Patents

Literature

996 results about "Allyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Allyl alcohol (IUPAC name: prop-2-en-1-ol) is an organic compound with the structural formula CH₂=CHCH₂OH. Like many alcohols, it is a water-soluble, colourless liquid. It is more toxic than typical small alcohols. Allyl alcohol is used as a raw material for the production of glycerol, but is also used as a precursor to many specialized compounds such as flame-resistant materials, drying oils, and plasticizers. Allyl alcohol is the smallest representative of the allylic alcohols.

Coatings for implantable medical devices

InactiveUS20060121089A1Improve hydrophobicityLong-term biocompatibilityBiocideSurgeryPropanolBiocompatibility

The present application teaches a coating having a biologically compatible compound conjugated to, or blended with, a polymer, wherein the polymer includes at least one olefin-derived unit and at least one unit derived from a vinyl alcohol, an allyl alcohol, or derivatives thereof.

Owner:ABBOTT CARDIOVASCULAR

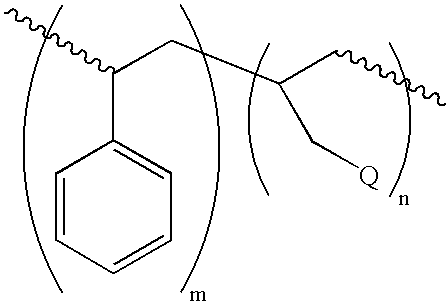

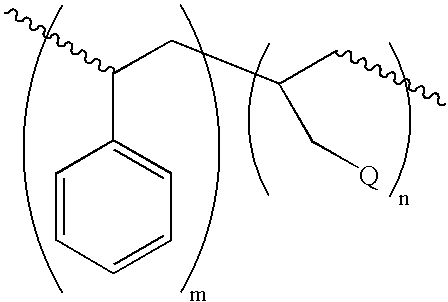

Derivatives of poly(styrene-co-allyl alcohol) and methods for use thereof

ActiveUS20080017308A1Low in ionic impurityEasy to convertAdhesive processes with surface pretreatmentSolid-state devicesCombinatorial chemistryMonomer

The invention provides derivatives of poly(styrene-co-allylalcohol). These materials are useful as thermosetting monomers that can be incorporated into adhesive compositions. In some embodiments, the adhesive compositions are useful in the microelectronic packaging industry.

Owner:DESIGNER MOLECULES

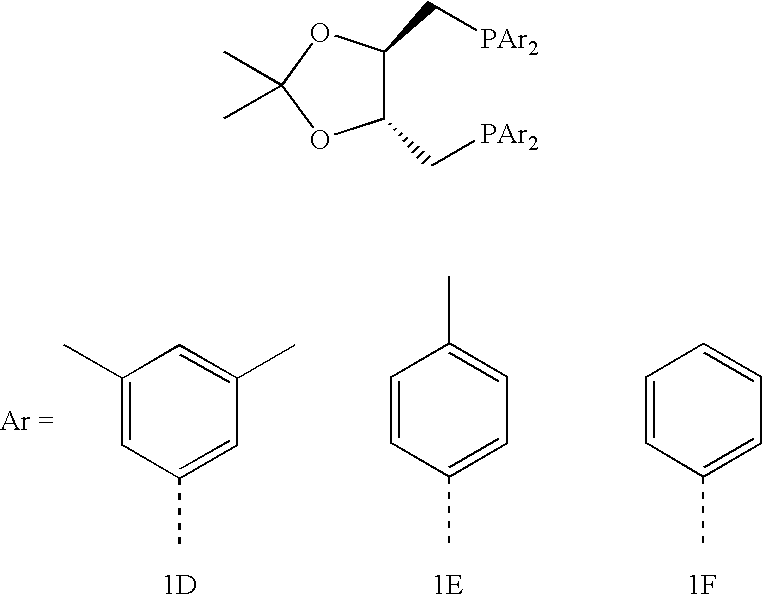

Hydroformylation process

ActiveUS7271295B1Raise the ratioOrganic compound preparationGroup 8/9/10/18 element organic compoundsHydrogenSolvent

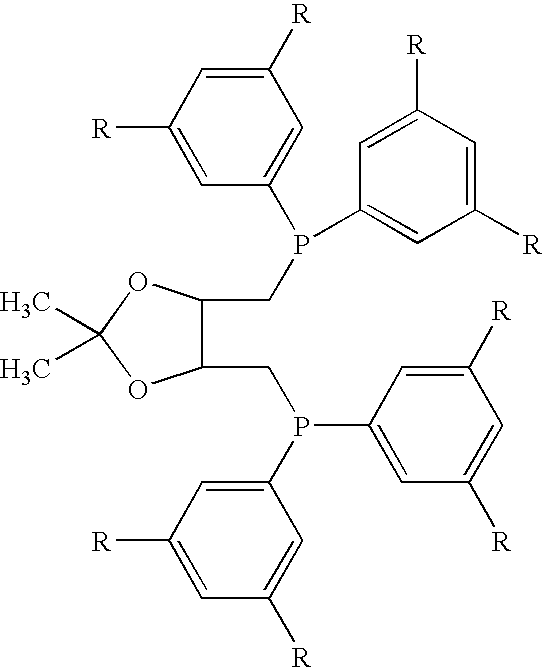

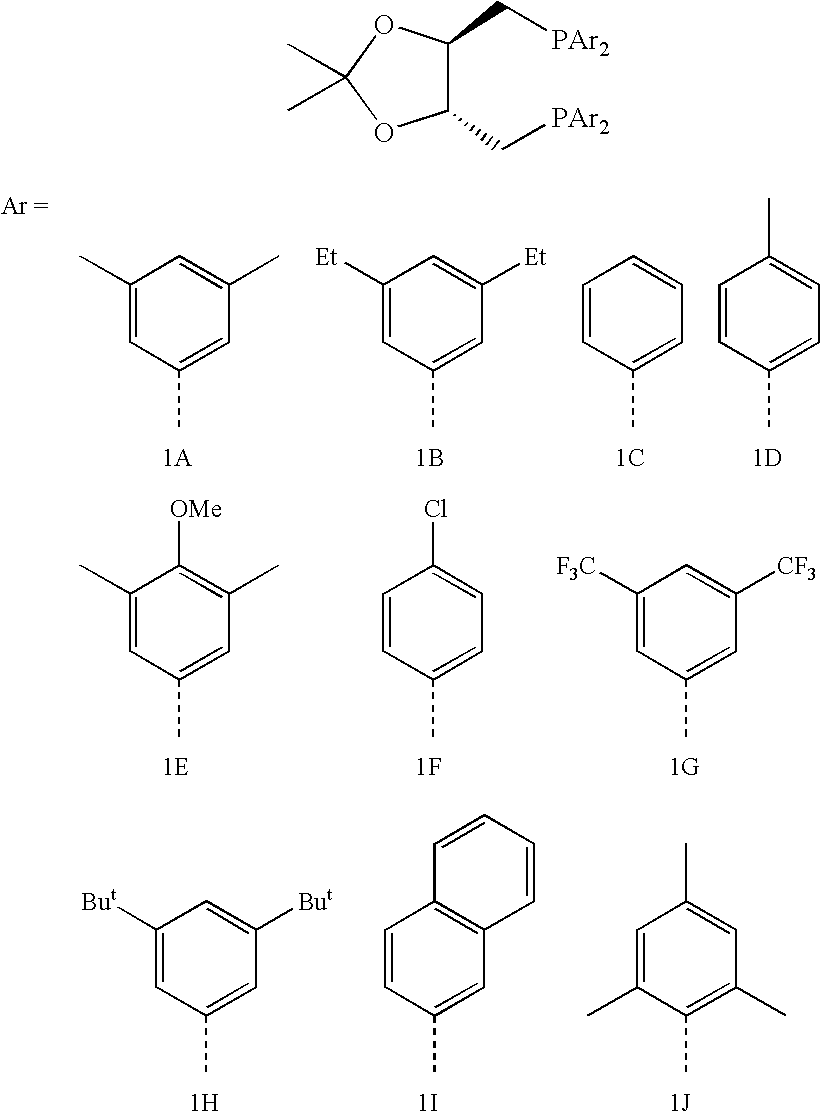

A process for the production of 4-hydroxybutyraldehyde is described. The process comprises reacting allyl alcohol with a mixture of carbon monoxide and hydrogen in the presence of a solvent and a catalyst system comprising a rhodium complex and a 2,3-O-isopropylidene-2,3-dihydroxy-1,4-bis[bis(3,5-di-n-alkylphenyl)phosphino]butane. The process gives high yield of 4-hydroxybutyraldehyde compared to 3-hydroxy-2-methylpropionaldehyde.

Owner:LYONDELL CHEM TECH LP

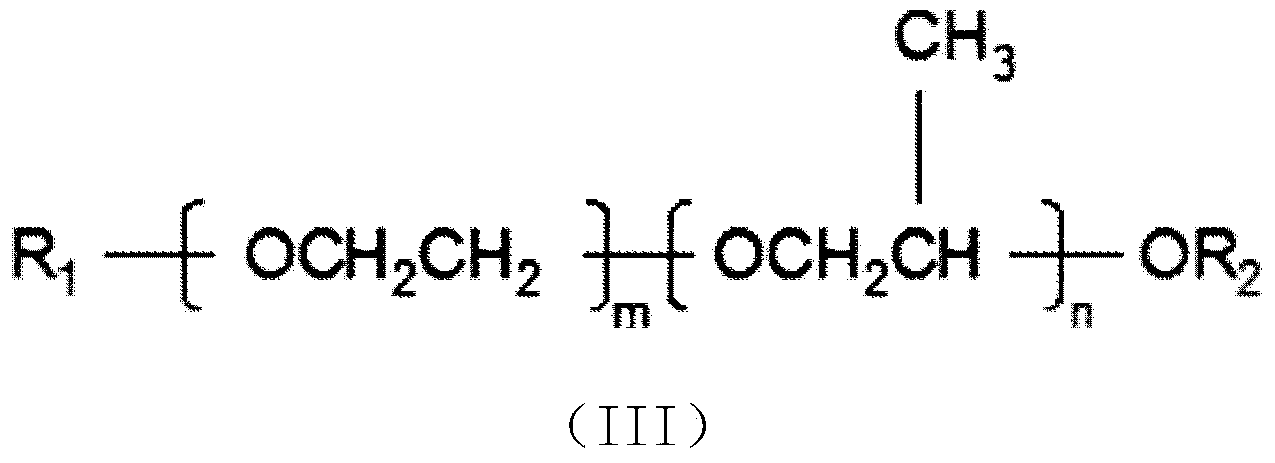

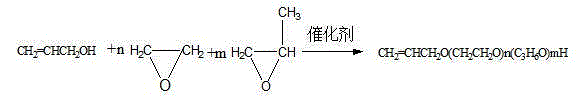

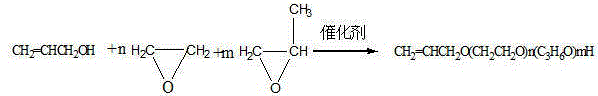

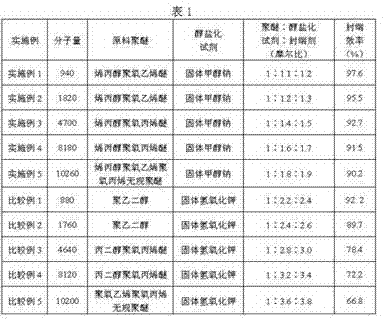

Preparation method and application of unsaturated polyether

The invention relates to a preparation method and application of unsaturated polyether. The preparation method comprises the following steps: (1) adding unsaturated alcohol and a catalyst into a first reactor, replacing with nitrogen, continuously adding epoxide with short branches and reacting to obtain an intermediate product A, wherein the unsaturated alcohol is one or a mixture of more than two of methyl allyl alcohol and isoamyl alcohol at any proportion and the mass ratio of the unsaturated alcohol to epoxide is 1.0:(0.1-5.0); and (2) putting the intermediate product A obtained in the step (1) and the catalyst into a second reactor, replacing with nitrogen, continuously introducing ethylene oxide and reacting to obtain polyether B, and neutralizing the pH value of the polyether B product to be 5-7 with a neutralizing reagent, wherein the mass ratio of the intermediate product A to ethylene oxide is 1.0:(15.0-51.0). The invention also provides the unsaturated polyether prepared by the preparation method, which is disclosed by the invention and application of unsaturated polyether in synthesis of polycarboxylic water reducer and the water reducer prepared from the unsaturated polyether synthesized by the method has the advantages of low doping amount, high water reduction rate, good slump-retaining agent and like.

