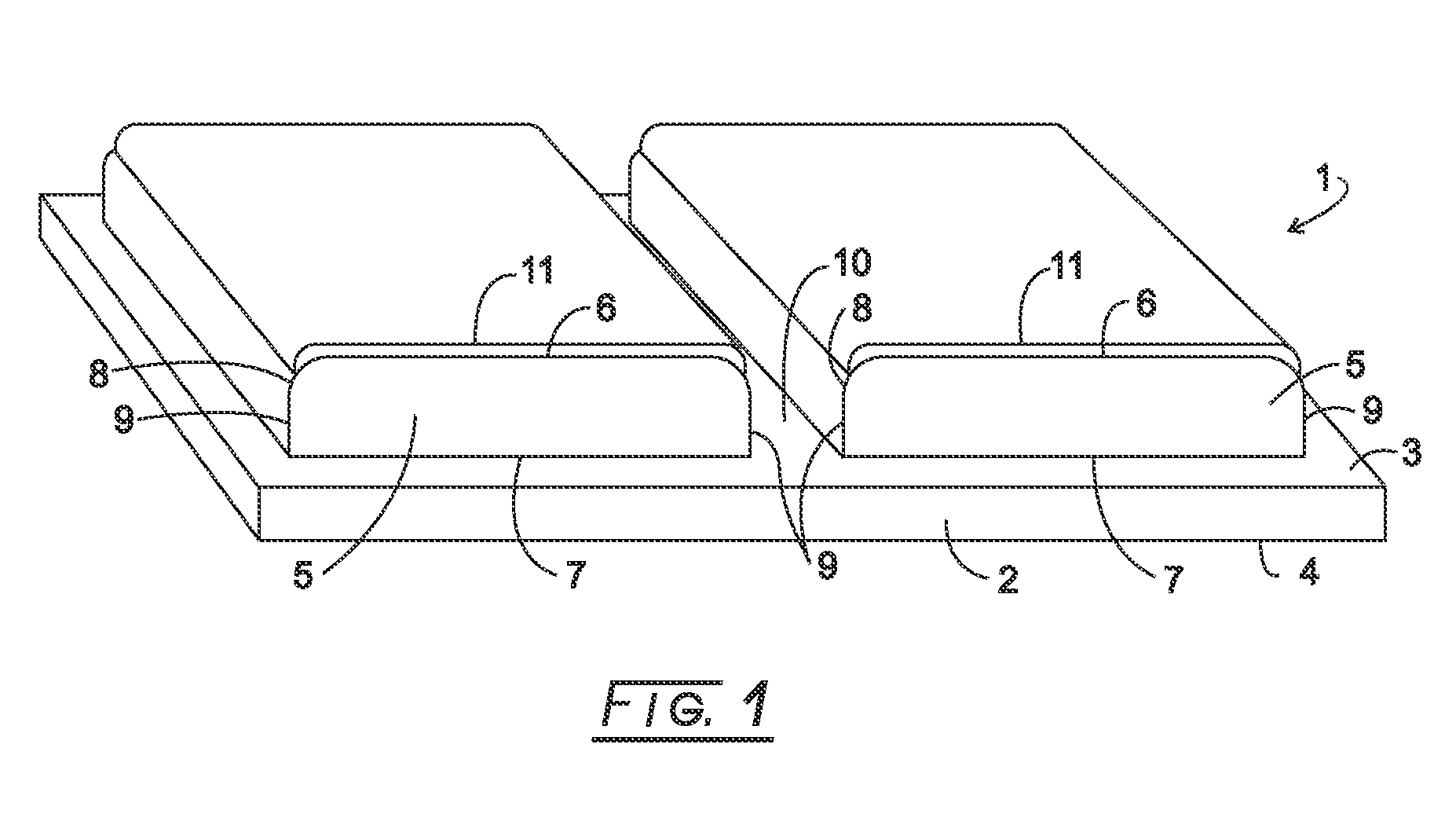

Bioabsorbable and biocompatible polyurethanes and polyamides for medical devices

ActiveUS20060188547A1Low toxicitySuture equipmentsOrganic active ingredientsAbsorbable polymersPolyester

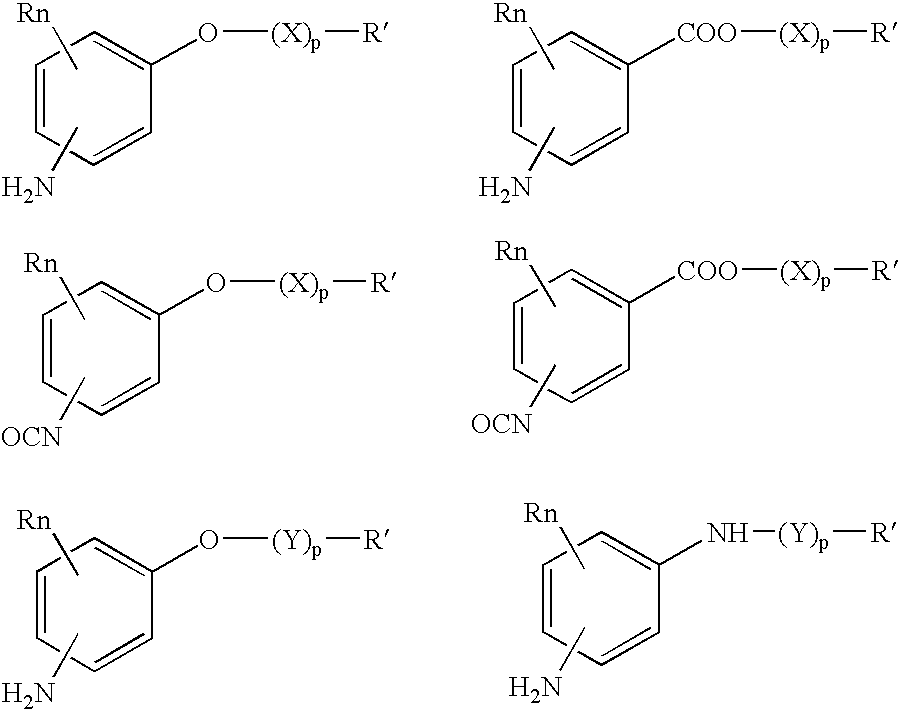

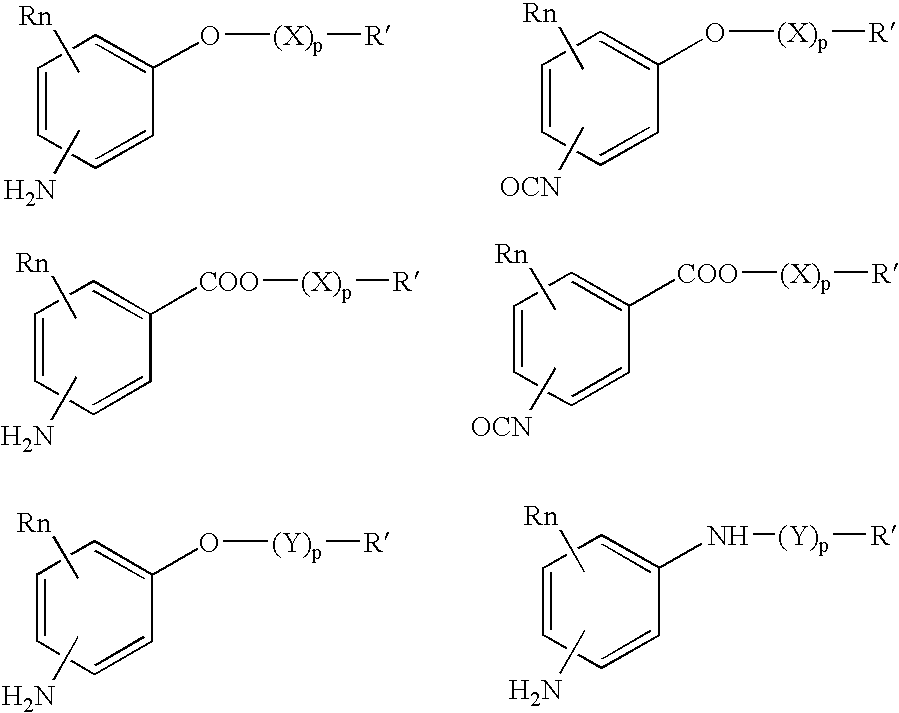

Absorbable polyurethanes, polyamides and polyester urethanes prepared from at least one compound selected from: or the diamines and diisocyanates thereof, wherein each X represents a member independently selected from —CH2COO— (glycolic acid moiety), —CH(CH3)COO— (lactic acid moiety), —CH2CH2OCH2COO— (dioxanone), —CH2CH2CH2CH2CH2COO— (caprolactone moiety), —(CH2)yCOO— where y is one of the numbers 2, 3, 4 or 6-24 inclusive, and —(CH2CH2O)z′CH2COO— where z′ is an integer between 2 and 24, inclusive; each Y represents a member independently selected from —COCH2O— (glycolic ester moiety), —COCH(CH3)O— (lactic ester moiety), —COCH2OCH2CH2O— (dioxanone ester), —COCH2CH2CH2CH2CH2O— (caprolactone ester), —CO(CH2)mO— where m is an integer between 2, 3, 4 or 6-24 inclusive, —COCH2O(CH2CH2O)n— where n is an integer between 2 and 24, inclusive; R′ is hydrogen, benzyl or an alkyl group, the alkyl group being either straight-chained or branched; p is an integer between 1 and 4, inclusive; and Rn represents one or more members selected from H, alkoxy, benzyloxy, aldehyde, halogen, carboxylic acid and —NO2, which is attached directly to an aromatic ring or attached through an aliphatic chain. Absorbable polymers prepared from these compounds are useful for drug delivery, tissue engineering, tissue adhesives, adhesion prevention and other implantable medical devices.

Owner:BEZWADA BIOMEDICAL LLC

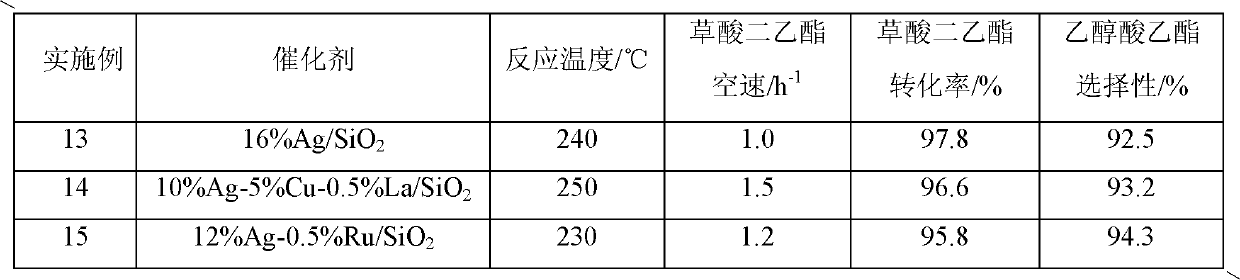

Method for preparing glycolate by catalyzing oxalate under action of hydrogenation

ActiveCN102001944AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationOxalateGlycolates

The invention relates to a method for preparing glycolate by catalyzing oxalate under the action of hydrogenation. The oxalate is used as the raw material, has hydrogenation under the action of catalyst at 120 to 300 DEG C under 0.2 to 10.0 MPa, and continuously reacts in a fixed bed tube type reactor so as to acquire the target product glycolate. The conversion ratio of the oxalate is more than or equal to 90% and the selectivity of the glycolate is more than or equal to 90%. Compared with the prior art, the method of the invention has high catalyst activity and selectivity and mild reaction condition, so the conversion ratio of the raw materials and the selectivity of the target product are both greatly increased.

Owner:SHANGHAI HUAYI GRP CO

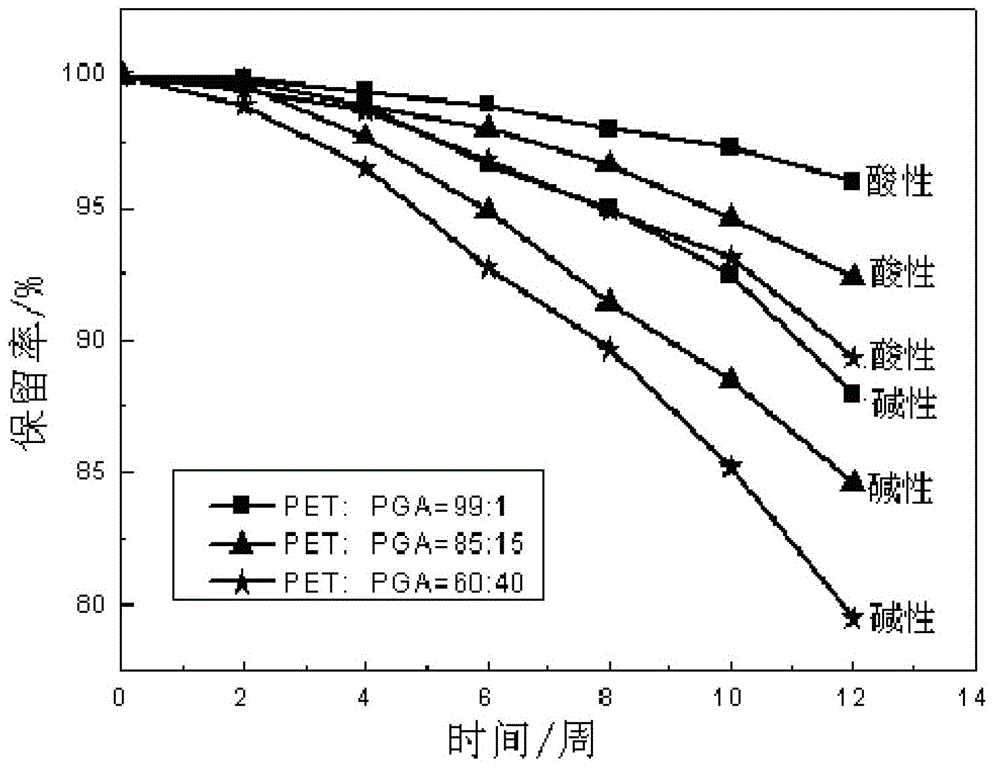

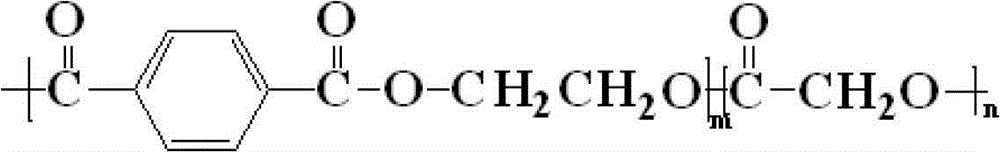

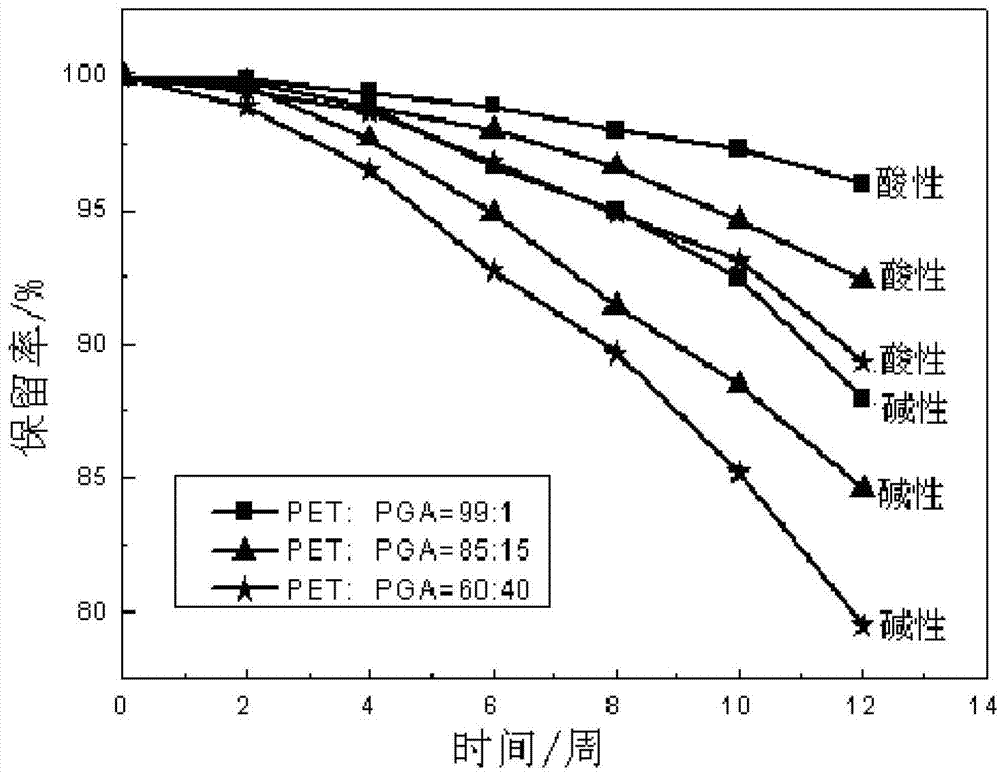

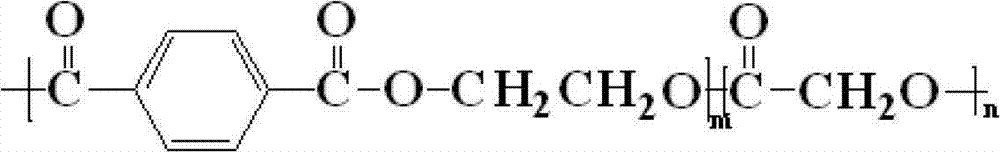

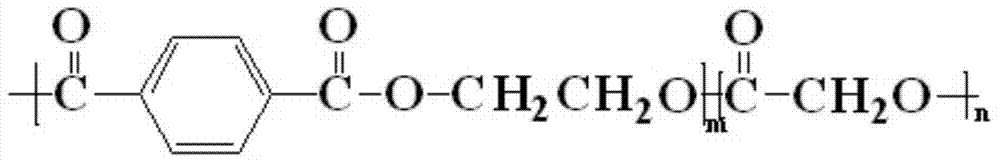

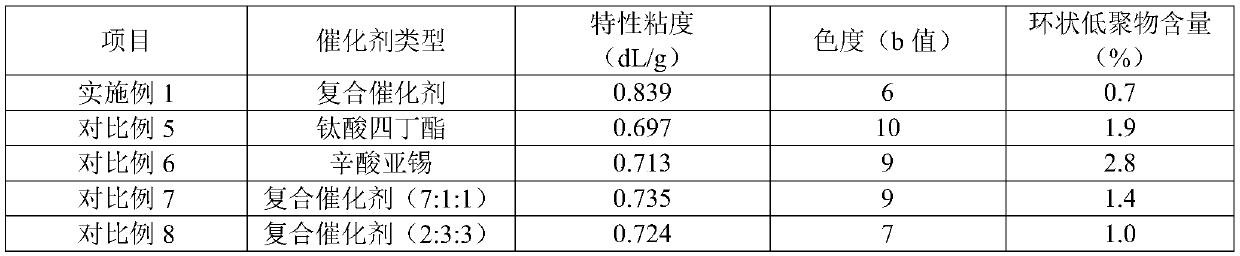

Poly(terephthalate glycol ester-CO-glycolate) copolyester and preparation method thereof

The invention relates to a poly(terephthalate glycol ester-CO-glycolate) copolyester and a preparation method thereof. The poly(terephthalate glycol ester-CO-glycolate) copolyester has the melting point of 200-250 DEG C, has the intrinsic viscosity of 0.6-1.2 dL / g, and is biodegradable. The preparation method is simple; raw materials are low in cost; the product performance has a smaller difference from that of PET (polyethylene terephthalate); and the copolyester can be applied to preparation of fibers, films, sheets, bottles and other plastic products.

