Patents

Literature

686results about How to "High opacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biaxially stretchable outer cover for an absorbent article

ActiveUS20070287348A1Improve versatilityImprove fitPersonal careSynthetic resin layered productsFiberElastic component

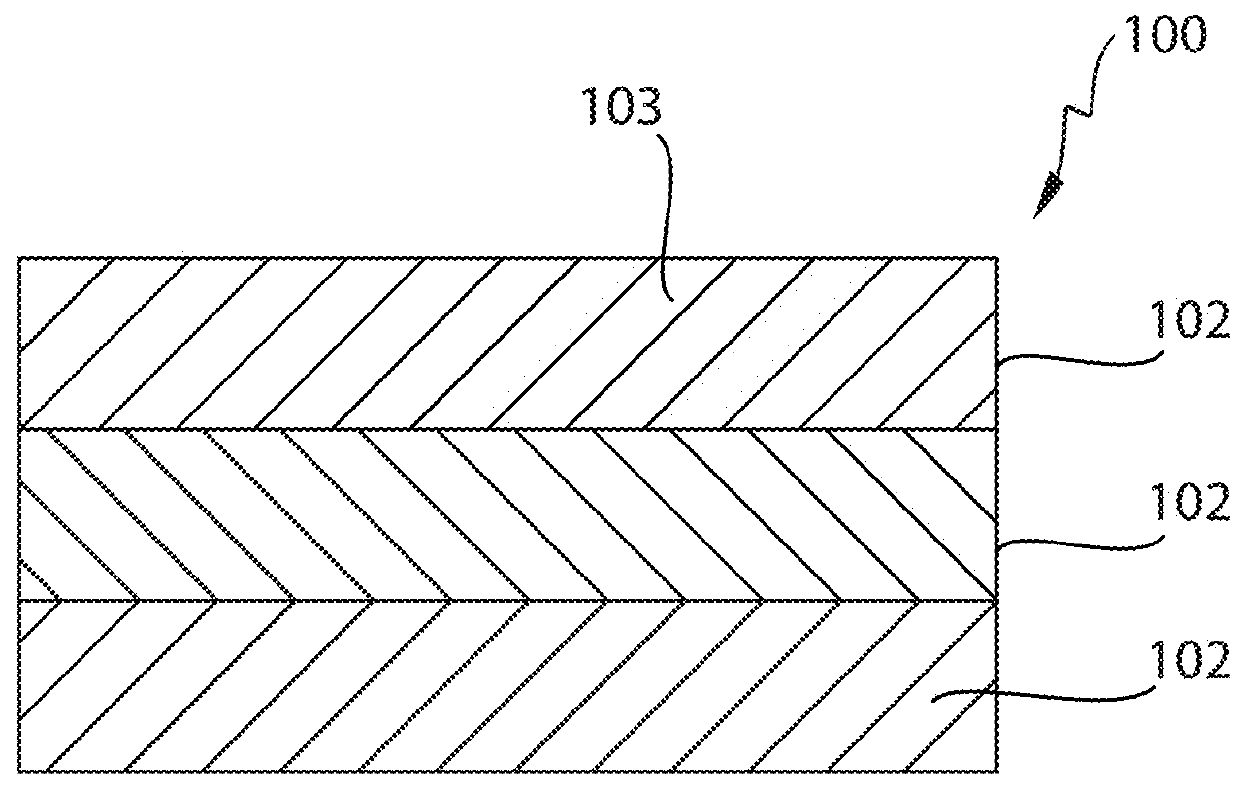

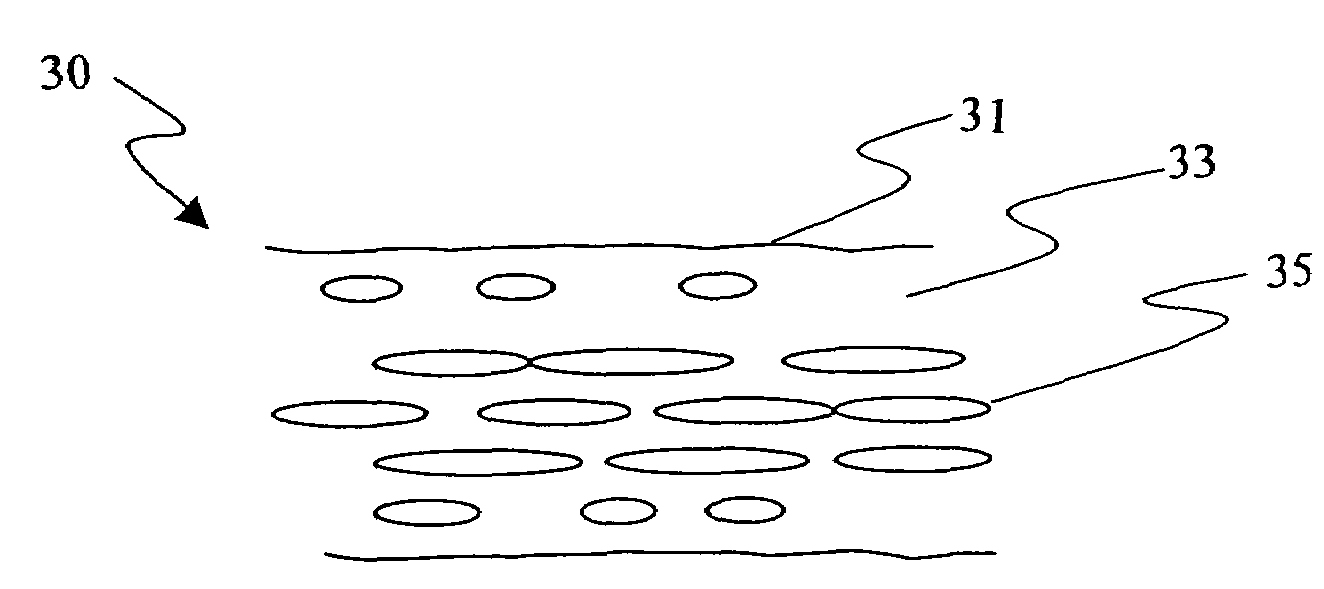

An outer cover for use with an absorbent article having a layer of nonwoven fibrous material and optionally including a polymeric layer laminated or printed onto the layer of nonwoven fibrous material. The outer cover includes at least one plastic component and at least one elastic component in the nonwoven fibrous material and / or optional polymeric layer. The outer cover can have different structural combinations of spunbond fibers, meltblown fibers, and / or nanofibers. The combination of plastic and elastic components results in an outer cover that has favorable mechanical, physical, and aesthetic properties. The outer cover can be rendered either uniaxially or biaxially stretchable via a mechanical activation process.