Owner:HONGBAOLI GRP CO LTD

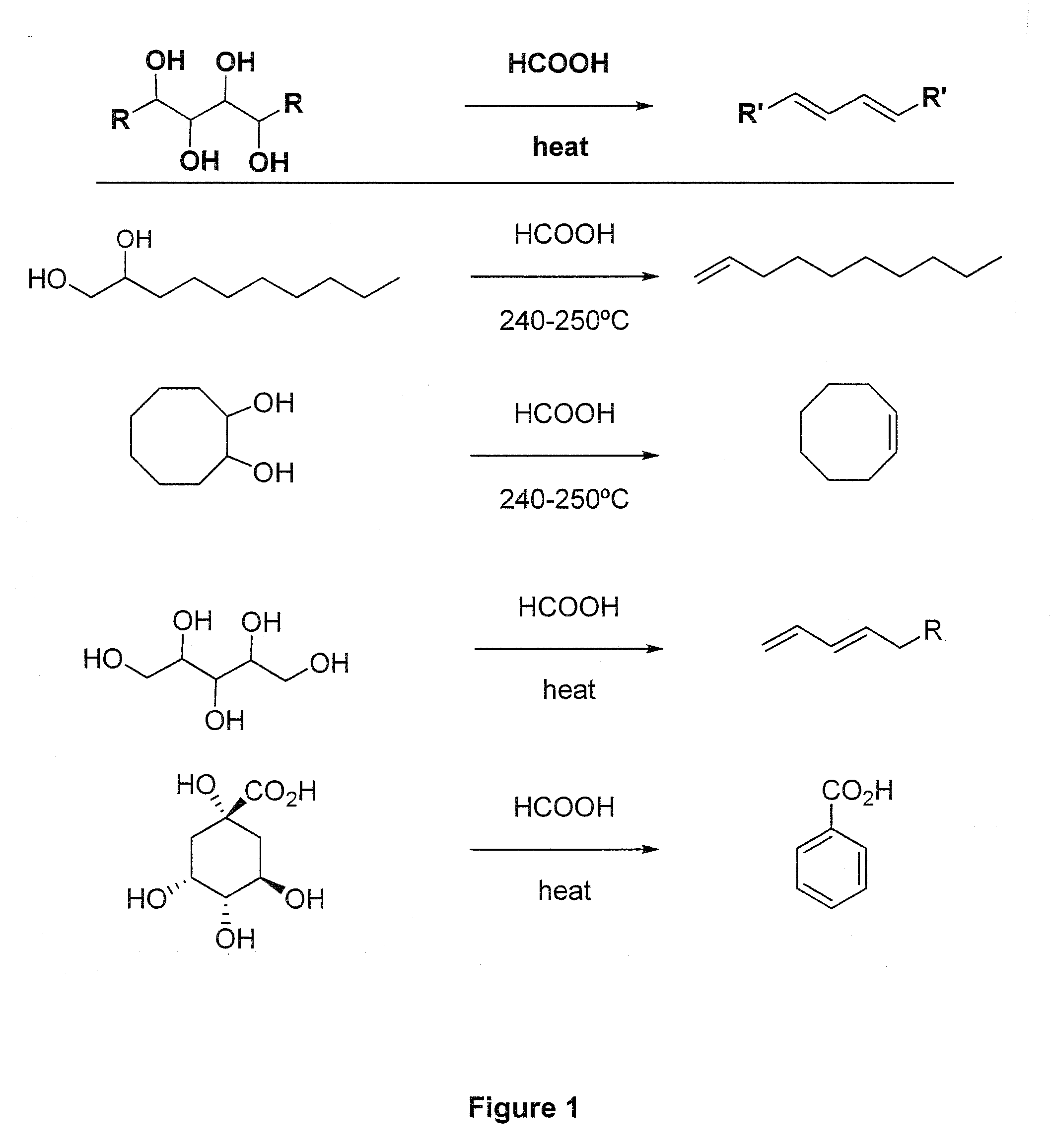

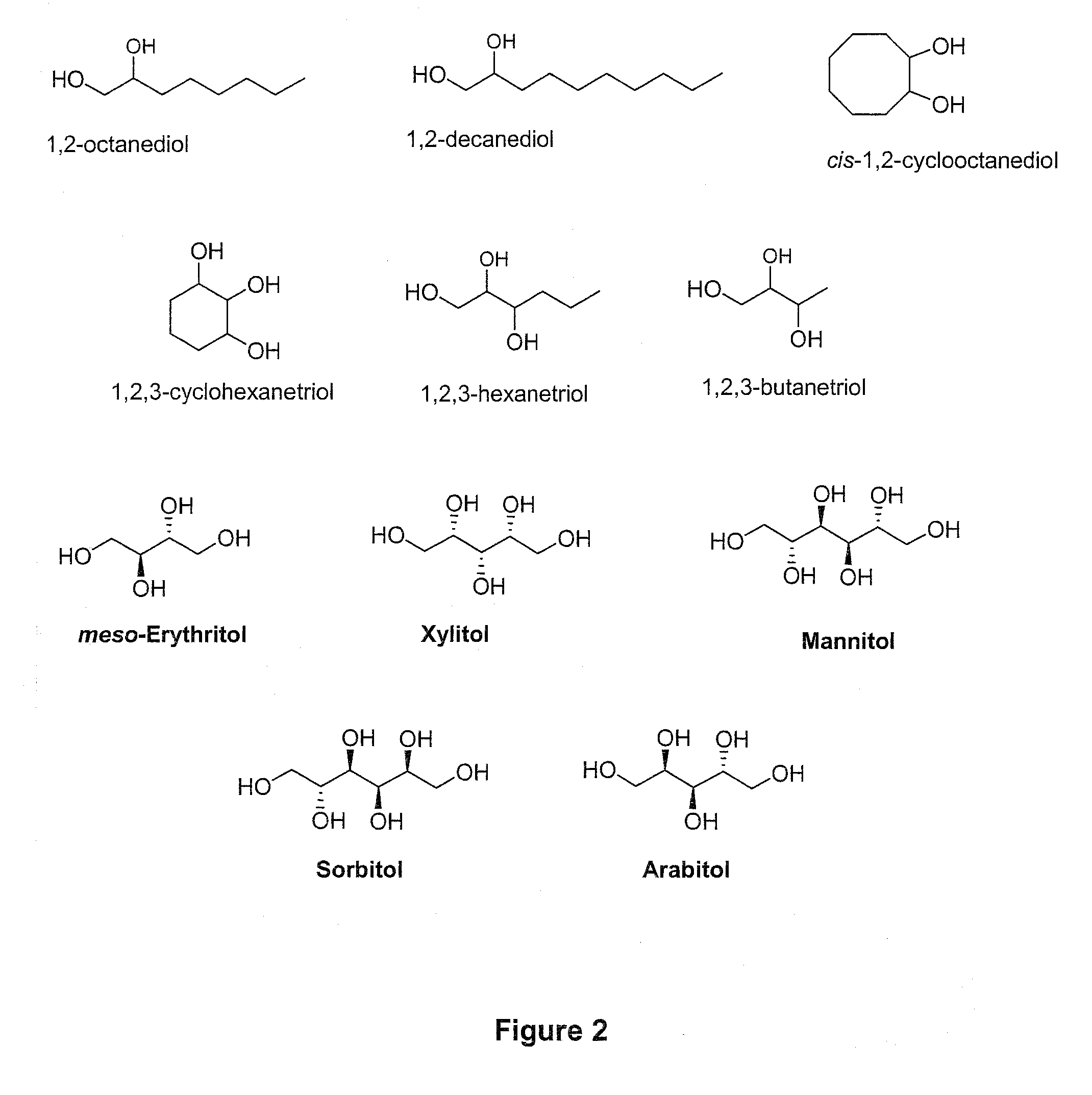

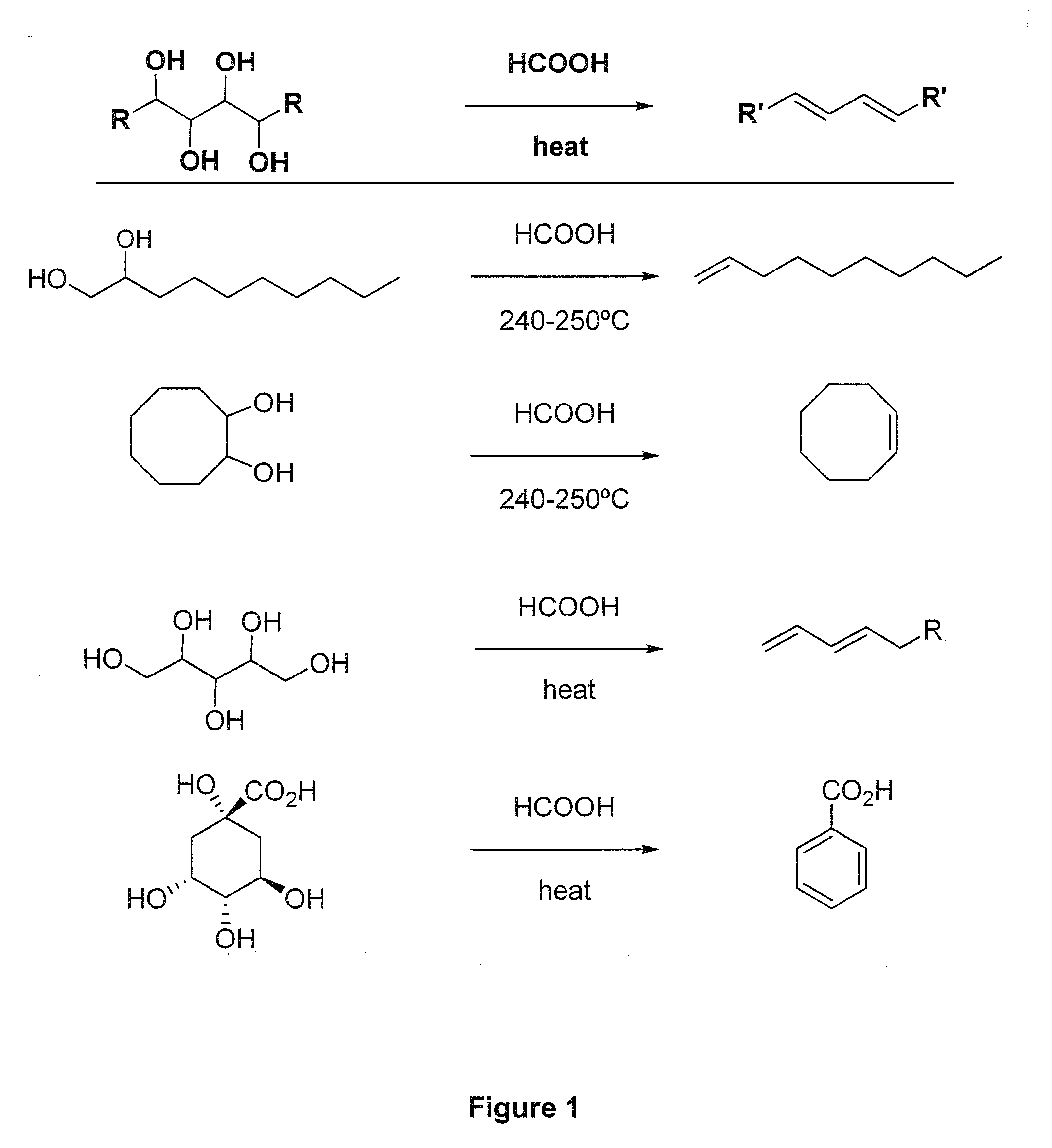

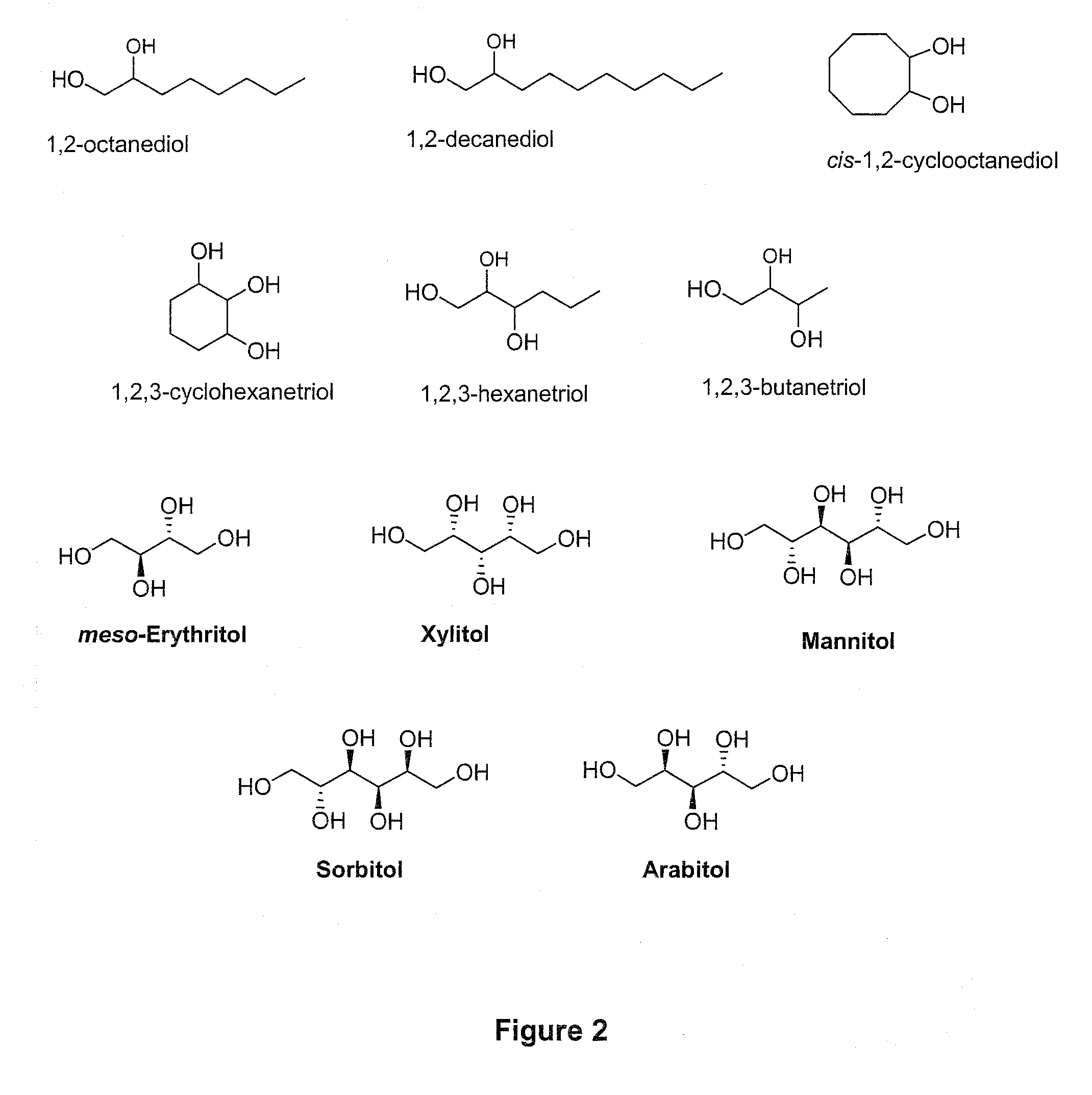

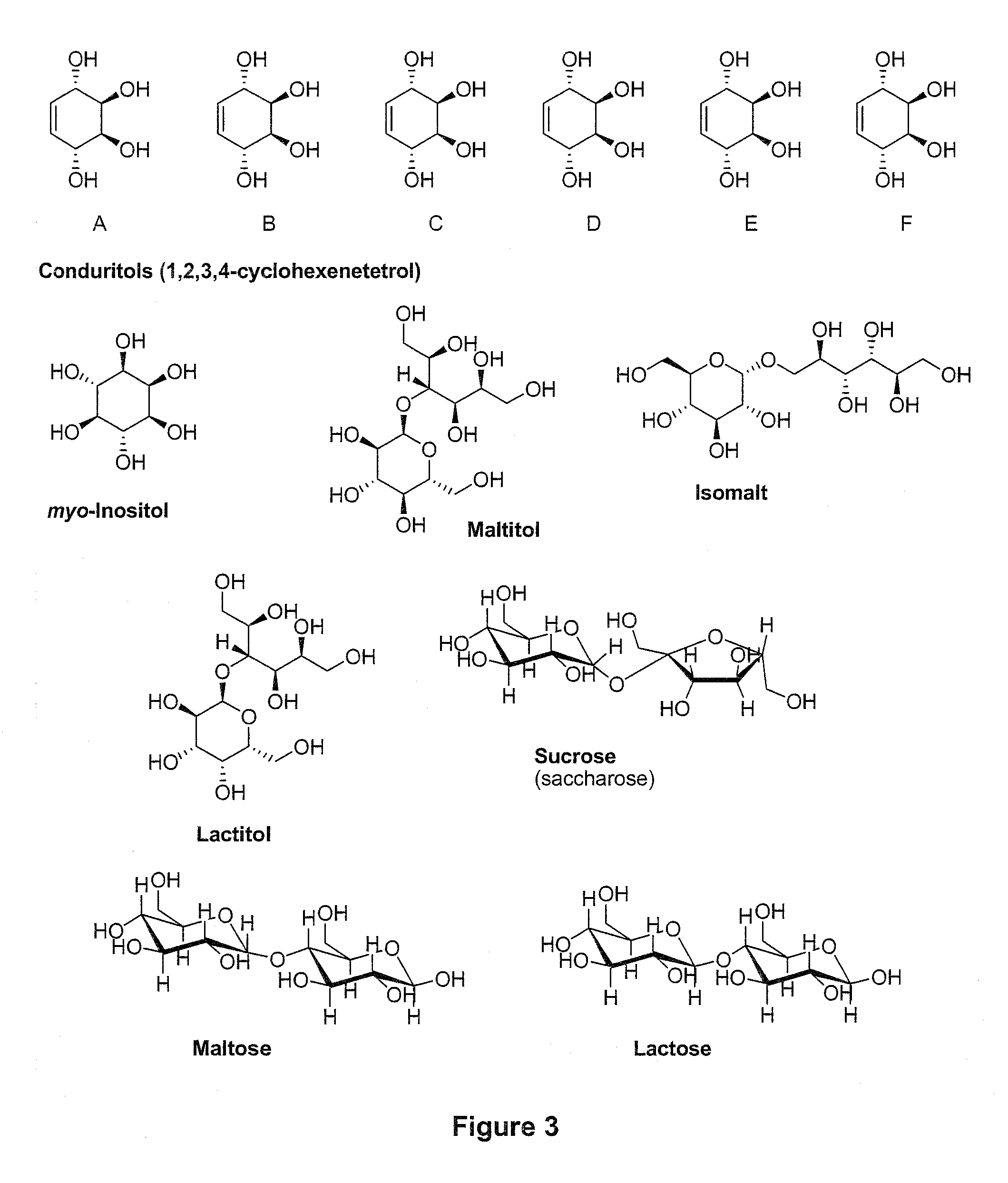

Method of Converting a Polyol to an Olefin

ActiveUS20090287004A1High purityHigh yieldOxygen-containing compound preparationOrganic compound preparationPolyolCarboxylic acid

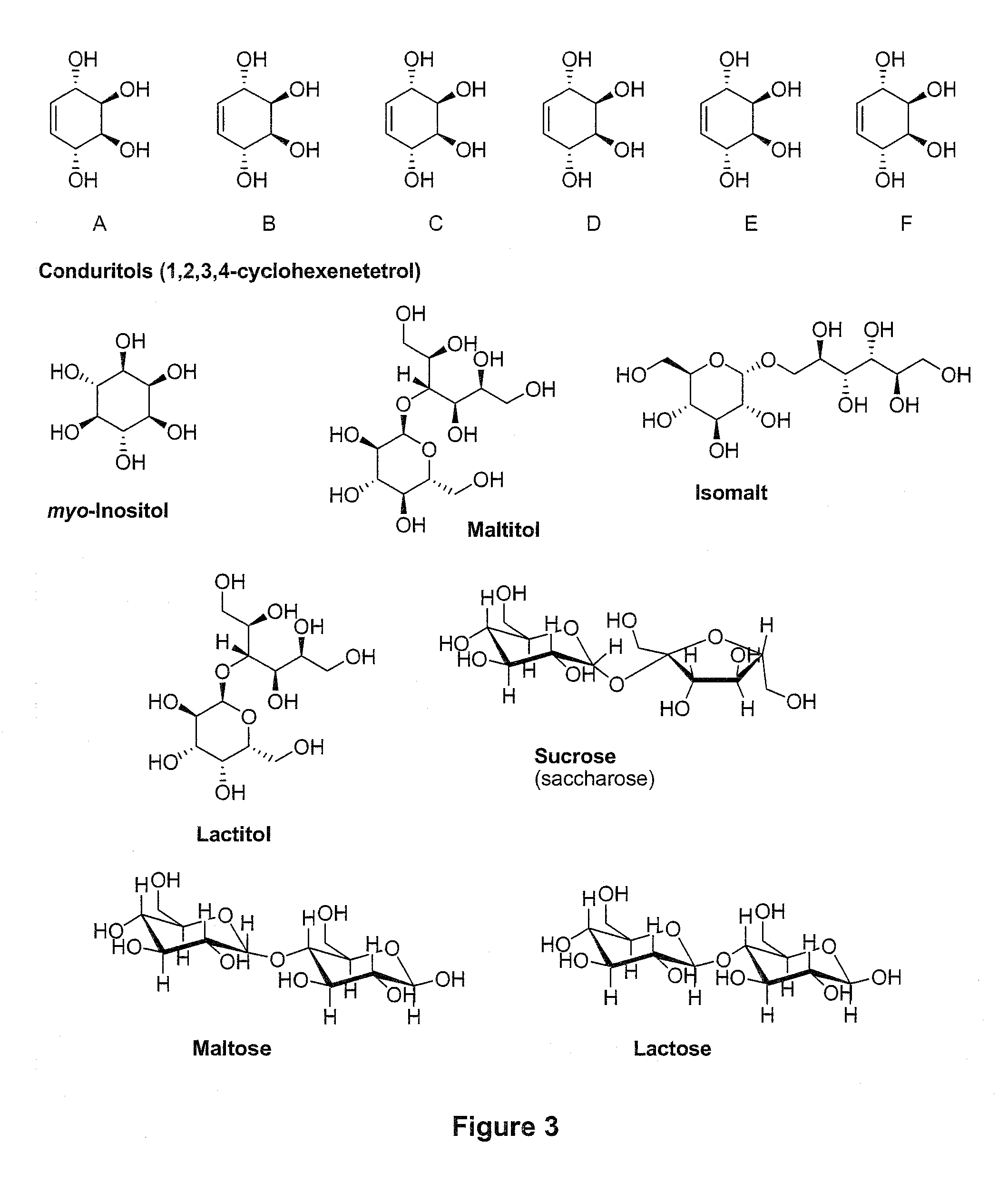

A method of preparing an olefin comprising: reacting a polyol in the presence of a carboxylic acid, such that an olefin is produced by the deoxygenation of the polyol. The reacting step can comprise (a) providing a composition comprising the polyol, (b) heating the composition, and (c) introducing the carboxylic acid to the composition wherein the introducing step occurs prior to, at the same time as, or subsequent to the heating step. In one embodiment, the polyol is glycerol, the carboxylic acid is formic acid, and the olefin is allyl alcohol, which is produced at a yield of about 80% or greater.

Owner:RGT UNIV OF CALIFORNIA

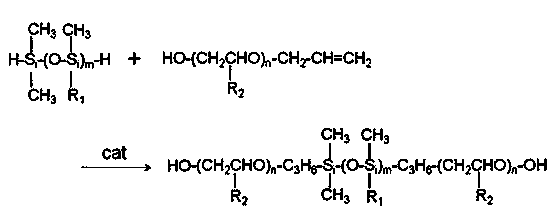

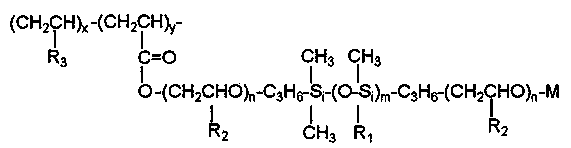

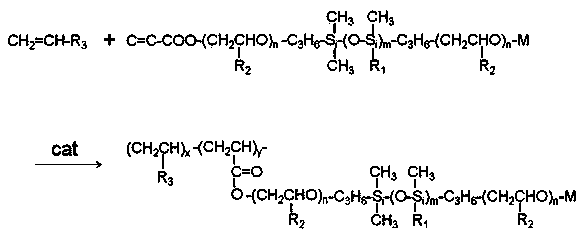

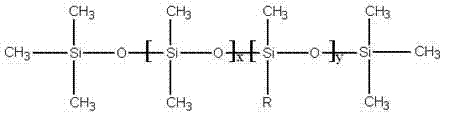

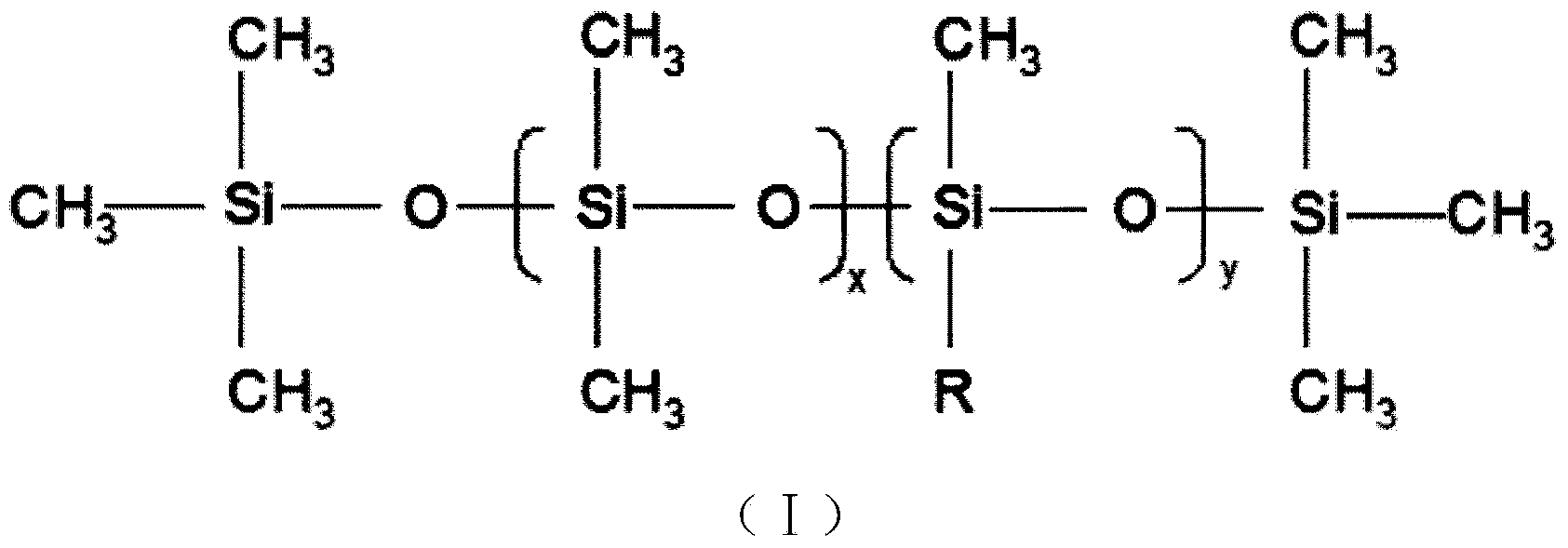