Owner:南通海晴医药科技有限公司

Absorbable copolyesters of poly(ethoxyethylene diglycolate) and glycolide

A semi-crystalline, absorbable copolyester composition comprising the reaction product of a polycondensation polyester and at least one lactone, wherein the polycondensation polyester comprises the reaction product of diglycolic acid and / or a derivative thereof and diethylene glycol; and the copolyester comprises about 30 to 60% by weight of the polycondensation polyester based on the total weight of the copolyester. Also medical devices such as absorbable sutures comprising such copolyesters and absorbable microspheres comprising such copolyesters and methods of making of such absorbable microspheres. Additionally, a method of melt blowing an absorbable copolyester composition and a nonwoven construct are disclosed.

Owner:ETHICON INC

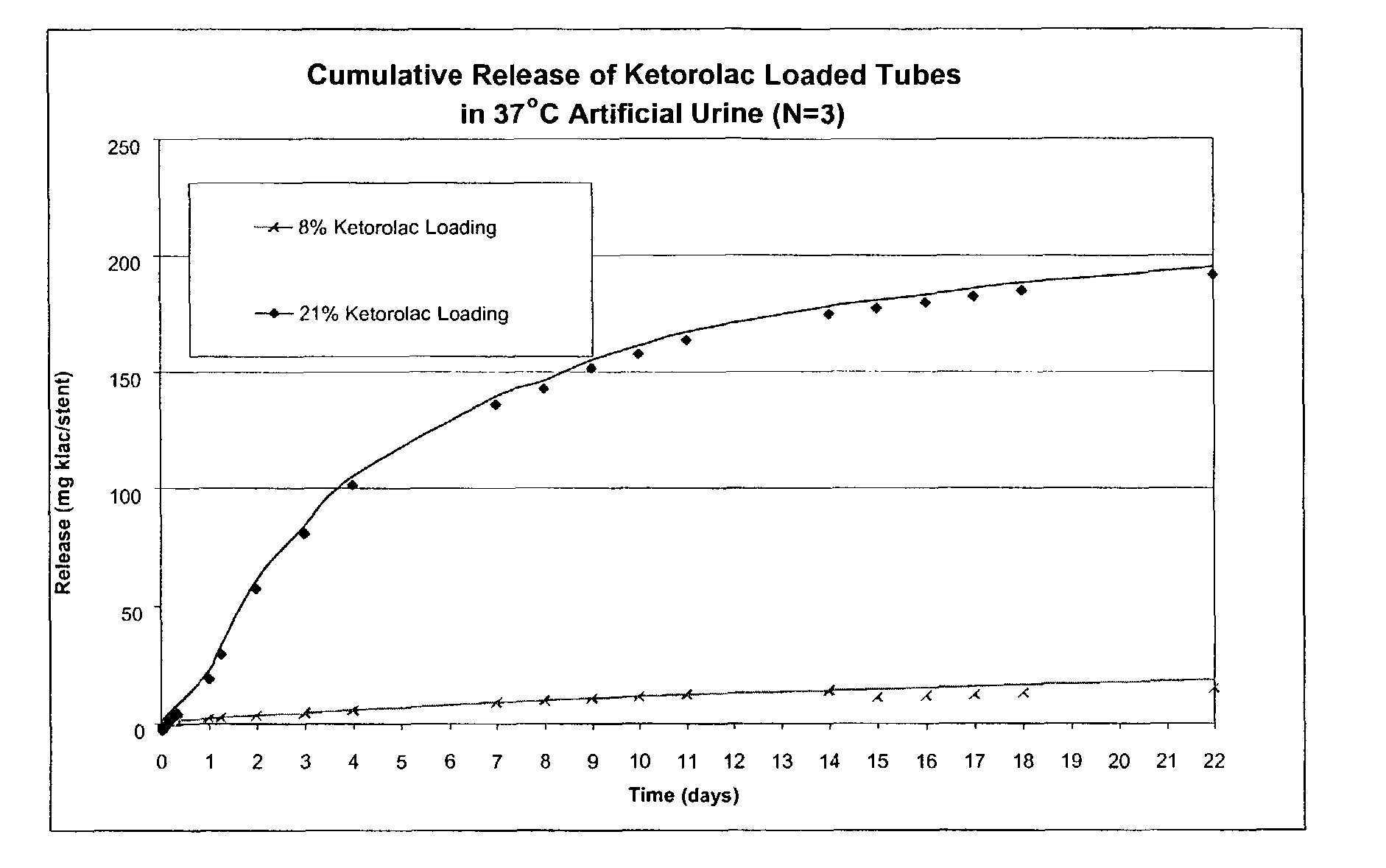

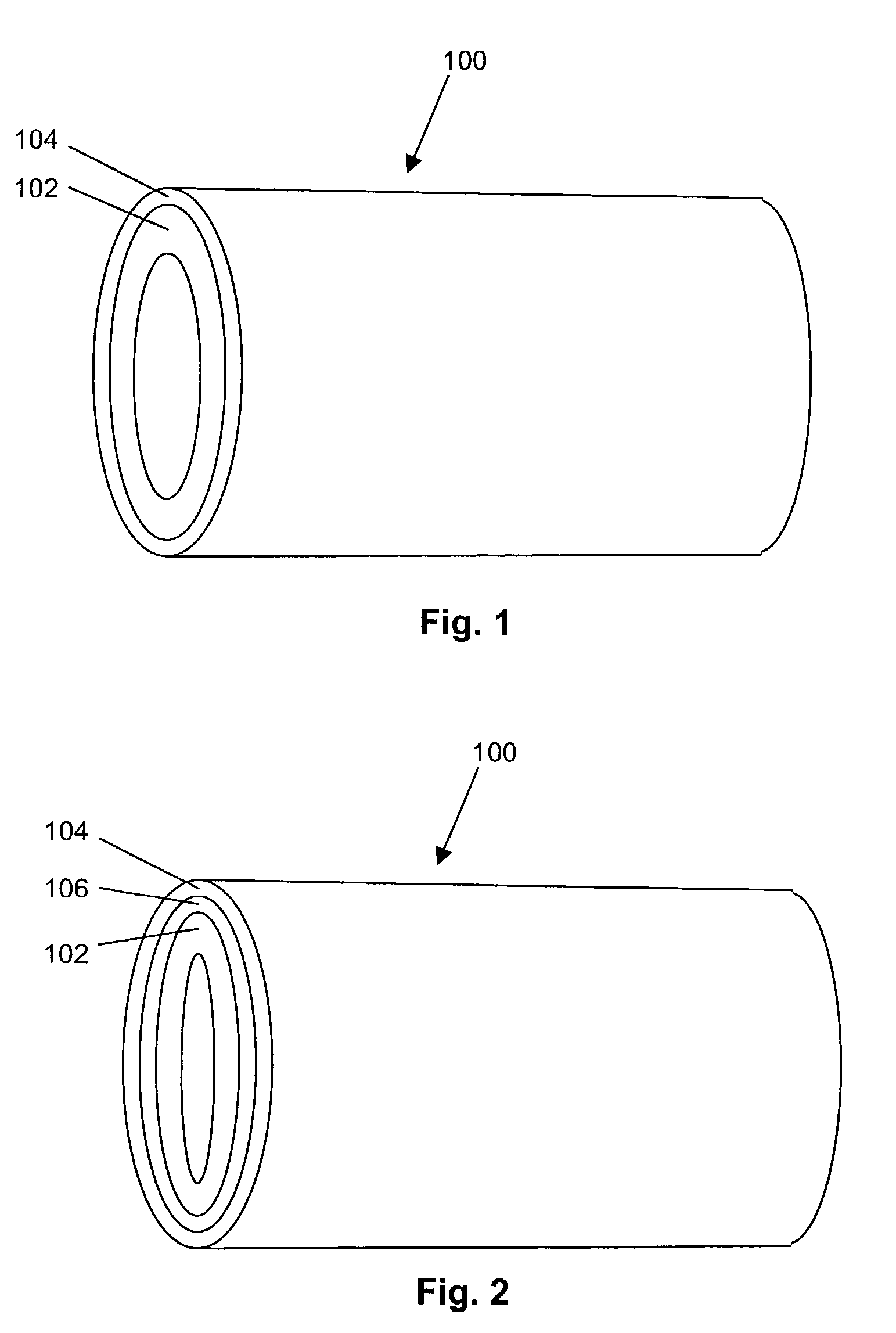

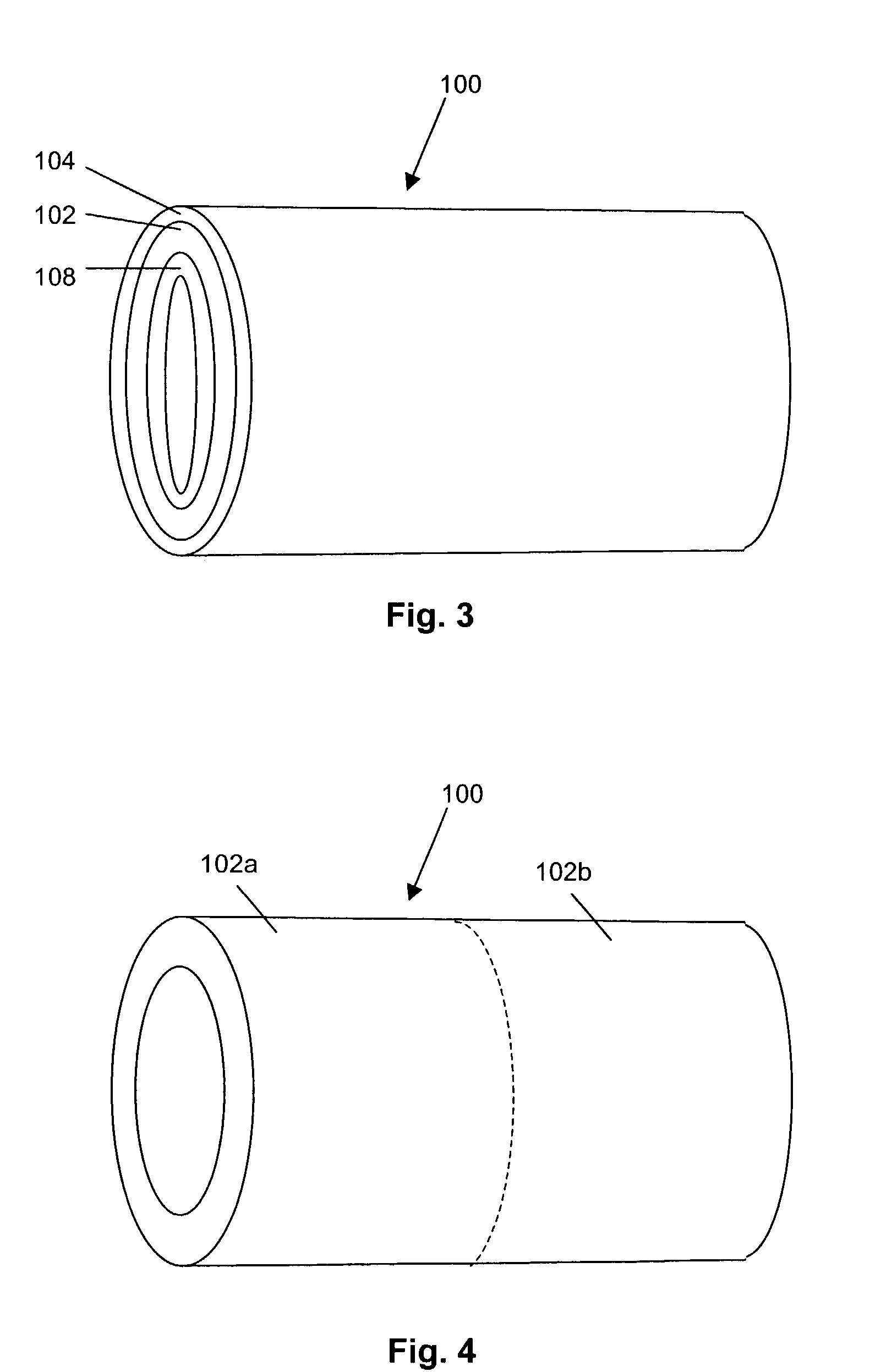

Implantable or insertable medical devices for controlled drug delivery

Implantable or insertable medical devices are provided, which comprises: (a) a biocompatible polymer; and (b) at least one therapeutic agent selected from an anti-inflammatory agent, an analgesic agent, an anesthetic agent, and an antispasmodic agent. The medical devices are adapted for implantation or insertion at a site associated with pain or discomfort upon implantation or insertion. In many embodiments, the therapeutic will be selected from at least one of (i) ketorolac and pharmaceutically acceptable salts thereof (e.g., ketorolac tromethamine) and (ii) 4-diethylamino-2-butynylphenylcyclohexyl glycolate and pharmaceutically acceptable salts thereof (e.g., oxybutynin chloride). Also provided are uses for the implantable or insertable medical devices, which uses comprise reducing pain or discomfort accompanying the implantation or insertion of such devices. Further uses may comprise reducing microbial buildup along the device. Methods for manufacturing implantable or insertable medical devices are also provided.

Owner:BOSTON SCI SCIMED INC

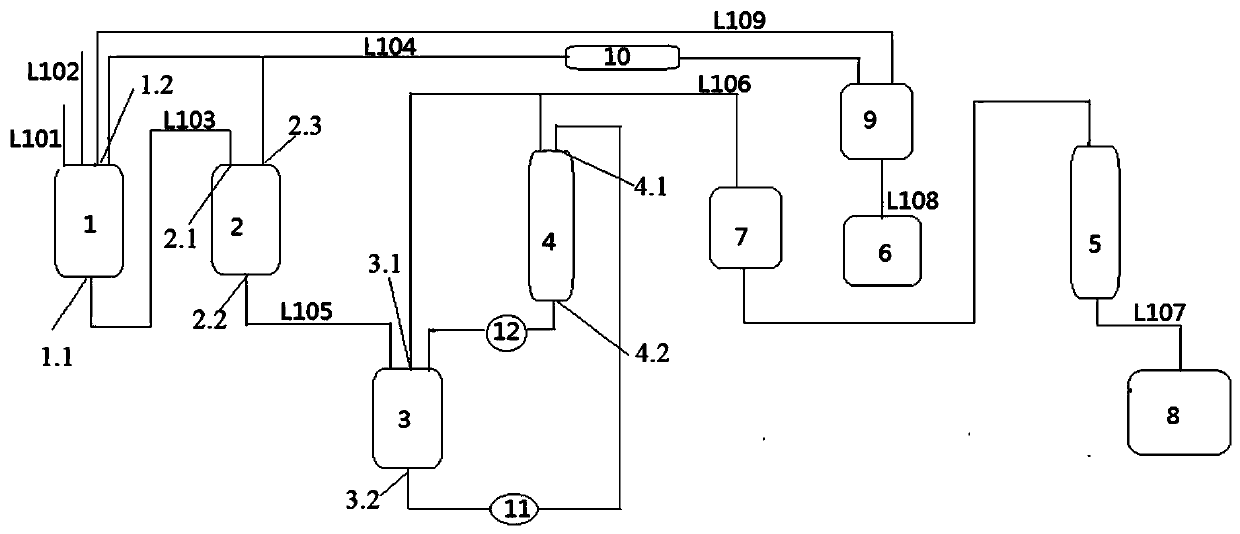

Process method for preparing glycolide from glycolate

PendingCN111548339ALow reaction temperatureShort reaction timeOrganic chemistryGlycolatesDepolymerization

The invention discloses a process method for preparing glycolide from glycolate, and belongs to the technical field of chemical products. The method comprises the following steps: carrying out primaryreaction on reaction raw materials glycollate and a catalyst in a pre-polymerization kettle; transferring the obtained mixture into a final polymerization kettle connected with a pre-polymerization kettle; oligomers formed by the reaction in the final polymerization kettle flow into a depolymerization kettle to be subjected to a depolymerization reaction; enabling a part of the crude product glycolide obtained in the depolymerization kettle directly to directly flow into a crude product storage tank; and feeding the rest of depolymerized materials into the wiped film evaporator by a circulating pump; separating out a crude product glycolide and other materials in the wiped film evaporator, collecting the crude product glycolide in a crude product storage tank, enabling the other materialsto flow into the depolymerization kettle again for further depolymerization reaction; and purifying the crude product glycolide collected in the crude product storage tank through a melting crystallizer to obtain a pure product glycolide. The polymerization process designed by the invention is divided into two steps, so that the production energy consumption is effectively reduced; meanwhile,, bymeans of the thin-film evaporator, side reactions such as further polymerization and coking caused by the fact that the oligomer stays in the depolymerization kettle for a long time are avoided.

