Patents

Literature

454results about How to "Fast curing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

High-solid-content UV (Ultraviolet)-curing aqueous urethane acrylate dispersion liquid and preparation method thereof

InactiveCN102030884AImprove curing efficiencyReduce consumptionPolyurea/polyurethane coatingsDistillationAdhesive

The invention discloses a high-solid-content UV-curing aqueous urethane acrylate dispersion liquid and a preparation method thereof, wherein the method comprises the following steps of: firstly carrying out the monoesterfication reaction on the partial hydroxide group at the tail end of hyperbranched polyester and the anhydride group of dicarboxylic anhydride to obtain an intermediate I; carrying out the end capping reaction on an isocyanate group in diisocyanate and the hydroxide group in a hydroxyalkyl methacrylate monomer to obtain a reaction intermediate II; carrying out the reaction on the residual hydroxide group of the intermediate I and the residual isocyanate group of the reaction intermediate II to obtain a reaction intermediate III; and carrying out alkali neutralization, aqueous dispersion and reduced-pressure distillation on the reaction intermediate III to remove an organic solvent to obtain the UV-curing urethane acrylate aqueous dispersion liquid. The dispersion liquid has the characteristics of high solid content, relatively low viscosity, UV curability, good mechanical performance of a paint film and the like, conforms to the concept of environmental protection, can be applied to the fields of environment-friendly coatings, aqueous ink, aqueous adhesives, fabric coating agents and the like and has broad prospect.

Owner:SOUTH CHINA UNIV OF TECH

Organic silicon-modified water-based UV (ultraviolet) coating and preparation method thereof

ActiveCN103555192AStir wellFast curing ratePolyurea/polyurethane coatingsUrethane acrylateAcrylate ester

The invention relates to an organic silicon-modified water-based UV (ultraviolet) coating and a preparation method thereof, and belongs to the technical field of environment-friendly coatings. The organic silicon-modified water-based UV coating comprises the following components in percentage by mass: 30 to 55 percent of organic silicon-modified hyperbranched water-based urethane acrylate, 20 to 50 percent of filler, 1 to 10 percent of photoinitiator, 0 to 3 percent of auxiliaries and 5 to 30 percent of water. The preparation method comprises the following steps: fully grinding the organic silicon-modified hyperbranched water-based urethane acrylate, the filler and water in a proportion, performing dispersion for 1 to 2 hours at 40 to 50 DEG C at a rotating speed of 400 to 600rpm, adding the photoinitiator and the auxiliaries, and uniformly stirring and standing a mixture to obtain the water-based UV coating. The coating is environment-friendly, nontoxic, high in curing speed, stability, aging resistance, solvent resistance, adhesive power and abrasion resistance and suitable for a plurality of coating modes and production requirements, and can be widely applied to the surfaces of automobiles, electronic products, ships, furniture and packaging printing materials.

Owner:WUHAN UNIV

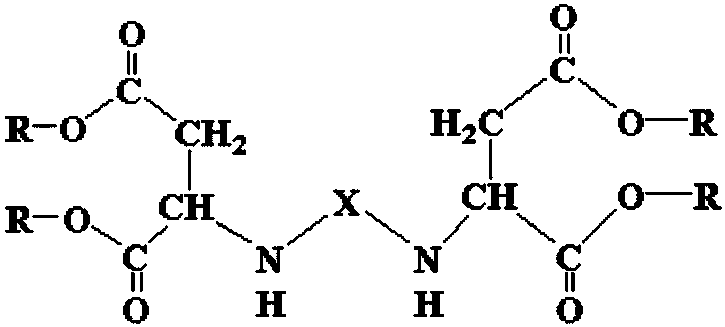

Flexible bismaleimide, benzoxazine, epoxy-anhydride adduct hybrid adhesive

ActiveUS20140199549A1Improve thermal stabilityLow water absorptionSilicaAcid polymer adhesivesPolyethylene terephthalate glycolThermal expansion

A resin composition which has low stress, and good adhesive property in high temperature and high moisture environments and which is useful in adhesive applications in low stress, high moisture sensitivity level electronic packages. Preferably, a flexible epoxy anhydride adduct modified solid bismaleimide and solid benzoxazine resin composition that can survive high temperature and high moisture conditions and maintain good adhesion strength and minimize the stress resulting from a coefficient of thermal expansion mismatch between a silicon die and a substrate which is Ball Grid Array solder mask or a smart card polyethylene terephthalate or silver or copper metal lead frame.

Owner:PROTAVIC KOREA

Silicone adhesive composition and method for preparing the same

InactiveCN101627077AFast curing rateLow curing temperatureElectrically-conducting adhesivesPolymer scienceHydrogen atom

A thermal interface material composition including a blend of a polymer matrix and a thermally conductive filler having particles having a maximum particle diameter no greater than about 25 microns, wherein the polymer matrix includes an organopolysiloxane having at least two silicon-bonded alkenyl groups per molecule, an organohydrogenpolysiloxane having at least two silicon-bonded hydrogen atoms per molecule and a hydrosilyation catalyst comprising a transition metal, wherein the transition metal is present in an amount of from about 10 to about 20 ppm by weight based on the weight of the non-filler components and the molar ratio of the silicon- bonded hydrogen atoms to the silicon-bonded alkenyl groups ranges from about 1 to about 2. A method is also provided.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Water-soluble (Ultra Violet) curing ink and preparation method thereof

The invention relates to a water-soluble (Ultra Violet) curing ink and a preparation method thereof, and belongs to the technical field of environmental protection ink. The water-soluble UV curing ink comprises the following components by mass percent: 60 to 85% of silica sol modified water-soluble urethane acrylate prepolymer, 1 to 10% of photoinitiator, 5 to 15% of pigment, 5 to 20% of solvent and 0 to 1% of assistant. The water-soluble UV curing ink is environment-friendly, nontoxic, fast in curing rate, high in stability, excellent in ageing resistance and solvent resistance, outstanding in adhesive force and wear resistance and suitable for a plurality of printing modes, meets the production requirement, and can be widely applied to the surfaces of printing materials such as paper materials, wood materials, plastics, metals and glass.

Owner:WUHAN UNIV

3D printing photosensitive resin material

InactiveCN107868443ALow viscosityReduce the smellAdditive manufacturing apparatusOligomerReactive diluent

The invention discloses a 3D printing photosensitive resin material. The 3D printing photosensitive resin material comprises the following components in parts by weight: 10-50 parts of a low-viscosityphotosensitive resin oligomer, 10-50 parts of organosilicone modified epoxy acrylate, 30-50 parts of a reactive diluent, 1-5 parts of a photoinitiator, 1-5 parts of an auxiliary agent and 0.01-1 partof a pigment. The 3D printing photosensitive resin material is very low in viscosity and odor, high in curing rate, high in precision of a printed product and universal in universality; meanwhile, the organosilicone modified epoxy acrylate resin is obtained by grafting silicon onto a molecular chain of epoxy resin, so that the polarity of an organosilicone component is reduced and the compatibility thereof in the photosensitive resin material can be improved; in addition, the content of the organosilicone is high, and the organosilicone component in a branched-chain state contributes to movement of the molecular chain and can easily migrate to an interface between a 3D printing trough and the photosensitive resin material, so that the 3D printing photosensitive resin material shows excellent release capability.

Owner:HUIZHOU YOUHENGKE 3D MATERIAL TECH CO LTD

Application of low-viscosity light-cured resin in 3D (three-dimensional) printing materials

ActiveCN104893224ALow viscosityFast curing rateAdditive manufacturing apparatusPolymer scienceAcrylate ester

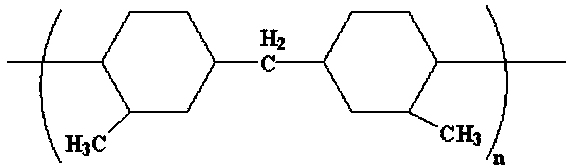

The invention relates application of low-viscosity light-cured resin in 3D (three-dimensional) printing materials. The low-viscosity light-cured resin is (branched) polyether acrylate or heterocyclic amine modified (branched) polyether acrylate. A 3D printing material prepared from the low-viscosity light-cured resin is of low viscosity and high curing speed, is low in curing shrinkage, low in yellowing property, moderate in rigidity and flexibility, high in forming speed and high in product dimensional precision, is free of curing incompleteness, edge warping and the like, and is very suitable for being applied to 3D printing materials based on the SLA (stereolithography) or 3DP (three-dimensional printing) technology.

Owner:新丰博兴聚合材料有限公司

Ultraviolet-cured weather-proof self-cleaning coating composition

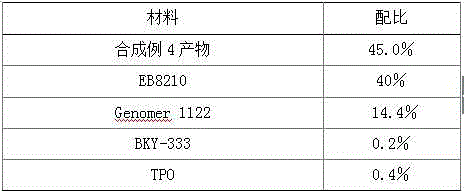

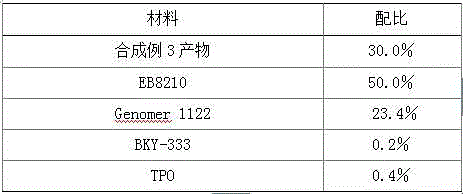

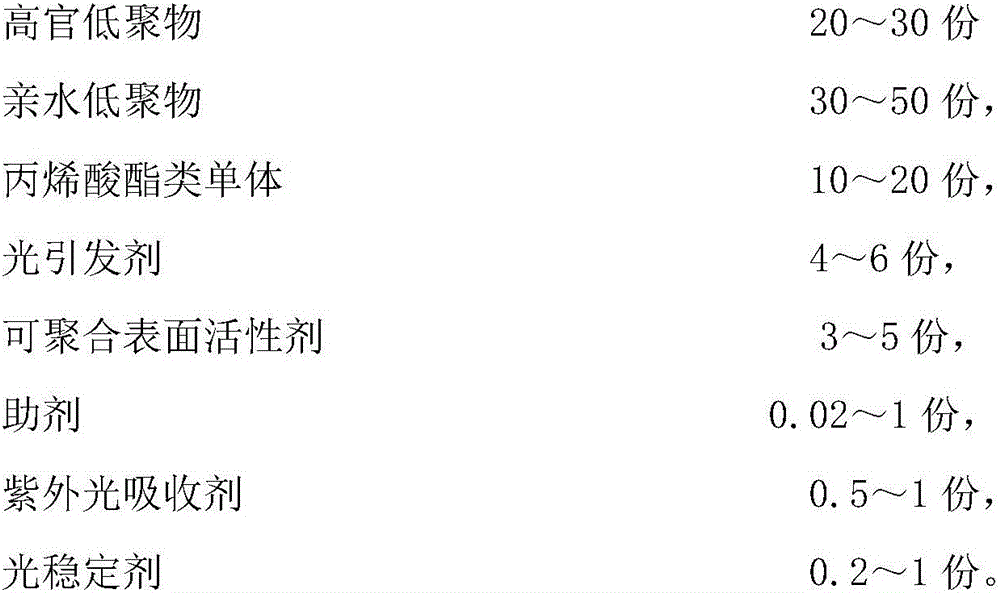

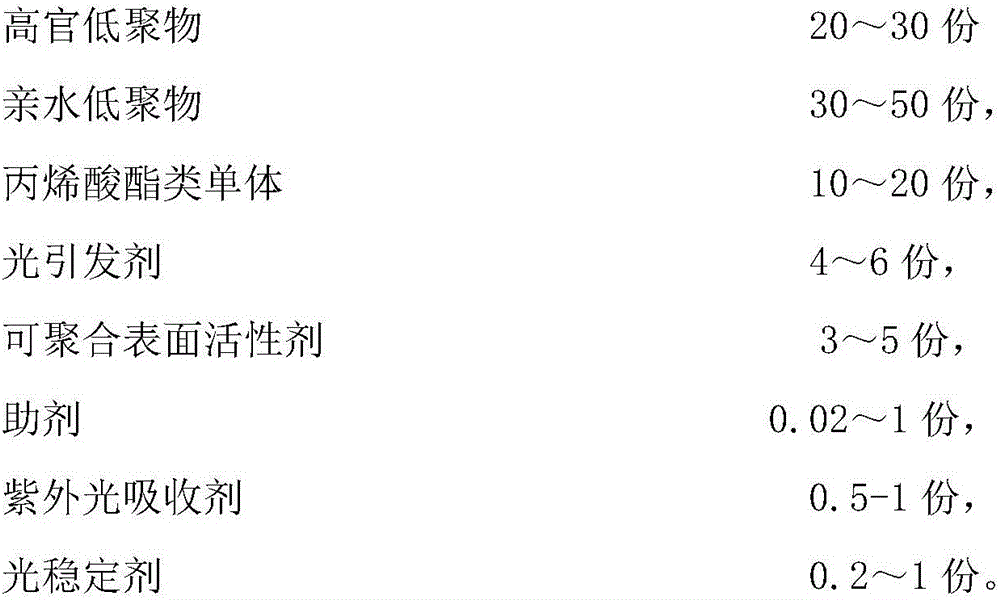

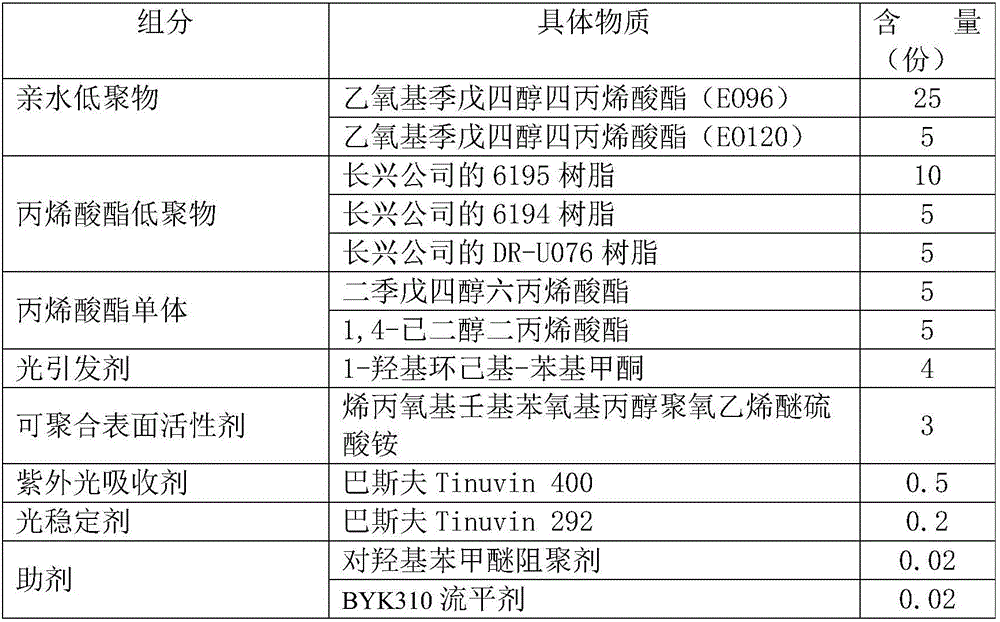

InactiveCN106497391AHigh energy consumptionLow efficiencyPolyurea/polyurethane coatingsEpoxy resin coatingsOligomerUltraviolet

