Patents

Literature

760 results about "Cooling cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

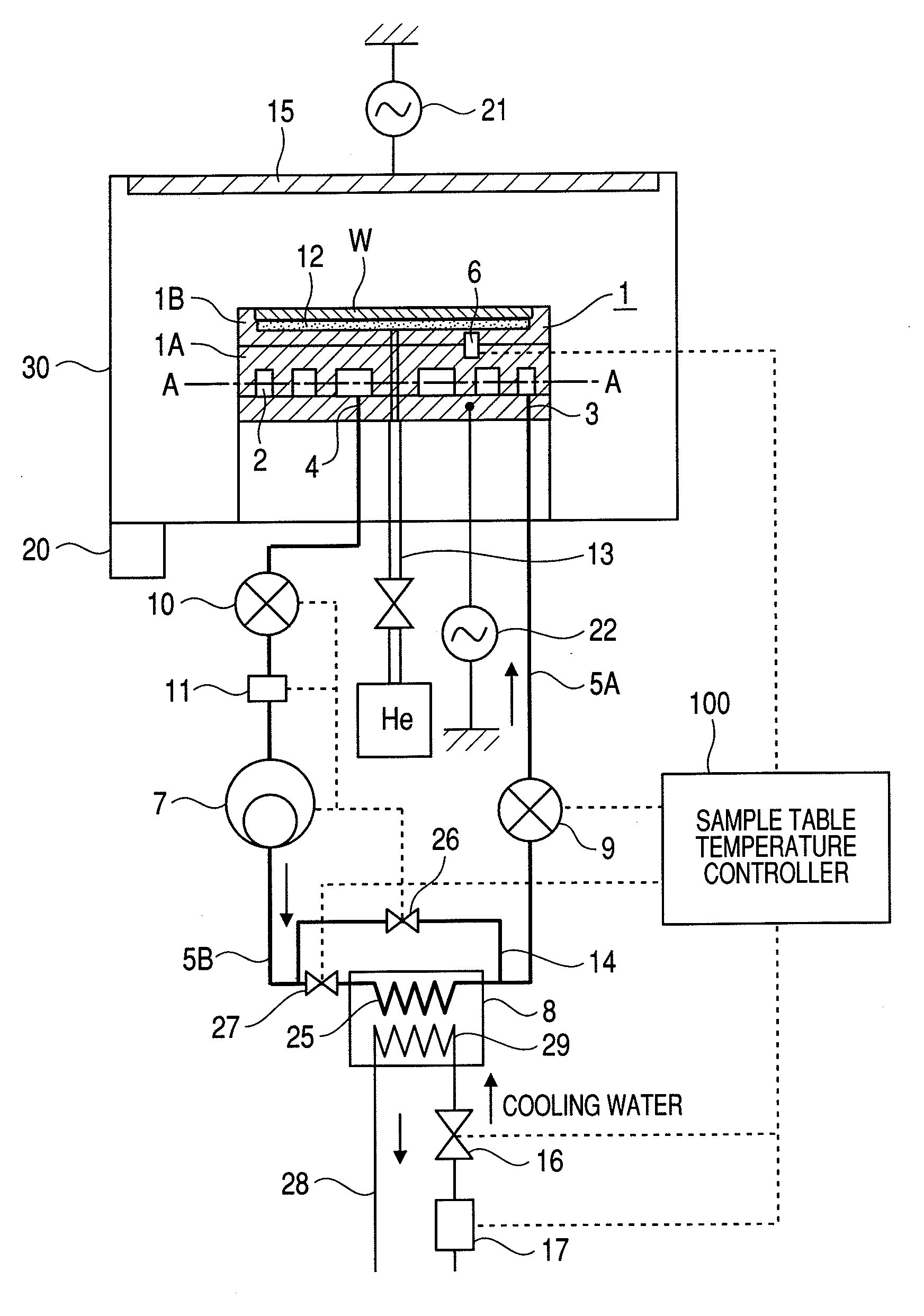

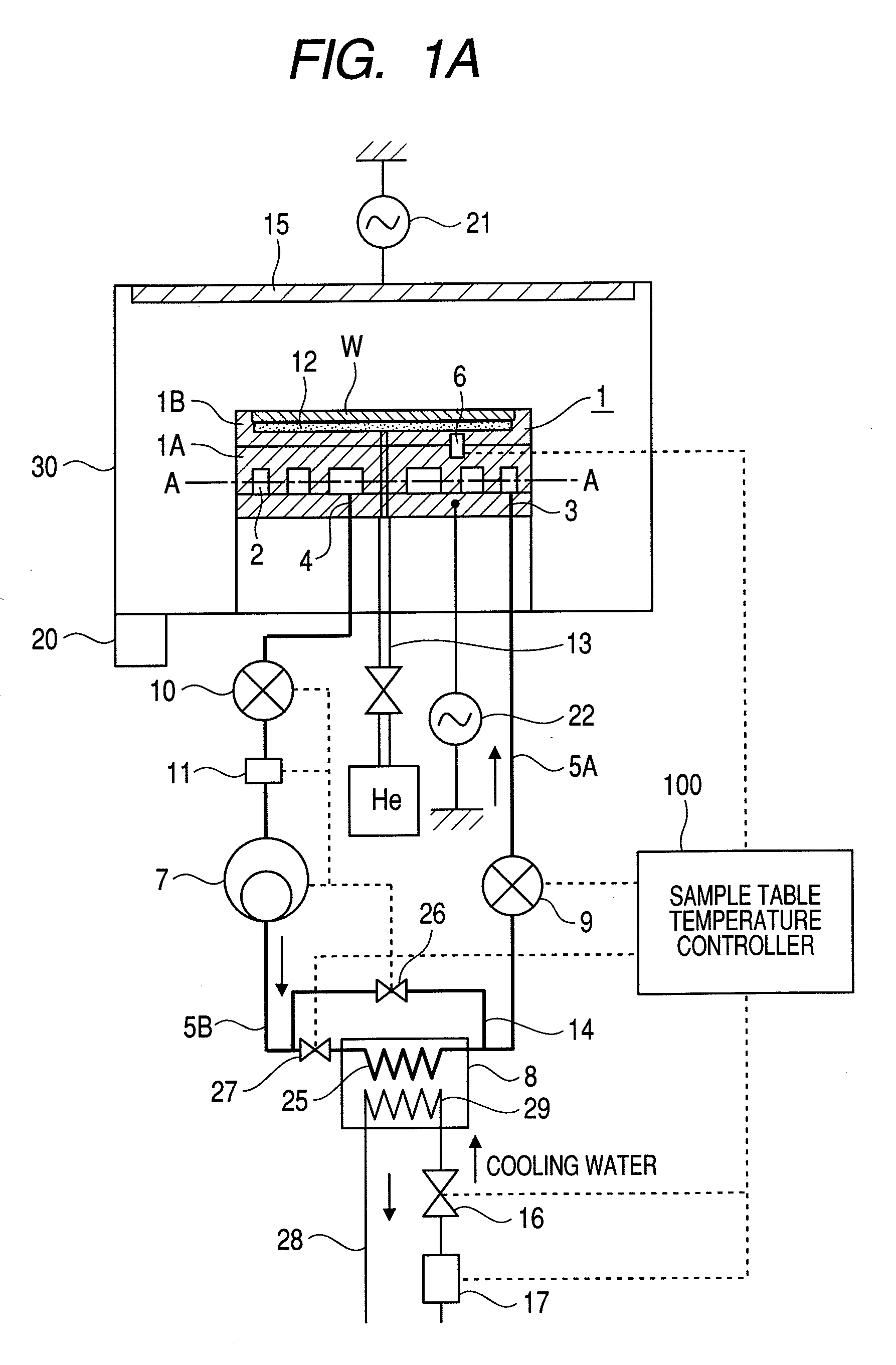

Plasma processing apparatus

InactiveUS20100126666A1Uniform processingUnified controlElectric discharge tubesSemiconductor/solid-state device manufacturingIn planeEngineering

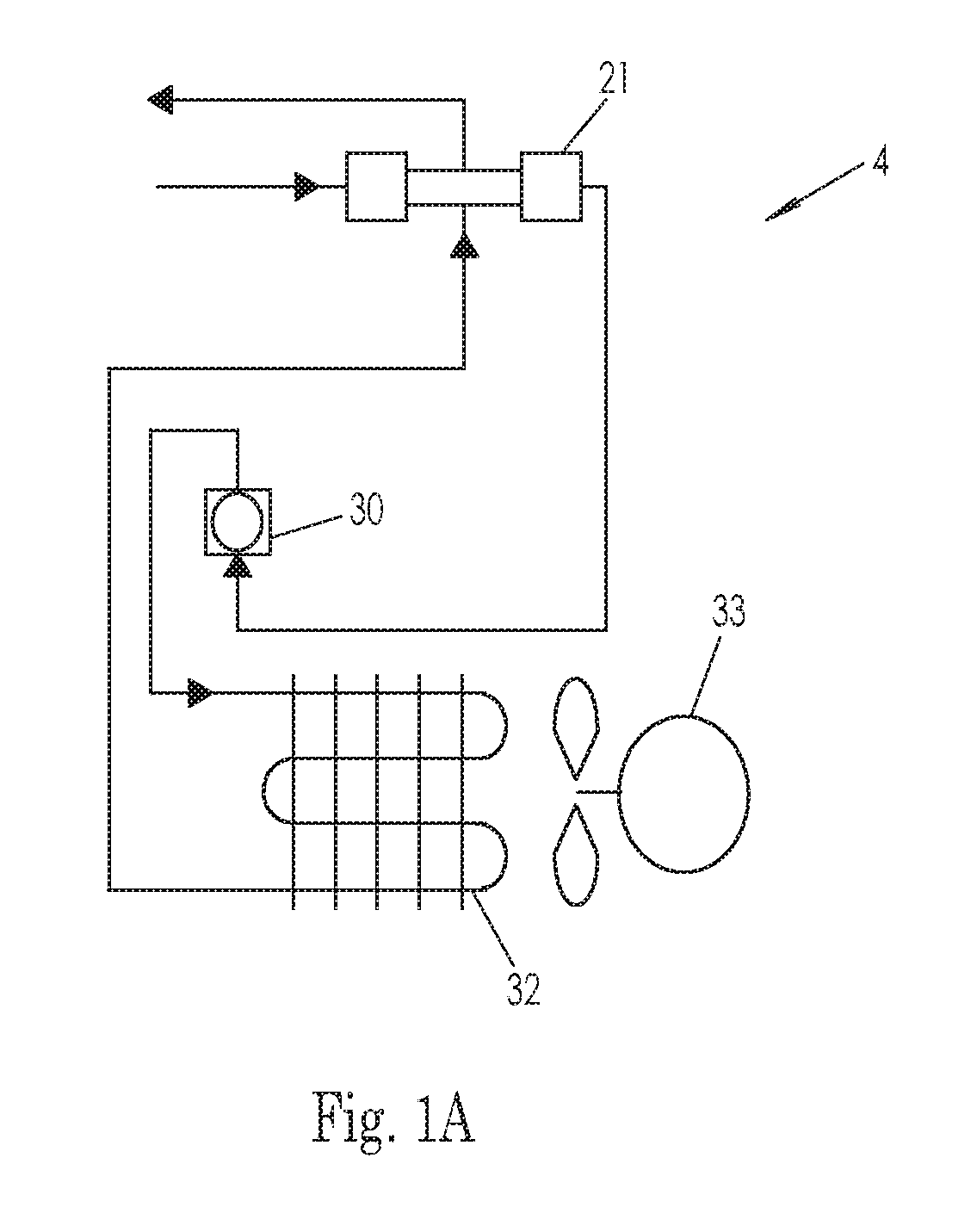

In a plasma processing apparatus; a refrigerant flow passage being formed in the sample table and constituting an evaporator of a cooling cycle and the in-plane temperature of the sample to be processed is controlled uniformly by controlling the enthalpy of the refrigerant supplied to the refrigerant flow passage and thereby keeping the flow mode in the refrigerant flow passage, namely in the sample table, in the state of a gas-liquid two-phase. If by any chance dry out of the refrigerant occurs in the refrigerant flow passage because the heat input of plasma increases with time or by another reason, it is possible to increase speed of a compressor and inhibit the dry out from occurring in the refrigerant flow passage. Further, if the refrigerant supplied to the refrigerant flow passage is liquefied, it is kept in the gas-liquid two-phase state.

Owner:HITACHI HIGH-TECH CORP

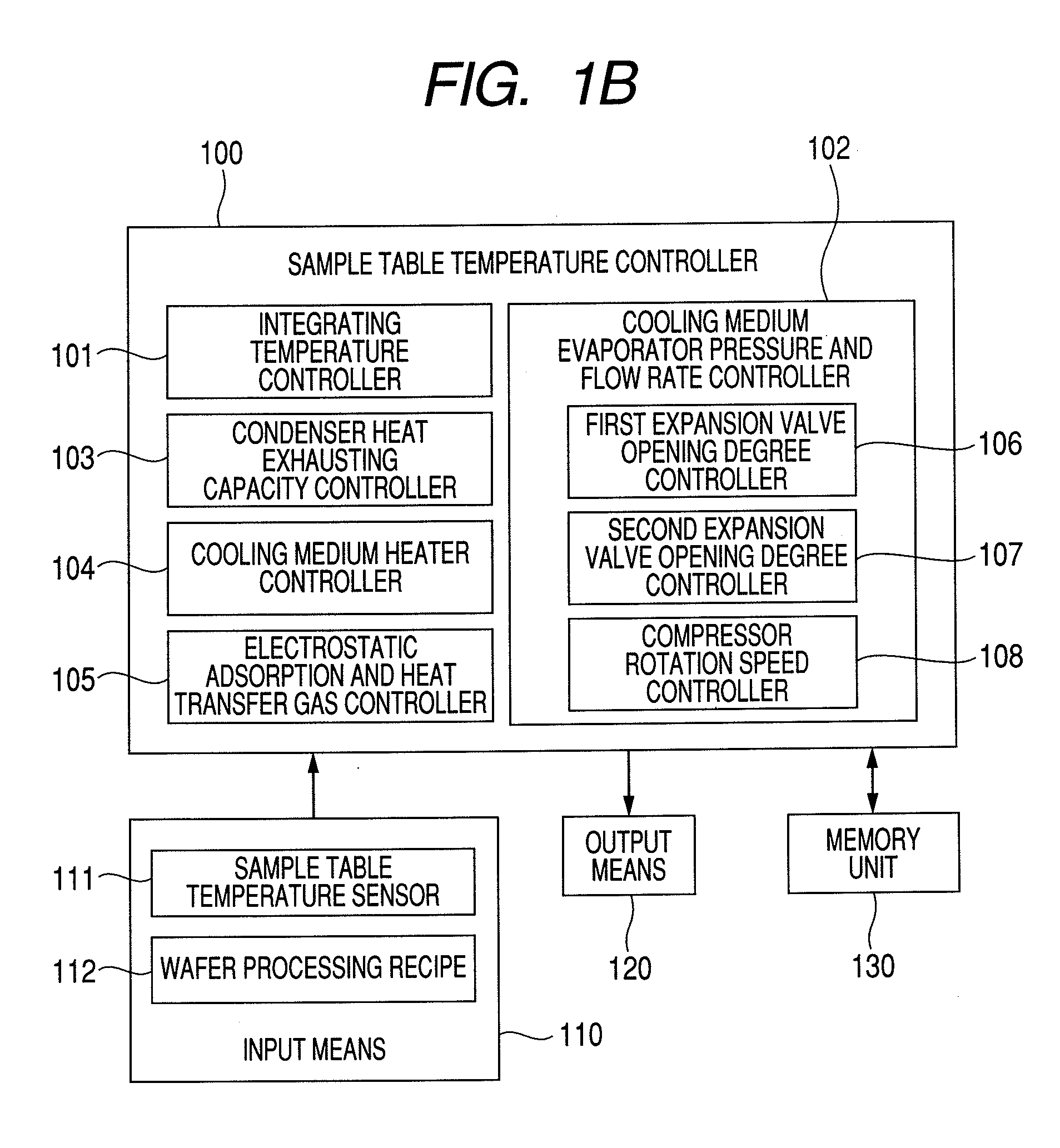

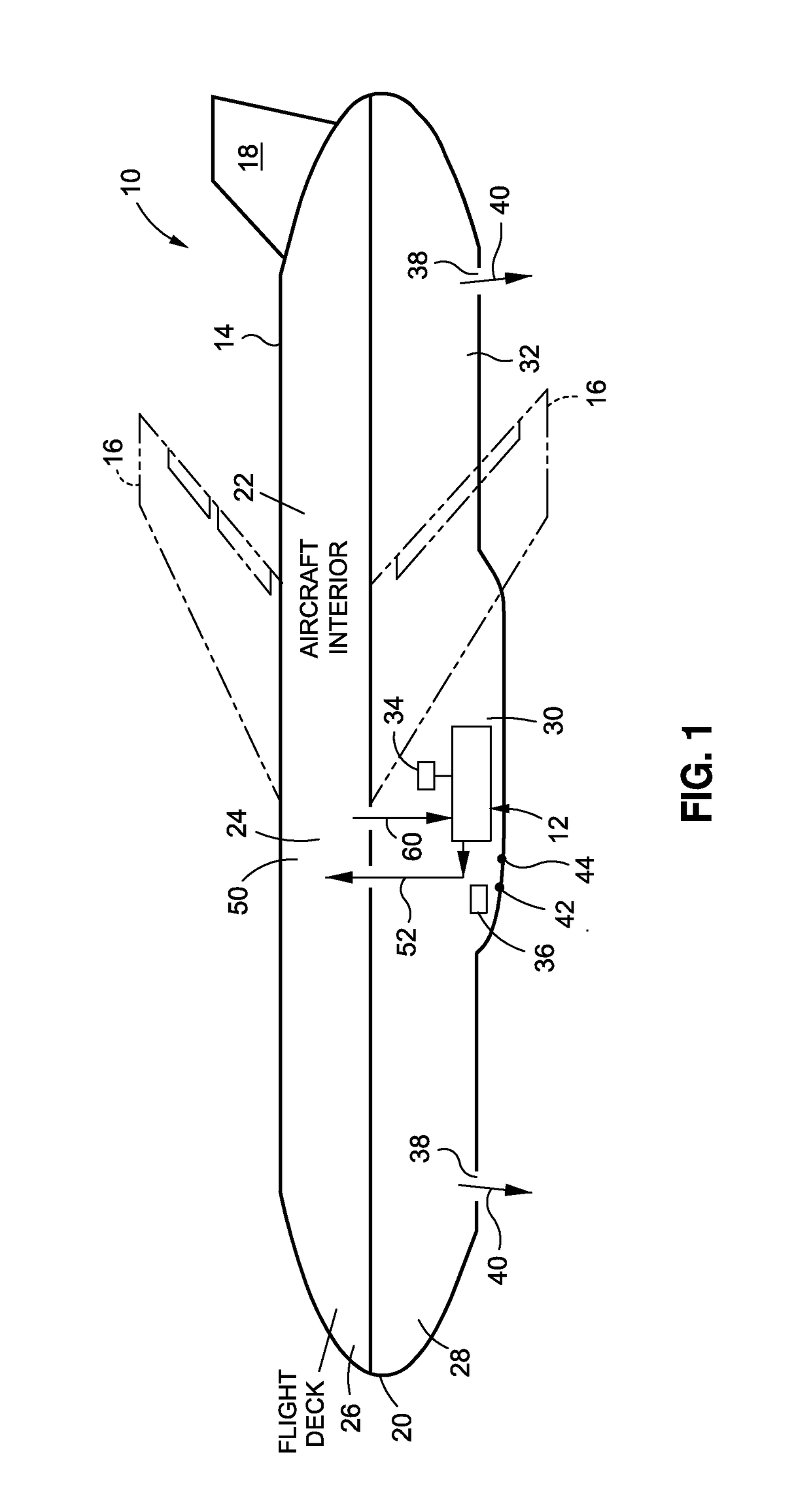

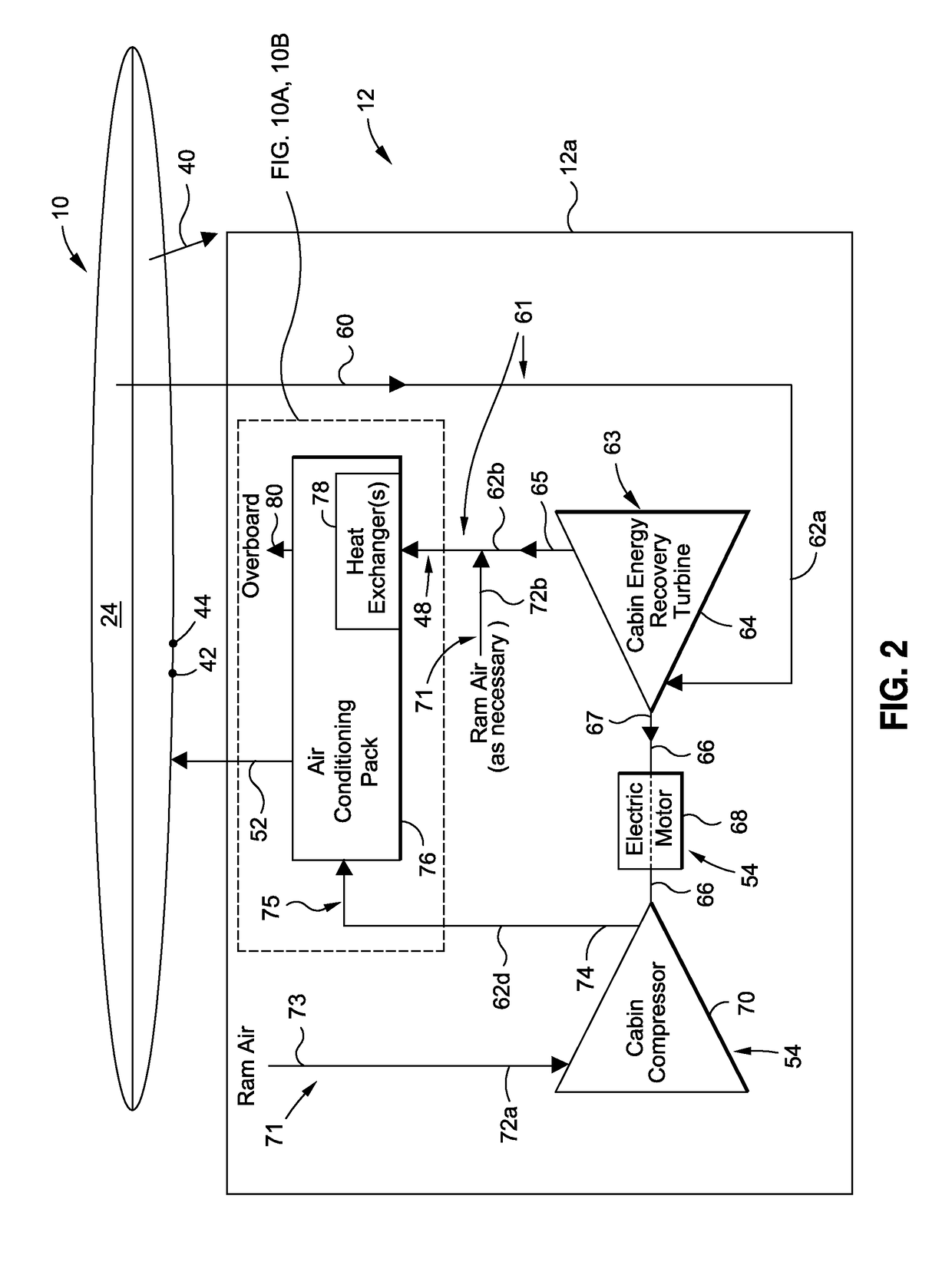

Aircraft air conditioning systems and methods

ActiveUS9669936B1Meet actual needsReduce the temperatureAir-treatment apparatus arrangementsEnergy efficient board measuresControl systemAir conditioning

There are provided aircraft air conditioning systems and methods. The aircraft air conditioning system has a duct in an aircraft connected to an aircraft cabin and configured to flow pressurized cabin outflow air from the aircraft cabin. The aircraft air conditioning system further has a turbine connected to the duct and configured to reduce a temperature of the pressurized cabin outflow air and to generate power, and further has a compressor configured to generate a compressed inlet air stream, and further has an air conditioning pack configured to receive a reduced temperature cabin outflow air from the turbine and configured to receive the compressed inlet air stream from the compressor. The air conditioning pack has a cooling cycle system, a humidity control system, and one or more heat exchangers configured to use the reduced temperature cabin outflow air as a heat sink.

Owner:THE BOEING CO

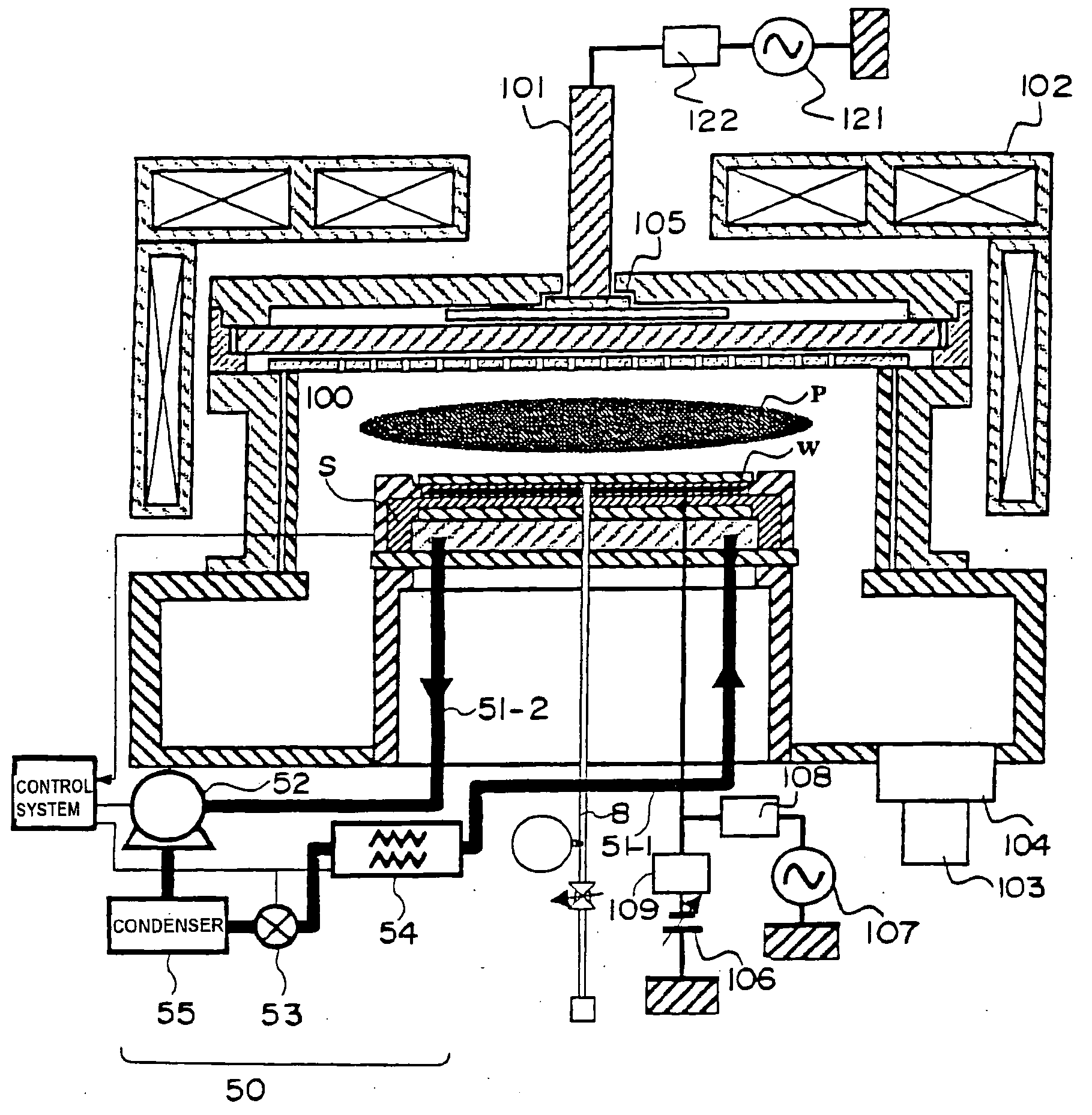

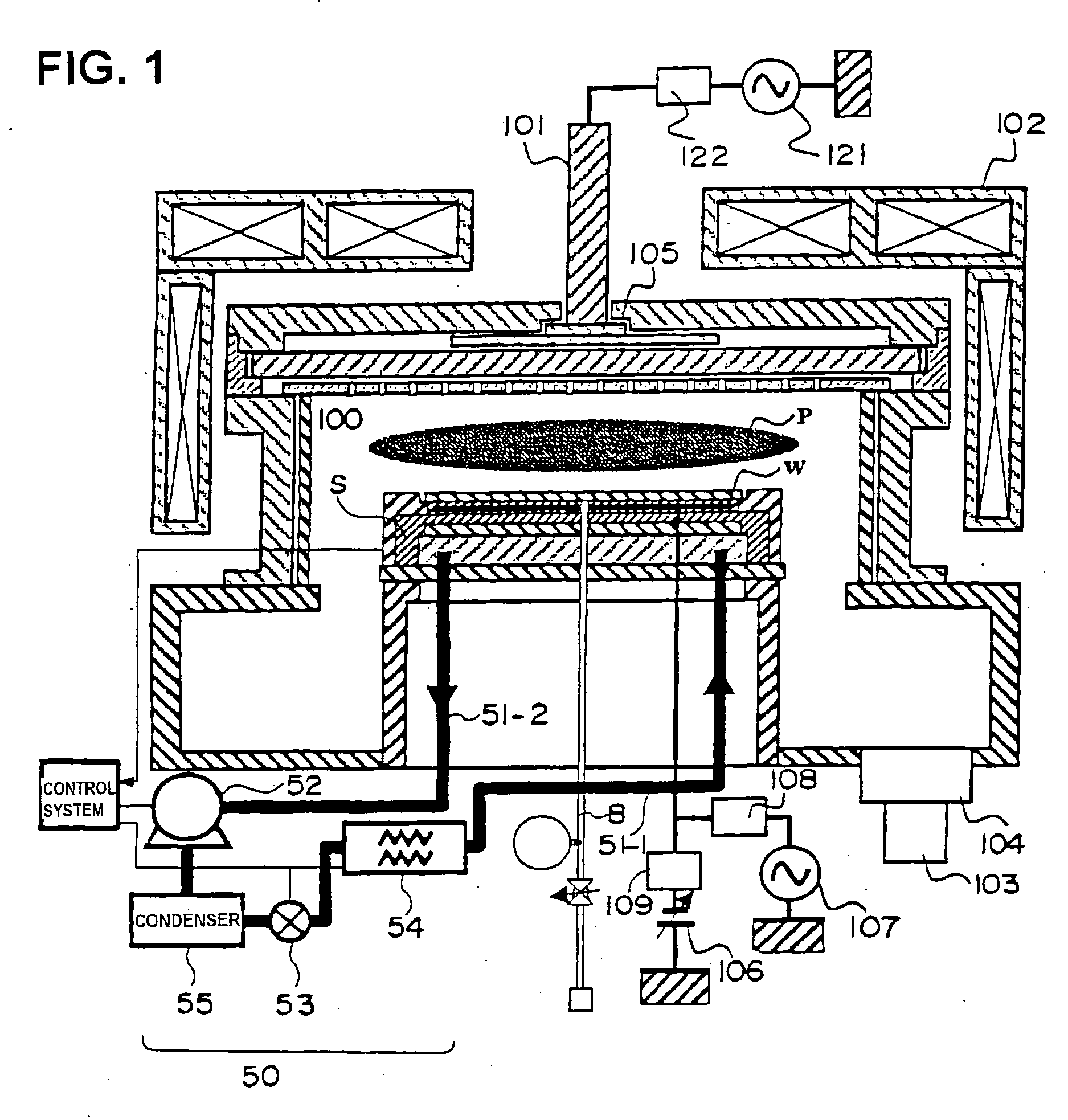

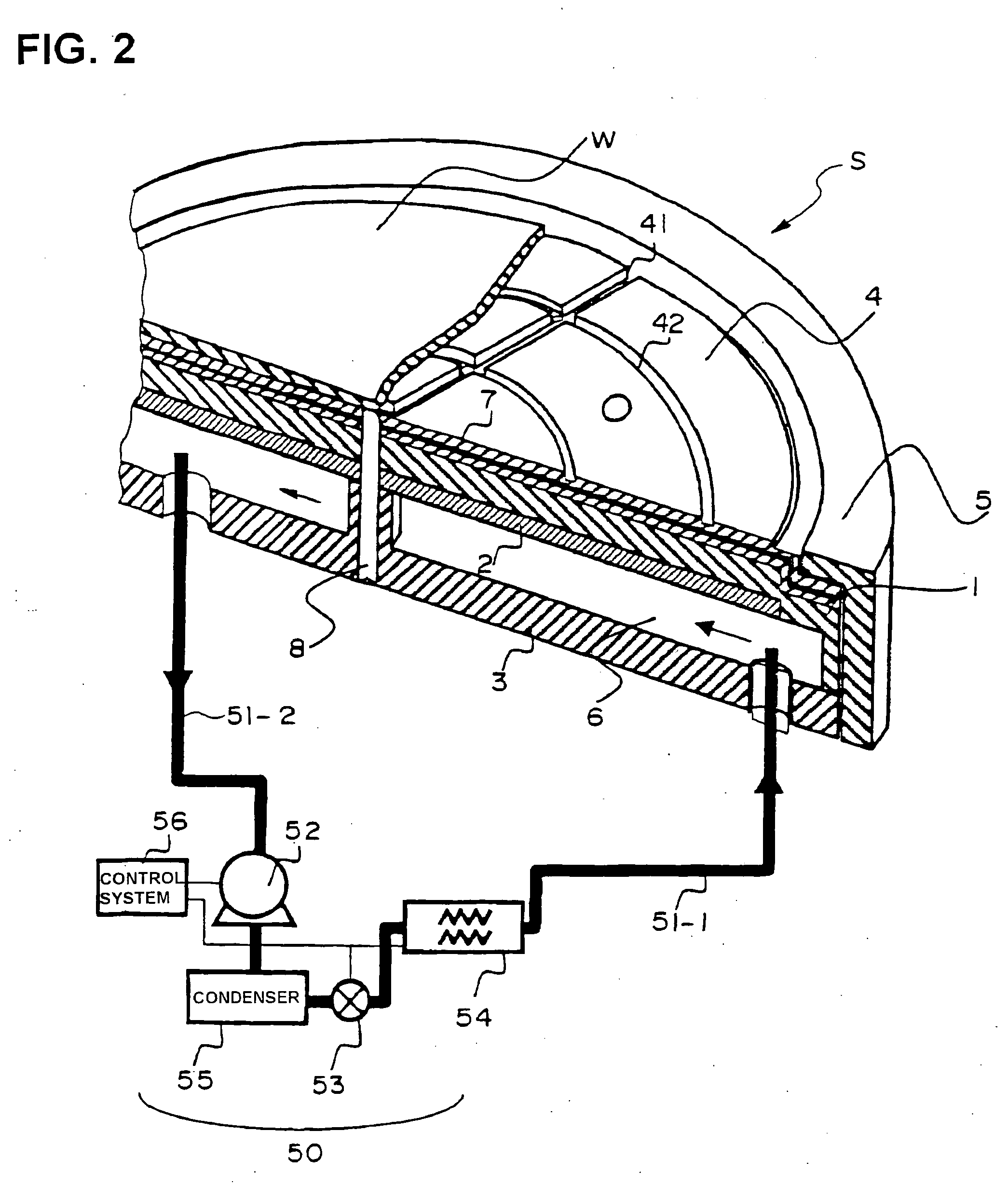

Plasma processing apparatus

InactiveUS20050045104A1Electric discharge tubesCompression machines with non-reversible cycleTemperature controlCoolant flow

A plasma processing apparatus having an electrostatic chucking electrode that allows temperature control of a semiconductor wafer during etching process with high efficiency comprises: a holder stage comprising an electrode block S having a dielectric film 4 on the surface thereof and a coolant flow passage 6 therein, in which temperature control is performed while holding a semiconductor wafer W on the dielectric film on the surface of the electrode block; and a cooling cycle 50 including a compressor 52, a condenser 55, an expansion valve 53, a heat exchanger 54 having a heater built therein, and an evaporator, wherein the temperature control of the electrode block S is performed by using a direct-expansion-type temperature controller in which the electrode block S is used as the evaporator of the cooling cycle, and the coolant is directly circulated and expanded inside the electrode block.

