Method for synthesizing rosin or rosin derivatives allyl ester

A technology of rosin derivatives and allyl esters, which is applied in the field of preparation of rosin allyl esters, can solve the problems of incomplete reaction and complex process, and achieve the effects of high production efficiency, high purity and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of synthetic method of rosin or rosin derivative allyl ester comprises the following steps,

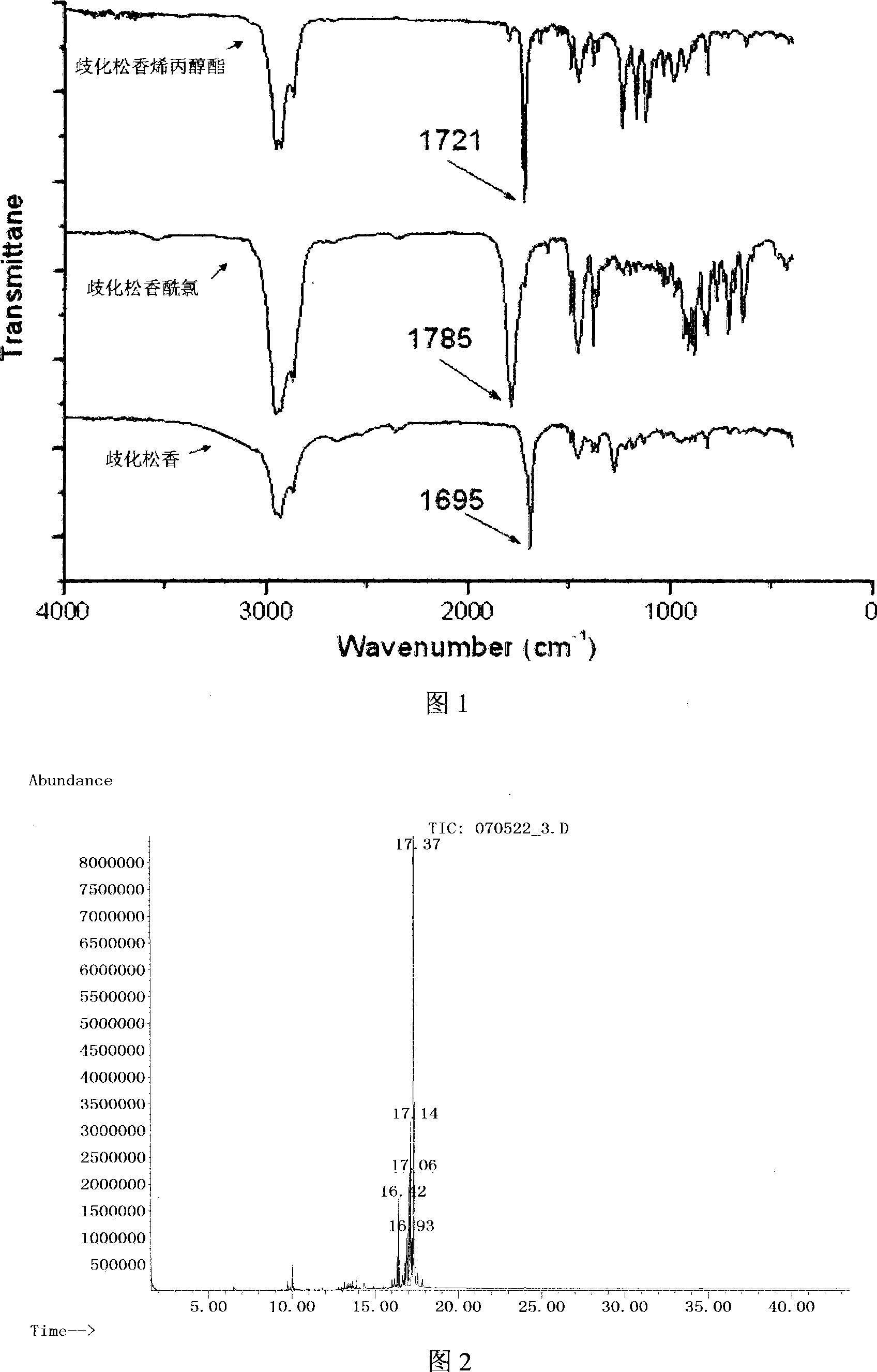

[0036]The first step, the acyl chloride reaction of rosin or rosin derivatives: dissolve one of rosin or rosin derivatives in an aprotic solvent, and the aprotic solvent used is one of benzene, methylene chloride, toluene , and the water content of the solvent is lower than 0.02%, add an acid chloride reagent, heat to make the reaction temperature 20-85°C, for example, the temperature can be selected as: 5°C, 10°C, 15°C, 20°C, 25°C, 30°C, 35°C, 40°C, 45°C, 50°C, 52°C, 55°C, 60°C, 65°C, 70°C, 75°C, 80°C, react for 0.5-5 hours, the time can be selected as: 0.5 hours, 1 hour, 1.5 hours, 2 hours, 2.5 hours, 3 hours, 3.5 hours, 4 hours, 4.5 hours, 4.8 hours, make the carboxylic acyl chloride in rosin or rosin derivative (also can according to in infrared spectrum, carboxyl peak disappears, the acyl chloride peak Formation to judge, for example, for acid chloride...