Owner:THE PROCTER & GAMBLE COMPANY

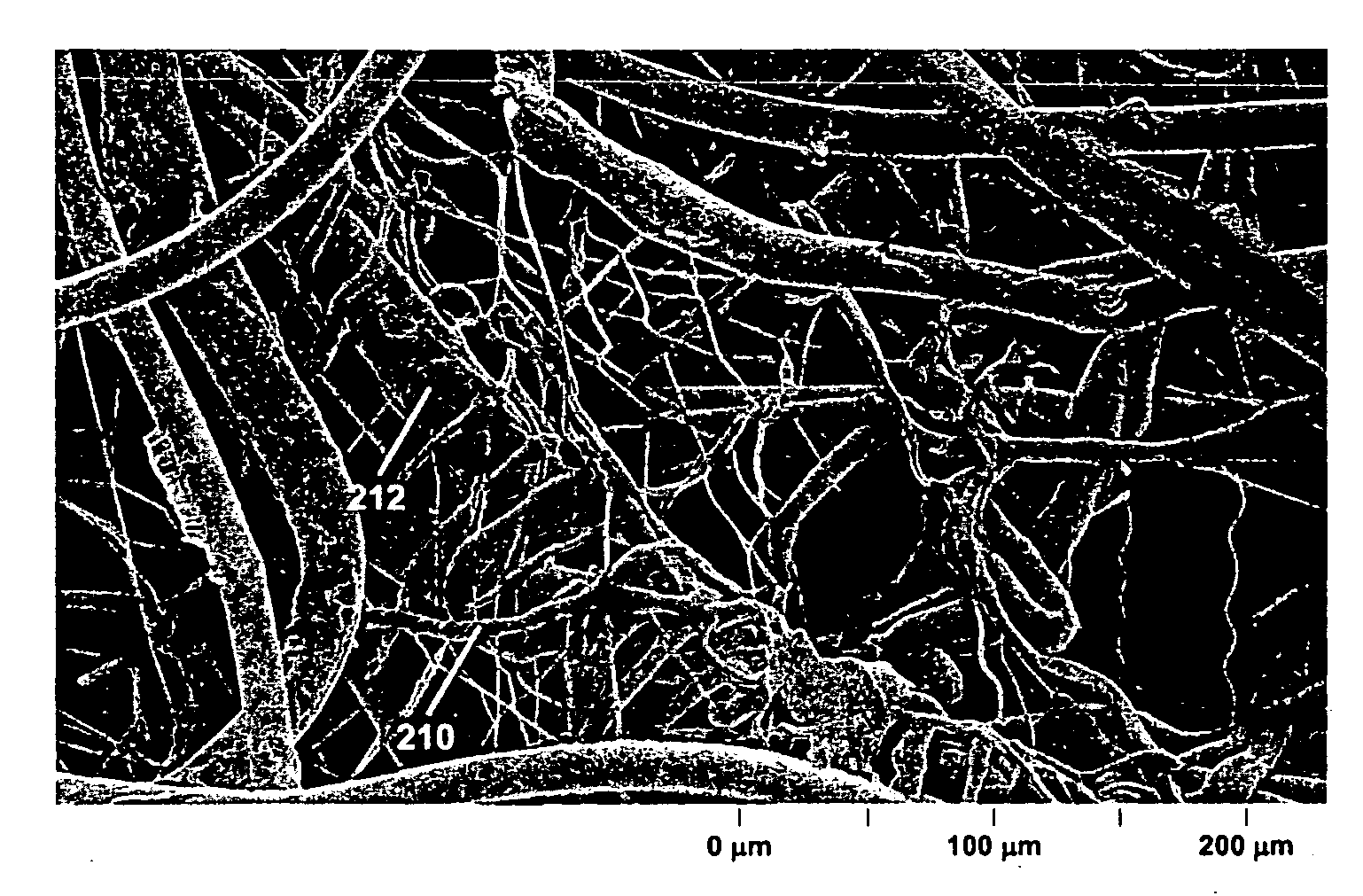

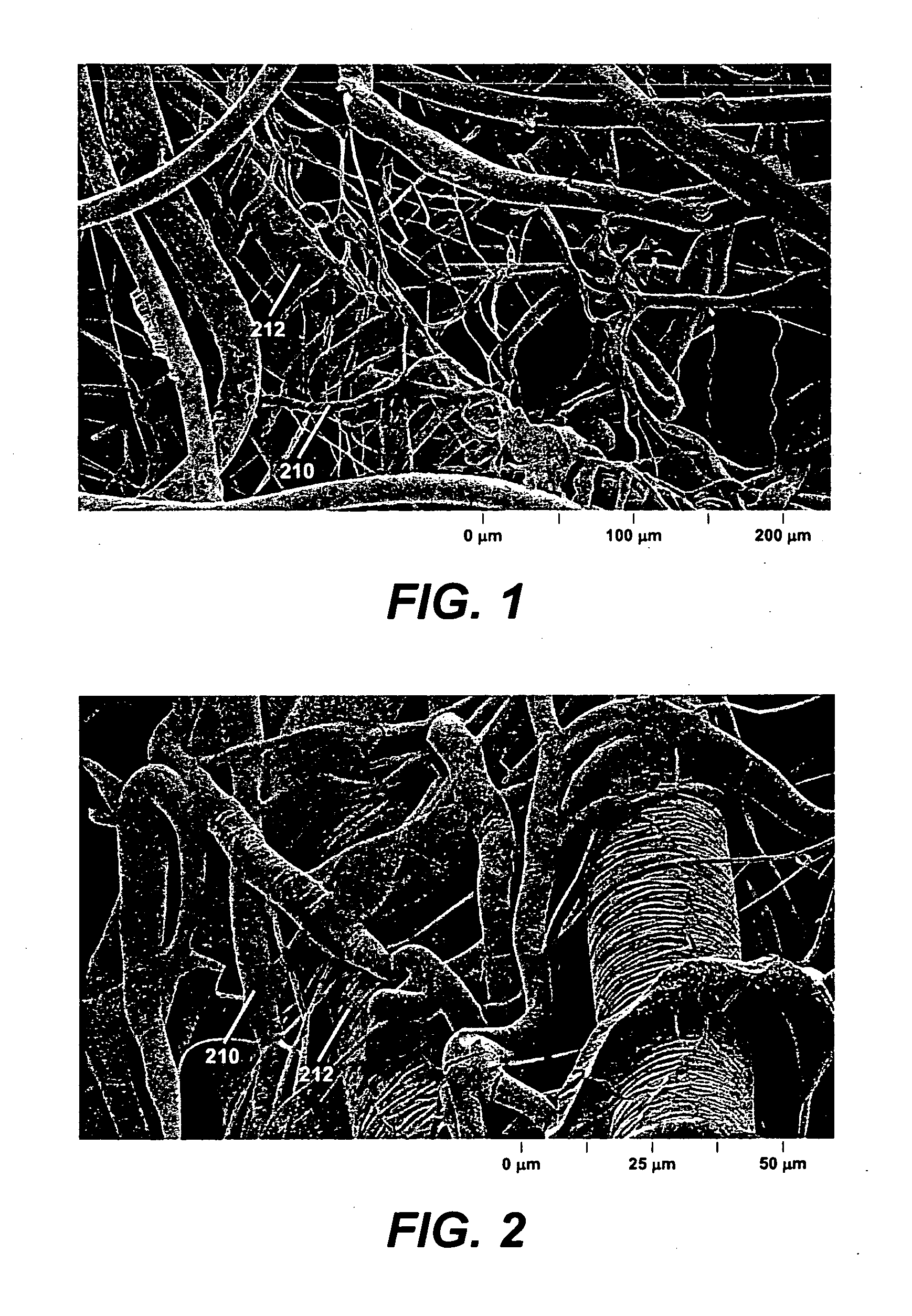

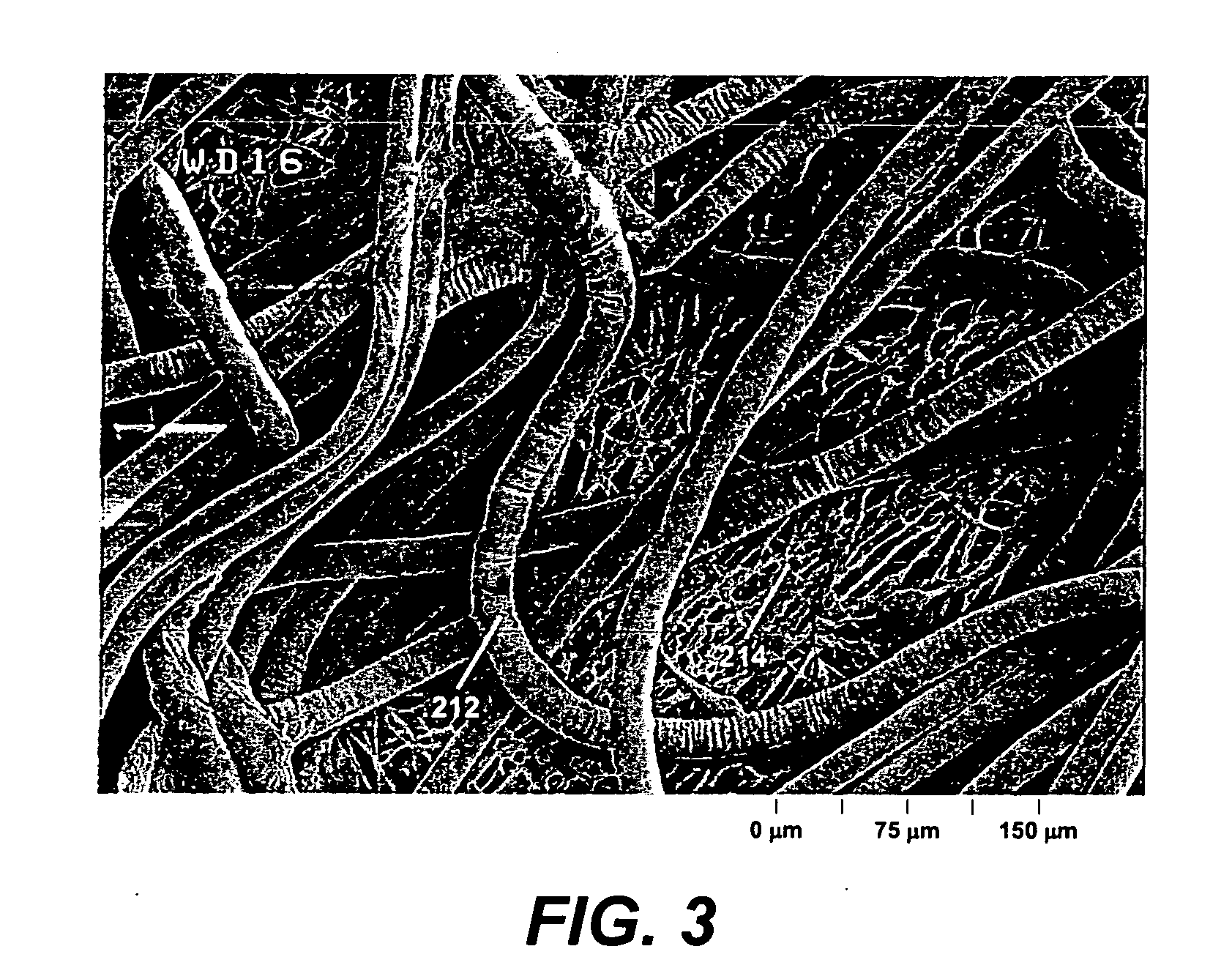

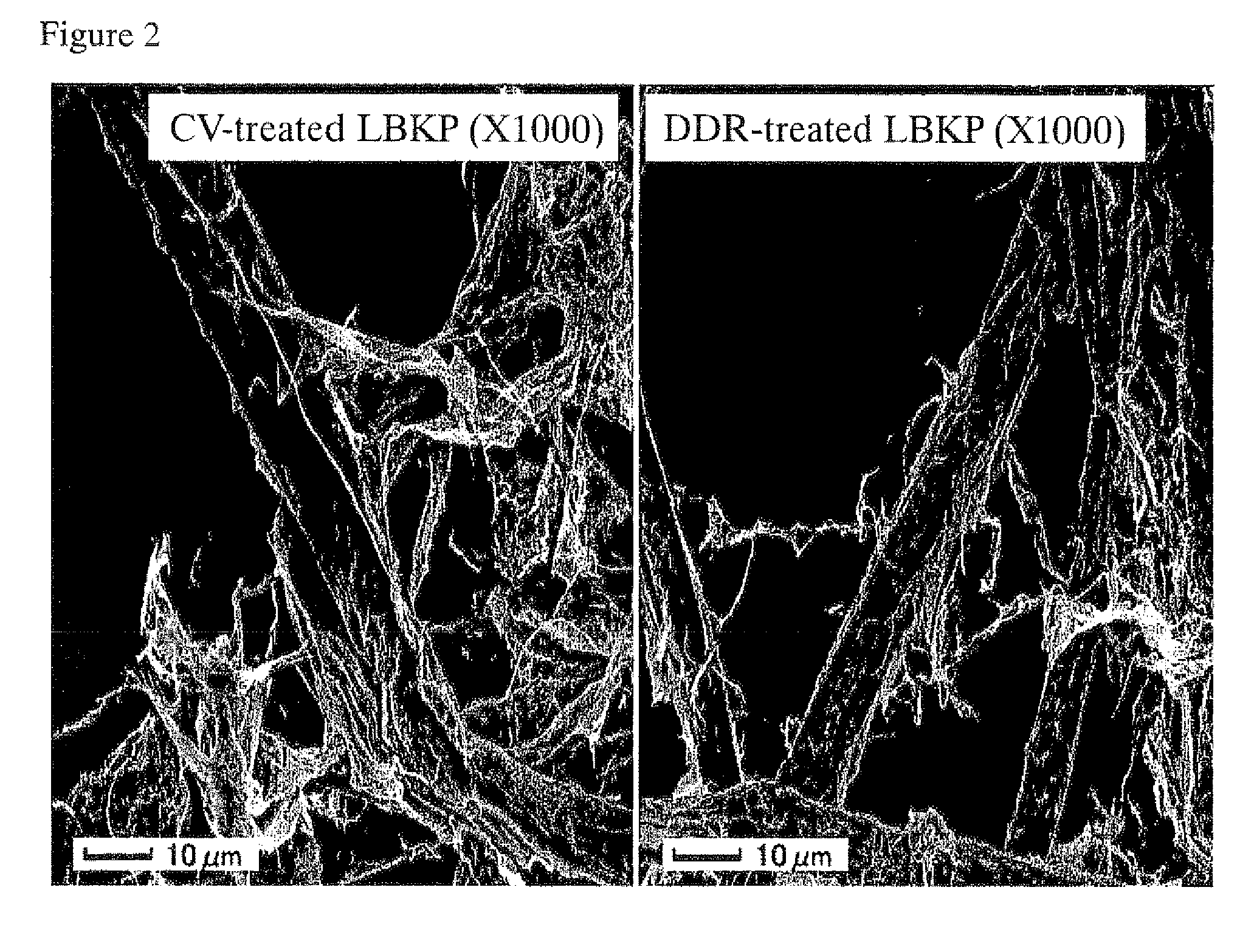

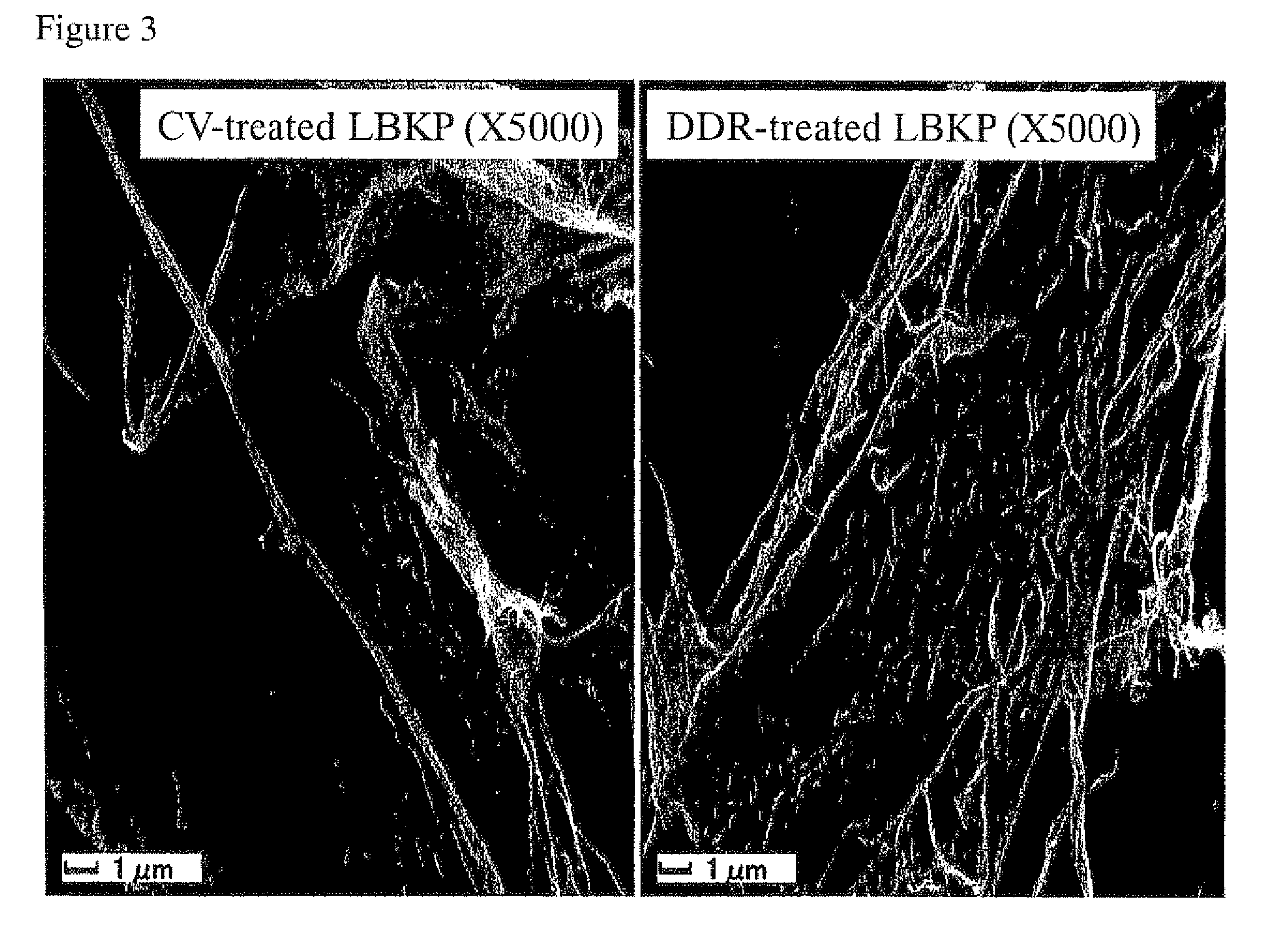

Cellulose-based fibrous materials

InactiveUS8012312B2Low densityImprove surface qualityCellulosic pulp after-treatmentCalendersFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