Owner:HITACHI HIGH-TECH CORP

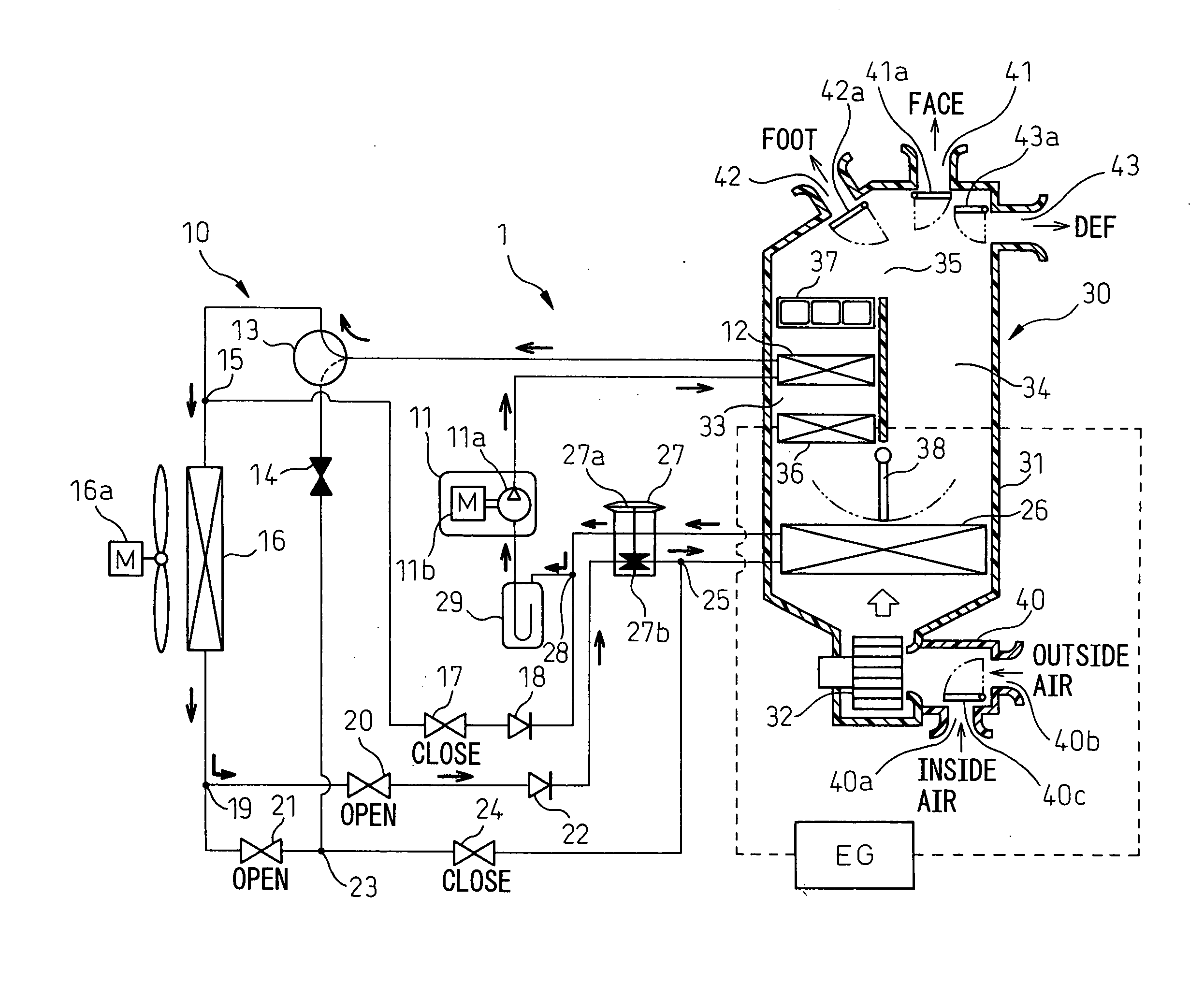

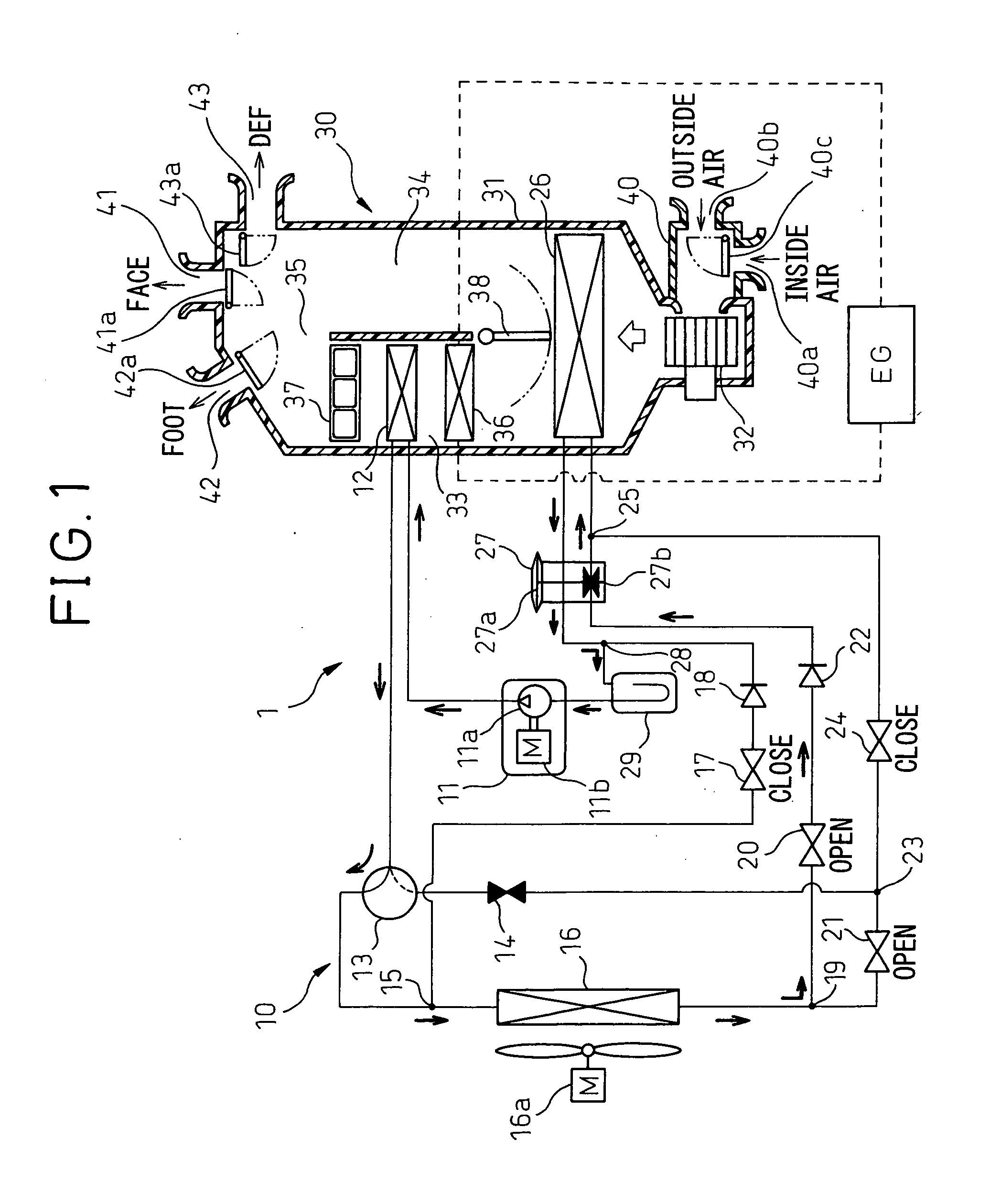

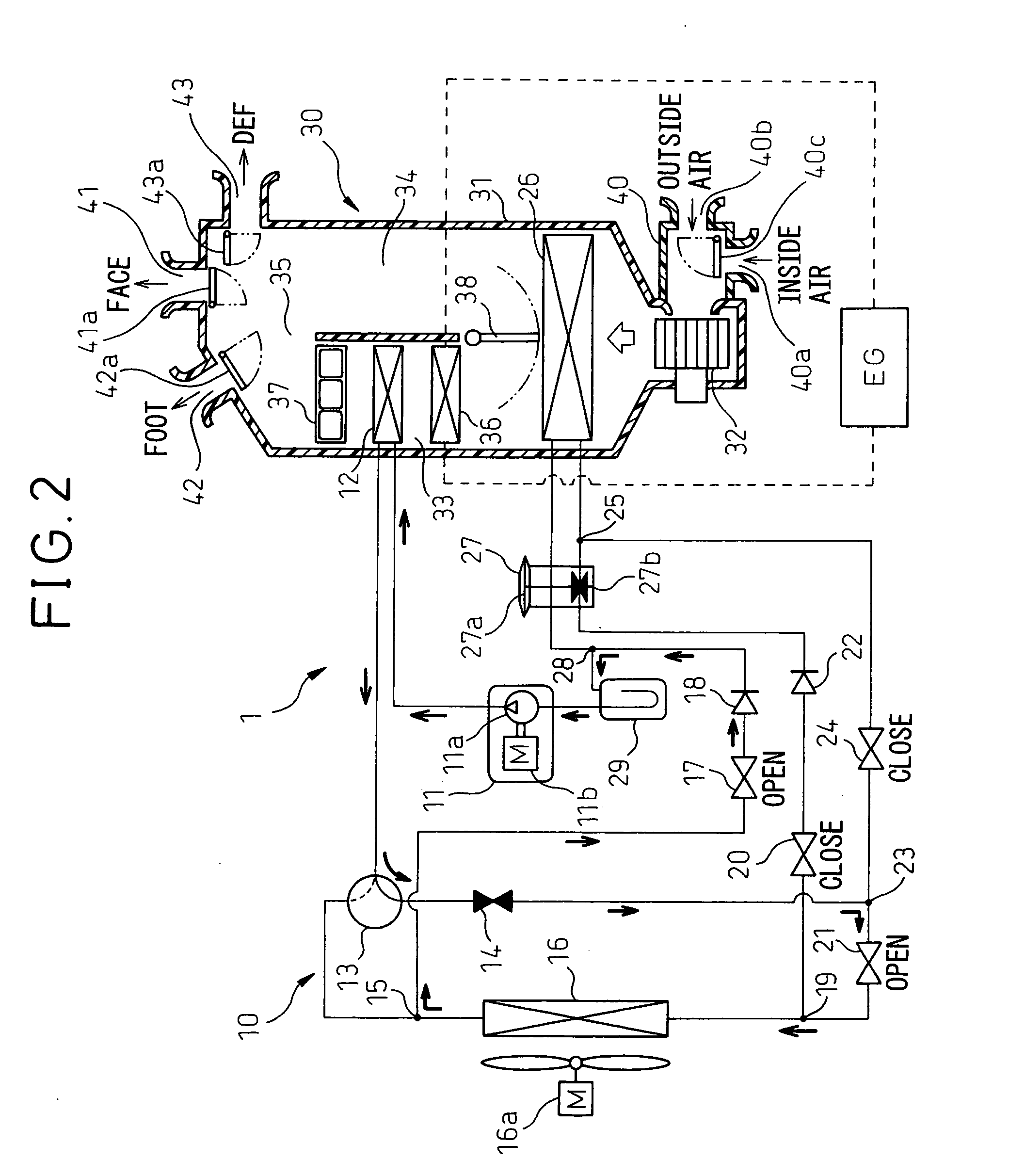

Vehicular air-conditioning system

InactiveUS20110005255A1Improve defogging effectImprove practicalityAir-treating devicesVehicle heating/cooling devicesEngineeringControl switch

A vehicular air-conditioning system provided with a vapor compression type refrigerating machine improved in practicality, provided with a vapor compression type refrigeration cycle 10 having a compressor 11 compressing and discharging a refrigerant and an outside heat exchanger 16 exchanging heat with the air outside of the cabin and the refrigerant and designed to be able to switch between a cooler cycle cooling vented air blown into the cabin and a heat pump cycle heating the vented air, a heating means 36 for using cooling water of an internal combustion engine EG as a heat source for heating the vented air, a vent mode switch 60c setting a defogging mode blowing out vented air toward the vehicle window glass by operation by a passenger, and a control means 50 controlling switching between the cooler cycle and heat pump cycle, the control means 50 selecting the cooler cycle and outputting a signal requesting operation to the internal combustion engine EG when the vent mode switch 60c is used to set the defogging mode.

Owner:DENSO CORP

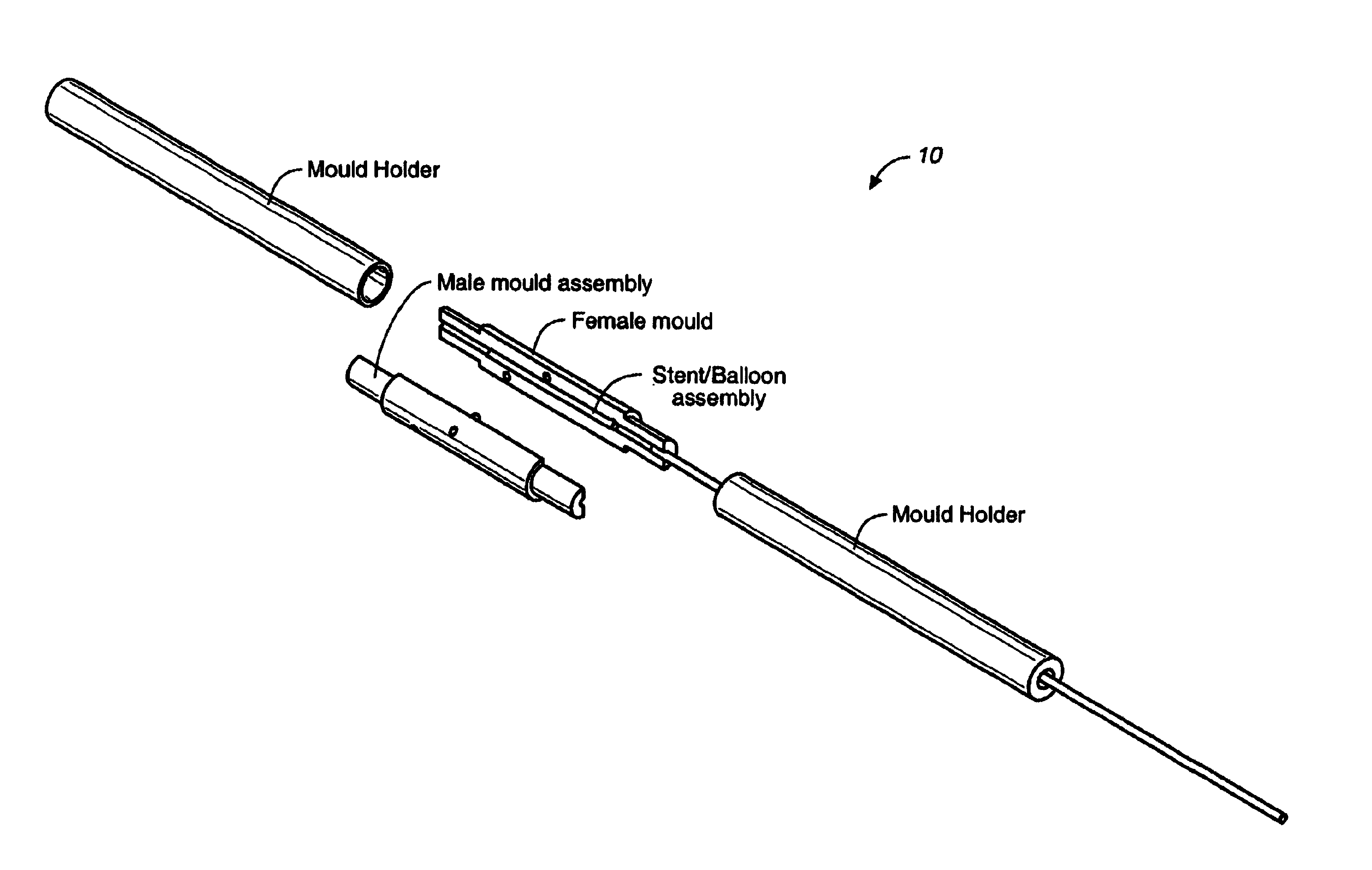

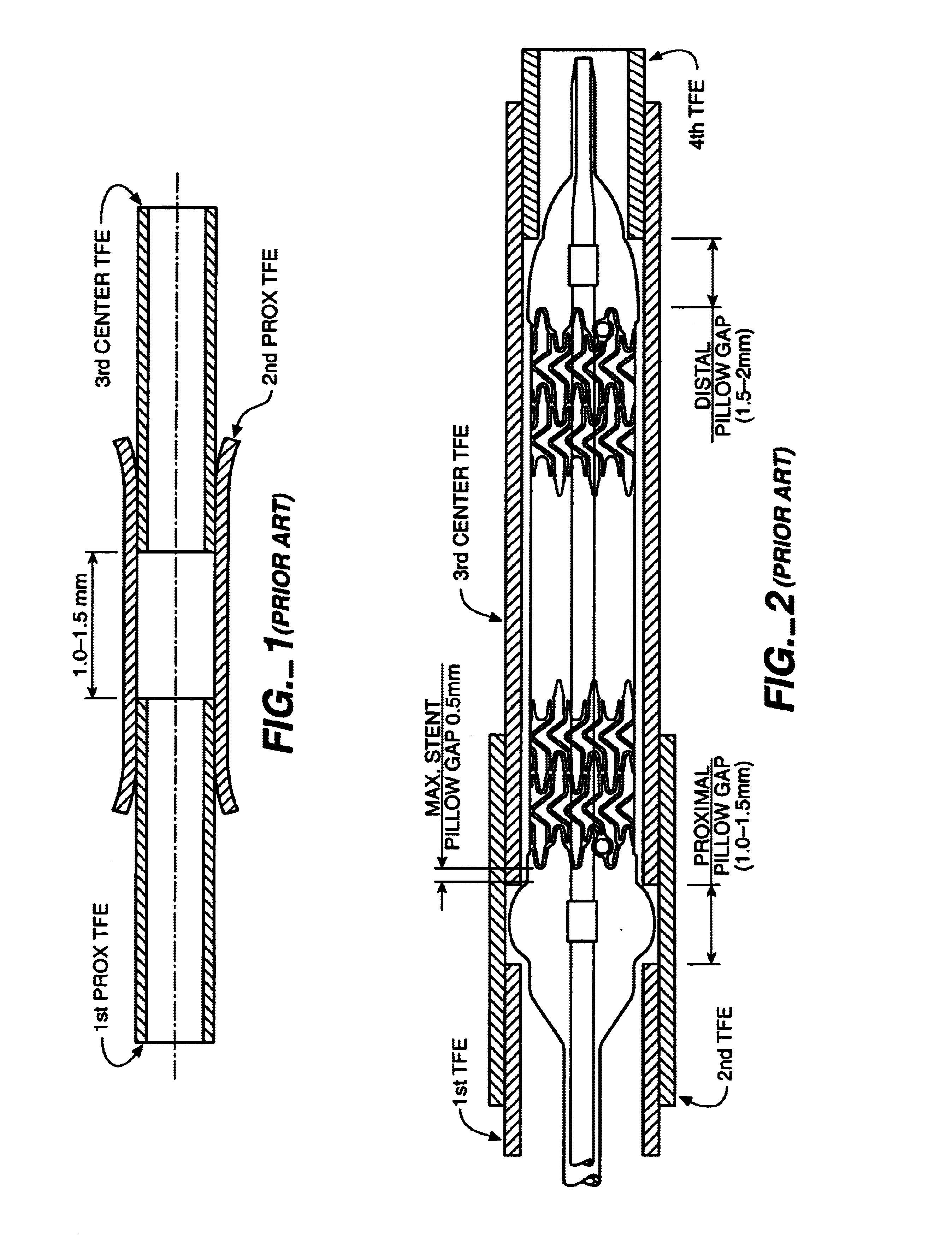

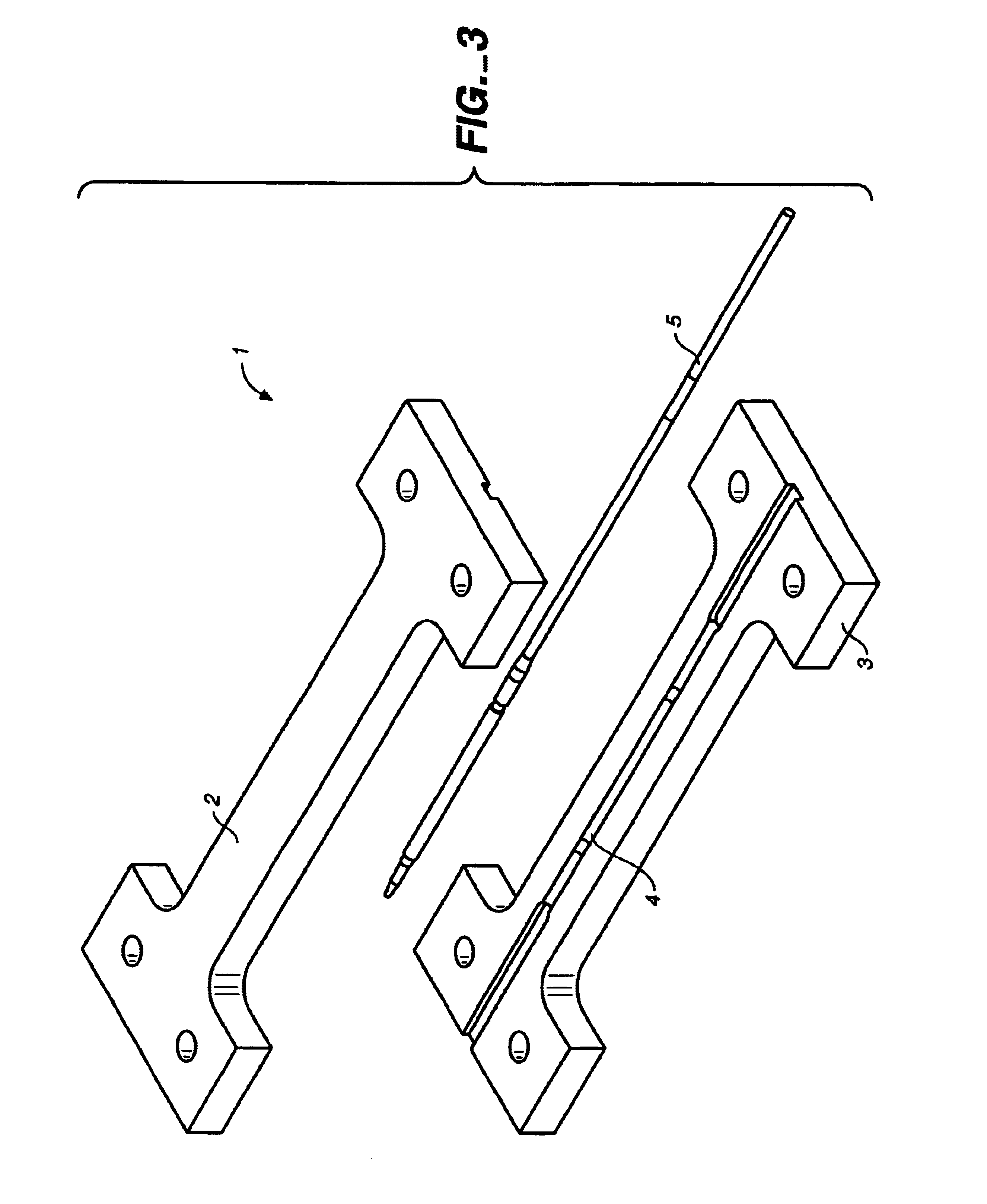

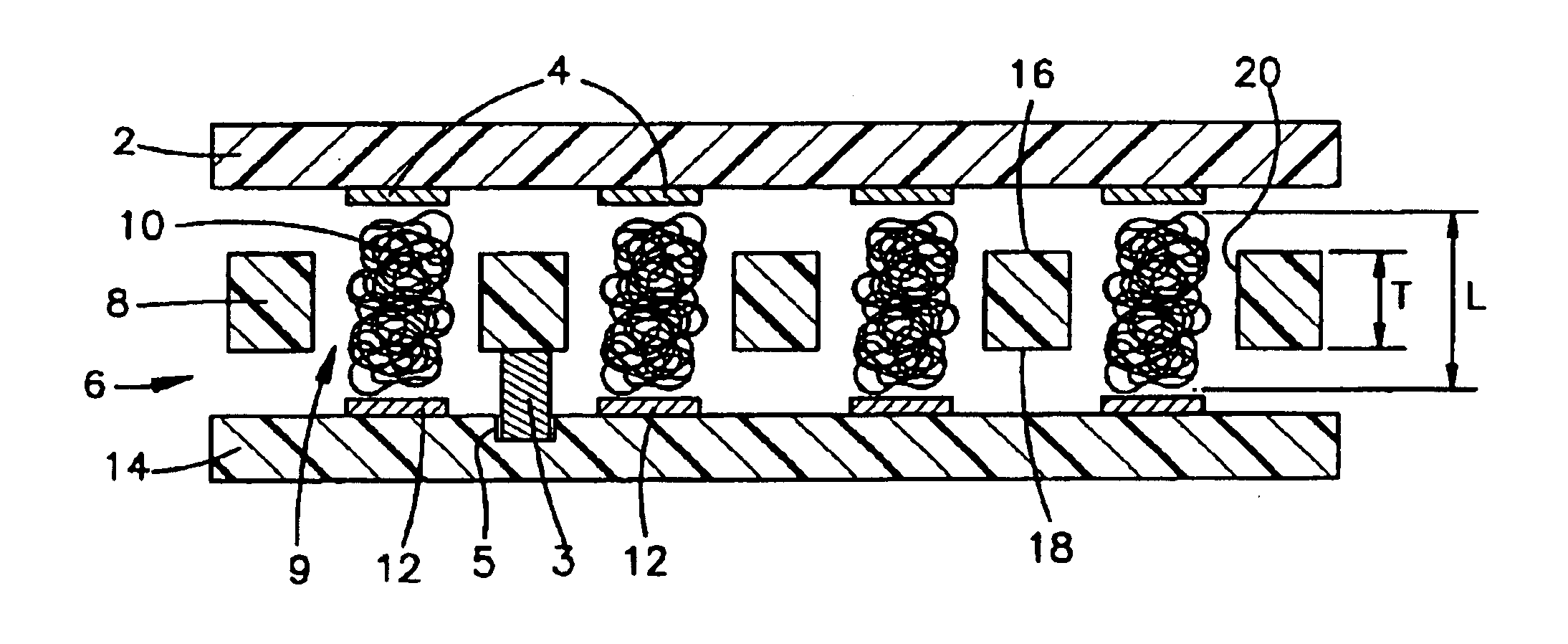

Apparatus for mounting a stent onto a stent delivery system

InactiveUS6948223B2Effective installationEasy to operateStentsShaping toolsInsertion stentDelivery system

The present invention provides a method and apparatus for mounting a stent onto a balloon on a stent delivery system. A stent is then loaded onto the delivery system and the resulting stent / balloon assembly is positioned in a first section of a mould and a second section of the mould is closed onto the first section and locked in place. Pressure is applied to the delivery system through a luer and the mould is heated. The pressure and heat are discontinued and the mould is cooled; this combination of heat and pressure secures the stent to the balloon. The method may include a cooling cycle to help retain the profile of the final stent delivery assembly.

Owner:MEDTRONIC VASCULAR INC

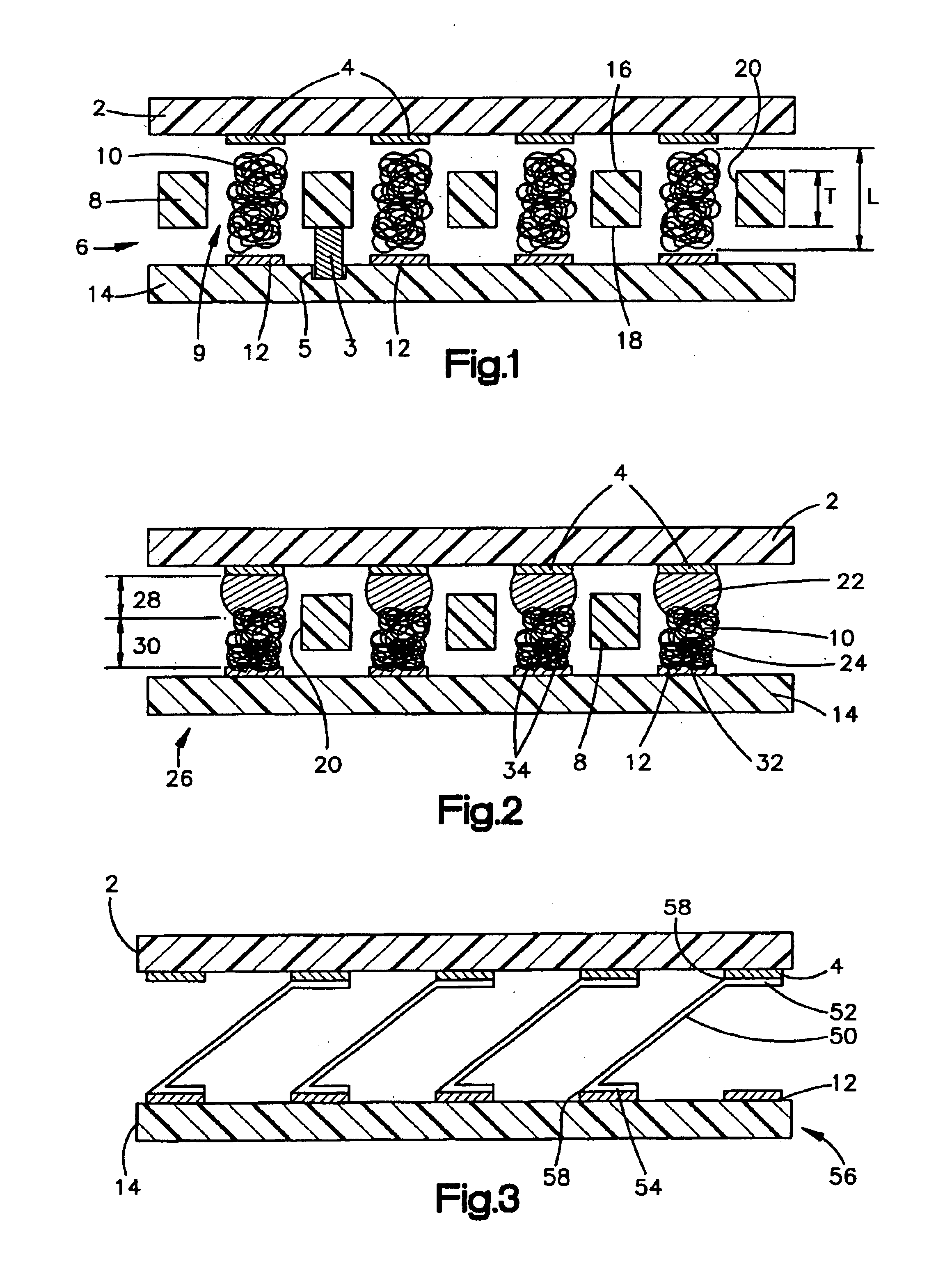

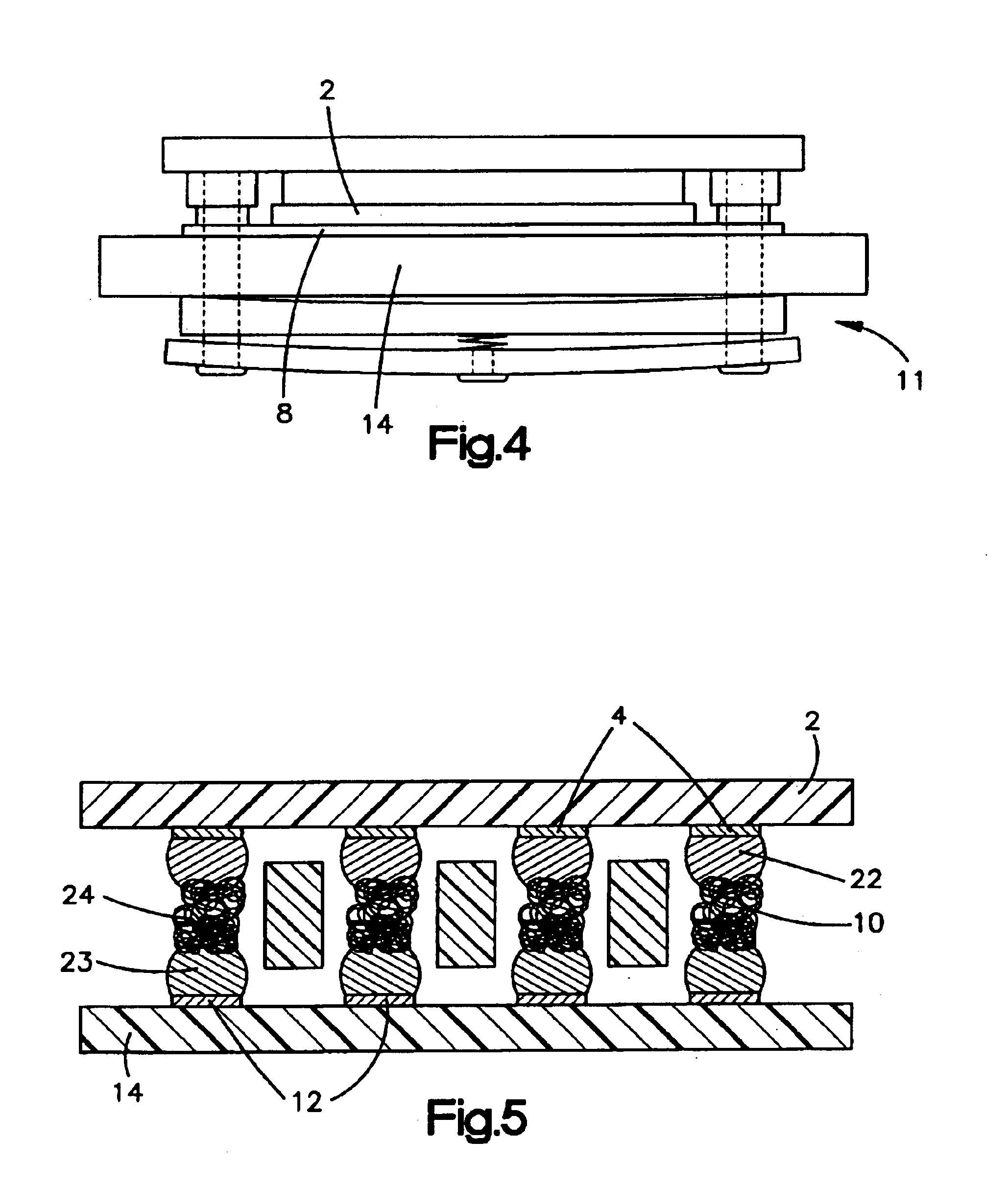

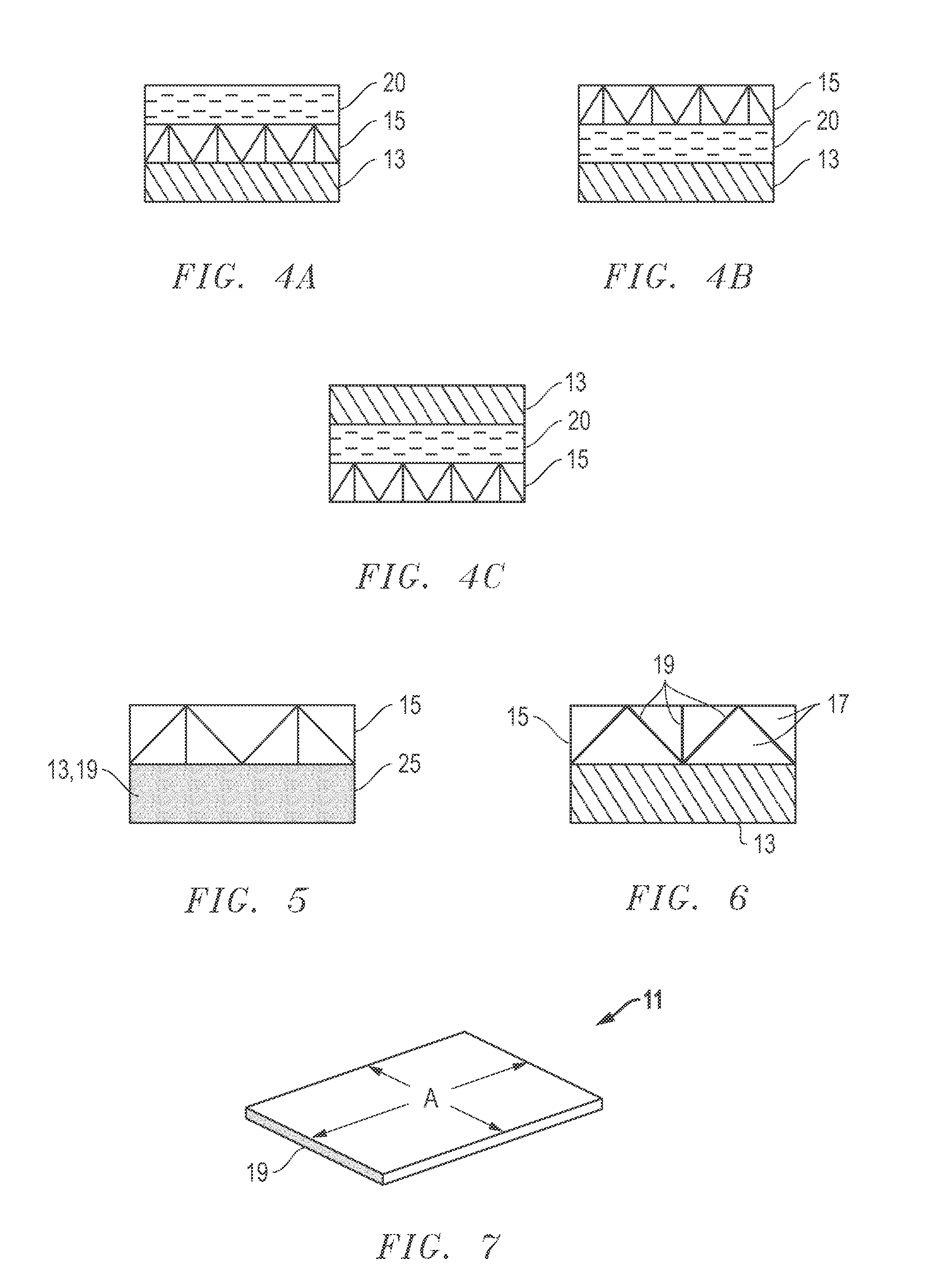

Enhanced electrical/mechanical connection for electronic devices

InactiveUS6695623B2Printed circuit assemblingElectrically conductive connectionsElectrical conductorAdhesive

A method and structure for electrically and mechanically interconnecting an array of printed circuit board contacts to an array of module contacts with a plurality of deformable resilient electrical conductors with two ends. Each of the conductor ends are electrically connected to one of the contact arrays. A portion of the conductor may deform longitudinally and laterally responsive to movement of the printed circuit board relative to the module responsive to heating and cooling cycles and mechanical vibrations, while maintaining the electrical connection of the contact arrays. An interposer with apertures extending through the interposer carries the conductors in the apertures and is used to align the conductors with the contacts. A method for excluding a rigid adhesive means from a portion of the resilient conductor is also taught.

Owner:GOOGLE LLC

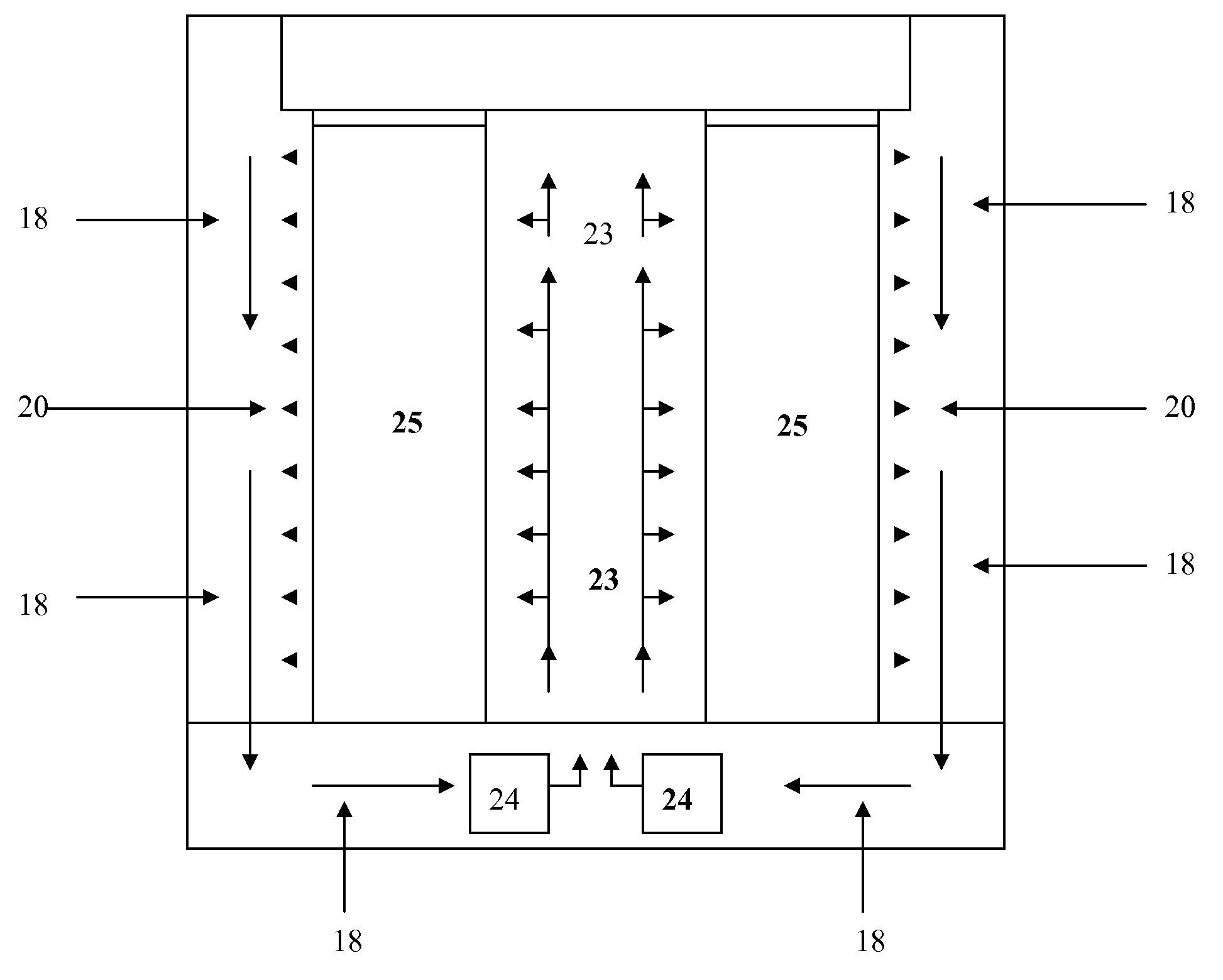

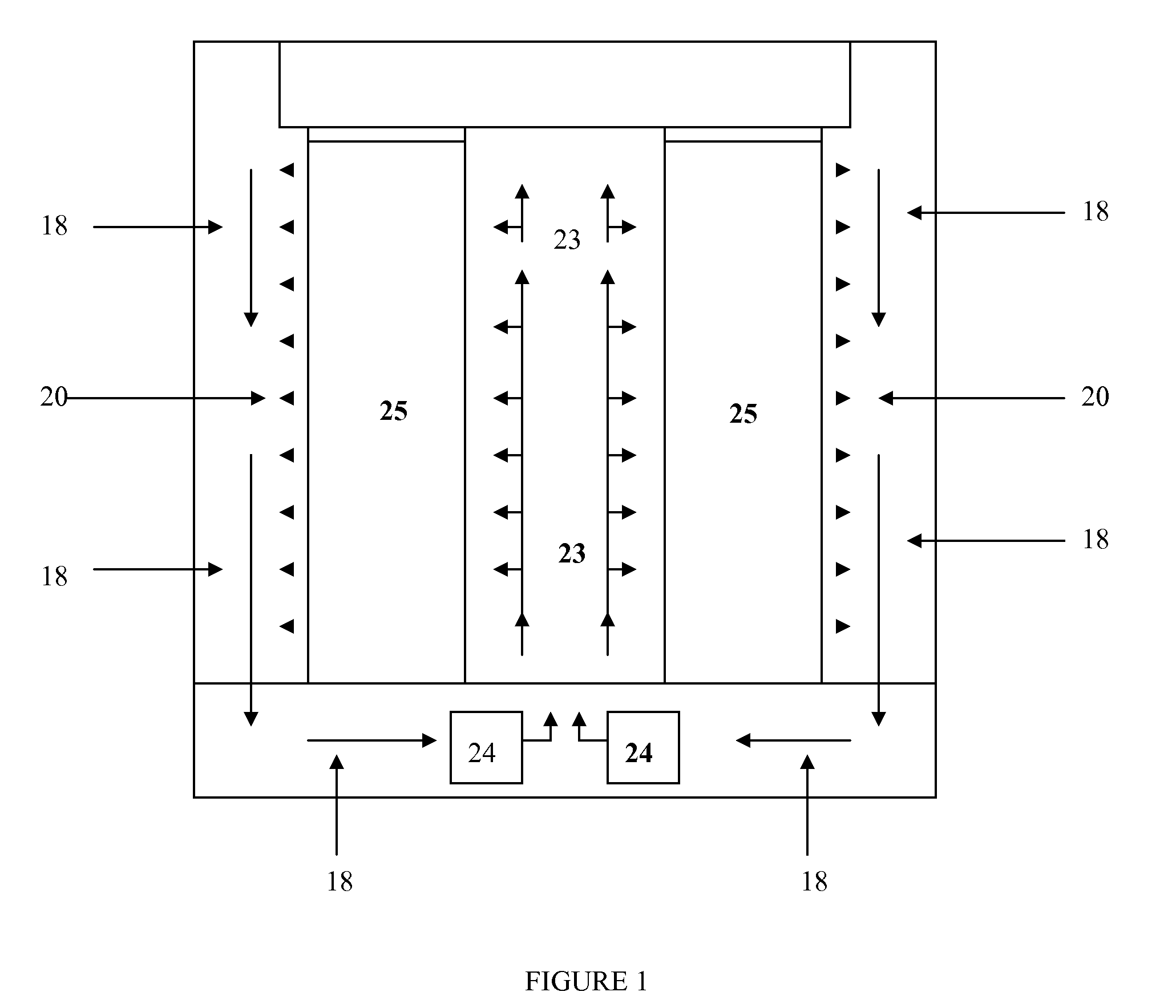

Method and apparatus for data center air conditioning

Modular data center containers with modular components suitable for use with rack or shelf mount computing systems currently use cooling methods that do not include economizers due to size constraints of structural steel support infrastructure associated with modular data centers and removable economizers to facilitate portability of modular data centers. The modules allows introduction of outside air to the cooling cycle with the unique elements embodied within airside economizer components. The modules in conjunction with the data center represents a new and useful process to allow the economizer elements to bring outside air into the modular data center cooling cycle.

