Patents

Literature

401 results about "Disiloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

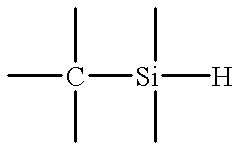

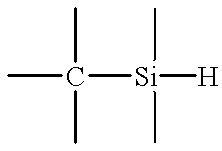

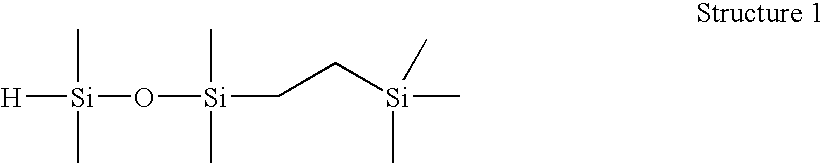

Disiloxane has the chemical formula Si₂H₆O. It is the simplest known siloxane with hydrogen only R groups. The molecule contains six equivalent Si-H bonds and two equivalent Si-O bonds. Disiloxane exists as a colorless, pungent gas under standard conditions. However, it is generally safe for human use as evidence in its widespread use in cosmetics. It is also commonly known as disilyl ether, disilyl oxide, and perhydrodisiloxane...

Plasma processes for depositing low dielectric constant films

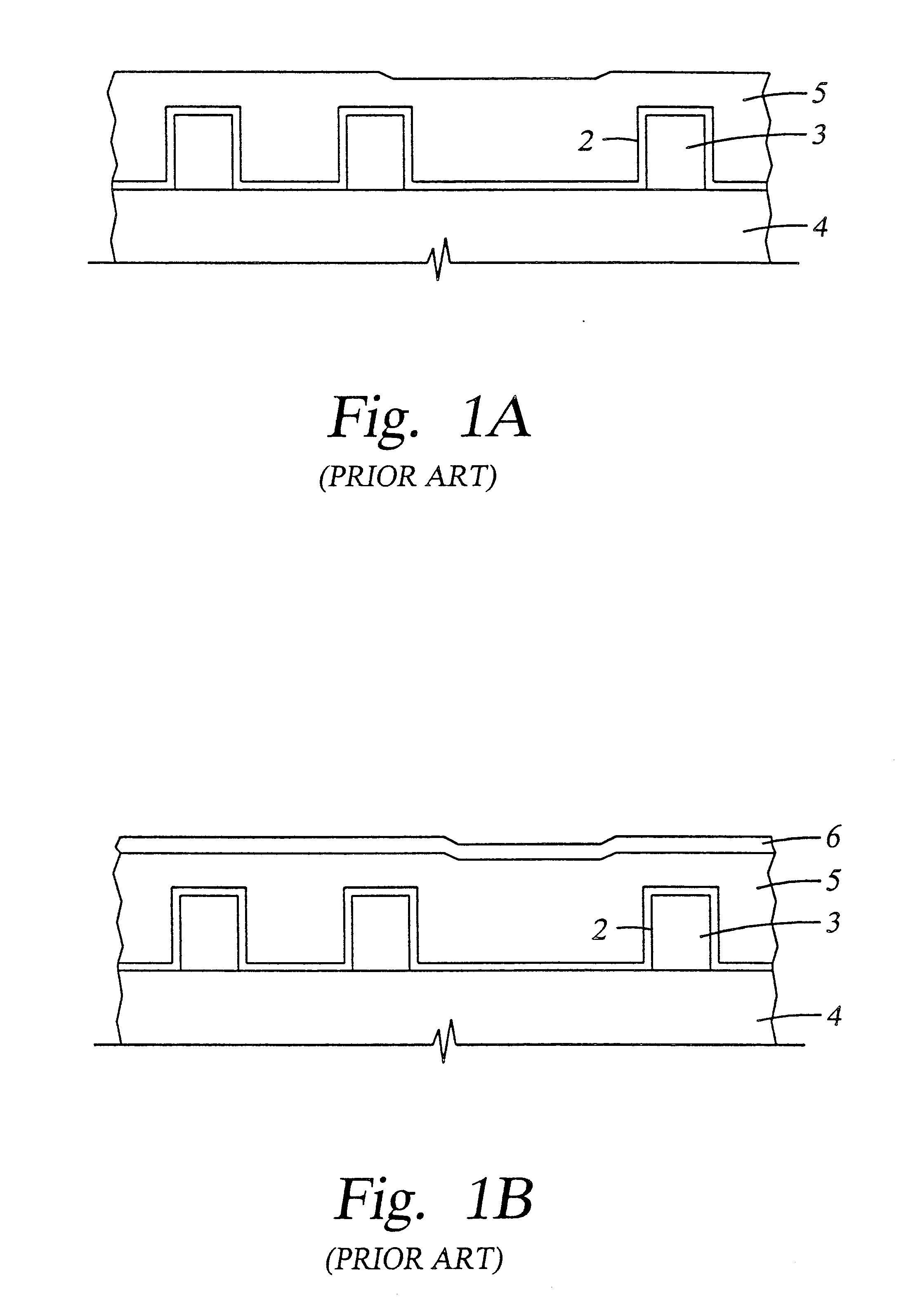

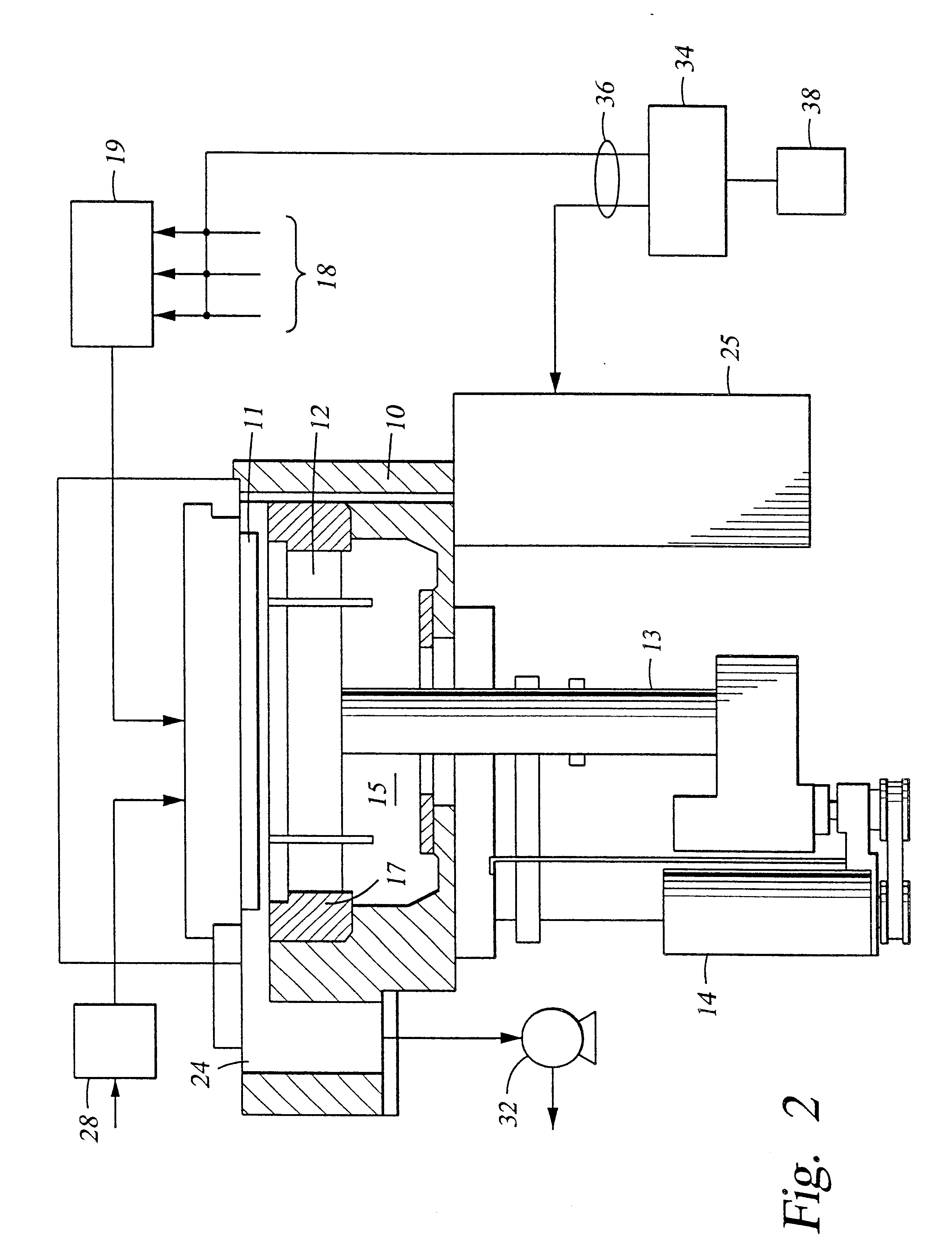

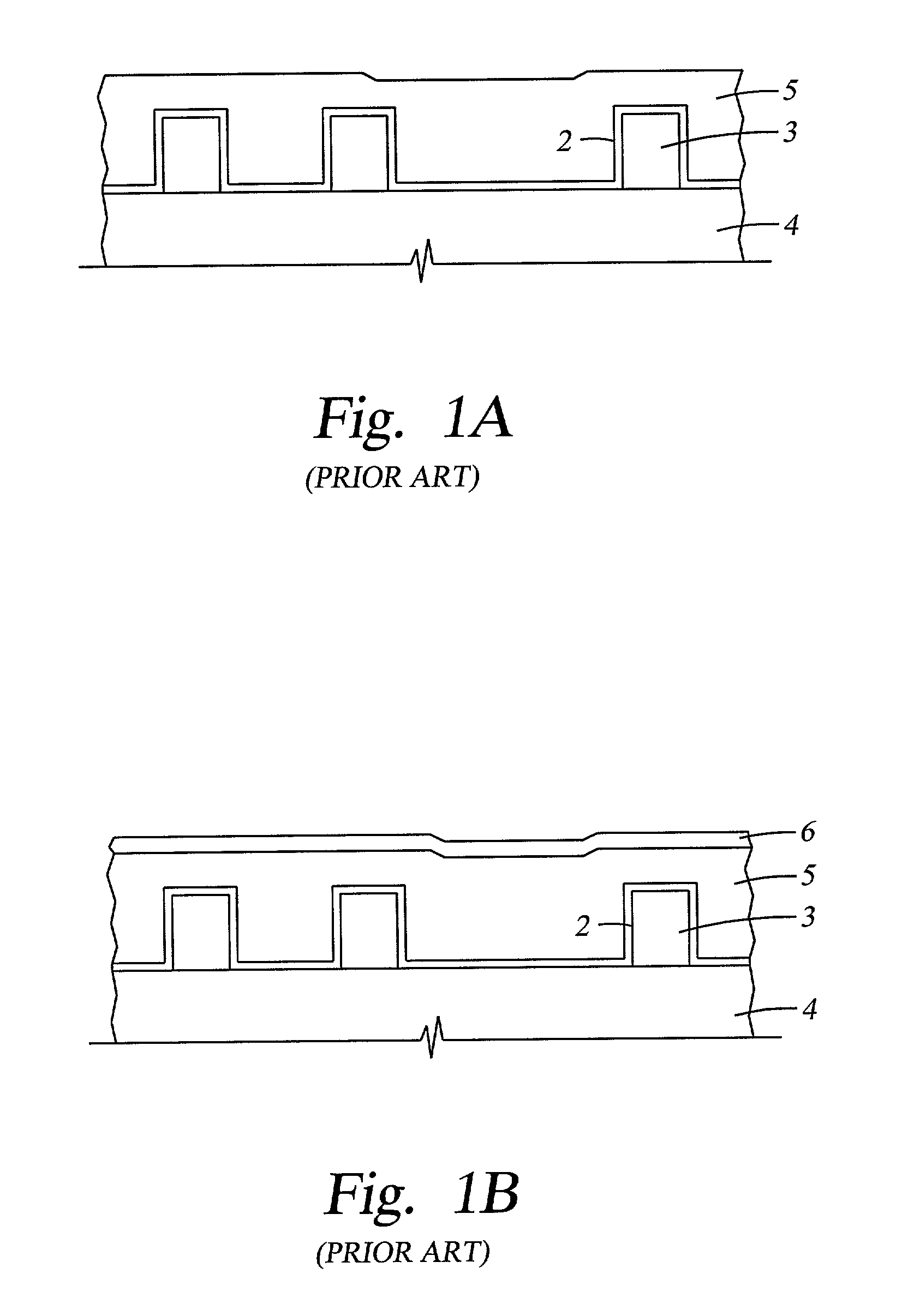