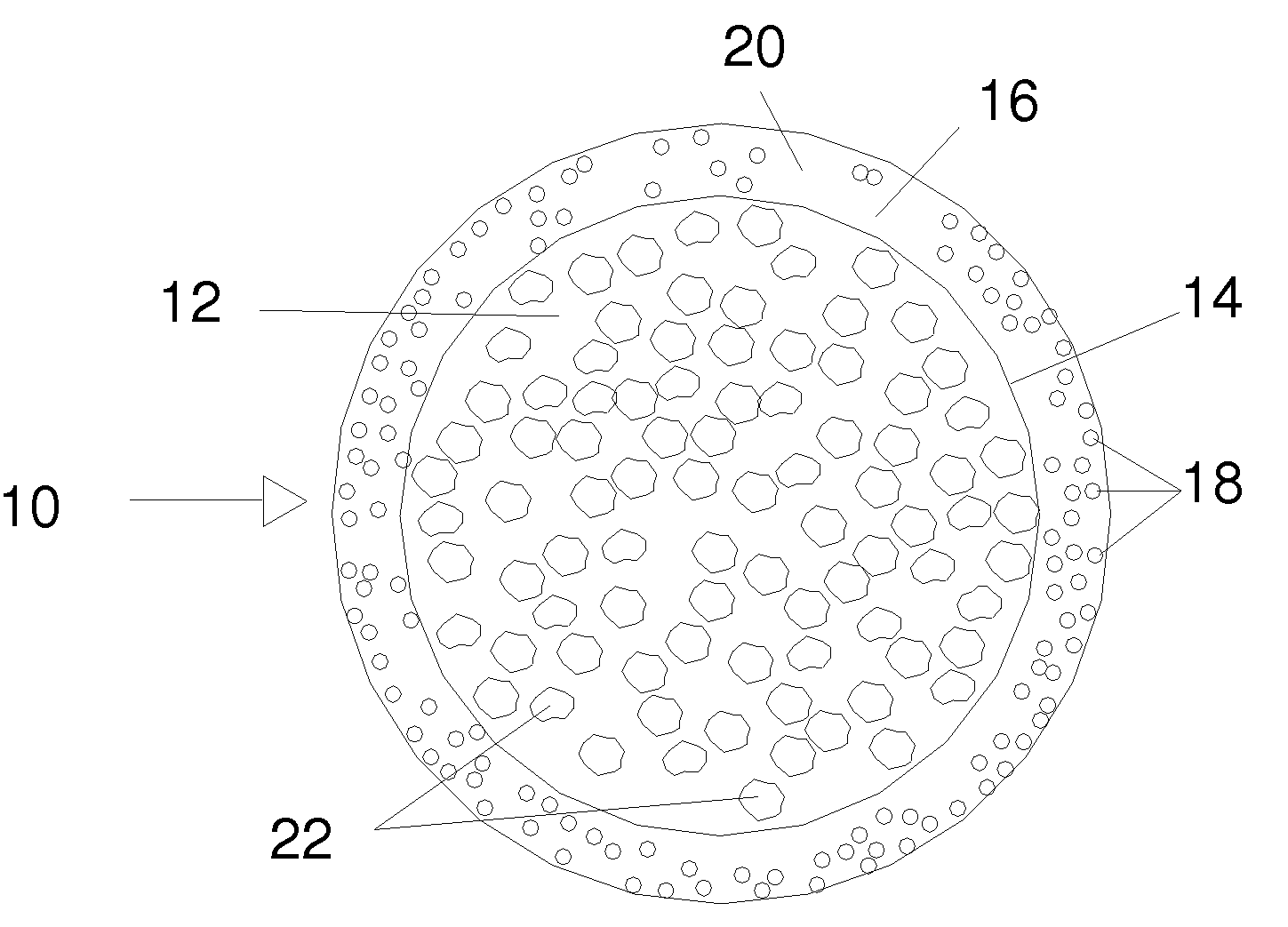

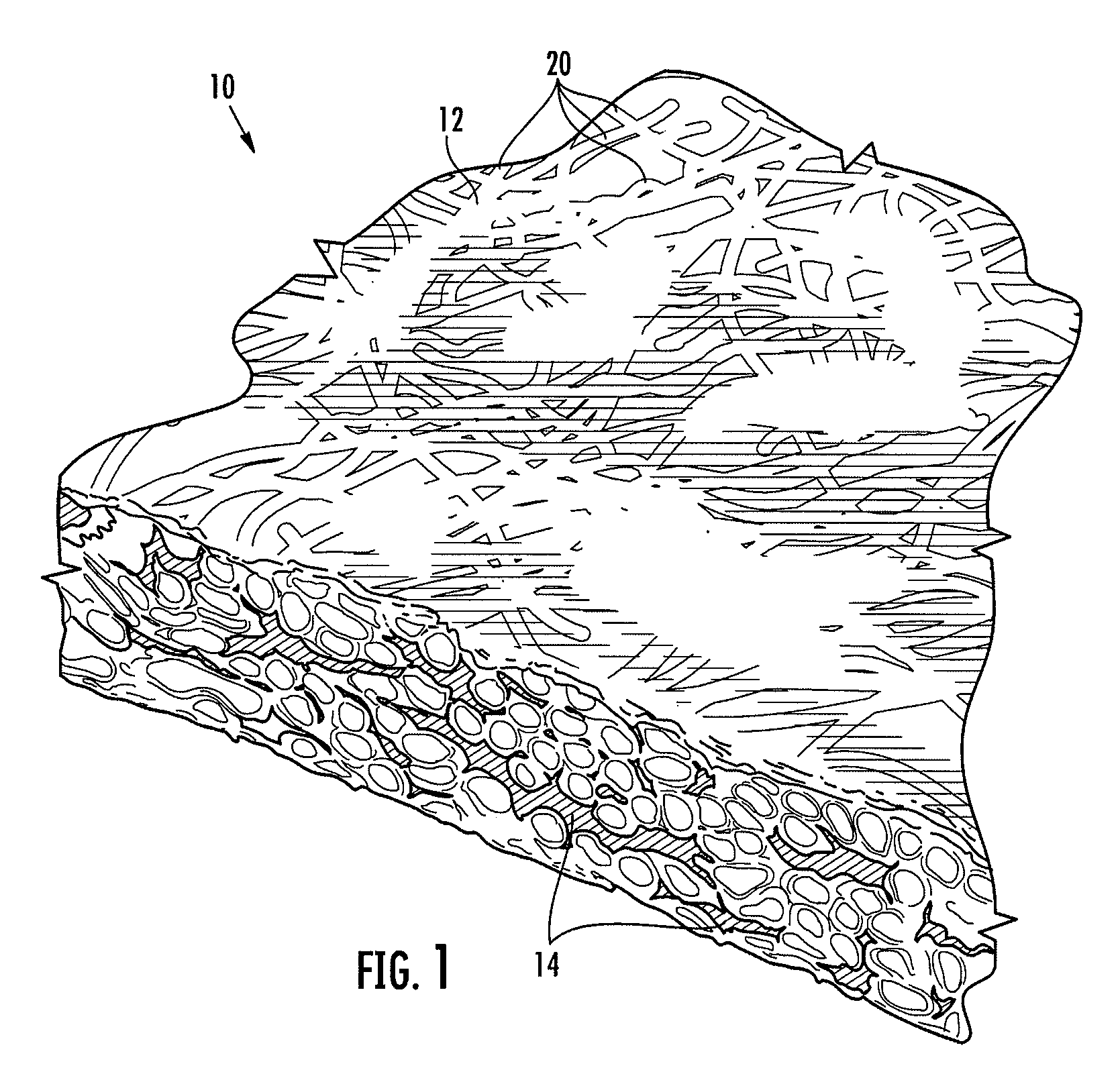

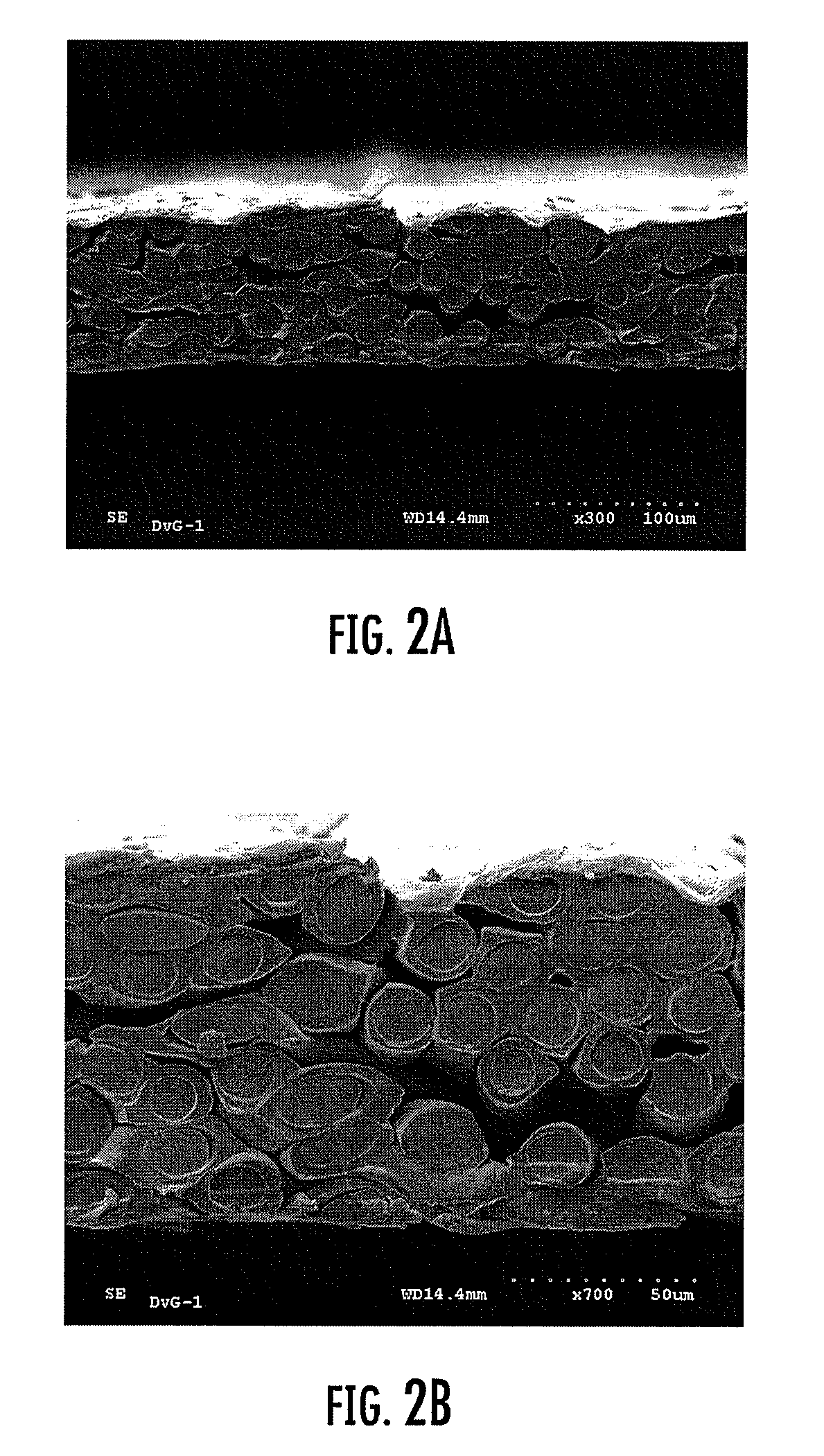

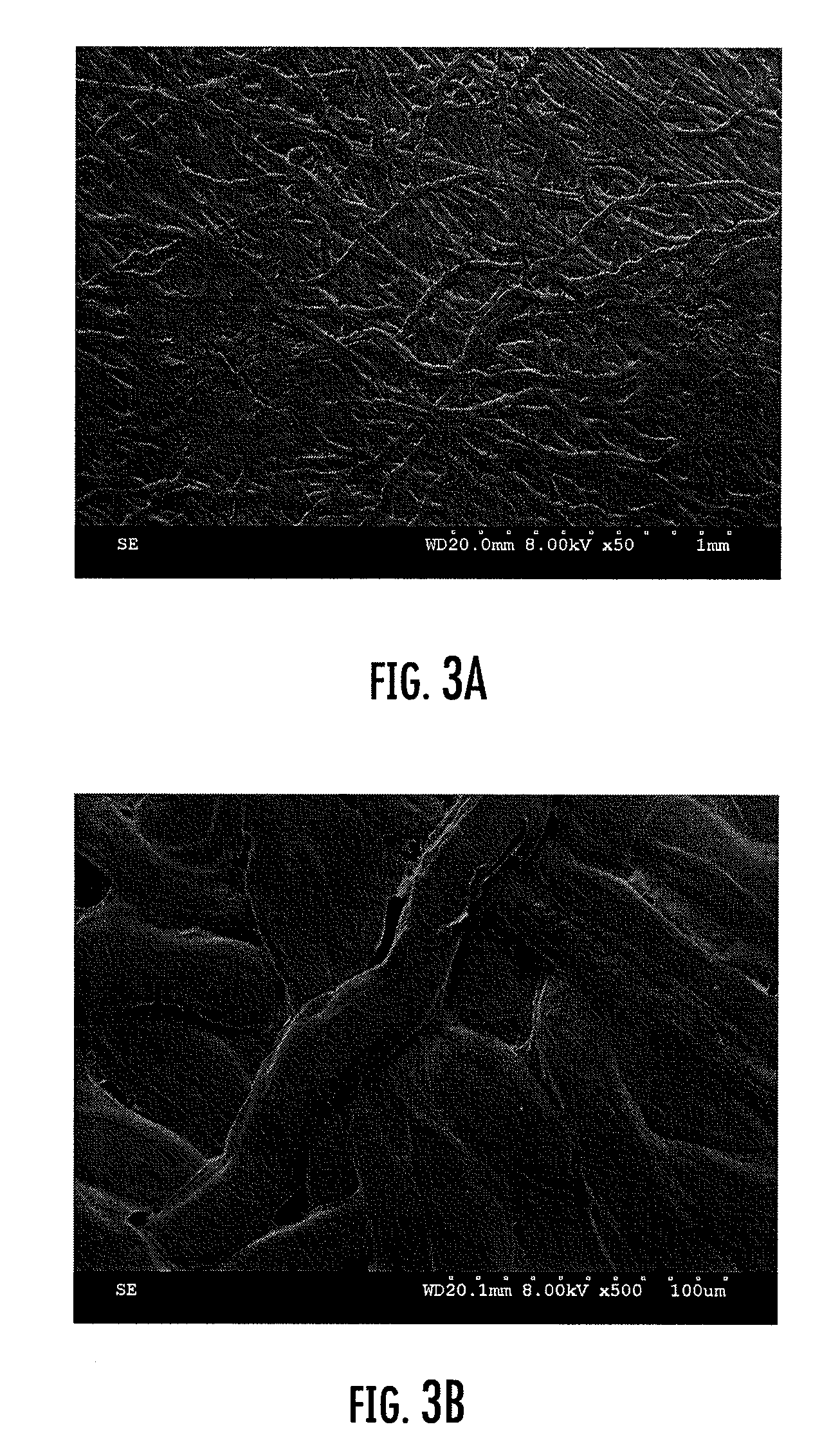

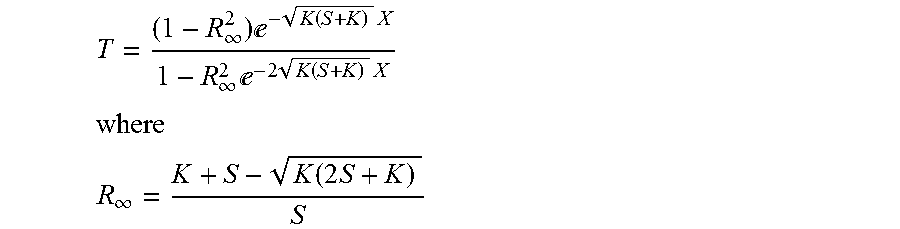

Roofing granules with high solar reflectance, roofing materials with high solar reflectance, and the process of making the same

ActiveUS20100151199A1Uniform applicationHigh opacityLiquid surface applicatorsRoof improvementNear infrared reflectanceTransmittance

Roofing granules include a core having an average ultraviolet transmission of greater than sixty percent and an average near infrared reflectance of greater than sixty percent and a UV coating layer on the exterior surface. The coating provides UV opacity, while the core provides near infrared reflectance.

Owner:CERTAINTEED CORP

Polymer-pigment composites

InactiveUS6214467B1Good viscosity stabilityEnhanced resistance to flocculation during preparationSynthetic resin layered productsCellulosic plastic layered productsOligomerPigment

Owner:ROHM & HAAS CO

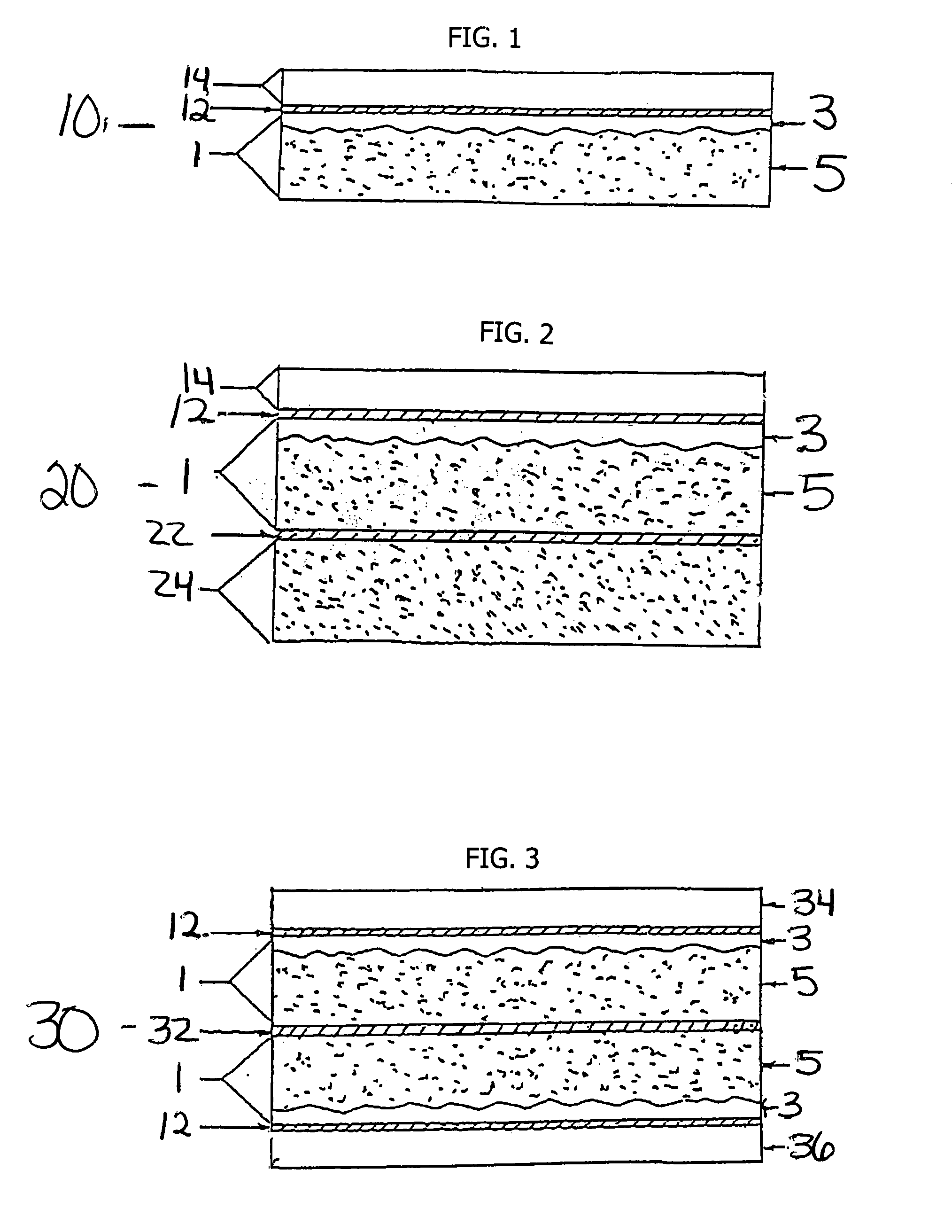

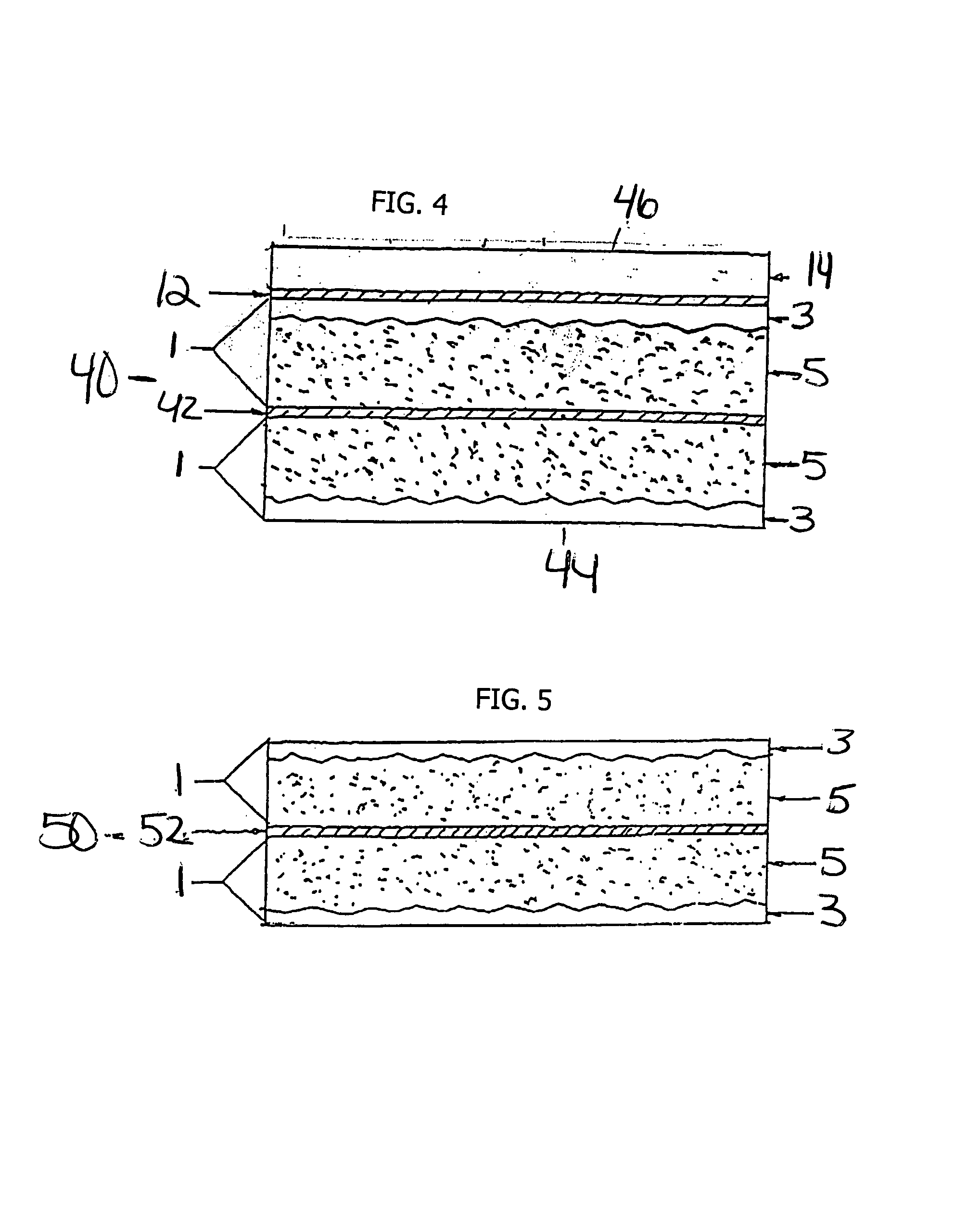

Bicomponent sheet material having liquid barrier properties

ActiveUS20070054579A1Improve breathabilityMaintain good propertiesGarment special featuresSynthetic resin layered productsPolymer scienceNonwoven fabric

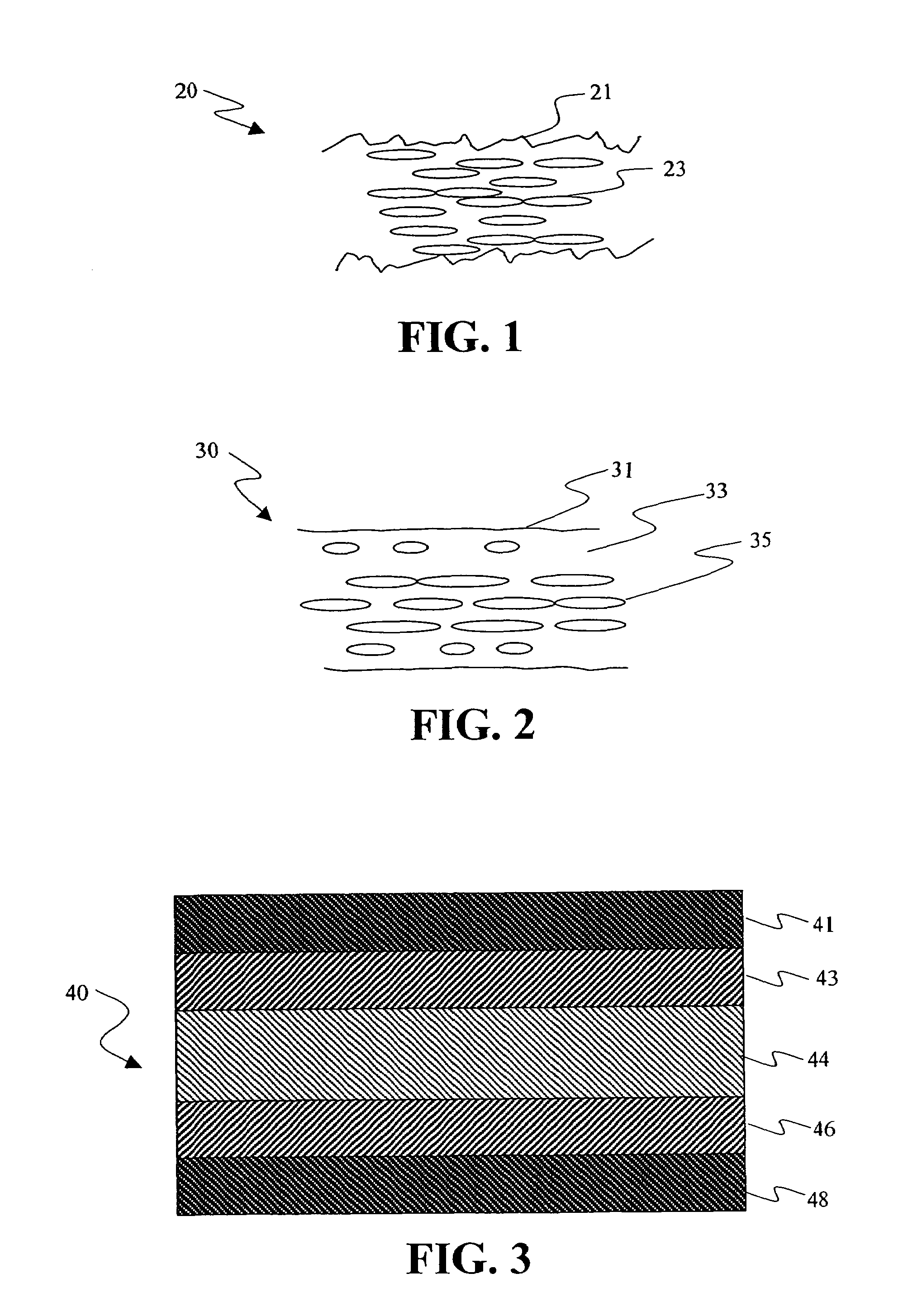

The invention provides a sheet material comprising bicomponent filaments having first and second polymer components that are arranged in substantially distinct zones within the filaments, with the first polymer component formed of a relatively lower melting polymer and the second component formed of a relatively higher melting polymer. The filaments of the nonwoven fabric layer are densely arranged and compacted against one another to form smooth, substantially nonporous opposite outer surfaces, and the nonwoven fabric layer are calendered such that the lower melting sheath polymer is fused to the contacting surface portions of adjacent filaments to impart strength and coherency to the nonwoven fabric layer. The sheet material has excellent breathability and liquid barrier properties and may be useful in house wrap, medical garments, and envelope applications.