The invention provides an ultraviolet-cured weather-proof self-cleaning coating composition. The coating composition comprises, by weight, 20-30 parts of high-functionality oligomer, 30-50 parts of hydrophilic oligomer, 10-20 parts of acrylic monomer, 4-6 parts of photoinitiator, 3-5 parts of polymerizable surfactant, 0.02-1 part of auxiliary, 0.5-1 part of ultraviolet absorber and 0.2-1 part of light stabilizer. After ultraviolet curing, the prepared coating is high in curing rate, free of high temperature baking and environmentally friendly and saves energy. The coating obtained after curing is good in adhesive force, high in hardness, good in wear resistance and excellent in weather fastness and has a self-cleaning effect.

Owner:SHANGHAI WEIKAI CHEM

Environment-friendly stemming for blast furnace and preparation method thereof

The invention provides environment-friendly stemming for a blast furnace. The stemming is prepared from aggregate, silicon carbide, titanium dioxide, white mud, coke dust, micropowder and a binding agent. The method for preparing the stemming comprises the following steps: proportioning aggregate, silicon carbide, titanium dioxide, white mud, coke dust and micropowder according to the mass percentage; performing dry mixing and grinding, adding the binding agent, and performing wet mixing and grinding to obtain the environment-friendly stemming for a blast furnace. The stemming has the advantages of small shrinkage rate, excellent thermal shock resistance, excellent washing resistance and excellent erosion resistance, and once tapping time reaches 100-180 minutes; in-situ generated TiC has an effect of protecting the furnace, and the service life of the furnace can be prolonged; T60 carbon-containing resin and phenolic resin are used as the binding agent to reduce generation of cancerogenic smoke and improve the operation environment.

Owner:BEIJING JINGYEYUAN NEW MATERIALS

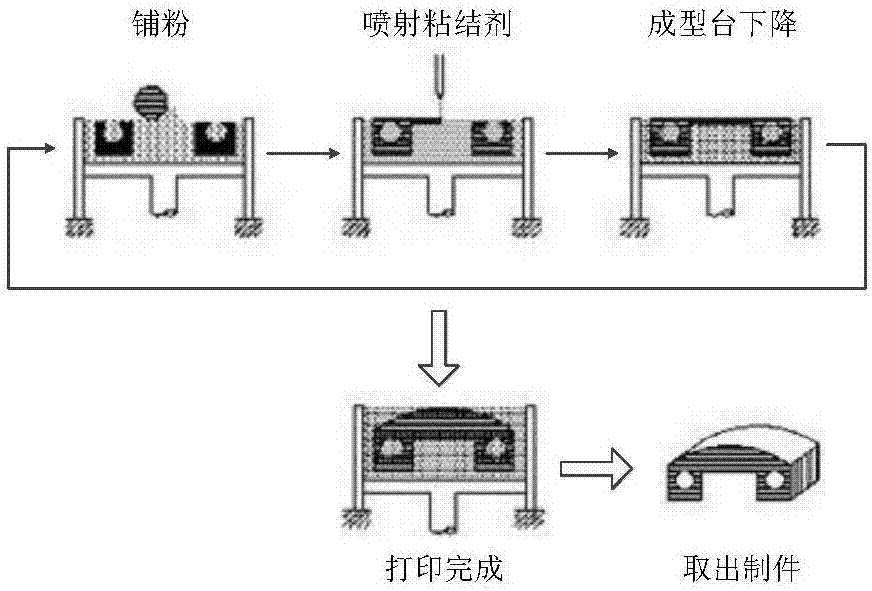

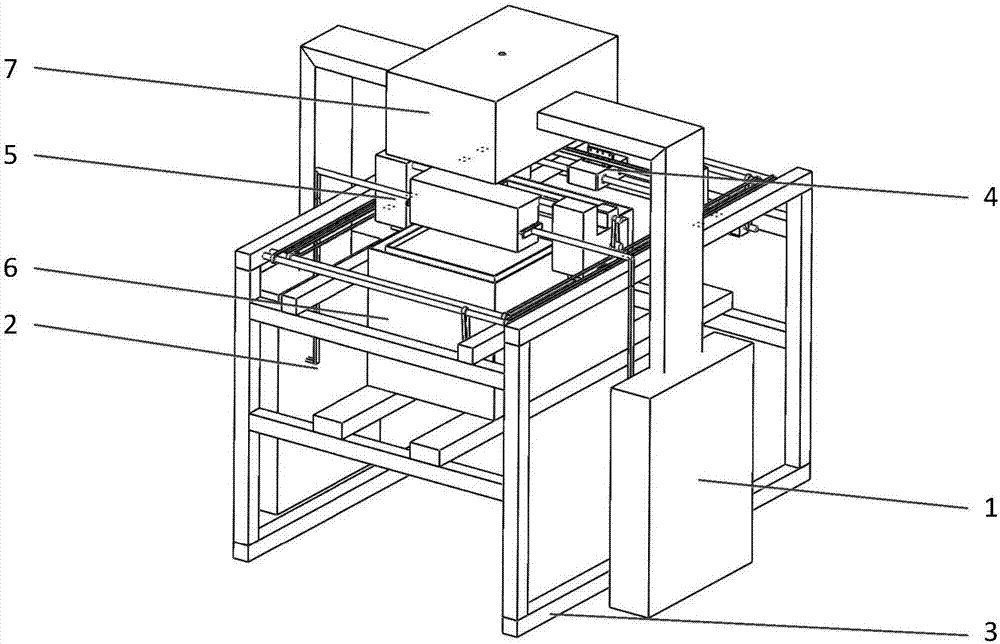

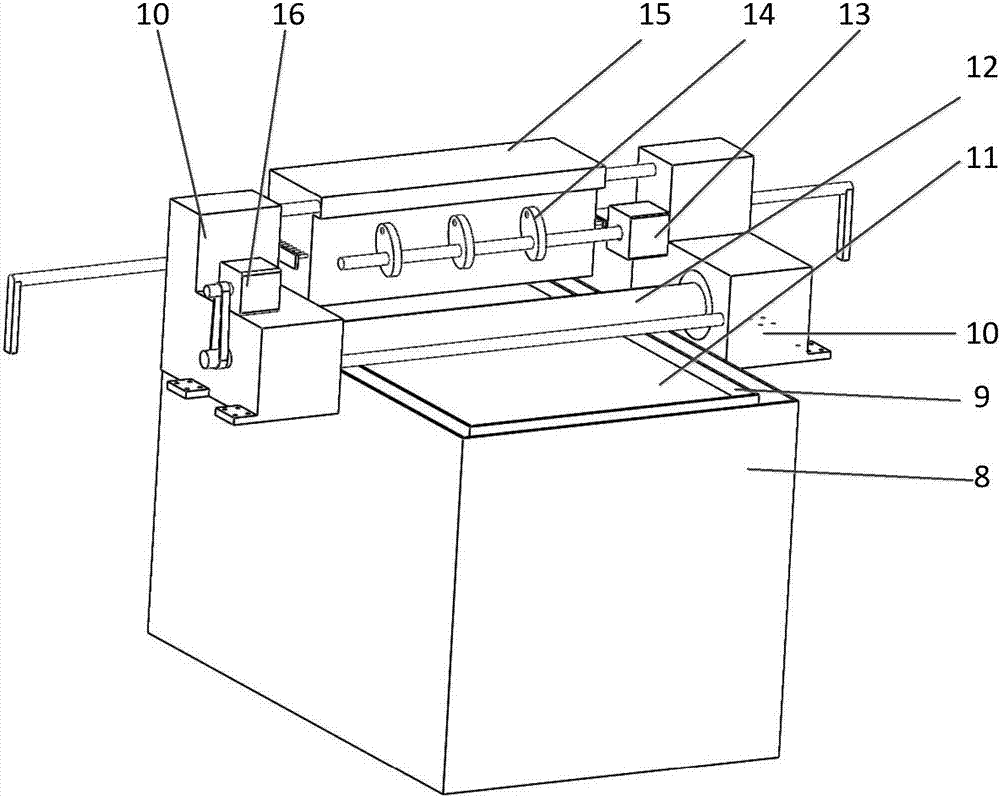

3DP process forming system and operation method thereof

ActiveCN108000870AAvoid cloggingExtend working life3D object support structuresAdditive mnaufacturing with solid and fluidEngineeringMetal

The invention discloses a 3DP process forming system and an operation method thereof. The 3DP process forming system comprises a rack of a metal frame structure. A modular forming cylinder is arrangedin the rack. A printing device and a powder feeding device are arranged at the position, on the upper portion of the modular forming cylinder, of the rack. The printing device and the powder feedingdevice are connected with Y-direction linear guide rails on the rack through sliding blocks and are used for moving on the Y-direction linear guide rails to carry out powder laying and printing. A part taking auxiliary device is arranged at the top of the rack. A physical curing device is arranged in the part taking auxiliary device. Powder storage boxes are arranged on the two sides of the rack.According to the 3DP process forming system and the operation method thereof, the problem that the uniformity of powder particles laid on a powder bed and the density of the powder bed cannot be guaranteed at the same time is solved, the problem of nozzle blocking caused by raising dust caused by laid powder motion is effectively avoided, and the equipment forming efficiency and the part taking efficiency are greatly improved.

