Patents

Literature

954 results about "UV coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A UV coating is a surface treatment which either is cured by ultraviolet radiation, or which protects the underlying material from such radiation's harmful effects.

UV-light solidifying paint having decorative effect and preparation method thereof

The invention relates to a UV-light solidifying paint having decorative effect and preparation method thereof, in particular to a light solidifying paint containing mica coated with metallic oxides as a paint. The paint is composed of the followings in proportions: the content of low polymer is 30-70wt%; the content of reactive diluent is 25-65wt%; the content of light trigger is 0.5-10wt%; the content of pearlescent pigment is 3-30wt%; the content of accessory ingredient is 0.2-8wt%; the content of solvent is 0-50wt%. As added pearlescent pigment has strong metallic performance, the prepared light solidifying paint has the character of strong pearl effect and also has very good water resisting property, higher rigidity and abrasive resistance. The paint can be applied to decoration on the surfaces of motor vehicles, electric appliance, furniture, articles for daily use, toys, walls, leather products, etc.

Owner:SICHUAN UNIV

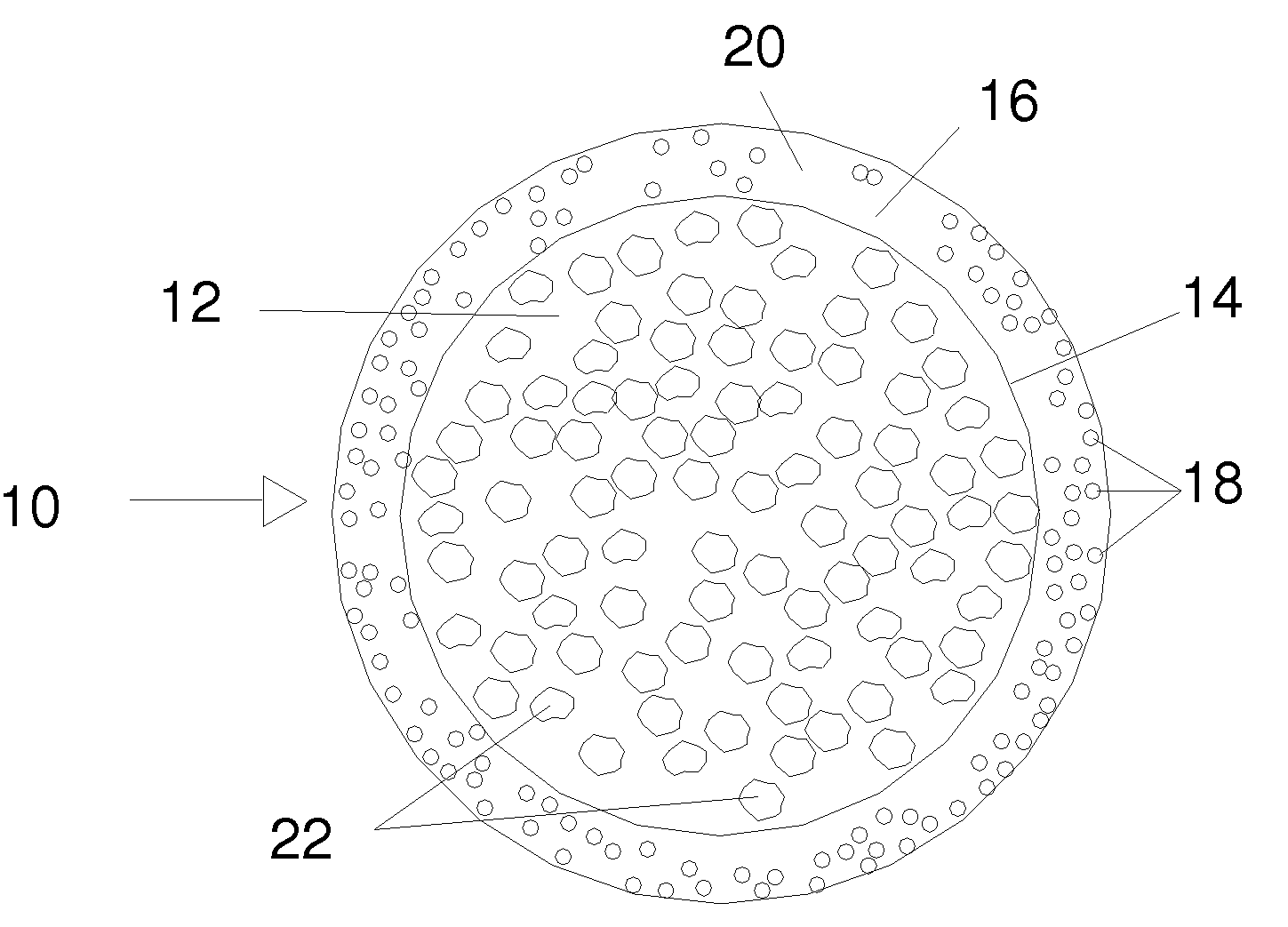

Roofing granules with high solar reflectance, roofing materials with high solar reflectance, and the process of making the same

ActiveUS20100151199A1Uniform applicationHigh opacityLiquid surface applicatorsRoof improvementNear infrared reflectanceTransmittance

Roofing granules include a core having an average ultraviolet transmission of greater than sixty percent and an average near infrared reflectance of greater than sixty percent and a UV coating layer on the exterior surface. The coating provides UV opacity, while the core provides near infrared reflectance.

Owner:CERTAINTEED CORP

Ultraviolet cured paint for plastics and its production process

InactiveCN1772820AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsPolyester coatingsUltravioletDiluent

The present invention relates to one kind of ultraviolet cured paint for plastics and its production process. The paint includes matrix resin, active diluent, light initiator and solvent and features its antiwear hardness additive accounting for 0.1-8.0 wt% of the paint. The paint has high hardness, high antiwear performance, forms smooth paint coating through spraying, high toughness, high adhesion and high chemical corrosion resistance.

