Patents

Literature

537 results about "Vacuum extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Overview. A vacuum extraction — also called vacuum-assisted delivery — is a procedure sometimes done during the course of vaginal childbirth. During a vacuum-assisted vaginal delivery, a health care provider applies the vacuum — a soft or rigid cup with a handle and a vacuum pump — to the baby's head to help guide the baby out of the birth canal.

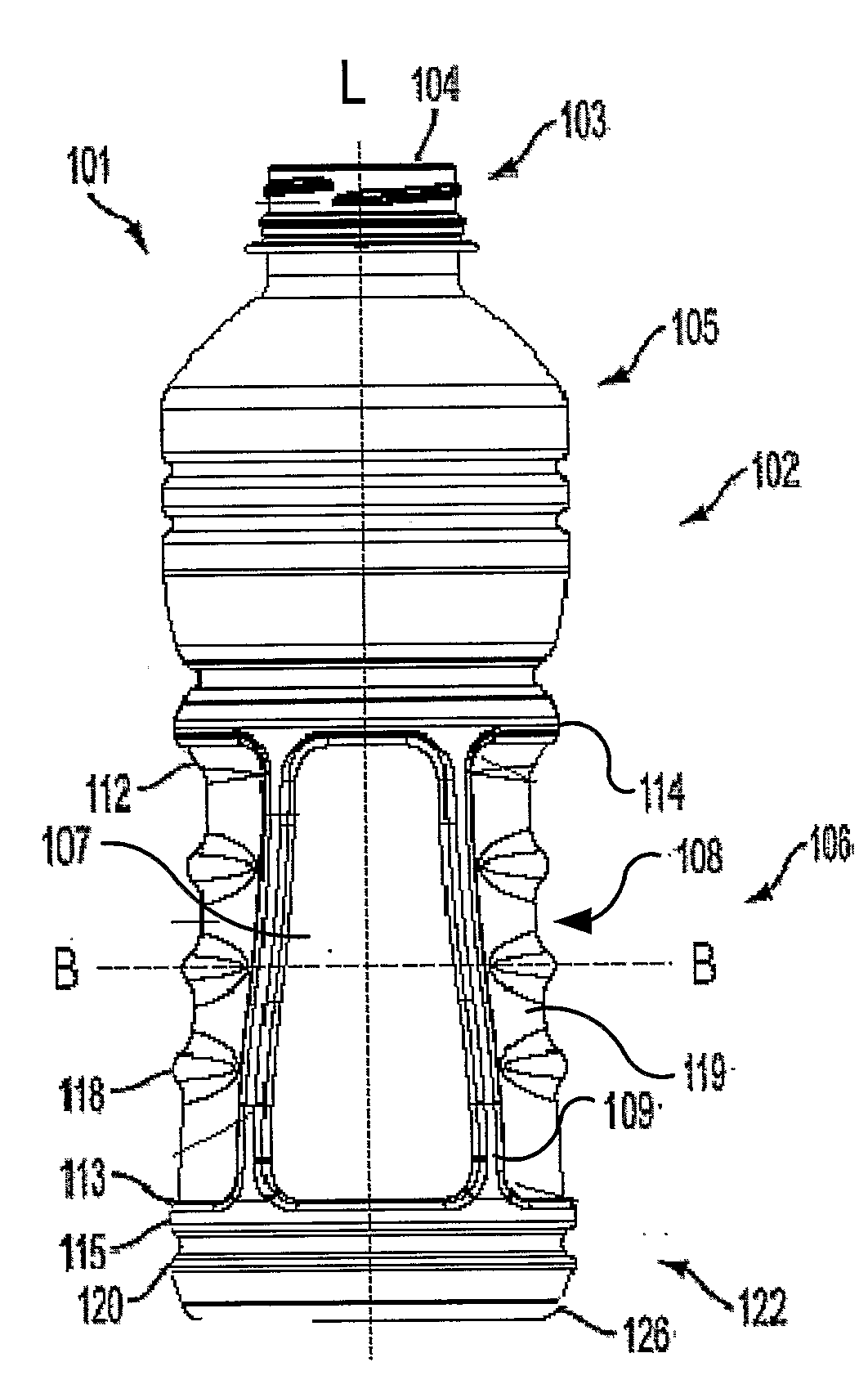

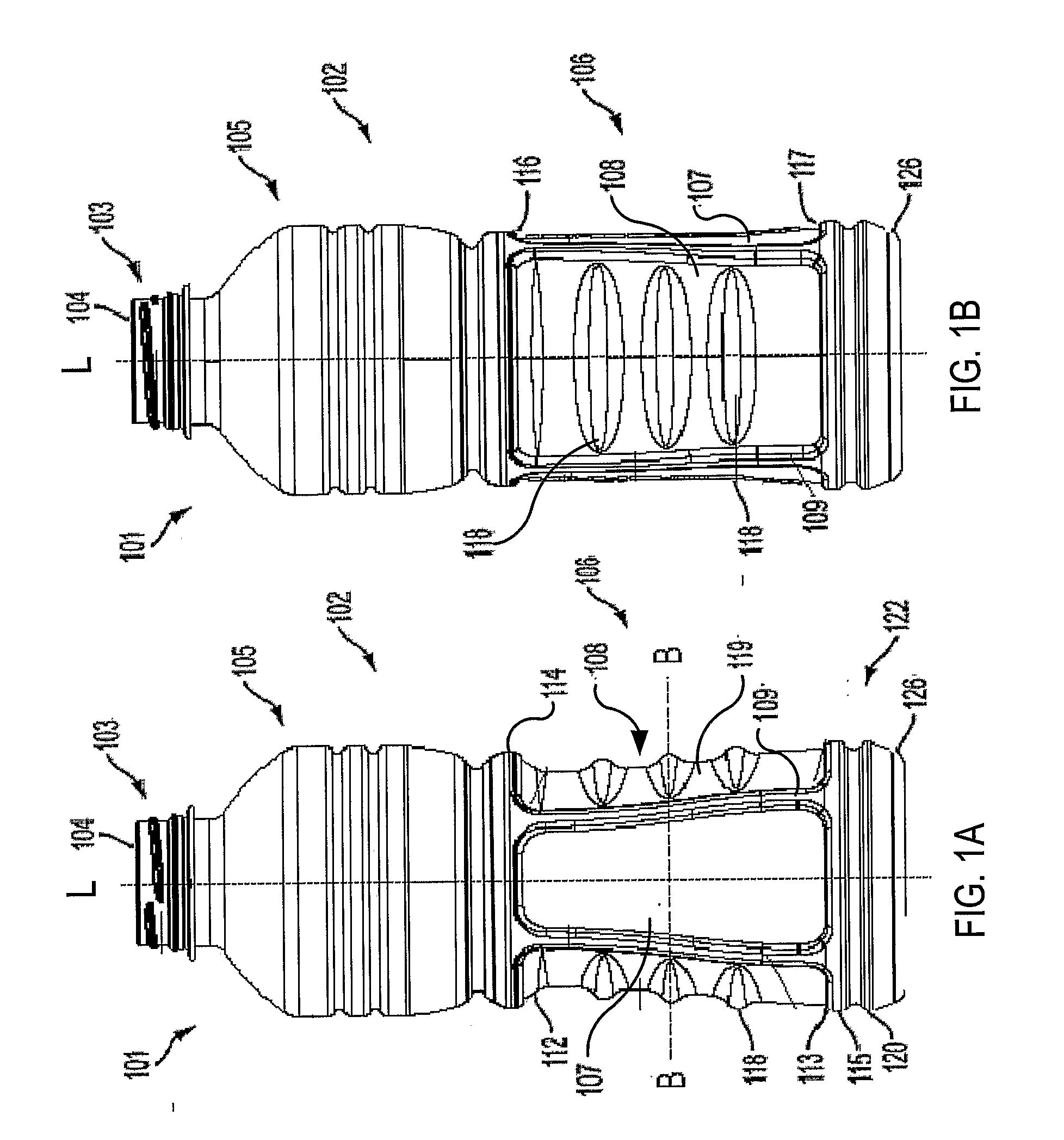

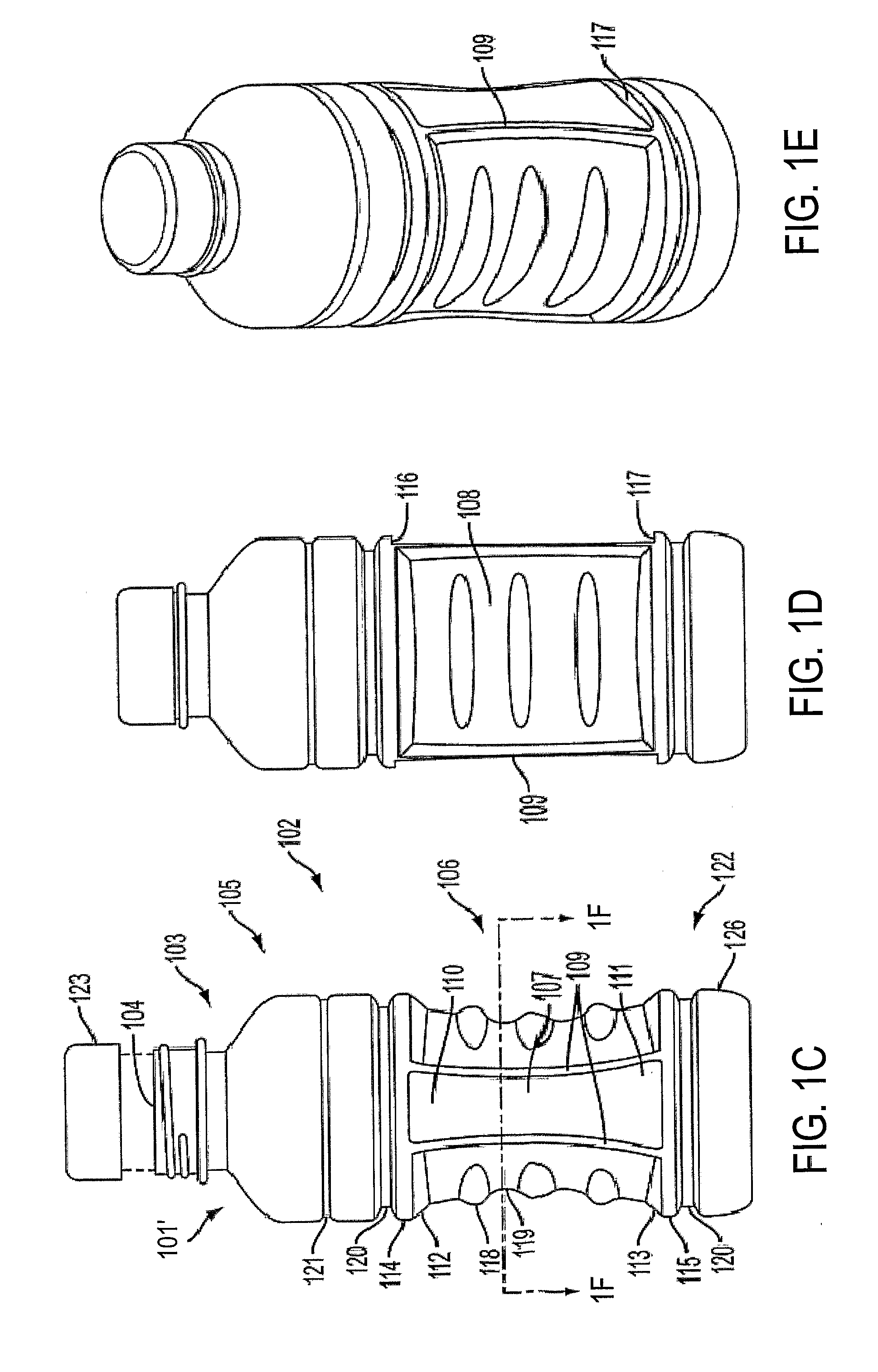

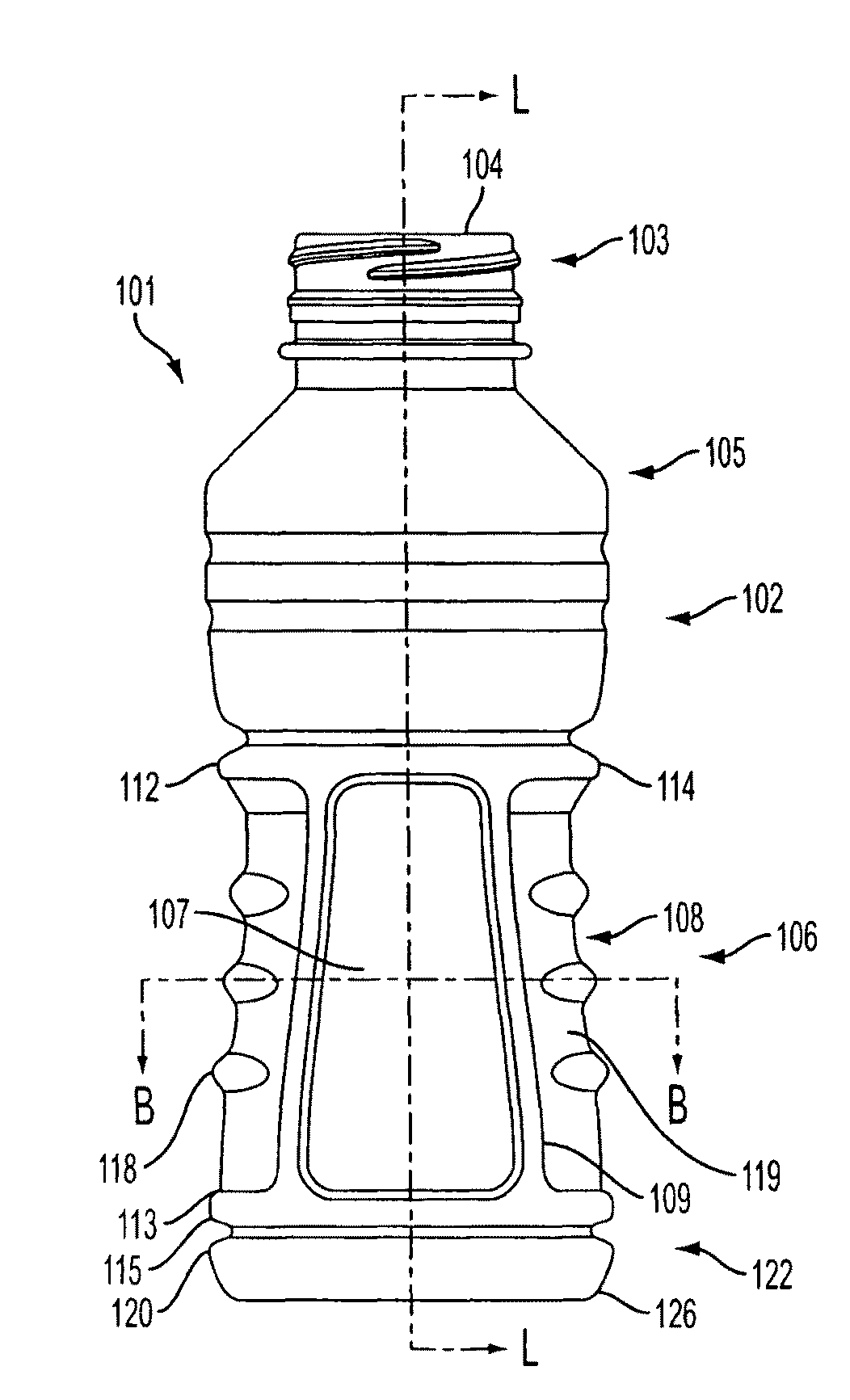

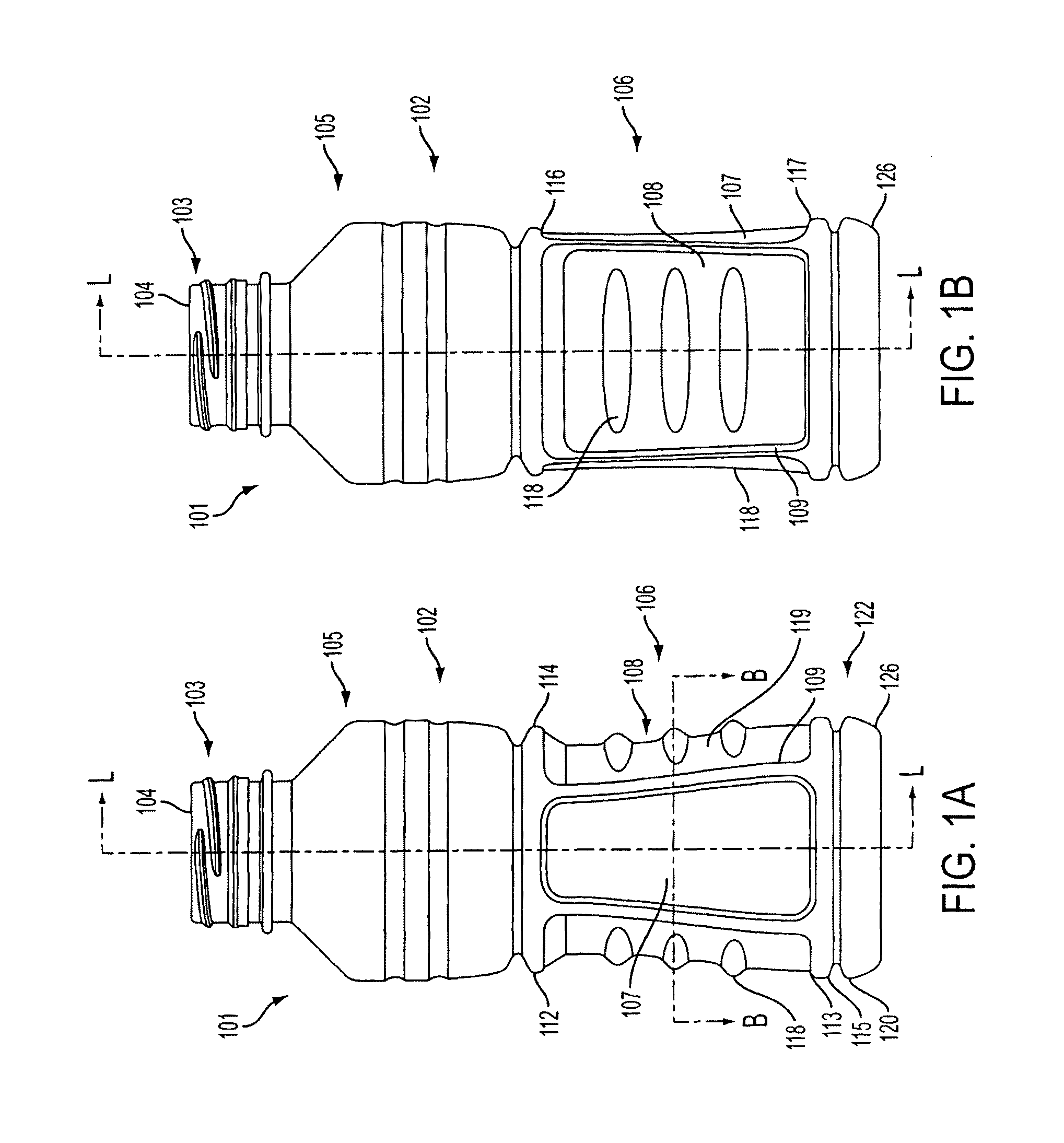

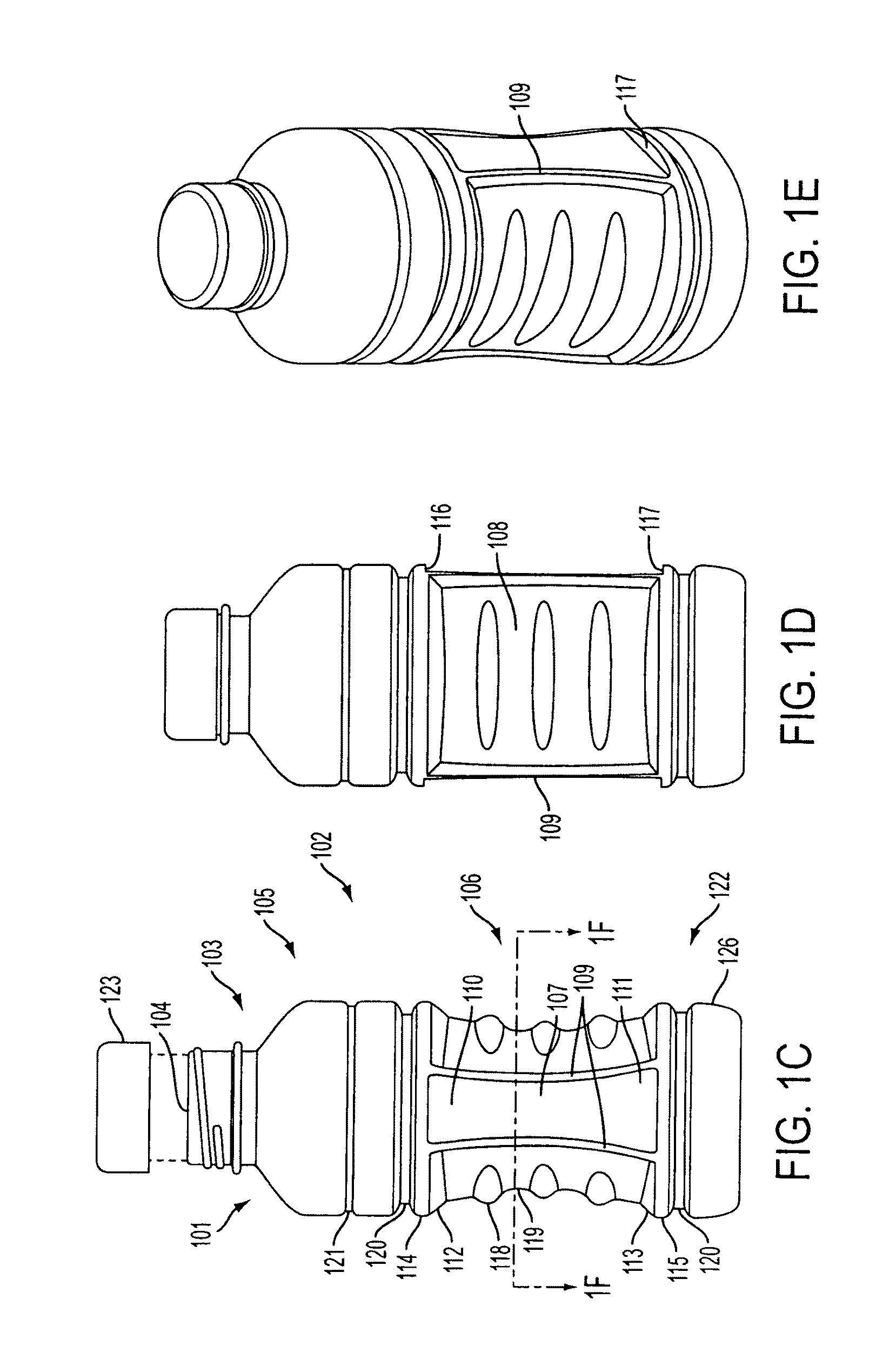

Pressure Container With Differential Vacuum Panels

ActiveUS20080257856A1Controlled overall response to vacuum pressureImprove dent resistanceLarge containersRigid containersVacuum extractionVacuum pressure

An improved blow molded plastic container having generally rounded sidewalls that are adapted for hot-fill applications has two adjacent sides and two pairs of controlled deflection panels, each pair reacting to vacuum pressure at differing rates of movement, whereby one pair inverts under vacuum pressure and the other pair remains available for increased squeezability or extreme vacuum extraction. The opposing sidewalls are symmetric relative to vacuum panel and rib shape and placement. The ribs and controlled deflection panels cooperate to retain container shape upon filling and cooling and also improves bumper denting resistance, decreases vacuum pressure within the container, and increases light weight capability.

