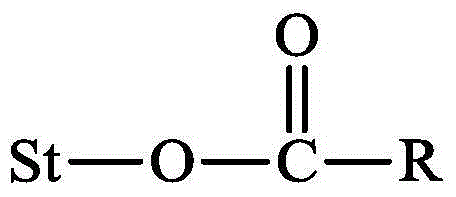

Starch-based composite and preparation method thereof

A composite material, starch-based technology, applied in the field of starch, can solve the problems that the material properties are difficult to stabilize, cannot solve the problems of strong hydrophilicity and water resistance, and achieves the effects of low cost, easy industrial production and good resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

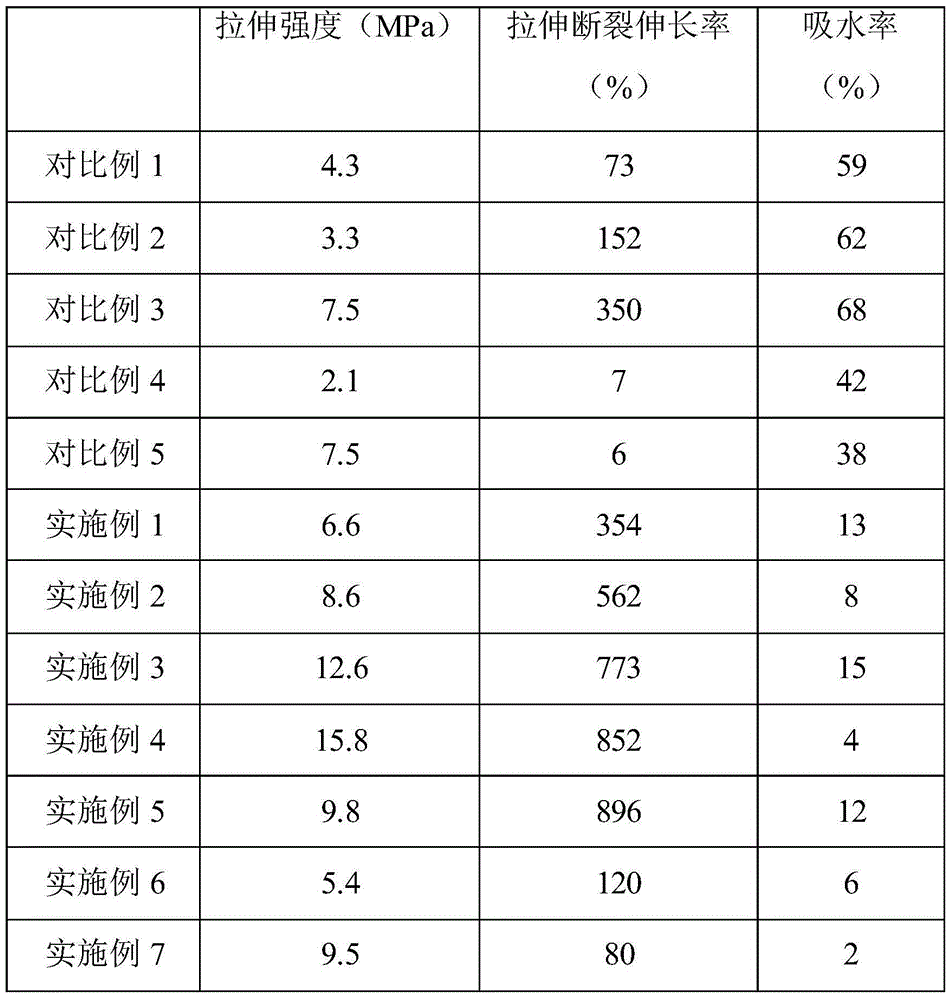

[0059] Mix 100 parts of modified starch 1 with 10 parts of polycaprolactone (PCL) (manufactured by Shenzhen Guanghua Weiye Co., Ltd.), and place the premix in a torque rheometer (RM-200 manufactured by Harper Co., Ltd.) , blending at 50 rpm for 10 min at 70°C.

[0060] The blend was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, and was cut into a standard sample according to relevant standards for mechanical performance testing. The test results were listed in Table 1. Water absorption, the test results are listed in Table 1.

Embodiment 2

[0062] Mix 100 parts of modified starch 2 with 10 parts of polycaprolactone (PCL) (manufactured by Shenzhen Guanghua Weiye Co., Ltd.), and place the premix in a torque rheometer (RM-200 manufactured by Harper Co., Ltd.) , blending at 50 rpm for 10 min at 70°C.

[0063] The blend was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, and was cut into a standard sample according to relevant standards for mechanical performance testing. The test results were listed in Table 1. Water absorption, the test results are listed in Table 1.

Embodiment 3

[0065] Mix 100 parts of modified starch 3 with 30 parts of polybutylene adipate / terephthalate (PBAT) (produced by Shenzhen Guanghua Weiye Co., Ltd.), and place the premix in a torque rheometer (Haber Co., Ltd. In the RM-200 type prepared by the company), blending at 50 rpm for 10 minutes at 70°C.

[0066] The blend was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, and was cut into a standard sample according to relevant standards for mechanical performance testing. The test results were listed in Table 1. Water absorption, the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com