Owner:SHENZHEN ESUN IND +1

Quaternary Ammonium Salts as a Conversion Coating or Coating Enhancement

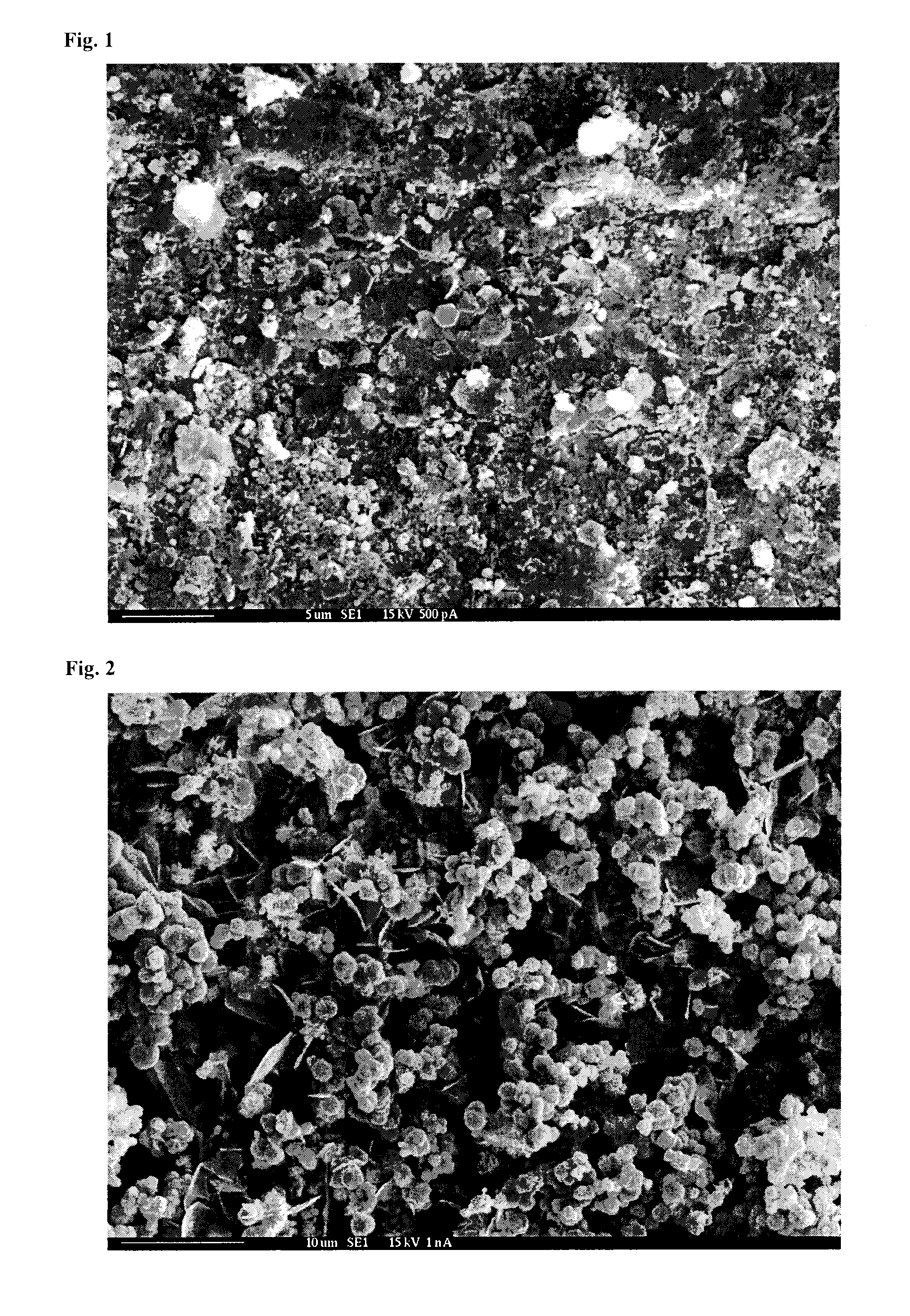

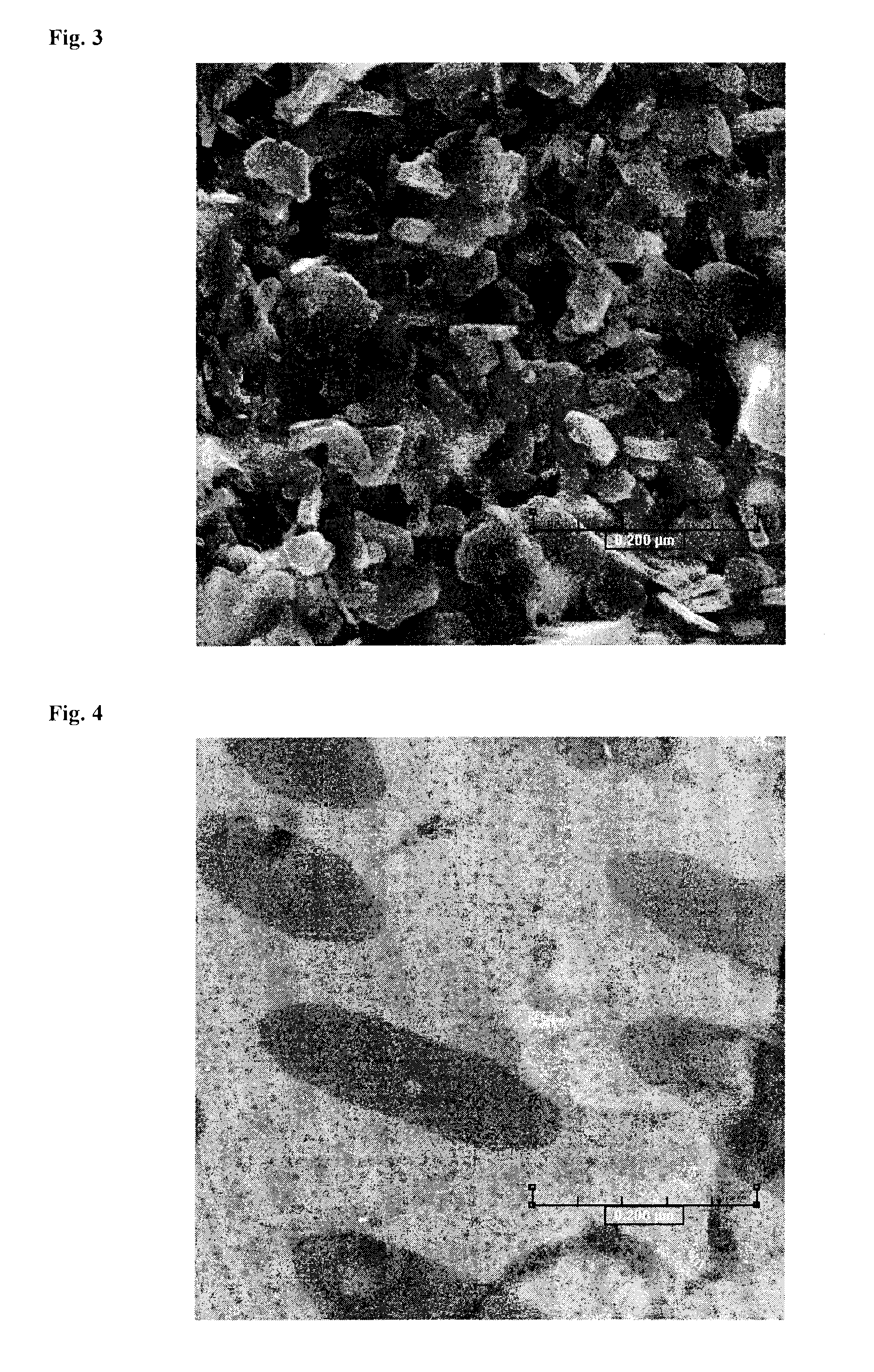

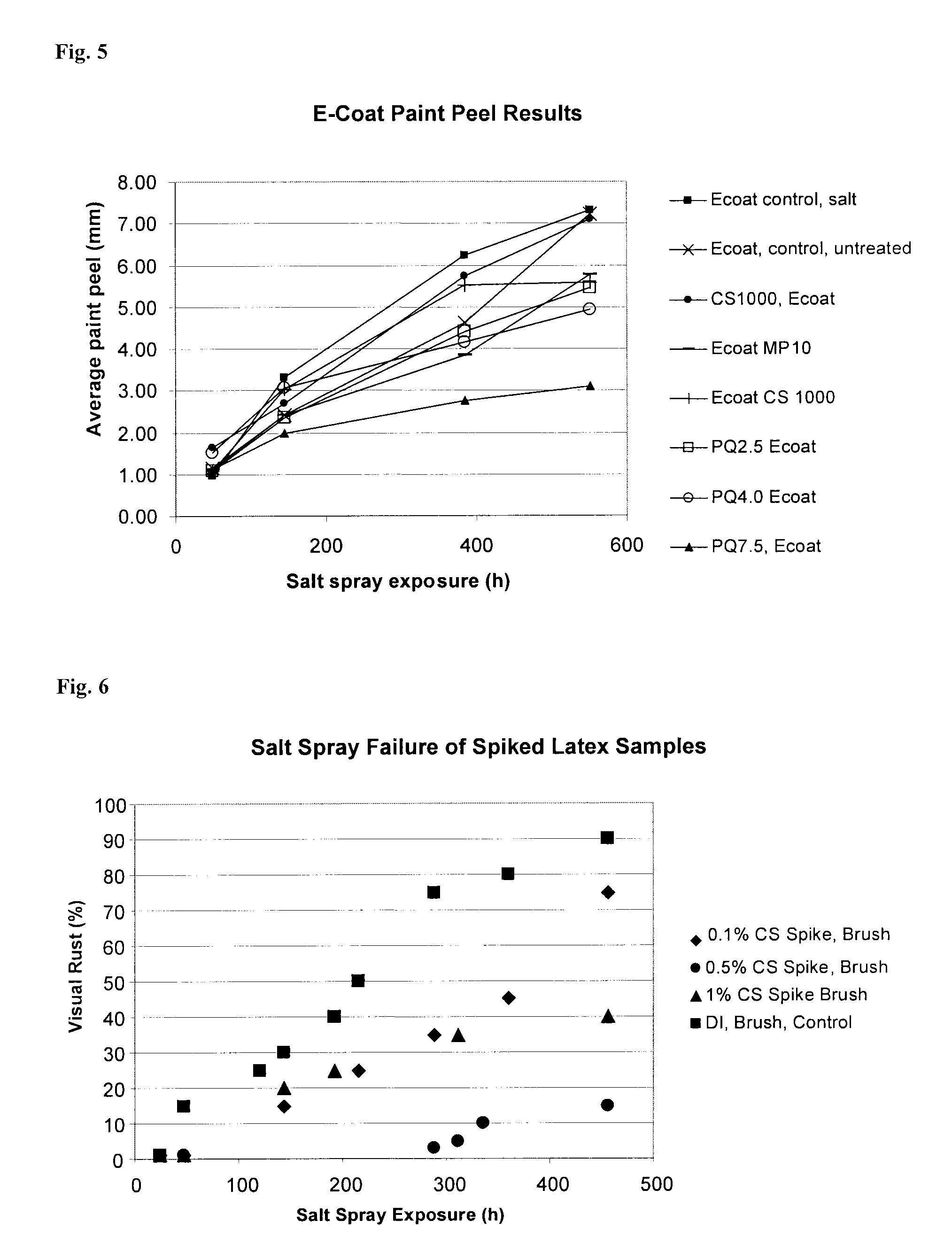

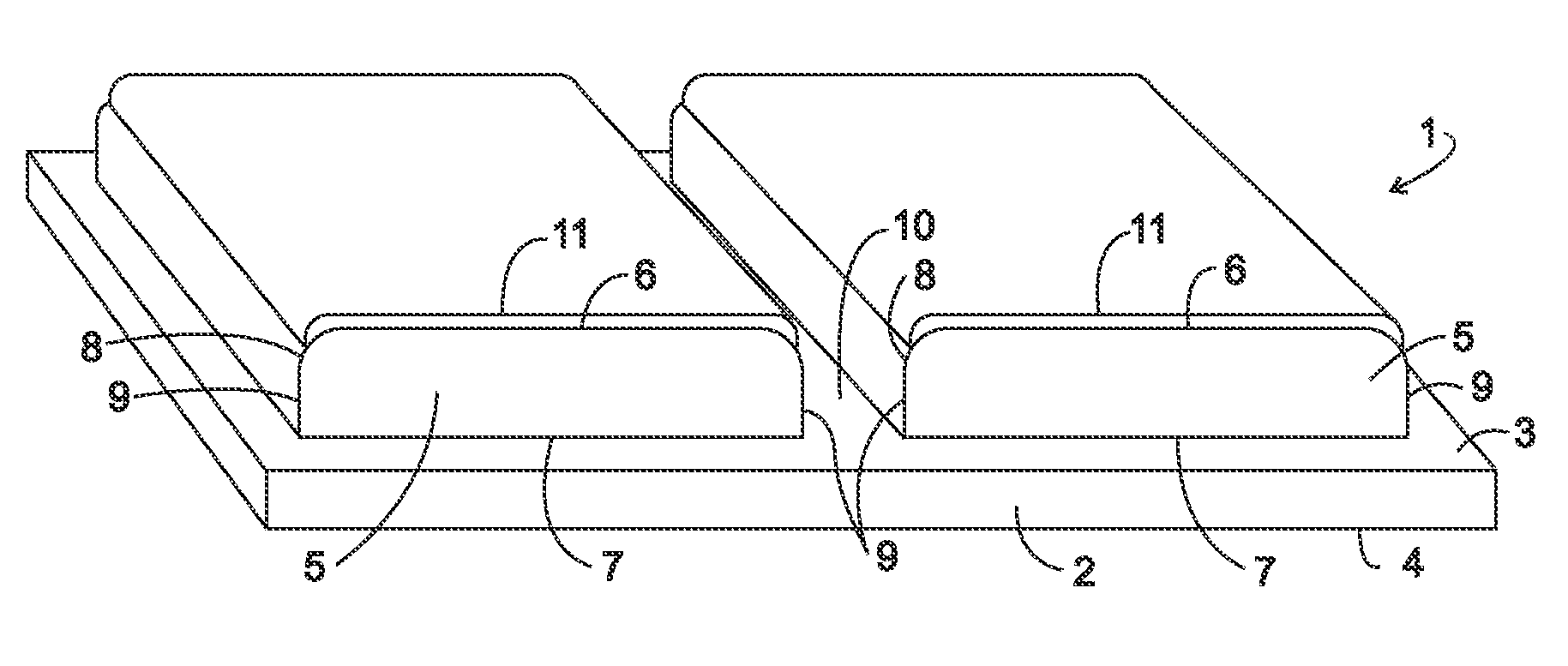

InactiveUS20110100512A1Improve adhesionGood paint adhesionSolid state diffusion coatingAnti-corrosive paintsGlycolatesQuaternary ammonium cation

Disclosed are quaternary ammonium salts containing non-halogen anions such as carbonates, bicarbonates, phosphates, glycolates and mixtures thereof as conversion coatings or additives imparting anti-corrosive properties to paints. The invention relates to a method for inhibiting the corrosion of metal surfaces by applying a composition containing one or more quaternary ammonium carbonate or bicarbonate. The disclosure is also directed to anti-corrosive coatings for metal substrates containing these compounds and to metal substrates having these anticorrosive coatings.

Owner:LONZA INC

Method for increasing selectivity of glycollic acid ester

ActiveCN102649742AImprove technical effectOrganic compound preparationCarboxylic acid esters preparationGlycolatesOxalate

The invention relates to a method for increasing selectivity of glycollic acid ester. The technical problem of low selectivity of the glycollic acid ester in the prior art is solved. The method comprises the following steps of: taking oxalate as a raw material, and contacting the raw material with a copper-containing oxide catalyst under the conditions of reaction temperature at 100-210 DEG C, weight hourly space velocity at 0.2-5 per hour, mole ratio of hydrogen to ester at (10-100):1 and reaction pressure at 0.5-6.0MPa, thereby generating a reaction effluent containing the glycollic acid ester, wherein the reaction is started by the copper-containing oxide catalyst under oxide state, and on the basis of weight part of the catalyst, the copper-containing oxide catalyst comprises 10-60 weight parts of copper and copper oxide components. According to the technical scheme, the problem is more efficiently solved. The method is suitable for the industrial production for increasing the yield of glycollic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

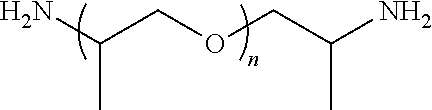

Structural urethane adhesives comprising amide polyols

InactiveUS20110059318A1Simple and fast and economicalIncrease flexibilityAdhesive processesPolyureas/polyurethane adhesivesGlycolatesPolyol

Urethane adhesive compositions comprising amide based polyols. The amide polyols comprise the reaction product of a reactant selected from the group consisting of lactic acid, lactic acid esters, lactone, glycolic acid, glycolic acid esters, and combinations thereof with one or more amines. The urethane adhesive compositions may be applied in methods of manufacturing a tile installation.