Owner:FIBERWEB LLC

Compositions for the preparation of void-containing articles

ActiveUS7273894B2Efficiently formedEfficient voidingSynthetic resin layered productsFoundry mouldsPolyesterCellulose

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

Light blocking articles having opacifying layers

ActiveUS20150234098A1Increased durabilityIncrease flexibilityDiffusing elementsSynthetic resin layered productsClear LayerVitrification

A light-blocking article is designed to be lightweight but effective to block most incident actinic radiation and can be designed into fabrics, curtains, and other materials. Such an article has an opacifying layer that is capable of blocking predetermined electromagnetic radiation. The article contains (a) porous particles comprising a continuous polymeric binder and pores within the continuous polymeric binder, the porous particles having a glass transition temperature of at least 25° C. and a mode particle size of at least 2 μm and up to and including 50 μm. The article also contains an opacifying colorant that absorbs the predetermined electromagnetic radiation (such as within 400 nm to 700 nm), in an amount of at least 0.001 weight % based on the total dry weight of the opacifying layer, and a matrix polymer in which the porous particles and opacifying colorant are dispersed.

Owner:EASTMAN KODAK CO

Compositions for the preparation of void-containing articles

InactiveUS20070004813A1Improve performanceEfficient voidingLayered productsFoundry mouldsPolyesterCellulose

Disclosed are novel compositions for the preparation of void-containing articles comprising a polymer matrix and a voiding agent The voiding agent comprises at least one first polymer and at least one second polymer, which are selected on the basis of physical properties such as glass transition temperature, tensile modulus, melting point, surface tension, and melt viscosity. Shaped articles such as sheet, film, bottles, tubes, labels, and sleeves may prepared from these compositions. Also disclosed are polyester shrink films prepared using a voiding agent comprising a novel blend of cellulosic and olefinic polymers. The resulting shrink films have better opacity, lower density, reduced shrink force, and improved printability as compared with most standard voiding agents. The films are useful for sleeve label and other shrink film applications and their lower density allows them to be readily separated from soft drink bottles, food containers and the like during recycling operations.

Owner:EASTMAN CHEM CO

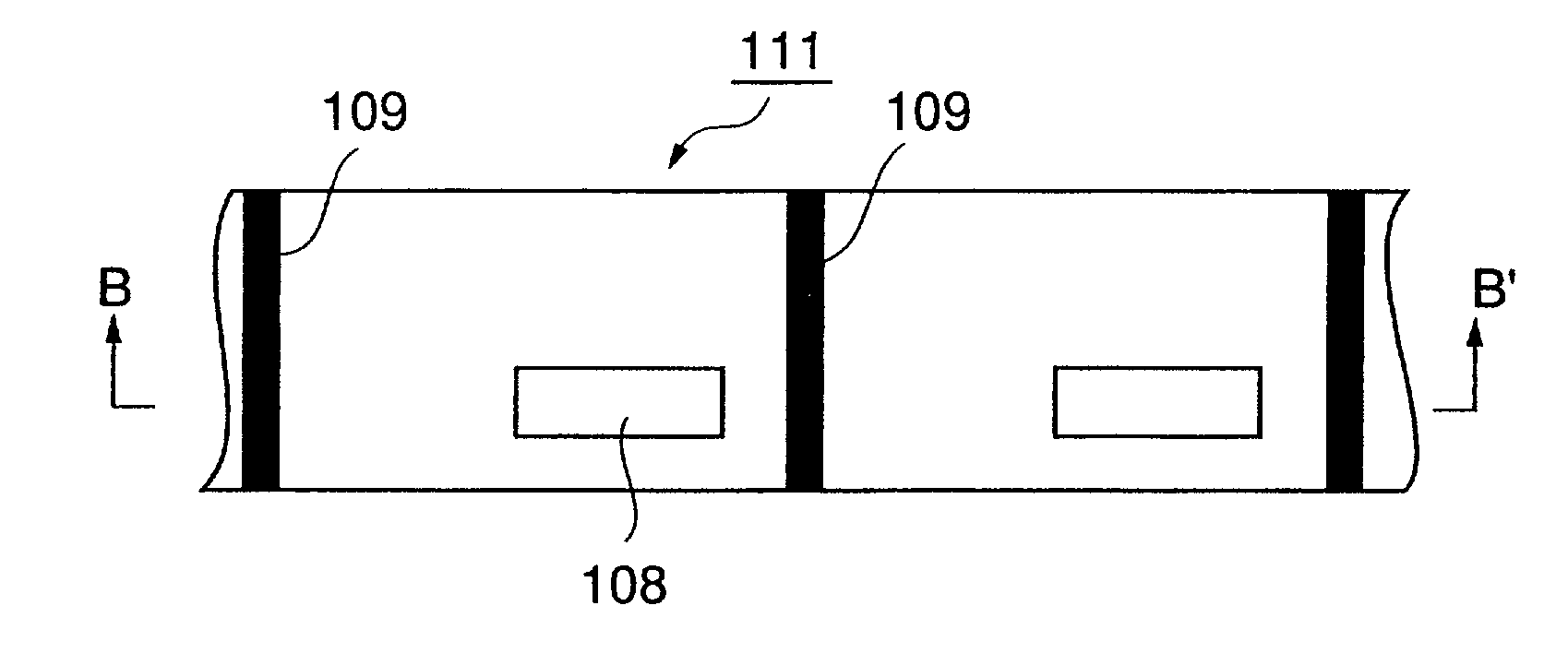

Crimped fiber spunbond nonwoven webs / laminates

An article includes a chassis having a topsheet, backsheet and an absorbent core disposed between the topsheet and backsheet; and an ear joined to the chassis. The ear includes a ring-rolled laminate having a first nonwoven web and an elastomeric film; wherein the first nonwoven web has a crimped spunbond fiber nonwoven web.

Owner:THE PROCTER & GAMBLE COMPANY

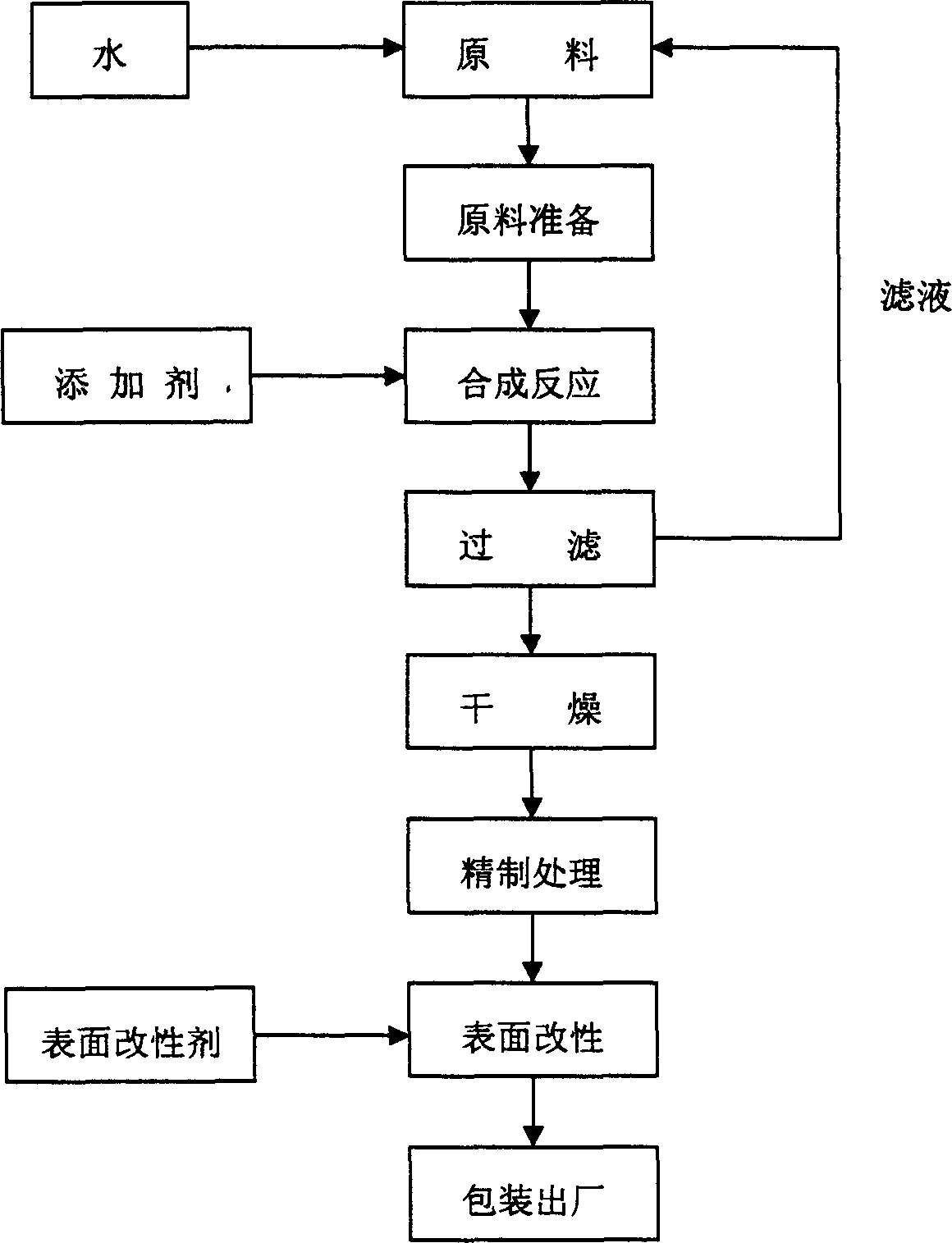

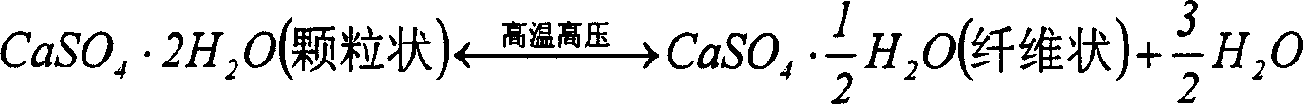

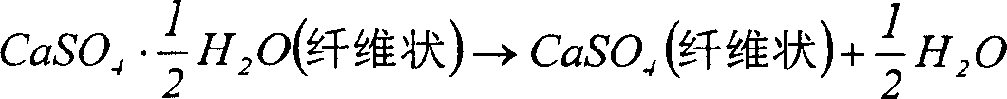

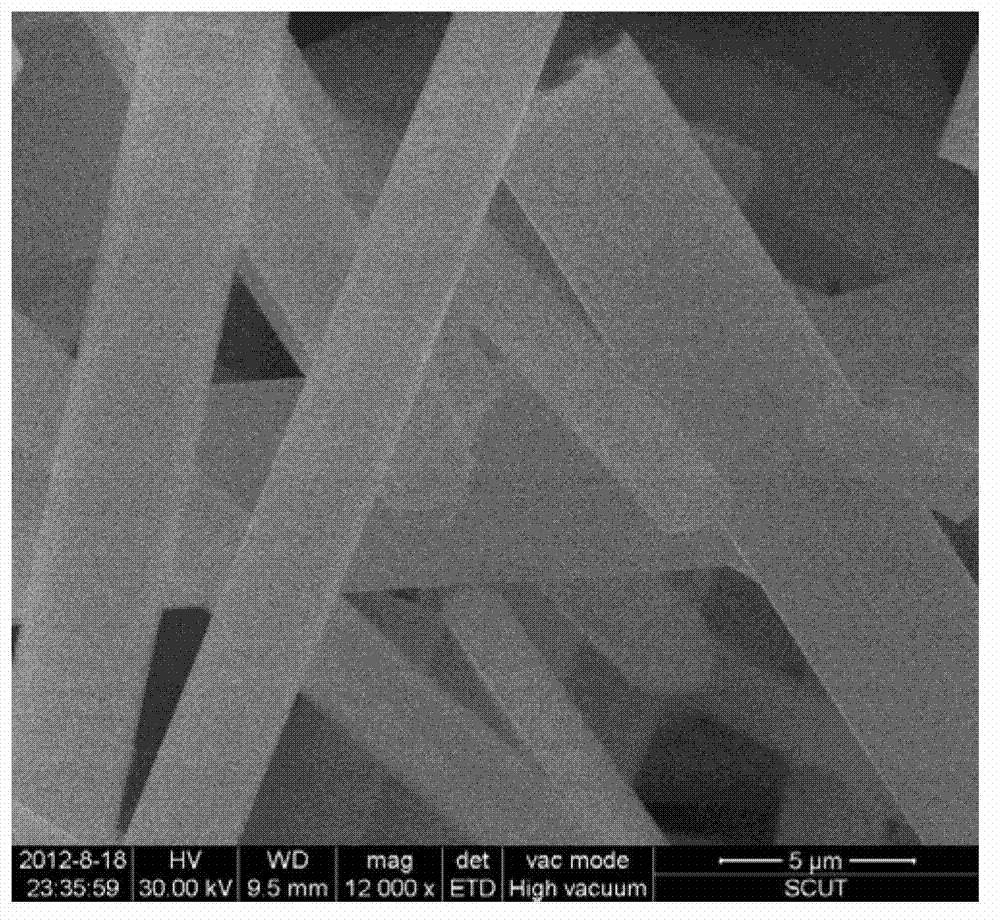

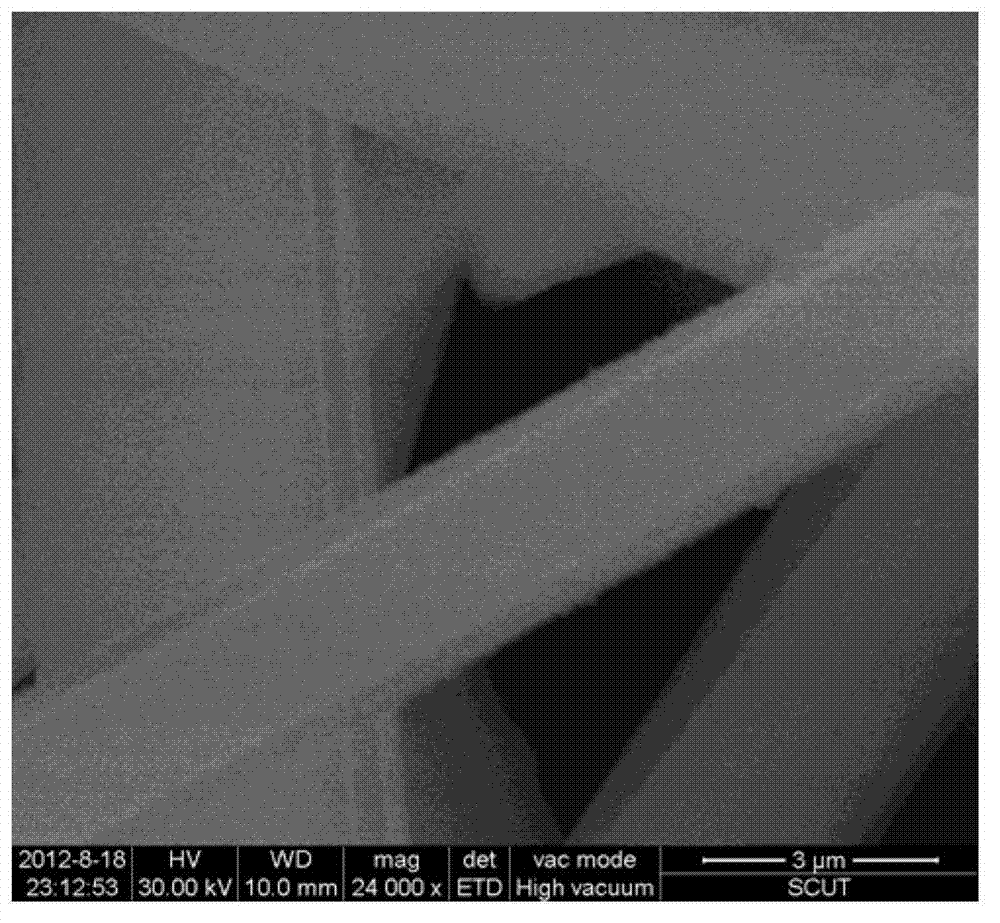

Process for preparing calcium sulfate whisker

InactiveCN1598083AControl lengthIncrease production capacityPolycrystalline material growthCalcium/strontium/barium sulfatesChemical reactionSulfate

This invention is a preparation method of calcium sulfate crystal whisker. The material is plaster stone (CaSO4.2H2O) and water in the entire production. After raw material preparation, building up reactions, dehydrate, refine and edulcoration. Its characteristic is that the active content of plaster stone up to above 95%, the whiteness is above 90%. Mixed with water and turn into plaster stone slime, then put them into reactor to make them have chemical reaction, then on the other procedures. The calcium sulfate crystal whisker made by this method has good performance, low cost, and can be used in all kinds of industries.