Owner:MELROSE DAVID MURRAY +1

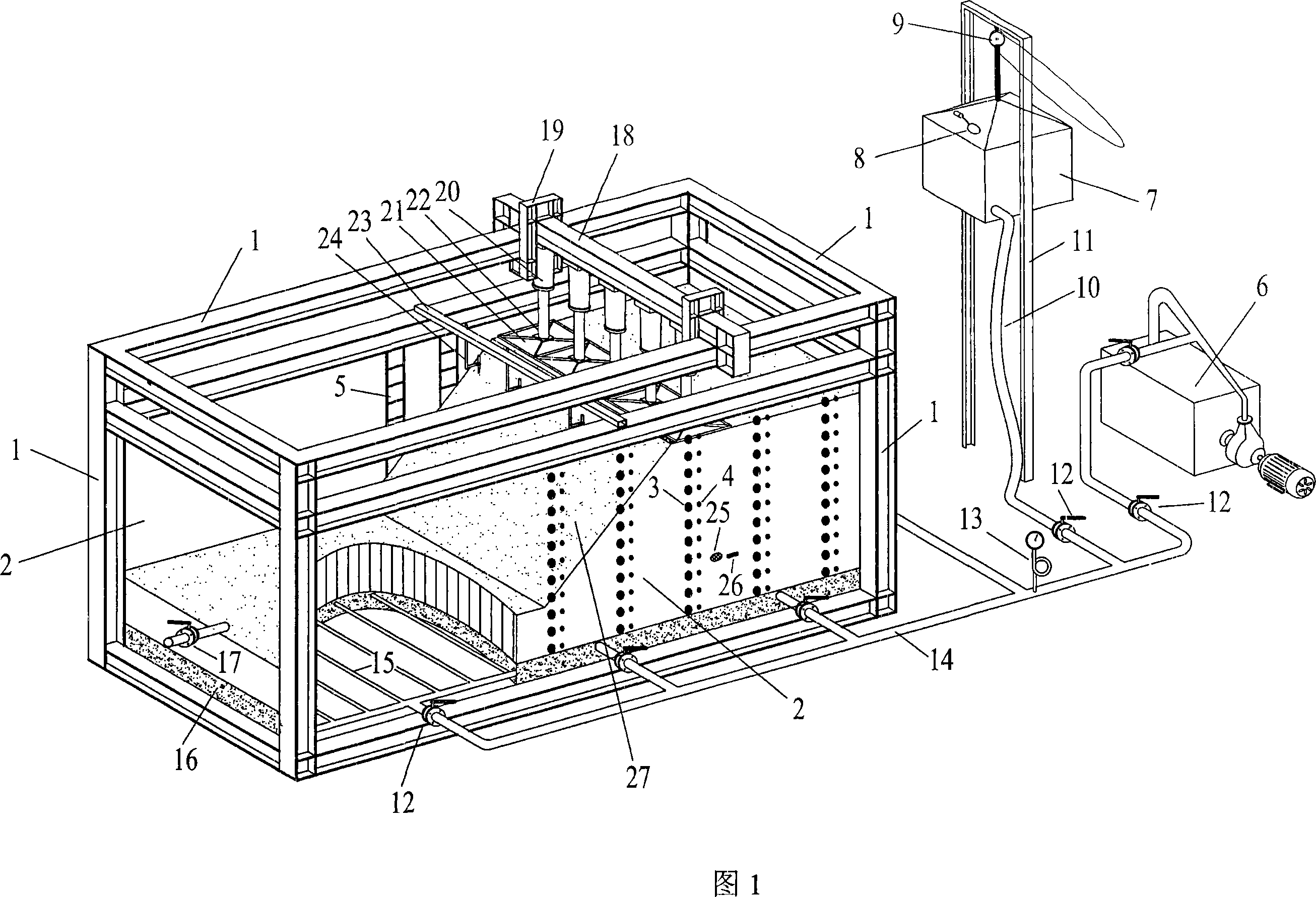

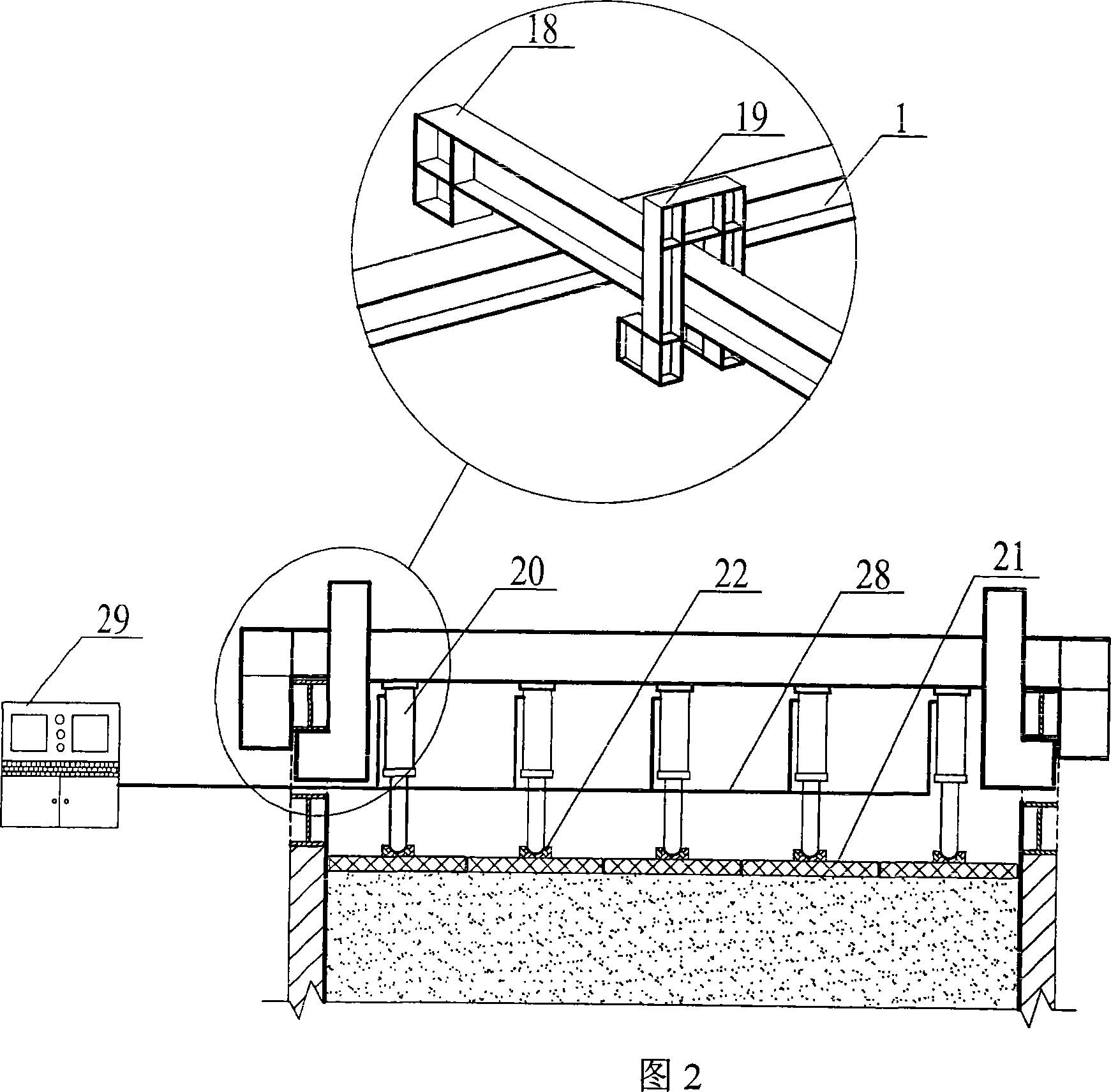

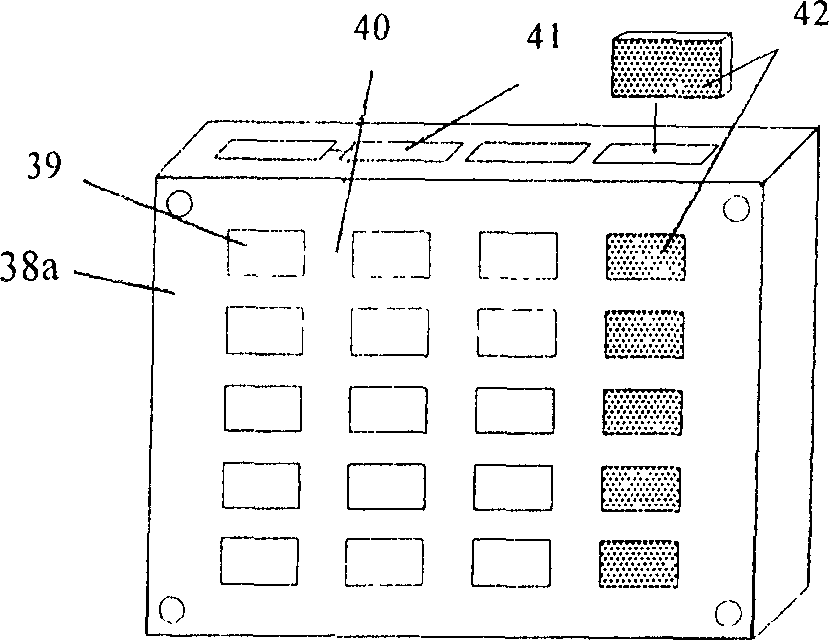

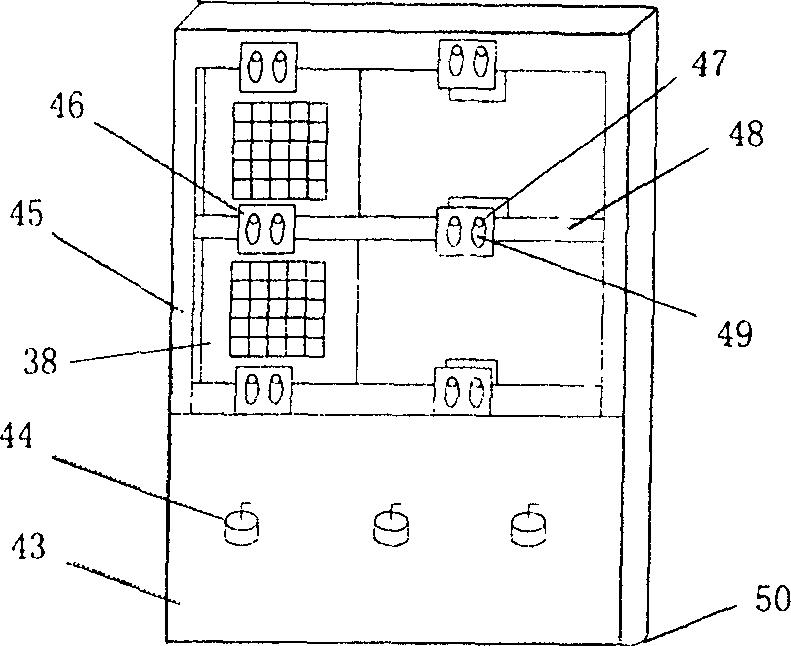

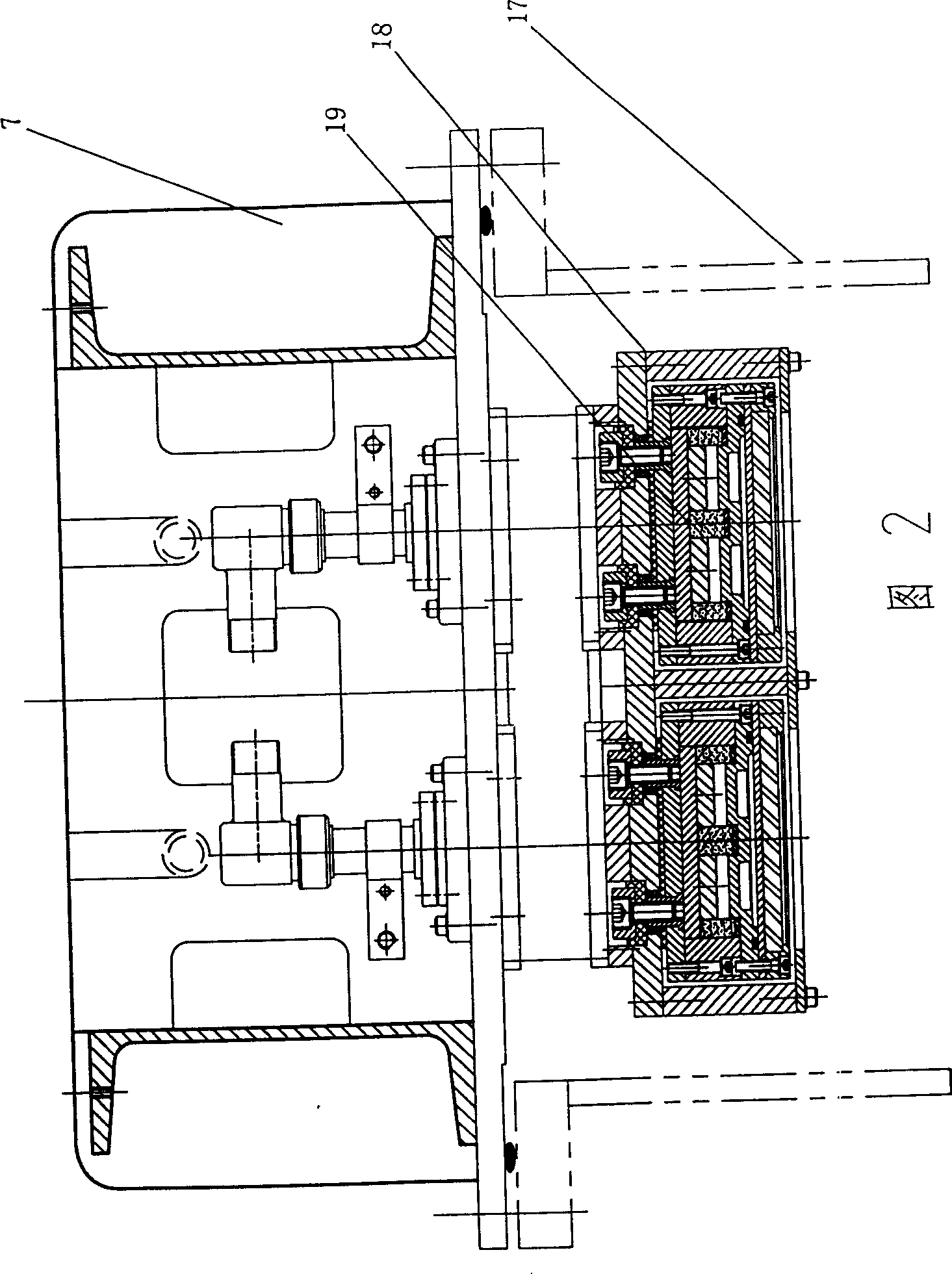

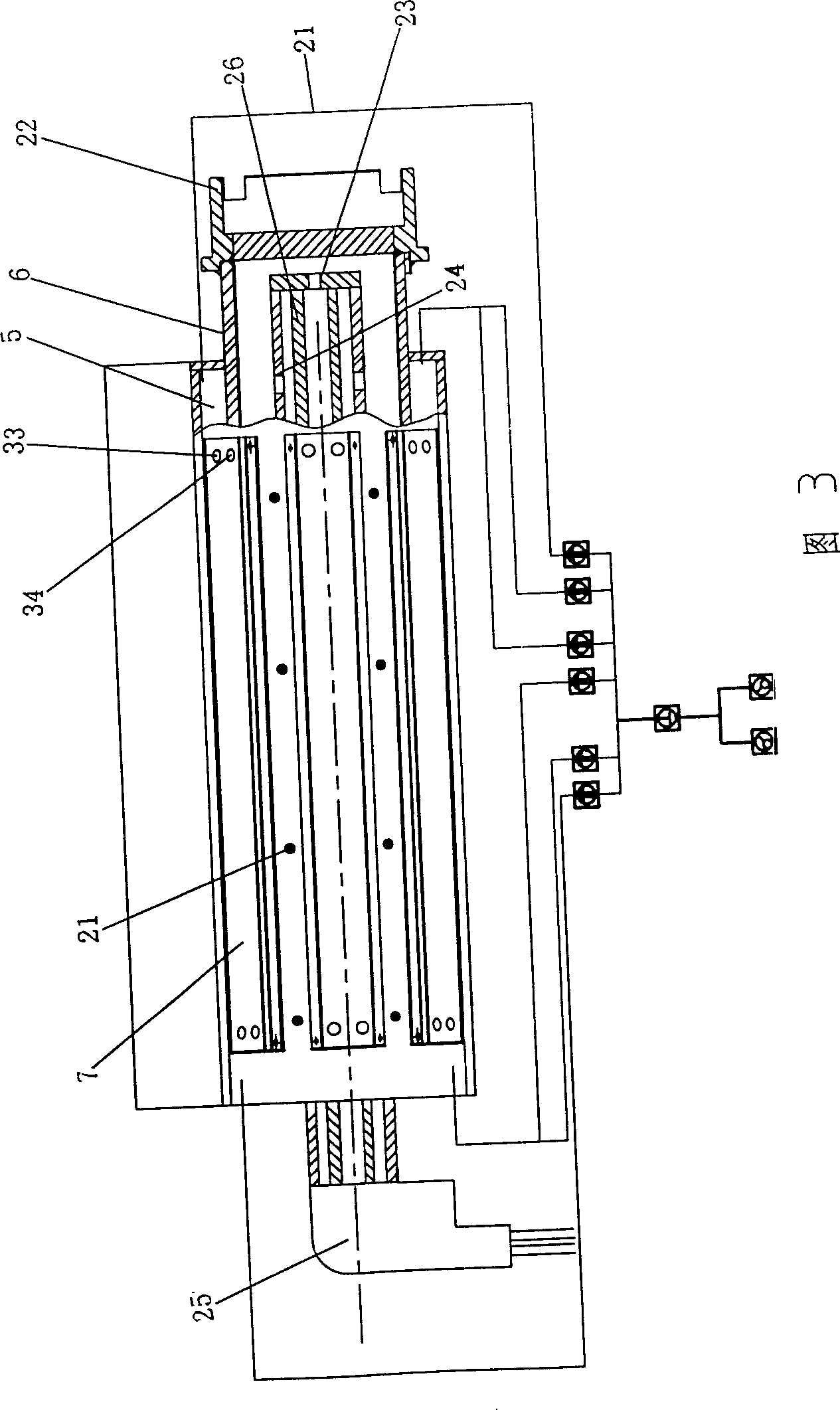

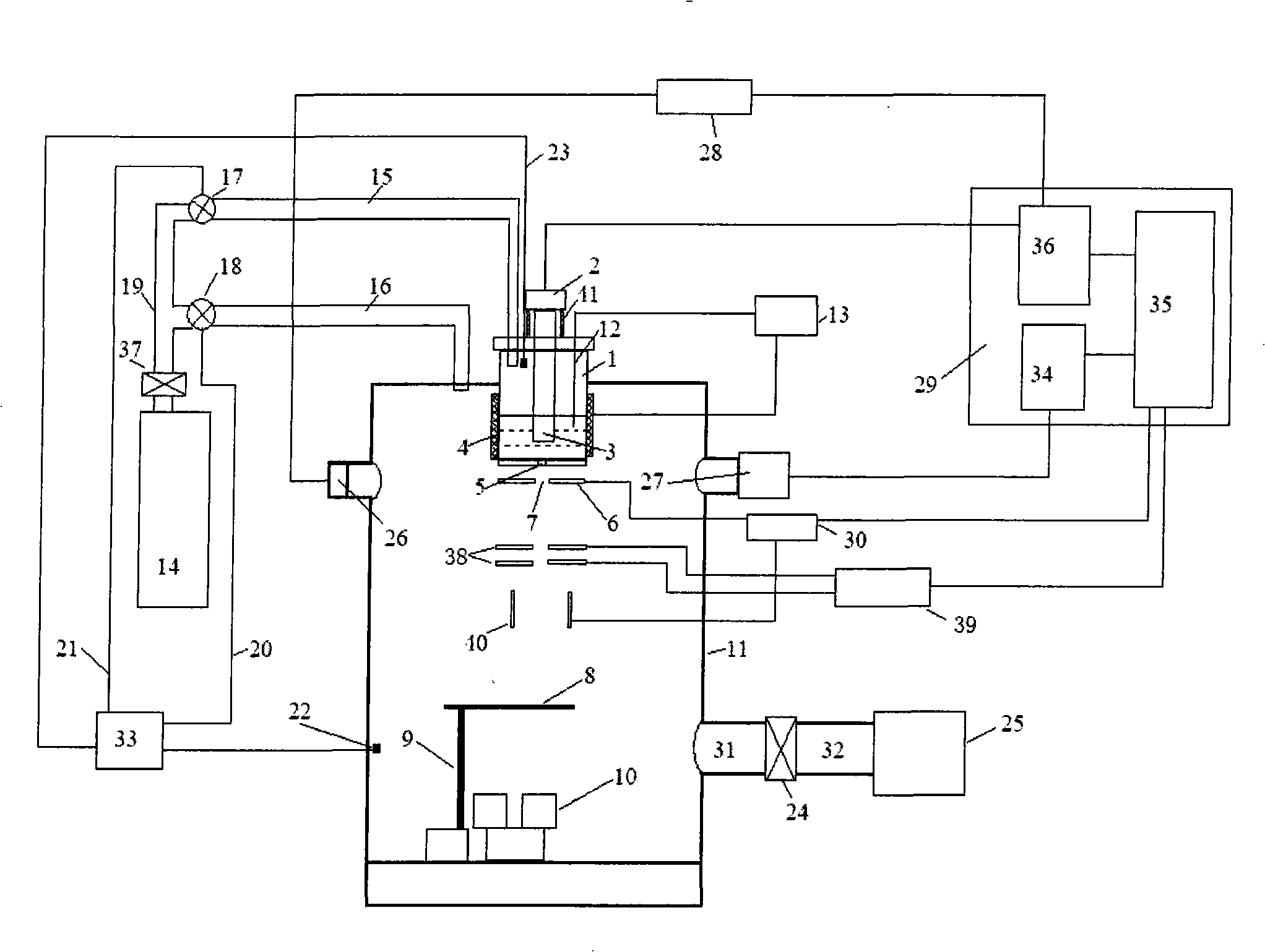

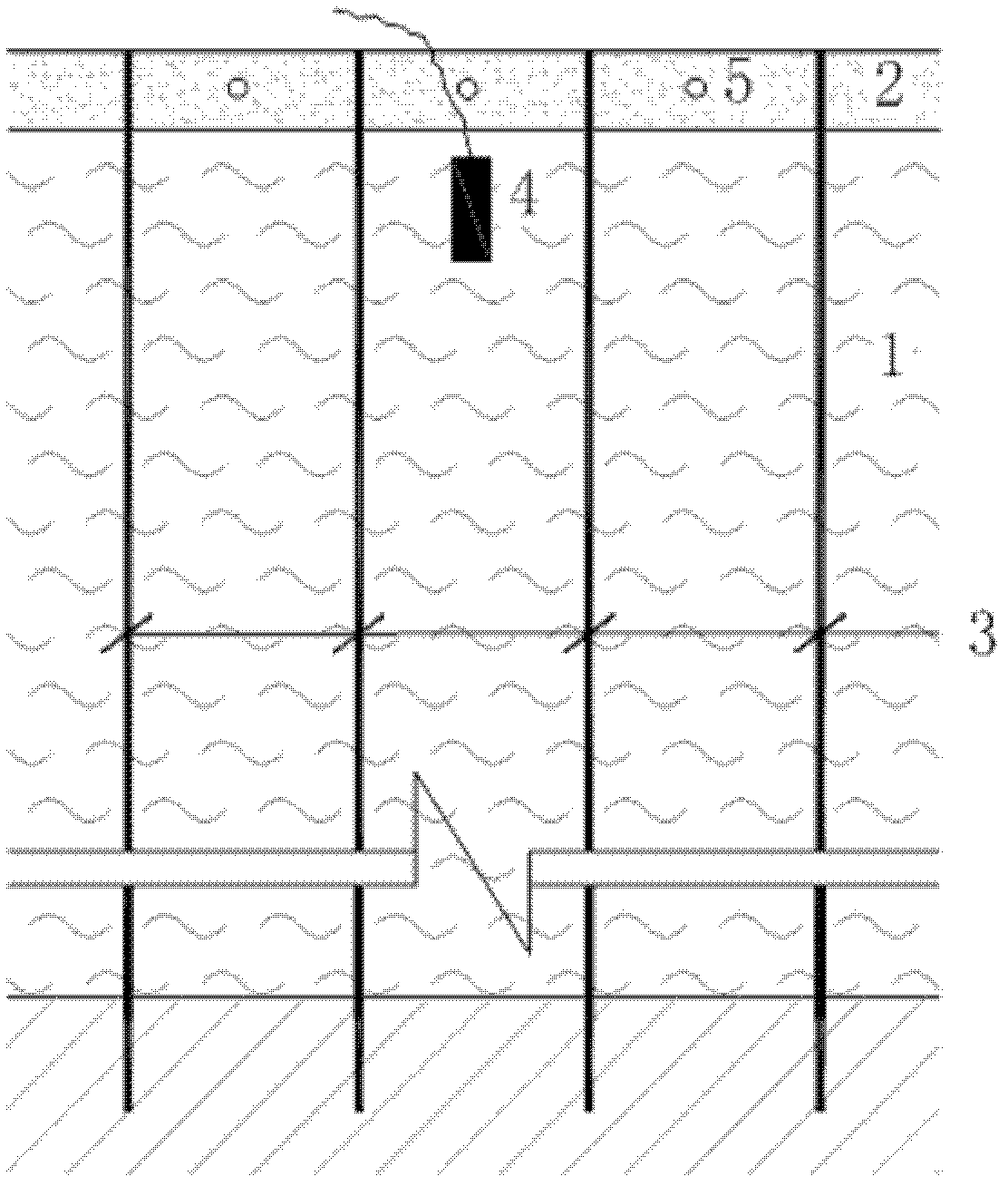

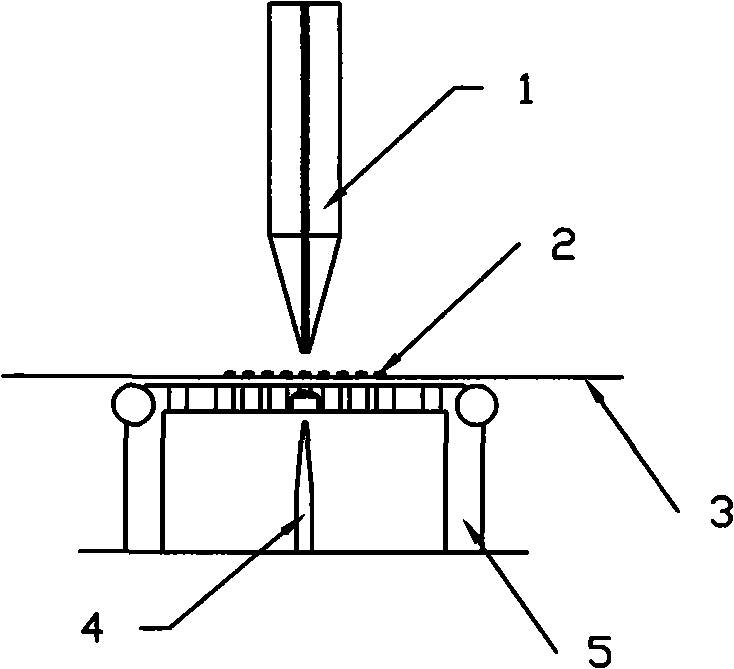

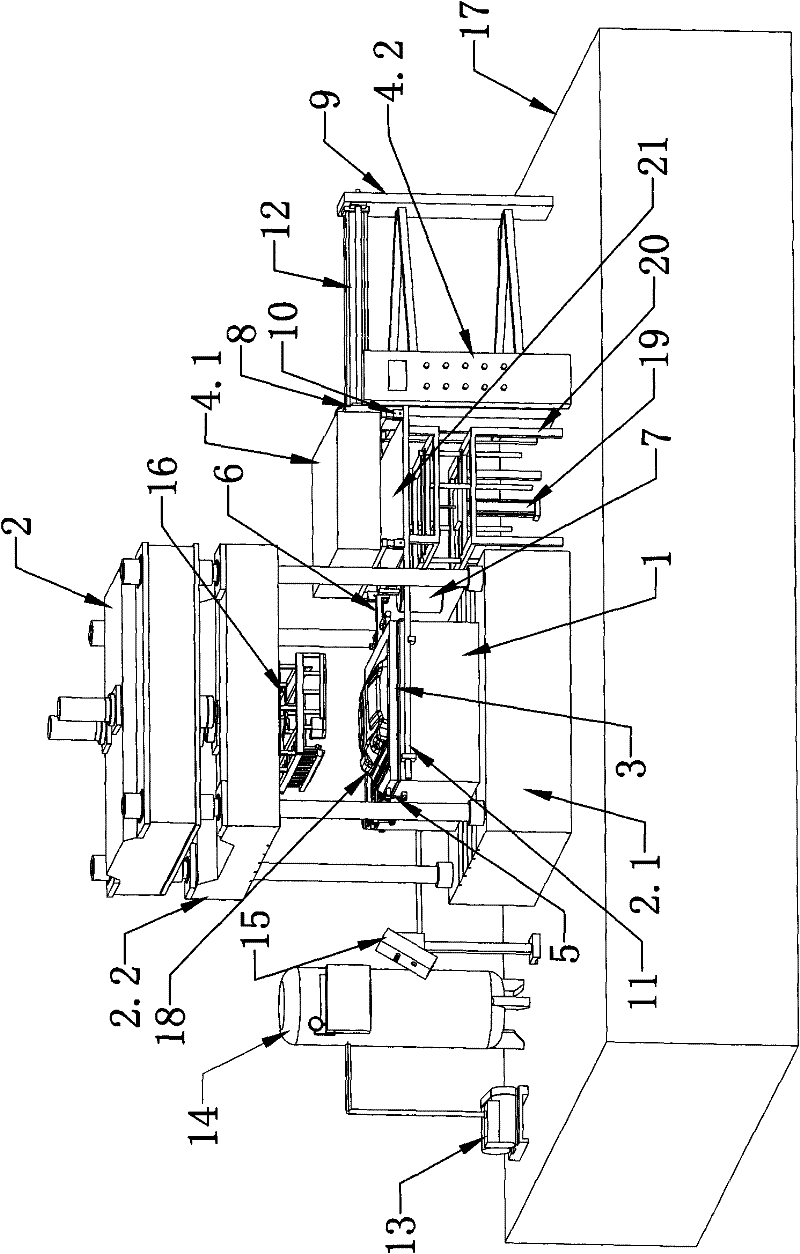

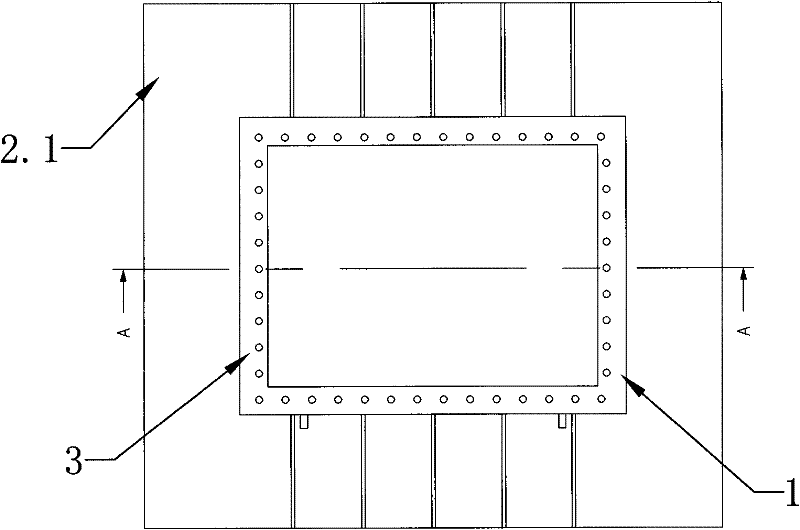

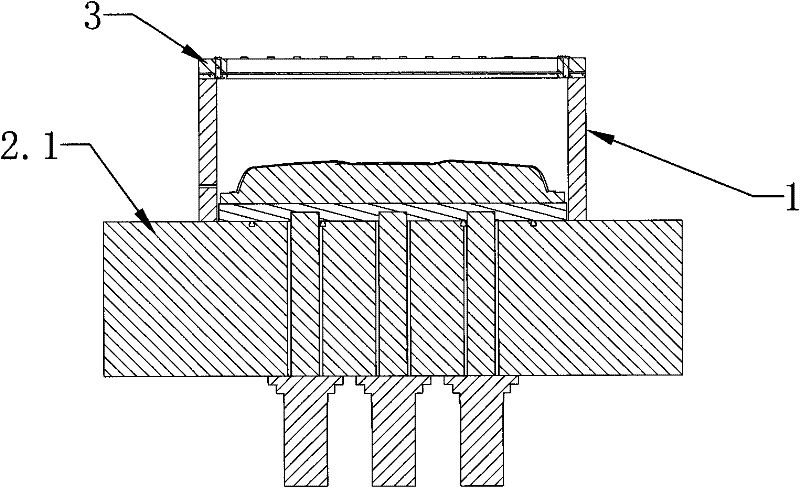

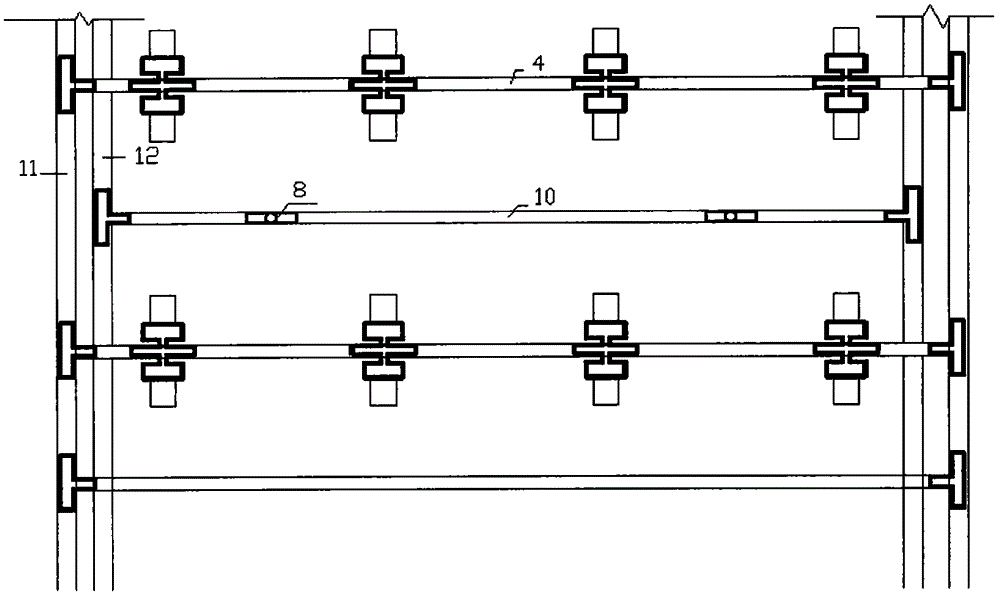

Foundation and slope engineering model test platform

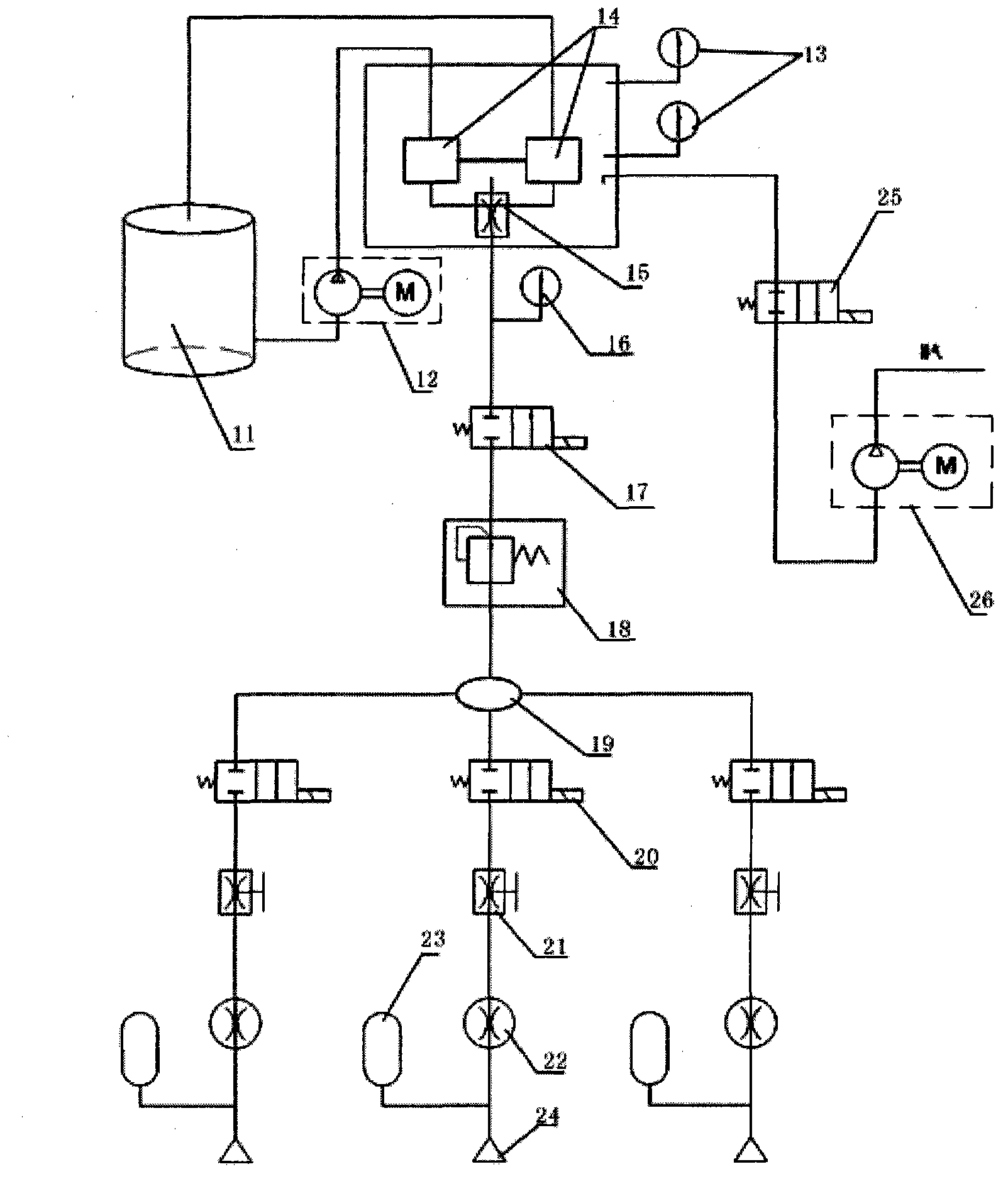

InactiveCN101086494ASoil conditions are controllableControllable groundwater levelFoundation testingMaterial analysisVacuum extractionPore water pressure

The invention relates to a testing platform with ground and slope engineering module. Long edge at one side of the main structure side steel plate has an instrument burying hole and data leading out hole, the other side having viewing window, bottom of the rectangular structural module slot rubble and sand cushion having water pipe supply net that connects with the water tank and vacuum extraction device, one side of the short edge of the main body structural side steel plate having discharge hole, two sides of the main structural beam post overpass the latched