Owner:XI AN JIAOTONG UNIV

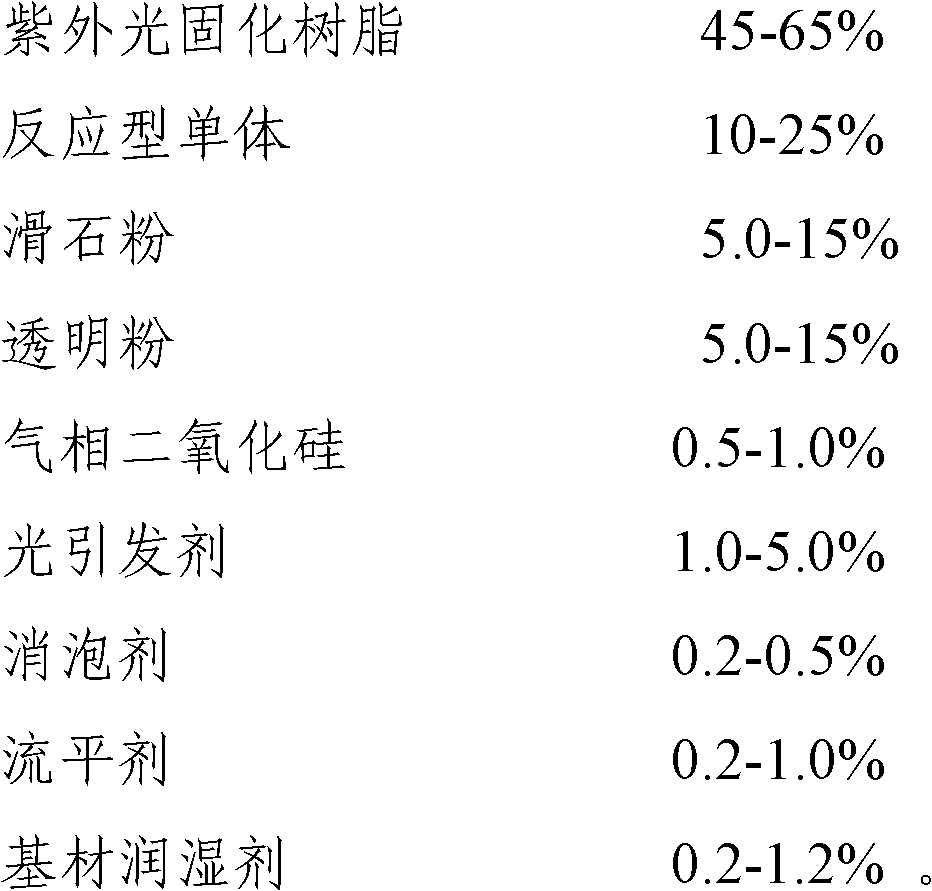

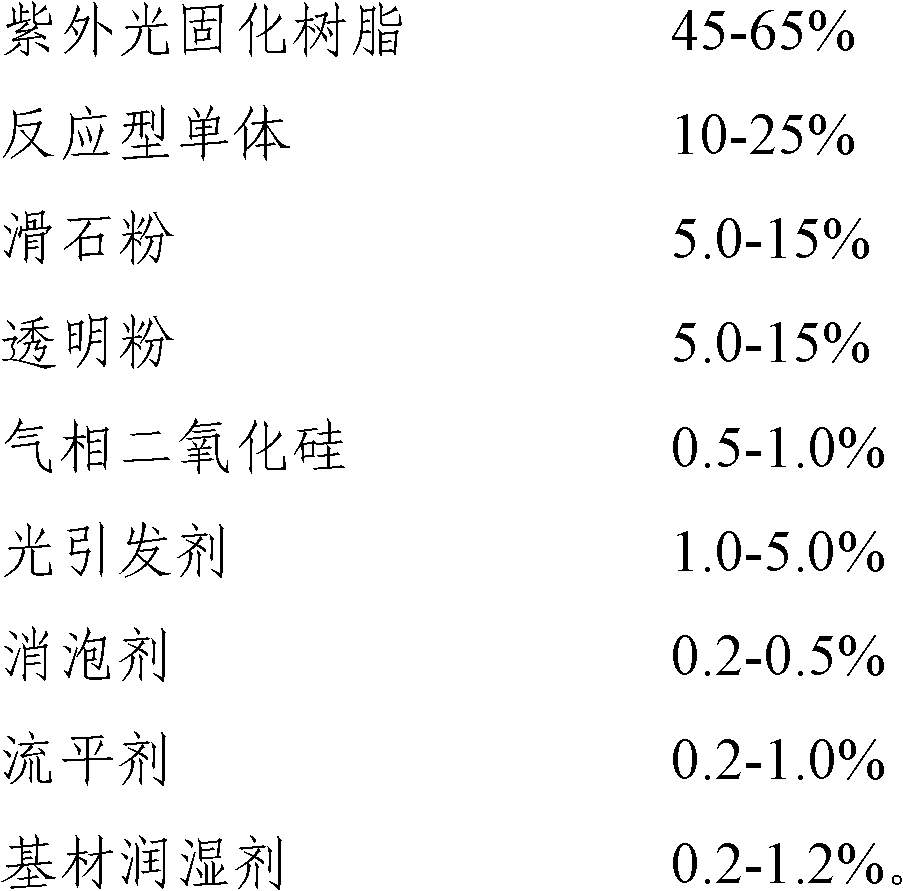

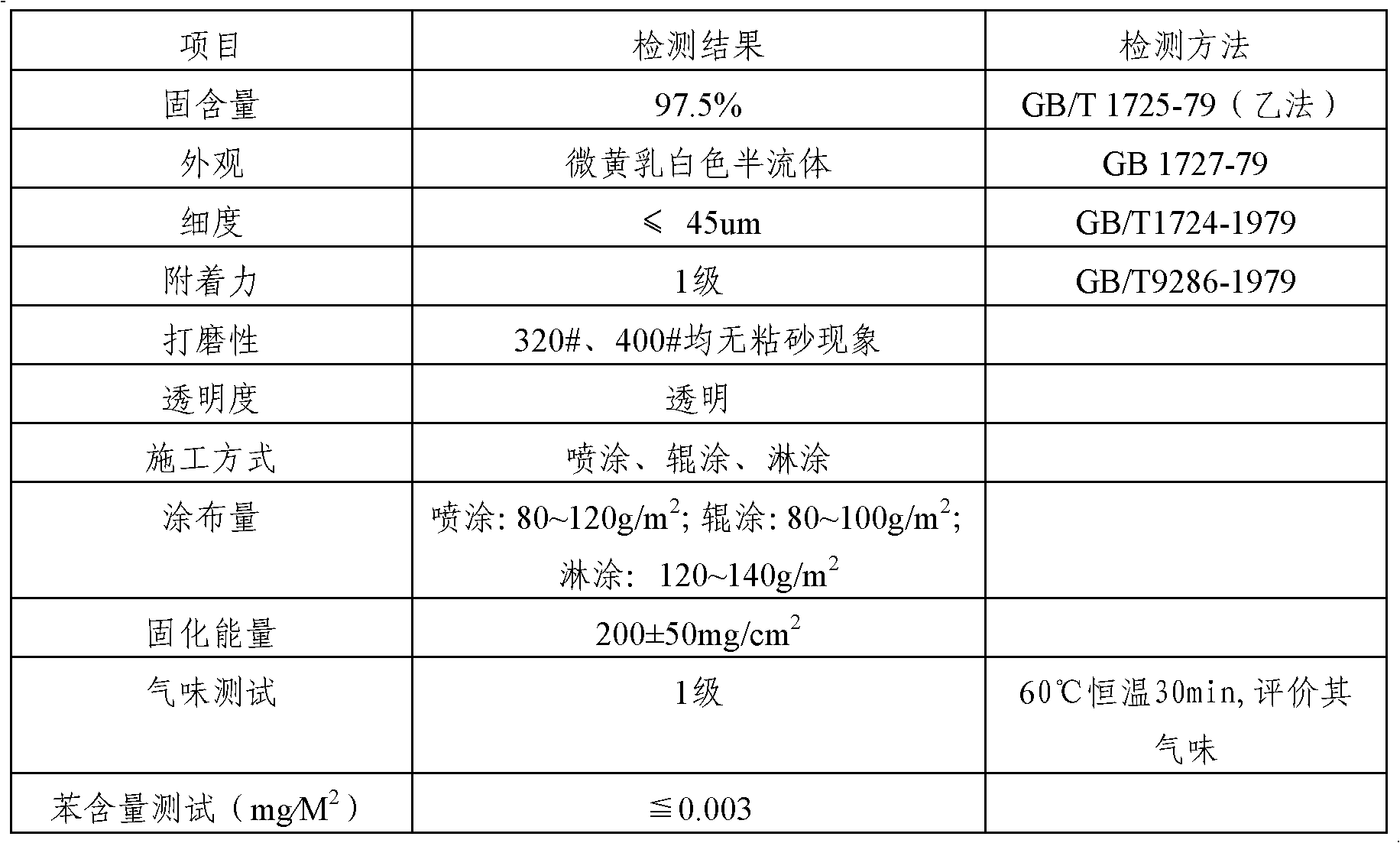

Odorless ultraviolet-curing wood lacquer and preparation method thereof

ActiveCN102352173AEnvironmental protection is goodReduce heavy metal contentEpoxy resin coatingsPolyesterBenzene

The invention relates to an odorless ultraviolet-curing wood lacquer and a preparation method thereof. The wood lacquer is prepared from the following components in percentage by weight: 45-65% of ultraviolet-curing resin, 10-25% of reactive monomer, 5.0-15% of talcum powder, 5.0-15% of transparent powder, 0.5-1.0% of gas-phase silicon dioxide, 1.0-5.0% of photoinitiator, 0.2-0.5% of defoaming agent, 0.2-1.0% of leveling agent and 0.2-1.2% of wetting agent. The odorless ultraviolet-curing wood lacquer does not have irritating odor before and after construction, does not contain benzene, and can be used immediately after construction; and meanwhile, the surface effect and fullness are not inferior to those of nitrocellulose dope, unsaturated paint or polyester paint.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

Quick-curing high-strength single-component silane modified polyurethane sealing gum preparation method

ActiveCN107841277AHigh strengthImprove mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceSilanes

The invention discloses a quick-curing high-strength single-component silane modified polyurethane sealing gum preparation method. The preparation method comprises the steps: adding polyether glycol into a reaction kettle which is provided with a thermometer and a stirrer and protected by dry nitrogen; starting stirring; warming to 120 DEG C; vacuum drying for dewatering for 2h; cooling to 40 DEGC or less; sequentially adding polyisocyanate, a first catalyst and a first plasticizer; warming to 45 to 60 DEG C; reacting and stopping reacting when a NCO% content reaches to 1% to 5%; cooling to 40 DEG C or less; adding a silane coupling agent into the reaction kettle and sealing ends; sampling and detecting NCO% every 15 minutes until the NCO% content is 0 to obtain SPU prepolymer; sealing, storing and standing for standby application. The preparation method disclosed by the invention has the advantages avoiding side reaction under high temperature, effectively controlling a molecular weight of the SPU prepolymer within a narrower range (generally 5000 to 9000), ensuring quality of the prepolymer and effectively improving the curing speed of SPU sealing gum.

Owner:SHANDONG NORTH MODERN CHEM IND

Epoxy resin solvent-free low temperature curing agent, preparation method and application thereof

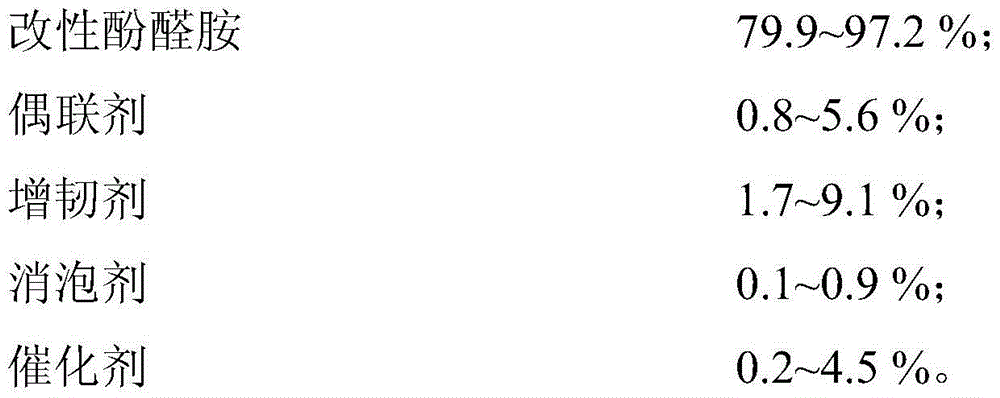

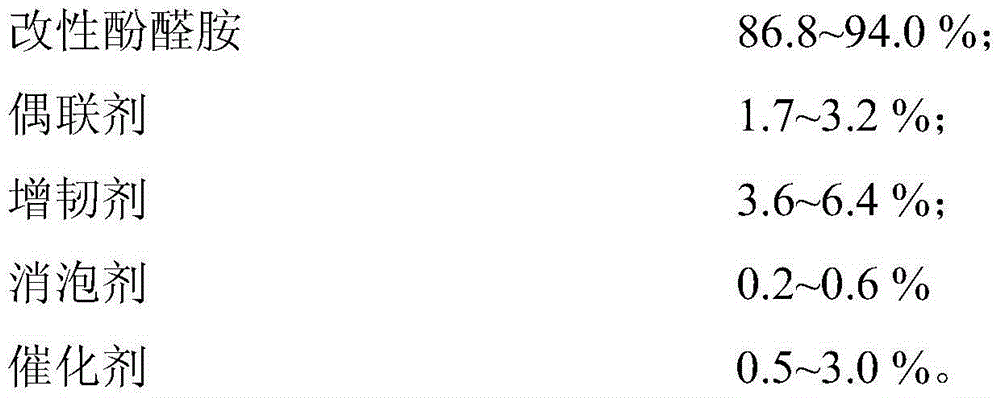

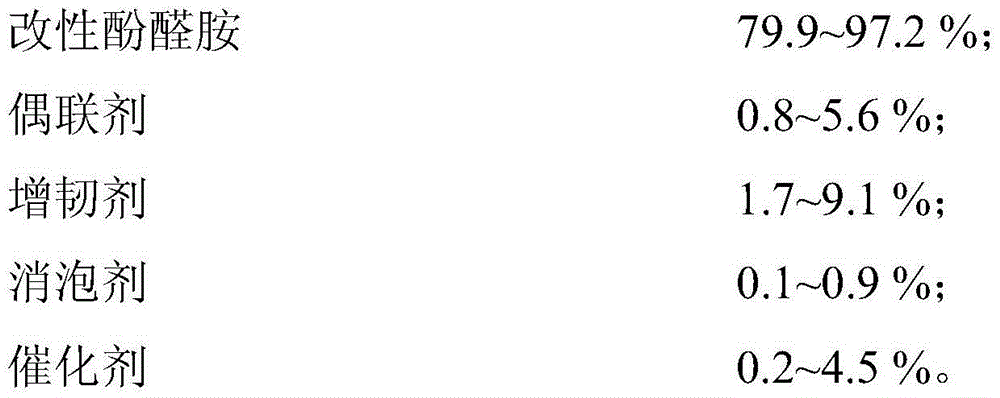

The invention belongs to the technical field of epoxy resin curing agent preparation technology, and discloses an epoxy resin solvent-free low temperature curing agent, a preparation method and an application. The curing agent can be better used in cement mortar and used for preparing epoxy grouting material under low temperature in water environment. The curing agent comprises the following components by mass percentage: 79.9-97.2% of modified phenolic amine, 0.8-5.6% of coupling agent, 1.7-9.1% of flexibilizer, 0.1-0.9% of antifoaming agent and 0.2-4.5% of catalyst. According to the invention, thiourea group is introduced, thiourea modified amine, polyamine, long chain alkylphenol and paraformaldehyde are performed a Mannich reaction to synthesize novel thioureido-containing Mannich base, so that solidification rate under low temperature environment is increased, disadvantage of poor solidification efficiency under wet surface and water can be overcome, and a silane coupling agent is added for improving surface tension of system contact surface and increasing the solidification efficiency under water environment.