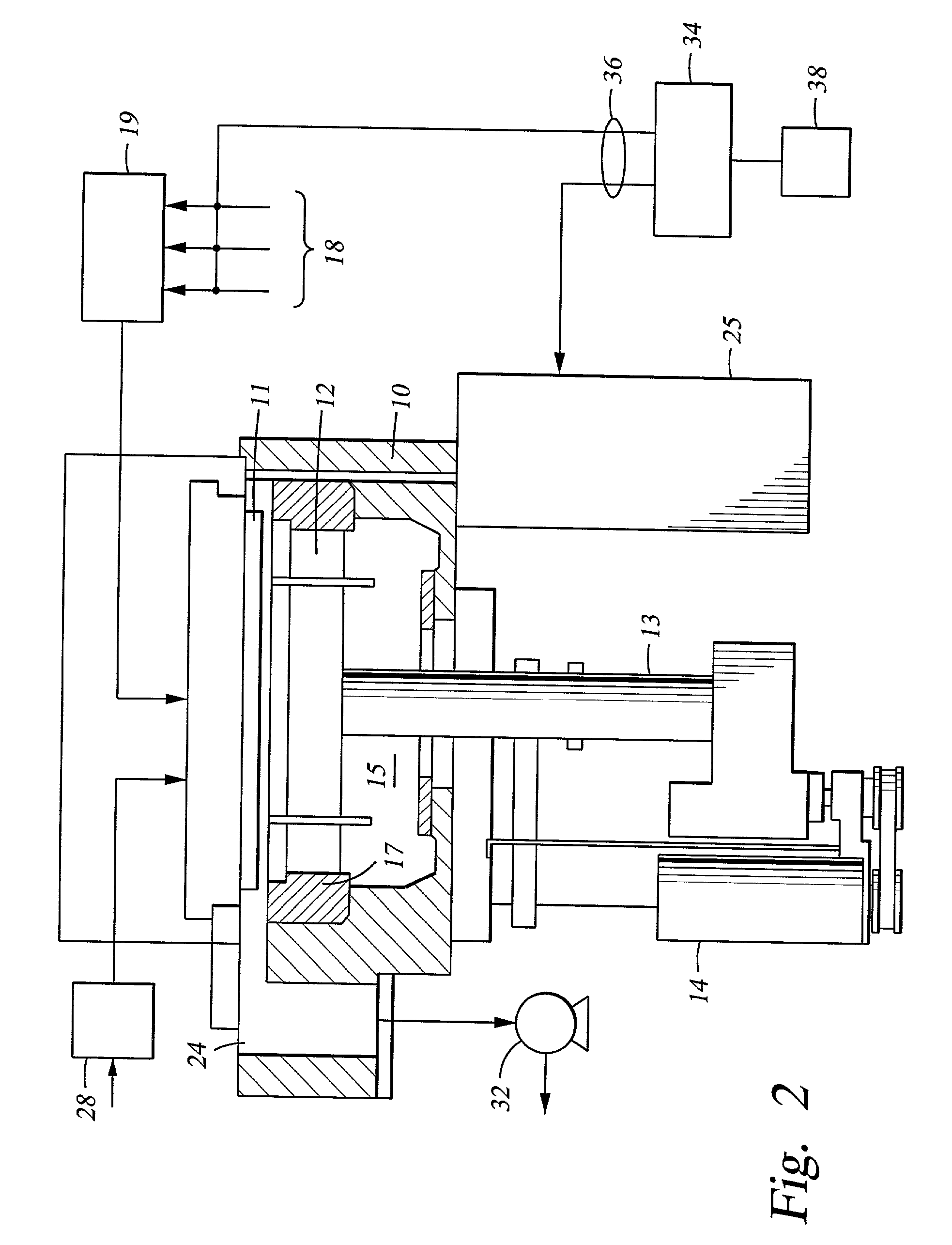

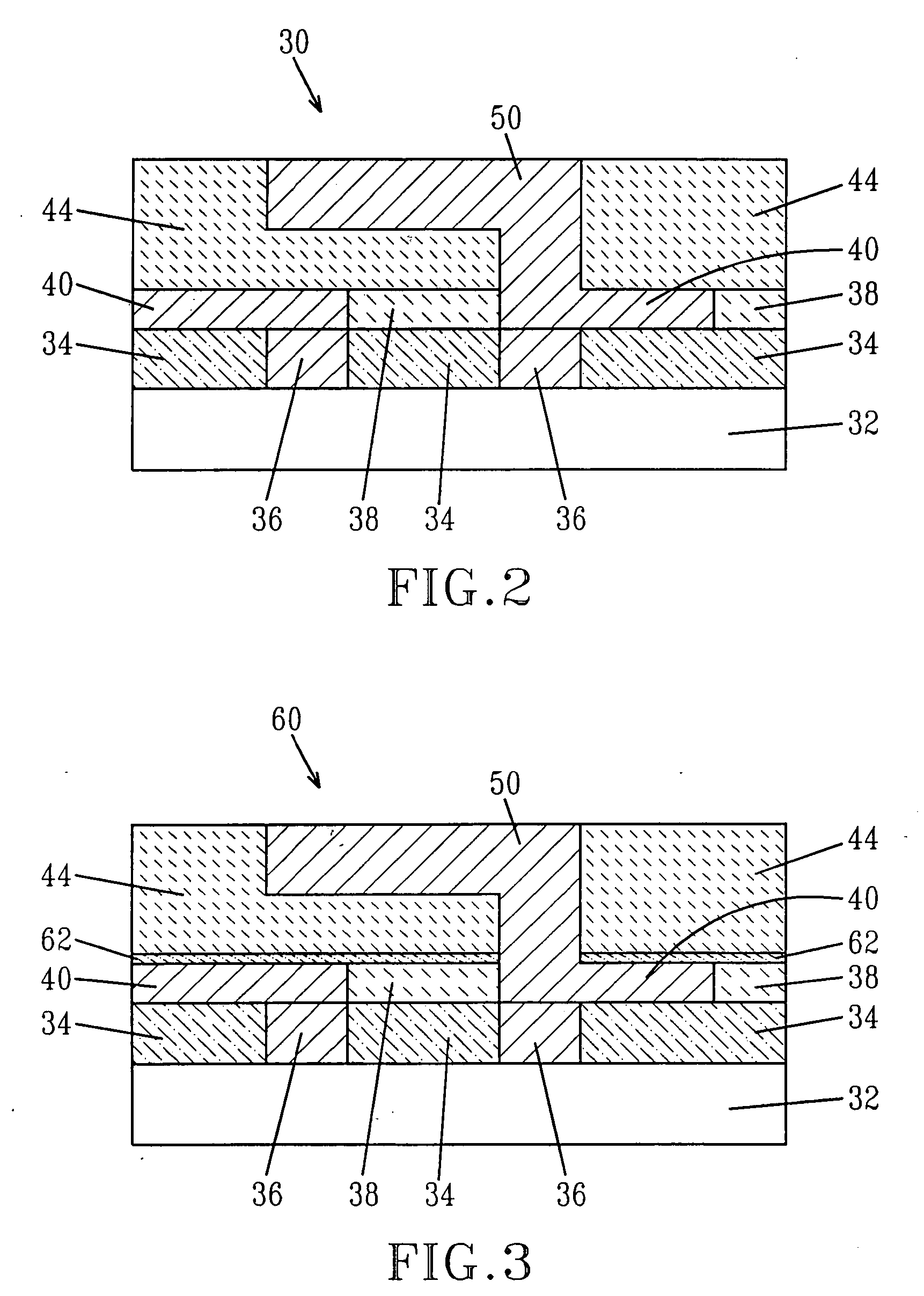

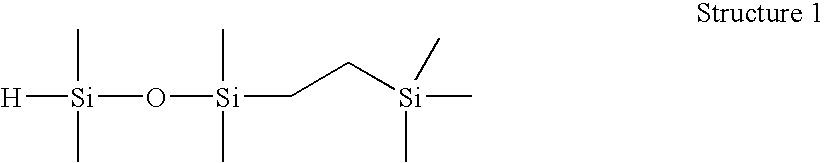

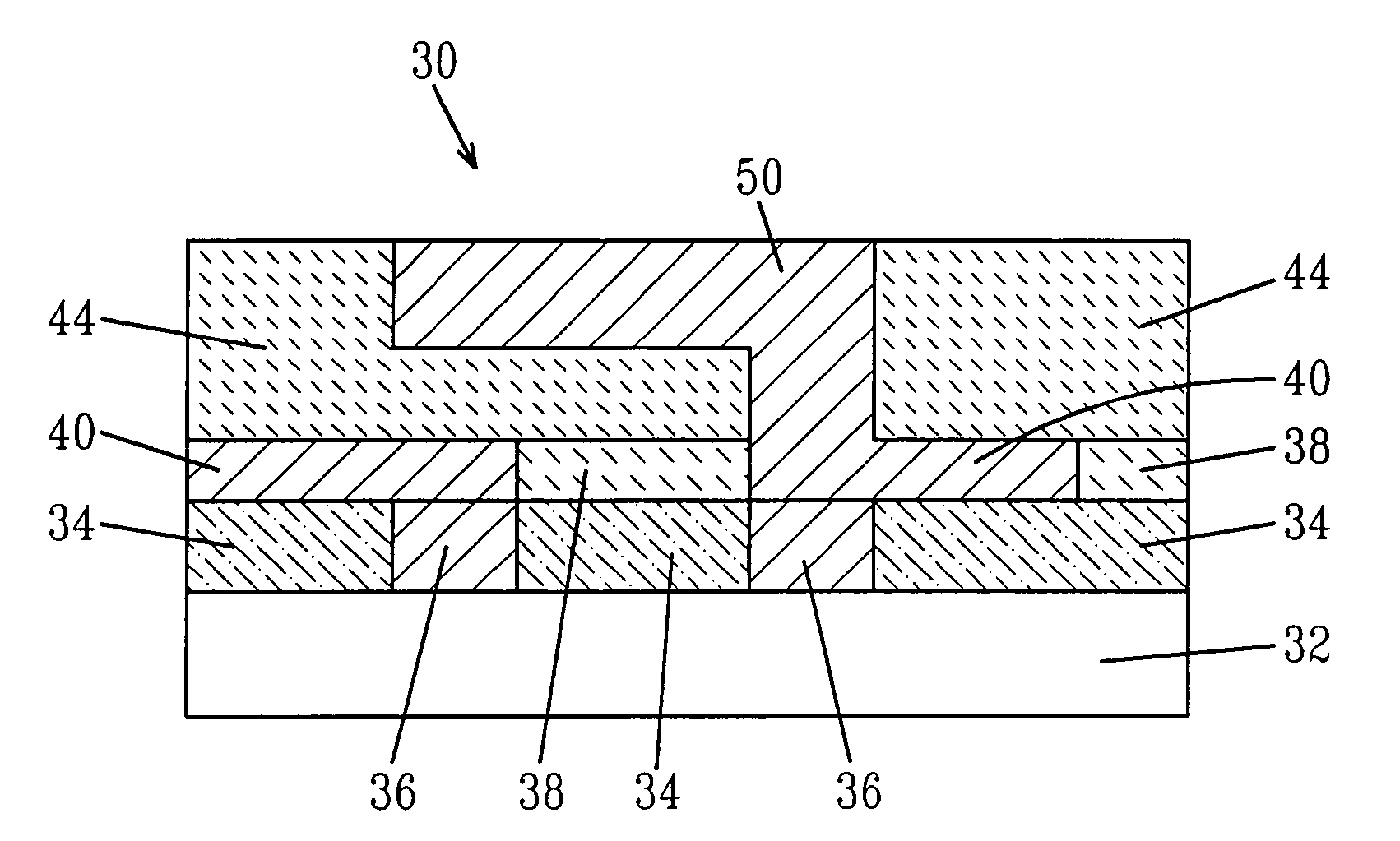

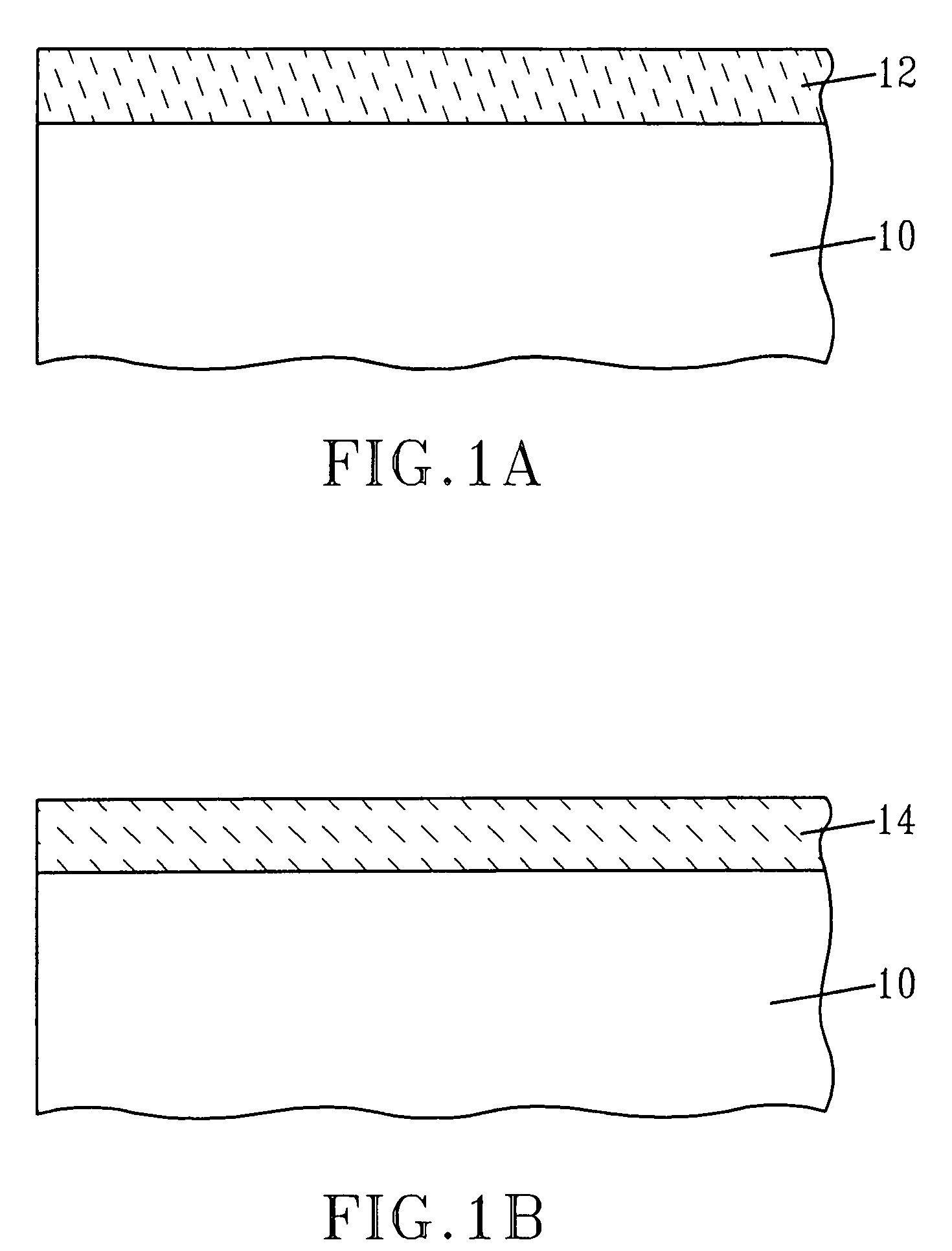

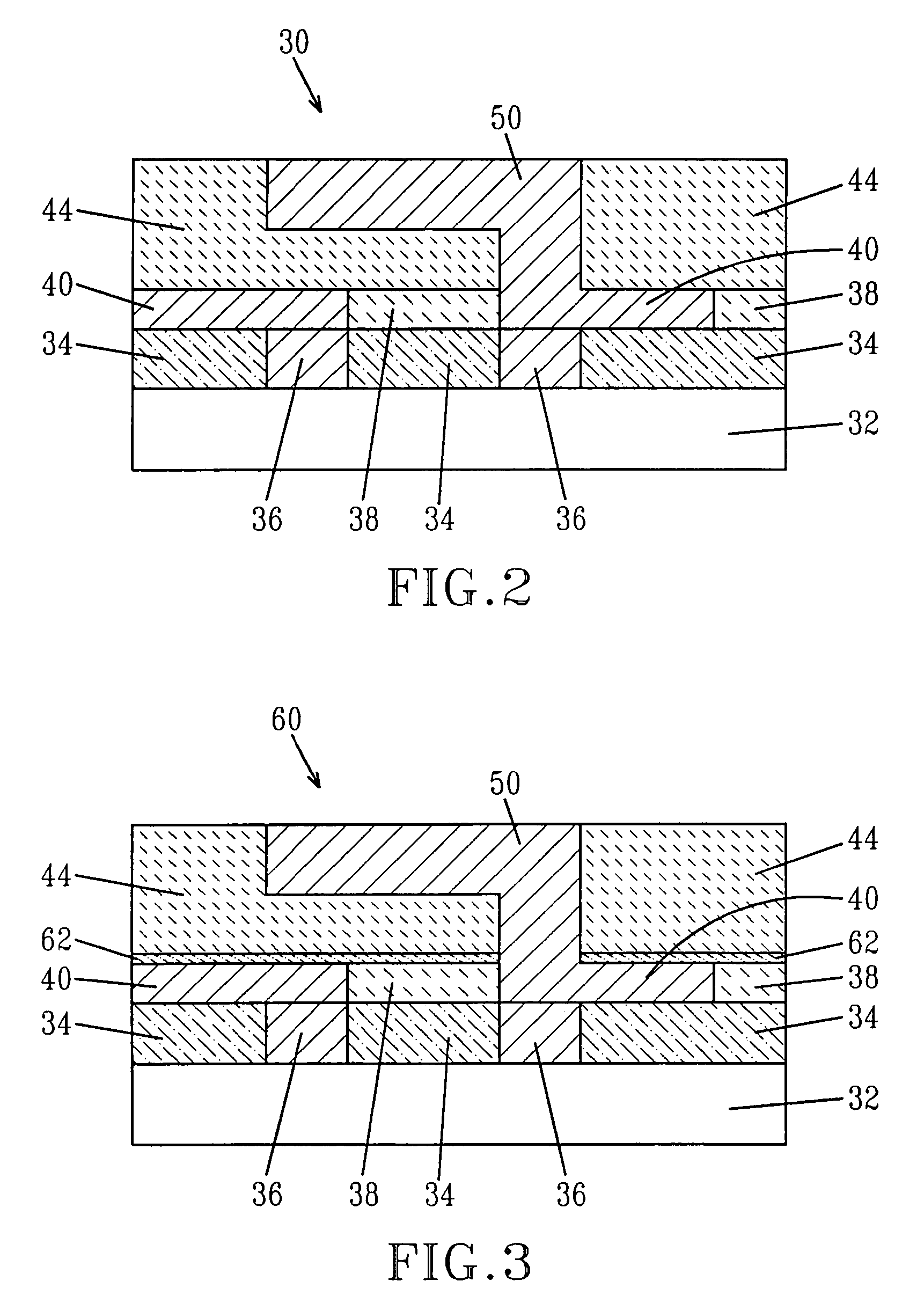

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Plasma processes for depositing low dielectric constant films

InactiveUS20010005546A1Semiconductor/solid-state device detailsSolid-state devicesDisiloxaneMicrowave

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Ultra low k plasma enhanced chemical vapor deposition processes using a single bifunctional precursor containing both a SiCOH matrix functionality and organic porogen functionality

InactiveUS20060079099A1Easy to controlImprove film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDisiloxaneEpoxy

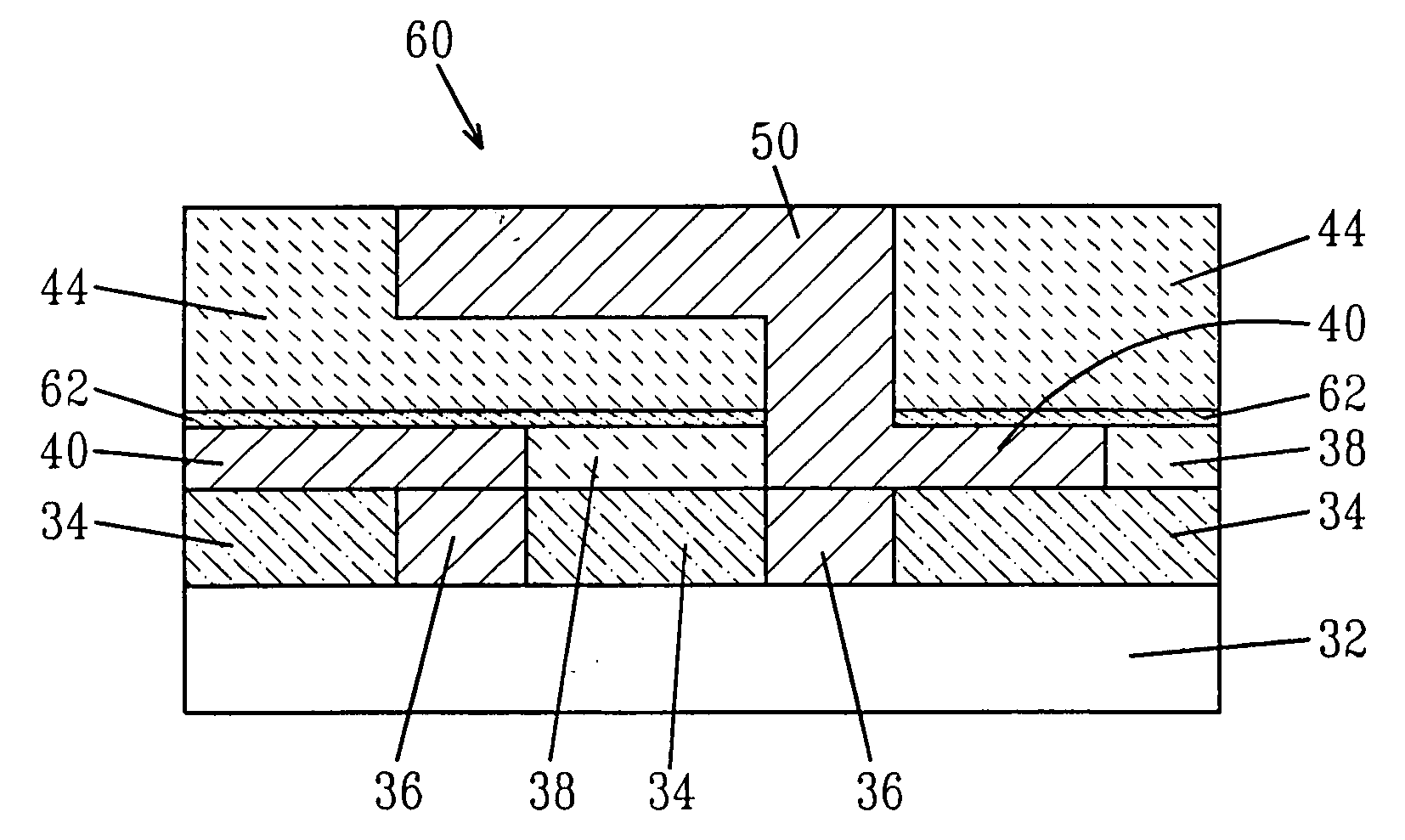

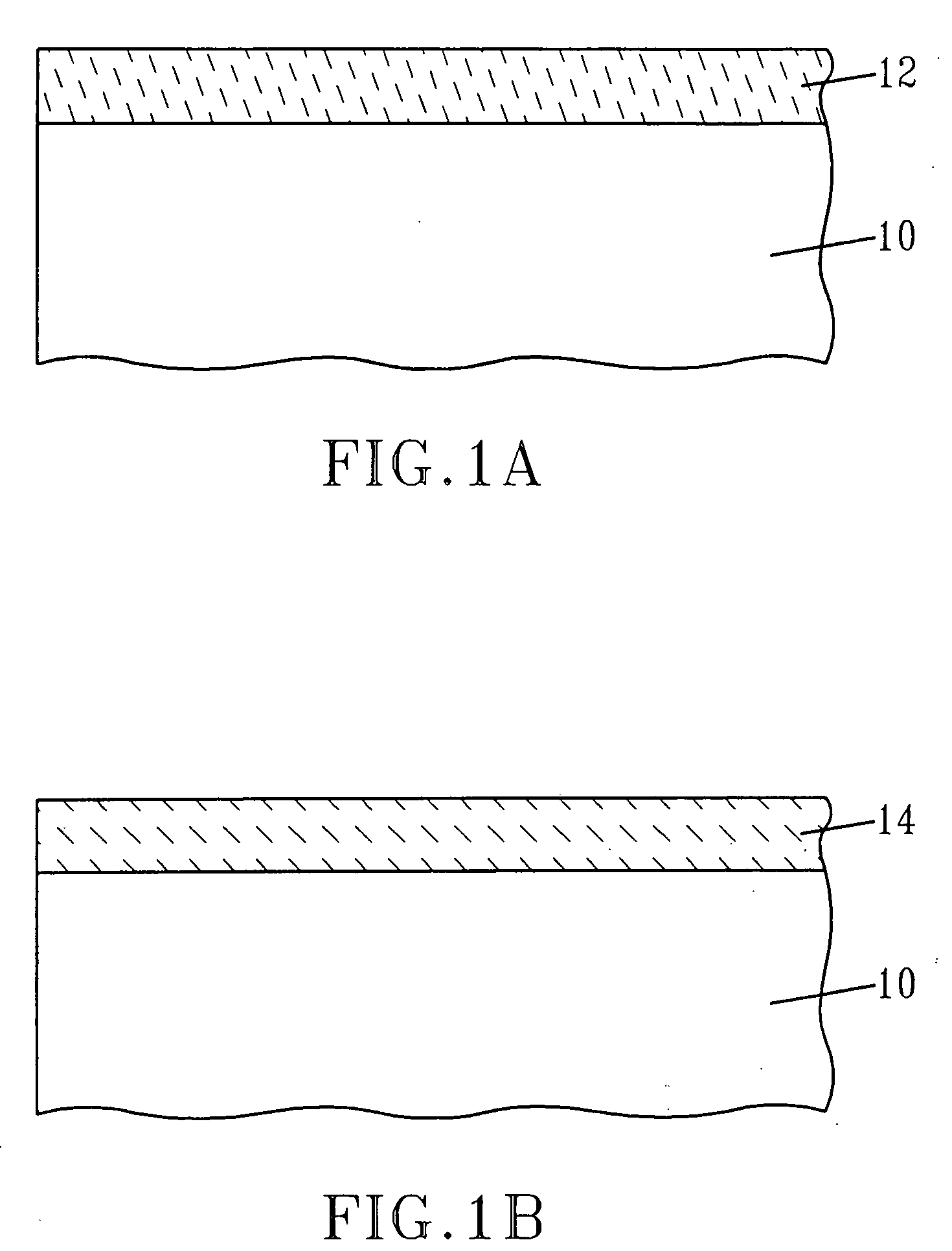

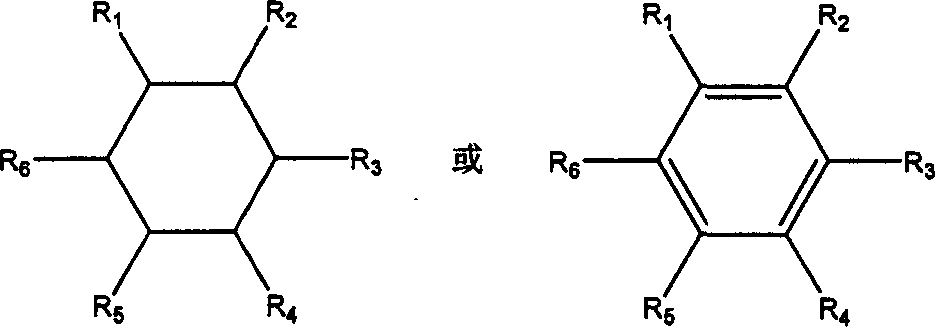

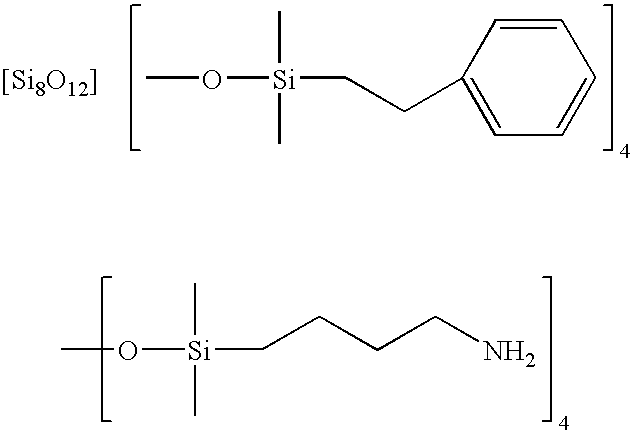

A method for fabricating a SiCOH dielectric material comprising Si, C, O and H atoms from a single organosilicon precursor with a built-in organic porogen is provided. The single organosilicon precursor with a built-in organic porogen is selected from silane (SiH4) derivatives having the molecular formula SiRR1R2R3, disiloxane derivatives having the molecular formula R4R5R6—Si—O—Si—R7R8R9, and trisiloxane derivatives having the molecular formula R10R11R12—Si—O—Si—R13R14—O—Si—R15R16R17 where R and R1-17 may or may not be identical and are selected from H, alkyl, alkoxy, epoxy, phenyl, vinyl, allyl, alkenyl or alkynyl groups that may be linear, branched, cyclic, polycyclic and may be functionalized with oxygen, nitrogen or fluorine containing substituents. In addition to the method, the present application also provides SiCOH dielectrics made from the inventive method as well as electronic structures that contain the same.

Owner:GLOBALFOUNDRIES INC

Hydrolysis resistant organomodified disiloxane surfactants

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Ultra low k plasma enhanced chemical vapor deposition processes using a single bifunctional precursor containing both a SiCOH matrix functionality and organic porogen functionality

InactiveUS7491658B2Improve film propertiesEasy to controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricEpoxy

A method for fabricating a SiCOH dielectric material comprising Si, C, O and H atoms from a single organosilicon precursor with a built-in organic porogen is provided. The single organosilicon precursor with a built-in organic porogen is selected from silane (SiH4) derivatives having the molecular formula SiRR1R2R3, disiloxane derivatives having the molecular formula R4R5R6—Si—O—Si—R7R8R9, and trisiloxane derivatives having the molecular formula R10R11R12—Si—O—Si—R13R14—O—Si—R15R16R17 where R and R1-17 may or may not be identical and are selected from H, alkyl, alkoxy, epoxy, phenyl, vinyl, allyl, alkenyl or alkynyl groups that may be linear, branched, cyclic, polycyclic and may be functionalized with oxygen, nitrogen or fluorine containing substituents. In addition to the method, the present application also provides SiCOH dielectrics made from the inventive method as well as electronic structures that contain the same.

Owner:GLOBALFOUNDRIES INC

Extreme environment surfactant compositions comprising hydrolysis resistant organomodified disiloxane surfactants

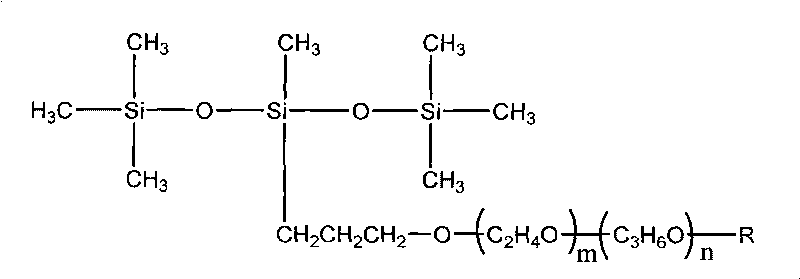

Compositions comprising an asymmetric disiloxane surfactant composition comprising a silicone composition comprising a silicone having the formula: MM′where M or M′ comprises an alkylpolyalkyleneoxide bearing substituent selected from the group consisting of: R13(C2H4O)a(C3H6O)b(C4H8O)cR14 and R12SiR5R6(R13(C2H4O)a(C3H6O)b(C4H8O)cR14) that exhibit resistance to hydrolysis over a wide pH range.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

