Room temperature curable organopolysiloxane composition

A polysiloxane, organo-based technology, applied in the field of organopolysiloxane compositions, can solve the problems of unacceptable, negative impact of working environment, expensive industrial applications, etc., to maintain adhesion and firm adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

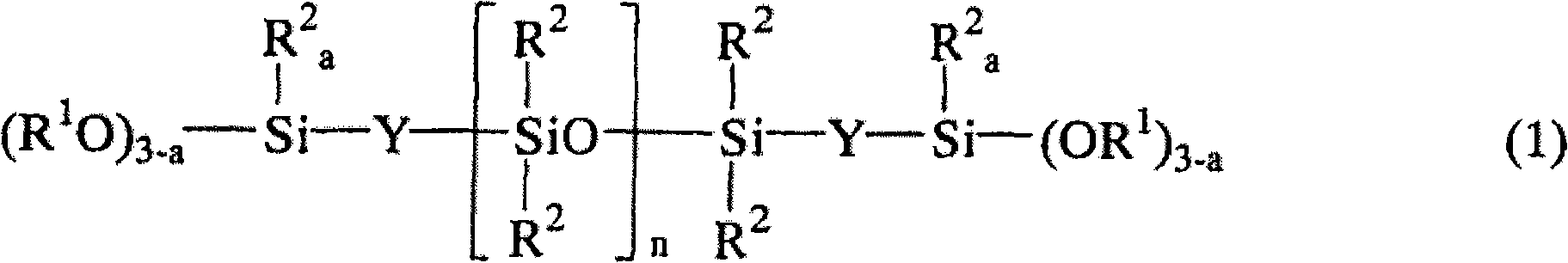

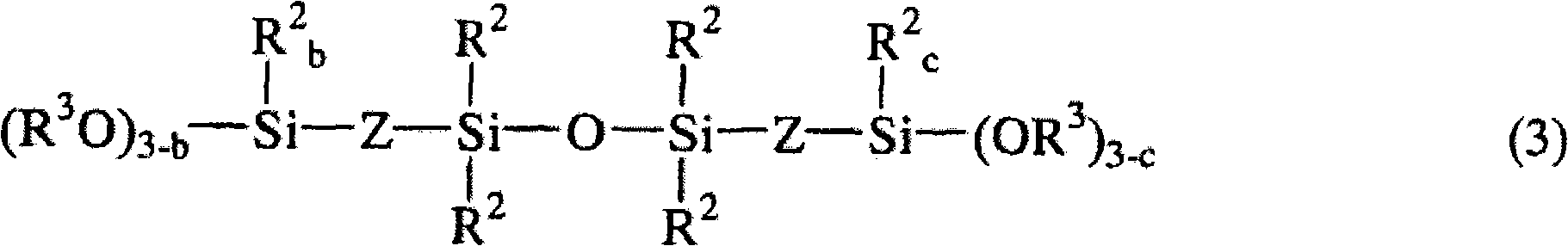

Method used

Image

Examples

Embodiment 1

[0067] Add 100 parts of colloidal calcium carbonate ( 300, Maruo Calcium Co., Ltd.). The mixture was homogeneously ground on a three-roll mill to form a base compound.

[0068] By combining 25 parts of polydimethylsiloxane with a viscosity of 5,000 mPa·s at both ends terminated with trimethylsiloxy groups, 10 parts of carbon black, 30 parts of bis(alkoxysilylalkyl) dimethicone Siloxane I (in Synthesis Example 1), 3 parts of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane and 0.1 part of dimethyltin dineodecanoate were mixed to prepare a curing agent. The base compound and curing agent were mixed at a weight ratio of 10:1 to obtain an RTV organopolysiloxane composition.

Embodiment 2

[0074] An RTV organopolysiloxane composition was prepared as in Example 1, except that 5 parts of N,N'-bis[3-(trimethoxysilyl)propyl]ethylenediamine was used instead of 3 parts of N-β-( Aminoethyl)-γ-aminopropyltrimethoxysilane, and the amount of dimethyltin dineodecanoate was changed from 0.1 part to 0.05 part.

Embodiment 3

[0078] An RTV organopolysiloxane composition was prepared as in Example 1, except that 3 parts of 3-(N-aminomethylbenzylamine)propyltrimethoxysilane and 2 parts of N,N,N',N' were used - Tetramethylguanidine instead of 3 parts of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com