Owner:NORTHEASTERN UNIV

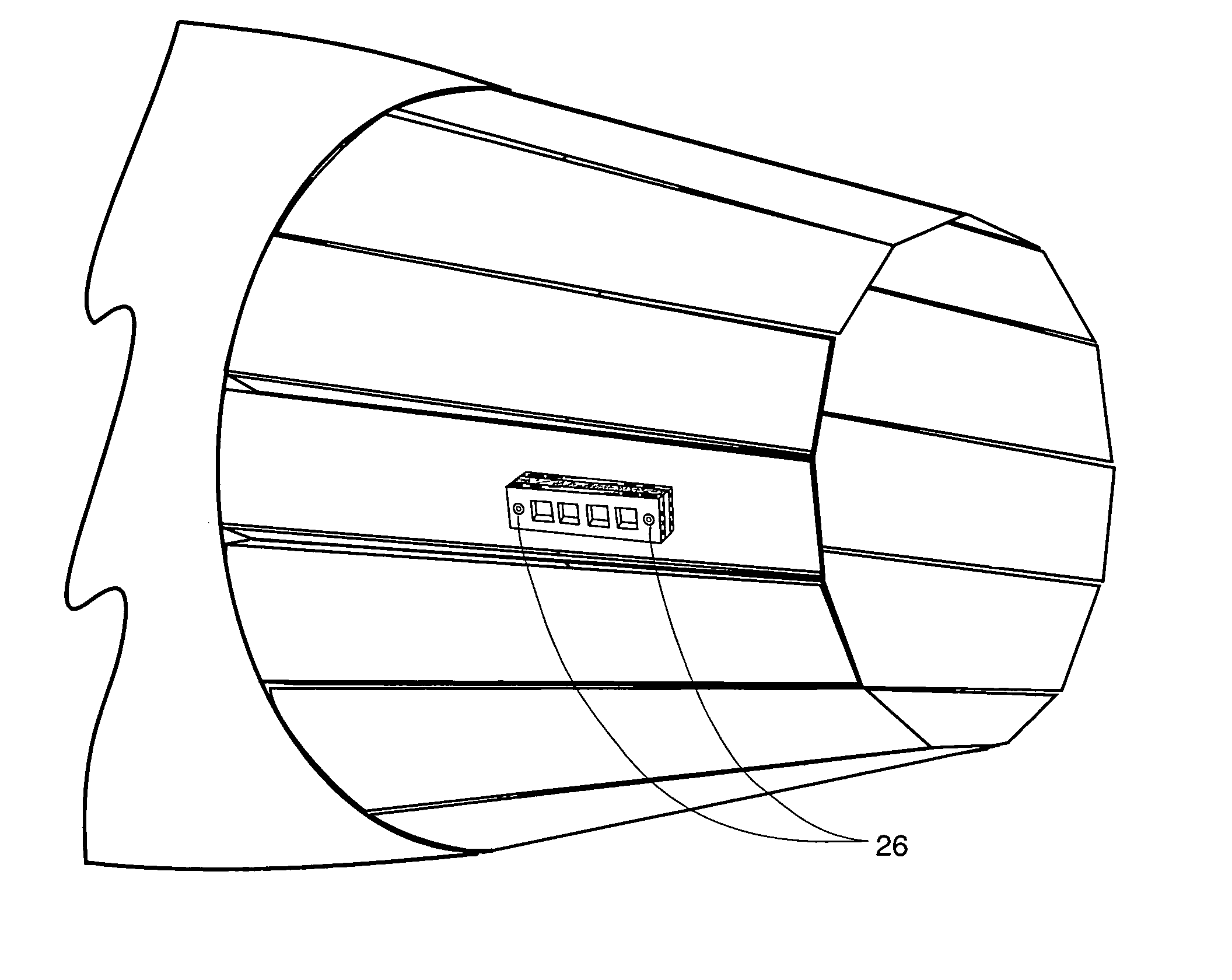

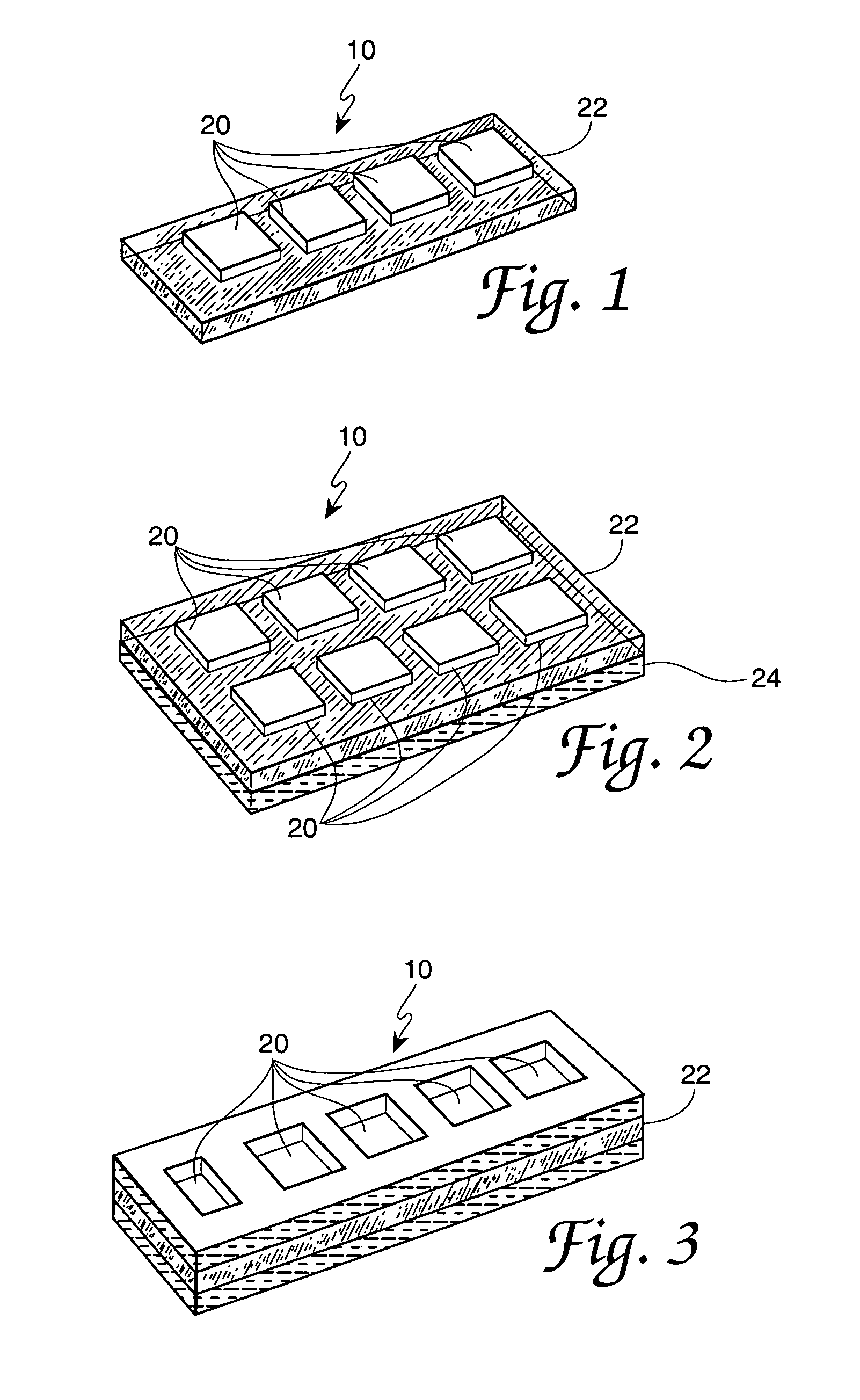

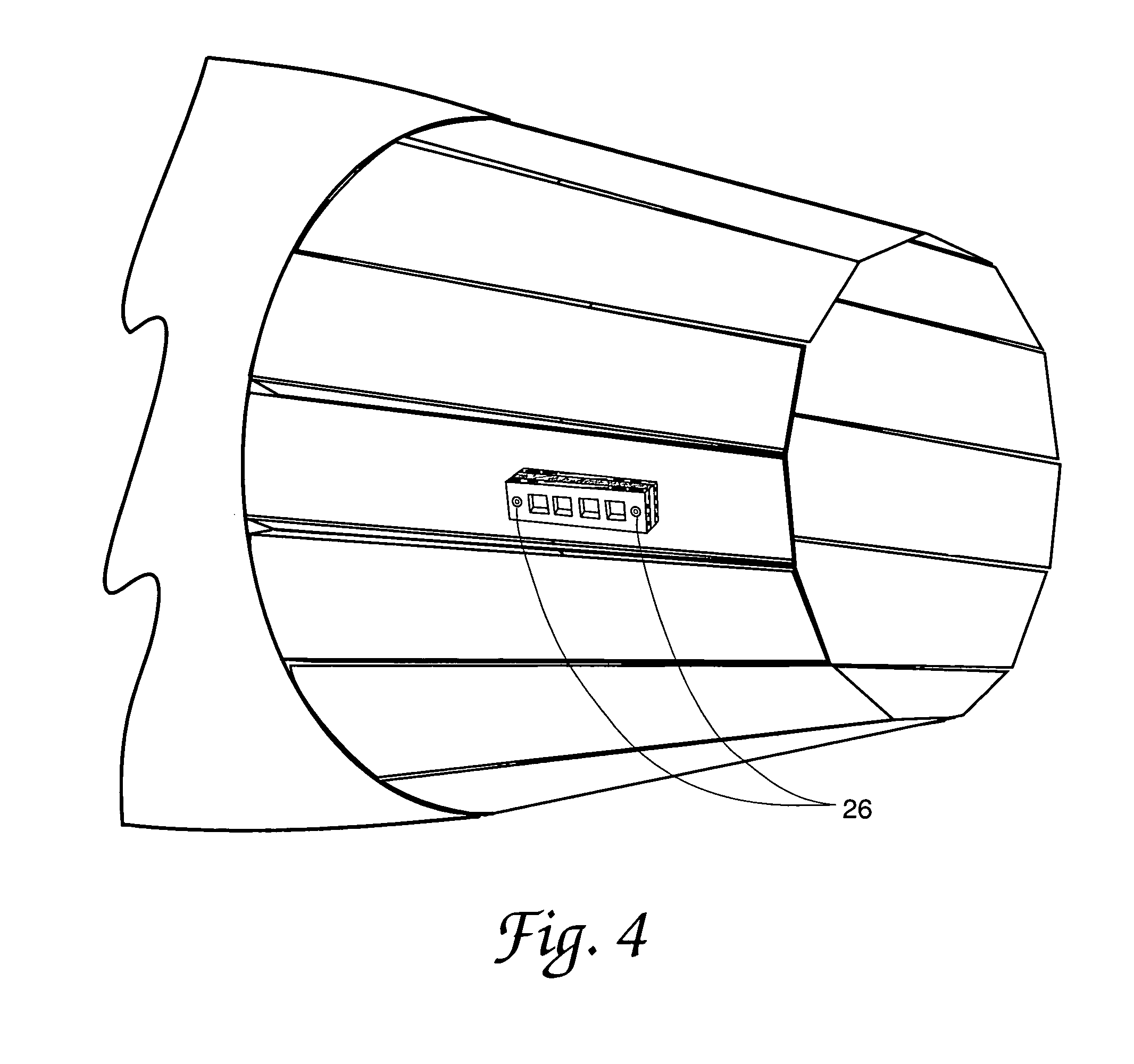

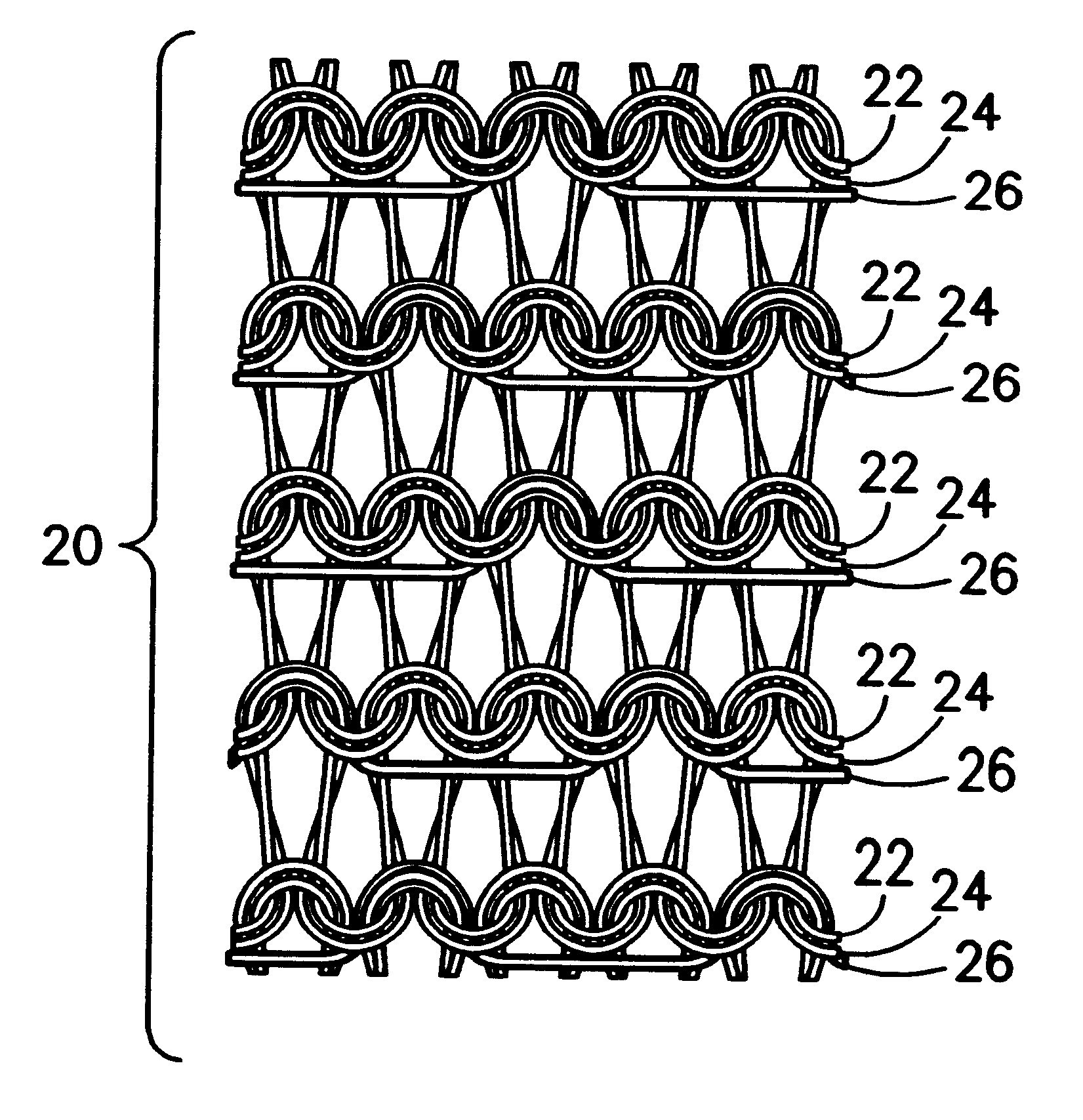

Thermal history sensor

InactiveUS6974249B1Accurate informationHigh opacityThermometers using mean/integrated valuesThermometers using physical/chemical changesBaseline dataMetallurgy

An improved thermal history sensor having multiple glass ceramic substrates with unique compositions is disclosed. By positioning the sensor adjacent to a component subject to thermal stressors, each of the glass ceramic substrates react with a different rate of nucleation and crystal growth and thus yield a specific measure of opacity. By comparing these values representing the opacity for each glass ceramic substrate, or thermal history fingerprint, to baseline data, information about the expected remaining useful lifetime of the component may be obtained.

Owner:AIR FORCE US SEC THE THE

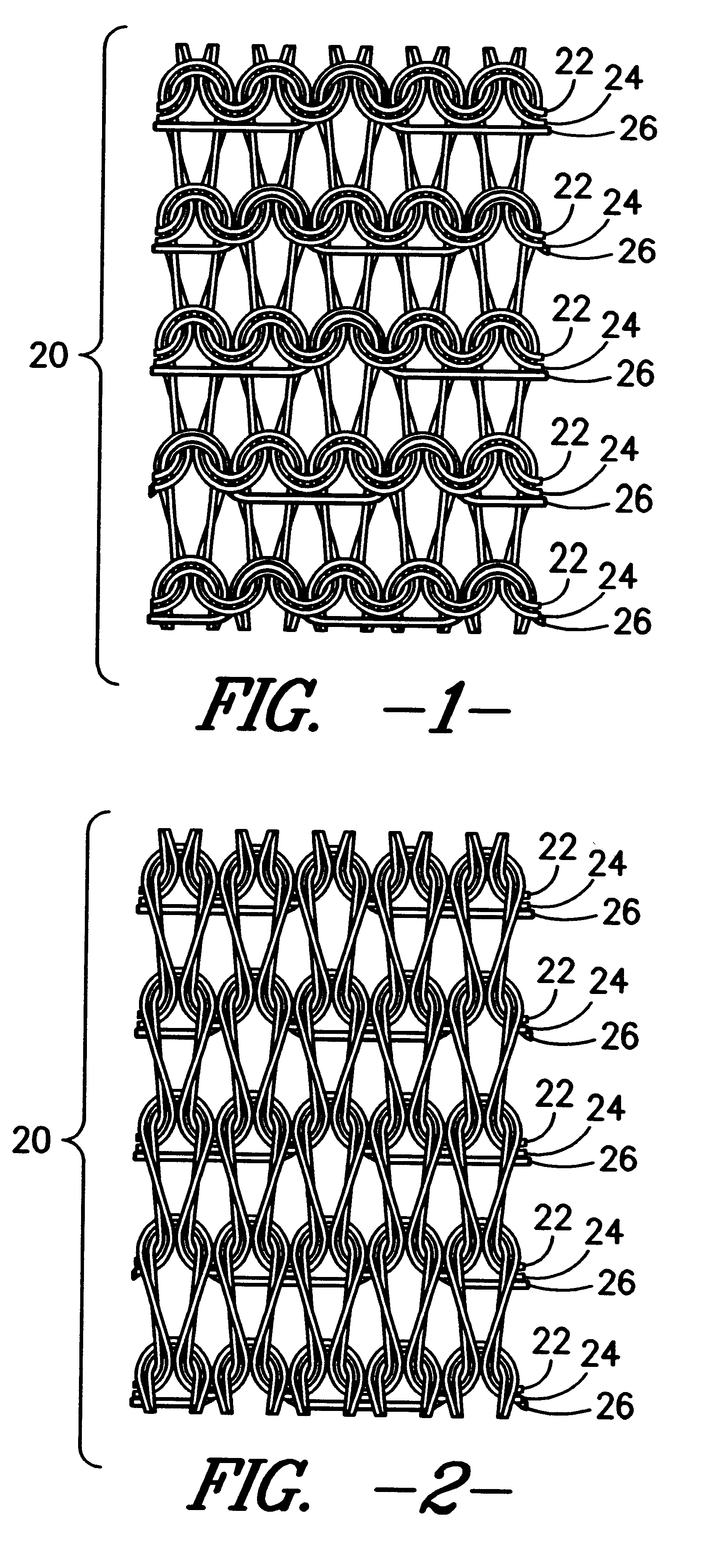

Opaque heat-moldable circular knit support fabrics having very high spandex content

InactiveUS6263707B1Consistent comfortabilityHigh densityCircular knitting machinesStraight-bar knitting machinesFiberShell molding

A fabric and method to support garments comprising opaque heat-moldable circular knit fabrics having relatively high amounts of spandex material as well as sufficient amounts of other fibers to simultaneously provide maximum support and maximum comfort to a wearer and which can be easily molded to the specifications of a wearer's body dimensions. Such high-spandex content, moldable garment fabrics are novel to the industry since the permissible added amount of spandex within such fabrics has been limited due to the power, modulus strength, and elongation of such fibers. Furthermore, the ability to provide moldable, high-spandex circular knit fabrics has been limited, if not impossible, due to the above-noted characteristics of the spandex fibers themselves. The inventive moldable fabrics and garments provide such desirable spandex properties while also increasing the comfortability to the wearer. The method of producing such fabrics is also contemplated within this invention. Both the fabric and the method state that the amount of spandex in the fabric is at least 24% of the total fiber weight in the fabric.

