Hyperbranched polyester modified itaconic acid-based water-based photocurable resin and preparation method thereof

An itaconic acid-based water-based, hyperbranched polyester technology, applied in polyester coatings, coatings, etc., can solve the problems of decreased flexibility, loss of green environmental protection of light-curing coatings, poor resin flexibility and poor light-curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

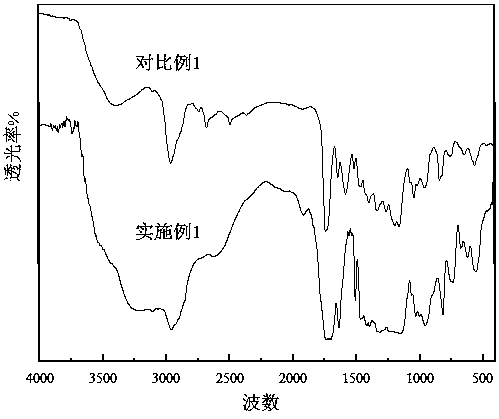

Image

Examples

preparation example Construction

[0061] The preparation method reference example 1 of the second generation molecule of type polyester polyol

[0062] Mix 6.8g of pentaerythritol (0.05mol), 82.1g of dimethylolpropionic acid (98% by mass, 0.6mol) and 0.4g of p-toluenesulfonic acid in a three-necked flask, under nitrogen protection, at 130°C , after heating and reacting for 1 hour, at 130°C and a vacuum of 0.03MPa, heat-preserve and reduce pressure to react until no more water comes out and stop the reaction. Add 200g of n-hexane to the obtained product for precipitation, washing and purification for 3 times, and at 80°C and a vacuum of 0.06MPa Under vacuum drying for 1 hour, the second-generation molecule of Boltorn type polyester polyol was obtained.

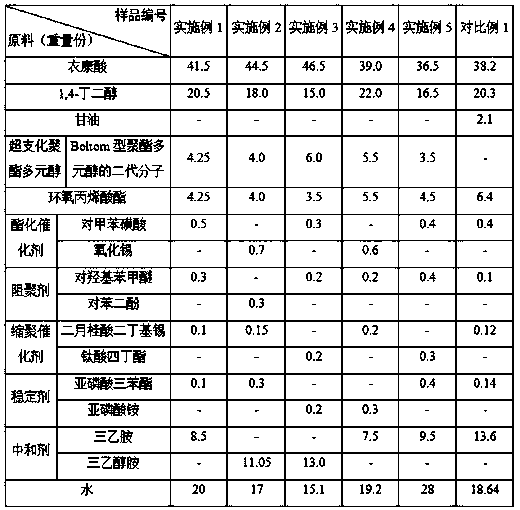

[0063] Hyperbranched polyester modified itaconic acid-based water-based photocurable resin Examples 1-5 and comparative example 1 itaconic acid-based water-based UV resin

[0064] The parts by weight of each raw material are as shown in Table 1:

[0065] Tabl...

Embodiment 1

[0070] (1) According to the raw materials and dosage of Example 1 in Table 1, put itaconic acid, 1,4-butanediol, hyperbranched polyester polyol, epoxy acrylate, esterification catalyst and polymerization inhibitor in a three-necked bottle Mixing, under the protection of nitrogen, at 130 ° C, after heating reaction for 1 hour, at 130 ° C, 0.02 MPa vacuum degree, heat preservation and decompression reaction until no water comes out and stop the reaction, after cooling to room temperature, the precondensed polymer is obtained;

[0071] (2) Add a polycondensation catalyst and a stabilizer to the precondensed polymer obtained in step (1), and conduct a reaction under reduced pressure and heating for 4 hours at 140°C and a vacuum of 0.09MPa. After cooling down to 80°C, add a neutralizer to adjust the pH value to 7.0, and finally add water to adjust the solid content to 80% to obtain a hyperbranched polyester modified itaconic acid-based water-based photocurable resin.

[0072] Such ...

Embodiment 2

[0074] (1) According to the raw materials and dosage of Example 2 in Table 1, put itaconic acid, 1,4-butanediol, hyperbranched polyester polyol, epoxy acrylate, esterification catalyst and polymerization inhibitor in a three-necked bottle Mix, under the protection of nitrogen, at 120°C, conduct heating reaction for 1.5h, then at 120°C, 0.03MPa vacuum degree, heat preservation and decompression reaction until no water comes out and stop the reaction, after cooling down to room temperature, the precondensed polymer is obtained ;

[0075](2) Add a polycondensation catalyst and a stabilizer to the precondensed polymer obtained in step (1), and conduct a reaction under reduced pressure and heating for 3.5 hours at 150°C and a vacuum of 0.08MPa. After cooling down to 75°C, add a neutralizer to adjust The pH value was adjusted to 7.5, and finally water was added to adjust the solid content to 83% to obtain a hyperbranched polyester-modified itaconic acid-based water-based photocurabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com