Owner:ASHLAND LICENSING & INTPROP LLC

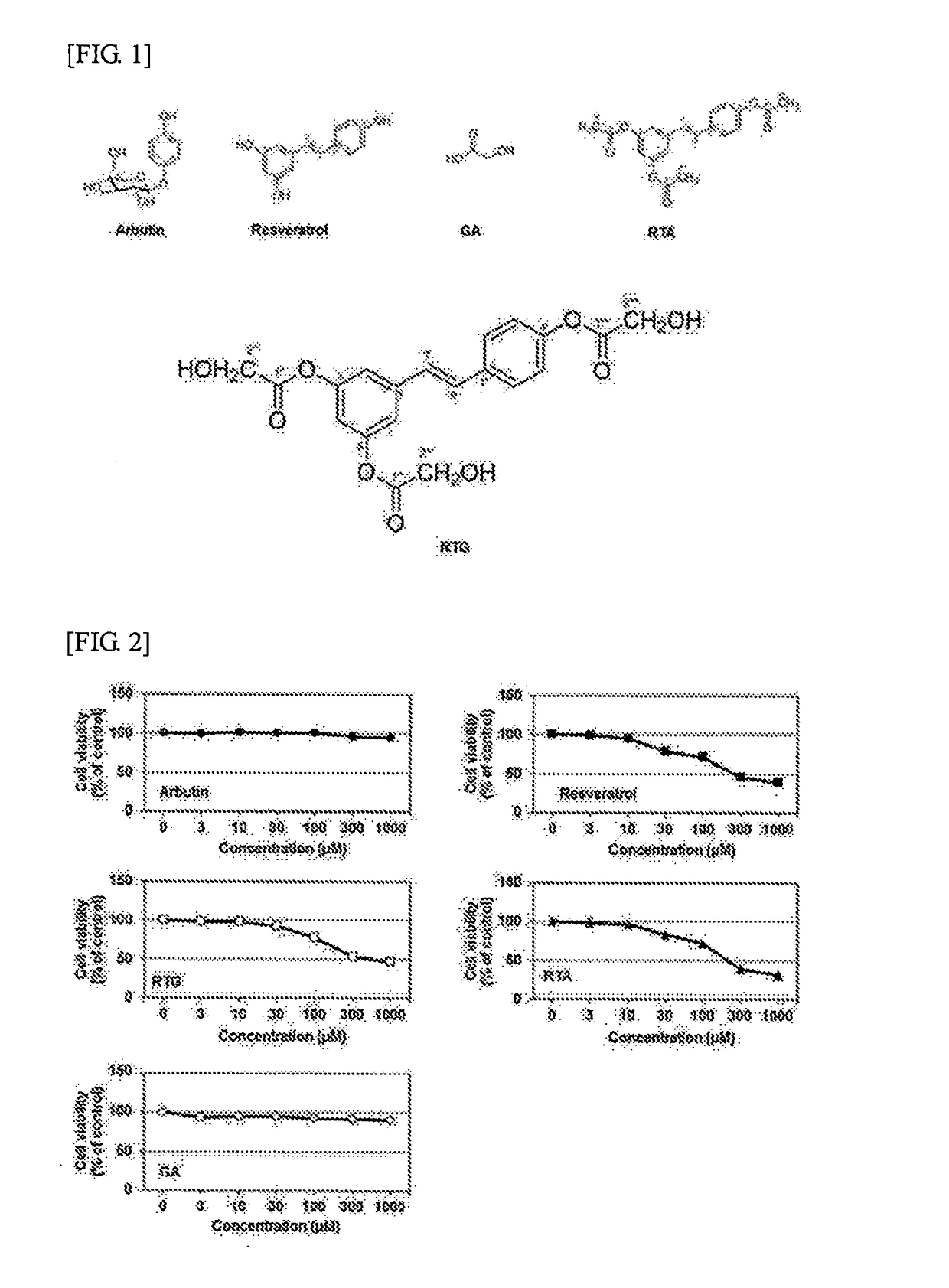

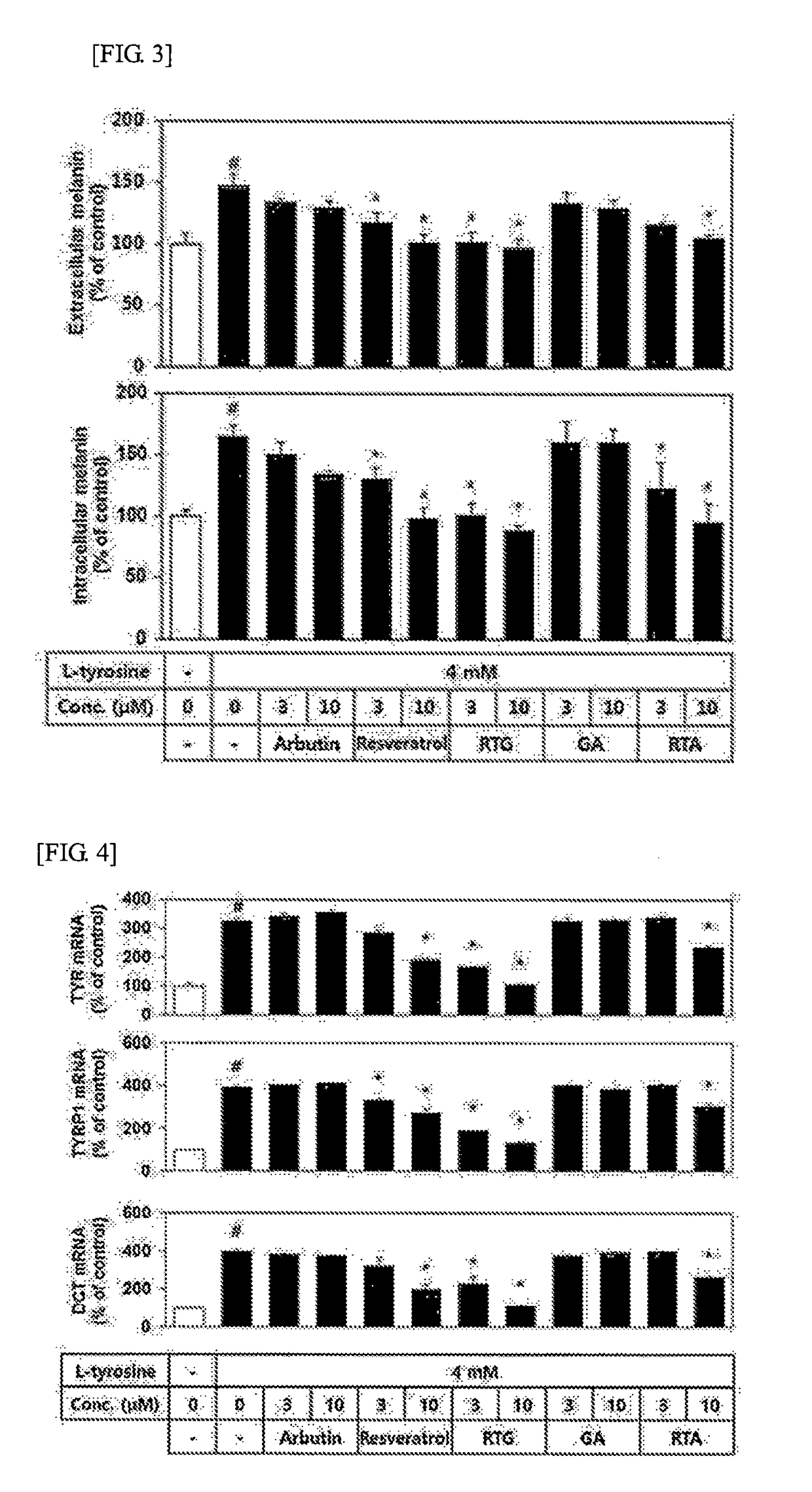

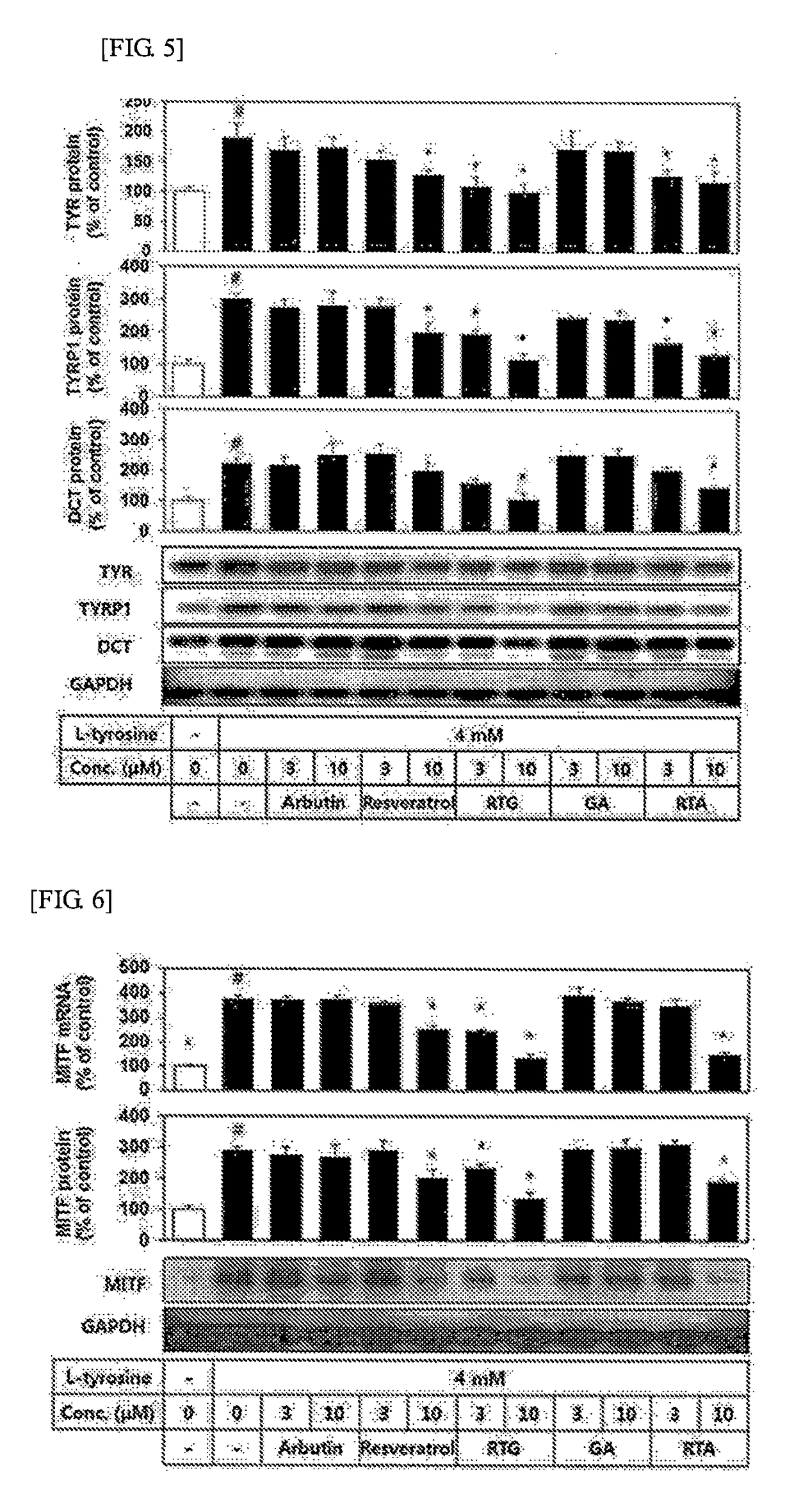

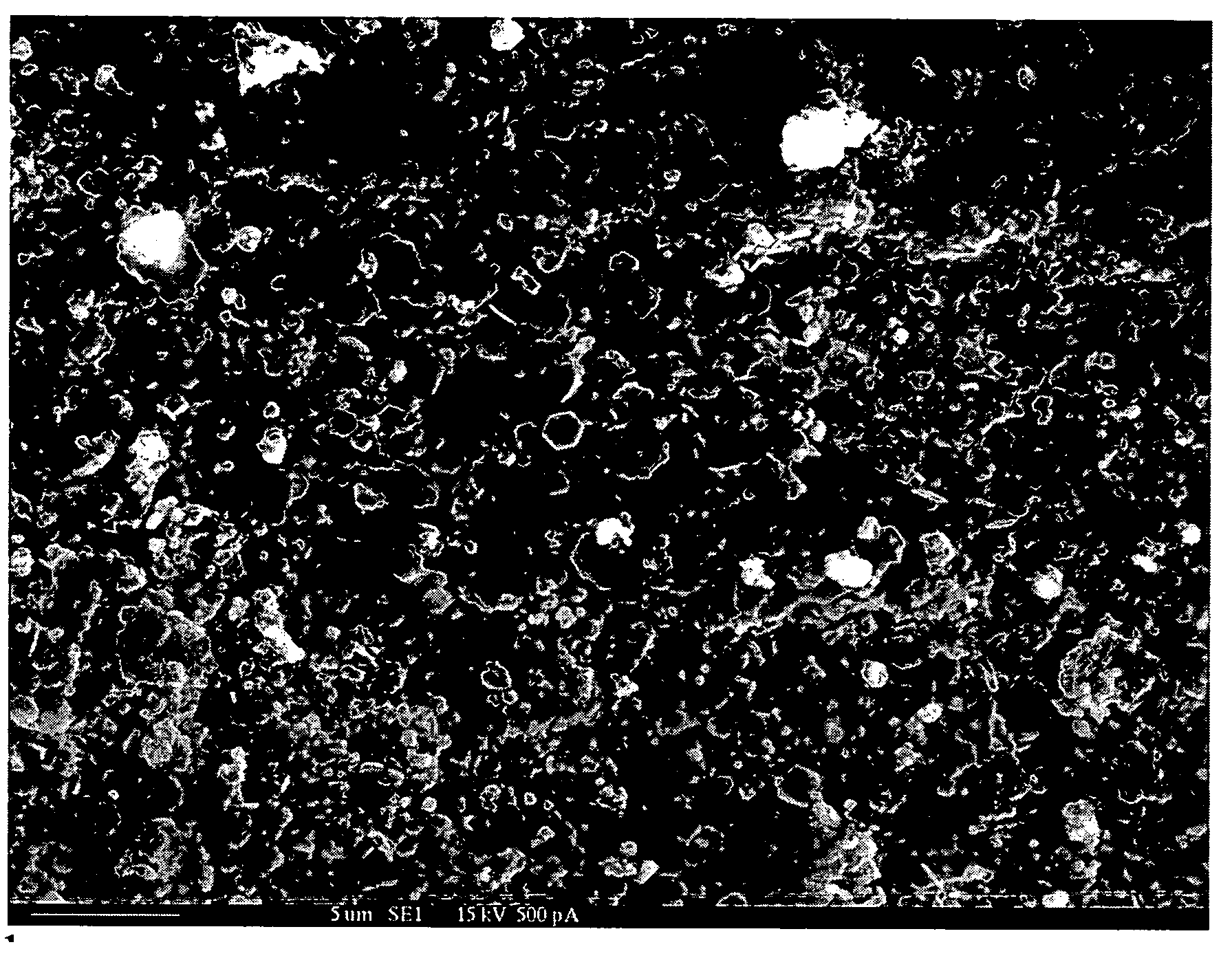

Method for skin-whitening using composition containing resveratryl triglycolate

ActiveUS20170210694A1Effectively compositionEffectively used cosmeticCosmetic preparationsOrganic compound preparationAdditive ingredientMedicine

The present invention relates to a method for skin-whitening using a composition containing resveratryl triglycolate as an active ingredient, and more specifically, relates to a composition for skin-whitening containing resveratryl triglycolate or a cosmetically or pharmaceutically acceptable salt thereof as an active ingredient, a method for skin-whitening including applying or administering a composition containing resveratryl triglycolate or an acceptable salt thereof as an active ingredient to a subject, and a resveratryl triglycolate compound which has a skin-whitening effect.Since resveratryl triglycolate of the present invention can inhibit melanin synthesis and brighten skin tone, it can be effectively used as a cosmetic composition and a pharmaceutical composition for skin-whitening.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

Method for preparing high-purity glycolide

The invention belongs to the technical field of organic synthesis, and particularly discloses a method for preparing high-purity glycolide. The method comprises the following steps: heating glycollic acid or glycolate under the action of a catalyst to dehydrate or dealcoholize to obtain a glycollic acid oligomer, and then performing heating and decompressing cracking in a depolymerization kettle to obtain crude glycolide; and recrystallizing the crude glycolide with a solvent under the protection of protective gas, carrying out vacuum drying on a crystal substance, and carrying out melt crystallization separation to obtain the polymer-grade glycolide with the purity of more than or equal to 99.9%. The crude glycolide is purified by using a recrystallization and melt crystallization coupling method, so that the cyclic utilization of materials can be realized, no waste is generated, and meanwhile, a high-purity (greater than or equal to 99.9%) glycolide product is prepared at a high yield. The method is a high-efficiency, environment-friendly and high-purity glycolide synthesis method, and is suitable for industrial production.

Owner:SHANGHAI DONGGENG CHEM TECH CO LTD

Catalyst for production of hydroxyacetic acid ester by oxalate through hydrogenation

InactiveCN102649062AImprove technical effectOrganic compound preparationCarboxylic acid esters preparationGlycolatesSilicon oxide

The invention relates to a catalyst for production of hydroxyacetic acid ester by oxalate through hydrogenation, which mainly solves the technical problem of low selectivity of hydroxyacetic acid ester in hydrogenated products in the prior art. The catalyst comprises the following components as per parts by weight: 5 to 80 parts of active component, 0 to 40 parts of assistant and 1 t0 30 parts of carriers, wherein the active component is copper, oxide of copper of copper mixture; the assistant is at least one of zinc, lanthanum, barium, nickel or iron or oxide of zinc, lanthanum, barium, nickel or iron; and the carrier is a complex carrier chosen from alumina and silicon oxide, and the weight ratio of the alumina and silicon oxide is 0.01 to 30:1. The catalyst for production of hydroxyacetic acid ester by oxalate through hydrogenation can solve the problem well, and can be used for industrial production of hydroxyacetic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polyglycolic acid

The invention relates to a preparation method of polyglycolic acid, and mainly solves the problem that a polymer with a weight-average molecular weight Mw of more than 20,000 cannot be obtained by a poly-condensation reaction of polyglycolic acid. The technical scheme is as follows: the preparation method of polyglycolic acid is adopted; the preparation method comprises the following steps: step 1, reacting glycolic acid or glycolate to obtain polyglycolic acid with a weight-average molecular weight Mw lower than 20000, and step 2, adding a dehydrating agent into the obtained polyglycolic acidto carry out further polymerization; the problems are well solved, polyglycolic acid with higher weight-average molecular weight can be obtained, and the preparation method can be used for industrialproduction of polyglycolic acid with a high weight-average molecular weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

Quaternary ammonium salts as a conversion coating or coating enhancement

InactiveUS20060151071A1Improve adhesionGood paint adhesionAnti-corrosive paintsMetallic material coating processesGlycolatesHalogen

Disclosed are quaternary ammonium salts containing non-halogen anions such as carbonates, bicarbonates, phosphates, glycolates and mixtures thereof as conversion coatings or additives imparting anti-corrosive properties to paints. The invention relates to a method for inhibiting the corrosion of metal surfaces by applying a composition containing one or more quaternary ammonium carbonate or bicarbonate. The disclosure is also directed to anti-corrosive coatings for metal substrates containing these compounds and to metal substrates having these anticorrosive coatings.