Owner:MILLIKEN & CO

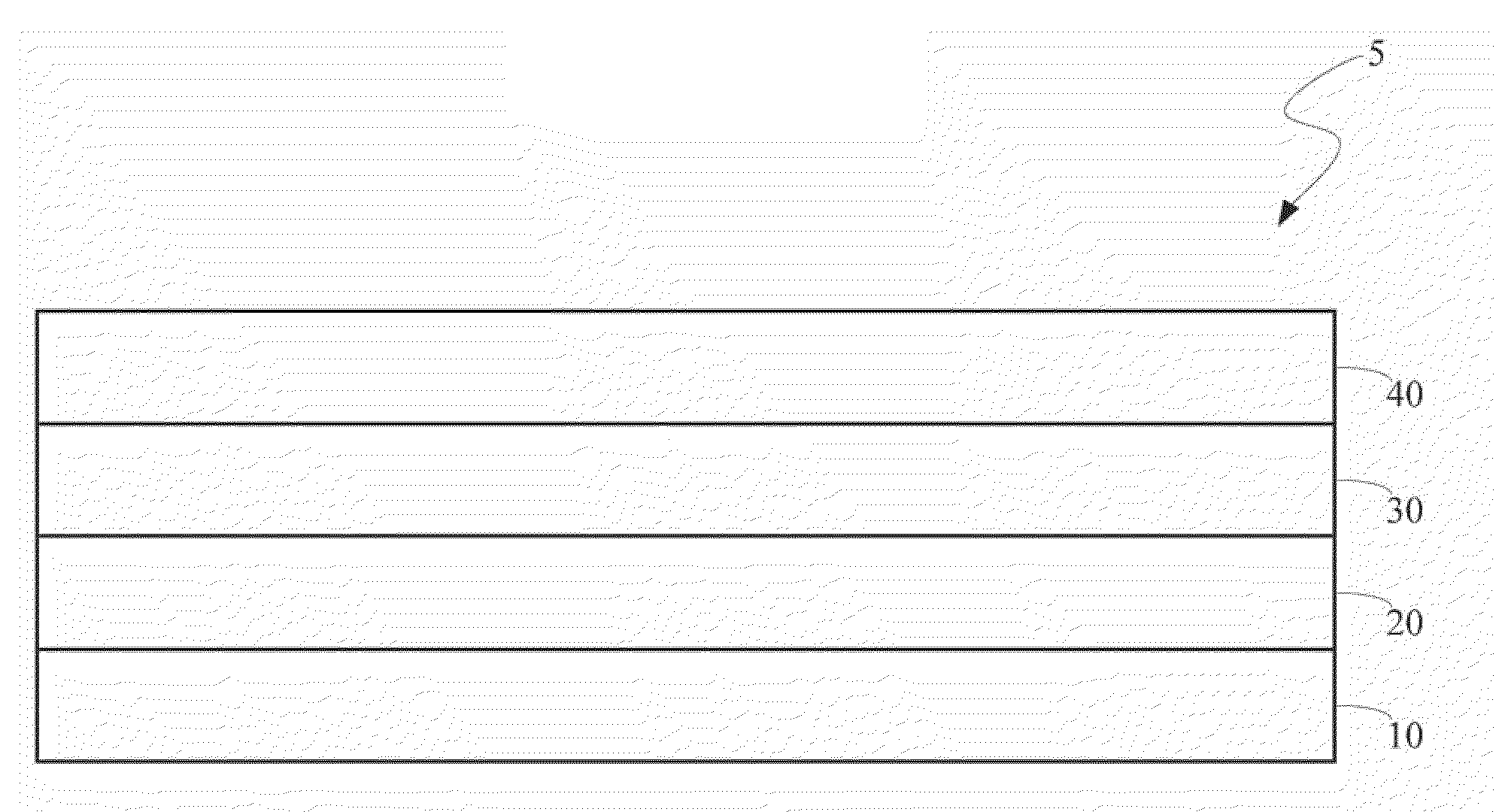

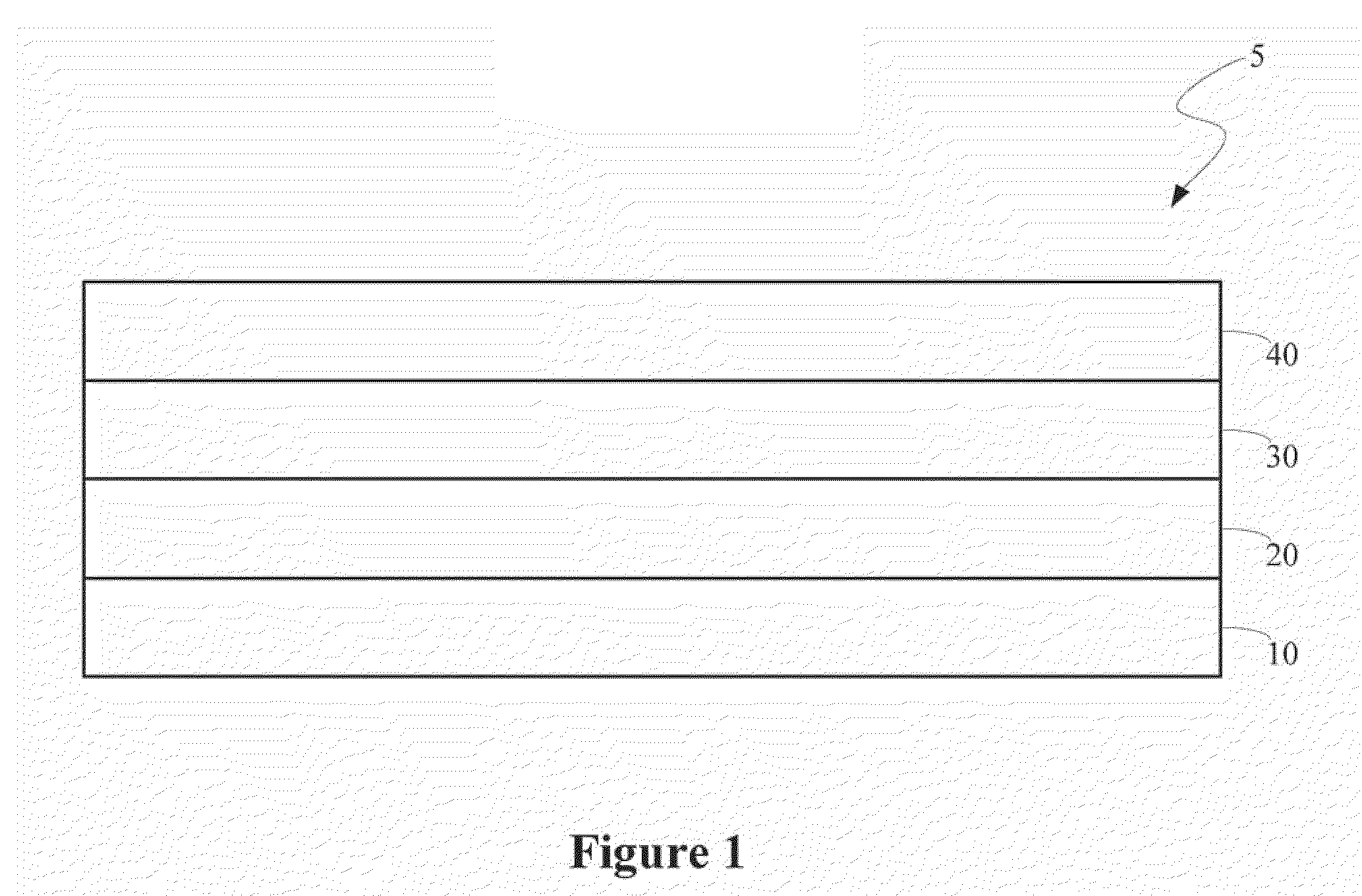

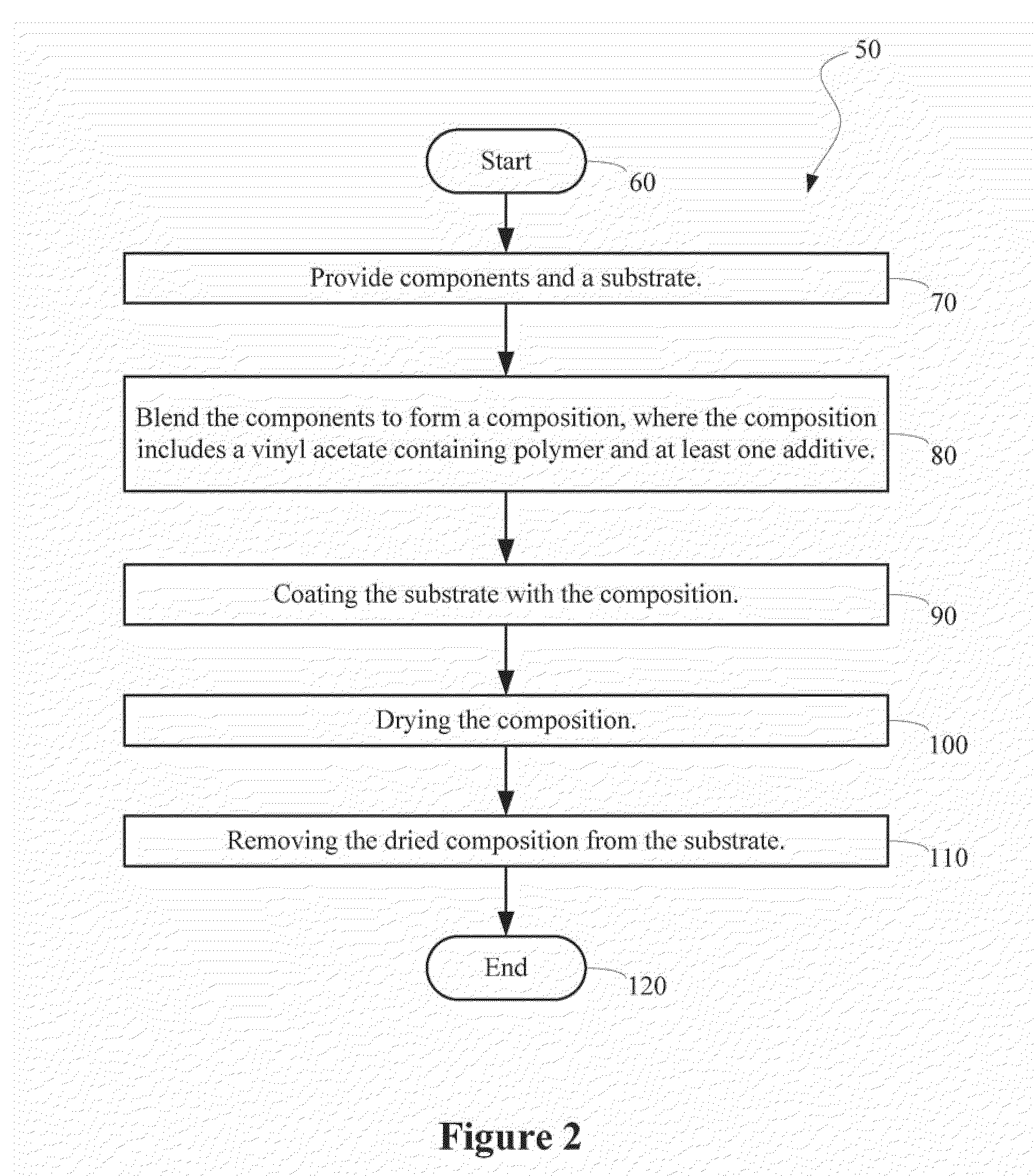

Composition, film and related methods

ActiveUS20100009108A1Easy to printGood colorDuplicating/marking methodsSynthetic resin layered productsUltravioletSolvent

A composition that is configured for use in creating a film. The composition includes a vinyl acetate containing polymer, such as a vinyl acetate ethylene (VAE) copolymer, and at least one additive that is a pigment, a surfactant, a dispersant, a wetting agent, a plasticizer, a defoamer, a coupling agent, a solvent, a UV absorber, a fire retardant, or a light stabilizer.

Owner:AVERY DENNISON CORP

Fibrous substrate containing fibers and nanofibrillar polysaccharide

A single-layer fibrous substrate comprising, by dry weight compared with the weight of the substrate:between 39.9 and 87.9% natural fibers refined to above 50° SR;between 12 and 60% nanofibrillar polysaccharide; andbetween 0.1 and 4% of at least one retention agent.

Owner:AHLSTROM MUNKSJO OYJ

Foam core imaging element with gradient density core

InactiveUS7585557B2Increase stiffnessImprove smoothnessNatural cellulose pulp/paperDecorative surface effectsFoaming agentVolumetric Mass Density

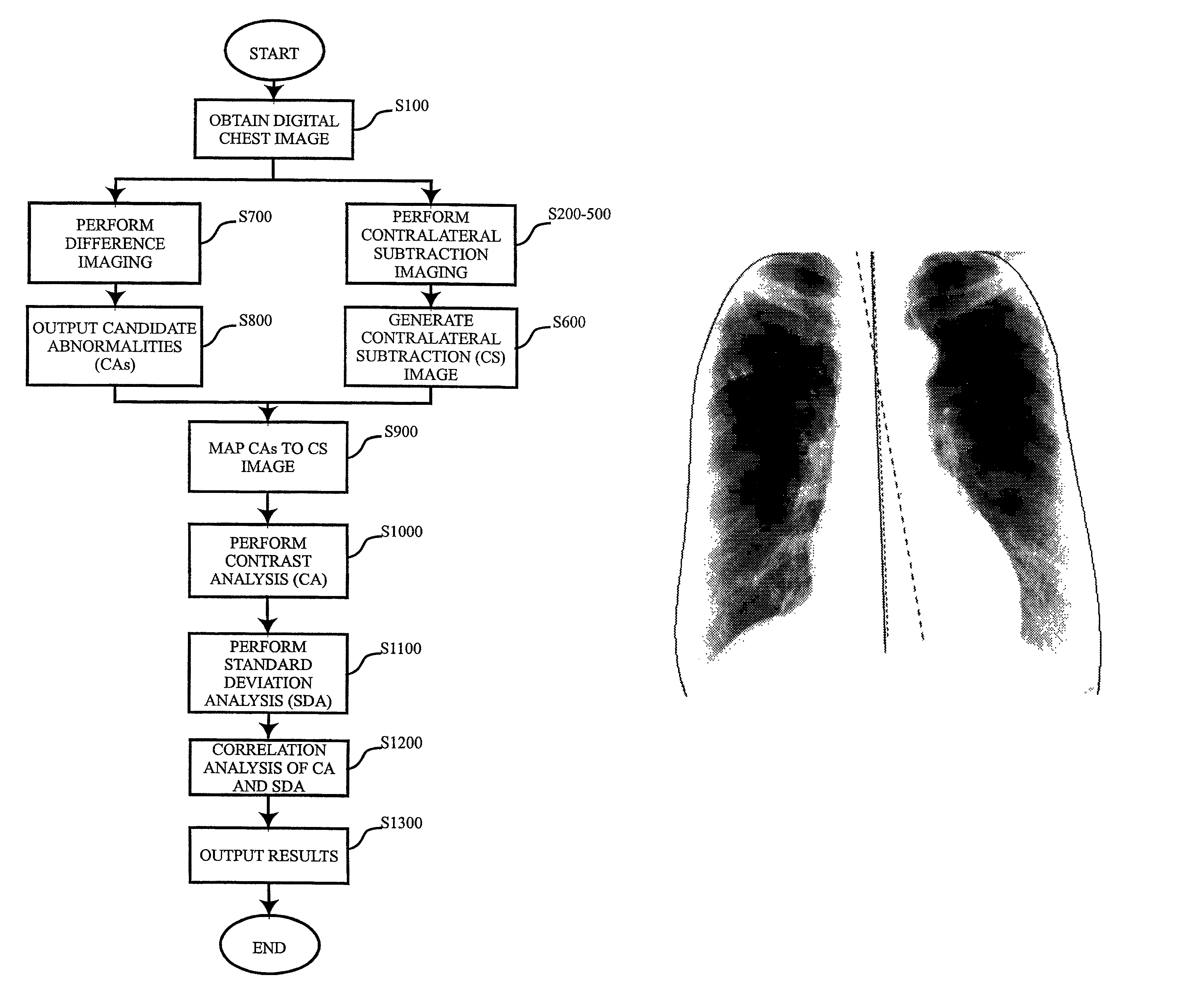

The invention relates to a base comprising a closed cell foam core sheet having a closed cell foam layer with a density gradient between the center of the core and the surfaces of the core. The invention also relates to a method of making such a base by adding a first concentration of a first blowing agent to a first polymer to form a first mixture, adding a second concentration of a second blowing agent to a second polymer to form a second mixture, and extruding the mixtures to form the closed cell foam core sheet. The invention also relates to a method of making such a closed cell foam core sheet base comprising the steps of adding a blowing agent to a polymer to form a mixture, melting the mixture, extruding the mixture from a die, and rapidly quenching the mixture against a high heat transfer surface.