Owner:BYD CO LTD

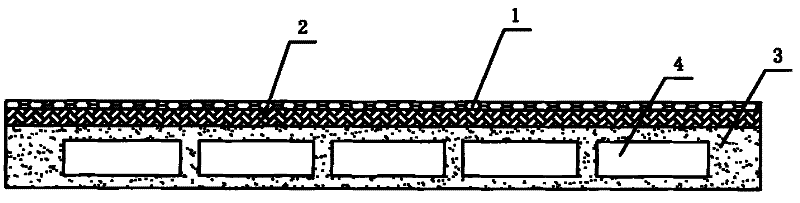

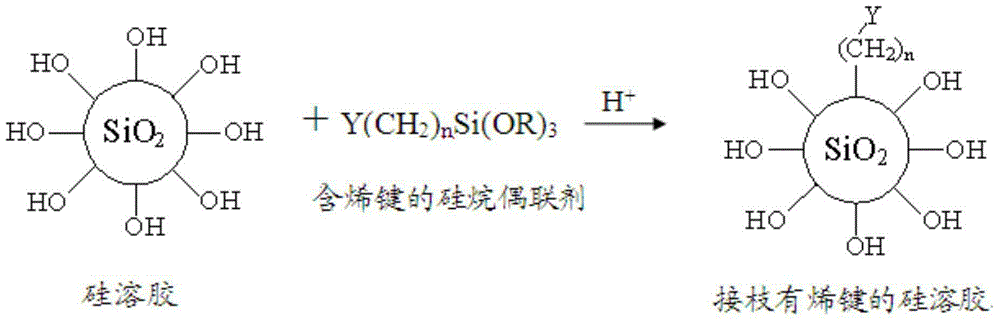

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

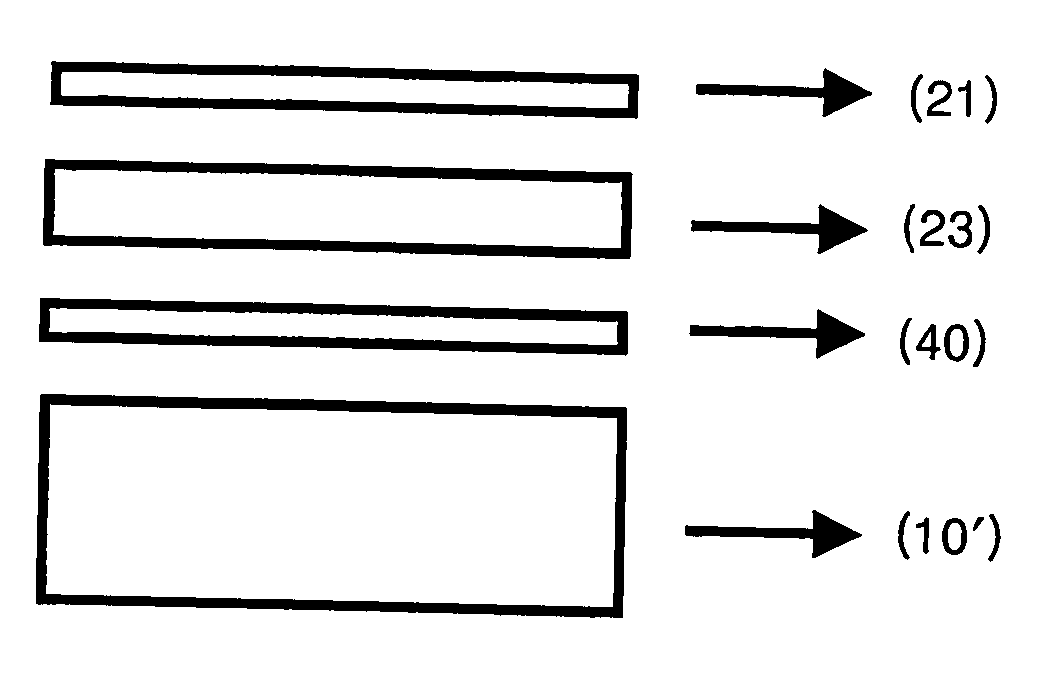

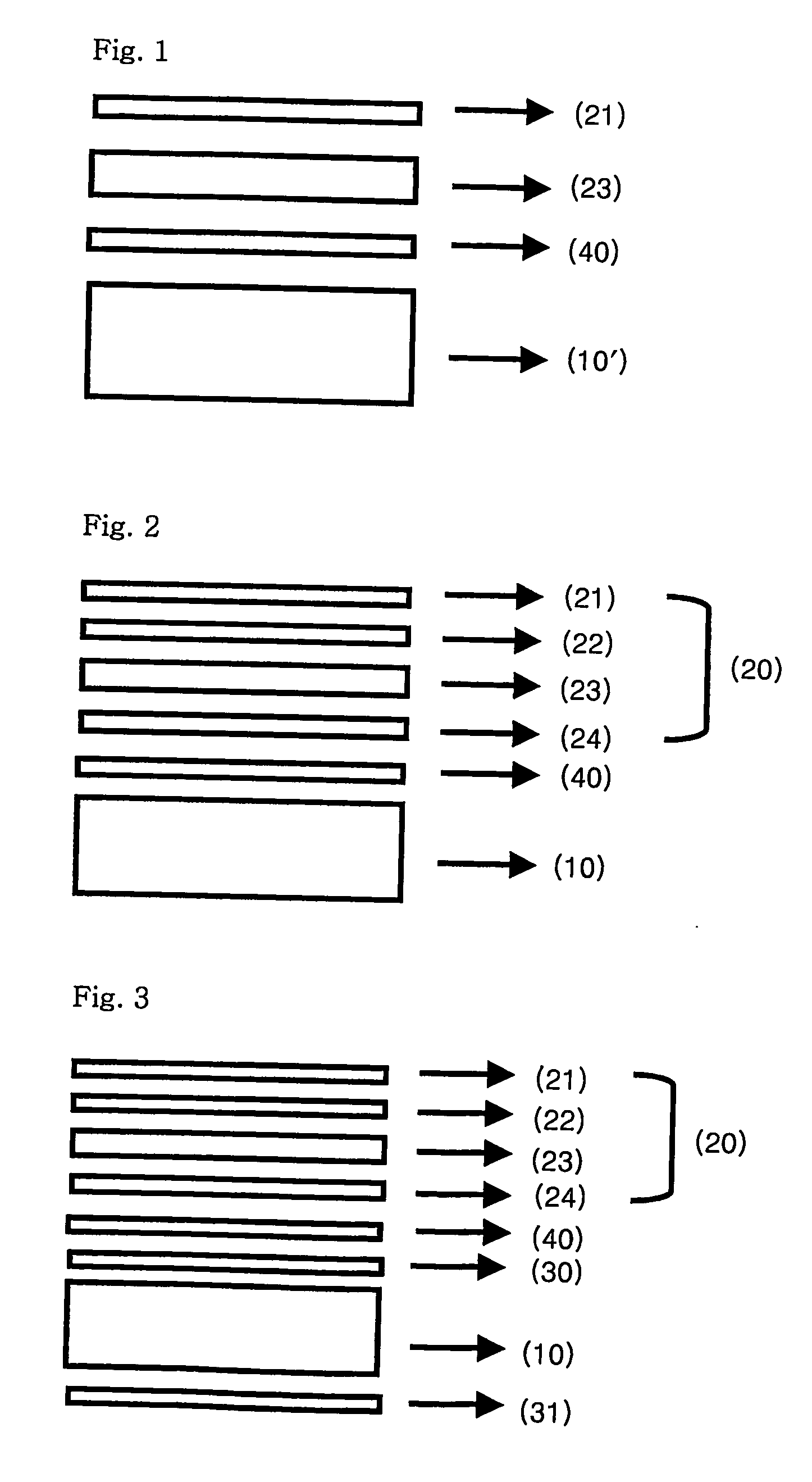

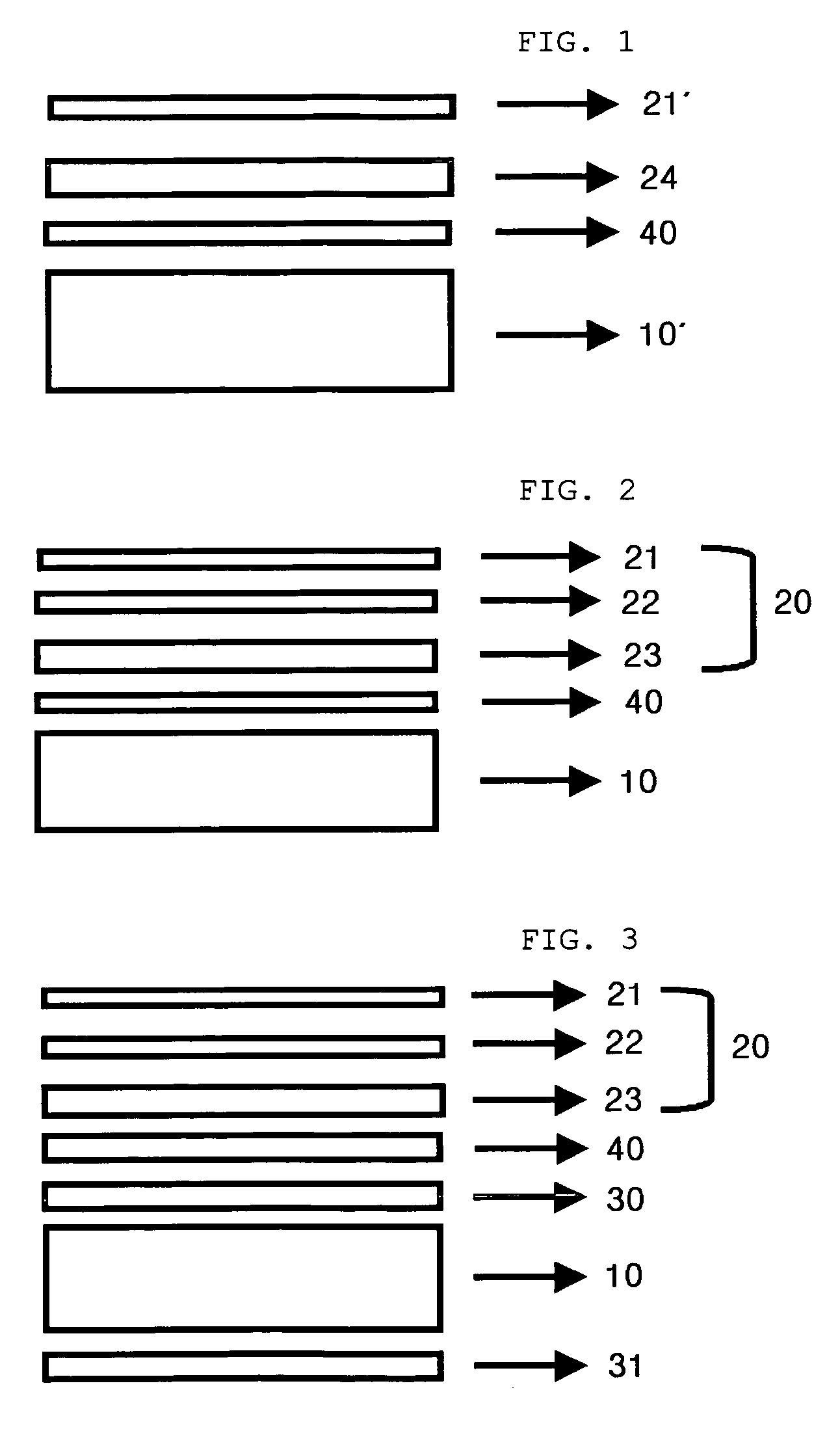

Limited play data storage media and method for limiting access to data thereon

InactiveUS20030002431A1Improve reflectivityGuaranteed playabilityPhotography auxillary processesPhotosensitive materialsOptical storageEngineering

The present disclosure relates to a limited play optical storage media and a method for limiting access to data thereon. This storage media comprises: an optically transparent substrate; a reflective layer; a data storage layer disposed between said substrate and said reflective layer; an oxygen penetrable UV coating disposed on a side of said substrate opposite said data storage layer; and a reactive layer disposed between said UV coating and said substrate, said reactive layer having an initial percent reflectivity of about 50% or greater and a subsequent percent reflectivity of about 45% or less.

Owner:NBCUNIVERSAL

Ultraviolet curing paint and preparation method and application thereof

ActiveCN102070981AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsPolyether coatingsPolyesterPliability

The invention discloses an ultraviolet (UV) curing paint and a preparation method and application thereof. The preparation method comprises the following steps: weighting modified SiO2 sol to place in a container, adding water-soluble UV-cured resin, solvent and additive in turn, stirring for 10min, then adding photoinitiator, and stirring for 5min to obtain the UV curing paint, wherein the contents of the water-soluble UV-cured resin, the solvent, the additive and the photoinitiator are 10-60%, 7-33%, 0.1% and 2% respectively. The UV curing paint prepared by the method of the invention has the advantages of inorganic materials such as high hardness, high wear resistance, scratch resistance and good thermal stability and also has the advantages of organic materials such as adhesivity and relative flexibility; and the UV curing paint is suitable to be used as the protective coatings on the surfaces of all kinds of optical plastic products such as polyester which contains polycarbonate, polymethylmethacrylate, polyethylene terephthalate (PET) and the like. By adopting the UV curing paint of the invention, the defects of the existing UV curing paint in the aspects of hardness, wear resistance, scratch resistance and light transmittance, can be overcomed to a certain extent.