the reverse beam, whose lower end having hydraulic jack, ball hinges and bearing plate formed servo bearing system, displacement sensor, sand pressure sensor and gap water pressure connected to form the monitoring system. It can be deployed to prevent disasters.

Owner:ZHEJIANG UNIV

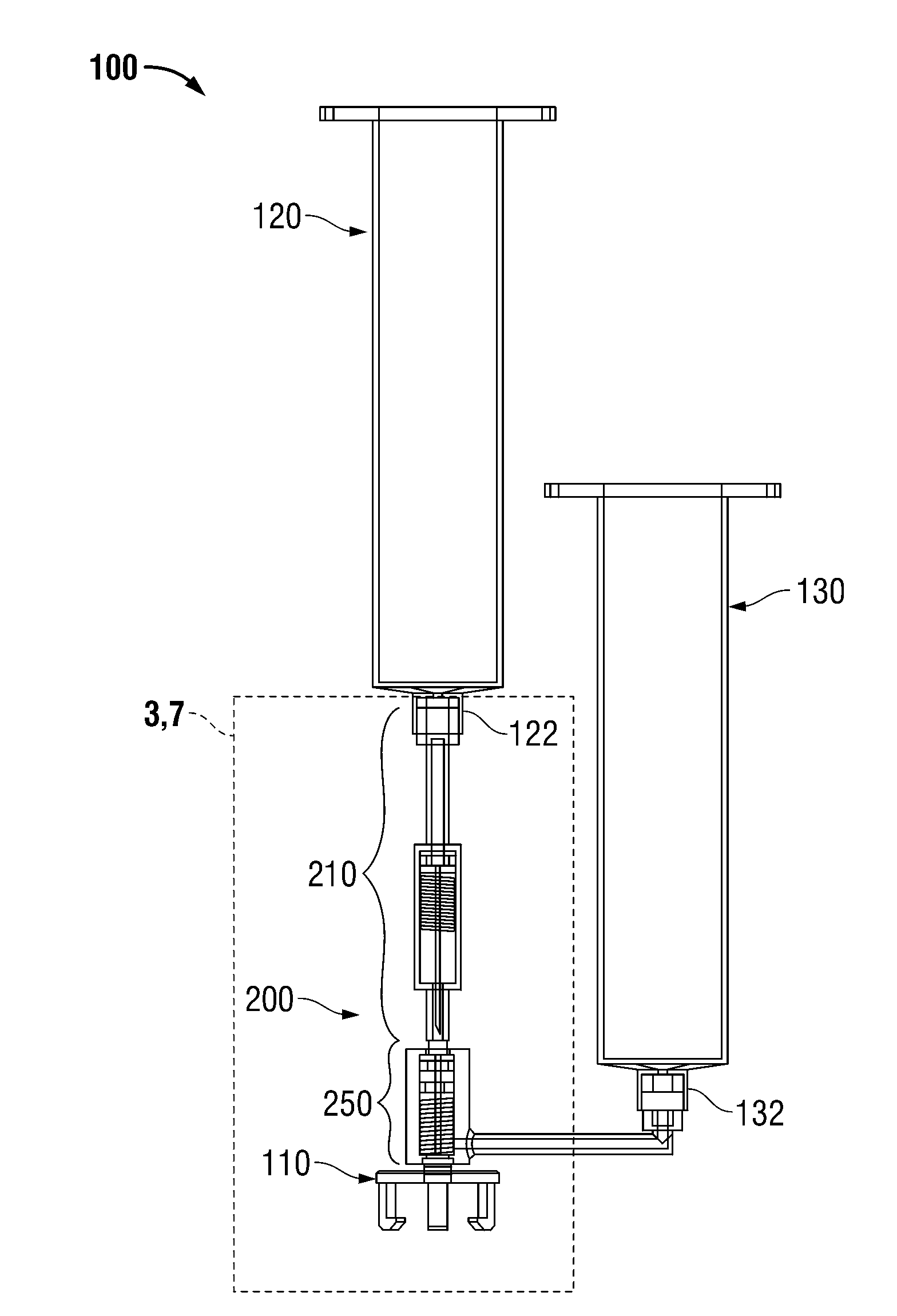

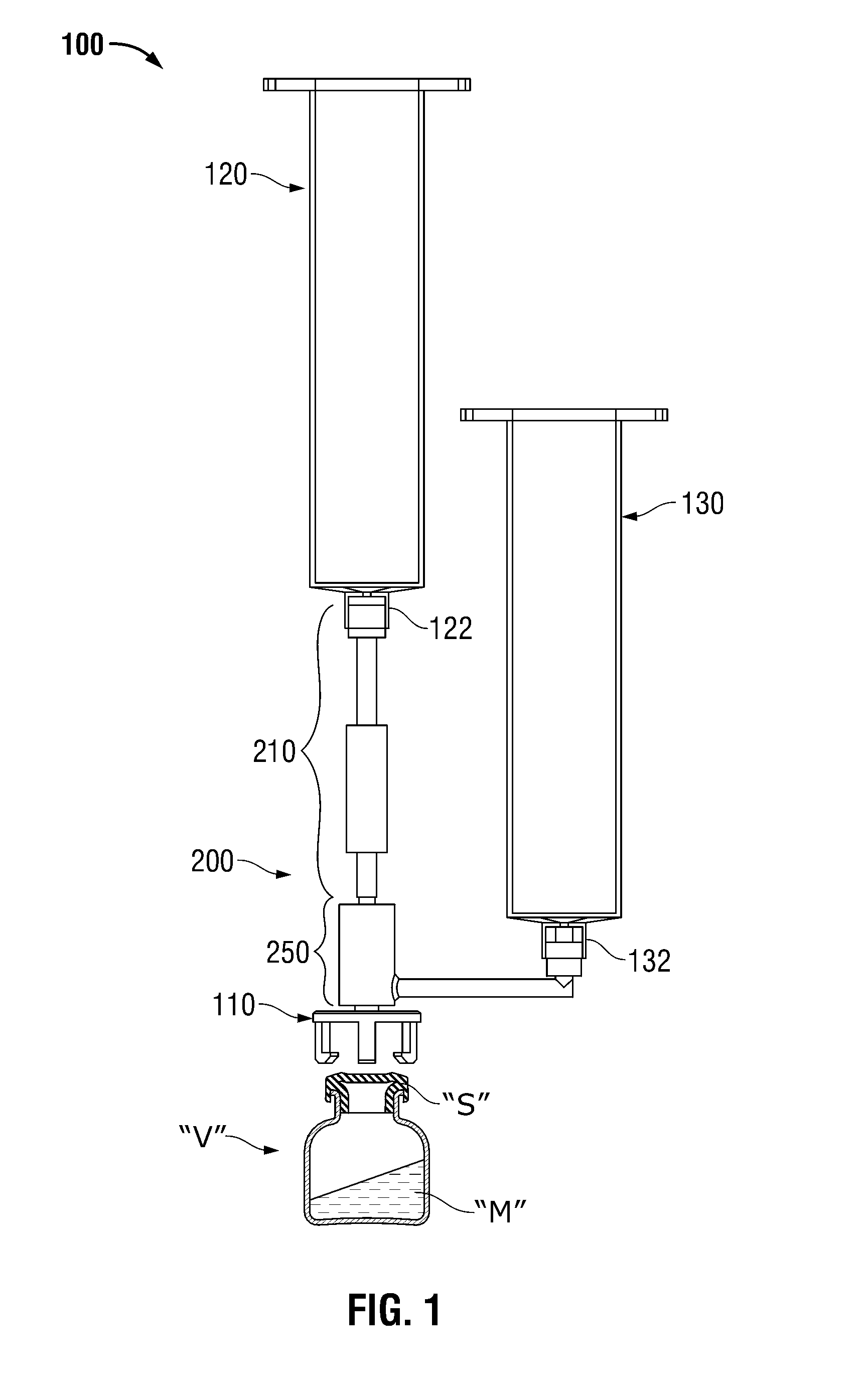

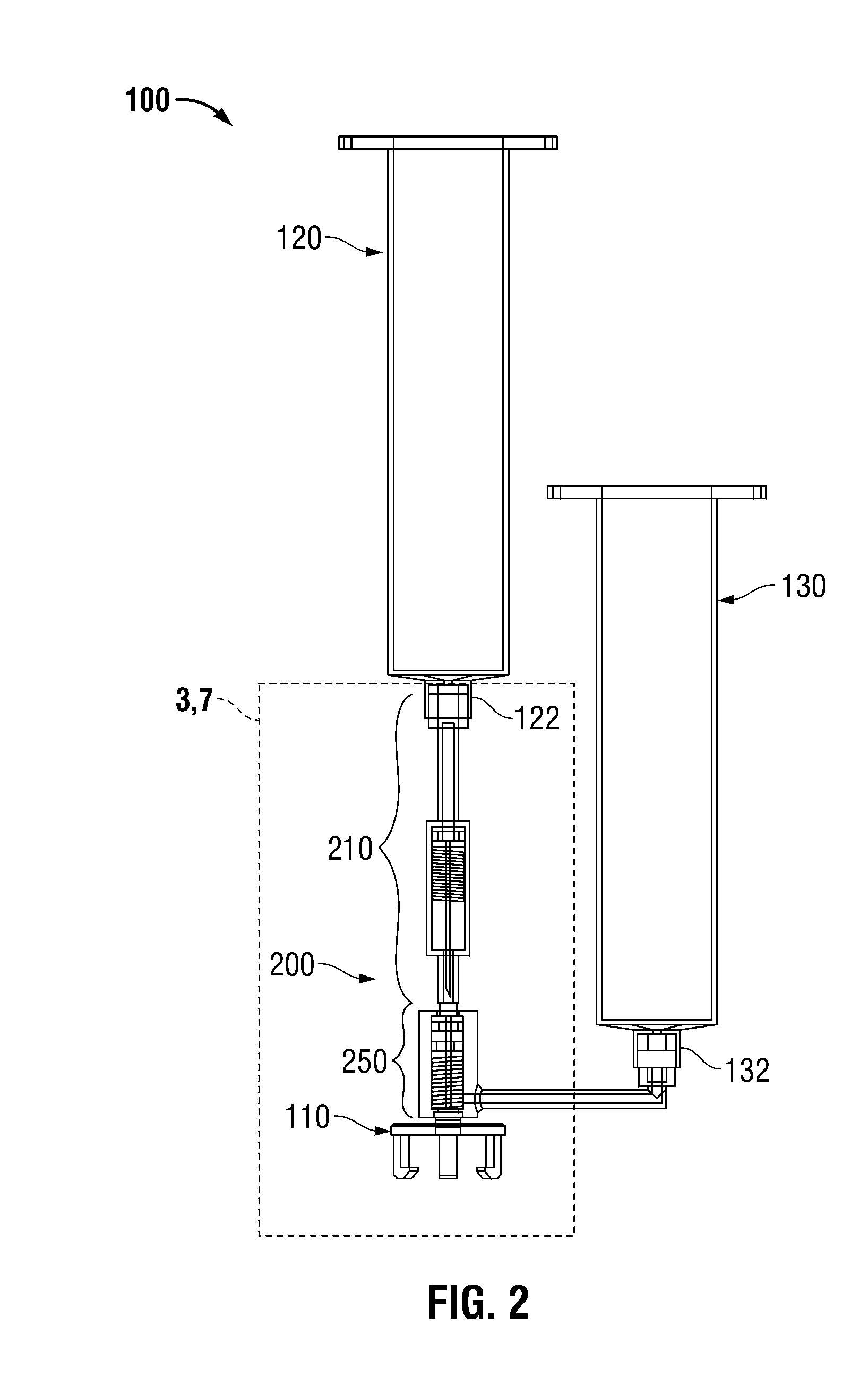

Systems and methods for safe medicament transport

A medicament transport system includes a syringe adapter assembly; and a vial adapter assembly including a base defining an opening having a seal member disposed therewithin, a stem extending from the base and defining a lumen therethrough and an opening through a wall thereof, a needle shuttle valve slidably disposed within the lumen of the stem and supporting a transfer needle and a vacuum needle; and a vacuum cup slidably supported on the stem, wherein a vacuum chamber is defined in the space between the base, the stem and the vacuum cup. The medicament transport system includes a condition where the transfer needle and the vacuum needles penetrate the seal member of the vial adapter assembly, and the vacuum cup is moved to draw a vacuum through the vacuum needle. An automation system is provided that utilizes a medicament transport system for forming a medicament solution from a liquid / non-liquid solution.