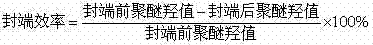

Polyether modified organic silicon defoamer, and preparation method and application thereof

ActiveCN103819630AImprove surface activityGood defoaming activityFoam dispersion/preventionAlkanePolymer science

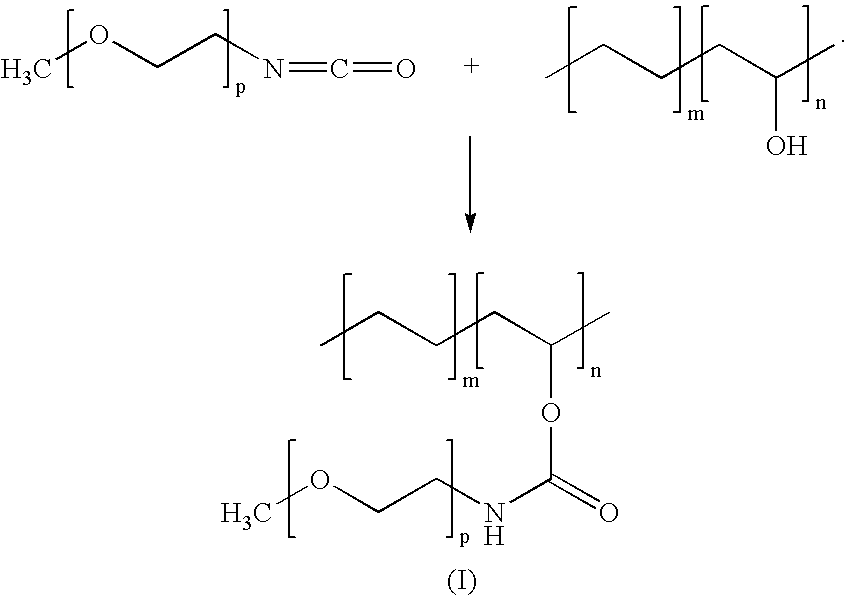

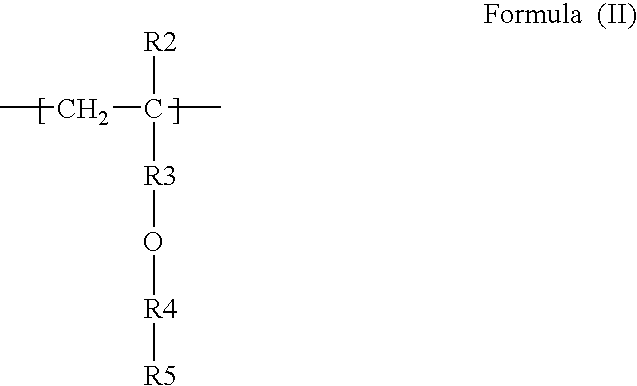

The invention belongs to the technical field of chemical engineering, and discloses polyether modified organic silicone oil that adopts a comb structure shown in formula (1) and a preparation method and application as a defoamer, and overcomes the service restrictions of conventional organic silicone defoamers. The preparation method comprises the following steps: compounds such as short polyols polydimethyl siloxane or polymethyl phenyl siloxane in which end groups are hydrogen, allyl alcohol polyether, aliphatic esters or alkanes amides that contain end alkenyl are selected as raw materials to synthesize the polyether modified organic silicone oil. According to the invention, as a defoamer, the polyether modified organic silicone oil has good characteristics of self-emulsifying property, self-dispersing property, steady emulsifying property, good defoaming and foam inhibiting performance, high temperature resistance, and acid and alkali resistance.