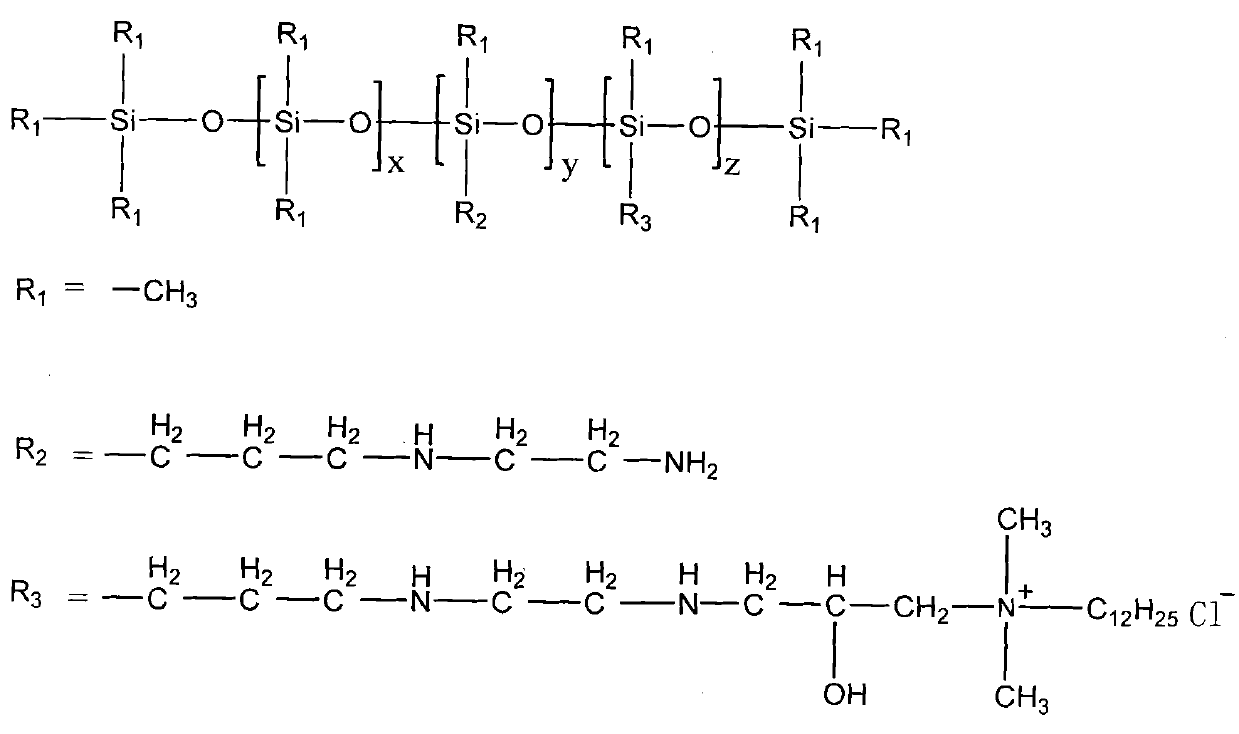

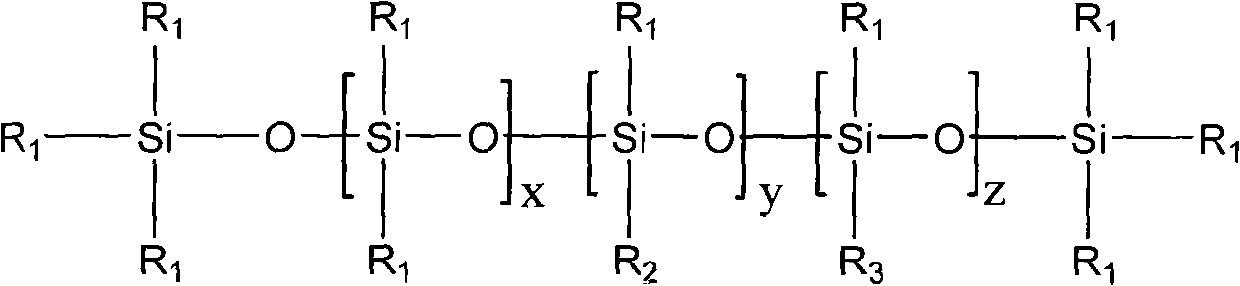

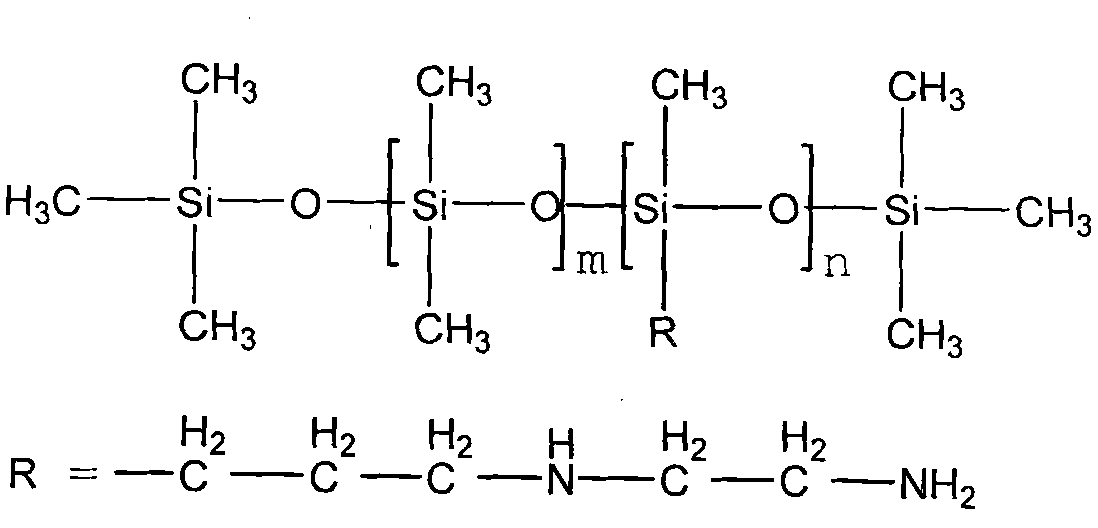

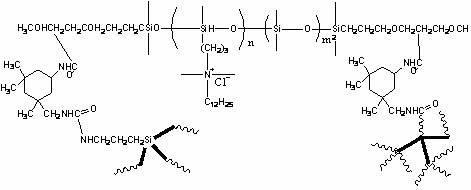

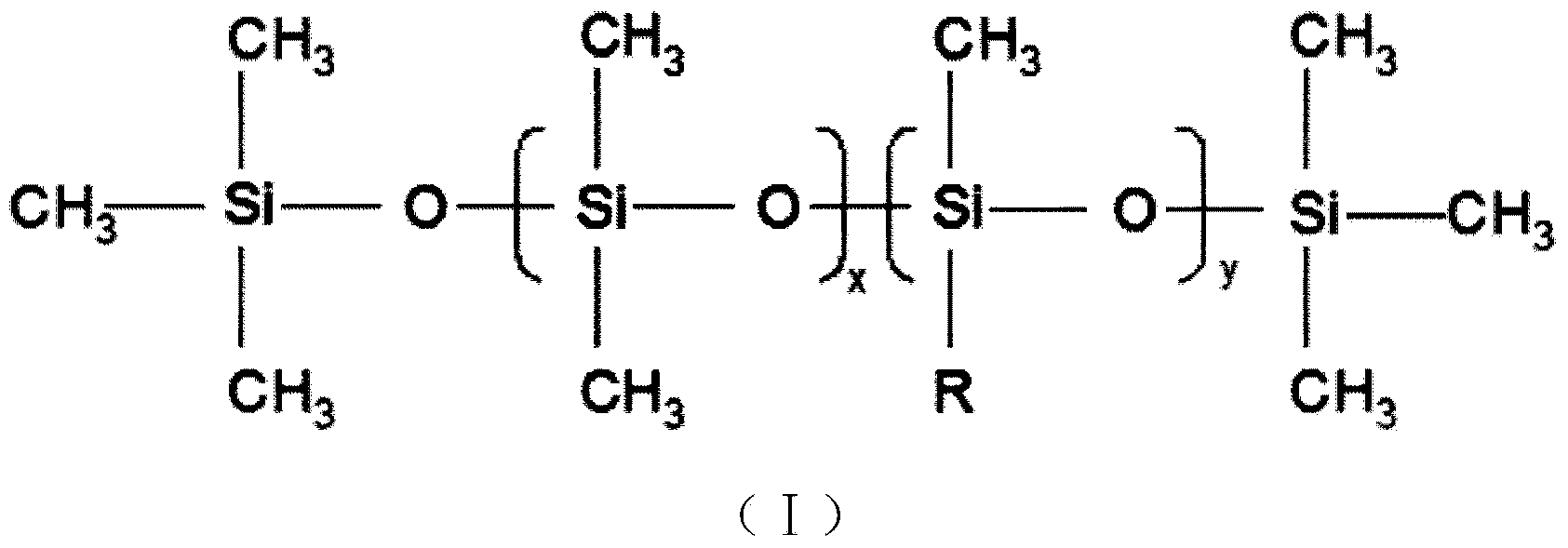

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

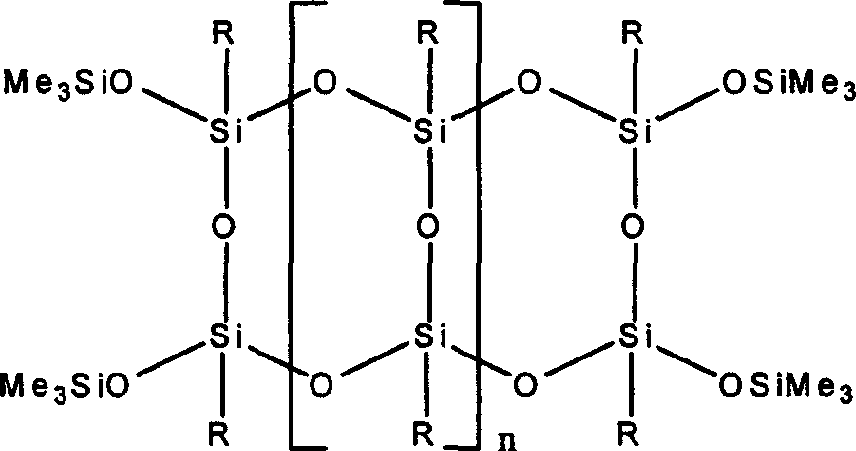

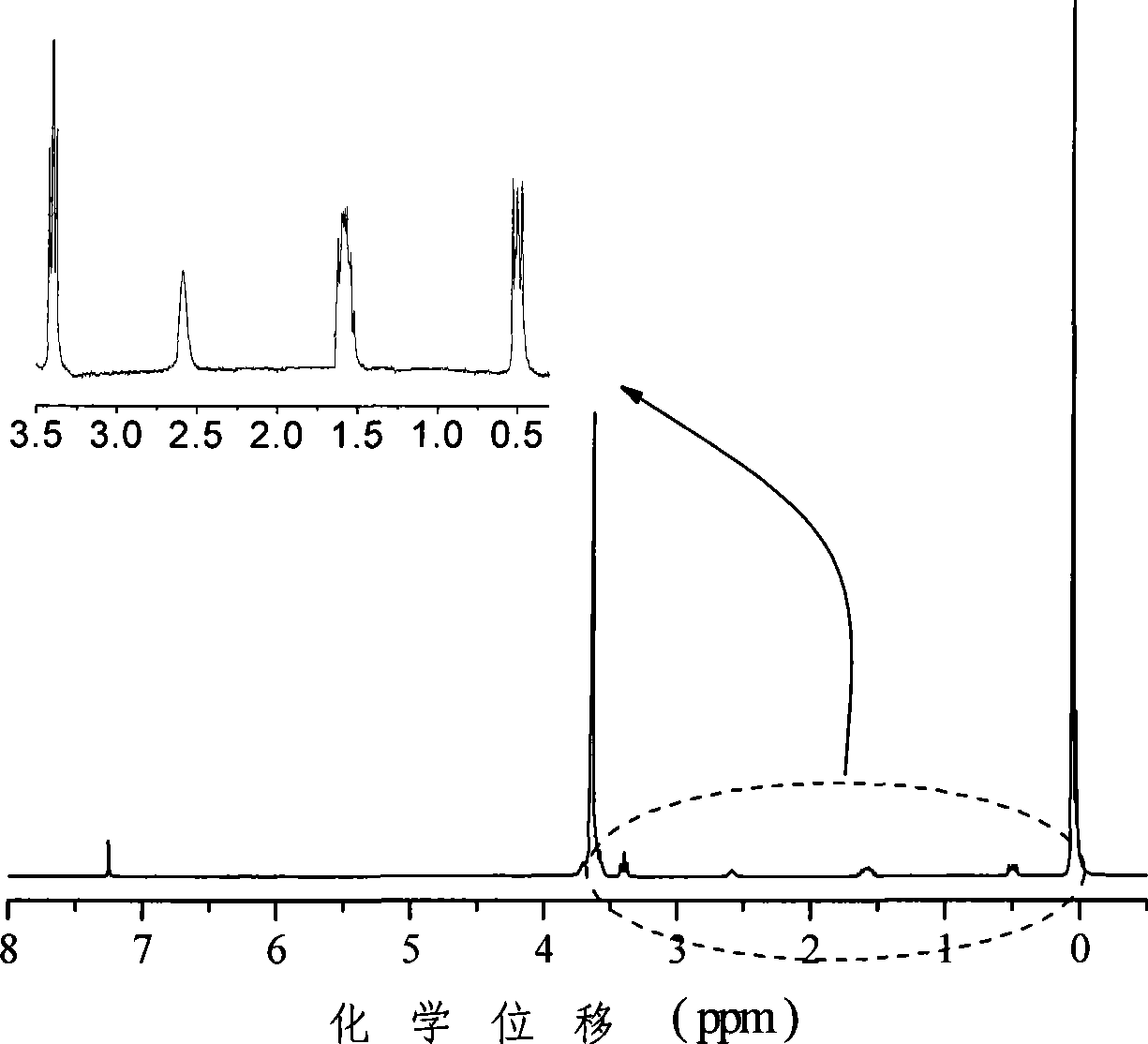

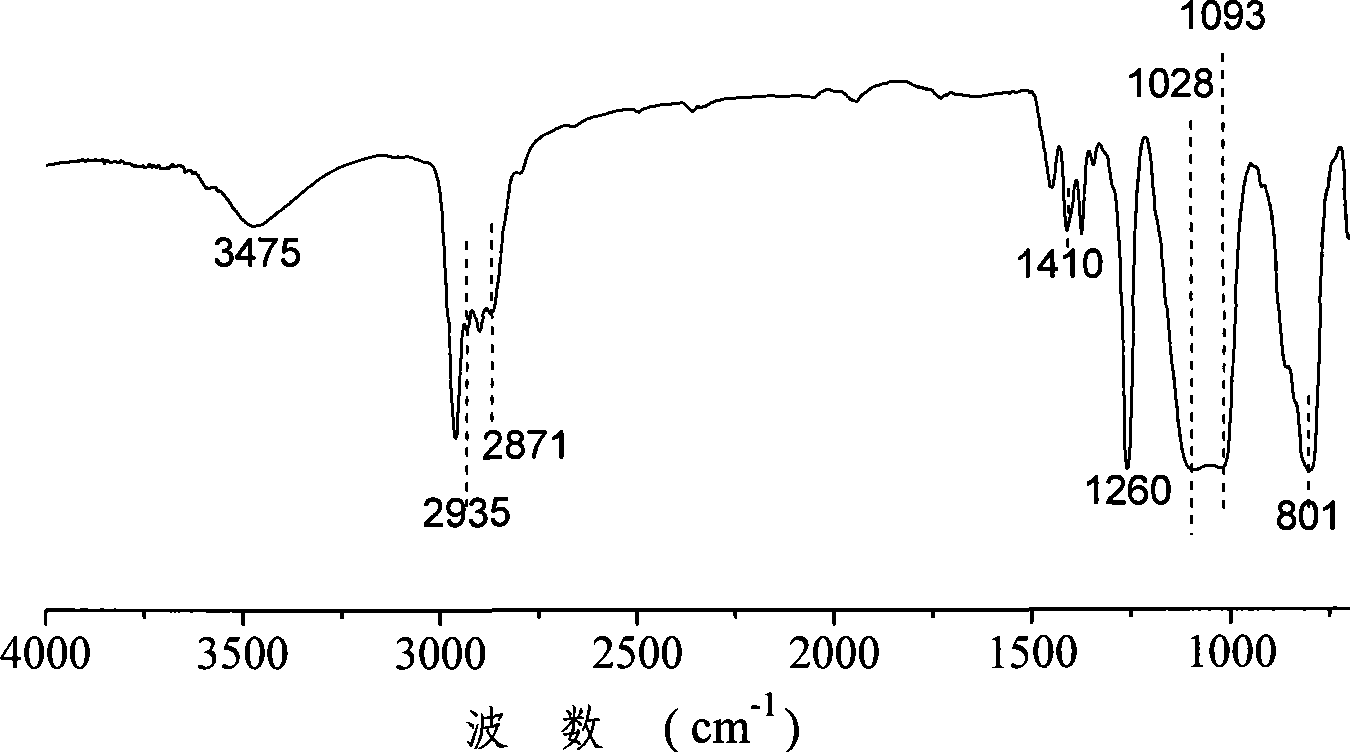

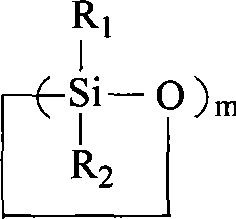

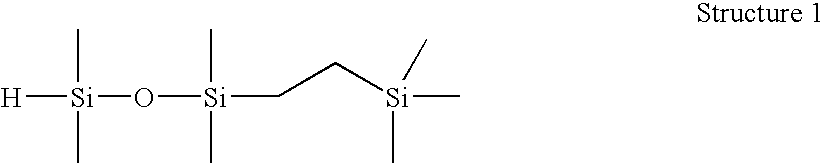

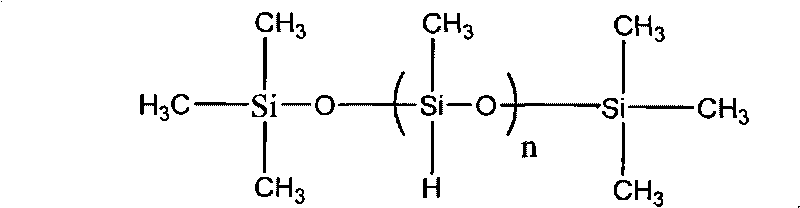

Hydrophilic block polyether amino silicone oil with amino branched chain, and preparation method and application thereof

The invention discloses hydrophilic block polyether amino silicone oil with an amino branched chain and a preparation method thereof. The hydrophilic block polyether amino silicone oil with the amino branched chain has the following structure as shown in the specification, wherein R1 is represented by formulas shown in the specification. The preparation method comprises the following steps: carrying out mixing reaction of tetramethyl dihydro disiloxane, polysiloxane and concentrated sulfuric acid, neutralizing with anhydrous sodium carbonate, carrying out reduced pressure pumping to remove a low-boiling-point substance, and thus obtaining silicone oil with the end containing hydrogen; carrying out mixing reaction of the silicone oil with the end containing hydrogen, allyl epoxy polyether and a catalyst, and thus obtaining epoxy silicone oil; carrying out mixing reaction of the epoxy silicone oil, polyether amine and a solvent, and thus obtaining block polyether amino silicone oil; and carrying out mixing reaction of the block polyether amino silicone oil, a silane coupling agent hydrolysate and an alkali catalyst, neutralizing with glacial acetic acid, and thus obtaining the hydrophilic polyether amino silicone oil with the amino branched chain.

Owner:江阴市诺科科技有限公司

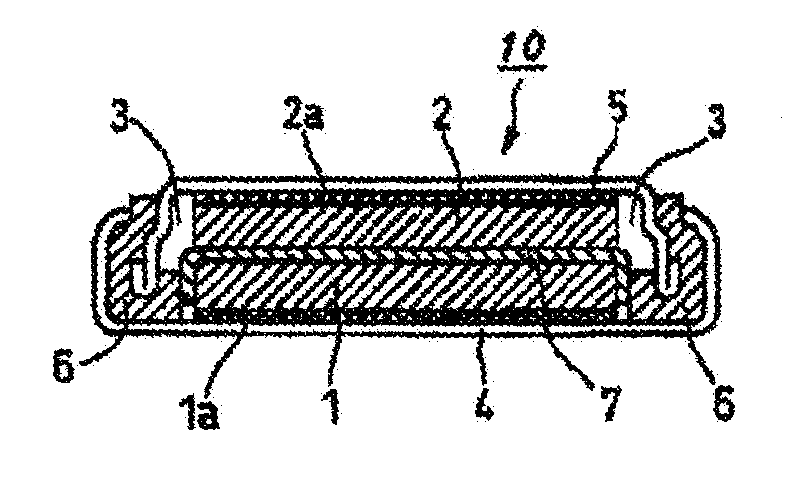

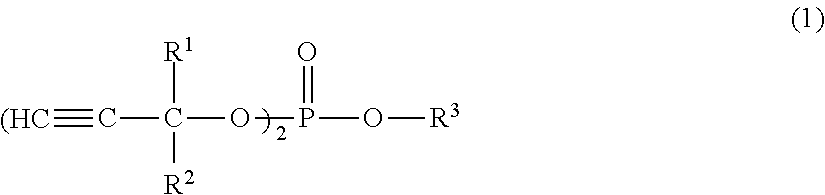

Nonaqueous electrolyte solution for batteries, and nonaqueous electrolyte secondary battery using same

InactiveUS20130323605A1Small internal resistanceIncrease capacitanceCell electrodesOrganic electrolyte cellsElectrolytic agentCapacitance

A nonaqueous electrolyte solution for secondary batteries, which maintains small internal resistance and high electrical capacitance in long-term use in a nonaqueous electrolyte secondary battery uses, as an active material, a crystalline carbon material having a high crystallinity, and a negative electrode produced using a polymeric carboxylic compound as a binding agent. The nonaqueous electrolyte solution contains: (A) at least one compound selected from a group consisting of an unsaturated phosphate ester compound represented by a general formula (1) and an unsaturated phosphate ester compound represented by a general formula (2); (B) at least one compound selected from a group consisting of a sulfite ester compound, a sulfonate ester compound, an alkali metal imide salt compound, a fluorosilane compound, an organic disilane compound or an organic disiloxane compound; (C) an organic solvent, and (D) an electrolyte salt. A secondary battery using such nonaqueous electrolyte solution is also described.