Owner:国科广化(南雄)新材料研究院有限公司

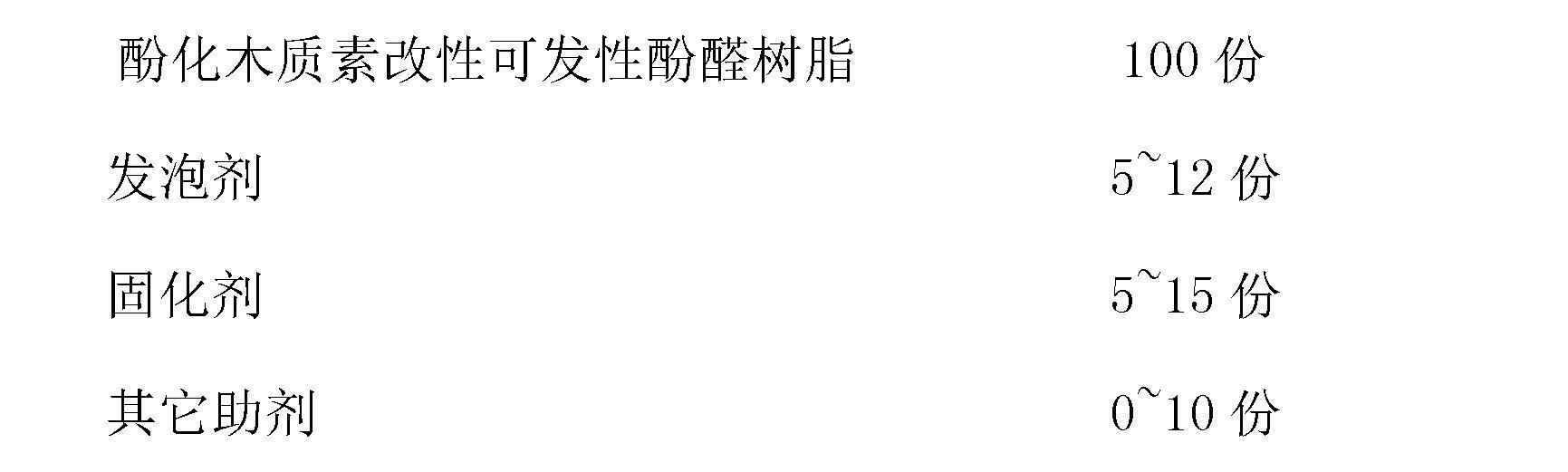

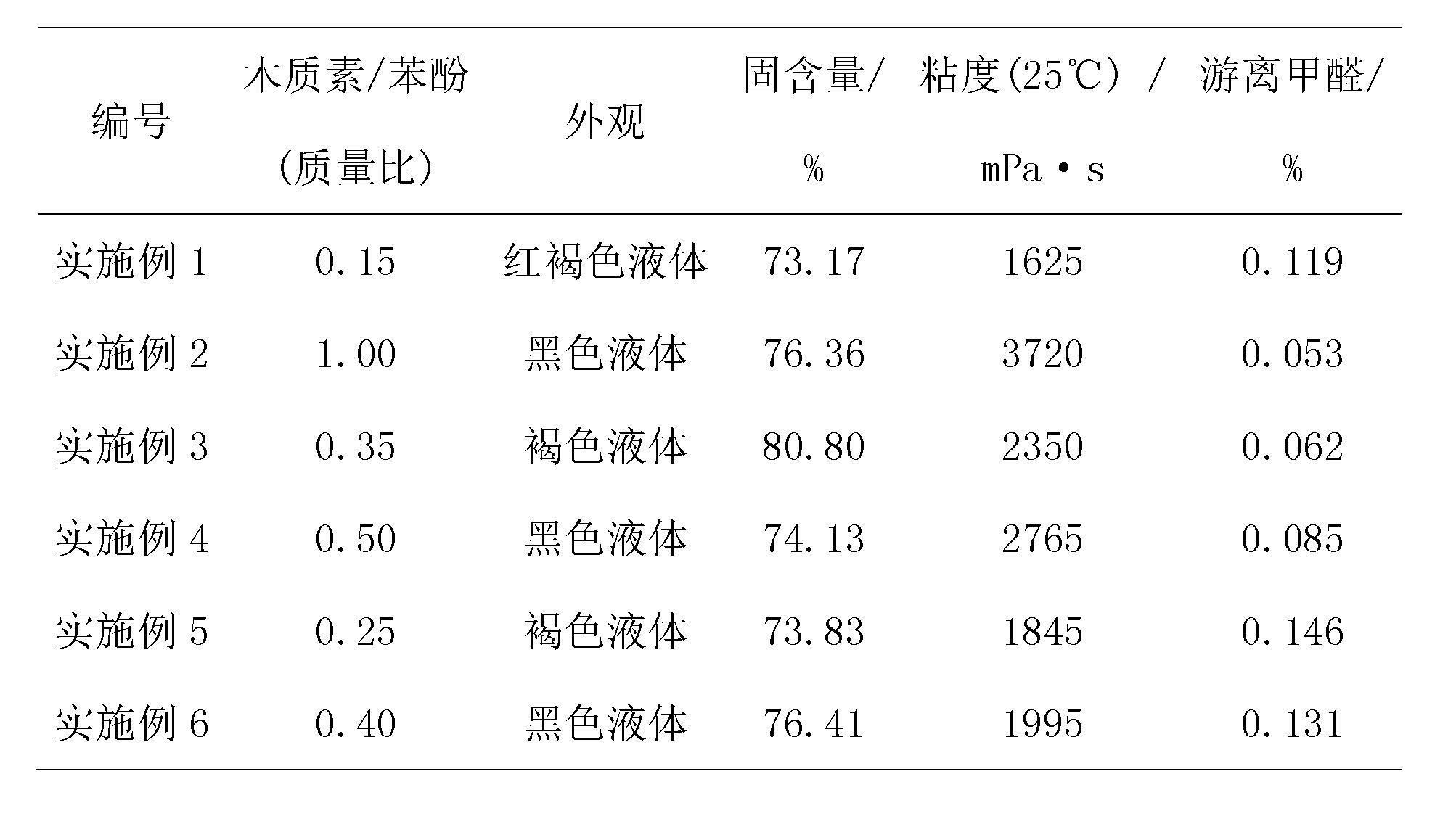

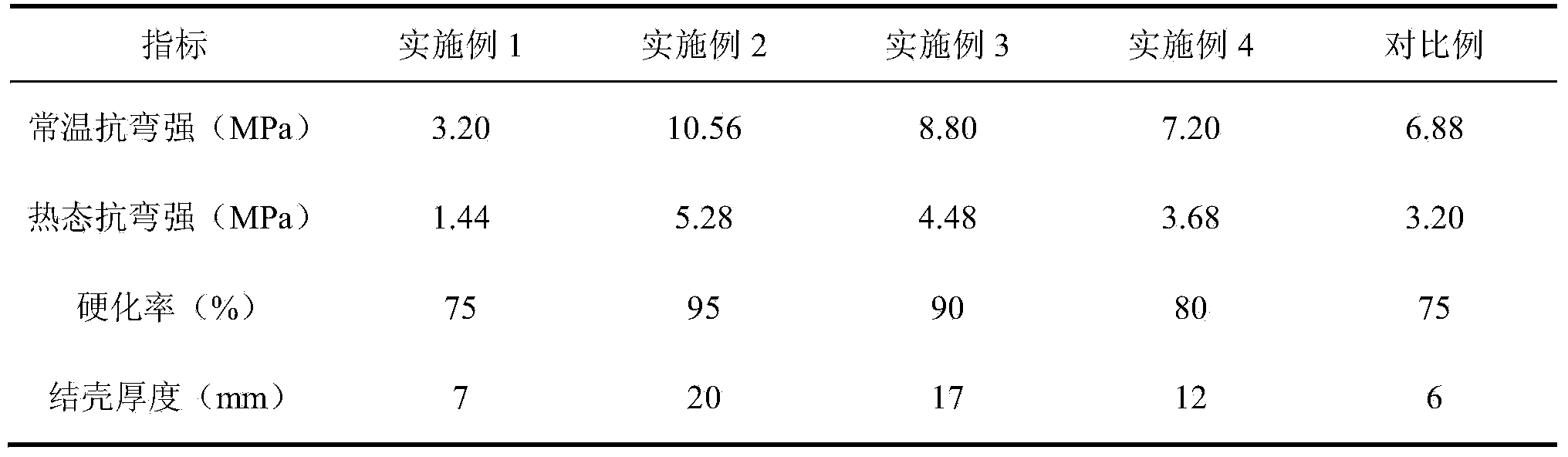

Phenolic lignin-based modified foaming phenolic resin, foamed plastic and preparation method of phenolic lignin-based modified foaming phenolic resin

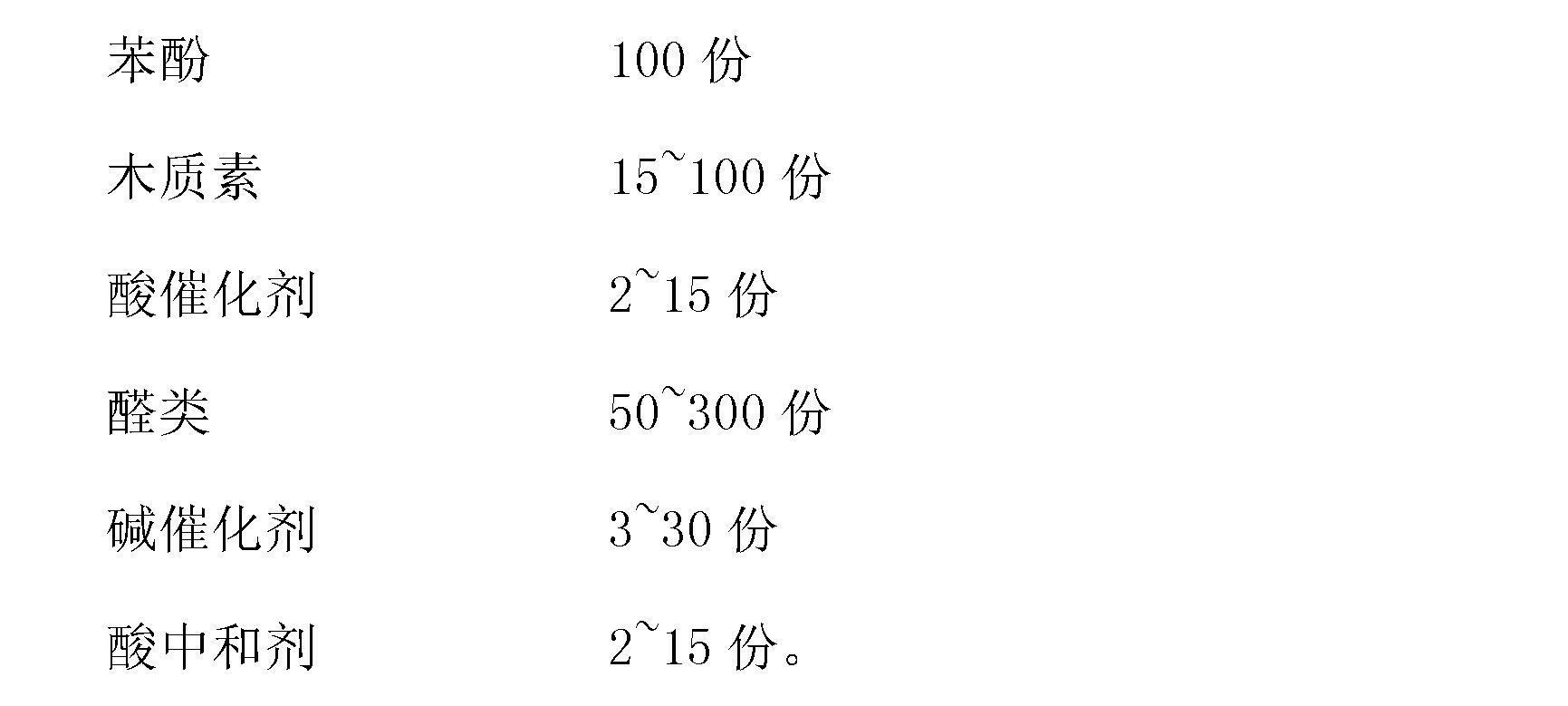

The invention discloses a phenolic lignin-based modified foaming phenolic resin, foamed plastic and a preparation method of the phenolic lignin-based modified foaming phenolic resin. The foaming phenolic resin comprises phenol, lignin, an acid catalyst, aldehydes, a base catalyst and an acid neutralizer. Compared with the existing lignin-based phenolic resin and the foamed plastic of the lignin-based phenolic resin, the phenolic lignin-based modified foaming phenolic resin has the beneficial effects that a high-activity lignin phenolized liquid is directly adopted to replace phenol for preparing the foaming phenolic resin, so that the foaming phenolic resin has less free formaldehyde (with the content of less than or equal to 0.15%), and has the advantages of being lower in production cost, rapider in curing speed and the like; and compared with the traditional phenolic resin foamed plastic, the foamed plastic prepared by the phenolic lignin-based modified foaming phenolic resin has the advantages of lower coefficient of heat conductivity and higher compression strength.