Owner:CORVIDA MEDICAL INC

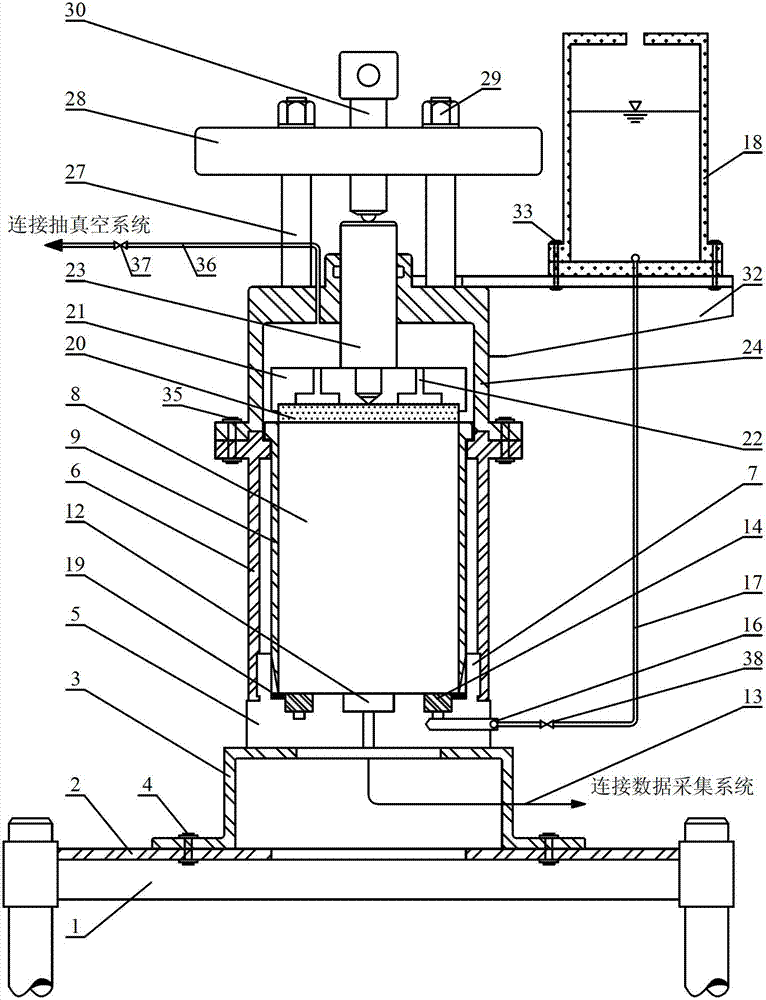

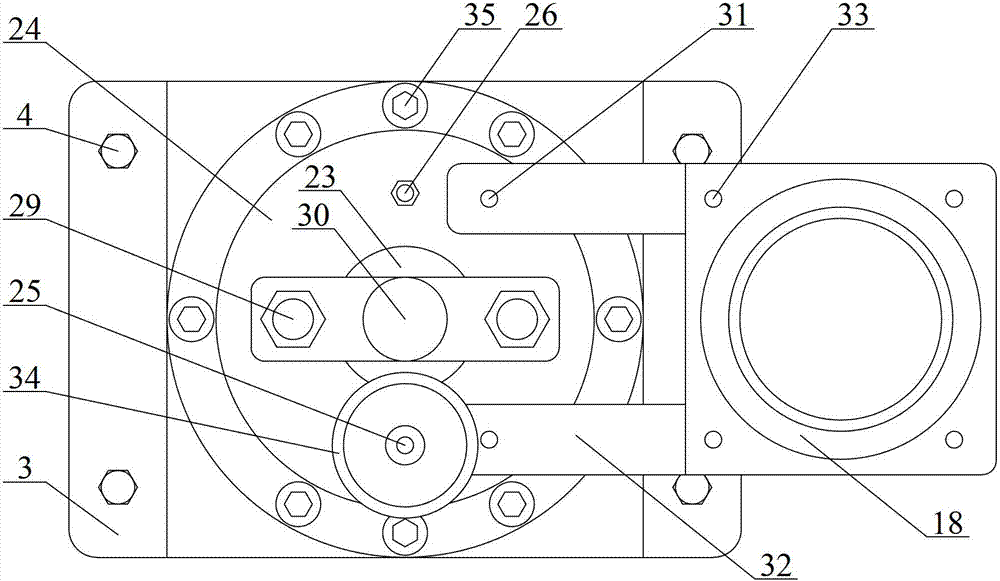

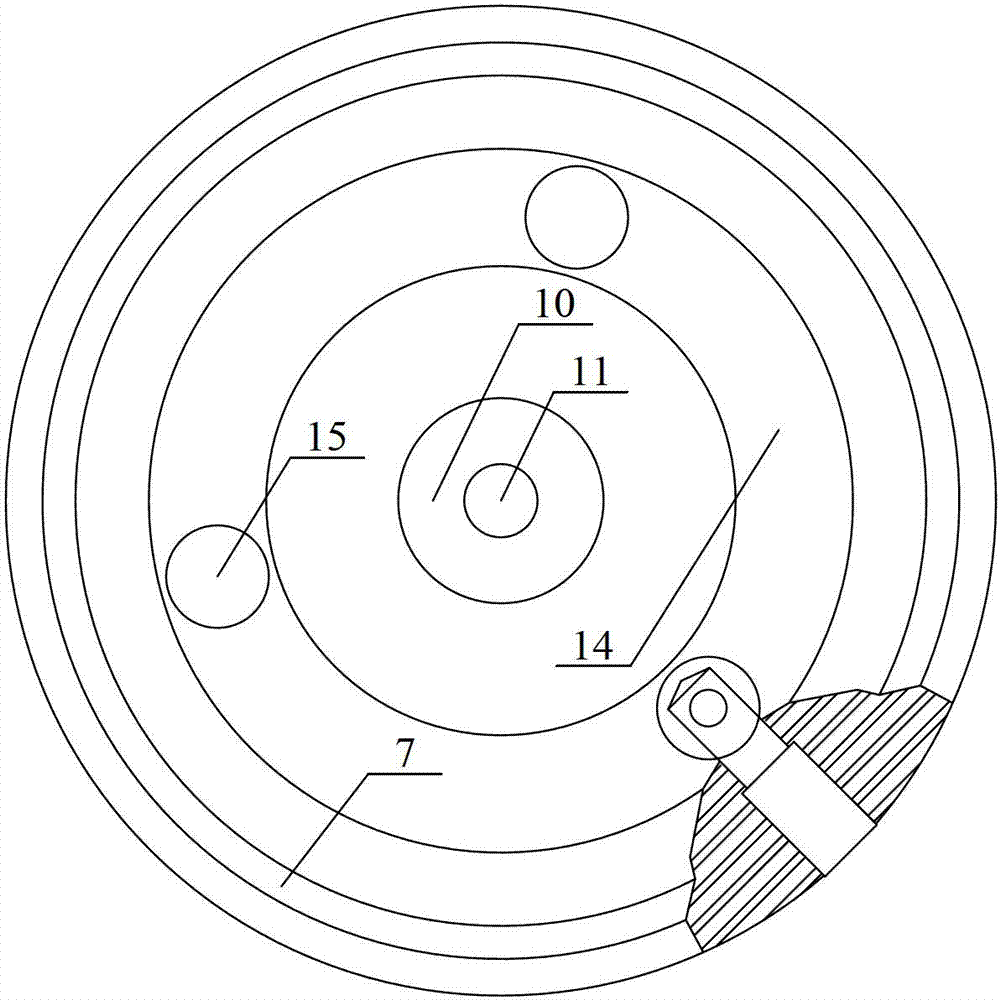

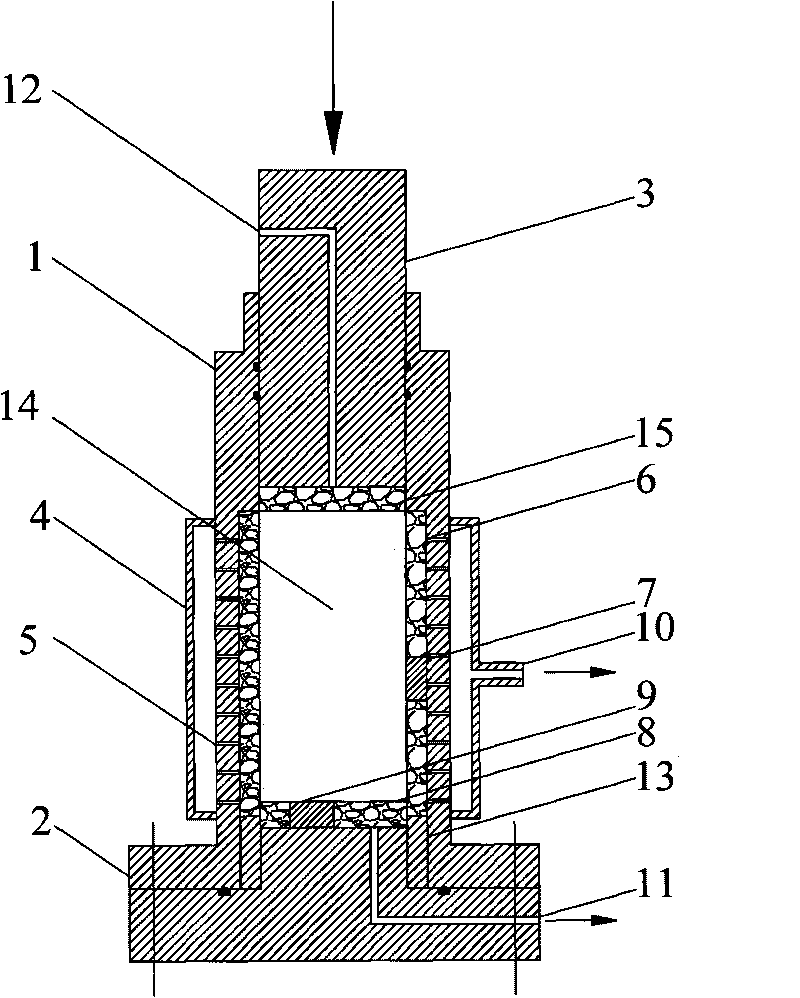

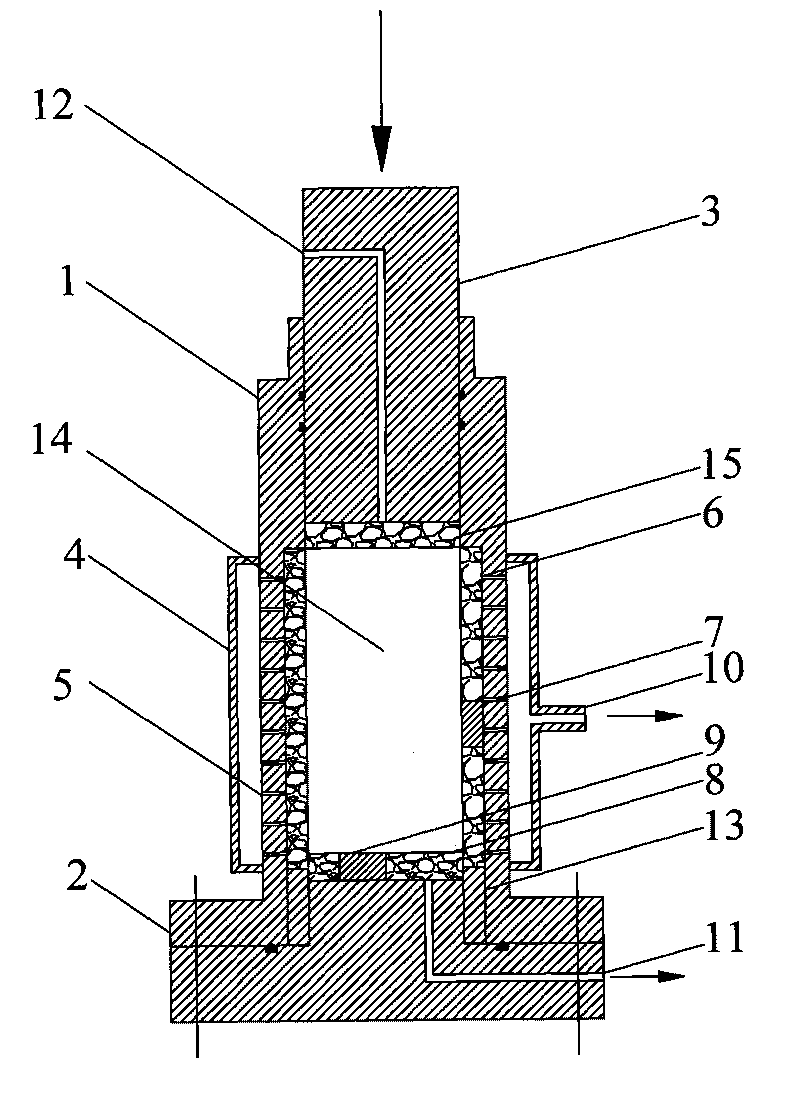

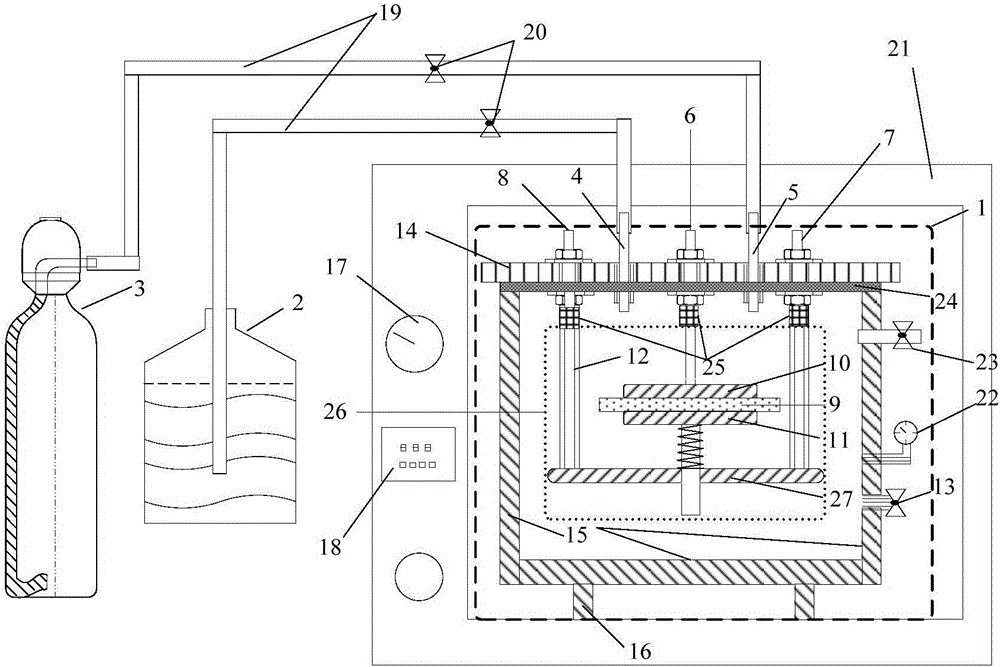

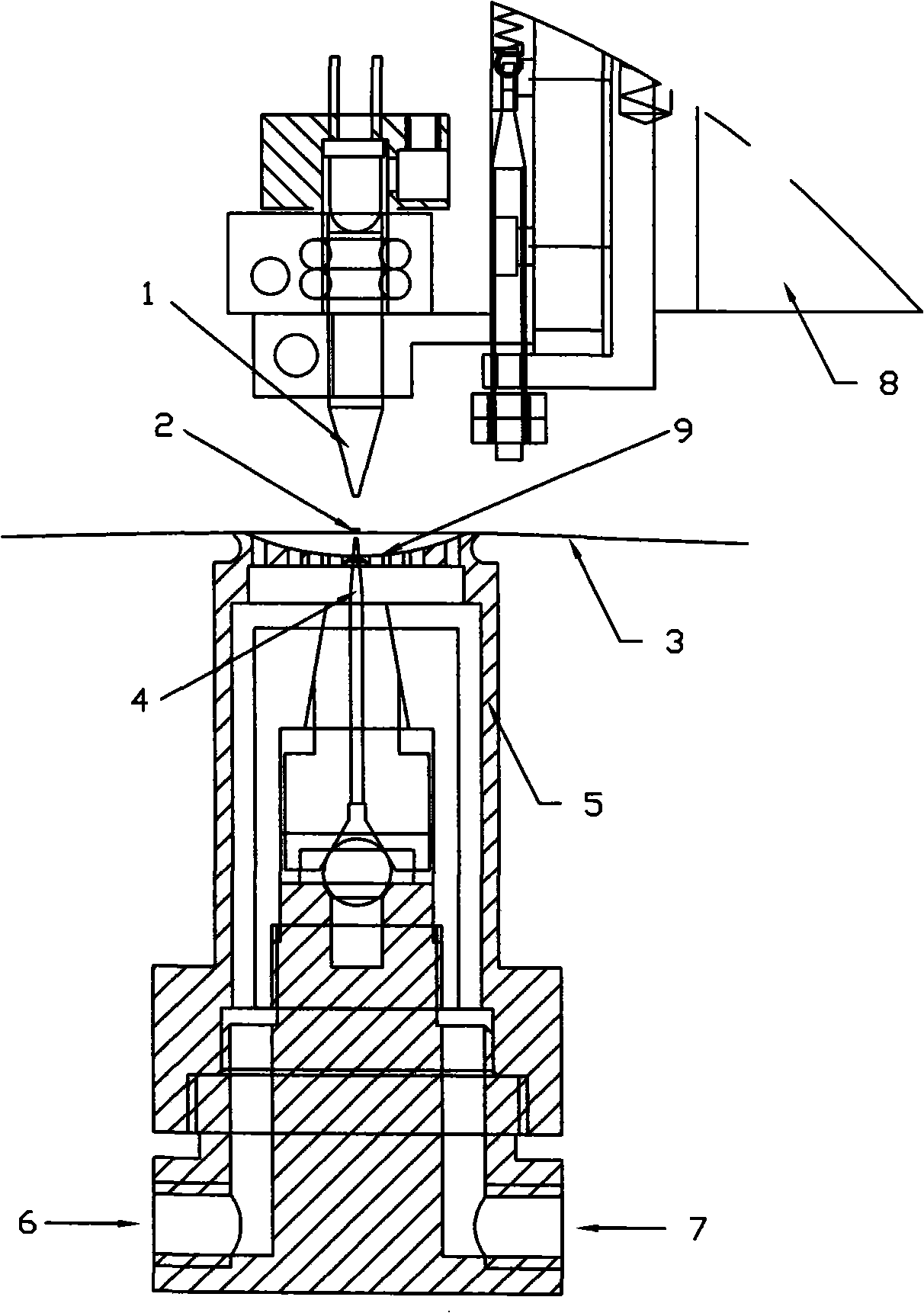

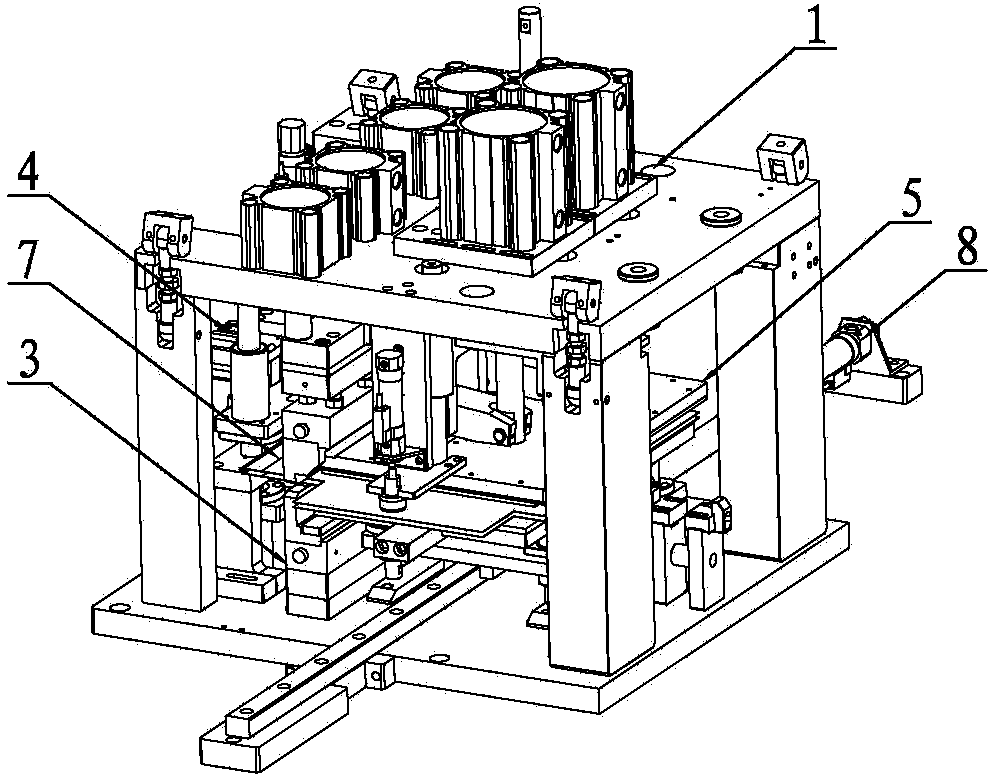

Undisturbed soil sample expansion force testing device capable of controlling saturation

ActiveCN102809641ANo disturbanceControlled Saturation Without DisturbanceEarth material testingApparatus for force/torque/work measurementSupporting systemControl saturation

The invention discloses an undisturbed soil sample expansion force testing device capable of controlling the saturation. The device comprises a base supporting system, wherein a lower disc is fixed on the base supporting system, a cutting ring base and a cutting ring are arranged on the lower disc, and the upper part of the cutting ring base is provided with an upper cover; a central circular groove and an annular groove are formed on the lower disc, a soil pressure sensor is arranged in the central circular groove, an annular water penetration plate is arranged in the annular groove, water-immersion circular grooves are formed on the annular water penetration plate, water-permeable stones are uniformly placed in the water-immersion circular grooves, and the bottom of the annular groove is connected with an external water injection system through a pipeline; a soil sample is placed between the lower disc and the cutting ring, and a water-permeable plate base which is provided with a water-permeable plate and water-permeable holes is arranged on the top of the soil sample; and a plunger, overflow equipment and vacuum extraction equipment are arranged on the upper cover. The device effectively solves the problems that testing devices for an expansion back pressure method, a pressurization expansion method and a balance pressurization method have relatively large disturbance on soil sample structures, cannot effectively control strict saturation states and are relatively long in testing time consumption.

Owner:XIAN UNIV OF TECH

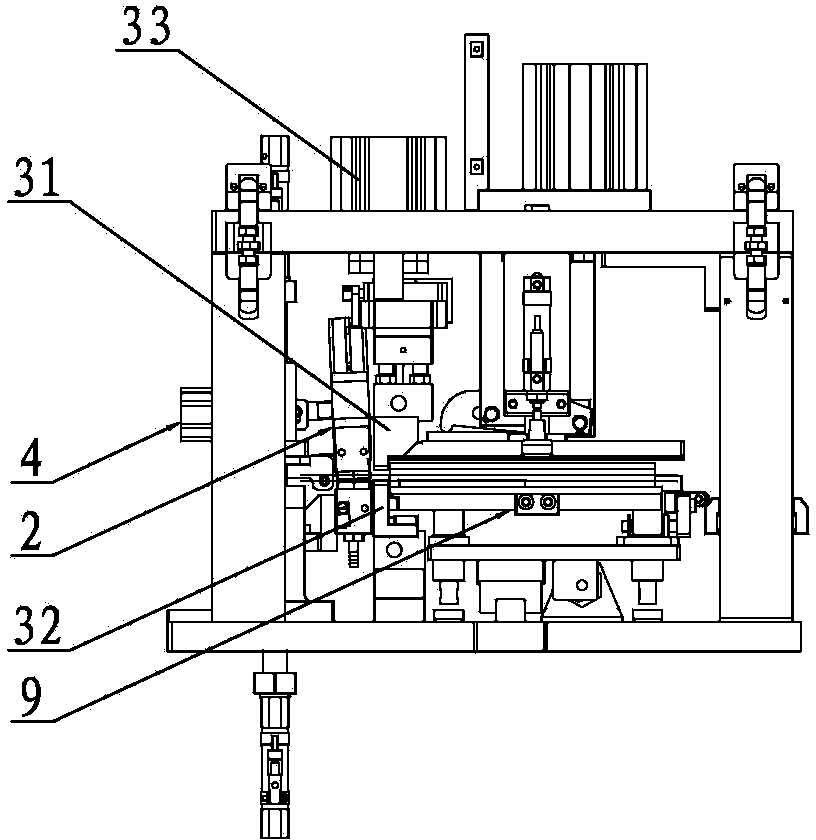

Quick preparation device and method of saturated soil sample

InactiveCN101738337AIncrease flexibilityShorten the timePreparing sample for investigationMaterial strength using tensile/compressive forcesHorizontal stressVacuum extraction

The invention relates to quick preparation device and method of a saturated soil sample. Saturated clay is extruded by utilizing a load-vacuum combined consolidation principle so as to obtain a saturated clay sample with a low water content (the water content is lower than a plastic limit). The device comprises a sleeve, a base, a piston, a vacuum cavity and a fixing sleeve, wherein the sleeve is sequentially and respectively provided with a slide-fit piston, a cylindrical porous stone internally embedded with a horizontal pressure sensor and the fixing sleeve; the piston, the base and the sleeve are respectively provided with upper draining holes, lower draining holes and side draining holes; and a vacuum extraction hole is arranged on the vacuum cavity. The draining process of the saturated clay is accelerated under the extruding effect of the piston through the negative pressure (about 101.325kPa) condition of the vacuum cavity, and meanwhile, horizontal stress and vertical stress applied on the saturated clay are obtained through the horizontal pressure sensor and a vertical pressure sensor so as to further obtain a coefficient k0 of earth pressure at rest (a specific value of the horizontal pressure to the vertical pressure applied to the soil sample under the condition of no lateral deformation).

Owner:CHINA UNIV OF MINING & TECH

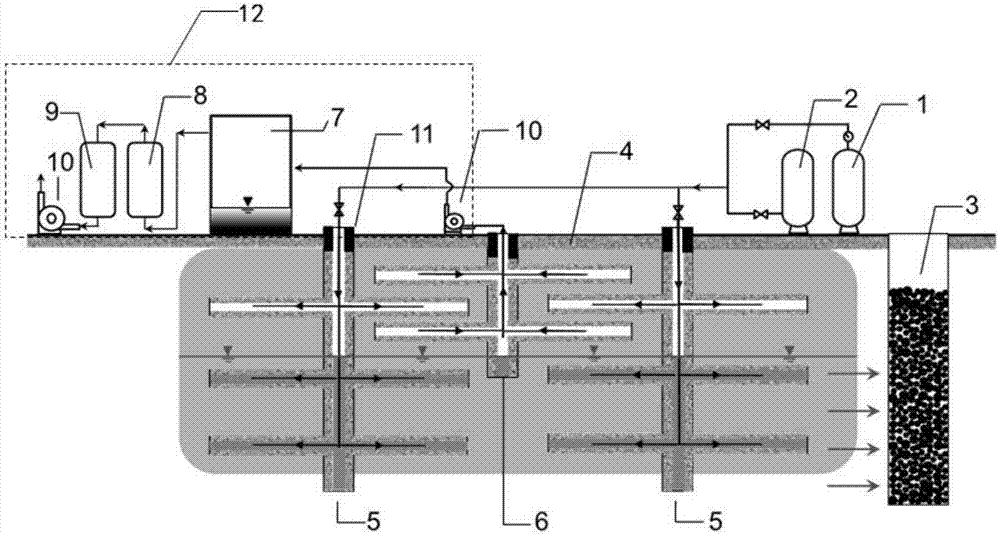

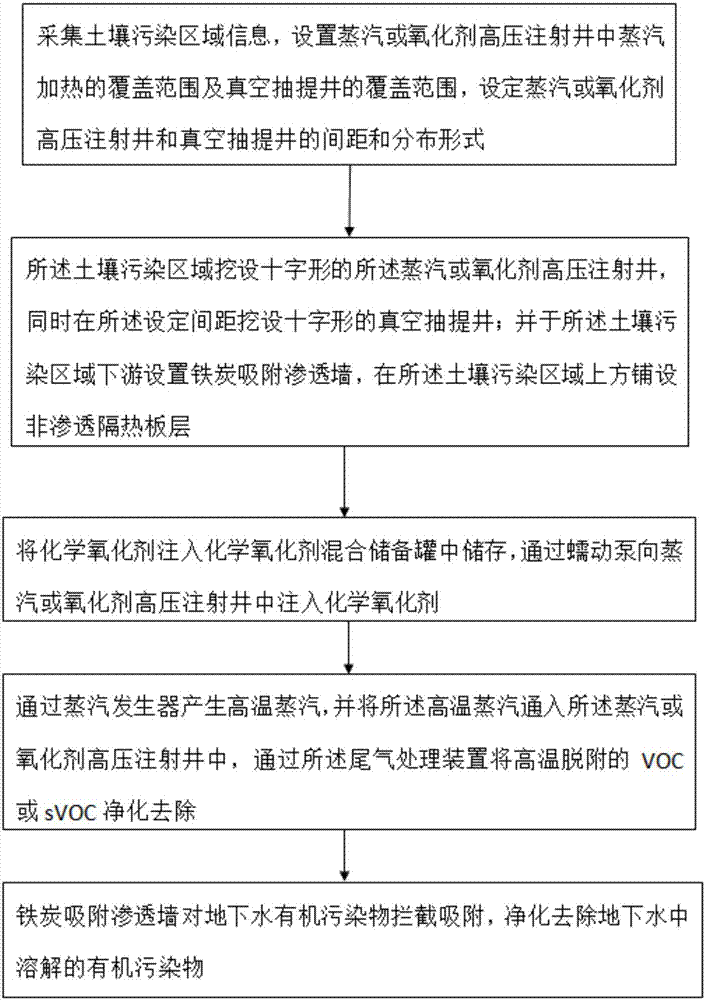

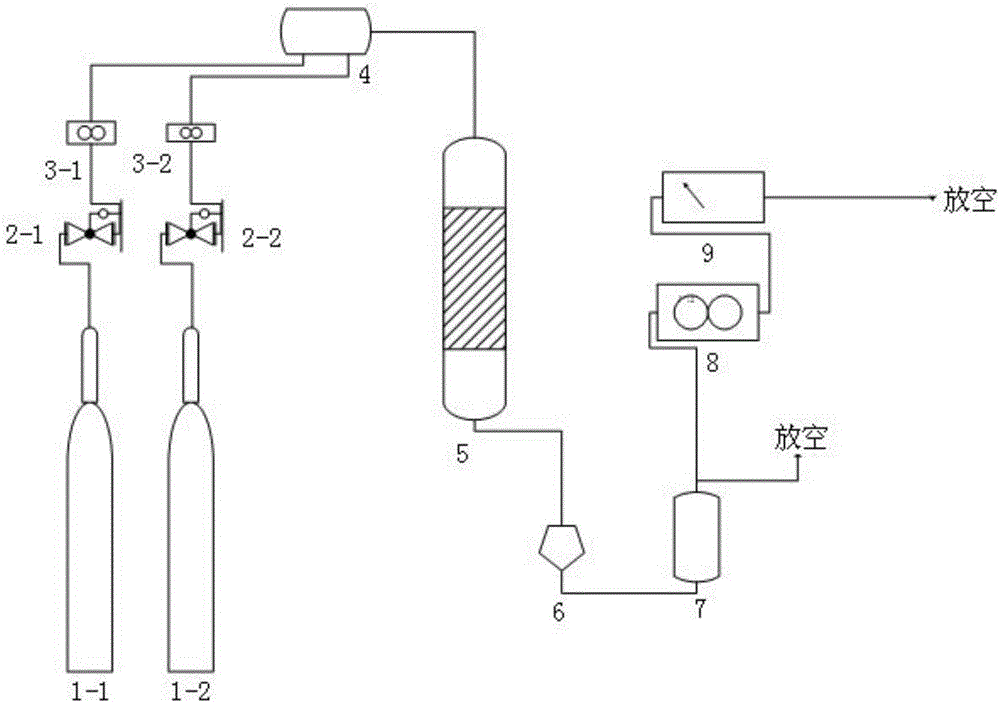

In-situ remediation system and method for synergistically removing organic pollutants of soil and underground water