Owner:威尔(福建)生物有限公司

High-Temperature Crosslinked Polymer for Use in a Well

A method comprising the steps of: (A) forming a fluid comprising a crosslinked polymer, wherein the crosslinked polymer comprises: (i) a first monomeric unit of one or more N-vinyl lactams; and (ii) a crosslinker selected from the group consisting of: divinyl ether, diallyl ether, vinyl or allyl ethers of polyglycols or polyols, divinylbenzene, 1,3-divinylimidazolidin-2-one, divinyltetrahydropyrimidin-2(1H)-one, dienes, allyl amines, N-vinyl-3(E)-ethylidene pyrrolidone, ethylidene bis(N-vinylpyrrolidone), and any combination of any of the foregoing; and (B) introducing the fluid into a portion of a well. The crosslinked polymer may additionally comprise: a second monomeric unit selected from the group consisting of: acrylamide, N-substituted acrylamides, methacrylamide, N-substituted methacrylamides, acrylates, methacrylates, acrylic acid, methacrylic acid, N-vinylamides, N-allyl amides, vinyl alcohol, vinyl ethers, vinyl esters, allyl alcohol, allyl ethers, allyl esters, vinylpyridine, vinyl sulfonates, allyl sulfonates, vinylimidazole, allylimidazole, diallyldimethylammonium chloride, and any combination of any of the foregoing.

Owner:HALLIBURTON ENERGY SERVICES INC

Medical device with plasma cross-linked hydrophilic coating

InactiveUS7217769B2Increased wear and resistance characteristicLubricity be alteredChiropractic devicesPretreated surfacesCross-linkPlasma deposition

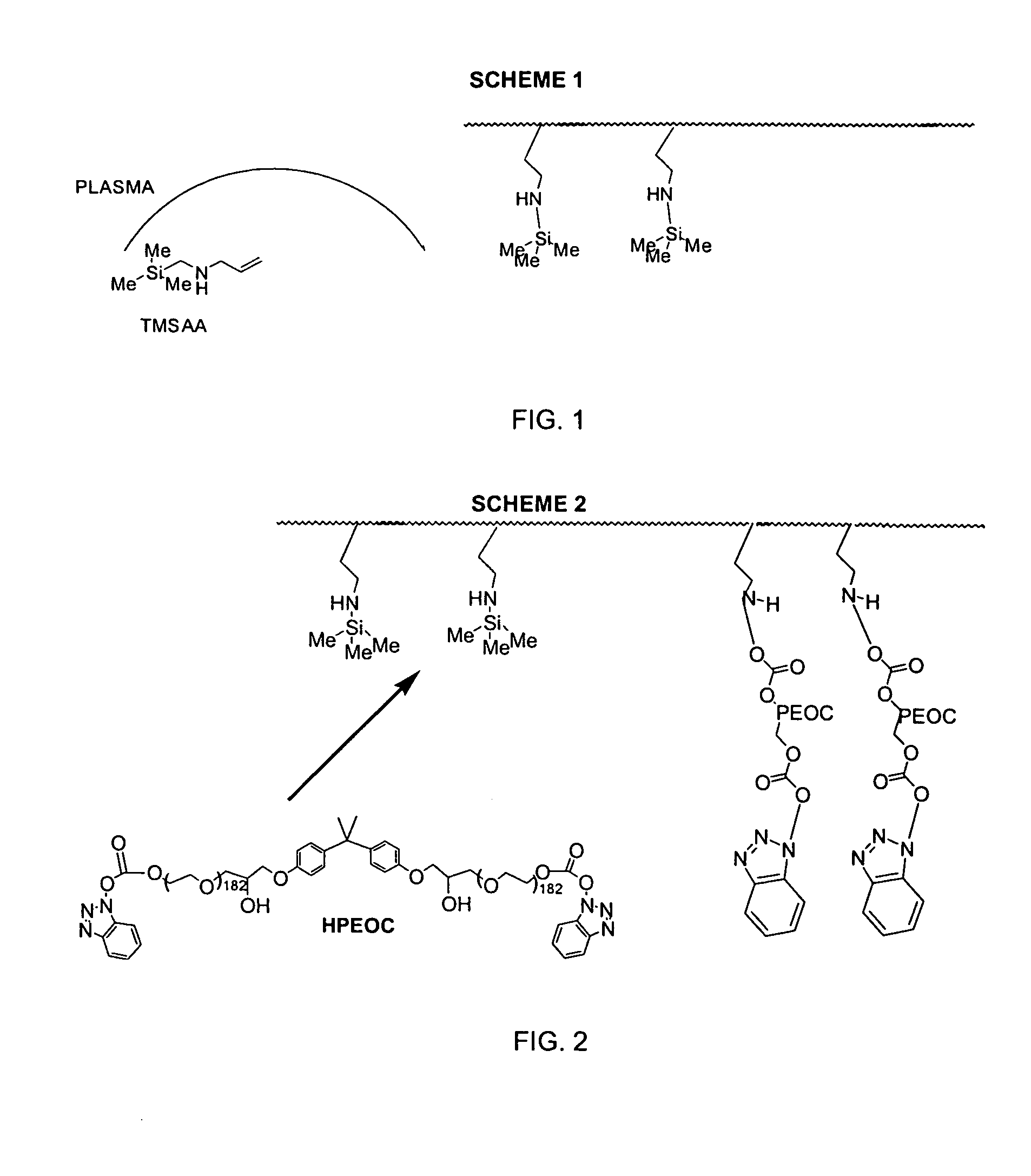

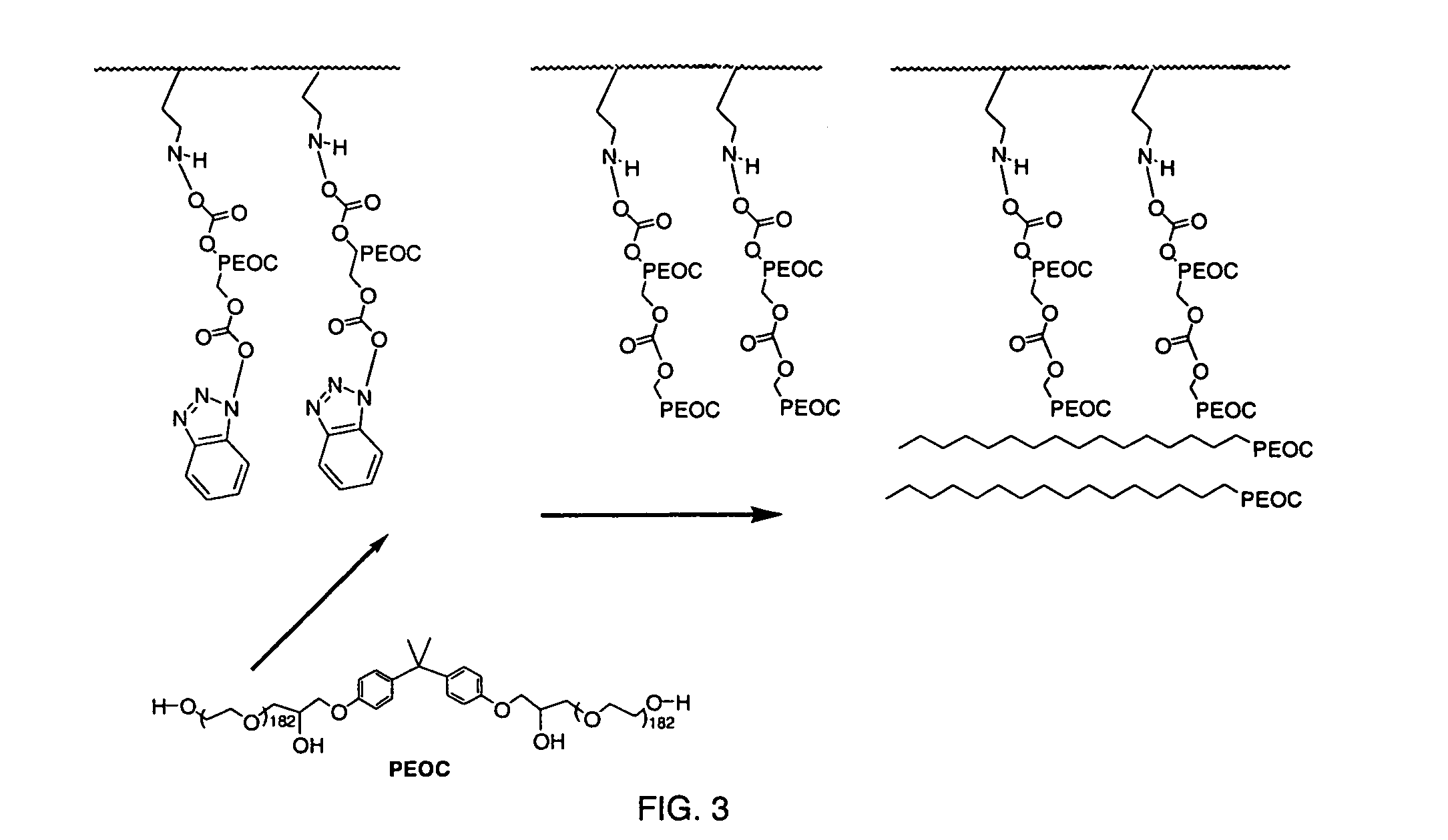

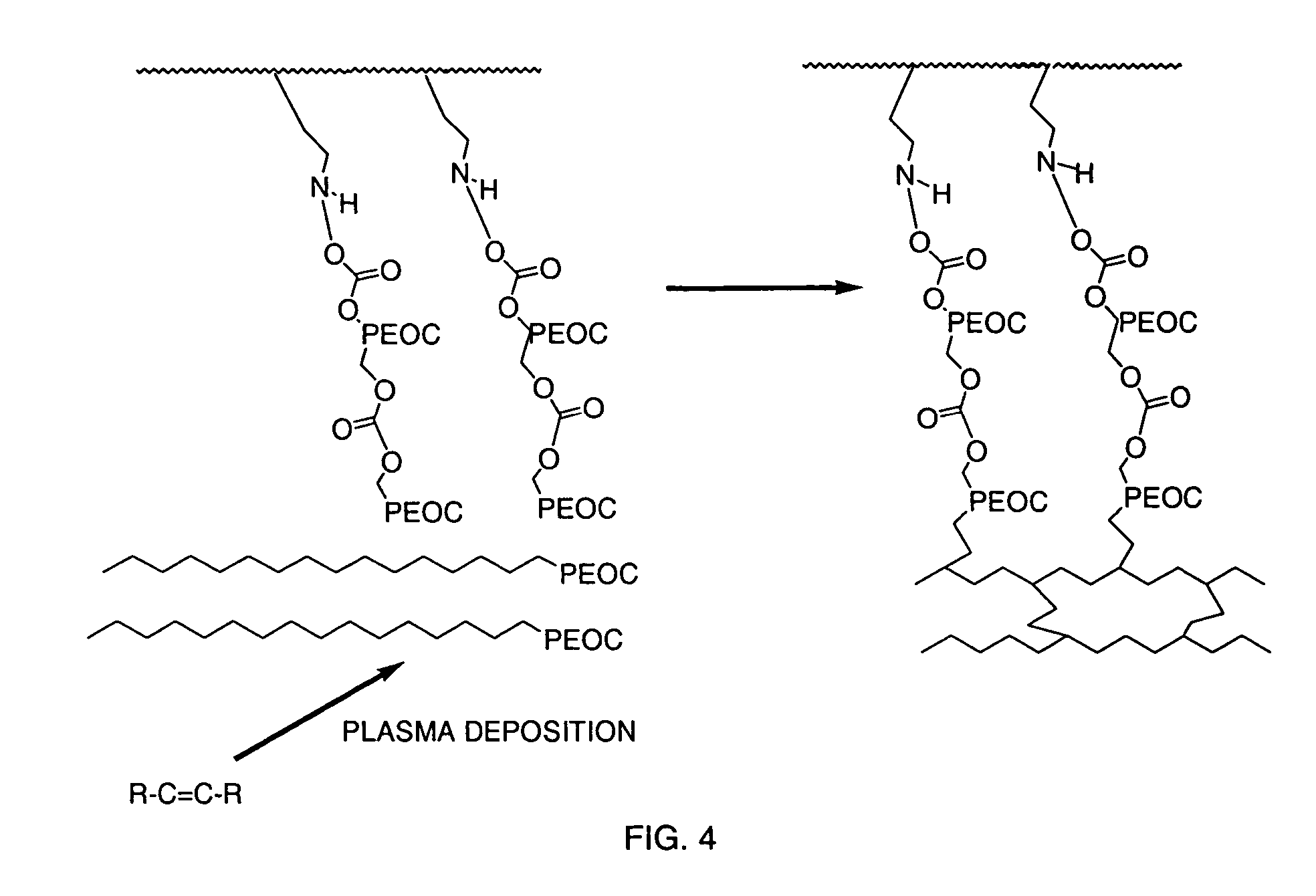

A medical device with a hydrophilic and lubricious coating, wherein the coating includes a hydrophilic polymeric unit layer deposited on the medical device and cross-linked with a plasma deposited double bond monomer. The hydrophilic polymeric unit can include ethylene oxide with one or more primary or secondary alcohol groups or glycosaminoglycans such as hyaluronic acid, and the double bond monomer includes monomers containing at least one double bond, preferably a C═C, C═N or C═O bond, including N-trimethylsilyl-allylamine, ethylene, propylene and allyl alcohol.