Owner:LONZA INC

Method for producing glyoxylate through oxidation of glycollate

The invention relates to a method for producing glyoxylate through oxidation of glycollate. The invention mainly aims to overcome the problem of low yield of glyoxylate in the prior art. The method provided by the invention comprises a reaction step of contacting a nitrogen oxide and oxygen-containing gas with glycollate to produce glyoxylate. A catalyst used in the invention comprises the following components by weight: a) 0.5 to 30 parts of at least one active component selected from a group consisting of iron and iron oxides; b) 0 to 10 parts of an auxiliary agent which is at least one metal selected from a group consisting of group IA or group IIA elements or oxides thereof; and c) 70 to 99 parts of a carrier. With such a technical scheme, the above problem is overcome, and the method is applicable to industrial production of glyoxylate through oxidation of glycollate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing glycolic acid ester through adding hydrogen in oxalic ester

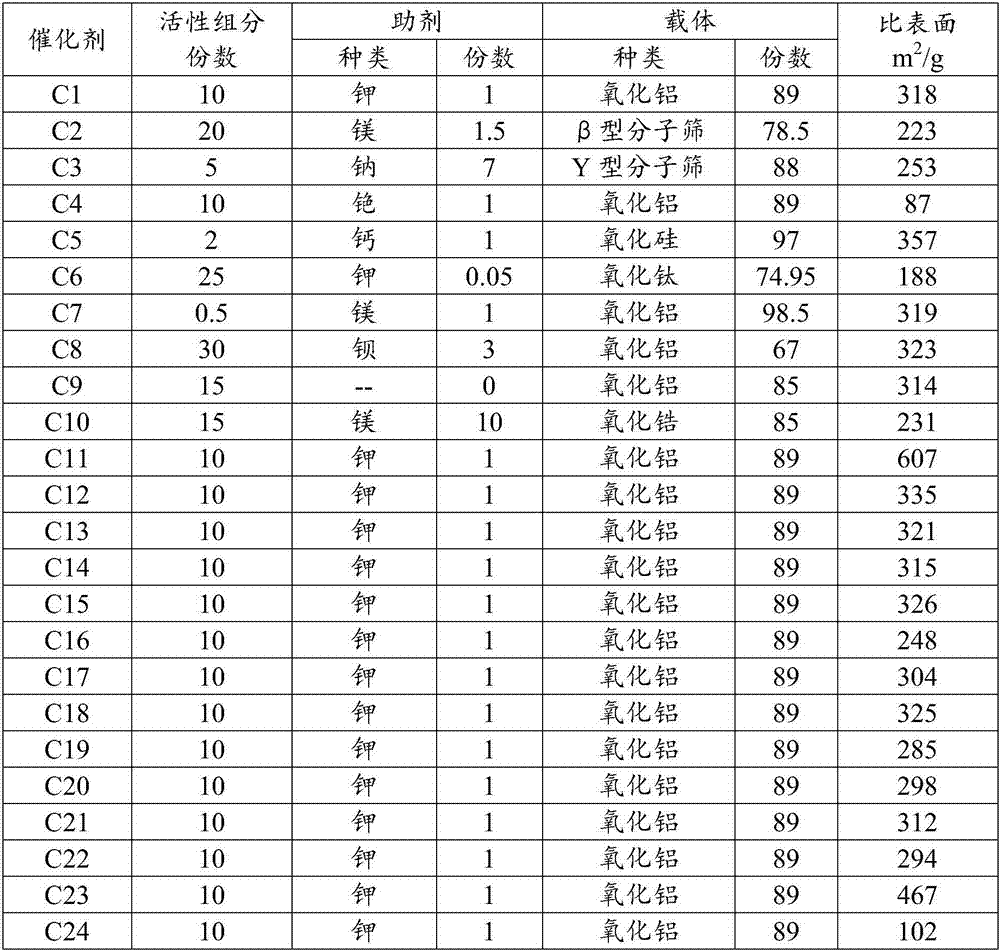

InactiveCN102649746AImprove technical effectMolecular sieve catalystsOrganic compound preparationGlycolatesHydrogen

The invention relates to a method for producing glycolic acid ester through adding hydrogen in oxalic ester, which mainly solves the technical problem in the prior art that the selectivity of the glycolic acid ester is low in a hydrogenated production. The invention adopts the technical scheme that under conditions that the reaction temperature is 100-250 DEG C, the weight space velocity is 0.2-5 h<-1>, the molar ratio of hydrogen to ester is (10-100):1, and the reaction pressure is 0-6.0 MPa, raw materials, namely the oxalic ester, are in contact with a catalyst to generate an effluence containing the glycolic acid ester, wherein the catalyst, in parts by weight, comprises 5-80 parts of active component, 0-40 parts of additive and 1-90 parts of carrier. Due to the adoption of the technical scheme, the problem is better solved, and the method can be used in the industrial production of glycolic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

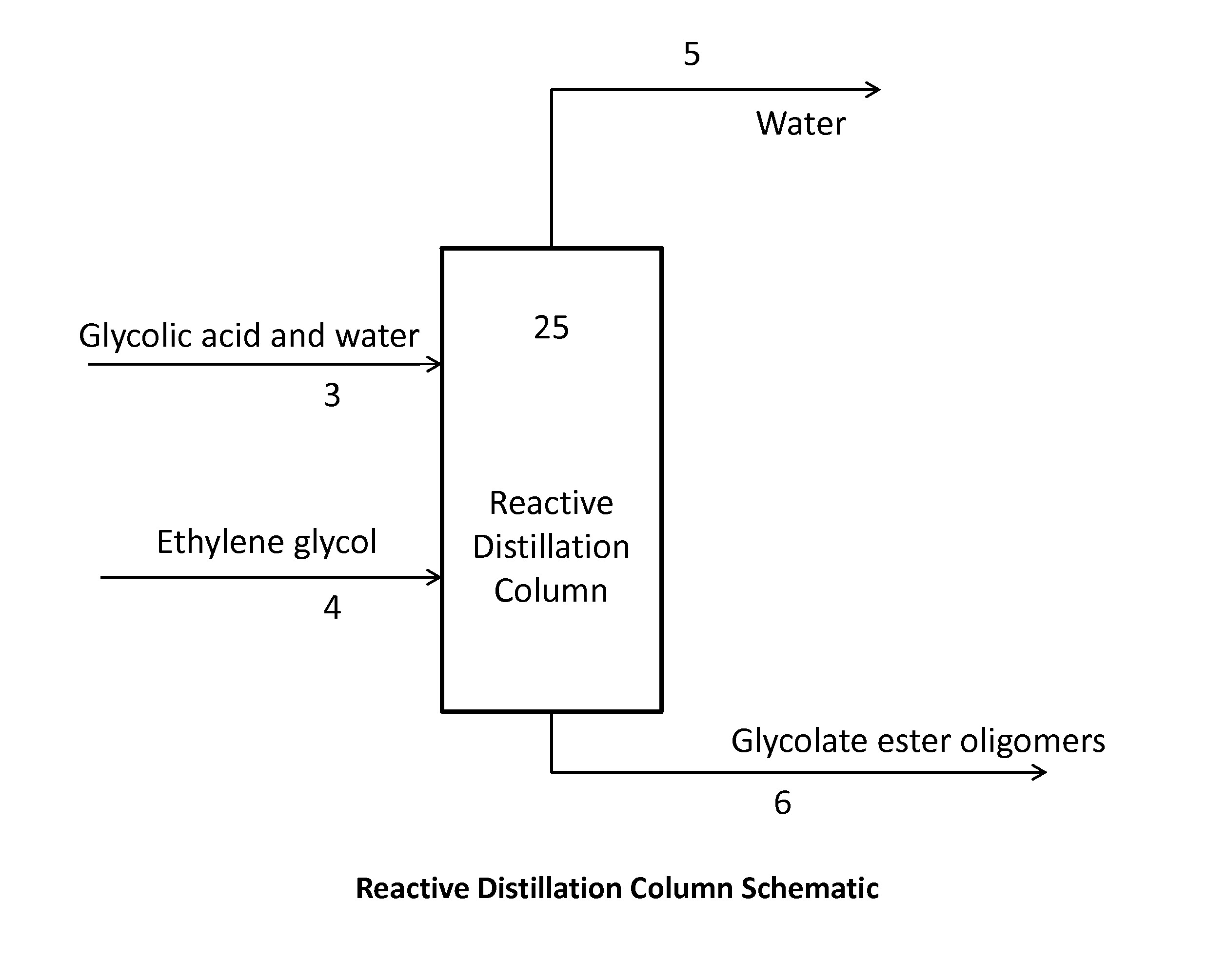

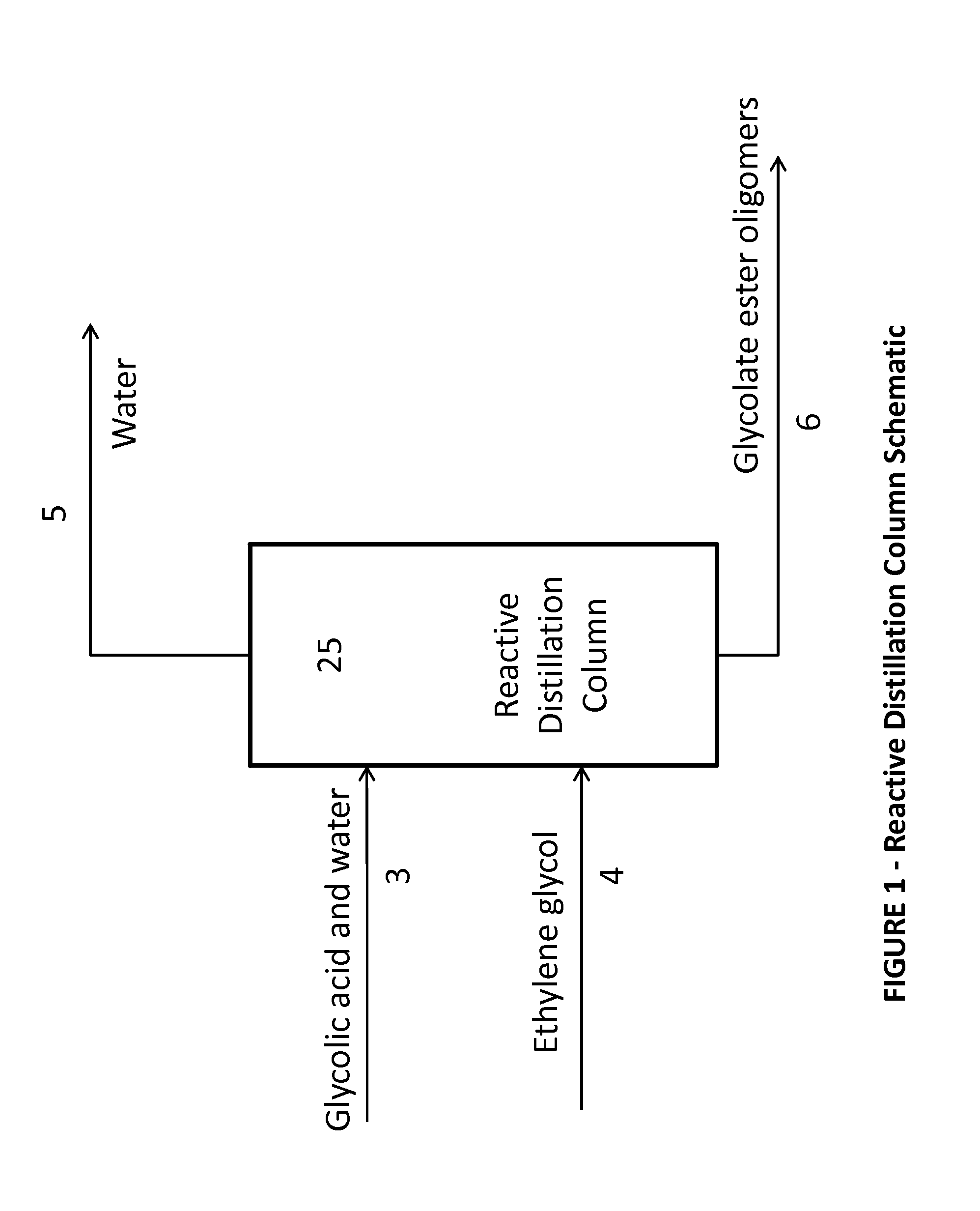

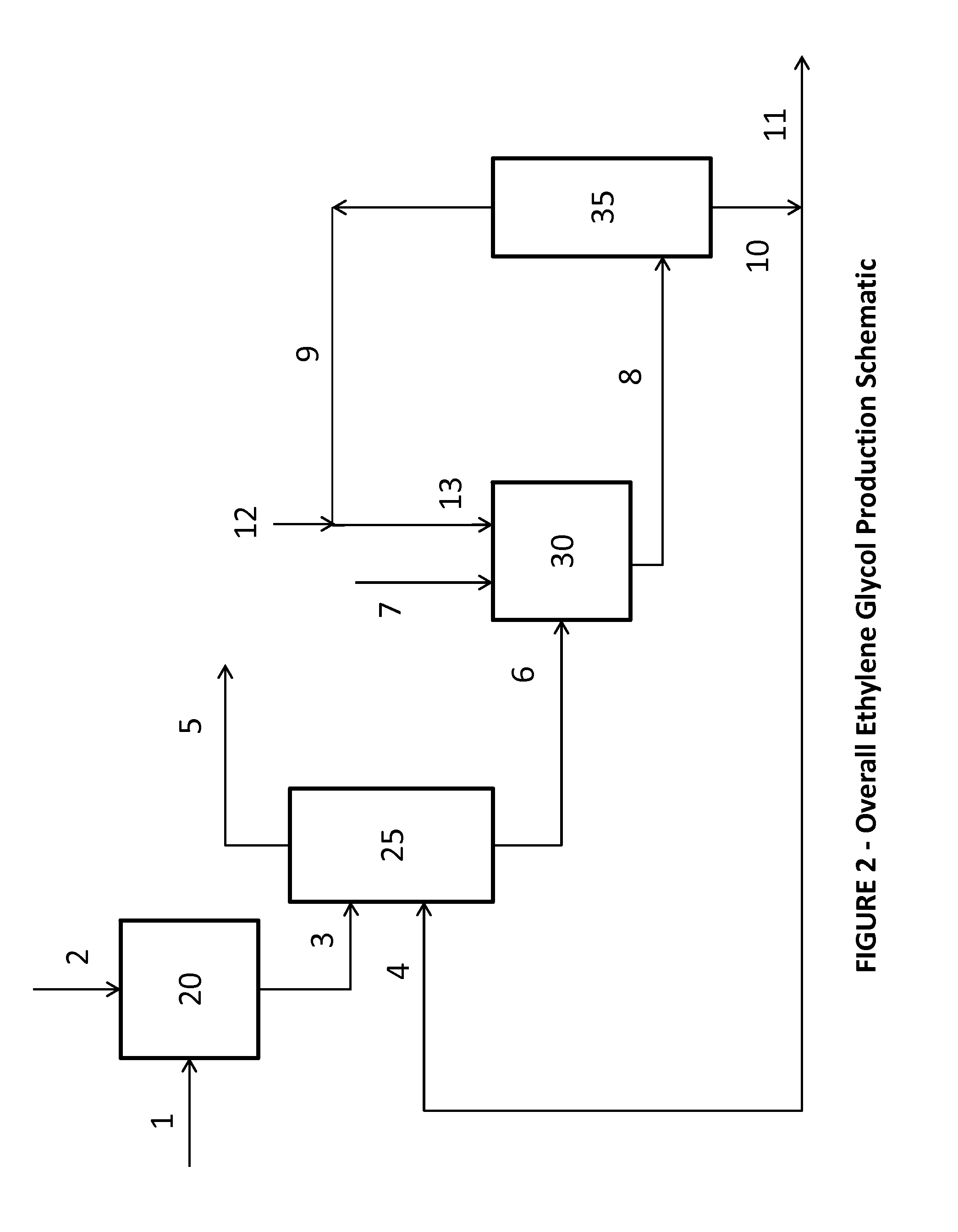

Reactive Distillation of a Carboxylic Acid and a Glycol

Disclosed is a process for producing glycolate ester oligomers. The process comprises reacting ethylene glycol and glycolic acid to produce a stream of glycolate ester oligomers and glycolic acid oligomers while simultaneously removing water. The stream of glycolate ester oligomers and glycolic acid oligomers has a low concentration of water and glycolic acid-ends, and thus is useful in a subsequent hydrogenation reaction to produce ethylene glycol.

Owner:EASTMAN CHEM CO

Absorbable copolyesters of poly(ethoxyethylene diglycolate) and glycolide

A semi-crystalline, absorbable copolyester composition comprising the reaction product of a polycondensation polyester and at least one lactone, wherein the polycondensation polyester comprises the reaction product of diglycolic acid and / or a derivative thereof and diethylene glycol; and the copolyester comprises about 30 to 60% by weight of the polycondensation polyester based on the total weight of the copolyester. Also medical devices such as absorbable sutures comprising such copolyesters and absorbable microspheres comprising such copolyesters and methods of making of such absorbable microspheres.

Owner:ETHICON INC

Synthesis method of high-purity glycolide

The invention belongs to the technical field of organic synthesis, and particularly discloses a synthesis method of high-purity glycolide. The synthesis method comprises the following steps: heating glycollic acid or glycolate under the action of a catalyst to realize dehydration or dealcoholization so as to obtain a glycollic acid oligomer, and then carrying out heating, decompressing and cracking in a depolymerization kettle to obtain crude glycolide; and rectifying the crude glycolide under high vacuum, and subjecting a rectification product to melt crystallization separation to obtain the polymer-grade glycolide with a purity of greater than or equal to 99.9%. According to the synthesis method disclosed by the invention, the crude glycolide is purified by using a rectification-melt crystallization coupled method, no reagent is added, materials can be recycled, and a high-quality glycolide product can be obtained at a high yield. The method is an efficient, environment-friendly and high-purity glycolide synthesis method, and is suitable for industrial production.