ActiveCN107350278AImprove repair effectAvoid secondary pollutionContaminated soil reclamationVacuum extractionDesorption

The invention discloses an in-situ remediation system and method for synergistically removing organic pollutants of soil and underground water. The method comprises the following steps: uniformly injecting chemical oxidants in chemical oxidant mixing storage tank into the soil and the underground water; generating high-temperature steam through a steam generator, and injecting the high-temperature steam into the soil and the underground water; starting a vacuum pump to extract gas from a vacuum extraction well, forming negative pressure in the well, and promoting desorption of volatile and semi-volatile organic compounds from the soil; and treating and discharging the volatile and semi-volatile organic compounds through a gas-liquid separation tank and an activated carbon adsorption tank. The high-temperature steam heat can activate the chemical oxidants so that degradation and removal of the organic pollutants in the underground water can be further accelerated, the underground water organic pollutants which are not completely degraded are further adsorbed, intercepted and degraded through an iron carbon adsorption permeation wall, so that the purpose of synergistically remediating the soil and the underground water is achieved, and secondary pollution of the soil and the underground water is avoided.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

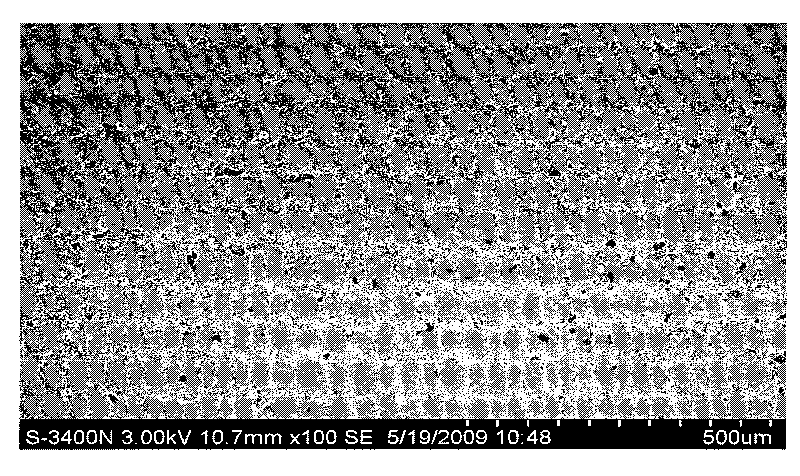

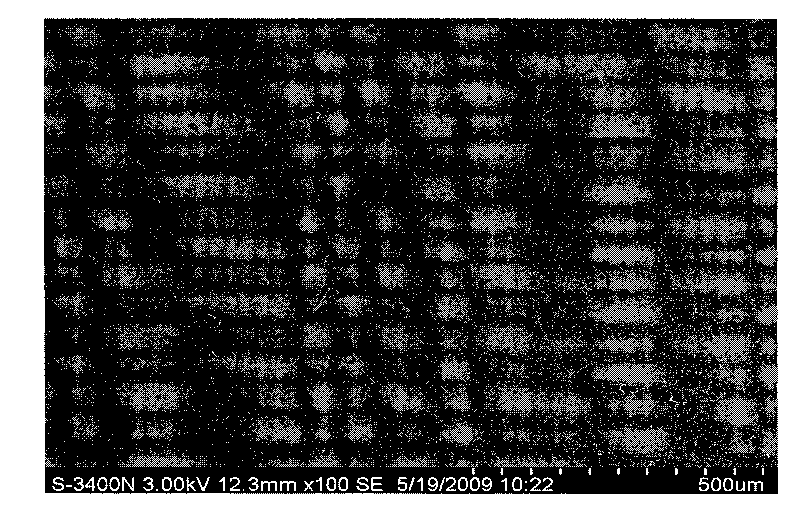

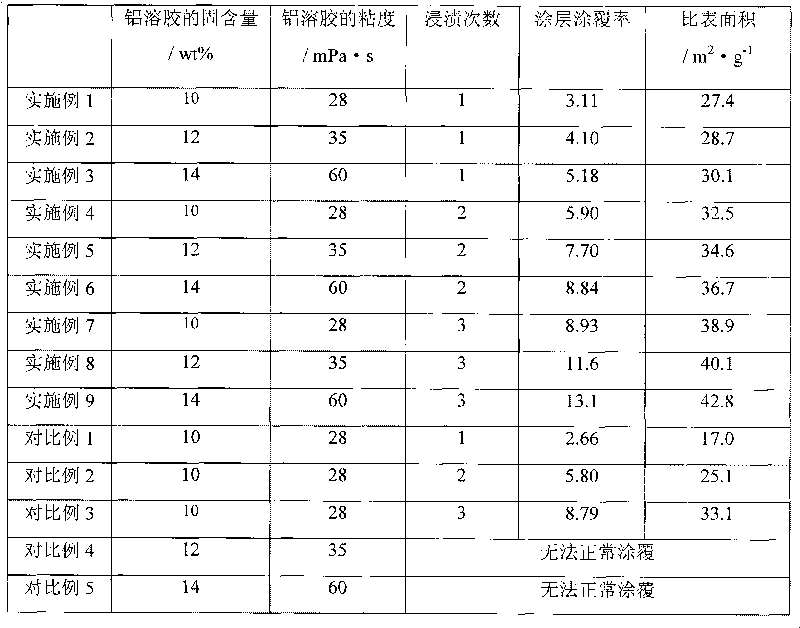

Method for applying coating on cordierite honeycomb ceramics and applications thereof

ActiveCN101734946AIncrease coverageIncrease the areaCatalyst carriersCatalyst activation/preparationVacuum extractionHoneycomb

The invention discloses a method for applying a coating on cordierite honeycomb ceramics and applications thereof. Started with the improvement of the immersion coating technique, the invention applies a thick dense alumina coating with uniform distribution, high coating rate and high specific area on the surface of pore canals of the cordierite honeycomb ceramics by using a vacuum extraction immersion method. In particular, when the viscosity of the alumina sol is greater than or equal to 35 mPa.s, the alumina sol can not easily enter the interior of the pore canals of the honeycomb ceramics by using the common immersion method, and the coating can not be applied normally, while the vacuum extraction immersion technique of the invention does not have the defect, and can be used for uniformly applying the alumina coating with high coating rate. When the honeycomb ceramics applied with the alumina coating by using the method of the invention is loaded with an integral catalyst prepared from noble metal Pd and used for cleaning treatment of toluene catalytic combustion, the percent conversion of toluene can reach 99% at the low temperature of 215 DEG C, and the concentration of toluene is reduced to below 40 mg / m<3>.

Owner:FOSHAN SHUNDE KINGLEI ENVIRONMENT & TECH CO LTD

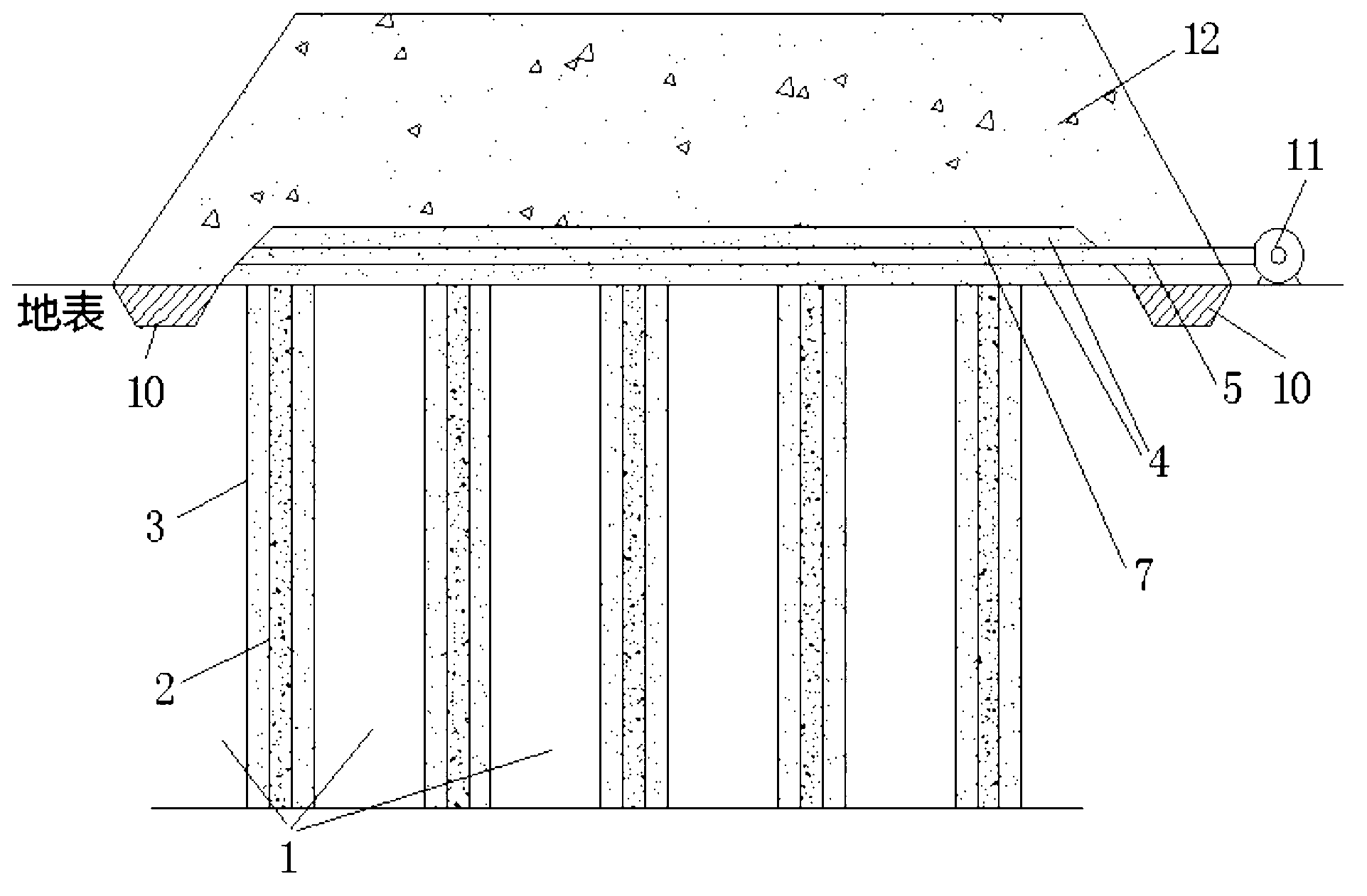

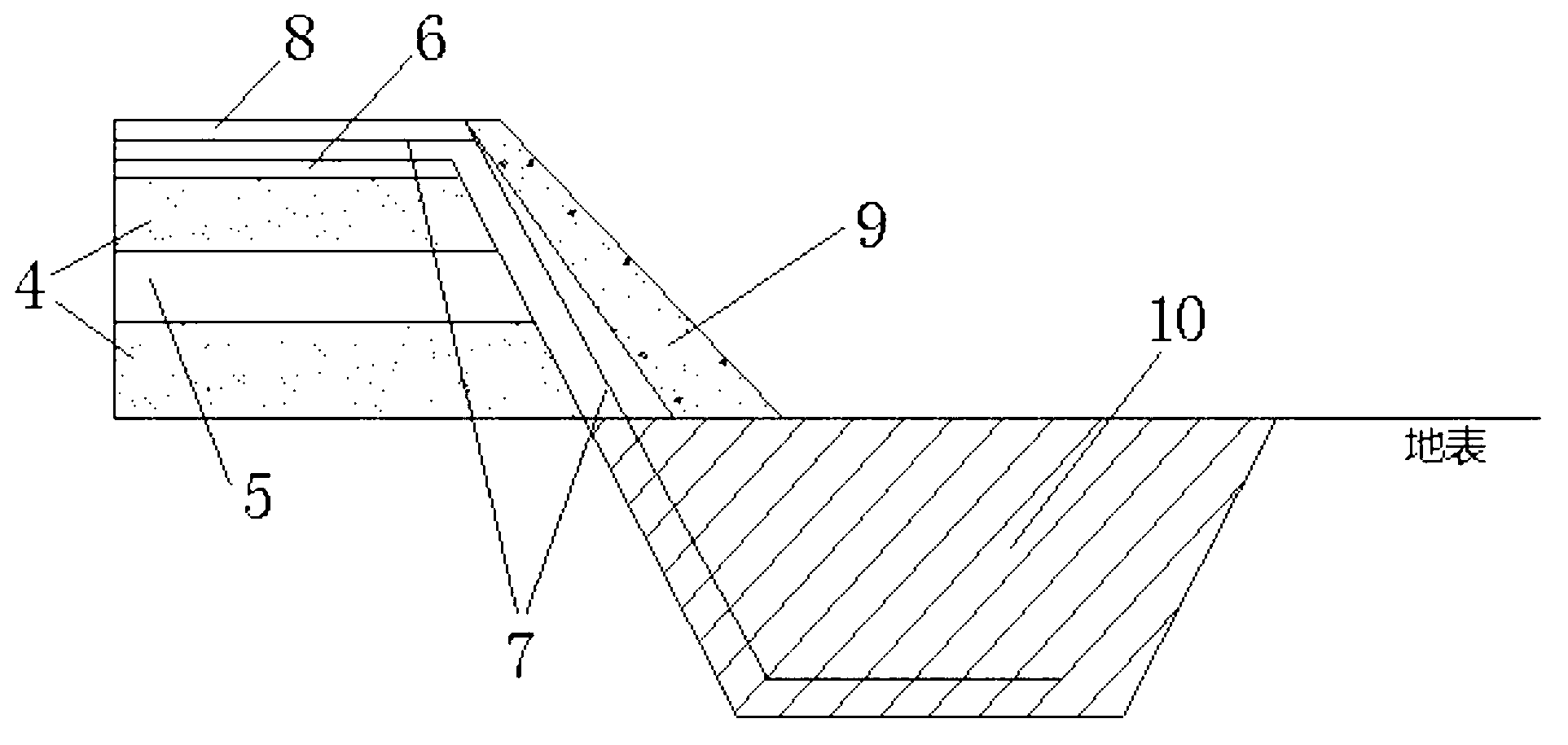

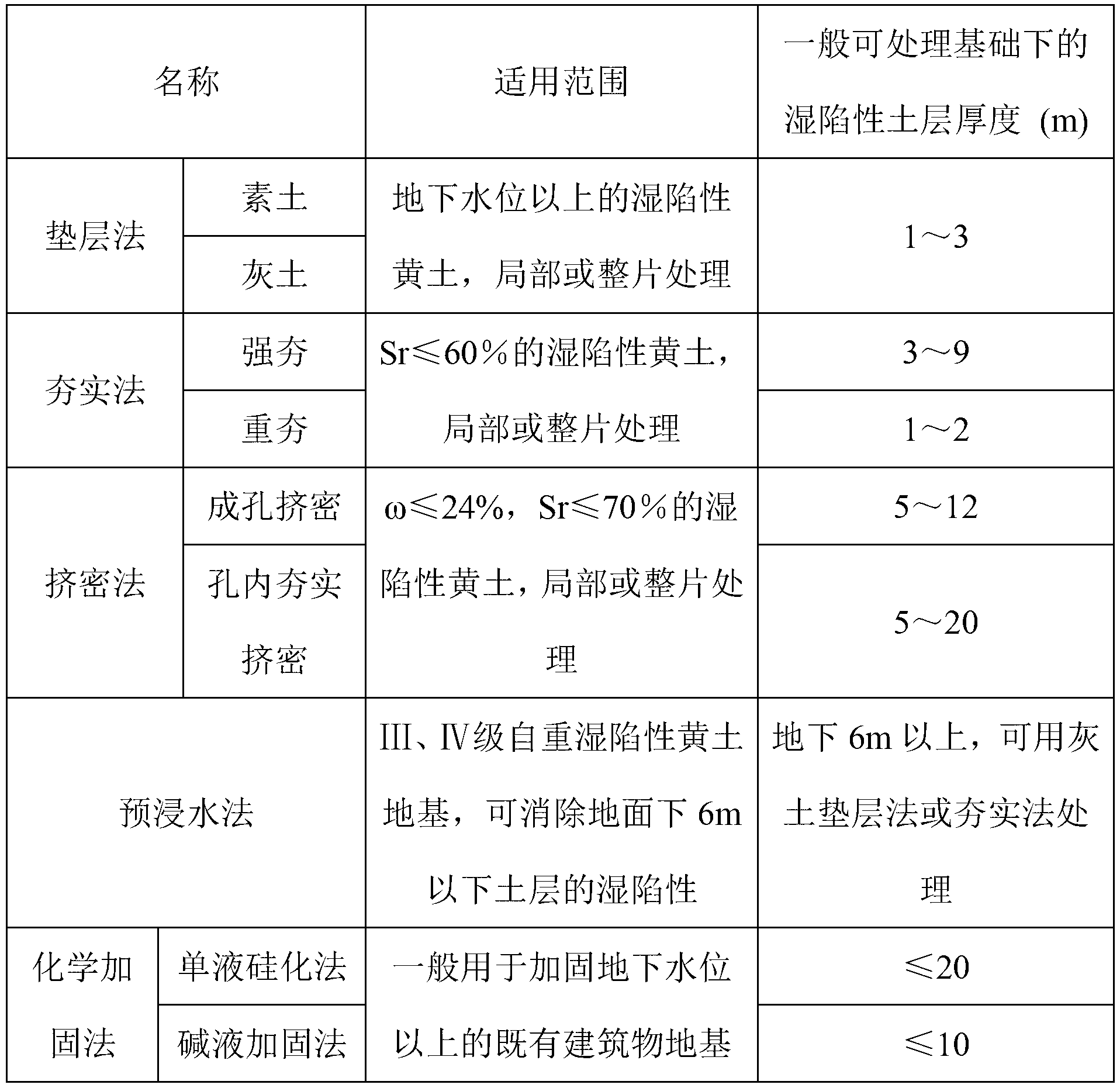

Processing method of soaking, vacuum preloading and slurry injecting for sand piles of collapsible loess foundation

InactiveCN103233454AIncrease the compressive stress of collapsible deformationImprove the level ofSoil preservationVacuum pumpingVacuum extraction

The invention discloses a processing method of soaking, vacuum pre-pressing and slurry injecting for sand piles of a collapsible loess foundation, which comprises the following steps: 1, manufacturing pile pipes in a collapsible loess stratum in a pre-pressing region, embedding a slurry injection steel pipe in each pile pipe, pouring sand at circumferences of the slurry injection steel pipes to form the sand piles, and laying a sand mat at the upper ends of all the sand piles while laying a vacuum extraction pipe; 2, digging sealing ditches at the periphery of the pre-pressing region, sequentially laying a first layer of geotextile, a diaphragm seal and a second layer of geotextile above the sand mat, backfilling clay layers and a heaping load body, filling water in the collapsible loess foundation of the sand piles, performing vacuum-pumping after saturation of the foundation, and completing consolidation and deformation under action of vacuum preloading; and 3, digging out the heaping load body, filling slurry into the slurry injection steel pipes, and pulling out the slurry injection steel pipes to form the slurry injected sand piles. The method provided by the invention has a better effect for the processing of the collapsible loess foundation.

Owner:XIAN UNIV OF TECH +1

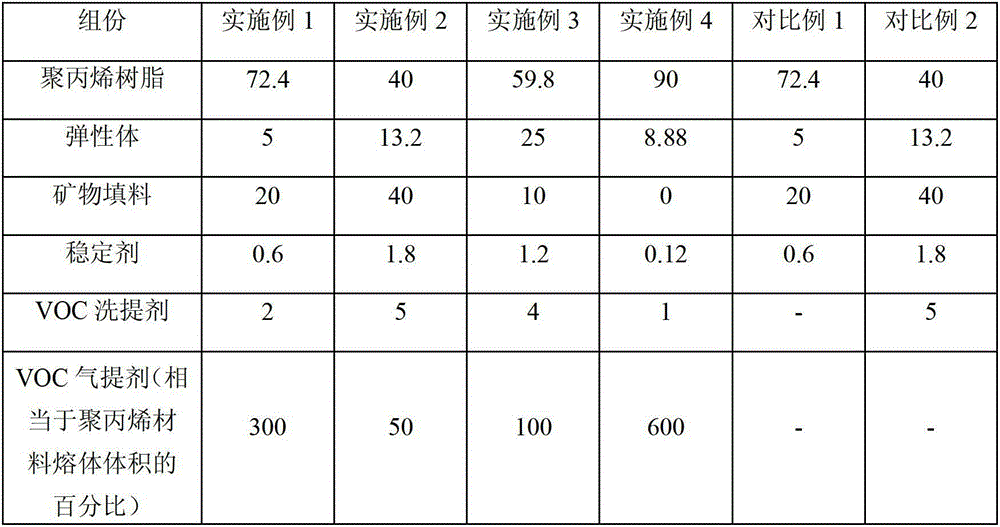

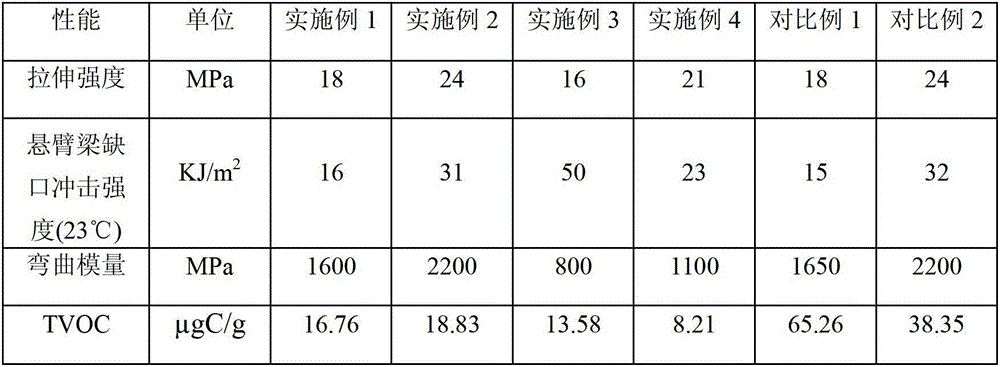

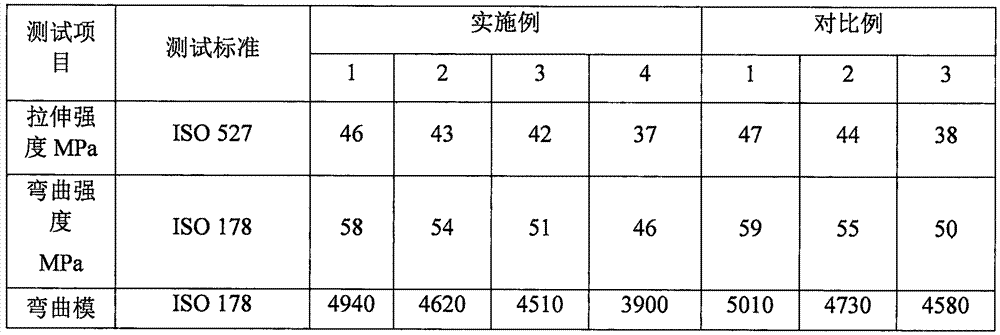

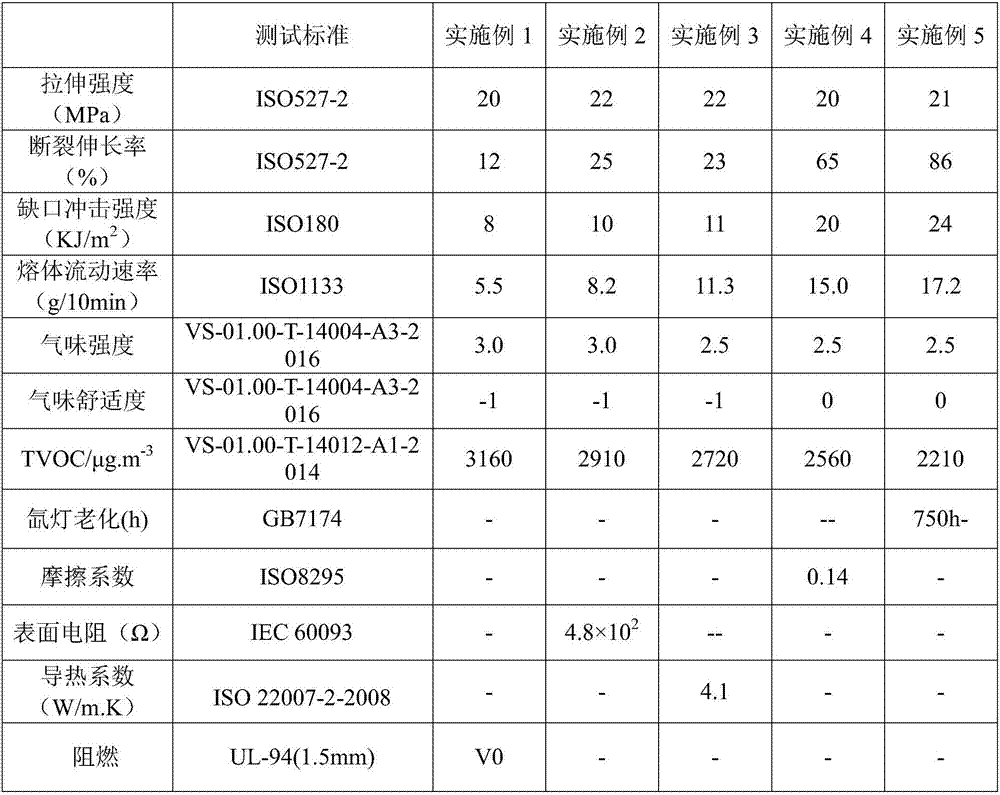

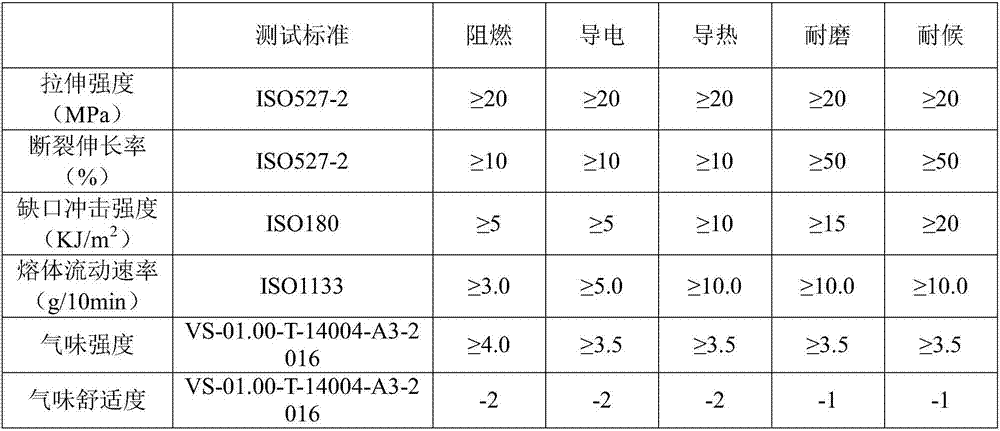

Low-emission type polypropylene material and preparation method and application thereof

ActiveCN102875895AGet rid of completelySolve the defect of premature volatilizationElastomerVacuum extraction

The invention discloses a low-emission type polypropylene material and a preparation method and application thereof. The polypropylene material is prepared from 40-90% of polypropylene, 5-25% of elastomers, 0-40% of mineral fillers, 1-5% of VOC (volatile organic compound) eluting agents, 0.1-2% of stabilizers and VOC gas stripping agents, wherein the use amount of the VOC gas stripping agents accounts for 50-600% of the volume of polypropylene material melts, the VOC eluting agents refer to more than one kind of alcohol, and the VOC gas stripping agents are N2. The VOC eluting agents are fed from a side feed port of a double-screw extruder, so that the defect of premature volatilization of the VOC eluting agents due to a low boiling point when main feed is added is overcome. Besides, the VOC eluting agents are atomized by the aid of the foam plastic foaming principle, then the VOC gas stripping agents are brought to the polypropylene material melts to enable the VOC eluting agents and the polypropylene material melts to be more uniformly mixed, VOCs are removed more thoroughly after vacuum extraction, and TVOC (total volatile organic compound) remnants are not more than 20 microgram C / g.