Owner:LARSEN ARTHUR E

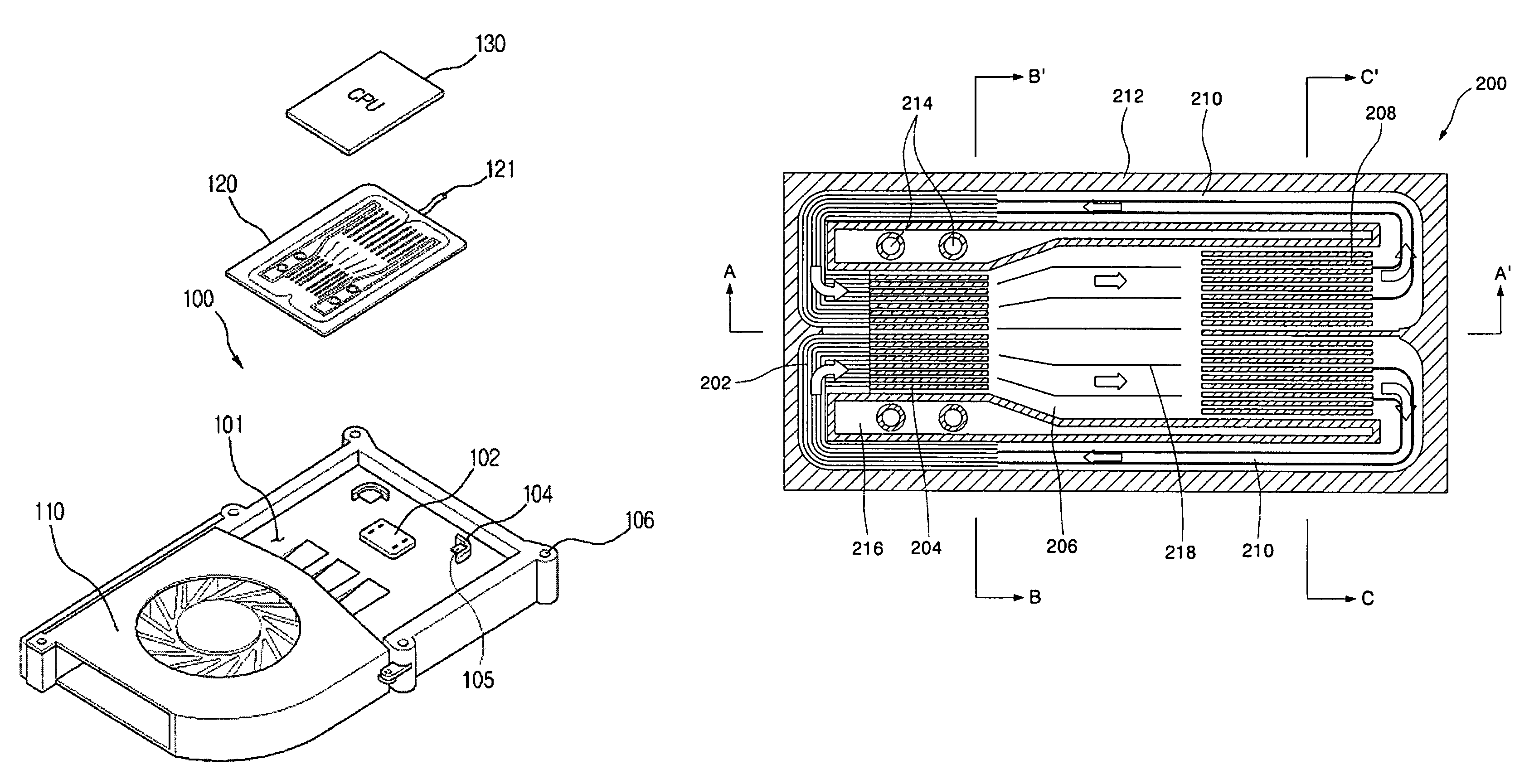

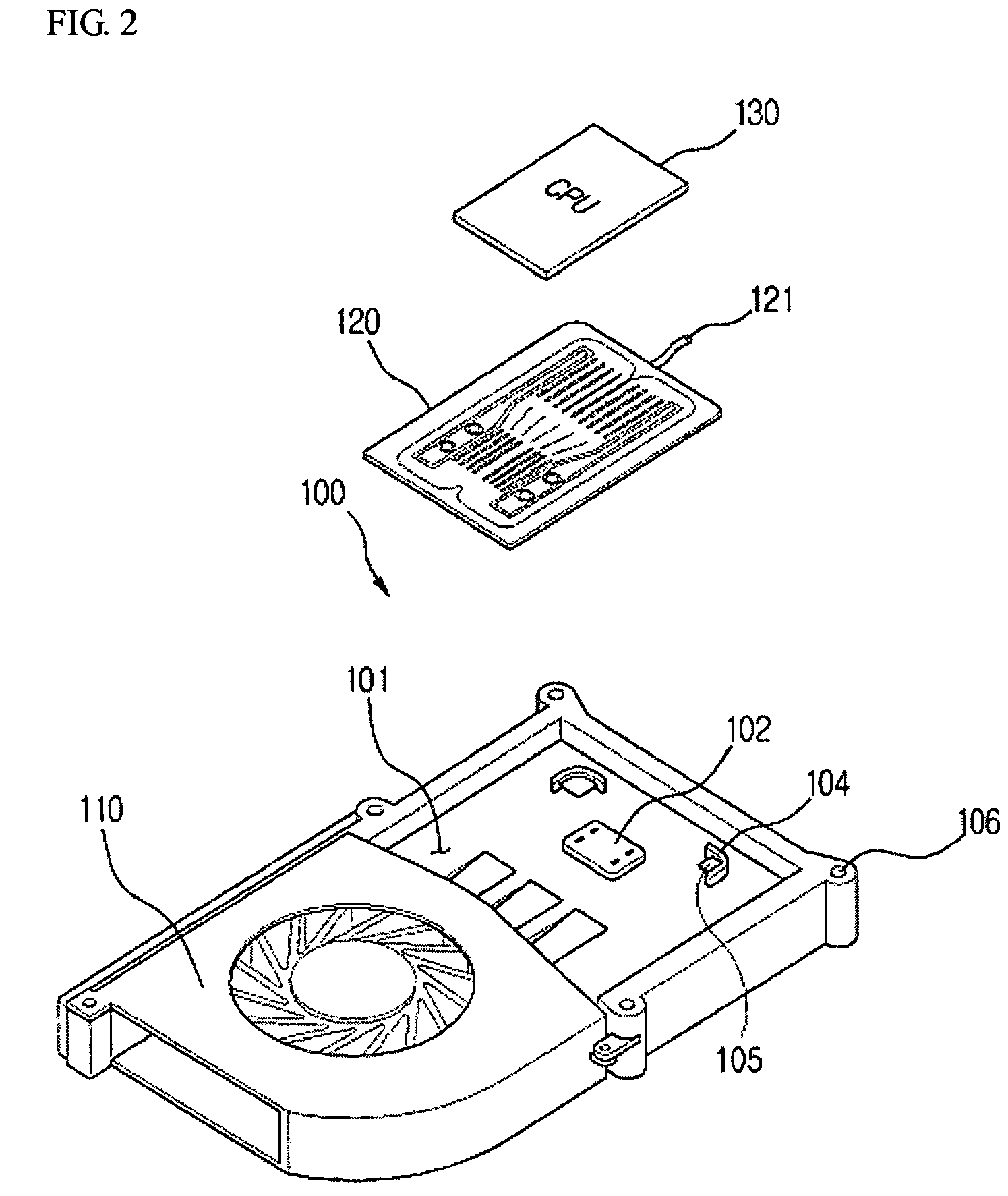

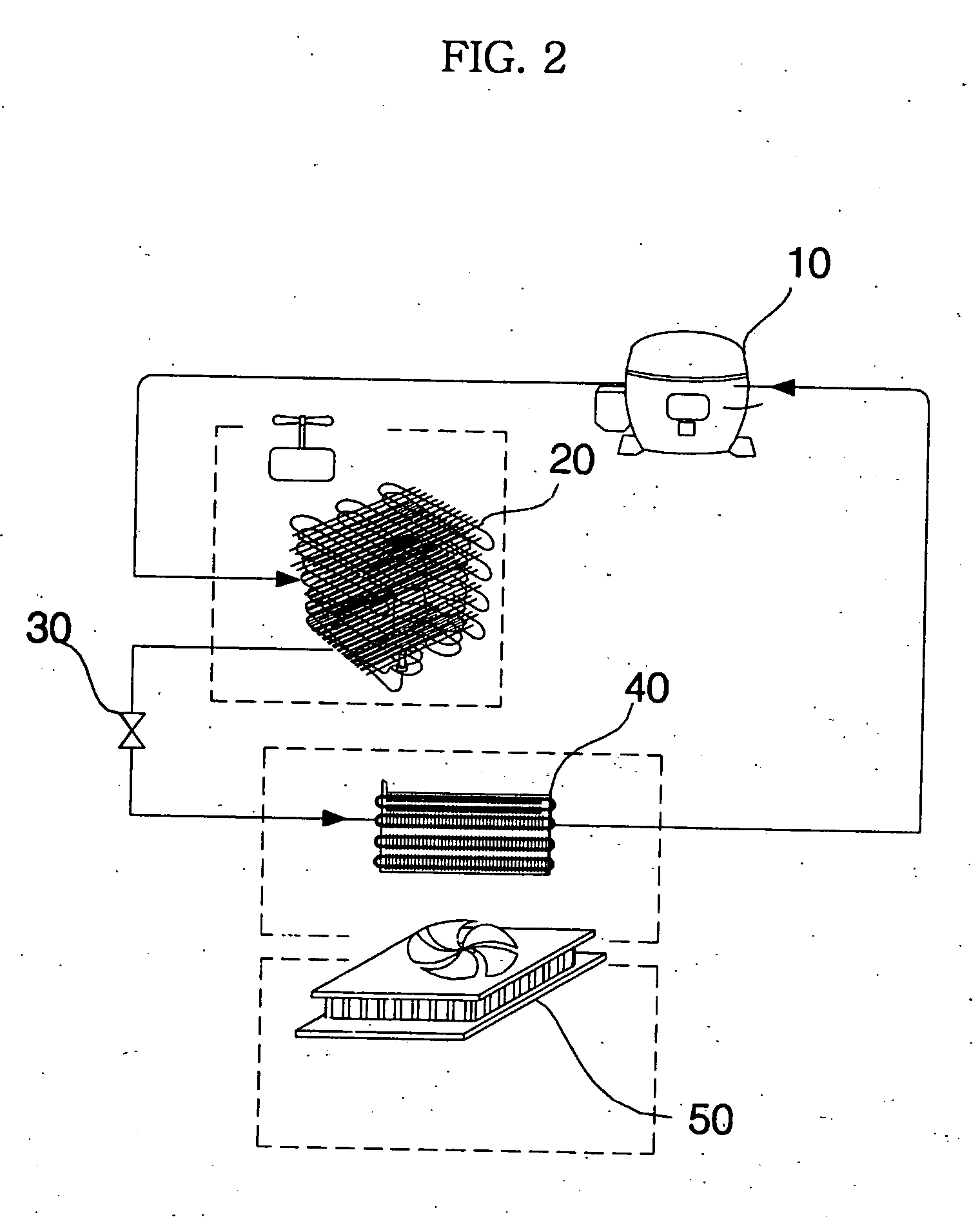

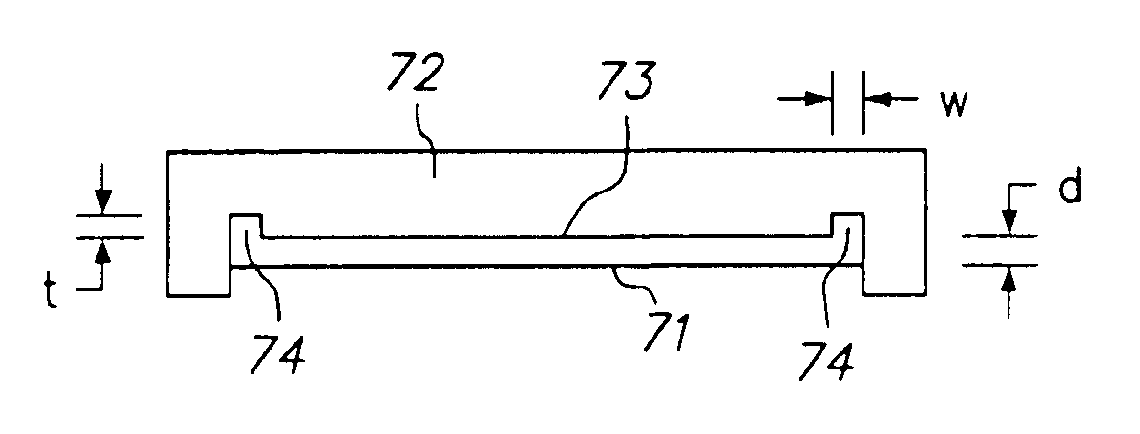

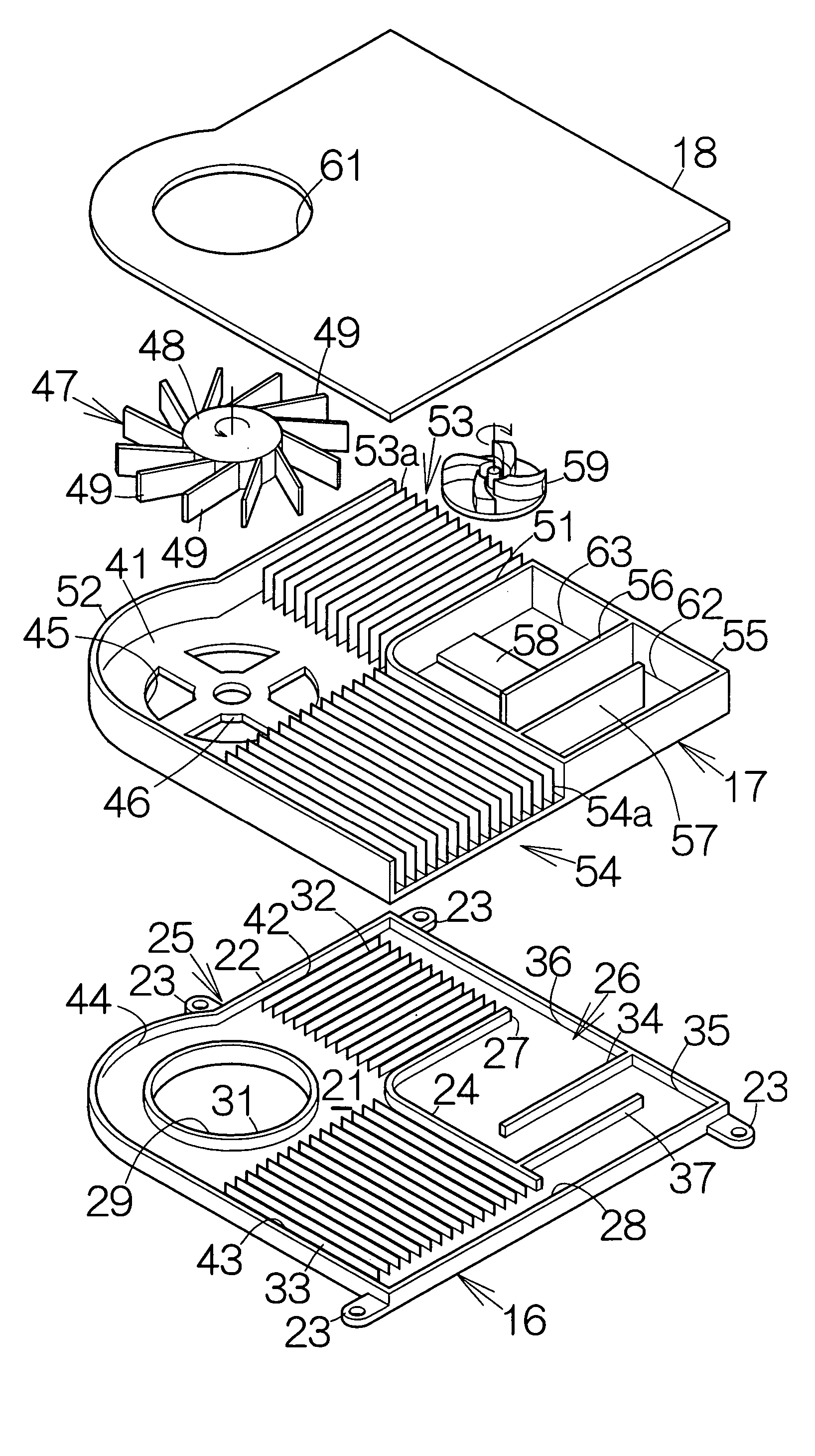

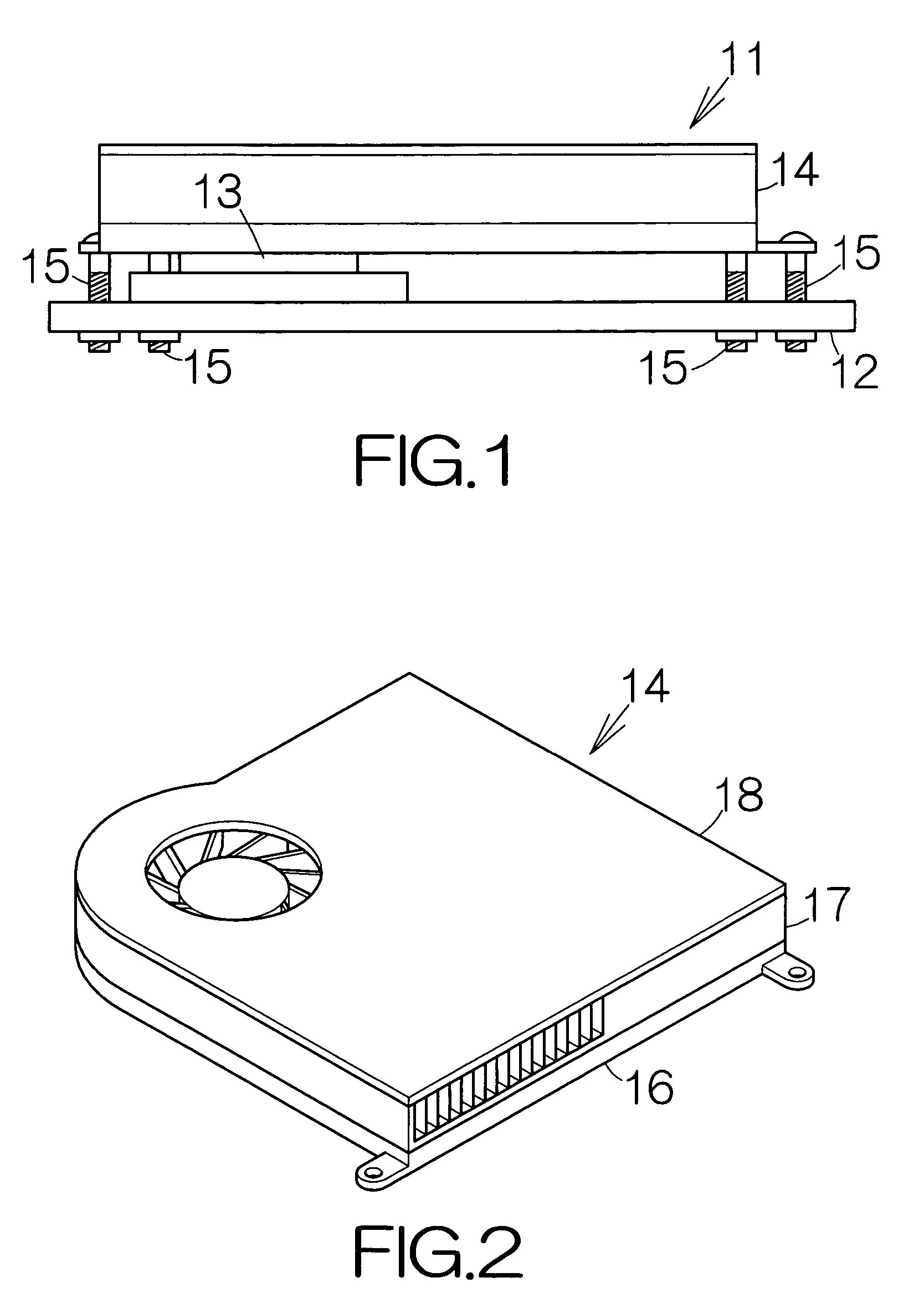

Cooling system for a portable computer

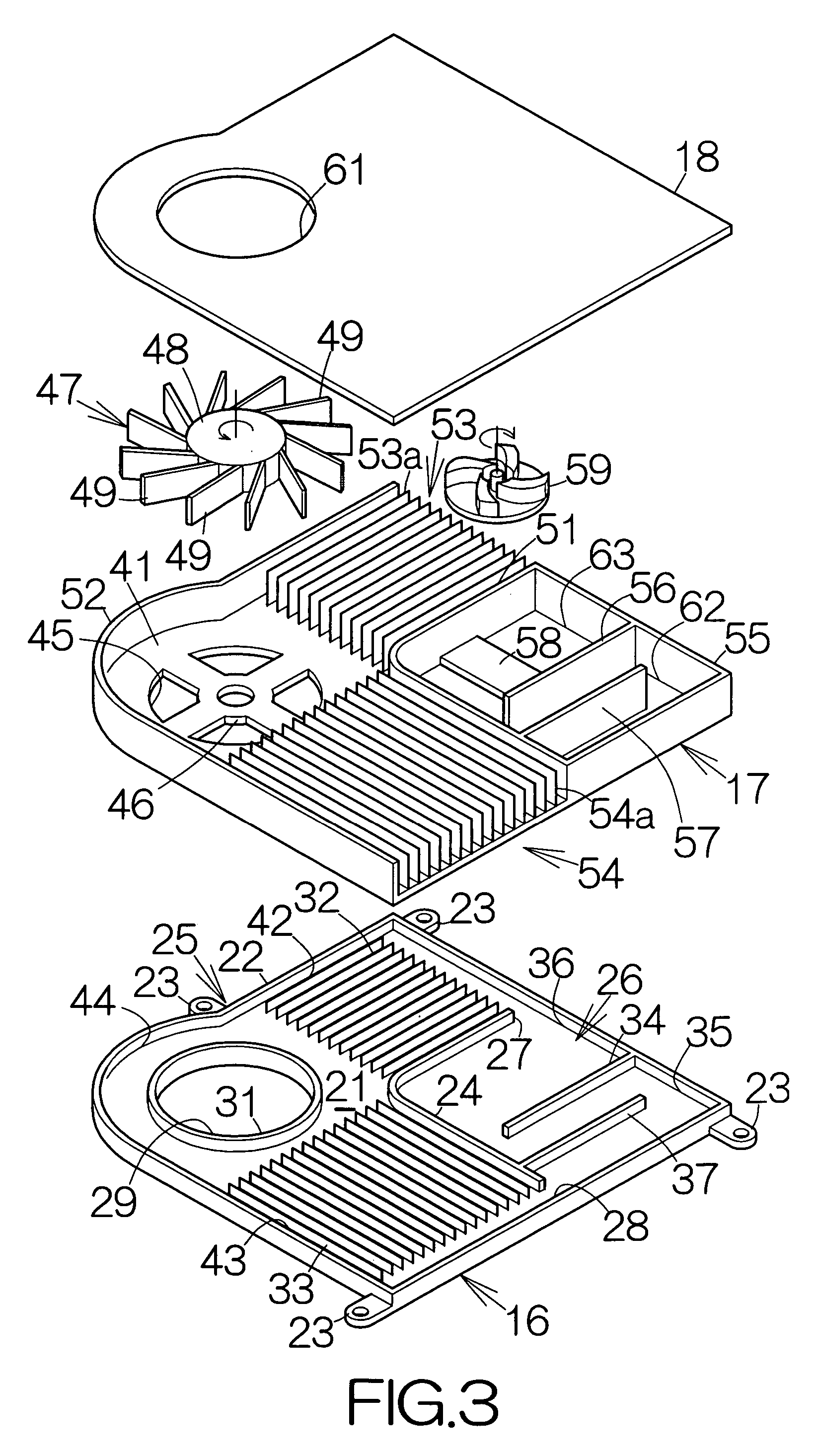

InactiveUS7184265B2Reduce and minimize thicknessReduce thicknessDigital data processing detailsSemiconductor/solid-state device detailsEngineeringPhase change

A cooling system for a portable computer can include a frame having a heat-source connecting unit in its one side and having a fan housing unit in its other side. A dissipating unit on one side of the fan housing unit performs heat exchange and a dissipating fan forms an air stream that can pass through the dissipating unit. A plate-shaped cooling unit coupled to one side of the frame can deliver heat from the heat-source connecting unit to the dissipating unit. The cooling unit can include a micro cooling unit that performs heat exchange using a cooling cycle through phase change or a plate-heat pipe filled with liquid. According to embodiments of the present invention, a thickness of the cooling system can be reduced and cooling capability efficiency can be increased.

Owner:LG ELECTRONICS INC

Austenitic stainless steel

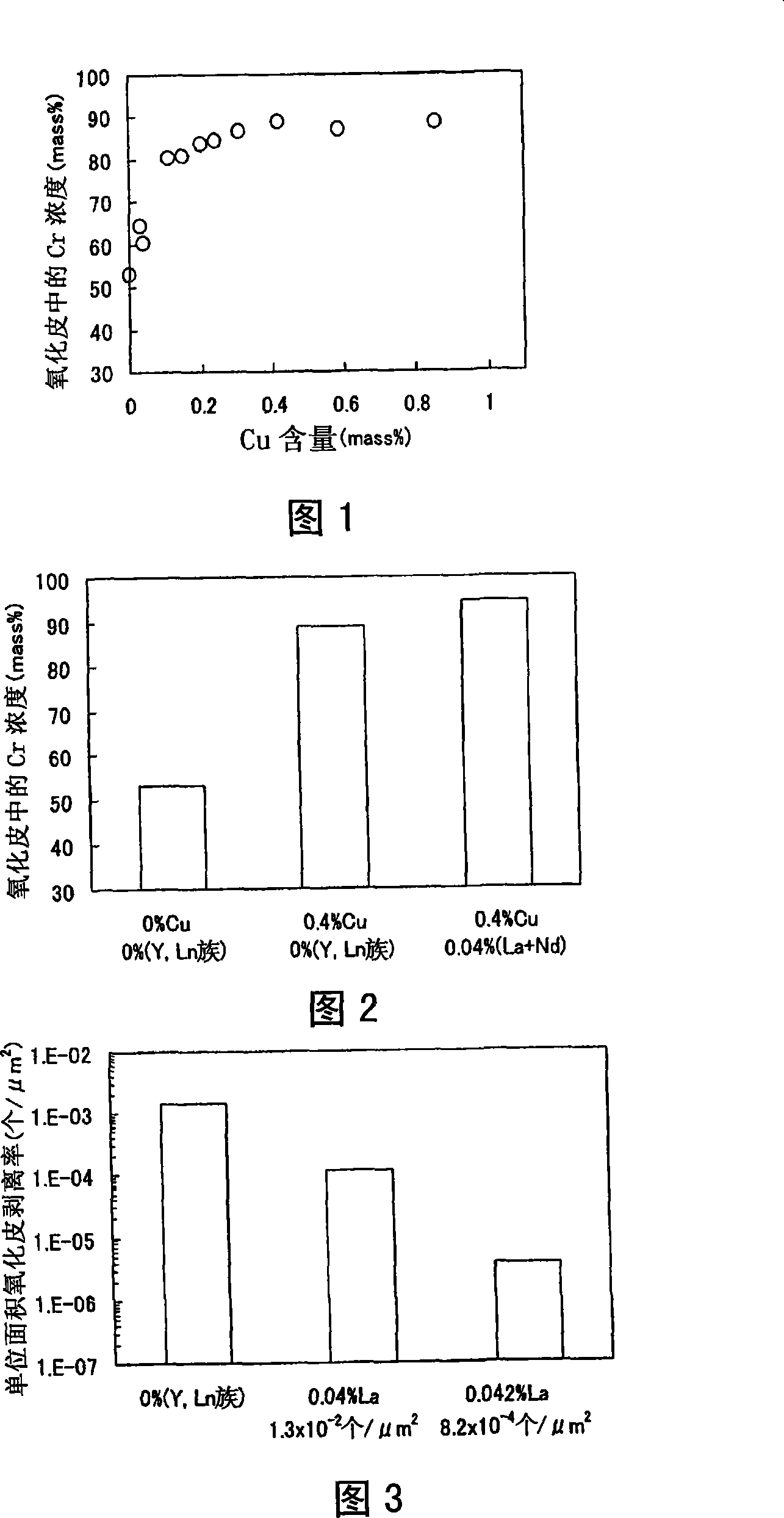

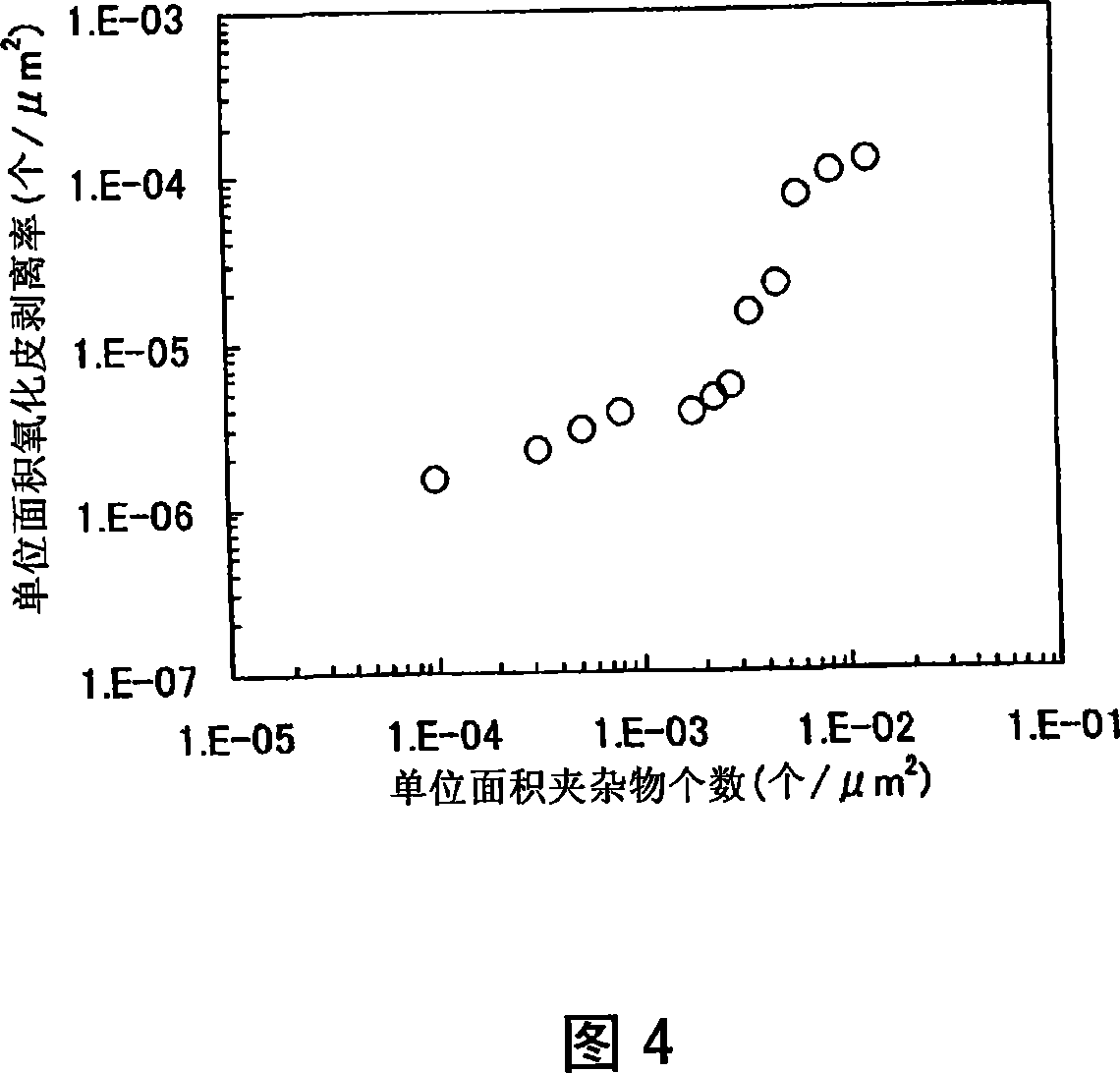

ActiveCN101194037APrevent peelingIncreased durabilityHeat exchange apparatusRare-earth elementSS - Stainless steel

Even after repeated high-temperature heating-cooling cycles, it still has excellent scale peeling resistance that can inhibit the peeling of protective oxide scales formed on the steel surface, and can be used in high temperature, especially high temperature humidified gas environments above 1023K. System stainless steel with the following steel composition: C: 0.01-0.15%, Si: 0.01-3%, Mn: 0.01-2%, Cu: 0.1-2.5%, Cr: 23-30%, Ni: 16-25% , Al: 0.005 to 0.20%, N: 0.001 to 0.40%, P: 0.04% or less, S: 0.01% or less, and one or more rare earth elements selected from the Y and Ln groups: total 0.005 to 0.1%, the balance is substantially composed of Fe and unavoidable impurities, and the inclusions containing Y and Ln group elements on the steel surface are 5×10-3 / μm2 or less.