Owner:GUANGZHOU HUMAN CHEM

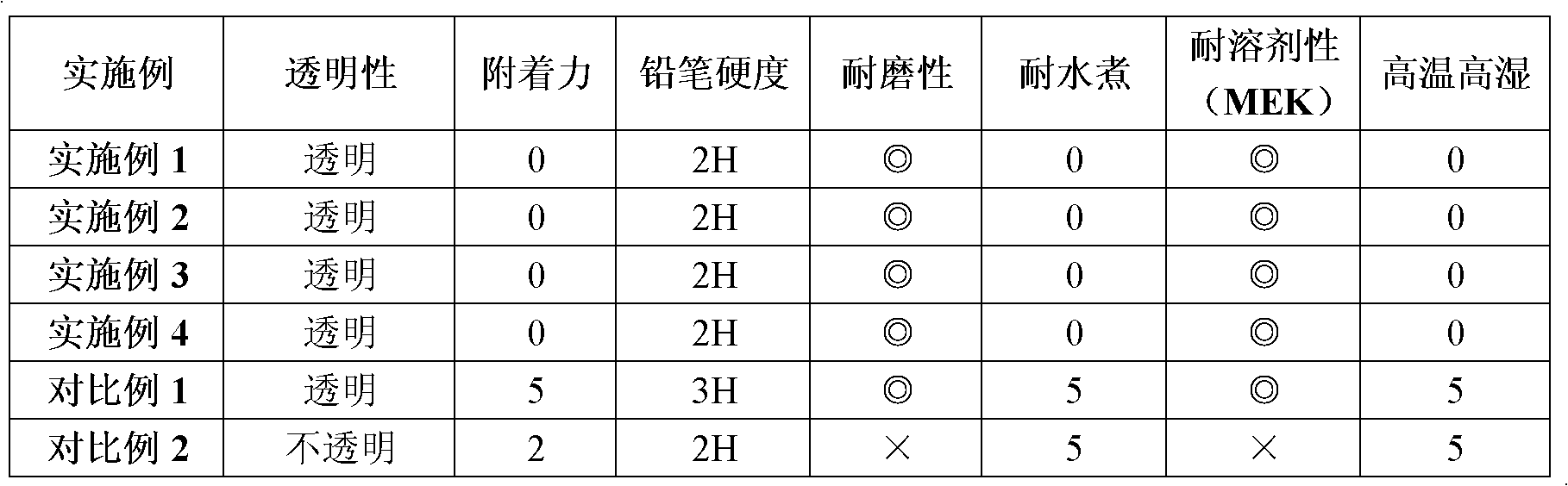

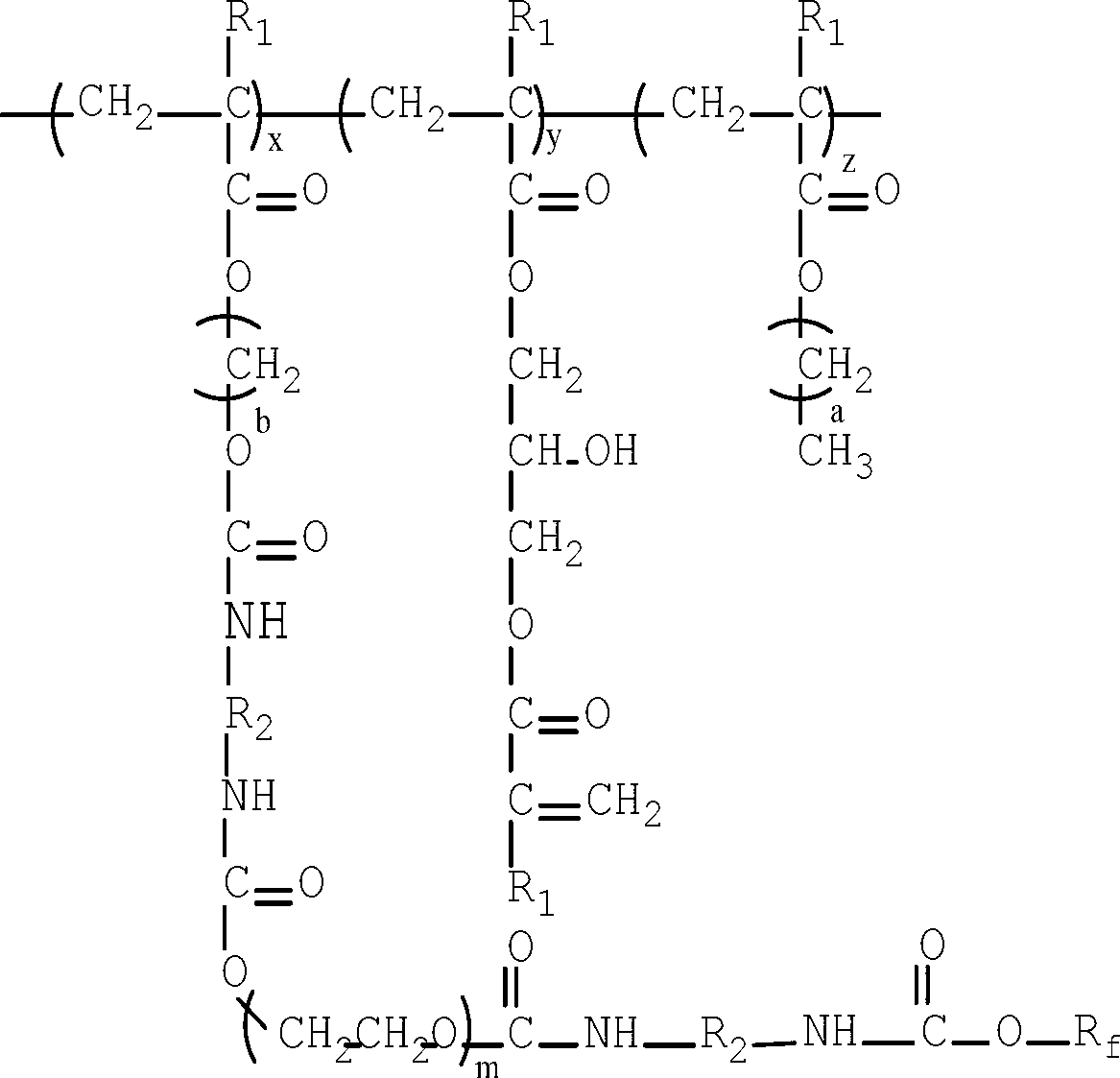

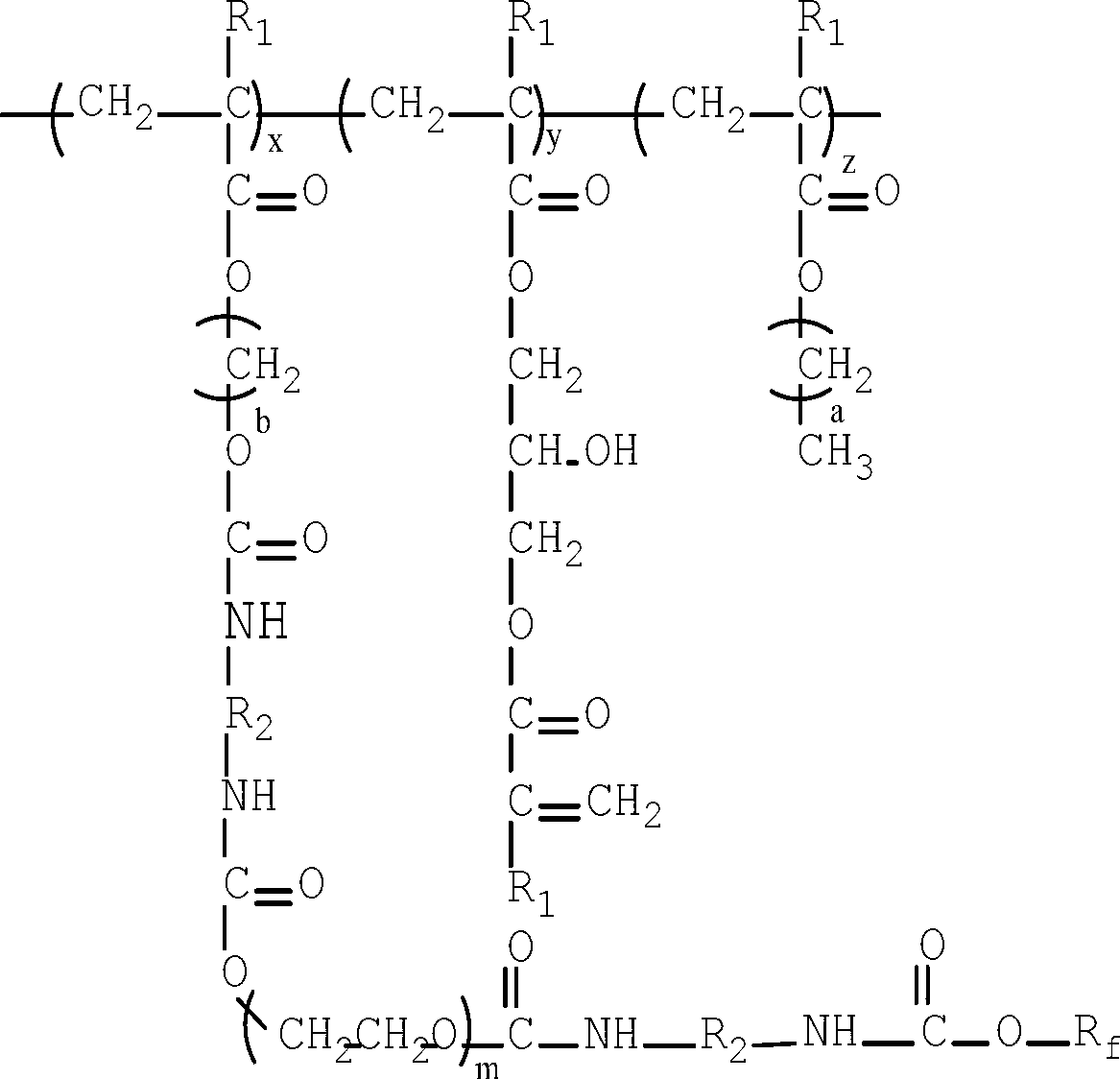

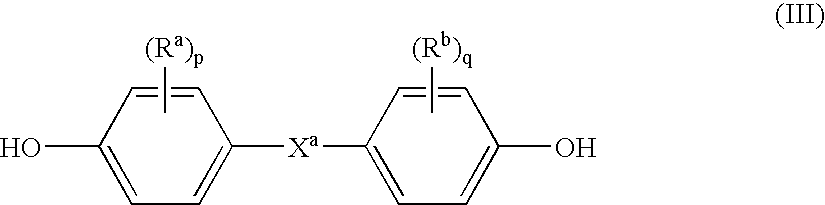

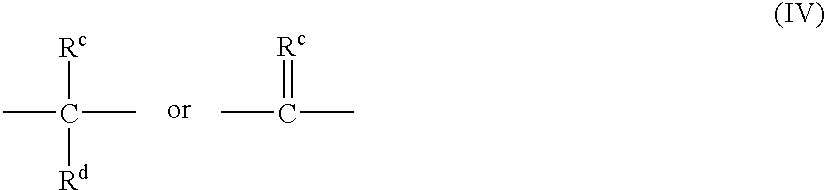

Polyurethane/polyacrylate copolymer modified by organic fluoride and ultraviolet curing coating prepared by polyurethane/polyacrylate copolymer

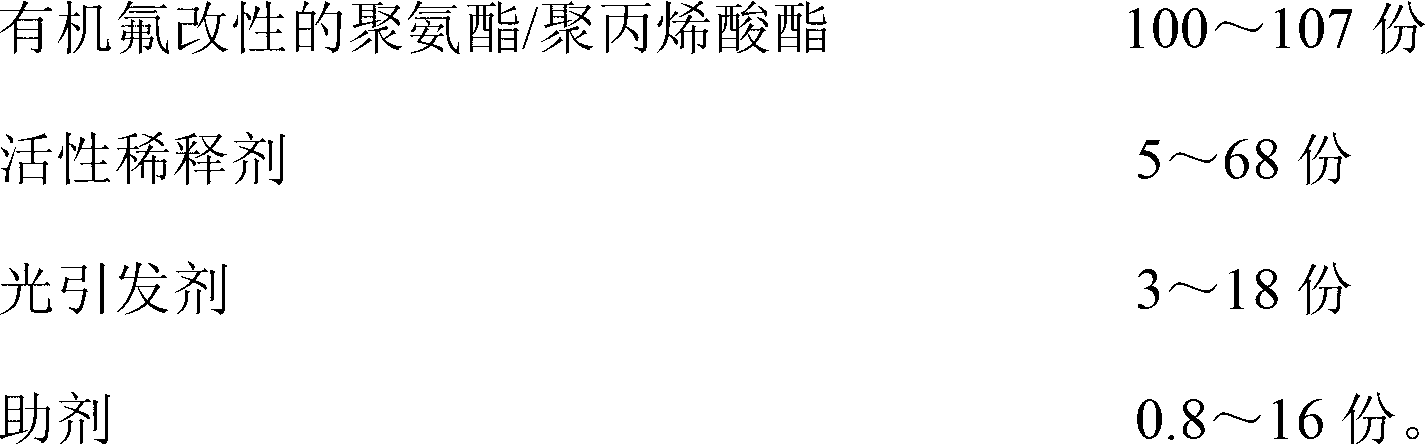

The invention belongs to the field of coatings, and particularly relates to a polyurethane / polyacrylate copolymer modified by organic fluoride and an ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer. A method for preparing the polyurethane / polyacrylate copolymer modified by organic fluoride comprises the following steps: 1), preparing a polyurethane prepolymer modified by organic fluoride; 2), preparing a (methyl) acrylate prepolymer; and 3), preparing the polyurethane / polyacrylate copolymer modified by organic fluoride. A method for preparing an ultraviolet curing agent by taking the polyurethane / polyacrylate copolymer modified by organic fluoride as a raw material comprises the steps that taking 100-107 parts of polyurethane / polyacrylate, 50-68 parts of an reactive diluent, 13-18 parts of a photoinitiator and 8-16 parts of an auxiliary; stirring fully for 5-15 minutes until all the materials are mixed uniformly; and obtaining the polyurethane / polyacrylate copolymer modified by organic fluoride and the ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Limited play data storage media and method for limiting access to data thereon

InactiveUS6733950B2Reducing percent reflectivityReduce the amount requiredPhotography auxillary processesPhotosensitive materialsEngineeringOptical storage

The present disclosure relates to a limited play optical storage media and a method for limiting access to data thereon. This storage media comprises: an optically transparent substrate; a reflective layer; a data storage layer disposed between said substrate and said reflective layer; an oxygen penetrable UV coating disposed on a side of said substrate opposite said data storage layer; and a reactive layer disposed between said UV coating and said substrate, wherein said optical storage media has an initial percent reflectivity of about 50% or greater and a subsequent percent reflectivity of about 45% or less.

Owner:NBCUNIVERSAL

Ultraviolet curing coating for preventing static on plastic surface and method for preparing the same

InactiveCN101423675ALight weightGood electrical conductivityElectrically-conductive paintsSolventPhotoinitiator

The invention relates to an ultraviolet photo-cured coating for the electrostatic prevention of the surface of plastic and a preparation method thereof, in particular to a photo-cured coating containing conductive powder of a metal oxide system or composite conductive powder. The coating comprises the following compositions in weight percent: 30 to 70 percent of oligomer, 25 to 65 percent of active thinner, 0.5 to 10 percent of light evocating agent, 5 to 40 percent of conductive powder, 0.2 to 8 percent of additive and 0 to 50 percent of solvent. As the added conductive powder of the metal oxide system and the composite conductive powder is white or light color, the prepared photo-cured has the characteristic of easy color modulation, has lasting antistatic property, high rigidity and wearing resistance, can be used for electrostatic prevention of the surface of electronic equipment, plastic vessel, shell of an electric appliance, office supplies, sports equipment and other plastic products.