Owner:EASTMAN KODAK CO

Titanium dioxide pigment and method for producing the same and resin composition using the same

InactiveUS20050228112A1High opacityLow hardnessInorganic pigment treatmentTitanium dioxideColor toneChemistry

The titanium dioxide pigment of the present invention contains an anatase type crystal in an amount of 98-100% and has an average particle diameter of 0.2-0.4 μm and a whiteness of 95-97 in terms of L value of linseed oil. The titanium dioxide pigment of the present invention has characteristics peculiar to anatase type, for example, optical characteristics such as bluish color tone and physical characteristics such as low hardness, and furthermore has high opacity which is not possessed by conventional anatase type titanium oxide pigments.

Owner:ISHIHARA SANGYO KAISHA LTD

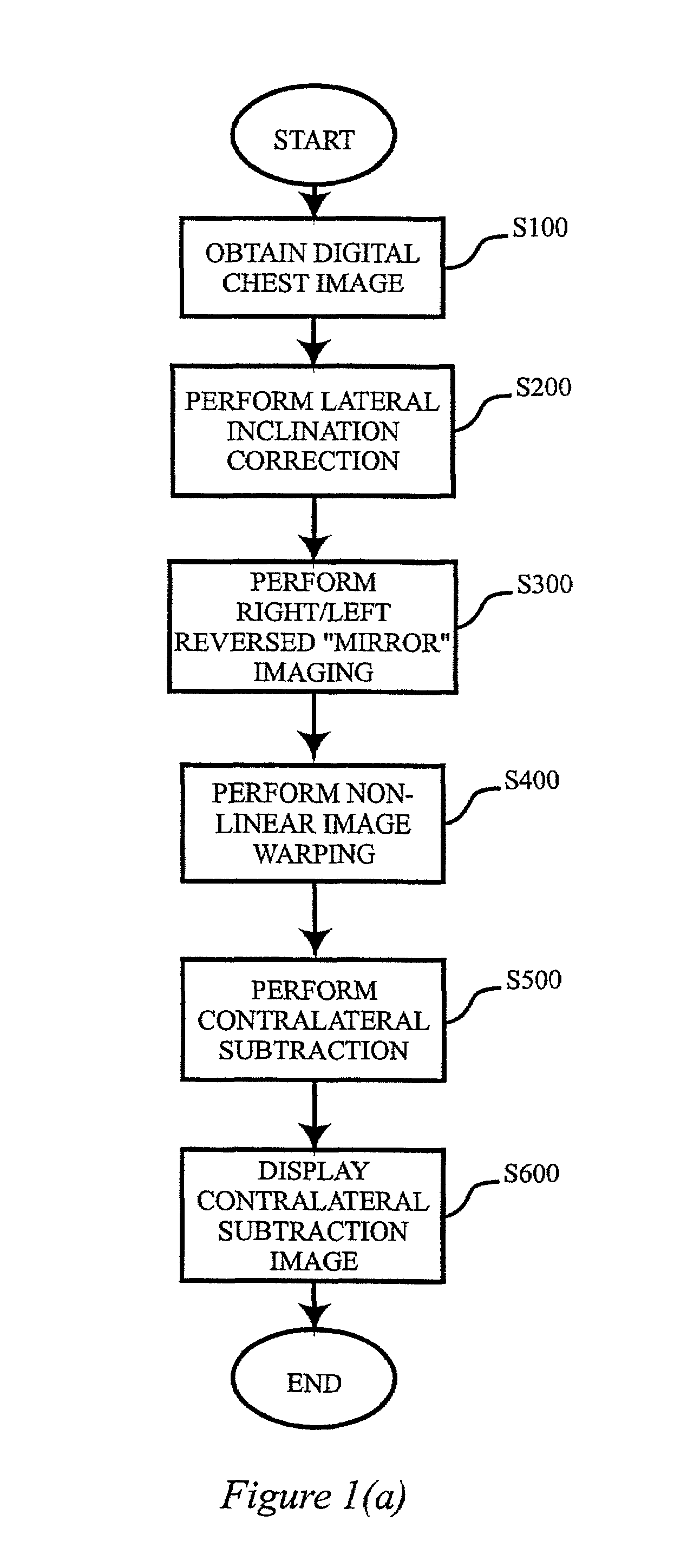

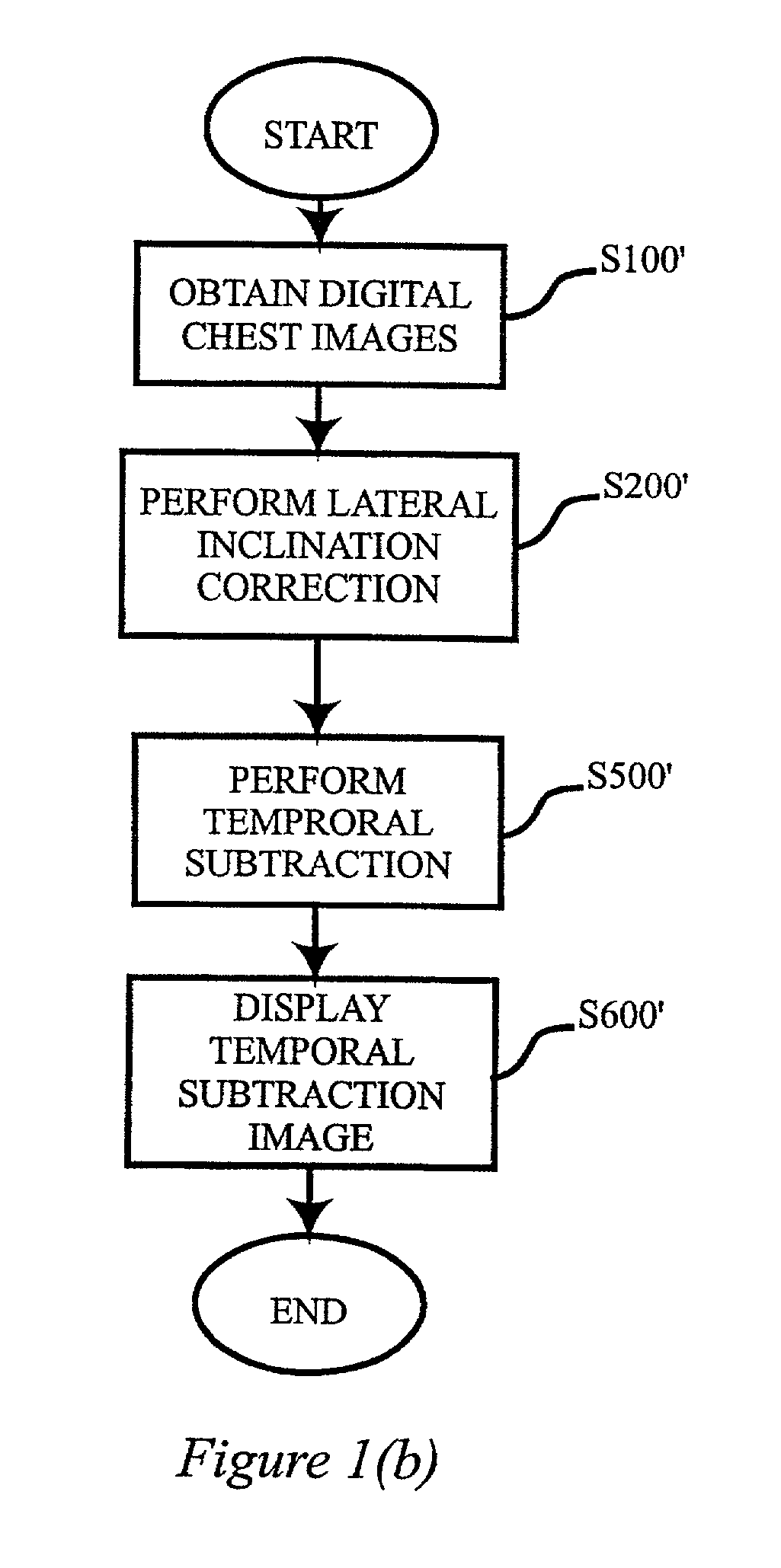

System for computerized processing of chest radiographic images

InactiveUS7043066B1Improved subtraction imageEnhance asymmetrical opacityImage enhancementImage analysisImage warpingMirror image

Owner:ARCH DEVMENT

Coated paper and process for producing same

InactiveUS20040180184A1Less smoothnessHigher proportion of mechanical fiberLayered productsCoated paper substrateChemical pulpFiber

In the conventional process of producing a coated paper, the use of a furnish that is characterized by a base sheet fiber content made of about 60 to 85 weight percent of a bleached thermomechanical pulp (TMP), about 10 to 35 weight percent of a bleached chemical pulp and 0 to about 15 weight percent of a deinked pulp, and also comprising about 12 to 20 weight percent of an inorganic filler, with a freeness below 50 ml Csf and a brightness over 75° ISO, gives a coated paper of the same or superior quality and at a much lower cost than the usual coated paper obtained through a conventional process.

Owner:BPR

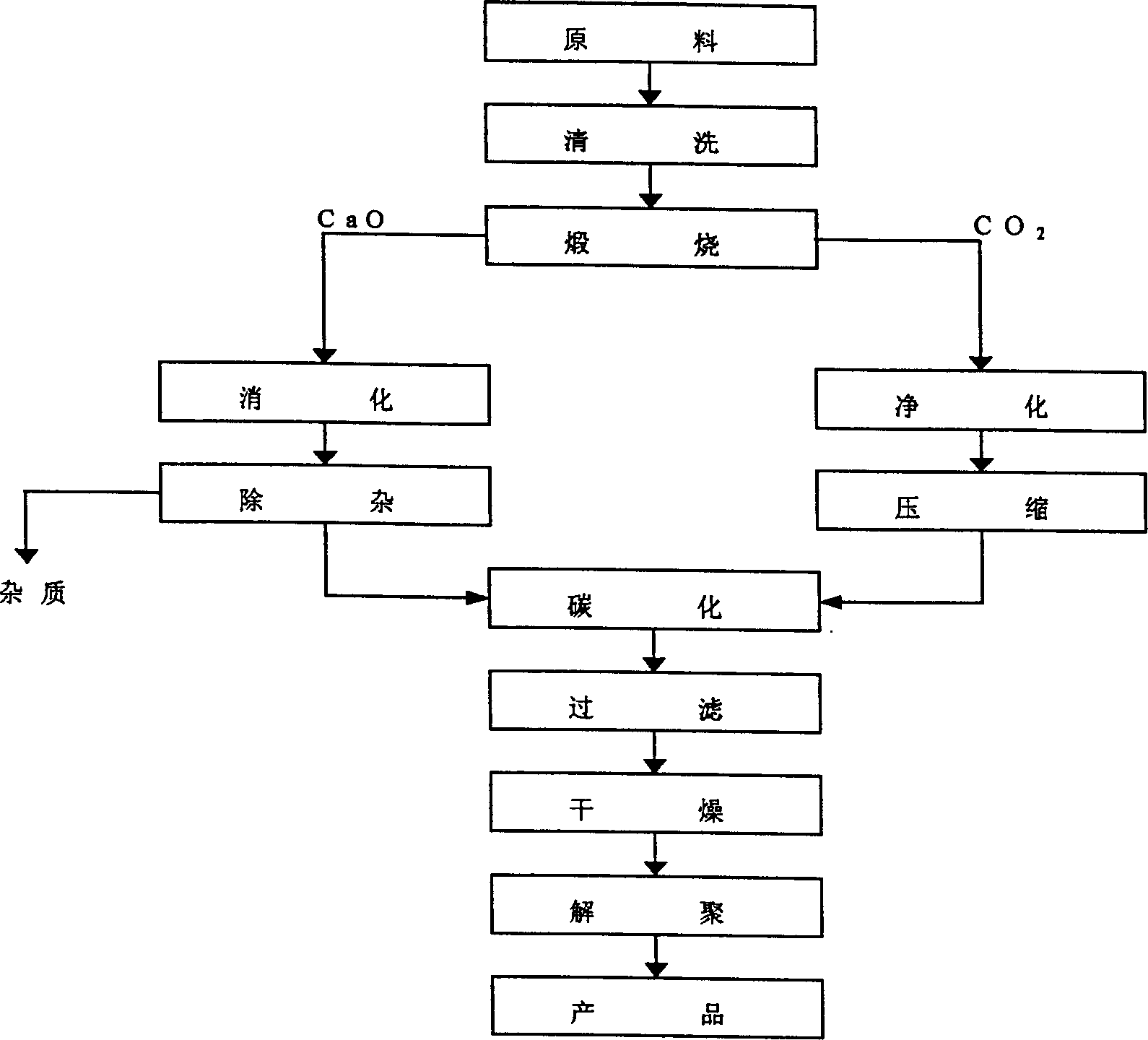

Method for preparing high-white ness nano calcium carbide

InactiveCN1438279AIncrease productivityImprove product qualityInorganic pigment treatmentDepolymerizationFiltration

The invention is a method of preparing high-whiteness degree nano CaCO3. It uses limestone, CaCO3 content>98%, whiteness degree>92% as raw material, washes to calcine into CaO, then adds in the cleaned hot water to get Ca(OH)2, prepares milk of lime by purifying, the concentration 2-10%, uses the cleaned flue gas of CaCO3, calcinations as CO2 source, makes the solution of milk of lime react with CO2 in special synthesis reactor, and adds in crystal-shaped controlling agent to control the time, temperature and stirring speed of the reaction, and after the reaction is finished, makes filtration, drying and depolymerization on the solution. The whole course adopts the technique of controlling whiteness degree.