Owner:NIPPON STEEL CORP

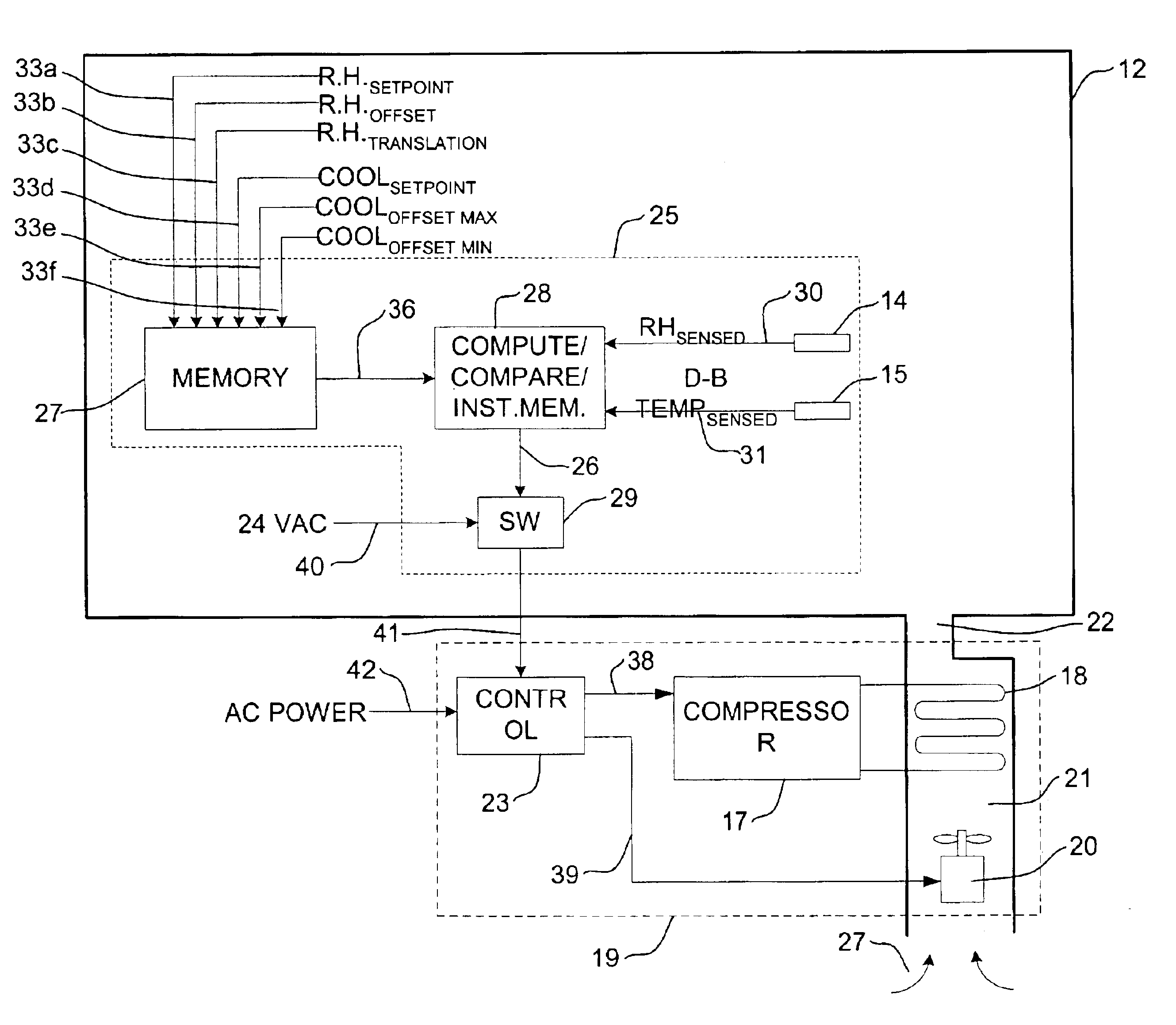

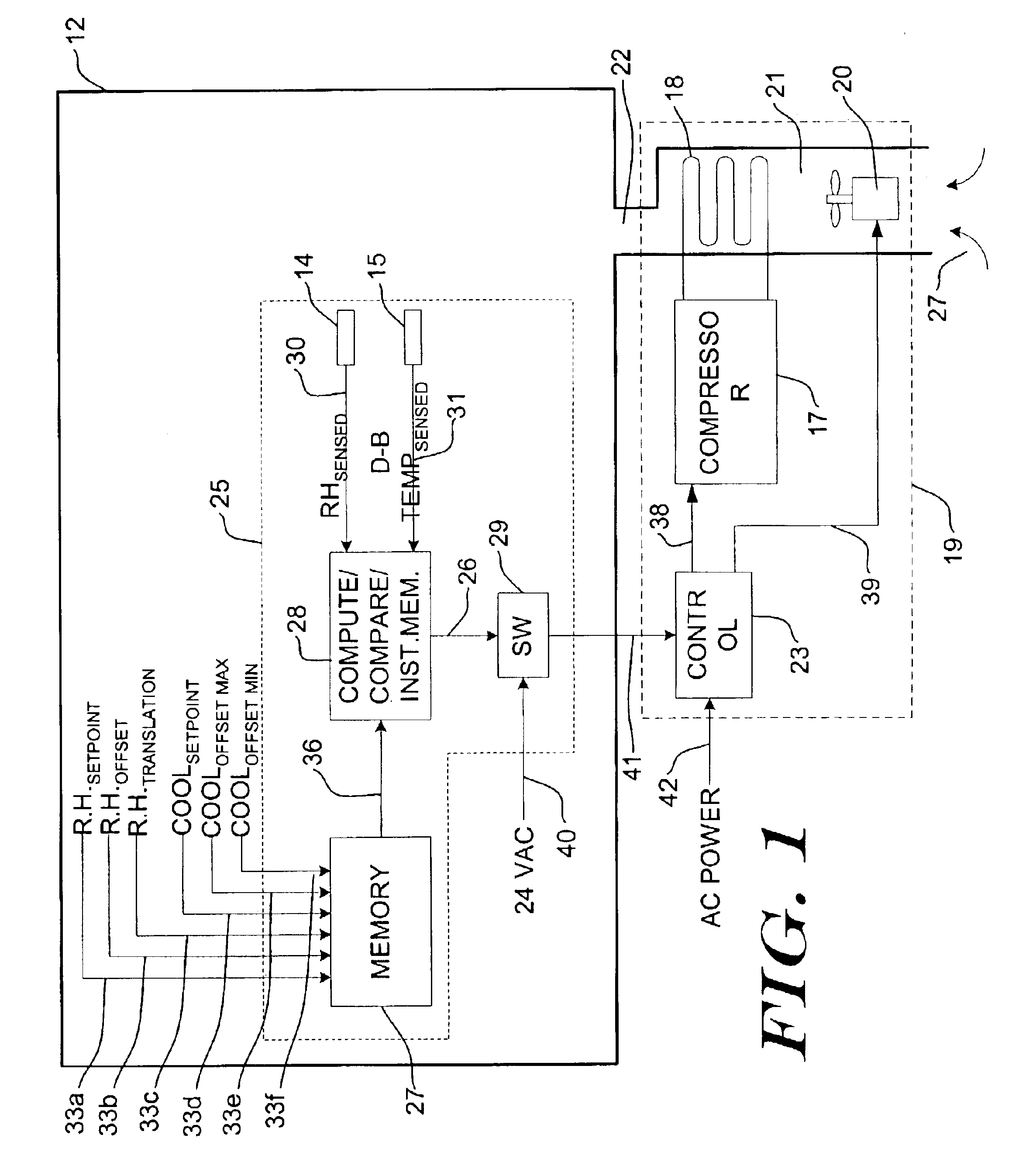

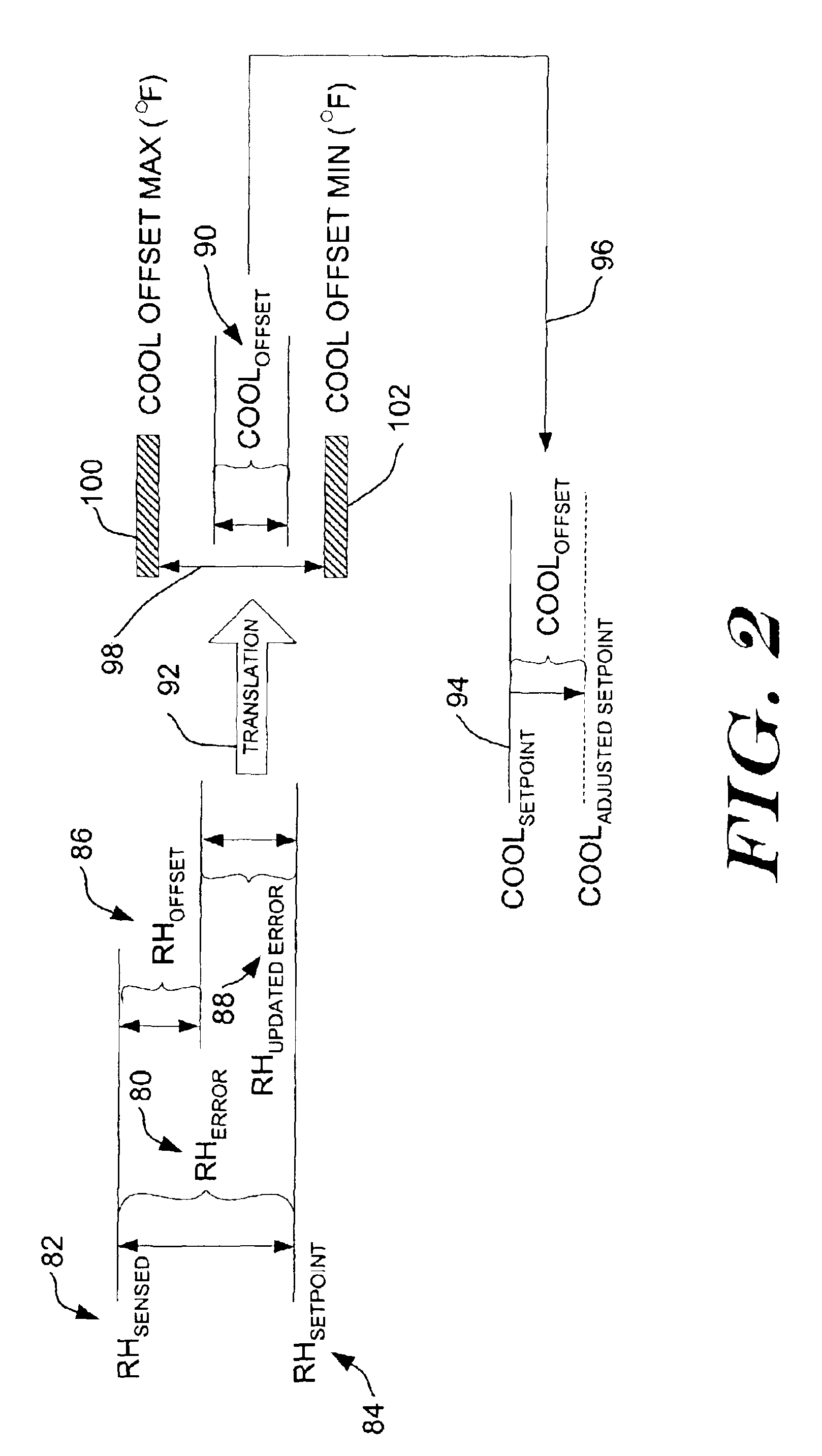

Cooling set point control

InactiveUS6892547B2Improve comfortReduce energy consumptionMechanical apparatusSpace heating and ventilation safety systemsInterior spaceControl system

Methods and apparatus for controlling the cooling set point value of a climate control system are provided. In one illustrative embodiment, a humidity error is determined as a function of the actual humidity in the inside space and a humidity set point value. The cooling set point value is then adjusted by a cooling offset that is a function of the humidity error. Under humid conditions, and when insufficient dehumidification occurs during a normal cooling cycle, lowering the cooling set point may provide further dehumidification, which may improve comfort in the inside space. Under less humid conditions, and when the humidity level in the inside space is already below the humidity set point value, increasing the cooling set point value may lower the energy usage of the climate control system while still providing comfort.

Owner:ADEMCO INC

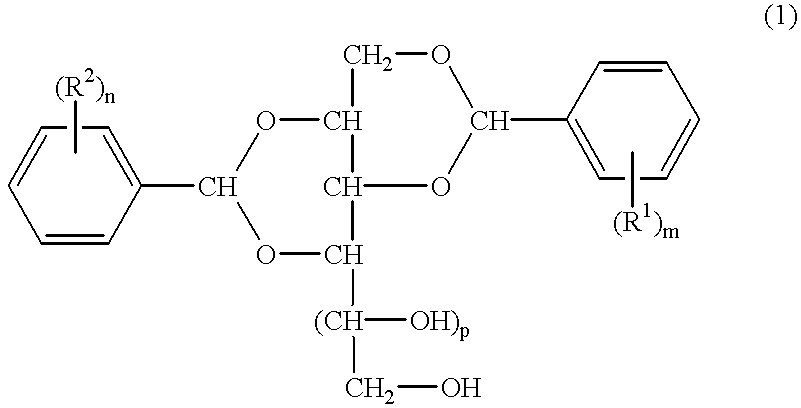

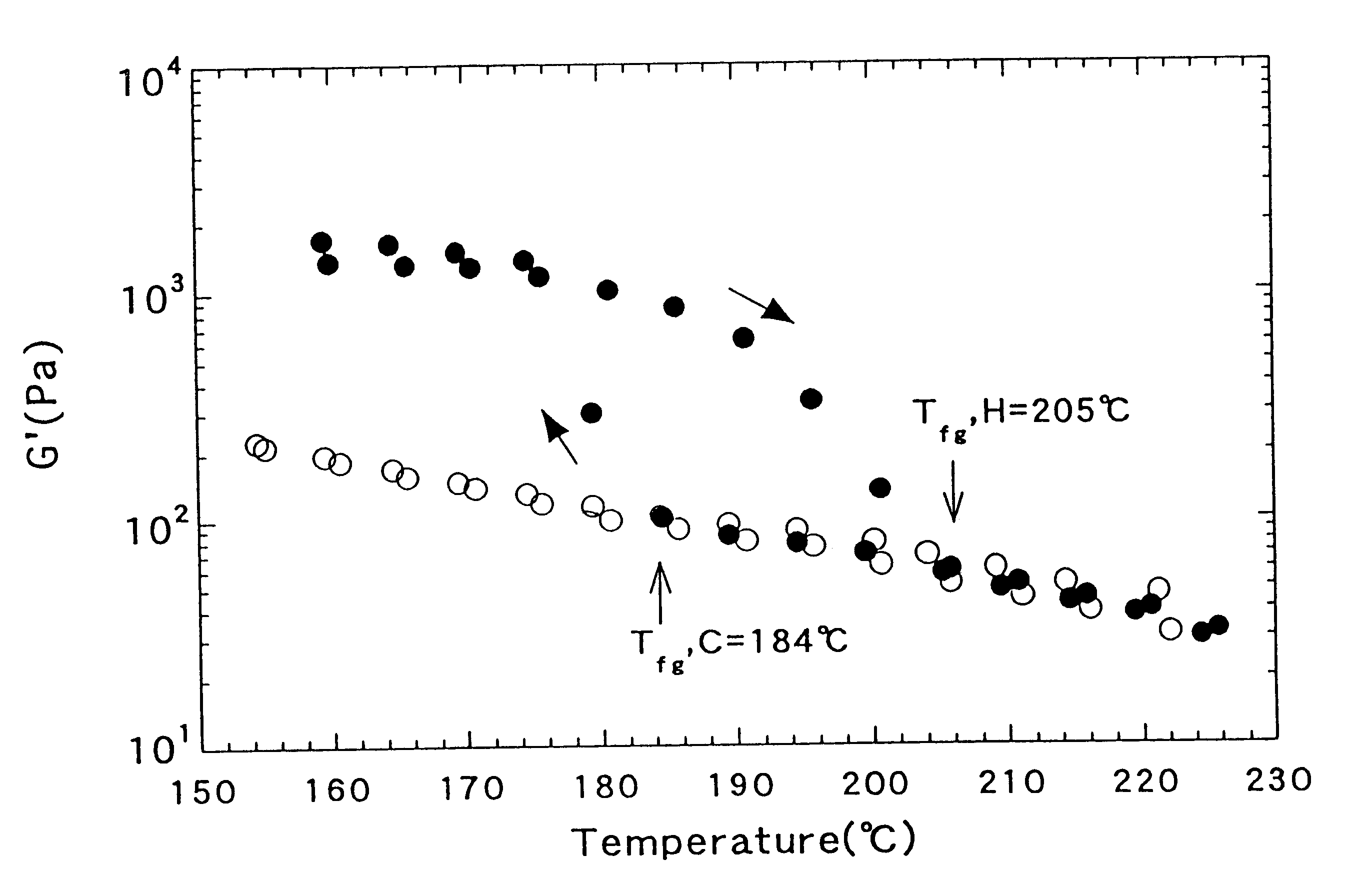

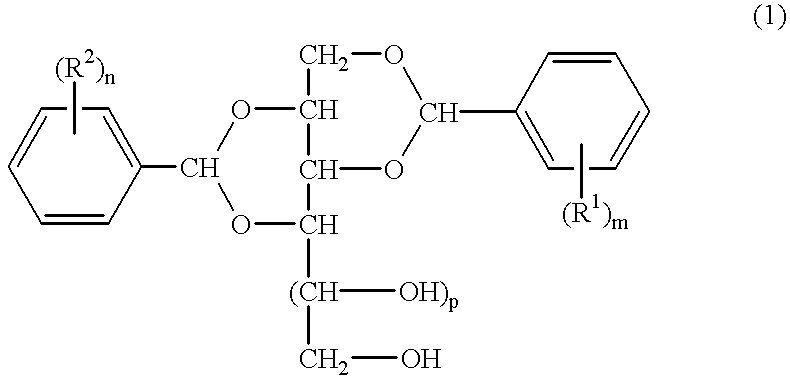

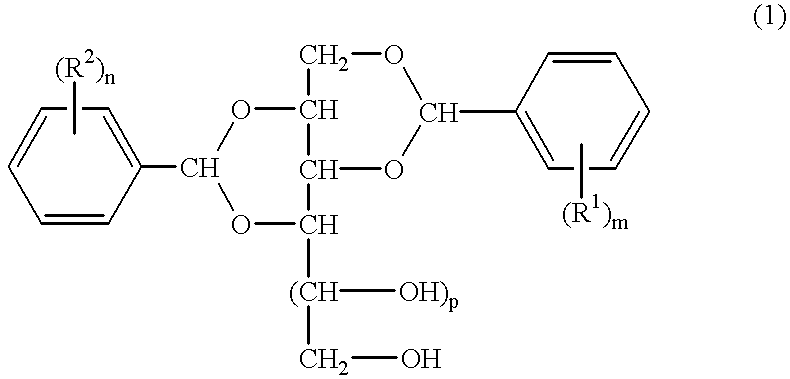

Orientated gel molding method of polyolefin based resin composition

InactiveUS6238615B1Organic detergent compounding agentsFilament/thread formingCyclic processPolyolefin

The present invention provides method of molding a polyolefin-based resin comprising the steps of dissolving at least one dibenzylidene sorbitol compound in a molten polyolefin resin, cooling the molten resin to a temperature not higher than the sol-gel transition temperature during the cooling cycle to form network-like crystals of the dibenzylidene sorbitol compound, and molding the resulting resin composition at a temperature not lower than the melting temperature of the polyolefin-based resin but not higher than the sol-gel transition temperature during the heating cycle; and a polyolefin resin molded article obtainable by this molding method.

Owner:NEW JAPAN CHEM CO

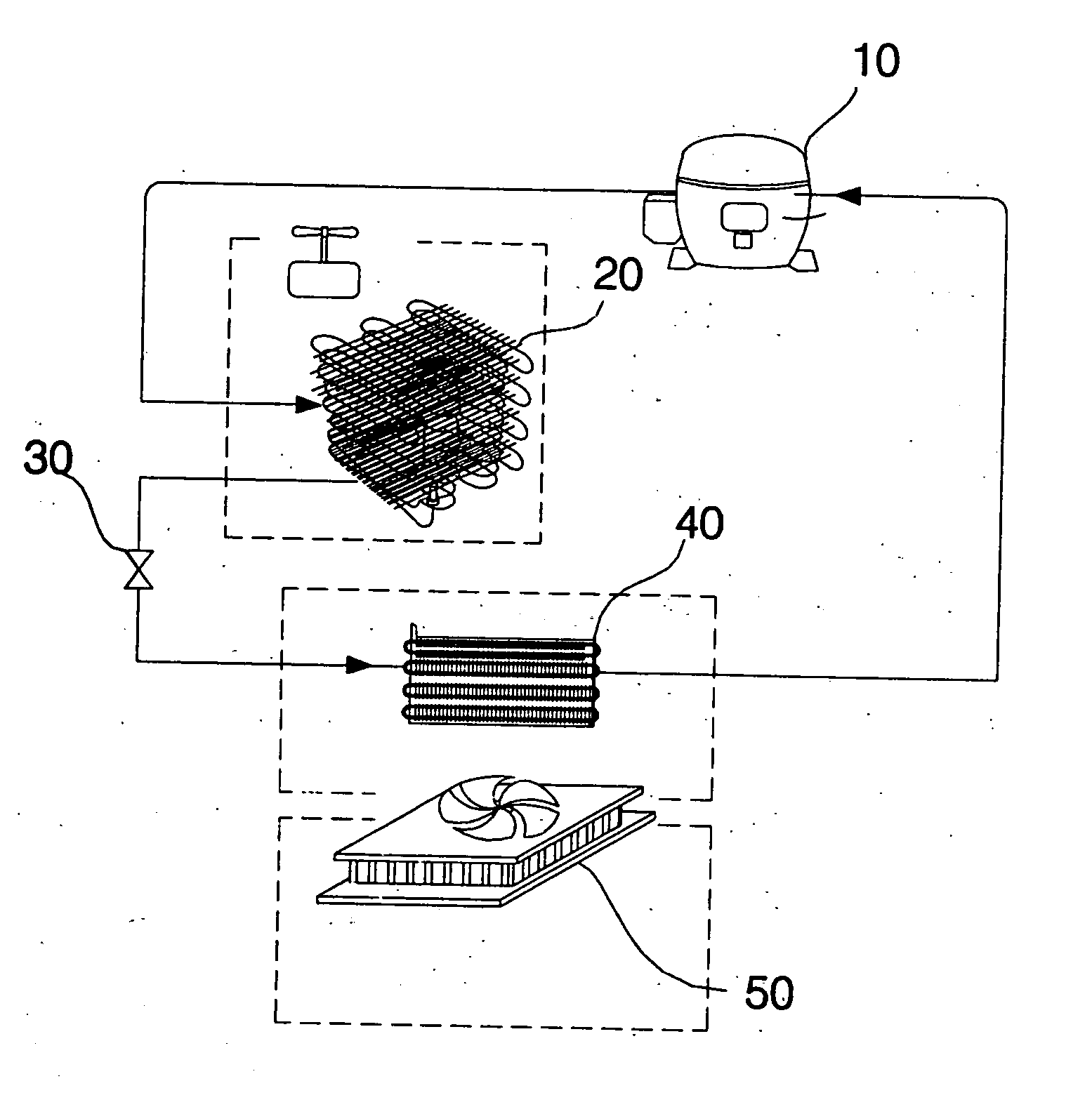

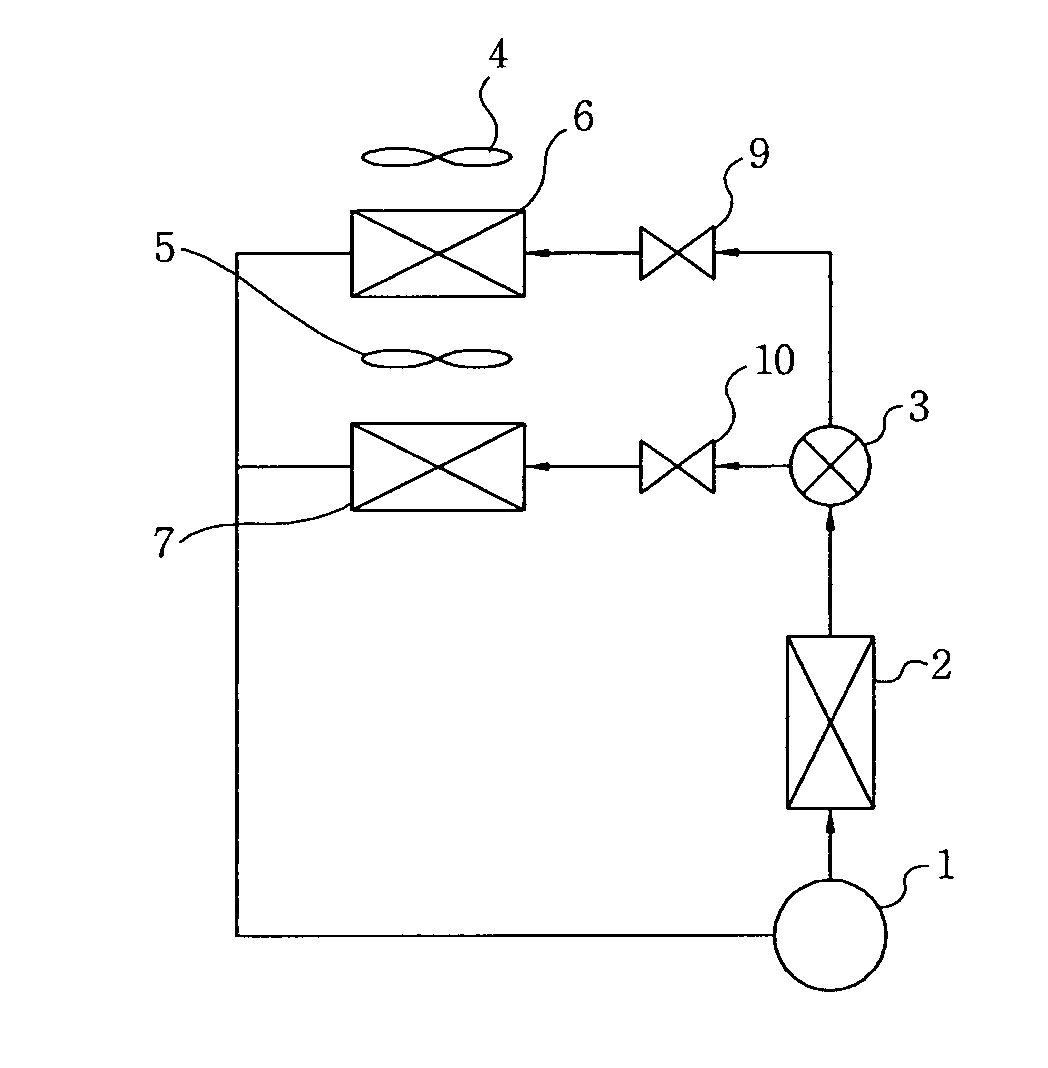

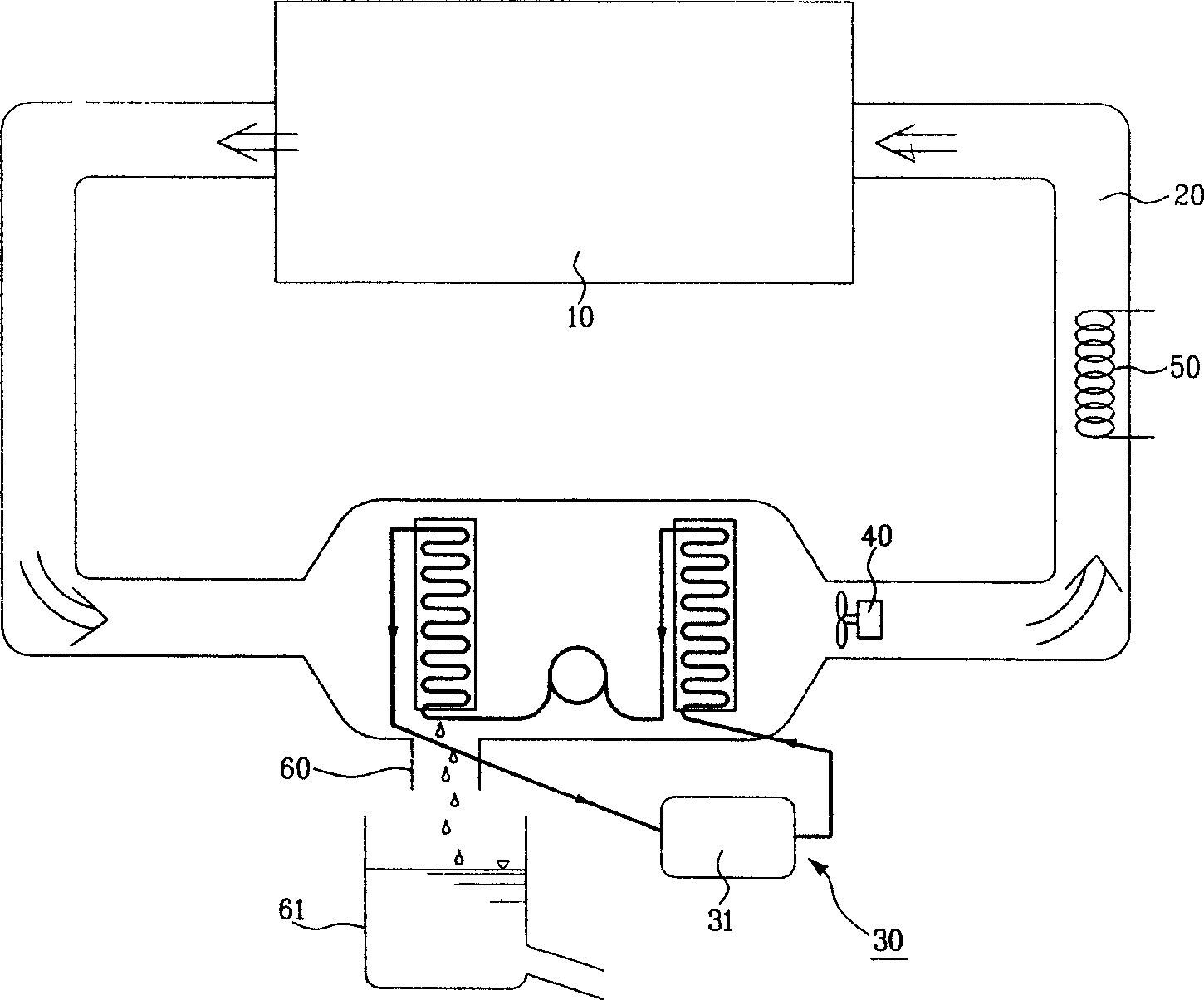

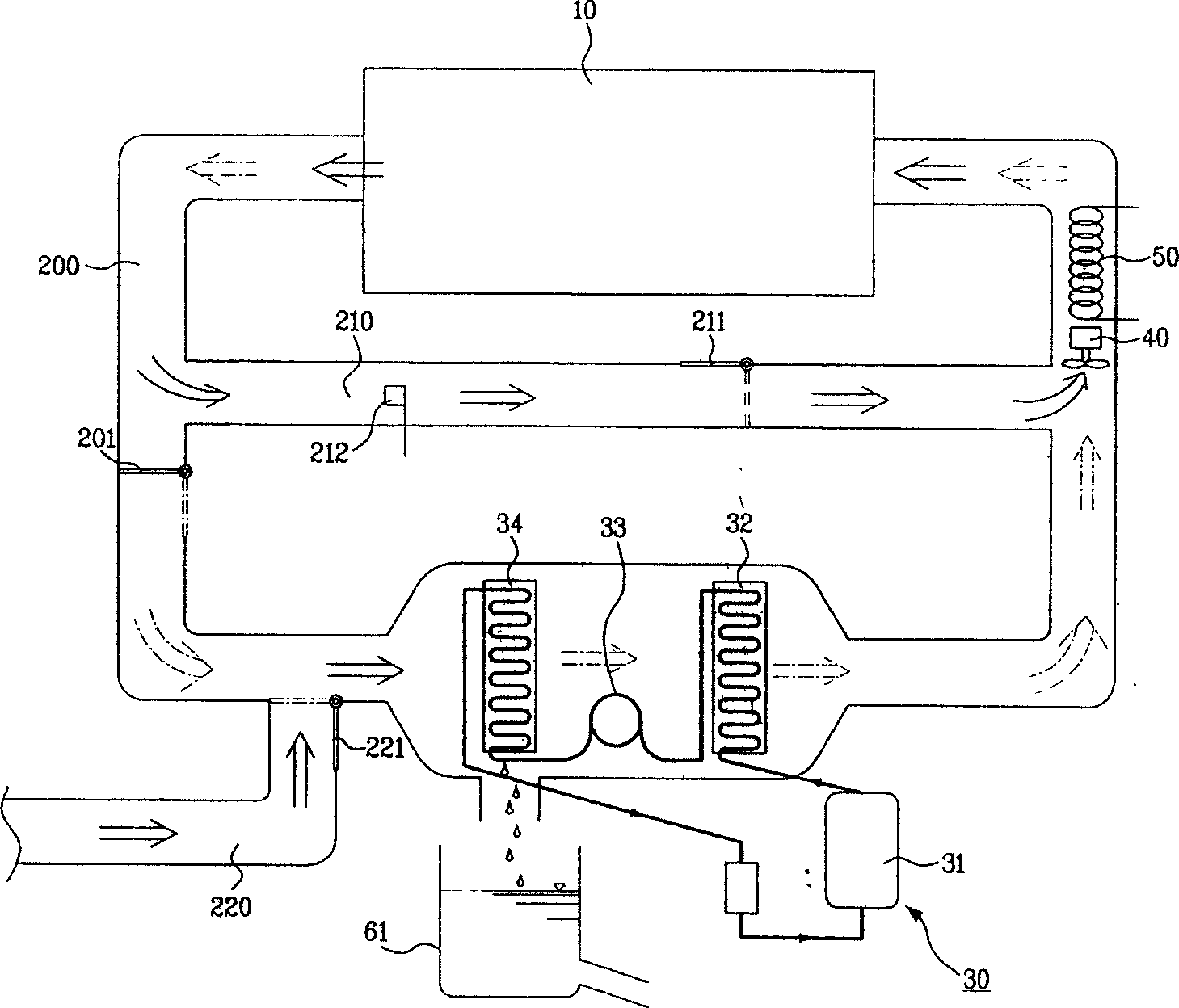

Hybrid cooling system, and refrigerator and freezer using the same

InactiveUS20060144073A1Reduce the temperatureDomestic refrigeratorsMachines using electric/magnetic effectsNuclear engineeringRefrigerated temperature

A cooling system includes a cooling cycle which includes an evaporator for cooling air; and a thermoelectric module using a Peltier effect to provide a heat absorption portion and a heat discharge portion, the air cooled by the evaporator being further coolable by the heat absorption portion.

Owner:LG ELECTRONICS INC

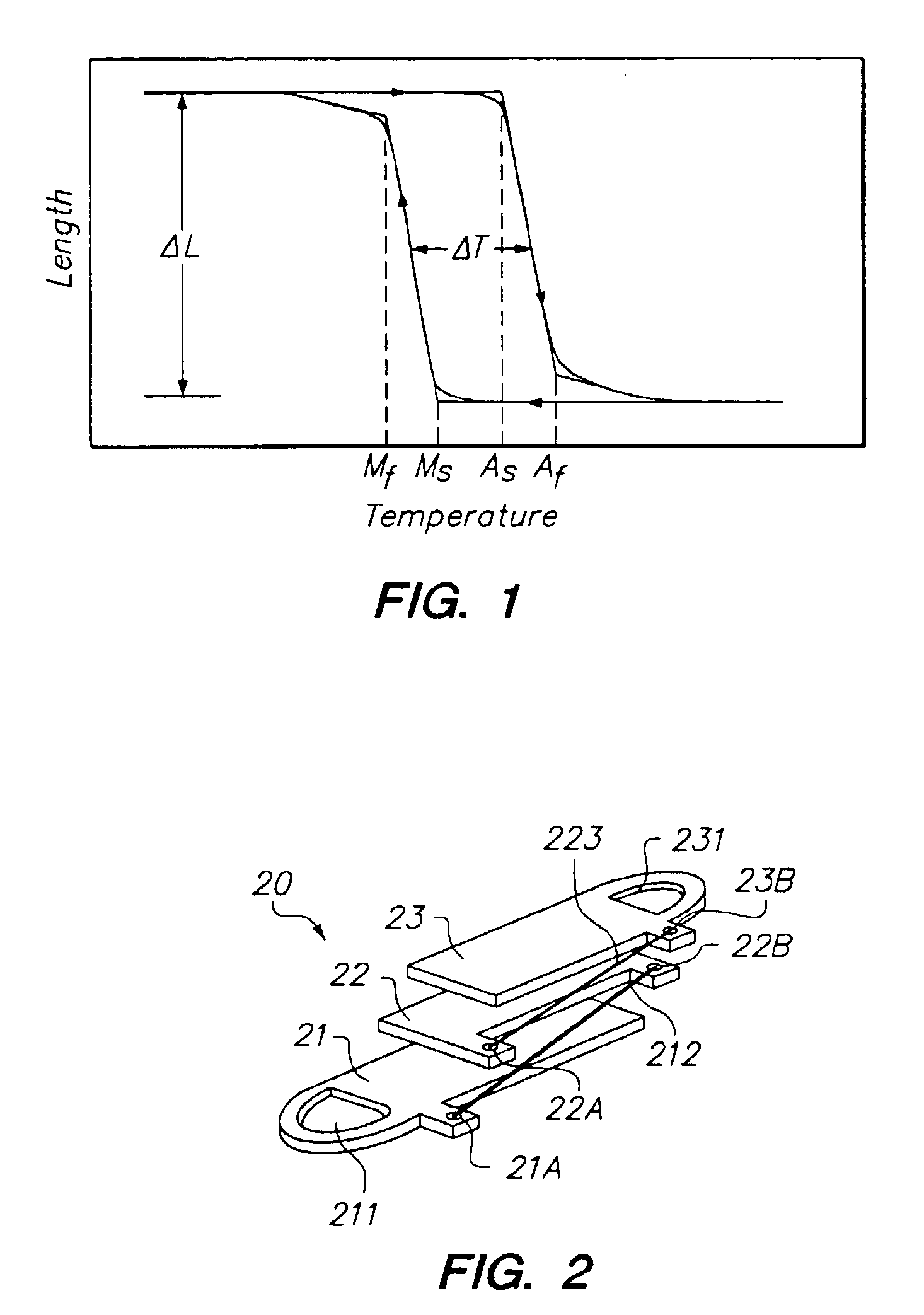

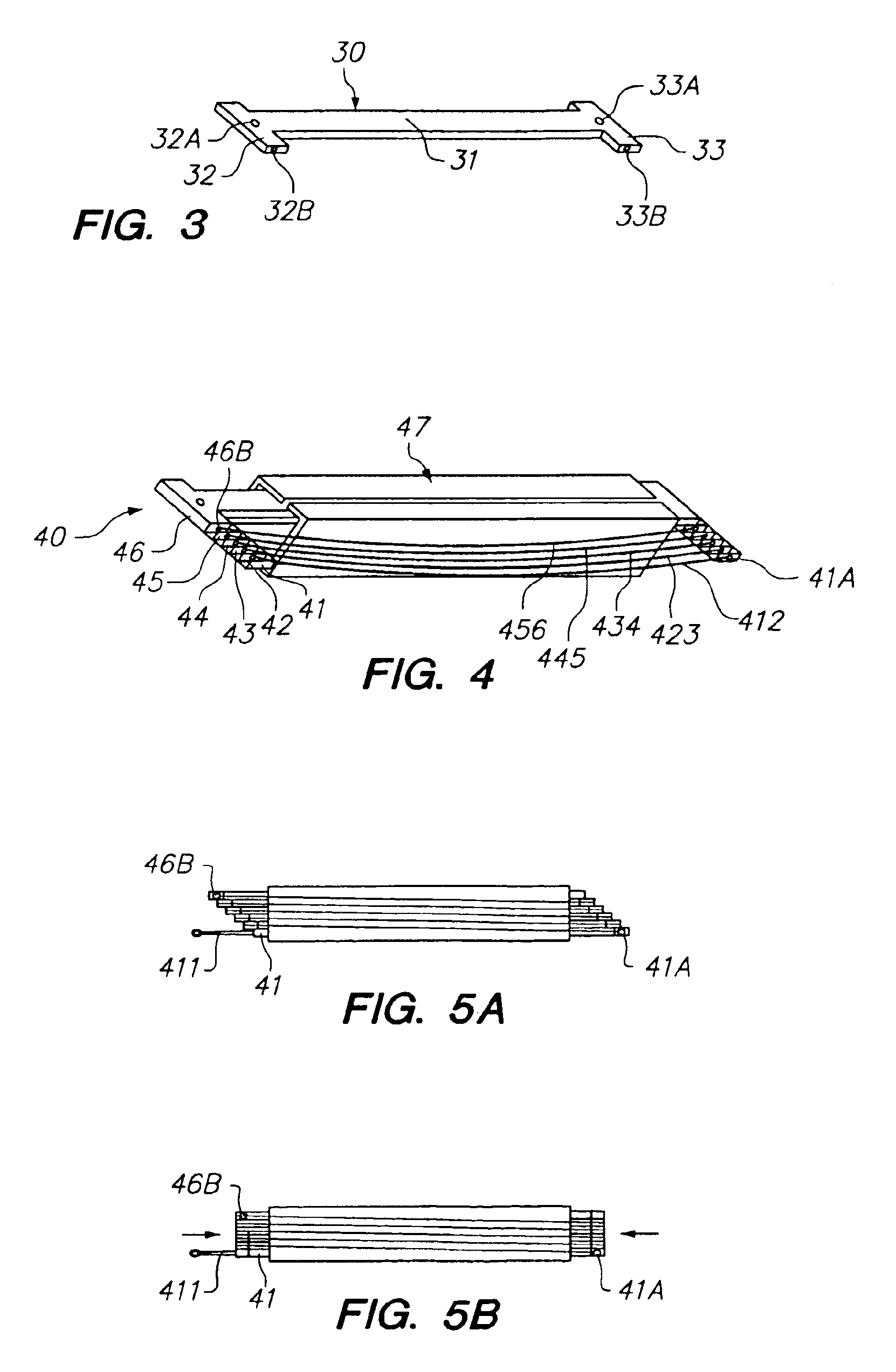

SMA actuator with improved temperature control

InactiveUS6981374B2Improve cooling effectRapid responseEngine componentsMechanical power devicesTemperature controlActive cooling

A SMA actuator having rigid members and SMA wires, in which improved temperature control of the SMA wires of the actuator is provided by a heat sink, which may be the rigid members themselves, in close proximity to at least a central portion of the wires. Optionally, the heat sink is sized and placed such that the end portions of the wires where they are attached to the rigid members are not in close proximity to the heat sink. Where the heat sink is external, it optionally has a cooling element that acts passively as a heat sink during the heating cycle of the actuator and that acts as an active cooling element during the cooling cycle of the actuator. An SMA actuator having a desired contraction limit and a power supply circuit has a switch in the power supply circuit that is normally closed when the actuator is contracted to less than the desired contraction limit and is opened by the actuator reaching the desired contraction limit. This improved temperature control provides greater cooling of the SMA wires for a faster response and an extended working life of the actuator.