Owner:SHANGHAI DONGGENG CHEM TECH CO LTD

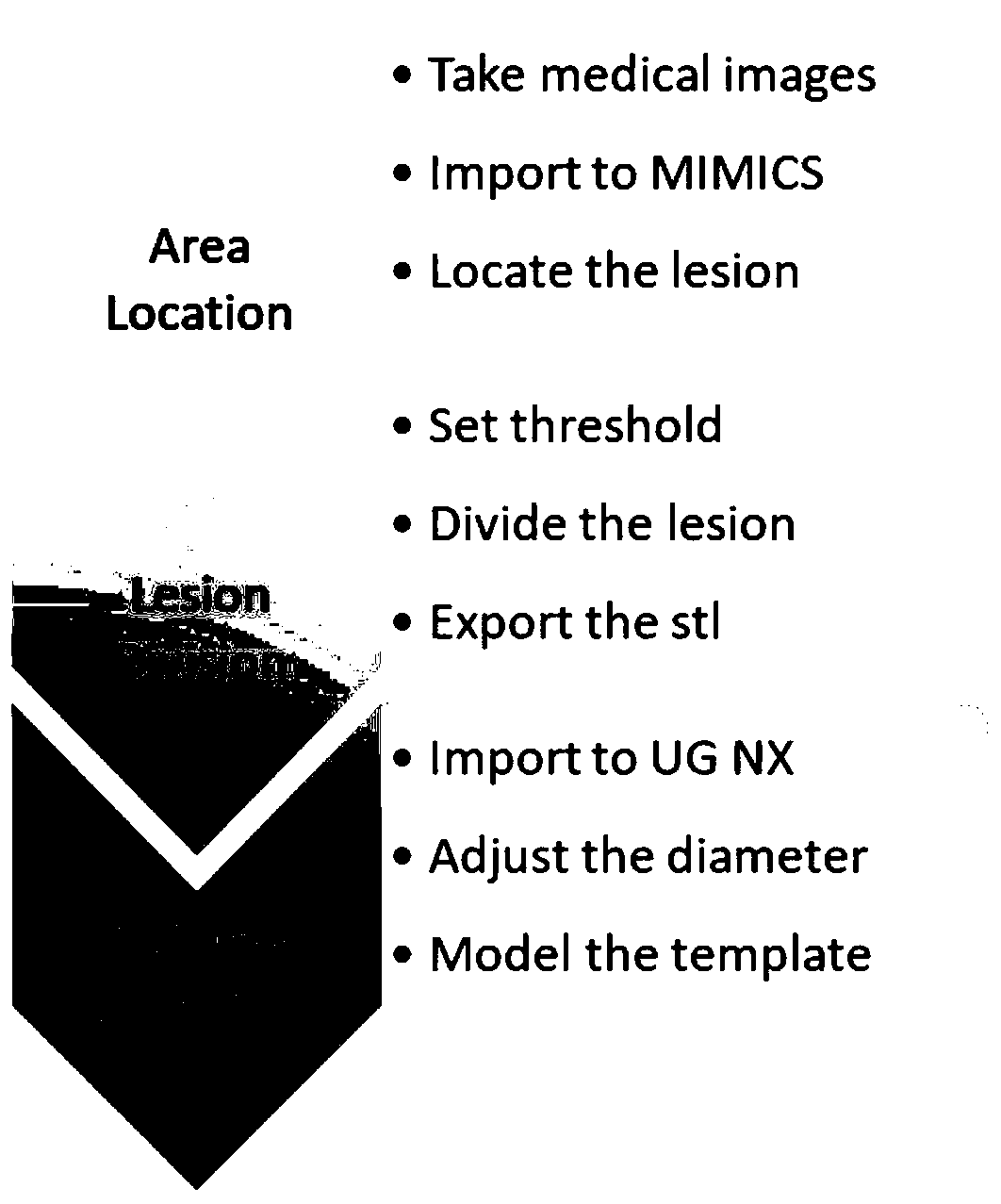

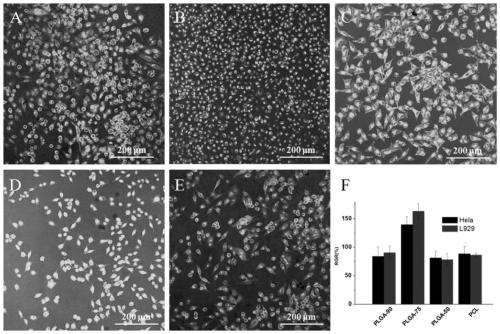

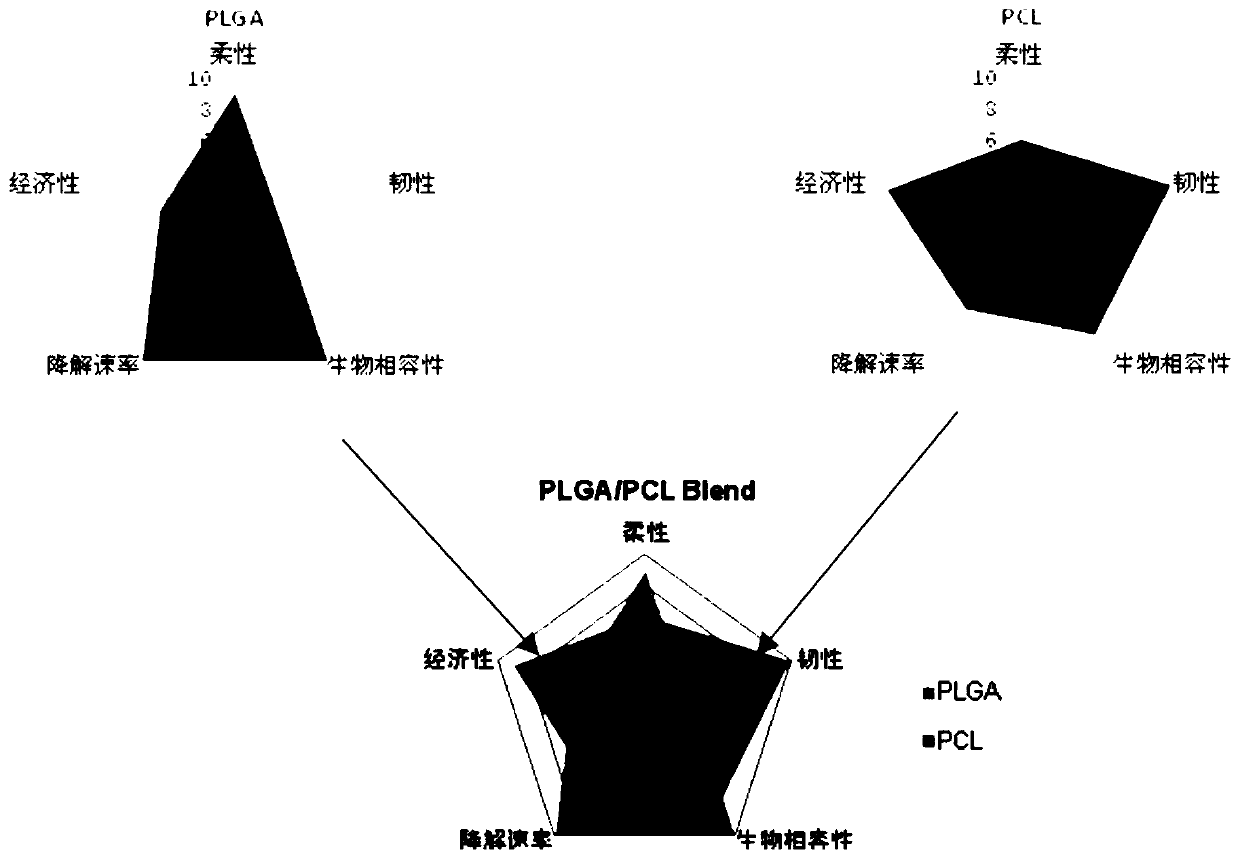

Biodegradable tissue engineering urethral stent and preparation method thereof

InactiveCN111450317AImprove toughnessStay flexibleStentsAdditive manufacturing apparatusUrethral stentsGlycolates

The invention discloses a biodegradable tissue engineering urethral stent and a preparation method thereof. The biodegradable tissue engineering urethral stent is made of a copolymer formed by polylactic acid-co-glycolate, polycaprolactone and a solubilizer according to the weight ratio of 70 to 30 to (2-10). The preparation method of the biodegradable tissue engineering urethral stent comprises the following steps of a) blending preparation of a modified material solution, b) medical image processing and modeling, c) 3D template printing and d) stent preparation. PLGA and PCL biodegradable polymers are subjected to solution co-mixing modification, and triethyl citrate is added as the solubilizer, and the blending ratio and the content of the solubilizer are adjusted, so that the toughnessof the modified material is relatively and greatly improved while the flexibility and the tensile strength are kept; and based on a 3D printing technology and in combination with medical image data and software processing, a soluble template can be printed for the focus of a patient, and the personalized tissue engineering urethral stent is prepared.

Owner:ZHEJIANG SINOU ENVIRONMENTAL PROTECTION EQUIP CO LTD

Preparation method of fluid catalyst for production of hydroxyacetic acid ester by oxalate through hydrogenation

InactiveCN102649074AImprove technical effectImprove catalytic performanceMolecular sieve catalystsOrganic compound preparationGlycolatesSlurry

The invention relates to a preparation method of fluid catalyst for production of hydroxyacetic acid ester by oxalate through hydrogenation, which mainly solves the problem of low hydroxyacetic acid ester selectivity in hydrogenated products in the prior art. The preparation method comprises following steps: (a), preparing required mixed nitrate solution and sodium carbonate solution of copper element and auxiliary agent element; (b), performing coprecipitation to the required mixed nitrate solution and sodium carbonate solution at the temperature of 50 to 90 DEG C, continuously stirring during coprecipitation, and ensuring that the PH value ranges from 5 to 9 when the coprecipitation is ended; (c), washing the precipitated slurry with deionized water repeatedly, and adding a carrier and an adhesion agent for pulping until no Na<+> ion is caused; (d), performing spray forming as per required particle size: the average diameter of catalyst particles is 50 to 300 micrometers, and the catalyst particulars are spheroidal; (e), drying for 4 to 20 hours at the temperature of 80 to 120 DEG C, and roasting for 2 to 8 hours at the temperature of 300 to 550 DEG C. The preparation method solves the problem better and can be used for industrial production of hydroxyacetic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

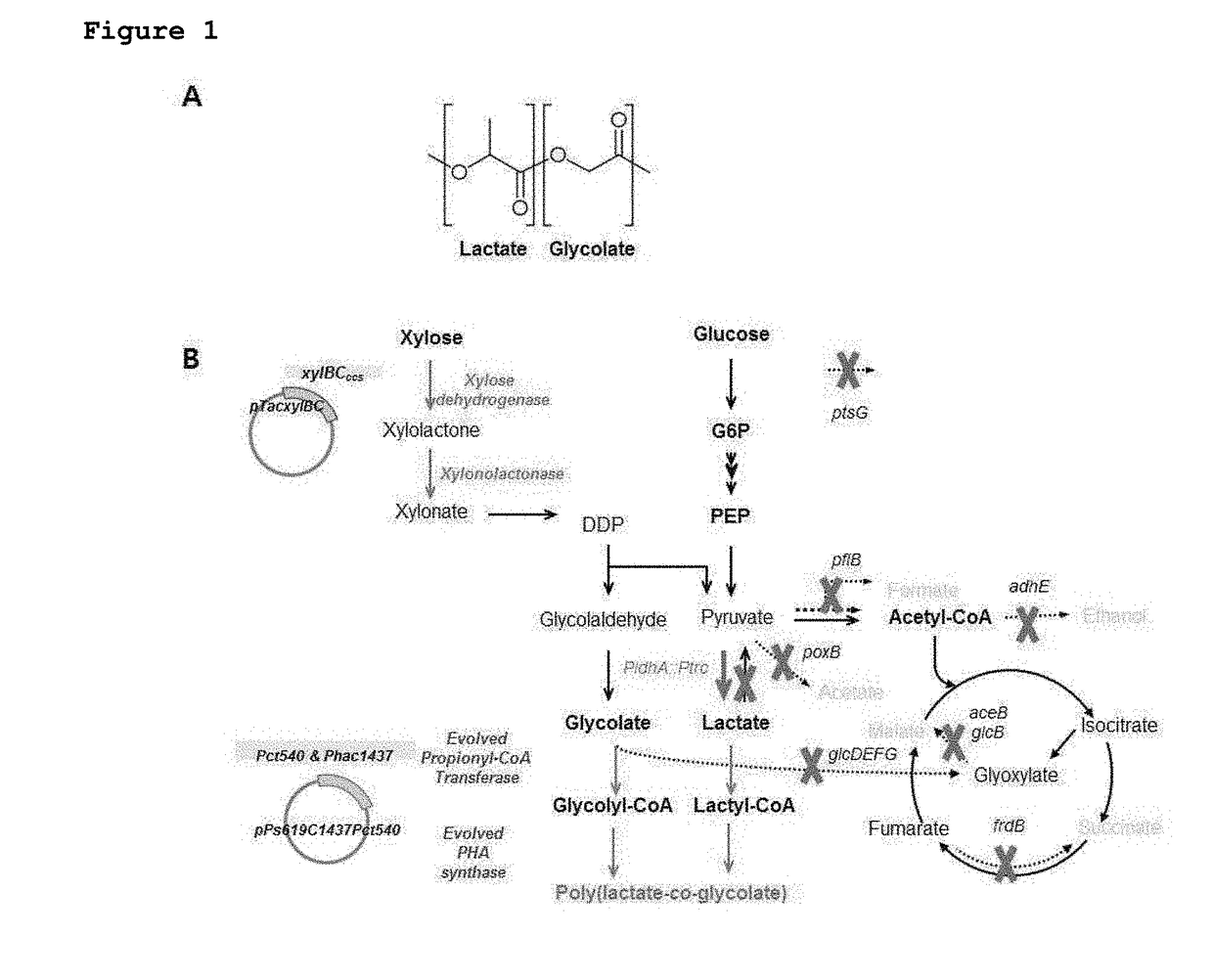

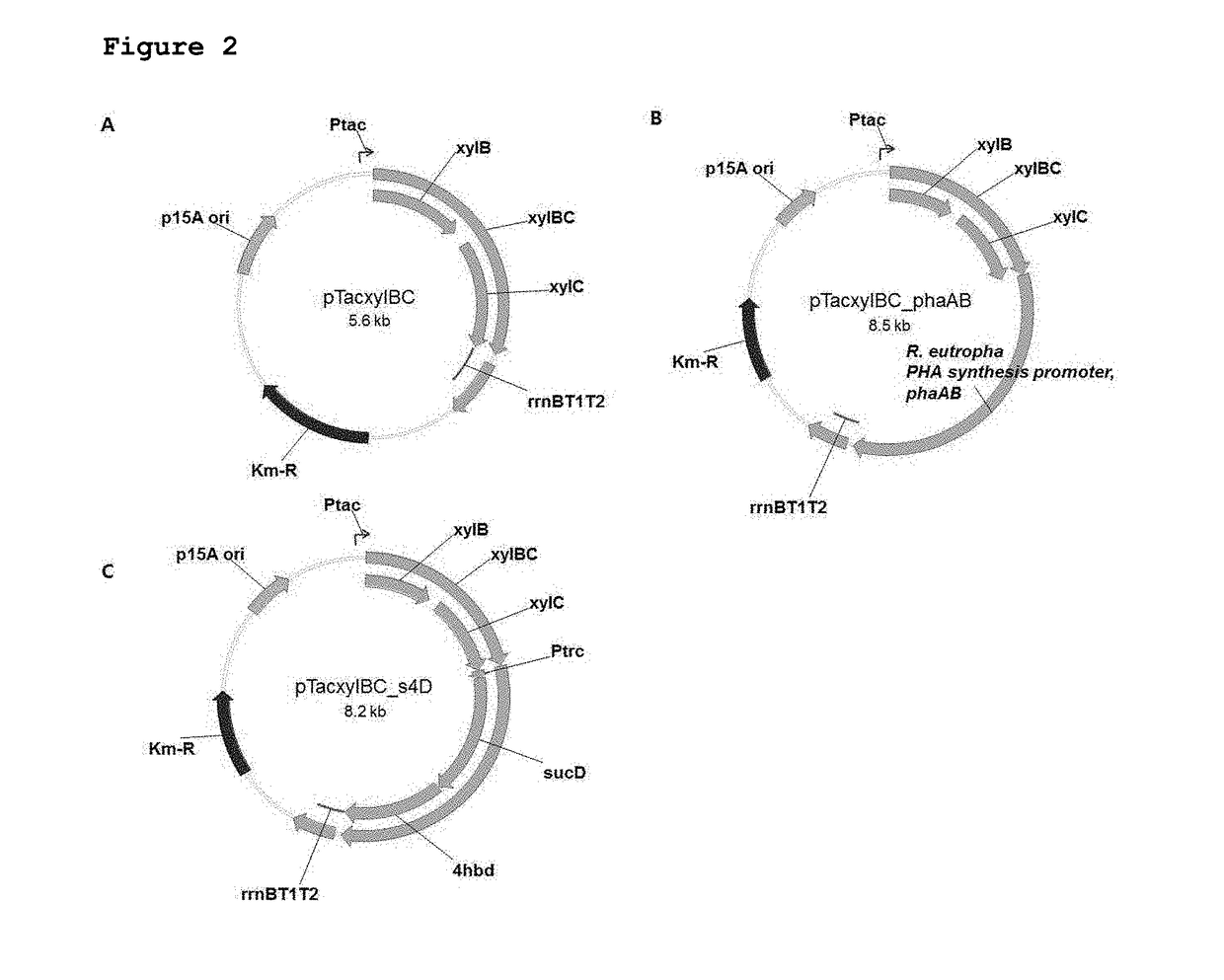

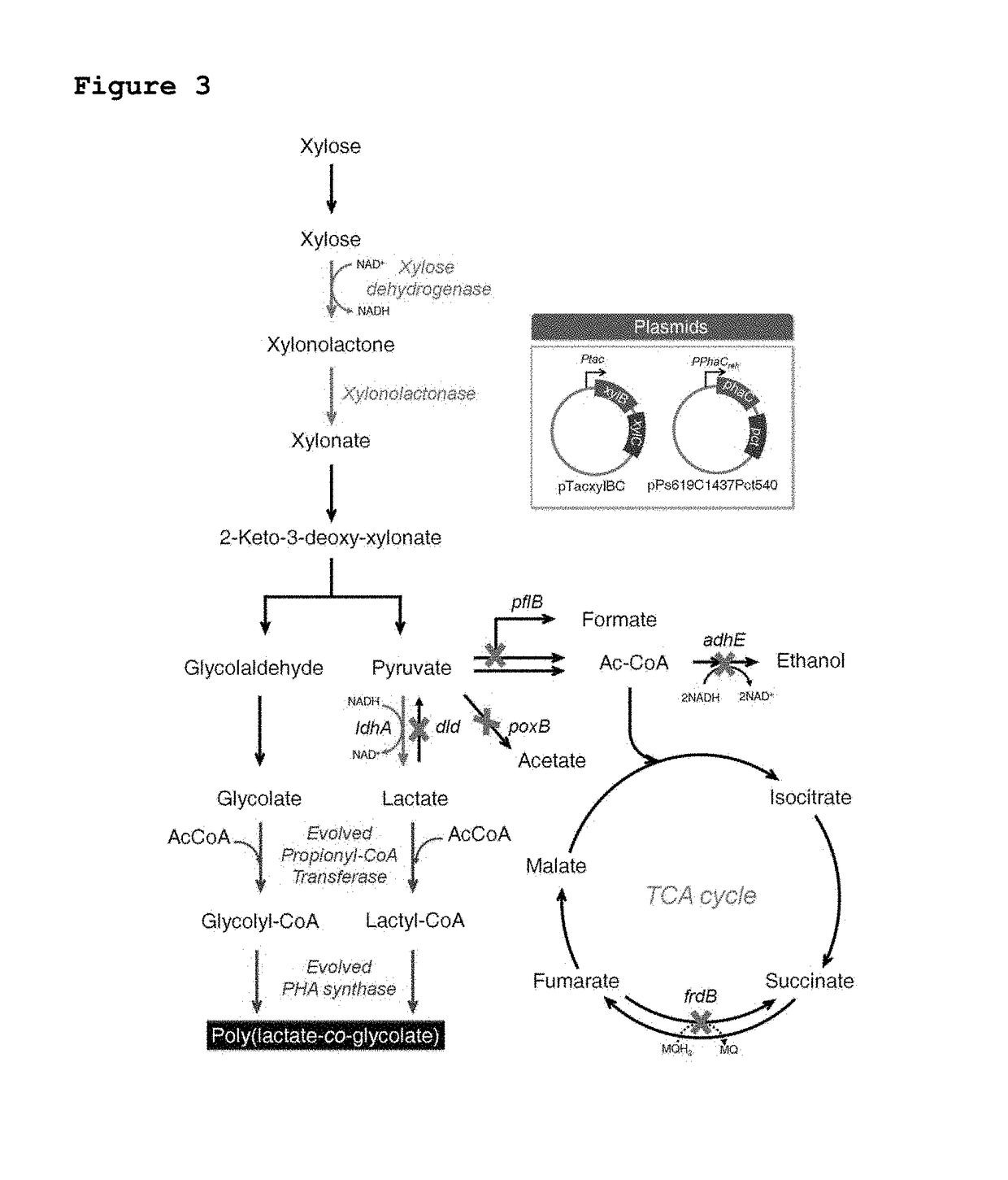

Recombinant microorganism having ability to produce poly(lactate-coglycolate) or copolymer thereof from xylose and method for preparing poly(lactate-coglycolate) or copolymer thereof by using same

The present invention relates to a recombinant microorganism having the ability to produce poly(lactate-co-glycolate) and its copolymers from xylose, and more particularly to a recombinant microorganism having the ability to produce poly(lactate-co-glycolate) and its copolymers without having to supply a glycolate precursor from an external source, and a method of producing a poly(lactate-co-glycolate) copolymers using the same.