Owner:HUANGSHAN UNIV

Shelling resistant pre-coated sand and preparation method thereof

ActiveCN104014718AFast curing rateIncrease hardening rateFoundry mouldsFoundry coresFirming agentUltimate tensile strength

The invention discloses shelling resistant pre-coated sand and a preparation method thereof. The shelling resistant pre-coated sand is characterized by comprising raw sand, a bonding agent the weight of which is 1-4% that of the raw sand, a curing agent the weight of which is 1-15% that of the bonding agent, 0.1-0.5% of coupling agent and 0.1-1.0% of additive. By adding the additive, the curing speed of the curing agent to the bonding agent is increased, the hardening rate of the pre-coated sand is improved and the shelling tendency is reduced; by optimizing the content of each component, the overall strength of the pre-coated sand is improved, the gas evolution amount of the pre-coated sand is greatly reduced and the defect of core piercing is alleviated; the shelling resistant pre-coated sand has strong shell resistance, is high in strength and low in gas evolution amount, is capable of remarkably alleviating or eliminating defects such as shelling and core piercing and effectively improving qualities of the inner and outer surface of a shell core, and is suitable for production of shell core sand cores.

Owner:CHENGDE BEIYAN CASTING MATERIAL

Epoxy resin concrete material and microwave-coagulation preparation method thereof

InactiveCN102584109AFast curing rateSimple preparation processCeramic shaping apparatusEpoxyMicrowave

The invention relates to an epoxy resin concrete material and a microwave-coagulation preparation method thereof and comprises the composition of raw materials, the mix proportion, the preparation method, the mechanics performance testing and the like of the epoxy resin concrete material. The epoxy resin concrete material can be coagulated in a few minutes under the condition of microwave and has the advantages of even coagulation, high strength of condensate, good interface cohesiveness and excellent road performance, thus the concrete material can be used for rapid mending of concrete road surface.

Owner:雷运波

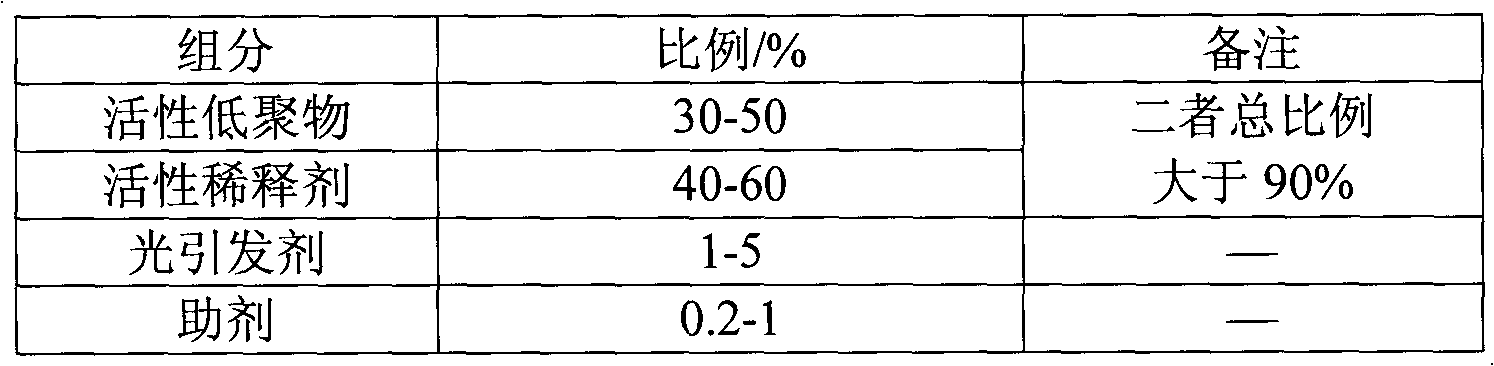

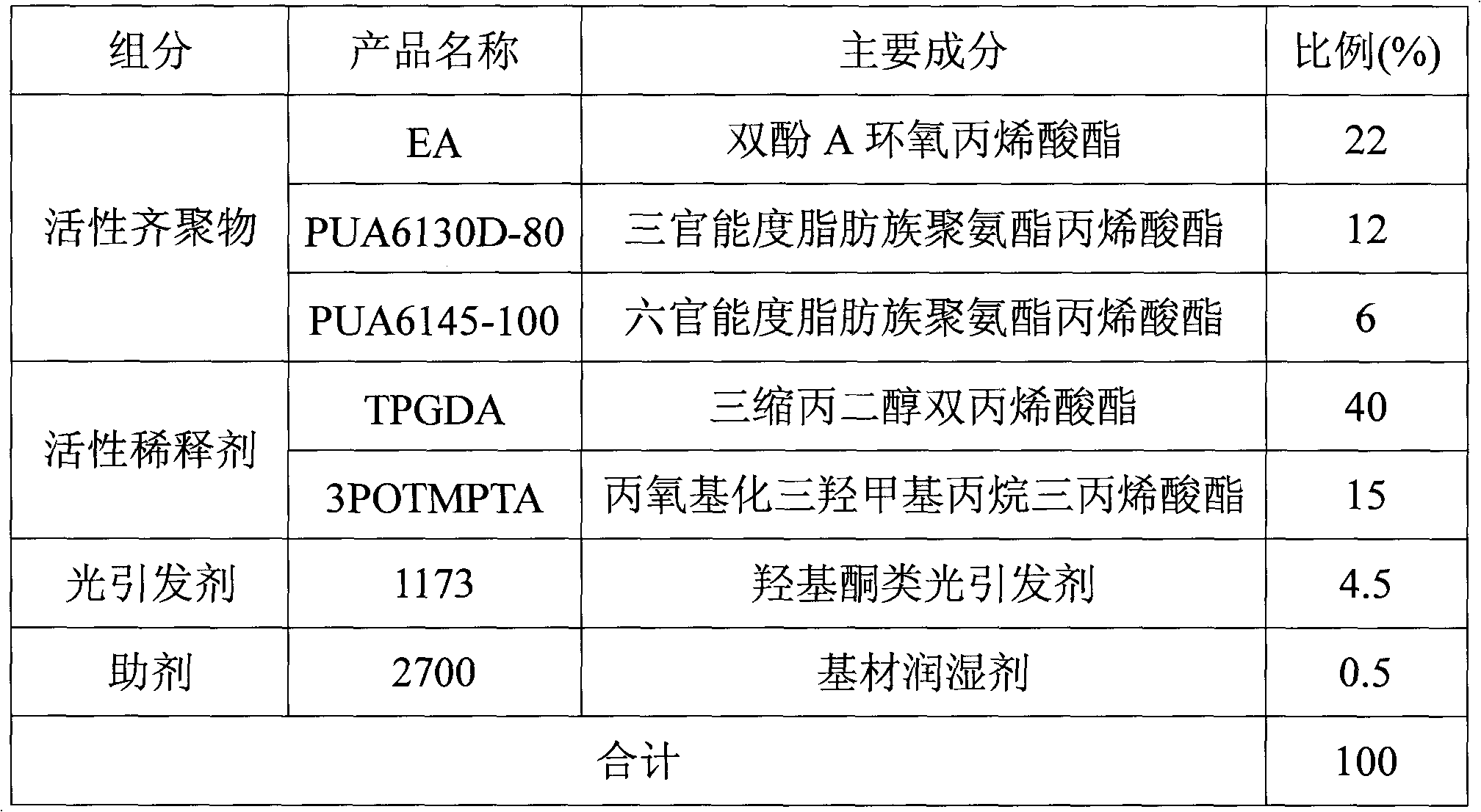

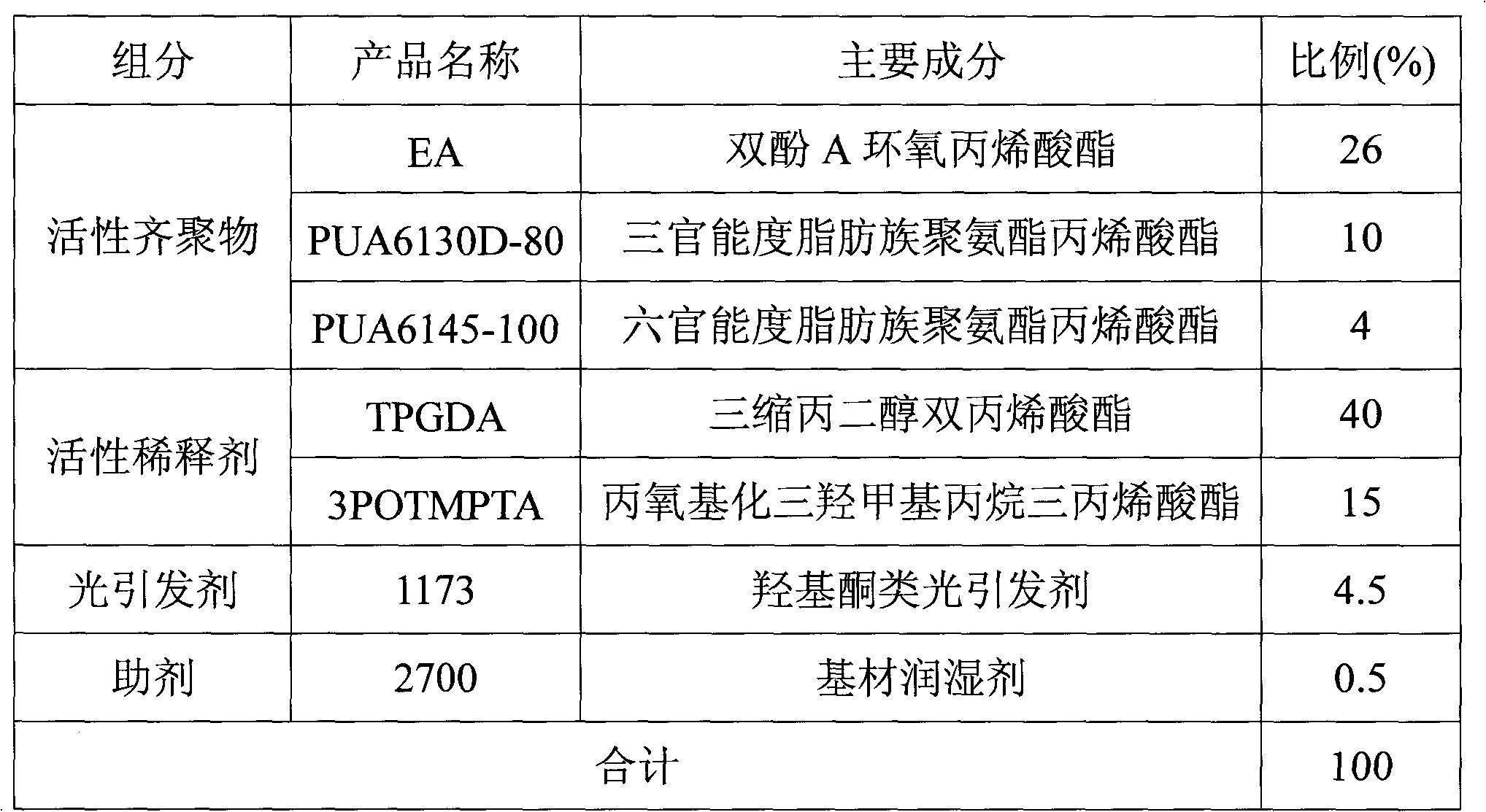

Spraying type ultraviolet cured woodware varnish

The invention belongs to a coating, and in particular relates to a spraying type ultraviolet cured woodware varnish, which is particularly suitable for finishing various wood substrate (such as solid wood, veneers, flakeboards, density boards and the like) products. The spraying type ultraviolet cured woodware varnish consists of activated oligomer, an activated thinner, a photoinitiator and an aid, wherein the activated oligomer consists of bisphenol A epoxy acrylate, aliphatic polyurethane tri-acrylate and hexafunction aliphatic urethane acrylate; and the activated thinner consists of tripropylene glycol diacrylate and trimethylolpropane propoxylate triacrylate. By utilizing reasonable combination of various raw materials, the coating has the characteristics of low viscosity, good construction (spraying) performance, sufficient flexibility on the premise of hardly reducing hardness and the like, and the like, and effectively avoids the problems of orange peel, sinking and the like.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD

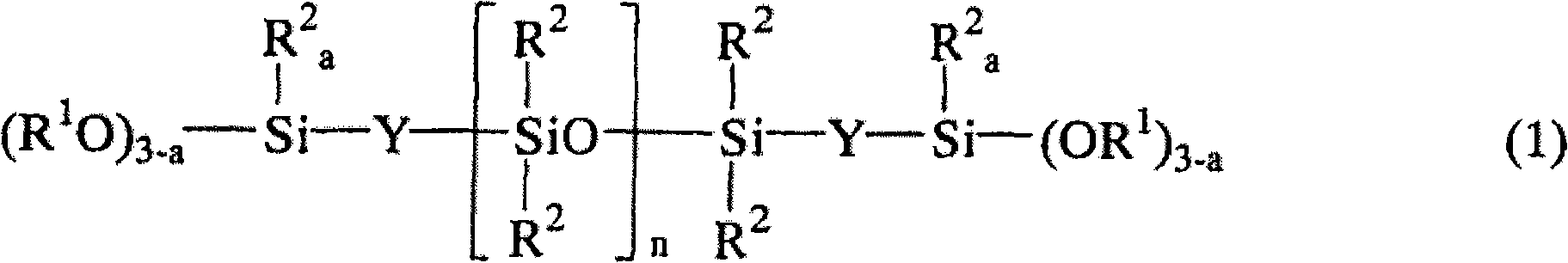

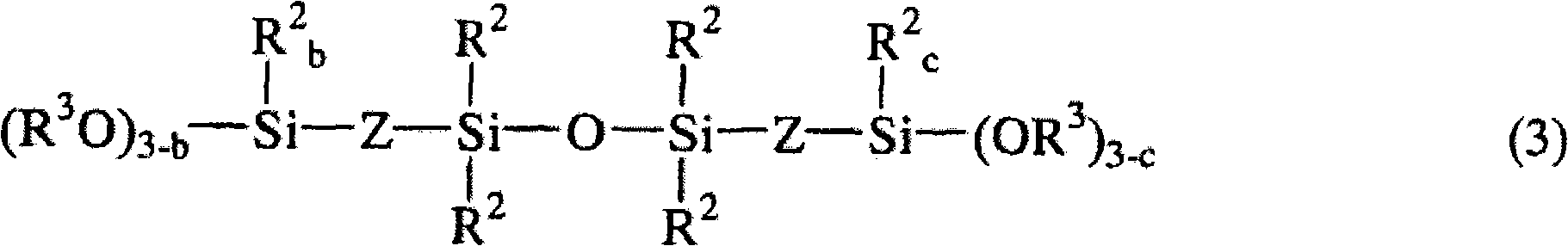

Room temperature curable organopolysiloxane composition

An RTV organopolysiloxane composition is provided comprising (A) a diorganopolysiloxane capped at both ends of its molecular chain with hydroxysilyl, alkoxysilyl or alkoxyalkoxysilyl and having a viscosity of 20-1,000,000 mPa-s at 25 DEG C, (B) a bis(alkoxysilylalkyl)disiloxane compound, and (C) a curing catalyst. The composition is fast curable into a silicone rubber which establishes a firm adhesion to substrates with an active surface such as float glass and maintains the adhesion even in a harsh environment as immersed in hot water over a long term.