Embodiment 2

[0038] Embodiment 2 Synthesis of disproportionated rosin allyl ester.

[0039] The synthesis of disproportionated rosin allyl ester comprises the following steps:

[0040] The first step is the acyl chloride reaction of disproportionated rosin. 10g of disproportionated rosin (relative molecular weight, 300g / mol) is added in the reactor, dissolved with 20g of benzene, and 2.18g of phosphorus trichloride (PCl 3 ), reacted at 55°C for 3 hours. Phosphorous acid (H 3 PO 3 )precipitation.

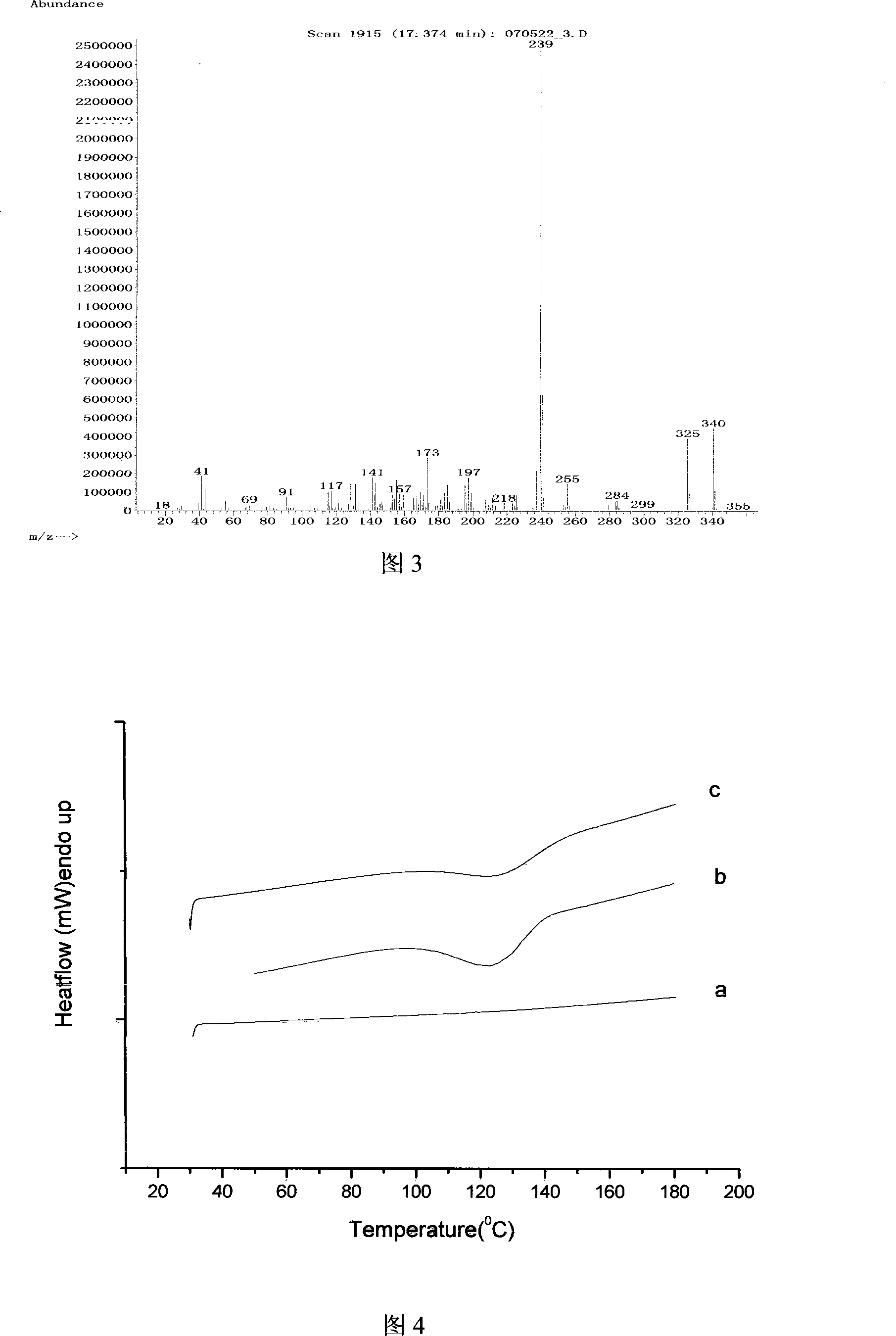

[0041] The second step, allyl alcohol esterification. The acid-binding agent pyridine (C 5 h 5 N) 3.42g, polymerization inhibitor p-hydroxyanisole 0.003g and allyl alcohol 2.33g were added to the reaction product of the first step, and reacted at 50°C for 2-5 hours. The precipitate is filtered off, and the obtained filtrate is subjected to vacuum extraction to remove the solvent to obtain disproportionated rosin allyl ester. The theoretical molecular weight is 340 g / mol.