Owner:SICHUAN UNIV

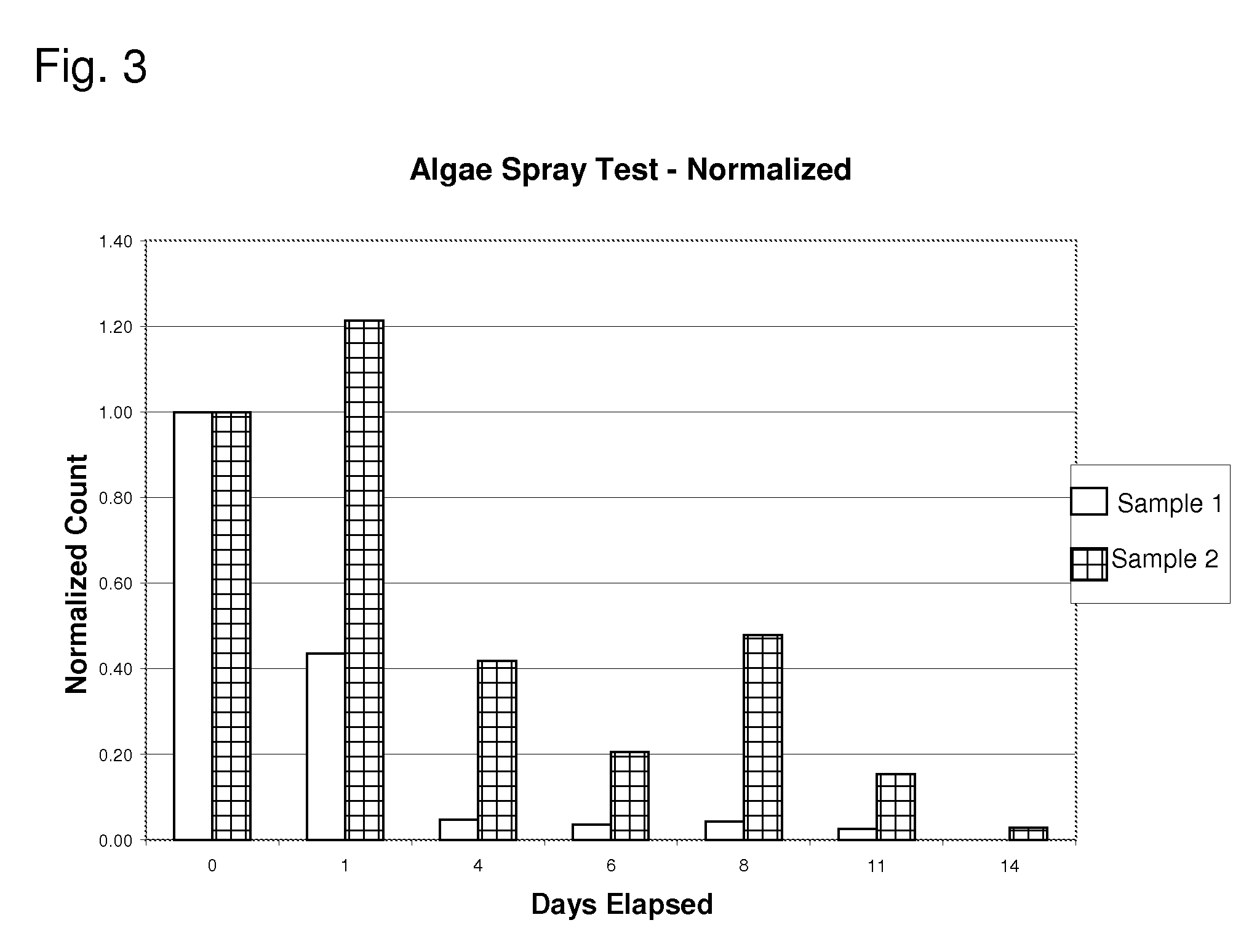

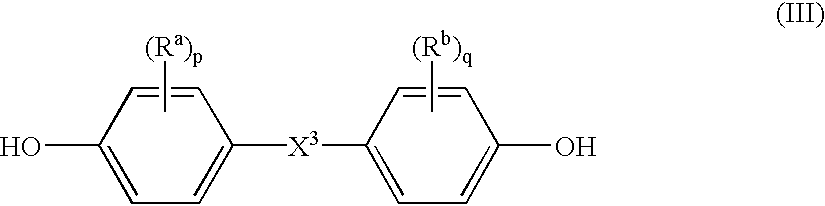

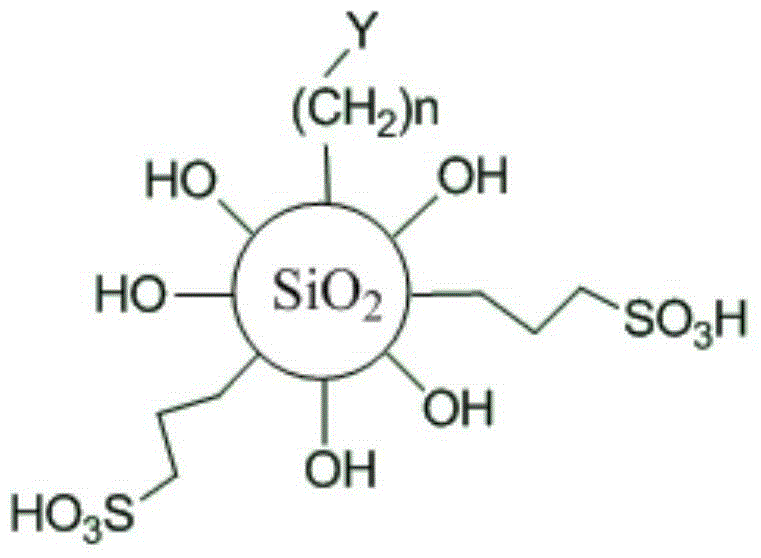

Reactive surfactants for emulsion polymerization, pigment dispersion, and UV coatings

ActiveUS20130047892A1Reduce the amount requiredIncrease in coating repellencyPigmenting treatmentTransportation and packagingArylEmulsion polymerization

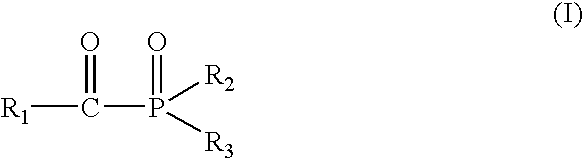

The present invention provides reactive surfactants of the formulaR1O—(CH2CHR2O)x—(CH2CH2O)y—(CH2CHR3O)z—R4 where R1 is either alkyl, aryl, alkylaryl, or aralkylaryl of 8-30 carbon atoms, R2 is —CH2OCH2CH═CH2 (AGE); R3 is either H, CH3, or CH2CH3; R4 is H or —SO3M or —PO3M where M is H or K, Na, NH4, NR4, alkanolamine, or other cationic species and x=2-100; y=4-200 and z=0-50.