Owner:SHIN ETSU CHEM CO LTD

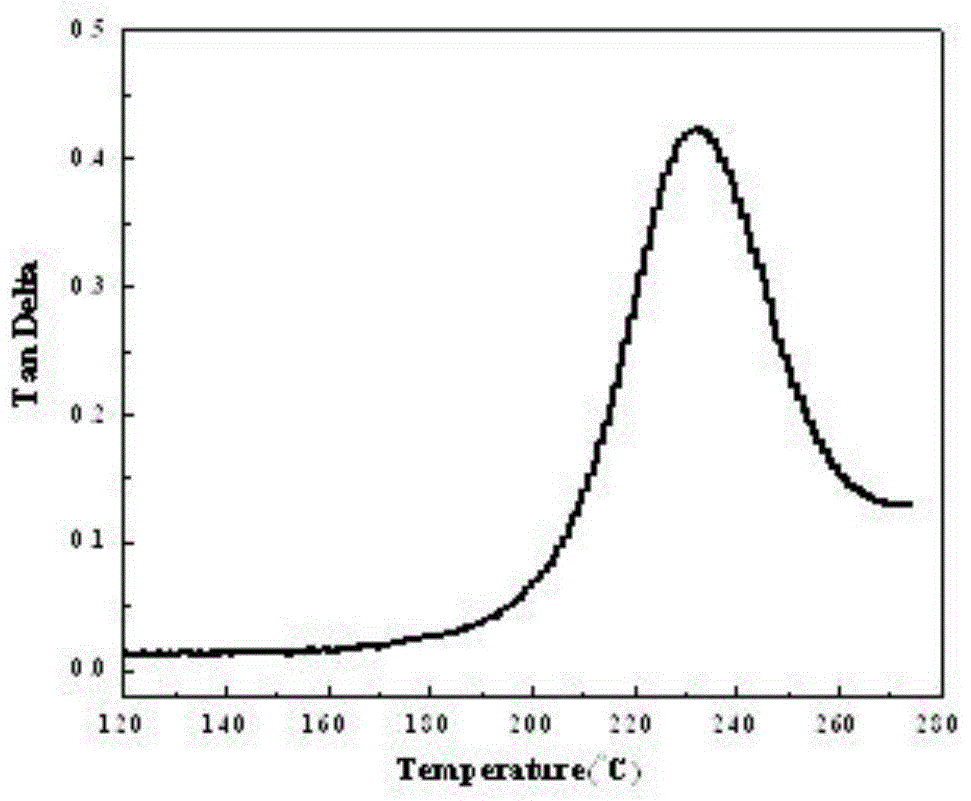

Preparation method of in situ intercalated solution of carboxyl graphene oxide benzoxazine nano-composite resin

ActiveCN104262622AGood compatibilityUniform and stable dispersionNanotechnologyChloroacetic acidsResin-Based Composite

The invention discloses a preparation method of in situ intercalated solutionof carboxyl graphene oxide benzoxazine nano-composite resin. The method comprises the following steps of: preparing graphene oxide by using natural crystalline flake graphite as raw materials by utilizing an improved Hummers method; chemically modifying the graphene oxide by utilizing a chloroacetic acid method to obtain carboxyl graphene oxide; ultrasonically dispersing carboxyl graphene oxide into an organic solvent to obtain carboxyl graphene oxide solution; dissolving benzoxazine prepolymer into the organic solvent to obtain benzoxazine prepolymer solution; blending the carboxyl graphene oxide solution with the benzoxazine prepolymer solution to obtain the in situ intercalated solution by utilizing an in situ intercalated solution polymerization method. The preparation method is simple in process, and the raw materials are easily obtained. By adding carboxyl graphene oxide, the curing temperature of the composite resin is reduced, the processibility and glass-transition temperature are improved, and the heat resistance of resin is increased. Moreover, the preparation method has wide application prospect in the fields of copper-cladding boards, laminated boards, spacecrafts and the like.

Owner:淮北绿洲新材料有限责任公司

Functionalized graphene oxide enhanced benzoxazine-based composite resin and preparation method thereof

The invention relates to a functionalized graphene oxide enhanced benzoxazine-based composite resin and a preparation method thereof. The resin is prepared by: 1, preparing natural flake graphite into graphene oxide by a modified Hummers method; 2, chemically modifying the graphene oxide to obtain carboxylated graphene oxide or aminated graphene oxide; 3, physically mixing, by weight, 0.1-10% of the carboxylated graphene oxide or aminated graphene oxide with 90-99.9% of benzoxazine binary resin prepolymer or benzoxazine ternary resin prepolymer to obtain a mixed sample; 4, evacuating the mixed sample at 80-100 DEG C for 1-2h, and allowing curing reaction at 100-220 DEG C for 4-24h so as to obtain the functionalized graphene oxide enhanced benzoxazine-based composite resin. The prepared composite resin cures without shrinking and has good heat resistance, moisture resistance, mechanical performances and electrical performances.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Aqueous silicon dioxide-fluorinated acrylate polyurethane ultraviolet-curing coating, preparation method and application thereof

InactiveCN102816515AEasy to prepareFast curing ratePolyurea/polyurethane coatingsTetraethyl orthosilicatePrepolymer

The present invention discloses an aqueous silicon dioxide-fluorinated acrylate polyurethane ultraviolet-curing coating, a preparation method and an application thereof, and belongs to the technical field of polymer synthesis. The preparation method comprises: preparing a tetraethyl orthosilicate sol; dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt to prepare an aqueous polyurethane acrylate prepolymer emulsion; adding hexafluorobutyl acrylate and trimethylolpropane triacrylate to prepare an aqueous fluorinated acrylate polyurethane prepolymer emulsion; adding gamma-methacryloxy propyl trimethoxyl silane to the prepolymer emulsion, mixing, and adding the prepared tetraethyl orthosilicate sol; and finally adding 2-hydroxy-2-methyl-1-propiophenone to prepare the finished product. The coating of the present invention has advantages of rapid curing, excellent mechanical properties, low surface tension, aging resistance, yellowing resistance, good water resistance, and the like, and can be used as coatings for building and furniture.

Owner:JIANGSU UNIV

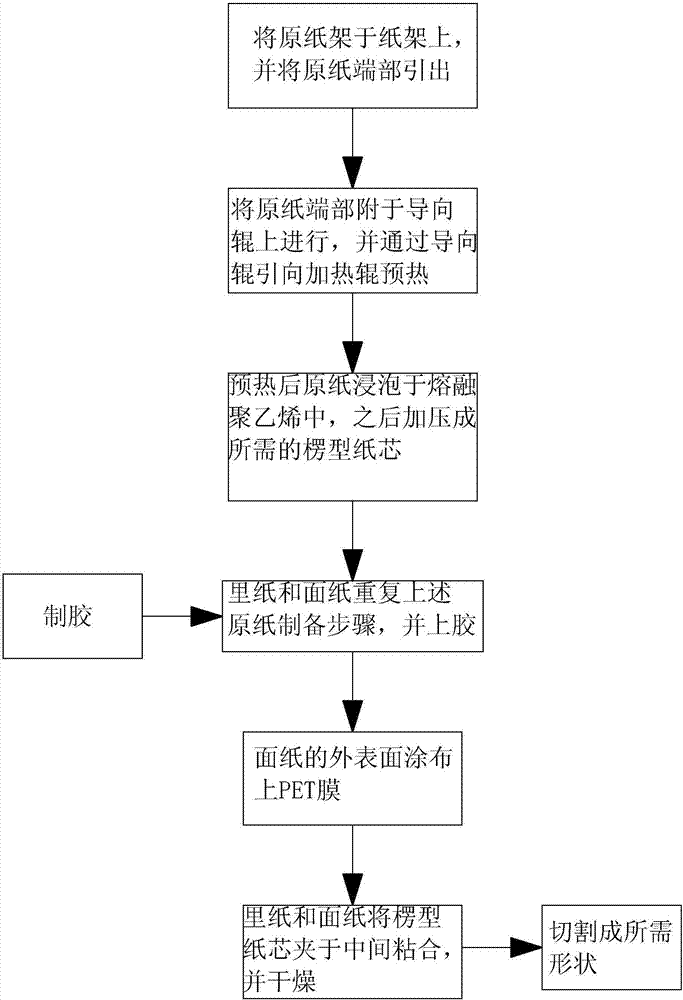

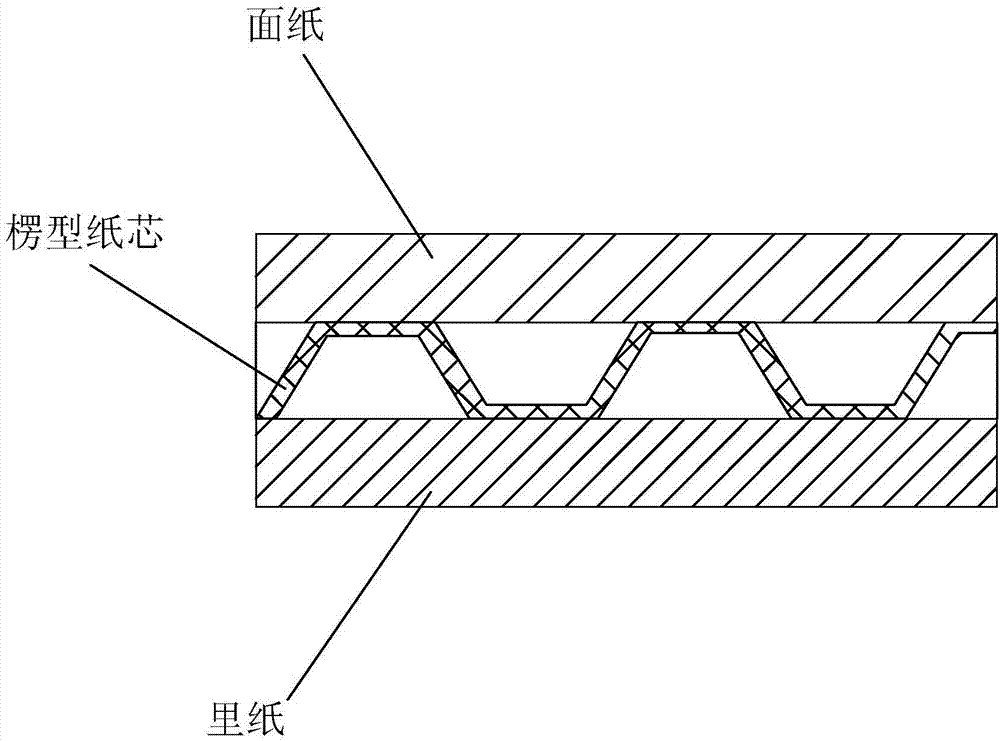

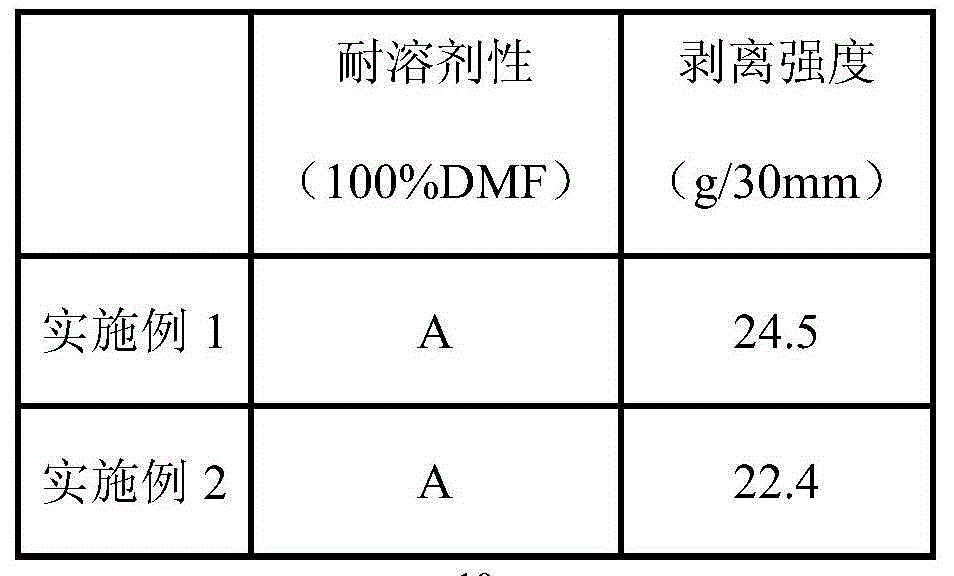

Energy-saving and environment-friendly corrugated board production technique

ActiveCN106915123AFast curing rateIncrease productivityMechanical working/deformationPaper sheetWork in process

The invention provides an energy-saving and environment-friendly corrugated board production technique. The energy-saving and environment-friendly corrugated board production technique comprises the following steps that S1, adhesives are prepared; S2, a paper tube of raw paper is mounted on a paper holder, and the end of the raw paper is led out from the paper holder; S3, the led-out end of the raw paper is attached to a paper guide roller, and the raw paper is led onto a heating roller so as to be preheated; S4, the raw paper passing through the heating roller is conveyed onto a single side machine to be pressurized into a required corrugated paper core; S5, operation in the step S2 and operation in the step S3 are conducted on inner paper and face paper correspondingly, then the sides, facing the corrugated paper core, of the inner paper and the face paper are coated with the adhesives prepared in the step S1; S6, the paper core is clamped between the inner paper and the face paper, so that a semi-finished corrugated board is prepared, and the semi-finished corrugated board is dried through a conveying belt type drying box; and S7, the dried semi-finished corrugated board is cut into a finished corrugated board through a longitudinal-transverse cutting machine according to requirements. In the production process, the water-based adhesives are used, so that the environment is effectively protected, the glued corrugated board has excellent water resistance and is high in utilization rate and curing speed, and production efficiency is greatly improved.