Owner:NORTHEASTERN UNIV +1

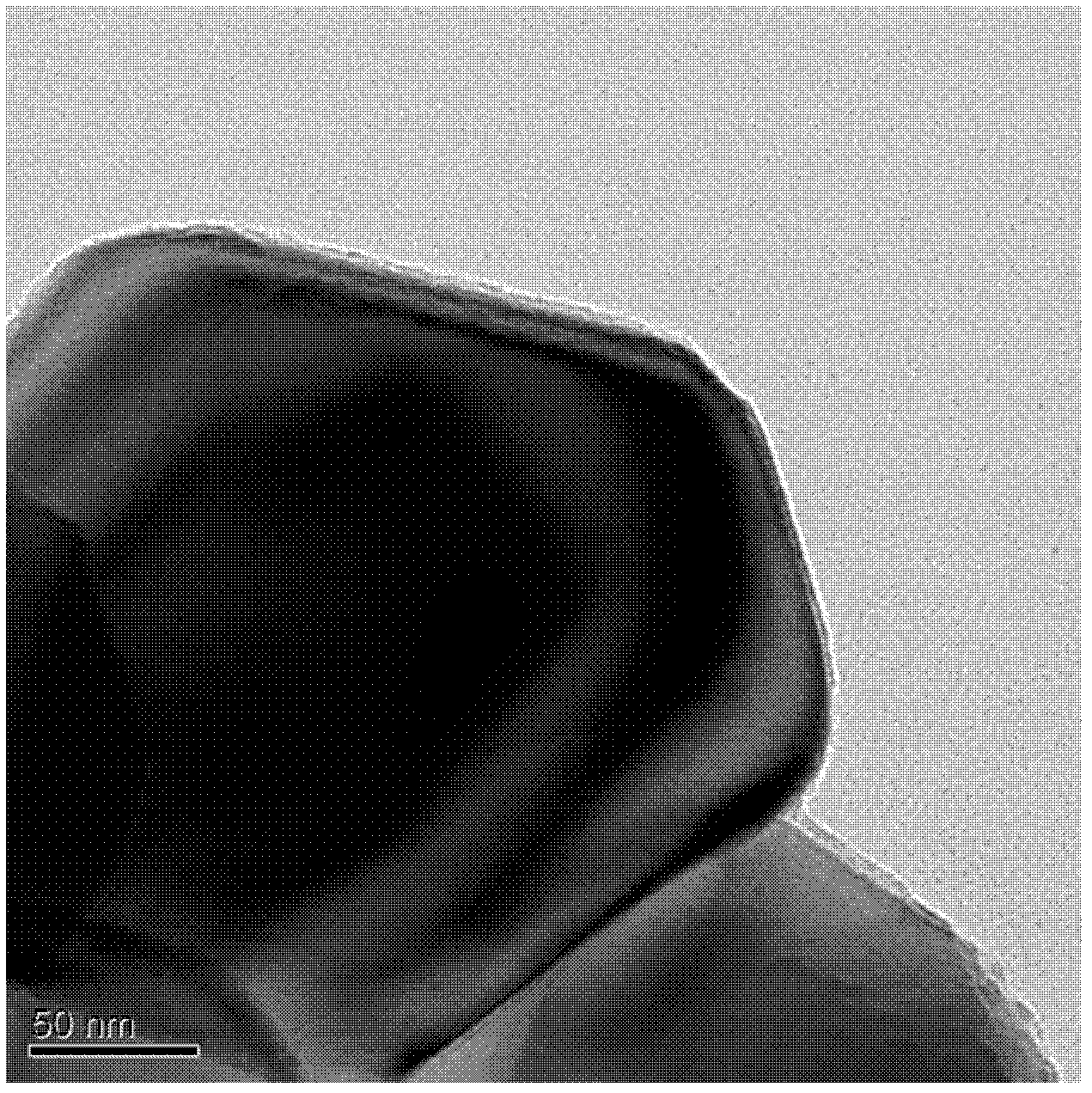

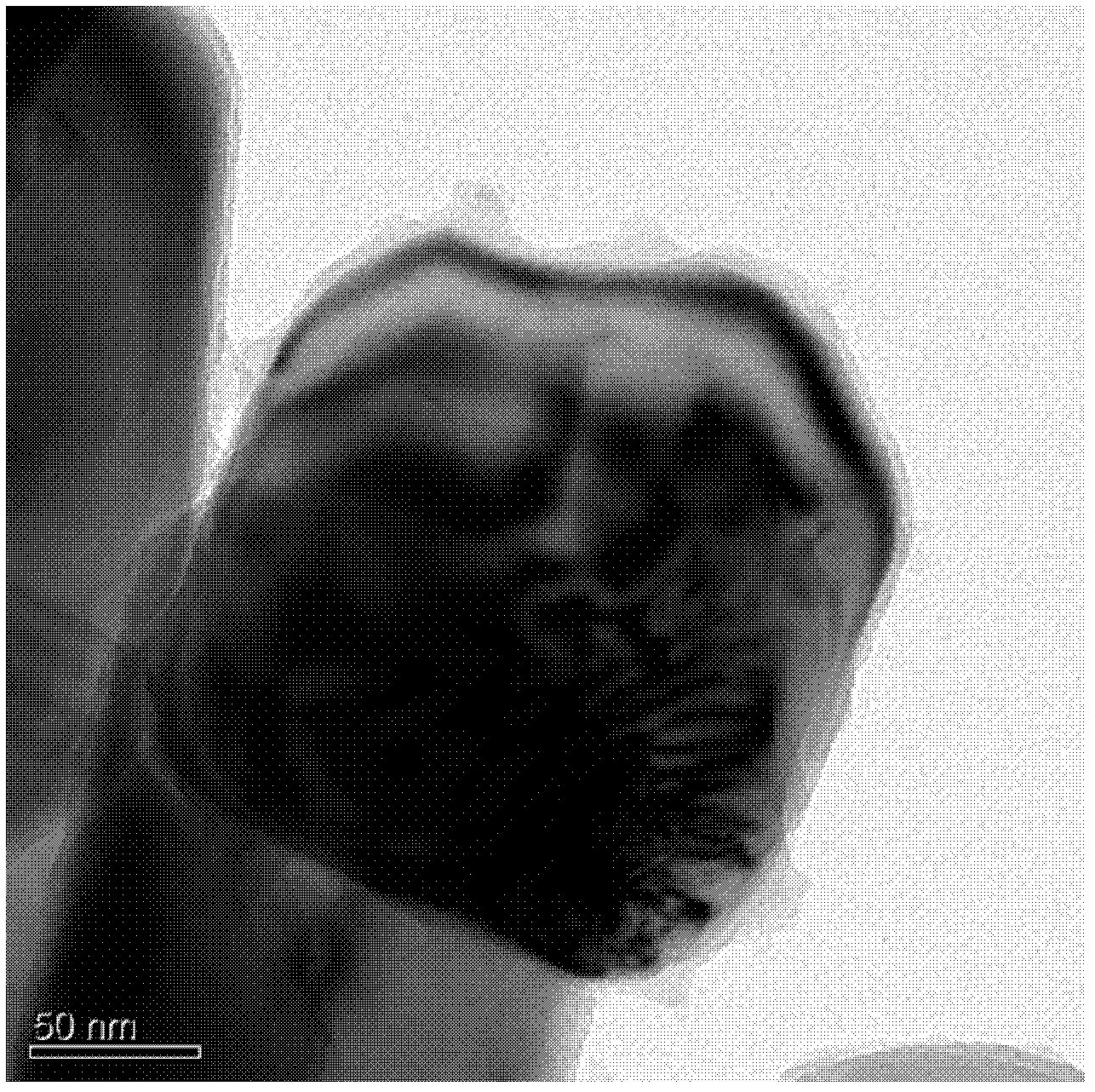

Preparation method for high-light fastness titanium dioxide pigment

ActiveCN102585559AImprove controllabilityGood reproducibilityInorganic pigment treatmentInorganic compound additionAluminium hydroxidePhosphoric acid

The invention discloses a preparation method for a high-light fastness titanium dioxide pigment. The preparation method comprises the following steps of: preparing aqueous suspension of a titanium dioxide initial product; depositing a layer of dense silicon dioxide cladding layer on a titanium dioxide pigment; depositing an aluminum phosphate compound on the silicon dioxide-coated titanium dioxide pigment; depositing aluminum hydroxide by using a parallel-flow method; after the aluminum hydroxide is coated, stirring and aging; and filtering, washing, drying, and performing fluid energy milling and organic treatment to obtain the high-light fastness titanium dioxide pigment. The method provided by the invention has the advantages of high controllability, reproducibility, high operability and the like, facilitates industrial production and has a good application prospect. The titanium dioxide pigment prepared by the method has the advantages of high light fastness, high light resistance, high non-transparency, high color-change resistance and the like, and can be used in decoration paper, laminated paper and coating and plastic products which have high requirements on the light resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

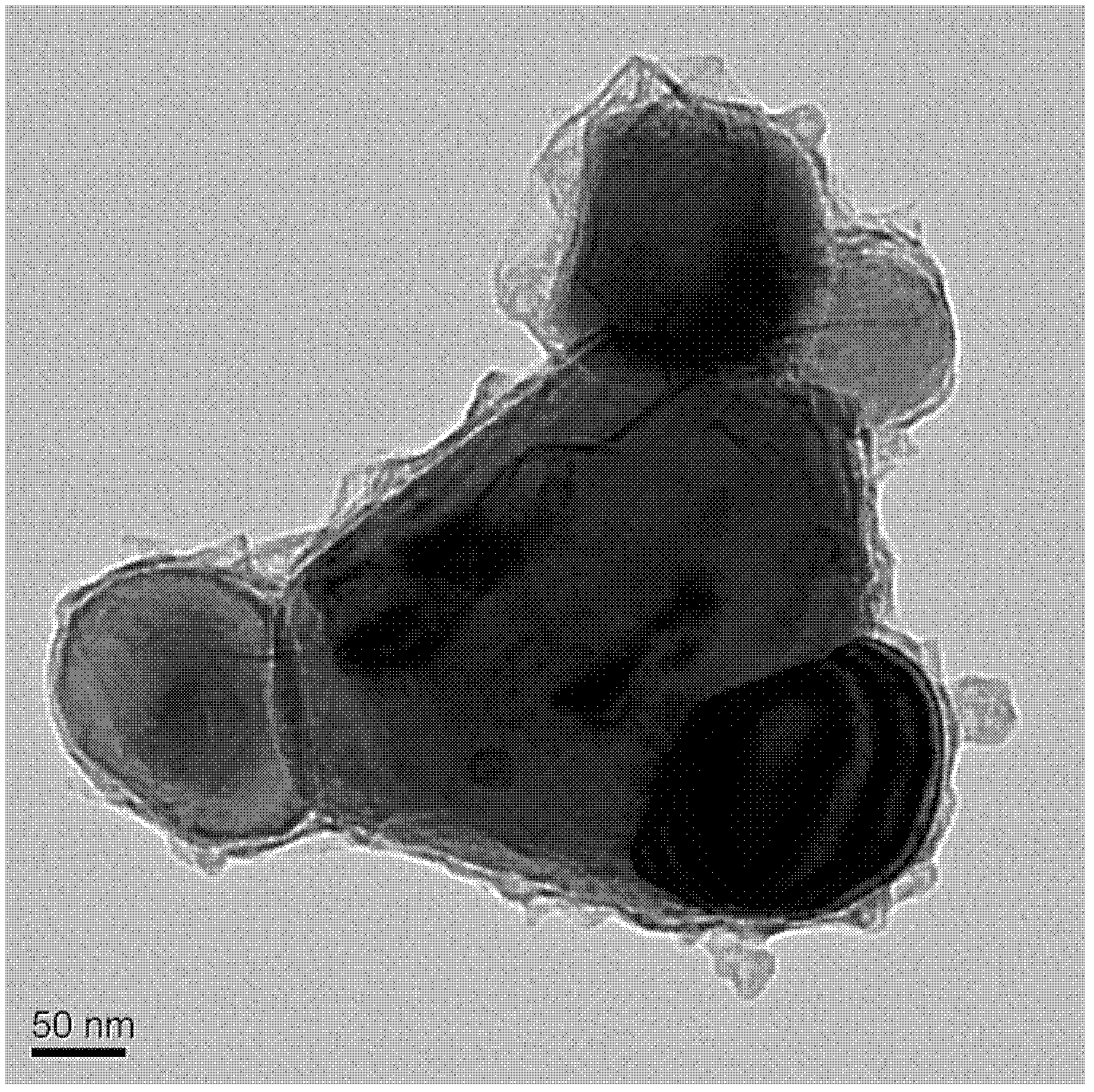

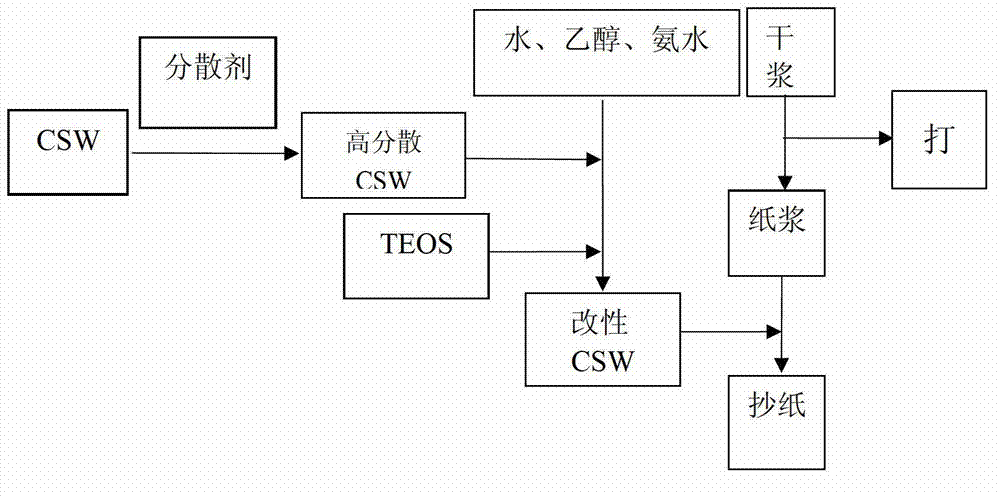

Method for coating and modifying surface of inorganic paper making fiber calcium sulfate whisker and application

ActiveCN103074800AEvenly dispersedImprove hydrophobicityPolycrystalline material growthInorganic compound additionFiberSulfate

The invention discloses a method for coating and modifying surface of inorganic paper making fiber calcium sulfate whisker, which comprises the following steps: 1) mixing the calcium sulfate whisker with a dispersant relative to 1-10% of mass fraction of calcium sulfate whisker, dispersing the calcium sulfate whisker; filtering and drying after treating to obtain the calcium sulfate whisker with high dispersion; 2) measuring water, ethanol, ammoniacal liquor and organosilicon source with set volume ratio, placing the water, ethanol and ammoniacal liquor in a three-mouth flask, performing magnetic stirring, adding a proper amount of surfactant, uniformly mixing for standby; 3) adding the prepared calcium sulfate whisker with high dispersion in the three-mouth flask filled with a mixed solution, uniformly mixing, slowly adding the measured organosilicon source by batches; and 4) stirring and modifying the prepared mixed solution at the temperature of below than 25 DEG C, subsiding for 8-10 hours, filtering, and drying under the temperature of 95% to prepare the modified calcium sulfate whisker.

Owner:SHANGHAI UNIV

Fluoropolymer/particulate filled protective sheet

InactiveUS20100092759A1Low moisture transmissionOpacity of be controlMouldsSynthetic resin layered productsEngineeringElectrical and Electronics engineering

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Light blocking articles having opacifying layers

ActiveUS9891350B2High opacityImprove reflectivityRadiation-absorbing paintsTextiles and paperPolymer scienceElectromagnetic radiation

A light-blocking article is designed to be lightweight but effective to block most incident actinic radiation and can be designed into fabrics, curtains, and other materials. Such an article has an opacifying layer that is capable of blocking predetermined electromagnetic radiation. The article contains (a) porous particles comprising a continuous polymeric binder and pores within the continuous polymeric binder, the porous particles having a glass transition temperature of at least 25° C. and a mode particle size of at least 2 μm and up to and including 50 μm. The article also contains an opacifying colorant that absorbs the predetermined electromagnetic radiation (such as within 400 nm to 700 nm), in an amount of at least 0.001 weight % based on the total dry weight of the opacifying layer, and a matrix polymer in which the porous particles and opacifying colorant are dispersed.

Owner:EASTMAN KODAK CO

Intermediate transfer recording medium, print, and method for image formation thereby

InactiveUS6984281B2Transparency is deterioratedHigh opacityDecorative surface effectsStereotype printingImage formationEngineering

There is provided a print which has been produced by providing an intermediate transfer recording medium comprising a substrate film and a transfer portion, comprising at least a receptive layer, provided separably on the substrate film, forming a thermal transfer image onto the transfer portion, and retransferring the transfer portion onto an object while accurately and stably forming a non-transferred portion onto a part of the object and, in addition, does not increase a production cost for providing a final print. The intermediate transfer recording medium comprises a substrate film and a transfer portion comprising at least a receptive layer, the transfer portion being provided separably on the substrate film. The print has on its at least one side a transfer portion-non-retransferred portion.

Owner:DAI NIPPON PRINTING CO LTD

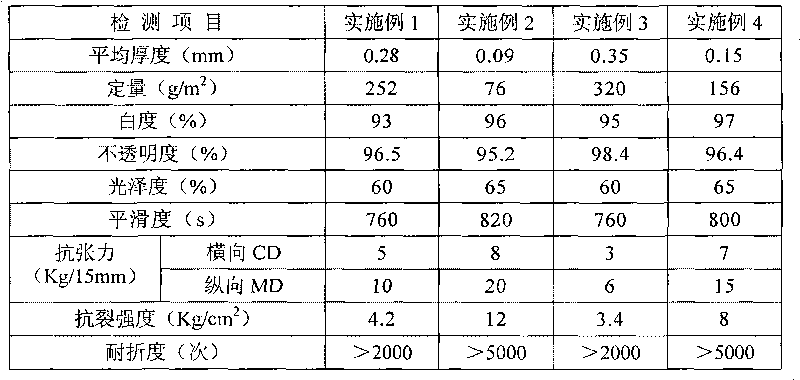

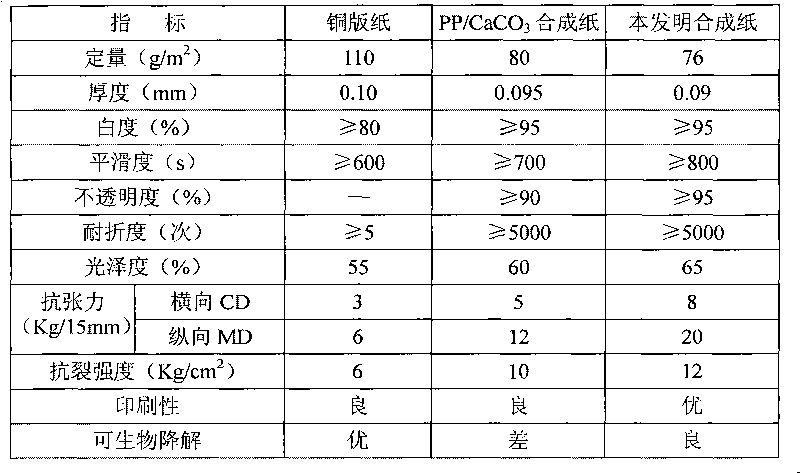

Paper making material, preparation method and paper making method of environment-friendly synthetic paper

ActiveCN101760990AImprove stabilityImprove heat resistanceNon-fibrous pulp additionSpecial paperFiberBlow molding

The invention relates to a paper making material, a preparation method and a paper making method of environment-friendly synthetic paper. The material comprises modified mineral fiber, thermoplastic starch, cellulose derivative, compatilizer, auxiliary components and the like, wherein the average particle diameter of the modified mineral fiber is 5-10 micrometers, the ratio of the length of the modified mineral fiber to the diameter of the modified mineral fiber is 8-15:1, and the modified mineral fiber is treated by fibrosis ultrafine grinding and surface recombination modification; the thermoplastic starch is formed by performing micronization and plasticization modification on norm starch; and the auxiliary components comprise lubricant and colorant. The paper making material is prepared by sequentially mixing the raw material components fully and then extruding and granulating the mixture by a screw extruder at 60-180 DEG C. According to the plastic process mode, the material can be treated by blow molding through a calender or a paper film machine for carrying out two-way stretch to prepare corresponding paper products. The paper making material can overcome the defects of the current synthetic paper and can be widely applied to the fields of commercial printing, publications, office paper, packing and the like, and the processing procedure of making paper by using plastic processing equipment has environmental protection and low cost.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Biaxially oriented cavitated polylactic acid film

InactiveUS20120141766A1Low costRemain biodegradableSynthetic resin layered productsVacuum evaporation coatingPolystyreneMaterials science

Disclosed are biaxially oriented laminate films including a core layer including a blend of crystalline polylactic acid polymer and crystalline polystyrene. The films are biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the crystalline polystyrene such that a white opaque cavitated appearance and lower film densities are obtained. The laminate films may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

Hollow organic pigment core binder coated paper and paperboard articles and methods for making the same

InactiveUS20080081175A1High opacityLow costNon-fibrous pulp additionNatural cellulose pulp/paperPaperboardGlass transition

A coating for paperboard comprises an aqueous dispersion of a hollow core binder comprising a first polymer that, when dry, has at least one void, the first polymer being substantially encapsulated by at least one second polymer having a glass transition temperature (Tg) ranging from more than −15° C. and up to and including 30° C., wherein the weight ratio of the said second polymer to the said first polymer ranges from 1:1 to 4:1. One or both of the first polymer and the second polymer may be formed from, as polymerized units, at least one ethylenically unsaturated monomer. The hollow core binder allows for glossy, bright and smooth paperboard coatings while reducing the amount of binder and opacifying pigment necessary to achieve such coating properties. The present invention also provides coated paperboard articles, as well as paper and paperboard that is made from a mixture of pulp with the inventive hollow core binder.

Owner:ROHM & HAAS CO

Composite paperboards and method of making composite paperboards

InactiveUS7348067B1Unnecessary additionAvoid print qualityAdhesive processesNon-fibrous pulp additionCardboardAdhesive

A laminate composite sheet comprising a two-ply base layer comprised of a bottom ply and a top ply, wherein the bottom ply is comprised of unbleached cellulosic fibers and wherein the top ply is comprised of bleached or brightened cellulosic fibers and a further layer attached to the top ply with a layer of adhesive; said further layer having a top and a bottom surface, said further layer selected from the group consisting of paper or film; said layer of adhesive containing no pigment, and said top surface of said further layer having no coating.

Owner:LAMINA PACKAGING INNOVATIONS LLC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com