Owner:ETHOX CHEM LLC

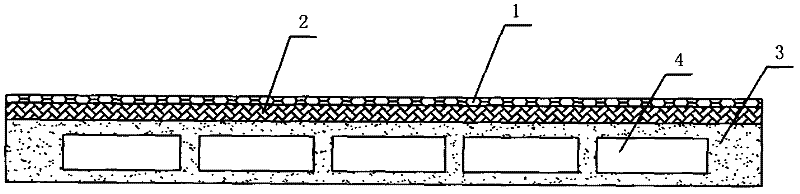

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

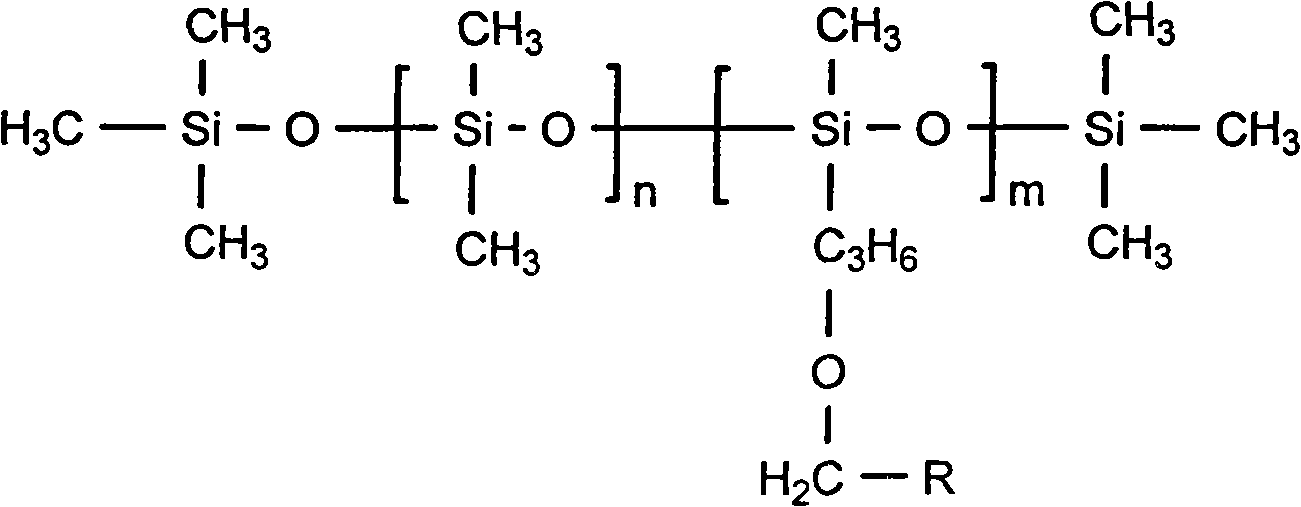

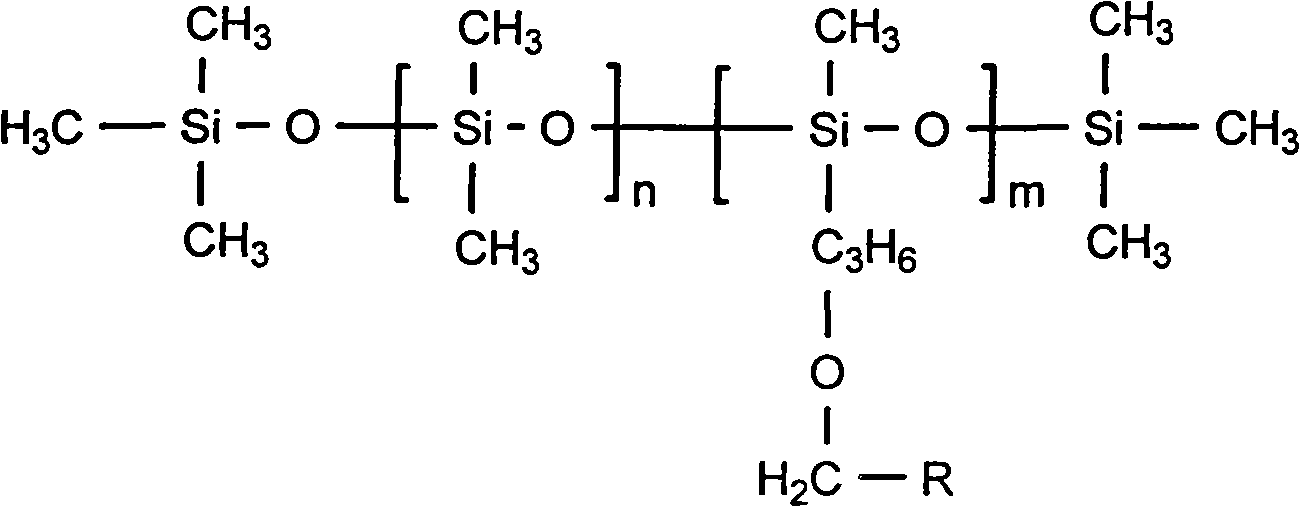

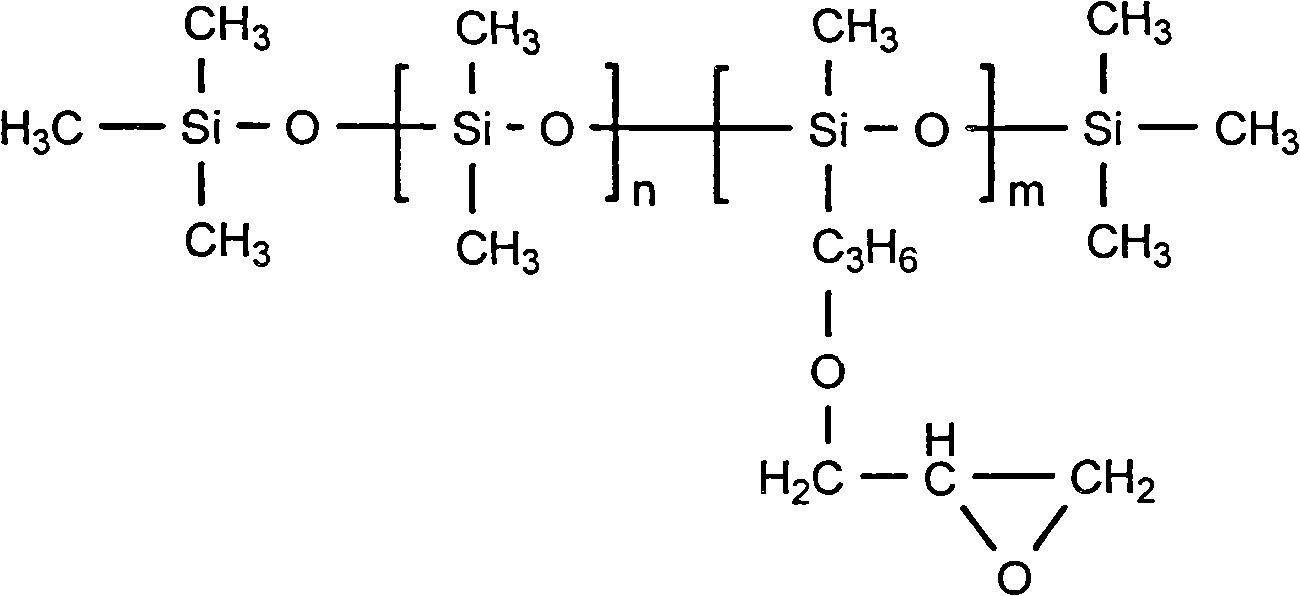

Organic silicon-modified water-based UV (ultraviolet) coating and preparation method thereof

ActiveCN103555192AStir wellFast curing ratePolyurea/polyurethane coatingsUrethane acrylateAcrylate ester

The invention relates to an organic silicon-modified water-based UV (ultraviolet) coating and a preparation method thereof, and belongs to the technical field of environment-friendly coatings. The organic silicon-modified water-based UV coating comprises the following components in percentage by mass: 30 to 55 percent of organic silicon-modified hyperbranched water-based urethane acrylate, 20 to 50 percent of filler, 1 to 10 percent of photoinitiator, 0 to 3 percent of auxiliaries and 5 to 30 percent of water. The preparation method comprises the following steps: fully grinding the organic silicon-modified hyperbranched water-based urethane acrylate, the filler and water in a proportion, performing dispersion for 1 to 2 hours at 40 to 50 DEG C at a rotating speed of 400 to 600rpm, adding the photoinitiator and the auxiliaries, and uniformly stirring and standing a mixture to obtain the water-based UV coating. The coating is environment-friendly, nontoxic, high in curing speed, stability, aging resistance, solvent resistance, adhesive power and abrasion resistance and suitable for a plurality of coating modes and production requirements, and can be widely applied to the surfaces of automobiles, electronic products, ships, furniture and packaging printing materials.

Owner:WUHAN UNIV

Epoxy organosilicone ultraviolet curing coating modified by (methyl) acrylic acid and preparation method thereof

ActiveCN101555386AEasy to synthesizeIncrease crosslink densityEpoxy resin coatingsPhotoinitiatorWeather resistance

The invention discloses epoxy organosilicone ultraviolet curing coating modified by (methyl) acrylic acid and a preparation method thereof. The coating comprises epoxy organosilicone modified by (methyl) acrylic acid, an epoxy (methyl) acrylate resin, active diluent, a photoinitiator, an epoxy hardener and an auxiliary agent. The coating not only has the advantages of the epoxy organosilicone modified by (methyl) acrylic acid, has high toughness, weather resistance and water resistance, but also needs no organic solvents in the process of preparing the coating and enjoys simple required curingconditions.

