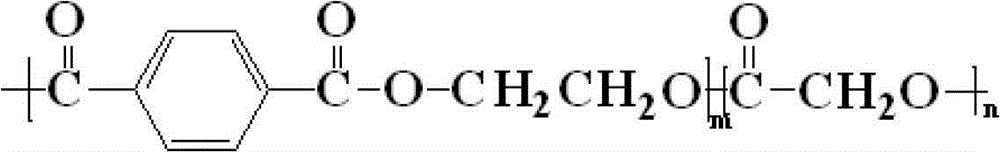

Poly(terephthalate glycol ester-CO-glycolate) copolyester and preparation method thereof

A technology of ethylene terephthalate and terephthalate is applied in the field of poly(ethylene terephthalate-CO-glycolate) copolyester and its preparation, and can solve the problem of copolyester. The performance of polyester is very different, stainless steel is corrosive, and the preparation method is complicated, so as to achieve the effect of low cost, cost reduction and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

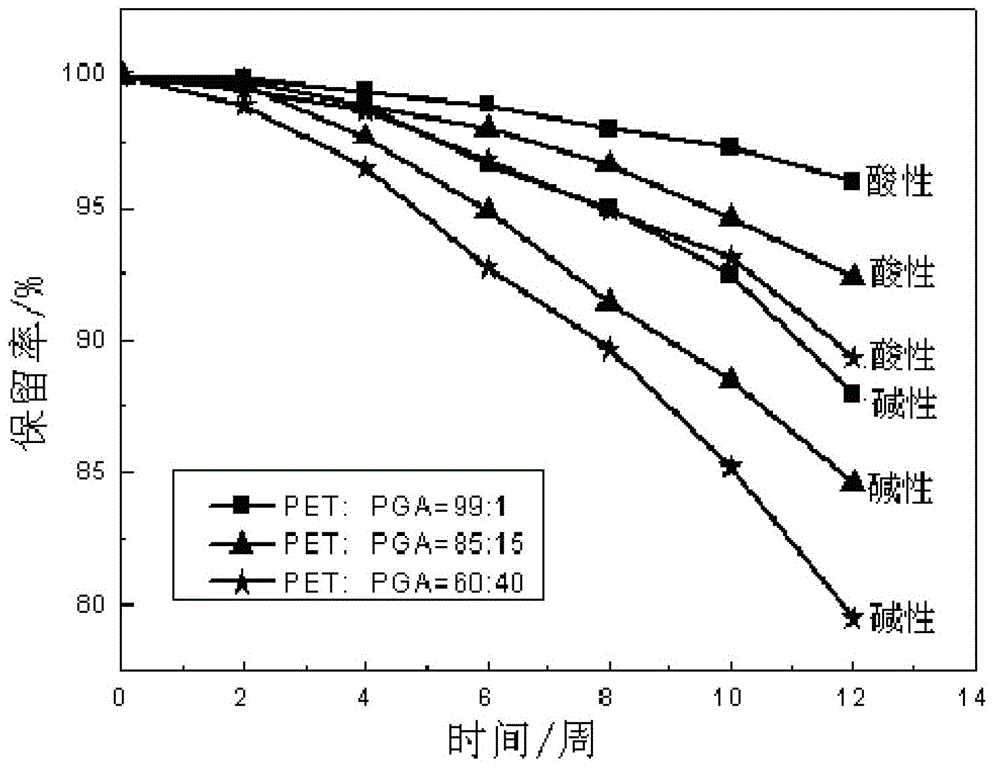

[0035] Add 0.99mol of terephthalic acid, 1.28mol of ethylene glycol, 0.045g of antimony trioxide, 0.035g of polyphosphoric acid into a batch reactor, and esterify at 230-235°C and a pressure of 0.43MPa (gauge pressure). React for 2 hours, fractionate the water, and stop the esterification when the fractionated water is greater than or equal to 95% of the theoretical water mass. The temperature of the reaction system is lowered to 200-210°C. After adding 0.01mol of polyglycolic acid ester oligomers, gradually reduce the pressure and increase the temperature. After 90 minutes, the vacuum degree of the reactor reaches 100Pa (absolute pressure), and the reaction temperature is maintained at 260- At 265°C, after 120 minutes of polymerization, when the rated stirring power is reached, the polymerization reaction is terminated, and the vacuum is replaced by nitrogen, and a poly(ethylene terephthalate-CO-glycolate) copolymer can be obtained through cold water and pelletizing. polyeste...

Embodiment 2

[0037] Add 0.95mol of terephthalic acid, 1.23mol of ethylene glycol, 0.050g of ethylene glycol antimony, and 0.040g of polyphosphoric acid into a batch reactor, and esterify at 230-235°C and a pressure of 0.43MPa (gauge pressure). React for 2 hours, fractionate the water, and stop the esterification when the fractionated water is greater than or equal to 95% of the theoretical water mass. The temperature of the reaction system is lowered to 200-210°C. After adding 0.05mol of polyglycolic acid ester oligomers, gradually reduce the pressure and increase the temperature. After 90 minutes, the vacuum degree of the reactor reaches 100Pa (absolute pressure), and the reaction temperature is maintained at 260- At 265°C, after 120 minutes of polymerization, when the rated stirring power is reached, the polymerization reaction is terminated, and the vacuum is replaced by nitrogen, and a poly(ethylene terephthalate-CO-glycolate) copolymer can be obtained through cold water and pelletizing...

Embodiment 3

[0039] Add 0.85mol of terephthalic acid, 1.1mol of ethylene glycol, 0.046g of complexed titanium, and 0.033g of polyphosphoric acid into a batch reactor, and perform esterification reaction at 230-235°C and a pressure of 0.43MPa (gauge pressure). 2h, fractionate the water, when the fractionated water is greater than or equal to 95% of the theoretical water mass, stop the esterification. The temperature of the reaction system was lowered to 200-210°C. After adding 0.15mol of polyglycolic acid ester oligomers (without catalyst), the pressure was gradually reduced and the temperature was raised. After 90 minutes, the vacuum degree of the reactor reached 100Pa (absolute pressure), and the reaction temperature Maintain at 260-265°C, end the polymerization reaction when the rated stirring power is reached after 135 minutes of polymerization, replace the vacuum with nitrogen, and get a poly(ethylene terephthalate-CO-ethanol) through cold water and cutting into pellets ester) copolyes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com