Owner:ALFMEIER PRAZISION BAUGRUPPEN & SYSTLOSUNGEN

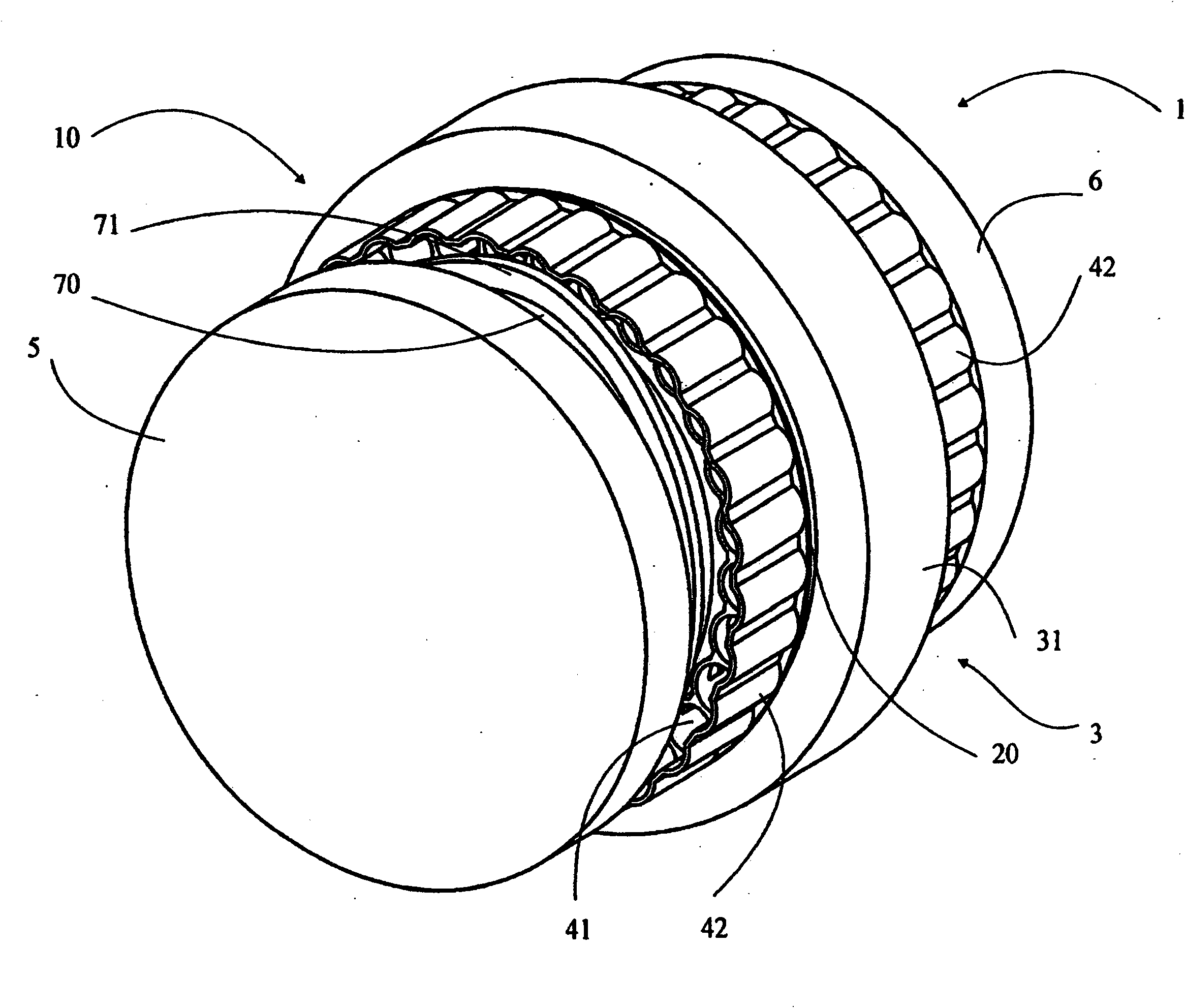

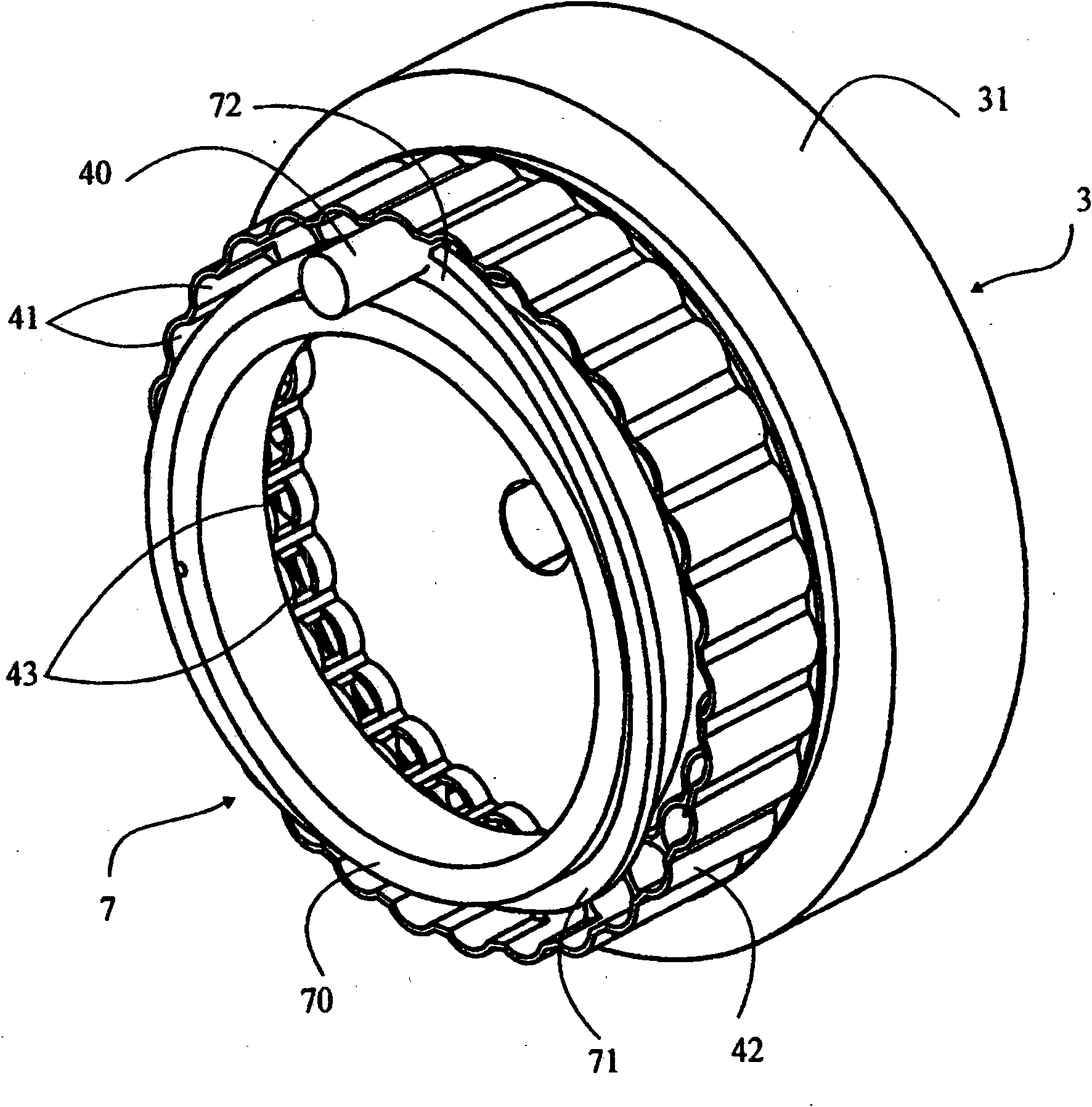

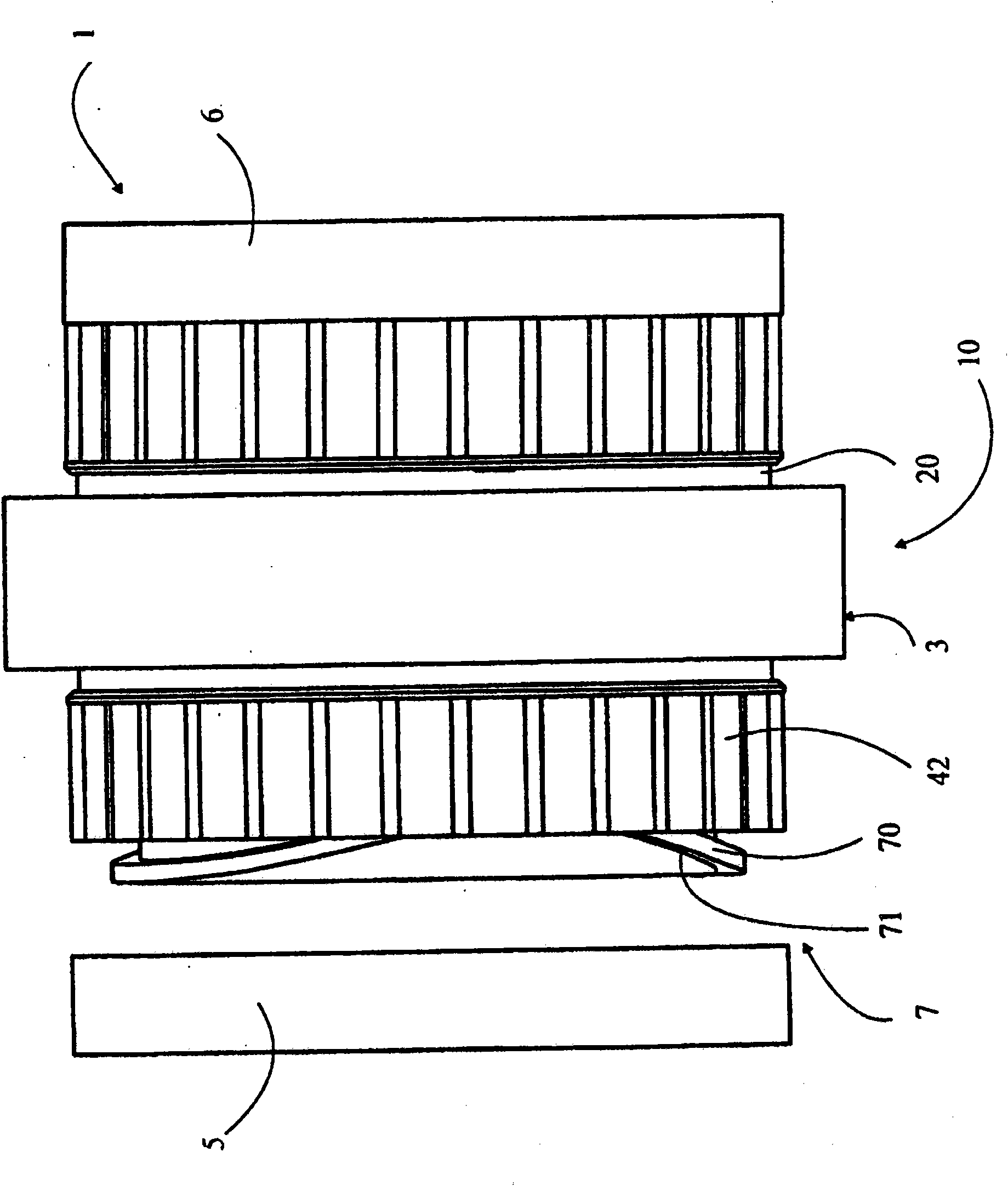

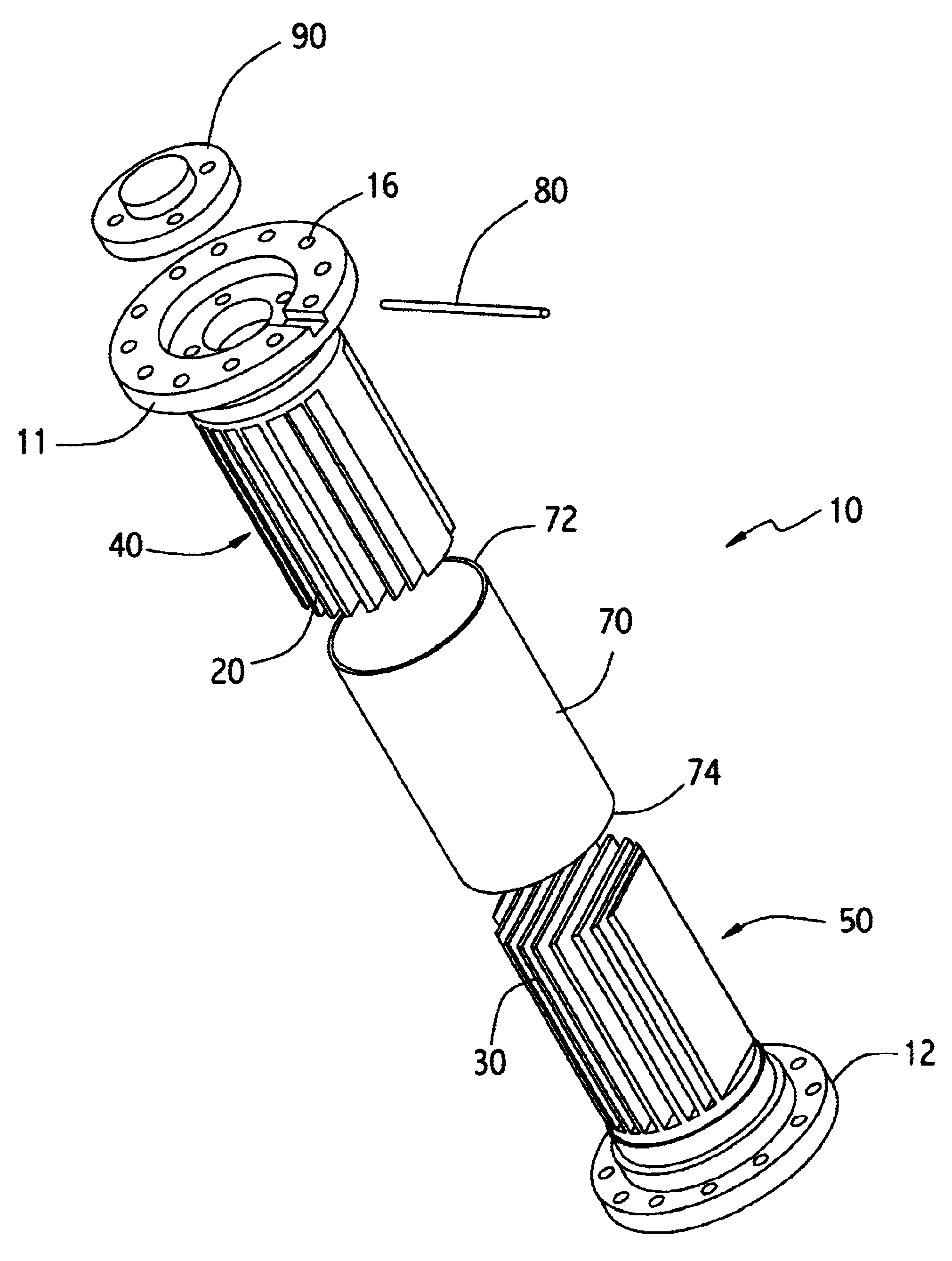

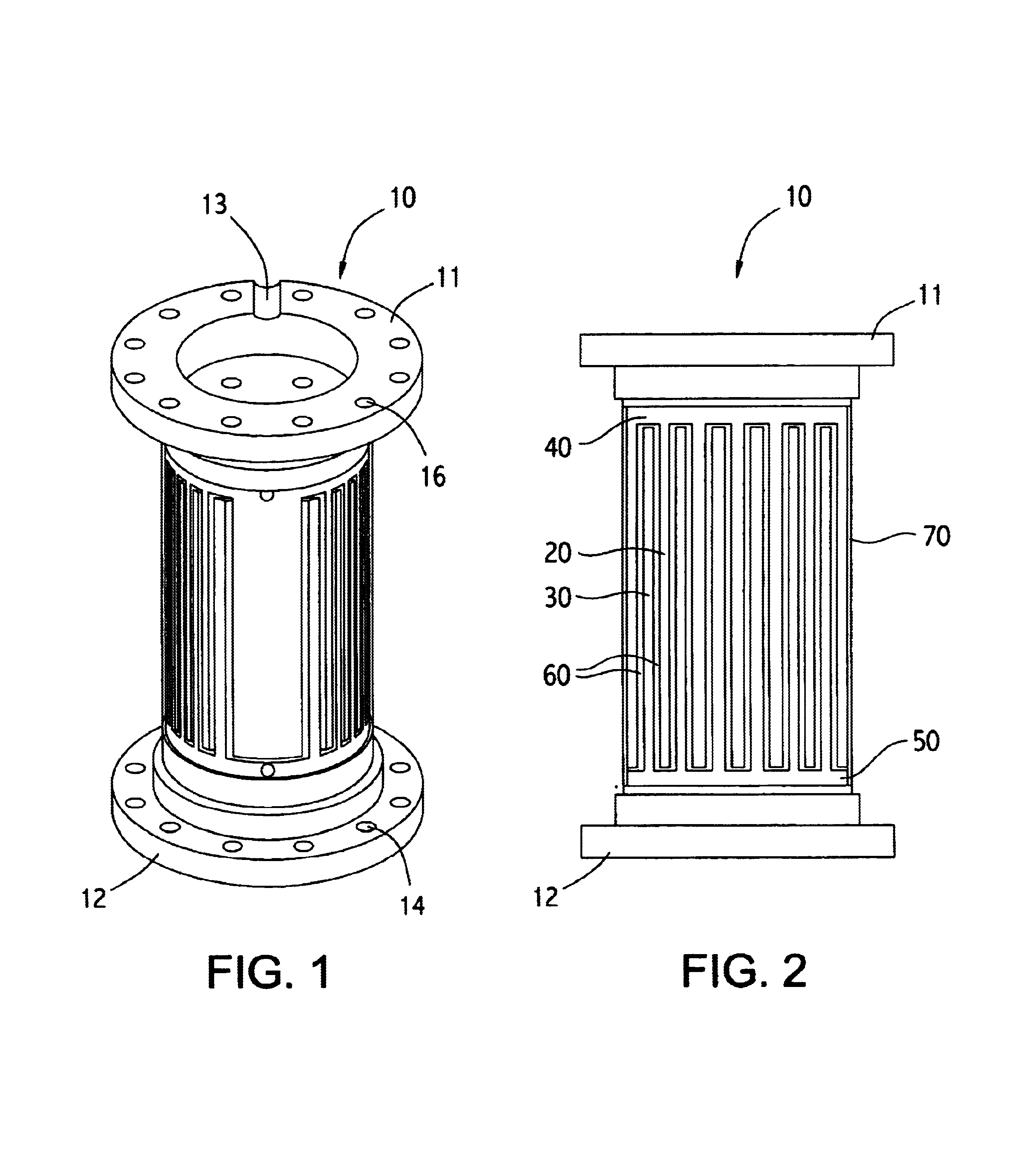

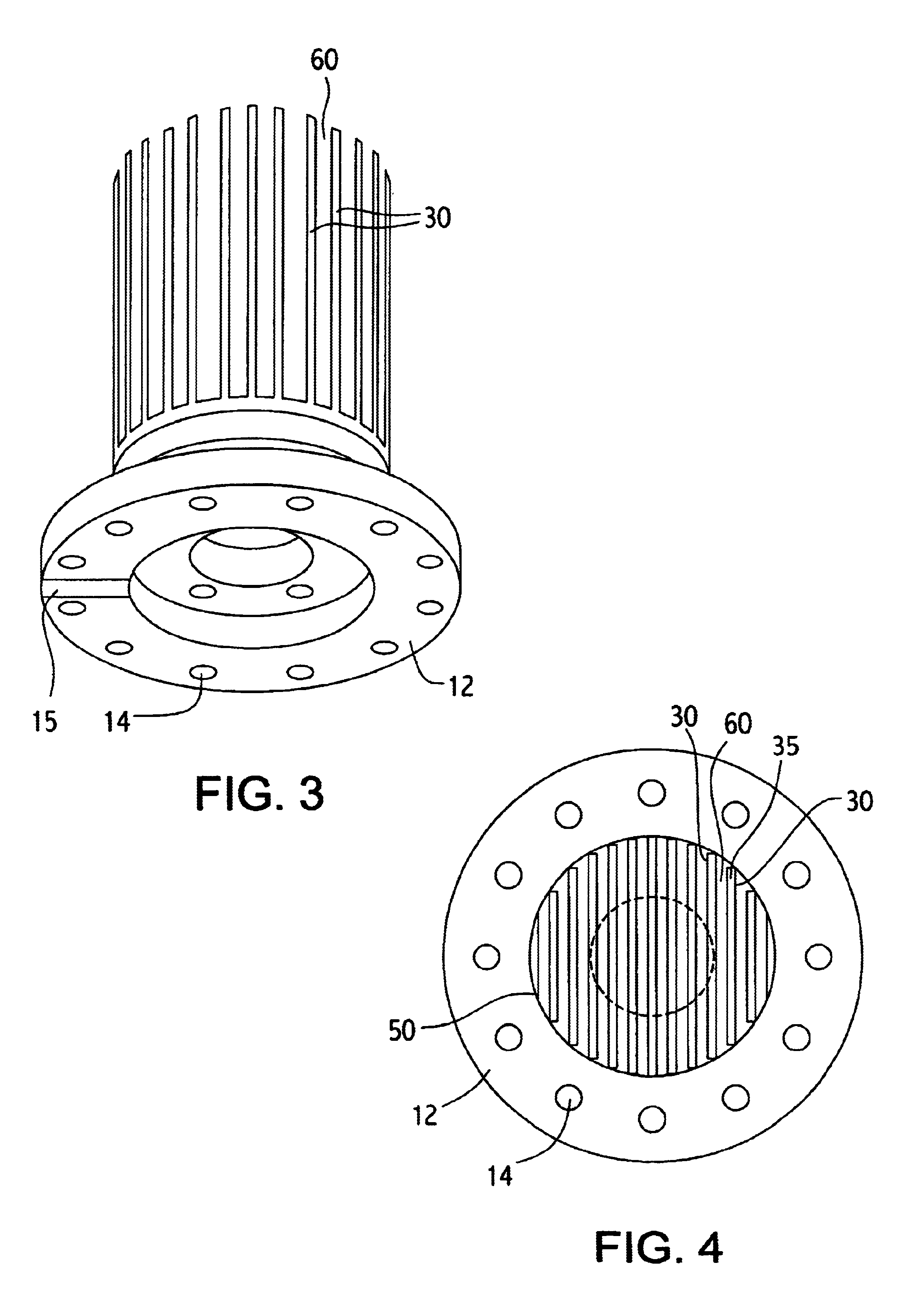

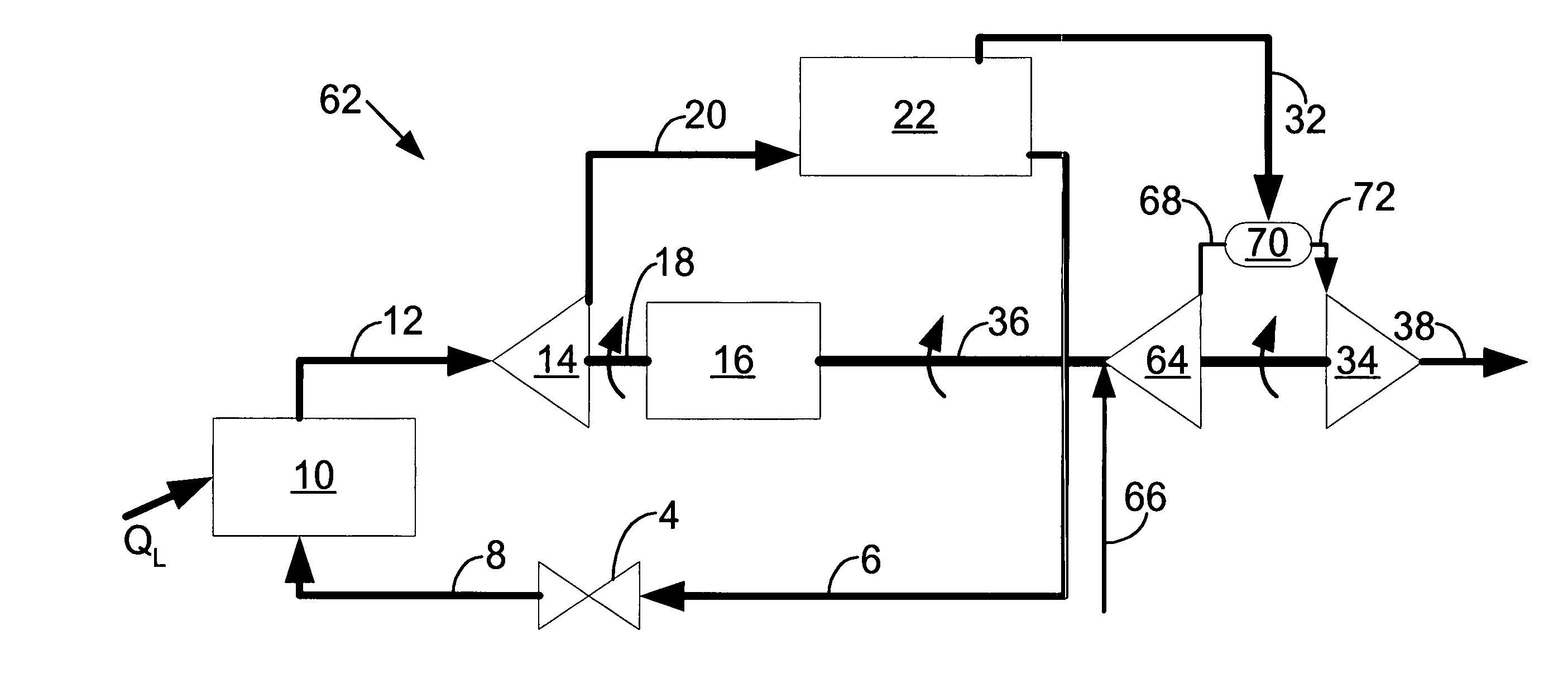

Thermal generator with magneto-caloric material

ActiveCN101842647AEnergy efficient heating/coolingMachines using electric/magnetic effectsHeat carrierReciprocating motion

The invention relates to a thermal generator (1) characterised in that it comprises at least one thermal module (10) including N adjacent magneto-caloric members (2) arranged in a circle about a central axis (A) and submitted to a magnetic field variation generated by a magnetic means (3) in order to vary their temperature. The magneto-caloric members (2) are associated with N pistons (40) driven according to a reciprocating translation movement by a control cam (70) in order to move the heat-carrier fluid contained in the thermal module (10) simultaneously in two opposite directions, so that a first fraction of the heat-carrier fluid flows towards a hot exchange chamber (5) through the magneto-caloric members (2) submitted to a heating cycle, and so that a second fraction of the heat-carrier fluid flows towards a cold exchange chamber (6) through the magneto-caloric members (2) submitted to a cooling cycle, and vice versa. The exchange chambers (5, 6) are coupled to outer calorie- and frigorie-consuming circuits, such as heating circuits, air conditioning circuits, tempering circuits, etc.

Owner:马格诺里克公司

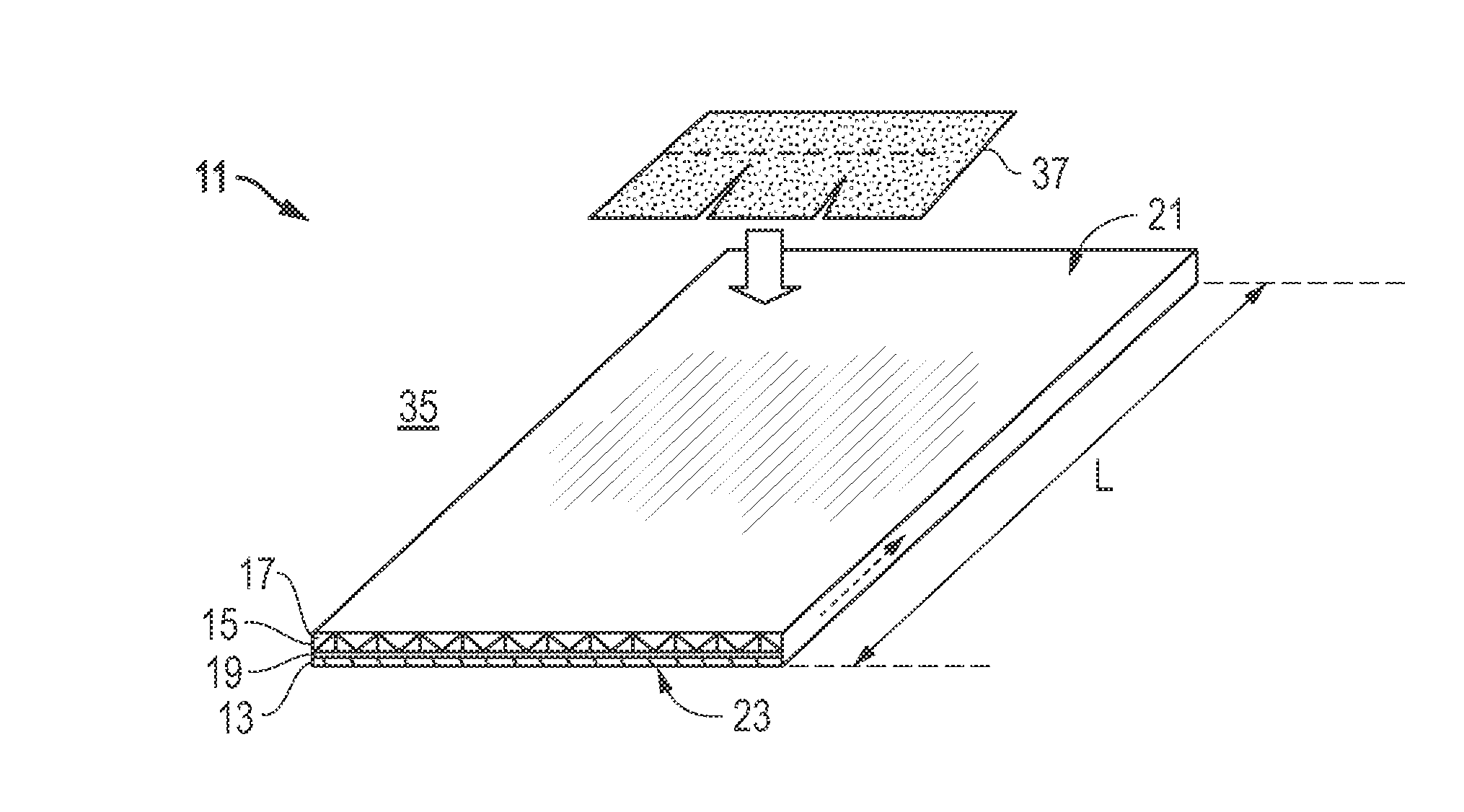

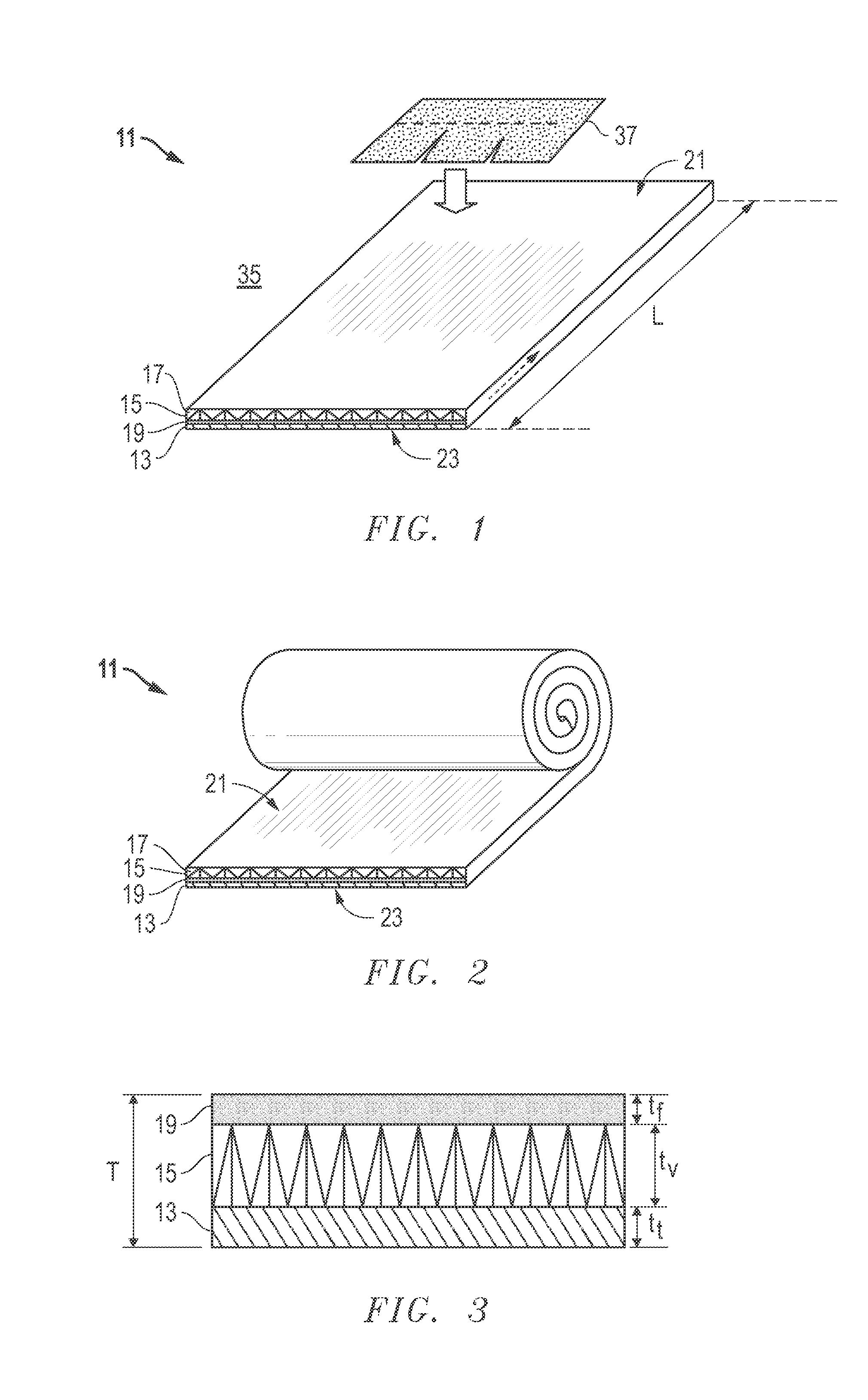

System, method and apparatus for thermal energy management in a roof

A roof product has a thermal heat storage layer, a vent layer with channels for transferring excess heat through a length of the roof product, and a flame retardant to suppress fire through the vent layer. These three materials form a unitary structure. The roof product may have a radiant layer, the thermal heat storage layer and the vent layer to form the unitary structure. The roof products are assembled in an abutting configuration on the roof of a building. The vent layer vents excess heat from an eave of the roof up to a ridge of the roof and out to atmosphere. The roof products manage thermal energy in the roof by storing thermal heat with the unitary roof product during a heating cycle; venting excess heat through the unitary product; and releasing the stored thermal heat from the unitary product into or out of the building during a cooling cycle.

Owner:CERTAINTEED CORP

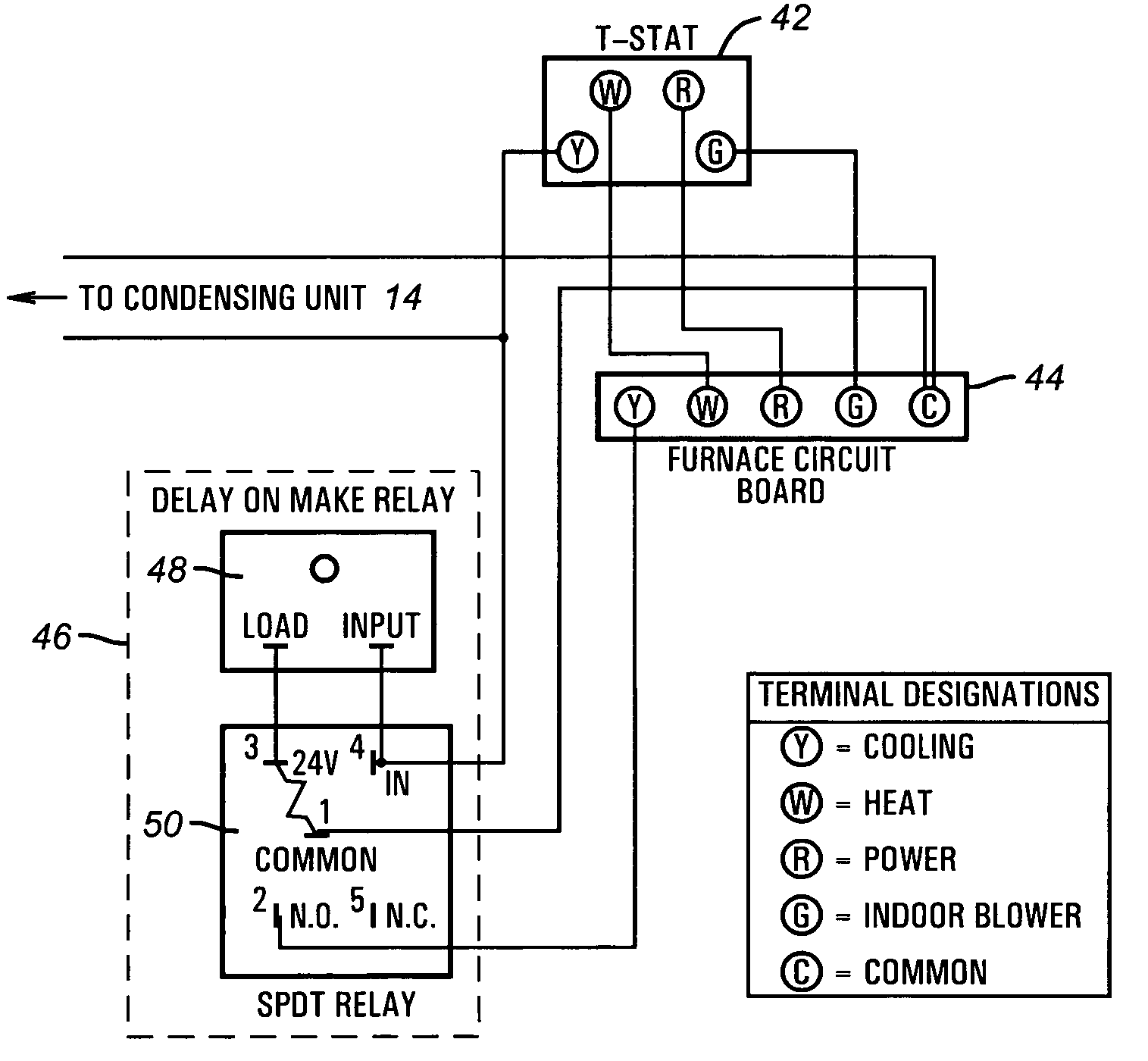

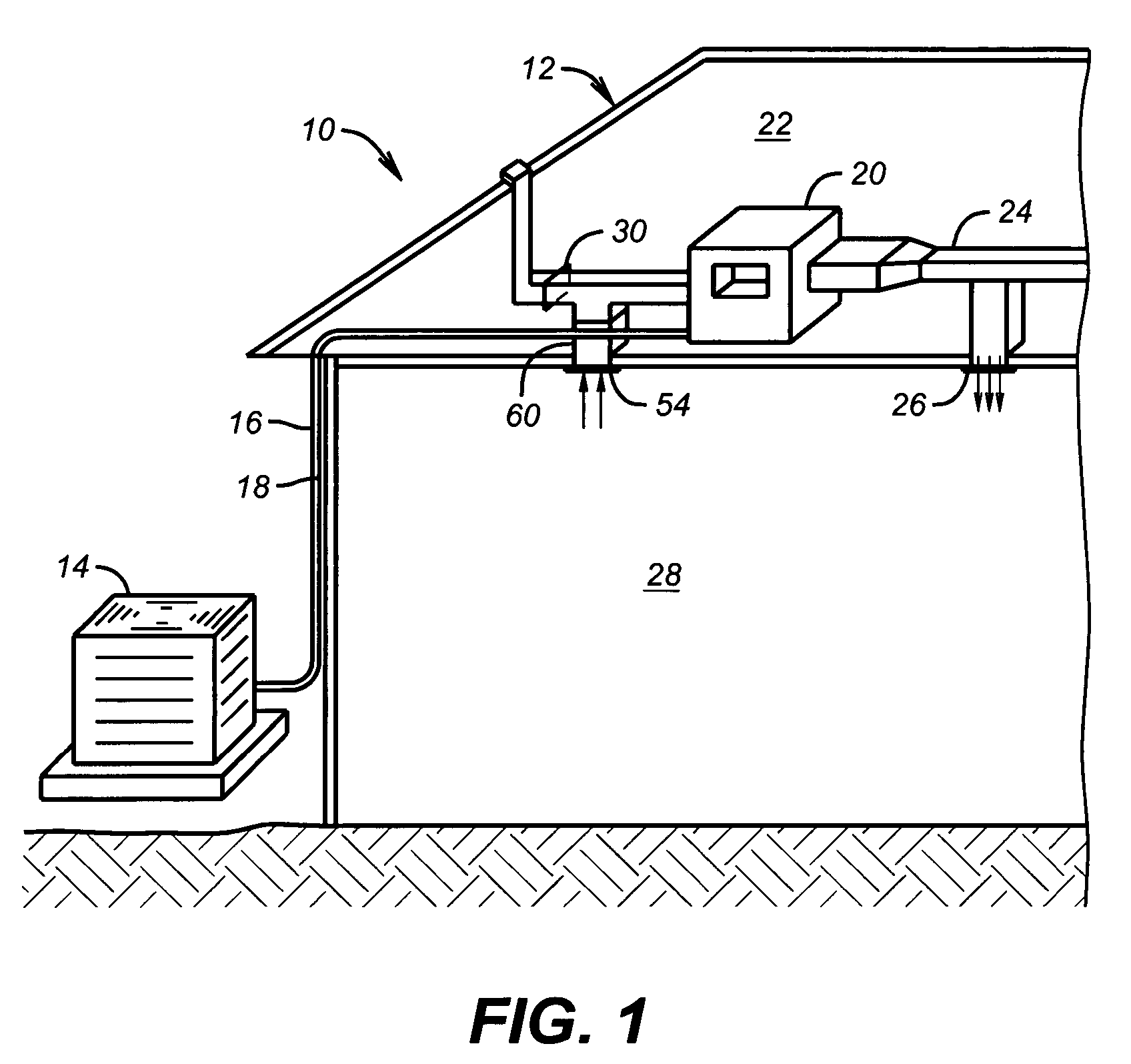

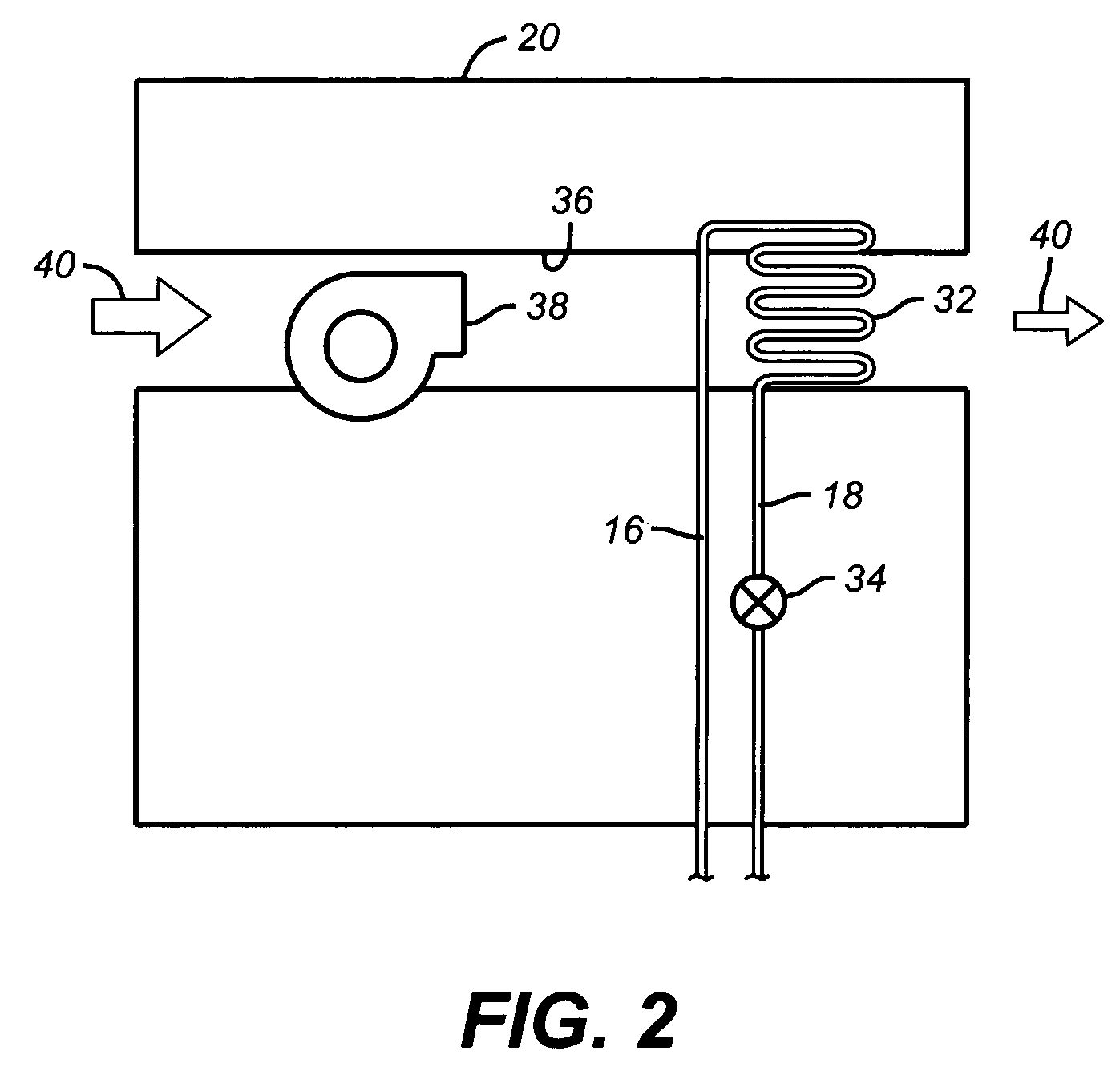

Air conditioning system with moisture control

ActiveUS7191607B2Speed up dehumidificationPrevent buildupDC motor speed/torque controlSpace heating and ventilationAir cycleLow speed

Devices and methods for moisture removal from conditioned air. A speed control is provided that selectively operates the blower motor of an air conditioning system at a lower speed. The speed control may include a time delay circuit and single pole, double throw relay. The speed control is used to slow the speed of the air cycler during the initial stage of a cooling cycle. This initial stage is typically the first 5–7 minutes of the air conditioning cycle. In a further aspect, a humidistat is operably associated with the system for detection of humidity levels within the air of a home or other structure. The system is programmed to close the motorized outside air damper in the event that humidity levels exceed a predetermined level, thereby limiting further entry of humid outside air into the home.