Owner:CHANGXING PHOTOELECTRIC MATERIAL

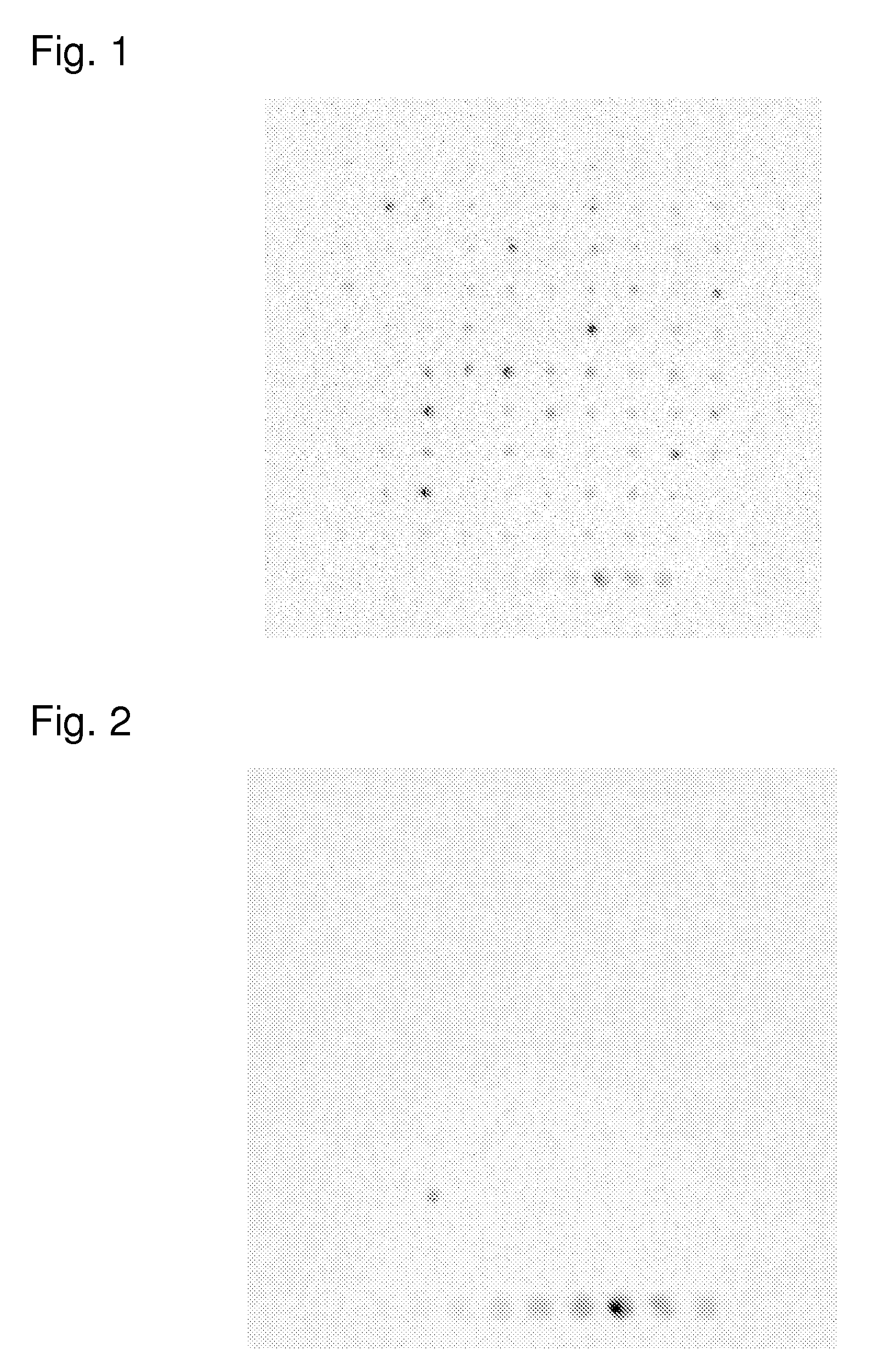

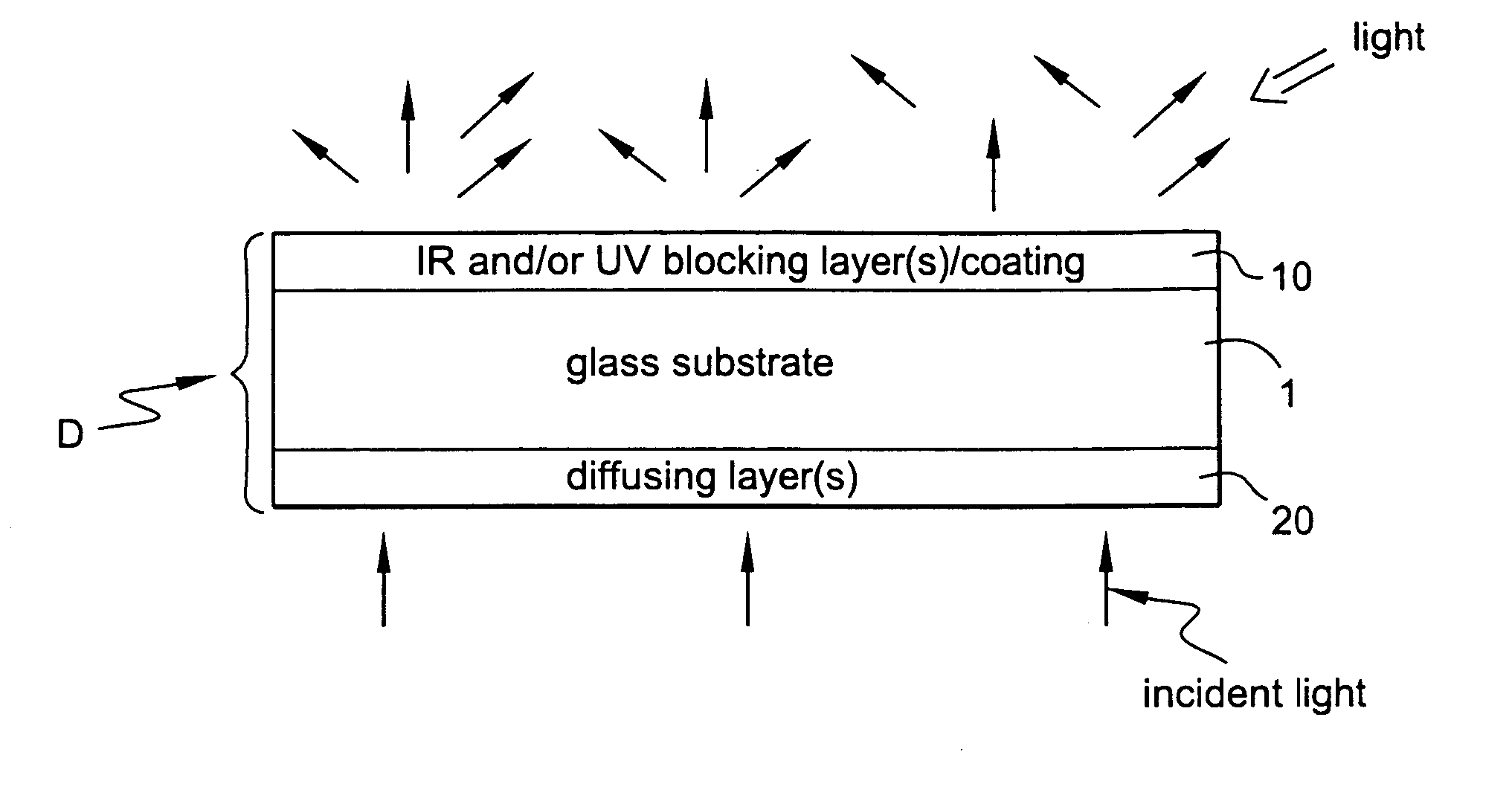

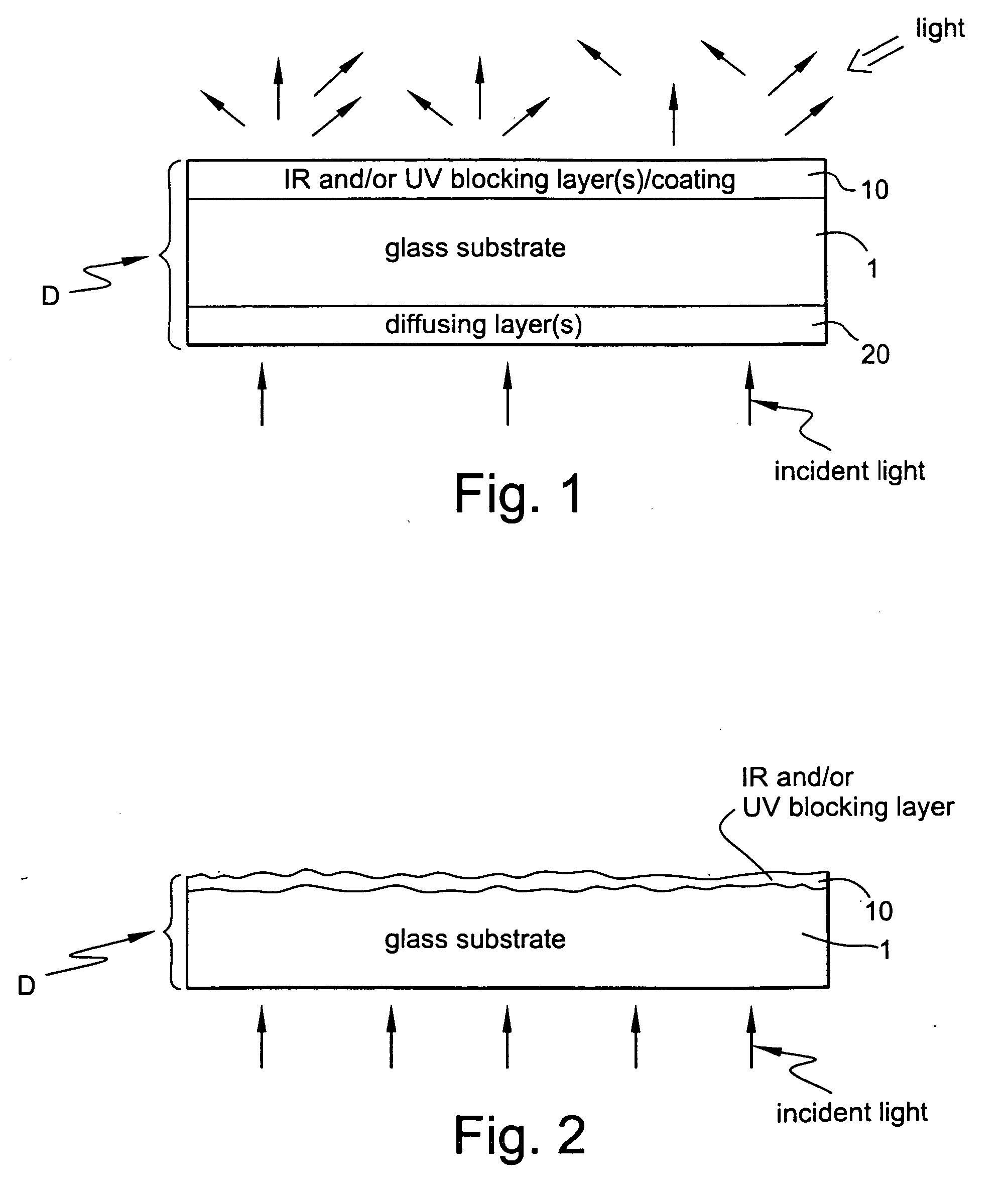

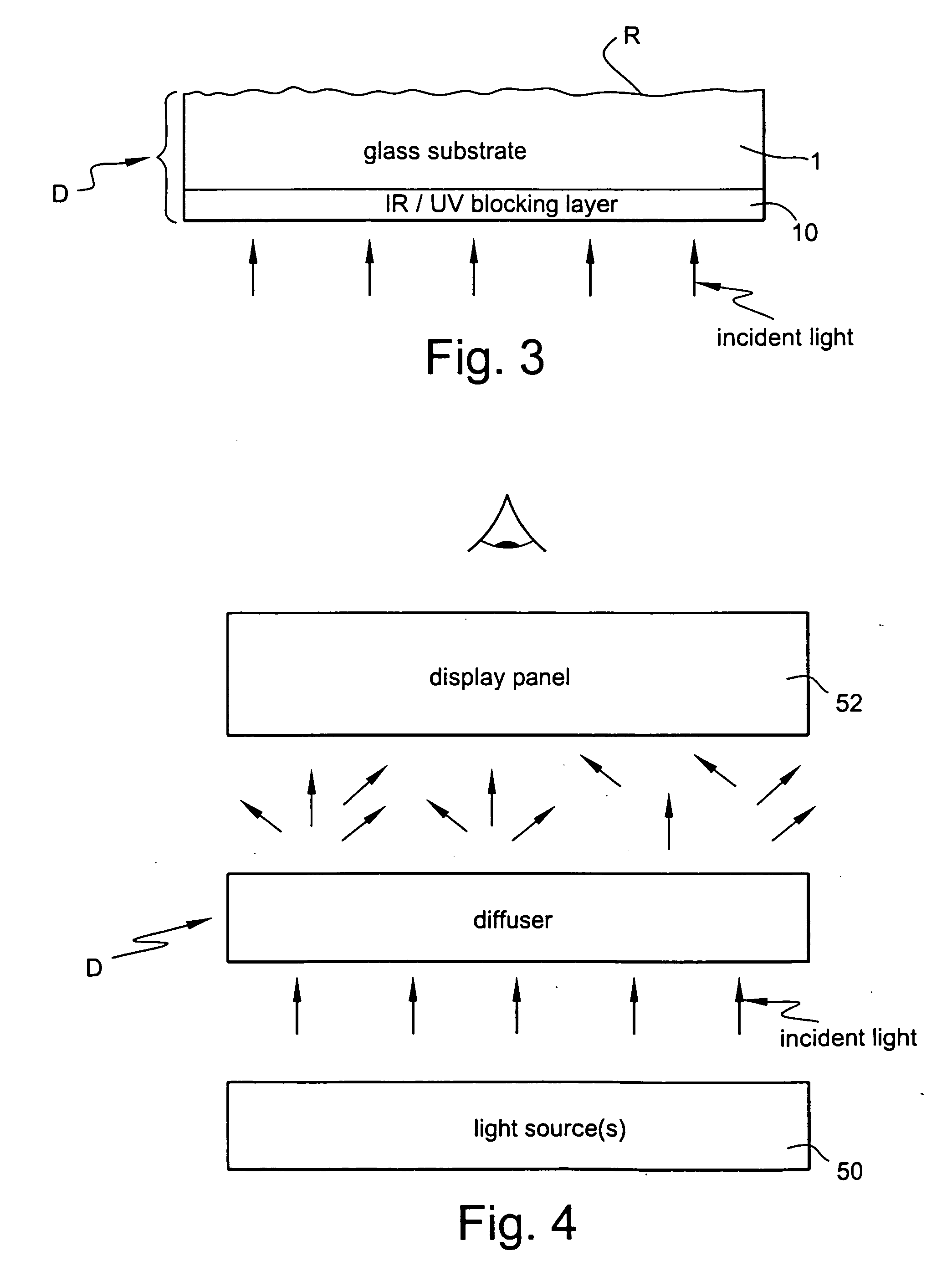

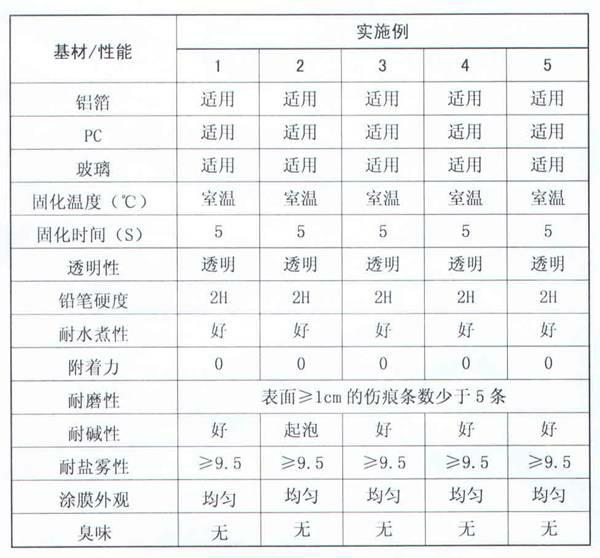

Optical diffuser with IR and/or UV blocking coating

InactiveUS20070064446A1Reduce amountBlock significant amountGlass/slag layered productsCoatingsParticulatesFrit

A diffuser is provided in an illumination system, where the diffuser is capable of blocking significant amounts of infrared (IR) and / or ultraviolet (UV) radiation. In certain example embodiments of this invention, the diffuser includes a glass substrate which supports an IR / UV coating(s) that blocks significant amounts of IR and / or UV radiation thereby reducing the amount of IR and / or UV radiation which can makes its way through the diffuser. In certain example embodiments, the coating may include particulate in a frit matrix so that the coating may both diffuse visible light and perform IR and / or UV blocking.

Owner:GUARDIAN GLASS LLC

Fluoropolymer/inorganic nano-hybrid particle modified ultraviolet photocured paint and preparation method thereof

InactiveCN101824273AFunctionalDoes not affect transparencyPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceFluoropolymer

The invention discloses a fluoropolymer / inorganic nano-hybrid particle modified ultraviolet photocured paint and a preparation method thereof. The paint consists of ultraviolet photocured substrate resin added with a fluorine-containing acrylate monomer and an active ingredient which is fluoropolymer / inorganic nano-hybrid particles; the preparation process of the hybrid particles comprises the following steps of: firstly, grafting an ATRP evocating agent or an RAFT chain transfer agent on the surfaces of the inorganic nano-particles; and then, performing surface graft polymerization and modification on the inorganic nano-particles to obtain the fluoropolymer / inorganic nano-hybrid particles. The paint has both super-hydrophobic and super-oleophobic functions; and the contact angle reaches between 153 and 175 degrees.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

