Special-purpose gas supplying device for coke dry quenching unit

A technology of gas supply device and CDQ, which is applied in coke oven, petroleum industry, coke cooling, etc. It can solve the problem that it is difficult for the CDQ furnace to reach the designed processing capacity, the coke in the furnace cannot be uniformly cooled, and it is difficult to reach the design capacity. To deal with problems such as capacity, to achieve the effects of non-circulating cooling gas leakage, reasonable structural layout, and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

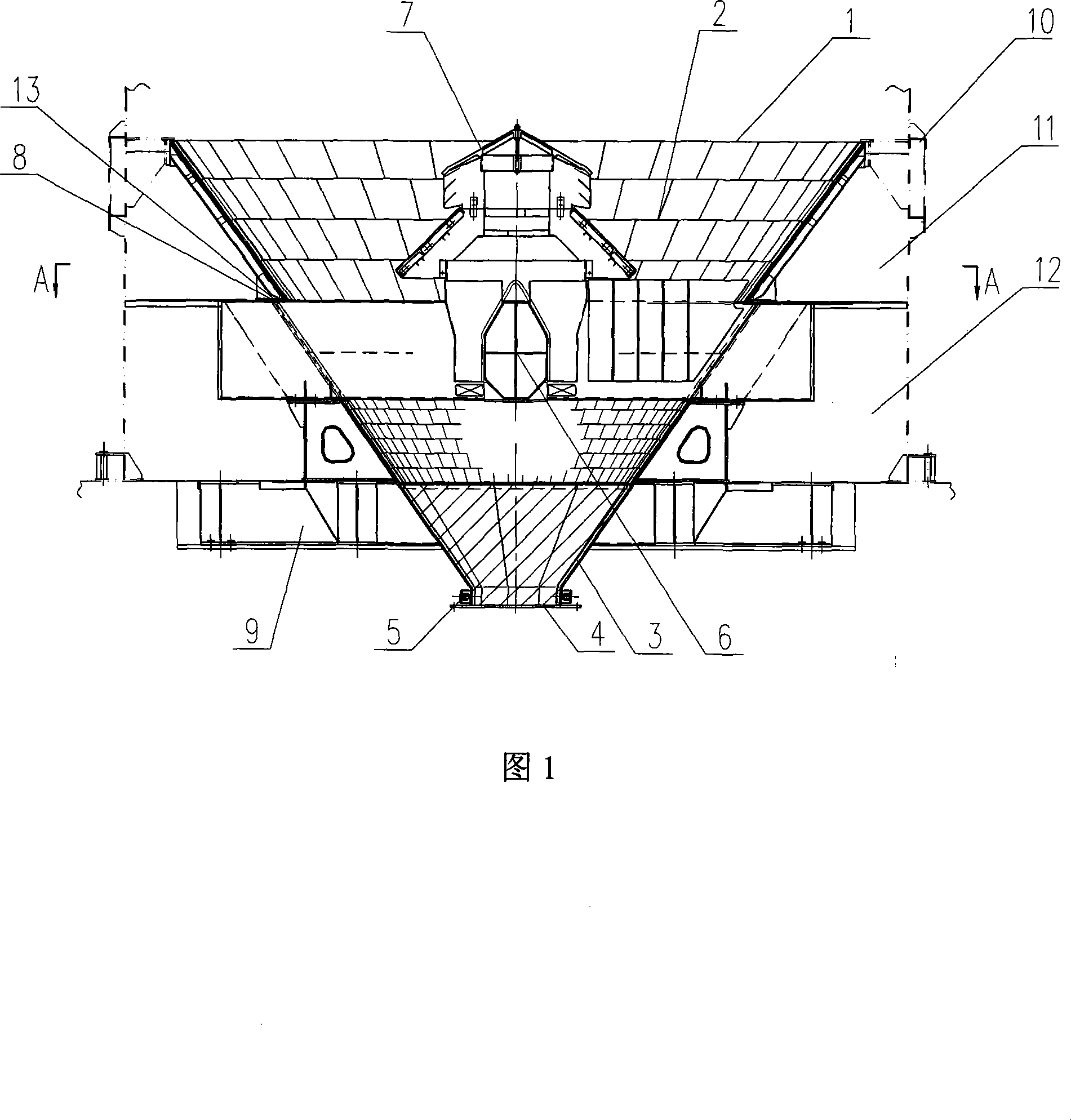

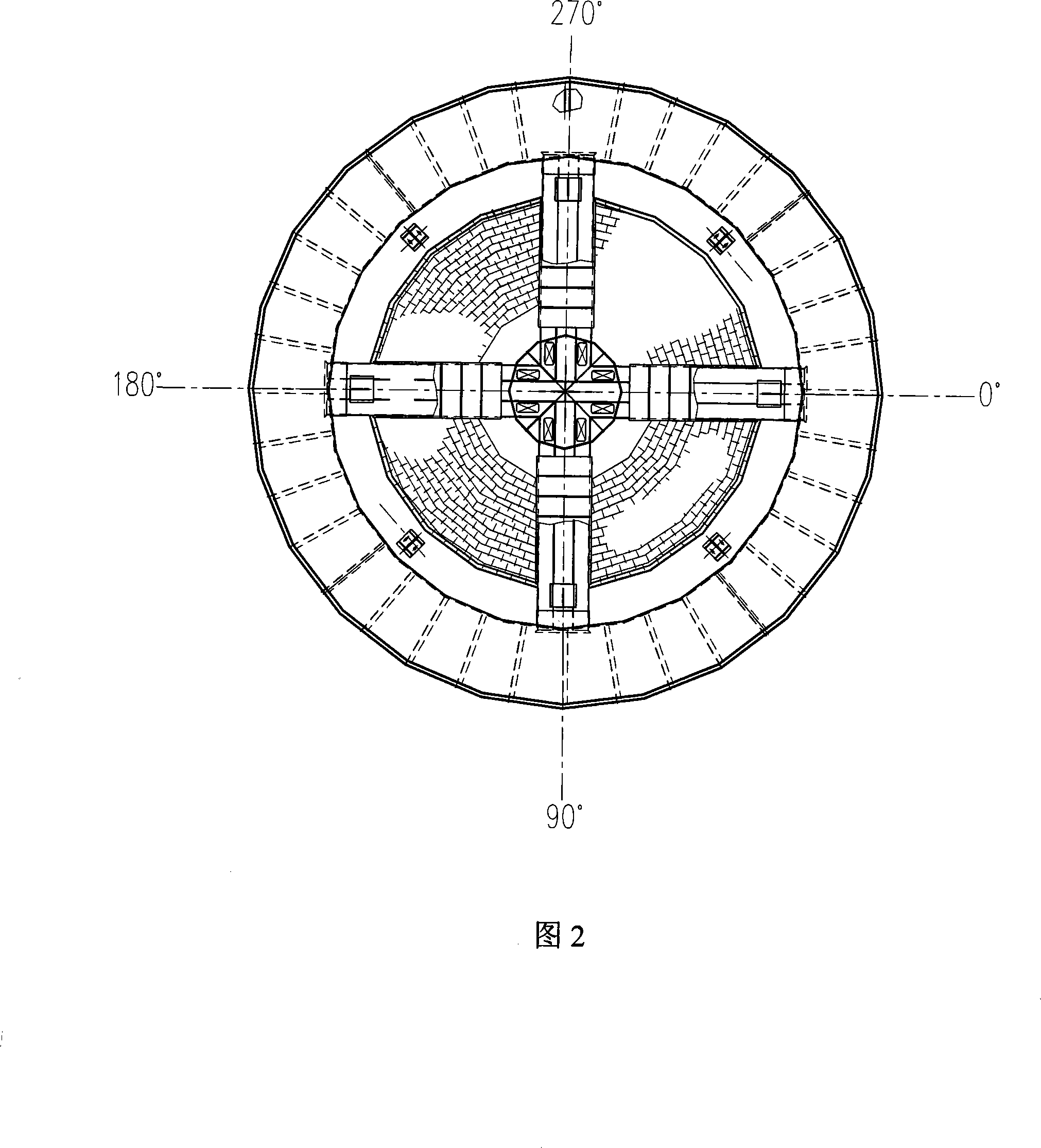

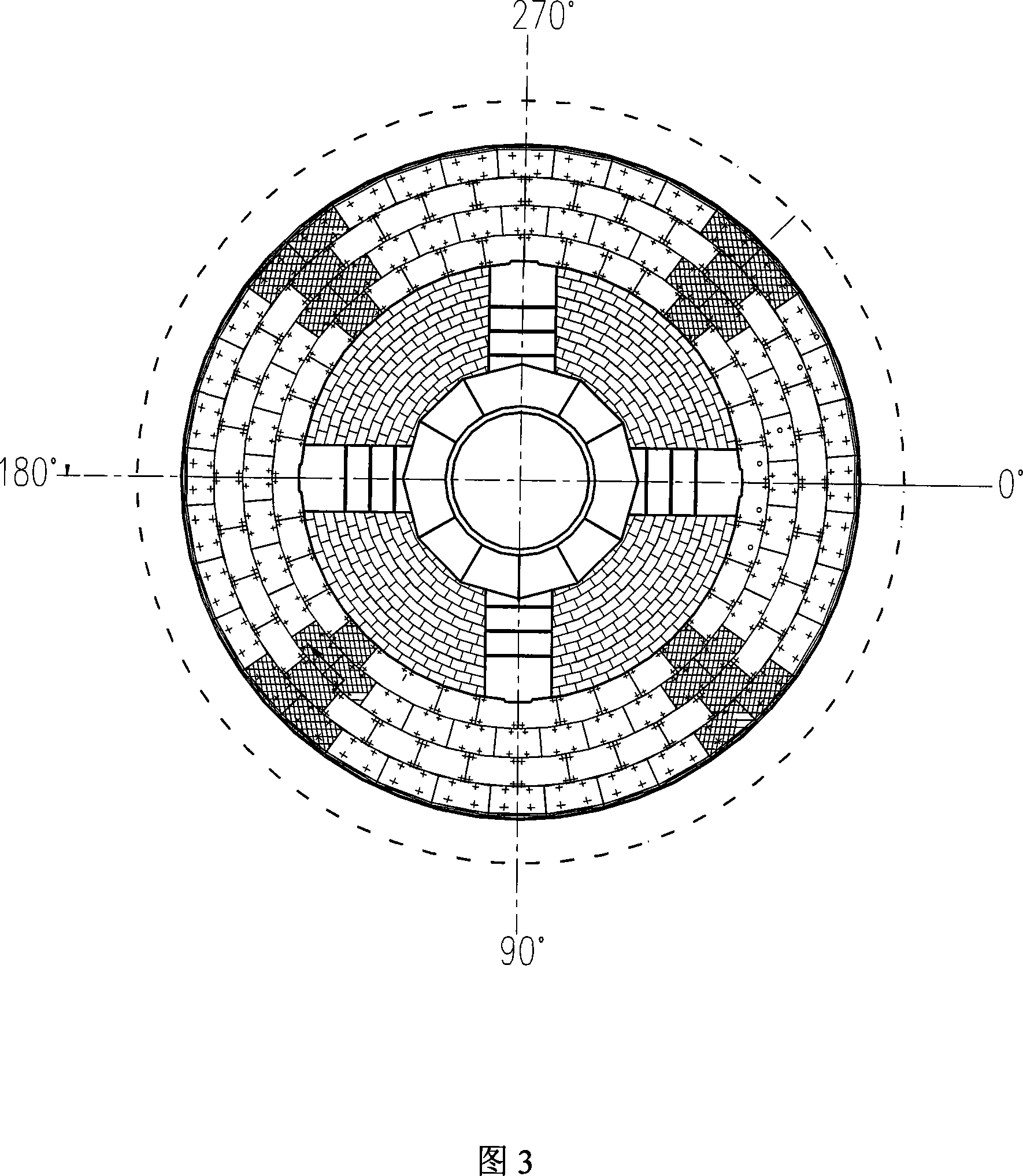

[0020] See Figure 1, Figure 2, Figure 3, and Figure 4. The device consists of an upper cone bucket 1, a lower cone bucket 3, a CDQ furnace shell 10, an annular air duct 13, a cross air duct 6, and a central air cap 7. The upper cone Bucket 1 and lower cone bucket 3 are inserted together, and the annular gap formed by the sleeve inserting eaves forms an annular air duct 13, and an air volume regulating plate is provided at this place, and its air volume control is completed by the air volume regulating plate 8. The cross air duct 6 is located on the upper part of the lower cone 3 and is set horizontally. Its center coincides with the center of the CDQ and extends upward to communicate with the central wind cap 7 arranged on the upper part of the cone; the upper cone 1 and the lower cone 3 are connected to the CDQ The gas distribution chamber composed of the casing 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com