Owner:CURTIS MORTON

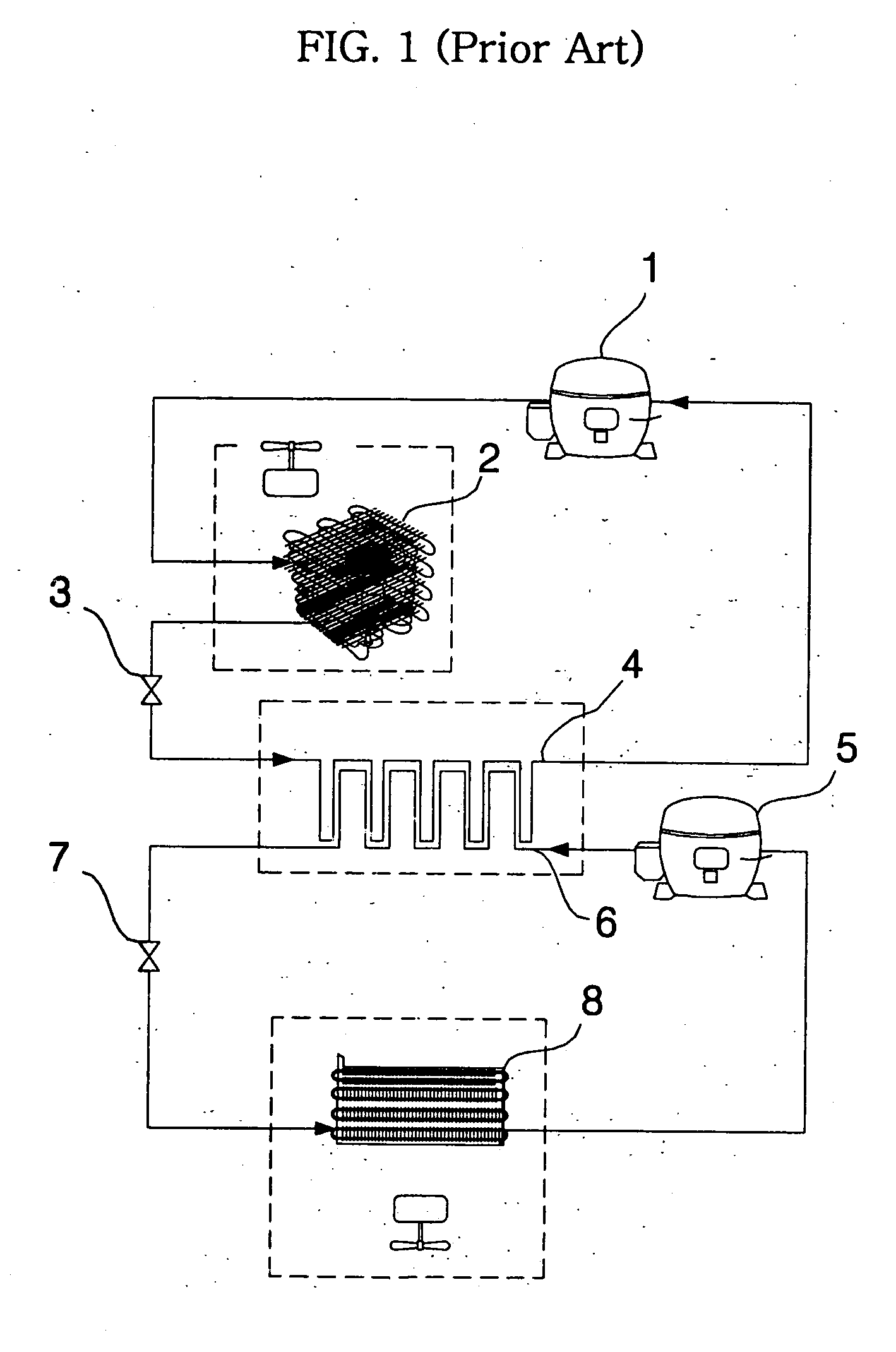

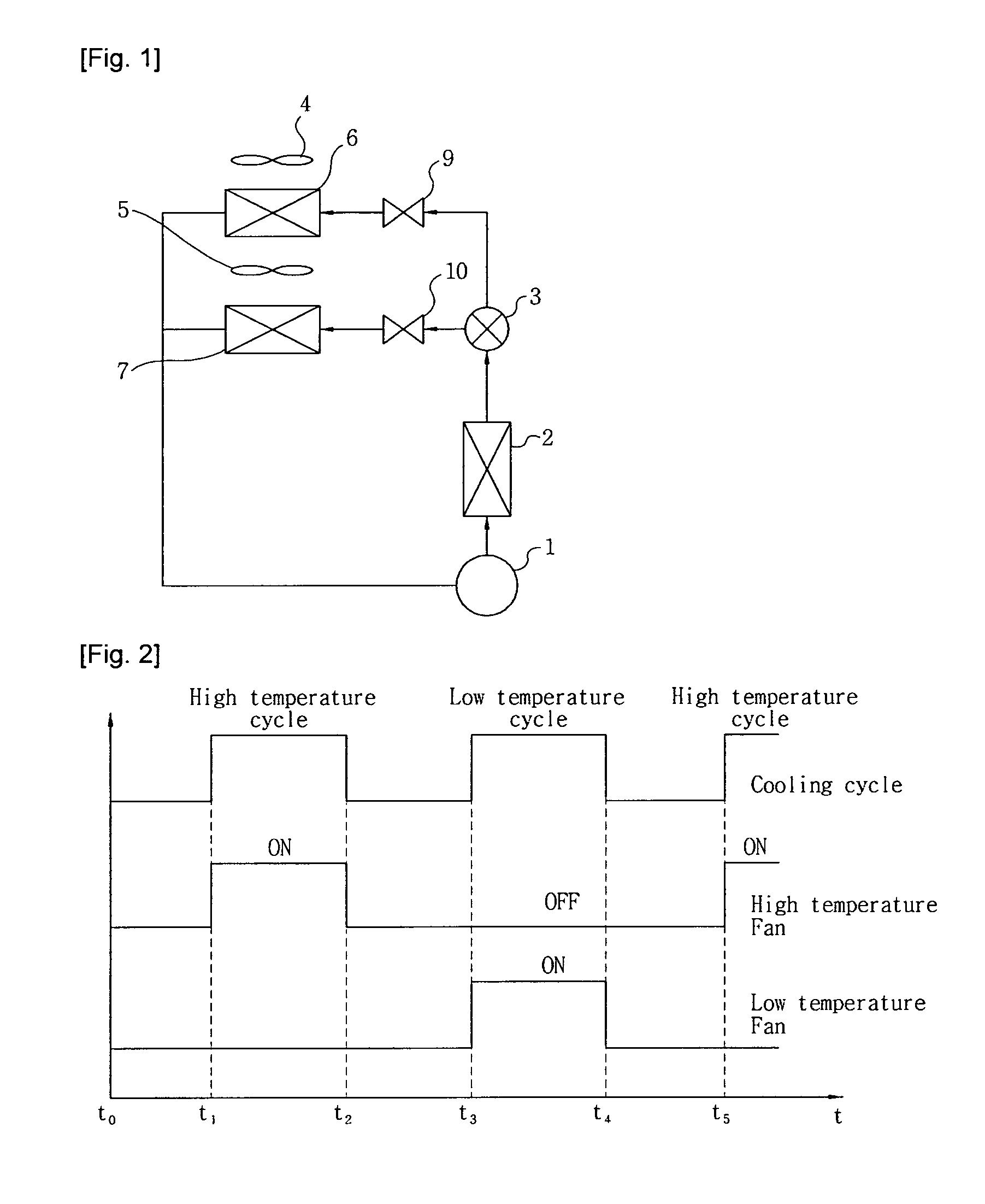

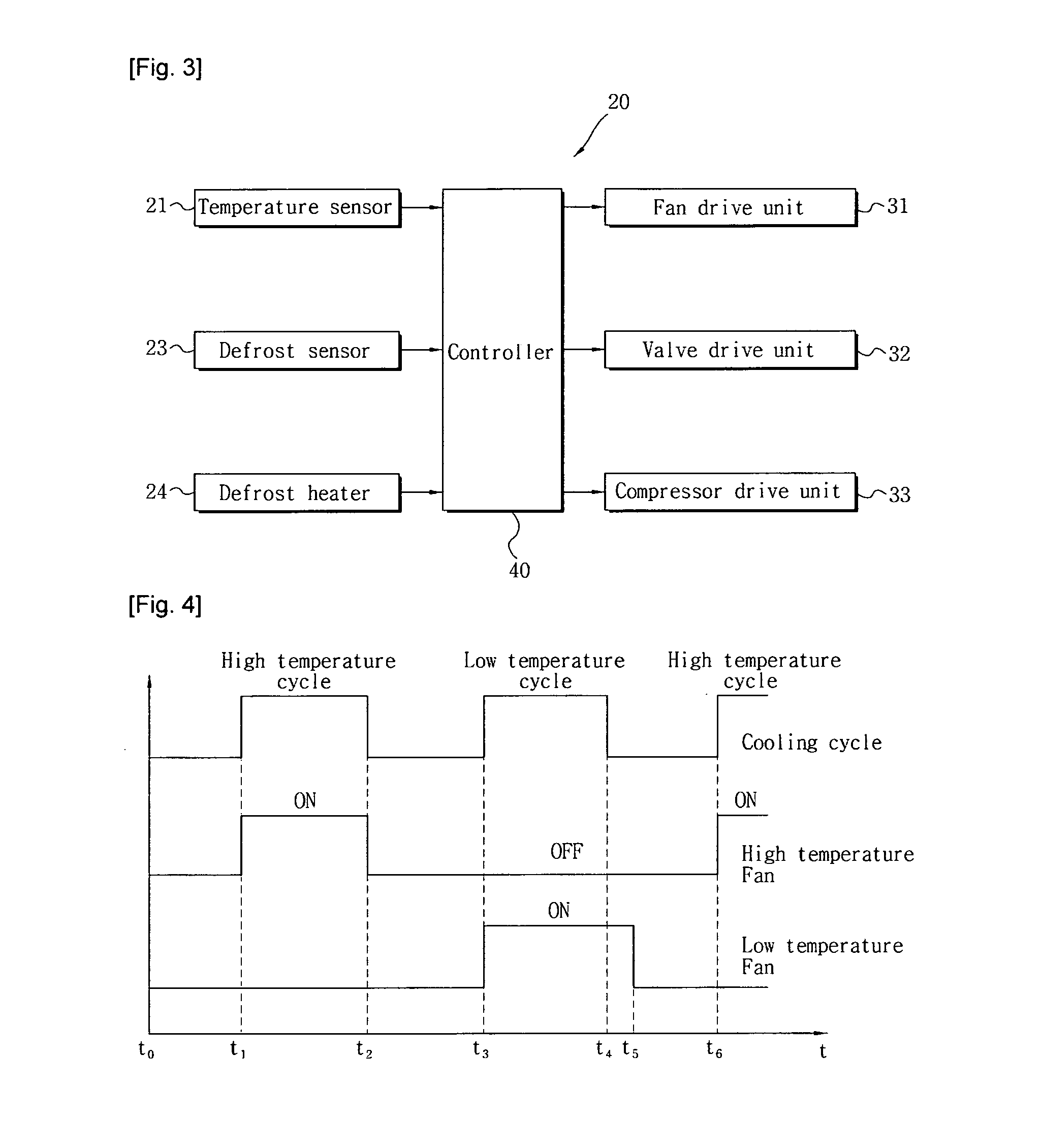

Control method of refrigerator

ActiveUS20110041525A1Promote circulationIncrease temperatureDomestic refrigeratorsCompression machines with several evaporatorsEngineeringRefrigerant

The present invention relates to a control method of a refrigerator which operates a cooling cycle including two storage compartments, a compressor, a condenser, a valve, fans, and evaporators for cooling the respective storage compartments, with one of the fans (5) corresponding to the storage compartment for storing items at relatively low temperatures being activated for a set amount of time even after the compressor is deactivated at the completion of cooling of the storage compartment for storing items at relatively low temperatures. In a refrigerator comprising a first storage compartment for storing an item, a second storage compartment for storing an item at a lower temperature than the first storage compartment, a cooling cycle including a compressor, a condenser for condensing a refrigerant from the compressor, a valve for directing the refrigerant from the condenser to first and second evaporators, with the first and second evaporators evaporating supplied refrigerants to cool the first and second storage compartments, respectively, and first and second (5) fans for circulating cool air from the first and second evaporators, respectively, and a controller for controlling the first and second (5) fans, the valve and the compressor, a control method of the refrigerator comprising: a first step of the controller activating the compressor if cooling of the second storage compartment is required and activating the second fan (5); and a second step of the controller deactivating the operation of the compressor, if the cooling of the second storage compartment is completed, and deactivating the operation of the second fan (5) after the operation of the compressor is deactivated.

Owner:LG ELECTRONICS INC

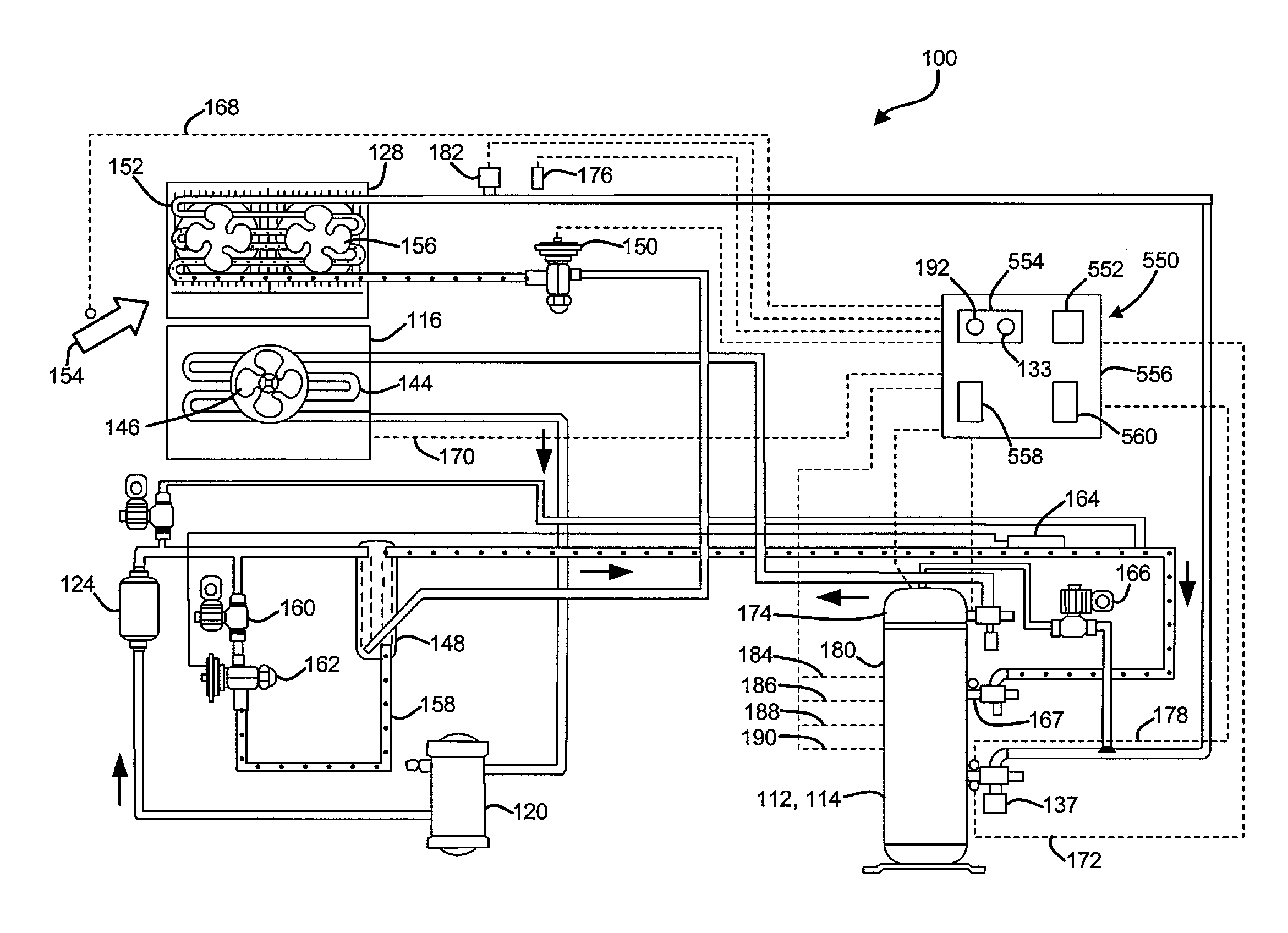

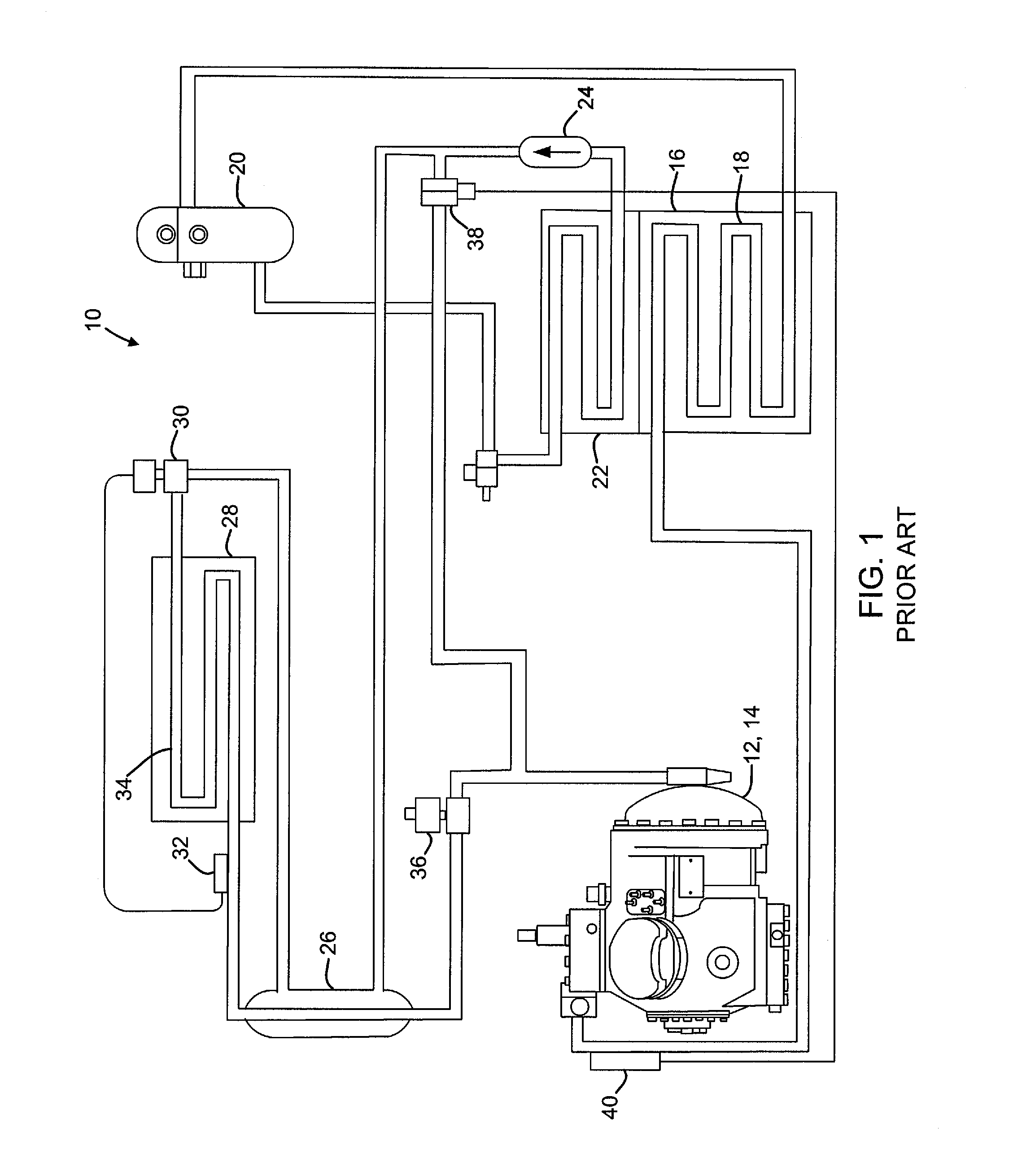

Compressor discharge control on a transport refrigeration system

ActiveUS20110132007A1Compression machines with non-reversible cycleFluid circulation arrangementRefrigerationSet point

In a refrigeration system having a compressor, a condenser, an evaporator, and a controller for controlling an expansion valve, a process for controlling compressor discharge during a cooling cycle comprising the steps of monitoring a compressor discharge parameter, comparing the compressor discharge parameter to a set point stored in a controller memory, and selectively operating the expansion valve upstream of the evaporator in response to a difference between the compressor discharge parameter and the set point.

Owner:CARRIER CORP

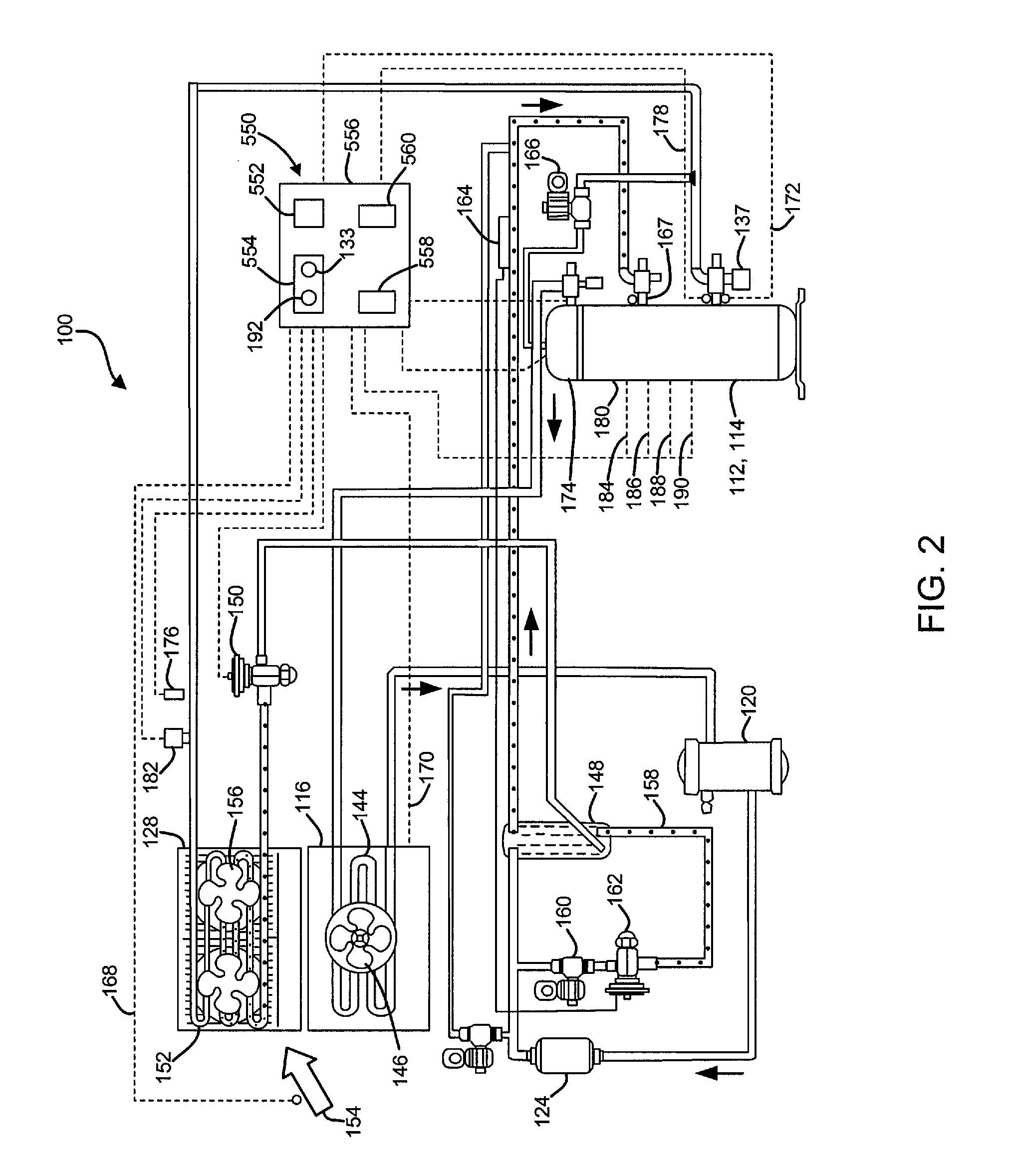

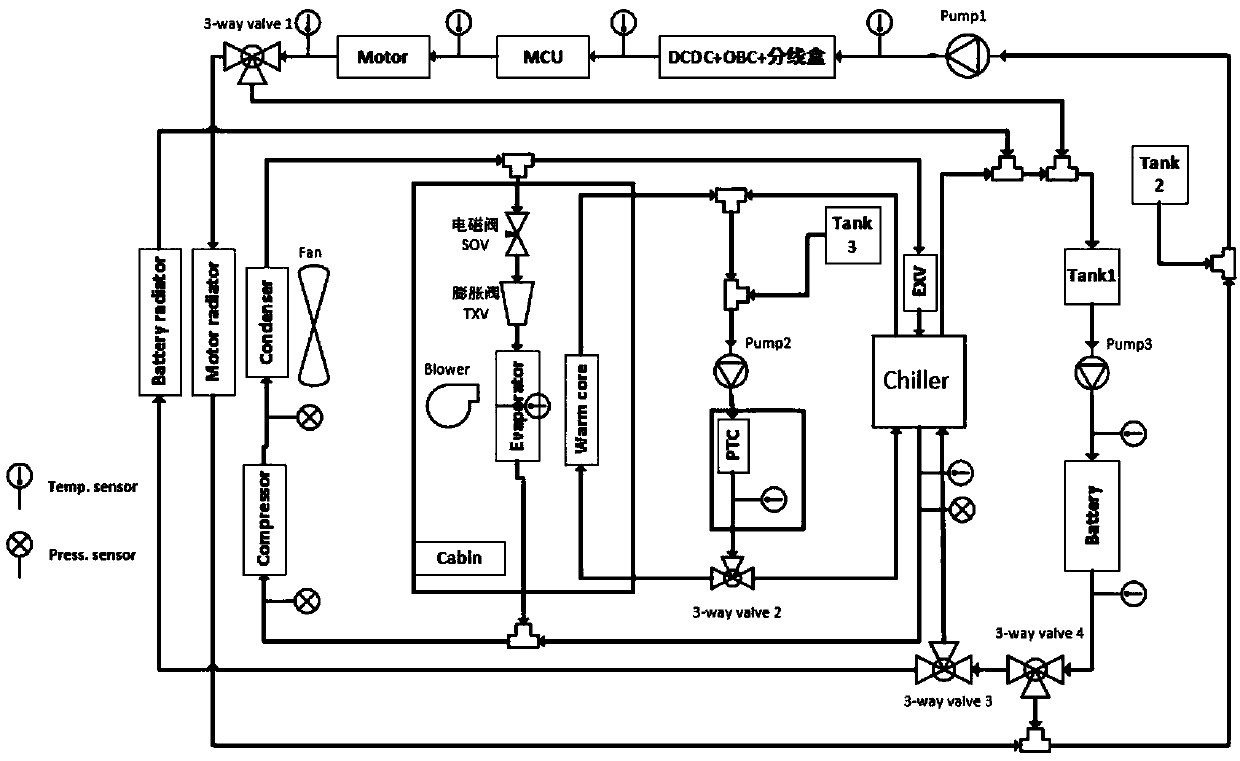

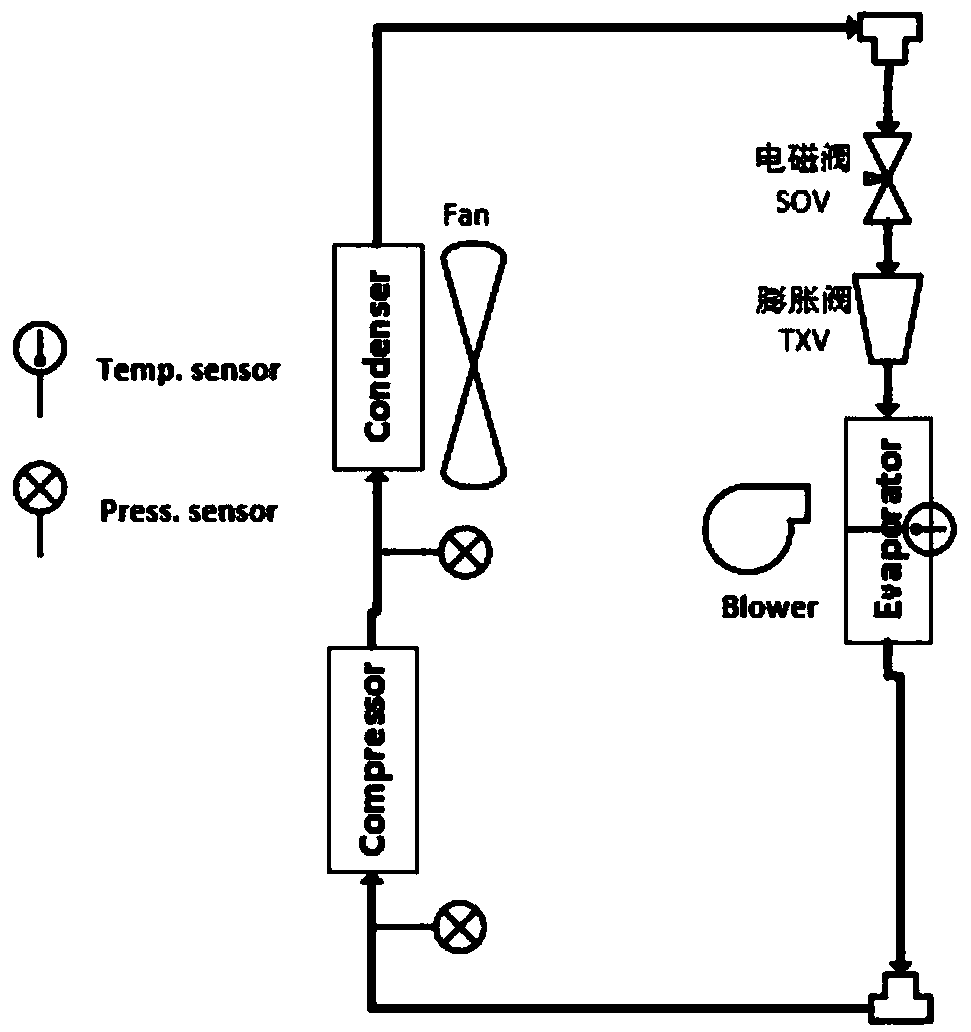

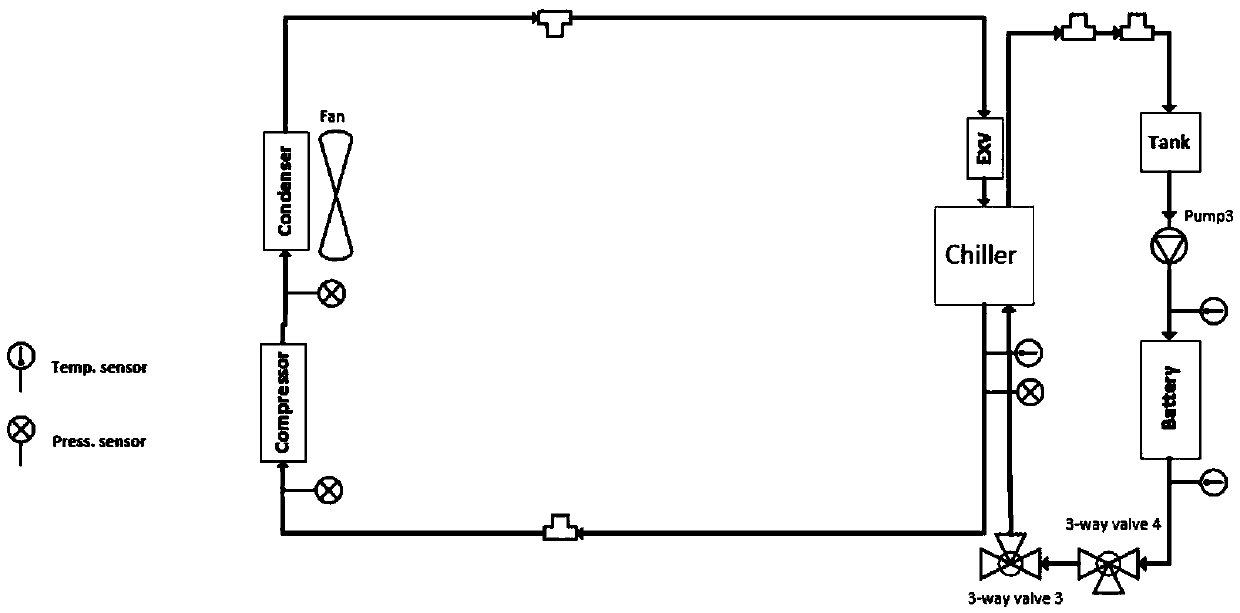

Low-power-consumption heat management system of electric car

InactiveCN109532563AReduce heating effectReduce cooling effectAir-treating devicesSecondary cellsElectrical batterySolenoid valve

The invention relates to an electric car heat management system, in particular to a low-power-consumption heat management system of an electric car. The low-power-consumption heat management system comprises an electric compressor, a condenser, a refrigerant solenoid valve, a thermostatic expansion valve, an HVAC assembly, an electronic expansion valve, a cooler, a first expansion kettle, a thirdelectronic water pump, a fourth three-way valve and a third three-way valve. After the components are combined, a passenger compartment refrigerating cycle loop, a battery forced cooling cycle loop, abattery low-temperature heat radiation cycle loop, a passenger compartment heating cycle loop, a battery forced heating cycle loop, a battery waste heat utilization cycle loop, a battery temperatureequalization cycle loop and a motor cooling cycle loop are formed. According to the low-power-consumption heat management system, the situation that a PTC and the electric compressor are utilized forheating and cooling a battery can be effectively reduced, and therefore the whole car power consumption is reduced, and the driving mileage is increased.