Owner:KOREA ADVANCED INST OF SCI & TECH

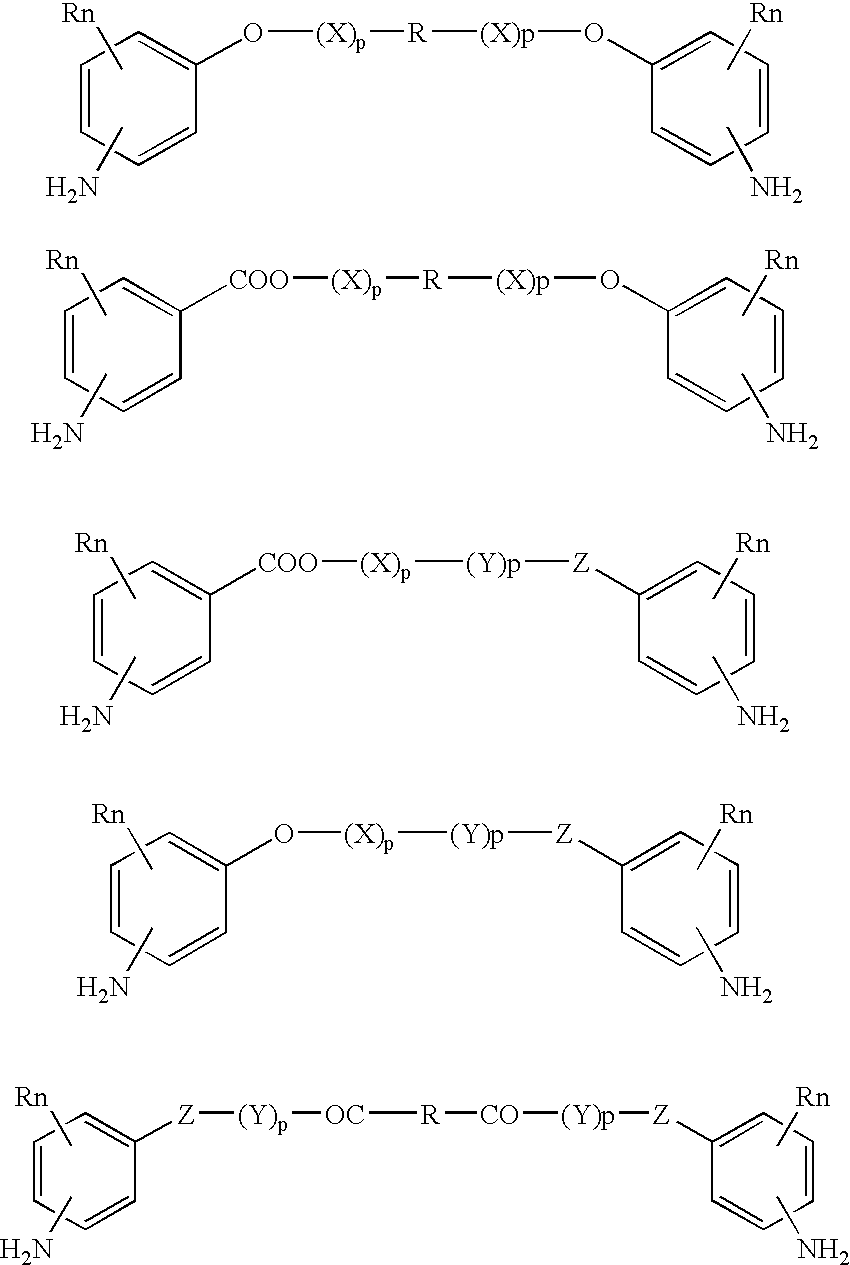

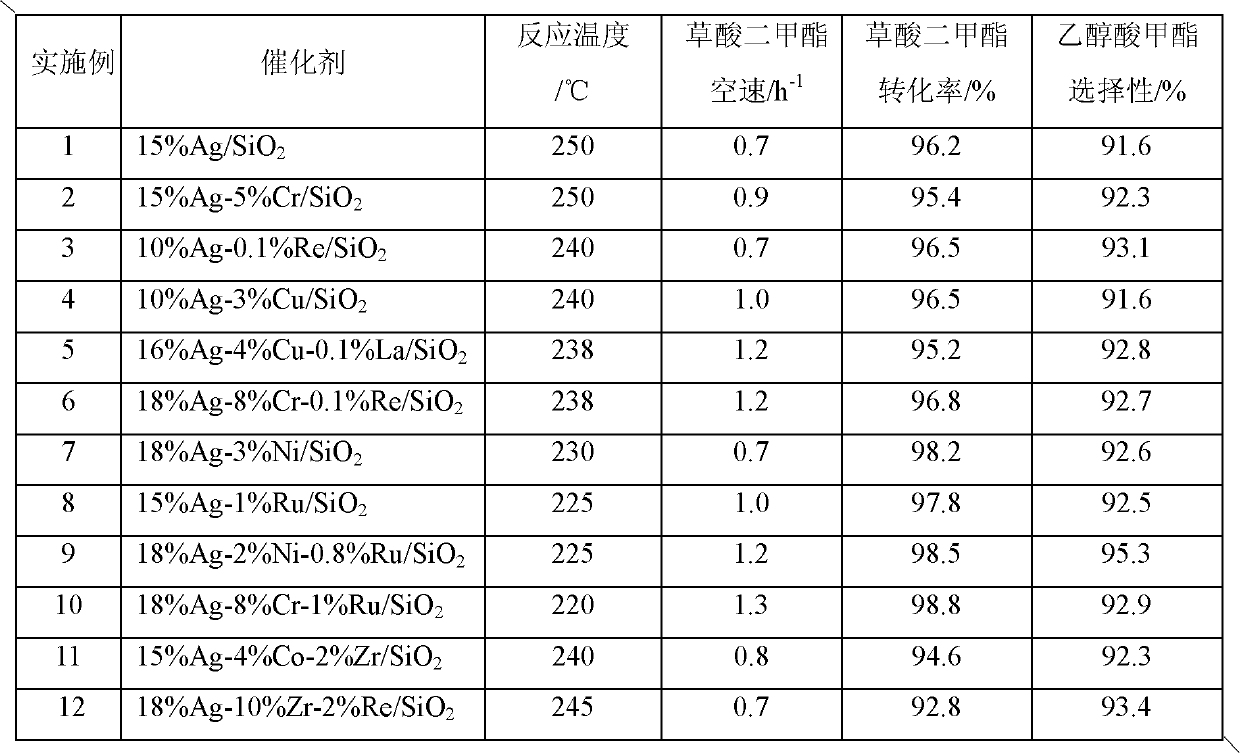

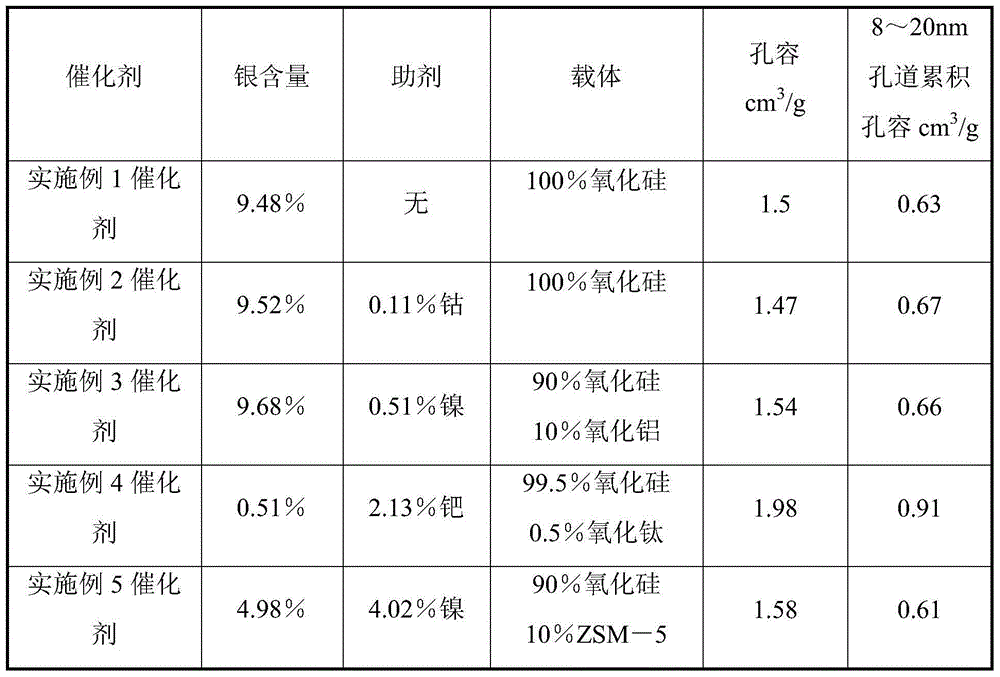

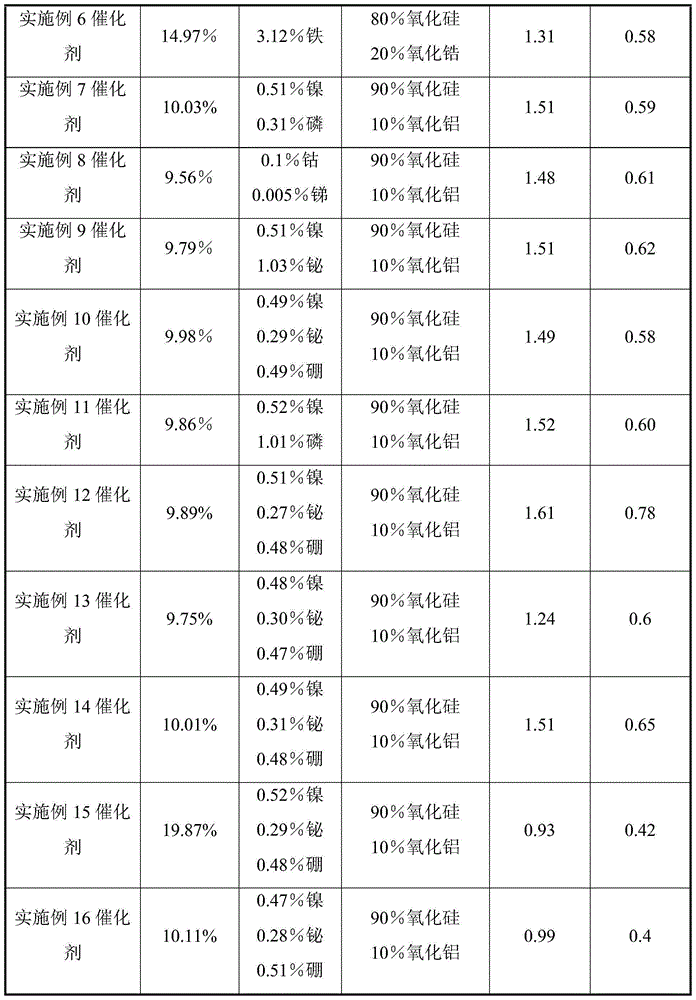

Catalyst for preparing glycolate through hydrogenating oxalate, preparation method for catalyst and use of catalyst

InactiveCN105582915AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationOxalateMolecular sieve

The invention relates to a catalyst for preparing glycolate through hydrogenating oxalate, a preparation method for the catalyst and use of the catalyst. The catalyst is mainly used for solving the problem in the prior art that catalysts are poor in activity and low in glycolate selectivity. Through adopting the technical scheme that the catalyst which contains the following ingredients in percentage by weight is prepared by in-situ synthesis: (1) 0.5-15wt% of silver or oxides thereof; (2) 0-4wt% of at least one metal of VIII-group metals or oxides thereof; (3) 0-3wt% of at least one element of VA-group elements or oxides thereof; and (4) 78-99.5wt% of at least one carrier selected from silica, alumina, zirconia, titania and molecular sieves, the problem is better solved, and the catalyst can be applied to the industrial production for preparing glycolate through hydrogenating oxalate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal-phase carrier-loaded type catalyst, and preparation method and application thereof

ActiveCN105289649AStable structureImprove thermal conductivityOrganic compound preparationCarboxylic acid esters preparationDimethyl oxalatePalladium

The invention discloses a metal-phase carrier-loaded type catalyst, and a preparation method and application thereof. The metal-phase carrier-loaded type catalyst is composed of a metal-phase carrier, and palladium and gold or palladium-gold which are loaded on the carrier, wherein the palladium and the gold or the palladium-gold in the metal-phase carrier-loaded type catalyst has the following contents by weight percentage: the content of the palladium by weight percentage is 0.1 to 2.0%; (2) the content of the gold by weight percentage is 0.1 to 3.0%; or (3) the content of the palladium-gold by weight percentage is 0.1 to 5.0%. The metal-phase carrier-loaded type catalyst can be used as a catalyst in the reaction of hydrogenation synthesis of ethylene glycol or / and glycolate from dimethyl oxalate.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