Owner:BIOSURFACE ENG TECH

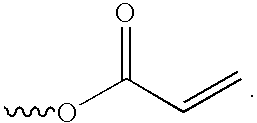

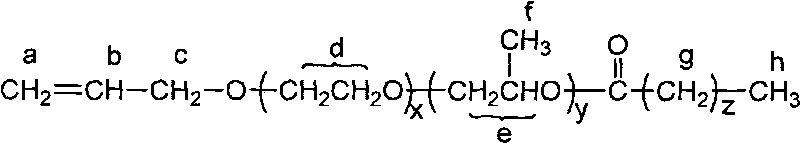

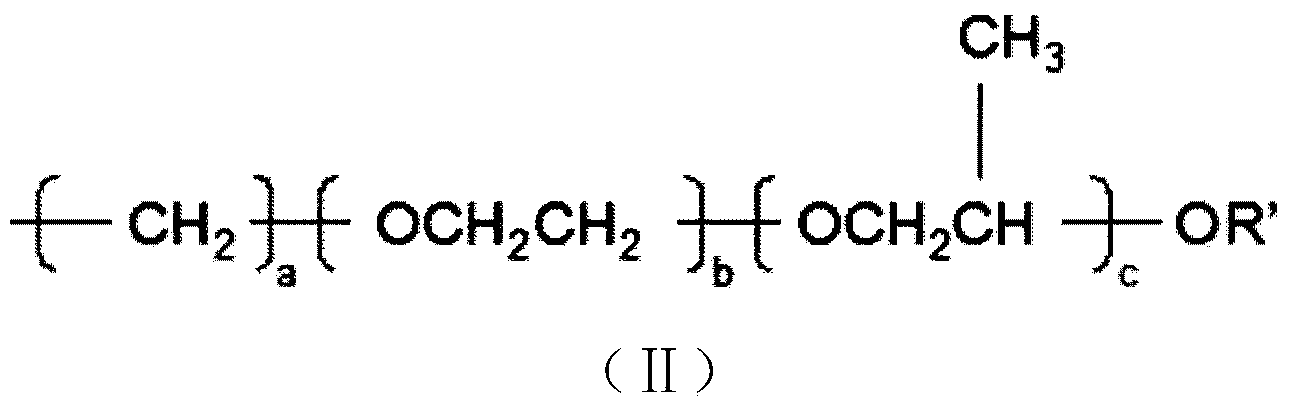

Method for preparing ester terminated allyl alcohol polyether

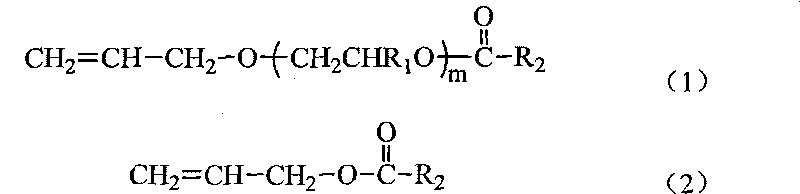

ActiveCN101701064AMolecular structure diversificationHydrophilic and lipophilic adjustableOrganic compound preparationCarboxylic acid esters preparationOrganic solventRing-opening polymerization

The invention provides a method for preparing ester terminated allyl alcohol polyether, which has simple process and realizes diversity of ester terminated allyl alcohol polyether monomer structure. The method for preparing the ester terminated allyl alcohol polyether comprises the following steps: allyl alkyl acid ester is used as initiator and ternary metal oxide is used as catalyst to ensure that oxirane and / or propylene epoxide perform a ring-opening polymerization reaction at 100-140 DEG C under the pressure of 0.1 to 0.6MPa; the ester terminated allyl alcohol polyether can be obtained after the catalyst is filtered and removed, wherein the ternary metal oxide catalyst is prepared from soluble salt of Mg, Al and Ca through alkaline precipitation and calcination. The preparation process is simple without using organic solvent, can be completed in one step by continuously adding materials in the same reactor. The prepared ester terminated allyl alcohol polyether monomer molecule has diverse structures, adjustable amphipathic property and controllable molecular weight, and can be polymerized with multiple unsaturated monomers.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

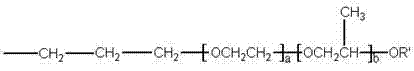

Preparation method of polyurethane foam stabilizer

The invention discloses a preparation method of a polyurethane foam stabilizer. The method comprises the following steps: (1) reacting allyl alcohol with oxirane and epoxypropane with an effect of a basic catalyst under conditions of a temperature of 90 to 130 DEG C and a pressure of not more than 0.5 MPa to obtain allyl-terminated copolyether; (2) reacting octamethylcyclotetrasiloxane with hexamethyldisiloxane and high hydrogenous silicone oil with a hydrogen content of 1.2% to 5% in the presence of an acidic ion exchanger under the condition of the temperature of 30 to 80 DEG C to obtain low hydrogenous silicone oil with the hydrogen content of 0.1% to 1%; and (3) adding the allyl-terminated copolyether obtained in step (1), the low hydrogenous silicone oil obtained in step (2), the catalyst and 1 to 5 wt% of amine ether to a reaction kettle under the conditions of the reaction temperature of 80 to 120 DEG C and the reaction pressure of 0.5 to 2 atm to obtain the polyurethane foam stabilizer. Compared with the prior art, the method of the present invention has the advantages of less pollution and cost reduction.

Owner:苏州思德新材料科技有限公司

Synthesis method of methyl allyl alcohol polyethenoxy ether

ActiveCN102898639AHigh effective contentNarrow molecular weight distributionPtru catalystPolyethylene glycol

The invention discloses a synthesis method of methyl allyl alcohol polyethenoxy ether, which comprises the following steps: 1) reacting 5-20 wt% of prescribed methyl allyl alcohol and a catalyst, adding the reaction product into residual prescribed methyl allyl alcohol, and introducing epoxyethane to react, thereby obtaining methyl allyl alcohol polyethenoxy ether low polymer; and 2) reacting 5-20 wt% of prescribed methyl allyl alcohol polyethenoxy ether low polymer obtained in the step 1) and a catalyst, adding the reaction product into residual prescribed methyl allyl alcohol polyethenoxy ether low polymer, and introducing epoxyethane to react, thereby obtaining the methyl allyl alcohol polyethenoxy ether. The methyl allyl alcohol polyethenoxy ether product prepared by the method disclosed by the invention has the advantages of low content of byproducts (polyethyleneglycol and the like), narrow molecular weight distribution, high double-bond protective rate and the like, and is suitable for synthesizing polycarboxylic-acid high-performance water reducing agents.

Owner:ZHEJIANG HUANGMA TECH

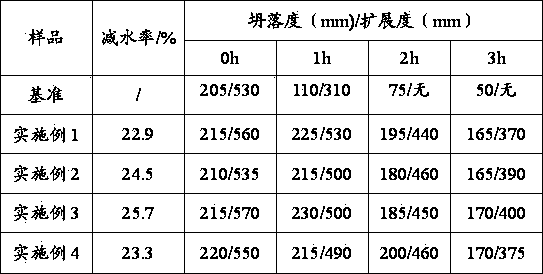

Preparation method for high-slump-retention polycarboxylate water reducer

InactiveCN103450411AIncreased steric hindranceSolve problems such as difficult pumpingMeth-Ptru catalyst

The invention discloses a preparation method for a high-slump-retention polycarboxylate water reducer. The preparation method comprises the following steps of: esterifying methoxylpolyethylene glycol monomethyl ethers with different molecular weights with methacrylic acid and a mixed polymerization inhibitor for a period of time under the action of a catalyst and at a certain temperature, then adding allyl alcohol in one time, further esterifying in the same conditions to obtain an esterified macromonomer MP containing crosslinking monomer allyl methacrylate; then performing aqueous solution polymerization on the MP, unsaturated sulfonate, (meth)acrylate unsaturated monomers and a chain transfer agent in a low-temperature condition and within a redox initiation system; and finally adding caustic soda liquid to neutralize, so as to obtain the polycarboxylate water reducer with a certain concentration. The high-slump-retention polycarboxylate water reducer prepared by the preparation method disclosed by the invention is a high-performance water reducer which is prepared at a low temperature by virtue of a molecular structure design, as well as is high in slump retention, excellent in dispersing performance, good in adaptability, simple in process, pollution-free, low in energy consumption, and easy to realize industrialized production.

Owner:KZJ NEW MATERIALS GROUP CO LTD

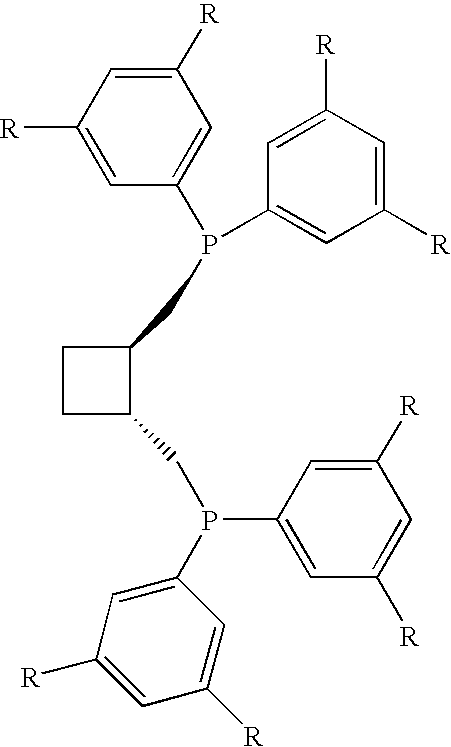

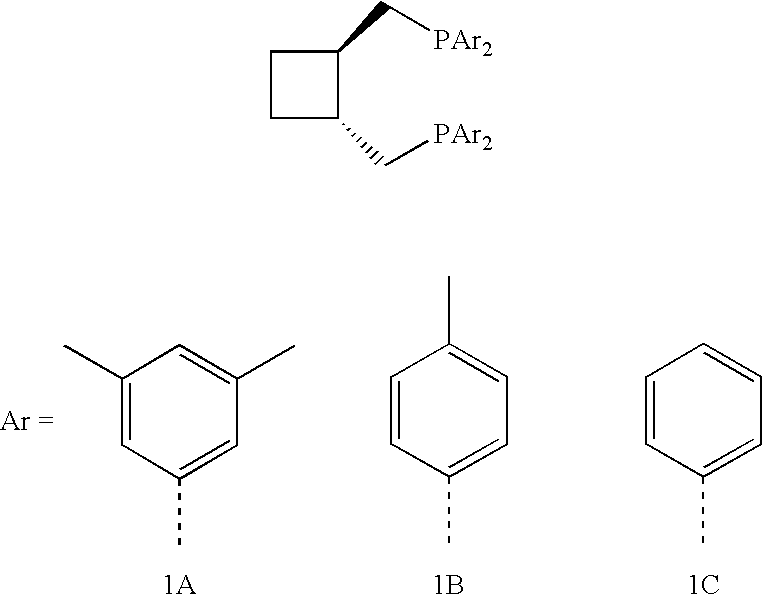

Hydroformylation process

ActiveUS7294602B1Organic compound preparationGroup 5/15 element organic compoundsHydrogenCyclobutane

A process for the production of 4-hydroxybutyraldehyde is described. The process comprises reacting allyl alcohol with a mixture of carbon monoxide and hydrogen in the presence of a solvent and a catalyst system comprising a rhodium complex and a trans-1,2-bis(bis(3,5-di-n-alkylphenyl)phosphinomethyl)-cyclobutane. The process gives high yield of 4-hydroxybutyraldehyde compared to 3-hydroxy-2-methylpropionaldehyde.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC

Cement dispersant and methods of making and using the same

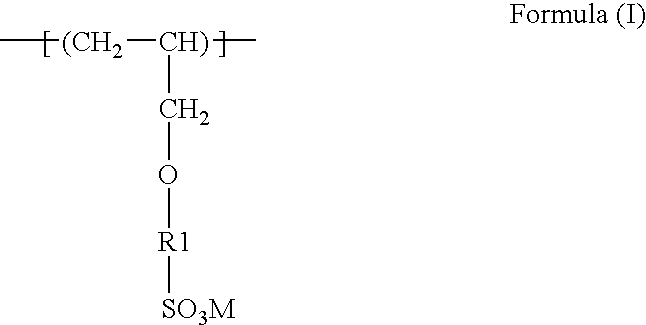

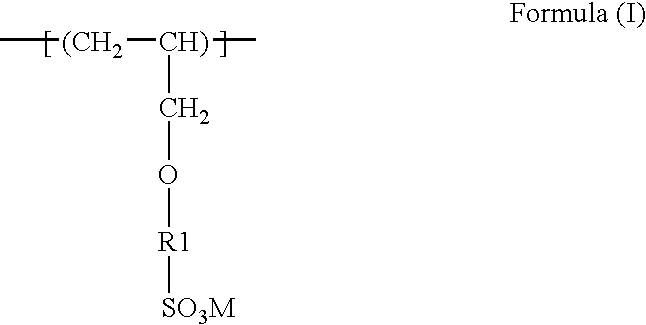

The present invention relates to cement dispersant that is a copolymerization product of a first monomer (A) comprising a carboxylic acid, a second monomer (B) comprising an alkoxylated allyl alcohol sulfate, and, optionally, a third monomer (C) comprising an alkoxylated allyl alcohol. The cement dispersant according to the invention provides improved slump life properties and water reduction properties in cement admixtures.

