Pneumatic thermal loading simulation test device for thermal shielding materials

A thermal protection material and load simulation technology, applied in the direction of material thermal development, can solve the problems of cumbersome operation, high cost, and inability to realize the decoupling analysis of aerodynamic load and thermal load, etc., and achieve simple operation, low cost, and wide adjustment range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

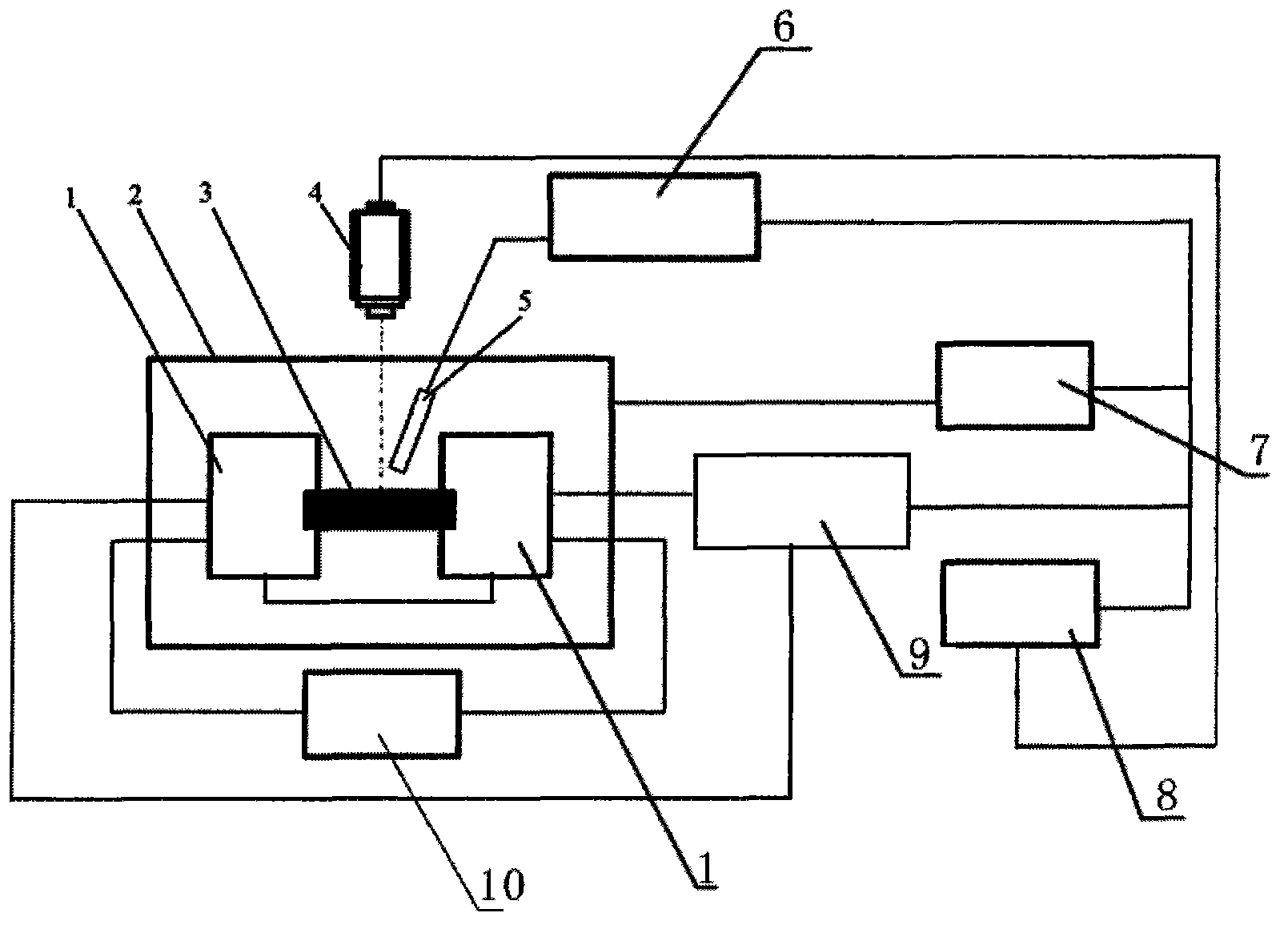

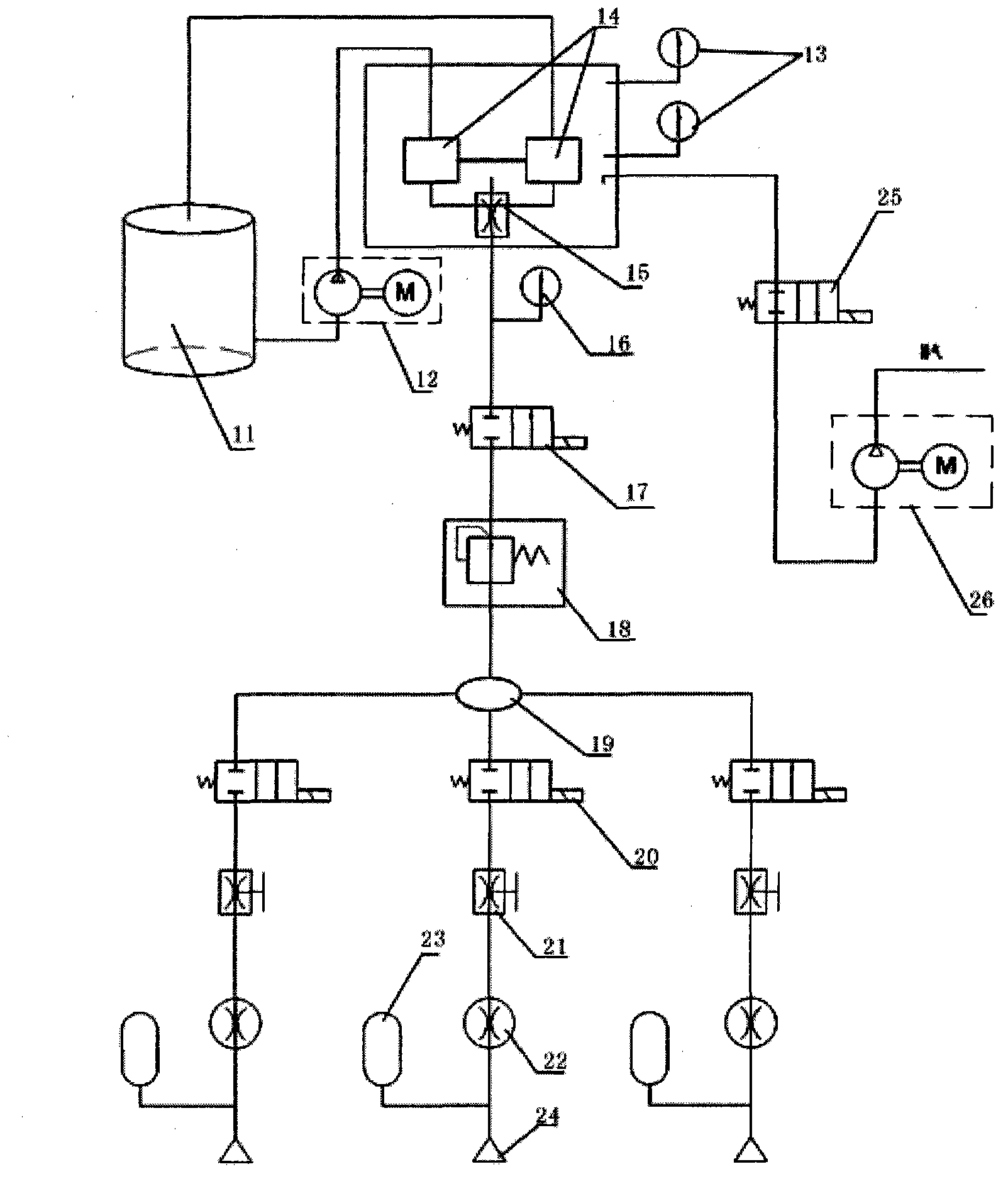

Method used

Image

Examples

Embodiment 1

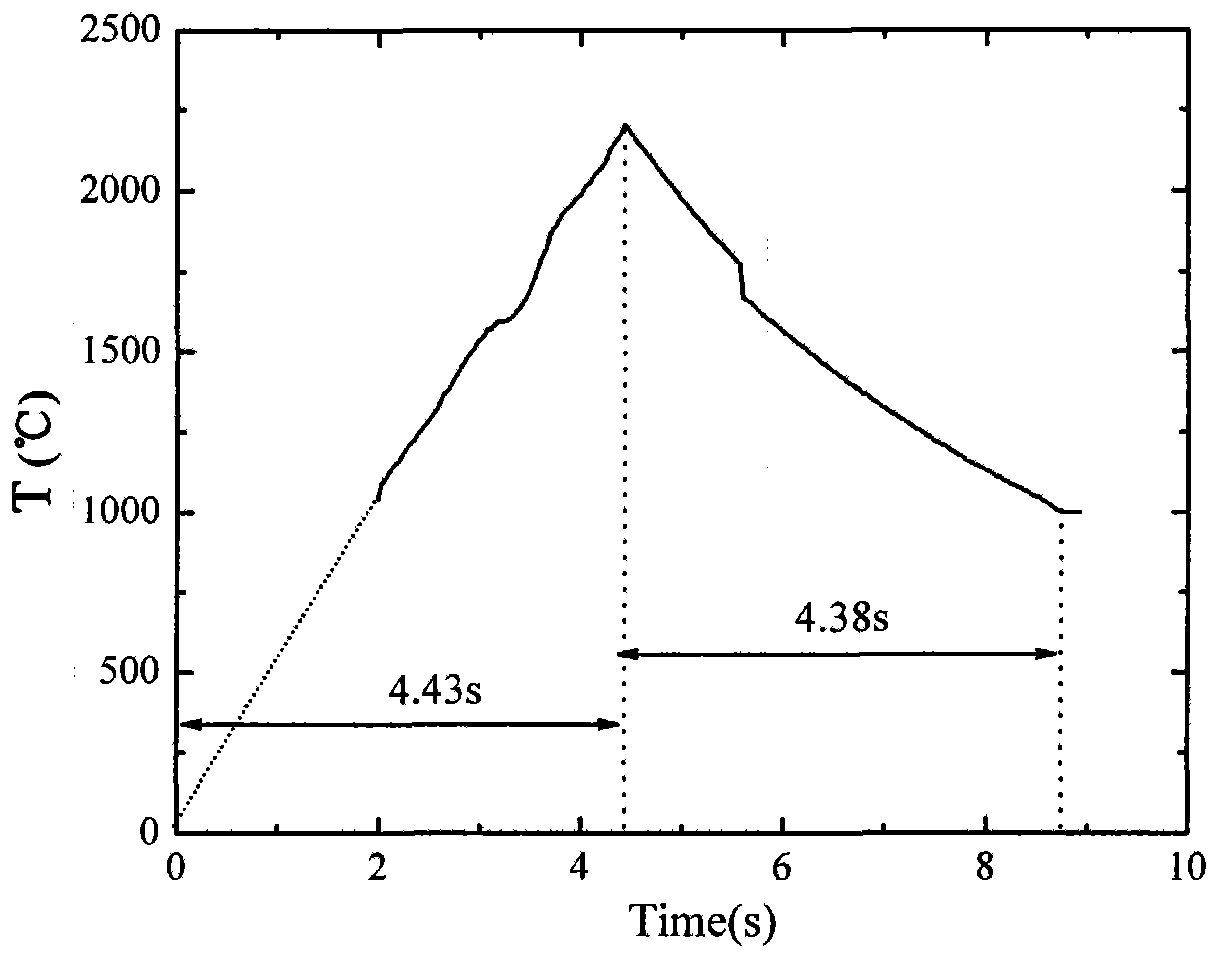

[0032] Using ZrB 2 - The test sample made of 20SiC-10AlN ceramic matrix composite material has a size of 3mm×4mm×36mm, and the surface of the sample is polished to a smoothness of less than 1 μm with diamond abrasive paste. Clamp the polished sample in a copper fixture, the distance from the nozzle to the sample is 5mm, the center of the