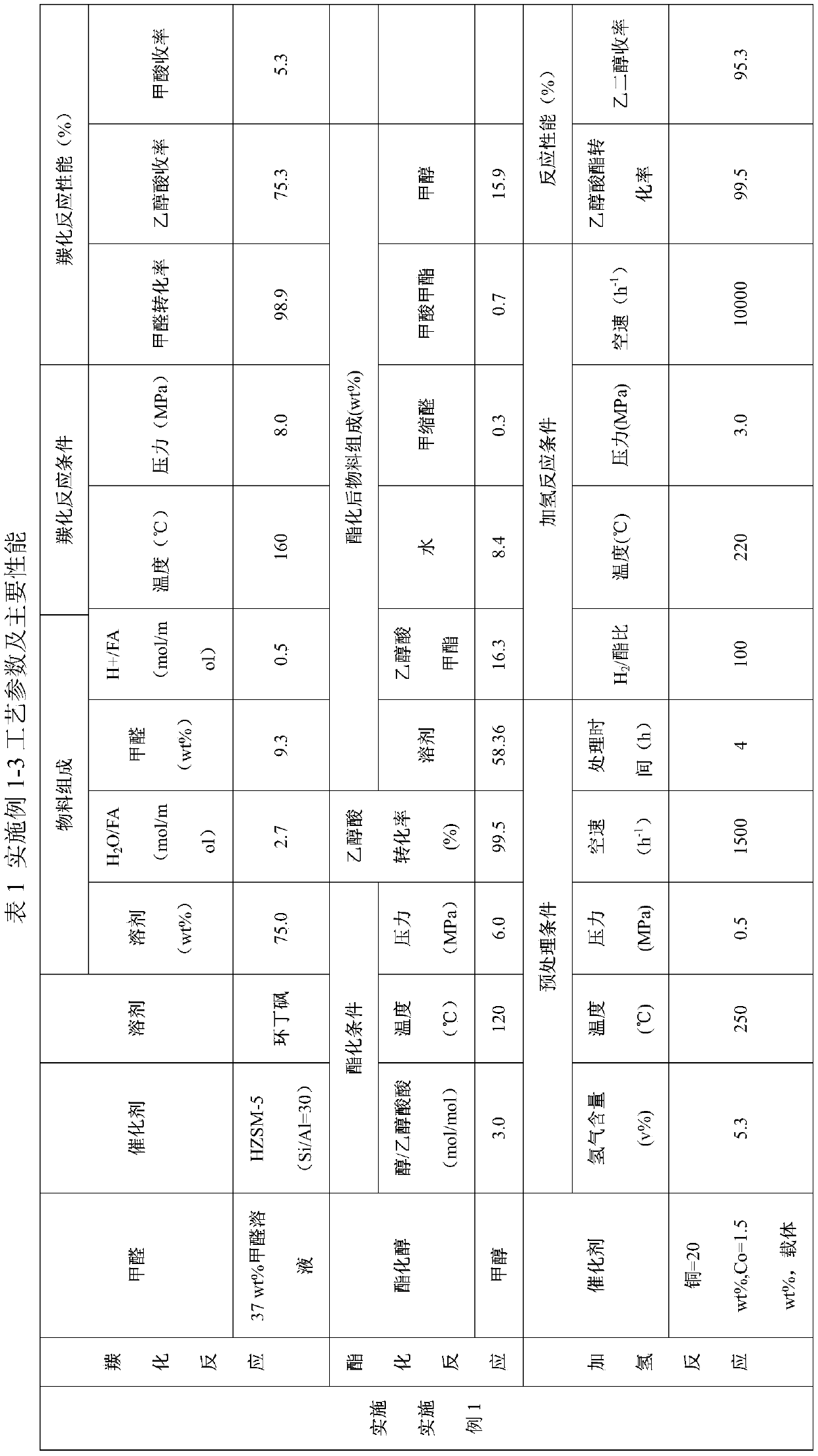

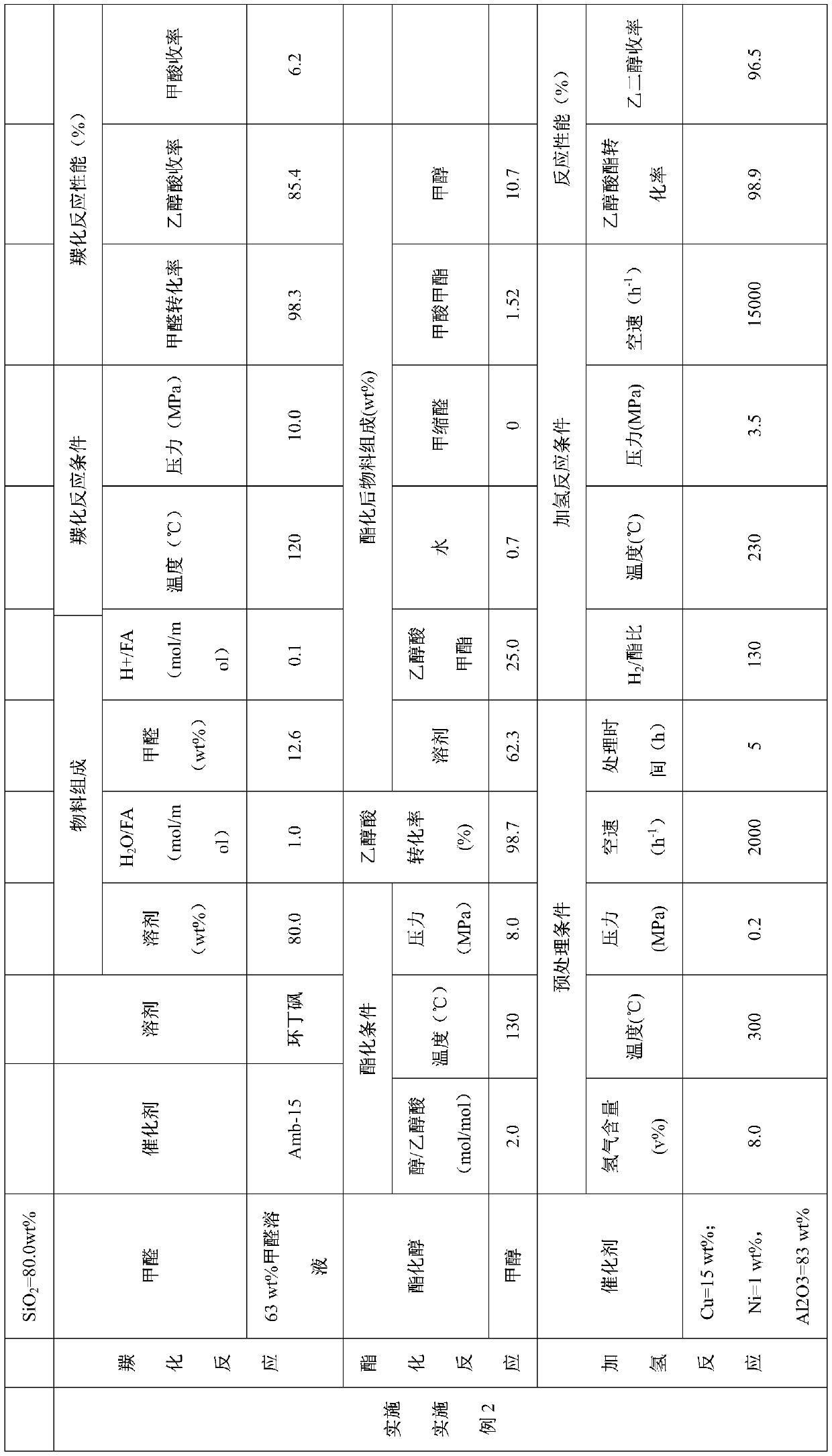

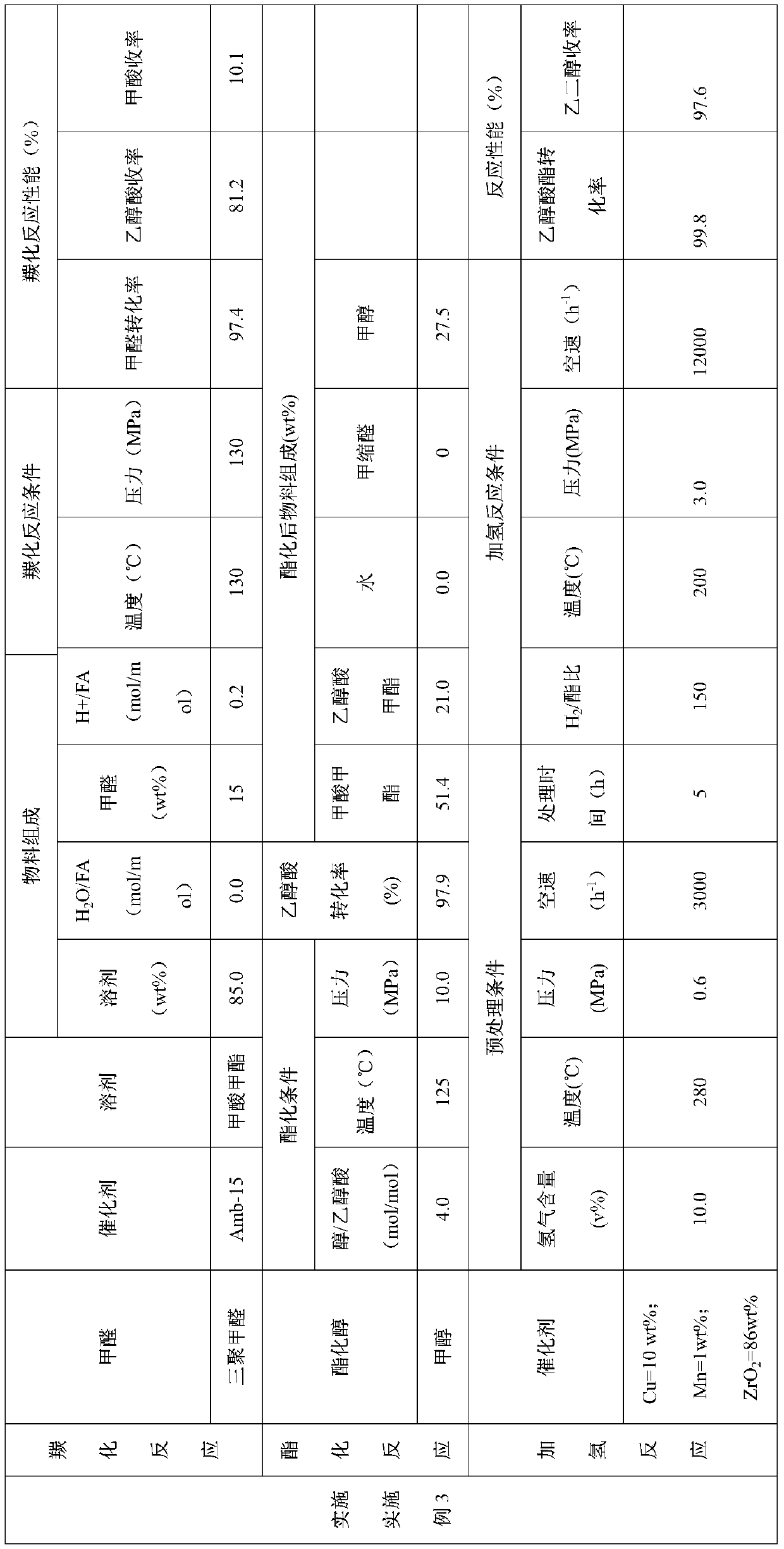

Method for producing ethylene glycol from formaldehyde

InactiveCN111039754AHigh yieldReduce carbonylation reaction pressureOrganic compound preparationCarboxylic acid esters preparationGlycolatesPtru catalyst

The invention relates to a method for producing ethylene glycol from formaldehyde. The method comprises the following steps: carrying out a carbonylation reaction process on formaldehyde, CO and a solvent under the action of an acidic catalyst to generate a glycollic acid-based product, then, carrying out an esterification reaction process on the glycolic acid-based product and an esterification agent alcohol to generate glycolate, and finally, hydrogenating glycolate to generate ethylene glycol. The method has the beneficial effects that the technological process is short, the investment costis low, the pressure of a formaldehyde carbonylation reaction is reduced, the yield of glycollic acid is increased, and then the yield of ethylene glycol in the whole technological process is increased.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

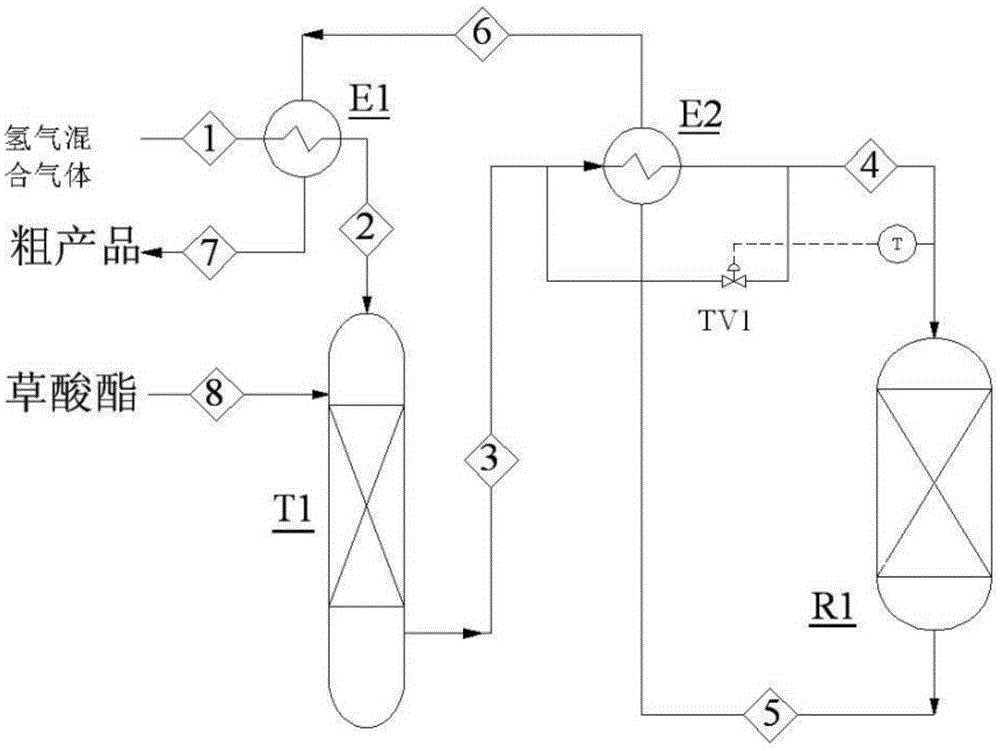

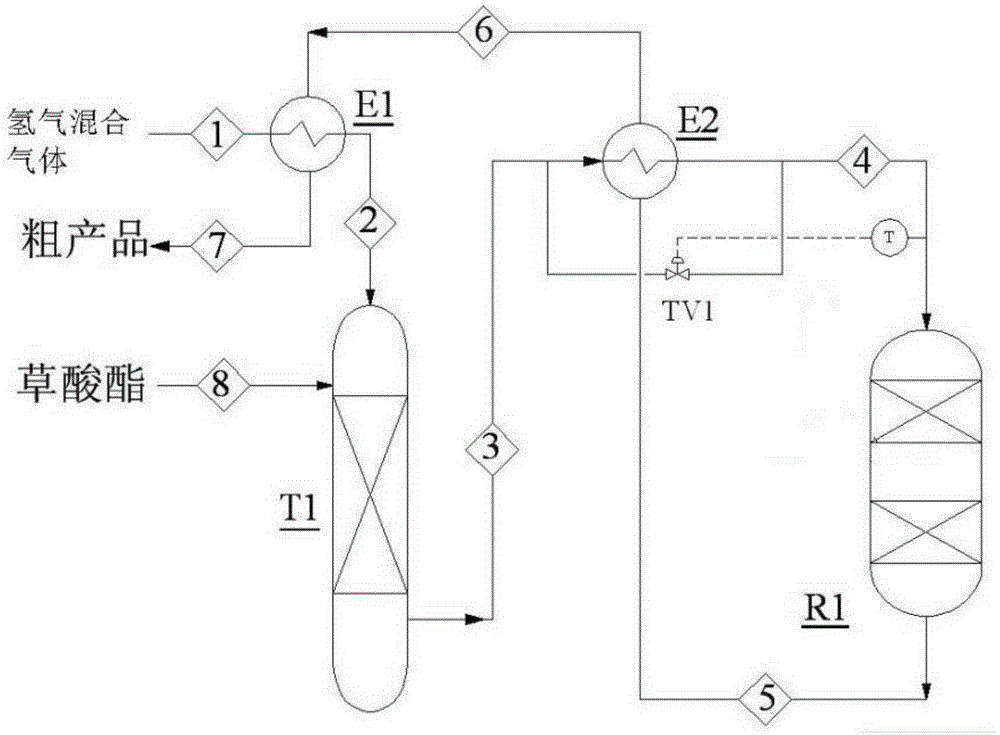

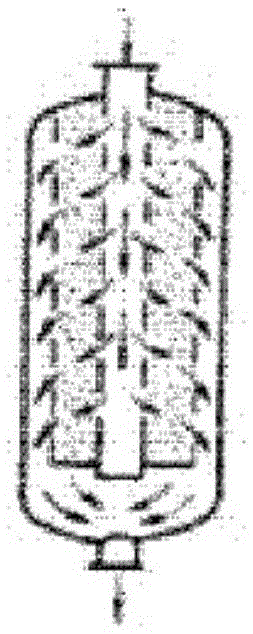

Heat-insulation reaction system and process for preparing glycolate through oxalate hydrogenation

ActiveCN105348102AInhibit side effectsImprove activity and longevityOrganic compound preparationCarboxylic acid esters preparationChemistryExothermic reaction

The invention relates to a heat-insulation reaction system for preparing glycolate through oxalate hydrogenation, belonging to the technical field of glycolate preparation. The system comprises a circulating gas preheater, a vaporization tower, a reaction gas preheater and a hydrogenation reactor communicated in sequence, wherein an outlet of the hydrogenation reaction is communicated with the reaction gas preheater, and the reaction gas preheater is communicated with the circulating gas preheater. The invention also relates to a process for preparing glycolate by using the heat-insulation reaction system. By using the system and process disclosed by the invention, the exothermic reaction temperature rise can be favorably controlled, side reaction can be inhibited, the activity of a catalyst can be improved, the service life of the catalyst can be prolonged, the problems of low oxalate conversion rate, low selectivity of glycolate serving as a product and the like are solved, and the energy consumption is reduced because heating is realized by virtue of system reaction heat. The heat-insulation reaction system and process for preparing glycolate through oxalate hydrogenation have the advantages that the oxalate conversion rate is high, the selectivity of glycolate serving as the product is high, waste heat of the system can be sufficiently utilized, and the energy consumption and the cost can be reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Poly(terephthalate glycol ester-CO-glycolate) copolyester and preparation method thereof

The invention relates to a poly(terephthalate glycol ester-CO-glycolate) copolyester and a preparation method thereof. The poly(terephthalate glycol ester-CO-glycolate) copolyester has the melting point of 200-250 DEG C, has the intrinsic viscosity of 0.6-1.2 dL / g, and is biodegradable. The preparation method is simple; raw materials are low in cost; the product performance has a smaller difference from that of PET (polyethylene terephthalate); and the copolyester can be applied to preparation of fibers, films, sheets, bottles and other plastic products.

Owner:南通海晴医药科技有限公司

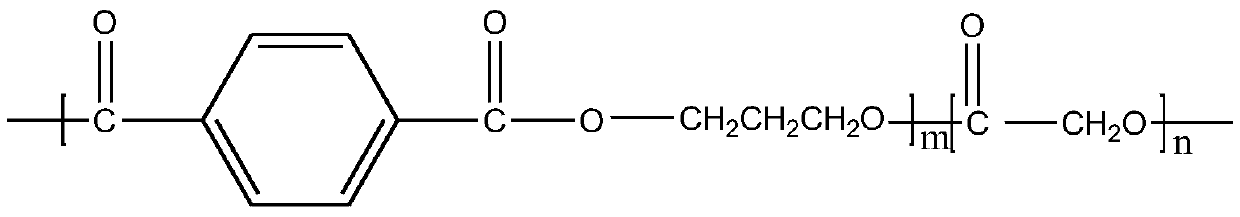

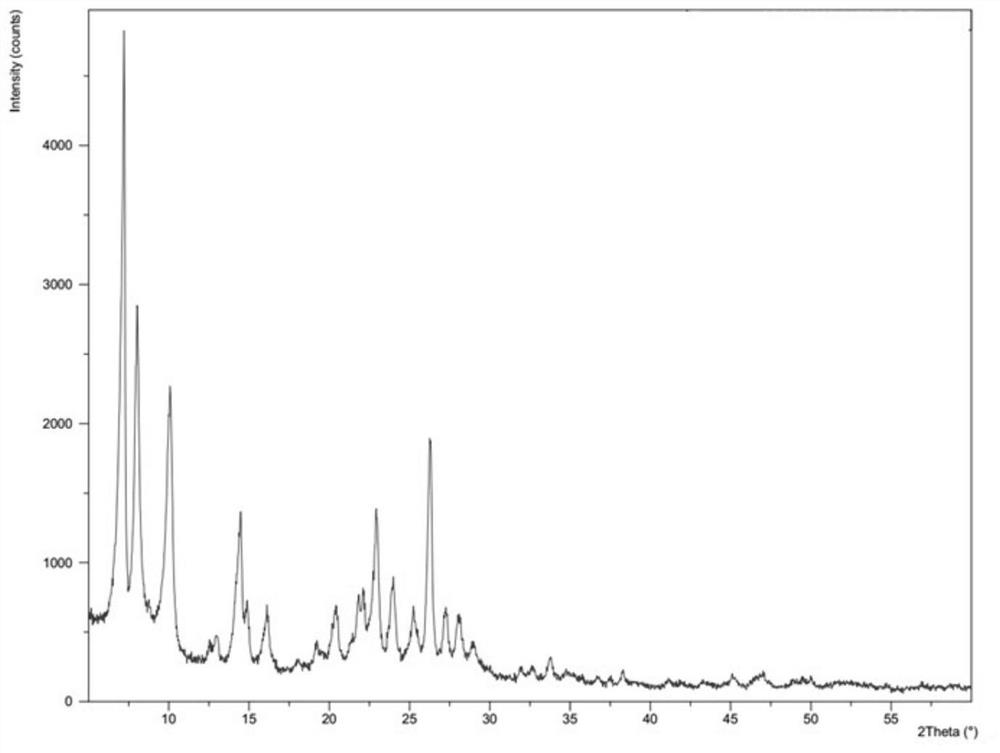

Preparation method of degradable polytrimethylene terephthalate copolyester

The invention discloses a preparation method of degradable polytrimethylene terephthalate copolyester, and relates to the field of preparation of degradable copolyester. The preparation method comprises the following steps: (1) preparation of low-molecular-weight polyglycolic acid: putting glycolic acid and a catalyst into a reaction kettle, and polymerizing to obtain the low-molecular-weight polyglycolic acid; (2) preparation of esterification liquid: putting terephthalic acid and propylene glycol into a reaction kettle for esterification reaction to prepare the esterification liquid; (3) adding low-molecular-weight polyglycolic acid into the esterification liquid, then adding a composite catalyst and a stabilizer, and carrying out pre-polycondensation and final polycondensation to prepare degradable polytrimethylene terephthalate copolyester. Low-molecular-weight polyglycolic acid is prepared from glycolic acid monomers and then copolymerized, the molecular structure can be effectively controlled, and the degradation performance of polyglycolic acid is adjusted according to the proportion of the addition amount of low-molecular-weight polyglycolic acid.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Preparation method of glycolide

ActiveCN112794839AImprove conversion rateHigh selectivityOrganic chemistryMolecular sieve catalystsMolecular sieveGlycolates

The invention provides a preparation method of glycolide. According to the preparation method of the glycolide, gaseous glycolate is subjected to a cyclization reaction under the catalytic condition of a titanium-containing molecular sieve, and the product glycolide is obtained. The preparation method provided by the invention has the advantages of mild reaction conditions and high product yield, can be continuously carried out, and does not need the participation of high vacuum and high-boiling-point solvents.

Owner:CHINA CATALYST HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com