Owner:DENSO CORP +1

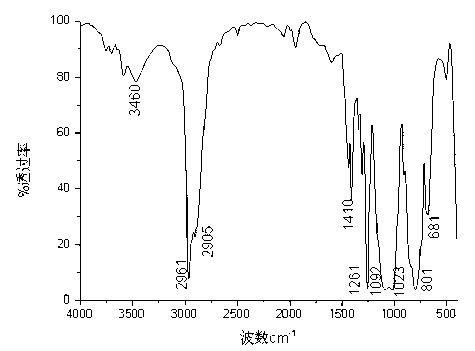

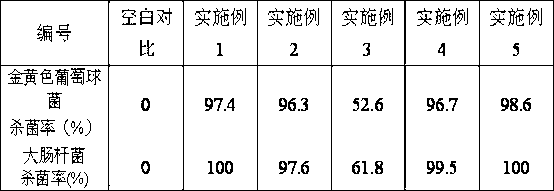

Quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint and preparation method and application thereof

ActiveCN102220080AInhibition of adsorptionReduce usageAntifouling/underwater paintsPaints with biocidesDisiloxaneQuaternary ammonium cation

The invention discloses a quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint, the structure is shown as the formula (1); in the formula, an organosilicon soft segment containing quaternary ammonium salt side chain is an isocyanate hard segment; the quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint is prepared by the following steps: preparing 2,4,6-tri(3- chlorine propyl group)-2,4,6- trimethyl-ring trisiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing dihydroxy ended chloropropylated polysiloxane; preparing polysiloxane compound containing the quaternary ammonium salt and hydroxyl; mixing the compound with the isocyanate, and adding gamma-aminopropyl triethoxy silane for chain extension to obtain a prepolymer, and the prepolymer being crosslinked and condensed in air. In the invention, the double effect of low surface energy and poison killing are achieved, so as to suppress the adsorption of marine organisms and kill bacteria adsorbed on the surface of a ship body through the quaternary ammonium salt.

Owner:ZHEJIANG UNIV

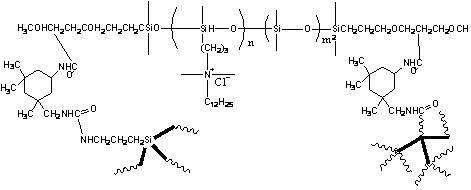

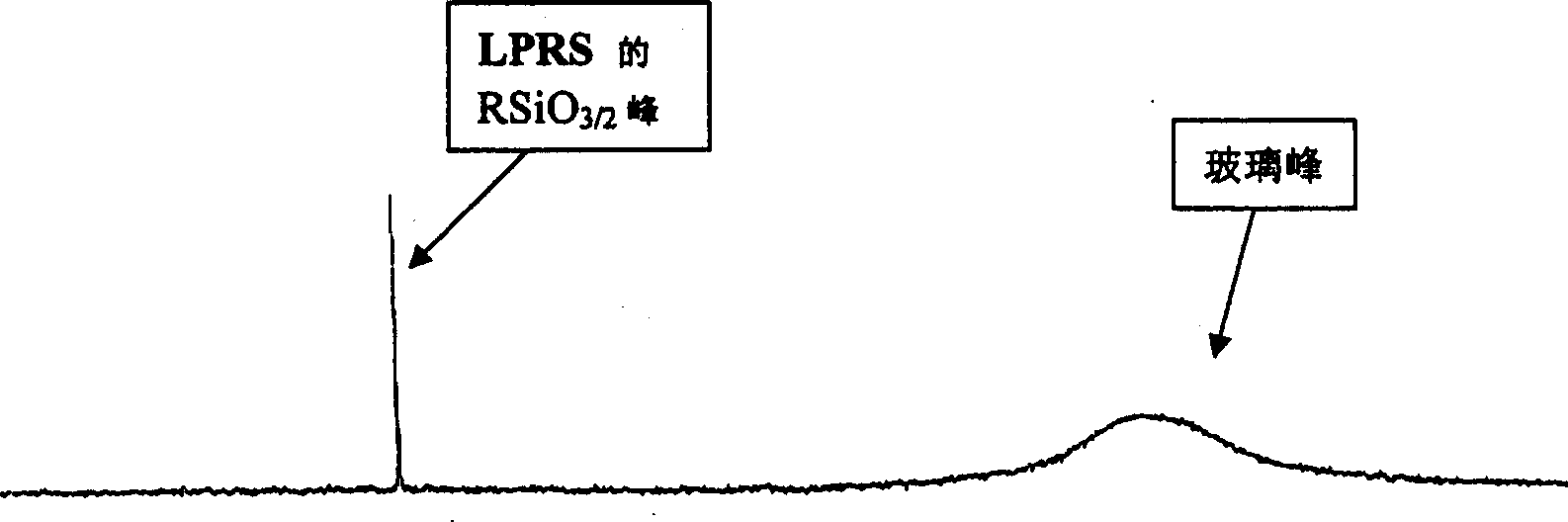

Trapezoidal organic poly sesquisiloxane and preparation method

A preparation method for highly tactic ladder-like polysilsequioxane with solubility, high molecular weight and different organic side groups is introduced in this invention. Trichlorosilicane with different substituents reacts with template-1, 4-dianiline or its derivatives with ladder-brace template method to produce conjugate precursor containing four silicon-chlorine bonds, which self-assembles into ladder polymers by hydrogen bond template function of p-dianiline and transforms into silanol end-capping organic bridging siloxane polymers after hemihydration-hydrolysis-condensation. Such a compound is then end-capped with trimethylsiloxyl and hydrolyzed to remove p-dianiline, and ladder-like polysilsequioxane can be obtained after further condensation. Or tetrafunctional disiloxane monomers with template-function side groups self-assemble into ladder-like polymers, which are then condensation-polymerized and end-capped with trimethylsiloxyl to obtain ladder-like polysilsequioxane.

Owner:INST OF CHEM CHINESE ACAD OF SCI

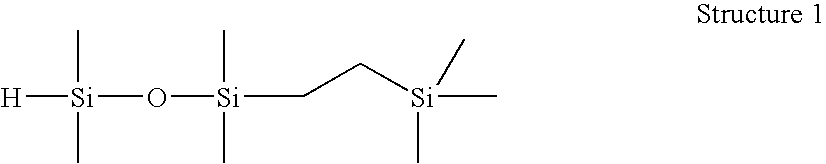

Extreme environment surfactant compositions comprising hydrolysis resistant organomodified disiloxane surfactants

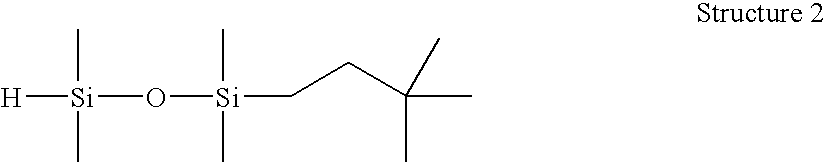

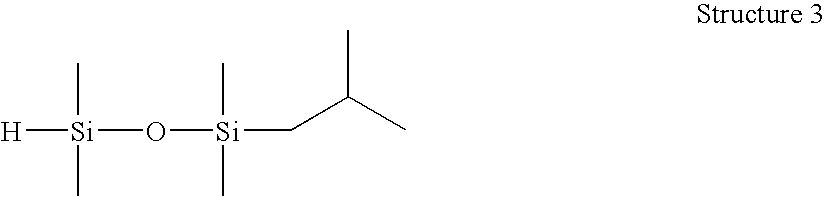

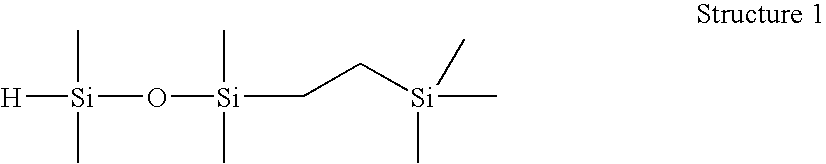

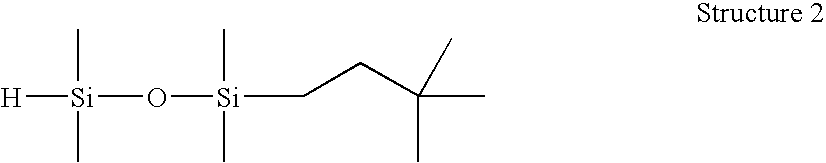

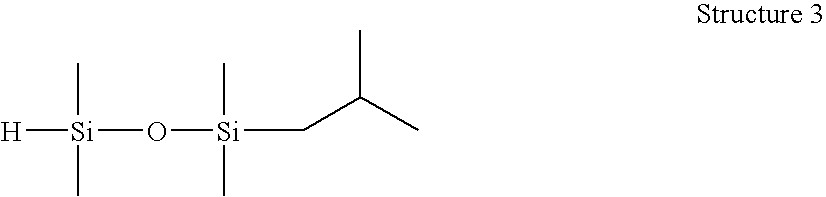

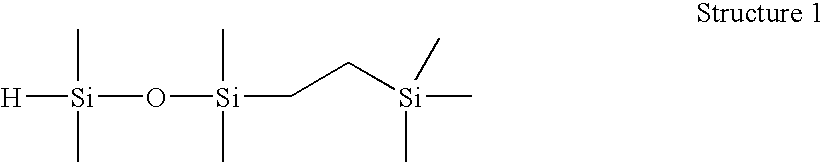

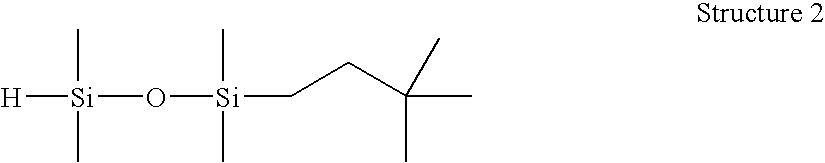

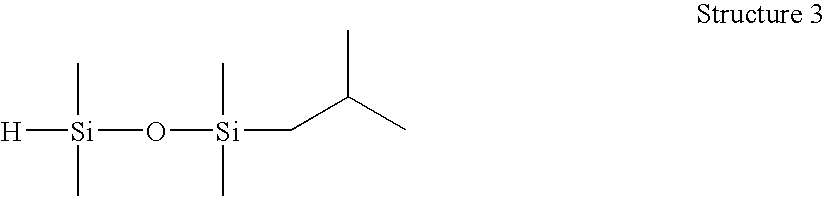

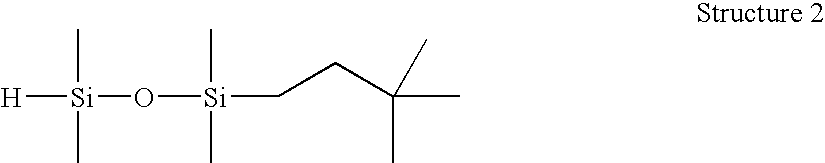

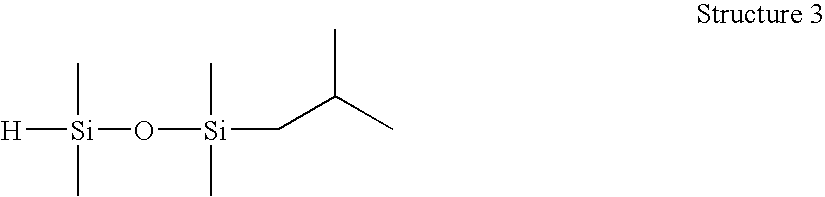

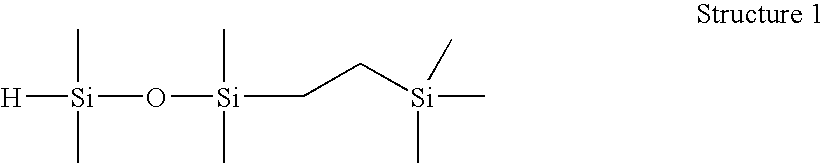

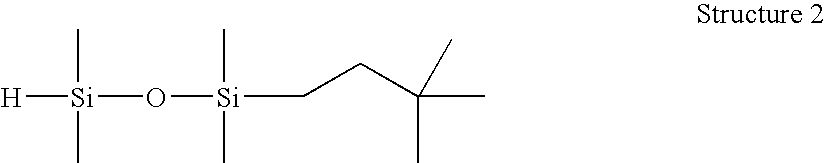

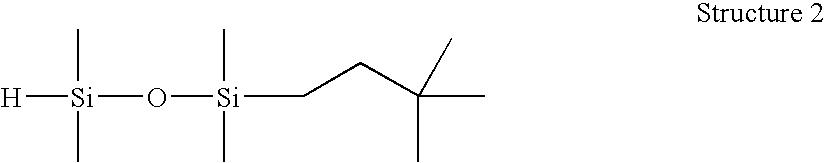

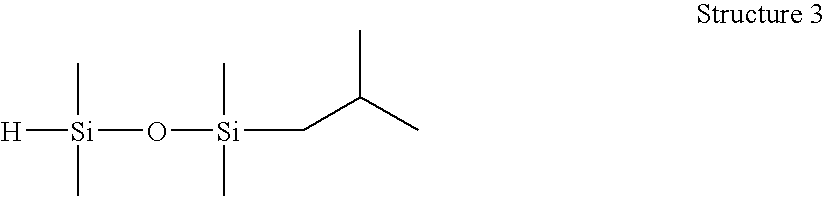

Compositions comprising disiloxane surfactant compositions comprising a silicone composition comprising a silicone having the formula:MM′whereM=R1R2R3SiO1 / 2;M′=R4R5R6SiO1 / 2;with R1 selected from the group consisting of branched monovalent hydrocarbon radical of from 3 to 6 carbon atoms and R7, where R7 has the formula:R8R9R10SiR12with R8, R9, and R10 each independently selected from the group of monovalent hydrocarbon radicals having from 1 to 6 carbon atoms and monovalent aryl or alkaryl hydrocarbon radicals having from 6 to 13 carbon atoms and R12 is a divalent hydrocarbon radical having from 1 to 3 carbon atoms,R2 and R3 are each independently selected from the group of from 1 to 6 carbon atom monovalent hydrocarbon radicals or R1, with R4 an alkylpolyalkyleneoxide of the general formula:R13(C2H4O)a(C3H6O)b(C4H8O)cR14where R13 is a divalent linear or branched hydrocarbon radical having the structure:—CH2—CH(R15)(R16)dO—where R15 is H or methyl; R16 is a divalent alkyl radical of 1 to 6 carbons where the subscript d may be 0 or 1;R14 is selected from the group consisting of H, monovalent hydrocarbon radicals of from 1 to 6 carbon atoms and acetyl where the subscripts a; b and c are zero or positive and satisfy the following relationships:2≦a+b+c≦20 with a≧2,and R5 and R6 are each independently selected from the group of monovalent hydrocarbon radicals having from 1 to 6 carbon atoms or R4 that exhibit resistance to hydrolysis over a wide pH range.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Vinyl silicon resin for reinforcing organic silicon pouring sealant and preparation method thereof

The invention discloses a vinyl silicon resin for reinforcing an organic silicon pouring sealant and a preparation method thereof. The preparation method comprises the following steps of: adding an appropriate amount of hexamethyl disiloxane and tetramethyl divinylsiloxane into a mixture of hydrochloric acid, an organic solvent and water to perform reaction for some time and then adding tetraethoxysilane and bis-functional or trifunctional siloxane to perform reaction; adding a certain amount of hexamethyl disiloxane and tetramethyl divinylsiloxane according to circumstances, standing and demixing after the reaction is finished, washing lower mixed liquor with deionized water until the liquor is neutral, and drying the liquor to obtain the vinyl silicon resin. The spherical core of the silicon resin prepared by the method, namely SiO2 has high content, and the spherical shell is tightly encircled by an R3SiO0.5 layer, so the silicon resin has good reinforcing effect; and the resin hashigh solubility or dispersibility in silicon rubber, can be separately used as a reinforcing filler for the organic silicon pouring sealant, and can also be matched with other fillers, so that the organic silicon pouring sealant with required performance can be obtained.