Owner:宁波和宝盛包装有限公司

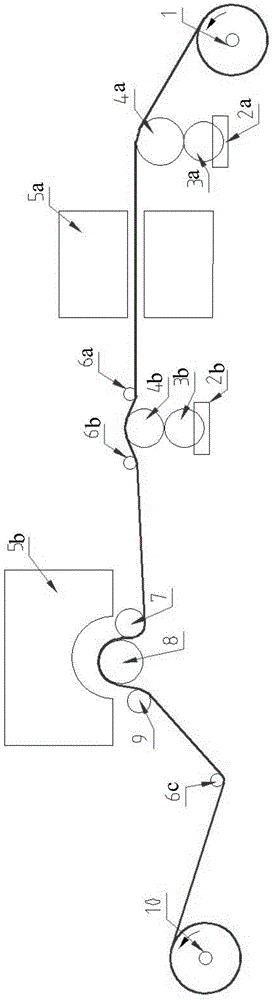

Method for making artificial leather release paper in radiation curing manner

The invention discloses a method for making artificial leather release paper in a radiation curing manner. A device for making artificial leather release paper in a radiation curing manner is adopted in the method, and is sequentially provided with a first coating device, a first radiation curing device, a second curing device, a patterned roll and a second radiation curing device from an unreeling device and a reeling device, wherein the second radiation curing device covers on the patterned roll. The method comprises the following steps: (1) performing first-time coating on base paper by adopting a coating solution, and then performing first-time radiation curing to obtain the base paper on which a first coating is coated; and (2) performing second-time coating on the base paper on which the first coating is coated by adopting the coating solution, and then embossing by virtue of the patterned roll and performing second-time radiation curing to obtain the artificial leather release paper. The method disclosed by the invention comprises two procedures, and the coating solution is divided into two parts which are singly and respectively subjected to radiation curing, so that the curing rate can be improved, the travel speed is increased, and the production efficiency is improved.

Owner:浙江池河科技有限公司

All-water foamed molding slow-rebound bloating foamed cotton of MDI (polymethylene polyphenyl isocyanate) with density of 45kg/m<3> and preparation method

The invention discloses all-water foamed molding slow-rebound bloating foamed cotton of MDI (polymethylene polyphenyl isocyanate) with the density of 45kg / m<3>. For the isocyanate in the MDI system, the functionality is 2-3 and the NCO value is 26-30; the polyether polyol is prepared by mixing the following materials: polyol A with the functionality being 3 and the hydroxyl value being 32-60mgKOH / g, polyol B with the functionality being 2 and the hydroxyl value being 240-260mgKOH / g, polyol C with the functionality being 3 and the hydroxyl value being 240-260mgKOH / g, polyol D with the functionality being 3 and the hydroxyl value being 20-28mgKOH / g; and a foaming agent is H2O. The molding slow-rebound bloating foamed cotton disclosed by the invention has the advantages that due to use of MDI for production, the harm can not be caused to a human body, water generates trace carbon dioxide in the foaming reaction, and the pollution to the atmosphere is almost zero; in conclusion, the use is safe and the processing is no-pollution.

Owner:FUJIAN GENEROUS SLEEP TECH CO LTD

Construction method of spray polyurea protection system for concrete base surface

ActiveCN108331279AFast curing rateAvoid bulgingCovering/liningsProtective foundationPolyolProtection system

The invention provides a construction method of a spray polyurea protection system for a concrete base surface. The construction method comprises the steps that a first primer layer, a first repair putty layer, a first polyurea spray layer, a second repair putty layer and a second polyurea spray layer coat the concrete base surface in sequence, wherein the first repair putty layer is formed by curing single-component polyurethane putty, and the single-component polyurethane putty is obtained by adding a latent curing agent for stirring and mixing when the content of isocyanate is up to 10%-15%by the reaction of polyols, isocyanate and a catalyst; and the surface defects of the first polyurea spray layer are repaired by the second repair putty layer, the second repair putty layer is formedby curing two-component polyurethane putty, the two-component polyurethane putty is composed of a component A and a component B, the component A is the single-component polyurethane putty, and the component B comprises 90.5-97.8 parts of polyaspartic acid ester.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

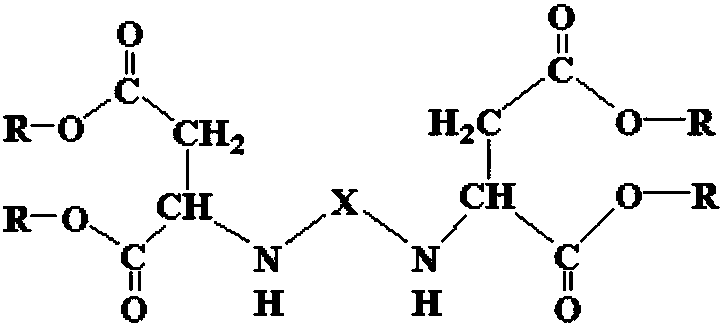

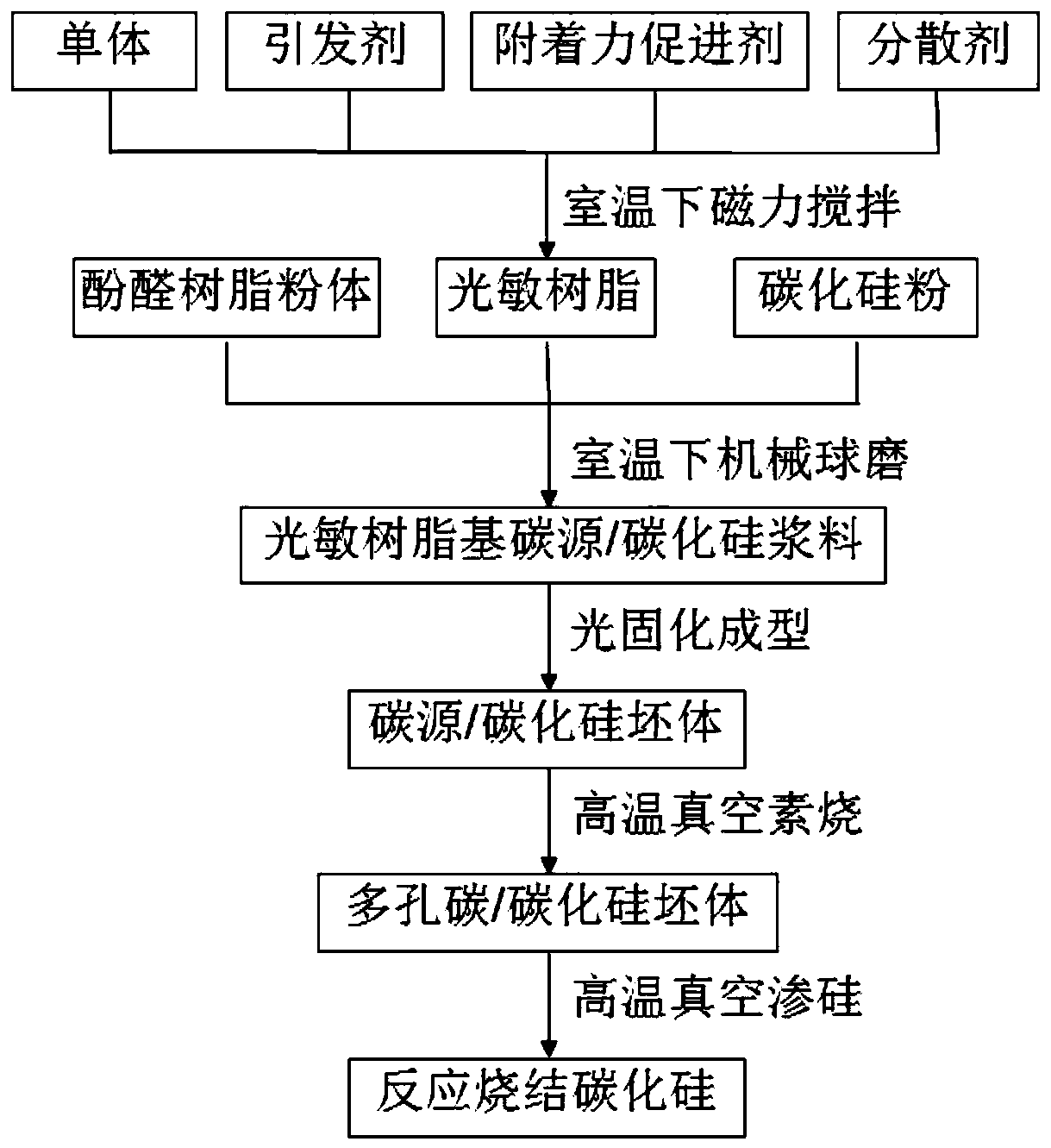

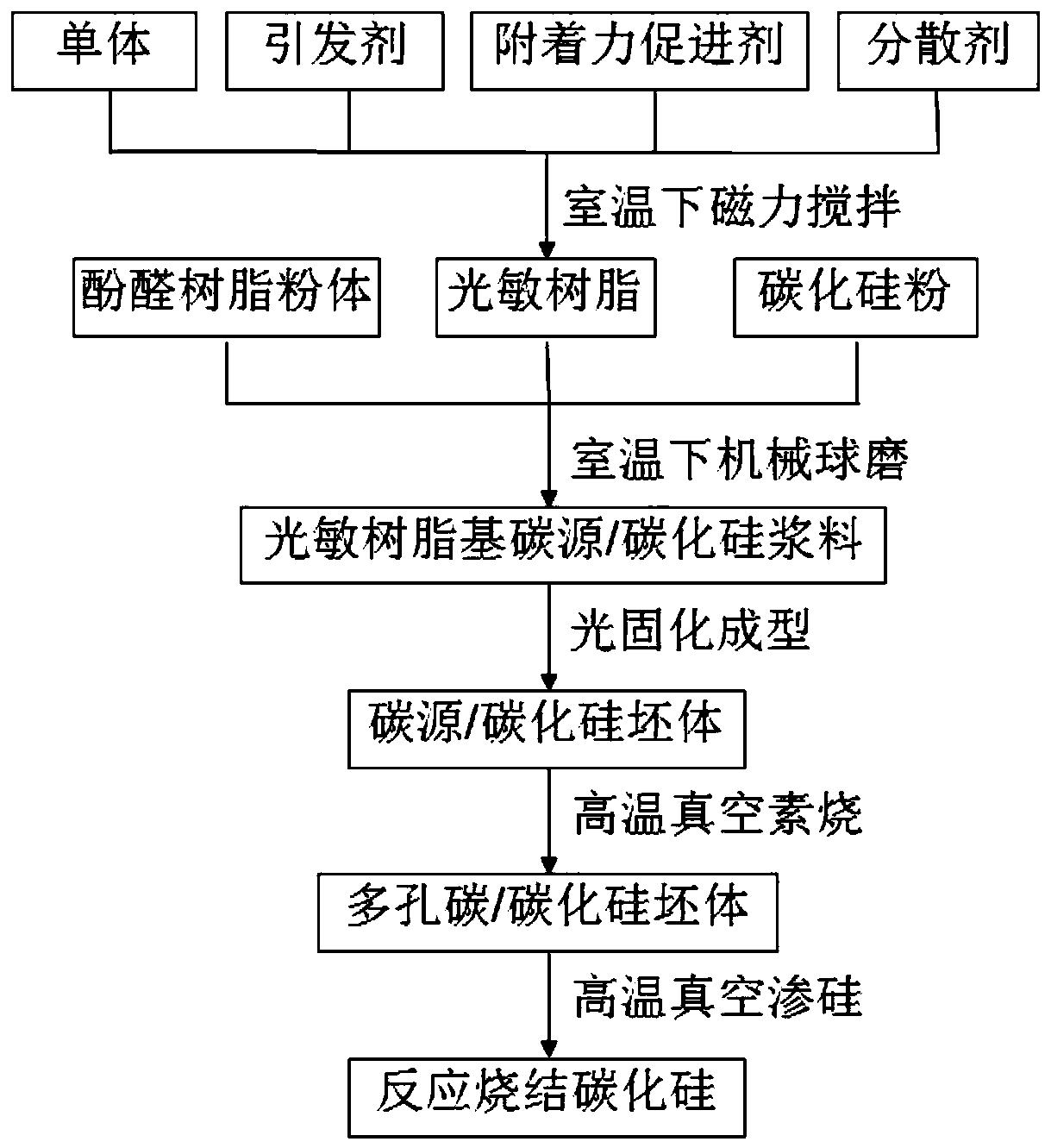

Photosensitive resin-based carbon source/silicon carbide ceramic slurry, method for preparing porous carbon/silicon carbide green body, structural member and preparation method of structural member

InactiveCN111116205AReduce viscosityHigh activityAdditive manufacturing apparatusCarbide siliconPorous carbon

The invention mainly aims to provide a photosensitive resin-based carbon source / silicon carbide ceramic slurry, a method for preparing a porous carbon / silicon carbide green body, a reaction sintered silicon carbide structural member and a preparation method of the reaction sintered silicon carbide structural member. The photosensitive resin-based carbon source / silicon carbide ceramic slurry comprises 50-70% of photosensitive resin and 30-50% of a powder material; the powder material comprises silicon carbide powder and phenolic resin powder; and the photosensitive resin comprises a monofunctional monomer, a bifunctional monomer, a trifunctional monomer, a photoinitiator, an adhesion promoter and a polymer dispersant. The preparation method of the porous carbon / silicon carbide green body comprises the following steps: preparing the photosensitive resin-based carbon source / silicon carbide ceramic slurry, carrying out photocuring 3D printing molding, and carrying out vacuum biscuiting; and carrying out high temperature siliconizing sintering. The technical problem to be solved is that a high-density and high-strength reactive sintering silicon carbide structural member can be manufactured, the density of the structural member is greater than or equal to 2.7 g / cm<3>, and the bending strength is greater than or equal to 270.0 MPa, so that the structural member is practical.