Owner:TIANJIN KINGFA NEW MATERIAL

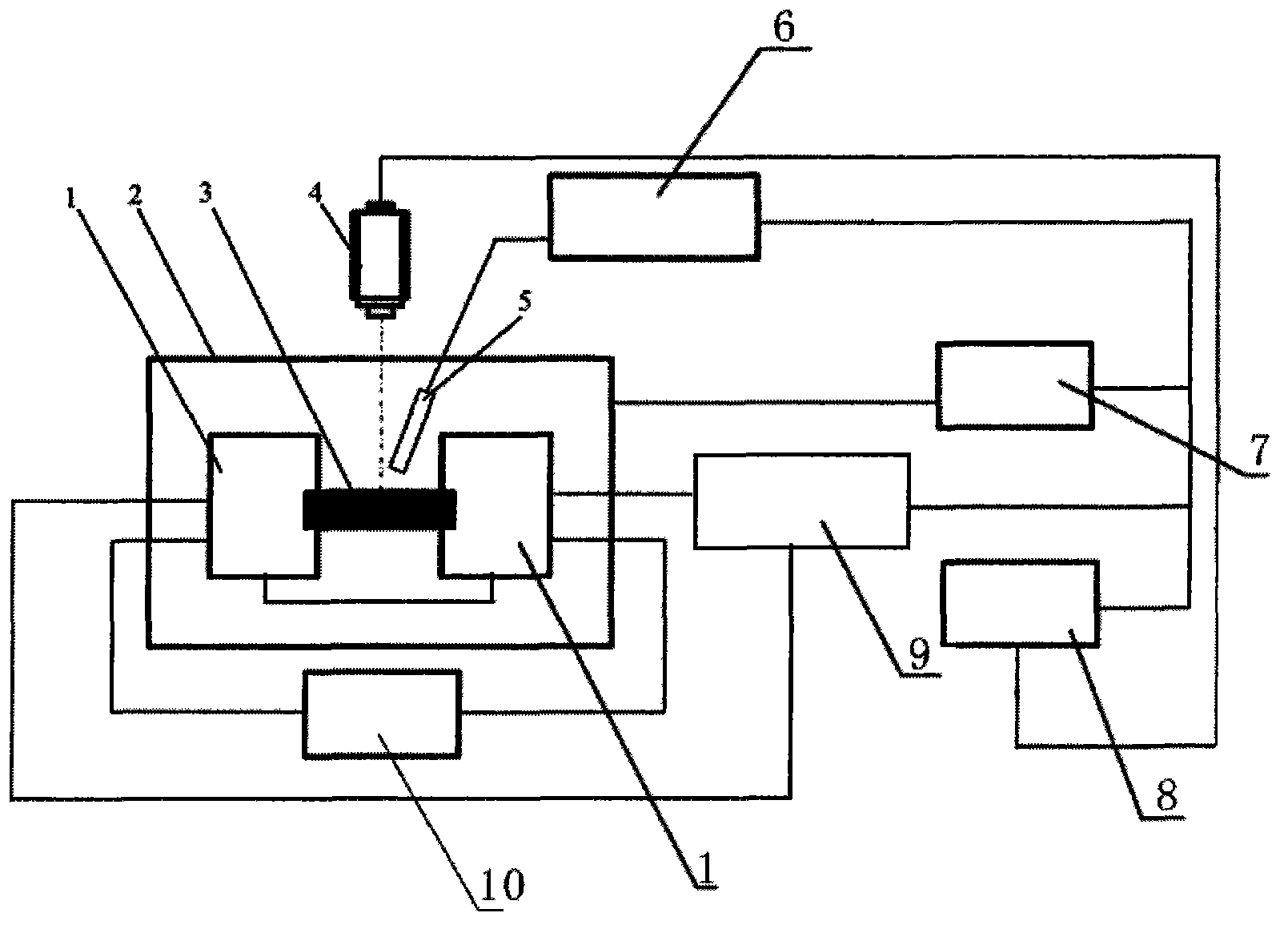

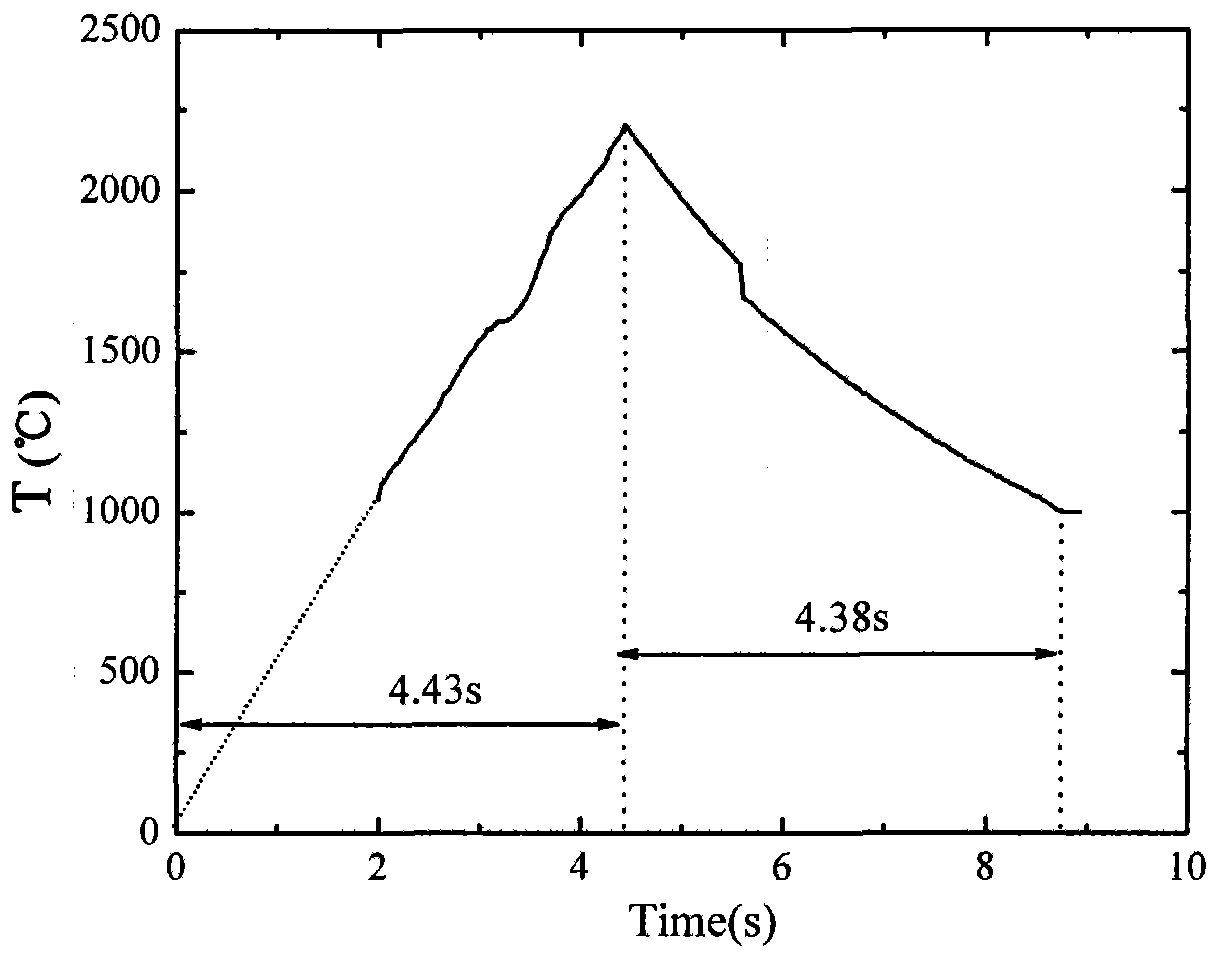

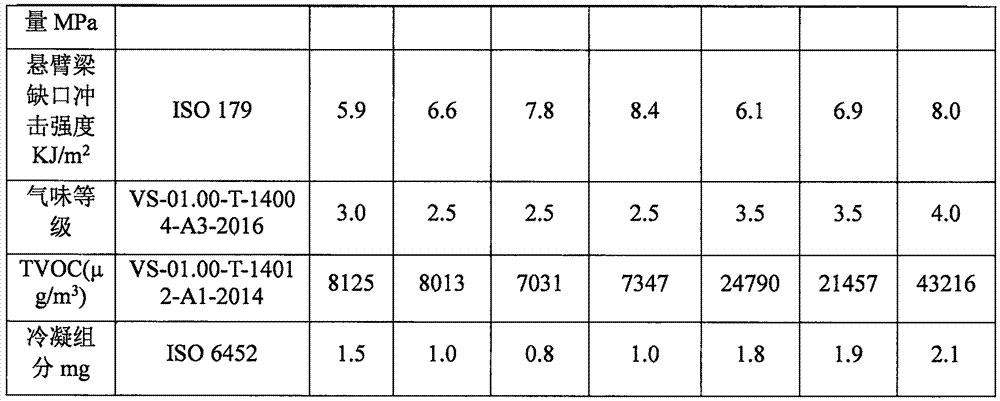

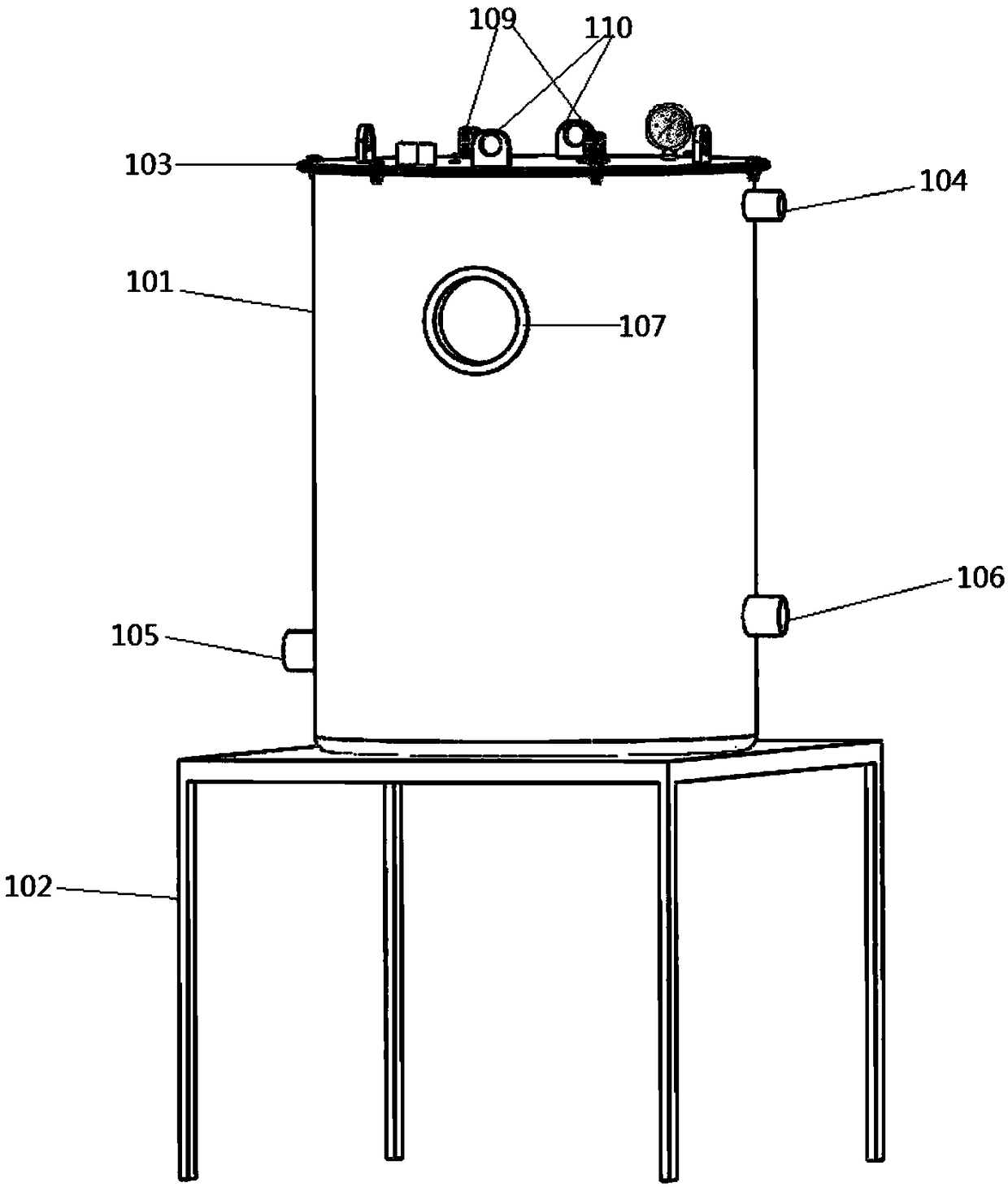

Pneumatic thermal loading simulation test device for thermal shielding materials

ActiveCN102841111AImplement decoupled testingEasy to operateMaterial heat developmentVacuum extractionSprayer

A pneumatic thermal loading simulation test device for thermal shielding materials comprises a stainless steel environmental chamber, two heating copper electrodes, a single / double colored infrared thermometer, a power supply secondary system, a gas supply secondary system, a vacuum extraction secondary system, a cooling cycle secondary system and a programmable logic controller (PLC) system. The stainless steel environmental chamber is fixed on the ground through supports and insulated from the ground. Three observation windows are arranged on the stainless steel environmental chamber, and the two heating copper electrodes are connected with the power supply secondary system through cables. A gas sprayer is arranged above thermal shielding material samples, and the vacuum extraction secondary system adjusts pressure in the stainless steel environmental chamber. The power supply secondary system is connected with an industrial power wire net. The heating copper electrodes are hollow and connected with the cooling cycle secondary system for cooling in water-cooling mode. The thermal shielding material samples are fixed between the two heating copper electrodes through a copper fixture. The single / double colored infrared thermometer is connected with the PLC system in electric signals mode. The pneumatic thermal loading simulation test device is simple to operate, wide in adjustment range, low in cost, and can be applied to principle researches of pneumatic thermal loading of the thermal shielding materials.

Owner:HARBIN INST OF TECH

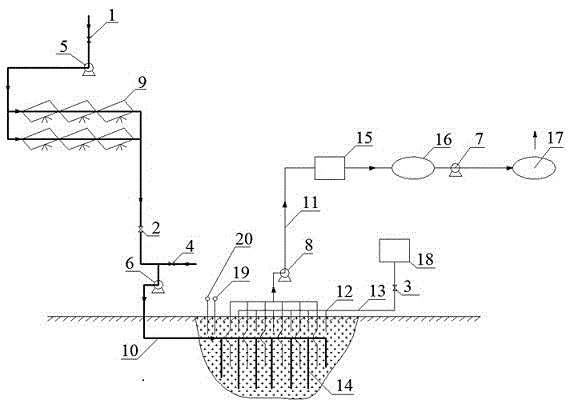

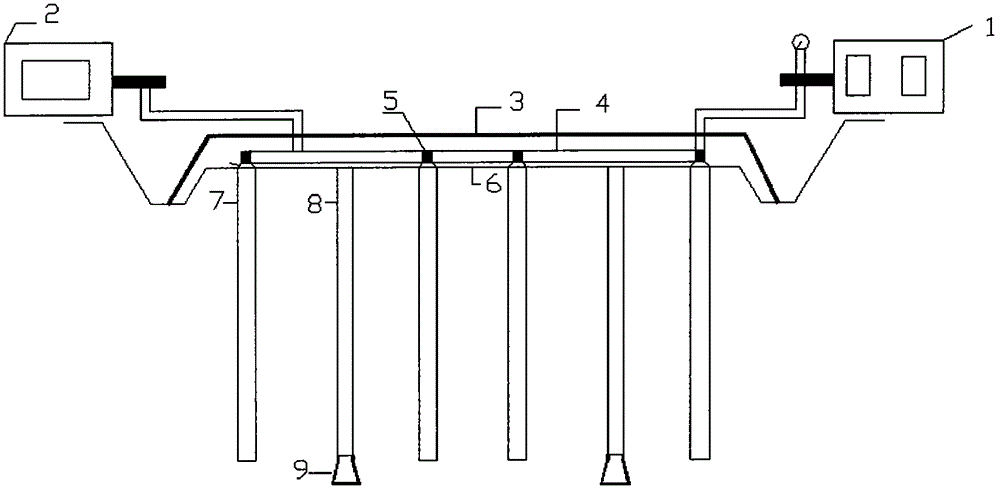

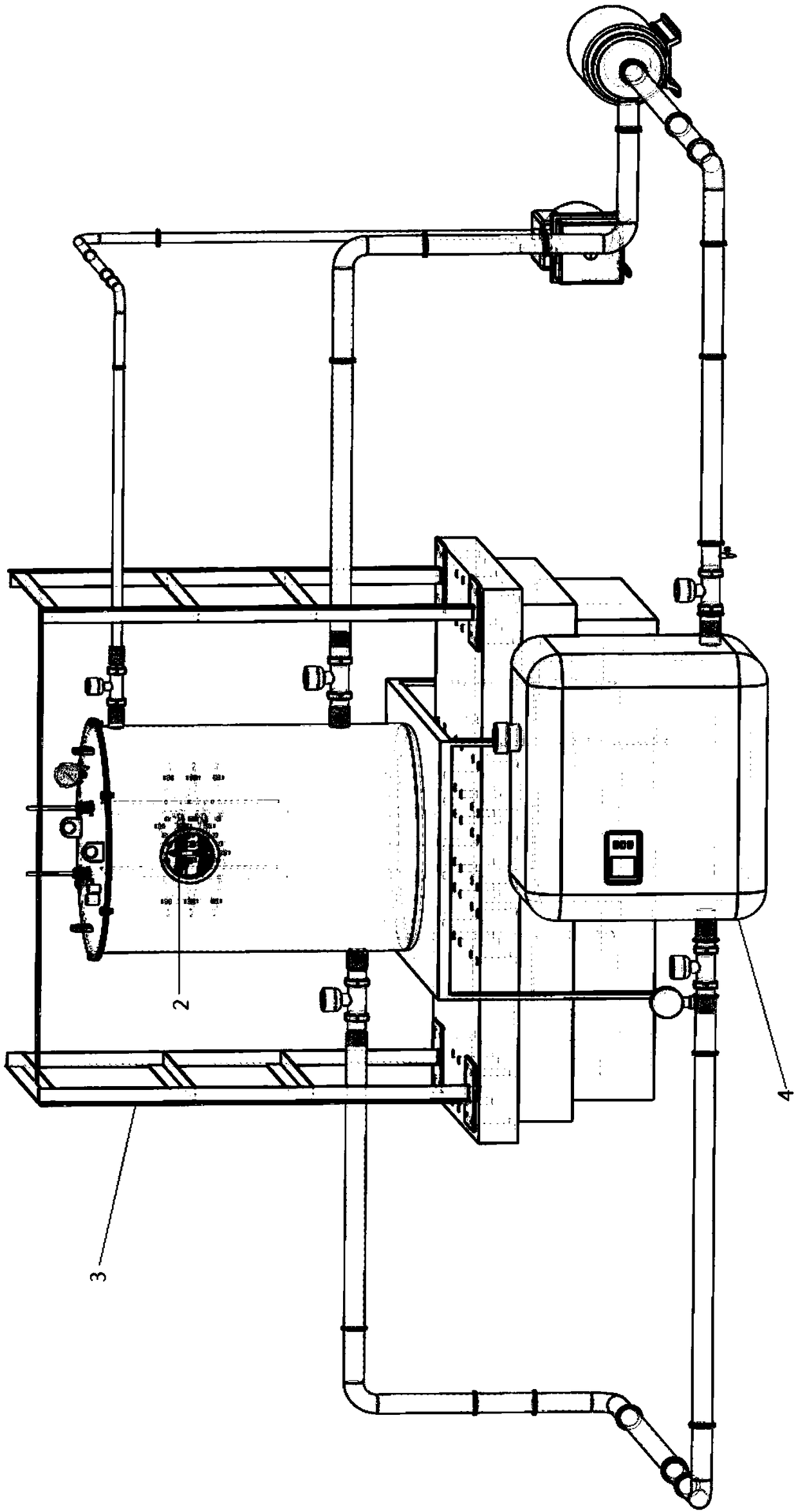

Solar hot air system enhanced in-situ bio-ventilation soil restoration system

InactiveCN105478468AAdjustable temperaturePromote degradationContaminated soil reclamationVacuum extractionCollection system

The invention relates to a solar hot air system enhanced in-situ bio-ventilation soil restoration system. The system comprises a solar air heat collection system, a ventilation system, a contaminant vacuum extraction system and a gas purification system. The ventilation system is a ventilation pipeline, and the solar air heat collection system is connected with the ventilation pipeline and used for heating air in the ventilation pipeline. The contaminant vacuum extraction system comprises a gas phase extraction pipe and a vacuum pump, the gas phase extraction pipe is directly buried in the heated contaminated soil area, and the upper portion of the gas phase extraction pipe is connected with the gas purification device. The solar hot air system enhanced in-situ bio-ventilation soil restoration system further comprises a nutrient solution injection system, and a nutrient solution is evenly pumped into organic matter contaminated soil through the nutrient solution injection system. According to the system, solar energy serves as a heat source, heated air is injected into a soil embedded radiating pipe, soil temperature is adjusted, soil microbial flora and the nutrition environment are optimized, degradation of microorganisms for organic matter in the contaminated soil is promoted, and then following vacuum extraction is facilitated. By means of the system, energy is saved, the emission of greenhouse gas is reduced, and secondary pollution generated by combustion of fossil fuel is avoided.