Owner:GEO SPECIALTY CHEM

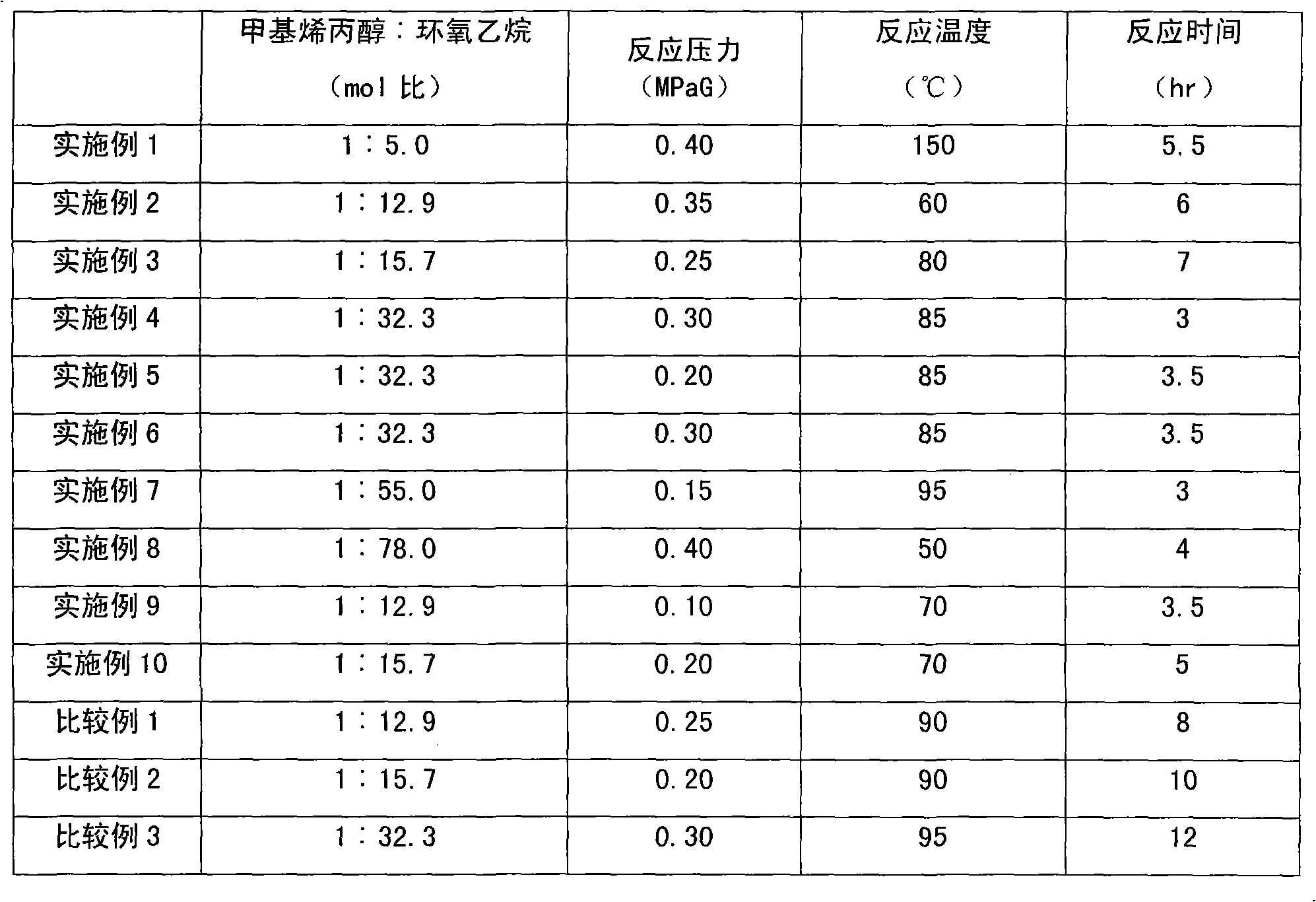

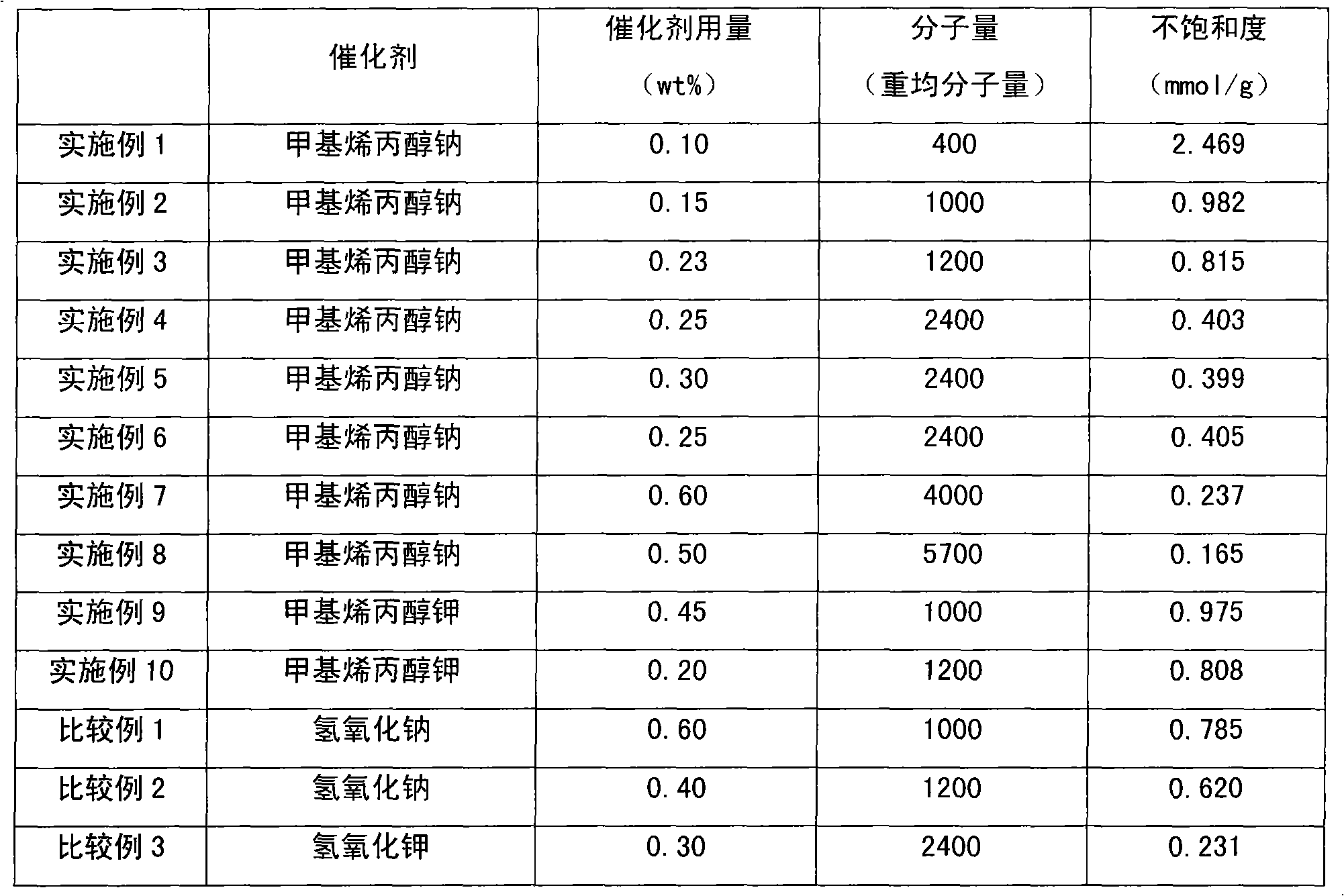

Method for preparing methyl allyl alcohol polyoxyethylene ether

The invention discloses a method for preparing methyl allyl alcohol polyoxyethylene ether. In the method, methallyl alcohol and ethylene oxide undergo a polymerization reaction in the presence of a catalyst to form the methyl allyl alcohol polyoxyethylene ether. The catalyst is sodium methyl allyl alcohol or potassium methyl allyl alcohol; the molar charge ratio of the methallyl alcohol to the ethylene oxide is 1.0:(5.0-78.0); the amount of the catalyst is 0.10 to 0.60 weight percent based on the methallyl alcohol; and the reaction pressure is 0.10 to 0.40MPaG, the reaction temperature is 50 to 150 DEG C, and the reaction time is 3 to 7 hours. The key technical point of the method is that the instauration of the product is increased by over 10 percent by using the more ideal catalyst. The method can be used for preparing methyl allyl alcohol polyoxyethylene ethers with a weight-average molecular weight of 150 to 6,000.

Owner:SHANGHAI DUOLUN CHEM

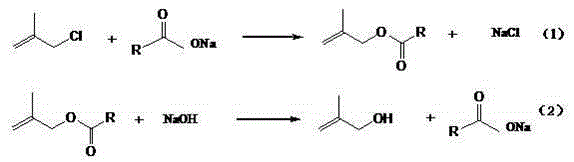

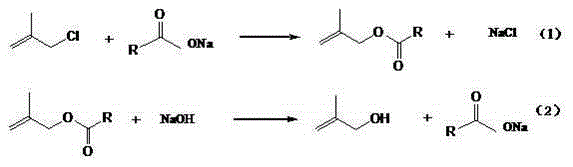

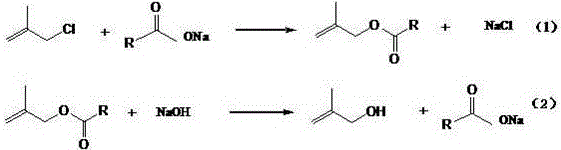

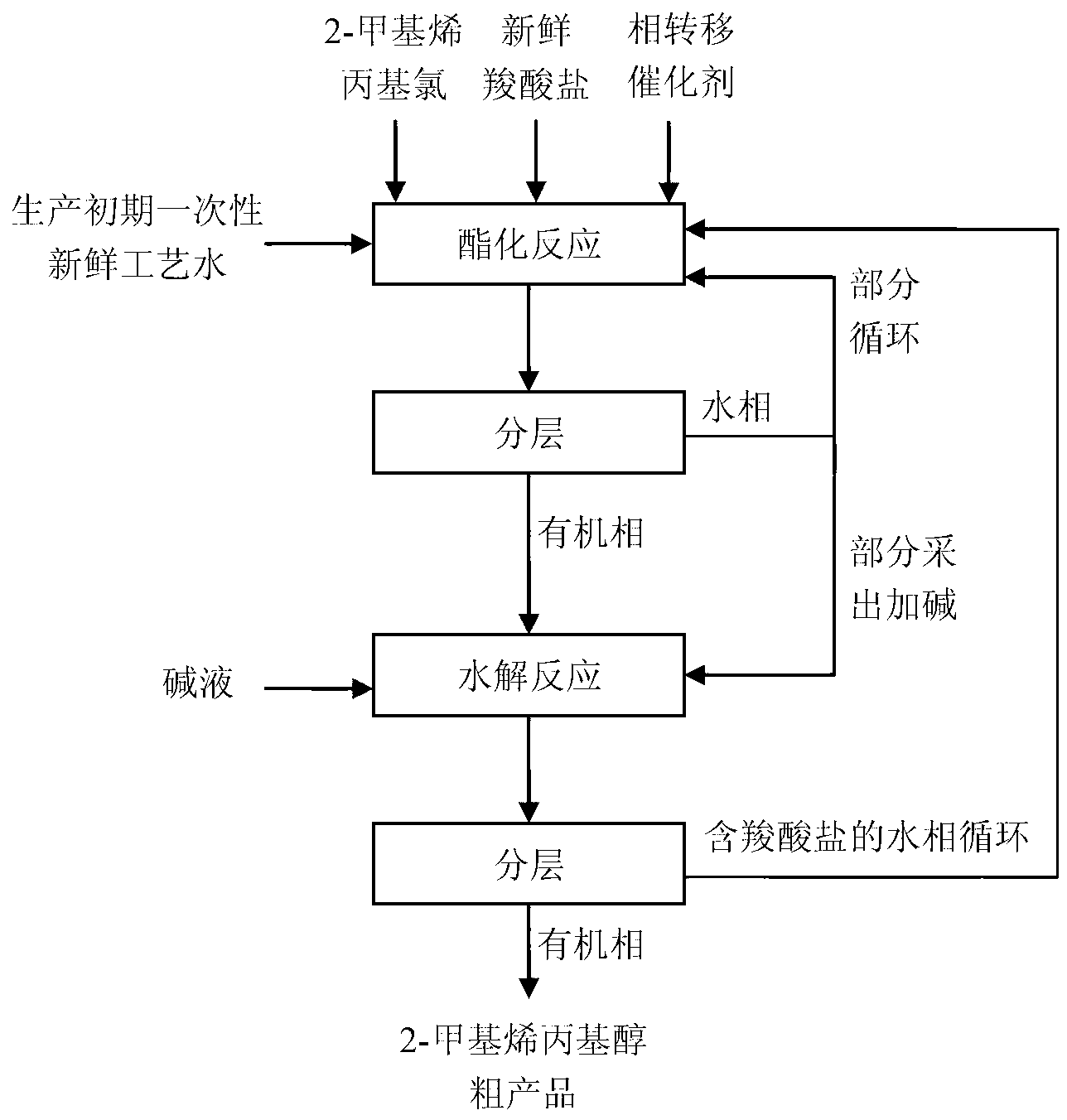

Synthetic method of 2-methallyl alcohol

InactiveCN105037097AAvoid corrosionLower requirementOxygen-containing compound preparationOrganic compound preparationCarboxylic acidHydrolysis

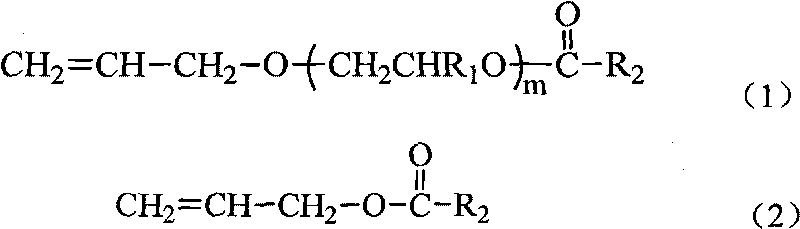

The invention relates to a synthetic method of 2-methallyl alcohol. The synthetic method comprises the step of carrying out esterification reaction, refinement and separation and hydrolysis reaction on 2-methallyl chloride and sodium carboxylate to prepare 2-methallyl alcohol, wherein the formulas of the esterification reaction and the hydrolysis reaction are respectively formula (1) and formula (2) both referring to the description; the R is CH3 or CH3CH2, namely, methyl or ethyl. According to the invention, the synthetic method is reasonable in technology and easy to operate; the product is high selectivity and relatively high in quality; carboxylic sodium in the esterification reaction stage and water in the hydrolysis reaction stage are recycled and need no external supplement, so that cyclic utilization is achieved, and the product yield is improved.

Owner:ZHEJIANG LYUKEAN CHEM

Coatings for drug delivery devices

A polymer coating for medical devices based on a polyolefin derivative. A variety of polymers are described to make coatings for medical devices, particularly, for drug delivery stents. The polymers include homo-, co-, and terpolymers having at least one olefin-derived unit and at least one unit derived from vinyl alcohol, allyl alcohol and derivatives thereof.