Owner:GUANGZHOU GLORYSTAR CHEM +1

Synthesis method for terpolymer block silicone oil

ActiveCN103214676ANo demulsification and delaminationNo self-emulsifying propertiesSilicon organic compoundsFibre treatmentDisiloxaneEpoxy

Owner:ZHEJIANG JIEFA TECH

Hydrolysis resistant organomodified disiloxane surfactants

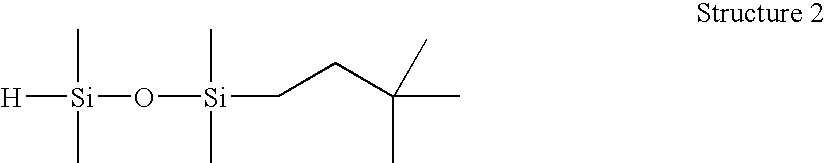

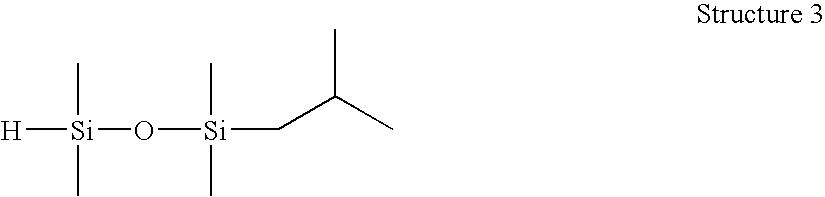

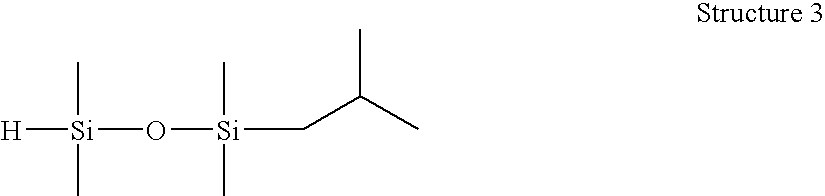

Disiloxane compounds of the formula MM′Where M comprises either branched allyl hydrocarbon substituents or silanyl substituents and M comprises an alkylpolyalkyleneoxide substituent The disiloxane compounds of the invention exhibit an enhanced resistance to hydrolysis outside a pH range ranging from 6 to 7.5, and are useful as surfactants.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

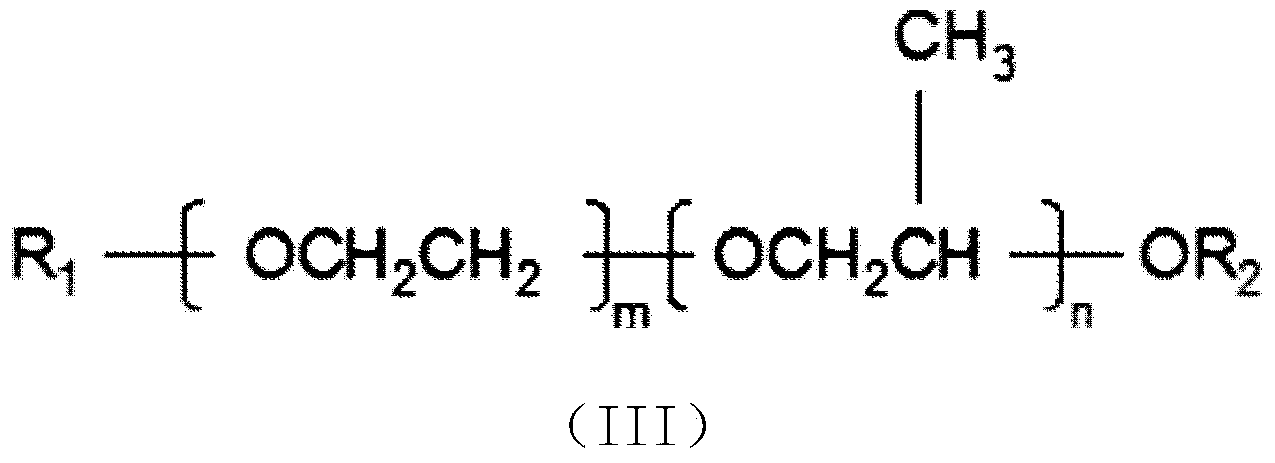

Polysiloxane binary alcohol with polyether block and preparation method thereof

ActiveCN101381462AIncrease polarityImprove the disadvantage of low reactivityDisiloxanePolymer science

The invention discloses polyether block polysiloxane diol and a method for preparing the same. The method is characterized by comprising the following steps: performing ring-opening polymerization through cyclic siloxane and dihydro terminated disiloxane first to obtain dihydro terminated polysiloxane, and then performing hydrosilylation reaction with mono-vinyl terminated polyether oligomer to form the polyether block polysiloxane diol the structural formula of which is shown in the graph, wherein R1 and R2 are CH3 and CH2CH3 and / or CH2CH2CH3 respectively, R3 is H or CH3, n is an integer between 1 and 1, 000, and p and q are integers between 1 and 100. The polyether block polysiloxane diol prepared by the method has the advantages of better hydrolysis resistance and storage stability, and high reactivity; in addition, the polyether block polysiloxane diol improves the problem of the unsatisfactory mechanical property of the prior siloxane diol in modifying copolymers.

Owner:兰州科天水性科技有限公司

Extreme environment surfactant compositions comprising hydrolysis resistant organomodified disiloxane surfactants

Compositions comprising an asymmetric disiloxane surfactant composition comprising a silicone composition comprising a silicone having the formula:MM′where M or M′ comprises an alkylpolyalkyleneoxide bearing substituent selected from the group consisting of:R13(C2H4O)a(C3H6O)b(C4H8O)cR14 andR12SiR5R6(R13(C2H4O)a(C3H6O)b(C4H8O)cR14)that exhibit resistance to hydrolysis over a wide pH range.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Reinforced Silicone Resin Film

InactiveUS20100129625A1Increase flexibilityImprove stabilityMaterial nanotechnologySynthetic resin layered productsDisiloxanePolymer science

Owner:DOW CORNING CORP

Hydrolysis resistant organomodified disiloxane surfactants

Compositions comprising an asymmetric disiloxane surfactant composition comprising a silicone composition comprising a silicone having the formula:MM′where M or M′ comprises an alkylpolyalkyleneoxide bearing substituent selected from the group consisting of:R13(C2H4O)a(C3H6O)b(C4H8O)cR14 andR12SiR5R6(R13(C2H4O)a(C3H6O)b(C4H8O)cR14)that exhibit resistance to hydrolysis over a wide pH range.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Method for preparing organosilicon quaternary ammonium salt modified polyurethane resin for marine antifouling coating

ActiveCN103304762AInhibition of adsorptionImprove protectionAntifouling/underwater paintsPaints with biocidesDisiloxaneQuaternary ammonium cation

The invention discloses a method for preparing organosilicon quaternary ammonium salt modified polyurethane resin for a marine antifouling coating. The method comprises the steps of: firstly, preparing double hydroxyl end-organosilicon quaternary ammonium salt from 1,3-bi[3-(1-methoxyl-2-hydroxy propoxy) propyl]-tetramethyl disiloxane, gamma-chlorinated propyl methyl dimethoxy silicone, dimethyl dimethoxy silicone, deionized water and dodecyl dimethyl tertiary amine; then mixing the prepared double hydroxyl end-organosilicon quaternary ammonium salt, the polyether polyol and the diisocyanate in a solvent; adding a curing agent to prepare the organosilicon quaternary ammonium salt modified polyurethane resin for the marine antifouling coating. The organosilicon quaternary ammonium salt modified polyurethane resin prepared by the method is combined with dual effects of low surface energy and killing, and used as the marine antifouling coating film forming matter. Thus, absorption of marine organism can be restrained; the bacteria absorbed at the surface of a ship body can be killed through the quaternary ammonium salt.

Owner:ZHEJIANG UNIV

Extreme environment surfactant compositions comprising hydrolysis resistant organomodified disiloxane surfactants

Compositions comprising disiloxane surfactant compositions comprising a silicone composition comprising a silicone having the formula: MM′where M=R1R2R3SiO1 / 2;M′=R4R5R6SiO1 / 2;with R1 selected from the group consisting of branched monovalent hydrocarbon radical of from 3 to 6 carbon atoms and R7, where R7 has the formula: R8R9R10SiRl2with R8, R9, and R10 each independently selected from the group of monovalent hydrocarbon radicals having from 1 to 6 carbon atoms and monovalent aryl or alkaryl hydrocarbon radicals having from 6 to 13 carbon atoms and R12 is a divalent hydrocarbon radical having from 1 to 3 carbon atoms, R2 and R3 are each independently selected from the group of from 1 to 6 carbon atom monovalent hydrocarbon radicals or R1, with R4 an alkylpolyalkyleneoxide of the general formula: R13(C2H4O)a(C3H6O)b(C4H8O)cRl4where R13 is a divalent linear or branched hydrocarbon radical having the structure: —CH2—CH(R15)(R16)dO—where R15 is H or methyl; R16 is a divalent alkyl radical of 1 to 6 carbons where the subscript d may be 0 or 1; R14 is selected from the group consisting of H, monovalent hydrocarbon radicals of from 1 to 6 carbon atoms and acetyl where the subscripts a; b and c are zero or positive and satisfy the following relationships: 2≦a+b+c≦20 with a≧2,and R5 and R6 are each independently selected from the group of monovalent hydrocarbon radicals having from 1 to 6 carbon atoms or R4 that exhibit resistance to hydrolysis over a wide pH range.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Fluorine-free disiloxane surfactant compositions for use in coatings and printing ink compositions

InactiveUS7399350B2Improve hydrolysis resistanceOther chemical processesTransportation and packagingDisiloxanePrinting ink

The present invention relates to coating and printing ink compositions possessing silicone surfactants compositions comprising fluorine-free organomodified disiloxanes which are resistant to hydrolysis between a pH of about 3 to a pH of about 12. The coatings and printing ink composition of the present invention exhibit enhanced wetting, flow and leveling properties.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Method for preparing oxane trisilicate of containing glucosyacylamino

InactiveCN1660882AAvoid toxicityAvoid the hydrosilylation reaction stepSugar derivativesDisiloxaneSolvent

A process for preparing trisiloxane containing glucosylamido used as the assistant of agricultural chemical to decrease the surface tension of water includes catalytic reaction between hexamethyl disiloxane and aminosilane to obtain aminotrisiloxane, and reacting on lacton gluconate in methanol.

Owner:CHINA RES INST OF DAILY CHEM IND

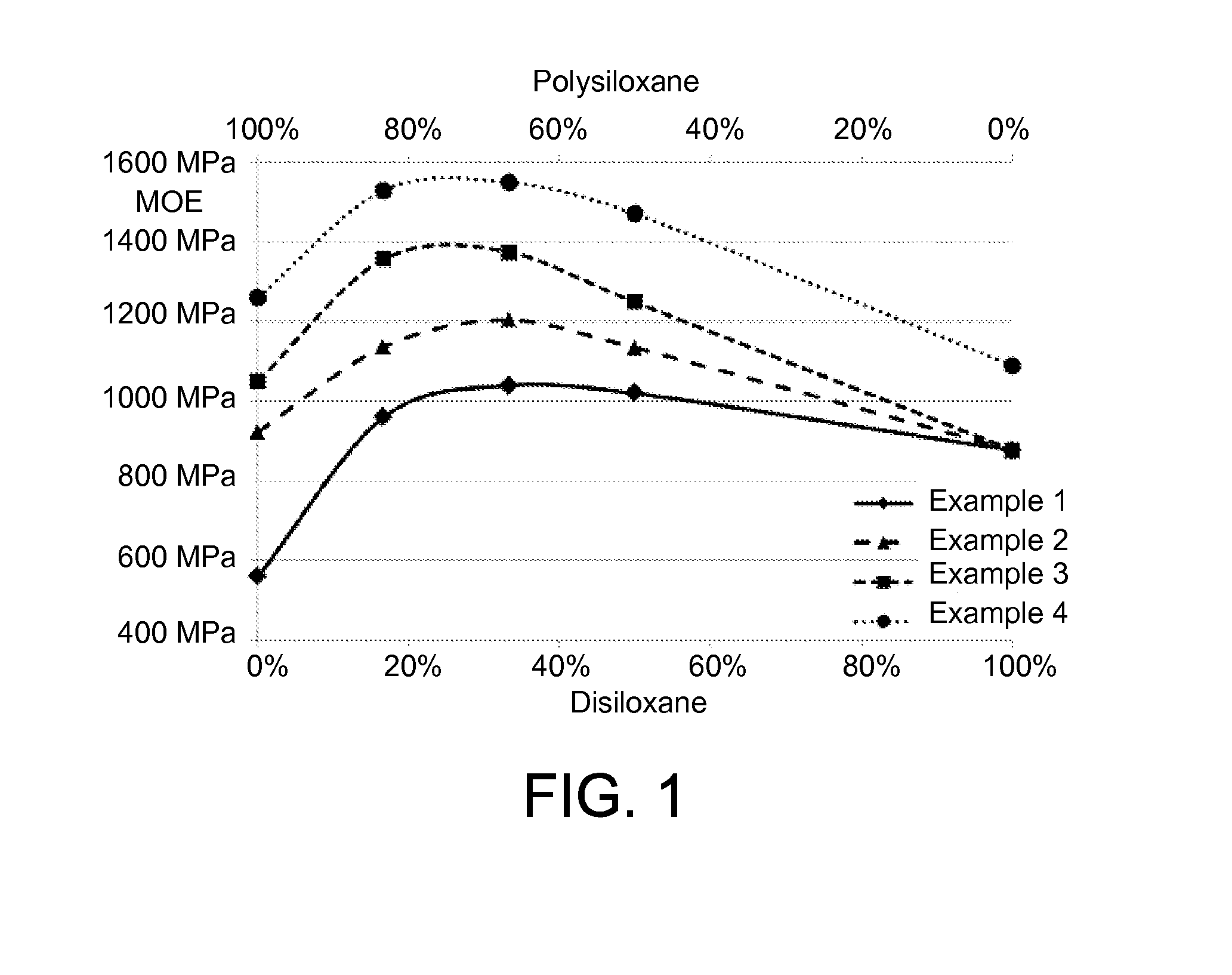

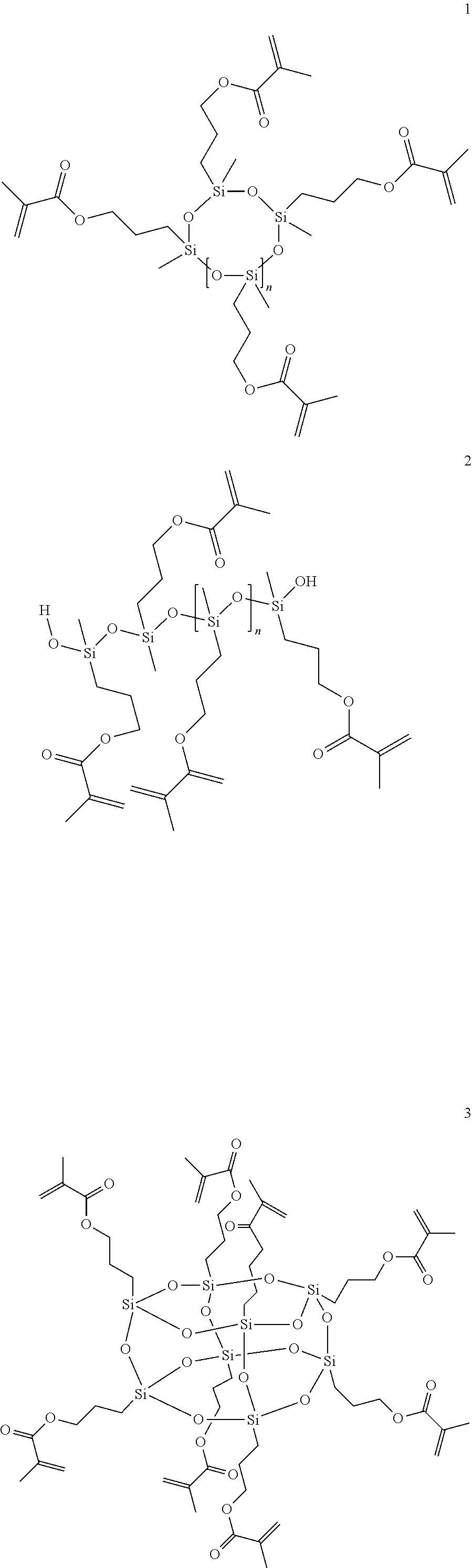

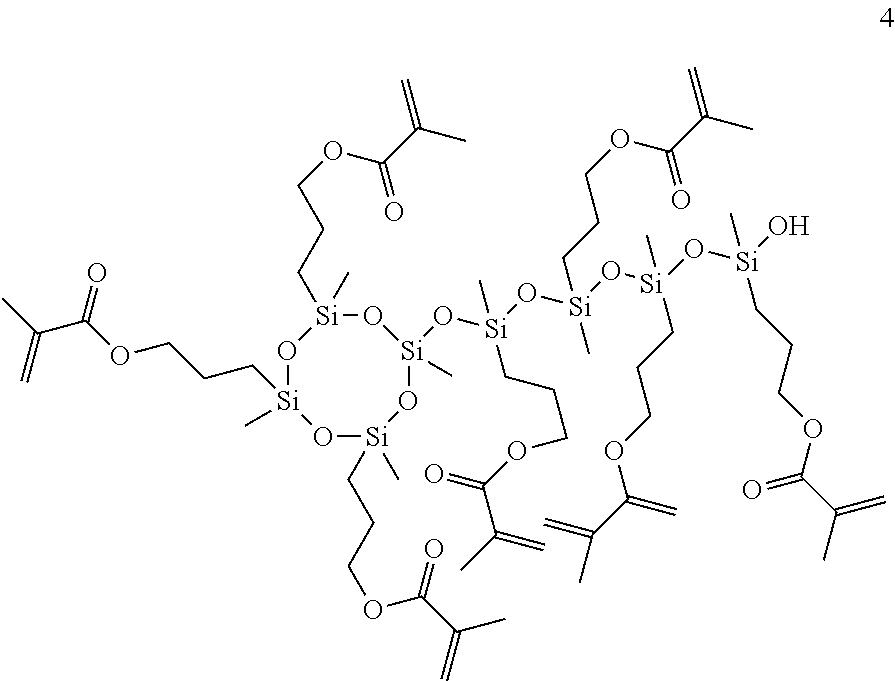

Use of free radically curable compositions in additive manufacturing methods

The present invention relates to the use of free-radically curable compositions, comprising chain-like and / or cyclic and / or cage-type polysiloxanes substituted by free-radically polymerizable groups and having at least 3 silicon atoms and / or mixed forms thereof, disiloxanes substituted by free-radically polymerizable groups, optionally one, two, three or more free-radically curable monomers having no silicon atom, fillers, initiators and / or catalysts for free-radical polymerization, and also further customary additives, in additive manufacturing methods, preferably in stereolithography (SL) and digital light processing (DLP). The present invention further relates to the use of the cured free-radically curable compositions, preferably for production of dental products.