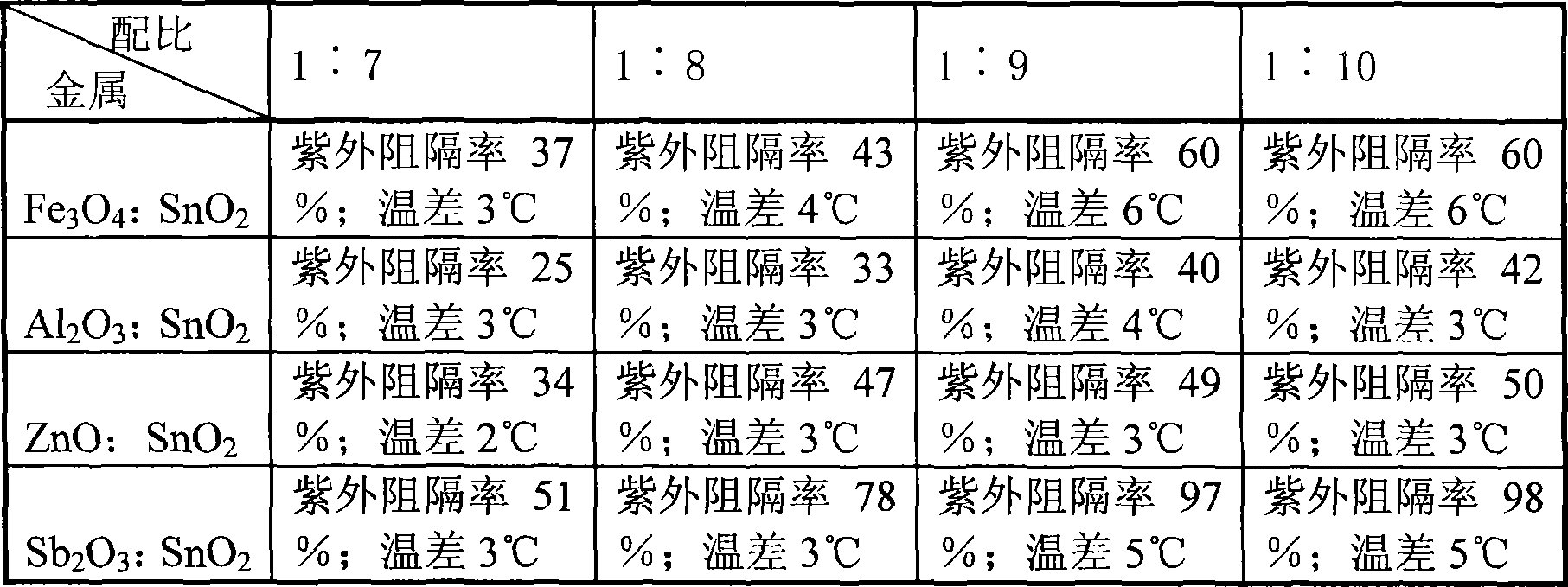

Organosilicon-modified polyurethane-acrylic ester photocurable coating and preparation method thereof

InactiveCN102559038AUniform particle size distributionSmall particle sizePolyurea/polyurethane coatingsPolymer scienceUrethane acrylate

The invention relates to an organosilicon-modified polyurethane-acrylic ester photocurable coating and a preparation method thereof. The photocurable coating comprises the following components in percentage by weight: 25 to 60 percent of polyurethane-acrylic ester, 20 to 55 percent of organic polysilane, 5 to 15 percent of solvent, 1 to 5 percent of photoinitiator and 0.05 to 4.5 percent of aid. The preparation method comprises the following steps of: weighing the organic polysilane according to the amount of a formula, putting into a container, sequentially adding a polyurethane-acrylic ester photocurable resin, the solvent and the aid, mixing uniformly, adding the photoinitiator, stirring uniformly to obtain an ultraviolet-photocurable coating, and preserving in a dark place. The ultraviolet-photocurable coating composition can be coated on base materials such as plastics, metals, glass and the like; a coating subjected to ultraviolet photocuring has excellent wear resistance and mechanical properties; and meanwhile, the coating has excellent adhesion, water resistance, salt fog resistance and alkali resistance.

Owner:CHANGSHA YUANPENG CHEM TECH

Ultraviolet curing coating composition and preparation method thereof

ActiveCN102807805AImprove the lubrication effectReduce coefficient of frictionEpoxy resin coatingsPhotoinitiatorPolymer chemistry

The invention provides an ultraviolet curing coating composition, wherein the ultraviolet curing coating composition comprises the following components, by mass, 30-65 wt% of an epoxy acrylic acid monoester, 15-50 wt% of a fluorine-modified epoxy acrylate, 5-20 wt% of an active diluent monomer, 3-10 wt% of a photoinitiator, 2-40 wt% of a pigment, and 0.5-6 wt% of an additive. The invention further provides a preparation method for the ultraviolet curing coating composition. The ultraviolet curing coating composition of the present invention has the following advantages that: complete curing is easily achieved, and the formed coating after curing does not have shrinkage holes and shrinkage patterns, has a good wetting performance, and provides good adhesion for substrates.

Owner:BYD CO LTD

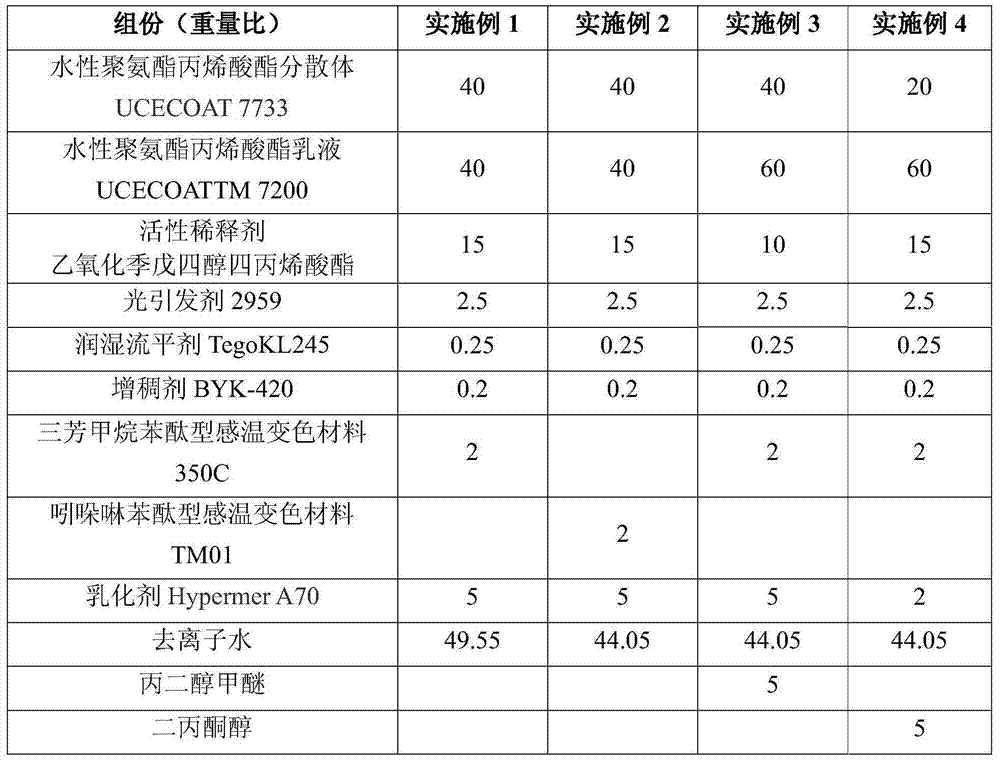

Method for preparing non-toxic visible ultraviolet heat insulating UV coating material

InactiveCN101423676AEasy to keep freshEasy to storeFlexible coversWrappersPolyesterUltraviolet lights

The invention relates to a method for preparing a nontoxic visible ultraviolet and heat insulation UV coating for food packaging and belongs to a composite material for packaging and the field of a photocuring technology. The invention relates to a white carbon black and metal doped tin oxide nanometer powder body composite ultraviolet photo-cured coating which can improve the capacity of ultraviolet insulation and heat insulation; the coating mainly comprises a photosensitive oligomer, an active thinner, a light evocating agent, white carbon black and metal doped tin oxide, a filler and an additive. The UV coating material has innocuity and harmlessness, can obstruct ultraviolet light of over 97 percent and infrared light of over 80 percent in daylight, has functions of transparence, heat insulation, sterilization and uneasy gleization, is in particular suitable for a visible plastic food packaging bag, a transparent polyester food vessel and the like, is convenient to keep food fresh and store food, prolongs guarantee period of food and reduces the deterioration and waste of food. The UV coating is not added with an organic solvent, is favorable for environmental protection, and has convenient construction and obvious environmental, social and economic benefits.

Owner:JIANGNAN UNIV

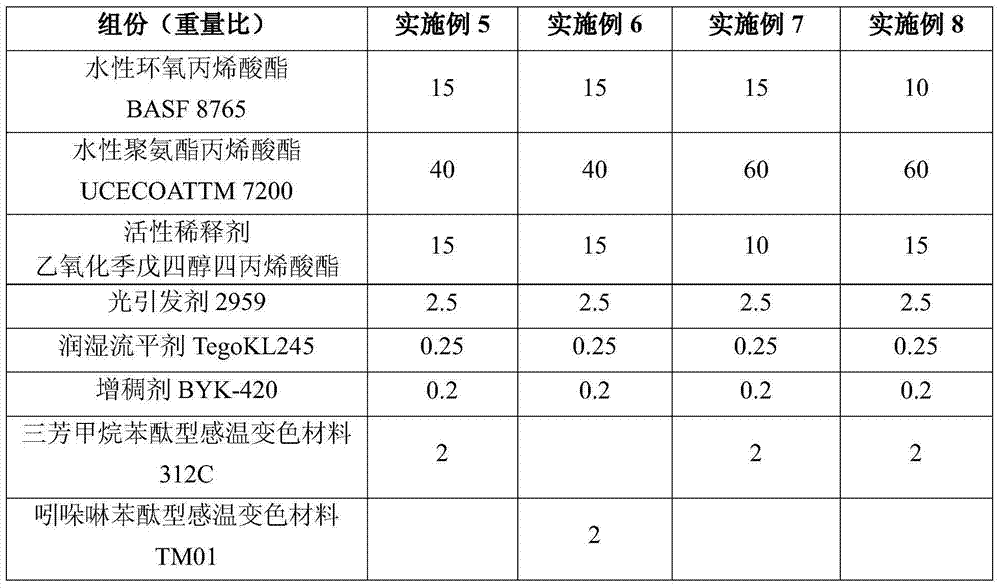

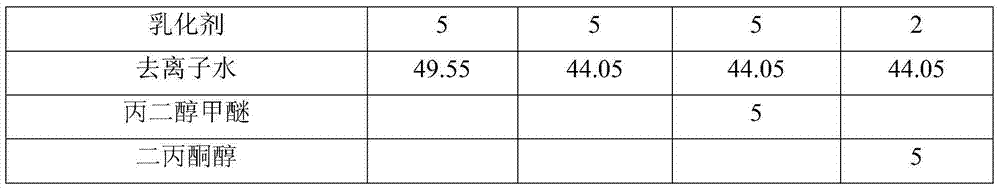

Thermochromic water-based UV coating and preparation method thereof

ActiveCN104497847ASimple preparation processEase of industrial productionPolyurea/polyurethane coatingsThermosensitive paintsWater basedReactive diluent

The invention discloses a thermochromic water-based UV coating which comprises the following components in percentage by mass: 30-60 percent of a water-based resin, 5-25 percent of a reactive diluent, 1-5 percent of a photoinitiator, 0.5-10 percent of a thermochromic material, 0.05-1 percent of a wet flatting agent, 0.05-2 percent of a thickening agent, 0.1-5 percent of an emulsifier, 0.1-2 percent of a defoaming agent, 0-8 percent of a coalescing agent and 25-60 percent of deionized water. The invention also discloses a method for preparing the thermochromic water-based UV coating. According to the thermochromic water-based UV coating provided by the invention, microcapsules do not need to be prepared in advance, the preparation process is simple and convenient, and large-scale industrial production is facilitated.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

UV curable coating composition

InactiveUS20050238815A1Impression capsPolyurea/polyurethane coatingsPolyesterPolyurethane dispersion

The present invention is directed to a composition curable by radiation having a wavelength of 300 nm or more, a method of producing a coated substrate using such composition and the coated product so-produced. More particularly, the composition of the present invention comprises A) from about 1 to about 99% by weight of a specific aqueous polyurethane dispersion having a solids content of from about 20 to about 50% by weight, B) from about 1 to about 99% by weight of an aqueous polyester acrylate / urethane dispersion having a solids content of from about 20 to about 60% by weight, C) one or more photoinitiators, and D) water or a mixture of water and solvent