Owner:ABBOTT CARDIOVASCULAR

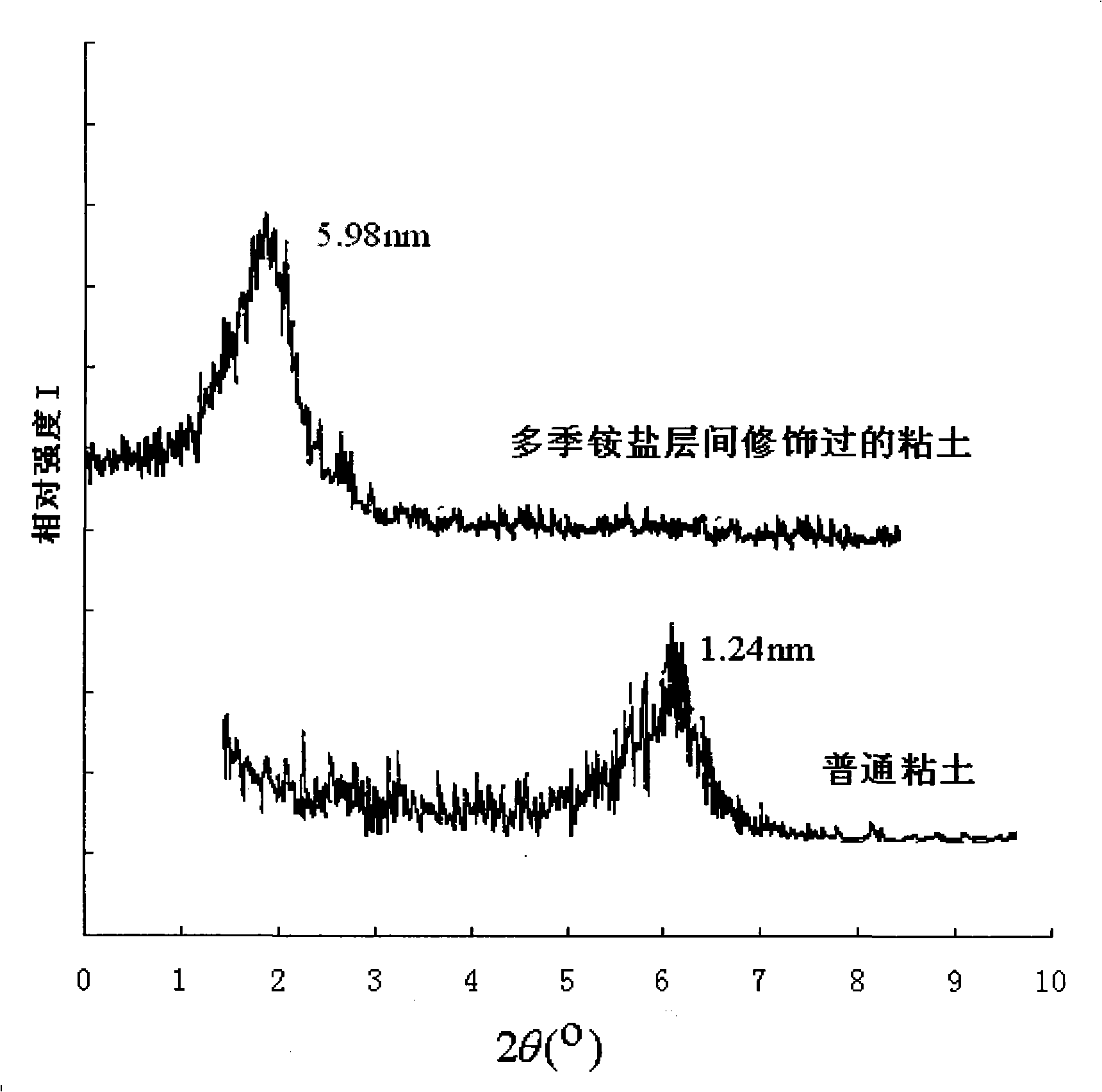

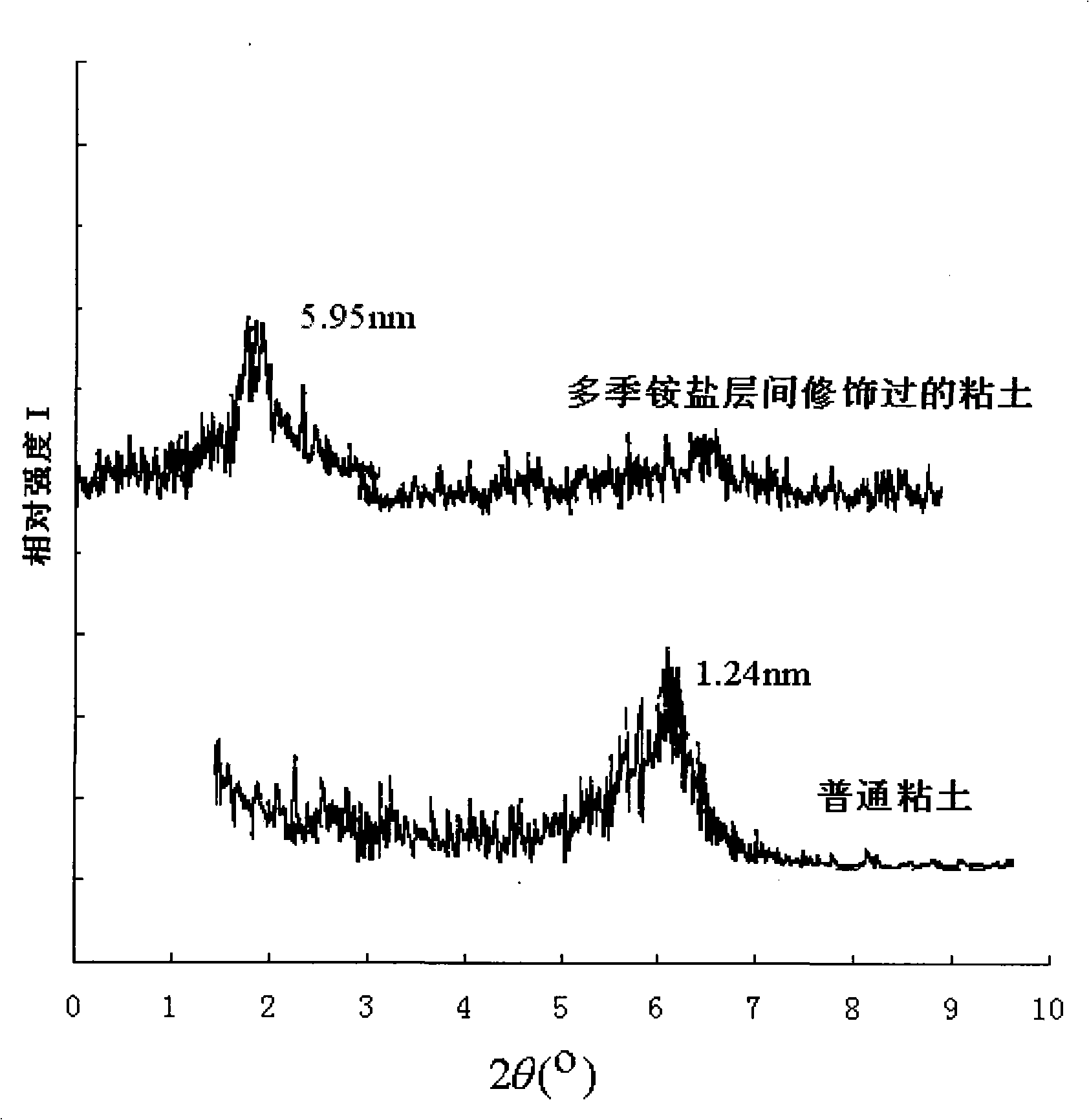

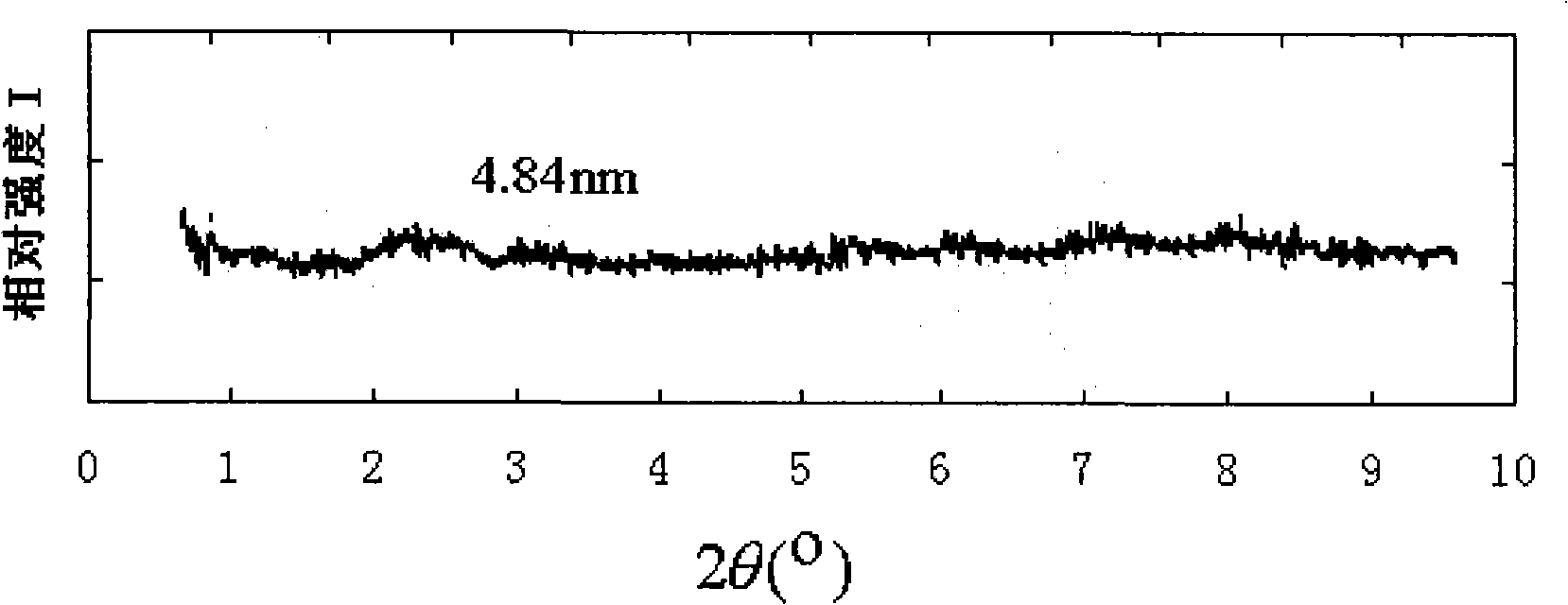

In-situ polymerization intercalated composite gel material and its preparation method and application

ActiveCN101260163AEstablishing the idea of in situ polymerization reactionSolve the problem that in-situ polymerization cannot occur to form intercalated compositesDrilling compositionRandom combinationPolymer science

The invention discloses an in-situ polymerization intercalation-type composite gel material and a preparation method and application thereof. The preparation method comprises the following steps: (1) interlayer dressing agent and clay are dissolved in water and are stirred 40 minutes to 60 minutes at a stirring speed of 10,000 to 15,000 r / min till the mixture is mixed evenly, thereby obtaining the mixing solution of the clay; (2) water-soluble monomer and initiator are added in the solution and are stirred 20 to 40 minutes at a stirring speed of 500 to 1,000 r / min till the mixture is mixed evenly; and (3) the reaction of the mixture is carried out under 80 to 140 DEG C for 6 hours to 12 hours. Moreover, the water-soluble monomer is one of or the random combination of acrylamide monomer, acrylic acid monomer, acrylonitrile monomer, acrylic ester monomer, allyl alcohol monomer, allyl urea monomer, allyl ether monomer, allyl ester monomer, allyl ether ester monomer and allyl azide monomer. Because the interlayer dimension of the composite gel material is between 4.5 nm and 6.0 nm, the composite gel material has excellent mechanical strength, injection performance, temperature resistance, salt resistance and plugging performance, thereby having a broad application prospect in the preparation of material for profile control and water shutoff.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of organosilicon foam stabilizer applied to single-component polyurethane foam sealing agent

The invention discloses a preparation method of an organosilicon foam stabilizer applied to a single-component polyurethane foam sealing agent. The preparation method comprises the steps of (1) adding allyl alcohol, ethylene oxide and propylene oxide to a reaction kettle, and reacting under the action of a base catalyst at the temperature of 90-130 DEG C and pressure not more than 0.5MPa for 4-6h to obtain allyl-terminated copolymer ether; (2) reacting the polyether prepared in the step 1 with sodium at 85-120 DEG C, introducing excess haloalkane, and reacting for 4-6h to obtain methyl-terminated copolymer ether; (3) reacting octamethyl cyclotetrasiloxane, hexamethyl disiloxane and high-hydrogen-content silicone oil with hydrogen content of 1-2% in the presence of an acid ion exchanger to obtain low-hydrogen-content silicone oil with hydrogen content of 0.05-1.0%; (4) mixing the products obtained in the steps 1,2, and 3, adding a catalyst, and reacting under the condition of pressure being 0.5-2atm for 3-8h to obtain the organosilicon foam stabilizer. During foaming, the foam stabilizer has excellent dimensional stability and high foaming ratio and fluidity.

Owner:苏州思德新材料科技有限公司

Poly carboxylic acid series water reducing agent with low content and high water-reducing rate, synthetic method and use method thereof

The invention belongs to the technical field of construction materials, and in particular relates to a poly carboxylic acid series water reducing agent with low content and high water-reducing rate, a synthetic method and a use method thereof. The water reducing agent comprises the following components: polyethylene glycol methyl ether methacrylate, 2-methyl allyl alcohol polyethenoxy ether, acroleic acid, methyl sodium allylsulfonate, ammonium persulfate, sodium hydroxide and water. The synthetic method comprises the following concrete steps: respectively preparing TPEG, SMAS, MPEGMA and AA into a mixed solution of which the concentration is 20%-50%, and simultaneously adding an amount of water to APS for dissolving; adding the prepared mixed solution of the TPEG and SMAS monomers to a reaction kettle, introducing nitrogen, inserting a condensing tube, stirring and heating to 60-100 DEG C, and respectively dropwise adding the mixed solution of the MPEGMA and AA monomers and the APS solution, wherein the time for dropwise adding the mixed solution of the monomers is 1-5 hours, and the time for dropwise adding the APS solution is 1.5-5.5 hours; after finishing dropwise adding, isothermally reacting for 0.5-1.5 hours; and cooling and neutralizing with an NaOH solution to obtain the required product. The invention has simple synthesizing process, stable performance of process products, low content, high water-reducing rate and good market prospect.

Owner:TONGJI UNIV

High-double bond content allyl polyether production method

ActiveCN105061750AReduce pollutionQuick responseEther preparation from oxiranesReaction rateDouble bond

The invention discloses a high-double bond content allyl polyether production method and belongs to the technical field of polyether compound synthesis in organic chemistry. In an anoxic environment, at a temperature of 110-140 DEG C, under catalysis action of an allyl alcohol solution of sodium allylate, allyl alcohol and an epoxy compound are mixed and undergo a reaction, the reaction product is aged and cooled to form an allyl polyether crude product, the allyl polyether crude product and water are mixed, the mixture is neutralized and filtered, and a liquid phase is collected and is allyl polyether. The prepared allyl polyether has molecular weight of 200-8000, double bond content greater than or equal to 98% and a molecular weight distribution coefficient less than or equal to 1.05. In catalyst preparation, an outer circulation reaction vessel with two condensers utilizing a freezing liquid for condensation is used so that a reaction rate is accelerated, an allyl alcohol loss is less than 0.2% and environmental pollution is reduced.

