Heat-resistant polylactic acid composition and preparation method thereof

A technology of composition and polylactic acid, which is applied in the field of heat-resistant polylactic acid composition and its preparation, can solve the problems of poor performance and poor compatibility of the blend, and achieve good heat distortion temperature, low cost and high biomass content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

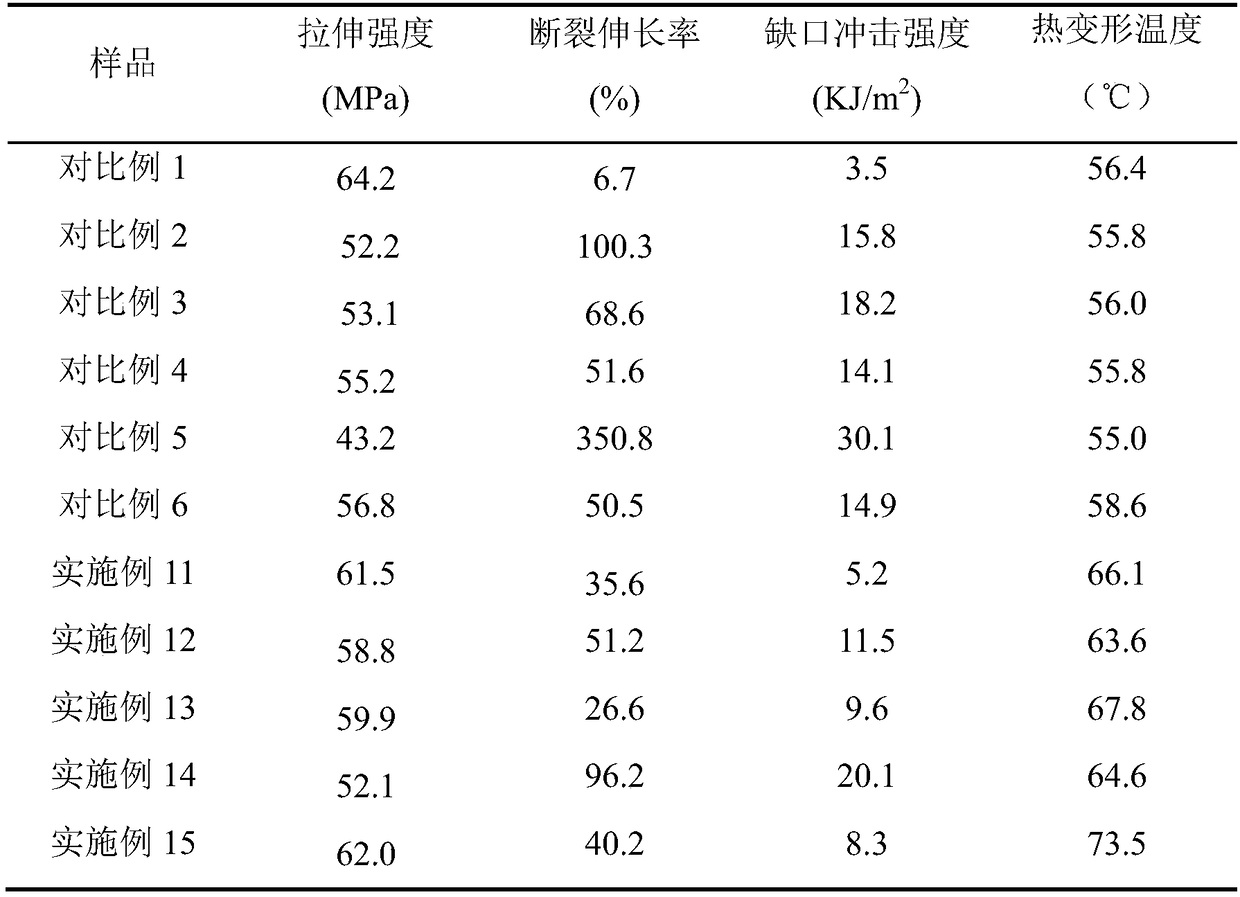

Examples

Embodiment 1

[0027] (1) Synthesis of modified starch: Weigh 100g of starch dried at 80°C for 24 hours and put it in a four-neck flask, and add a certain amount of ethyl acetate and a small amount of pyridine into the flask, stir vigorously for a period of time, and then add it dropwise to the flask Acryloyl chloride 3g, the reaction process does not need heating. After fully reacting, the modified starch is obtained by washing with absolute ethanol, centrifuging and drying.

[0028] (2) Preparation of starch graft copolymer: dry the prepared modified starch in a vacuum oven at 60°C for 24 hours, weigh a certain amount of starch and add it to a 500ml four-necked flask, and then take a certain amount of deionized Add water to the four-necked bottle, add ethyl acrylate, stir at high speed for pre-emulsification for a period of time, and then start to add potassium persulfate dropwise. After the reaction, the product was cooled to obtain a starch graft copolymer 1 emulsion. The mass ratio of...

Embodiment 2

[0030] (1) Synthesis of modified starch: Weigh 100g of starch dried at 80°C for 24 hours and place it in a four-necked flask, and add a certain amount of deionized water to the flask, adjust the pH to 8-9, and pour the starch into the flask after stirring for a period of time. 10g KH570 was added dropwise in the middle, the reaction temperature was 60°C, and the time was 6h. After fully reacting, the modified starch is obtained by washing with absolute ethanol, centrifuging and drying.

[0031] (2) Preparation of starch graft copolymer: dry the prepared modified starch in a vacuum oven at 60°C for 24 hours, weigh a certain amount of starch and add it to a 500ml four-necked flask, and then take a certain amount of deionized Add water to the four-necked bottle, add methyl acrylate, stir at high speed to pre-emulsify for a period of time, and then start to add potassium persulfate dropwise. After the reaction, the product was cooled to obtain the starch graft copolymer 2 emulsio...

Embodiment 3

[0033] (1) Synthesis of modified starch: Weigh 100g of starch dried at 80°C for 24 hours and place it in a four-necked flask, and add a certain amount of deionized water to the flask, adjust the pH to 8-9, stir for a period of time, and pour the starch into the flask Add 6g of GMA dropwise in the medium, the reaction temperature is 60°C, and the time is 6h. After fully reacting, the modified starch is obtained by washing with absolute ethanol, centrifuging and drying.

[0034] (2) Preparation of starch graft copolymer: dry the prepared esterified starch in a vacuum oven at 60°C for 24 hours, weigh a certain amount of starch and add it to a 500ml four-necked flask, and then take a certain amount of deionized Add water to the four-necked bottle, add butyl acrylate and methyl acrylate, stir at high speed for pre-emulsification for a period of time, and then start to add potassium persulfate dropwise. After the reaction, the product was cooled to obtain the starch graft copolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com