Owner:JIANGSU MINAN AUTOMOTIVE CO LTD

Passive gas-gap heat switch for adiabatic demagnetization refrigerator

InactiveUS6959554B1Fuel supply regulationTemperatue controlRefrigerated temperatureElectrical and Electronics engineering

Owner:NAT AERONAUTICS & SPACE ADMINISTATION UNITED STATES GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE

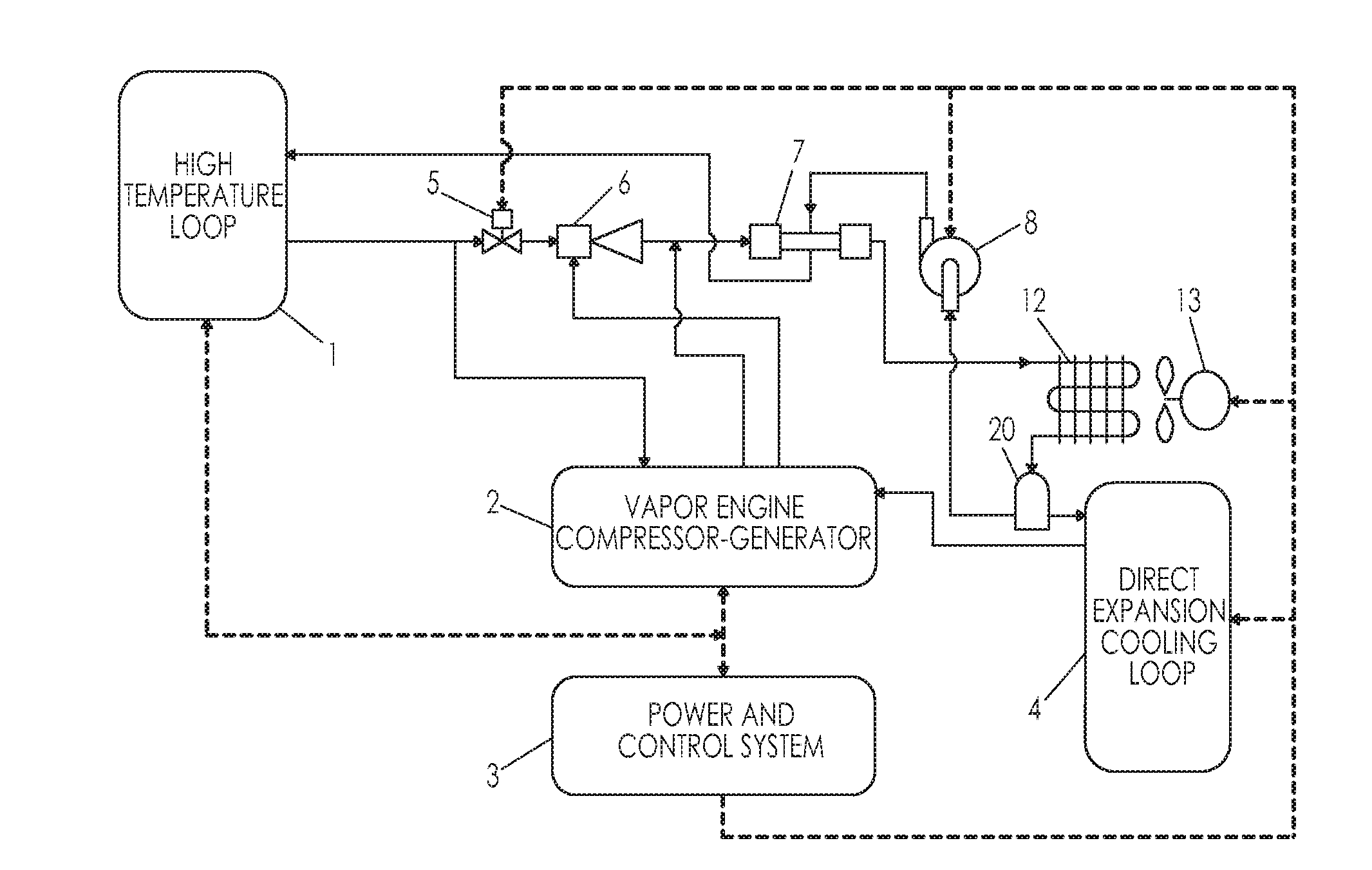

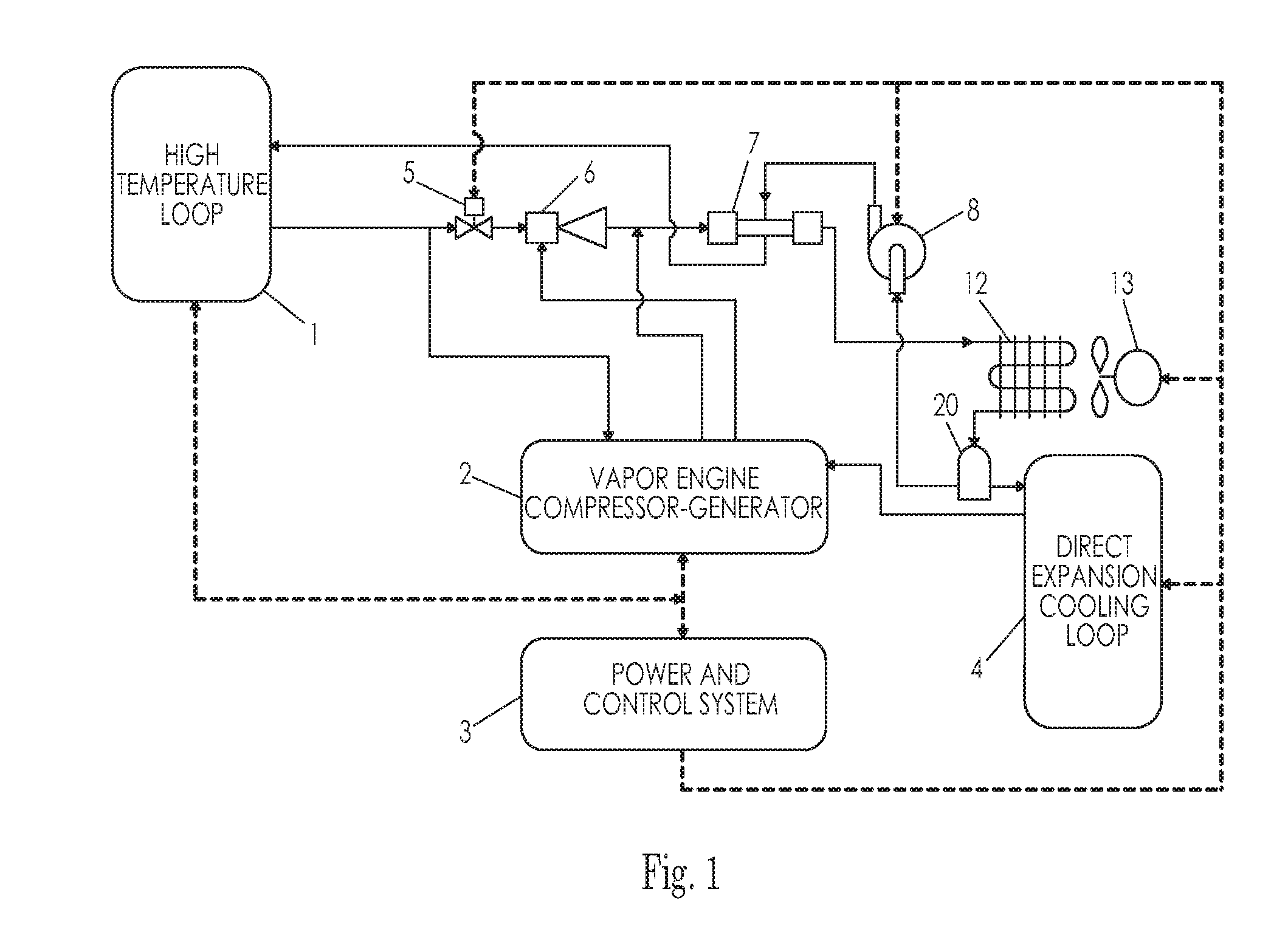

Expendable turbine driven compression cycle cooling system

A cooling system with a compression cooling cycle for a working fluid that passes an expendable fluid through a warm side heat exchanger for the cooling system to cause the expendable fluid to vaporise and thus absorb heat from the working fluid by way of latent heat or enthalpy of vaporisation and then running the vaporised expendable through a turbine that drives a compressor for the cooling system.

Owner:HAMILTON SUNDSTRAND CORP

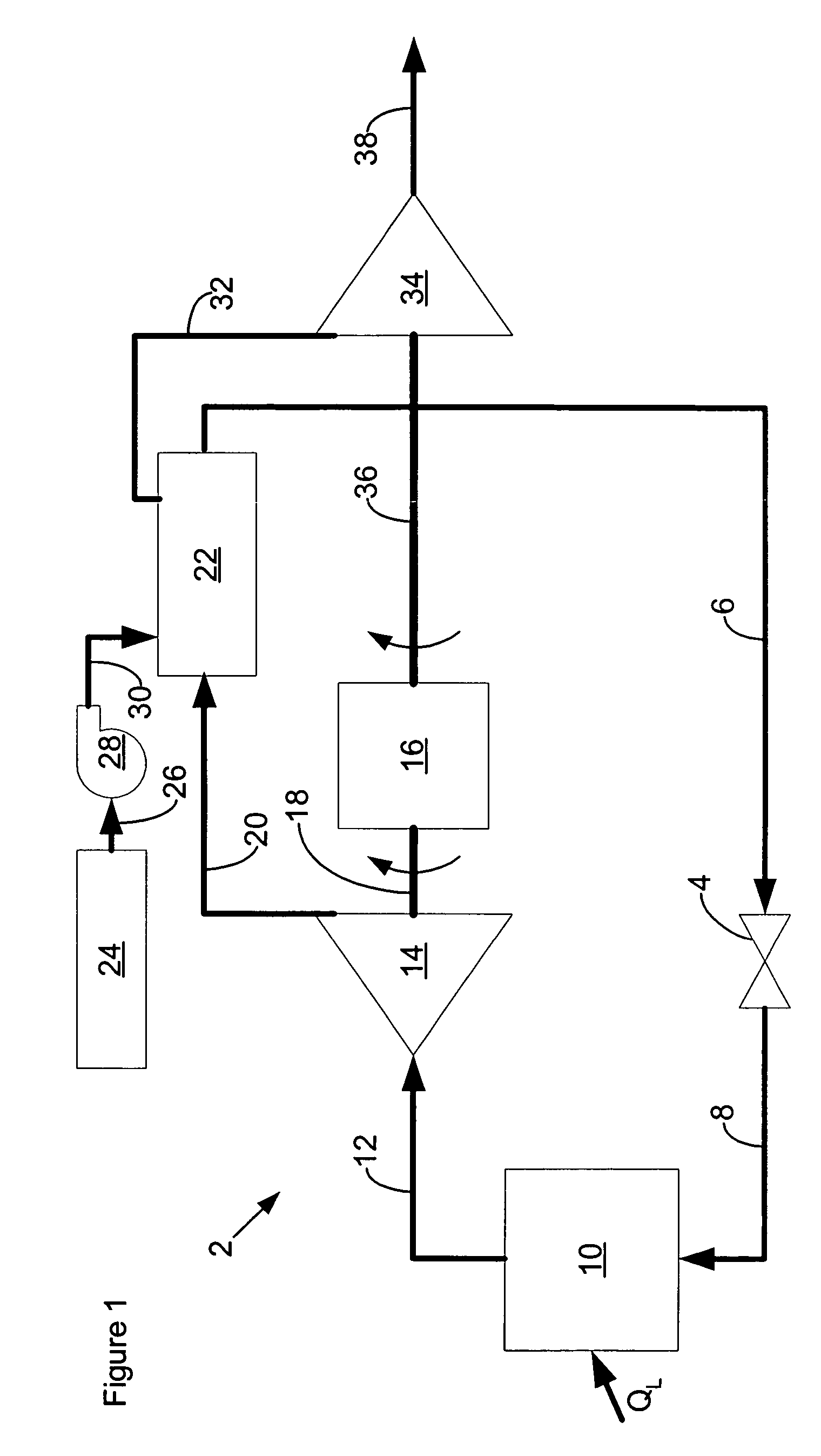

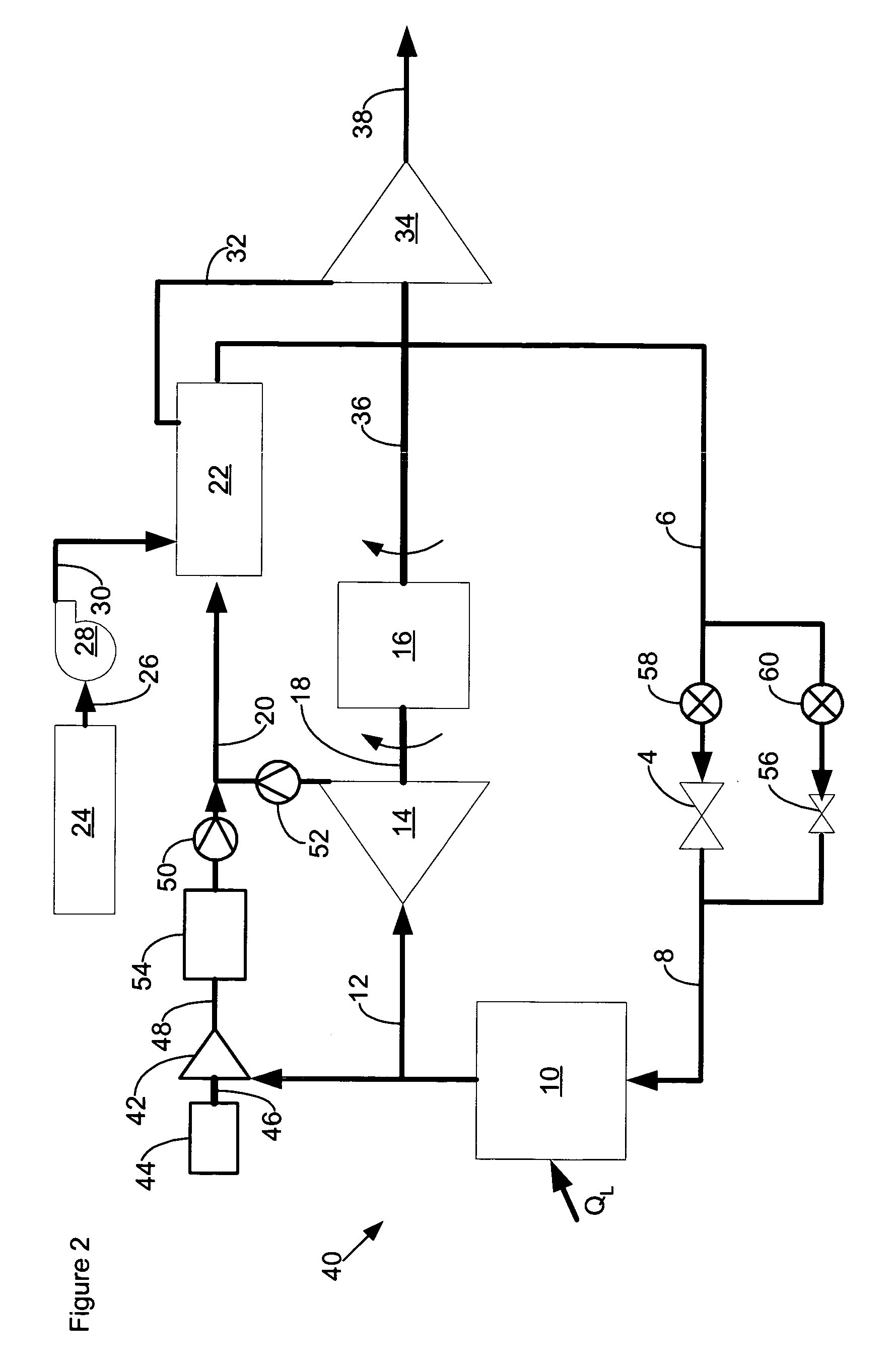

Mechanically Enhanced Ejector HVAC and Electric Power Generation System

InactiveUS20110247351A1Compression machines with non-reversible cycleVehicle heating/cooling devicesThermal energyElectrical battery

An HVAC system that uses a mechanical compressor powered by vaporized refrigerant and / or electric power, to increase efficiency in a jet ejector cooling cycle. The device is further able to convert thermal energy to electric power which may be used to meet internal or external requirements, for example, to activate control a system or charge a battery. Compatible input power includes only thermal energy, only electric energy or a combination of the two. Motive thermal energy may be input at a wide range of temperature and include both waste and non-waste heat sources such as that from an internal combustion engine and fuel-fired heater. Solar thermal and solar photovoltaic may also be used when collected from either concentrated or non-concentrated sources. Embodiments of the device are equally well suited to both mobile and stationary applications.

Owner:ALSTON GERALD ALLEN

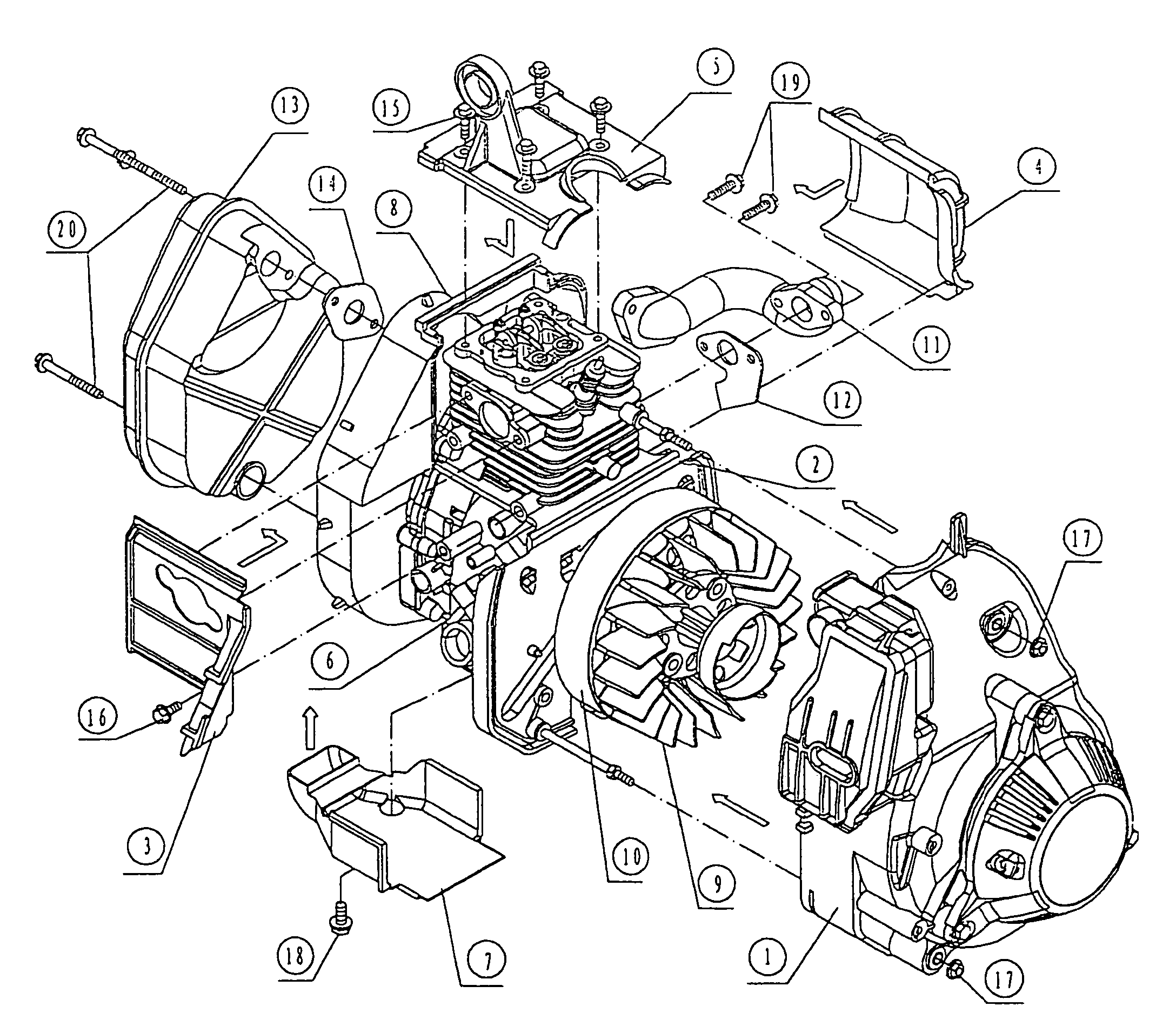

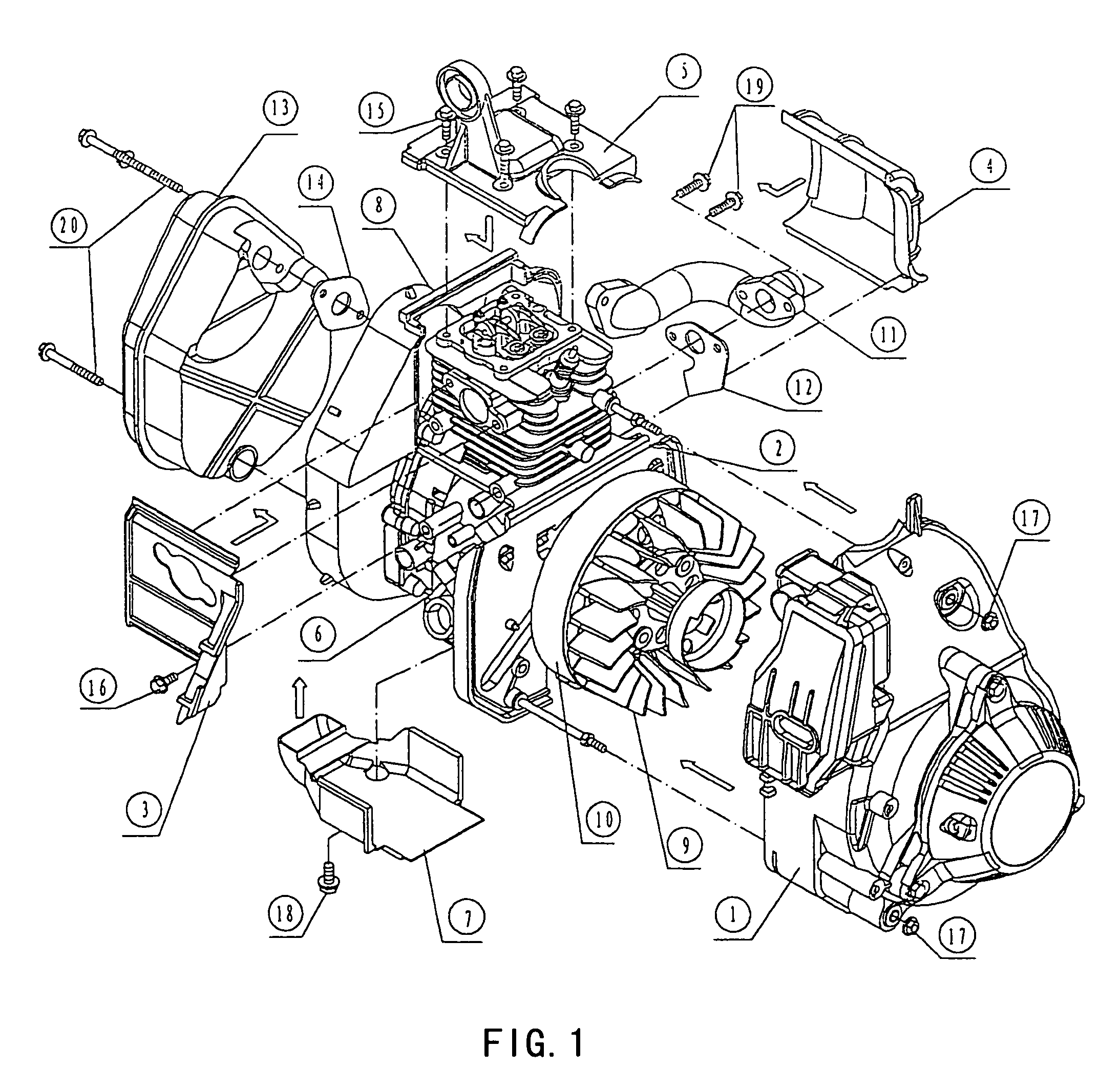

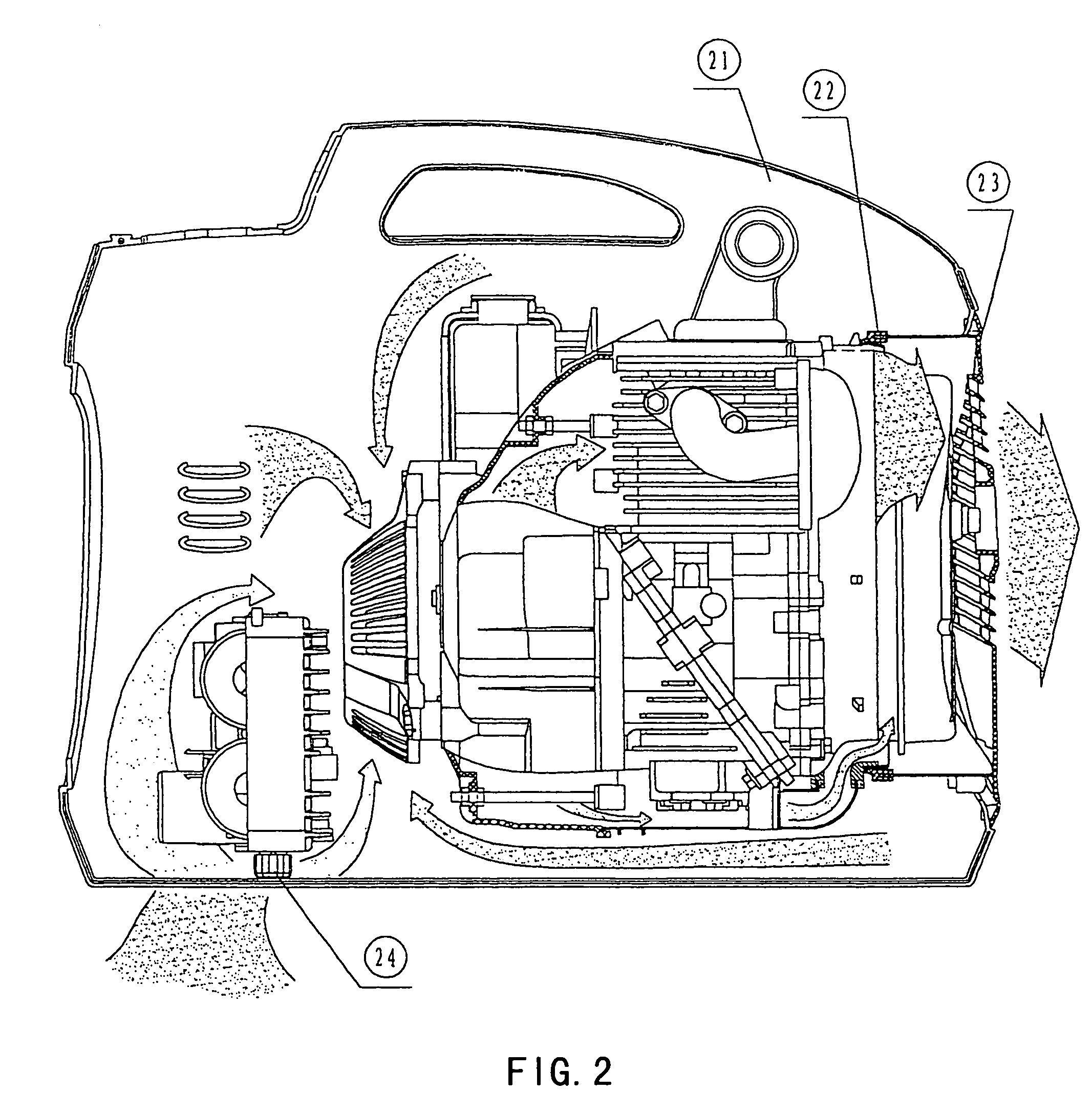

Cooling system of an engine for the inside of a generator

InactiveUS7392770B2Very high cooling effectImprove cooling effectNon-fuel substance addition to fuelAir coolingCold airExhaust pipe

The present invention relates to a cooling system for an engine inside a power generator, in the field of the power generator, which mainly includes a cool air suction hood, an engine housing side cover, an engine housing, a cool air cooling fan, an exhaust pipe; the cool air suction hood is jointed to the engine housing side cover, the left air guide plate and the right air guide plate on the upper of the engine secured to the engine housing, thus form two main cooling and ventilating chambers A and B on the left and right upper portion of the engine. An engine bottom air guide plate is secured to the bottom of engine housing side cover and forms the bottom cooling and ventilating chamber C of the engine with the side cover and an engine crank case rear cover. The engine crank case rear cover, the above-mentioned members, a heat insulation chamber body, a sealing ring and a heat insulation chamber rear hood form a double chamber cooling means of the secondary cooling cycle chamber D. The jointing surfaces of the cooling system are increased. The requirements for cooling the engine are more reasonable so that the portions of the engine with high heat are ensured to be timely cooled and provide a highly cooling effective for the engine.

Owner:WUXI KIPOR POWER CO LTD

Orientated gel molding method of polyolefin-based resin composition and molded article obtainable by the method

The present invention provides a method of molding a polyolefin-based resin comprising the steps of dissolving at least one dibenzylidene sorbitol compound in a molten polyolefin resin, cooling the molten resin to a temperature not higher than the sol-gel transition temperature during the cooling cycle to form network-like crystals of the dibenzylidene sorbitol compound, and molding the resulting resin composition at a temperature not lower than the melting temperature of the polyolefin-based resin but not higher than the sol-gel transition temperature during the heating cycle; and a polyolefin resin molded article obtainable by this molding method.

Owner:NEW JAPAN CHEM CO

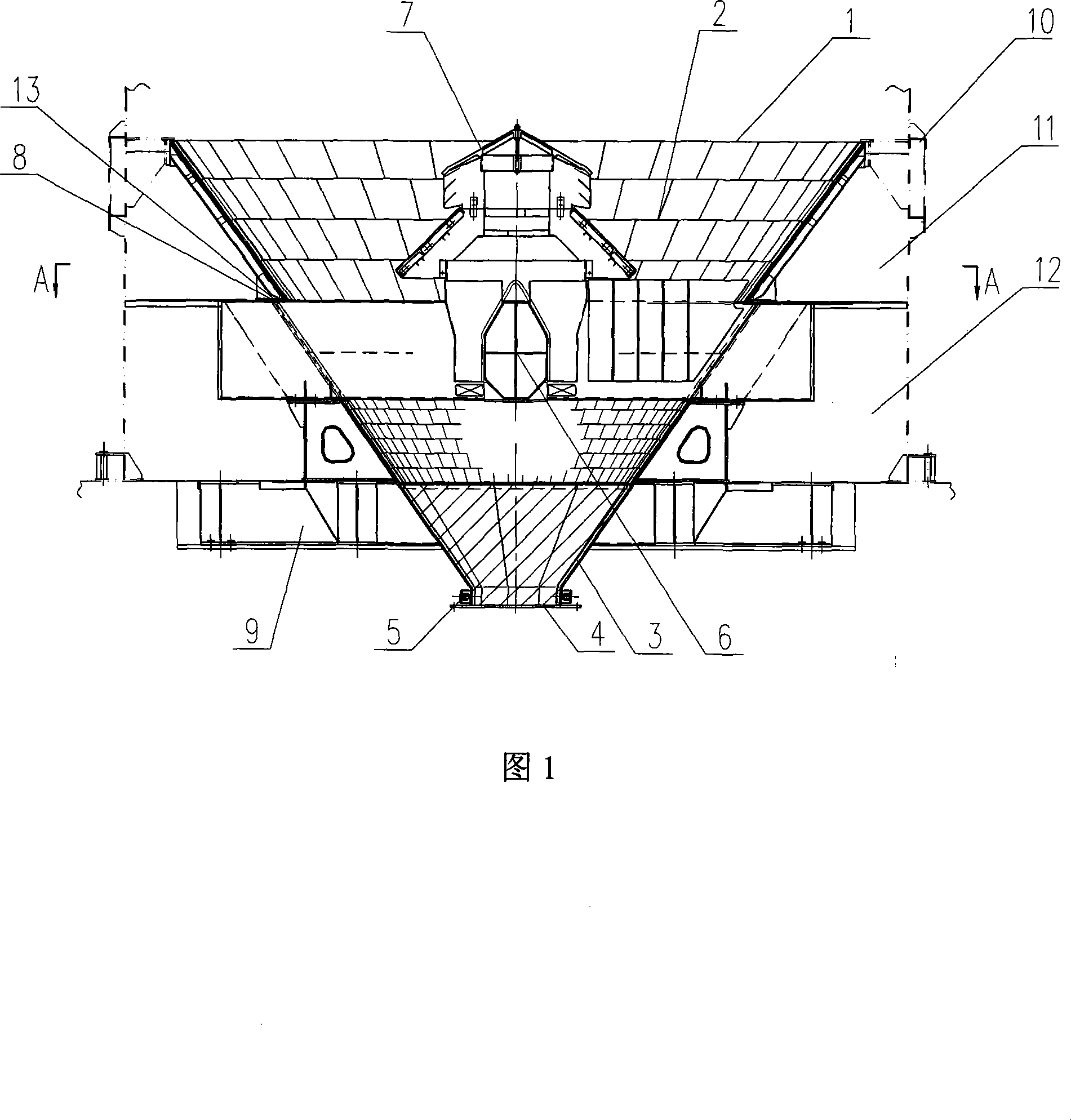

Special-purpose gas supplying device for coke dry quenching unit

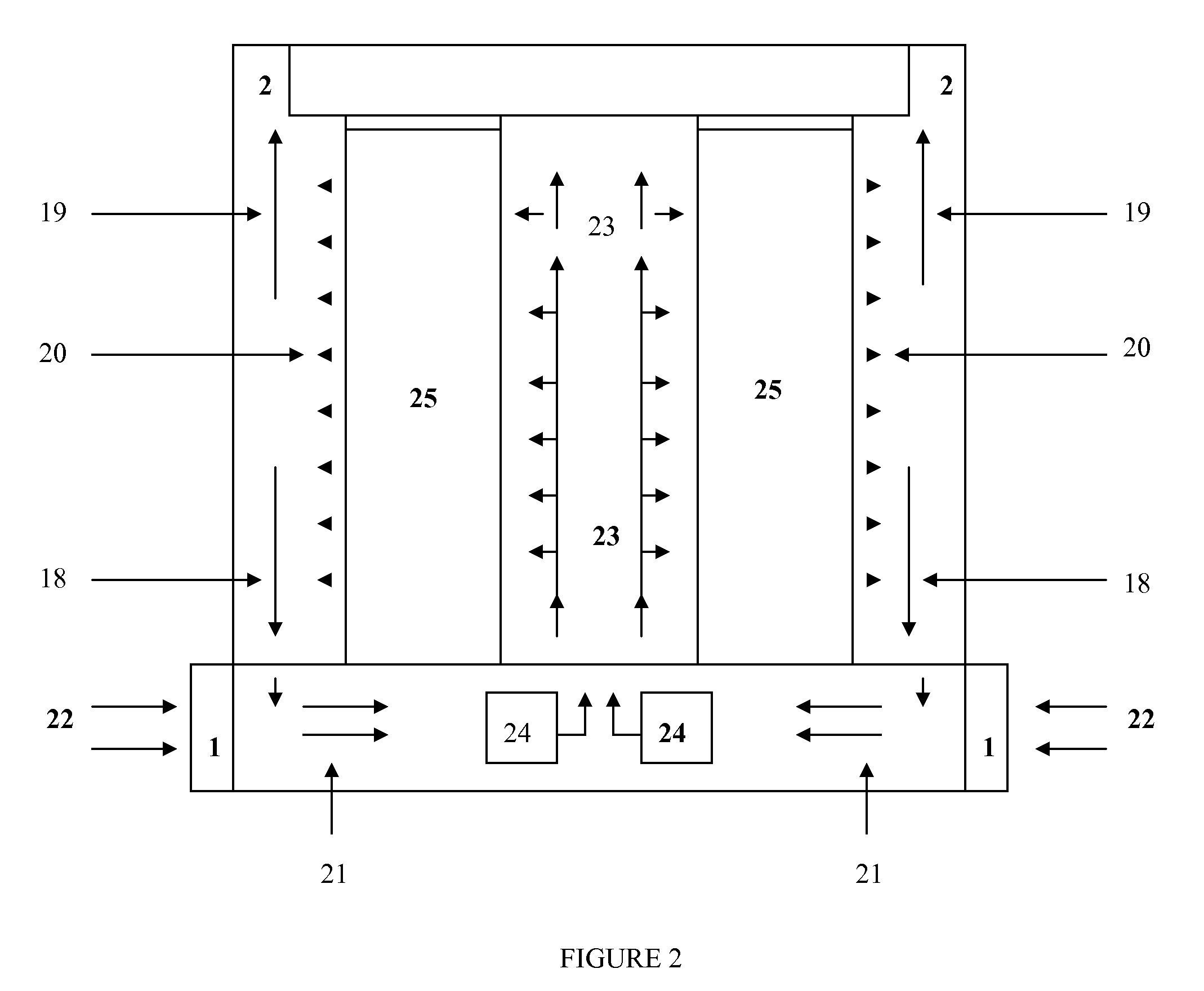

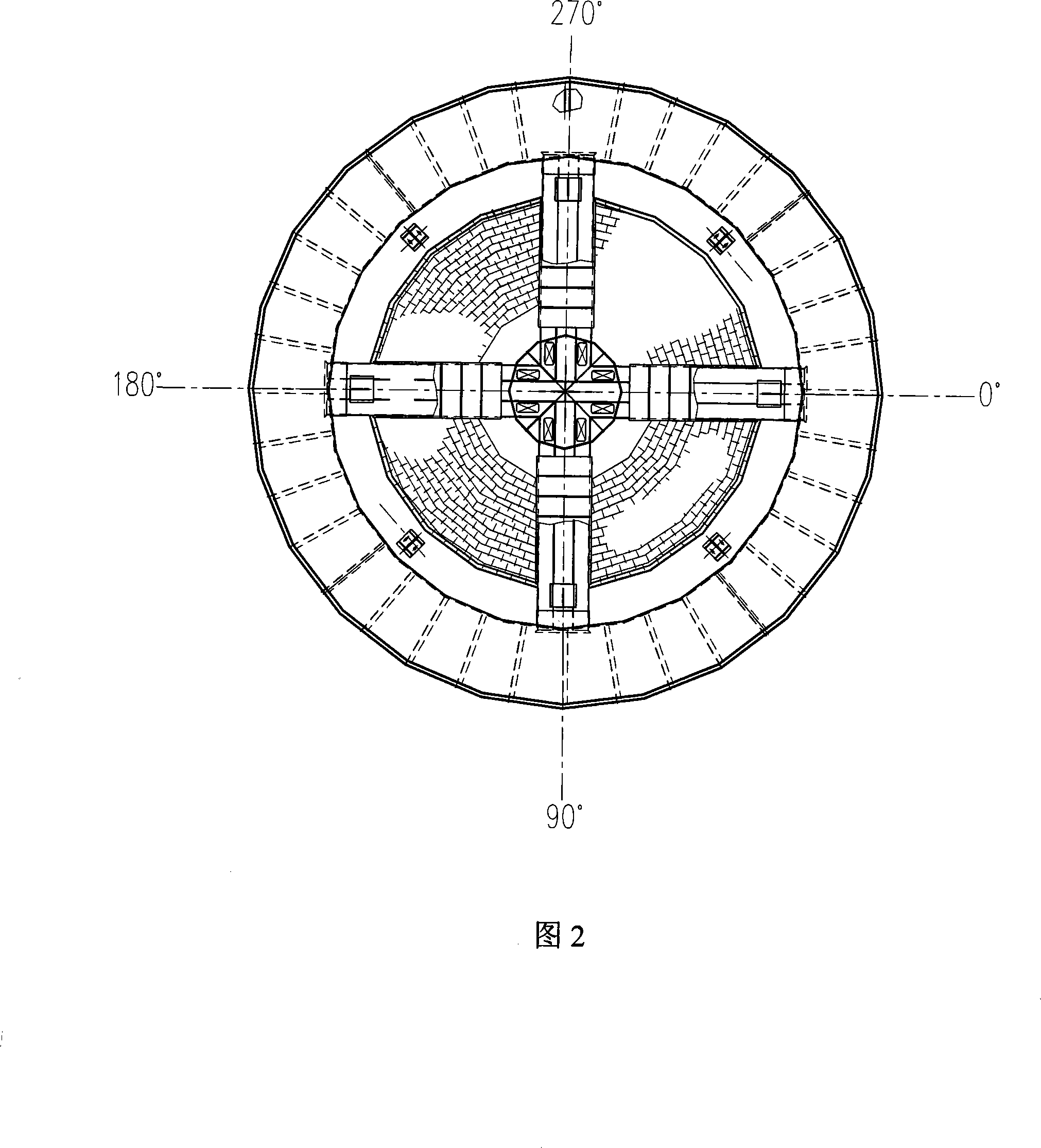

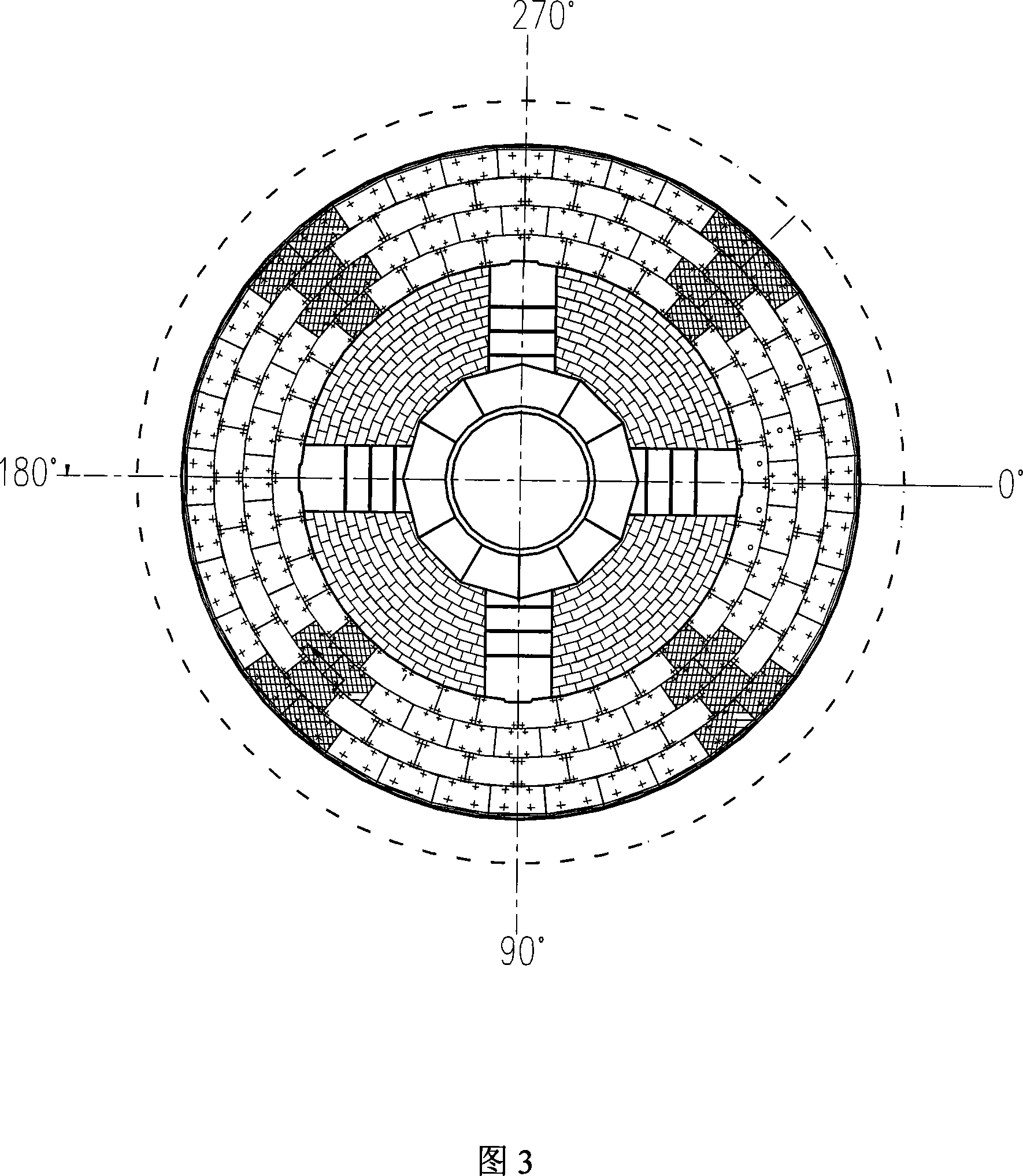

The invention relates to an air supply facility specially used for a dry out furnace. The facility is composed of an upper cone funnel, a lower cone funnel, a dry out furnace casing body, a ring-shaped air channel, a cross air channel, and a central windshield, wherein the upper cone funnel and the lower cone funnel are sleeved and inserted with each other, the ring-shaped air channel is composed of an annular gap which is formed by a sleeve and inserting ledge, and the cross air channel is positioned on the upper portion of the lower cone funnel and is horizontally arranged, the centre of the cross air channel coincides with the centre of the dry out furnace and extends upwards and is communicated with the central windshield which is arranged on the cone funnel, the facility employs a combining air supply form of that peripheral air rings supply air from outside in and the central windshield supplies air from inside out on the upper portion of the furnace body. The facility can effectively resolve the problem that the cooling cycle air entering the dry out furnace is uniformly distributed in the periphery direction of the dry out furnace, which is favorable for achieving uniform cooling of the coke in the furnace, thereby improving the cooling property of the dry out furnace, increasing the cooling efficiency of the dry out furnace, and reducing the dry out time of the coke in the dry out furnace.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