Owner:扬州晨化新材料股份有限公司

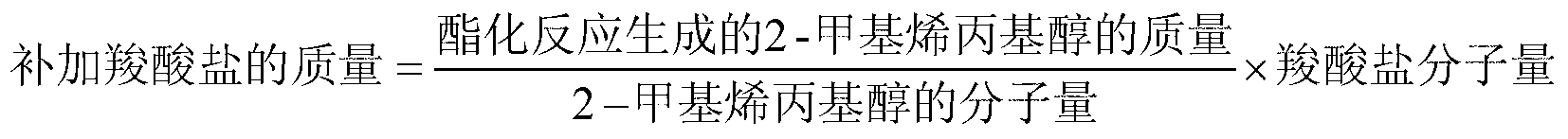

Method for preparing 2-methyl allyl alcohol by esterification and hydrolysis

ActiveCN103242139AImprove conversion rateHigh selectivityOxygen-containing compound preparationOrganic compound preparationChemical industryCarboxylic salt

The invention belongs to the field of chemical industry, and discloses a method for preparing 2-methyl allyl alcohol by esterification and hydrolysis. The method comprises the following steps of: first, performing esterification reaction of 2-methyl allyl chloride and carboxylate; and then, kalifying for hydrolysis reaction to synthesize 2-methyl allyl alcohol. The synthesizing steps are as follows: (1) esterification reaction: under the effect of a phase transfer catalyst, adding carboxylate, water and 2-methyl allyl chloride into a high pressure kettle for esterification reaction; after esterification reaction, cooling, standing and layering the reaction liquor to obtain an organic layer and a water layer, wherein the organic layer is a mixture which takes 2-methyl allyl carboxylate as a main product; (2) hydrolysis reaction: adding alkali liquor to the organic layer obtained in the esterification reaction stage for hydrolysis reaction; cooling, standing and layering the mixed liquor obtained by hydrolysis to obtain an organic layer and a water layer, wherein the organic layer is a target product, namely 2-methyl allyl alcohol. The method is high in material conversion ratio and product selectivity, the product yield is improved, and the separation energy consumption and material consumption are reduced.

Owner:NANJING UNIV OF TECH

Preparation method of polyether modified polysiloxane defoaming agent

InactiveCN102961895AExcellent anti-foam performanceNo pollution in the processFoam dispersion/preventionPolymer scienceOil emulsion

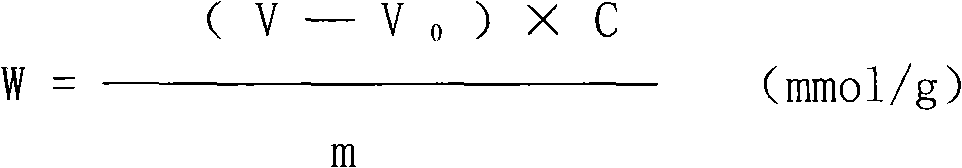

The invention relates to a preparation method of a polyether modified polysiloxane defoaming agent, which consists of a polyether modified polysiloxane polymer and a silicone oil emulsion. Specifically, the polyether modified polysiloxane polymer is prepared by employing a bulk polymerization method to react hydrogen-containing silicone oil, allyl alcohol polyether and a catalyst. The hydrogen-containing silicone oil has a hydrogen content of 0.01-0.3mol / 100g and a viscosity of 10-100cst. The allyl alcohol polyether has an average molecular weight of 200-3000g / mol and an unsaturation degree of 1-2mmol / g. The catalyst is chloroplatinic acid. The hydrogen-containing silicone oil and the allyl alcohol polyether are in a mole ratio of 1:(1-1.4). Compared with the solution method for preparation of the polyether modified polysiloxane polymer, the method provided in the invention has the advantages of no pollution, simple process, controllability, and low cost. The obtained polyether modified polysiloxane polymer can be compounded with the methyl silicone oil emulsion so as to obtain the polyether modified polysiloxane defoaming agent. With excellent defoaming and foam inhibiting properties, the defoaming agent is suitable for high temperature environment.

Owner:TIANJIN PHARMACN MEDICAL TECH

Direct hydrocarbonylation process

A direct hydrocarbonylation process for the production of 1,4-butanediol is described. The process comprises reacting allyl alcohol with carbon monoxide and hydrogen in an alcohol solvent in the presence of a catalyst system comprising a rhodium complex, a trialkyl phosphine, and a diphosphine. The process gives a high yield of 1,4-butanediol in a one-step reaction.

Owner:LYONDELL CHEM TECH LP

High-efficient agricultural chemicals suspension agent and disperser and method for preparing the same

ActiveCN101133731AGood dispersionReduce dosageBiocideTransportation and packagingChemical suspensionCarboxylic acid

The present invention relates to a new-type high-effective agricultural pesticide suspension dispersing agent. It is characterized by that said dispersing agent is obtained by using (by mass%) 50-95% of unsaturated macromonomer with long-chain, 4-49% of unsaturated carboxylic acid or its derivative which can be ionized into carboxylic acid ions in water and 1-46% of other comonomer containing ethylenic bond through a certain copolymerization reaction. The described unsaturated macromonomer with long-chain is polyoxyethylene (methyl) acrylate compound or allyl alcohol polyoxyethylene oxyethylene ether. Besides, said invention also provides its preparation method.

Owner:江苏钟山新材料有限公司

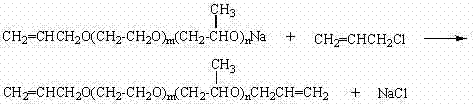

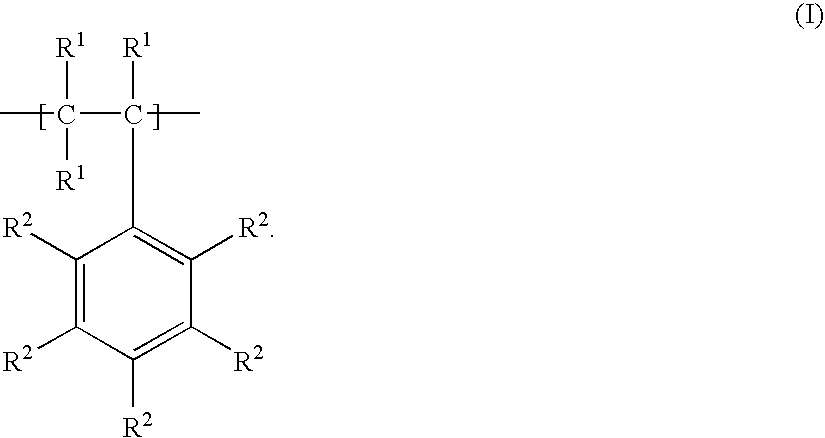

Method for synthetizing diallyl polyether

The invention discloses a method for synthetizing diallyl polyether. A polymerization product which is prepared from ethylene oxide and propylene oxide by using allyl alcohol as a starting agent is polyether with the following general formula (I). The method is carried out according to the following process steps of: 1, adding an alkoxidation reagent into the polyether to perform alkoxidation reaction and removing methanol generated during the reaction; 2, then filling allyl chloride into a reaction kettle to continuously perform the reaction, wherein the charging molar ratio of the polyether to the allyl chloride is 1: (1.0-2.0) and a by-product is sodium chloride or potassium chloride; and 3, refining the product, i.e. firstly, distilling and recovering the unreacted allyl chloride and then filtering a crude product to obtain the refined product. The problems of poor reaction activity and low yield of termination of polyether containing a secondary hydroxyl group, particularly high molecular weight polyether are solved. Due to the selection of the alkoxidation reagent, not only is the problem of generating a highly toxic allyl alcohol by-product in the conventional allylation process solved, but also the product has high yield of termination.

Owner:ZHEJIANG HUANGMA TECH

High-efficiency organic silicon defoaming agent

InactiveCN103041623AGood compatibilityImprove adaptabilityFoam dispersion/preventionFatty alcoholStearate

The invention discloses a high-efficiency organic silicon defoaming agent and belongs to the technical field of fine chemical engineering. The defoaming agent consists of the following components in part by weight: 50 to 90 parts of mixture of hydroxyl silicone oil and 201 silicone oil, 2 to 15 parts of gaseous phase white carbon black, 2 to 12 parts of condensation compound of fatty alcohol and ethylene oxide, 1 to 6 parts of modified nonionic surfactant, 1 to 10 parts of allyl alcohol polyoxyl alkyl ether, 1 to 8 parts of propylene glycol block polyether, 3 to 20 parts of sorbitol anhydride monostearate, 3 to 20 parts of dehydrated sorbitol monostearate polyoxyl vinethene and 10 to 30 parts of water. The defoaming agent has the characteristics of high defoaming speed, strong foam inhibiting ability, no toxicity, high adaptability, small using amount and the like.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

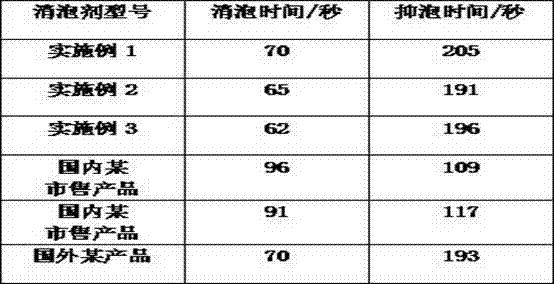

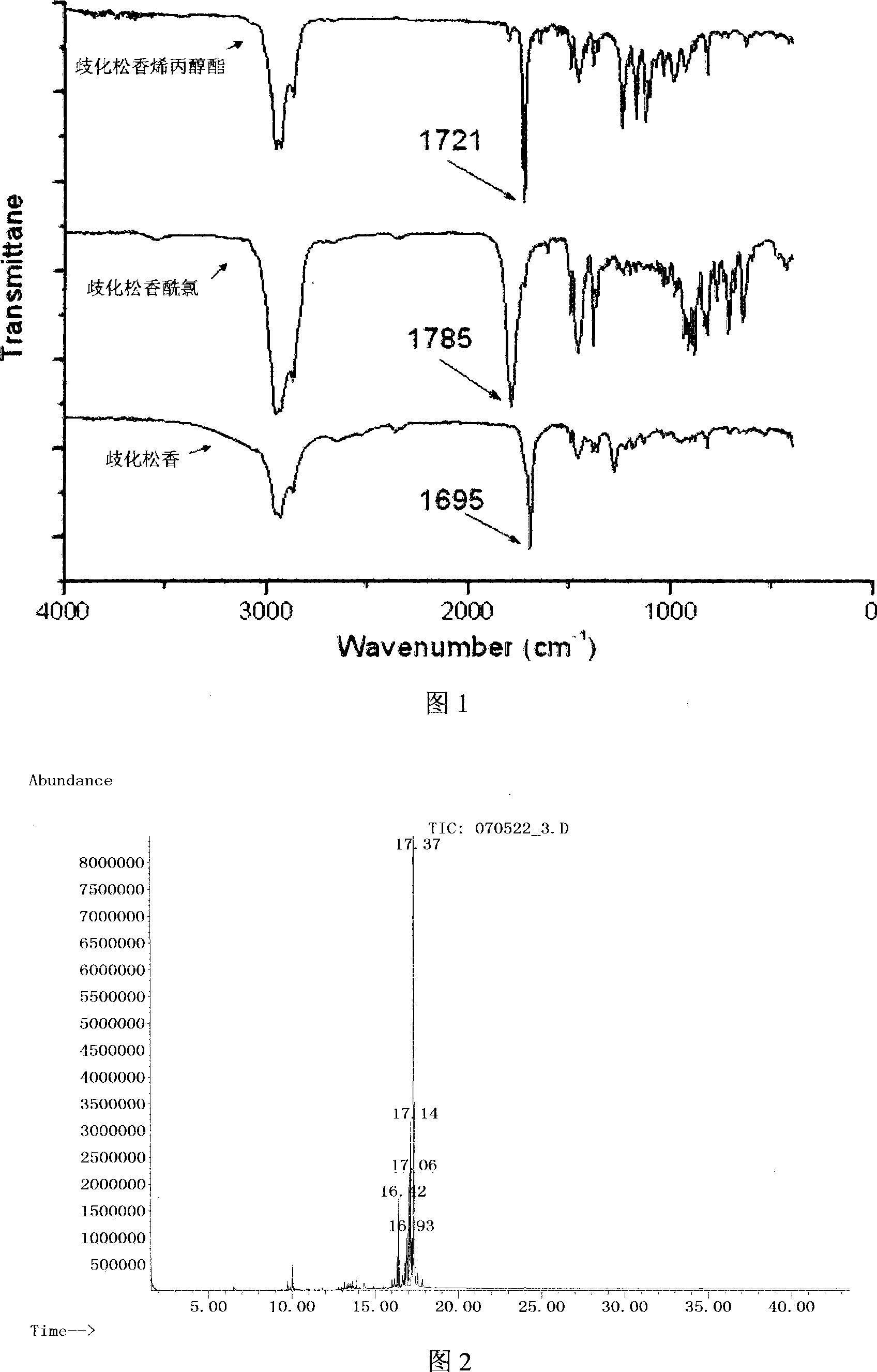

Method for synthesizing rosin or rosin derivatives allyl ester

InactiveCN101215445AImprove stabilityHigh purityNatural resin chemical modificationReaction temperaturePrinting ink

The invention discloses a method for synthesizing rosin or allyl ester which is rosin derivative, which comprises following steps: dissolving one of the rosin or the rosin derivative in aprotic solvent, adding acylate-chloridized agent, heating to enable reaction temperature to be in 0-85 DEG C, reacting for 0.5-5 hours, acylate-chlorizating carboxy group in the rosin or the rosin derivative, adding acid binding agent, polymerization inhibitor and allyl alcohol into the reaction product of the first step, reacting under 10-80 DEG C for 2-5 hours, removing the aprotic solvent, and obtaining the rosin or the rosin derivative, namely, allyl ester, wherein the using amount of the acid binding agent is 100-150% of the molar weight of carboxy group in the rosin or the rosin derivative and the using amount of the polymerization inhibitor is 1% of the allyl alcohol. Synthetical rosin or rosin derivative, namely, allyl ester, can generate radical polymerization and can be applied in the fields of coating material, cementing compound, printing ink, paper making and the like. The method has high technical efficiency and good product stability.

Owner:JIANGSU QIANGLIN BIO ENERGY

Spin-on protective coatings for wet-etch processing of microelectronic substrates

ActiveUS20090075087A1Decorative surface effectsSynthetic resin layered productsSilane compoundsOligomer

New protective coating layers for use in wet etch processes during the production of semiconductor and MEMS devices are provided. The layers include a primer layer, a first protective layer, and an optional second protective layer. The primer layer preferably comprises an organo silane compound in a solvent system. The first protective layer includes thermoplastic copolymers prepared from styrene, acrylonitrile, and compatible compounds such as monomers, oligomers, and polymers comprising epoxy groups; poly(styrene-co-allyl alcohol); and mixtures thereof. The second protective layer comprises a highly halogenated polymer such as a chlorinated polymer which may or may not be crosslinked upon heating.

Owner:BREWER SCI

Method of converting a polyol to an olefin

ActiveUS8273926B2Organic compound preparationPreparation by OH group eliminationPolyolCarboxylic acid

A method of preparing an olefin comprising: reacting a polyol in the presence of a carboxylic acid, such that an olefin is produced by the deoxygenation of the polyol. The reacting step can comprise (a) providing a composition comprising the polyol, (b) heating the composition, and (c) introducing the carboxylic acid to the composition wherein the introducing step occurs prior to, at the same time as, or subsequent to the heating step. In one embodiment, the polyol is glycerol, the carboxylic acid is formic acid, and the olefin is allyl alcohol, which is produced at a yield of about 80% or greater.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com