Owner:VOCO

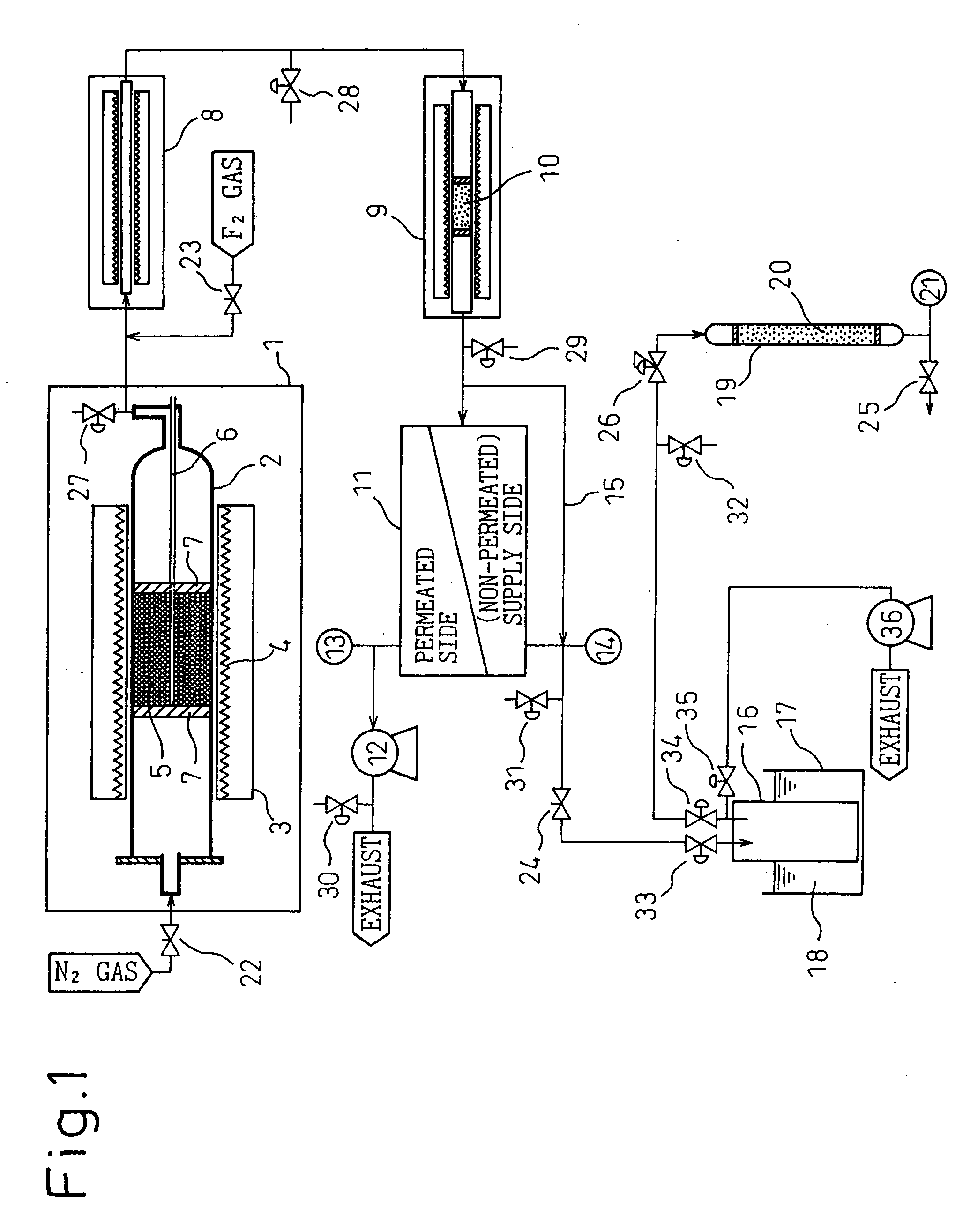

Production and use of tetrafluorosilane

Tetrafluorosilane is produced by a process comprising a step (1) of heating a hexafluorosilicate, a step (2-1) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a fluorine gas, a step (2-2) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a highvalent metal fluoxide, or a step (2-1) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a fluorine gas and a step (2-3) of reacting a tetrafluorosilane gas produced in the step (2-1) with a highvalent metal fluoride. Further, impurities in high-purity tetrafluorosilane are analyzed.

Owner:SHOWA DENKO KK

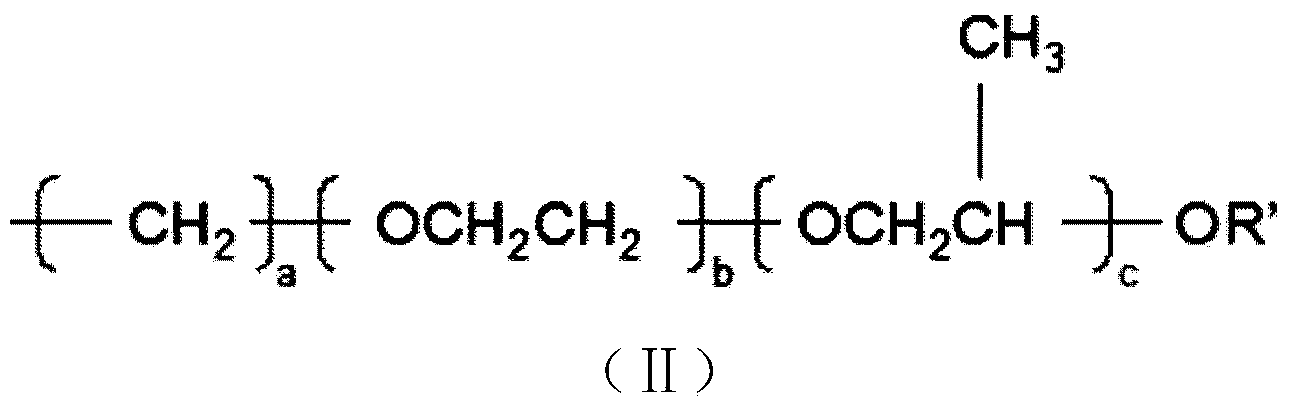

Preparation method of organosilicon foam stabilizer applied to single-component polyurethane foam sealing agent

The invention discloses a preparation method of an organosilicon foam stabilizer applied to a single-component polyurethane foam sealing agent. The preparation method comprises the steps of (1) adding allyl alcohol, ethylene oxide and propylene oxide to a reaction kettle, and reacting under the action of a base catalyst at the temperature of 90-130 DEG C and pressure not more than 0.5MPa for 4-6h to obtain allyl-terminated copolymer ether; (2) reacting the polyether prepared in the step 1 with sodium at 85-120 DEG C, introducing excess haloalkane, and reacting for 4-6h to obtain methyl-terminated copolymer ether; (3) reacting octamethyl cyclotetrasiloxane, hexamethyl disiloxane and high-hydrogen-content silicone oil with hydrogen content of 1-2% in the presence of an acid ion exchanger to obtain low-hydrogen-content silicone oil with hydrogen content of 0.05-1.0%; (4) mixing the products obtained in the steps 1,2, and 3, adding a catalyst, and reacting under the condition of pressure being 0.5-2atm for 3-8h to obtain the organosilicon foam stabilizer. During foaming, the foam stabilizer has excellent dimensional stability and high foaming ratio and fluidity.

Owner:苏州思德新材料科技有限公司

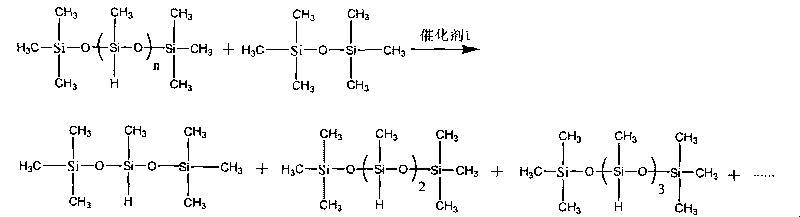

Method for manufacturing organosilicon surfactant with T-shaped structure for pesticide

InactiveCN101690878ANothing producedUseless amountBiocideSilicon organic compoundsCross-linkDisiloxane

The invention relates to a method for preparing an organosilicon surfactant with a T-shaped structure for a pesticide. The method comprises the following steps: (1) preparation of hydrogen containing trisiloxane, in which, full containing hydrogen silicone oil, hexamethyl disiloxane and catalyst are added into a reactor, the temperature of the mixture is controlled to be between 10 and 100 DEG C with stirring, after reacting for 0.5 to 12 hours, the mixture is cooled, and then distilled and purified to prepare the hydrogen containing trisiloxane; and (2) synthesis of the organosilicon surfactant, in which, the hydrogen containing trisiloxane and allyl polyether are added into the reactor, are heated to a temperature of between 60 and 120 DEG C under stirring in nitrogen, catalyst platinum-allyl polyether is added into the reactor to react for 2 to 12 hours, and the mixture is devolatilized in vacuum for 30 minutes and is cooled to a room temperature to prepare the organosilicon surfactant. The method has a simple process, easy industrial production and high product purity without cross linked polymer impurities.