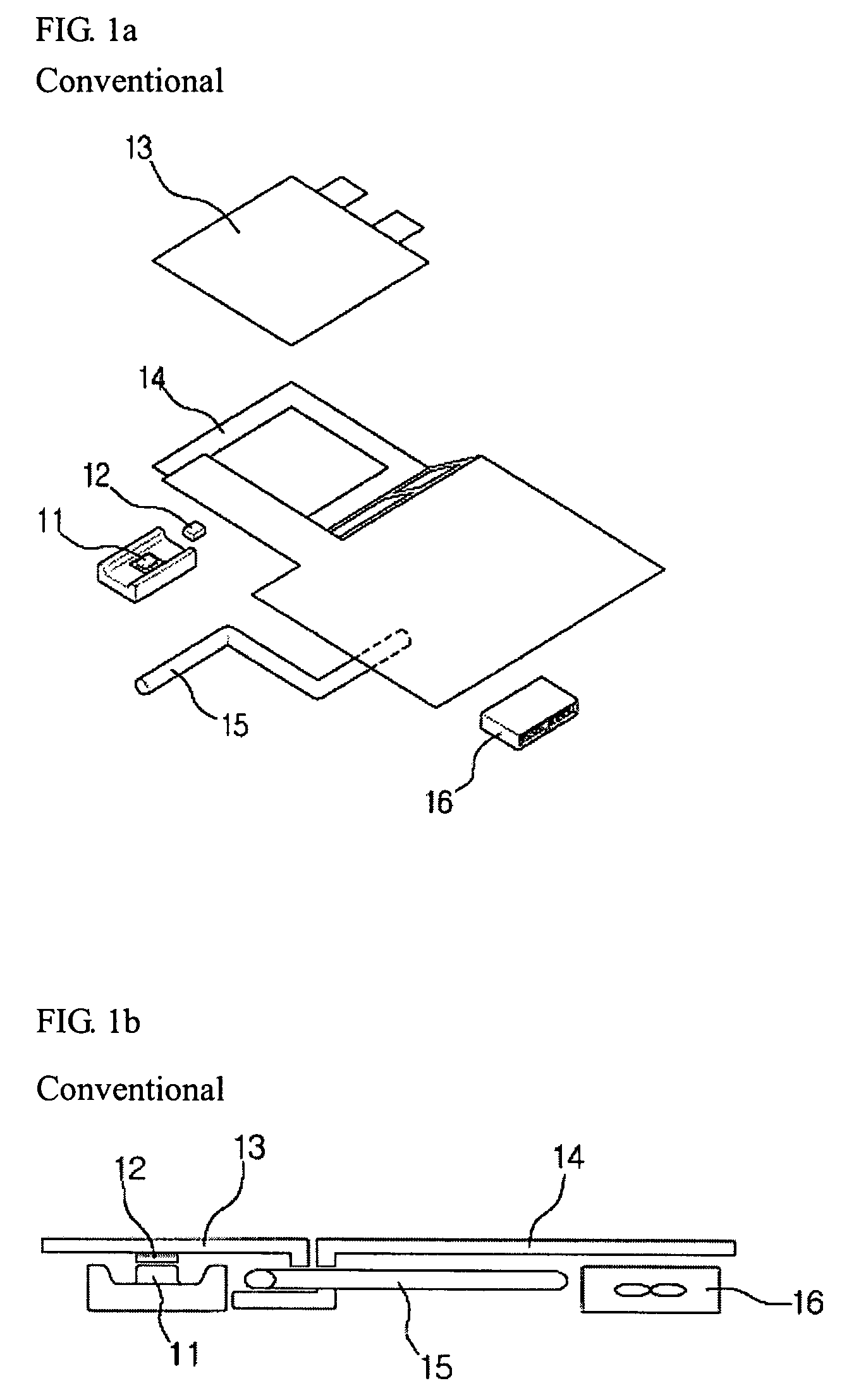

Cooling module

InactiveUS7222661B2Improve cooling effectReduced space requirementsSemiconductor/solid-state device detailsSolid-state devicesThermal energyEngineering

A cooling module includes a thermal conductive member. An endoergic chamber, a radiative chamber and a circulation pump chamber are defined along the thermal conductive member. The thermal conductive member contacts a heat generating object outside the endoergic chamber. The thermal energy is transferred to the coolant in the endoergic chamber. The coolant then flows into the radiative chamber. The thermal energy of the coolant is taken away in the radiative chamber. The thermal energy is radiated from the outer wall surface of the radiative chamber. This cooling cycle is repeated so that an efficient cooling operation can be realized in the cooling module. Arrangement of the endoergic, radiative and circulation pump chambers along the thermal conductive member leads to a minimized height of the cooling module.

Owner:FUJITSU LTD

Drying machine adopting freezing circulatory system

InactiveCN1766212AReduce the temperaturePrevent overloadTextiles and paperLaundry driersEngineeringCoolant temperature

The invention discloses a drying machine with cooling cycle system, which comprises: a rolling drum, a circulation pipe, a fan, an electric heater, a cooling cycle system, a out-gas inflow pipe connected with circulation pipe to make outer air flow said system, and a bypass pipe arranged on circulation pipe to make air from the drum do not pass evaporator and consender to return directly to said drum. This invention reduces coolant temperature, prevents over loading and interruption of drying, and increases drying efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

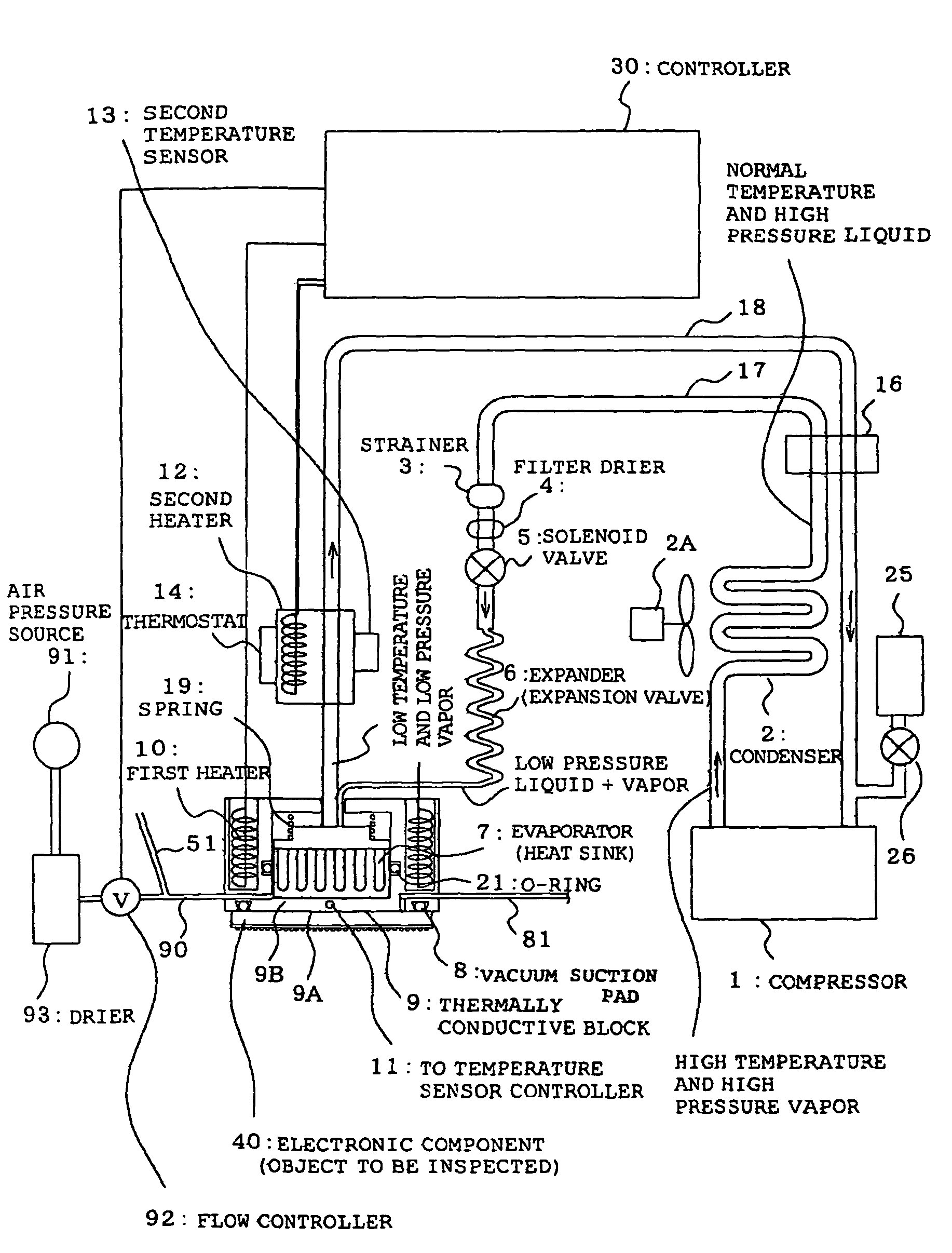

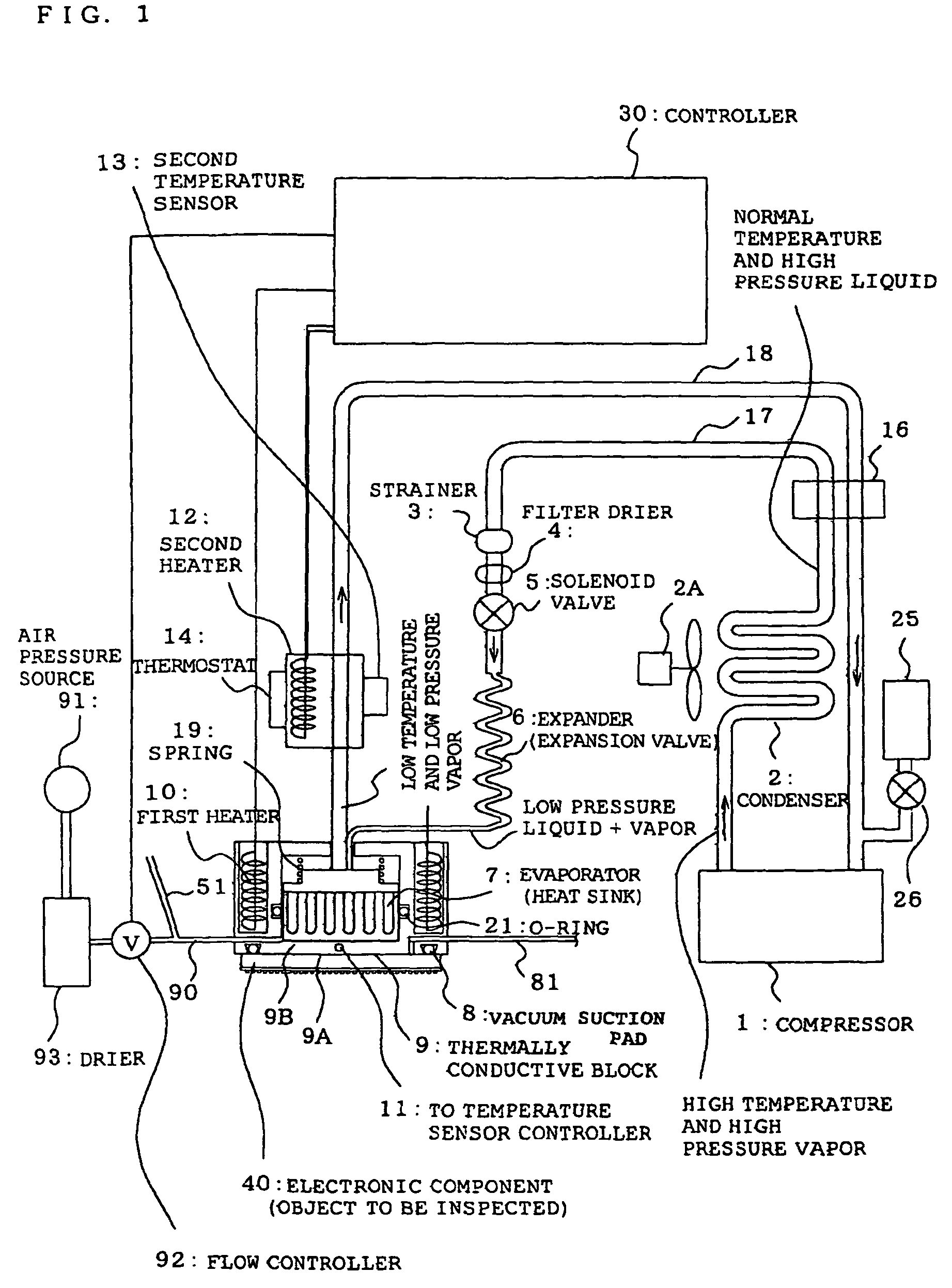

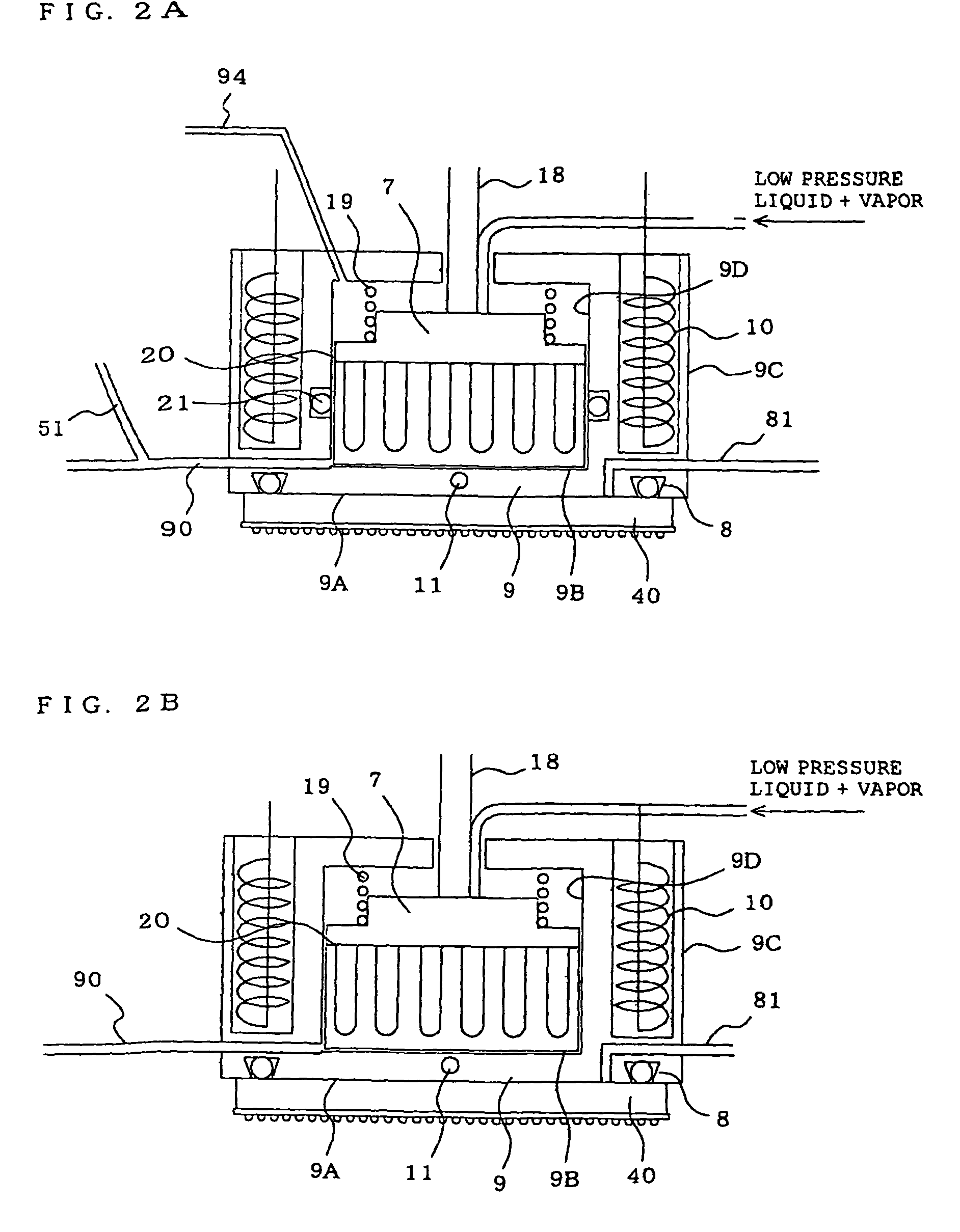

Temperature control unit for electronic component and handler apparatus

InactiveUS7726145B2Good responsibilityAvoid condensationSemiconductor/solid-state device testing/measurementDomestic cooling apparatusTemperature controlElectronic component

A temperature control unit for an electronic component and a handler apparatus, which are excellent in responsibility during cooling and heating, is obtained. The temperature control unit for an electronic component includes a cooling cycle device having a refrigerant passage circulating through a compressor, a condenser, an expander, and an evaporator; a thermally conductive block having an outer surface capable of coming in contact with the electronic component that is an object to be temperature-controlled, where an inner surface corresponding to the outer surface is placed opposite to the outer surface so as to be brought in contact with or apart from the evaporator; at least one first heater for heating the thermally conductive block; and a compressed air feeding circuit for feeding compressed air between facing surfaces of the evaporator and the thermally conductive block to part them.

Owner:NS TECH INC

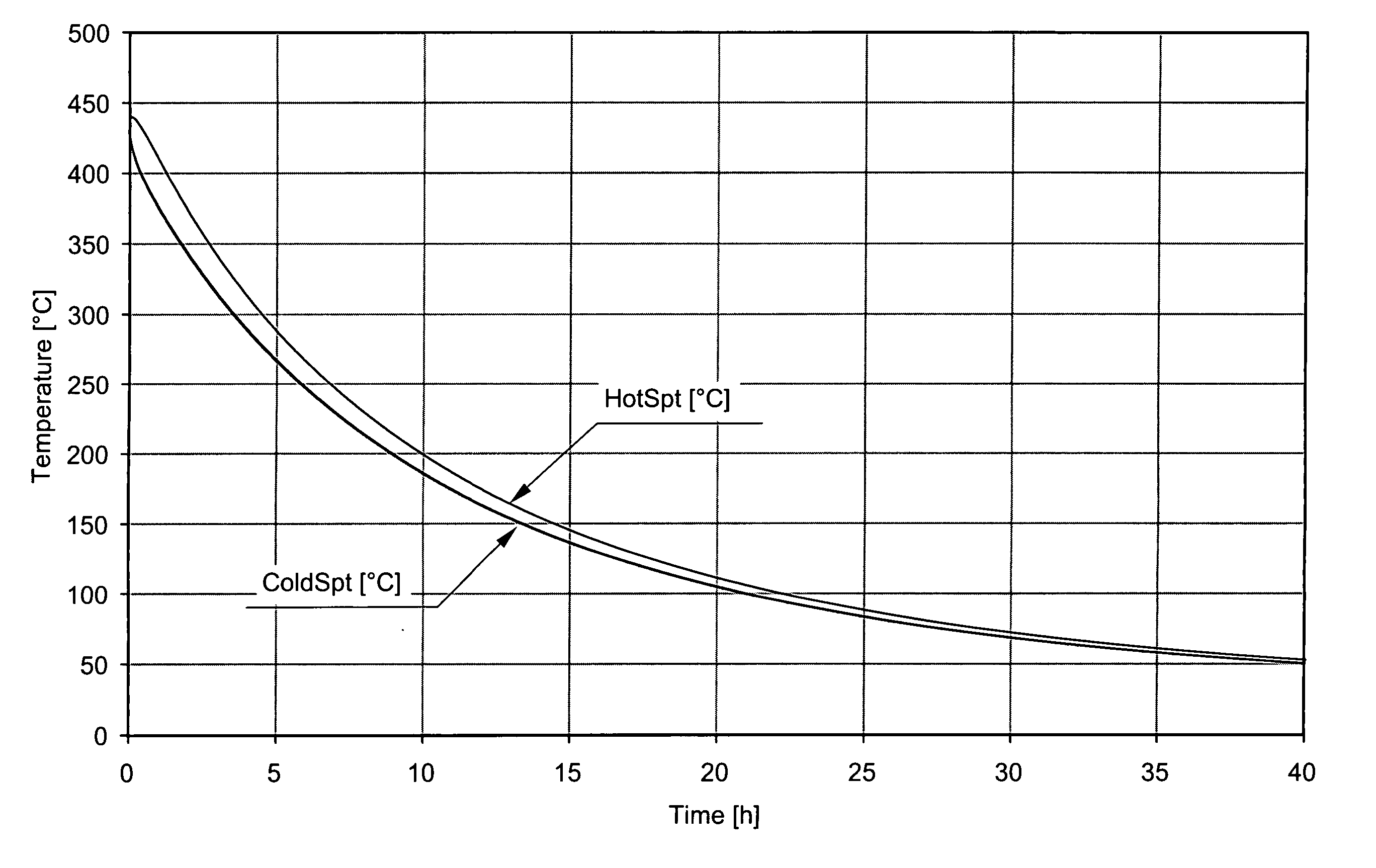

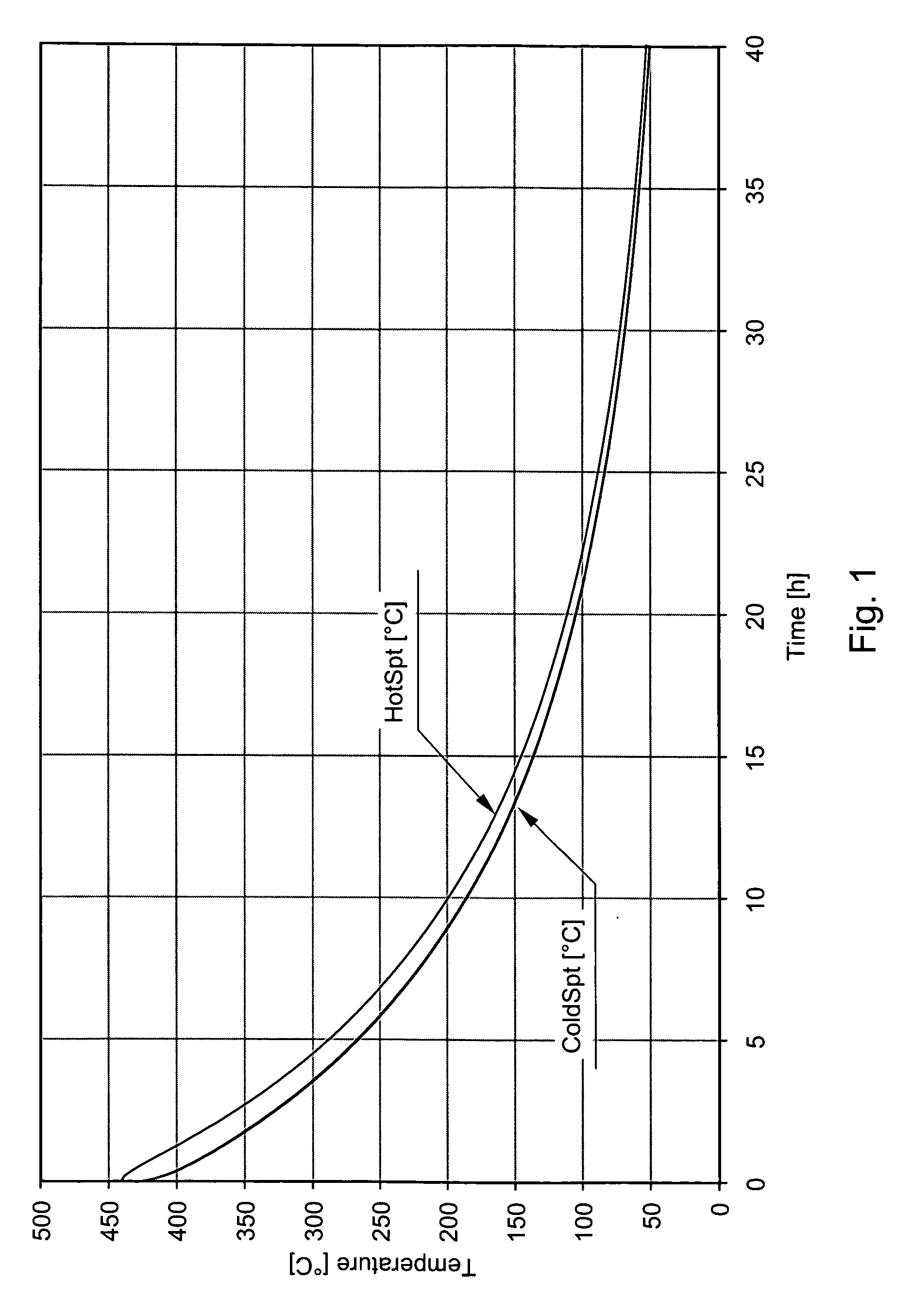

Method for producing a high damage tolerant aluminium alloy

The present invention relates to a method of producing a high damage tolerant aluminium alloy rolled product a high toughness and an improved fatigue crack growth resistance, including the steps of: a.) casting an ingot having a composition selected from the group comprising AA2000, AA5000, AA6000, and AA7000-series alloys; b.) homogenising and / or pre-heating the ingot after casting; c.) hot rolling the ingot into a hot rolled product and optionally cold rolling the hot rolled product into a cold rolled product, wherein the hot rolled product leaves the hot rolling mill at an hot-mill exit temperature (TExit) and cooling the hot rolled product from the TExit to 150° C. or lower with a controlled cooling cycle with a cooling rate falling within the range defined by: T(t)=50−(50−TExit)eαt and wherein T(t) is the temperature (° C.) as function in time (hrs), t is the time (hours) and α is in the range of −0.09±0.05 (hrs−1).

Owner:ALERIS ALUMINUM KOBLENZ GMBH

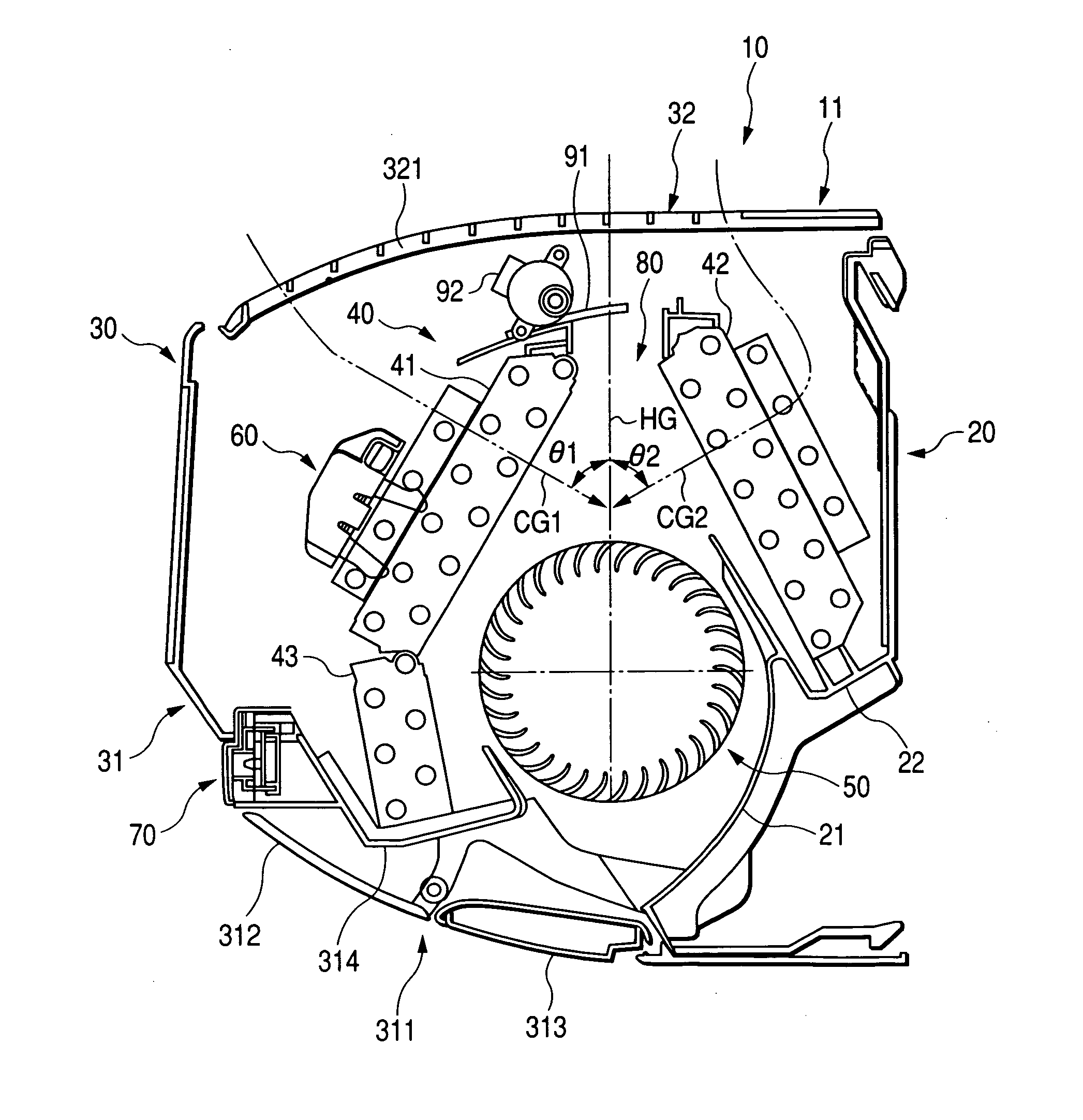

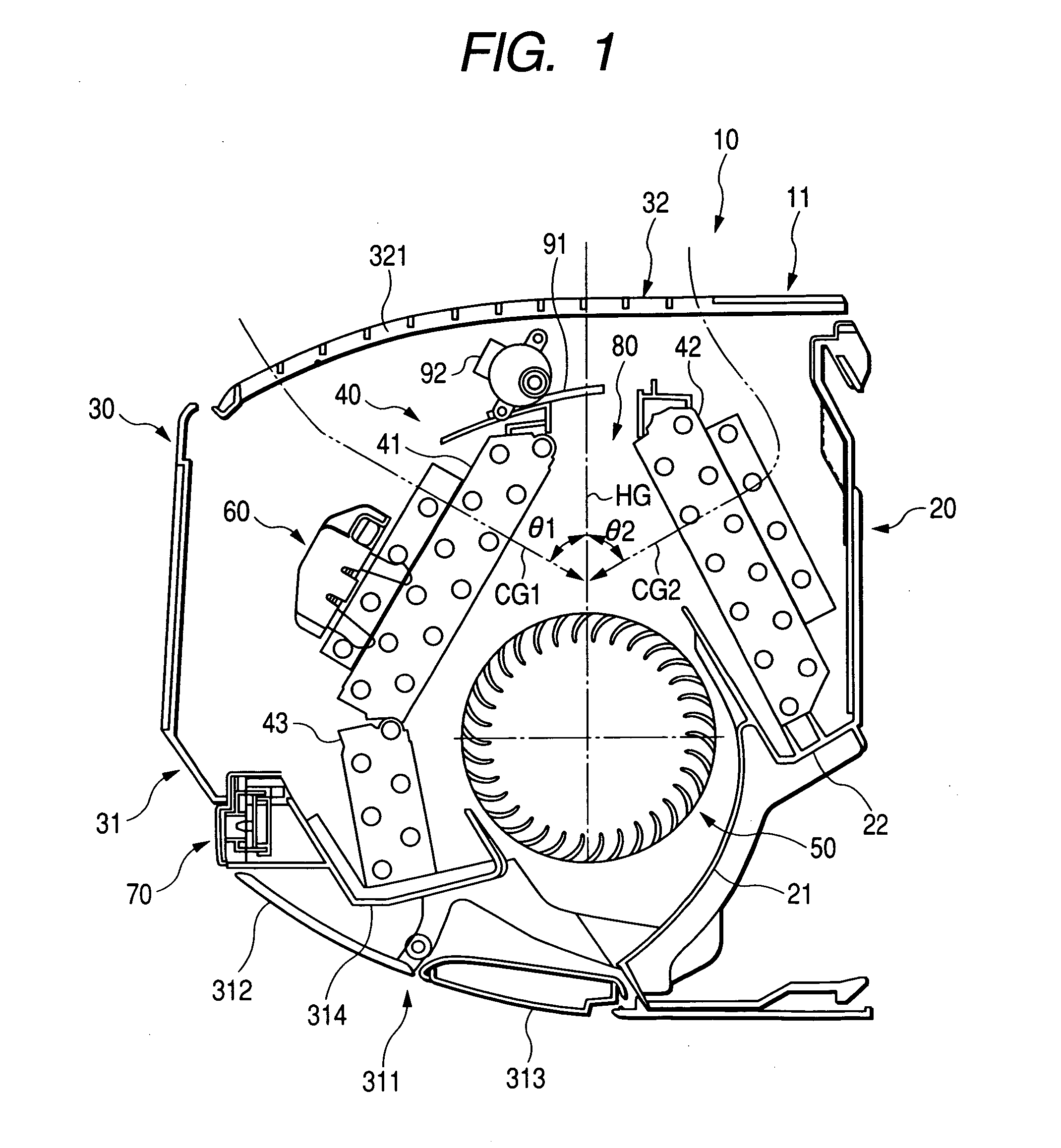

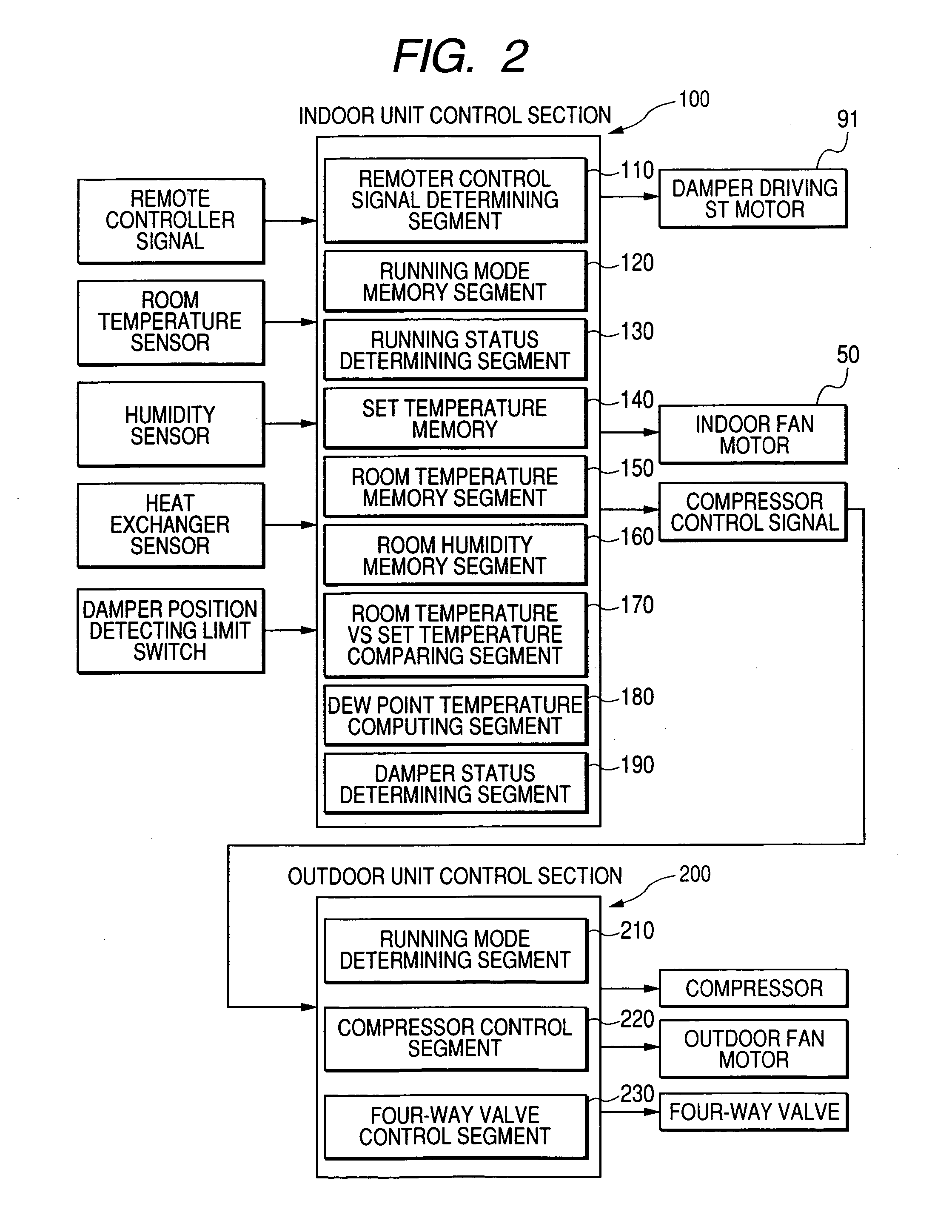

Air conditioner

ActiveUS20070079619A1Avoid condensationReduce temperature changesMechanical apparatusCondensate preventionEngineeringVALVE PORT

Between two heat exchangers of a first heat exchanger unit 41 and a second heat exchanger unit 42 included in an indoor heat exchanger 40, an opening 80 is arranged for introducing indoor air sucked from an air inlet 321 into an indoor blower 50 without being heat-exchanged. At the opening 80, a damper 91 is arranged for adjusting the opening rate of the opening 80, which is driven by a predetermined driving member 92. During a cooling cycle running of a freezing cycle, the opening rate of the opening 80 and / or the devices included in the freezing cycle such as a compressor, blower and expansion valve are controlled alone or in combination so that the temperature of the indoor heat exchanger 40 is lower than a dew point temperature of the indoor air.

Owner:FUJITSU GENERAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com