Owner:CHINA BUILDING MATERIALS ACAD

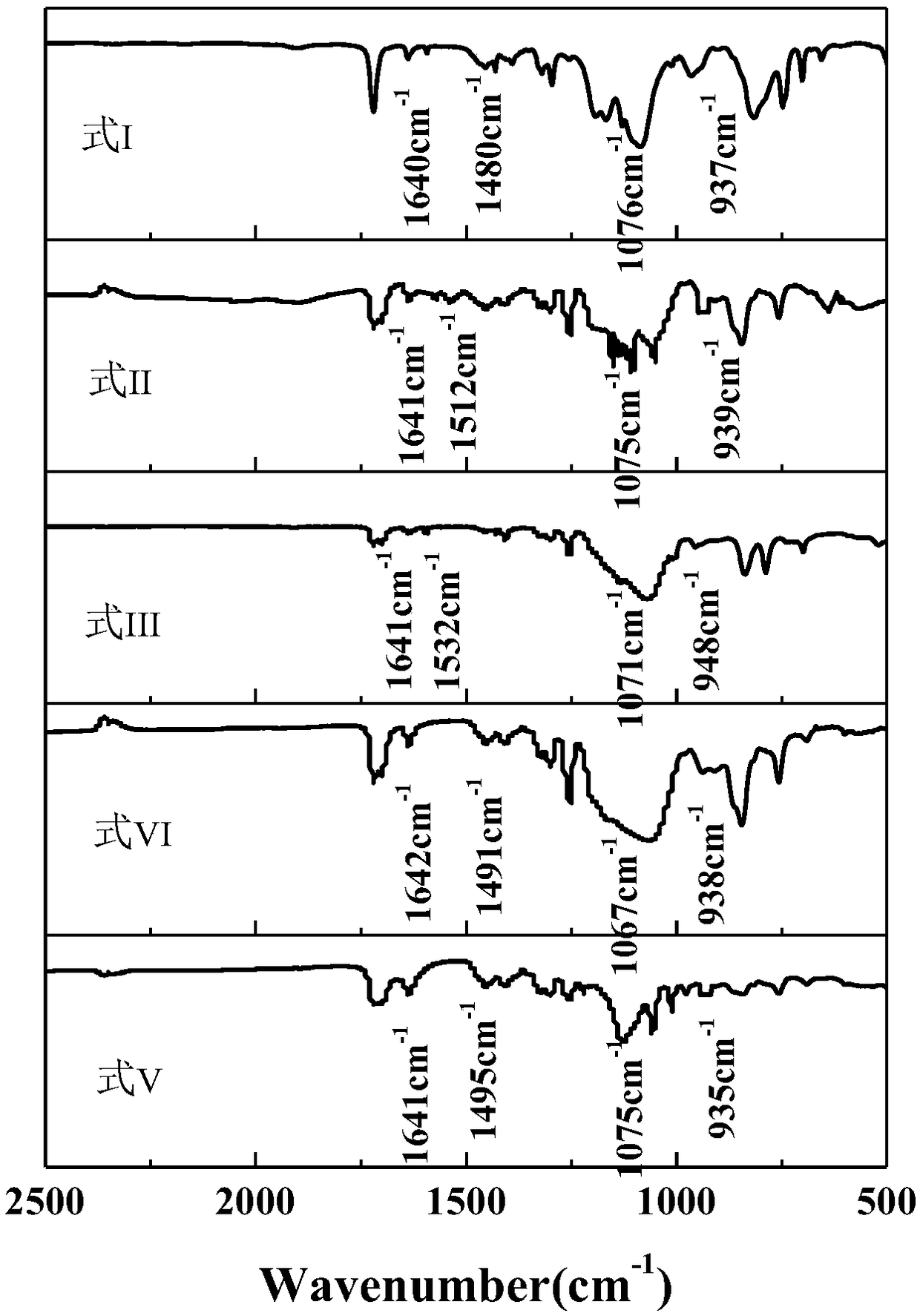

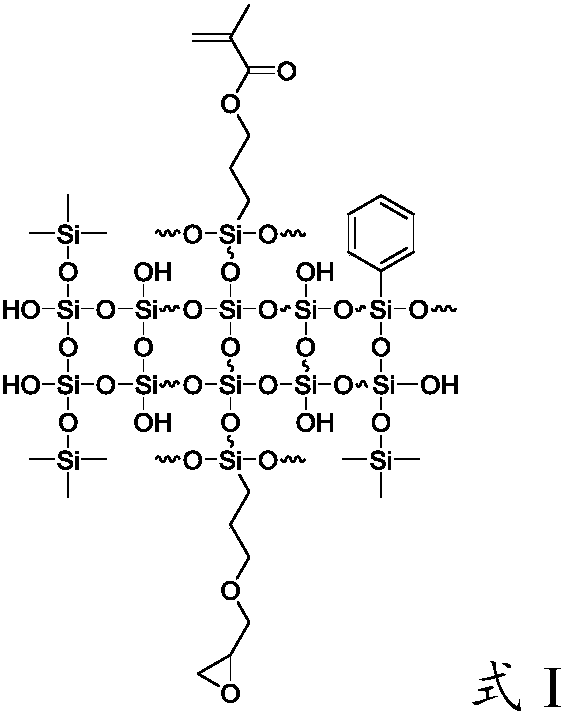

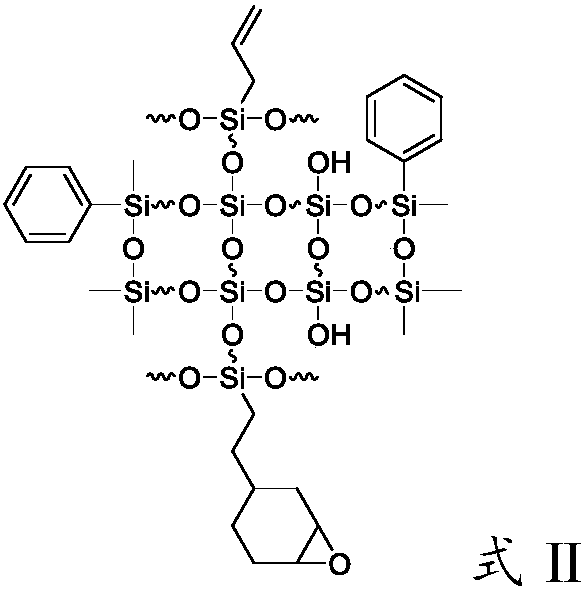

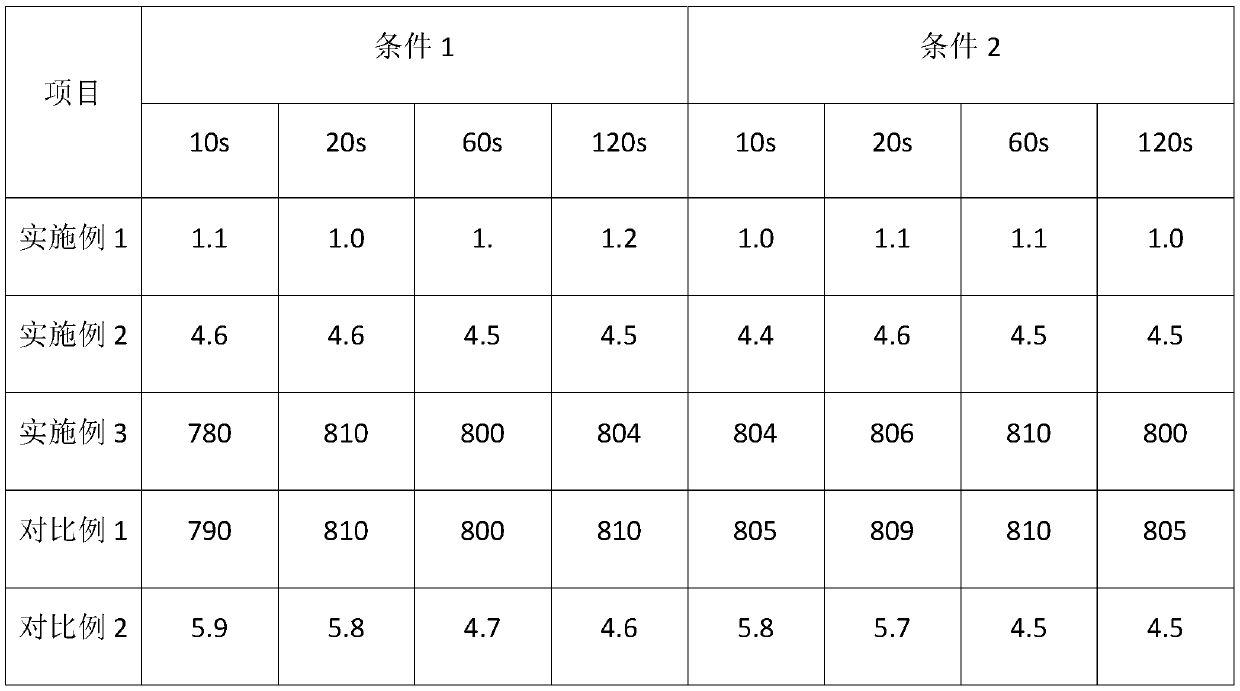

Light-cured organic silicon resin and preparation method thereof, photosensitive resin and application

The invention provides light-cured organic silicon resin. The light-cured organic silicon resin is prepared by performing cohydrolysis-polycondensation reaction on at least one of siloxane containingalkyl and siloxane containing aryl as well as siloxane containing epoxy group and siloxane containing unsaturated double bond under the action of a catalyst. Epoxy functional group and unsaturated double bond group in the light-cured organic silicon resin, serving as special functional groups, improve the curing property of organic silicon resin, improve the curing rate, reduce molding volume shrinking percentage and warping degree, and have important application in the fields of aviation, electronic engineering, light industry, mechanical engineering, chemical engineering and medicine.

Owner:GUANGDONG UNIV OF TECH

Quick-curing organosilicon pressure-sensitive adhesive and adhesive tape

InactiveCN110343483AFast cross-linking rateStable peel forceMacromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer scienceFunctional monomer

The invention discloses a quick-curing organosilicon pressure-sensitive adhesive, and belongs to the field of adhesives. The organosilicon pressure-sensitive adhesive is obtained by carrying out an addition reaction on a polysiloxane methyl vinyl MQ organosilicon tackifier containing vinyl under the action of a cross-linking agent, a reaction inhibitor and a platinum catalyst. According to the organosilicon pressure-sensitive adhesive provided by the invention, through selection of monomers, especially selection of functional groups and proportions of the functional monomers, optimization andimprovement of a process, and selection of a matching effect of the catalyst and the functional groups of the functional monomers, the adhesive can achieve the purpose of direct winding and quick curing after a base material is coated, and good viscous force and stripping force can be ensured.

Owner:太仓斯迪克新材料科技有限公司

Stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition and preparation method and application thereof

InactiveCN105278239AFast curing rateReduce system viscosityPhotosensitive materials for photomechanical apparatusLithographic artistHeat resistance

The invention relates to a stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition and its preparation method and application. The stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition mainly comprises the following raw materials (by weight): 10-85% of double-side acrylate polysiloxane, 3-21% of polyacrylate polysiloxane, 10-60% of an acrylate polysiloxane diluent, 10-60% of an acrylate diluents and 1.0-4.0% of a radical initiator. The raw materials are mixed according to the above ratio and the mixed raw materials are stirred and heated to obtain a transparent liquid, namely the stereo-lithography rapid-prototyping polysiloxane photosensitive resin. After stereo-lithography prototyping, the stereo-lithography rapid-prototyping polysiloxane photosensitive resin composition has rapid-prototyping characteristic of photosensitive resin and also has polysiloxane characteristic of high and low temperature resistance. A component molded by the use of the photosensitive resin has advantages of high precision, good heat resistance and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com