[0042] From t...

Embodiment 3

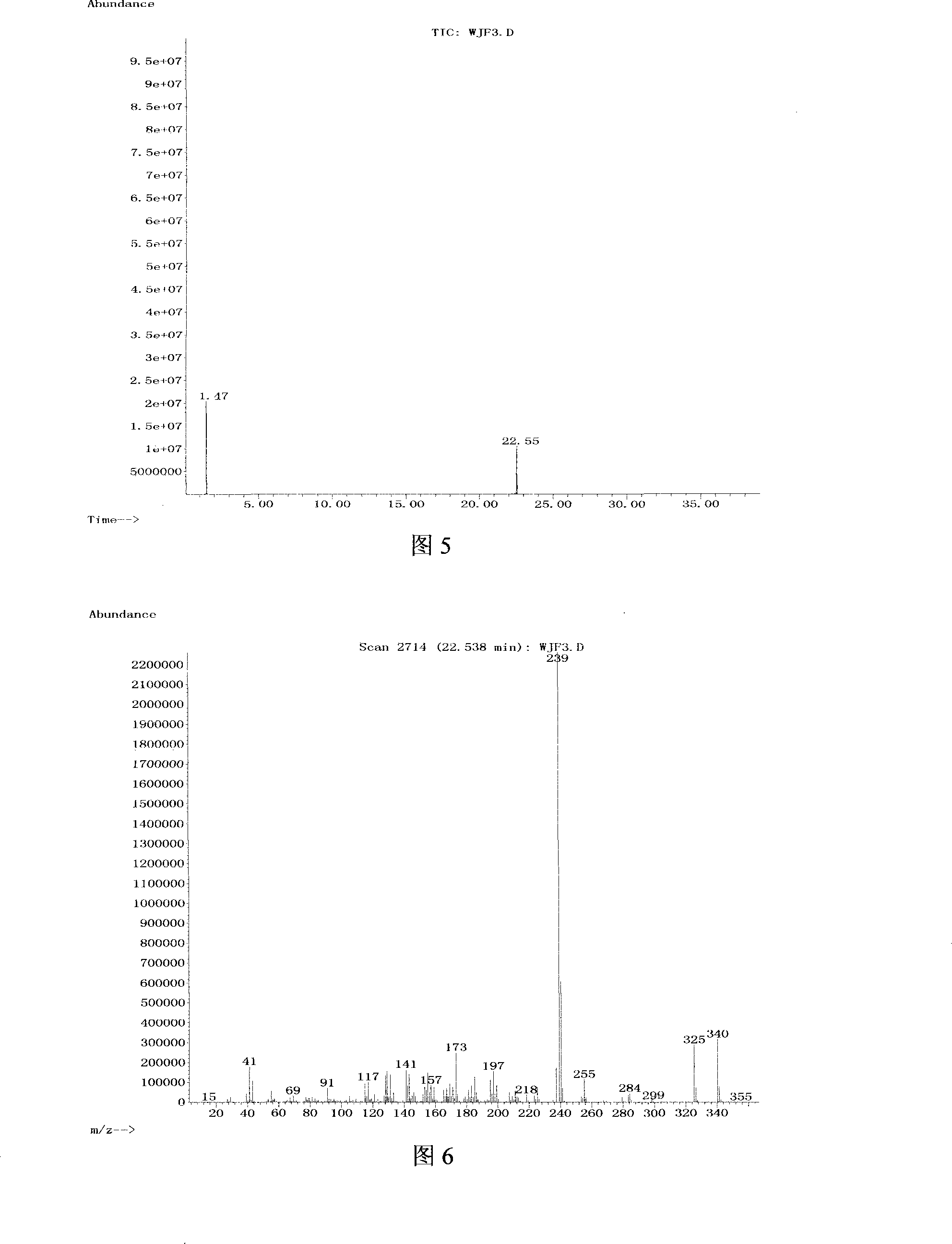

[0043] Synthetic formula one of embodiment 3 dehydroabietic acid allyl ester

[0044] Dehydroabietic acid is the main component of disproportionated rosin. After a series of related treatments, dehydroabietic acid can be separated from disproportionated rosin.

[0045] The synthesis of allyl dehydroabietic acid comprises the following steps: the first step, the acyl chloride reaction of dehydroabietic acid. 10g dehydroabietic acid (molecular weight, 300g / mol) is added in the reactor, dissolves with 20g benzene, adds 5.16g sulfur oxychloride (SOCl 2 ), reacted at 40°C for 3 hours.

[0046] The second step, allyl alcohol esterification. The acid-binding agent sodium carbonate (Na 2 CO 3 ) 5.42g, polymerization inhibitor p-hydroxyanisole 0.003g and allyl alcohol 2.13g were added to the reaction product of the first step, and reacted at 50°C for 2-5 hours. The precipitate was filtered off, and the obtained filtrate was vacuum extracted to remove the solvent to obtain allyl de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com