nozzle coincides with the center of the sample, control the regulating valve and pressure reducing valve, the outlet pressure is 10kPa, the output current is 320A; the surface temperature of the sample 2000±30°C, the heating rate is about 300°C / s, and the loading time is 6.67s.

Embodiment 2

[0034] Using ZrB 2 - The test sample made of 20SiC-10AlN ceramic matrix composite material has a size of 6mm×8mm×36mm, and the surface of the sample is polished to a smoothness of less than 1 μm with diamond abrasive paste. Clamp the polished sample in a copper fixture, the distance from the nozzle to the sample is 5mm, the center of the nozzle coincides with the center of the sample, control the regulating valve and pressure reducing valve, the outlet pressure is 10kPa, the output current is 1170A; the surface temperature of the sample 1800±30°C, the heating rate is about 200°C / s, and the loading time is 9.2s.

Embodiment 3

[0036] Using ZrB 2 -20SiC W The test sample made of ceramic matrix composite material has a size of 6mm×8mm×36mm, and the surface of the sample is polished to a smoothness of less than 1 μm with diamond abrasive paste. Clamp the polished sample in a copper fixture, the distance from the nozzle to the sample is 5mm, the center of the nozzle coincides with the center of the sample, control the regulating valve and pressure reducing valve, the outlet pressure is 40kPa, the output current is 1500A; the surface temperature of the sample 1600±30°C, the heating rate is about 300°C / s, and the loading time is 5.6s.

[0037] The present invention has the following main technical features:

[0038] 1. Monitor the current and voltage output of the device of the present invention through a Hall transformer and a voltmeter: current 0-5000A; voltage 0-10V;

[0039] 2. For thermal protection materials of different materials and structures, the test temperature range of single / double colori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com