Owner:中钢集团天澄环保科技股份有限公司

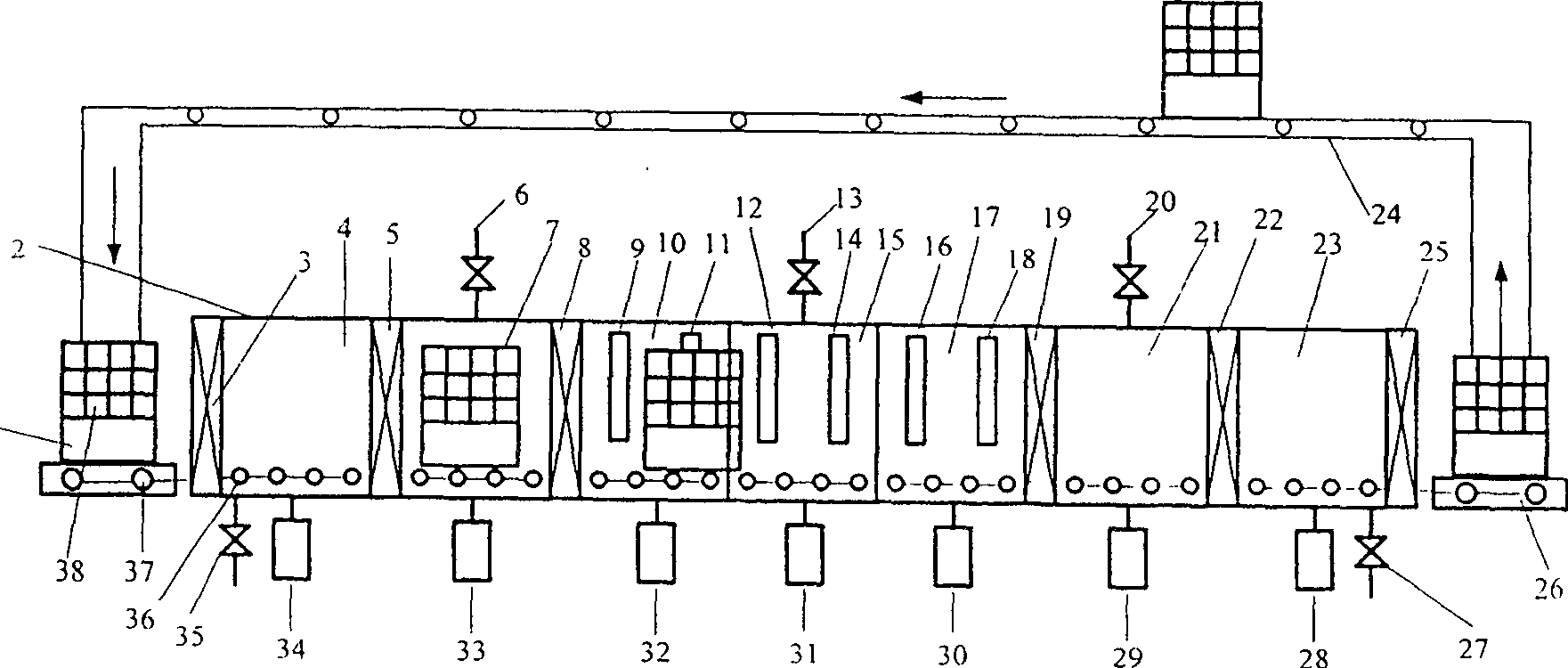

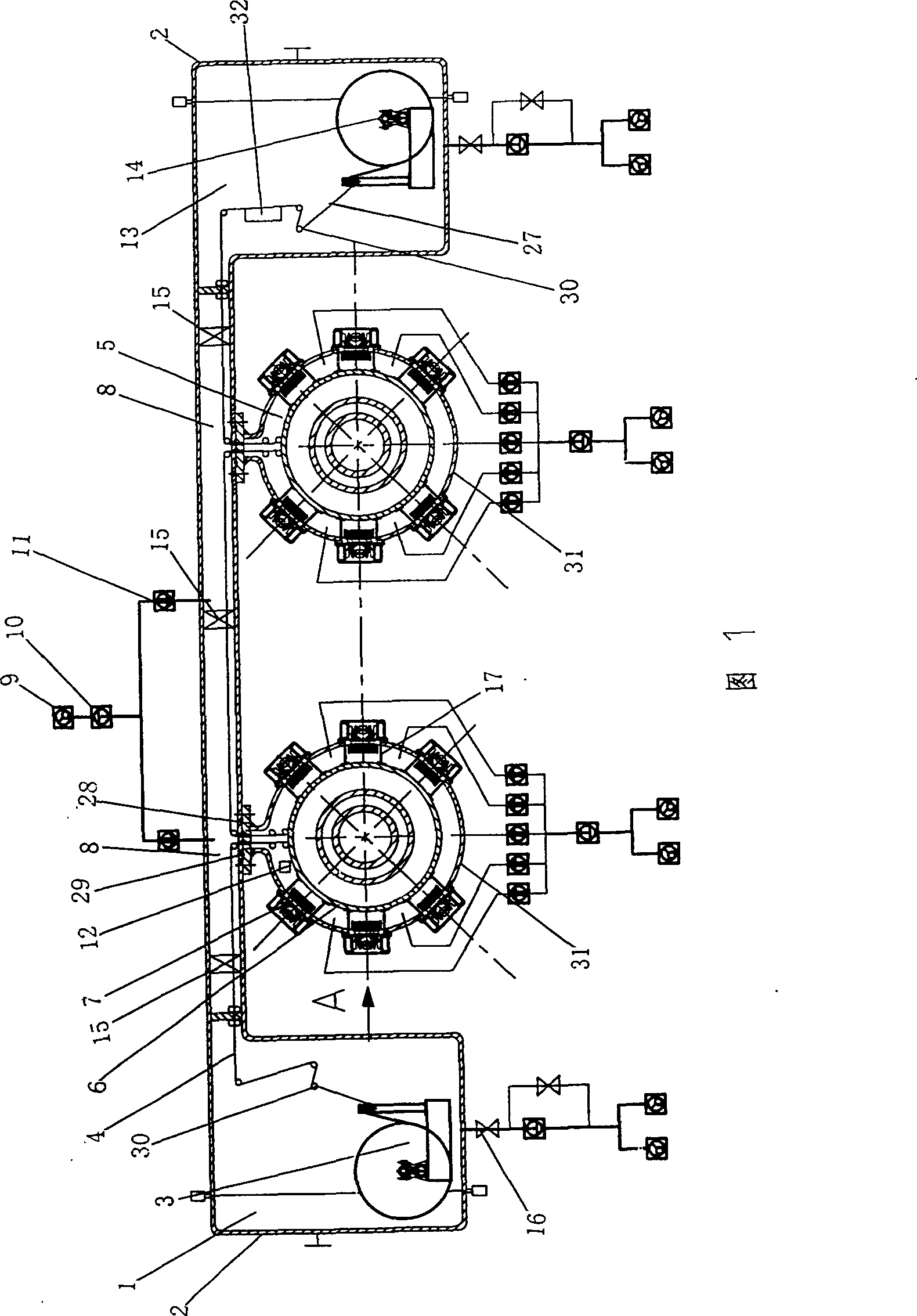

Electronic ceramic continuous sputtering coating equipment

InactiveCN1804112AImprove uniformityImprove consistencyVacuum evaporation coatingSputtering coatingIsolation valveVacuum extraction

The electronic ceramic continual sputter plating device comprises: a vacuum extraction device; and a body with five near vacuum chambers mutual connected insulating valves as the pre-pump chamber, front transition chamber, sputtering chamber with metal sputtering targets on mutual disposition, back transition chamber and the decompression chamber. Wherein, arranging a fitting friction piece transfer device and a piece frame can be convened to five chambers and outside by the transfer device; arranging a feeding table, an out-feeding table and a back mechanism all and said transfer device connected to a continual loop transfer line. This invention has large yield with low cost, strong bonding force and resistance to high temperature and corrosion.

Owner:ZHEJIANG UNIV

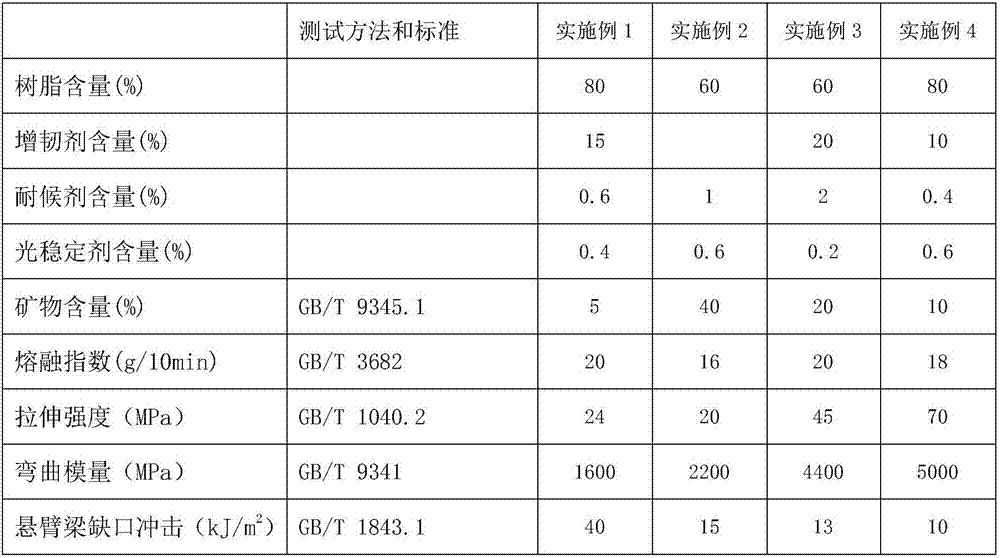

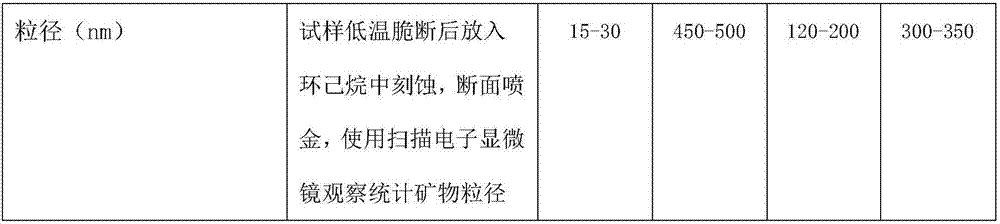

Preparation method for nanometer reinforced modified thermoplastic resin material

ActiveCN107090126AWide variety of sourcesLow priceBulk chemical productionVacuum extractionNanometre

The invention discloses a preparation method for a nanometer reinforced modified thermoplastic resin material. The preparation method comprises the following steps: preparing a mineral gel, preparing a premixture, preparing a nanometer reinforced material and drying, thereby acquiring the nanometer reinforced modified thermoplastic resin material. According to the invention, the hydrated expansion characteristic of the nanometer mineral powder is utilized to prepare the nanometer mineral gel and then the nanometer mineral gel is mixed with the other raw materials, extruded and pelletized. The pre-gelling process is beneficial to the dispersion of the nanometer mineral powder in the material in an extruding process; a supercritical fluid is introduced into the extruding pelletizing process, so that the problem of agglomeration of the nanometer material is solved; a double vacuum extraction process is performed in the preparation process, so that the removal of water and other volatile matters therein is benefited and the comprehensive property of the material is promoted.

Owner:ORINKO NEW MATERIAL CO LTD

Oil paper insulation electric heating combined aging sealing system

InactiveCN105044569AGuaranteed non-proliferationEnsure safetyTesting dielectric strengthVacuum extractionSystem pressure

The invention discloses an oil paper insulation electric heating combined aging sealing system, is used for a strict oil paper insulation electric heating combined aging experiment, and includes an electrical aging sealing system, a thermal aging sealing system, an oil storage tank and a nitrogen gas cylinder. The thermal aging sealing system includes a sealing cavity capable of being opened, and a thermal aging system pressure gauge and a temperature control meter are arranged on a side wall of the sealing cavity; and the electrical aging sealing system is arranged in the sealing cavity of the thermal aging sealing system, and includes a cavity with an upward opening, the top of the cavity is sealed through an epoxy sealing plate, an oil filling port and an inflation inlet are arranged on the epoxy sealing plate, an electrical aging system pressure gauge and a vacuum extraction opening are arranged on a cavity wall of the cavity, the cavity is internally provided with an electrical aging electrode used for an experiment, and a high voltage end and a grounding end of the electrical aging electrode are led out through the epoxy sealing plate; and the oil storage tank and the nitrogen gas cylinder are connected to the oil filling port and the inflation inlet respectively through high temperature pipes.

Owner:XI AN JIAOTONG UNIV

Preparation method of tobacco extract and product thereof

ActiveCN101624555AImprove qualityReduce manufacturing costTobacco treatmentEssential-oils/perfumesSolubilityVacuum extraction

The invention relates to a preparation method of a tobacco extract and a product obtained by using the method. The preparation method comprises the steps of low-temperature vacuum extraction, stirring and vacuum concentration and allows the circulation use of a solvent, so that the method is characterized by safety, environmental protection, high extraction efficiency, low production cost, high product yield and the like, can be simultaneously applicable to extracting a variety of types of tobacco extracts and can produce the high-quality tobacco extract. The extract product obtained by the preparation method has the beneficial effects of instant solubility and good dispersibility and is easy to add in tobacco essence and tobacco casing.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

Low-emission, low-odor automobile composite polypropylene material

InactiveCN107513211AImprove adsorption capacityRemove comprehensivelyOther chemical processesAlkali metal oxides/hydroxidesVacuum extractionAntioxidant

The invention provides a low-emission, low-odor automobile composite polypropylene material and a preparation method thereof. The low-emission, low-odor automobile composite polypropylene material is prepared from the following materials in percentage by weight: 55 to 85 percent of polypropylene; 0.8 to 3.5 percent of odor emission adsorbent; 15 to 40 percent of inorganic filler; 1 to 15 percent of flexibilizer; 1 to 6 percent of compatilizer; 0.2 to 1 percent of antioxidant; and 0.2 to 1 percent of anti-UV agent. The preparation method includes the following steps: the polypropylene resin, the compatilizer and the other auxiliaries are added according to a weight proportion requirement into a screw via a main feed inlet and conveyed, and the inorganic filler and the odor emission adsorbent are fed into a melting section by a side feeder. The invention adopts both an adsorption technique and a devolatilization technique, the odor adsorbent which is a self-made novel inorganic porous adsorbing material is adopted and supplemented with foamed polypropylene as a stripping agent, and by vacuum extraction, small-molecular volatile substances which are produced in the process of material processing can be fully removed; the preparation process is simple, and the low-emission, low-odor automobile composite polypropylene material has the advantages of high filling, low cost and low shrinkage.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Magnetic-control sputtering coiling film coating machine

ActiveCN101191195AFunction increaseIncrease productionVacuum evaporation coatingSputtering coatingVacuum extractionEngineering

The invention provides a magnetron sputtering winding coating equipment which at least comprises a vacuum chamber of a coil unwinding mechanism and / or a vacuum chamber of a winding mechanism, at least one coating vacuum chamber, and a vacuum connecting box used to be connected with a winding vacuum chamber, a unwinding vacuum chamber and coating vacuum chambers. The invention is characterized in that: the interior of at least one coating vacuum chamber is provided with a vacuum coating box, at least three groups of vacuum extraction systems consisting of cathodes, high / low pressure vacuum pumps and pipes are arranged around a cooling roll positioned in the vacuum coating box, the targets and the target centers of the cathodes of the magnetron sputtering are arranged in each vacuum coating box, the cathodes are arranged on the walls of the vacuum coating boxes through cathode flange connecting bases in a form of flange connection, gas connecting pipes and power supply connecting pipes as well as cooling water connecting pipes are arranged outside the vacuum coating boxes, gas baffles arranged among each group of cathodes isolate the gap between the shell of the vacuum coating box and the cooling roll into bleed-off passages. The coating equipment of the invention can make a multi-layer coating on the surface of plastic film; and the obtained coating has compact surface microscopic structure and smooth surface.

Owner:SICHUAN GOLDSTONE-ORIENT NEW MATERIAL TECH CO LTD

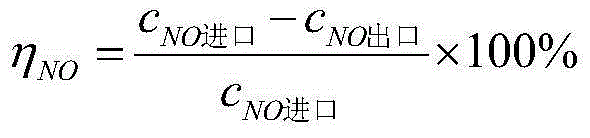

Coated low-temperature flue gas denitration catalyst, and preparation method and application thereof

InactiveCN105126827ALarge specific surface areaLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsVacuum extractionCordierite

The invention discloses a coated low-temperature flue gas denitration catalyst, and a preparation method and application thereof. The catalyst comprises a first carrier, a second carrier, active components and auxiliaries, wherein the first carrier adopts modified cordierite honeycomb ceramics; the second carrier adopts titanium dioxide; the active components comprise manganese oxide and vanadium oxide; the auxiliaries comprise cerium oxide and tungsten oxide; the catalyst is formed by coating the first carrier with catalyst size prepared from catalyst active component powder containing the second carrier, the active components and the auxiliaries through adopting a vacuum extraction method and then performing calcining; the catalyst active component powder comprises MnO2, V2O5, CeO2, WO3 and TiO2 with the mass ratio of (1-2) to (1-2) to (1-2) to (1-6.5) to (87.5-96). The catalyst is large in specific surface area and better in coating firmness, and has high catalytic activity at low temperature.

Owner:HAO HUA CHENGDU TECH

Method and device for preparing microparticles by splitting liquid drop using electric charge oscillation method

InactiveCN101279372AControllable pressure differenceStrong process controllabilityVacuum extractionMetallic materials

The invention discloses a method which adopts the charge oscillometry liquid drop breakup for preparing micro-particles, and the method comprises the following steps: (1) metal material to be melted is added in a crucible; (2) cooling liquid is added in collection devices; (3) the vacuum extraction of the crucible and a vacuum cavity is carried out, and protective gas is filled; (4) the metal material in the crucible is melted; (5) a piezoelectric oscillator is opened, and the voltage is added on a charging polar plate, thus ejecting the melted metal from a nozzle at the bottom part of the crucible with the form of laminar-flow jet and respectively charging the same amount of charge to the liquid drops with two sizes when passing through the middle gap of the charging polar plate; (6) the diameter of liquid drops is calculated; (7) the evenly charged liquid drops is broken up into main liquid drops with larger size and ultra-micro-liquid drops with smaller size by the charge oscillometry on the surface of the liquid drops when passing a high-frequency alternating electric field; (8) the main liquid drops and the ultra-micro-liquid drops are fallen into the respective collection devices after the separation of a deflecting polar plate. The method of the invention has strong process controllability, which can directly obtain the even particles with more micro-size, the process flow is short, the product quality is good, and the equipment investment is greatly reduced.

Owner:TIANJIN UNIV

Pressure container with differential vacuum panels

ActiveUS8186528B2Controlled overall response to vacuum pressureImprove dent resistanceLarge containersRigid containersVacuum extractionVacuum pressure

Owner:MELROSE DAVID MURRAY +1

Low-odor low-VOC polypropylene composite material, preparation device and method thereof

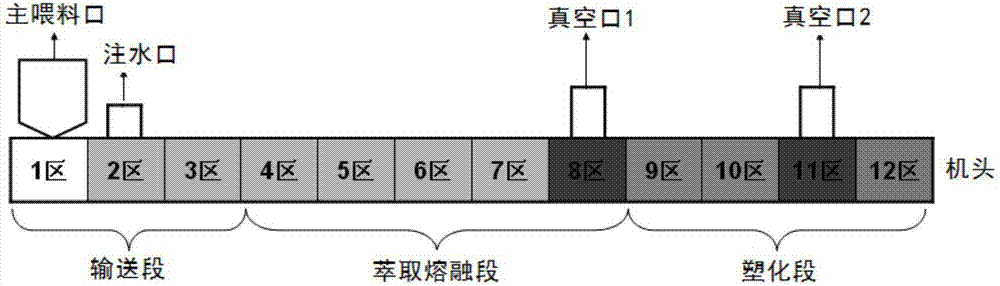

The invention relates to a low-odor low-VOC polypropylene composite material, a preparation device and a method thereof and belongs to the technical field of an organic polymer material. The material is prepared from polypropylene resin, filler, functional additive, processing heat stabilizer, processing lubricating agent and silicone oil at mass ratio of 55-97:(0-20):(0.5-20):(0.2-1):(0.1-2):(0.05-0.1). In the preparation process, water is taken as an extracting agent and is added through a water feeding port formed on an extruding machine, and meanwhile, the vacuum port position in the extruding machine is modified, so that the purpose of removing the harmful volatile organic compounds from the composite material in stages can be realized; vacuum extraction is adopted after the water extraction, so that the residue of the harmful volatile organic compounds in the composite material can be greatly reduced; the secondary pollution caused by the use of organic extraction agent can be avoided; the influence on the properties of the base material is reduced; and the low-cost, low-odor and low-VOC polypropylene composite material is finally prepared.

Owner:重庆科聚孚新材料有限责任公司 +1

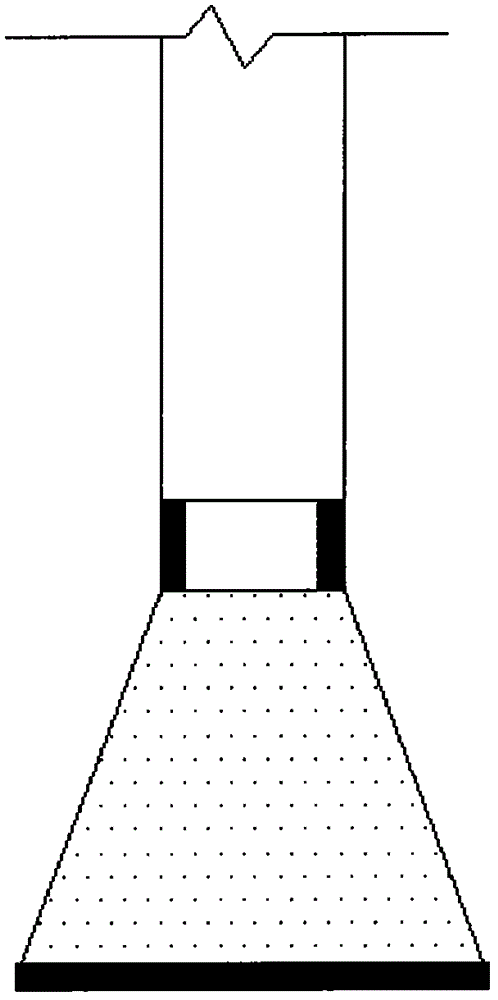

Method for reinforcing soft soil foundation by using calescence type vacuum preloading way

InactiveCN103255761AImprove bearing capacityDrain fastSoil preservationVacuum extractionVacuum pressure

The invention relates to a method for reinforcing a soft soil foundation by using a calescence type vacuum preloading way. The method comprises the steps of: introducing a foundation heating system on the basis of a regular vacuum preloading way; and keeping an under-film vacuum pressure and a temperature of shallow-layer soft soil in a reinforcing region respectively above 80 kPa and 62 DEG C within a period of time of a reinforcing period so as to rapidly vaporize pore water of foundation soil and pump the vaporized pore water by vacuum extraction equipment to cause sedimentation of the foundation. Compared with the prior art, the method for reinforcing the soft soil foundation by using the calescence type vacuum preloading way has the advantages of shorting the construction period, improving reinforcing effects, reducing settlement after the construction, increasing the bearing capacity of foundation soil and the like.

Owner:TONGJI UNIV

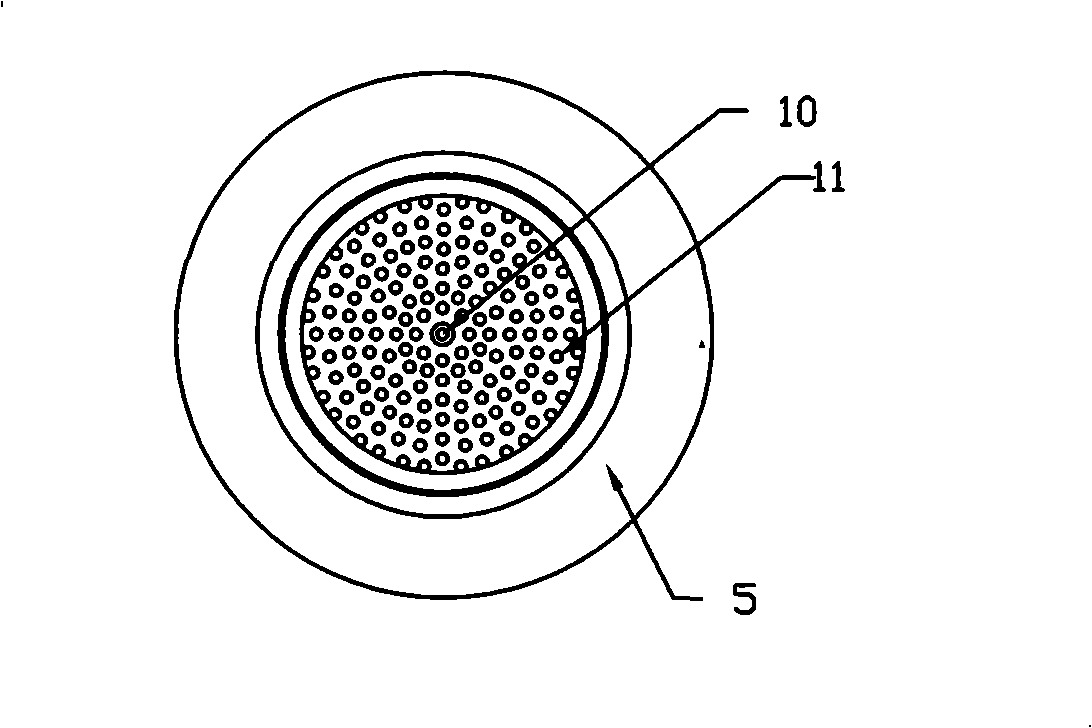

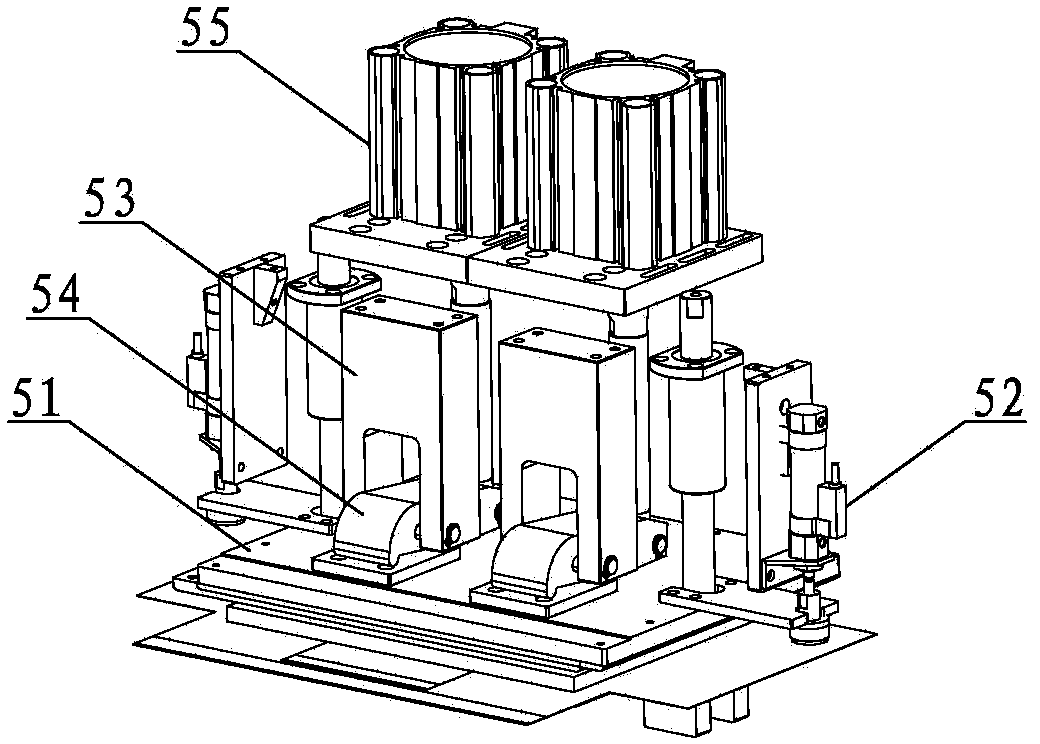

Thimble module and method for separating wafer and blue tape using the module

InactiveCN101323152ASimple structureReduce volumeWorking accessoriesFine working devicesVacuum extractionEngineering

The invention discloses a thimble module and a method for using the thimble module for separating wafer from blue film. The thimble module comprises a thimble ring and a thimble arranged in the thimble ring. The thimble ring is provided with a vacuum extraction pathway. The thimble ring is provided with an adsorption plane used for adsorbing a glue film. The adsorption plane is provided with a flow port and a center hole. The flow port is communicated with the vacuum extraction pathway. The invention is characterized in that one end of the thimble is fixed on the thimble ring and the other end of the thimble serves as a thimble point; the adsorption plane at the center hole is a concave-down surface; and the thimble point passes through the center hole. In use, the thimble jacks up the wafer. The blue film is pierced depending upon the relative downward movement of the blue tape instead of the upward movement of the thimble point. In the invention, the thimble is integrated with a thimble seat, so the thimble and the thimble seat move simultaneously. And only a set of drive mechanism is required. Therefore, the structure is more simplified; the size of equipment is reduced, operation frequency increases process time is shortened; and production efficiency gets improved.