Owner:BAYER MATERIALSCIENCE AG

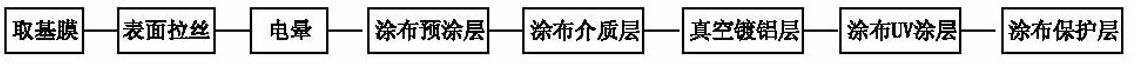

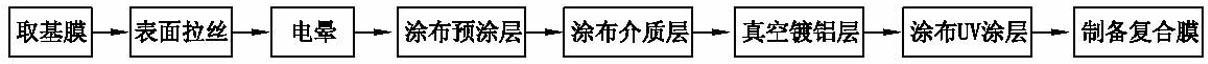

Manufacture process of imitation stainless steel metal drawbench film

InactiveCN102642439AIncrease the dyne coefficientHigh fastnessLamination ancillary operationsSynthetic resin layered productsPolyesterAcrylic coating

The invention discloses a manufacture process of an imitation stainless steel metal drawbench film, which comprises the following steps: 1 taking a base film which is a polyester (PET) film; 2 conducting surface drawbench and surface polishing one surface of the base film; 3 conducting surface corona and conducting corona processing on two surfaces of the base film, 4 conducting precoat coating and conducting network roller coating on the surface of the base film receiving surface drawbench and corona processing through methyl methacrylate coating, 5 conducting media layer coating and conducting network roller coating on a precoat through acrylic coating, 6 conducting vacuum aluminizing on the media layer, 7 conducting ultraviolet (UV) coating coating and conducting network roller coating on one face of the base film without surface drawbench through colored translucent UV coating, and 8 conducting protection layer coating and preventing an aluminizing layer from being oxidized. The manufacture process improves product structure firmness, and ensures optimum using effects of products. The products can show different gloss effects from dumb light to high light, thereby meeting requirements for environment protection.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Urethane acrylate waterborne UV coating and preparation method thereof

ActiveCN101629050ALow VOC contentPrevent extractionPolyurea/polyurethane coatingsPolyether coatingsSocial benefitsEmulsion

Owner:GUANGDONG HUARUN PAINT CO LTD

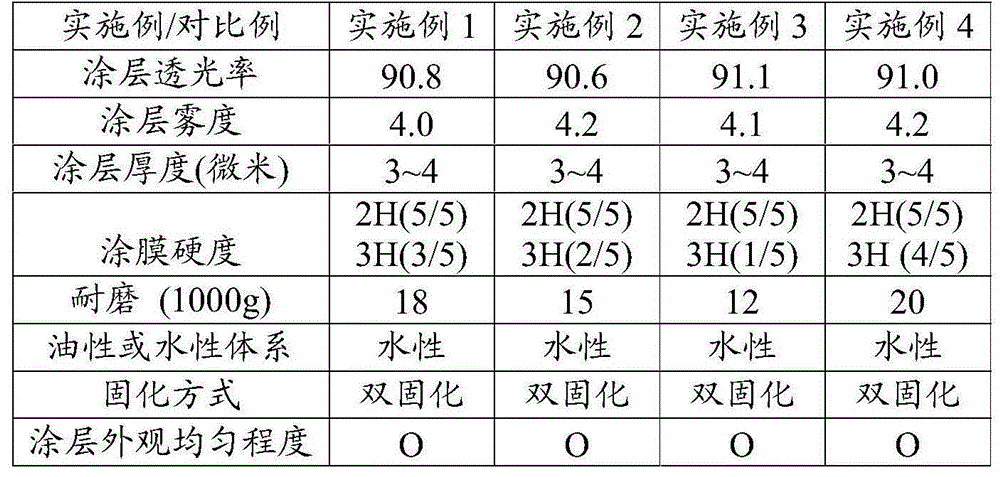

Water-based anti-dazzle UV coating, hard coated film and preparation method of hard coated film

The invention provides water-based anti-dazzle UV coating. The water-based anti-dazzle UV coasting comprises, by weight, 30-90 parts of waterborne polyurethane urethane acrylate prepolymer, 10-60 parts of diluting monomers, 5-100 parts of anti-dazzle particles, 0.05-10 parts of waterborne wetting dispersant, 0.05-5 parts of waterborne flatting agents, 1-20 parts of water, 0.5-10 parts of waterborne photoinitiator and 1-30 parts of waterborne isocyanate curing agents. The water-based anti-dazzle UV coating is water-based coating and is environmentally friendly, waterborne isocyanate curing agents are matched with the waterborne polyurethane urethane acrylate prepolymer and the diluting monomers, and the overall abrasion resistance of a coating obtained after the water-based anti-dazzle UV coating is cured can be obviously improved. The invention further provides a hard coated film and a preparation method of the hard coated film. An experimental result indicates that the rigidity of the hard coated film formed by the coating is 3 H, and no scratch is generated even though the hard collated film is rubbed by 1,000 g of loads 20 times.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Wood flooring laminated with high pressure veneer and impregnated low weight printing paper

InactiveUS20060062966A1Improves poor realityImprove surface strengthCovering/liningsSpecial ornamental structuresThermoplasticWood veneer

Disclosed herein is a UV surface-coated laminate wood flooring for an under-floor heating system comprising a back-grooved base, an adhesive layer and a printed wood veneer layer wherein the printed wood veneer layer is produced by impregnating and coating a low-basis weight printed paper with a thermoplastic or thermosetting resin, integrally forming the paper layer with a low-price reinforcing layer by pressing under high pressure, treating the surface of the paper layer with an acryl based primer, and coating the primer-treated paper layer with a solvent-free type UV coating paint, and wherein the back-grooved base and the printed wood veneer layer are adhered to each other by the adhesive layer.

Owner:LG CHEM LTD

Antistatic abrasion-resistant UV coating and preparation method thereof

InactiveCN101851466AReduce electrostatic adsorption capacityLow wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsUV coatingSodium hydroxide

The invention specifically relates to an antistatic abrasion-resistant UV coating and a preparation method thereof, and belongs to the field of materials. The antistatic abrasion-resistant UV coating comprises the following components in percentage by mass: 5 to 35 percent of multifunctional polyurethane acrylate, 15 to 45 percent of epoxy acrylate, 10 to 40 percent of reactive diluent, 2 to 12 percent of photoinitiator, 0.5 to 3 percent of other additives, 5 to 25 percent of conductive nano-attapulgite powder, and 0.05 to 0.5 percent of silane coupling agent. The coating of the invention has an appearance of white liquid or light yellow liquid; the surface resistance of a coat prepared by the coating of the invention is 4.8*10<6> to 6.5*10 <8> ohms; the 100-revolution weight loss in the Taber abrasion resistance test is 0.0045 to 0.0075 gram; and the surface hardness is more than or equal to 3 H; and the coating does not change after dipping in 5 percent sodium hydroxide for 24 hours. The antistatic abrasion-resistant UV coating of the invention has the advantages of simple preparation, low cost, convenient use, good effect and wide application prospect.

Owner:CHANGSHA HUALIANG COATING

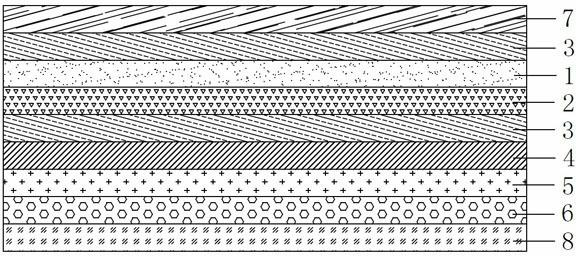

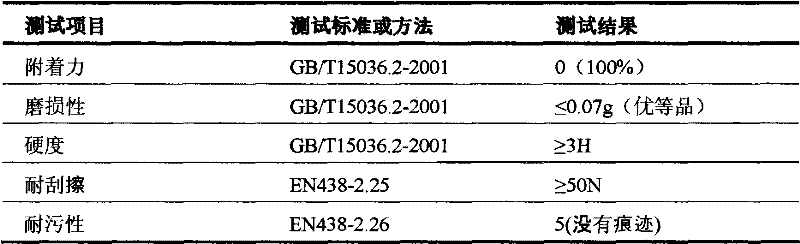

High-wear-resistance antiscratch and antifouling solid wood board ultraviolet (UV) curable coating system

The invention belongs to the field of ultraviolet curable new materials and particularly relates to a protective and decorative coating system for solid wood boards such as solid wood floorings, multilayer solid wood boards, bamboo floorings, reinforced composite floorings, furniture and the like. The invention provides a high-wear-resistance antiscratch and antifouling solid wood board ultraviolet curable coating system, which is abbreviated as 3N UV coating system coating. The high-wear-resistance antiscratch and antifouling solid wood board ultraviolet curable coating system consists of UVundercoat, UV wear-resistance topcoat and UV antifouling topcoat. Soft and hard or hard and soft alternating coating is performed according to the hardness and flexibility of films formed by the UV undercoat, the UV wear-resistance topcoat and the UV antifouling topcoat are coated, under the action of a photoinitiator, the UV wear-resistance topcoat and the UV antifouling topcoat are cured by ultraviolet to form films respectively, and thus, soft and hard alternating multilayer coating film structures with different flexibilities and high interlayer adhesive force are formed and the characteristics of high wear resistance, high scratch resistance and high fouling resistance are realized.

Owner:刘立新 +1

Ultraviolet light solidifying coating and preparation method thereof

The invention discloses au uv-curing coatings. It comprises main resin, diluting agent and light initiator, addictive or not. The coating also comprises hydroxy acrylate and isocyanate curing agent, which will solidify into membrane when heated at 60 Deg. C, the membrane enables the hardness and wear resistance of paint membrane to meet the demand, then cures the main resin under low UV light radiation.

Owner:BYD CO LTD

Stone plastic floor and processing method thereof

InactiveCN102304970ASatisfaction is not destroyedMeet the needs of useCeramic shaping apparatusFlooringSolid woodSurface layer

The invention discloses a stone plastic floor and a processing method thereof. The stone plastic floor consists of a bottom layer serving as a supporting main body, a surface layer bonded on the top face of the bottom layer, and an ultraviolet (UV) coating layer bonded on the surface layer, wherein the bottom layer is formed by mixing polyvinyl chloride resin and marble powder; the surface layer is a solid wood veneer; and the UV coating layer comprises an aqueous color addition primer, a UV sanding primer, a UV abrasion-proof finishing paint, a first UV curtaining finishing paint and a second UV abrasion-proof finishing paint from inside to outside in turn. Different functions are realized through performance characteristics of different layers, so that the stone plastic floor has the advantages of light weight, high abrasion resistance, high pressure resistance and impact resistance, good foot feeling, environment friendliness and energy conservation, can be recycled, fully meets a use requirement of the modern society on decorative materials and has a wide application range.

Owner:JINJIANG AIJIA FLOOR

Ultraviolet curing coating and preparation method thereof, and super-hydrophilic transparent antifogging coating layer and preparation method thereof

ActiveCN105176371AGuaranteed Super Hydrophilic PropertiesGood anti-fog performanceAntifouling/underwater paintsPretreated surfacesOligomerWeather resistance

The invention provides an ultraviolet curing coating and a preparation method thereof, and an super-hydrophilic transparent antifogging coating layer and the preparation method thereof. The ultraviolet curing coating comprises the following raw materials by weight: 10 to 50 parts of modified silica sol, 5 to 30 parts of an ultraviolet resin oligomer, 5 to 30 parts of an active diluent, 0.2 to 5 parts of a surfactant, 2 to 6 parts of a photoinitiator and 0 to 50 parts of a solvent. The coating layer prepared from the ultraviolet curing coating provided by the invention has the advantages of long-term super-hydrophilic property, excellent antifogging property and good water resistance, weather resistance, wear resistance, scratch resistance and stain resistance.

Owner:福建富兰光学股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com