Owner:GUANGZHOU TINCI SILICONE TECHNOLOGY CO LTD

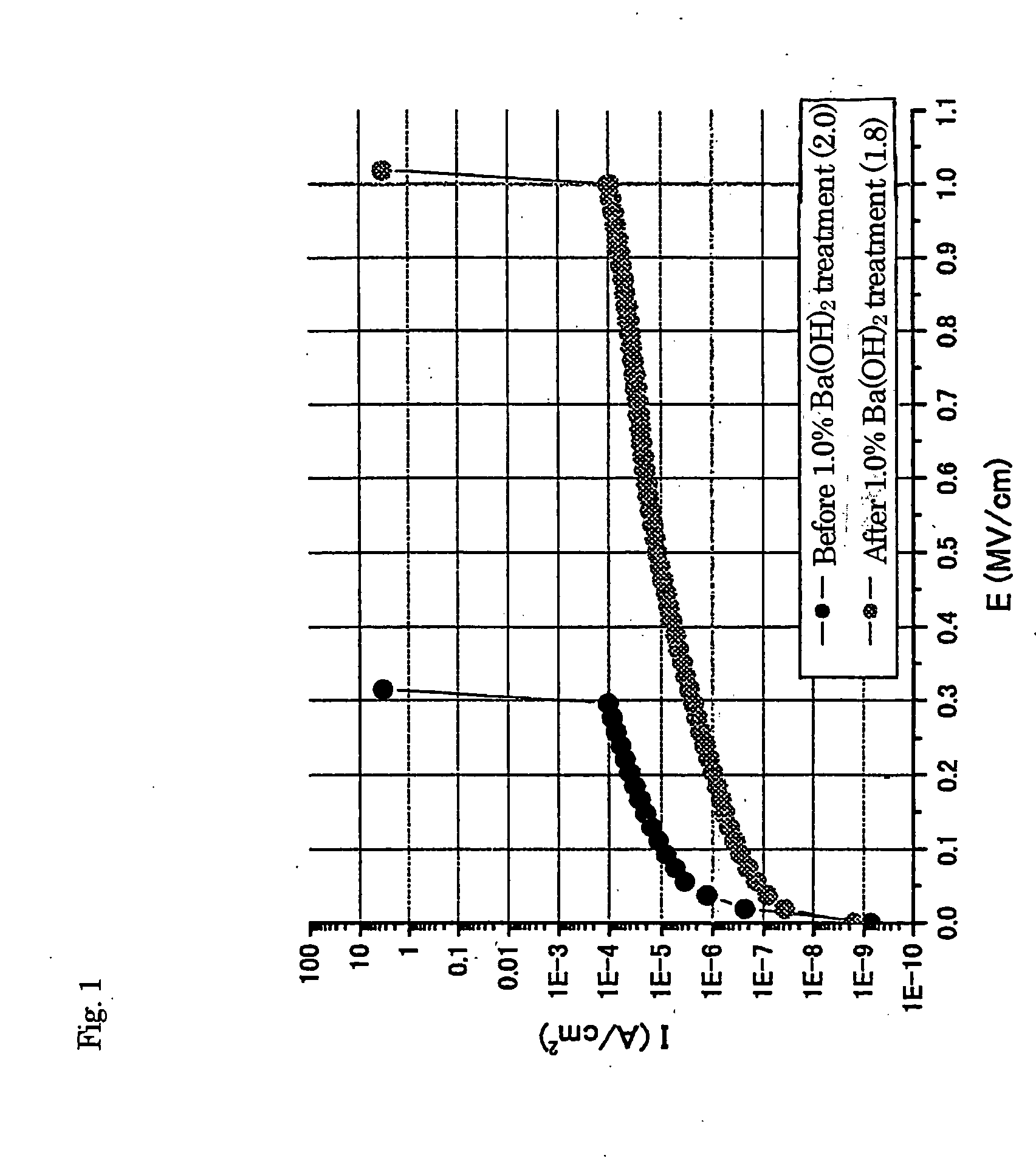

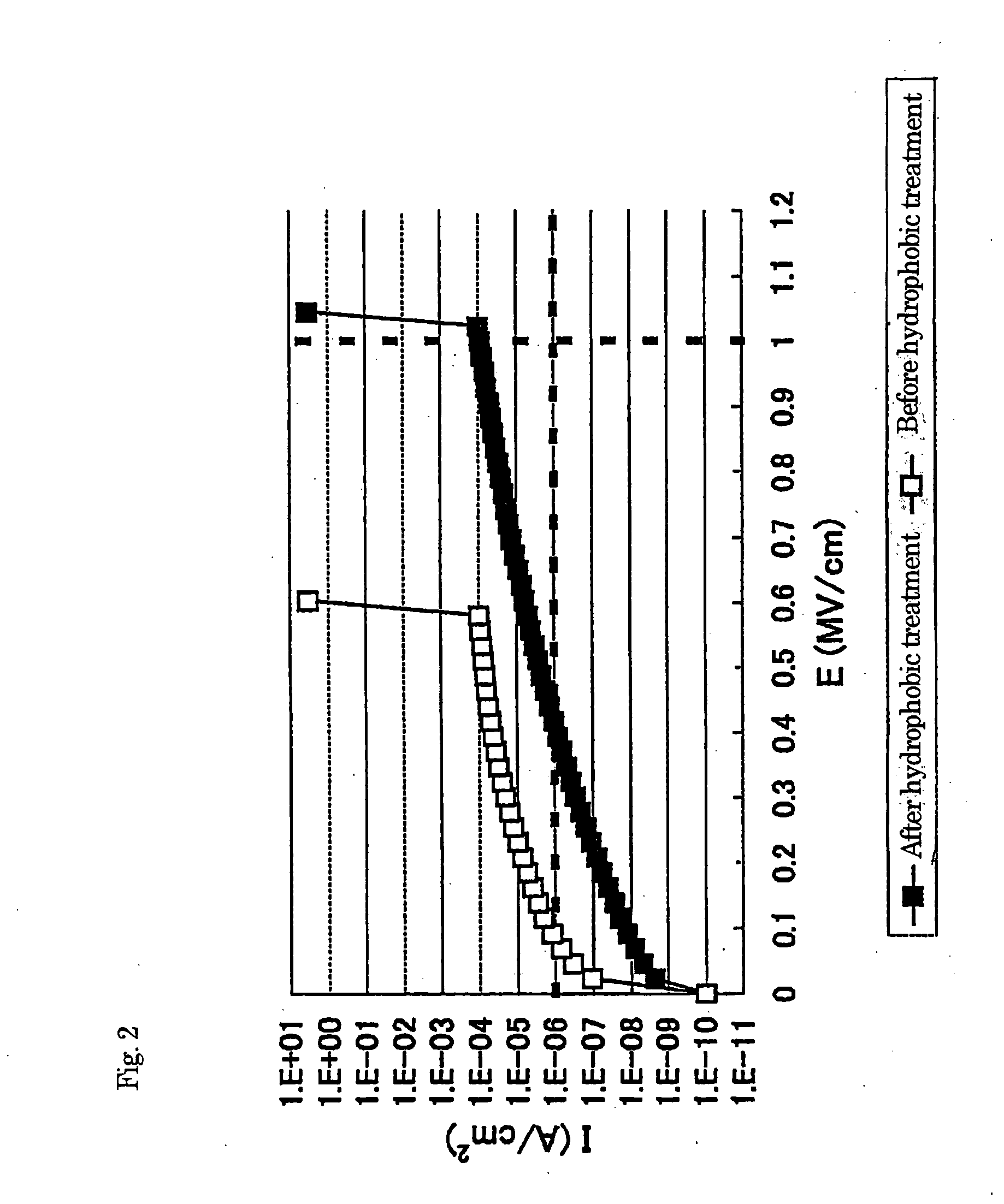

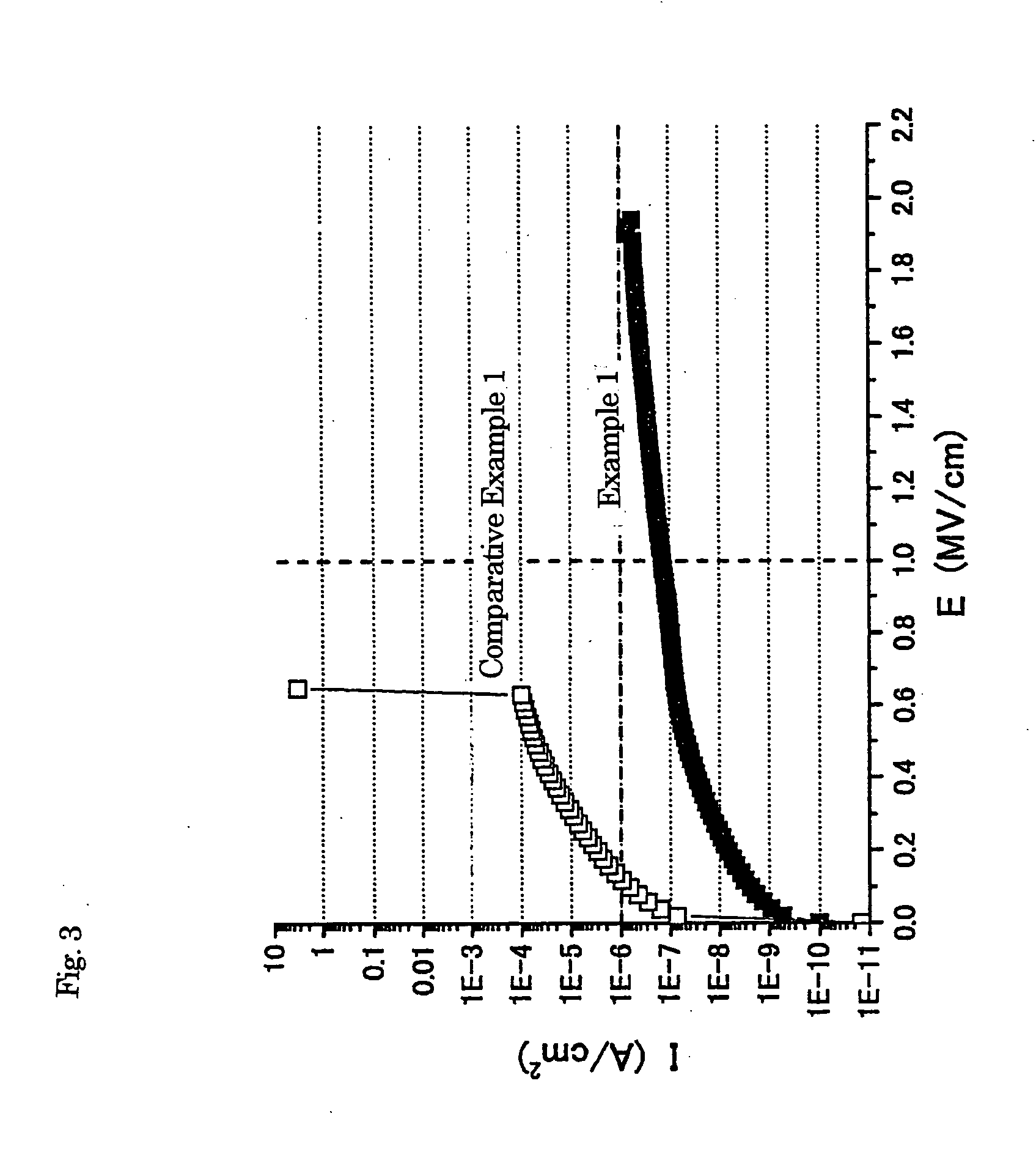

Low-dielectric films, and manufacturion method thereof, and electronic component using it

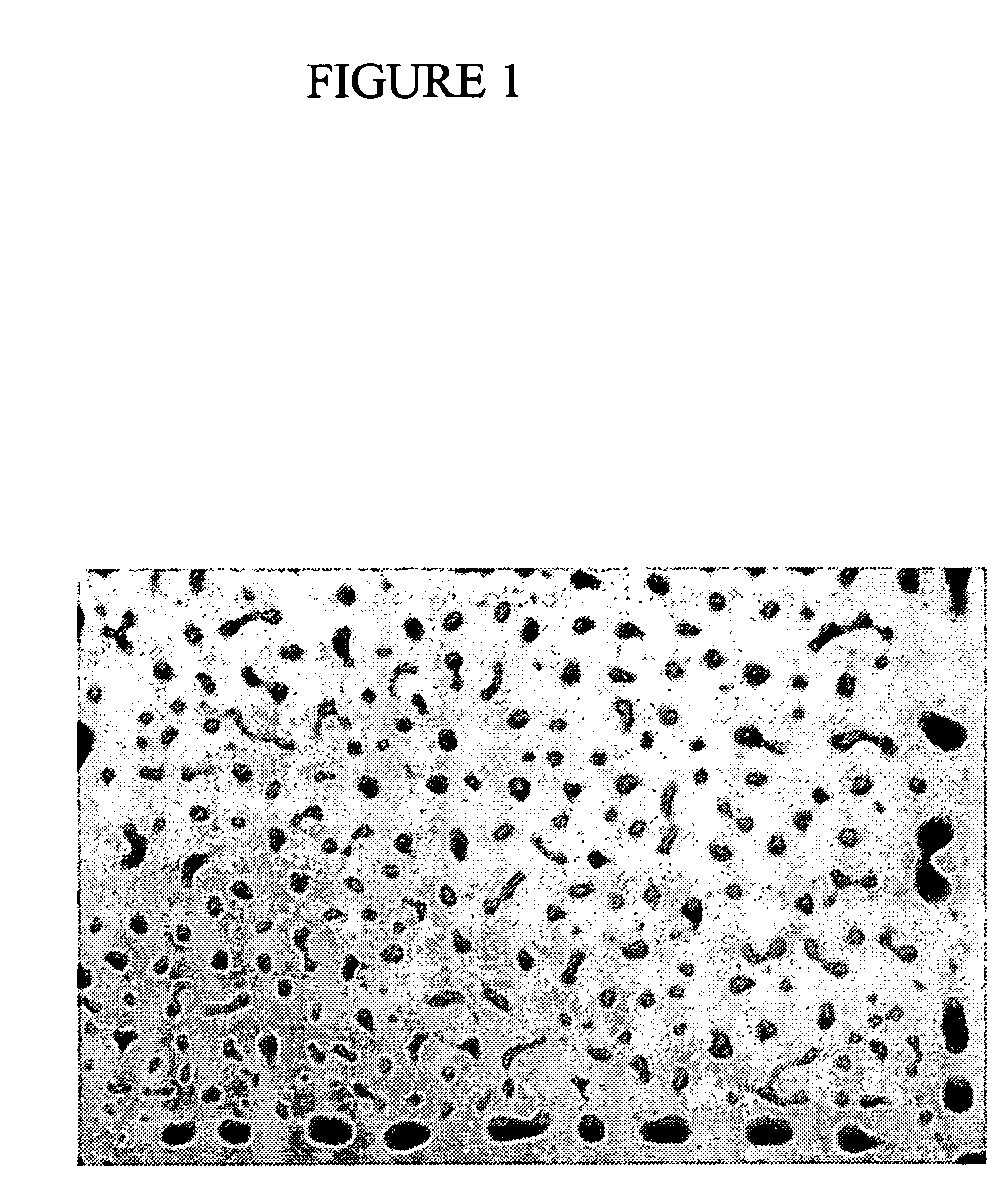

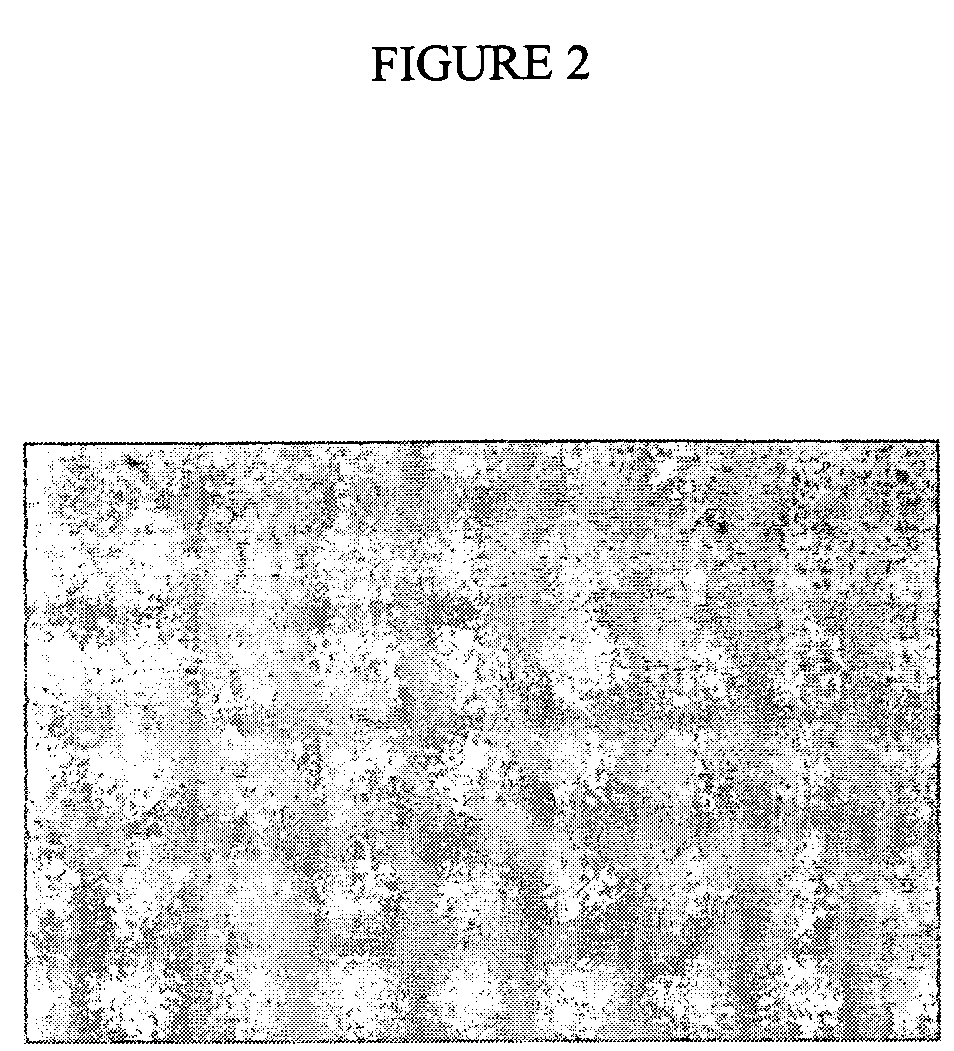

InactiveUS20060244034A1High insulation breakdown voltageGuaranteed functionTransistorSemi-permeable membranesDisiloxaneIntegrated circuit

While a fine porous diamond particle film has been known as a high heat resistant and low dielectric constant film and also has high mechanical strength and heat conductivity, and is expected as an insulating film for multi-layered wirings in semiconductor integrated circuit devices, it is insufficient in current-voltage characteristic and has not yet been put into practical use. According to the invention, by treating the fine porous diamond particle film with an aqueous solution of a salt of a metal such as barium and calcium, the carbonate or sulfate of which is insoluble or less soluble, and a hydrophobic agent such as hexamethyl disilazane or triethyl monochlolo silane, as well as a reinforcing agent containing one of dichlorotetramethyl disiloxane or dimethoxytetramethyl disiloxane, thereby capable of putting the dielectric breakdown voltage and the leak current within a specified range of a practical standard.

Owner:RORZE CORP

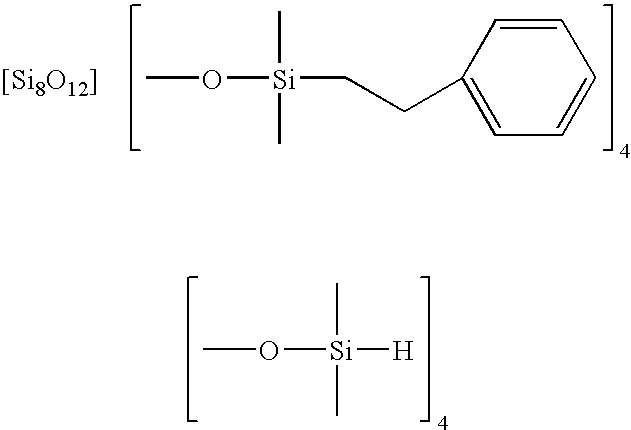

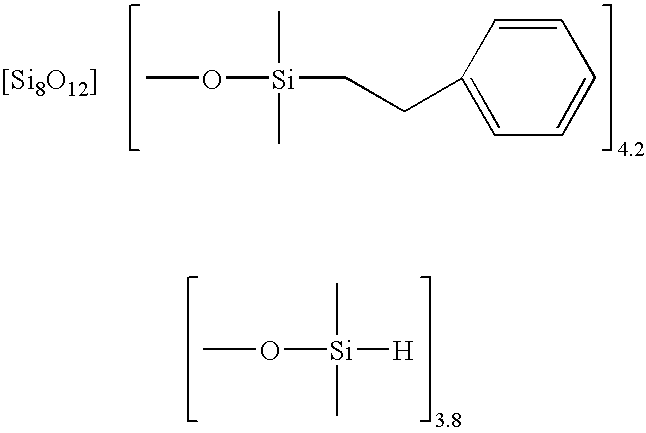

Facile synthesis of polyhedral silsesquioxane anions and use thereof

InactiveUS20050142054A1Less moleculeLow pour pointSilicon organic compoundsLiquid surface applicatorsDisiloxaneOrganic acid

Polyhedral silsesquioxane anions are economically prepared by reaction of a silica source derived from combusted organic material with a quaternary ammonium hydroxide compound. Reaction of the resulting anions with chlorosilanes may be effected in near stoichiometric fashion in organic solvent containing reactive quantities of organic acids such as formic acid. The functional groups on the resulting functionalized silsesquioxanes may be substituted for other functional groups by reaction with di- or polysiloxanes in the presence of a synthetic ion exchange resin.

Owner:RGT UNIV OF MICHIGAN

Long chain alkyl modified silicon oil and synthetic process thereof

The invention relates to long-chain alkyl modified silicone oil which is obtained by the reaction of methyl hydric silicone material containing dense hydrogen and hexamethyl disiloxane and being modified by Alpha-alkene. The long-chain alkyl modified silicone oil can be applied as an excellent metal release agent. The invention also relates to a synthetic process of the long-chain alkyl modified silicone oil; wherein, under the protection of nitrogen, 65g to 222g of methyl hydric silicone oil intermediate product is added in a dripping manner to 123g to 308g of Alpha-alkene which is prepared by weight ratio and with a carbon length of 8 to 20 and the mixture reacts for 1 hour to 4 hours at the temperature of 100 DEG C to 120 DEG C; at the temperature of 110 DEG C to 150 DEG C and under a pressure lower than 0.01 MPa, the low-volatile substance is removed until the content of the low-volatile substance is less than 2 percent; and the long-chain methyl modified silicone oil is obtained.The invention adopts a platinum catalysts-isopropanol-acetylacetone-acetoacetate acetoacetic ester system which is conducive to rendering the reaction condition of the invention milder and the reaction time shorter. The method is easier and quicker to be operated.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com