Owner:深圳市综科光电设备有限公司

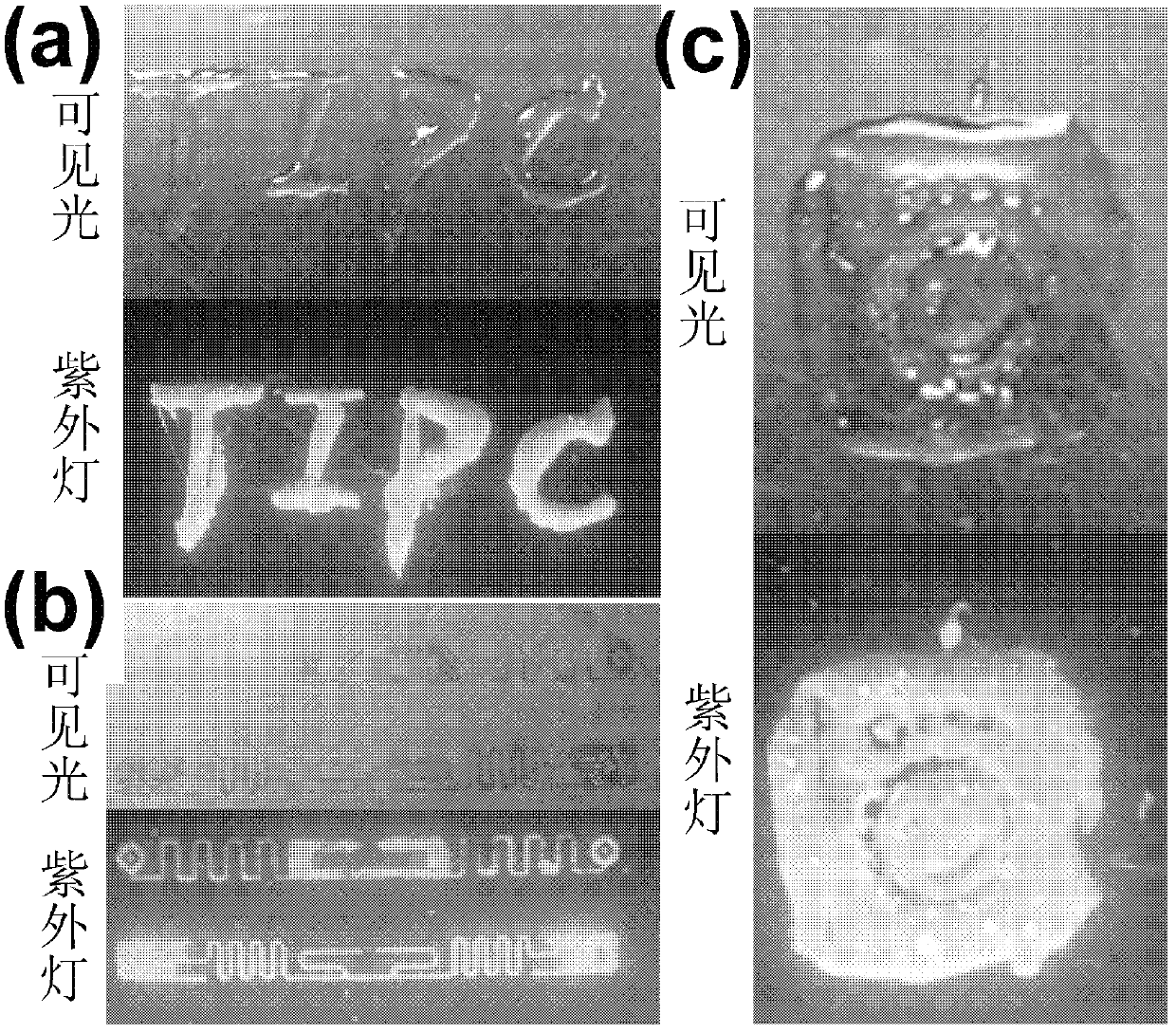

Fluorescent anti-counterfeiting ink based on light-emitting quantum dots and preparation method as well as application thereof

InactiveCN103289469AWith ultraviolet fluorescent anti-counterfeiting functionReduce dosageInksScreen printingVacuum extraction

The invention relates to fluorescent anti-counterfeiting ink based on light-emitting quantum dots. The ink comprises transparent gloss oil and light-emitting quantum dots. The weight ratio of the light-emitting quantum dots and transparent gloss oil in the fluorescent anti-counterfeiting ink to the ultraviolet fluorescent anti-counterfeiting function is (0.05-5):(99.95-95). A preparation method of the ink comprises the steps of: preparing the light-emitting quantum dots and dispersing the light-emitting quantum dots in acetone to obtain light-emitting quantum dot-acetone solution; and then adding the corresponding light-emitting quantum dot-acetone solution taken according to the content of the light-emitting quantum dots in the anti-counterfeiting ink to the transparent gloss oil and carrying out vacuum extraction on the solvent after uniform mixing to obtain the fluorescent anti-counterfeiting ink based on the light-emitting quantum dots. The anti-counterfeiting ink is invisible, is colorless and transparent under the natural light, can emit different colors of visible light under the ultraviolet light, has an obvious anti-counterfeiting effect, is suitable for the printing methods such as silk screen printing, seal printing and intaglio printing and can be applied to anti-counterfeiting of such bills as tickets, invoices and bank notes and packaging materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Vacuum adsorption forming device

ActiveCN102189675AReliable moldingRealize continuous productionDomestic articlesVacuum extractionEngineering

The invention discloses a vacuum adsorption forming device which can be suitable for mass production of formed pieces through polypropylene cavity plates. The device comprises a vacuum extraction module, a vacuum box, a hydraulic machine and a heating module, wherein the vacuum extraction module is connected with the vacuum box; the vacuum box is arranged on a fixed plate of the hydraulic machine; a load bearing lifting module which is used for arranging molds and can vertically lift or lower the molds is arranged in the vacuum box; a press frame which can fix a polypropylene cavity plate at the opening of the vacuum box is arranged at the opening of the vacuum box; the heating module is arranged on one side of the hydraulic machine and comprises a heating unit and a moving unit which canbe used for moving the heating unit to the upper side of the fixed polypropylene cavity plate to heat the polypropylene cavity plate and can be deviated from the polypropylene cavity plate after the polypropylene cavity plate is heated; and the heating unit is connected with the moving unit.

Owner:NINGBO SUNLIGHT MOTOR PARTS

Novel partial deep layer pressurizing type vacuum preloading soft soil foundation processing method

The invention relates to a novel partial deep layer pressurizing type vacuum preloading soft soil foundation processing method. According to the technical scheme, the method comprises a vertical drainage system, a transverse drainage system, vacuum extraction equipment, a pressurizing system, pressurizing equipment and a sealing system; a vertical drainage board adopts a novel anti-clogging drainage board, the vertical drainage board is divided into two parts to be driven, one part is driven into a soil body, and the other part is exposed out of the surface of the soil body. The technology enables a deep soil body to obtain higher air pressure, enables a larger pressure difference to be formed among the deep soil body, an upper soil body and the vertical drainage board, and enables the free water in the deep soil body to fast flow to the upper soil body and the drainage boards. In addition, the flow direction of airflow from a jet head obliquely upwards points to the drainage boards, therefore the seepage of the pore water in the deep soil body to the drainage boards can be accelerated, and the deep soil body can obtain better reinforcement effect.

Owner:WENZHOU UNIVERSITY

Transformer paper oil insulation multi-factor combined aging test device and life prediction method thereof

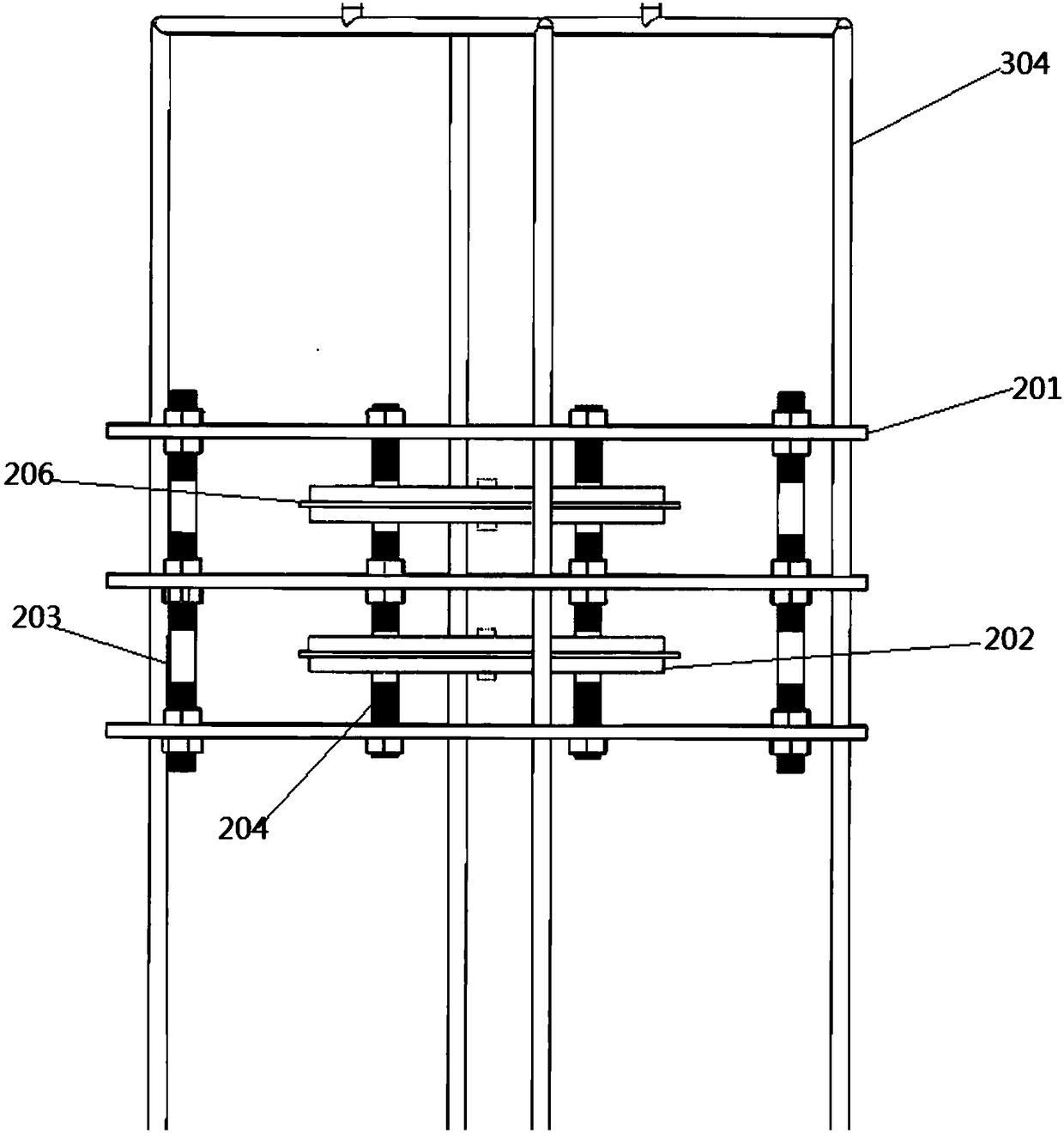

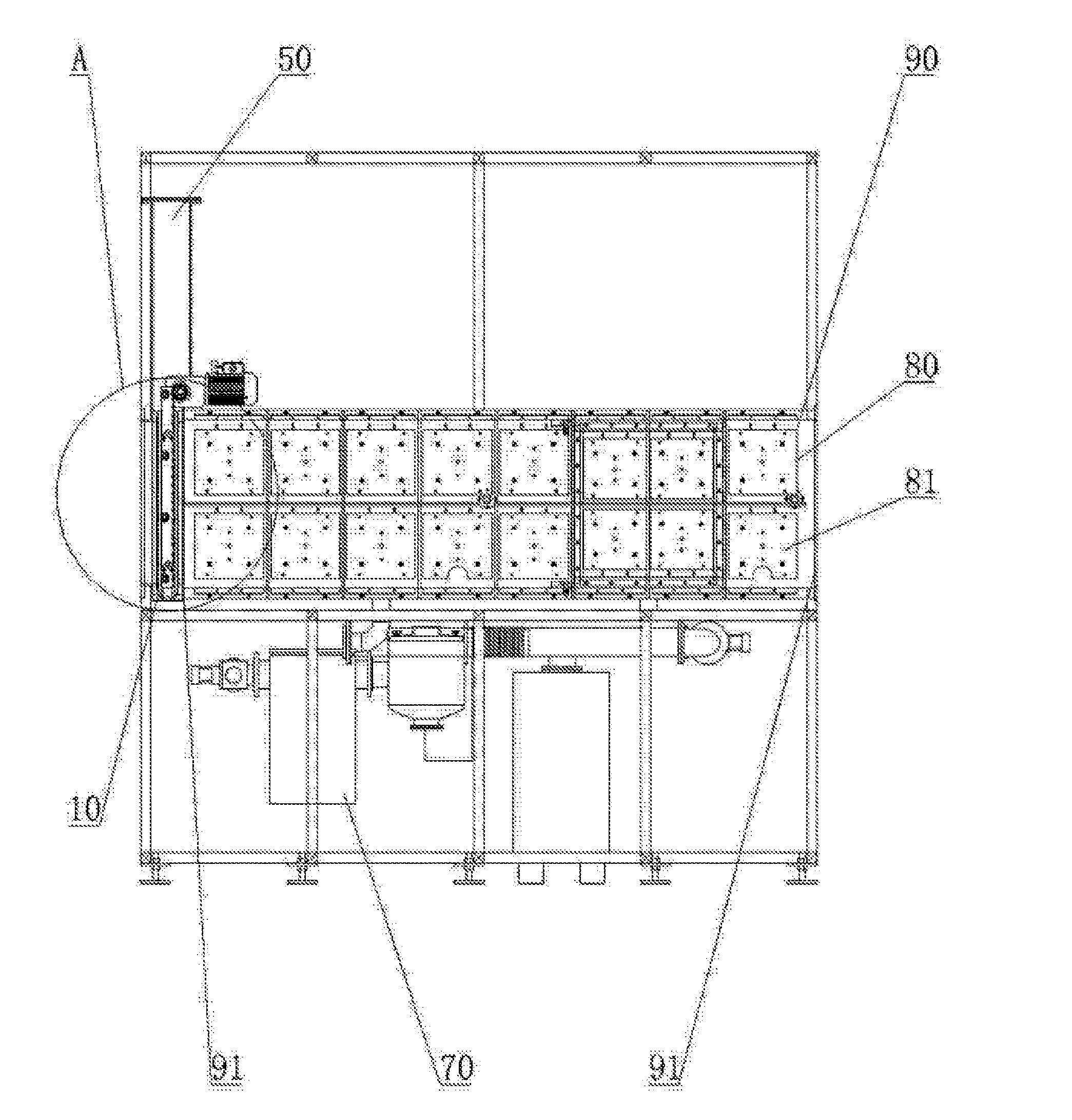

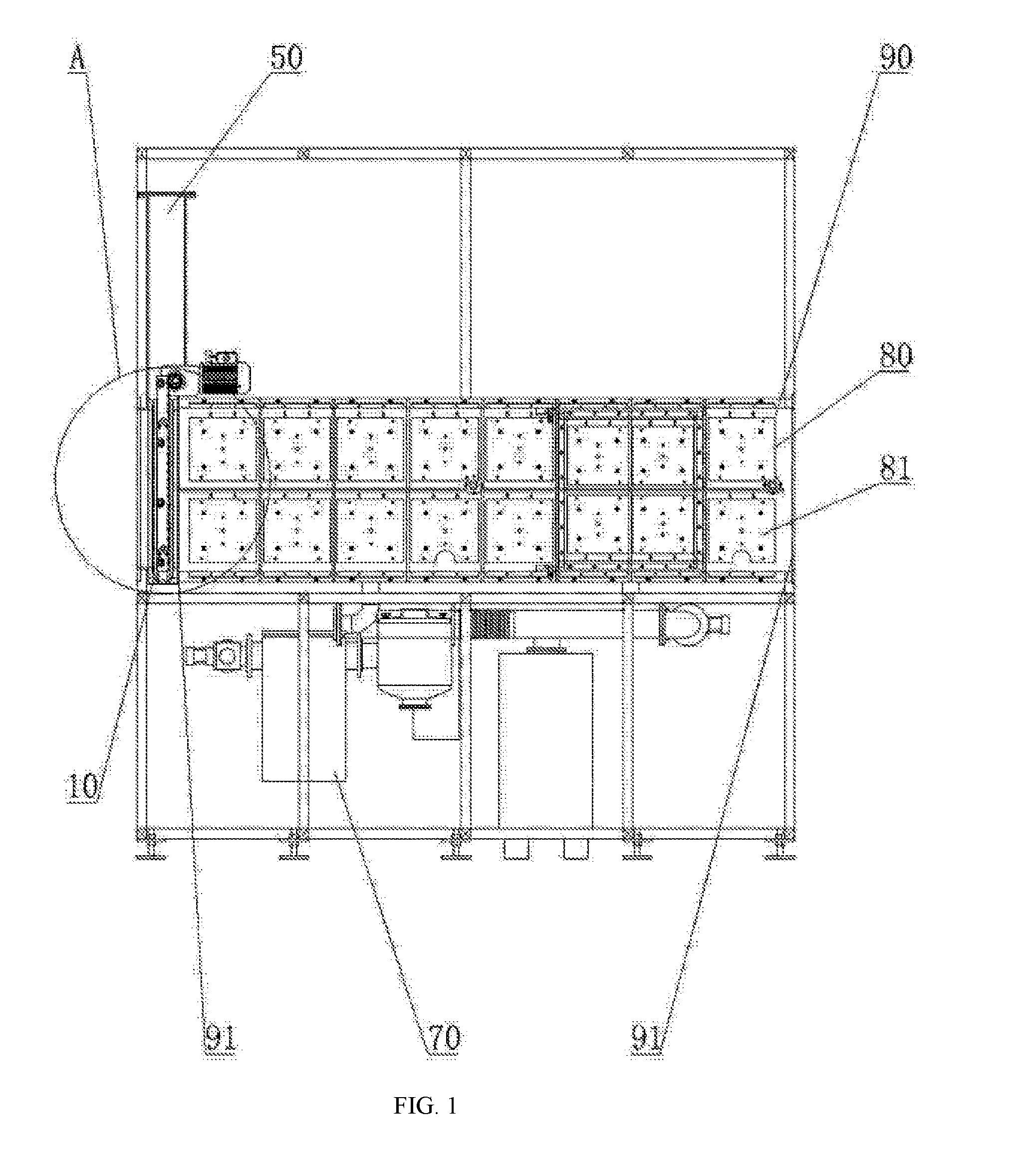

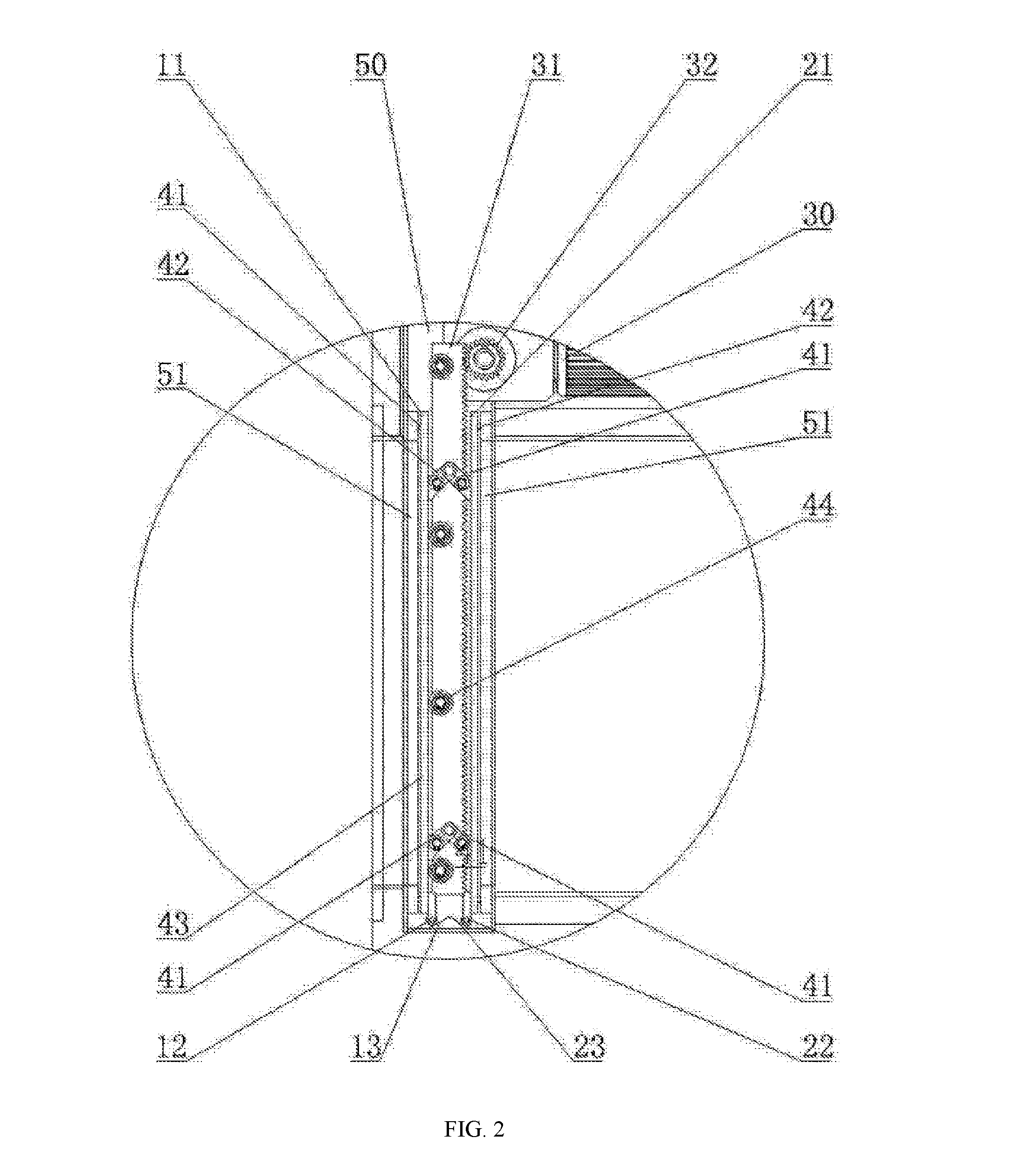

PendingCN108107291AReal-time online testAmount of performance degradation achievedTesting dielectric strengthEnvironmental/reliability testsExhaust valveVacuum extraction

The present invention relates to the technical field of transformer paper oil insulation aging test, especially to a transformer paper oil insulation multi-factor combined aging test device and a lifeprediction method thereof. The device comprises a test box body, a vibration transmission device, test sample clamping devices and an oil-way cycle device. The test box body is arranged on a bearingplatform, the test box body is internally provided with the plurality of test sample clamping devices arranged in parallel, the test sample clamping devices are connected with the vibration transmission device, a vacuum extraction opening, a cycle oil inlet and a cycle oil outlet are processed on the test box body, the cycle oil inlet and the cycle oil outlet on the test box body are connected with an oil-way cycle device through an oil-way cycle pipeline, the vacuum extraction opening on the test box body is provided with a vacuum pump through an exhaustion pipeline, and the extraction pipeline is provided with an exhaust valve. The transformer paper oil insulation multi-factor combined aging test device and the life prediction method thereof can achieve online detection of performance degradation amount of test samples, and employ a random model to combine a traditional life calculation model to predict the life of the transformer.

Owner:HARBIN UNIV OF SCI & TECH

Automatic vacuum drying device

ActiveUS20160258681A1Easy to install and repairEfficient dryingDrying using combination processesFinal product manufactureProduction lineVacuum extraction

An automatic vacuum drying device comprises a drying oven, a heating device used to heat the drying oven, a vacuum extraction device used to evacuate the drying oven, a nitrogen input device used to input nitrogen into the drying oven, and a transporting device located inside the drying oven and used to transport materials, two first openings are located at two opposite sides of the drying oven, an automatic sealing door is mounted on at least one of the first openings, the automatic sealing door includes a first door plank and a second door plank parallel to the first door plank, an elevator structure is located between the first door plank and the second door plank, the elevator structure is used to lift the first door plank and the second door plank. The automatic vacuum drying devices can form an automatic vacuum drying production line conveniently, and the automatic vacuum drying production line has high degree of automation, and high processing efficiency, such that it is possible to drastically improve the vacuum drying efficiency.

Owner:SHENZHEN TIME HIGH TECH EQUIP

Device and method for vacuumizing in membrane of soft packaged battery

ActiveCN104201422AEasy extractionQuick extractionAssembling battery machinesFinal product manufactureVacuum extractionEngineering

The invention relates to the technical field of battery packaging, and discloses a device for vacuumizing in a membrane of a soft packaged battery. The device comprises a fixed frame, and a positioning table for holding the battery and a vacuum clamping mechanism for vacuuming are arranged on the fixed frame. When the vacuumizing device works, vacuum extraction is only carried out near an extracting hole of a gas bag, then gas or liquid is extracted from the gas bag, and finally, a heat sealing mechanism performs heat sealing on the extracting hole after the extraction. The device is simple in structure and easy to use. According to a vacuumizing method with the vacuumizing device, the whole battery does not need to be arranged inside a vacuum chamber, and gas or liquid in the gas bag can be extracted rapidly after the gas bag is closely attached to an annular upper sucker and an annular lower sucker. Therefore, the cost time is relatively short, the working efficiency is relatively improved, and energy can be effectively saved.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

Preparation method for stainless steel clad plate

InactiveCN103157959AOmit the vacuum stepReduce investmentNon-electric welding apparatusVacuum extractionMaterials science

The invention discloses a preparation method for a stainless steel clad plate, and aims at solving the problem that through an existing vacuum rolling method for a metal clad plate, the time needed for vacuum extraction is long, and therefore the production cycle of the metal clad plate is quite long. The preparation method for the stainless steel clad plate includes the following steps: step 1, a first clad surface of a base material is subjected to surface treatment; step 2, a stainless steel plate is cut and shaped, a second clad surface is subjected to polishing treatment, and at the same time, a third surface is well cleaned, coated with a mold releasing agent and is ready for use; step 3, two stainless steel plates are combined together for form a cladding blank; step 4, base materials are arranged on the cladding blank and under the cladding blank, inlaid bars are arranged around the cladding blank, and a pressure welding machine is used for welding an initial blank to obtain a welding blank; and step 5, after the welding blank is heated, the welding blank is subjected to rolling and straightening, and then sides are further cut to obtain the stainless steel clad plate. According to the preparation method for the stainless steel clad plate, a vacuum extraction process is not needed, and the investment on vacuum extraction equipment can be effectively reduced; and meanwhile, production efficiency is improved, the production cycle is shortened, and the production cost of the stainless steel clad plate is lowered.

Owner:SICHUAN YOUQI DUEL METAL COMPOSITE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com